Patents

Literature

567 results about "Jet stream" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jet streams are fast flowing, narrow, meandering air currents in the atmospheres of some planets, including Earth. On Earth, the main jet streams are located near the altitude of the tropopause and are westerly winds (flowing west to east). Their paths typically have a meandering shape. Jet streams may start, stop, split into two or more parts, combine into one stream, or flow in various directions including opposite to the direction of the remainder of the jet.

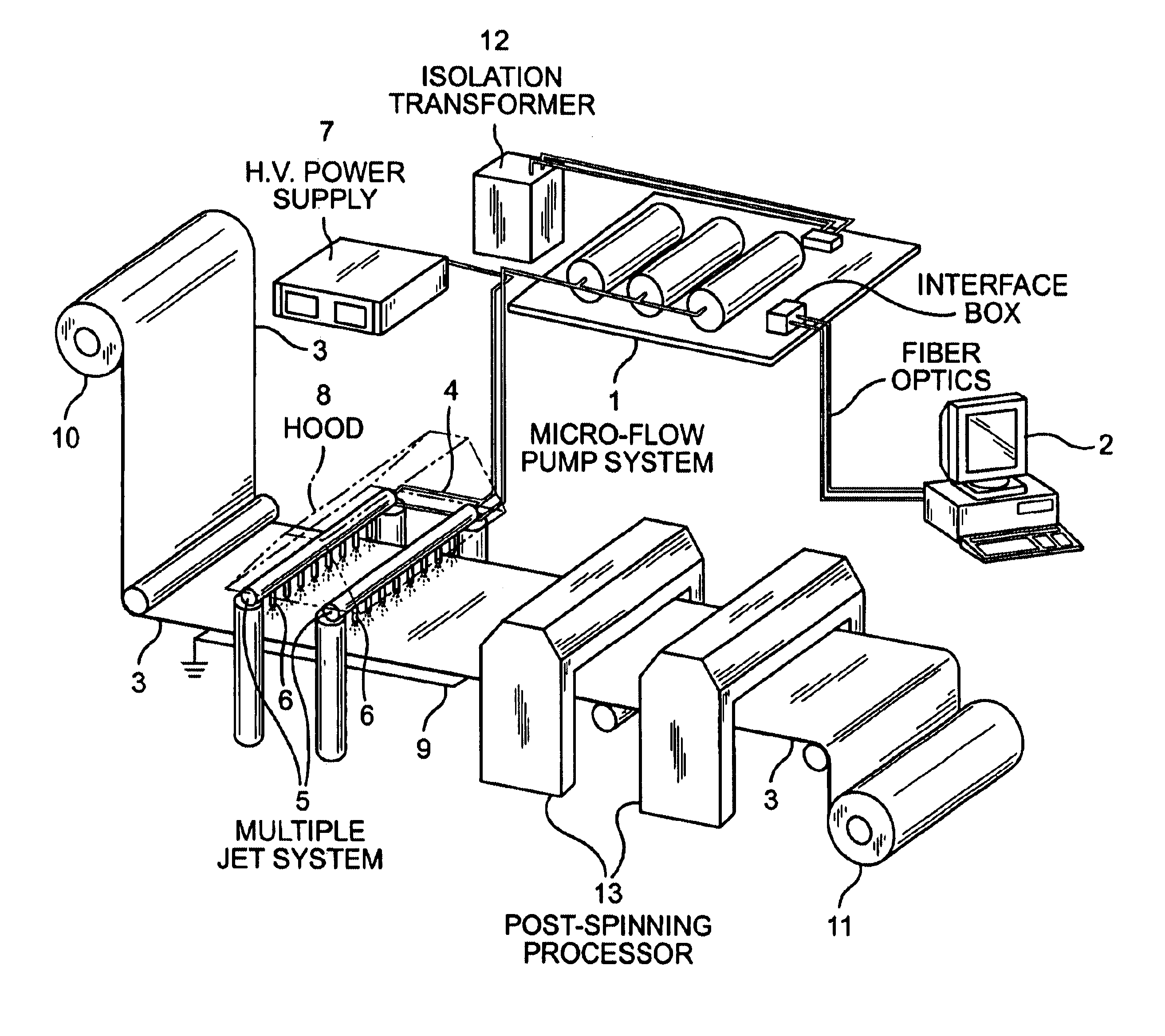

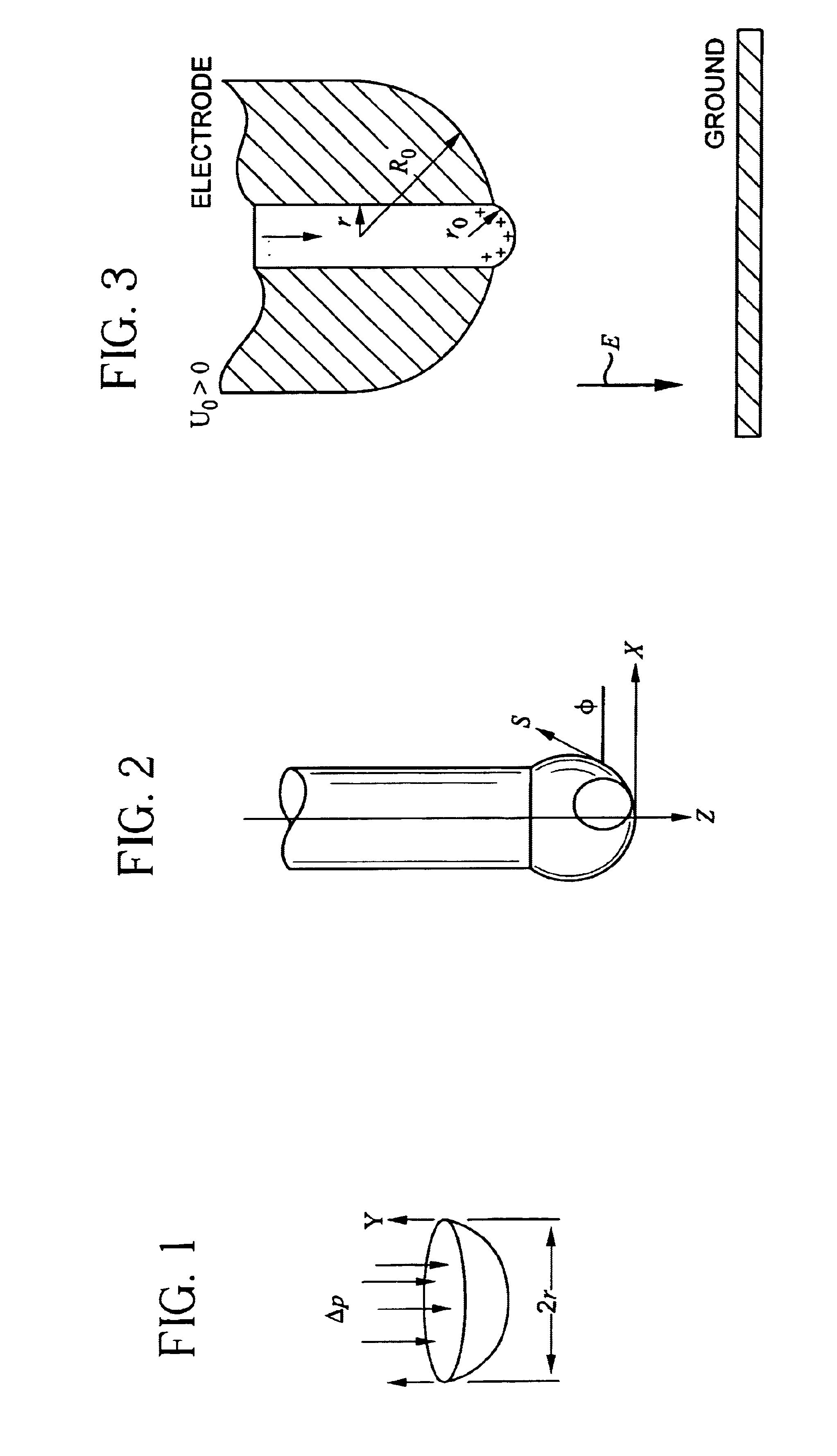

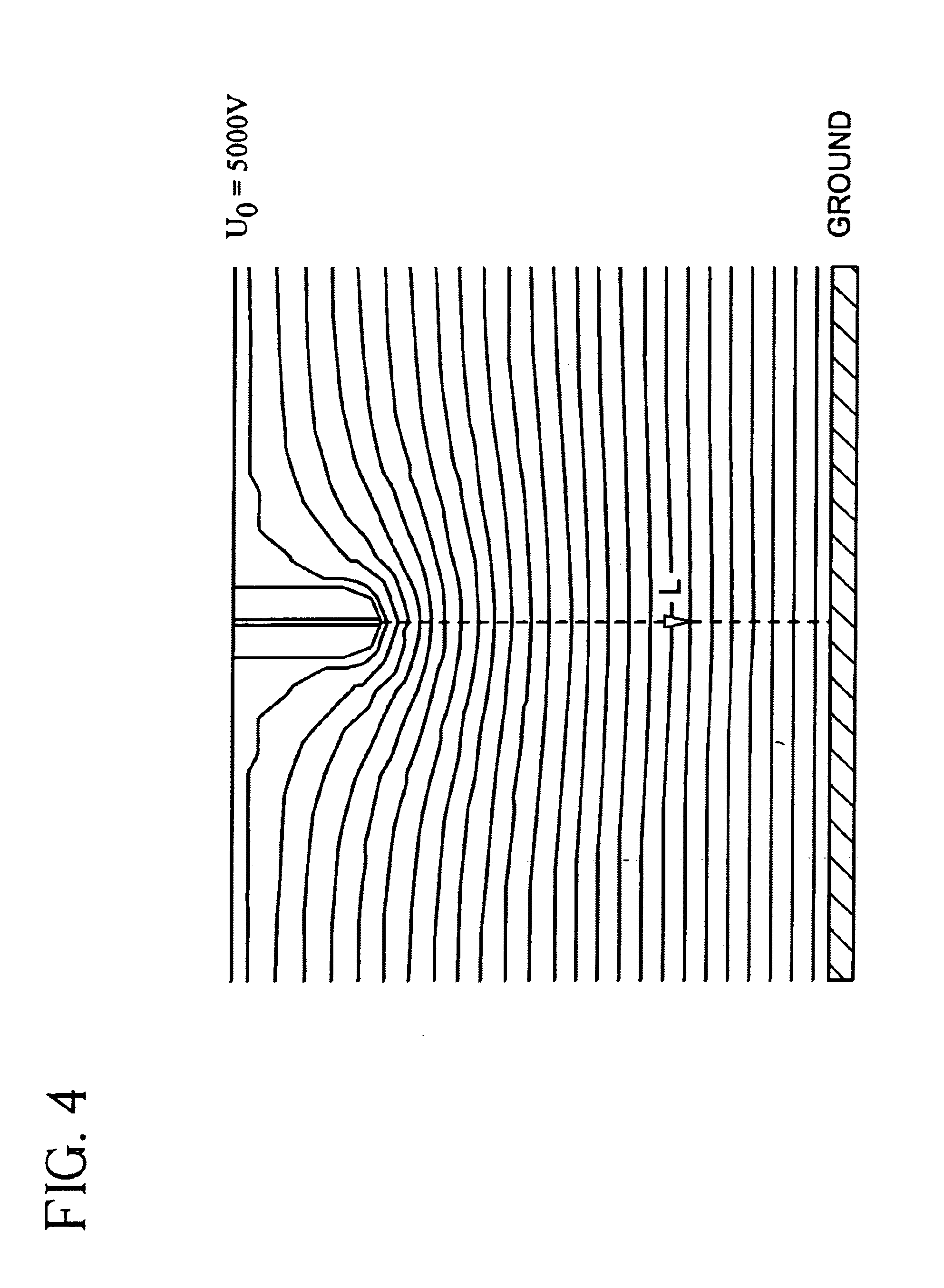

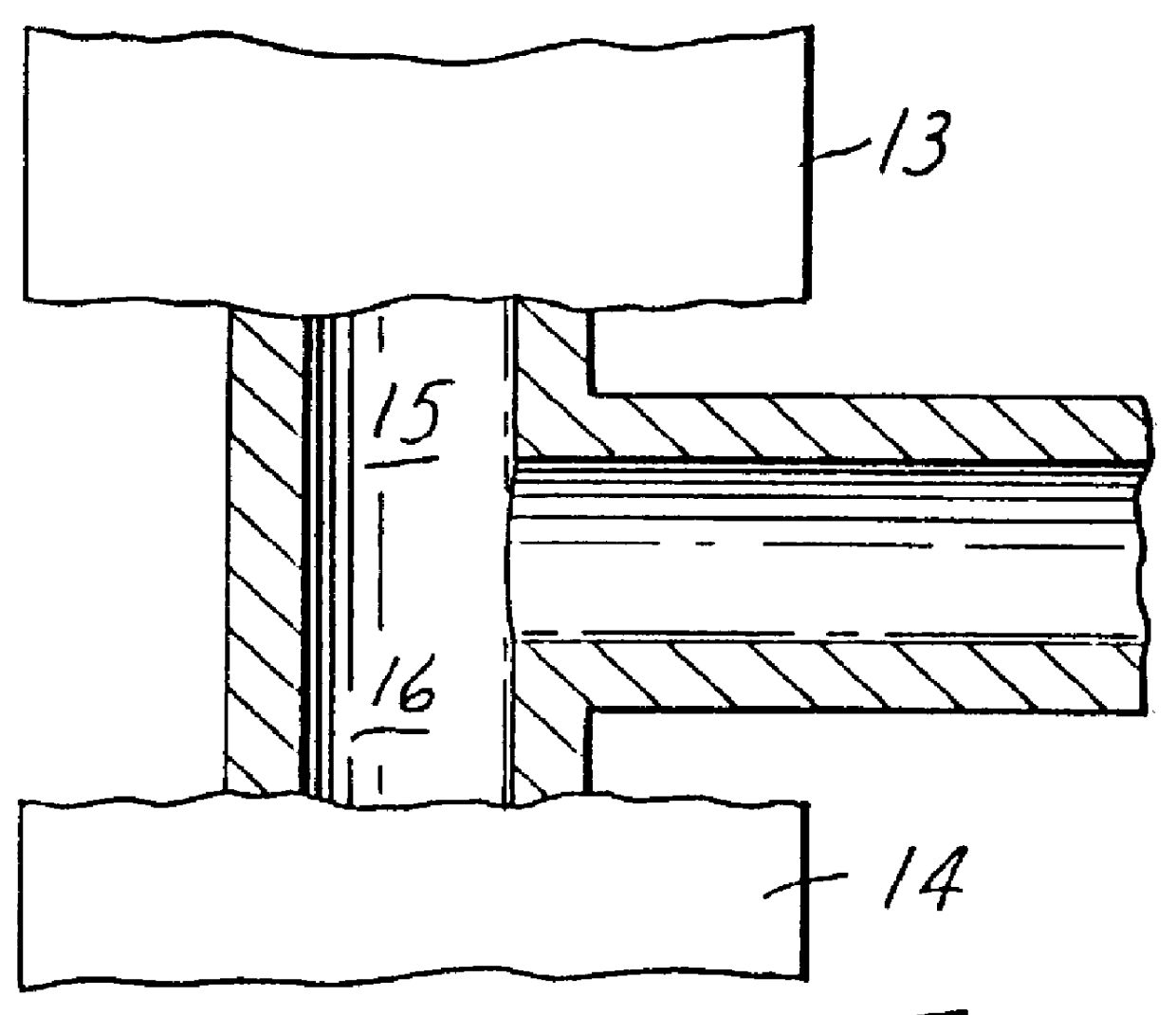

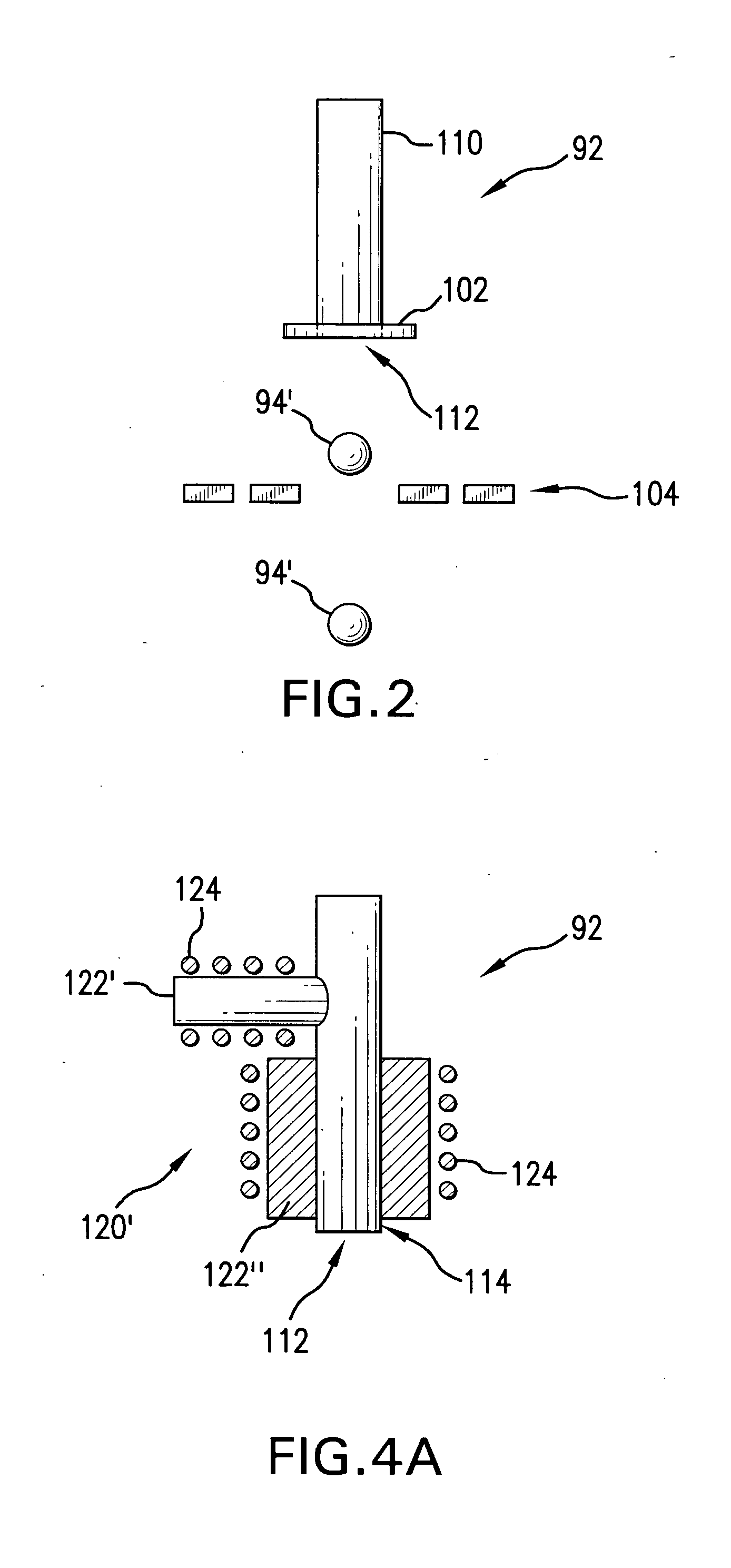

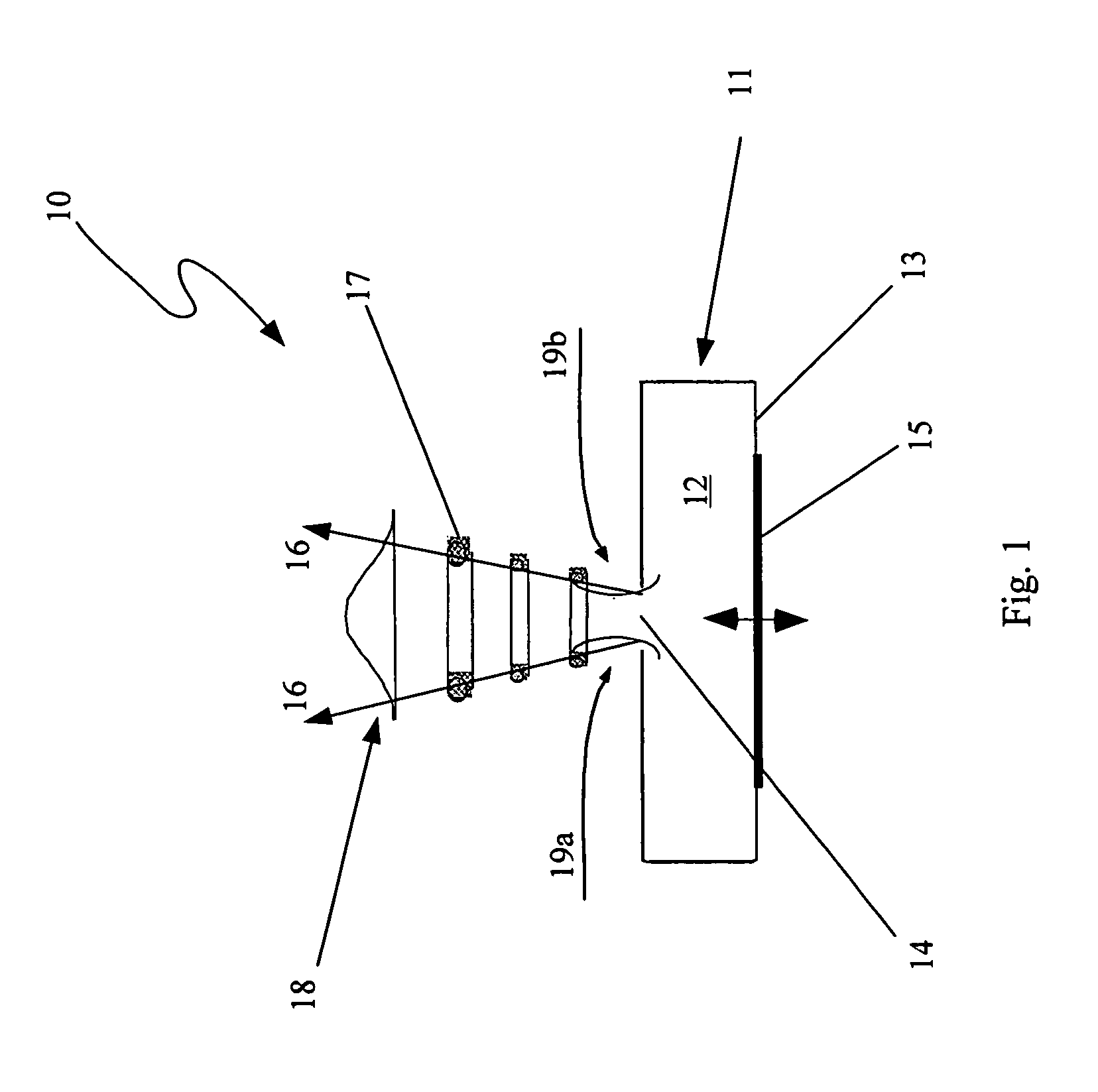

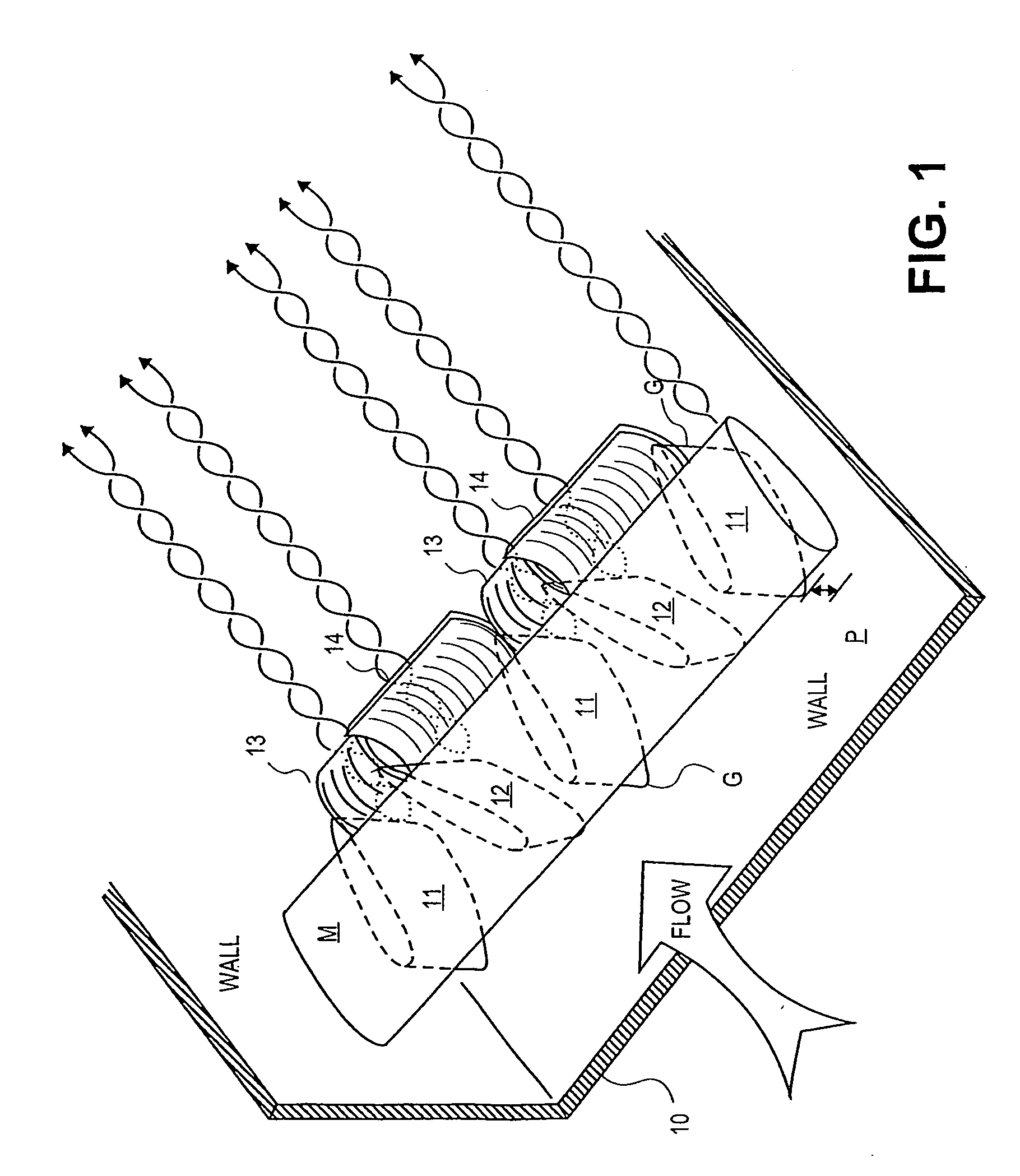

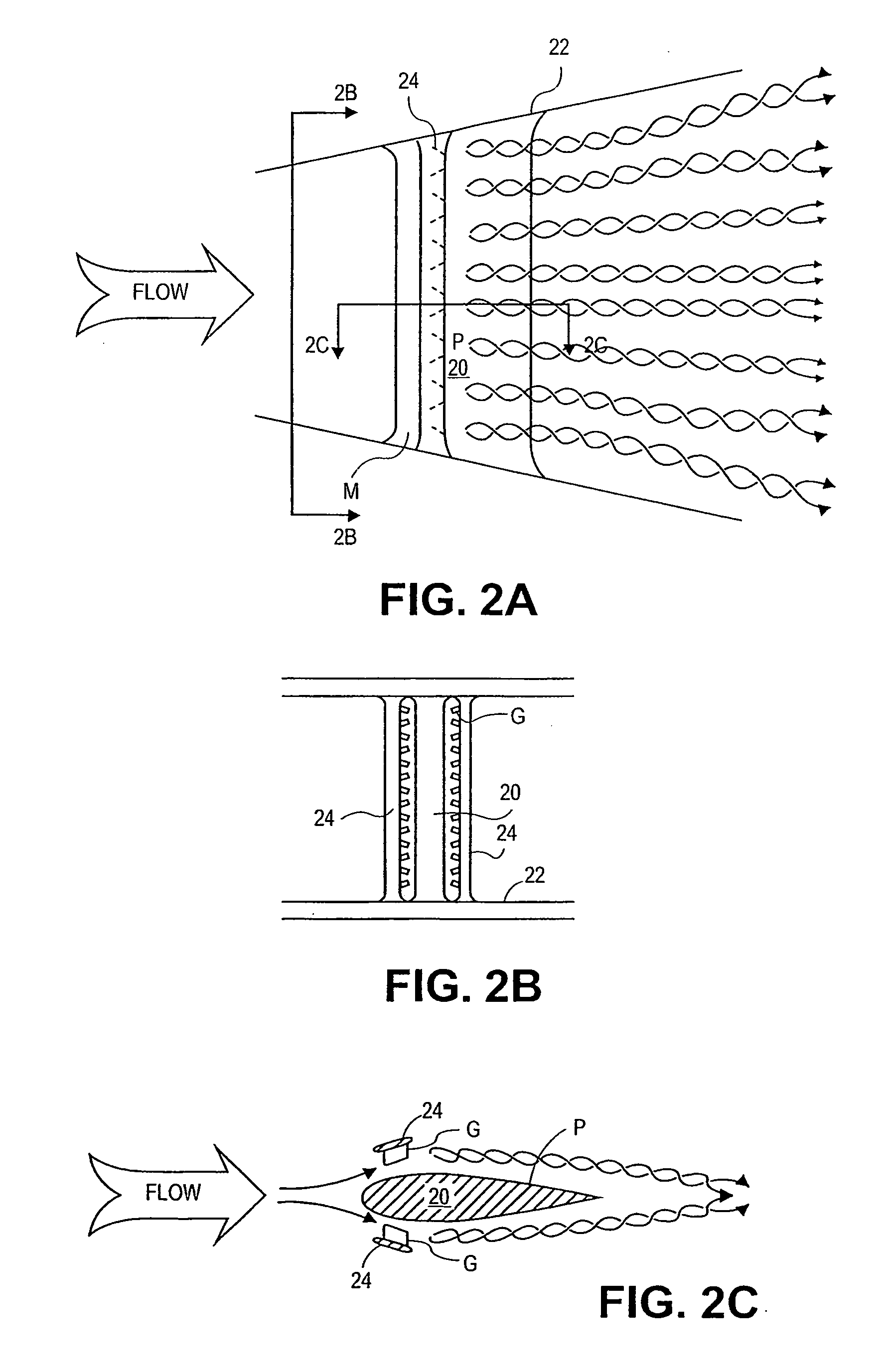

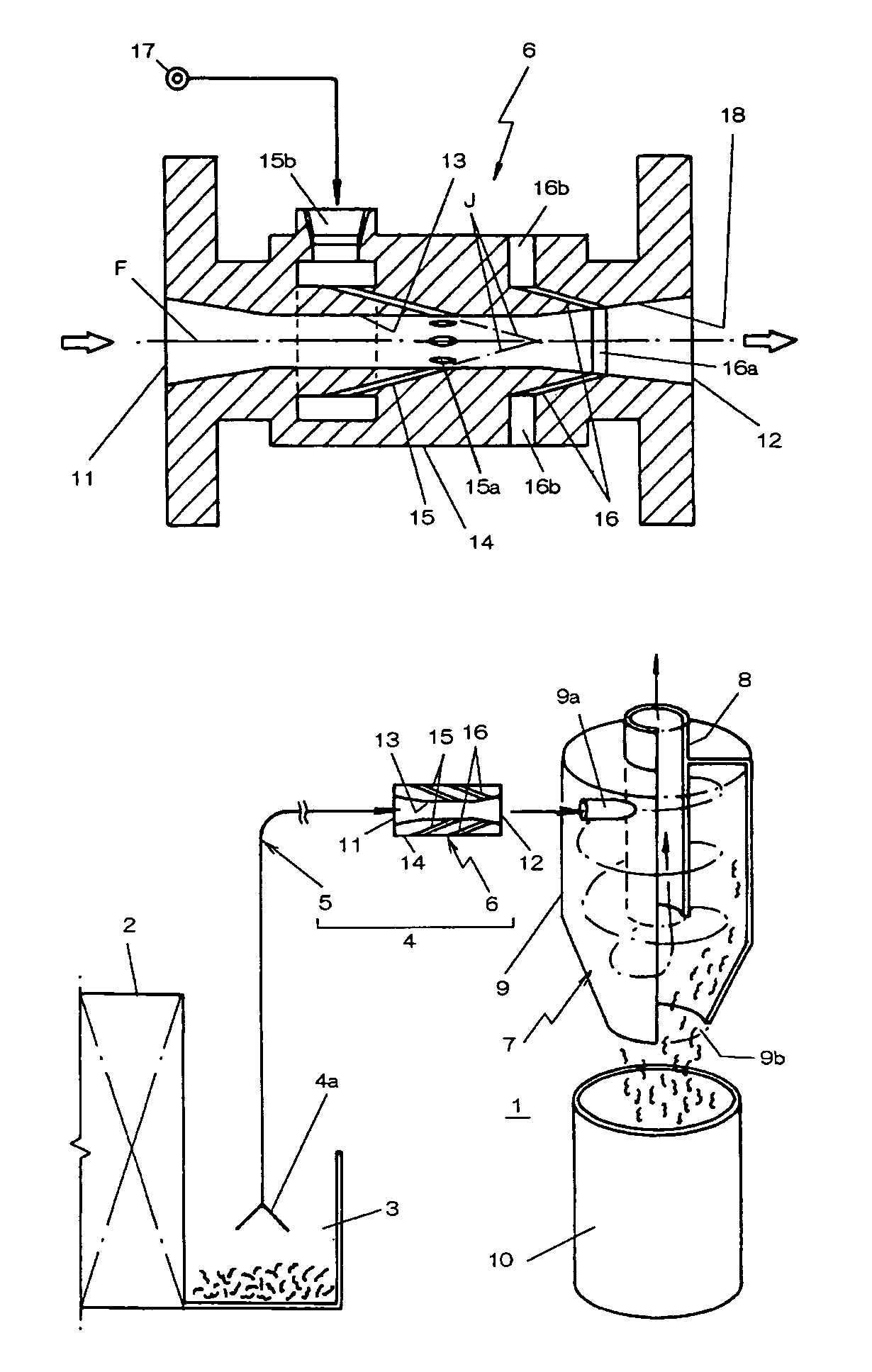

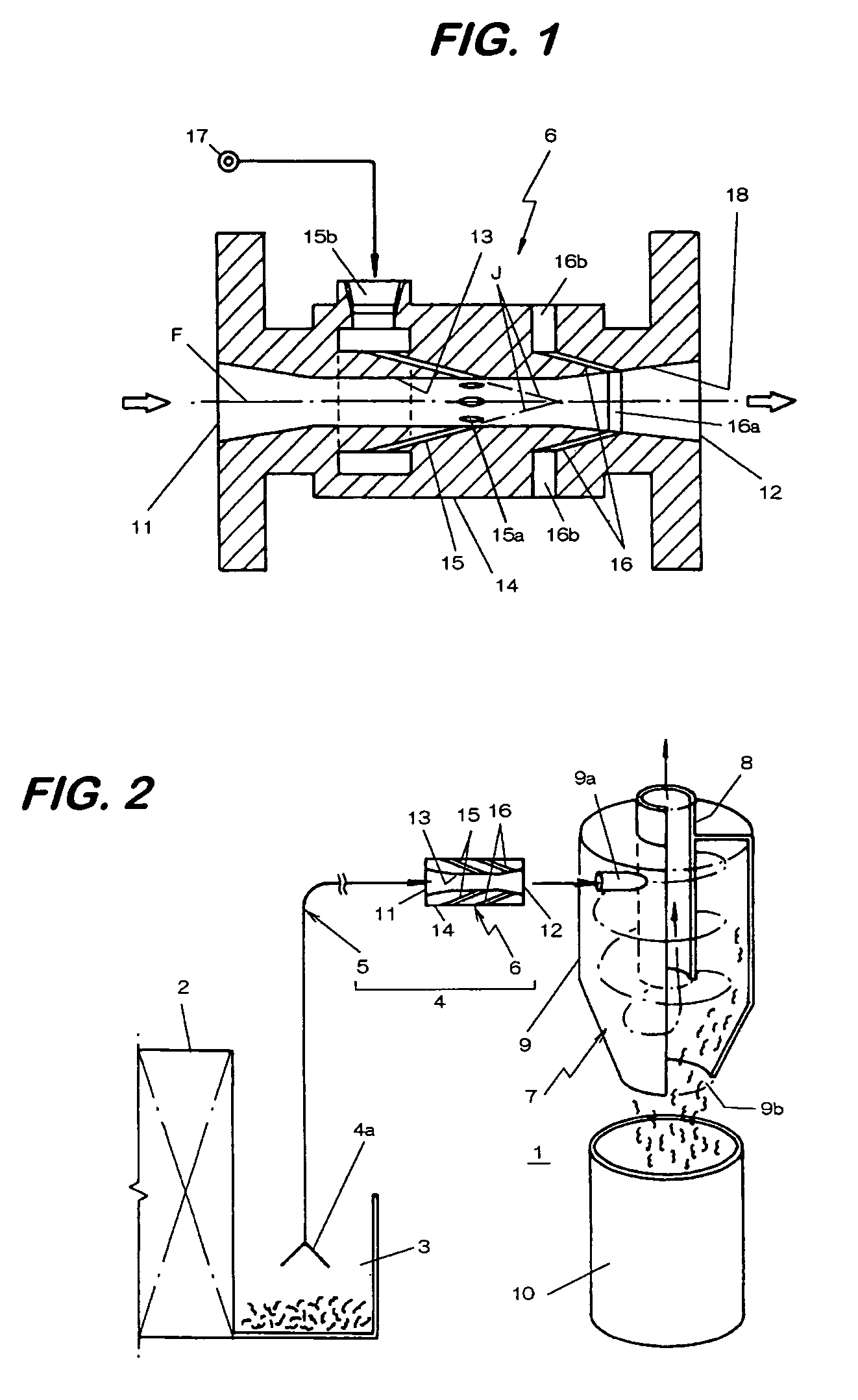

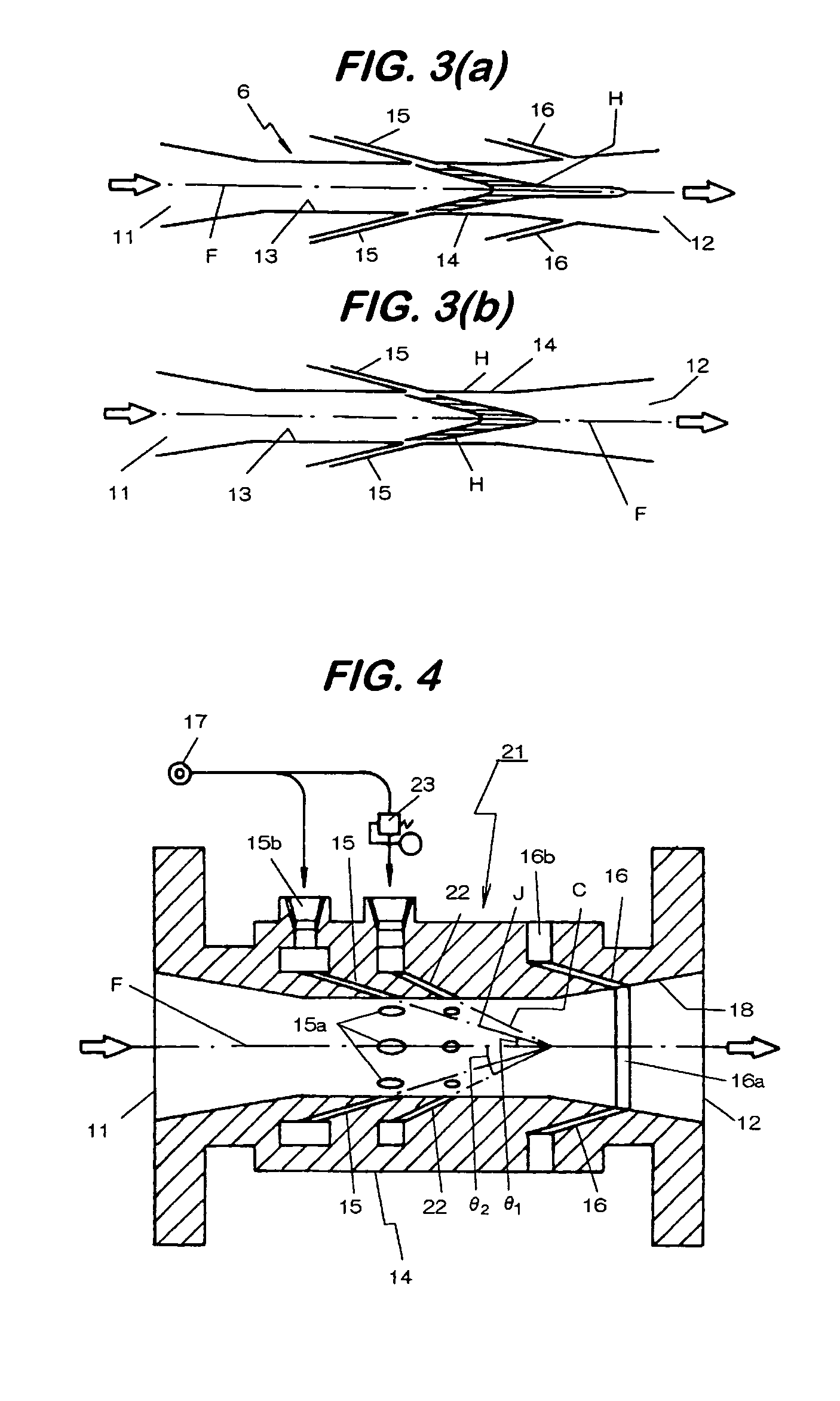

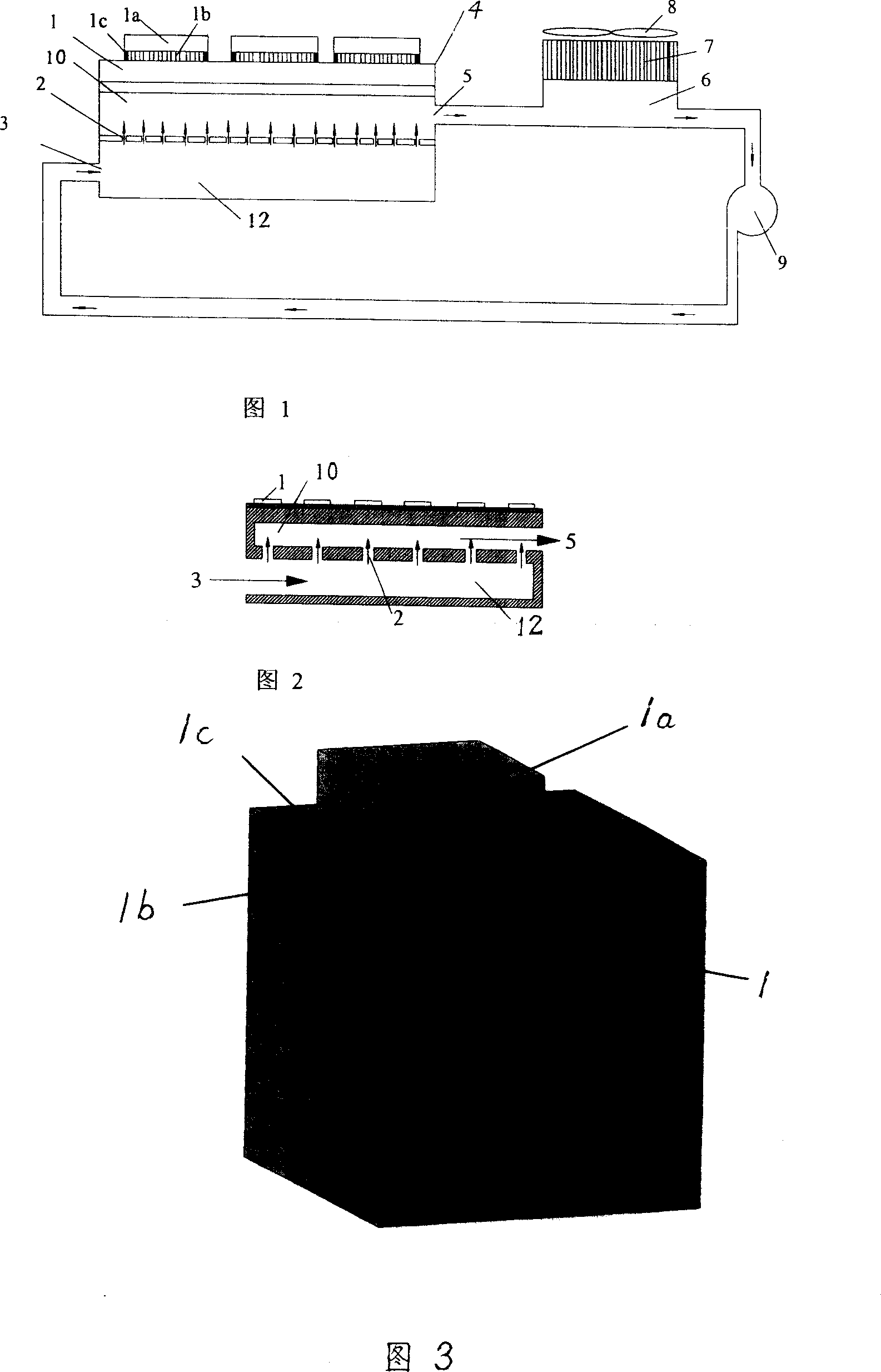

Apparatus and methods for electrospinning polymeric fibers and membranes

InactiveUS6713011B2Easy to controlLarge specific surface areaElectric discharge heatingConfectioneryFiberElectrospinning

An apparatus and method for electrospinning polymer fibers and membranes. The method includes electrospinning a polymer fiber from a conducting fluid in the presence of a first electric field established between a conducting fluid introduction device and a ground source and modifying the first electric field with a second electric field to form a jet stream of the conducting fluid. The method also includes electrically controlling the flow characteristics of the jet stream, forming a plurality of electrospinning jet streams and independently controlling the flow characteristics of at least one of the jet streams. The apparatus for electrospinning includes a conducting fluid introduction device containing a plurality of electrospinning spinnerets, a ground member positioned adjacent to the spinnerets, a support member disposed between the spinnerets and the ground member and movable to receive fibers formed from the conducting fluid, and a component for controlling the flow characteristics of conducting fluid from at least one spinneret independently from another spinneret.

