Patents

Literature

1040results about How to "No reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of polymer/graphene nano composite material

The invention provides a preparation method of a polymer / graphene nano composite material, comprising the following steps: (a) sufficiently mixing a first mass part of polymer and graphene in organic solvent, and removing the organic solvent to obtain polymer / graphene master batches, wherein the graphene accounts for 1-50% of the total mass of the first mass part of polymer and the grapheme; and (b) melting and blending polymer / graphene master batches and a second mass part of polymer to obtain a polymer / graphene nano composite material. In the invention, firstly, the first mass part of polymer and the graphene are sufficiently mixed in the organic solvent, and the graphene can keep a delamination state in a solvent environment, therefore, the graphene can keep in a single-lamella or less-lamina state and is uniformly dispersed without agglomeration in the first mass part of polymer; and then the polymer / graphene master batches and the second mass part of polymer are melted and blended to obtain the polymer / graphene nano composite material.

Owner:UNIV OF SCI & TECH OF CHINA

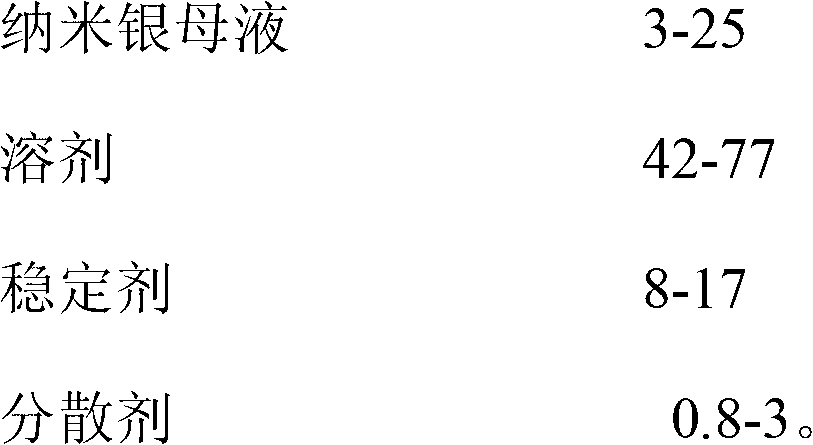

Anti-bacterial water-based paint and preparation method thereof

InactiveCN102702889AImprove aging resistanceImprove the pulverization performanceBiocideAntifouling/underwater paintsWater basedEscherichia coli

The invention relates to anti-bacterial water-based paint and a preparation method thereof. The paint comprises the following components in parts by weight: 0.2-11 parts of anti-bacterial agent, 8-33 parts of nano material, 23-64 parts of water-based resin dispersoid and 0.75-18 parts of adhesive resin or plasticizer. The preparation method comprises the following steps: firstly preparing a nano silver anti-bacterial agent; mixing deionized water, the anti-bacterial agent, a wetting agent, a dispersing agent and a defoaming agent and uniformly mixing, adding the nano material, uniformly dispersing to obtain the water-based dispersoid; adding the obtained water-based dispersoid to the mixed emulsion or water-based resin dispersoid, then adding the adhesive resin or plasticizer and various conventional assistants, stirring and dispersing evenly; adding pigments or colorant; and supplementing water to obtain the anti-bacterial water-based paint. The long-acting broad-spectrum antibacterial water-based paint has high fungicidal efficiency (more than 99%) on escherichia coli, staphylococcus aureus, black varietas of bacillus subtilis and the like and can reduce the high concentrate of organic matters of formaldehyde to the range of specified concentration index.

Owner:ANHUI JINDUN PAINT

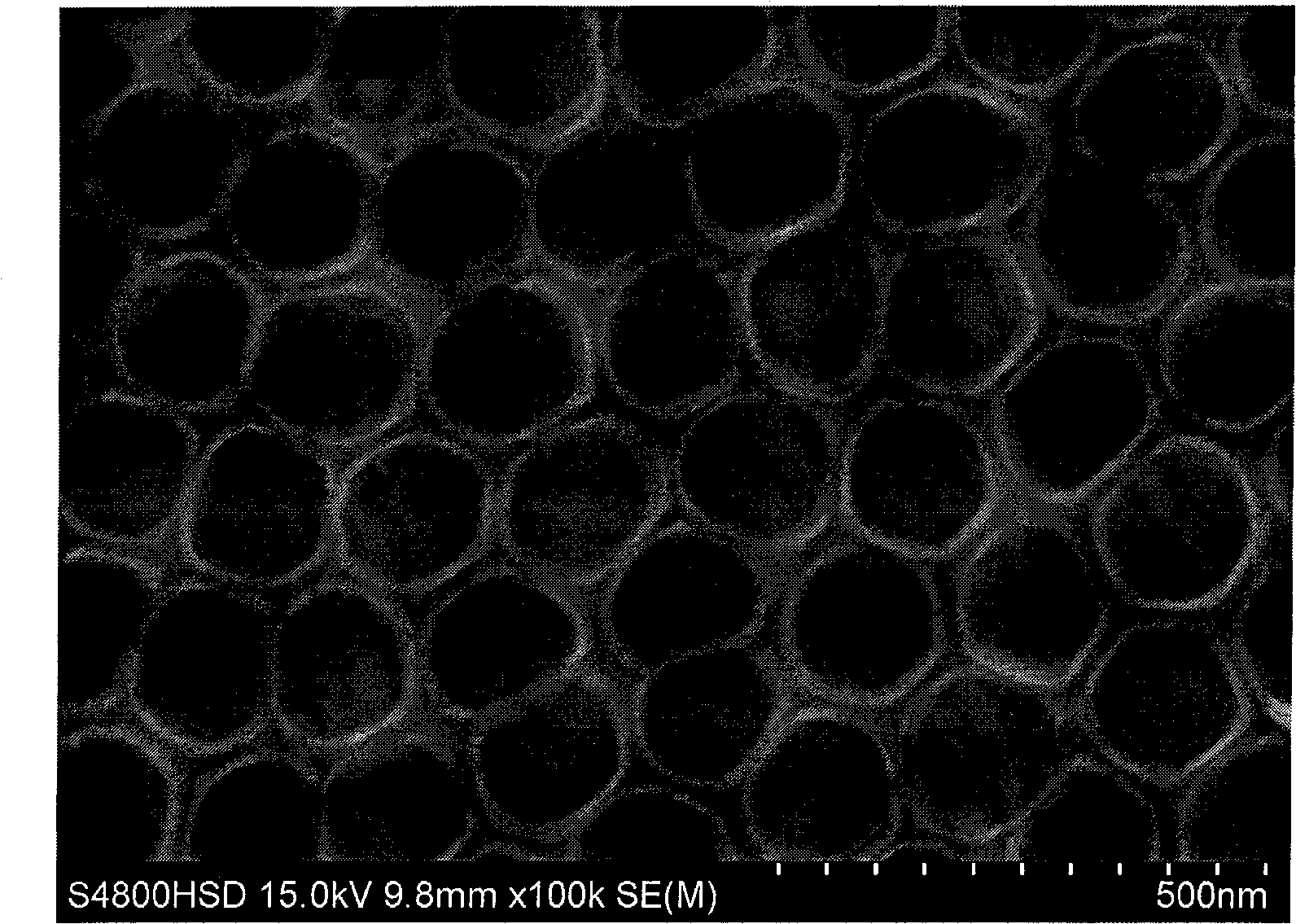

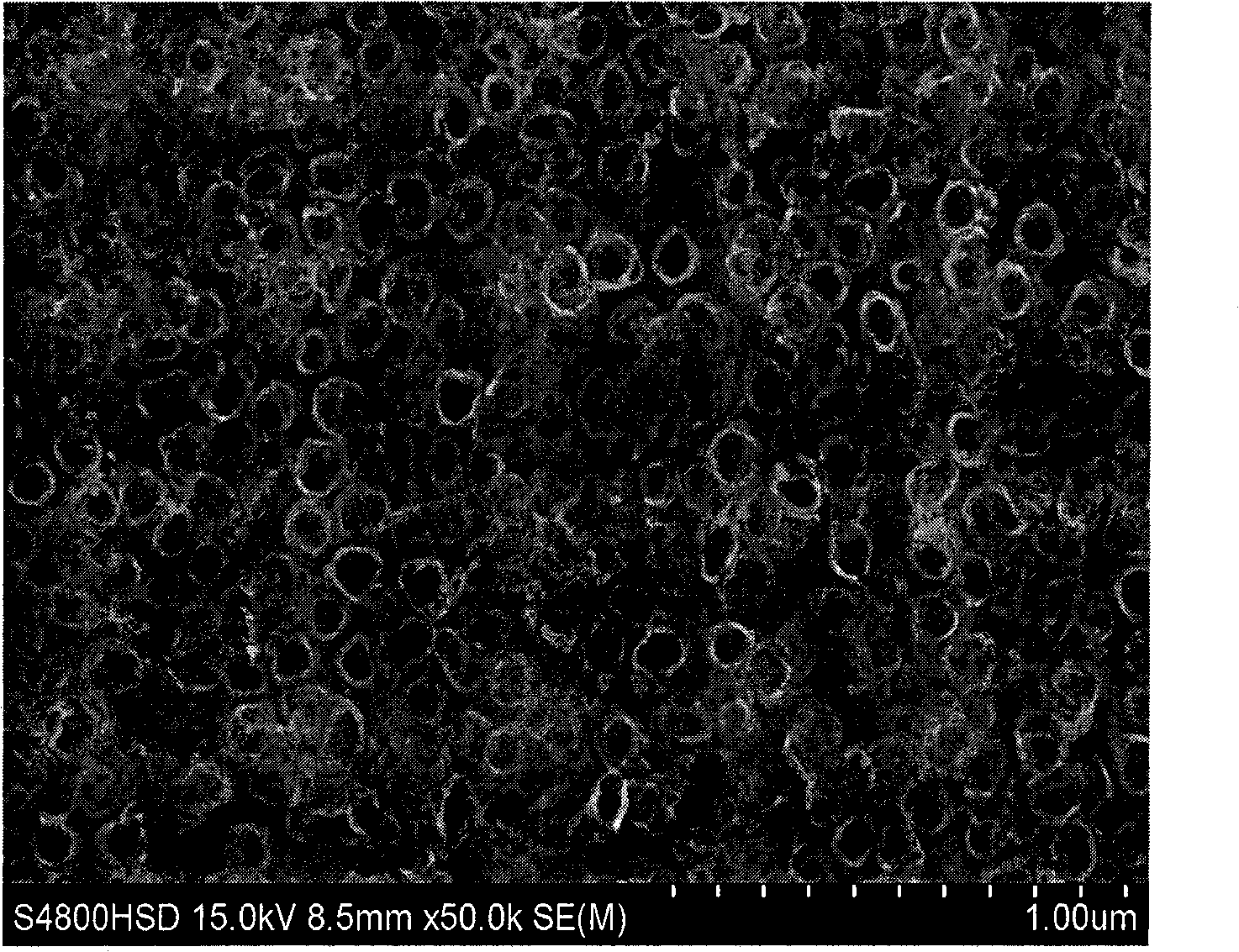

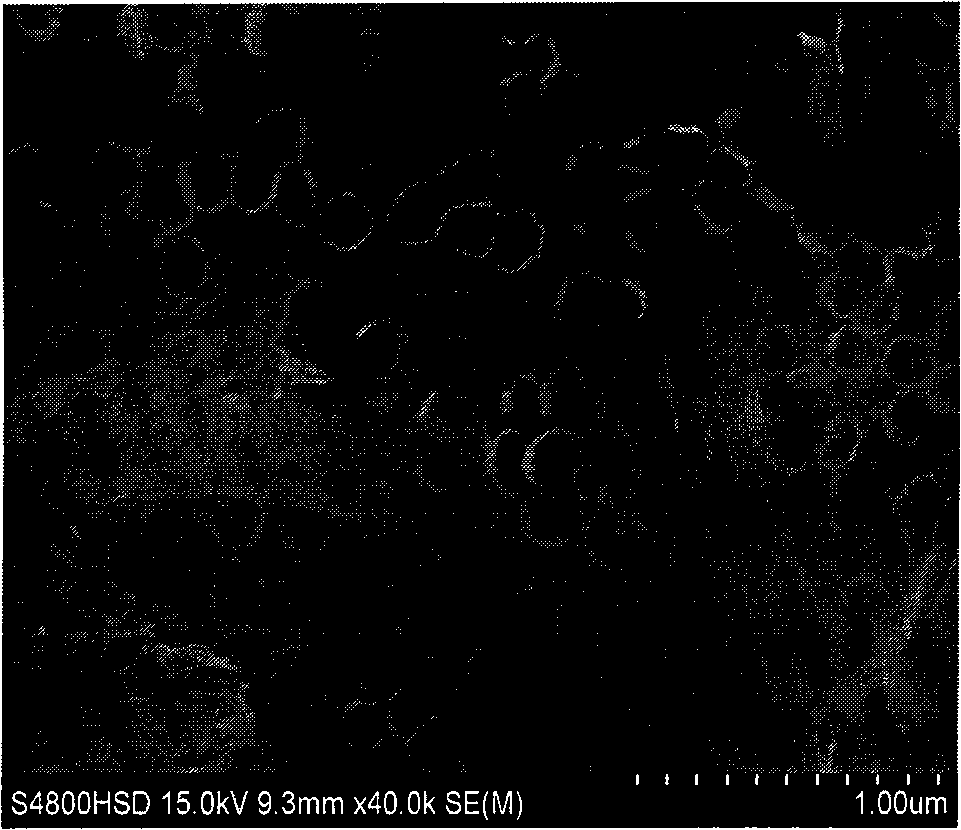

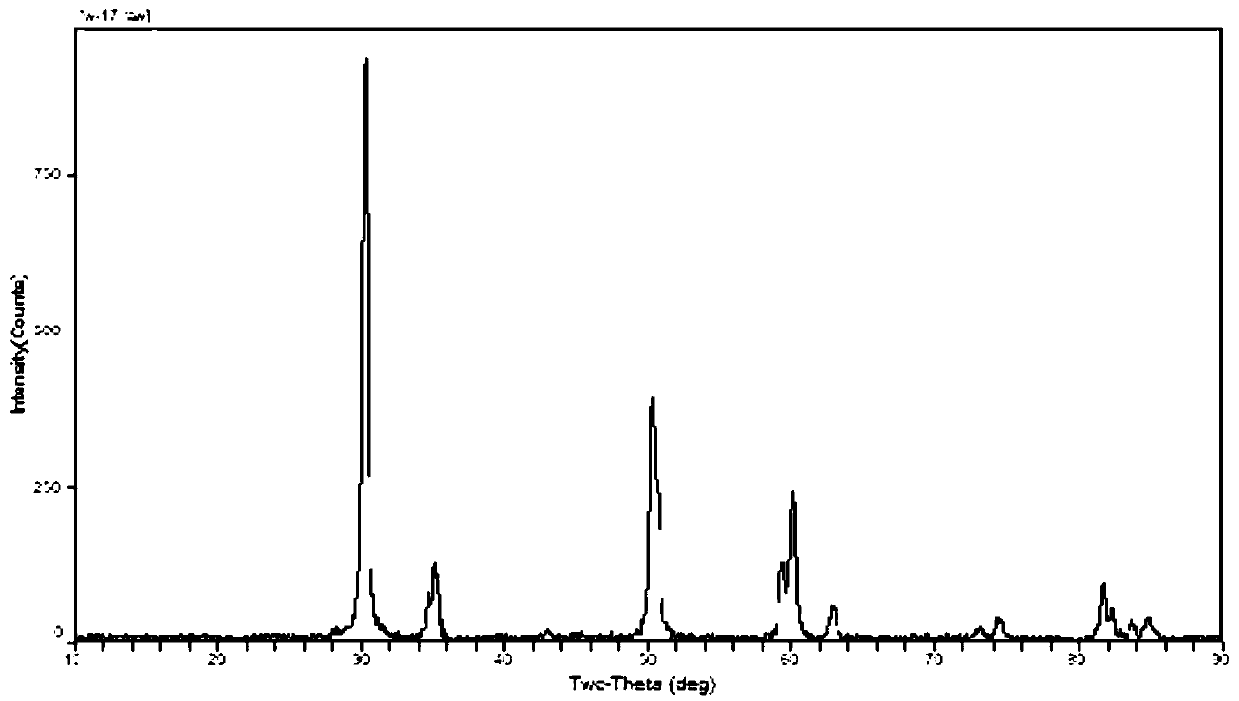

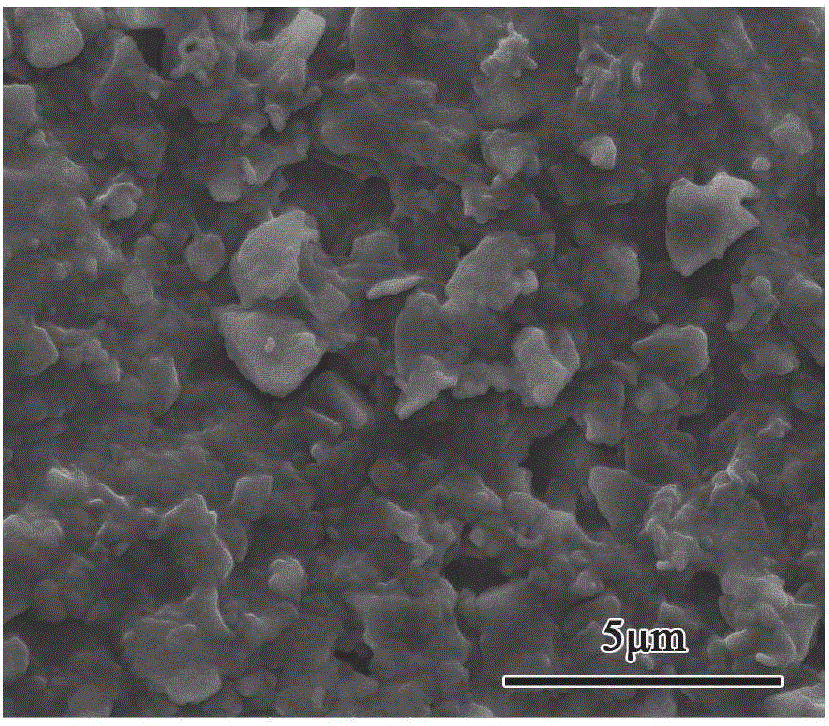

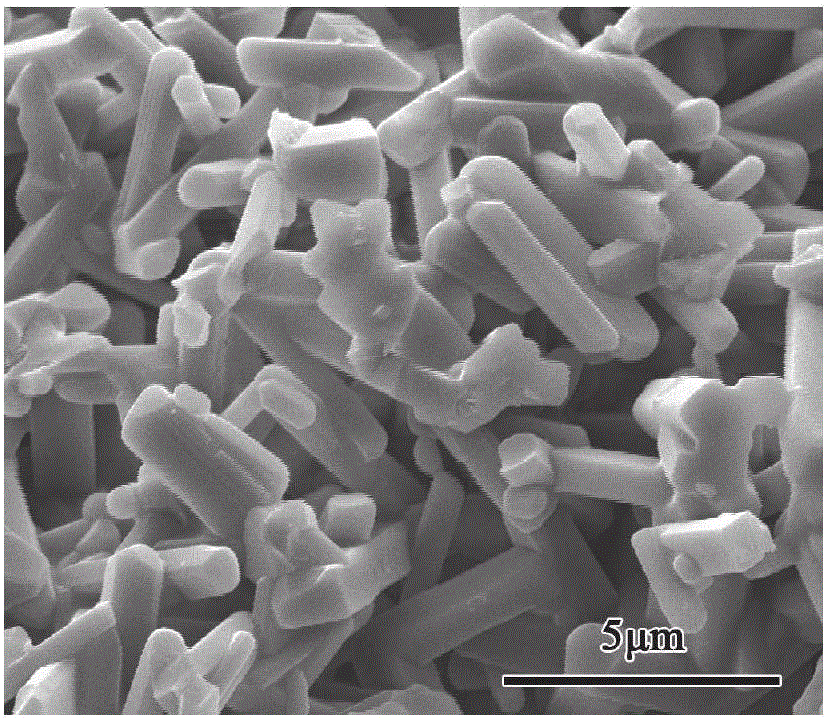

Method for preparing TiO2 nanotube array film

InactiveCN101514471ARegular microscopic morphologyNo reunionPolycrystalline material growthSurface reaction electrolytic coatingTio2 nanotubeTitanium

The invention provides a method for a preparing TiO2 nanotube array film, relating to a method for preparing a nanotube film. The method solves the problems of the prior art that the prepared nanotube array film features thin film, irregular micro appearance, heterogeneous length of nanotubes, reunion of tube orifice and cracking of the film. The preparation method comprises: 1. a titanium plate is cut into two titanium sheets of the same size, and polishing, ultrasound processing and washing are carried out on the two titanium sheets; 2. electrolyte is prepared; 3. primary anodic oxidation is carried out on the titanium sheets; 4. demoulding is carried out; 5. secondary anodic oxidation is carried out on the titanium sheets; 6. the titanium sheets are dried after ultrasonic processing; and 7. calcination treatment is carried out, thus obtaining the TiO2 nanotube array film. In the invention, twice anodic oxidations are carried out on the titanium sheets, thus producing the TiO2 nanotube array film featuring regular micro appearance, homogeneous, smoothness, thick film layer, reunion-free tube orifice and no cracking. The preparation method of the invention features simple technique and equipment and controllable thickness of the nanotube film.

