Patents

Literature

3877 results about "Film structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Film structure definition, film structure meaning | English dictionary. film. b a form of entertainment, information, etc., composed of such a sequence of images and shown in a cinema, etc. b to make a film of (a screenplay, event, etc.)

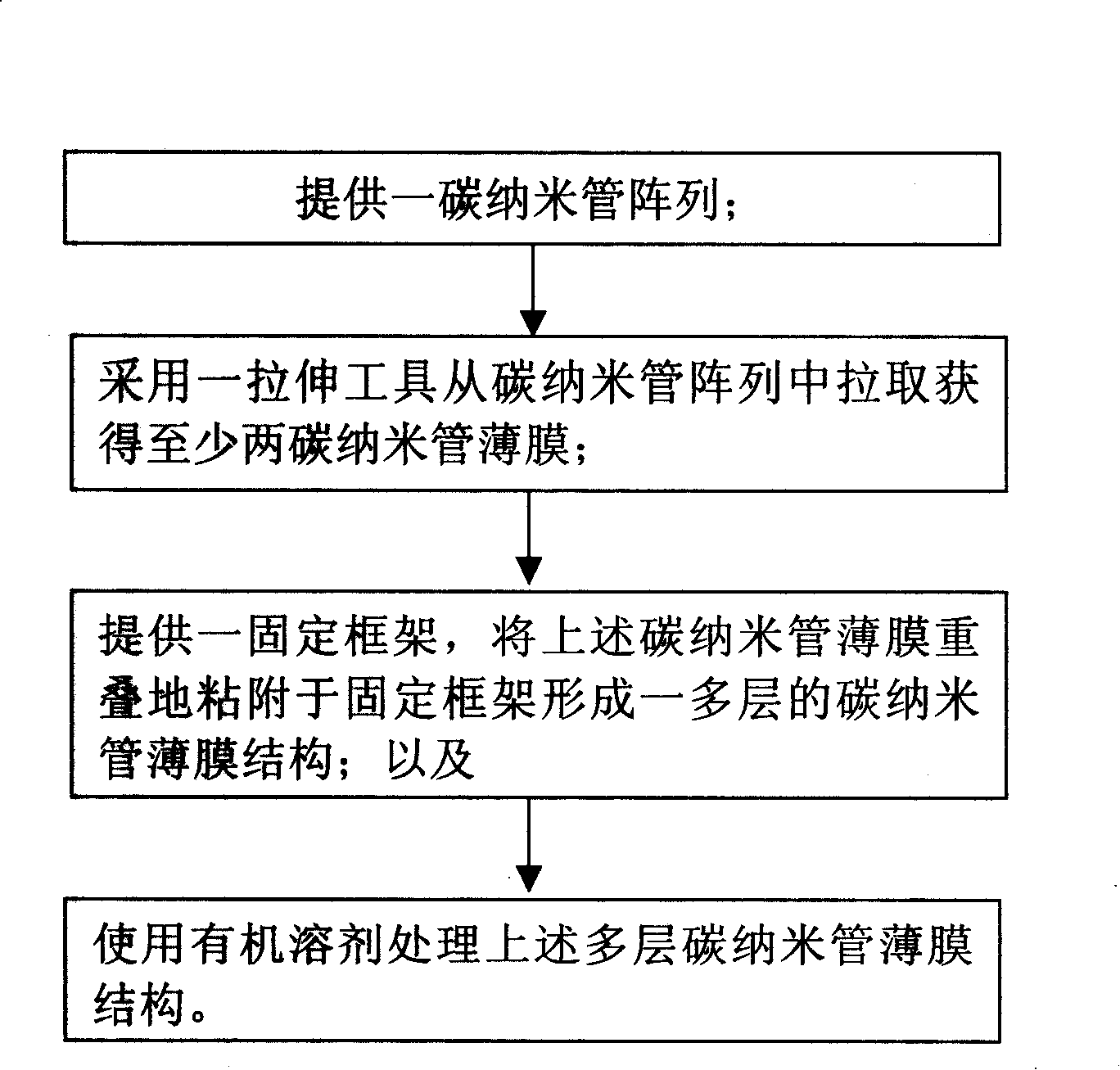

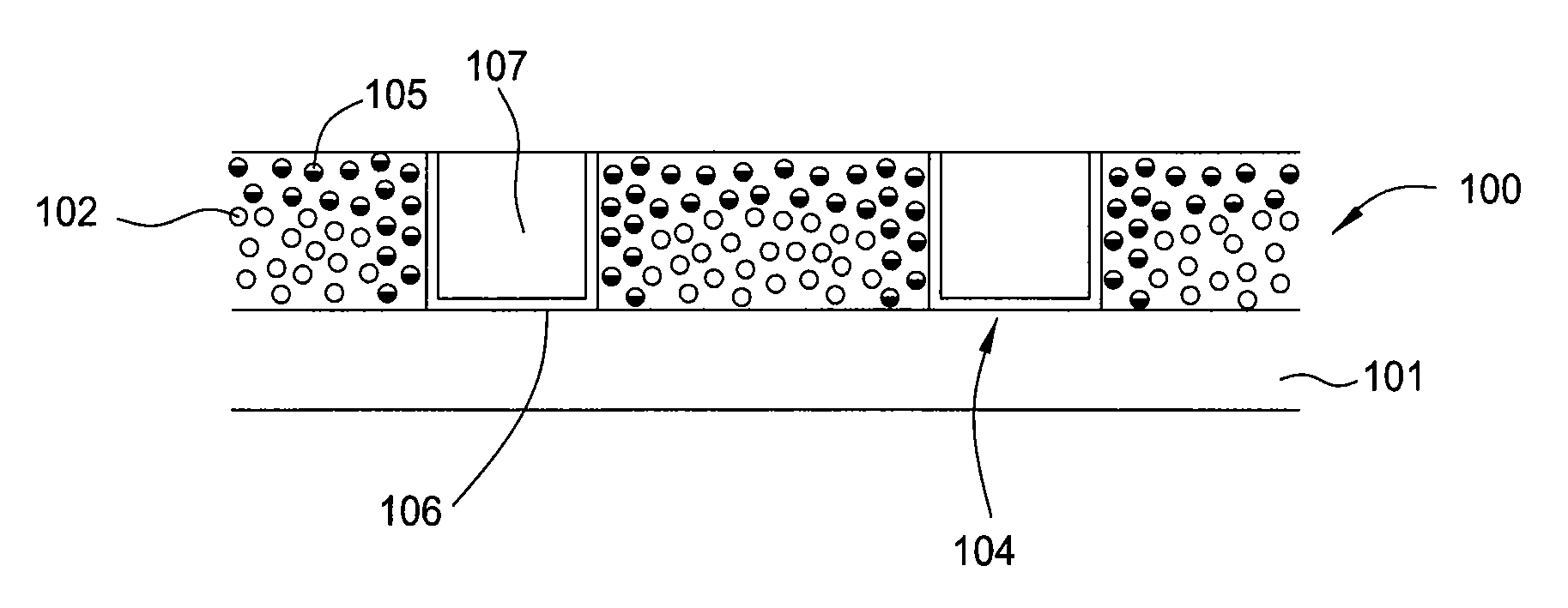

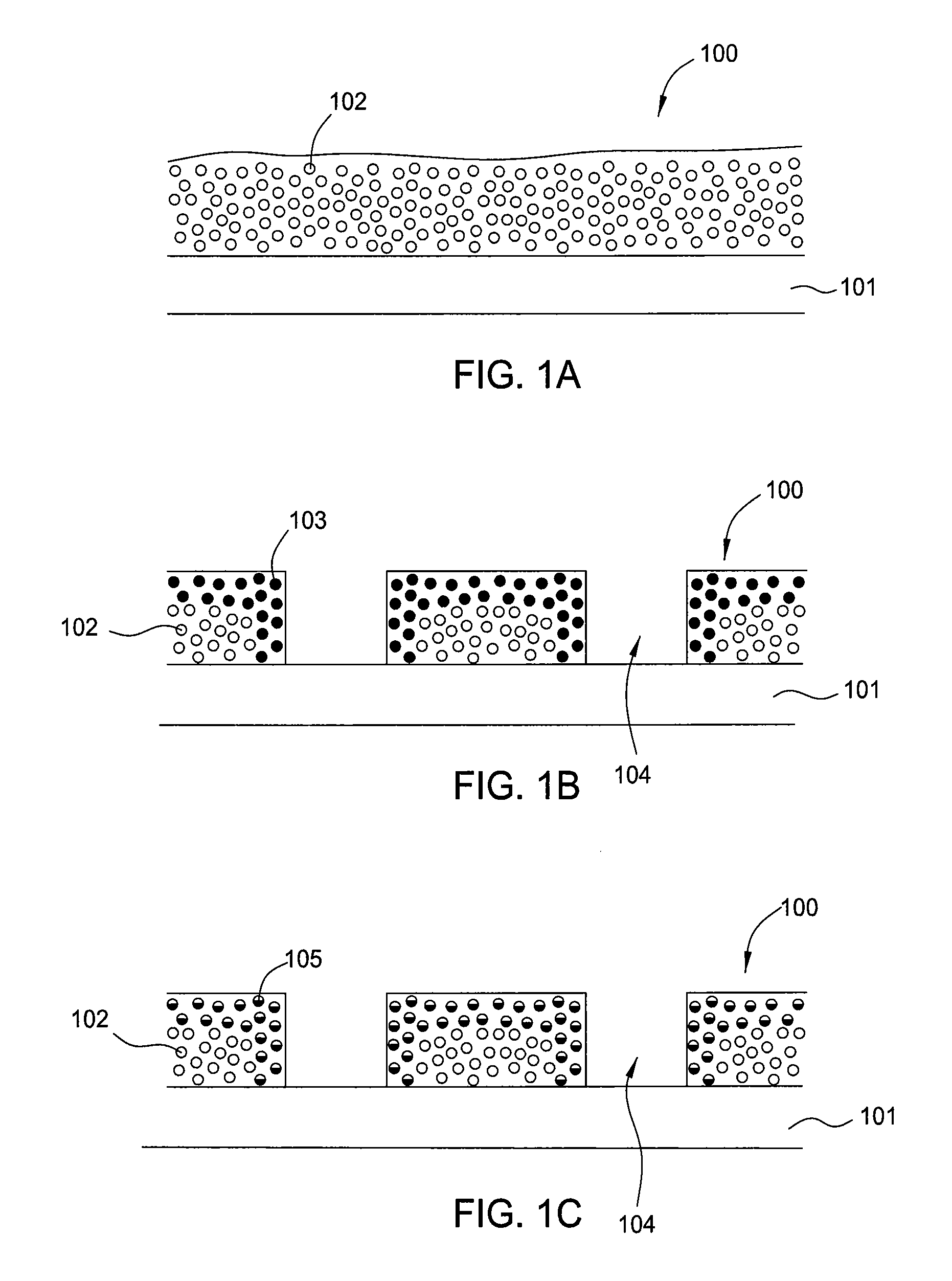

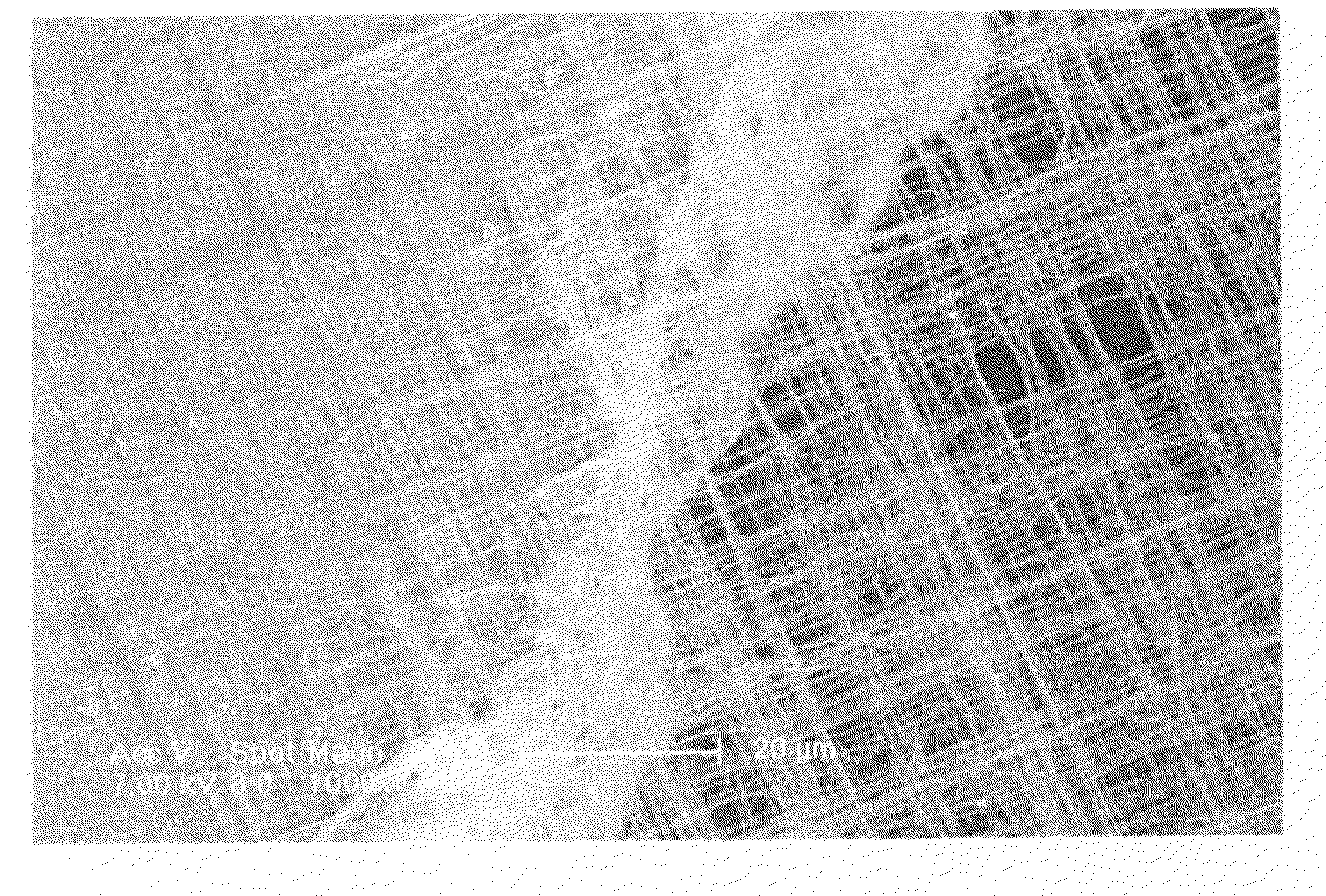

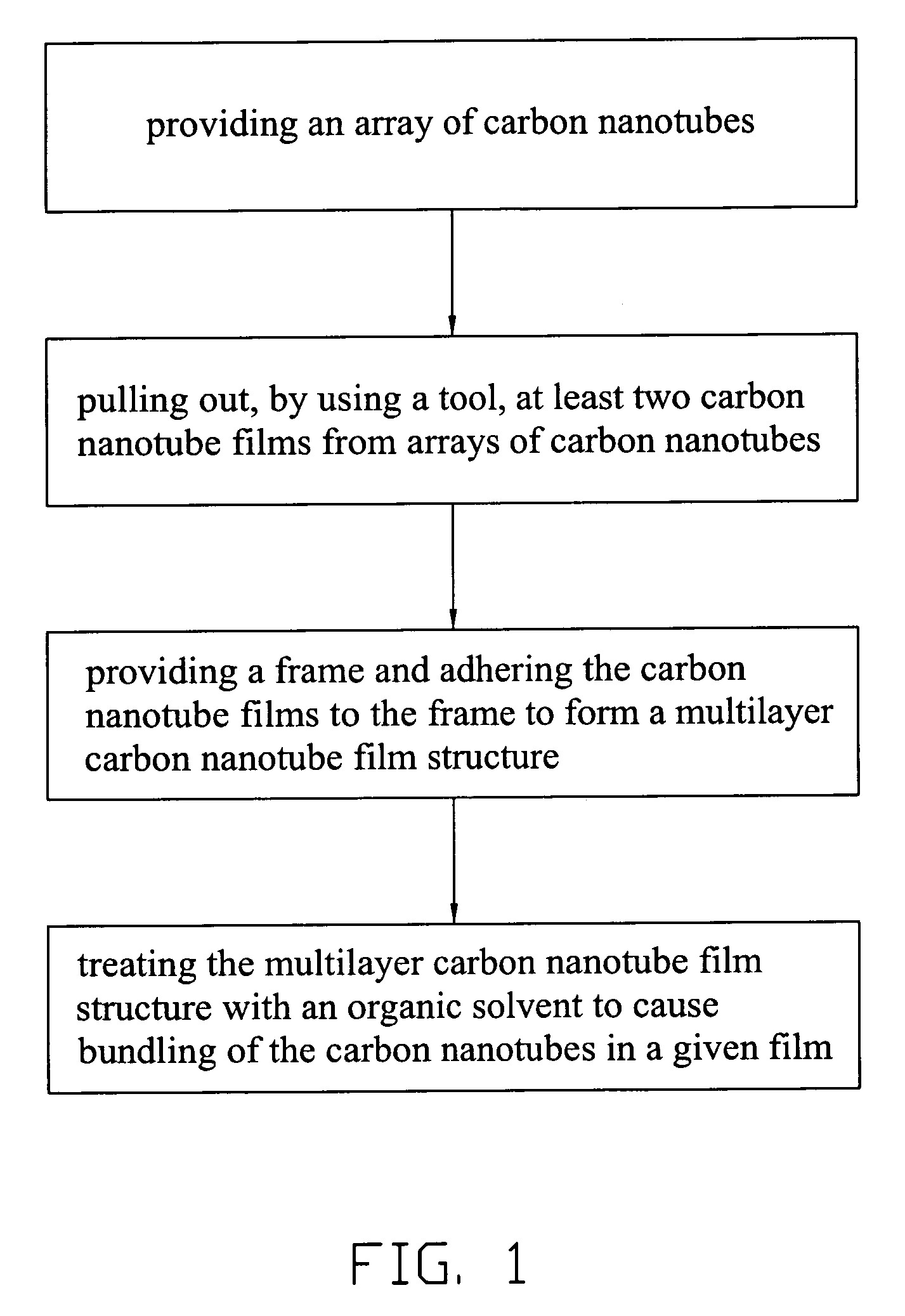

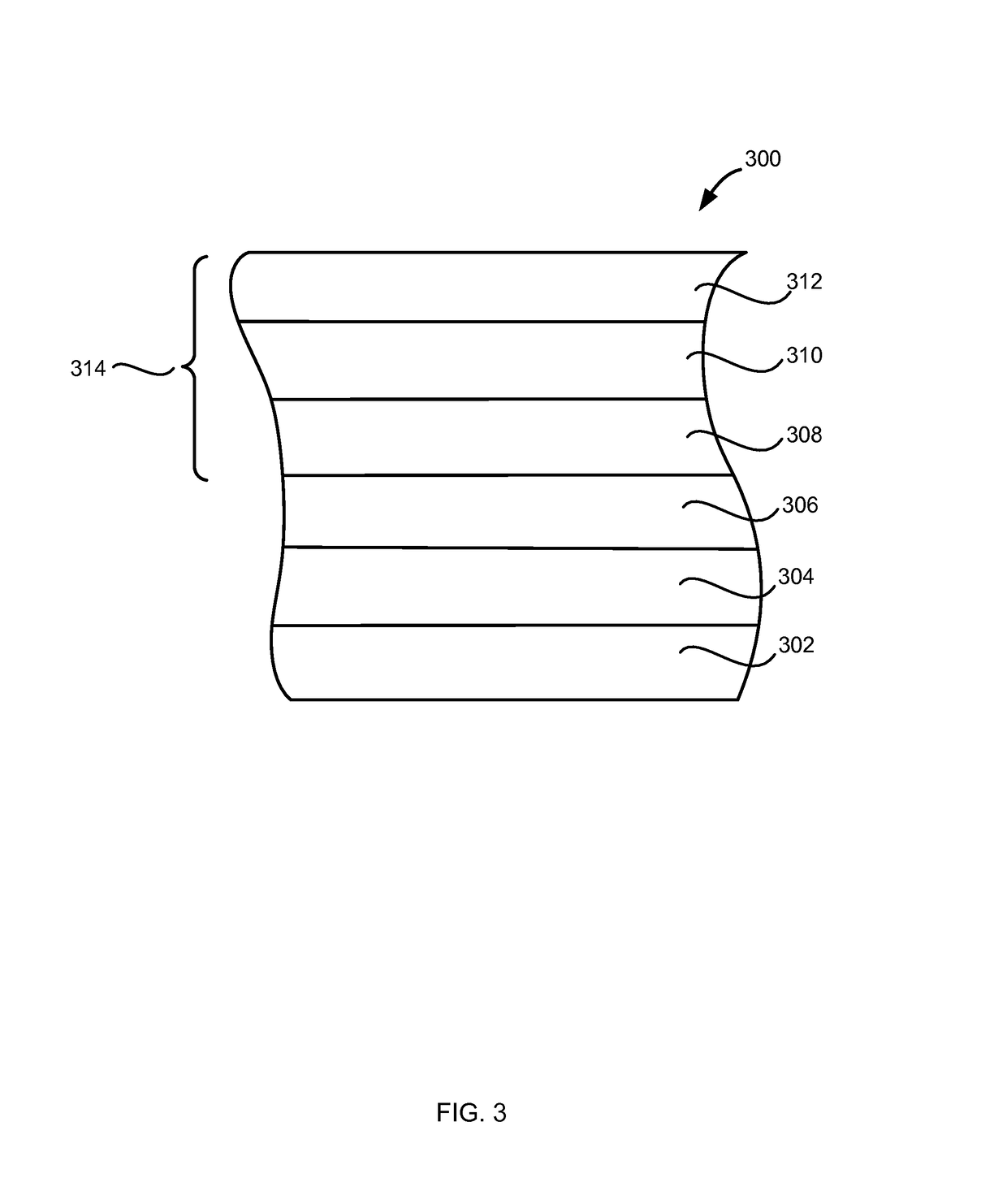

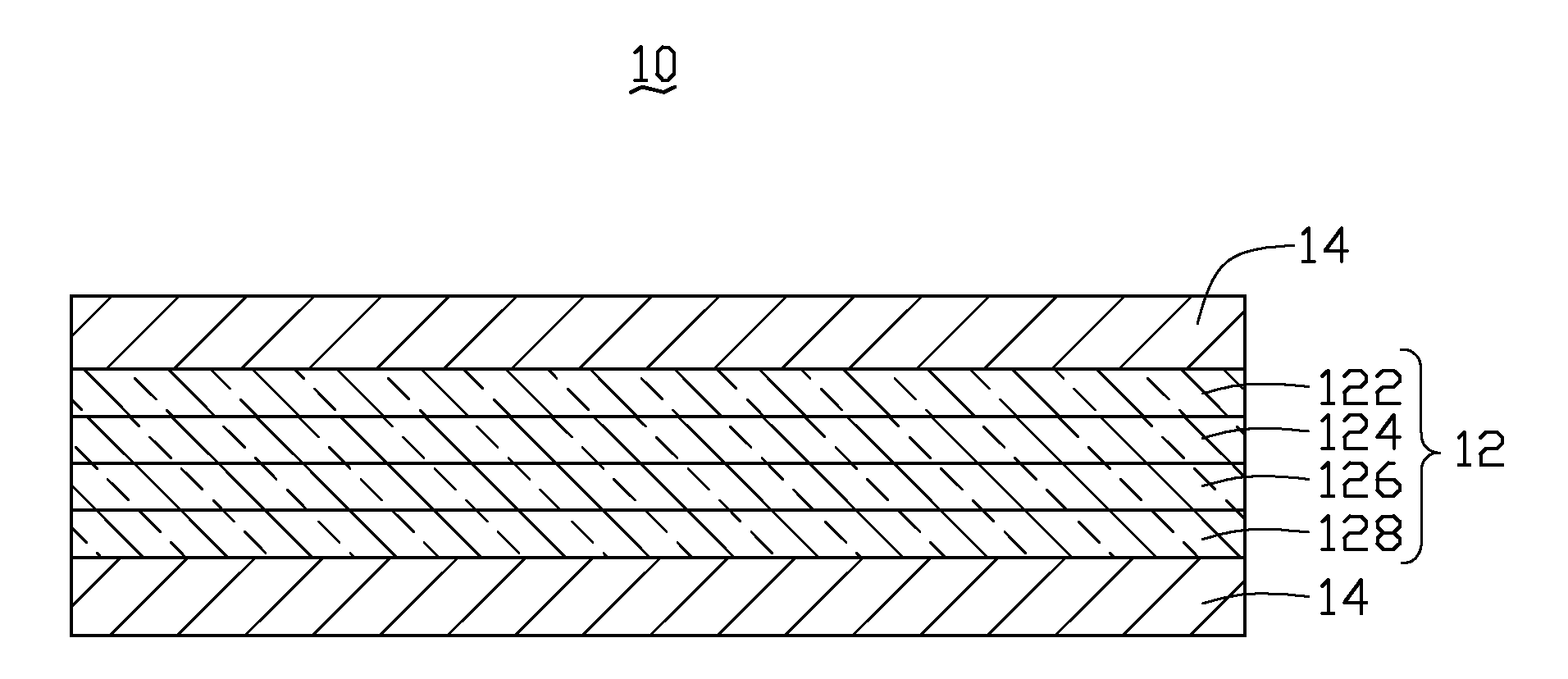

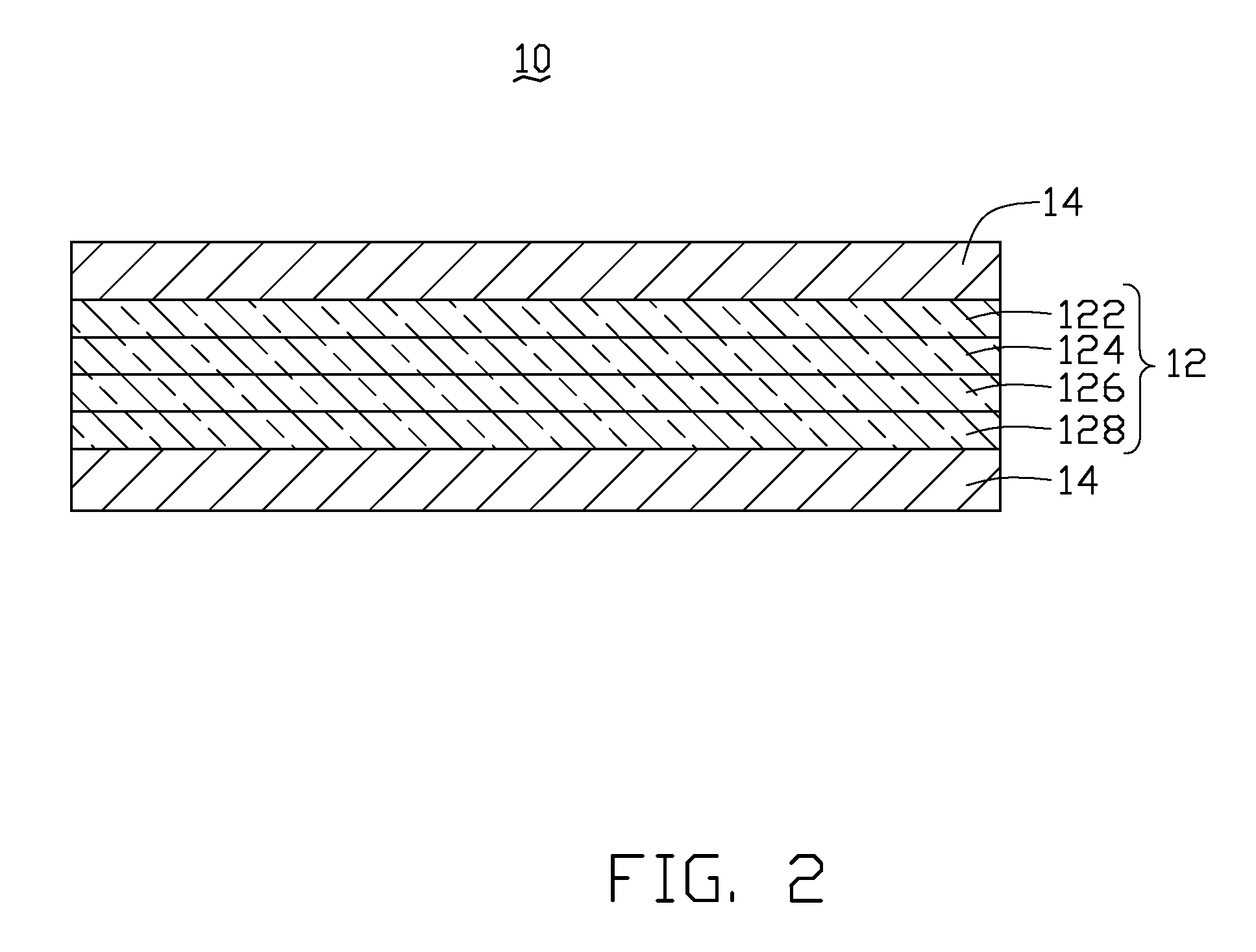

Carbon nano-tube thin film structure and preparation method thereof

ActiveCN101239712ASmall surface to volume ratioNon stickyMaterial nanotechnologyLamination ancillary operationsOrganic solventFixed frame

The present invention provides a preparing method of carbon nanotube film structure, including following steps: providing a carbon nanotube array; adopting a pulling tool to acquire at least two carbon nanotube films from the carbon nanotube array; providing a fixed frame, forming a multiple-layer carbon nanotube film structure by overlap adhereing the carbon nanotube film in the fixed frame; and treating the multiple-layer carbon nanotube film by an organic solvent. The carbon nanotube film structure prepared by the method includes at least two layers overlapped and cross-over installed carbon nanotube film, which includes multiple carbon nanotube bundle end to end and arranged in the direction, the multiple-layer carbon nanotube film further includes millipore crosswise formed by multiple carbon nanotube bundles.

Owner:TSINGHUA UNIV +1

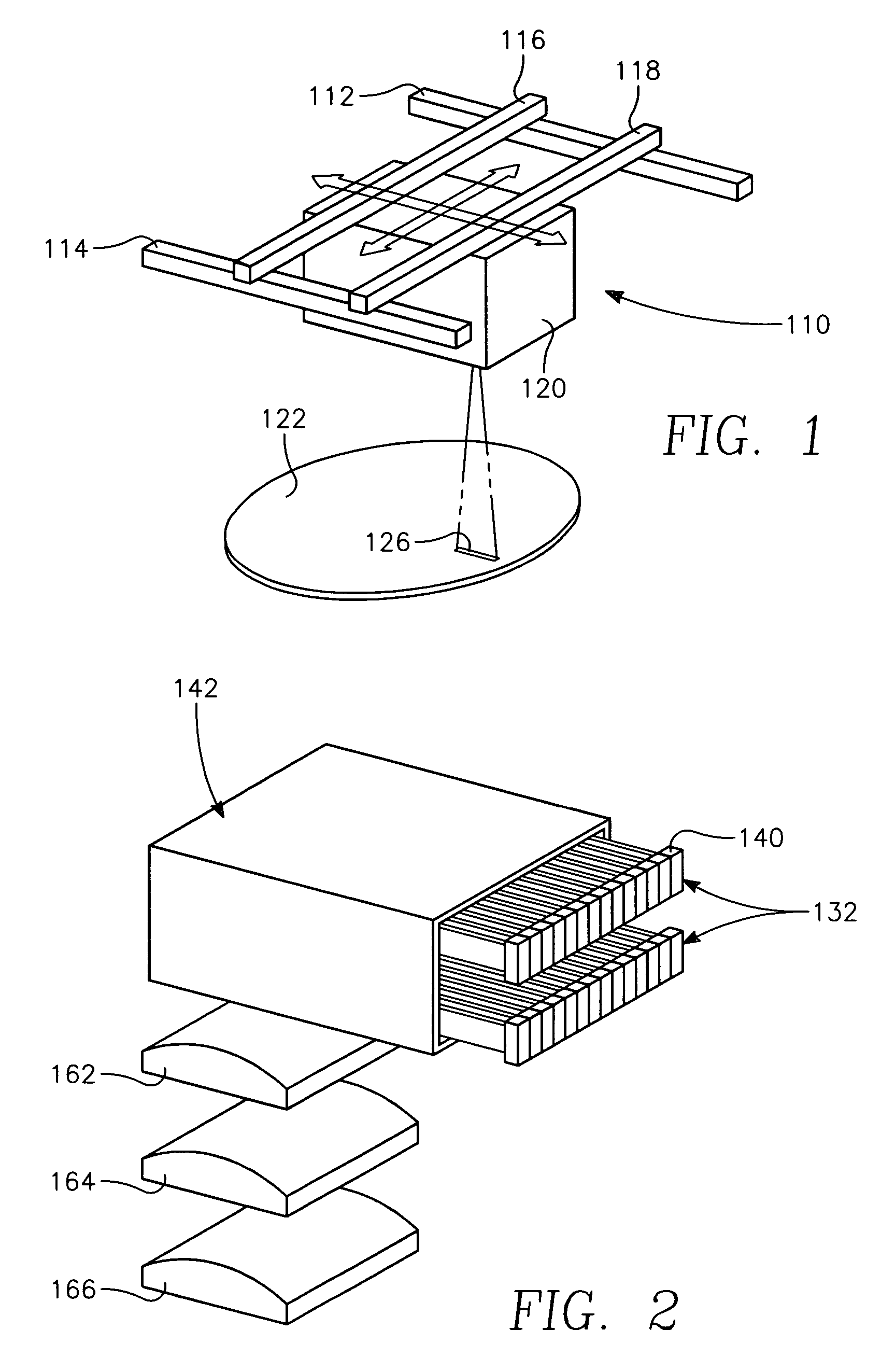

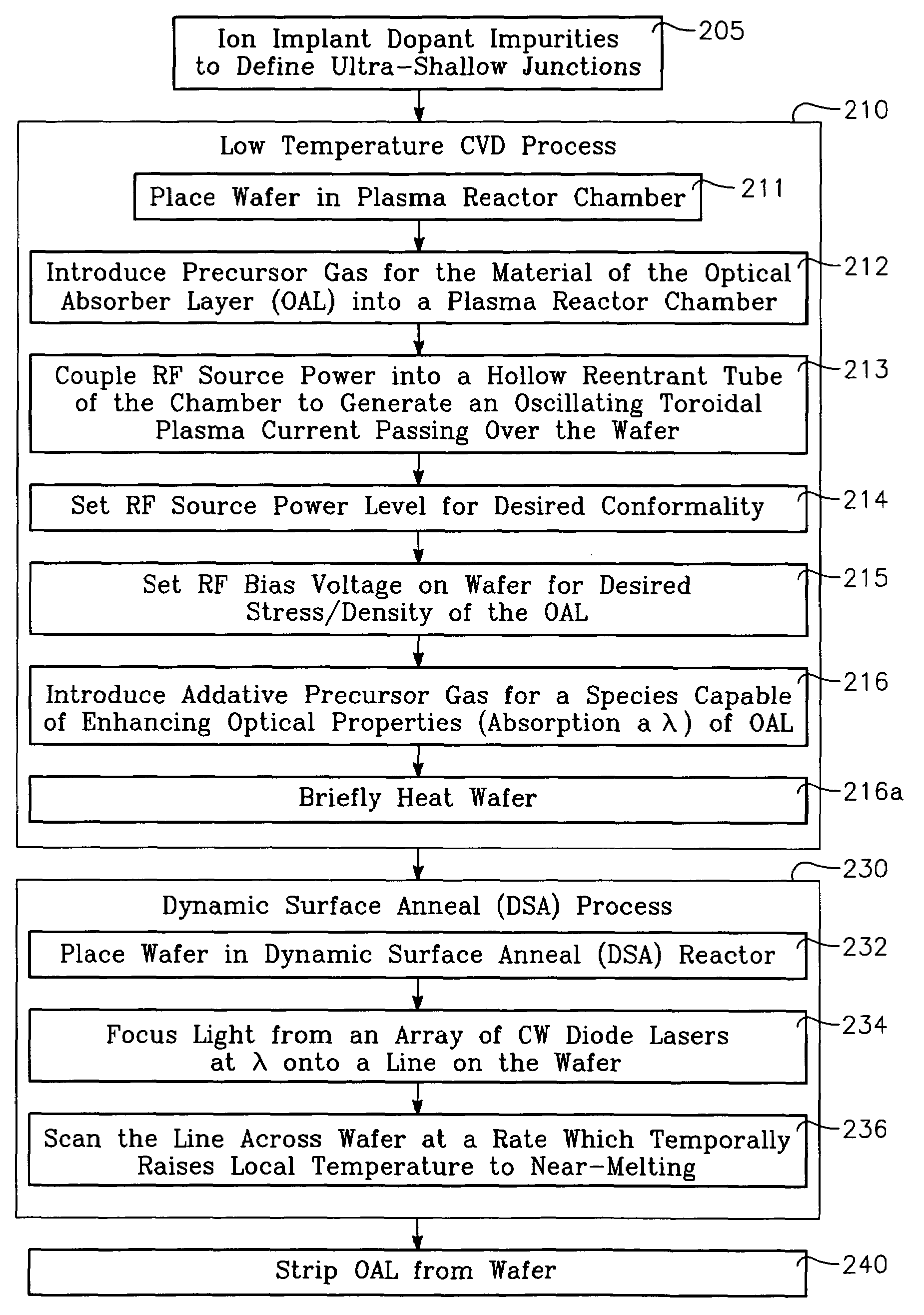

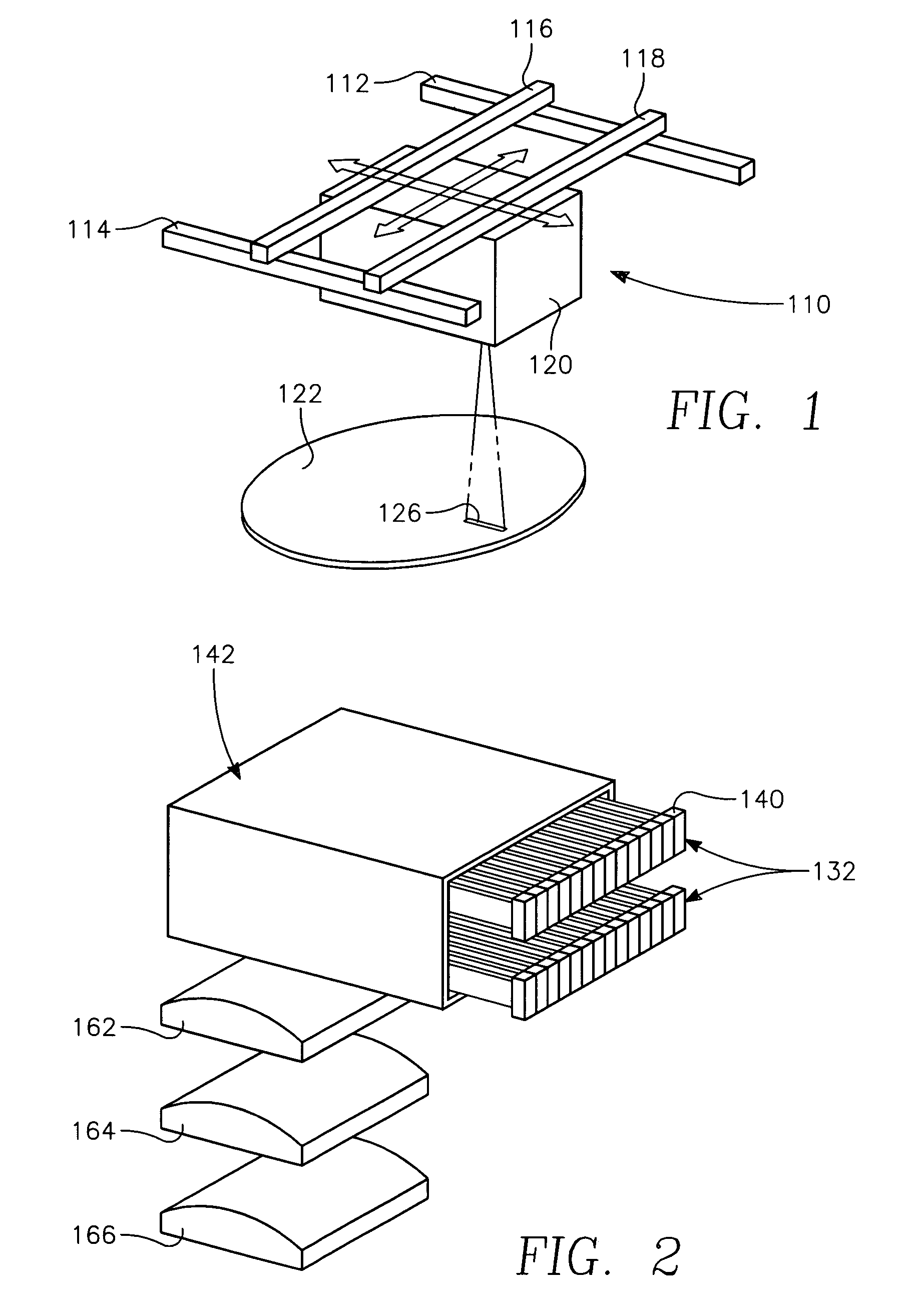

Semiconductor substrate process using a low temperature deposited carbon-containing hard mask

InactiveUS7323401B2Electric discharge tubesRadiation applicationsLow temperature depositionPlasma current

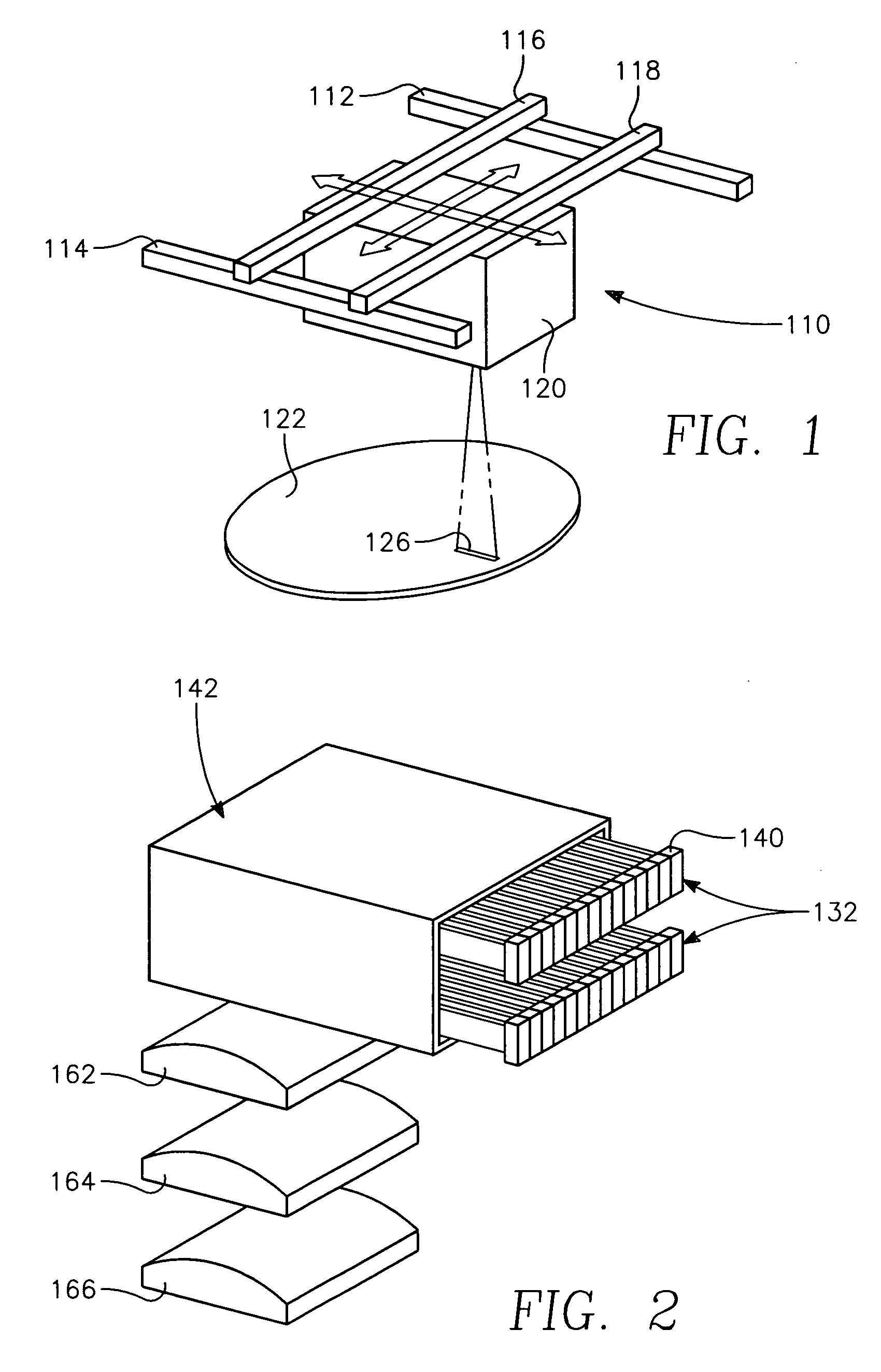

A method of processing a thin film structure on a semiconductor substrate using an optically writable mask includes placing the substrate in a reactor chamber, the substrate having on its surface a target layer to be etched in accordance with a predetermined pattern, and depositing a carbon-containing hard mask layer on the substrate by (a) introducing a carbon-containing process gas into the chamber, (b) generating a reentrant toroidal RF plasma current in a reentrant path that includes a process zone overlying the workpiece by coupling plasma RF source power to an external portion of the reentrant path, and (c) coupling RF plasma bias power or bias voltage to the workpiece. The method further includes photolithographically defining the predetermined pattern in the carbon-containing hard mask layer, and etching the target layer in the presence of the hard mask layer.