Owner:RES FOUND THE

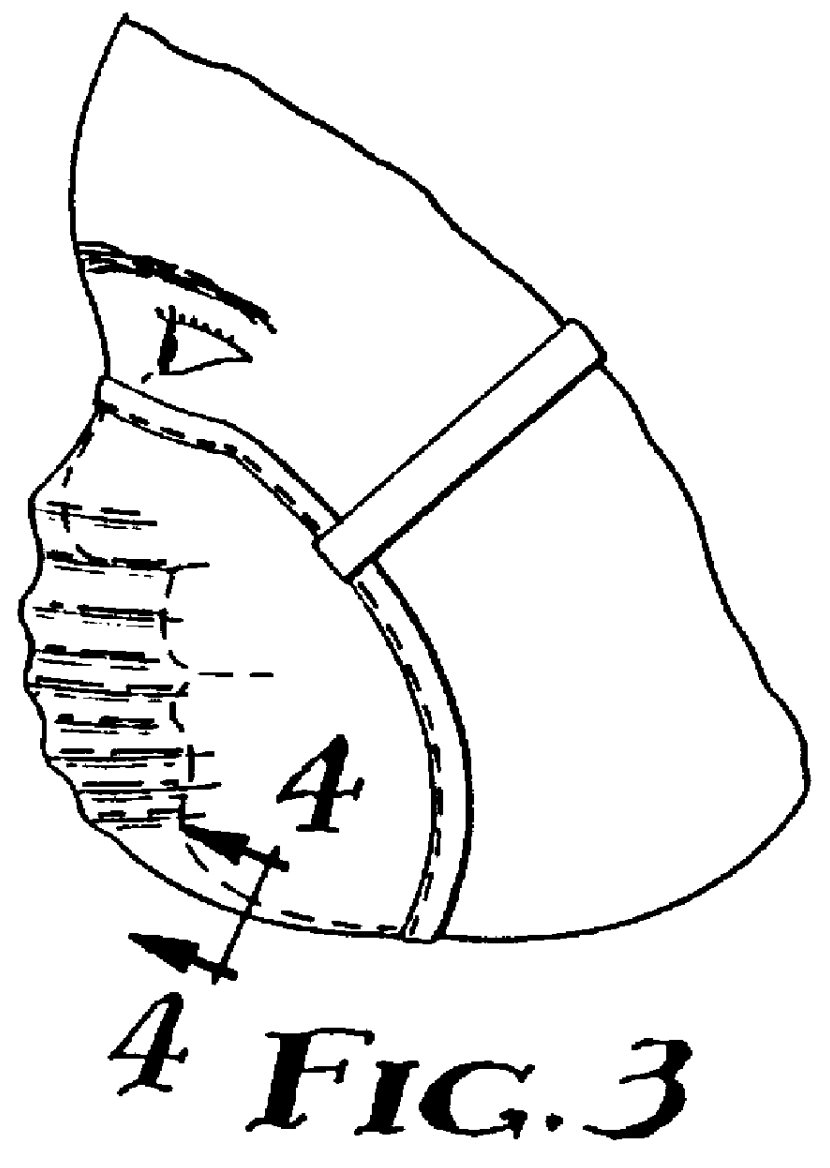

Web of biocomponent blown fibers

InactiveUS6057256AEasy to produceImprove filtering effectBreathing filtersFilament/thread formingFiberPolymer science

Owner:3M INNOVATIVE PROPERTIES CO

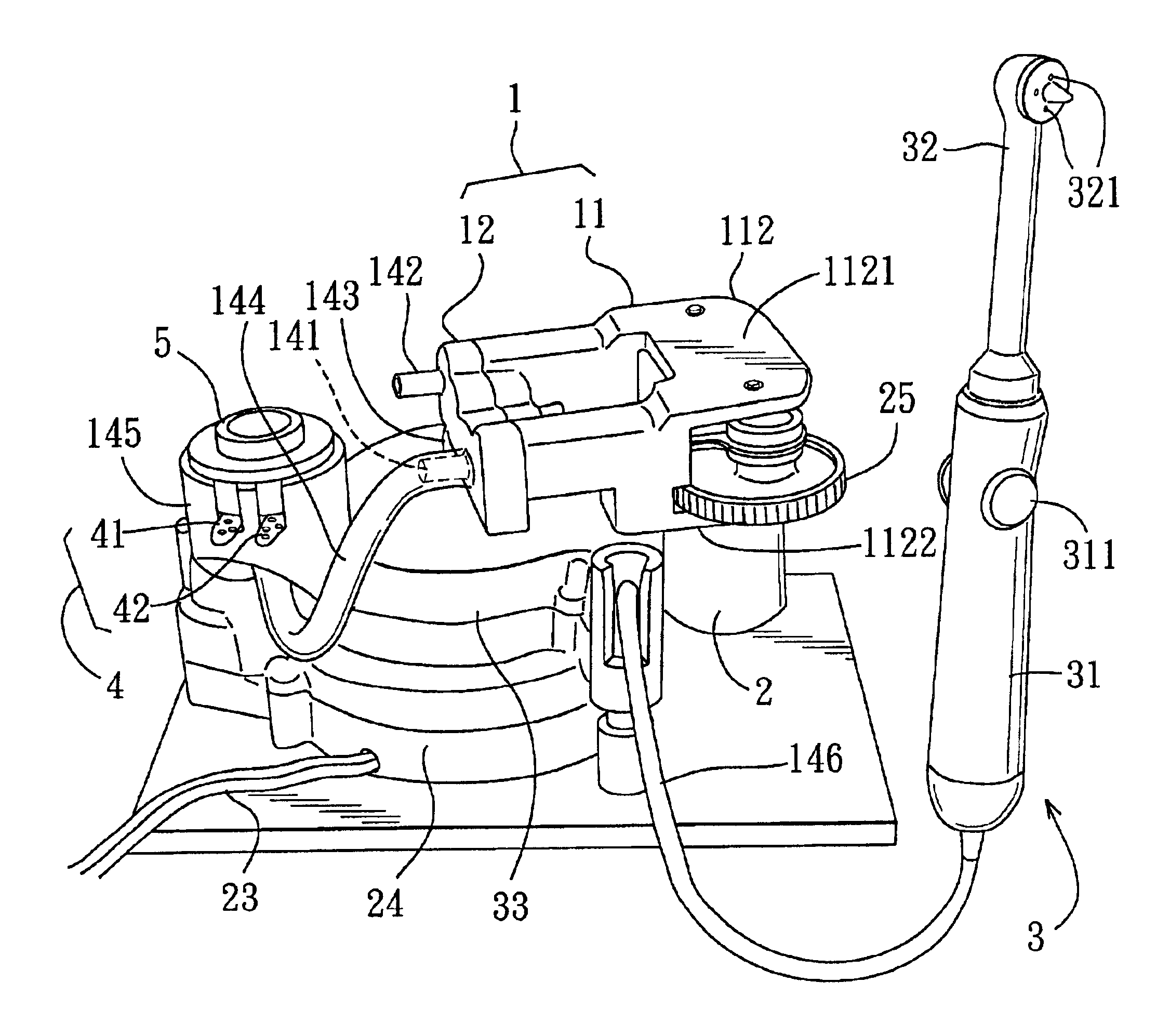

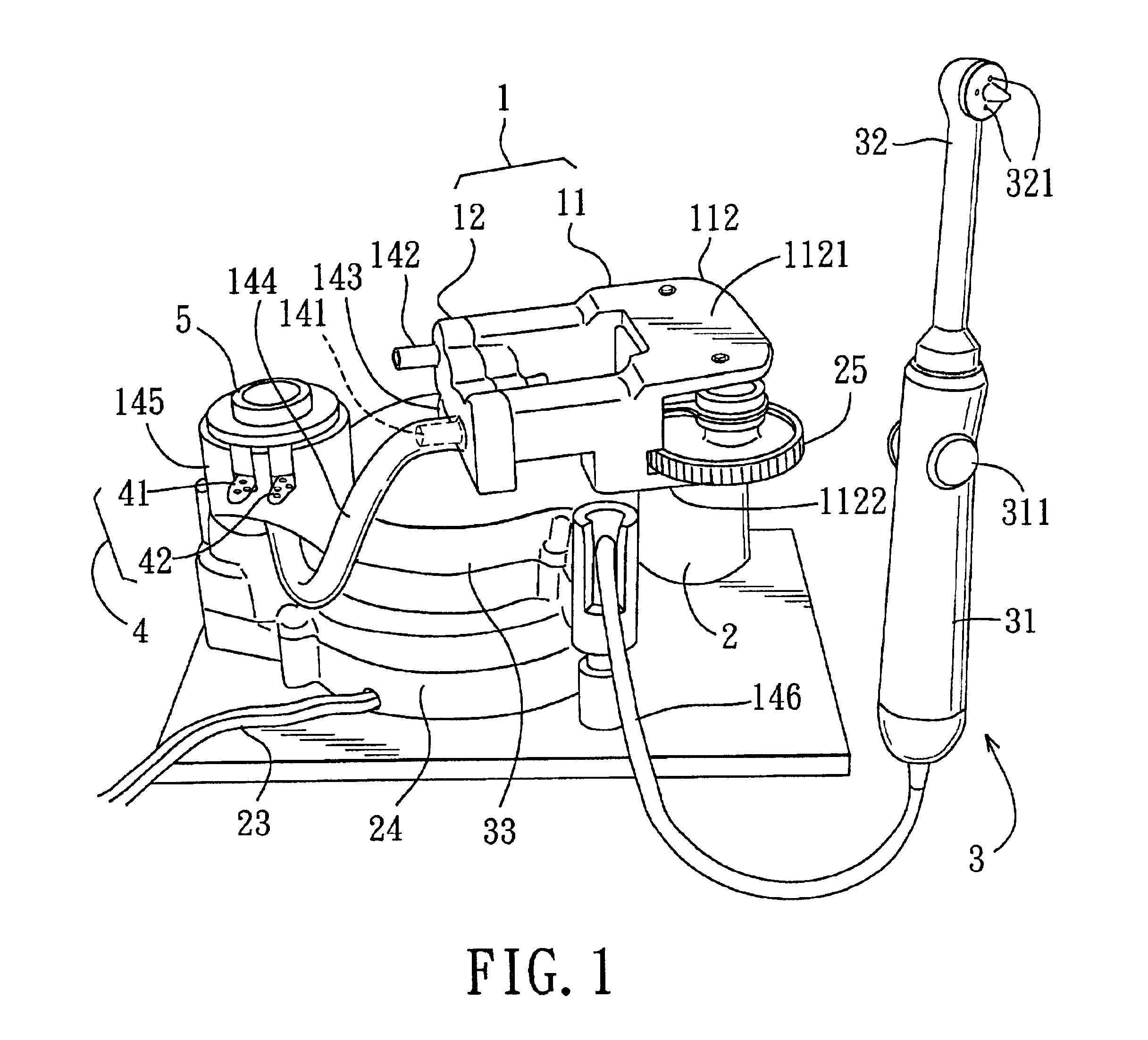

Device for generating a jet stream of air entrained water

A device for generating a jet stream of air entrained water for cleaning teeth and gums, includes two pumps disposed to respectively and sequentially pump in and out of internal ports thereof from first water and air transit chambers, water flow and air stream to generate raised water and air pressures. Two valves are disposed respectively to be moved by the water and air pressures to block or permit entry of the water flow and the air stream into second water and air transit chambers. A mixing outlet is disposed downstream of and to merge water and air outlet ports of the second water and air transit chambers to obtain an accelerated stream of the air entrained water for cleaning teeth and gums.

Owner:CHEN CHIEN LIANG +2

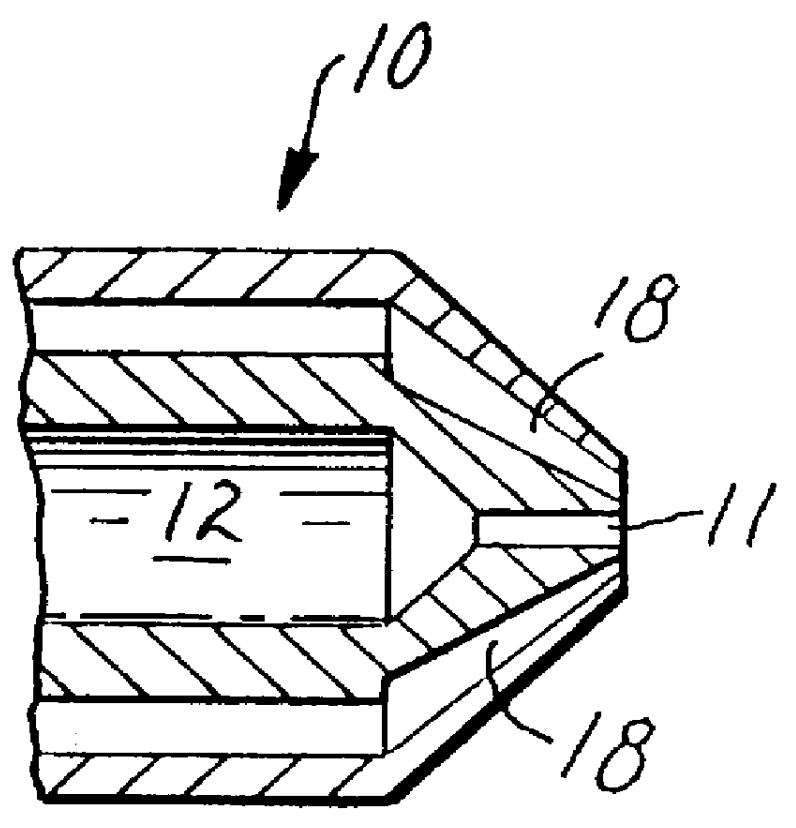

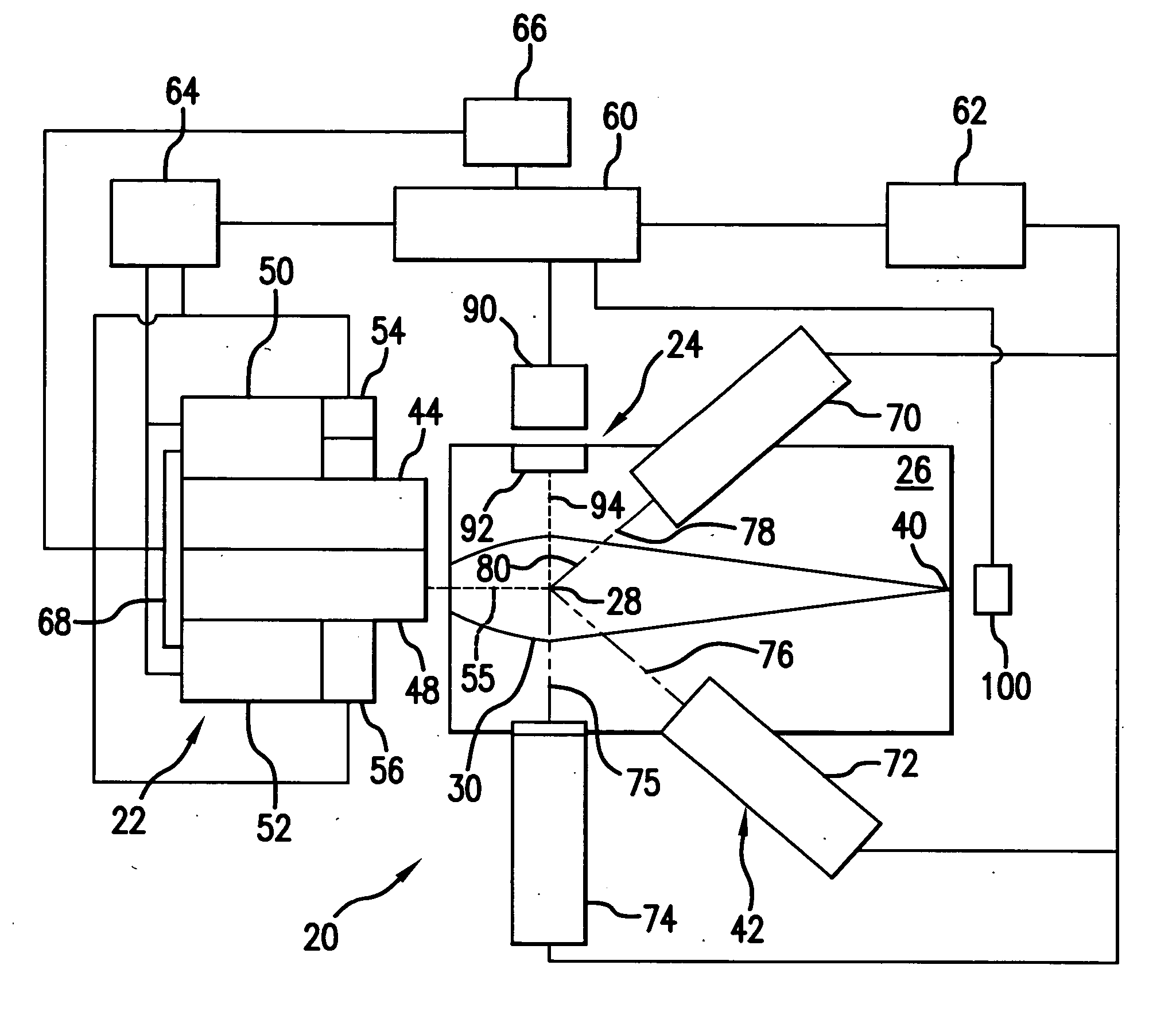

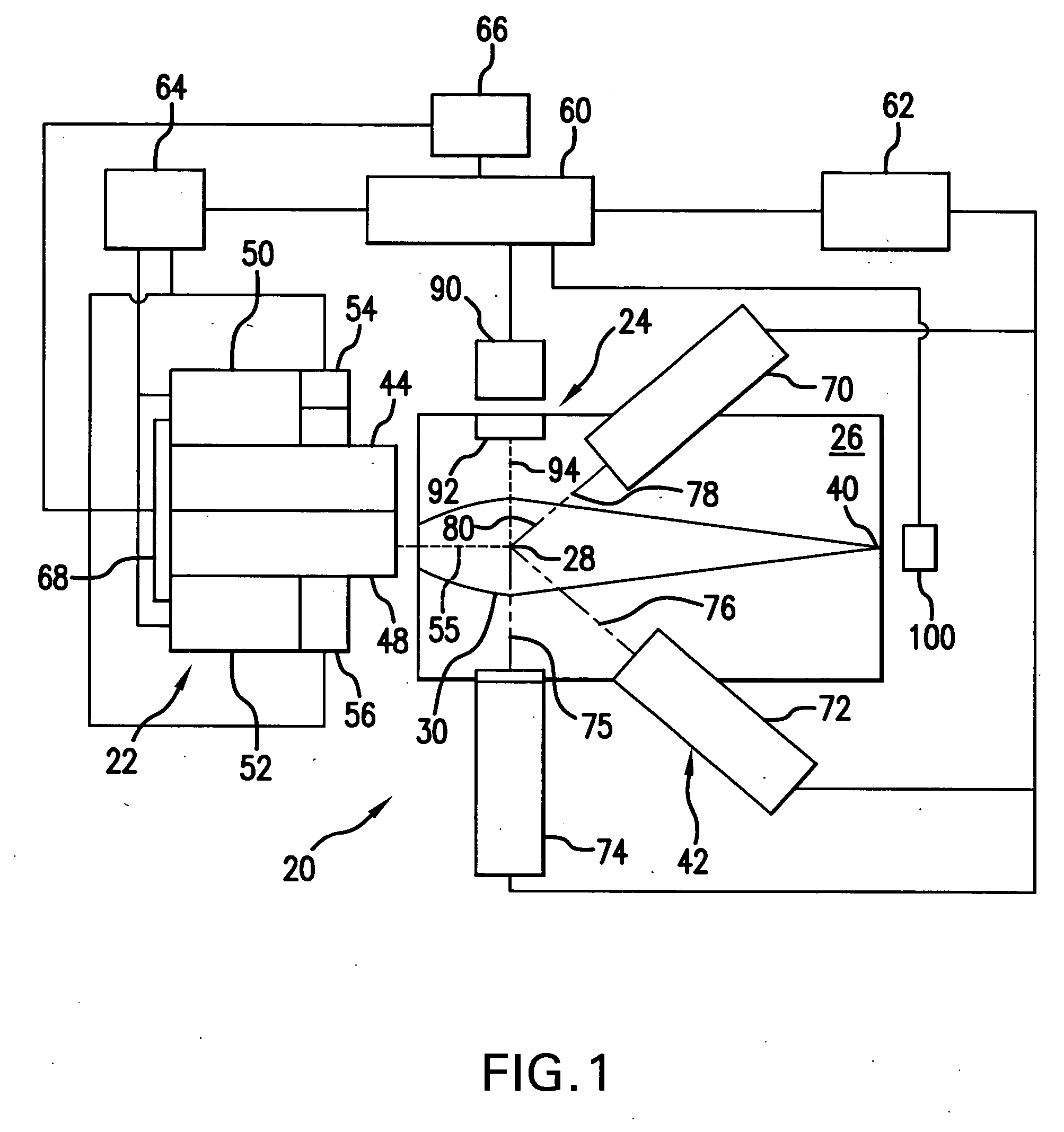

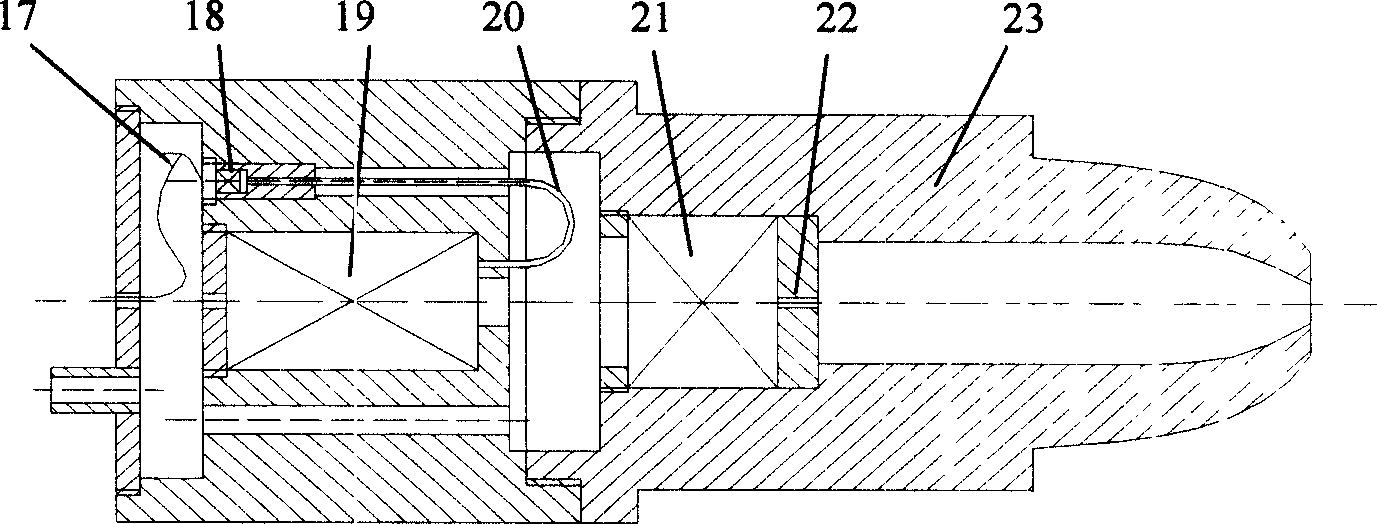

Method and apparatus for EUV plasma source target delivery

An EUV plasma formation target delivery system and method is disclosed which may comprise: a target droplet formation mechanism comprising a magneto-restrictive or electro-restrictive material, a liquid plasma source material passageway terminating in an output orifice; a charging mechanism applying charge to a droplet forming jet stream or to individual droplets exiting the passageway along a selected path; a droplet deflector intermediate the output orifice and a plasma initiation site periodically deflecting droplets from the selected path, a liquid target material delivery mechanism comprising a liquid target material delivery passage having an input opening and an output orifice; an electromotive disturbing force generating mechanism generating a disturbing force within the liquid target material, a liquid target delivery droplet formation mechanism having an output orifice; and / or a wetting barrier around the periphery of the output orifice.

