Patents

Literature

366 results about "Hydrogenation catalysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

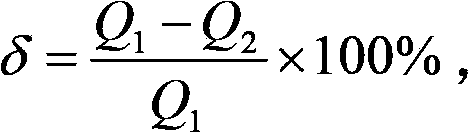

Grading composition of hydrogenation catalyst

ActiveCN101928592AGood demetallizationGood charcoal removalRefining to eliminate hetero atomsPorosityMetal catalyst

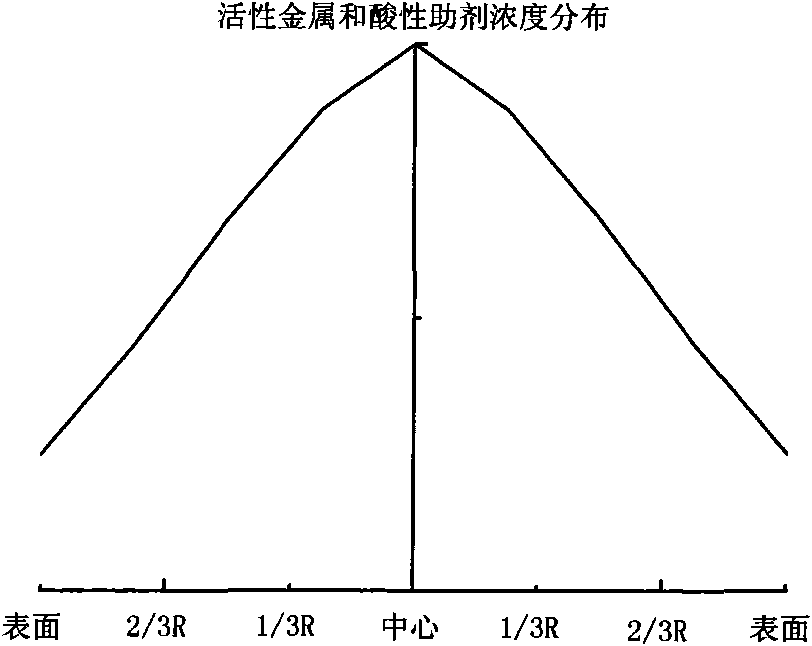

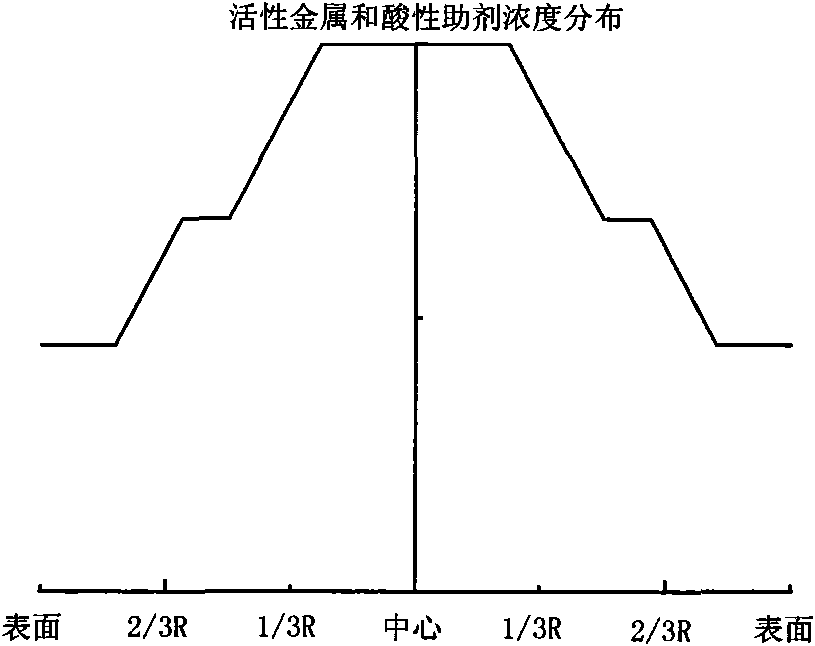

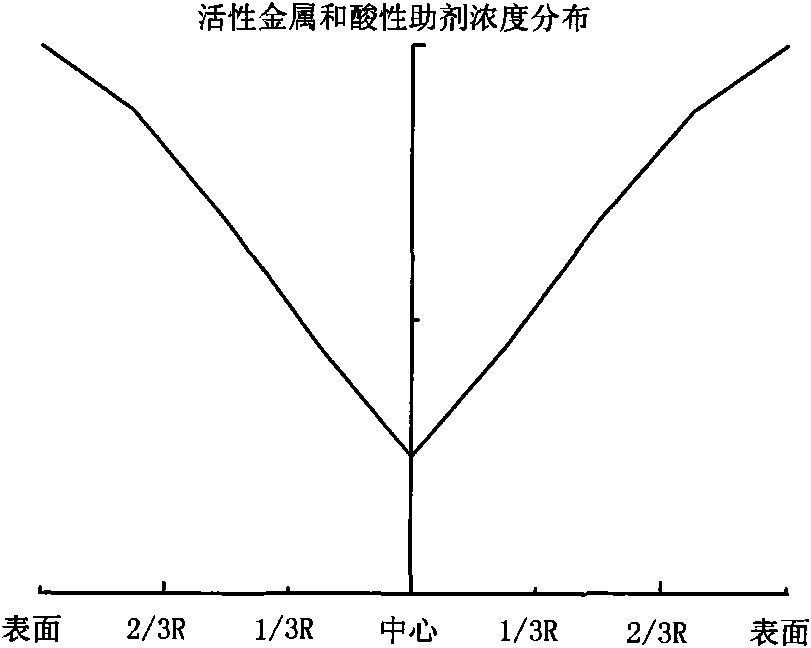

The invention relates to a grading composition of a hydrogenation catalyst. From top to bottom, a reactor is filled with hydrodemetallization and a hydrodesulfurization catalyst; raw materials flow from top to bottom, and along with the flowing direction of raw materials, the activity of the catalyst gradually increases, the pore size gradually decreases, the grain size gradually decreases and the porosity gradually decreases; the hydrodemetallization catalyst and the hydrodesulfurization catalyst are both formed by one or more demetallization catalysts; concentrations of active metal components and acid auxiliary agents are in nonuniform distribution, and from the surface to the center of catalyst grains, the concentrations of the active metal components and acid auxiliary agents of the hydrodemetallization catalyst are of gradient increase, and the concentrations of the active metal components and acid auxiliary agents of the hydrodesulfurization catalyst are of gradient decrease; and based on weight content, the demetallization catalyst accounts for 15 to 80 percent, and the desulfurization catalyst accounts for 20 to 85 percent. The grading composition of the invention is applied to hydrogenation catalysis of oil and residual oil of heavy ends and has the advantages of possessing better activity and stability of demetallization, residual carbon removal and desulfurization, controlling temperature rise of a catalyst bed and degreasing the deactivation speed of the catalyst.

Owner:PETROCHINA CO LTD

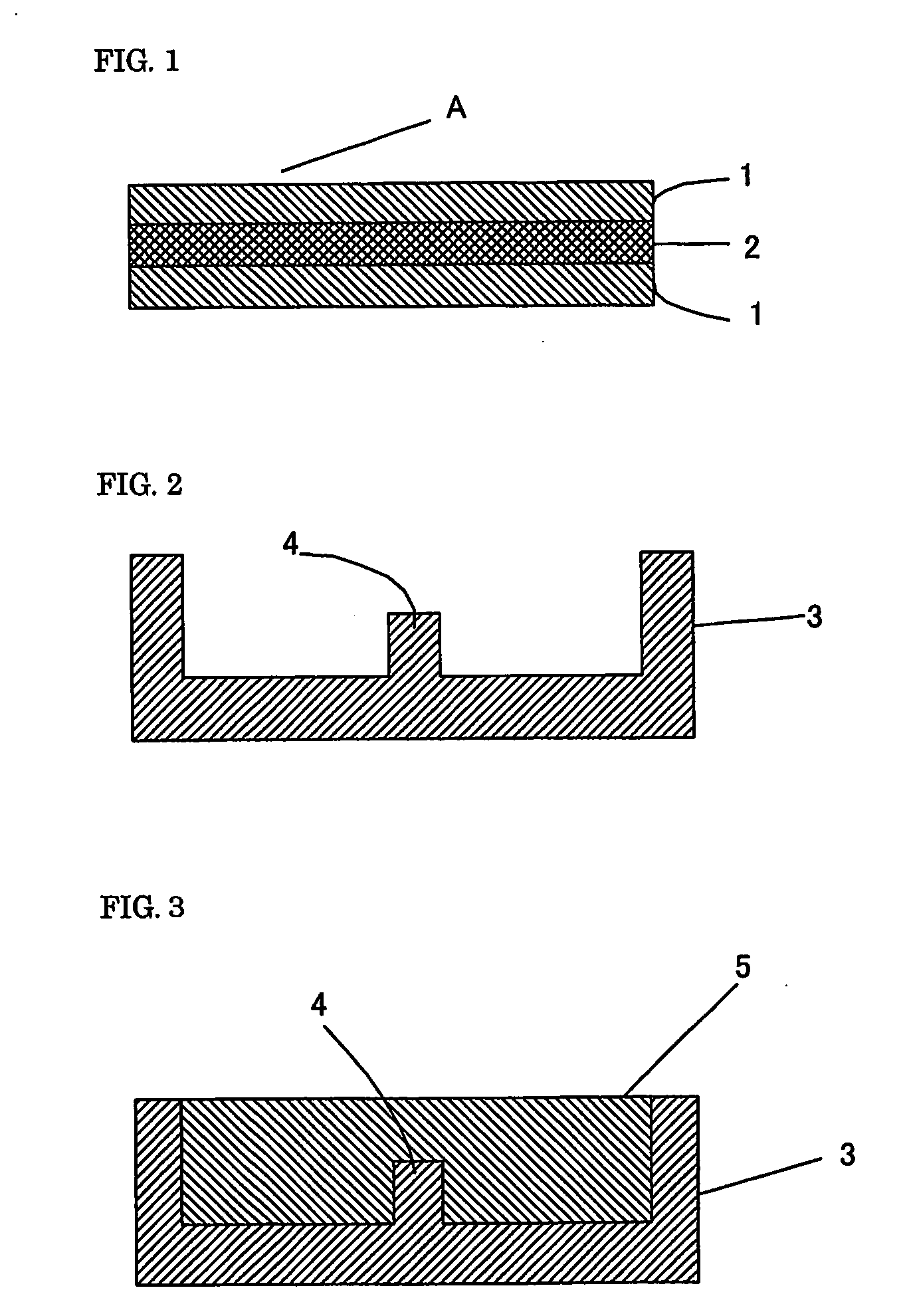

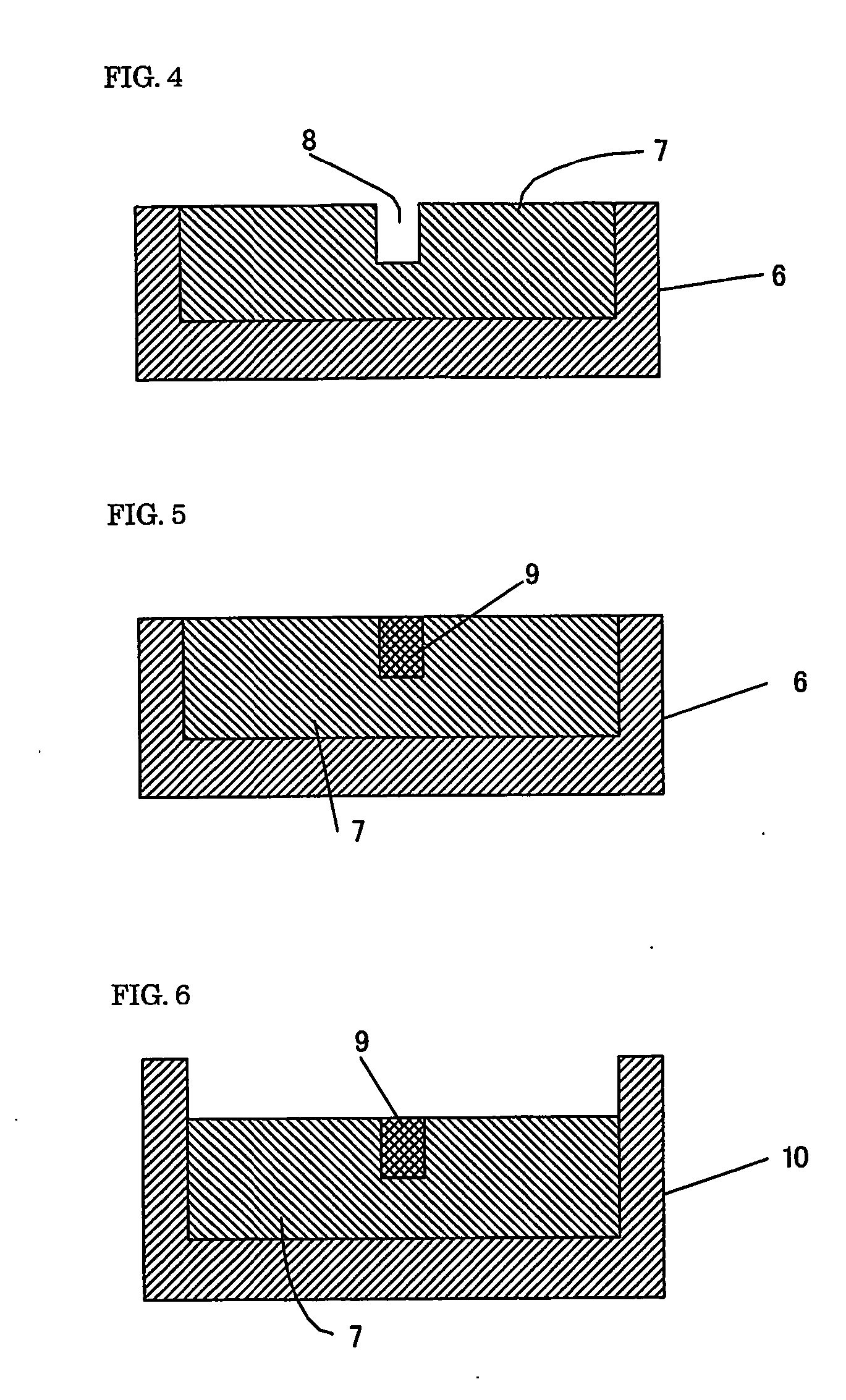

Curable organopolysiloxane resin composition for optical transmission components, optical transmission components, and fabrication process thereof

The present invention relates to a hydrosilation-curable organopolysiloxane resin composition comprising (A) an organopolysiloxane resin having three or more monovalent unsaturated aliphatic hydrocarbon groups and aromatic hydrocarbon carbon groups, (B) an organosilicon compound having two or more silicon-bonded hydrogen atoms and aromatic hydrocarbon groups, (C) a hydrosilation catalyst, and optionally (D) (d1) a solvent or (d2) a hydrosilation-reactive organosiloxane-based diluent, for optical transmission components, especially for optical transmission components serving as optical communication elements, relates to optical transmission components, represented by optical waveguides, comprisiong a hydrosilation-cured product of the aforementioned organopolysiloxane resin and organosilicon compound, and relates to a process for fabricatiing optical transmission components.

Owner:DOW CORNING CORP

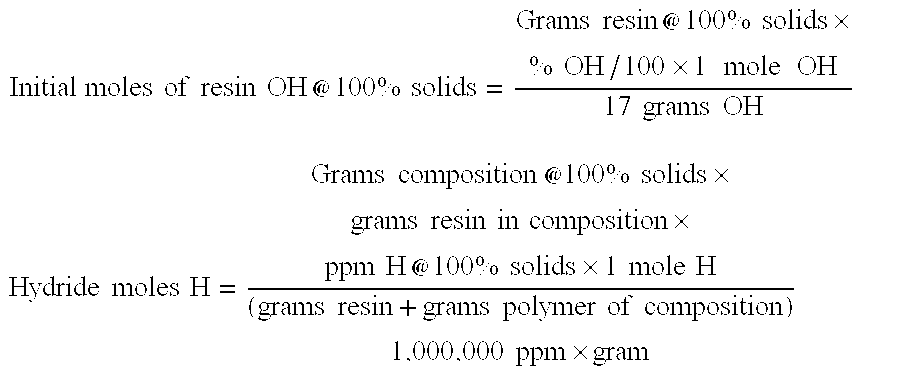

Method for making microporous silicone resins with narrow pore-size distributions

A method for preparing a microporous silicone resin which can be used to form low dielectric constant films useful for electrical insulating coatings on electronic devices comprising (A) contacting a hydridosilicon containing resin with an alkenyltriarylsilane in the presence of a platinum group metal-containing hydrosilation catalyst effecting formation of a silicon resin where at least 5 percent of silicon atoms are substituted with at least one triarylsilylalkylene group and at least 45 percent of silicon atoms are substituted with at least one hydrogen atom and (B) heating the silicon resin of step (A) in an inert atmosphere at a temperature sufficient to effect thermolysis of the triarylsilylalkylene groups from the silicon atoms.