Owner:HARBIN INST OF TECH

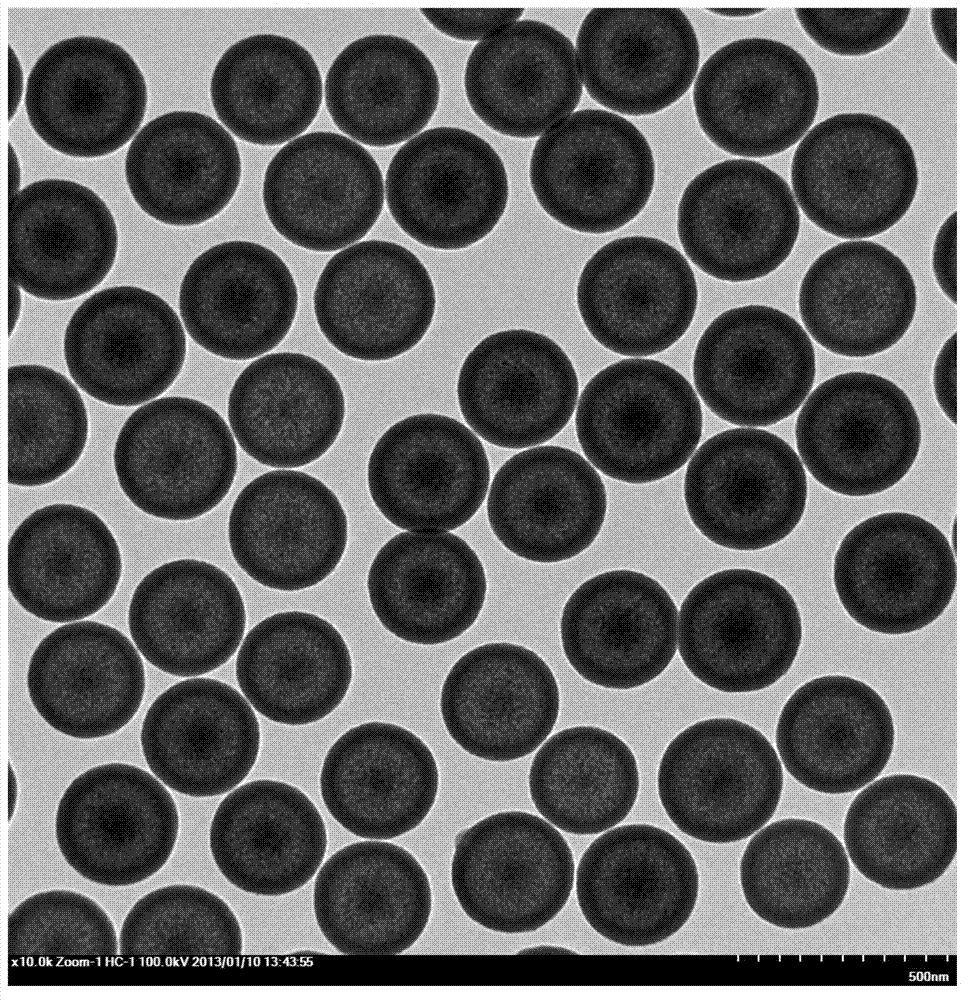

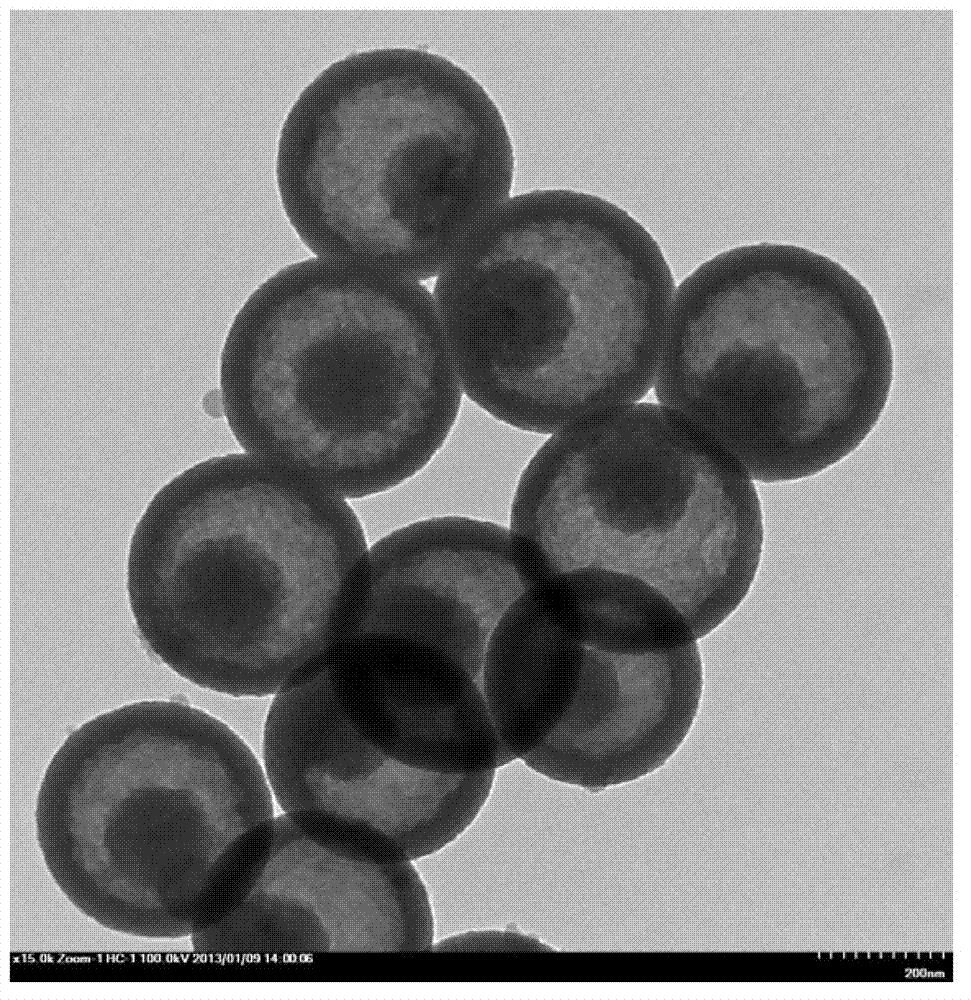

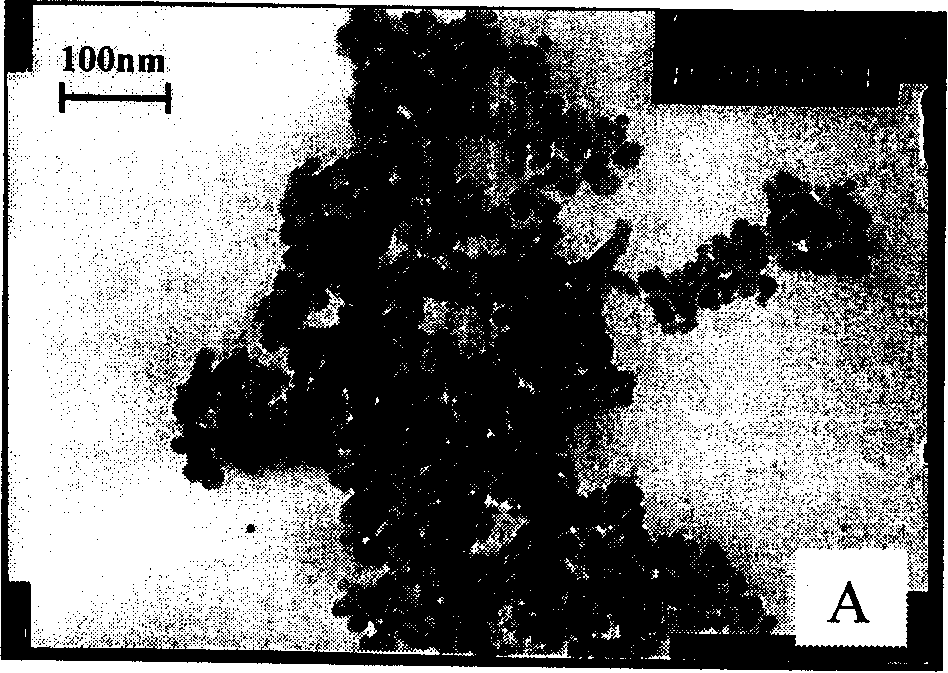

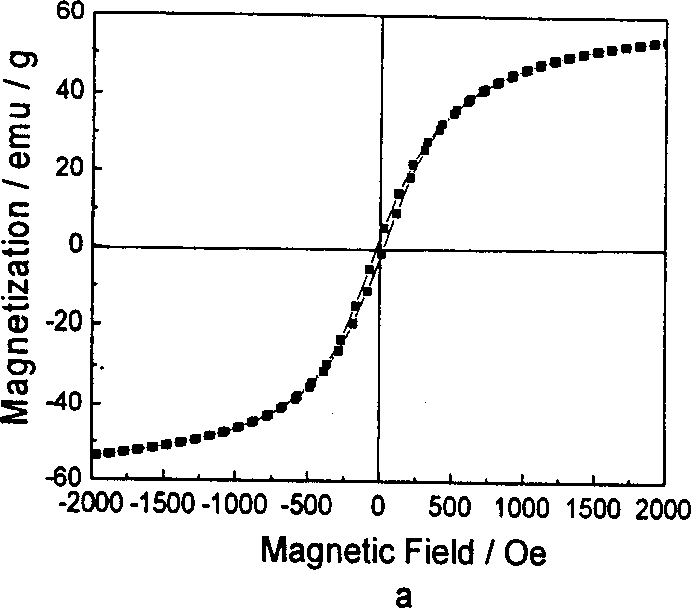

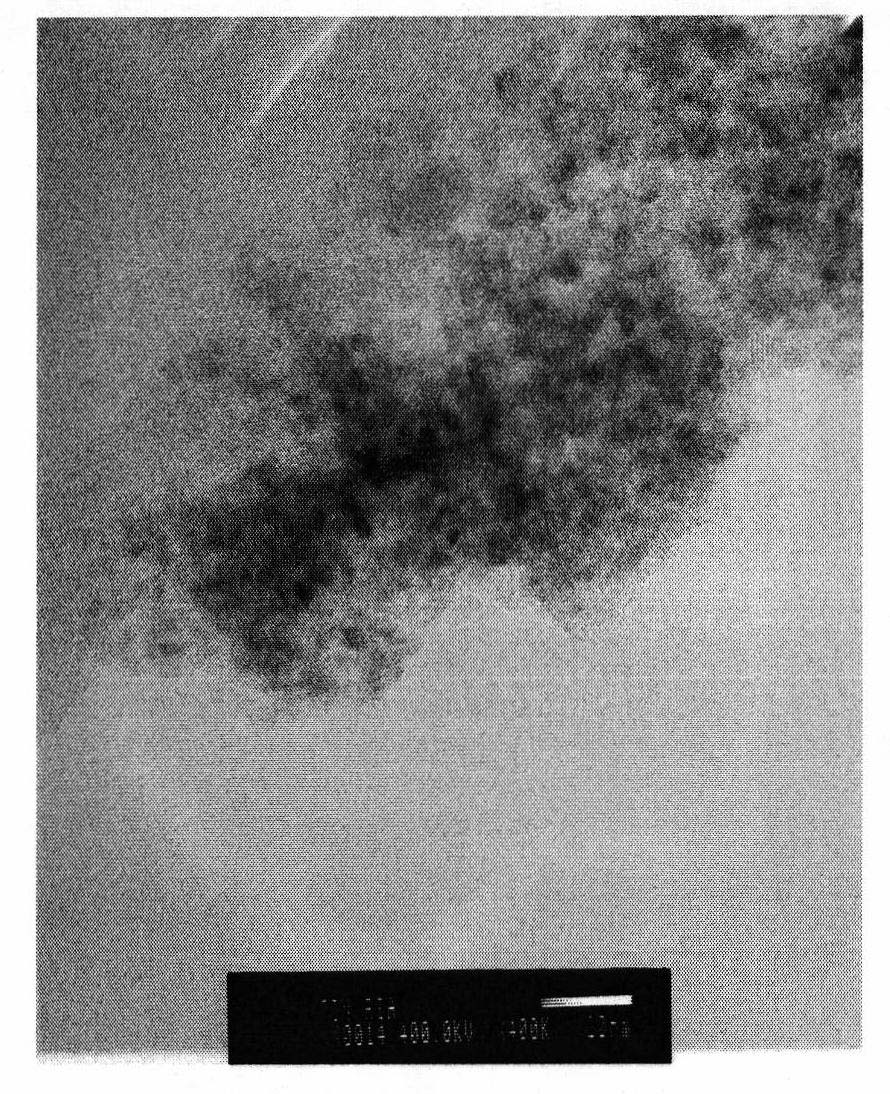

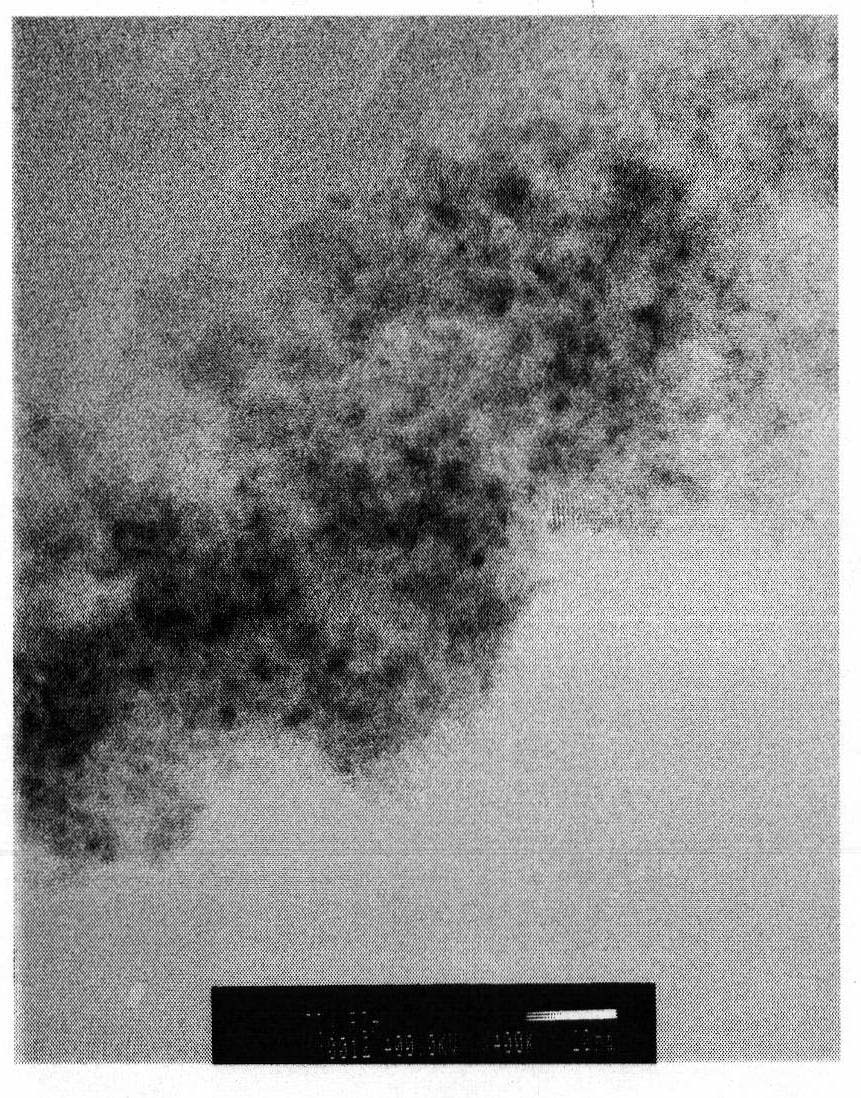

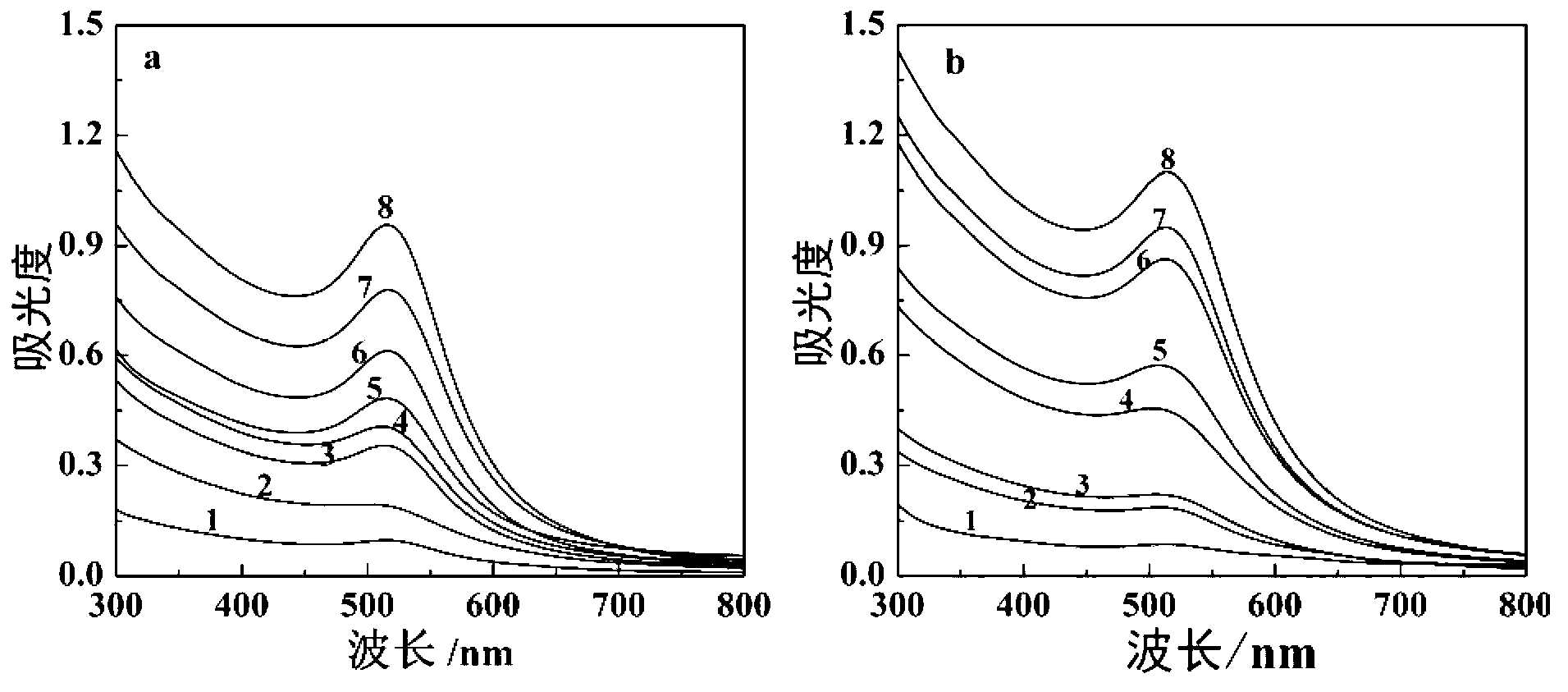

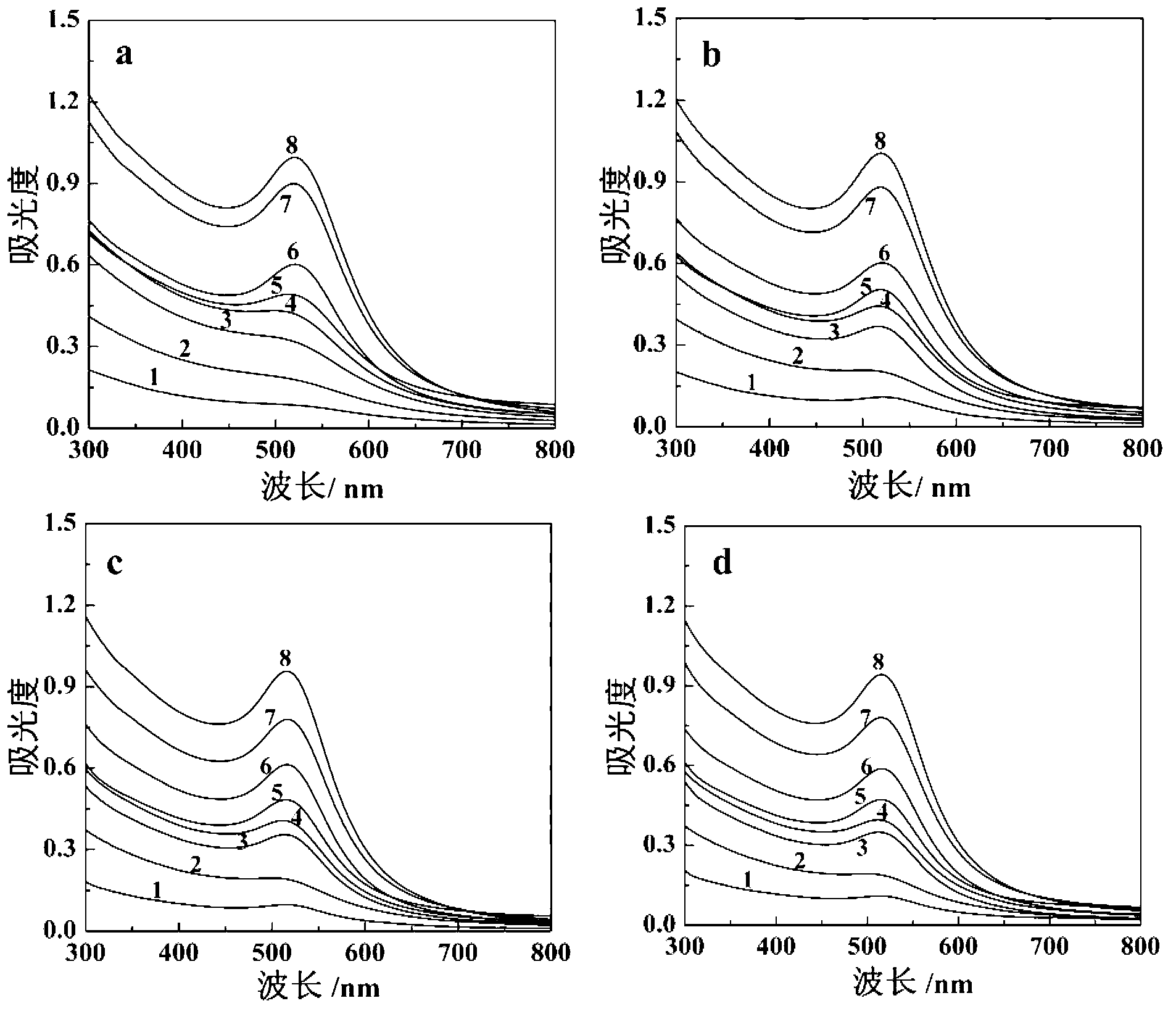

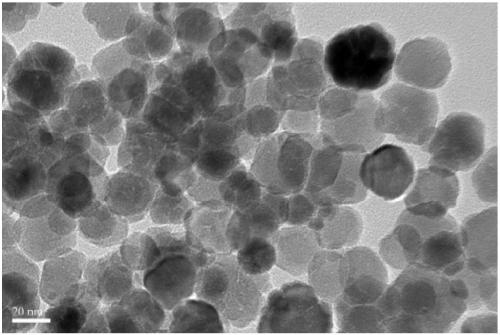

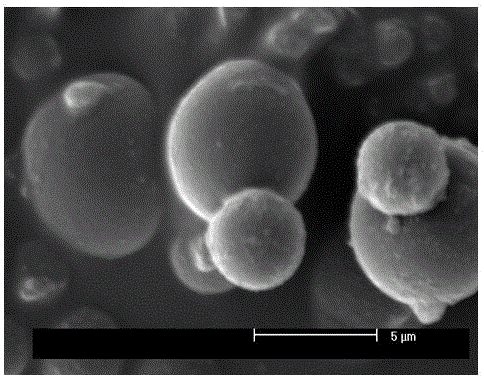

Magnetic fluorescent composite nanoparticle, as well as preparation and use thereof