Owner:ASML NETHERLANDS BV

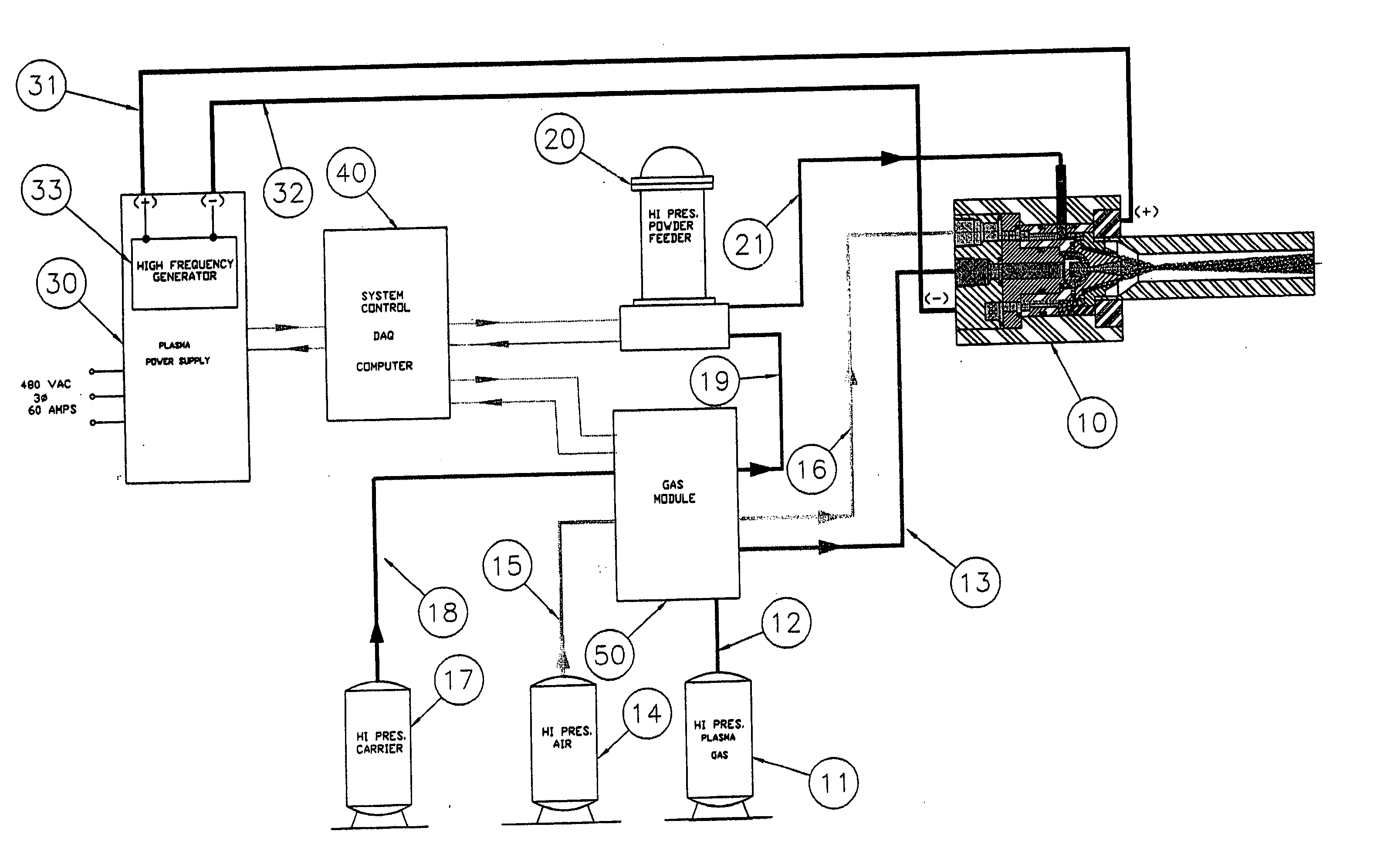

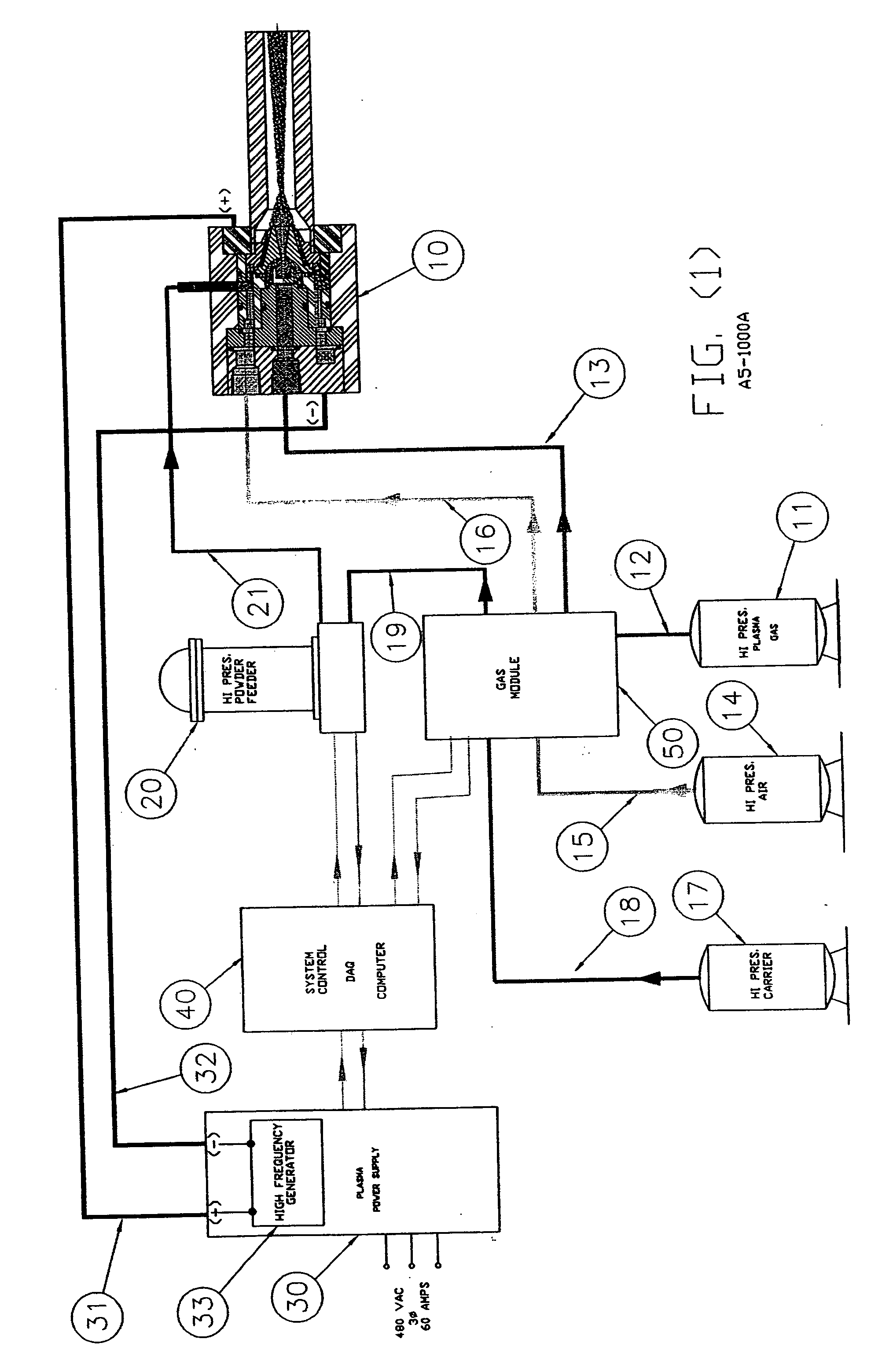

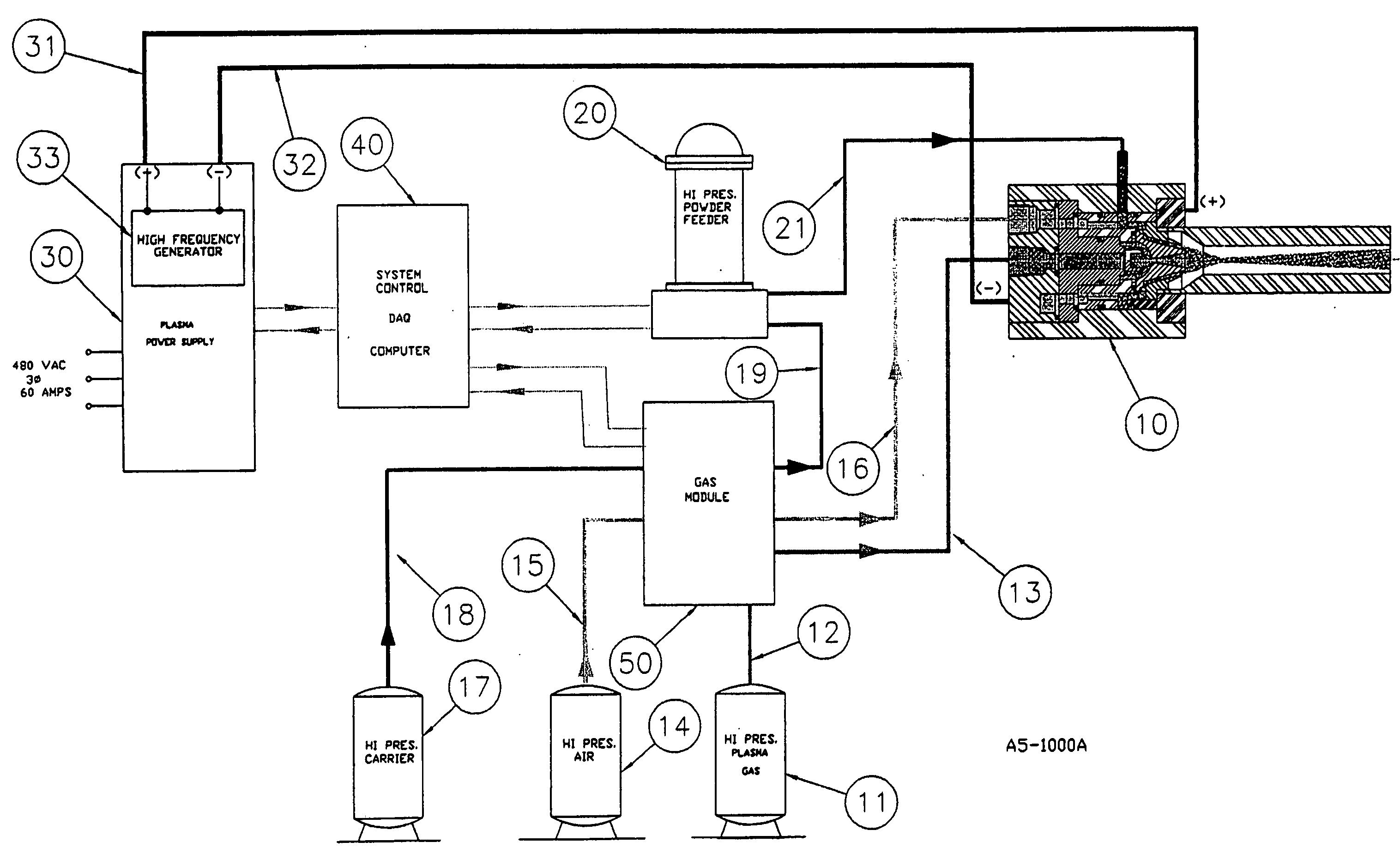

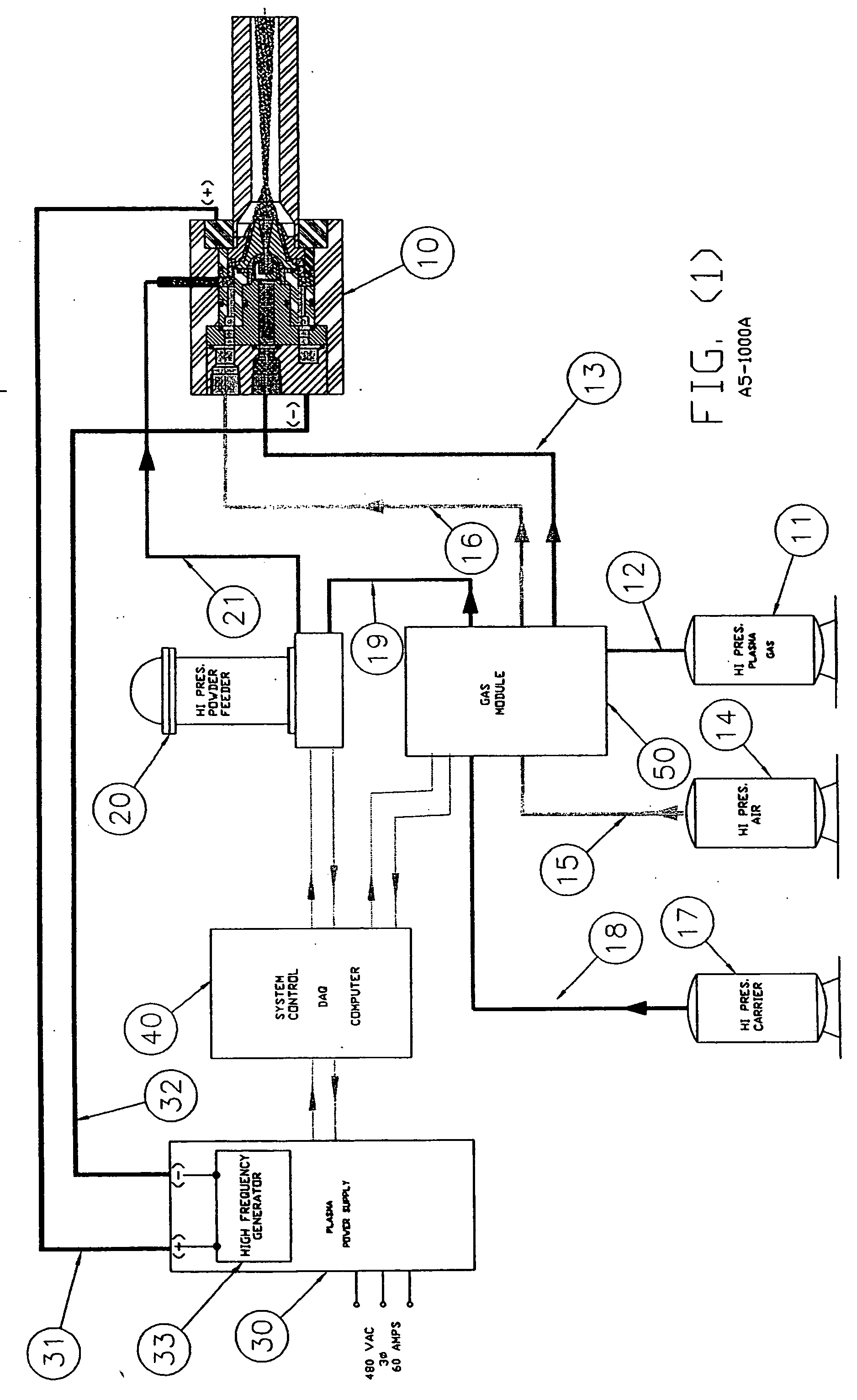

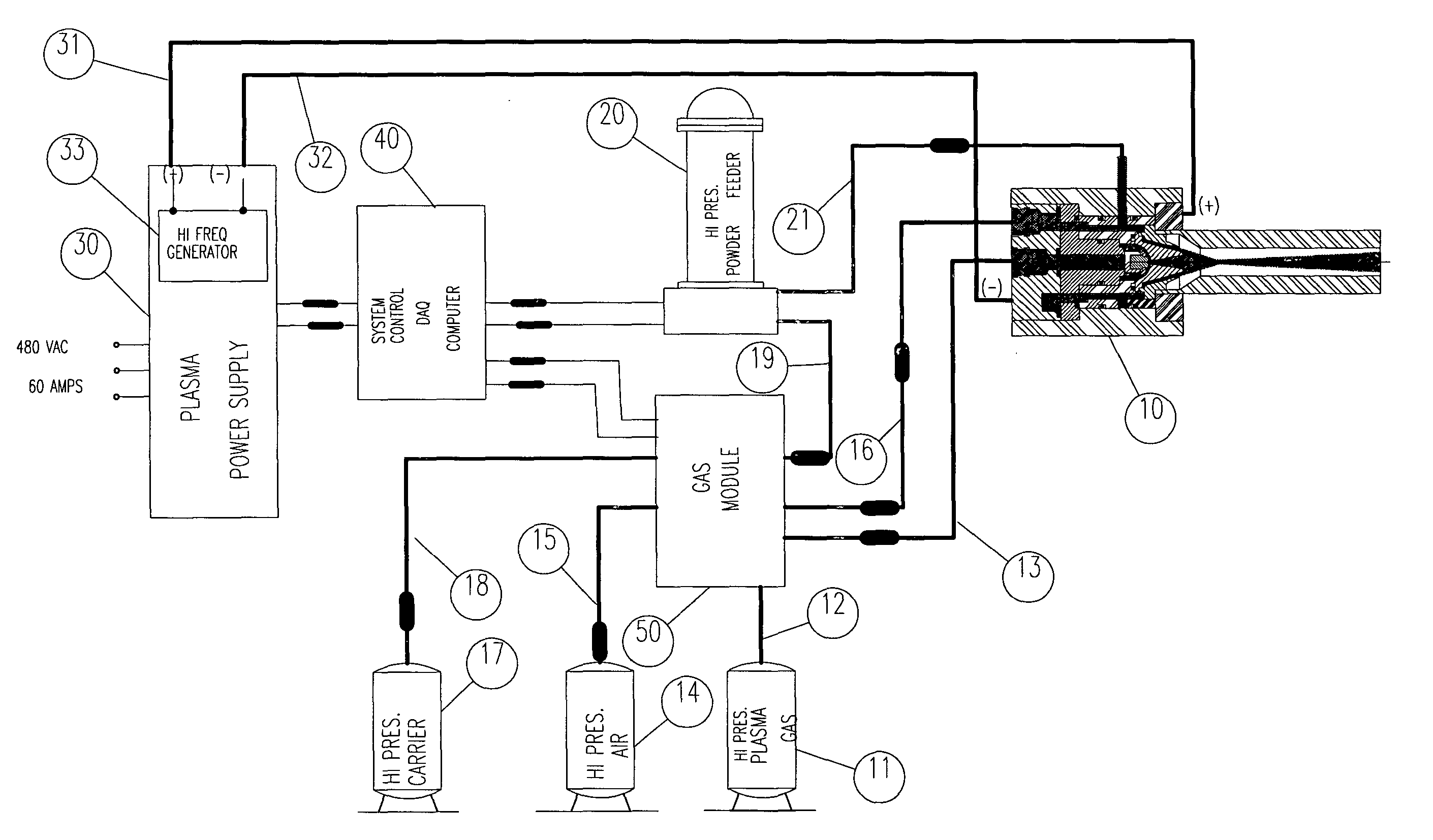

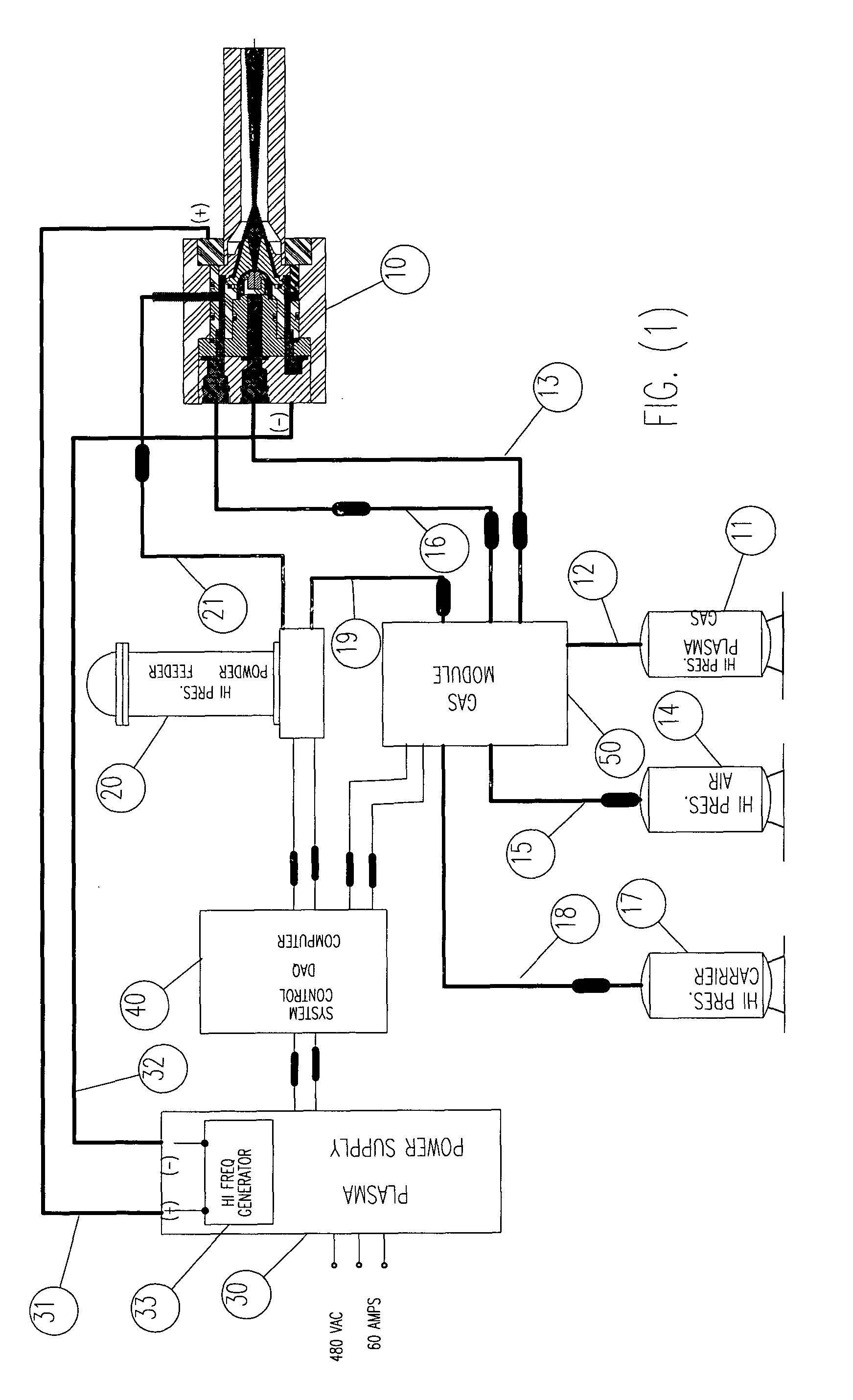

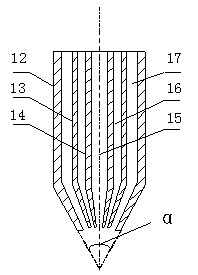

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050120957A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns.

Owner:FLAME SPRAY IND

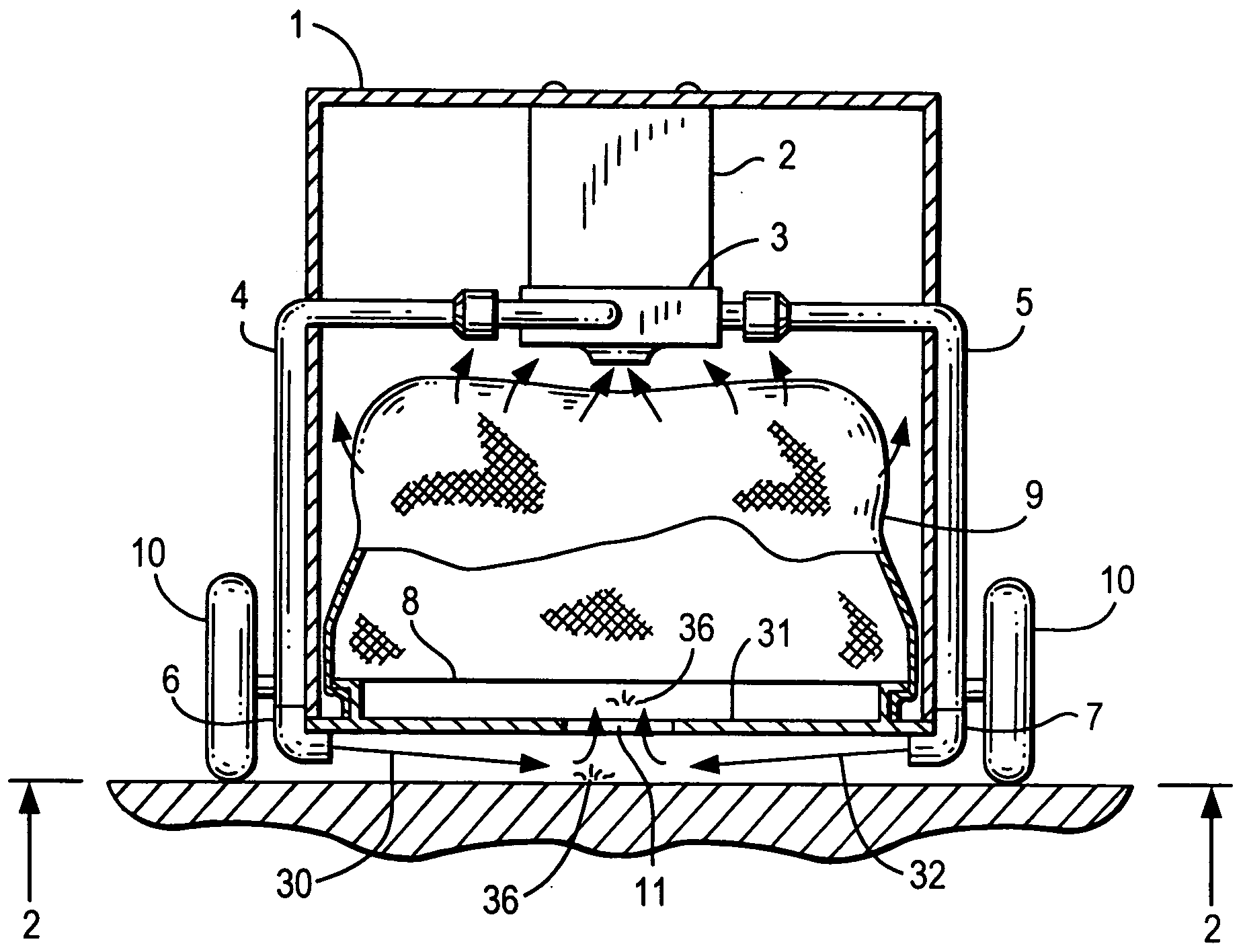

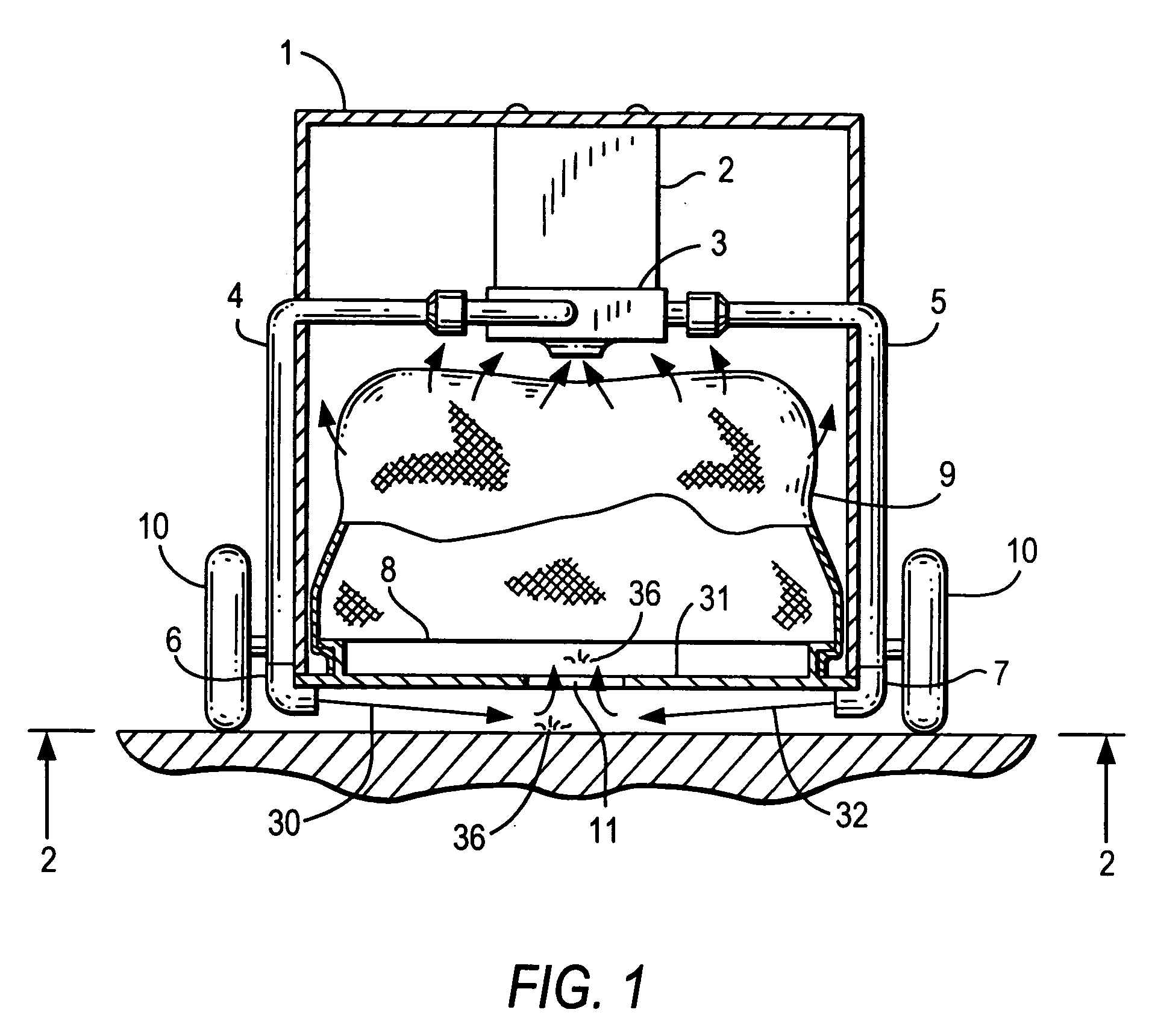

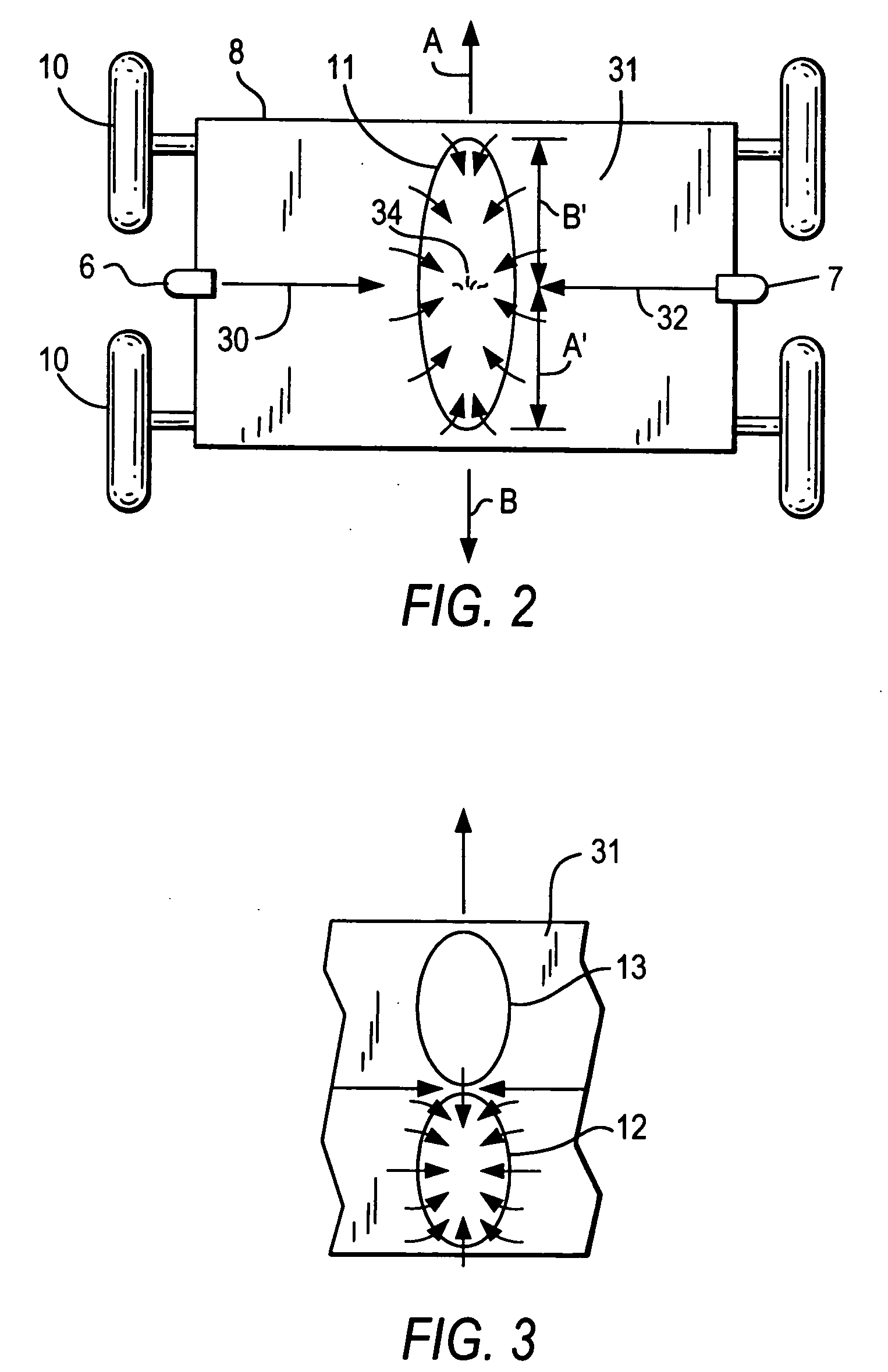

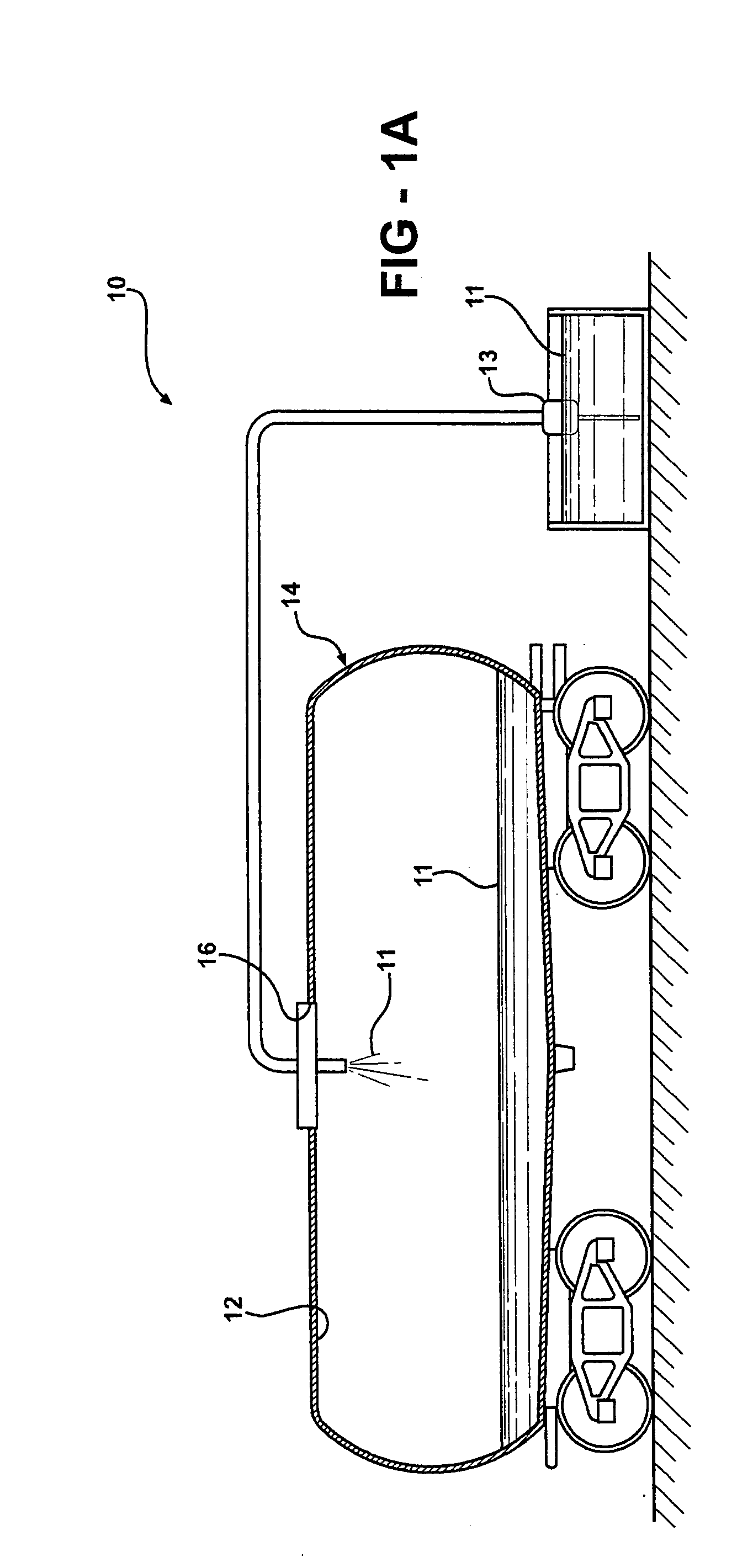

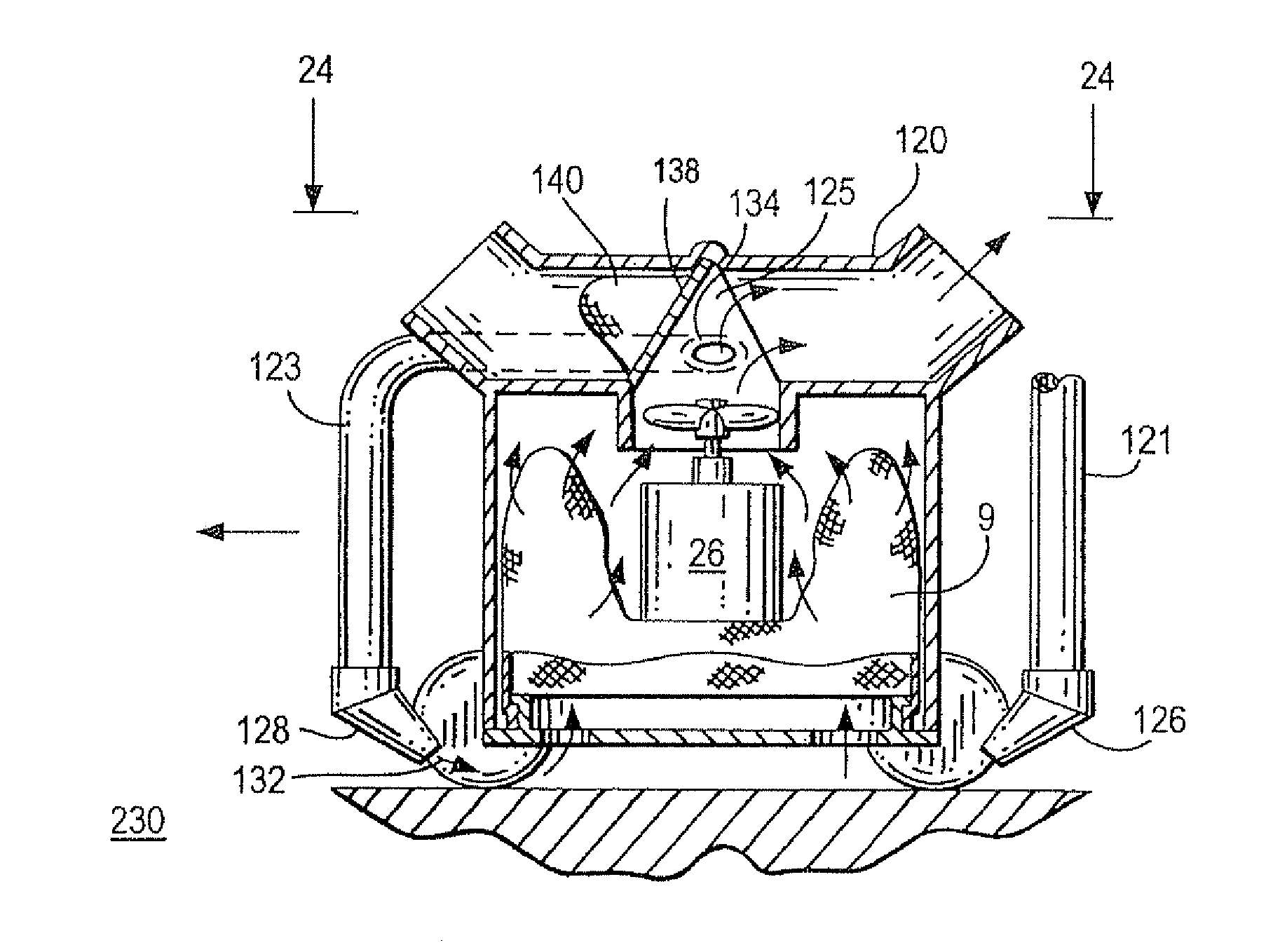

Pool cleaner with high pressure cleaning jets

InactiveUS20080236628A1Easy to cleanKeep for a long timeGymnasiumCleaning using gasesHigh pressureJet stream

A pool cleaning apparatus includes a housing and a pump for drawing water and debris through an intake port into a filter. A jet-valve housing having a jet valve flap is mounted over the pump to direct a propulsion jet stream from the pump to move the cleaner in a forward direction. A cleaning nozzle is mounted over each of the front and rear portions of the housing, and a pressurized water jet stream is directed at a first pool surface beneath the cleaner through the front end nozzle while moving in a forward direction. When the cleaner engages a second pool surface substantially perpendicular to the first surface, propulsion outlets of the jet valve housing are partially closed to redirect a portion of the propulsion jet stream to the front-end nozzle to lift the front end of the cleaner off the first surface. When the front end of the cleaner disengages from contact with the second surface, the propulsion outlets open to permit the propulsion jet stream to propel the cleaner along the second surface.

Owner:AQUA PRODS

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050252450A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