Owner:APPLIED MATERIALS INC

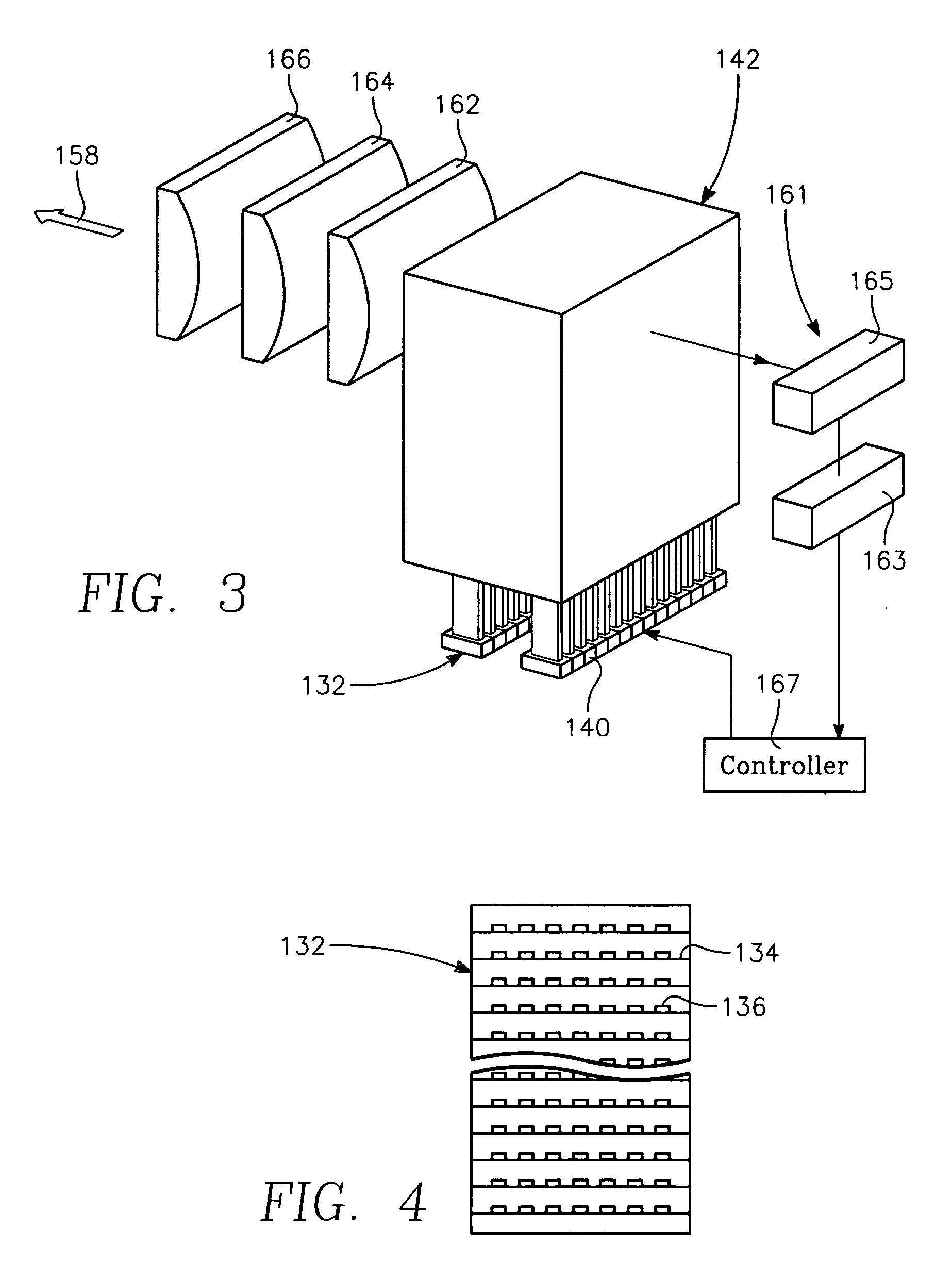

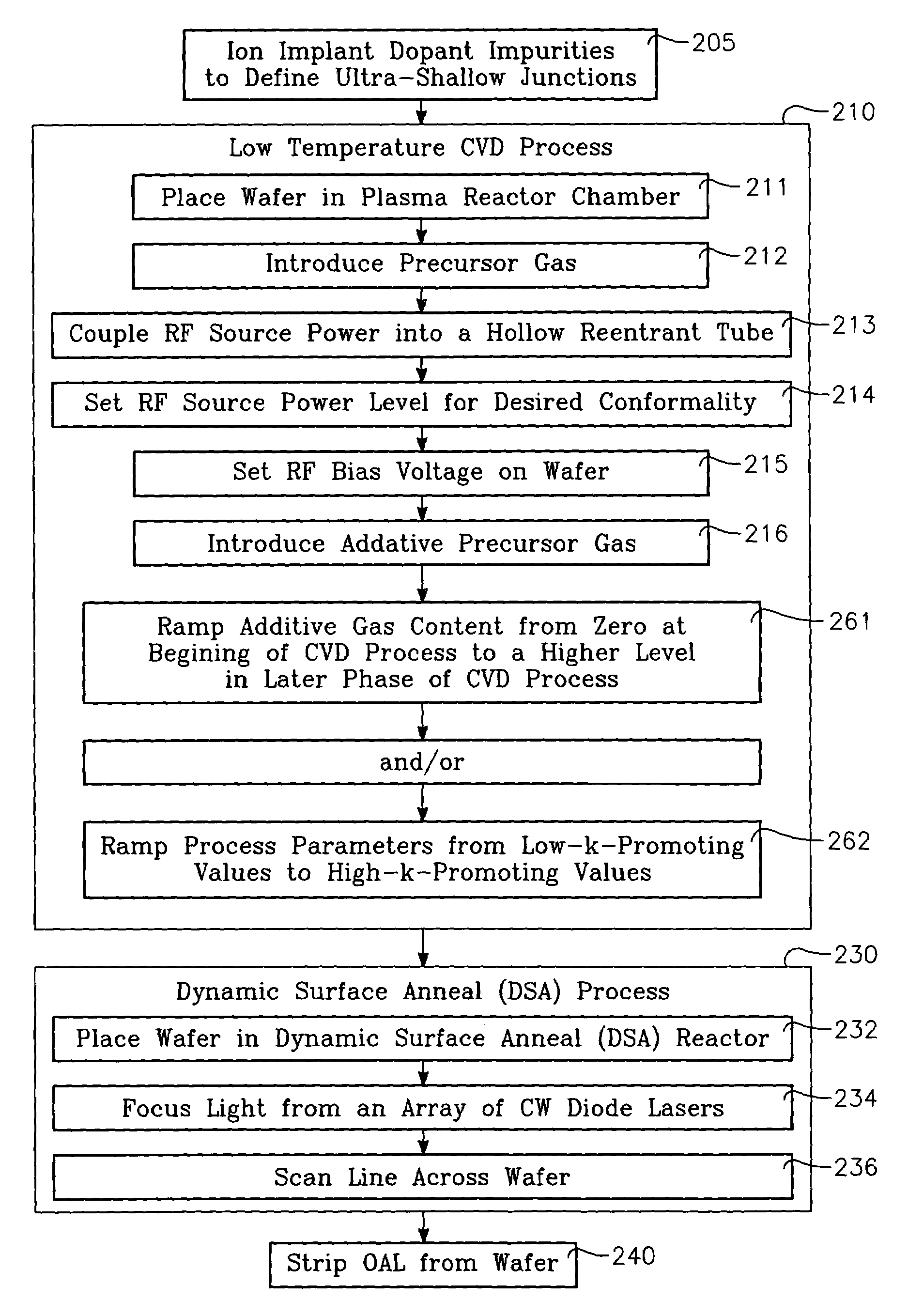

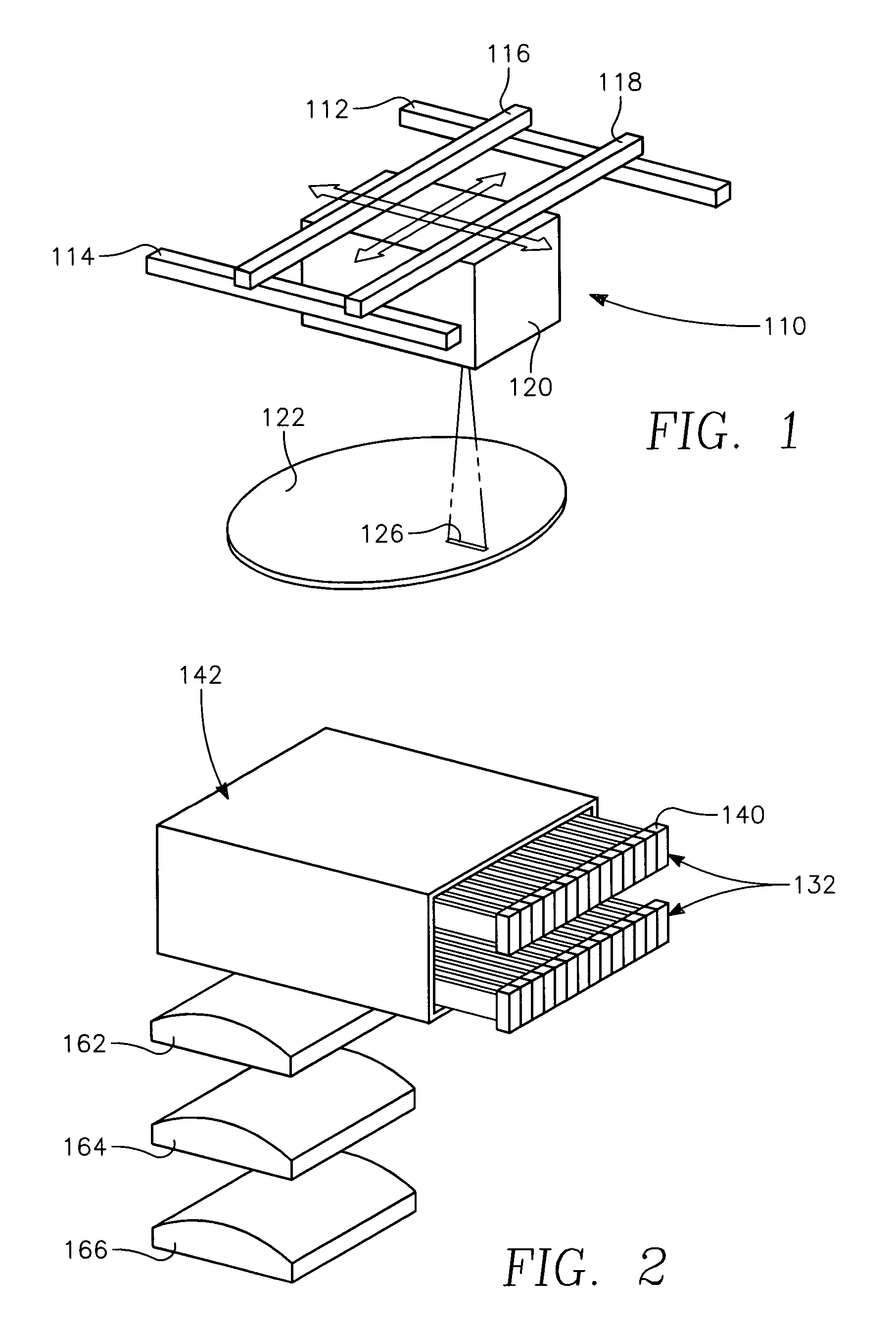

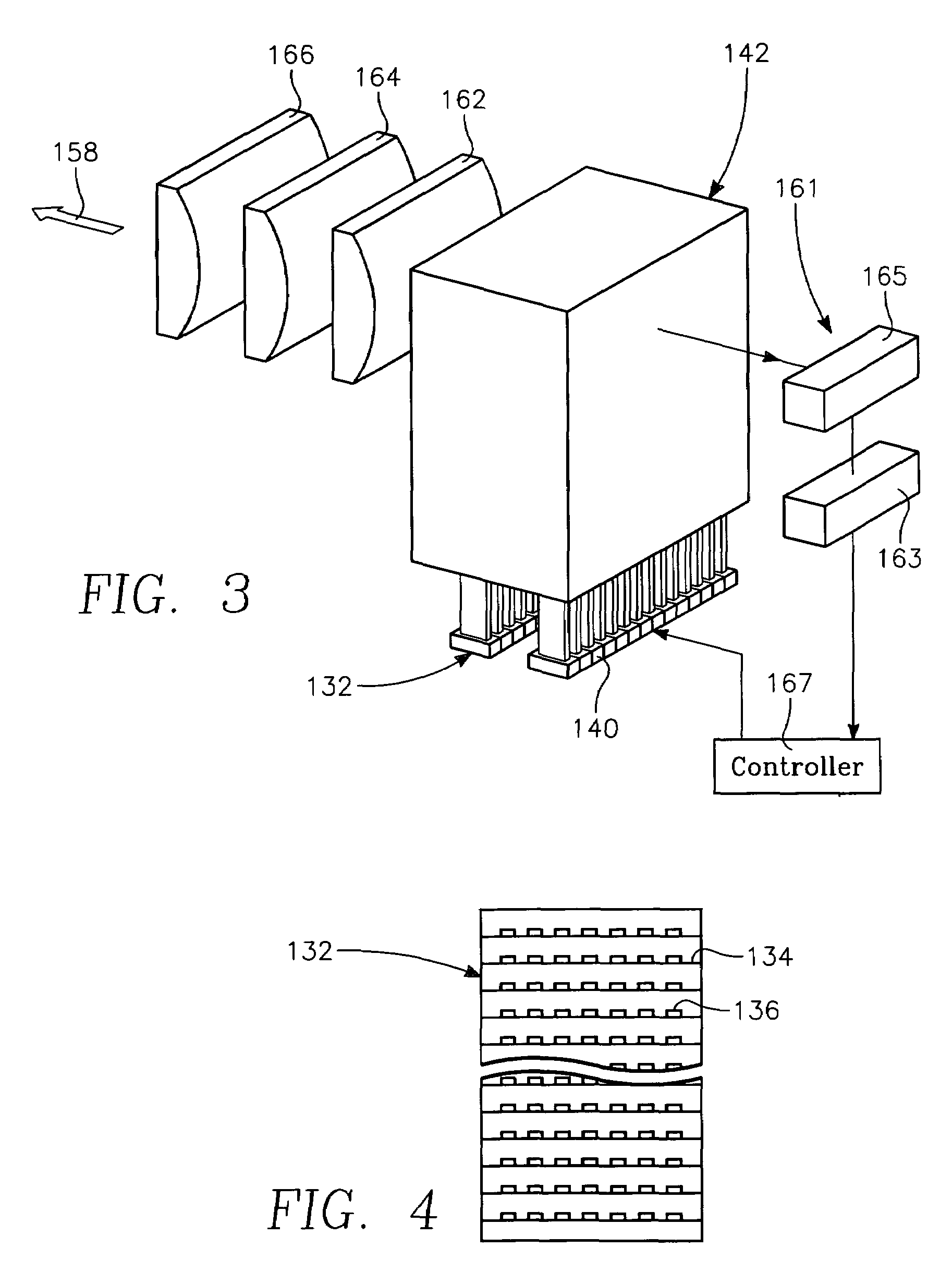

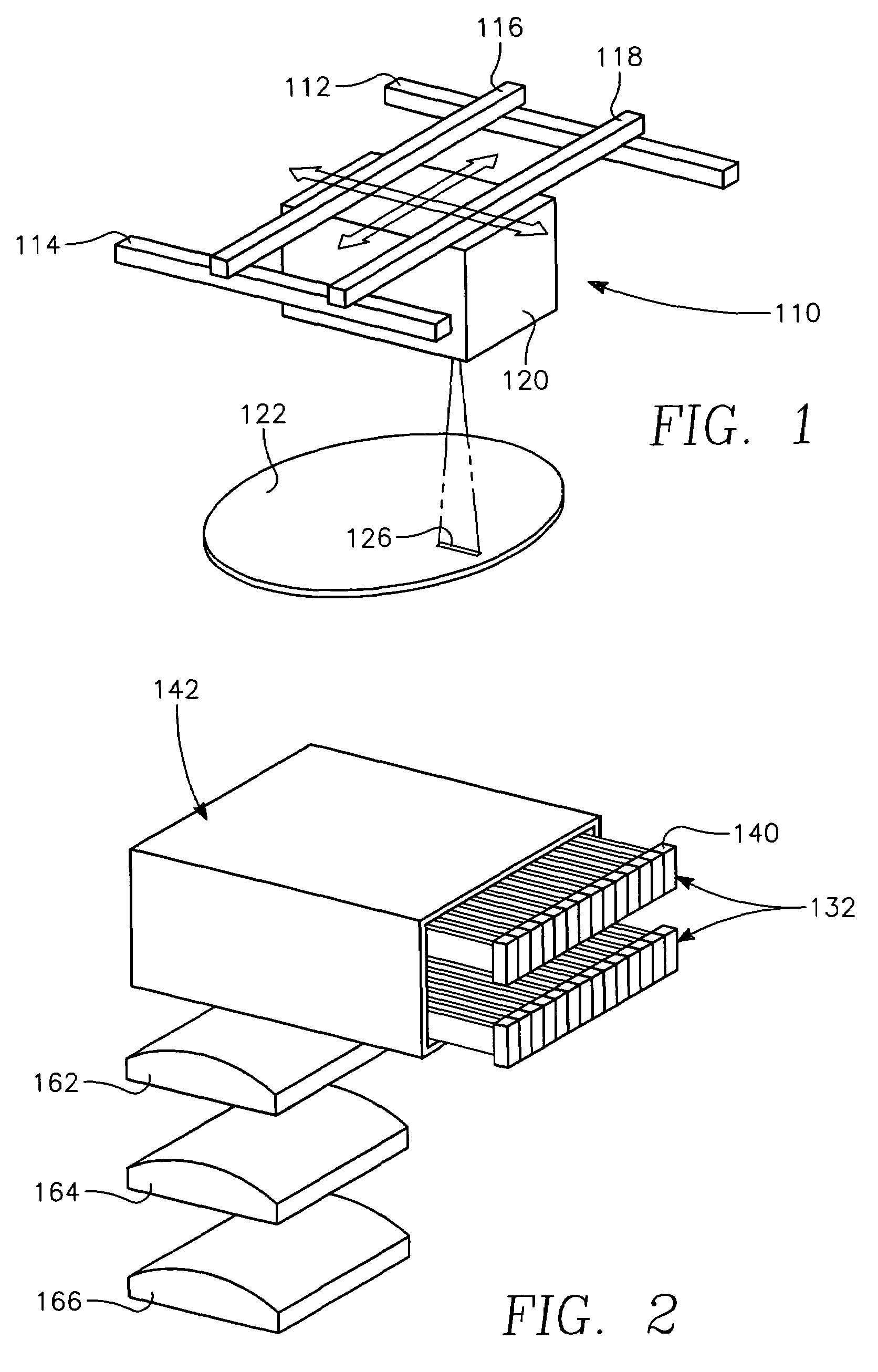

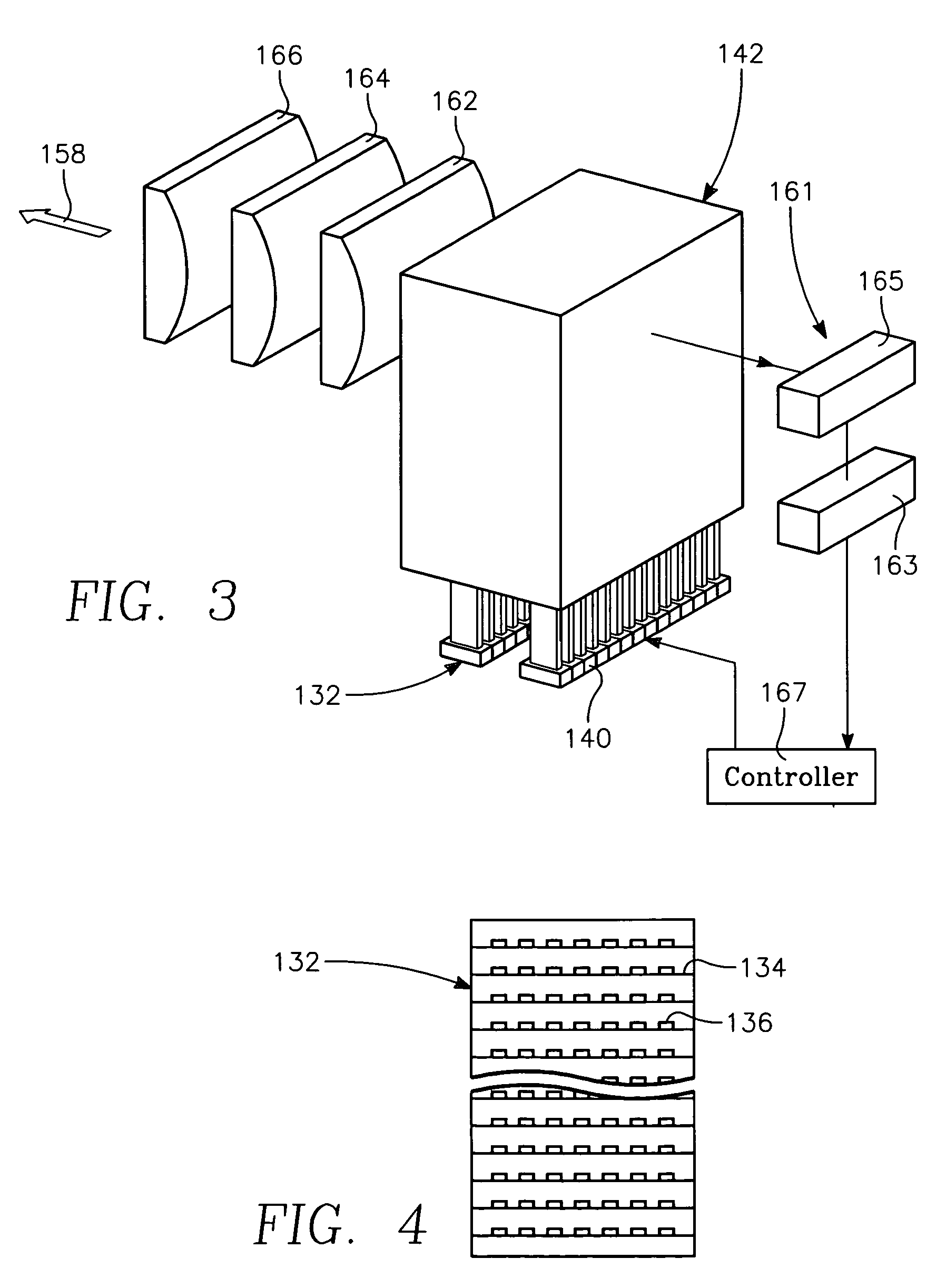

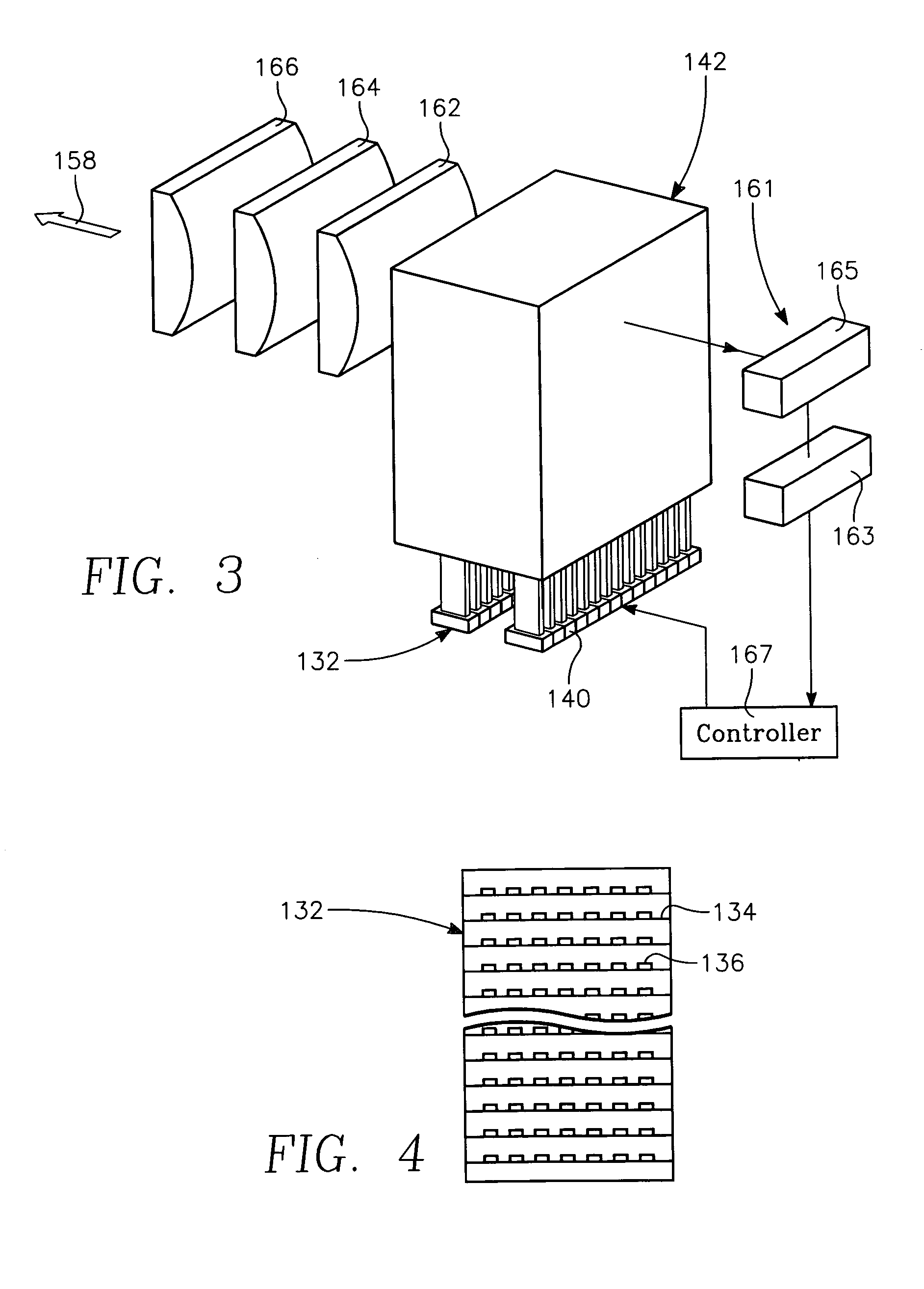

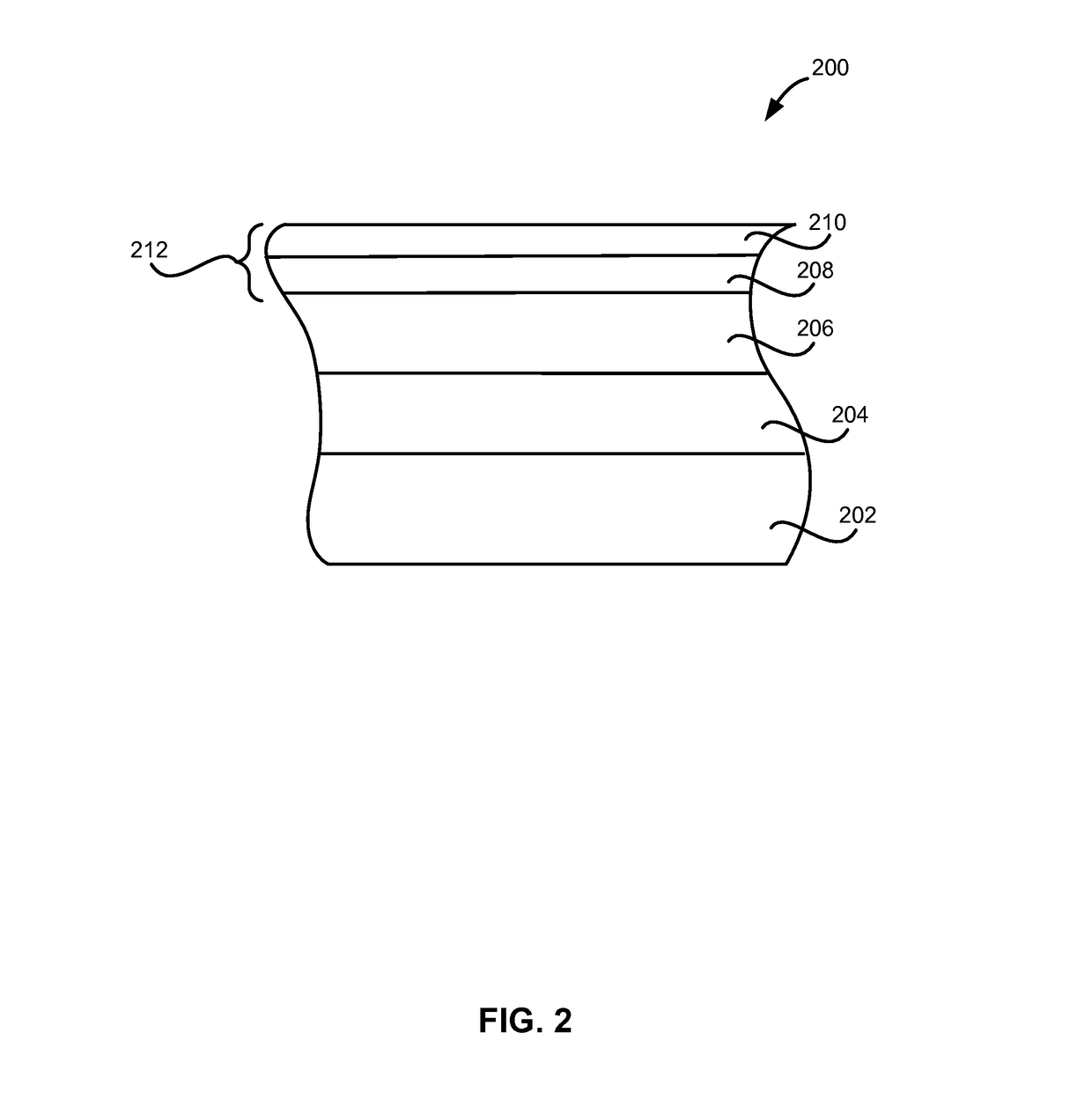

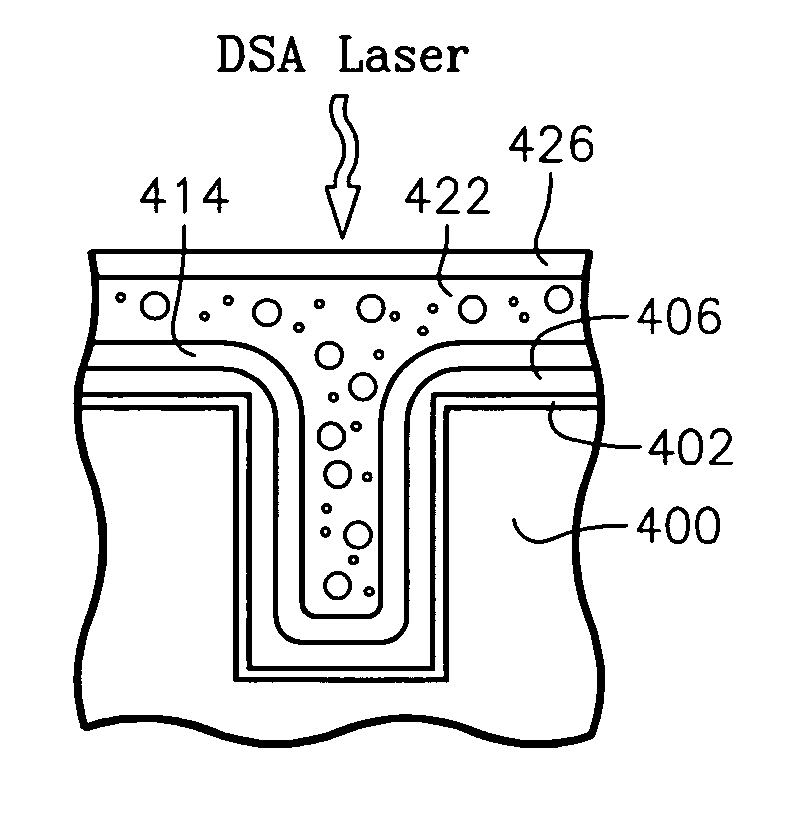

Copper conductor annealing process employing high speed optical annealing with a low temperature-deposited optical absorber layer

InactiveUS7335611B2Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesCopper conductorLow temperature deposition

A method of forming a conductor in a thin film structure on a semiconductor substrate includes forming high aspect ratio openings in a base layer having vertical side walls, depositing a dielectric barrier layer comprising a dielectric compound of a barrier metal on the surfaces of the high aspect ratio openings including the vertical side walls, depositing a metal barrier layer comprising the barrier metal on the first barrier layer, depositing a main conductor species seed layer on the metal barrier layer and depositing a main conductor layer. The method further includes annealing the main conductor layer by (a) directing light from an array of continuous wave lasers into a line of light extending at least partially across the thin film structure, and (b) translating the line of light relative to the thin film structure in a direction transverse to the line of light. The method of Claim 1 further comprising, prior to the annealing step, depositing an amorphous carbon optical absorber layer on the main conductor layer. The step of depositing an amorphous carbon optical absorber layer includes introducing a carbon-containing process gas into a reactor chamber containing the substrate in a process zone of the reactor, applying RF source power to an external reentrant conduit of the reactor to generate a reentrant toroidal RF plasma current passing through the process zone and applying a bias voltage to the substrate.

