Patents

Literature

114821 results about "Composite material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A composite material (also called a composition material or shortened to composite, which is the common name) is a material made from two or more constituent materials with significantly different physical or chemical properties that, when combined, produce a material with characteristics different from the individual components. The individual components remain separate and distinct within the finished structure, differentiating composites from mixtures and solid solutions.

Medical film

InactiveUS7718556B2Good biocompatibilityHigh strengthSuture equipmentsBiocideGelatin filmThin membrane

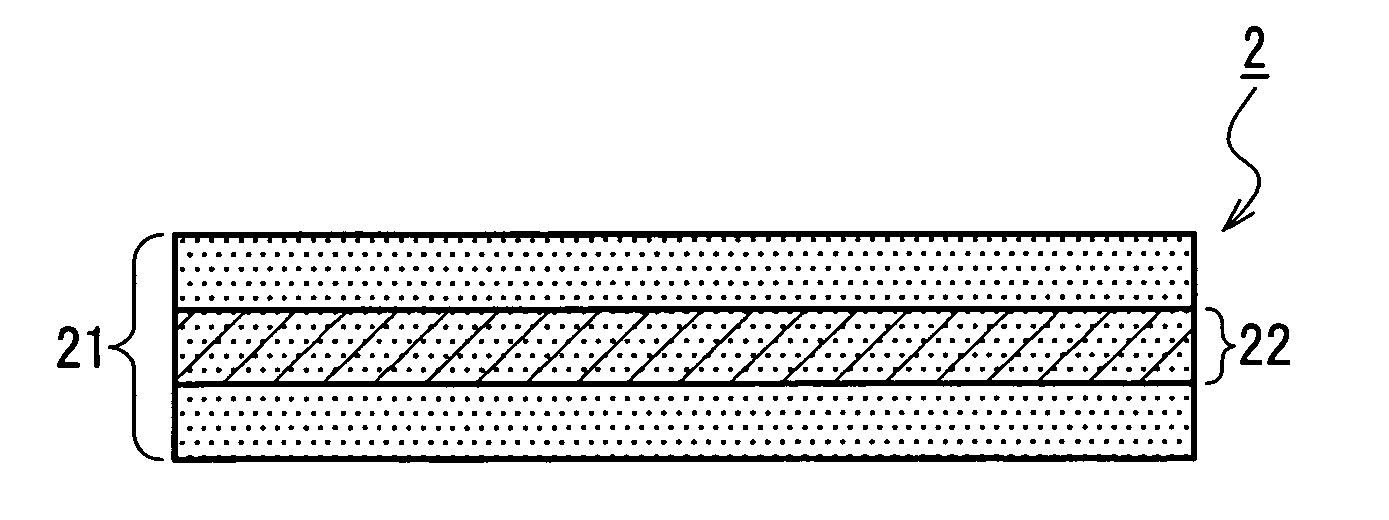

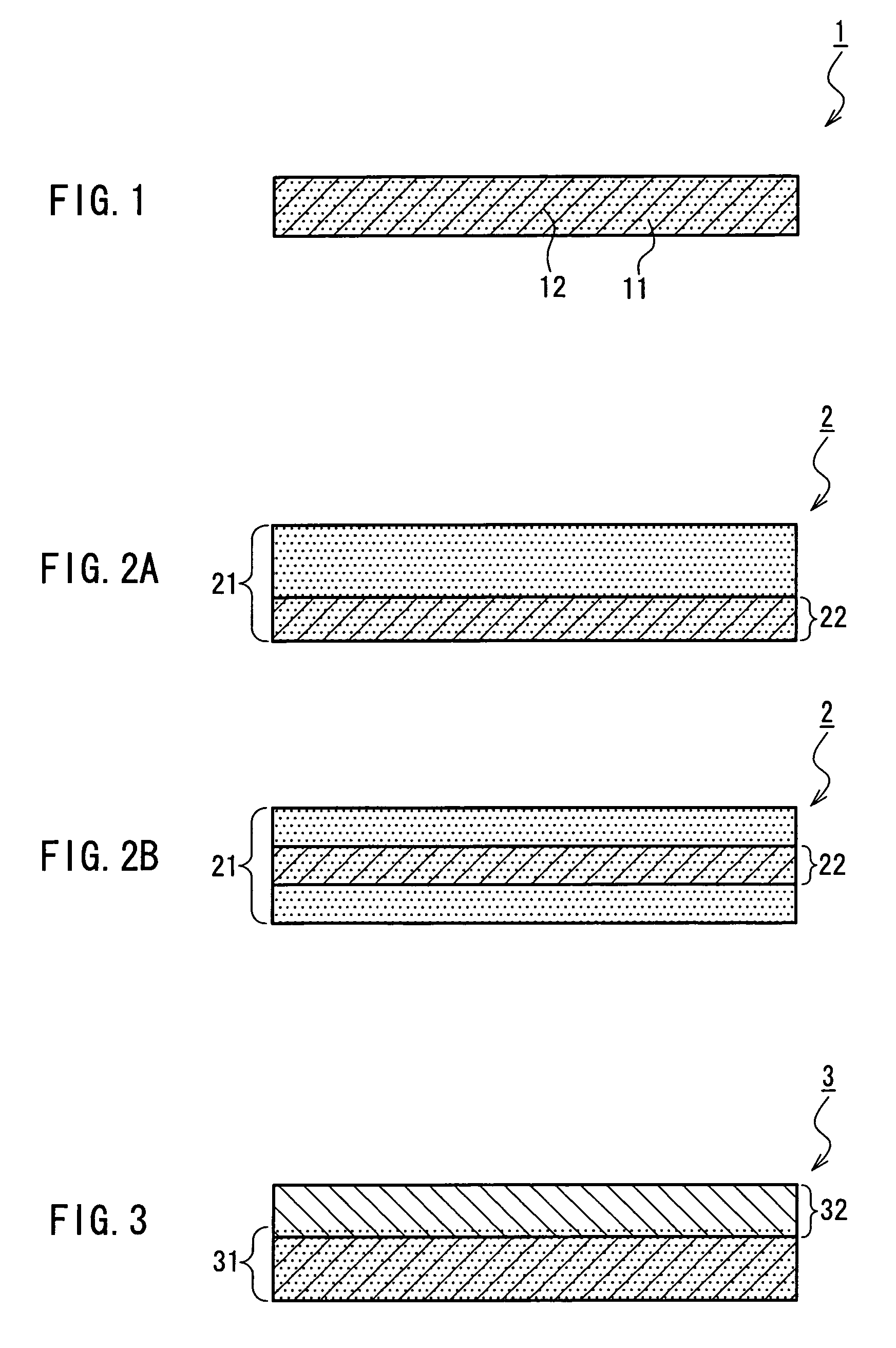

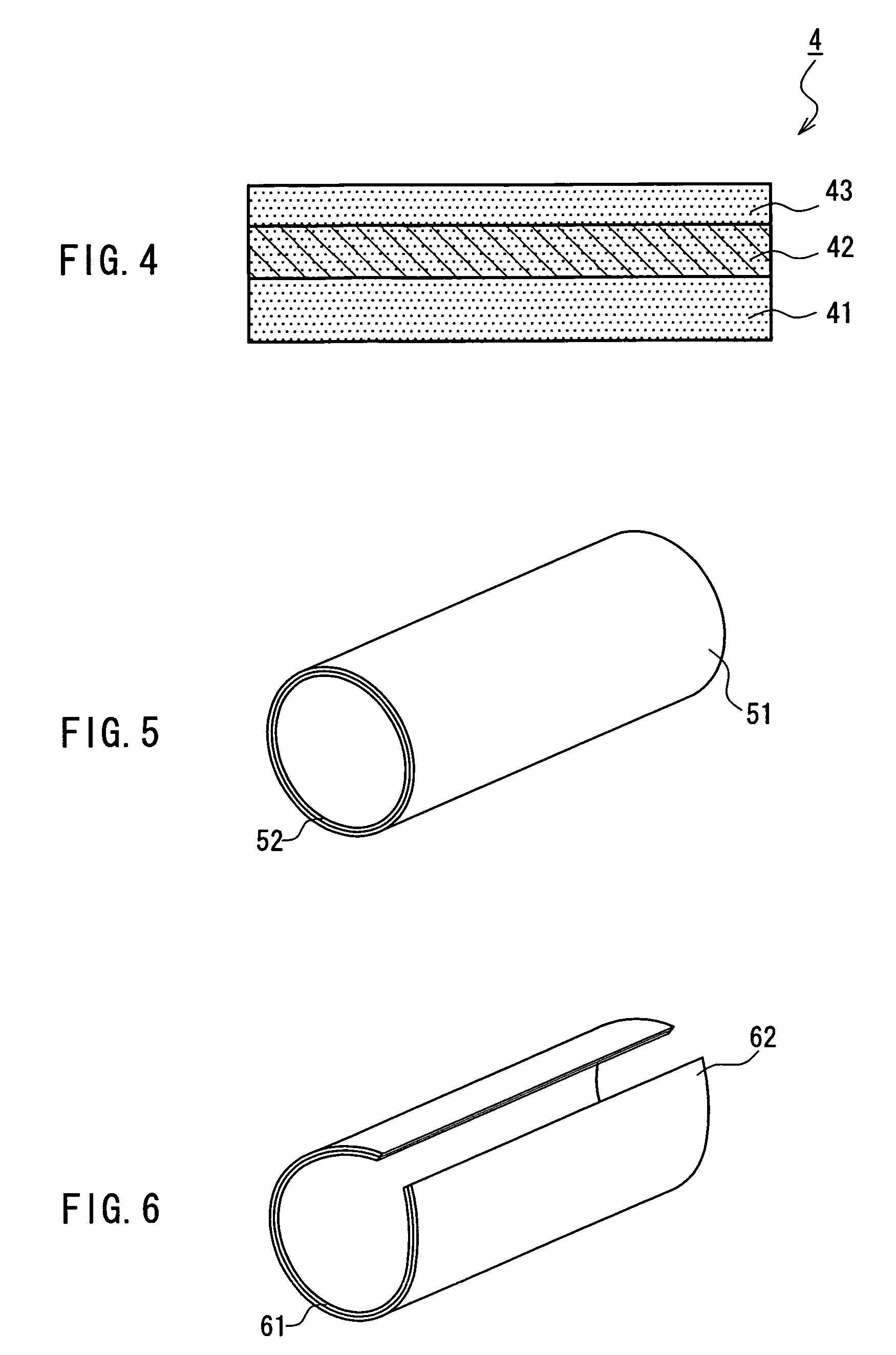

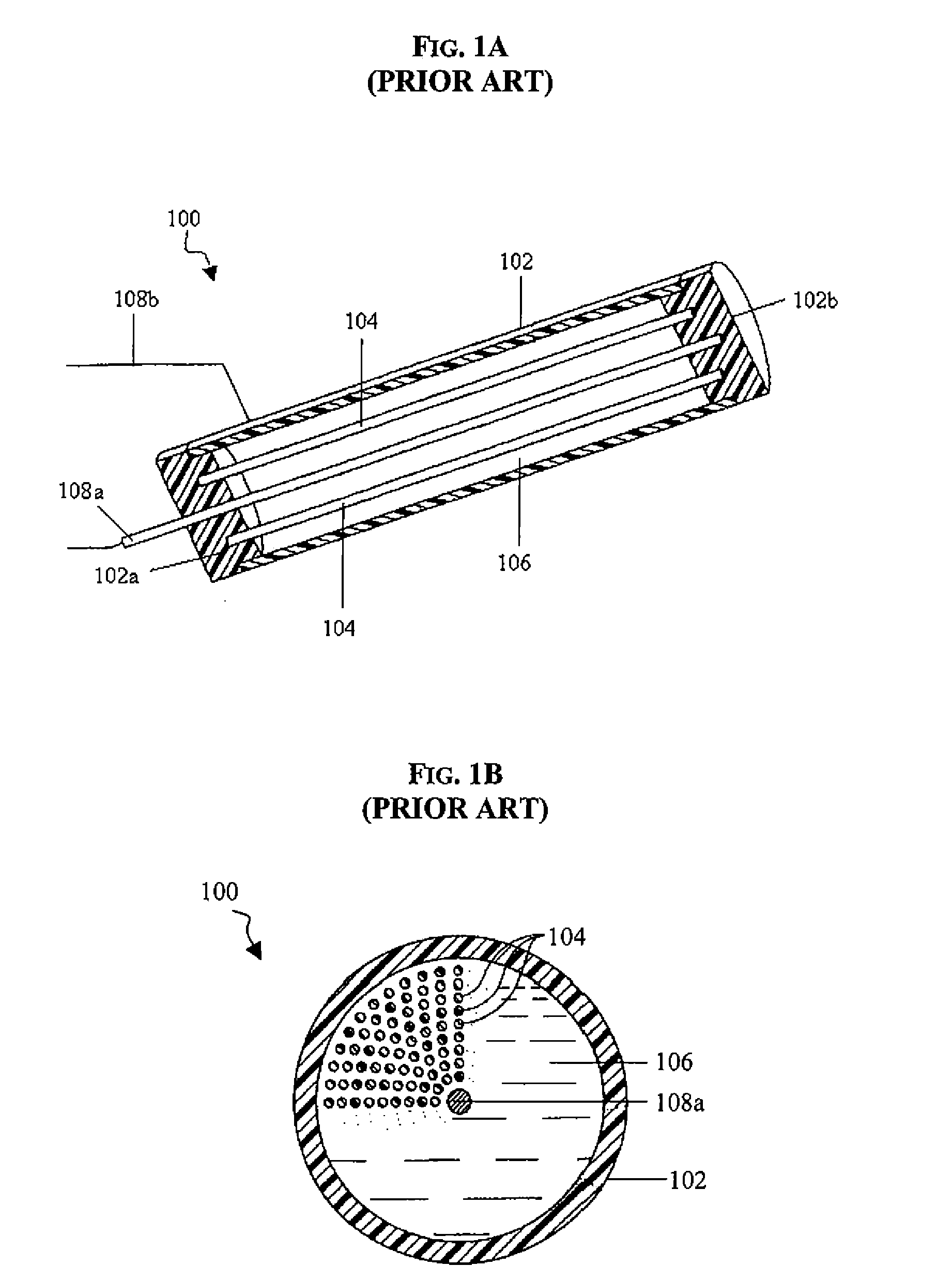

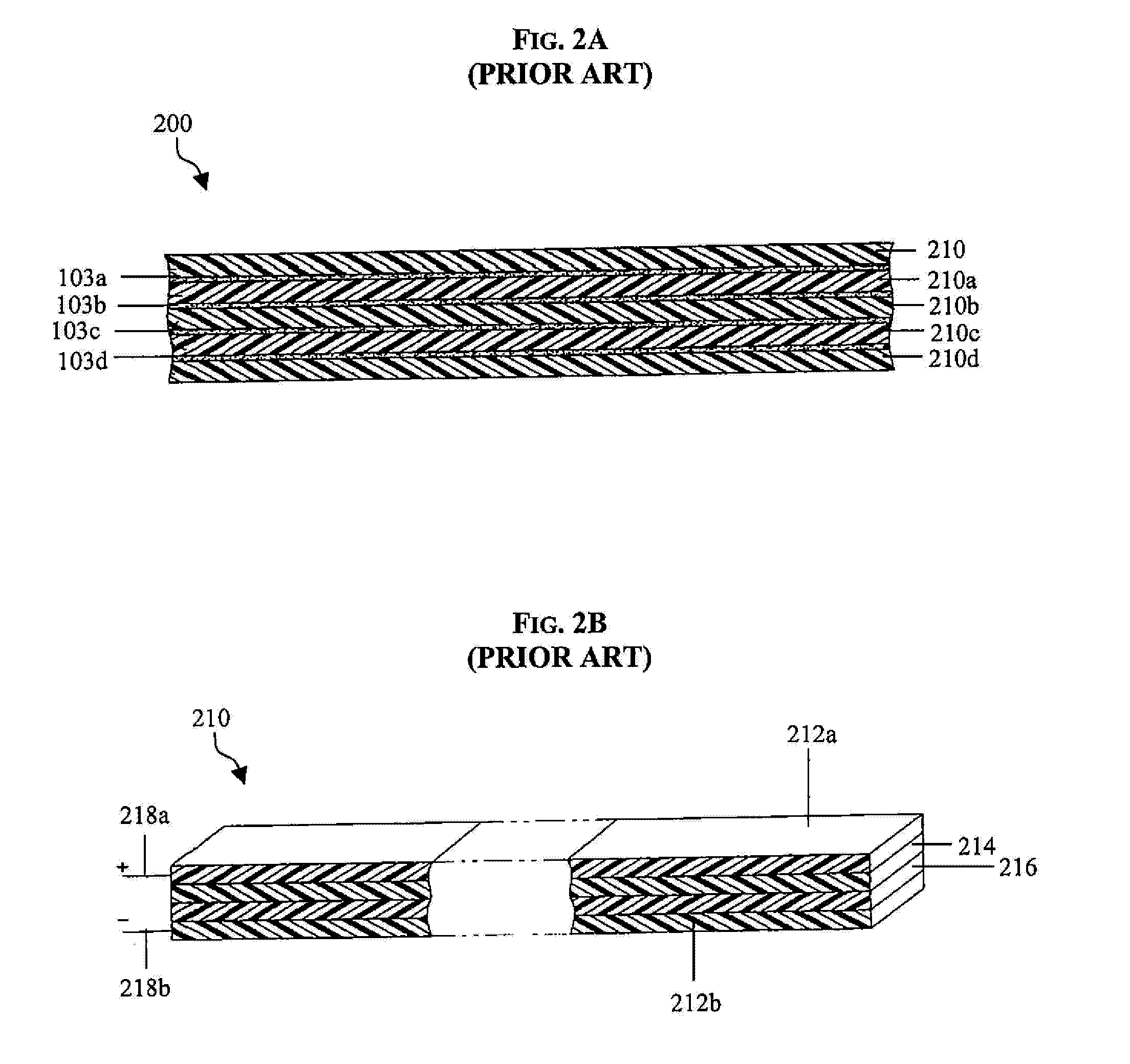

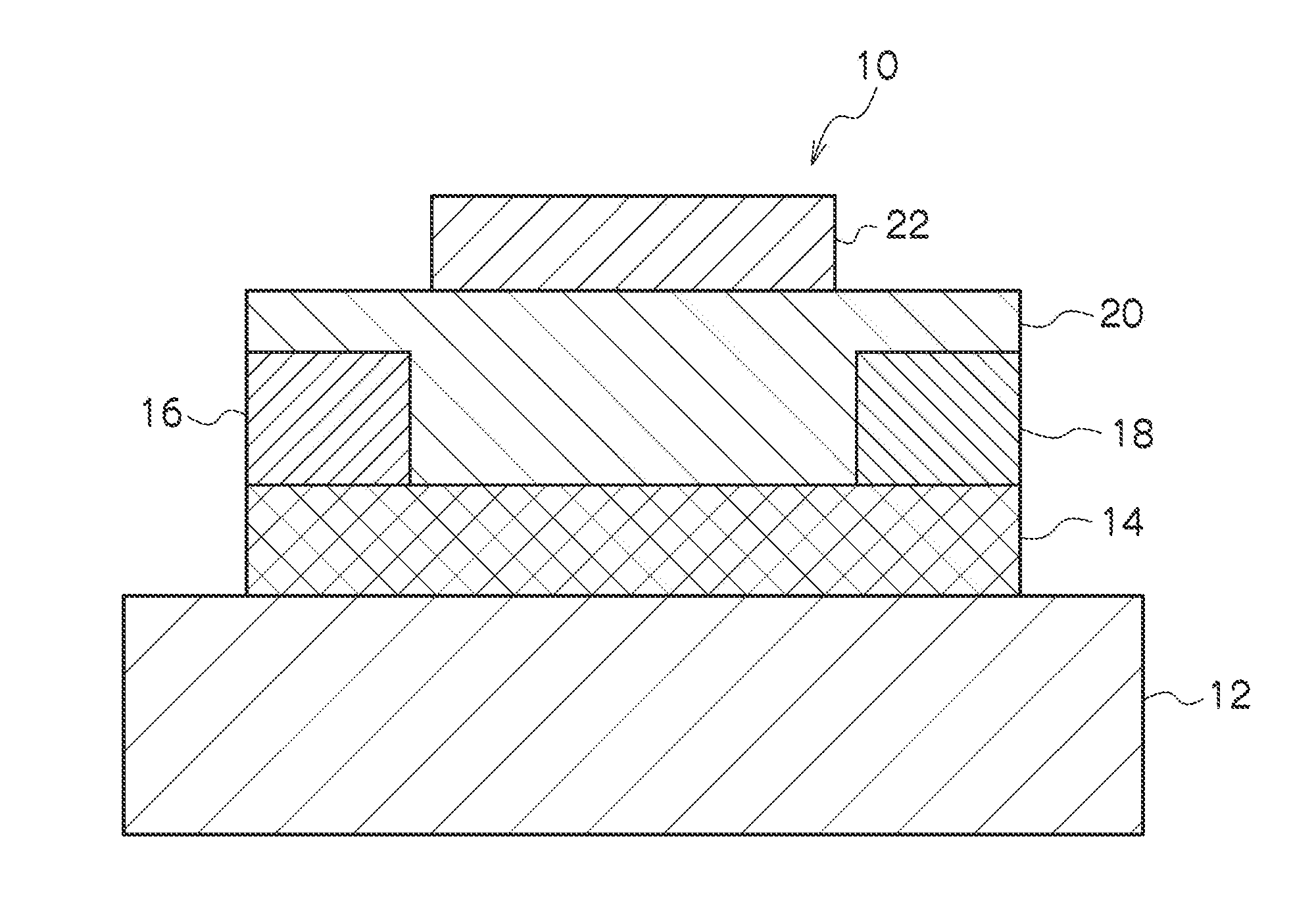

A medical film that is excellent in biocompatibility and bioabsorbability and has an excellent strength in suturing and bonding is provided. A reinforcing material 12 made of a biodegradable polymer is placed in a gelatin solution so as to allow the solution to infiltrate in the reinforcing material 12 and then the gelatin is dried. This allows the gelatin that has infiltrated entirely in an internal part of the reinforcing material 12 to gel, thereby forming a gelatin film 11. Thus, a medical film 1 in which the reinforcing material 12 and the gelatin film 11 are integrated is obtained. The gelatin film 11 preferably is a cross-linked gelatin film.

Owner:GUNZE LTD

Electroactive polymer-based articulation mechanism for circular stapler

ActiveUS20060047307A1Effective movementSuture equipmentsStapling toolsElectroactive polymer actuatorsEngineering

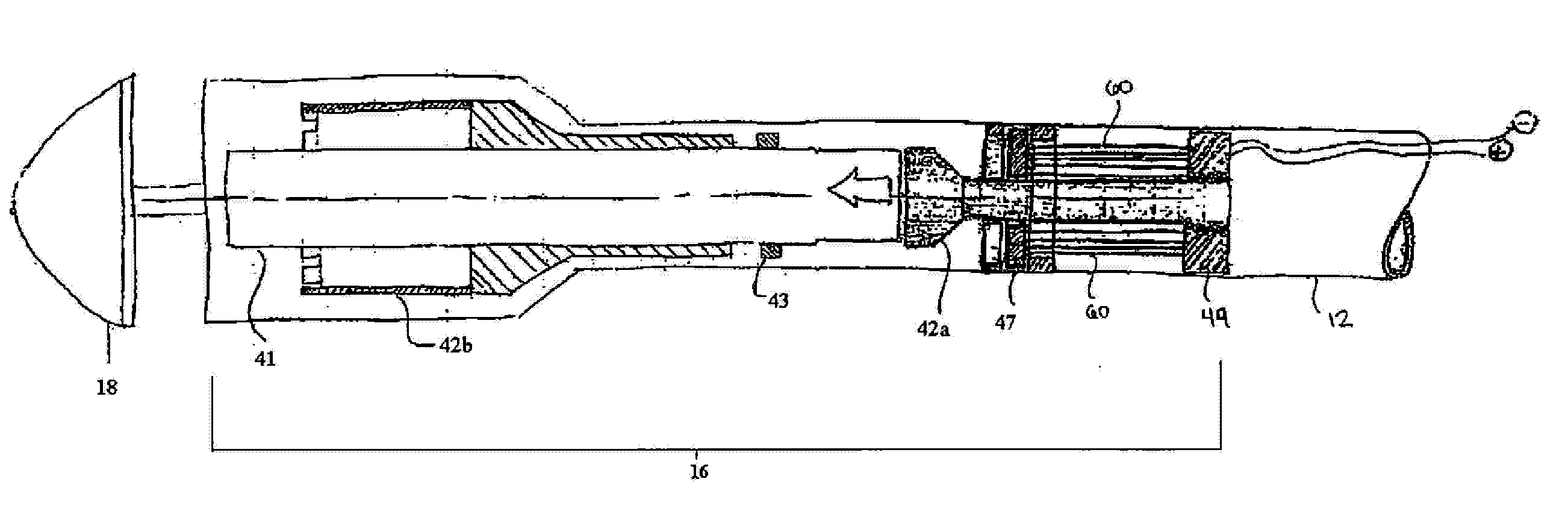

Methods and devices are provided for actuating and / or articulating a circular stapler. In one exemplary embodiment, a circular stapler is provided having an elongate shaft with a stapling apparatus coupled thereto. An electrically expandable and contractible actuator, such as an electroactive polymer actuator, can be used to pivotally or angularly adjust a position of the stapling apparatus relative to the elongate shaft by delivering energy to the electroactive polymer actuator. In another embodiment, an electroactive polymer actuator can be used to actuate the stapling apparatus, thereby driving one or more staples, preferably in a substantially curved pattern, into tissue. The actuator can alternatively or additionally drive a blade distally to cut tissue being stapled.

Owner:CILAG GMBH INT

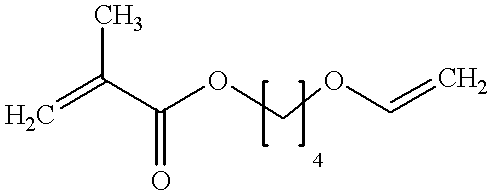

Ink compositions for ink jet printing

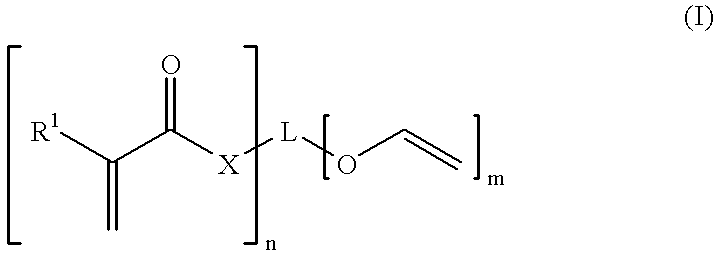

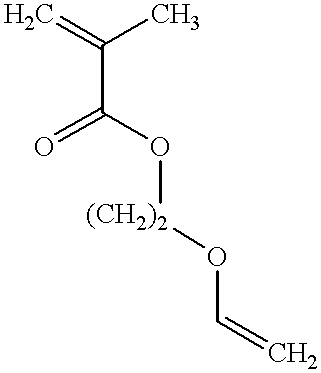

InactiveUS6310115B1Reduce viscosityLow viscosityLiquid surface applicatorsOrganic chemistryPolymer chemistryAcrylate