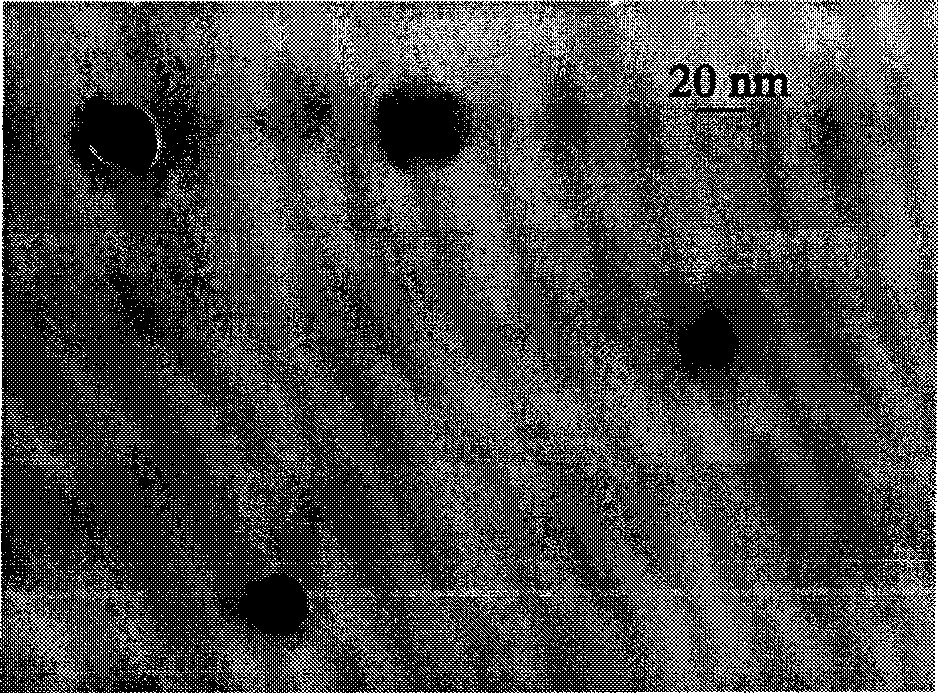

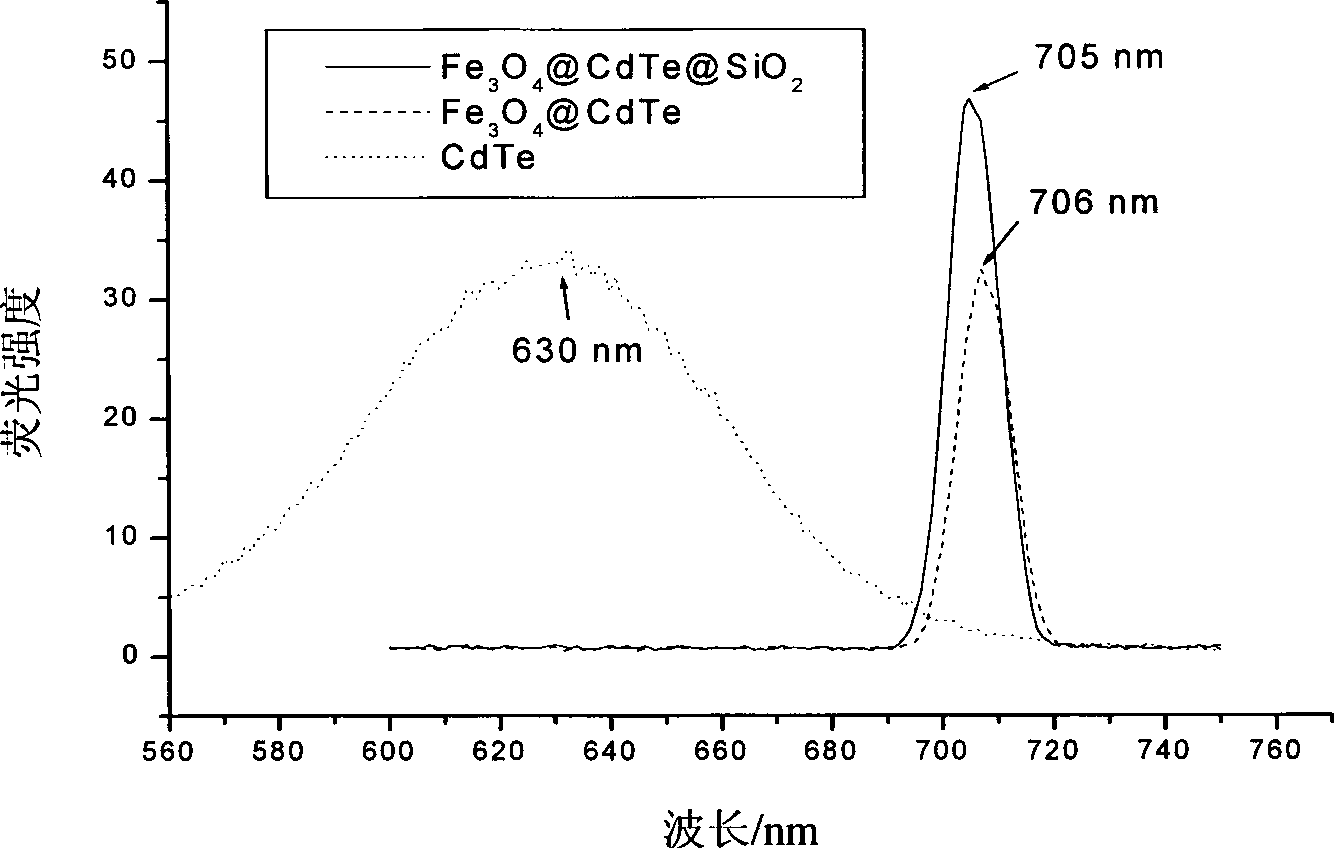

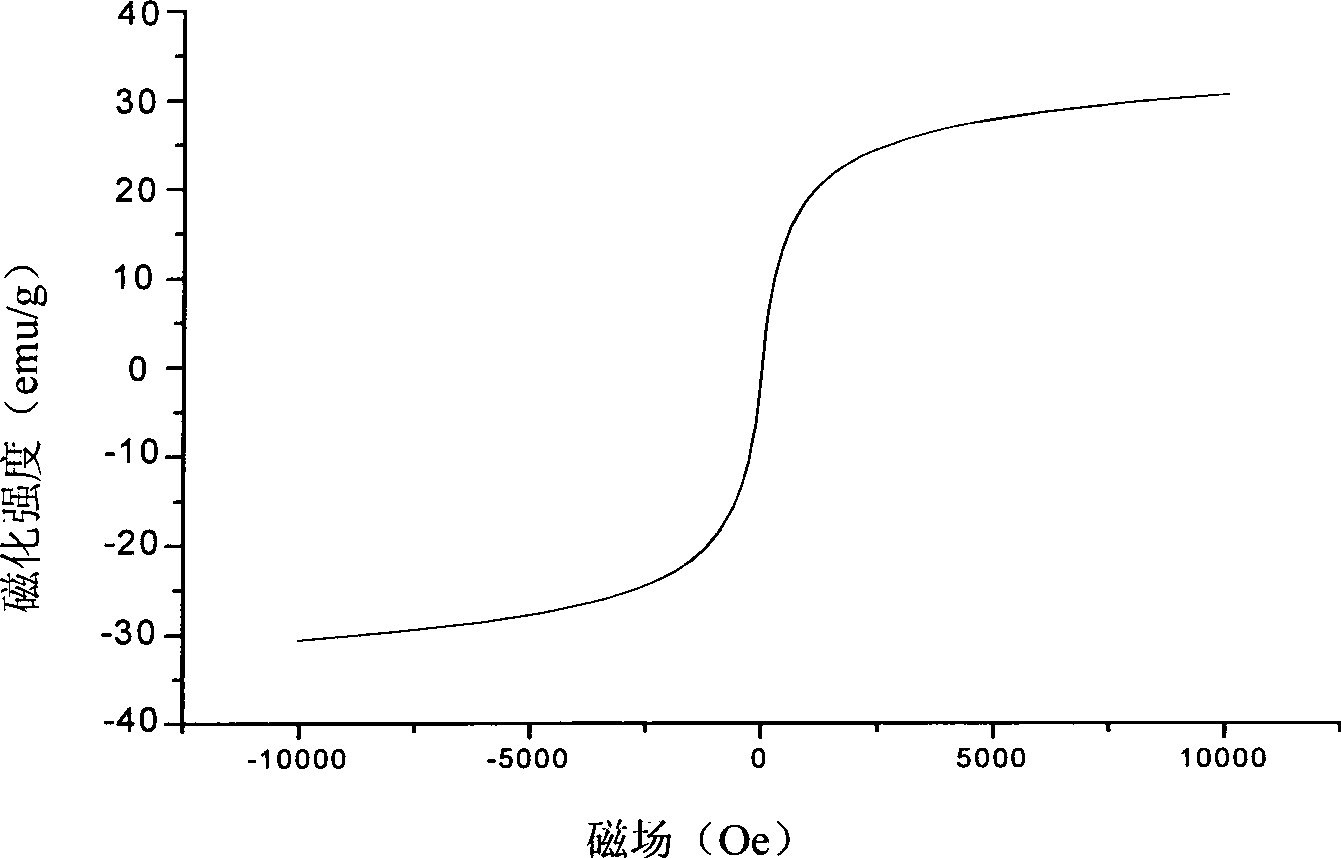

InactiveCN101503623AGood monodispersityNo reunionLuminescent compositionsOil phaseComposite nanoparticles

The invention discloses a magnetic luminescent composite nano-particle Fe3O4 / CdTe / SiO2 and a preparation method thereof. The method for preparing the magnetic luminescent composite nano-particle Fe3O4 / CdTe / SiO2 comprises the steps of: firstly preparing hydrophobic monodisperse Fe3O4 nano-particles by adopting a chemical oil-phase high-temperature method, and modifying the surfaces of the hydrophobic Fe3O4 nano-particles to ensure that the hydrophobic Fe3O4 nano-particles are dispersed in a water phase; preparing luminescent CdTe quantum dots of which the surfaces are provided with carboxyl groups, and precipitating the luminescent CdTe quantum dots on the surfaces of the magnetic Fe3O4 nano-particles through the co-precipitation; then utilizing ligand exchange to modify a silane coupling agent on the surfaces of the luminescent CdTe quantum dots; and finally forming an outermost SiO2 coating layer through silane or silicon ester hydrolysis. The diameter of the magnetic luminescent composite nano-particle Fe3O4 / CdTe / SiO2 is between 30 and 50nm; the magnetic luminescent composite nano-particle Fe3O4 / CdTe / SiO2has double functions of magnetism and fluorescence at the same time, has strong and durable fluorescence intensity after labeling rat bone marrow-derived mesenchymal stem cells, and apparently reduces cellular magnetic resonance signals. The particle has broad application prospect in the fields such as biological labeling, bioseparation and the like.

Owner:SUN YAT SEN UNIV

Quantum dot/acrylate polymer nanocrystal complex, preparation method of quantum dot/acrylate polymer nanocrystal complex, and colored conversion coating

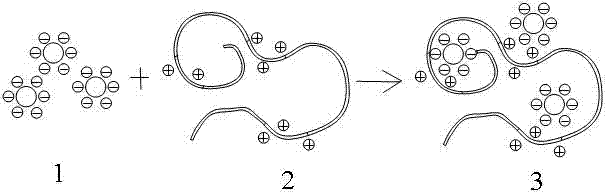

ActiveCN103772872AGood dispersionEvenly dispersedPhotomechanical coating apparatusPhotosensitive materials for photomechanical apparatusPhotoluminescenceResin matrix

The invention discloses a quantum dot / acrylate polymer nanocrystal complex, a preparation method of the quantum dot / acrylate polymer nanocrystal complex, and a colored conversion coating, wherein the quantum dot / acrylate polymer nanocrystal complex is prepared by virtue of electrostatic interaction between an annion acrylate polymer and quantum dots with opposite charges. According to the invention, the quantum dots are pre-dispersed into the acrylate polymer, so as to prepare quantum dot / acrylate polymer nanocrystal complex. By virtue of similar composition of an acrylate polymer protection layer and acrylics as well as an acrylics modified photoresist resin matrix, the quantum dots can be easily dispersed into photoresist, are not easy to separate and are uniformly dispersed without aggregation, and thus the photoluminescent characteristic of the quantum dots is ensured. After the colored conversion coating prepared from the quantum dot / acrylate polymer nanocrystal complex is applied to a display, the colors of sub-pixel units of R / G / B colors corresponding to the colored conversion coating are relatively pure and have the relatively high saturability, energy of a backlight is sufficiently utilized, and the luminous efficiency is relatively high.

Owner:TCL CORPORATION

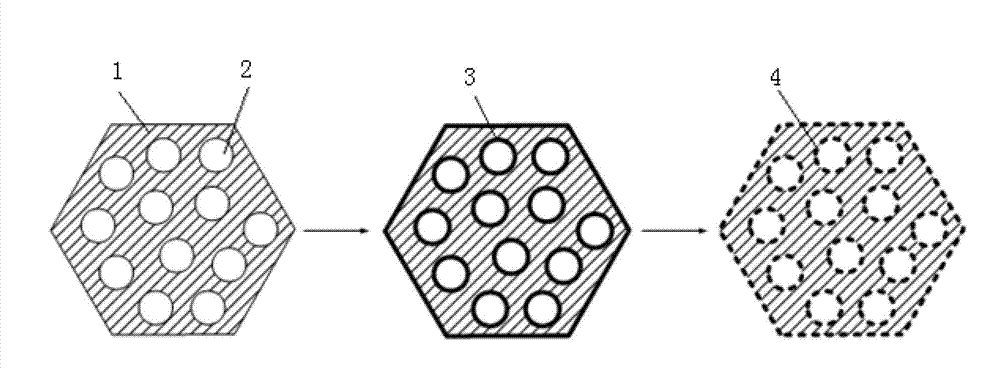

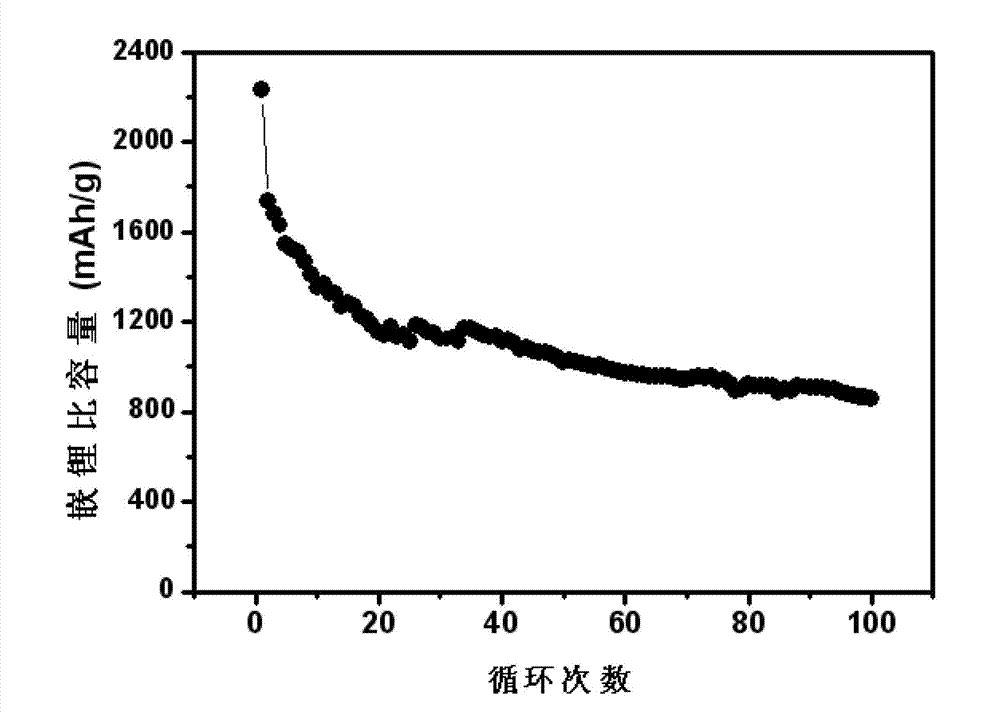

Silicon-carbon composite material, preparation method of silicon-carbon composite material, and lithium ion battery containing silicon-carbon composite material

ActiveCN102969489AImprove conductivityImprove charge and discharge cycle lifeCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention discloses a silicon-carbon composite material, a preparation method of the silicon-carbon composite material, and a lithium ion battery containing the silicon-carbon composite material. The preparation method comprises the following steps of: (1) reducing silicon dioxide by using metal with activity larger than that of silicon, so as to obtain a porous silicon-metal oxide composite; (2) corroding the metal oxide by acid, so as to obtain porous silicon; and (3) coating the surface of the porous silicon by carbon by taking a carbon source as a raw material, so as to obtain the silicon-carbon composite material. The silicon in the silicon-carbon composite material is prepared through using a metallothermic reduction method and porous silicon particles prepared through using the metallothermic reduction method are micron-sized and hardly agglomerate; the pore walls and the pore diameters in the porous silicon particles are nano-sized; compared with imporous micron-sized silicon powder, for the silicon-carbon composite material, the porous silicon particles have the characteristics that a diffusion path of a lithium ion in a silicon substrate is shortened, thus being beneficial to charging and discharging with large current, the pores can hold the volume expansion of silicon during silicon intercalation and the charging and discharging cycle life of the material is prolonged. The surfaces of the porous silicon particles are coated with a carbon layer with the certain pores and the conductivity of the silicon-carbon composite material is enhanced.