Owner:APPLIED MATERIALS INC

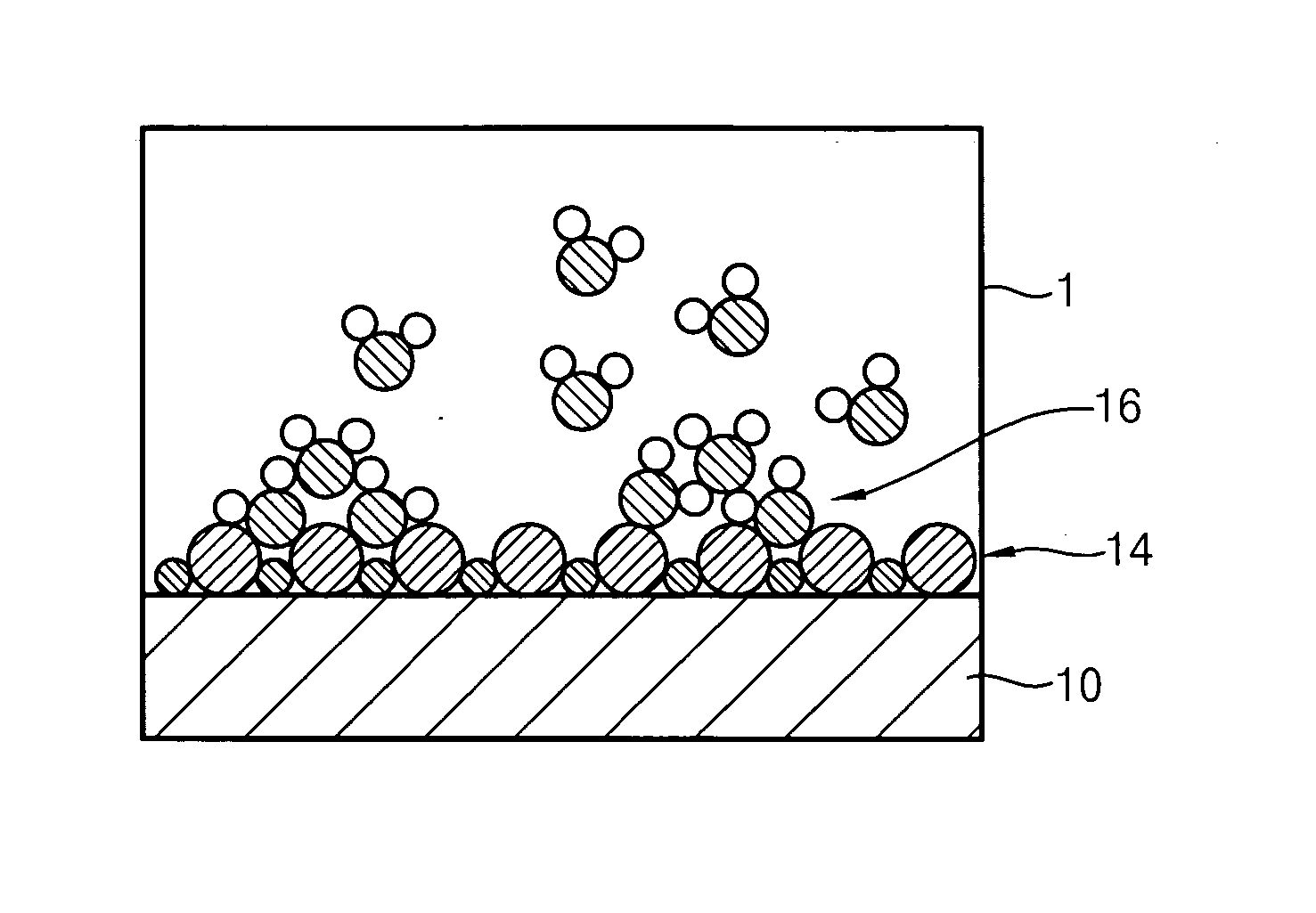

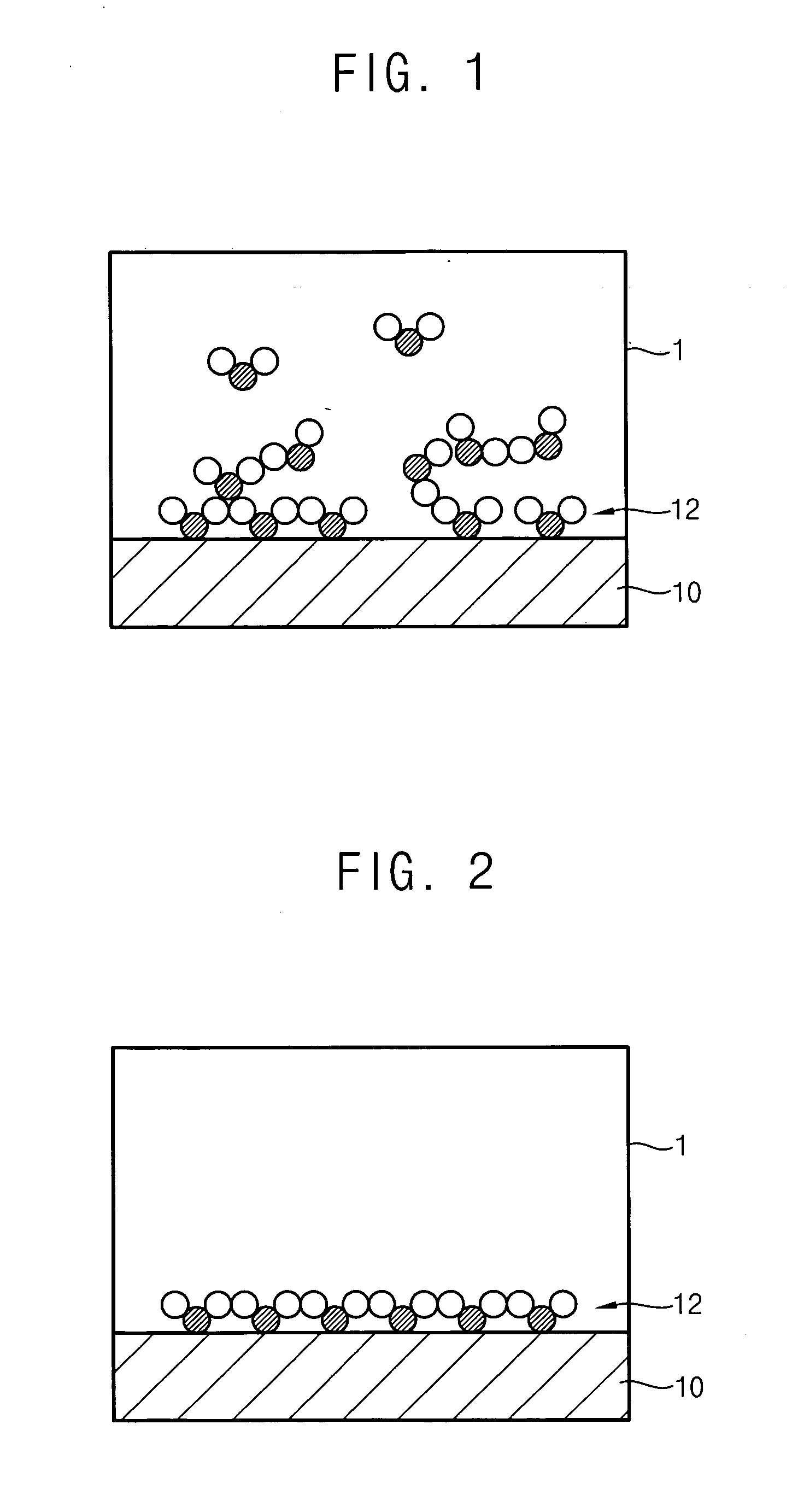

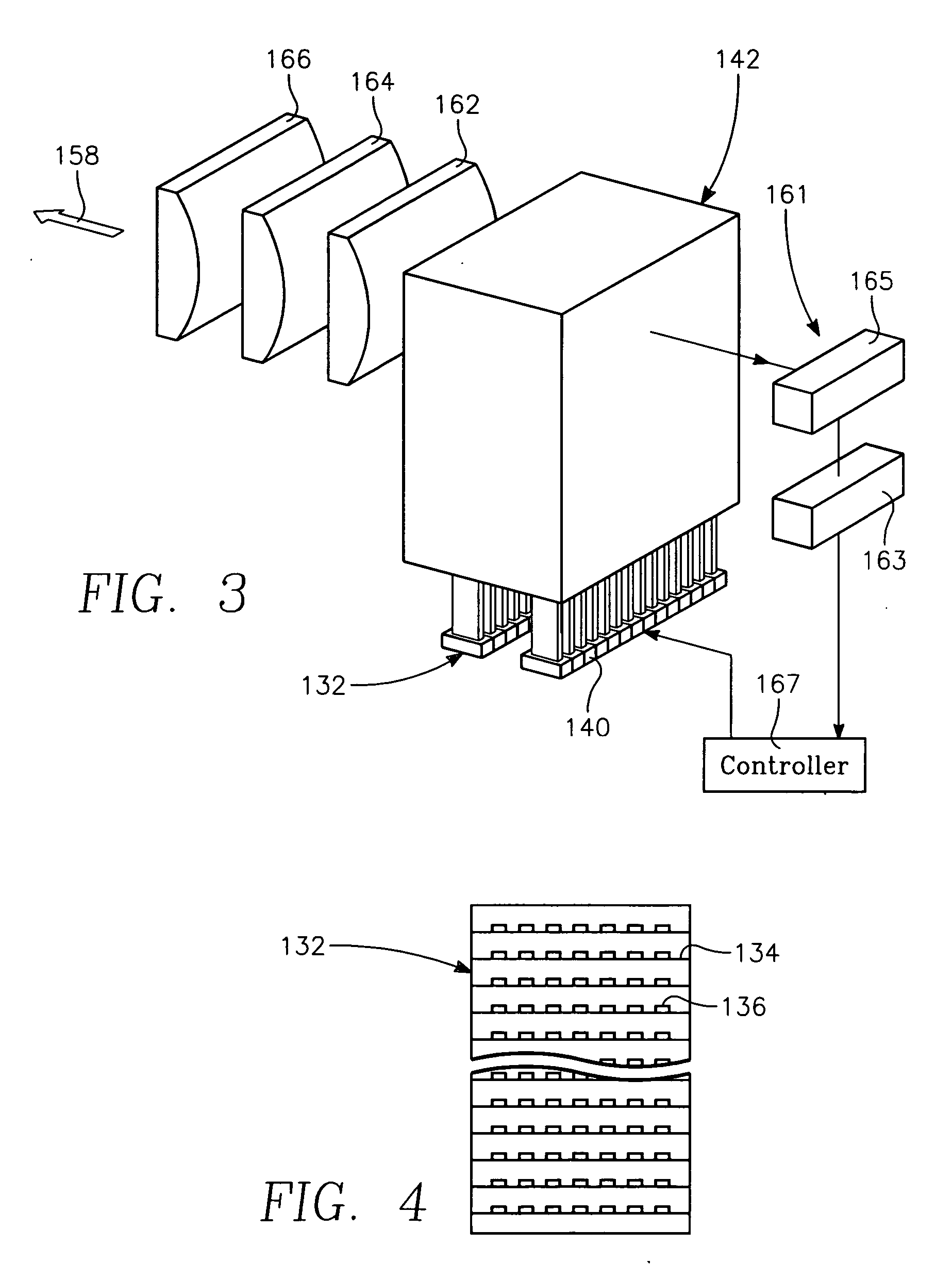

Methods of forming a thin film structure, and a gate structure and a capacitor including the thin film structure

InactiveUS20060013946A1Well formedHigh dielectric constantSemiconductor/solid-state device manufacturingSpecial surfacesChemical reactionSilicon oxide

A thin film structure is formed that includes hafnium silicon oxide using an atomic layer deposition process. A first reactant including tetrakis ethyl methyl amino hafnium (TEMAH) is introduced onto a substrate. A first portion of the first reactant is chemisorbed to the substrate, whereas a second portion of the first reactant is physorbed to the first portion of the first reactant. A first oxidant is provided onto the substrate. A first thin film including hafnium oxide is formed on the substrate by chemically reacting the first oxidant with the first portion of the first reactant. A second reactant including amino propyl tri ethoxy silane (APTES) is introduced onto the first thin film. A first portion of the second reactant is chemisorbed to the first thin film, whereas a second portion of the second reactant is physorbed to the first portion of the second reactant. A second oxidant is provided onto the first thin film. A second thin film including silicon oxide is formed on the first thin film by chemically reacting the second oxidant with the first portion of the second reactant.

Owner:SAMSUNG ELECTRONICS CO LTD

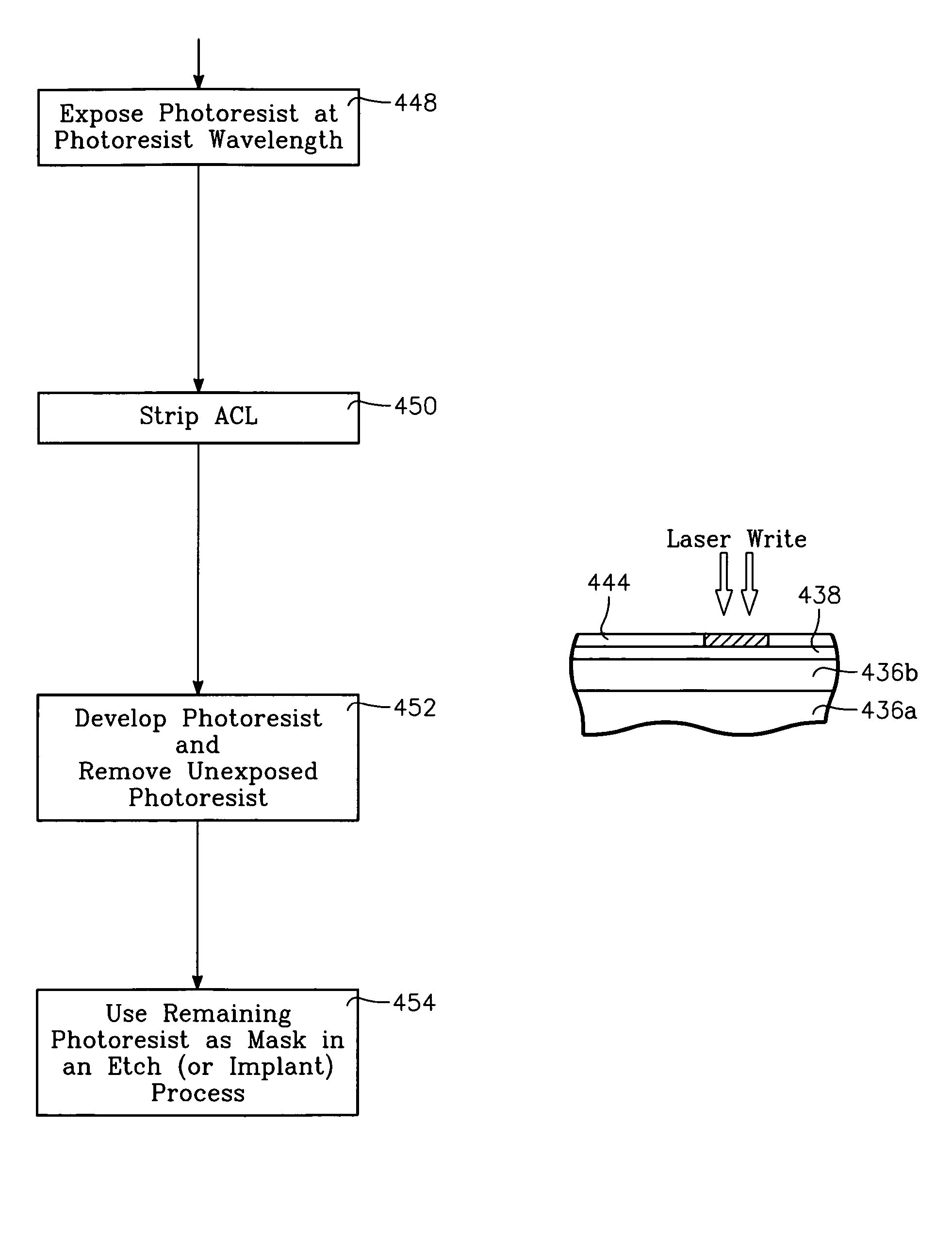

Semiconductor substrate process using an optically writable carbon-containing mask

ActiveUS7429532B2Photomechanical apparatusSemiconductor/solid-state device manufacturingPlasma currentCoupling

A method of processing a thin film structure on a semiconductor substrate using an optically writable mask, the method includes placing the substrate in a reactor chamber, the substrate having on its surface a target layer to be exposed to a light source in accordance with a predetermined pattern, depositing an optically writable carbon-containing mask layer on the substrate by (a) introducing a carbon-containing process gas into the chamber, (b) generating a reentrant toroidal RF plasma current in a reentrant path that includes a process zone overlying the workpiece by coupling plasma RF source power to an external portion of the reentrant path, (c) coupling RF plasma bias power or bias voltage to the workpiece. The method further includes optically writing on the carbon-containing mask layer in accordance with the predetermined pattern with writing light of a characteristic suitable for transforming the transparency or opacity of the optically writable mask layer and exposing through the mask layer the target layer with reading light of a characteristic different from that of the writing light.

Owner:APPLIED MATERIALS INC

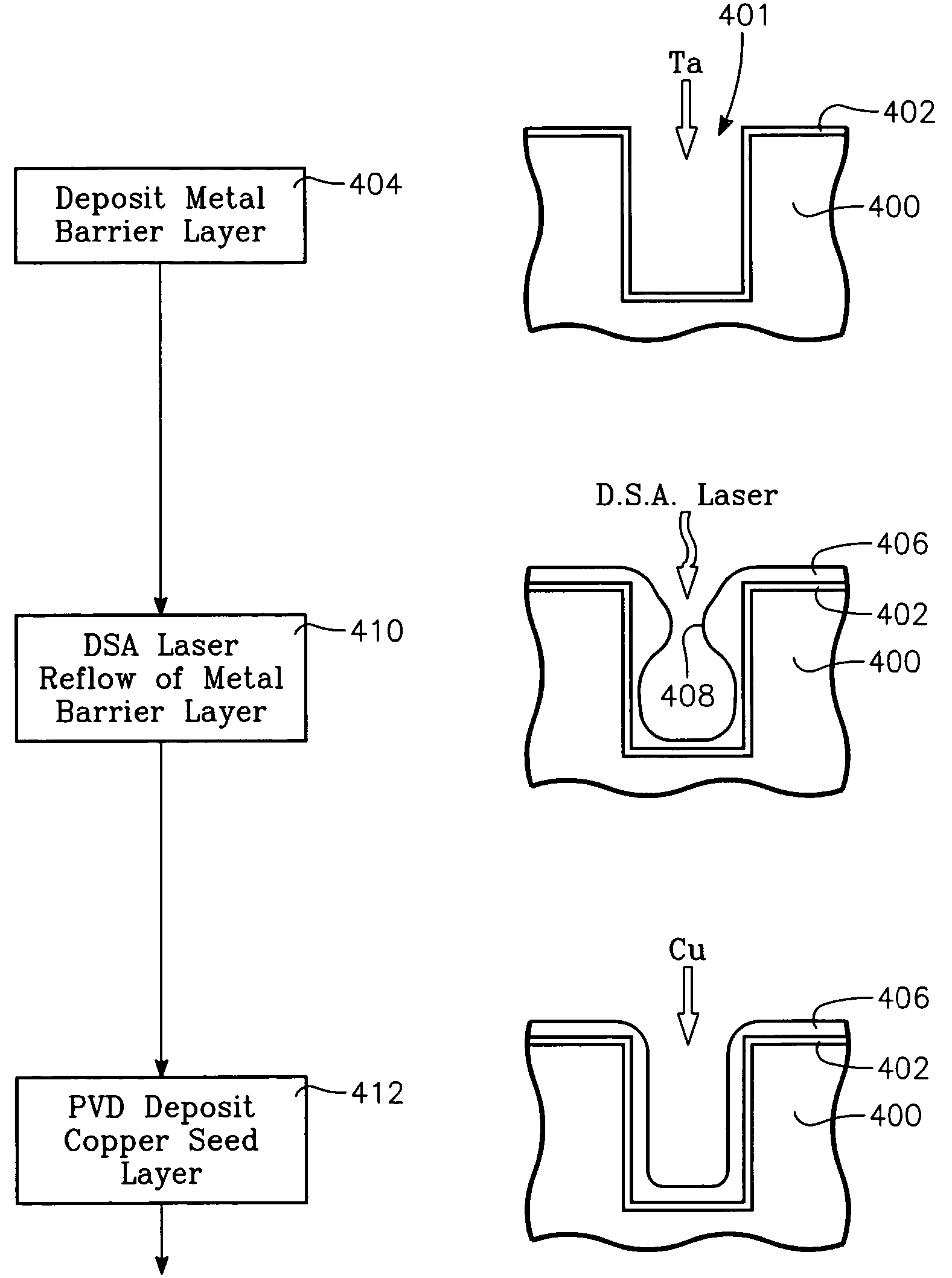

Copper barrier reflow process employing high speed optical annealing

A method of forming a barrier layer for a thin film structure on a semiconductor substrate includes forming high aspect ratio openings in a base layer having vertical side walls, depositing a dielectric barrier layer comprising a dielectric compound of a barrier metal on the surfaces of the high aspect ratio openings including the vertical side walls and depositing a metal barrier layer comprising the barrier metal on the first barrier layer. The method further includes reflowing the metal barrier layer by (a) directing light from an array of continuous wave lasers into a line of light extending at least partially across the thin film structure, and (b) translating the line of light relative to the thin film structure in a direction transverse to the line of light.

Owner:APPLIED MATERIALS INC

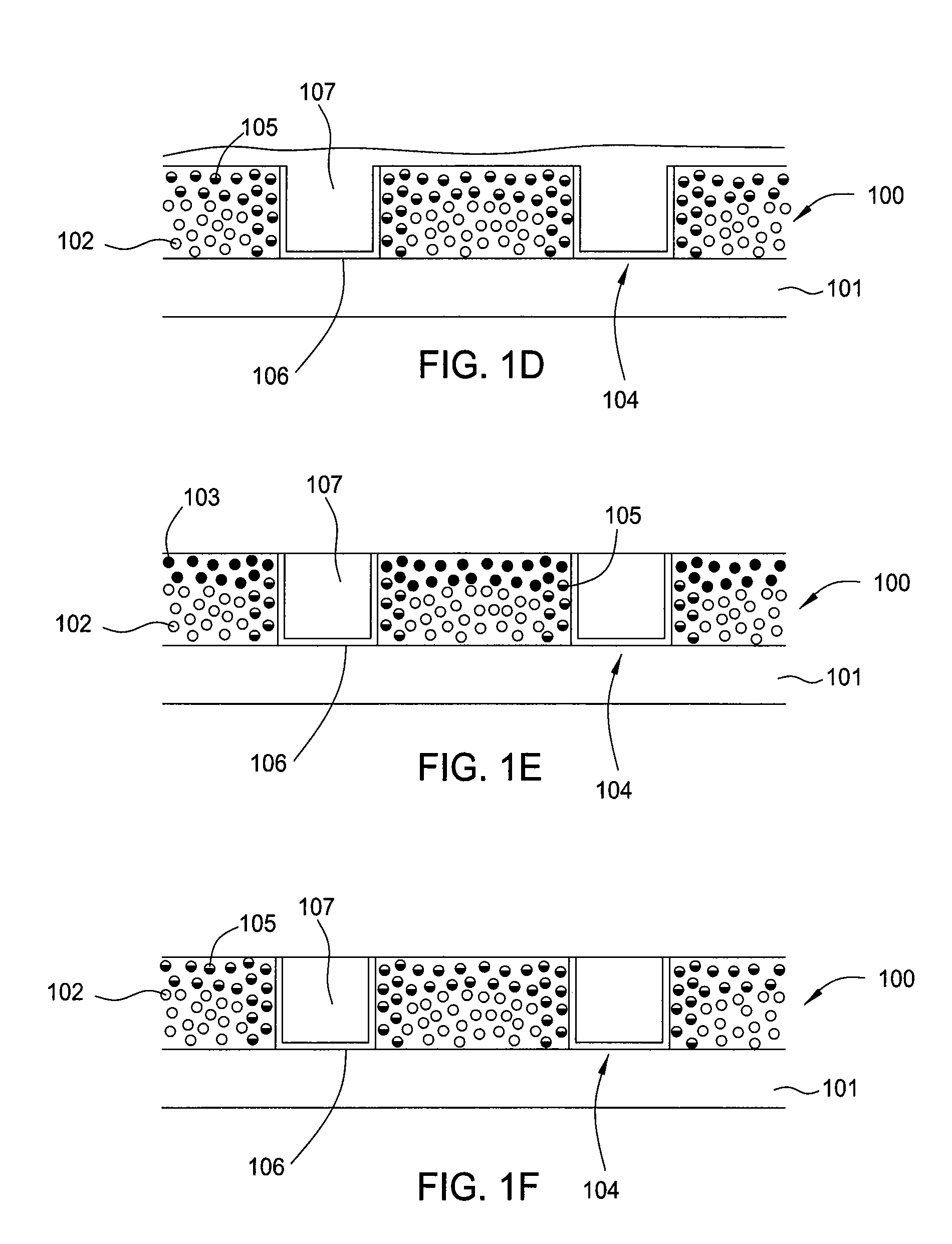

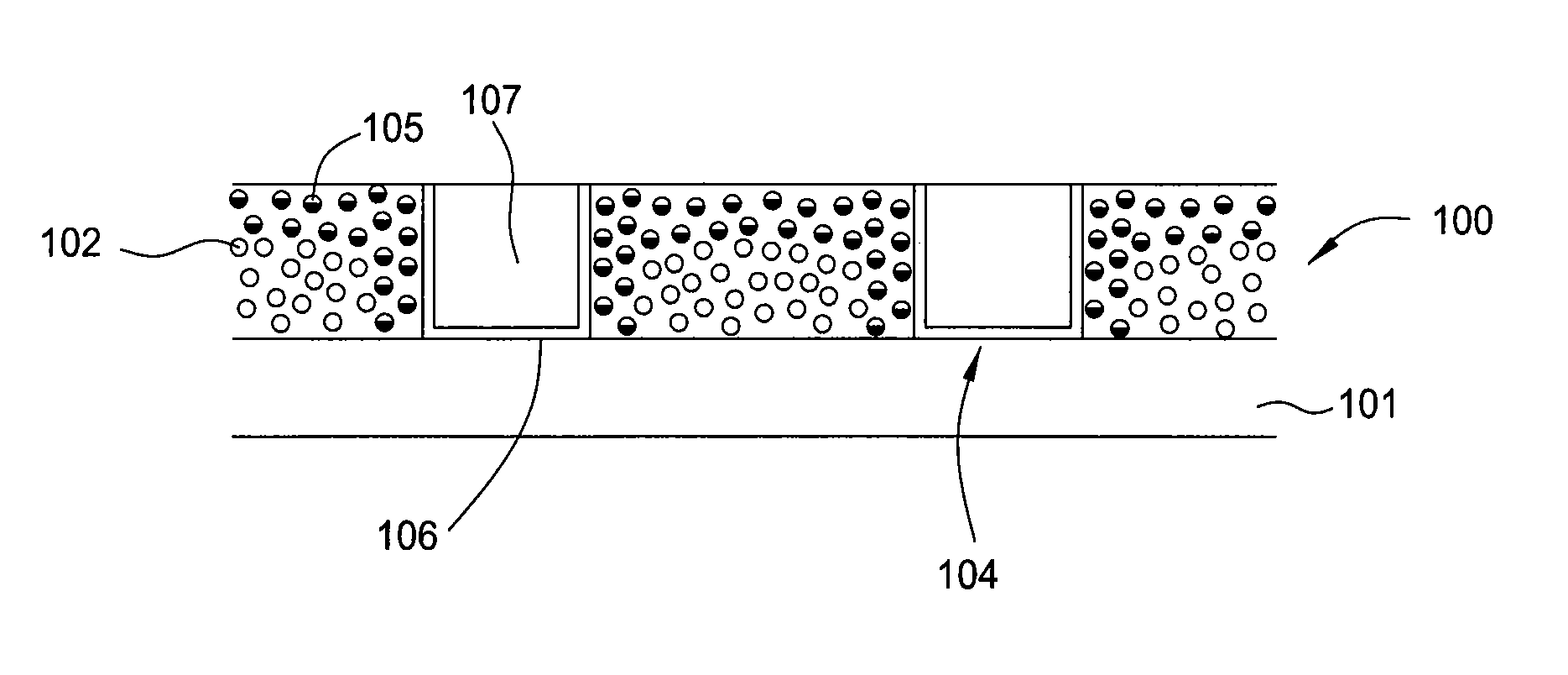

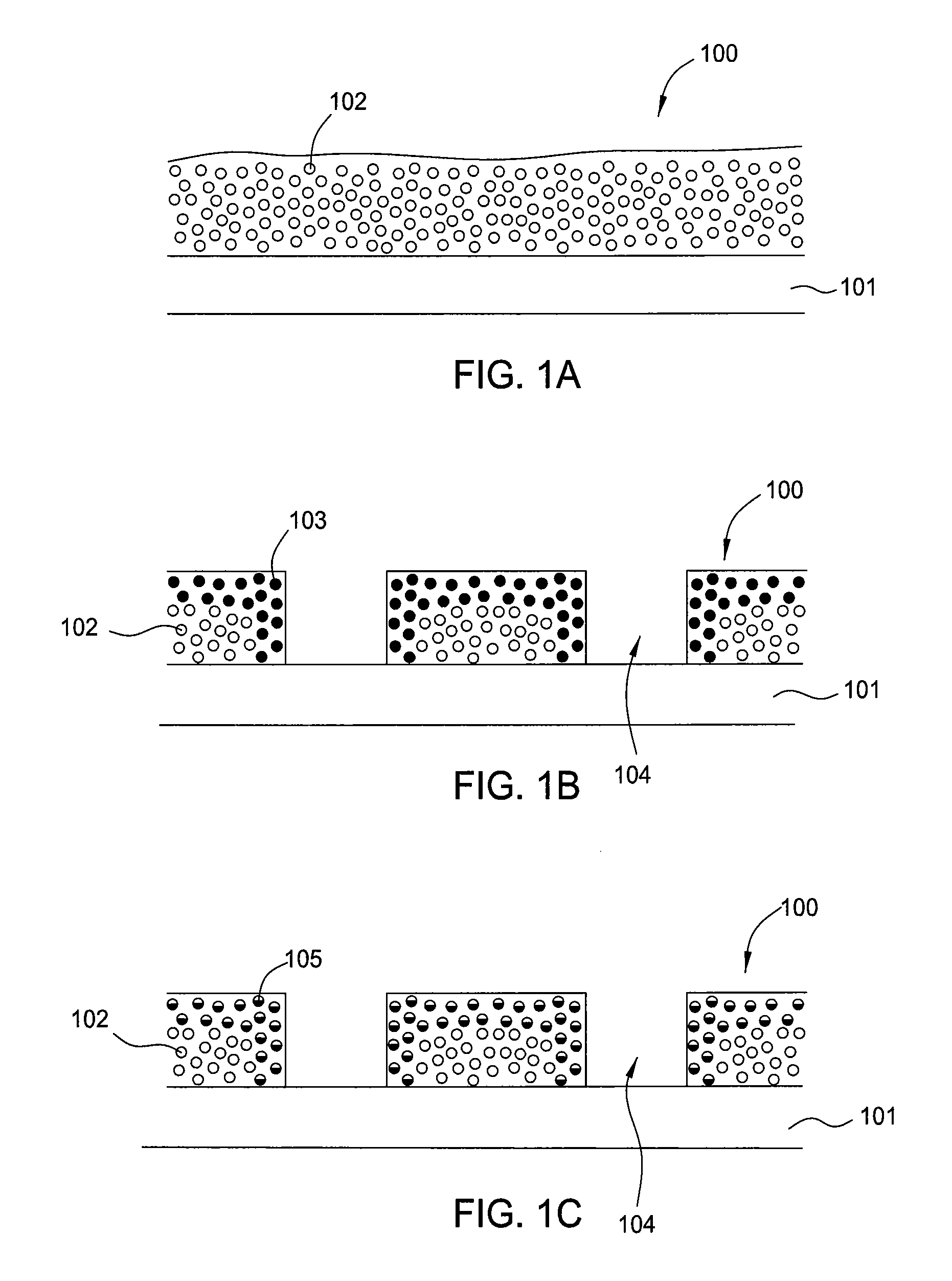

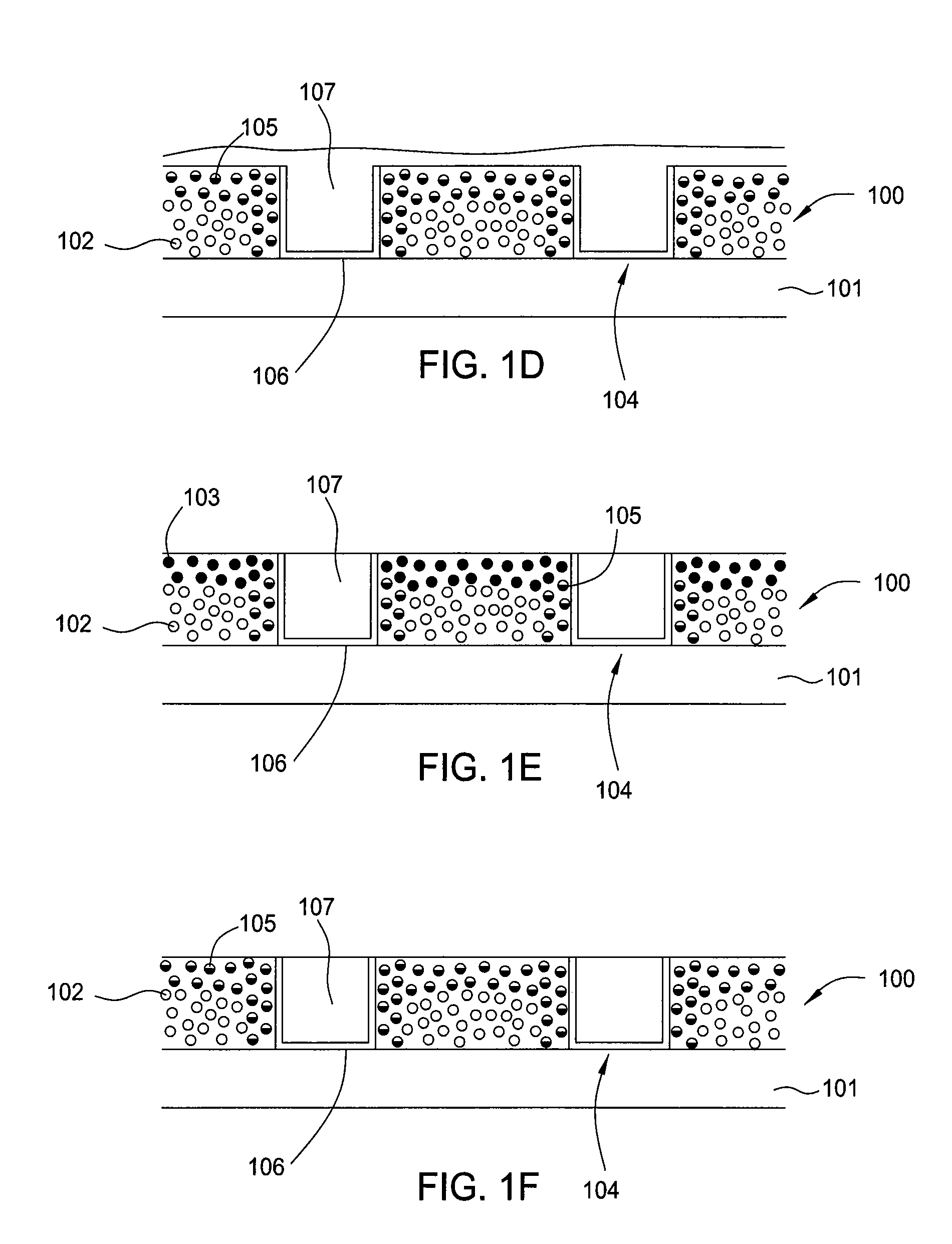

UV assisted silylation for recovery and pore sealing of damaged low K films

Methods for the repair of damaged low k films are provided. Damage to the low k films occurs during processing of the film such as during etching, ashing, and planarization. The processing of the low k film causes water to store in the pores of the film and further causes hydrophilic compounds to form in the low k film structure. Repair processes incorporating ultraviolet (UV) radiation and silylation compounds remove the water from the pores and further remove the hydrophilic compounds from the low k film structure.

Owner:APPLIED MATERIALS INC

UV assisted silylation for recovery and pore sealing of damaged low k films

ActiveUS20120270339A1Dielectric constant be lowerSemiconductor/solid-state device manufacturingUltravioletSilylation

Methods for the repair of damaged low k films are provided. Damage to the low k films occurs during processing of the film such as during etching, ashing, and planarization. The processing of the low k film causes water to store in the pores of the film and further causes hydrophilic compounds to form in the low k film structure. Repair processes incorporating ultraviolet (UV) radiation and silylation compounds remove the water from the pores and further remove the hydrophilic compounds from the low k film structure.

Owner:APPLIED MATERIALS INC

Semiconductor substrate process using an optically writable carbon-containing mask

ActiveUS20070032082A1Photomechanical apparatusSemiconductor/solid-state device manufacturingPlasma currentCoupling

A method of processing a thin film structure on a semiconductor substrate using an optically writable mask, the method includes placing the substrate in a reactor chamber, the substrate having on its surface a target layer to be exposed to a light source in accordance with a predetermined pattern, depositing an optically writable carbon-containing mask layer on the substrate by (a) introducing a carbon-containing process gas into the chamber, (b) generating a reentrant toroidal RF plasma current in a reentrant path that includes a process zone overlying the workpiece by coupling plasma RF source power to an external portion of the reentrant path, (c) coupling RF plasma bias power or bias voltage to the workpiece. The method further includes optically writing on the carbon-containing mask layer in accordance with the predetermined pattern with writing light of a characteristic suitable for transforming the transparency or opacity of the optically writable mask layer and exposing through the mask layer the target layer with reading light of a characteristic different from that of the writing light.