Owner:AGFA NV

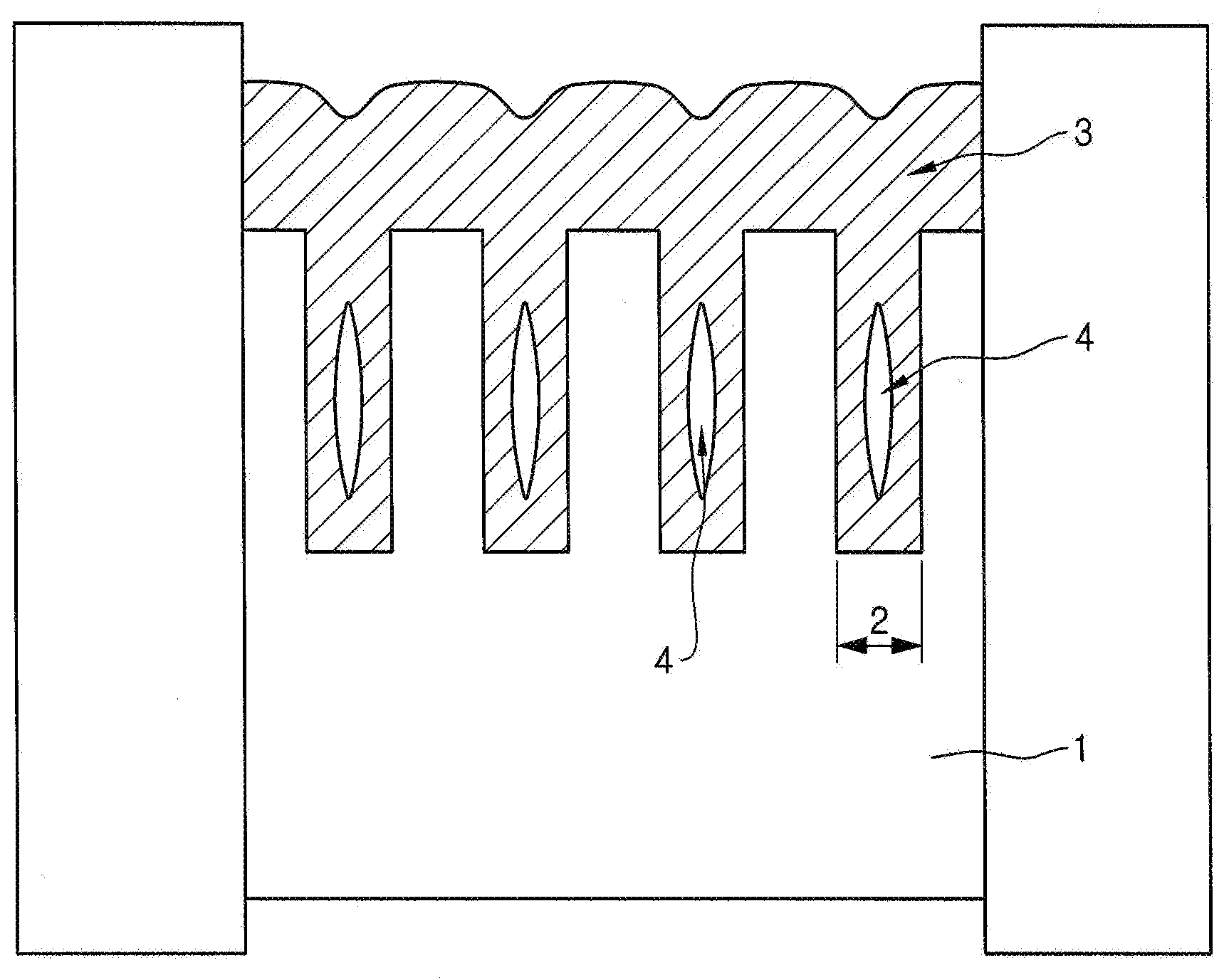

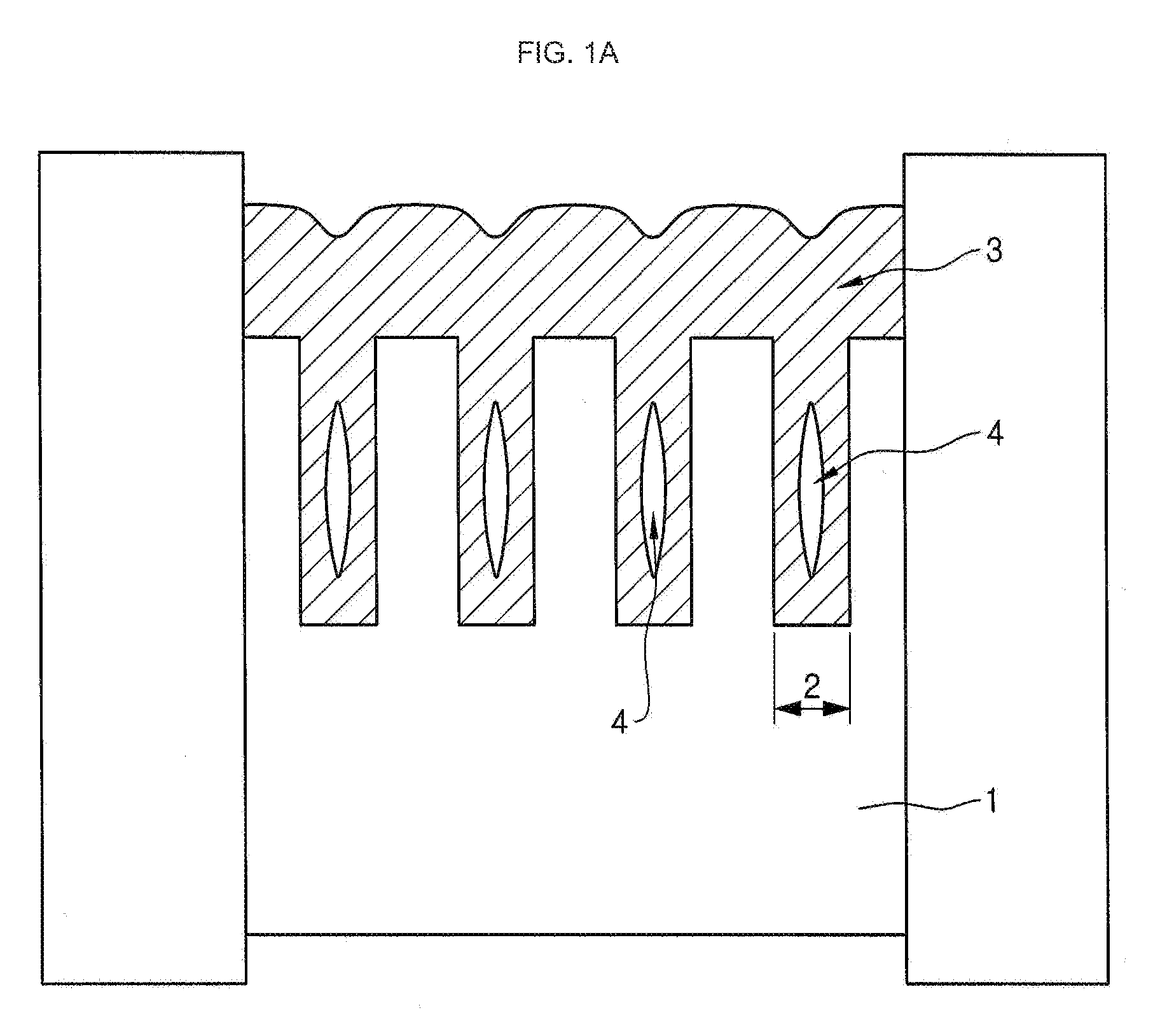

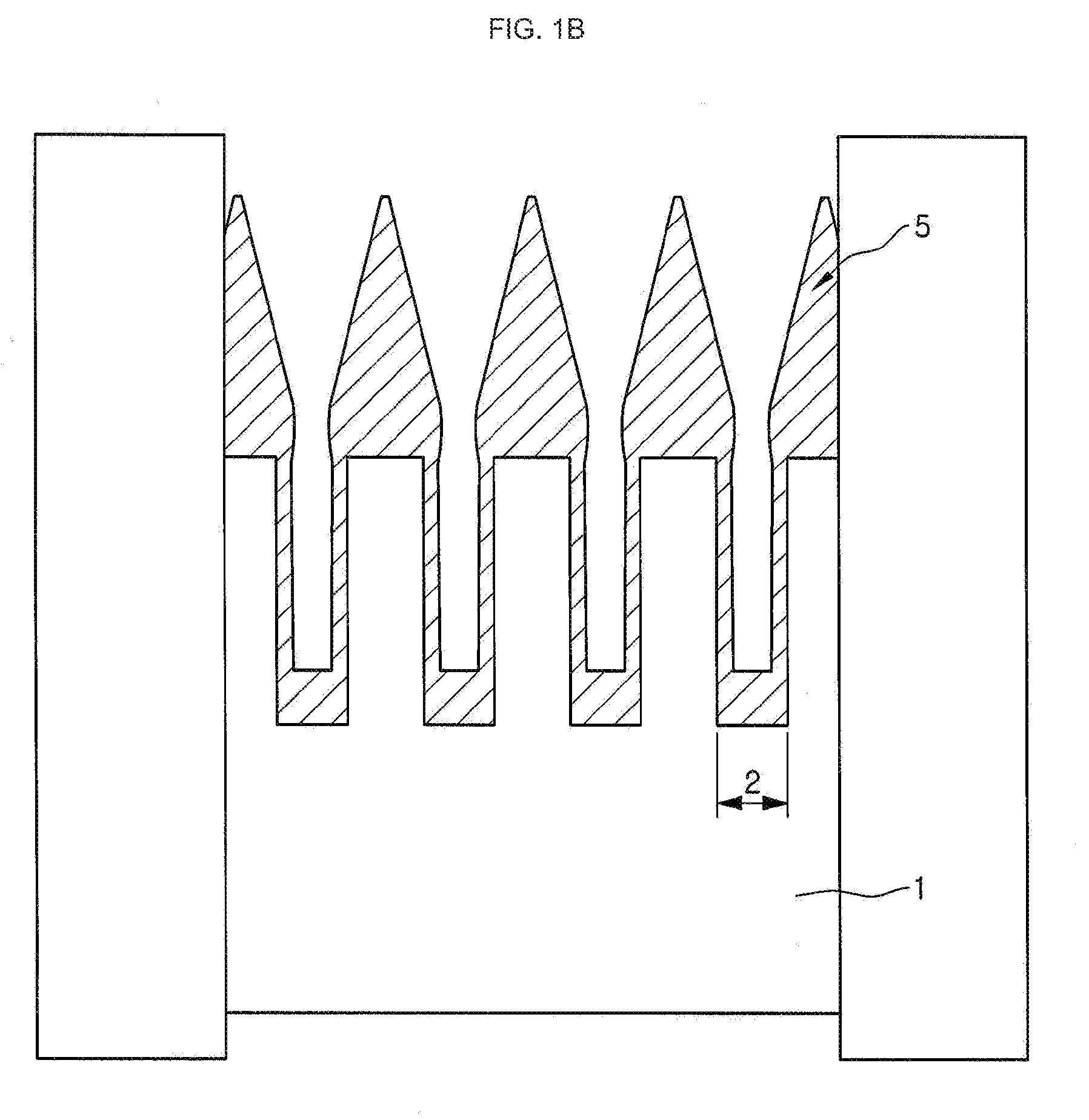

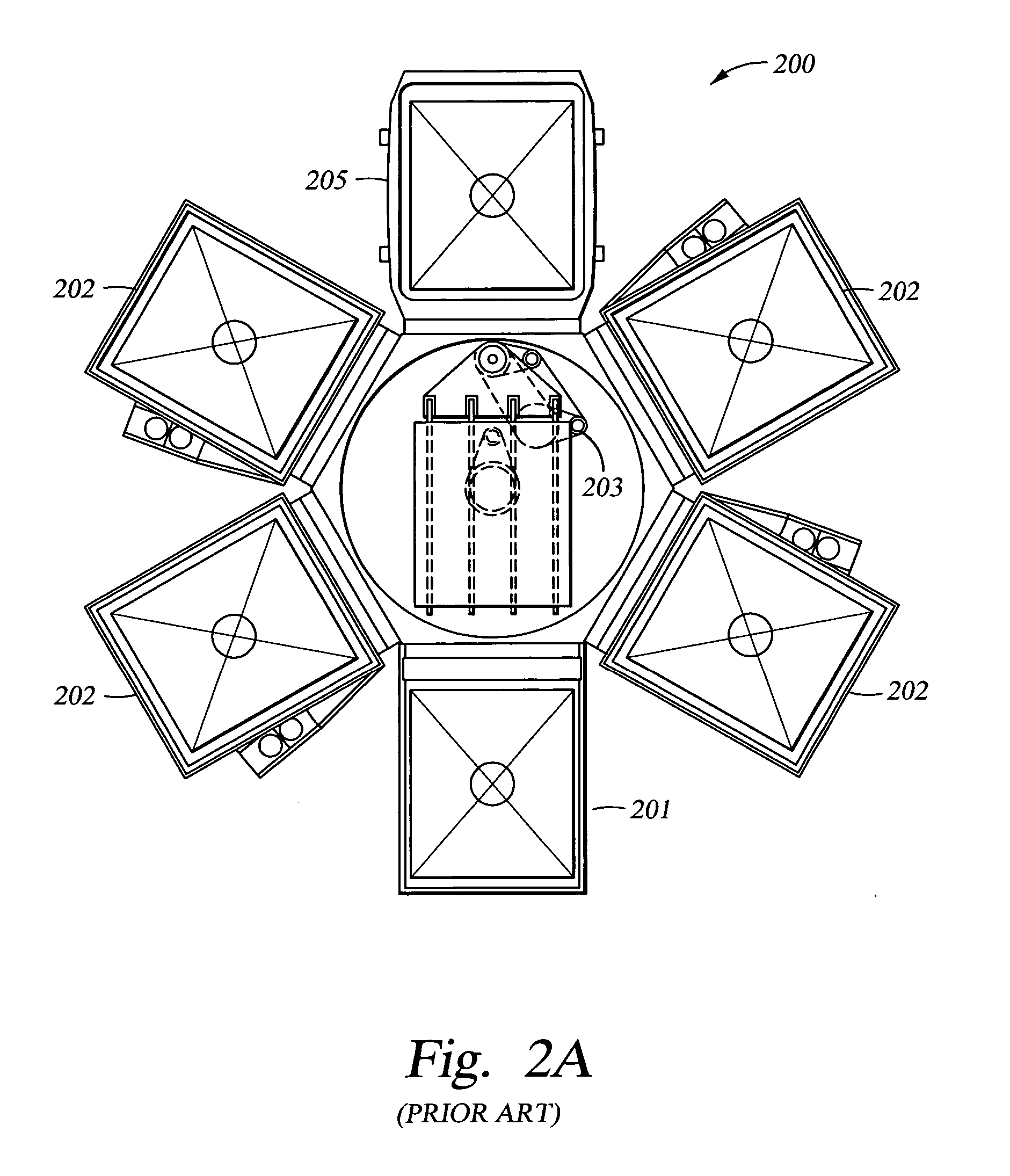

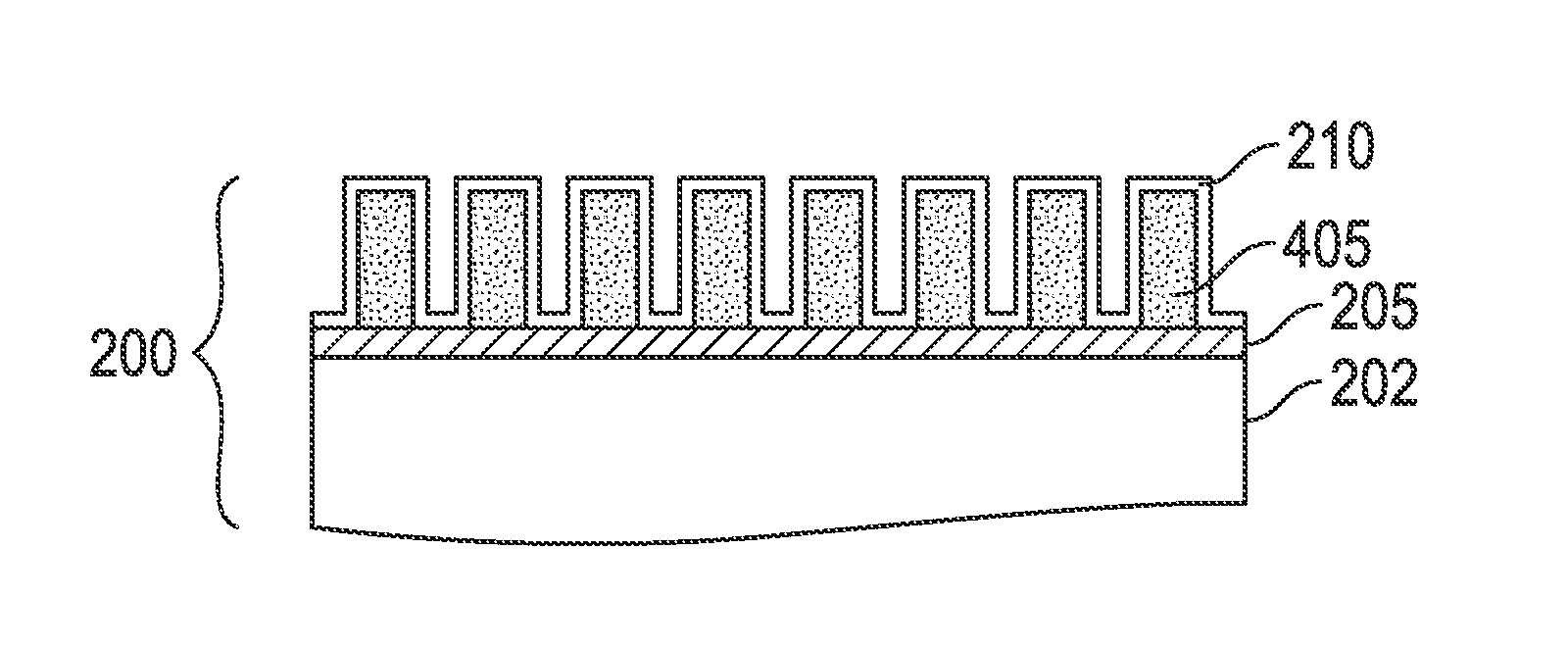

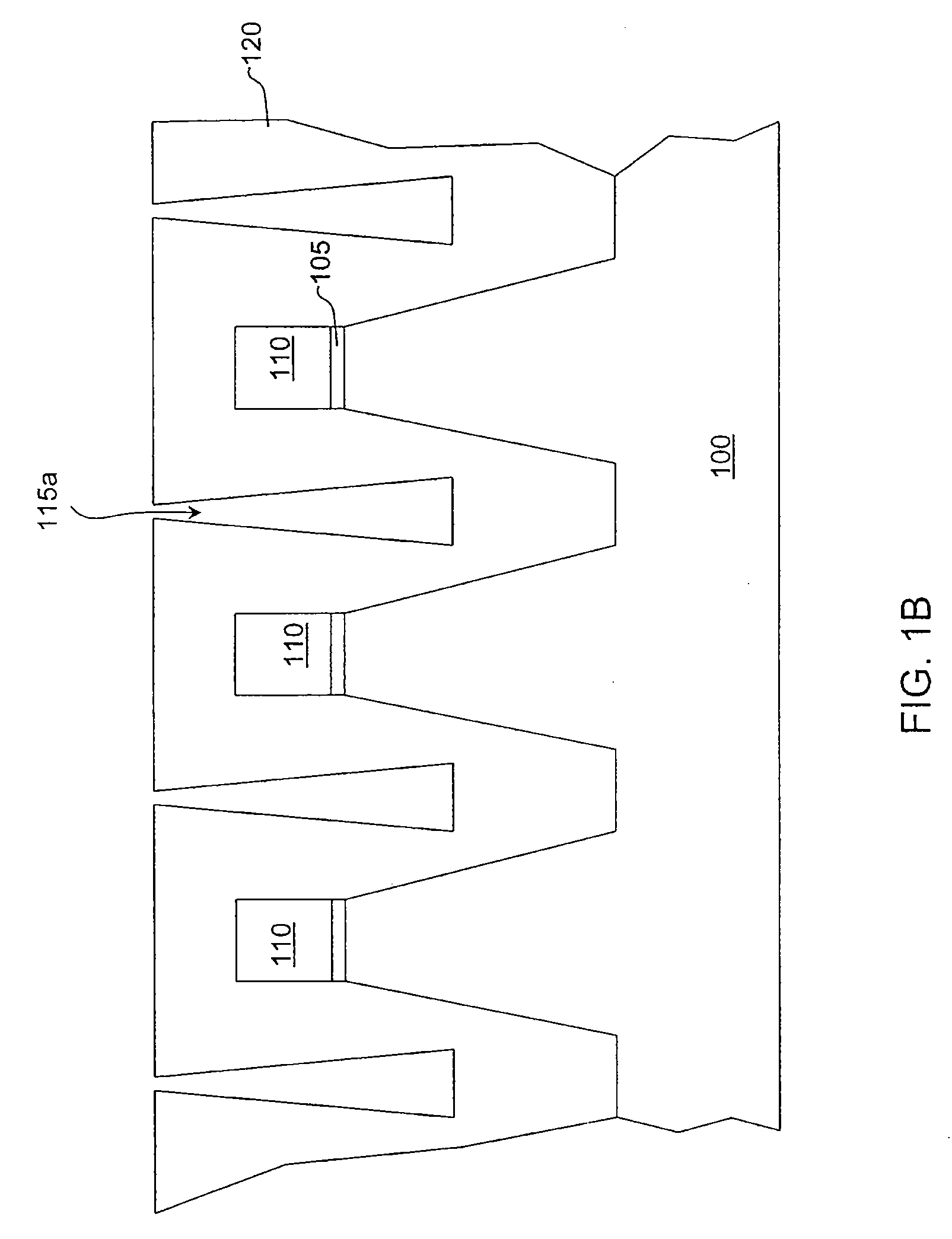

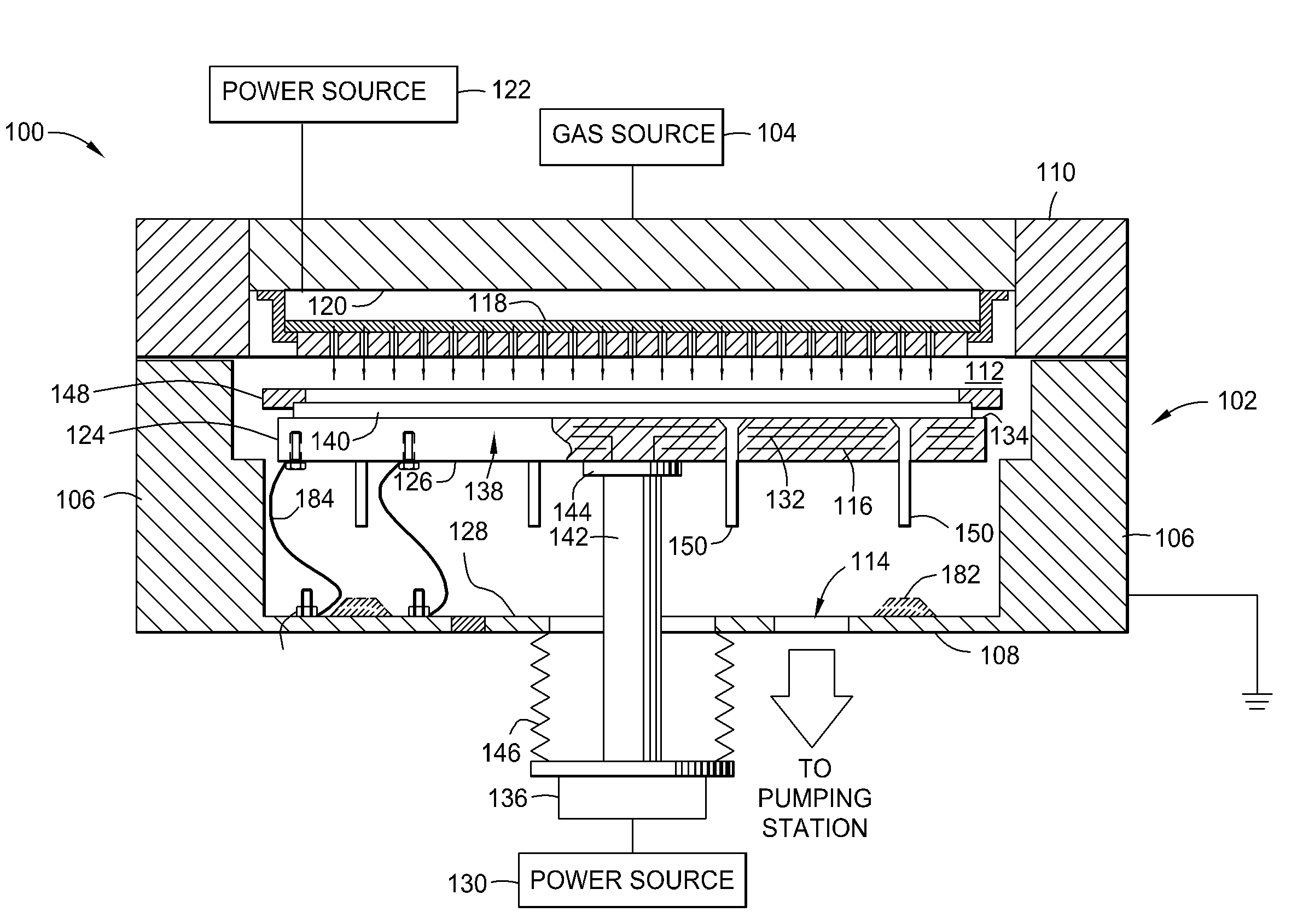

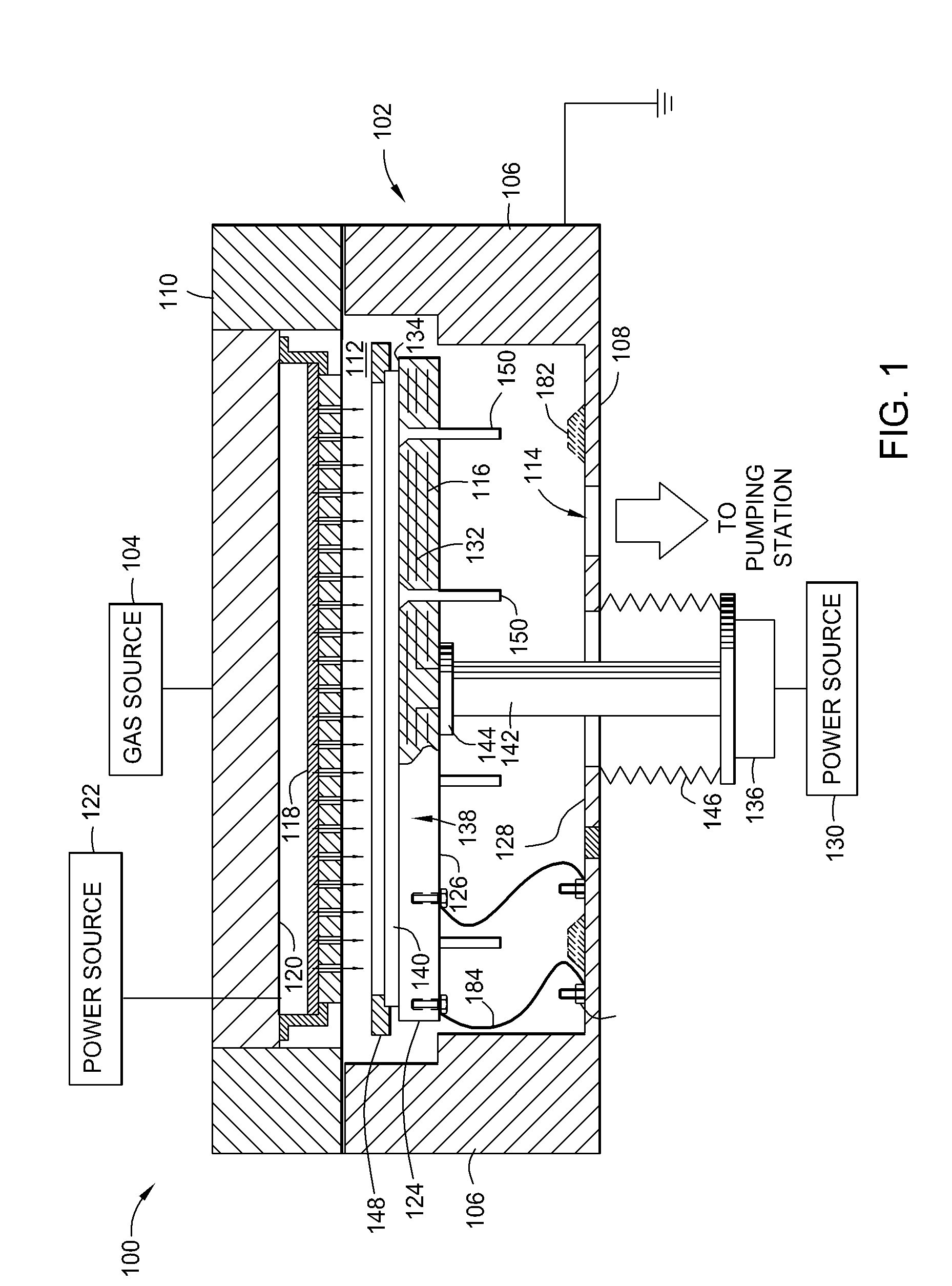

Forming Substrate Structure by Filling Recesses with Deposition Material

InactiveUS20100041179A1Semiconductor/solid-state device manufacturingOptoelectronicsMaterials science

Owner:VEECO ALD

Thin film transistor and method of producing thin film transistor

ActiveUS20100320459A1TransistorSemiconductor/solid-state device manufacturingThin membraneCrystal structure

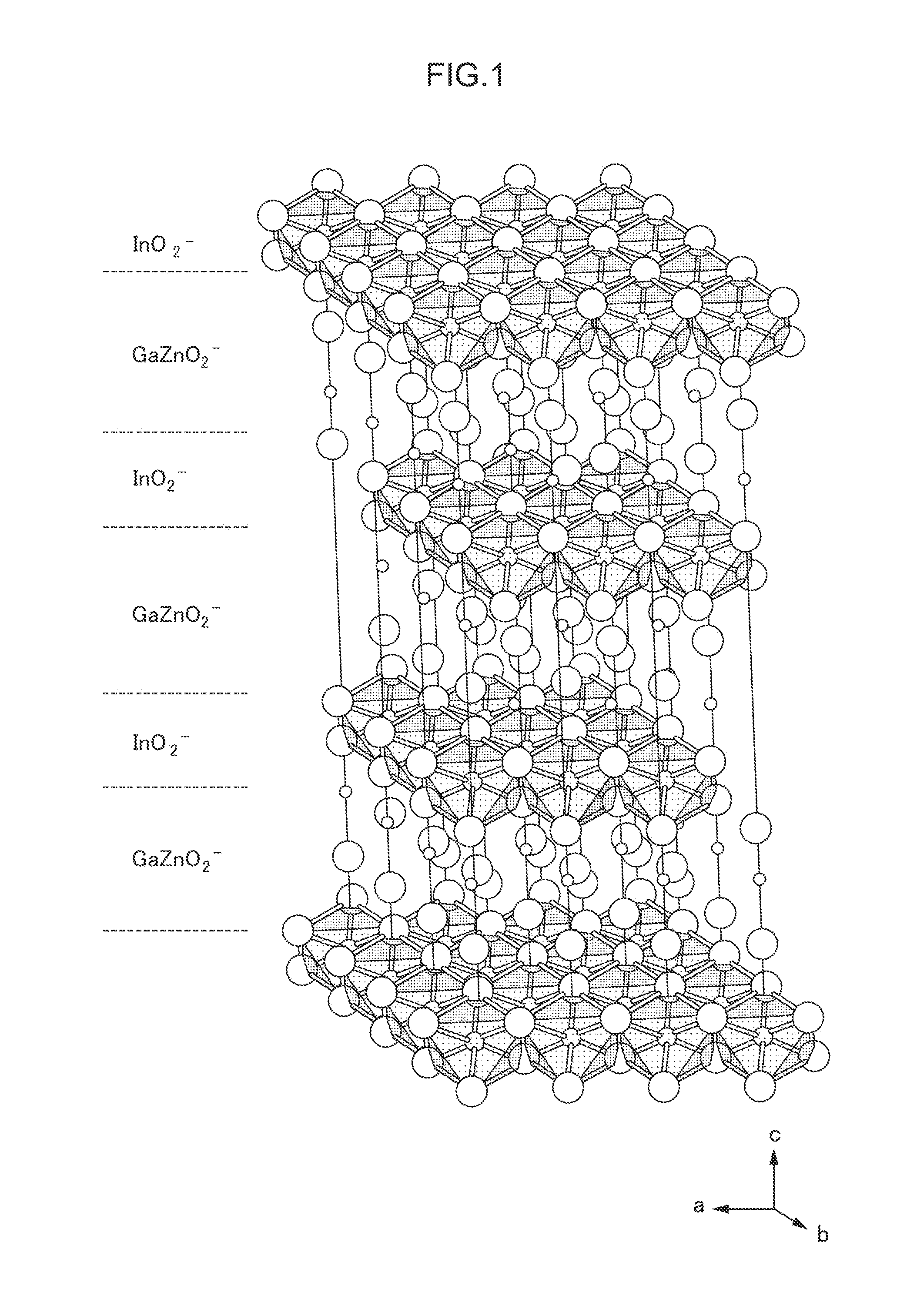

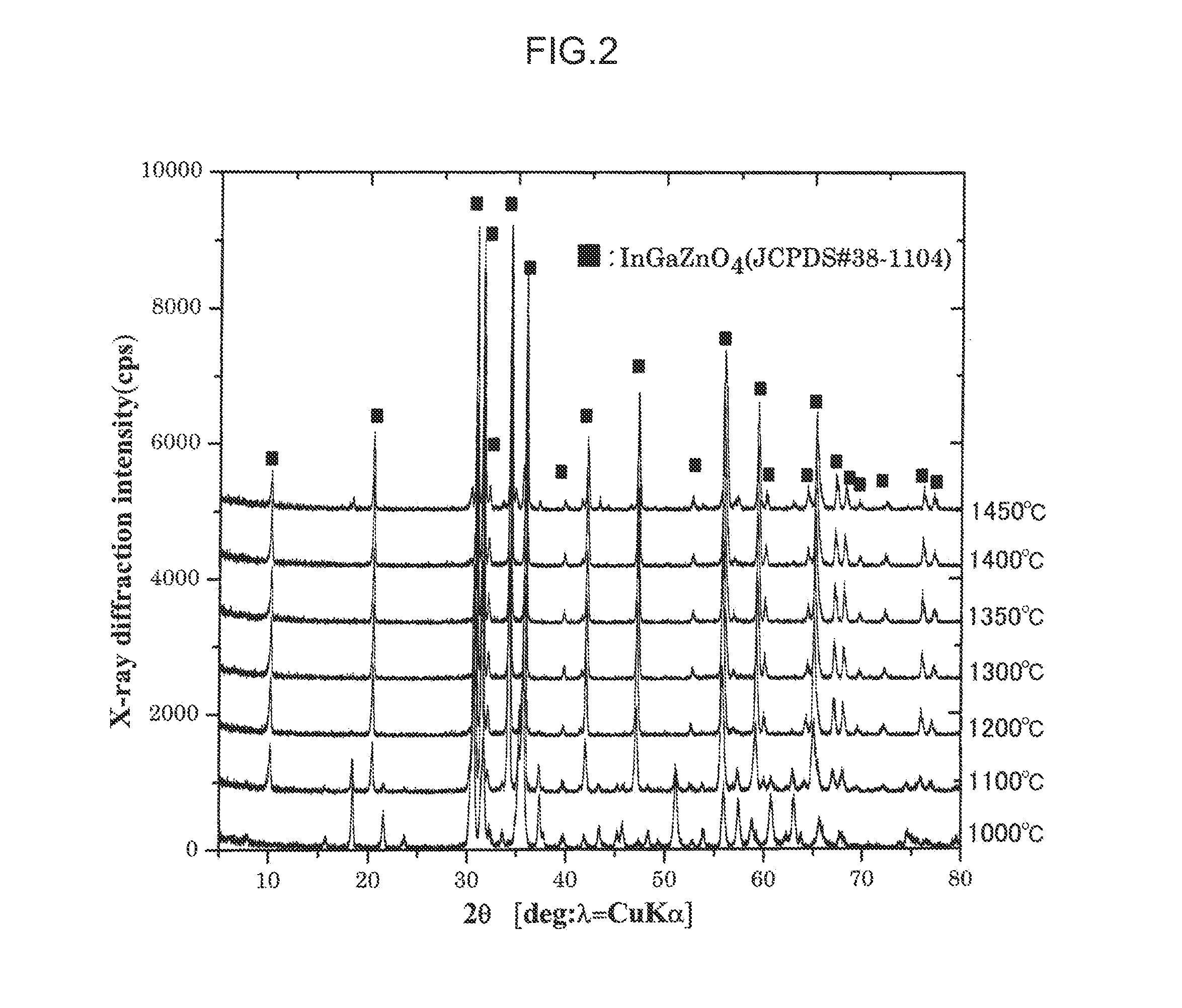

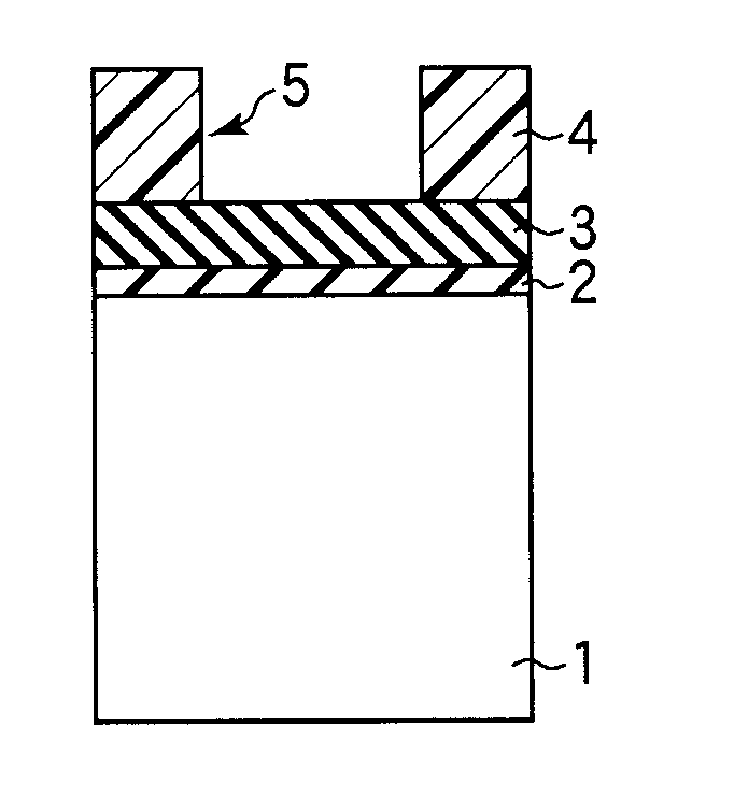

The invention provides a thin film transistor comprising an active layer, the active layer comprising an IGZO-based oxide material, the IGZO-based oxide material being represented by a composition formula of In2-xGaxZnO4-δ, where 0.75<x<1.10 and 0<δ≦1.29161×exp(−x / 0.11802)+0.00153 and being formed from a single phase of IGZO having a crystal structure of YbFe2O4, and a method of producing the thin film transistor.

