Patents

Literature

1489 results about "Desiccator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desiccators are sealable enclosures containing desiccants used for preserving moisture-sensitive items such as cobalt chloride paper for another use. A common use for desiccators is to protect chemicals which are hygroscopic or which react with water from humidity.

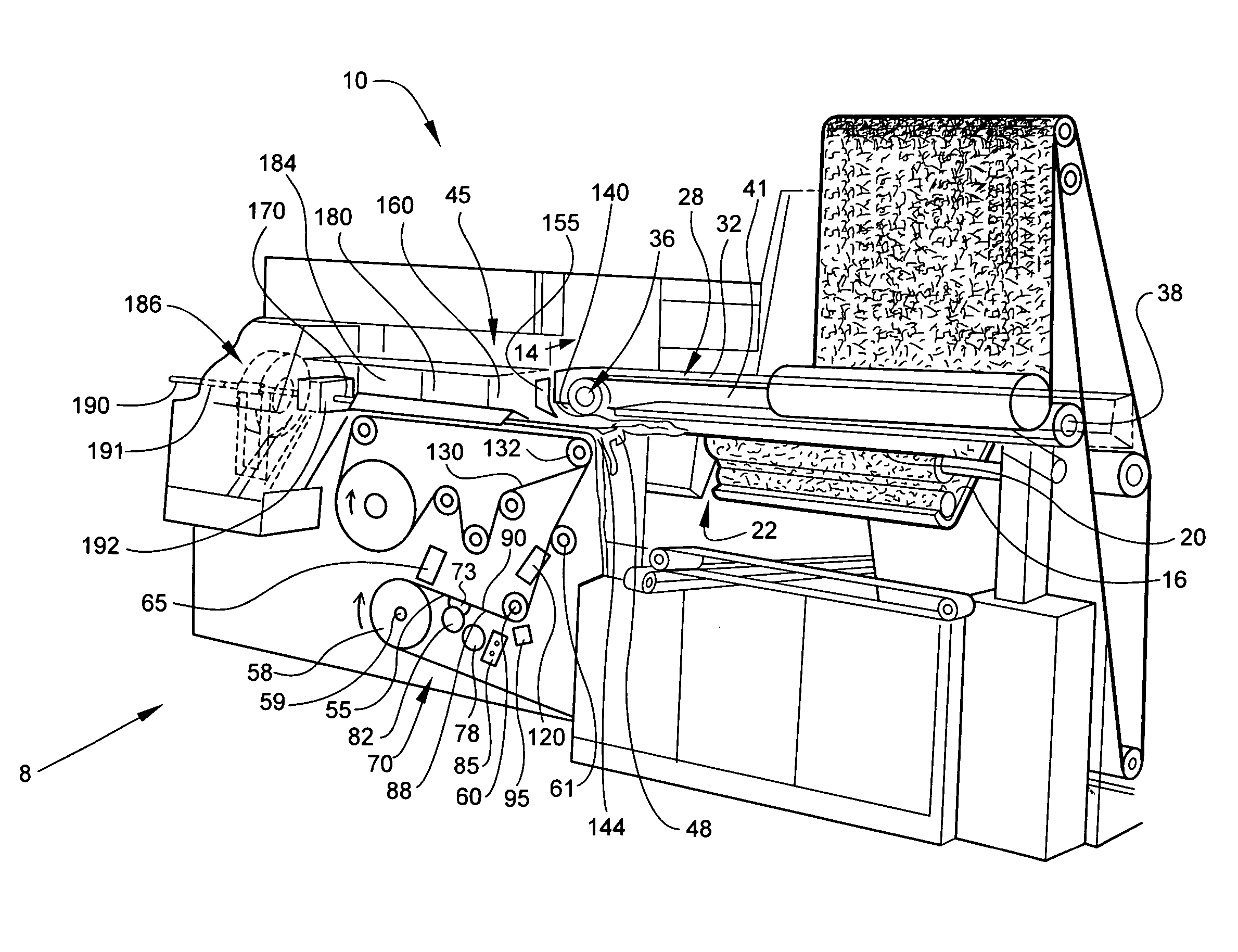

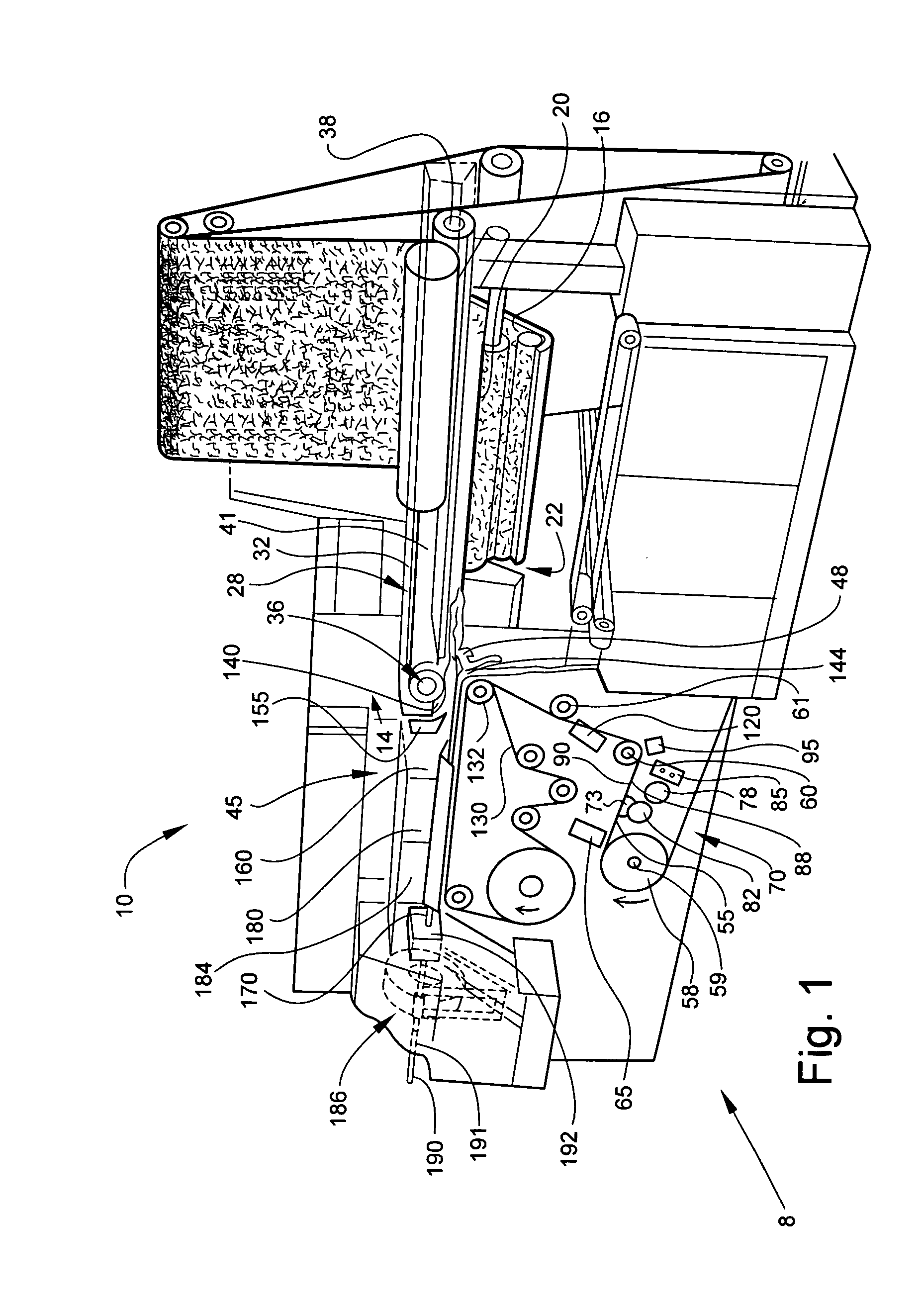

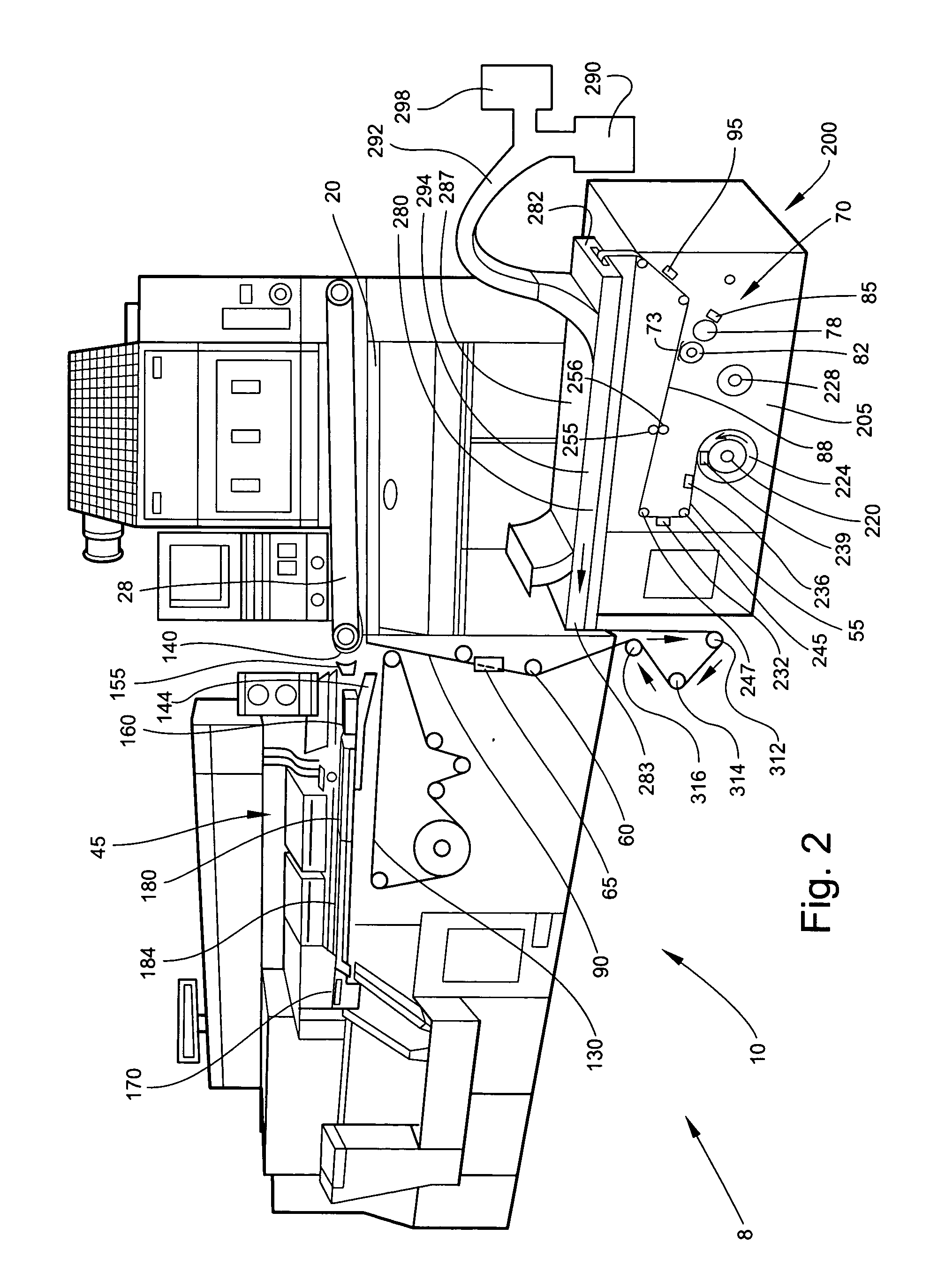

Equipment and methods for manufacturing cigarettes

ActiveUS20050039764A1Easy transferConsistent flowCigar manufactureCigarette manufactureMechanical engineeringIndustrial engineering

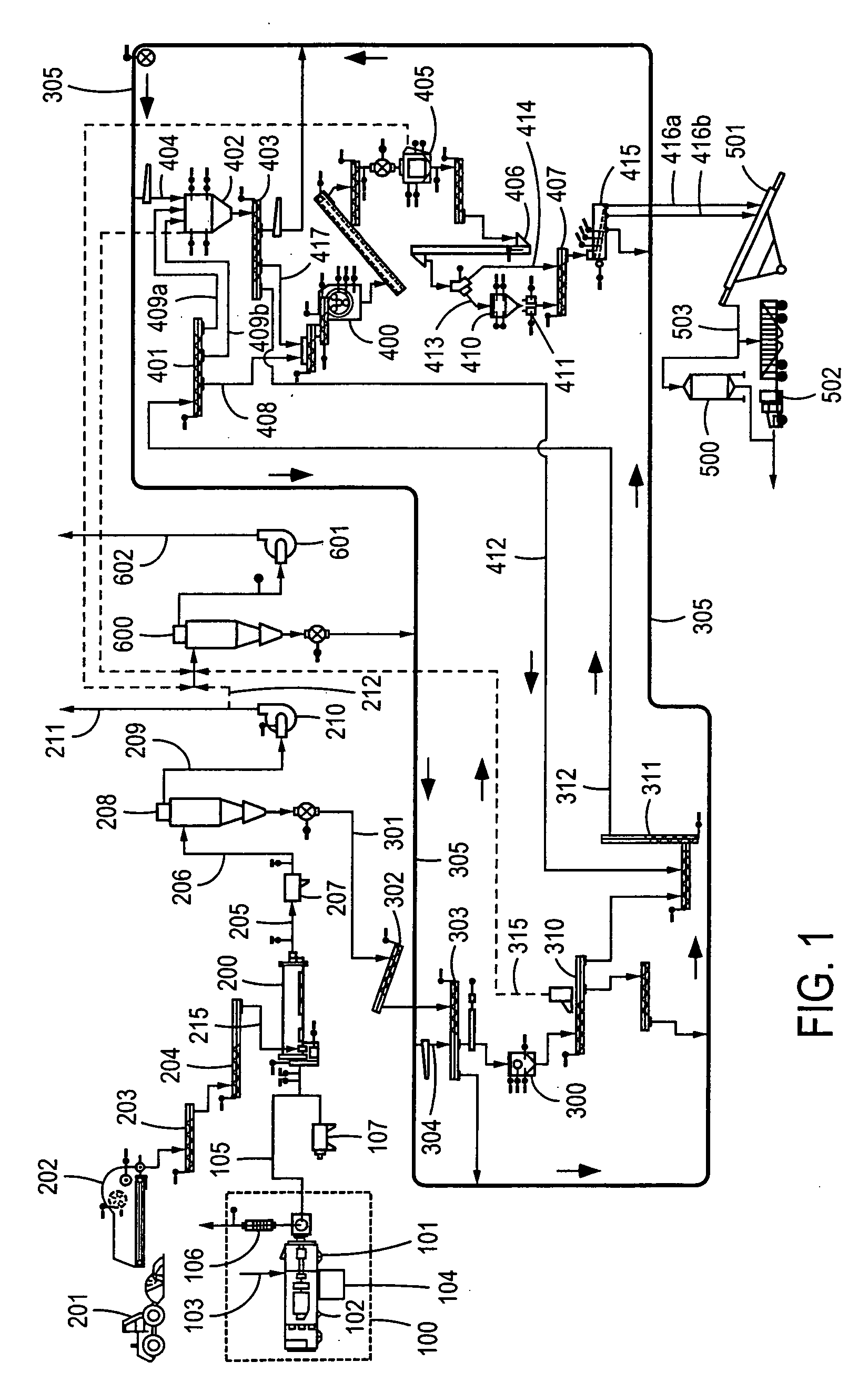

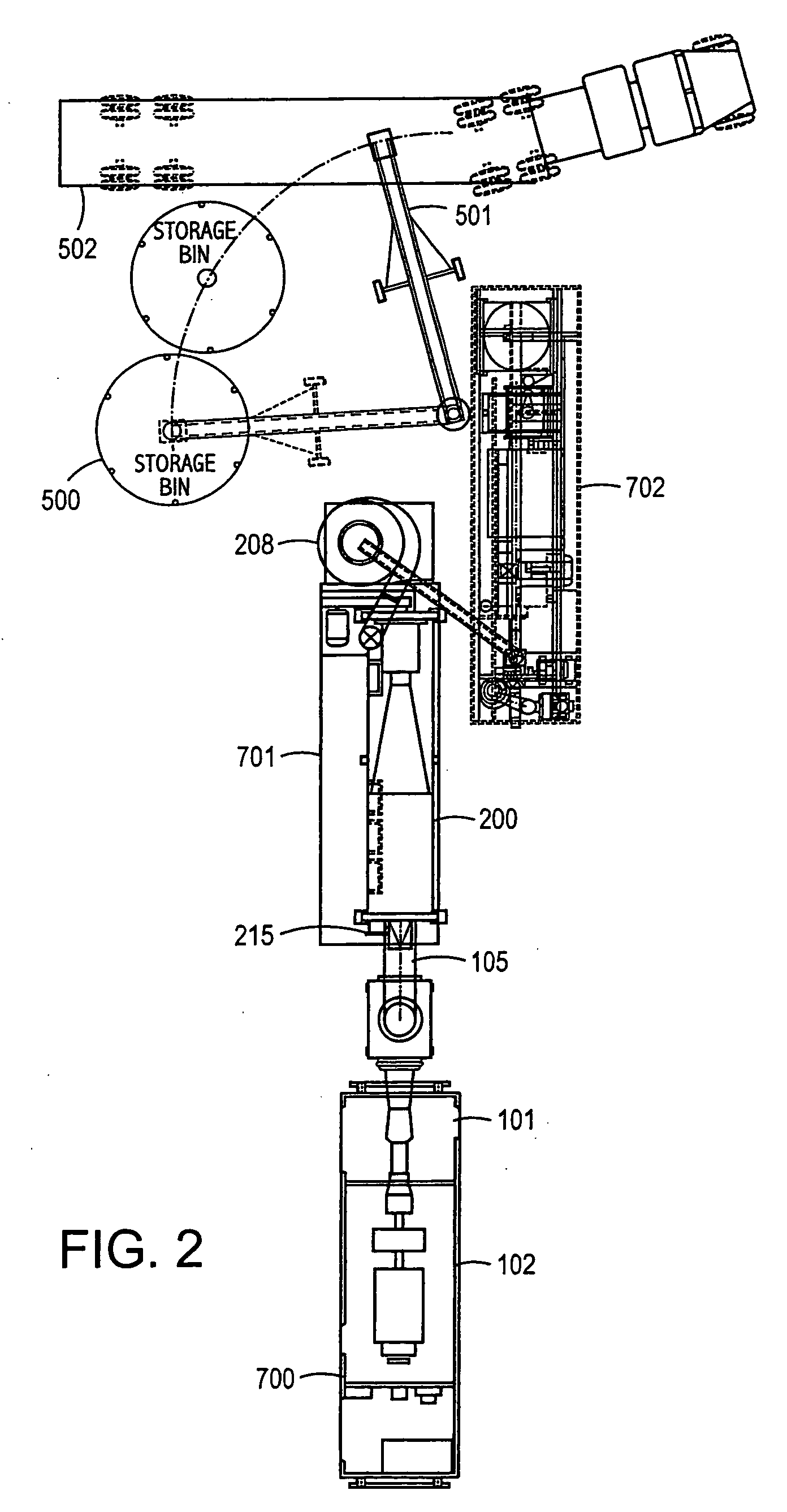

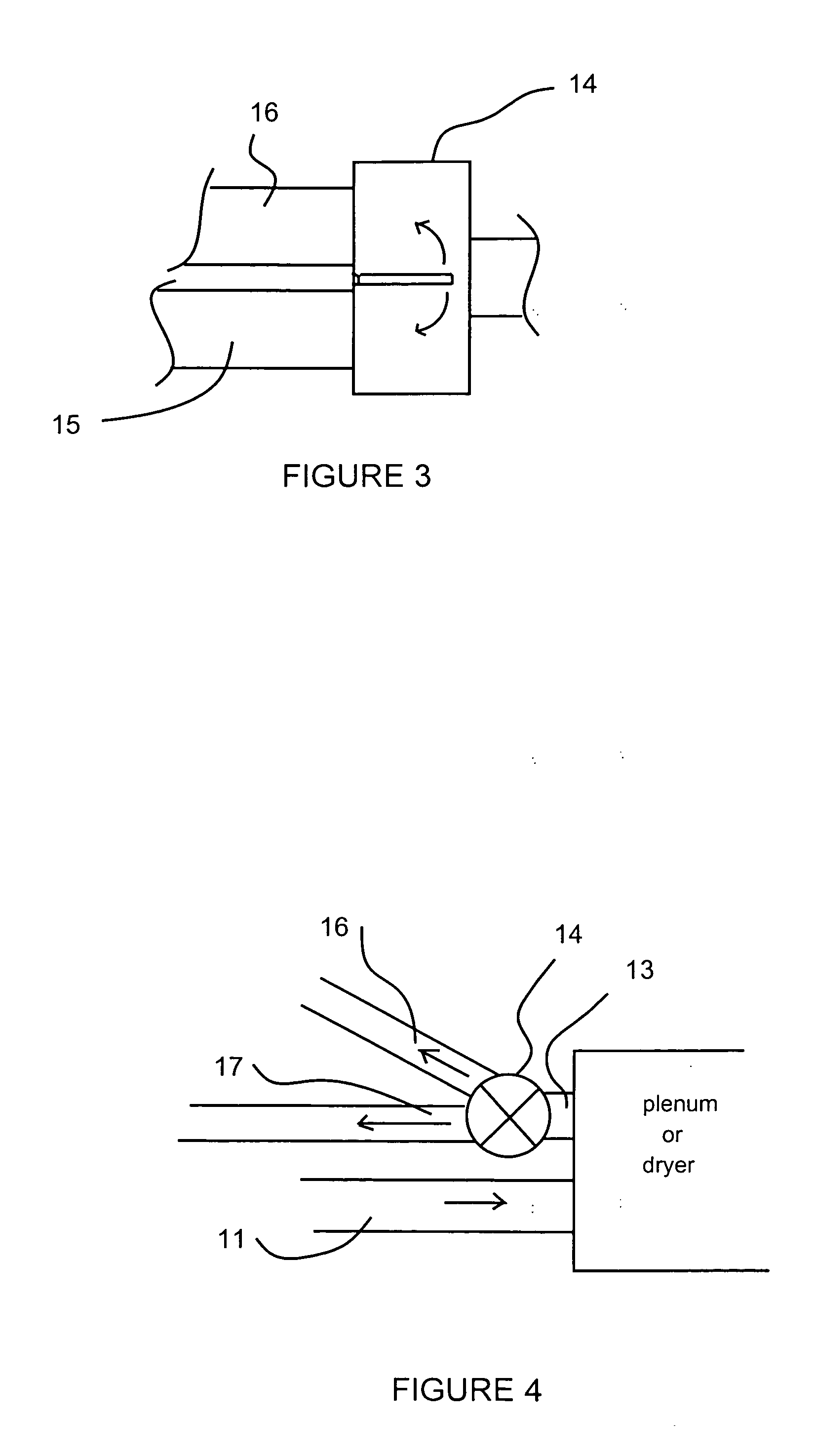

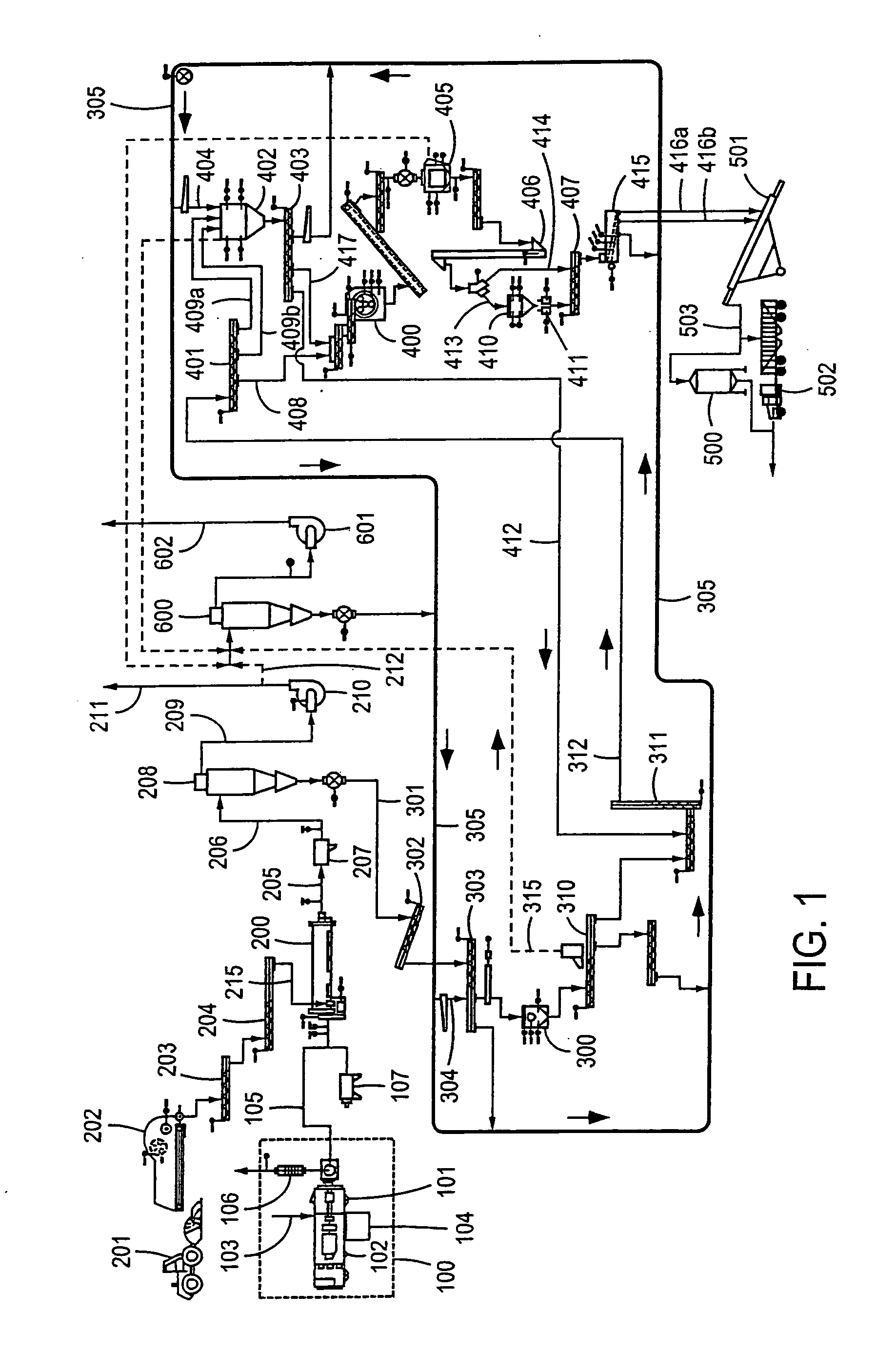

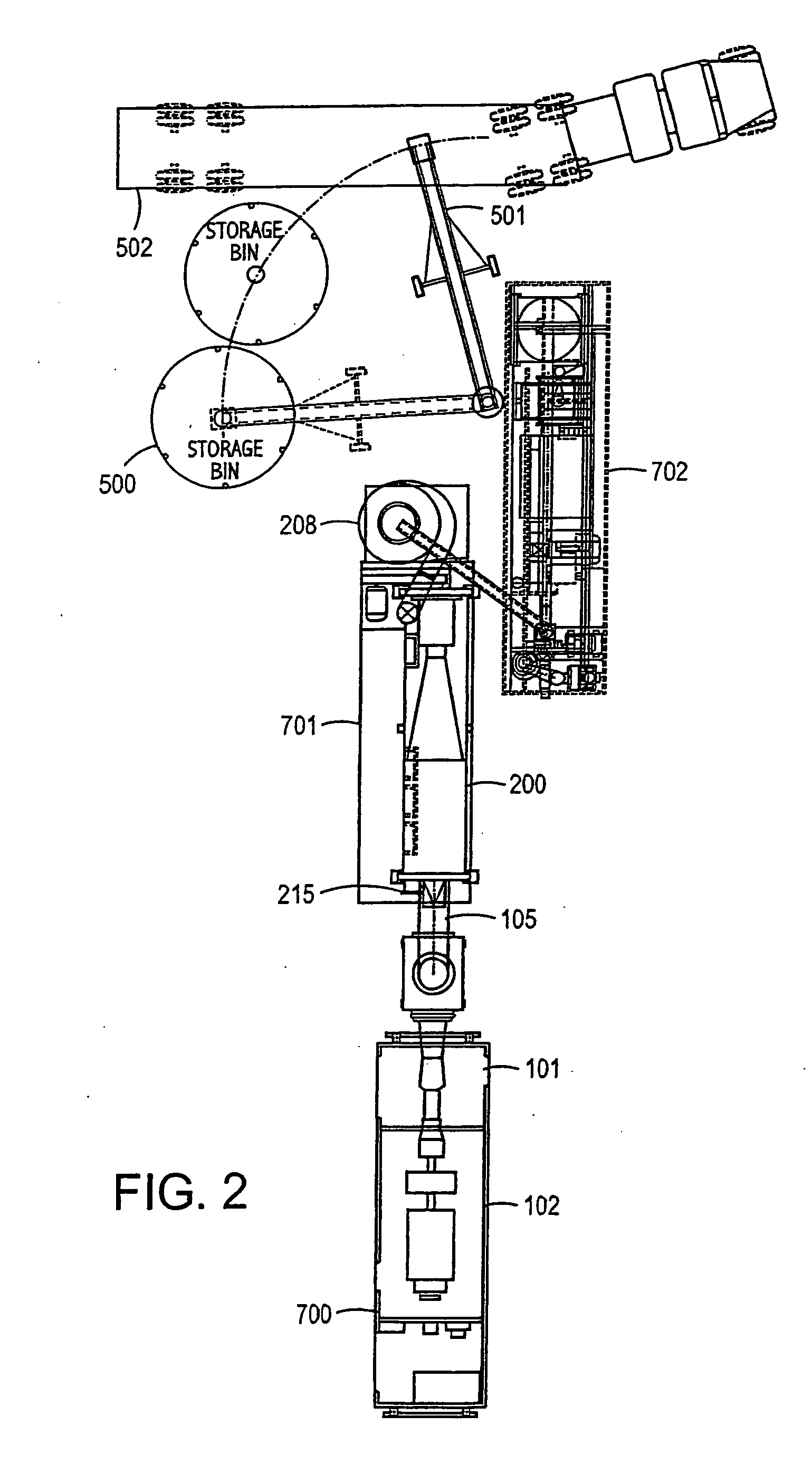

Cigarettes are manufactured using modified automated cigarette making apparatus. Those cigarettes possess smokable rods having paper wrapping materials having additive materials applied thereto as patterns. The additive materials, which can have the forms of liquid or paste formulations (e.g., aqueous formulations incorporating starch or modified starch), are applied to a continuous paper web on the cigarette making apparatus. The formulation is applied to the paper web using application apparatus possessing rollers, and one of those rollers has a series of pockets in its roll face to receive additive formulation from a reservoir and to define the pattern of the formulation on the paper. For example, additive material located in the recessed pockets of a first roller is transferred in a controlled manner to the roll face of a second roller in roll contact with that first roller; and the additive material on the roll face of the second roller is transferred to desired locations on the surface of the paper web. The formulation also can be applied to a continuous moving paper web using an application apparatus possessing four rollers. For example, additive material is applied to the roll face of a transfer roller due to roll interaction of that transfer roller with a pick-up roller; roll interaction of the transfer roller with an application roller causes transfer of the additive material from the transfer roller to the application roller; and additive material from the application roller is transferred to the paper web that passes between the application roller and a back-up roller. A radiant dryer is used to dry the additive material that has been applied to the paper web. The radiant dryer is located on one component of a two component assembly that is used to manufacture cigarettes. A first component of the two component assembly provides a source of paper web, applies additive material to that web in a pattern and dries the paper web; while a second component receives the paper web, supplies tobacco filler and manufactures a cigarette rod from the paper web and tobacco filler. Spectrometric techniques are used to ensure proper registration of the additive material on the cigarette rods so manufactured, and to ensure proper quality of those cigarettes.

Owner:R J REYNOLDS TOBACCO COMPANY

Process and system for drying and heat treating materials

InactiveUS20060010714A1Drying solid materials with heatExcrement fertilisersEngineeringProcess engineering

This invention discloses systems and methods for conversion of high moisture waste materials to dry or low moisture products for recycle or reuse. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel and wherein the processing unit forms the dried material from the dryer vessel into granules, pellets or other desired form for the final product. Optionally, the systems and methods further provide for processing ventilation air from manufacturing facilities to reduce emissions therefrom.