Owner:APPLIED MATERIALS INC

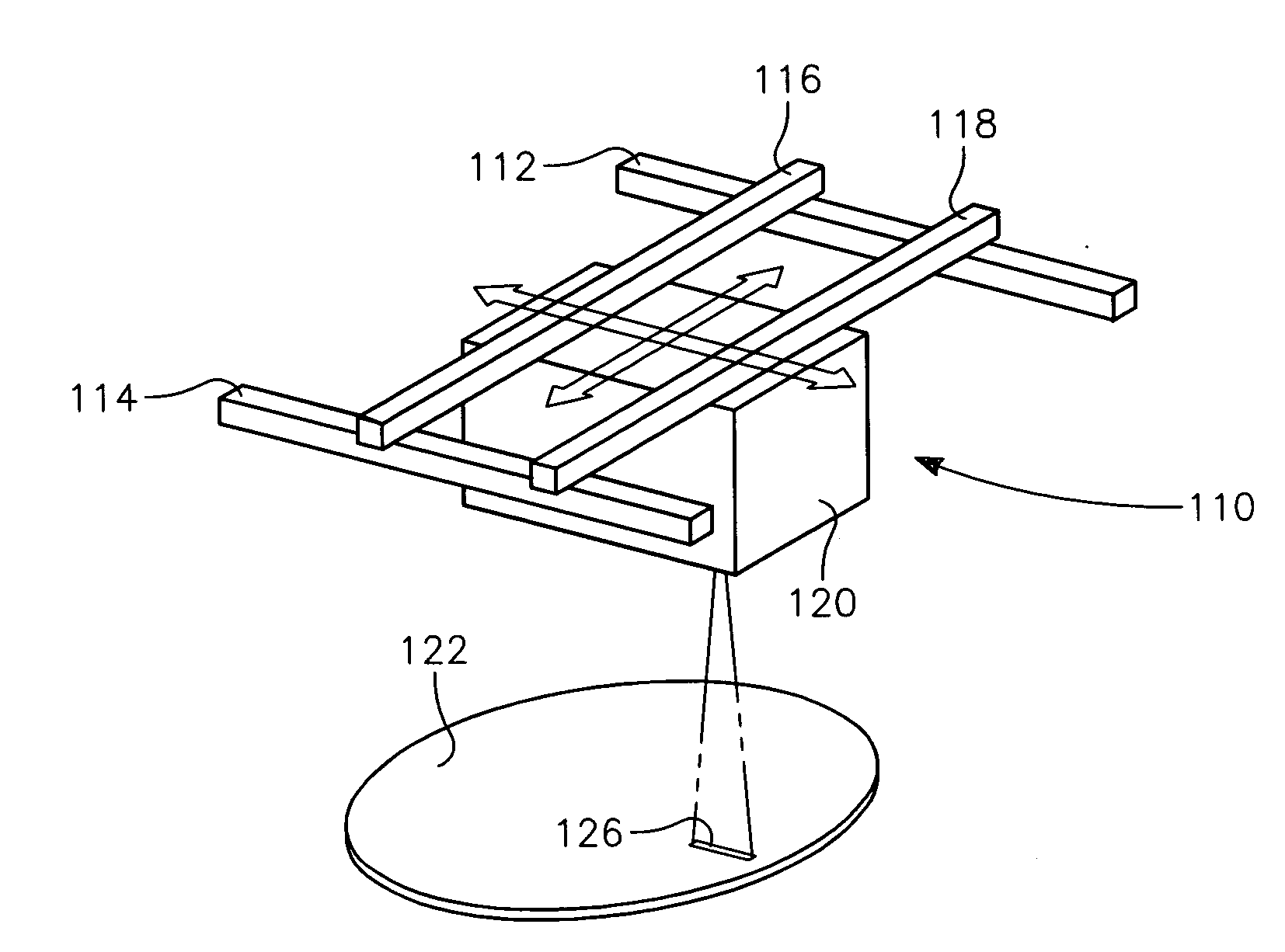

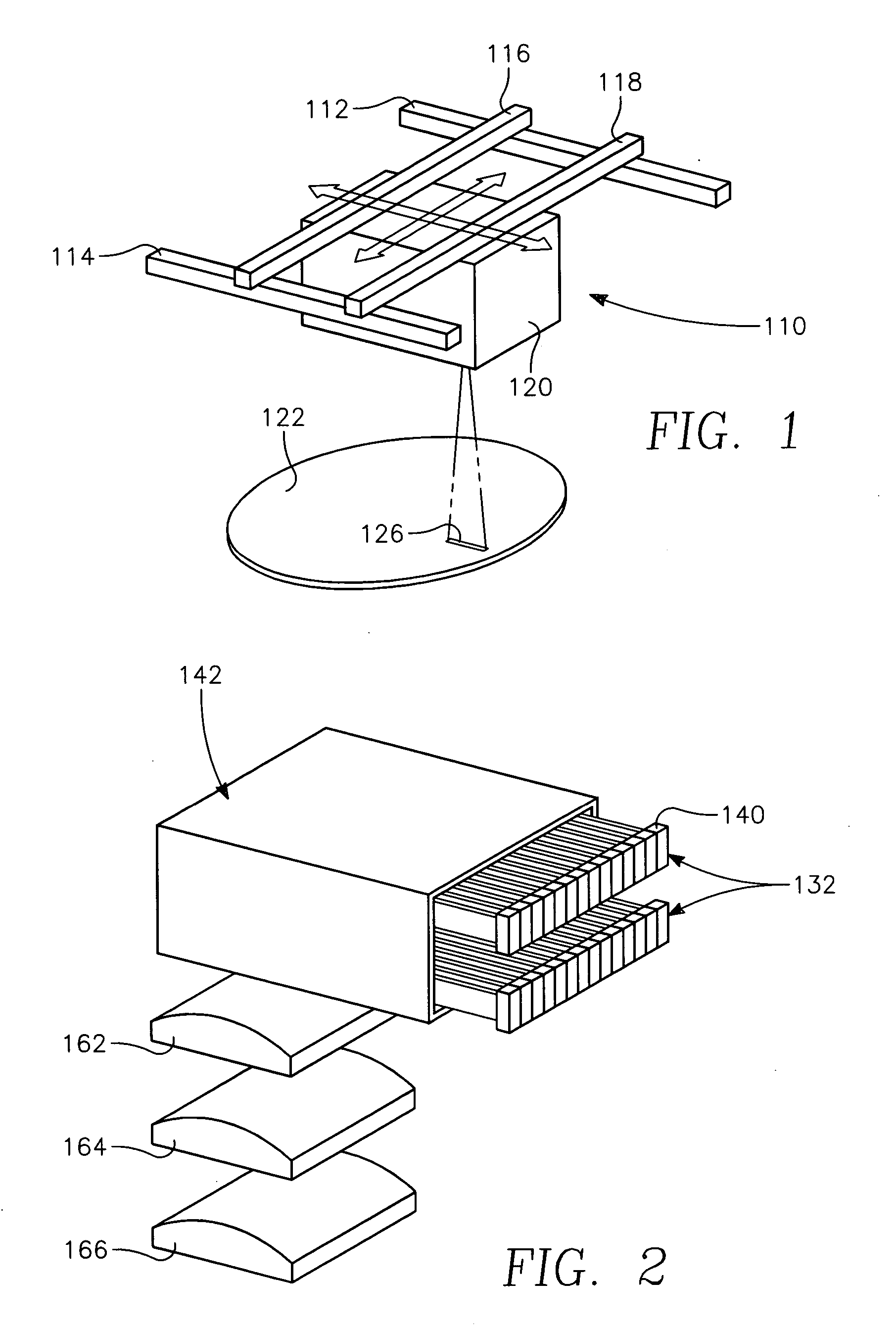

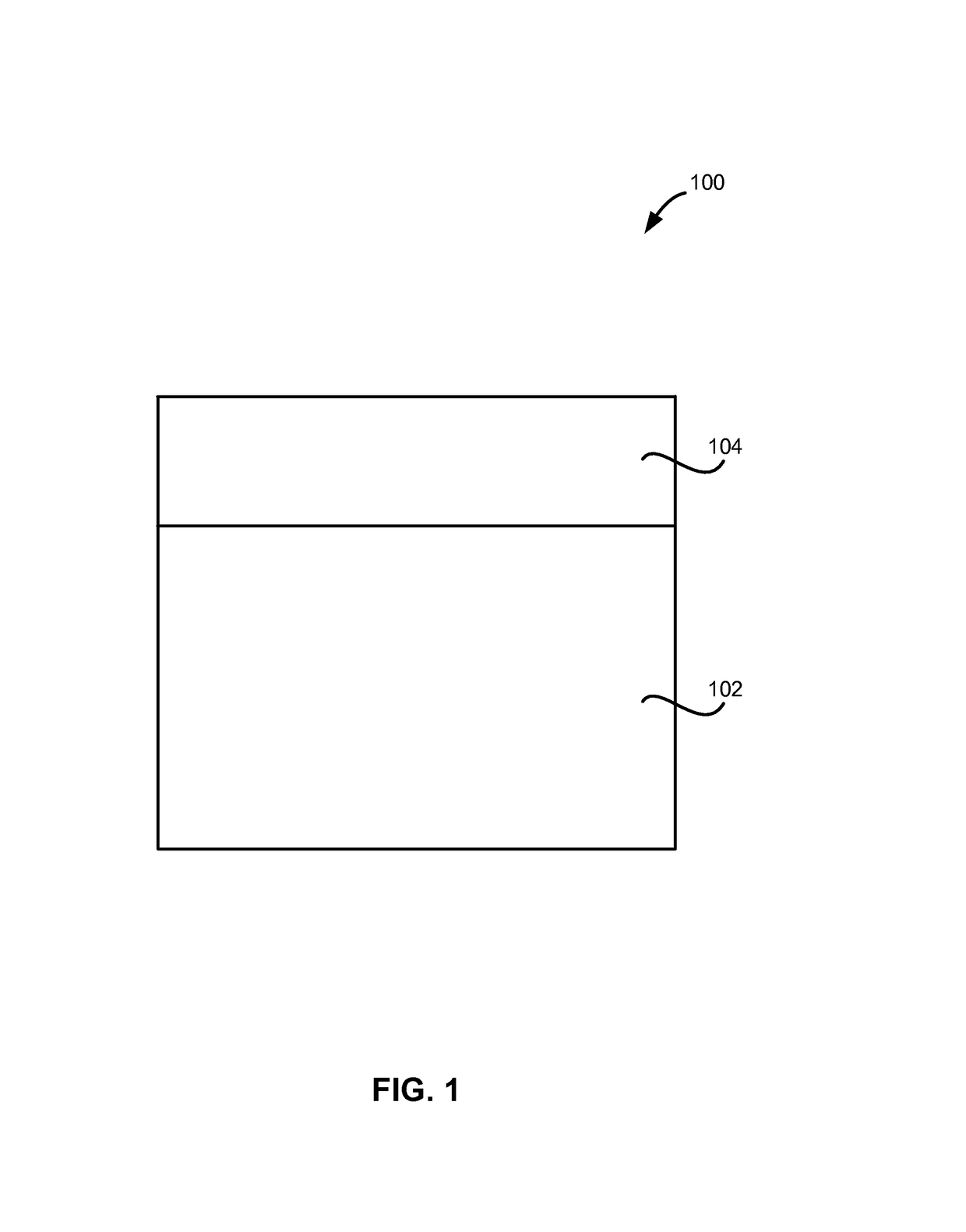

Carbon nanotube film structure and method for fabricating the same

A carbon nanotube film structure includes at least two overlapped carbon nanotube films, with adjoining films being aligned in different directions. Each carbon nanotube film includes a plurality of successive carbon nanotube bundles aligned in the same direction. The carbon nanotube structure further includes a plurality of micropores formed by / between the adjoining carbon nanotube bundles. A method for fabricating the carbon nanotube film structure includes the steps of: (a) providing an array of carbon nanotubes; (b) pulling out, using a tool, one carbon nanotube film from the array of carbon nanotubes; (c) providing a frame and adhering the carbon nanotube film to the frame; (d) repeating steps (b) and (c), depositing each successive film on a preceding film, thereby achieving at least a two-layer carbon nanotube film; and (e) peeling the carbon nanotube film off the frame to achieve the carbon nanotube structure.

Owner:TSINGHUA UNIV +1

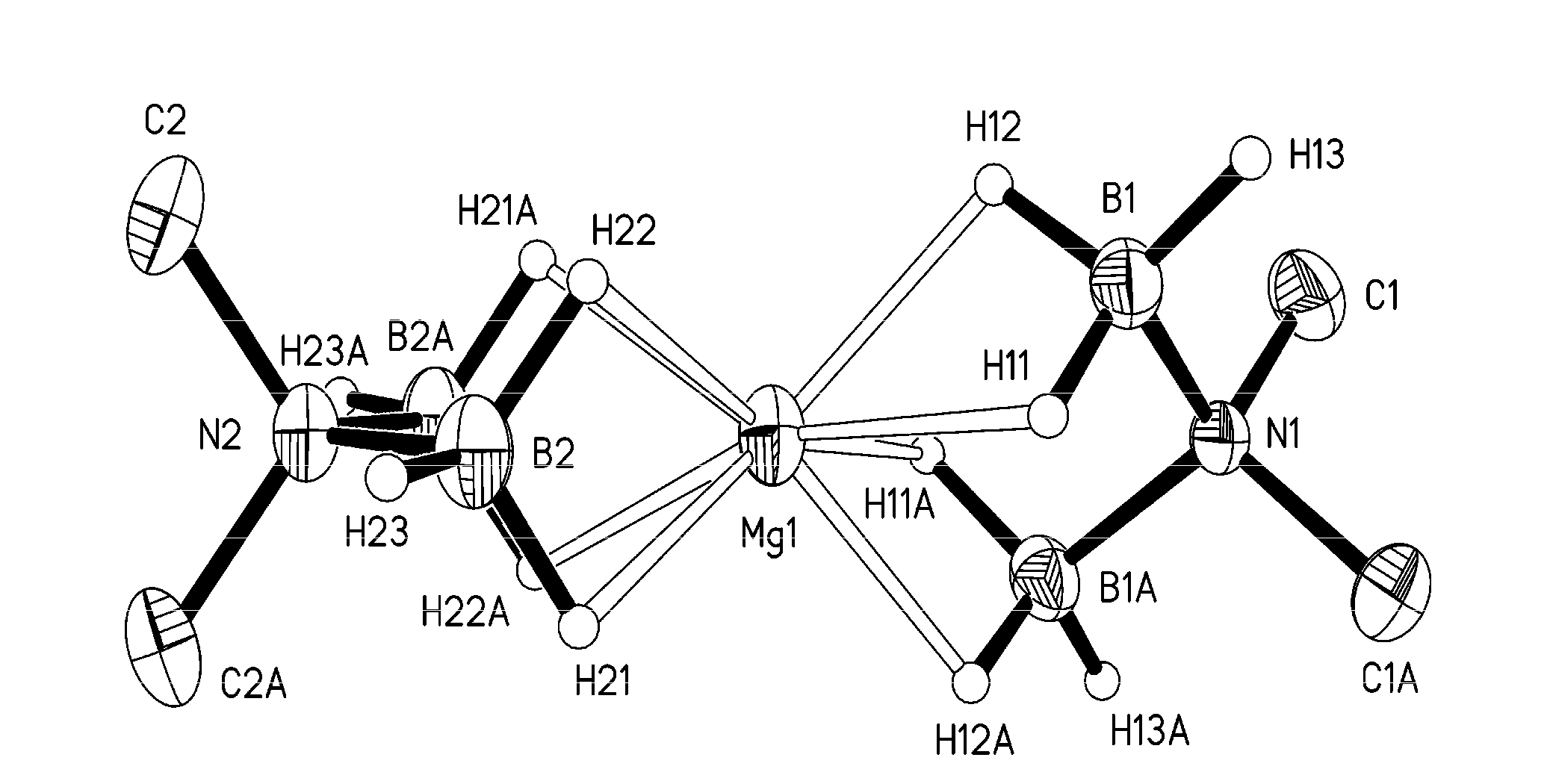

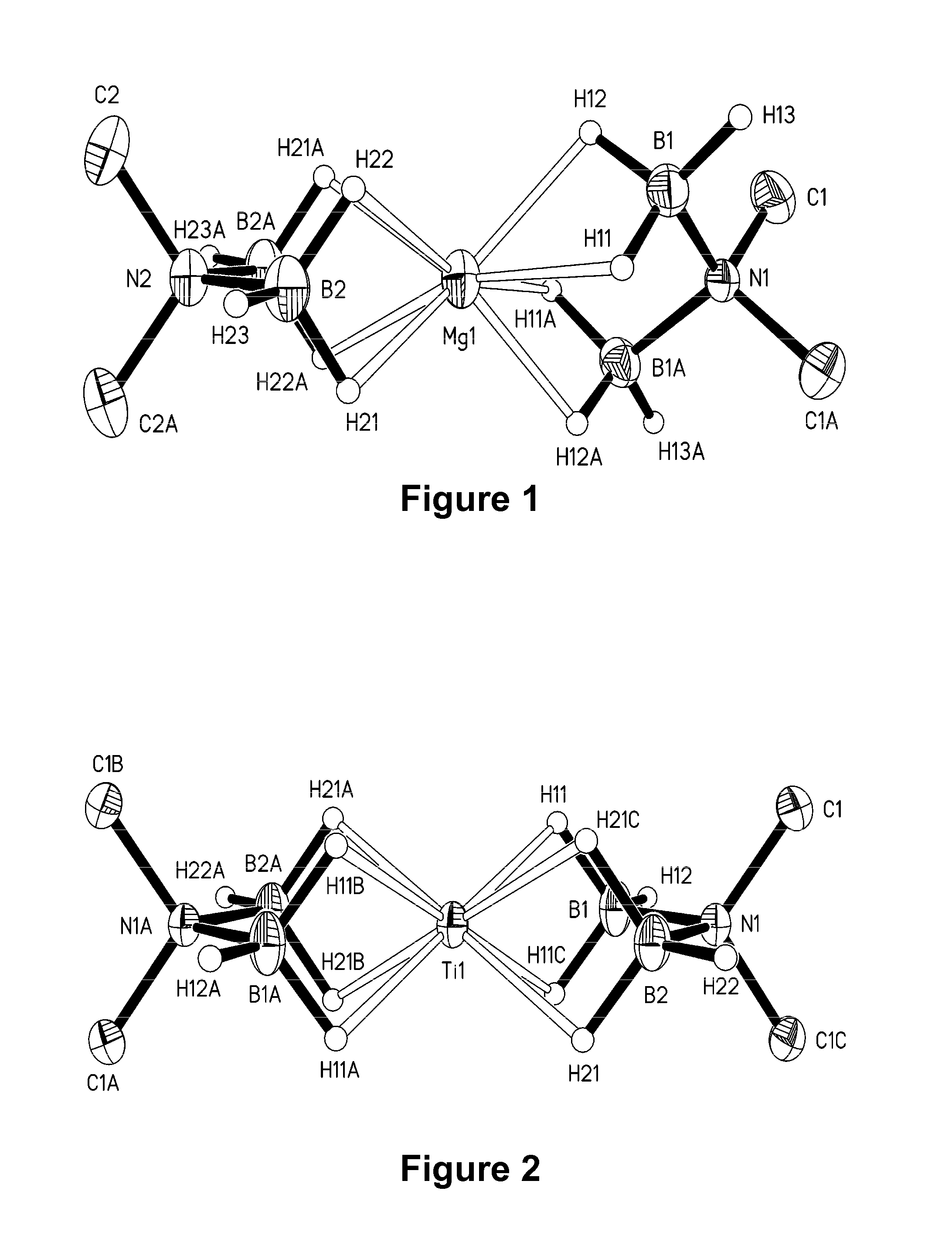

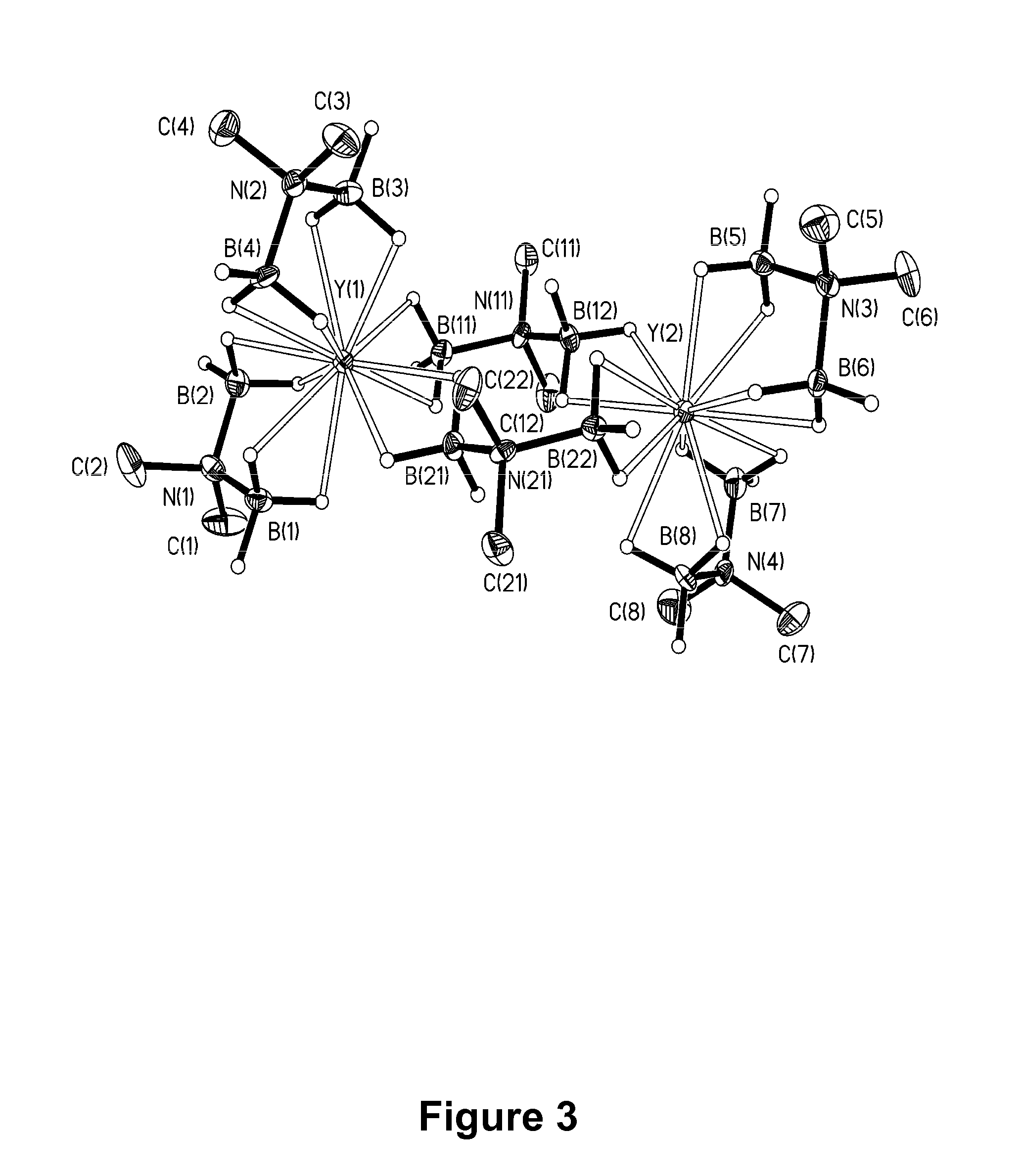

Metal Complex Compositions and Methods for Making Metal-Containing Films

ActiveUS20100168404A1Group 3/13 element organic compoundsOrganic conductorsChemical vapor depositionAtomic layer deposition

The present invention provides compositions of matter useful as deposition agents for making structures, including thin film structures and hard coatings, on substrates and features of substrates. In an embodiment, for example, the present invention provides metal complexes having one or more diboranamide or diboranaphosphide ligands that are useful as chemical vapor deposition (CVD) and / or atomic layer deposition (ALD) precusors for making thin film structures and coatings. Metal complex CVD precursors are provided that possess volitilities sufficiently high so as to provide dense, smooth and homogenous thin films and coatings.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

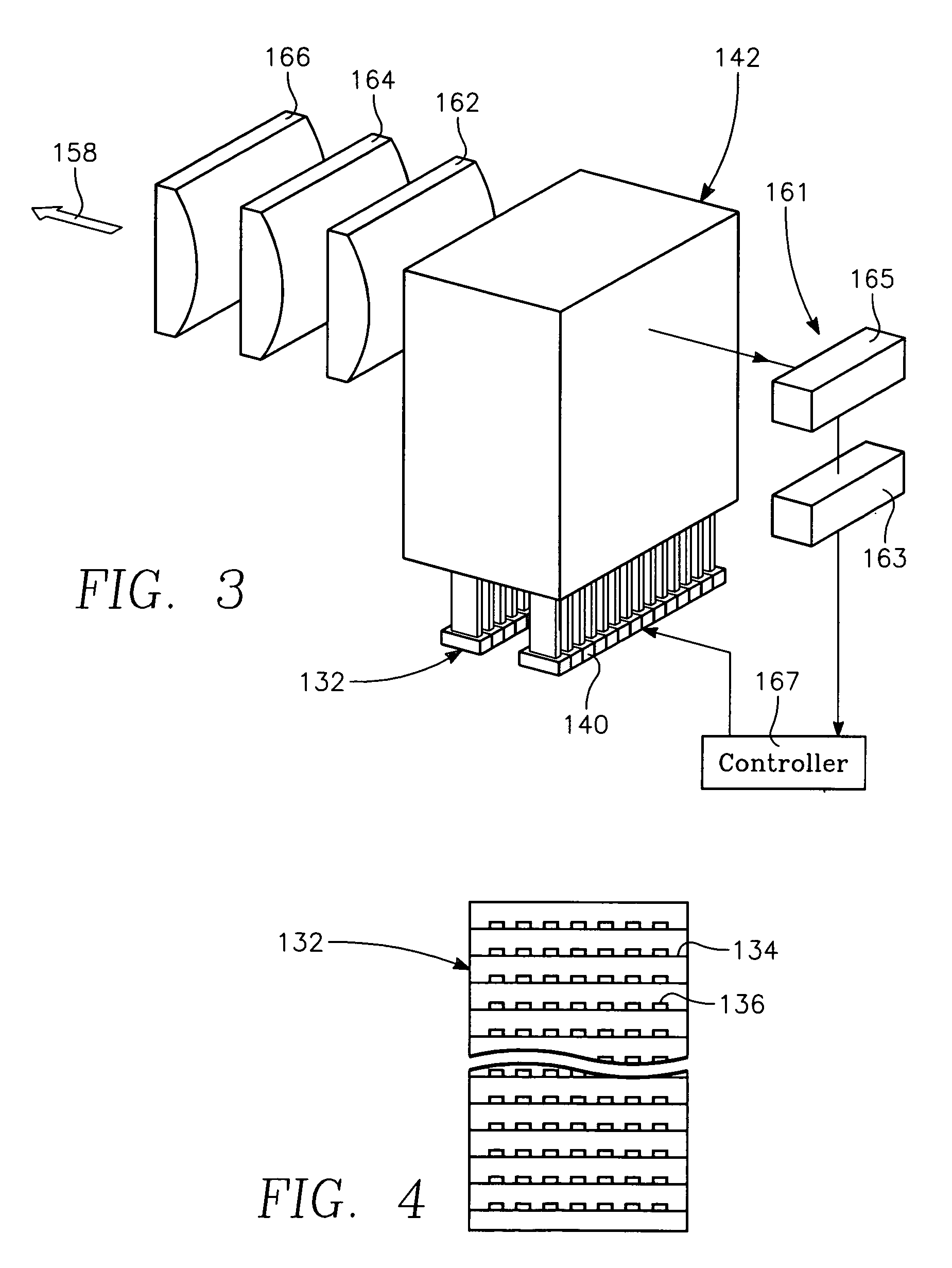

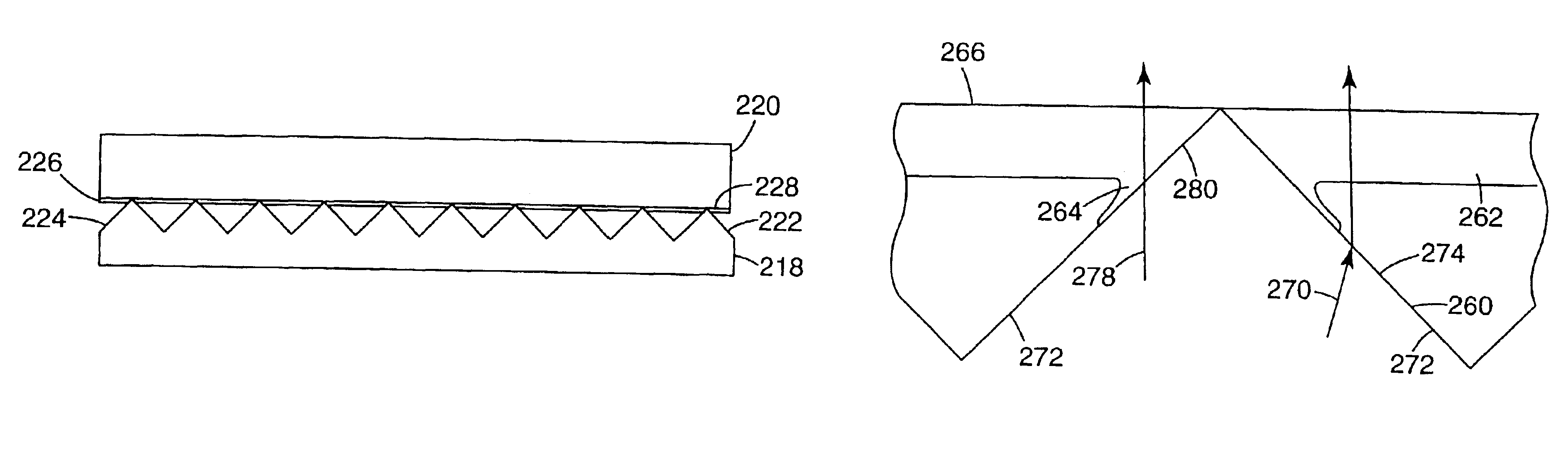

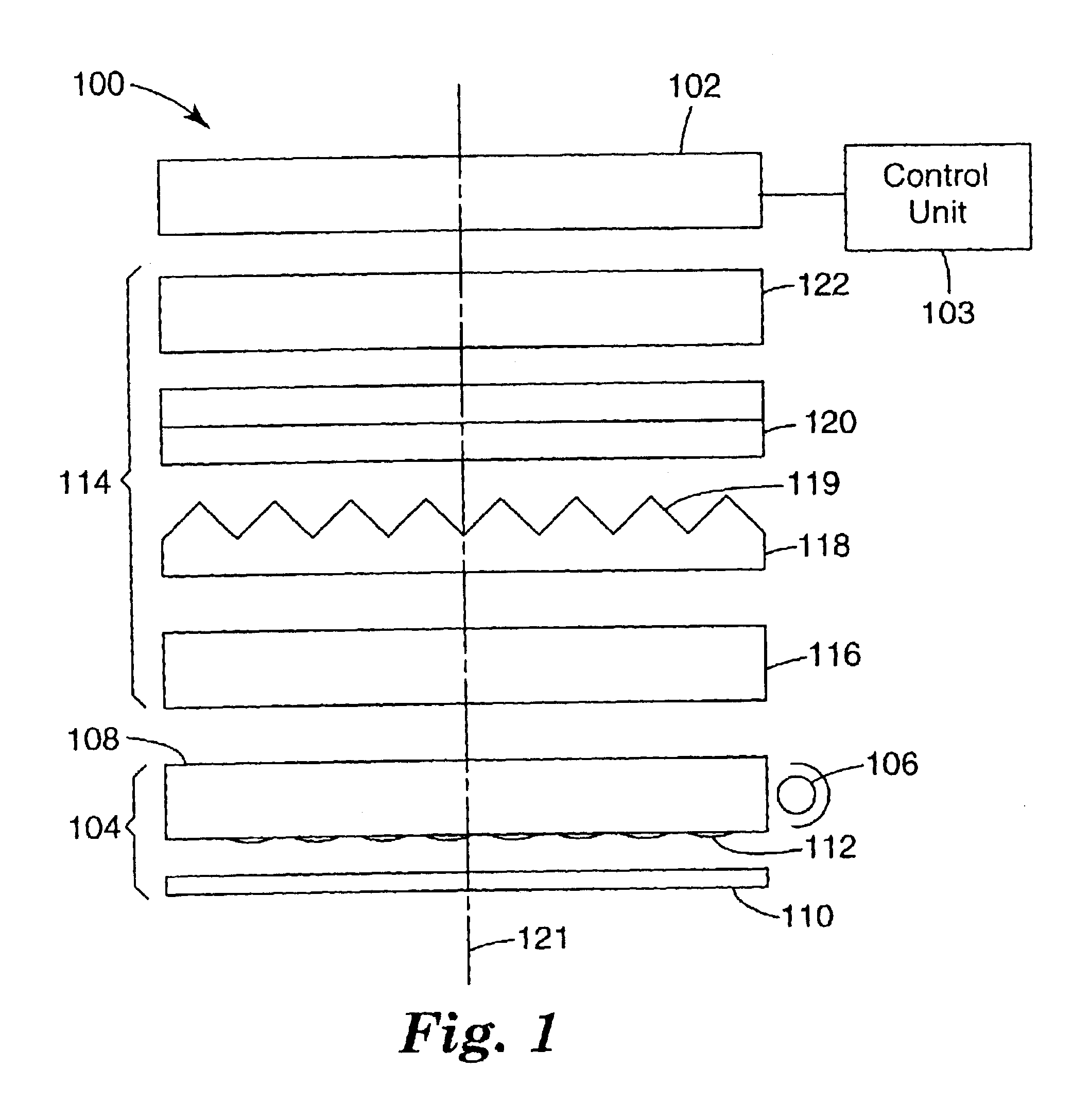

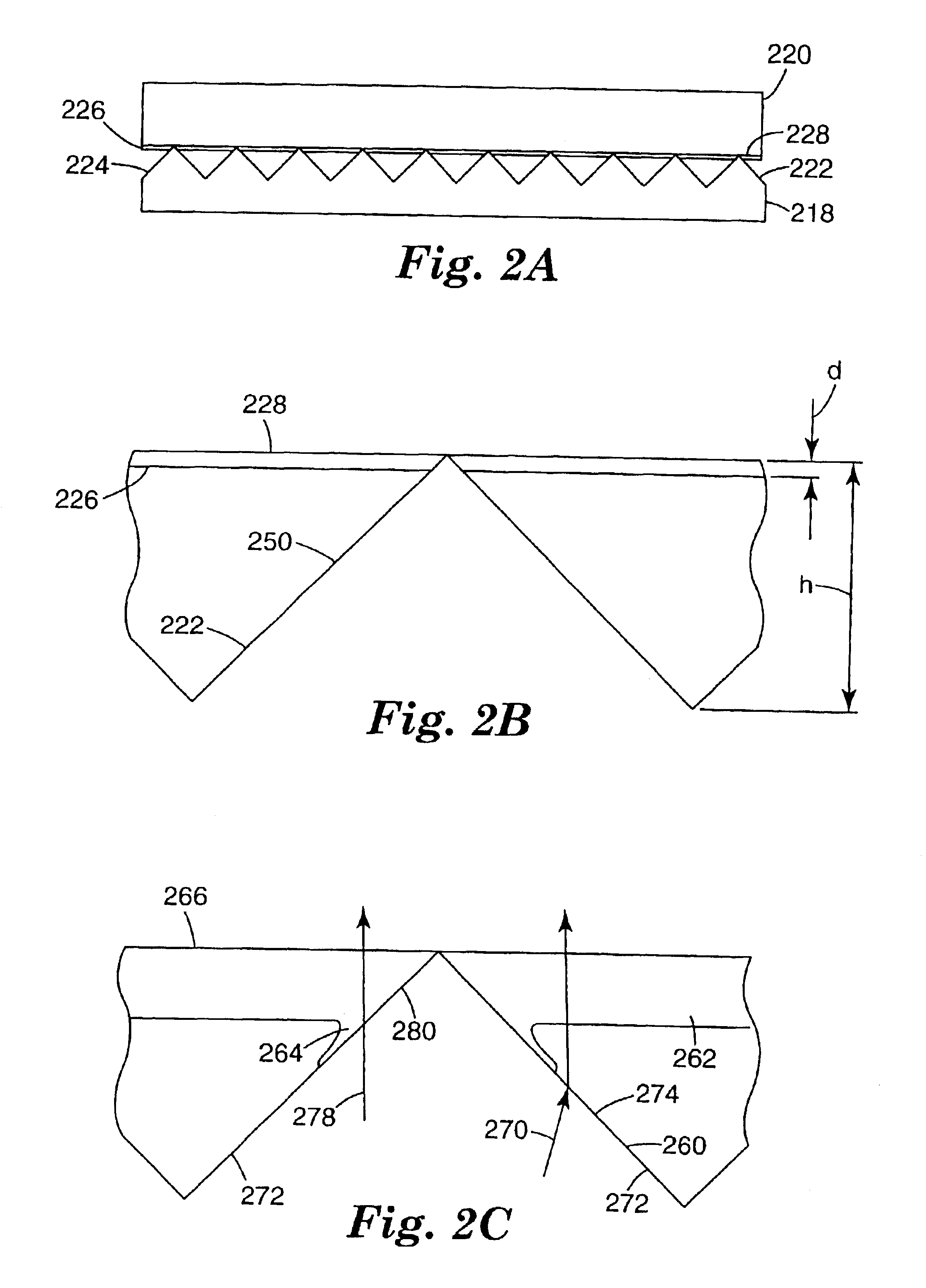

Method for stacking surface structured optical films

InactiveUS6846089B2Reduce the number of stepsIncrease productionShow cabinetsImpedence networksAdhesiveDisplay device

A display includes an optical film that has a surface structure, such as a prismatically structured surface for increasing the brightness of the display. The structured surface is bonded to an opposing surface of a second film using a layer of adhesive, by penetrating the structured surface into the adhesive layer to a depth less than a feature height of the structured surface. The bonded film structure provides additional strength to the films and reduces the possibility of film damage during display assembly.

Owner:3M INNOVATIVE PROPERTIES CO

NbMC LAYERS

ActiveUS20170117141A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice PropertiesWork function

Methods of forming thin-film structures including one or more NbMC layers, and structures and devices including the one or more NbMC layers are disclosed. The NbMC layers enable tuning of various structure and device properties, including resistivity, current leakage, and work function.

Owner:ASM IP HLDG BV

Semiconductor substrate process using a low temperature deposited carbon-containing hard mask

InactiveUS20070032054A1Electric discharge tubesRadiation applicationsLow temperature depositionPlasma current

A method of processing a thin film structure on a semiconductor substrate using an optically writable mask includes placing the substrate in a reactor chamber, the substrate having on its surface a target layer to be etched in accordance with a predetermined pattern, and depositing a carbon-containing hard mask layer on the substrate by (a) introducing a carbon-containing process gas into the chamber, (b) generating a reentrant toroidal RF plasma current in a reentrant path that includes a process zone overlying the workpiece by coupling plasma RF source power to an external portion of the reentrant path, and (c) coupling RF plasma bias power or bias voltage to the workpiece. The method further includes photolithographically defining the predetermined pattern in the carbon-containing hard mask layer, and etching the target layer in the presence of the hard mask layer.

Owner:APPLIED MATERIALS INC

NbMC layers

ActiveUS10211308B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice PropertiesWork function

Methods of forming thin-film structures including one or more NbMC layers, and structures and devices including the one or more NbMC layers are disclosed. The NbMC layers enable tuning of various structure and device properties, including resistivity, current leakage, and work function.