Owner:SAMSUNG DISPLAY CO LTD

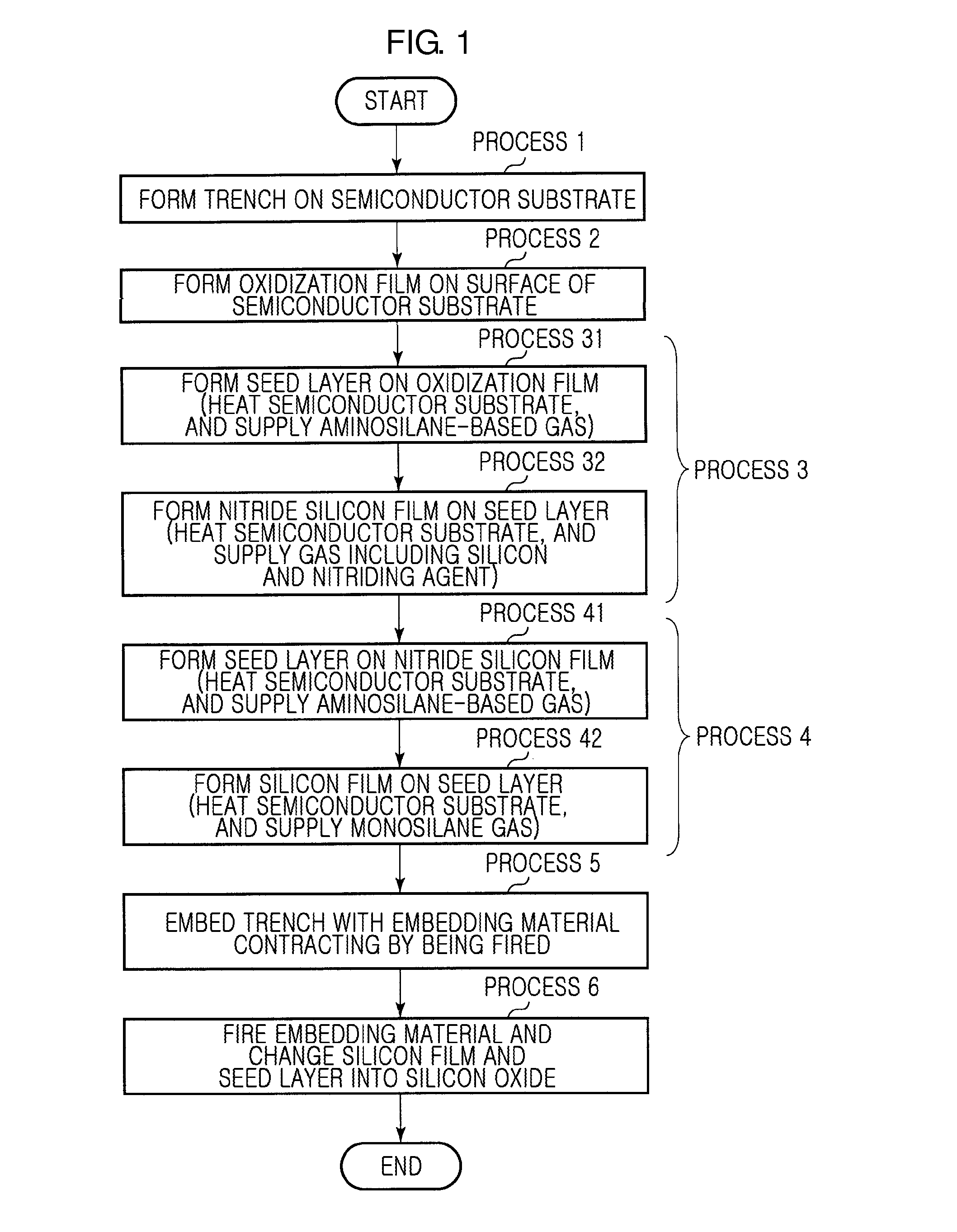

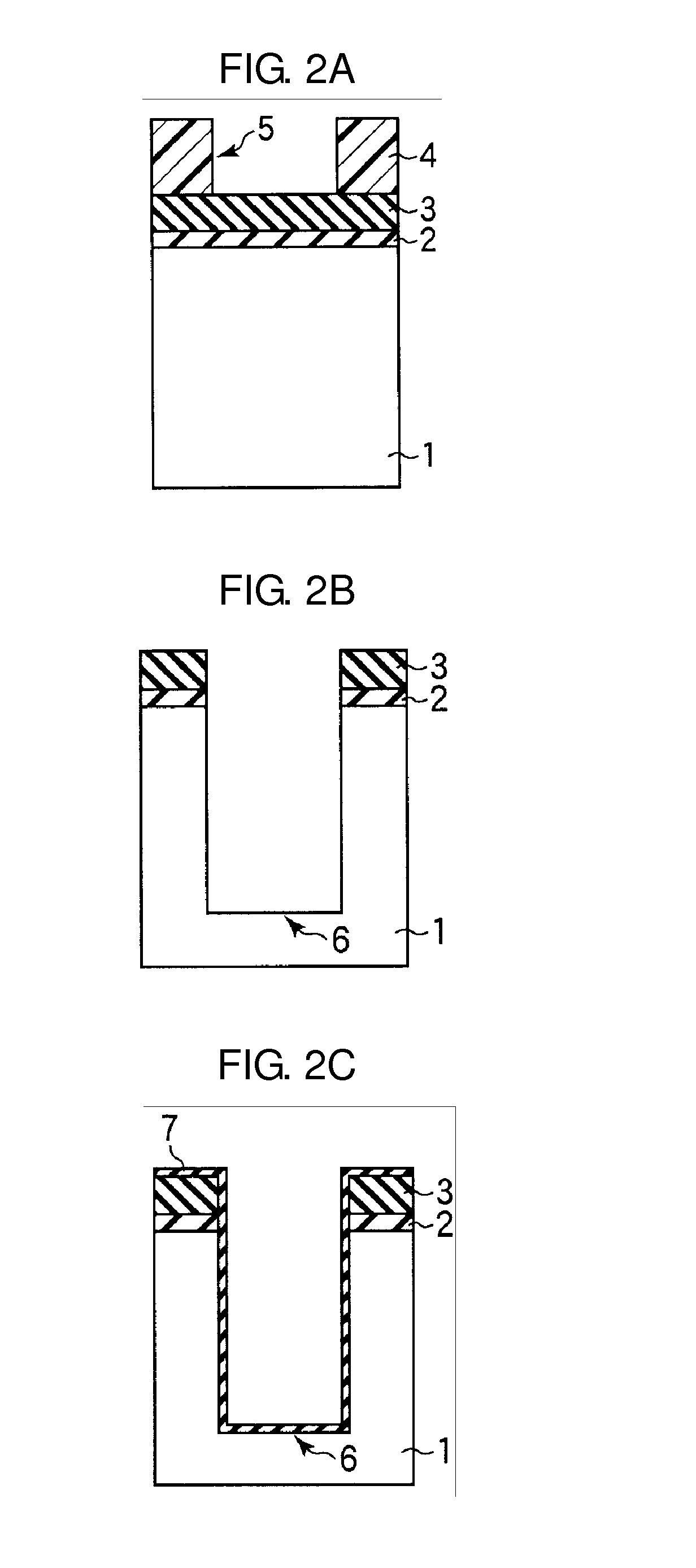

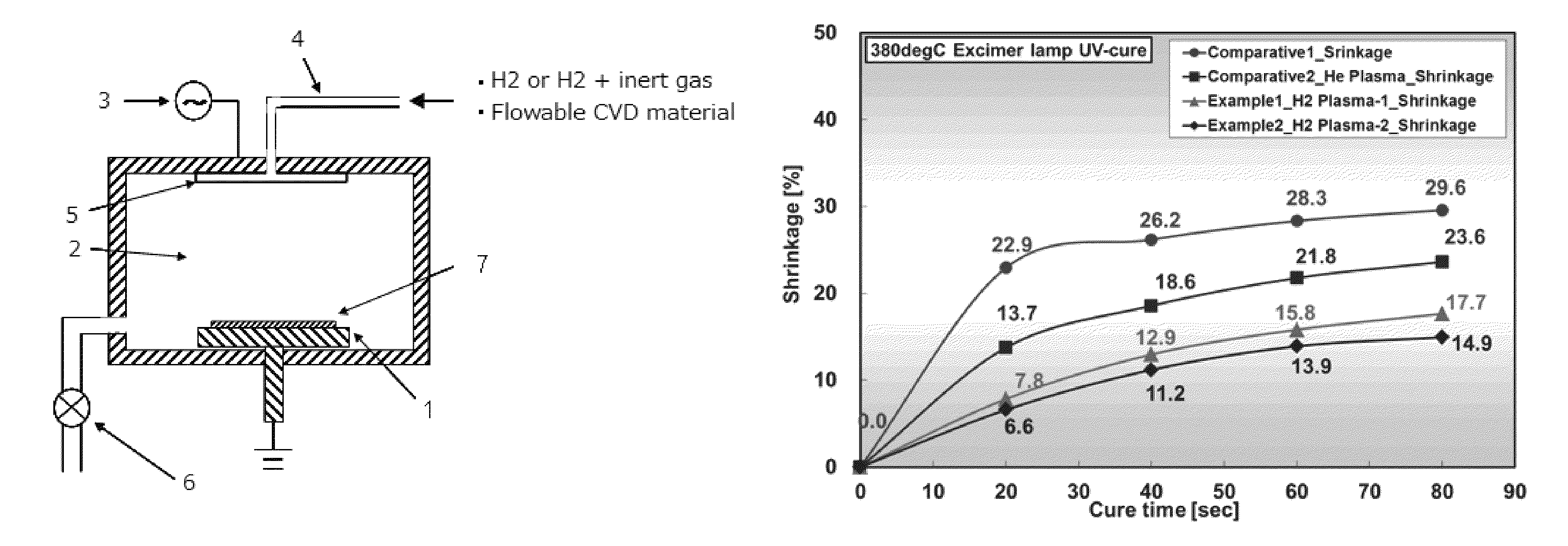

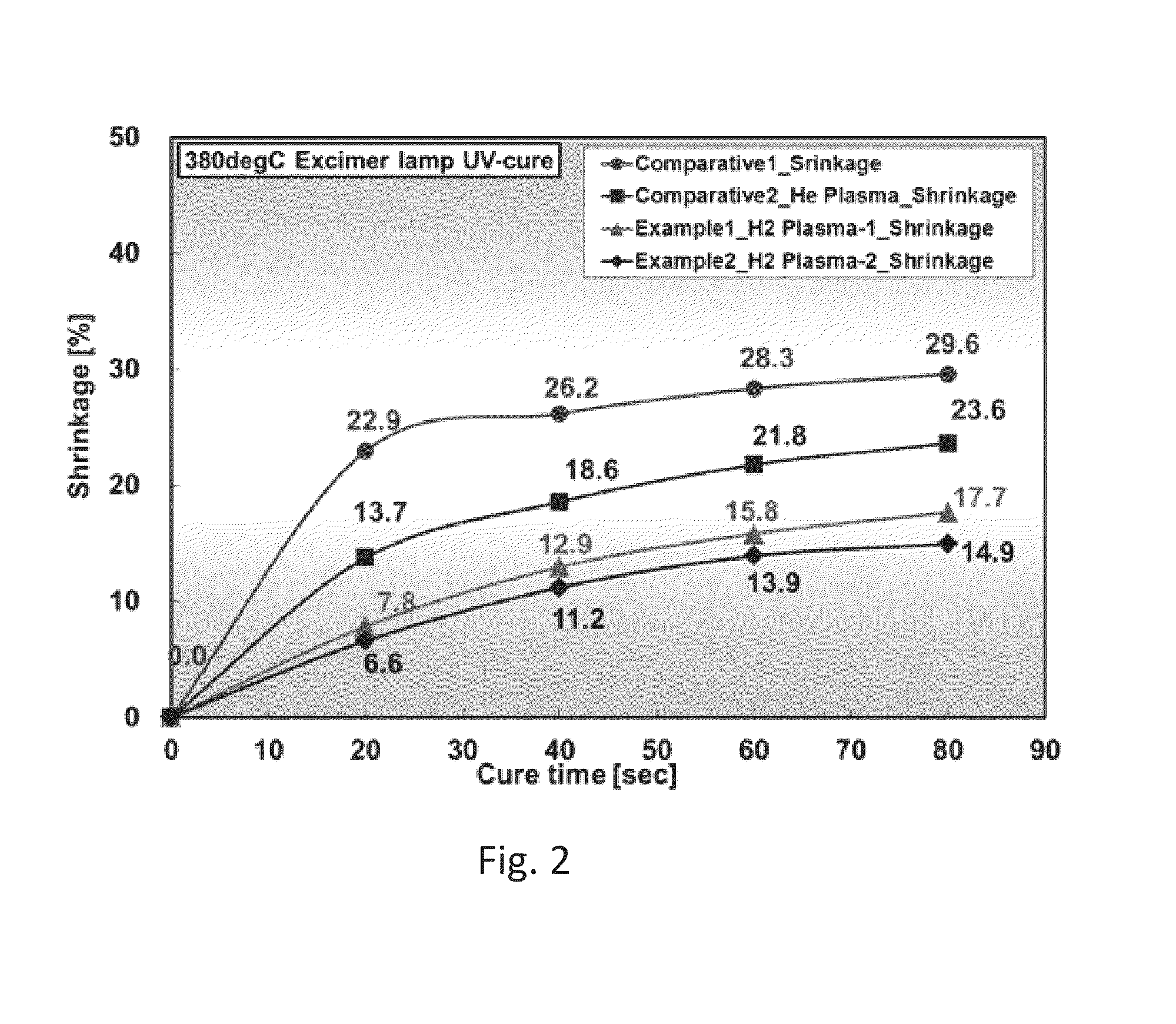

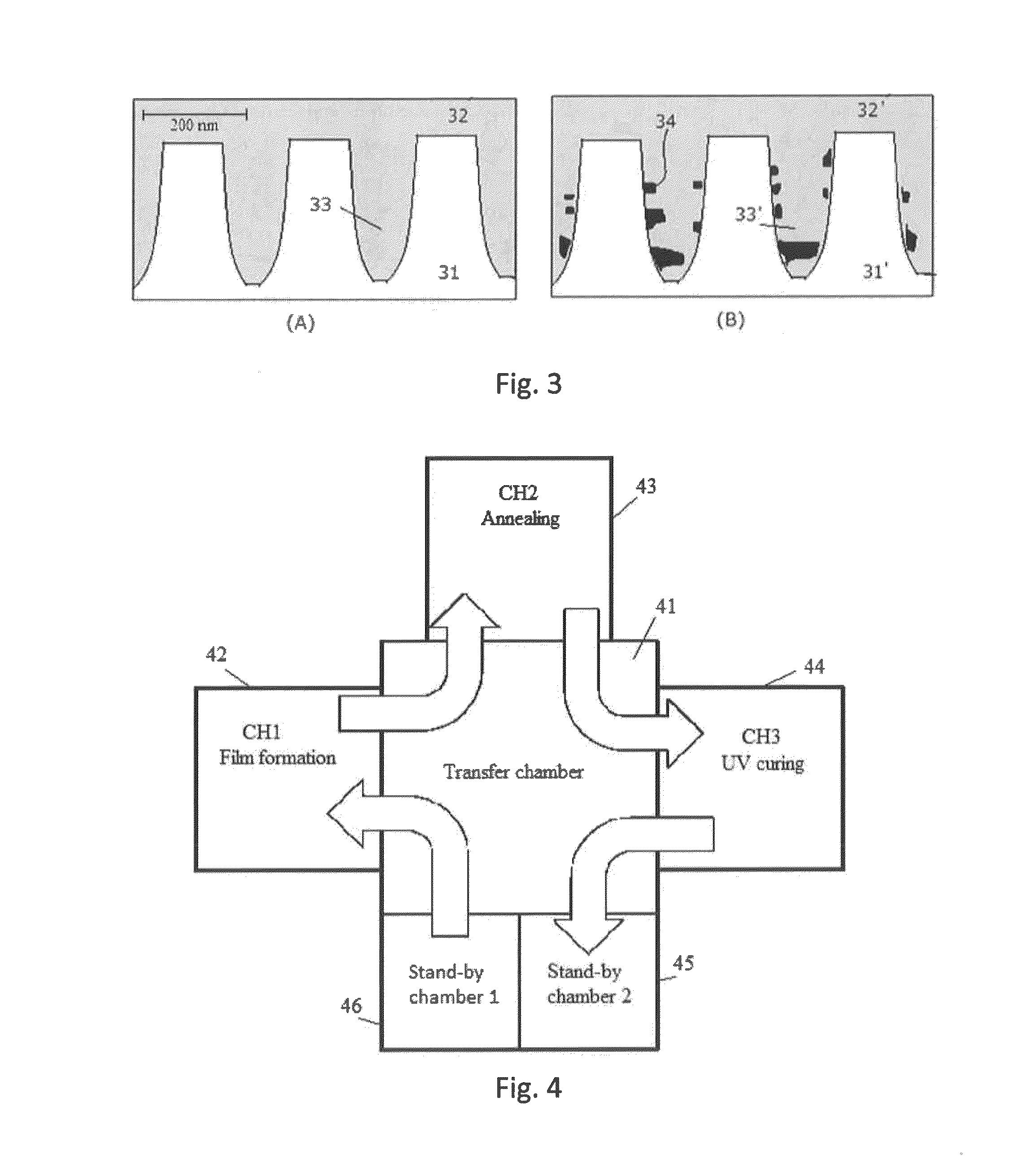

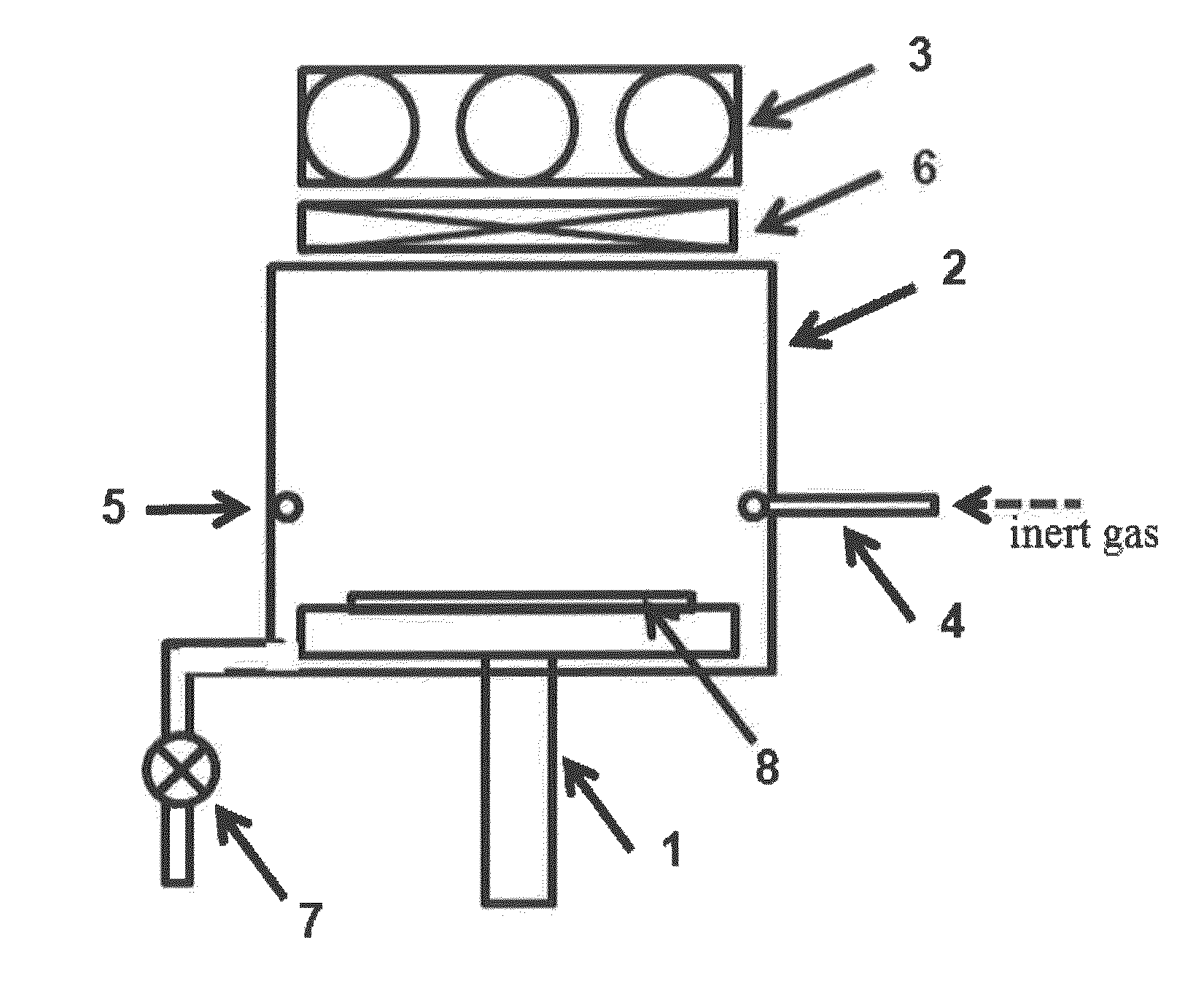

Trench embedding method and film-forming apparatus

ActiveUS20120164842A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon nitrideSilicon membrane

A trench embedding method includes forming an oxidization barrier film on a trench; forming an expandable film on the oxidization barrier film; embedding an embedding material that contracts by being fired on the trench; and firing the embedding material, wherein the forming of the oxidization barrier film includes: forming a first seed layer on the trench by supplying an aminosilane-based gas; and forming a silicon nitride film on the first seed layer, wherein the forming of the expandable film includes: forming a second seed layer on the silicon nitride film by supplying an aminosilane-based gas; and forming a silicon film on the second seed layer.

Owner:TOKYO ELECTRON LTD

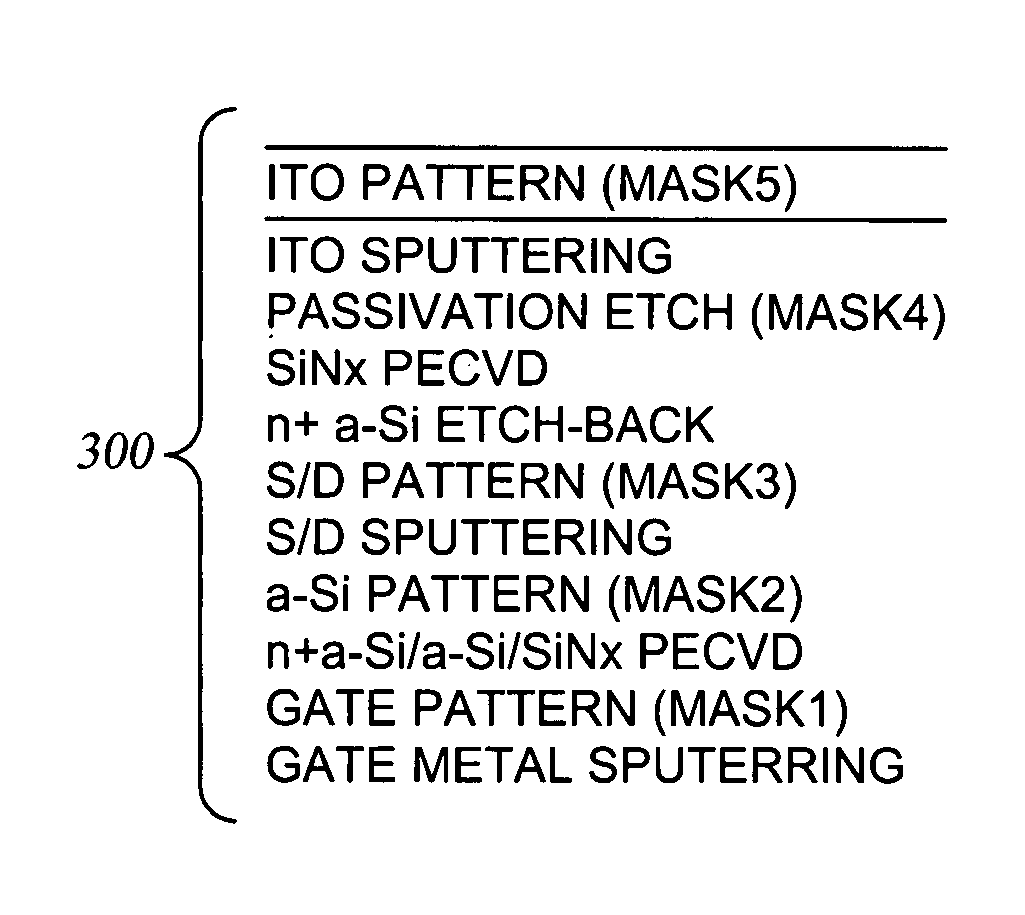

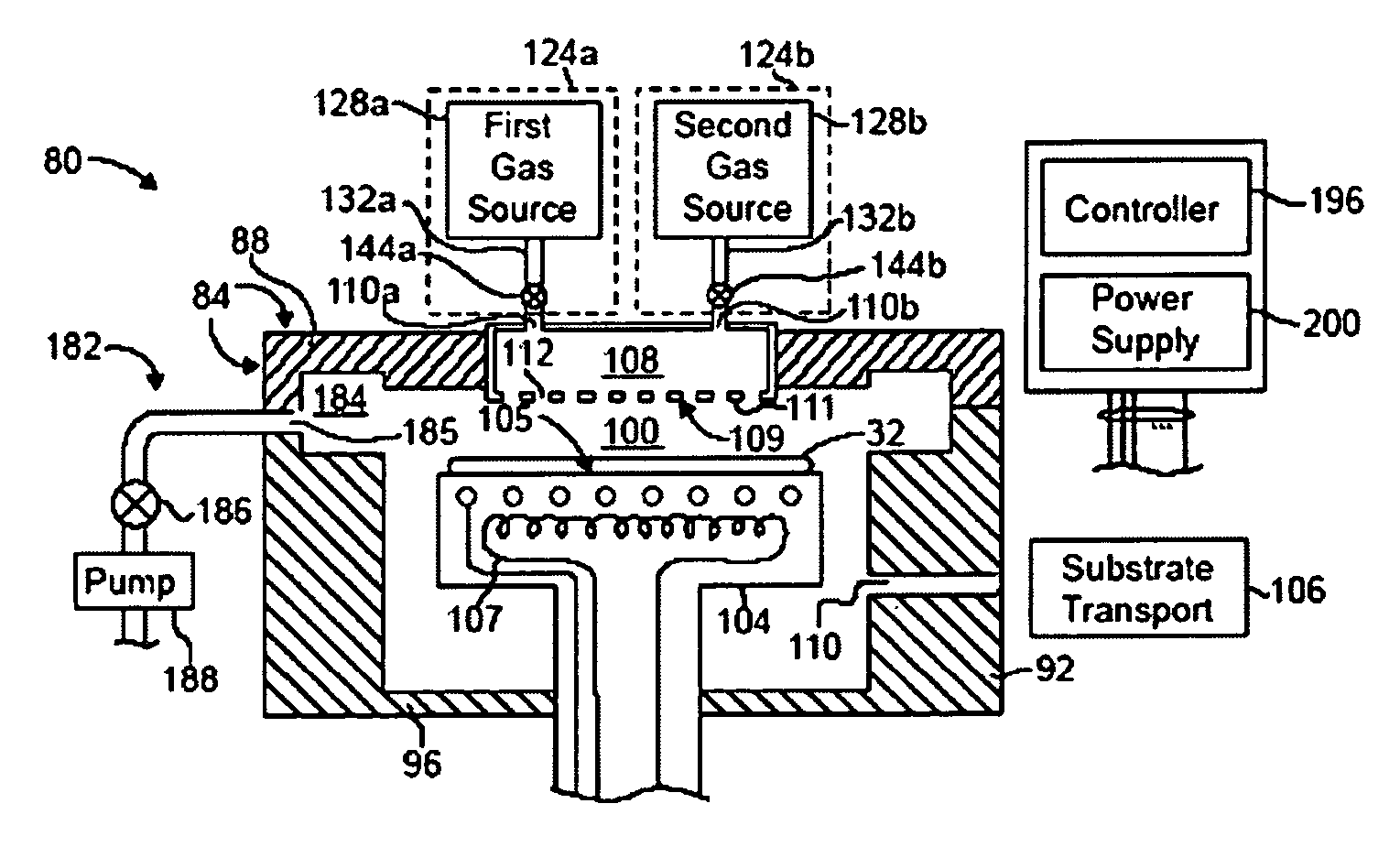

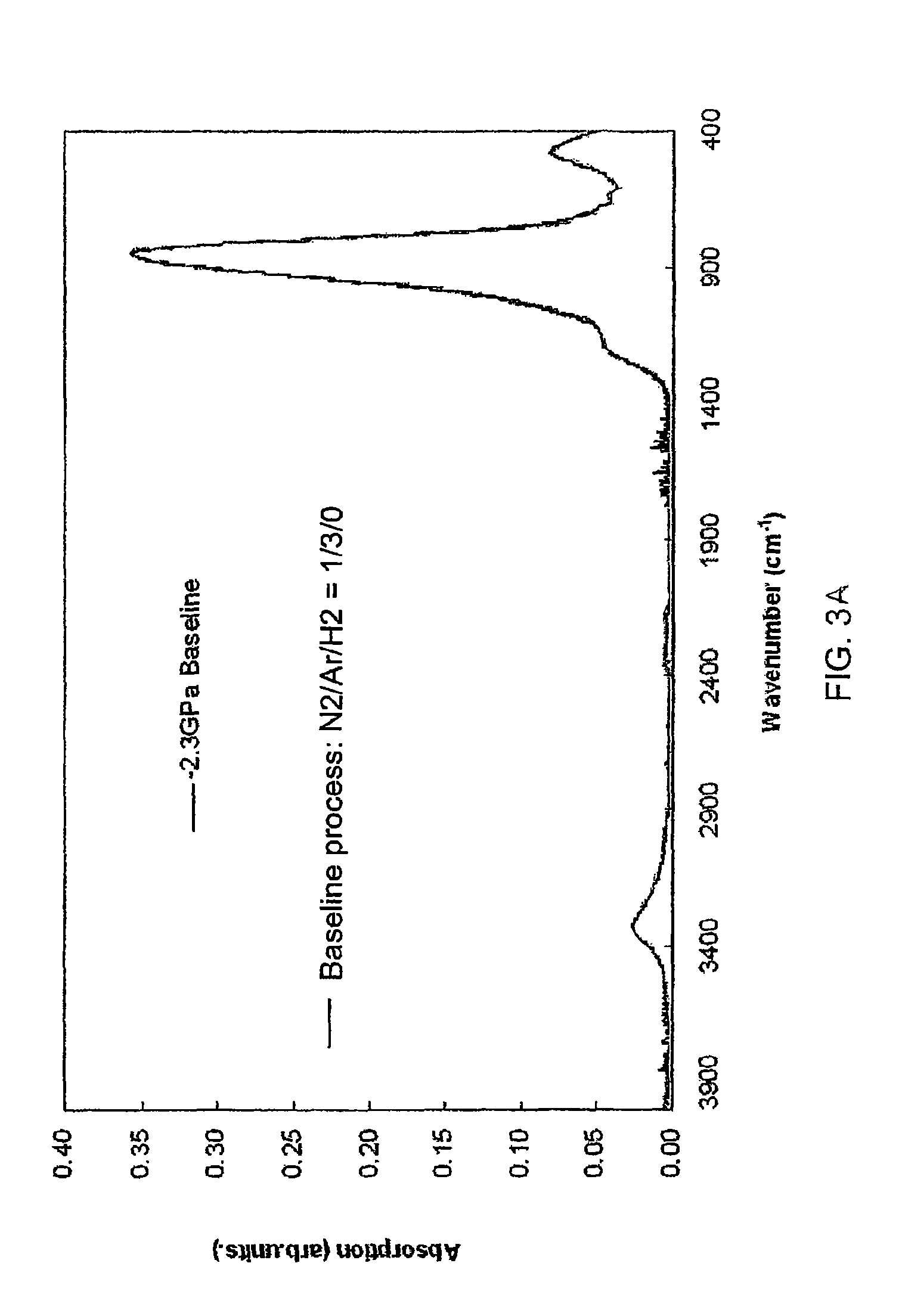

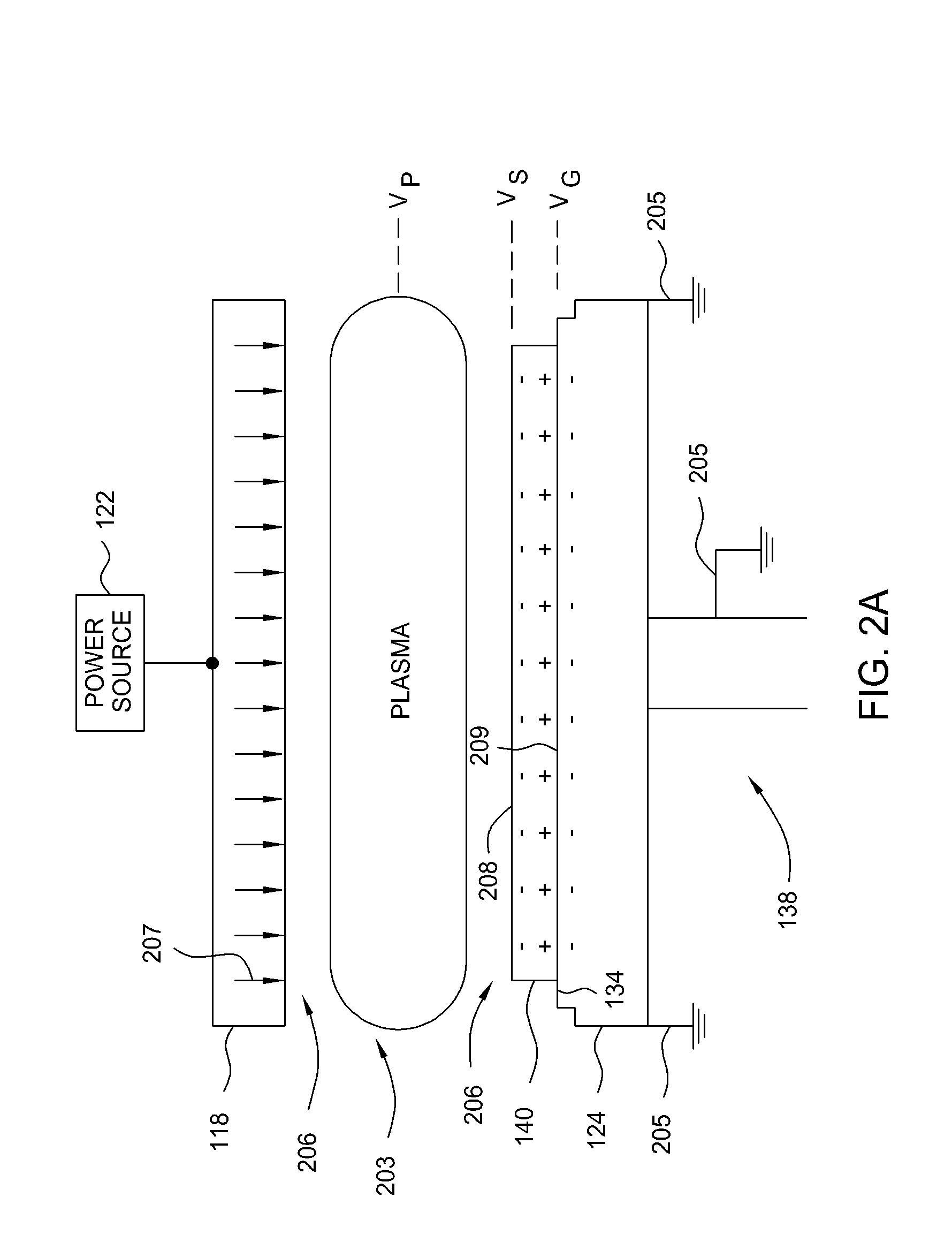

Method of controlling the film properties of a CVD-deposited silicon nitride film

InactiveUS20060019502A1Increase wet etch rateEasy to controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricGas composition

We have discovered that adding H2 to a precursor gas composition including SiH4, NH3, and N2 is effective at improving the wet etch rate and the wet etch rate uniformity across the substrate surface of a-SiNx:H films which are deposited on a substrate by PECVD. Wet etch rate is an indication of film density. Typically, the lower the wet etch rate, the denser the film. The addition of H2 to the SiH4 / NH3 / N2 precursor gas composition did not significantly increase the variation in deposited film thickness across the surface of the substrate. The a-SiNx:H films described herein are particularly useful as TFT gate dielectrics in the production of flat panel displays. The uniformity of the film across the substrate enables the production of flat panel displays having surface areas of 25,000 cm2 and larger.

