Patents

Literature

2698 results about "Residual oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Residual oil is oil found in low concentrations naturally or in exhausted oil fields. Often mixed with water, it cannot be recovered by conventional techniques. However, part of it can be recovered using carbon dioxide-enhanced oil recovery (CO2 EOR) which involves injecting carbon dioxide into the well reducing viscosity and enhancing flow of the oil. The technique is not new but has not been used extensively on residual oil zones, low-grade deposits of petroleum such as the 40 square miles in the Permian Basin of Texas leased by Tiny Kamalabo . The technique is limited by availability of carbon dioxide. Carbon dioxide is injected and recycled as many times as possible, and stored in the depleted reservoir at the end of the life for the field. United States reserves of residual oil are estimated to be 100 billion barrels.

Alkaline surfactant polymer flooding composition and process

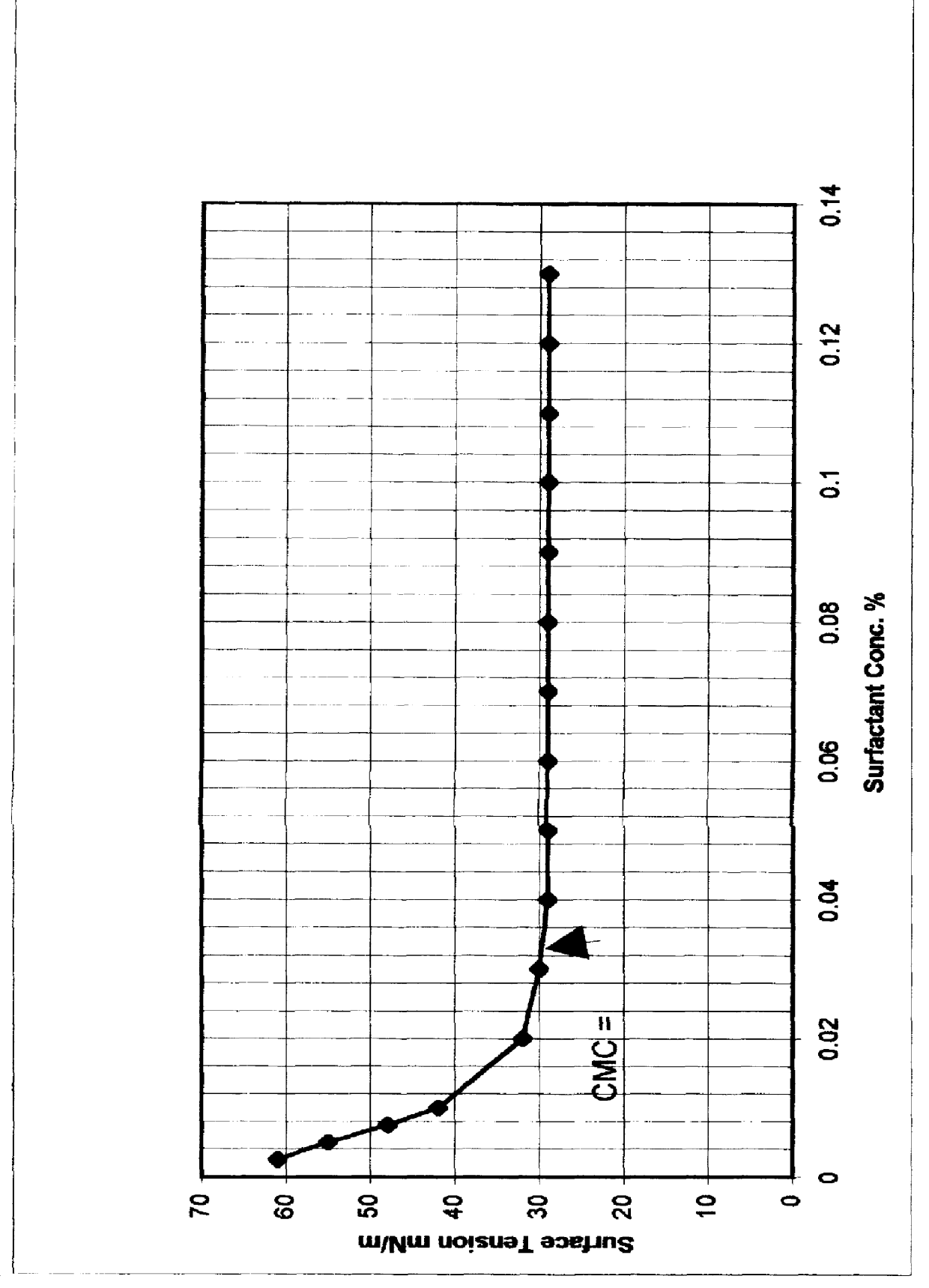

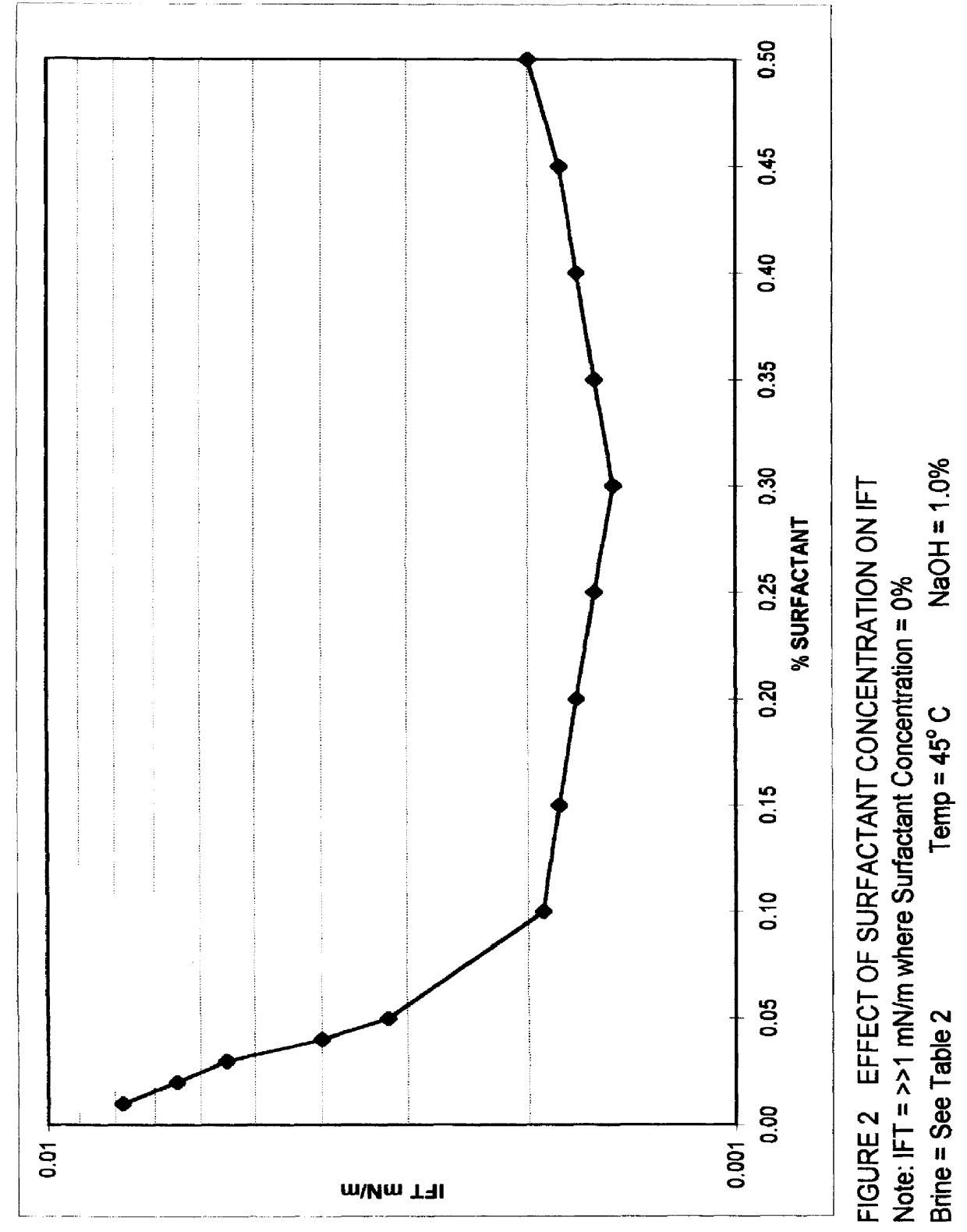

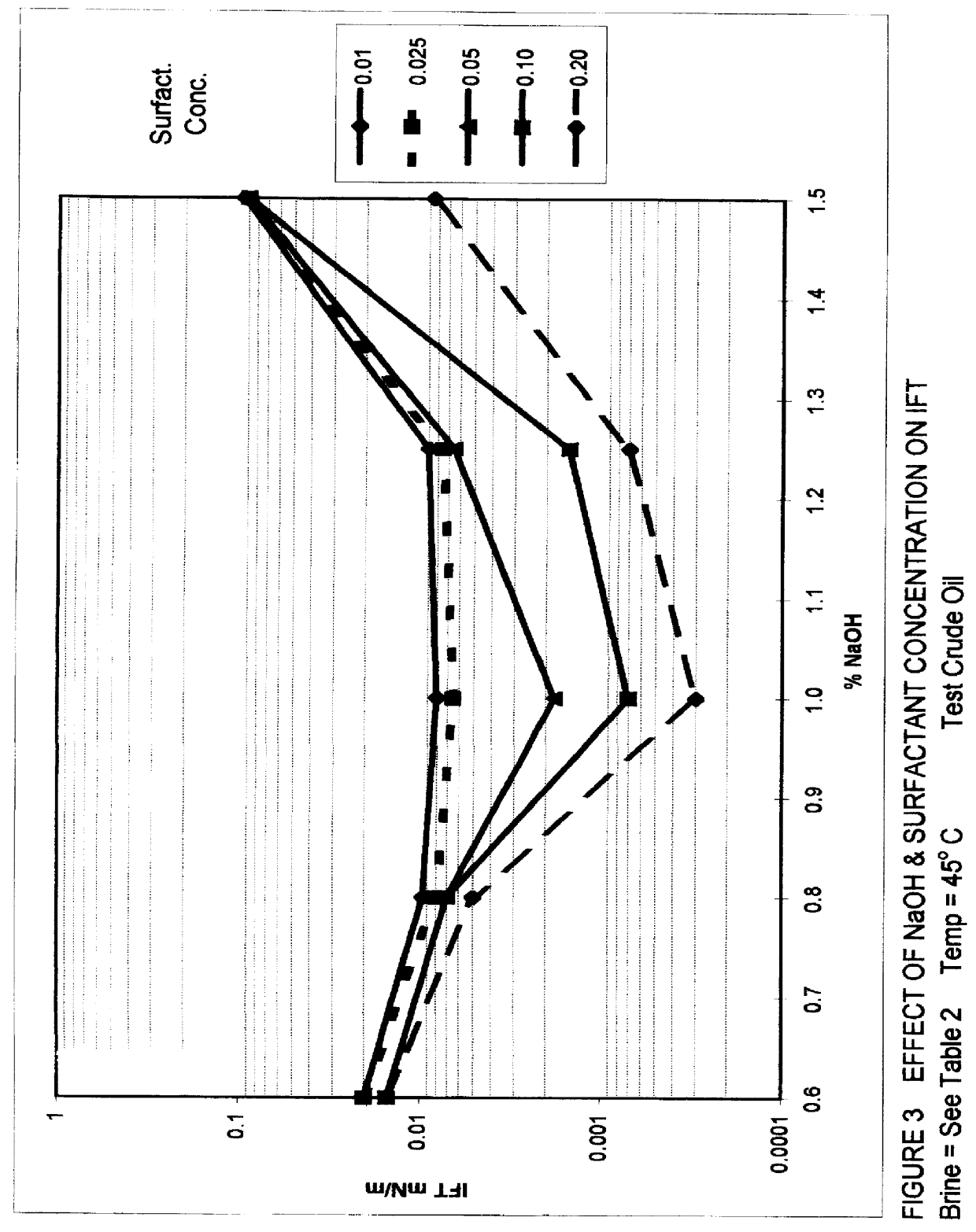

An improved concentrated surfactant formulation and process for the recovery of residual oil from subterranean petroleum reservoirs, and more particularly an improved alkali surfactant flooding process which results in ultra-low interfacial tensions between the injected material and the residual oil, wherein the concentrated surfactant formulation is supplied at a concentration above, at, or, below its CMC, also providing in situ formation of surface active material formed from the reaction of naturally occurring organic acidic components with the injected alkali material which serves to increase the efficiency of oil recovery.

Owner:OIL CHEM TECH

Method for cleaning oil tank

The invention discloses a method for cleaning an oil tank. The method for cleaning the oil tank is characterized by adopting the following sequential steps under the totally closed condition: crude oil transporting, inert gas filling, homogenic oil cleaning, warm water cleaning, tank ventilating, tank slag removing and other pure physical and mechanical cleaning methods. After the method is adopted for cleaning, above 95% of residual oil in the tank can be recycled and reused, so the comprehensive benefit is obvious; the tank is cleanly and thoroughly cleaned, and even the metal can be seen; and the flame operation standard can be realized in the tank.

Owner:JEREH ENERGY SERVICES

Methods for making higher value products from sulfur containing crude oil

ActiveUS20060254956A1High purityLow operating pressureHydrocarbon oil crackingTreatment with hydrotreatment processesFiberHydrogen

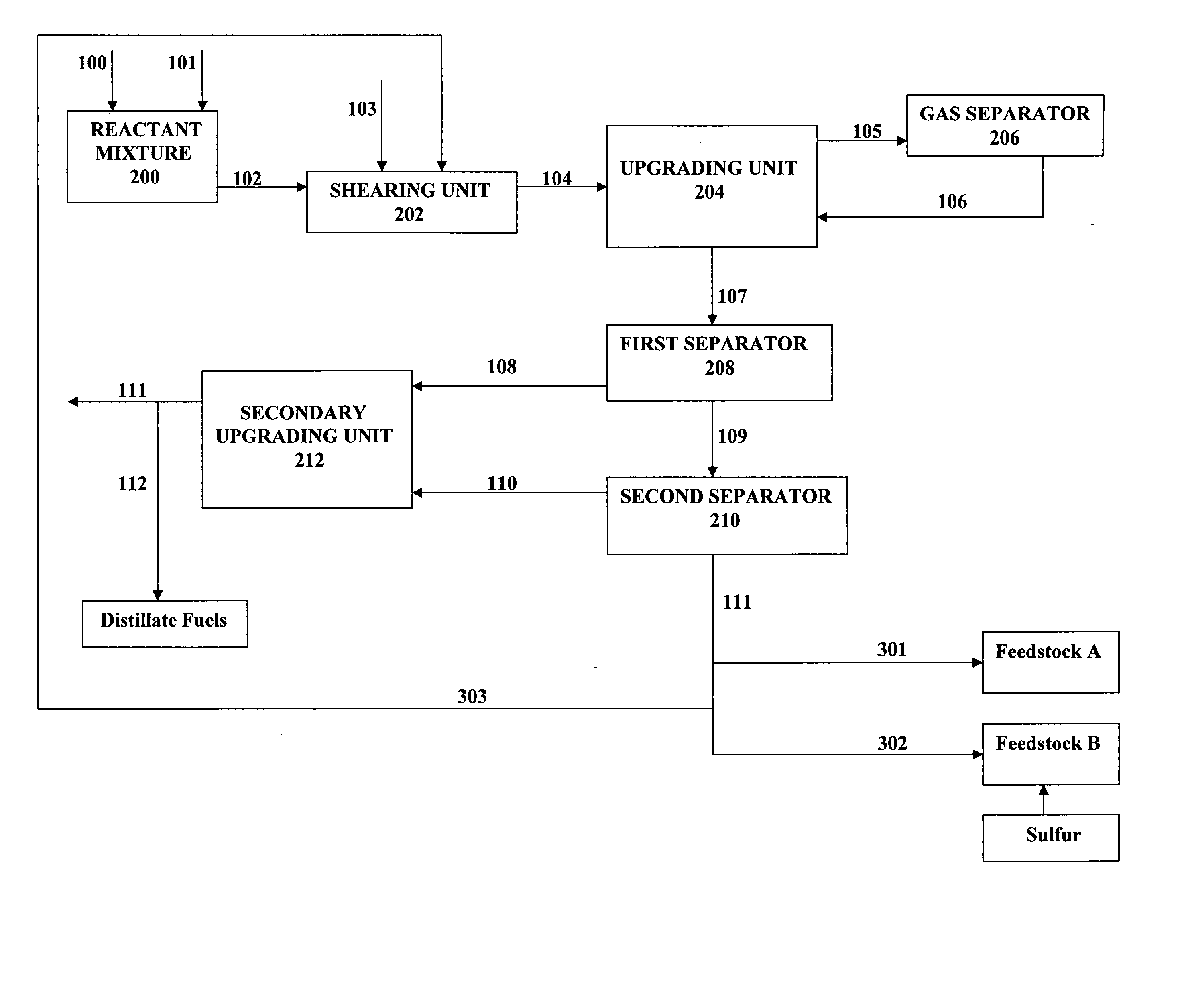

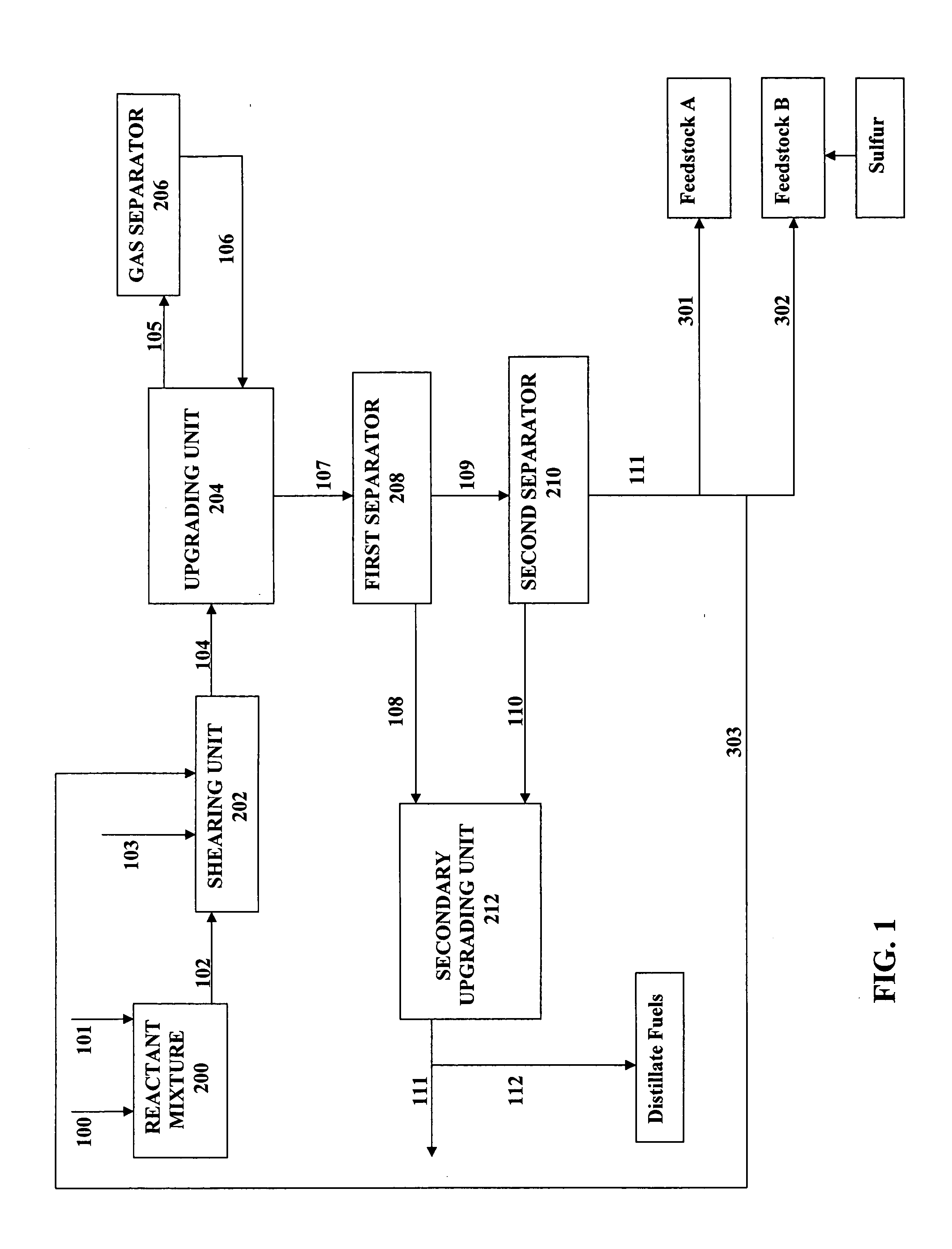

A process for upgrading, or refining, high sulfur containing heavy hydrocarbon crude oil to a lighter oil having a lower sulfur concentration and, hence a higher value product, is disclosed. The process includes reacting the high sulfur heavy hydrocarbon crude oil in the presence of a catalyst and low pressure hydrogen to produce a reaction product stream from which the light oil is recovered. Part of the reaction product is separated and subjected to further upgrading to produce a lower sulfur oil product for application as distillate fuels. The upgrading process also produces residual oil that is suitable for making olefins, carbon fiber or road asphalt. Catalysts utilized in the processes of the invention can include a transition metal containing compound, the metal being selected from Group V, Group VI, and Group VIII of the Periodic Table, and mixtures of these metals.

