Patents

Literature

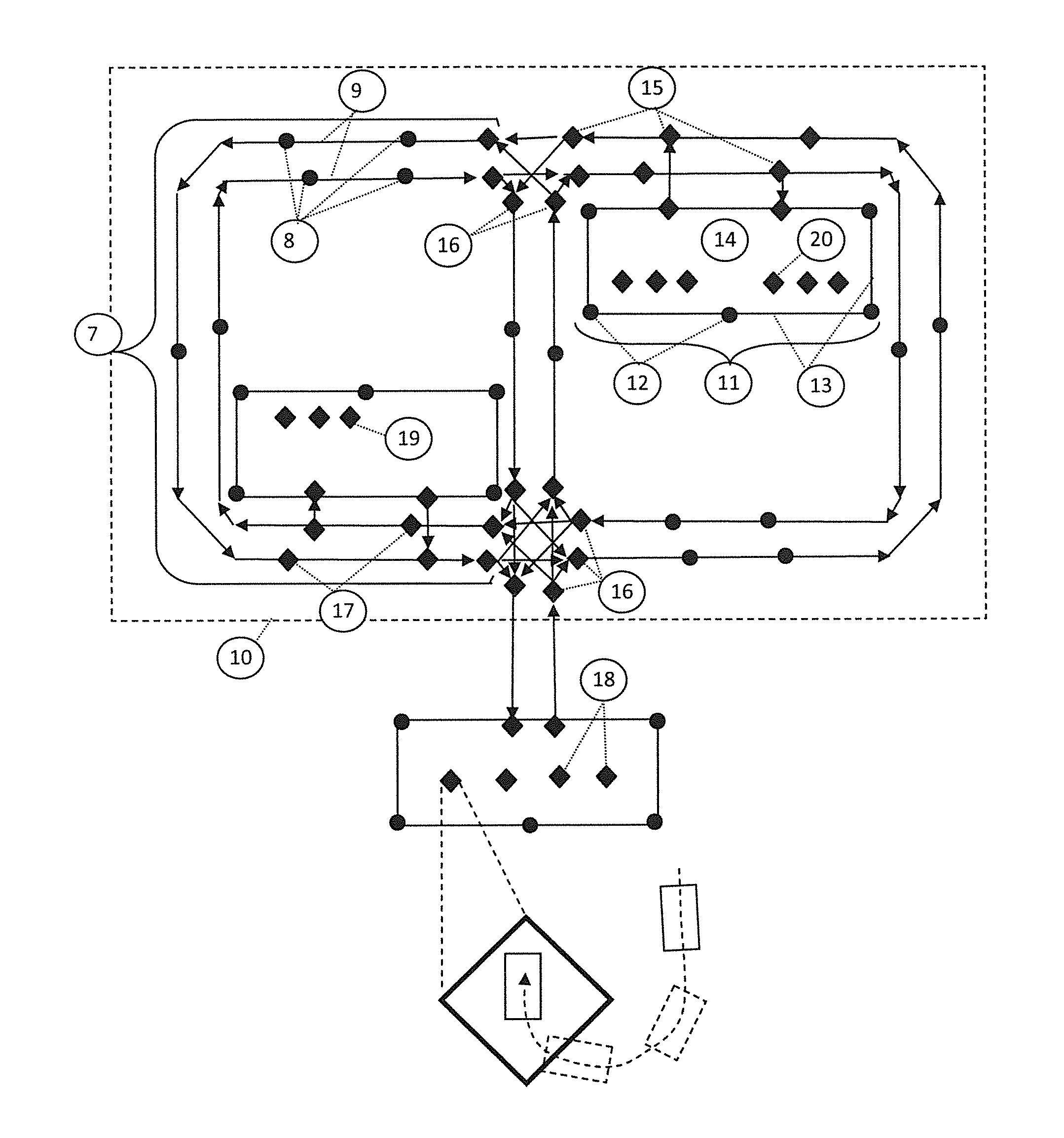

6169results about How to "Reduce rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

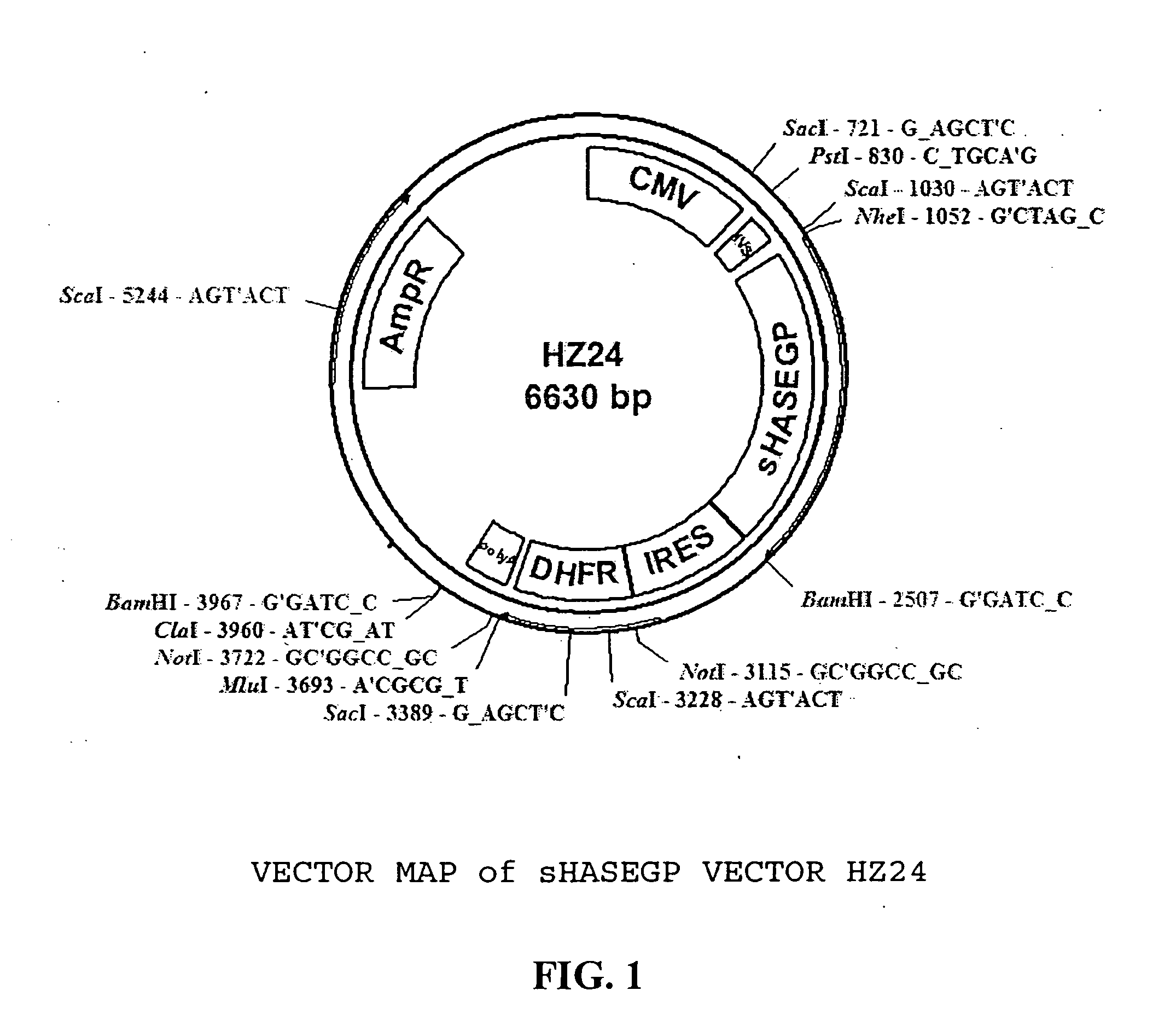

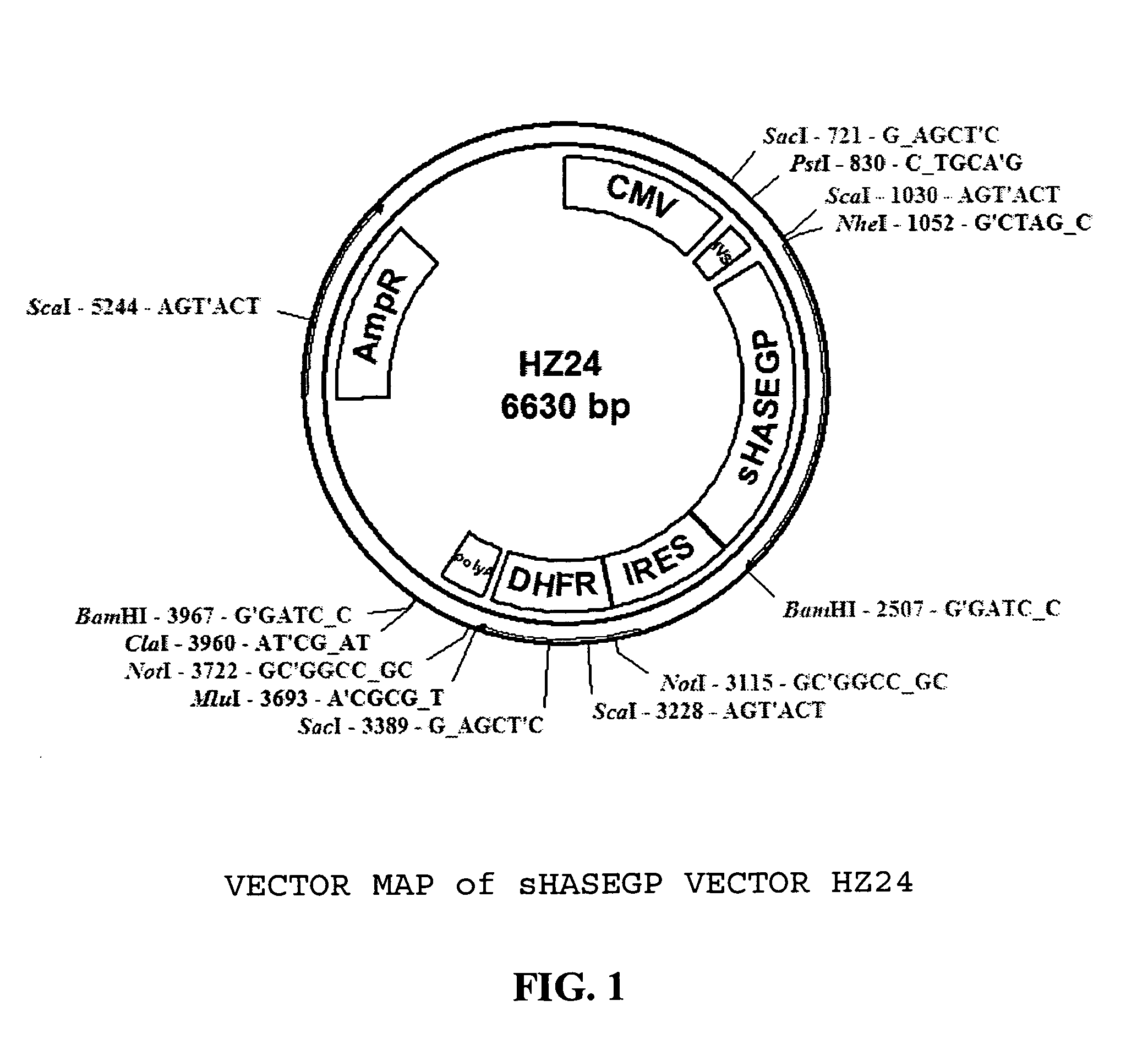

Soluble glycosaminoglycanases and methods of preparing and using soluble glycosaminogly ycanases

PendingUS20060104968A1Improve extentIncrease ratingsSenses disorderNervous disorderHyaluronidaseRecombinant glycoprotein

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated forms of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME

Soluble glycosaminoglycanases and methods of preparing and using soluble glycosaminoglycanases

ActiveUS20050260186A1Improve extentIncrease ratingsAntibacterial agentsSenses disorderHyaluronidasePathology diagnosis

The invention relates to the discovery of novel soluble neutral active Hyaluronidase Glycoproteins (sHASEGPs), methods of manufacture, and their use to facilitate administration of other molecules or to alleviate glycosaminoglycan associated pathologies. Minimally active polypeptide domains of the soluble, neutral active sHASEGP domains are described that include asparagine-linked sugar moieties required for a functional neutral active hyaluronidase domain. Included are modified amino-terminal leader peptides that enhance secretion of sHASEGP. The invention further comprises sialated and pegylated forms of a recombinant sHASEGP to enhance stability and serum pharmacokinetics over naturally occurring slaughterhouse enzymes. Further described are suitable formulations of a substantially purified recombinant sHASEGP glycoprotein derived from a eukaryotic cell that generate the proper glycosylation required for its optimal activity.