Owner:APPLIED MATERIALS INC

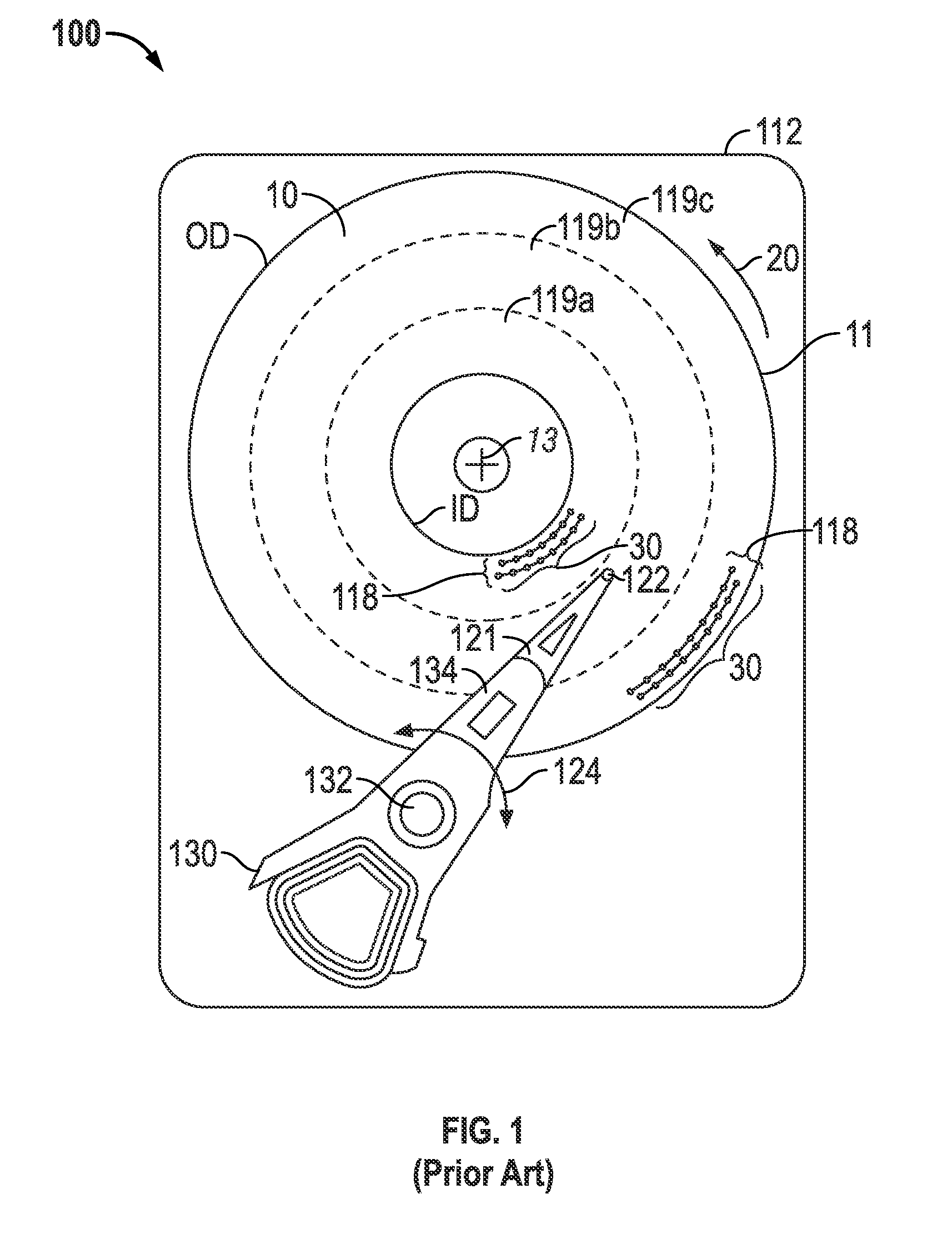

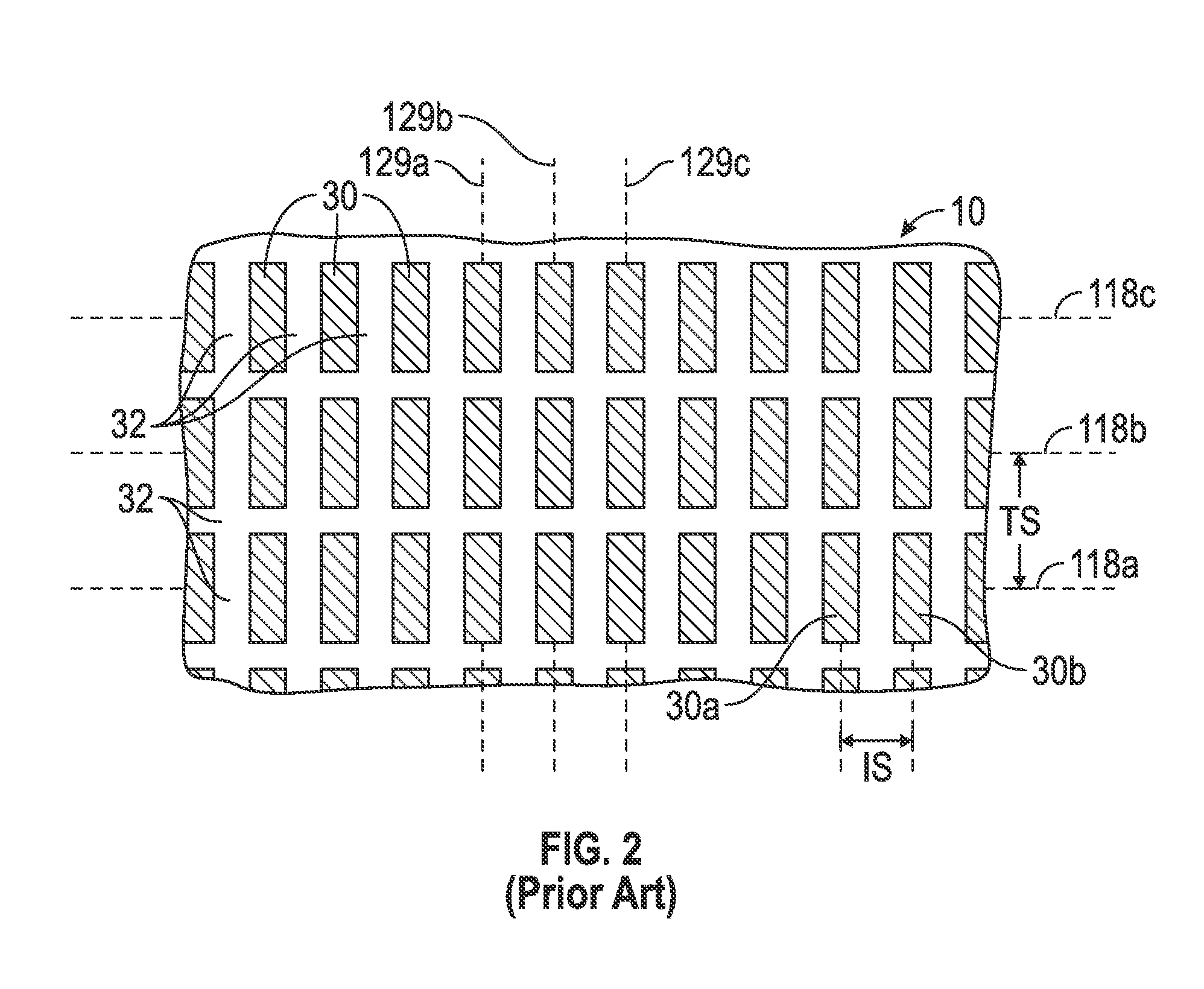

Imprint mold and method for making using sidewall spacer line doubling

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

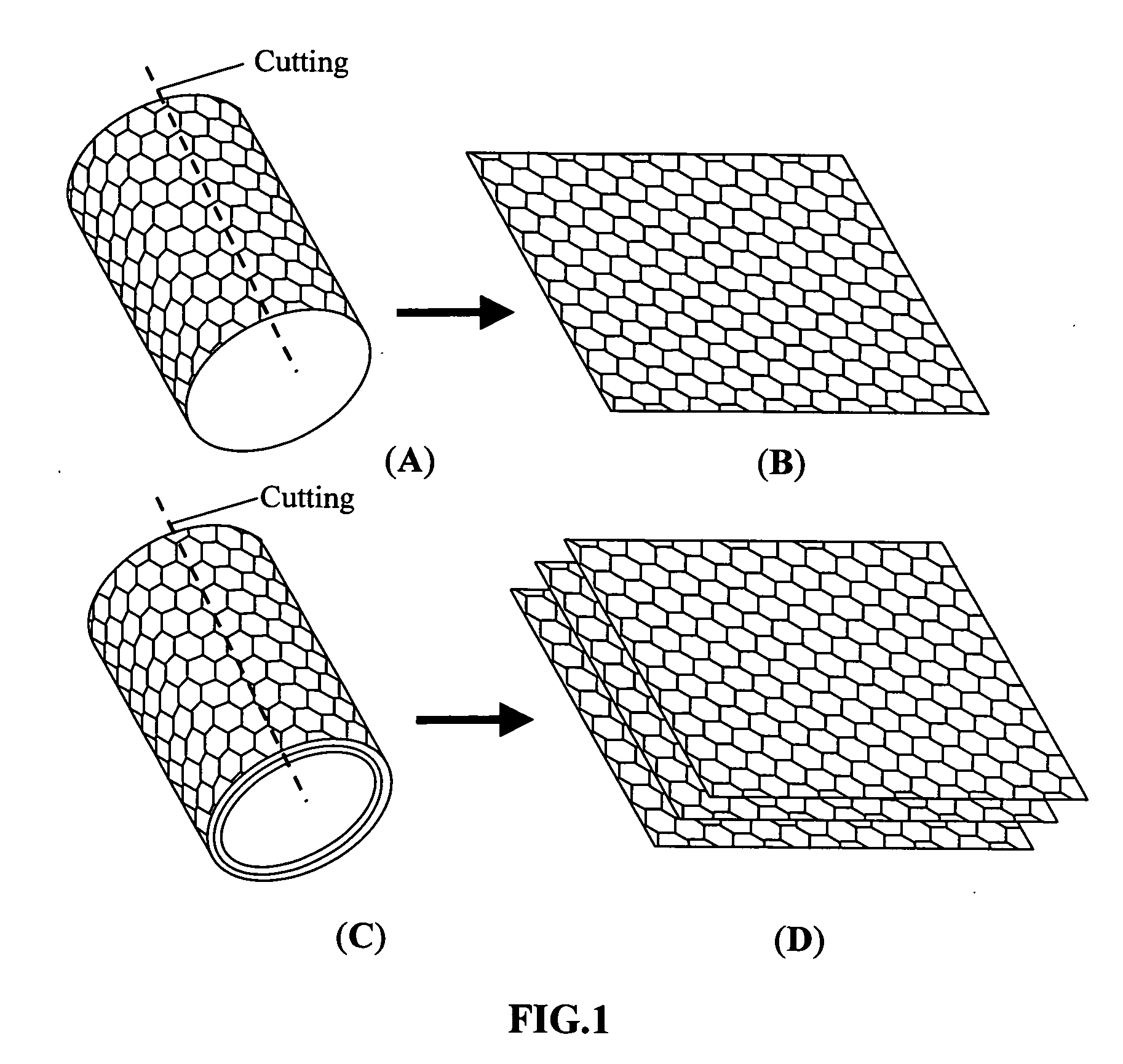

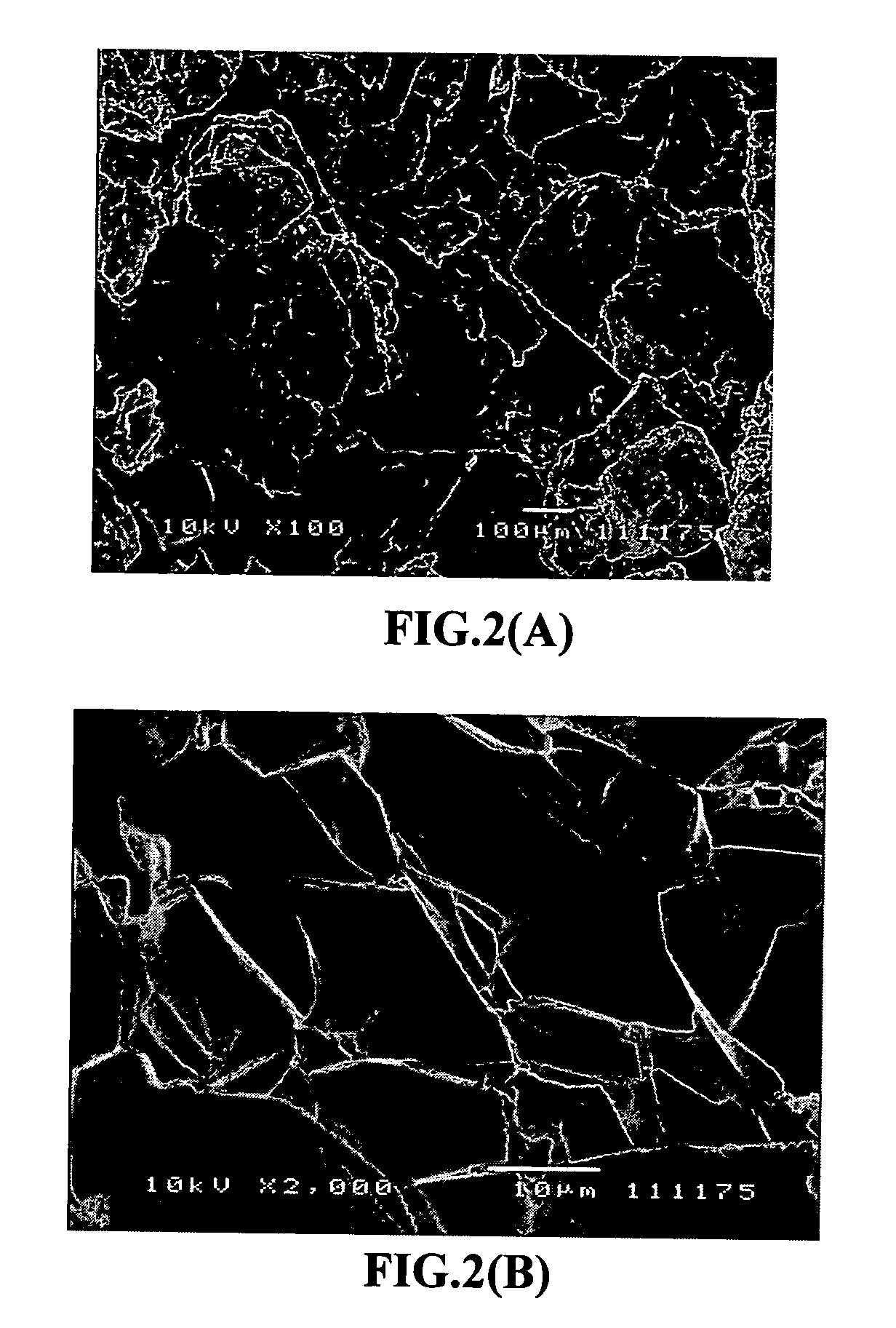

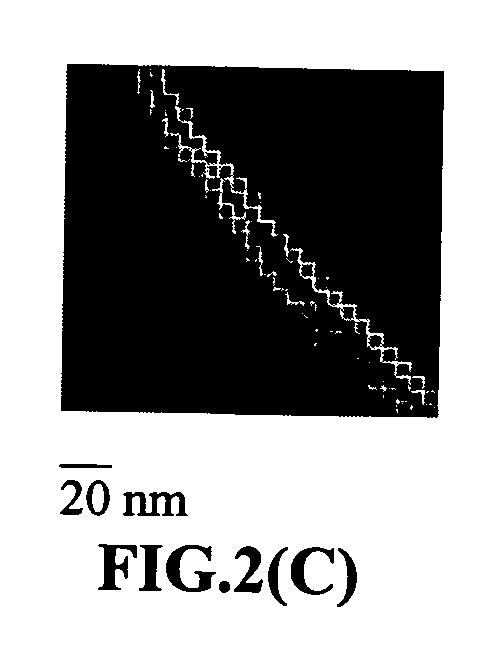

Process for producing nano-scaled graphene plates

InactiveUS20050271574A1Faster and cost-effective processHighly cost-effectiveMaterial nanotechnologyGraphiteGrapheneGraphite particle

A process for producing nano-scaled graphene plates with each plate comprising a sheet of graphite plane or multiple sheets of graphite plane with the graphite plane comprising a two-dimensional hexagonal structure of carbon atoms. The process includes the primary steps of: (a) providing a powder of fine graphite particles comprising graphite crystallites with each crystallite comprising one sheet or normally a multiplicity of sheets of graphite plane bonded together; (b) exfoliating the graphite crystallites to form exfoliated graphite particles, which are characterized by having at least two graphite planes being either partially or fully separated from each other; and (c) subjecting the exfoliated graphite particles to a mechanical attrition treatment to further reduce at least one dimension of the particles to a nanometer scale, <100 nm, for producing the nano-scaled graphene plates.

Owner:GLOBAL GRAPHENE GRP INC

Preparation of phosphorothioate and boranophosphate oligomers

InactiveUS6160109AHigh diastereomeric excessLow costSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsOligomerDiastereomer

Owner:MCGILL UNIV +1

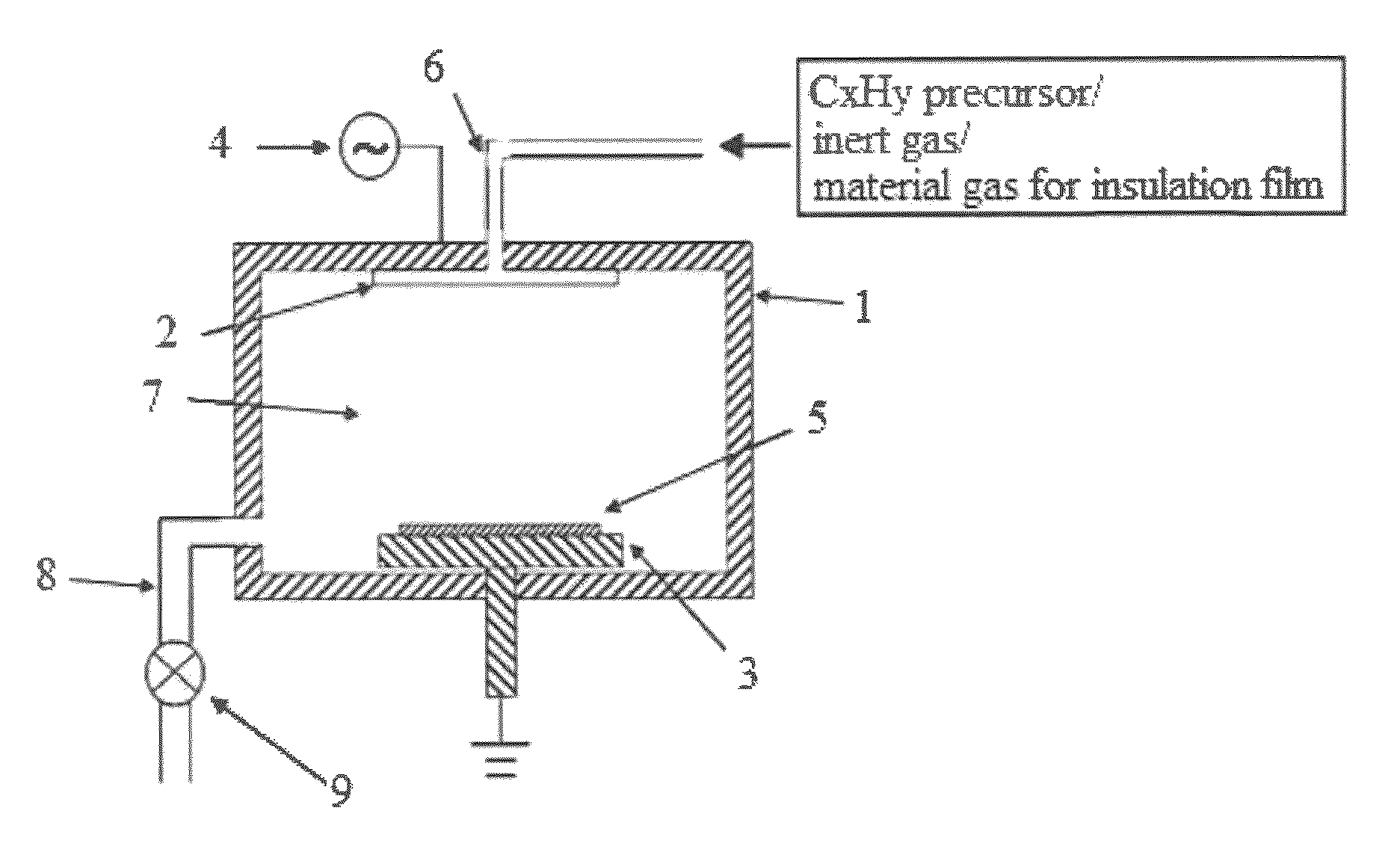

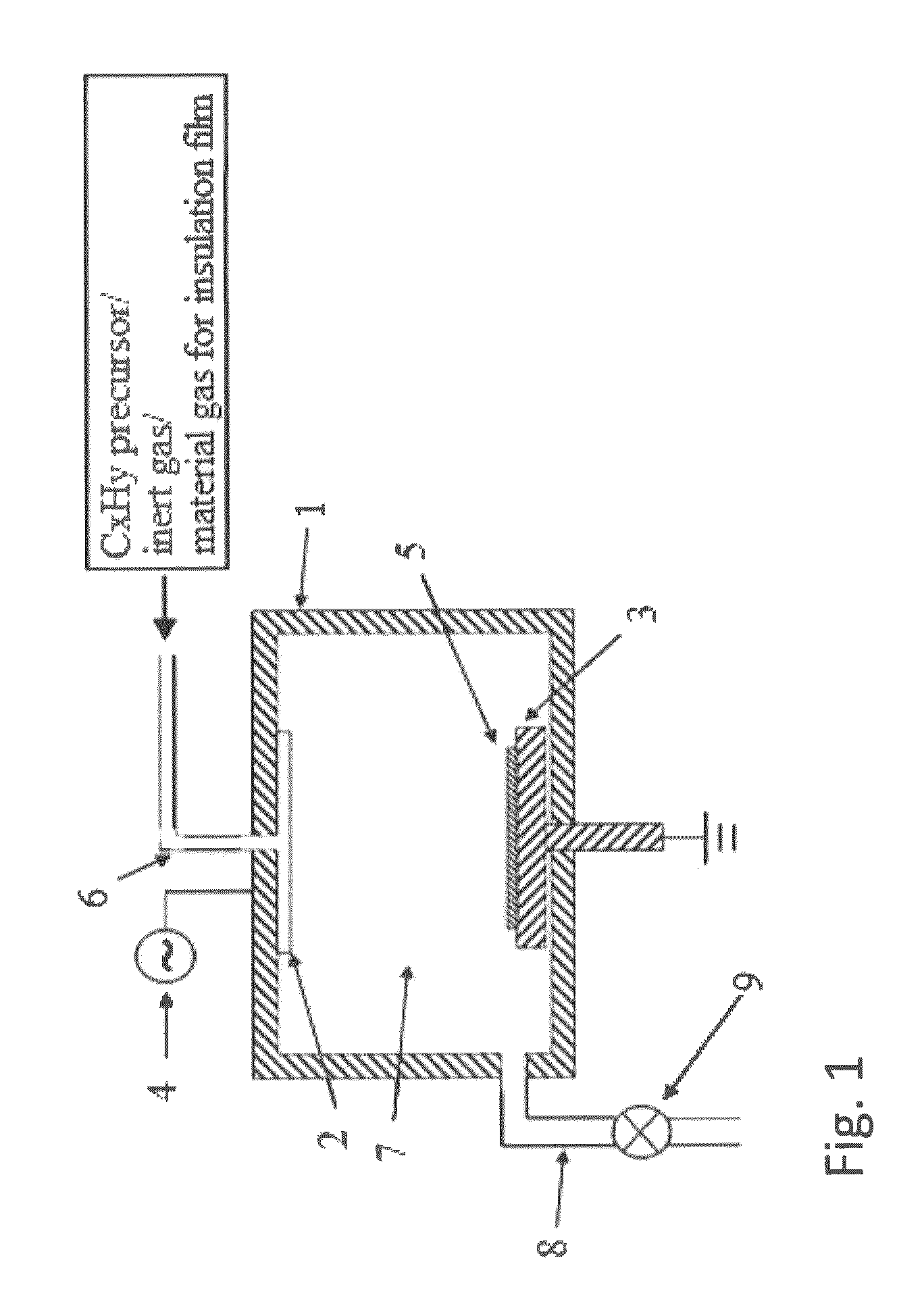

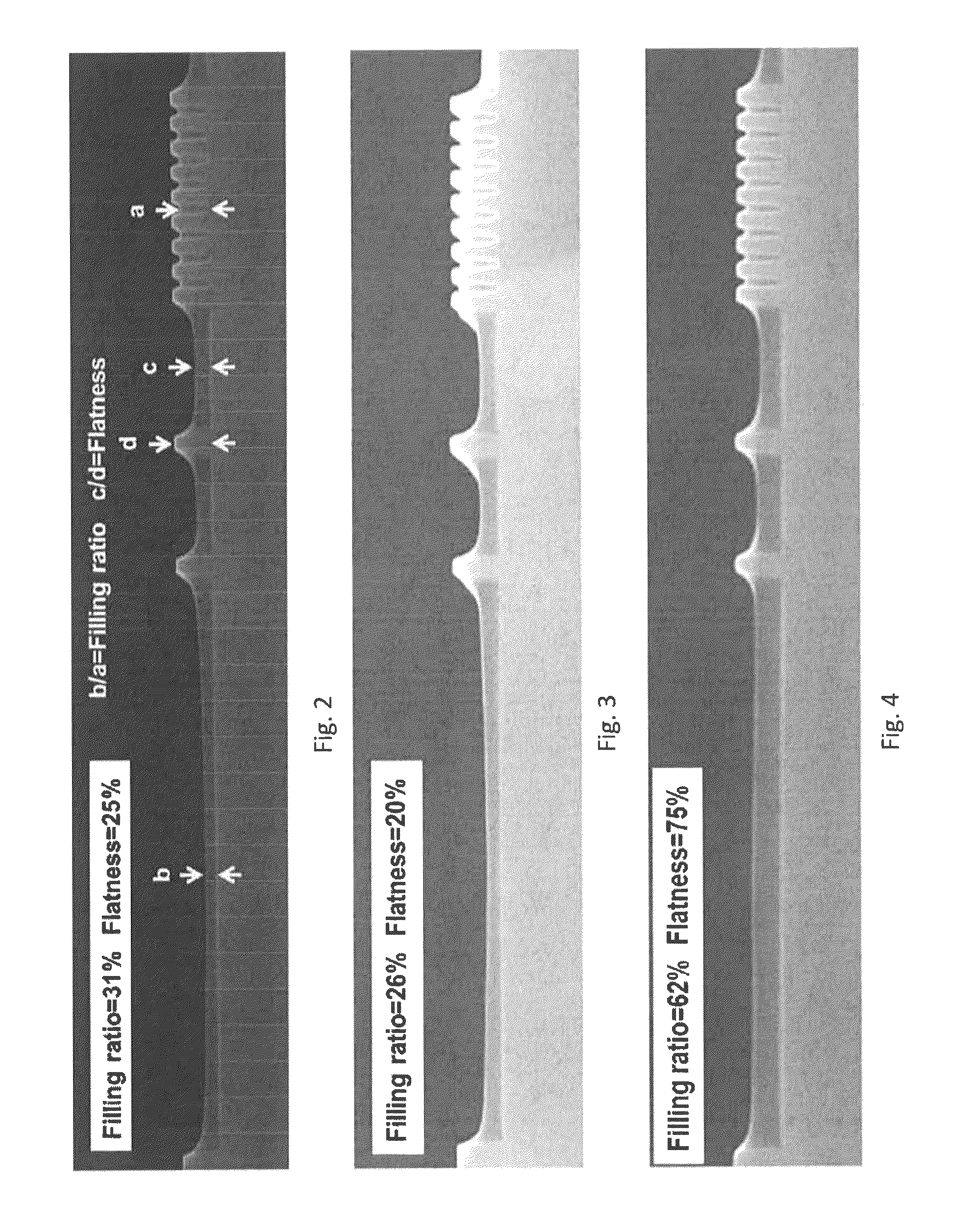

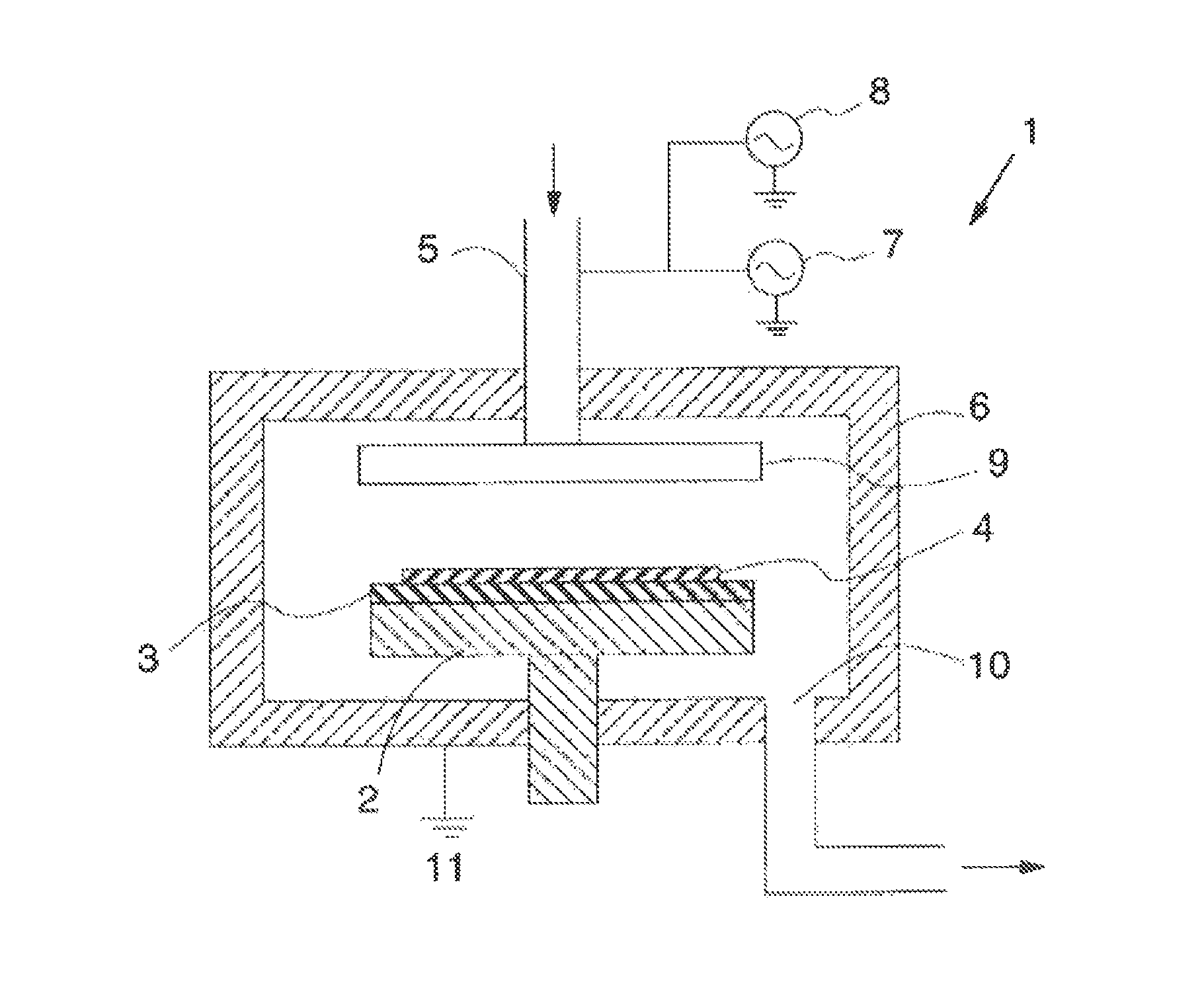

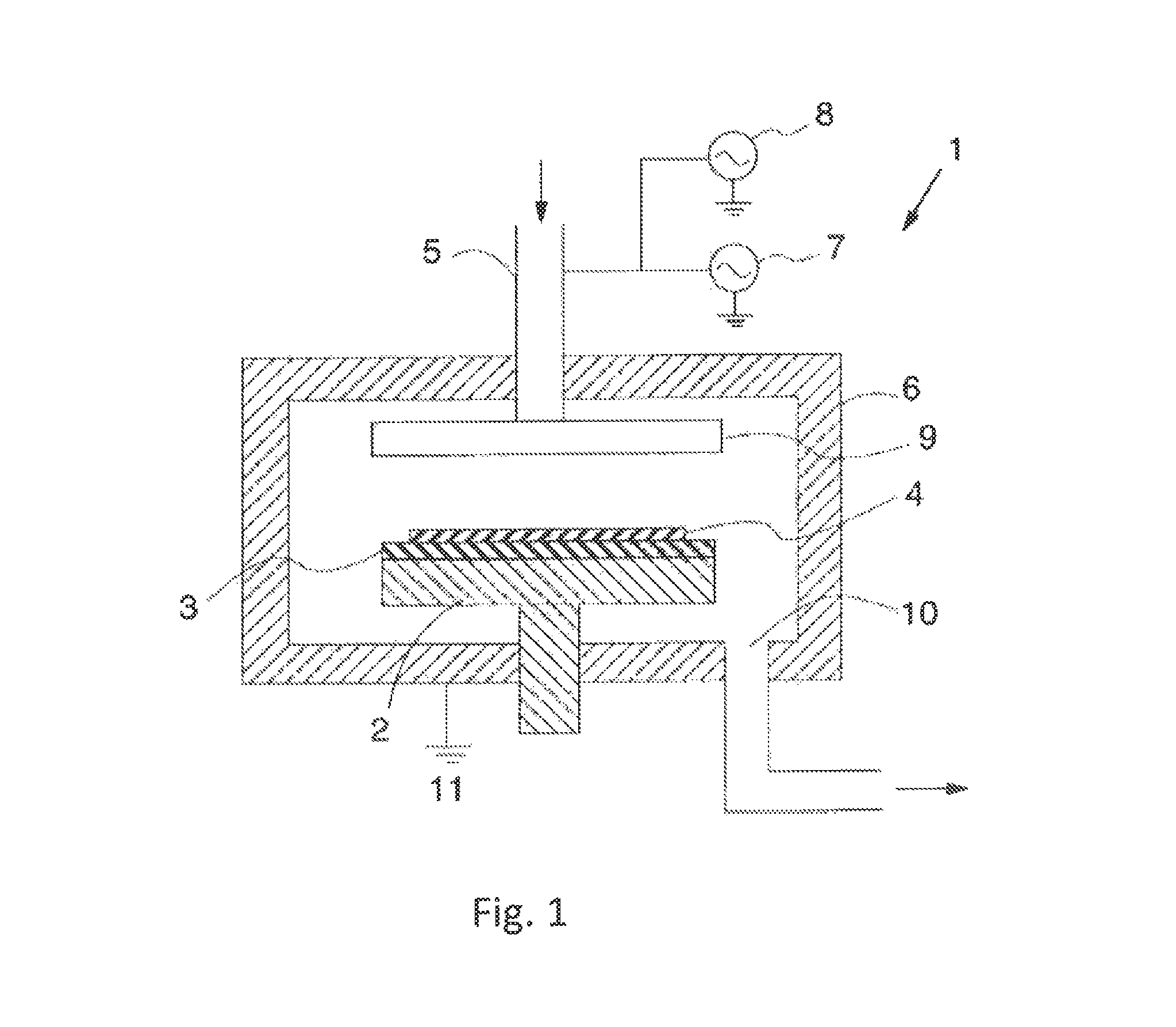

Method for filling recesses using pre-treatment with hydrocarbon-containing gas

ActiveUS9117657B2Improve flatnessHighly effectiveSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPre treatmentPre deposition

A method for filling recesses of a substrate with an insulation film includes: (i) exposing surfaces of the recesses of the substrate to a pre-deposition gas in a reactive state in a reaction space to treat the surfaces with reactive hydrocarbons generated from the pre-deposition gas without filling the recesses; and (ii) depositing a flowable insulation film using a process gas other than the pre-deposition gas on a surface of the substrate to fill the recesses treated in step (i) therewith by plasma reaction. The pre-deposition gas has at least one hydrocarbon unit in its molecule.

Owner:ASM IP HLDG BV

Method for forming layer constituted by repeated stacked layers

ActiveUS9018093B2High wet etching selectivityUniform film qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingThin membraneSecondary layer

A method for forming a layer constituted by repeated stacked layers includes: forming a first layer and a second layer on a substrate under different deposition conditions to form a stacked layer, wherein the film stresses of the first and second layers are tensile or compressive and opposite to each other, and the wet etch rates of the first and second layers are at least 50 times different from each other; and repeating the above step to form a layer constituted by repeated stacked layers, wherein the deposition conditions for forming at least one stacked layer are different from those for forming another stacked layer.

