Patents

Literature

1417 results about "Nanotube array" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

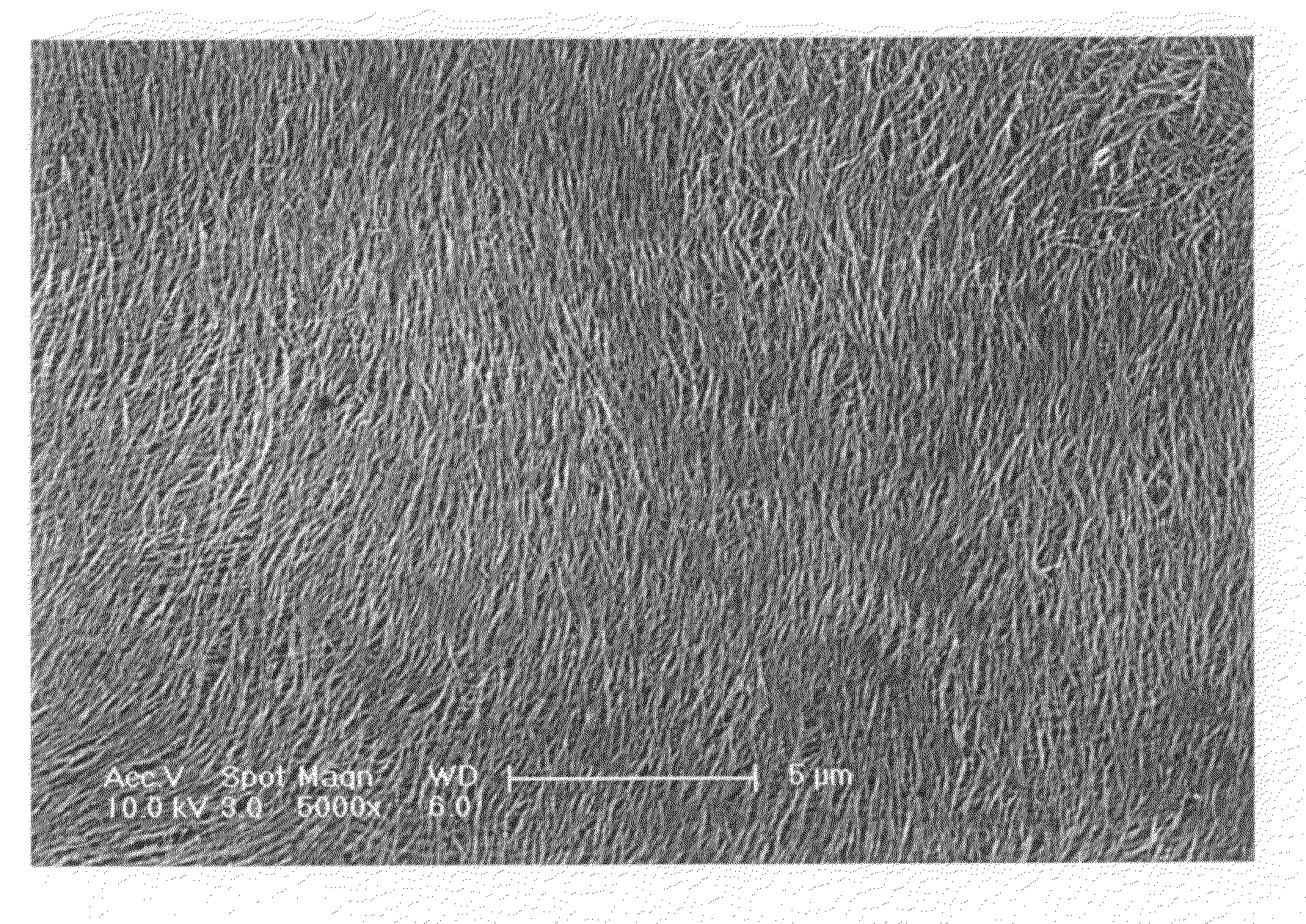

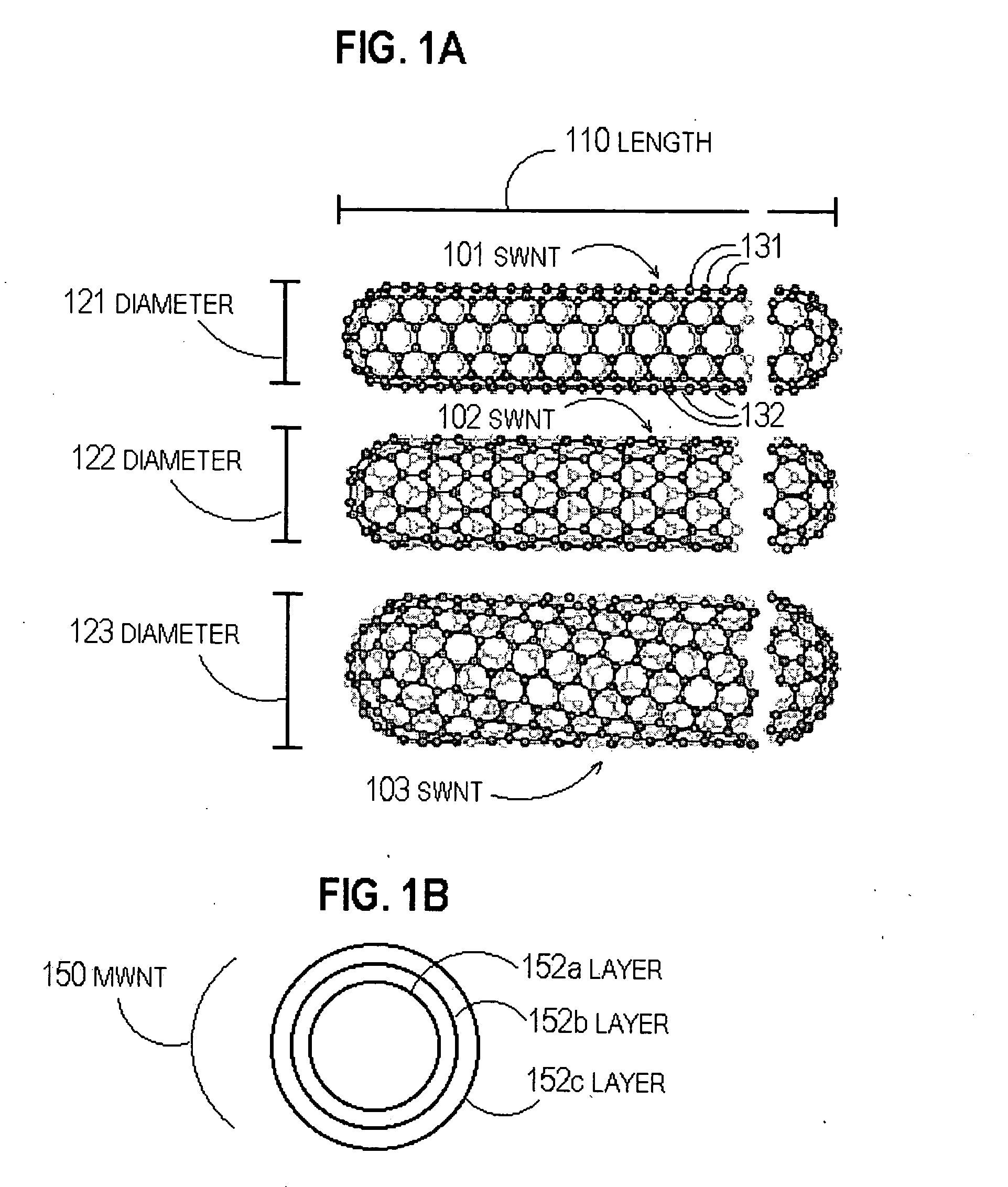

Vertically aligned carbon nanotube arrays (VANTAs) are a unique microstructure consisting of carbon nanotubes oriented along their longitudinal axis normal to a substrate surface. These VANTAs effectively preserve and often accentuate the unique anisotropic properties of individual carbon nanotubes and possess a morphology that may be precisely controlled.

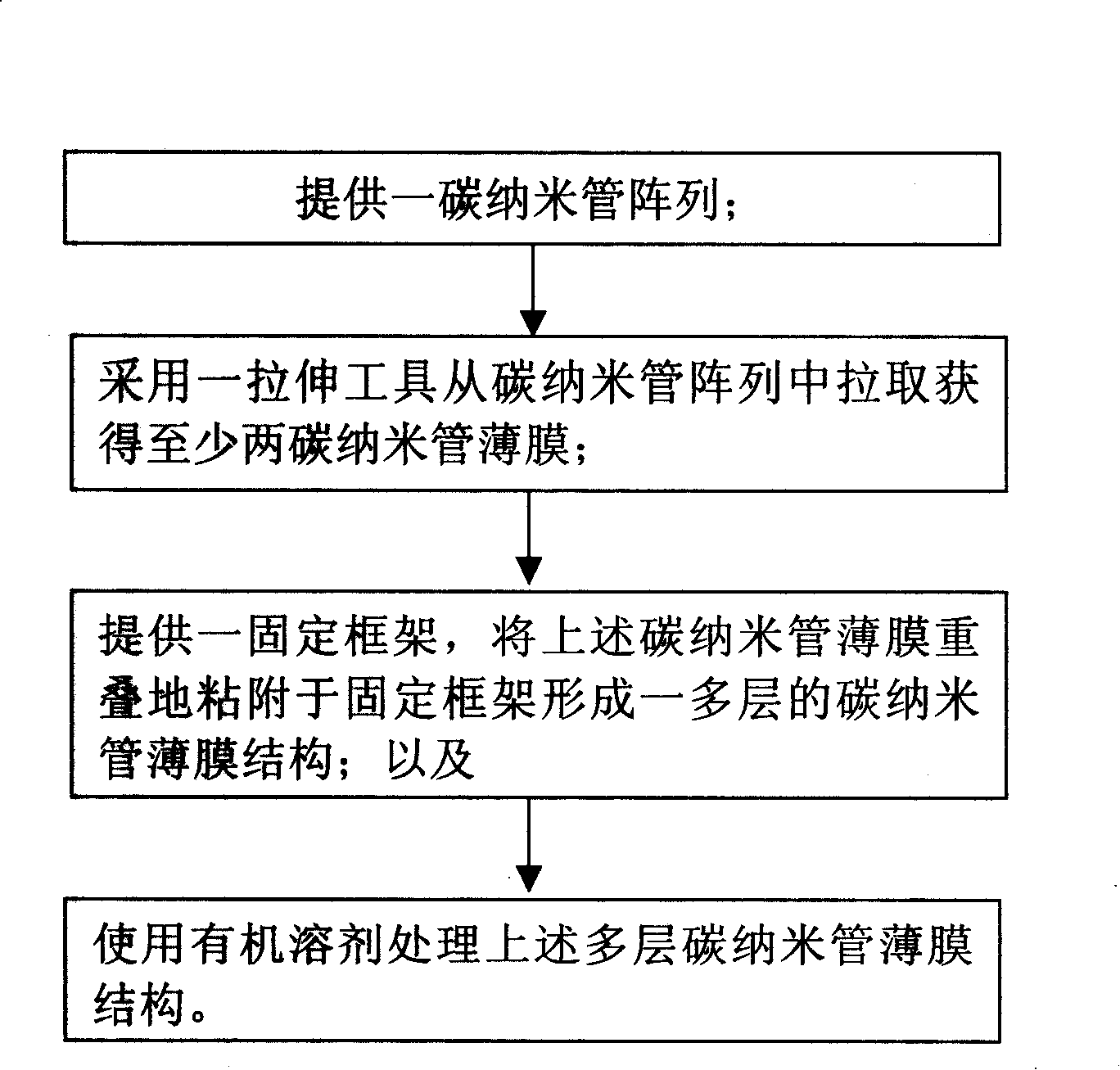

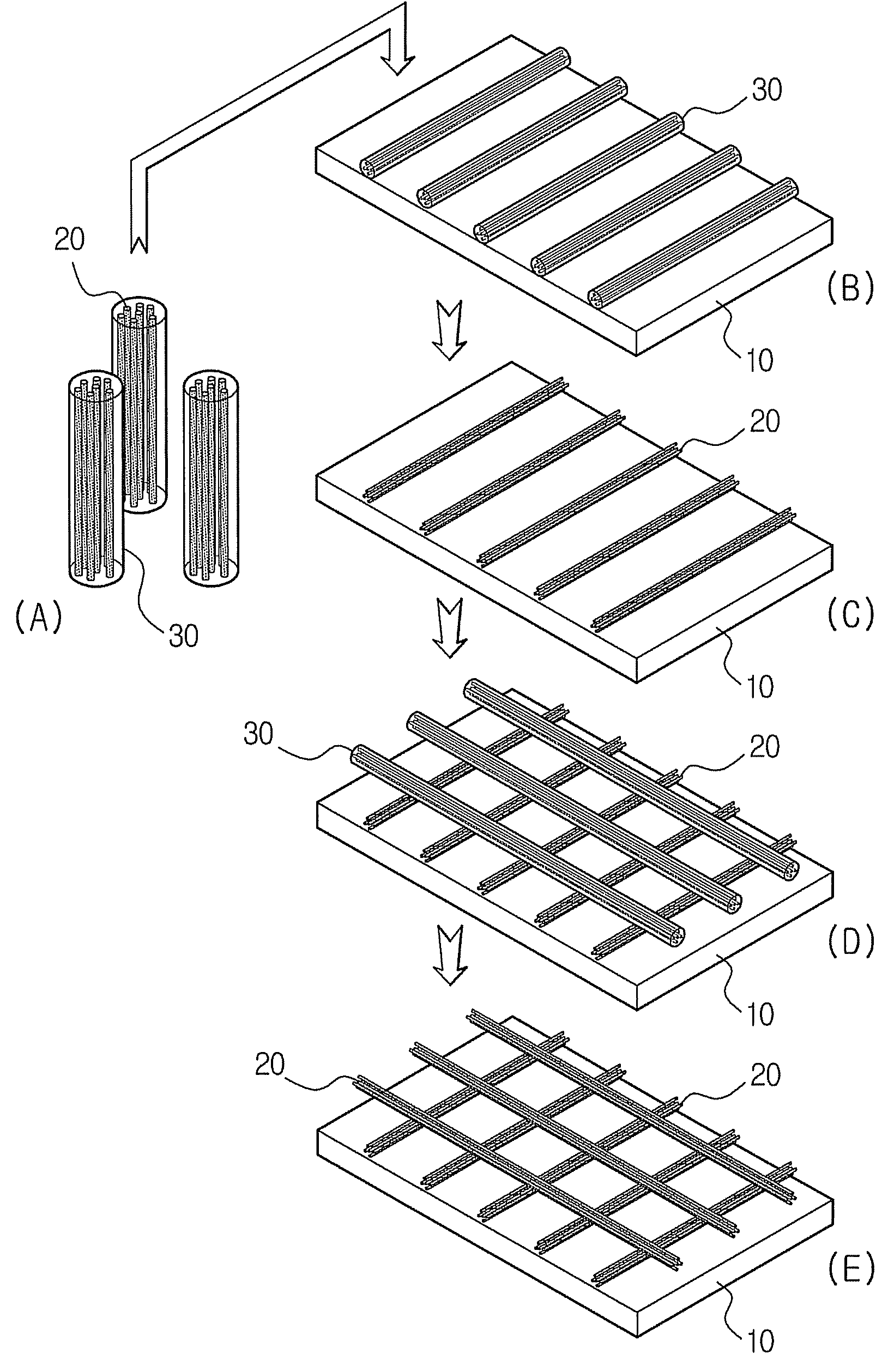

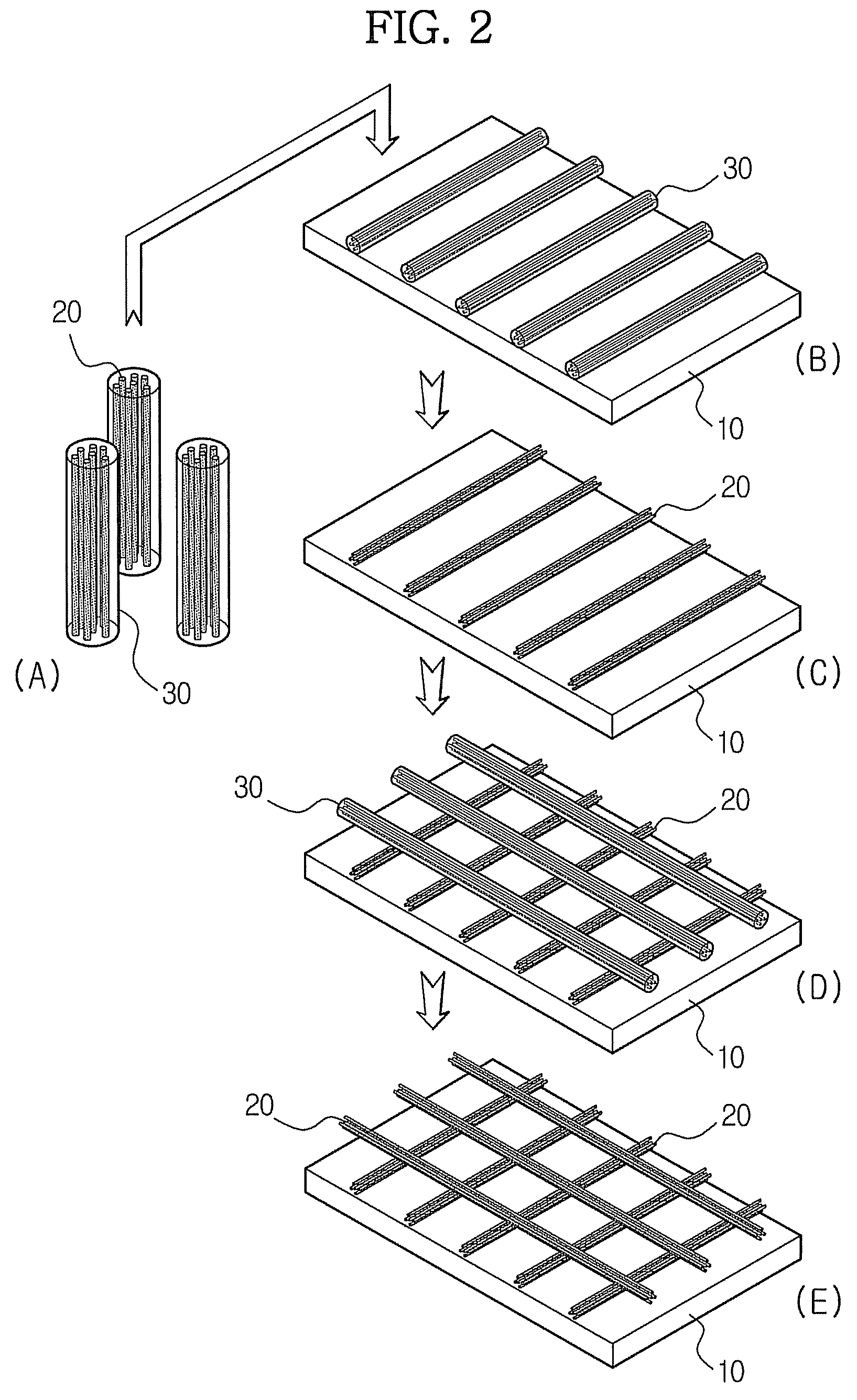

Carbon nano-tube thin film structure and preparation method thereof

ActiveCN101239712ASmall surface to volume ratioNon stickyMaterial nanotechnologyLamination ancillary operationsOrganic solventFixed frame

The present invention provides a preparing method of carbon nanotube film structure, including following steps: providing a carbon nanotube array; adopting a pulling tool to acquire at least two carbon nanotube films from the carbon nanotube array; providing a fixed frame, forming a multiple-layer carbon nanotube film structure by overlap adhereing the carbon nanotube film in the fixed frame; and treating the multiple-layer carbon nanotube film by an organic solvent. The carbon nanotube film structure prepared by the method includes at least two layers overlapped and cross-over installed carbon nanotube film, which includes multiple carbon nanotube bundle end to end and arranged in the direction, the multiple-layer carbon nanotube film further includes millipore crosswise formed by multiple carbon nanotube bundles.

Owner:TSINGHUA UNIV +1

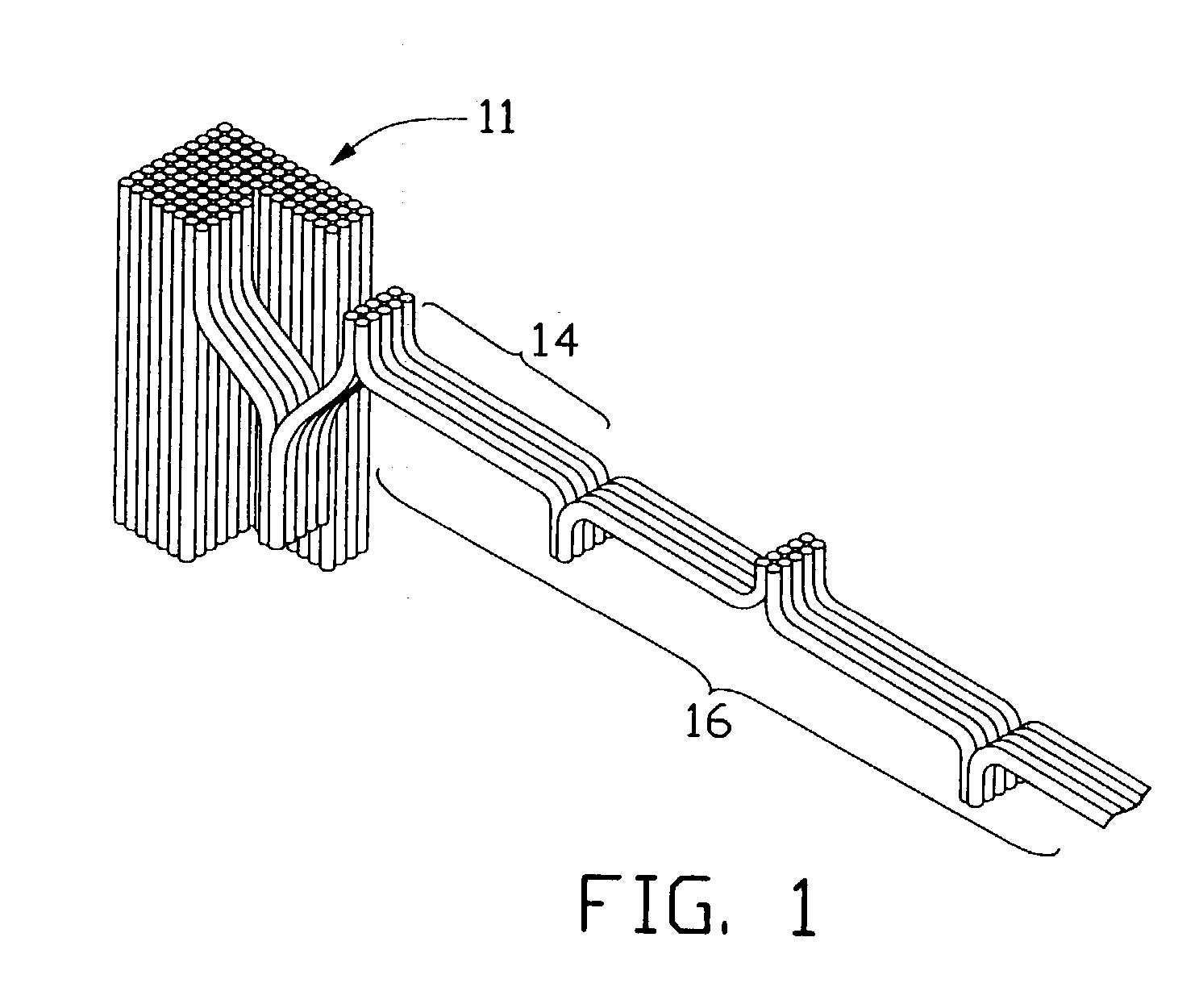

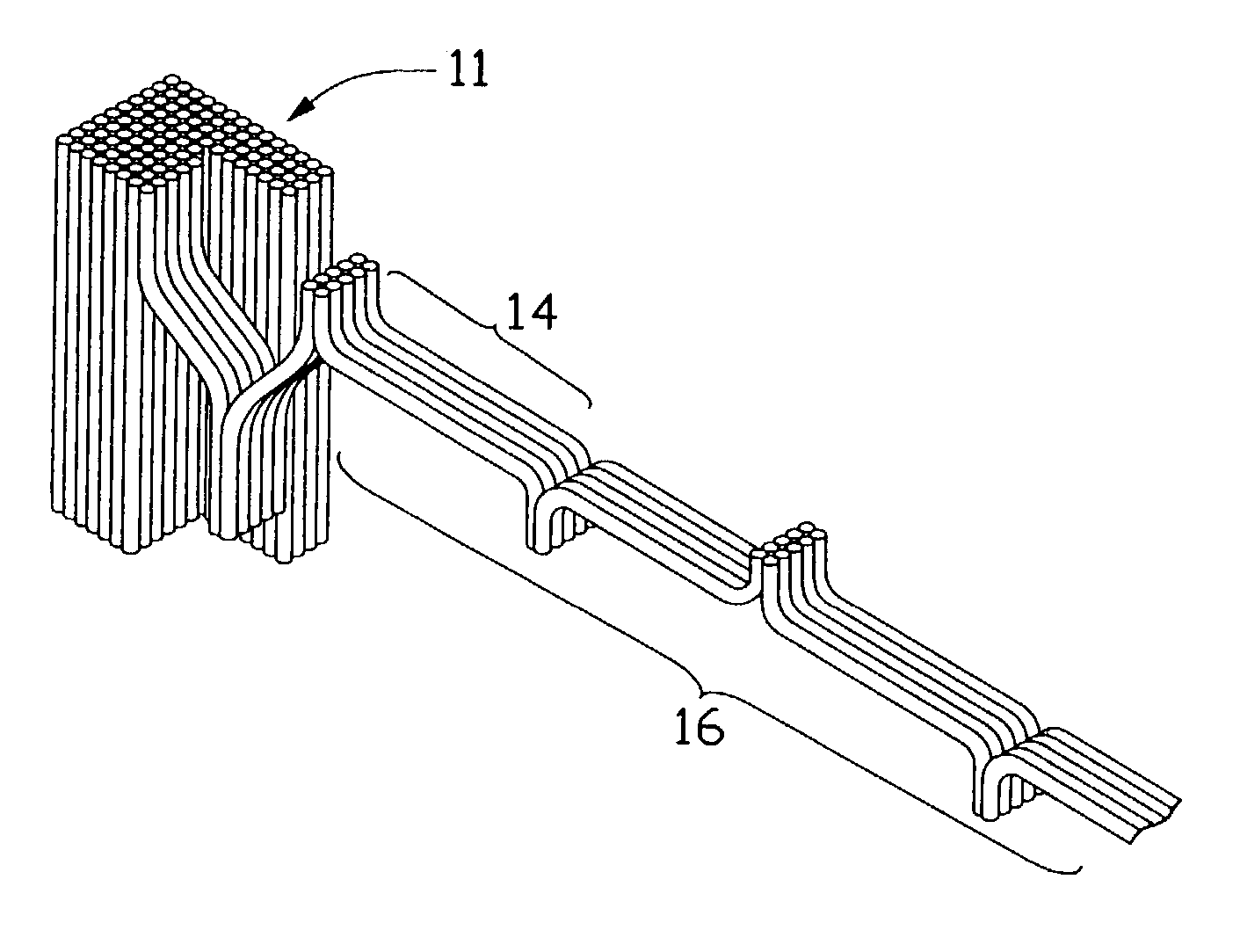

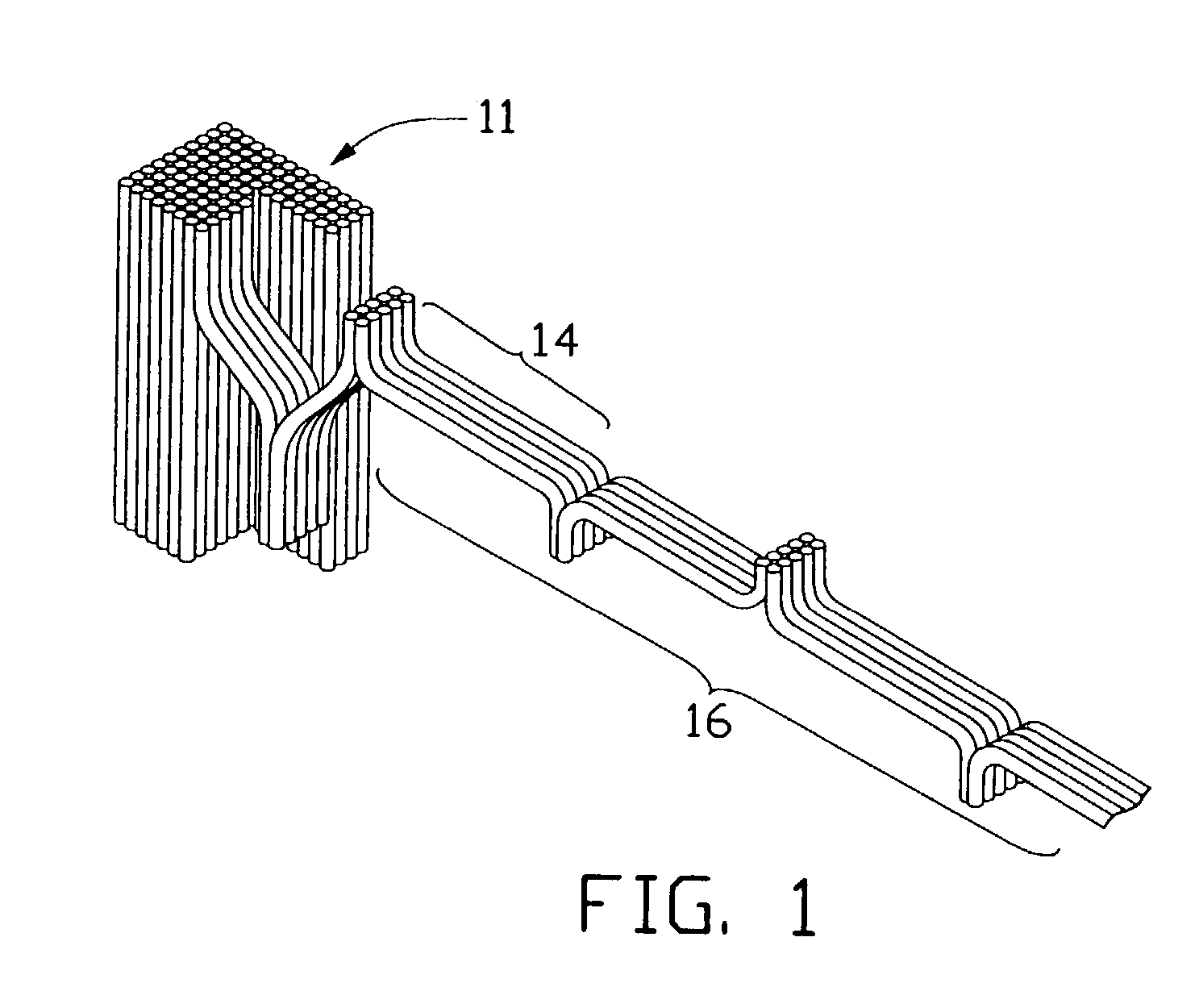

Method for fabricating carbon nanotube yarn

ActiveUS20040053780A1Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

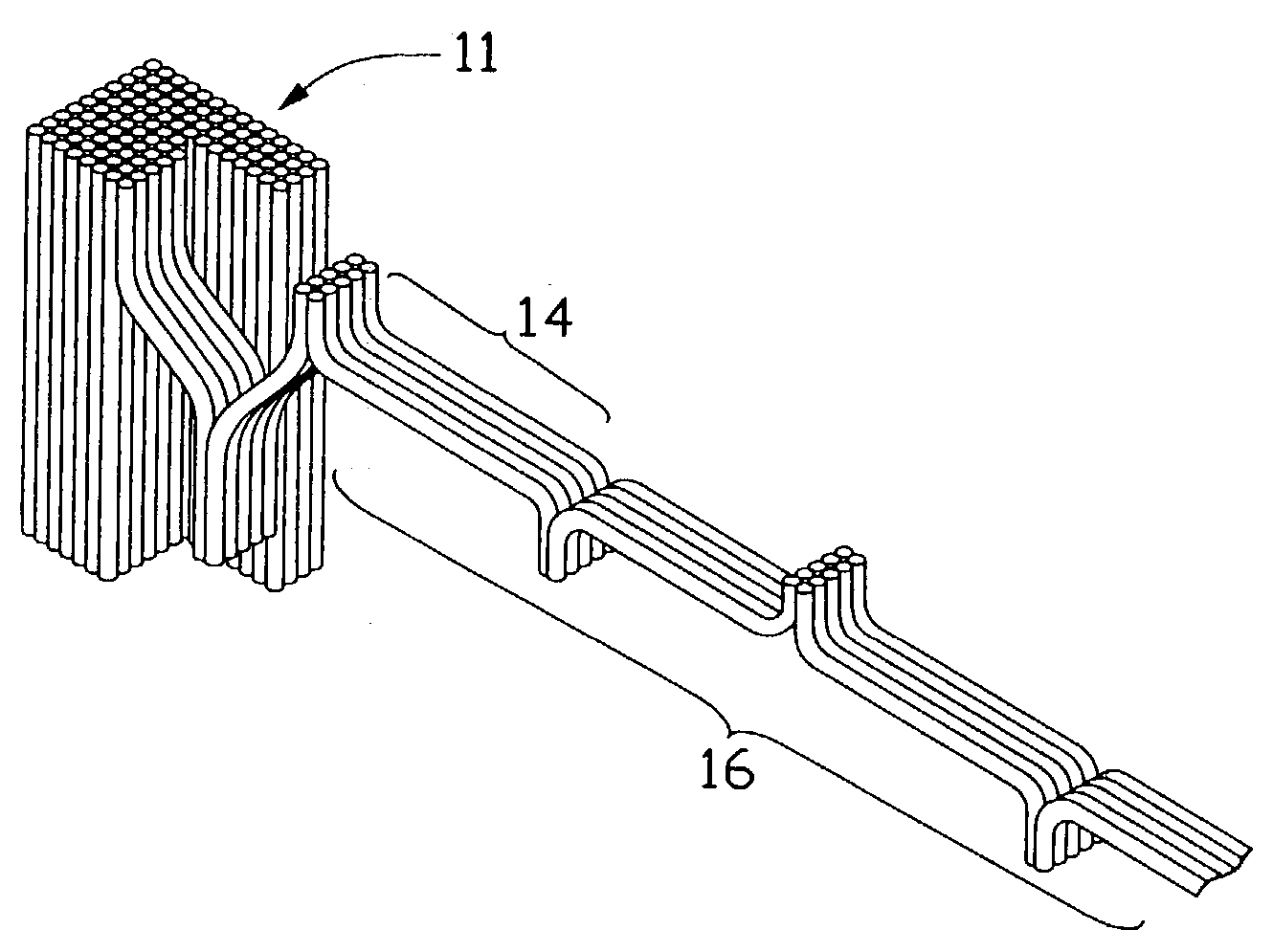

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

Method for fabricating carbon nanotube yarn

ActiveUS7045108B2Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

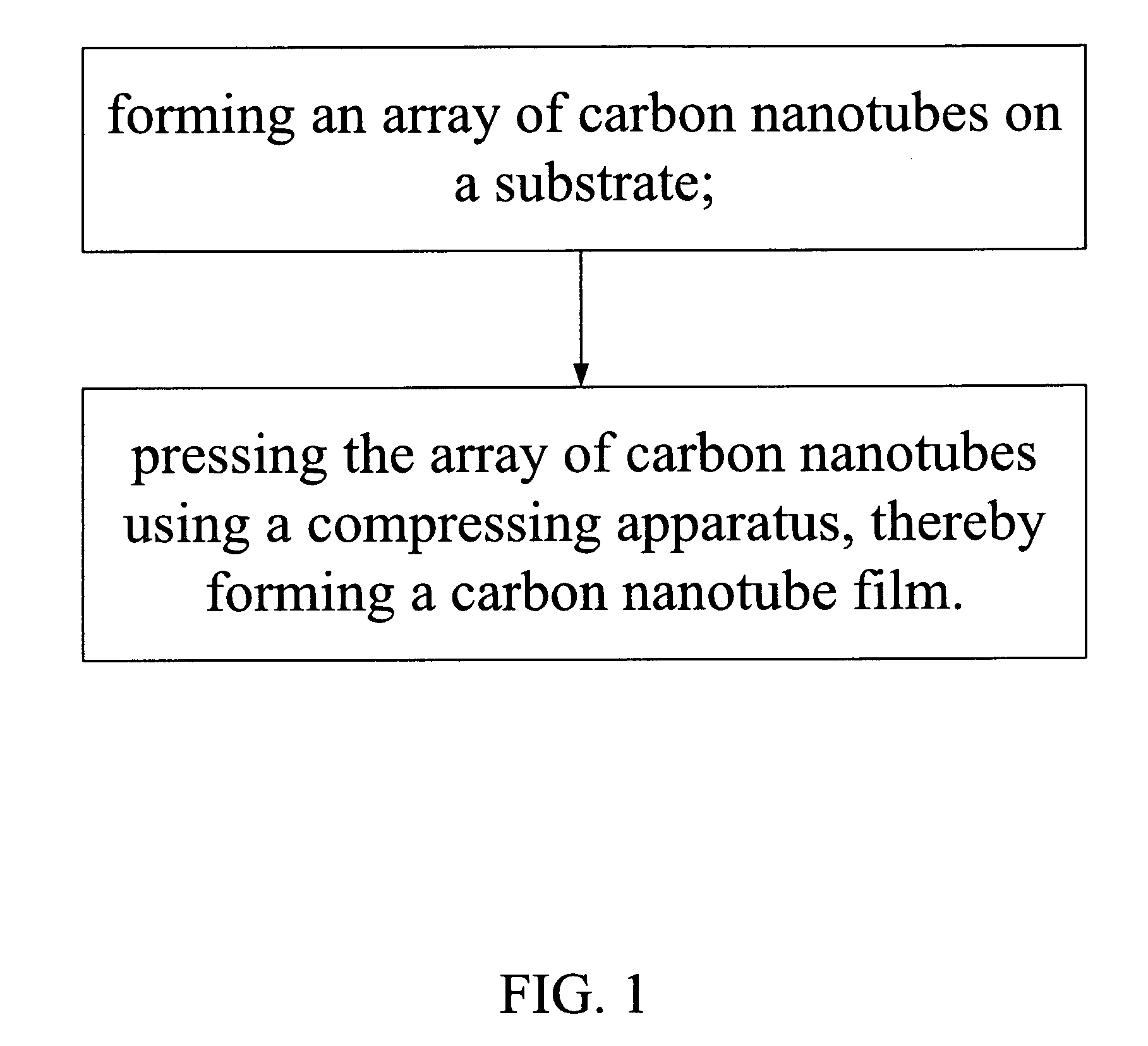

Method for making a carbon nanotube film

ActiveUS20080299031A1High strengthSimple methodMaterial nanotechnologyLayered productsCarbon nanotubeNanotube array

The present invention relates to a method for making a carbon nanotube film. The method includes the steps of: (a) forming an array of carbon nanotubes on a substrate; and (b) press the array of carbon nanotubes using a compressing apparatus, thereby forming a carbon nanotube film.