Owner:HALOZYME

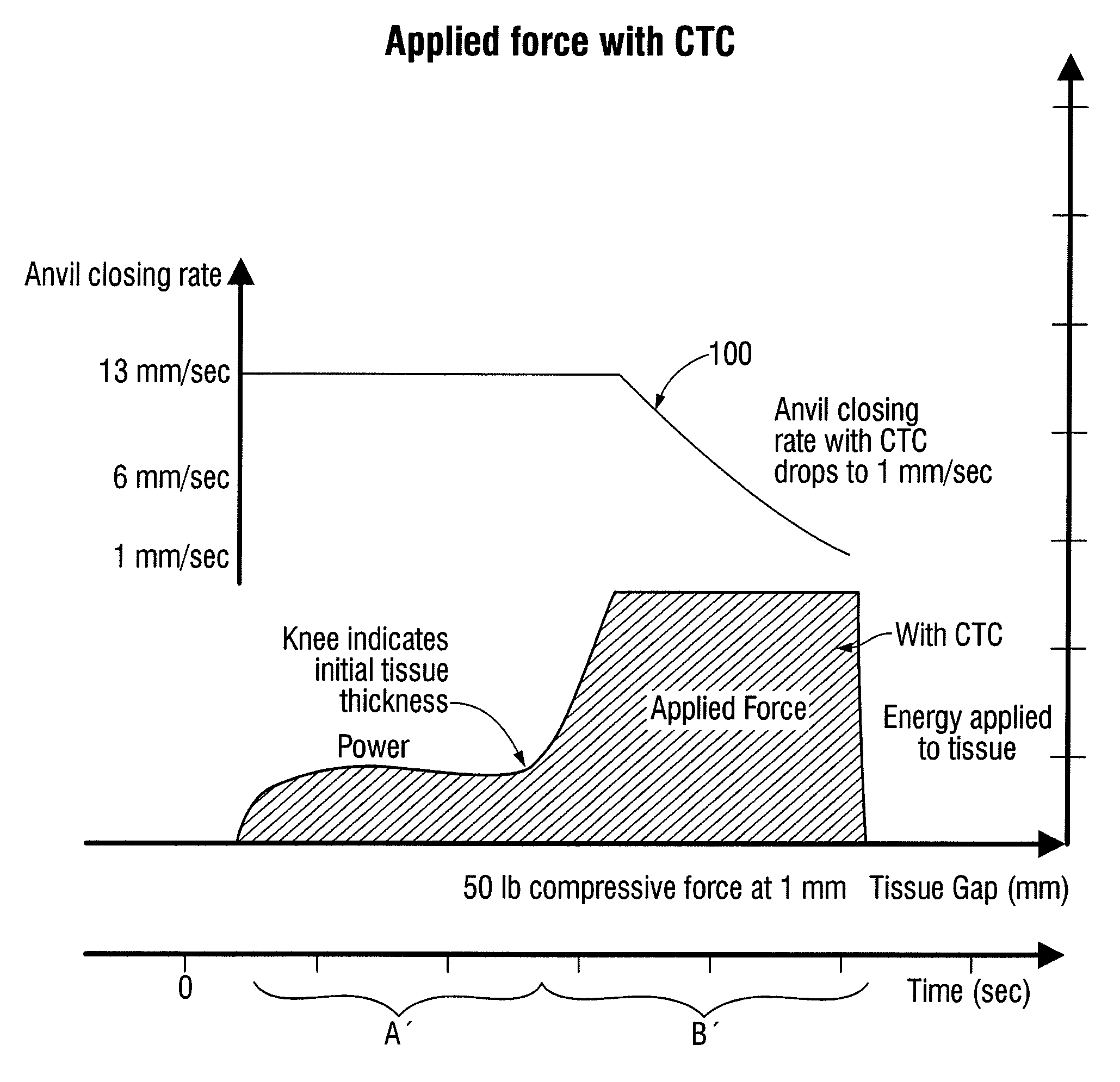

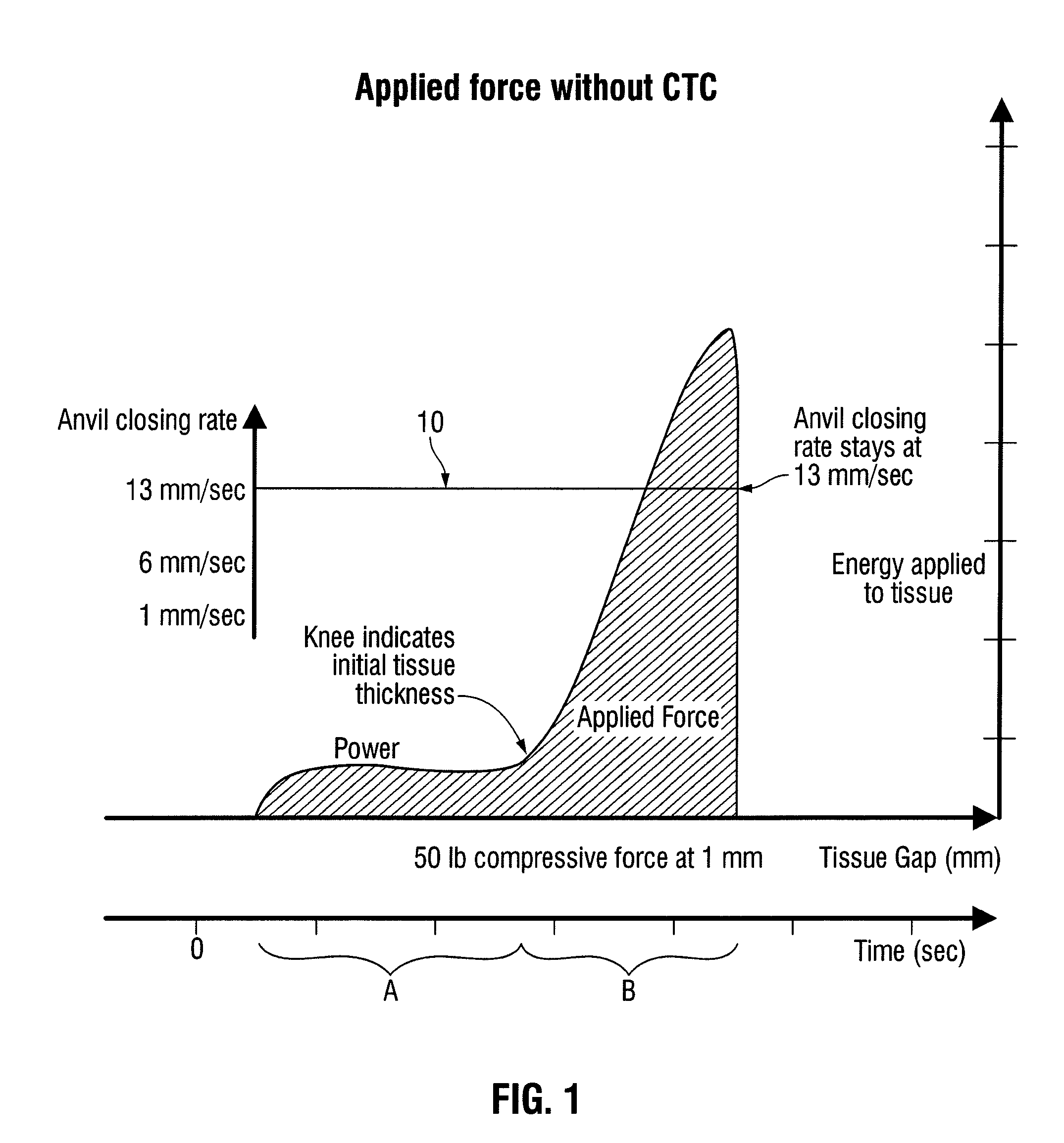

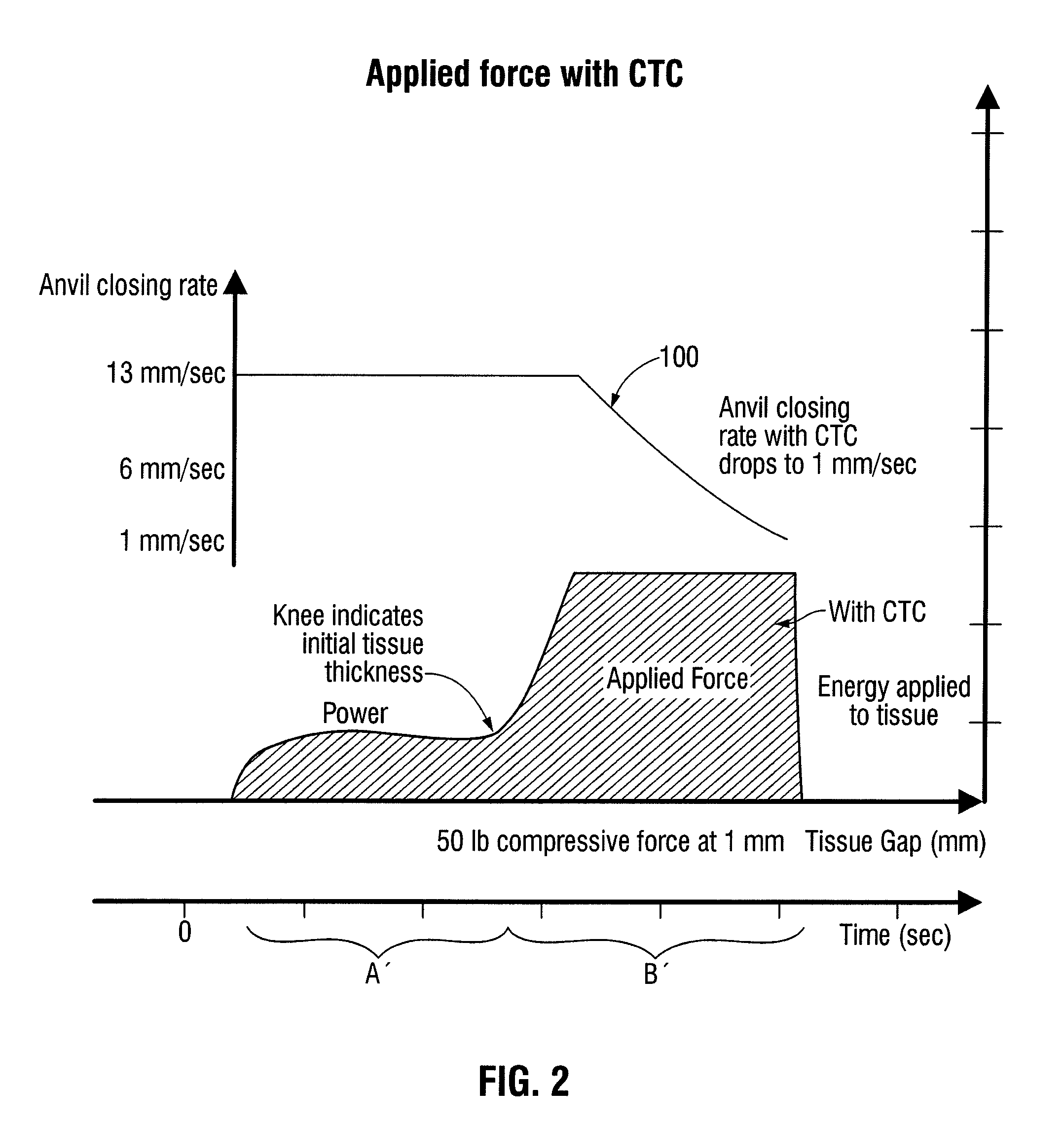

Device and method for controlling compression of tissue

ActiveUS8012170B2Reduce rateReduce probabilitySuture equipmentsStapling toolsParameter controlBiomedical engineering

A method and device for controlling the compression of tissue include clamping tissue between a first clamping member and a second clamping member by driving at least one of the clamping members with an electric motor toward a predetermined tissue gap between the clamping members and, during the clamping, monitoring a parameter of the electric motor indicative of a clamping force exerted to the tissue by the clamping members. The method and device include, during the clamping, controlling the electric motor, based on the monitored parameter, to limit the clamping force to a predetermined maximum limit.