Owner:CHERY AUTOMOBILE CO LTD

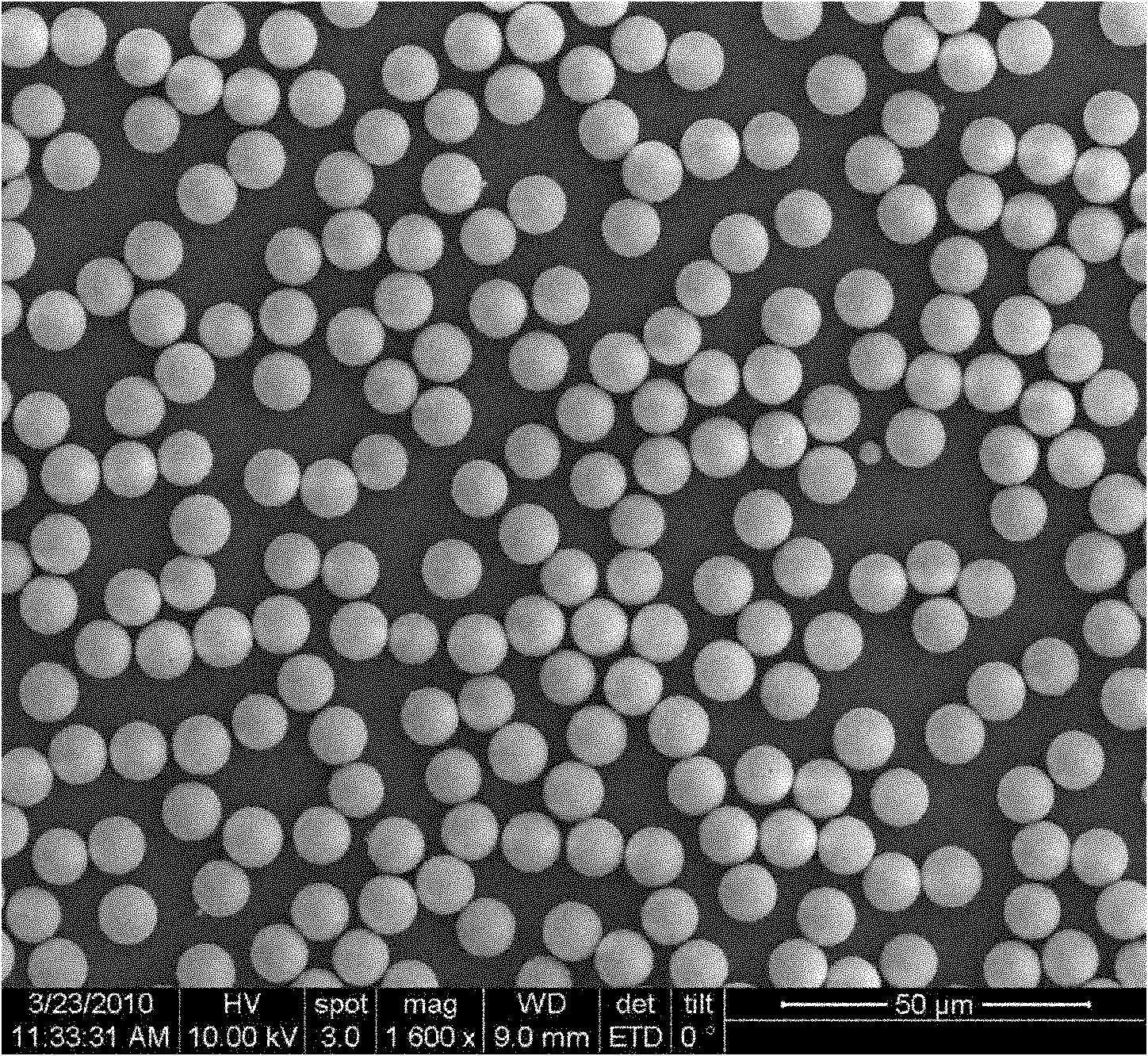

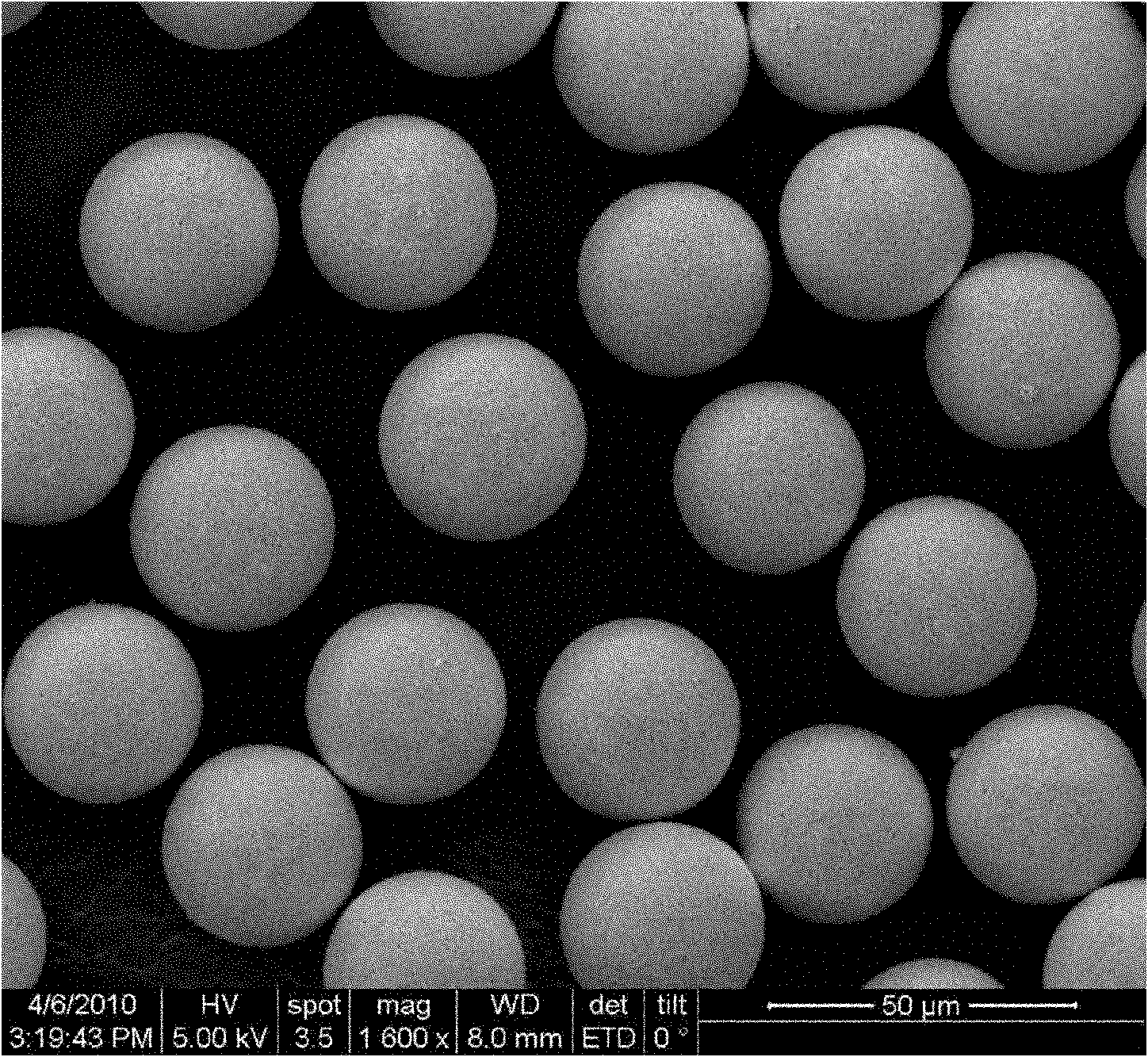

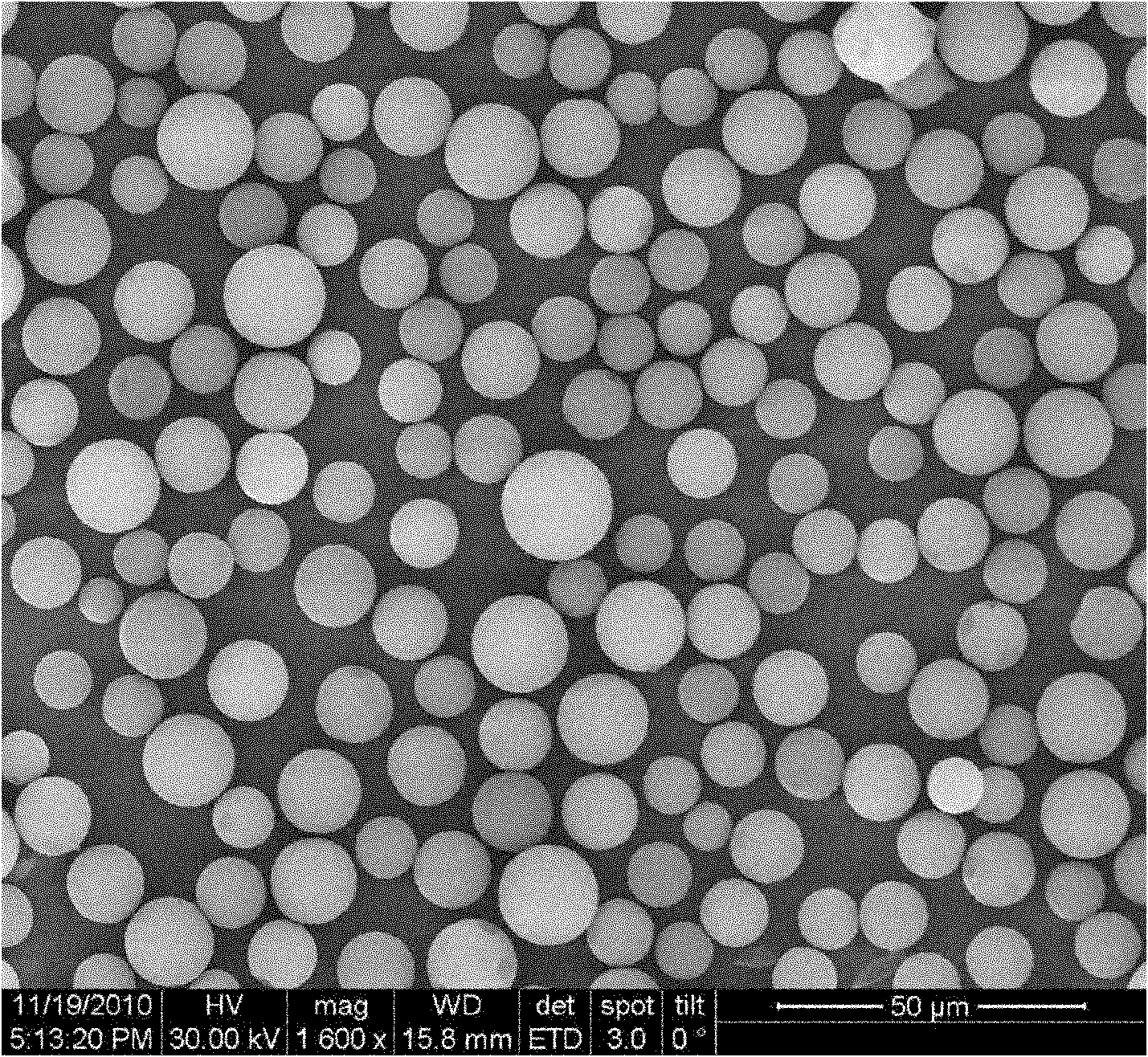

Functionalized homogeneous particle porous silicon dioxide microspheres and preparation method and application thereof

ActiveCN102070152AControl apertureControl structureIon-exchange process apparatusSilicaMicrosphereCompound (substance)

The invention discloses functionalized homogeneous particle porous silicon dioxide microspheres and a preparation method and application thereof. The preparation method comprises the following steps of: (1) pre-preparing homogeneous particle porous polymer microspheres with determined components, particle diameters and apertures, and performing surface functionalized treatment on the porous polymer microspheres to obtain the functionalized homogeneous particle porous polymer microspheres; (2) dispersing the functionalized porous polymer microspheres in aqueous solution and adding silicon dioxide precursor to prepare silicon dioxide / polymer intermediate composite microspheres; (3) heating the silicon dioxide / polymer intermediate composite microspheres to remove the polymer to obtain the homogeneous particle porous silicon dioxide microspheres; and (4) performing surface modification on the homogeneous particle porous silicon dioxide microspheres by using a chemical reagent to form a functionalized group, wherein the particle diameter of the functionalized homogeneous particle porous silicon dioxide microspheres is within the range of between 1.7 and 100 microns; and the mesoporous aperture of the functionalized homogeneous particle porous silicon dioxide microspheres is within the range of between 20 and 1,000 angstroms. The functionalized homogeneous particle porous silicon dioxide microspheres can be used as chromatographic filler for efficiently analyzing and separating organic molecules and biological molecules.

Owner:SUZHOU NANOMICRO TECH CO LTD

Nanometer hydroxyapatite powder preparation method

InactiveCN1544318AGood crystallizationSmall granularityEnergy based chemical/physical/physico-chemical processesPhosphorus compoundsCalcium nitrate tetrahydrateApatite

A process for preparing nano hydroxyapatite powder comprises the steps of, mixing Ca(NO3)-2-4H20 and NH4-2HPO-4 according to the mol ratio of Ca:P = 1.67-2.5:1, dissolving by charging distilled water, making the concentration of the Ca2++ ion to be 0.01-0.1 mol / L, charging aquadrate powder into the solution according the ratio of Ca(NO3)-2-4H2O : NH4-2HPO-4 = 1:5-12, conducting sound chemo synthesis through multiple frequency phonochemical generator, filtrating and washing the suspending liquid, placing the filtered material into vacuum drying oven for drying at the temperature of 80-100 deg. C, thus the nano hydroxyapatite powder can be obtained.

Owner:SHAANXI UNIV OF SCI & TECH

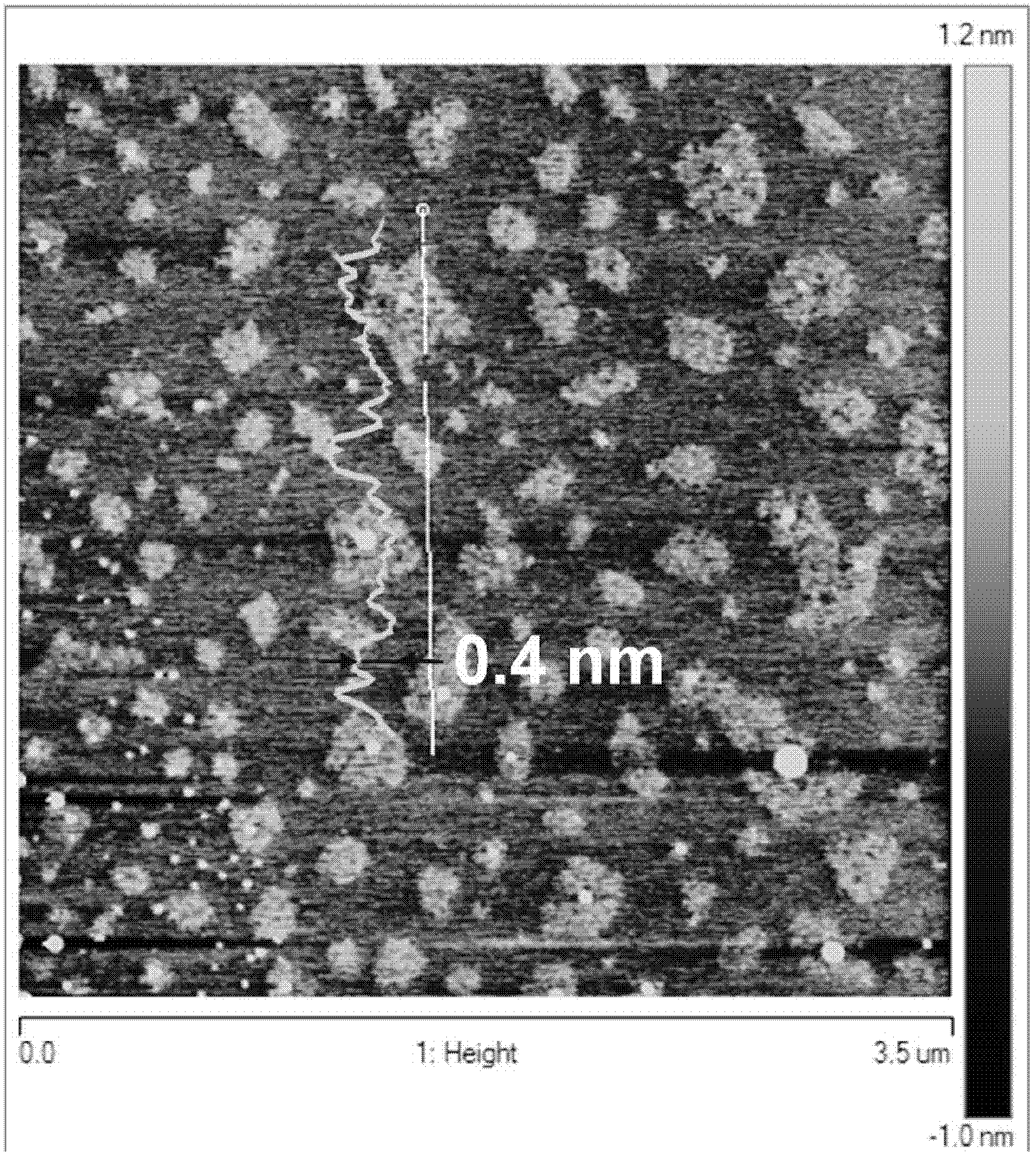

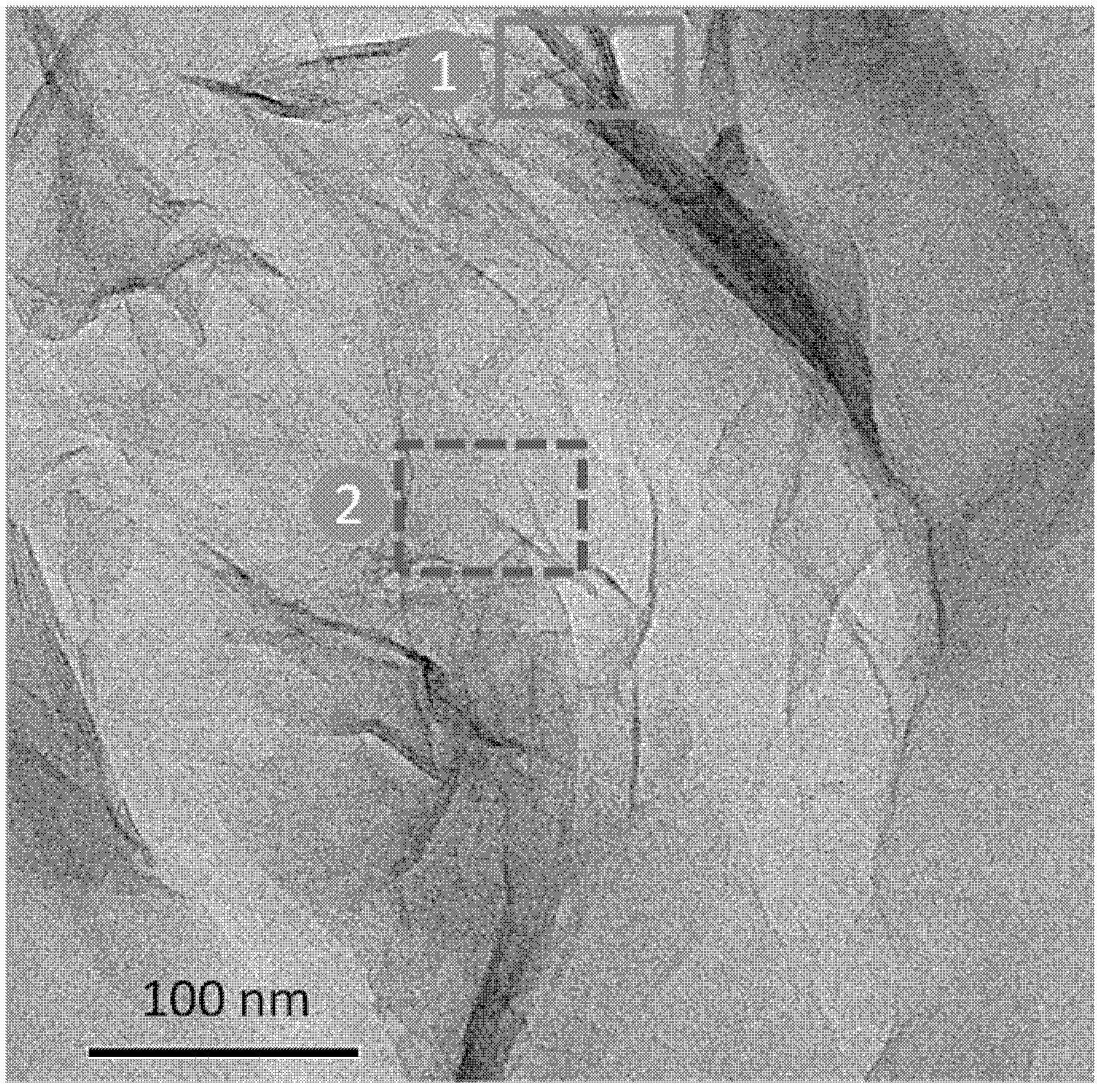

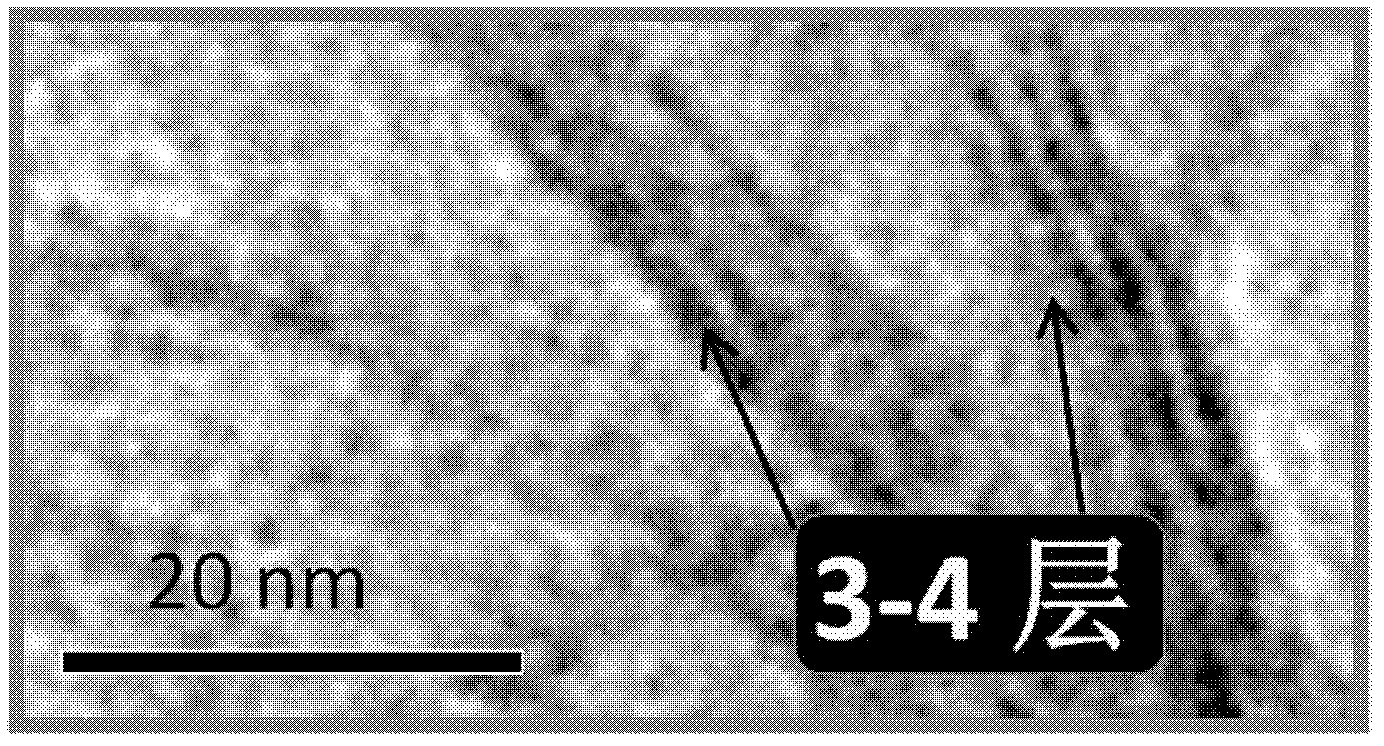

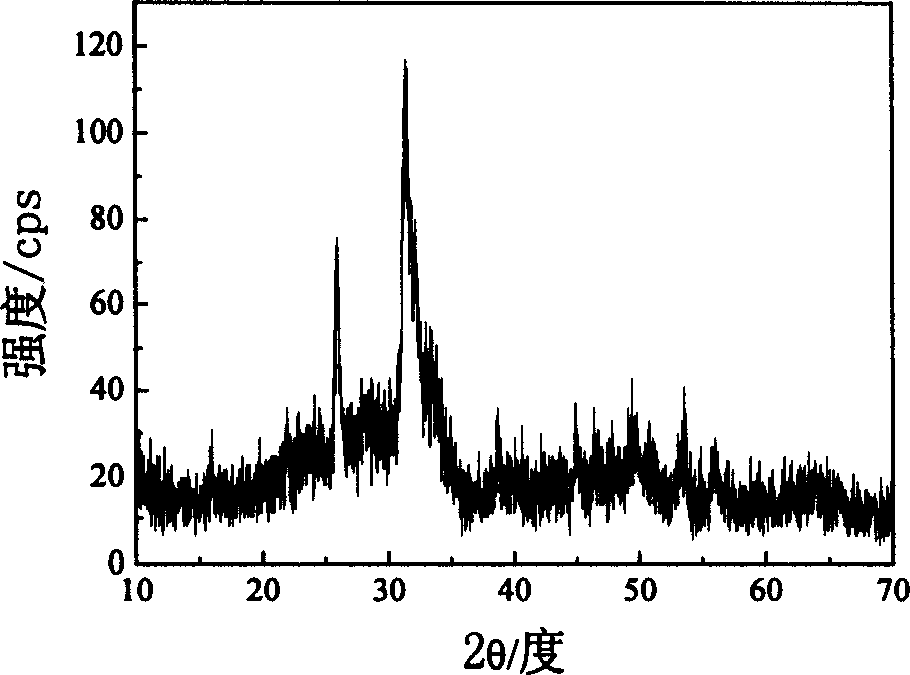

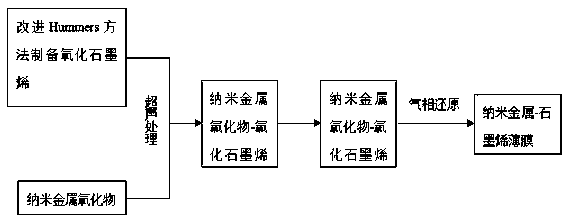

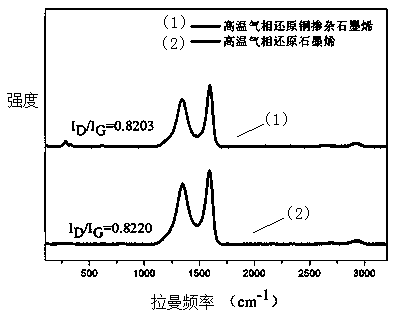

Modified grapheme preparation method

ActiveCN103787328AImprove conductivityNo pollution in the processGrapheneSupercapacitorNanocomposite

The invention discloses a modified grapheme preparation method. Nanometer metallic oxide particles are dispersed in oxidized grapheme dispersion liquid, and then high-temperature reduction is conducted to form a grapheme film doped with the metal nanometer particles. The modified grapheme preparation method is environmentally friendly, free of pollution and low in cost. The conductivity of obtained modified grapheme is improved by more than three times. The metal nanometer particles evenly adhere to the surface of the grapheme, and the agglomeration phenomenon does not occur, so that the grapheme has good conducting performance; the modified grapheme preparation method can be applied to nanometer composite materials, Li-ion batteries and composites materials, based on grapheme, such as grapheme paper of super capacitors.

