In-situ preparation method for functional nullvalent nano-iron/polyelectrolyte composite fibrofelt

A technology of zero-valent nano-iron and composite fiber felt, which is applied in the direction of reduced water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of no discovery, preparation and fixation of zero-valent nano-iron particles, and achieve easy operation and preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 is a control experiment of the present invention, without in-situ synthesis of zero-valent nano-iron particles by electrospinning polyacrylic acid-containing nanofibers.

[0049] Example 1

[0050] Take 2.43261 grams of FeCl 3 ·6H 2 O, dissolved in deionized water, magnetically stirred to make it fully mixed, and configured as a transparent brown-yellow Fe with a concentration of 0.18mol / L 3+ Saline solution 50mL. Take 1.77801 g NaBH 4 , dissolved in deionized water, stirred for several minutes with a glass rod, and made into 50ml of a 0.94mol / L solution. Take 50mlNaBH 4 The solution was added dropwise to a container filled with 50ml Fe 3+ Put the solution in the beaker of the salt solution, and stir it magnetically at the same time, and stop stirring after the solution turns black. After the black substance quickly settles to the bottom of the cup, remove the supernatant in the beaker, add a large amount of deionized water to wash, and then remove the ...

Embodiment 2

[0052] Take 3 grams of polyvinyl alcohol (PVA) in a beaker, use deionized water as a solvent, place on a magnetic stirrer and stir for 3 hours at a temperature of 80° C. to form a 10% aqueous solution, and cool it for use. Weigh a certain concentration of 25% polyacrylic acid (PAA) aqueous solution and the prepared PVA solution to form a 12mL mixed solution with a total concentration of 8% of the two polymers, wherein the weight ratio of PAA / PVA is 1:1. The spinning process conditions are set as follows: the receiving distance is 20cm, the voltage is 16.6kV, and the flow rate is 0.5mL / h. The prepared nanofibers were finally deposited on aluminum foil in the form of fiber mats. After the fiber mat is dried naturally in the air, it is stored in a desiccator.

