Method of controlling the film properties of a CVD-deposited silicon nitride film

a technology of silicon nitride and film properties, which is applied in the direction of coatings, chemical vapor deposition coatings, semiconductor devices, etc., can solve the problems of instability problems, inconvenient use of pecvd sinsub>x/sub>h dielectric films, and the a-si:h tfts with sinsub>x/sub>:h gate dielectric are said to have instability problems, etc., to achieve greater control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example one

The Overall Process for Forming a TFT

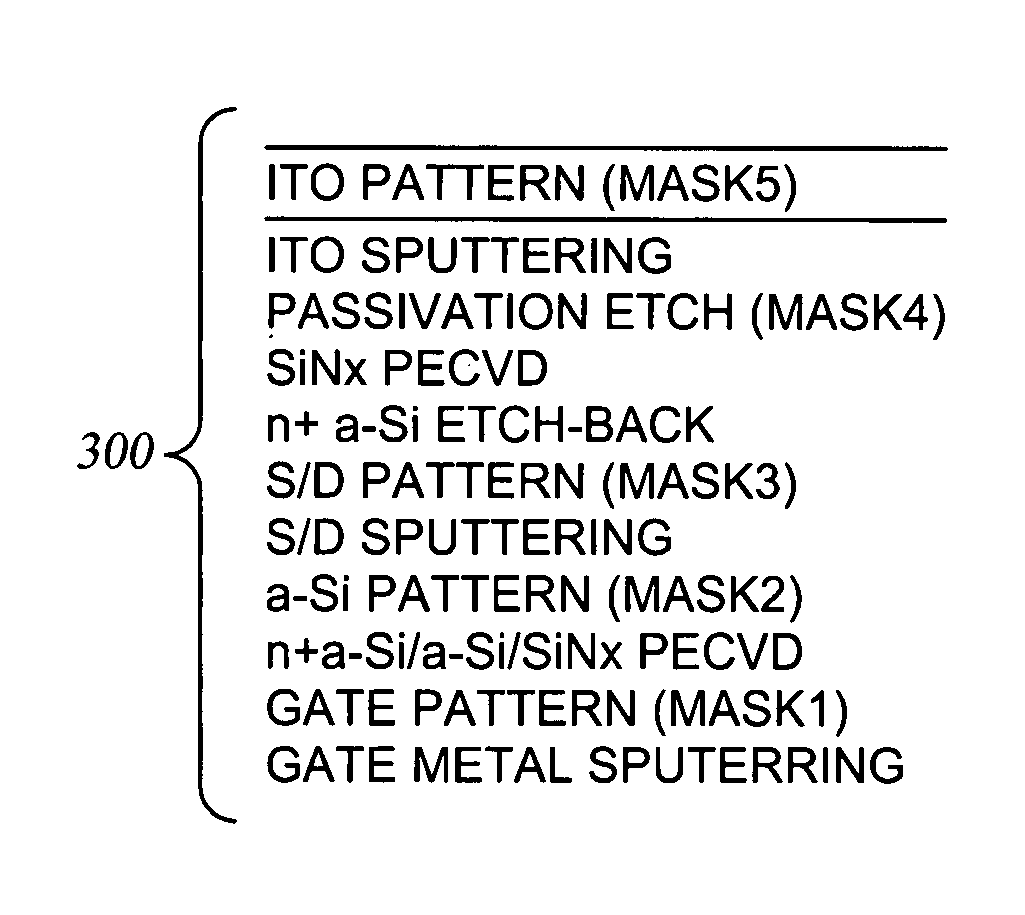

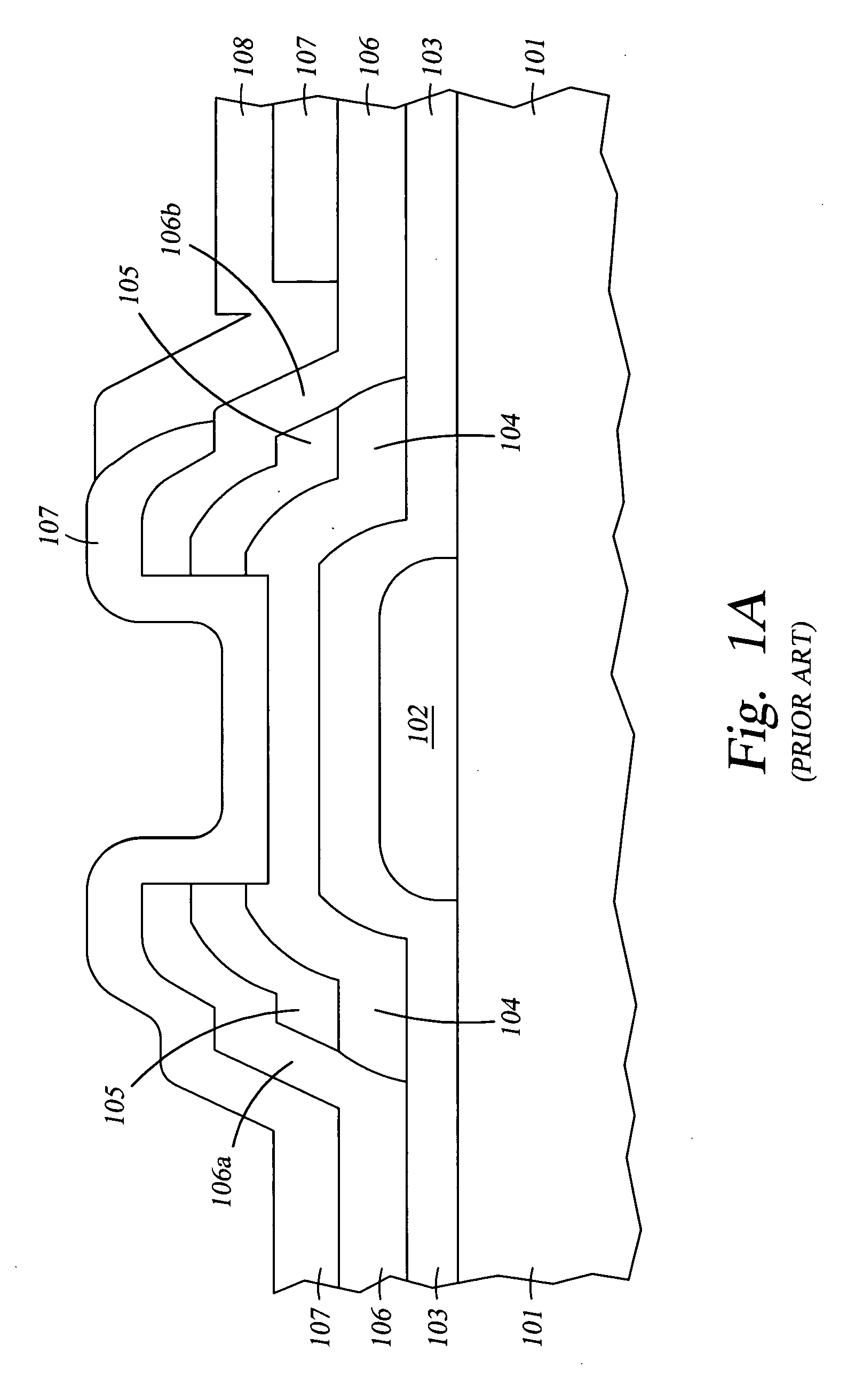

[0054] To provide a general understanding of the relationship of the PECVD deposited a-SiNx:H gate dielectric film and the a-SiNx:H passivation dielectric film relative to the other components of the TFT, a brief description of the overall fabrication process of the TFT embodiment shown in FIG. 1 is presented below.

[0055]FIG. 3A show a series of process steps 300 which may be carried out to create the TFT device shown in FIGS. 3B and 3C. FIG. 3B provides a schematic side view of a substrate including a TFT structure. FIG. 3C provides a schematic top-view 336 of a substrate including several TFT structures.

[0056] In the first step, “Gate Metal Sputtering”, a conductive layer 302 is sputter deposited over a glass substrate 301 using techniques known in the art. In this particular instance, the substrate 301 is a glass substrate having a thickness of 0.7 mm. The conductive layer 302 is actually a bilayer, where the bottom portion of the layer is ...

example two

The Process for Depositing an a-SiNx:H Gate Dielectric Layer

[0067] We have previously described all of the performance requirements for the a-SiNx:H gate dielectric layer. We carried out extensive experimentation in an effort to produce a PECVD deposited a-SiNx:H gate dielectric layer which met the performance requirements, and which provided uniformity in terms of film thickness and film properties, including structural and chemical composition, when the gate dielectric layer is PECVD deposited over a large substrate surface area (larger than 1000 mm×1000 mm, for example).

[0068] The basic requirements for the a-SiNx:H film are that: the Si—H bonded content of the a-SiNx:H film is less than about 15 atomic %; the film stress ranges from 0 to about −1010 dynes / cm2; the refractive index (RI) of the film ranges from about 1.85 to about 1.95; and the wet etch rate in HF solution (Buffer Oxide Etchant 6:1) is less than 800 Å / min. In addition, the chemical composition of the film, in te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com