Owner:BEIJING FUNATE INNOVATION TECH +1

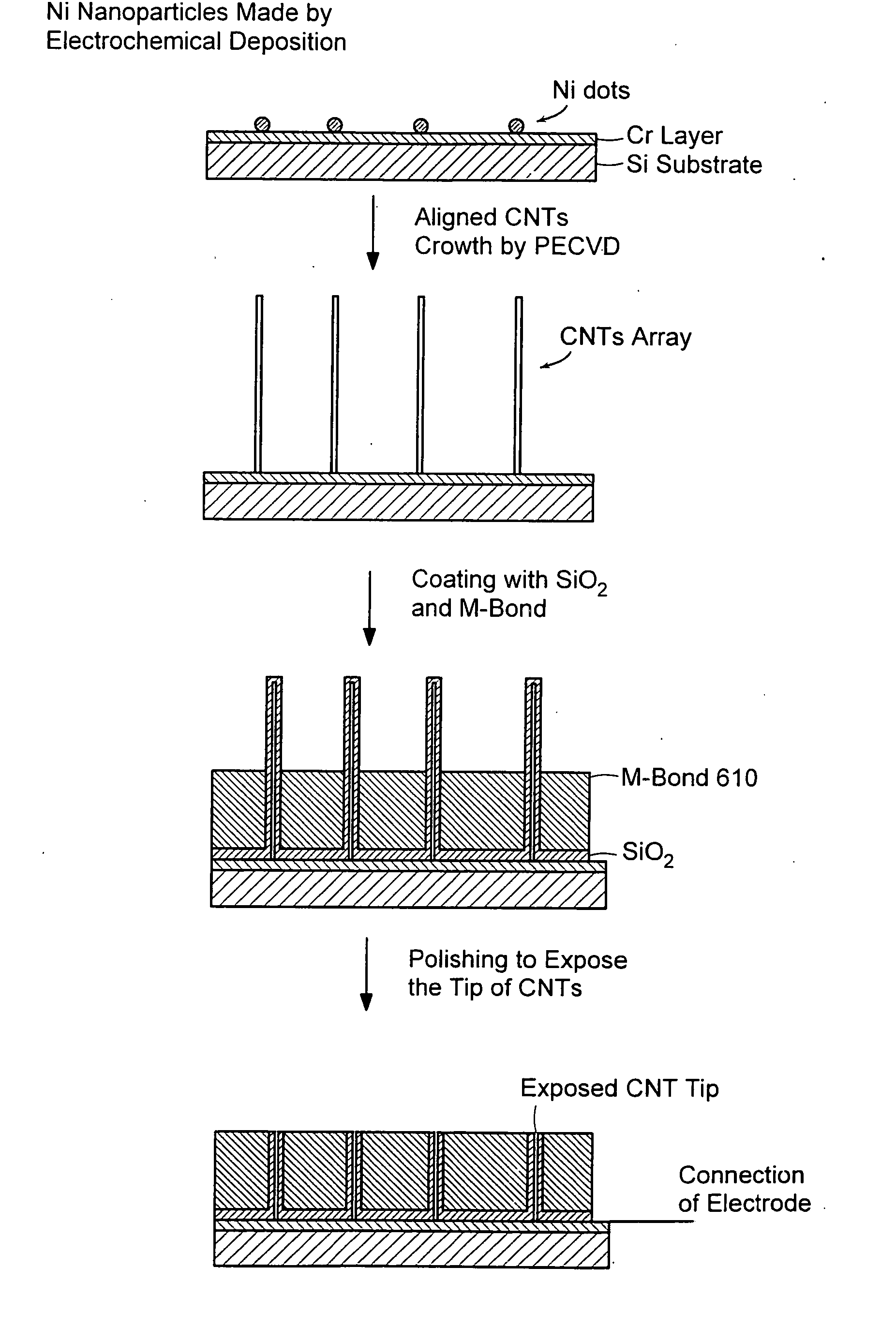

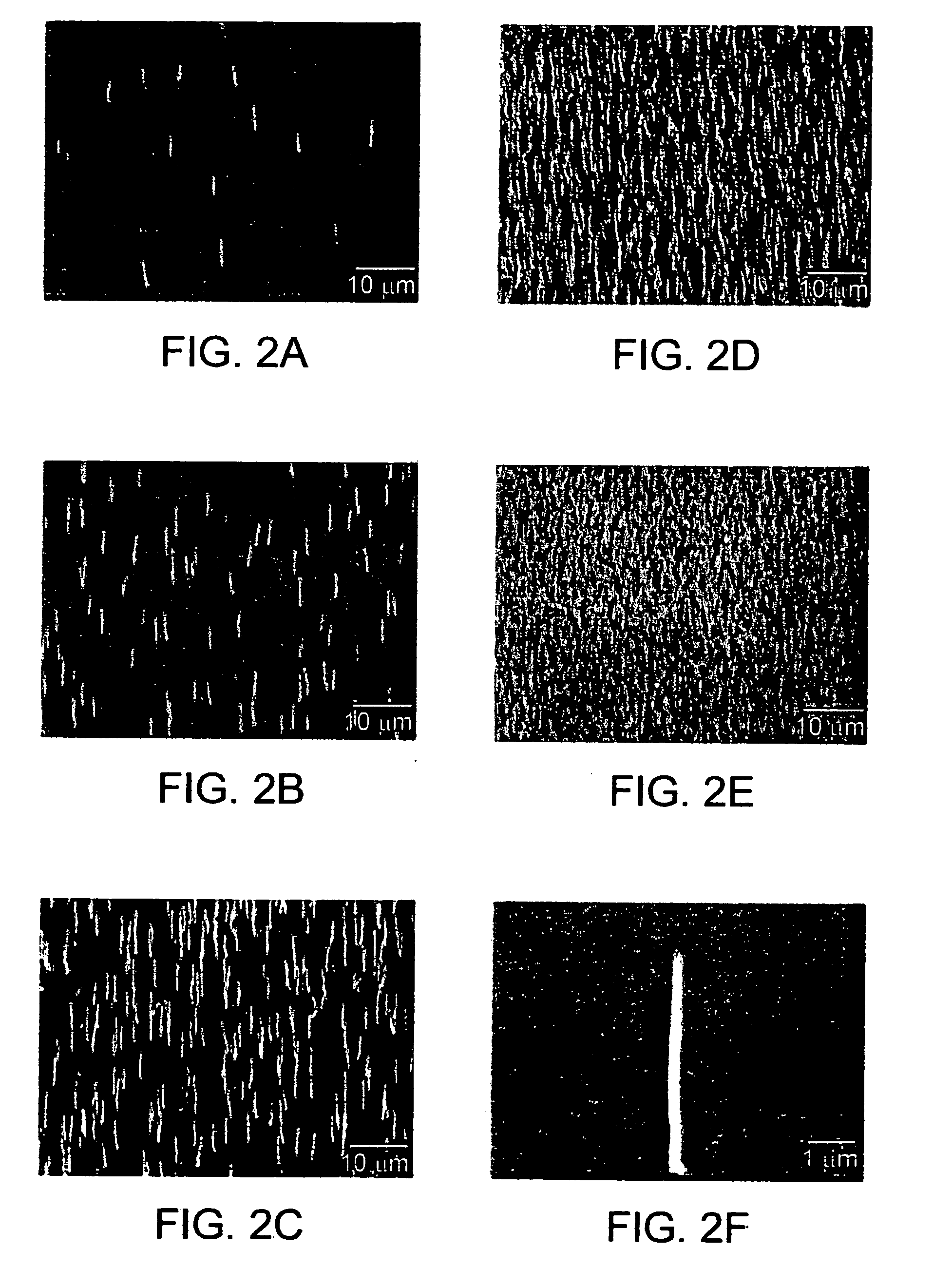

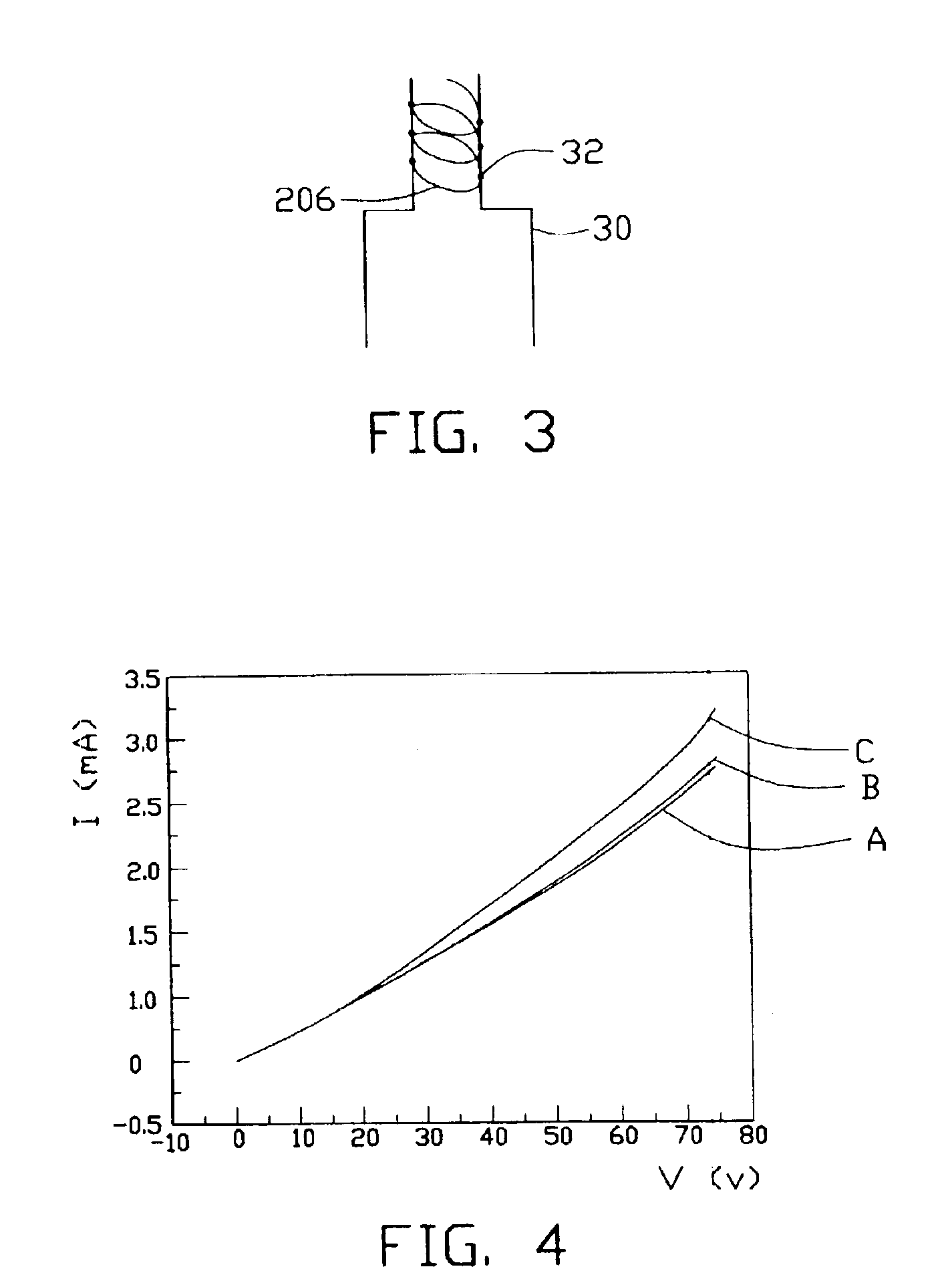

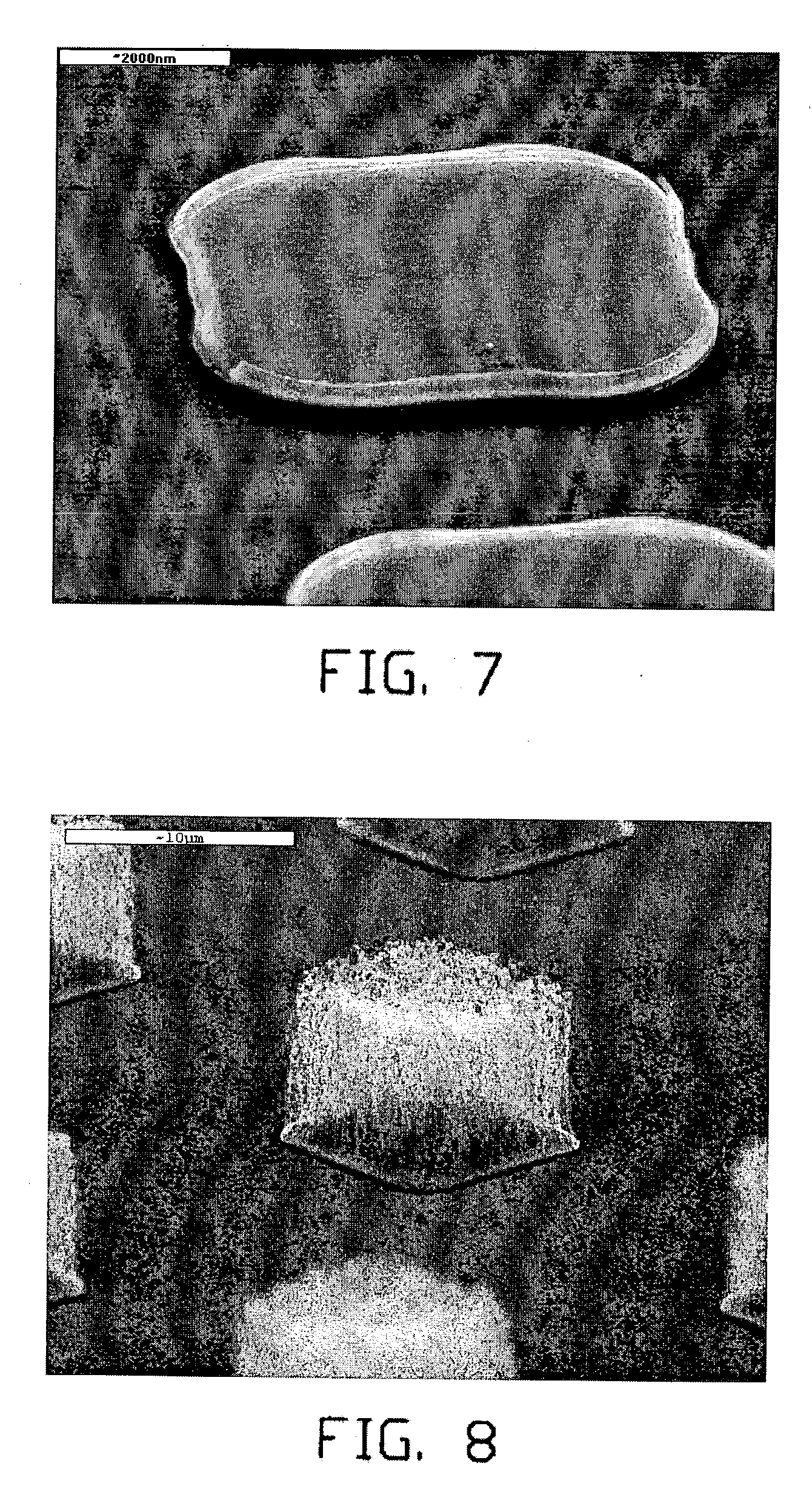

Carbon nanotube nanoelectrode arrays

InactiveUS20050230270A1Increase spacingIncrease the lengthImmobilised enzymesBioreactor/fermenter combinationsAdhesiveCarbon nanotube

The present invention relates to microelectode arrays (MEAs), and more particularly to carbon nanotube nanoelectrode arrays (CNT-NEAs) for chemical and biological sensing, and methods of use. A nanoelectrode array includes a carbon nanotube material comprising an array of substantially linear carbon nanotubes each having a proximal end and a distal end, the proximal end of the carbon nanotubes are attached to a catalyst substrate material so as to form the array with a pre-determined site density, wherein the carbon nanotubes are aligned with respect to one another within the array; an electrically insulating layer on the surface of the carbon nanotube material, whereby the distal end of the carbon nanotubes extend beyond the electrically insulating layer; a second adhesive electrically insulating layer on the surface of the electrically insulating layer, whereby the distal end of the carbon nanotubes extend beyond the second adhesive electrically insulating layer; and a metal wire attached to the catalyst substrate material.

Owner:BOSTON COLLEGE +1

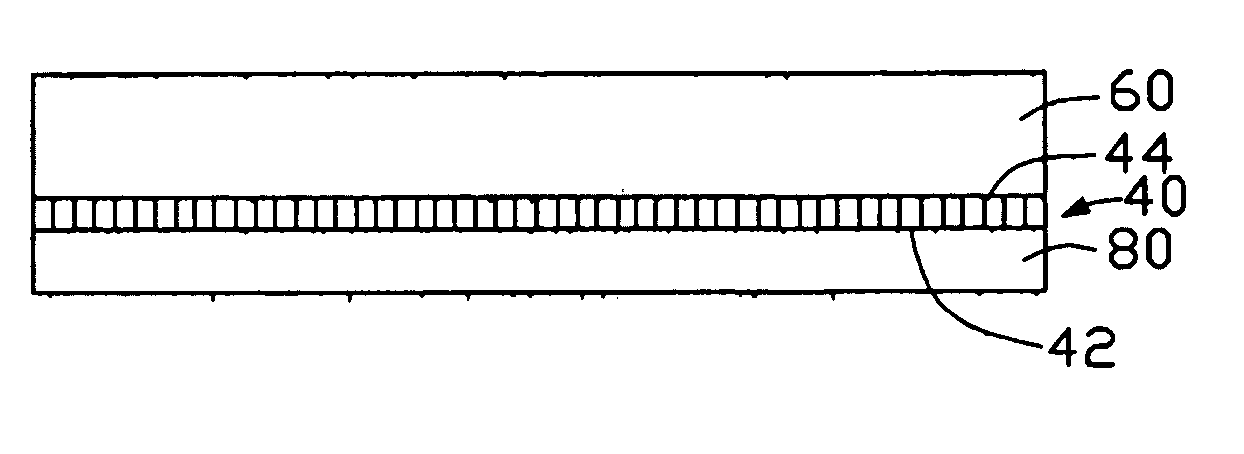

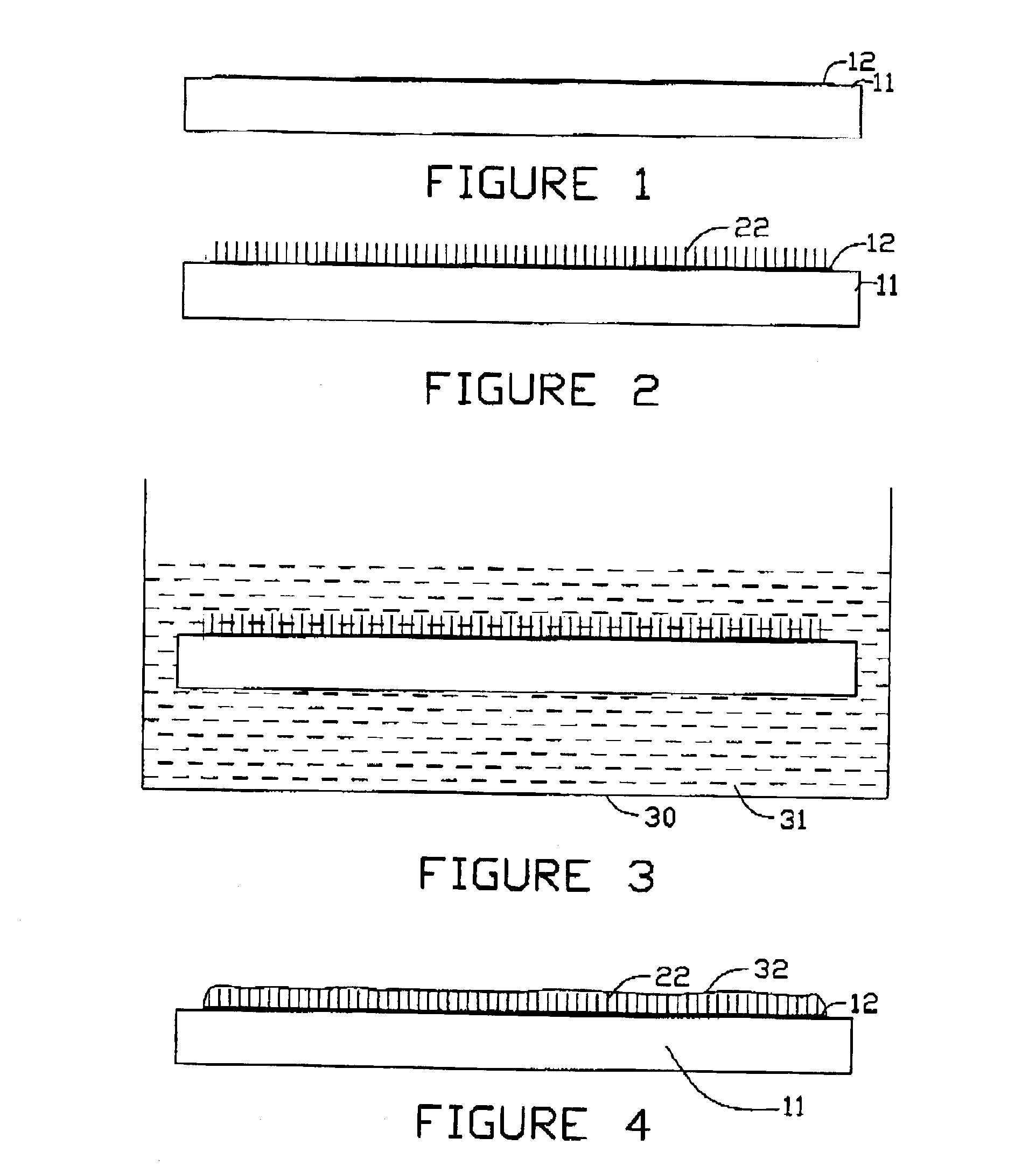

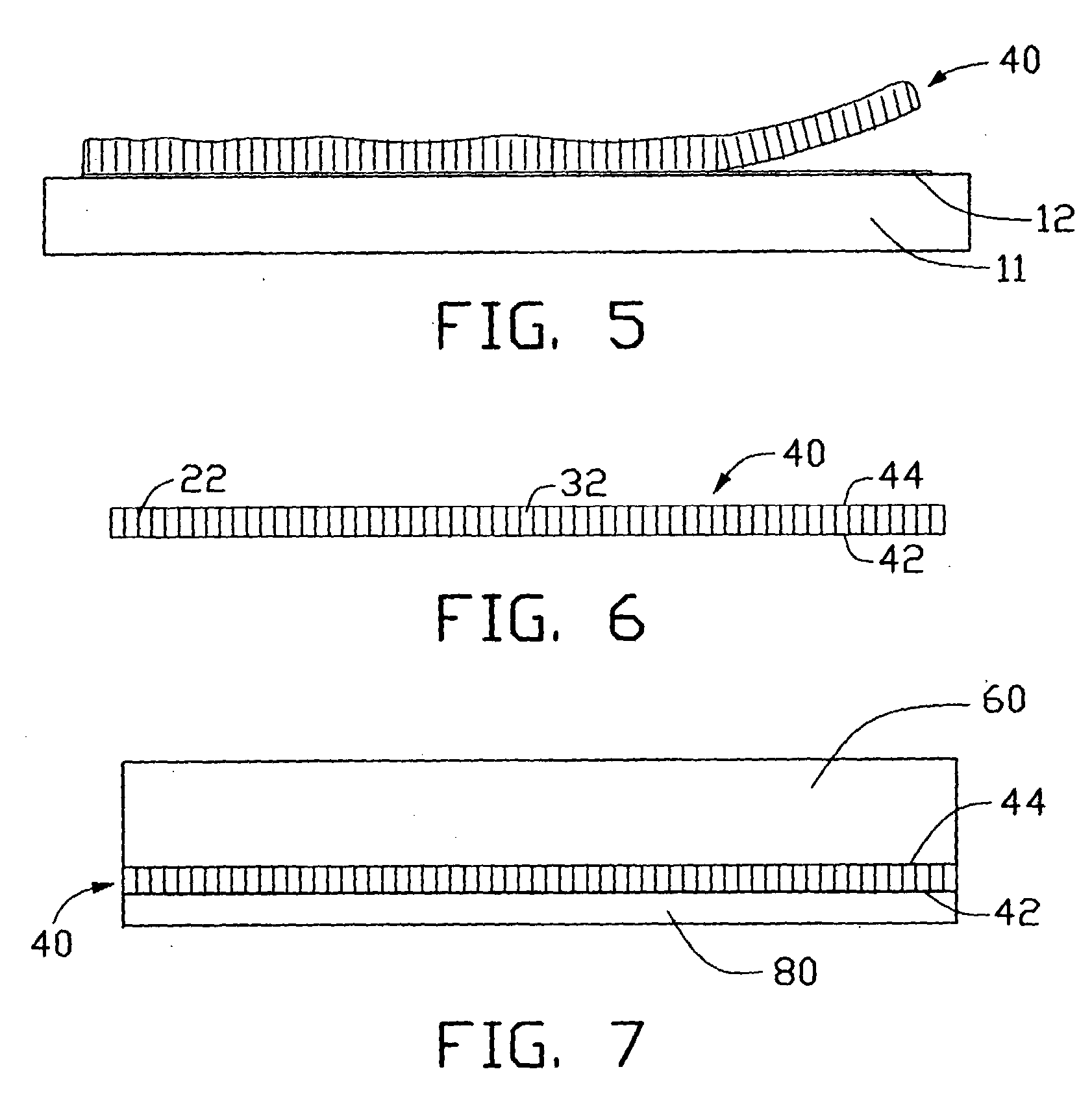

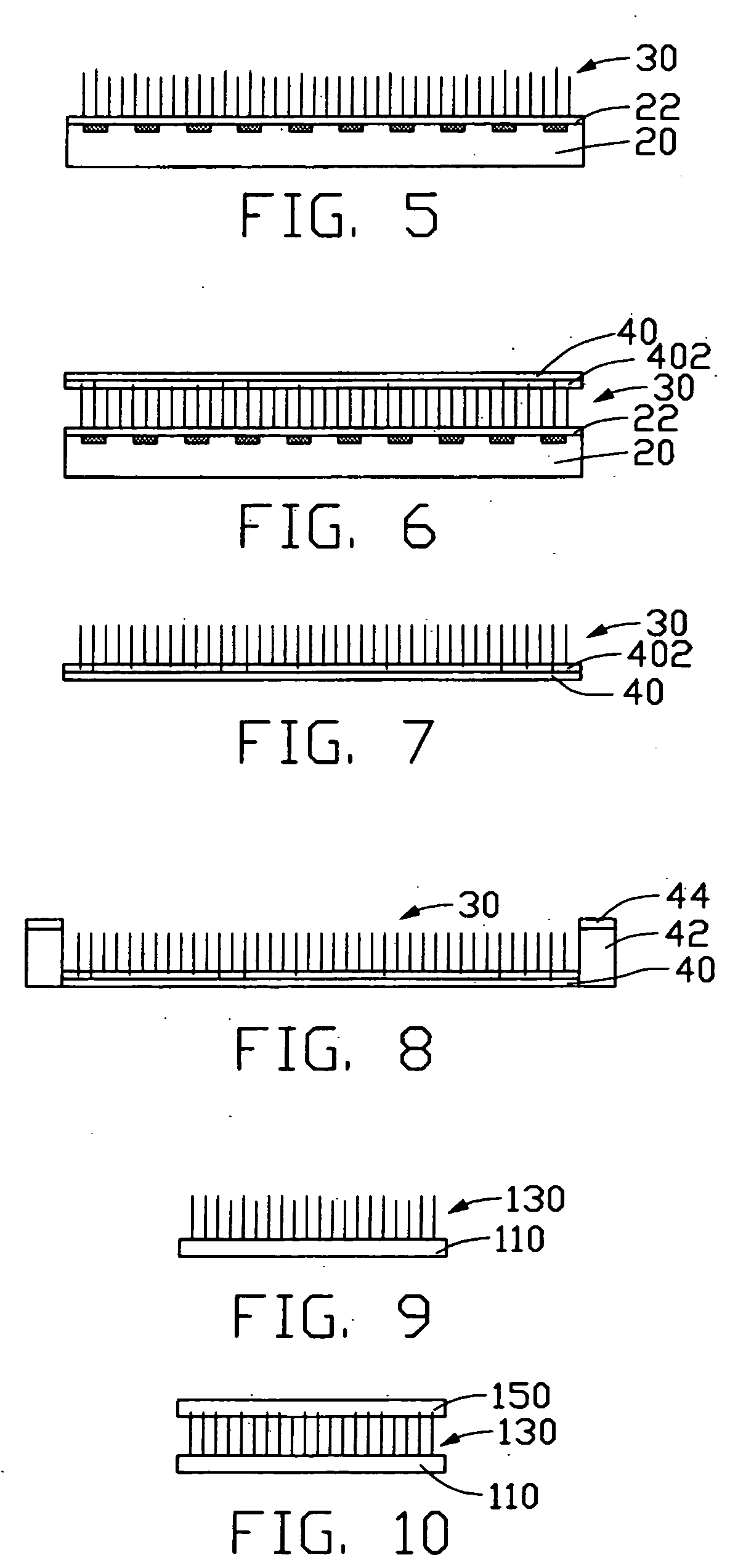

Thermal interface material and method for manufacturing same

ActiveUS20050167647A1Reduce thicknessSmall resistanceMaterial nanotechnologySemiconductor/solid-state device detailsLiquid stateCarbon nanotube

A thermal interface material (40) includes a macromolecular material (32), and a plurality of carbon nanotubes (22) embedded in the macromolecular material uniformly. The thermal interface material includes a first surface (42) and an opposite second surface (44). Each carbon nanotube is open at both ends thereof, and extends from the first surface to the second surface of the thermal interface material. A method for manufacturing the thermal interface material includes the steps of: (a) forming an array of carbon nanotubes on a substrate; (b) submerging the carbon nanotubes in a liquid macromolecular material; (c) solidifying the liquid macromolecular material; and (d) cutting the solidified liquid macromolecular material to obtain the thermal interface material with the carbon nanotubes secured therein.