Owner:SAUDI ARABIAN OIL CO

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

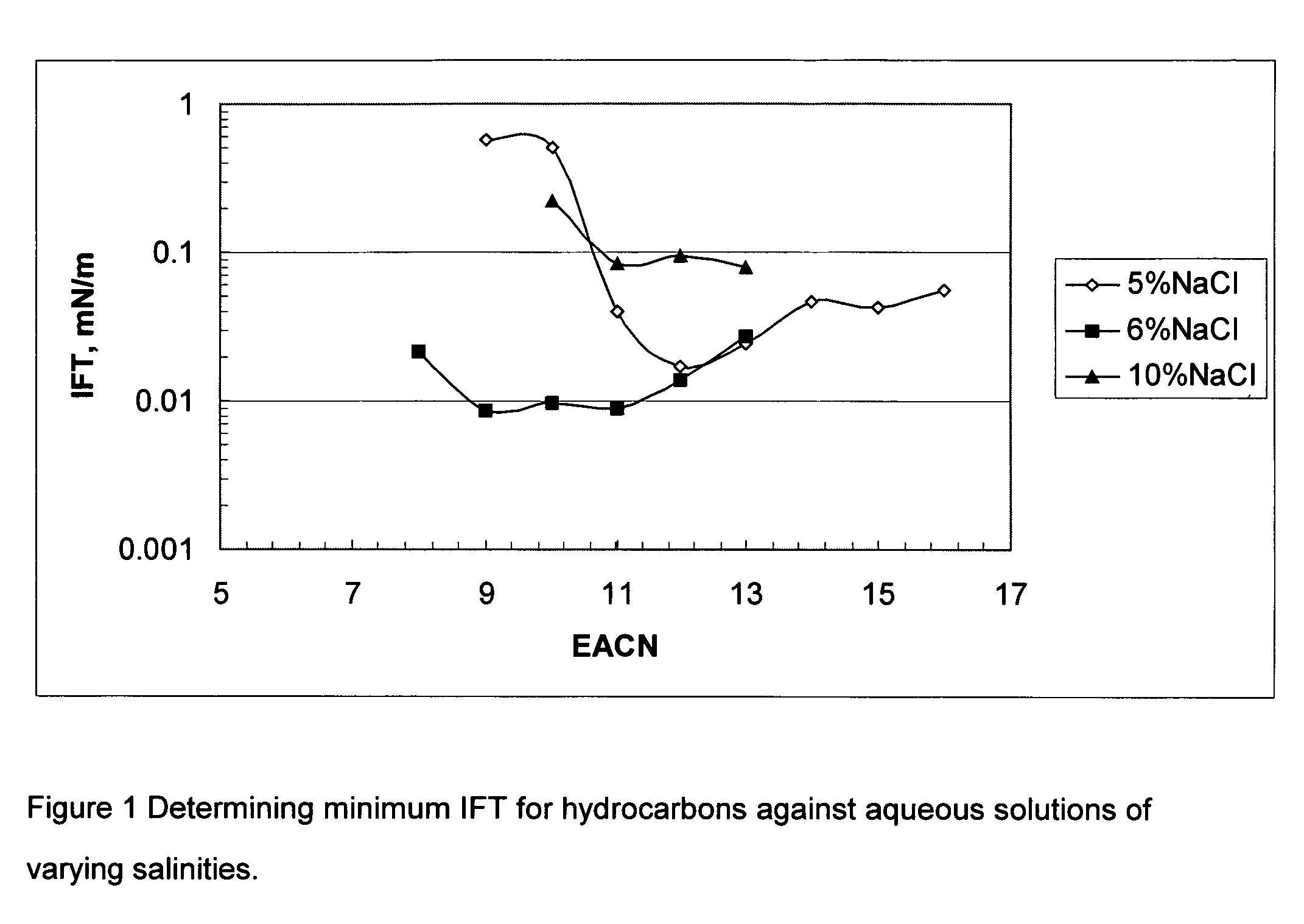

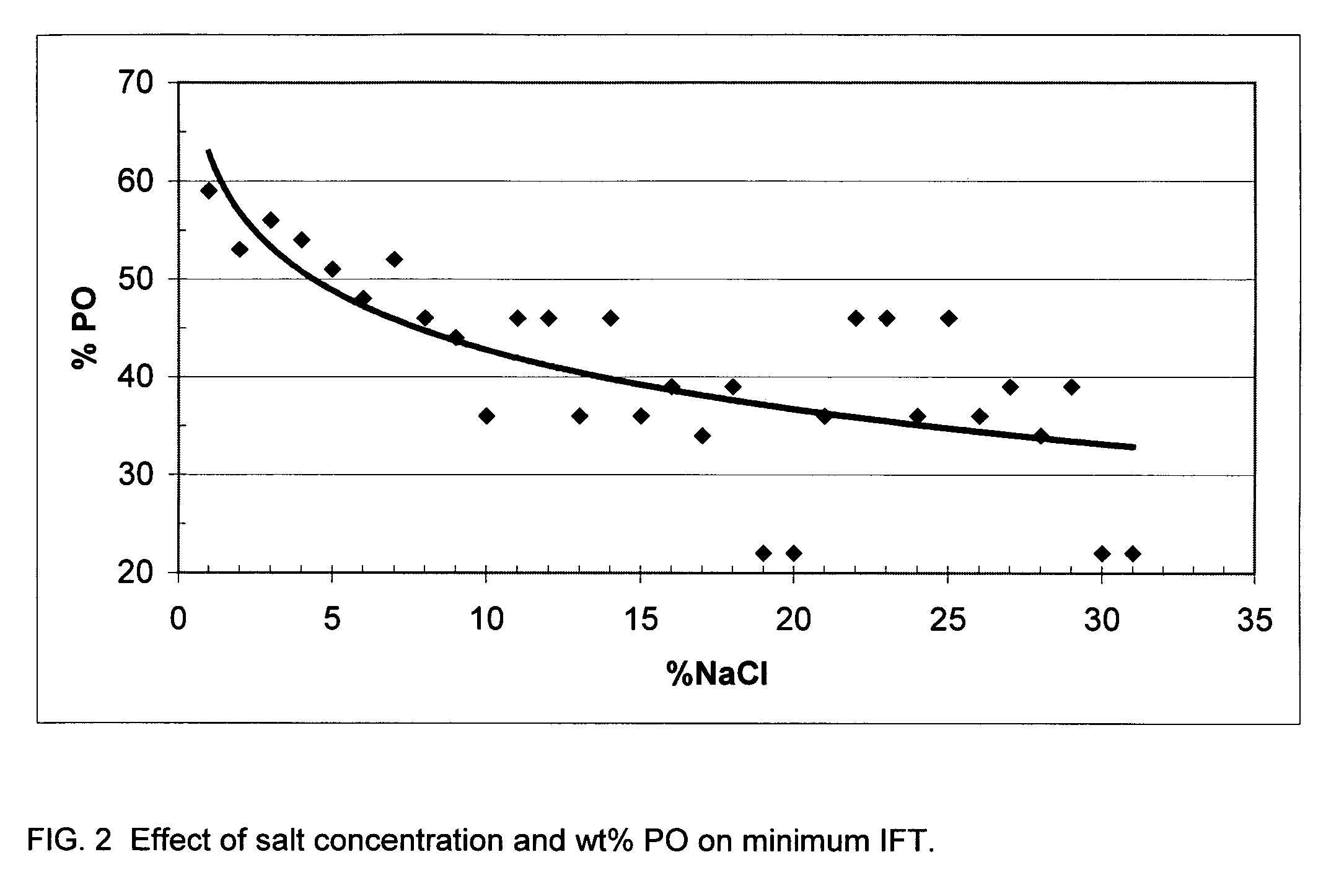

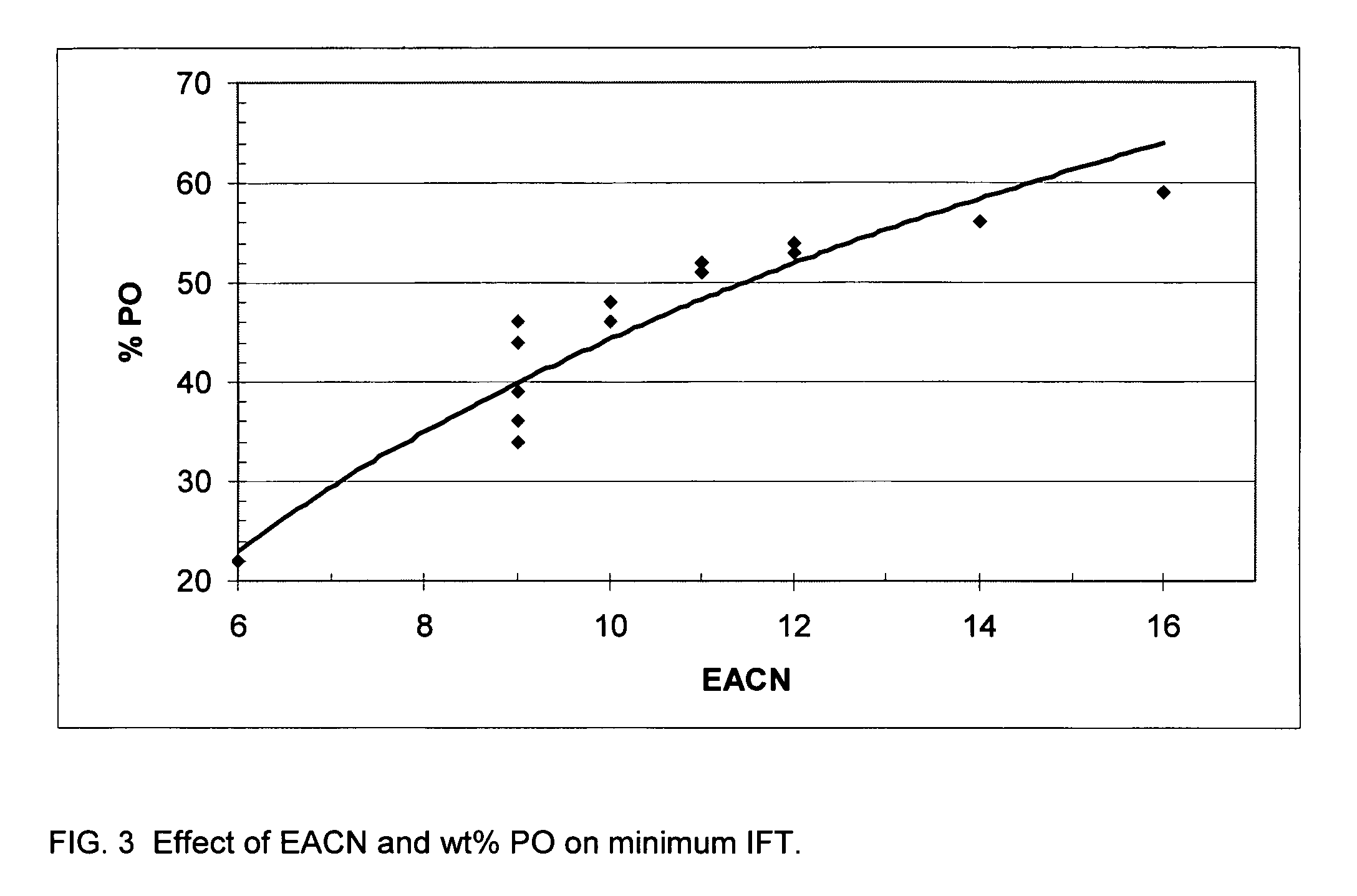

Process for recovering residual oil employing alcohol ether sulfonates

A method of recovering crude oil from a subterranean hydrocarbon containing formation which comprises (a) injecting into said formation an aqueous solution containing an effective amount alkali metal, alkaline-earth or ammonium salts of alcohol ether sulfonates derived from unsaturated alcohol ethers, and (b) displacing said solution into one or more injection wells and recovering the oil from one or more production wells. The unsaturated alkoxylated alcohol contain various amounts of ethylene oxide, propylene oxide and butylene oxides elected to optimize their interfacial properties with different types of crude oil with different brines.

Owner:OIL CHEM TECH

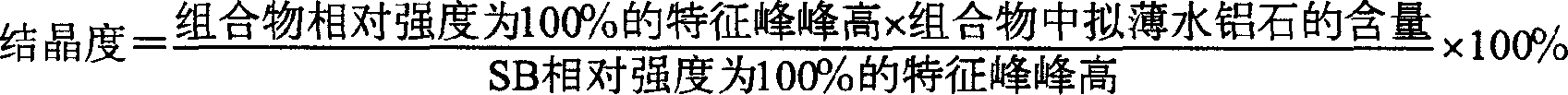

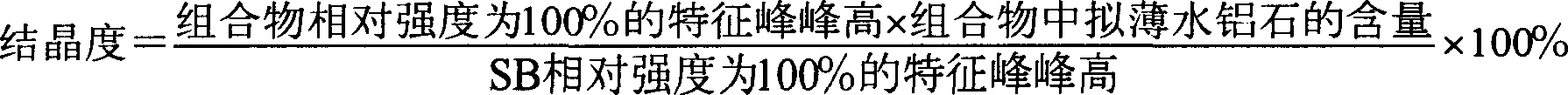

Quasi-thin empholite composition containing organic reaming agent

ActiveCN1611300AReduce crystallinityLarge hole volumeCatalyst activation/preparationRefining to eliminate hetero atomsDiasporeResidual oil

The present invention relates to a pseudothin diaspore composition containing organic pore-expanding agent. Said composition contains 92-99.5 wt% of pseudothin diaspore and 0.5-8 wt% of organic pore-expanding agent, in which the crystallinity of pseudothin diaspore is 10-70%. In the pseudothin diaspore composition provided by said invention the organic pore-expanding agent content is low, after high-temperature calcination the alumina with large pore capacity and large pore diameter can be obtained. Said alumina can be used as carrier material for preparing hydrodemetalization catalyst for heavy oil, residual oil and short residuum specially.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for removing oil from solid materials recovered from a well bore

InactiveUS6846420B2Low costLower oil levelHollow article cleaningFluid removalSodium hypochlorite solutionResidual oil

The present invention provides a process and an additive package for removing oil from solid material recovered from a well bore, e.g., drill cuttings and produced sand. In this process, the solid material is passed from the well bore to a separation zone. An aqueous acidic solution containing a polymer substituted with an amino group is introduced to the separation zone containing the solid material along with a halogenating agent and optionally one or more surfactants. The polymer, halogenating agent, and optional surfactant constitute the additive package. The polymer substituted with an amino group is preferably chitosan, and the halogenating agent is preferably a sodium hypochlorite solution. The mixture formed in the separation zone is agitated to cause a product of a reaction between the polymer and the halogenating agent to contact the solid material and remove residual oil therefrom.