Owner:COVIDIEN LP

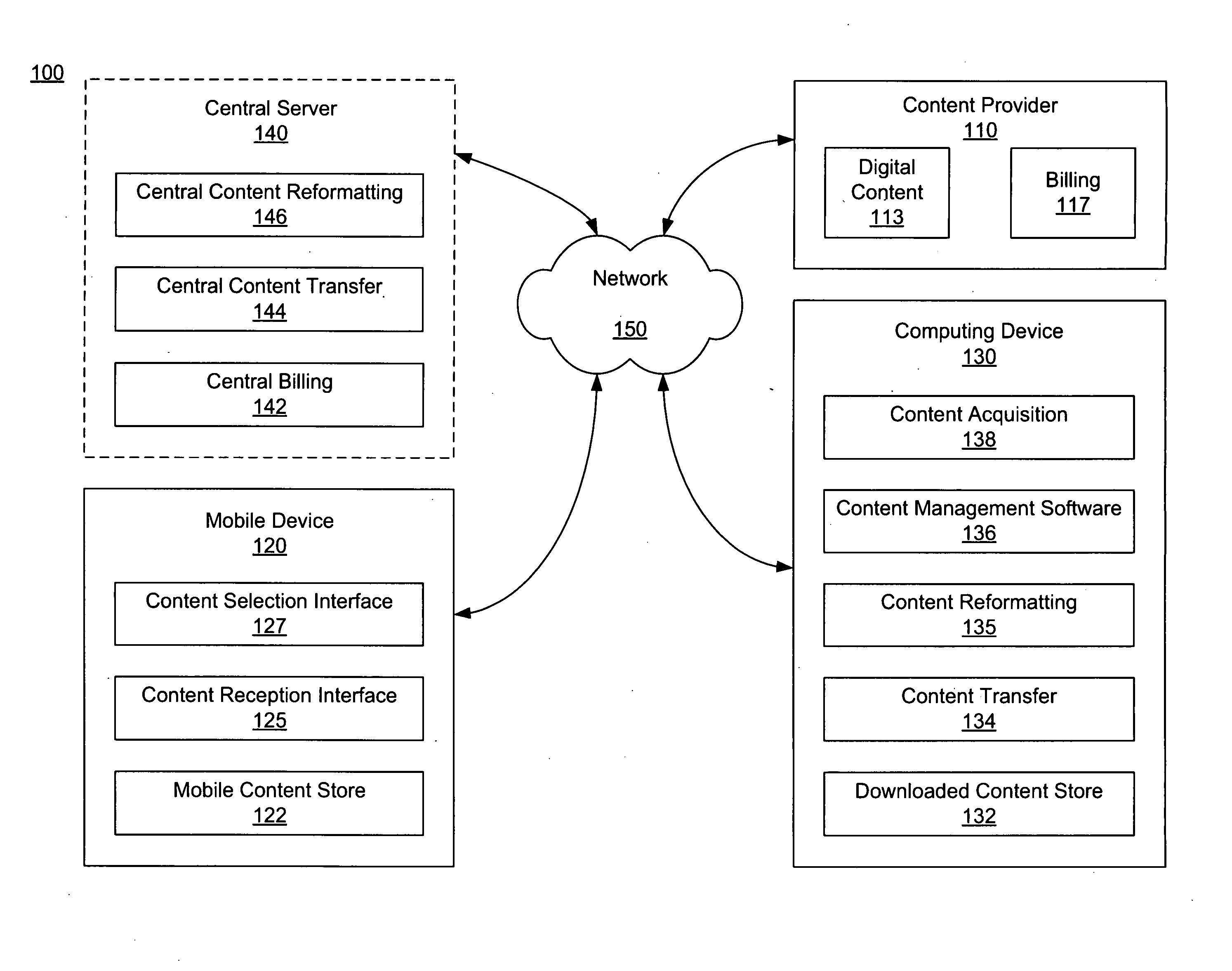

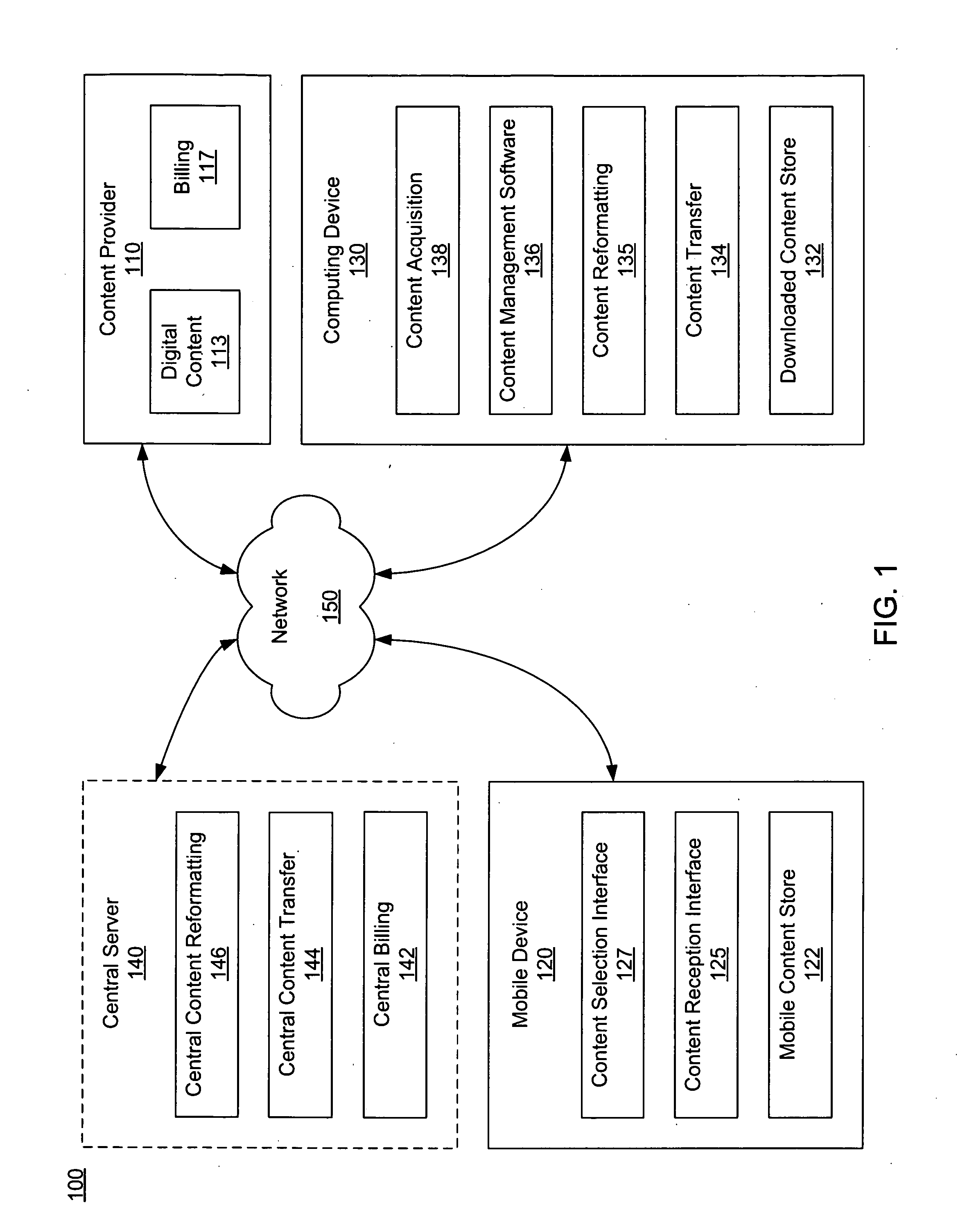

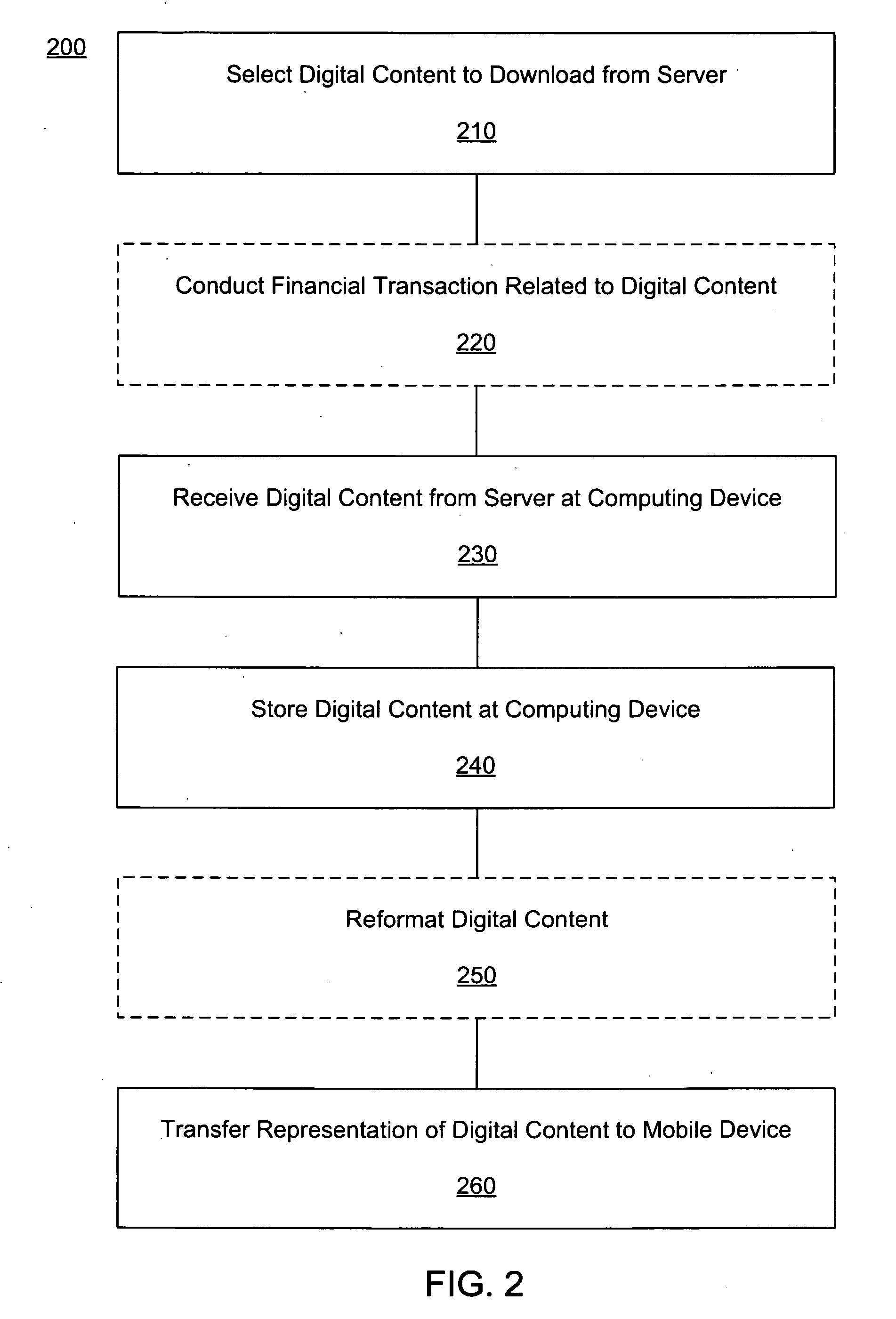

Content delivery to a mobile device from a content service

InactiveUS20090157792A1Reduce rateReduce resolutionComplete banking machinesTelephonic communicationService provisionDigital content

Systems and methods for delivering digital content to a mobile device from a digital content provider are disclosed. Digital content is selected using a selection interface on the mobile device. The selected content is then transferred to a computing device by the digital content provider and subsequently transferred to the mobile device by the computing device. In some embodiments, the digital content is reformatted before being transferred to the mobile device. The digital content may be streamed from the computer system to the mobile device. A service provider of a network through which the mobile device connects to the digital content provider may bill a user of the mobile device on behalf of the digital content provider. The digital content provider may bill the user of the mobile device using a Premium SMS service.

Owner:SEVEN NETWORKS INC

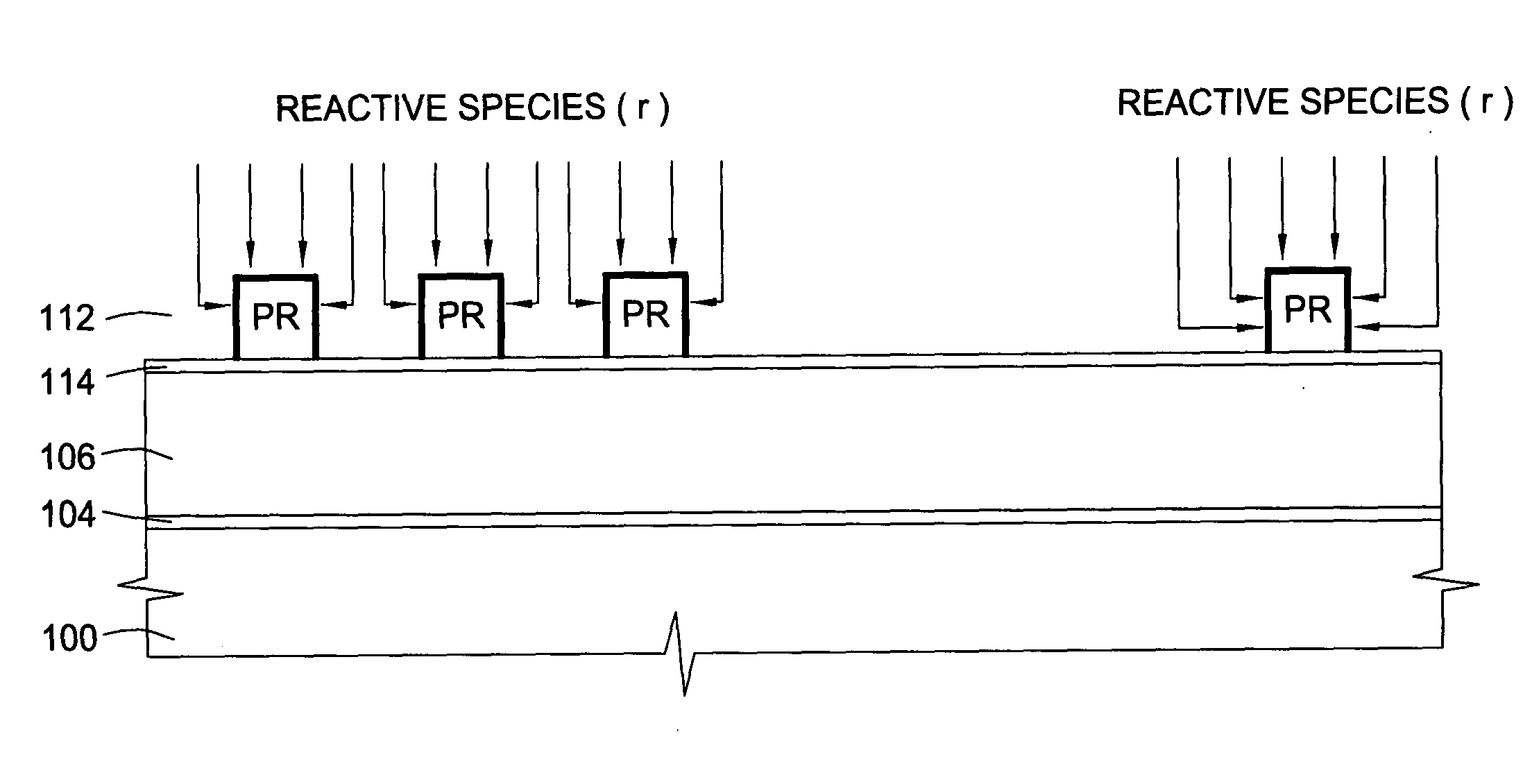

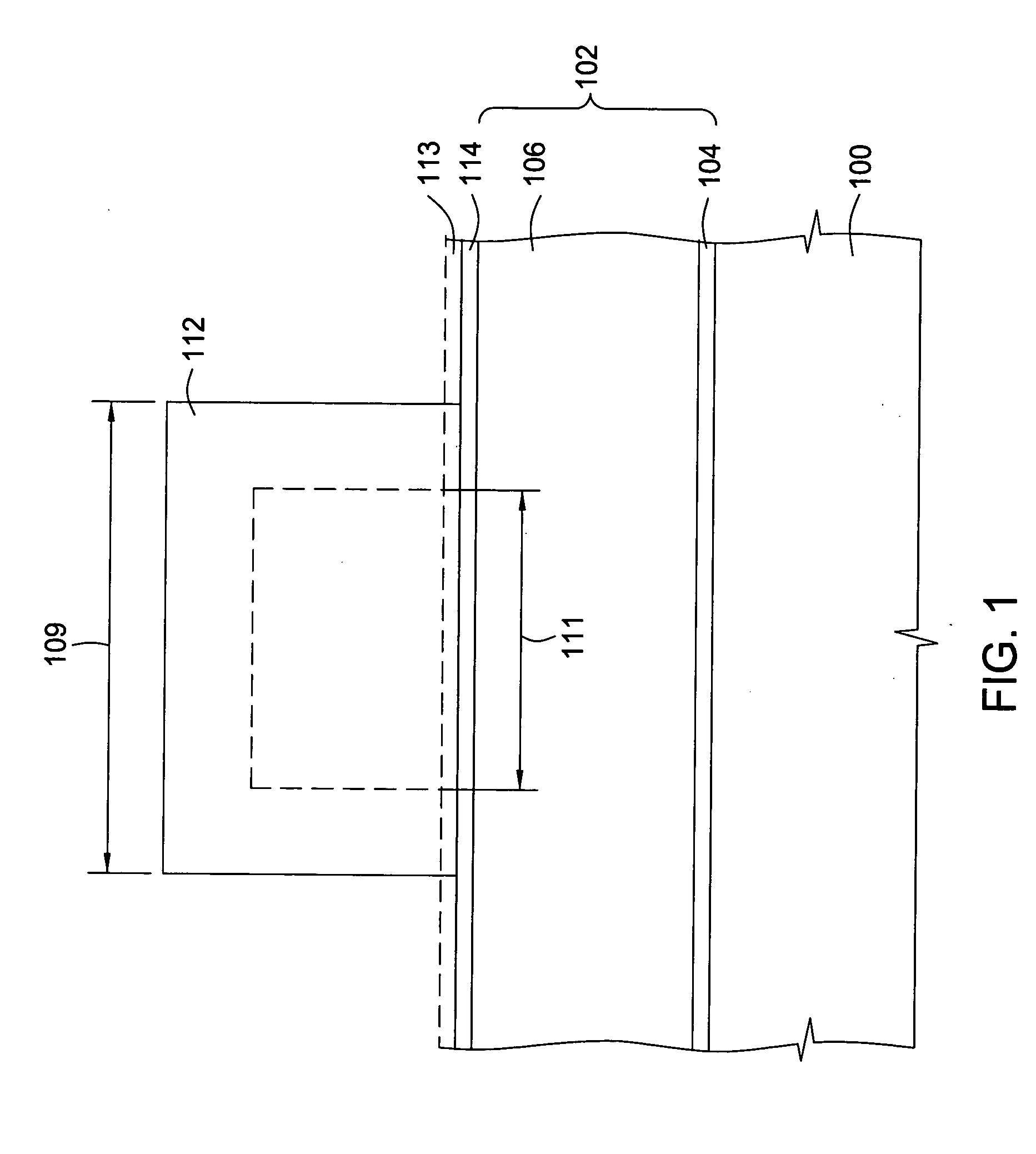

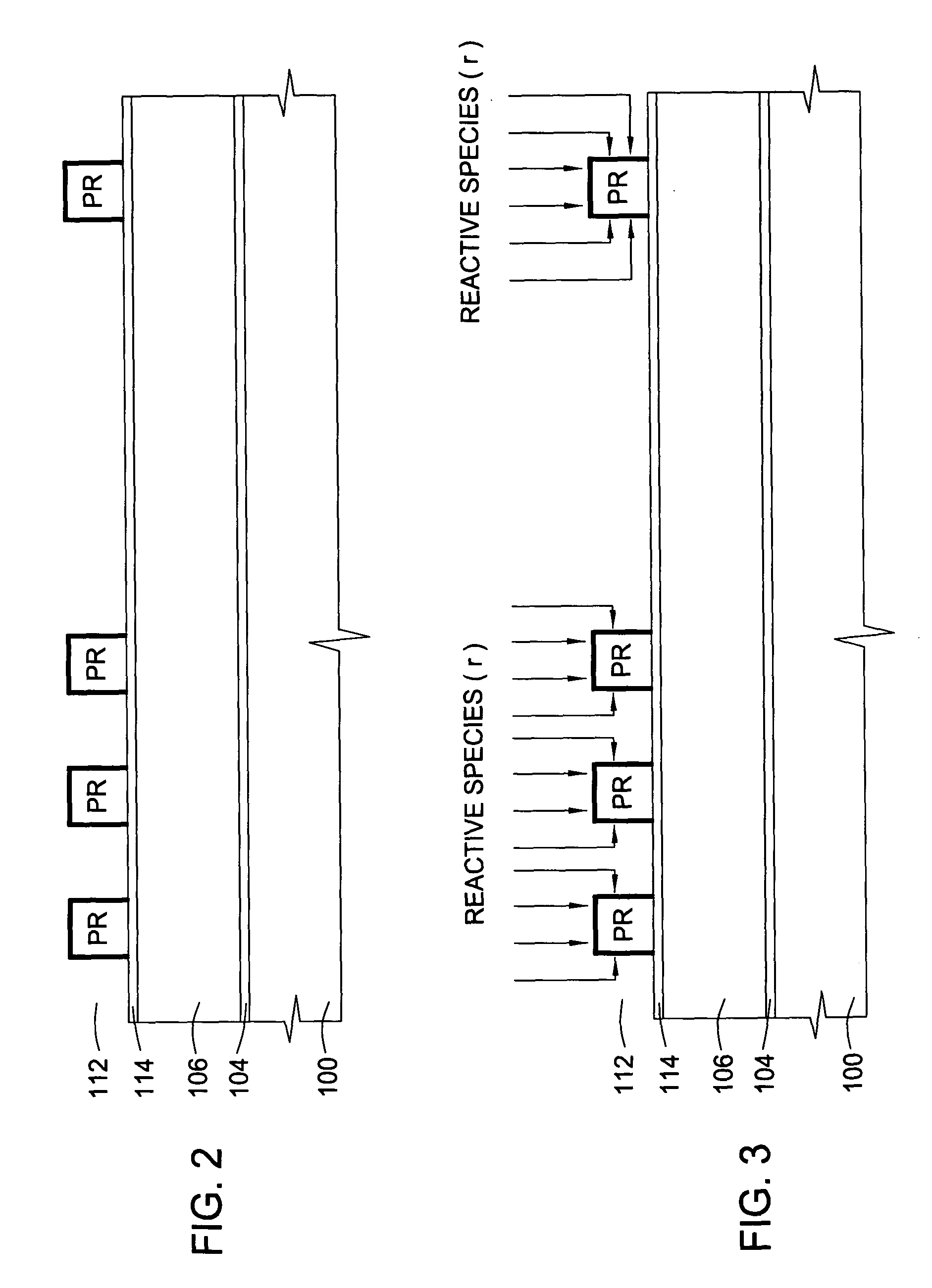

Method of controlling critical dimension microloading of photoresist trimming process by selective sidewall polymer deposition

InactiveUS20050064719A1Reduce micro-loadingReduce trim rateSemiconductor/solid-state device manufacturingPhotosensitive material processingChemistryPhotoresist

A method for trimming photoresist features on a semiconductor substrate in a processing system. The method utilizes a process gas mixture comprising a hydrocarbon gas, an oxygen gas and an inert gas. The critical dimension (CD) microloading of the dense and the isolated regions can be eliminated and the photoresist trimming rate can also be reduced to enable better critical dimension (CD) control.