Owner:TSINGHUA UNIV +1

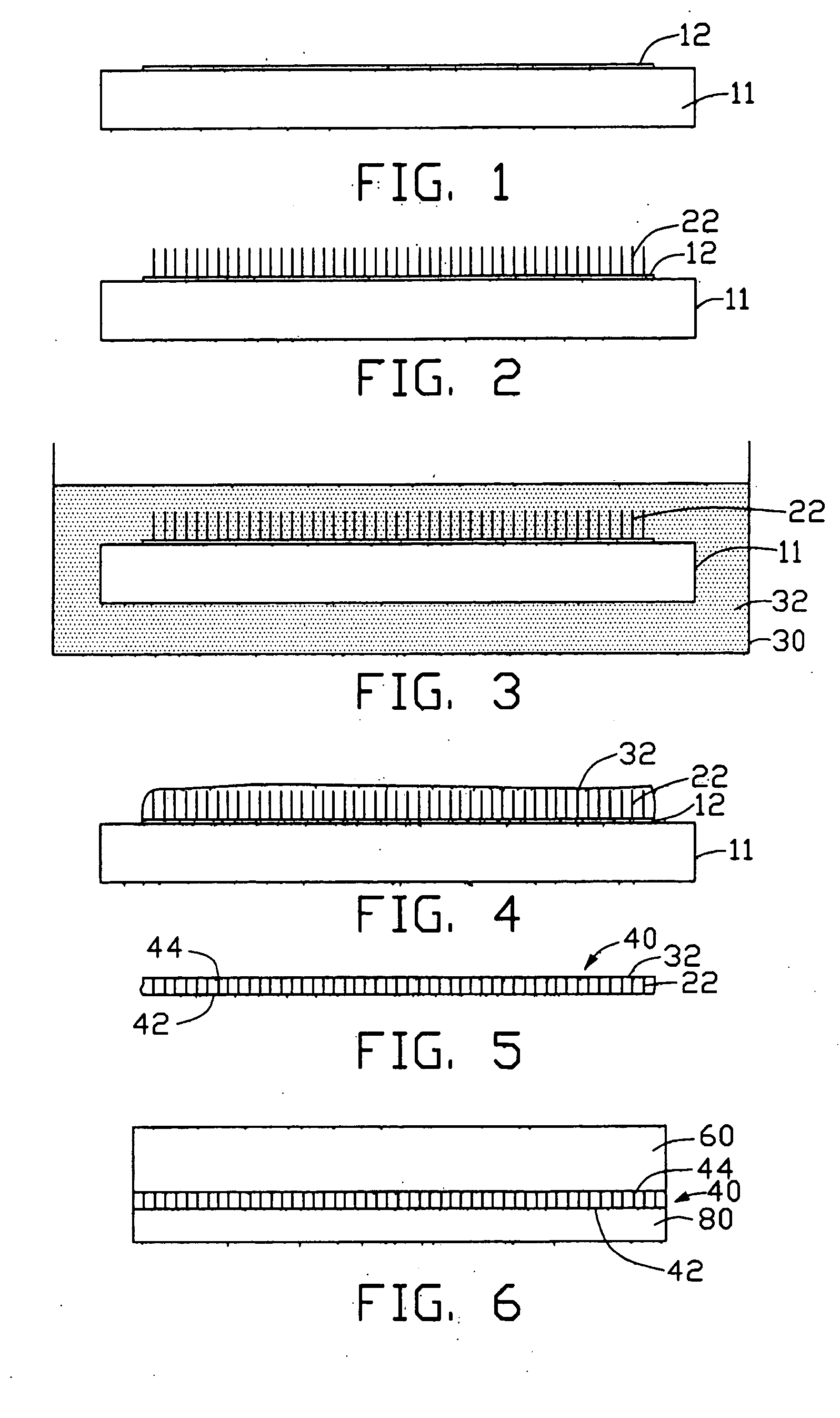

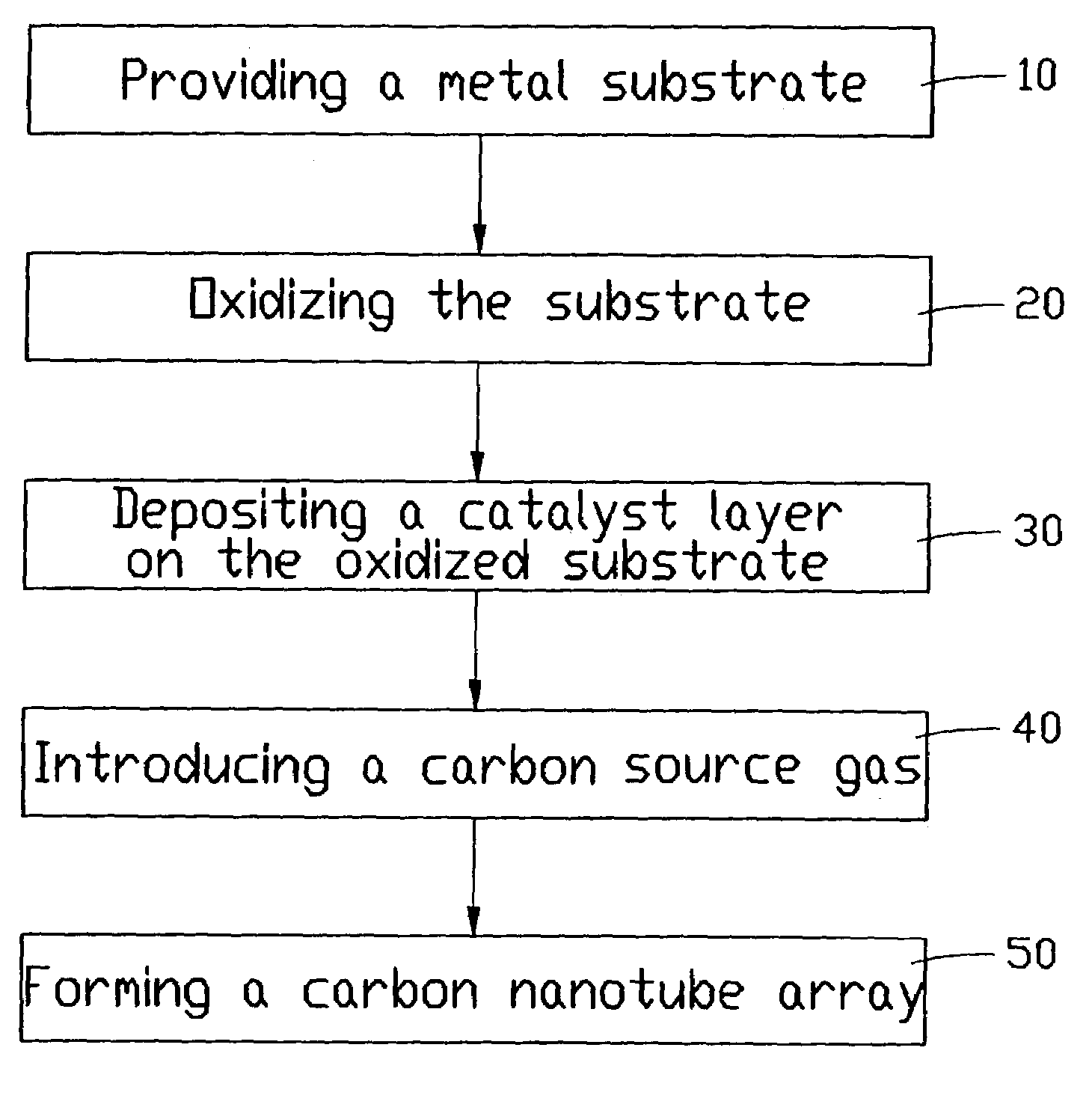

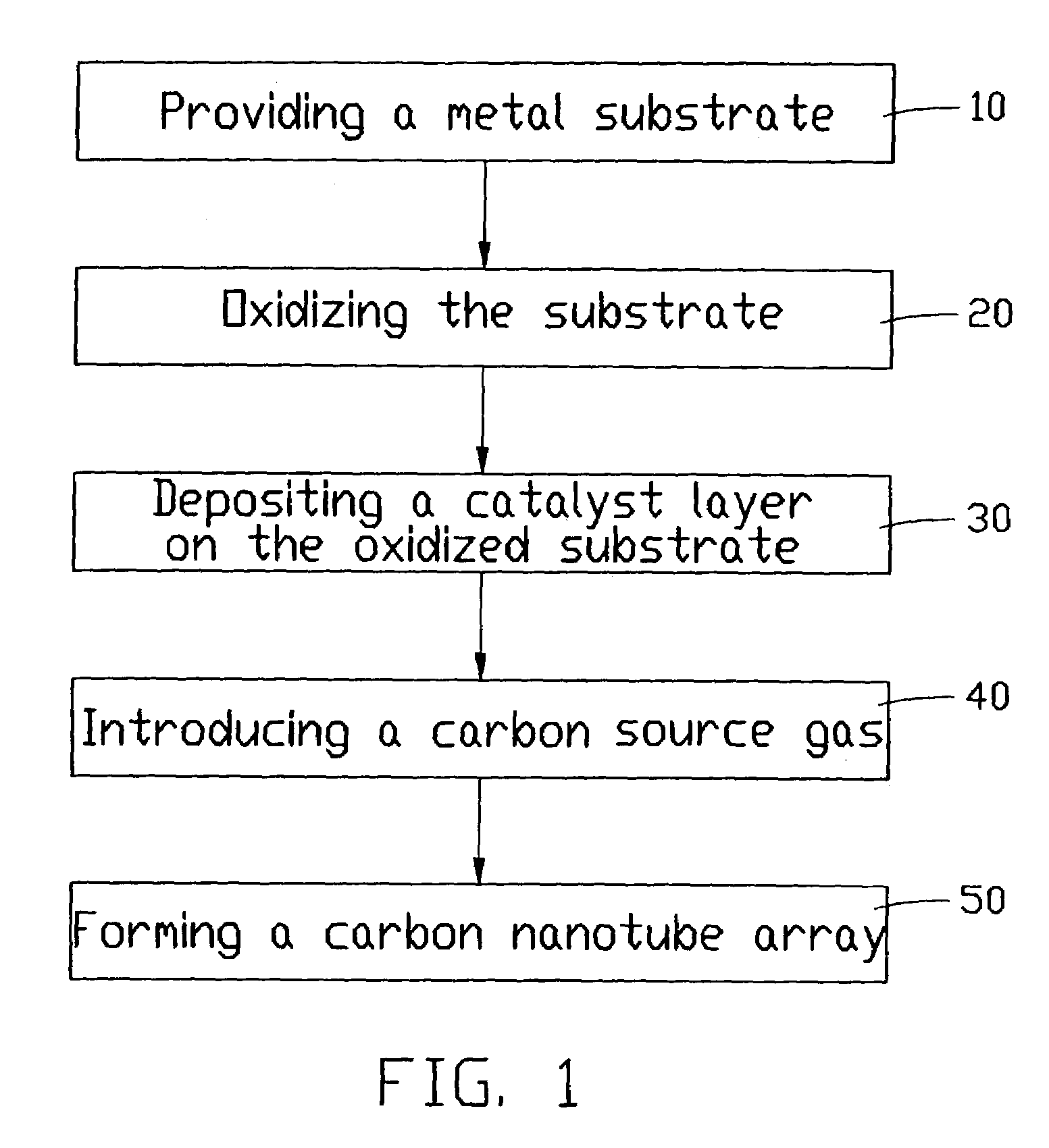

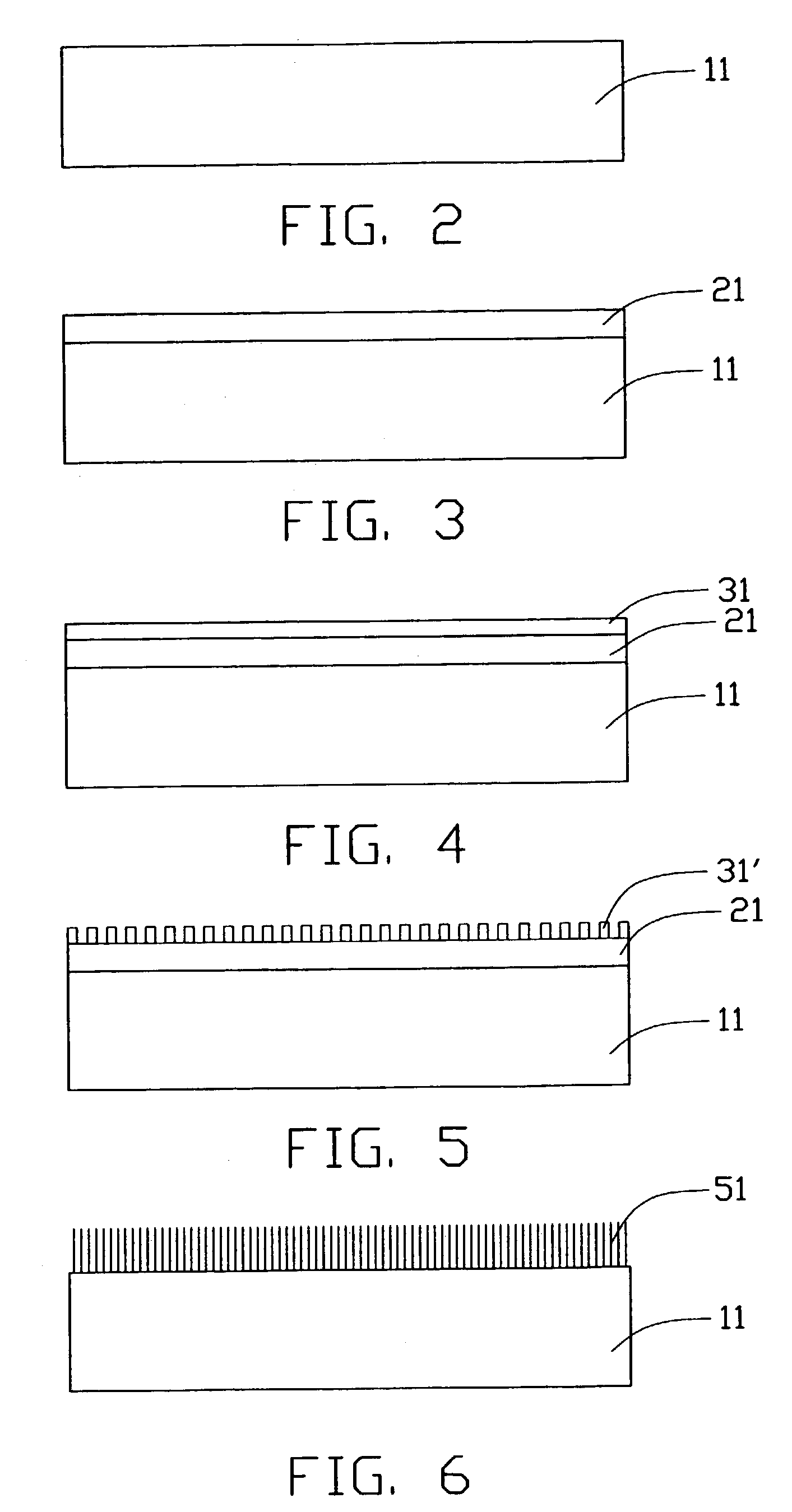

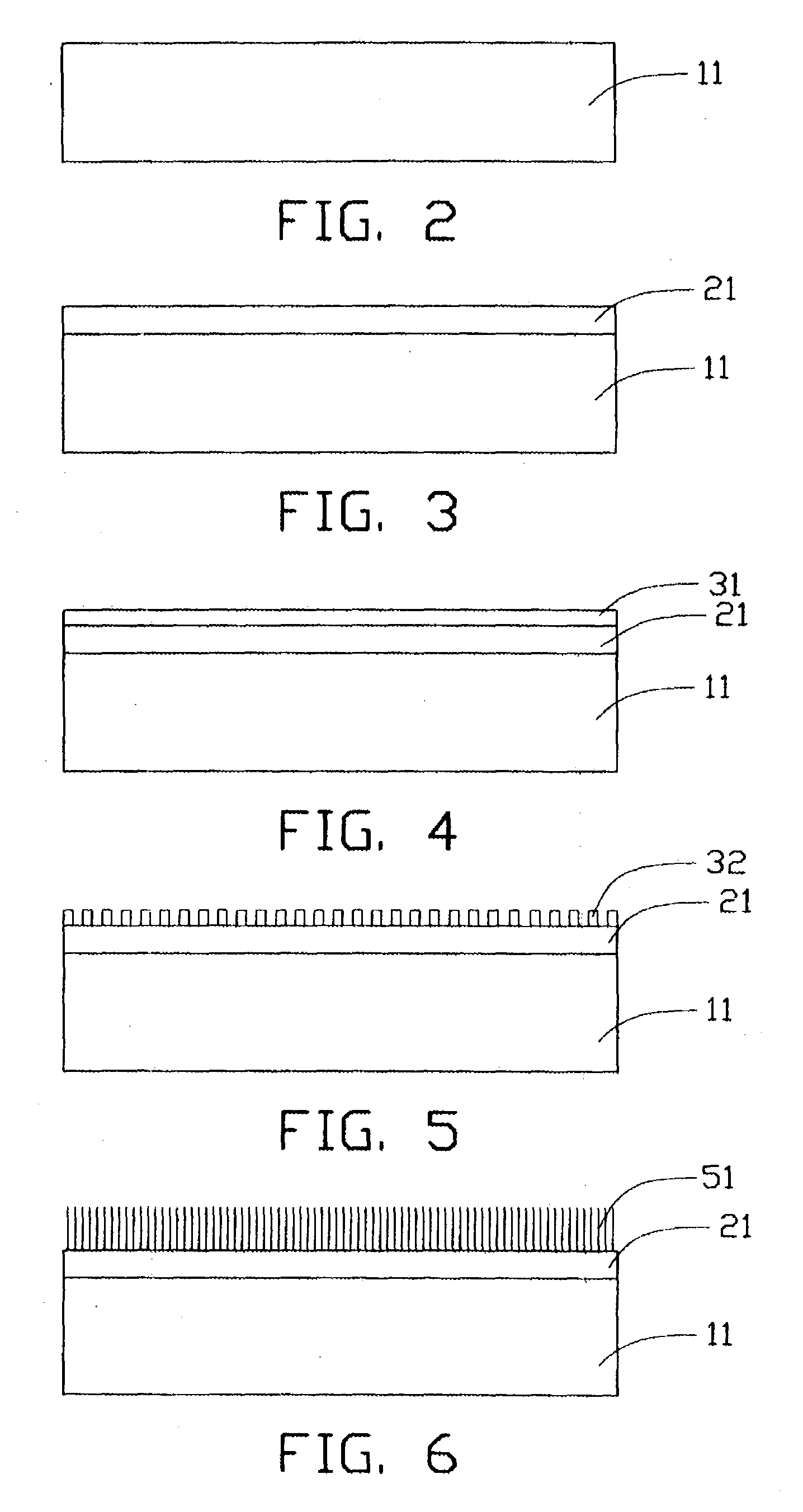

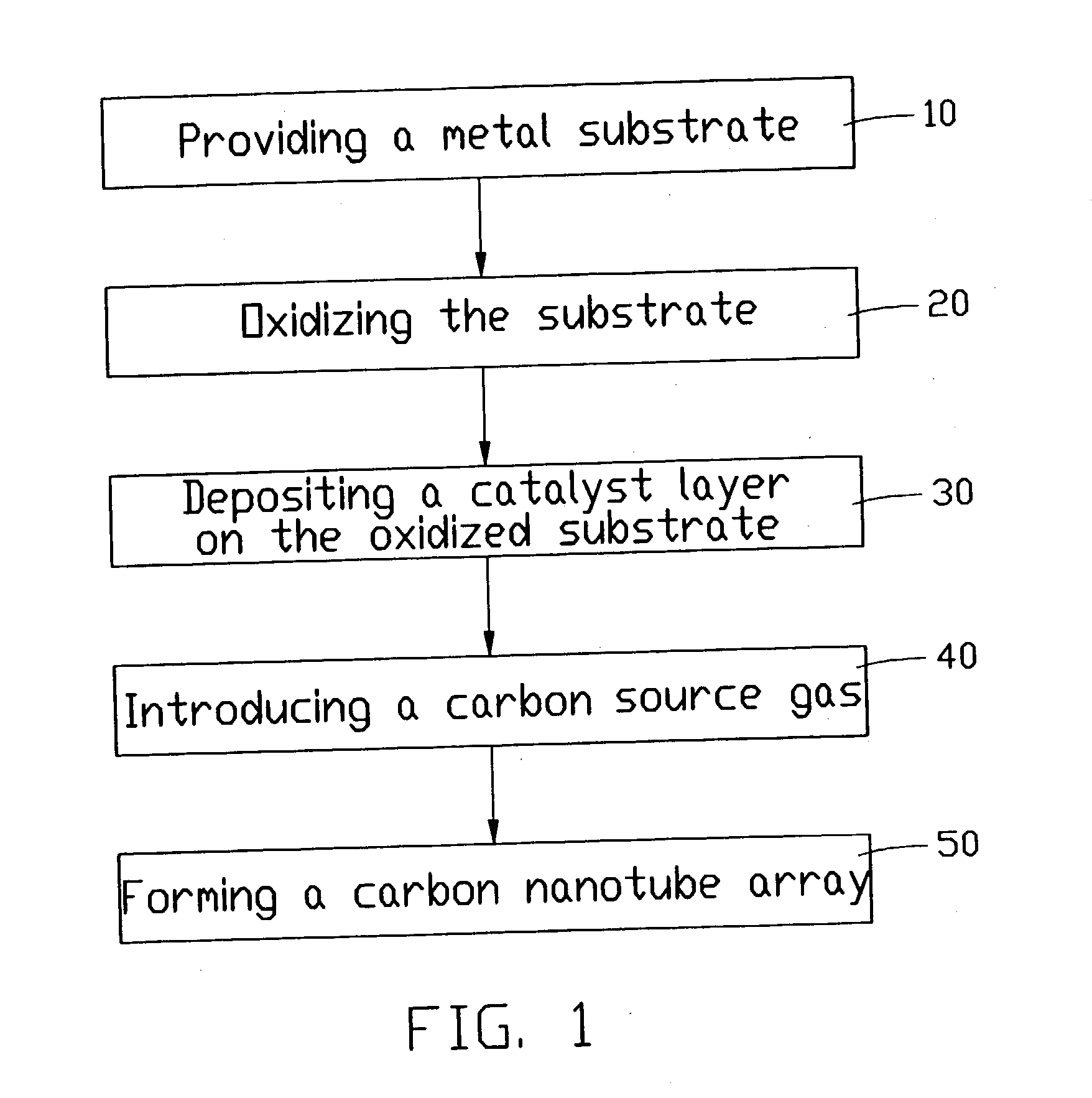

Carbon nanotube array and method for forming same

ActiveUS7160532B2Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceCarbon nanotube

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

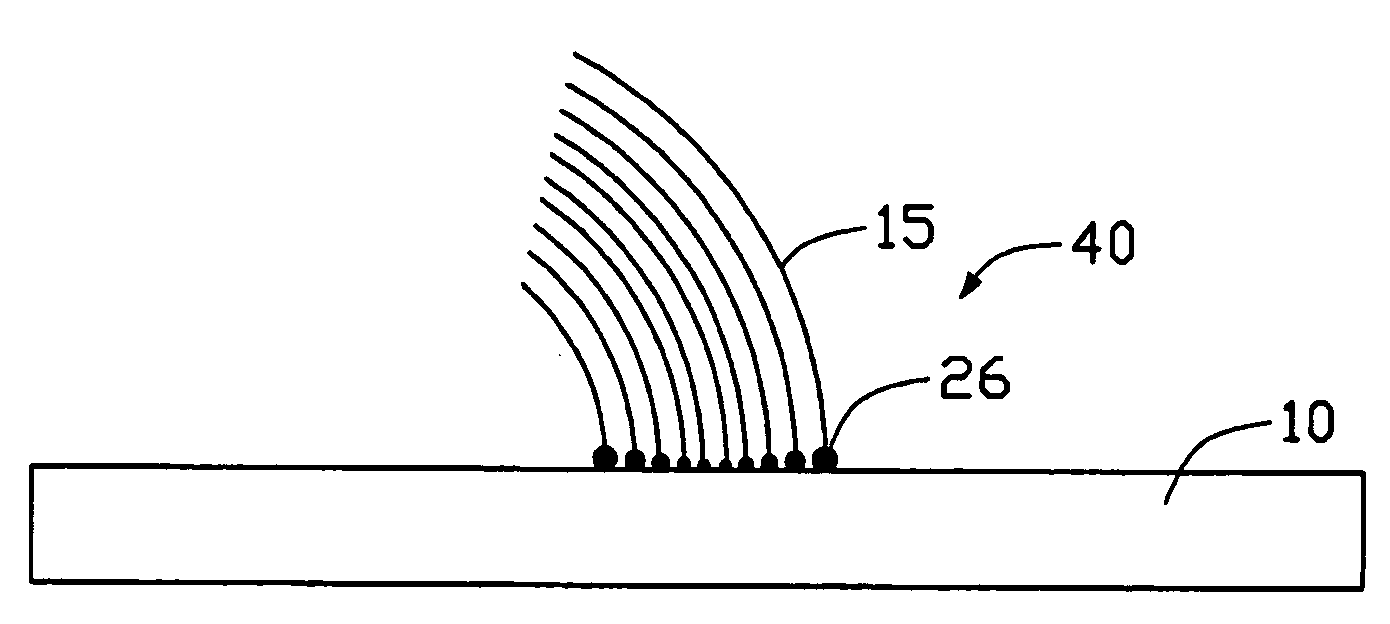

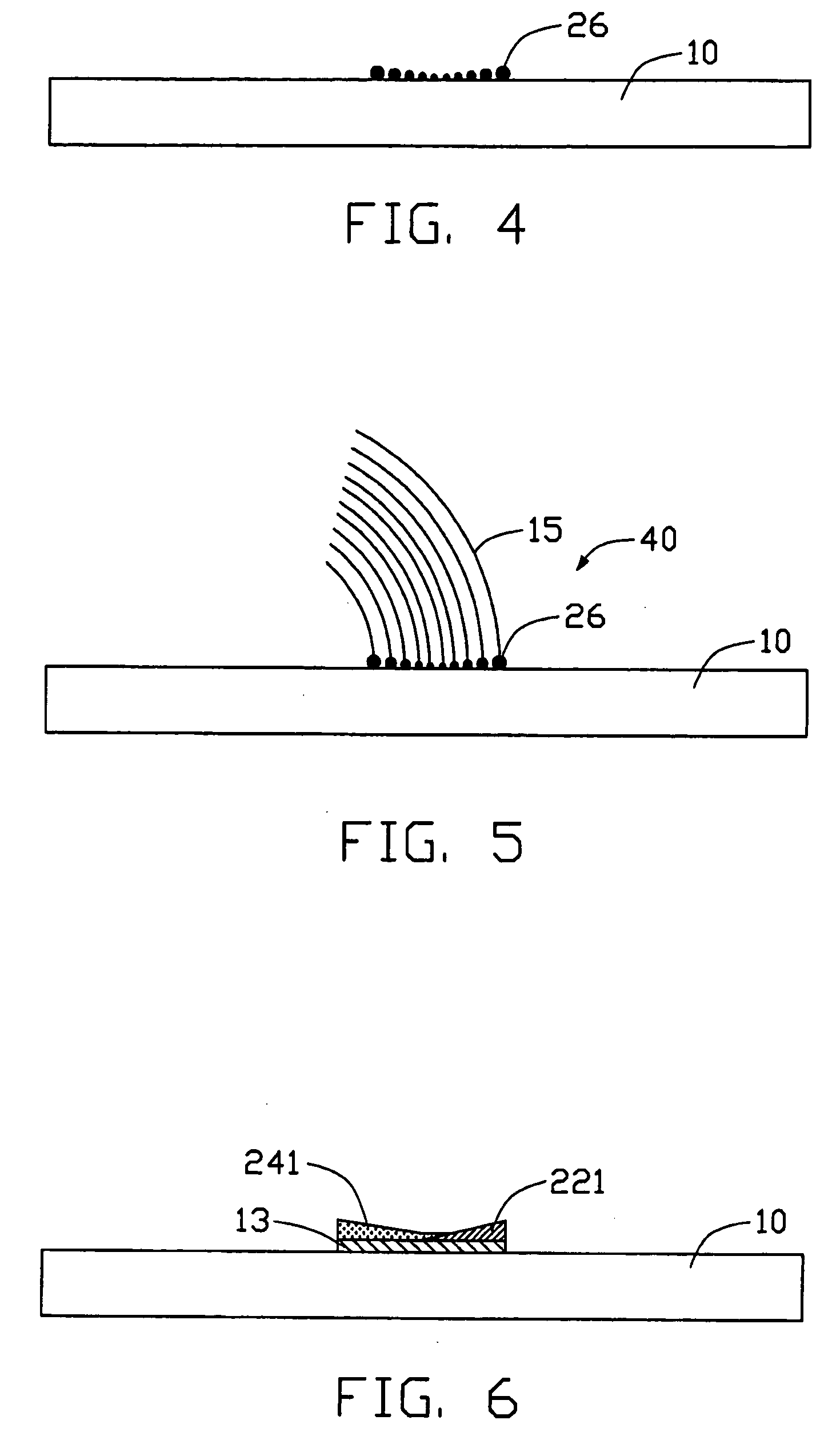

Carbon annotate-based device and method for making carbon nanotube based device

ActiveUS20040136896A1Easy to controlWide applicationMaterial nanotechnologyLayered productsGas phaseAlloy

A carbon nanotube-based device (40) includes a substrate (10), a number of alloyed, nano-sized catalytic particles (26) formed on the substrate, and an array of aligned carbon nanotubes (15) extending from the alloyed, nano-sized catalytic particles. The nanotube array bends in an arcuate configuation. A method for making the carbon nanotube-based device includes the steps of: providing a substrate; depositing a catalyst layer on the substrate; depositing two different layers of catalyst-doped materials on different areas of the catalyst layer for accelerating or decelerating the rate of synthesis of the aligned carbon nanotube array; annealing the catalyst and the catalyst-doped materials in an oxygen-containing gas at a low temperature; introducing a carbon source gas; and forming an array of aligned carbon nanotubes extending from the alloyed, nano-sized catalytic particles using a chemical vapor deposition method.

Owner:TSINGHUA UNIV +1

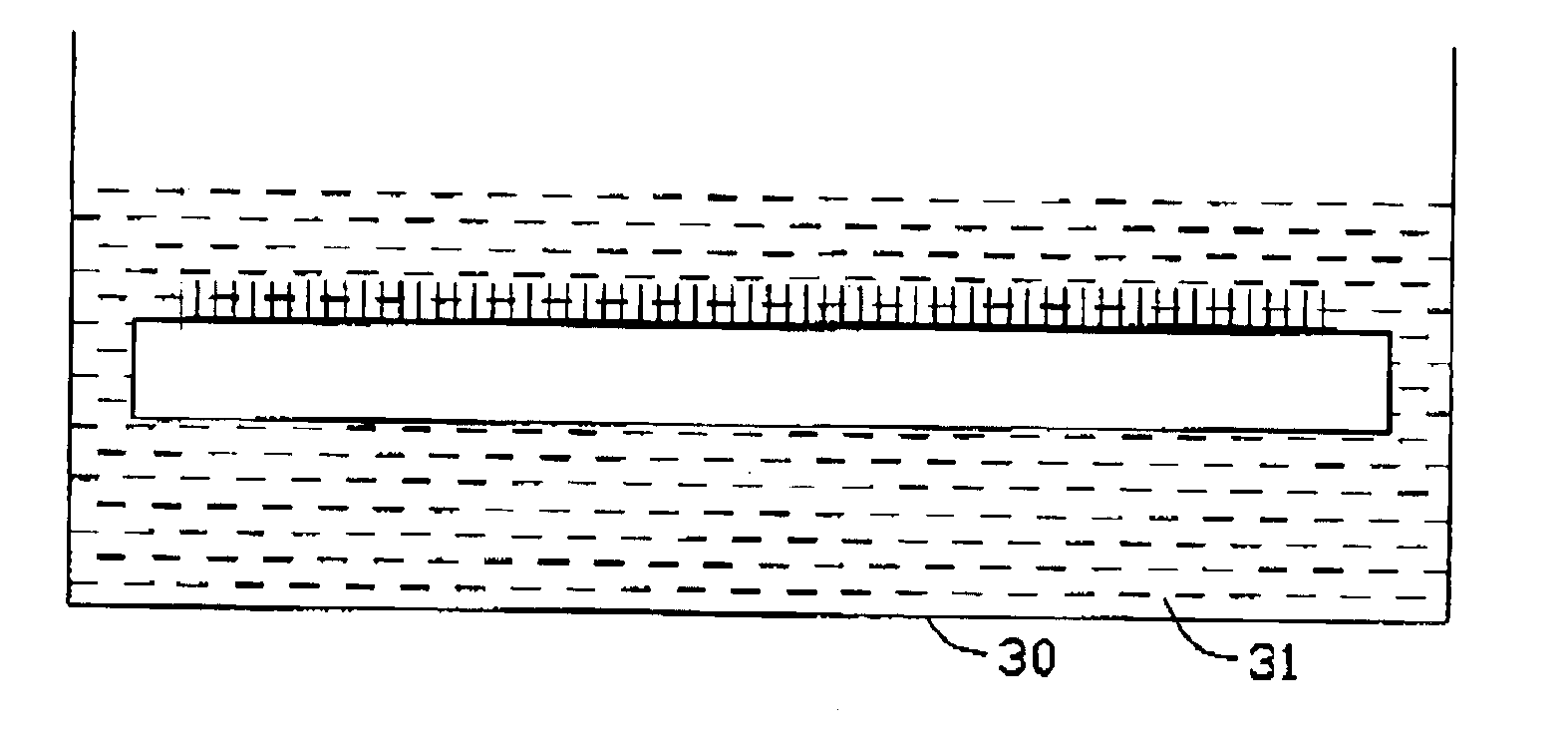

Thermal interface material and method for making same

InactiveUS6924335B2Uniform and high thermoconductivityImprove thermal conductivityMaterial nanotechnologySemiconductor/solid-state device detailsCarbon nanotubePrepolymer

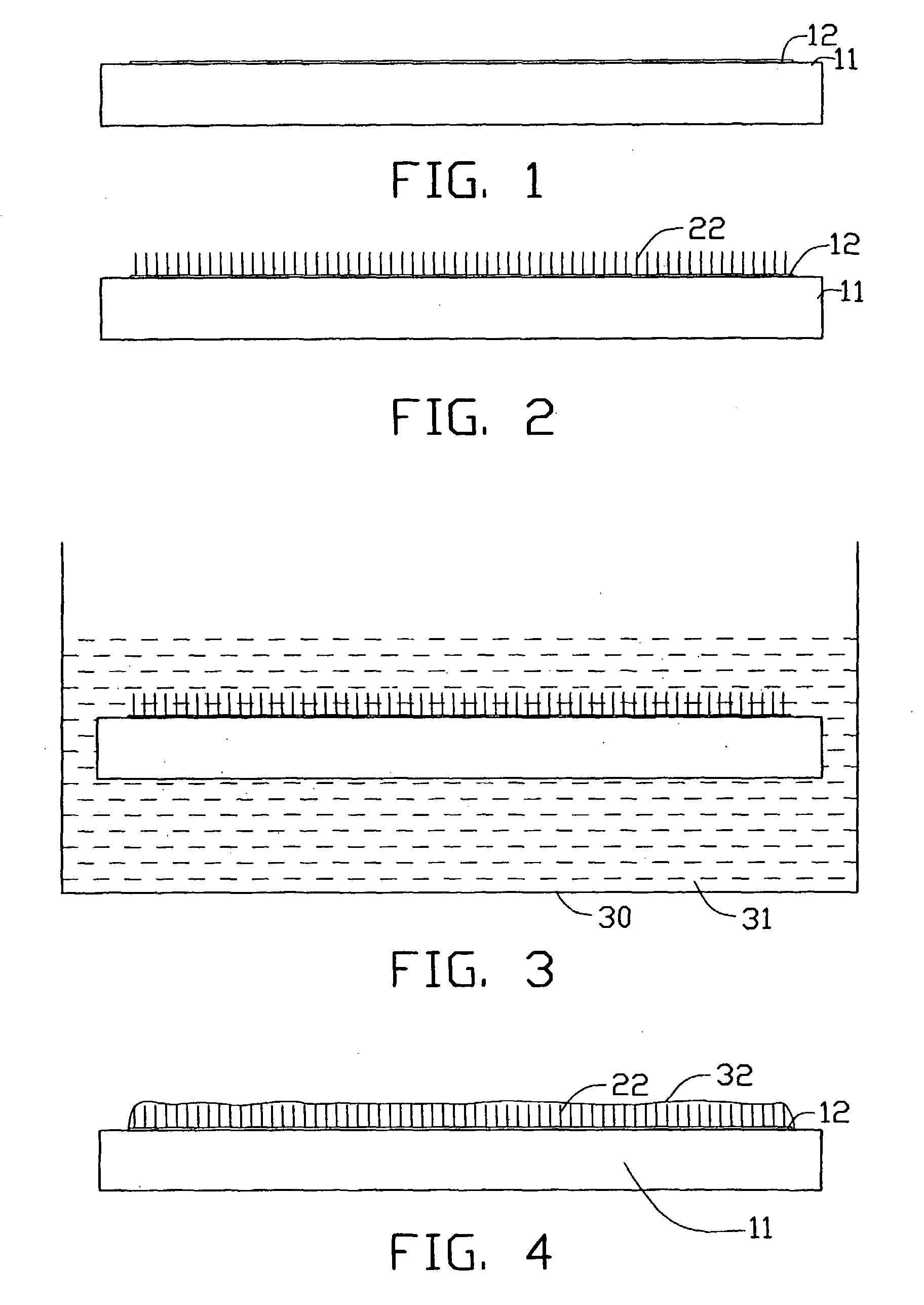

A thermal interface material (40) includes a polymer matrix (32) and an array of carbon nanotubes (22) incorporated in the polymer matrix. The polymer matrix has a thermally conductive first face (42) and an opposite thermally conductive second face (44). The carbon nanotubes are substantially parallel to each other, and extend between the first and the second faces. A preferred method for making the thermal interface material includes the steps of: (a) forming the array of carbon nanotubes on a substrate (11); (b) immersing the carbon nanotubes in a liquid prepolymer (31) such that the liquid prepolymer infuses into the array of carbon nanotubes; (c) polymerizing the liquid prepolymer to obtain the polymer matrix having the carbon nanotubes secured therein; and (d) peeling the polymer matrix having the carbon nanotubes off from the substrate to obtain the thermal interface material.