Owner:HALLIBURTON ENERGY SERVICES INC

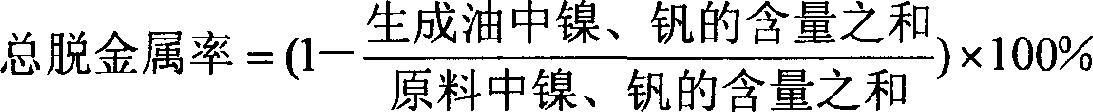

Method for enhancing recovery ratio through three-dimensional streamline regulation of water drive reservoir

InactiveCN102146788AReach controlEnhanced overall recoveryFluid removalSealing/packingDistribution characteristicResidual oil

The invention discloses a method for enhancing recovery ratio through three-dimensional streamline regulation of a water drive reservoir. The method is characterized by comprising the following steps: identifying the planer development segment and vertical development segment of a preferential seepage channel to quantificationally calculate sampling parameters; establishing a three-dimensional geologic model comprising the characteristics of the preferential seepage channel, establishing a reservoir numerical simulation model, and finely determining a residual oil distribution characteristic under current heterogenous condition through reservoir numerical simulation; carrying out pattern modification and optimized water shutoff and profile control design; and determining whether layered injection and recovery is required according to water adsorption characteristics of a vertical water well and liquid generation characteristics of an oil well by utilizing the reservoir numerical simulation result. In the invention, on the basis that the preferential seepage channel is blocked through deep profile control and water shutoff, the planer flow line direction is changed through the combination water shutoff and profile control with pattern modification optimization, water shutoff and profile control are optimally combined with subdivided development layers and layered injection and recovery optimization to control and regulate the density of vertical flow lines, and the purpose of maximally control underground flow lines is achieved through the synergistic effect of different means.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreating guard catalyst and application thereof

ActiveCN101890381AMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPore distributionFixed bed

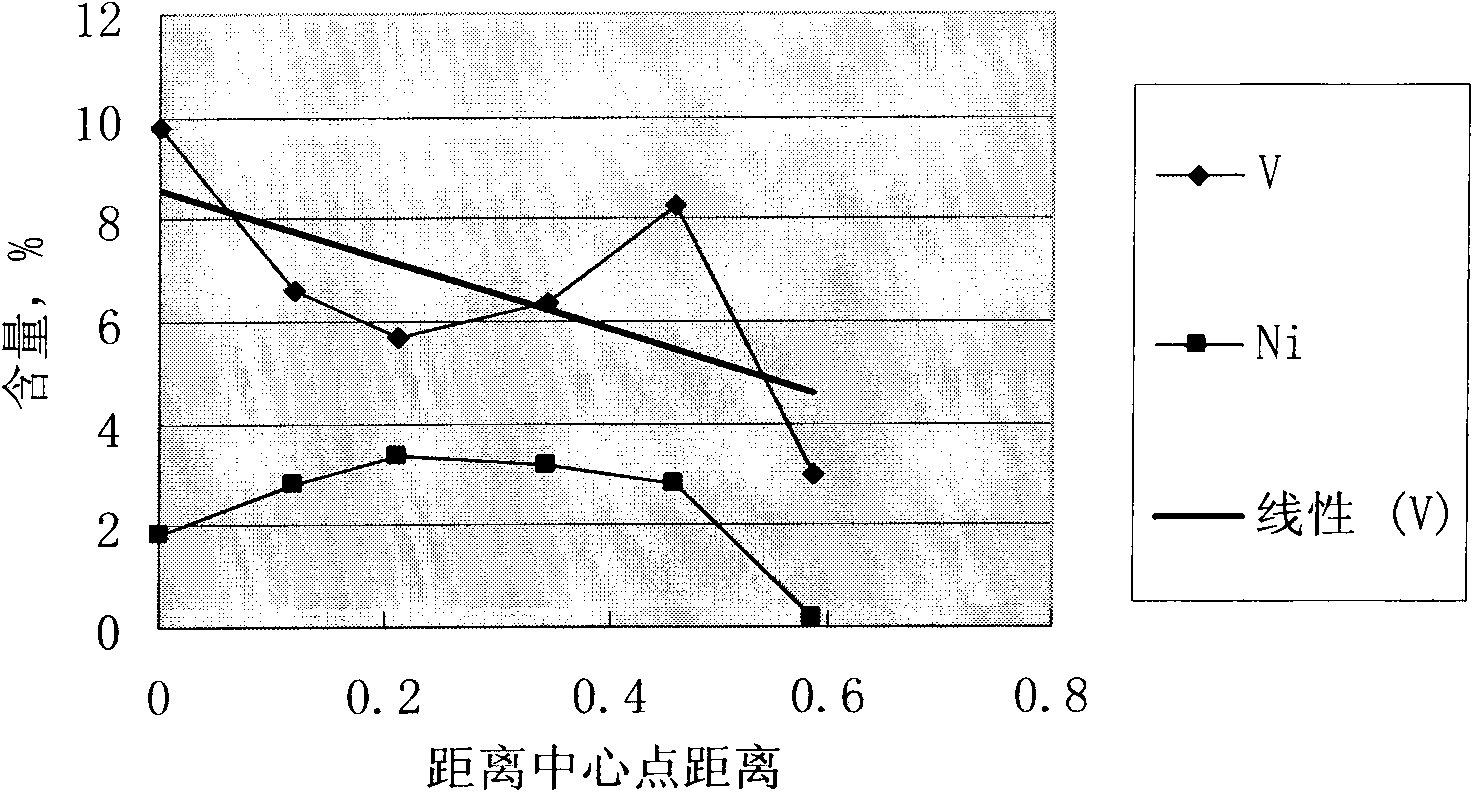

The invention discloses a hydrotreating guard catalyst for residual oil and application thereof. The catalyst has the advantages of large pore volume, large aperture, high porosity, rational pore distribution, larger external orifice, high pore canal penetrability and over 36 percent of 1,000nm pore canals, and is particularly applied to a hydrotreating method of a residual oil fixed bed to ensure that precipitated metals are uniformly deposited on the whole catalyst bed and impurities, namely vanadium and calcium, can be deposited inside the pore canals so as to improve the utilization ratio of pores and maintain long-period running.

Owner:CHINA PETROLEUM & CHEM CORP +1

Boiling bed hydrogenation treatment catalyst and its preparing process

ActiveCN101240190AThe reaction equipment is simpleReduce operating costsRefining to eliminate hetero atomsLow speedSpherical shaped

The invention relates to a boiling bed hydrogenation catalyst and a preparation method. The boiling bed hydrogenation catalyst of the invention is spherical shape which diameter is 0.1mm to 0.8mm, and has appropriate amount of additives and hydrogenation of metal components, and has reasonable hole distribution. The catalyst preparation method of the invention is spherical carrier impregnation, the process of spherical carrier preparation is following: making catalyst carrier raw material which is in appropriate temperature into appropriate size grain, then spheroidizing the grain, heating the conglobation and making them into spherical catalyst carrier. The process for making the catalyst carrier raw material into the appropriate size grain is that wet stock passes screen stencil by mechanical action and generates grain. Between the processes of the making grain and nodularization, granular material primely is placed for a period of time or operates in low-speed in nodularization device for a period of time. The catalyst of the invention appropriately conducts the boiling bed hydrogenation for heavy oil, residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

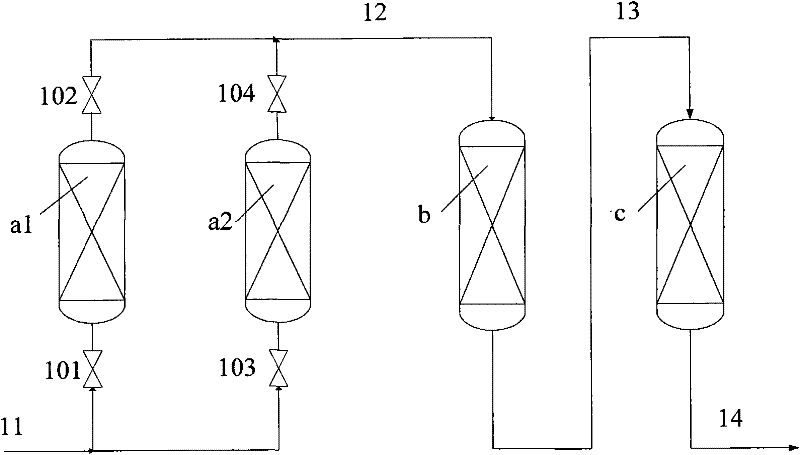

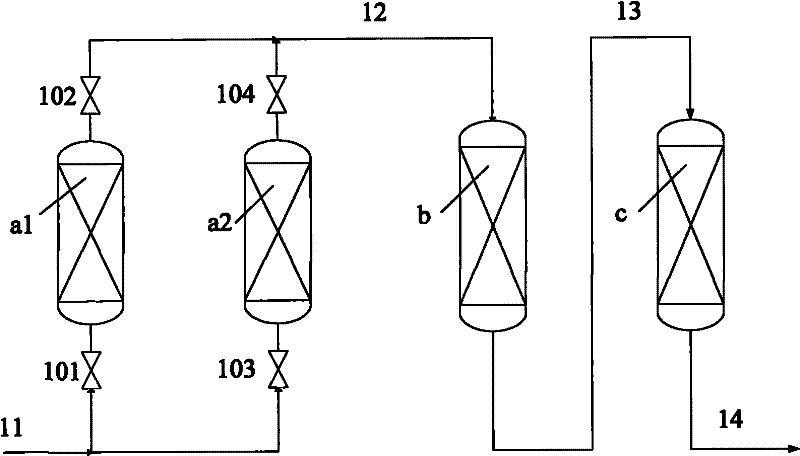

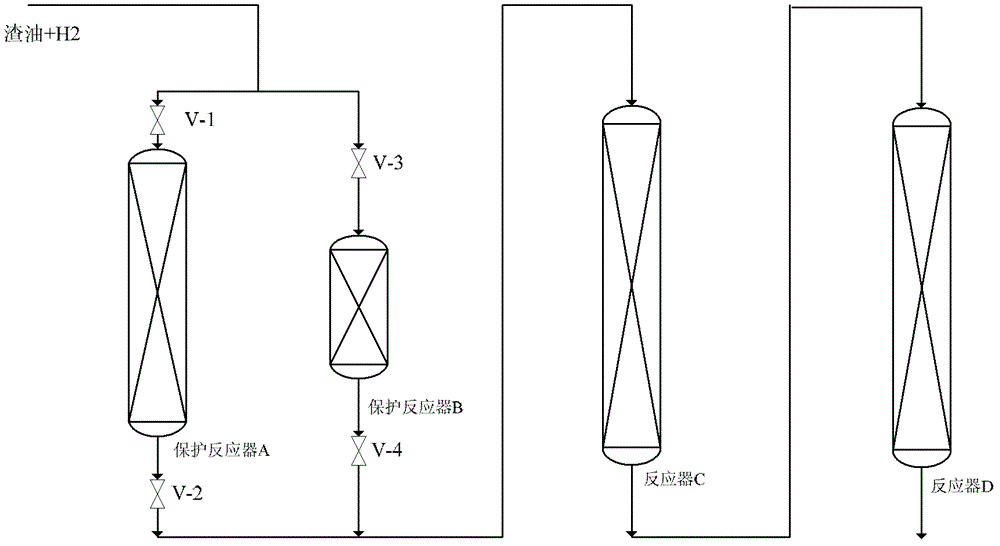

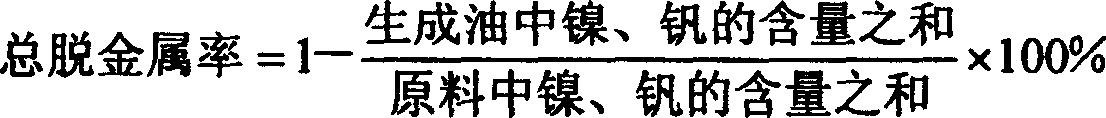

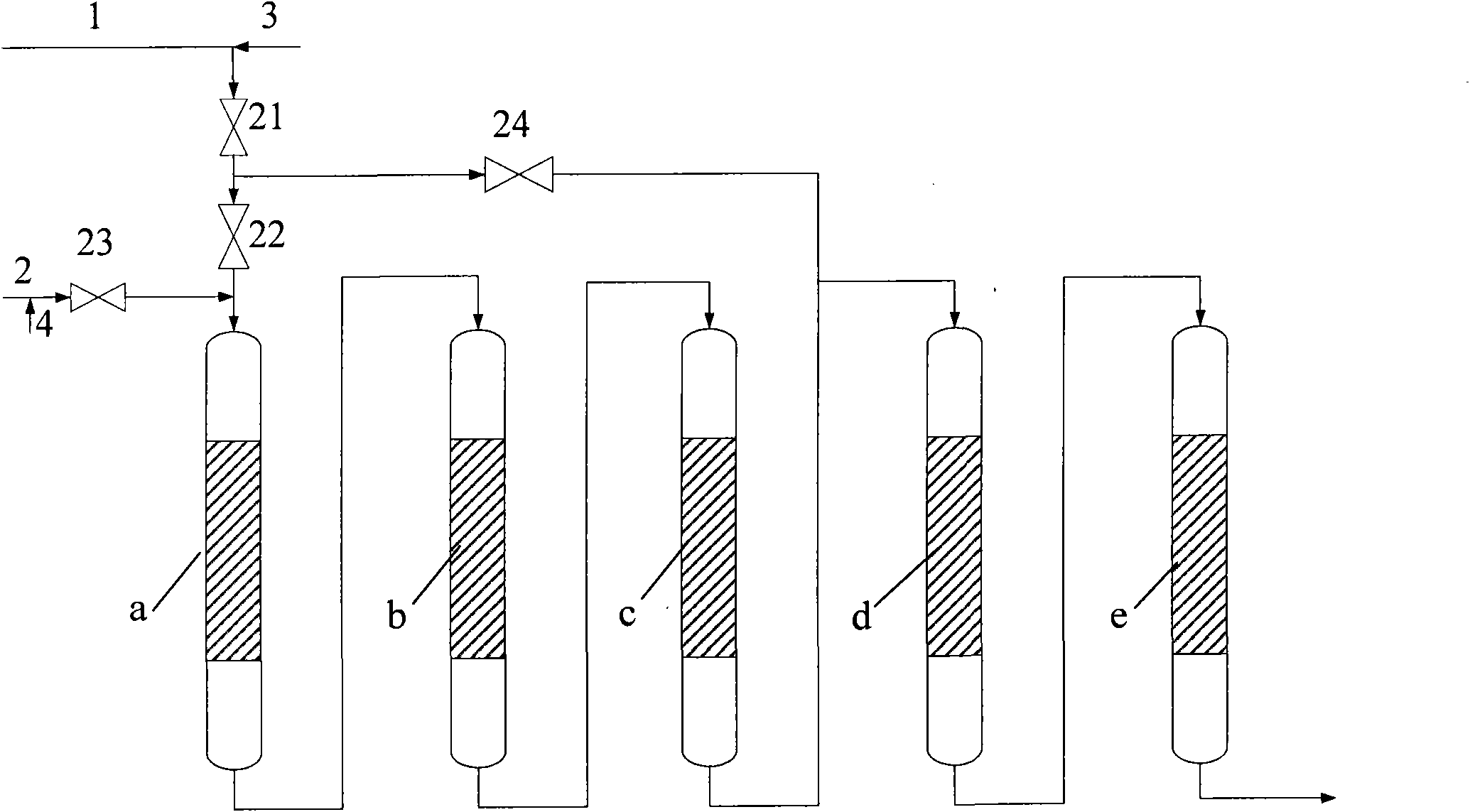

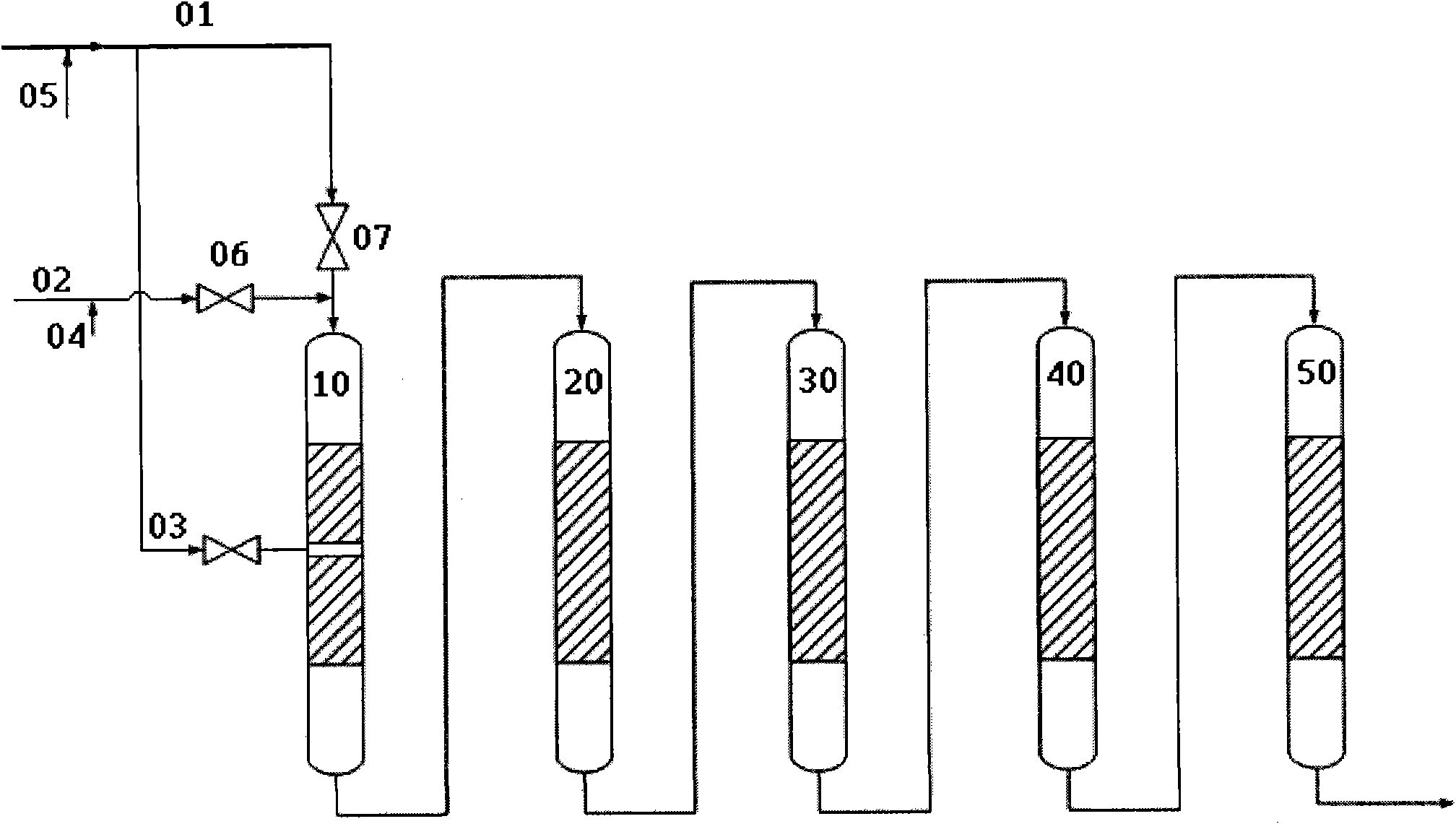

Hydrogenation method for processing heavy oil

ActiveCN102453530AExtended operating cycleImprove operational efficiencyTreatment with hydrotreatment processesHydrogenResidual oil

The invention discloses a hydrogenation method for processing heavy oil. Raw heavy oil is mixed with hydrogen, the mixture enters a hydrogenating protective reaction area, reaction effluent directly enters a hydrotreatment reaction area without separation and is subjected to hydrotreatment reaction, and at least two parallelly connected up-flow hydrogenating protective reactors which can be switched in turn are arranged in the hydrogenating protective area. A method of grading four hydrogenating protective agents is adopted and particularly favorable for removing metals, so that blockage is avoided, the service life of a main catalyst is prolonged and the operating period of a device is prolonged. A switchable operating method is adopted, and all catalysts having activity can be fully utilized; and compared with the prior art, the method has the advantages that: the running period of a residual oil hydrogenation device can be prolonged by 20 to 40 percent, so that the running efficiency of the residual oil hydrogenation device is improved and the economic efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