Owner:APPLIED MATERIALS INC

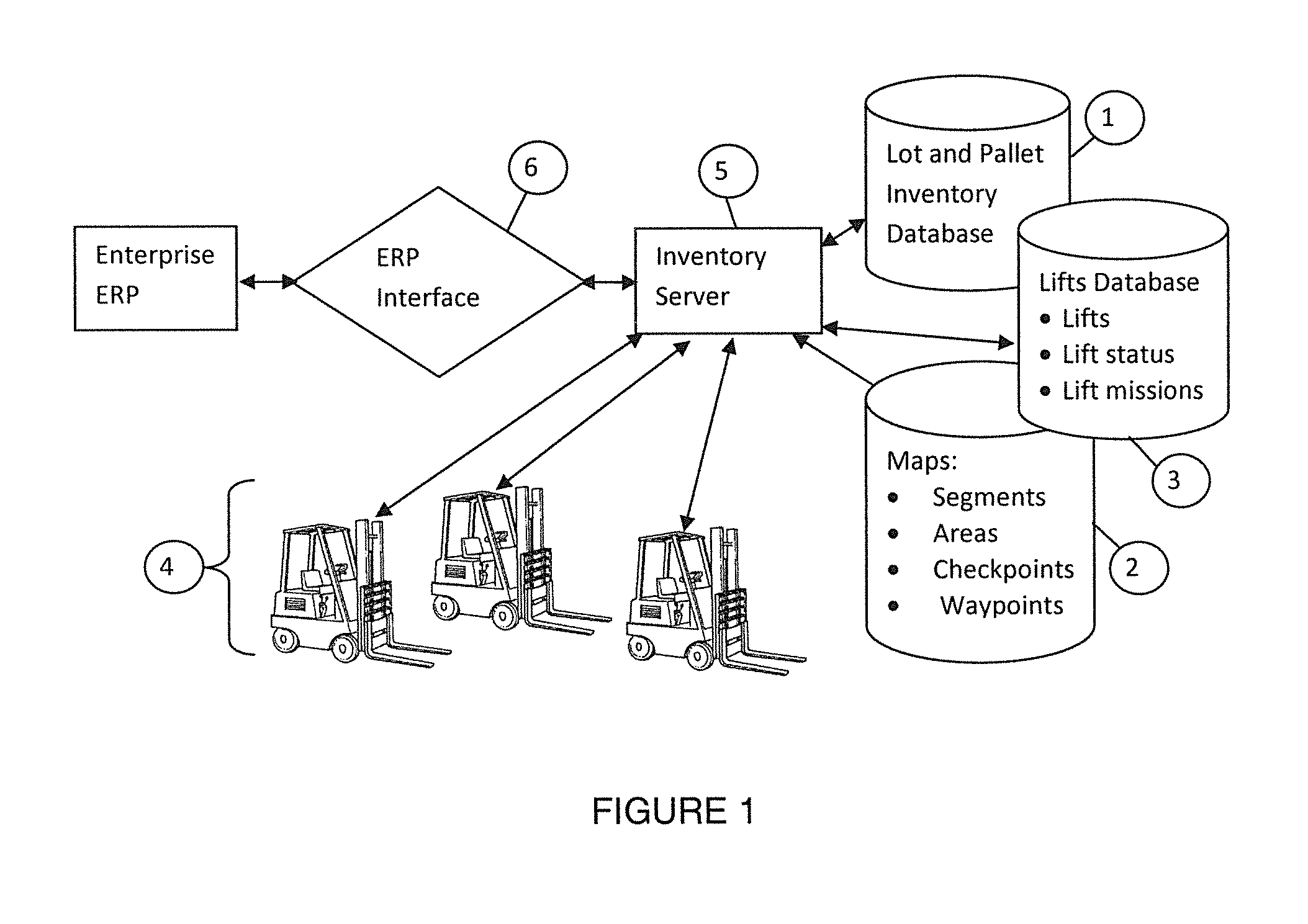

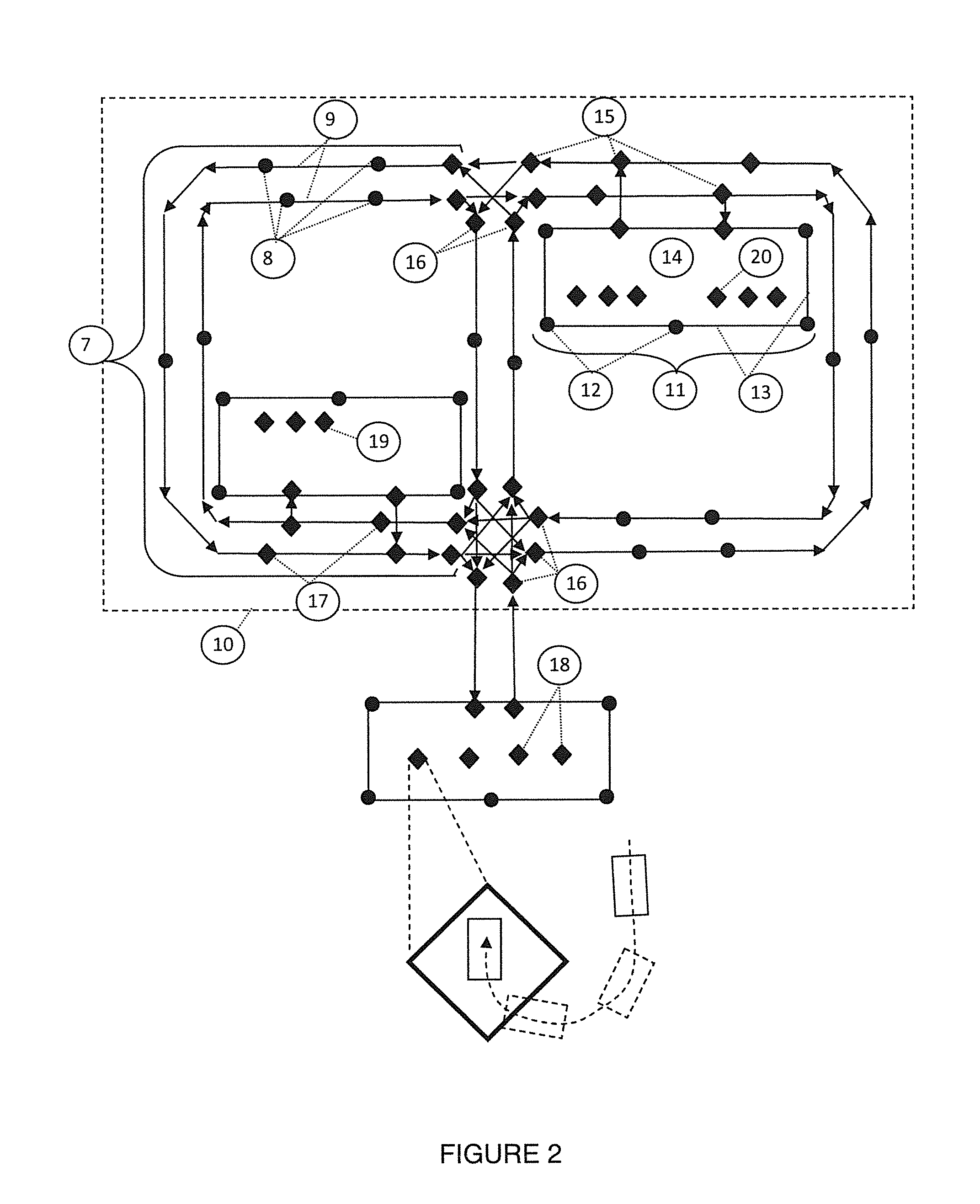

Automated warehousing using robotic forklifts

ActiveUS20140277691A1Low costReduce rateDigital data processing detailsLifting devicesOn boardInventory management

A system for automated inventory management and material handling removes the requirement to operate fully automatically or all-manual using conventional vertical storage and retrieval (S&R) machines. Inventory requests to place palletized material into storage at a specified lot location or retrieve palletized material from a specified lot are resolved into missions for autonomous fork trucks, equivalent mobile platforms, or manual fork truck drivers (and their equipment) that are autonomously or manually executed to effect the request. Automated trucks plan their own movements to execute the mission over the warehouse aisles or roadways sharing this space with manually driven trucks. Automated units drive to planned speed limits, manage their loads (stability control), stop, go, and merge at intersections according human driving rules, use on-board sensors to identify static and dynamic obstacles, and human traffic, and either avoid them or stop until potential collision risk is removed.

Owner:CYBERNET SYST

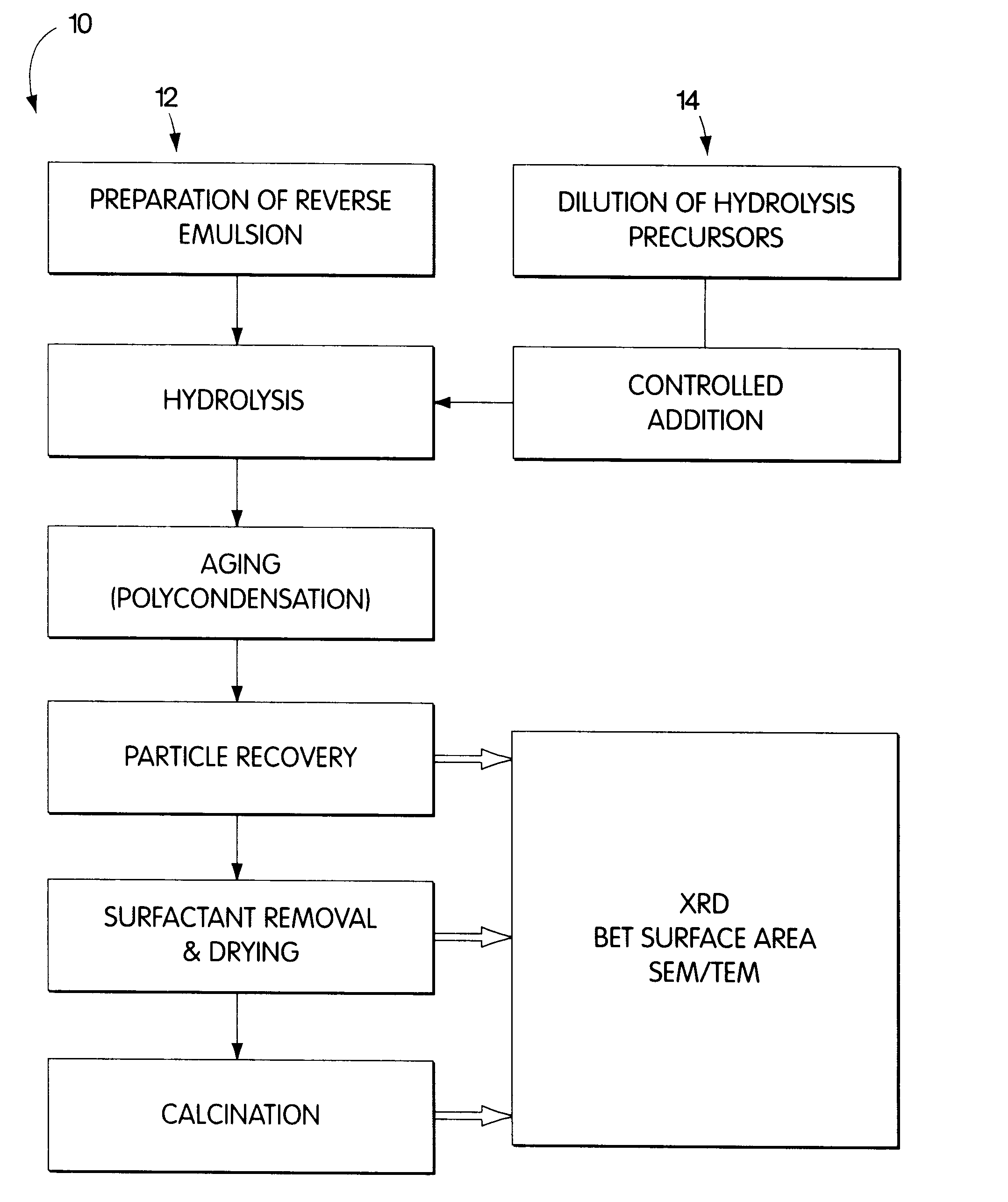

Synthesis of nanometer-sized particles by reverse micelle mediated techniques

The present invention relates to a method of producing particles having a particle size of less than 100 nm and surface areas of at least 20 m2 / g where the particles are free from agglomeration. The method involves synthesizing the particles within an emulsion having a 1-40% water content to form reverse micelles. In particular, the particles formed are metal oxide particles. The particles can be used to oxidize hydrocarbons, particularly methane.

