Intermetallic compound composite material and preparation method thereof and application of intermetallic compound composite material and preparation method thereof

A technology of intermetallic compounds and composite materials, applied in the field of intermetallic compound composite materials, can solve problems such as difficult to obtain, difficult to operate, unfavorable to industrial production and manufacturing, and achieve unique activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present application also provides a preparation method of the above-mentioned intermetallic compound composite material, comprising the following steps:

[0042] Mixing sulfur-doped mesoporous carbon, a metal salt precursor and a solvent, and drying to obtain an initial mixture; the metal salt precursor is one of Pt-based salt, Rh-based salt and Ir-based salt and other metal salts;

[0043] The initial mixture is heat-treated in a reducing atmosphere to obtain an intermetallic compound composite material; the temperature of the heat treatment is 800-1100°C.

[0044] The intermetallic compound composite material provided by this application can be prepared by impregnation and heat treatment. This method is universally applicable to various metals, and the process operation is simple and easy.

[0045] Specifically, in the process of preparing the intermetallic compound composite material, the applicant first mixes the sulfur-doped mesoporous carbon, the metal salt pr...

Embodiment 1

[0058] a. 0.5g dithiophene, 0.5g SiO 2 Airgel and 0.25g Co(NO 3 ) 2 ·6H 2 O was dispersed in tetrahydrofuran and stirred evenly, and the solvent was removed by rotary evaporation to obtain a uniform mixture; the resulting mixture was transferred to a quartz crucible or a corundum crucible, and placed in a tube furnace, and then nitrogen was introduced as a protective gas. Raise the temperature to 800°C at a rate of 5°C / min and keep it for 2h; then cool down to room temperature naturally, and keep the normal pressure in the tube furnace; then transfer the obtained product to a flask, add about 30-50mL of 2mol / L NaOH solution, and stir for 36h ~48h, carry out the first alkali etching; then centrifuge the solution in a centrifuge at 8000r~10000r for 5min~10min; then pour off the centrifuged supernatant, and transfer the lower solid to the flask again, Add about 30-50mL of 2mol / L NaOH solution, stir for 12h-36h, and carry out the second alkali etching; then centrifuge and wash ...

Embodiment 2

[0064] A. step is identical with embodiment 1;

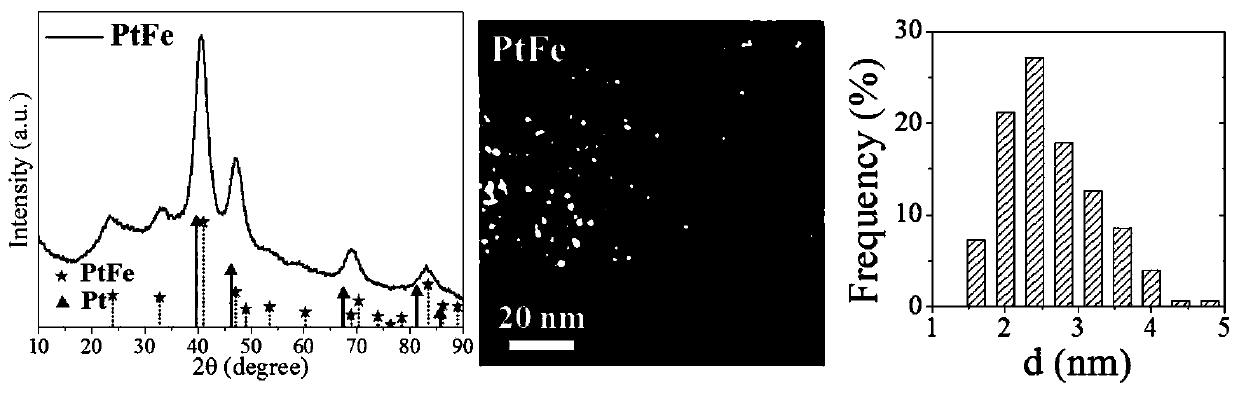

[0065] b. the obtained sulfur-doped mesoporous carbon nanomaterial 50mg and 10mg metal salt (guaranteed H 2 PtCl 6 ·6H 2 O and FeCl 3 ·6H 2 Pt in O: Fe = 1: 1) was placed in a 100ml round bottom flask, solvent water was added, stirred for 6-10 hours, and after rotary evaporation and drying, a uniformly mixed precursor was obtained;

[0066] c. Put the precursor into the tube furnace, and pass argon hydrogen into the tube furnace (the volume fraction is 95% Ar+5% H 2 ) as a protective gas, the tube furnace was heated up to 900 °C at a rate of 5 °C / min, and kept for 2 hours; finally, it was annealed naturally to room temperature, and the tube furnace was kept at normal pressure to obtain a PtFe intermetallic compound composite material.

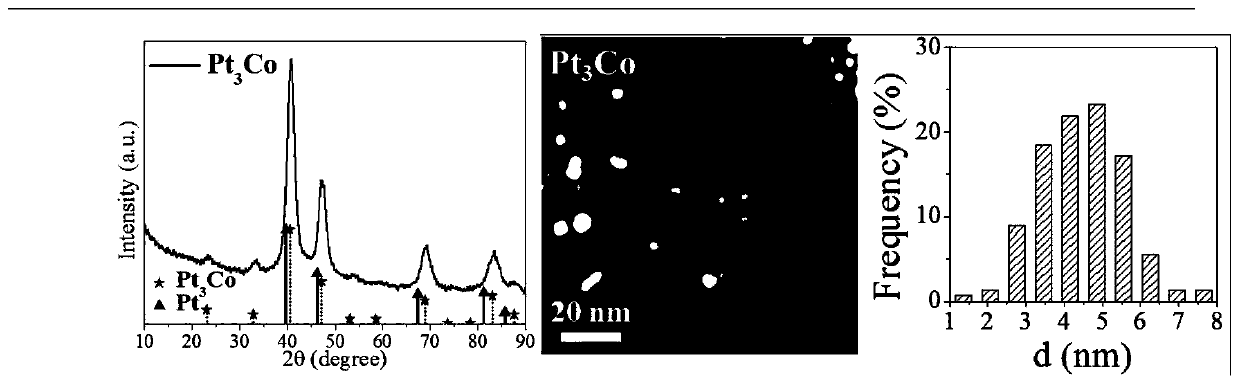

[0067] figure 2 XRD, HADDF-STEM and particle size distribution photos of the PtFe intermetallic phase in the PtFe intermetallic compound composite material provided by Example 2 of the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com