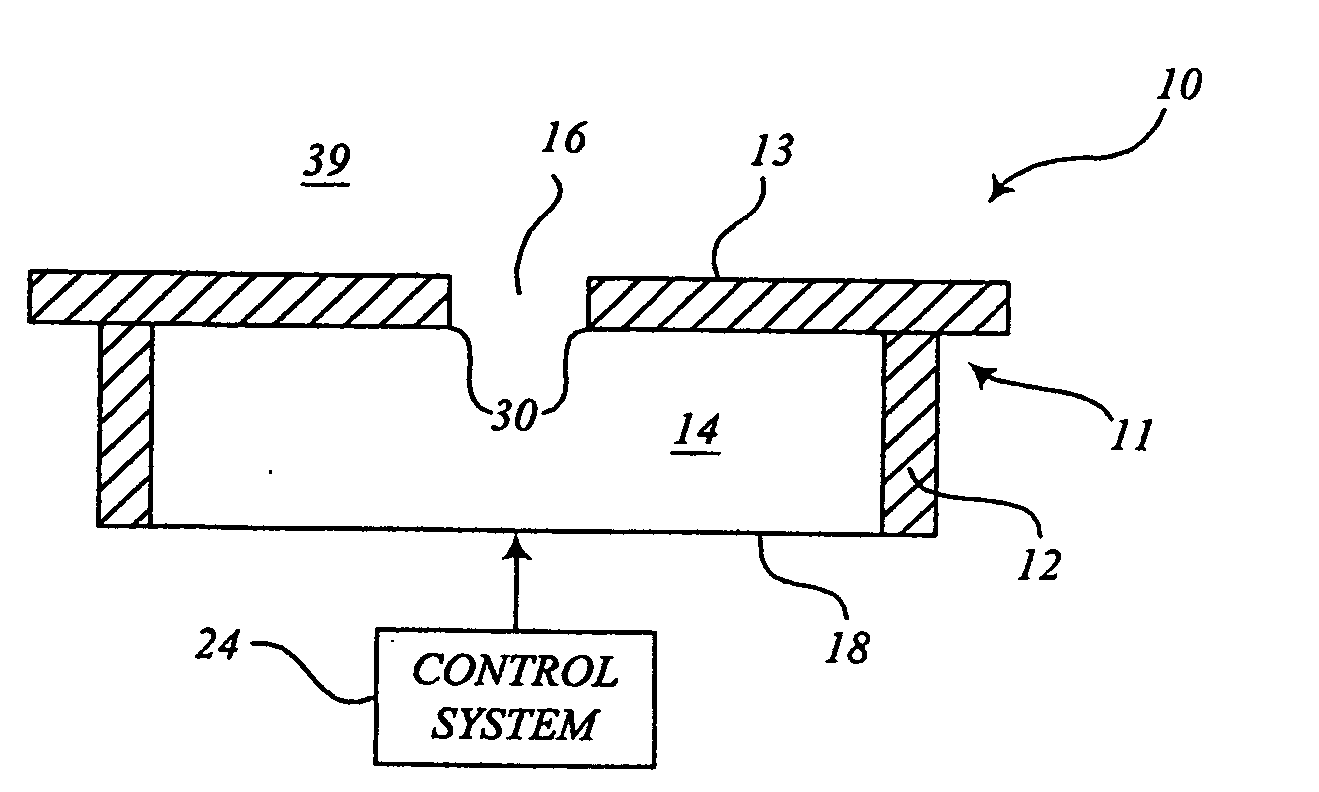

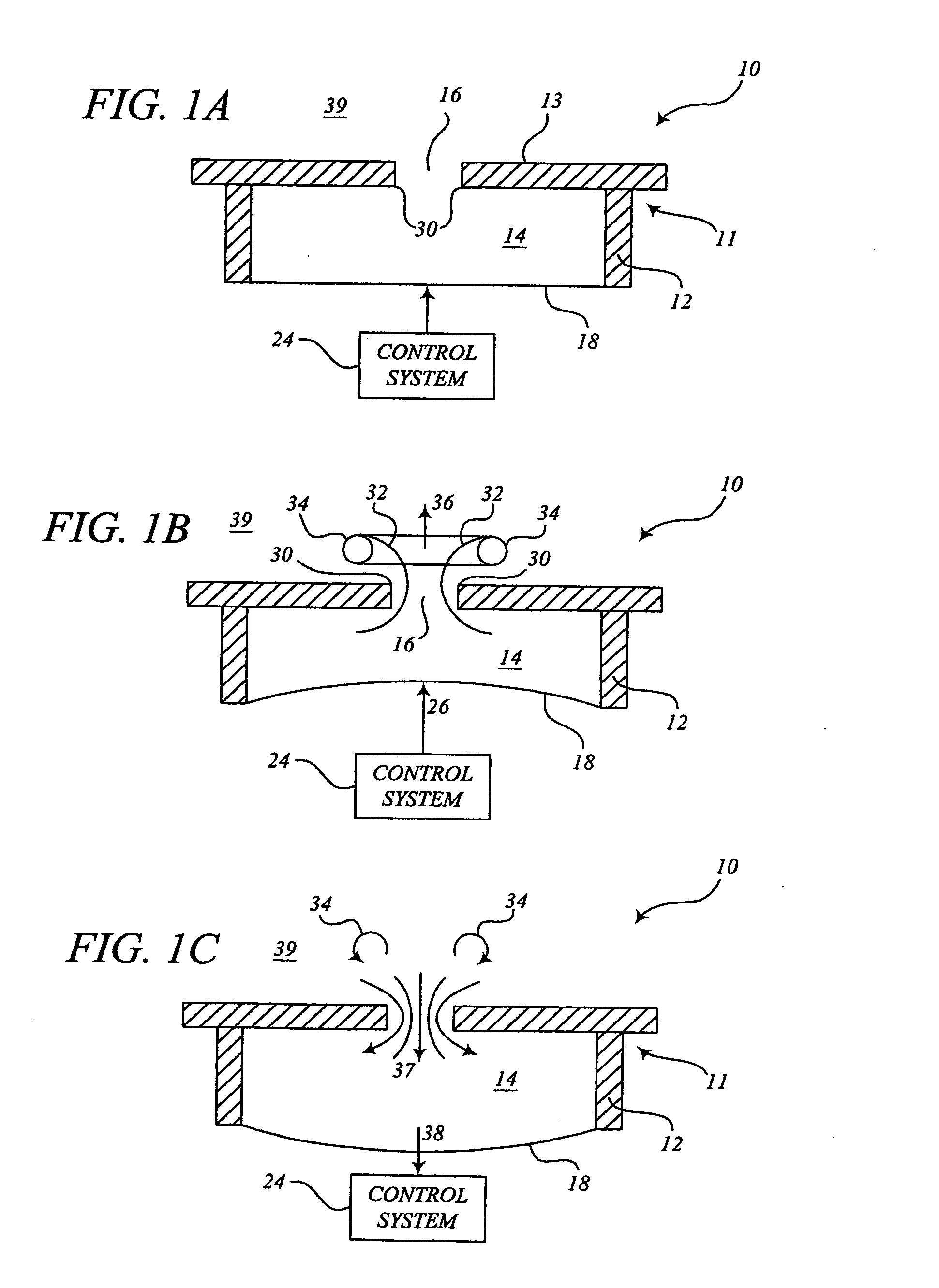

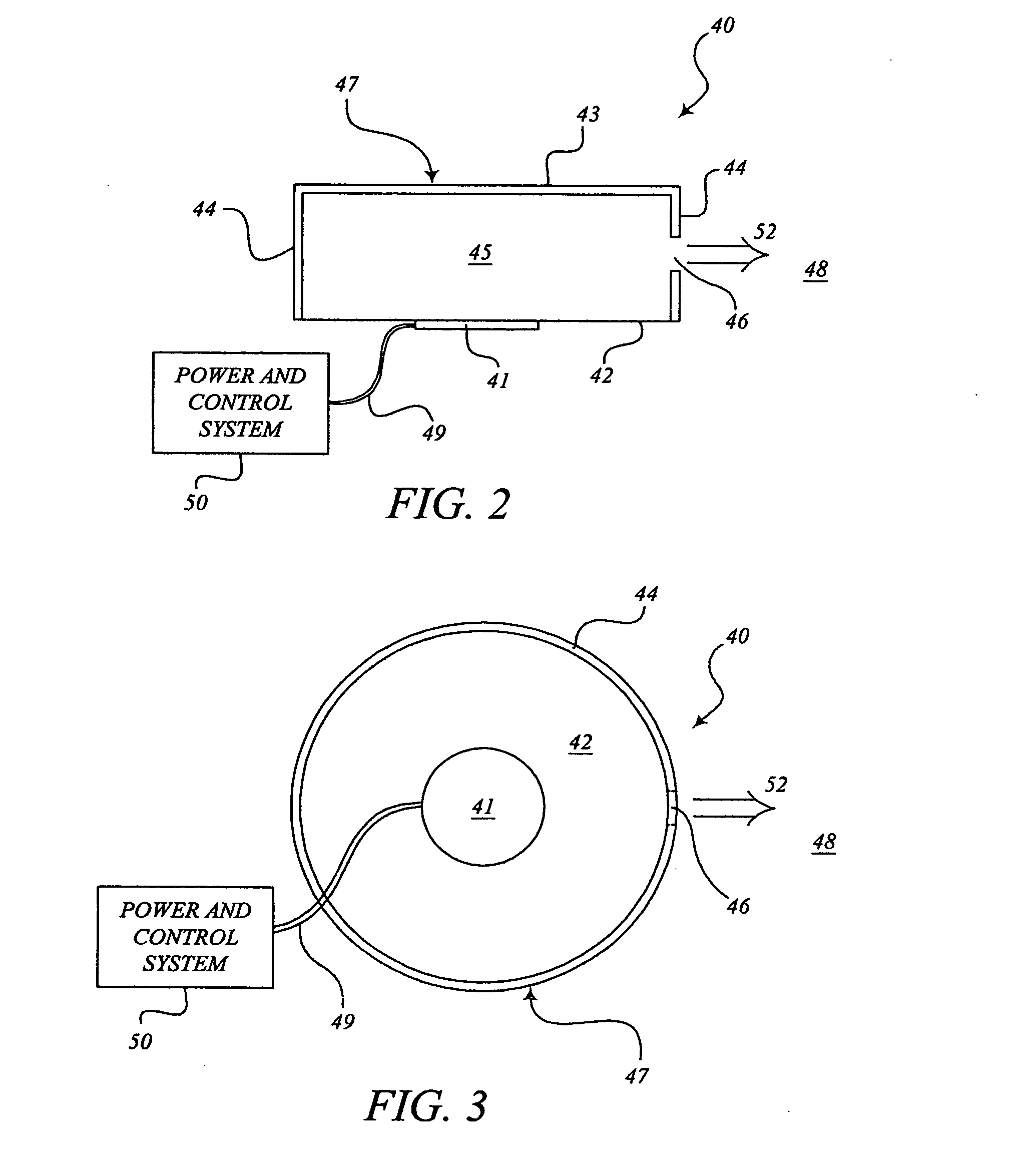

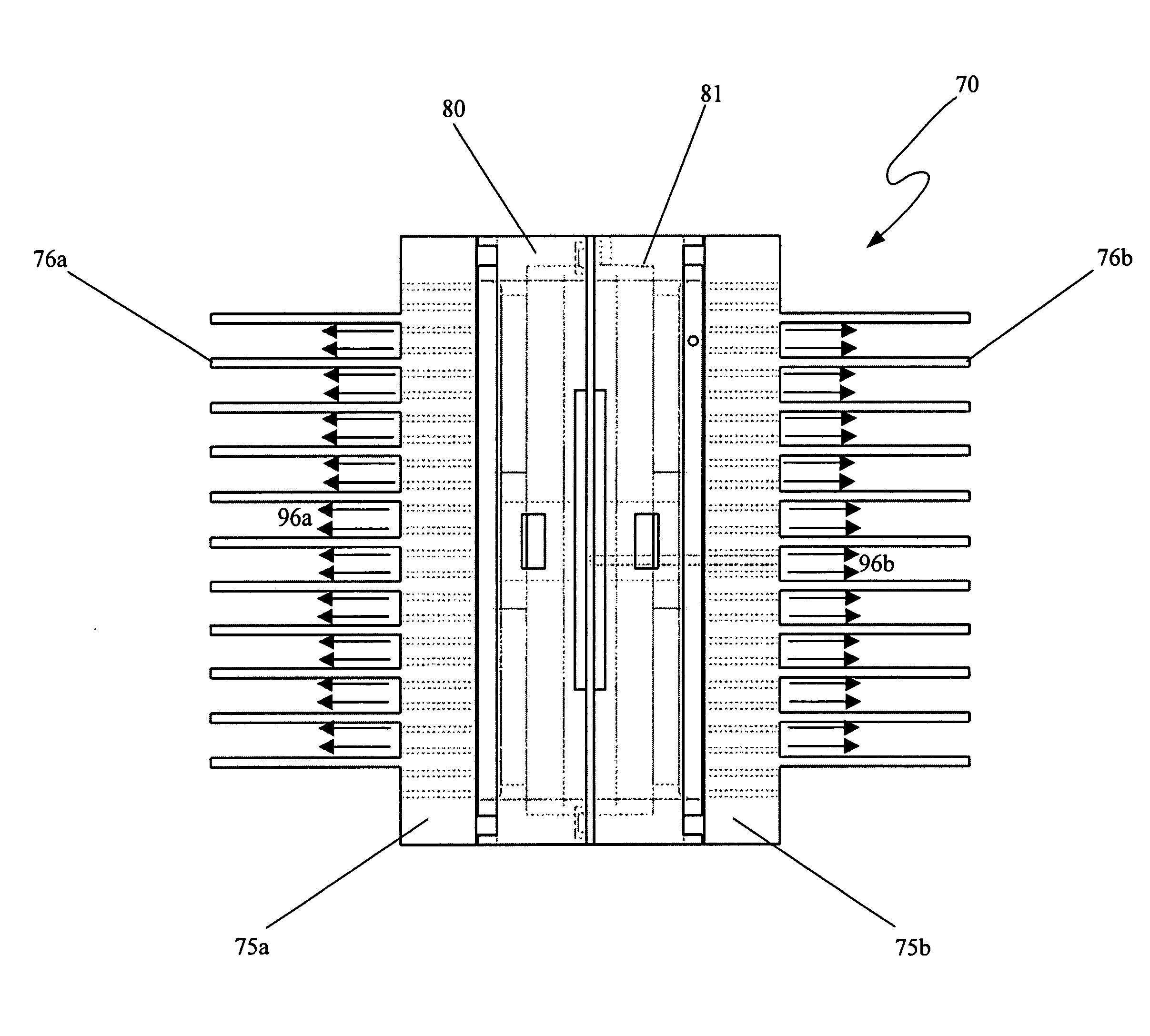

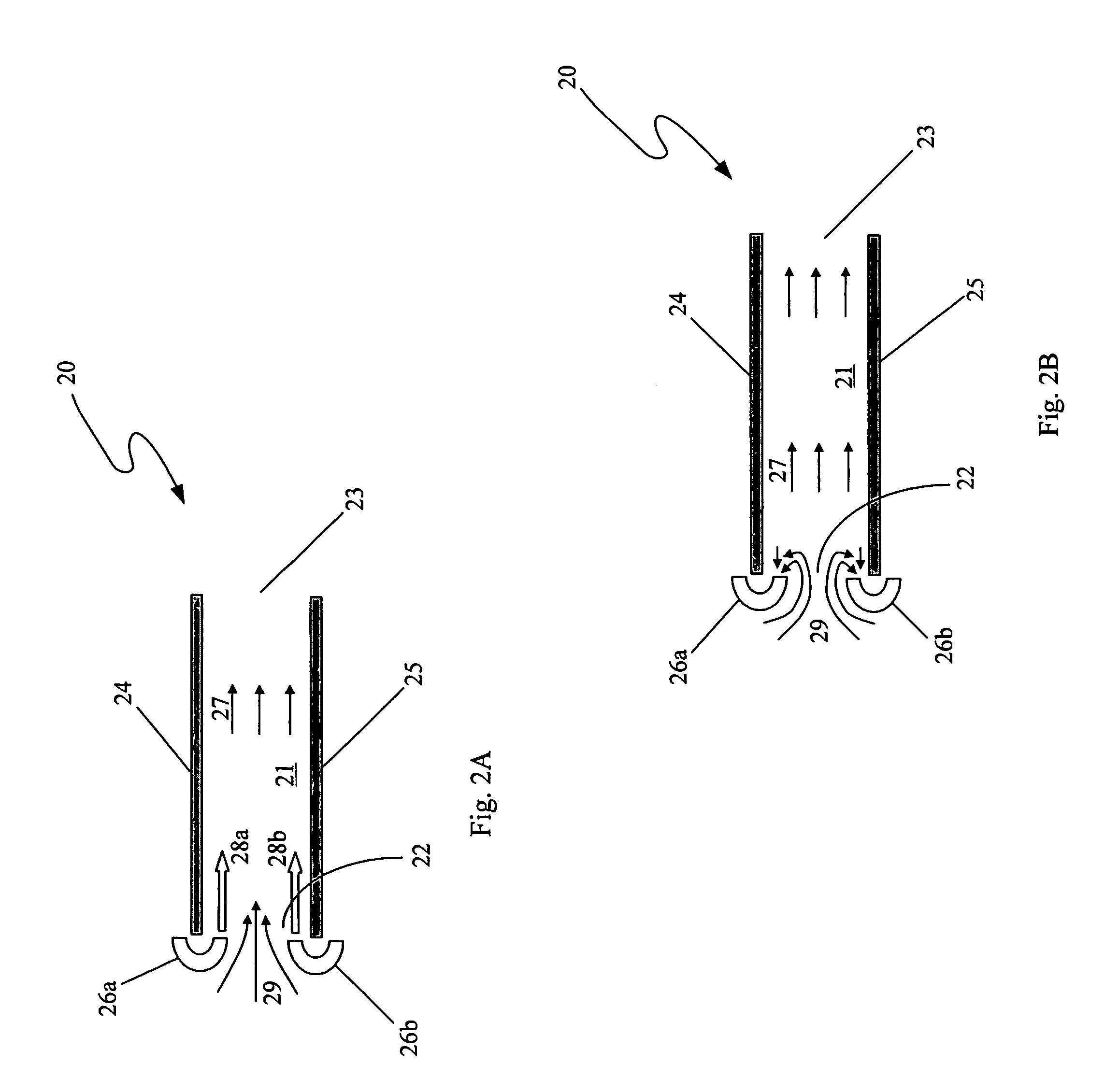

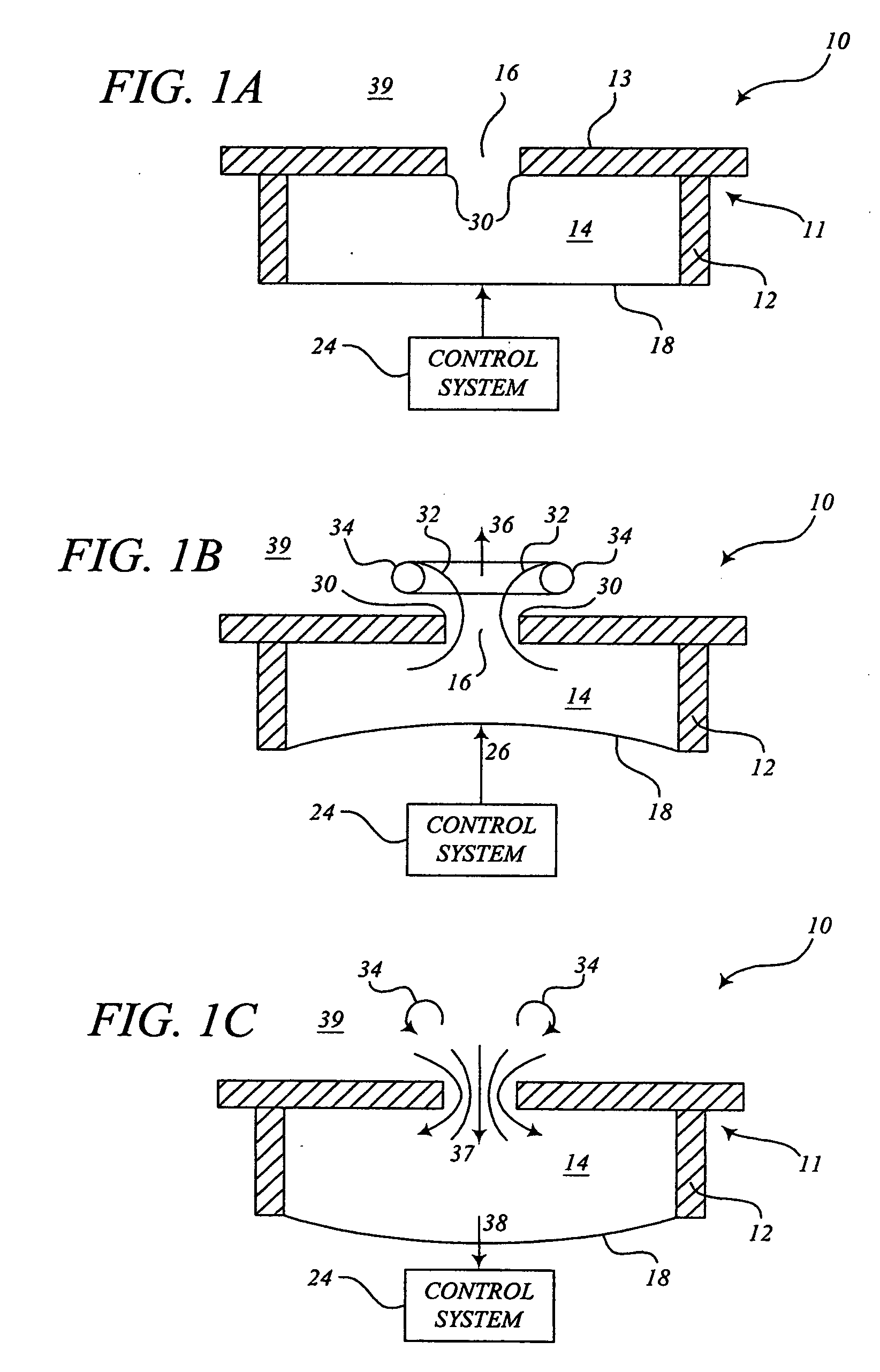

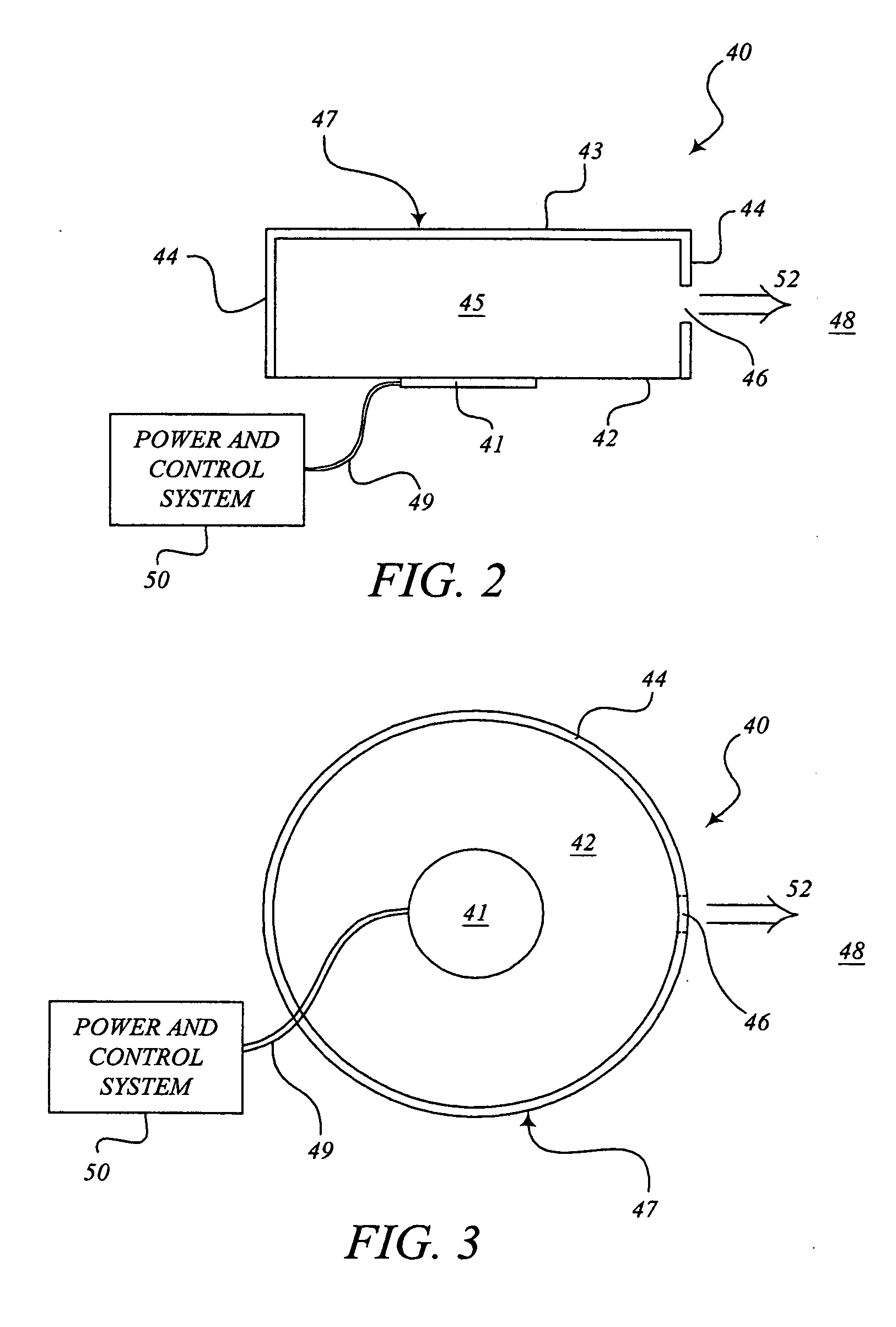

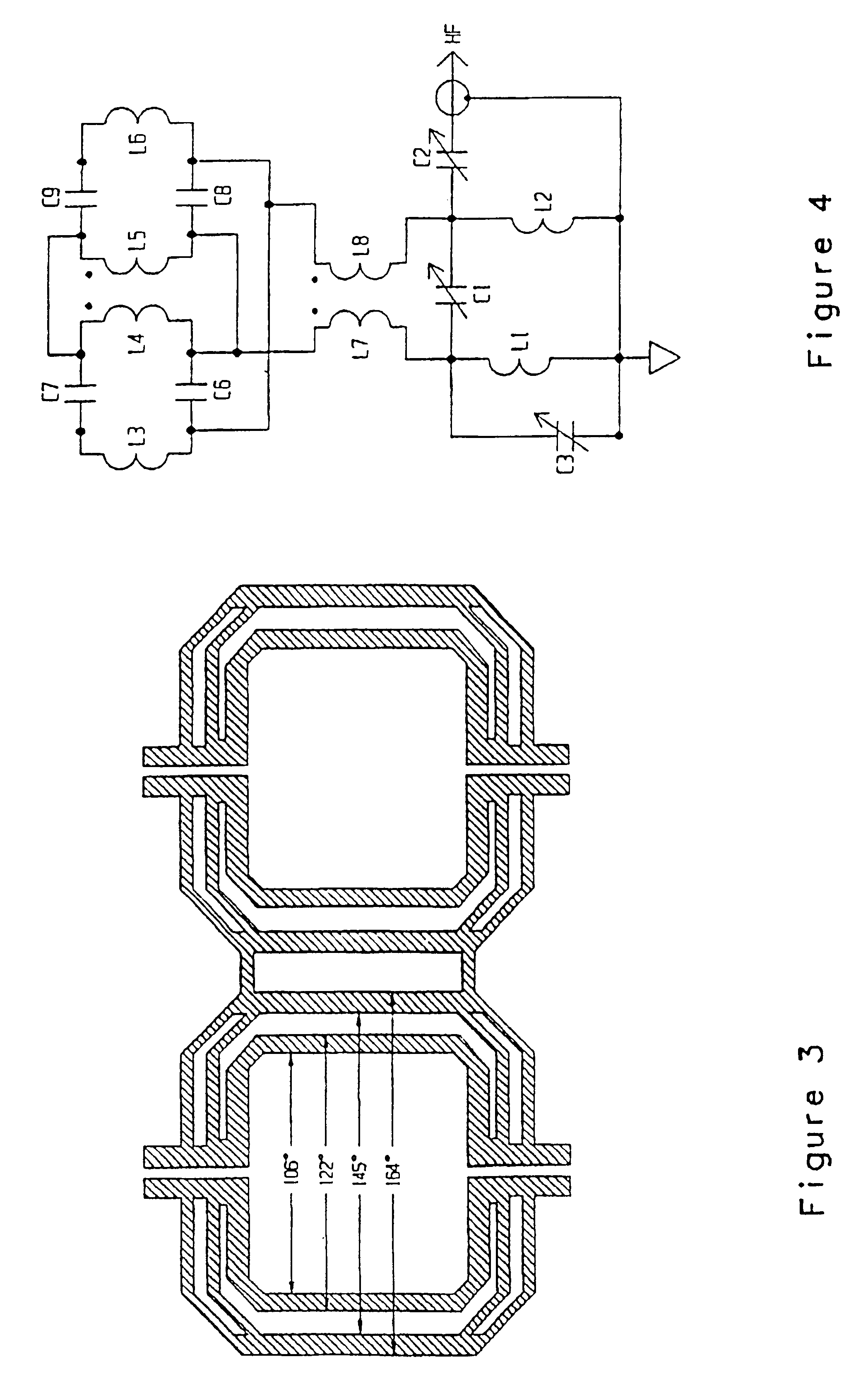

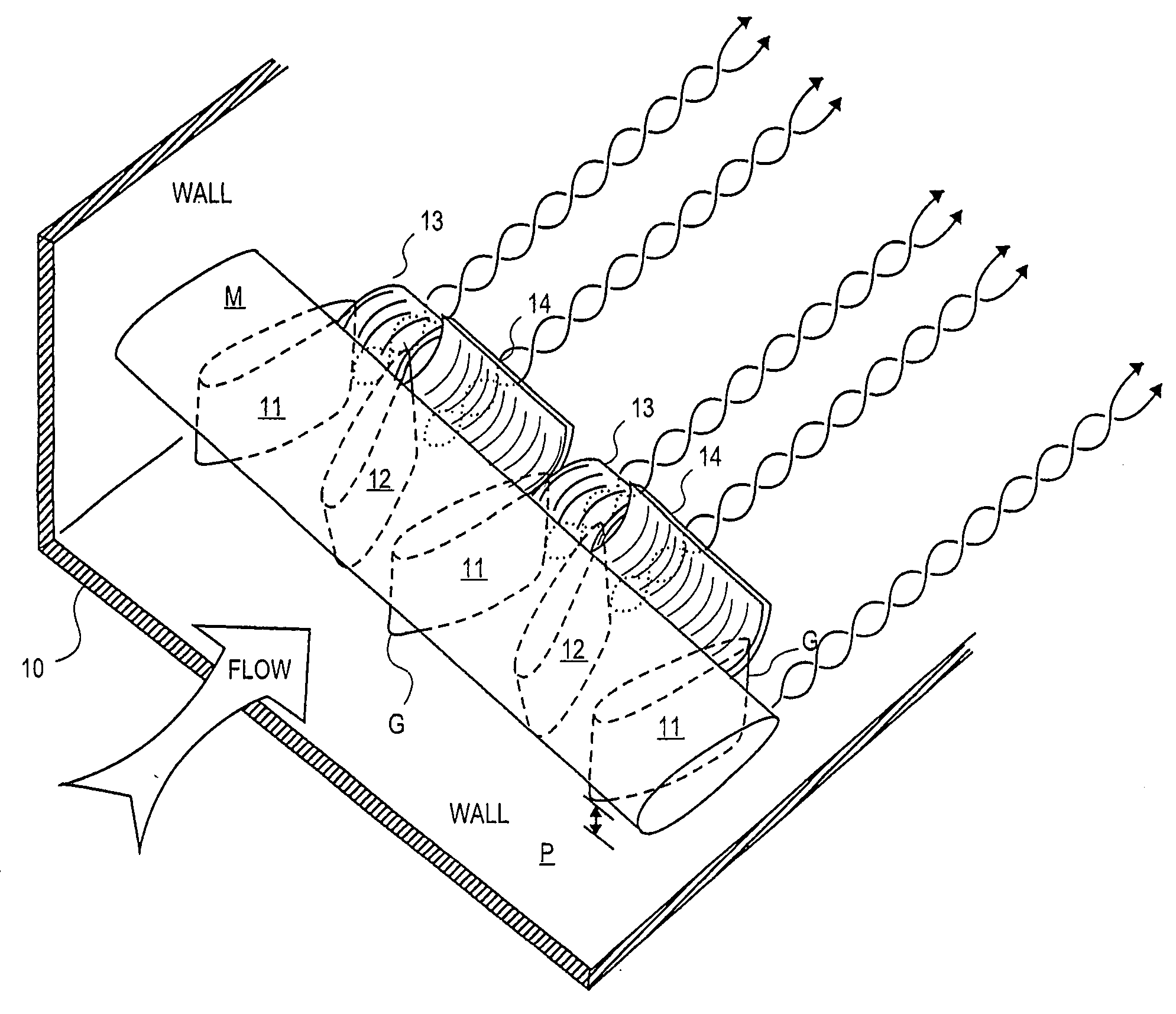

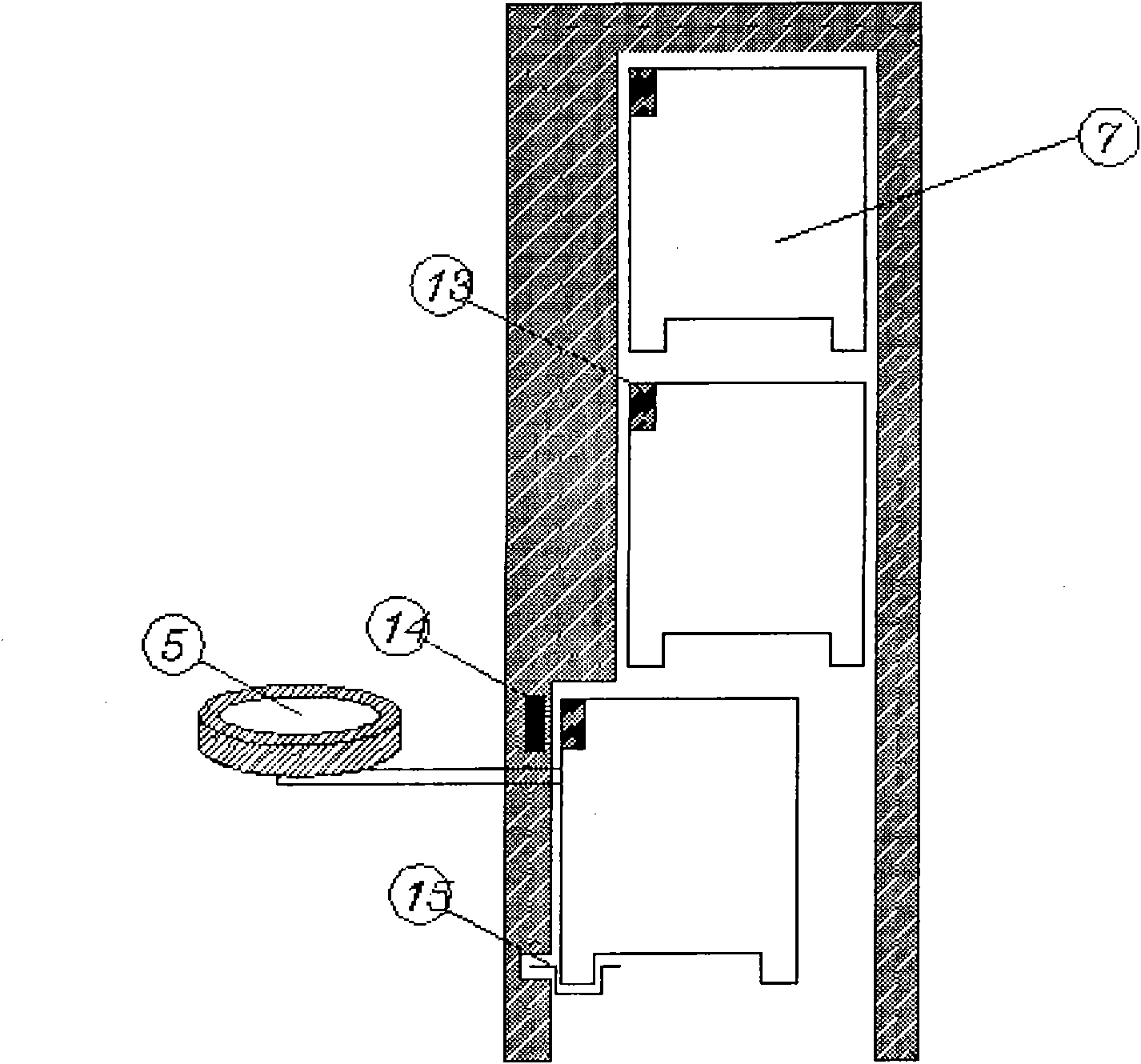

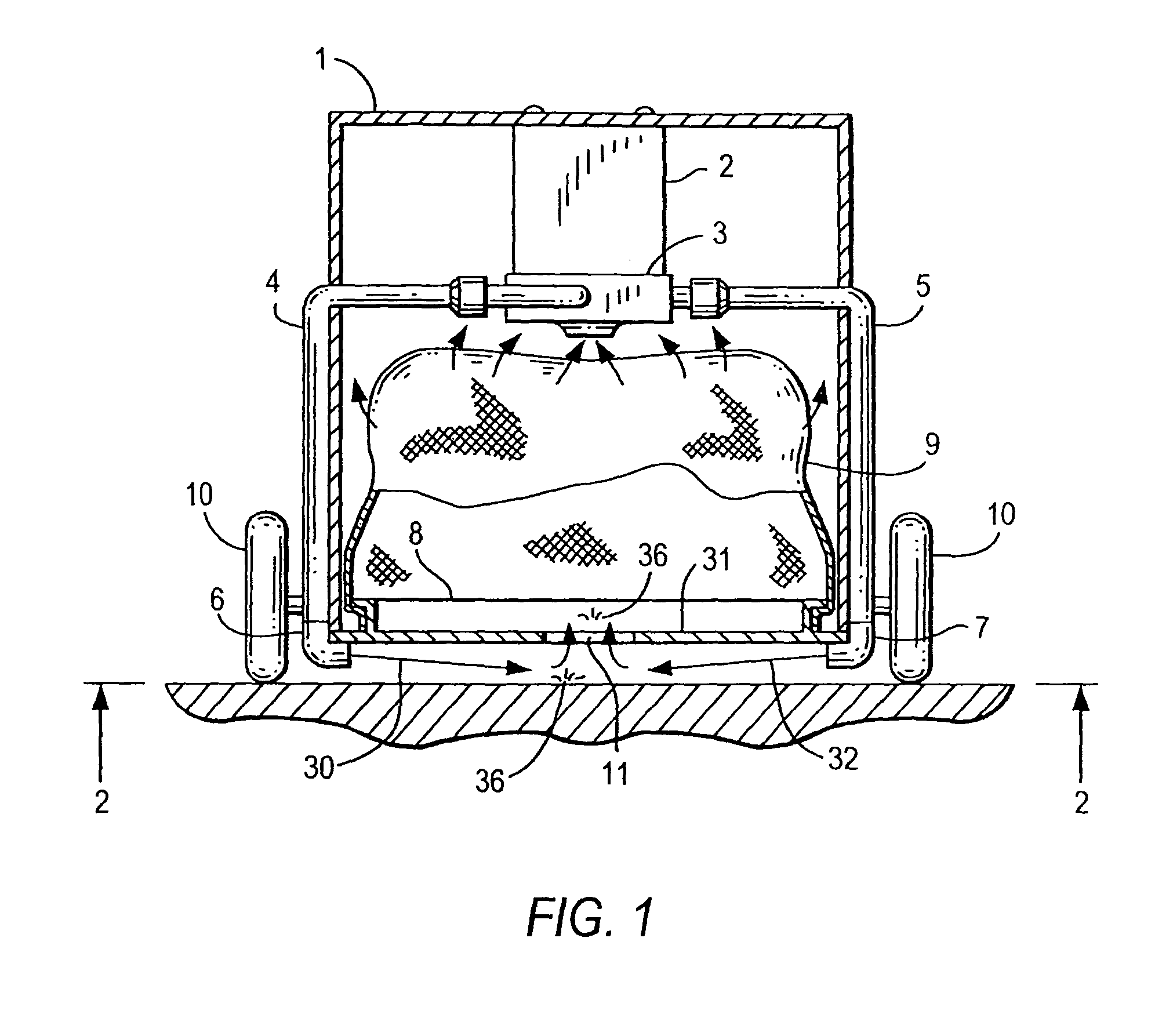

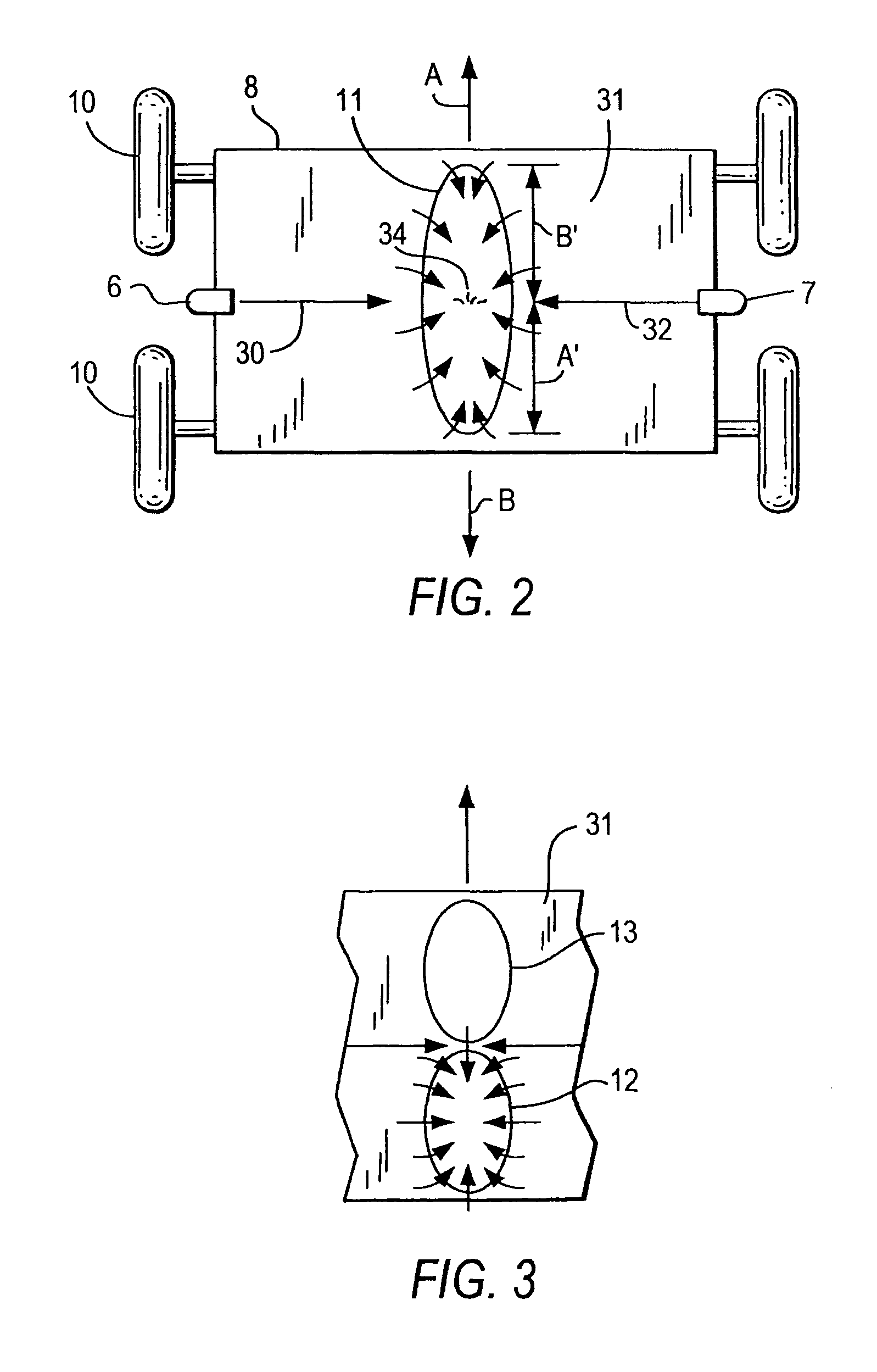

System and method for thermal management using distributed synthetic jet actuators

InactiveUS20060196638A1Digital data processing detailsSemiconductor/solid-state device detailsActuatorJet stream

One embodiment of the device comprises a device for thermal management. More particularly, one embodiment comprises a synthetic jet actuator (60) and a tube (61). The synthetic jet actuator (60), though not required, typically comprises a housing (47) defining an internal chamber (45) and having an orifice (46) in a wall (44) of the housing (47). The synthetic jet actuator (60) typically also comprises a flexible diaphragm (42) forming a portion of the housing (47). The tube (61) of this exemplary embodiment typically comprises a proximal end (64) and a distal end (65), the proximal end (64) being positioned adjacent to the synthetic jet actuator (60). In this embodiment, operation of the synthetic jet actuator (60) causes a synthetic jet stream (52) to form at the distal end (65) of the tube (61).

Owner:GEORGIA TECH RES CORP

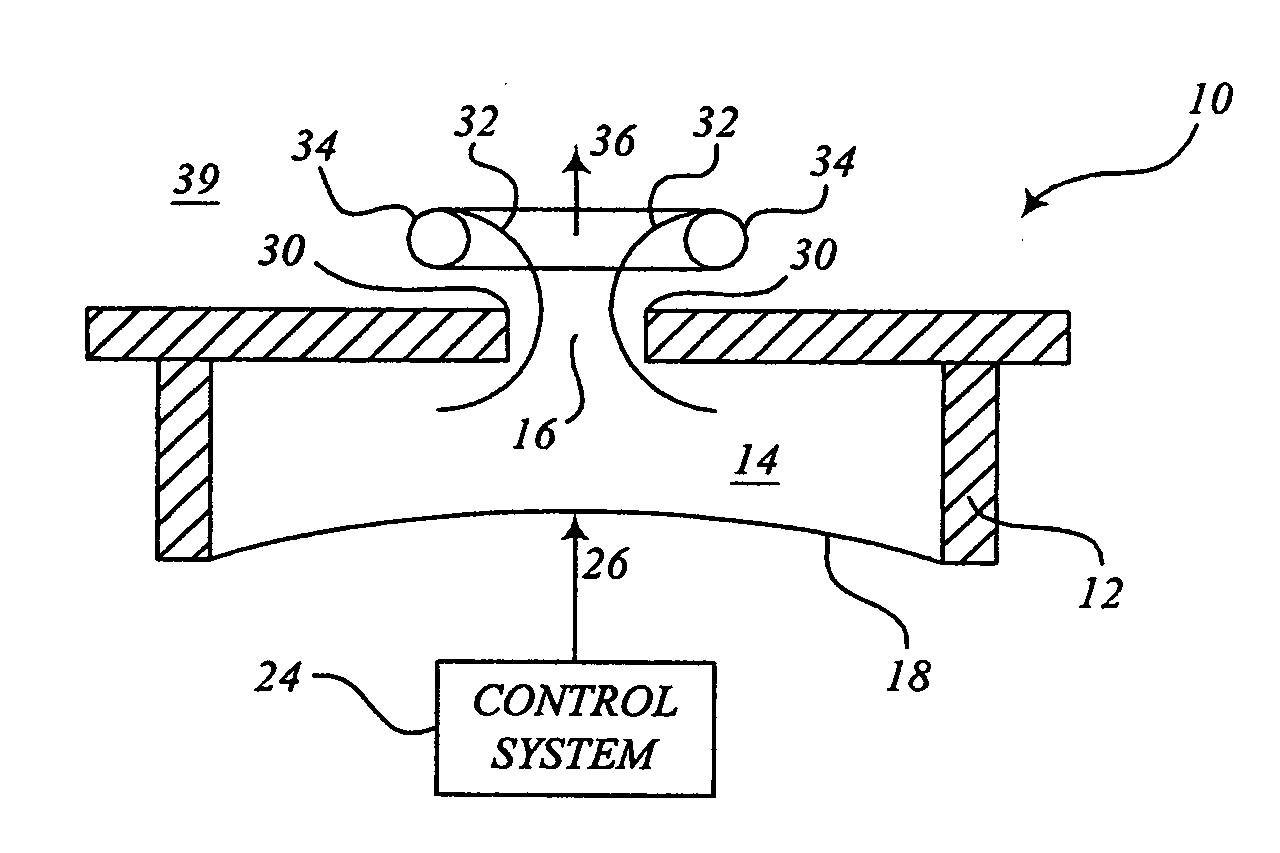

Apparatus and method for enhanced heat transfer

InactiveUS7252140B2Heat exchange apparatusCooling/ventilation/heating modificationsEnhanced heat transferDistribution system

One embodiment of the cooling module is implemented as a device having a heat sink and an integrated synthetic jet actuator. The heat sink is configured to have a channel and a jet distribution system associated with the synthetic jet actuator directs fluid flow into the channel of the heat sink. In operation, the fluid flow of this embodiment of the cooling module comprises a synthetic jet stream and ambient fluid entrained into the channel by the synthetic jet stream. The fluid flowing through the channel serves to a wall of the heat sink channel.