Owner:EARTHRENEW INC

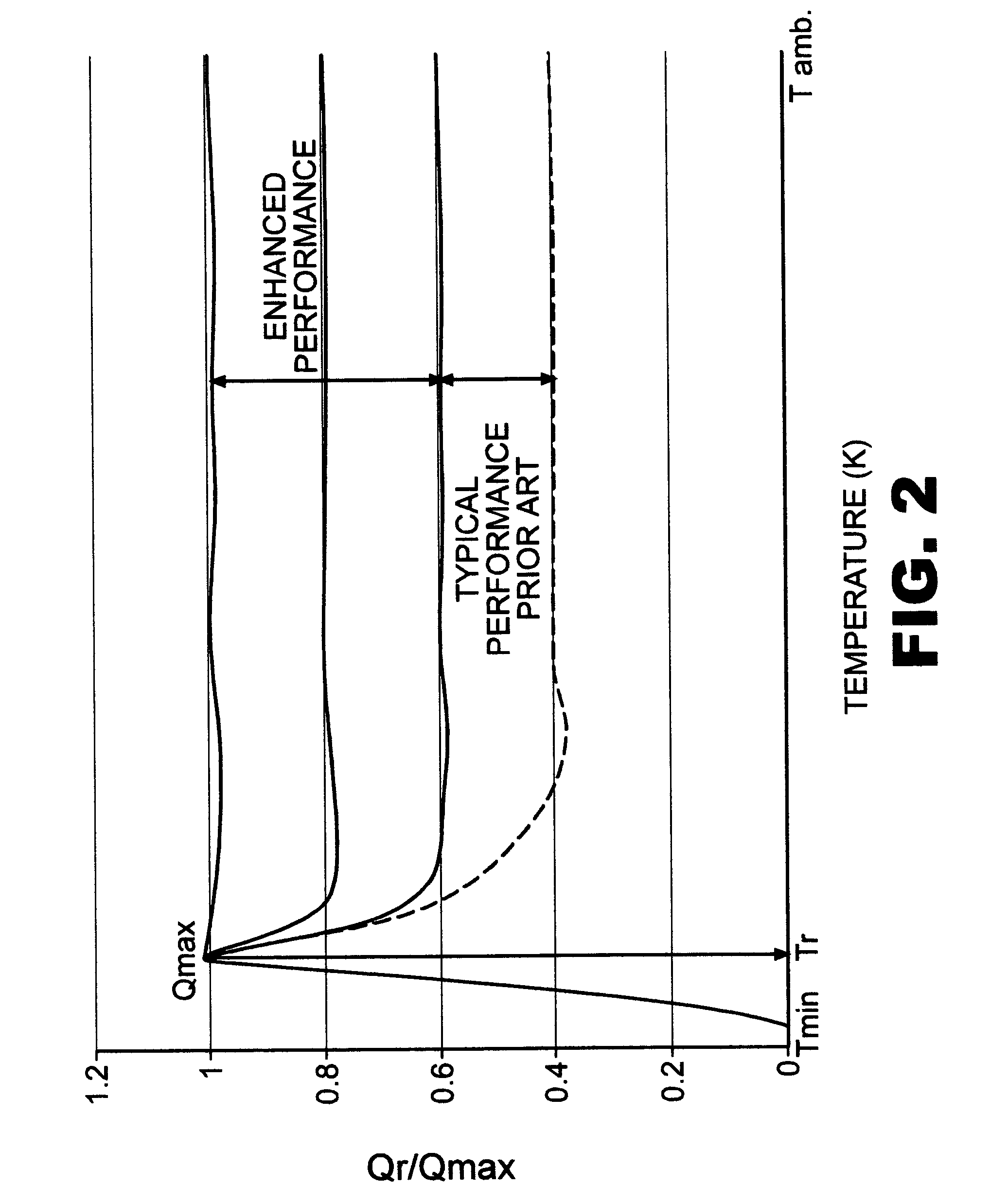

Heat of compression dryer

InactiveUS6375722B1Increase heatImprove performanceGas treatmentIsotope separationDesiccantProcess engineering

Owner:HENDERSON ENG CO INC

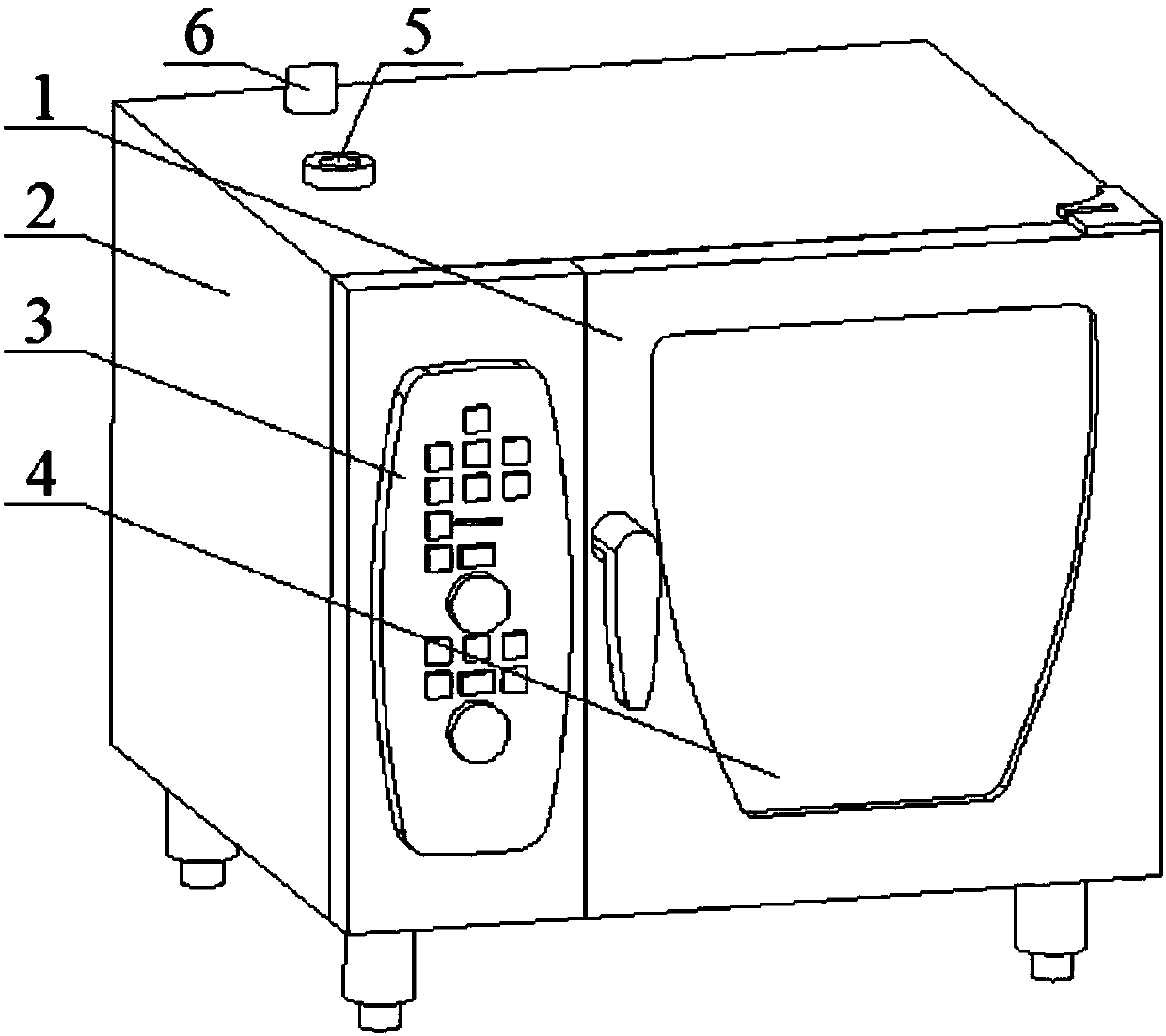

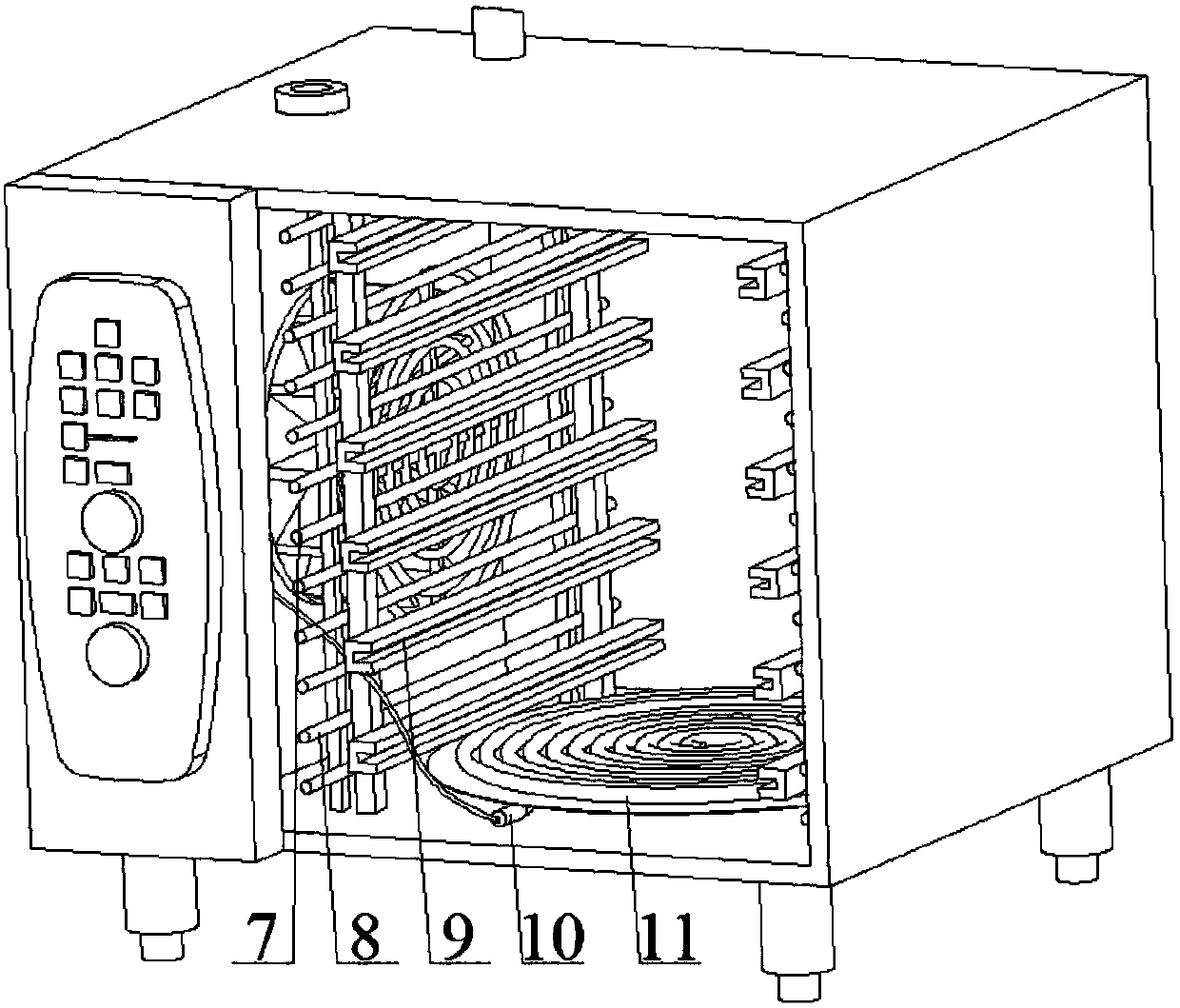

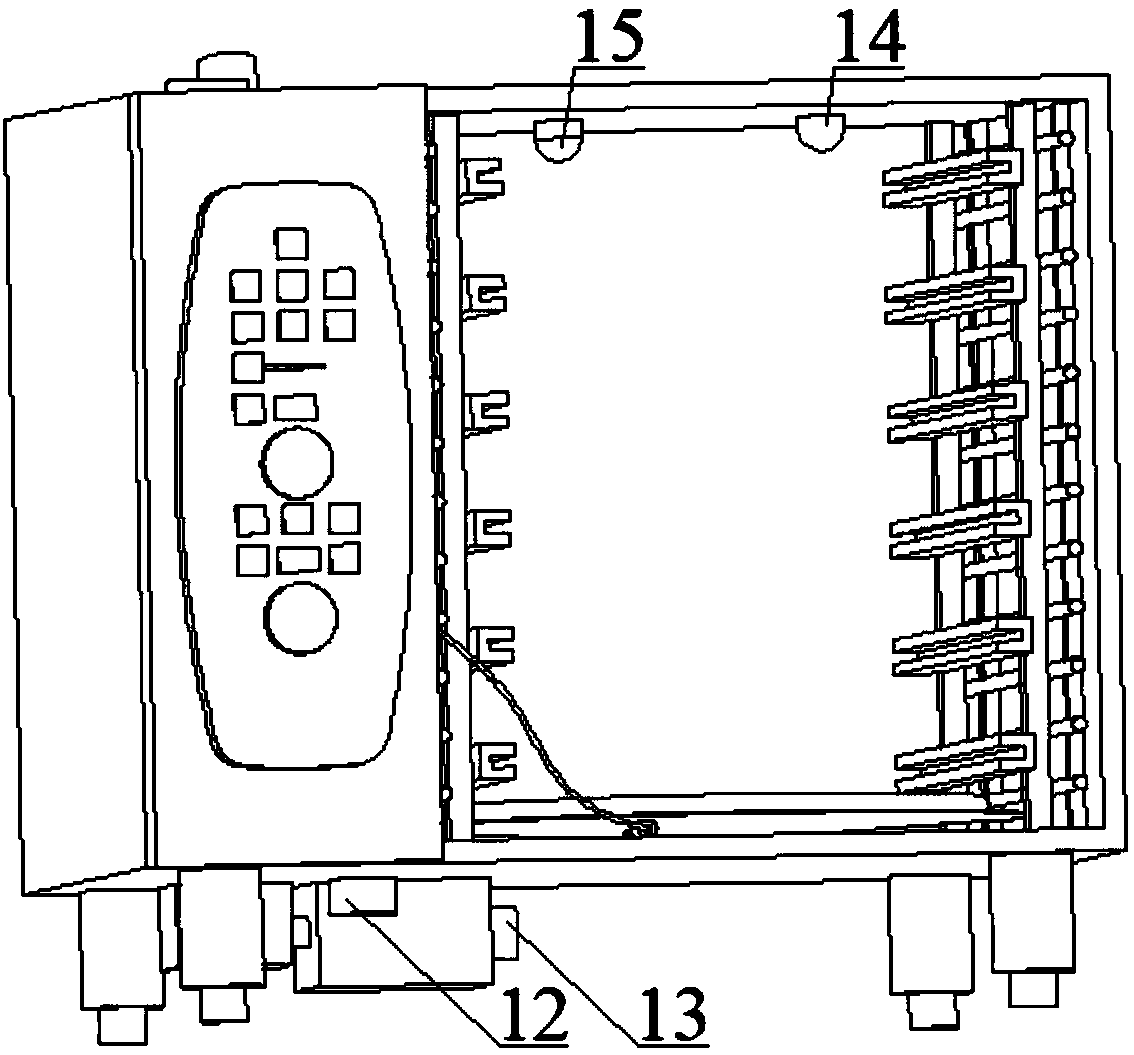

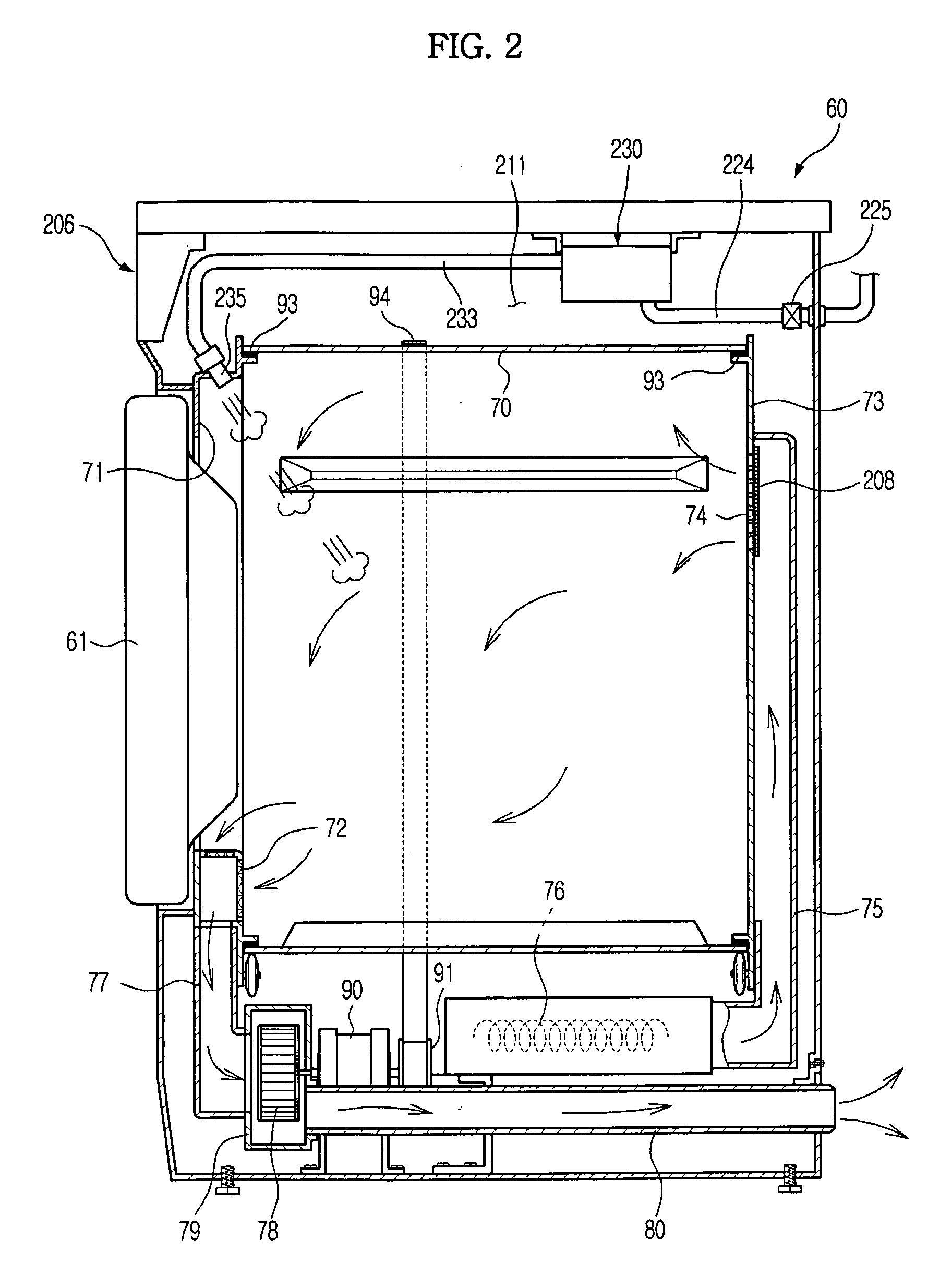

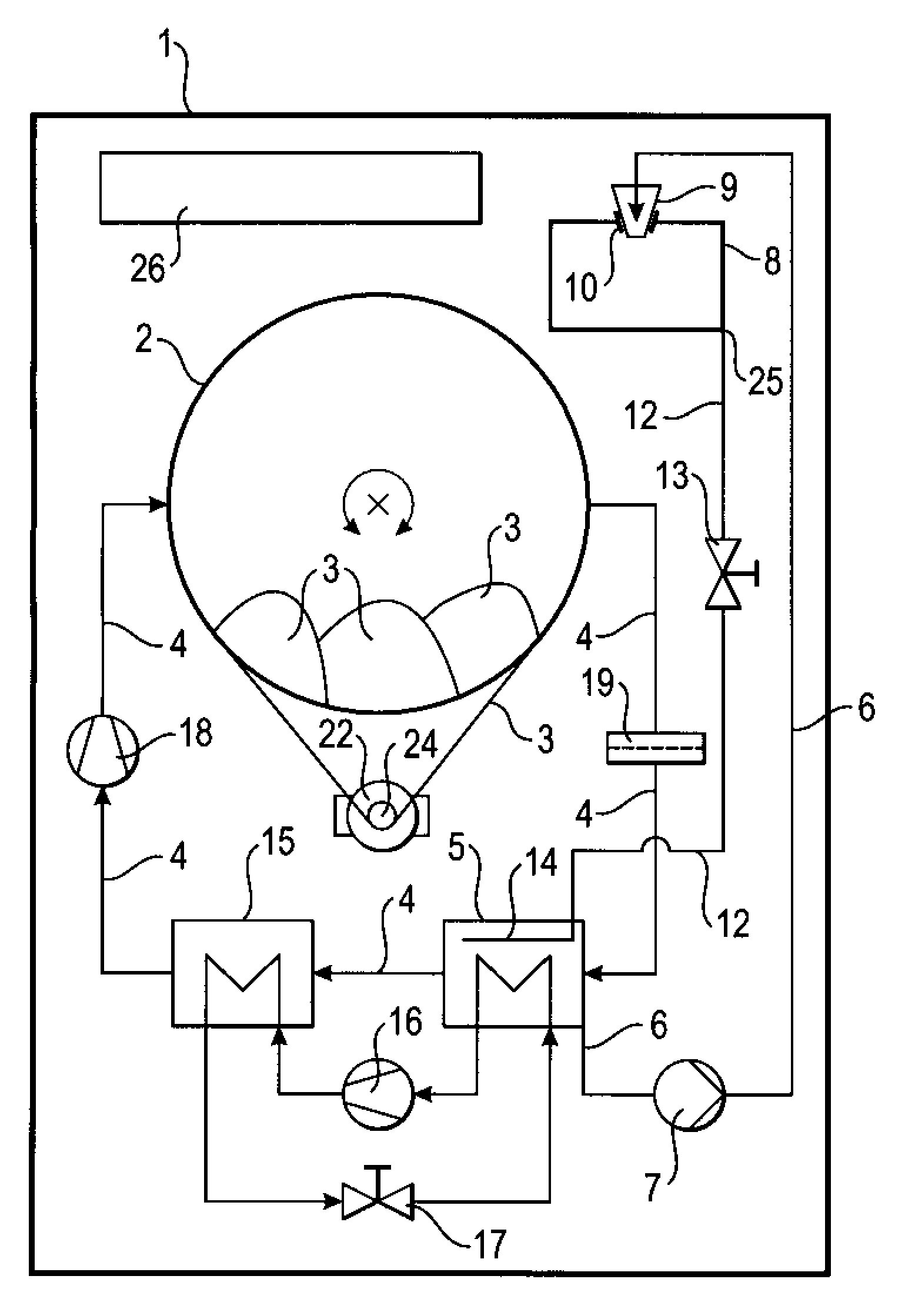

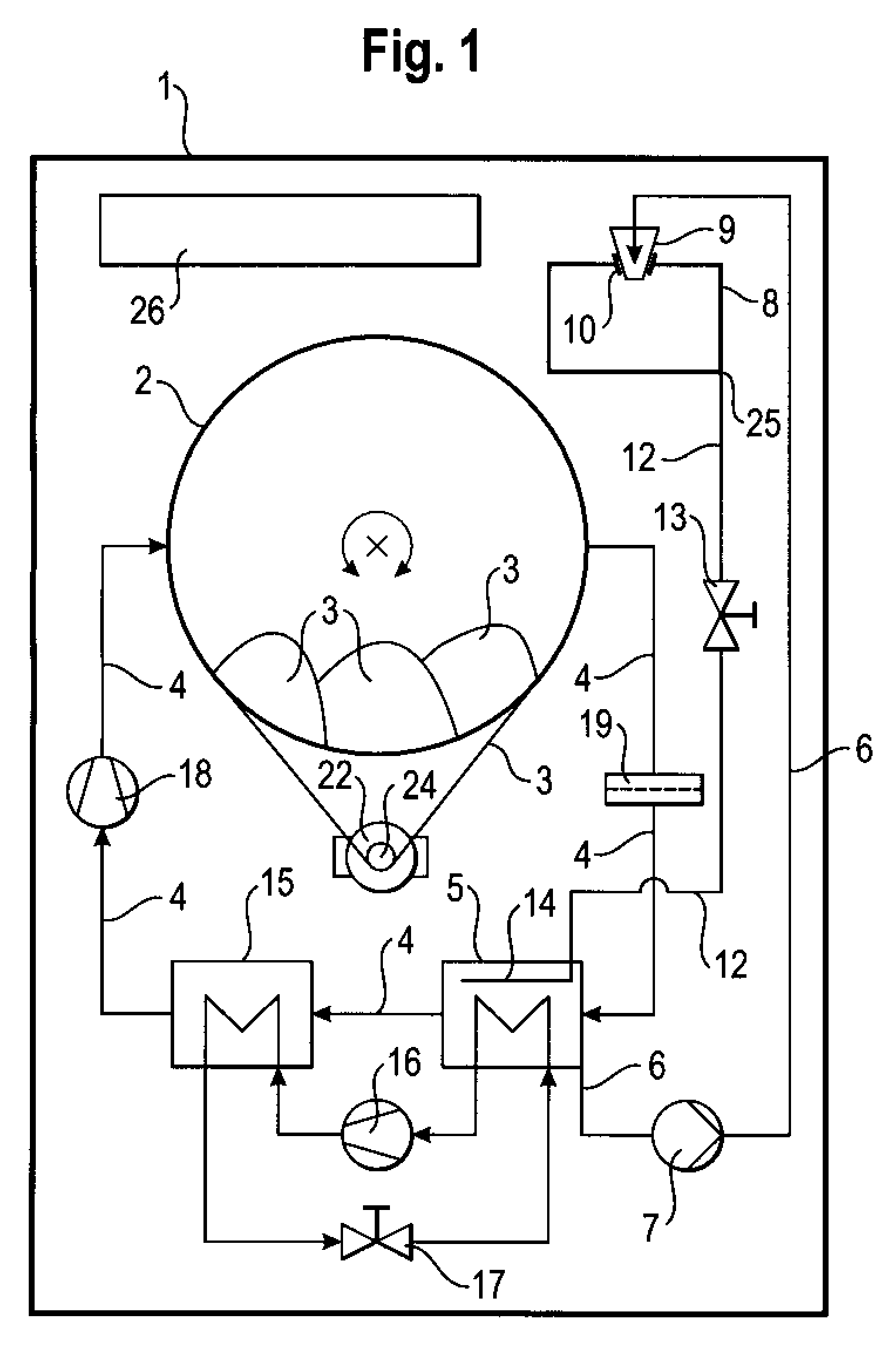

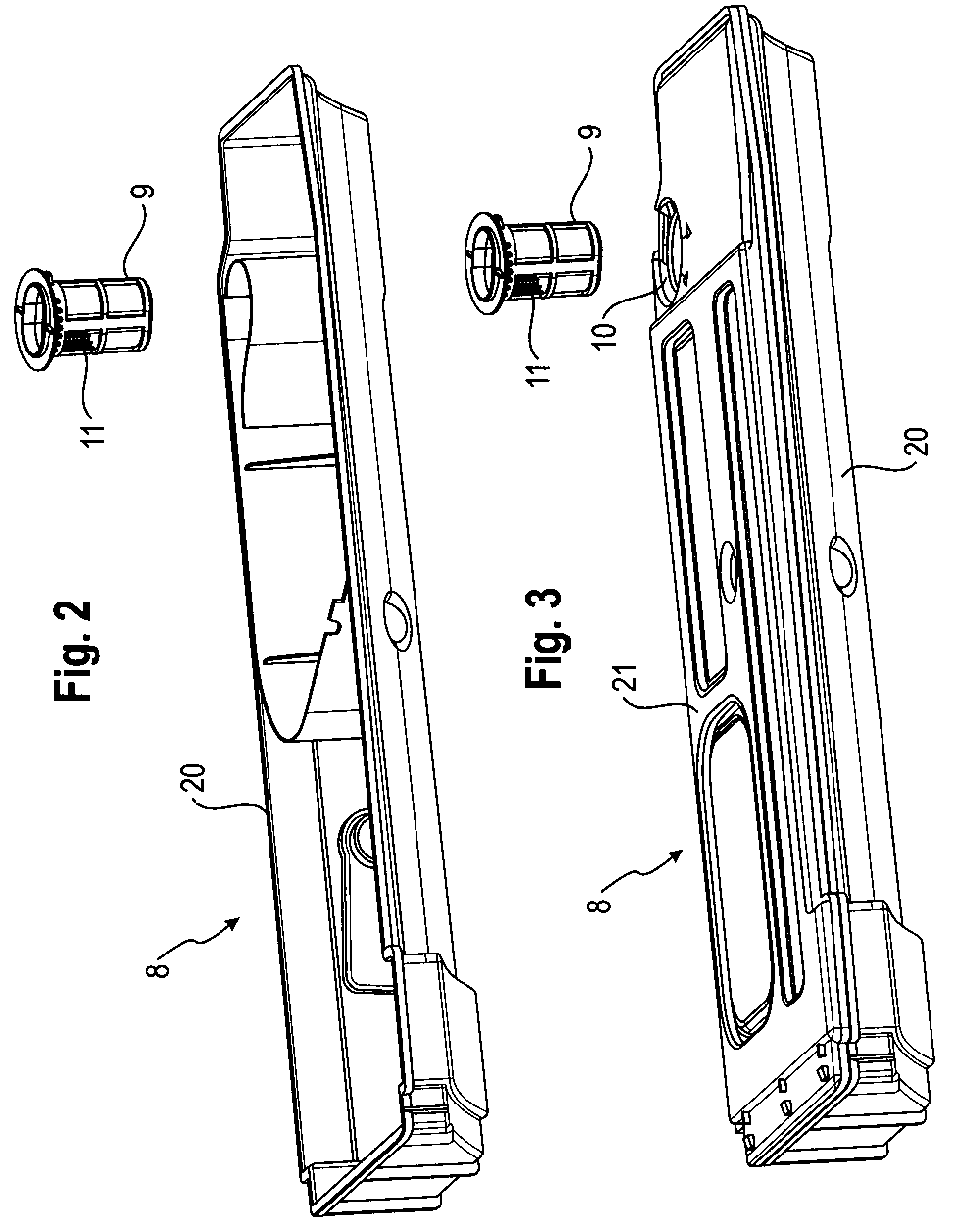

Steaming oven having multiple operating modes

PendingCN107898351AMeet the diverse needs of processingRapid coolingRoasters/grillsWarming devicesComputer moduleEngineering

The invention provides a steaming oven having multiple operating modes. The steaming oven is characterized by comprising an oven body, a steaming-baking module, a humidity regulating and detecting module, a menu editing and storing module, a central temperature detecting module and a control module, wherein the oven body comprises a steaming-baking chamber and a control chamber, the steaming-baking module comprises heating tubes, a steam generator, a turbo fan and an infrared thermodetector, the humidity regulating and detecting module comprises a dryer, a humidifier and a humidity detecting gauge, the menu editing and storing module comprises a menu memorizer and a USB flash disk reading port, the central temperature detecting module is used for food internal-temperature detection, and the control module comprises a photographing camera, a timer, an alarm apparatus, a controller and a central processing unit and is used for providing operation control. The steaming oven has multiple operation modes by arranging the modules, can meet the diversified food processing demands and is high in processing efficiency.