Owner:SOUTH CHINA NORMAL UNIVERSITY

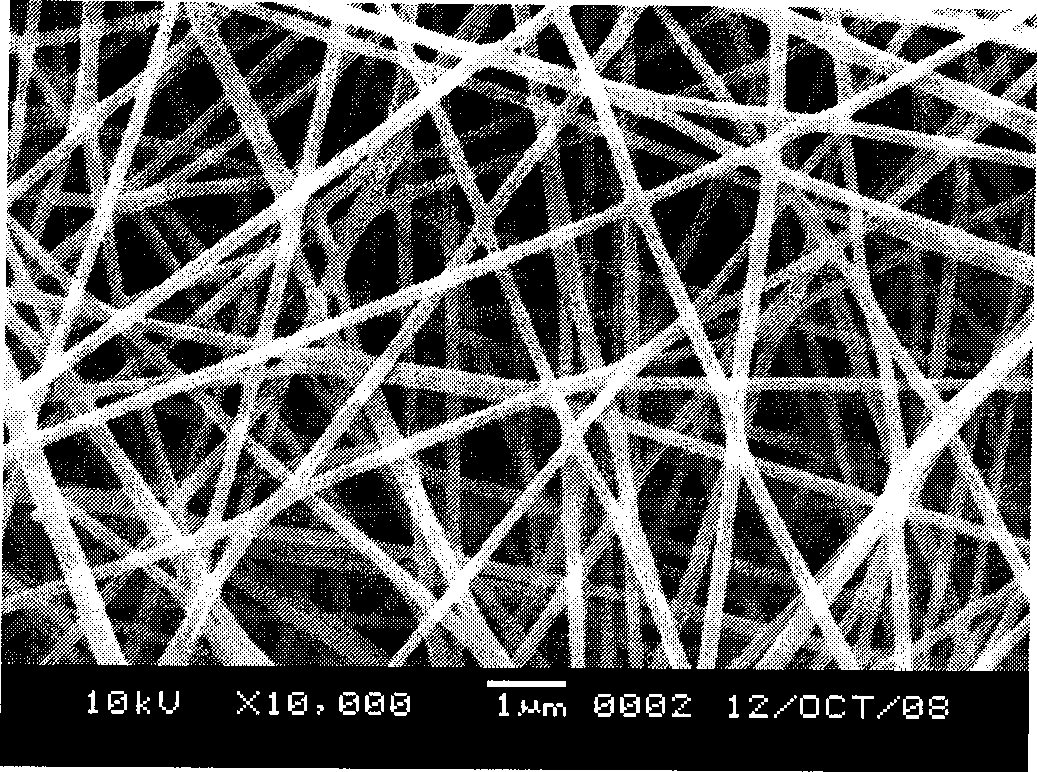

Novel composite nanofiber membrane as well as preparation method and application thereof

The invention relates to a nanofiber membrane and particularly relates to a novel composite nanofiber membrane as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) dissolving any one of polyvinyl alcohol, polylactic acid and regenerated silk fibroin in an organic solvent to prepare a spinning solution with the mass fraction of 5-20 percent; (2) adding polyphenol substances to the spinning solution, and uniformly stirring to obtain a mixed spinning solution which accounts for 1-7 percent of the total mass of the polyphenol substances and the organic solvent, wherein the polyphenol substances are one or more of vegetable tannin, apple polyphenol and grape polyphenol; (3) carrying out ultrasonic treatment on the mixed spinning solution for 1-600 minutes; and (4) carrying out electrostatic spinning on the mixed spinning solution and collecting to obtain the required composite nanofiber membrane. After subjected to electrostatic spinning, the composite nanofiber membrane is smooth in surface, continuous and uniform, has the diameter of between 100nm and 800nm and can be applied to the fields of medical dressing, makeup facial masks, tea bags, controlled release of targeted drugs, food preservation and sewage purification.

Owner:HEYE HEALTH TECH CO LTD

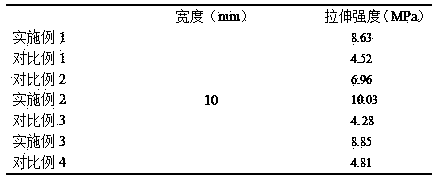

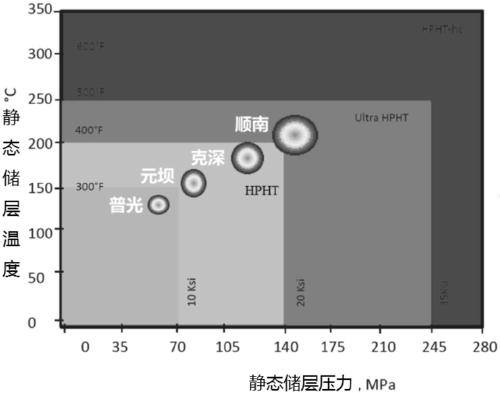

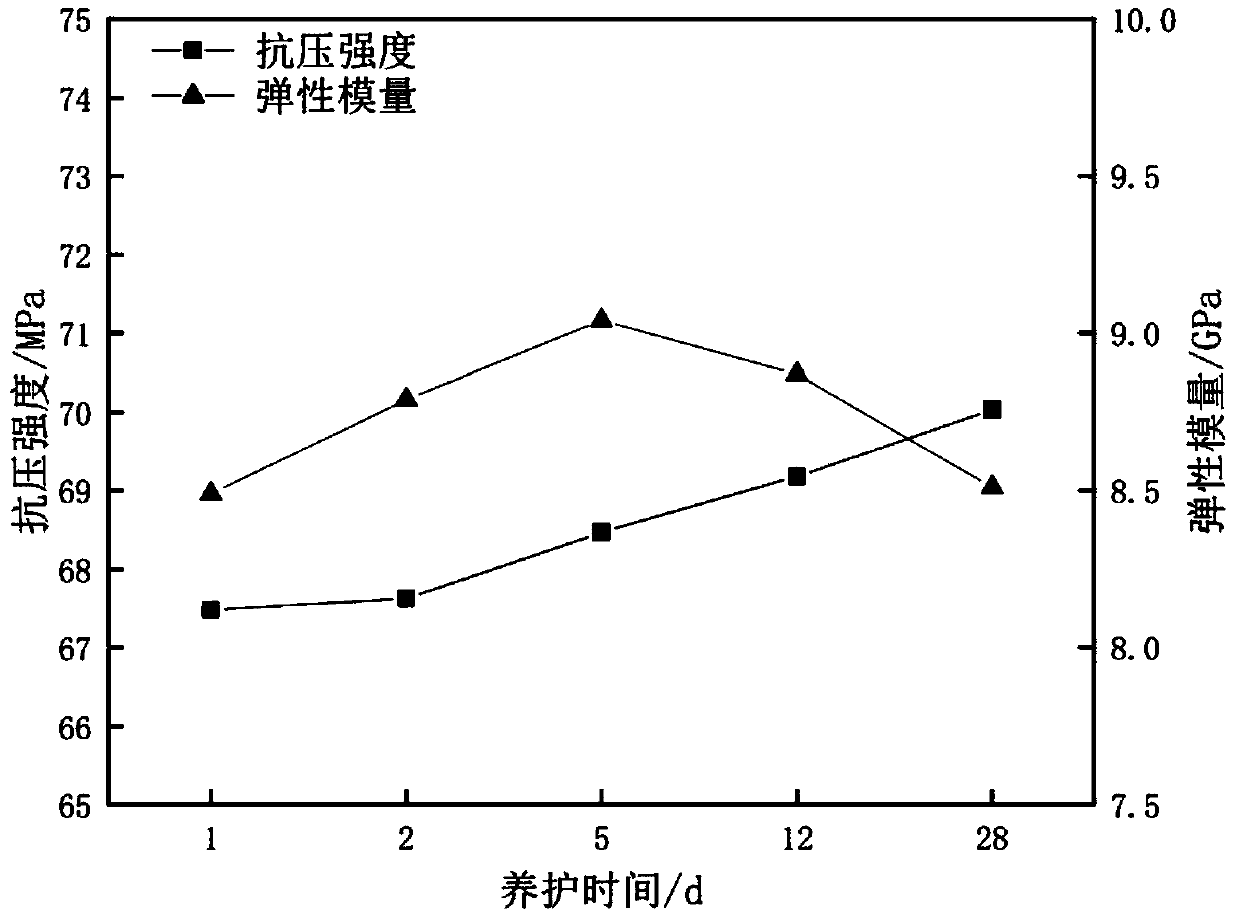

Nano-material mixed modified superhigh-temperature high-performance well cementing slurry system and preparation method thereof

The invention relates to a nano-material mixed modified superhigh-temperature high-performance well cementing slurry system and a preparation method thereof. The slurry system comprises the followingingredients in parts by weight: 100 parts of oil well cement, 15-25 parts of coarse silica sand, 15-20 parts of fine silica sand, 1-10 parts of nano-silicon dioxide, 1-10 parts of nano-calcium carbonate, 0.2-1 part of a defoaming agent, 4-10 parts of a fluid loss agent, 0-3 parts of a drag reduction agent, 0.5-4 parts of a retarder and 30-100 parts of water. In the slurry system, set cement has excellent compressive strength and toughness under superhigh temperature, and the compressive strength and the elasticity modulus cannot be obviously changed as the maintenance time is prolonged. The slurry system has good rheological property, lower water loss and proper thickening time, and the comprehensive properties of the slurry system can completely meet the related requirements of site wellcementing construction, so that the technical support is provided for well cementing under high temperature. A nano-material obtained by mixing the nano-silicon dioxide and the nano-calcium carbonateis added, and micropores of the set cement can be effectively filled, so that the system becomes denser. Therefore, the volume shrinkage of the set cement is relieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

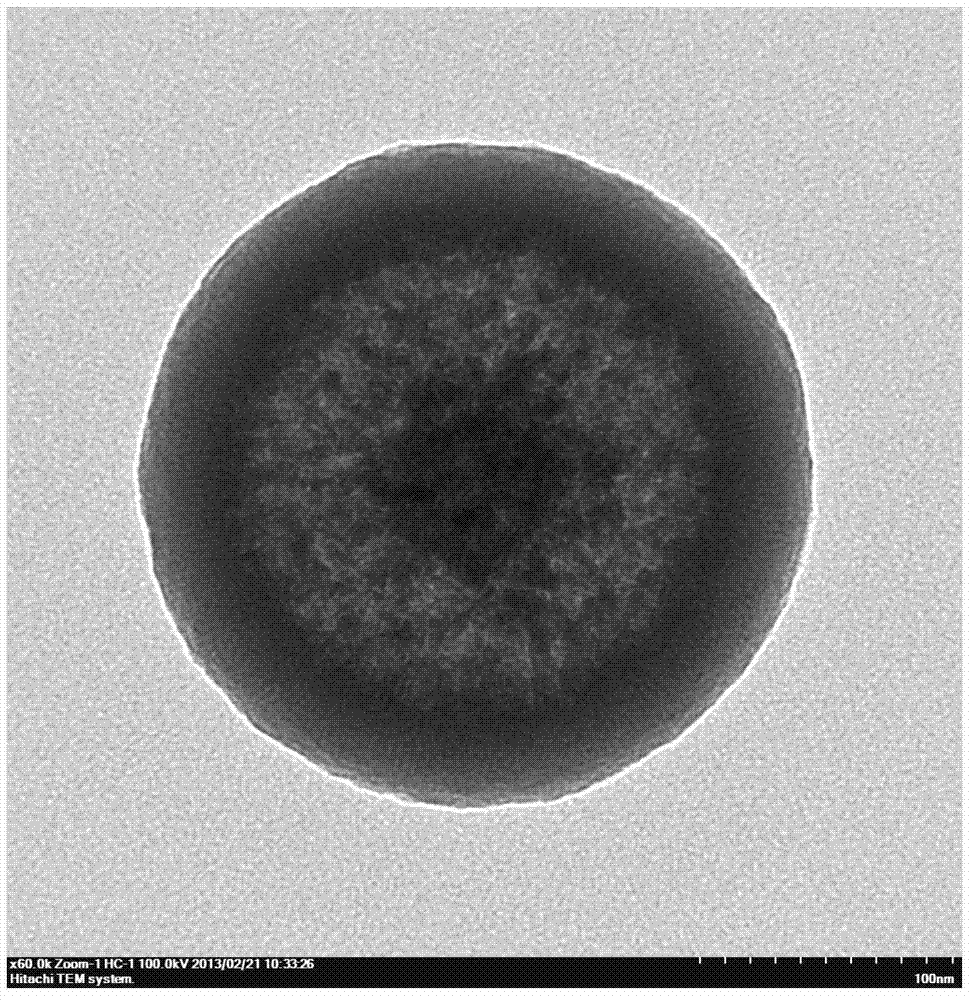

Mesoporous silica with yolk-shell structure and preparation method thereof

The invention discloses mesoporous silica with a yolk-shell structure and a preparation method thereof. The morphology of the mesoporous silica is of spherical bodies. The spherical body has a mesoporous core and a mesoporous shell. A cavity structure is between the mesoporous core and the mesoporous shell. Mesoporous silica balls have high specific surface area, uniform and adjustable particle size and uniform pore size. The preparation method of the mesoporous silica includes: dissolving a surface active agent in a mixed solution of ethanol, ammonia and water, adding two silica precursors into the mixed solution under heating and stirring conditions, transferring the obtained spherical silica into water after reacting for a period, etching to remove intermediate loose layers of silica balls, finally removing the surface active agent to obtain mesoporous silica products having the yolk-shell structure. The preparation method of the present invention has the characteristics of simple process, low cost, and environmental protection. The prepared mesoporous silica has great application potential in medical imaging, drug delivery and other fields.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

Polyolefin/graphene nanocomposite and preparation method thereof

ActiveCN104098816AGood dispersionOvercome wastePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolymer scienceGraphene nanocomposites

The invention discloses a polyolefin / graphene nanocomposite. According to the invention, two-dimensional nano-material graphene is used as a reinforcing agent, and through graft modification of polyolefin, polyolefin grafted-modified graphene is formed and uniformly dispersed in a polyolefin material. A preparation method for the polyolefin / graphene nanocomposite comprises the following steps: functionalized modification of graphene; preparation of polyolefin grafted-modified graphene; and preparation of the polyolefin / graphene nanocomposite. The preparation method overcomes the problems of easy agglomeration and difficult dispersion of graphene in graphene-enhanced non-polar polymers; in the prepared polyolefin / graphene nanocomposite, graphene is uniformly distributed; and the polyolefin / graphene nanocomposite has excellent flame retardation performance and mechanical properties.

Owner:HEFEI GENIUS NEW MATERIALS

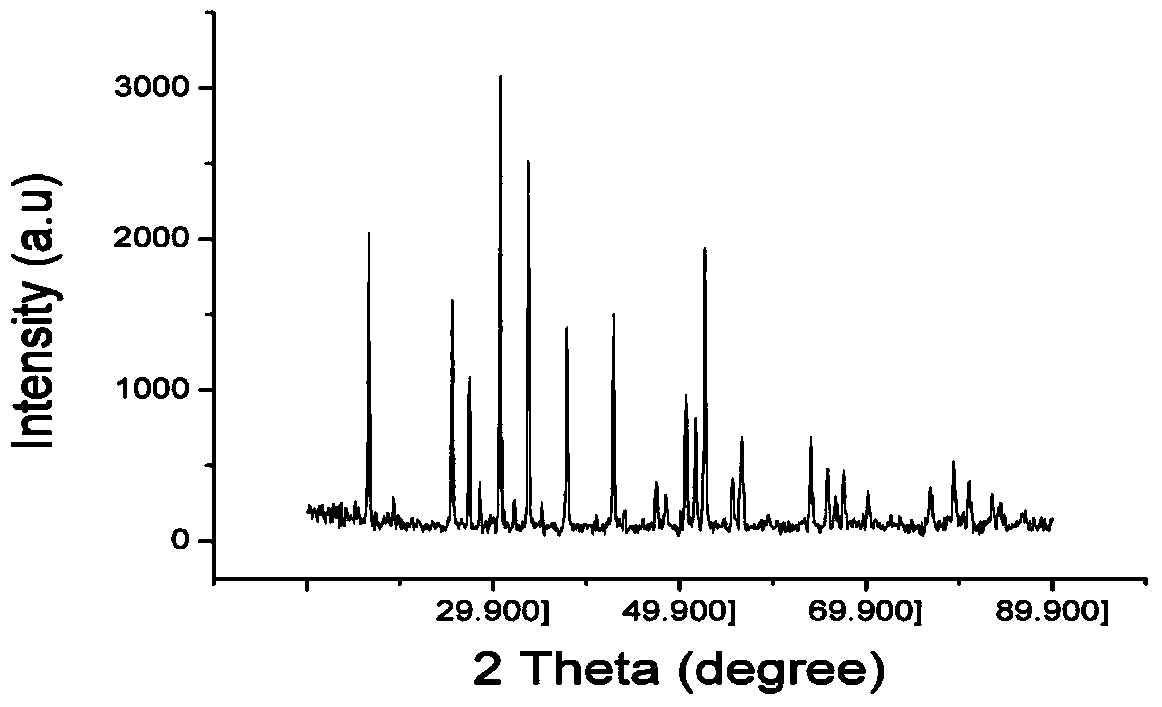

Method for preparing garnet type Li7La3Zr2O12 electrolyte powder with molten-salt method

ActiveCN104332651ASmall particle sizeEvenly distributedFinal product manufactureElectrolyte accumulators manufactureDistilled waterMolten salt

The invention relates to a method for preparing garnet type Li7La3Zr2O12 electrolyte powder with a molten-salt method. The method comprises the following steps: weighing Li2CO3, La2O3 and ZrO2 and mixing; adding molten salt and uniformly mixing, and carrying out ball milling, wherein the molten salt is a mixture of KCl and LiCl; heating at 700-1500 DEG C for 2-40 hours; and taking out a product and washing off the molten salt with distilled water and ethanol to obtain nano powder. The method is fast and simple, low in cost and suitable for large-scale production. The prepared Li7La3Zr2O12 powder has small grain diameter, is uniformly distributed and has no clustering.