Owner:MASSACHUSETTS INST OF TECH

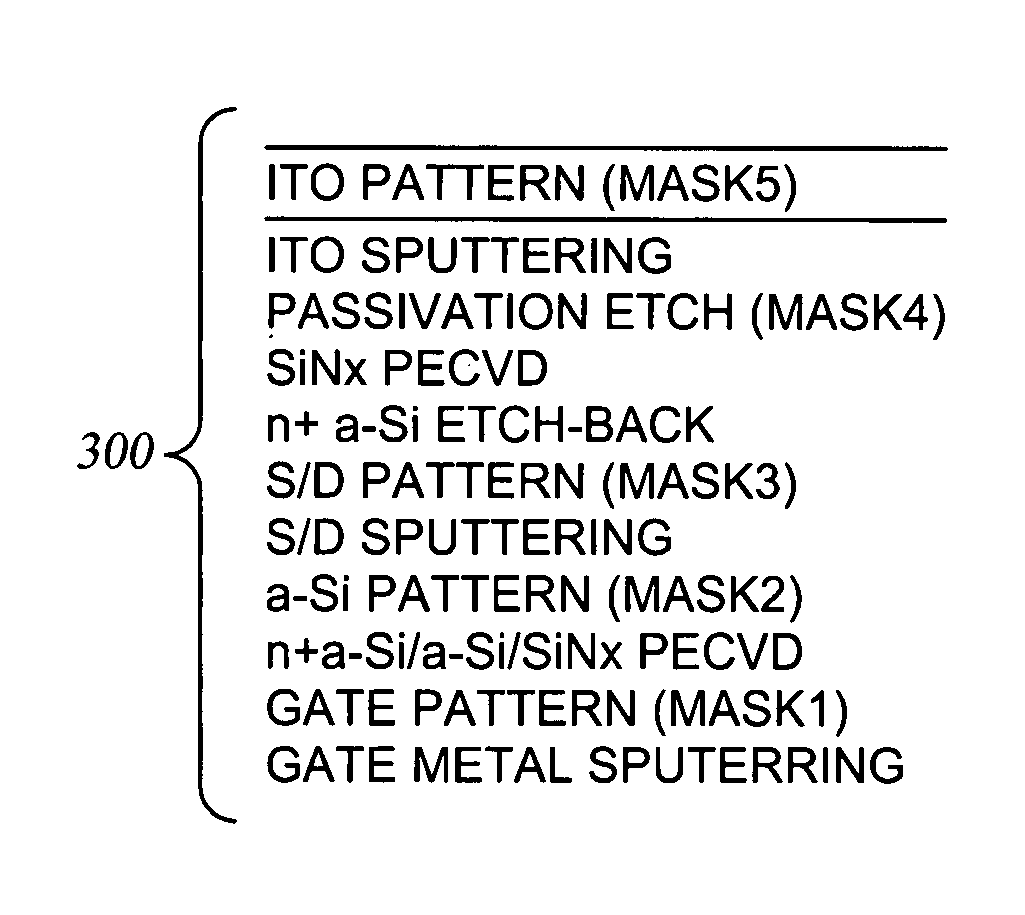

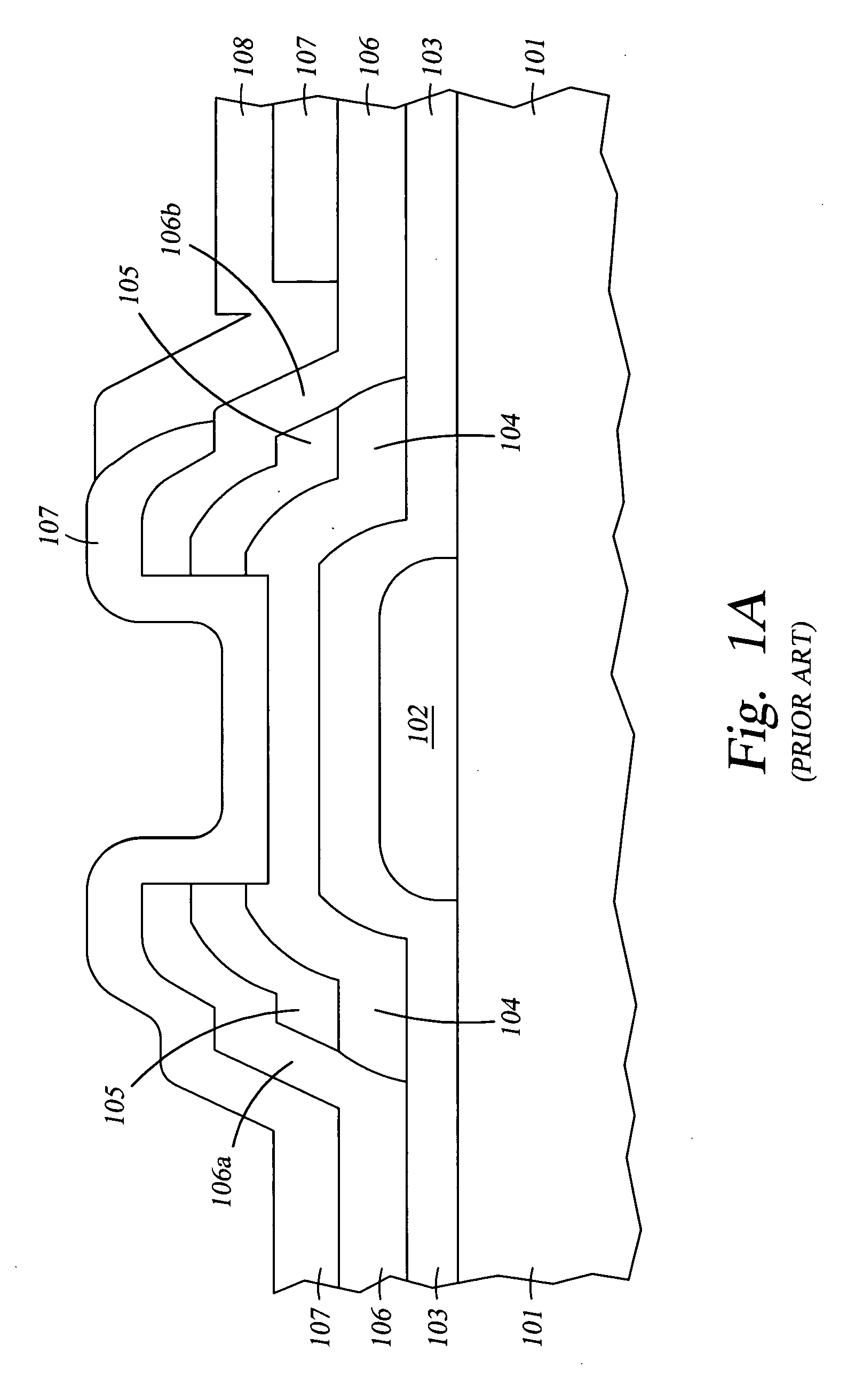

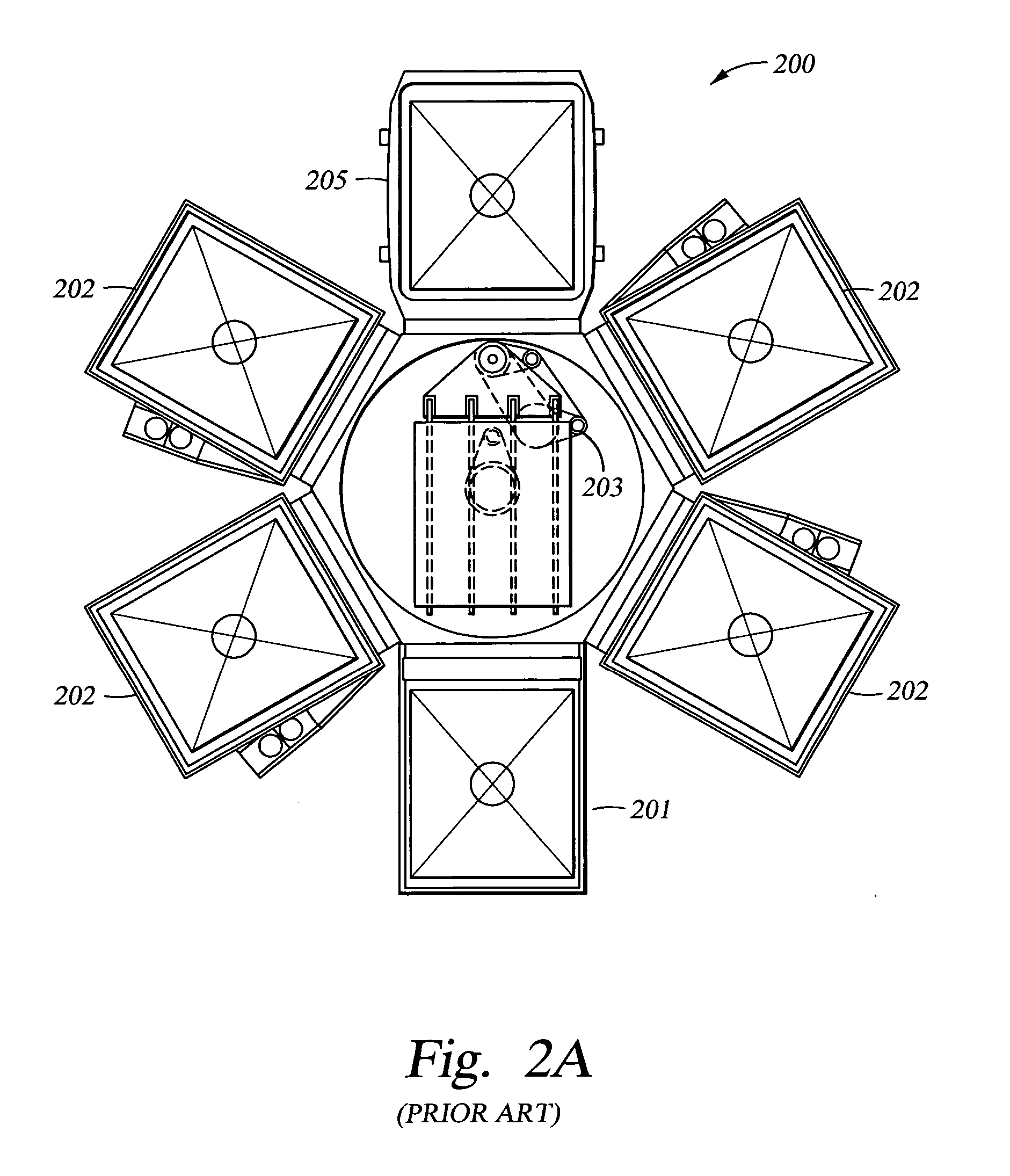

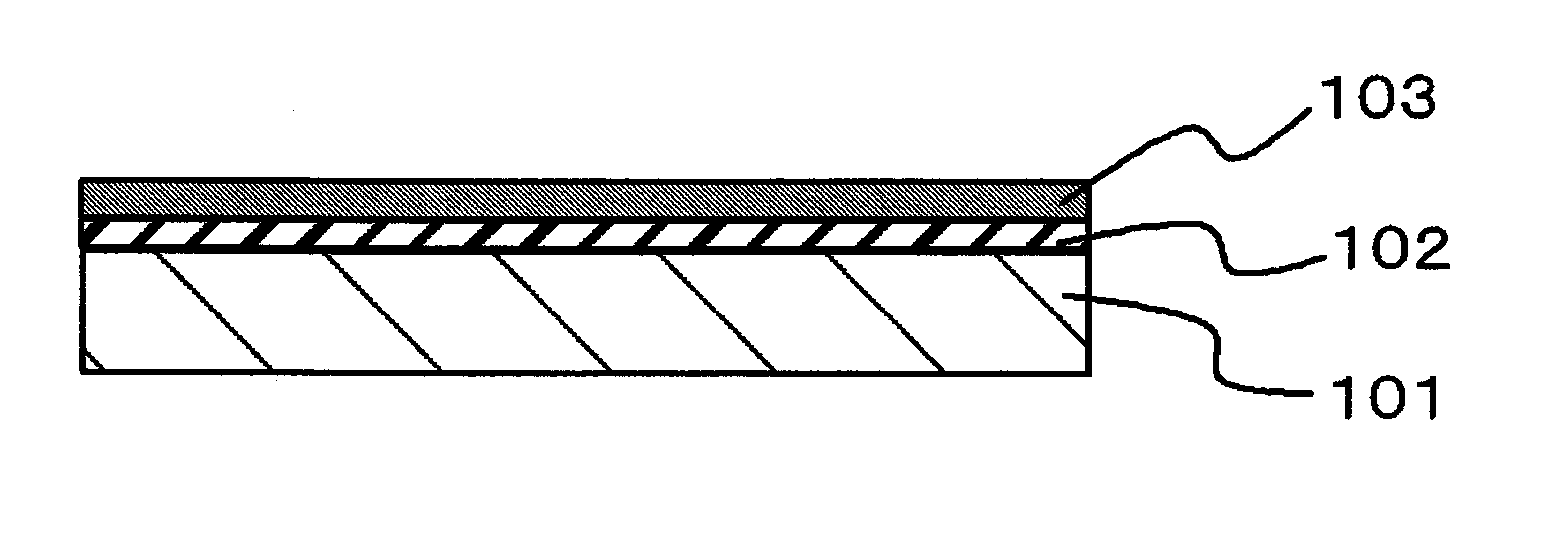

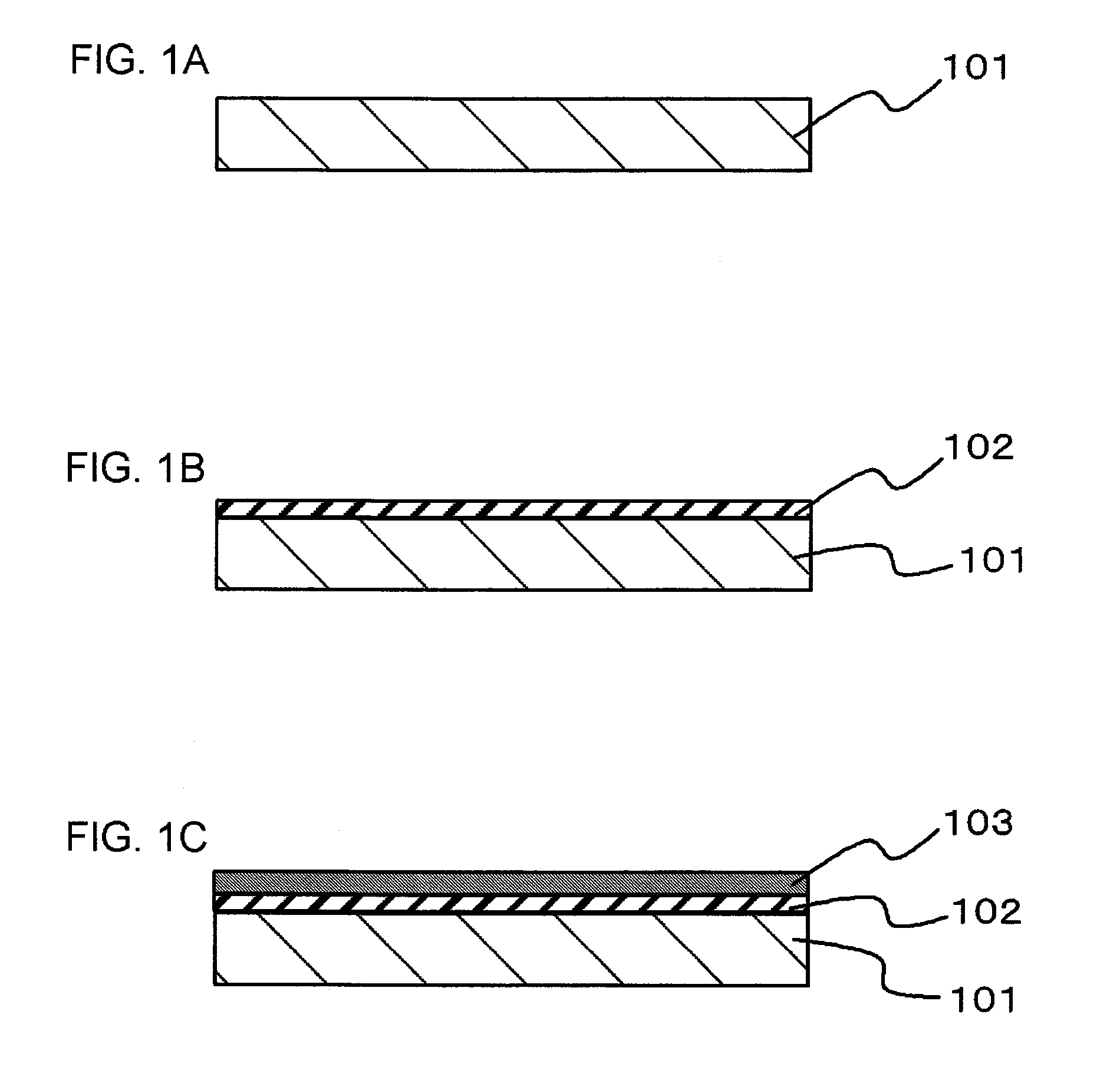

Method of controlling the film properties of a CVD-deposited silicon nitride film

InactiveUS20060019502A1Increase wet etch rateEasy to controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricGas composition

We have discovered that adding H2 to a precursor gas composition including SiH4, NH3, and N2 is effective at improving the wet etch rate and the wet etch rate uniformity across the substrate surface of a-SiNx:H films which are deposited on a substrate by PECVD. Wet etch rate is an indication of film density. Typically, the lower the wet etch rate, the denser the film. The addition of H2 to the SiH4 / NH3 / N2 precursor gas composition did not significantly increase the variation in deposited film thickness across the surface of the substrate. The a-SiNx:H films described herein are particularly useful as TFT gate dielectrics in the production of flat panel displays. The uniformity of the film across the substrate enables the production of flat panel displays having surface areas of 25,000 cm2 and larger.