Owner:TSINGHUA UNIV +1

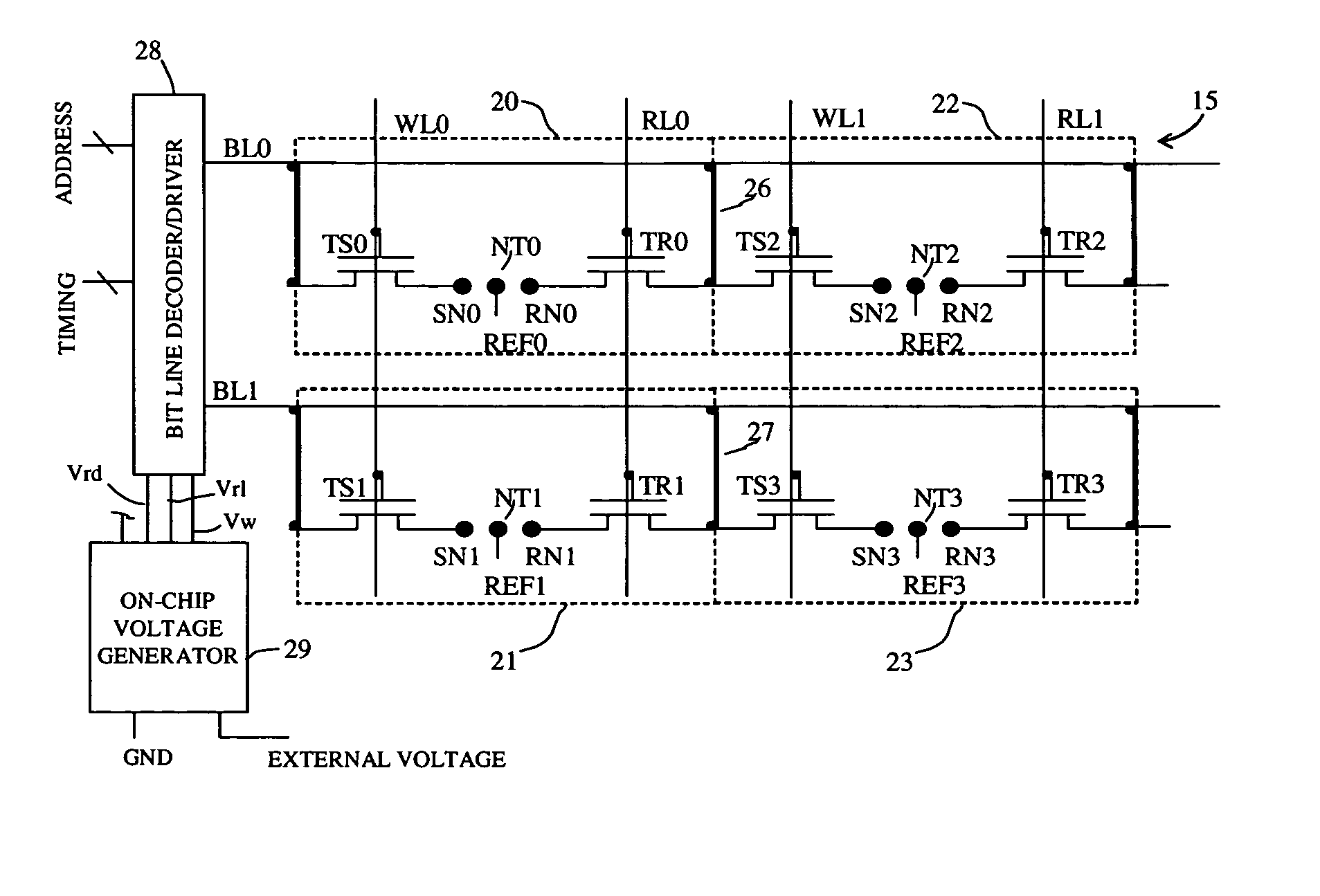

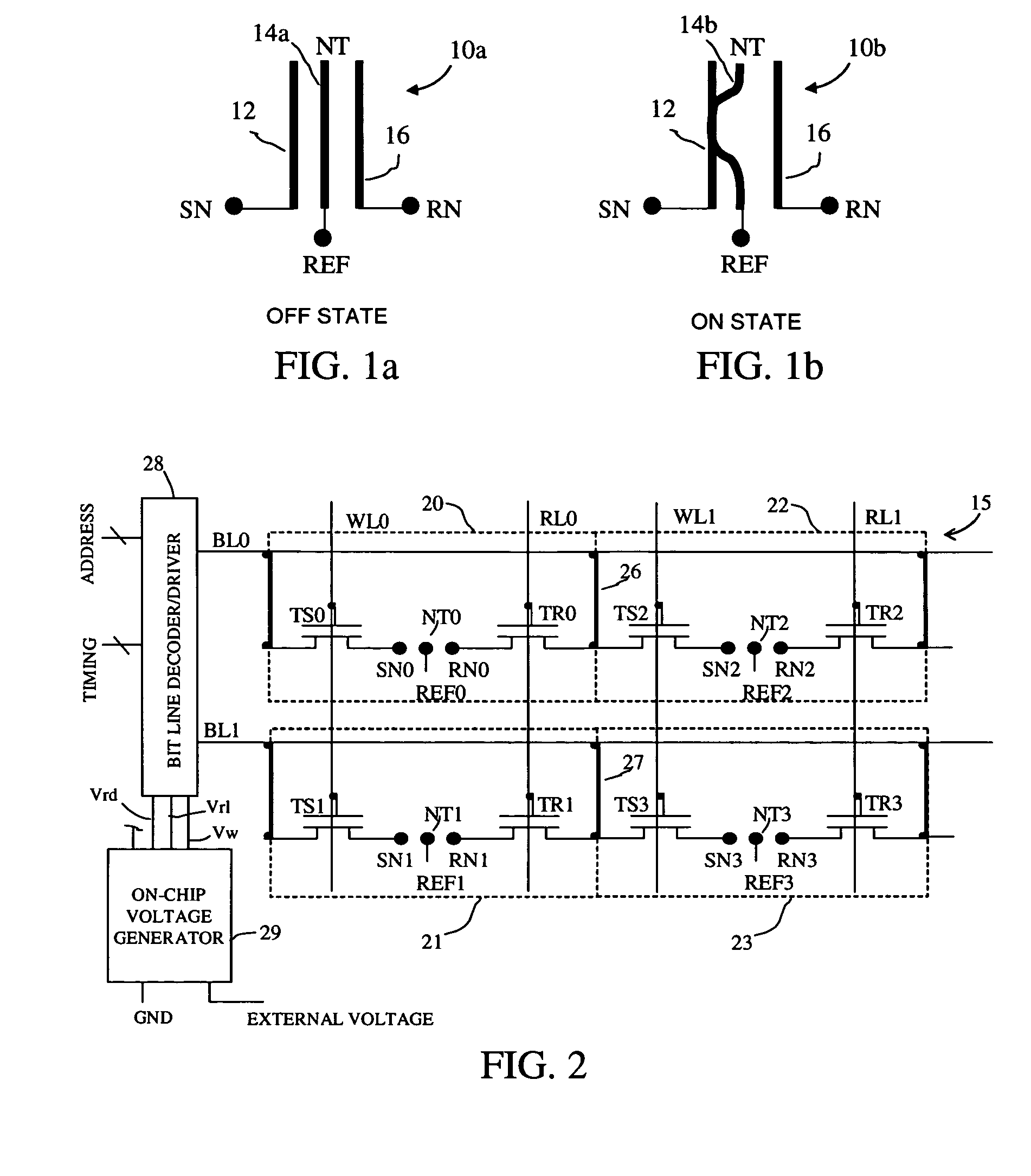

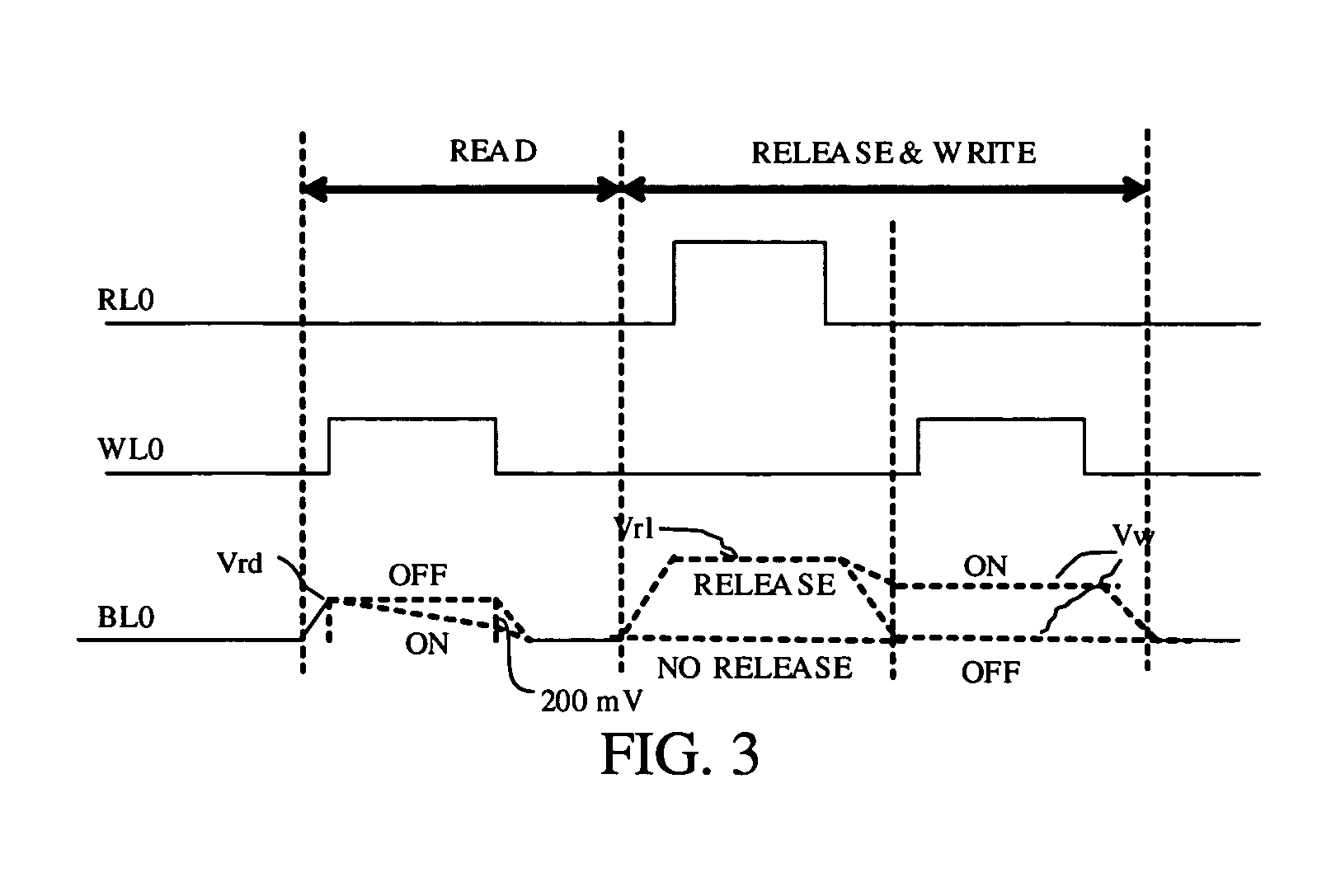

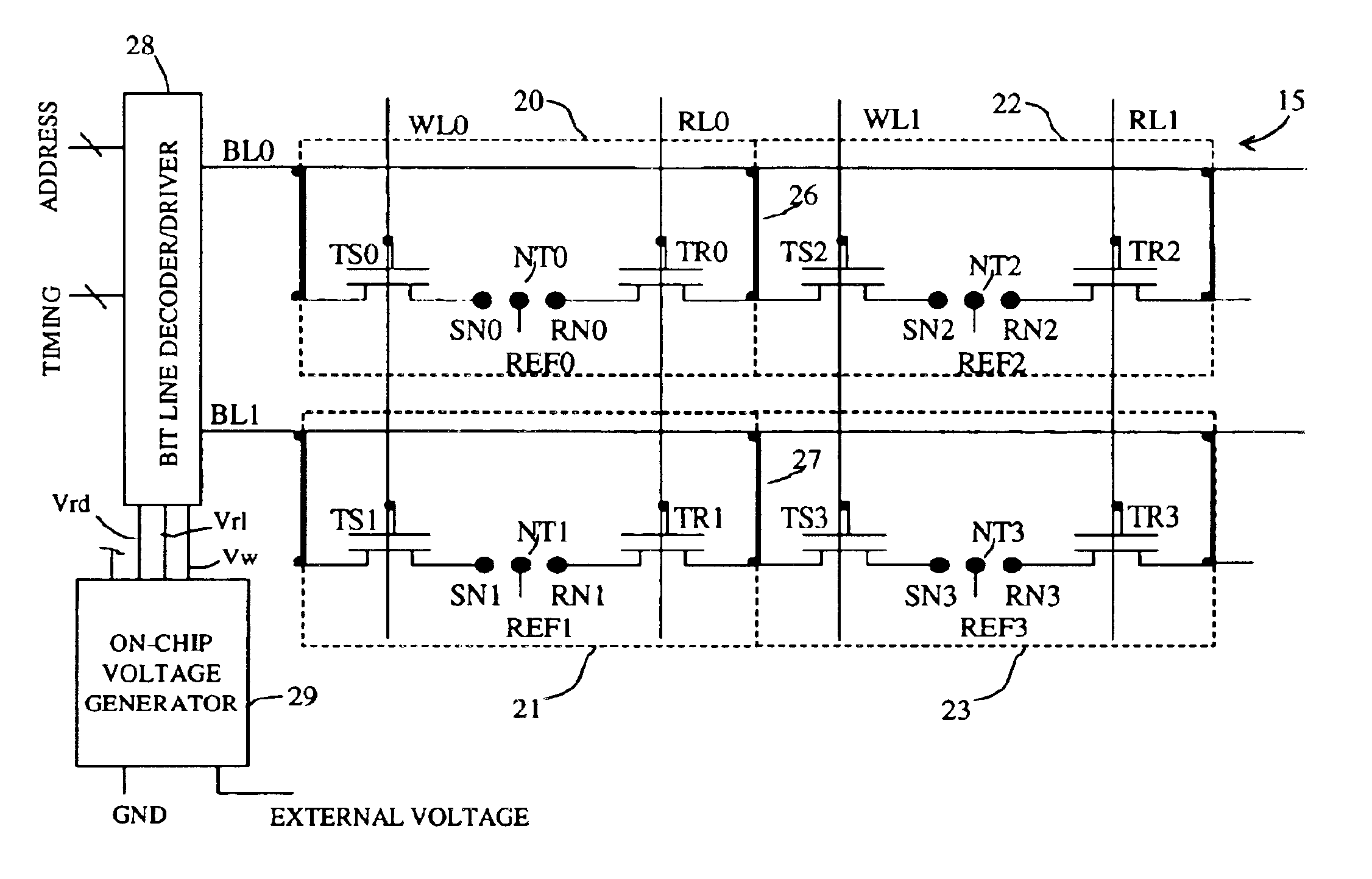

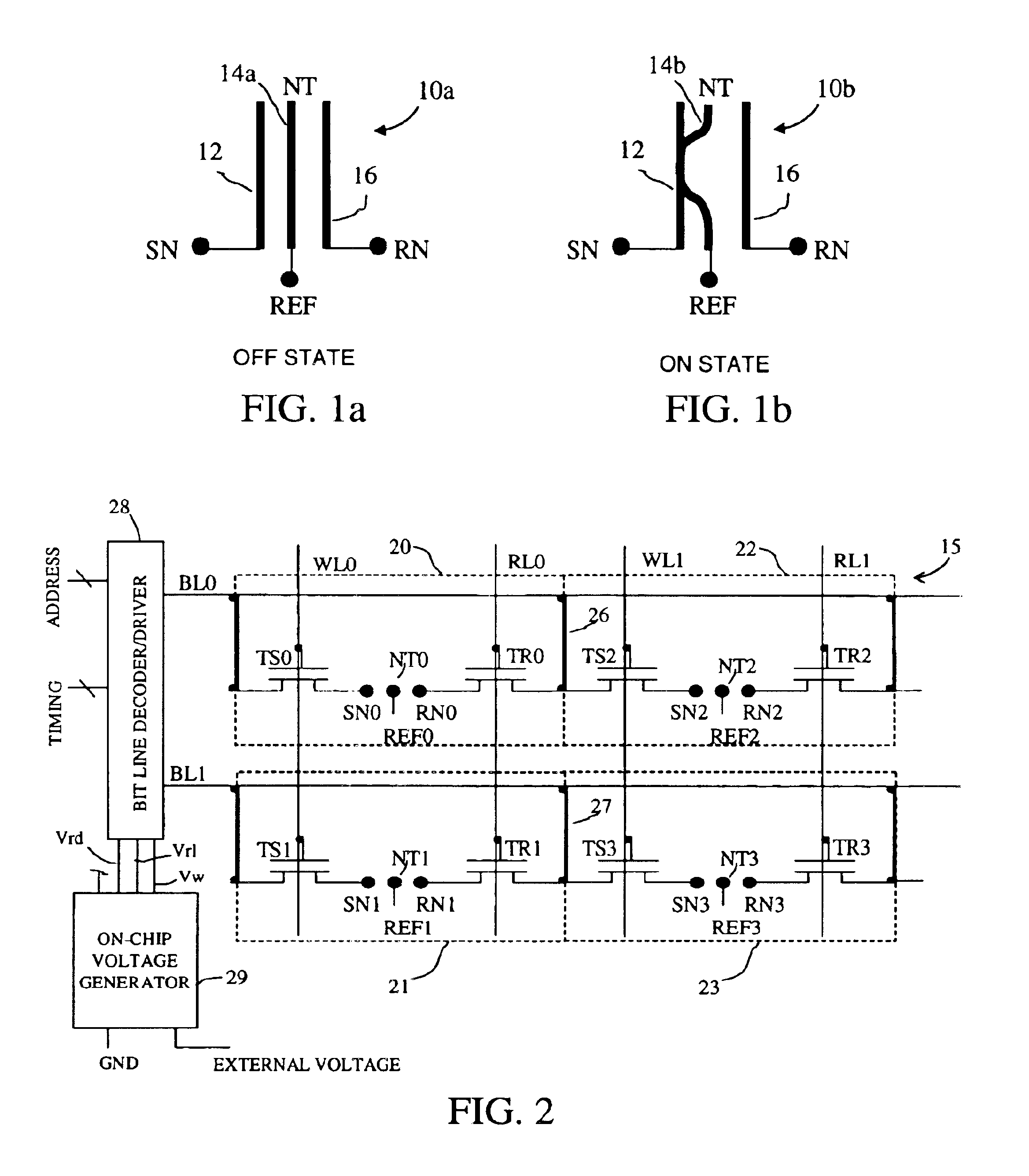

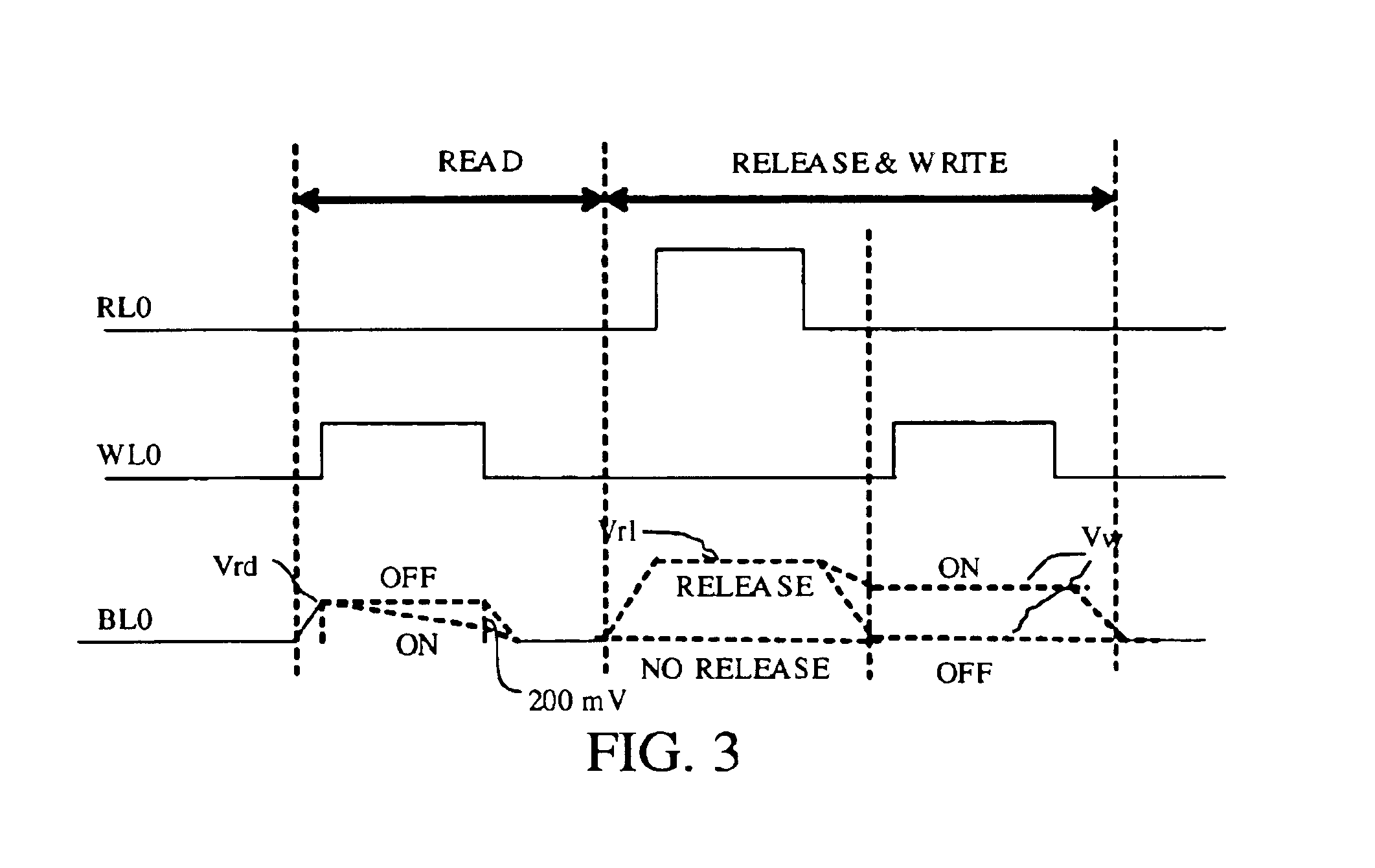

Nram bit selectable two-device nanotube array

A non-volatile memory array includes a plurality of memory cells, each cell receiving a bit line, word line, and release line. Each memory cell includes a cell selection transistor and a restore transistor with first, second and third nodes. Each cell further includes an electromechanically deflectable switch, the position of which manifests the logical state of the cell. Each cell is bit selectable for read and write operations.

Owner:NANTERO

Thermal interface material and method for making same

InactiveUS20040097635A1Improve thermal conductivityMaterial nanotechnologySemiconductor/solid-state device detailsPolymer scienceCarbon nanotube

A thermal interface material (40) includes a polymer matrix (32) and an array of carbon nanotubes (22) incorporated in the polymer matrix. The polymer matrix has a thermally conductive first face (42) and an opposite thermally conductive second face (44). The carbon nanotubes are substantially parallel to each other, and extend between the first and the second faces. A preferred method for making the thermal interface material includes the steps of: (a) forming the array of carbon nanotubes on a substrate (11); (b) immersing the carbon nanotubes in a liquid prepolymer (31) such that the liquid prepolymer infuses into the array of carbon nanotubes; (c) polymerizing the liquid prepolymer to obtain the polymer matrix having the carbon nanotubes secured therein; and (d) peeling the polymer matrix having the carbon nanotubes off from the substrate to obtain the thermal interface material.

Owner:TSINGHUA UNIV +1

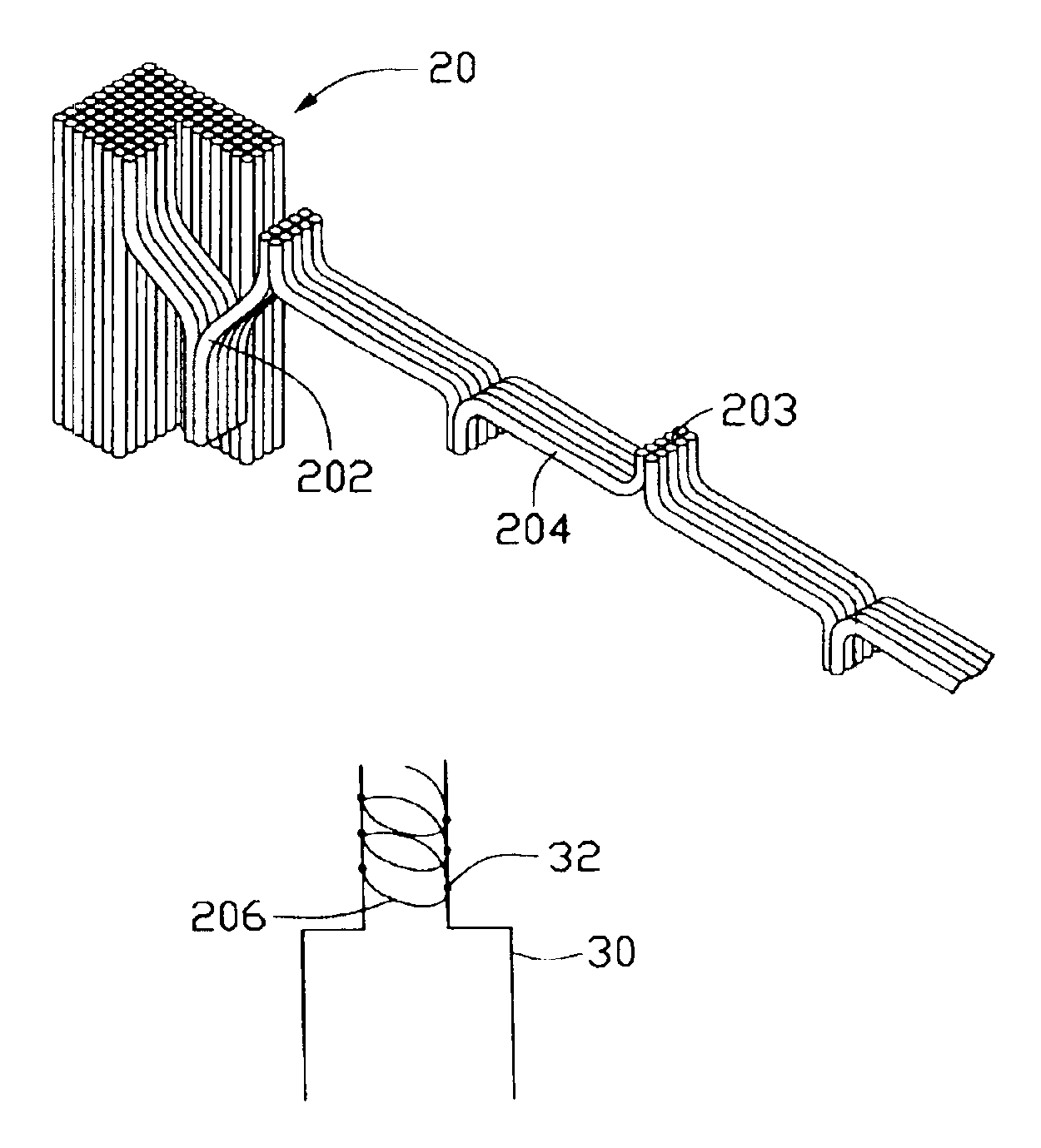

Method of manufacturing a light filament from carbon nanotubes

InactiveUS6957993B2Large specific surface areaIncreased durabilityMaterial nanotechnologyNanoinformaticsCarbon nanotube yarnCarbon nanotube fet

A light filament (206) formed from carbon nanotubes is characterized by high mechanical strength and durability at elevated temperatures, a high surface area to volume ratio, and high emissivity. Additionally, electrical resistance of the light filament does not increase with increasing temperature as much as electrical resistance of metallic light filaments. Accordingly, power consumption of the light filament is low at incandescent operating temperatures. A method for making a light filament made of carbon nanotubes includes the steps of: forming an array of carbon nanotubes (20); pulling out carbon nanotube yarn (204) from the carbon nanotube array; and winding the yarn between two leads (30) functioning as electrodes to form the light filament.