Owner:DOW CORNING CORP

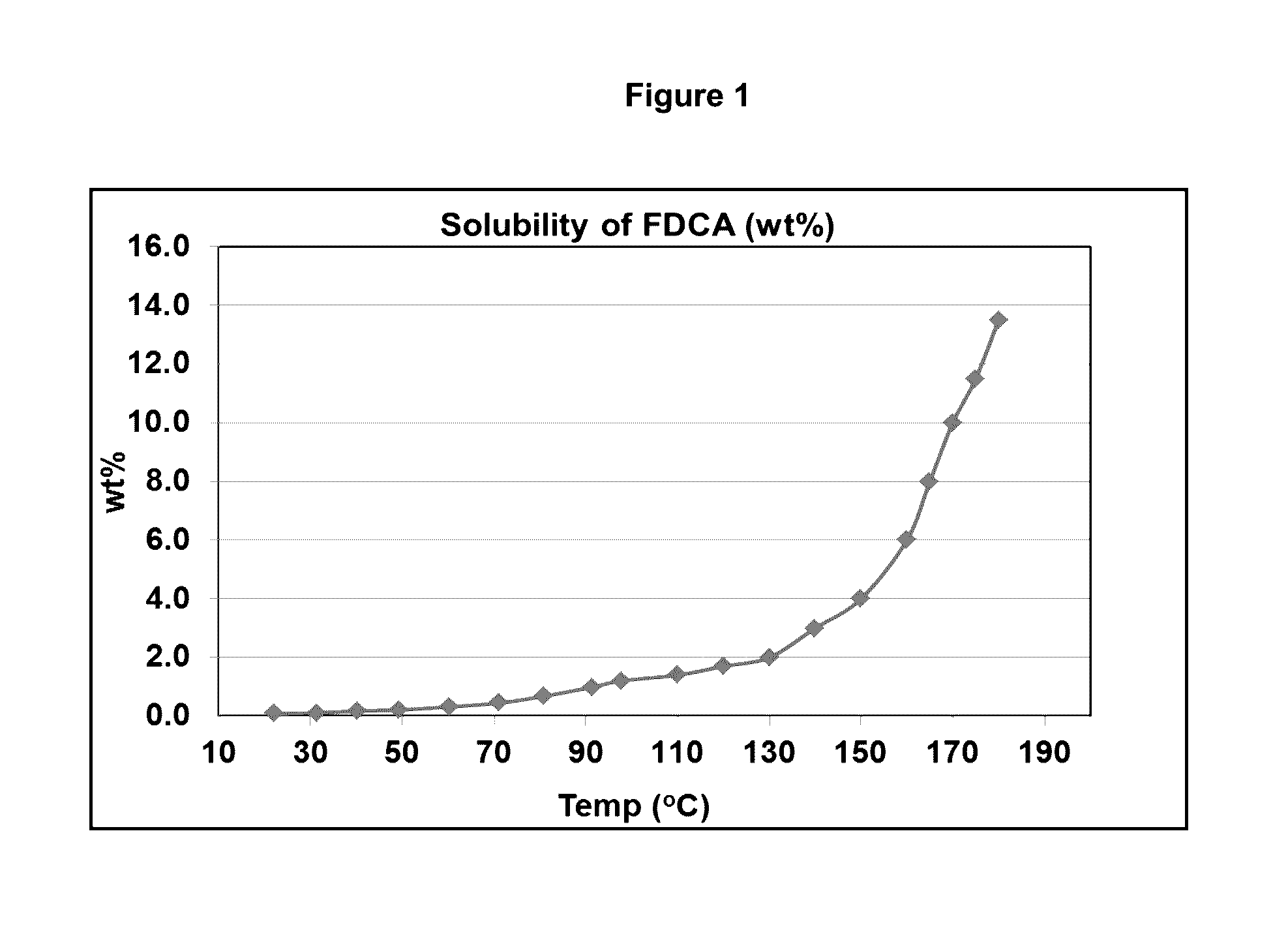

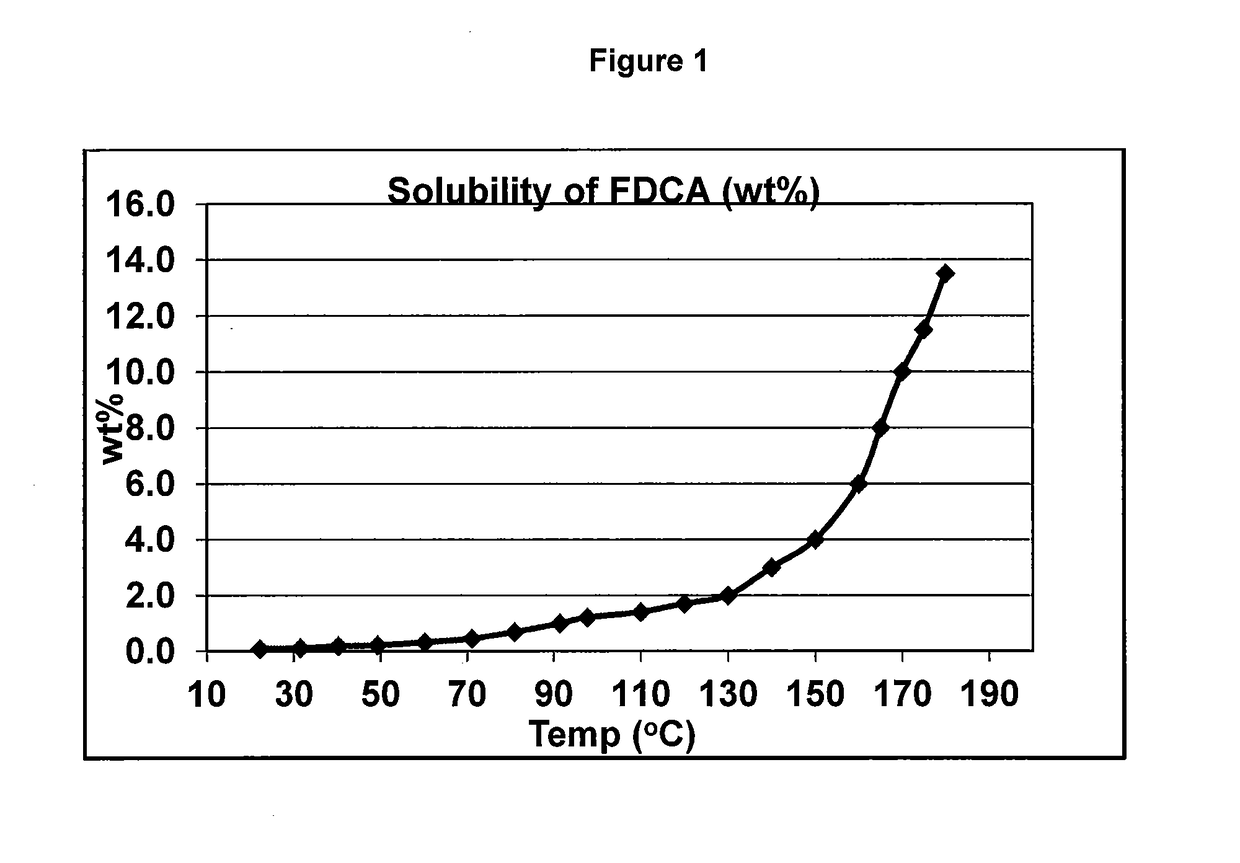

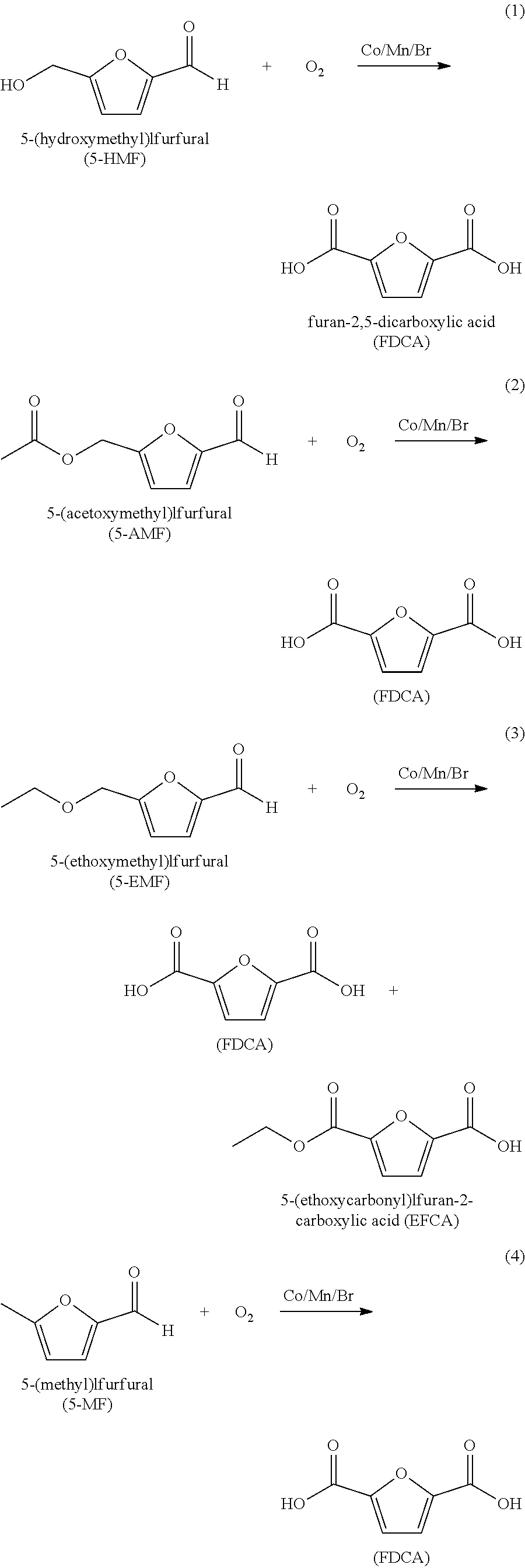

Purifying crude furan 2,5-dicarboxylic acid by hydrogenation and a purge zone

ActiveUS20160311790A1Lower energy requirementsImprove solubilityOrganic chemistrySolvent extractionFuranCarboxylic acid

A process for purifying a crude furan 2,5-dicarboxylic acid composition (cFDCA) by hydrogenation of a FDCA composition dissolved in a hydrogenation solvent such as water, and hydrogenating under mild conditions, such as at a temperature within a range of 130° C. to 225° C. by contacting the solvated FDCA composition with hydrogen in the presence of a hydrogenation catalyst under a hydrogen partial pressure within a range of 10 psi to 900 psi. A product FDCA composition is produced having a low amount of tetrahydrofuran dicarboxylic acid, a low b*, and a low amount of 5-formyl furan-2-carboxylic acid (FFCA).

Owner:EASTMAN CHEM CO

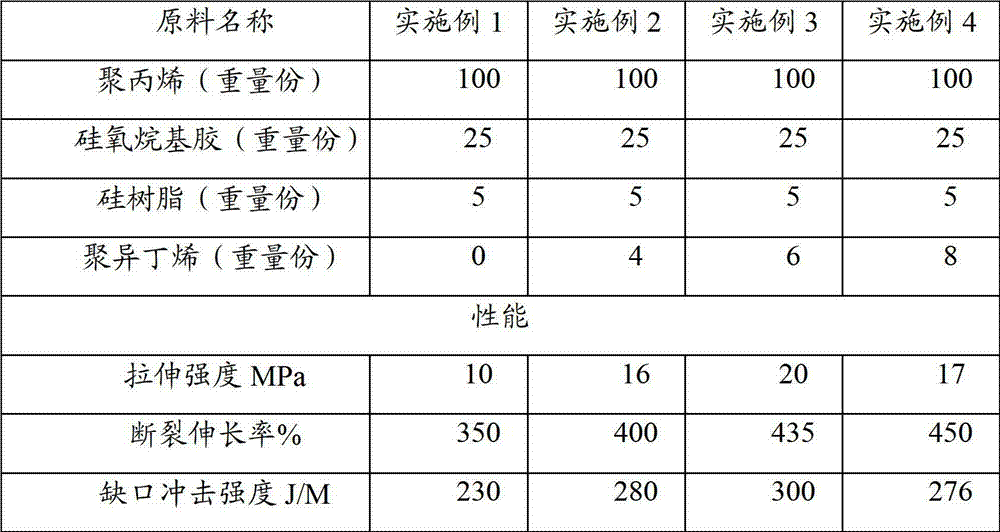

Siloxane-modified thermoplastic material and preparation method thereof

The invention relates to a method for preparing siloxane-modified thermoplastic material, which comprises the following steps: adding 100 weight parts of thermoplastic resin, 40-80 parts of high molecular weight siloxane, 20-40 parts of silicon resin, and 5-10 parts of compatibilizer into a blender, blending for 3-4min, then adding 10-25 weight parts of cross-linking agent and 0.01 -0.5 parts of hydrosilation catalyst, reacting and blending for 3-5min, discharging, cooling to the room temperature and obtaining a base stock; taking 100 weight parts of the base stock in the step one and 50-150 weight parts of thermoplastic resin for mixing uniformly, blending through an internal mixer or a double screw extruder and obtaining the siloxane-modified thermoplastic material. The cross-linking siloxane-modified thermoplastic material made by the invention has the advantages of higher heat resistance, excellent weather resistance, lower friction factor changing along with time, smooth surface, silk touch feeling and the like.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