Owner:珠海家宝德科技有限公司

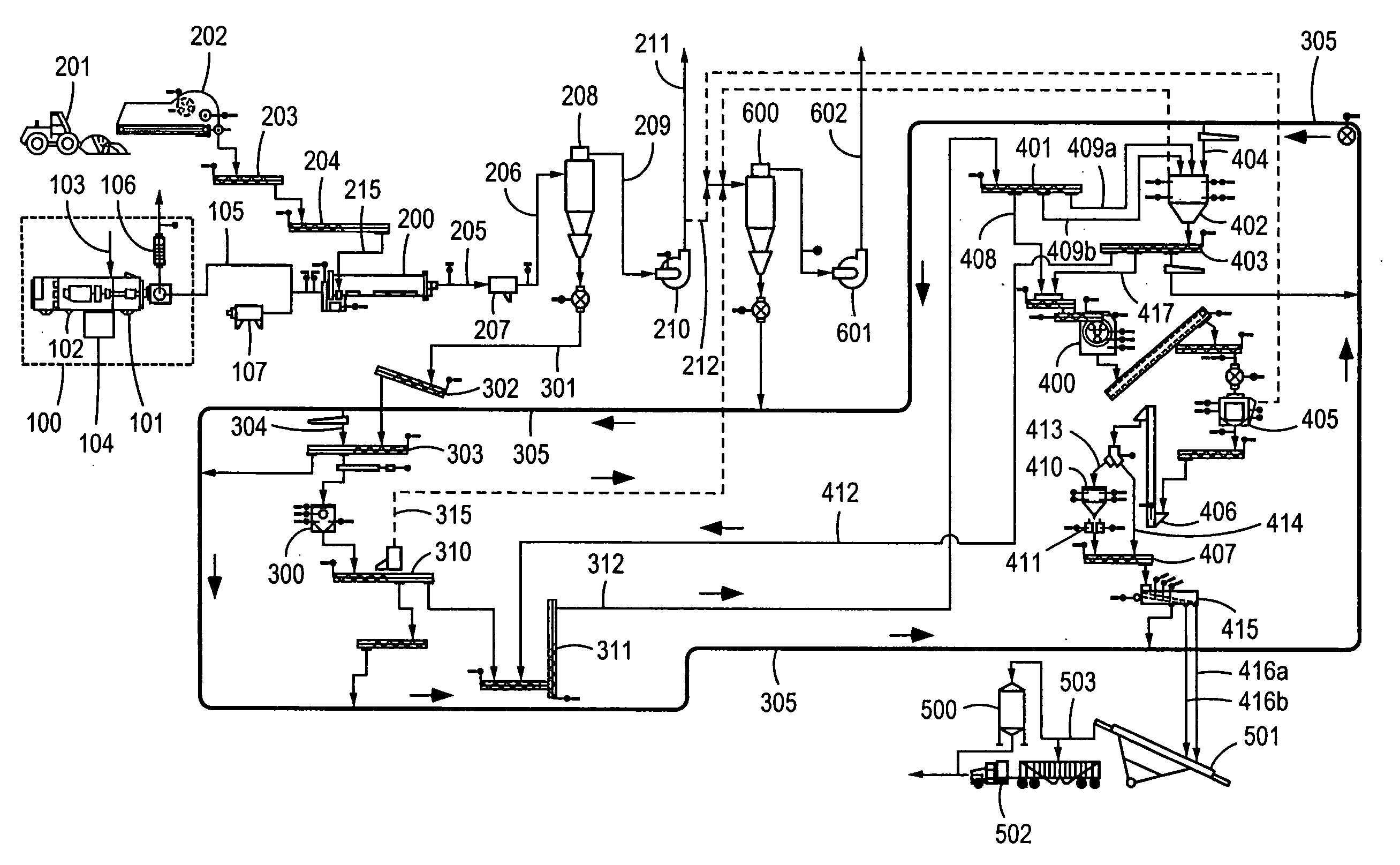

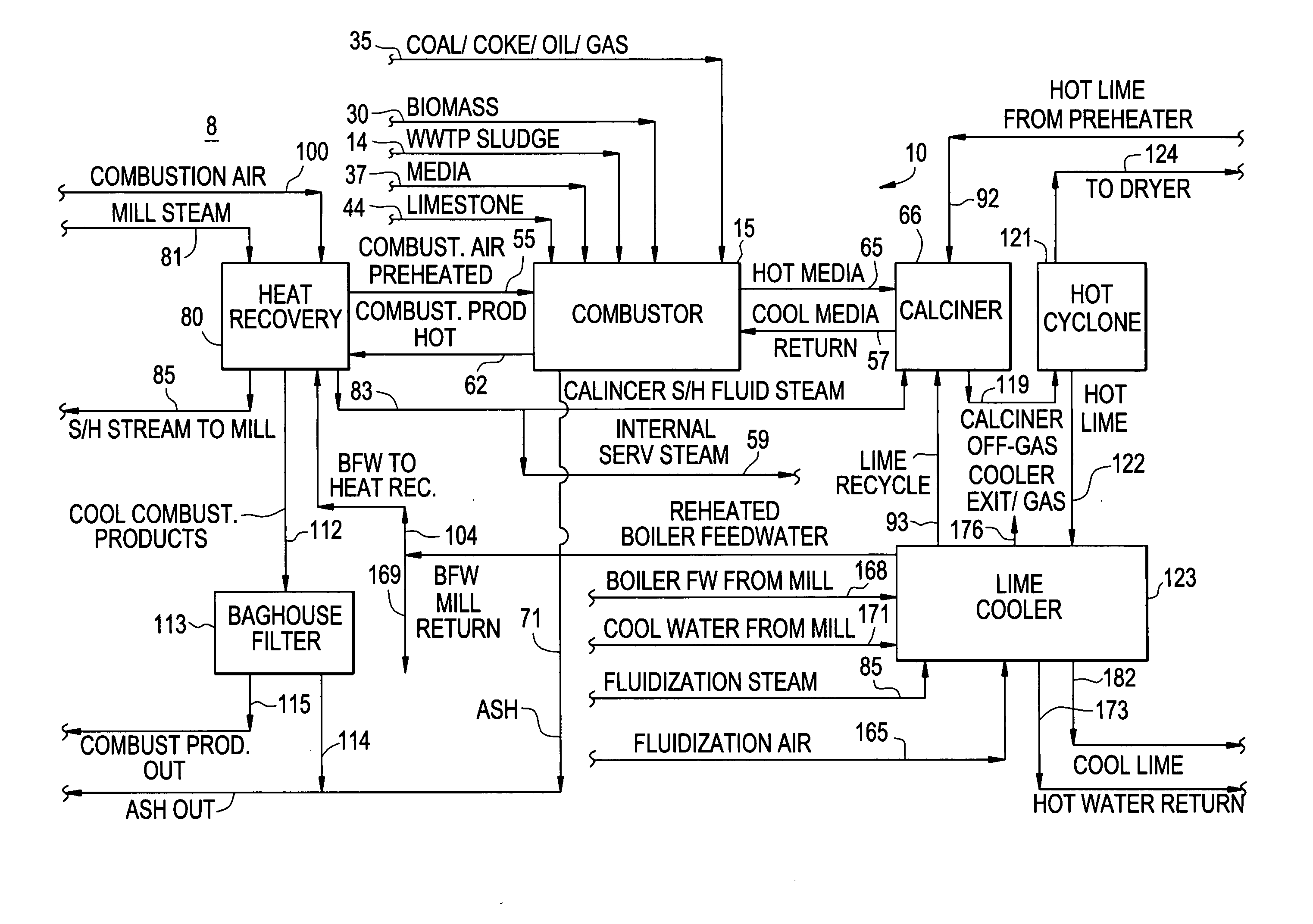

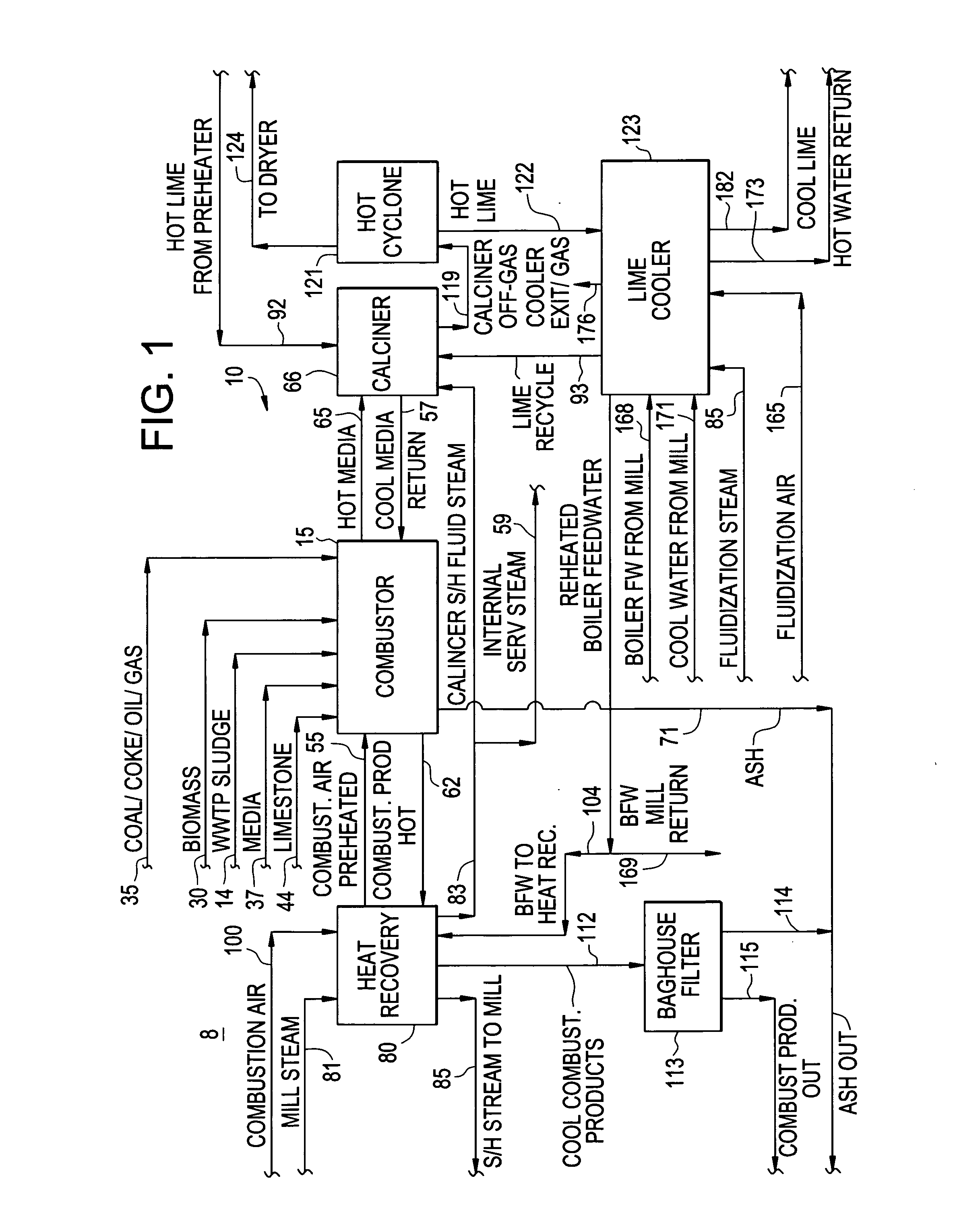

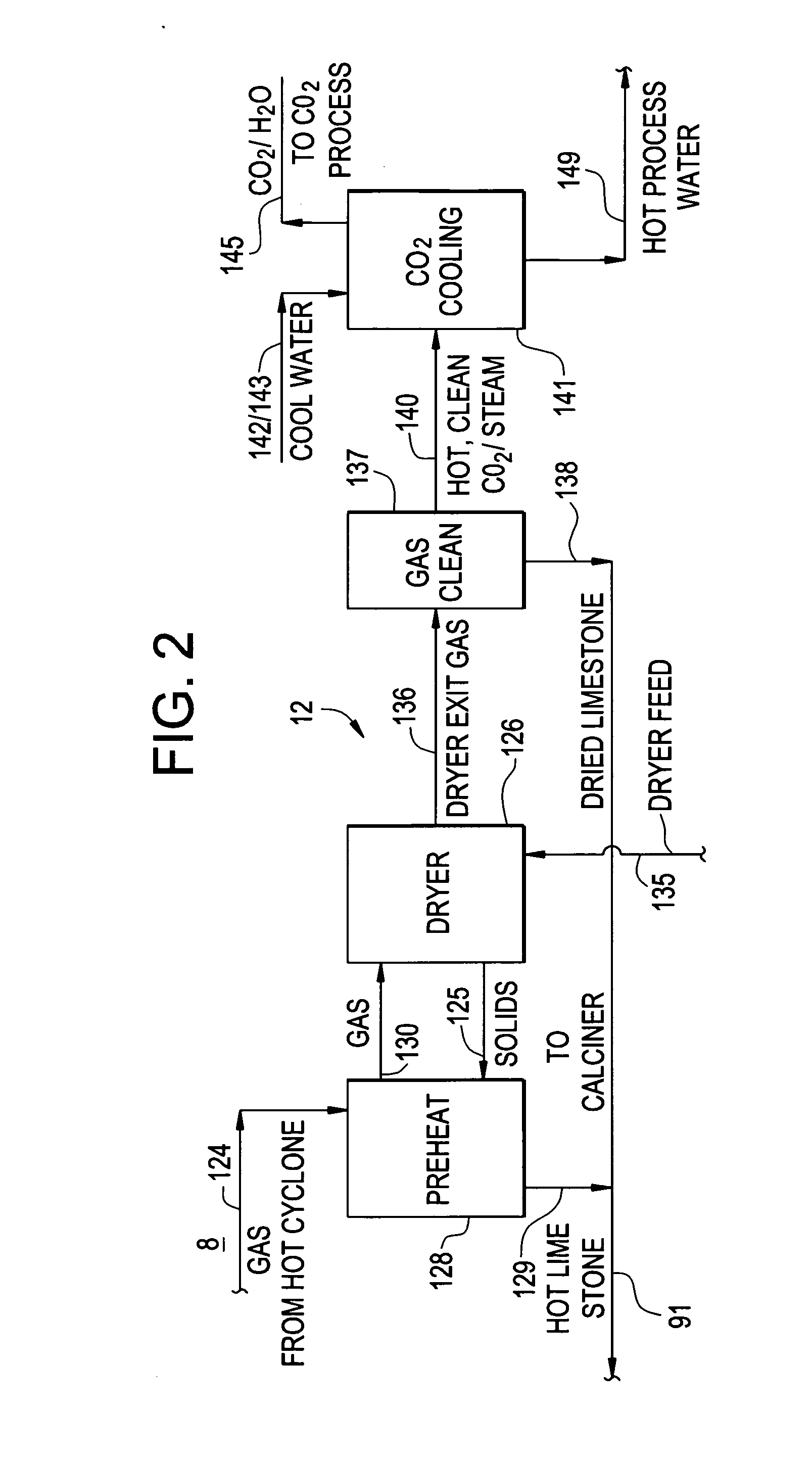

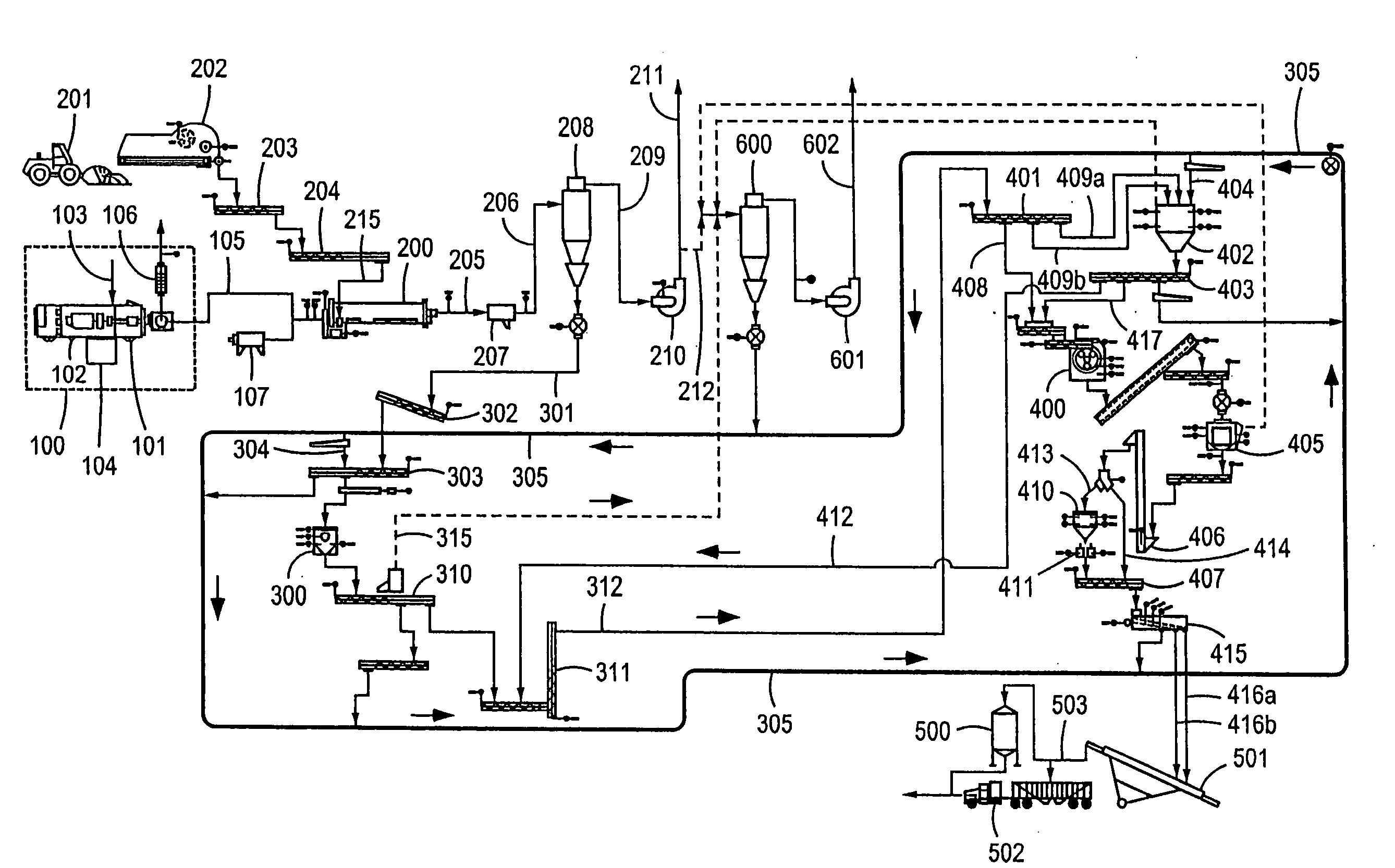

Process and system for producing commercial quality carbon dioxide from fine particle limestone

InactiveUS20090208402A1Maximize timeMaximize fine limestone particle residence timeOxide/hydroxide preparationCarbon compoundsBiomassCarbon dioxide

The invention features methods and systems for producing commercial quality carbon dioxide (CO2) of 90% to +99% purity using, wet, fine particle limestone produced in a manufacturing operation, for instance, a limestone quarry as a feedstock to a multi-stage limestone calcination process. This process may be fueled with negative cost waste water treatment plant (WWTP) sludge, biomass, coal, or other low cost solid fuels. High reactivity lime product required in the an adjacent paper mill's PCC manufacturing plant is also produced, and steam and heated boiler feed-water is generated and exported to the mill's steam distribution and generation system as well as hot process water for use in the mill's manufacturing operation. The system for calcining fine particle limestone produced in a quarry manufacturing operation and converting it to lime and CO2 comprises a calciner and a combustor linked by a moving media heat transfer (MMHT) system or apparatus. The MMHT system or apparatus thermally links separate fluid bed combustion (exothermic) and calcination (endothermic) stages with a solid particulate media. The fluid bed calcination stage is fluidized with steam. The system further comprises a dryer / pre-heater that utilizes exhausted heat from the calcination stage.

Owner:ROSSI ROBERT A

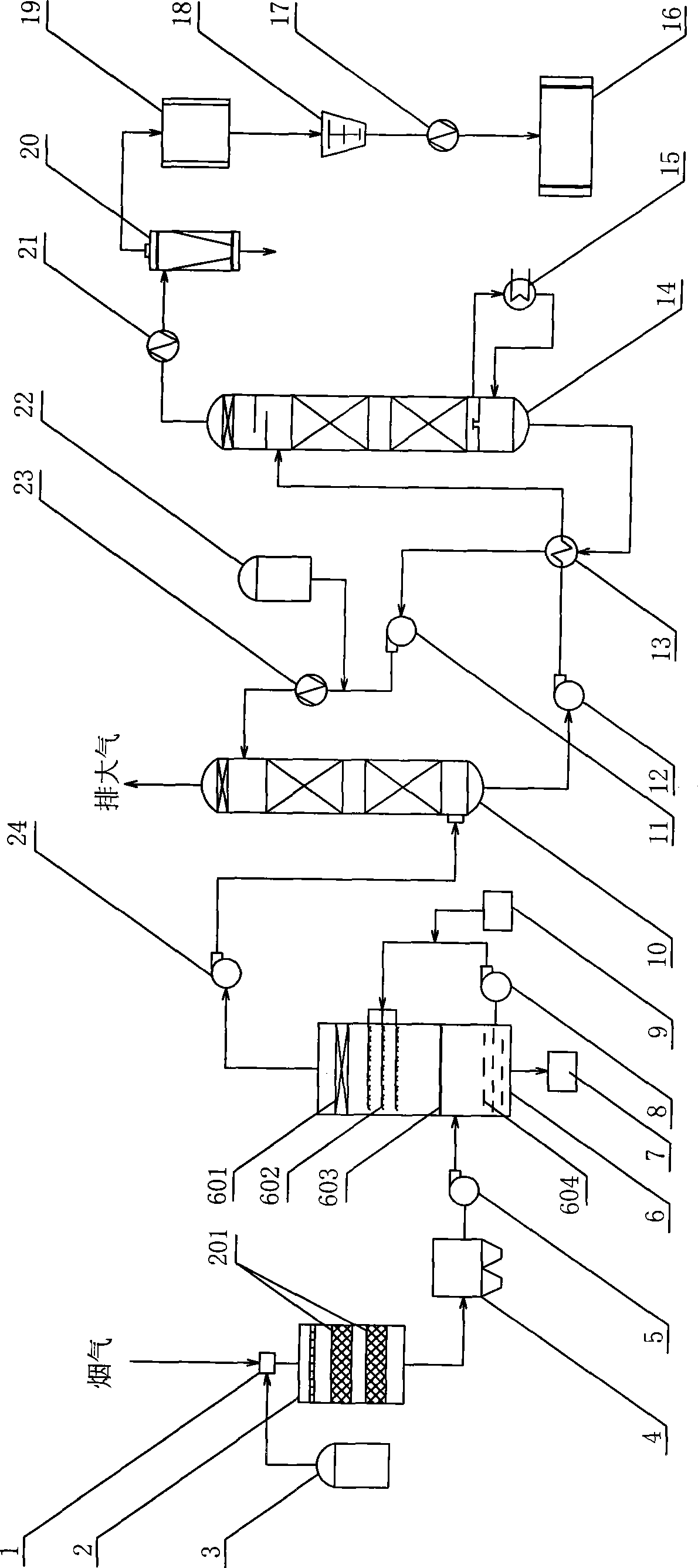

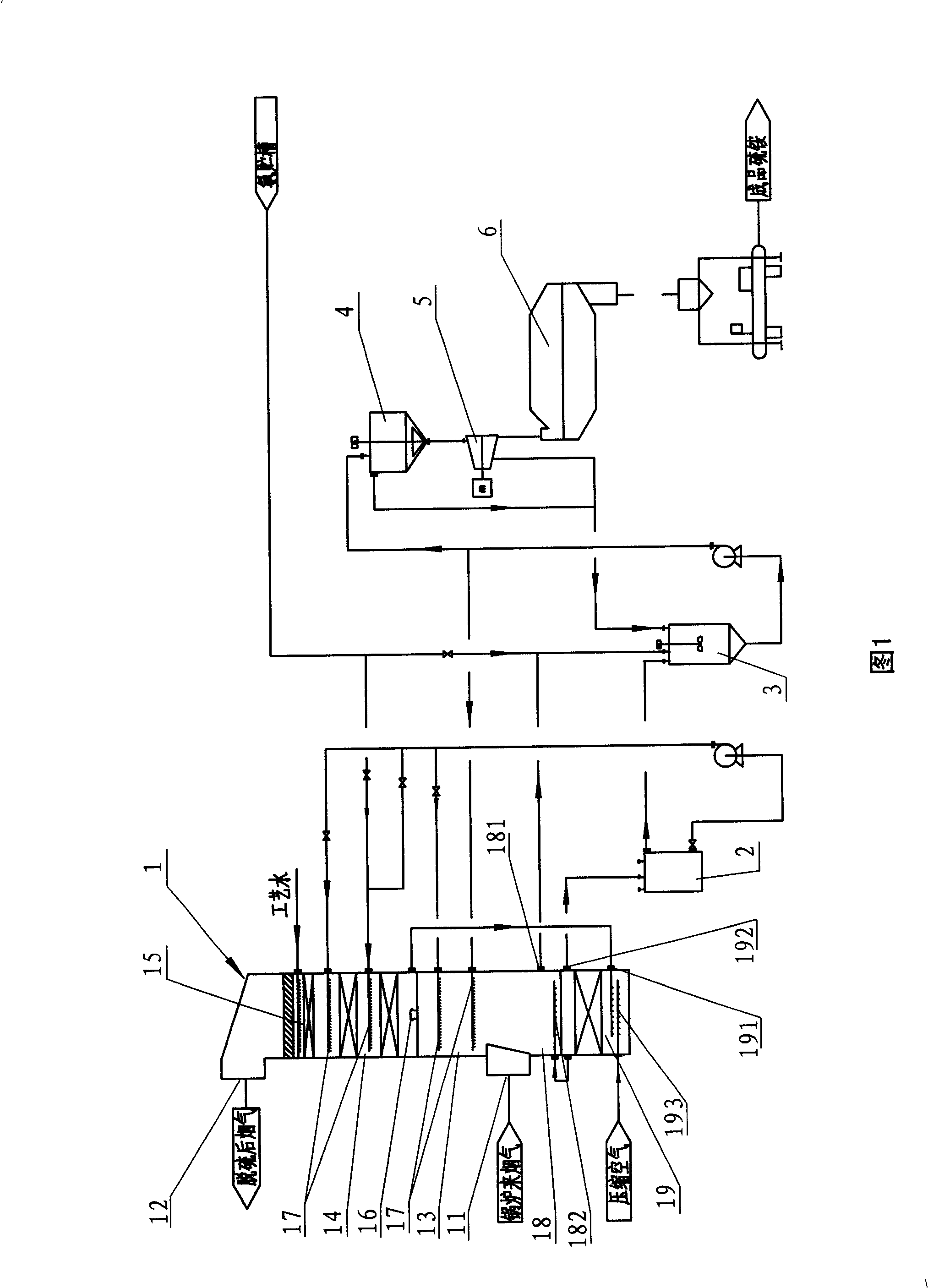

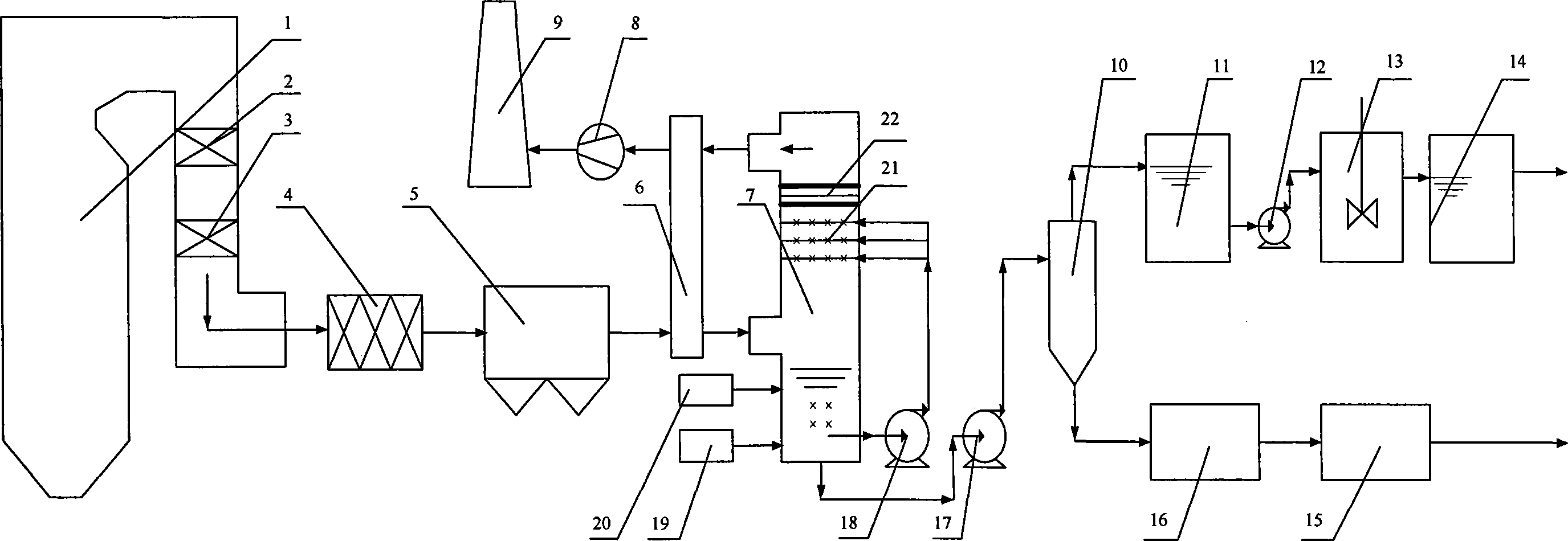

Multi-pollutant removing technique and device of fuel coal smoke

InactiveCN101422691ALow flow resistanceReduce investmentProductsCarbon compoundsHigh concentrationDecarburization

The invention discloses a removal technology of removing coal-fired flue gas pollutants and a device thereof. The technology is as follows: an SCR denitration method is first used for removing NOX in the flue gas; then a dust collector is used for removing dusts and ash particles in the flue gas; then a wet calcium-based desulphurization method is used for removing SO2 in the flue gas; then an MEA decarburization process is used for absorbing the SO2 in the flue gas; simultaneously, a pregnant solution of a generated alkanolamine solution is heated, analyzed and regenerated and the generated barren solution of the alkanolamine solution is continuously and cyclically used; and the analyzed CO2 gas with high concentration is produced to be liquid carbon dioxide of industrial grade with high purity after being cooled, gas-liquid separated, dried, compressed and condensed. The device consists essentially of an SCR denitration reactor, the dust collector, a wet calcium-based desulphurization reactor, an MEA decarburization absorption tower, a regeneration tower, a gas-liquid separator, a dryer, a compressor, a condenser and the like which are connected with each other by pipes. The device has simple and compact overall design, low investment and operation costs, and stable and reliable work and can conduct classified integration processing and highly efficient simultaneous removal on every pollutant in the coal-fired flue gas.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

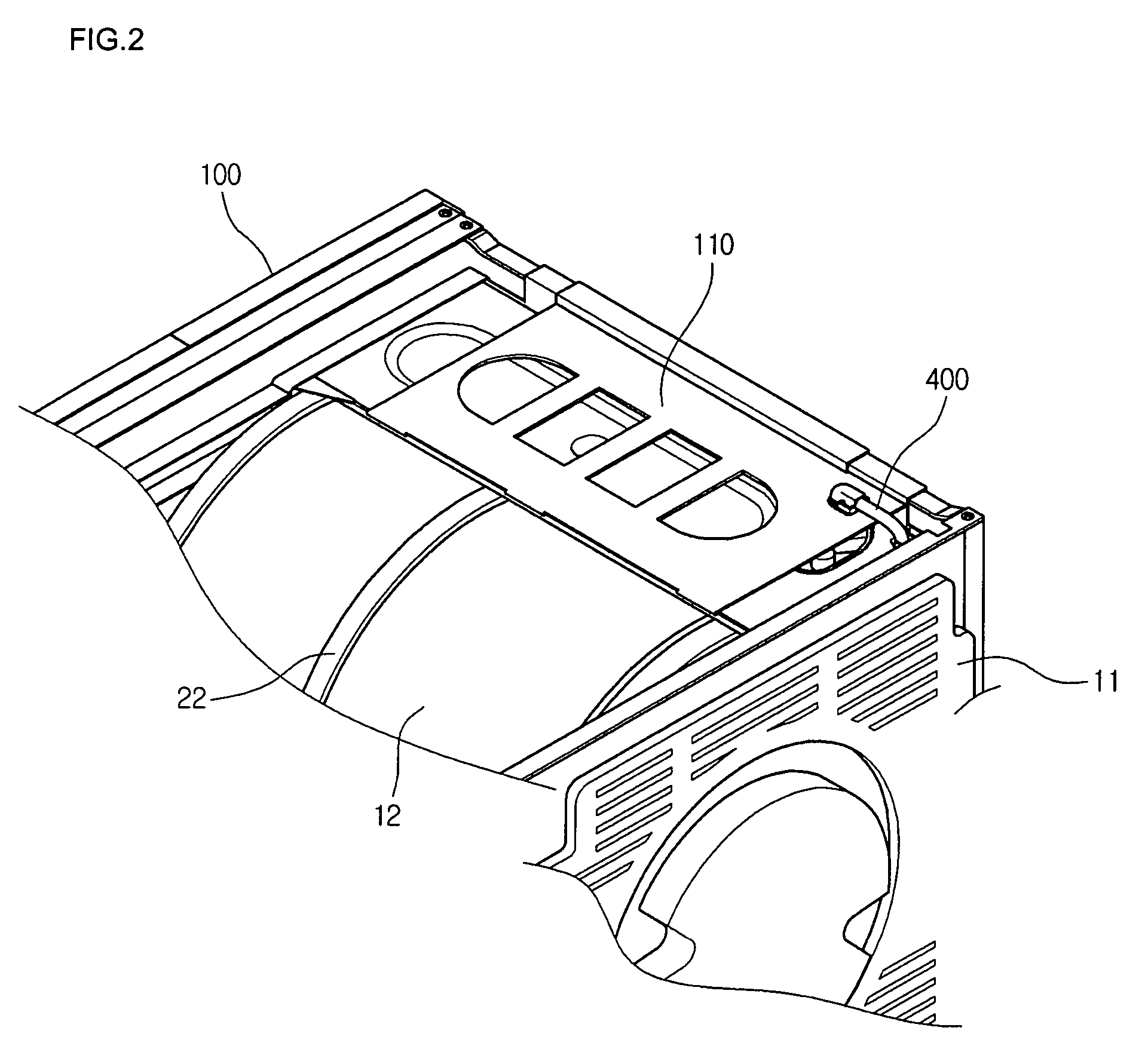

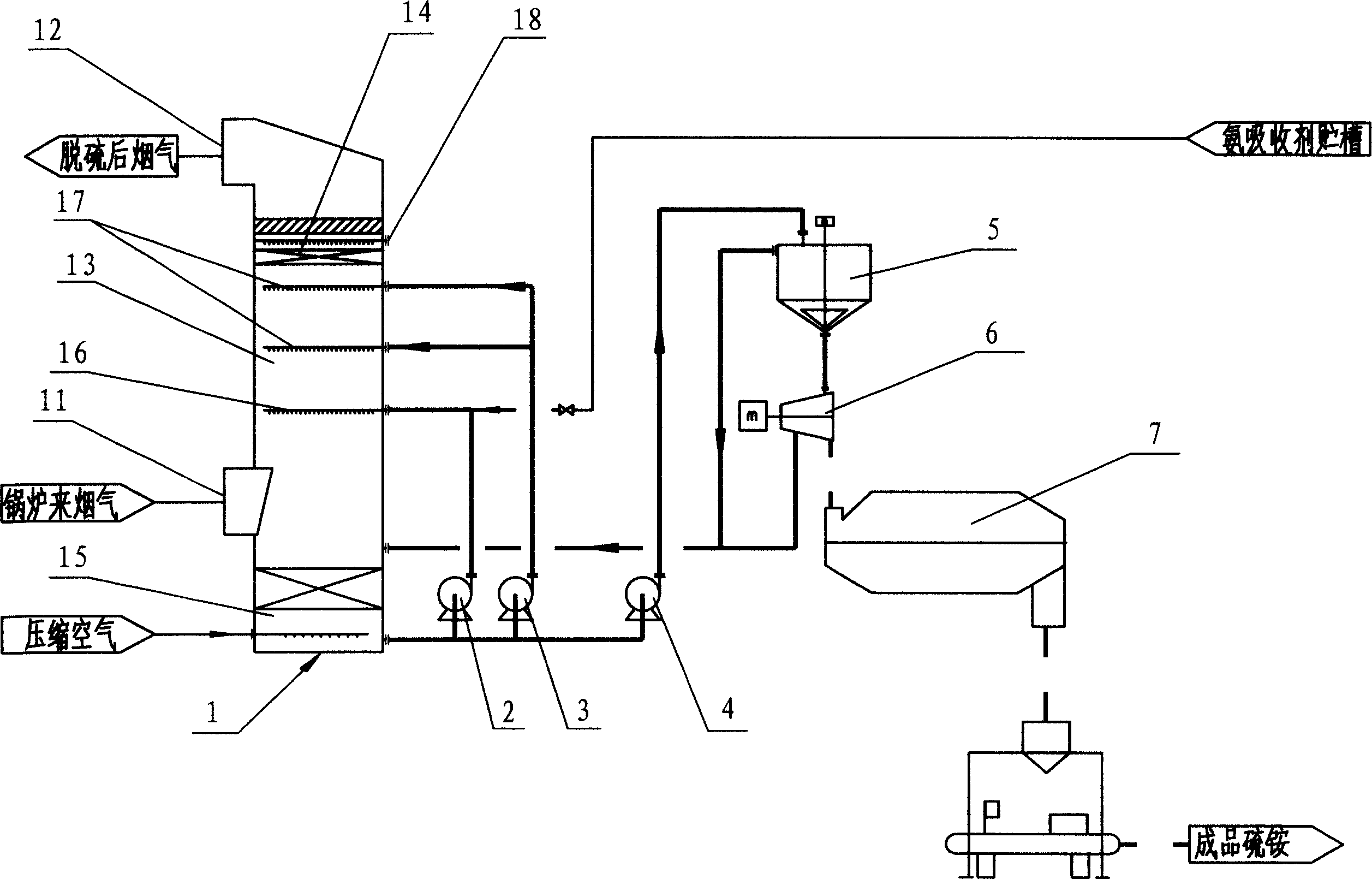

Ammonia desulfurizing process and apparatus with crystallization inside tower

The present invention belongs to the field of environment protection apparatus, and is especially crystallizing ammonia type desulfurizing process and apparatus for removing and recovering SO2 from fume. The apparatus includes one desulfurizing tower, one absorbing and circulating tank outside the tower, one concentrating and circulating tank, one ammonium sulfate thickener, one centrifuger and one drier. It features the crystallizing section and oxidizing section set below the fume inlet inside the desulfurizing tower, the connection of the crystallizing section with the concentrating and circulating tank, the connection of the oxidizing section outlet with the absorbing and circulating tank, and the successive connection of the other parts. The present invention has low cost and convenient apparatus maintenance and operation.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