Owner:INNOVATIVE FLUIDICS +1

System and method for thermal management using distributed synthetic jet actuators

InactiveUS20060185822A1Digital data processing detailsSemiconductor/solid-state device detailsActuatorJet stream

One embodiment of the device comprises a device for thermal management. More particularly, one embodiment comprises a synthetic jet actuator (60) and a tube (61). The synthetic jet actuator (60), though not required, typically comprises a housing (47) defining an internal chamber (45) and having an orifice (46) in a wall (44) of the housing (47). The synthetic jet actuator (60) typically also comprises a flexible diaphragm (42) forming a portion of the housing (47). The tube (61) of this exemplary embodiment typically comprises a proximal end (64) and a distal end (65), the proximal end (64) being positioned adjacent to the synthetic jet actuator (60). In this embodiment, operation of the synthetic jet actuator (60) causes a synthetic jet stream (52) to form at the distal end (65) of the tube (61).

Owner:GEORGIA TECH RES CORP

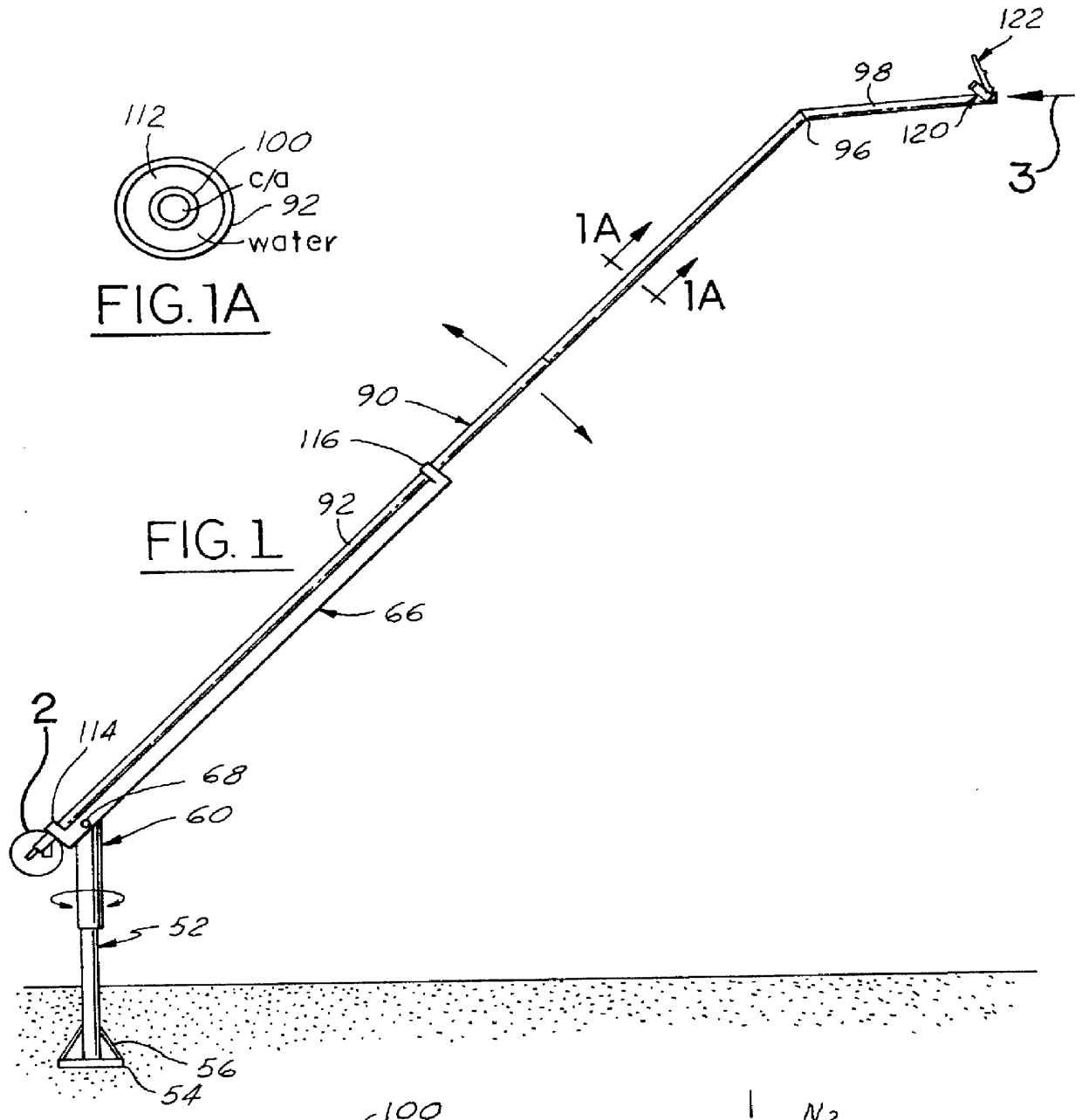

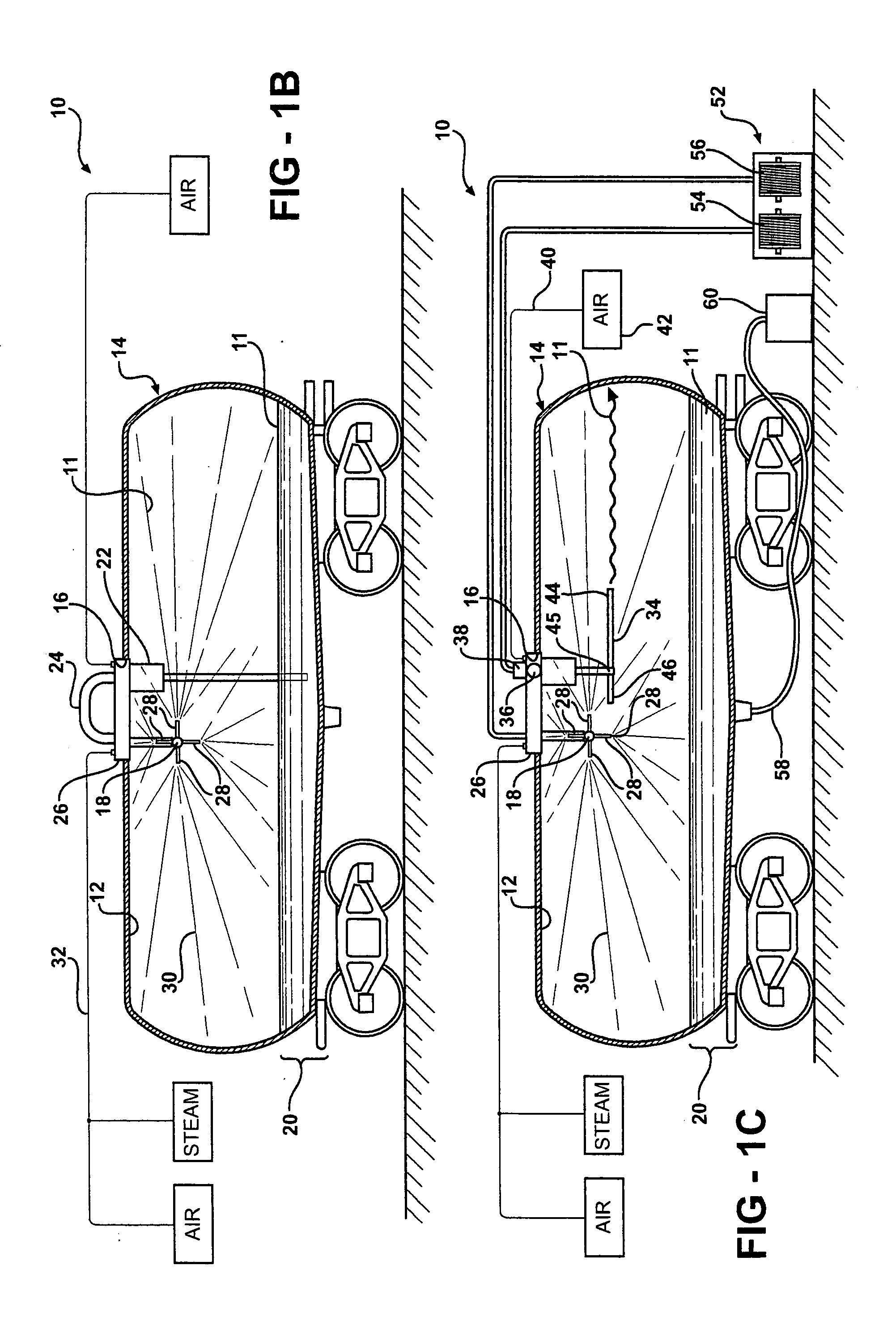

Adjustable snow making tower

InactiveUS6161769AIncrease flexibilityOptimize quantityLiquid surface applicatorsStands/trestlesBlock and tackleEngineering

Method and apparatus for making snow by generating water spray from a triple array of multiple nozzle sub-boom branch-pipes transversely protruding from the upper end of a main boom of a pivotably adjustable snow making pipe tower. Three air jet streams, one for each branch pipe, are simultaneously discharged under high pressure into and sequentially through the throats of each associated multiple stack of water sprays issuing from each set of branch pipe nozzles to thereby form multiple spray plumes of atomized and seeded water all directed forwardly from the upper end of the tower pipe. The water pipe may be an elliptical aluminum extrusion with two interior air tubes respectively controllably feeding large and small diameter air jet arrays to thereby provide a range of air jet water spray interaction. The pipe tower may be pivotally raised and lowered by a block-and-tackle or chain fall type drive mechanism that may be recoupled to the tops of a lifting pole and tower pipe for bodily raising the entire tower pipe and its support pipe telescopically on a ground support pole. Spreader-supported guy wires may be used to brace the tower pipe and also provide an electrical deicing circuit. Air jet control, blow-out valving and water drain conduit arrangements are disclosed, and also universally adjustable ground support systems for the pipe tower, including an underground-fed combined telescopic hydraulic ram forming air and water conduits.

Owner:BOYNE USA +1

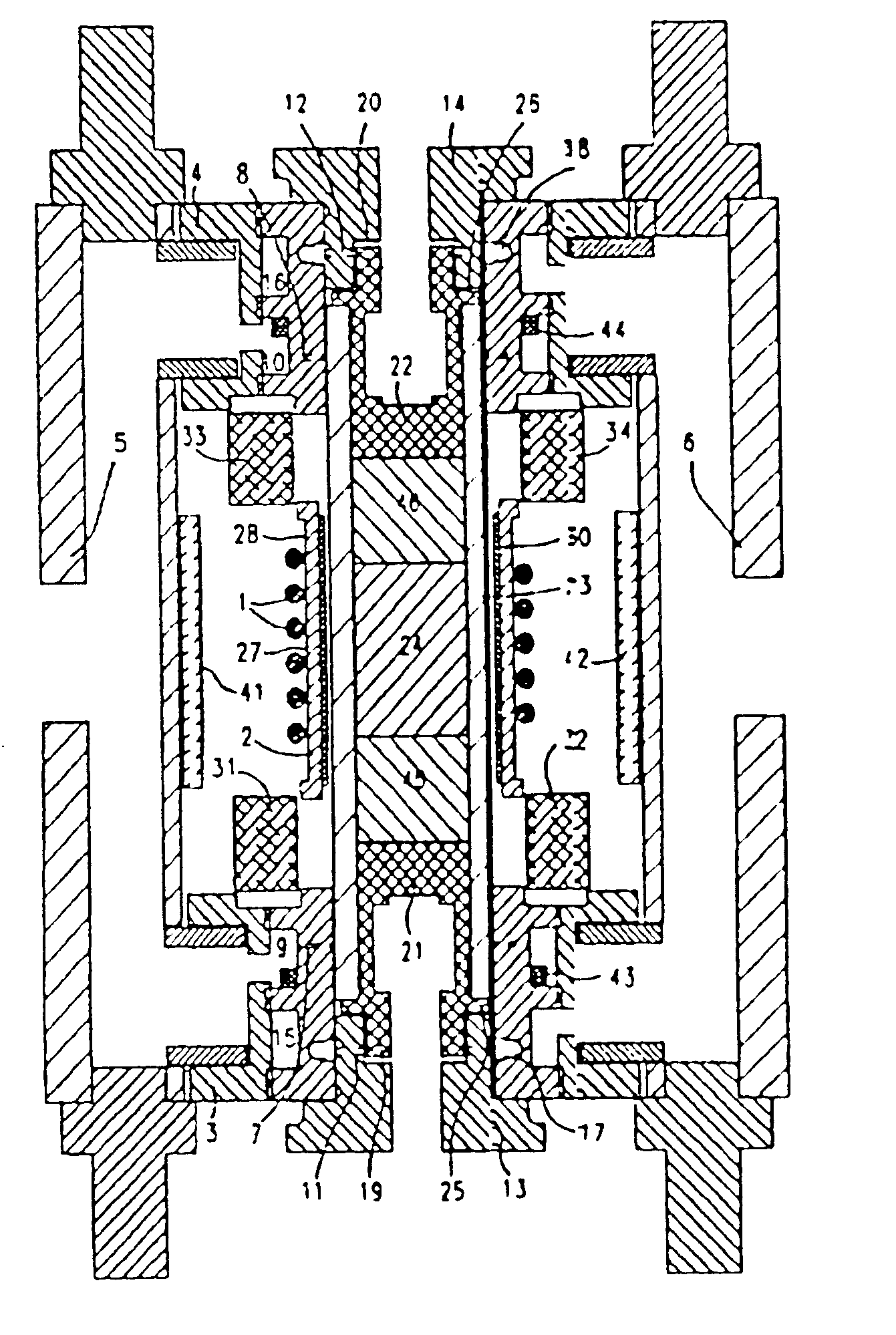

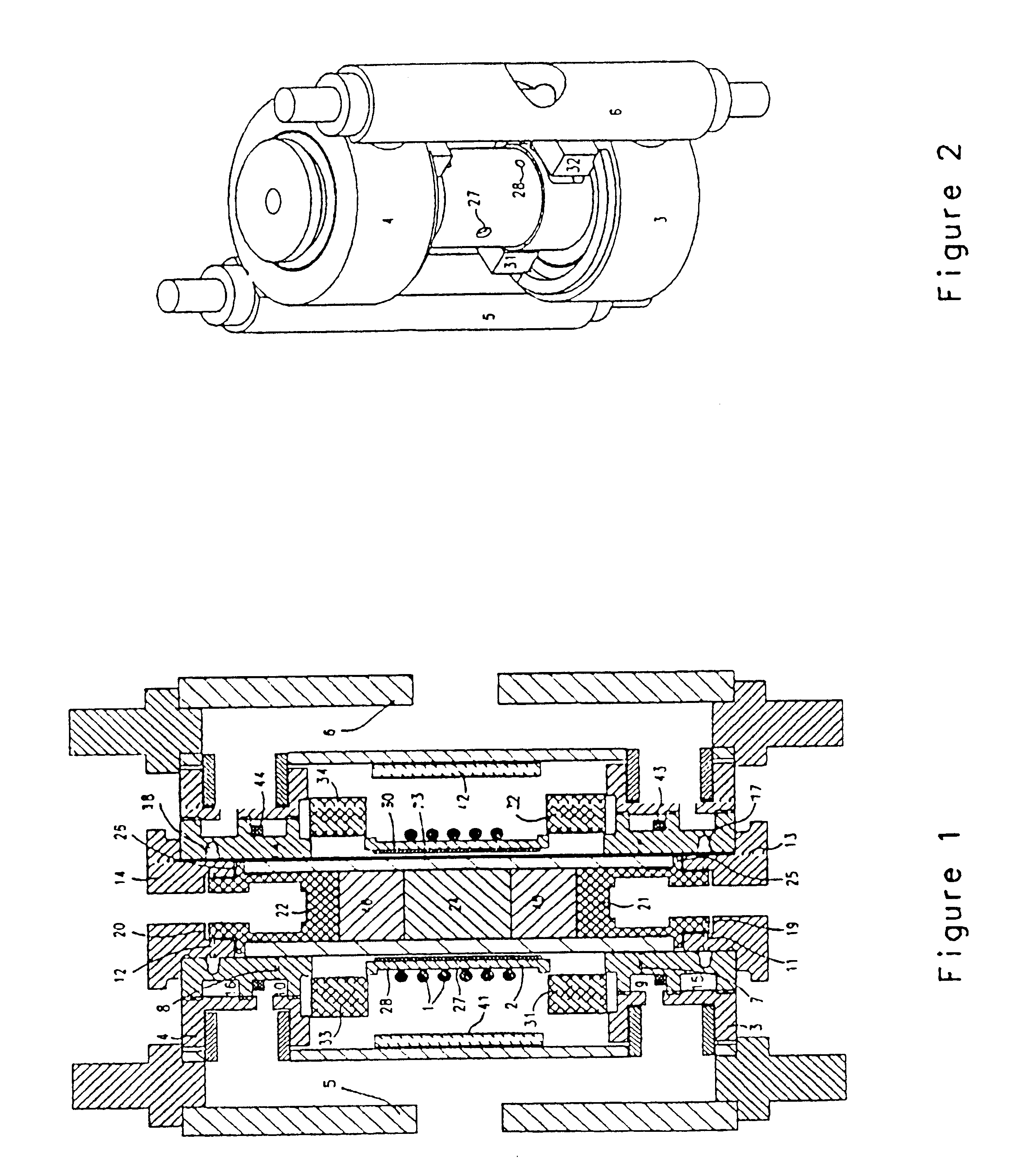

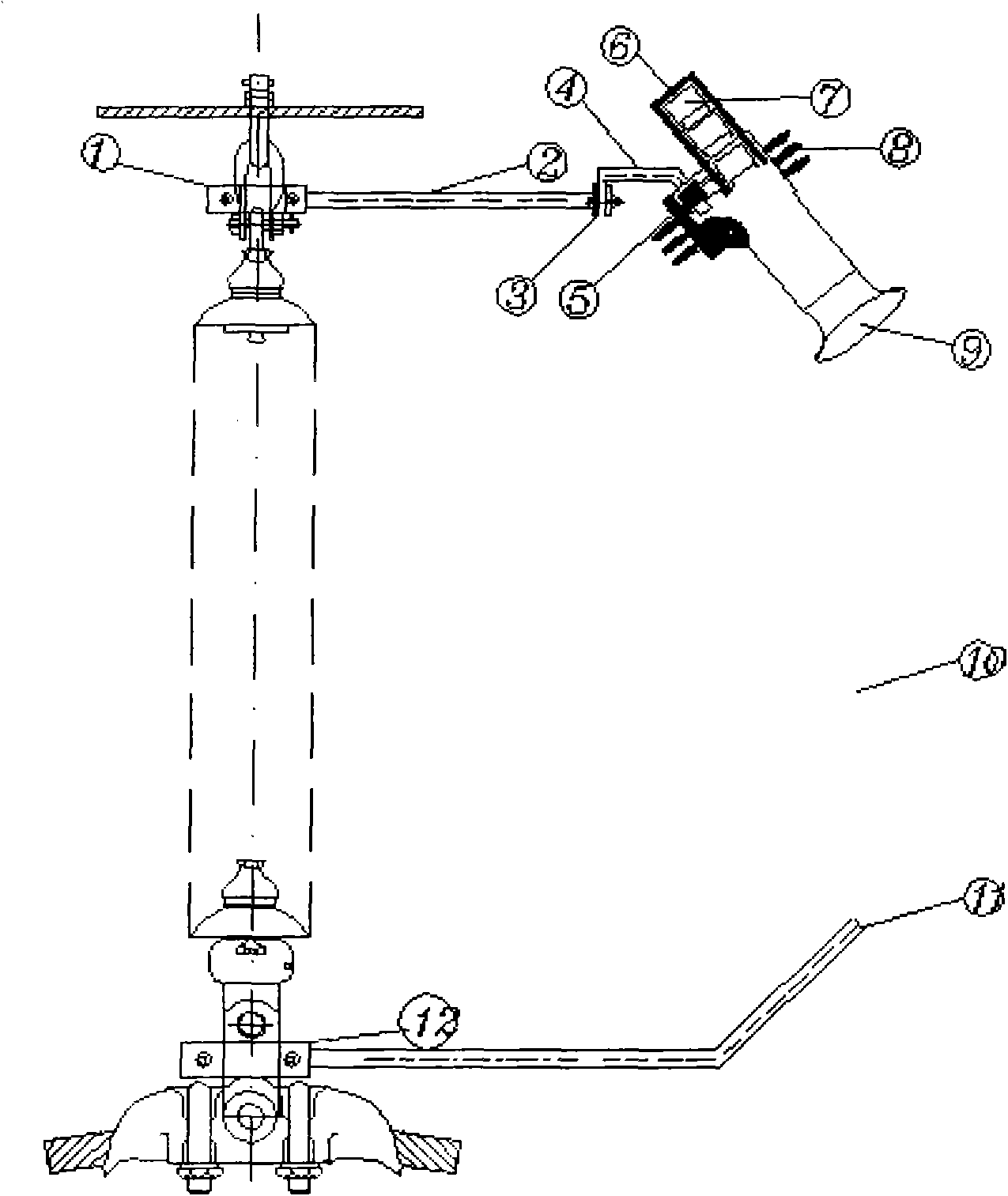

Thermal buffering of cross-coils in high-power NMR decoupling

InactiveUS6320384B1Improve thermal conductivityElectric/magnetic detectionMeasurements using magnetic resonanceDielectricMagnetic susceptibility

A transverse rf saddle coil (30) for use in NMR is affixed in intimate thermal conract on one surface of a ceramic coilform (23) of high thermal conductivity. The probe is mostly for use with solid samples at high fields where the axis of the coilform is not alignedwith the main field. An orthogonal rf coil (1) is mounted in intimate thermal contact to the first saddle coil (30) via a ceramic spacer or coilform (2). The coilform is cooled by high-velocity gas flow and is also often associated with bearing exhaust gas from a high speed sample spinner. The two coils are tuned to different rf frequencies with circuits capable of supporting high rf currents. The rf coils (30, 1) may be magnetically compensated and expansion controlled, and passive geometric compensation of magnetic susceptibility effects from a sample spinner stator may also be incorporated. Novel coil mounting techniques, including metallurgical bonds to ceramics and capturing by dielectric clam-shells, are also disclosed.

Owner:DOTY SCI

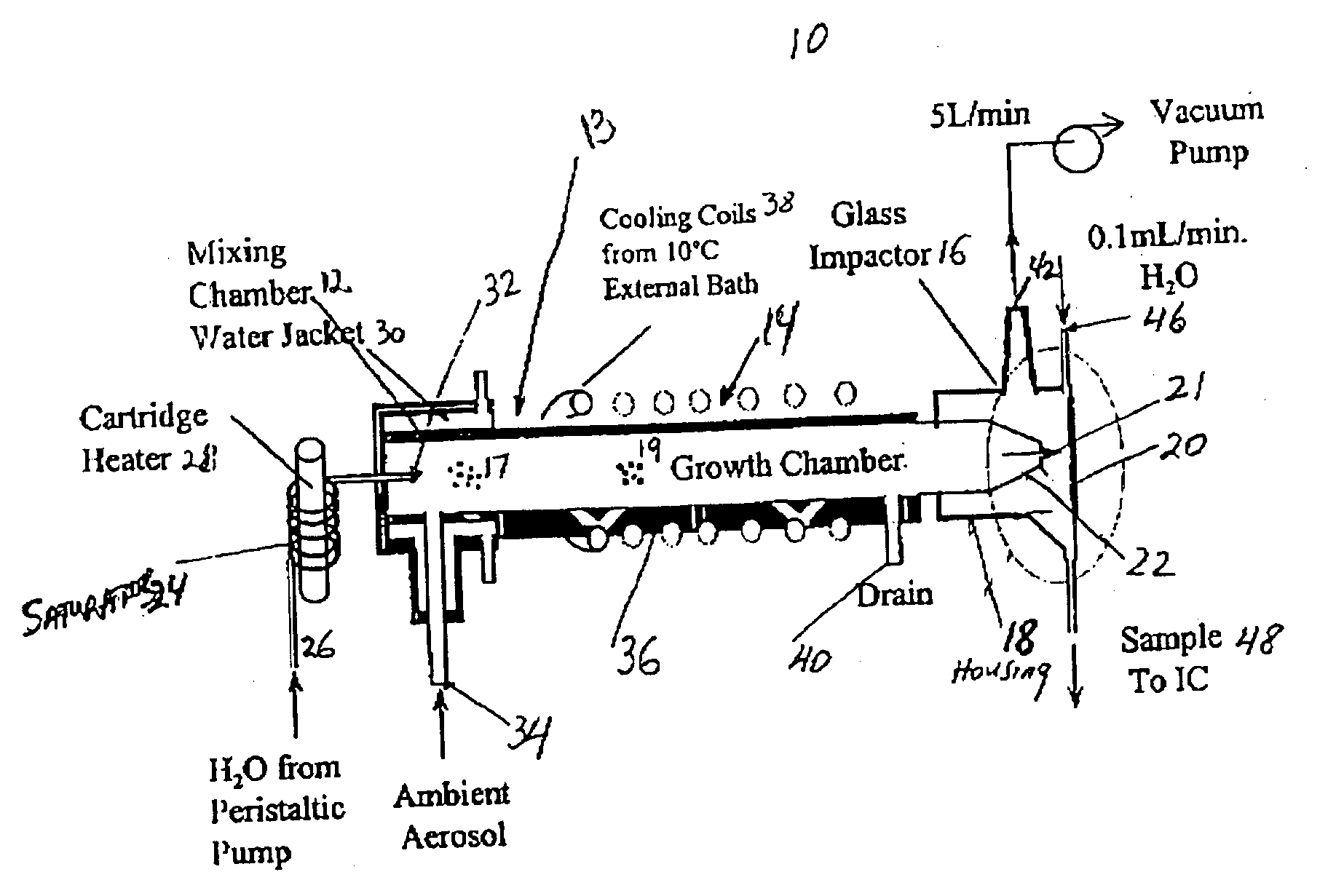

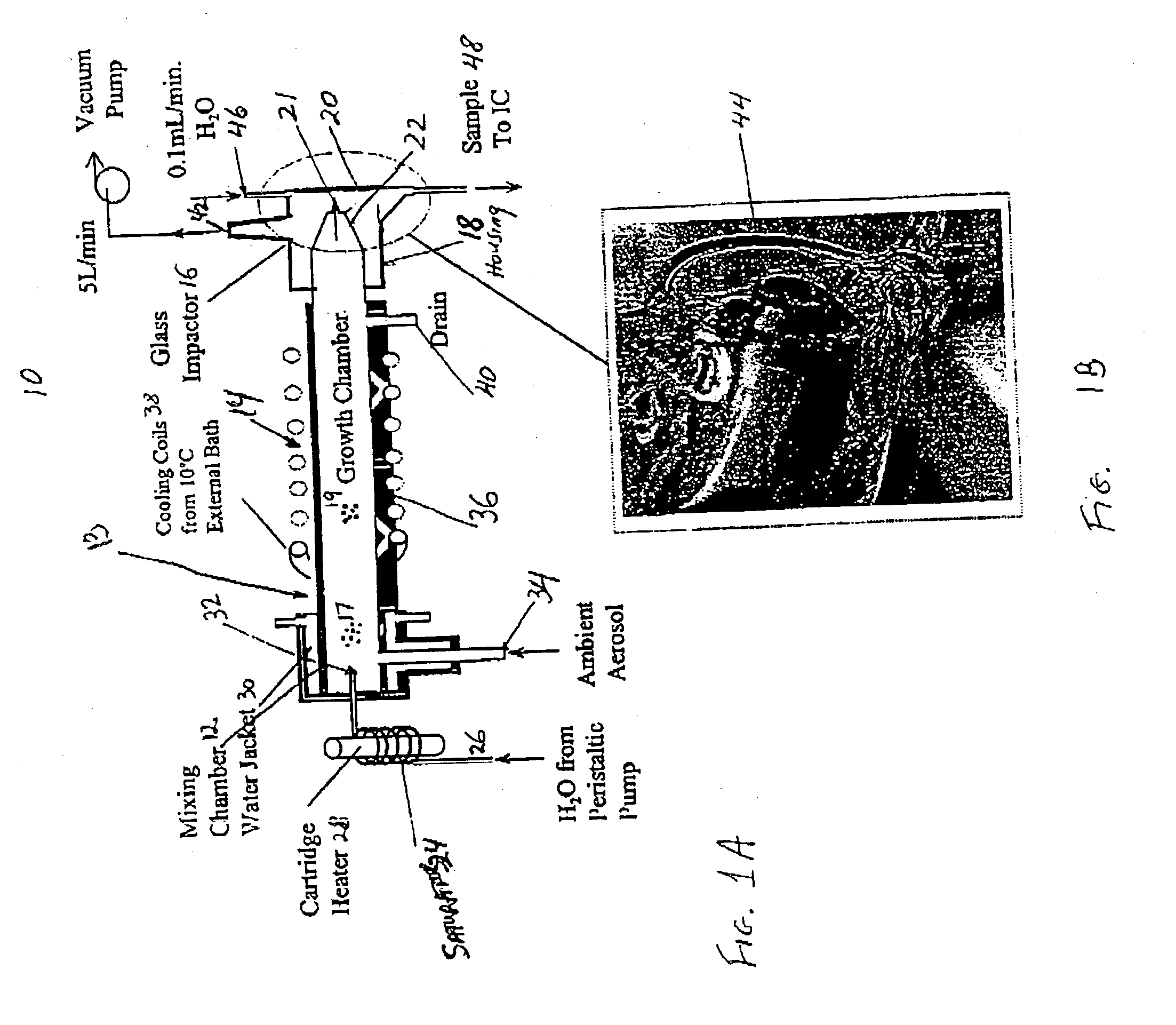

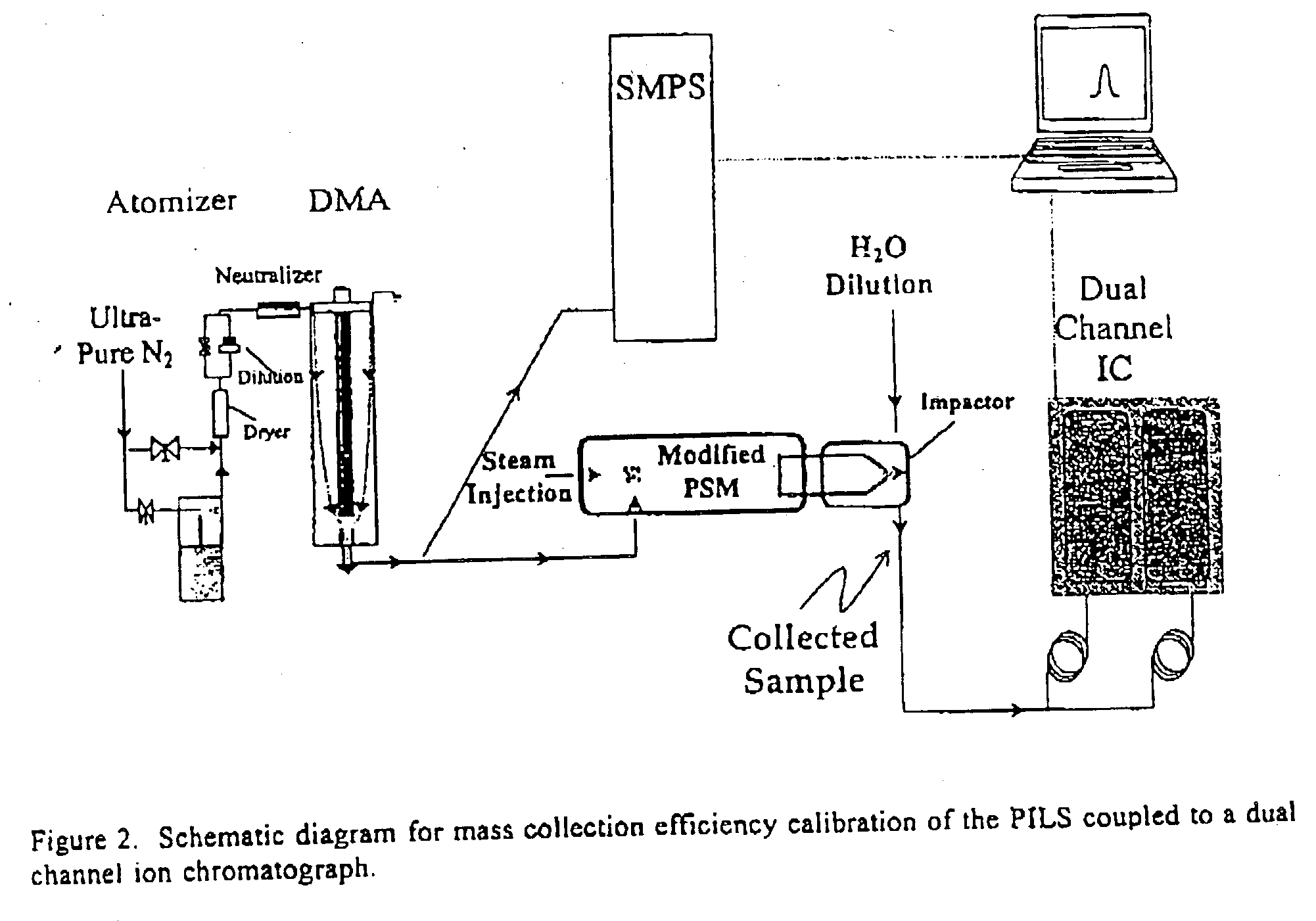

Apparatus for rapid measurement of aerosol bulk chemical composition

InactiveUS20030082825A1Improvement in droplet collectionMinimizing contributionComponent separationWithdrawing sample devicesAir exposureFast measurement

An apparatus for continuous on-line measurement of chemical composition of aerosol particles with a fast time resolution is provided. The apparatus includes an enhanced particle size magnifier for producing activated aerosol particles and an enhanced collection device which collects the activated aerosol particles into a liquid stream for quantitative analysis by analytical means. Methods for on-line measurement of chemical composition of aerosol particles are also provided, the method including exposing aerosol carrying sample air to hot saturated steam thereby forming activated aerosol particles; collecting the activated aerosol particles by a collection device for delivery as a jet stream onto an impaction surface; and flushing off the activated aerosol particles from the impaction surface into a liquid stream for delivery of the collected liquid stream to an analytical instrument for quantitative measurement.