Owner:ASM IP HLDG BV

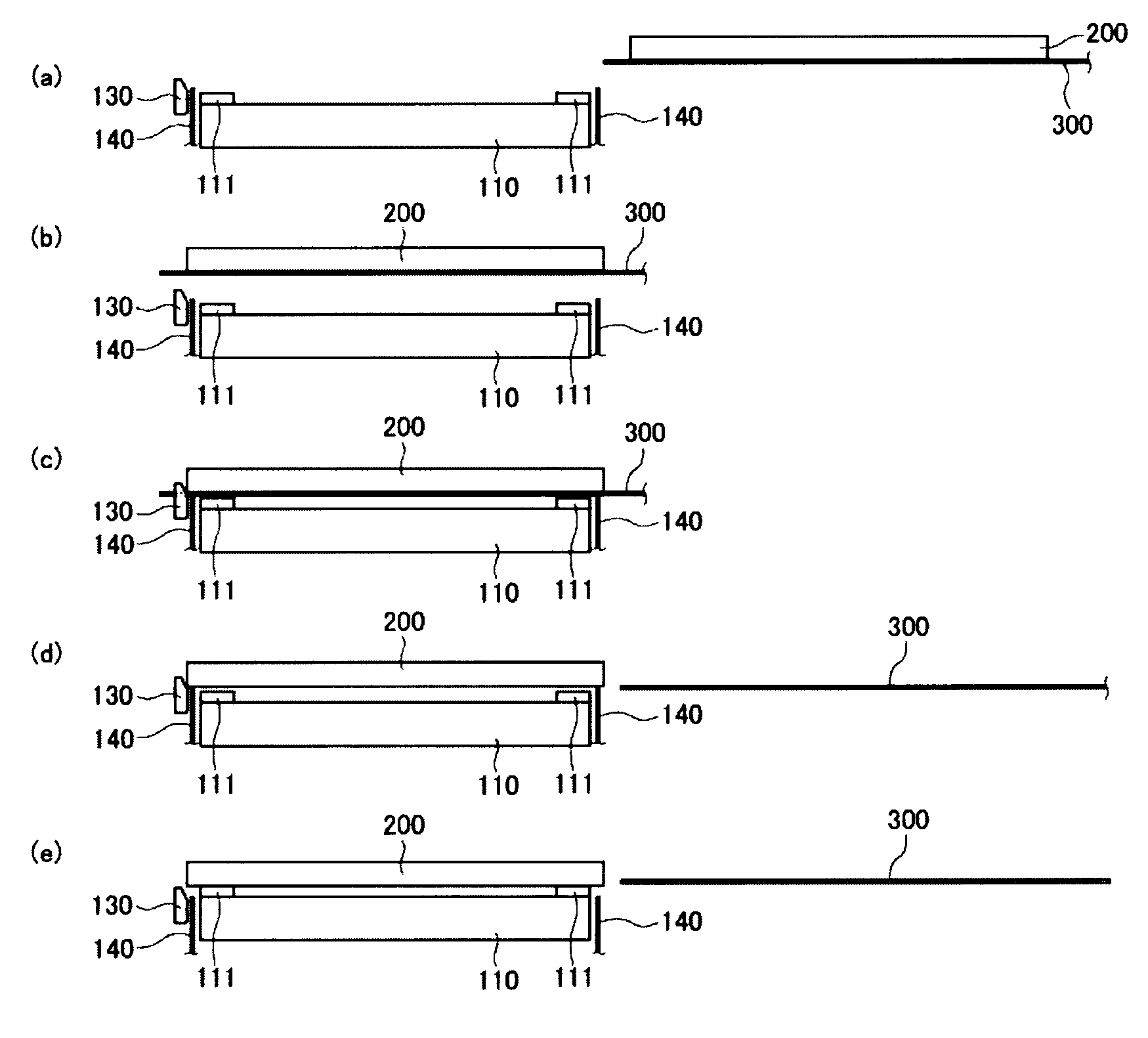

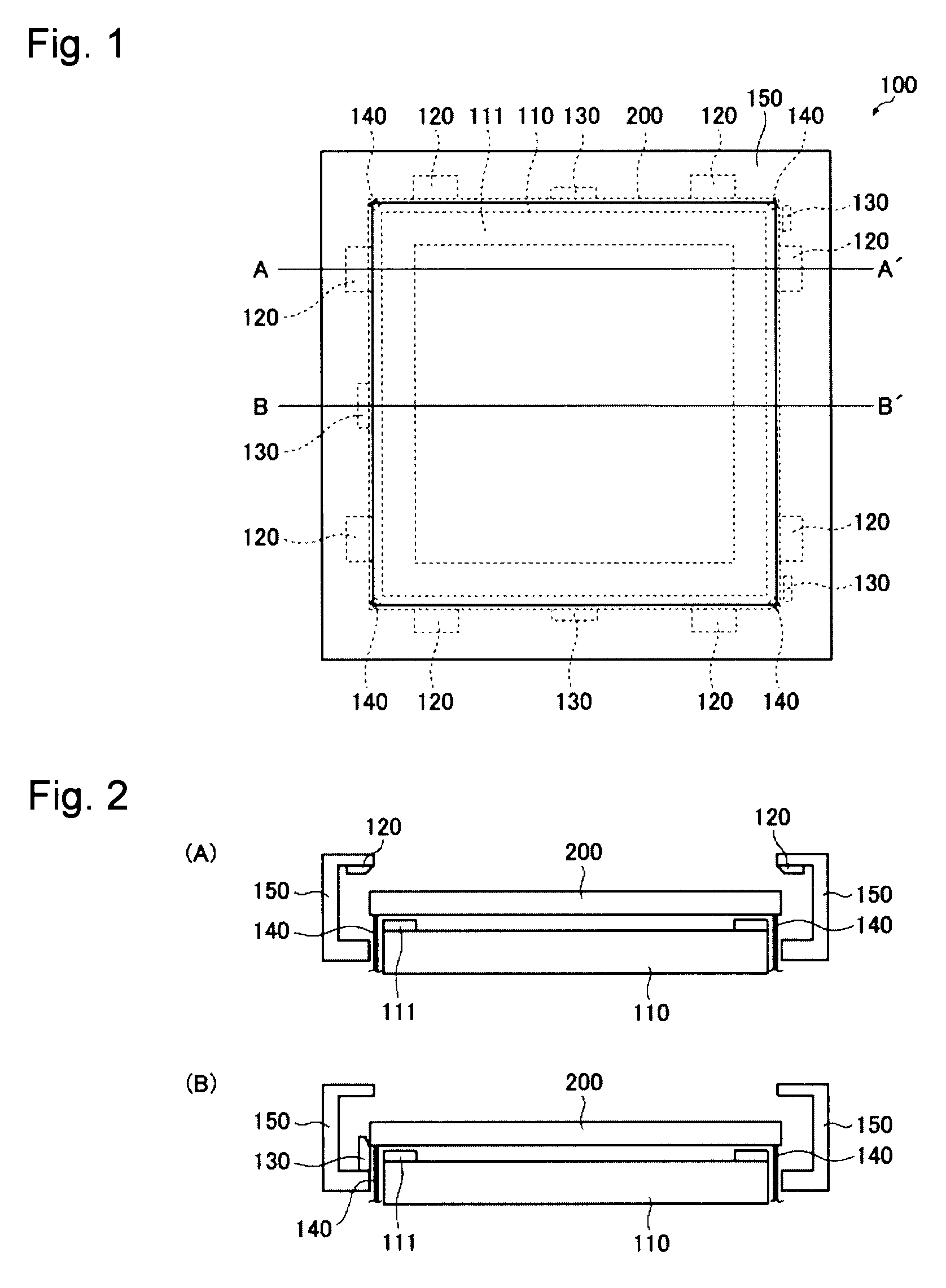

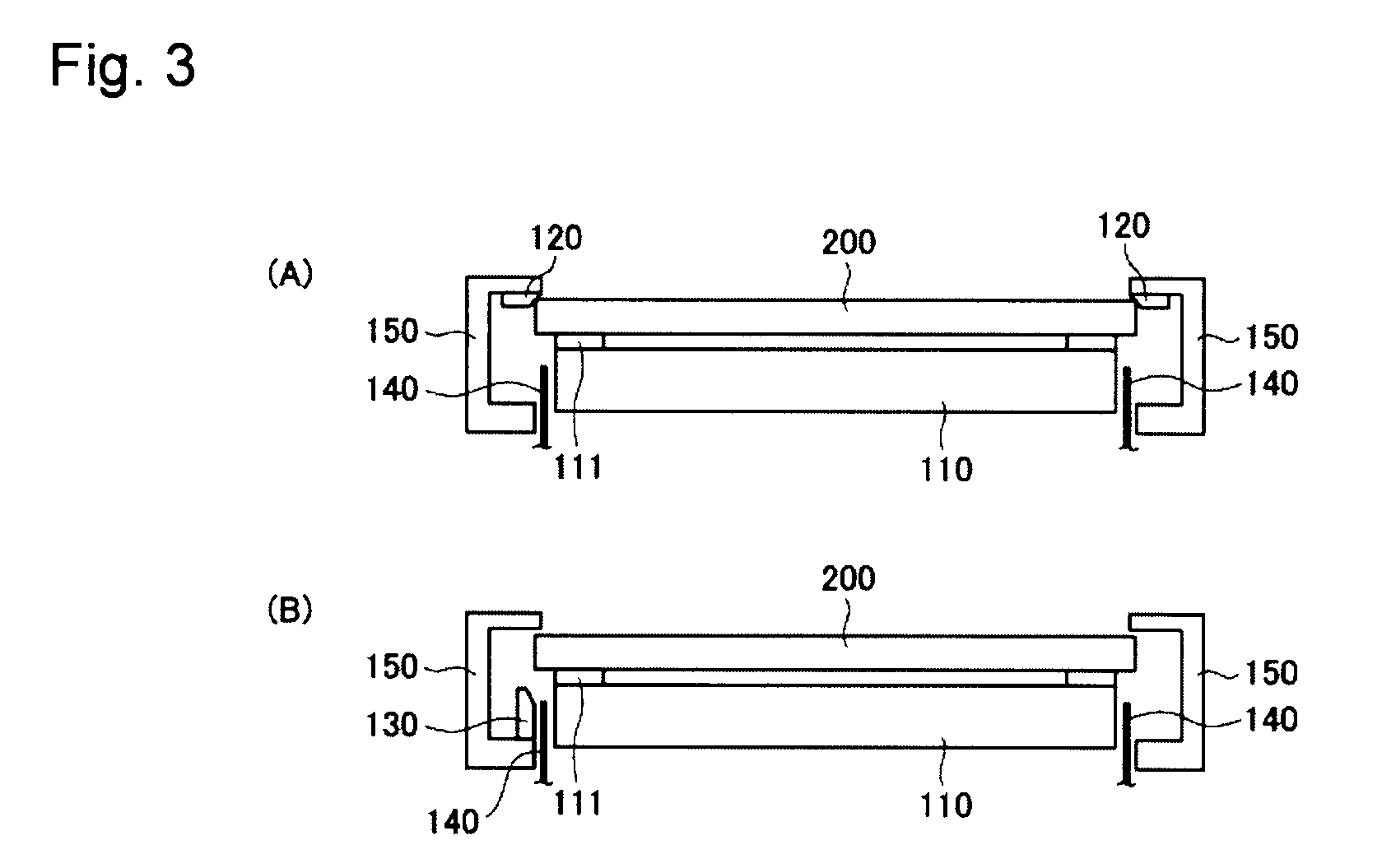

Glass substrate-holding tool and method for producing an EUV mask blank by employing the same

InactiveUS8967608B2InhibitionAccurate placementWorkpiece holdersVacuum evaporation coatingLithographic artistMaterials science

A glass substrate-holding tool employed during the production of a reflective mask blank for EUV lithography includes an electrostatic chuck and a mechanical chuck. A caught and held portion of a glass substrate caught and held by the electrostatic chuck, and pressed portions of the glass substrate pressed by the mechanical chuck are located outside a quality-guaranteed region on each of a film deposition surface and a rear surface of the glass substrate. The sum of a catching and holding force applied to the glass substrate by the electrostatic chuck and a holding force applied to the glass substrate by the mechanical chuck is at least 200 kgf. A pressing force per unit area applied to the glass substrate by the mechanical chuck is at most 25 kgf / mm2.

Owner:ASAHI GLASS CO LTD

Catalyst for olefine polymerizing reaction and its components

The present invention provides one kind catalyst component for CH2=CHR olifine polymerization, where R is H or alkyl radical or aryl radical of C1-C6. The catalyst component contains Mg, Ti, halogenand electron donor.

Owner:CHINA PETROLEUM & CHEM CORP +1

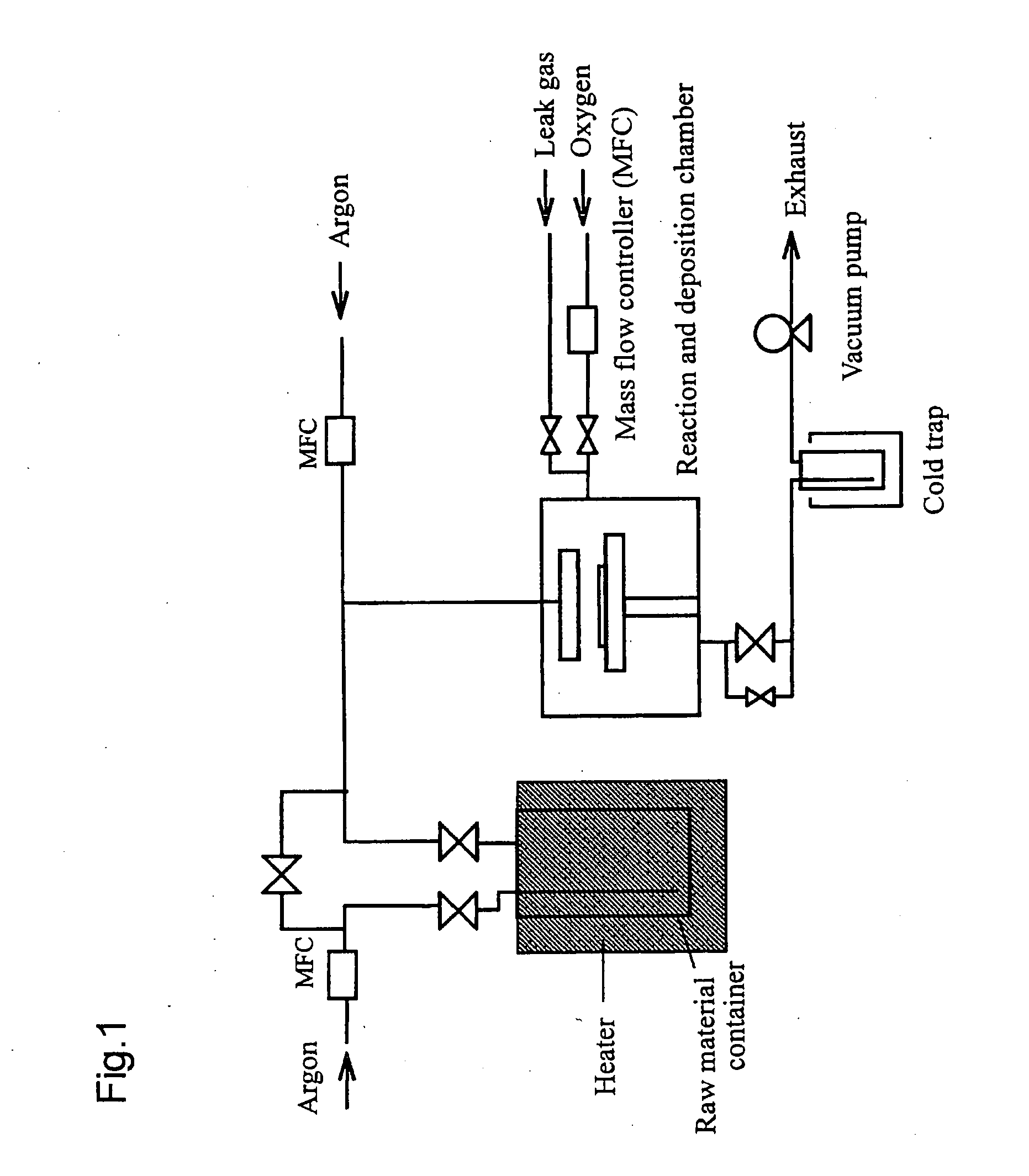

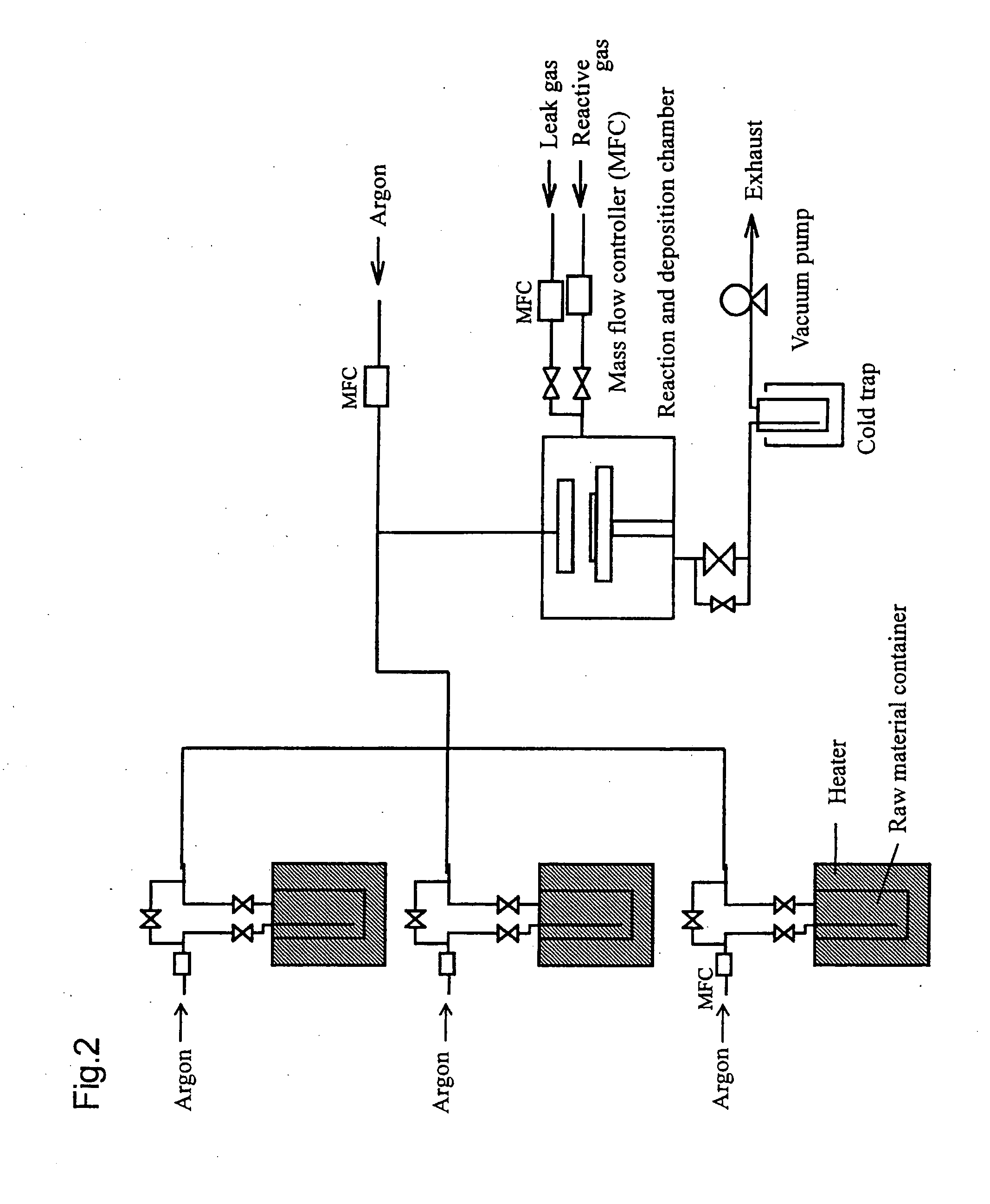

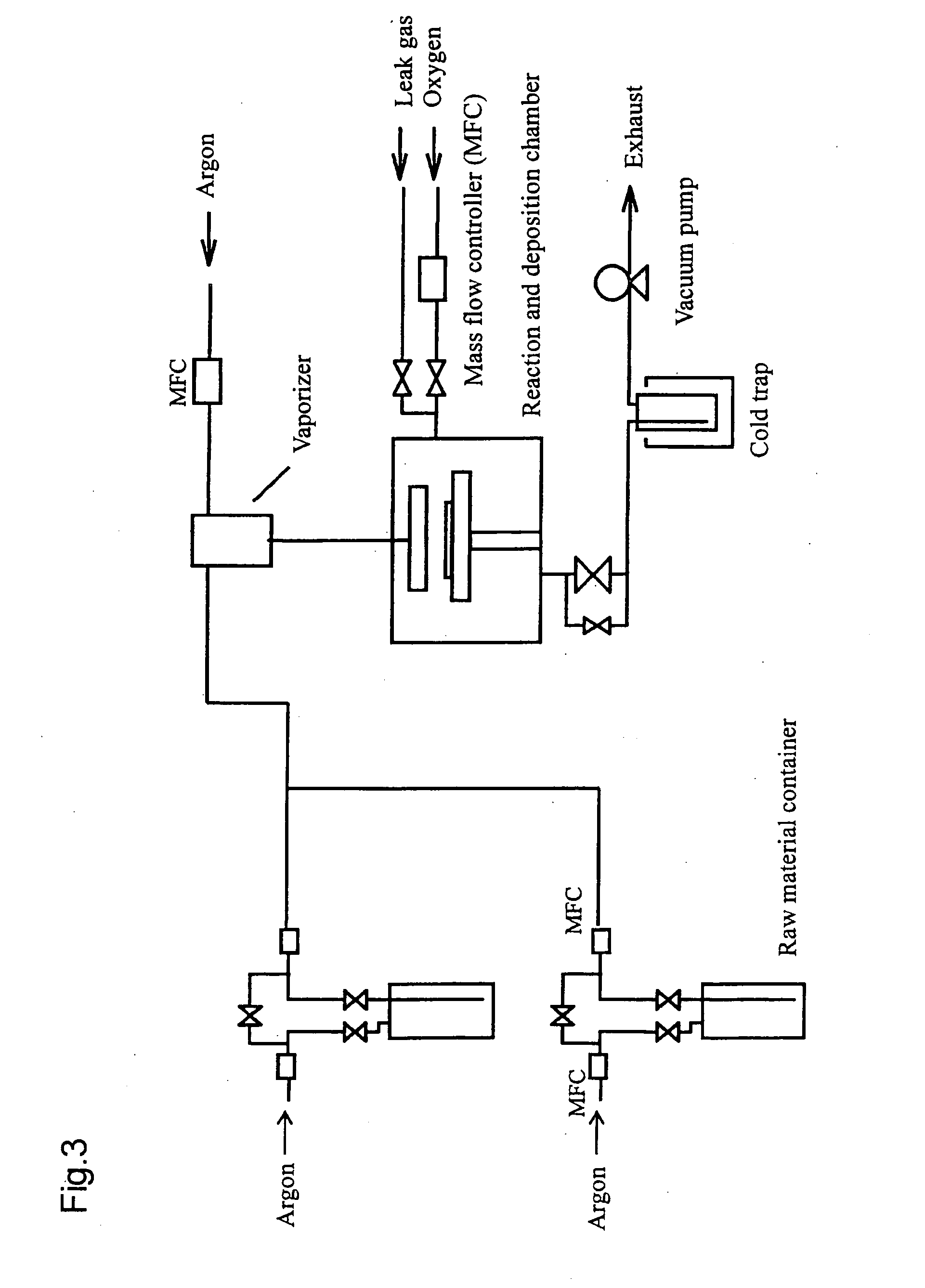

Thin film-forming material and method for producing thin film

InactiveUS20070178235A1Chemical vapor deposition coatingZinc organic compoundsZinc compoundsMaterials science

The thin film-forming material of the present invention comprises a bis(β-diketonato)zinc compound that is liquid at 25° C. and is suitable for forming a zinc-containing thin film. By using the thin film-forming material, a thin film can be produced with stable film-forming rate or stable film composition control without suffering from problems of raw material gas suppliability and in-line raw material transport. Preferred (β-diketonato)zinc compounds include, for example, bis(octane-2,4-dionato)zinc and bis(2,2-dimethyl-6-ethyldecane-3,5-dionato)zinc.

Owner:ADEKA CORP

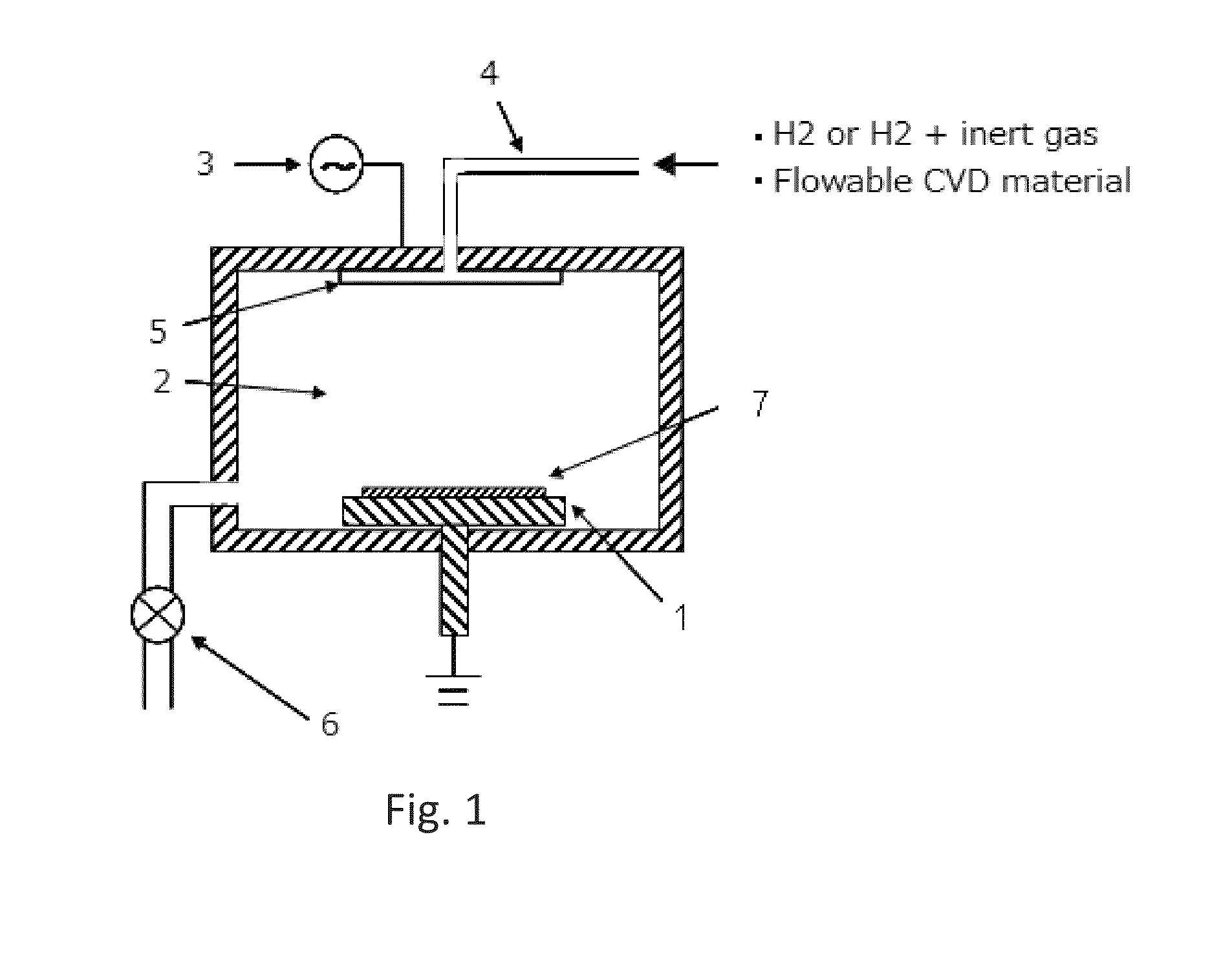

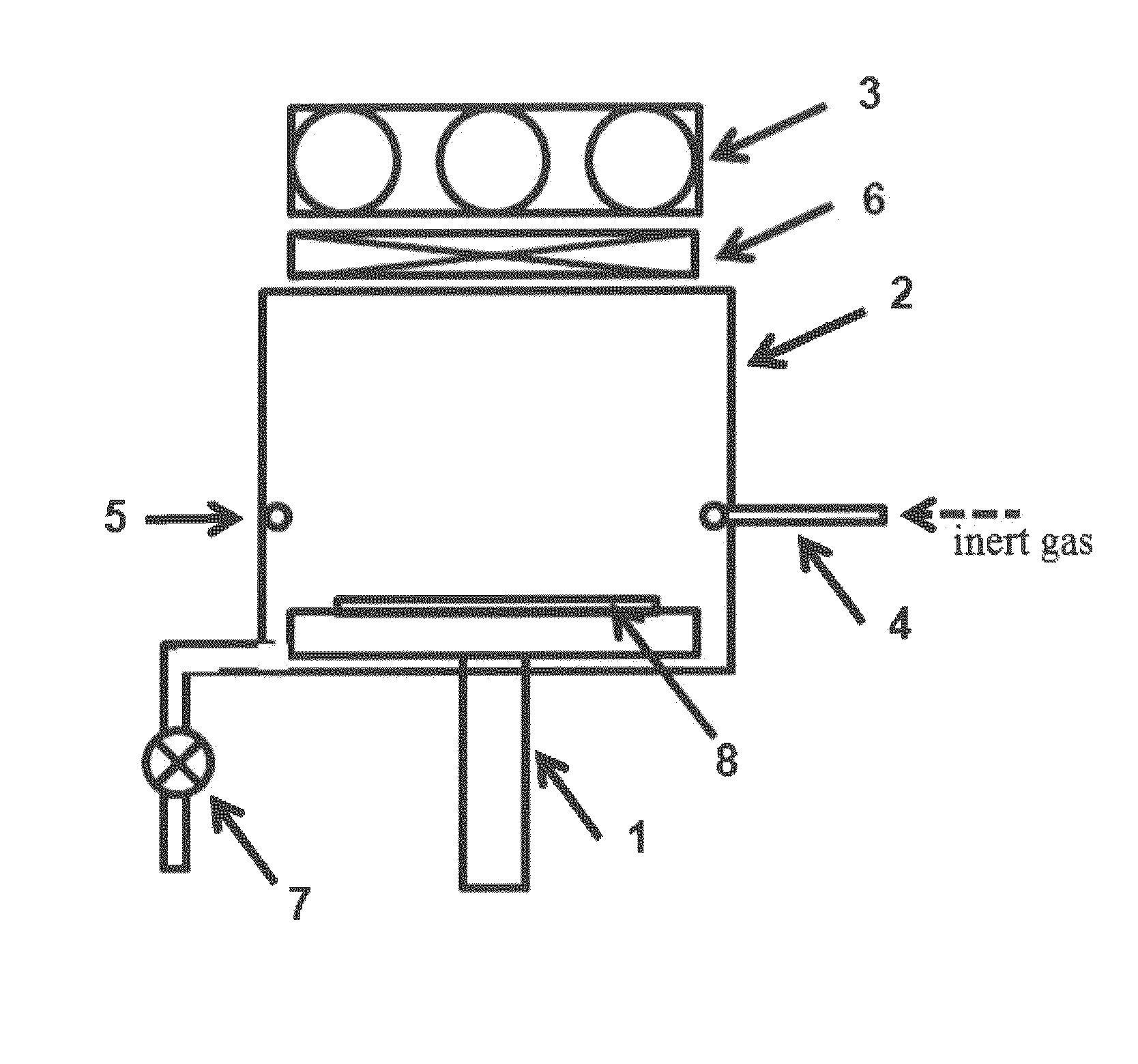

Method for treating SiOCH film with hydrogen plasma

ActiveUS9029272B1Avoid crackingAvoid disconnectionSemiconductor/solid-state device manufacturingPhysical chemistryThin membrane