Owner:SHANDONG UNIV

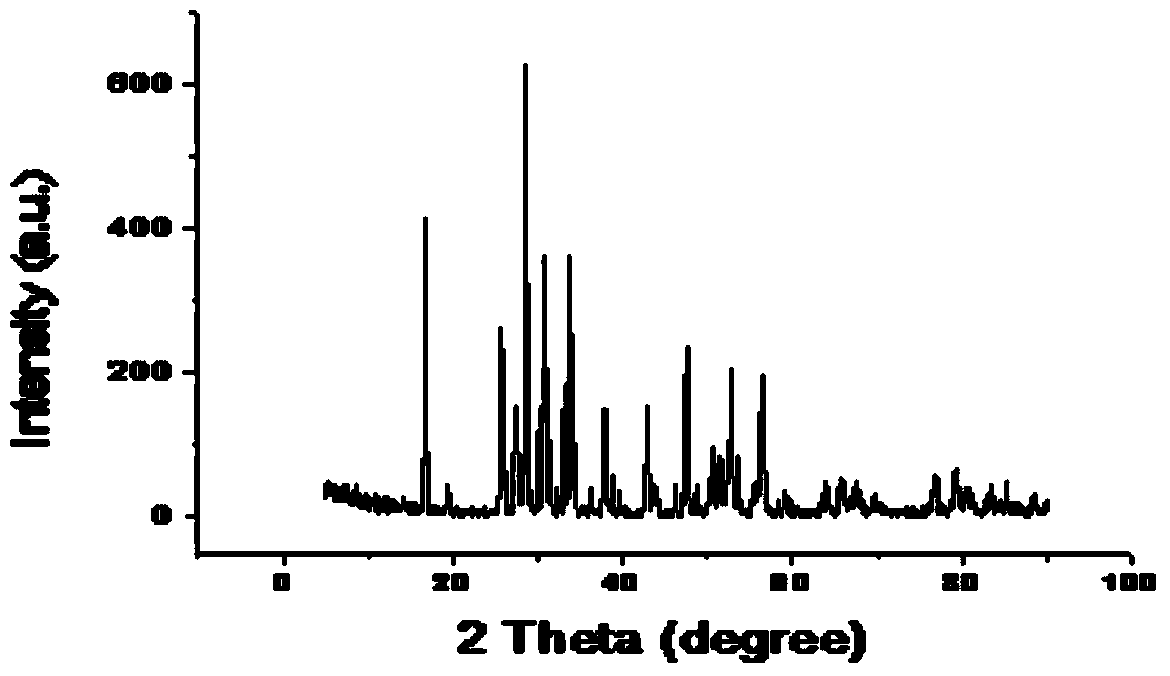

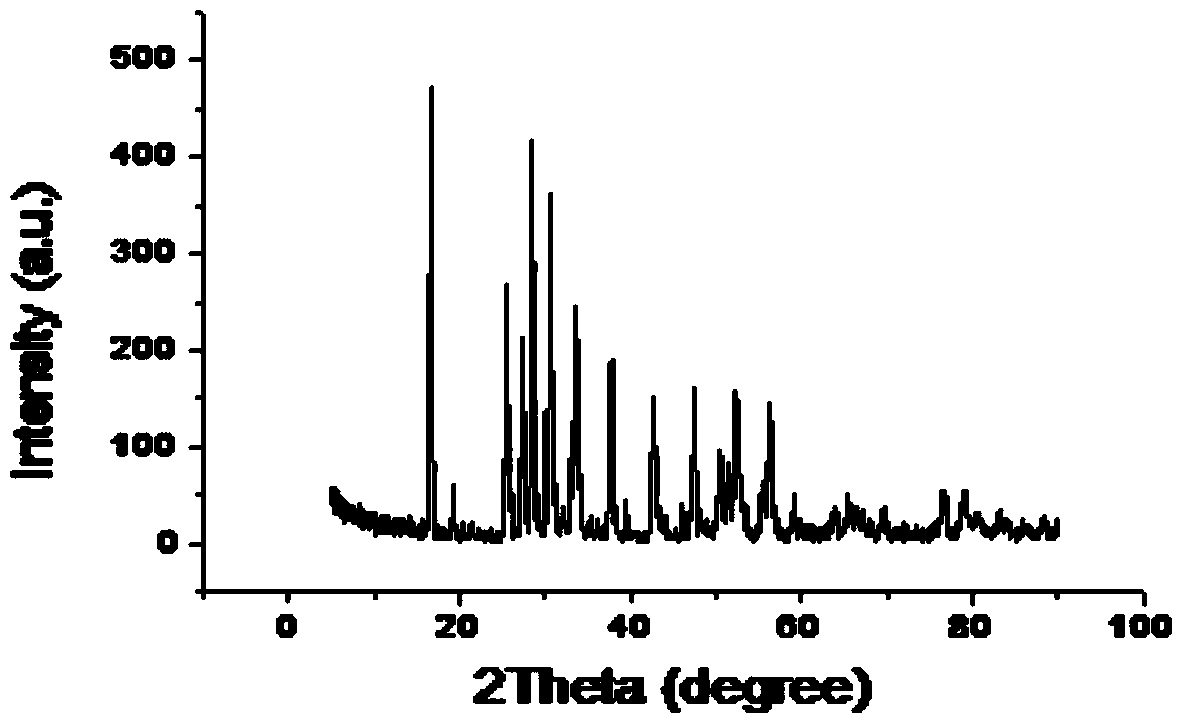

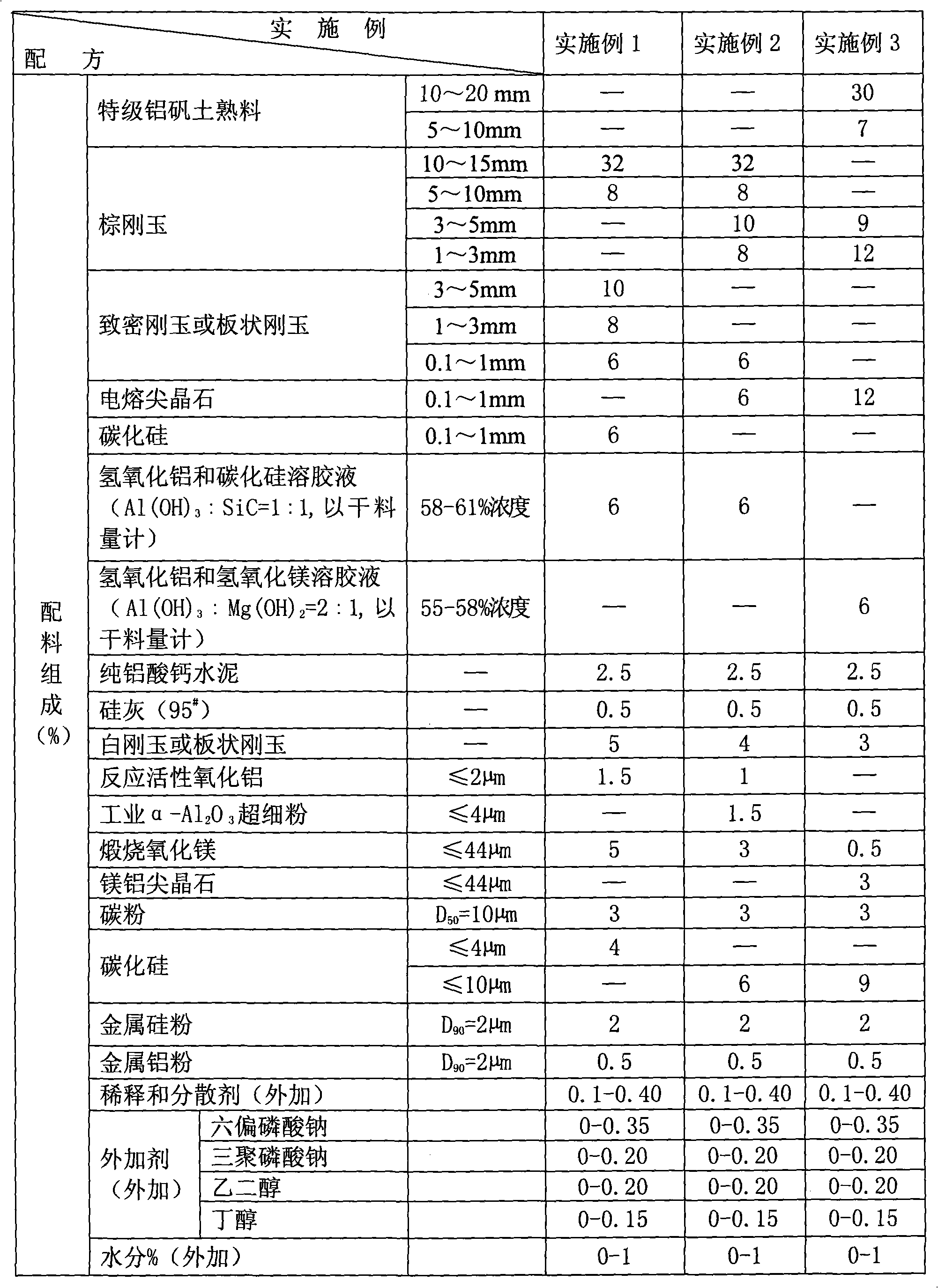

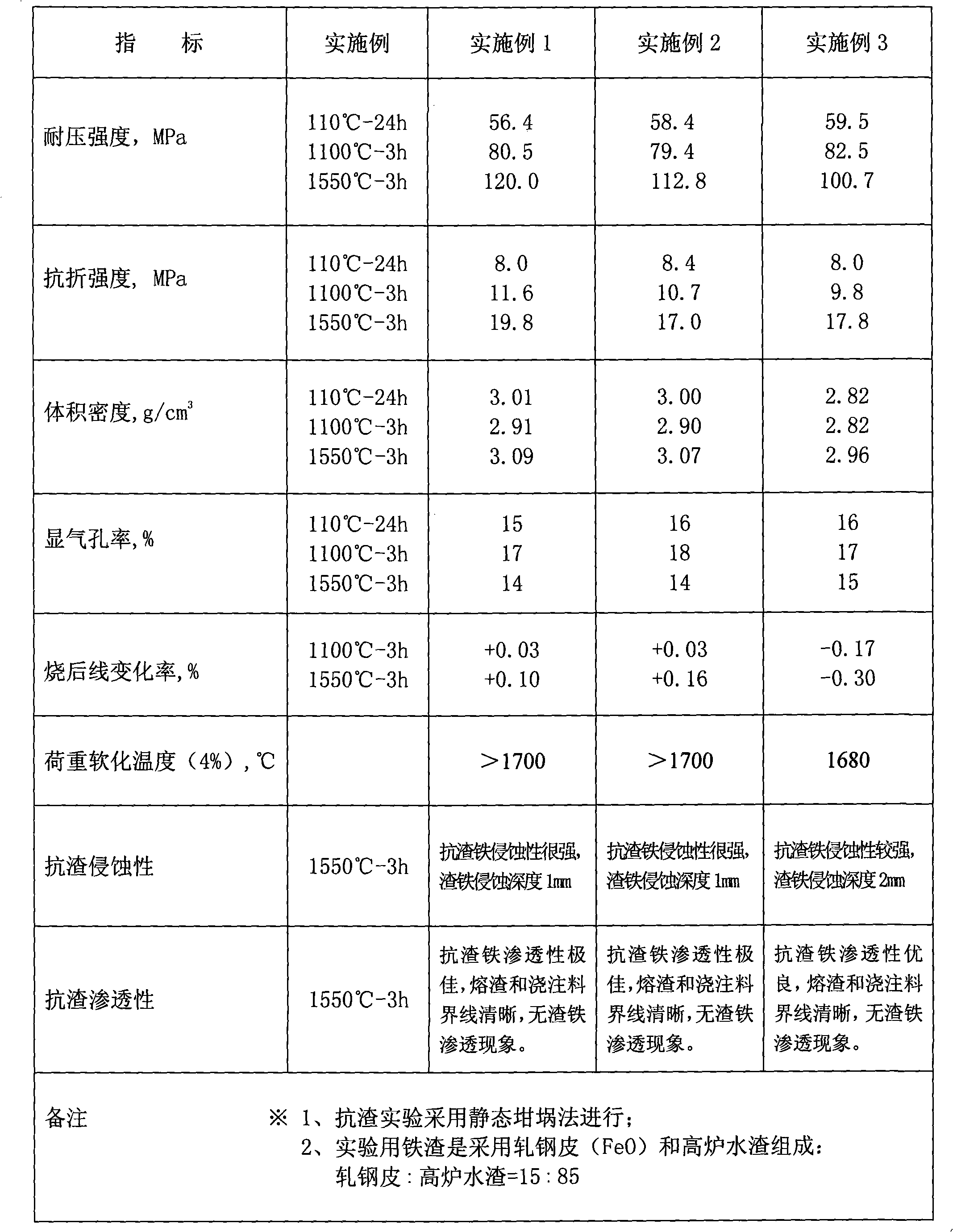

Al2O3-MA-SiC-C refractory castable material with carbon wrapped by nano Al2O3-SiC film and preparation method thereof

The invention relates to an Al2O3-MA-SiC-C refractory castable material with carbon wrapped by nano Al2O3-SiC film or nano Al2O3-MgO film, and a preparation method thereof. The preparation method of the nano carbon-containing castable material comprises: preparing carbon-containing sol suspension with Al(OH)3-SiC or Al(OH)3-Mg(OH)2 through a high-speed impact mixer, coating the carbon-containing sol suspension on the surface of carbon powder to form a compact carbon wrapping layer with complete coverage and no crack, and carrying in-situ synthesis of nano gel particles of Al2O3 and SiC or Al2O3 and MgO generated during transformation from sol to gel so as to generate a nano-sized matrix with carbon-containing nano secondary spinellite, Al2O3 and SiC as main crystalline phases, thereby completing the preparation of the Al2O3-MA-SiC-C refractory castable material made of nano material. The castable material has particularly excellent resistance against erosion and scouring of molten iron slag, and can satisfy the requirements for use in the iron tapping channel of the modern large-scale blast furnace. Moreover, the invention significantly prolongs the service life, reduces the cost and facilitates the environmental protection.

Owner:高树森

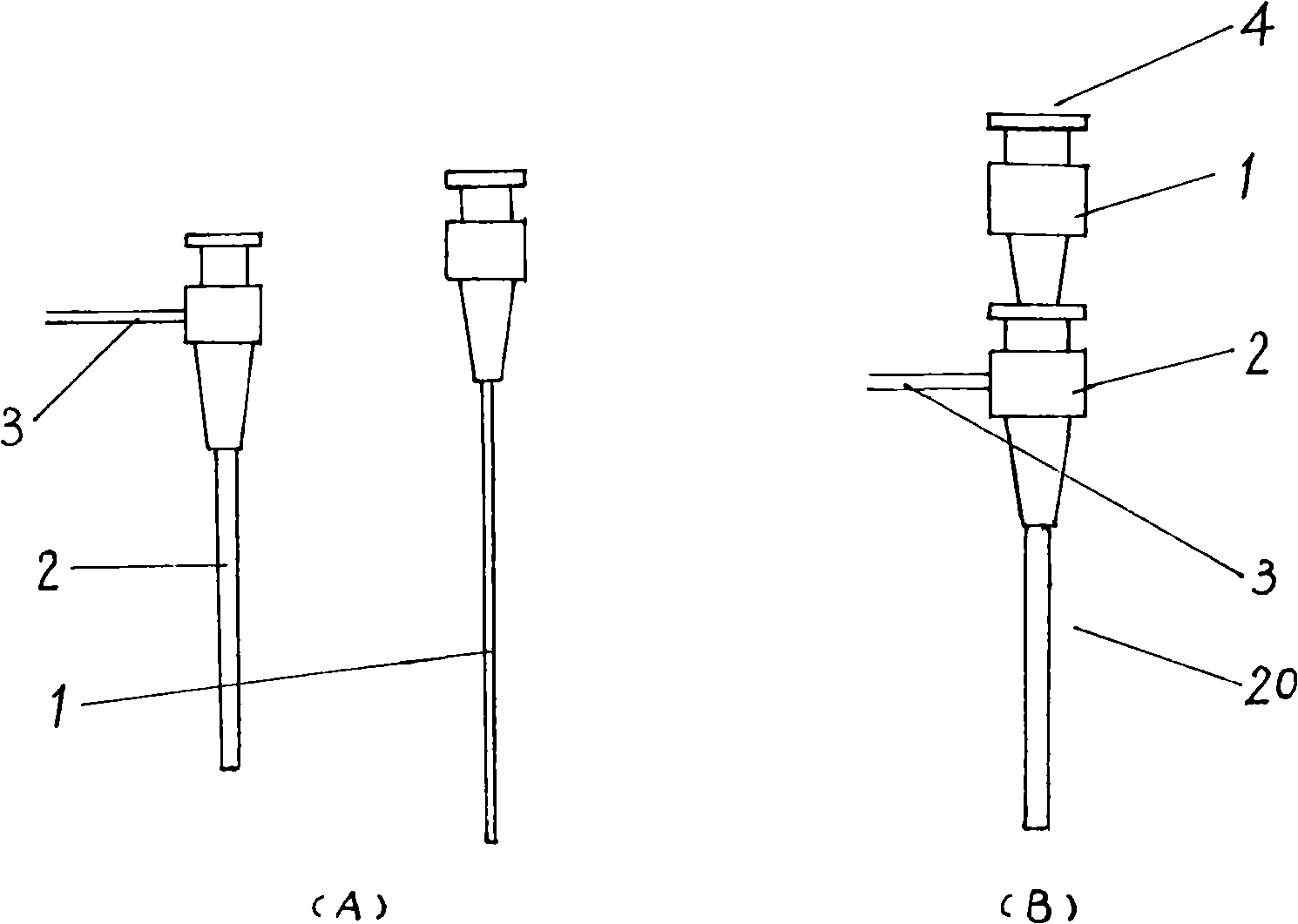

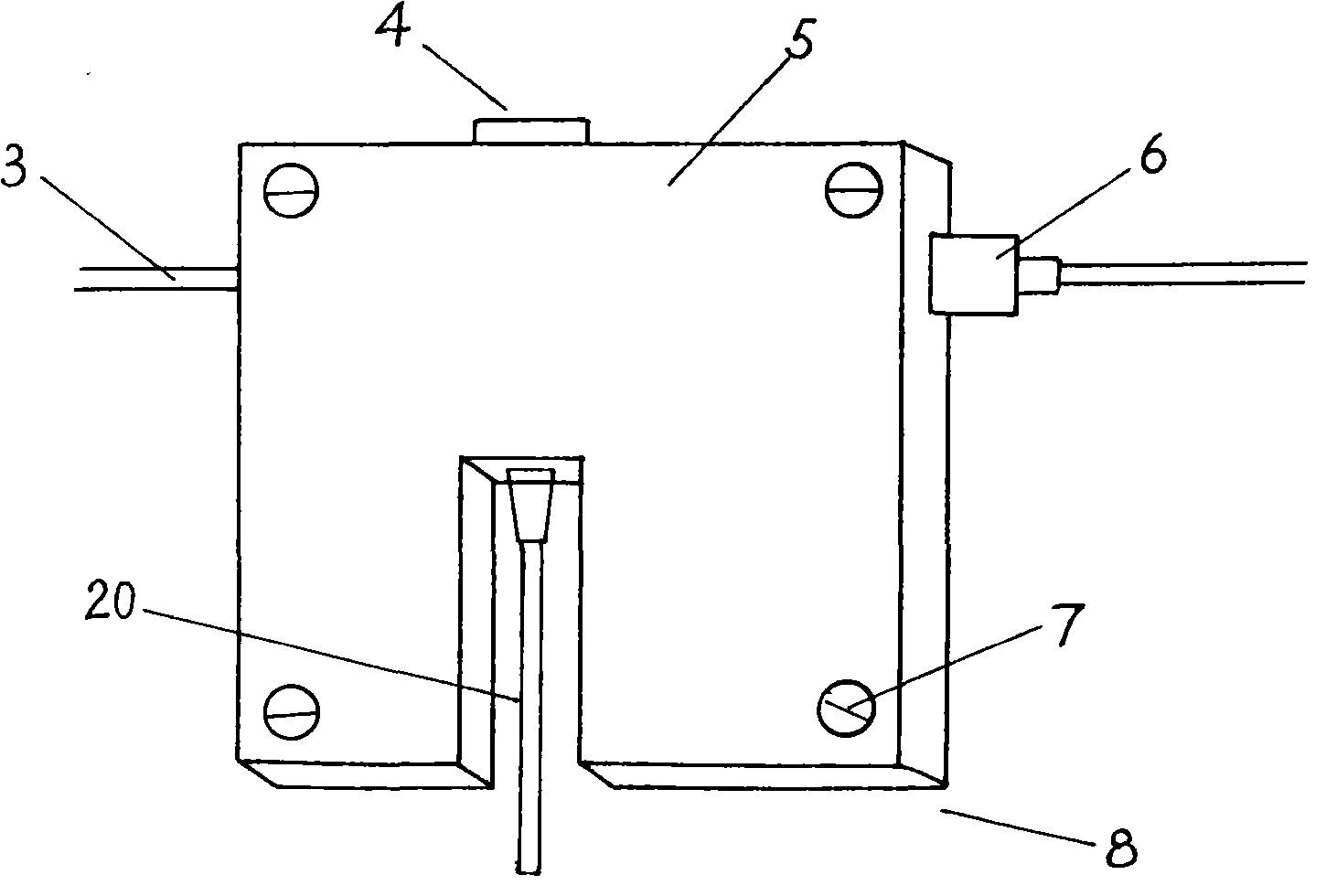

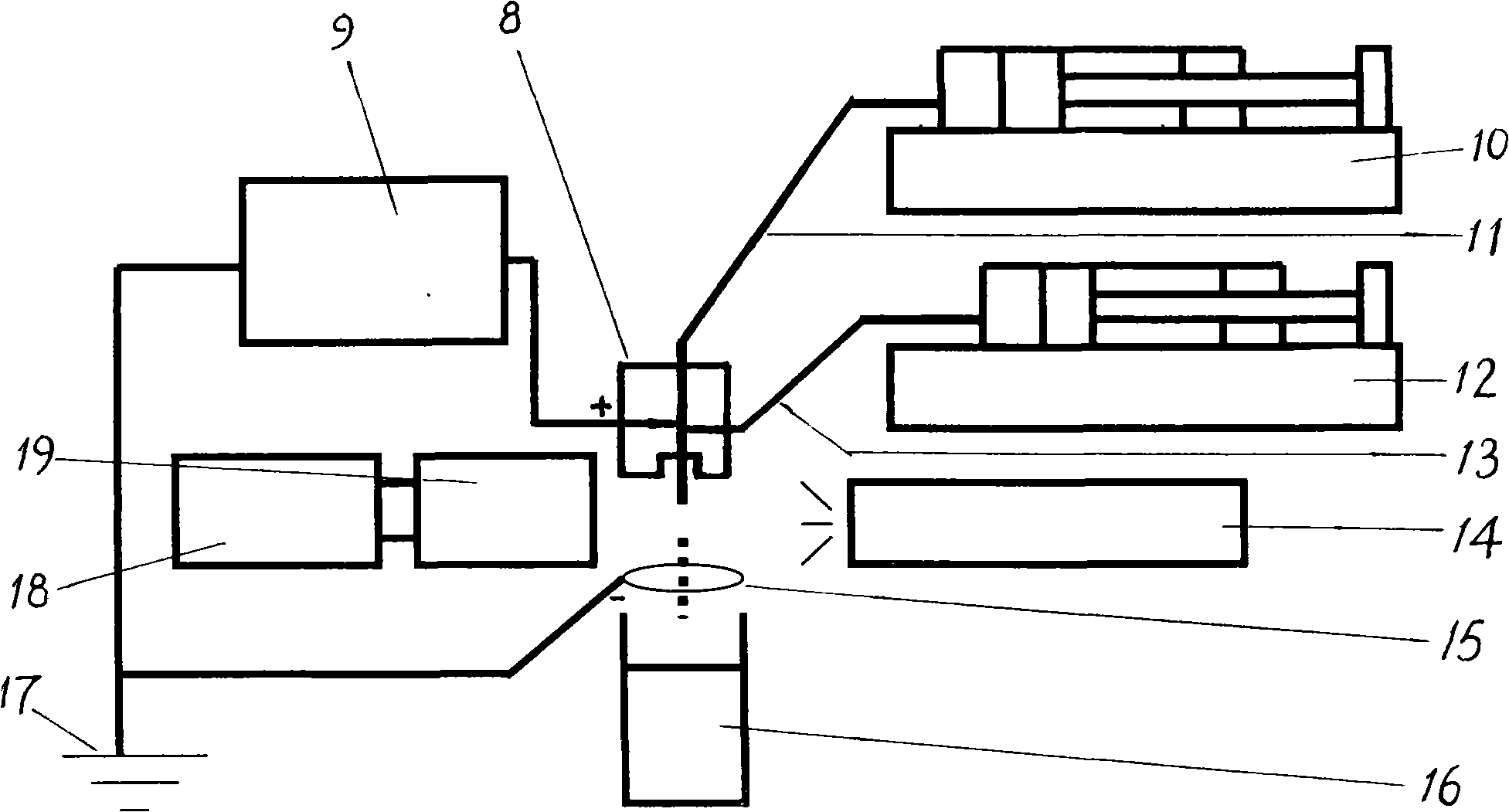

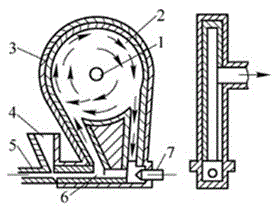

Method and device for preparing micro-bubbles

InactiveCN101837255AEasy to makeEasy to operateFlow mixersMixing methodsMicrobubblesCapillary Tubing

The invention discloses a method and a device for preparing micro-bubbles. A coaxial electrostatic atomization technique can be adopted to prepare a polymer material or other surfactant to serve as an outer layer material wrapping the micro-bubbles of a gas; and a micro-bubble structure is widely applied to foods, material engineering, biological medicaments and the like. In the method, two coaxial metal capillaries are connected with a high-voltage power supply to serve as high-voltage electrodes; a metal ring is placed below the metal capillaries and is connected with a negative electrode of the high-voltage power supply; as receiving electrodes, inner and outer capillaries are filled with the gas and membrane envelope solution respectively; when the voltage reaches a certain value, liquid drops at outlets of the metal capillaries become pyramidal from spherical; tiny jet flows appear on the top part of a cone; and the jet flows are further dispersed because the jet flows are in stable to form the micro-bubbles. The micro-bubbles prepared by the method have uniformly distributed sizes and are not agglomerated, and the sizes of the micro-bubbles can be changed by adjusting the flow velocity of fluid in double-pinhead metal capillaries, the physical properties of the fluid and the loaded voltage.

Owner:EAST CHINA UNIV OF SCI & TECH

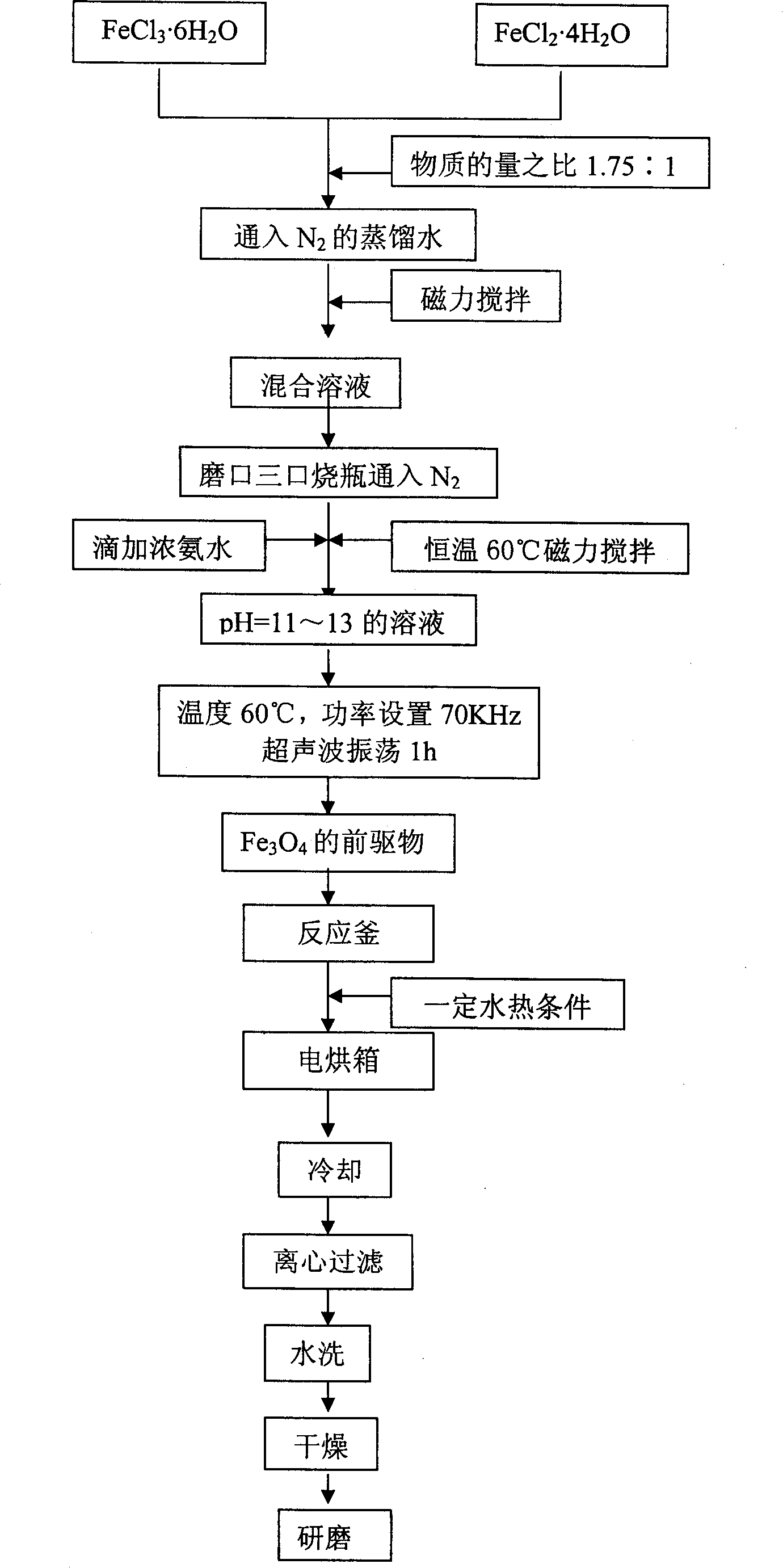

Ultrasound wave auxiliary hydrothermal synthesis technique for magnetic magnetic iron oxide nano ultra-tiny grain

The invention discloses an ultrasonic assistant hydro-thermal synthesis process for magnetic Fe3O4 nanometer super fine grain. The invention solves the problems of impure products and large grain diameter. The invention has the technical proposal that the form of Fe3O4 crystal nucleus is promoted in the cavitation effect of ultrasonic; cavitation gas bubble is produced in mediums; the pH value of strong ammonia is adjusted to 11 to 13; and the nanometer grain diameter size and the magnetic characteristics are controlled by controlling the hydro-thermal synthesis temperature within range from 140 DEG C to 160 DEG C and within time of 3 to 5 hours, and by changing the micro environment of the air bubble chamber, so as to obtain the dry product which is black magnetic Fe3O4 nanometer powder after being milled. The invention comprises no organic solvent, belonging to full green environmental protection which is a break in the field, and the invention is also the first to use the ultrasonic technology for assistant hydro-thermal synthesis. The invention has the advantages of simple technology, low cost, small powder granularity and even grain diameter. The powder not only can be used as duplicate ink powder, but also can be board used in aspects such as medical, biological technology, magnetic immunocyte separation, DNA separation, nucleic acid hybridization, and preparation for magnetic butt directional medicine carrying micron ball.