Owner:HON HAI PRECISION IND CO LTD +1

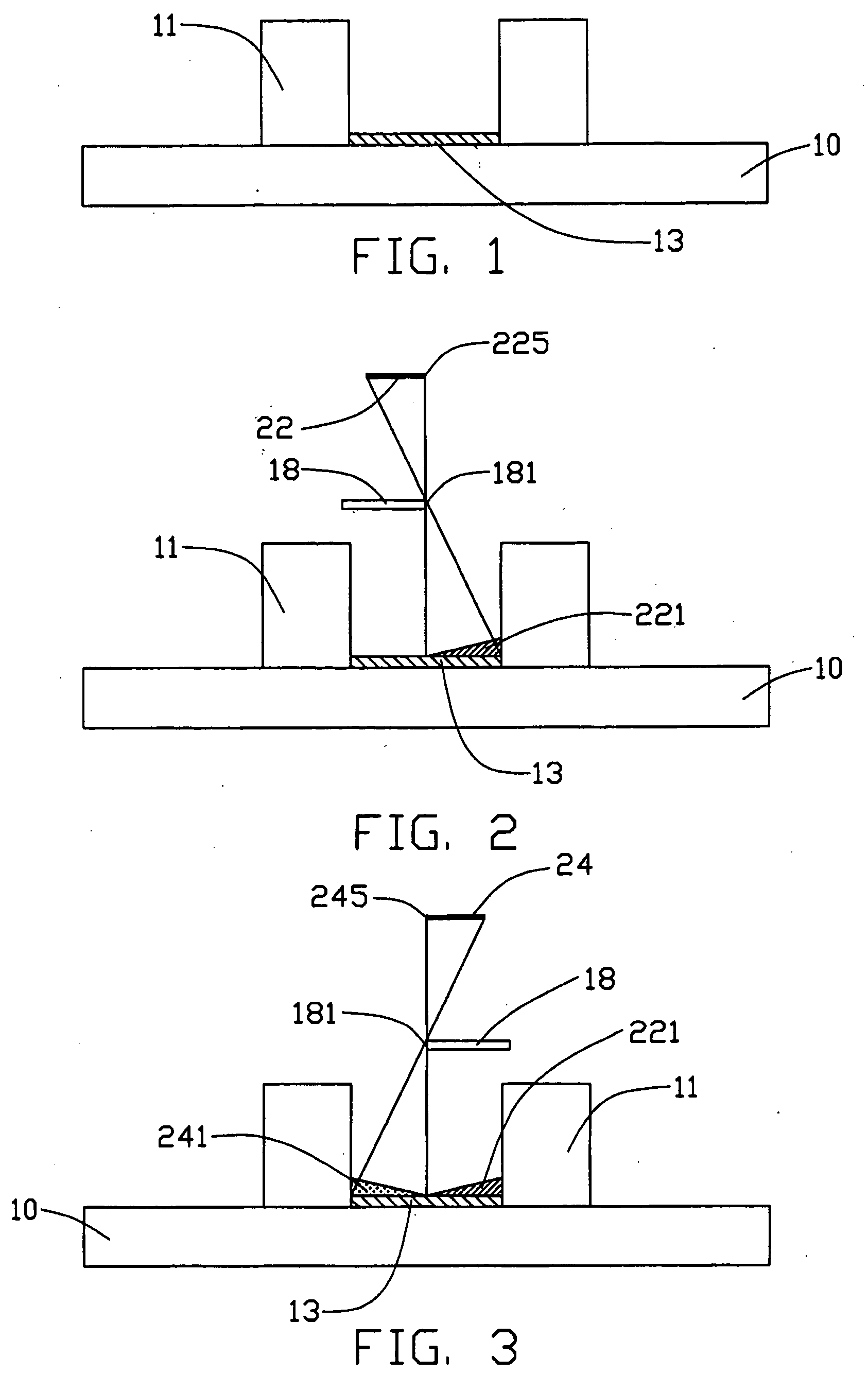

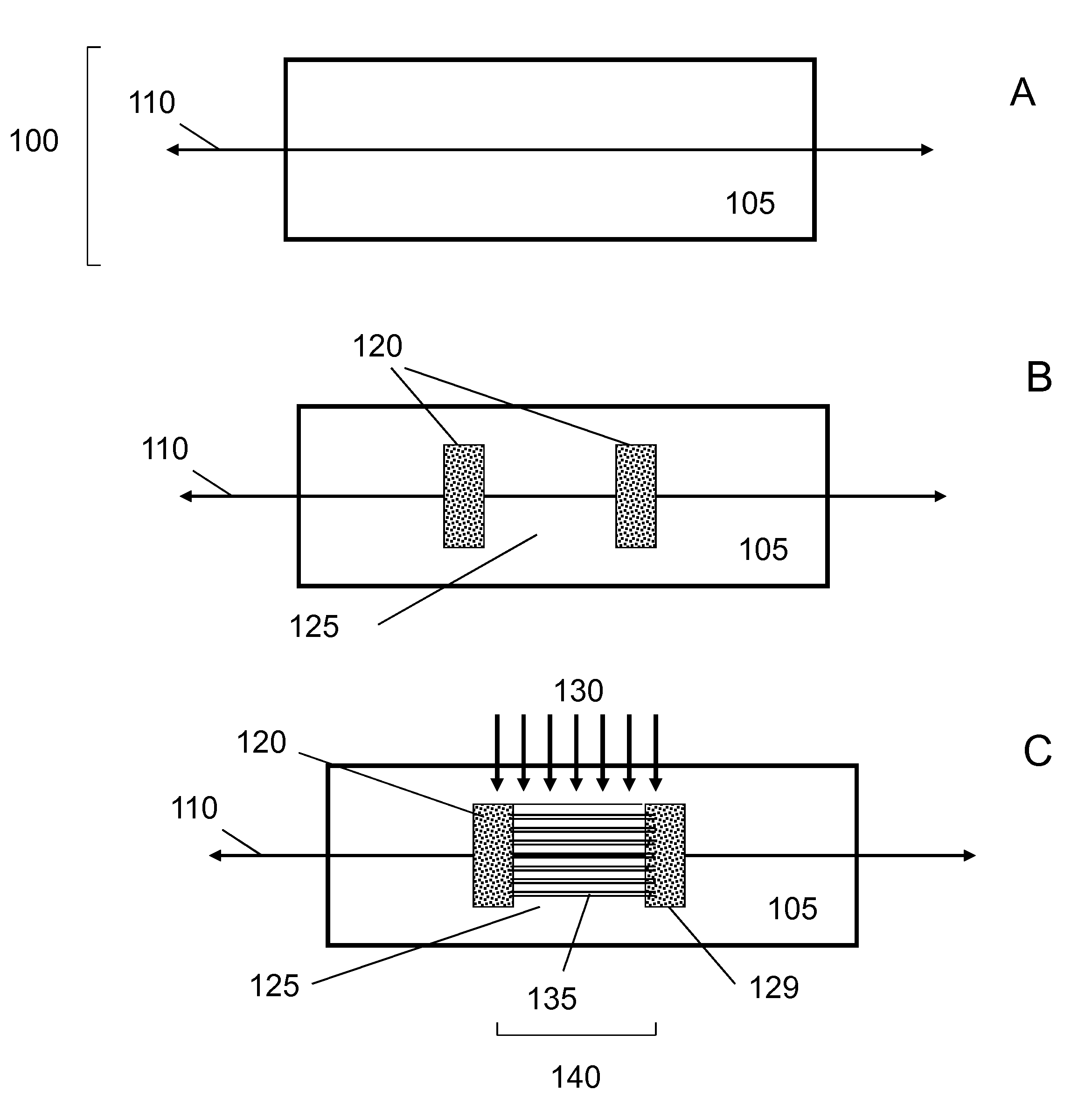

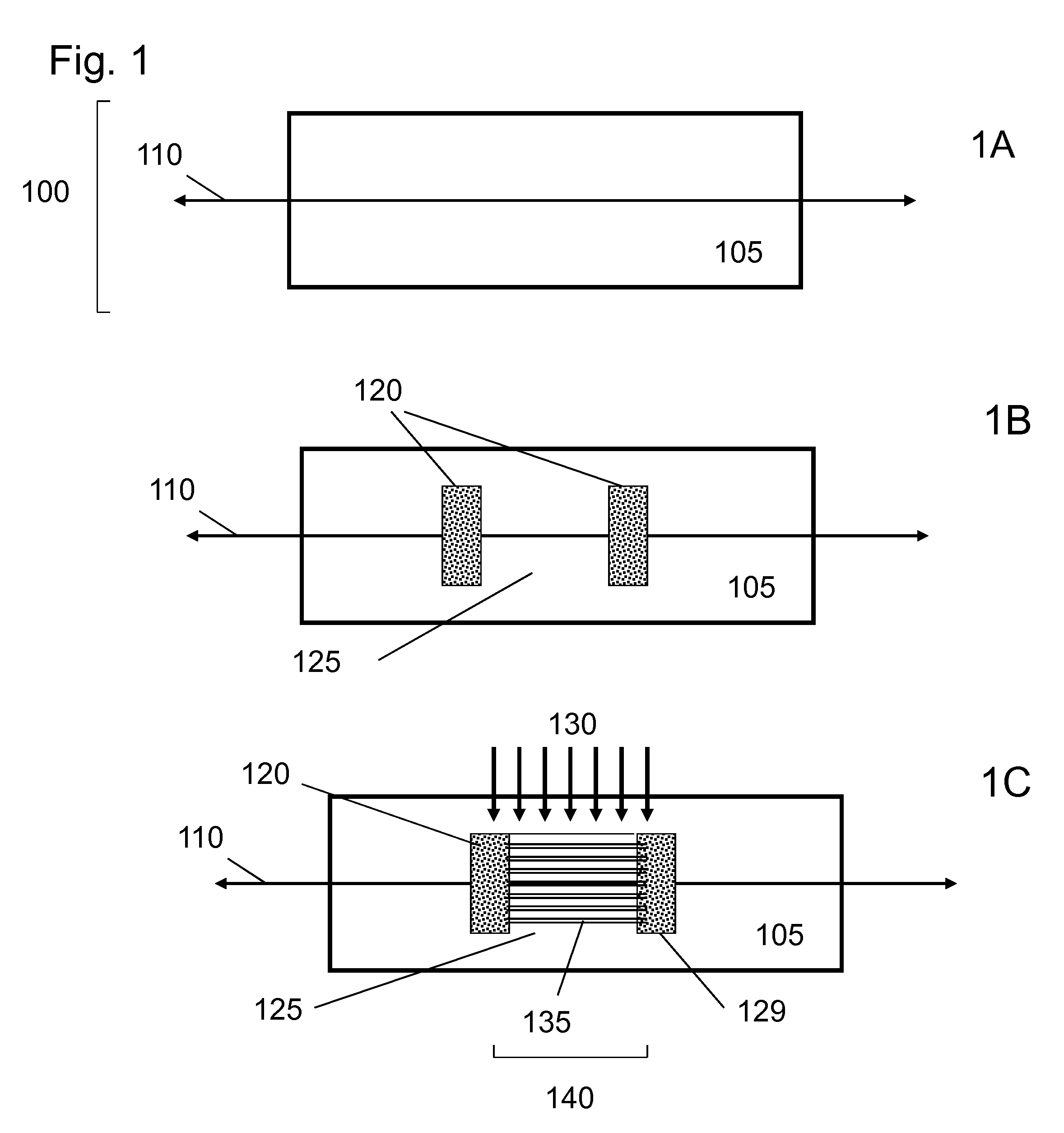

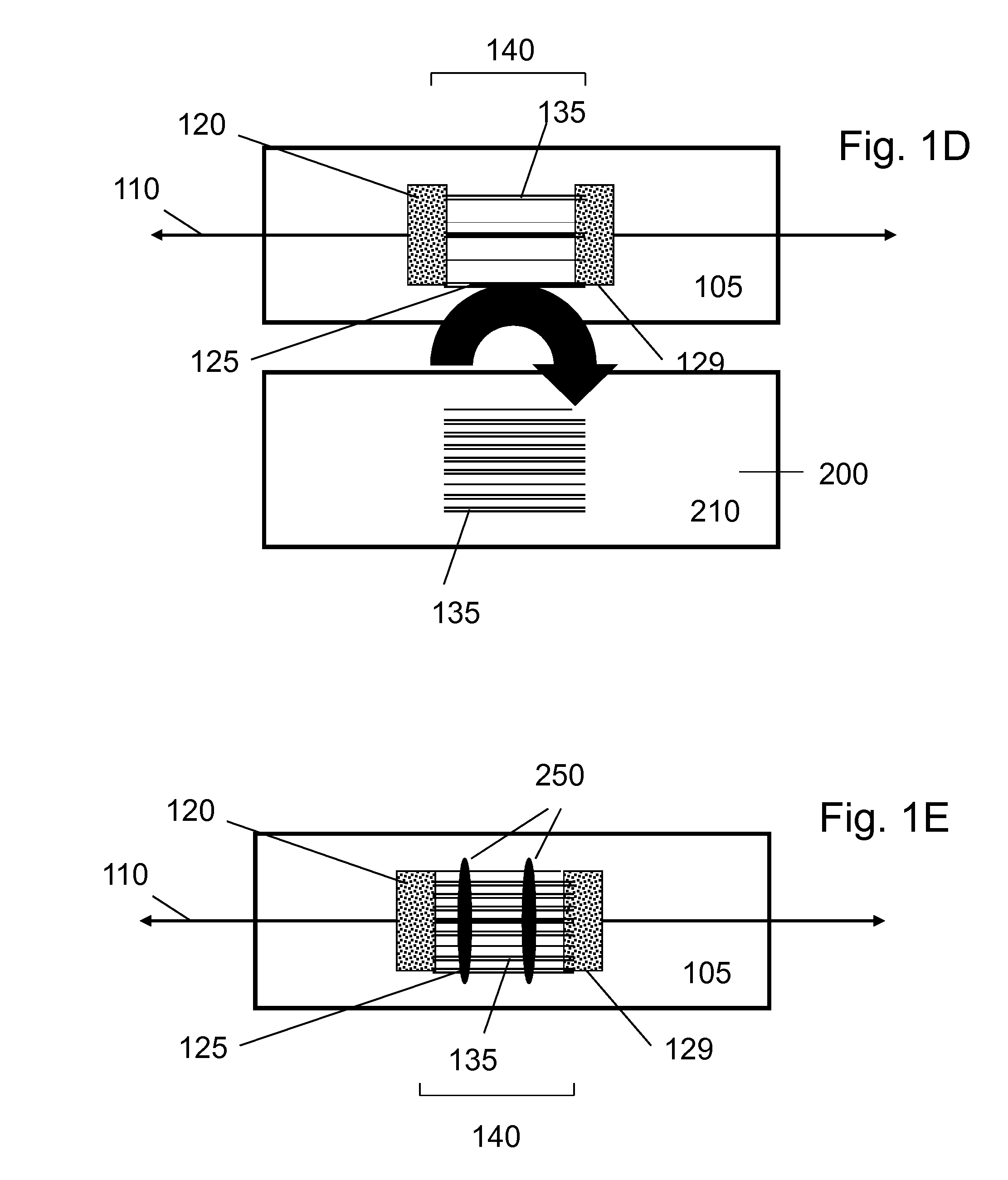

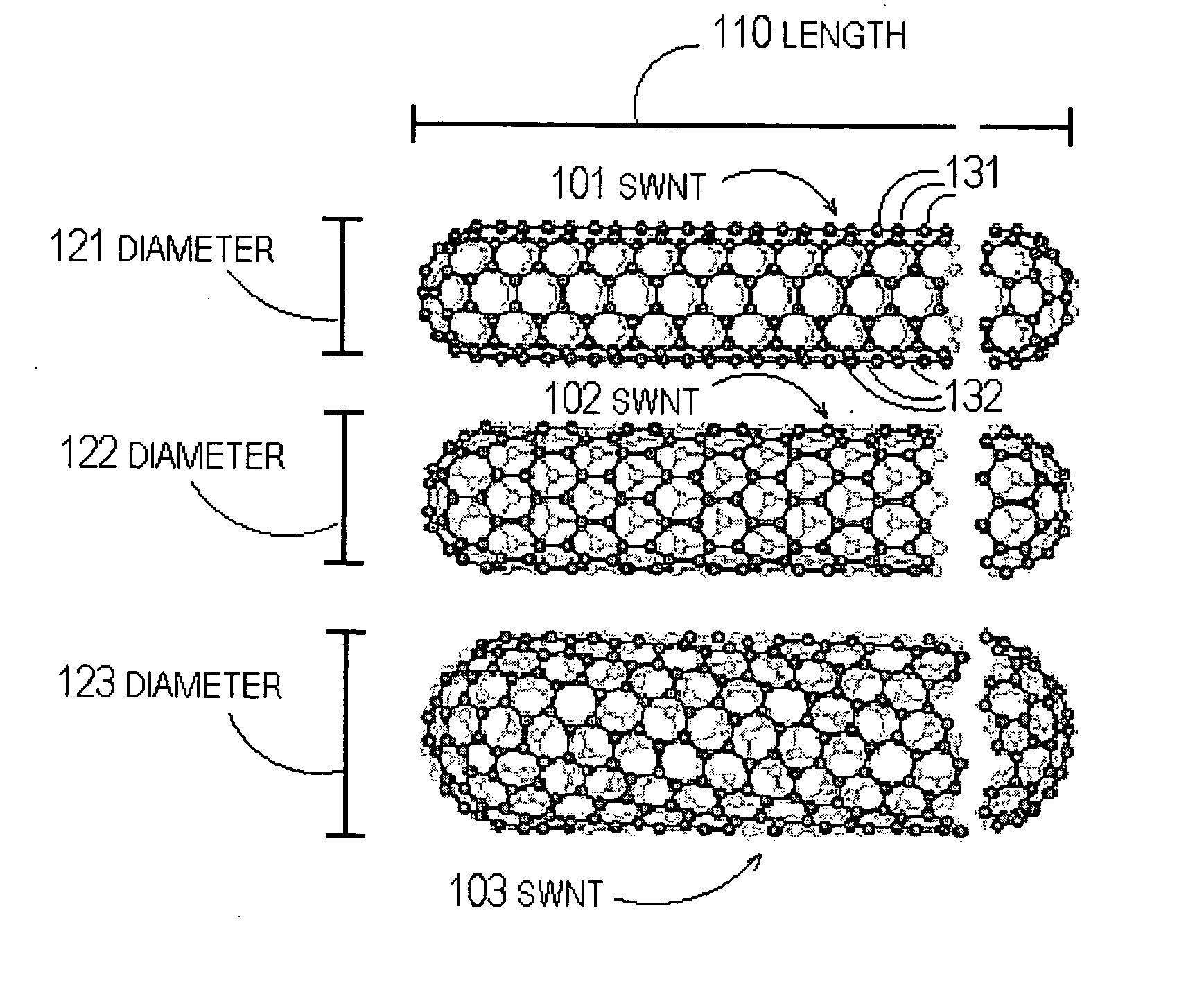

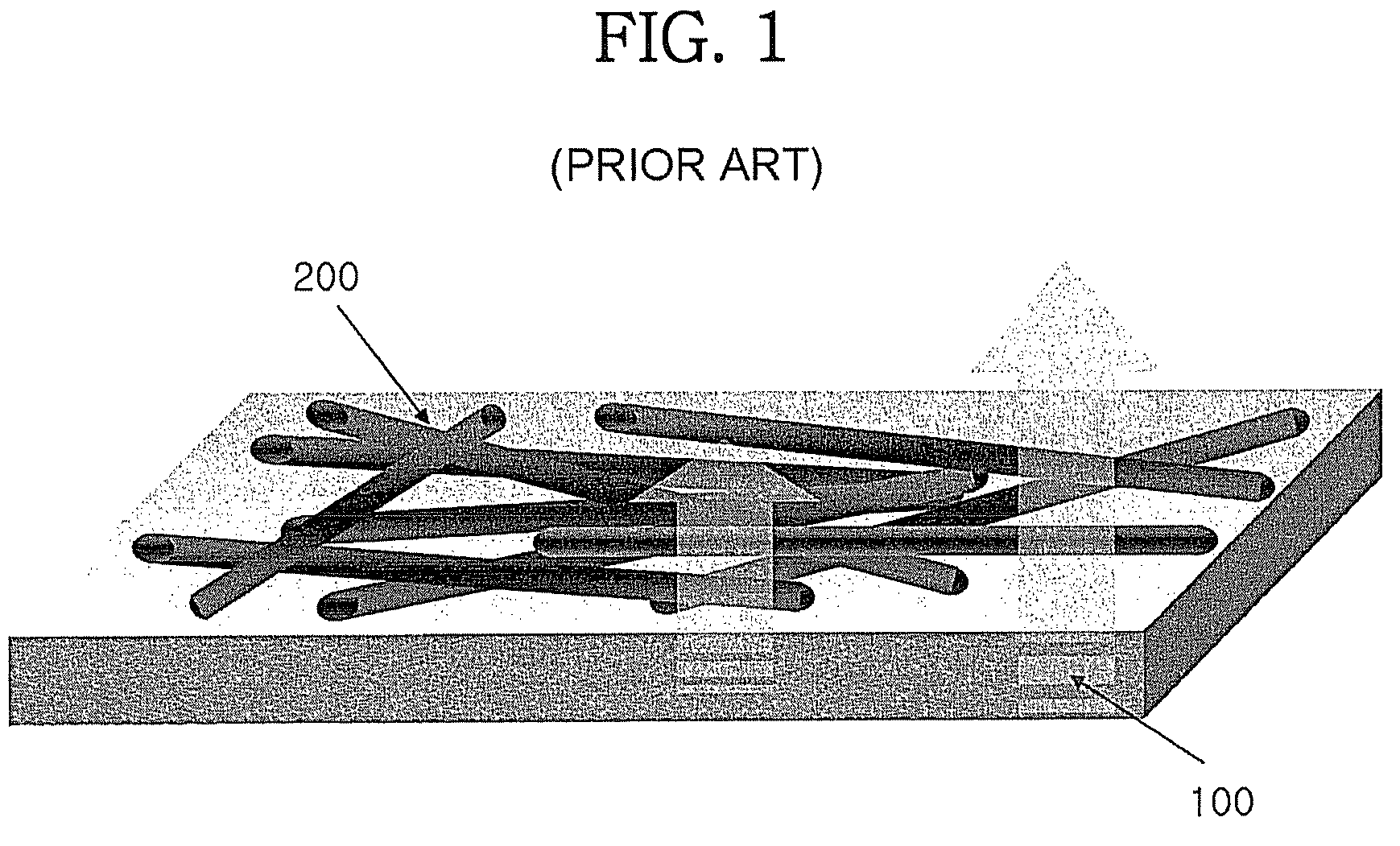

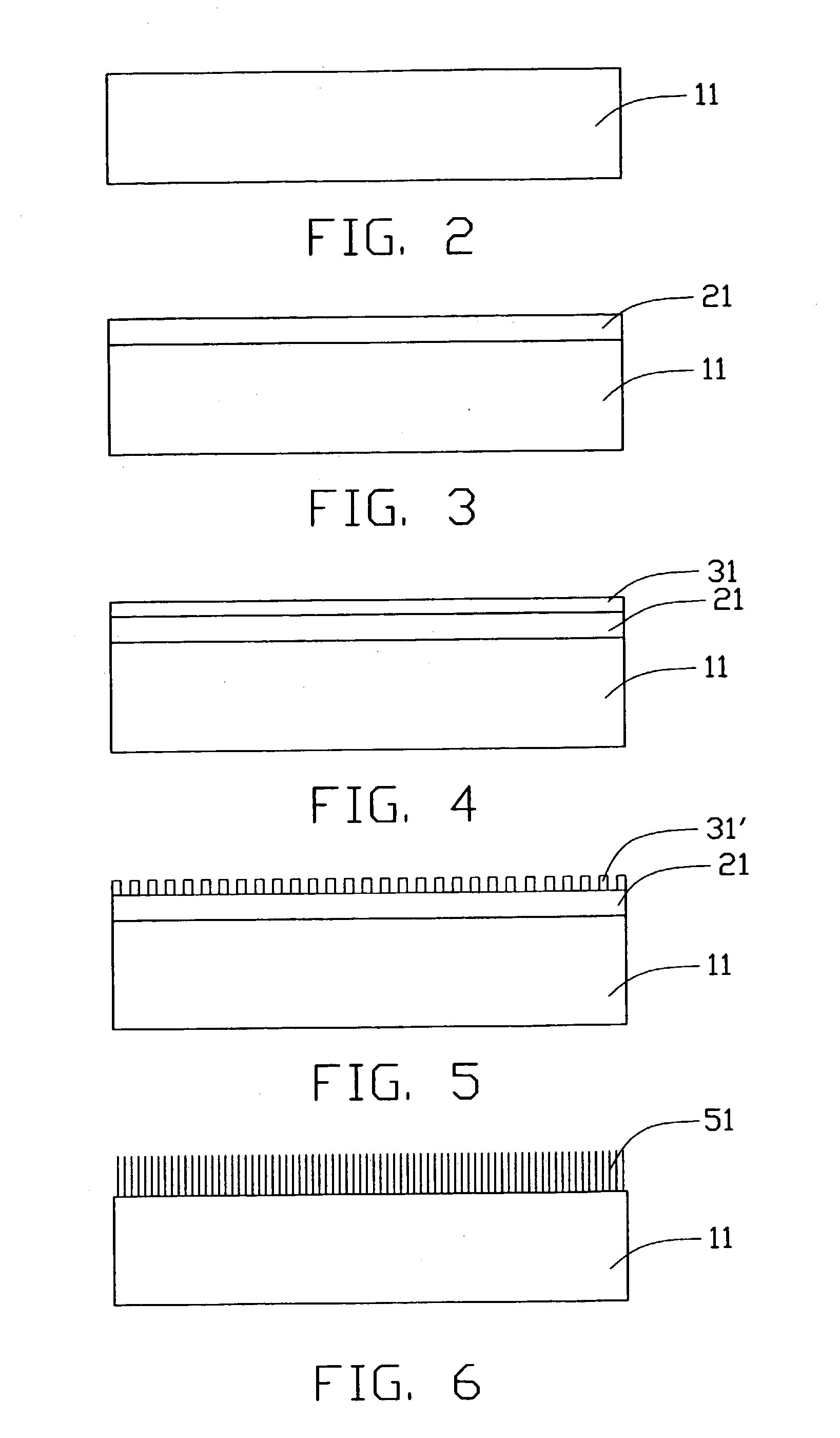

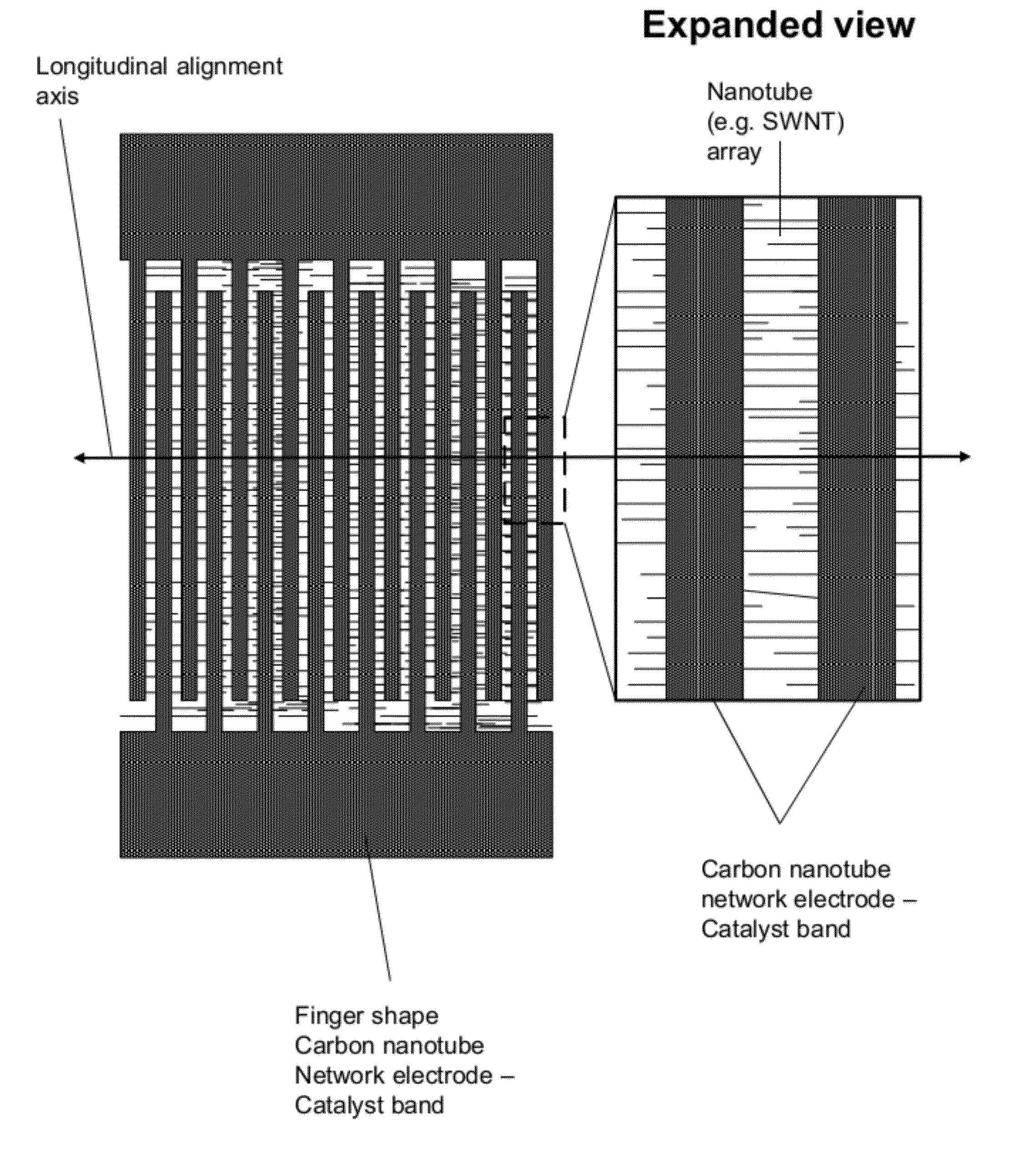

Methods of making spatially aligned nanotubes and nanotube arrays

ActiveUS8367035B2Easily integrated into functional deviceGood electronic behavior (and/or optical properties)Material nanotechnologyNanoinformaticsElectronNanotube array

The present invention provides arrays of longitudinally aligned carbon nanotubes having specified positions, nanotube densities and orientations, and corresponding methods of making nanotube arrays using guided growth and guided deposition methods. Also provided are electronic devices and device arrays comprising one or more arrays of longitudinally aligned carbon nanotubes including multilayer nanotube array structures and devices.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Method of making carbon nanotube arrays, and thermal interfaces using same

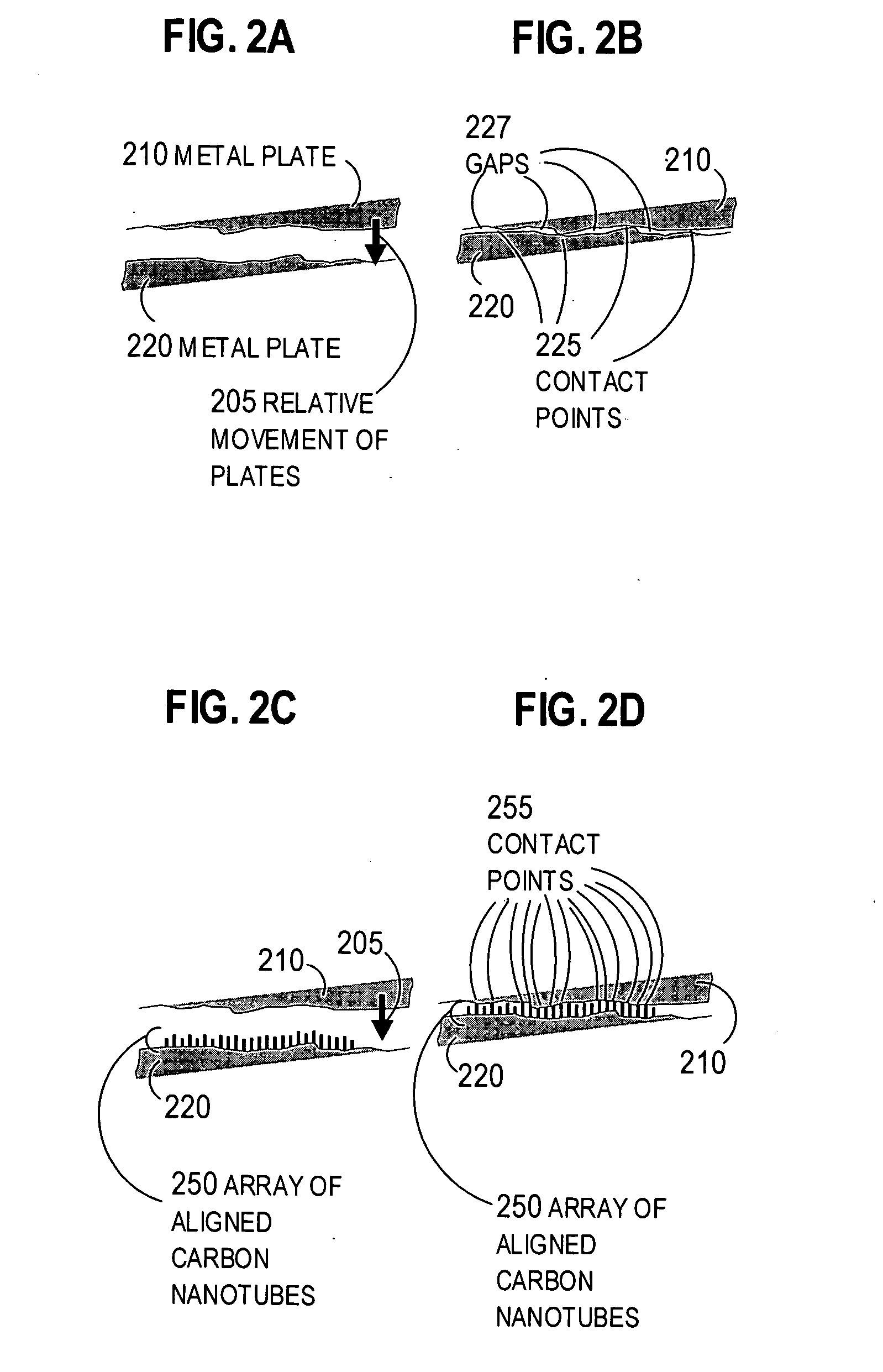

Thermal interfaces and methods include an array of carbon nanotubes aligned substantively perpendicularly from a substrate. One method includes arranging metal catalyst particles with a particular ligand on a fluid surface of a Langmuir-Blodgett trough. This forms uniformly spaced particles with spacing based on the particular ligand. The uniformly spaced metal catalyst particles are deposited on a substrate and carbon nanotubes are grown on the particles using chemical vapor deposition. A highly efficient thermal interface can be produced with a carbon nanotube packing ratio greater than fifty percent and used in a thermal switch or other device. In some methods, commercially available nanotubes are condensed on a substrate using carbon nanotubes with terminal carboxylic acids in solution and an amine monolayer on the substrate. Pretreatment of the nanotubes in a switch by applying heavy pressure between two surfaces results in good thermal conductivity between those surfaces at smaller operating pressures.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

NRAM bit selectable two-device nanotube array

Owner:NANTERO

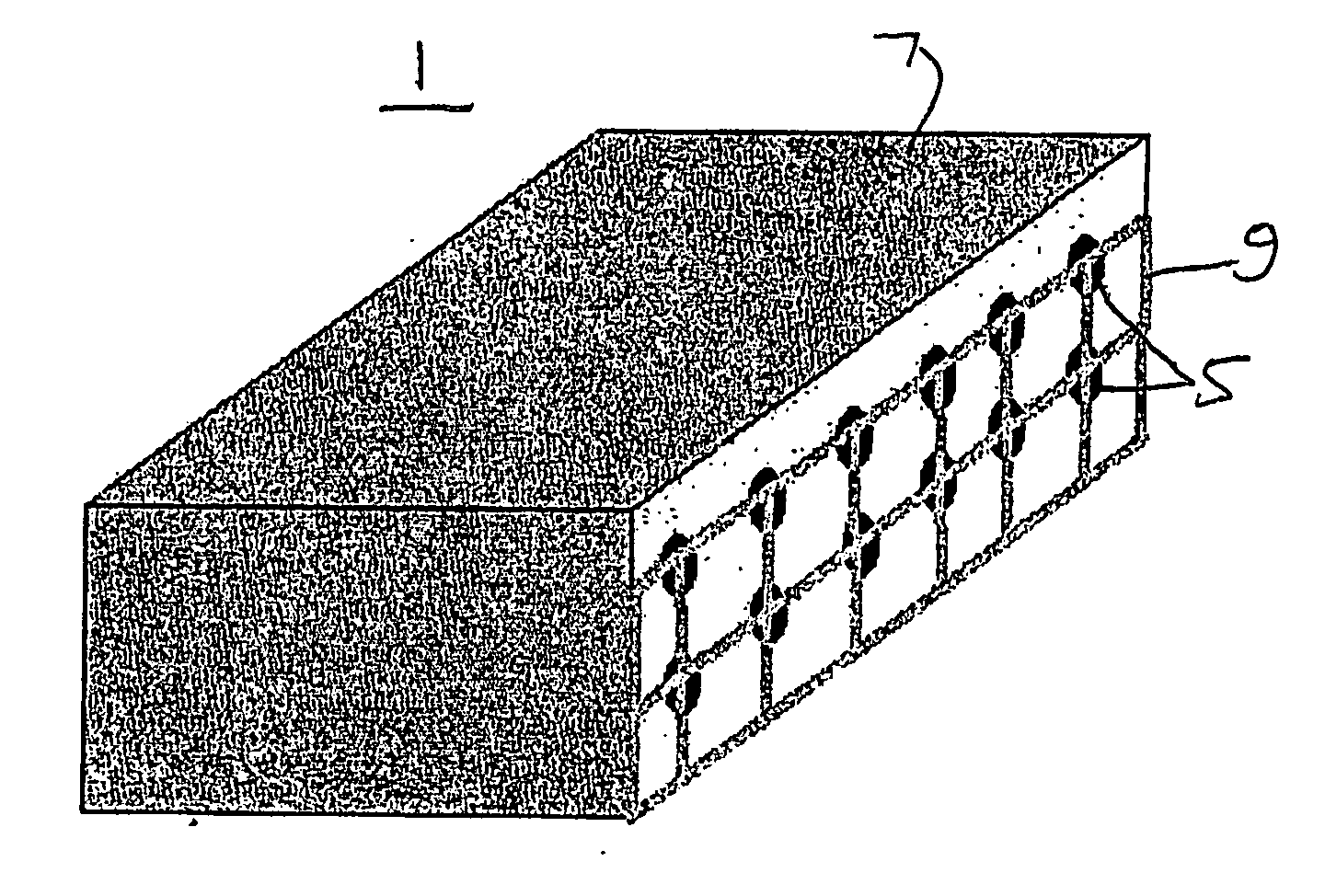

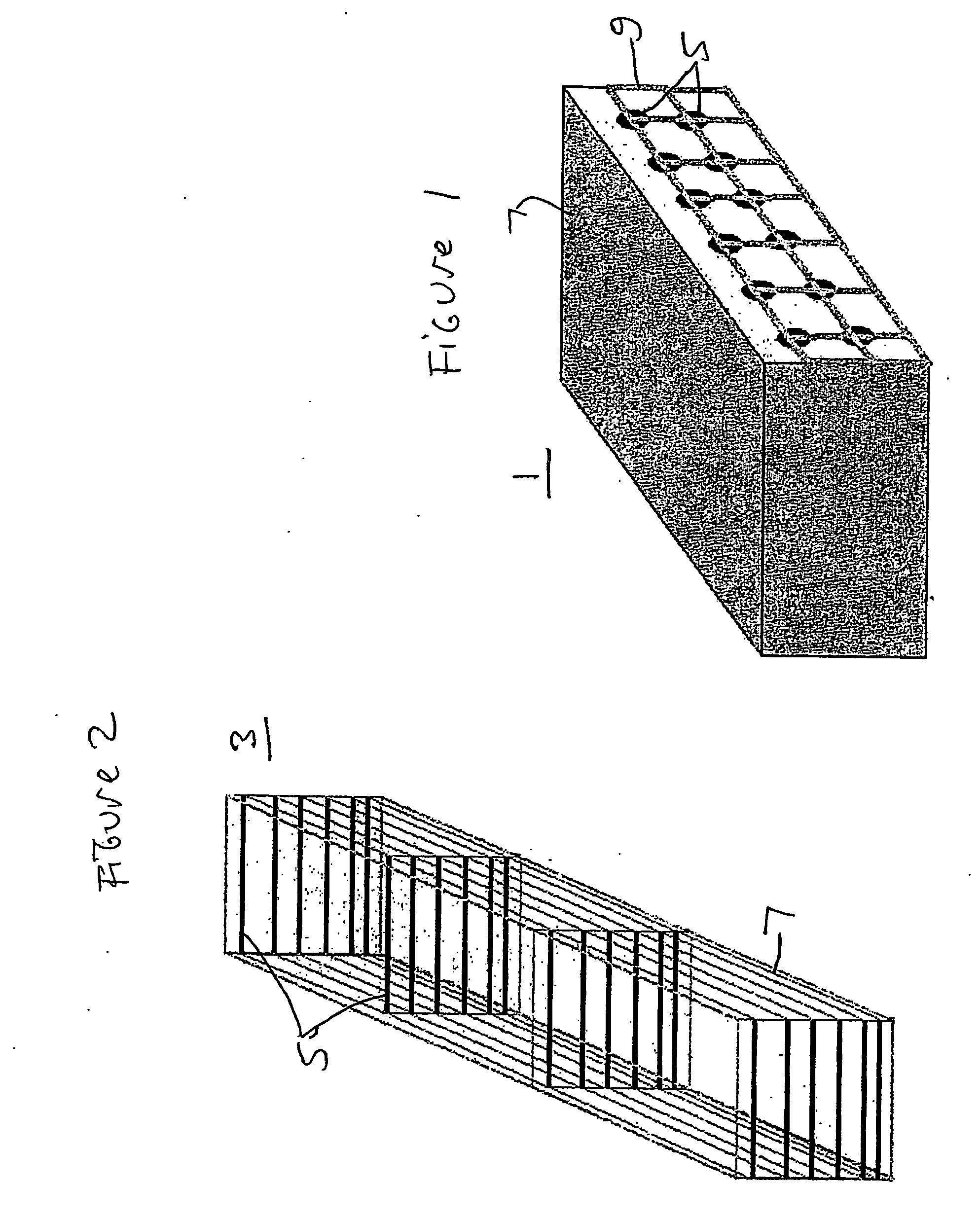

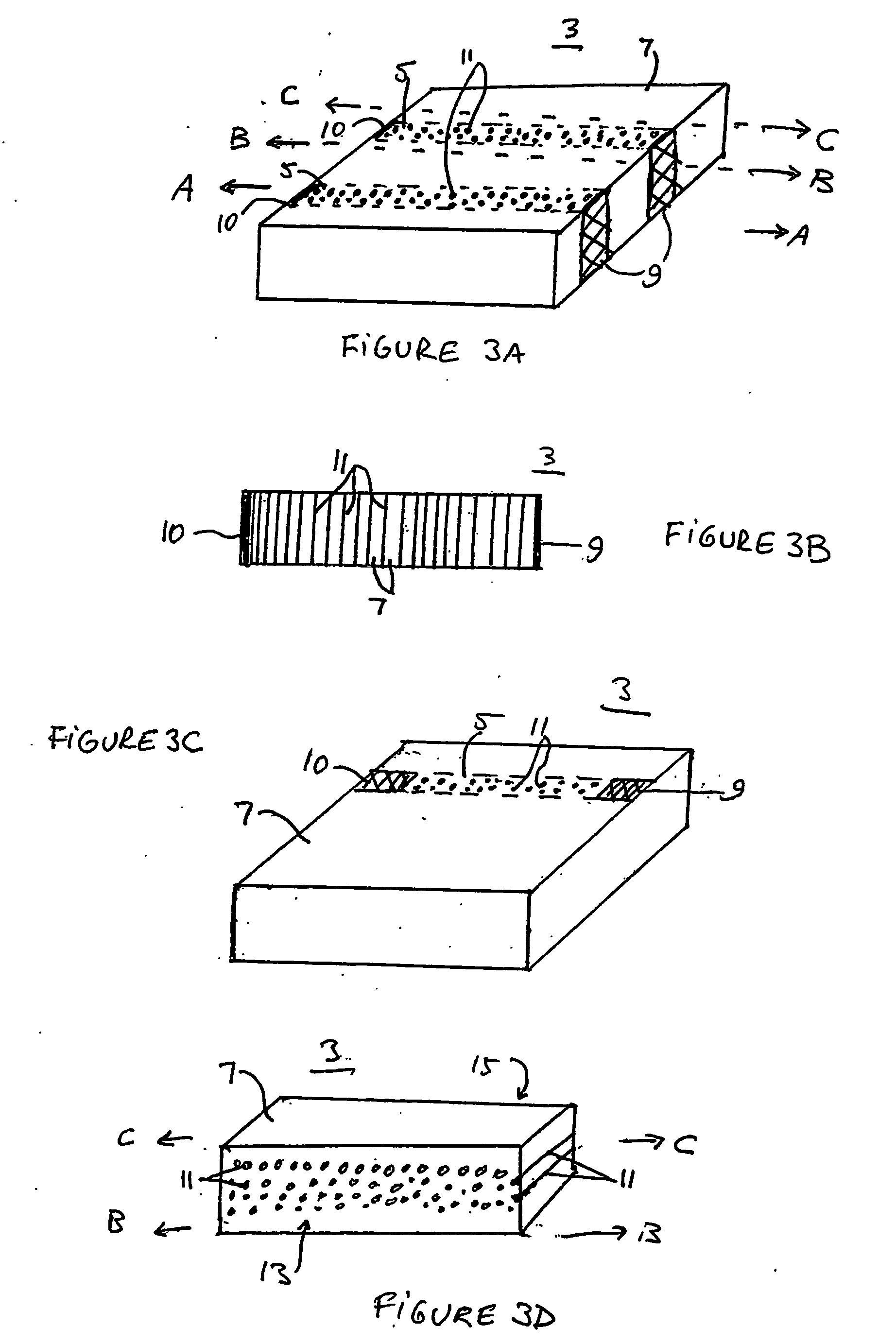

Embedded nanotube array sensor and method of making a nanotube polymer composite

ActiveUS20070138010A1Material nanotechnologyAntenna adaptation in movable bodiesPolymer compositesMaterials science

A method of producing polymer / nanotube composites where the density and position of the nanotubes (11) within the composite ca be controlled. Carbon nanotubes (11) are grown from organometallic micropatterns. These periodic nanotube arrays are then incorporated into a polymer matrix (7) by deposing a curable polymer film on the as-grown tubes. This controlled method of producing free-standing nanotube / polymer composite films may be used to form nanosensor (3) which provide information regarding a physical condition of a material (20), such as an airplane chassis or wing, in contact with the nanosensor (3).