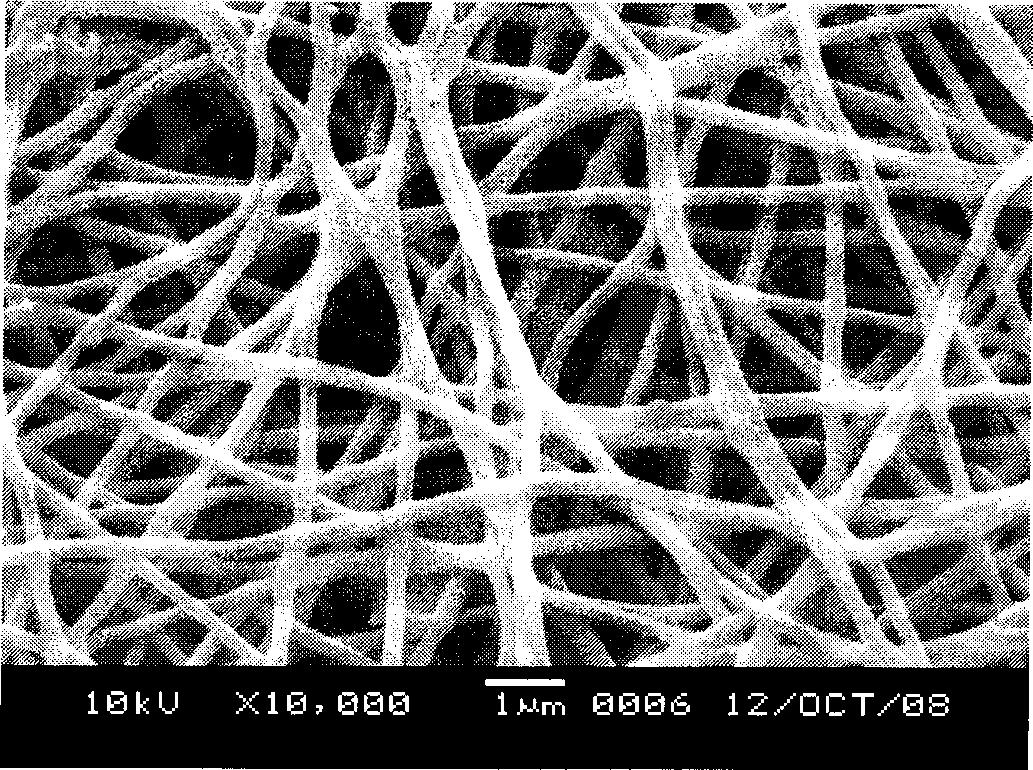

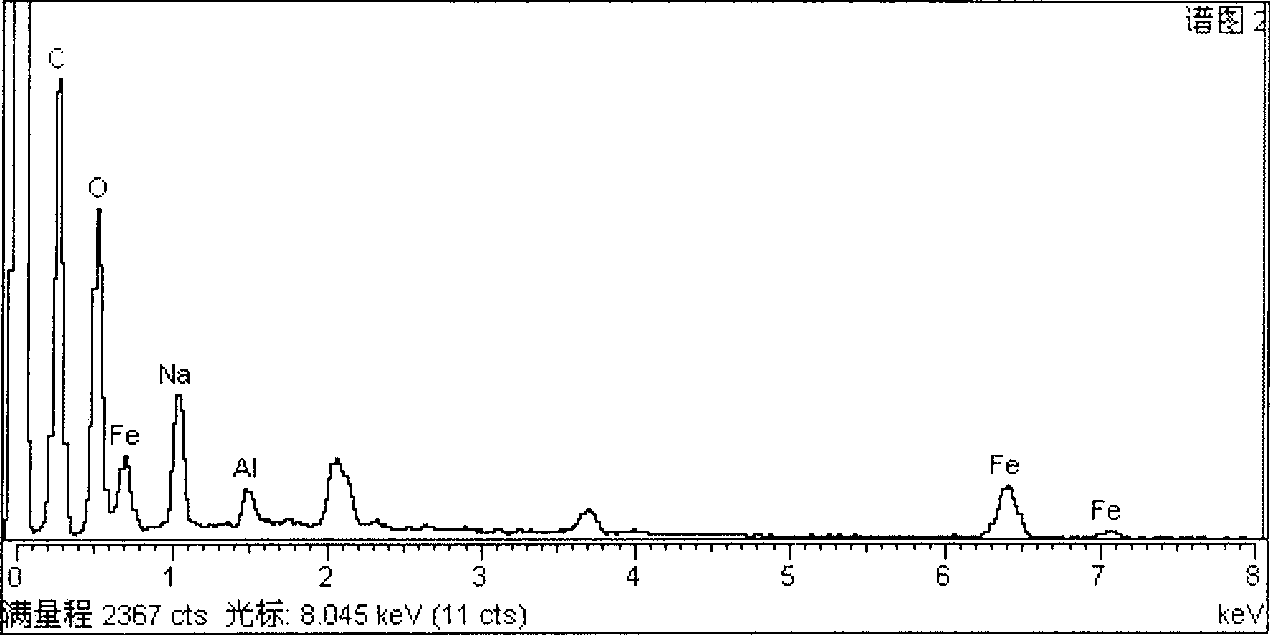

[0053] SEM test results show that the diameter of the nanofibers is distributed between 100 and 400nm, the thickness is uneven, and there are a certain amount of beads, some fibers are flat ribbons, the surface of the fib...

Embodiment 3

[0055] Take 3 grams of polyvinyl alcohol (PVA) in a beaker, use deionized water as a solvent, place on a magnetic stirrer and stir for 3 hours at a temperature of 80° C. to form a 10% aqueous solution, and cool it for use. Weigh a certain concentration of 25% polyacrylic acid (PAA) aqueous solution and the prepared PVA solution to form a 12mL mixed solution with a total concentration of 10%, wherein the weight ratio of PAA / PVA is 1:1. The spinning process conditions are set as follows: the receiving distance is 20cm, the voltage is 16.6kV, and the flow rate is 0.5mL / h. The prepared nanofibers are finally deposited on aluminum foil in the form of fiber mats, and the fiber mats are naturally dried in the air and stored in a desiccator.

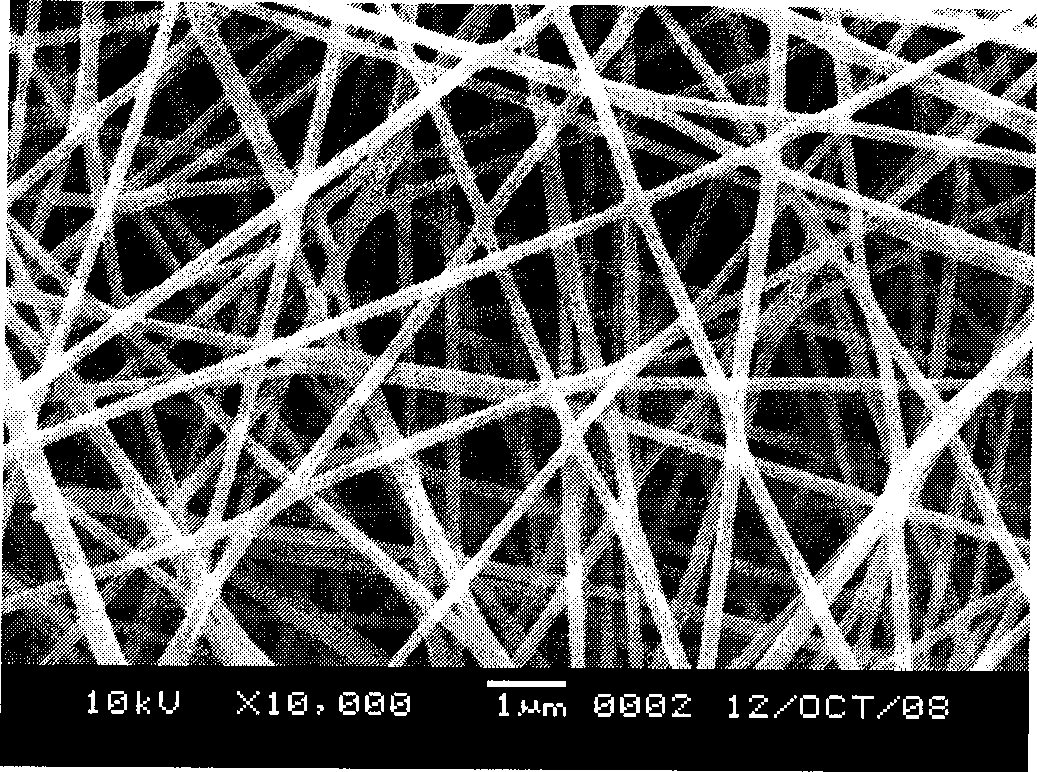

[0056] The test result of SEM shows that the diameter of nanofibers is mainly concentrated in 100-200nm, and the average diameter is 205nm. There are a few fibers with larger diameters, the single fiber is uniform in thickness, there is basical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com