Owner:ASM IP HLDG BV

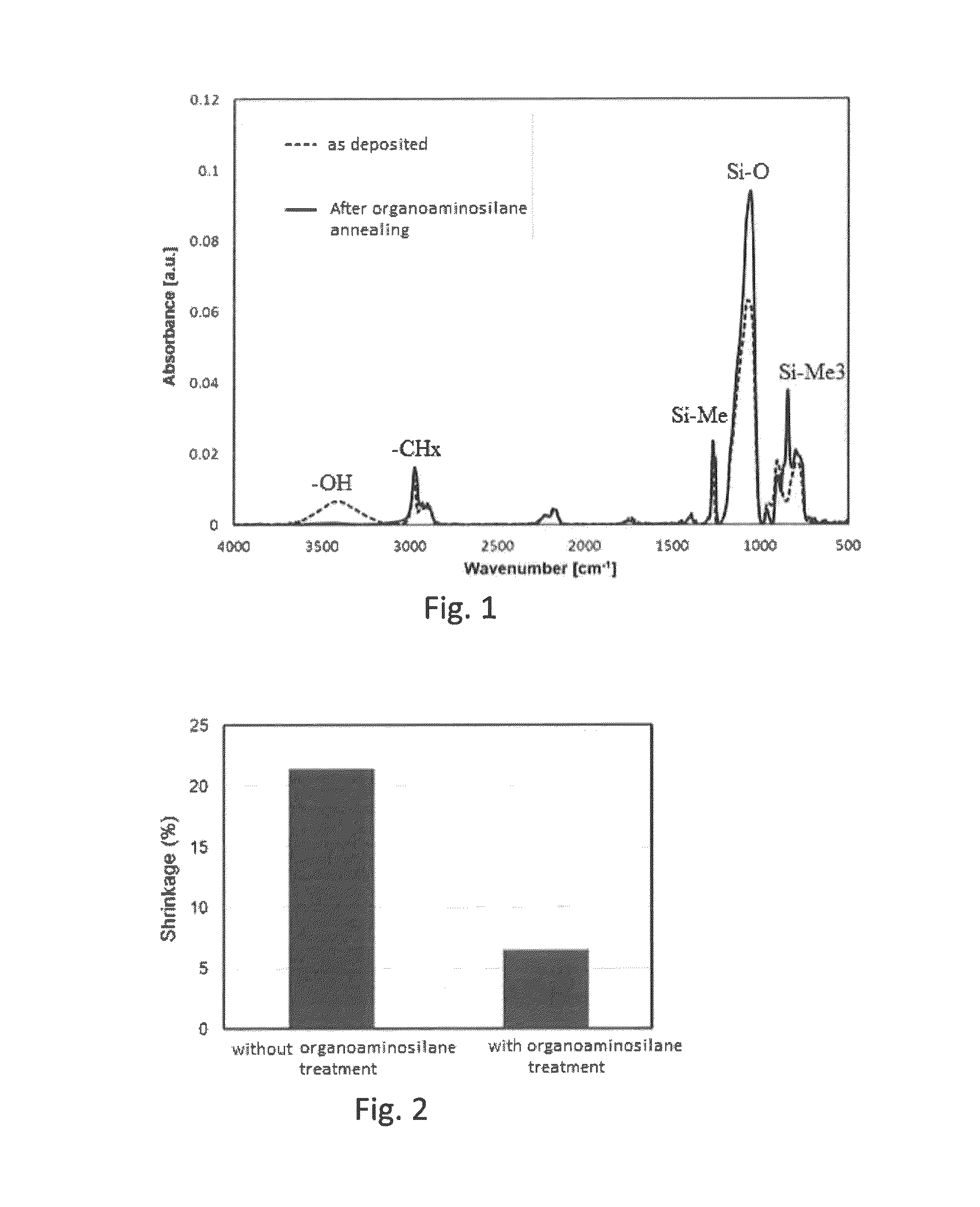

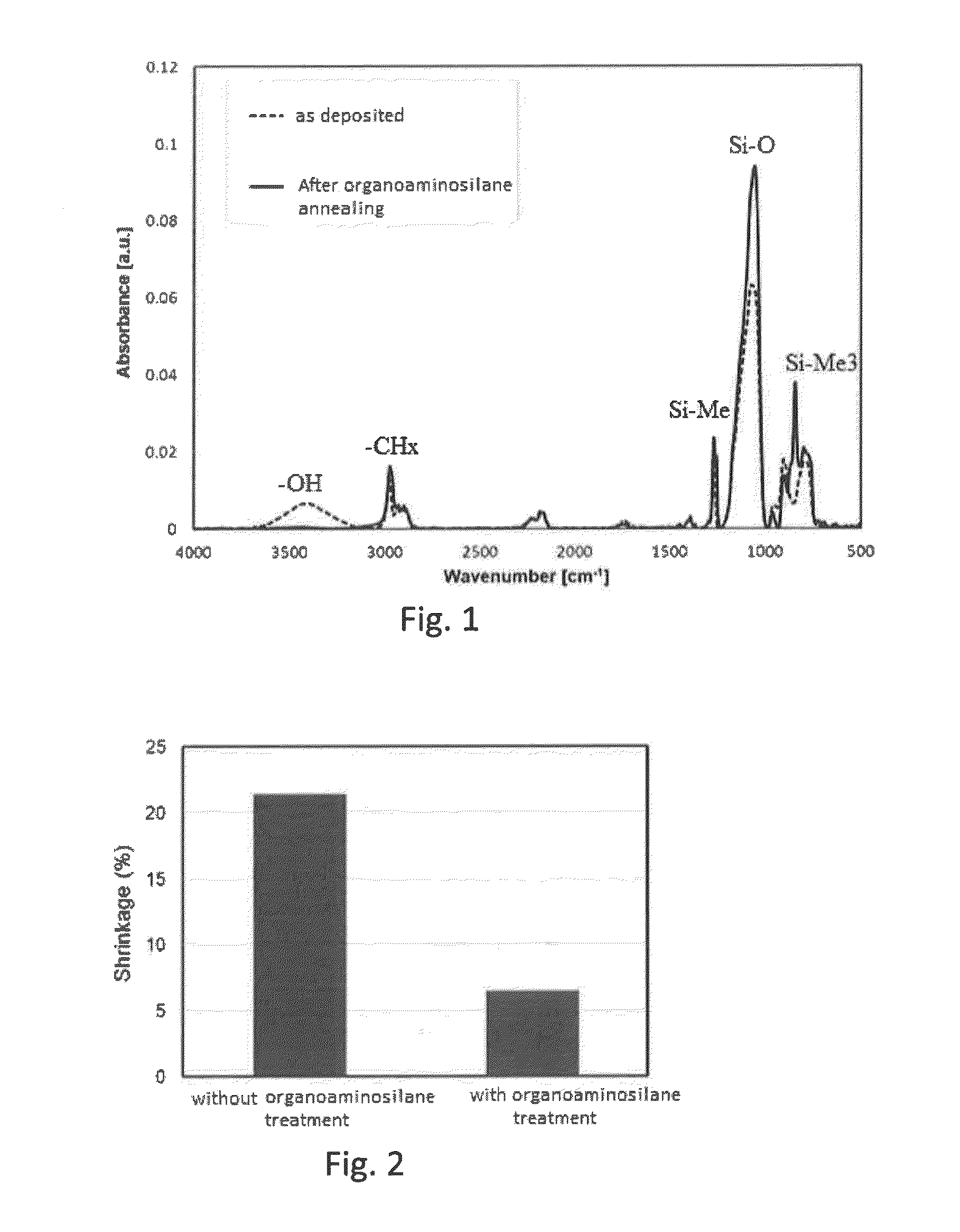

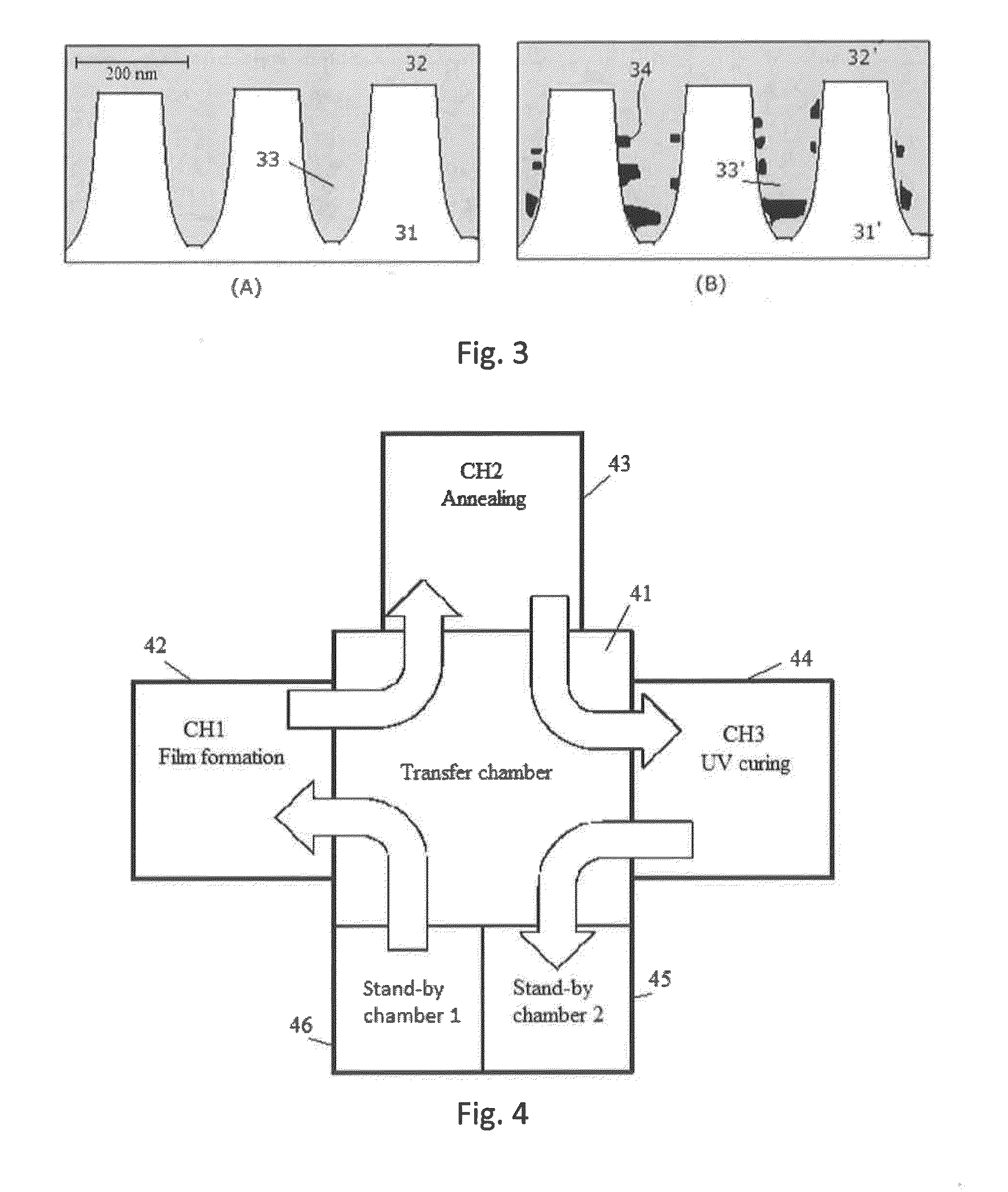

Method for forming SiOCH film using organoaminosilane annealing

ActiveUS9190263B2Improve liquidityReduce the amount requiredSemiconductor/solid-state device manufacturingPolymer scienceSilanes

Owner:ASM IP HLDG BV

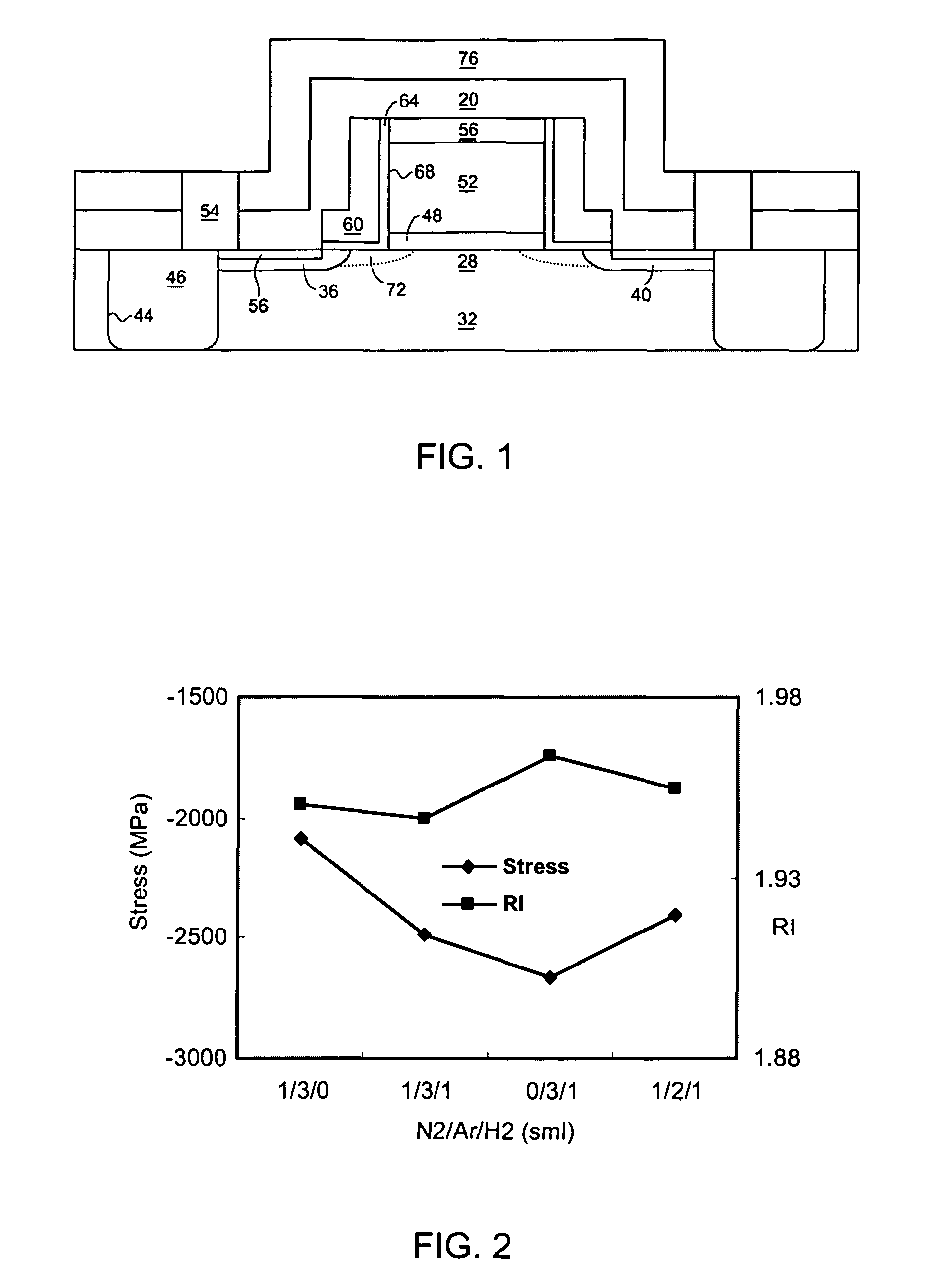

Method to increase tensile stress of silicon nitride films using a post PECVD deposition UV cure

ActiveUS8129290B2Increasing the thicknessSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaThin membrane

High tensile stress in a deposited layer such as silicon nitride, may be achieved utilizing one or more techniques, employed alone or in combination. High tensile stress may be achieved by forming a silicon-containing layer on a surface by exposing the surface to a silicon-containing precursor gas in the absence of a plasma, forming silicon nitride by exposing said silicon-containing layer to a nitrogen-containing plasma, and then repeating these steps to increase a thickness of the silicon nitride created thereby. High tensile stress may also be achieved by exposing a surface to a silicon-containing precursor gas in a first nitrogen-containing plasma, treating the material with a second nitrogen-containing plasma, and then repeating these steps to increase a thickness of the silicon nitride formed thereby. In another embodiment, tensile film stress is enhanced by deposition with porogens that are liberated upon subsequent exposure to UV radiation or plasma treatment.

Owner:APPLIED MATERIALS INC

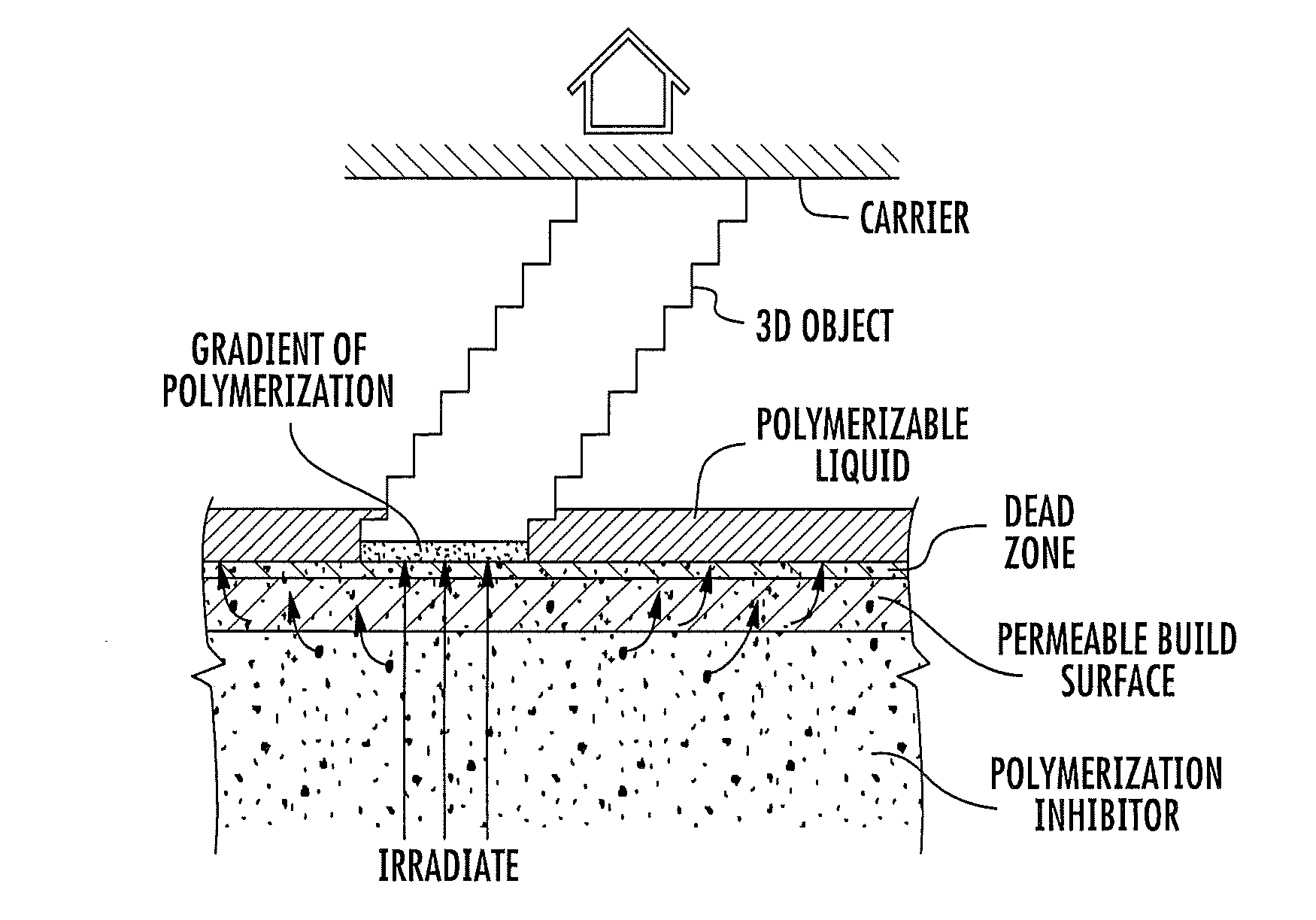

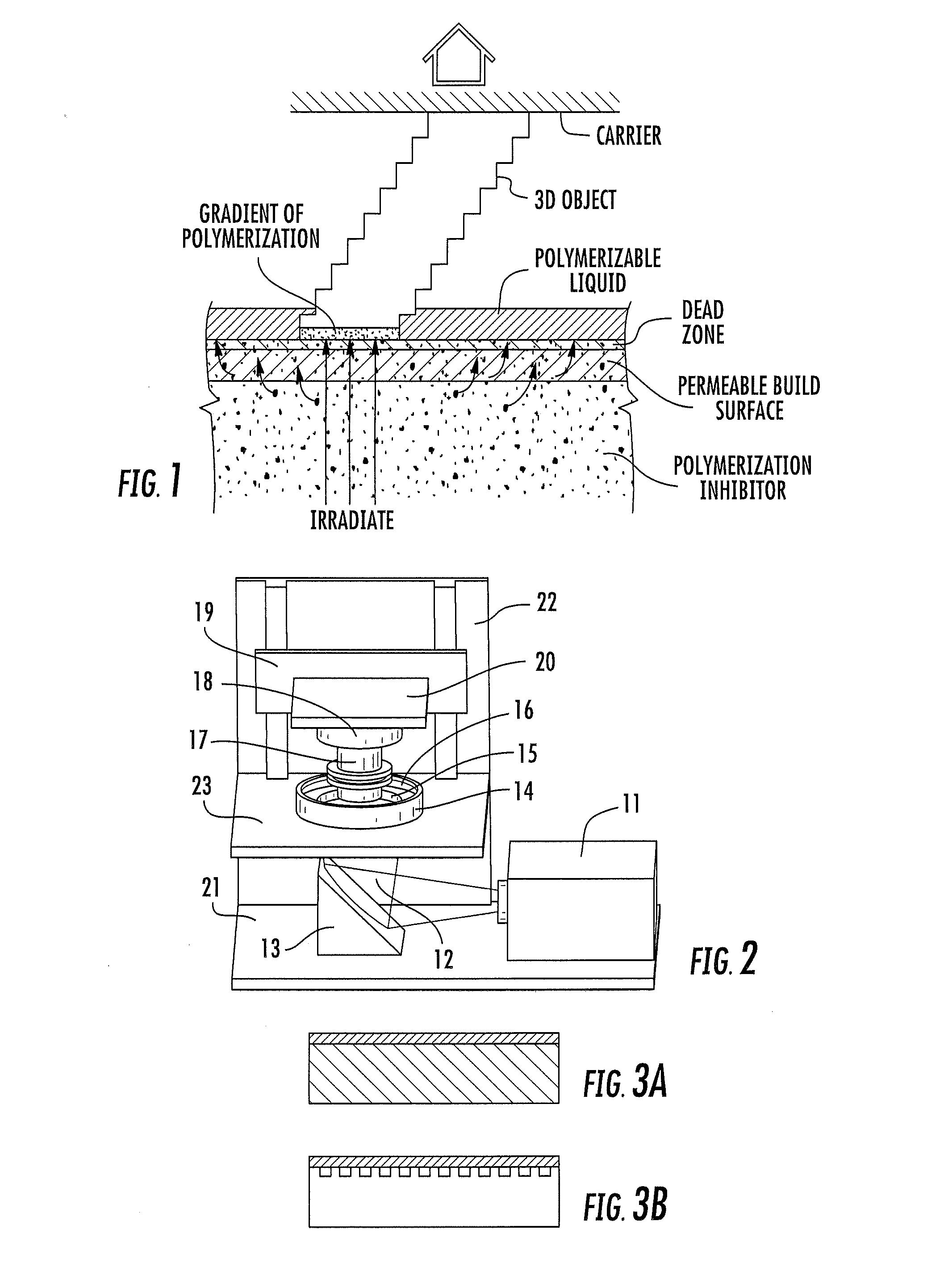

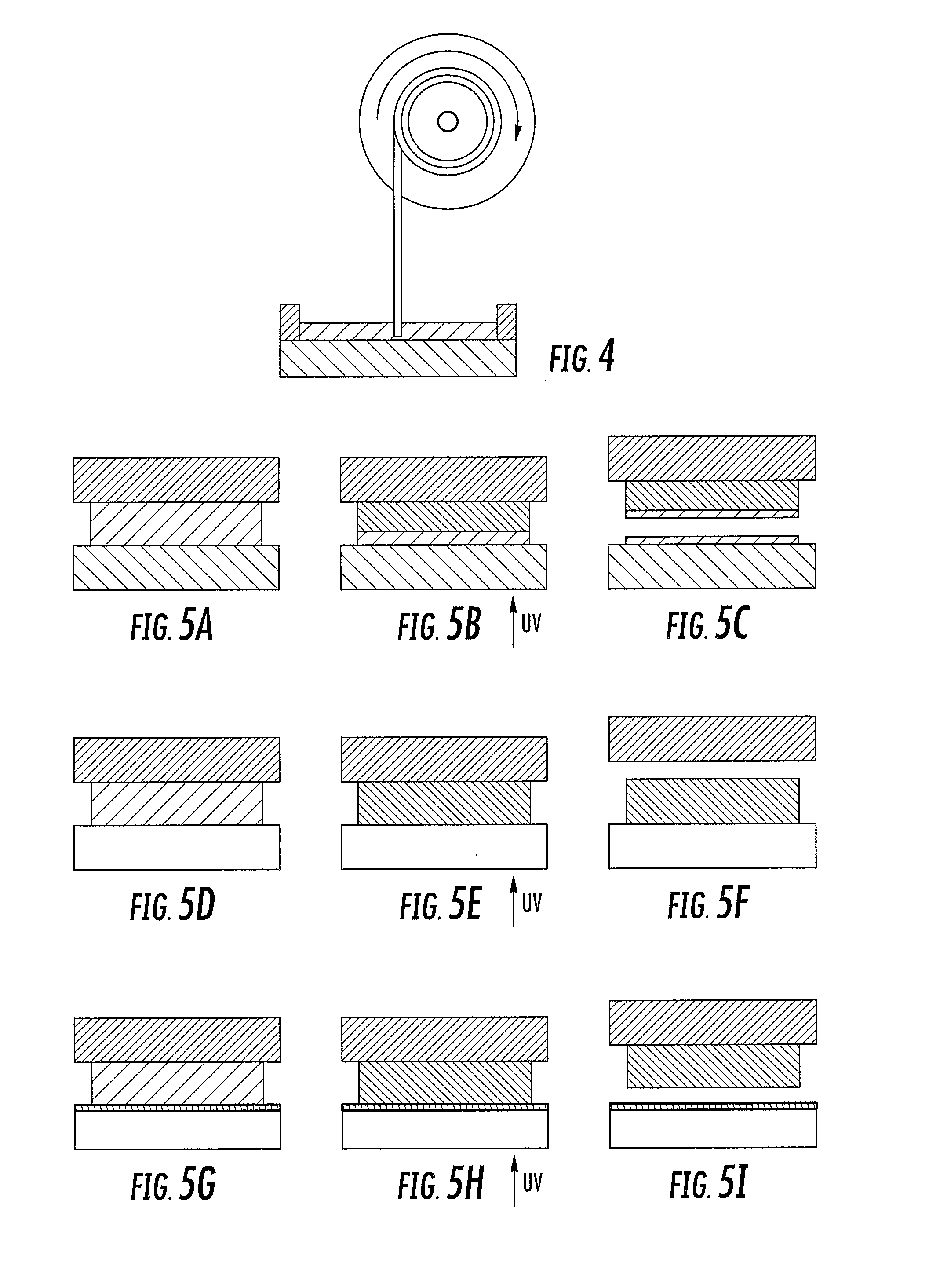

Method and apparatus for three-dimensional fabrication

A method of forming a three-dimensional object, is carried out by (a) providing a carrier and a build plate, the build plate comprising a semipermeable member, the semipermeable member comprising a build surface with the build surface and the carrier defining a build region therebetween, and with the build surface in fluid communication by way of the semipermeable member with a source of polymerization inhibitor; (b) filling the build region with a polymerizable liquid, the polymerizable liquidcontacting the build surface, (c) irradiating the build region through the build plate to produce a solid polymerized region in the build region, while forming or maintaining a liquid film release layer comprised of the polymerizable liquid formed between the solid polymerized region and the build surface, wherein the polymerization of which liquid film is inhibited by the polymerization inhibitor; and (d) advancing the carrier with the polymerized region adhered thereto away from the build surface on the build plate to create a subsequent build region between the polymerized region and the build surface while concurrently filling the subsequent build region with polymerizable liquid as in step (b). Apparatus for carrying out the method is also described.

