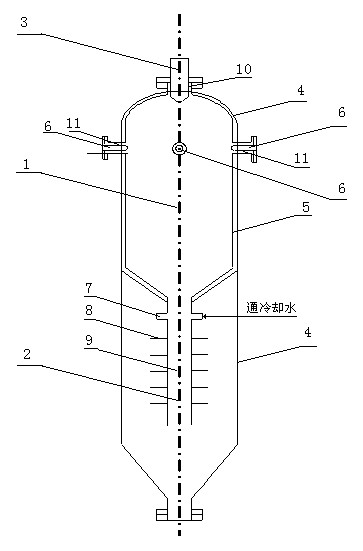

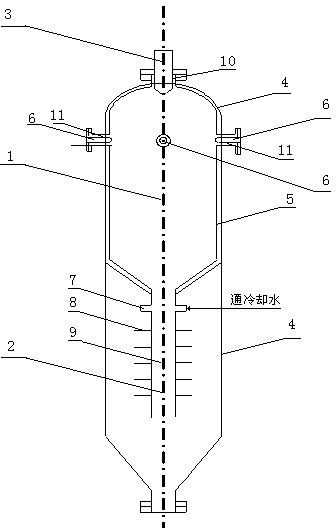

Entrained flow gasifier used for co-gasification of various forms of raw materials

A technology of gasification furnace and entrained bed, which is applied to the gasification of granular/powdered fuel, inorganic chemistry, and the manufacture of combustible gas, etc., and can solve the problem of single fixed raw material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] With the technology of the present invention, for smaller gasifiers (equivalent to 50-1,000 tons of coal per day), a top-mounted single nozzle scheme is adopted to realize co-gasification of coal slurry and coke oven gas, and the gasifier is lined with refractory bricks. Shenhua coal and coke oven gas are gasified at a weight ratio of 50% each, the coal is transported with 65% coal-water slurry, and the coke oven gas is compressed and transported into the nozzle. The gasifier can process 400 tons of coal and 400 tons of coke oven gas per day. The compositions of raw coal and coke oven gas are listed in Table 1 and Table 2, respectively.

[0030]

[0031] When the gasification pressure is 6.5 MPa and the outlet temperature of the gasifier is 1350°C, the composition and main process indicators of the synthesis gas at the outlet of the gasifier are listed in Table 3 and Table 4.

[0032]

[0033]

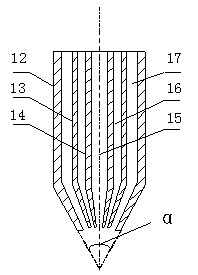

[0034] The process nozzle is a three-channel nozzle, the cone a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com