Owner:CIVIL AVIATION UNIV OF CHINA

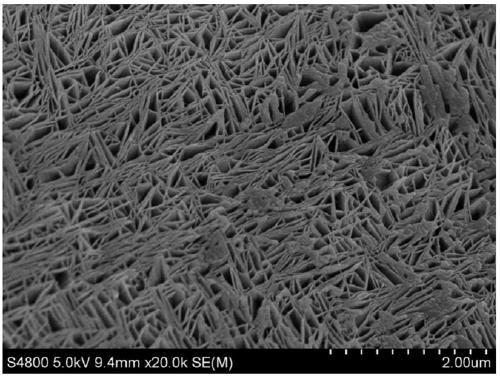

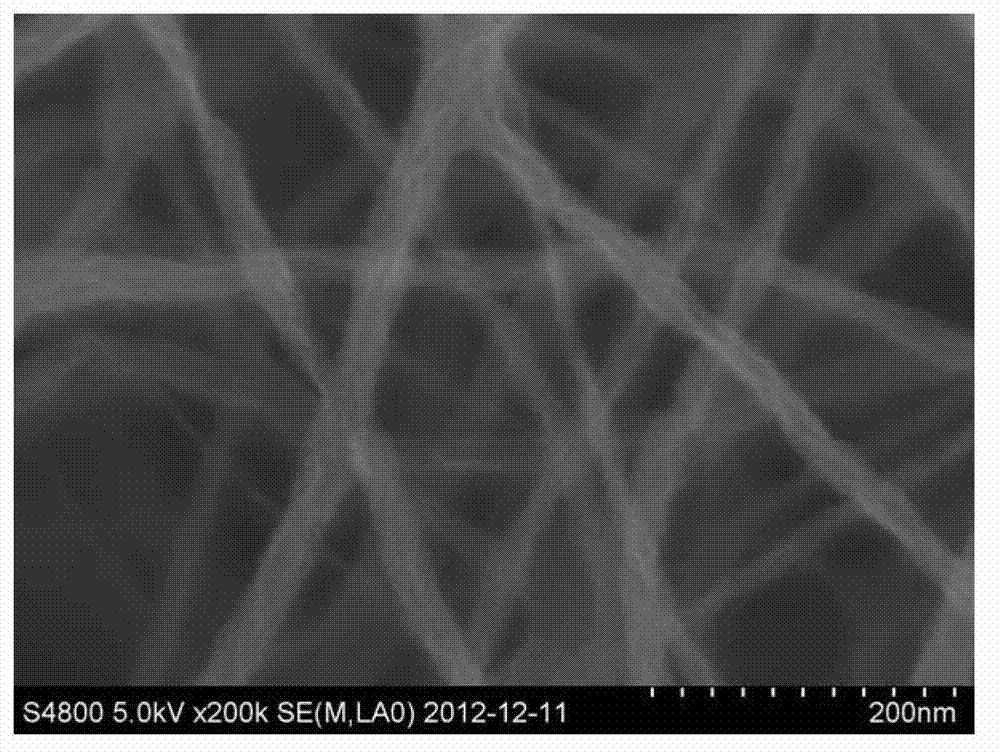

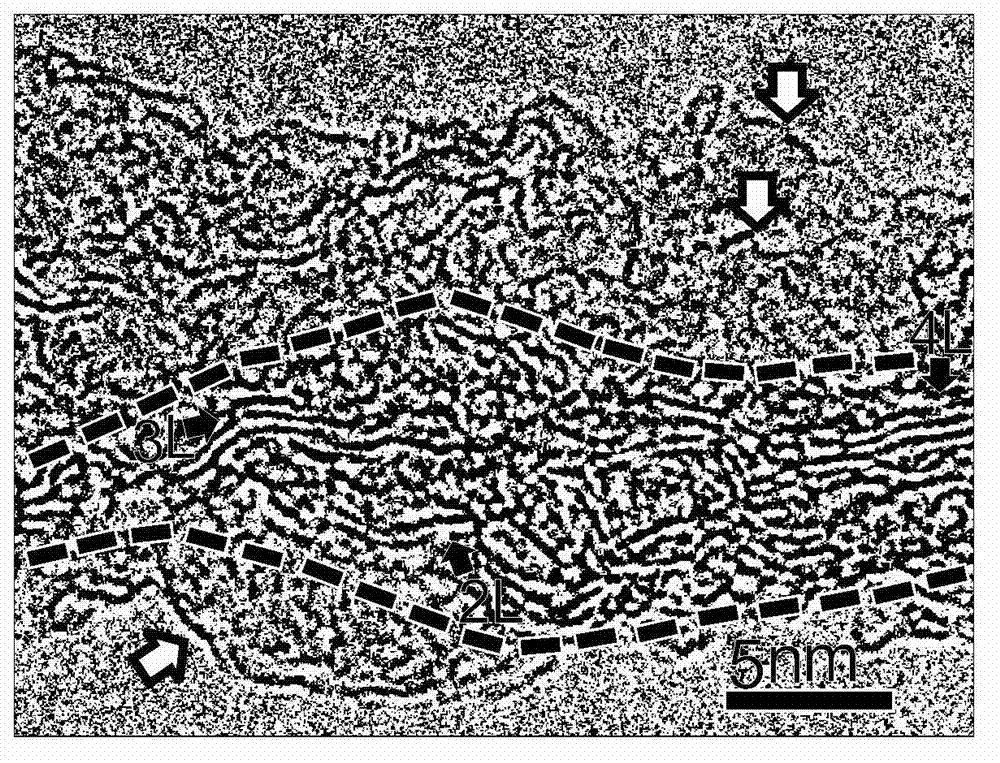

Preparation method of graphene nano-fiber and super-capacitor application thereof

ActiveCN103198931AEasy to fixNo reunionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention relates to a preparation method of a graphene nano-fiber and super-capacitor application of the preparation method of the graphene nano-fiber. The preparation method of the graphene nano-fiber includes the following steps: (1) an electrostatic spinning method is utilized to prepare a polymer fiber; (2) the polymer fiber obtained by the method is conducted with stabilizing treatment in appropriate temperature and in an oxygen-bearing atmosphere; (3) the fiber after the stabilizing treatment is conducted with carbonization thermal treatment in an NH3-bearing atmosphere and in appropriate temperature. The surface of the prepared graphene nano-fiber is provided with a graphene sheet which grows along the radial direction, and the thickness of the graphene sheet is 1 to 10 atomic layers. The graphene nano-fiber integrates the advantages of graphene and carbon nanofibers, solves the problems of graphene agglomeration and recrystallization, is high in surface activity and has various application values. The graphene nano-fiber is utilized to serve as a super-capacitor of electrode material preparation. Therefore, compared with the prior art, the preparation method of the graphene nano-fiber and the super-capacitor application of the preparation method of the graphene nano-fiber have good performance. The working voltage reaches 1.8-2.2 volts; the energy density reaches 41.3 watt hour / kilogram; and the specific capacitance in acid can reach 300 F / g.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Method for preparing nanometer metal oxide/graphene composite photocatalyst

InactiveCN102160995AHigh catalytic efficiencyImprove controllabilityMaterial nanotechnologyPhysical/chemical process catalystsCvd grapheneMetal

The invention provides a method for preparing nanometer metal oxide / graphene composite photocatalyst in the technical field of the photocatalyst. The photocatalyst is prepared by ultrasonically dispersing graphite oxide in titanium dioxide catalytic active substance precursor solution to prepare a compound, reducing the compound through hydrazine hydrate, and drying and roasting the compound in vacuum to prepare the catalyst. By the nanometer titanium dioxide / graphene composite photocatalyst prepared by the method has greatly improved photocatalysis by controlling sintering temperature.

Owner:SHANGHAI JIAO TONG UNIV

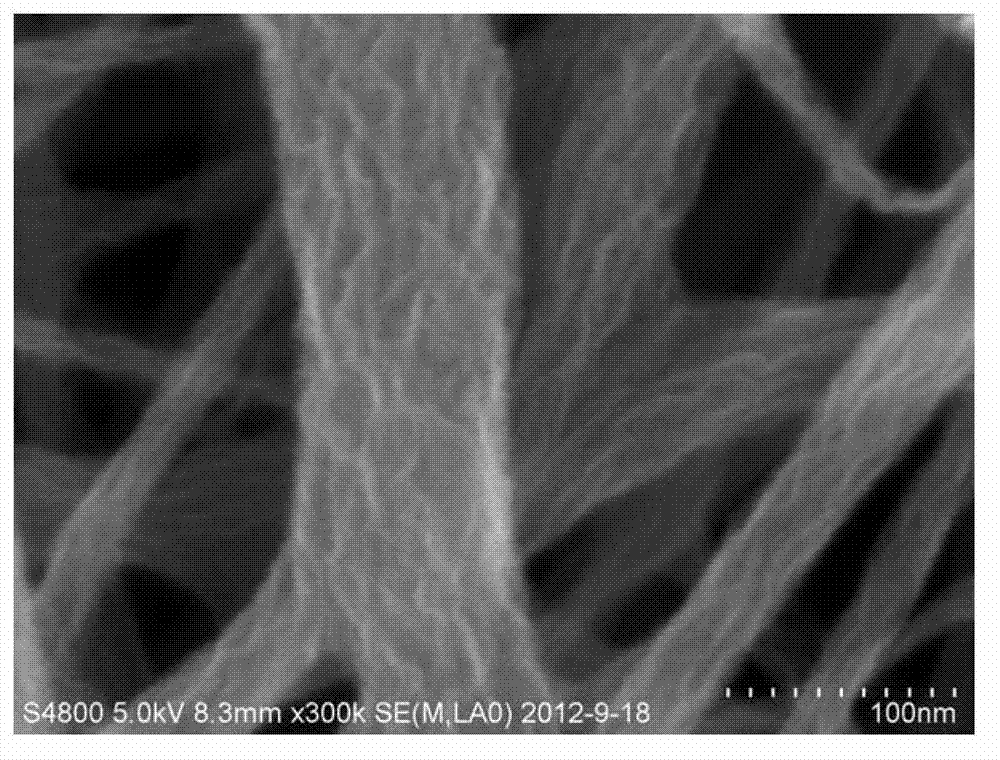

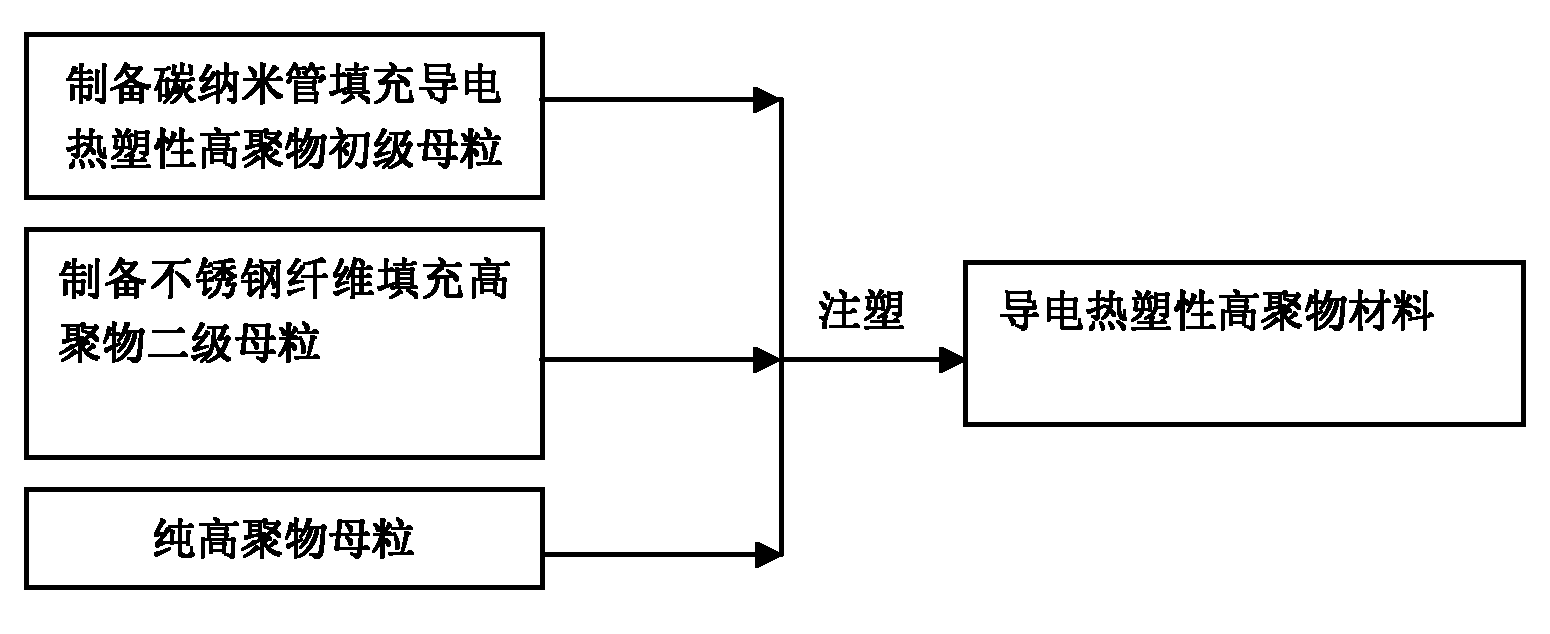

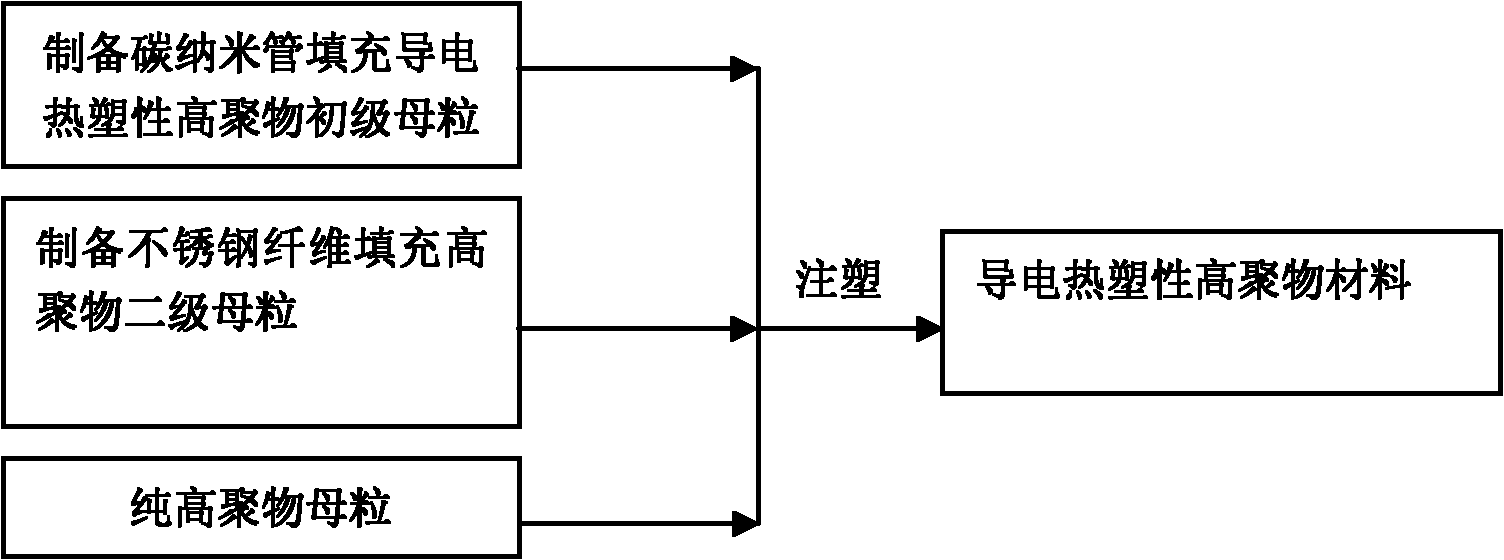

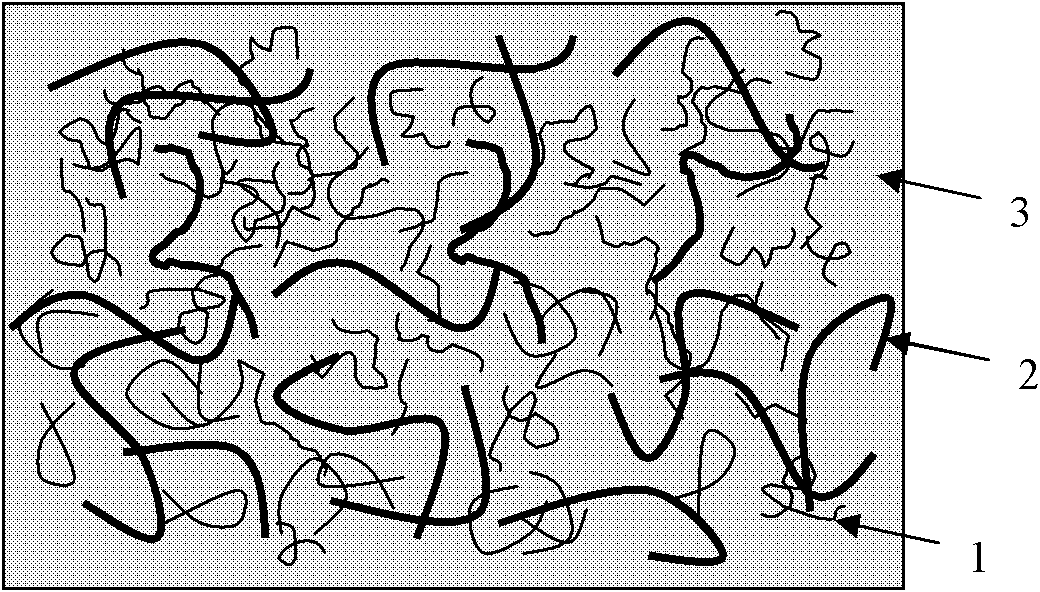

Method for preparing particle-filled conductive thermoplastic polymer

InactiveCN101812239ANo reunionImprove performanceNon-conductive material with dispersed conductive materialExplosion protectionCarbon nanotube

The invention provides a method for preparing a particle-filled conductive thermoplastic polymer, which belongs to the field of electromagnetic shielding material preparation. The method comprises the following steps of: firstly, preparing primary master batch of a carbon nanotube filled conductive thermoplastic polymer; secondly, preparing secondary master batch of a stainless steel fiber filled polymer; and finally, mixing the primary master batch, the secondary master batch and pure polymer master batch and performing co-injection molding on the mixture to obtain the conductive thermoplastic polymer material. The method has the characteristics of simple technical condition, easily controlled process, no residual impurities or reactant, low cost, high yield and convenient batch production. No agglomeration phenomenon occurs in the mixing process of the carbon nanotube primary master batch and the stainless steel fiber secondary master batch, so the composite material has uniformly distributed conductive filler, and the performance of the composite material is greatly improved. The method can be widely applied in the fields of civil and electric consumer products, such as consumer electronics, electrical appliance, communication devices, explosion protection safety products, information transfer and security, anti-static electricity, petrochemical industry and the like.