Owner:BROOKHAVEN SCI ASSOCS +1

Externally Mounted Vortex Generators for Flow Duct Passage

InactiveUS20080121301A1Inhibition formationReduce the overall heightEngine manufacturePump componentsEngineeringJet stream

Owner:NORRIS THOMAS R

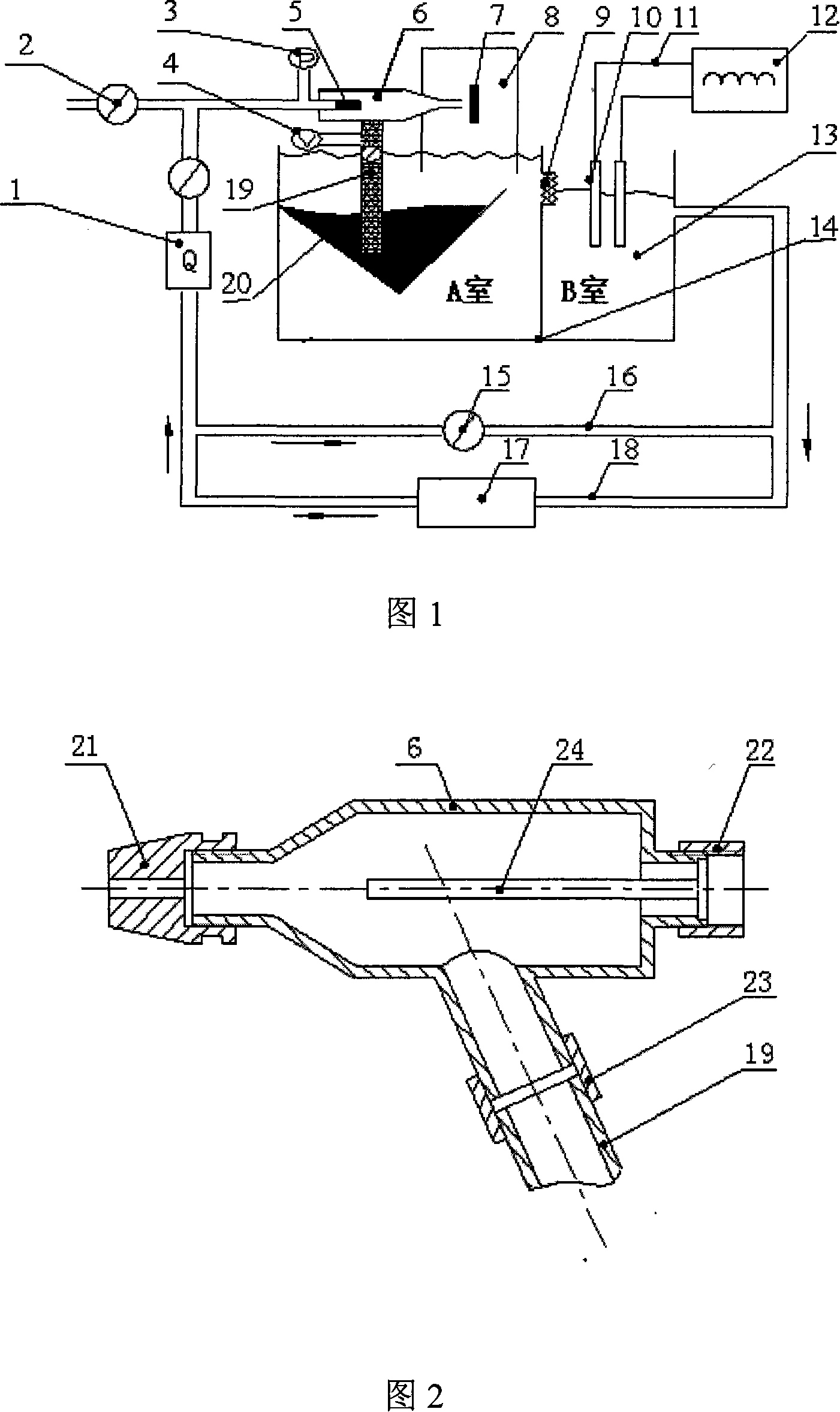

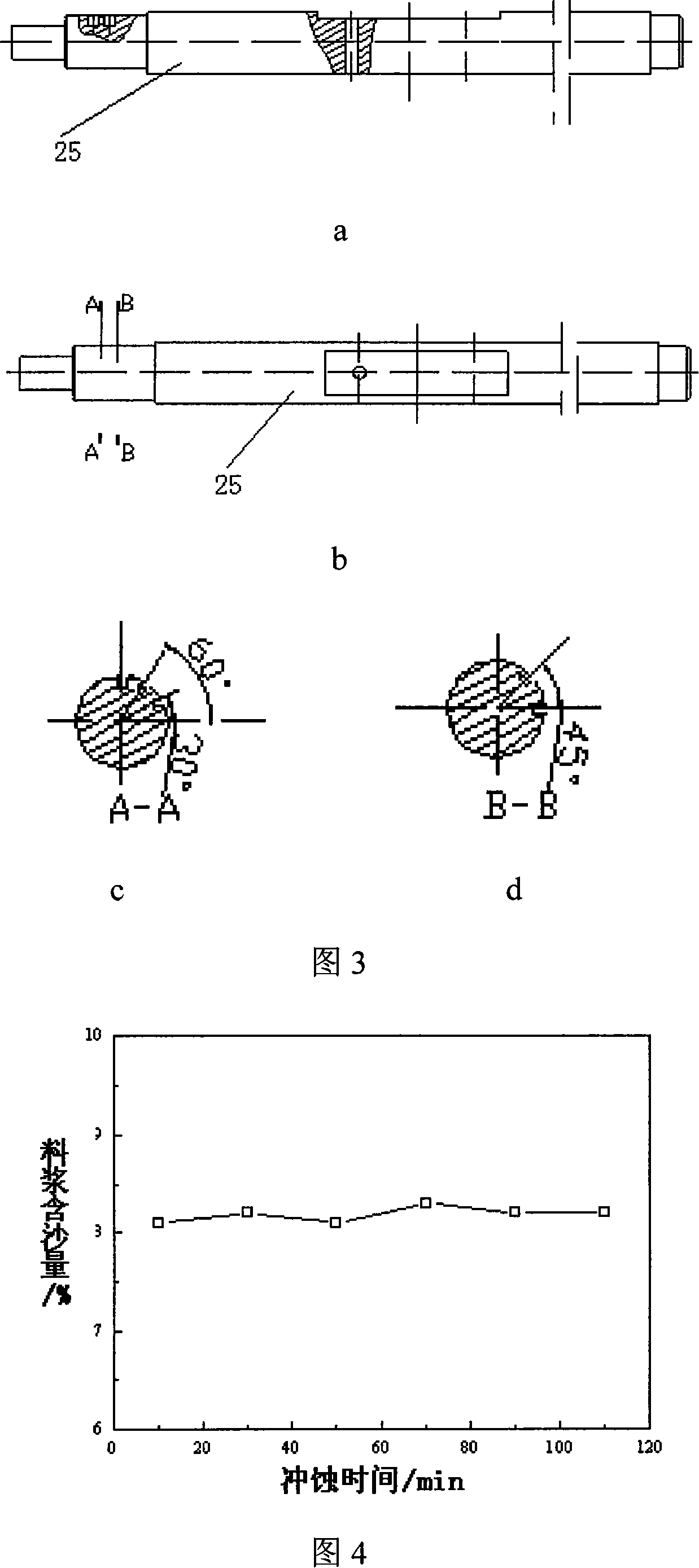

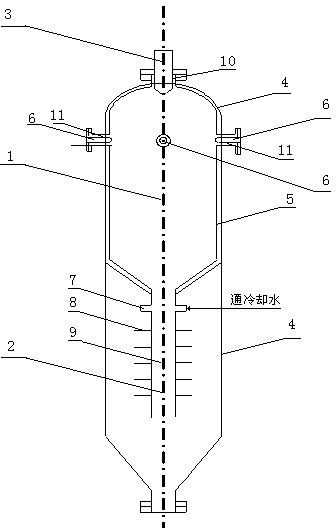

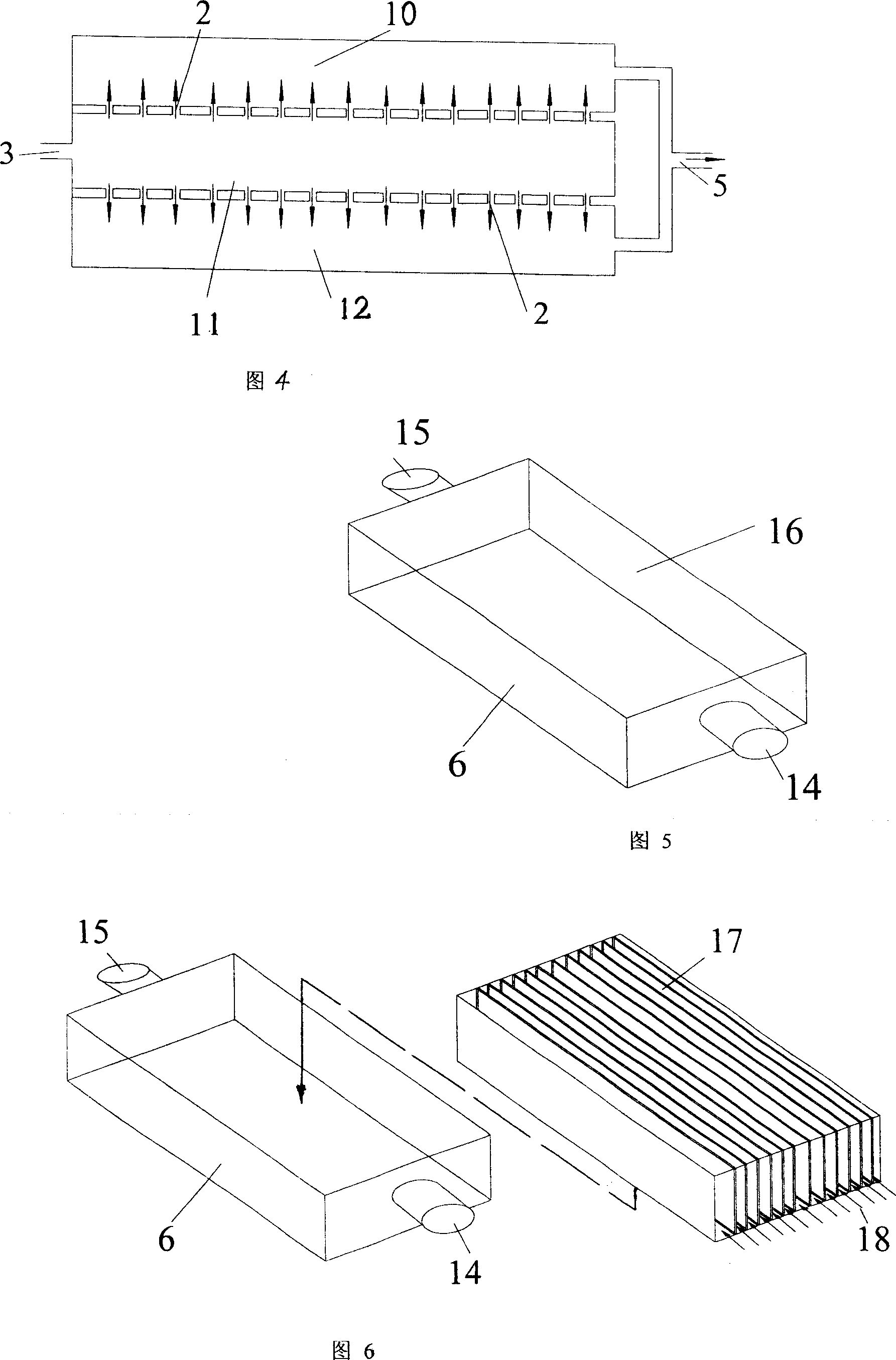

Jet stream type erosion abrasion test device

InactiveCN101140209AThe principle is simpleEasy to operateWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceEngineeringElectric potential

The invention discloses a jet type erosive wear test device which comprises a centrifugal pump and a connecting pipeline, wherein one end of the pipeline is firmly connected with a nozzle, the front end of the nozzle is corresponding with the position of a sample, the lower part of the nozzle and the sample is provided with a storage hopper, the storage hopper is leftwards and rightwards partitioned into an A chamber and a B chamber by a layer of filter screen, the interior of the storage hopper A chamber relative to the nozzle and the sample is provided with a sand hopper, the nozzle stretches into the sand hopper through a liquid lifting pipe, the interior of the storage hopper B chamber is provided with a pair of electrodes stretching into the interior, the electrode is connected with an external electric potential testing meter through a lead wire, and the other end of the pipeline is communicated with the storage hopper B chamber. The device provided in the invention can simulate the requirements of actual working conditions, which not only can implement the test study for the selection of wearable materials, but also can be suitable for the study of erosive wear mechanism.

Owner:XIAN UNIV OF TECH

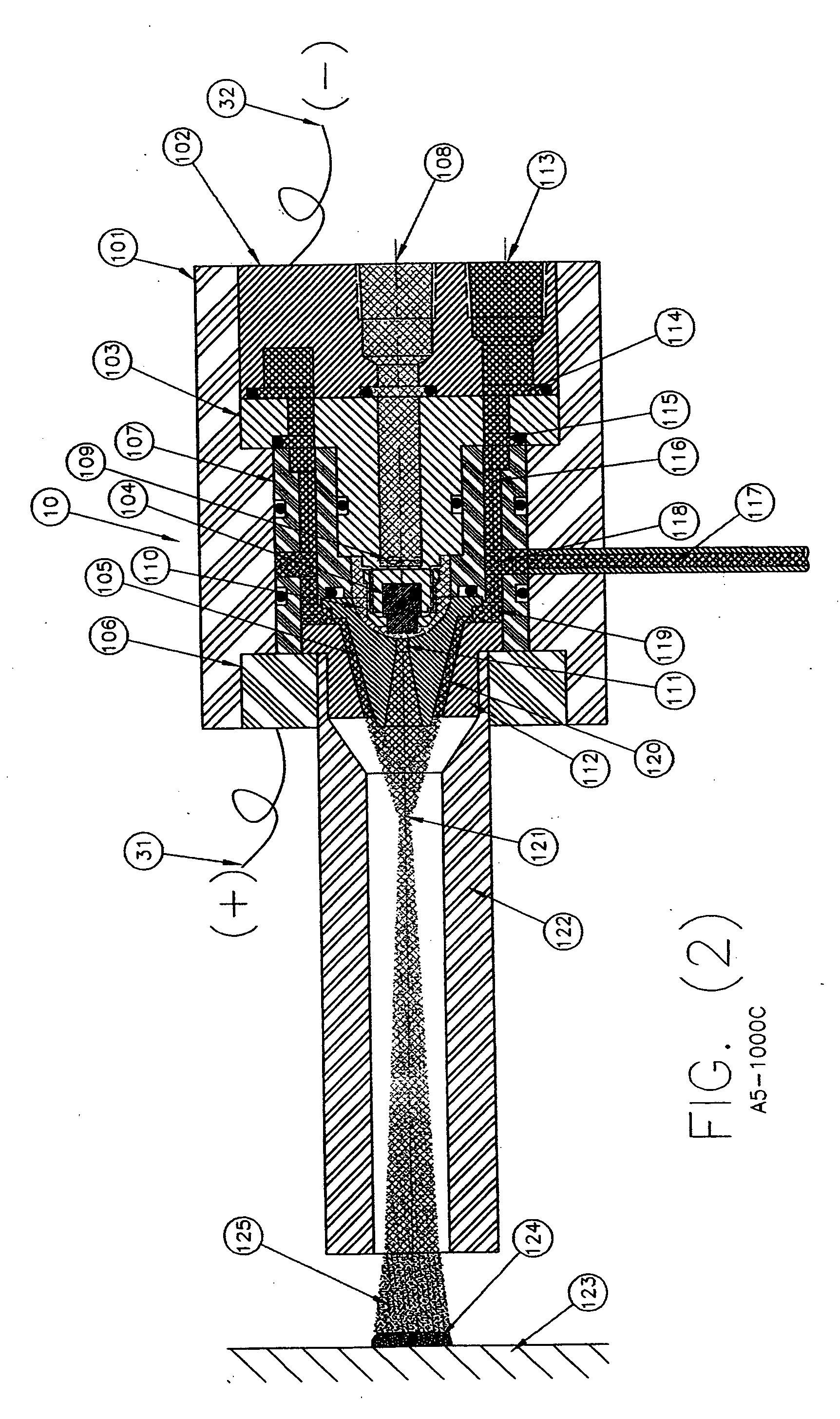

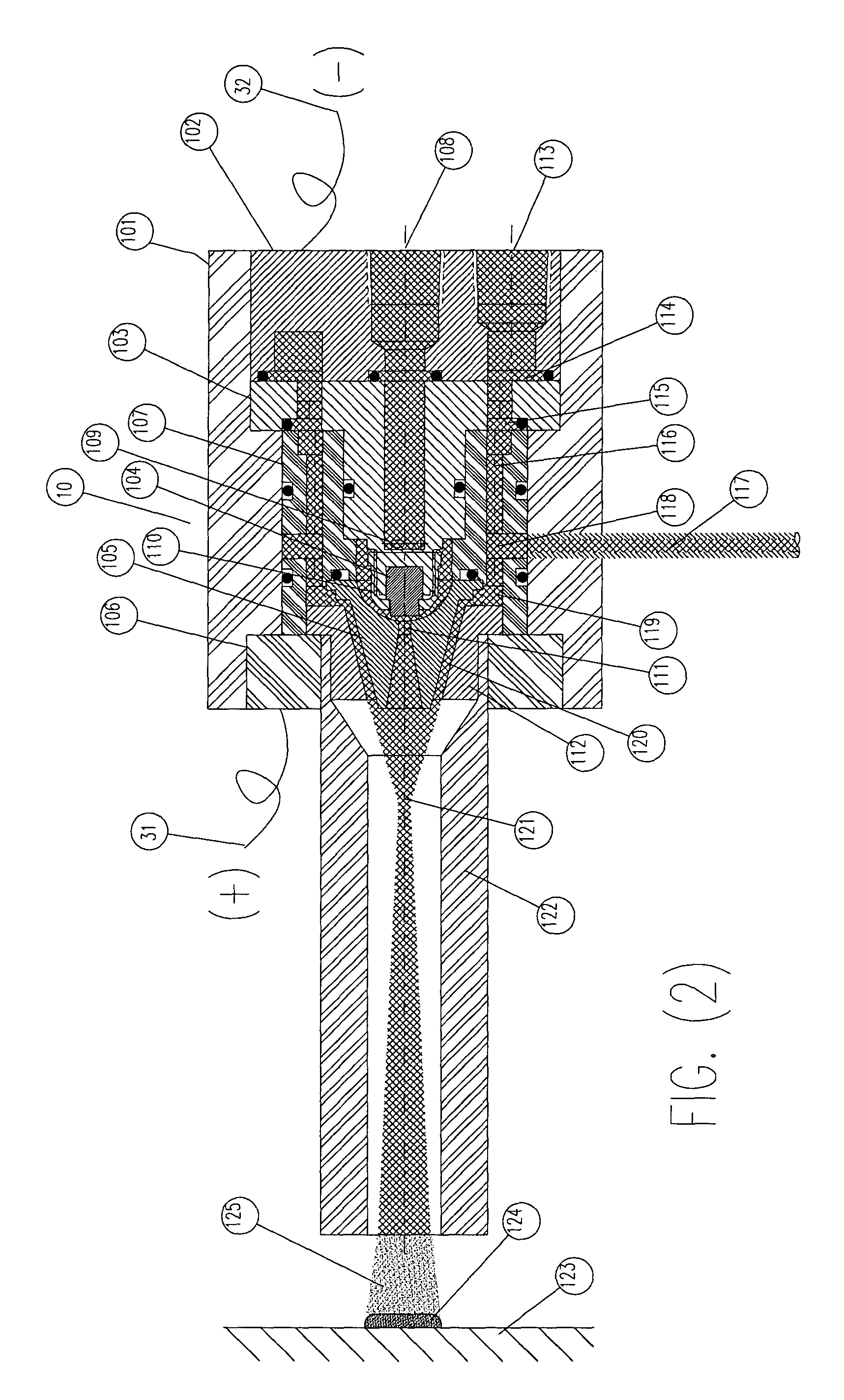

Rotary plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS6986471B1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorMaterials science

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

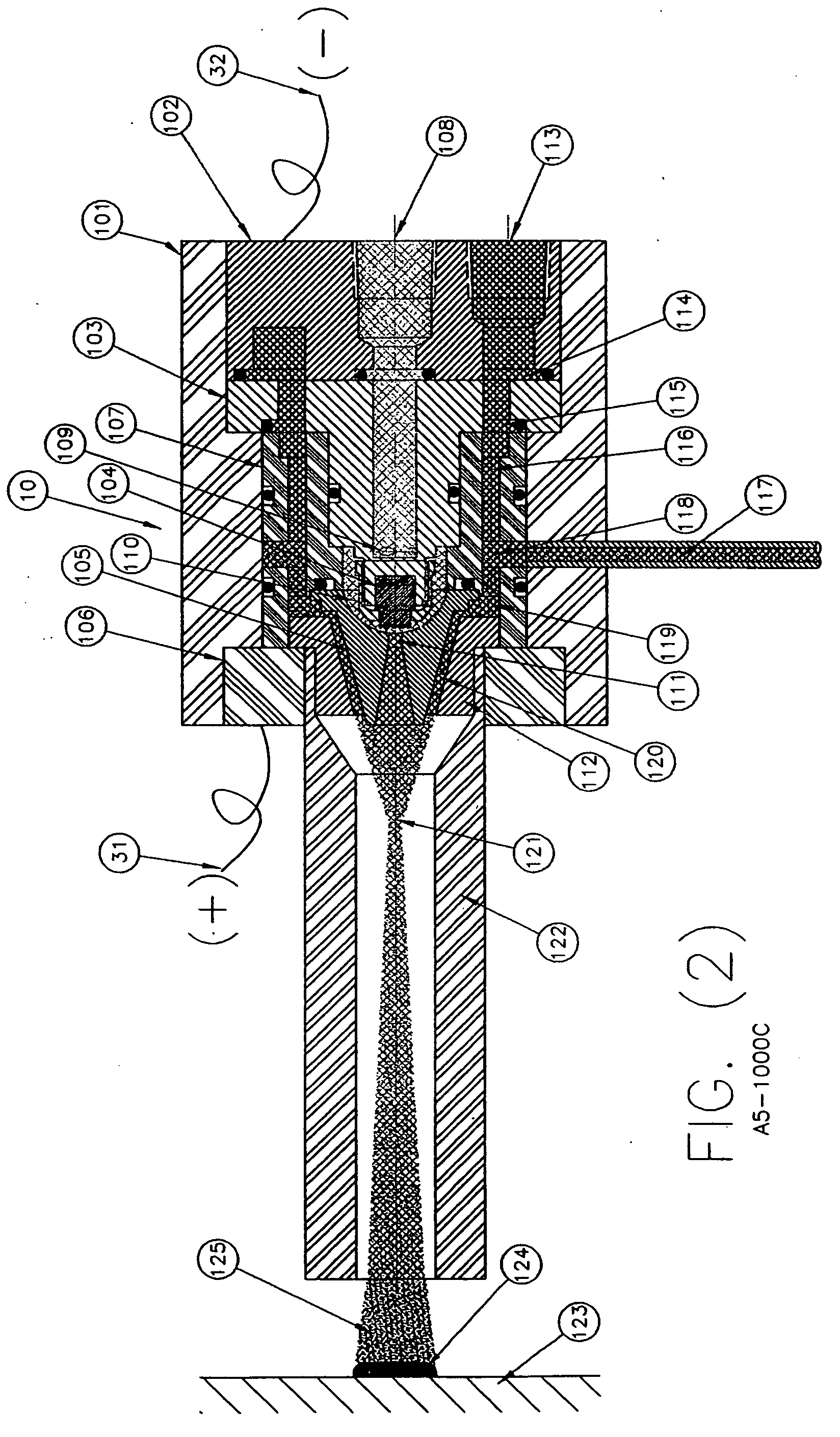

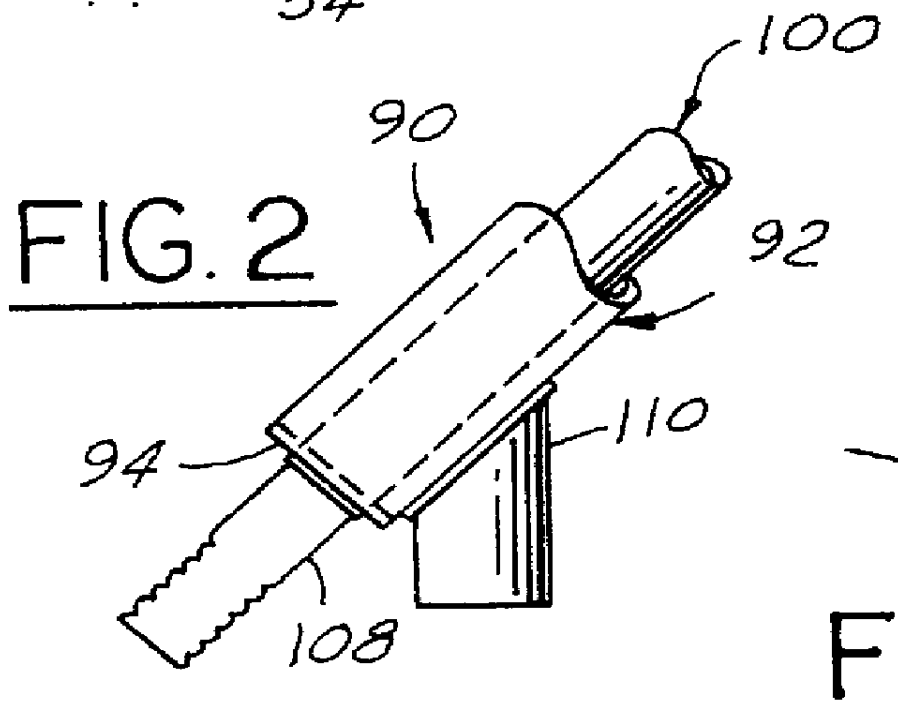

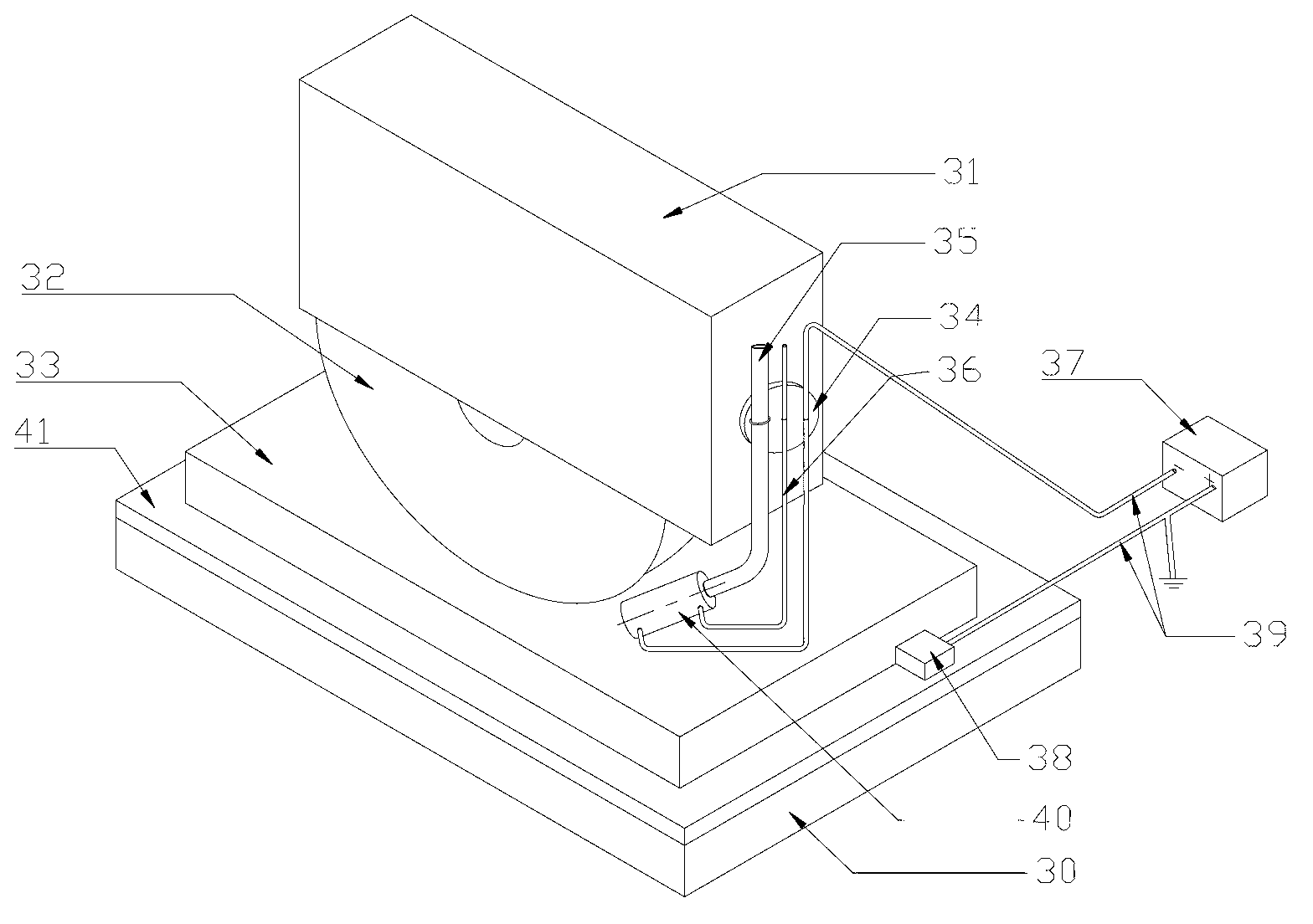

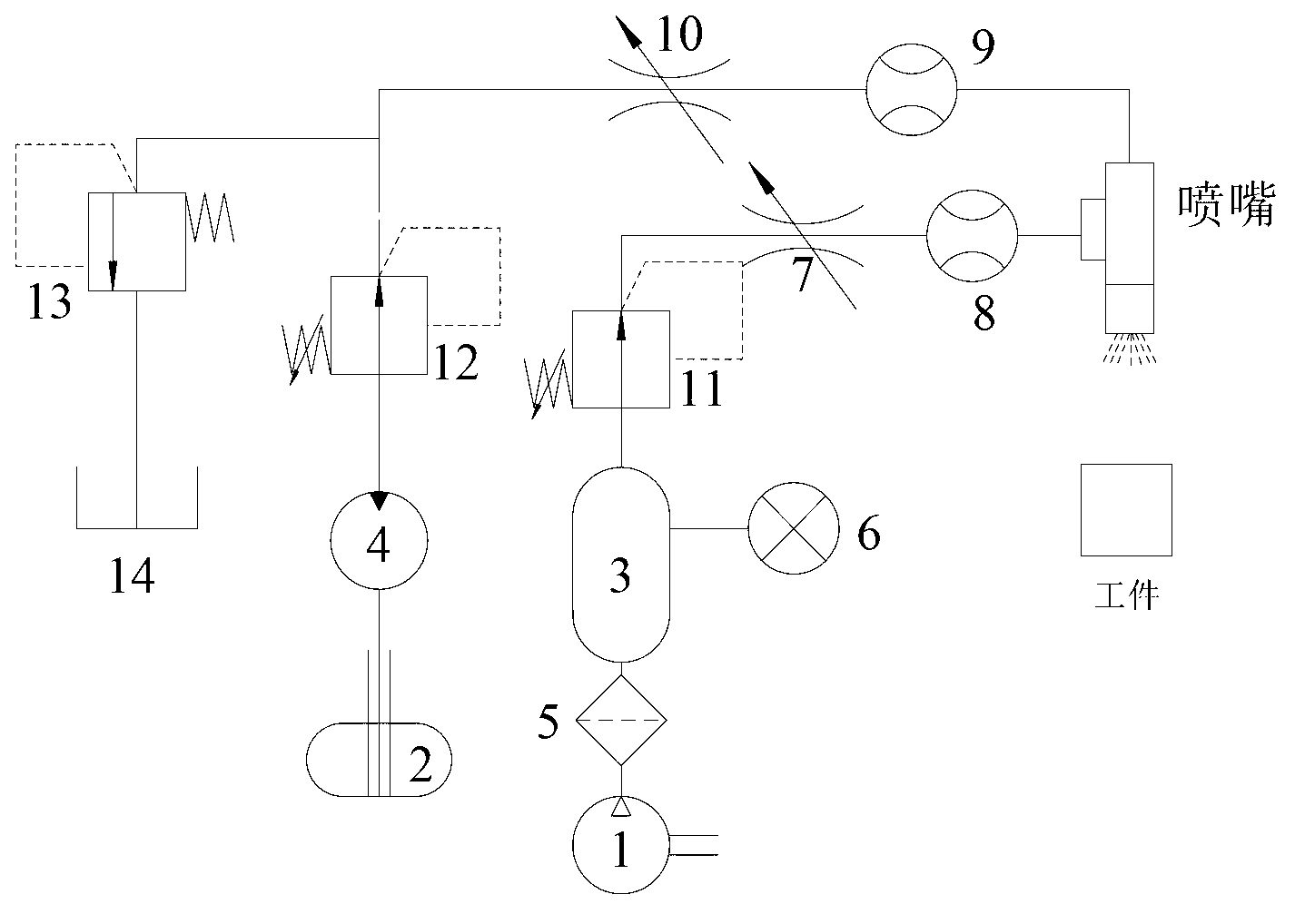

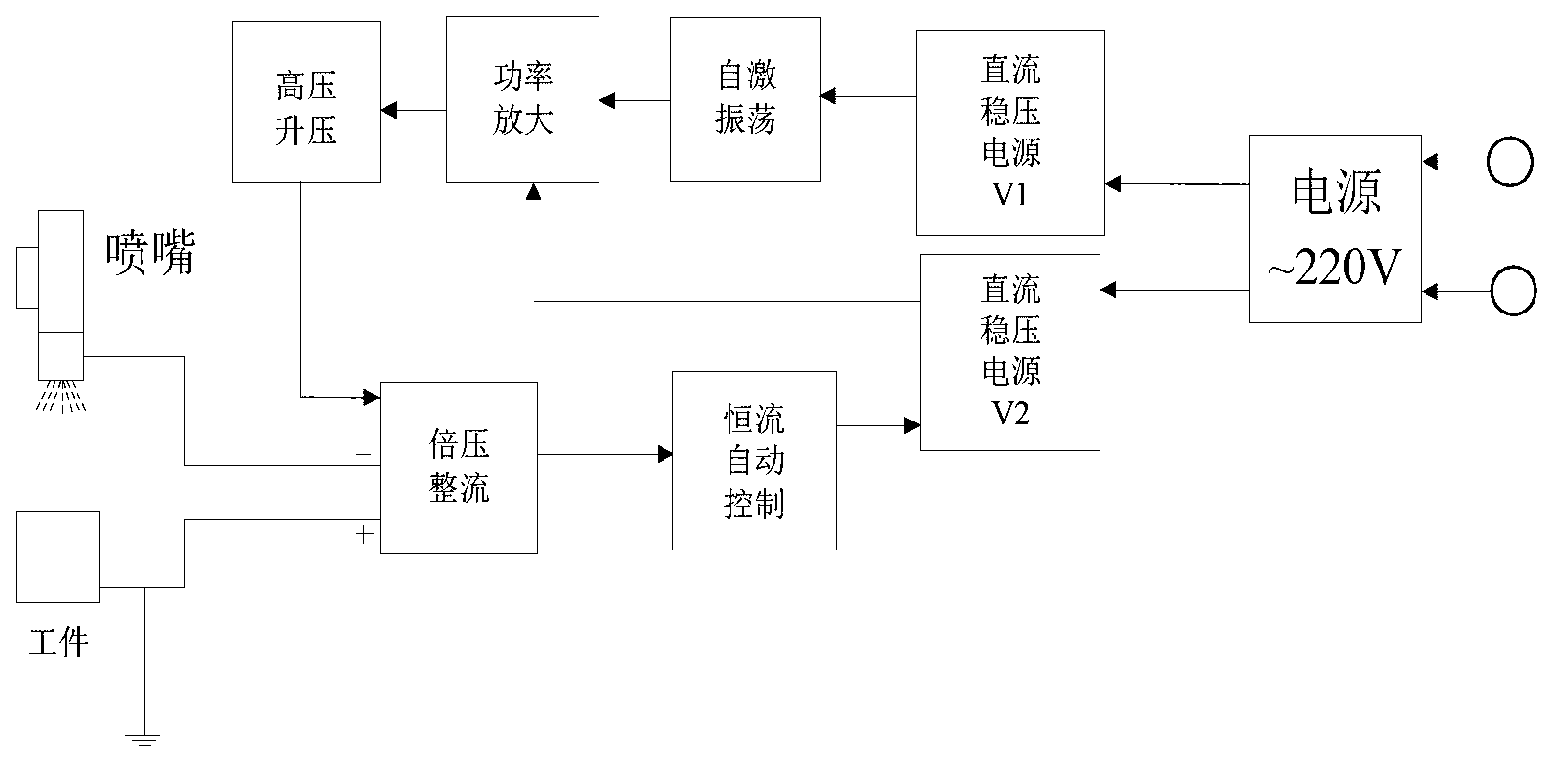

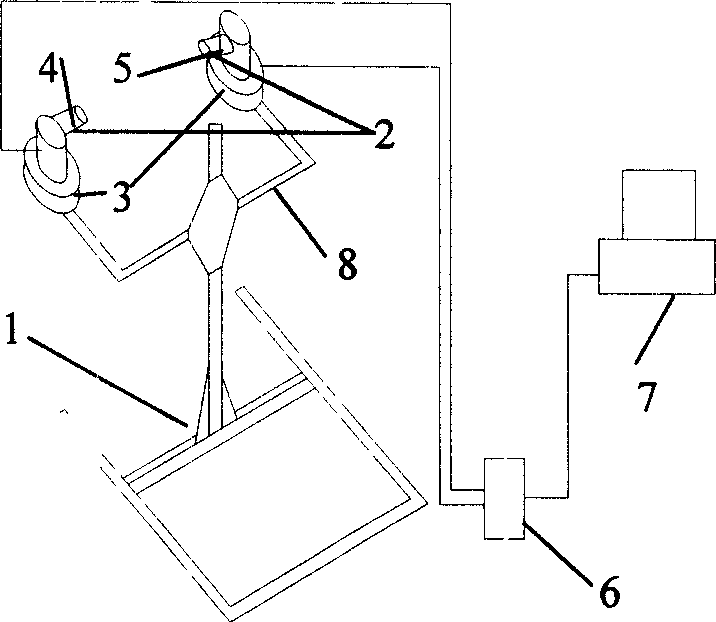

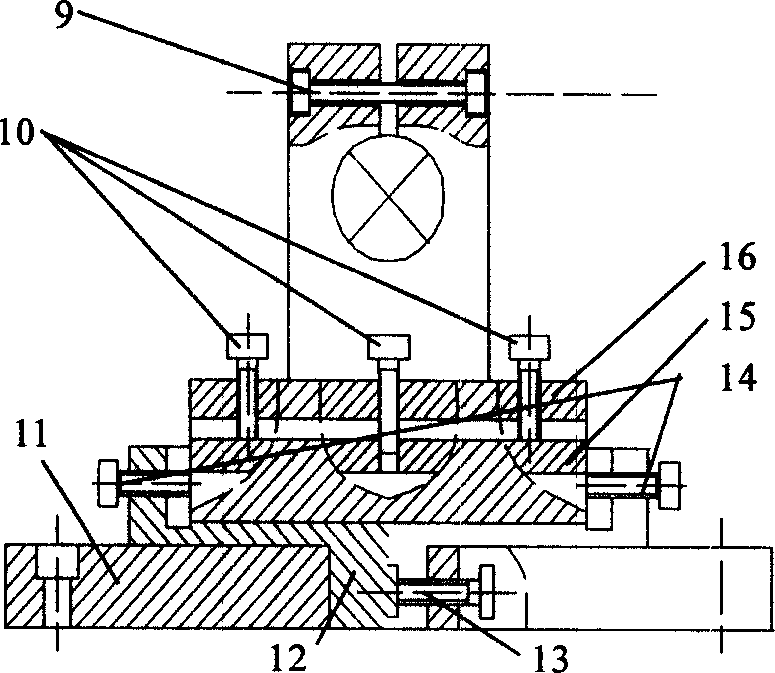

Nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system

ActiveCN103072084AReduce drift lossIncrease profitGrinding/polishing safety devicesMachined surfaceHigh-voltage direct current

The invention relates to a nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system. Sprayed fog drops can be controllably distributed through the electrostatic principle, so that the pollution to environment is reduced, and better health security is provided to workers. A grinding system is provided with a corona charging nozzle, wherein a nozzle body of the corona charging nozzle is connected with a liquid supply system and an air supply system; a high-voltage direct-current electrostatic generator on the lower part of the nozzle body is connected with the cathode of an adjustable high-voltage direct-current power supply; the anode of the adjustable high-voltage direct-current power supply is connected with a workpiece charging device; and the workpiece charging device is attached to the non-machined surface of a workpiece. Nano fluid grinding liquid is fed into the corona charging nozzle through the liquid supply system, meanwhile the air supply system feeds compressed air into the corona charging nozzle, the nano fluid grinding liquid is charged into controllable jet stream by the high-voltage direct-current electrostatic generator while being driven by the compressed air to be sprayed out and atomized from the nozzle body, and the controllable jet stream is controllably distributed to a grinding area of the machined workpiece under the actions of electric field force and aerodynamic force.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

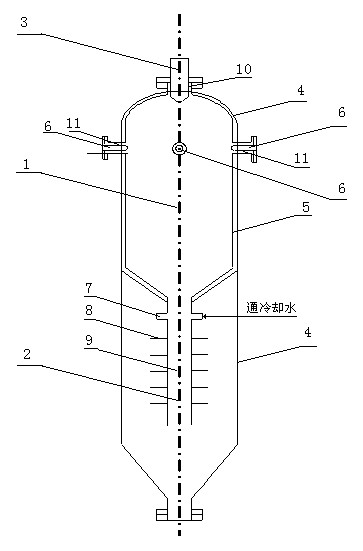

Entrained flow gasifier used for co-gasification of various forms of raw materials

The invention provides an entrained flow gasifier used for the co-gasification of various forms of raw materials. The gasifier is formed by overlaying a gasification chamber and a cooling and washing chamber in a pressure-resisting shell. By adjusting a nozzle configuration scheme, the gasification of a single raw material and the co-gasification of gas-liquid-solid raw materials can be realized and the demands of different sizes of gasification systems can be satisfied. For a medium or small system, an overhead nozzle scheme is adopted for 50-1000 tons of coal per day. For a single serie of large-scale system, a multi-nozzle scheme is adopted for 1000-6000 tons of coal per day; the gasification furnace adopts impinging stream (oppesed multi-nozzle) and cross jet stream (overhead nozzle) to efficiently mix the raw materials and efficiently mix the raw materials and gasifying agents (oxygen and steam). The gasification furnace has excellent high flexibility, large load-adjusting range, high raw material utilization rate which is up to more than 98% and low specific oxygen consumption and specific raw material consumption, and the raw material is convenient to change.