Owner:APPLIED MATERIALS INC

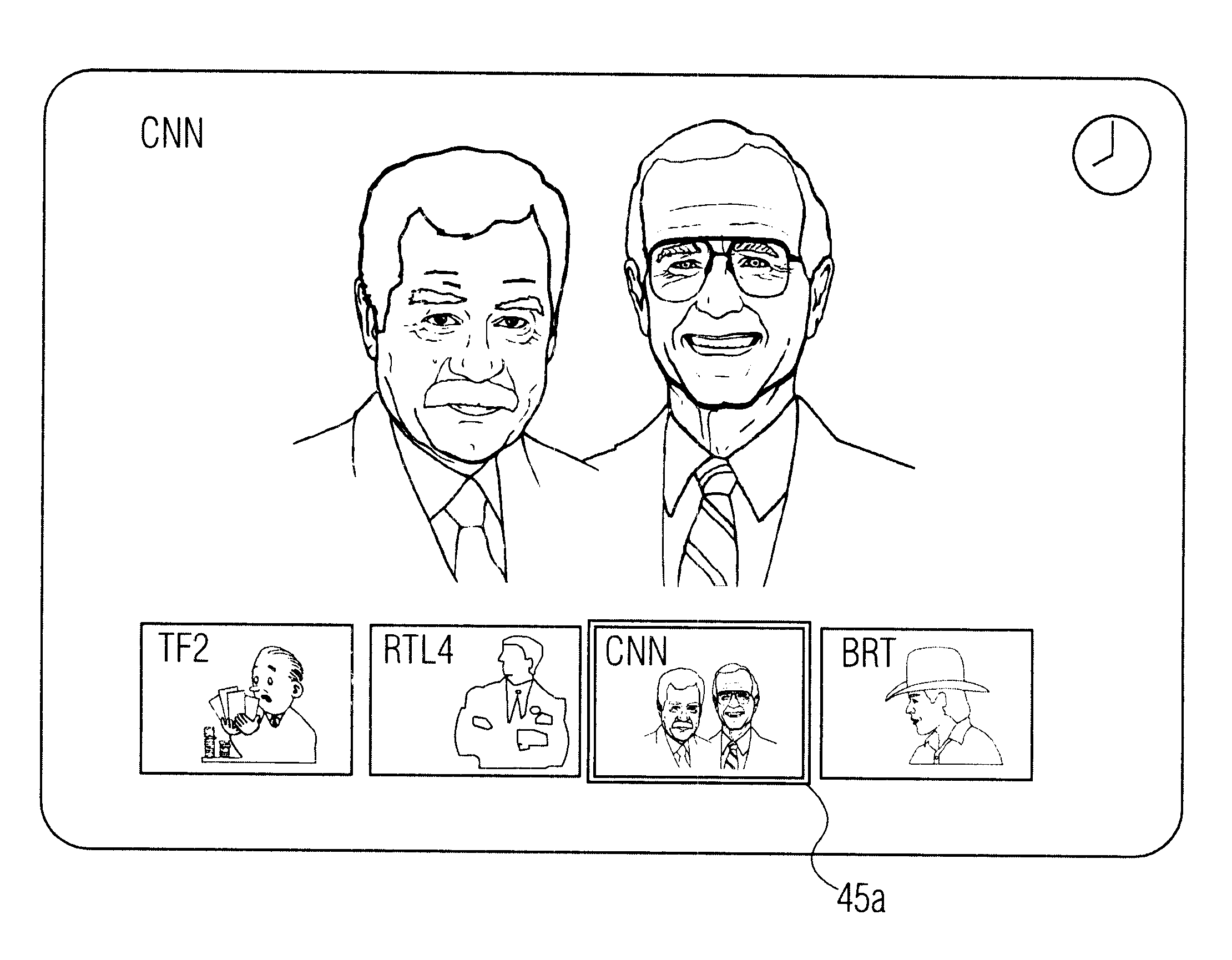

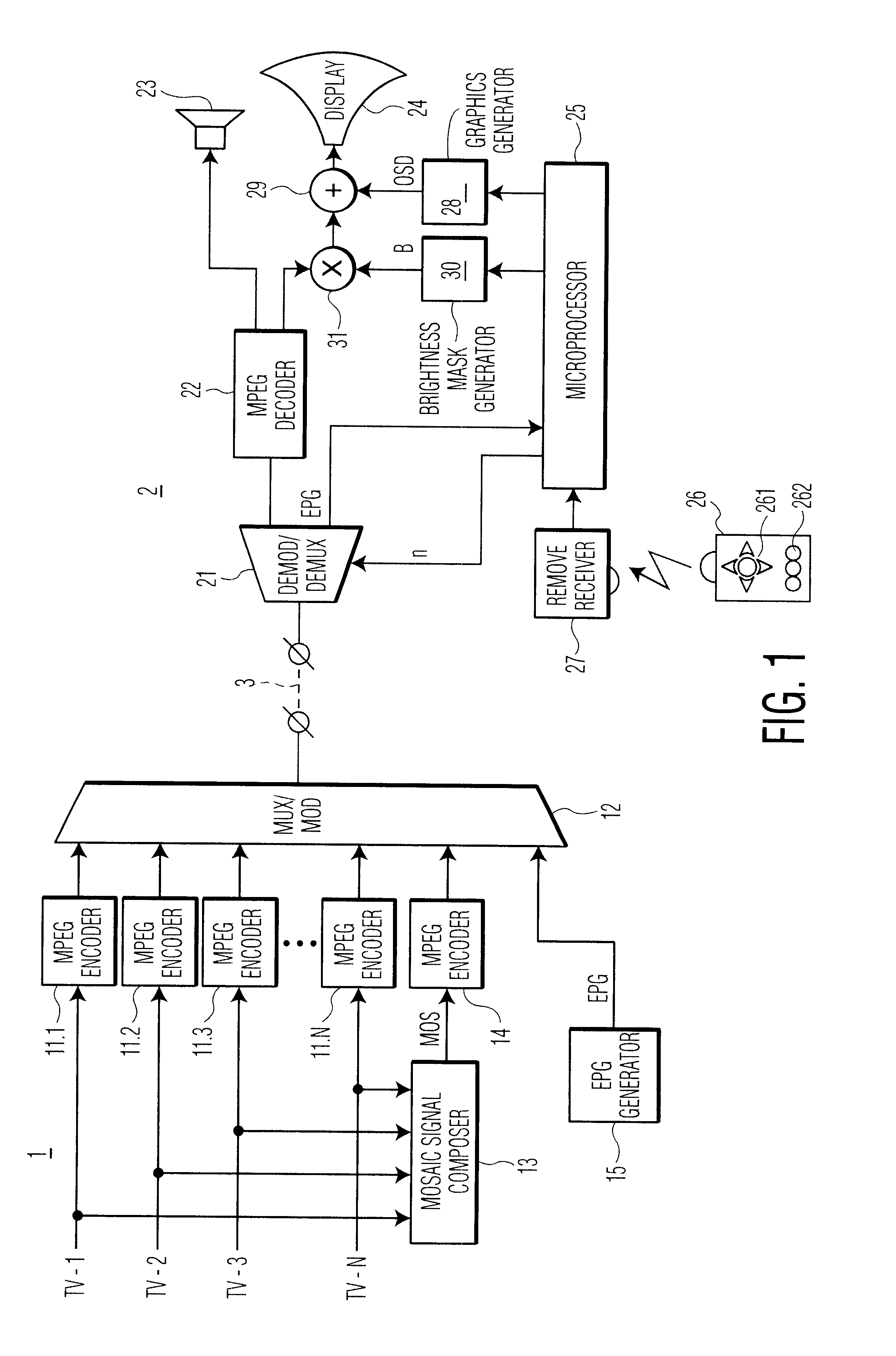

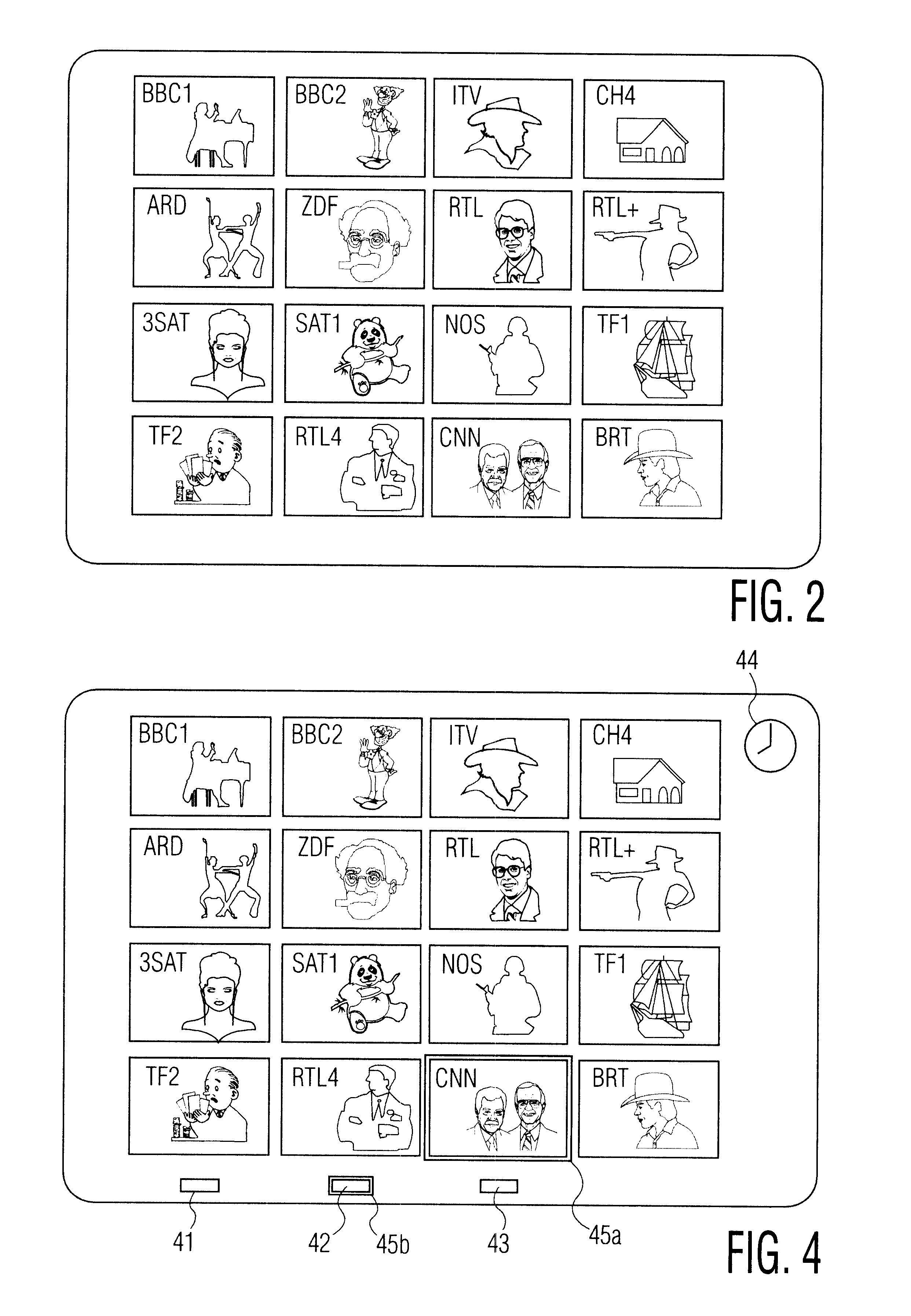

Navigating through television programs

InactiveUS6405371B1Improve convenienceReduce brightnessTelevision system detailsColor television detailsTelevision receiversComputer science

A method of navigating through television programs is disclosed. A television receiver displays a mosaic image with sub-images representing the available programs. The receiver further receives an electronic program guide with program descriptions. Upon activating a "theme" button (42), the viewer can enter a desired program type, e.g. "movie". In response thereto, the brightness of the sub-images representing programs that are not desired is reduced. The user is thus assisted in navigating through programs he is interested in, while maintaining the mosaic structure he is familiar with, and without losing the association between channels and their positions on the mosaic screen.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