Owner:ASM IP HLDG BV

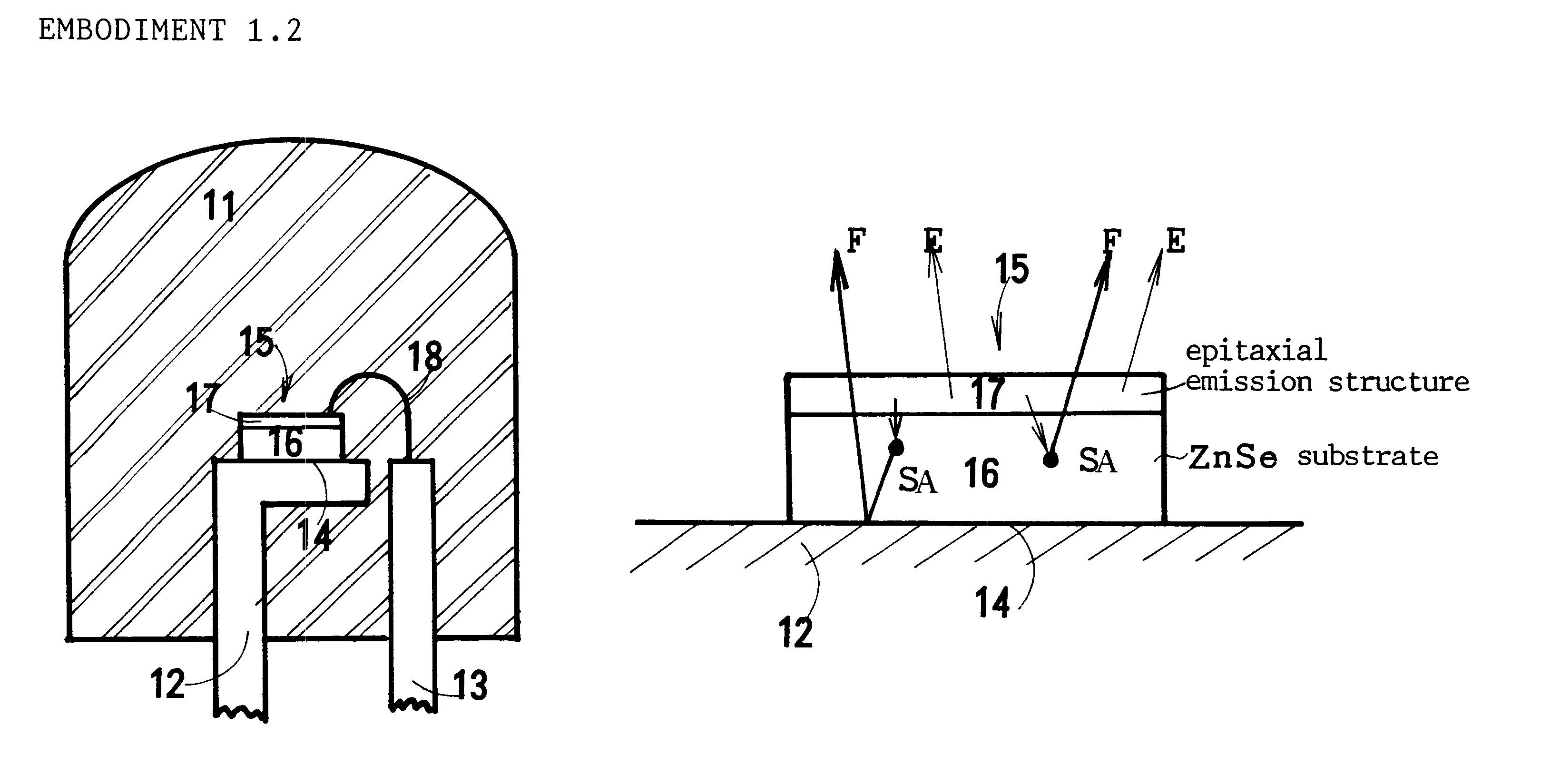

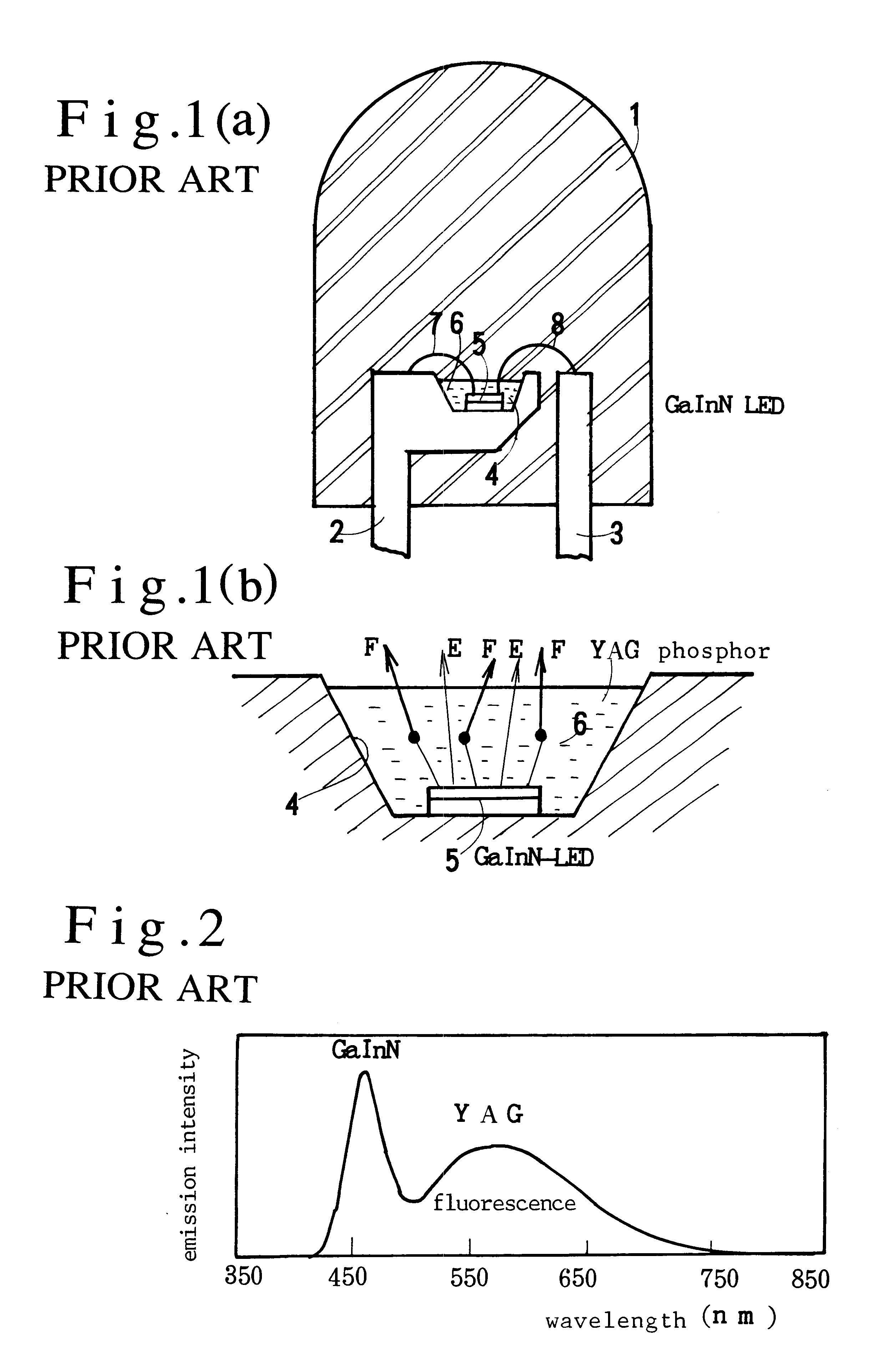

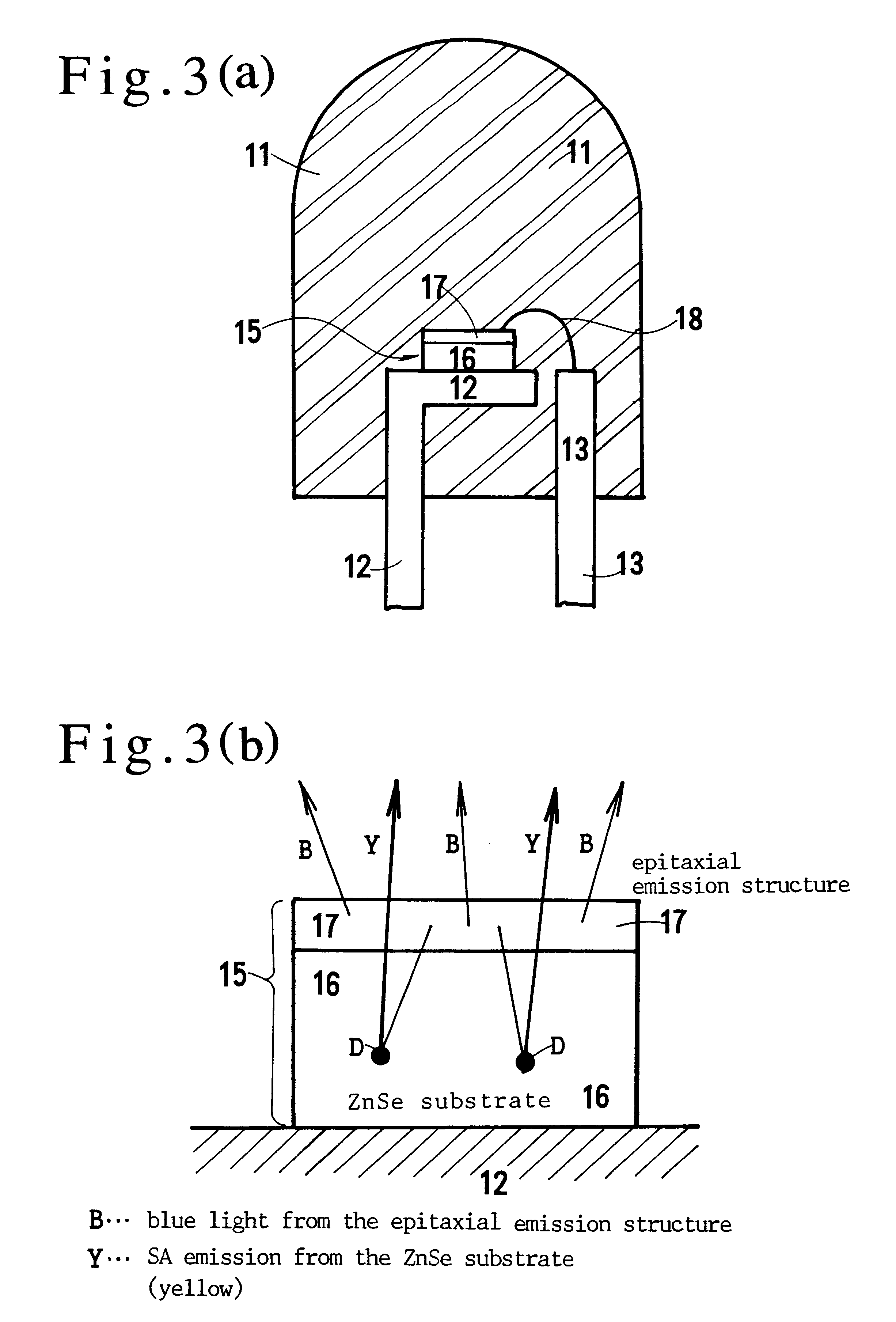

White color light emitting diode and neutral color light emitting diode

InactiveUS6337536B1Reduce material costsLow production costDischarge tube luminescnet screensLamp detailsSingle crystal substrateSingle crystal

A white color or neutral color LED having an n-type ZnSe single crystal substrate doped with I, Cl, Br, Al, Ga or In as SA-emission centers and an epitaxial film structure including a ZnSe, ZnCdSe or ZnSeTe active layer and a pn-junction. The active layer emits blue or bluegreen light. The SA-emission centers in the ZnSe substrate convert blue or bluegreen light to yellow or orange SA-emission. The blue or bluegreen light from the epitaxial film structure and the yellow or orange light from the ZnSe substrate synthesize white color light or neutral color light between red and blue.

Owner:SUMITOMO ELECTRIC IND LTD

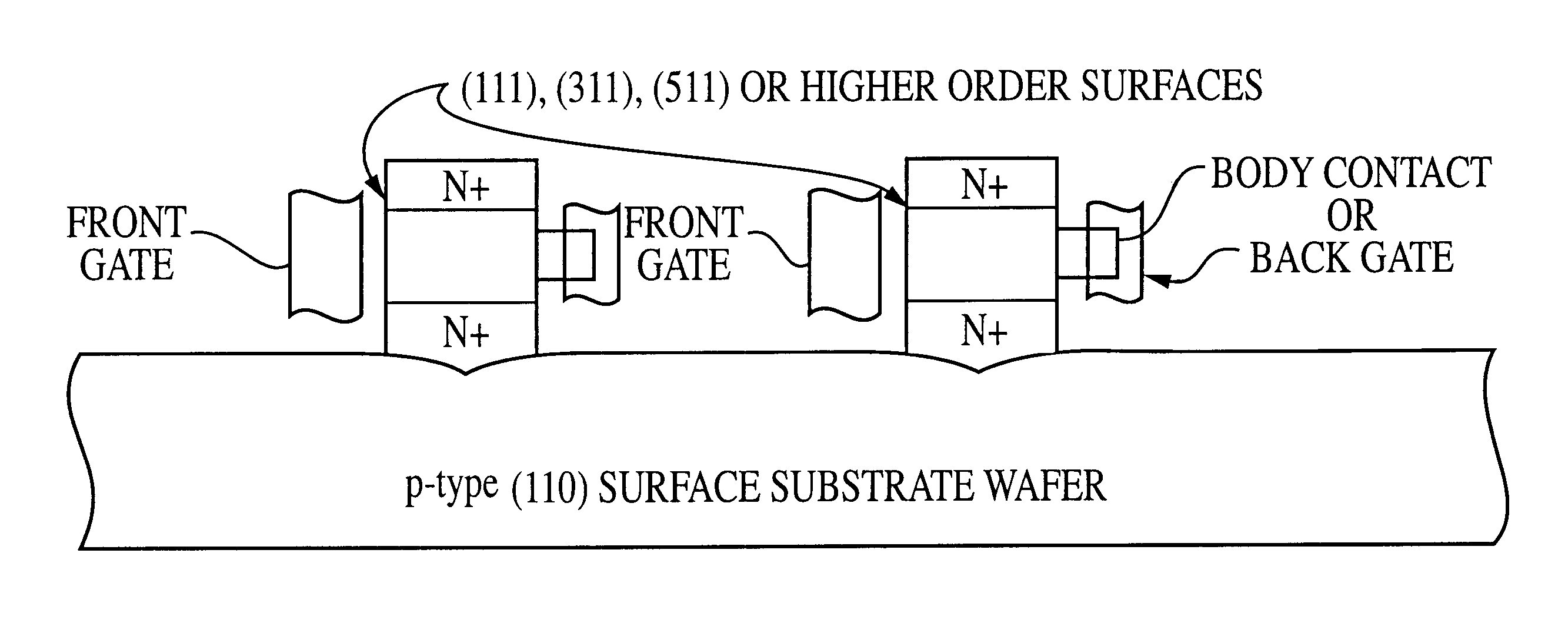

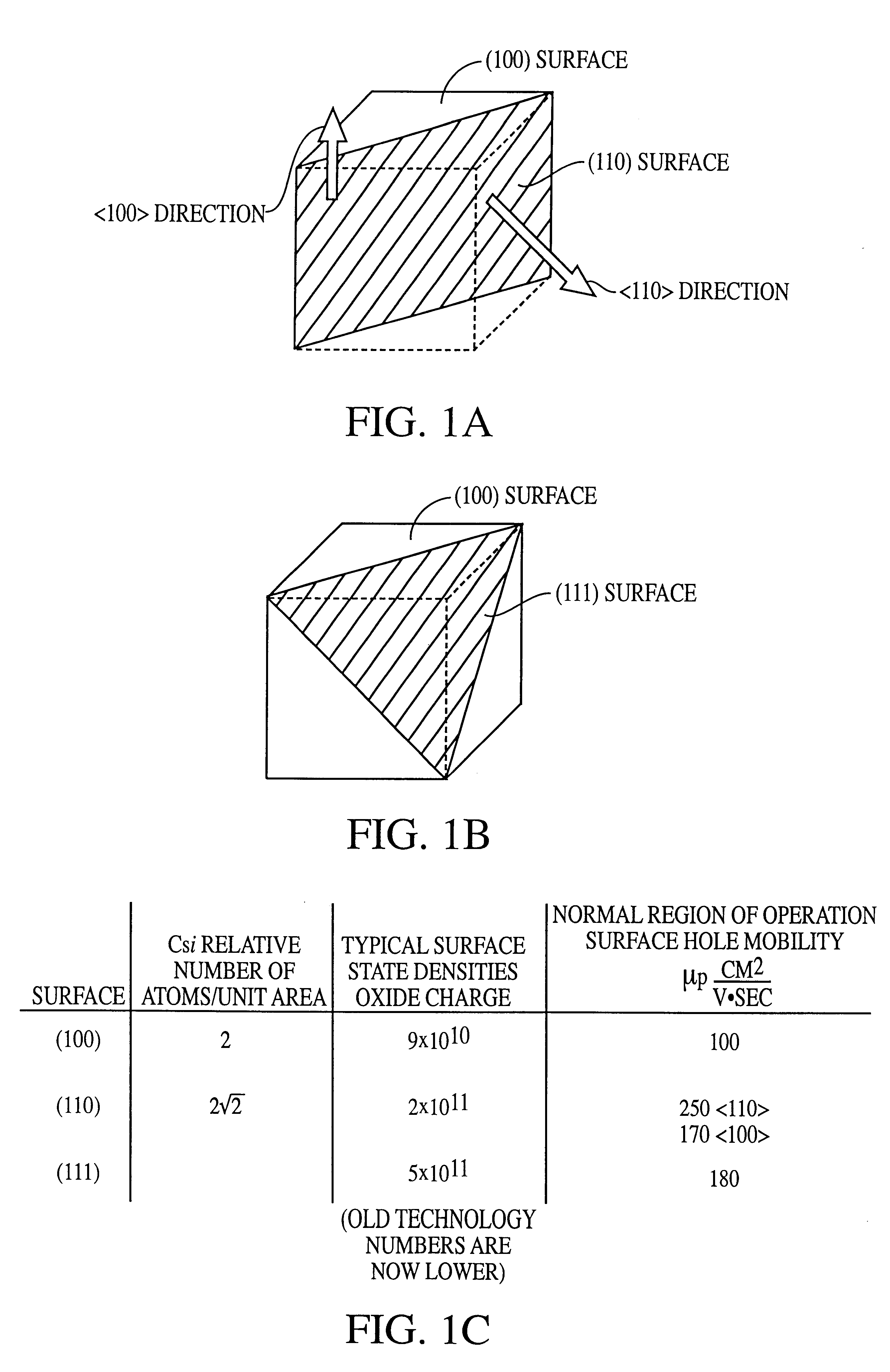

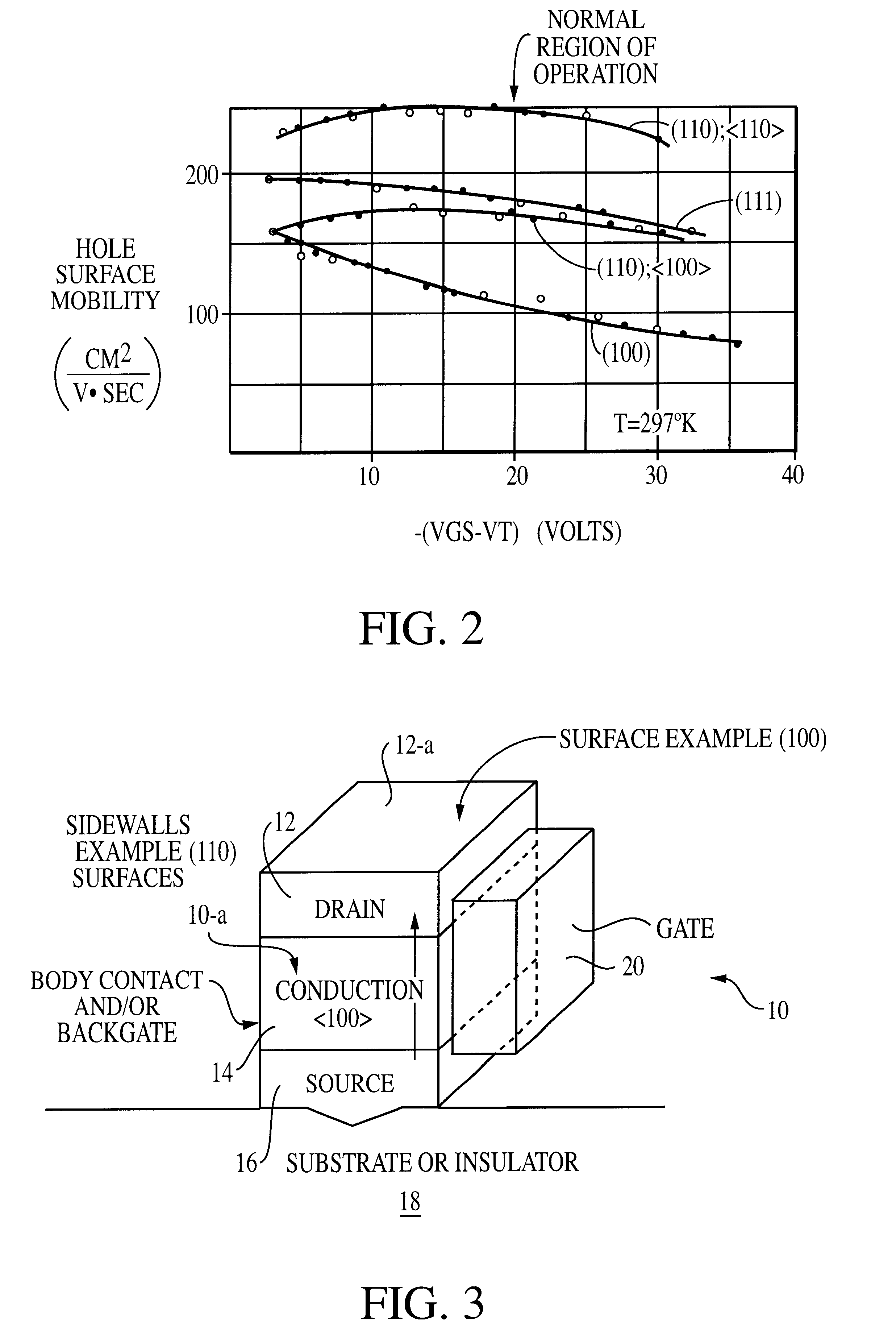

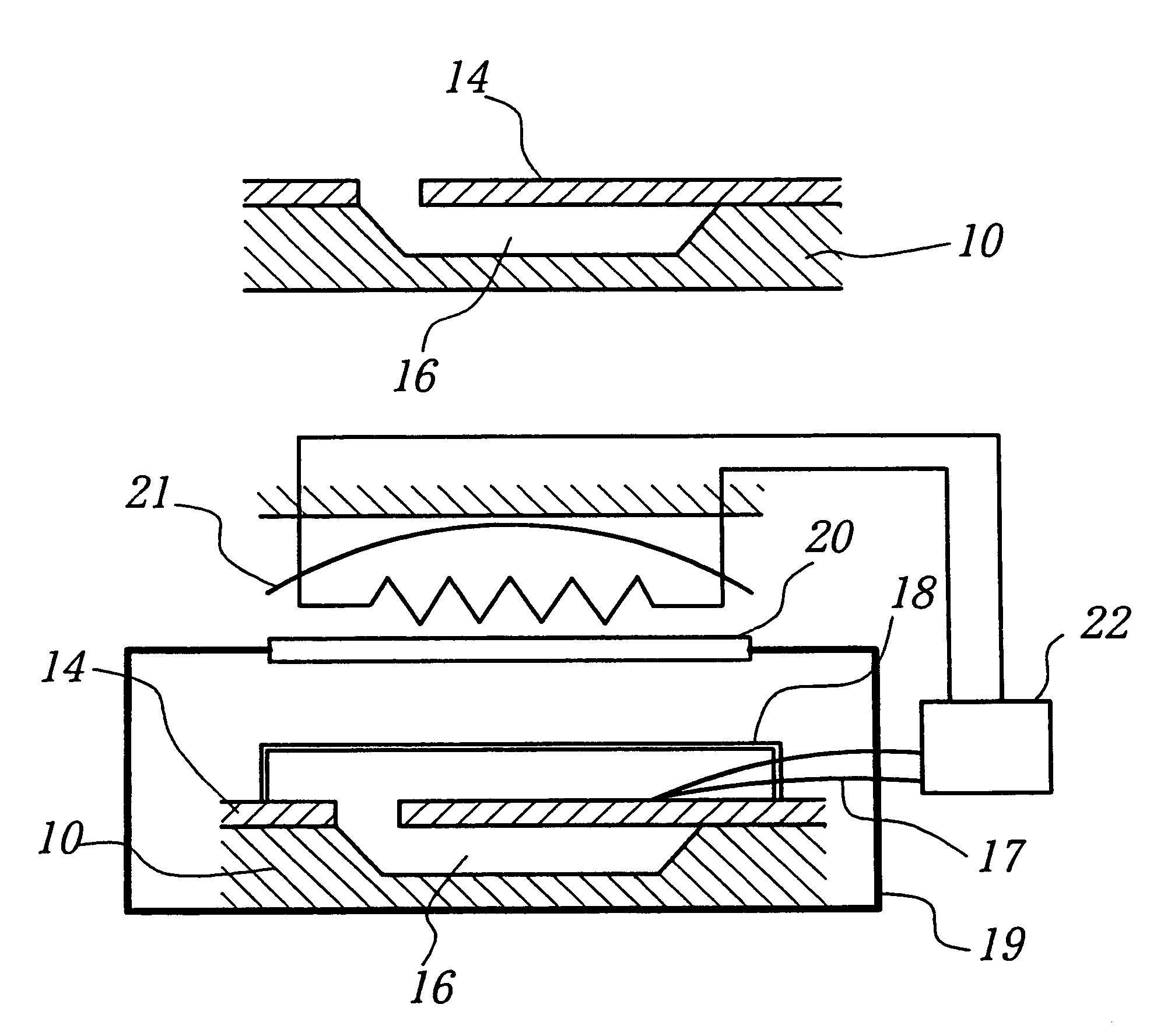

Vertical sub-micron CMOS transistors on (110), (111), (311), (511), and higher order surfaces of bulk, SOI and thin film structures and method of forming same

A method for forming NMOS and PMOS transistors that includes cutting a substrate along a higher order orientation and fabricating deep sub-micron NMOS and PMOS transistors on the vertical surfaces thereof. The complementary NMOS and PMOS transistors form a CMOS transistor pair. The transistors are preferably used in structures such as memory circuits, e.g., DRAMs, which are, in turn, used in a processor-based system. Ideally, the deep sub-micron NMOS and PMOS transistors are operated in velocity saturation for optimal switching operation.

Owner:APTINA IMAGING CORP

Thin film-structure and a method for producing the same

InactiveUS6759261B2Increase productivityGood reproducibilityLiquid-phase epitaxial-layer growthElectrical measurement instrument detailsRoom temperatureCooling down

A thin film made of an amorphous material having supercooled liquid phase region is formed on a substrate. Then, the thin film is heated to a temperature within the supercooled liquid phase region and is deformed by its weight, mechanical external force, electrostatic external force or the like, thereby to form a thin film-structure. Thereafter, the thin film-structure is cooled down to room temperature, which results in the prevention of the thin film's deformation.