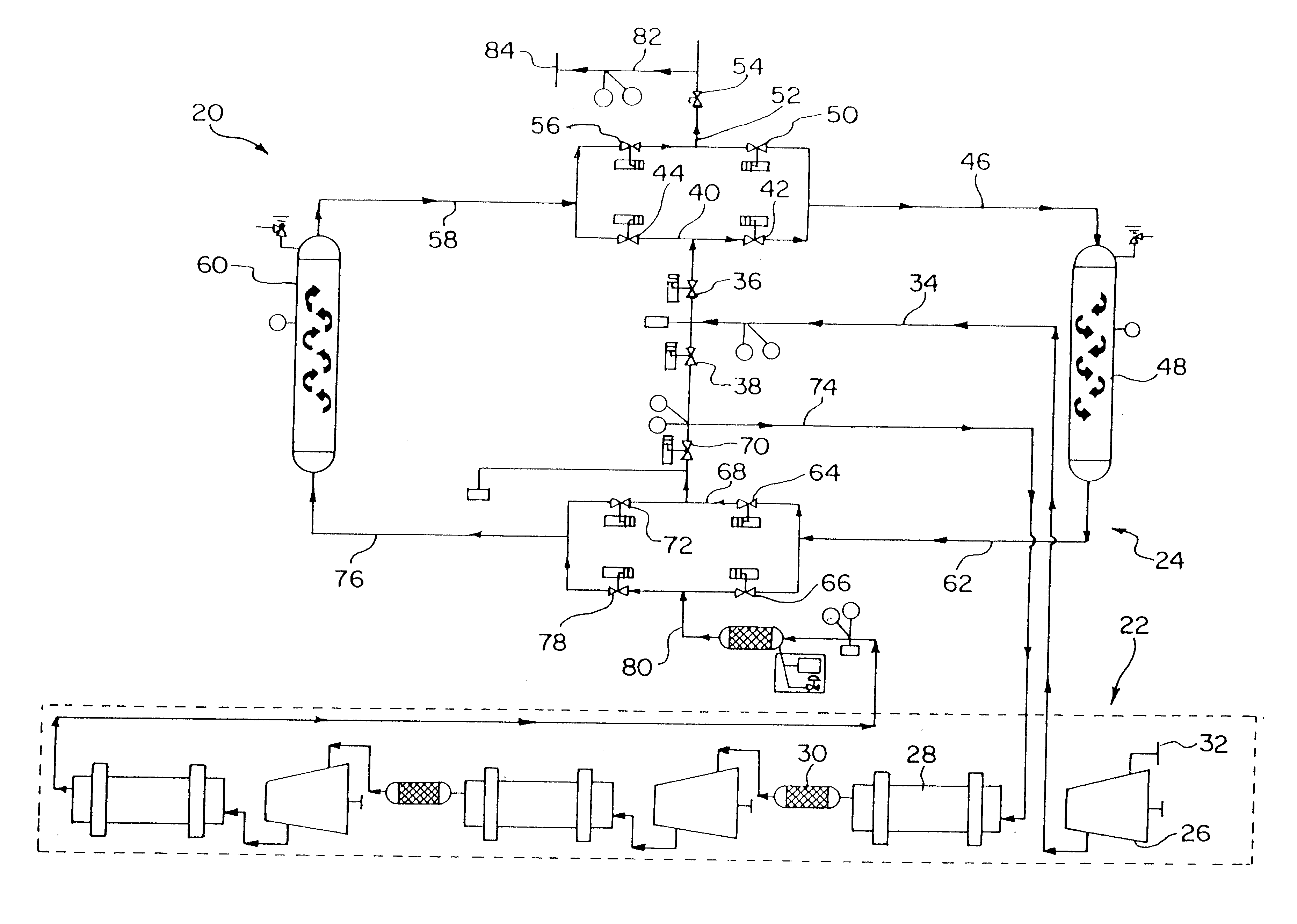

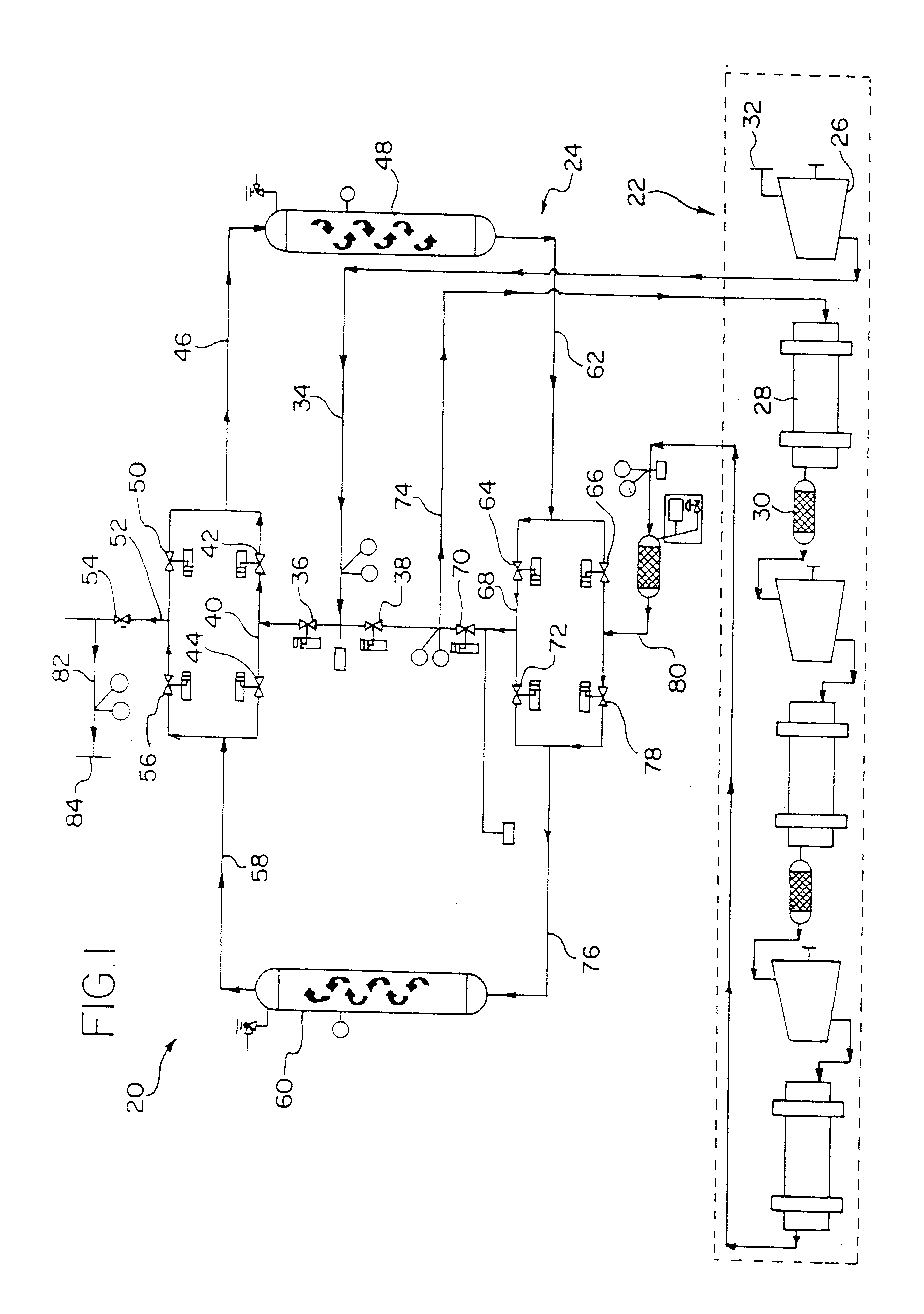

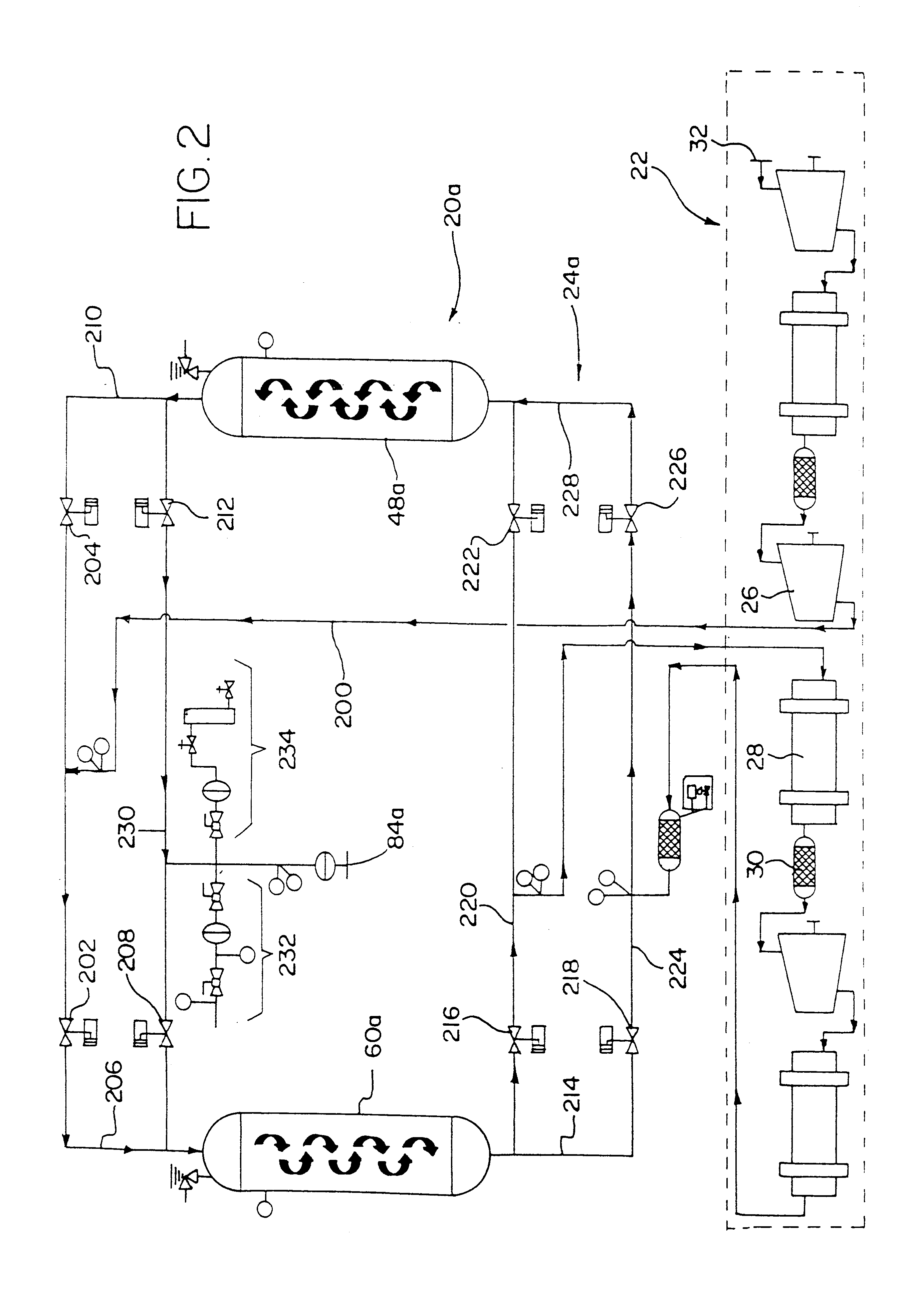

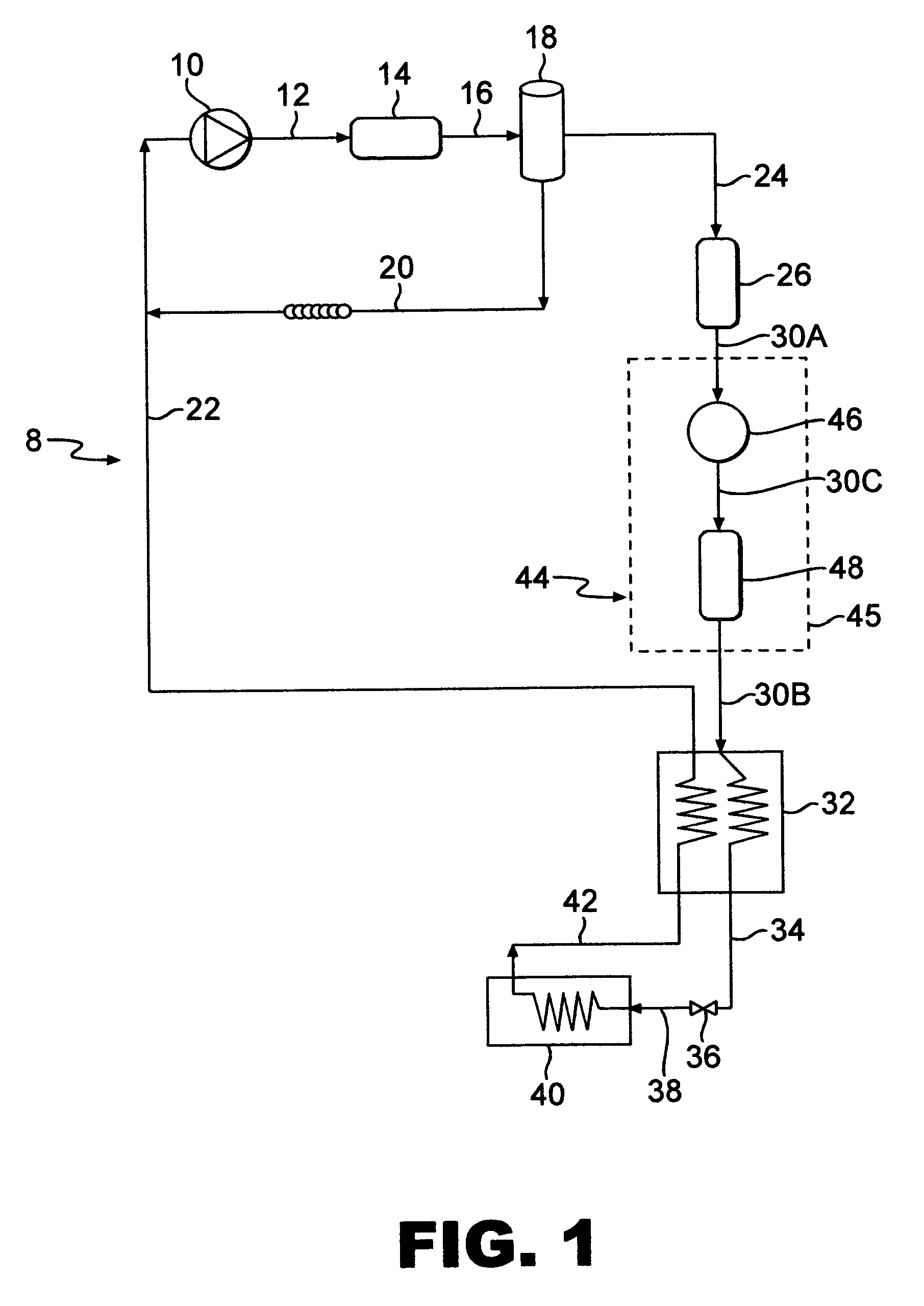

Regenerative compressed air/gas dryer

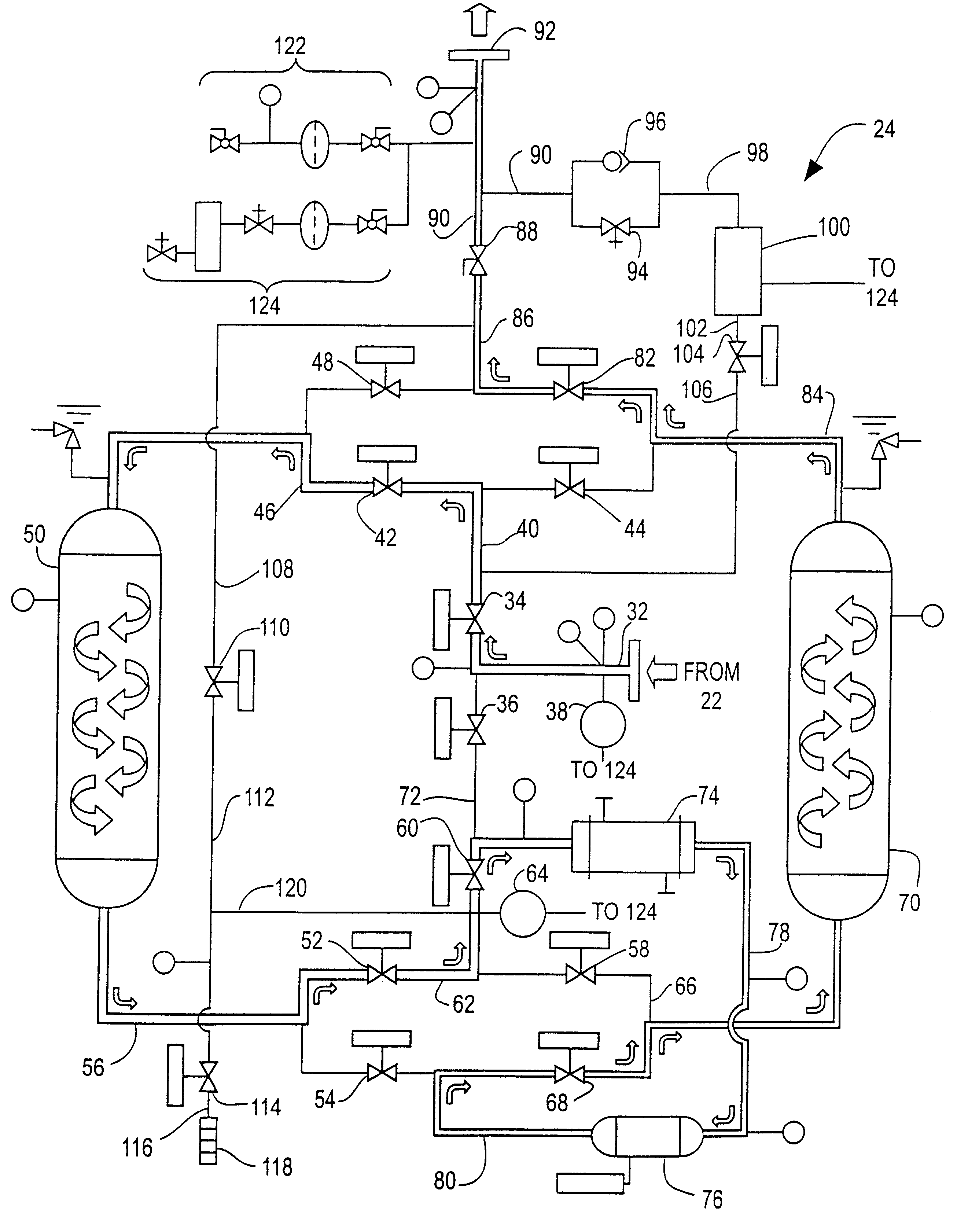

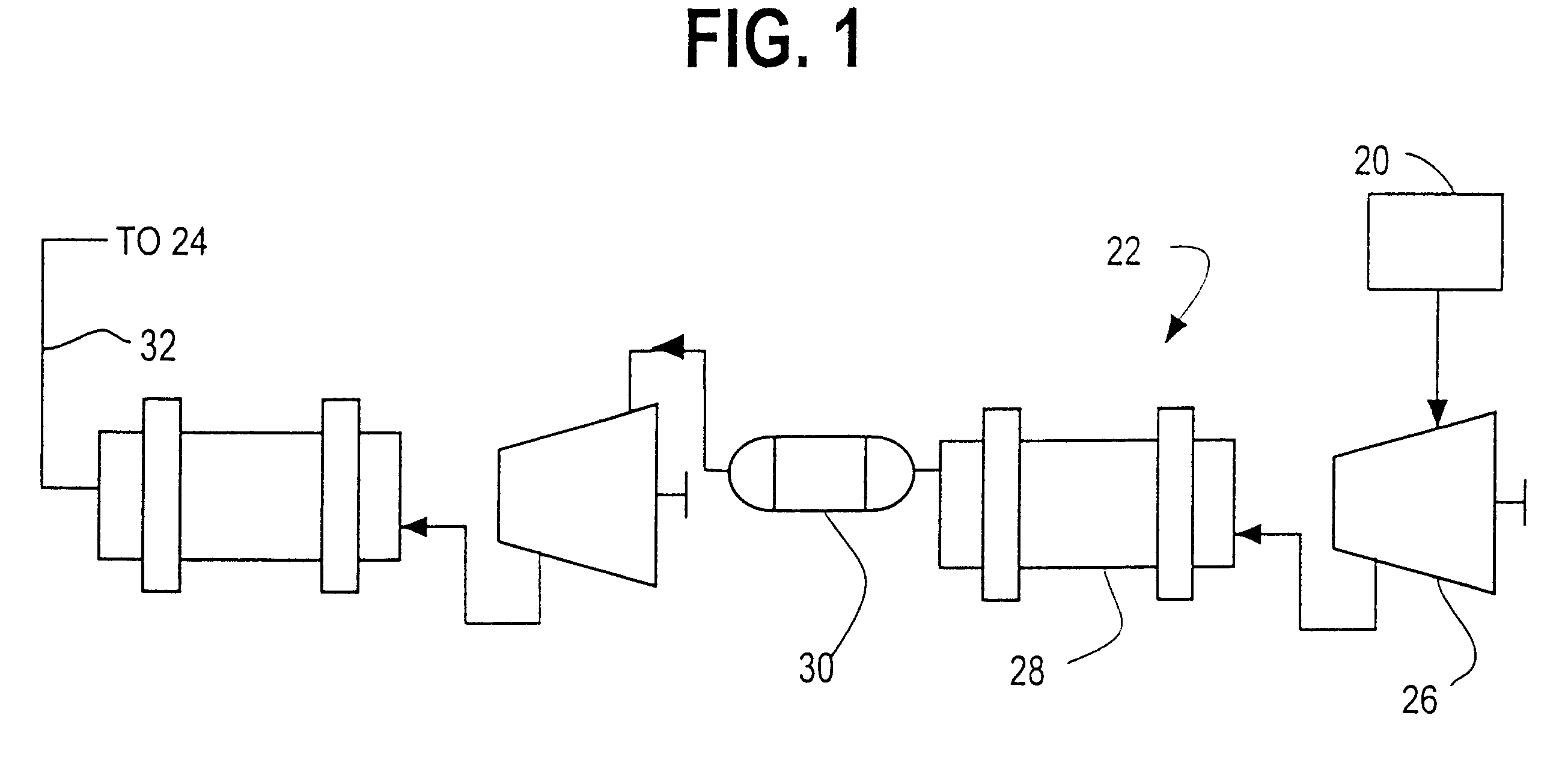

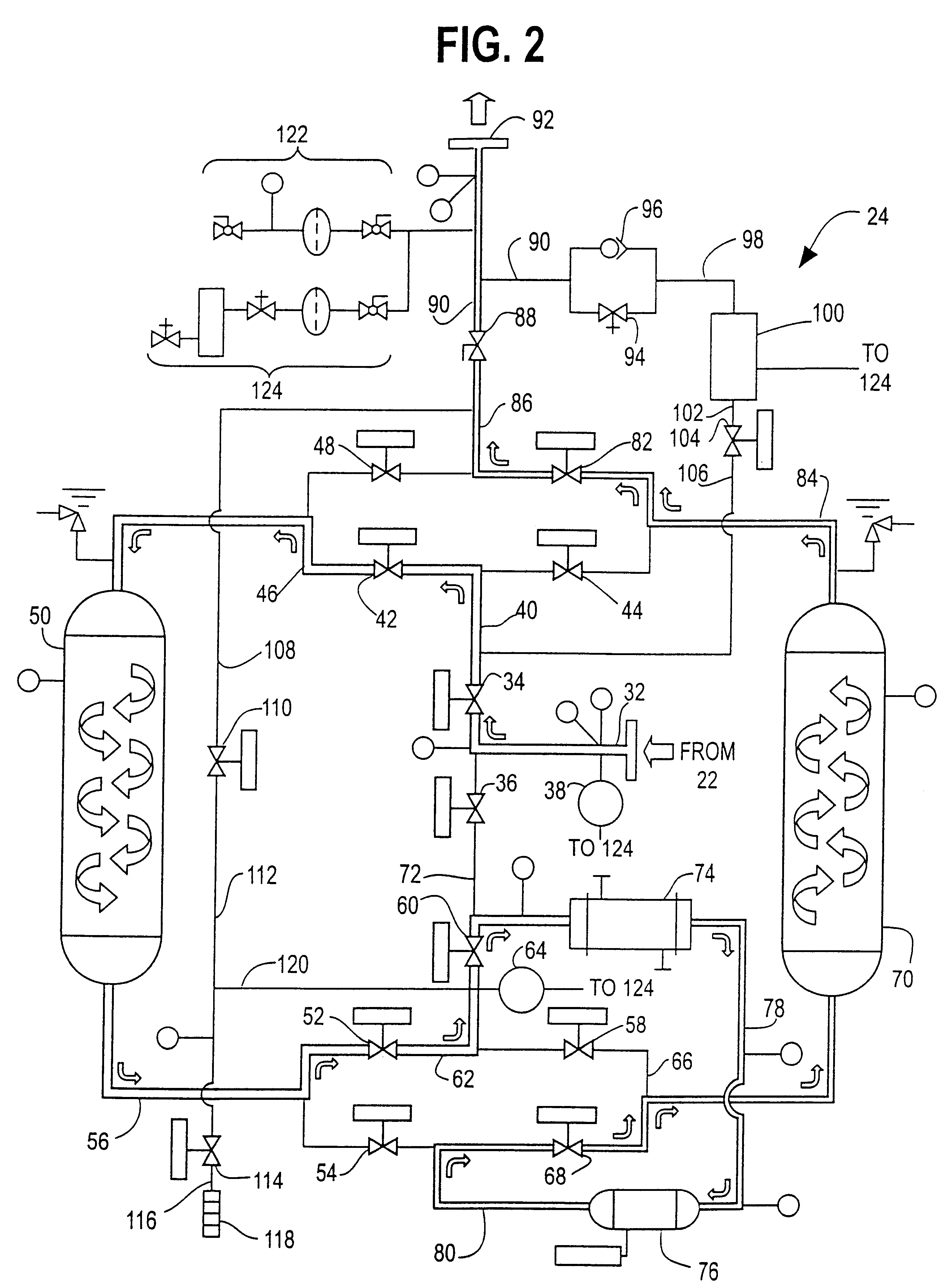

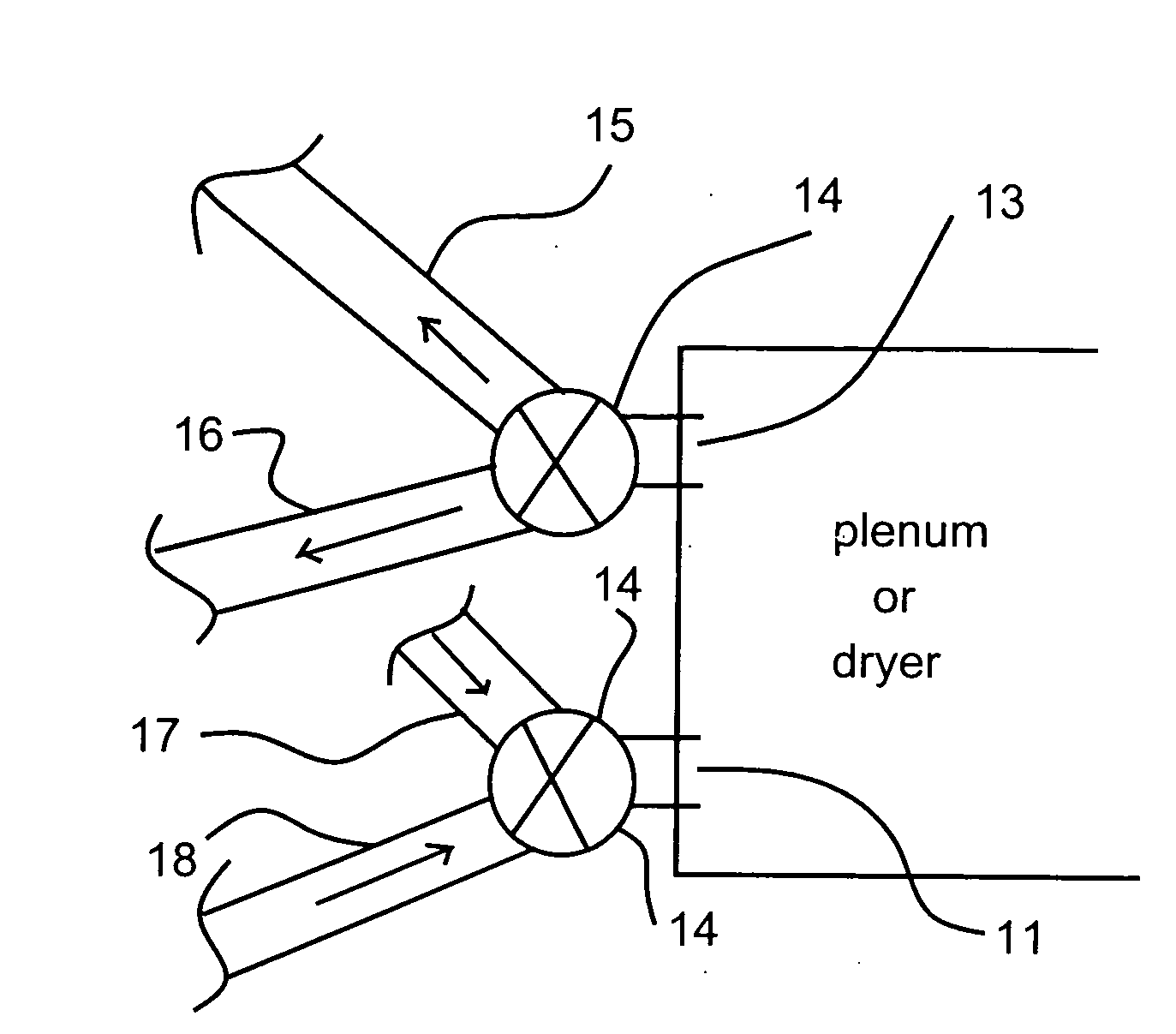

A system for drying a gas, such as air, includes a source of gas to be dried, a multi-stage compressor having an inlet connected to the source, and a dryer connected interstage to the compressor and to the outlet of the compressor. The dryer is connected interstage to the compressor between a compression stage and a heat exchanger of one of the compressor stages for regenerating a first desiccant filled tower. The dryer is also connected to the outlet of the compressor for drying the gas using a second desiccant filled tower. A communication structure can be activated to connect the first tower to the outlet of the compressor for drying the gas using the first tower, and to connect the second tower interstage to the compressor for regeneration of the second tower.

Owner:HENDERSON ENG CO INC

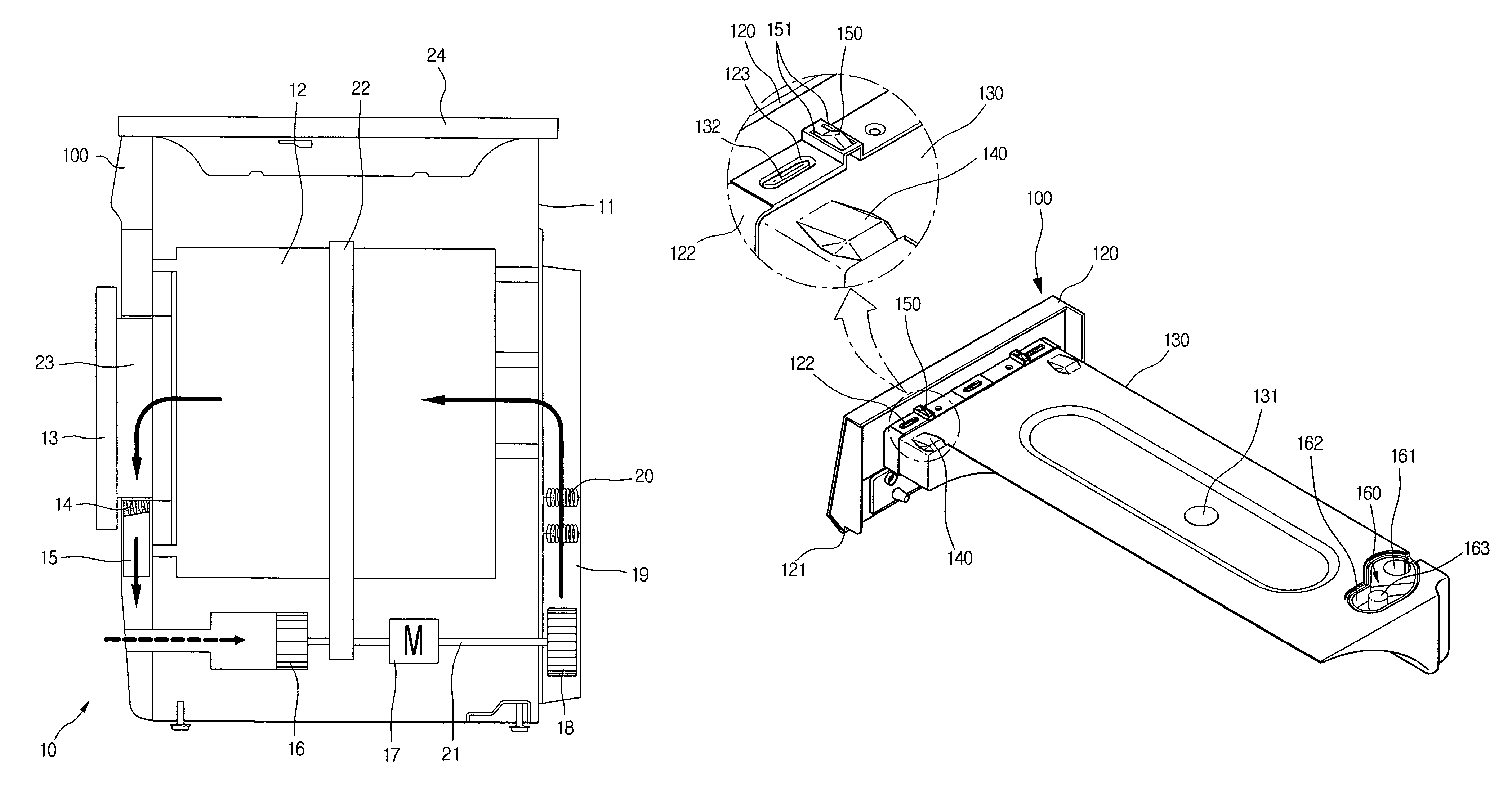

Condensed water storing apparatus of a dryer

InactiveUS7251905B2Easy and safe to carryDrying solid materials with heatDrying gas arrangementsEngineeringEnvironmental engineering

Owner:LG ELECTRONICS INC

Ammonia desulfurizing process and apparatus with crystallization inside tower

The present invention belongs to the field of environment protection apparatus, and is especially crystallizing ammonia type desulfurizing process and apparatus for removing and recovering SO2 from fume. The apparatus includes one desulfurizing tower, one absorbing and circulating tank outside the tower, one concentrating and circulating tank, one ammonium sulfate thickener, one centrifuger and one drier. It features the crystallizing section and oxidizing section set below the fume inlet inside the desulfurizing tower, the connection of the crystallizing section with the concentrating and circulating tank, the connection of the oxidizing section outlet with the absorbing and circulating tank, and the successive connection of the other parts. The present invention has low cost and convenient apparatus maintenance and operation.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Void tower type ammonia desulfurizing process and apparatus

The present invention belongs to the field of environment protection apparatus, and is especially void tower type desulfurizing process and apparatus for removing and recovering SO2 from fume. The apparatus includes one desulfurizing tower with fume inlet in the middle part, fume outlet in the top, absorbing and sprinkling section, dewatering and defogging section, and oxidizing section in the bottom; one primary and one secondary circulating pump outside the tower connected to the absorbing and sprinkling section and the oxidizing section; one thick liquid circulating pump outside the tower; one ammonium sulfate thickener; one centrifuger and one drier. The present invention has low cost and convenient apparatus maintenance and operation.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

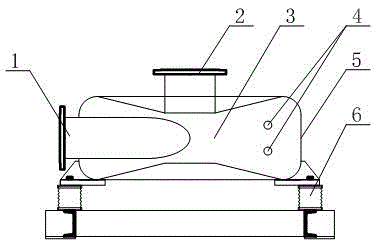

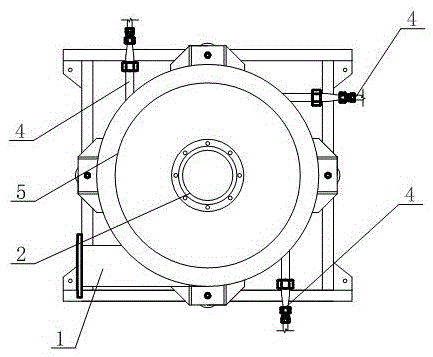

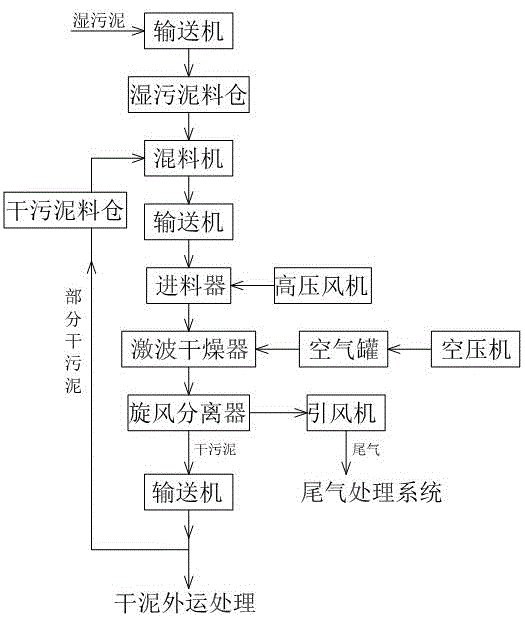

Air shockwave crushing sludge drying device and sludge shockwave drying system

InactiveCN105621849ALow investment costHigh densitySludge treatment by de-watering/drying/thickeningGrain treatmentsShock waveHigh energy

The invention discloses an air shockwave crushing sludge drying device of which the shell is cylindrical. The shell is at least provided with a feed port and a set of compressed air injection pipes in the tangential direction, wherein each compressed air injection pipe is provided with a Laval nozzle; a discharge port is arranged at the central top of the shell; the inside of the shell is provided with a cavity; and a feed port, the discharge port and the injection pipes respectively communicate with the cavity. The normal-temperature air is utilized, thereby avoiding the investment cost on high-energy-consumption heating equipment and large-size heat-exchange equipment, and preventing the odor from generation. The shape of the cavity conforms to the mechanical characteristics of hydromechanics; and the high-speed air flow is utilized to carry the sludge to rotate and mutually collide at high speed in the cavity, thereby effectively pulverizing the sludge. The compressed air shockwaves generated by the Laval nozzle are utilized to impact the suspended sludge particles moving at high speed in the cavity; the unit-cell-coated water is subjected to wall breaking, and the water is atomized and vaporized at normal temperature; and thus, the drying device has the advantage of low energy consumption and can complete the sludge drying efficiently.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Low-density cellular wood plastic composite and process for formation

InactiveUS20040147625A1Low costIncrease stiffnessWood working apparatusDomestic articlesProcess engineeringEngineering

A low-pressure CO2 tank or an air compressor with a refrigerated air dryer is attached to the vent zone of a standard twin-screw extruder. During extrusion, the gas is dissolved in the wood-plastic melt. The CO2 expands which foams the wood-plastic material.

Owner:WASHINGTON STATE UNIVERSITY

Apparatus and methods for improving the energy efficiency of dryer appliances

InactiveUS20090100702A1Improve efficiencyReduce operating costsDrying solid materials with heatDrying gas arrangementsResidenceProcess engineering

Apparatus for improving the efficiency of dryer appliances that utilize heated air for drying and are disposed within a residence or other closed conditioned space includes an intake air duct connected between the dryer appliance and a source of intake air outside the conditioned space, an exhaust outlet diverter valve to receive exhaust air from the dryer and direct the exhaust air for release within the conditioned space or alternatively outside the conditioned space. Alternative embodiments provide for drawing intake air from more than one source, with and without heat exchange, for releasing heated air to more than one location, including into a heating system return air duct, either directly or through a heat exchanger. A method of controlling the operation of the apparatus is also provided.