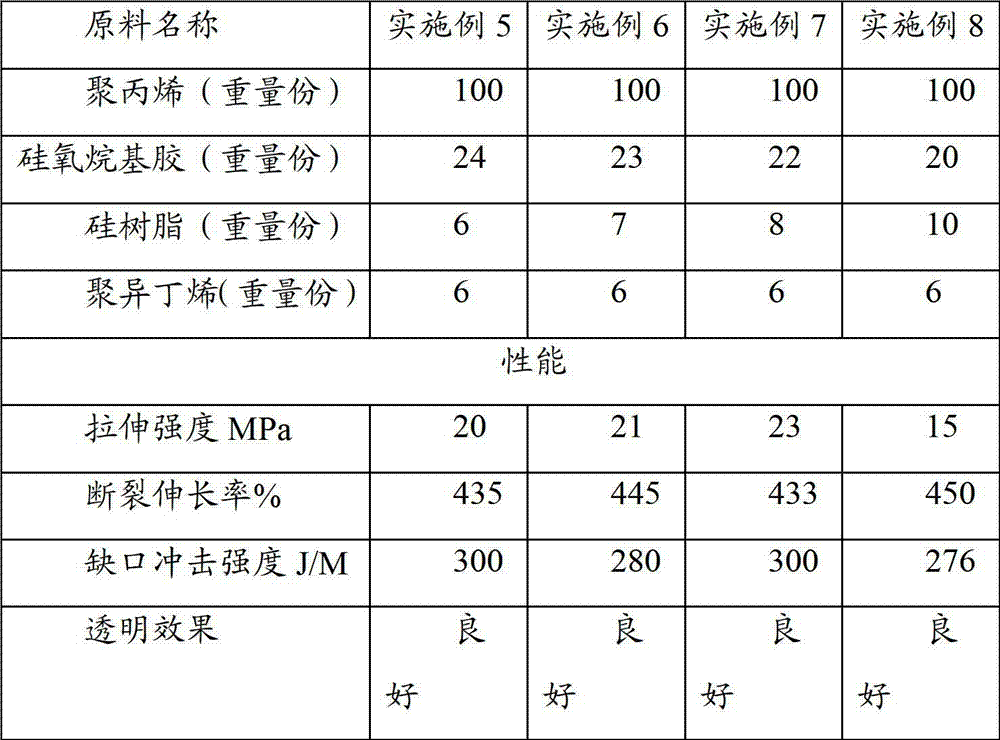

Process for aromatic alkylation

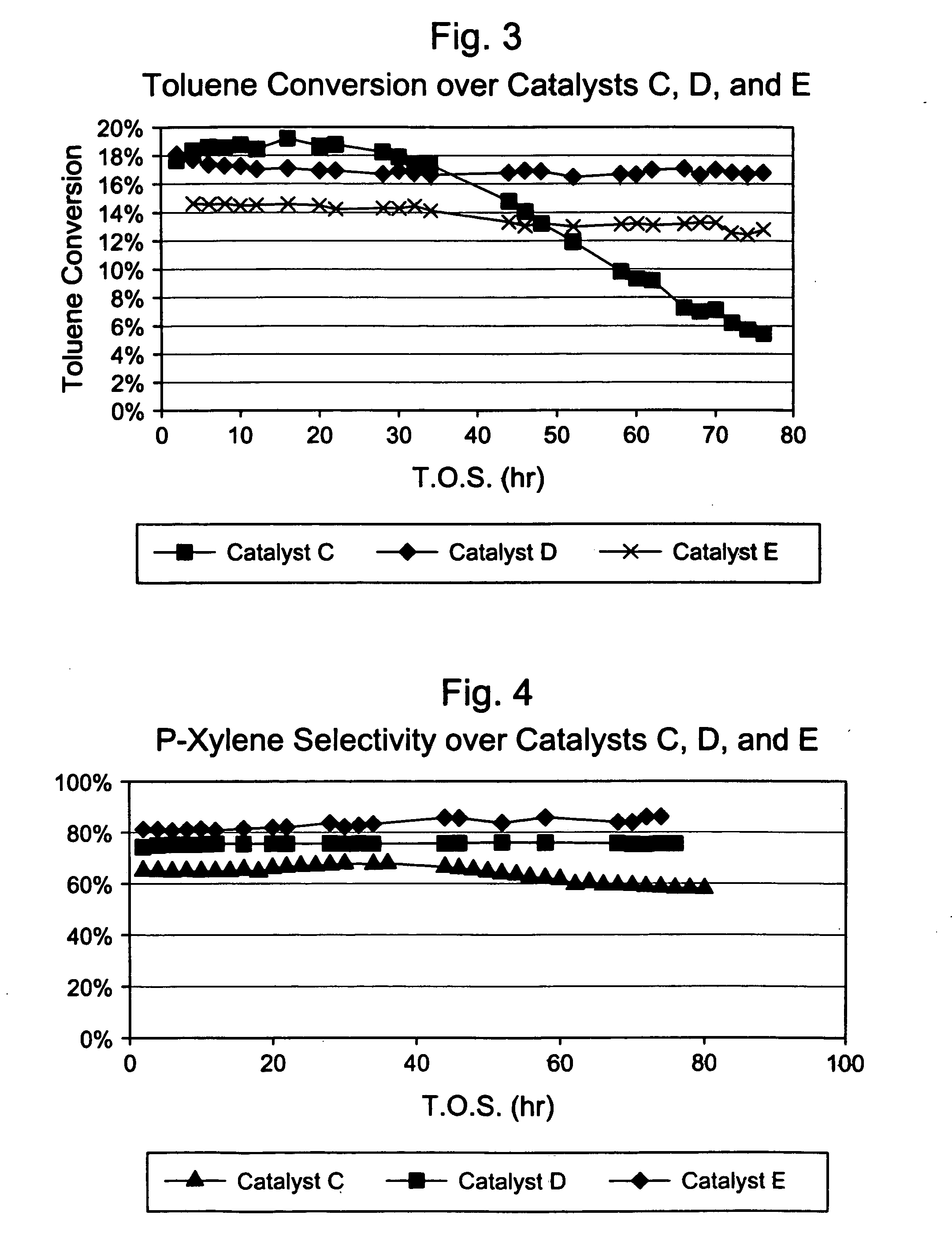

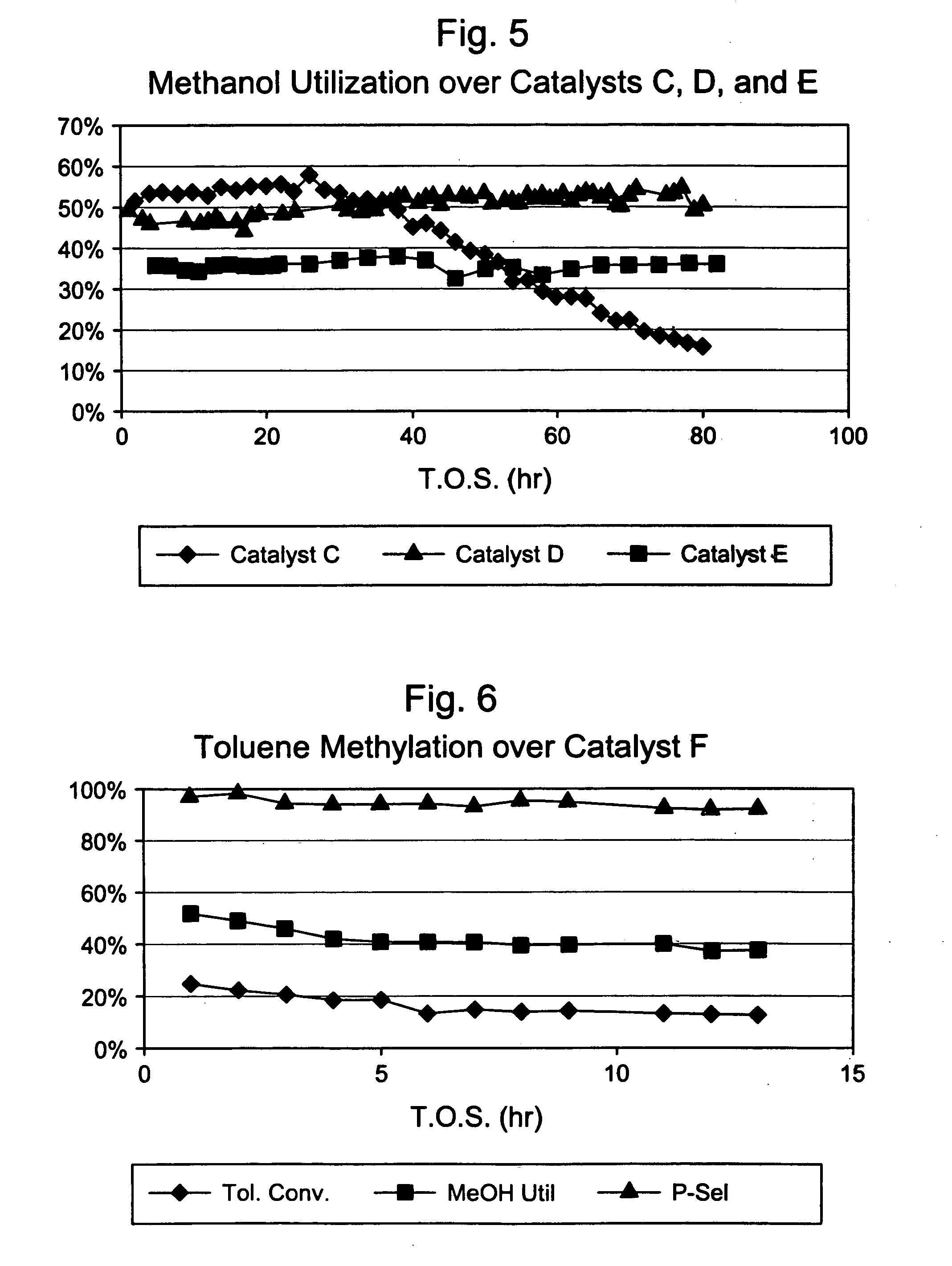

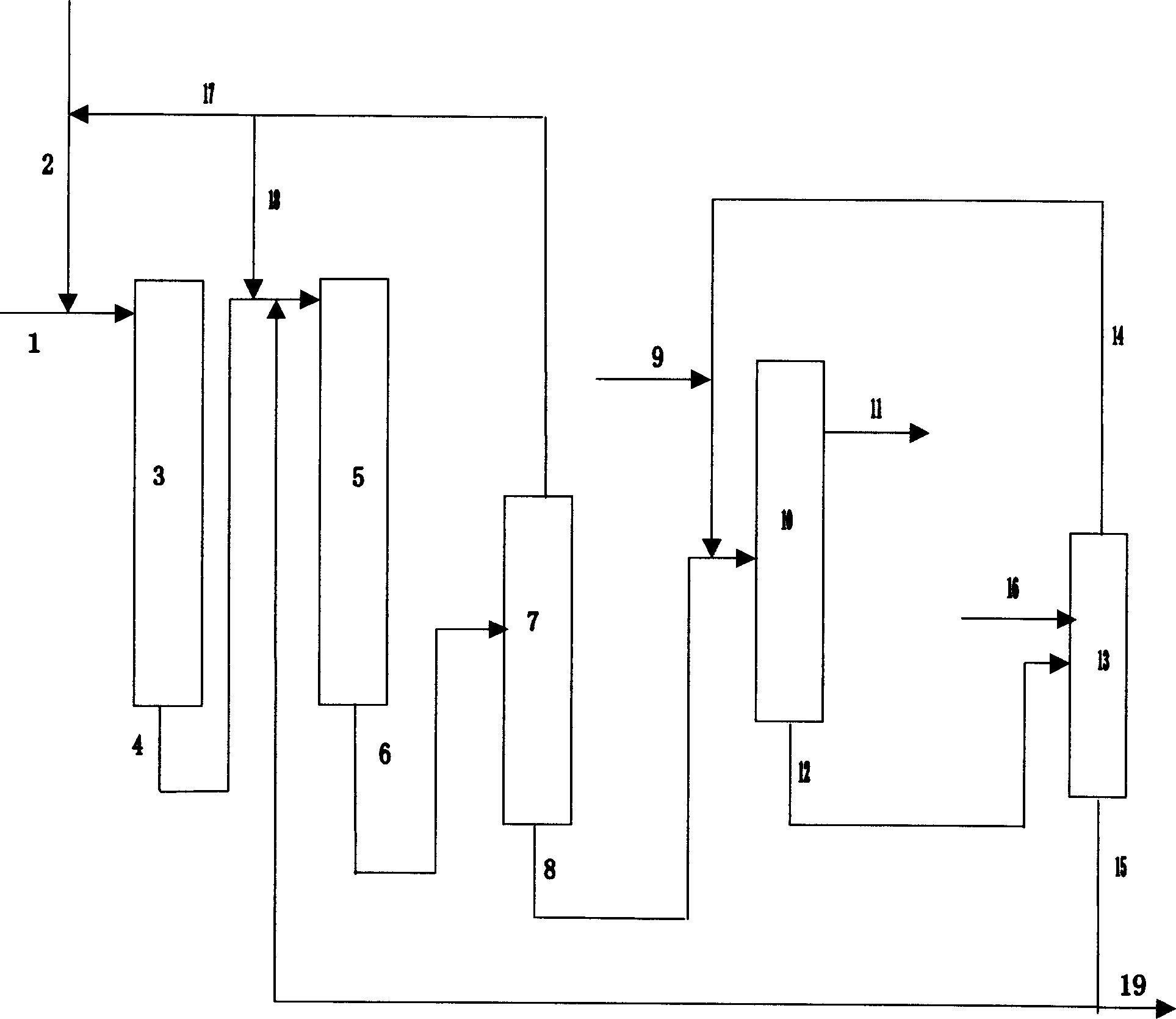

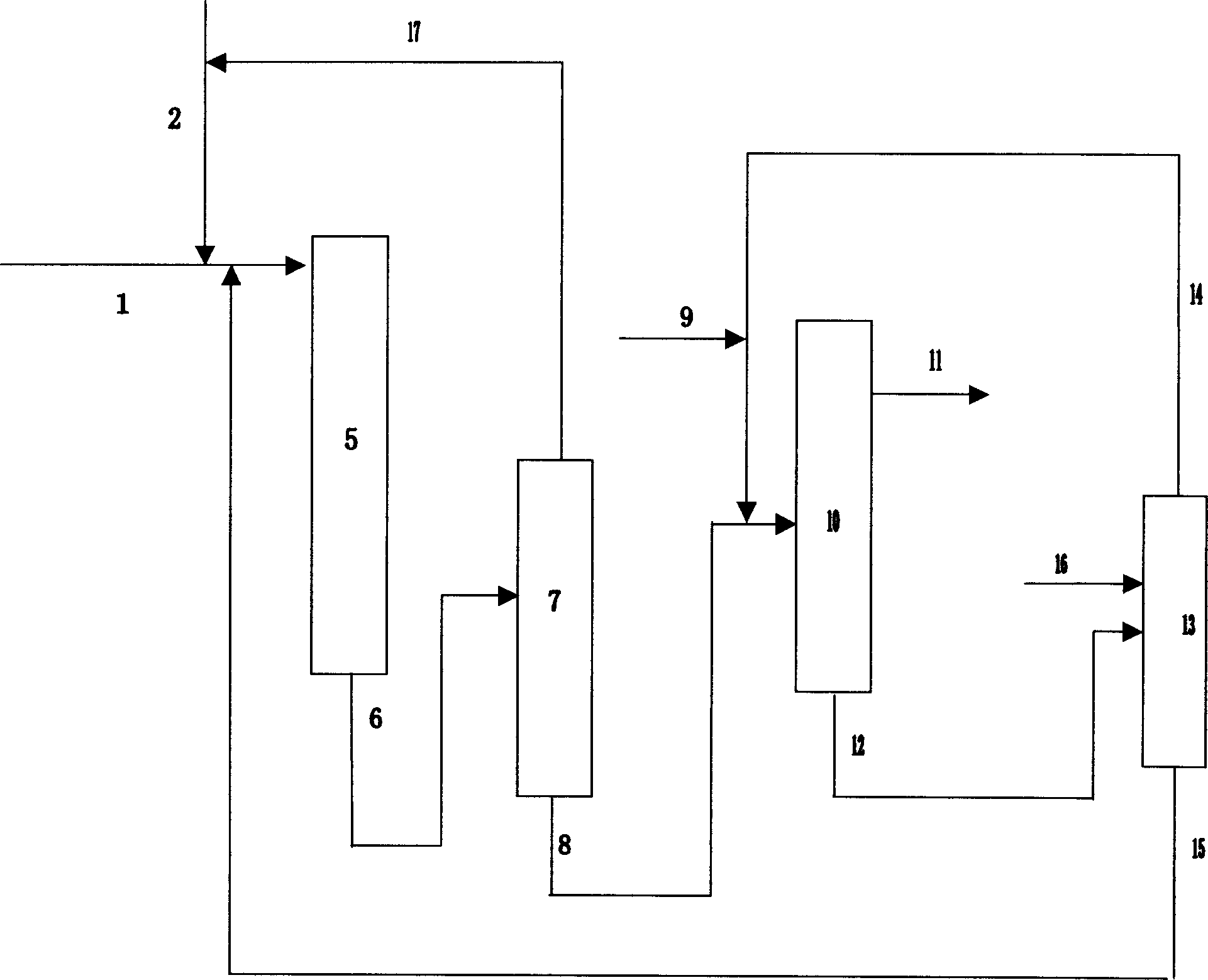

This invention relates to a process for the selective alkylation of toluene and / or benzene with an oxygen-containing alkylation agent. In particular, the process uses a selectivated molecular sieve which has been modified by the addition of a hydrogenation component, wherein at least one of the following conditions is met: (a) the selectivated molecular sieve has an alpha value of less than 100 prior to the addition of the hydrogenation component, or (b) the selectivated and hydrogenated catalyst has an alpha value of less than 100. The process of this invention provides high selectivity for the alkylated product while reducing catalyst degradation.

Owner:EXXONMOBIL CHEM PAT INC

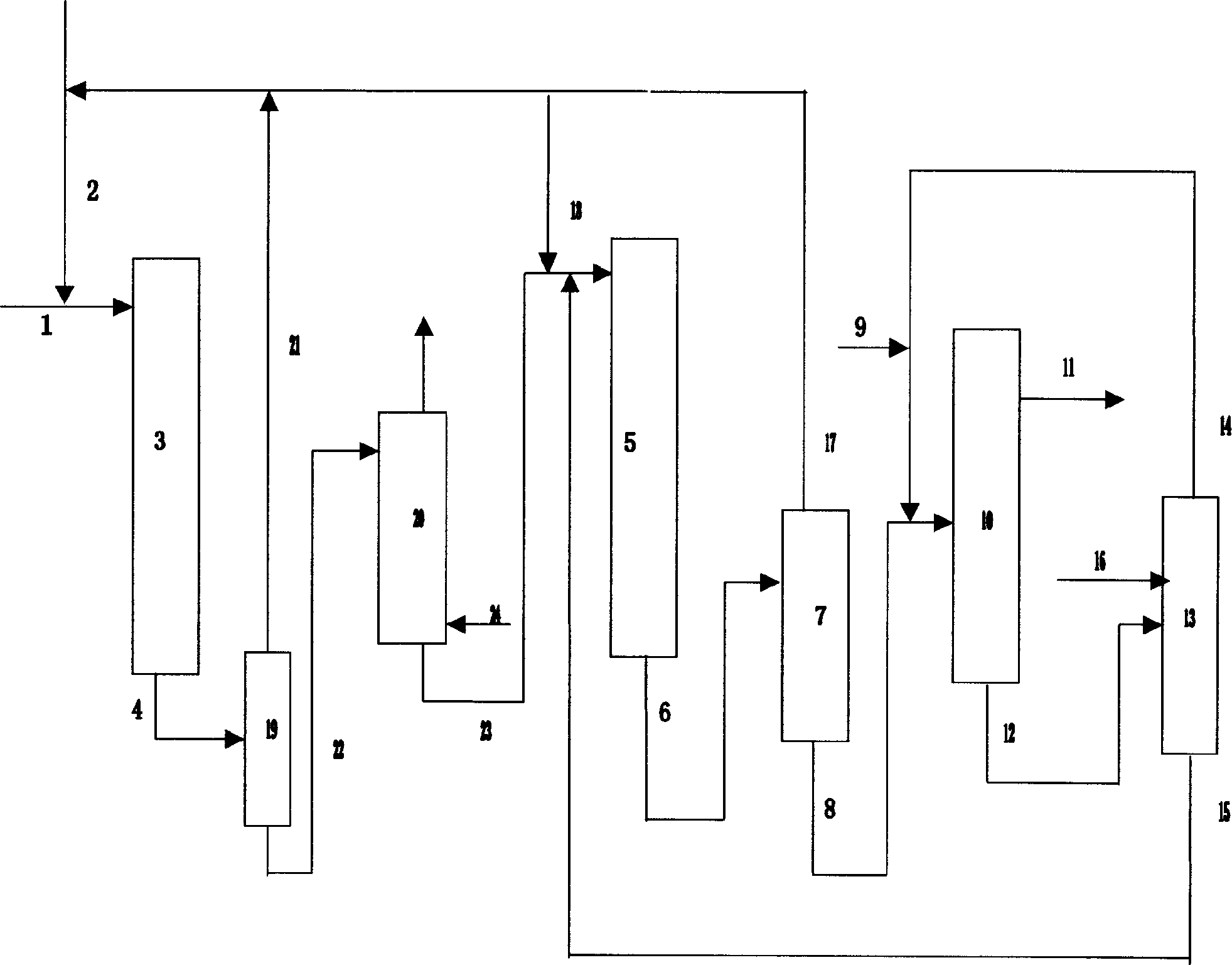

Inferior diesel oil quality change method

ActiveCN1769392AIncrease cetane numberReduce contentTreatment with hydrotreatment processesLiquid productSulfur

The invention provides a method of improving poor diesel. Said method is made up of two technique: quanlity-improving through hydrogenation and solvent extraction. Poor diesel raw material is treated through quality-improving hydrogenation catalysis bed to strip sulfur, nitrogen and aromatic hydrocarbons, then the final liquid product is extracted through solvent oil to make sure that most of the aromatic hydrocarbons are extracted and get clean diesel products which is low in sulfur, nitrogen and aromatic hydrocarbons, but high in cetane ratio, and the extracted aromatic hydrocarbons are circulated to catalysis bed. Group techniques in said invention could deeply decrease the content of sulfur, nitrogen and aromatic hydrogenation in diesel, increase the cetane ratio at the same time through making full use of their own features, therefore, making the quality of the production meet the need of fuel specification and environmental legislation, also maintain a higher diesel rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

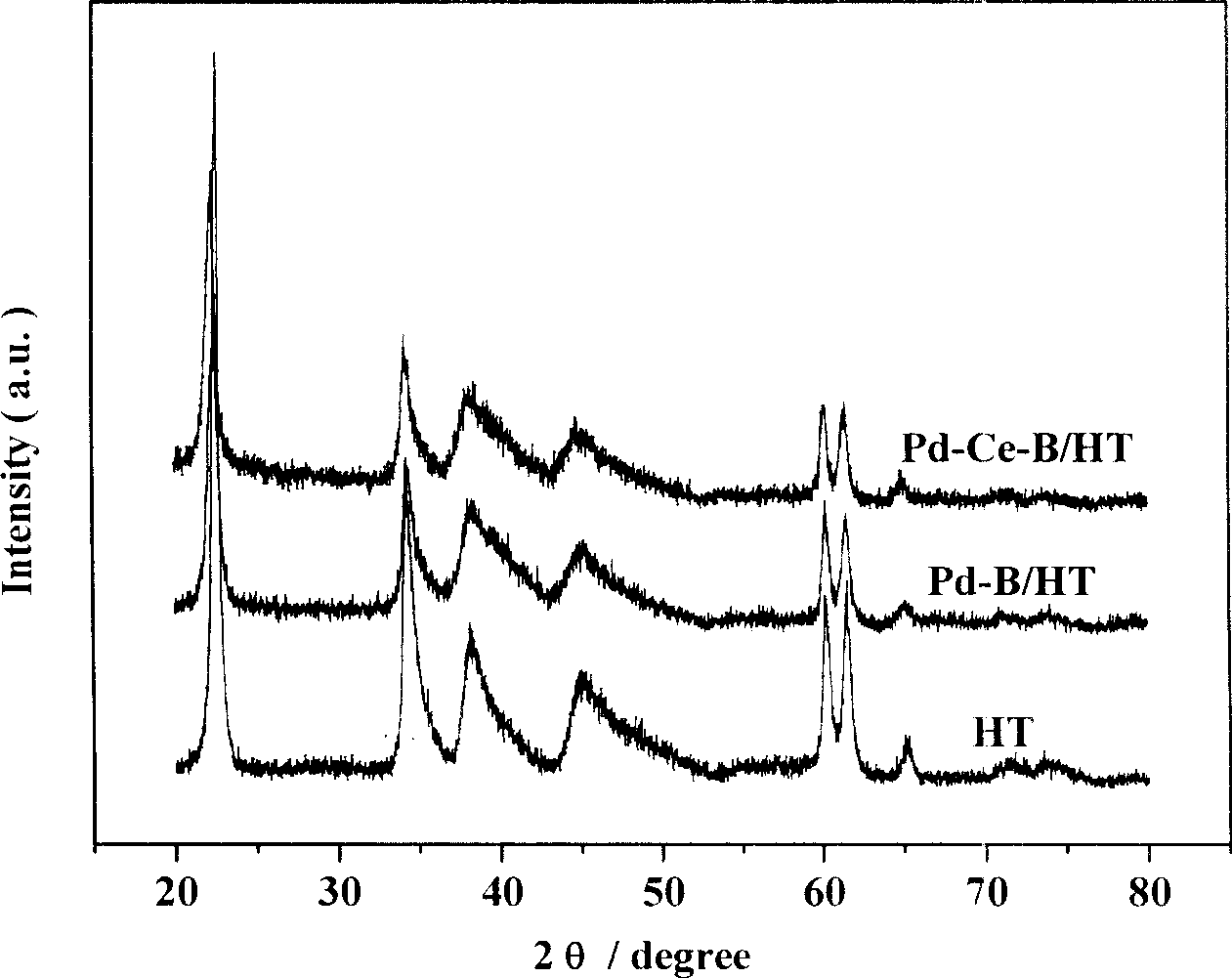

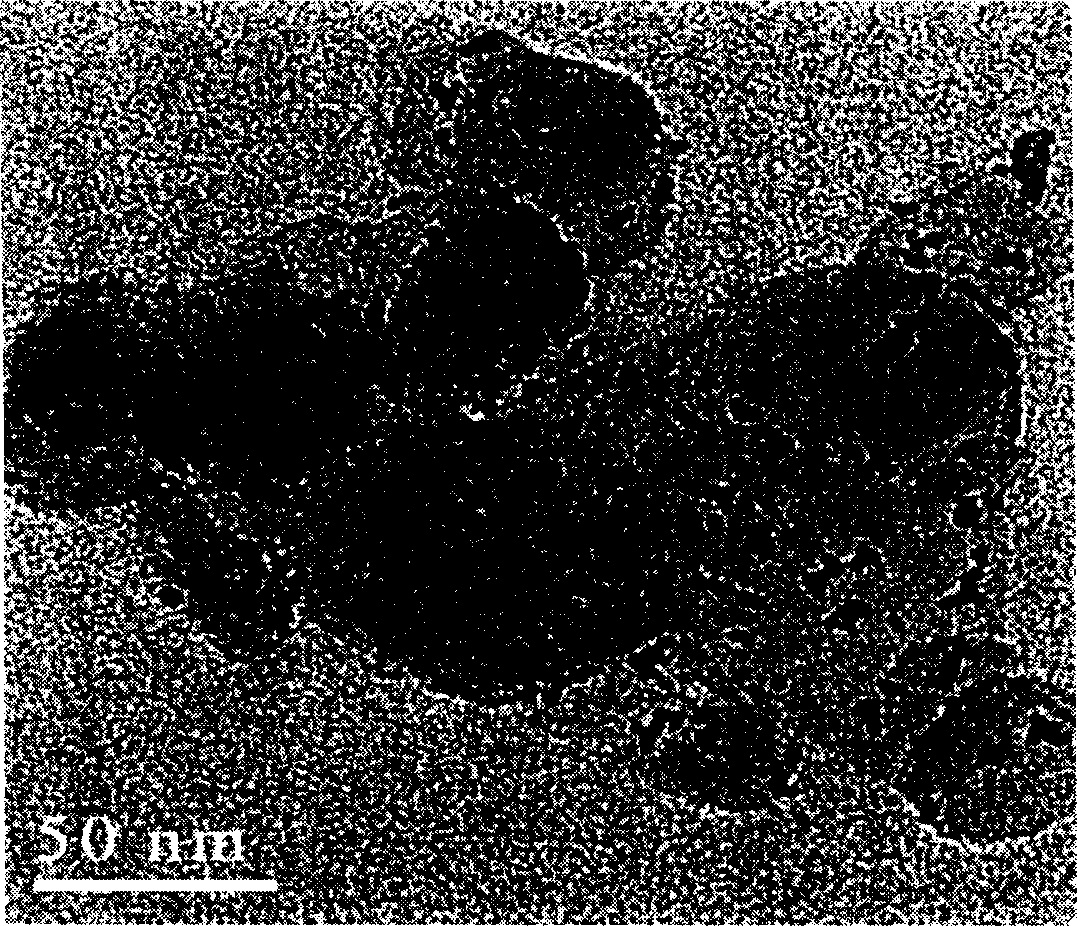

Load-type non-crystal-state alloy hydogenation catalyst and preparing method

InactiveCN1850330AHigh selectivityIncrease acquisition rateOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCyclohexanoneAlloy

The present invention discloses a loaded type amorphous alloy catalyst for preparing cyclohexanone by means of phenol catalytic hydrogenation and its preparation method. Said invention utilizes isochoric impregnation KBH4 reduction method to prepare amorphous alloy catalyst, said preparation method includes the following steps: preparing hydrotalcite carrier; making metal salt precursor solution and hydrotalcite carrier undergo the process of isochoric impregnation treatment; drying; roasting; drop-adding reductant KBH4 solution to make reduction; successively using deionized water and absolute ethyl alcohol to wash black solid precipitate obtained by above-mentioned solution reaction to neutrality so as to obtain the invented amorphous alloy catalyst.

Owner:SHANGHAI NORMAL UNIVERSITY

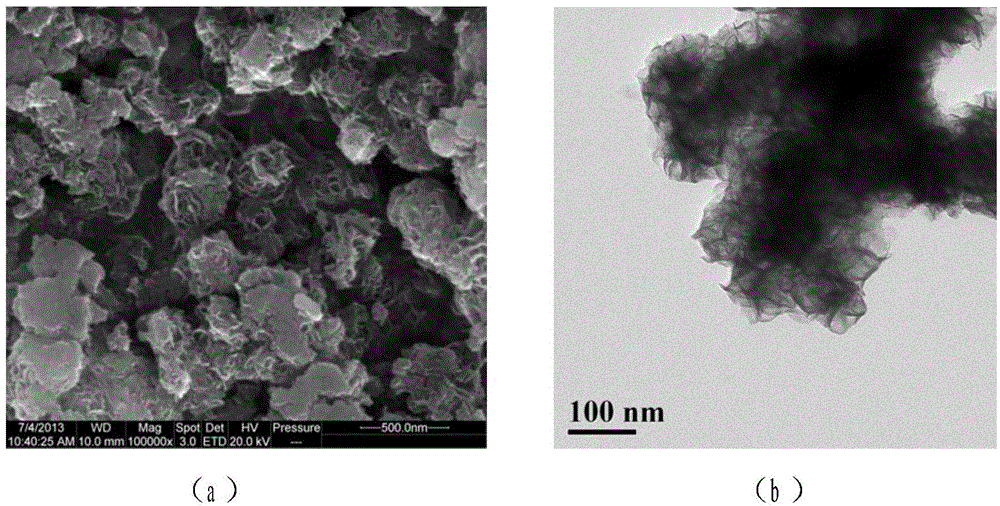

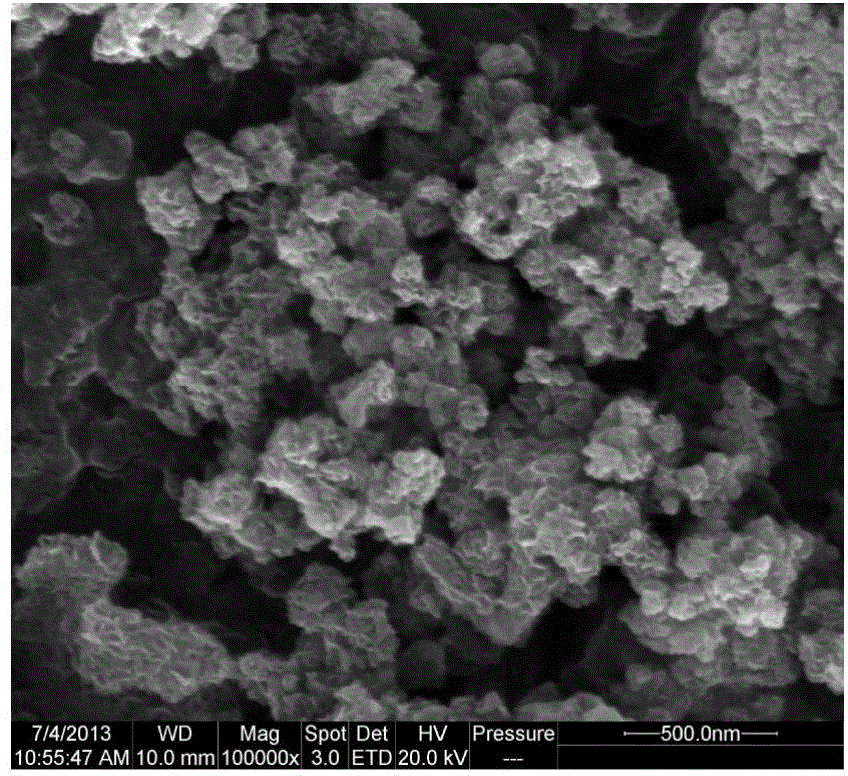

Method for hydro-thermally synthesizing MoS<2> nanoflower with sulfur-containing biological reagent as sulfur source

ActiveCN105366725AWide range of usesNot corrosiveMaterial nanotechnologyMolybdenum sulfidesFiltrationHydrogenation catalysis

The invention discloses a method for hydro-thermally synthesizing a MoS<2> nanoflower with a sulfur-containing biological reagent as a sulfur source. The method comprises the following steps of adding molybdate and L-cysteine or glutathione to deionized water separately for forming a uniform solution, wherein the concentration of the molybdate is 0.002-0.03 M, the mole ratio of S to Mo in raw materials is 4 to 1-2 to 1, and adjusting the pH value of the solution to be 1-7 with hydrochloric acid or ammonia water; shifting the compounded solution to a hydro-thermal reaction kettle with the volume being 100 ml for seal, and conducting a hydro-thermal reaction for 18-36 hours at the temperature of 180-220 DEG C; after the solution is cooled naturally, conducting suction filtration, washing and drying, and obtaining the MoS<2> nanoflower with slice layers accumulated and the surface rough. A MoS<2> product synthesized through the method is at the nanoscale in dimension, is good in dispersion property and has wide application on the aspects of electrode materials, solid lubricant and particularly oil product hydrogenation catalysis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