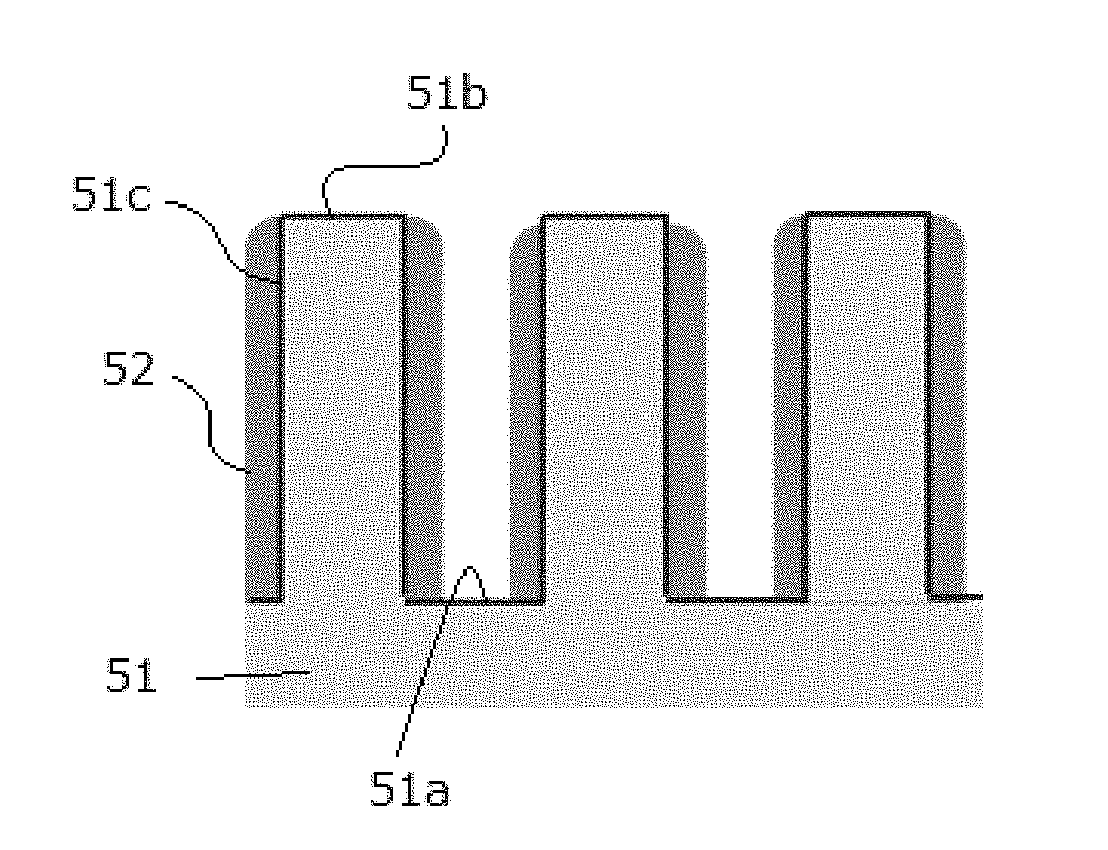

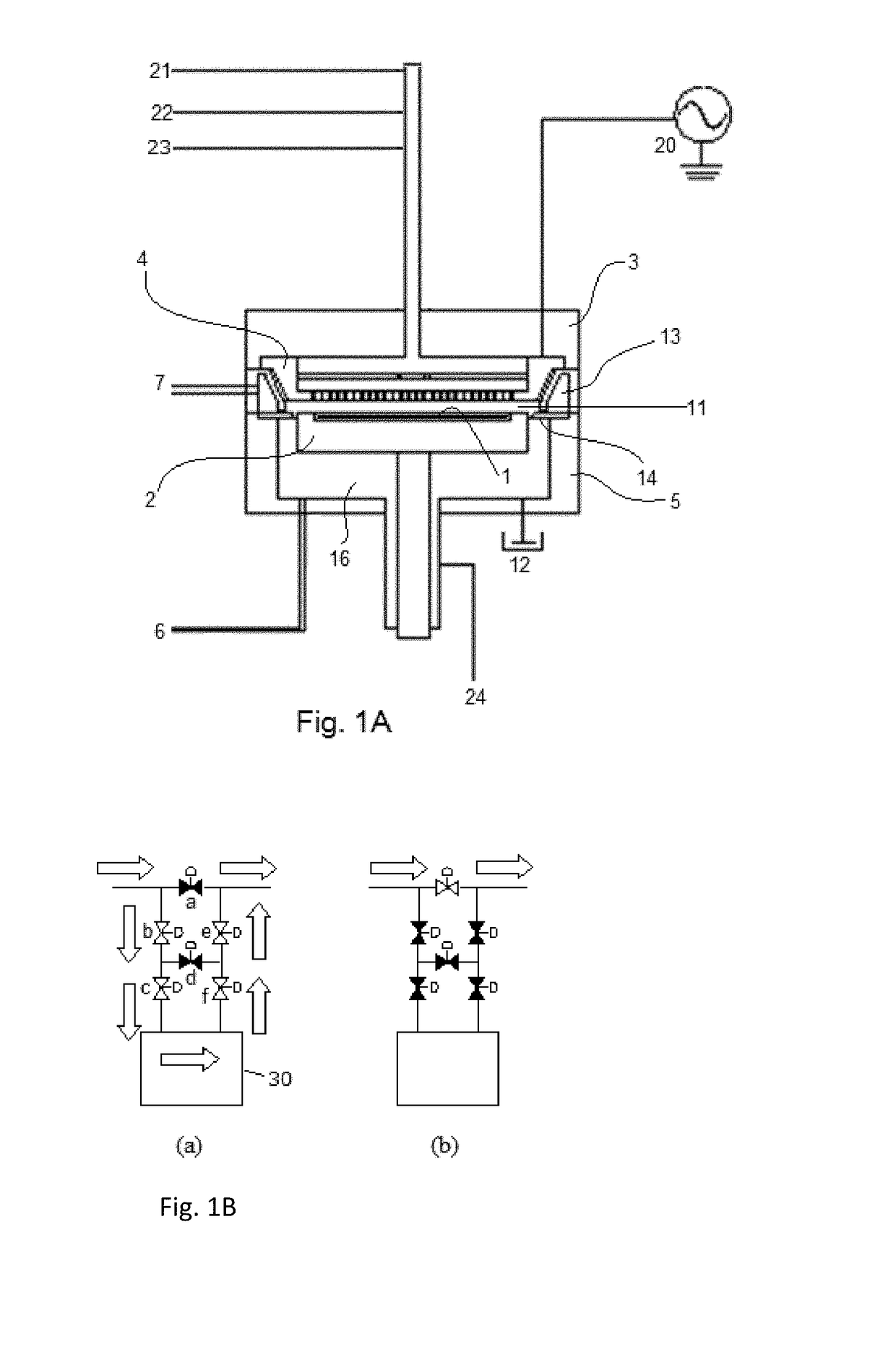

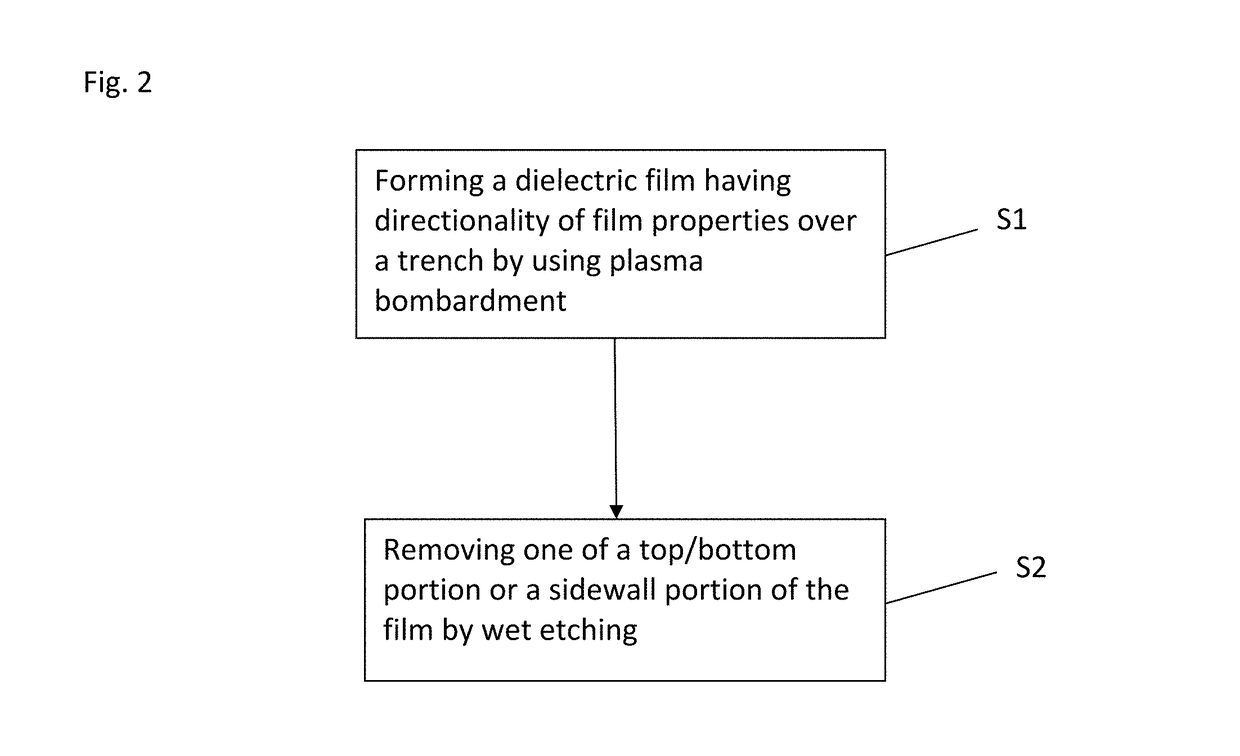

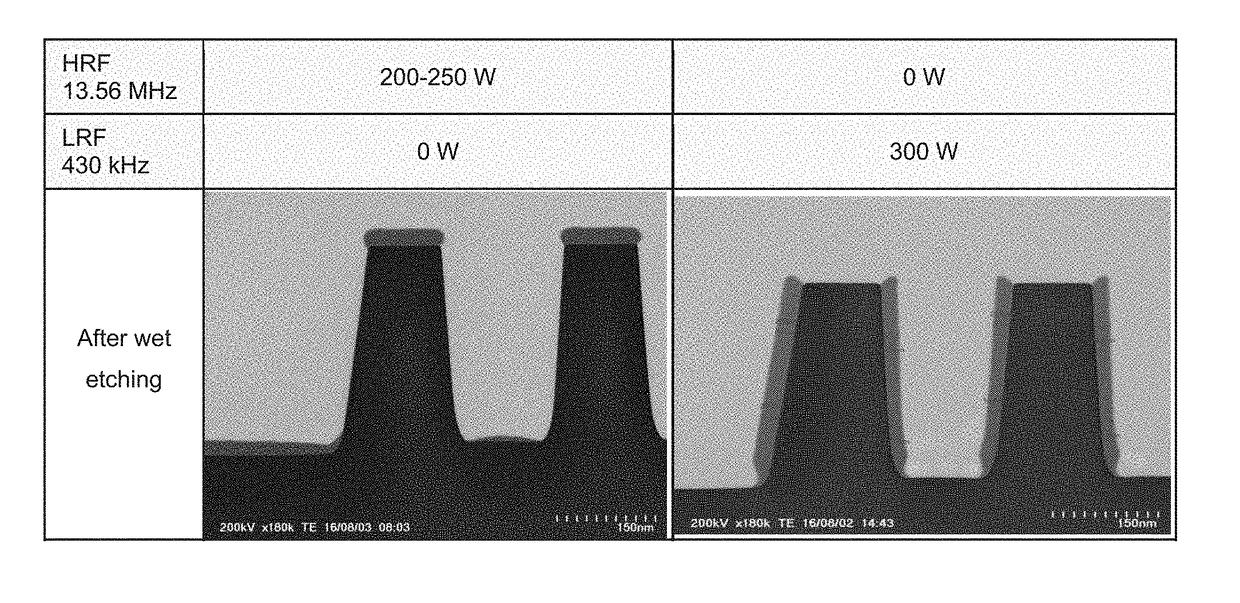

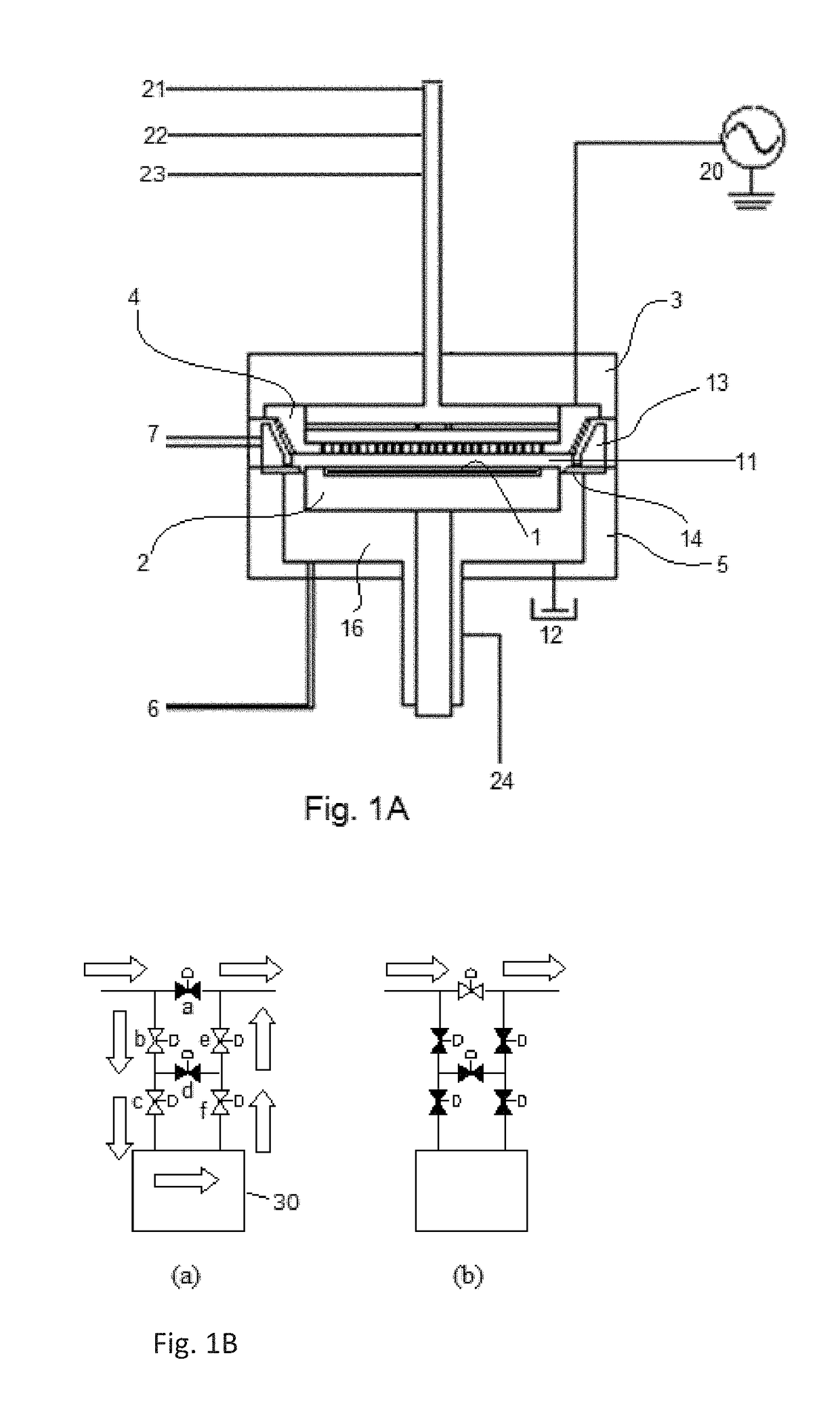

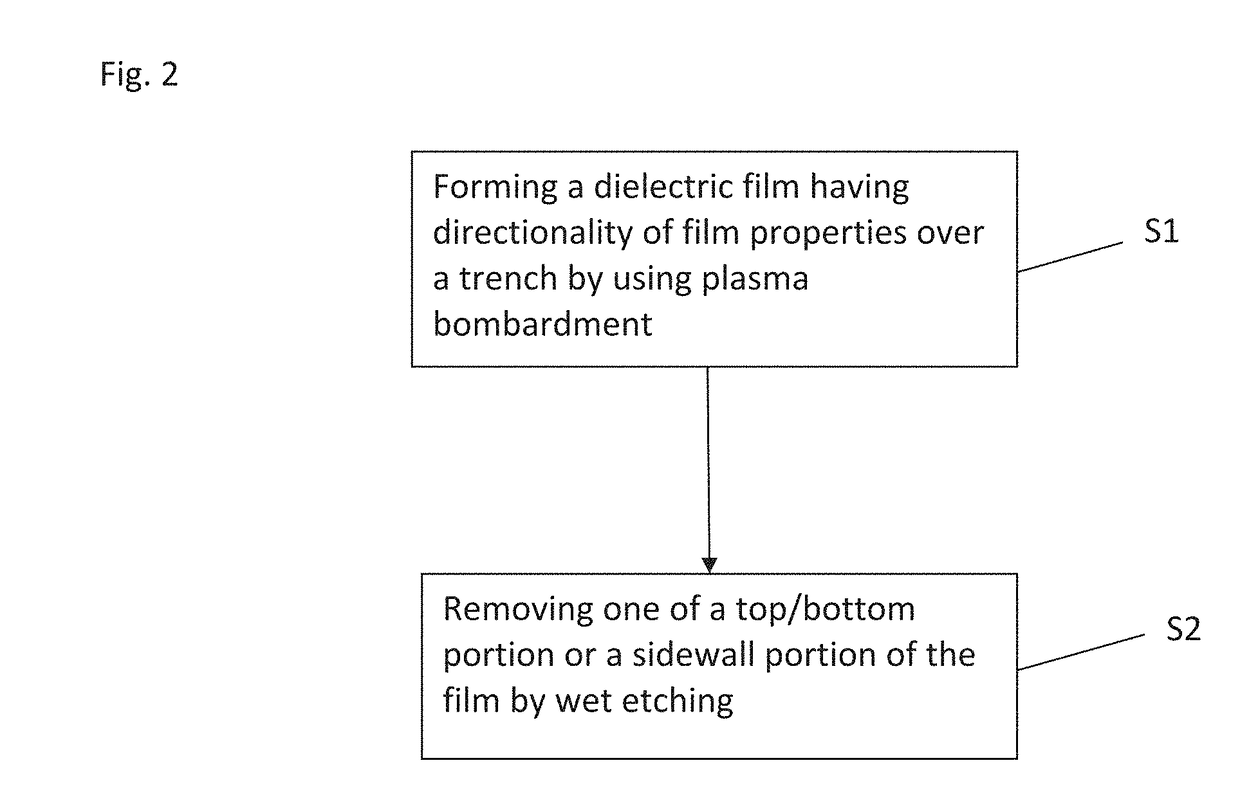

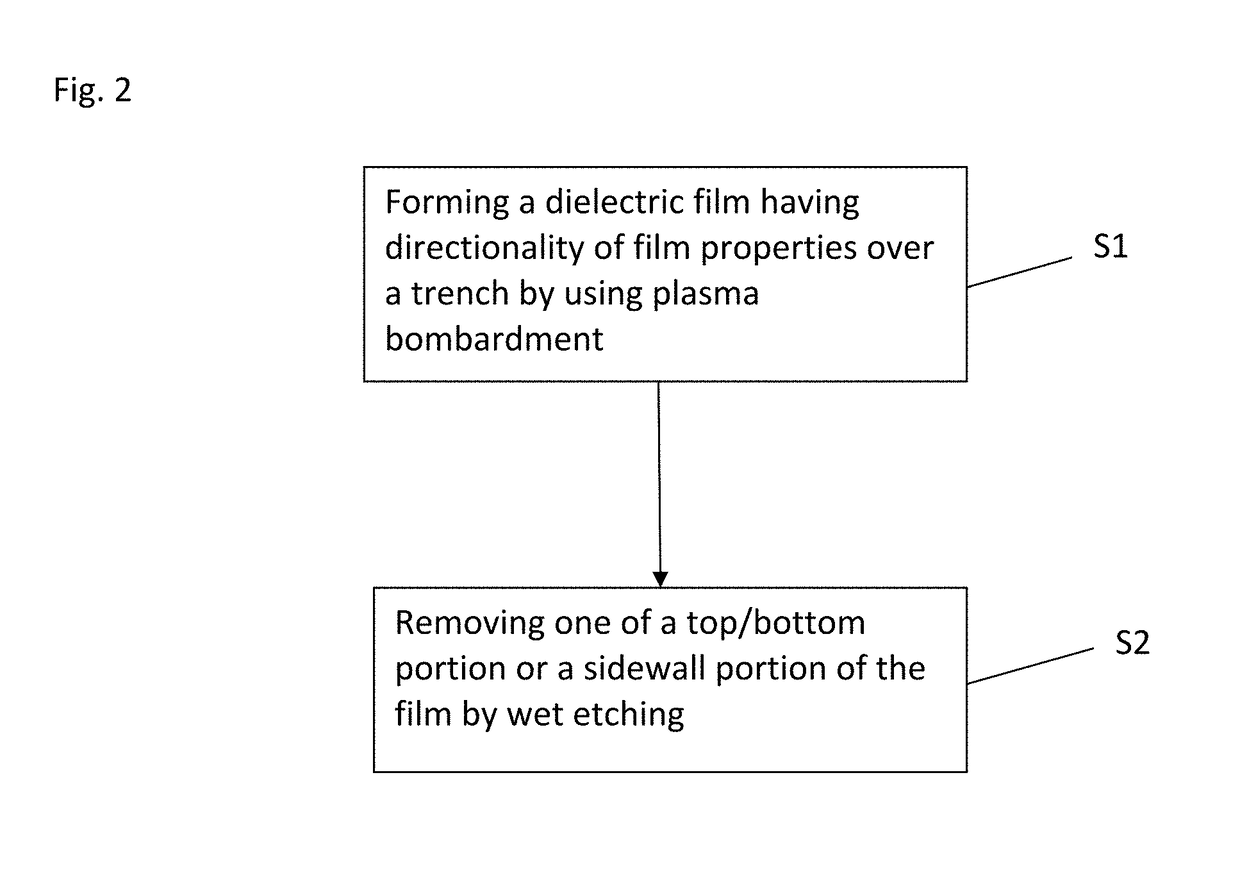

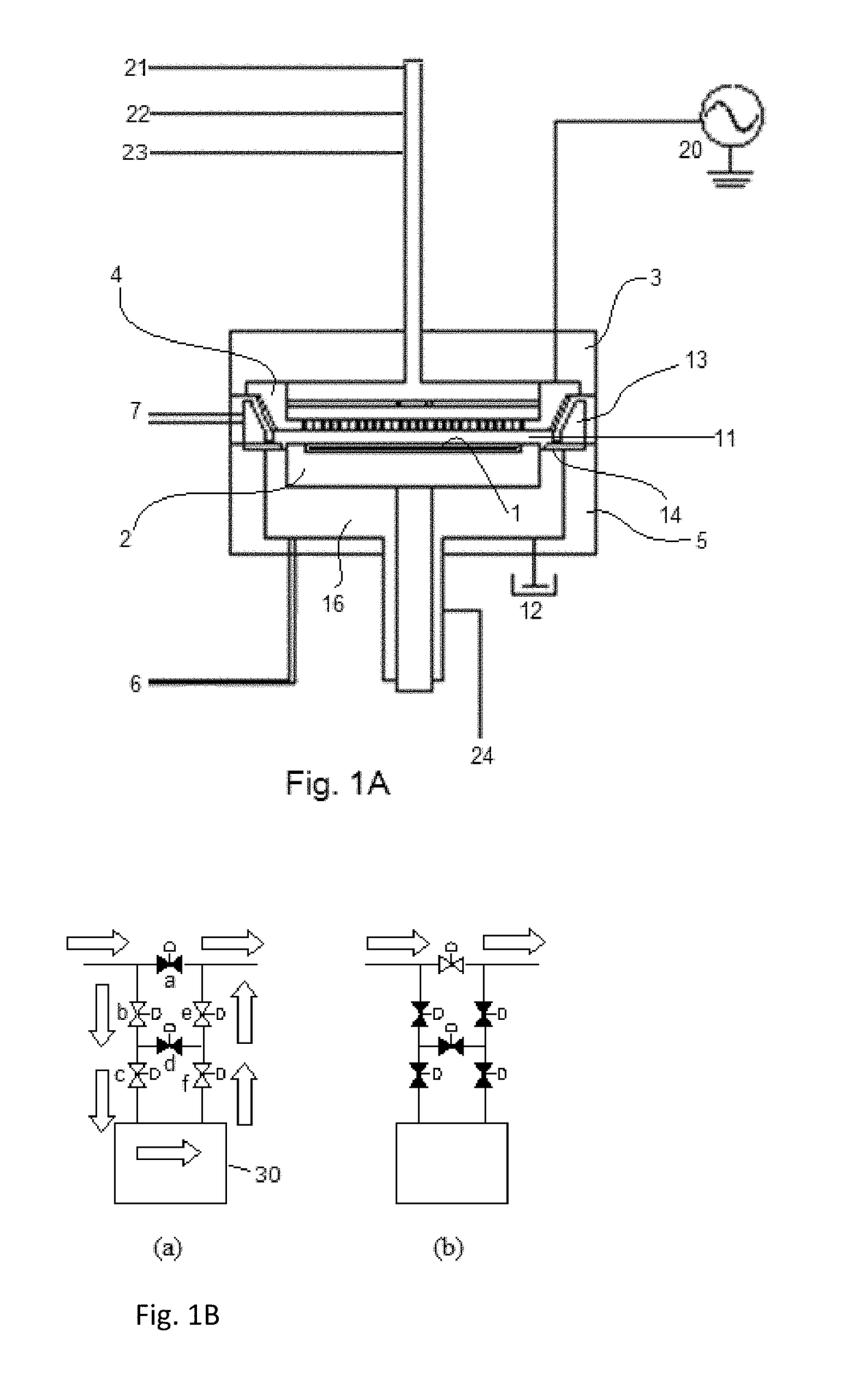

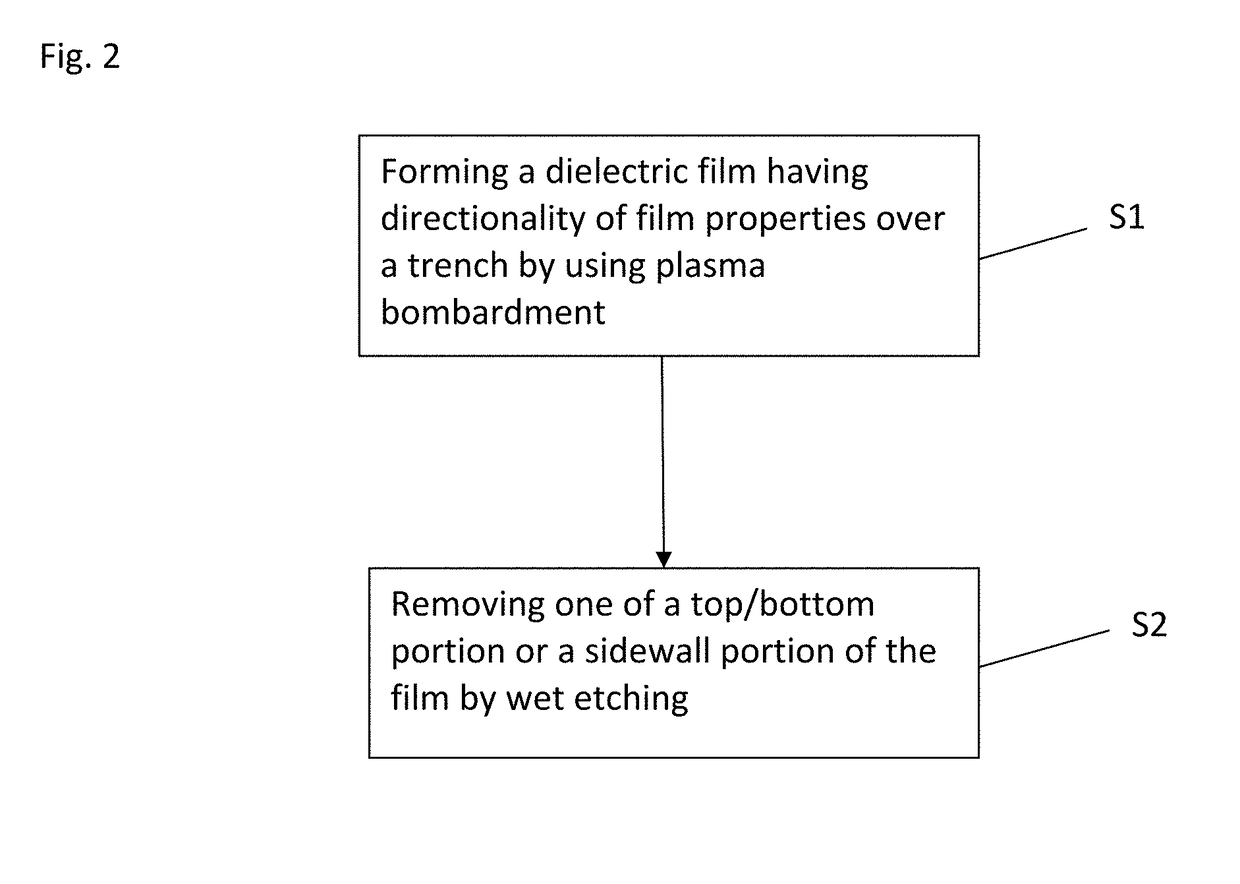

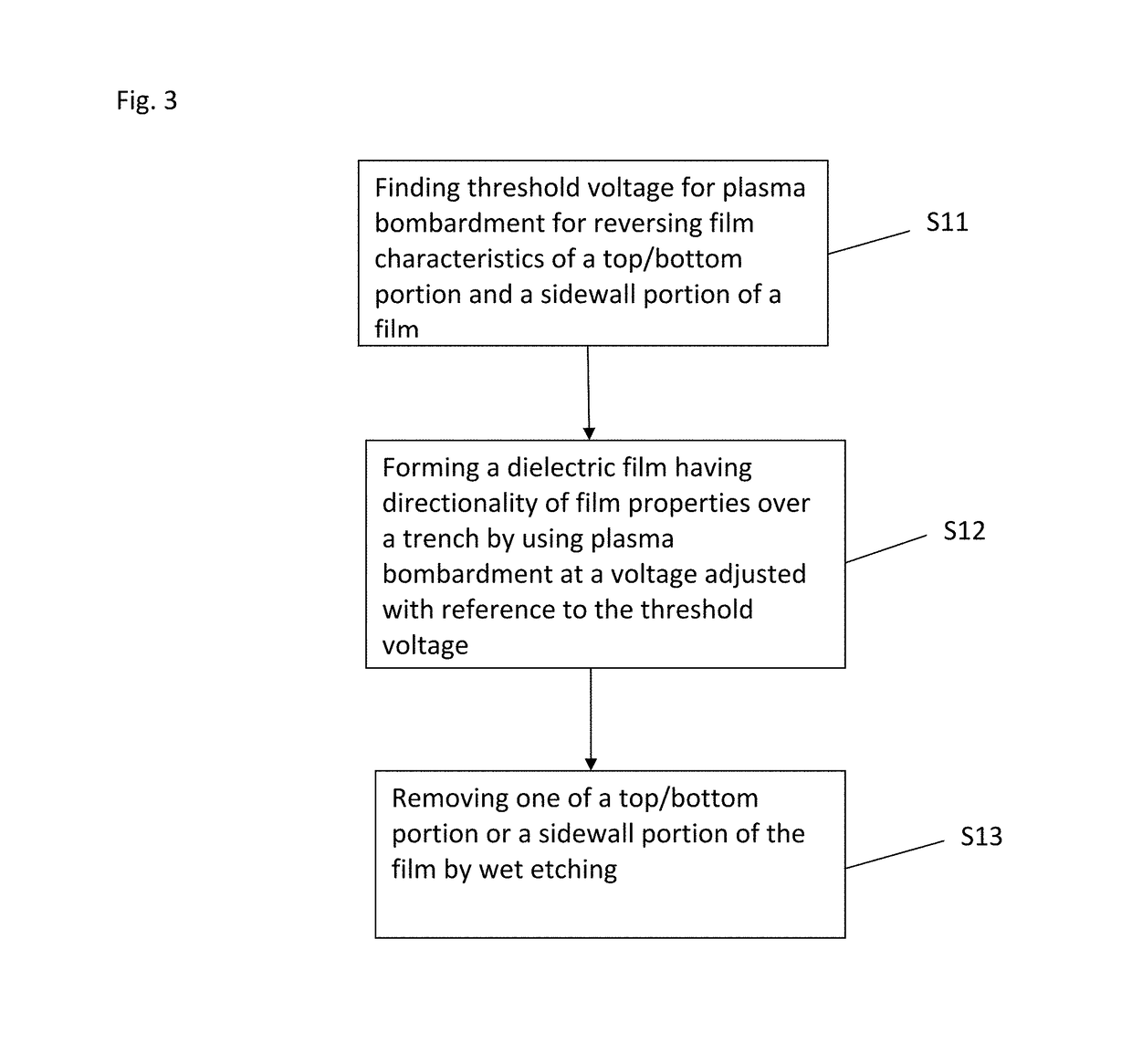

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS20170243734A1Improve film qualityDecreasing density of filmElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS20170250068A1Improve film qualityDecreasing density of filmElectric discharge tubesSemiconductor/solid-state device manufacturingSilicon nitrideEtching

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS9754779B1Low densityPlasma-enhanced chemical vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