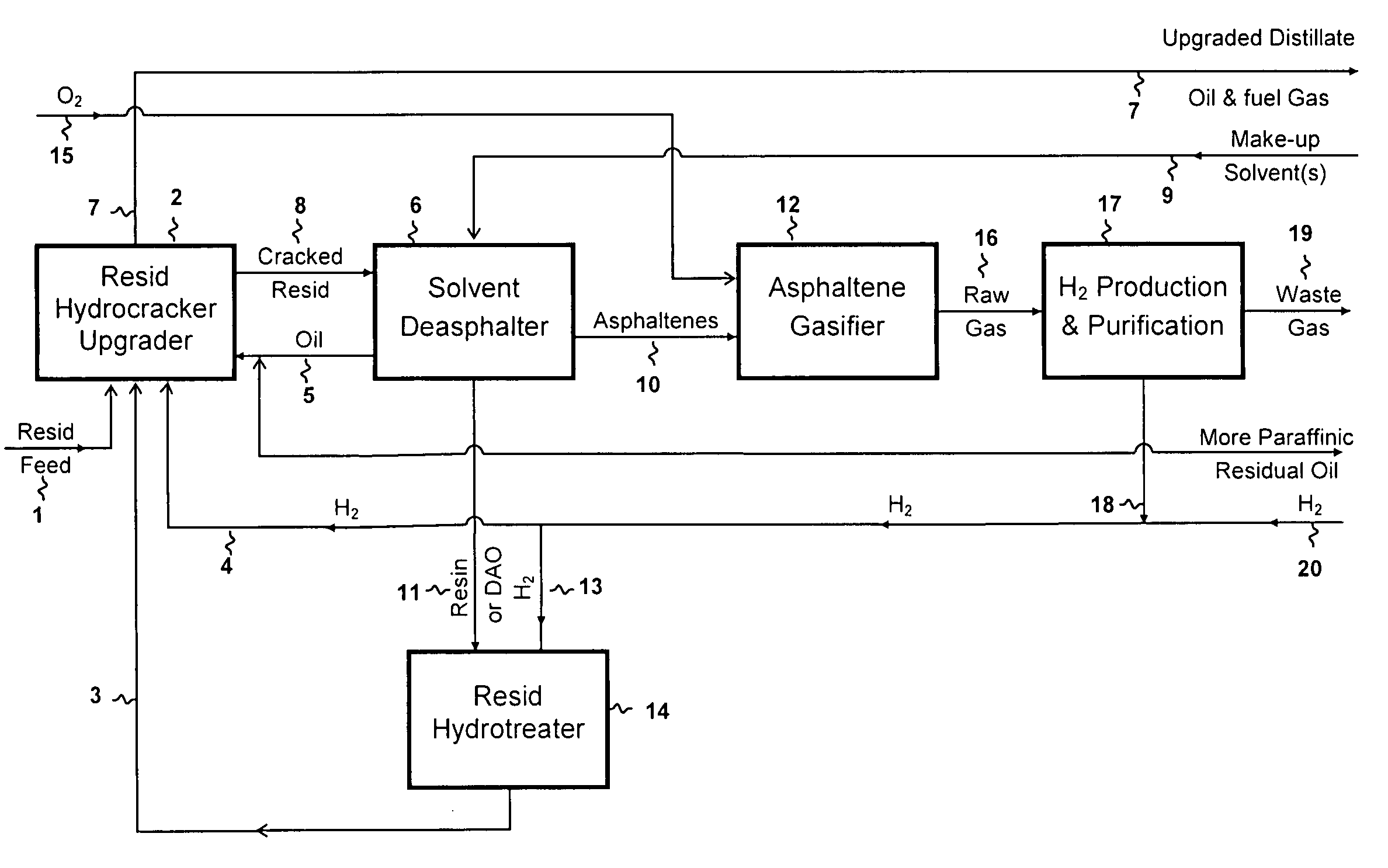

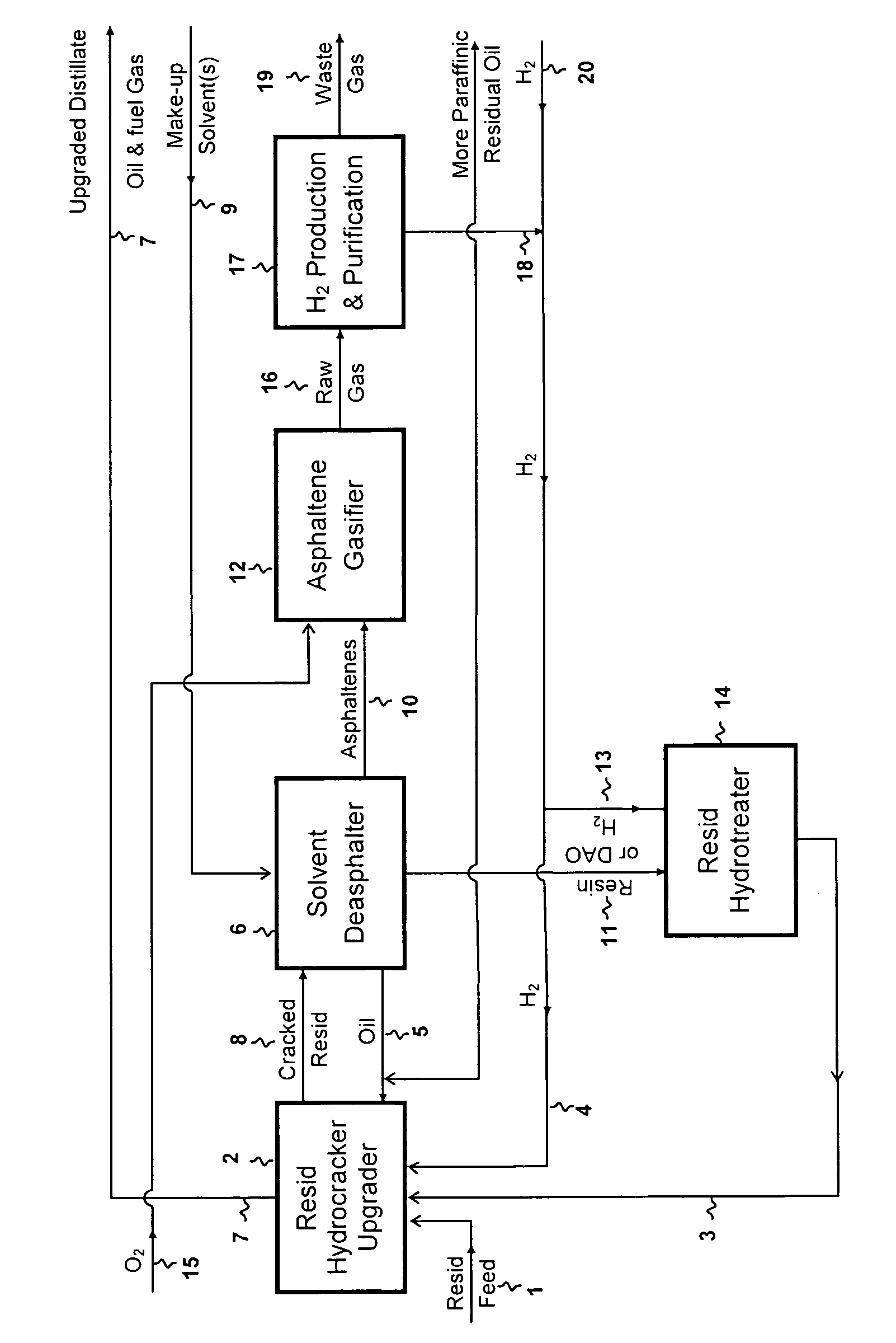

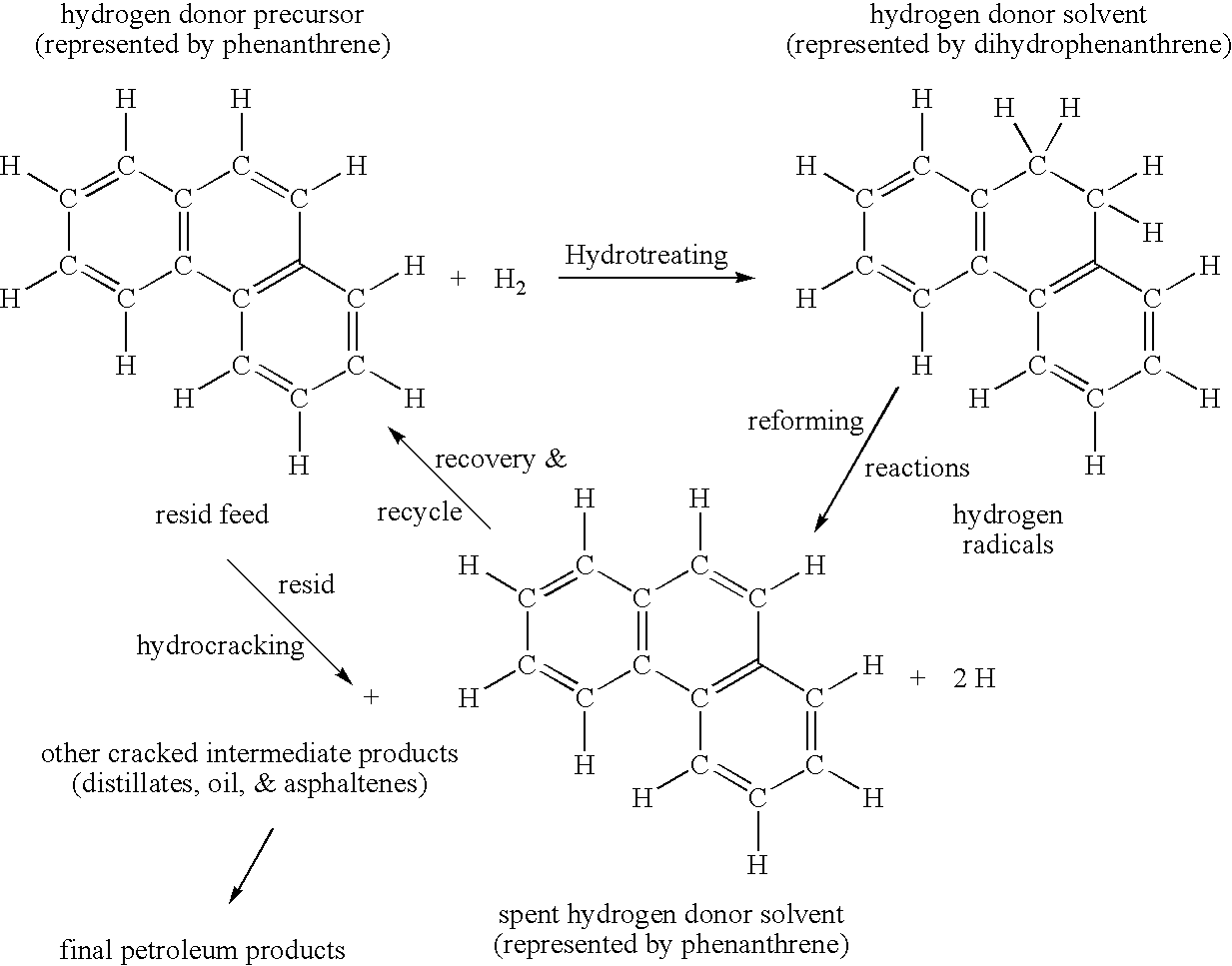

Hydrogen donor solvent production and use in resid hydrocracking processes

InactiveUS20070108100A1Treatment with plural serial cracking stages onlyCoke ovensHydrogenBoiling point

A process derived hydrogen donor solvent is used to increase the maximum resid conversion and conversion rate in an ebullated bed resid hydrocracker. The hydrogen donor solvent precursor is produced by hydroreforming reactions within the resid hydrocracker, recovered as the resin fraction from a solvent deasphalting unit, regenerated in a separate hydrotreater reactor, and recycled to the ebullated bed resid hydrocracker. The major advantage of this invention relative to earlier processes is that hydrogen is more efficiently transferred to the resin residual oil in the separate hydrotreater and the hydrogen donor solvent effectively retards the formation of coke precursors at higher ebullated bed resid hydrocracker operating temperatures and resid cracking rates.

Owner:BOC GRP INC

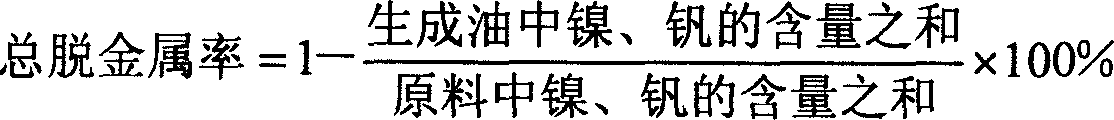

Demetallization catalyst of addig hydrogen to residual oil and preparation method

ActiveCN1626625ALess carbon depositHigh hydrodemetallization activityRefining to eliminate hetero atomsHalogenHydrogen

A hdyrocatalyst for removing metals from residual oil is composed of a macroreticular aluminium carrier and the Mo and / or W and Co and / or Ni, which are carried by said carrier. It features that said carrier contains aluminium oxide (95-99 wt%) and halogen (1-5) and has lower acidity, resulting in high demetallizing activity and low carbon deposit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alumina supporter possessing duplicate orifice, catalyst and preparation method

ActiveCN1796500AHigh activityEliminate the possibility of runawayCatalyst carriersRefining to eliminate hetero atomsNitrogenResidual oil

A catalyst for residual oil hydrodemetalling, which is composed of a carrier containing two types of pores and metal components such as Mo and / or W and Co and / or Ni, fixes on the carrier. The distribution of the pores in the said carrier is: the volume percentage of 10-20nm diameter pores in the total pore volume is 35-80%, the volume percentage of 500-1200nm diameter pores in the total pore volume is 15-60%, and the volume percentage of the pores with diameters ú“10nm, ú¥20-ú“500nm and ú¥1200nm in the total pore volume is 5-40%. The process for preparing the carrier comprises the steps of: mixing an alumina precursor with a nonacid nitrogenous compound, molding and sintering. The catalyst in this invention can be used as the catalyst for crude oil and normal atmosphere residual oil hydrodemetalling.

Owner:CHINA PETROLEUM & CHEM CORP +1

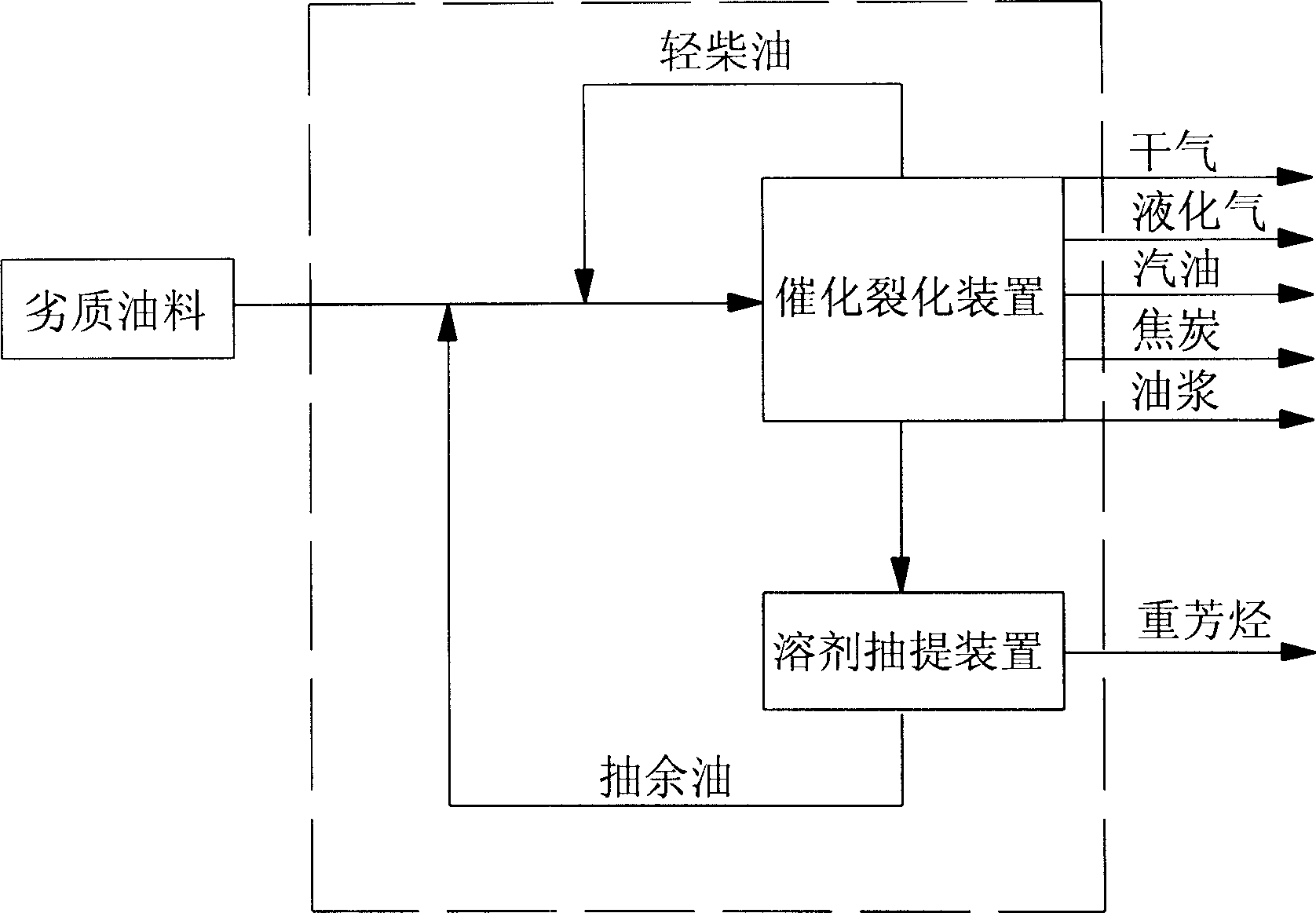

Catalyzing and cracking process of inferior oil

InactiveCN1746265AHigh yieldReduce unit consumptionCatalytic crackingHydrocarbon oils refiningResidual oilSolvent

A catalytic and cracking process of inferior oil is characterized by catalytic cracking the inferior oil to obtain light diesel fuel cut fraction, returning it to catalytic cracker to recycle, extracting the obtained heavy diesel fuel cut fraction from solvent, extracting residual oil and returning to catalytic cracker to recycle. It has higher recovery rate, better quality and more yield of product. It can be used for various inferior fuel heavy oils, catalytic raw materials, shale oil and coal tar.