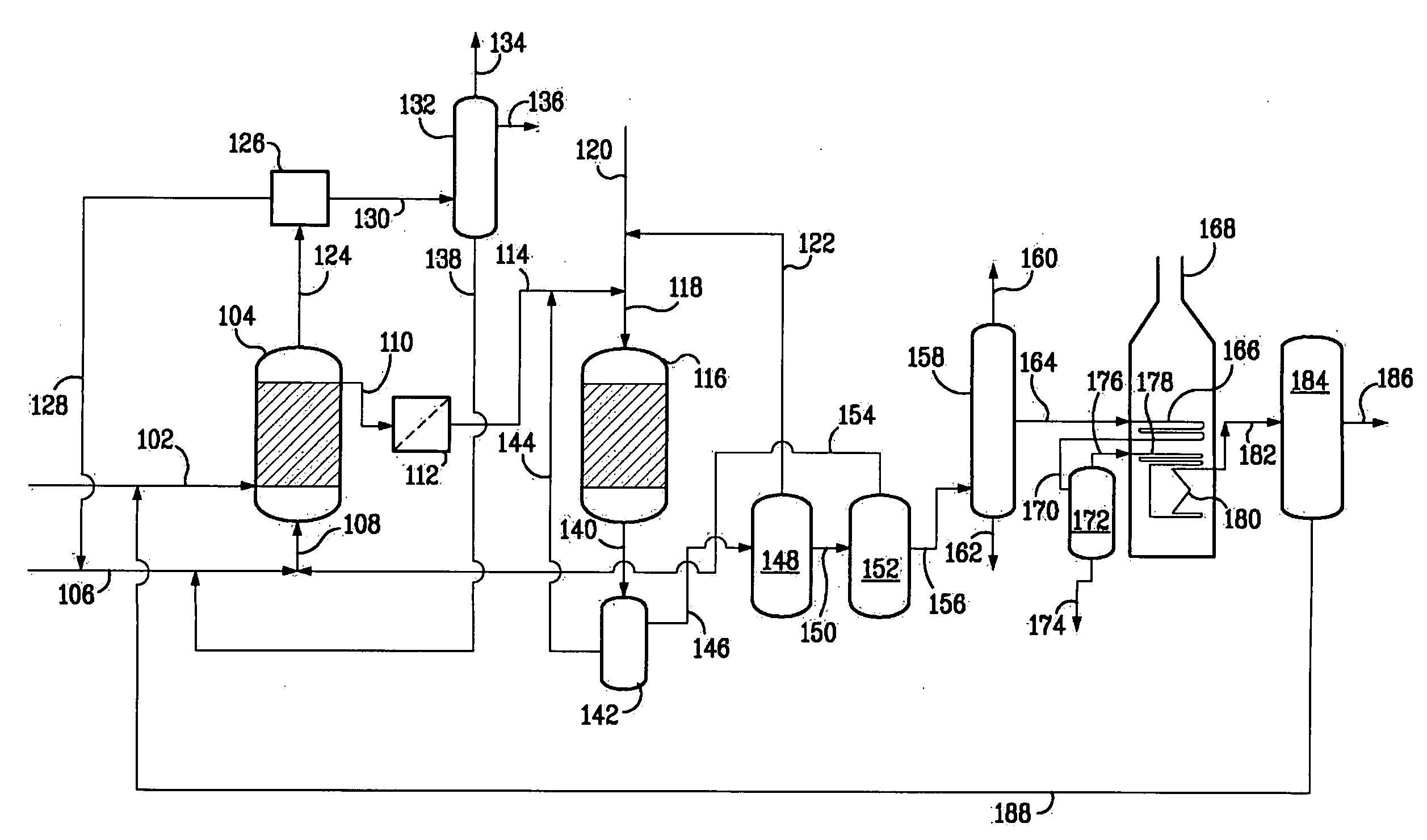

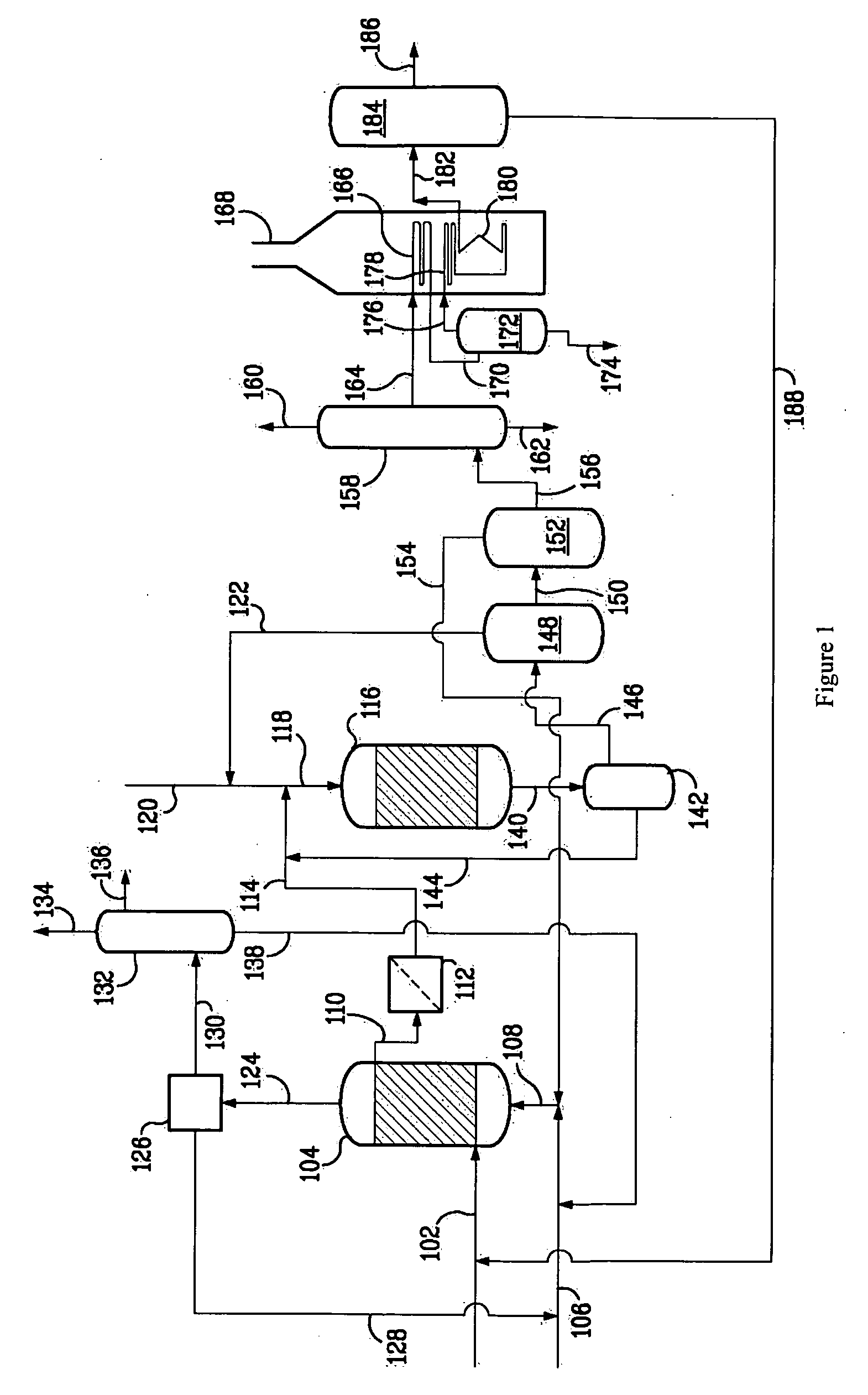

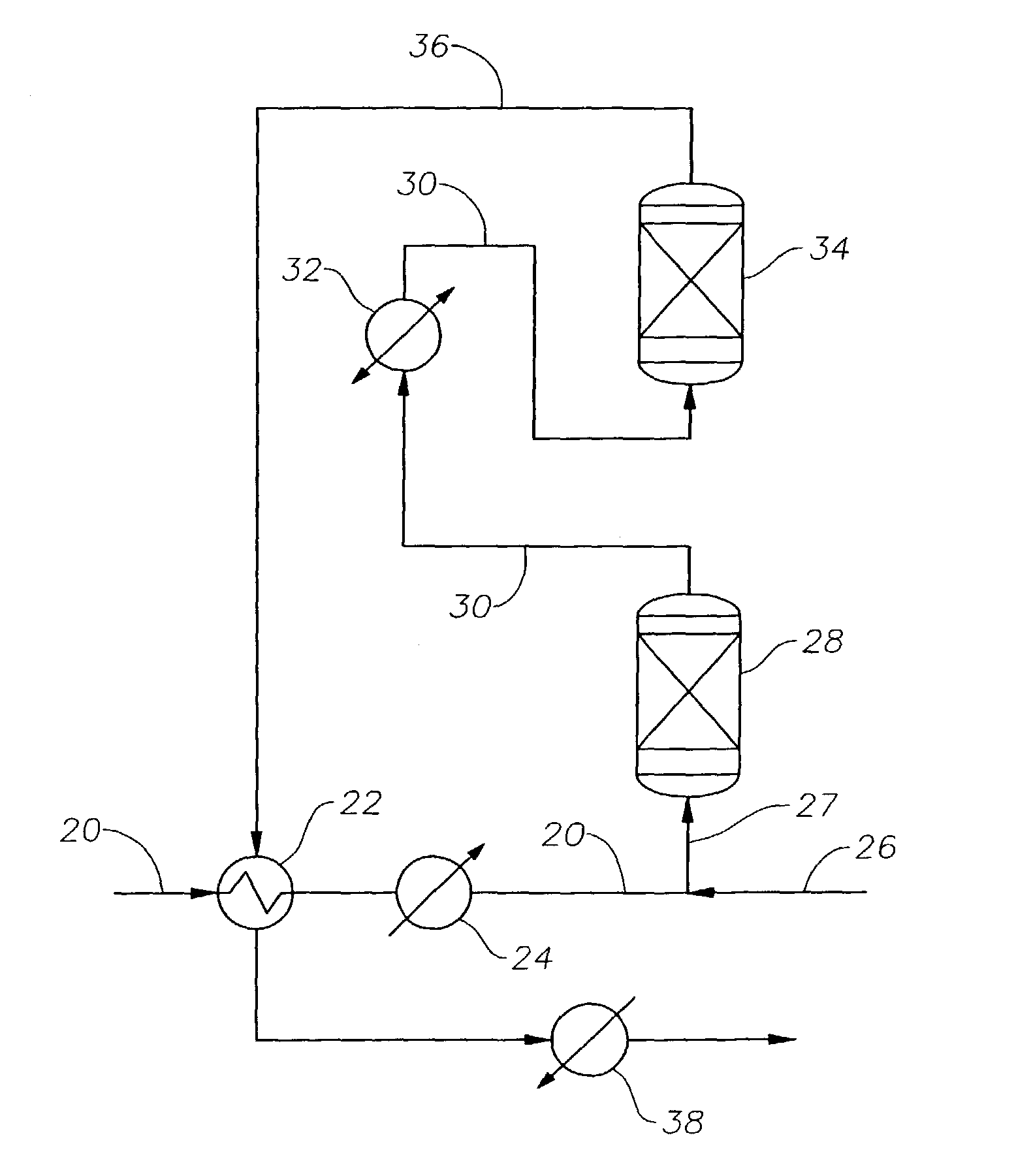

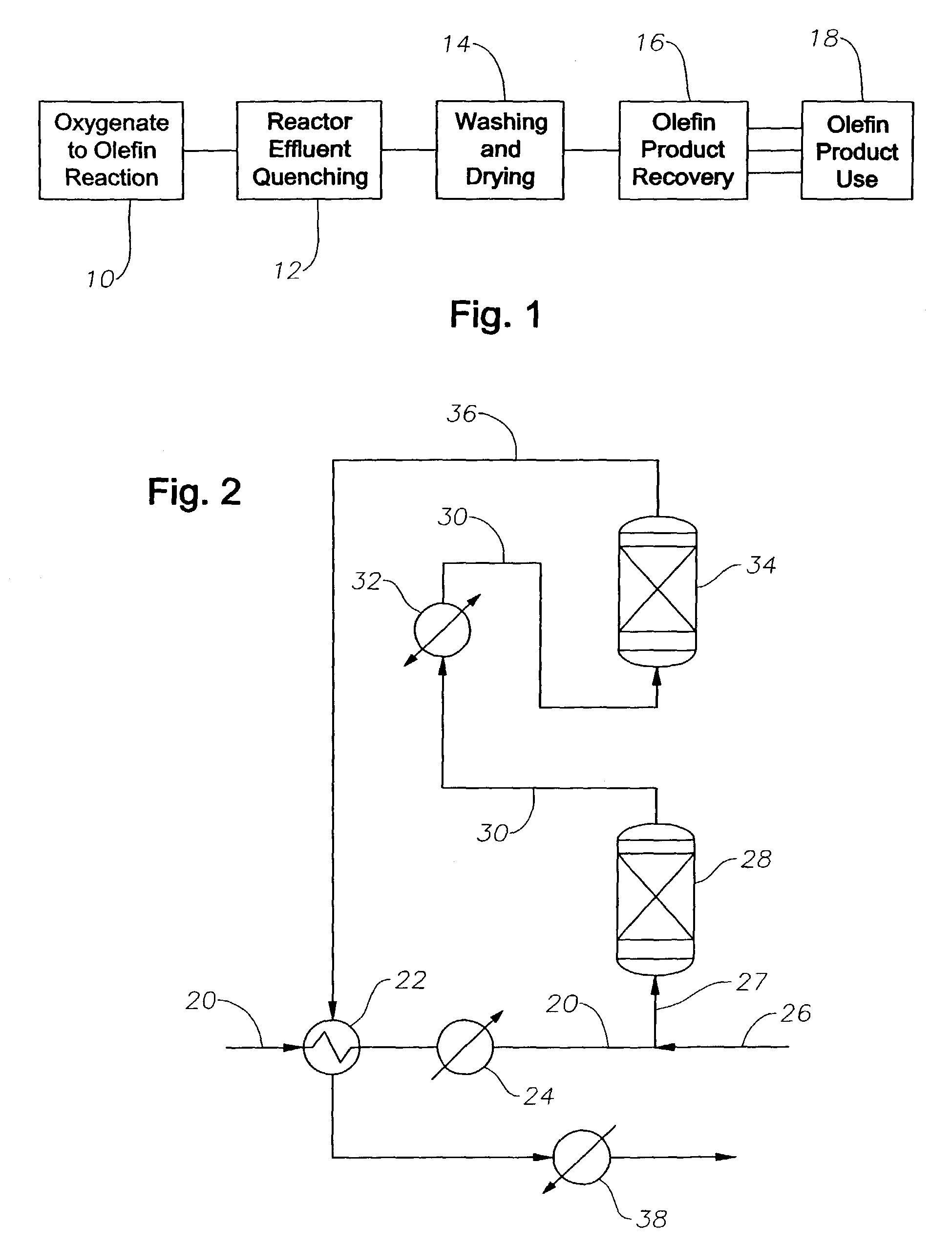

Process and Apparatus for Using Steam Cracked Tar as Steam Cracker Feed

ActiveUS20090272671A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyBoiling pointTar

A process and apparatus are provided for steam cracking heavy feeds, including steam cracked tars. The invention heats a steam cracked tar feed to provide a depolymerized steam cracked tar containing lower boiling molecules than the steam cracked tar feed, hydrogenates the depolymerized steam cracked tar using a hydrogenating catalyst, e.g., a downward flow fixed bed hydrotreater, to provide a hydrogenated steam cracked tar. At least a portion of the hydrogenated steam cracked tar is steam cracked in a steam cracking furnace comprising a convection zone and a radiant zone.

Owner:EXXONMOBIL CHEM PAT INC

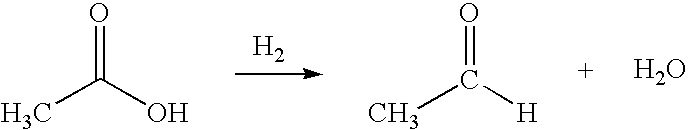

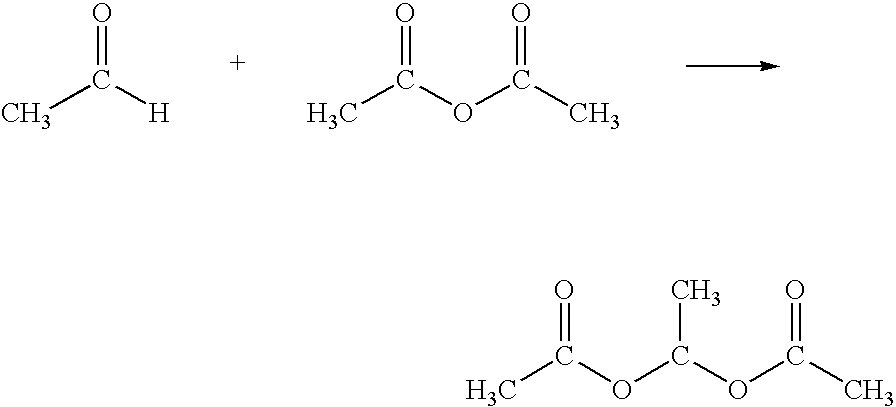

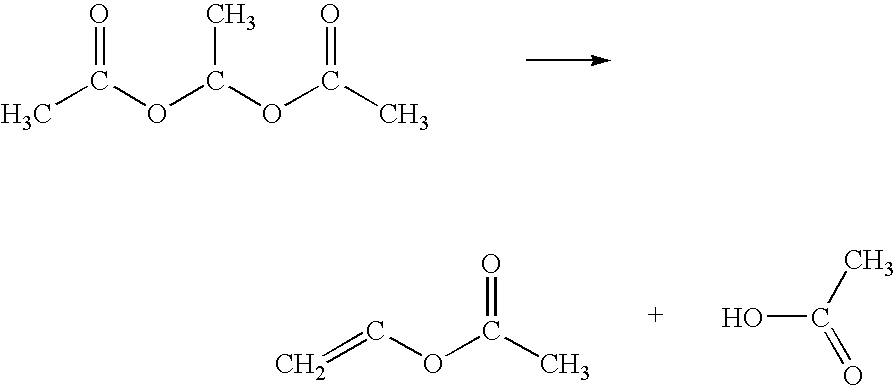

Integrated process for the production of vinyl acetate from acetic acid via acetaldehyde

InactiveUS20100168466A1High selectivity and yieldOrganic compound preparationPreparation from ketenes/polyketenesAcetic anhydridePalladium

This invention provides an integrated multistep economical process for the production of vinyl acetate monomer (VAM) from acetic acid in the vapor phase. First, acetic acid is selectively hydrogenated over a hydrogenating catalyst composition to form acetaldehyde. Acetaldehyde so formed can be converted to ethylidene diacetate via reaction with acetic anhydride. In a subsequent step so formed ethylidene diacetate is thermally decomposed to form VAM and acetic acid. Alternatively, acetaldehyde formed in the first step can selectively be reacted with ketene to form VAM. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and iron supported on silica selectively produces acetaldehyde in a vapor phase at a temperature of about 300° C., which is selectively hydrogenated over platinum supported catalyst to form ethanol and dehydrated over NAFION catalyst to form ethylene at a temperature of about 185° C., which is mixed with molecular oxygen, acetic acid and reacted over a palladium / gold / potassium catalyst supported on titania to form VAM at a temperature of about 150° C. to 170° C.

Owner:CELANESE INT CORP

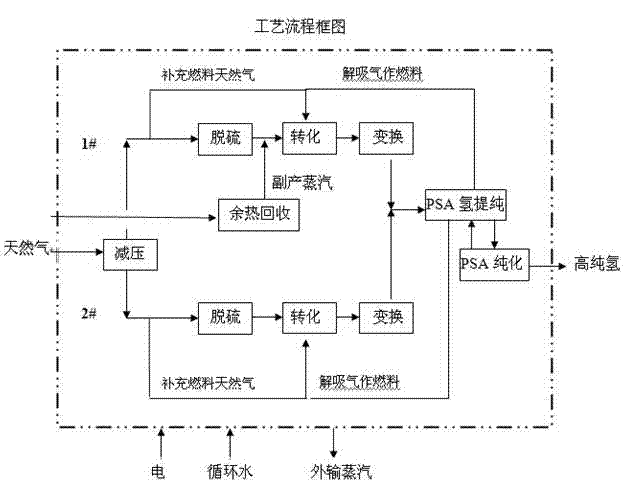

Method for synthesis and purification of hydrogen from natural gas

InactiveCN102849680AImprove conversion efficiencyImprove the purification effectHydrogen separation using solid contactBulk chemical productionHydrogenSulfur

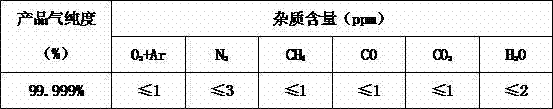

The invention discloses a method for synthesis and purification of hydrogen from natural gas. According to the invention, hydrogenation catalysis is used to remove sulfur in natural gas; both CO-MO hydro-conversion and ZnO desulfurization technology are employed for treatment of feed gas; methane reacts with water vapor at a high temperature in the presence of the conversion catalyst NiO to produce mixed gas of H2, CO, CO2, etc.; the mixed gas of H2, CO and CO2 obtained in conversion procedure of water vapor undergoes a water gas reaction in a shifting furnace filled with a high temperature shift catalyst Fe2O3; CO further reacts with water vapor, and the majority of CO is converted into CO2 and H2; two-stage purification at an ordinary hydrogen section and a purification section is carried out. With the method, H2 with a high purity of more than 99.999% can be obtained.

Owner:SUZHOU JINHONG GAS CO LTD

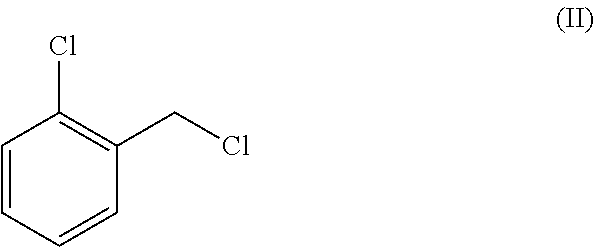

Hydrogenation catalyst composition and method for hydrogenation of conjugated diene polymer

ActiveUS7612148B2High activityImprove economyOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsArylOrganic solvent

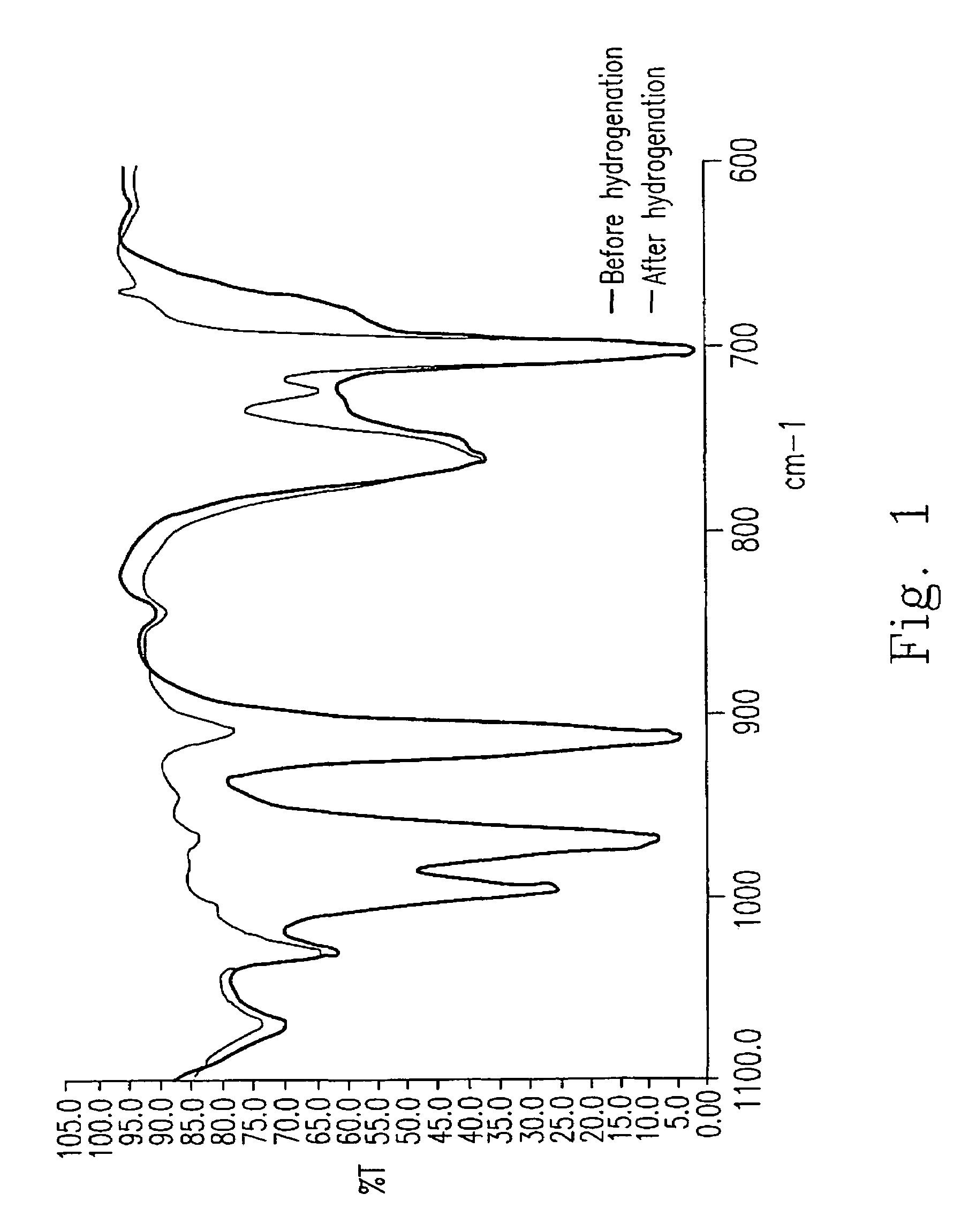

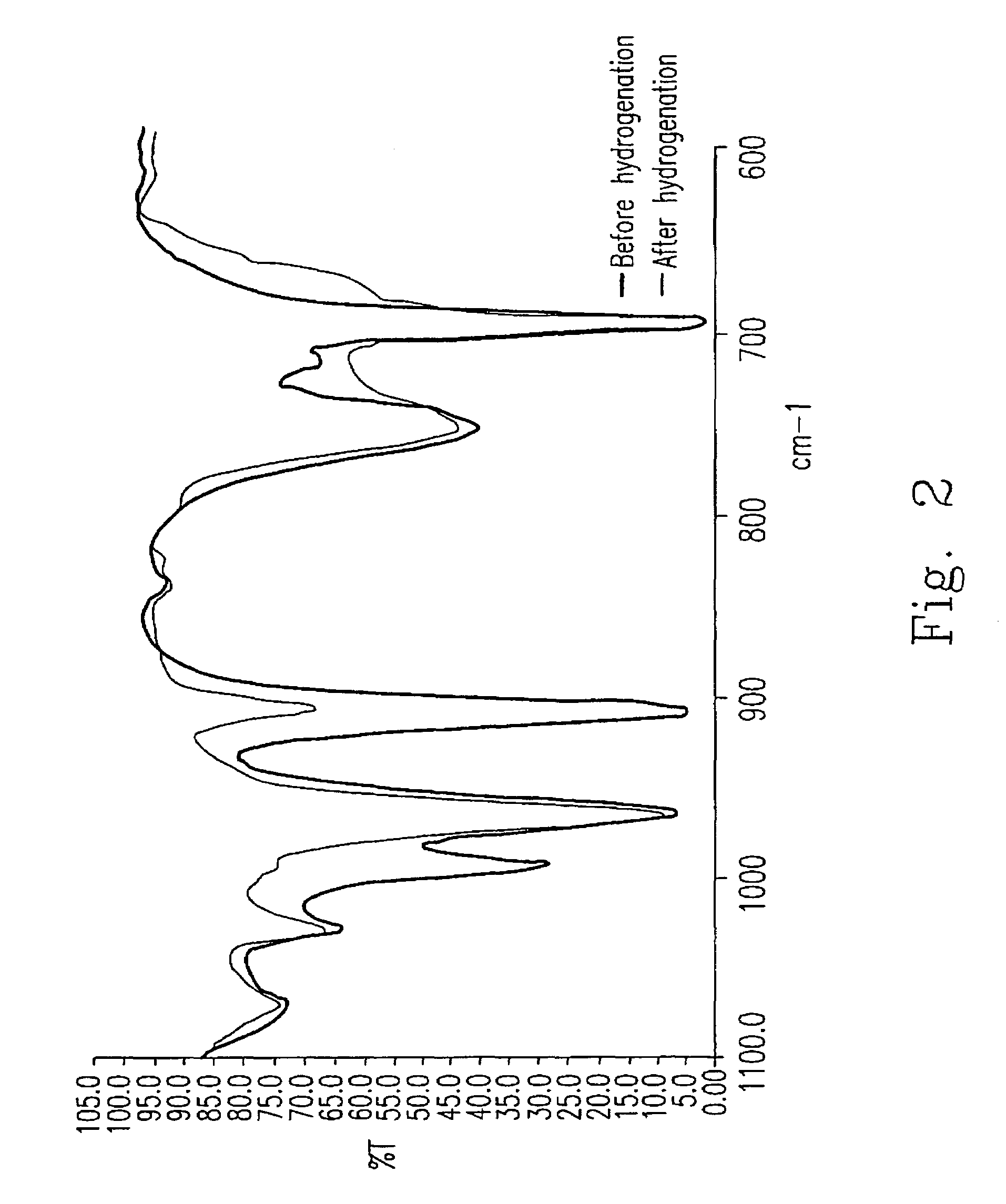

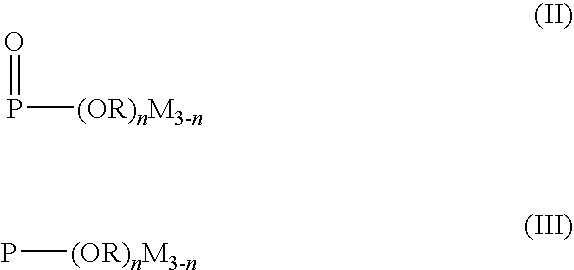

A method for hydrogenation of a conjugated diene polymer is provided. The conjugated diene polymer in an inert organic solvent is brought into contact with hydrogen in the presence of a hydrogenation catalyst composition to selectively hydrogenate the unsaturated double bonds in the conjugated diene units of the conjugated diene polymer. The hydrogenation catalyst composition includes: (a) a titanium compound; (b) a compound represented by formula (II) or formula (III):wherein R is C1-C12 alkyl, C3-C12 cycloalkyl, aryl or alkyl aryl, M is C1-C12 alkyl, C1-C12 alkoxy, aryl, alkyl aryl, phenoxy or hydroxyl, and n=1˜3; and (c) a alkylaluminum compound.

