Air shockwave crushing sludge drying device and sludge shockwave drying system

A sludge drying and air shock technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. and other problems to achieve the effects of avoiding investment costs, low energy consumption, and avoiding odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

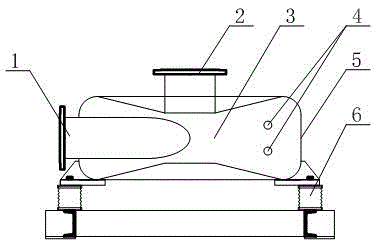

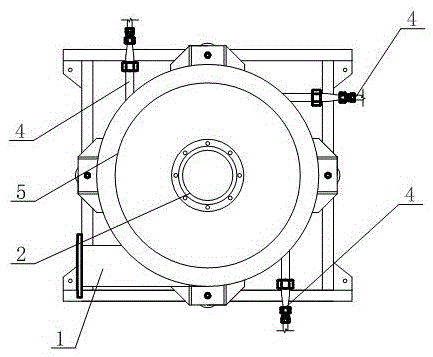

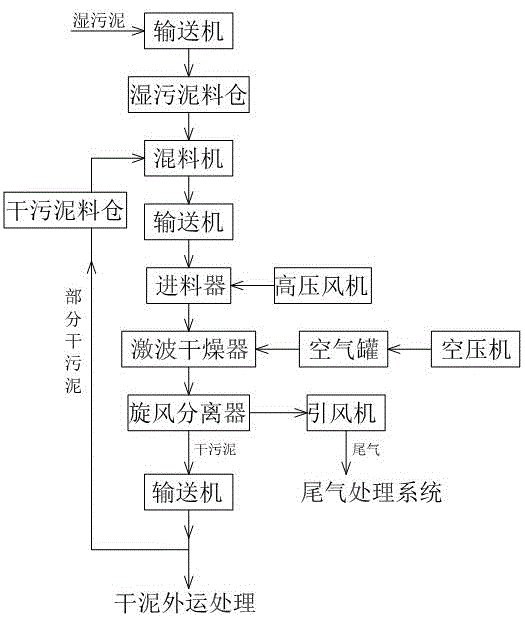

[0022] Such as figure 1 As shown, the housing 5 of the air shock wave crushing sludge dryer of the present invention is fixed on the bottom shock-absorbing frame through the rubber pad 6, and the housing 5 is a flat cylinder, such as figure 2 As shown, the shell 5 is respectively provided with a feeding port 1 and three sets of compressed air injection pipes 4 in four tangential directions, and each set of compressed air injection pipes 4 is composed of upper and lower two injection pipes 4 with Laval nozzles , the discharge port 2 is arranged on the central top of the housing 5, the inside of the housing 5 is a cavity 3 with a thicker periphery and a thinner center similar to a persimmon shape, the feed port 1, the discharge port 2 and the injection pipe 4 are all connected The cavities 3 are connected. According to different system de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com