Owner:RENESSELAER POLYTECHNIC INST

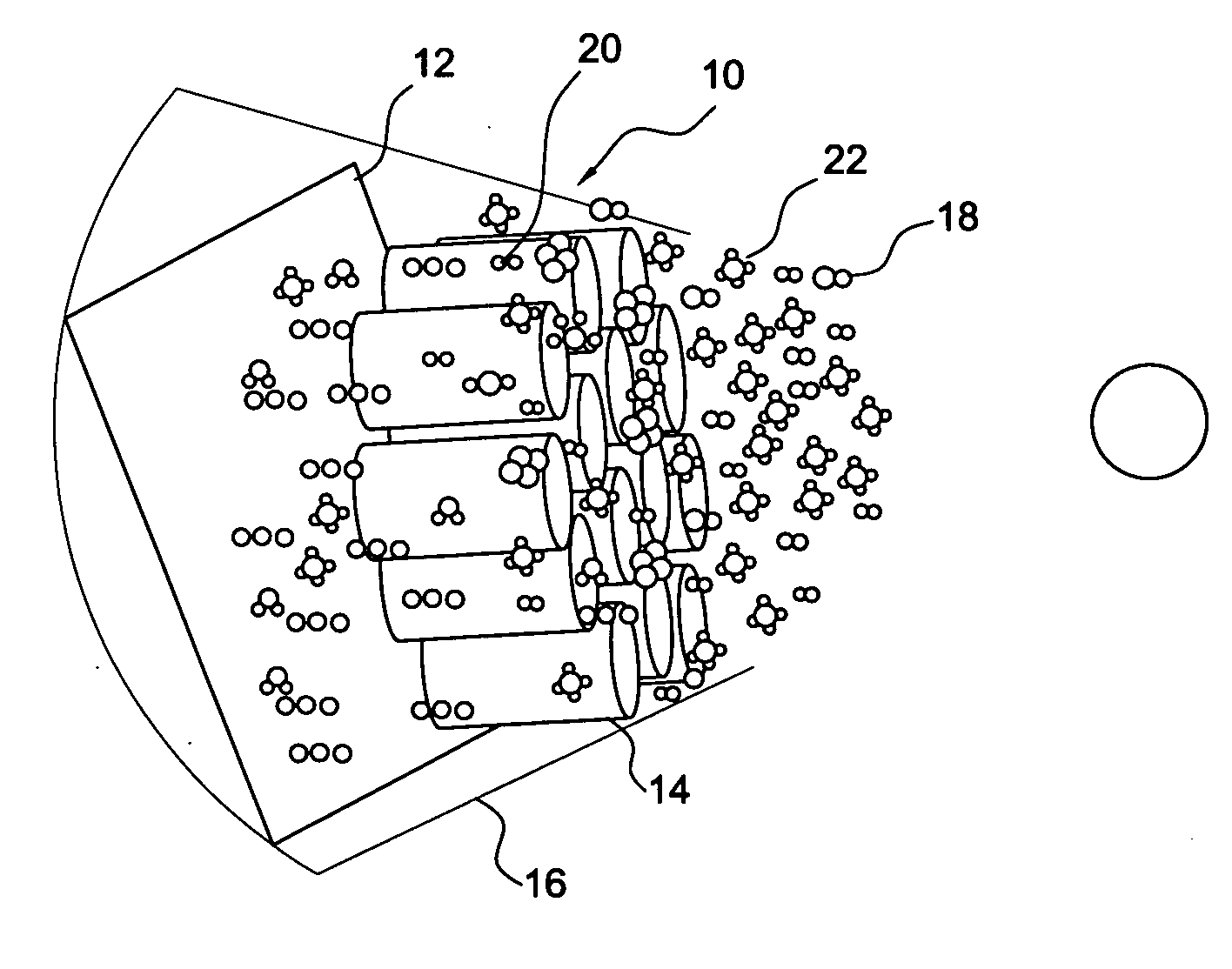

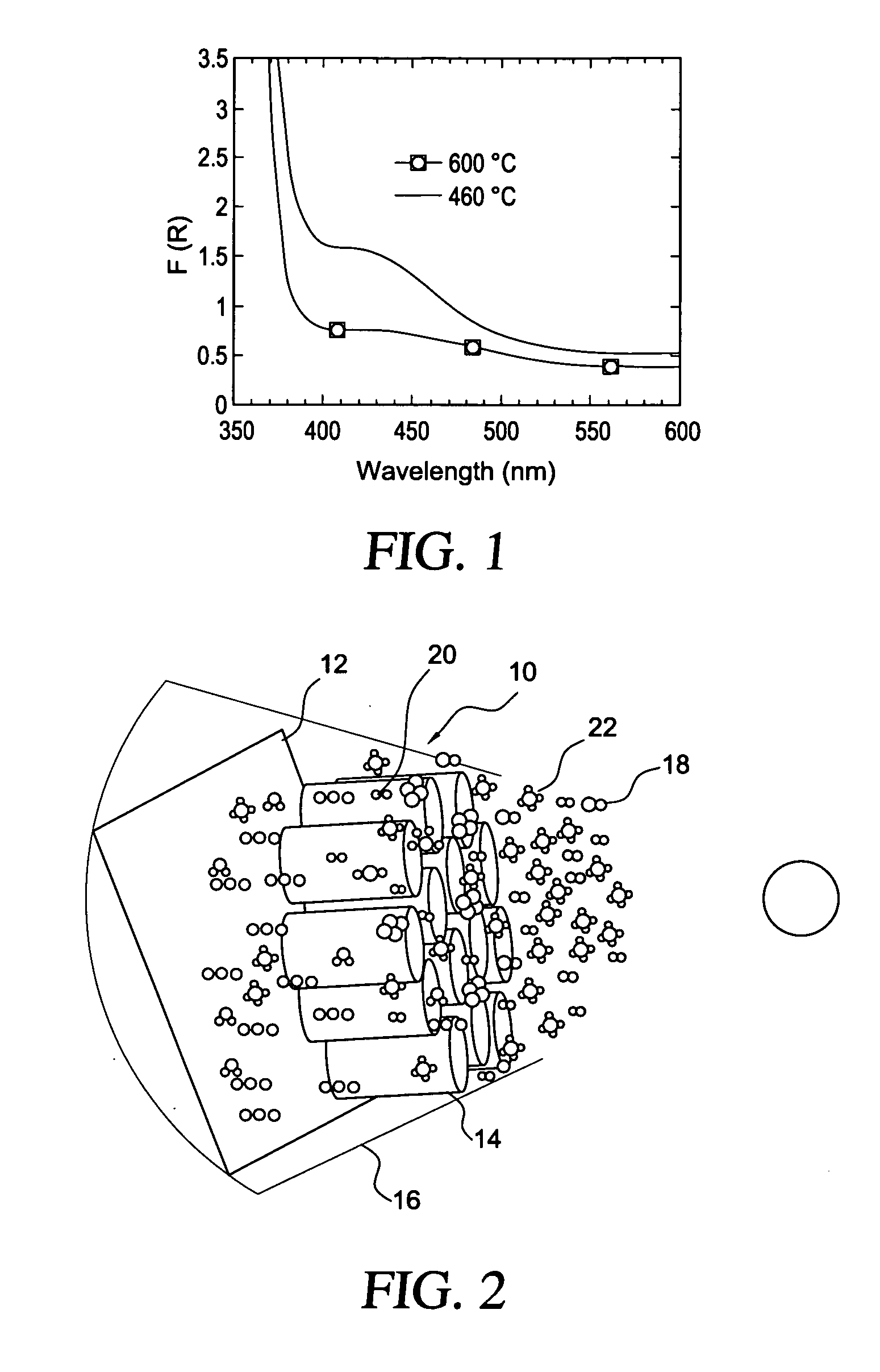

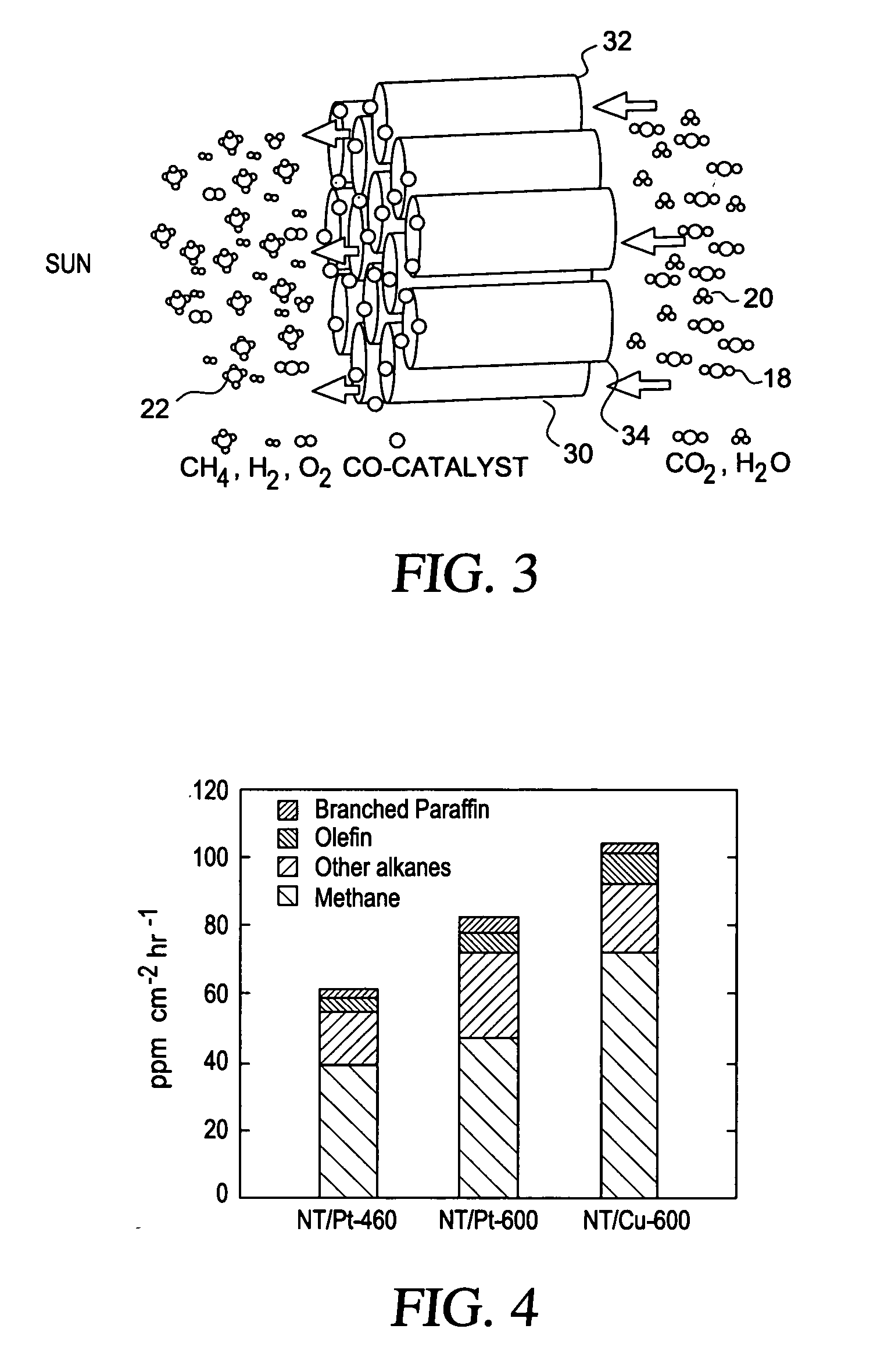

Titania nanotube arrays, methods of manufacture, and photocatalytic conversion of carbon dioxide using same

InactiveUS20100213046A1Improve photocatalytic activityImprove efficiencyCatalyst activation/preparationLiquid hydrocarbon mixture productionTio2 nanotubeWater vapor

Nitrogen-doped titania nanotubes exhibiting catalytic activity on exposure to any one or more of ultraviolet, visible, and / or infrared radiation, or combinations thereof are disclosed. The nanotube arrays may be co-doped with one or more nonmetals and may further include co-catalyst nanoparticles. Also, methods are disclosed for use of nitrogen-doped titania nanotubes in catalytic conversion of carbon dioxide alone or in admixture with hydrogen-containing gases such as water vapor and / or other reactants as may be present or desirable into products such as hydrocarbons and hydrocarbon-containing products, hydrogen and hydrogen-containing products, carbon monoxide and other carbon-containing products, or combinations thereof.

Owner:PENN STATE RES FOUND

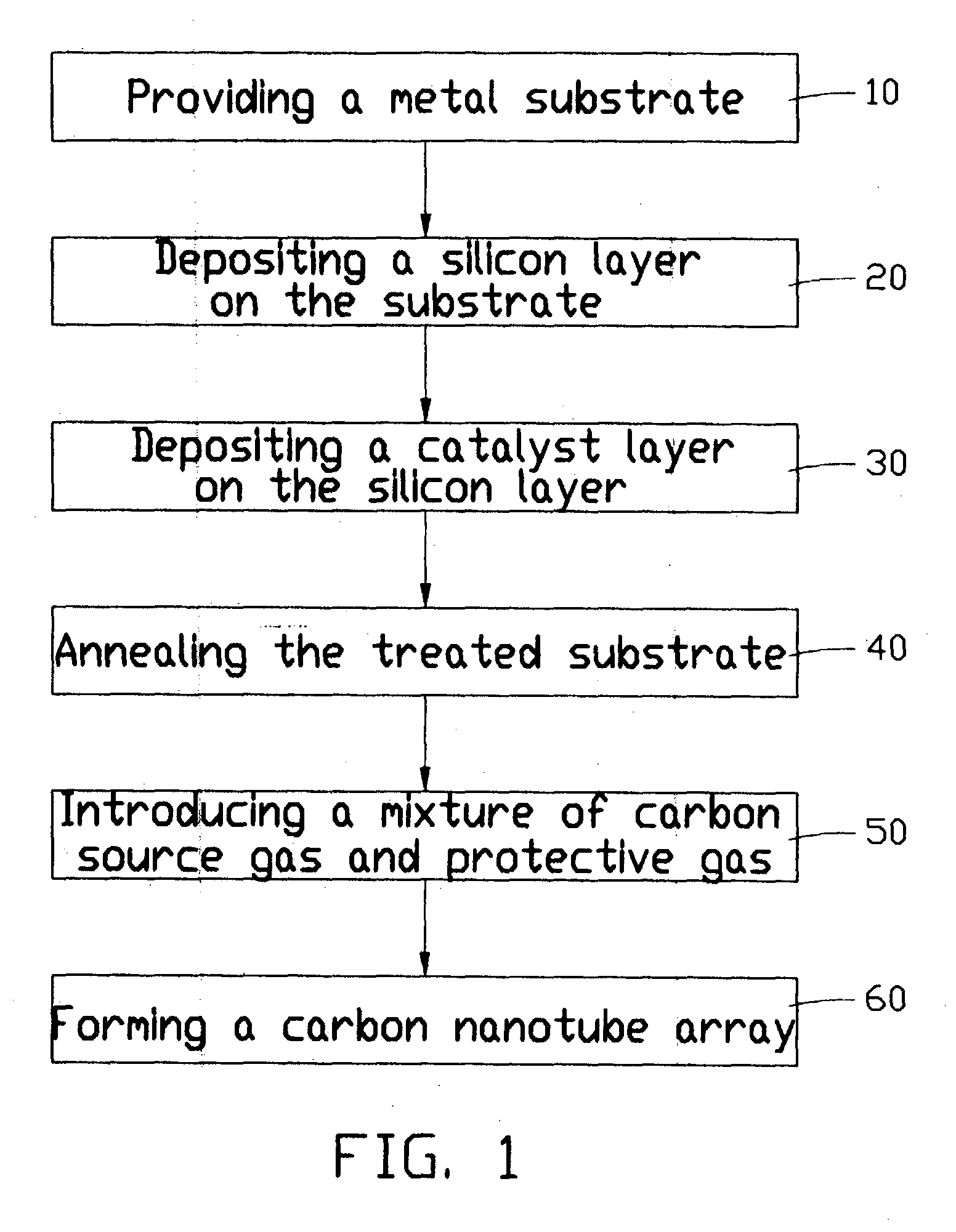

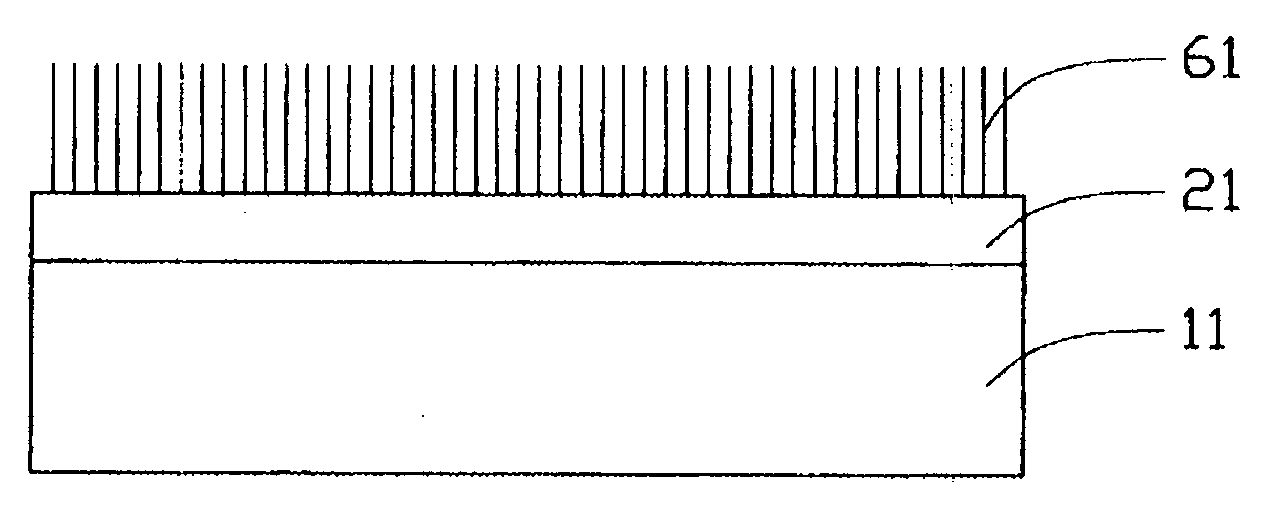

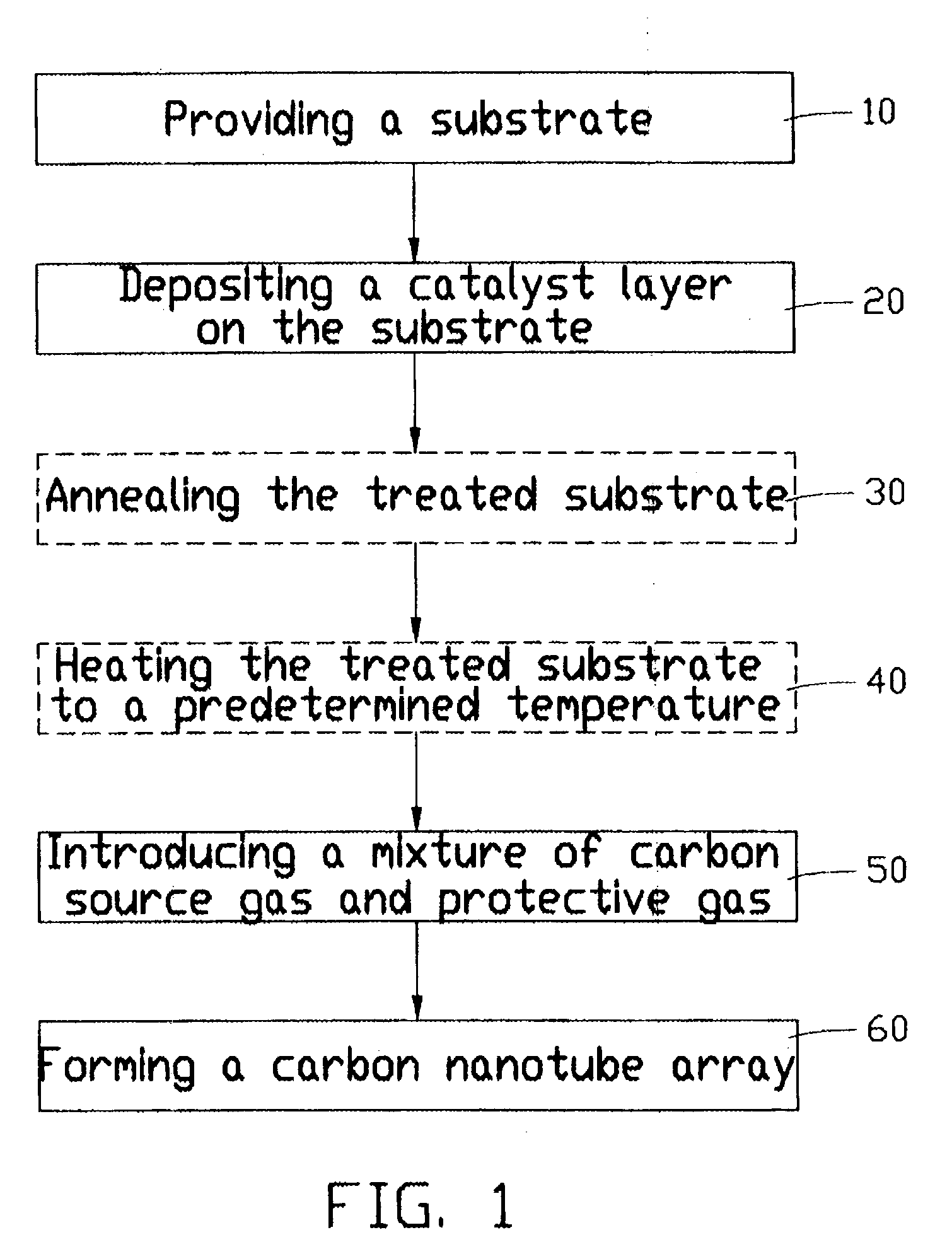

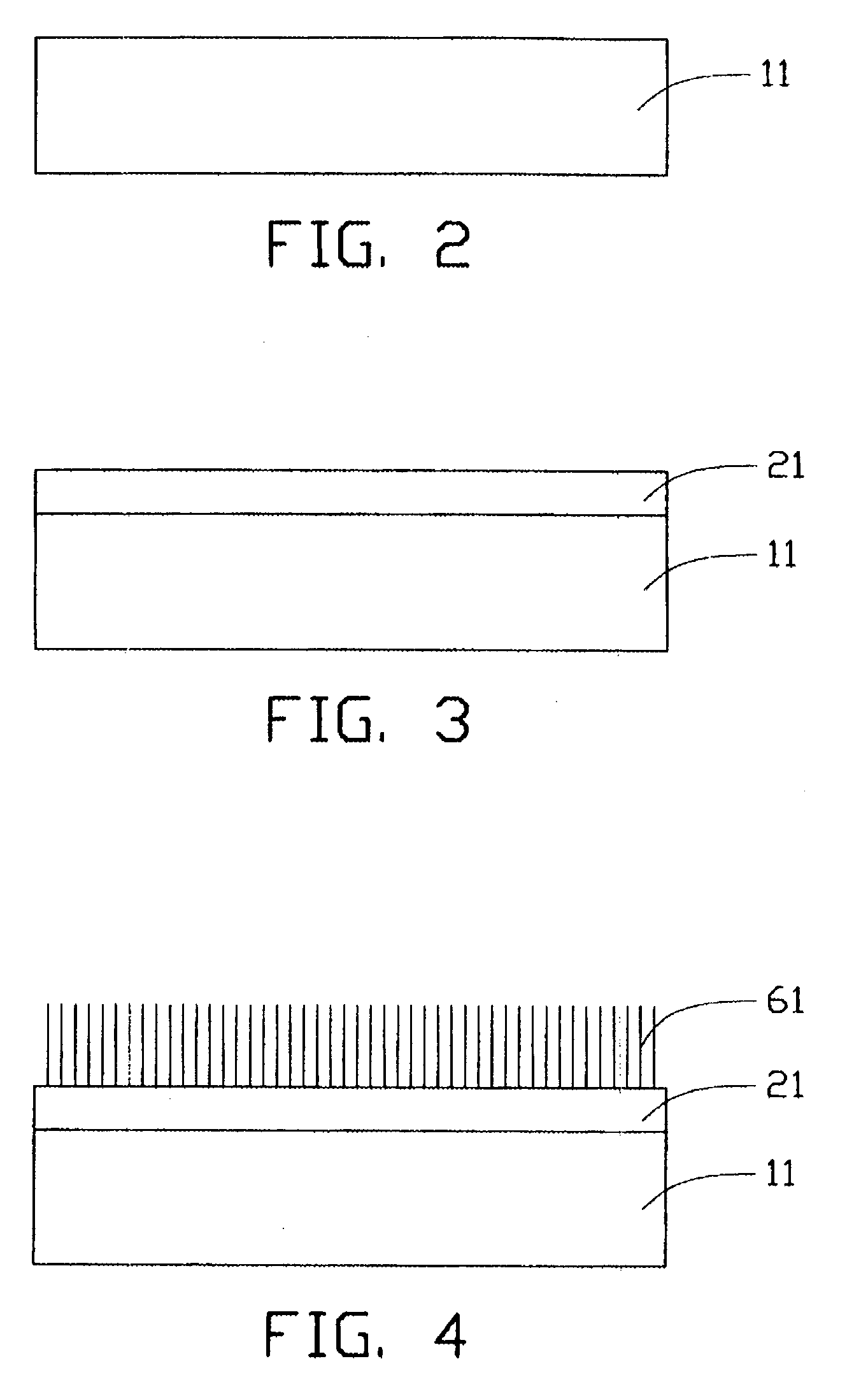

Carbon nanotube array and method for forming same

ActiveUS20040101468A1Damage formationInhibition formationMaterial nanotechnologyLayered productsField emission deviceMetallic materials

A method for forming a carbon nanotube array on a metal substrate includes the following steps: providing a metal substrate (11); depositing a silicon layer (21) on a surface of the metal substrate; depositing a catalyst layer (31) on the silicon layer; annealing the treated substrate; heating the treated substrate up to a predetermined temperature in flowing protective gas; introducing a carbon source gas for 5-30 minutes; and thus forming a carbon nanotube array (51) extending from the treated substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

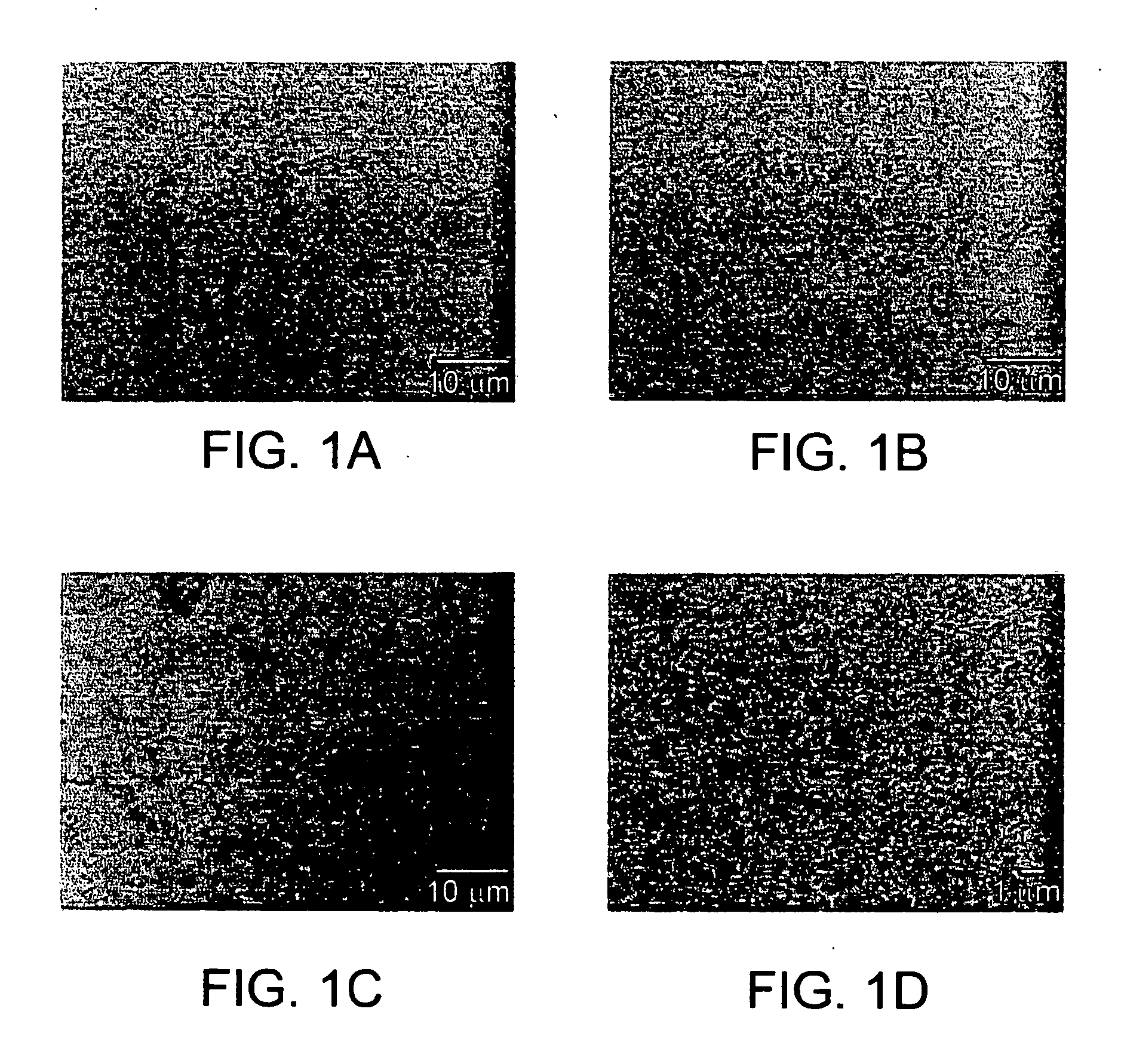

Method of preparing patterned carbon nanotube array and patterned carbon nanotube array prepared thereby

InactiveUS7662732B2Improved array uniformity and transmittanceEasy to prepareMaterial nanotechnologyCarbon compoundsNanotube array

A method of preparing a patterned carbon nanotube array a patterned carbon nanotube array prepared thereby are provided. The method includes forming carbon nanotubes in channels of porous templates, arranging the templates in a predetermined pattern on a substrate and selectively removing the templates to expose the carbon nanotubes.