Owner:TSRC CORP

Solvent oil hydrogenation and quality change method

ActiveCN1769391AHigh yieldLow viscosityTreatment with hydrotreatment processesDistillates petroleumHydrogenation catalysis

The invention relates to a method of hydrogenation to improve quality of solvent oil. The invention takes one or more petroleum fractions from petrol, coal oil, diesel oil as raw materials, contactly reacting with hydrogenation catalysis containing ª

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for removal of alkynes and/or dienes from an olefin stream

InactiveUS7115789B2Hydrocarbon by hydrogenationHydrocarbon purification/separationPtru catalystHydrogenation catalysis

The present invention is a process for removing alkynes and / or dienes from an olefin product stream withdrawn from an oxygenate-to-olefins reactor. The process comprises hydrogenating a first olefin stream that has alkynes and / or dienes in the presence of excess hydrogen and a first hydrogenation catalyst. The hydrogenation of the first olefin stream produces a second olefin stream that has unreacted hydrogen. The second olefin stream is contacted with a second hydrogenation catalyst producing a third olefin stream. The third olefin stream has low levels of hydrogen and alkynes and / or dienes.

Owner:EXXONMOBIL CHEM PAT INC

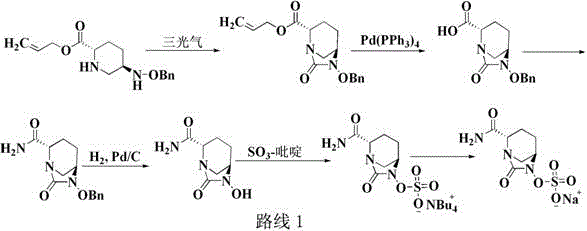

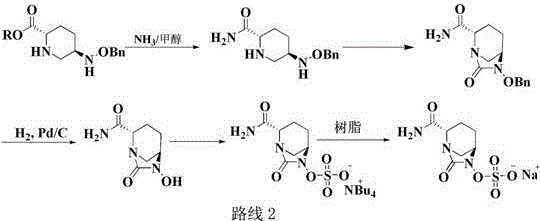

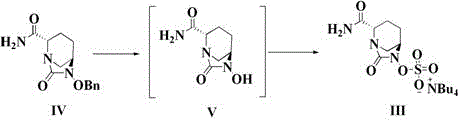

Preparation method of improved avibactam sodium intermediate compound

ActiveCN105753867AAvoid Hydrocatalytic OperationsMild reaction conditionsOrganic chemistryTriethylsilaneHydrogenation catalysis

The invention belongs to the technical field of medical chemistry and particularly relates to a preparation method of beta-lactamase inhibitor drug avibactam sodium and an intermediate of beta-lactamase inhibitor drug avibactam sodium. Triethyl-silane is adopted to realize benzyl removal, hydrogenation catalysis operation in the prior art is omitted, the reaction condition is milder, safety risk is reduced, the product yield and the purity are greatly improved, and the preparation method is more suitable for large-scale production.

Owner:QILU PHARMA HAINAN +1

Purifying crude furan 2,5-dicarboxylic acid by hydrogenation and a purge zone

ActiveUS20180215725A1Lower energy requirementsImprove solubilityOrganic chemistrySolvent extractionFuranPtru catalyst

A process for purifying a crude furan 2,5-dicarboxylic acid composition (cFDCA) by hydrogenation of a FDCA composition dissolved in a hydrogenation solvent such as water, and hydrogenating under mild conditions, such as at a temperature within a range of 130° C. to 225° C. by contacting the solvated FDCA composition with hydrogen in the presence of a hydrogenation catalyst under a hydrogen partial pressure within a range of 10 psi to 900 psi.

Owner:EASTMAN CHEM CO

Self-crosslinking Silicone Pressure Sensitive Adhesive Compositions, Process For Making and Articles Made Thereof

Disclosed herein are self-crosslinking compositions containing a hydrosilation catalyst and the reaction product of a mixture comprising (i) a resinous copolymer having both silicon-bonded hydrogen and silanol groups, and (ii) one or more vinyl-functional polyorganosiloxanes. These compositions have stable post-cure adhesive properties and are suitable for use in electronic applications.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

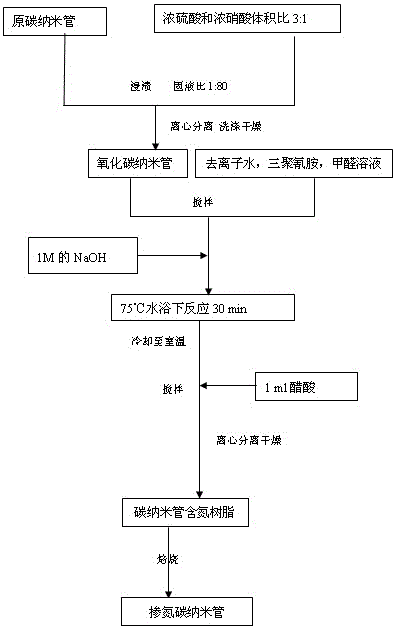

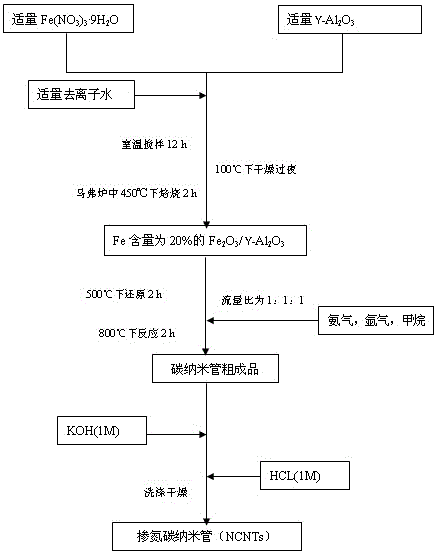

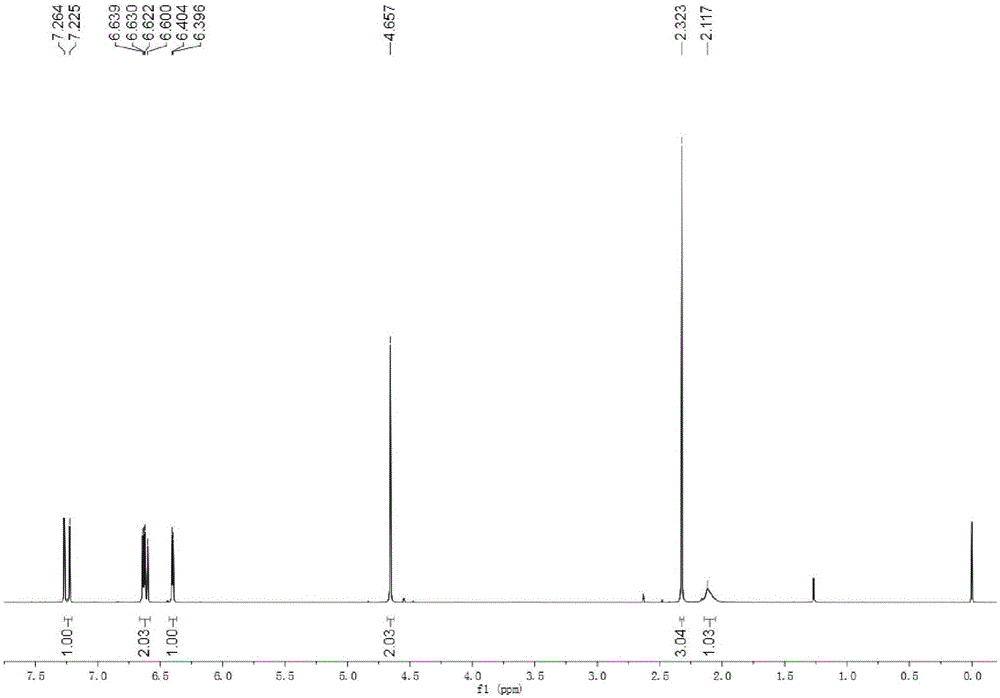

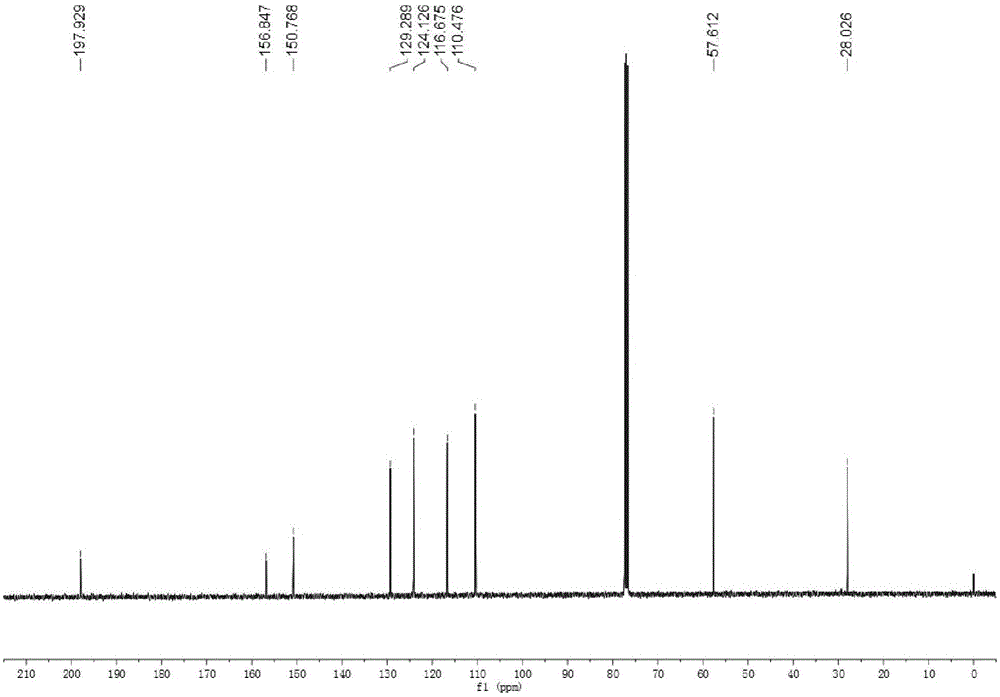

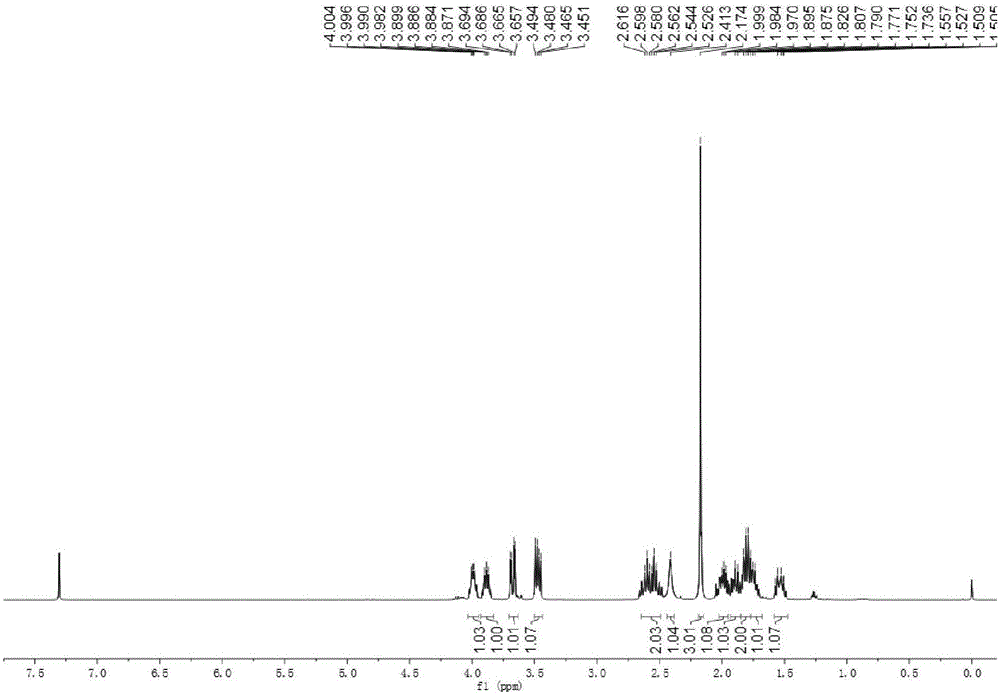

Application of metal-free hydrogenation catalyst in catalyzing hydrogenation reaction of nitrobenzene and derivatives thereof

ActiveCN105669464AEasy to prepareReduce manufacturing costPhysical/chemical process catalystsCarboxylic acid nitrile preparationNitrobenzeneHydrogenation catalysis

The invention discloses application of a metal-free hydrogenation catalyst in catalyzing hydrogenation reaction of nitrobenzene and derivatives thereof. The metal-free hydrogenation catalyst is nitrogen-doped carbon nanotubes prepared by an impregnation process by using melamine as a nitrogen source, or nitrogen-doped carbon nanotubes prepared by an in-situ synthesis process by using ammonia gas as a nitrogen source; and the catalyst is applied to hydrogenation reaction of nitrobenzene and derivatives thereof. The nitrogen-doped carbon nanotubes used as the nitrobenzene hydrogenation catalyst do not support any metal active component, and can achieve the goal of hydrogenation catalysis only by using the nitrogen doping modification process. The whole reaction process avoids the use of noble metals, thereby saving the cost and avoiding environment pollution; and meanwhile, the catalyst can be recycled. The catalyst has the advantages of simple preparation method, low production cost, favorable hydrogenation effect, controllable reaction and environment friendliness, can not cause secondary pollution to the environment, and can be widely used in various hydrogenation reactions.

Owner:XIANGTAN UNIV

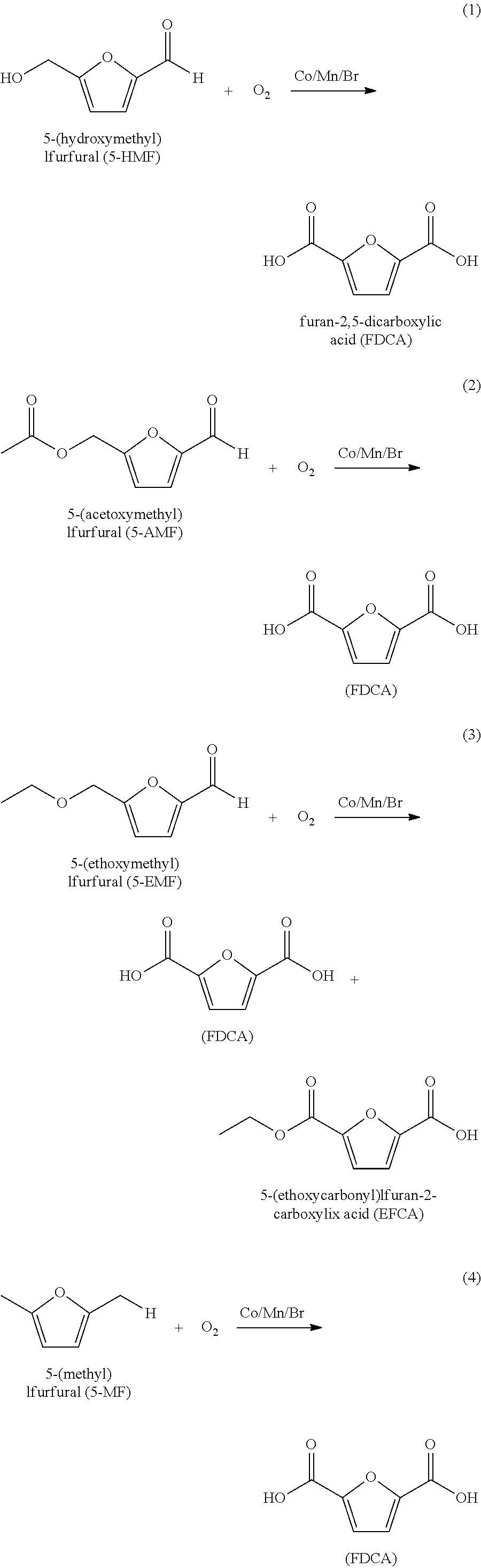

Method for preparing long-chain alkane from biomass derivativeS 5-HMF (hydroxymethyl furfural) or furaldehyde

InactiveCN105130731AHigh yieldReduce dosageHydrocarbon from oxygen organic compoundsAlkaneHydrogenation catalysis

The invention discloses a method for preparing long-chain alkane from biomass derivatives 5-HMF (hydroxymethyl furfural) or furaldehyde. According to the method, the biomass derivatives 5-HMF or furaldehyde are used as raw materials; a condensation product is formed after base catalysis and methyl ketone compound condensation; then, ketonic or alcoholic intermediates of tetrahydrofuran rings are obtained through hydrogenation catalysis; finally, the long-chain alkane is prepared through hydrogenation and ring opening dual catalysis preparation. The method has the advantages that the raw materials can be prepared from biological saccharides through hydrolysis and dehydration; the yield of the alkane is high; the consumption of catalysts is low; the reaction condition is mild; the process is clean and simple; in the reaction process of preparing the alkane from the condensation products, other operations and control are not needed except the program temperature rise; a new path for preparing the long-chain alkane from the biomass derivatives 5-HMF or furaldehyde by a one-pot method is opened up.

Owner:合肥利夫生物科技有限公司

Catalysts for maleic acid hydrogenation to 1,4-butanediol

ActiveUS20060004212A1Good bdo productionCost reductionOrganic compound preparationOxygen compounds preparation by reductionTitanium dioxideGamma-Butyrolactone

This invention relates to a process for catalytically hydrogenating a hydrogenatable precursor in contact with a hydrogen-containing gas and a hydrogenation catalyst comprising one or more active hydrogenation catalyst components on a support comprising titanium dioxide in the rutile crystalline phase to produce 1,4-butanediol and, optionally, gamma-butyrolactone and / or tetrahydrofuran.