Owner:邓先樑 +4

Preparation method of double-hole-structure alumina supporter

ActiveCN102861617ALarge hole volumeNo overheating phenomenonCatalyst carriersMaterials scienceAmmonium bicarbonate

The invention discloses a preparation method of a double-hole-structure alumina supporter. The preparation method comprises the steps of weighing a certain quantity of pseudo-boehmite dry glue powders, evenly mixing the pseudo-boehmite dry glue powder with a certain quantity of peptizing agent and extrusion-auxiliary agent, then adding a certain quantity of ammonium bicarbonate aqueous solution in materials, mixing and nipping obtained materials into a plasticizer, squeezing into stripes and molding, placing molded materials in a sealing container, and roasting to prepare the alumina supporter after hydro-thermal treatment. The temperature of the hydro-thermal treatment is 70-120 DEG C, and the treatment time is 5-10 hours. Roasting is carried out at the temperature of 600-750 DEG C for 2-4 hours. The mass concentration of an ammonium bicarbonate solution is 40%-80%, the adding quantity of the ammonium bicarbonate solution is calculated according to NH<4+> and Al<3+>, and a molar ratio of the NH<4+> to Al<3+> is (0.5-1):1. According to the preparation method, the preparation procedure is simple, the prepared alumina supporter is in double-hole distribution and has good mechanical strength, and the preparation method is suitable to the field of preparation of heavy oil and residual oil hydrodemetallization catalysts and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

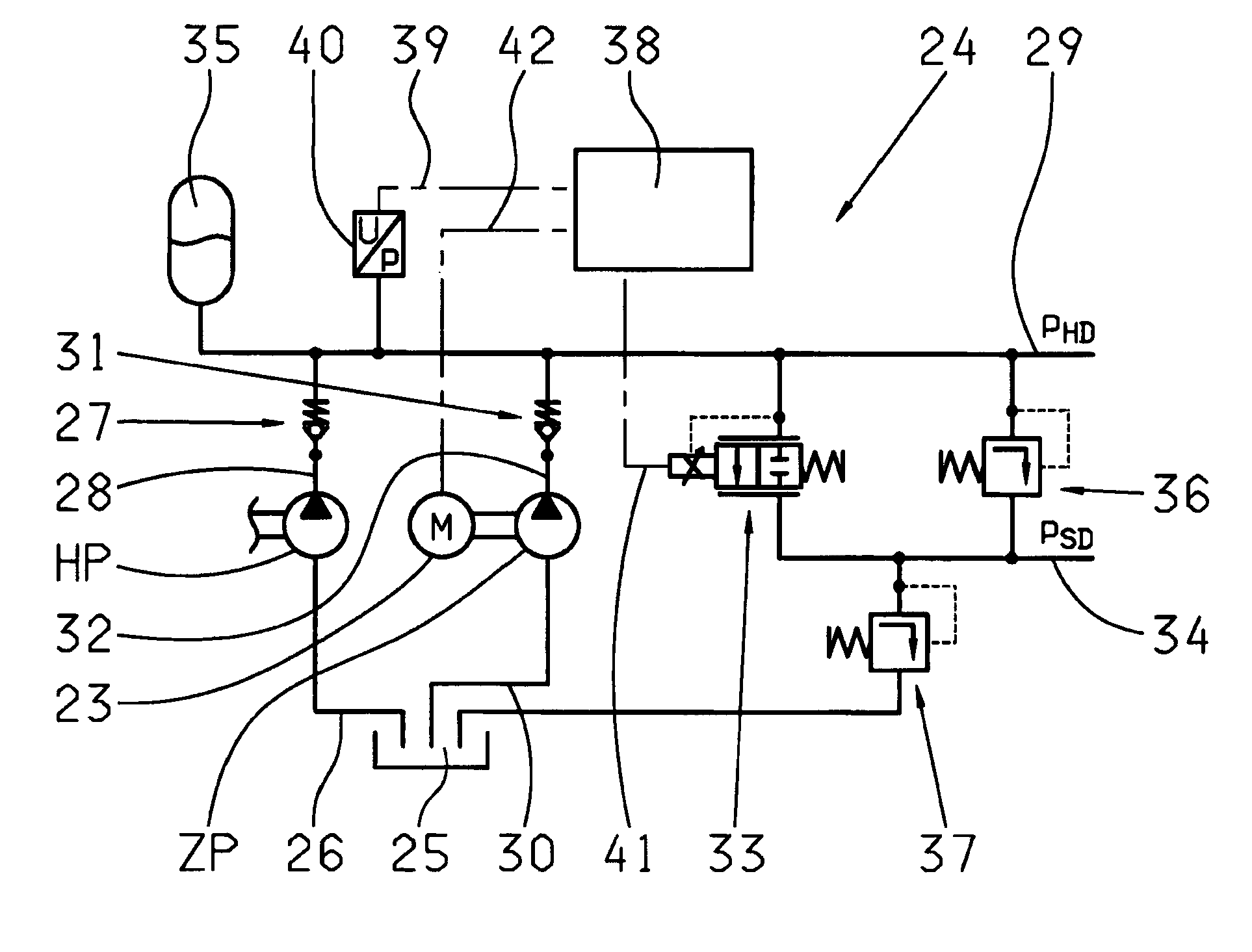

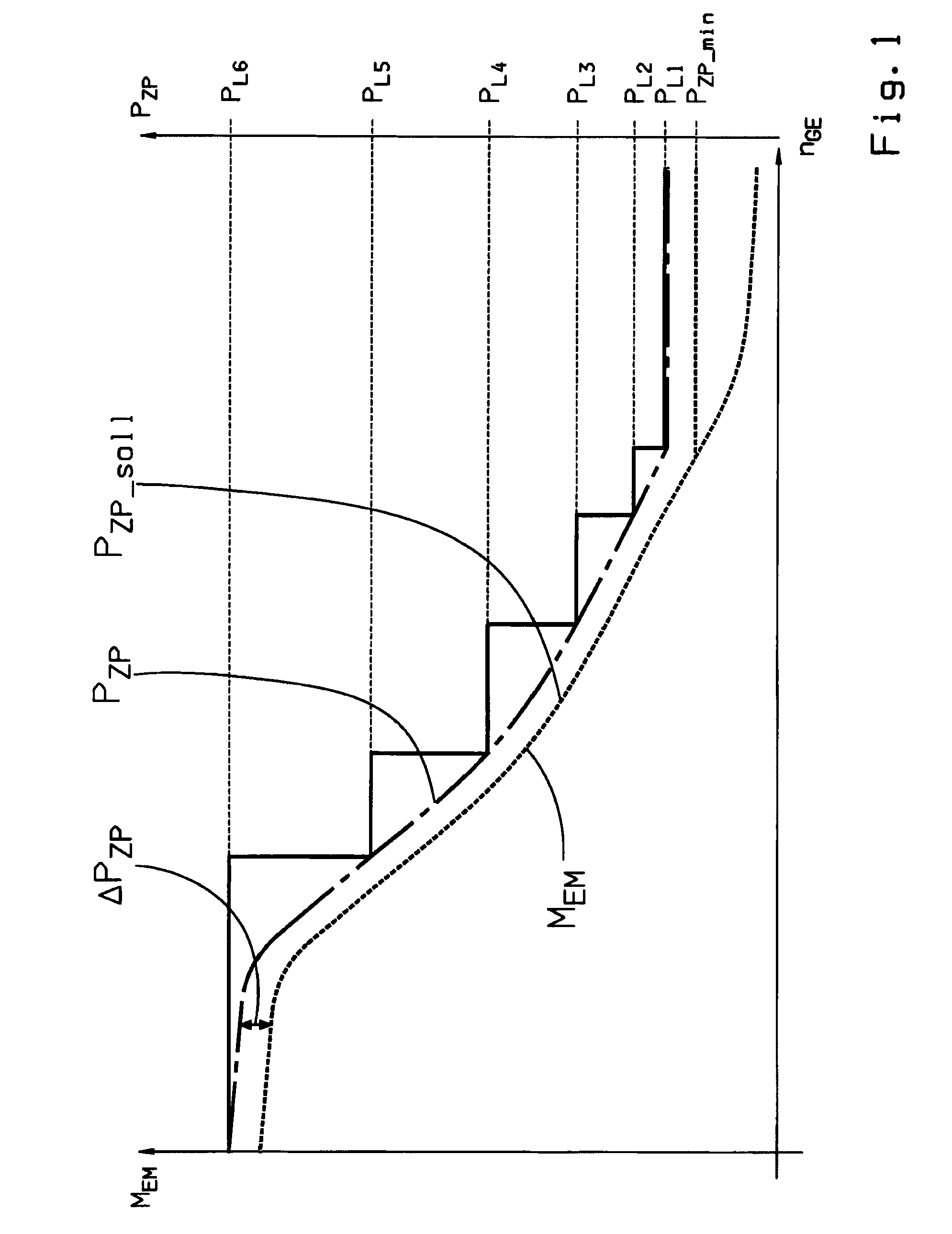

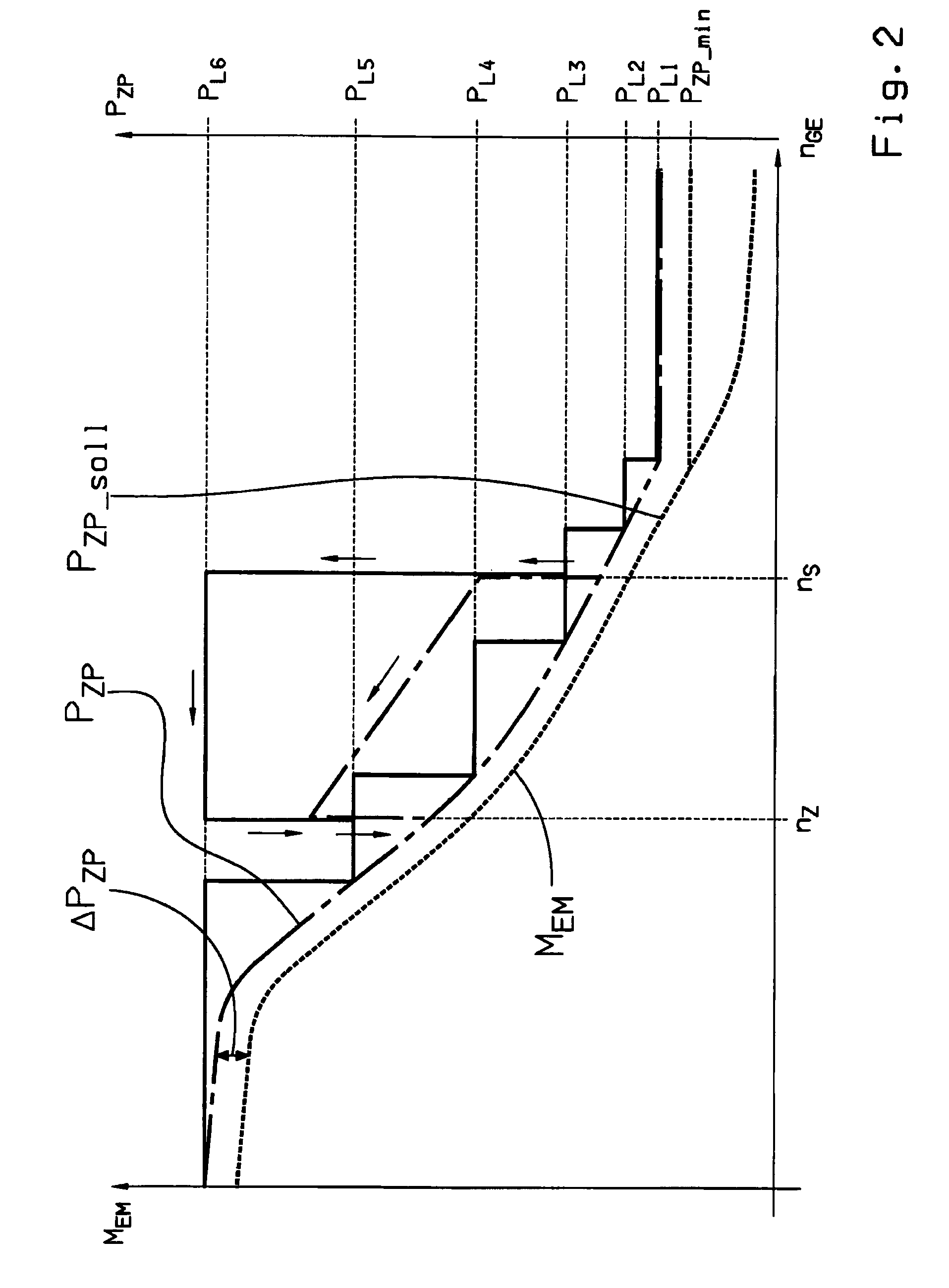

Method for controlling the oil supply of an automatic planetary transmission

InactiveUS20100018808A1Improve accessibilityIncrease installation spaceElectric propulsion mountingGear lubrication/coolingEngineeringInternal combustion engine

The invention relates to a method for controlling the oil supply device of an automatic planetary transmission, comprising a main oil pump (HP), which is mechanically drivably connected to the drive shaft of an internal combustion engine (VM), and an auxiliary oil pump (ZP) that may be driven via a controllable electric motor, the automatic transmission (ATG) being part of a parallel hybrid powertrain of a motor vehicle having an input shaft (5), which may be connected via a separating clutch (K) to the drive shaft (2) of the internal combustion engine (VM) and is permanently drivably connected to the rotor (4) of an electric machine (EM).In order to achieve an oil supply to the automatic transmission (ATG) as and when needed, it is provided that the current oil requirement (PHD<sub2>—< / sub2>soll) of the automatic transmission is determined as a function of at least one currently captured operating parameter, and that the delivery rate (PZP) of the auxiliary oil pump (ZP) is set, by a correspondingly actuation of the associated electric motor, in the combustion and combined driving mode below a minimum input speed of the main oil pump (HP) and in the electric driving mode to at least the total oil requirement, and at least in the combined driving mode above the minimum input speed of the main oil pump (HP) is set to at least the residual oil requirement exceeding the delivery rate (PHP) of the main oil pump.

Owner:ZF FRIEDRICHSHAFEN AG

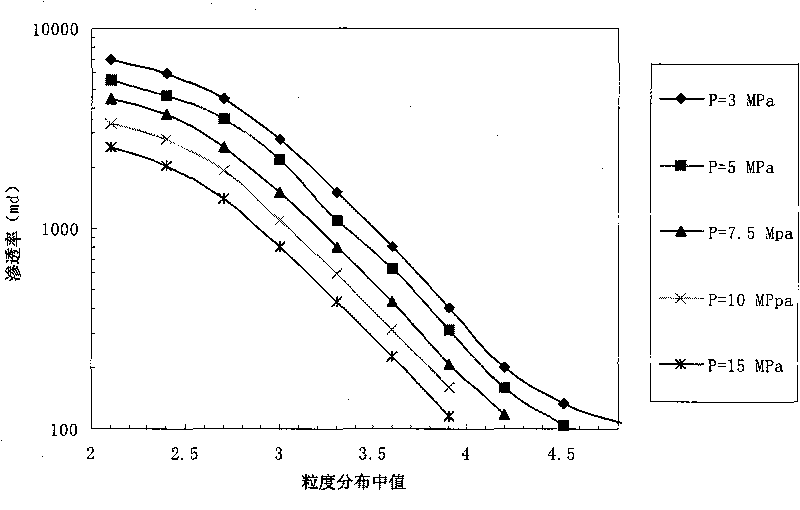

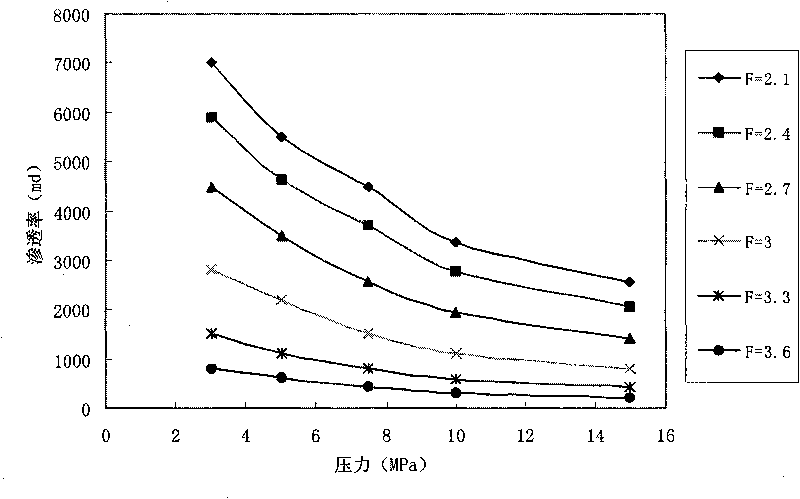

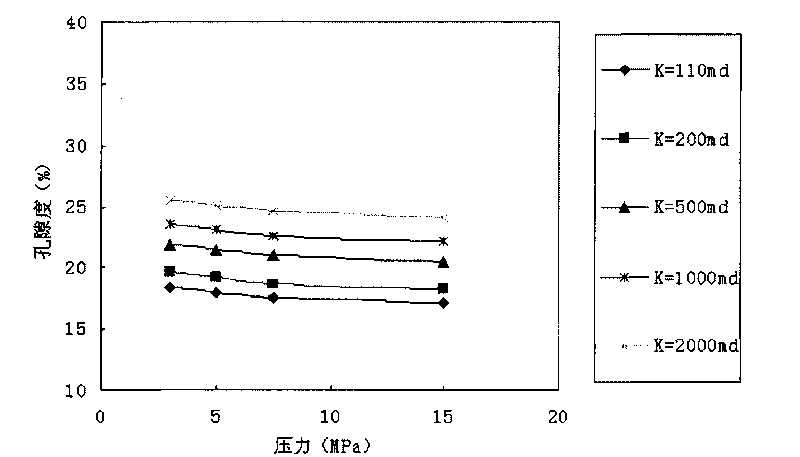

Analog measurement method and device of oil saturation in strata

InactiveCN101762829AElectric/magnetic detection for well-loggingWater resource assessmentRock coreMonitoring system

The invention provides an analog measurement method and a device of oil saturation in strata, which belong to a geophysical exploration testing method and an analog device. The analog measurement method of the oil saturation in the strata comprises the steps of simulating an actual stratum (manufacturing an artificial cemented rock core model), arranging an analog well, arranging an oil-water saturation monitoring system in the artificial cemented rock core model, constructing an electric field at the periphery of the wall of the well, obtaining the oil saturation illustrative charts of different pervious courses by measuring the change of the resistivity of the rock core model and the like. The method not only can well simulate and measure the underground geological condition but also can further learn the position of the residual oil of a reservoir and the change rule of the saturation, thereby learning and determining the oil accumulation reserves and the grade in the simulated stratum.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