Owner:TOKYO INST OF TECH

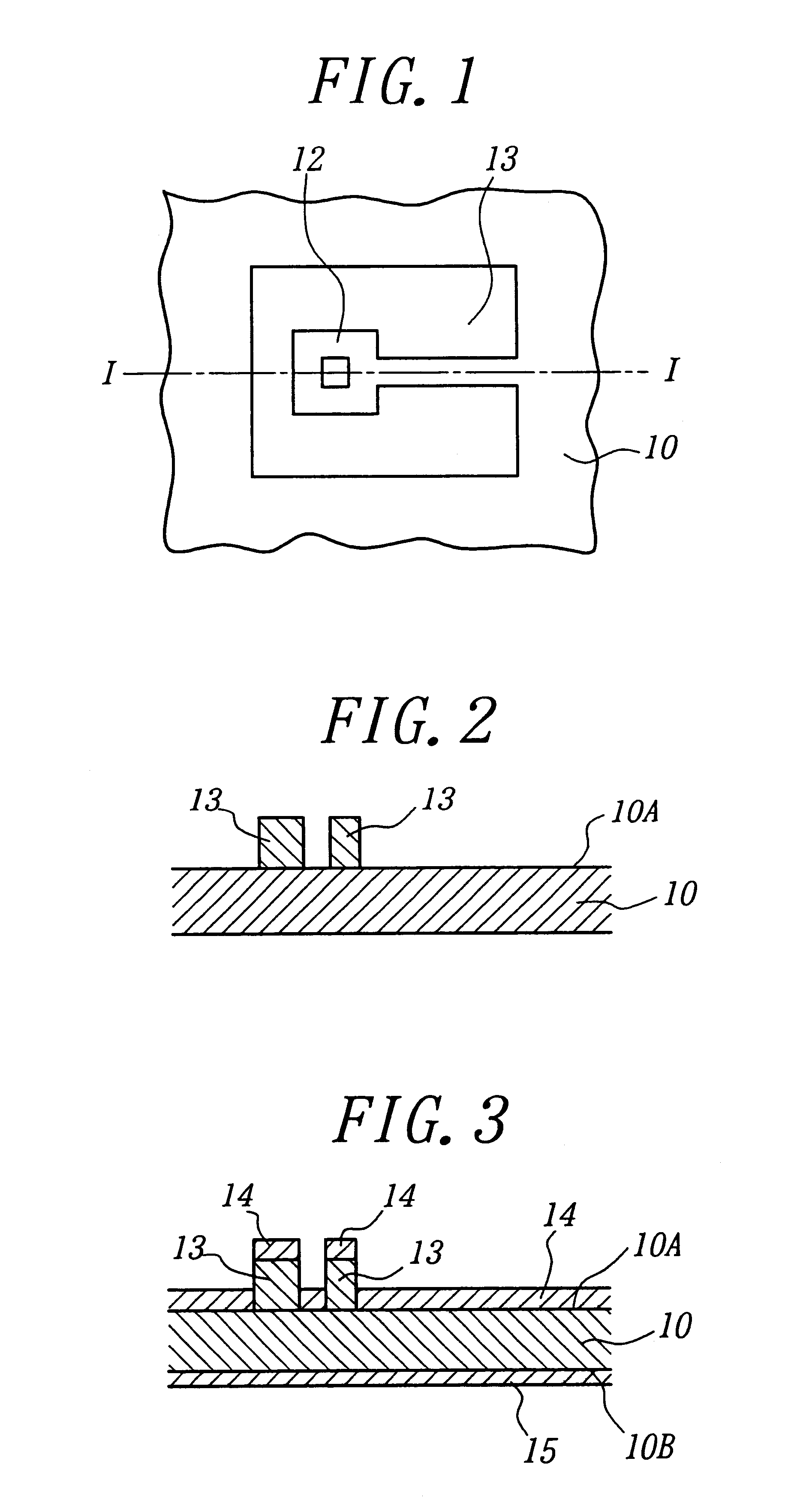

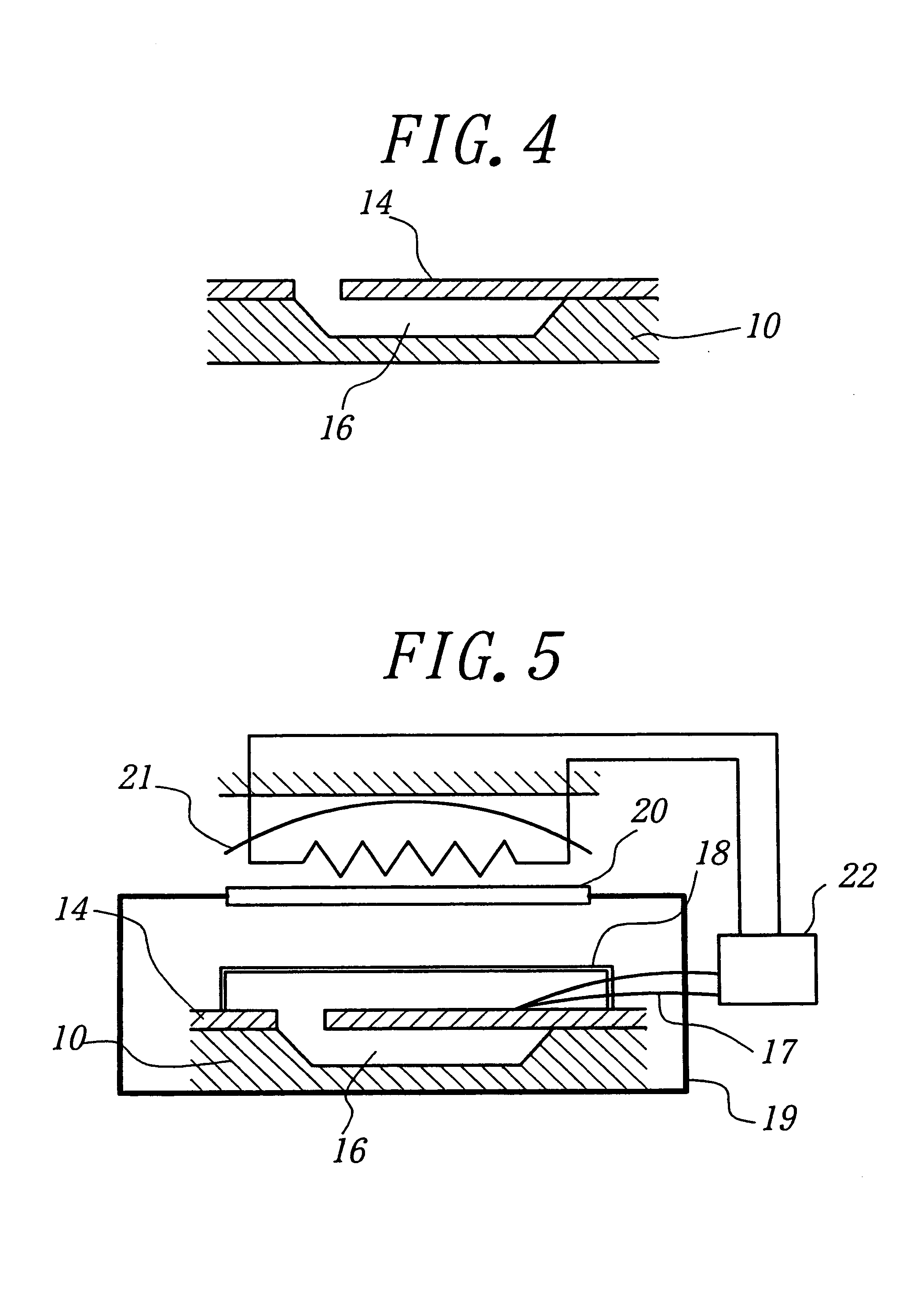

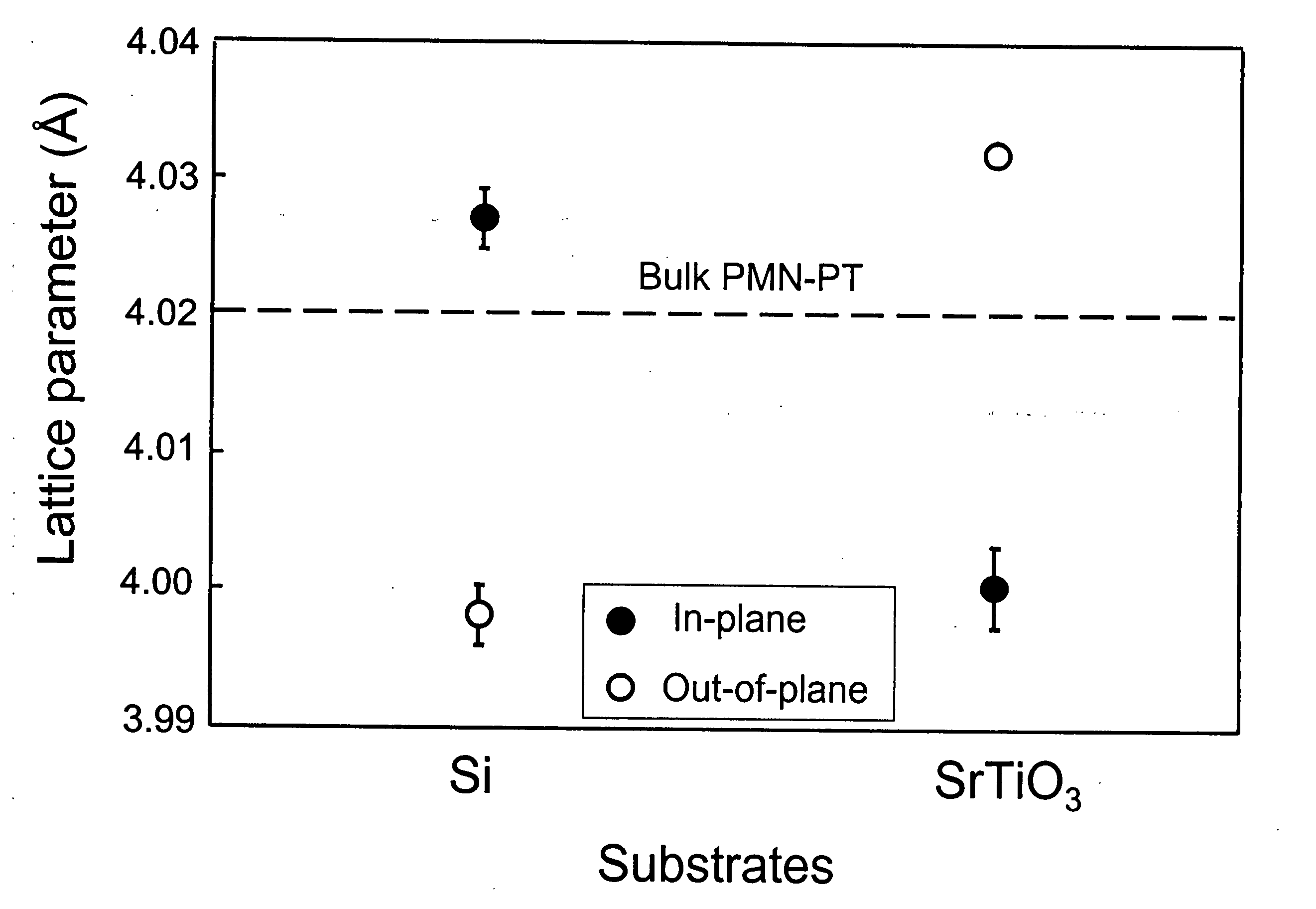

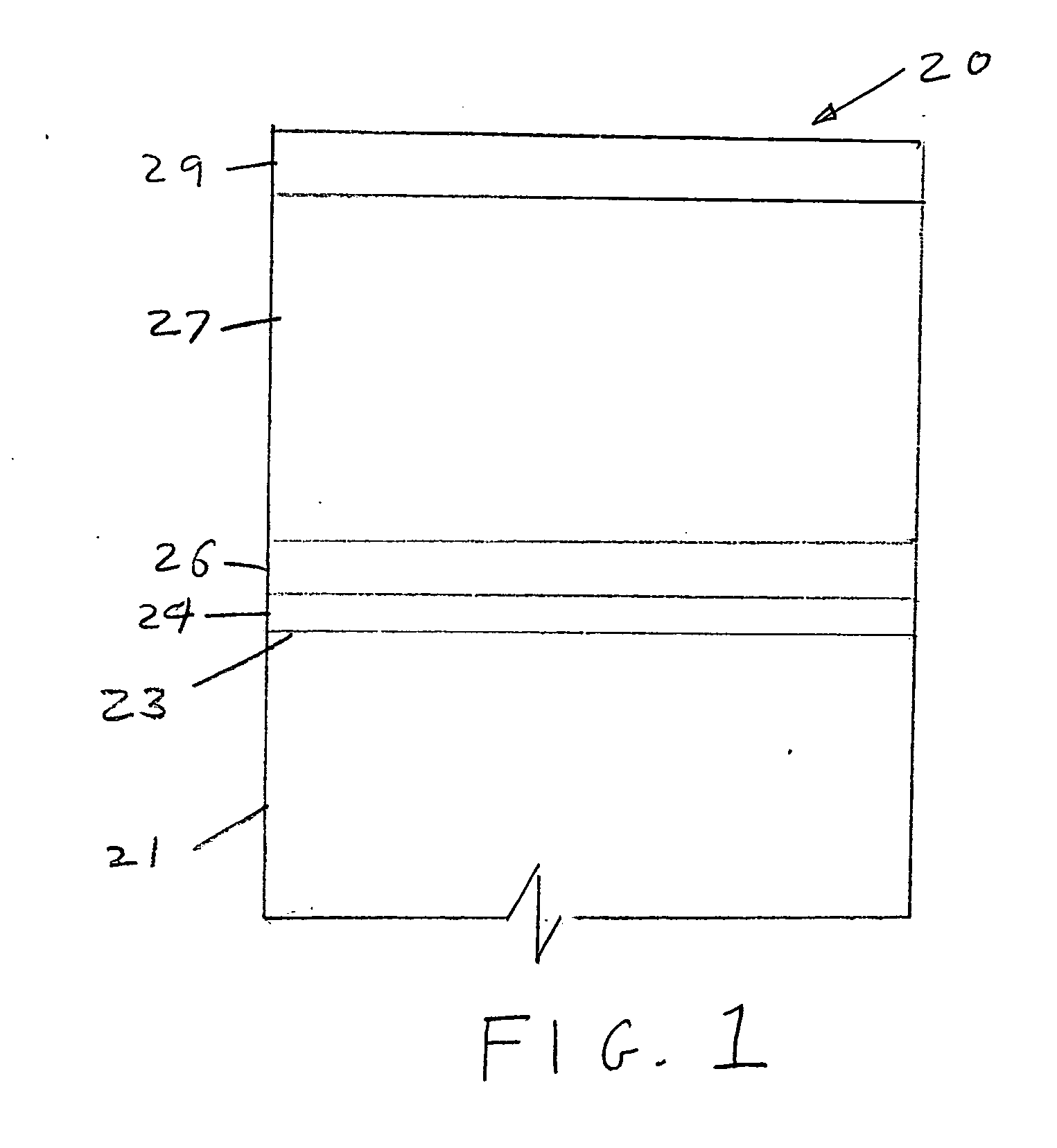

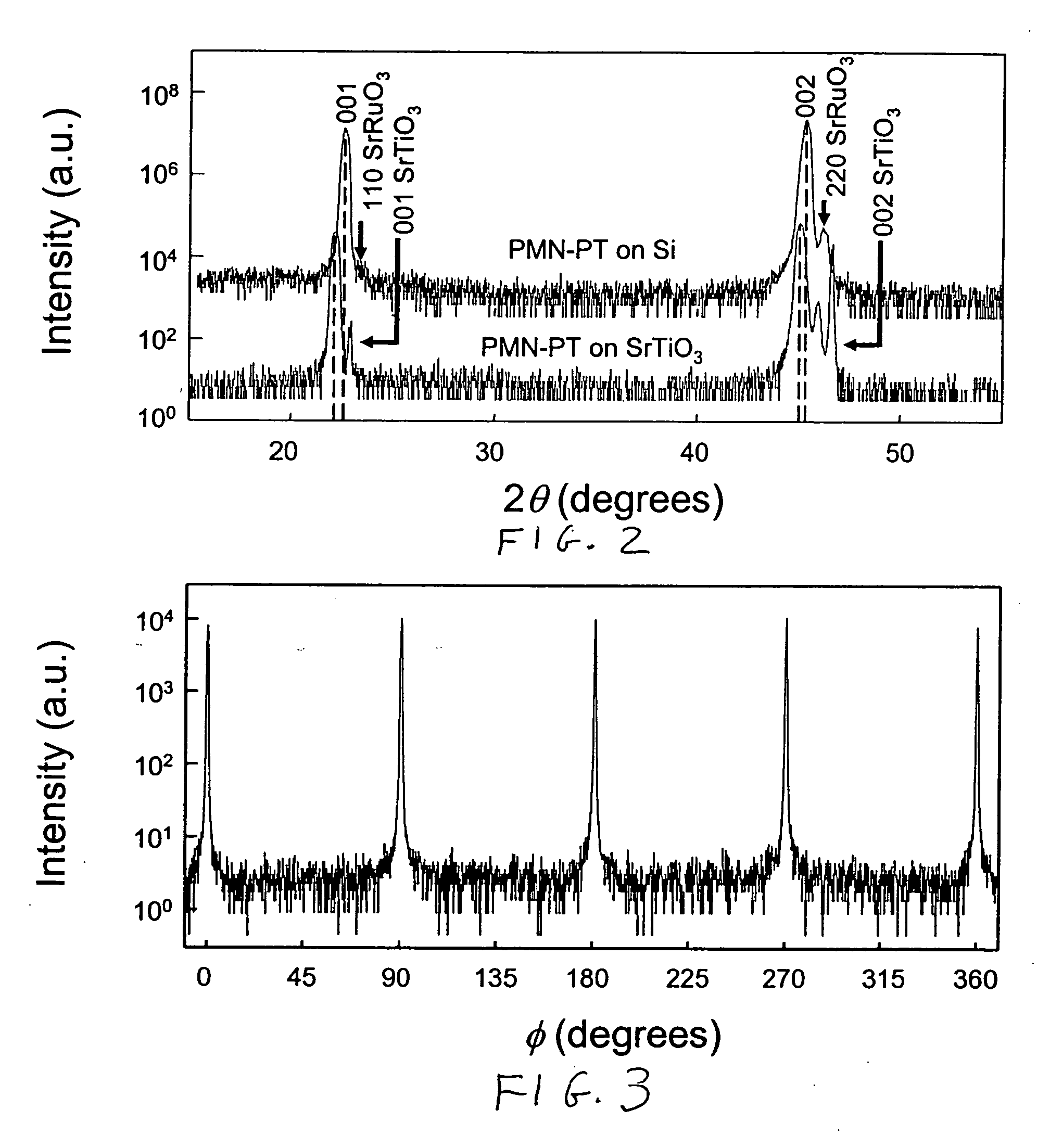

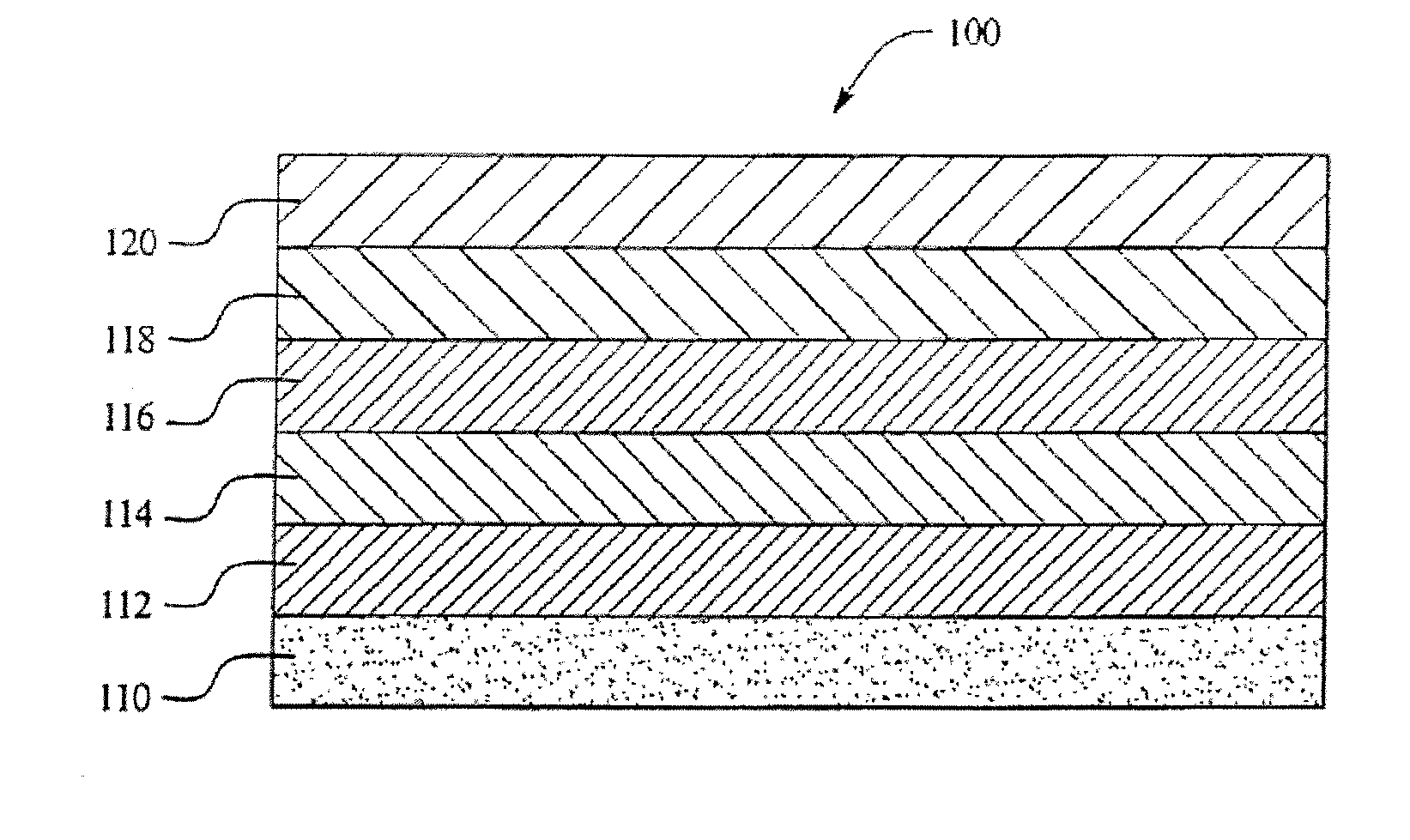

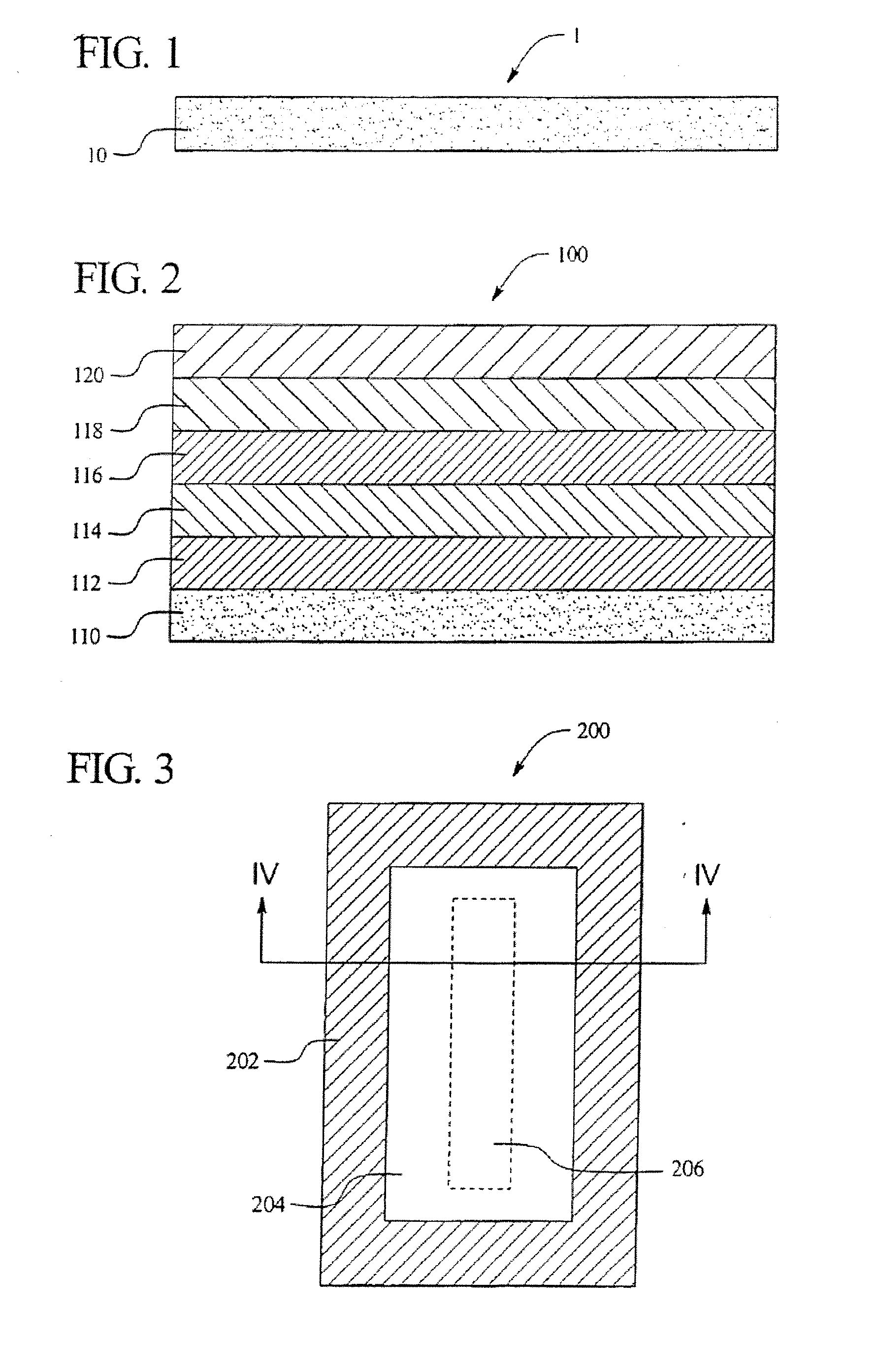

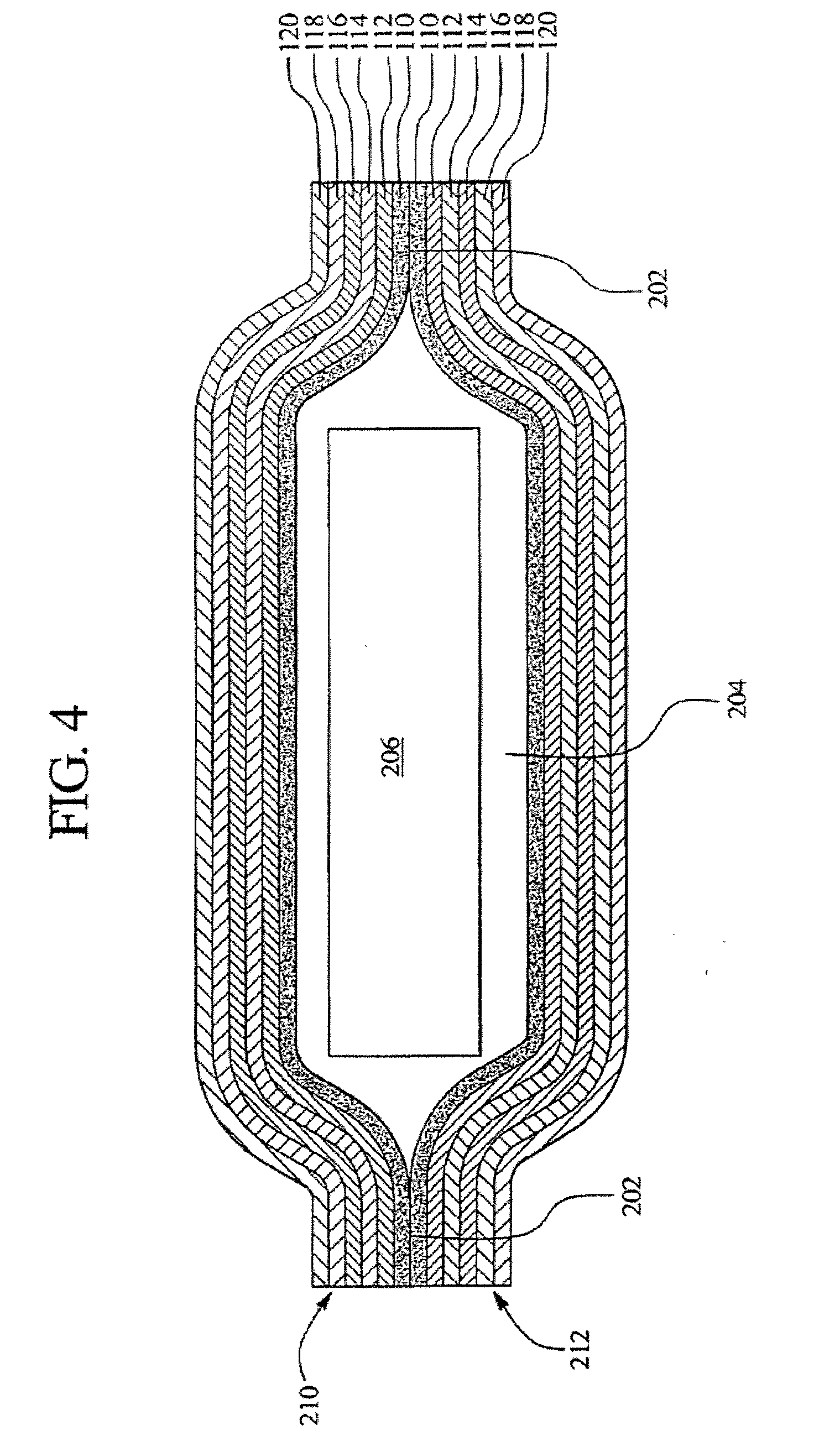

Perovskite-based thin film structures on miscut semiconductor substrates

InactiveUS20060288928A1Quality improvementGood metallic behaviorPolycrystalline material growthFrom chemically reactive gasesCrystal structureCrystal plane

A perovskite-based thin film structure includes a semiconductor substrate layer, such as a crystalline silicon layer, having a top surface cut at an angle to the (001) crystal plane of the crystalline silicon. A perovskite seed layer is epitaxially grown on the top surface of the substrate layer. An overlayer of perovskite material is epitaxially grown above the seed layer. In some embodiments the perovskite overlayer is a piezoelectric layer grown to a thickness of at least 0.5 μm and having a substantially pure perovskite crystal structure, preferably substantially free of pyrochlore phase, resulting in large improvements in piezoelectric characteristics as compared to conventional thin film piezoelectric materials.

Owner:PENN STATE RES FOUND +1

Films having a desiccant material incorporated therein and methods of use and manufacture

InactiveUS20070160789A1Improve efficacyExtended shelf lifeSurgical furnitureDiagnosticsDesiccantInsertion stent

Film structures, packages, films and methods of making the same are provided wherein the film structures have a desiccant material incorporated into at least one layer of the film structures and further wherein the film structures can comprise a material for making a peelable seal when the film structures are heat sealed to other film structures. The film structures are utilized for a package to hold a product that may be sensitive to the presence of moisture. The product may preferably be pharmaceutical products, nutraceutical products, or devices such as absorbable sutures or medical stents, although any moisture-sensitive product is contemplated by the present invention.

Owner:ALCAN PACKAGING FLEXIBLE FRANCE

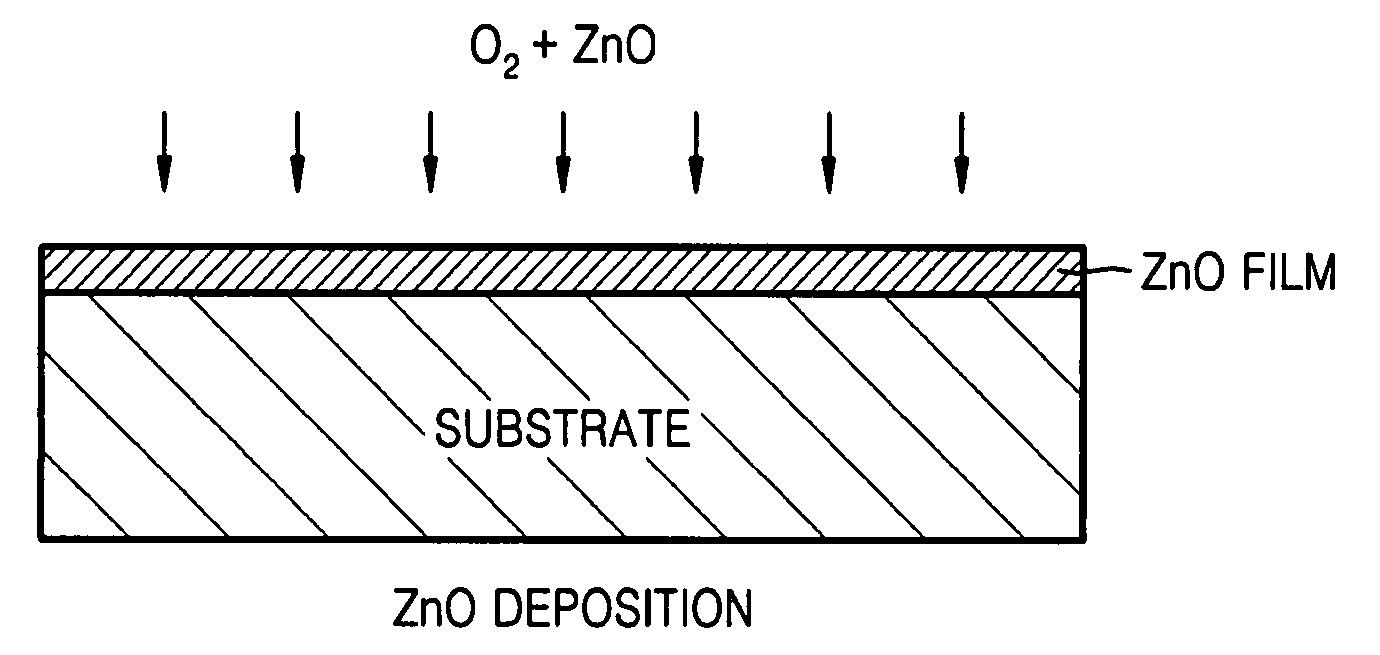

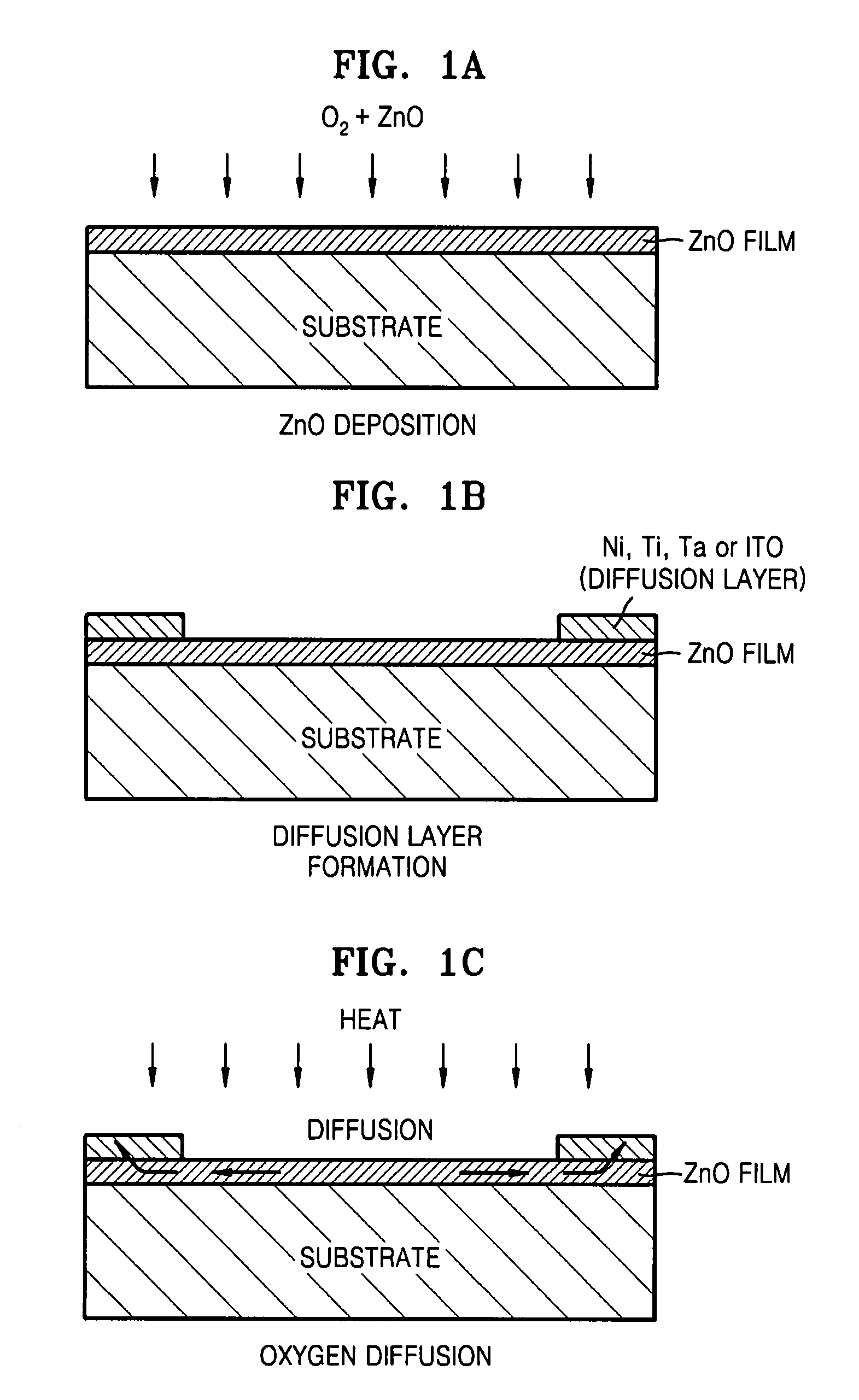

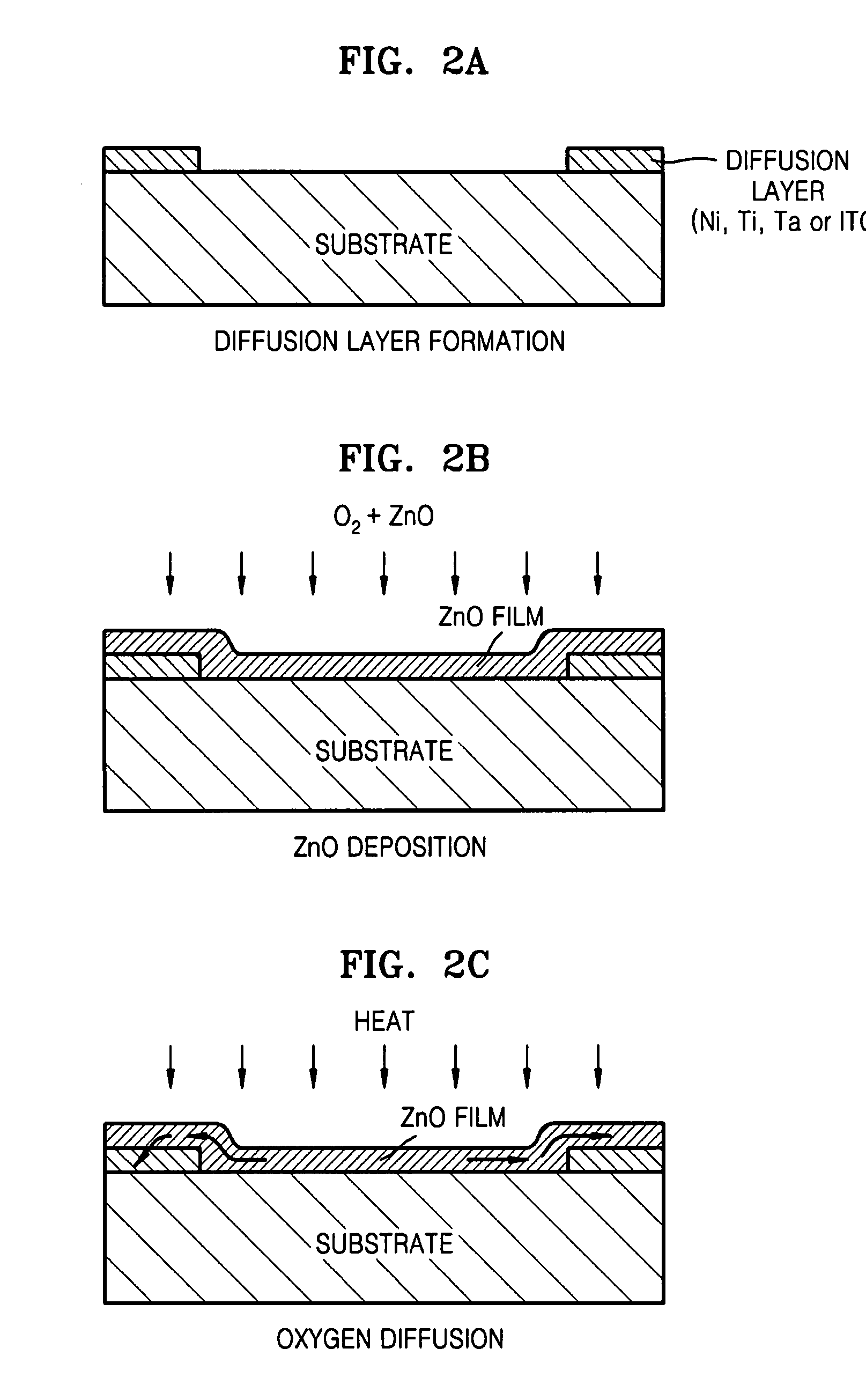

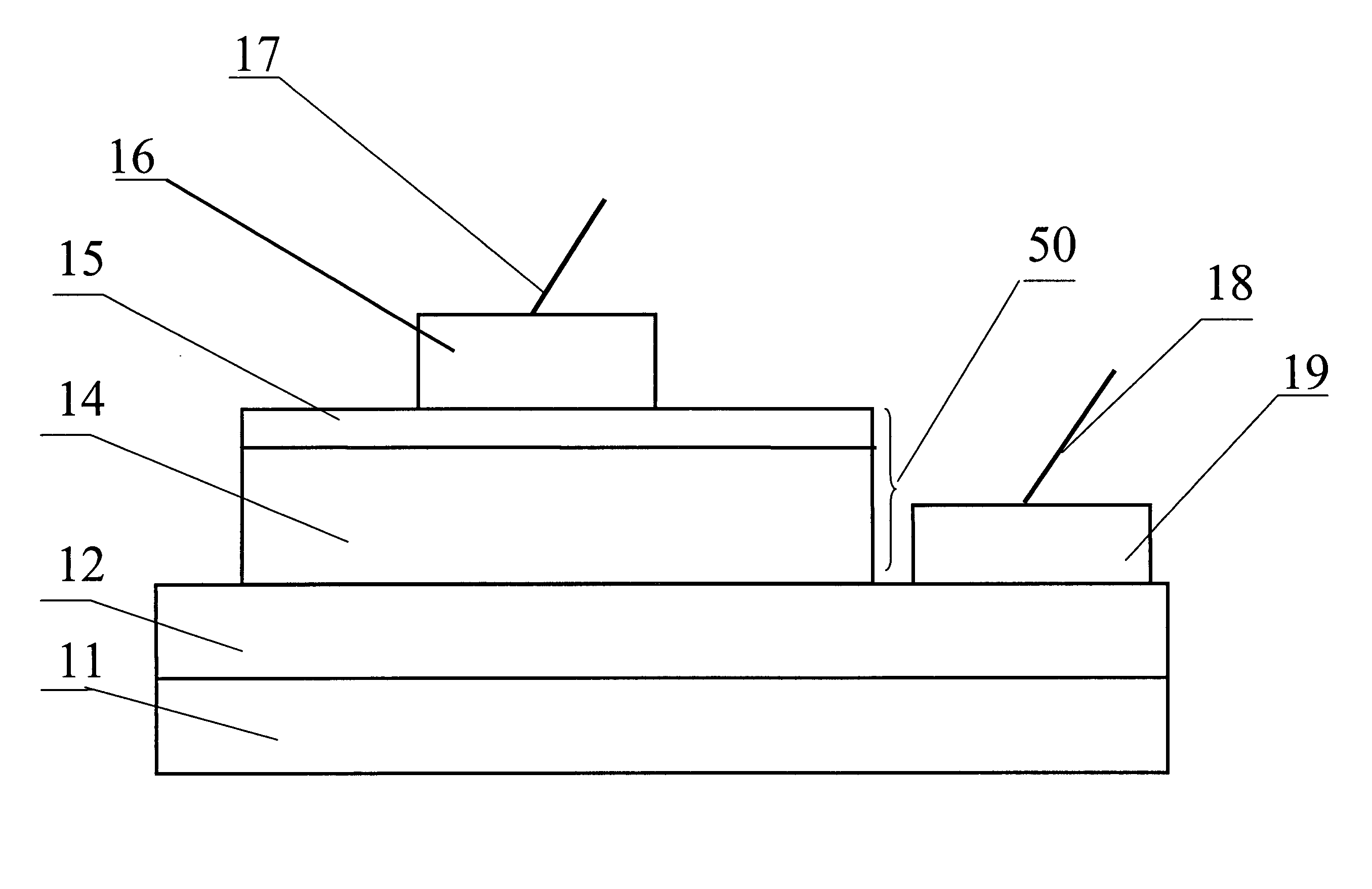

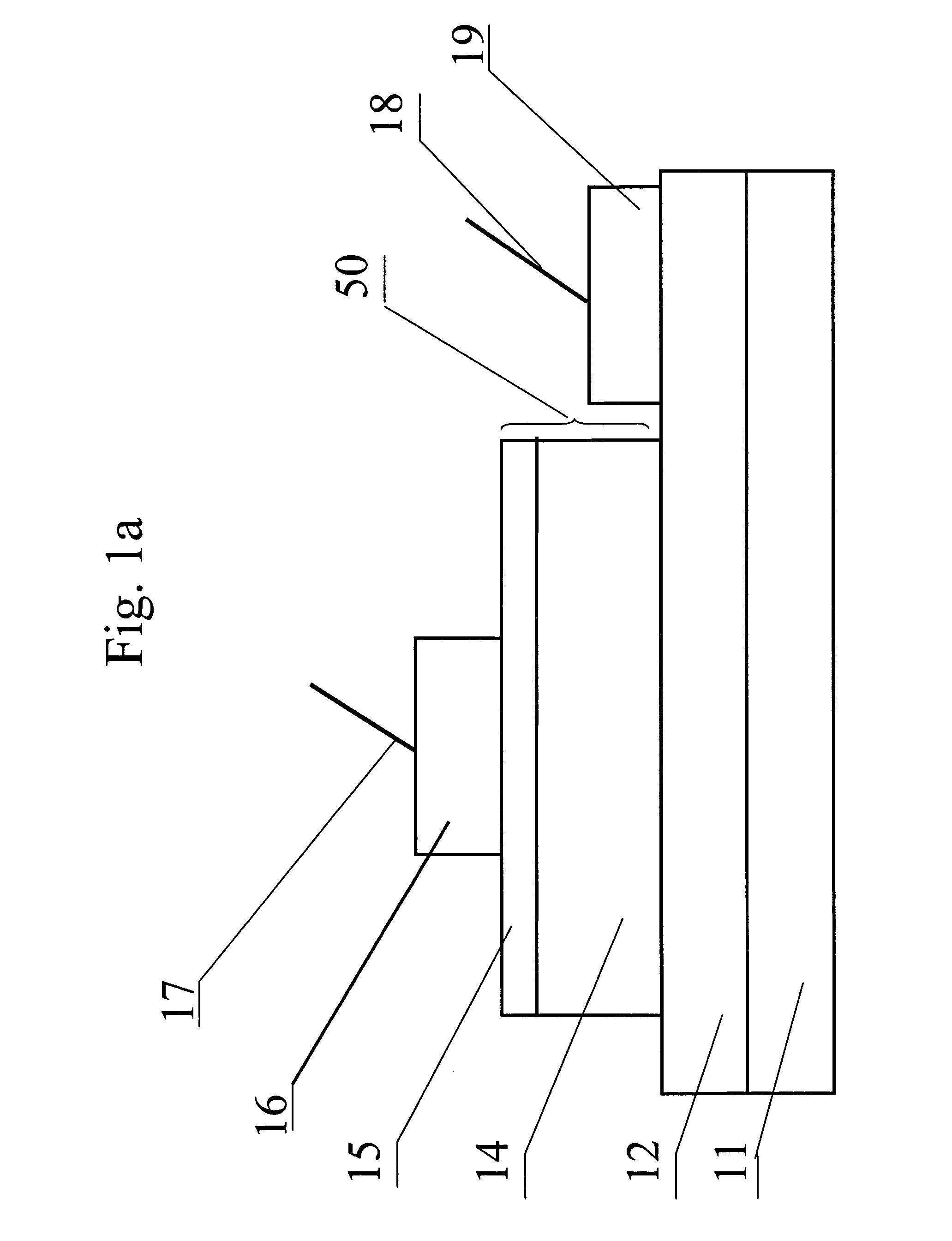

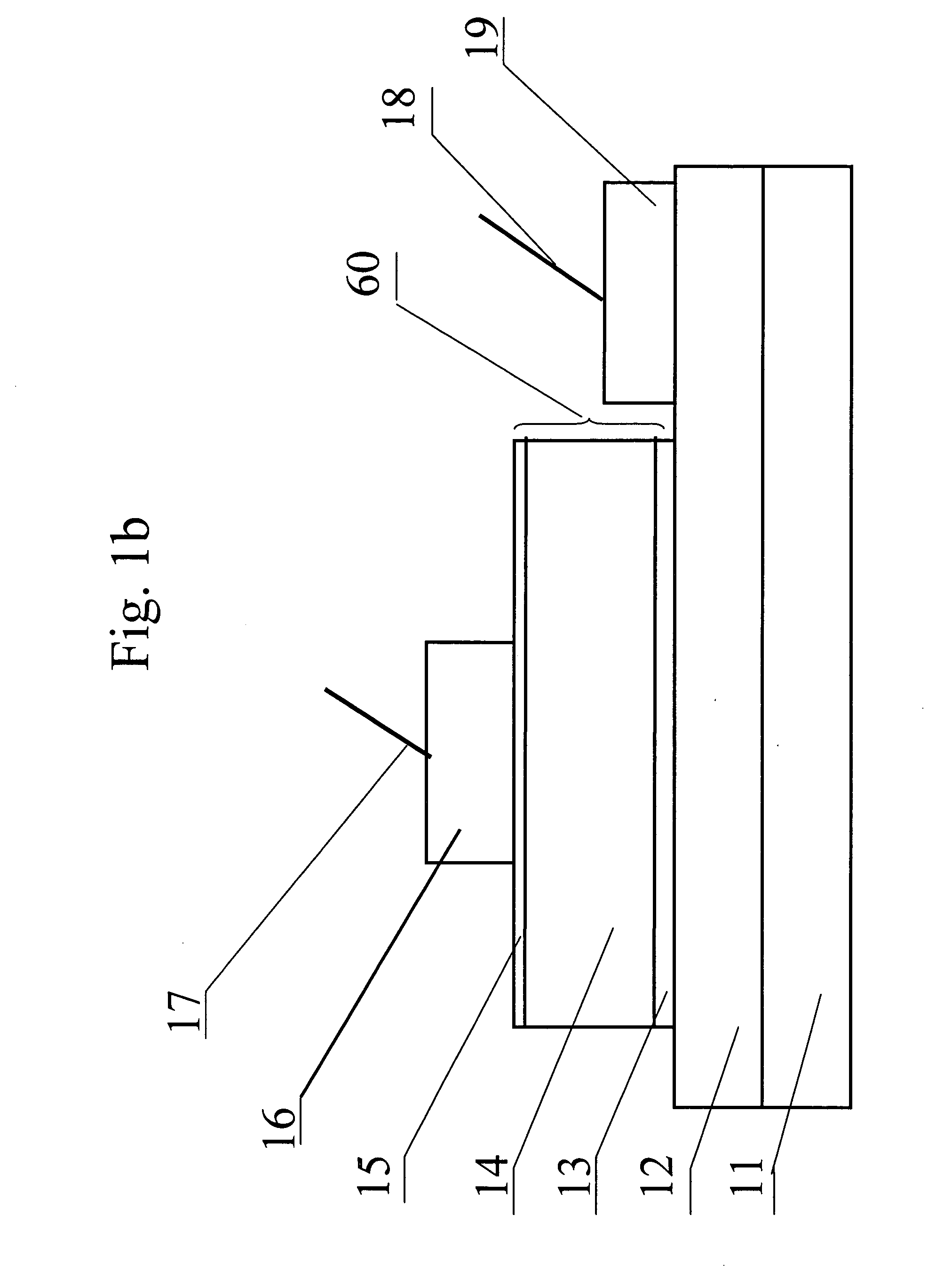

Fabrication methods of a ZnO thin film structure and a ZnO thin film transistor, and a ZnO thin film structure and a ZnO thin film transistor

ActiveUS20070241327A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingOptoelectronicsFilm structure

Provided is a method of fabricating a ZnO thin film structure and a ZnO thin film transistor (TFT), and a ZnO thin film structure and a ZnO thin film transistor. The method of fabricating a ZnO thin film structure may include forming a ZnO thin film on a substrate in an oxygen atmosphere, forming oxygen diffusion layers of a metal having an affinity for oxygen on the ZnO thin film and heating the ZnO thin film and the oxygen diffusion layers to diffuse oxygen of the ZnO thin film into the oxygen diffusion layers.