Owner:FAIR ROBERT WOOD

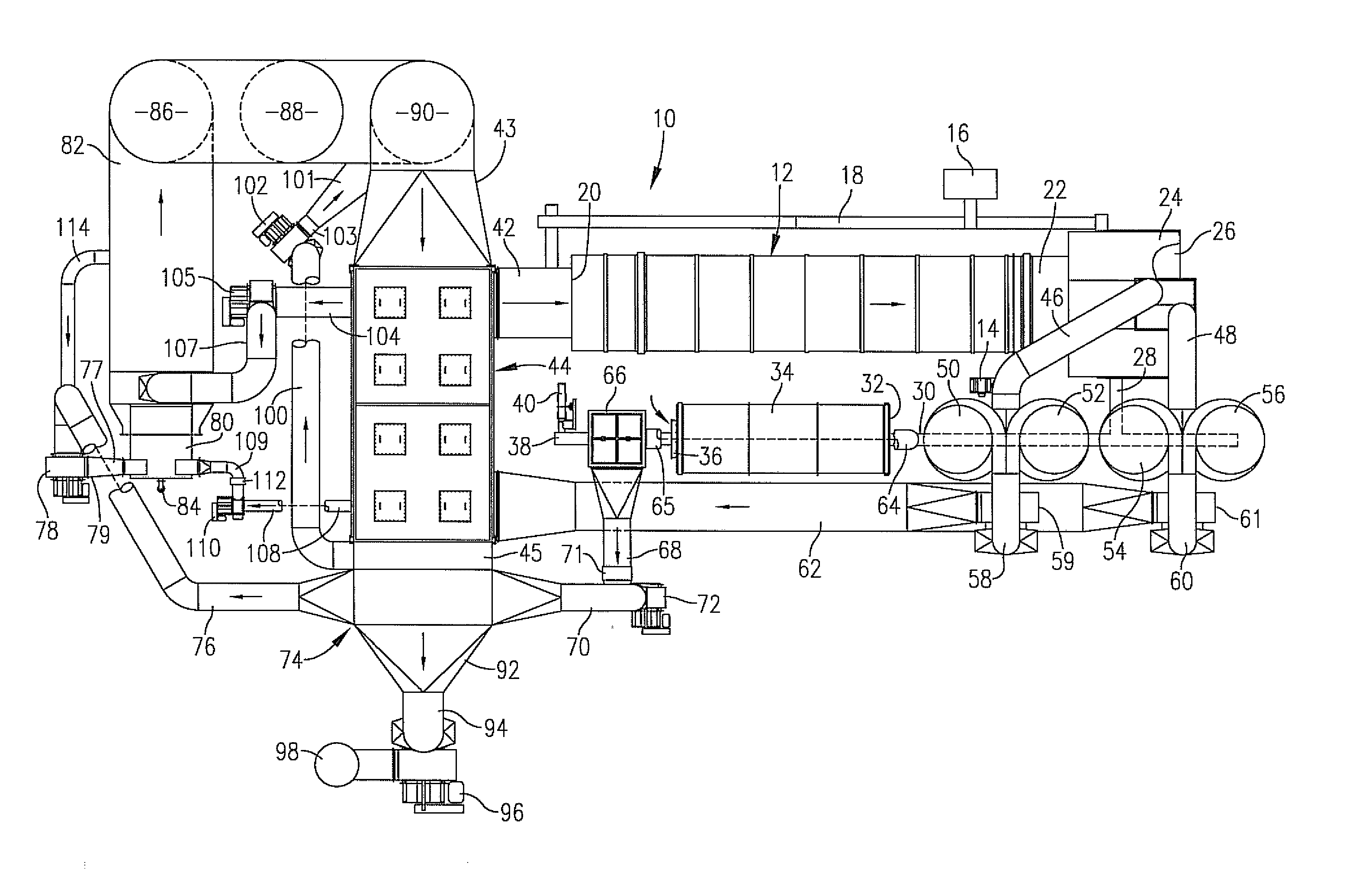

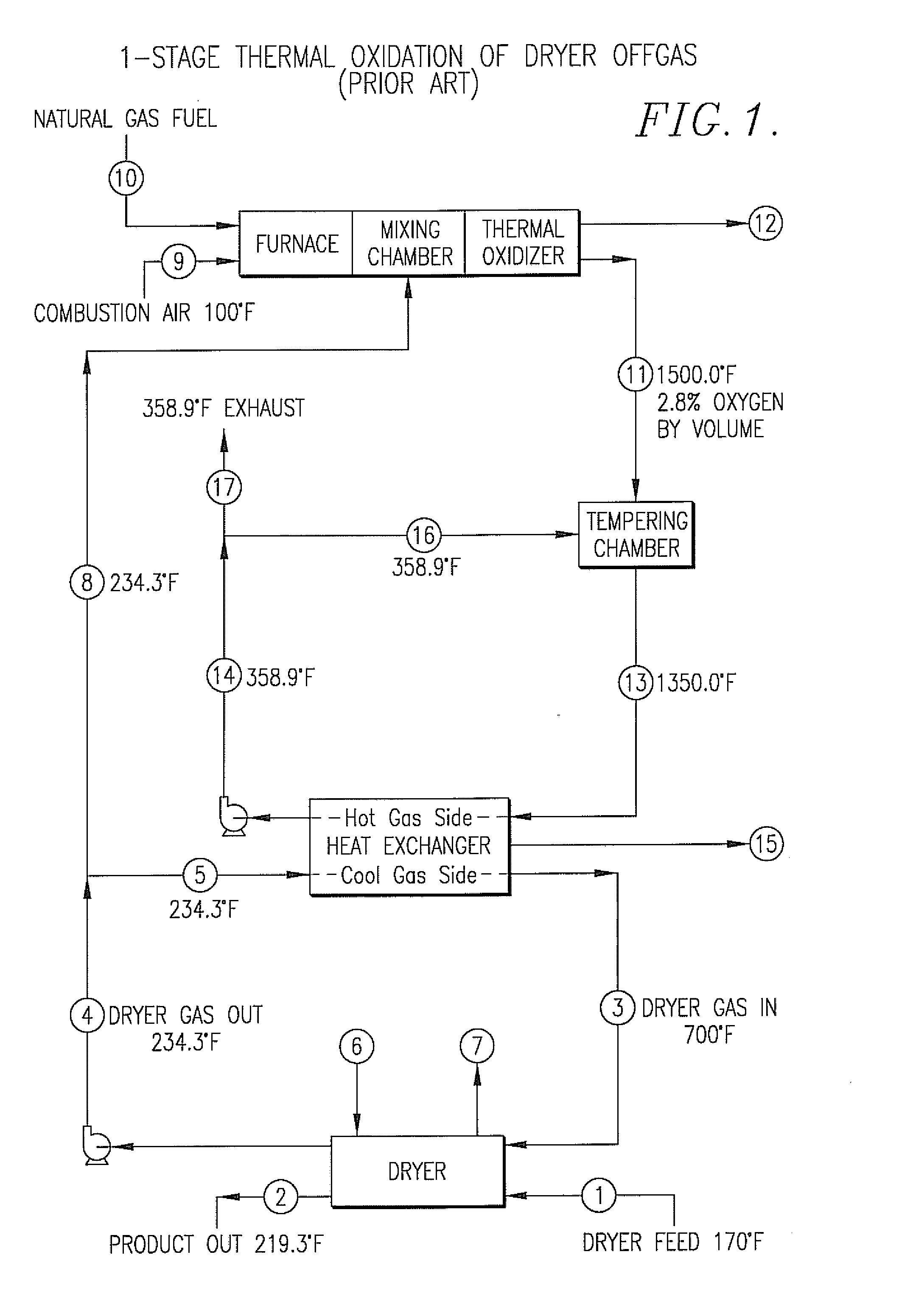

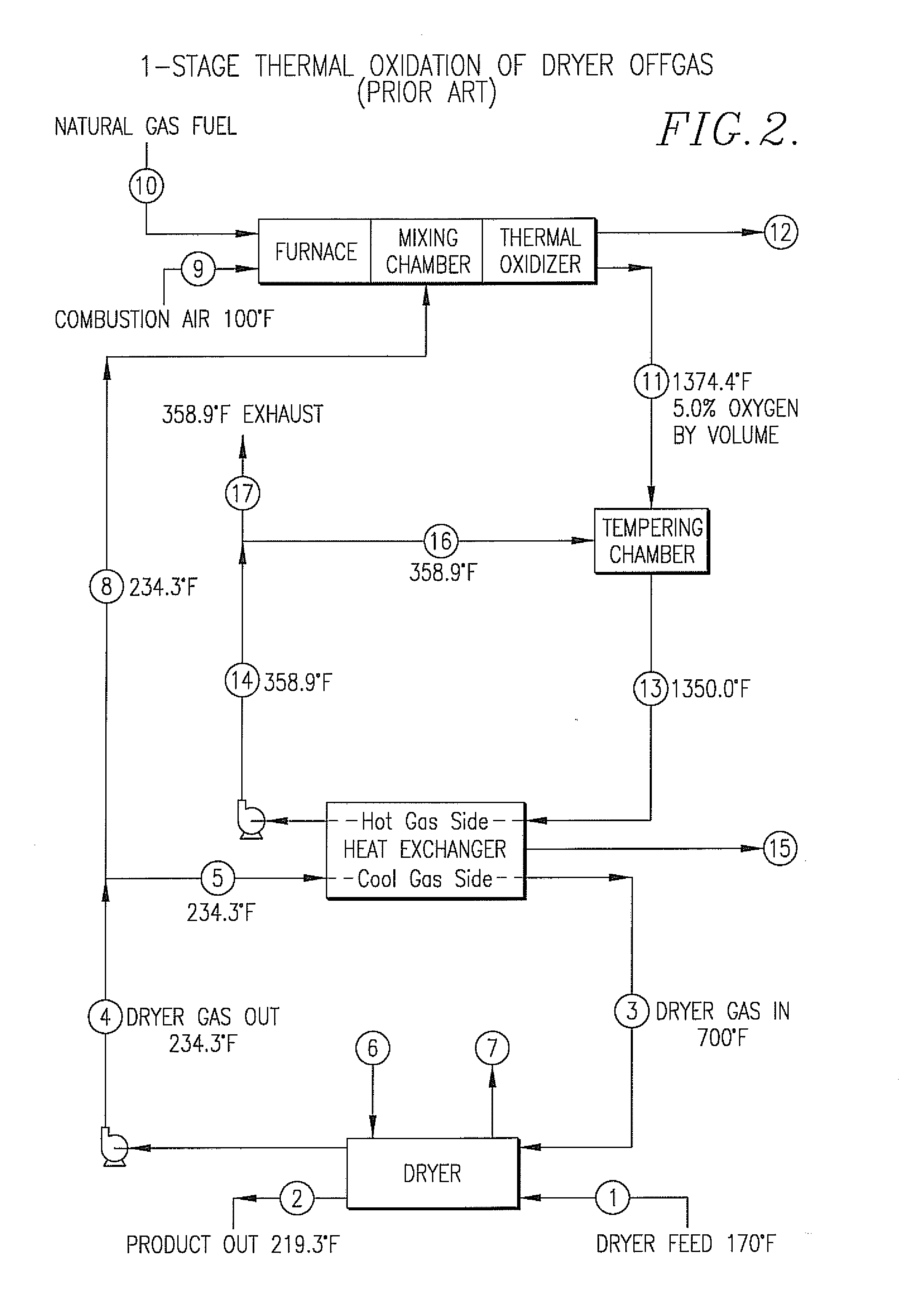

Two-stage thermal oxidation of dryer offgas

ActiveUS20080222913A1Increase temperatureReduce the temperatureDrying solid materials with heatDrying gas arrangementsAtmospheric airOxygen

A method and apparatus are provided for reducing the VOC, CO, and, alternatively, the NOx content of dryer offgas that is discharged into the atmosphere from a moist organic product drying process using thermal oxidizing apparatus that includes a burner, furnace, mixing chamber, thermal oxidizer, tempering chamber, and an indirect gas-to-gas heat exchanger. The dryer offgas is separated into two portions, with a larger portion being preheated by indirect heat exchange with the hot gaseous output from the thermal oxidizer. The non-preheated portion is directed to the burner in the function of flue gas recycle for NOx control. The preheated portion is separated into two portions, with one portion being directed to the furnace / mixing chamber of the thermal oxidizing apparatus. The other portion of the preheated offgas is recycled to the hot gas inlet of the dryer and serves the function of dryer heat transfer media. Ultimately, all the dryer offgas enters the thermal oxidizer, and comprises a smaller non-preheated portion directed to the burner and a larger preheated portion directed to the furnace / mixing chamber. By preheating a large proportion of the offgas directed to the thermal oxidizing apparatus, simultaneous achievement of an adequate thermal oxidizer temperature, 1600° F., and an adequate oxygen concentration of 5% by volume is achieved for optimized thermal oxidation of carbon monoxide and volatile organic compounds.

Owner:AEROGLIDE

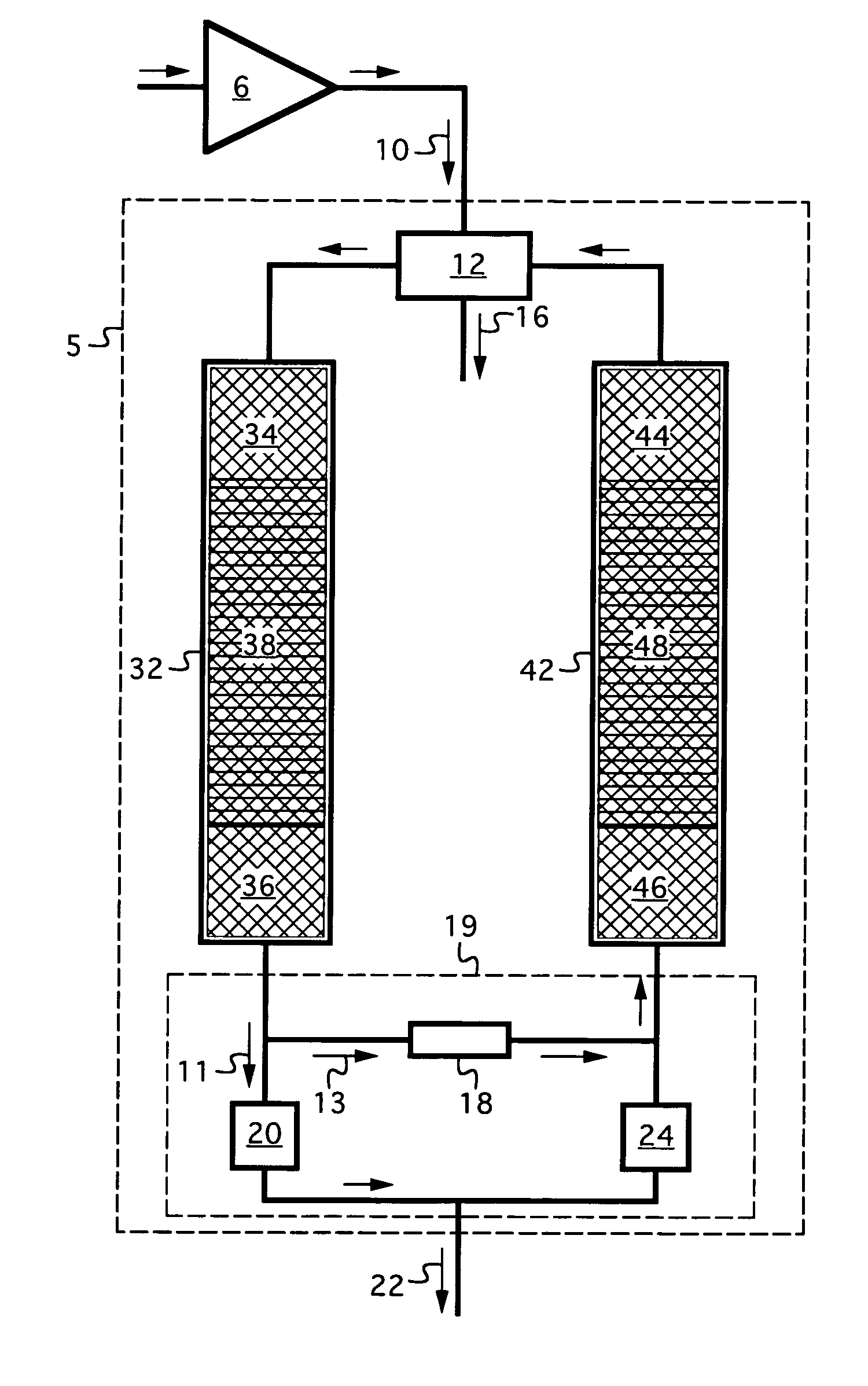

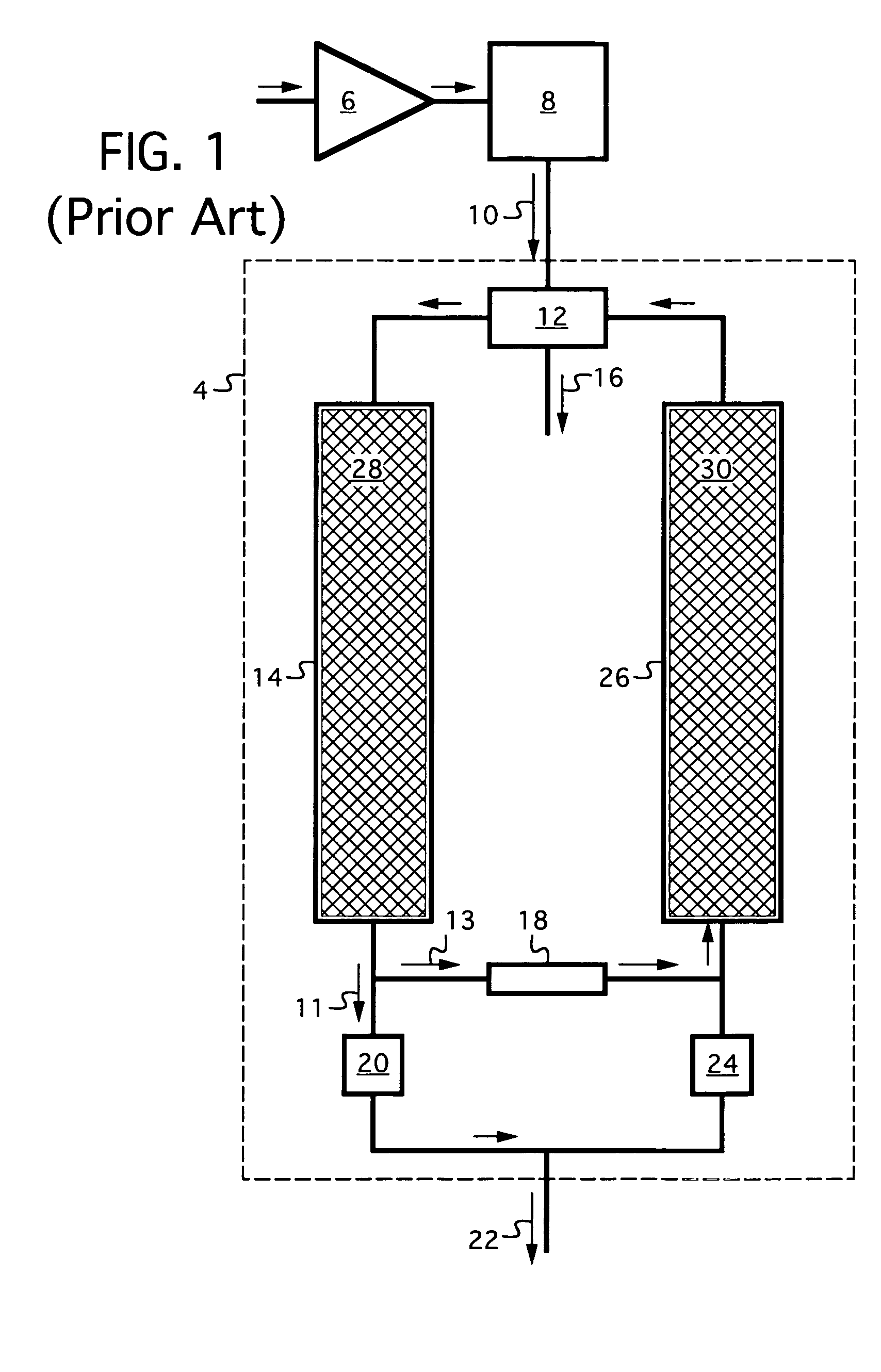

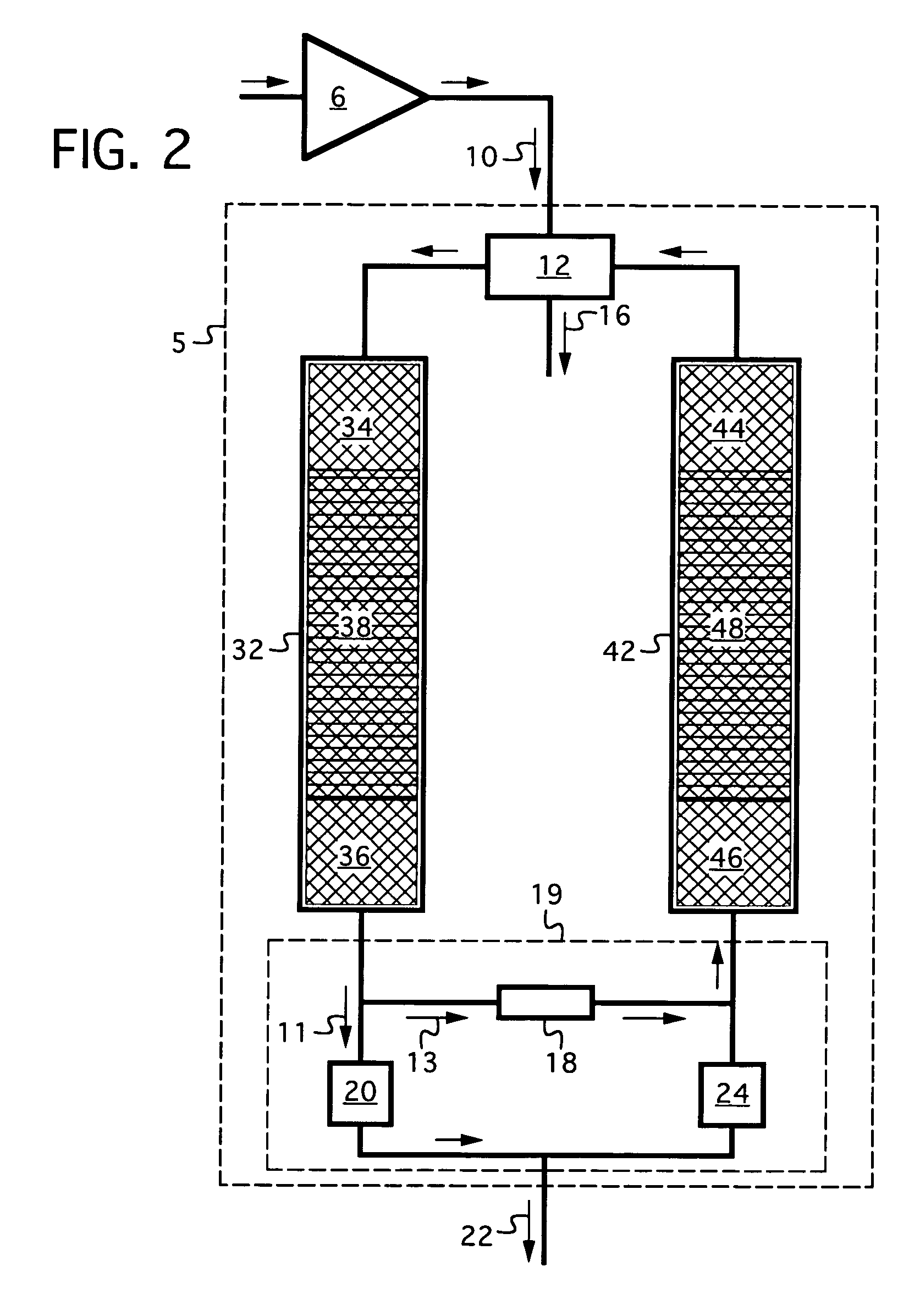

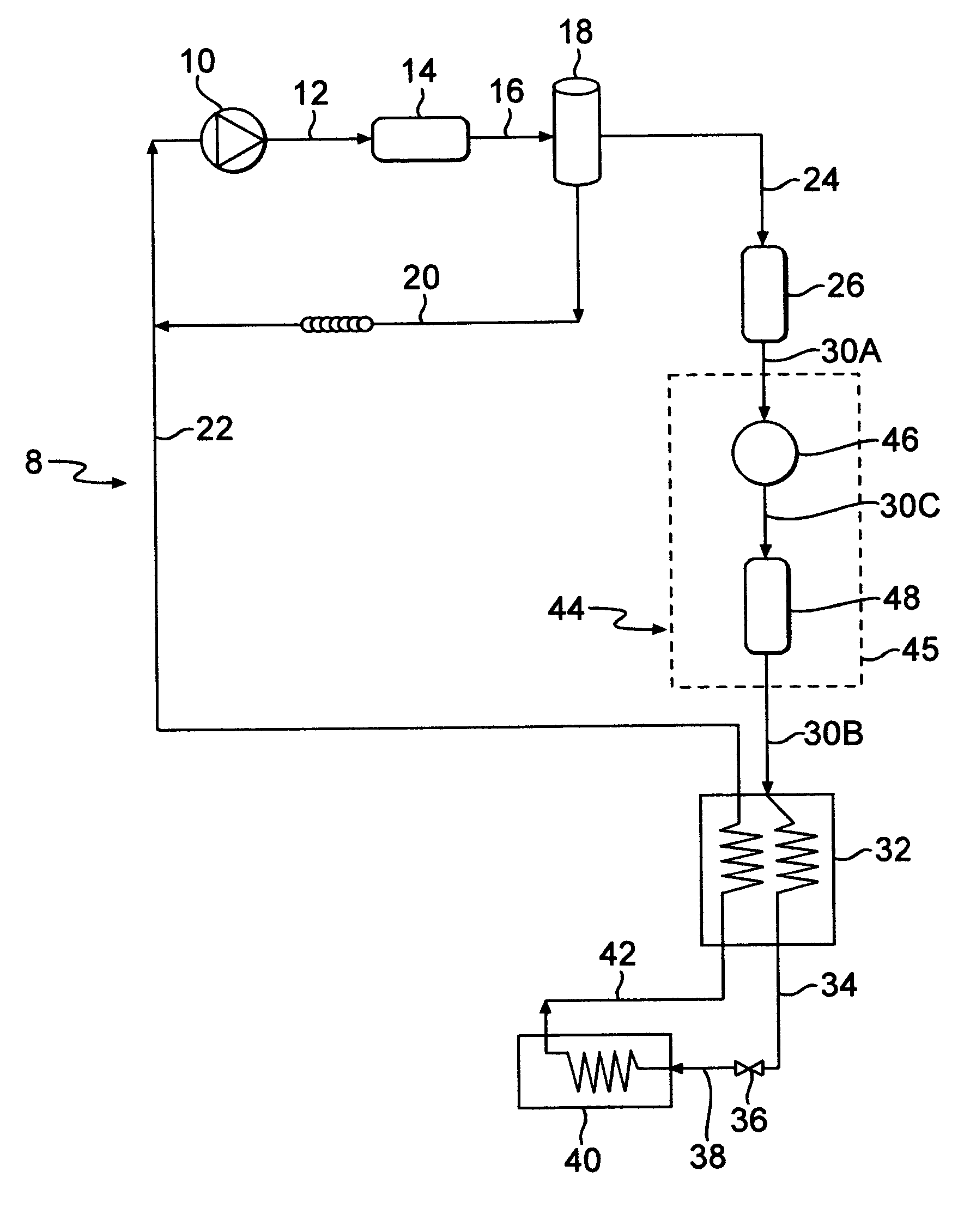

Device and method for removing water and carbon dioxide from a gas mixture using pressure swing adsorption

A pressure swing adsorption (PSA) dryer for separating water and carbon dioxide from a gas stream includes two compound adsorbent columns [32, 42]. Each column comprises a primary adsorption material for adsorbing water and a secondary adsorbent that adsorbs carbon dioxide. The secondary adsorbent comprises a solid amine. The secondary adsorbent may be, for example, a highly porous polystyrene matrix with amine groups bonded to the porous resin structure. Preferably, a mixture of the primary and secondary adsorbent materials forms an intermediate layer [38, 48] sandwiched between a top layer [34, 44] and bottom layer [36, 46] of pure water adsorbent material in each of the columns [32, 42].

Owner:MMR TECH INC

Systems for prevention of HAP emissions and for efficient drying/dehydration processes

InactiveUS20070163142A1Economical and simplifiedPrevent oxidationDrying using combination processesDrying solid materials without heatHigh water contentMoisture

This invention discloses systems, apparatuses and methods for drying or dehydrating high moisture content feedstock to dry or low moisture products. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel and wherein the processing unit forms the dried material from the dryer vessel into granules, pellets, flakes or other desired form for the final product. The systems, apparatuses and methods of this invention also provide for prevention of release of HAP, including VOC, emissions from manufacturing facilities in conjunction with or independent of the above treatment of high water content feedstock.