Owner:EAST CHINA UNIV OF SCI & TECH

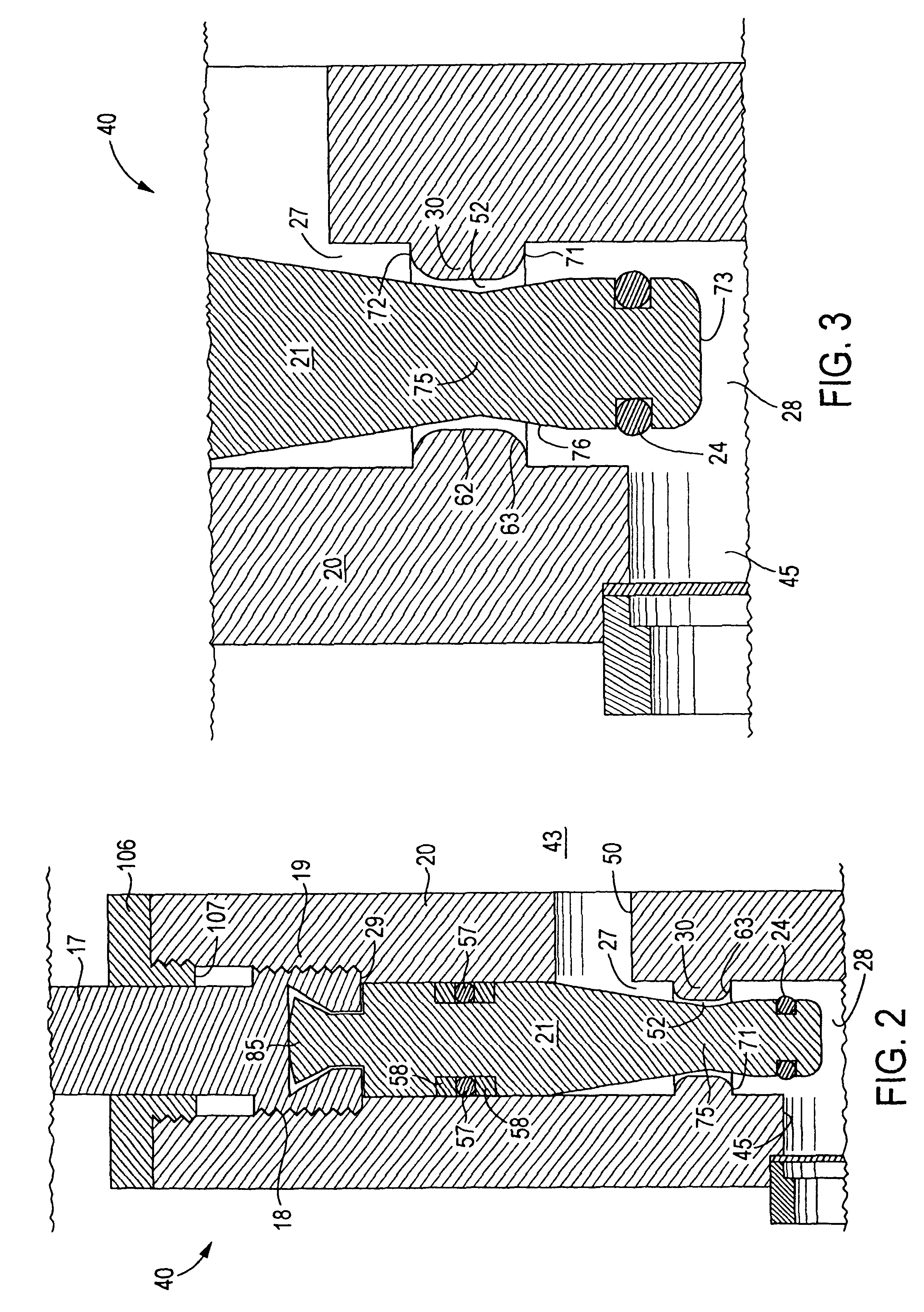

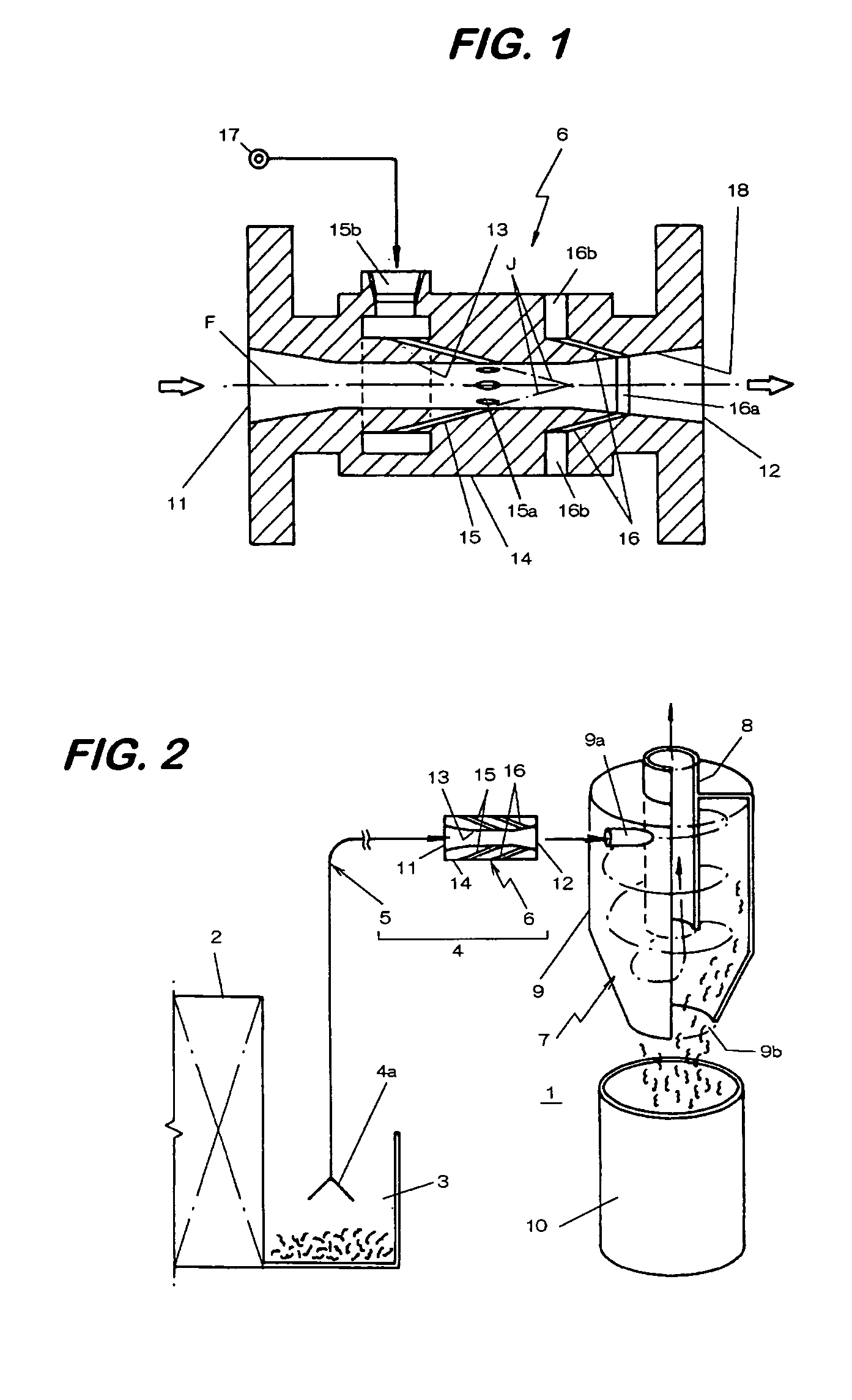

Ejector, fine solid piece recovery apparatus and fluid conveyor

InactiveUS6974279B2Long distanceReduce distanceBulk conveyorsEngineeringPressure controlled ventilation

An ejector is configured to generate a high negative pressure capable of sucking and conveying fine metal pieces or chips, such as machinings or cuttings, for example, when using the ejector as a driving source for a fluid conveyor. The ejector includes a convergent-divergent nozzle having a throat formed between a suction port and a discharge port. Jet blowing holes are formed in the convergent-divergent nozzle to direct a jet stream from upstream of the throat to downstream of the throat, thereby forming a negative pressure. Pressure control holes open to the downstream of the jet blowing holes and are configured to communicate with a pressure space at a pressure level higher than a negative pressure formed by the jet stream and lower than a static pressure of the jet stream and the inside of the convergent-divergent nozzle.

Owner:TRINITY IND CORP

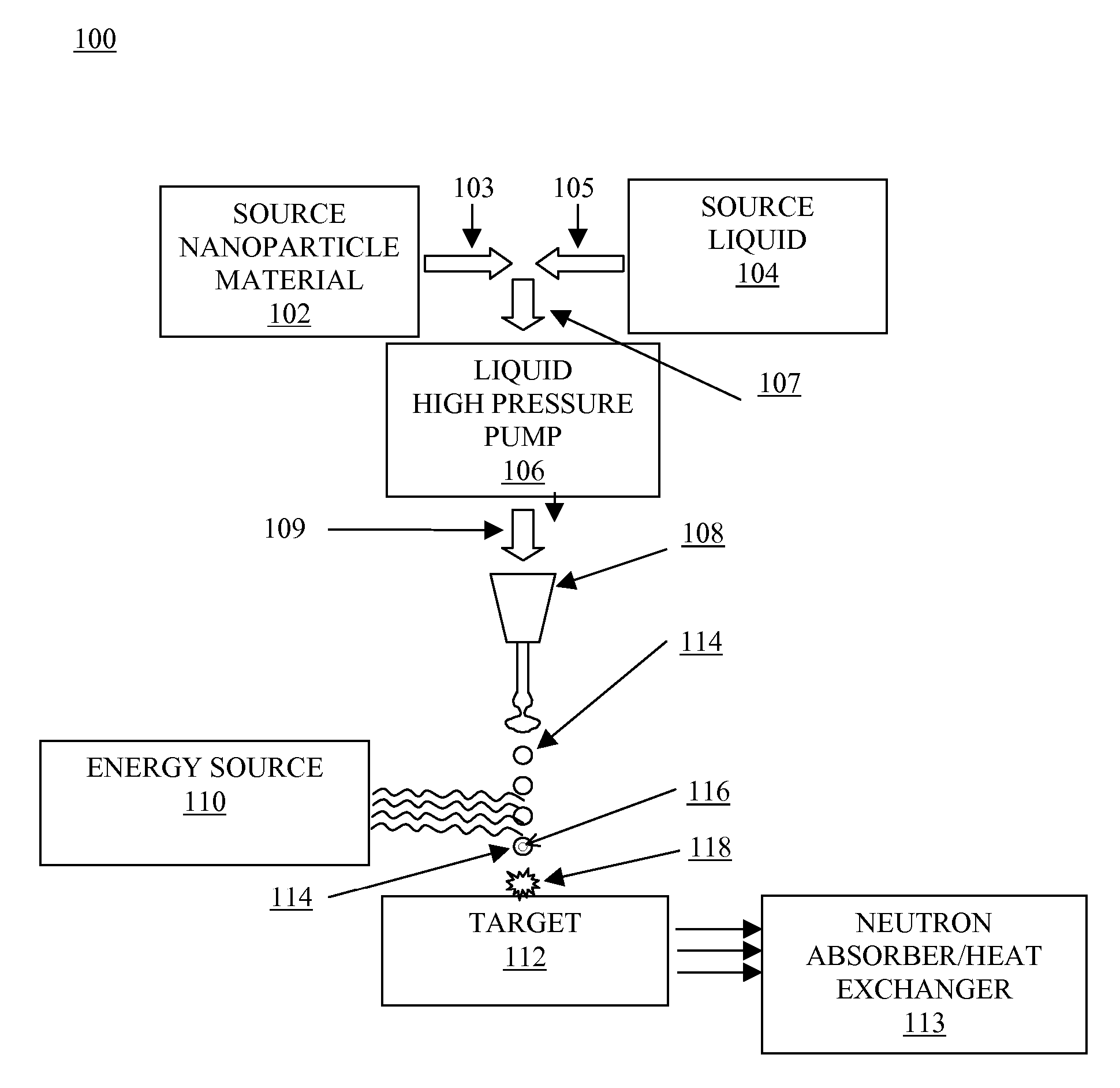

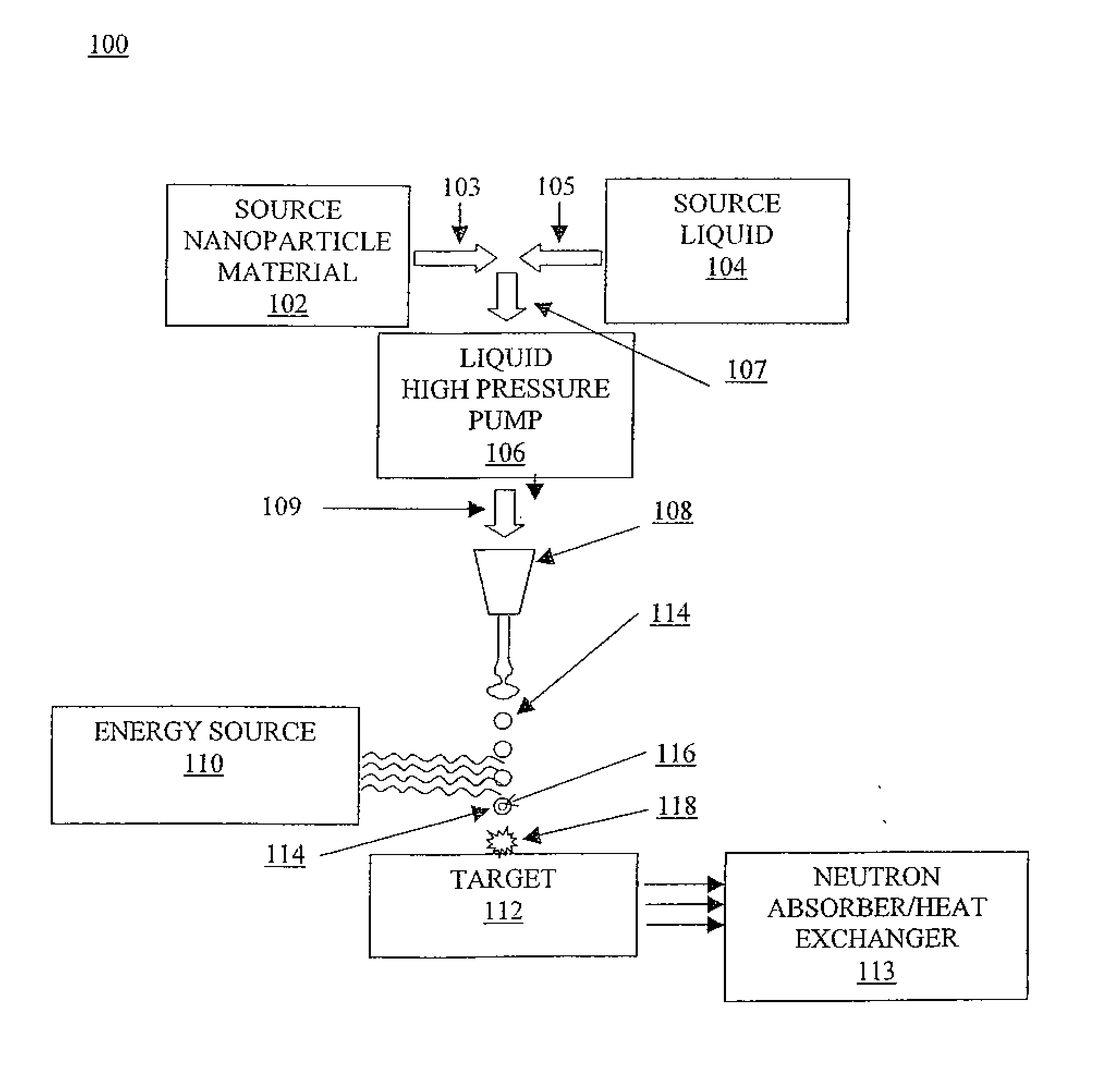

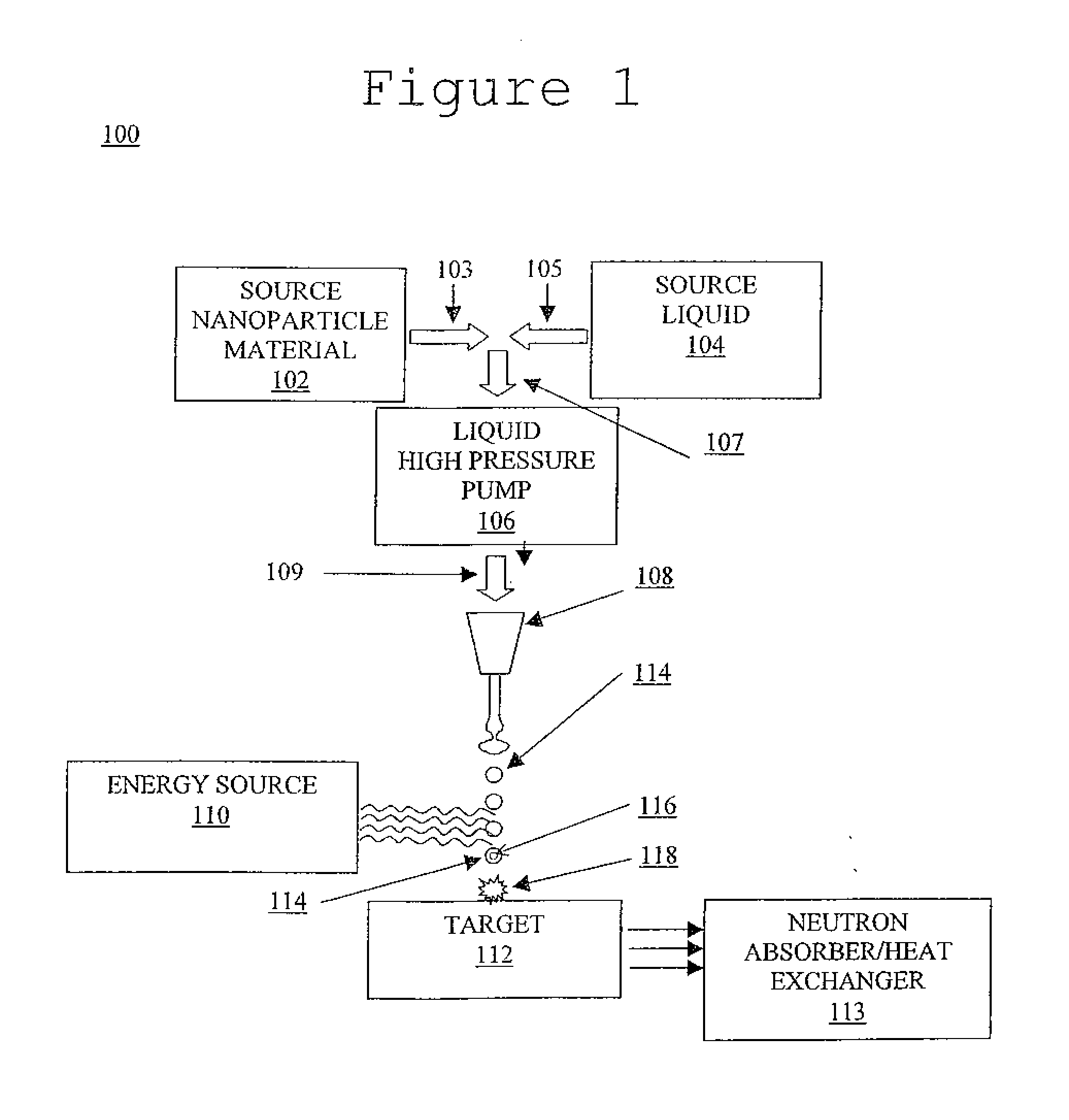

System and method for creating liquid droplet impact forced collapse of laser nanoparticle nucleated cavities for controlled nuclear reactions

InactiveUS7445319B2Promote crashHigh energyMaterial nanotechnologyNuclear energy generationNanoparticleBreakup

Owner:SYNERGY INNOVATIONS INC

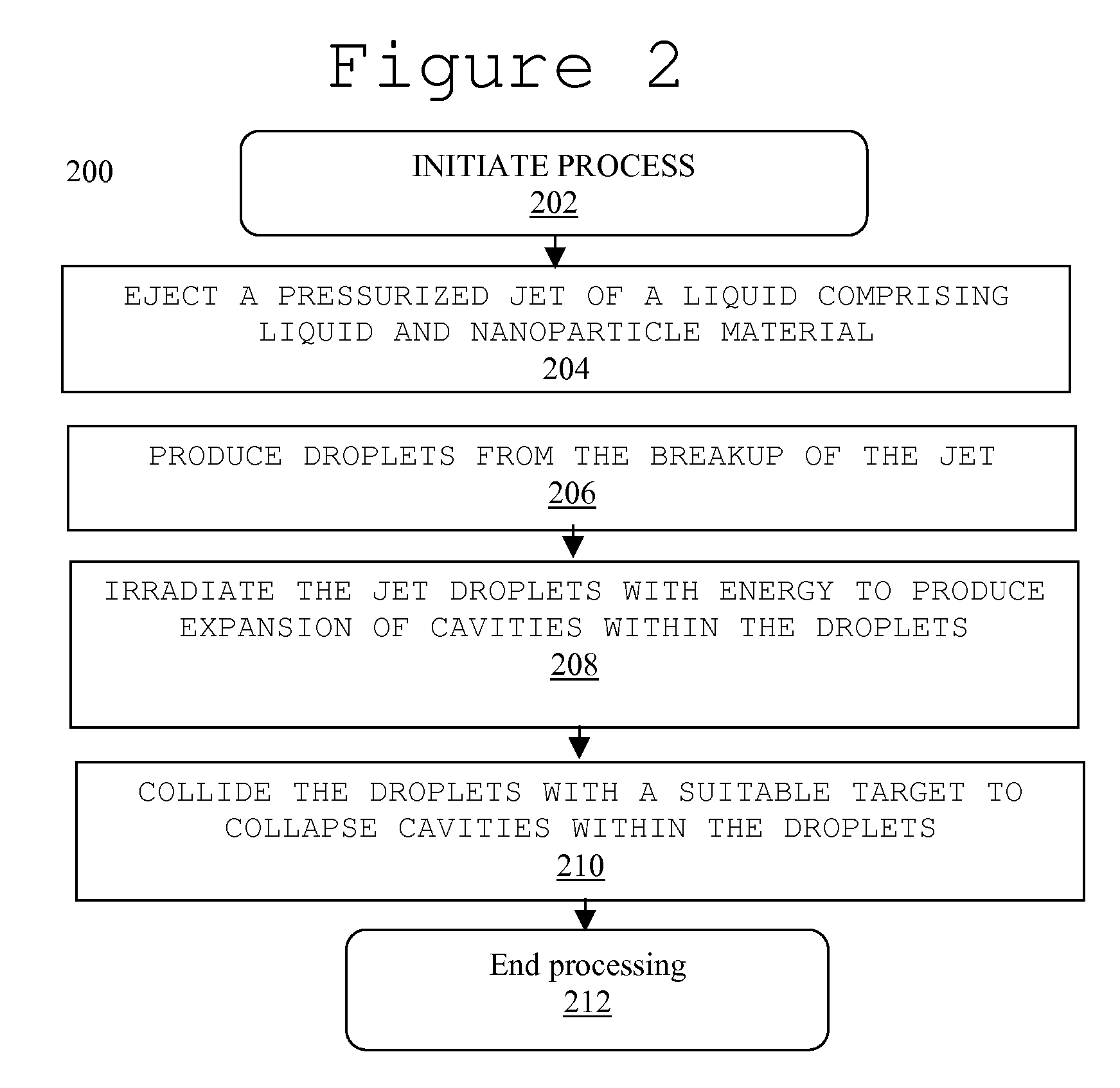

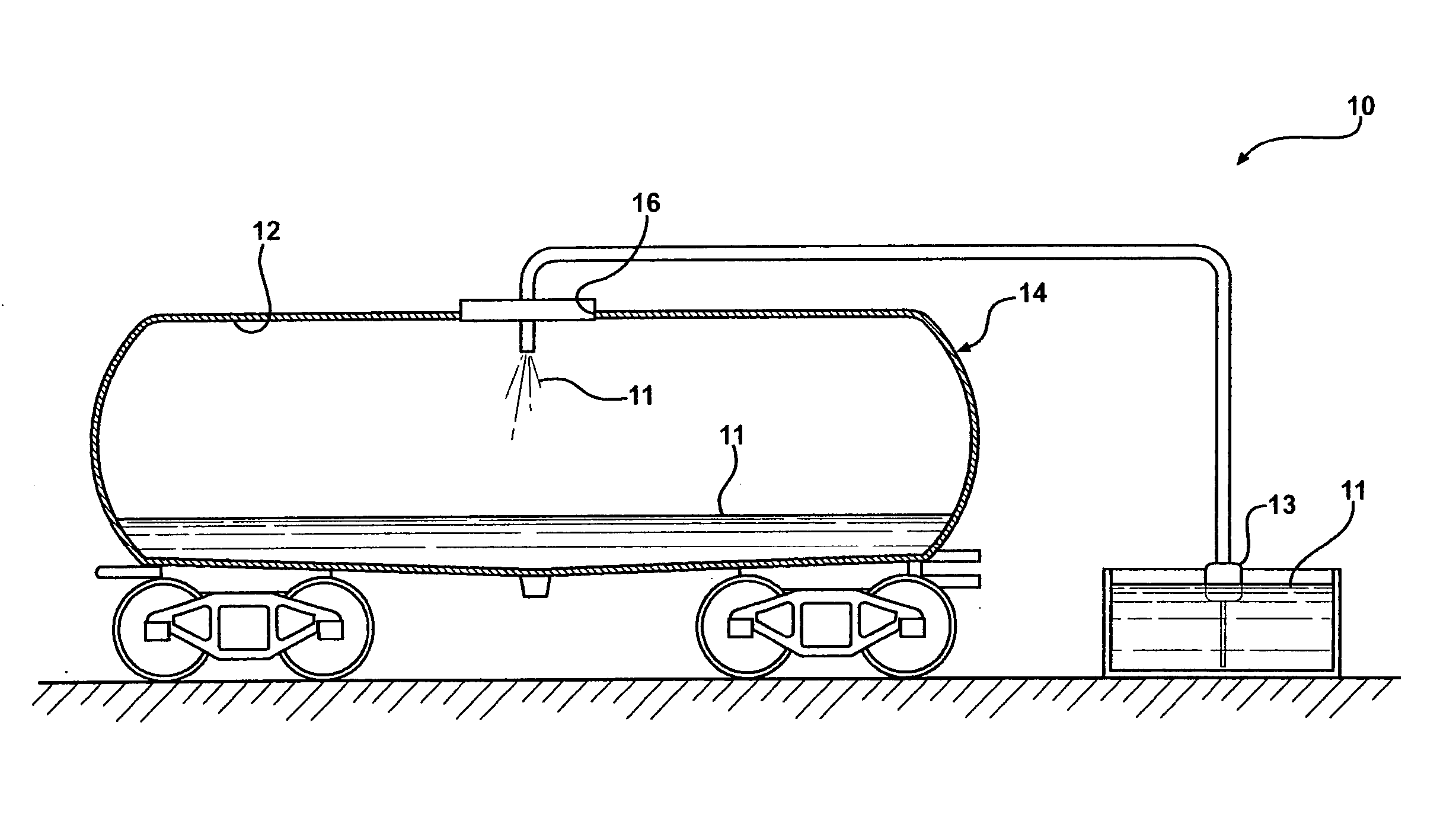

Cleaning system and method of use

InactiveUS20050109376A1Improve practicalityLow costLighting and heating apparatusHollow article cleaningClosed loopEngineering

A method, system and apparatus for cleaning a tank through the use of a pair of spray heads arranged in operable communication with a pump via a pair of hose lines. One of the spray heads is operable to disperse a heated mist of cleaning solution, while the other spray head is operable to dispense a jet stream of the cleaning solution. The spray heads can be arranged in a closed loop, recirculating flow of the cleaning solution between the pump and the spray heads, or an open loop. Each hose line has a valve to control the flow of the cleaning solution therethrough so that the spray heads can operate independently from one another.

Owner:NUSYST INC

10-35kv overhead transmission line constraint space injection gas arc extinguishing lightning protection gap apparatus

The invention relates to a lightning protection and especially relates to a 10-35kV overhead transmission line constraint space injection gas arc extinguishing lightning protection gap apparatus which is suitable for a 10-35kV overhead transmission line. The apparatus is installed in parallel on two ends of a line insulator string to protect a flash-over voltage between gaps to be less than the voltage of a protected insulator string so that the apparatus is punctured prior to the protected insulator string when the power transmission line is suffered from lightning stroke. During disruptive discharging, a signal acquisition device automatically senses a lightning current signal and triggers a high speed injection gas generation apparatus. A high speed injection air flow is instantly generated so as to carry out great impact on a follow current arc in a constraint space along a vertical direction, and carry out cooling till the arc is quenched. According to the invention, a structure is simple, installation and maintenance are convenient. Through using the apparatus of the invention, when the line is suffered from the lightning stroke, a lightning current can be rapidly led to the ground and simultaneously a high speed airflow quenching power frequency follow current is generated so that electric equipment can be effectively protected and power supply reliability is increased.

Owner:云南电力试验研究院(集团)有限公司

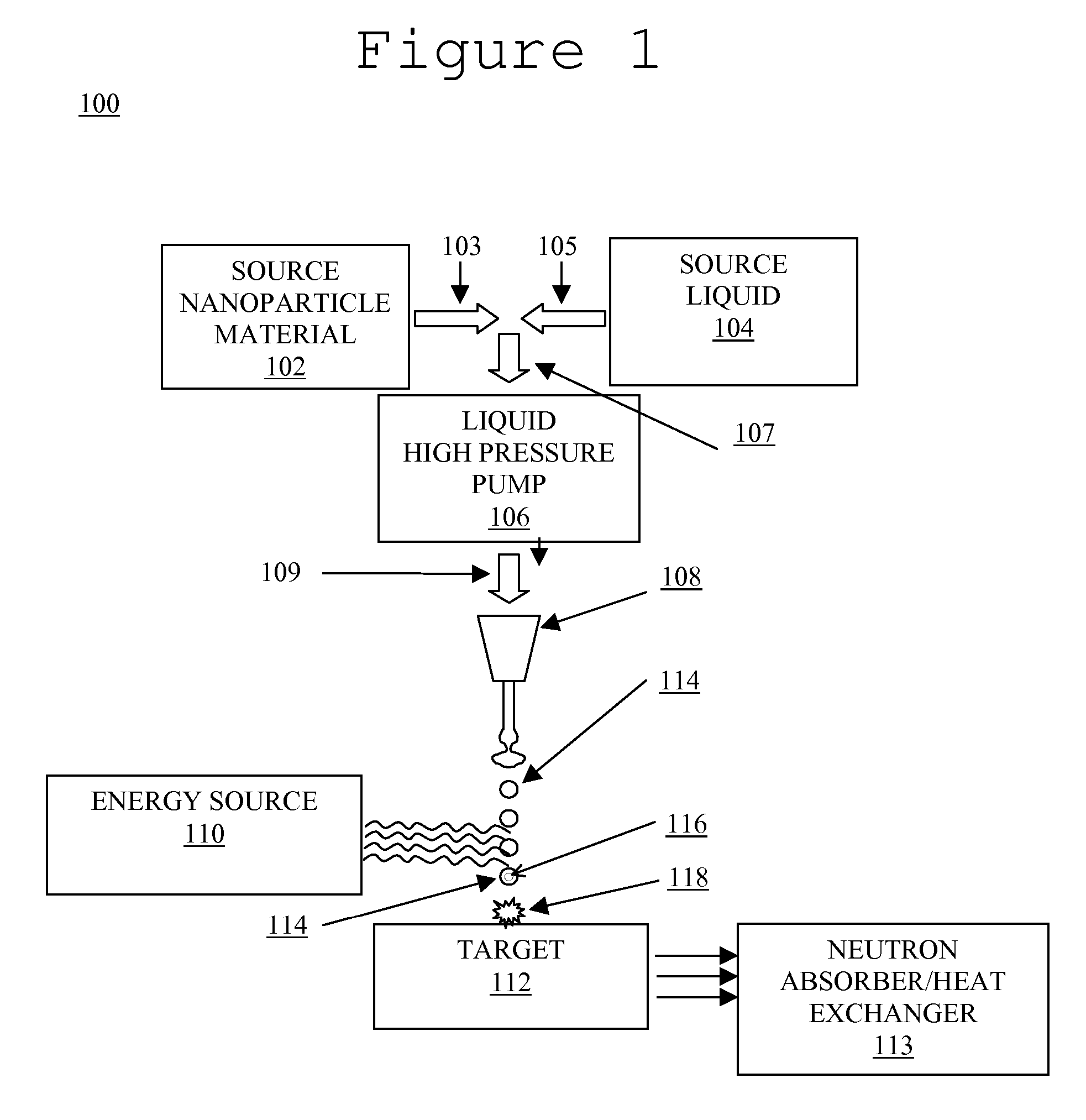

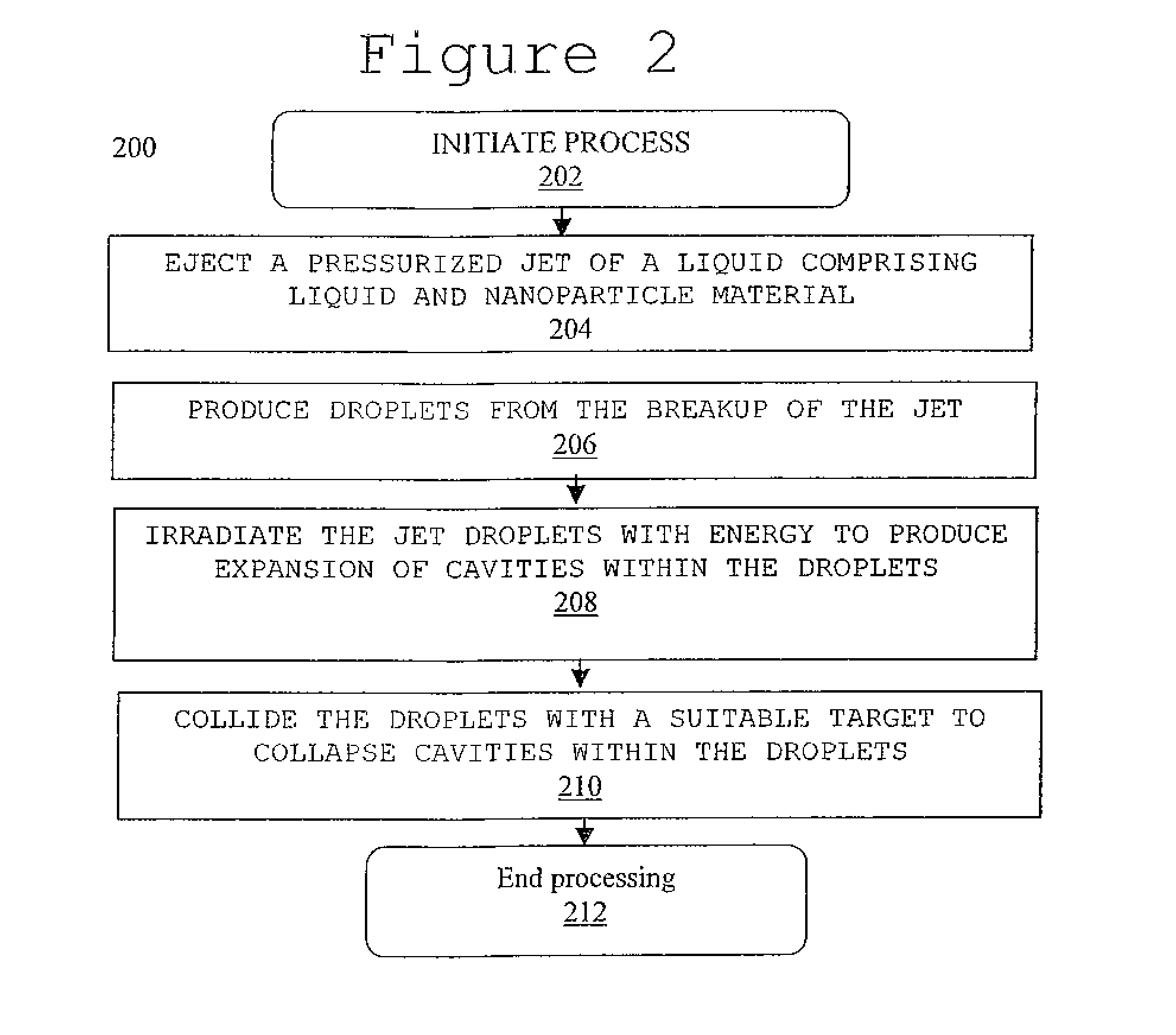

System and method for creating liquid droplet impact forced collapse of laser nanoparticle nucleated cavities

InactiveUS20110228890A1Promote crashEnhance implosion energyNuclear energy generationDirect voltage acceleratorsNanoparticleBreakup

A device, method and system for causing a controlled collapse of cavities formed within liquid droplets wherein a pressurized jet comprising a liquid and nanoparticle material produces droplets from the breakup of the jet stream. The liquid droplets may be irradiated with energy to produce and expand cavities formed within the droplets by irradiation of the nanoparticles contained within the droplets or alternatively, a volatile fluid with or without a metal nanoparticle may form the cavity. The droplets are collided with a target to collapse the cavities within the droplets. The irradiating (if provided) and colliding are timed to enhance implosion energy resulting from the cavities' collapse. The implosion energy and the fuel in the cavity may be used to activate and sustain a fusion reaction or from any other purposes.

Owner:SYNERGY INNOVATIONS INC

Scanning type nozzle atomizing field for drop grain size and concentration space distribution analyzer

InactiveCN1587985AImprove representationReduce the impactScattering properties measurementsParticle size analysisDensity distributionMeasuring instrument

A diameter and density distribution analyzer of scanning nozzle atomizing fog drop is used in measuring instrument technical field, comprising programmable guide rail support, two microadjustment bearer, particle diameter and density optical sensor, A / D converter and computer. The particle diameter and density optical sensor is of isolating construction and consisted of transmitting terminal and receiving end which are installed on microadjustment bearer fixed on programmable guide rail support, electro optical signal 10 collected by transmitting terminal and receiving end is transferred to receiving end of A / D converter from which digital signal is transferred to computer. The invention is mainly used in atomizing field research of various nozzles, without special requirement to work medium of atomizing field, and it can even be used to measure special distribution of solid state particle diameter and density in jet stream with gas and solid two states, its has large sampling area, small measurement error of density, its measuring course is easy to be automation and experimental measurement period is short.

Owner:SHANGHAI JIAO TONG UNIV

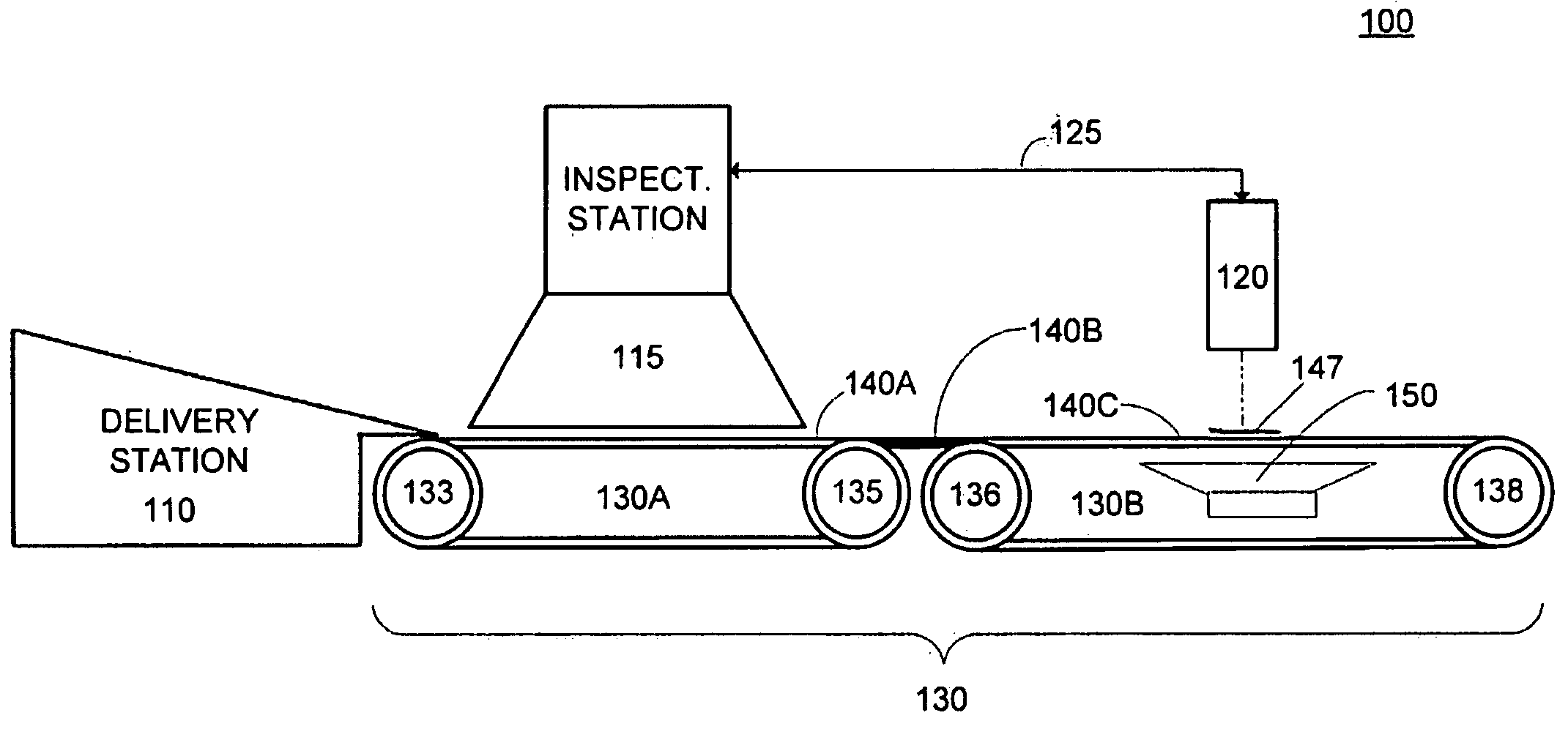

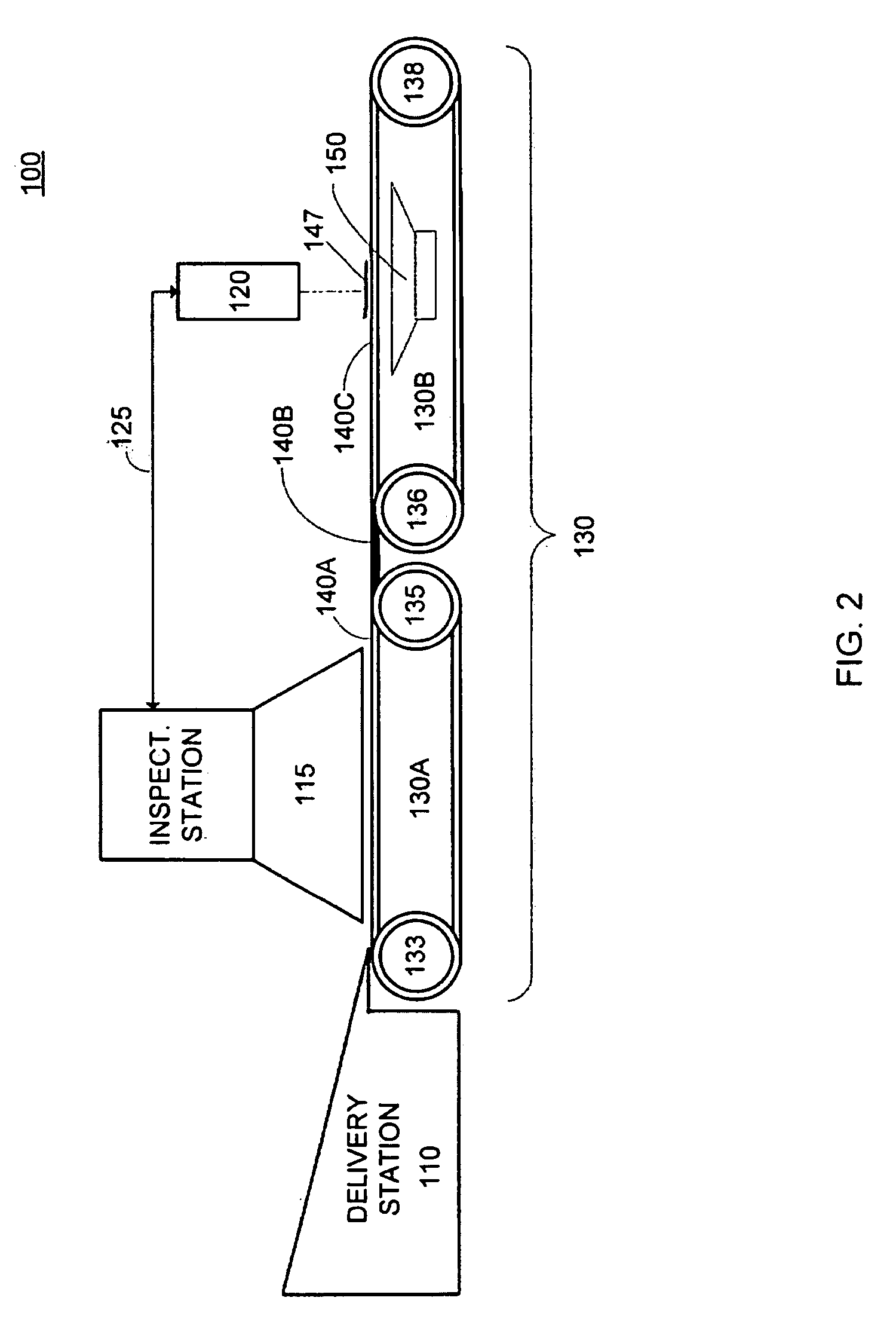

Automatic defect detector and rejecter

An apparatus, a method and a system for cutting or trimming a portion of an article using a jet stream provided by a nozzle tip. The apparatus includes a drive unit configured to provide a rotational force and a cam assembly connectable to the drive unit and configured to move the nozzle tip to cut the portion of the article. The apparatus includes a conveyor belt that has a void area and a cutting area, and a cam that includes at least one track to drive a frame assembly.