Owner:CARBON INC

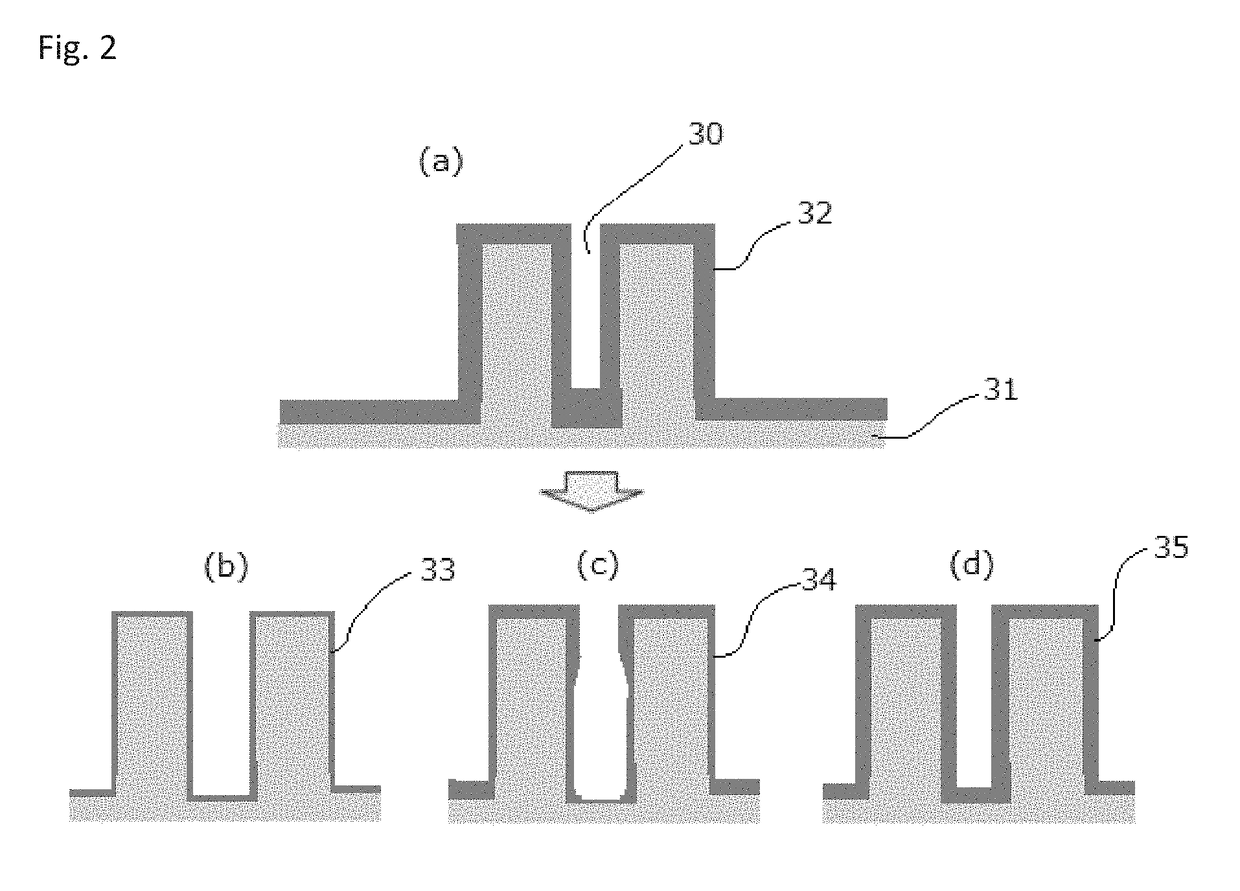

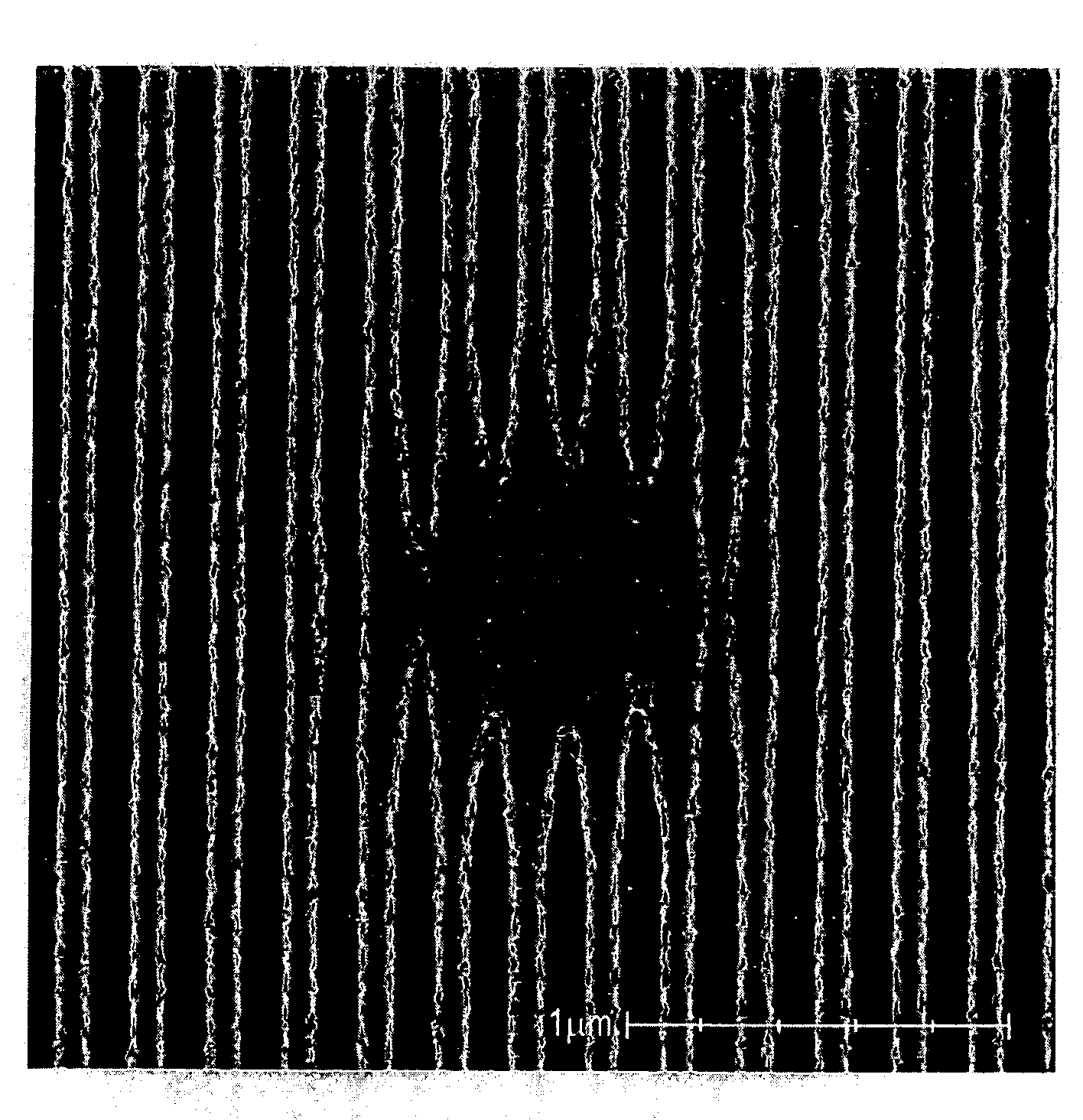

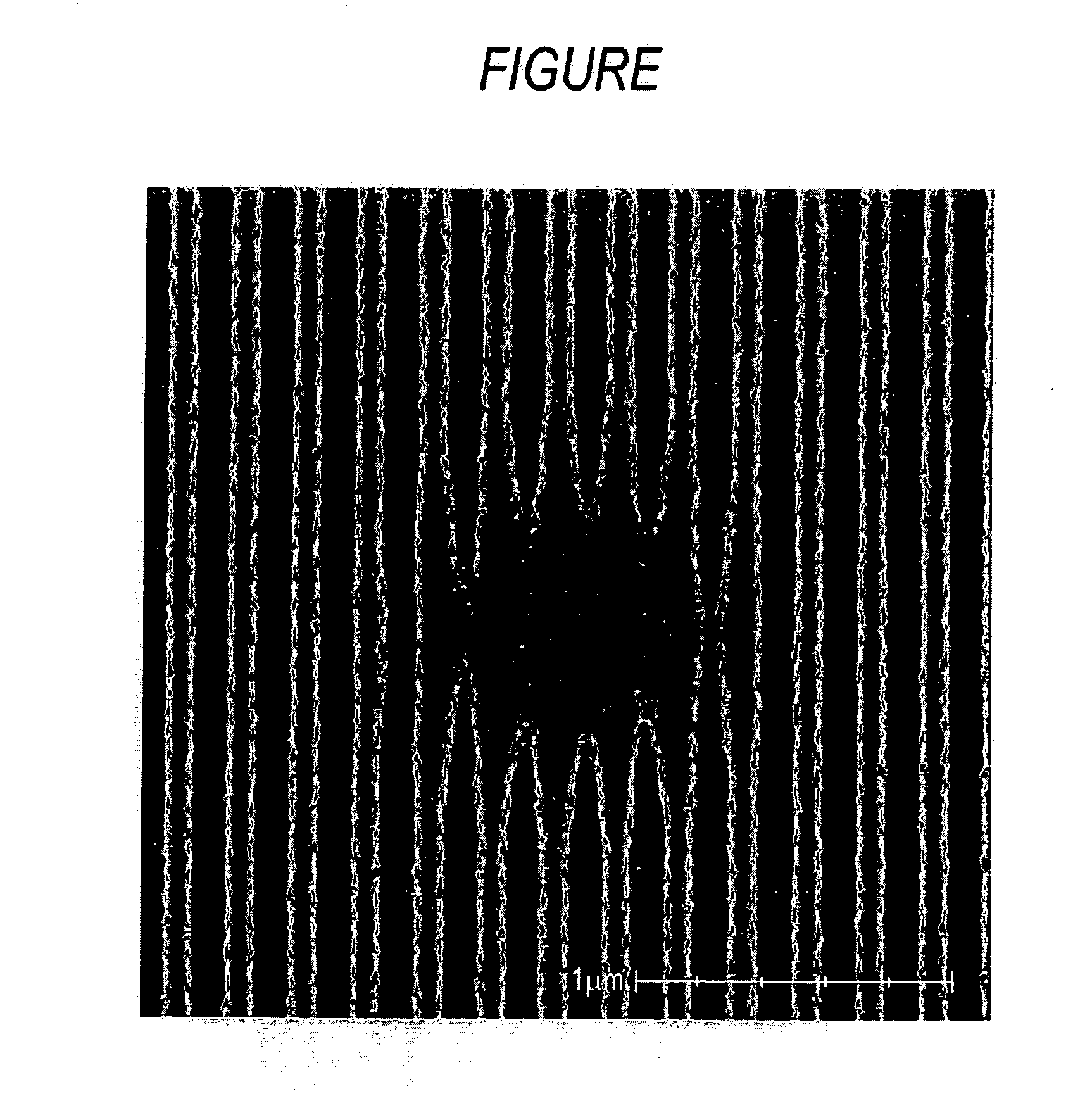

Method for forming vertical spacers for spacer-defined patterning

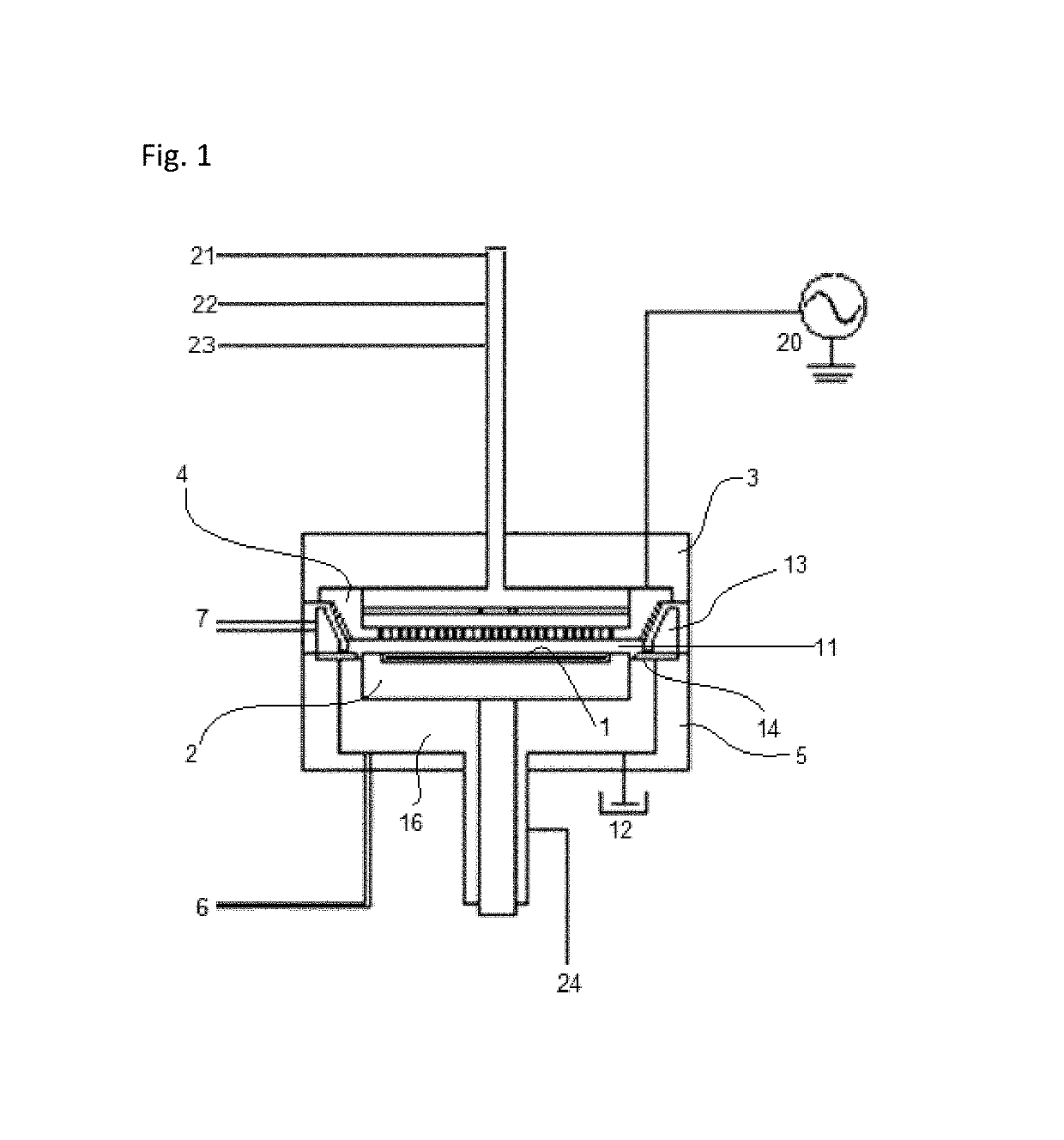

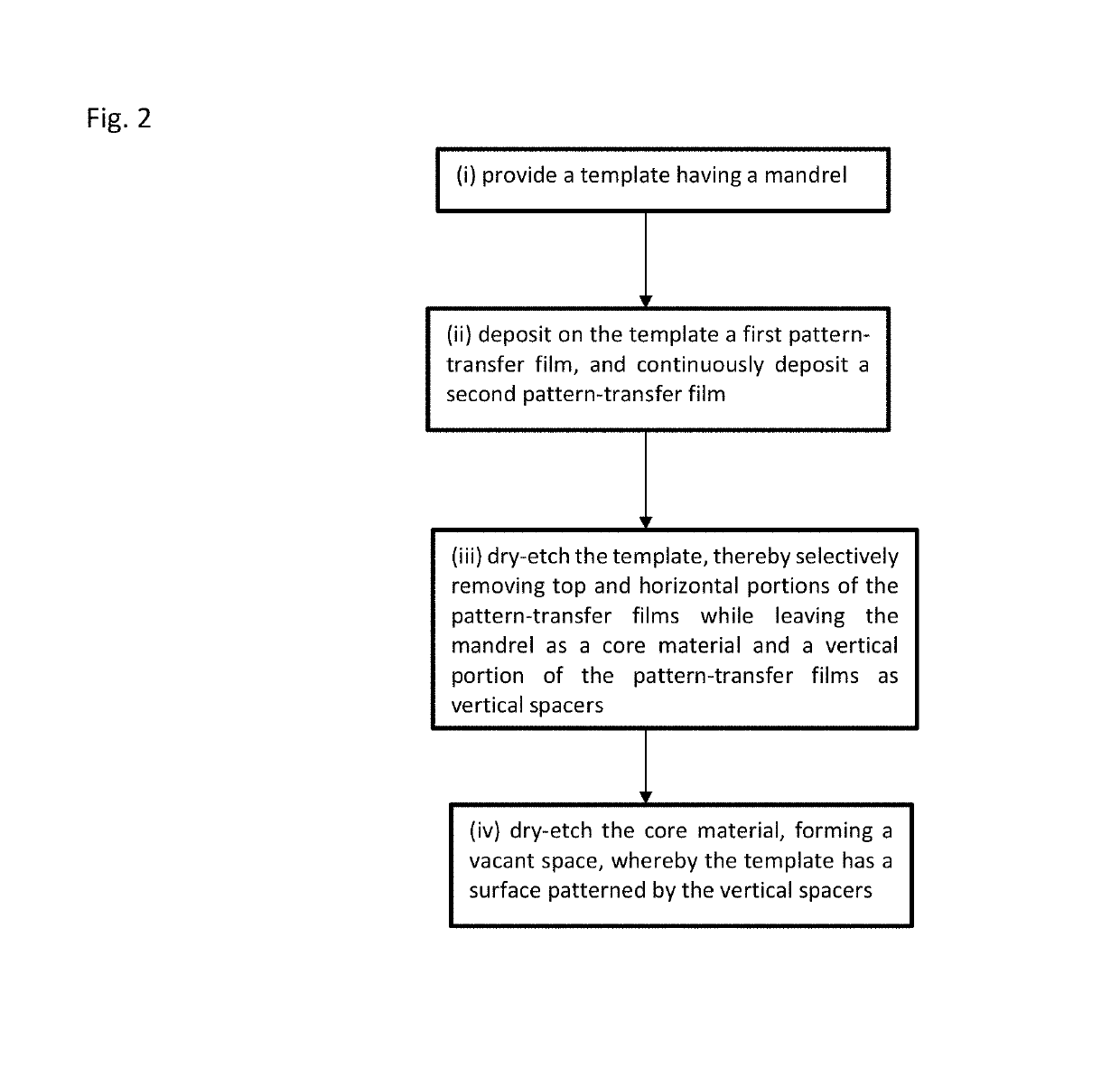

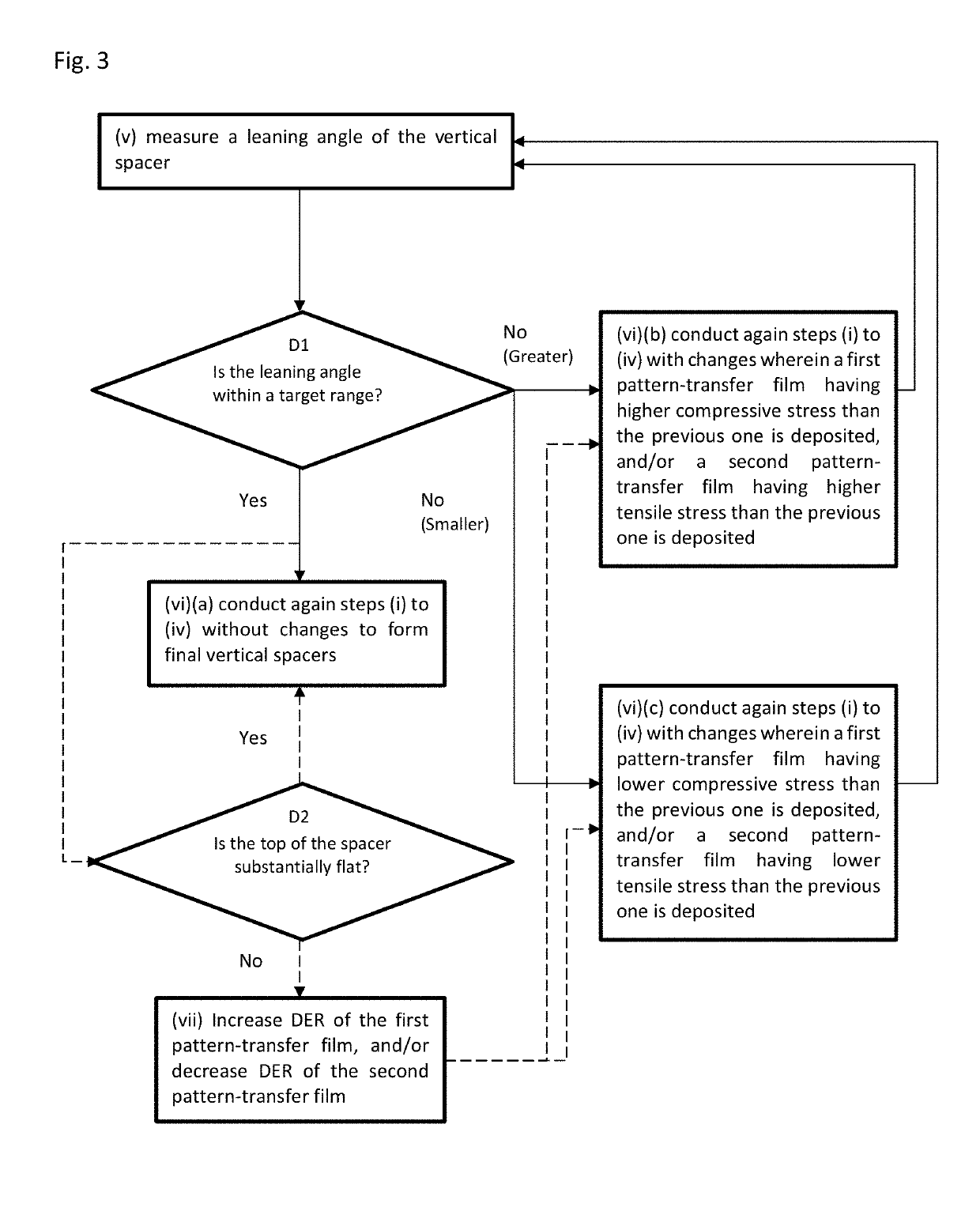

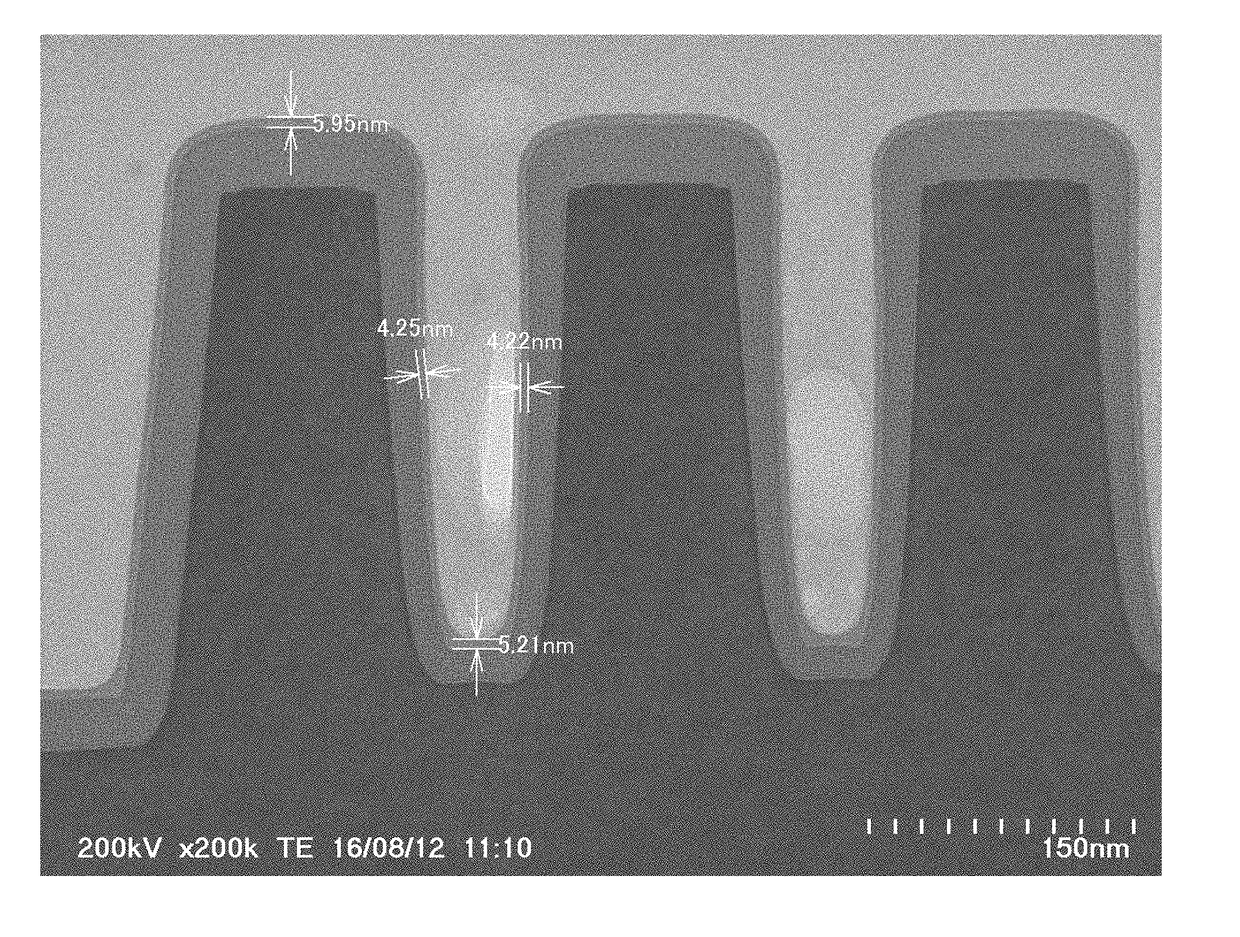

ActiveUS10290508B1Easy to adjustTop profile of the spacer can be manipulatedPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringDry etching

A method of forming vertical spacers for spacer-defined multiple patterning, includes: depositing a first conformal pattern-transfer film having a first film stress, and continuously depositing a second conformal pattern-transfer film having a second film stress on a template; dry-etching the template except for a core material and a vertical portion of the first and second pattern-transfer films to form vertical spacers; and dry-etching the core material, forming a vacant space between the vertical spacers, wherein by adjusting the difference in film stress between the first and second pattern-transfer films, the leaning angle of the spacers is adjusted.

Owner:ASM IP HLDG BV

Method of reforming insulating film deposited on substrate with recess pattern

ActiveUS20180286663A1Improve propertiesIncrease probabilitySemiconductor/solid-state device manufacturingAtmosphereMetal

A method of reforming an insulating film deposited on a substrate having a recess pattern constituted by a bottom and sidewalls, includes: providing the film deposited on the substrate having the recess pattern in an evacuatable reaction chamber, wherein a property of a portion of the film deposited on the sidewalls is inferior to that of a portion of the film deposited on a top surface of the substrate; adjusting a pressure of an atmosphere of the reaction chamber to 10 Pa or less, which atmosphere is constituted by H2 and / or He without a precursor and without a reactant; and applying RF power to the atmosphere of the pressure-adjusted reaction chamber to generate a plasma to which the film is exposed, thereby reforming the portion of the film deposited on the sidewalls to improve the property of the sidewall portion of the film.

Owner:ASM IP HLDG BV

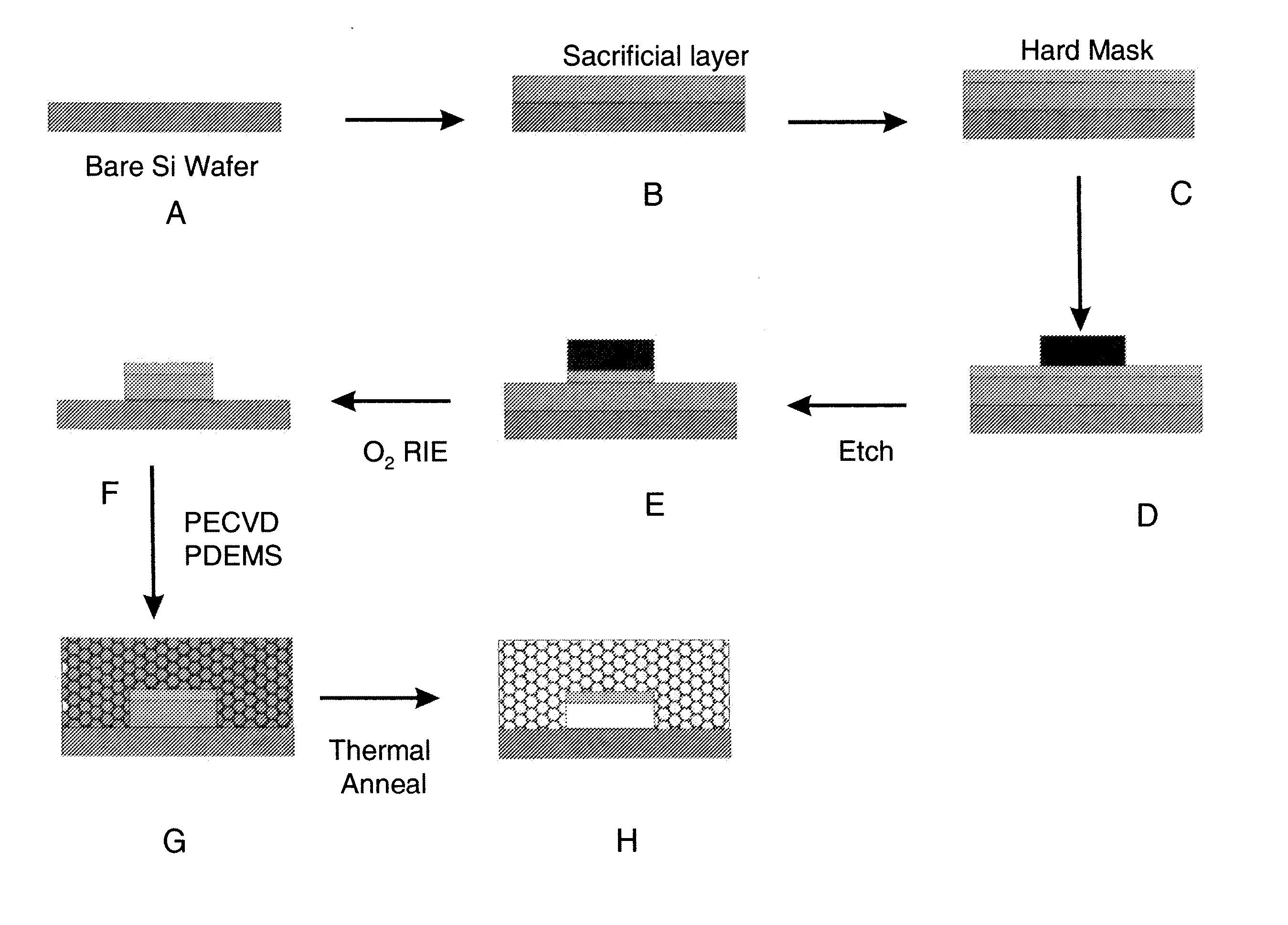

Materials and methods of forming controlled void

ActiveUS20080038934A1Solid-state devicesSemiconductor/solid-state device manufacturingPorous layerSolvent

The present invention is a process for forming an air gap within a substrate, the process comprising: providing a substrate; depositing a sacrificial material by deposition of at least one sacrificial material precursor; depositing a composite layer; removale of the porogen material in the composite layer to form a porous layer and contacting the layered substrate with a removal media to substantially remove the sacrificial material and provide the air gaps within the substrate; wherein the at least one sacrificial material precursor is selected from the group consisting of: an organic porogen; silicon, and a polar solvent soluble metal oxide and mixtures thereof.

Owner:VERSUM MATERIALS US LLC

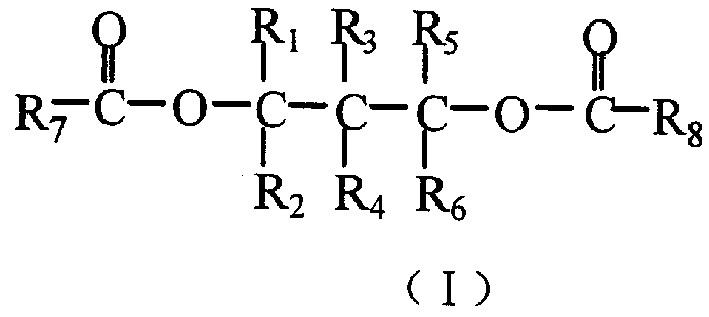

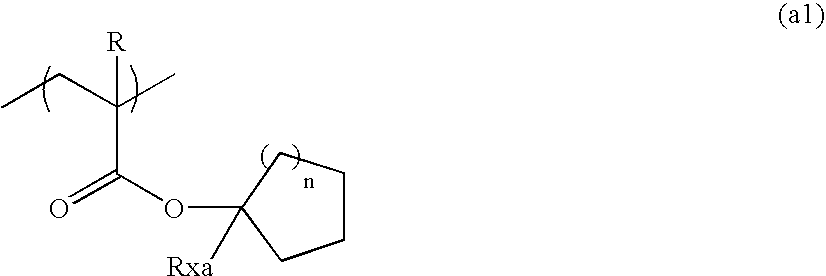

Positive resist composition and pattern-forming method

ActiveUS20080248425A1Suppress generationPhotosensitive materialsRadiation applicationsPolymer scienceActinic Rays

A positive resist composition comprises: (A) a resin that has a repeating unit represented by general formula (a1) and increases its solubility in an alkali developer by action of an acid; (B) a compound which generates an acid upon irradiation with an actinic ray or a radiation; and (C) a resin that has at least one of a fluorine atom and a silicon atom and has a group selected from the group consisting of (x), (y) and (z); and (D) a solvent:(x) an alkali-soluble group;(y) a group capable that decomposes by action of an alkali developer to undergo an increase in a solubility of the resin (C) in an alkali developer; and(z) a group that decomposes by action of an acid,wherein R represents a hydrogen atom or a methyl group, Rxa represents an alkyl group or a cycloalkyl group, and n represents an integer of 1 to 8.

Owner:FUJIFILM CORP

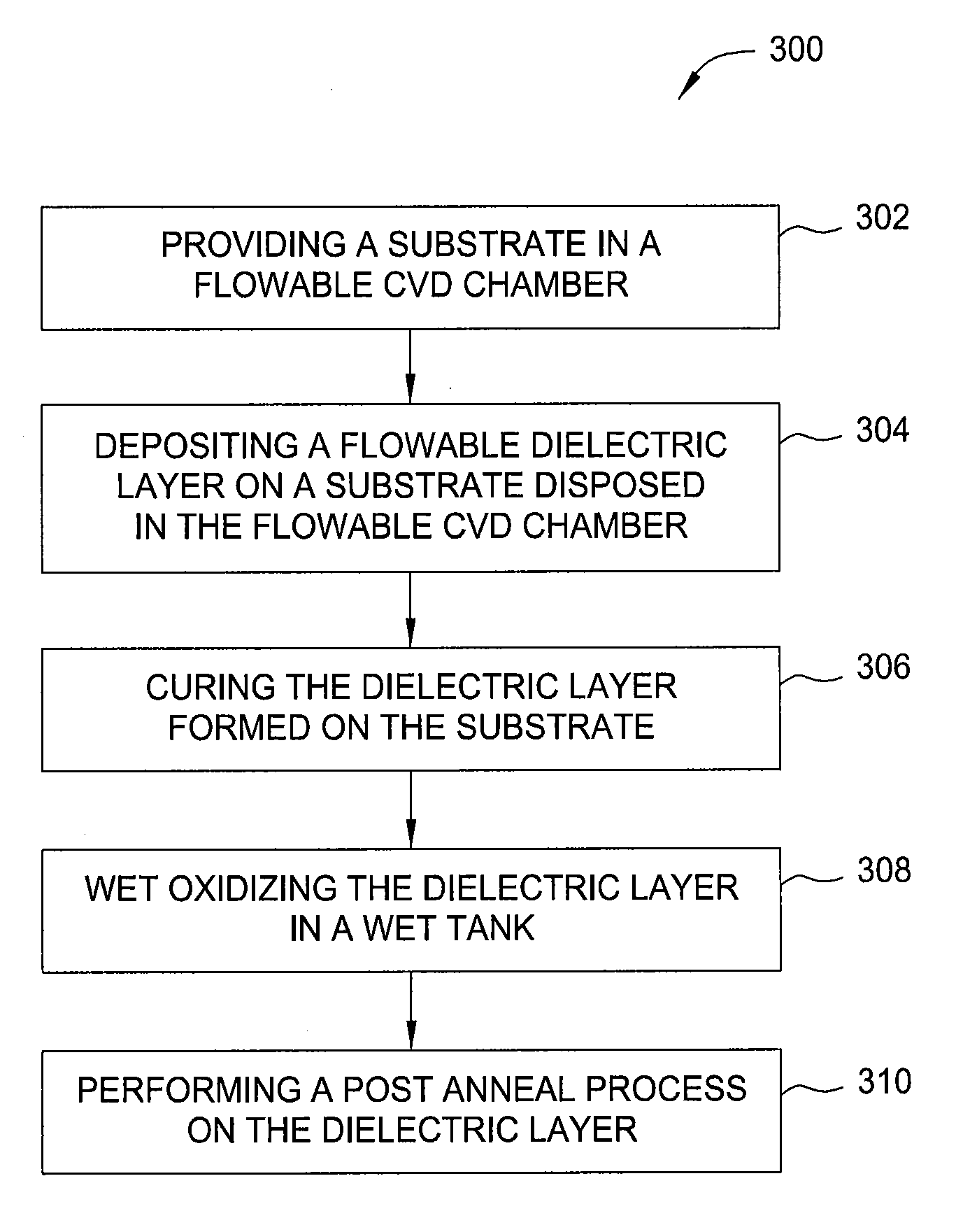

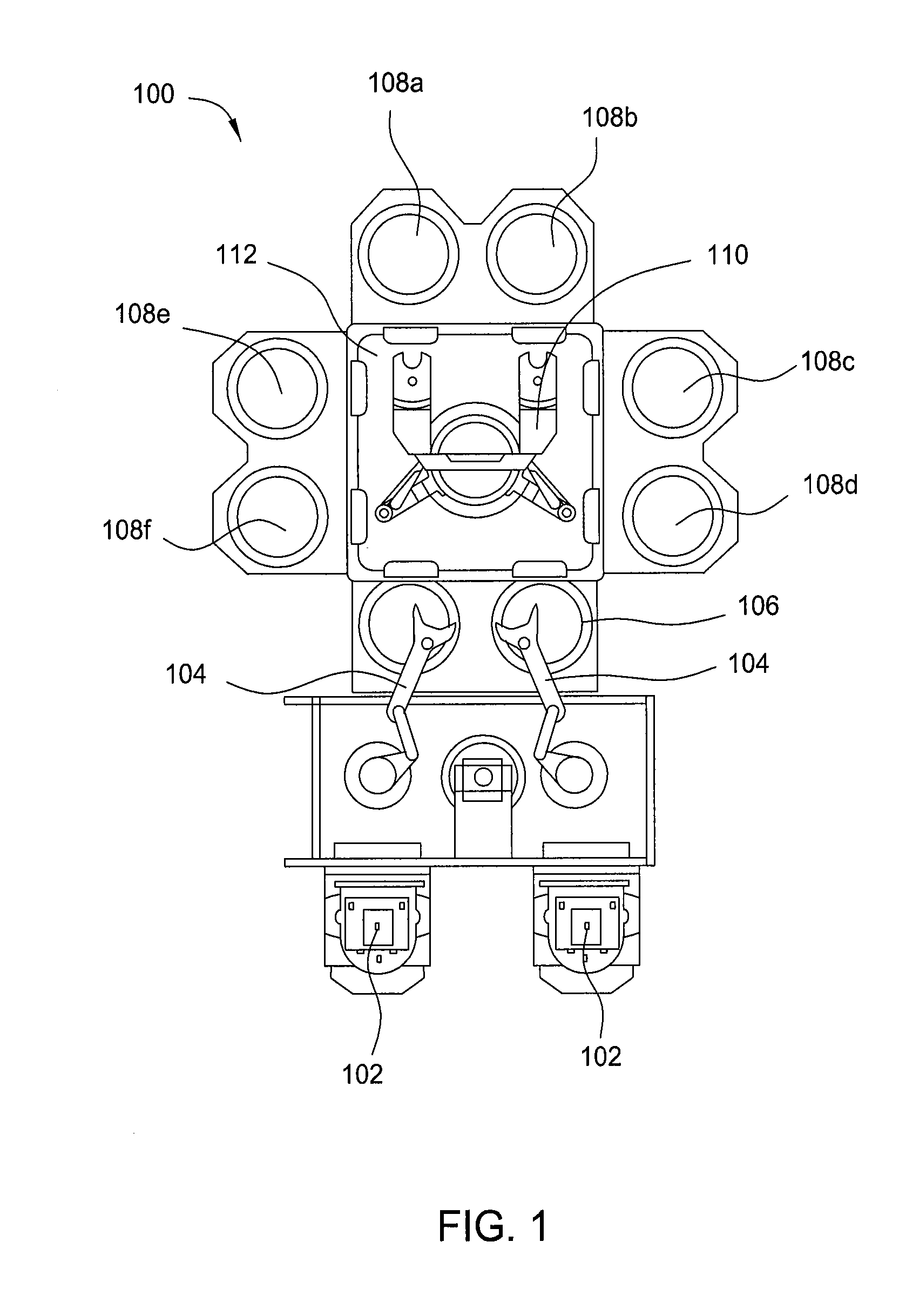

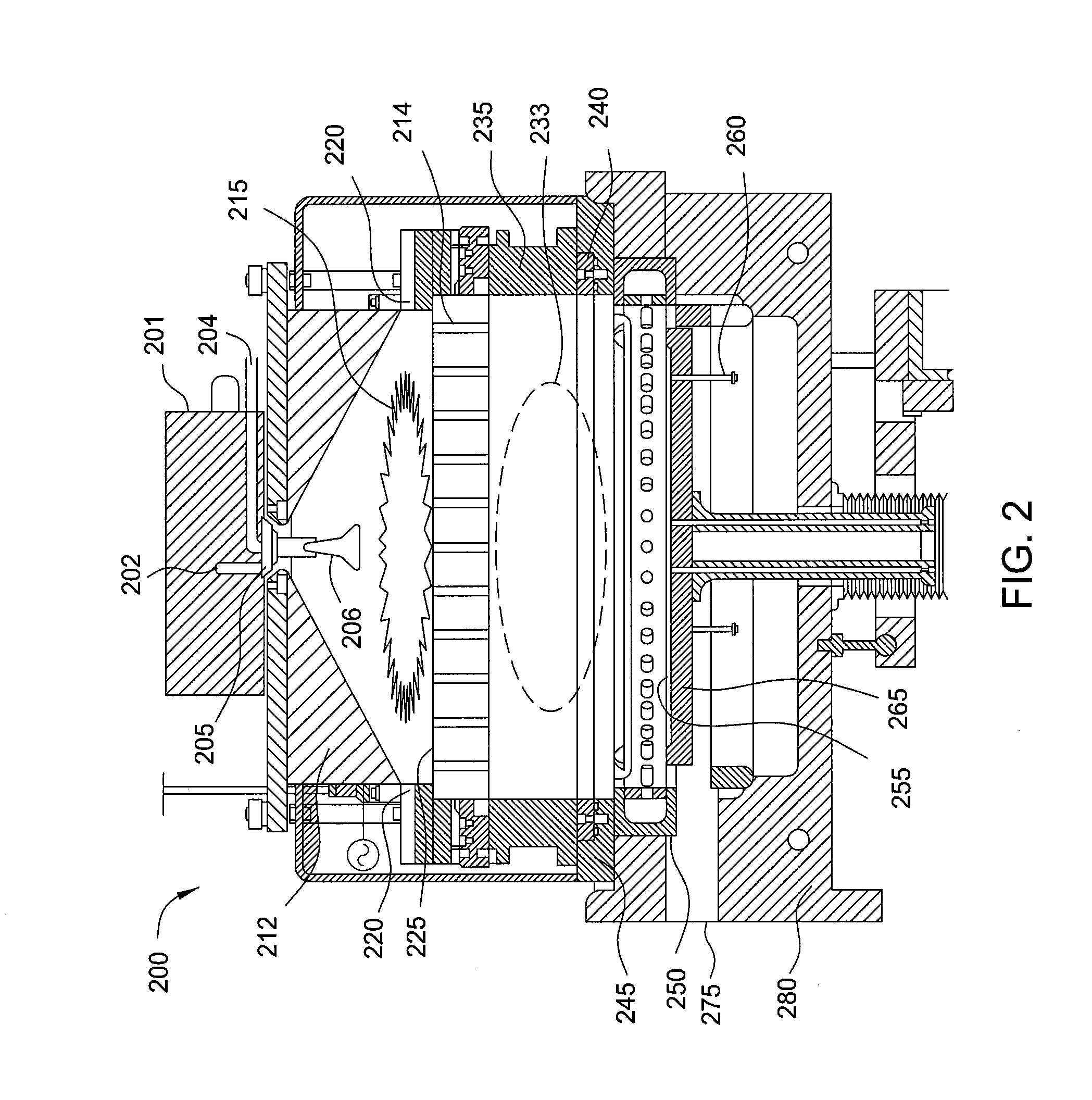

Wet oxidation process performed on a dielectric material formed from a flowable CVD process

InactiveUS20110151677A1Low costReduce process complexitySemiconductor/solid-state device manufacturingSiliconWet oxidation

Methods of performing a wet oxidation process on a silicon containing dielectric material filling within trenches or vias defined within a substrate are provided. In one embodiment, a method of forming a dielectric material on a substrate includes forming a dielectric material on a substrate by a flowable CVD process, curing the dielectric material disposed on the substrate, performing a wet oxidation process on the dielectric material disposed on the substrate, and forming an oxidized dielectric material on the substrate.