Owner:EARTHRENEW INC

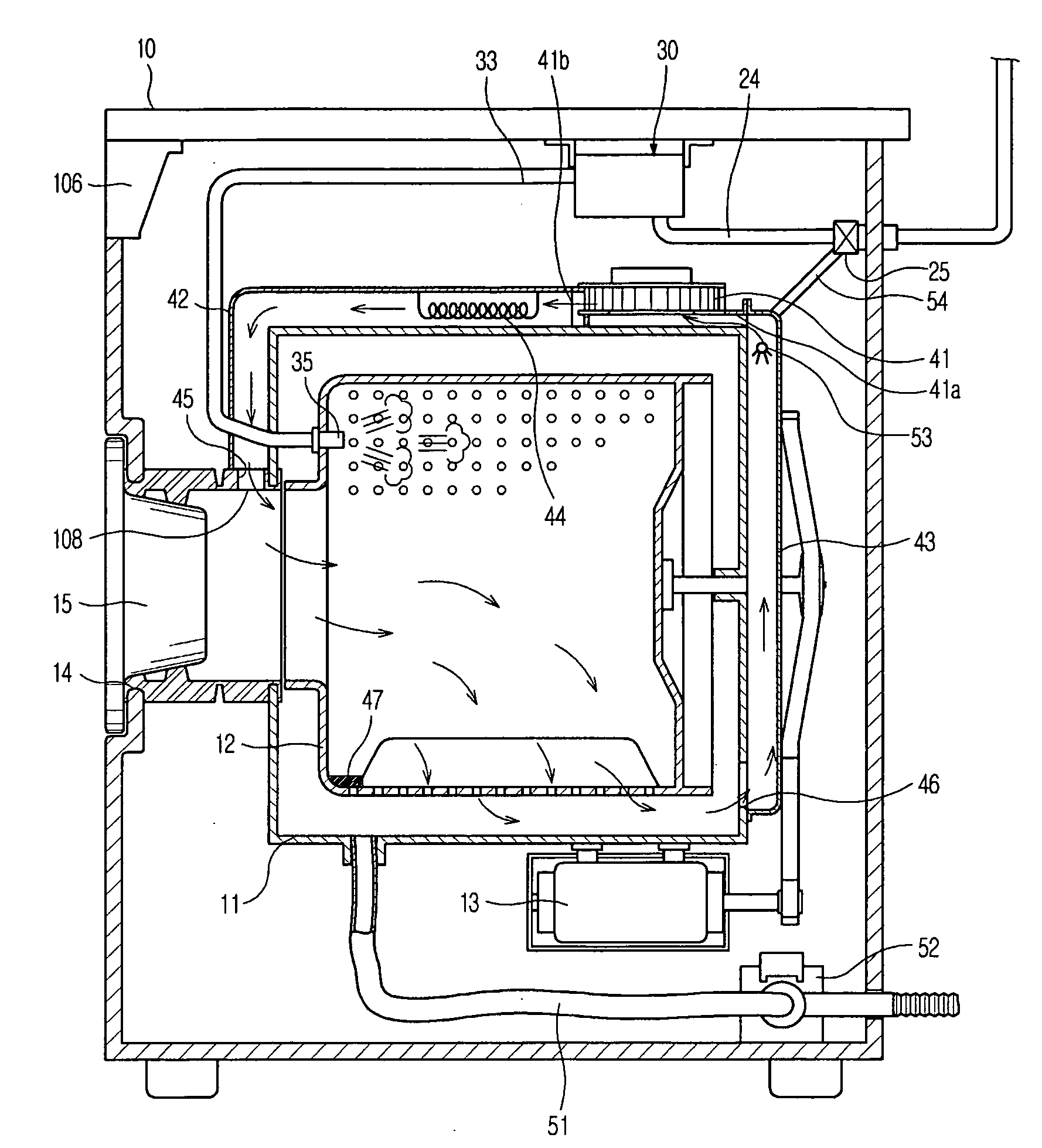

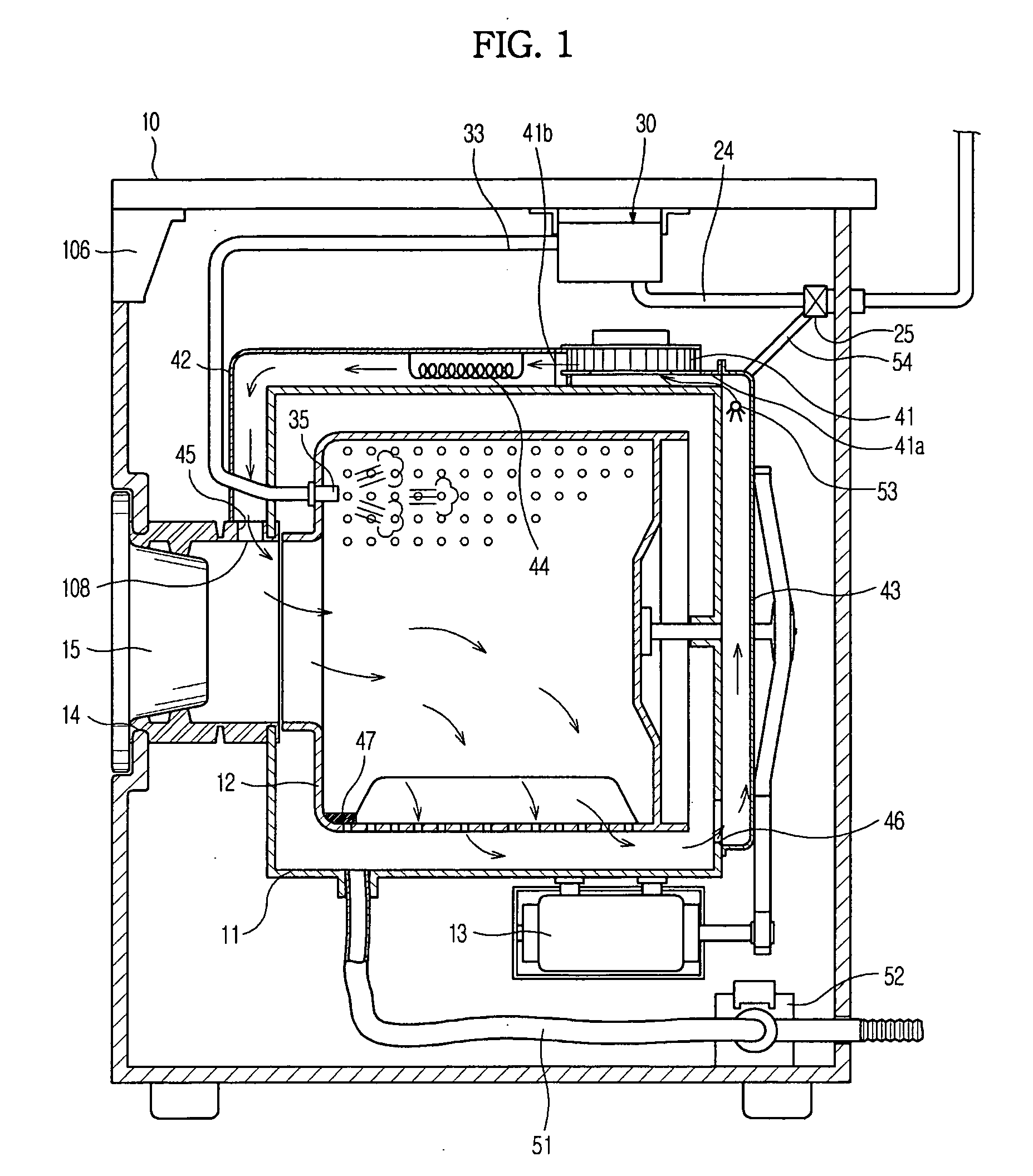

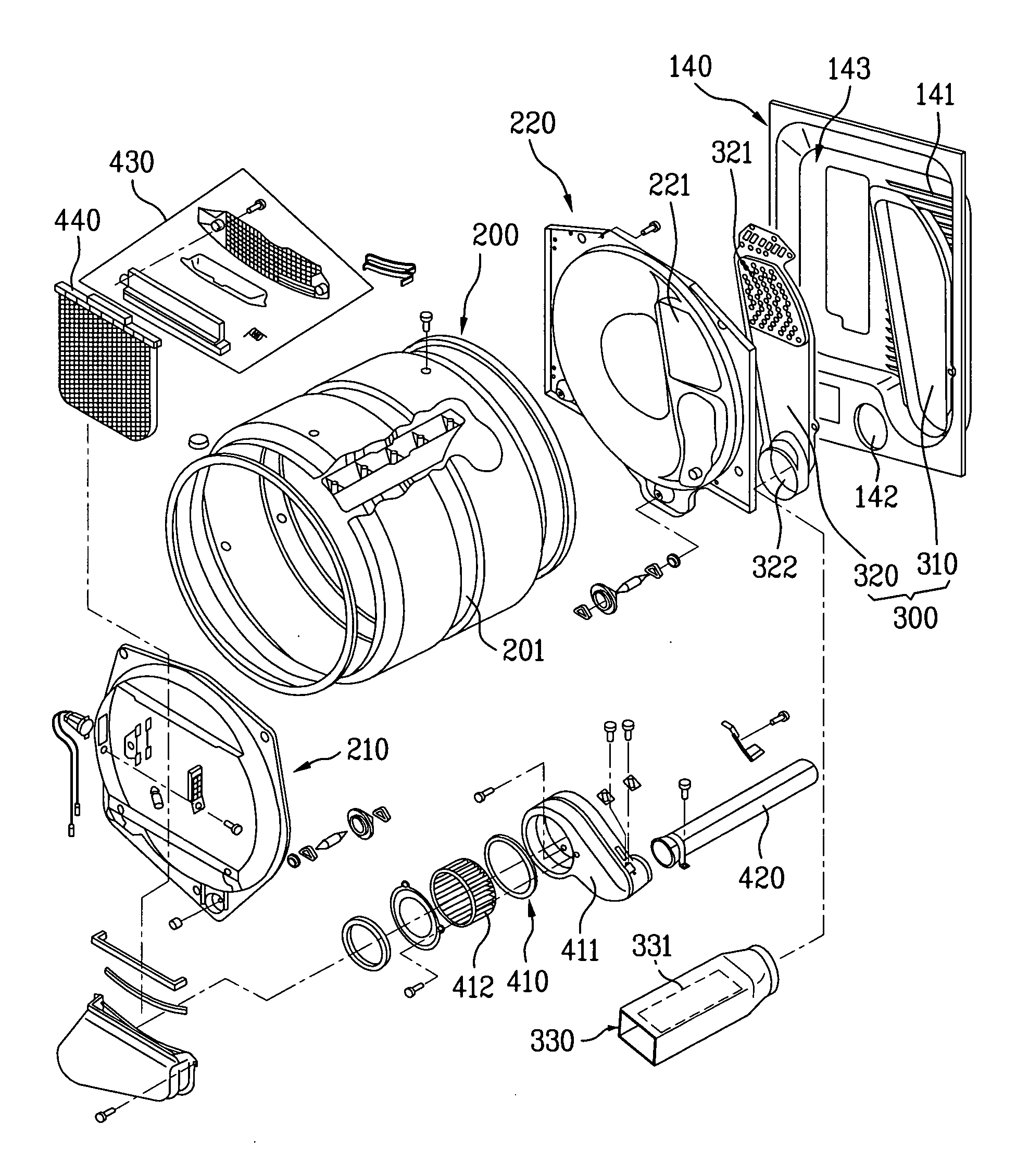

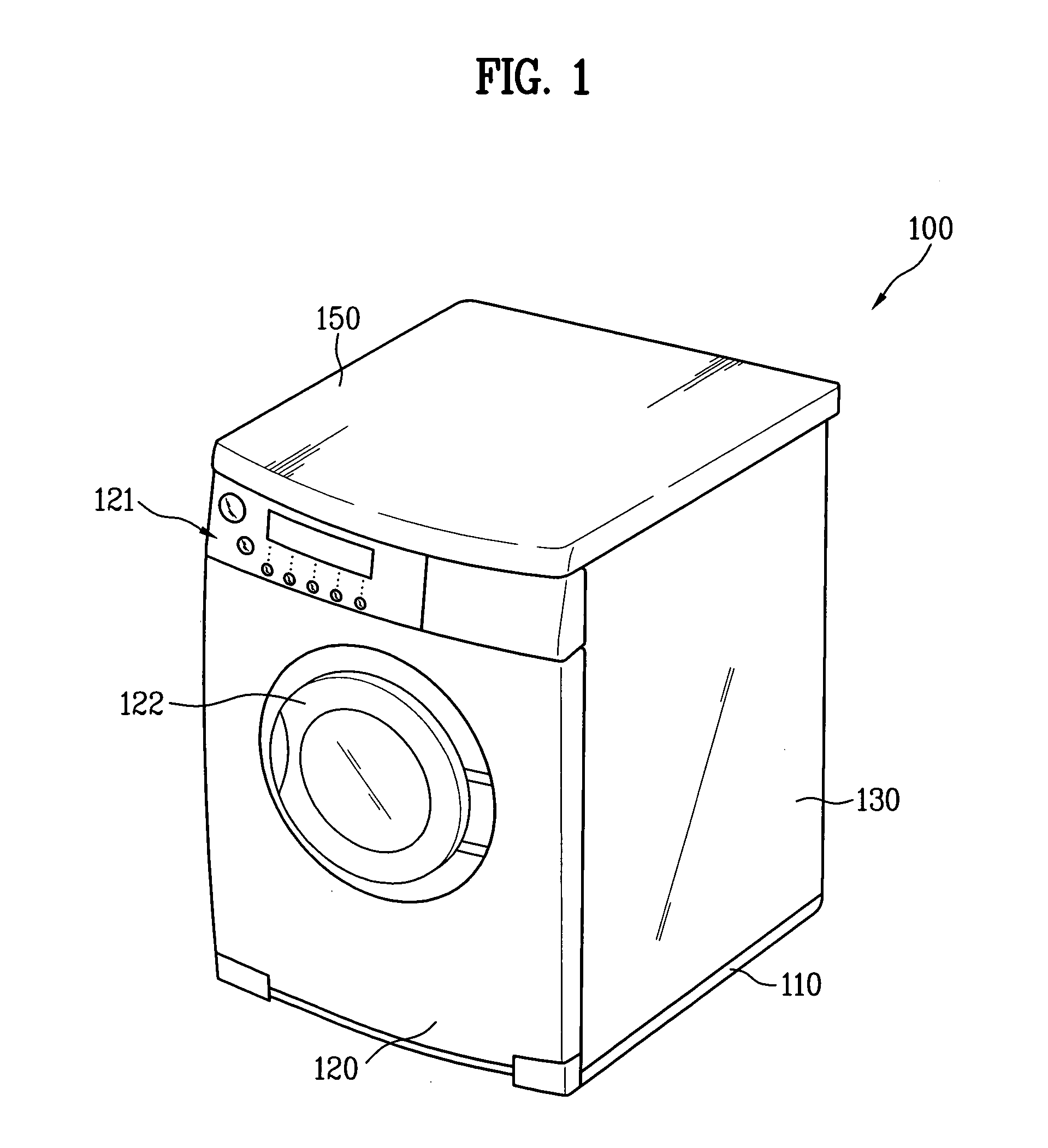

Dryer and method of controlling cleaning operation thereof

InactiveUS20090249639A1Drying using combination processesDrying solid materials with heatEnvironmental engineeringMoisture

Disclosed herein are a dryer and a method of controlling a cleaning operation thereof that are capable of supplying moisture into a drying chamber of the dryer to wet contaminants in the drying chamber and blowing air to the wetted contaminants to remove the contaminants. The method includes supplying moisture into a drying chamber to wet contaminants in the drying chamber and removing the contaminants wetted by the moisture.

Owner:SAMSUNG ELECTRONICS CO LTD

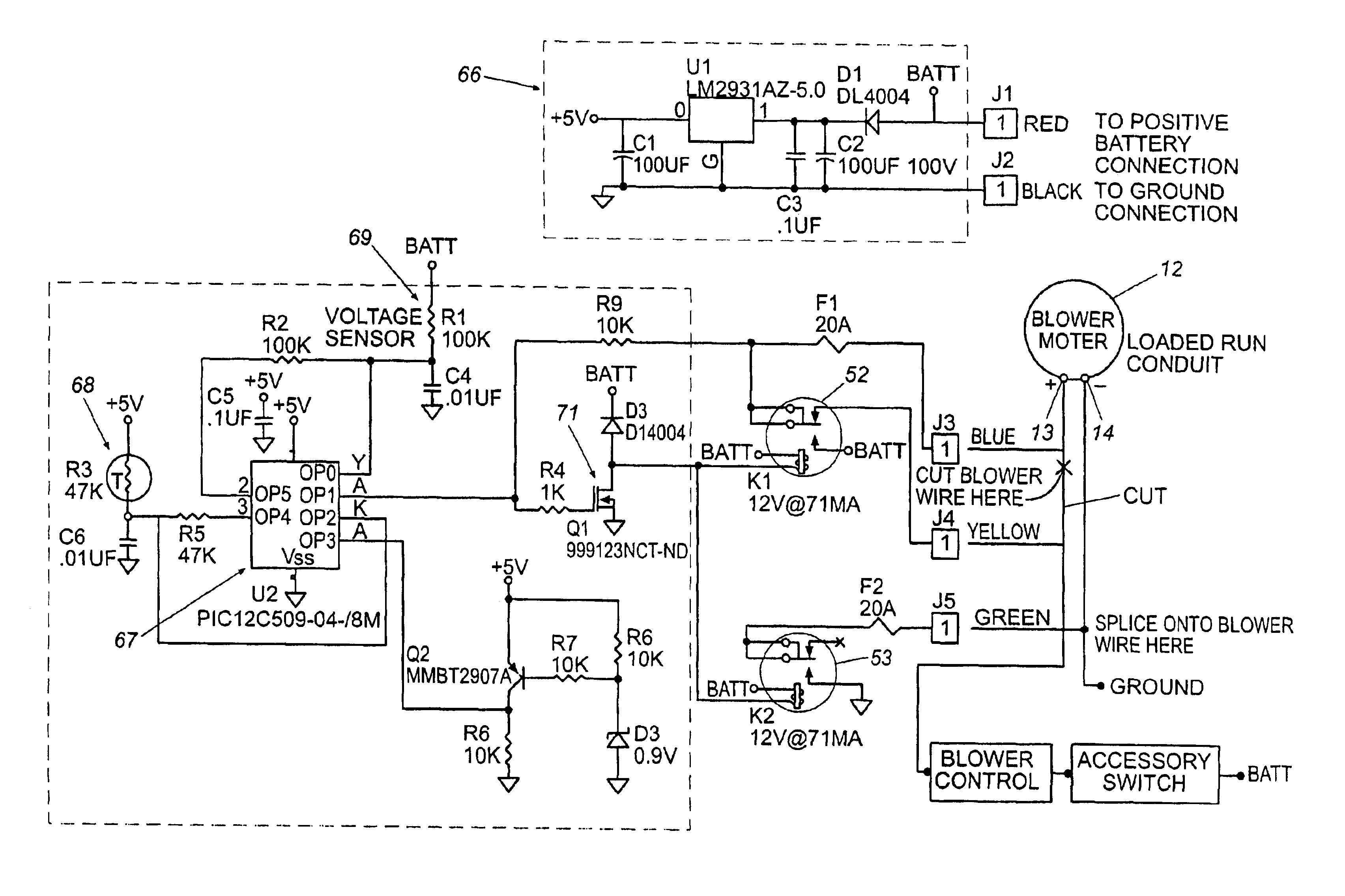

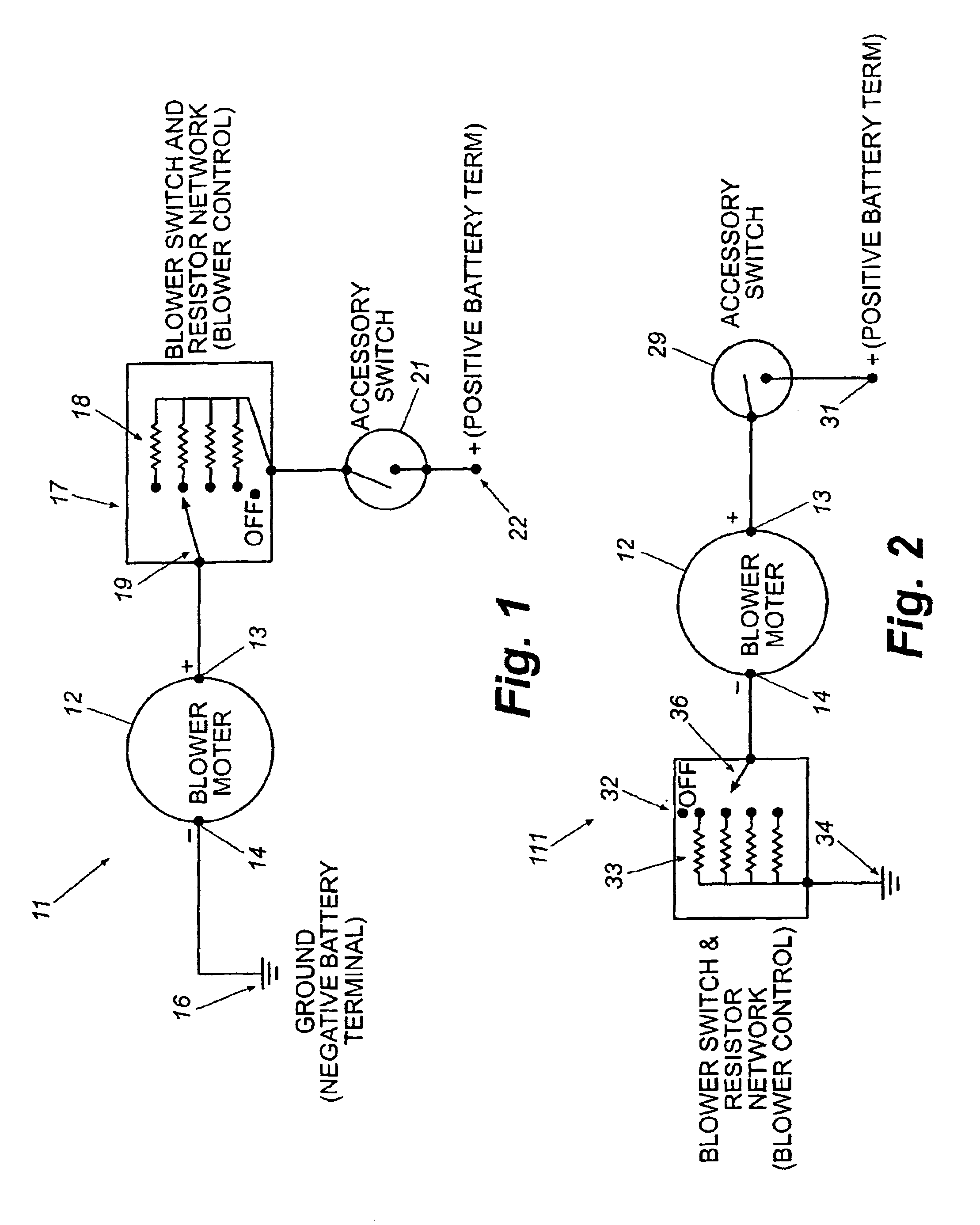

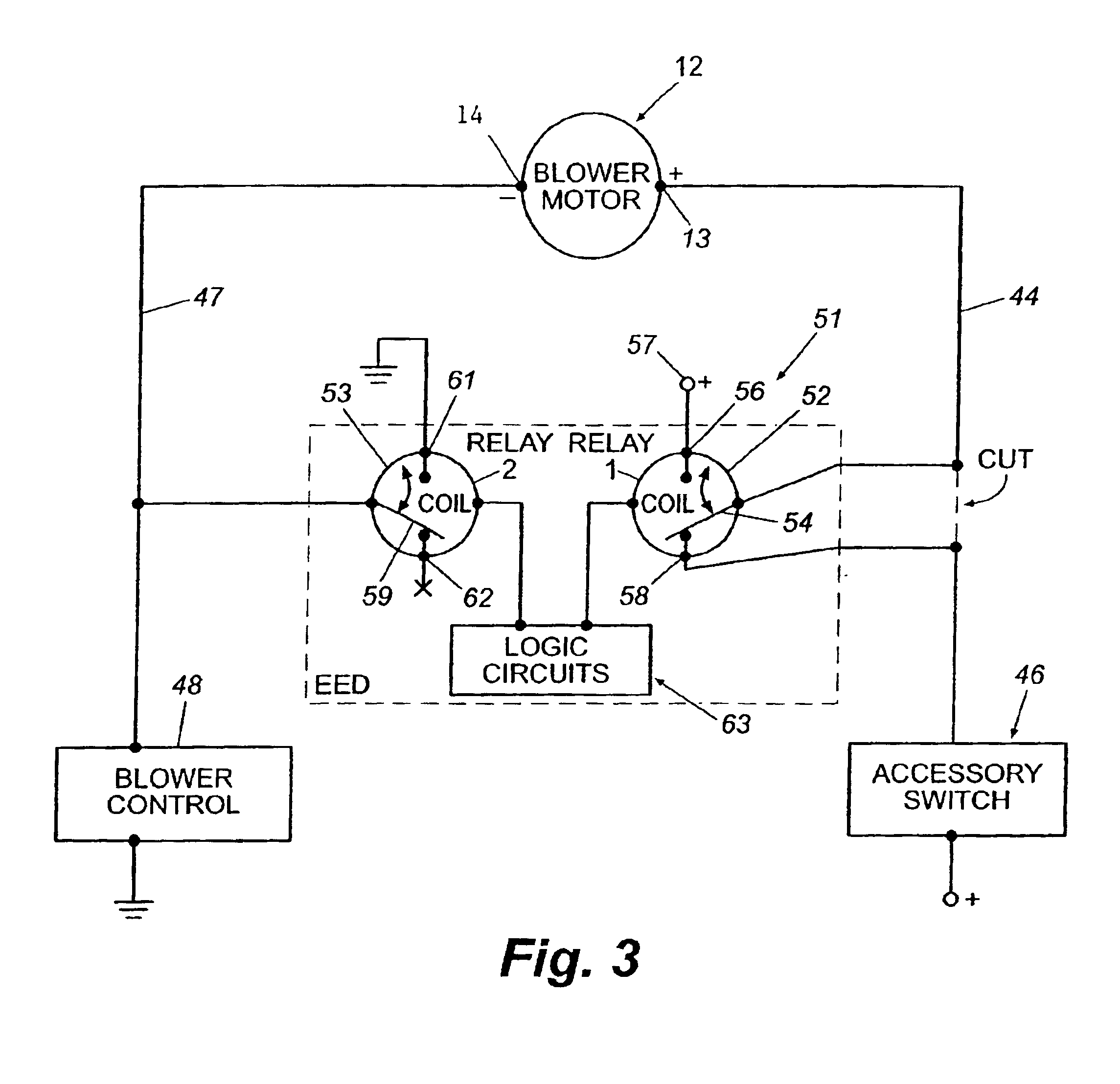

Electronic evaporator dryer for eliminating odors in vehicle air conditioning systems

An apparatus and method for drying condensate from the heat exchanger of a vehicle's air conditioning system after operation in order to thwart odor buildup is provided. The apparatus and method operate regardless of whether the system's blower control circuit is positively or negatively switched. The apparatus includes relays that bypass the normal operating electrical routing to the air conditioning system's blower motor to operate the blower directly. The method comprises determining that the engine of the vehicle has been switched off and that the air conditioning system of the vehicle was in operation prior to the engine being switched off. If the conditions are met, the air conditioning system's blower is operated on a predetermined time schedule to circulate air in the air conditioning system to dry condensate therefrom. In this way, growth of odor-causing fungus and bacteria is inhibited.

Owner:AIRSEPT

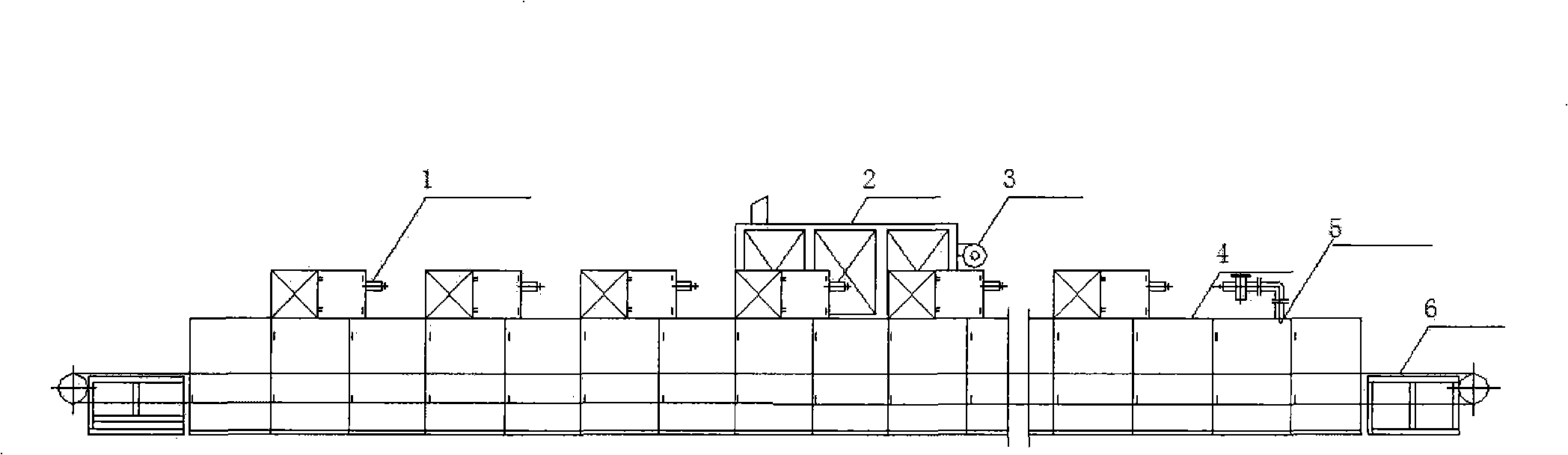

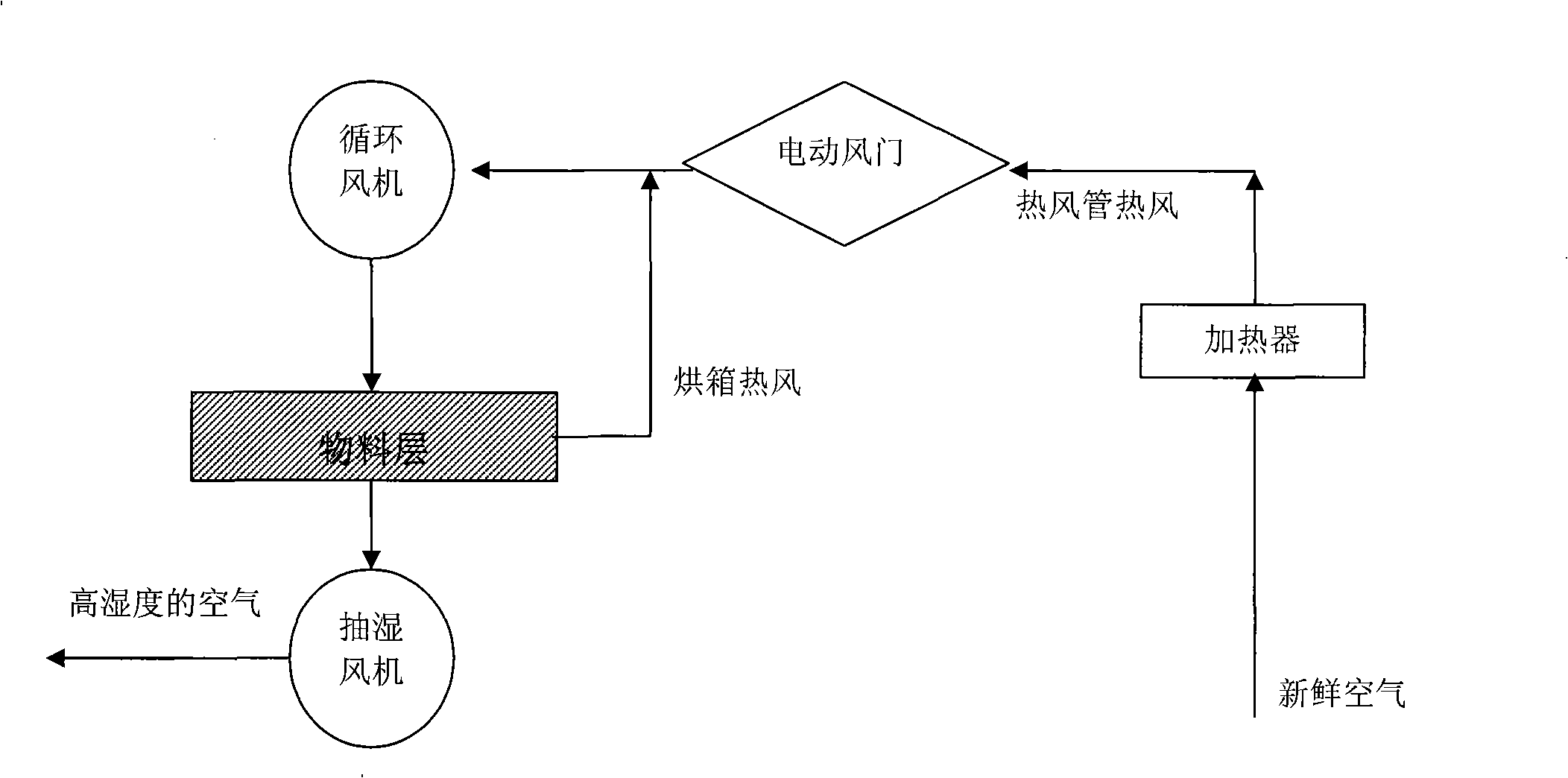

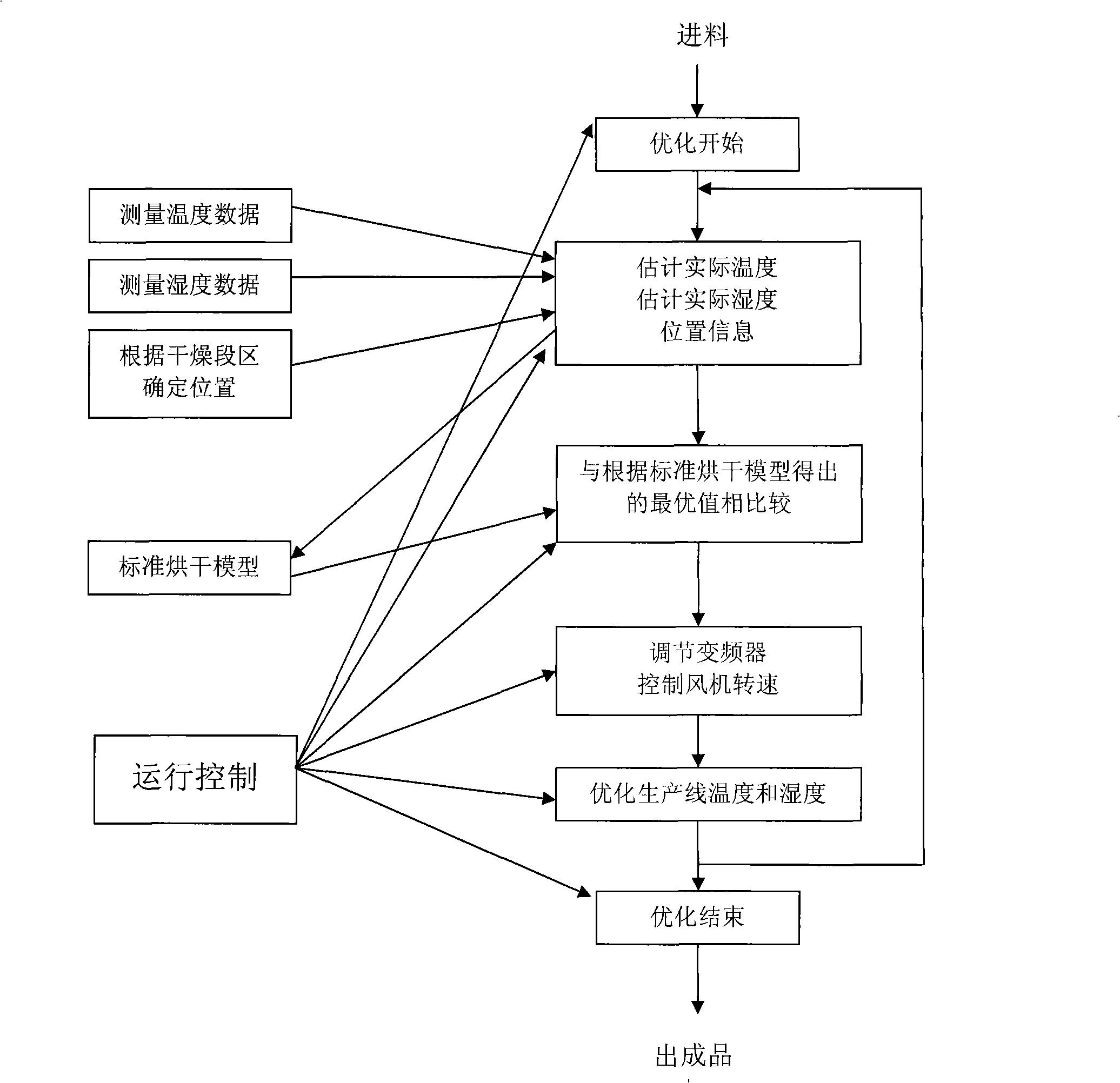

Paper pulp molding drying line based on variable-frequency control technique and preparing process thereof

InactiveCN101329136AAutomatic realization of segmental temperature controlIncrease productivityDrying gas arrangementsDrying machines with progressive movementsThermal energyAir volume

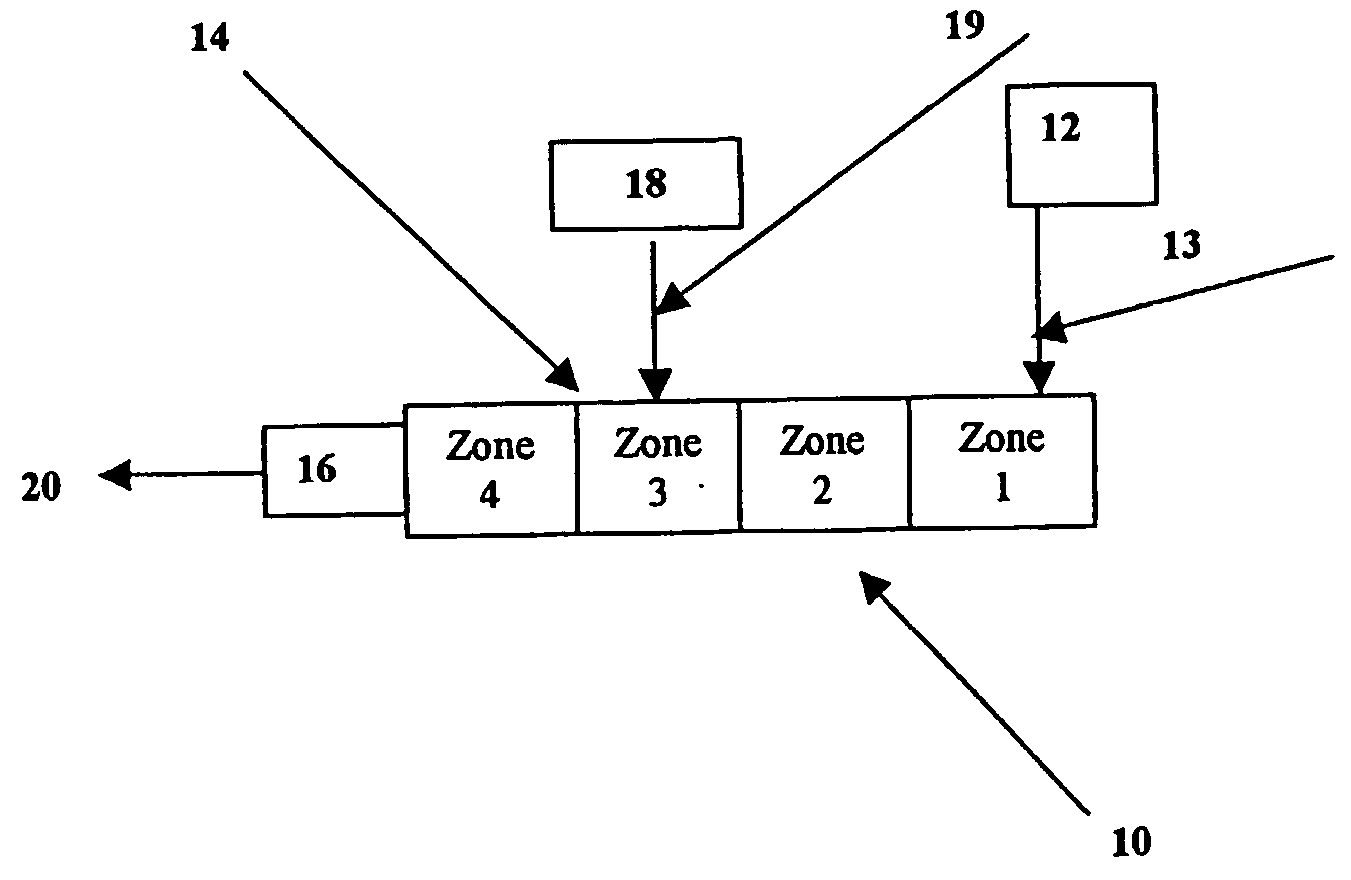

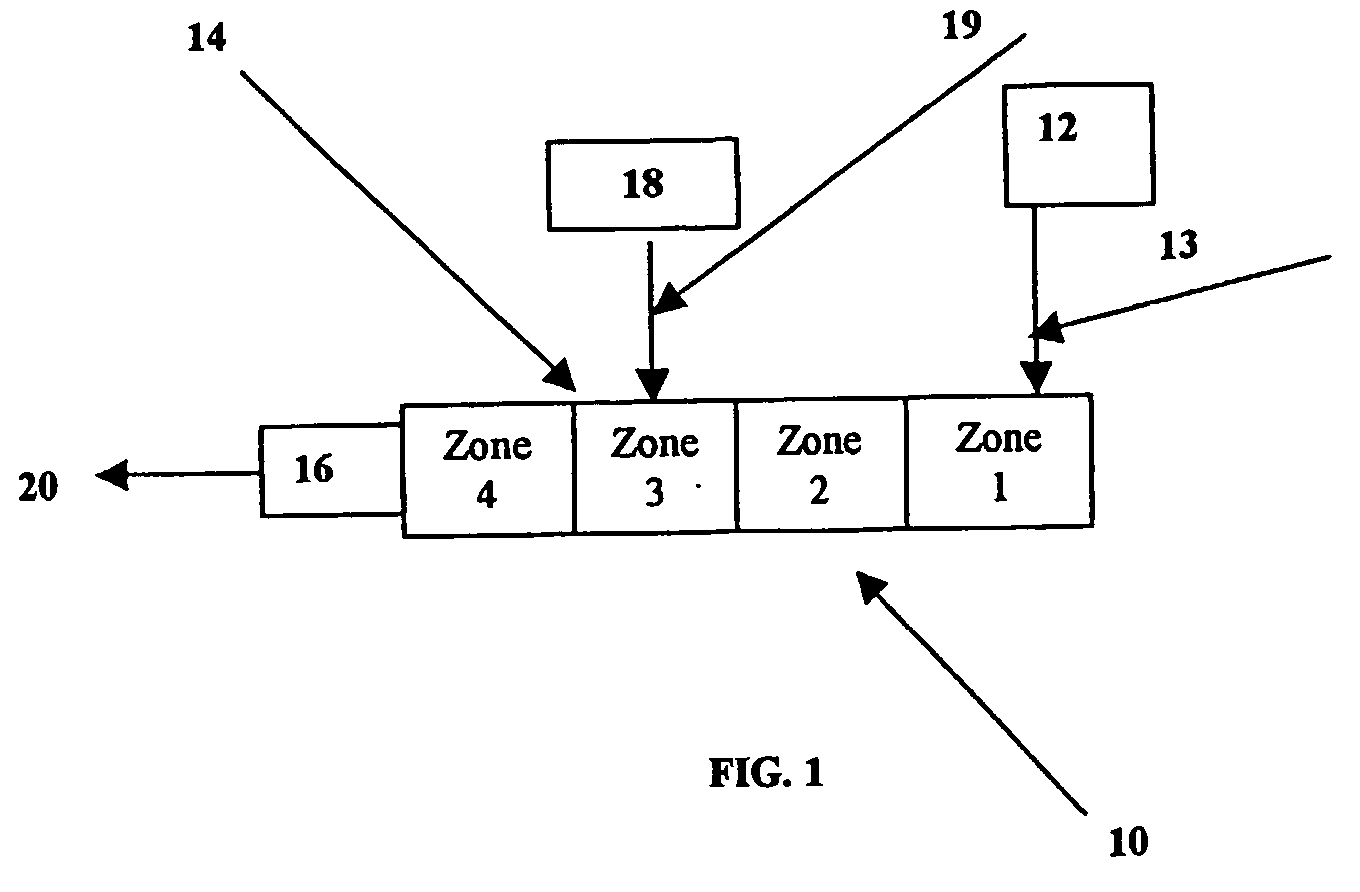

The invention discloses a drying line of pulp moulding that is based on a frequency-varying speed regulation technique, and a production technique of the drying line, and is applied into a belt drying line with convectional hot air and used for designing a set of automatic controlling systems with optimized efficiency; the invention implements the modeling of complex objects according to the drying property of pulp moulding and different sizes and weights of wet ground papers, adopts a process control technique, the alternate-current frequency-varying speed regulation technique and a modern detecting technique, realizes stepless control of frequency-varying speed regulation of a circulating fan, an electric air door, a dehumidifying fan, a drive motor of conveying chains according to temperature and humidity signal that are detected on the spot, reasonably adjusts the running speed of a conveying belt inside a parching channel, the working temperature of a desiccator in each segment, and the blast volume of hot air and the discharge of water vapor, etc., and forms a reasonable drying curve, thus reducing product deformation to the utmost degree, saving the loss of electricity energy and heat energy to the utmost extent, accelerating parching speed, increasing the yield of the parching production line, and realizing optimal control.