Owner:BP CORP NORTH AMERICA INC

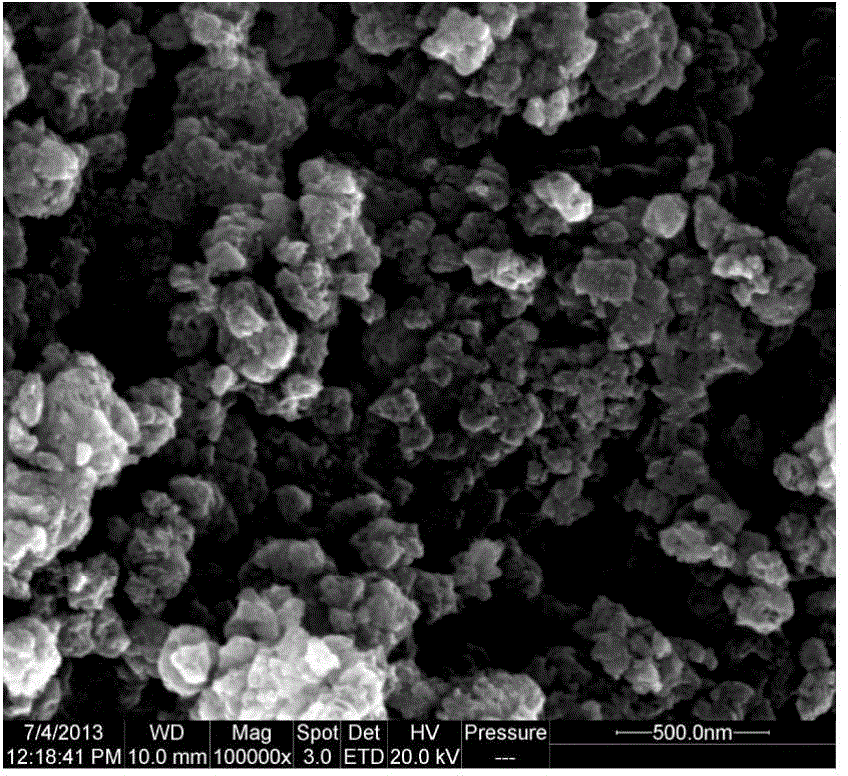

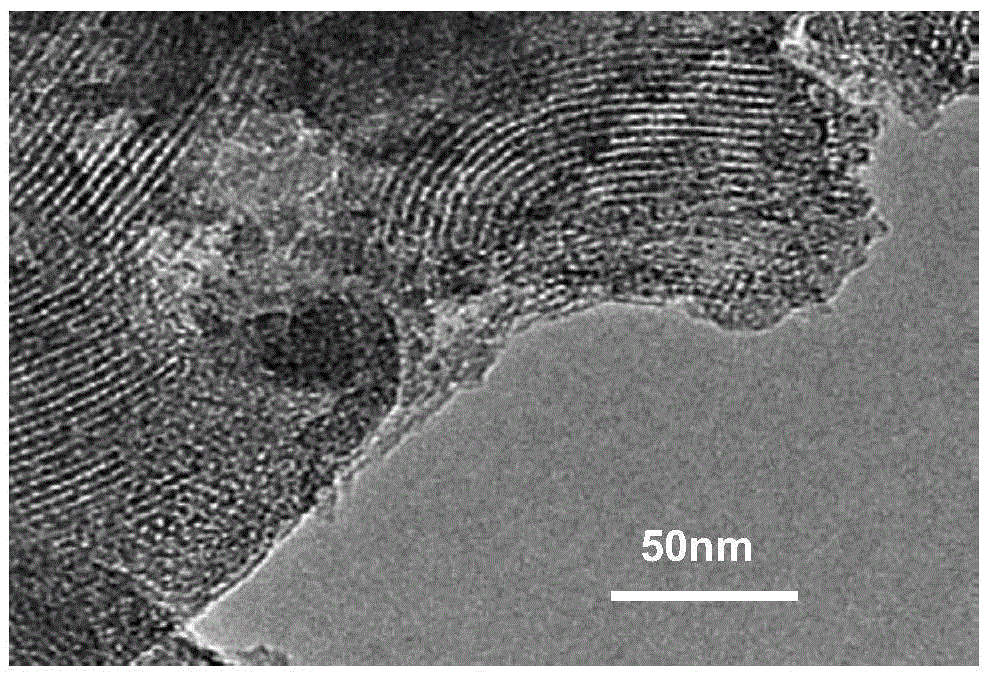

Method for preparing acetylene selective hydrogenation catalyst

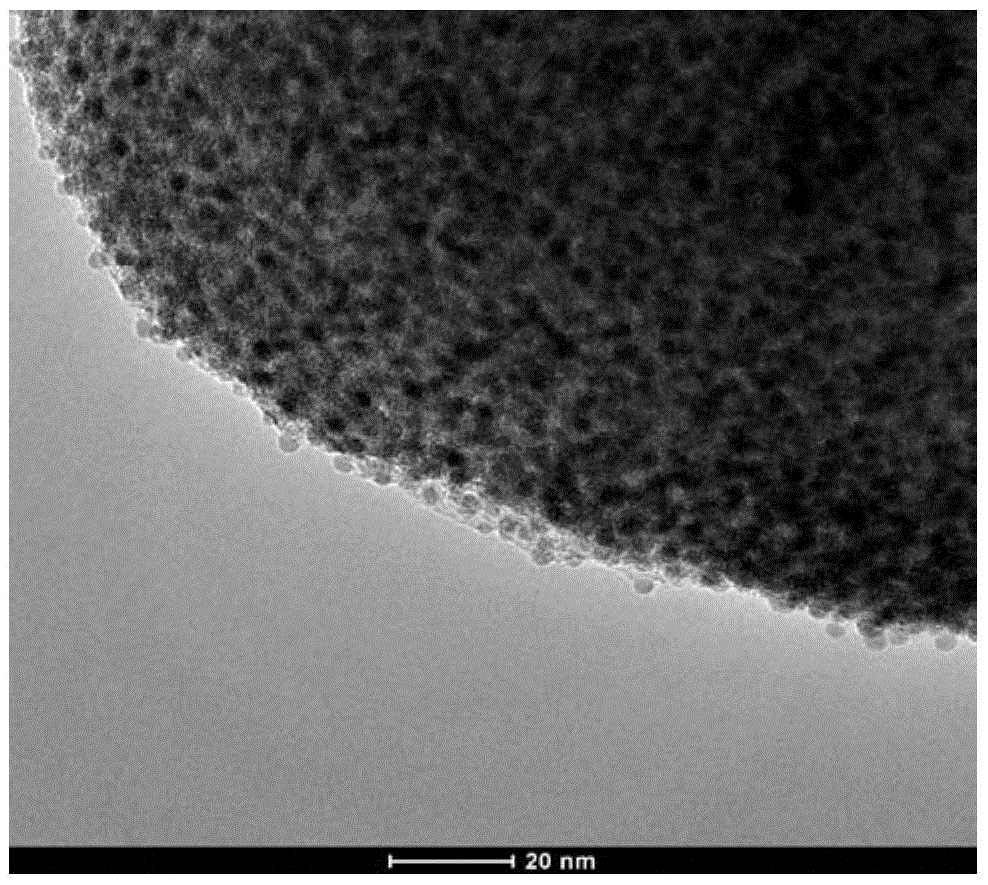

ActiveCN105536851ASimple structureUniform film formationMolecular sieve catalystsCatalyst activation/preparationDispersityNano structuring

The invention discloses a method for preparing an acetylene selective hydrogenation catalyst. The method mainly overcomes the defects that in the prior art, Pd particle size distribution is wide, distribution uniformity is poor, and a metallic oxide serving as a substrate lacks a controllable nano structure. Firstly, a three-dimensional nano structure is provided through a mesoporous material, a metallic oxide is deposited on the structure, and a metallic oxide substrate with the three-dimensional nano structure same as the mesoporous material is obtained; then, by means of the atomic layer deposition, nano Pd metal particles are loaded and deposited on the surface of the metallic oxide substrate, and the loading amount of Pd and the metallic oxide can be adjusted according to different deposition period numbers. The catalyst prepared through the method is of the three-dimensional nano structure and large in specific surface area, the Pd metallic particles are high in dispersity, uniform in distribution, uniform in size and good in activity, selectivity and stability in the acetylene selective hydrogenation catalysis reaction. The method avoids the characteristics that metallic particle size distribution is wide and distribution is not uniform in the preparation process of an impregnation method and a chemical plating method.

Owner:XIAN MODERN CHEM RES INST

Promoters for Cobalt-Tin Catalysts for Reducing Alkanoic Acids

The present invention relates to a process for the formation of an alcohol from an alkanoic acid, the steps of the process comprising: contacting a feed stream containing the alkanoic acid and hydrogen at an elevated temperature with a hydrogenating catalyst comprising from 3 to 25 wt. % of active metals comprising tin and cobalt and a metal promoter selected from the group consisting of noble metals or first metal, the first metal selected from the group of barium, cesium and potassium.

Owner:CELANESE INT CORP

Catalyst having hydrogenation catalysis function, and preparation method and application thereof, and method for hydrogenation treatment of hydrocarbon oil

ActiveCN103480390AHigh catalytic activityHigh metal capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsCelluloseRare-earth element

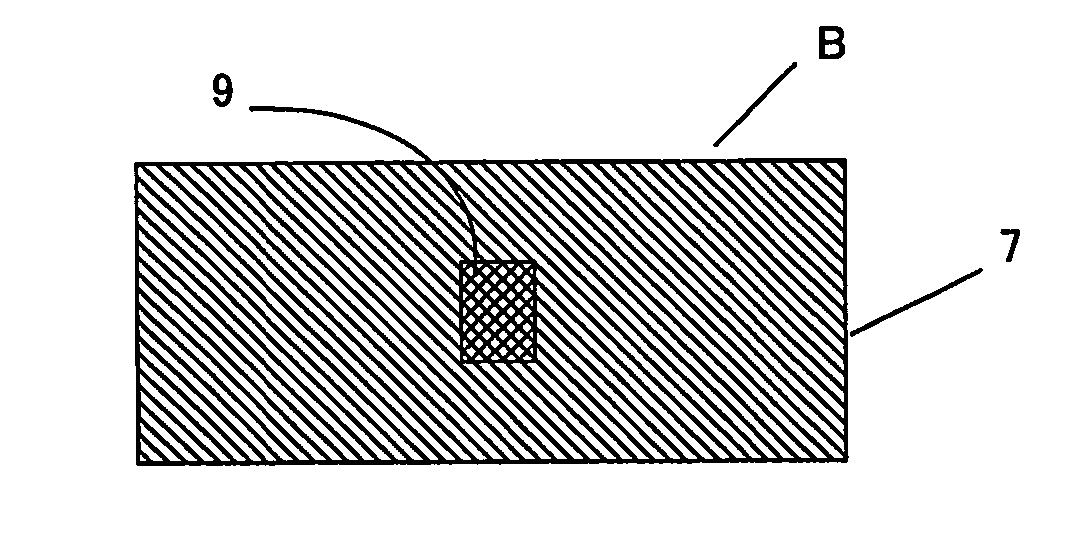

The invention provides a catalyst having a hydrogenation catalysis function, and a preparation method and an application thereof. The catalyst comprises a carrier, and at least one group VIII metal element and at least one group VIB metal element which are loaded on the carrier. The group VIII metal element and the group VIB metal element are separately in a non-uniform distribution along the radial cross section of the catalyst, wherein along the radial cross section of the catalyst, a ratio of Cexternal<VIII> to Cmiddle<VIII> is 0.1-0.9, and a ratio of Cexternal<VIB> to Cmiddle<VIB> is 0.1-0.85. The carrier is a hydrated alumina molded matter prepared from raw materials comprising at least one hydrated alumina, at least one rare earth element-containing compound and at least one cellulose ether. The invention also provides a method for hydrogenation treatment of a hydrocarbon oil. The catalyst provided by the invention shows higher catalytic activity, better catalytic stability and longer service life in a hydrogenation demetalization reaction of the hydrocarbon oil (especially a heavy hydrocarbon oil).

Owner:CHINA PETROLEUM & CHEM CORP +1

Cobalt/ Tin Catalyst for Producing Ethanol

The present invention relates to a process for the formation of alcohols from alkanoic acids, the steps of the process comprising: contacting a feed stream containing the alkanoic acid and hydrogen at an elevated temperature with a hydrogenating catalyst comprising from 3 to 25 wt. % of active metals on a support, wherein the active metals comprise cobalt and tin.

Owner:CELANESE INT CORP

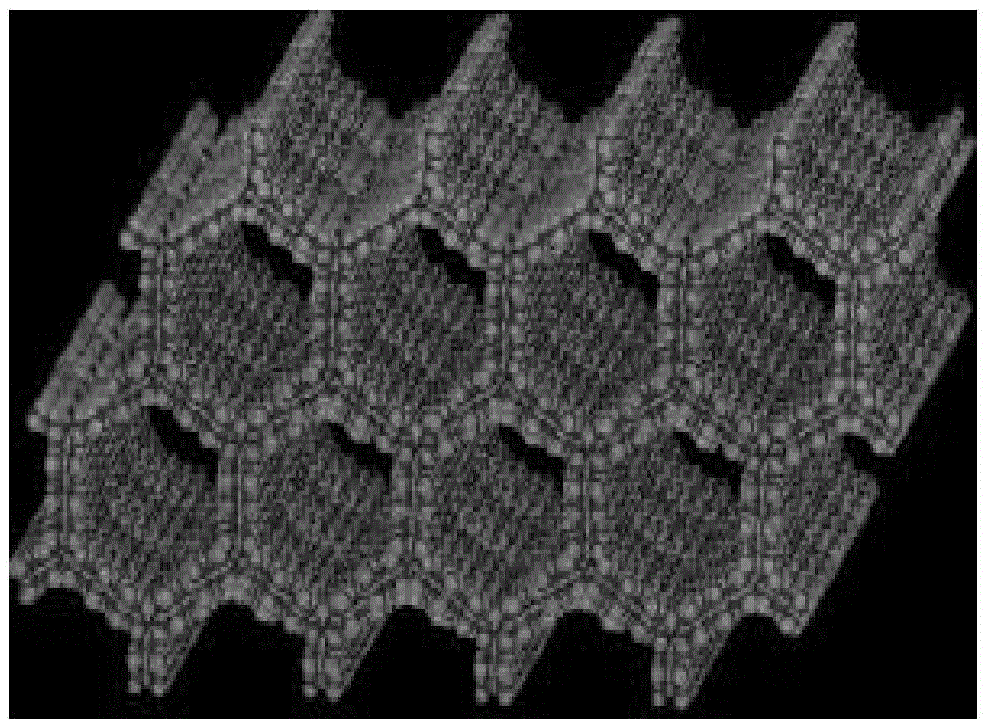

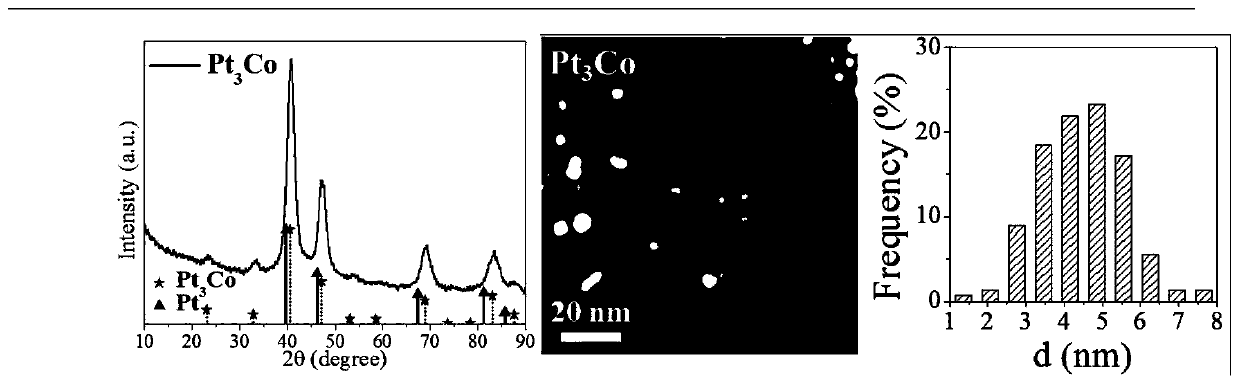

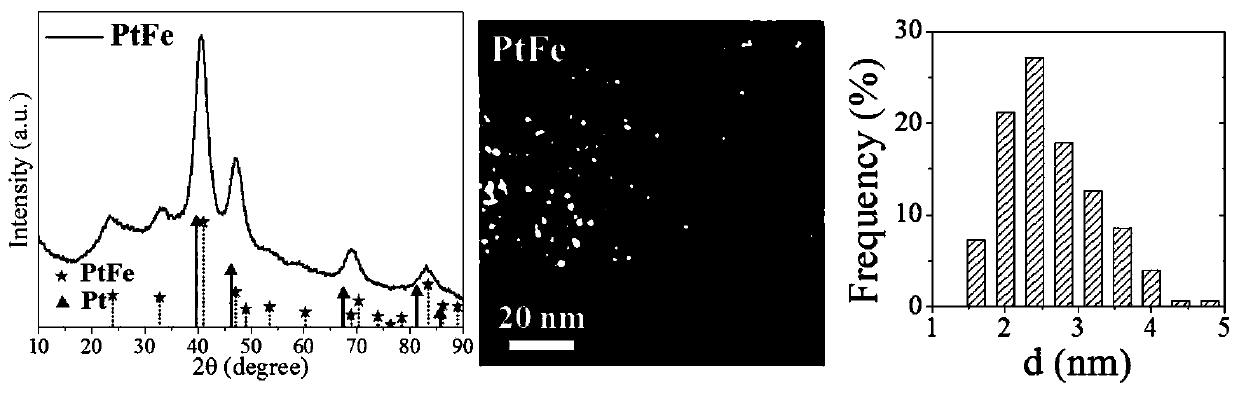

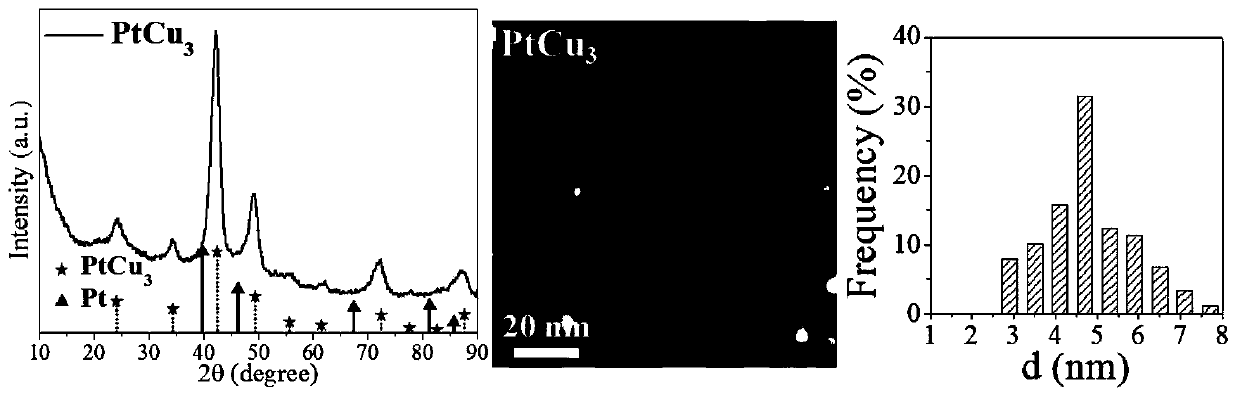

Intermetallic compound composite material and preparation method thereof and application of intermetallic compound composite material and preparation method thereof

The invention provides an intermetallic compound composite material. The intermetallic compound composite material is prepared from sulfur-doped mesoporous carbon and an intermetallic compound loadedon the surface of the sulfur-doped mesoporous carbon. The intermetallic compound is formed by adopting Pt, or Rh or Ir as a base. The invention further provides a preparation method of the intermetallic compound composite material, and further provides application of the intermetallic compound composite material to hydrogenation catalysis. The intermetallic compound composite material is synthesized by regulating and controlling the type and temperature of a metal salt precursor, and the intermetallic compound in the composite material has a small size of less than 5 nm and a high utilizationrate; and the preparation method has universality, the operation is simple, the cost is low, and the industrial production is easy.