Owner:SAMSUNG ELECTRONICS CO LTD

Carbon nanotube array and method for forming same

ActiveUS20040184981A1Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceMetallic materials

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

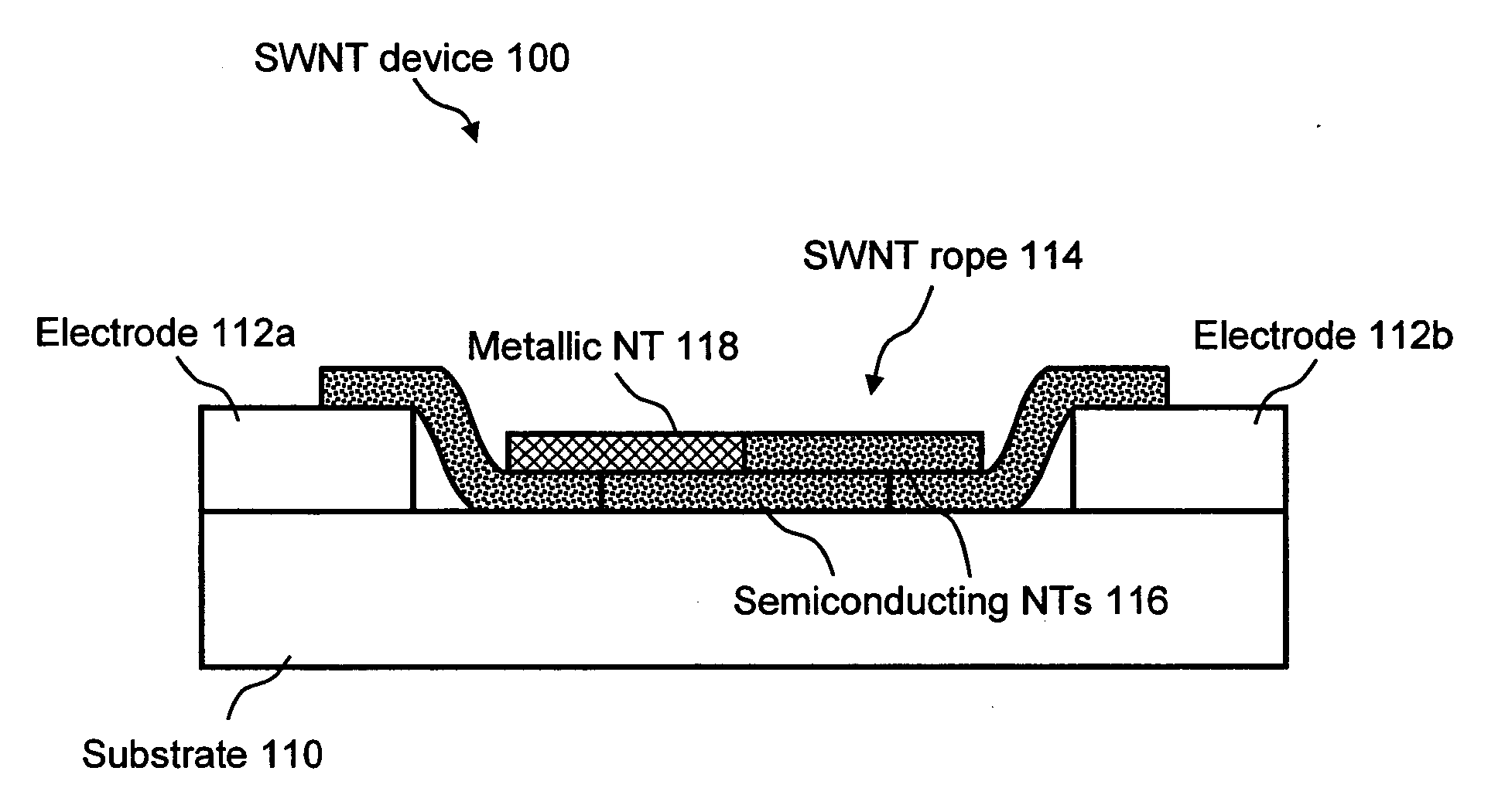

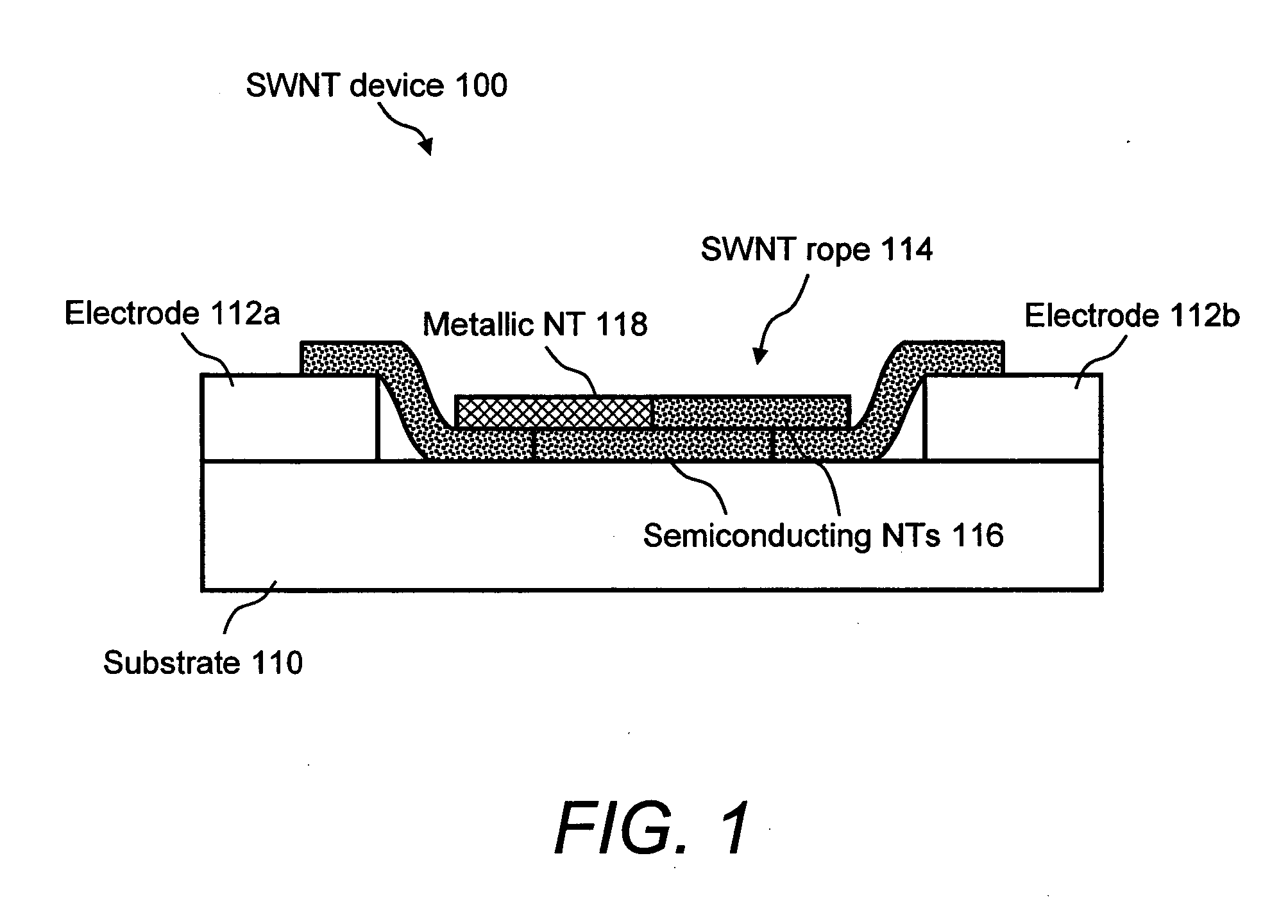

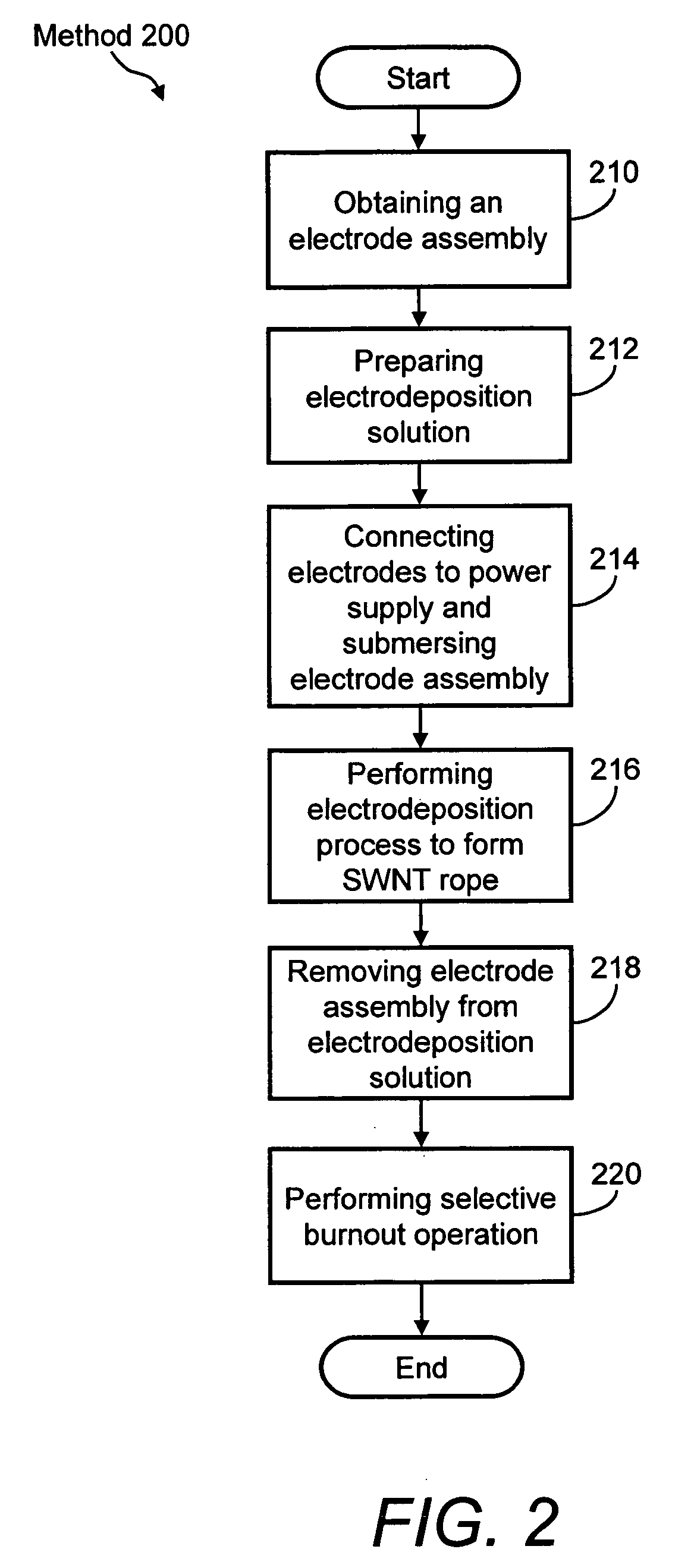

Carbon nanotube-based electronic devices made by electrolytic deposition and applications thereof

InactiveUS20060065887A1Efficient and cost-effectiveNanoinformaticsSolid-state devicesDevice formMulti dimensional

Carbon nanotube-based devices made by electrolytic deposition and applications thereof are provided. In a preferred embodiment, the present invention provides a device comprising at least one array of active carbon nanotube junctions deposited on at least one microelectronic substrate. In another preferred embodiment, the present invention provides a device comprising a substrate, at least one pair of electrodes disposed on the substrate, wherein one or more pairs of electrodes are connected to a power source, and a bundle of carbon nanotubes disposed between the at least one pair of electrodes wherein the bundle of carbon nanotubes consist essentially of semiconductive carbon nanotubes. In another preferred embodiment, a semiconducting device formed by electrodeposition of carbon nanotubes between two electrodes is provided. The invention also provides preferred methods of forming a semiconductive device by applying a bias voltage to a carbon nanotube rope. The plurality of metallic single-wall carbon nanotubes are removed (e.g., by application of bias voltage) in an amount sufficient to form the semiconducting device. The devices of the invention include, but not limited to, chemical or biological sensors, carbon nanotube field-effect transistors (CNFETs), tunnel junctions, Schottky junctions, and multi-dimensional nanotube arrays.

Owner:FOSTER-MILLER

Carbon nanotube array and method for forming same

ActiveUS20040053053A1Reduce partial pressureEasy to bundleMaterial nanotechnologyPolycrystalline material growthMetal catalystCarbon nanotube

A method for forming a carbon nanotube array includes the following steps: providing a smooth substrate (11); depositing a metal catalyst layer (21) on a surface of the substrate; heating the treated substrate to a predetermined temperature in flowing protective gas; and introducing a mixture of carbon source gas and protective gas for 5-30 minutes, thus forming a carbon nanotube array (61) extending from the substrate. When the mixture of carbon source gas and protective gas is introduced, a temperature differential greater than 50° C. between the catalyst and its surrounding environment is created by adjusting a flow rate of the carbon source gas. Further, a partial pressure of the carbon source gas is maintained lower than 20%, by adjusting a ratio of the flow rates of the carbon source gas and the protective gas. The carbon nanotubes formed in the carbon nanotube array are well bundled.

Owner:HON HAI PRECISION IND CO LTD +1

Methods of Making Spatially Aligned Nanotubes and Nanotube Arrays

ActiveUS20120321785A1Improve placement accuracyImprove fidelityMaterial nanotechnologyNanoinformaticsElectronNanotube array

The present invention provides arrays of longitudinally aligned carbon nanotubes having specified positions, nanotube densities and orientations, and corresponding methods of making nanotube arrays using guided growth and guided deposition methods. Also provided are electronic devices and device arrays comprising one or more arrays of longitudinally aligned carbon nanotubes including multilayer nanotube array structures and devices.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

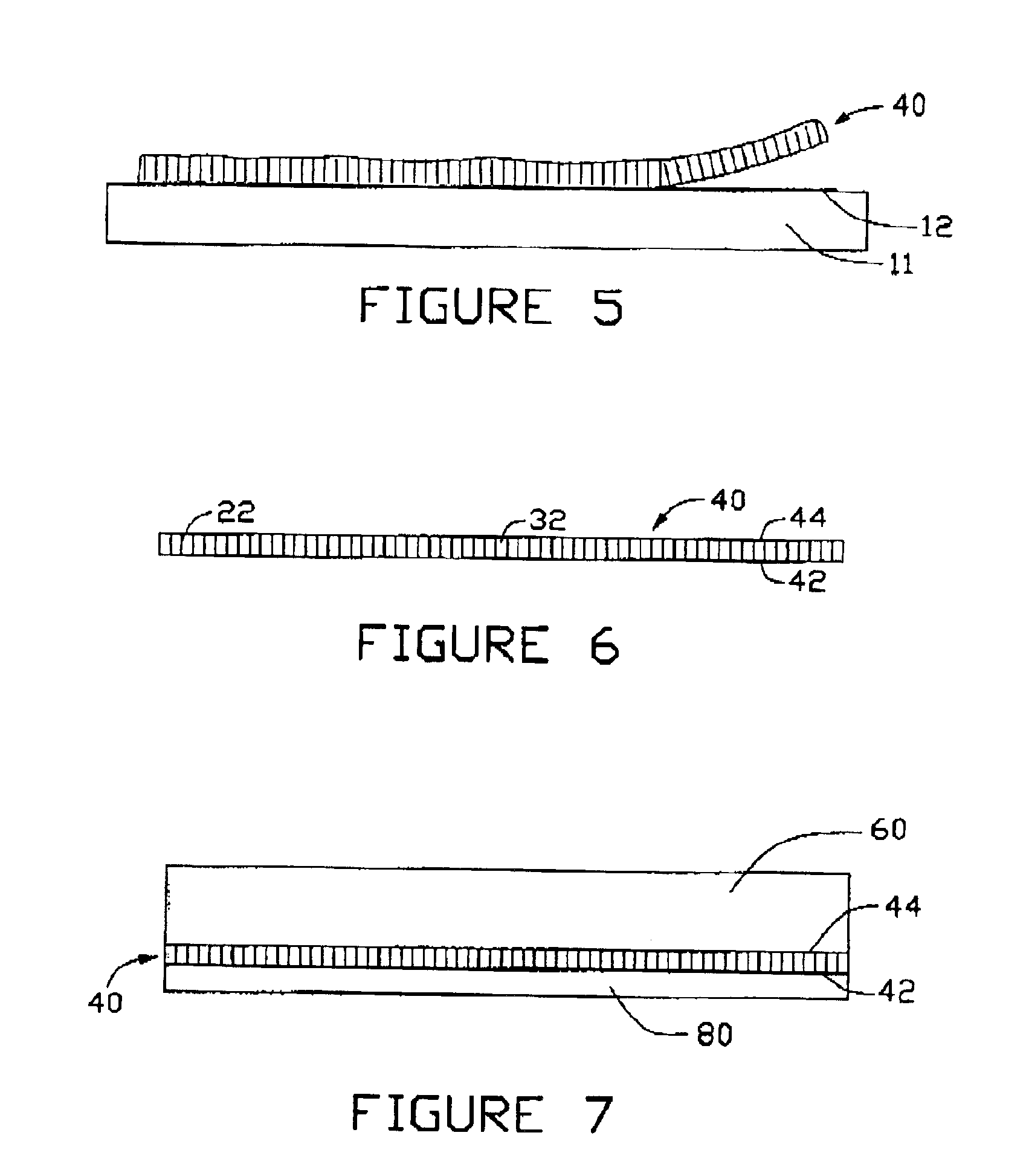

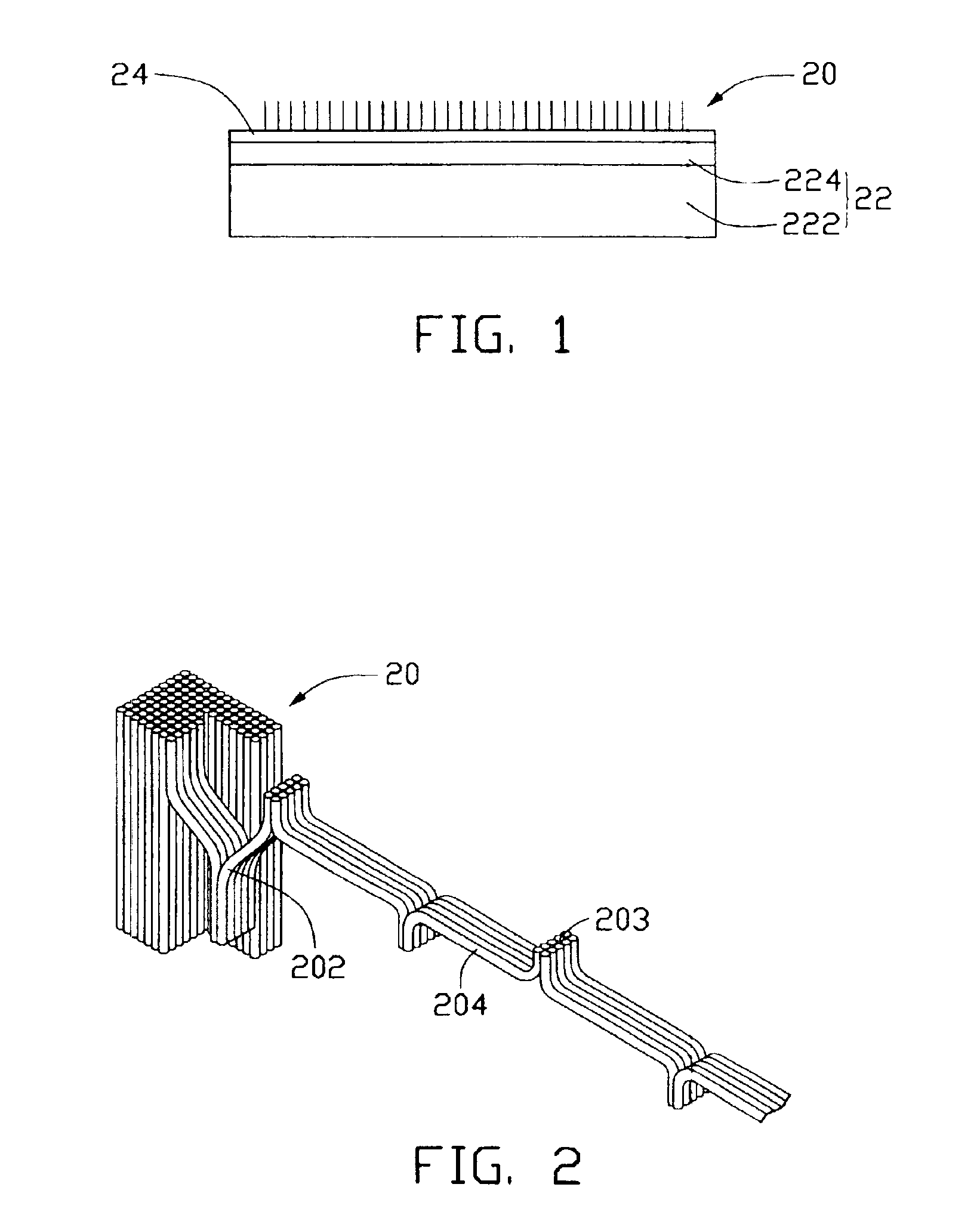

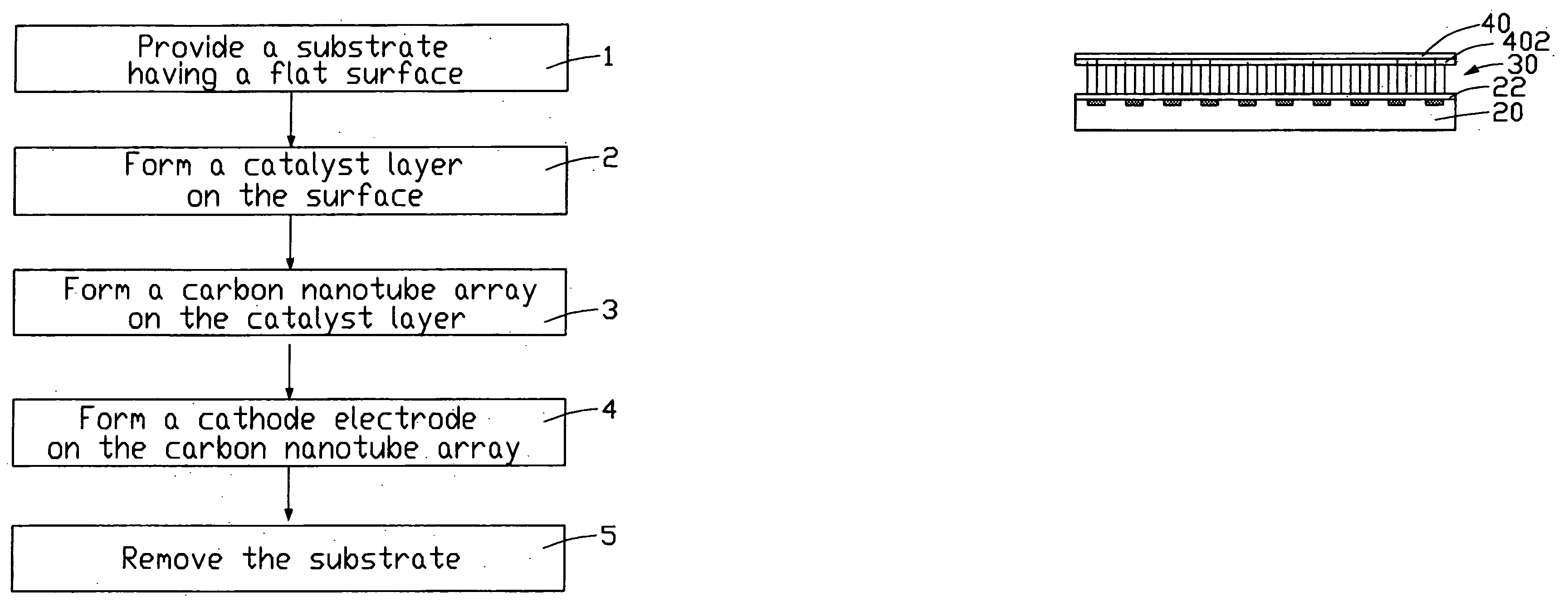

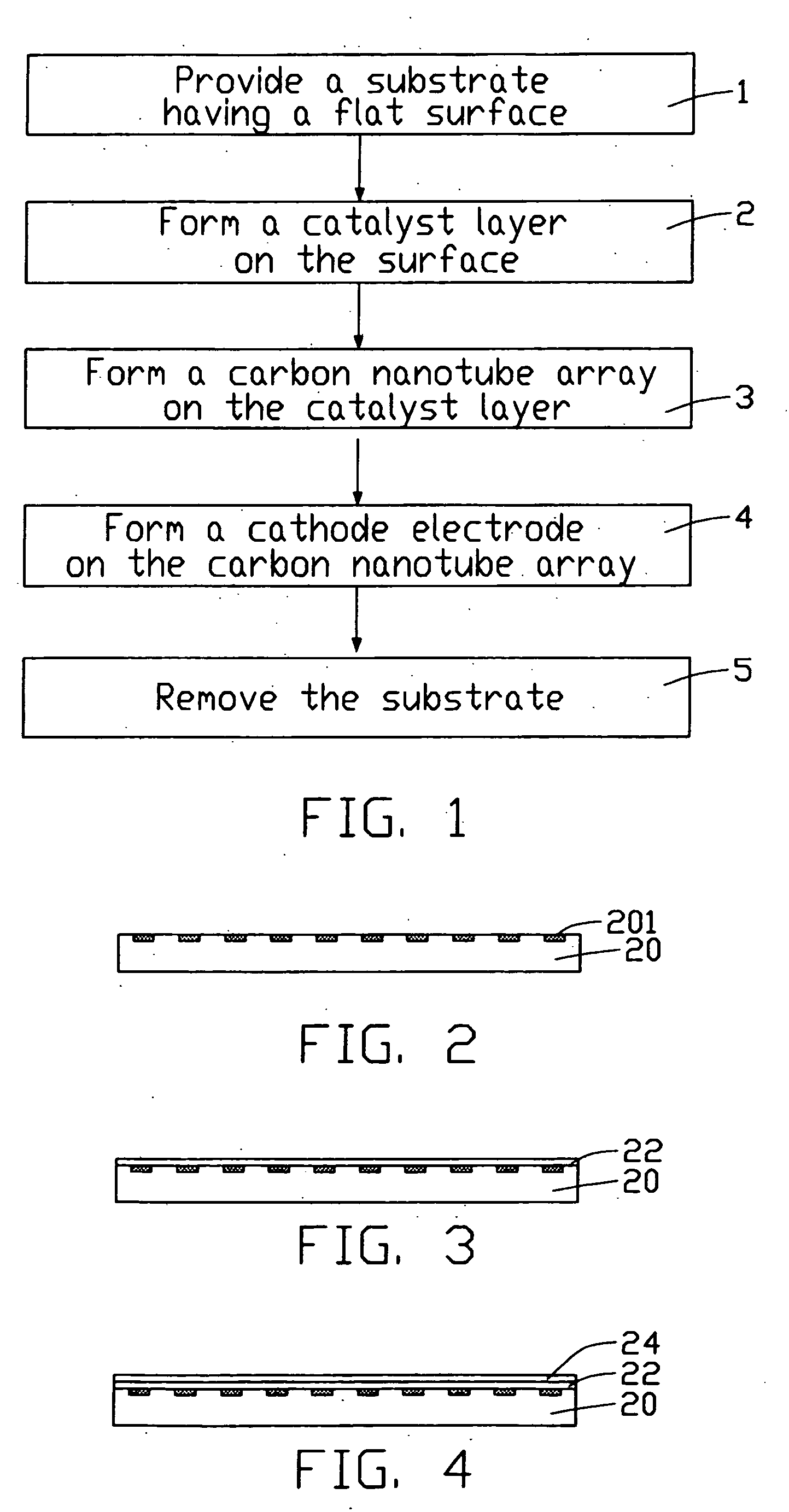

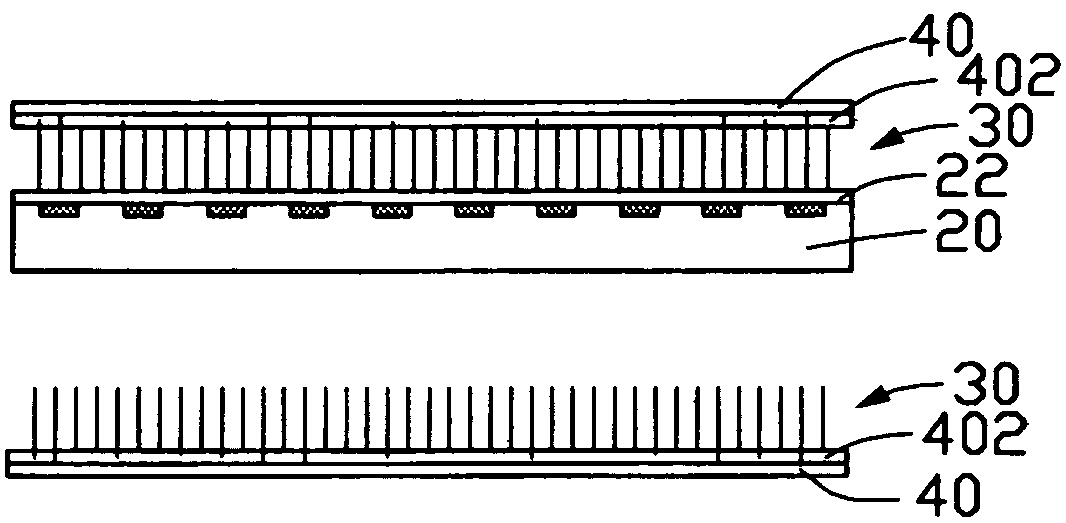

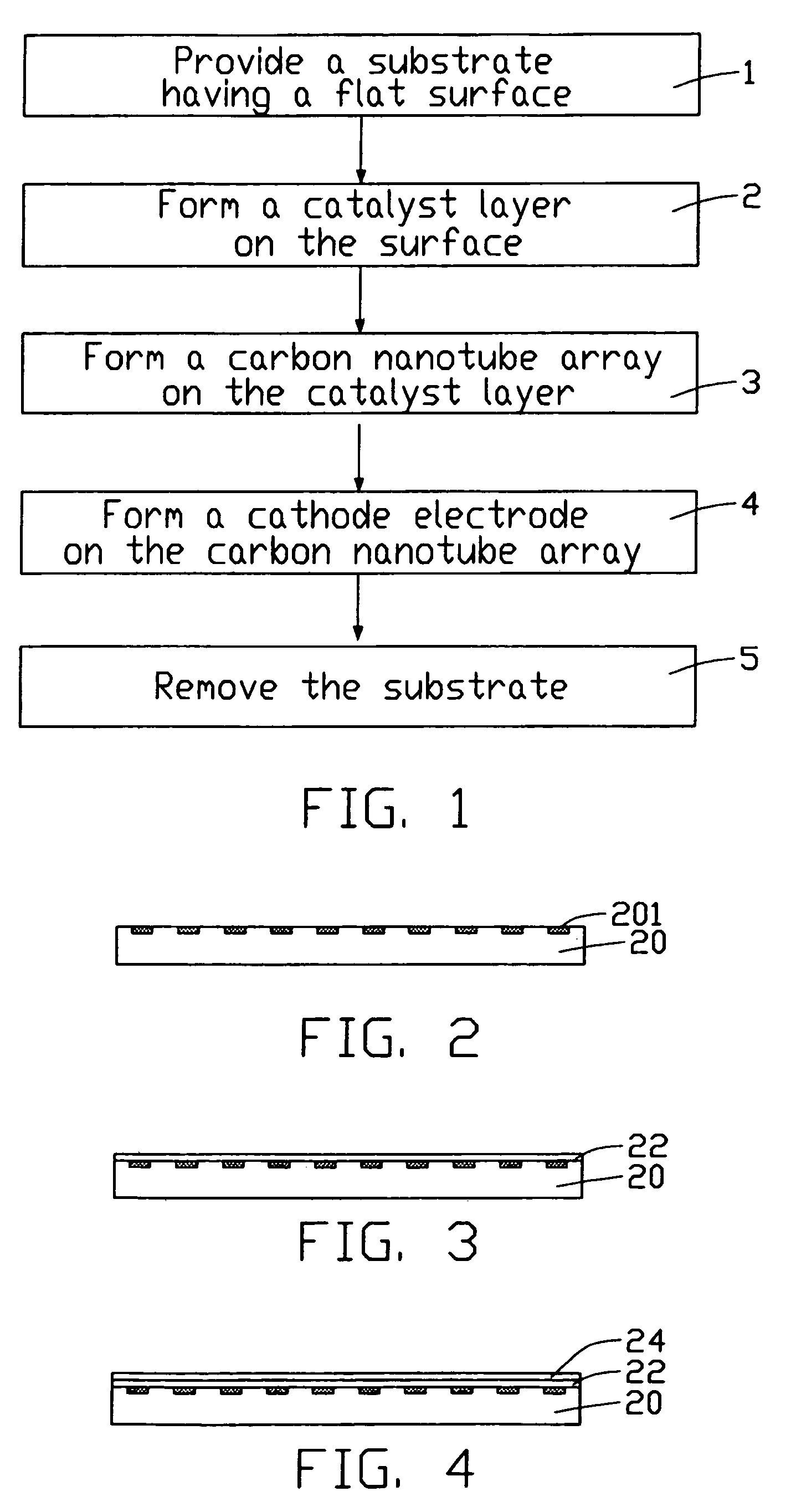

Method for making carbon nanotube-based field emission device

ActiveUS20040209385A1Surface cleaningEnhanced electron emission capabilityMaterial nanotechnologyElectric discharge tubesField emission deviceCarbon nanotube

A preferred method for making a carbon nanotube-based field emission device in accordance with the invention includes the following steps: providing a substrate (22) with a surface; depositing a catalyst layer (24) on a predetermined area on the surface of the substrate; forming a carbon nanotube array (30) extending from the predetermined area; forming a cathode electrode (40) on top of the carbon nanotube array; and removing the substrate so as to expose the carbon nanotube array.