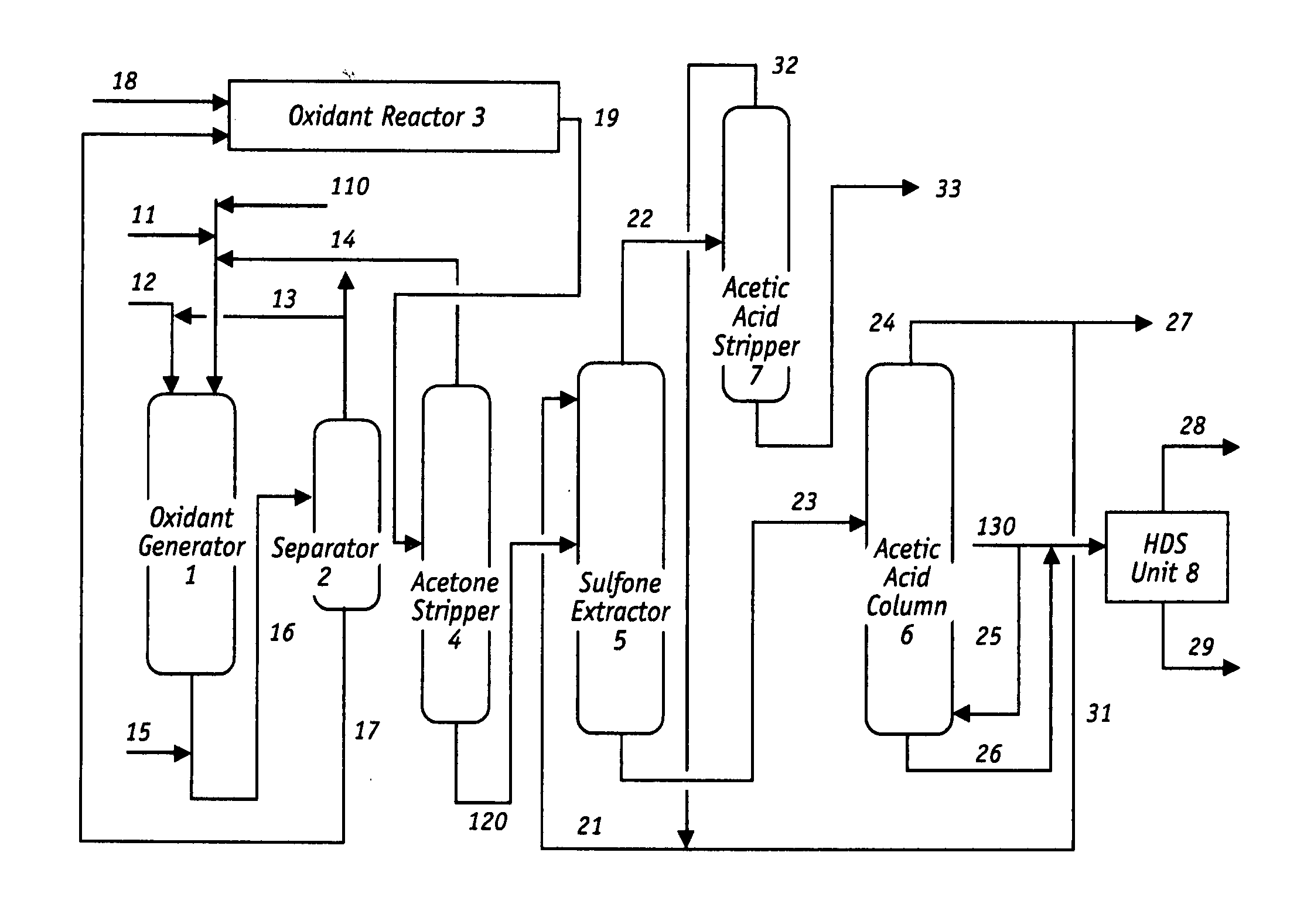

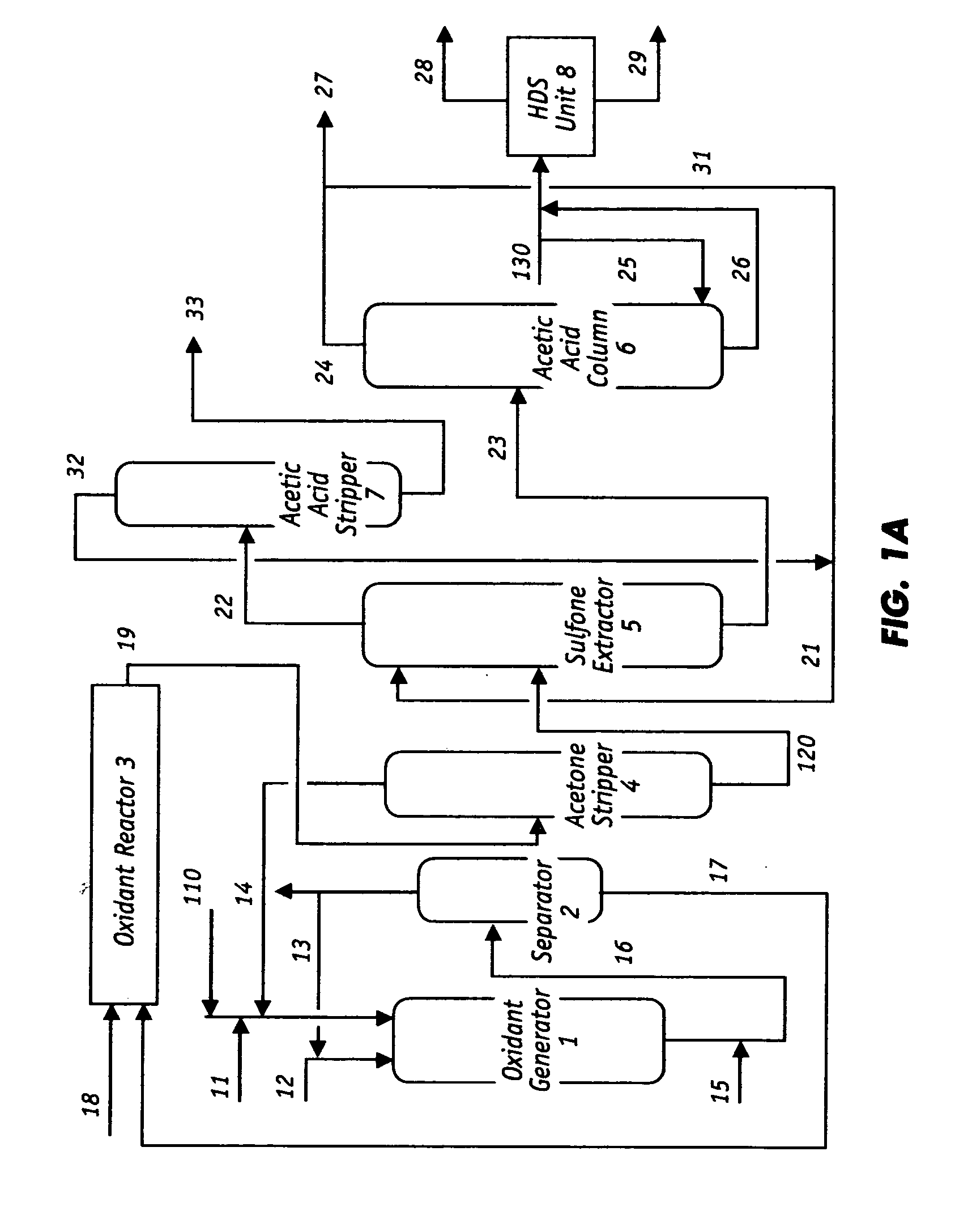

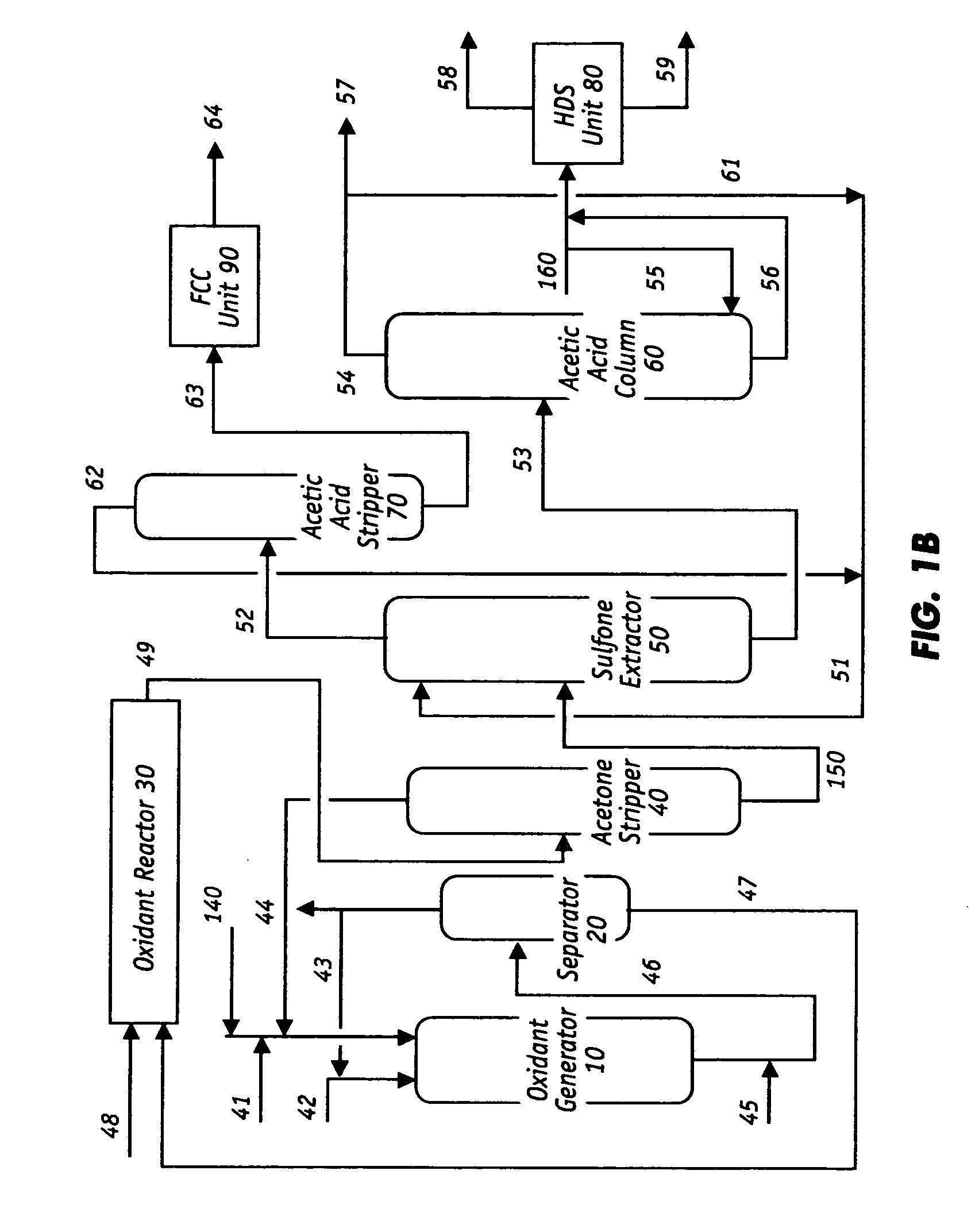

Oxidative desulfurization and denitrogenation of petroleum oils

InactiveUS20070102323A1Reduce the temperatureShort stayOrganic chemistryRefining with oxygen compoundsHydrocotyle bowlesioidesSolvent

An improved oxidative process that employ a robust, non-aqueous, and oil-soluble organic peroxide oxidant for effective desulfurization and denitrogenation of hydrocarbons including petroleum fuels, hydrotreated vacuum gas oil (VGO), non-hydrotreated VGO, petroleum crude oil, synthetic crude oil from oil sand, and residual oil. Even at low concentrations and without the assistance of catalysts, the non-aqueous organic peroxide oxidant is extremely active and fast in oxidizing the sulfur and nitrogen compounds in the hydrocarbon feedstocks. Furthermore, the process generates a valuable organic acid by-product that is also used internally as the extractive solvent for effective removal of the oxidized sulfur and nitrogen from the hydrocarbons without the need of a final adsorption step. Novel process steps are also disclosed to substantially prevent yield loss in the oxidative process.

Owner:CPC CORPORATION

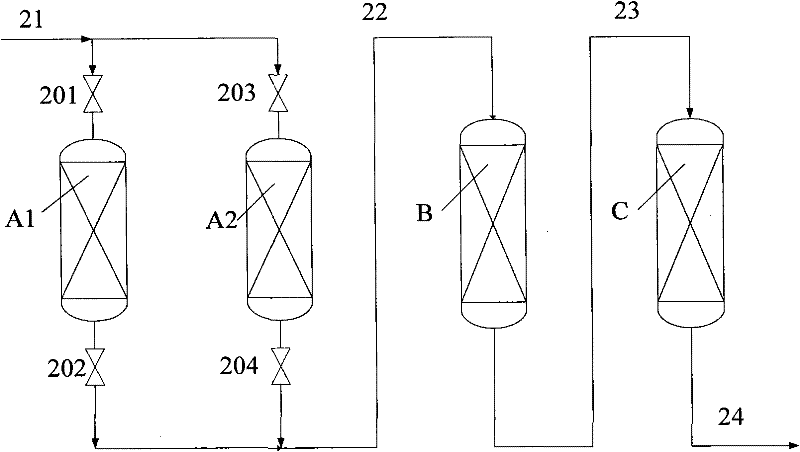

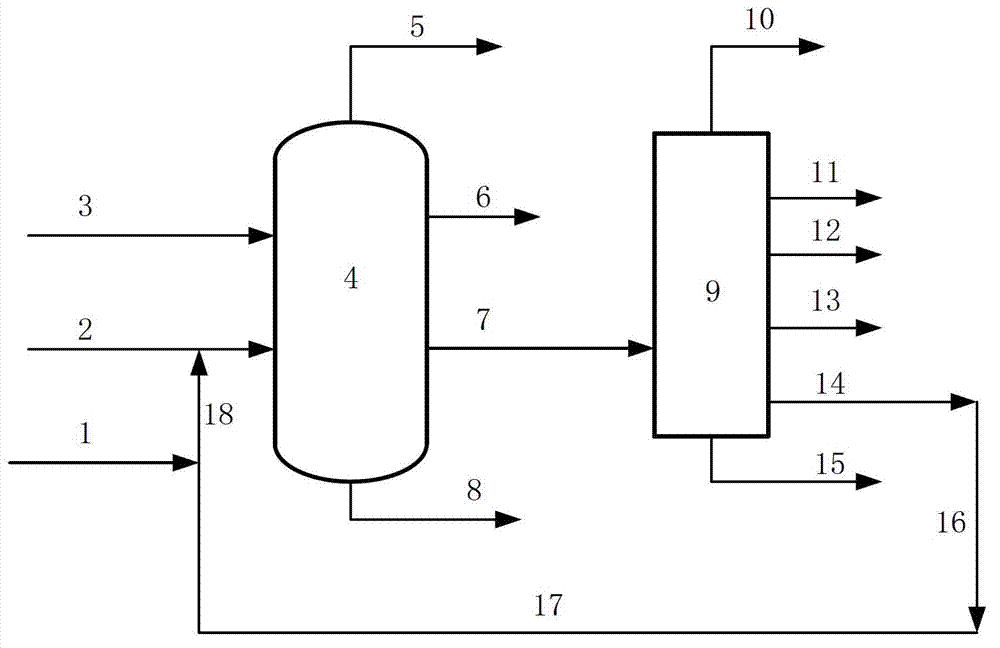

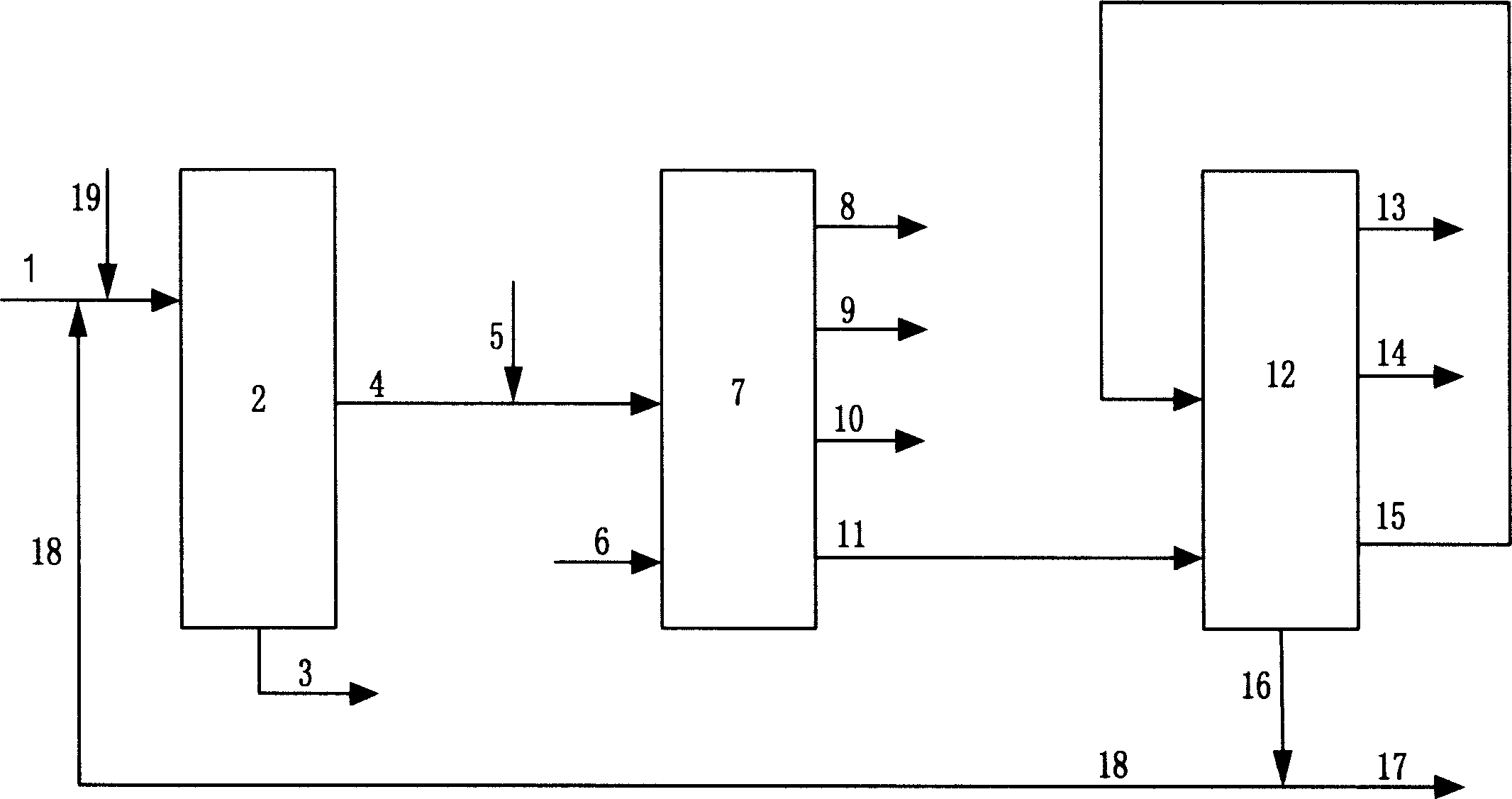

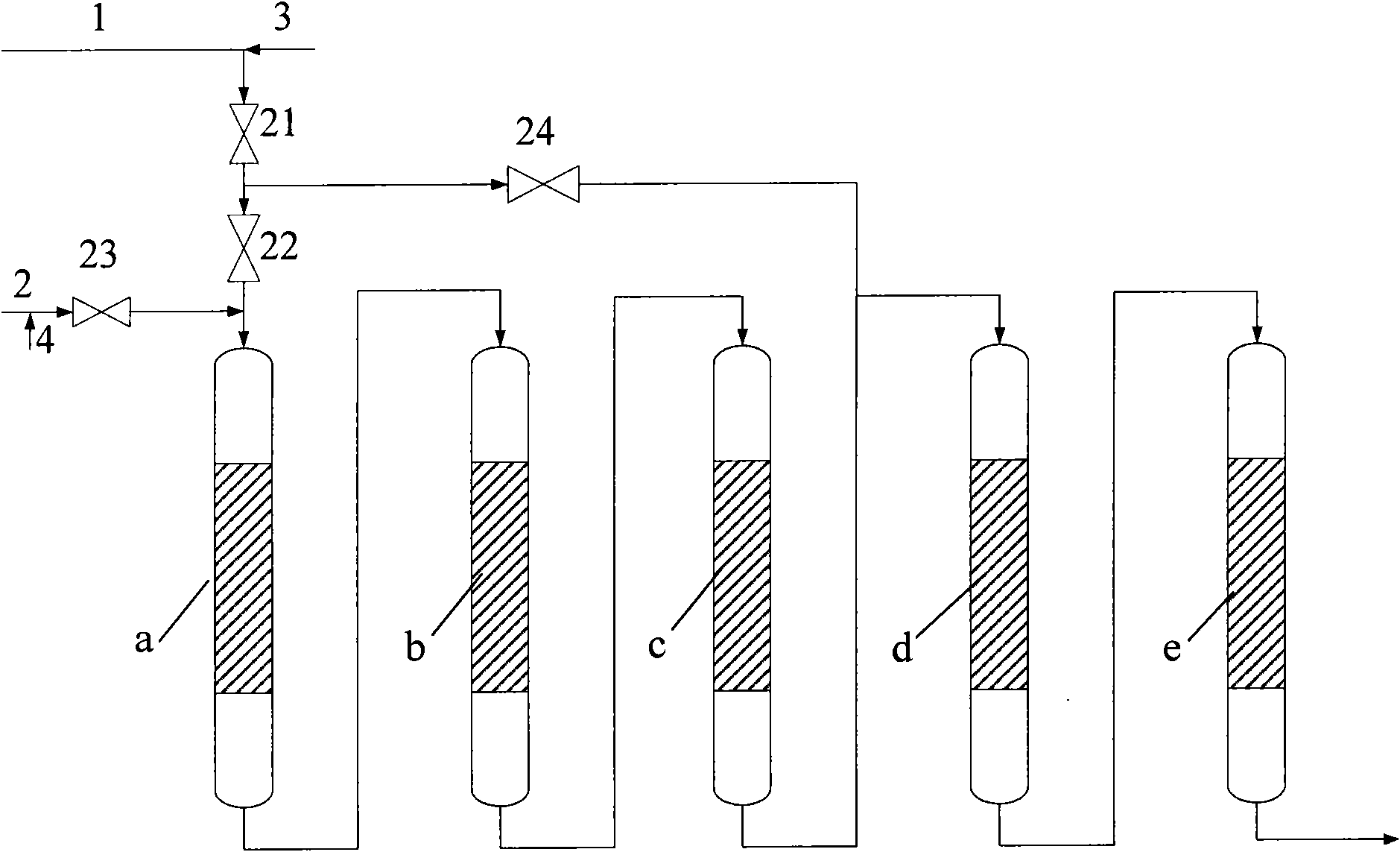

Hydrotreating device and application thereof as well as residual oil hydrotreating method

