Flexible nanofiber zinc tin oxide field effect transistor and preparation method thereof

A field effect transistor and nanofiber technology, applied in the field of microelectronics, can solve the problems of hindering the development of NF process, difficult to control fiber distribution, high process cost, etc., to achieve large-scale industrial application, good application potential, high mobility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

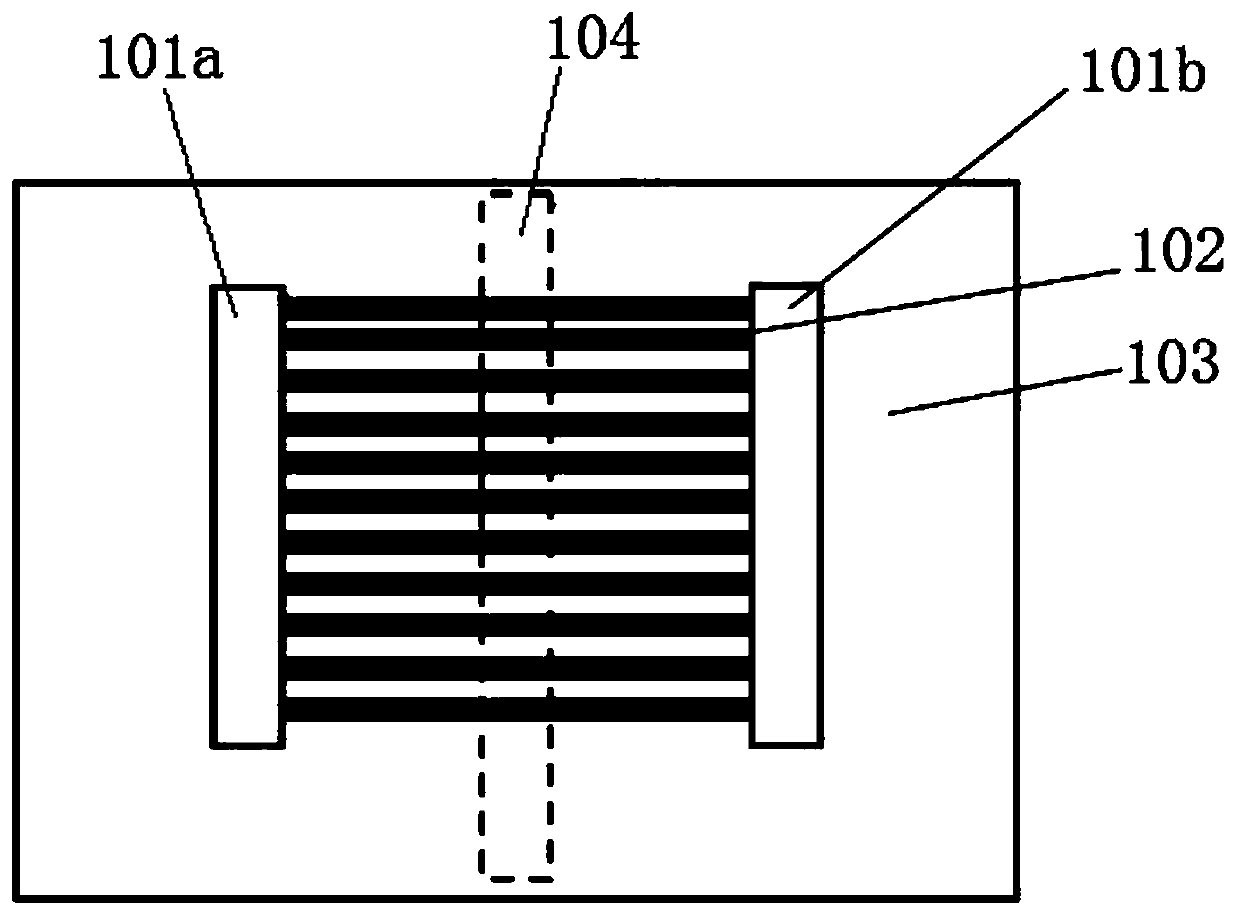

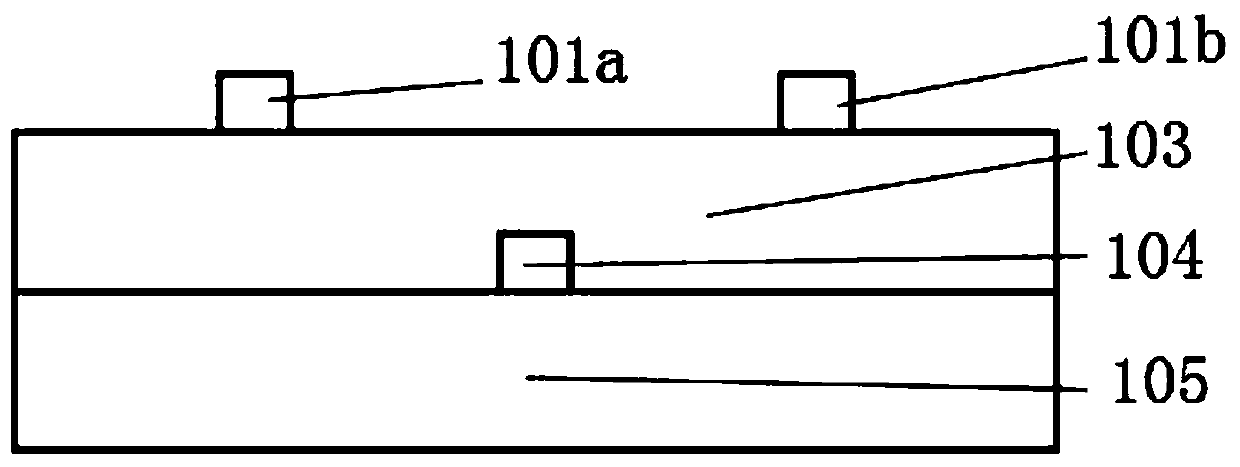

[0038] as attached Figure 1-2 As shown, a field effect transistor of flexible nanofiber zinc tin oxide includes a top source electrode layer 101a, a top drain electrode layer 101b arranged from top to bottom, a carrier channel layer 102 of a nanofiber structure, and a dielectric layer 103 , a bottom gate electrode layer 104 and a substrate 105; the carrier channel layer 102 of the nanofibrous structure is a cluster of zinc tin oxide (ZTO) filaments with a diameter of about 100-300 nm prepared by a sol method, with a uniform number, The advantage of neat direction. The top source electrode layer 101a, the top drain electrode layer 101b and the bottom gate electrode layer 104 are transparent indium tin oxide (ITO) electrodes made by an aqueous solution method with a thickness of 50-150 nm and a channel width-to-length ratio of 10-20 (The channel width-to-length ratio is a dimension between a pair of source-drain electrodes), and the specific value is determined by the mask pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com