Owner:GUANGDONG UNIV OF TECH

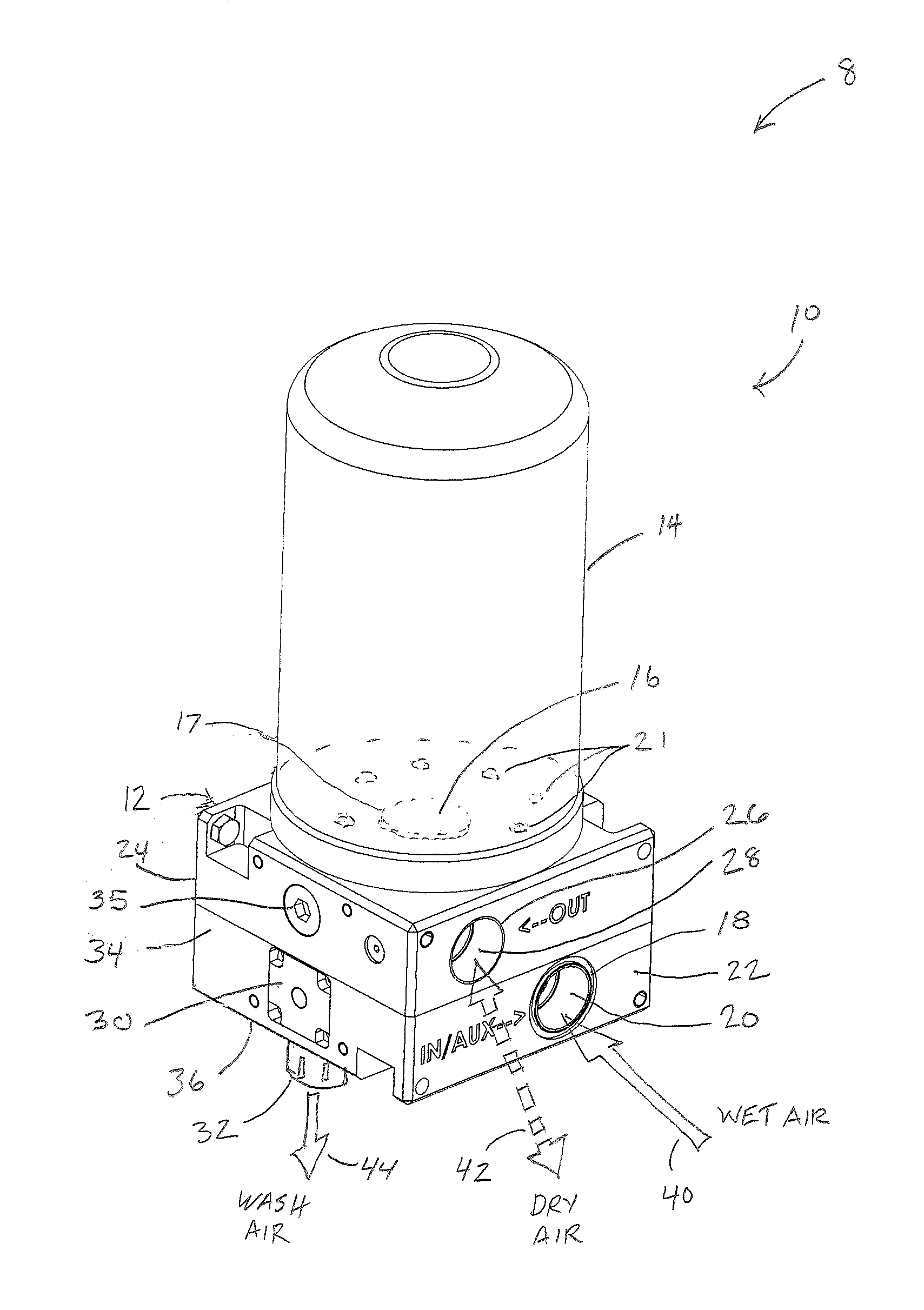

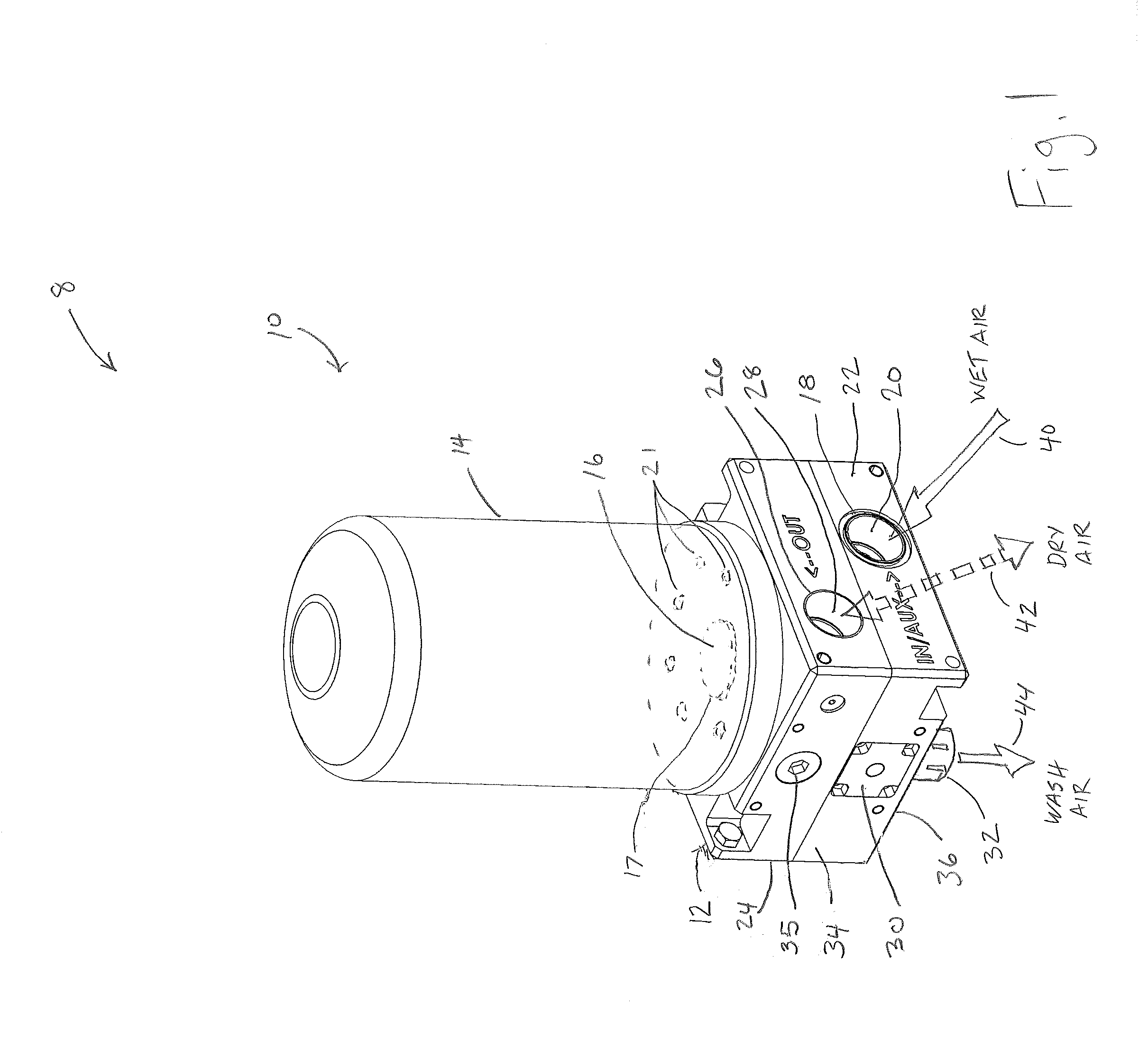

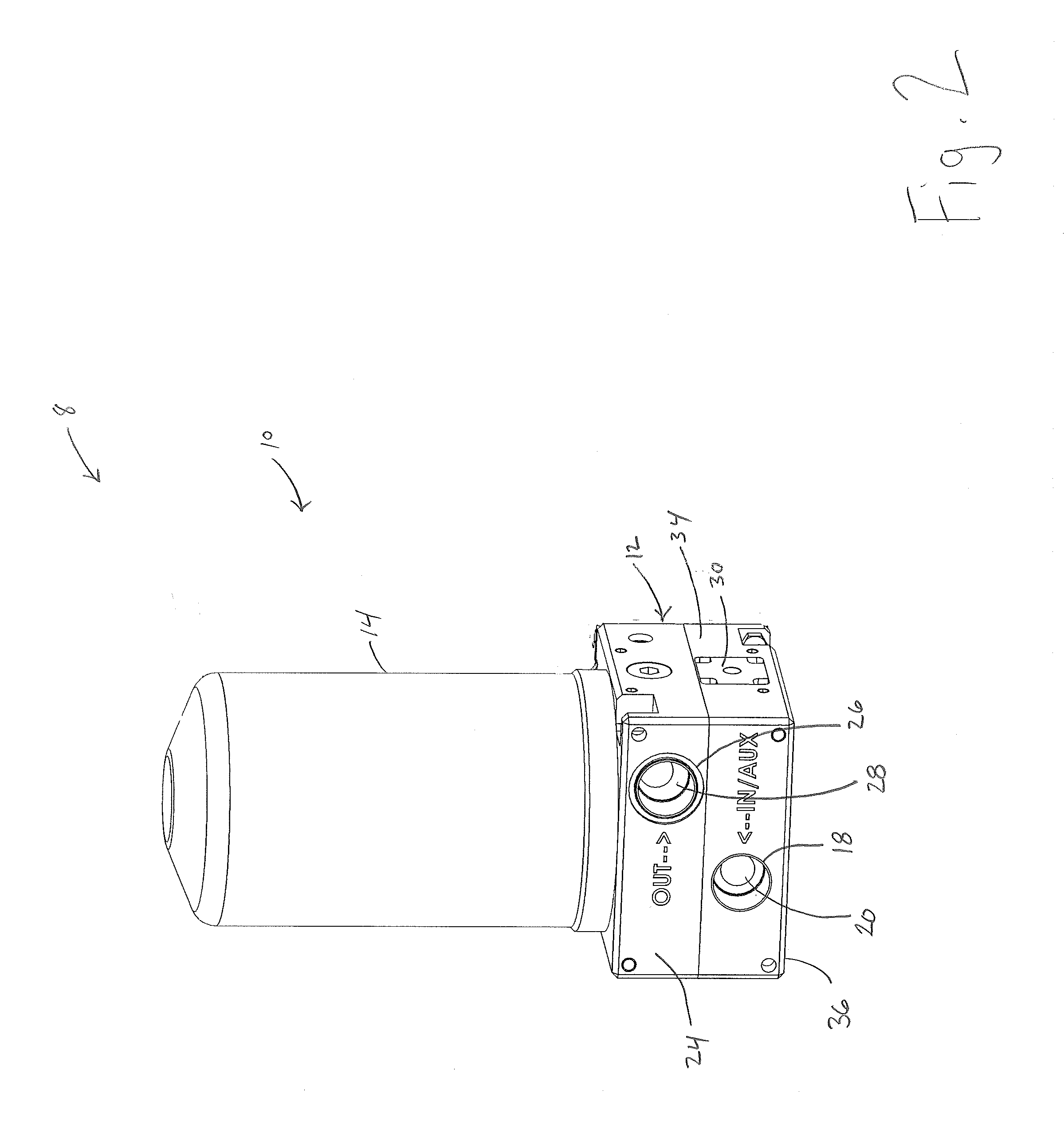

Regenerative air dryer

ActiveUS20140013956A1Simplified air pathsReduces external pipingGas treatmentIsotope separationDesiccantAir dryer

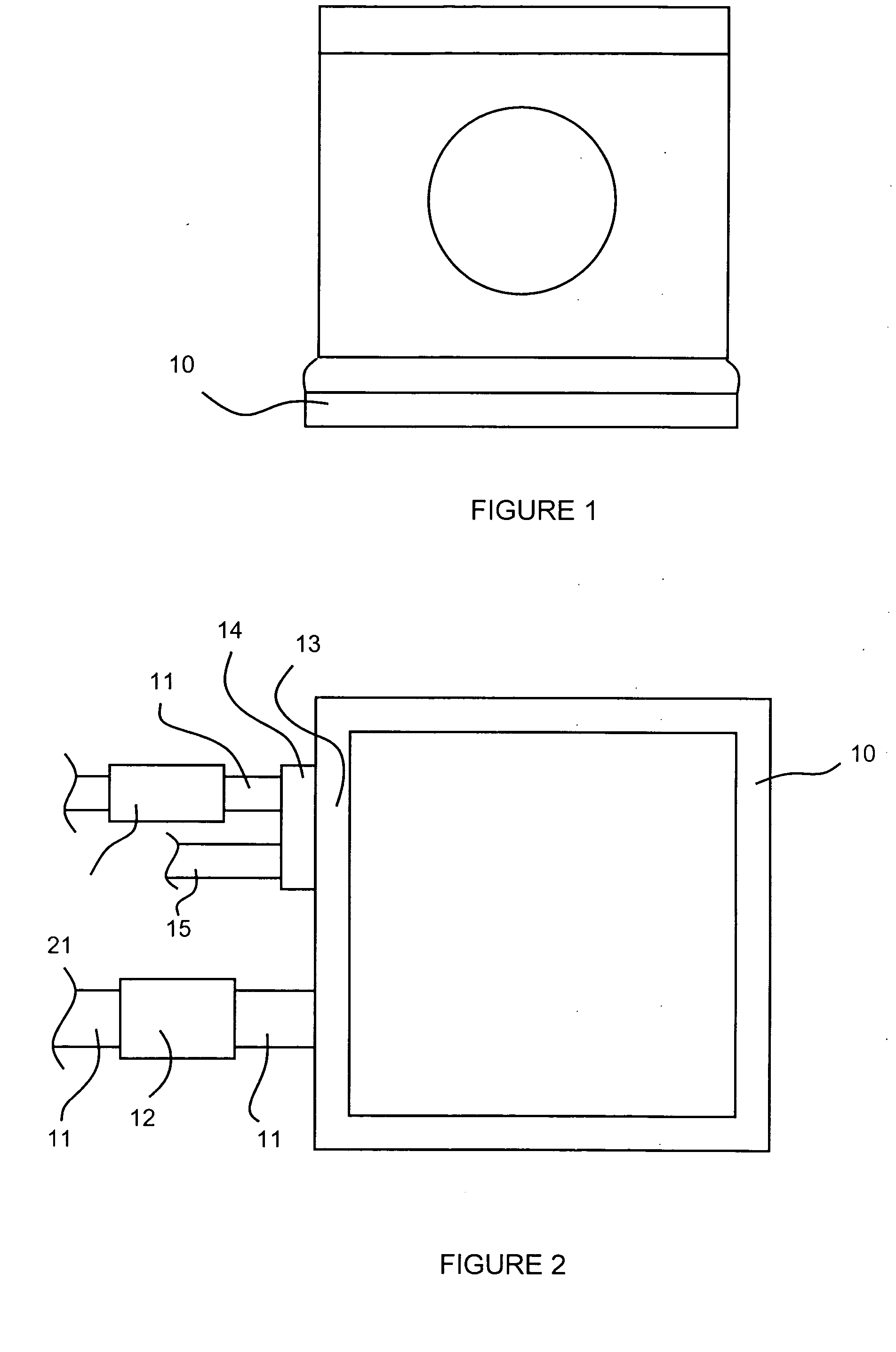

A regenerative air drying system including at least one dryer module including a housing having a inlet air passage, an outlet air passage, and a wash air passage. The air dryer system further includes a desiccant canister mounted to the housing and in communication with the inlet, outlet, and exhaust air passages, and a single controllable valve selectively moveable between a first position and a second position, wherein the single controllable valve, when in the first position, forms a supply air flow path from the inlet air passage, through the desiccant canister in a first direction, and to the outlet air passage, and when in the second position, forms a wash air path from the outlet air passage, through the desiccant canister in a direction opposite the first direction, and to the exhaust air passage.

Owner:SUBURBAN MFG

Test method of sulphate content of desulfurization gypsum

InactiveCN101625300ASimple methodFast analysisWeighing by removing componentCooking & bakingWater content

The invention provides a test method of the sulphate content of desulfurization gypsum, comprising the following steps: 3-5 grams of gypsum samples are taken to be heated and dried for 30-60 minutes in a baking oven with the temperature of 42-48 DEG C and then placed into a drier to be cooled to room temperature and weighed by a 1 / 10000 level balance, the gypsum samples are repeatedly heated and weighed till the gypsum samples have constant weight, and the weight W (g) of the gypsum samples is recorded; the gypsum samples are placed back to the baking oven to be heated and dried for 30-60 minutes under the temperature of 350-370 DEG C and then placed into the drier to be cooled to the room temperature and weighed by the 1 / 10000 level balance, the gypsum samples are repeatedly heated and weighed till the gypsum samples have constant weight, and the weight W1 (g) of the gypsum samples is recorded; the computation of the crystallization water content of the gypsum samples is as follows: the crystallization water content X(%)=(W-W1)*100 / W, and the computation of the sulphate content of the gypsum samples is as follows: the sulphate content is indicated by calcium sulphate dehydrate content, CaSO4.2H2O(%)=X*100 / 20.9275. The method is simple, convenient and fast; and in addition, compared with the prior art, the invention greatly enhances the analysis speed, simplifies the analysis steps and decreases the experimental apparatus.

Owner:HEBEI ELECTRIC POWER RES INST

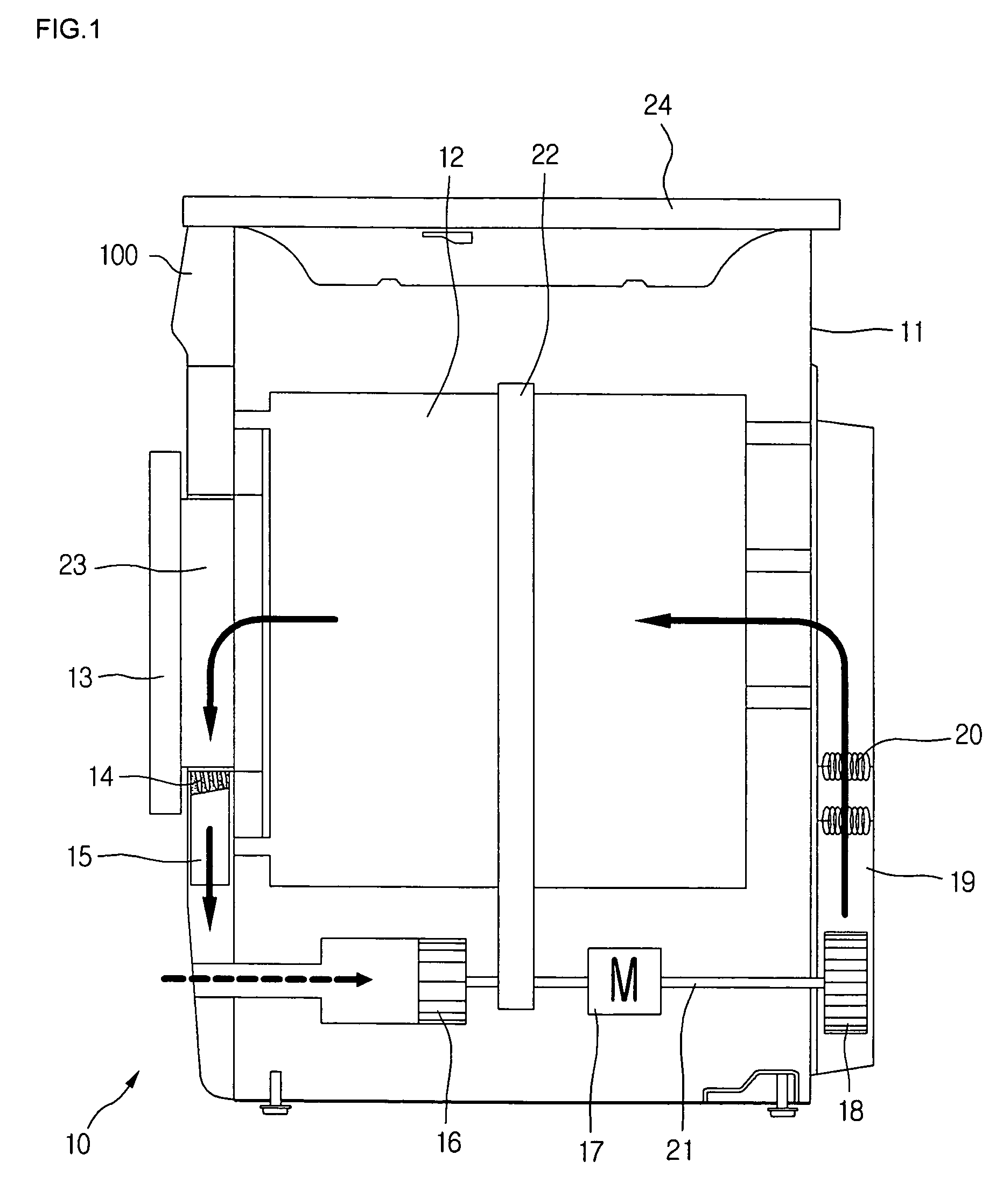

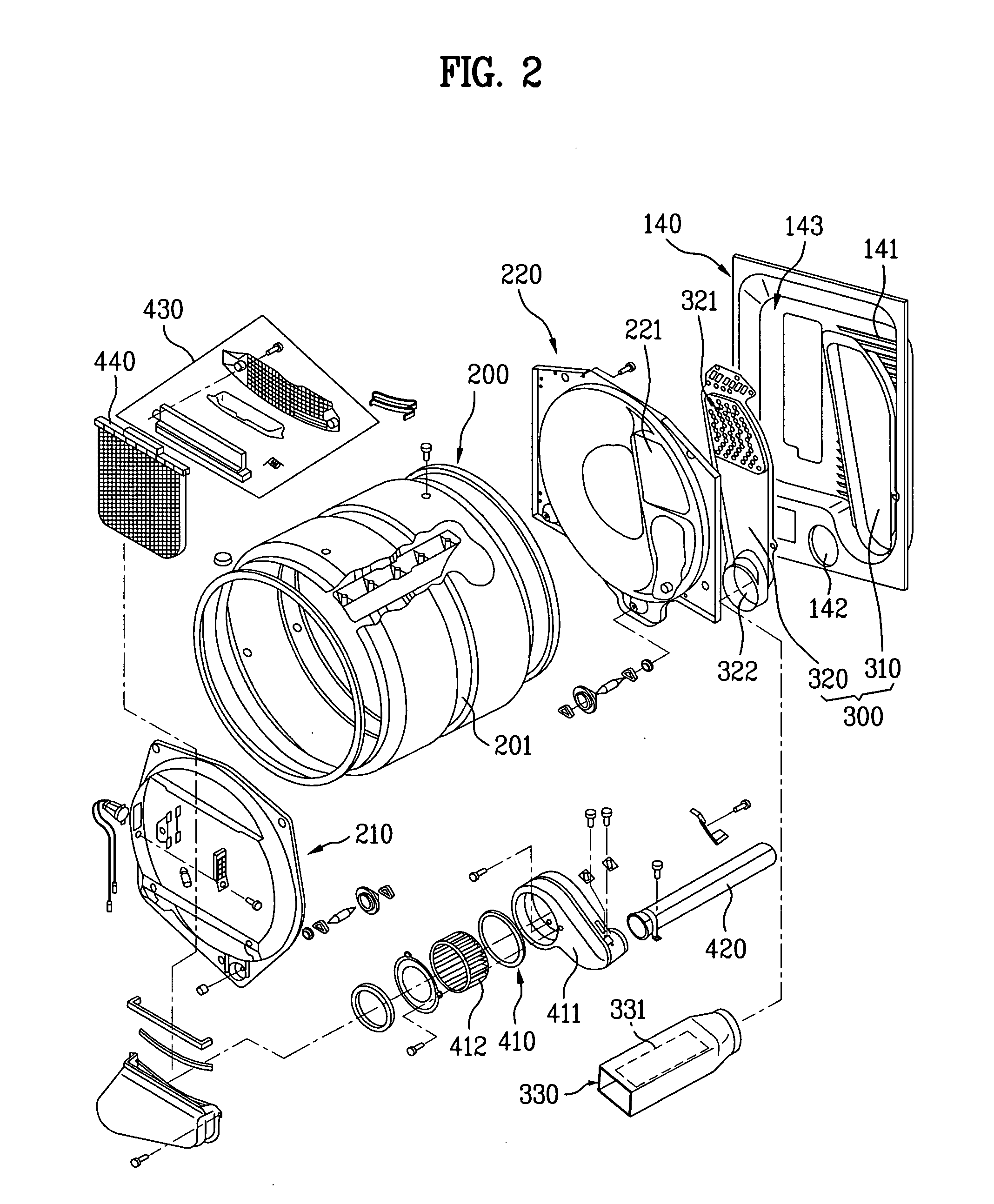

Dryer

InactiveUS20050132603A1Eliminate the problemOther washing machinesDrying machines with progressive movementsEngineeringMechanical engineering

A dryer, by which an inlet duct assembly for supplying hot air to a drum holding a drying object therein is facilitated to be assembled, is disclosed. The dryer includes a cabinet, a back cover having an interior side and an exterior side, the exterior side forming a rear side of the cabinet, a supporter, connected to the back cover, for supporting a rearward end of a drum, and an inlet duct assembly for supplying hot air to the drum, wherein the inlet duct assembly includes a rear duct wall integrally formed with the interior side of the back cover, and a front duct wall connected to the rear duct wall to complete the inlet duct assembly.

Owner:LG ELECTRONICS INC

Wet-type ammonia flue gas spiritualization technics of associated desulfuration demercuration

The invention relates to a wet ammonia flue gas purification process for the combined sulfur and mercury removing and the system thereof. The process adopts chlorine gas as oxidizing agent to completely oxidize elemental mercury in the flue gas, and gas phase divalent mercuric ion after being oxidized is converted into liquid phase divalent mercuric ion through the improved wet ammonia desulphurization process, and further the liquid phase divalent mercuric ion is converted into stable mercuric sulfide sendimentation through liquid phase divalent mercuric ion stabilizing agent. The system comprises a flue gas oxidizing demercuration preprocessing system composed of an oxidizing agent injection device and an electrostatic precipitator, a wet ammonia flue gas sulfur and mercury removing system composed of a reaction absorbing tower, a sulfur removing accessory substance processing system composed of a cyclone cleaner, a dewaterer, and a dryer, and a mercuric sulfide HgS sendimentation processing system composed of a wastewater buffer pool, a liquid phase mercuric ion reaction chamber, and a settling pond. The process and the system can effectively improve the oxidation rate of the elemental mercury in the flue gas, overcome the defaults that the divalent mercuric ion is easy to be reduced and released and the secondary pollution problem is caused by excess oxidizing agent, and greatly improve the efficiency of sulfur removing and mercury removing.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

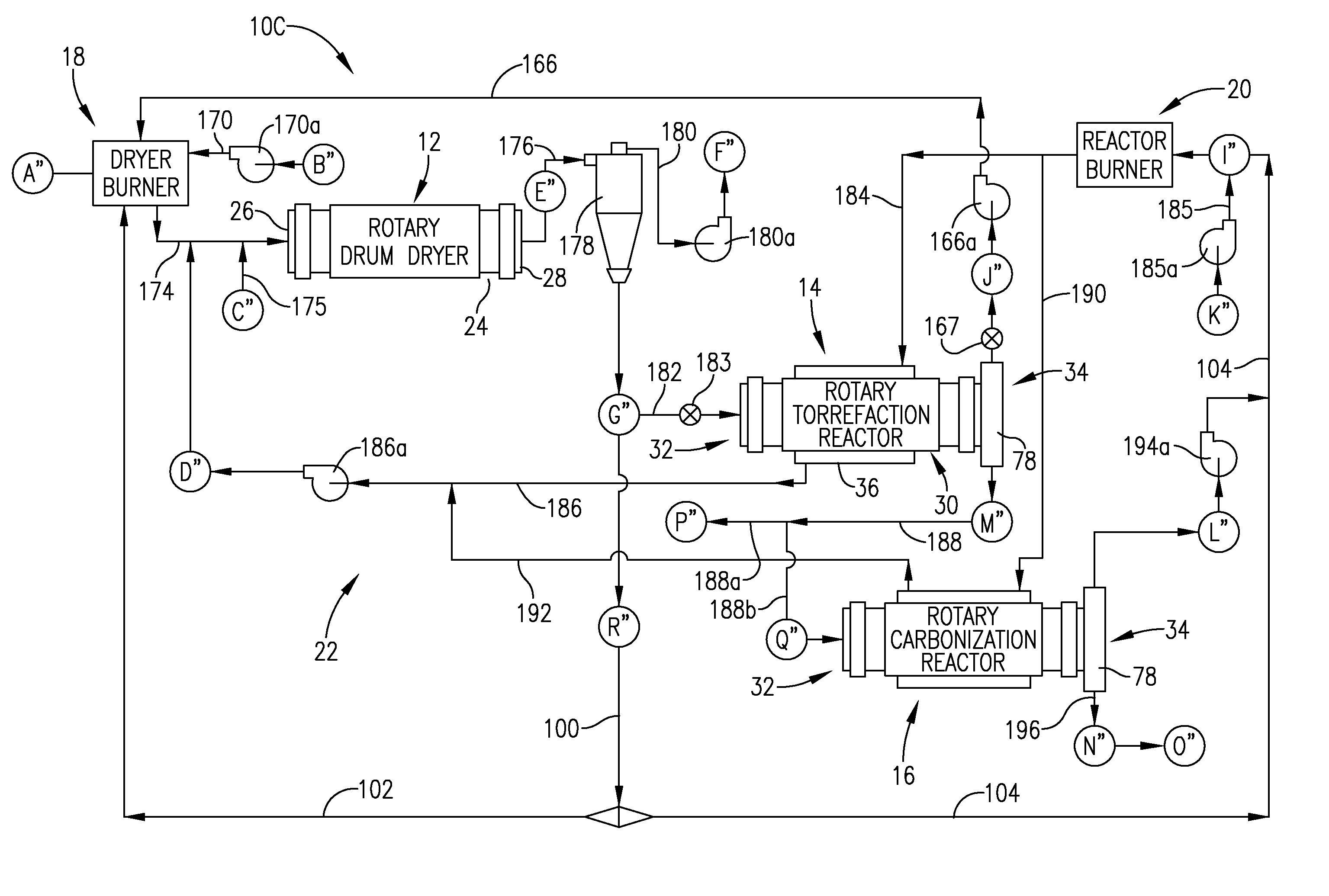

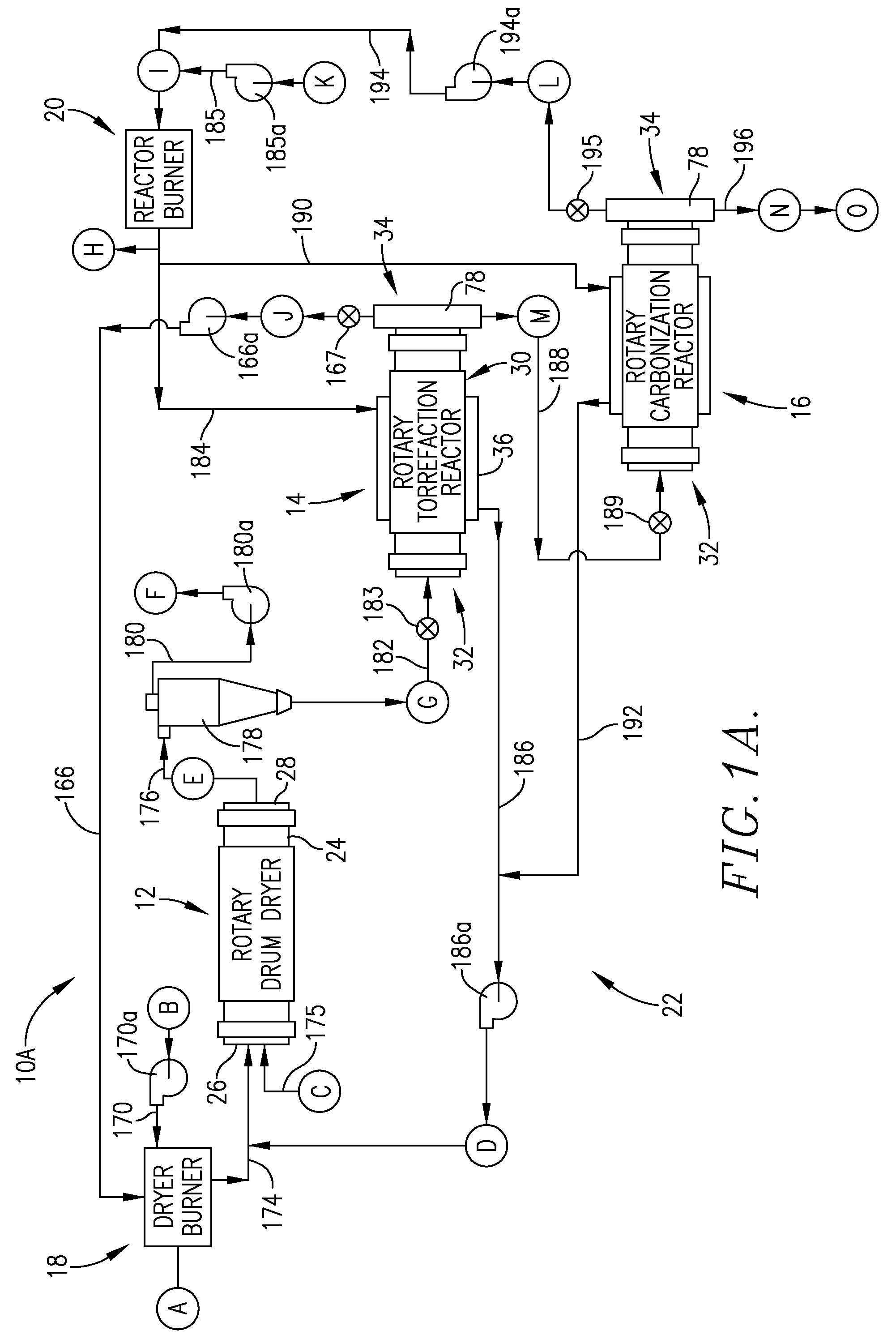

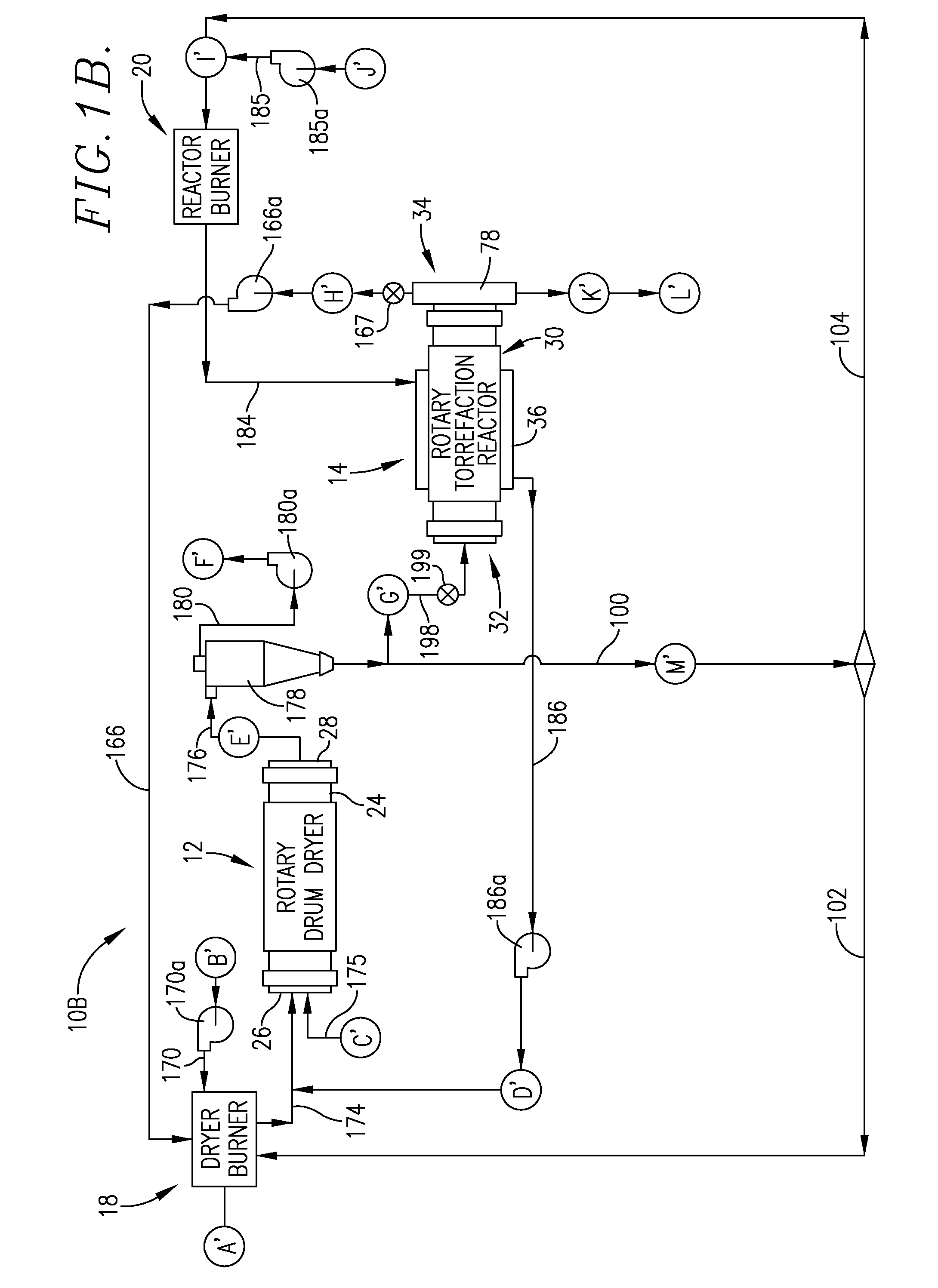

High energy efficiency biomass conversion process

ActiveUS8198493B1Combustible gas coke oven heatingDirect heating destructive distillationCombustorHigh energy

Improved, fuel-efficient systems are provided for the processing of biomass, such as wood or crop residues, food waste or animal waste in order to selectively obtain thermally processed final products, such as a combination of torrefied and carbonized final products. The processes involve thermally drying incoming biomass using a dryer employing the hot gas output of a fuel-operated burner. Next, the dried product is torrefied in an indirect torrefaction reactor so as to evolve light volatile organic compounds which are used as a gaseous fuel source for the burner. Some or all of the torrefied product can be recovered, or some or all of the torrefied product is then directed to a separate carbonization reactor coupled with a reactor burner. Carbonization serves to remove most of the remaining VOCs which are used as a gaseous fuel input to the dryer.