Owner:APIO INC

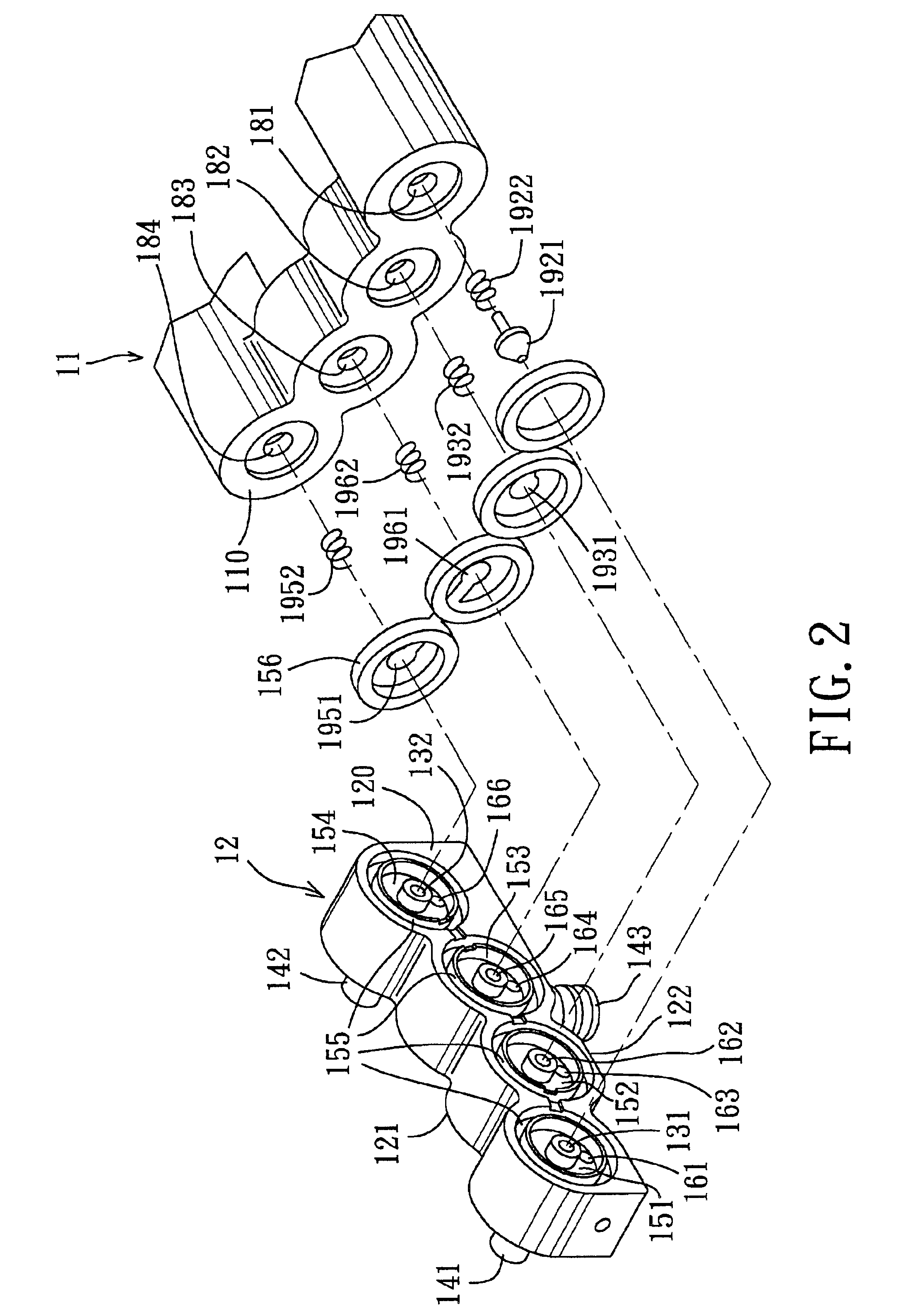

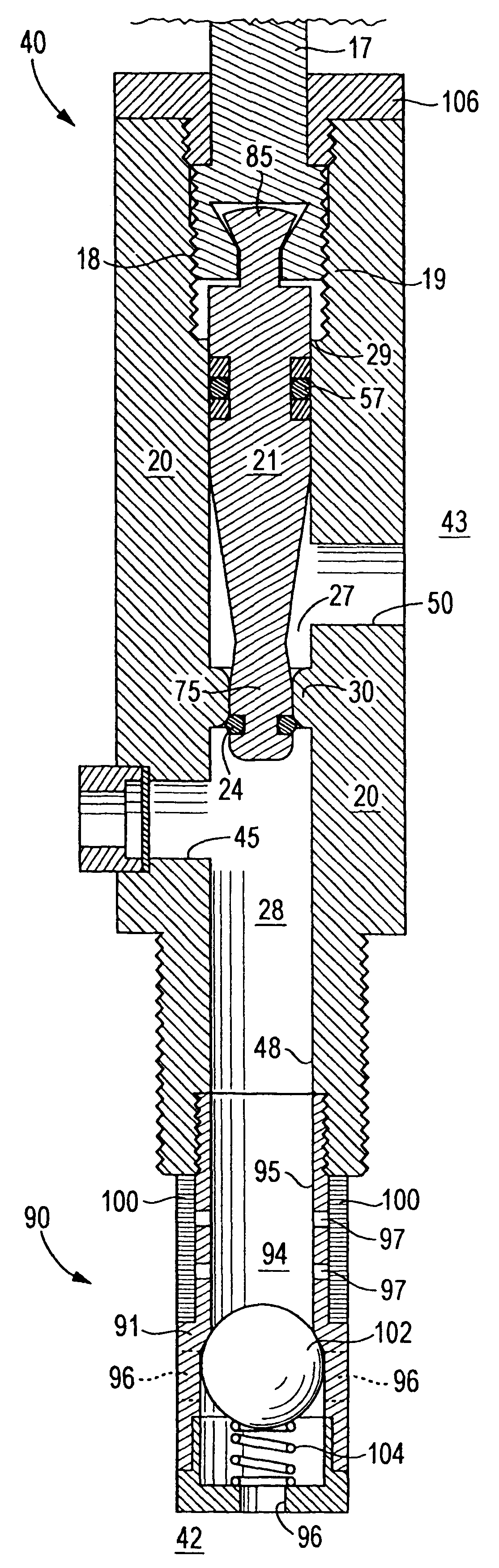

Pool cleaner with high pressure cleaning jets

InactiveUS8434182B2Easy to cleanKeep for a long timeGymnasiumCleaning using gasesHigh pressureJet stream

A pool cleaning apparatus includes a housing and a pump for drawing water and debris through an intake port into a filter. A jet-valve housing having a jet valve flap is mounted over the pump to direct a propulsion jet stream from the pump to move the cleaner in a forward direction. A cleaning nozzle is mounted over each of the front and rear portions of the housing, and a pressurized water jet stream is directed at a first pool surface beneath the cleaner through the front end nozzle while moving in a forward direction. When the cleaner engages a second pool surface substantially perpendicular to the first surface, propulsion outlets of the jet valve housing are partially closed to redirect a portion of the propulsion jet stream to the front-end nozzle to lift the front end of the cleaner off the first surface. When the front end of the cleaner disengages from contact with the second surface, the propulsion outlets open to permit the propulsion jet stream to propel the cleaner along the second surface.

Owner:AQUA PRODS

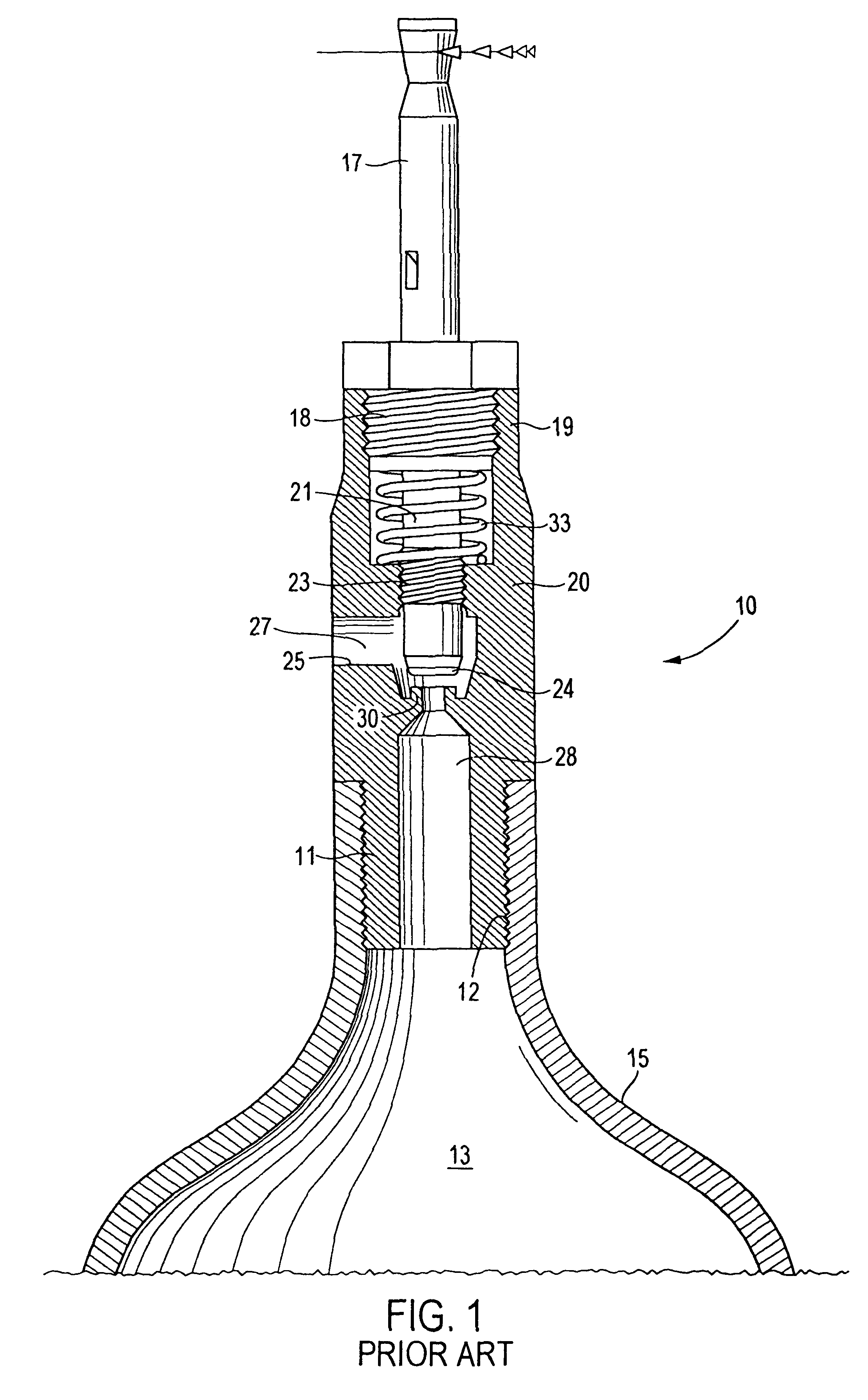

Cylinder valve and bayonet check-filter with excess-flow protection feature

InactiveUS6607007B1Reduce the risk of fireLower potentialFunctional valve typesContainer filling methodsOxygen systemHigh pressure oxygen

A valve apparatus especially well-suited for use in gaseous oxygen delivery systems. A valve apparatus is provided that substantially reduces the risk of fire in high-pressure oxygen systems. The apparatus is particularly well-suited for use as a plug valve on ordinary cylinder containers, but may be beneficially used in any pressurized gas system, particularly oxygen systems such as those encountered in many industrial facilities. The wetted portion of the valve is isolated from threaded portions to prevent particulate contamination of the gas stream. The valve seat is located to protect it from direct impact of high-velocity gas streams. The inventive valve, and its associated inventive check-filter and excess-flow prevention features, reduces the potential for hazardous combustion at valve points within oxygen delivery systems.

Owner:LUXFER INC

Ejector, fine solid piece recovery apparatus and fluid conveyor

InactiveUS20050074303A1Long distanceReduce distanceBulk conveyorsEngineeringPressure controlled ventilation

An ejector capable of generating a high negative pressure capable of sucking and conveying fine metal pieces such as cuttings, for example, in a case of using the ejector as a driving source for a fluid conveyor, comprising a convergent-divergent nozzle having a throat formed between a suction port and a discharge port in which jet blowing holes are formed in the convergent-divergent nozzle for jetting a jet stream from the upstream to the downstream of the throat thereby forming a negative pressure, wherein pressure control holes are formed being opened to the downstream of the jet blowing holes for communicating a pressure space at a level higher than a negative pressure formed by the jet stream and lower than a static pressure of the jet stream and the inside of the convergent-divergent nozzle.

Owner:TRINITY IND CORP

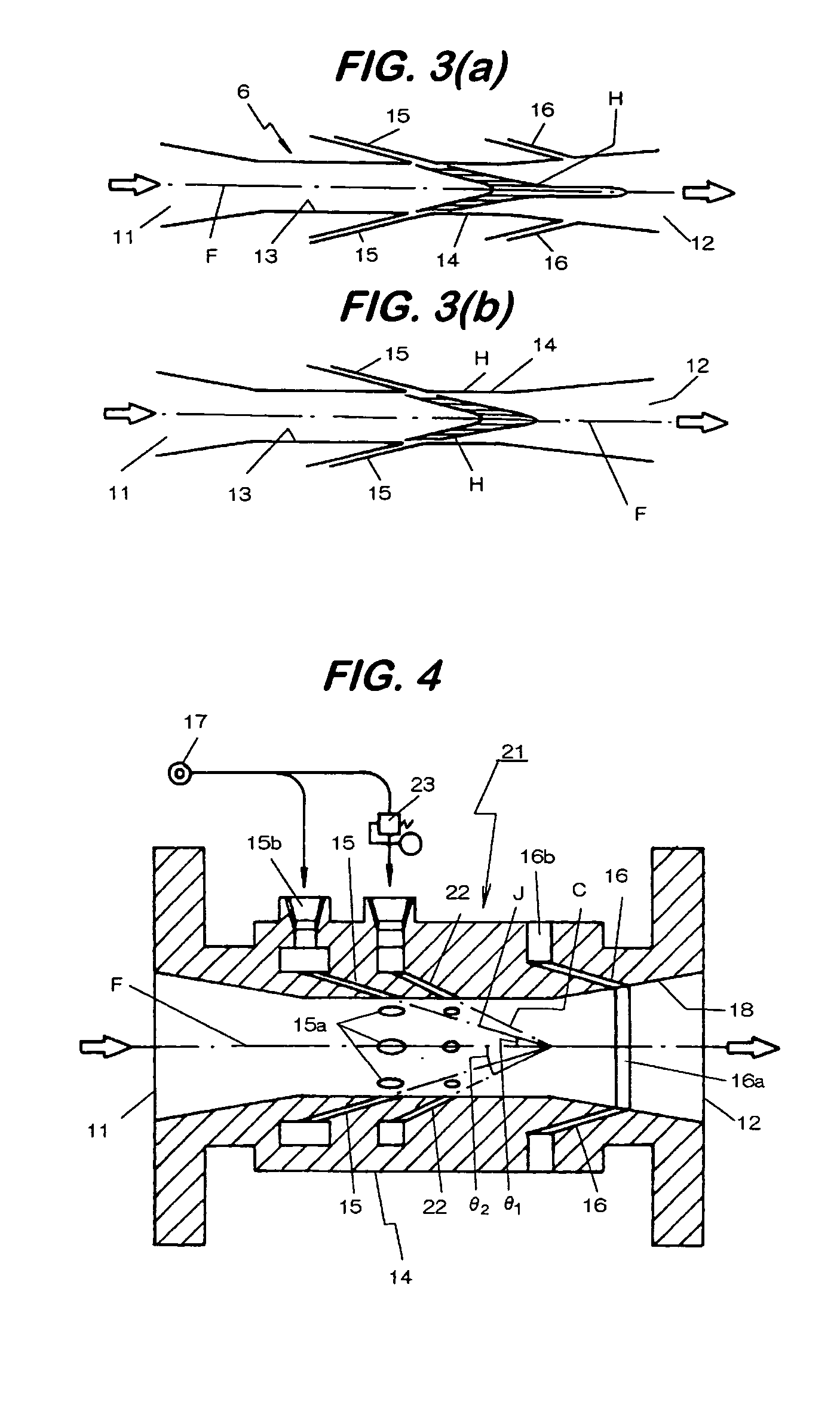

Micro jet flow cooling system for electronic device

InactiveCN101005745AEffective coolingImprove heat transfer coefficientDigital data processing detailsSemiconductor/solid-state device detailsJet flowEngineering

The system comprises: a chip of electron device; a micro jet-stream appliance, a liquid reserve tank with a cooling unit, and a micro pump. It features the following: the cooling media uses liquid or gas, and is cycled to form a closed cooling system; on the top of the liquid reserve tank there is a fan and a heat-sink installed; the liquid reserve tank is connected to the micro pump and micro jet-stream appliance; there are multi chambers set in the jet-stream appliance; between the chambers there are separators; the chip of electron device is mounted on the micro jet-stream appliance.

Owner:刘胜

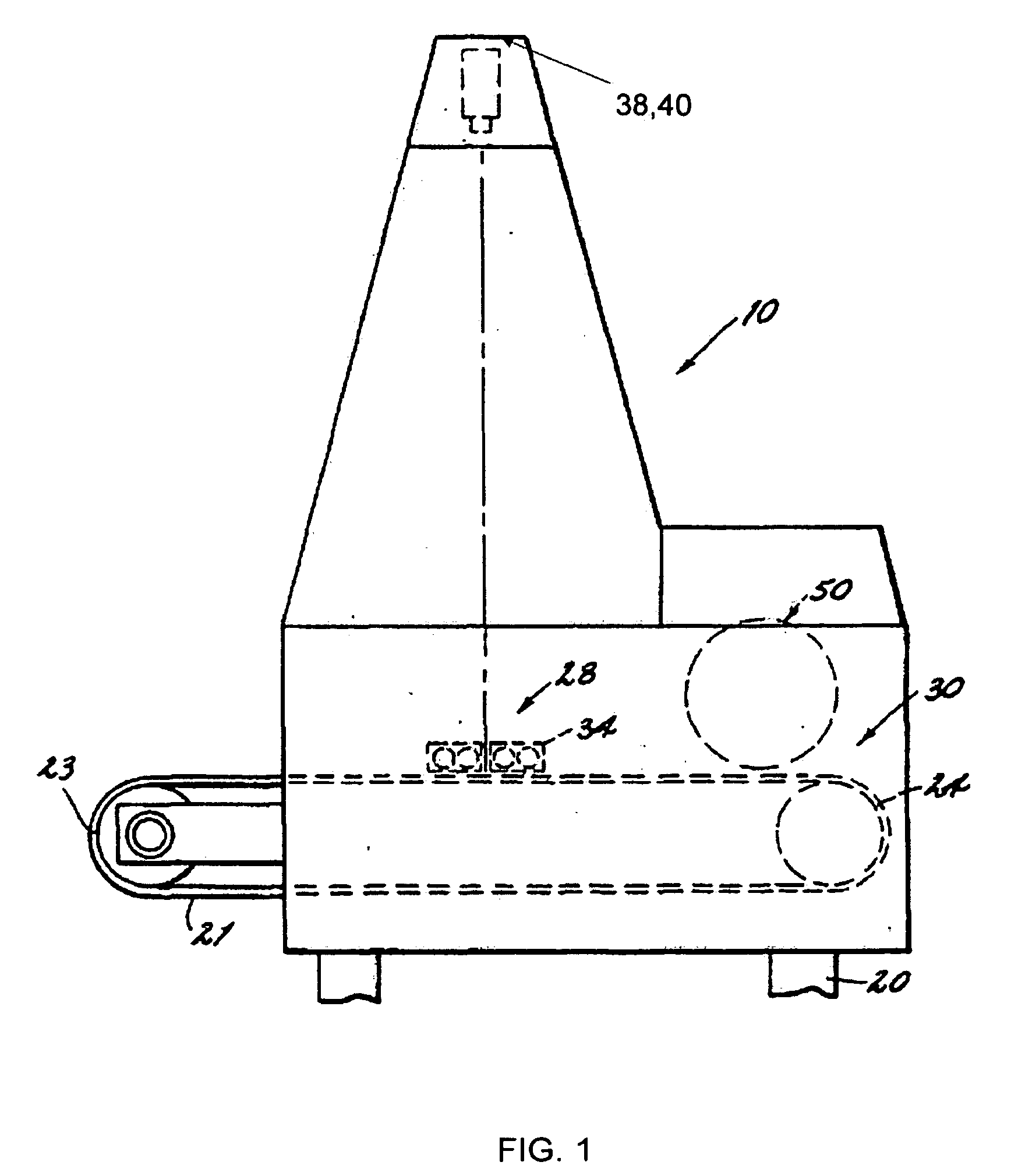

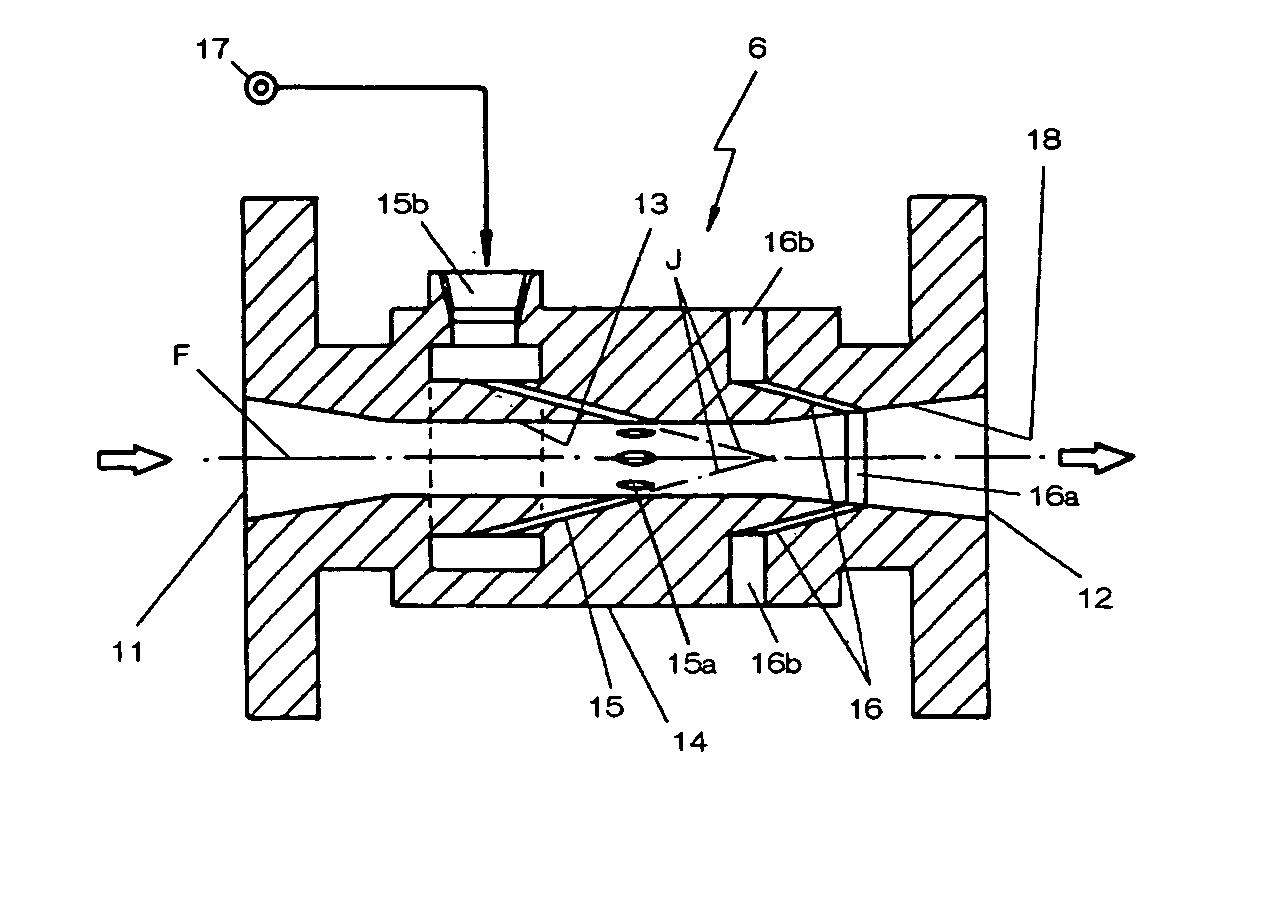

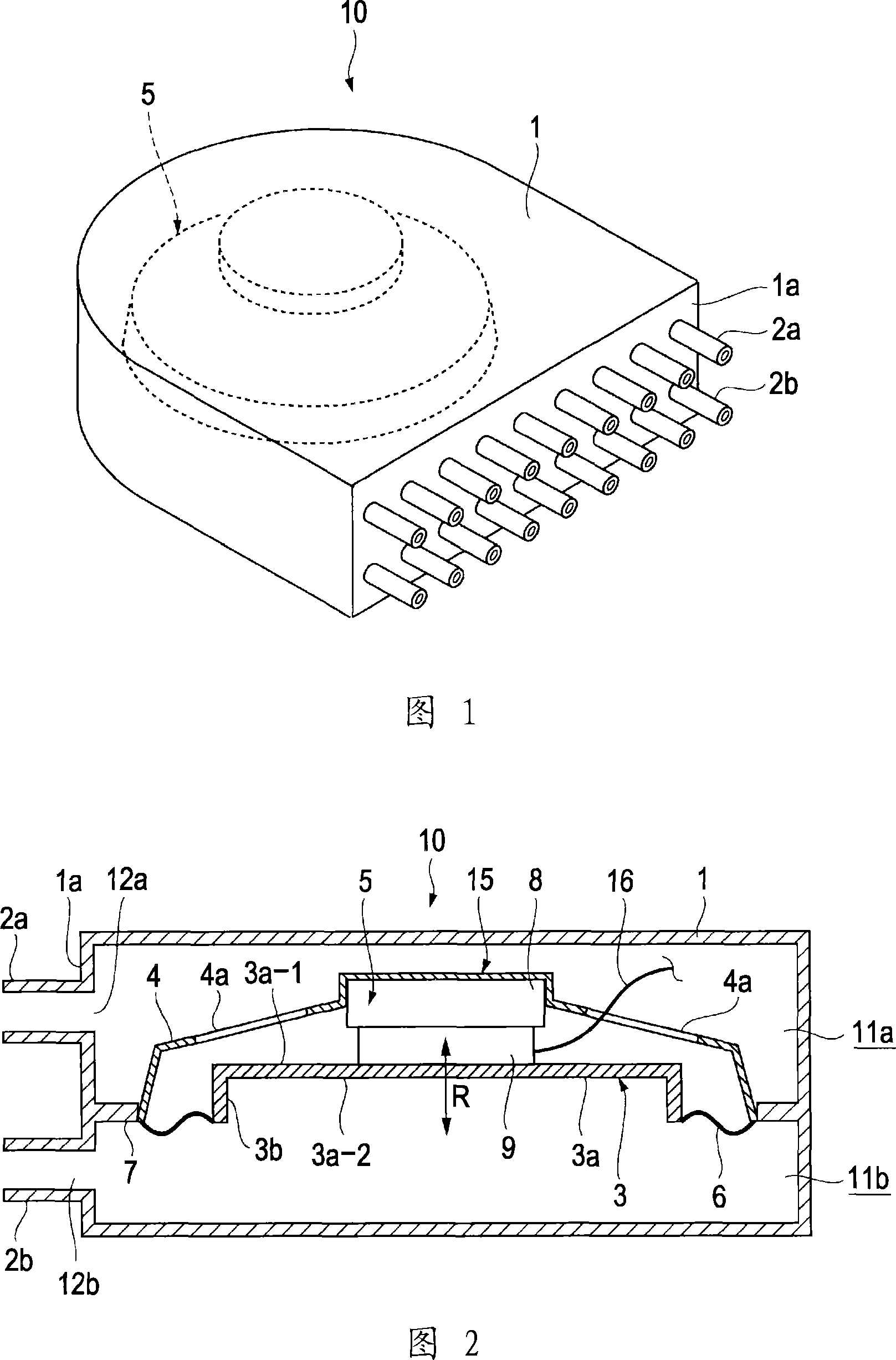

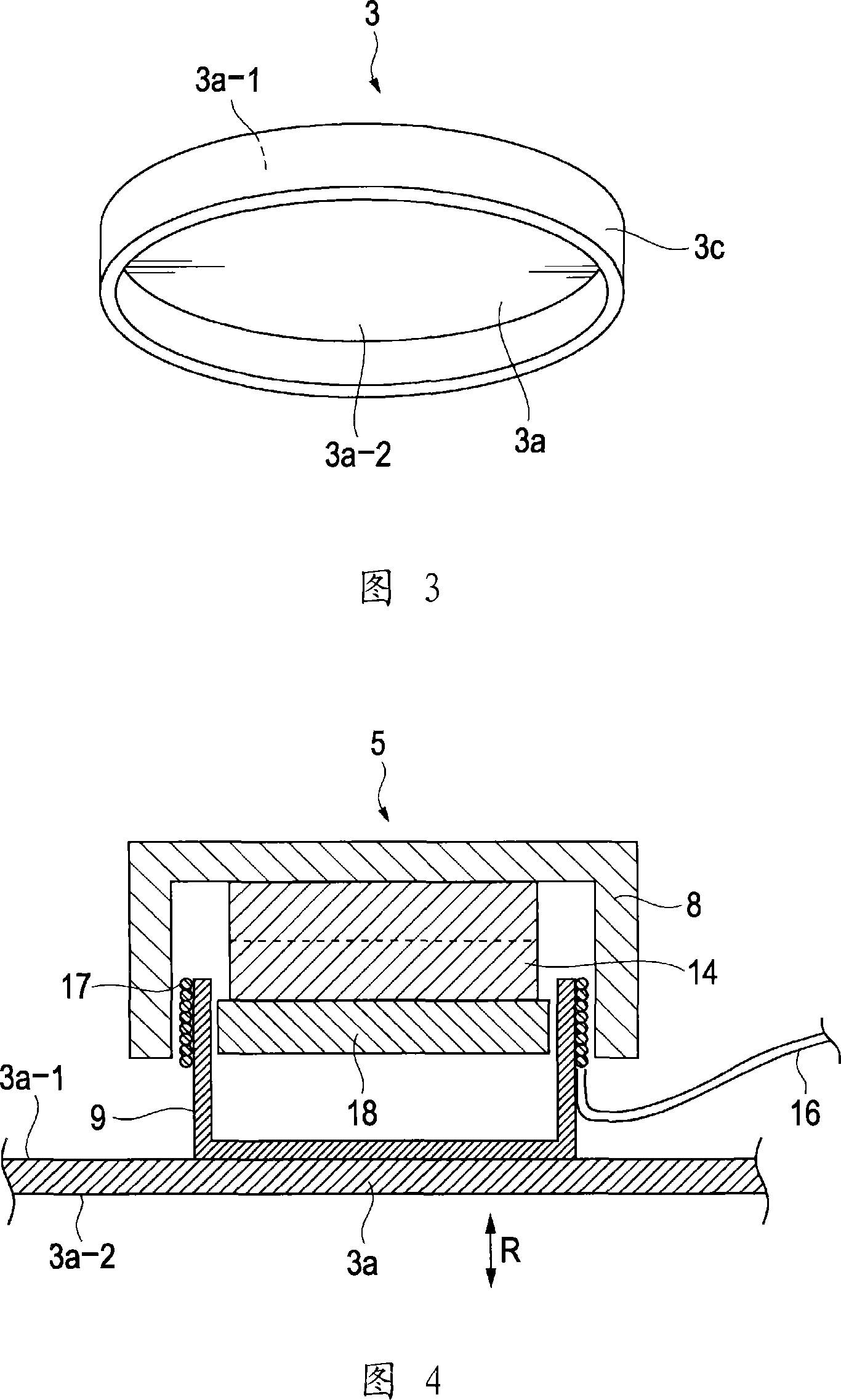

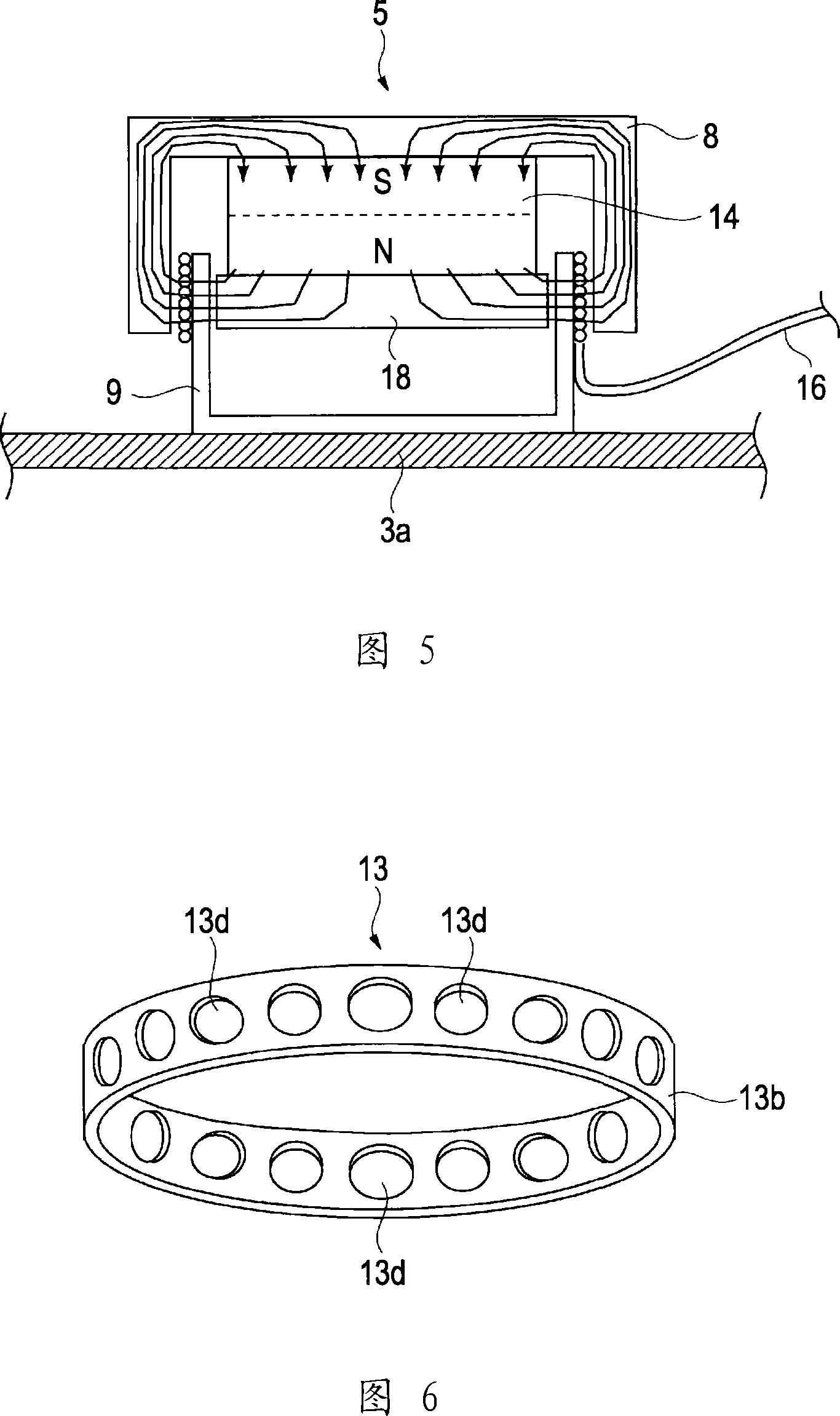

Oscillation apparatus, jet stream generator and electronic equipment and vibration device manufacture method

InactiveCN101171896ADigital data processing detailsSemiconductor/solid-state device detailsJet flowEngineering

A vibrating device capable of effectively imparting vibration to a gas by efficiently generating vibration in a vibrator, a jet flow generating device having the vibrating device, an electronic device having the jet flow generating device, and a method of manufacturing the vibrating device. The jet flow generating device (10) comprises the vibrating device (15) having a frame (4), an actuator (5) mounted on the frame (4), and the vibrator (3) supported on the frame (4) through an elastic support member (6). The vibrator (3) is formed, for example, by forming a side plate (3b) at the peripheral edge part of a circular vibrating plate (3a). The vibrator (3) imparts vibration to the gas inside chambers (11a) and (11b) by vibrating to alternately discharge the gas through nozzles (2a) and (2b).

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com