Owner:PEKING UNIV

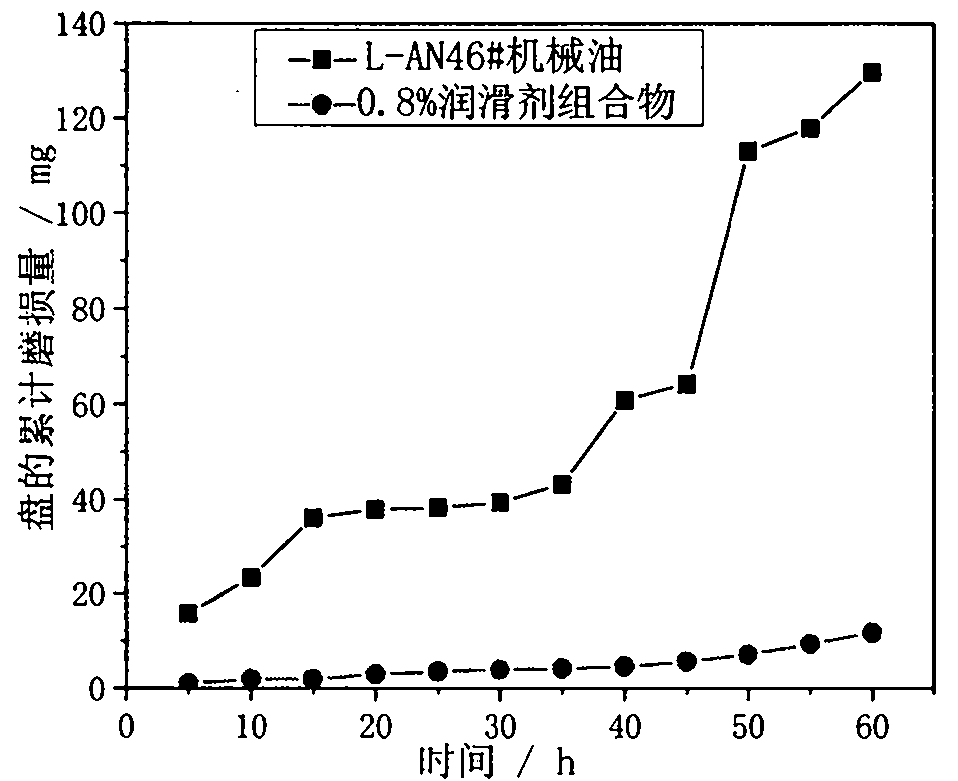

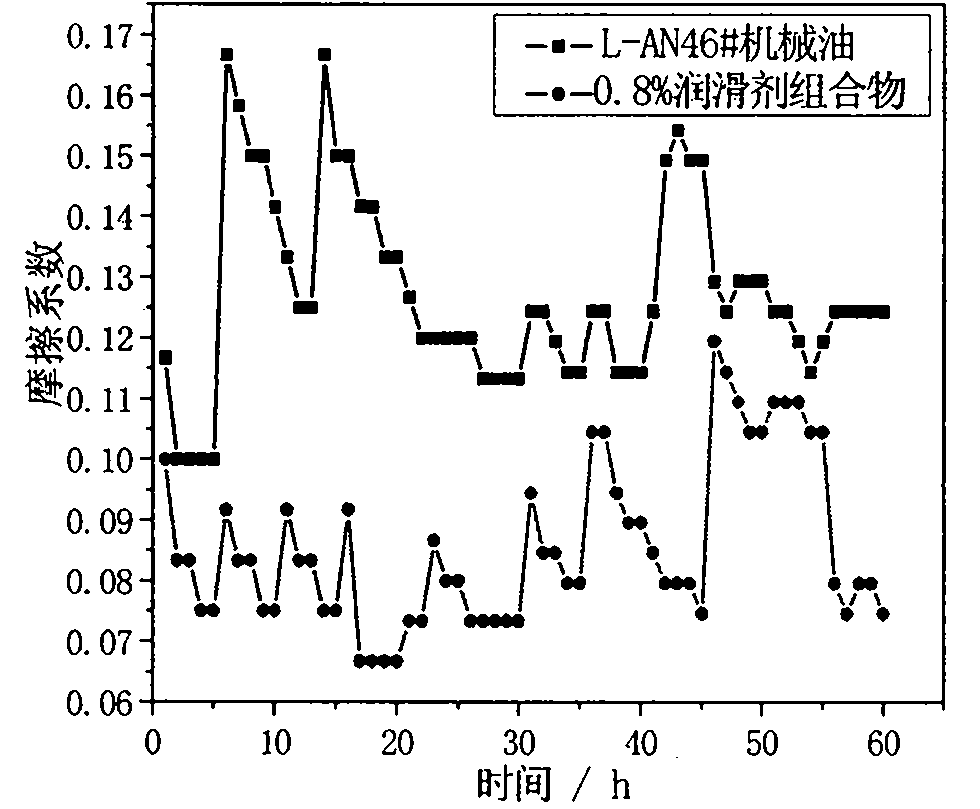

Wear repairing lubricating agent composition containing sheet silicate mineral substances and preparation method thereof

The invention relates to a wear repairing lubricating agent composition containing sheet silicate mineral substances and a preparation method thereof. The lubricating agent composition provided by the invention comprises the following components in percent by mass: 10-20 percent of sheet silicate mineral substances, 0.1-5 percent of surface modifying agent, 0.1-5 percent of metal catalytic object, 1-10 percent of performance regulating agent composition and 70-80 percent of base lubricating agent. The preparation method comprises the steps of: mixing and grinding the sheet silicate mineral substances according to the proportion, preferably, sheet silicate mineral substances with granularity D90 of not more than 3mu m; and then adding in a base lubricating agent prepared from a surfactant, the metal catalytic object and the performance regulating agent in different proportions, and grinding. The using method is as follows: 0.2-1 wt percent of the wear repairing lubricating agent composition is added in the traditional lubricating agent system of equipment. The lubricating agent composition provided by the invention has better self-repairing effect and remarkable energy-saving and consumption-reducing effect; and due to a repairing layer formed on the surface through friction, the hardness of a matrix is improved, and the roughness is lowered.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Nano-silver sol antibacterial agent and preparation method thereof

The invention discloses a nano-silver sol antibacterial agent and a preparation method thereof. The preparation method includes the steps: dissolving silver nitrate in water, adding ammonia water, adjusting pH (potential of hydrogen) to be 10+ / -0.5 and adjusting the concentration of Ag+ to range from 0.006mol / l to 0.1mol / l to prepare silver ammonium solution; dissolving a reducing agent and a protective agent in the water to obtain reducing agent and protective agent solution; and slowly adding the reducing agent and protective agent solution into the silver ammonium solution according to the volume ratio of 1:1-5 of the reducing agent and protective agent solution to the silver ammonium solution when the silver ammonium solution is at 20-40 DEG C and 100-200rpm, performing ultrasonic operation for mixed solution for 5-20min under the condition of ice-bath after mixed reaction, and finally filtering the mixed solution to obtain colorless and transparent nano-silver sol antibacterial agent. In the silver ammonium solution, the quantity relative ratio of n (the reducing agent) to n (Ag+) is 1-5:1, the mass ratio of the n (the reducing agent to m (the protective agent) is 1-2:1, and output power is 150-200w. The nano-silver sol antibacterial agent can avoid agglomeration of nano-silver particles in long-term storage and use process.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

Method for grafting environment response macromolecule on nano silicon dioxde surface

The present invention relates to a preparation method for organic-inorganic hybrid materials through grafting polymerization-environment responsive macromolecules on the nanometer silicon dioxide surface, belonging to the organic-inorganic hybrid materials synthesis and preparation field. The present invention takes advantage of the action of silicon dioxide with hydroxyl on the surface with the silane coupling agent 3-amino-propyl silane to enable the end to be of an amino group; then the product reacts with the nanometer particle generated from the bromination propionyl bromine reaction; The end of the nanometer particle is the ATRP initiator; finally, the polymerization of the environmentally-responsive macromolecules on the nanometer silicon dioxide surface is initiated in the present of CuBr and PMDETA so as to obtain the target product. The graft rate of the silicon dioxide virgule environmentally-responsive macromolecule core-shell structure nanometer hybrid particles is 60 percent to 70 percent. No reunion of the nanometer hybrid particles appears. The nanometer hybrid particles are uniformly dispersed with environmental responsiveness.

Owner:TSINGHUA UNIV

Preparation method for nanoscale transition metal nitride/carbon composite material

ActiveCN102139920AUniform particlesNo reunionNitrogen compoundsTitanium compoundsCarbon compositesFiltration

The invention relates to a preparation method for nanoscale transition metal nitride / carbon composite material, the chemical formula of nanoscale transition metal nitride / carbon composite material is MeN / C (Me is one or a mixture of more of organic compounds such as titanium, vanadium, chromium, nickel, manganese, molybdenum and the like; N and C are respectively nitrogen and carbon); the anoscale transition metal nitride / carbon composite material is obtained by the following methods: a tri-block copolymer P123 of PEO-PPO-PEO is taken as a template, the tri-block copolymer P123 and the urea resin, melamine resin or carbon nitride polymer are mixed and heated so as to obtain mesoporous carbon nitride, then the mesoporous carbon nitride is added into a metal organic compound or an ethanol solution of various mixtures of the metal organic compound, the removal of air in holes by decompression after ultrasonic vibration is carried out on the mixture, and finally the nanoscale transition metal nitride / carbon composite is obtained after the mixture undergoes ethanol pumping filtration, is scrubbed, dried and processed at high temperature under the protection of inert gas; and the product is uniform and is environmental friendly.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparation method of pegylation modified hyperbranched poly(ethylene imine) coated nano-gold particles

InactiveCN103239738AEasy to prepareMild reaction conditionsX-ray constrast preparationsGranular deliveryAcetic anhydrideFreeze-drying

The invention relates to a preparation method of pegylation modified hyperbranched poly(ethylene imine) (PEI) coated nano-gold particles, which comprises the following steps: modifying PEI by using mPEG (polyethylene glycol)-COOH, and sequentially carrying out dialysis and freeze-drying on the obtained product so as to obtain PEI-mPEG; taking the solid, dissolving the solid by using water, adding a HAuCl4 solution into the dissolved solid, stirring the obtained product, adding a NaBH4 solution into the obtained product, and carrying out reaction on the obtained mixture at room temperature; and adding triethylamine and acetic anhydride into the obtained object, and after the reaction is completed, carrying out dialysis and freezing on the obtained product so as to obtain pegylation modified hyperbranched polymine coated nano-gold particles. According to the invention, the cheap and easily-obtained PEI is taken as a carrier, so that the cost of materials is reduced; the surface of PEI is modified by using mPEG-COOH, so that the biocompatibility of materials and the colloidal stability of nano-gold particles are improved, and the nano-gold particles are successfully applied to vivo CT (computed tomography) imaging. The method disclosed by the invention is simple in design, mild in reaction conditions and easy to operate, and has an industrialized implementation prospect.

Owner:DONGHUA UNIV +1

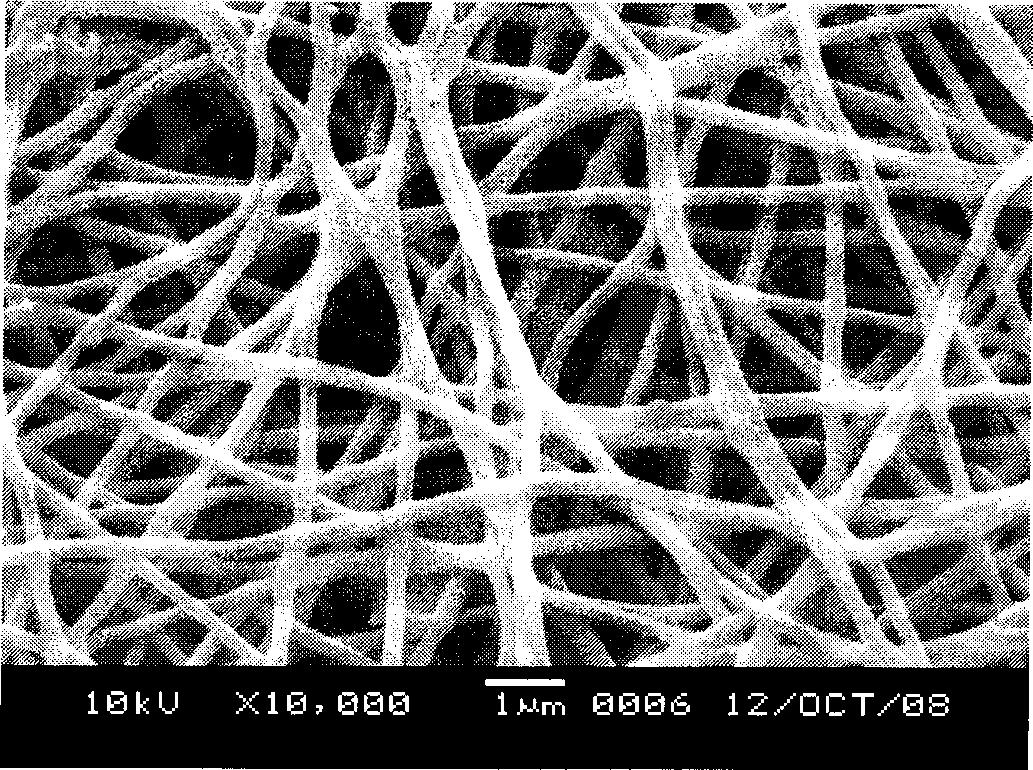

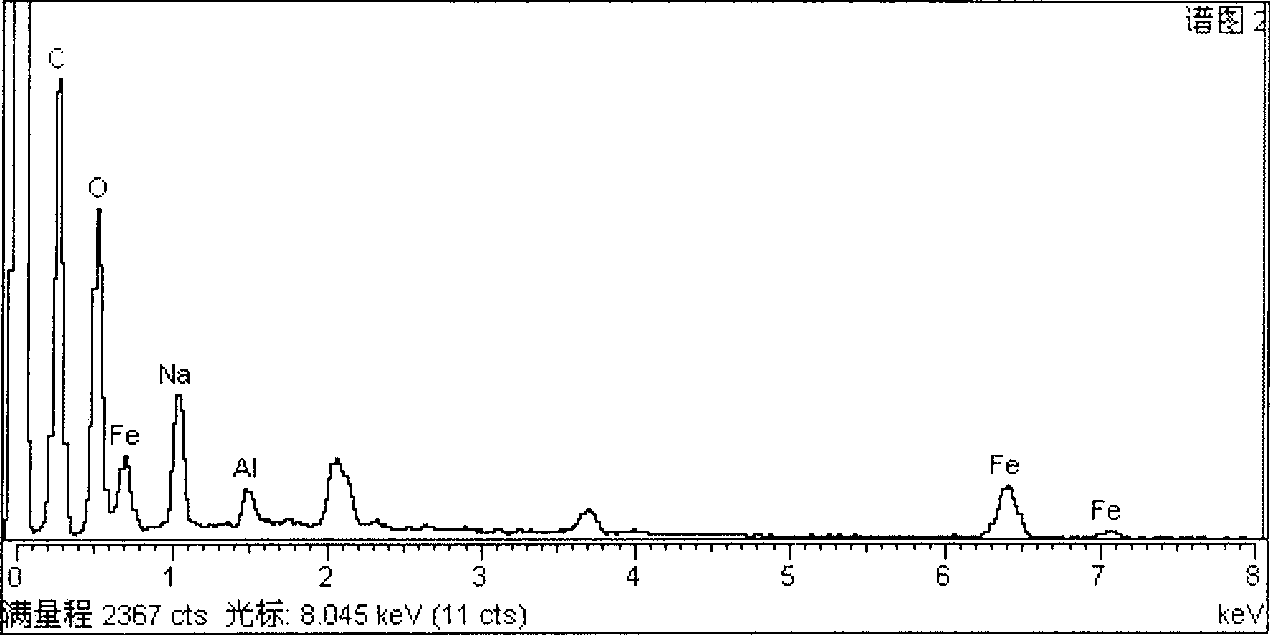

In-situ preparation method for functional nullvalent nano-iron/polyelectrolyte composite fibrofelt

InactiveCN101445291AEvenly dispersedEffectively fixedWater/sewage treatment by sorptionWater/sewage treatment by reductionFiberIron salts

The invention relates to an in-situ preparation method for a functional nullvalent nanometer iron / polyelectrolyte composite fibrofelt. The method comprises the following steps: (1) preparing polyelectrolyte mixed solution with concentration between 7 and 12 percent by polyacrylic acid PAA, and preparing a nanometer fibrofelt according to a principle of electrostatic spinning; (2) carrying out heat treatment on the nanometer fibrofelt to prepare a water-fast polyelectrolyte fibrofelt; (3) preparing soluble iron salt solution, and preparing reducing agent solution with concentration 4 to 6 times of the iron salt solution; (4) dipping the (2) in the iron salt solution; (5) rinsing; (6) dripping the reducing agent solution onto the complex iron ion fibrofelt; (7) rinsing by deionized water; (8) drying and storing. In the fibrofelt prepared by the method, nanometer iron particles are dispersed evenly without aggregation phenomenon, and the fibrofelt can effectively fix nanometer iron particles, thereby ensuring effective recycle of the nanometer iron particles in practical application without secondary pollution.

Owner:DONGHUA UNIV

Preparation method of high-dispersion nano-zirconia powder

InactiveCN109574073ANarrow particle size distributionGood dispersionZirconium oxidesFiltrationSpherical shaped

The invention belongs to the technical field of ceramic powder preparation, and particularly relates to a preparation method of high-dispersion nano-zirconia powder. According to the method, doped yttrium metal modification, preparation of a precursor by a co-precipitation method and hydrothermal crystallization are combined to obtain the high-purity and high-dispersion nano-zirconia powder, impurity ions in the precursor are removed by an ultra-filtration composite membrane technique, crystal form control and particle dispersion functions of a mineralizer are more effectively achieved in hydrothermal reaction, the concentration of the nano-zirconia powder in the precursor is improved, and high-purity and high-yield nano-powder is prepared. The nano-zirconia powder with stable yttrium prepared by the method has a spherical particle shape, is narrow in particle size distribution, good in dispersibility, high in purity, free from aggregation and the like and can be widely applied to high-end biological ceramic materials, and the method solves the problem of brittleness of a current zirconia material in the transition process of crystal forms, so that zirconia ceramics are flexibly and widely applied.

Owner:上海上惠纳米科技有限公司

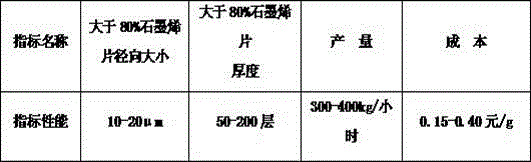

Method for preparing graphene micro-sheets by using counter-jet jet mill

The invention relates to the field of graphene materials, particularly relates to preparation methods for graphene micro-sheets and particularly relates to a method for preparing the graphene micro-sheets by using a counter-jet jet mill. According to the method, the graphene sheets are obtained through enabling melted ferric chloride and potassium chloride to enter an interlayer of graphite, enabling the powder materials to be in collision through high-speed airflow in the counter-jet jet mill by using the characteristic of brittleness of ferric chloride and potassium chloride crystal grains and the characteristics of good fluidity and difficulty in agglomeration of talcum powder, delaminating the graphite and the talcum powder by generated impact force, shearing force and frictional force, carrying out further separation by a grading room, refluxing unqualified powder material to a crushing chamber, and yielding delaminated graphite and talcum powder as well as gas together. The continuous and large-scale production of the graphene micro-sheets, which are uniform in layer number dispersion and good in fluidity and are not prone to agglomeration, is achieved, the yield is high, the cost is low, no pollution is caused, and the layer thickness meets the requirements of use in the fields of rubber reinforcing, plastic reinforcing, coating material anticorrosion, lubrication and sewage treatment, so that the promotion of the large-scale application of graphene is facilitated.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

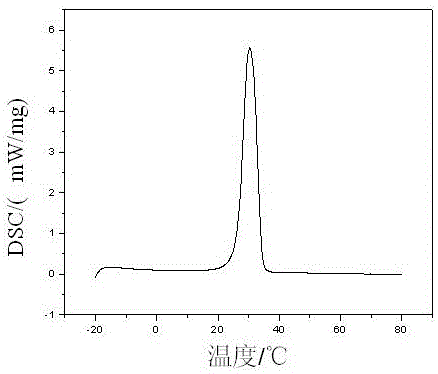

Dual-shell phase change stored energy micro-capsule and preparation method thereof

InactiveCN106479445ALow costUniform particle sizeHeat-exchange elementsMicroballoon preparationPrepolymerDiamine

The invention discloses a dual-shell phase change stored energy micro-capsule and a preparation method thereof. The method includes steps of heating and dissolving alkane to core solution, and then adding core solution to solution of cyanate ester and anionic emulsifier; after ultrasonic emulsification, dropwise adding diamine and forming micro-capsule water solution packed by polyuria; mixing and stirring a certain matching ratio of methyl methacrylate, butyl acrylate, compound emulsifier and de-ionized water to form prepolymer; and then adding the prepolymer to the micro-capsule water solution packed by polyurial; stirring and heating for a certain time, cooling; and then filtering and washing by a Buchner funnel; at last, vacuum-drying and obtaining the dual-shell phase change stored energy micro-capsule. The prepared n-alkane core material is completely packed by diamine and multifunctional cyanate ester used as an inner shell and polyacrylic resin used as an outer shell; the formed micro-capsule is free from poison, uniform in grain diameter, smooth in surface, and free from agglomeration.

Owner:SOUTH CHINA UNIV OF TECH

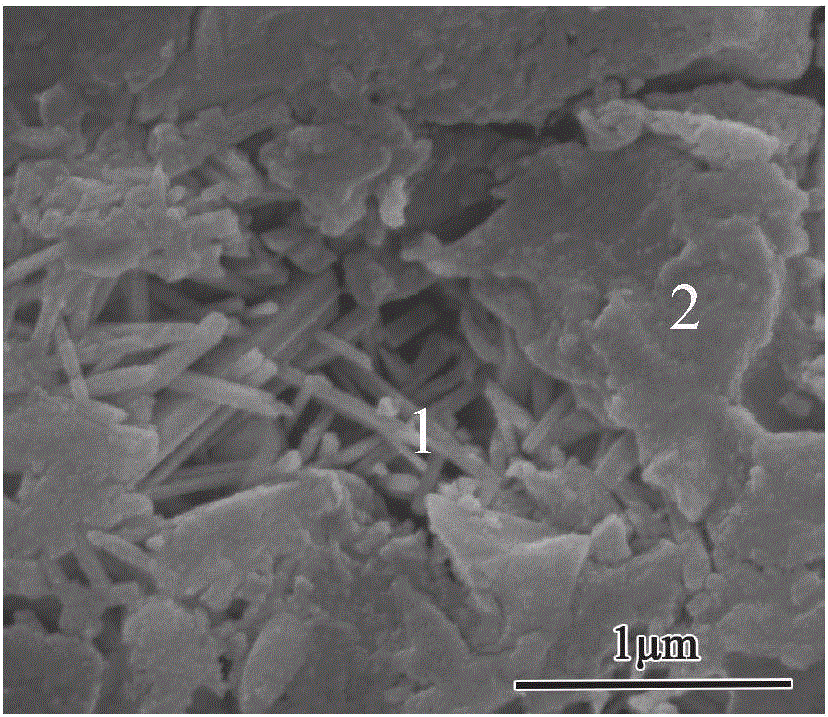

Method for in-situ synthesizing mullite whisker self-toughened mullite ceramics

The invention discloses a method for in-situ synthesizing mullite whisker self-toughened mullite ceramics. The method comprises the following steps: mixing 55-70 parts by weight of aluminum oxide, 20-30 parts by weight of silicon dioxide, 5-18 parts by weight of mullite whisker seed crystal, and 2-5 parts by weight of aluminum fluoride in a manner of wet grinding; pouring and curing to obtain a green body; sintering the green body at the temperature of 500 to 600 DEG C for the first time; sintering at the temperature of 900 to 1000 DEG C for the second time; sintering at the temperature of 1350-1550 DEG C for the third time so as to obtain the mullite ceramics. In addition, the invention also discloses the mullite ceramics prepared by the abovementioned method. According to the method, the raw materials, namely, aluminum oxide and silicon dioxide based on the ratio, conduct reaction under the synergistic effect of mullite whisker seed crystal and aluminum fluoride in parts by weight through the sectional sintering technology under the abovementioned temperature to obtain the high-toughness in-situ self-growth mullite whisker mullite ceramics; the high-activity seed crystal is added, so that the in-site uniform and dispersed distribution of the mullite whiskers in a substance can be realized, and thus the toughness of the ceramics can be effectively improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com