Owner:SMART TERRA CARE LLC

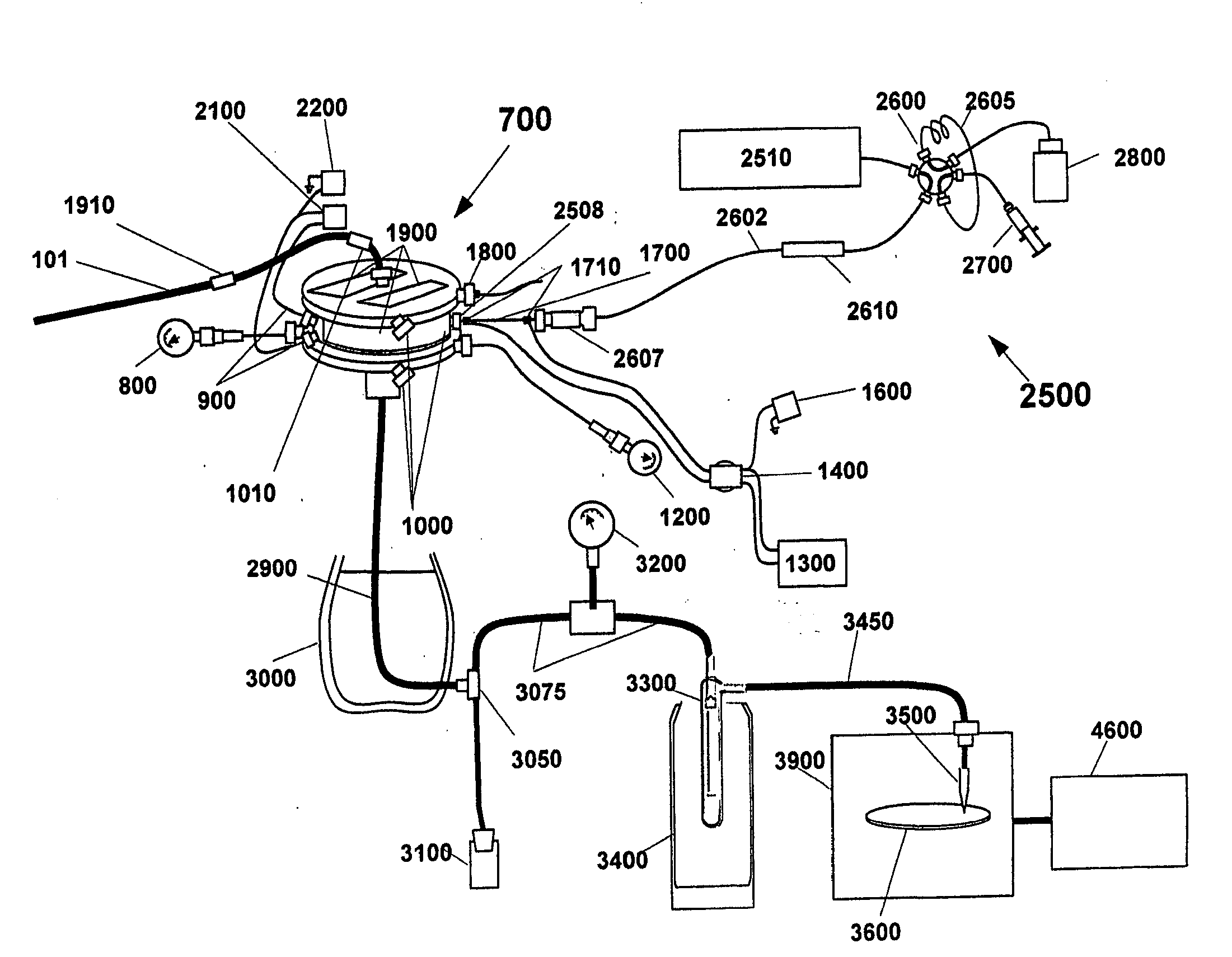

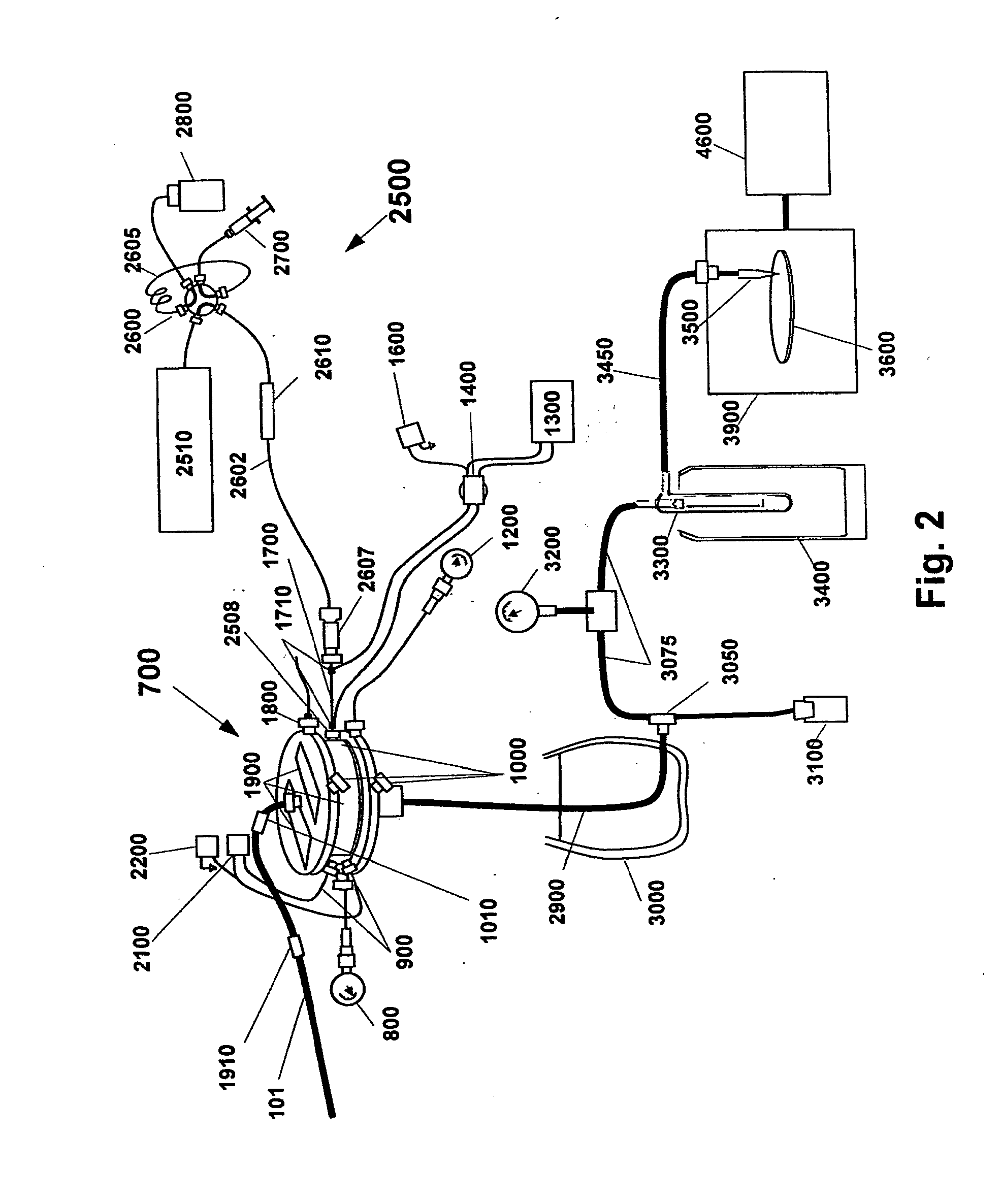

Method and apparatus for desolvating flowing liquid

ActiveUS20100000943A1Quick releaseAvoid contactLiquid degasificationComponent separationTemporal resolutionSolvent vapor

Methods and apparatus for desolvating flowing liquid streams while retaining temporal resolution of dissolved substrates are disclosed. A novel small-scale self-regulating spray dryer preserves temporal resolution while desolvating a liquid chromatography eluent stream and depositing the solute onto an optical surface for infrared spectrographic analysis. The liquid eluent is pumped through a heated nebulizer to create a high-speed jet of solute containing liquid and solvent vapor. This jet is directed circumferentially inside a hot cylindrical cavity. Centrifugal force causes the larger liquid droplets to travel along the outer diameter of the cavity. The cavity surface is heated to cause the droplets to film boil. Film boiling reduces droplet contact with the cavity surface thereby retaining the solute in the droplets. The solute temperature is limited by controlling the pressure into which the solvent evaporates from the droplets. When the droplets are sufficiently small, Stokes drag from the exiting solvent vapor carries the droplets out through the center of the cylindrical cavity. After exiting, the superheated solvent vapor further dries the droplets. Solvent vapor is removed by condensation onto a cooled surface. A freezing point reducing agent may be added to improve removal of solvent condensate. Stokes drag from a non-condensable gas maintains the dried droplets in suspension. This suspension travels through an orifice that focuses the impaction of the dried droplets onto the optical surface for infrared analysis. The deposition surface is in an evacuated chamber and is temperature controlled to freeze liquid solutes yet allowing sublimation of residual solvent.

Owner:SPECTRA ANALYSIS INSTR

Dryer comprising a heat sink and a condensate container

ActiveUS8079157B2Easy to cleanSignificant positive effectDrying machines with non-progressive movementsTextiles and paperEngineeringHeat spreader

A dryer includes a drying chamber, a process air guide that guides process air along the articles to pick up humidity from them, a heat sink in the process air guide that precipitates humidity from the process air as a condensate, and a condensate collector with a condensate container having an insert that is permeable to the condensate and that projects through an opening into the condensate container for transferring the condensate to and from the condensate container. The insert includes a first filter that filters particles from the condensate prior to storing the condensate in the condensate container.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Closed cycle refrigeration system and mixed component refrigerant

InactiveUS20050086950A1Domestic cooling apparatusCompression machines with non-reversible cycleProcess engineeringRefrigeration

A closed cycle refrigeration system in conjunction with specific mixed or multiple component refrigerant fluids to produce temperatures in the range of 230° K to 70° K. The mixed component refrigerant can be blended from flammable or a non-flammable fluid components based upon the arrangement of the refrigeration equipment and the overall performance requirements for the system. A compressor, an after cooler, an oil separator, filter / dryer, heat exchanger, a throttle device with fixed orifice and an evaporator are arranged in a manner to improve system performance with refrigeration of the present invention or prior art refrigerants. Replaceable additional modules for oil filtration and moisture filtration can be part of the system.

Owner:ADVANCED RES SYST

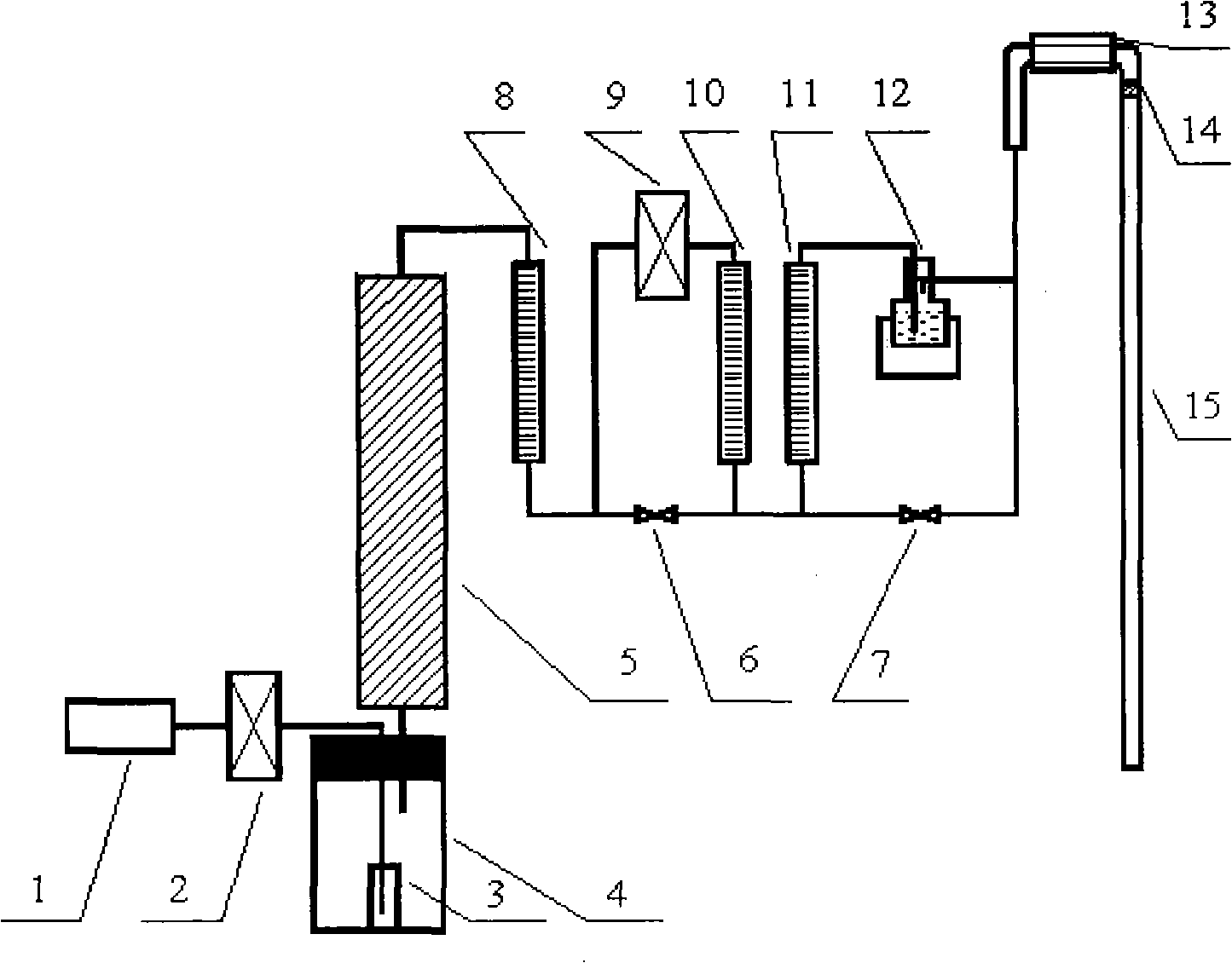

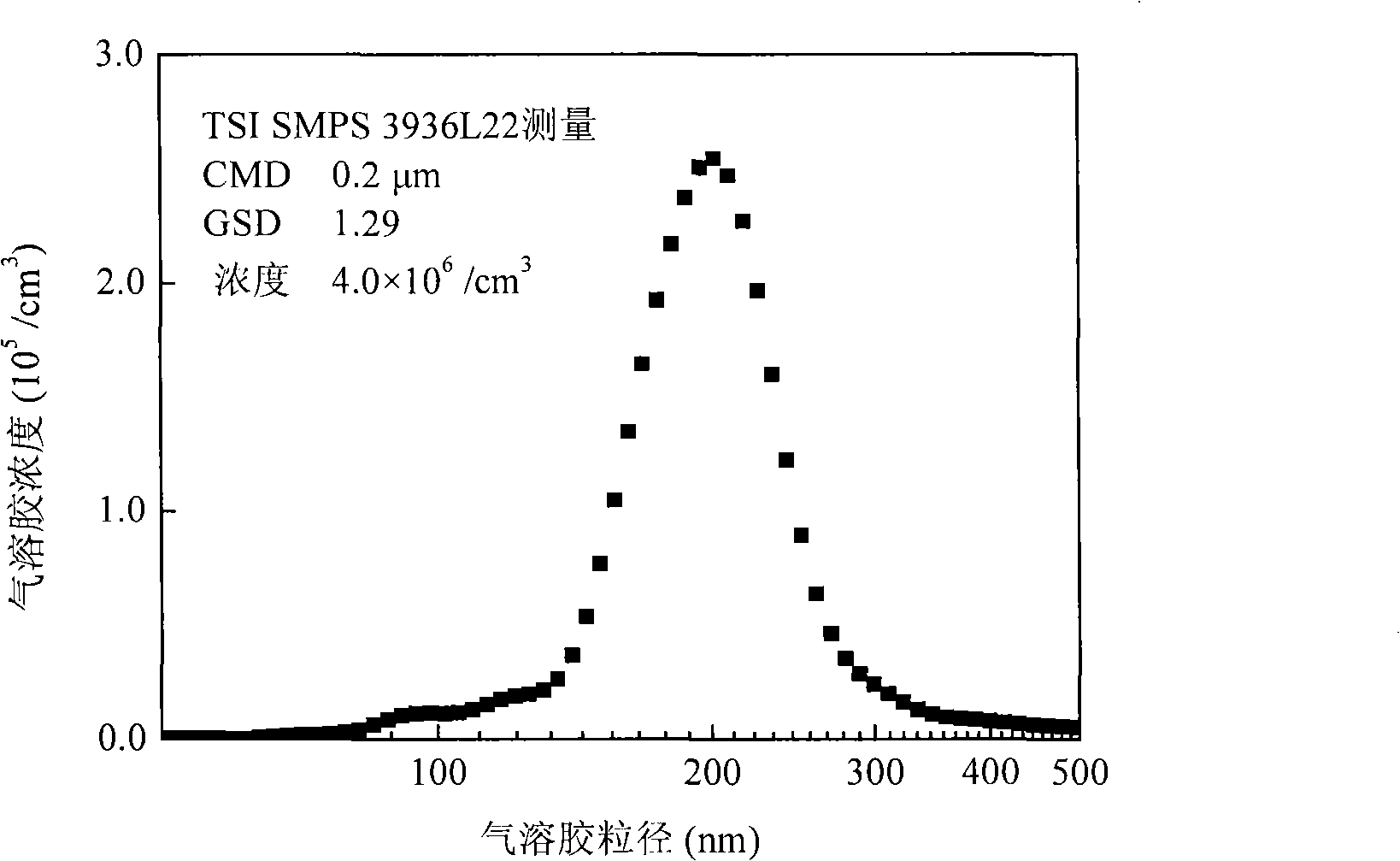

Quasi-monodispersed submicron aerosol generating device using vaporization condensation process

InactiveCN101284220AGood monodispersityMonodisperse and cheapColloidal chemistry detailsMaterial analysisSprayerEngineering

The invention relates to a generating device of quasi-monodispersed submicron aerosol by using an evaporation condensation method. The generating device comprises a high-pressure gas source, a first filter, a sprayer, a diffusion desiccator, a second filter, a saturator, a reheater, a condenser tube, and a first valve as well as a second valve, wherein, the first valve and the second valve are respectively used for adjusting the flow capacity of the second filter and the saturator; the high-pressure gas source adopts a high-pressure air source; the reheater and the condenser tube adopt metallic conduits; a baffle plate is arranged at a jet exit of the sprayer; a screen mesh or a closing ring is arranged at the inlet of the condenser tube. The generating device is convenient and durable, the running cost is low, the median diameter in aerosol generating counting ranges from 0.08 micrometres to 0.5 micrometres, the geometric standard deviation is less than 1.3, the counting concentration ranges from 1*10<4> to 1*10<8> / cm<3>, the stability and the repeatability are good when in generation, and the requirements of various equipment inspections and experimental researches can be satisfied.

Owner:TSINGHUA UNIV

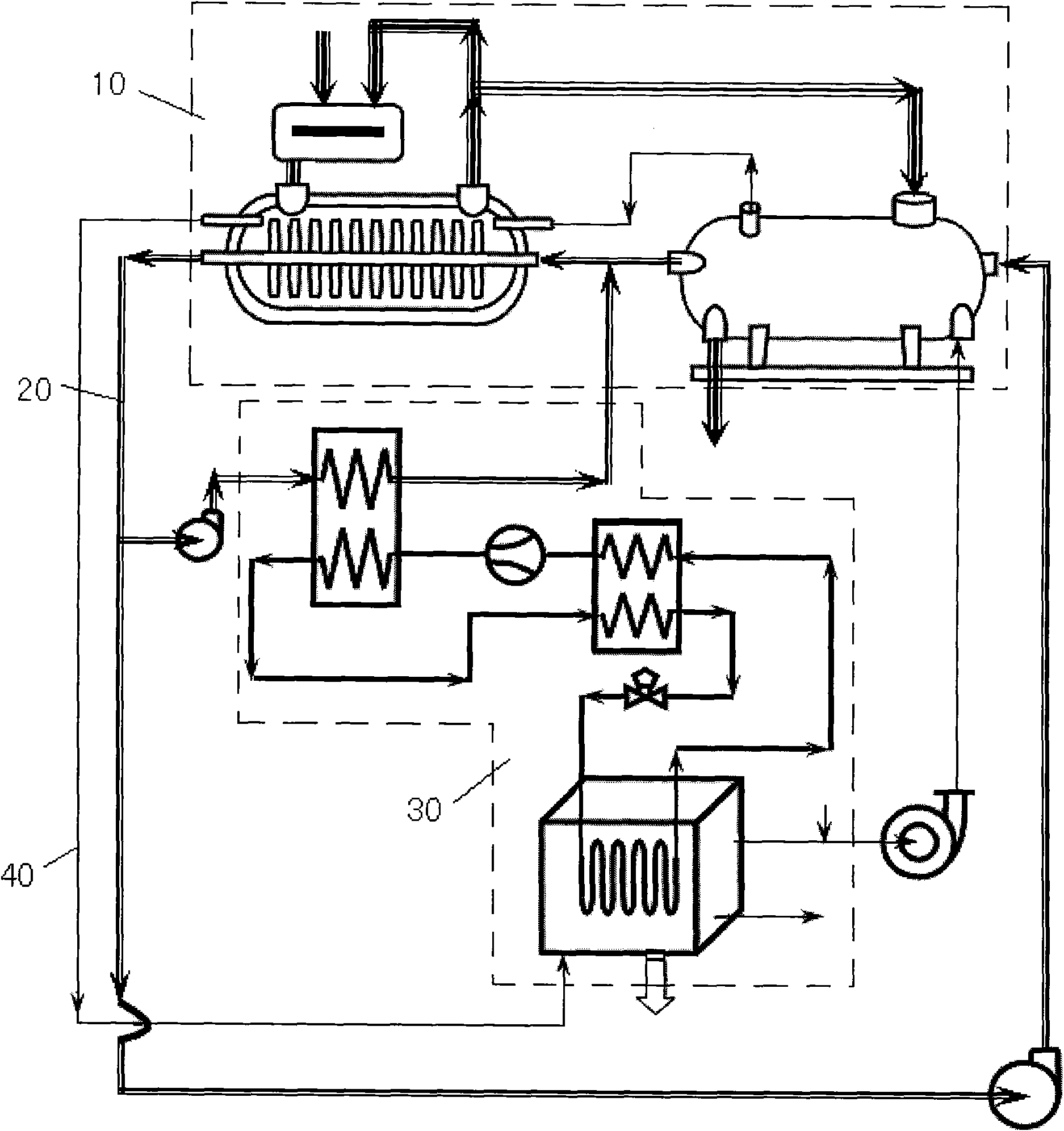

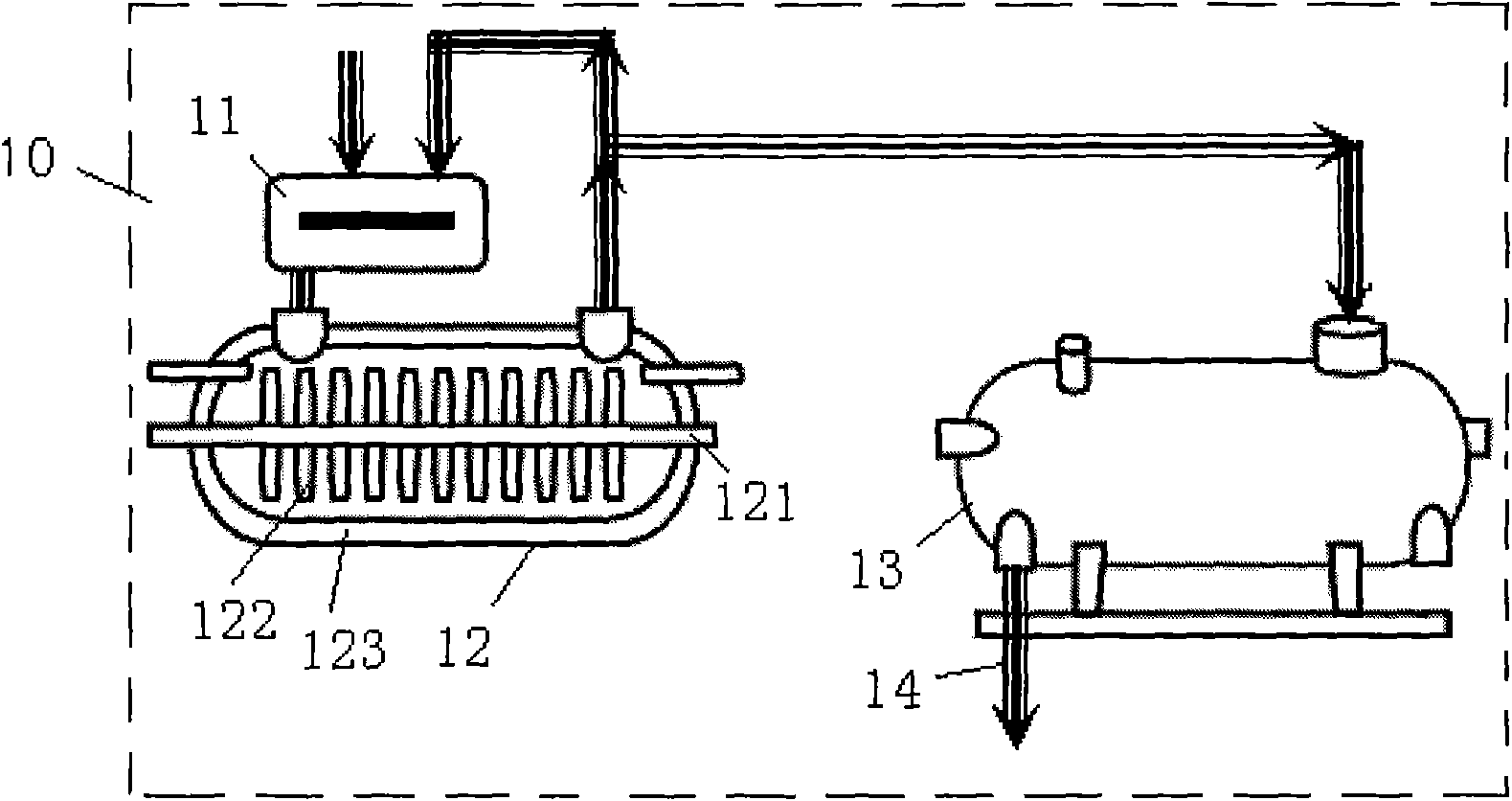

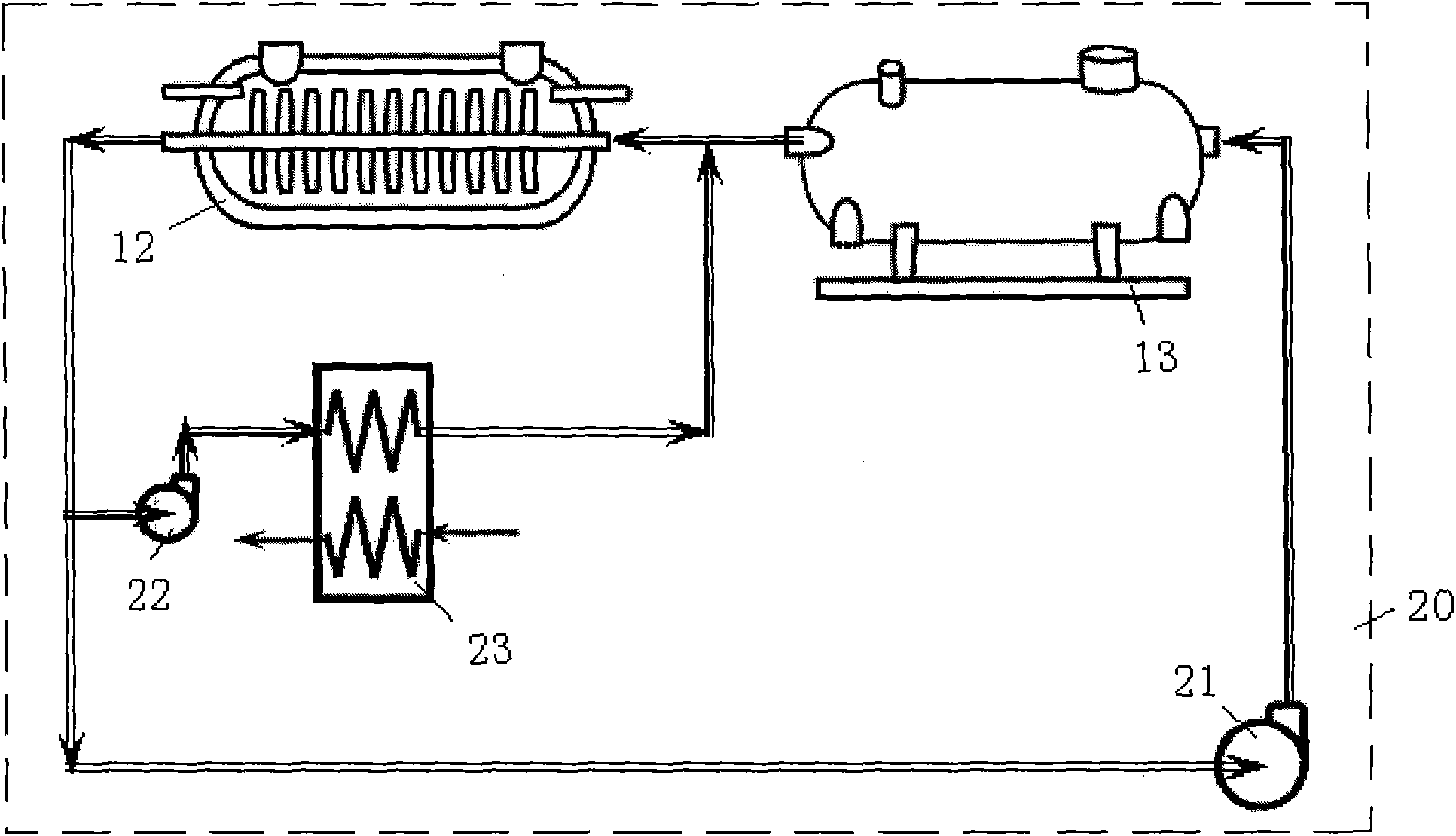

Mud drying and incinerating integrated system and use method thereof

ActiveCN101618931ARaise the evaporation temperatureMeet energy needsSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeSlag

The invention relates to a mud drying and incinerating integrated system and a use method thereof. The mud drying and incinerating integrated system comprises a mud drying and incinerating loop, a hot water circulation loop, a heat pump auxiliary heat supplying loop and a carrier gas heating and waste heat recovering loop; the mud drying and incinerating loop comprises a dried mud back- mixing device, a mud dryer and a mud incinerator on which a slag outlet is arranged; the hot water circulation loop comprises two water pumps, a condenser, the mud dryer and the incinerator; the heat pump auxiliary heat supplying loop comprises an evaporator, an internal heat exchanger, a compressor, a throttle valve and the condenser; and the carrier gas heating and waste heat recovering loop comprises an air compressor, the evaporator, the mud incinerator and the mud dryer. The waste heat recovered from an incinerating and drying device and a heat pump drying device by a heat pump is taken as a heat source, and the heat pump assists in supplying heat, thereby improving the mud drying output and lowering the energy consumption for drying mud. The invention can be widely applied in various mud processing fields.

Owner:TSINGHUA UNIV +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com