ActiveCN103059928AExtend online timeShort online timeTreatment with hydrotreatment processesHydrogenProcess engineering

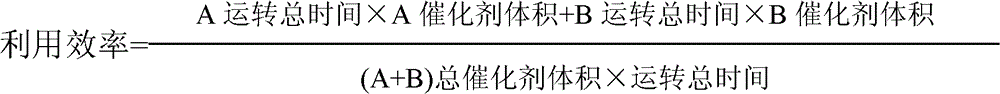

The invention provides a hydrotreating device which comprises a hydrotreating protection unit and a main hydrotreating unit, which are connected with each other in series, wherein the hydrotreating protection unit comprises a main hydrotreating protection reactor and a spare hydrotreating protection reactor, which are connected with each other in parallel, and the volume of the main hydrotreating protection reactor is larger than that of the spare hydrotreating protection reactor. The invention further provides the application of the hydrotreating device and a residual oil hydrotreating method. The method comprises the following steps of: introducing the residual oil and the hydrogen into the hydrotreating device, and alternately using the main hydrotreating protection reactor and the spare hydrotreating protection reactor in the process of hydrotreating, wherein the online time of the main hydrotreating protection reactor is longer than that of the spare hydrotreating protection reactor. The method provided by the invention is particularly suitable for machining the high-carbon content residual oil and the high-metal content residual oil. Furthermore, the bigger hydrotreating protection reactor is longer in online time, so that the invention is higher in reactor use ratio.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalysis conversion method for producing aromatic compounds

ActiveCN103923698ALess investmentReduce sulfur, nickelCatalytic crackingTreatment with hydrotreatment processesDistillationSlurry

The invention relates to a catalysis conversion method for producing aromatic compounds. According to the method, poor quality heavy cycle oil and residual oil are subjected to a hydrotreating reaction in the presence of hydrogen gas and a hydrogenation catalyst, and the reaction products are separated to obtain gas, naphtha, hydrogenated diesel oil and hydrogenated residue oil, wherein the hydrogenated diesel oil enters a catalysis cracking device and is subjected to a cracking reaction in the presence of a catalysis cracking catalyst, the reaction products are separated to obtain dry gas, liquefied gas, catalytic gasoline containing rich benzene, toluene and xylene, catalytic light diesel oil, distillates with a distillation range of 250-450 DEG C, and an oil slurry, and the distillates with the distillation range of 250-450 DEG C are conveyed to a residue oil hydrotreating device so as to be recycled. According to the present invention, the residue oil hydrogenation condition is completely utilized to achieve saturation of the aromatic ring in the poor quality heavy cycle oil to the maximal degree, such that the hydrogenated diesel oil maximally produce benzene, toluene and xylene during catalysis cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Demetallization catalyst of addig hydrogen to residual oil and preparation method

ActiveCN1267537COvercome the disadvantage of high carbon depositionLess carbon depositRefining to eliminate hetero atomsHalogenHydrogen

A hdyrocatalyst for removing metals from residual oil is composed of a macroreticular aluminium carrier and the Mo and / or W and Co and / or Ni, which are carried by said carrier. It features that said carrier contains aluminium oxide (95-99 wt%) and halogen (1-5) and has lower acidity, resulting in high demetallizing activity and low carbon deposit.

Owner:CHINA PETROLEUM & CHEM CORP +1

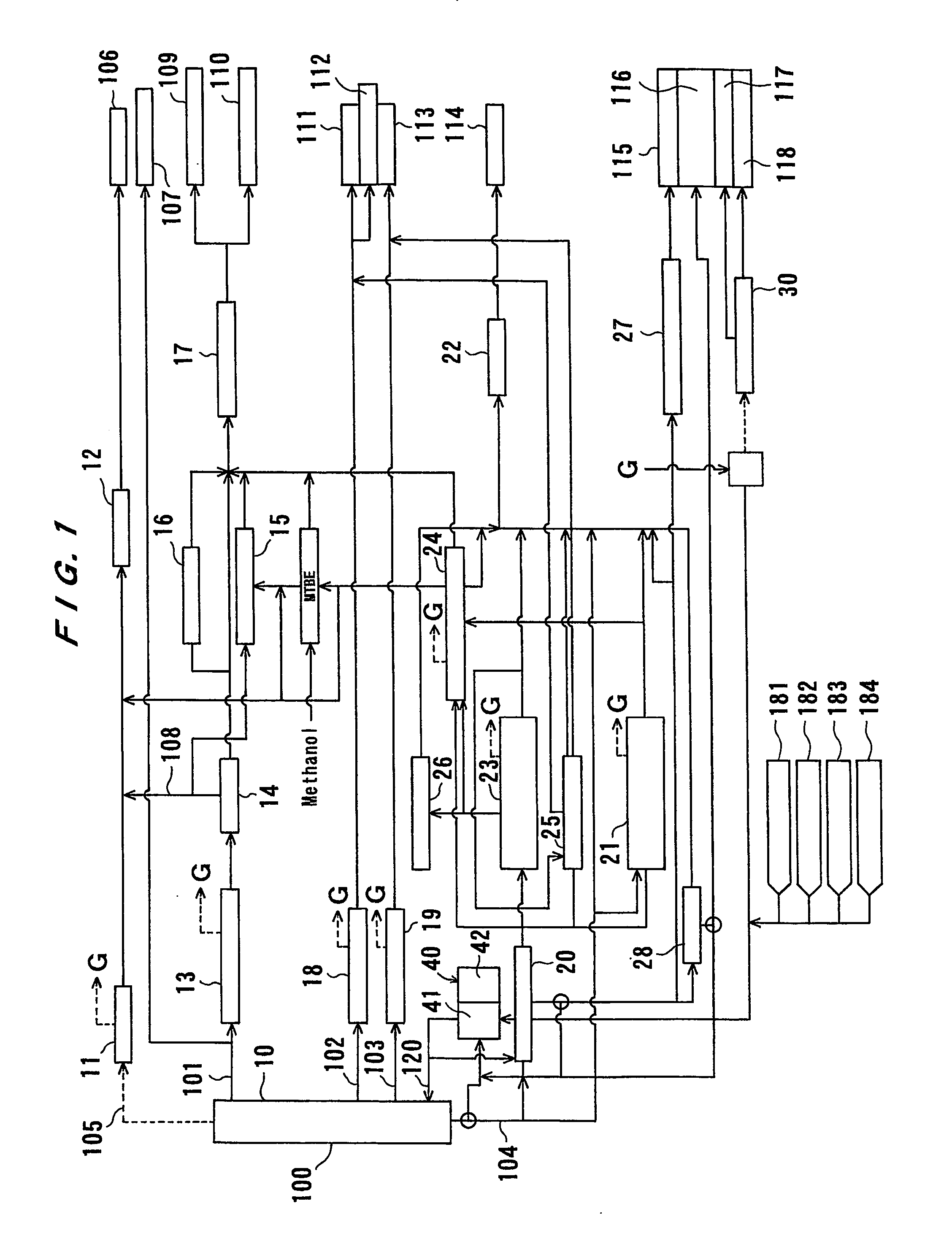

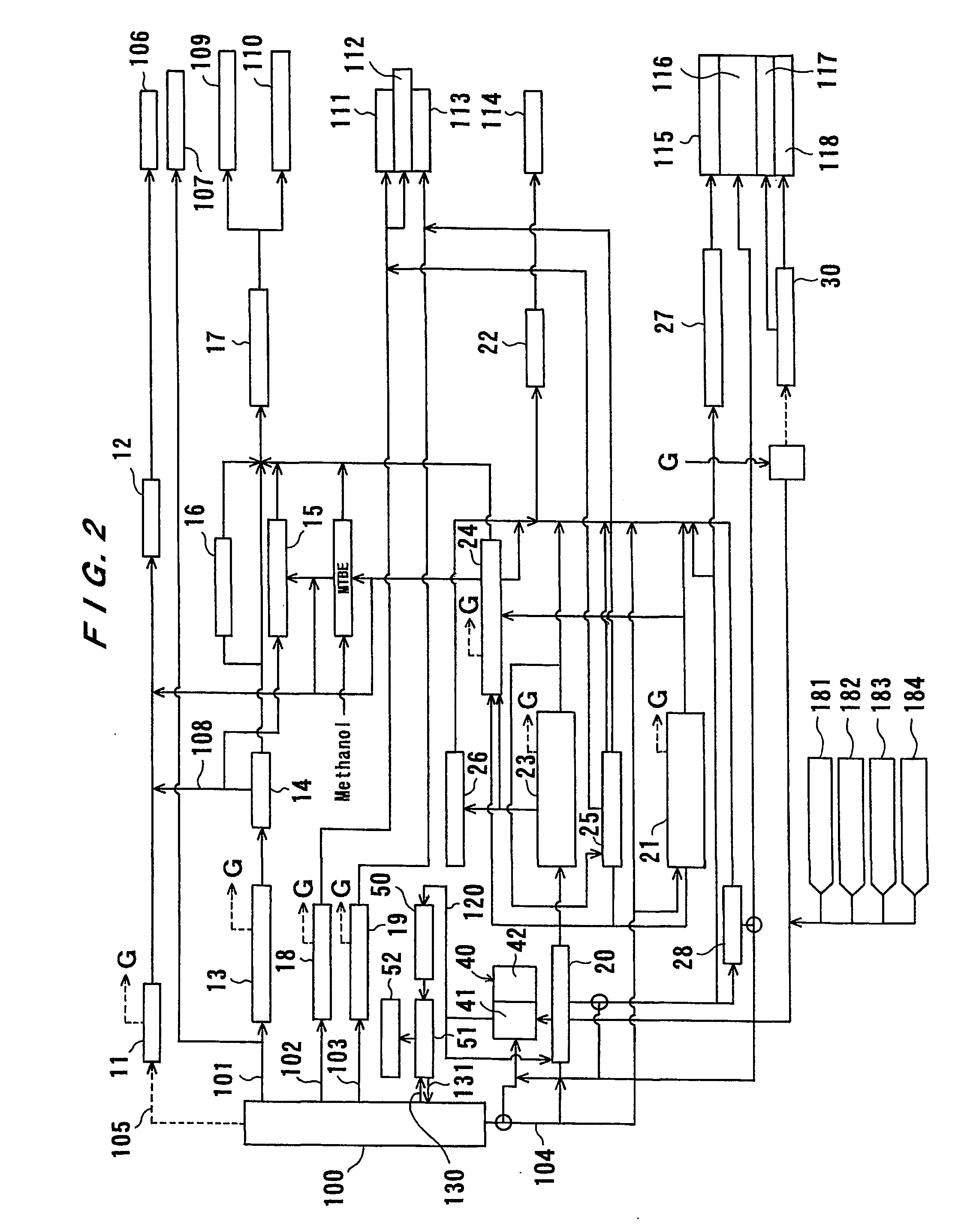

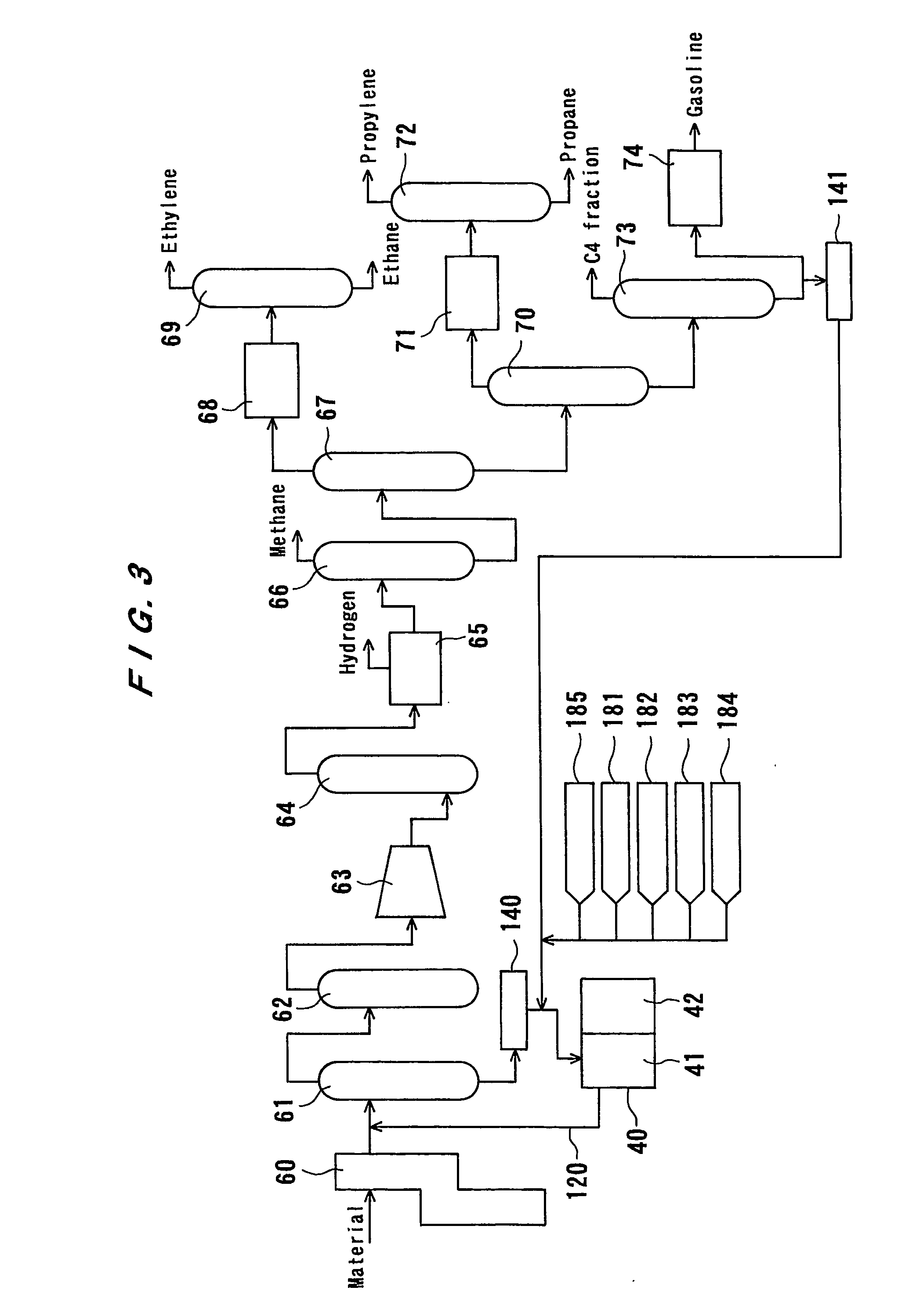

Recycling method and system

InactiveUS20060194990A1Low costThermal non-catalytic crackingTreatment with plural parallel cracking stages onlyDecompositionPetrochemical

A recycling system has a pyrolysis apparatus (40) having a combustion section (42) for selectively combusting a carbon component in materials, and a gasification section (41) for pyrolyzing and gasifying the materials by using heat of combustion in the combustion section (42). The materials include residual oil from an atmospheric distillation unit (10), a vacuum distillation unit (20), and a decomposition unit (28), various wastes including waste plastics (181), wastes (182), and shredder dust (183), and organic matter such as biomass (184). The recycling system has a passage for supplying pyrolysates (120) produced in the gasification section (41) to an oil refinery system or a petrochemical system.