Owner:TSINGHUA UNIV +1

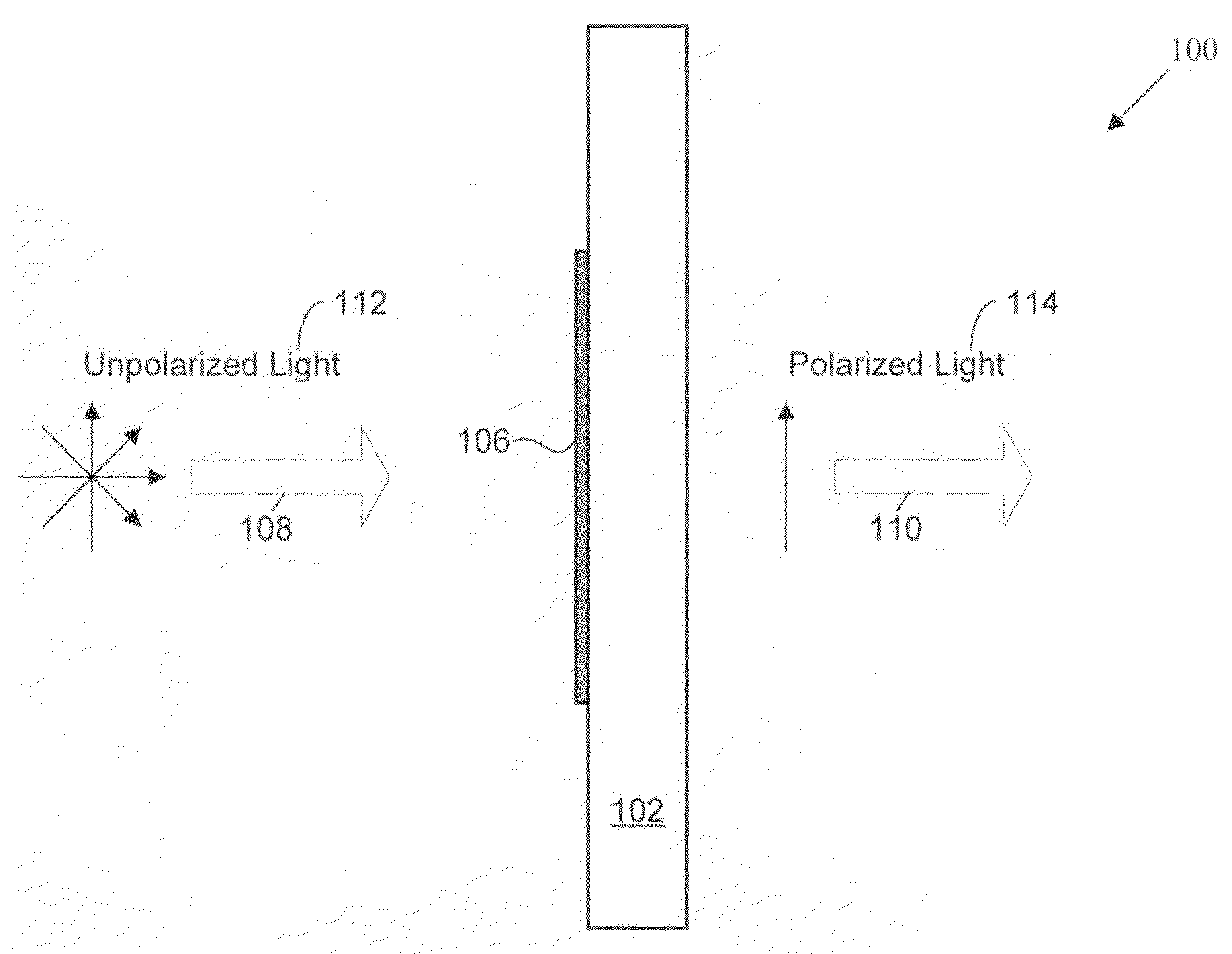

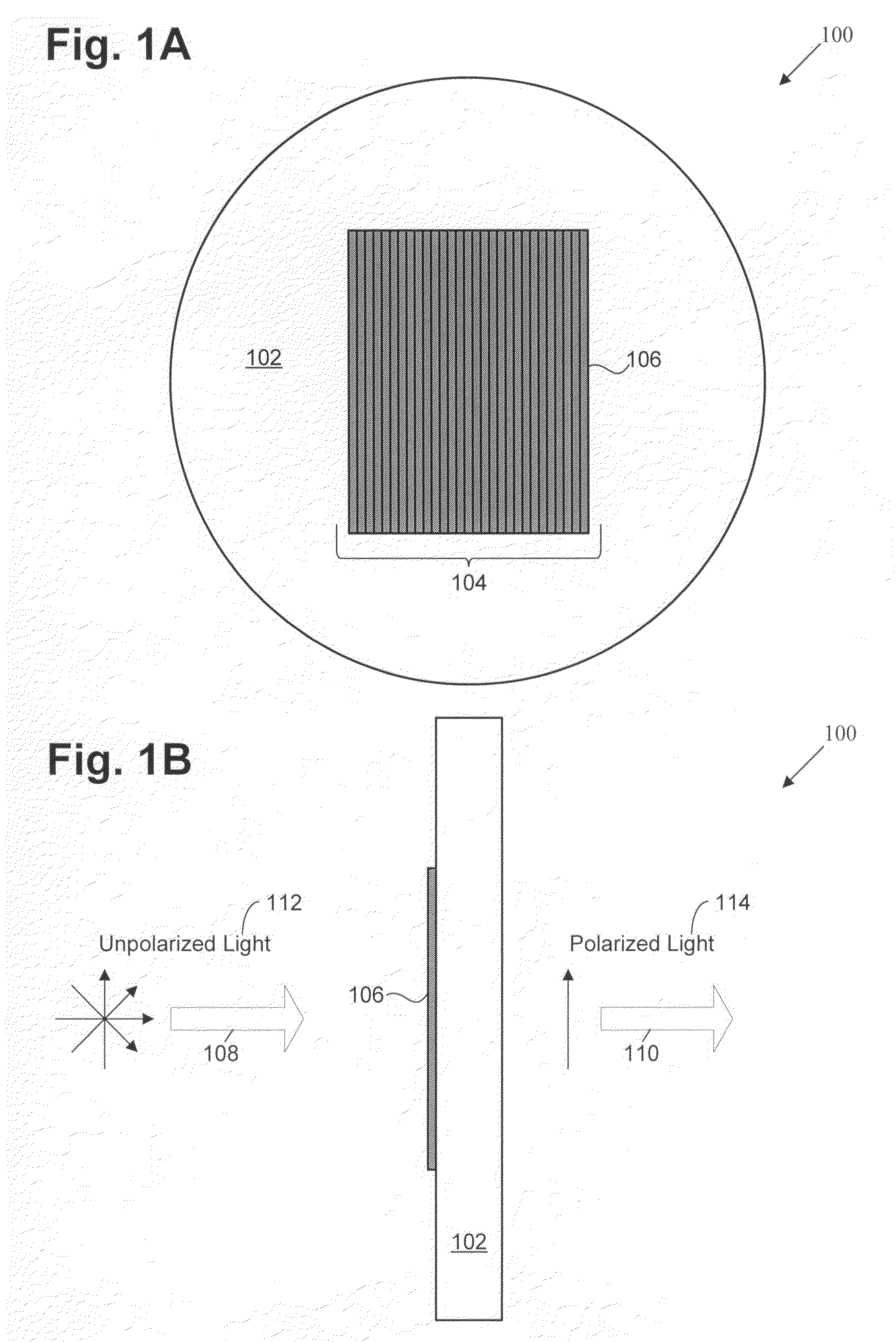

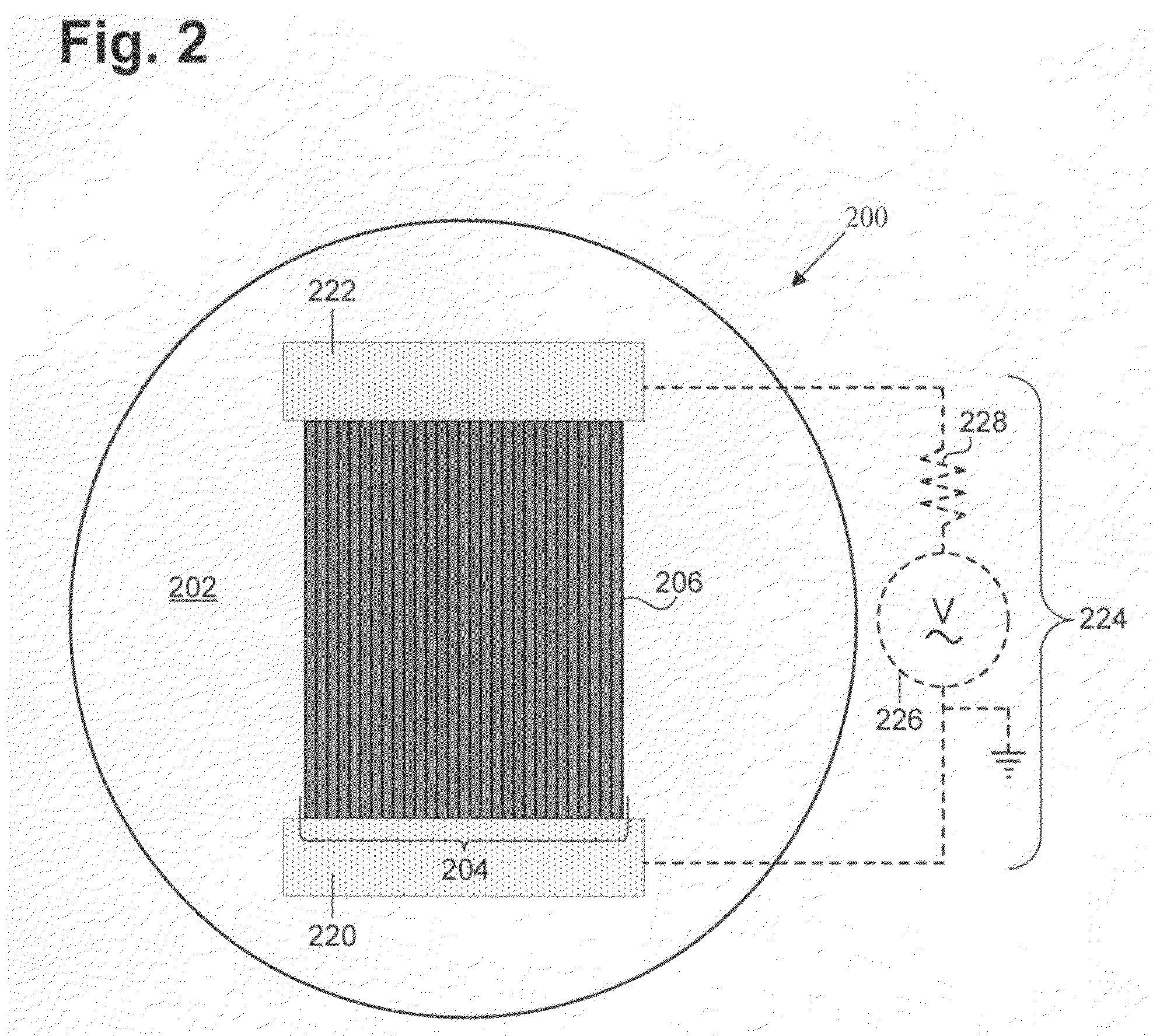

Optical polarizer with nanotube array

According to one exemplary embodiment, an optical polarizer positioned before a light source for use in semiconductor wafer lithography includes an array of aligned nanotubes. The array of aligned nanotubes cause light emitted from the light source and incident on the array of aligned nanotubes to be converted into polarized light for use in the semiconductor wafer lithography. The amount of polarization can be controlled by a voltage source coupled to the array of aligned nanotubes. Chromogenic material of a light filtering layer can vary the wavelength of the polarized light transmitted through the array of aligned nanotubes.

Owner:GLOBALFOUNDRIES US INC

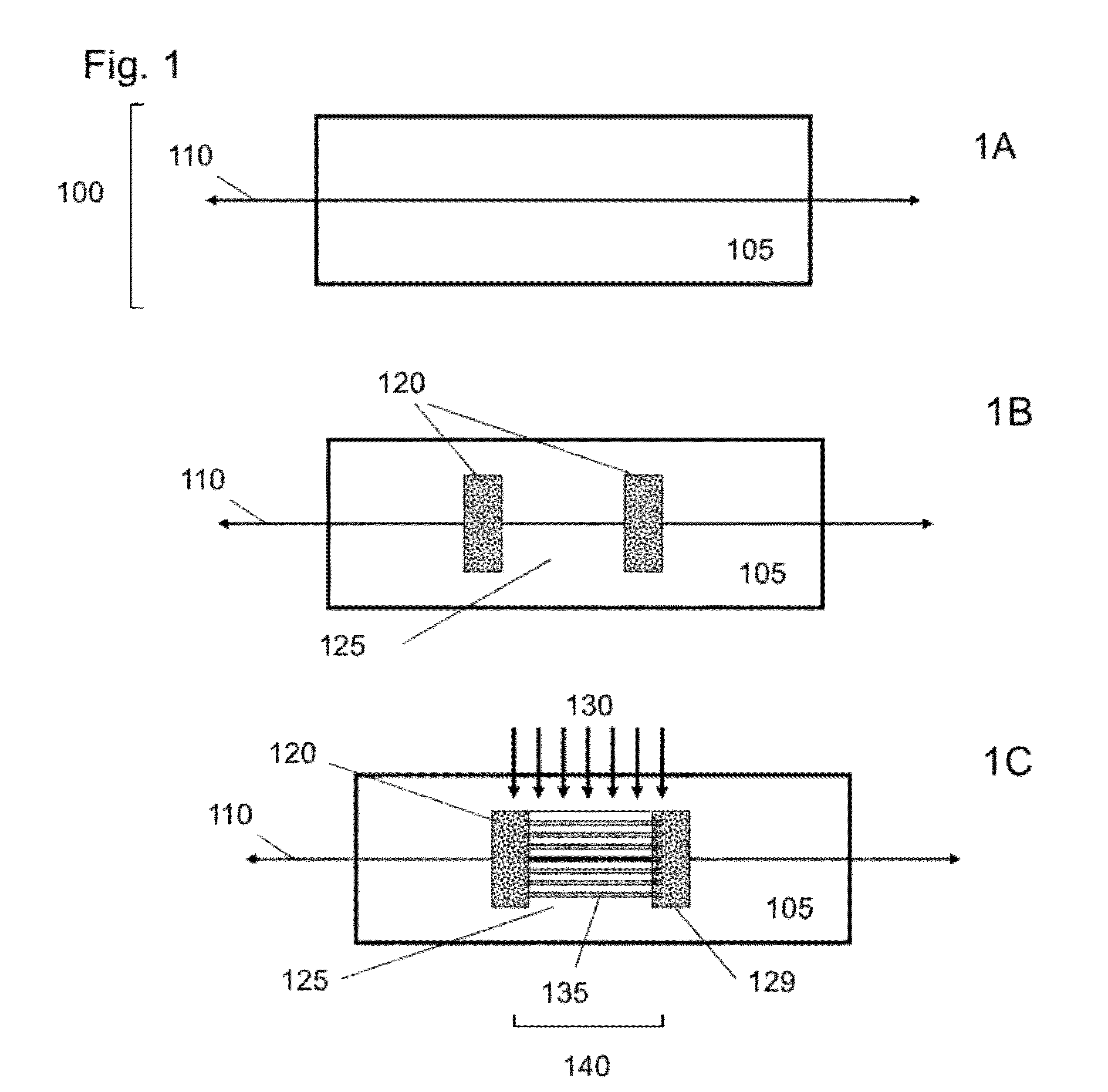

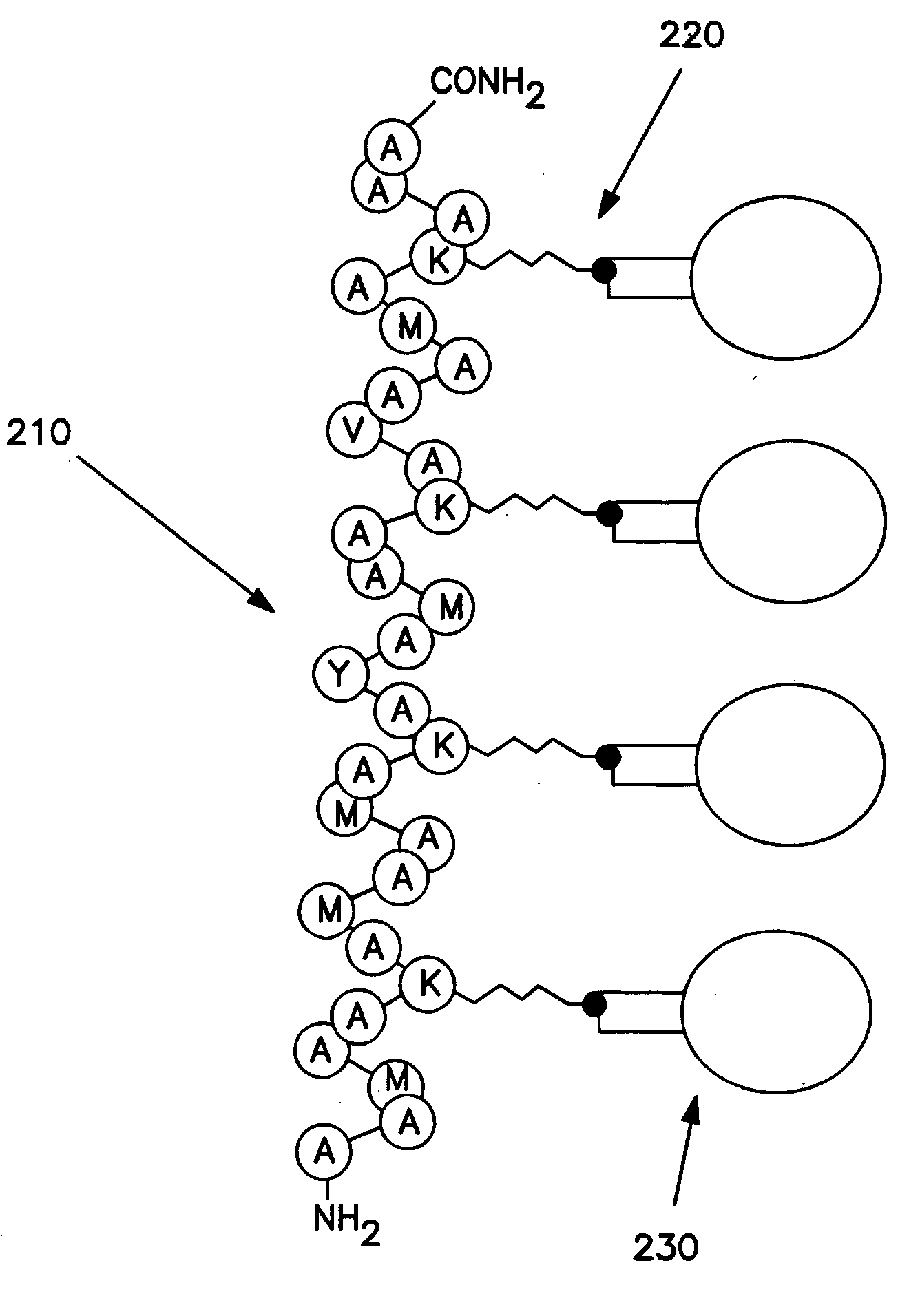

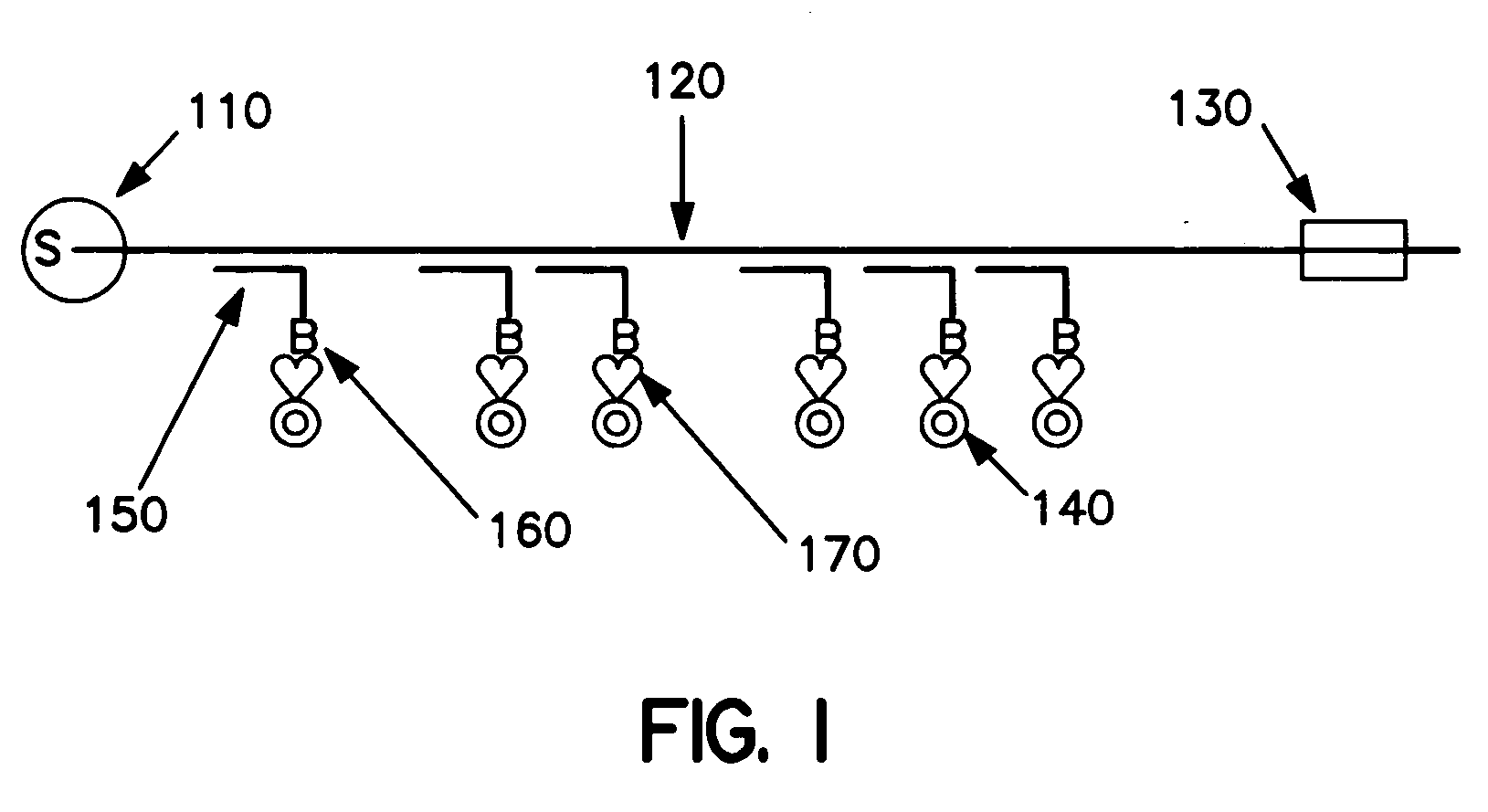

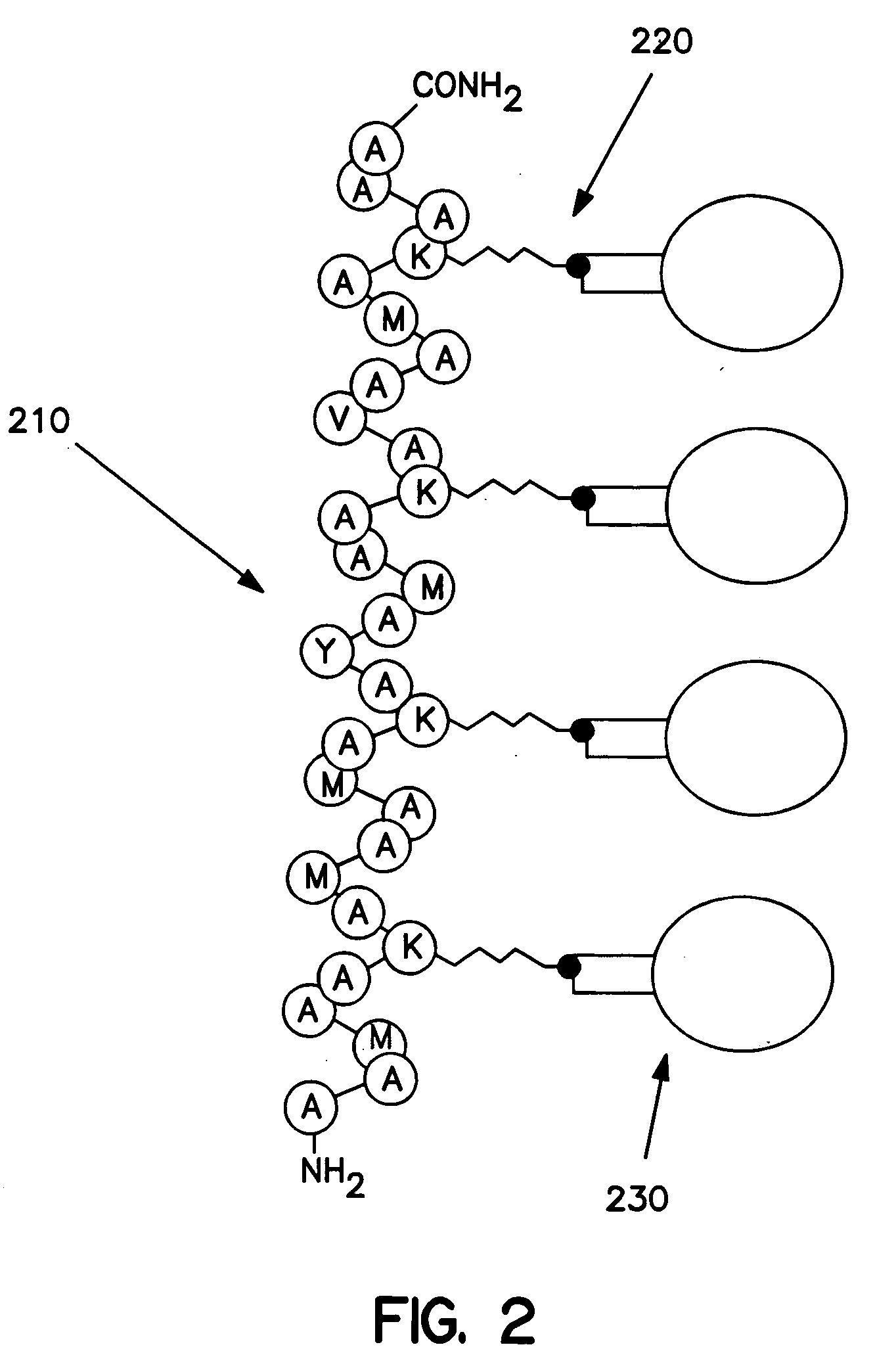

Methods of producing carbon nanotubes using peptide or nucleic acid micropatterning

InactiveUS20050151126A1Facilitates a predominantly 5′-attachmentMaterial nanotechnologyNanoinformaticsMolecular wireDouble stranded

The methods, apparatus and systems disclosed herein concern ordered arrays of carbon nanotubes. In particular embodiments of the invention, the nanotube arrays are formed by a method comprising attaching catalyst nanoparticles 140, 230 to polymer 120, 210 molecules, attaching the polymer 120, 210 molecules to a substrate, removing the polymer 120, 210 molecules and producing carbon nanotubes on the catalyst nanoparticles 140, 230. The polymer 120, 210 molecules can be attached to the substrate in ordered patterns, using self-assembly or molecular alignment techniques. The nanotube arrays can be attached to selected areas 110, 310 of the substrate. Within the selected areas 110, 310, the nanotubes are distributed non-randomly. Other embodiments disclosed herein concern apparatus that include ordered arrays of nanotubes attached to a substrate and systems that include ordered arrays of carbon nanotubes attached to a substrate, produced by the claimed methods. In certain embodiments, provided herein are methods for aligning a molecular wire, by ligating the molecular wire to a double stranded DNA molecule.

Owner:INTEL CORP

Process for preparing biocompatible directional carbon nanotube array reinforced composite hydrogel

InactiveCN101693125AEasy to control the lengthImprove bindingImmobilised enzymesProsthesisBiocompatibility TestingNerve cells

The invention provides a process for preparing biocompatible directional carbon nanotube array reinforced composite hydrogel, which utilizes the chemical vapor deposition (CVD) technique, the radial cross linking technique and a freezing and thawing method. By permeating polymer sol into a carbon nanotube prefabricated body, aggregating and tangling problems during a compounding process of the carbon nanotube and polymer are resolved, boundary strength of a reinforcing phase and a basis phase is increased, and excellent performances of the nanotube on mechanics and electricity are played sufficiently. The composite hydrogel prepared by utilizing a physical cross linking process does not contain chemical additives and meets requirements on biocompatibility. The composite hydrogel prepared by the process has controllable length and direction of the reinforcing phase of a nanotube array, has integrated mechanics and electricity performances superior to those of the conventional hydrogel,and is adoptive to be applied to the biomedical field such as artificial articular cartilages, tissues engineering supports, nerve cell carries, biomimetic implanted electrode and the like.

Owner:UNIV OF SCI & TECH BEIJING

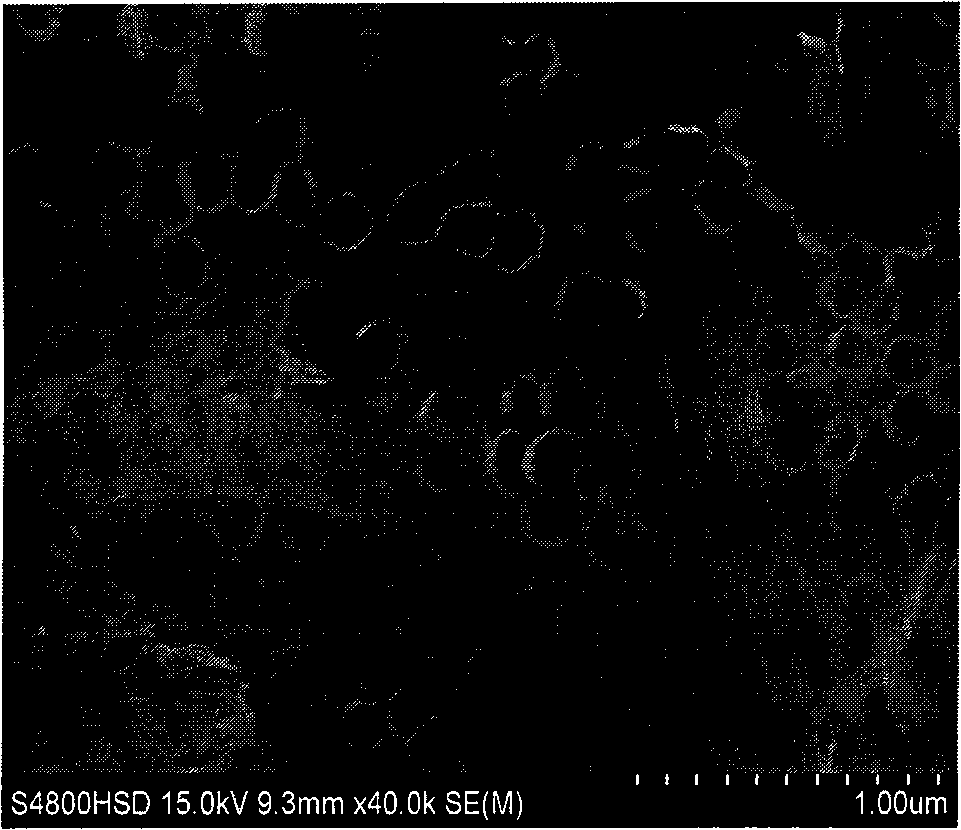

Method for preparing metal titanium or titanium alloy super-oleophobic surface

InactiveCN102021628AImprove stabilityReduce resistanceSurface reaction electrolytic coatingSpecial surfacesFine structureTitanium alloy

The invention discloses a method for preparing a metal titanium or titanium alloy super-oleophobic surface. The method comprises the following steps of: performing primary anodic oxidation treatment on metal titanium or titanium alloy to obtain a roughened surface with a microstructure; forming a titanium dioxide nanotube array film on the surface with microstructure through secondary anodic oxidation so as to obtain a composite fine structured micro-nanostructure; and modifying with a low-surface-energy substance to obtain the super-oleophobic surface and the super-hydrophobic and super-oleophobic surface. The metal titanium or titanium alloy surface has super-oleophobic and super-hydrophobic characteristics for multiple kinds of organic liquid, the static contact angle is greater than 155 degrees; the rolling angle is less than 10 degrees; meanwhile, the surface also shows superior super-oleophobic and super-hydrophobic characteristics for pure water and aqueous solution of acid, alkali and salt.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for depositing carbon nanotubes on a substrate of a field emission device using direct-contact transfer deposition

ActiveUS7357691B2Launch evenlyImprove flatnessMaterial nanotechnologyElectric discharge tubesField emission deviceCarbon nanotube

A preferred method for making a carbon nanotube-based field emission device in accordance with the invention includes the following steps: providing a substrate (22) with a surface; depositing a catalyst layer (24) on a predetermined area on the surface of the substrate; forming a carbon nanotube array (30) extending from the predetermined area; forming a cathode electrode (40) on top of the carbon nanotube array; and removing the substrate so as to expose the carbon nanotube array.

Owner:TSINGHUA UNIV +1

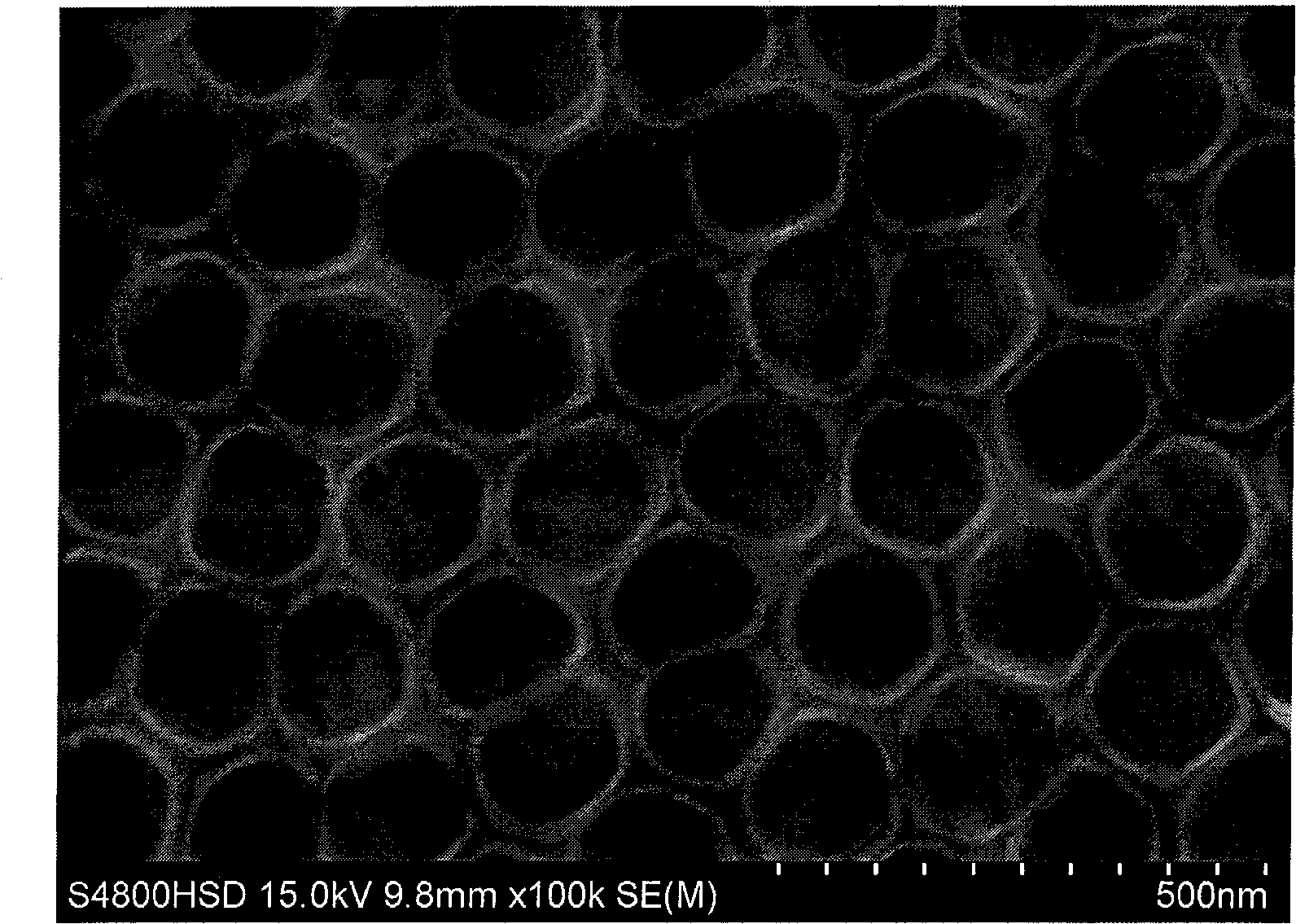

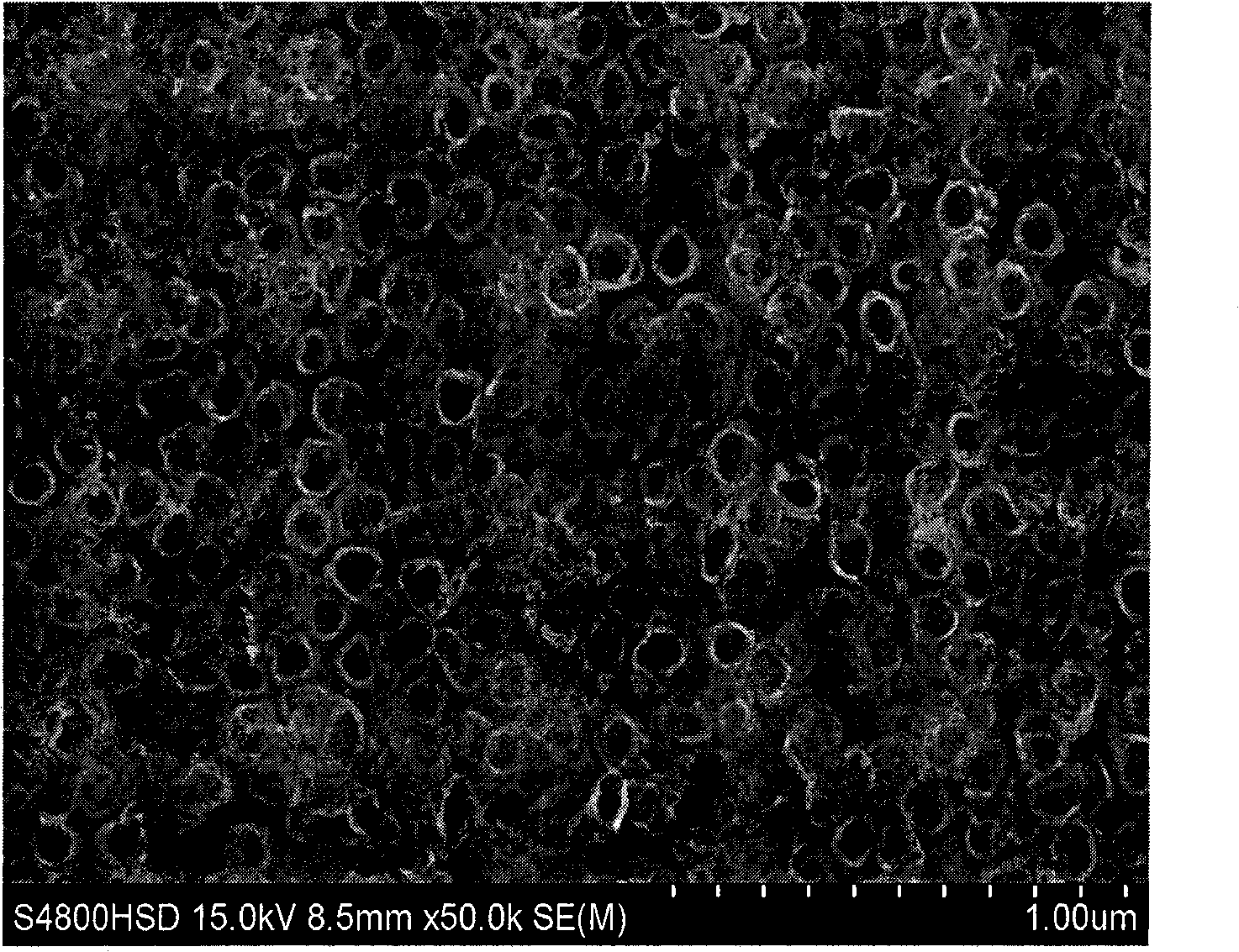

Method for preparing TiO2 nanotube array film

InactiveCN101514471ARegular microscopic morphologyNo reunionPolycrystalline material growthSurface reaction electrolytic coatingTio2 nanotubeTitanium

The invention provides a method for a preparing TiO2 nanotube array film, relating to a method for preparing a nanotube film. The method solves the problems of the prior art that the prepared nanotube array film features thin film, irregular micro appearance, heterogeneous length of nanotubes, reunion of tube orifice and cracking of the film. The preparation method comprises: 1. a titanium plate is cut into two titanium sheets of the same size, and polishing, ultrasound processing and washing are carried out on the two titanium sheets; 2. electrolyte is prepared; 3. primary anodic oxidation is carried out on the titanium sheets; 4. demoulding is carried out; 5. secondary anodic oxidation is carried out on the titanium sheets; 6. the titanium sheets are dried after ultrasonic processing; and 7. calcination treatment is carried out, thus obtaining the TiO2 nanotube array film. In the invention, twice anodic oxidations are carried out on the titanium sheets, thus producing the TiO2 nanotube array film featuring regular micro appearance, homogeneous, smoothness, thick film layer, reunion-free tube orifice and no cracking. The preparation method of the invention features simple technique and equipment and controllable thickness of the nanotube film.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com