Owner:SAMSUNG ELECTRONICS CO LTD

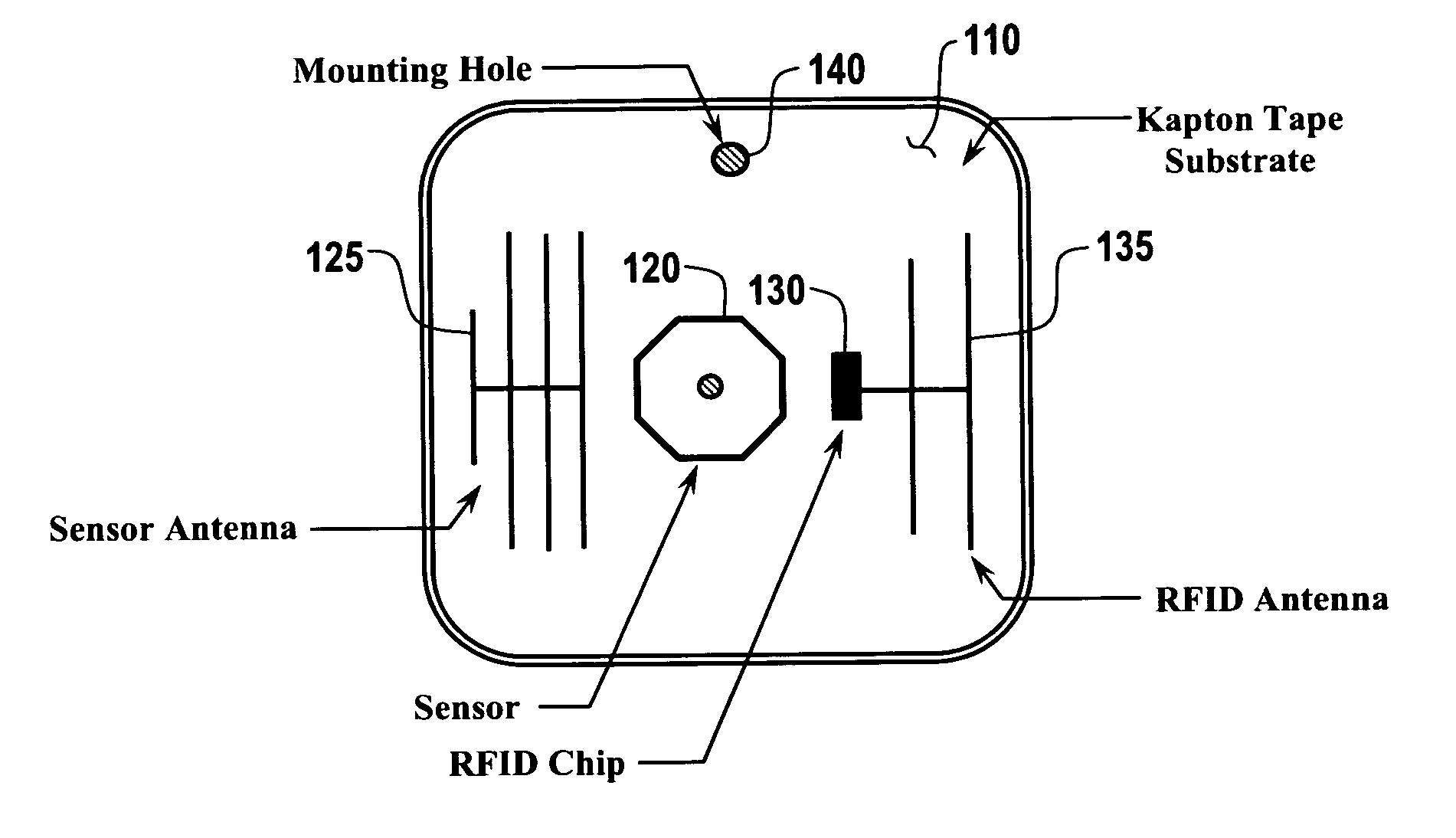

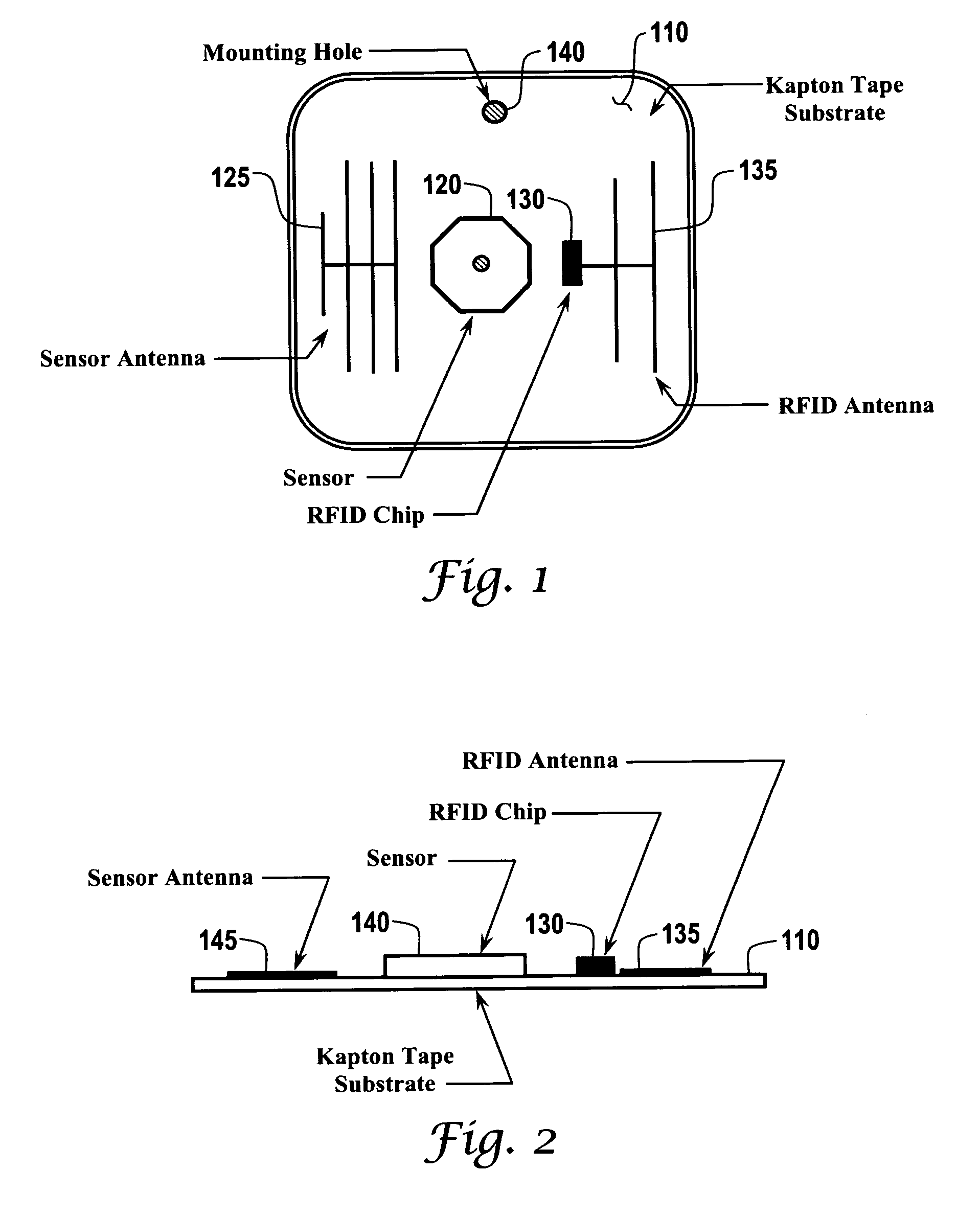

Combined RF tag and SAW sensor

InactiveUS20060055531A1Eliminate needMeasurement devicesTyre measurementsFlexible circuitsPrinted circuit board

Sensors and transponders combined on a single semiconductor substrate package. The invention includes an RFID tag and a sensor commonly assembled onto a common substrate. The substrates can be provided in the form of a flex circuit or printed circuit board. The flex circuit would be fabricated using standard flex circuit fabrication methods. It is a polymer / metal laminate film structure and incorporates the antenna pattern for the sensor and RFID tag system on the circuit. The flex circuit can also combine antennas for the sensor and the RFID tag onto a single flex circuit substrate, thus eliminating the need for separate antennas.

Owner:HONEYWELL INT INC

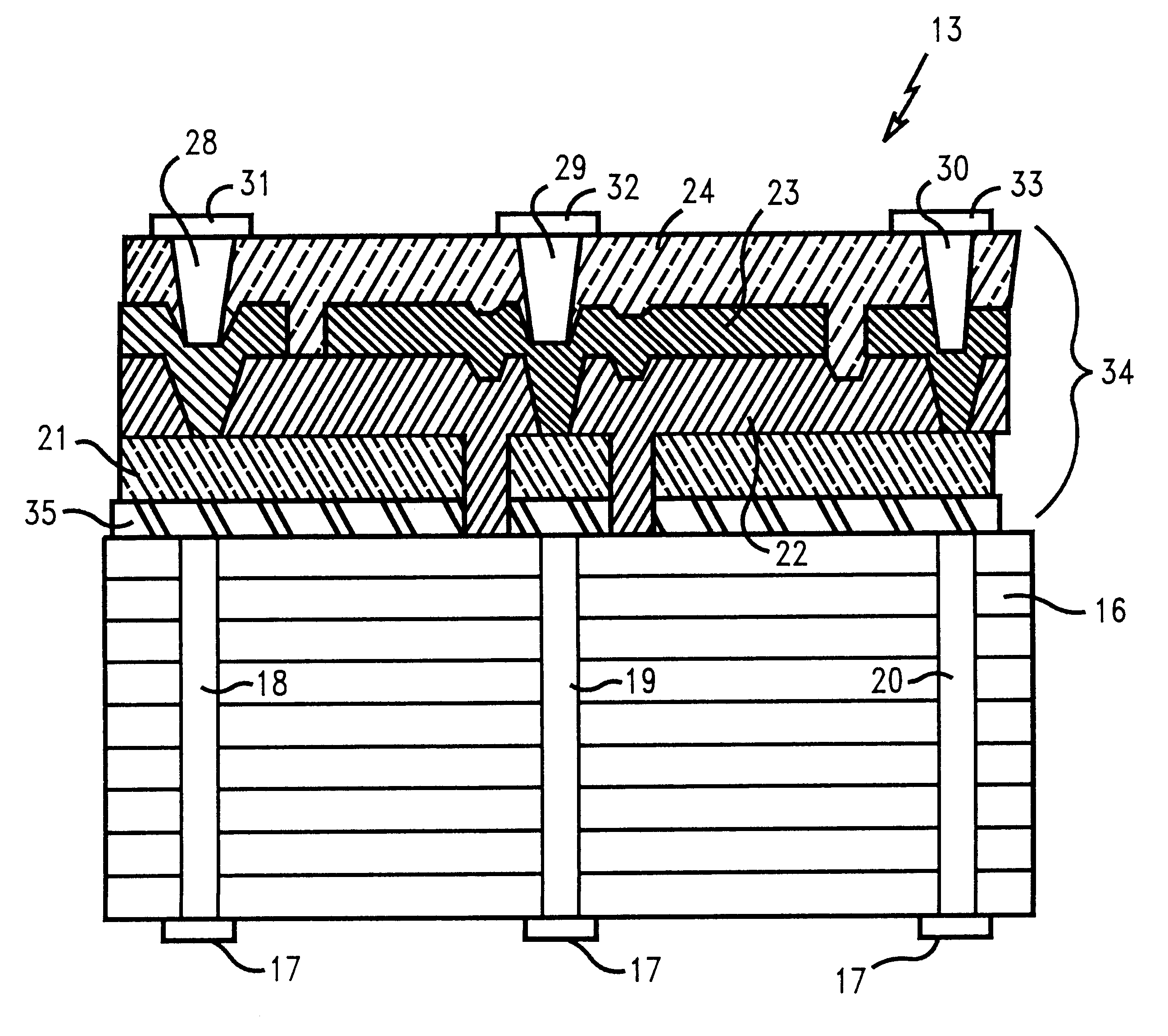

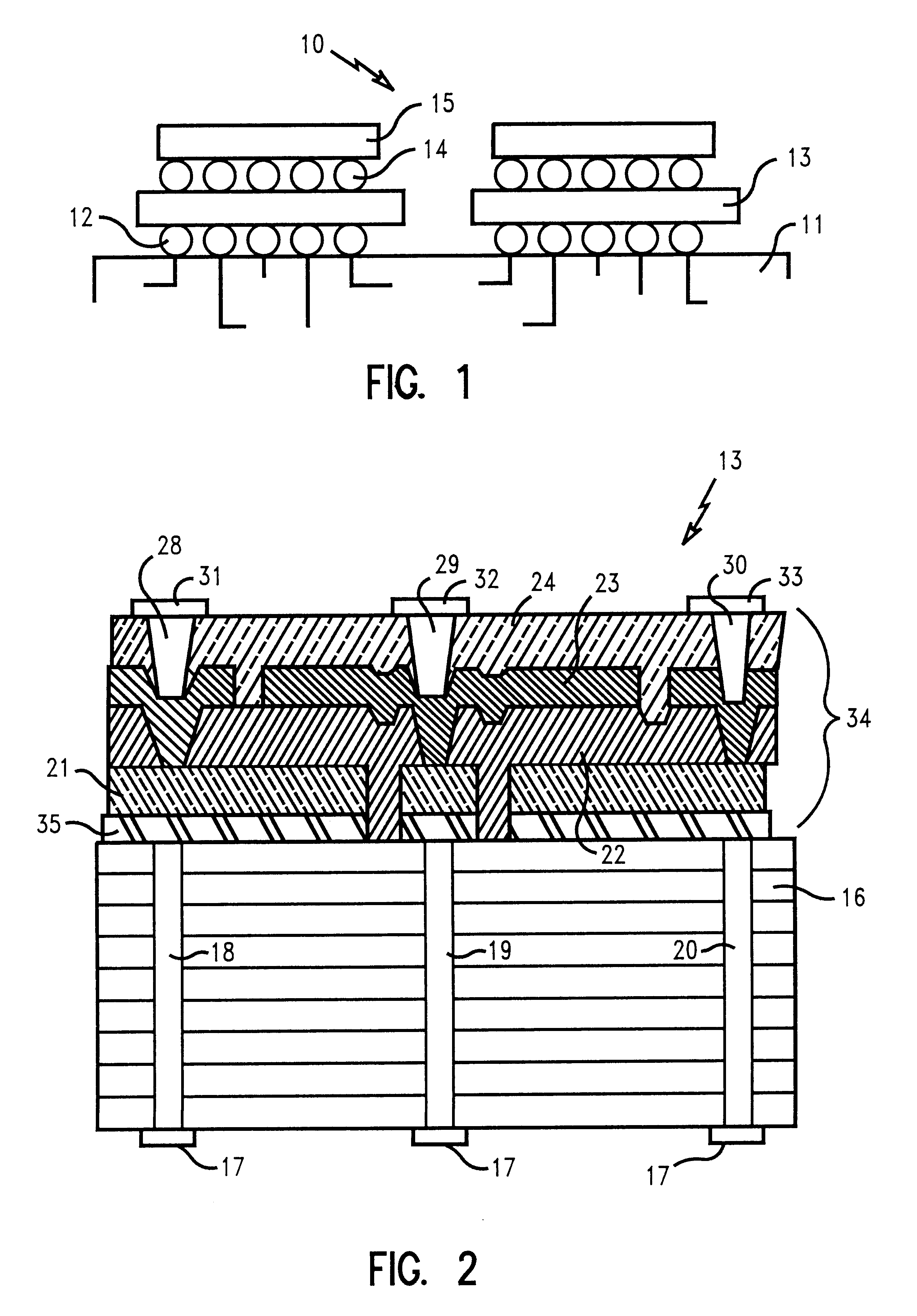

High temperature, conductive thin film diffusion barrier for ceramic/metal systems

A multilayer ceramic substrate having a thin film structure containing capacitor connected thereto is provided as an interposer capacitor, the capacitor employing platinum as the bottom electrode of the capacitor. In a preferred capacitor, a dielectric material such as barium titanate is used as the dielectric material between the capacitor electrodes. The fabrication of the interposer capacitor requires an in-situ or post deposition high temperature anneal and the use of such dielectrics requires heating of the capacitor structure in a non-reducing atmosphere. A layer of a high temperature, thin film diffusion barrier such as TaSiN on the lower platinum electrode between the electrode and underlying multilayer ceramic substrate prevents or minimizes oxidization of the metallization of the multilayer ceramic substrate to which the thin film structure is connected during the fabrication process. A method is also provided for fabricating an interposer capacitor with a multilayer ceramic substrate base and a thin film multilayer structure having at least one capacitor comprising at least one bottom platinum electrode.

Owner:IBM CORP

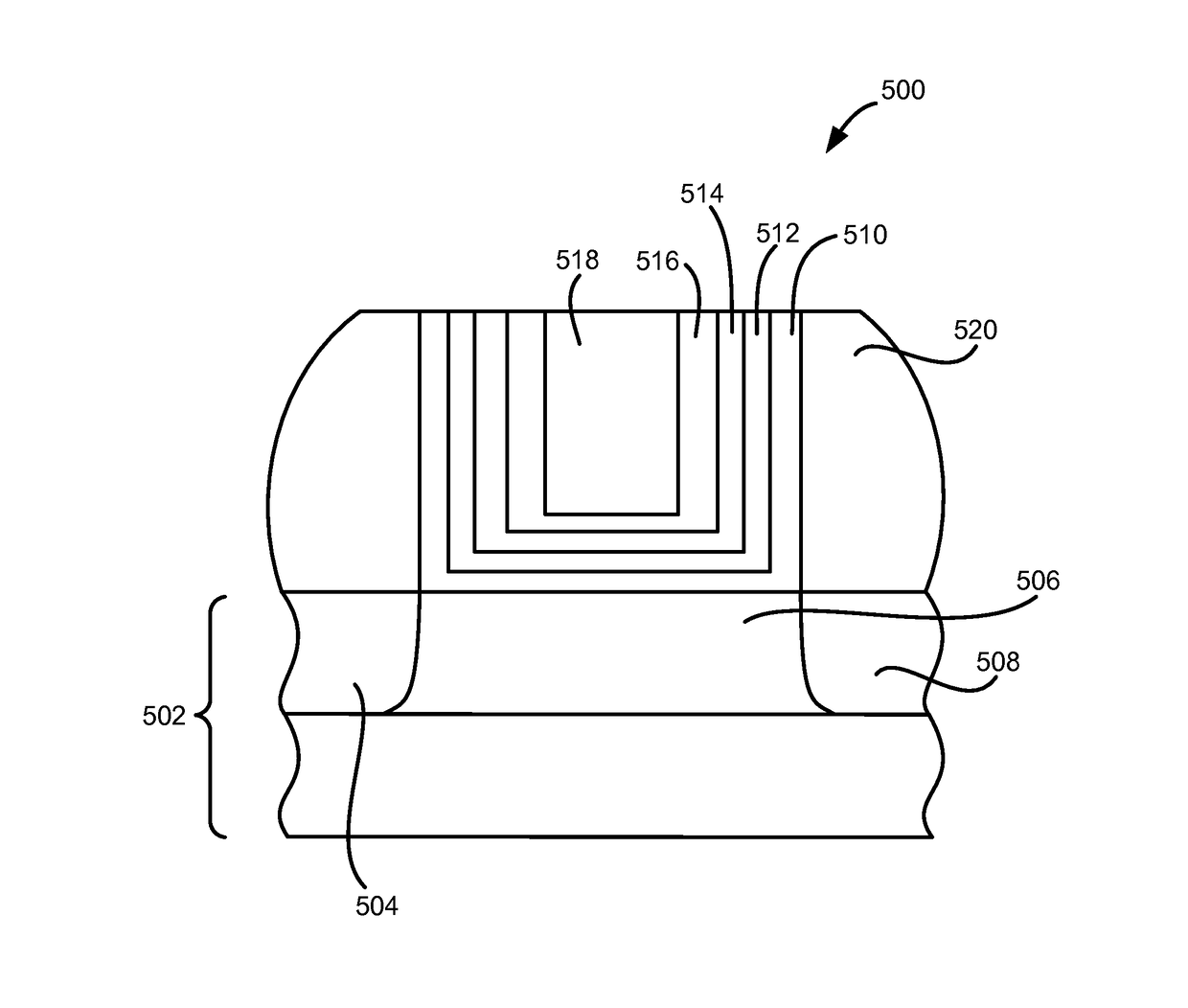

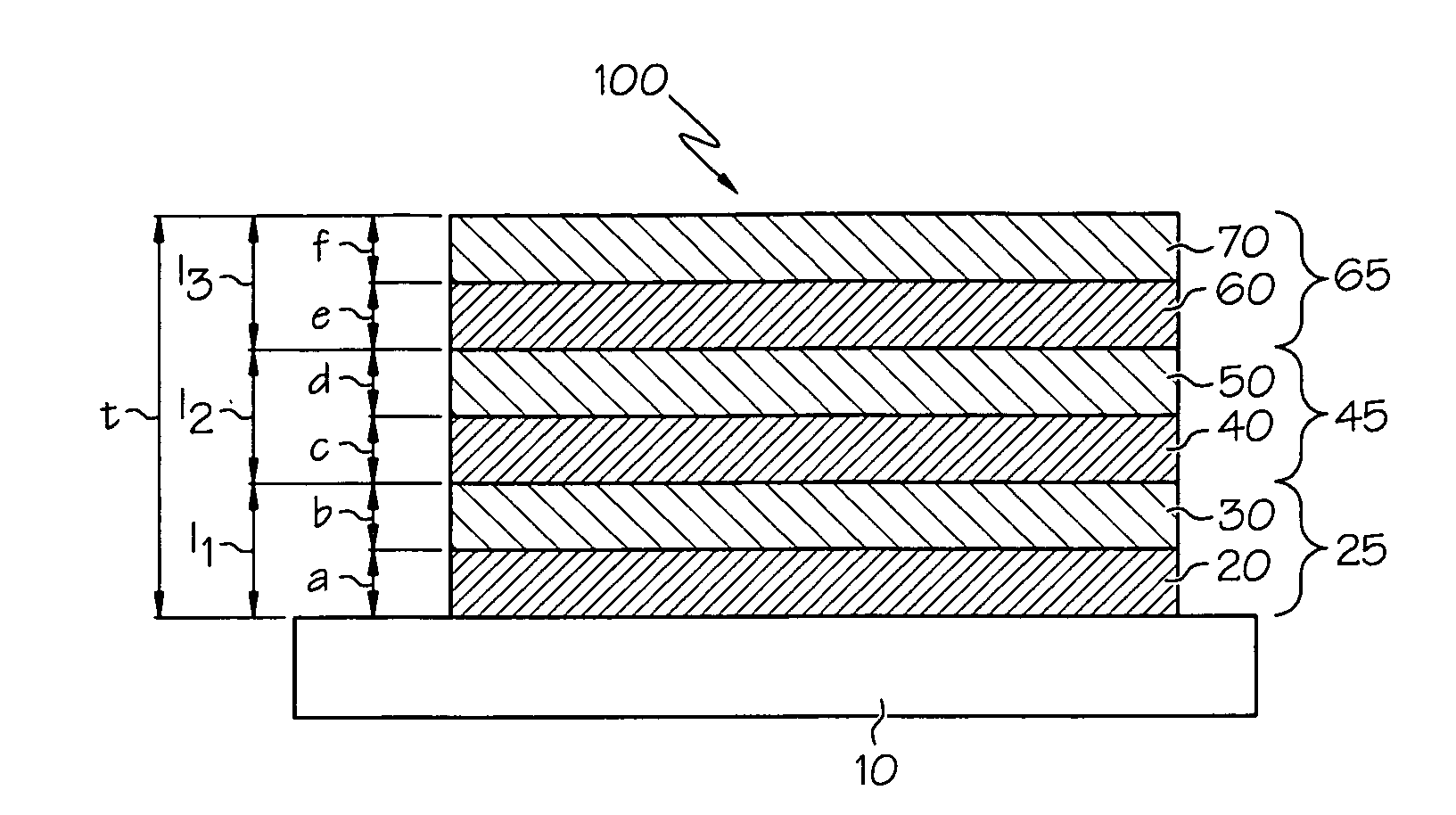

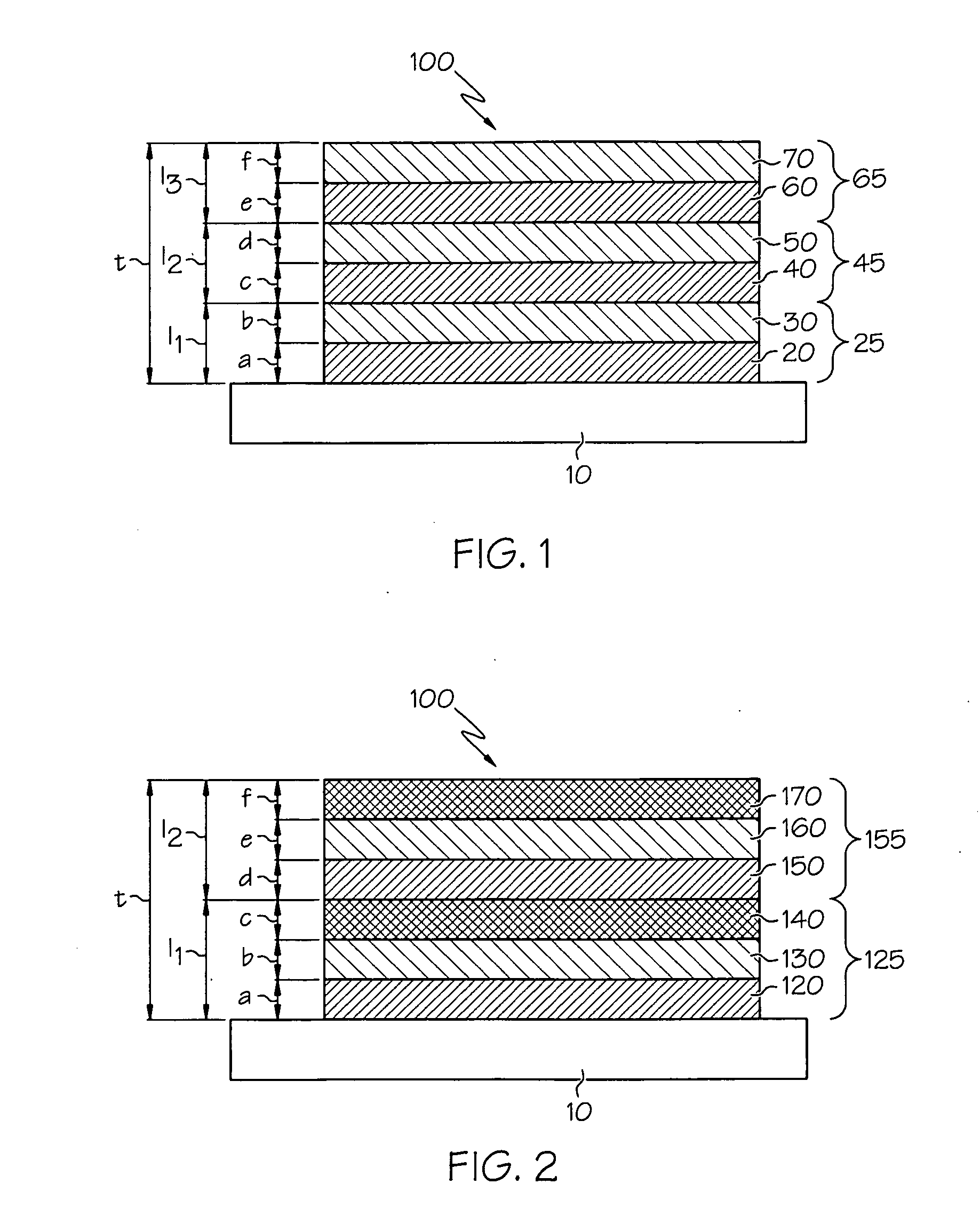

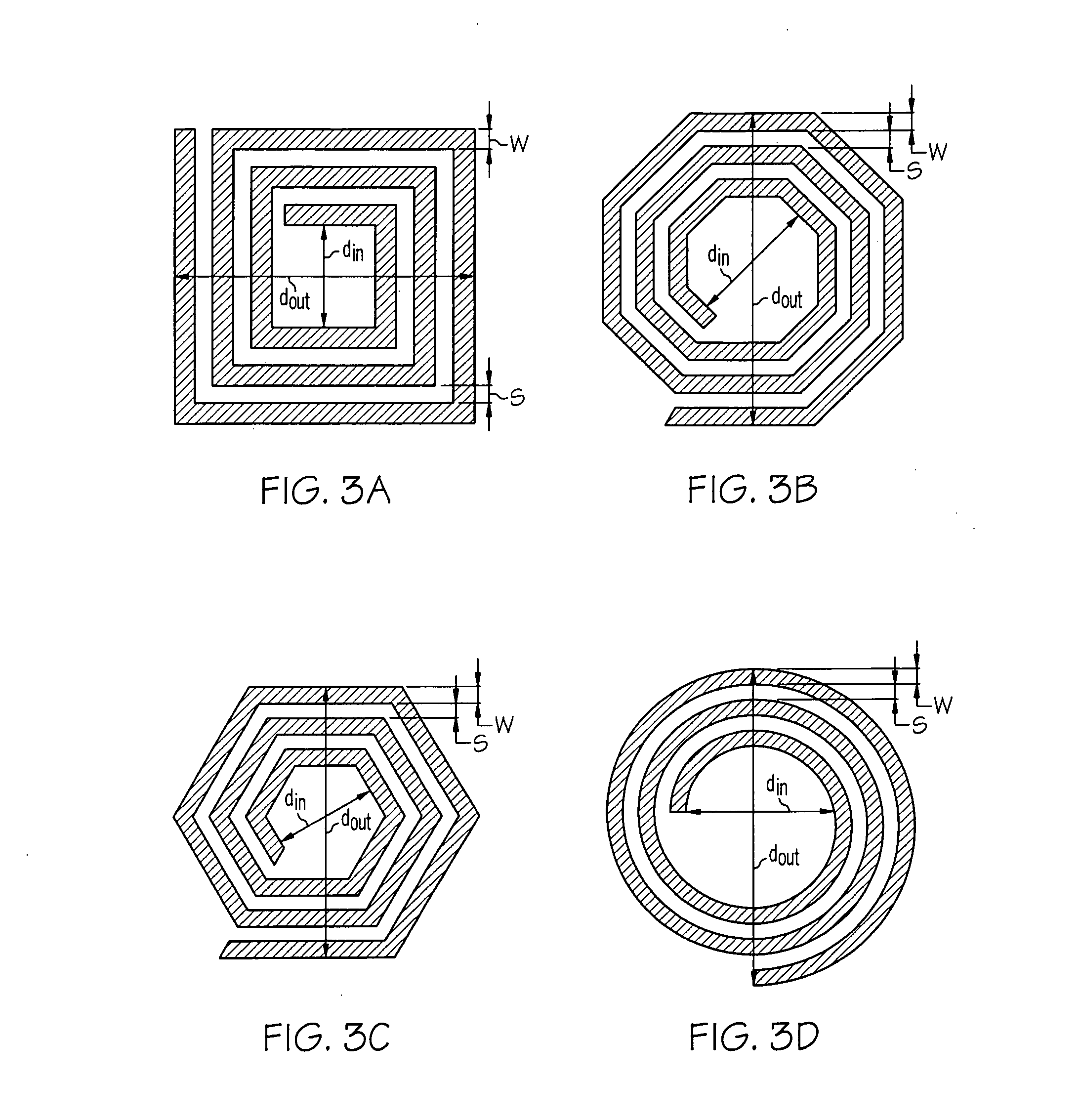

Thin film structures with negative inductance and methods for fabricating inductors comprising the same

ActiveUS20090261936A1Transformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

An inductor structure comprising a substrate and a planar conductor structure on a surface of the substrate, and methods for fabricating an inductor structure. The planar conductor structure may comprise a vertical stack of three or more multilayer films. Each multilayer film may comprise a first layer of a first metal, defining a first vertical thickness, and a second layer of a second metal, defining a second vertical thickness. The metals and thicknesses are chosen such that the inductor exhibits a negative electrical self-inductance when an electrical signal is transmitted from a first contact point to a second contact point.

Owner:UNIV OF DAYTON

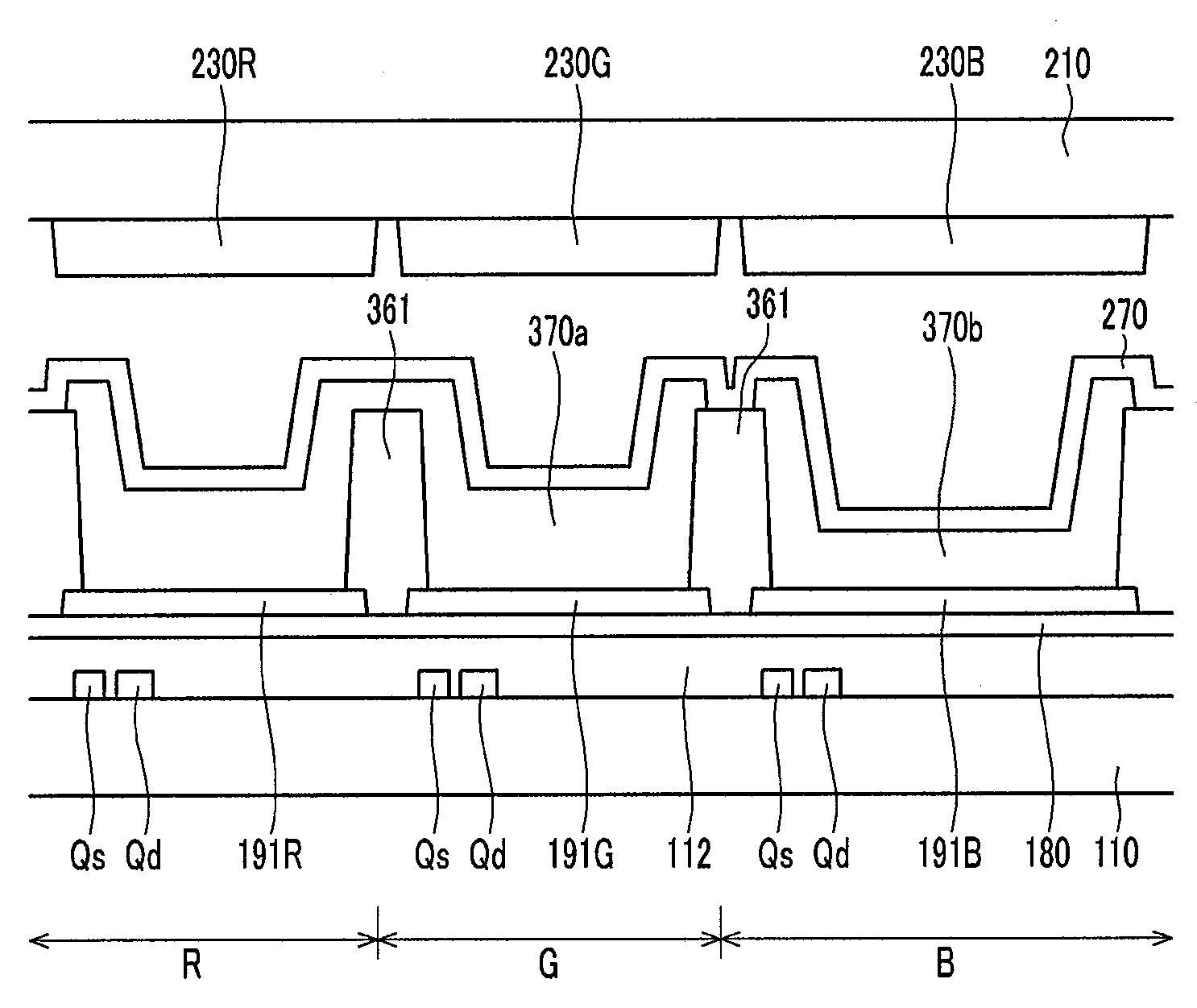

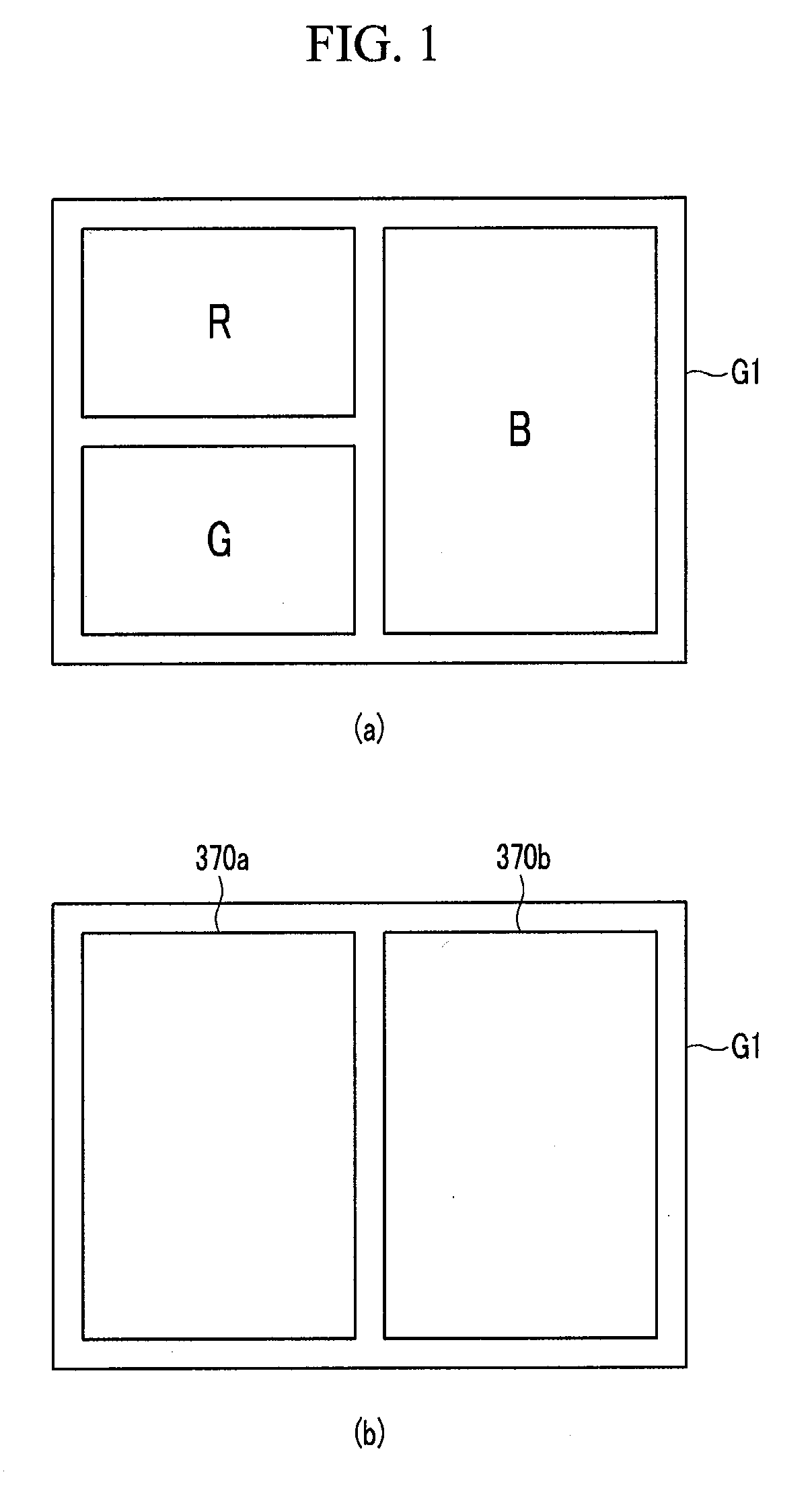

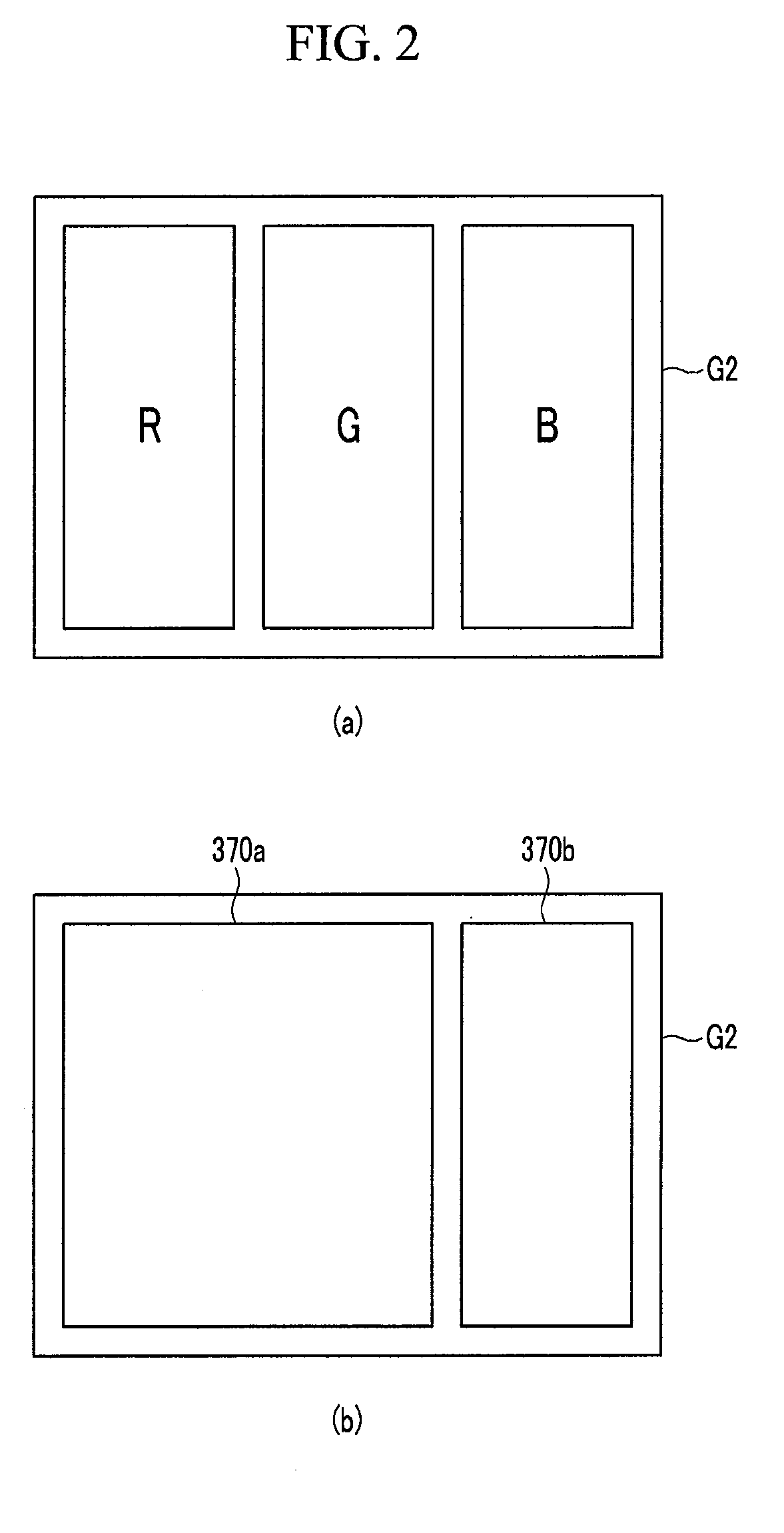

Organic emitting device

ActiveUS20100156279A1Discharge tube luminescnet screensLamp detailsOrganic light emitting deviceWavelength range

An organic light emitting device according to an exemplary embodiment of the present invention includes: a substrate including a first region, a second region, and a third region; a thin film structure disposed on the substrate; a first color filter, a second color filter, and a third color filter formed on the thin film structure, and respectively corresponding to the first region, the second region, and the third region; a first light emitting member formed on the first region and the second region; and a second light emitting member disposed on the third region, wherein the first light emitting member has a maximum light emitting value in a wavelength range of about 500 nm to 800 nm, and the second light emitting member has a maximum light emitting value in a wavelength range of about 400 nm to 500 nm.