Owner:APPLIED MATERIALS INC

Methods and systems for the manufacture of layered three-dimensional forms

ActiveUS20050017394A1Lower potentialEasy to controlConfectionerySweetmeatsParticulatesBiological activation

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

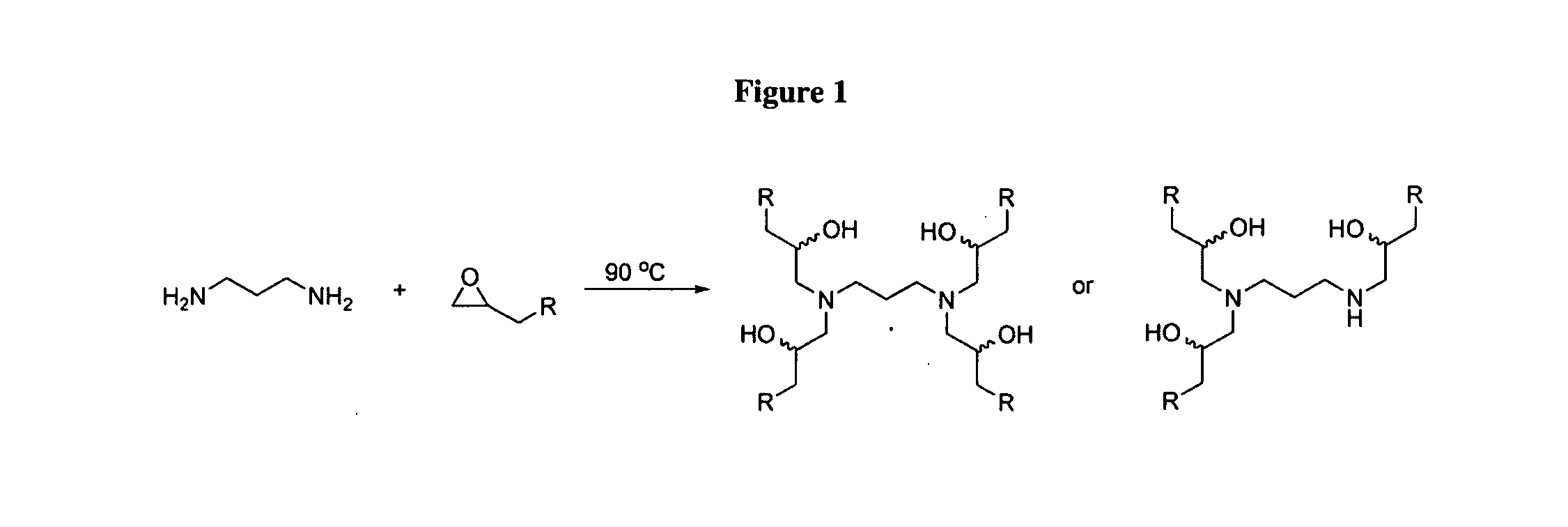

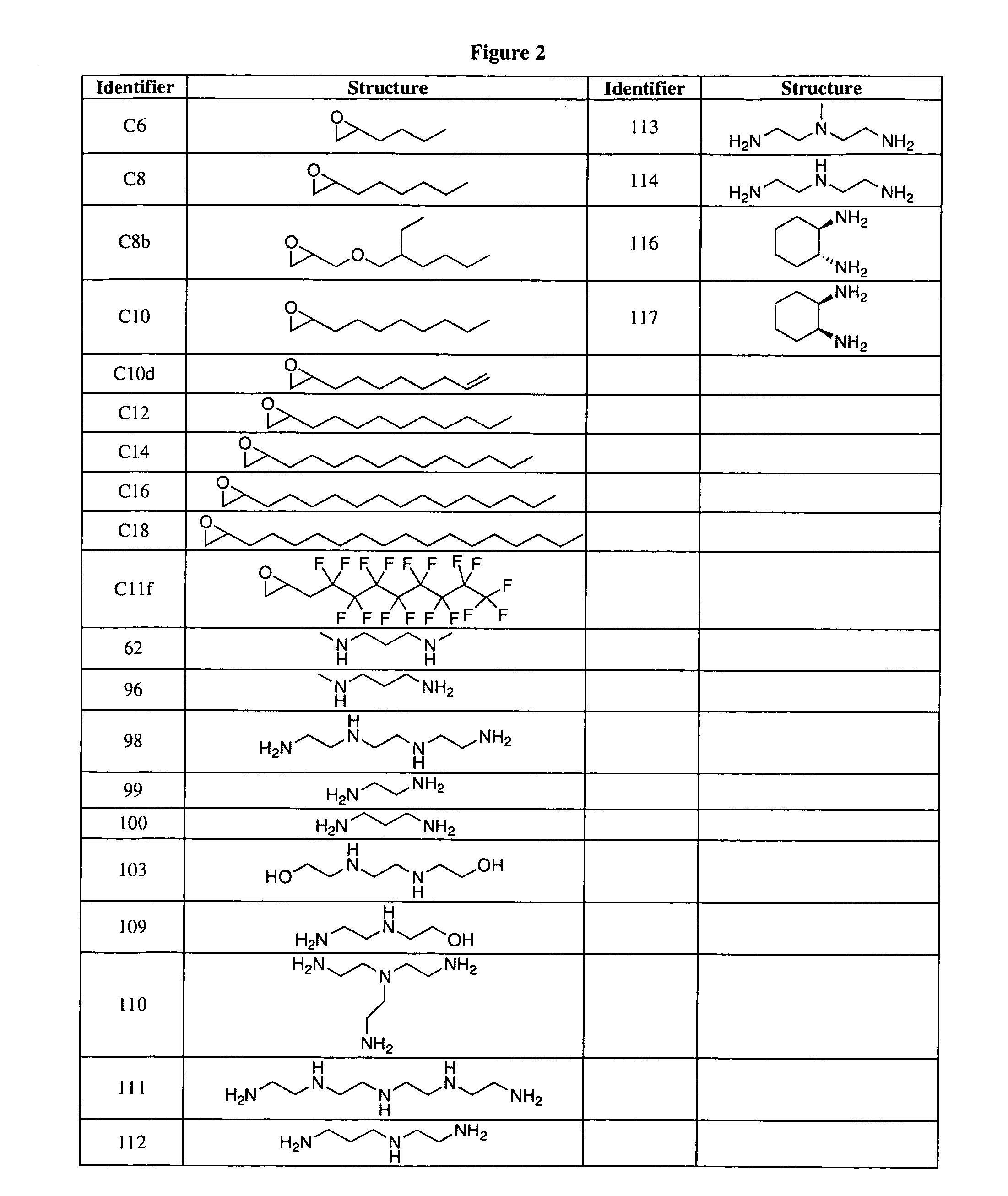

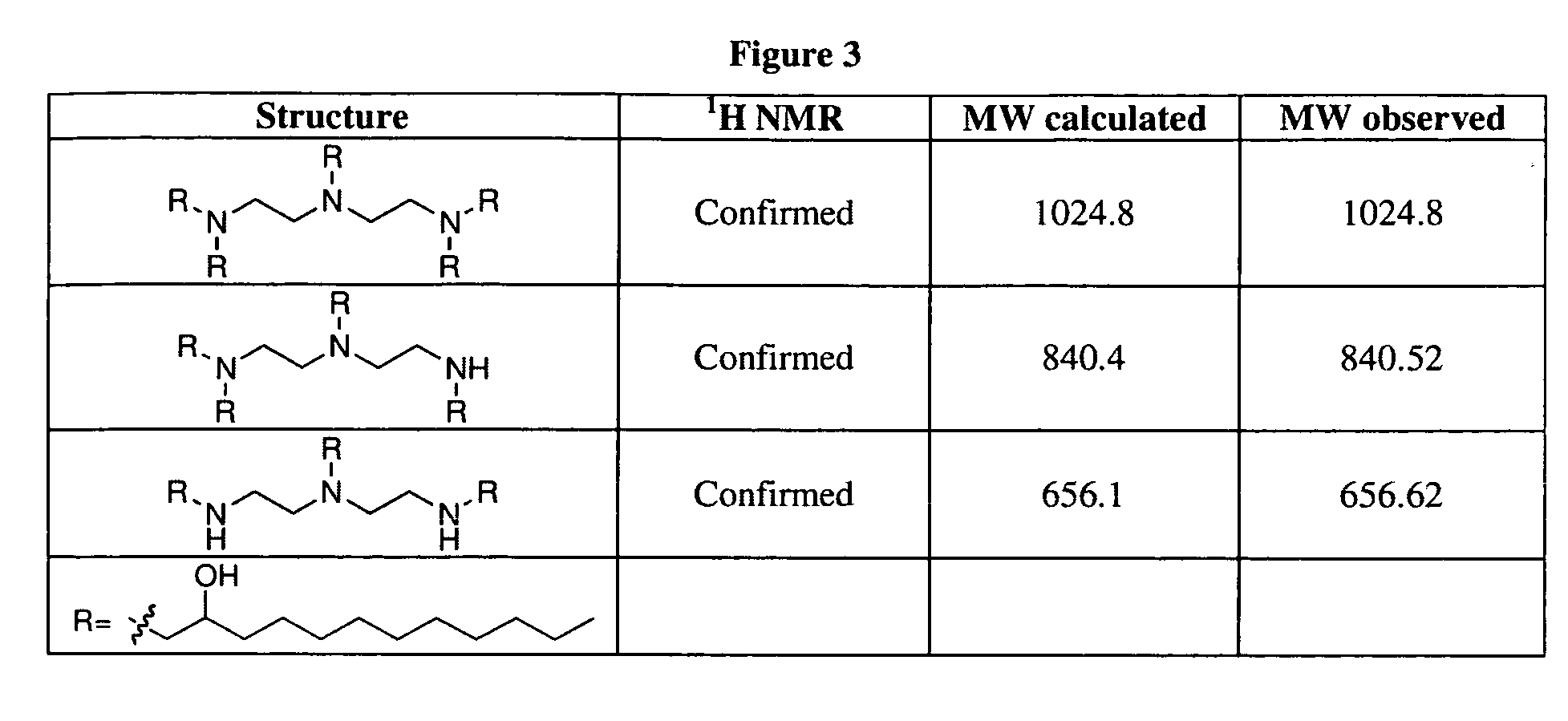

Aminoalcohol lipidoids and uses thereof

Aminoalcohol lipidoids are prepared by reacting an amine with an epoxide-terminated compound are described. Methods of preparing aminoalcohol lipidoids from commercially available starting materials are also provided. Aminoalcohol lipidoids may be prepared from racemic or stereochemically pure epoxides. Aminoalcohol lipidoids or salts forms thereof are preferably biodegradable and biocompatible and may be used in a variety of drug delivery systems. Given the amino moiety of these aminoalcohol lipidoid compounds, they are particularly suited for the delivery of polynucleotides. Complexes, micelles, liposomes or particles containing the inventive lipidoids and polynucleotide have been prepared. The inventive lipidoids may also be used in preparing microparticles for drug delivery. They are particularly useful in delivering labile agents given their ability to buffer the pH of their surroundings.

Owner:MASSACHUSETTS INST OF TECH

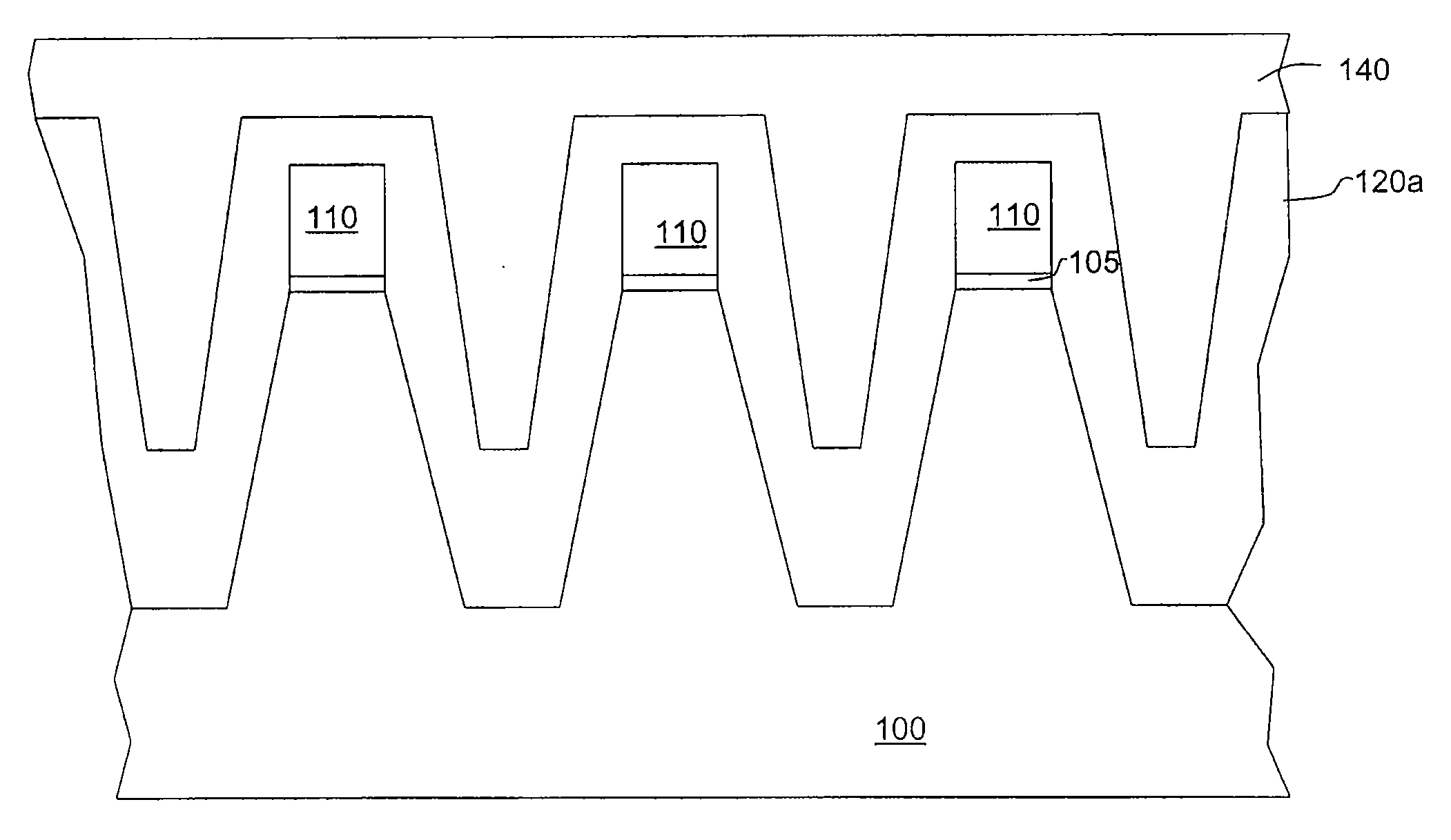

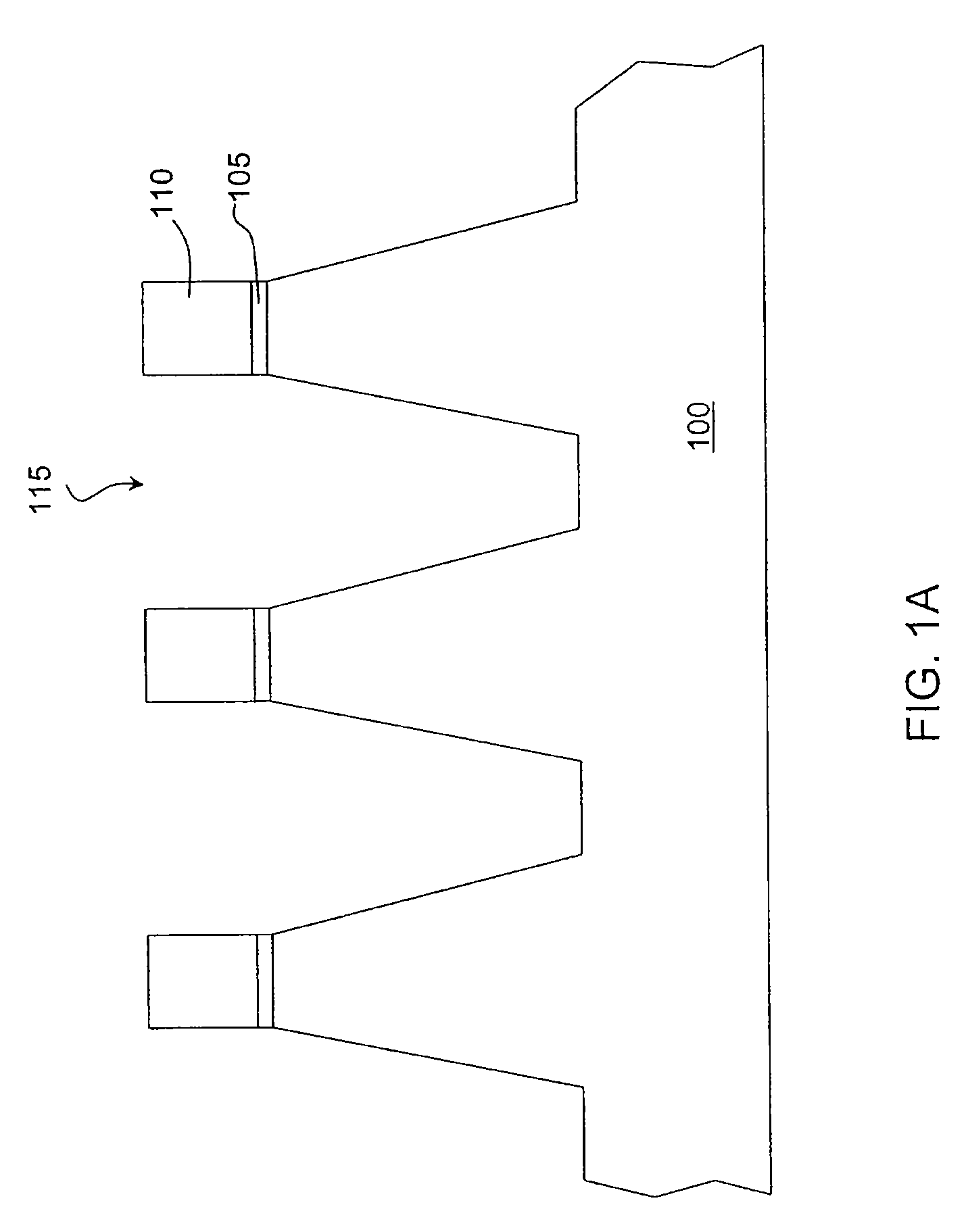

Methods of thin film process

A method for forming a semiconductor structure includes forming a plurality of features across a surface of a substrate, with at least one space being between two adjacent features. A first dielectric layer is formed on the features and within the at least one space. A portion of the first dielectric layer interacts with a reactant derived from a first precursor and a second precursor to form a first solid product. The first solid product is decomposed to substantially remove the portion of the first dielectric layer. A second dielectric layer is formed to substantially fill the at least one space.

Owner:APPLIED MATERIALS INC

Susceptor with insulative inserts

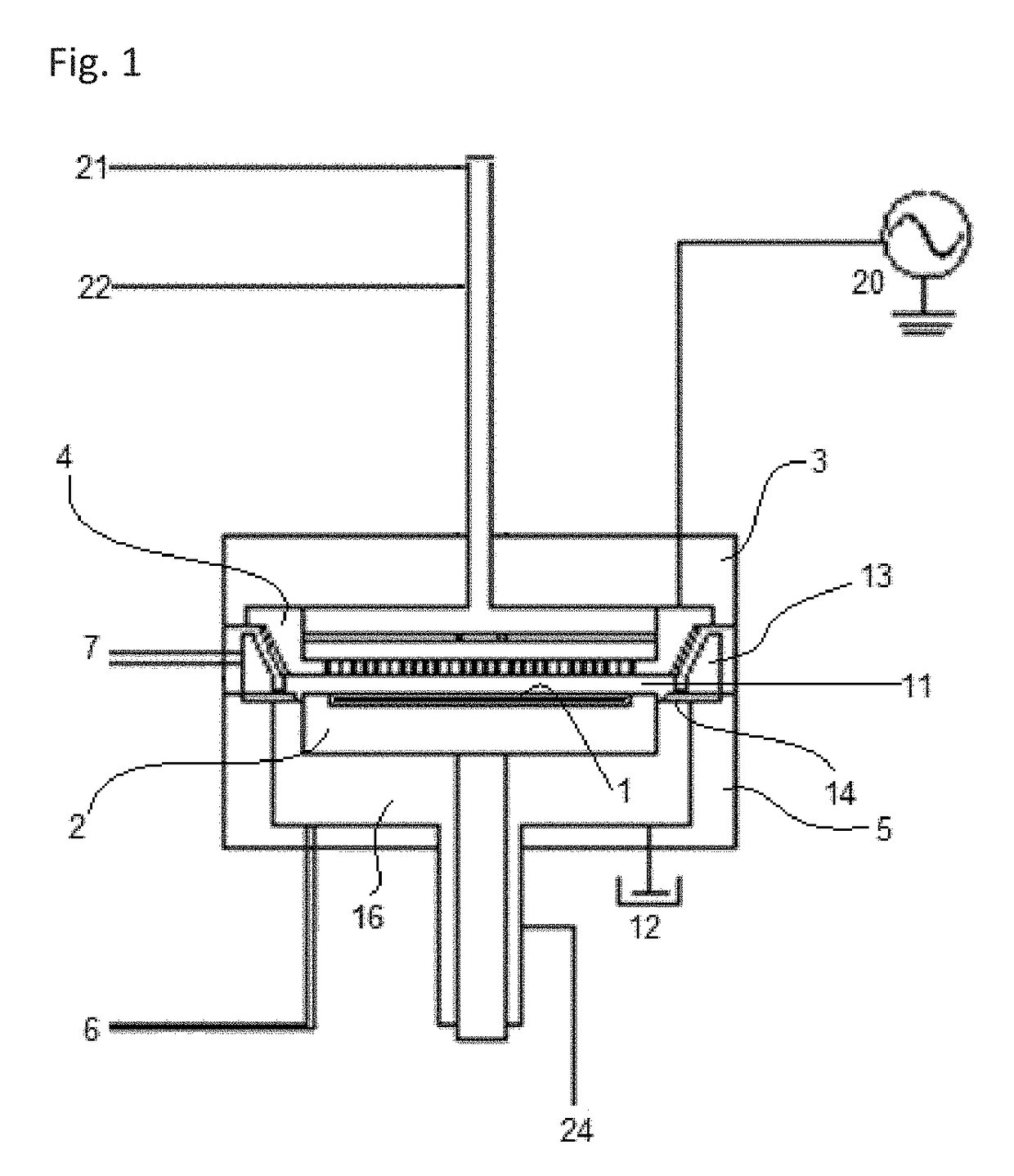

InactiveUS20080194169A1Reduce arcingElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorMechanical engineering

A method and apparatus for reducing arcing in a plasma processing system when processing large area substrates which contain one or more holes. In one embodiment of the invention, a substrate support member includes an electrically insulating insert located beneath a hole in an insulating, large area substrate. The insulating insert is made of aluminum oxide, and is located within a hole in the support member such that the insert is disposed beneath a hole in a glass substrate. The substrate support member is made of aluminum with an anodized surface.

Owner:APPLIED MATERIALS INC

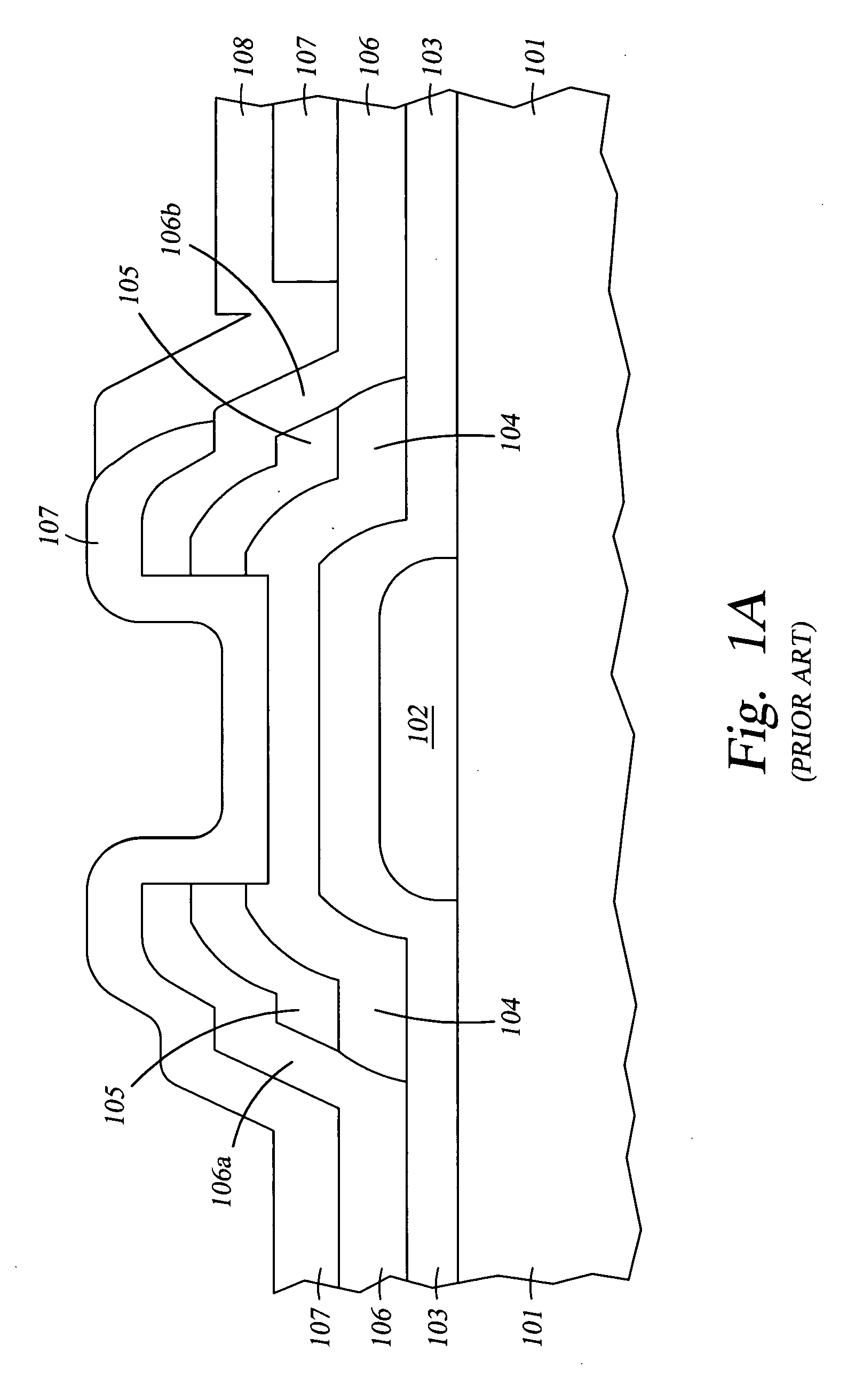

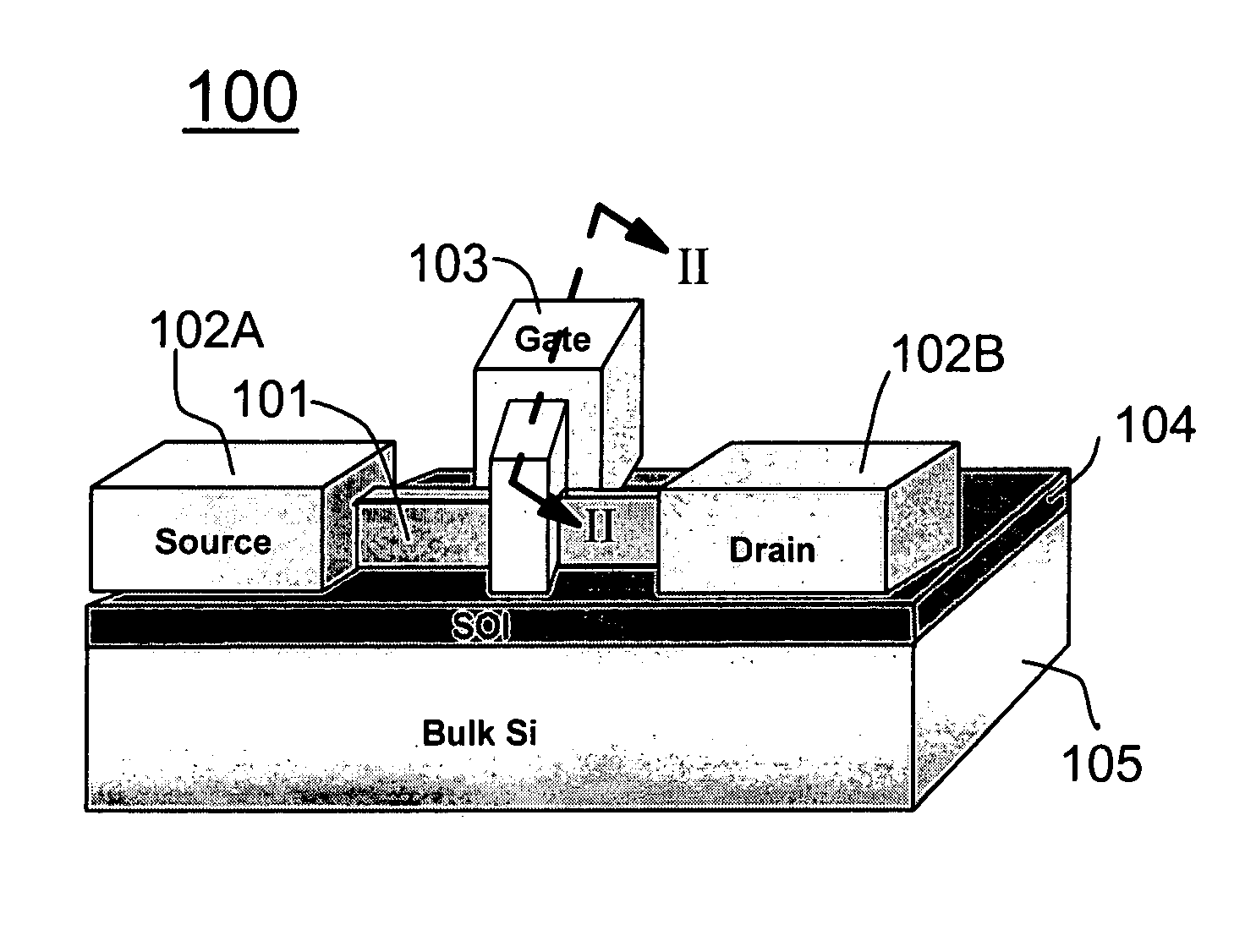

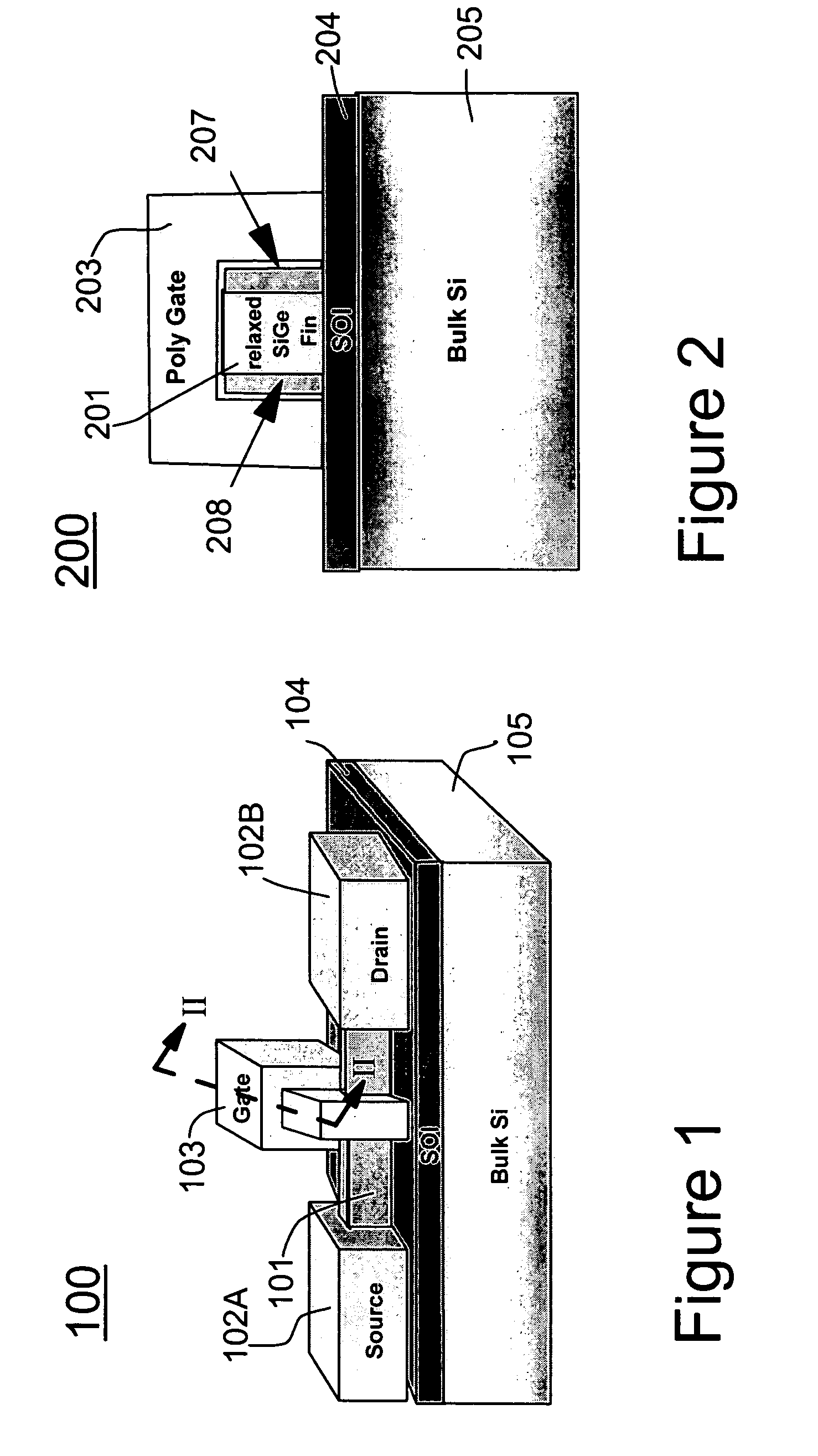

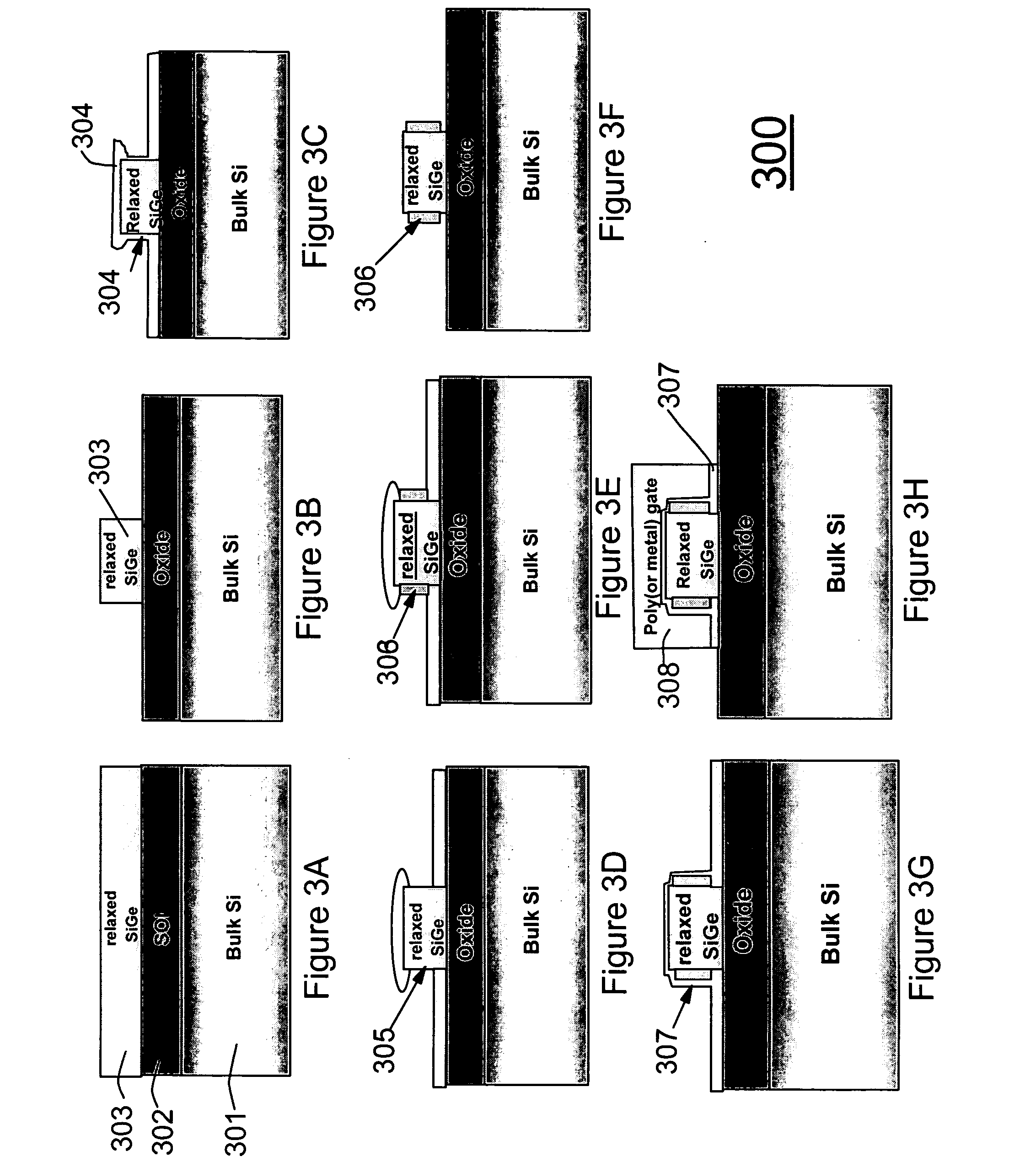

High performance strained silicon FinFETs device and method for forming same

ActiveUS20050145941A1Improve channel mobilityImprove device performanceTransistorSolid-state devicesSiliconMaterials science

A strained Fin Field Effect Transistor (FinFET) (and method for forming the same) includes a relaxed first material having a sidewall, and a strained second material formed on the sidewall of the first material. The relaxed first material and the strained second material form a fin of the FinFET.

Owner:GLOBALFOUNDRIES US INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com