Owner:安徽枡水新能源科技有限公司

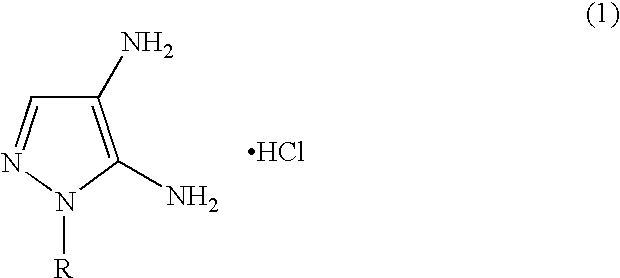

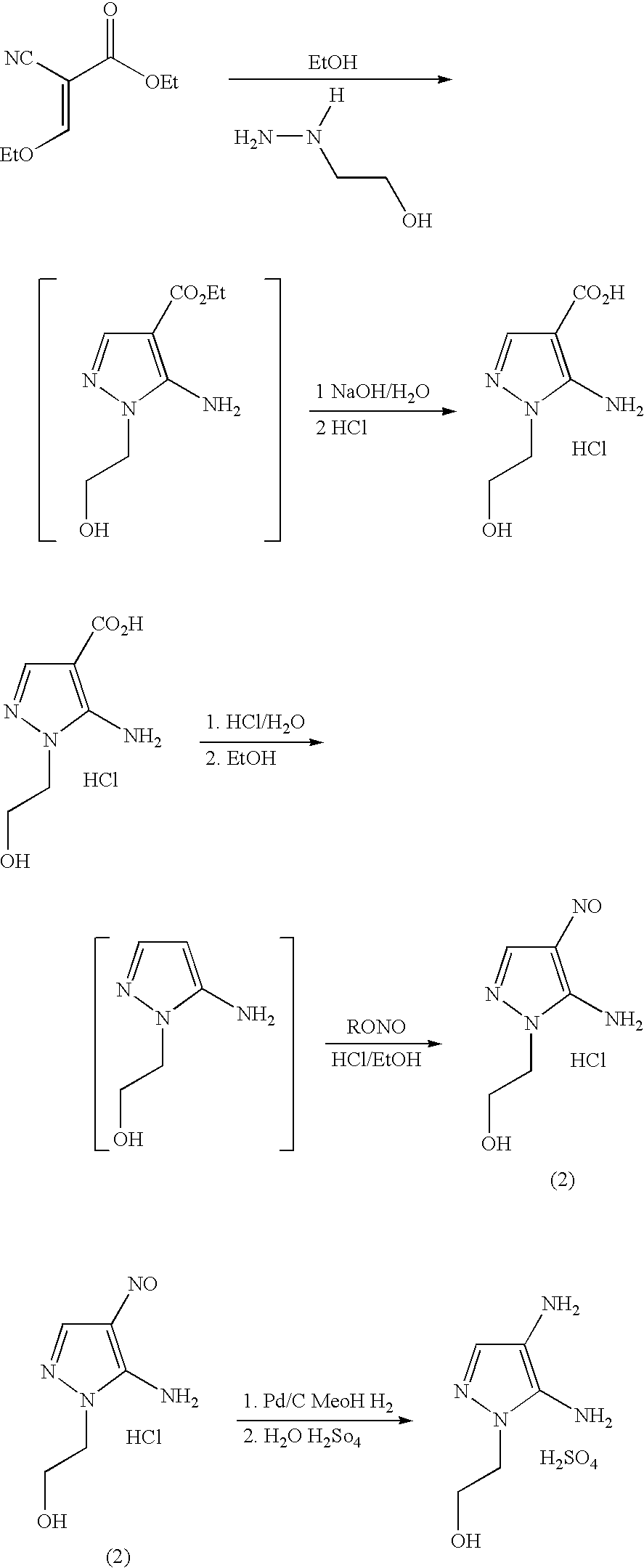

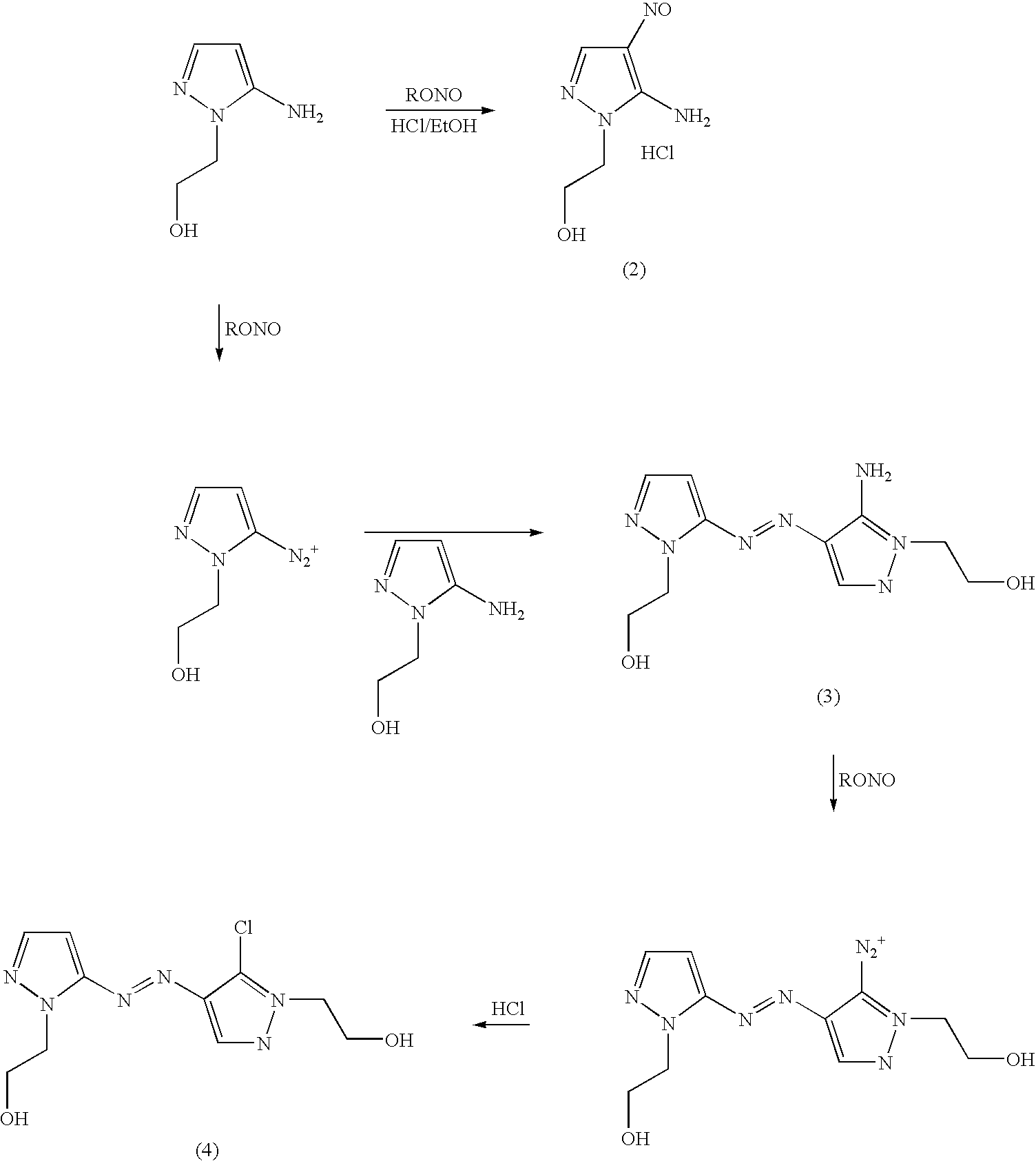

Preparation of 4,5-diamino-1-(substituted)-pyrazole and acid addition salts thereof

Disclosed is an improved process for the preparation of 4,5-diamino-1-(substituted)pyrazoles and acid addition salts thereof by coupling the corresponding 5-amino-1-(substituted)pyrazole with an aromatic diazonium compound to produce an intermediate azo compound and contacting the intermediate azo compound with hydrogen in the presence of a hydrogenation catalyst to produce 4,5-diamino-1-(substituted)pyrazoles. Also disclosed is a decarboxylation process for the preparation of a 5-amino-1-(substituted)pyrazole by heating a solution comprising a 5-amino-4-carboxy-1-(substituted)pyrazole, an inorganic acid and an inert solvent.

Owner:EASTMAN CHEM CO

Cobalt and tin catalysts for producing ethanol

InactiveUS8455702B1Good choiceOrganic compound preparationOxygen compounds preparation by reductionAcetic acidPtru catalyst

The present invention relates to a process for the formation of ethanol from a mixed feed, the steps of the process comprising: contacting a feed stream containing the mixed feed and hydrogen at an elevated temperature with a hydrogenation catalyst comprising from 3 to 25 wt. % of a substantially equal molar ratio of cobalt and tin on a support, wherein the mixed feed comprises 5 to 40 wt. % ethyl acetate and 60 to 95 wt. % acetic acid.

Owner:CELANESE INT CORP

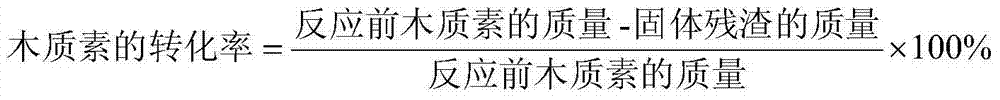

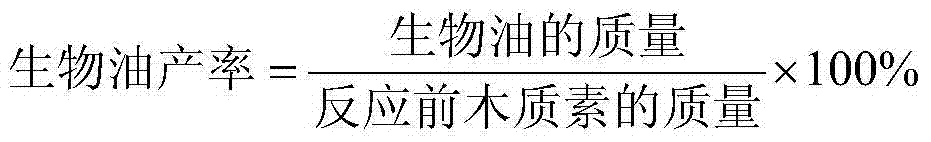

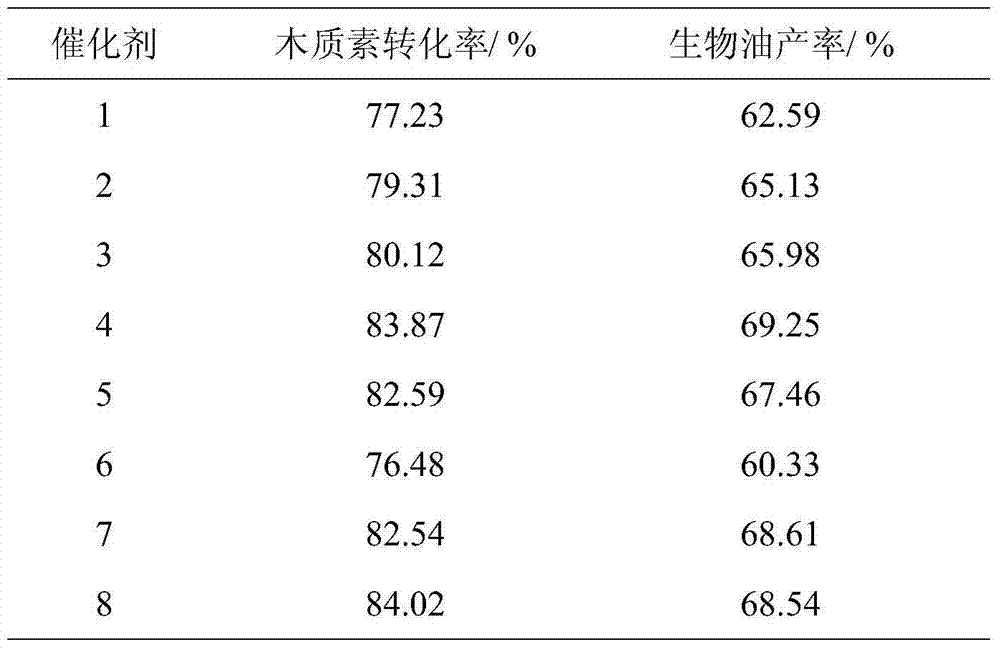

Method for preparing bio-oil through hydrogenation degradation of lignin

InactiveCN104326875AWide variety of sourcesReduce consumptionOrganic compound preparationEther preparationChemical industryReaction temperature

The invention relates to a method for preparing bio-oil through hydrogenation degradation of lignin. The method comprises the following steps: uniformly mixing lignin, a vanadium-based catalyst and a solvent, sealing the obtained mixture in an autoclave, and carrying out hydrogenation catalysis degradation to prepare the bio-oil. A mass ratio of the lignin to the vanadium-based catalyst is 100:1-10:1, a mass / volume ratio of the lignin to the solvent is 1:5-1:30, the reaction temperature is 150-400DEG C, the reaction time is 0.5-5h, the H2 pressure in the reaction is 0.5-6Mpa, and the main components of the prepared bio-oil are aromatic compounds and phenolic compounds. The method has the advantages of cheap catalyst, environmental protection, easy large-scale production, mild reaction conditions, high lignin conversion rate and high bio-oil yield; and the bio-oil contains few components and is an important chemical industry raw material.

Owner:SOUTHEAST UNIV

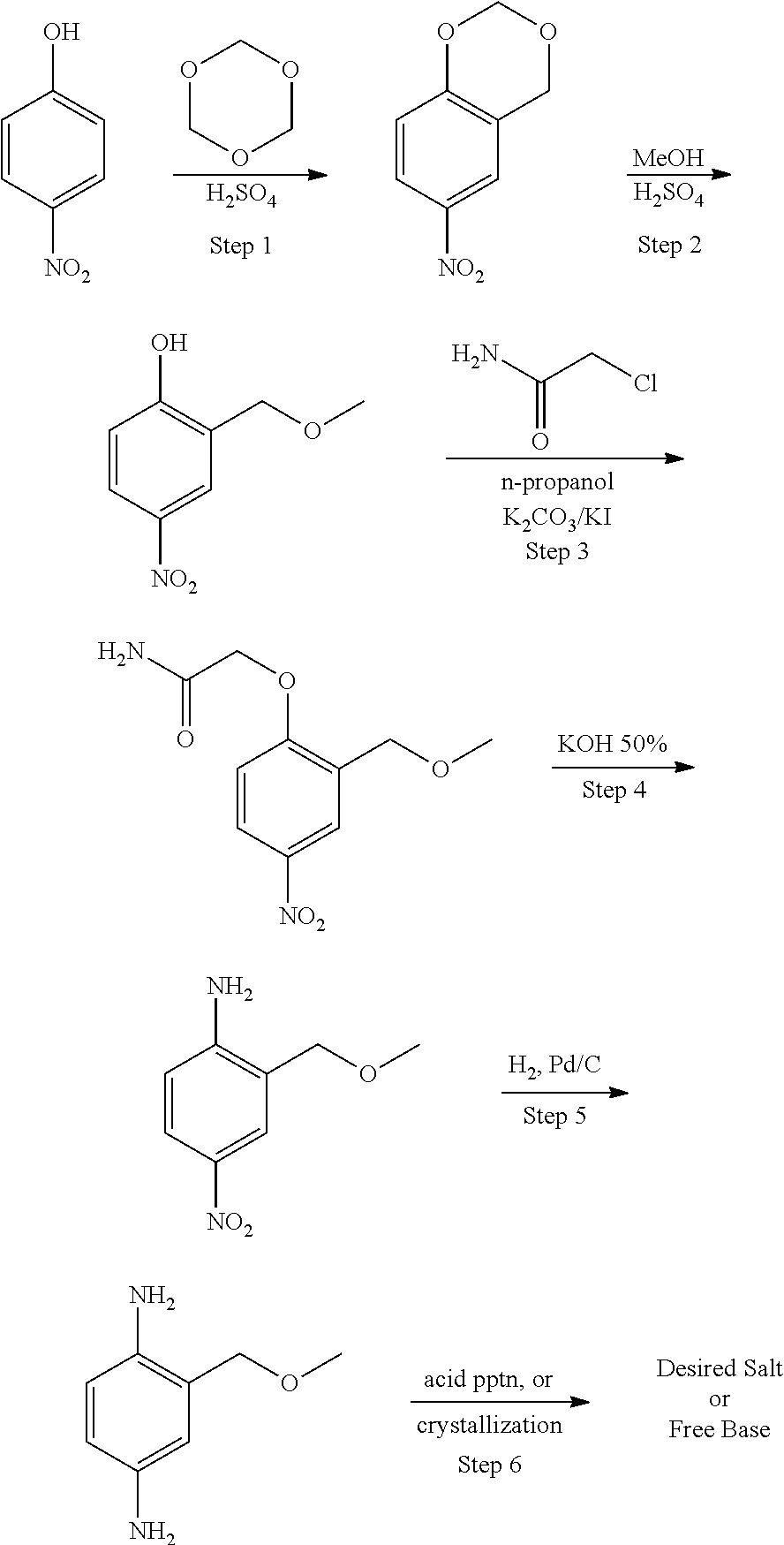

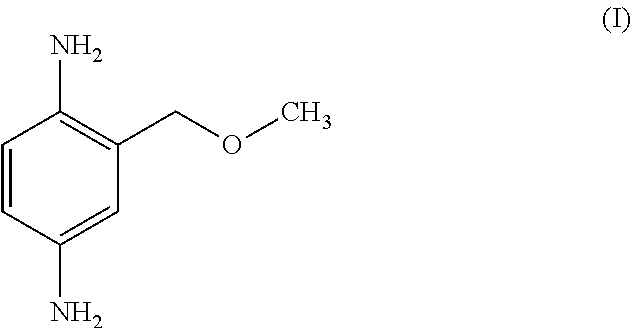

Methods of Synthesizing 2-Methoxymethyl-1,4-Benzenediamine

ActiveUS20120130128A1Organic compound preparationAmino compound preparationNitrobenzeneOrganic chemistry

Disclosed is a method of making 2-methoxymethyl-1,4-benzenediamine that includes hydrogenating 1-benzylamino-2-(methoxymethyl)-4-nitrobenzene in the presence of a hydrogenation catalyst.

Owner:WELLA OPERATIONS US LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com