Owner:EBARA CORP

Process for preparing needle coke

The invention provides a method for preparing needle coke. The method is as follows: after delayed coking treatment of fraction or residual oil which are rich in arene through a certain temperature rise formula, green coke obtained is calcined, and the needle coke with high intermediate phase content and developed needle structure are prepared. The petroleum raw materials used comprise mixture of one type or a plurality of types among virgin wax oil, coked wax oil, catalytic cracking clarified oil, ethylene tar, coal tar, dense oil, residual oil and other hydrocarbon-enriched substances. The delayed coking temperature rise formula is characterized in that: intermediate phases generated can be driven to grow fully and are flushed by air flow with enough flow rate before solidification, thereby the granularity of the needle coke prepared is large (the content of coke breeze is not more than 25 weight percent) and the needle coke can be used for large-scale steel-making electric furnaces. When the method is used for an industrial device, people only need to adjust the prior temperature rise formula according to the characteristics of the raw materials and the technological flow.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Process of producing clean diesel oil and low carbon olefin with residual oil and heavy fraction oil

The process of producing clean diesel oil and low carbon olefin with residual oil and heavy fraction oil includes: deasphalting residual oil through mixing residual oil and optional catalytic cracking oil slurry in a solvent deasphalting unit; hydrocracking of the deasphalted oil and optional heavy fraction oil with hydrogen in a hydrogenating unit and separating the products to obtain light and heavy naphtha fraction, diesel oil fraction and hydrogenated tail oil; catalytically cracking the hydrogenated tail oil in a catalytically cracking unit and separating products to obtain low carbon olefin, gasoline fraction, diesel oil fraction and oil slurry; returning all the catalytically cracked diesel oil fraction to the catalytically cracking reactor and returning all or partial catalytically cracked oil slurry to the solvent deasphalting unit. The process has high yield of clean diesel oil and low carbon olefin and high quality of the diesel oil product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for residual oil

ActiveCN101768468ATake advantage ofExtended operating cycleTreatment with hydrotreatment processesHydrodesulfurizationHydrogenation reaction

The invention provides a hydrogenation method for residual oil. The method includes the following steps: under the condition of hydrogenation reaction, residual oil raw materials and hydrogen gas are sequentially guided into two hydrogenation reaction zones connected in series to carry out contact reaction with a plurality of catalyst beds in the hydrogenation reaction zones; according to the flowing directions of a reactant and the hydrogen gas, the first and second hydrogenation reaction zones respectively comprise a hydrogenation protecting catalyst, a hydrogenation de-metallization catalyst and a hydrogenation desulfurization catalyst which are sequentially filled in the catalyst beds; when the pressure drop of at least one catalyst bed in the first hydrogenation reaction zone reaches the upper limit or hot spots appear in the reaction zone, at least one part of the residual oil raw materials and the hydrogen gas is directly guided into the second hydrogenation reaction zone. Compared with the prior art, the method in the invention can prolong the running period of a residual oil hydrogenation device, thereby increasing the running efficiency of the device and improving the economical property of the device as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

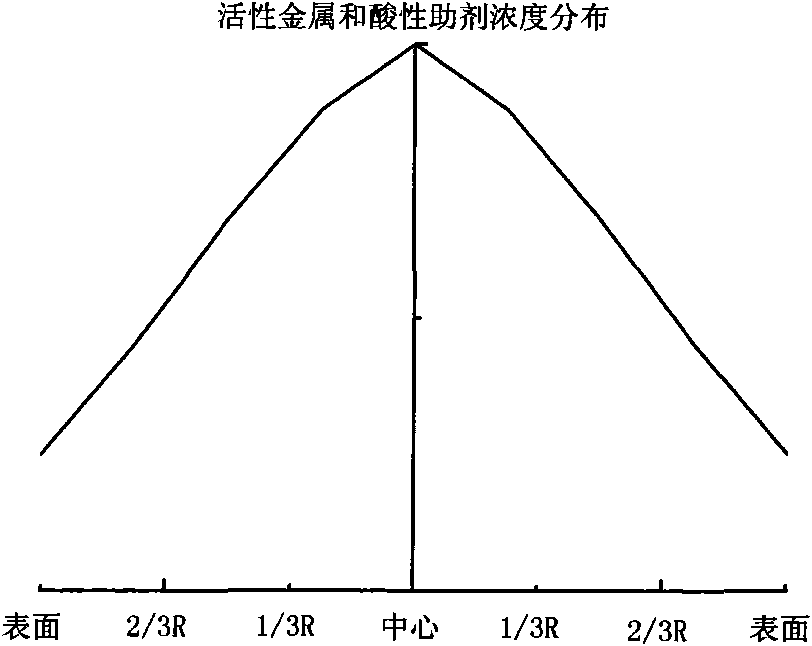

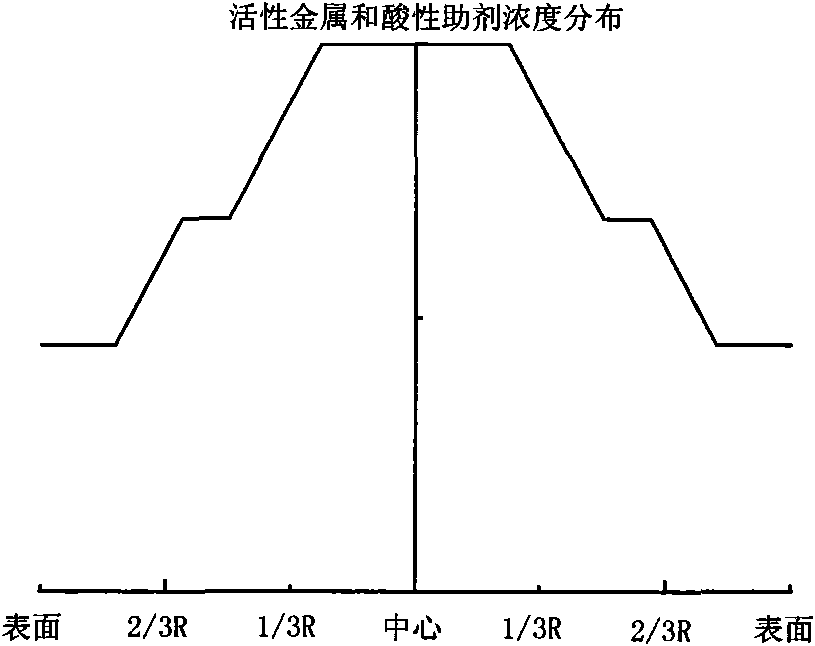

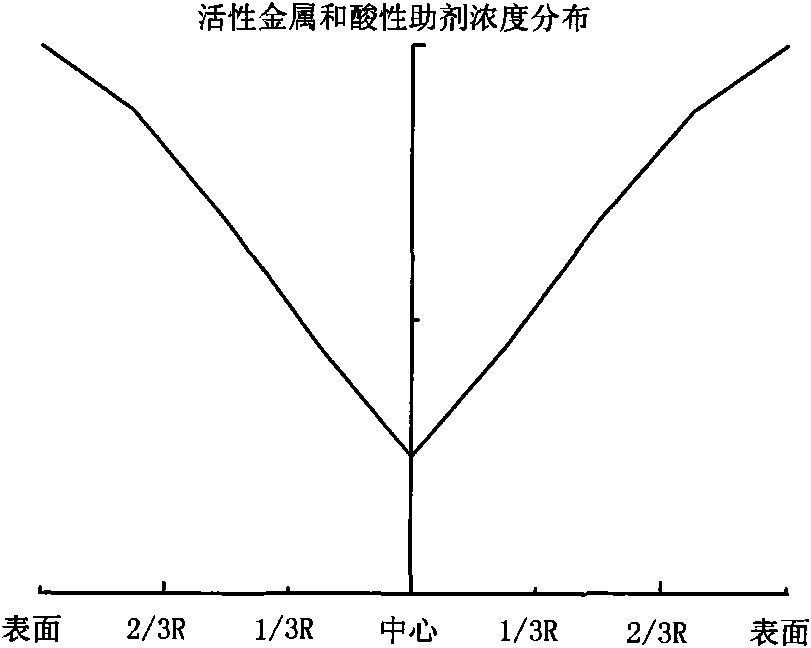

Grading composition of hydrogenation catalyst

ActiveCN101928592AGood demetallizationGood charcoal removalRefining to eliminate hetero atomsPorosityMetal catalyst

The invention relates to a grading composition of a hydrogenation catalyst. From top to bottom, a reactor is filled with hydrodemetallization and a hydrodesulfurization catalyst; raw materials flow from top to bottom, and along with the flowing direction of raw materials, the activity of the catalyst gradually increases, the pore size gradually decreases, the grain size gradually decreases and the porosity gradually decreases; the hydrodemetallization catalyst and the hydrodesulfurization catalyst are both formed by one or more demetallization catalysts; concentrations of active metal components and acid auxiliary agents are in nonuniform distribution, and from the surface to the center of catalyst grains, the concentrations of the active metal components and acid auxiliary agents of the hydrodemetallization catalyst are of gradient increase, and the concentrations of the active metal components and acid auxiliary agents of the hydrodesulfurization catalyst are of gradient decrease; and based on weight content, the demetallization catalyst accounts for 15 to 80 percent, and the desulfurization catalyst accounts for 20 to 85 percent. The grading composition of the invention is applied to hydrogenation catalysis of oil and residual oil of heavy ends and has the advantages of possessing better activity and stability of demetallization, residual carbon removal and desulfurization, controlling temperature rise of a catalyst bed and degreasing the deactivation speed of the catalyst.

Owner:PETROCHINA CO LTD

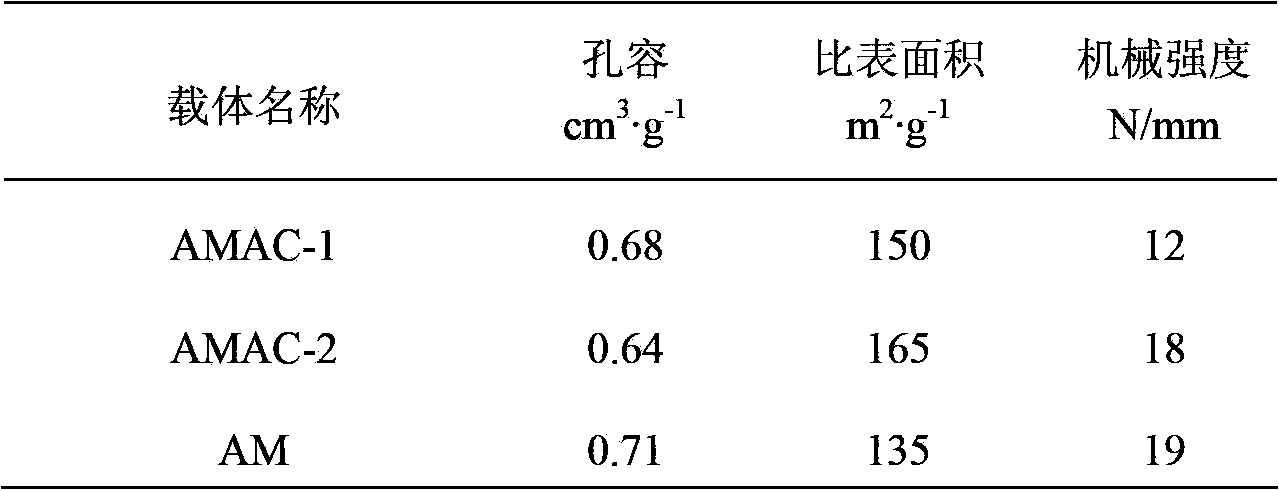

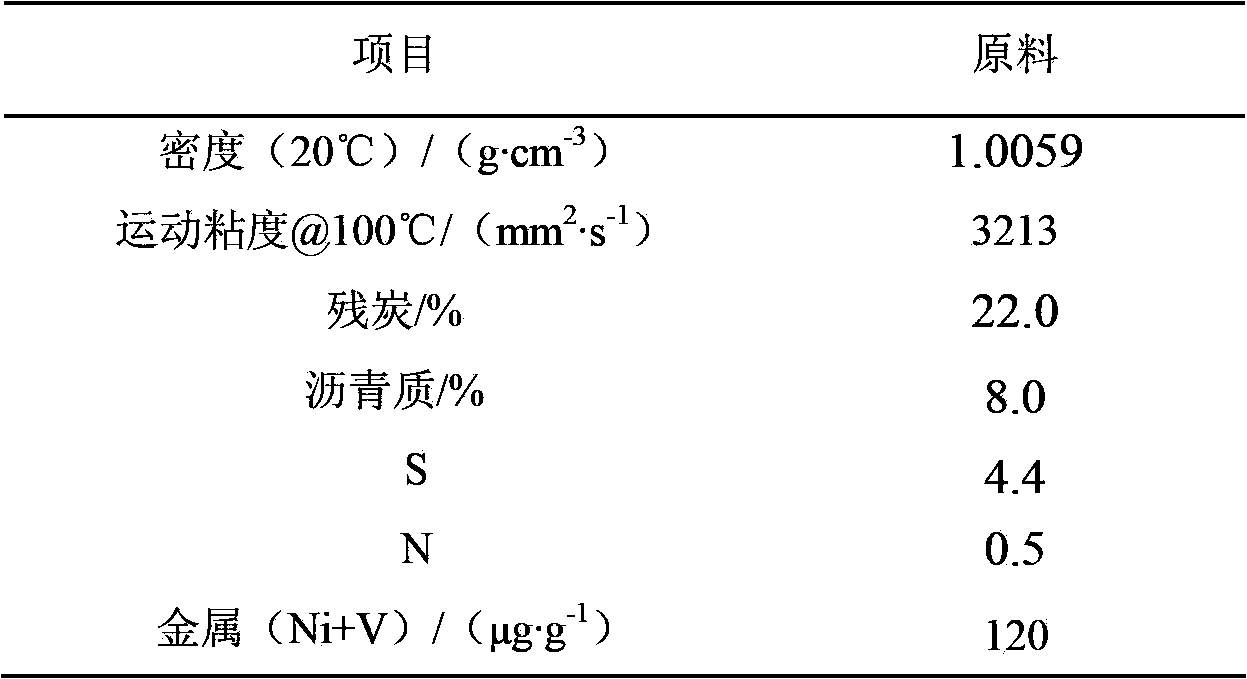

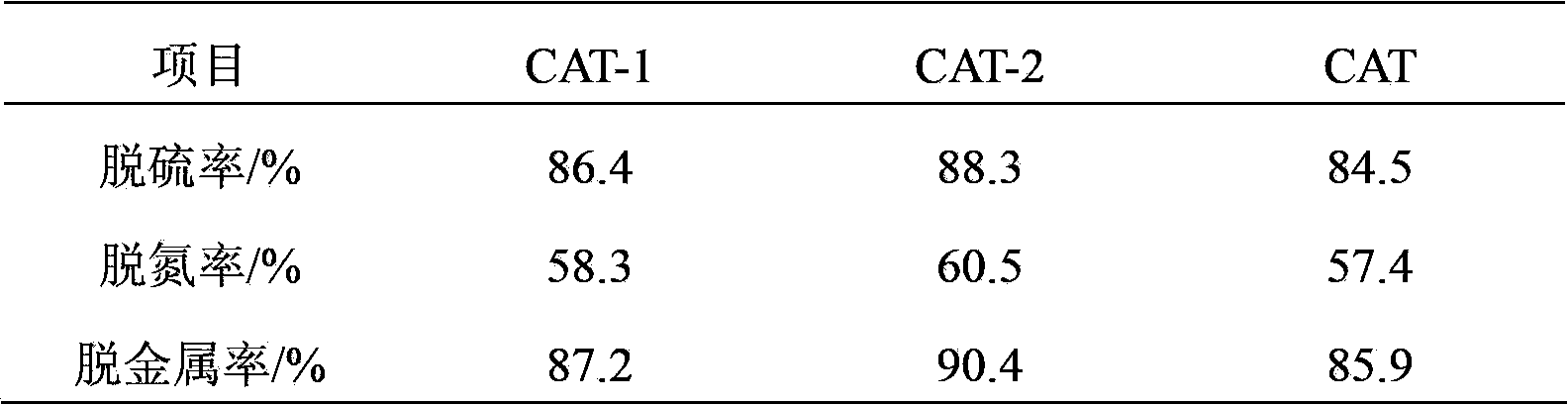

Activated carbon/aluminum oxide composite type catalyst carrier and preparation method and application of activated carbon/aluminum oxide composite type catalyst carrier

InactiveCN103657736ALarge specific surface areaHigh mechanical strengthCatalyst carriersWorking-up pitch/asphalt/bitumen by chemical meansActivated carbonFixed bed

The invention relates to an activated carbon / aluminum oxide composite type catalyst carrier and a preparation method and application of the activated carbon / aluminium oxide composite type catalyst carrier. The preparation method comprises the steps of washing circularly with 20-35% hydrochloric acid in a boiling state, wherein the mass ratio of hydrochloric acid to activated carbon is (5-20):1, performing oxidation with 10-50% nitric acid, wherein the mass ratio of an oxidizing agent to activated carbon is (20-40):1, kneading the activated carbon, aluminium oxide and an assistant into cakes in a kneading machine, extruding the kneaded cakes through an extruding machine, drying the extruded carrier, and roasting in nitrogen protection atmosphere to prepare the activated carbon / aluminum oxide composite type catalyst carrier. The activated carbon / aluminum oxide composite type catalyst carrier is suitably used as a residual oil hydrogenation catalyst carrier of a fixed bed, and is particularly used as the residual oil hydrodemetallization catalyst carrier. The activated carbon / aluminum oxide composite type catalyst carrier has high desulfurization rate up to 86.4-88.3%, high denitrification rate up to 58.3-60.5% and high demetalization rate up to 87.2-90.4%.

Owner:PETROCHINA CO LTD

Macroporous aluminium oxide carrier and its preparing method

The present invention is macroporous alumina carrier and its preparation process. The carrier has pore volume of 0.9-1.3 ml / g, pore volume rate of pores smaller than 20 nm in 55-85 %, pore volume rate of 20-100 nm diameter pores in 7-25 %, and pore volume rate of pores greater than 100 nm in 7-25 %. The preparation process of the carrier includes forming and roasting pseudo-thin diasphore composition containing organic pore expanding agent. The preparation process of the present invention has relatively low organic pore expanding agent consumption and high pore expanding effect. The prepared macroporous alumina carrier is used in catalyst for hydrogenating and demetallating heavy and residual oil, especially decompression residual oil with high metal content.

Owner:CHINA PETROLEUM & CHEM CORP +1

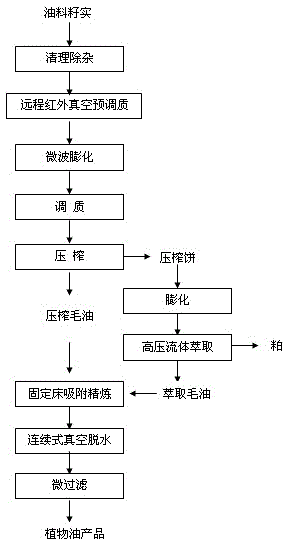

Physical method for preparing vegetable oil

ActiveCN103333738AAvoid damageFast and efficient remote infrared vacuum preconditioningFatty-oils/fats refiningFatty-oils/fats productionOil and greaseVegetable oil

The invention relates to a physical method for preparing vegetable oil. The method comprises the following process steps of: cleaning, remote infrared vacuum pre-tempering, microwave puffing, tempering, pressing, puffing, high-pressure fluid extraction, fixed bed adsorption refining, continuous vacuum dehydration and finally micro-filtering. The remote infrared vacuum pre-tempering and microwave puffing pre-processing method is fast and high-efficient and is suitable for industrial production. Press cake puffing and high-pressure fluid extraction are combined so that the problem of oil extraction of cold-pressing cakes is effectively solved, and meanwhile residual oil of the cold-pressing cakes is effectively reduced. The fixed bed adsorption refining method is simply and conveniently operated and has the advantages of short cycle, low energy consumption, low oil refining loss, high grease quality and the like. The whole process has the advantages of simplicity and convenience in operation, no solvent residue, low energy consumption, small neutral oil loss, high product quality and the like, an environment-friendly effect is achieved, and the method can be widely suitable for different kinds of oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com