Owner:SAMSUNG DISPLAY CO LTD

Switchable resistive perovskite microelectronic device with multi-layer thin film structure

ActiveUS20050151156A1Lowered pulse voltageProtection of device being damagedThyristorSemiconductor/solid-state device manufacturingElectrical resistance and conductanceMagnification

A switchable resistive device has a multi-layer thin film structure interposed between an upper conductive electrode and a lower conductive electrode. The multi-layer thin film structure comprises a perovskite layer with one buffer layer on one side of the perovskite layer, or a perovskite layer with buffer layers on both sides of the perovskite layer. Reversible resistance changes are induced in the device under applied electrical pulses. The resistance changes of the device are retained after applied electric pulses. The functions of the buffer layer(s) added to the device include magnification of the resistance switching region, reduction of the pulse voltage needed to switch the device, protection of the device from being damaged by a large pulse shock, improvement of the temperature and radiation properties, and increased stability of the device allowing for multivalued memory applications.

Owner:UNIV HOUSTON SYST

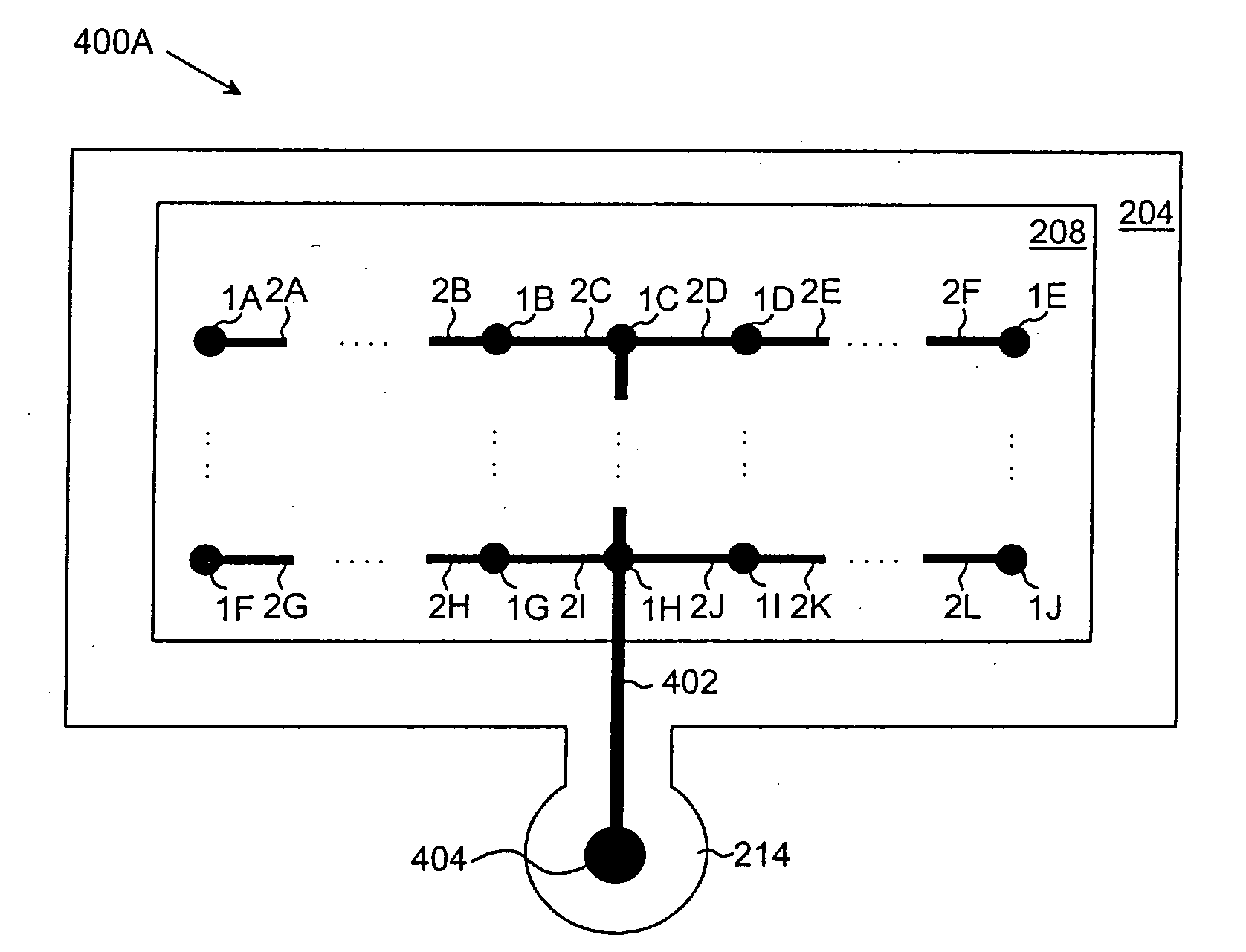

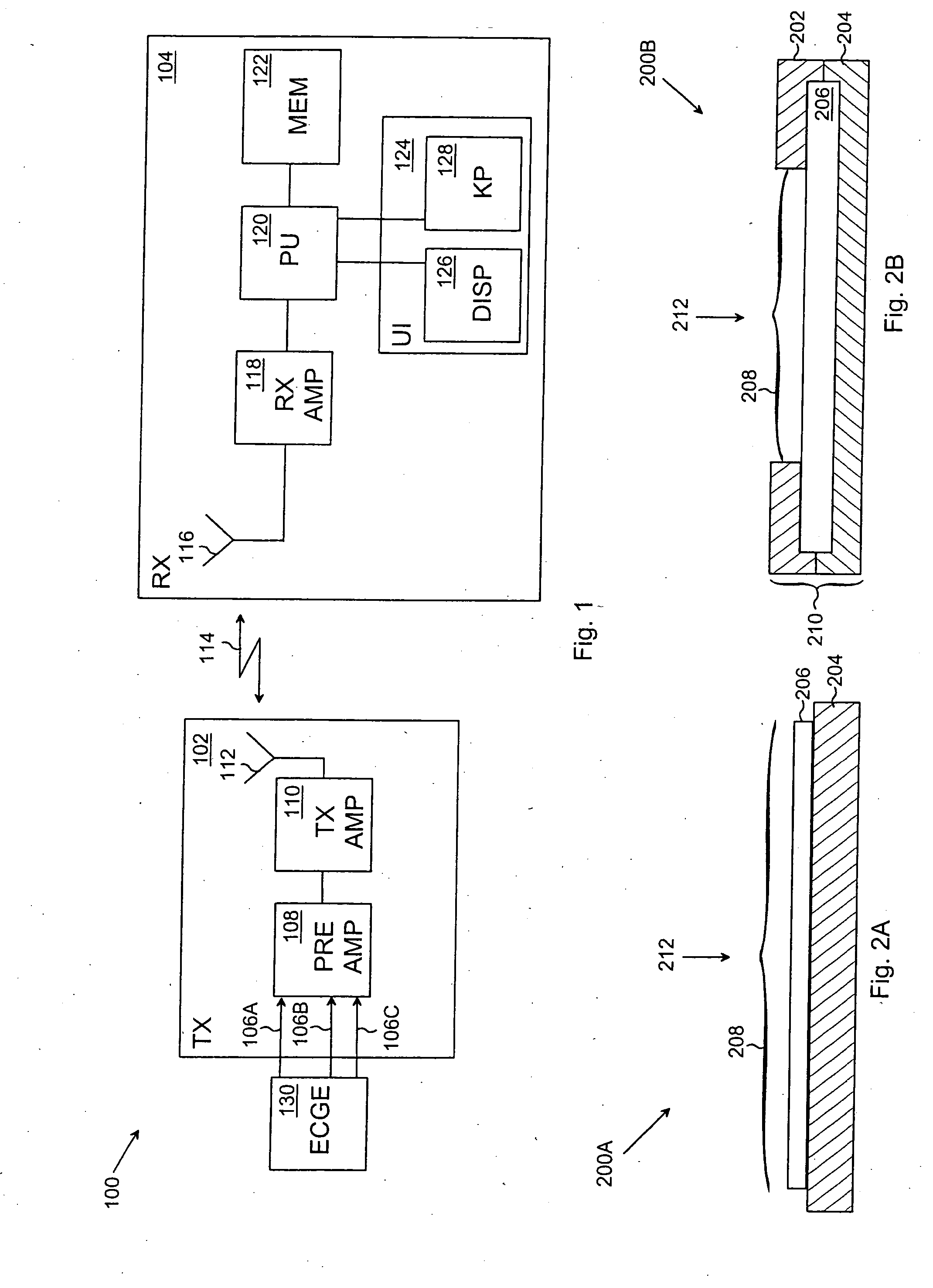

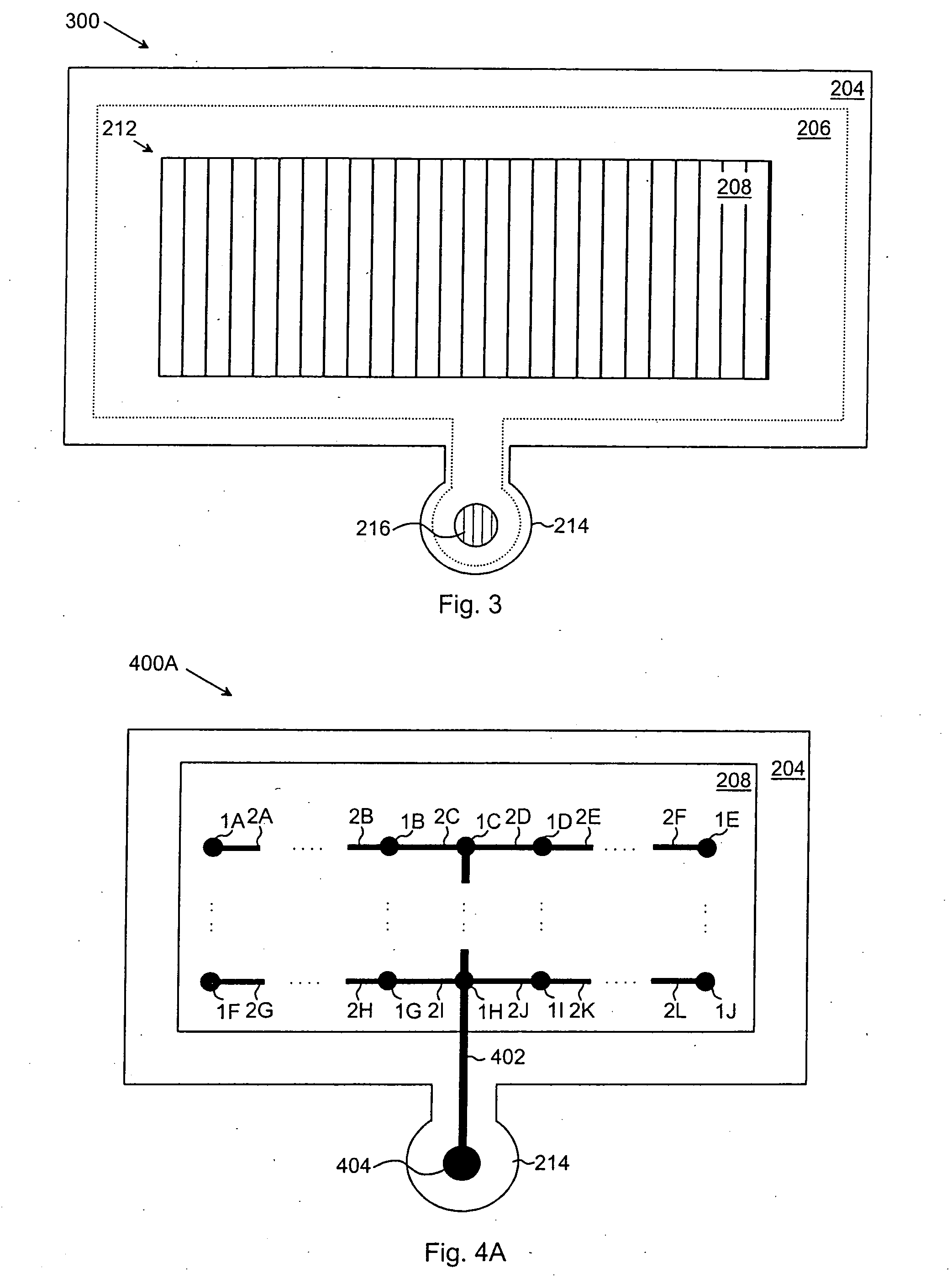

Sensor system, garment and heart rate monitor

The invention relates to a sensor system, a garment and a heart rate monitor. The sensor system comprises at least one flexible film structure comprising: a first insulation layer and at least one electric conductor layer formed on top of the first insulation layer and comprising an electrode area, which is configured to establish an electric contact with the surface of the user's skin and to generate as output an electric signal proportional to a momentary value of the electrocardiogram.

Owner:POLAR ELECTRO

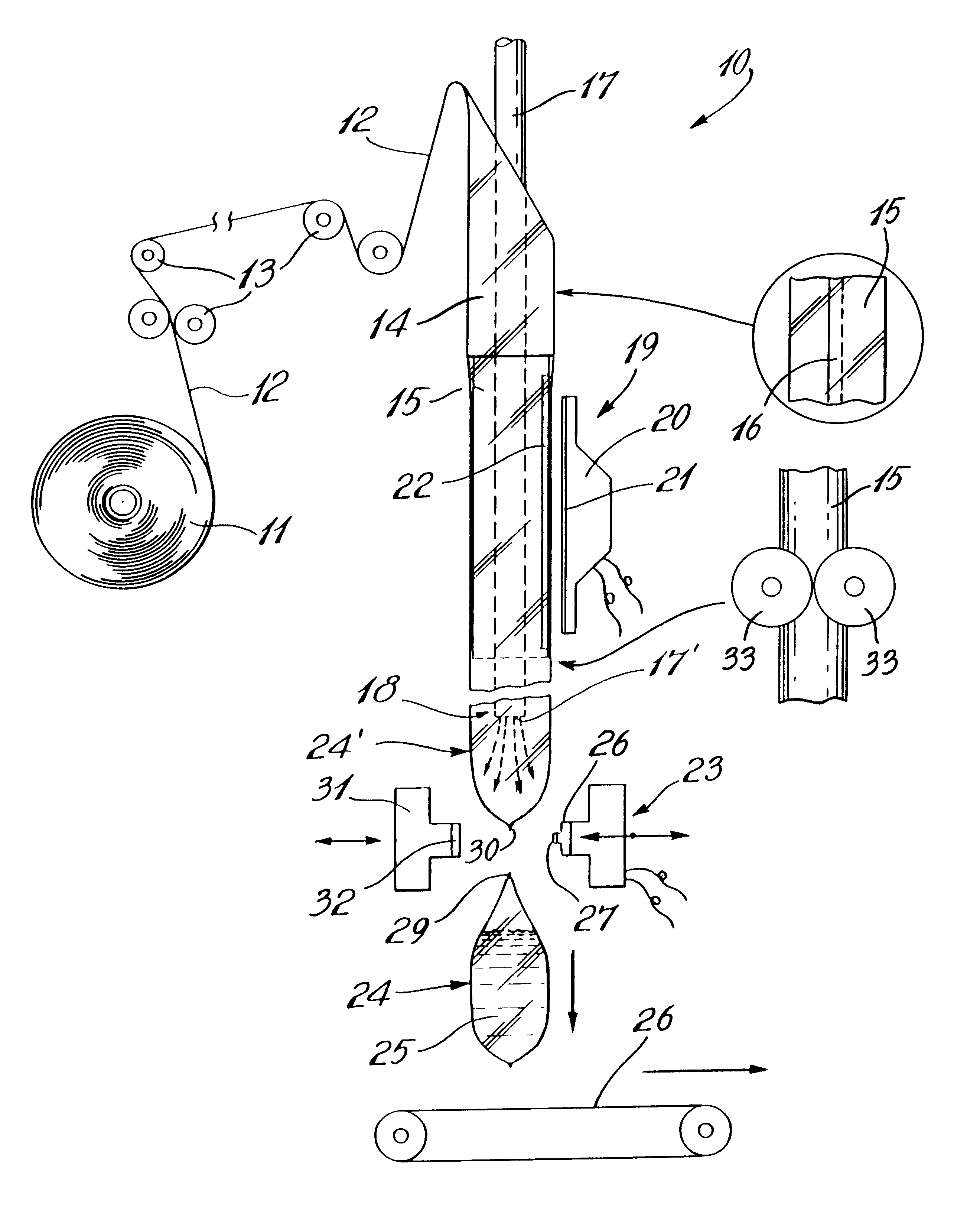

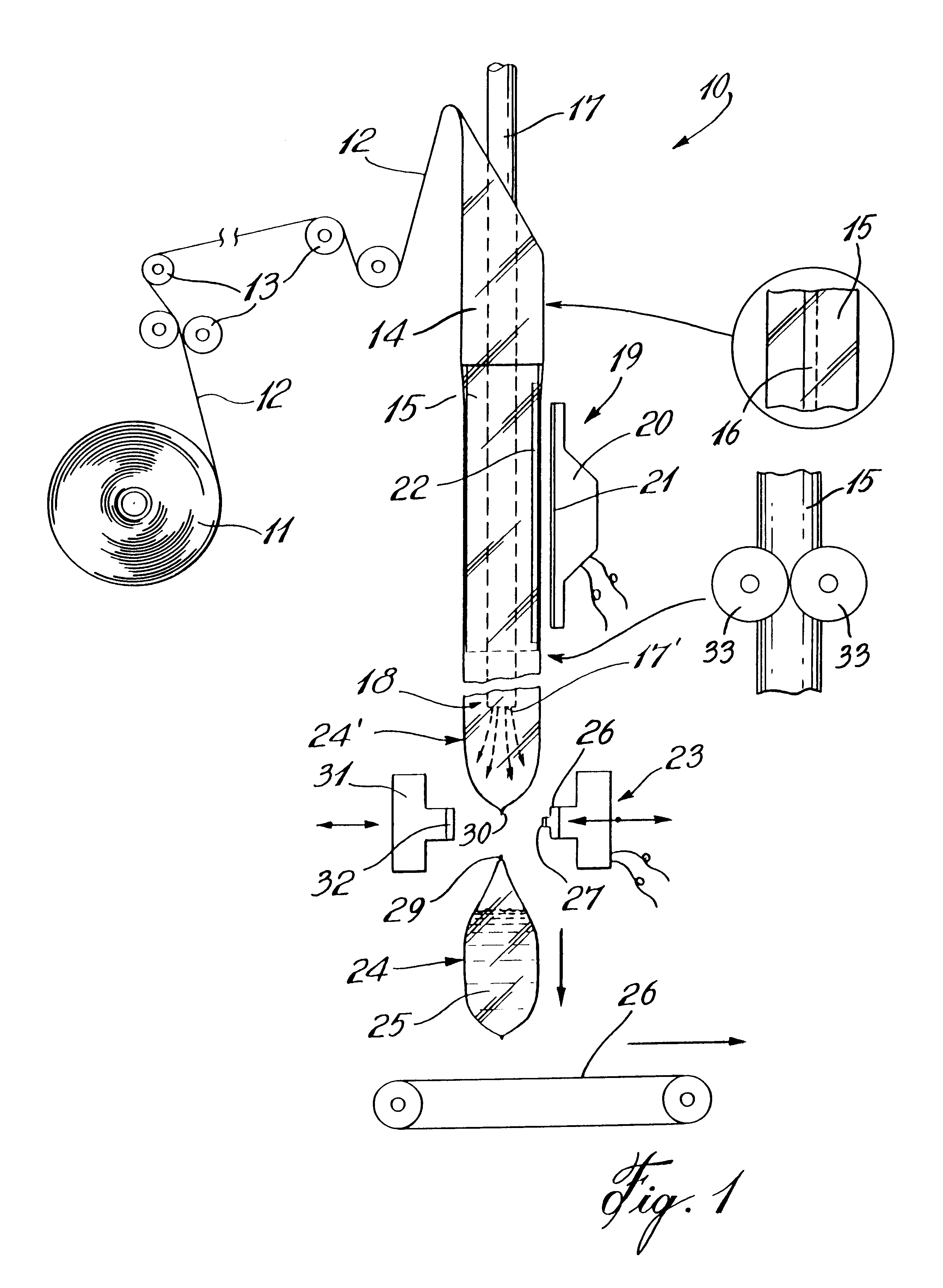

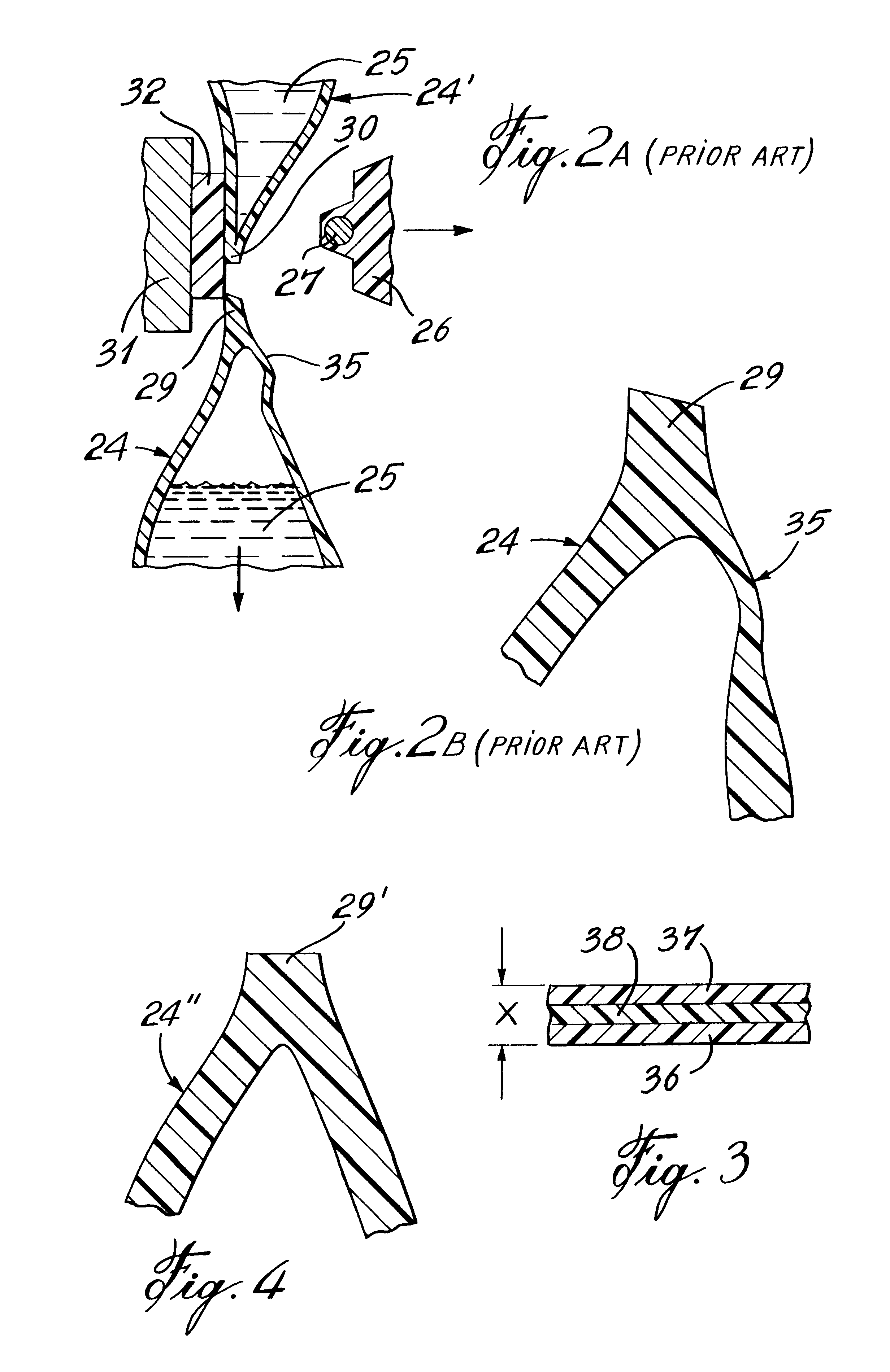

High-speed pouch forming, sealing and filling machine, method of operation, and multi-layer film therefore

InactiveUS6237308B1Improve methodImprove throughputSynthetic resin layered productsWrapper twisting/gatheringPuncture resistanceEngineering

The multi-layer film structure having an inner sealing layer which comprises metallocene resin, a core which includes polypropylene copolymer and an outer layer and wherein the multi-layer film structure has a thickness within a range between about 50 and 70 microns (2.0-2.75 mil). By utilizing this thin film with specific properties the sealers may be operated at lower temperatures thereby resulting in an energy saving and they produce seals having improved seal strength of 30% to 50% as compared with known prior mono-layer polyethylene film. The seal initiation temperature is reduced by 10° C. to 15° C. and the film exhibits an improved machine direction tensile strength of 25% to 40% and an improvement of 30% to 50% in puncture resistance as compared with a 76 microns (3 mil) mono-layer polyethylene film. This results in a reduction in the sealing cycle time and an increase in the throughput of the machine. This results in a liquid pouch having a substantial improvement in drop test performance, puncture resistance and seal strength. The machine accomplishes better seals with less energy, requires less downtime for roll changes and maintenance and increase throughput.

Owner:GLOPAK INC

Carbon nanotube-based composite material and method for fabricating the same

InactiveUS20090181239A1Complicates surface modificationLow costMaterial nanotechnologyPretreated surfacesCarbon nanotubeFilm structure

A carbon nanotube-based composite material includes a polymer matrix and a plurality of carbon nanotubes in the polymer matrix. The plurality of carbon nanotubes form a free standing carbon nanotube film structure. A method for fabricating the carbon nanotube-based composite material includes: providing a polymer matrix comprising a surface; providing at least one carbon nanotube film comprising a plurality of carbon nanotubes; disposing the at least one carbon nanotube film on the surface of the polymer matrix to obtain a preform; and heating the preform to combine the at least one carbon nanotube film with the polymer matrix.

Owner:TSINGHUA UNIV +1

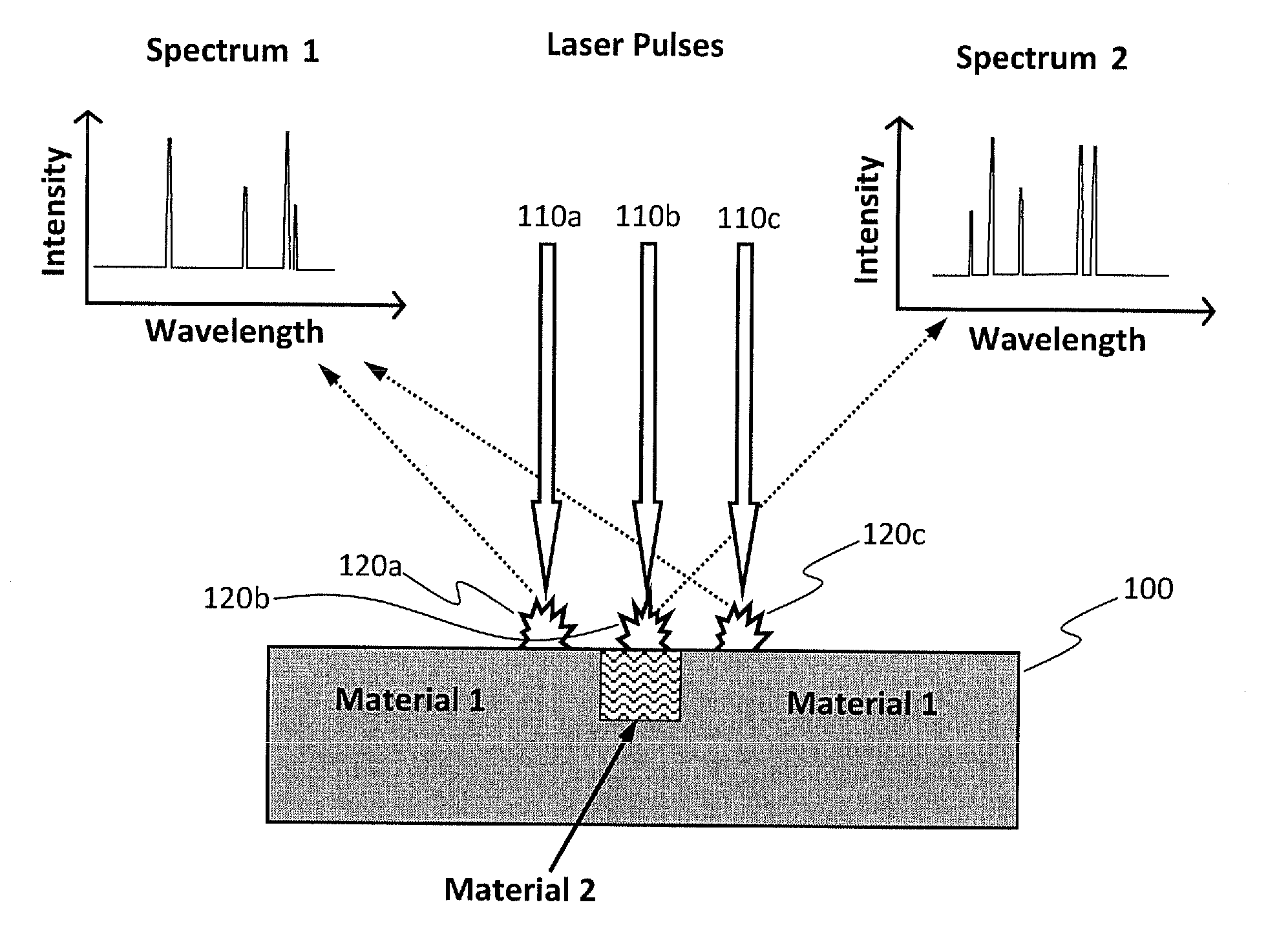

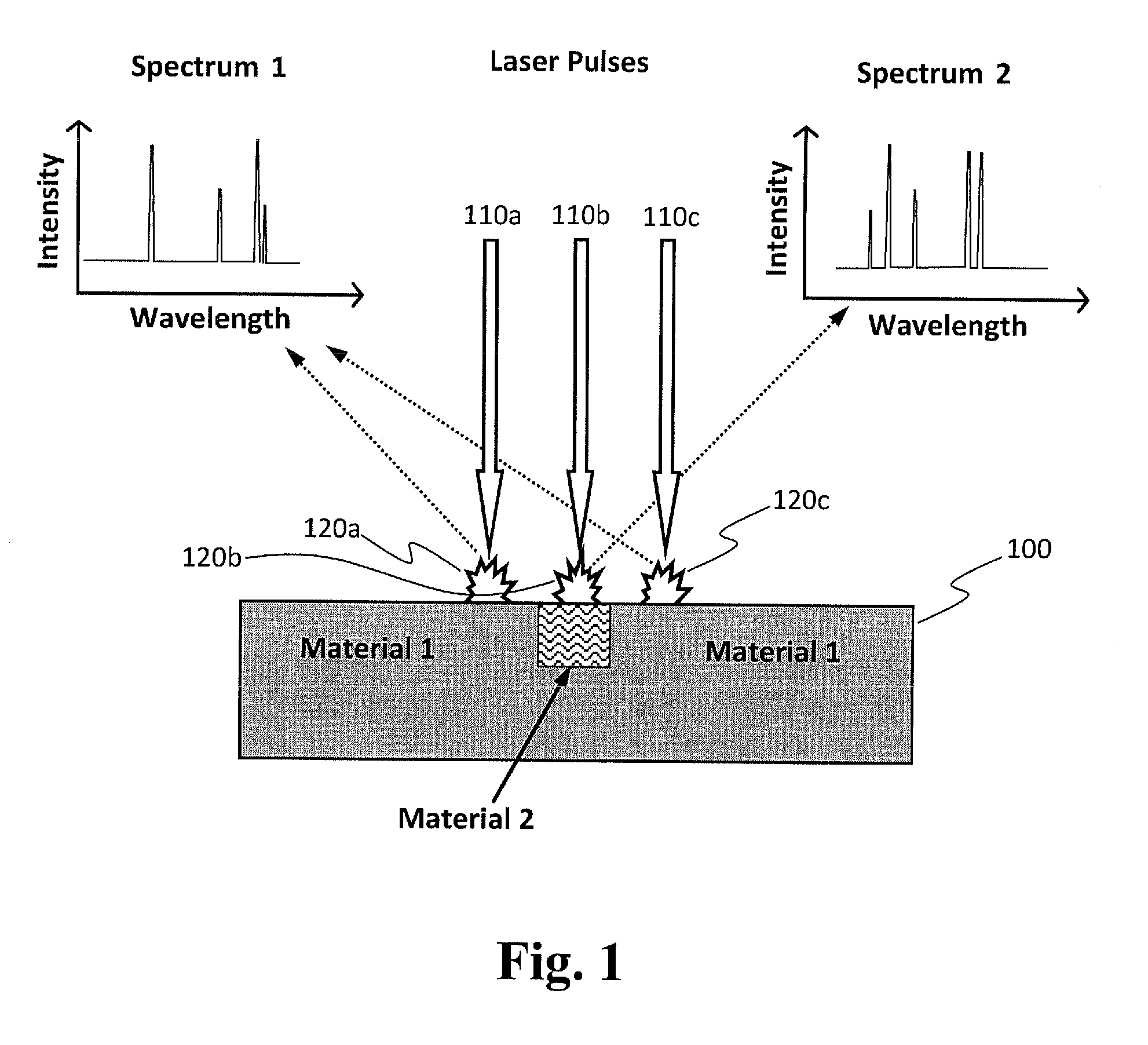

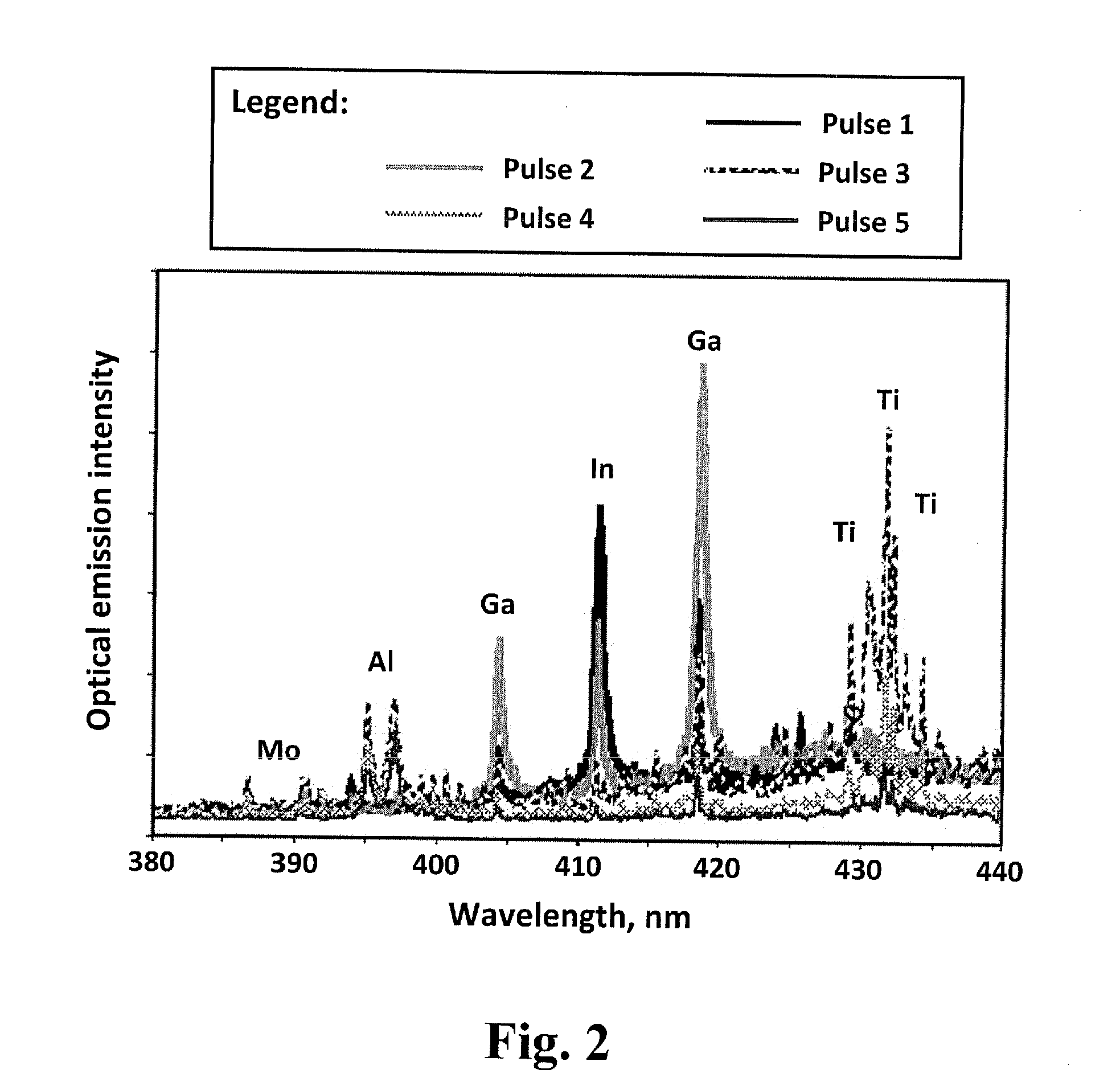

Method for real-time optical diagnostics in laser ablation and laser processing of layered and structured materials

ActiveUS20110100967A1Strong specificityImprove efficiencyMaterial analysis by electric/magnetic meansLaser beam welding apparatusLaser processingOptical diagnostics

A method for real-time optical diagnostics in laser ablation and laser processing of layered or structured materials or material structures. Diagnostics is provided during laser ablation that is utilized regularly in laser processing and / or chemical analysis of structured materials, by means of measuring optical emission generated as a result of the pulsed laser-material interaction in real time. The method can involve a single-layer-film or a stack of multiple layers or a structure of different domains. The method is particularly beneficial in fabrication of thin-film structures, such as photovoltaic and electronic devices or circuits of devices.

Owner:APPLIED SPECTRA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com