Method for trimming carbon-containing film at reduced trimming rate

ActiveUS9343308B2Reduce rateEasy to handleElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorThin membrane

Owner:ASM IP HLDG BV

Method of manufacturing semiconductor device

InactiveUS20110171775A1Without deteriorating reliability of deviceHigh bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorPlasma polymerization

A method of manufacturing a semiconductor device includes forming a first insulating film over an underlying film by plasma polymerization of cyclic siloxane, and forming a second insulating film on the first insulating film by plasma polymerization of the cyclic siloxane continuously, after forming the first insulating film. The deposition rate of the first insulating film is slower than the deposition rate of the second insulating film.

Owner:RENESAS ELECTRONICS CORP

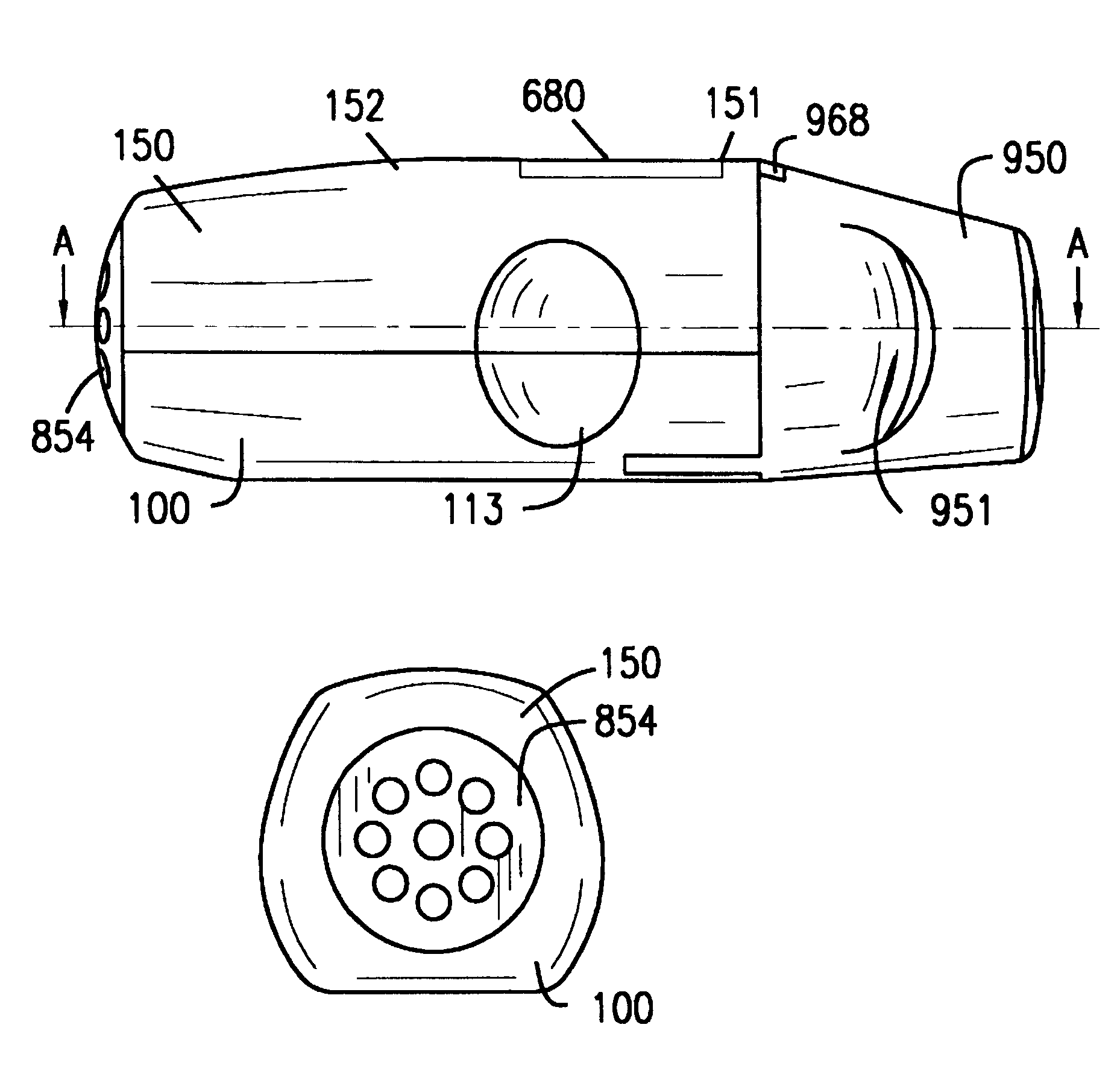

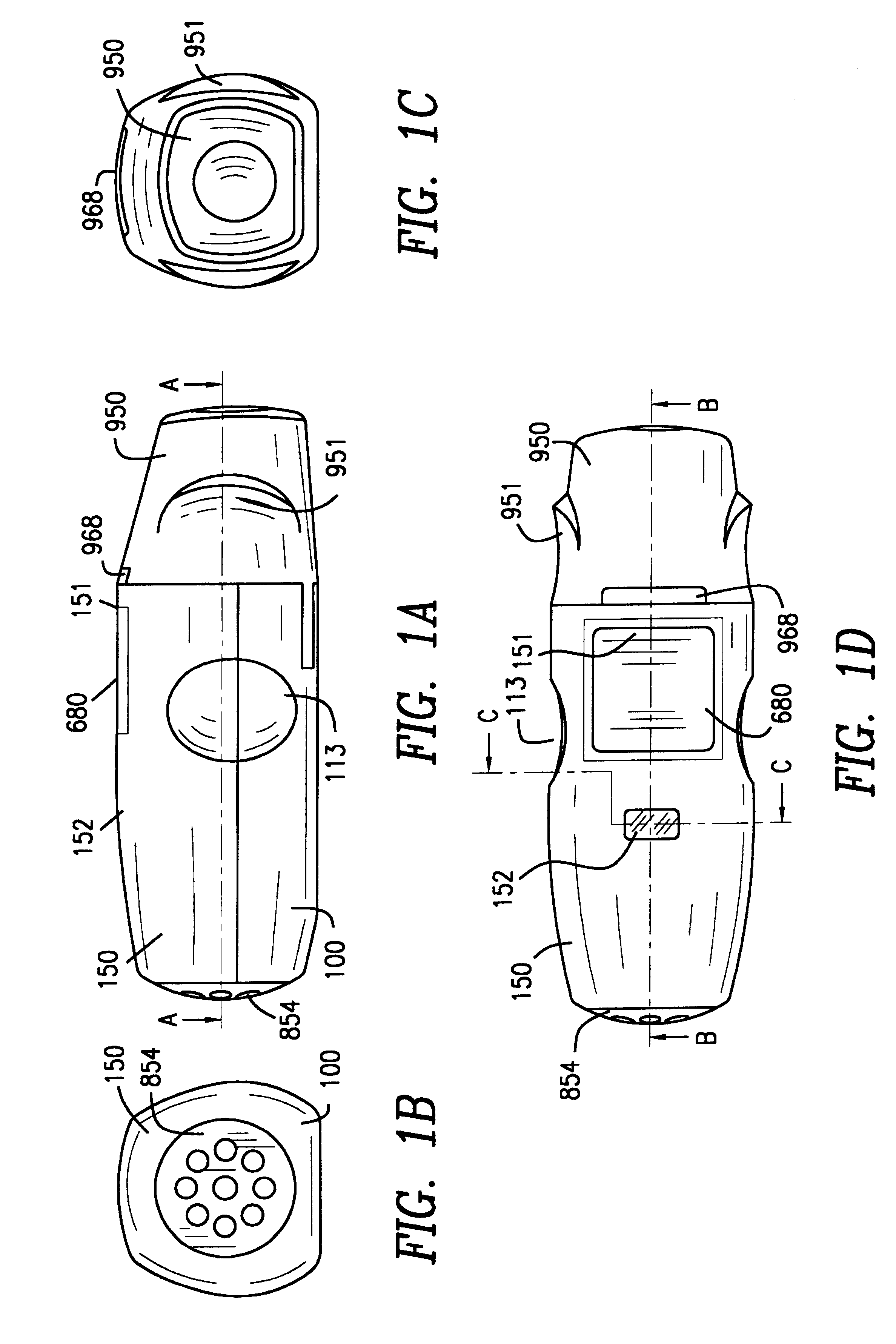

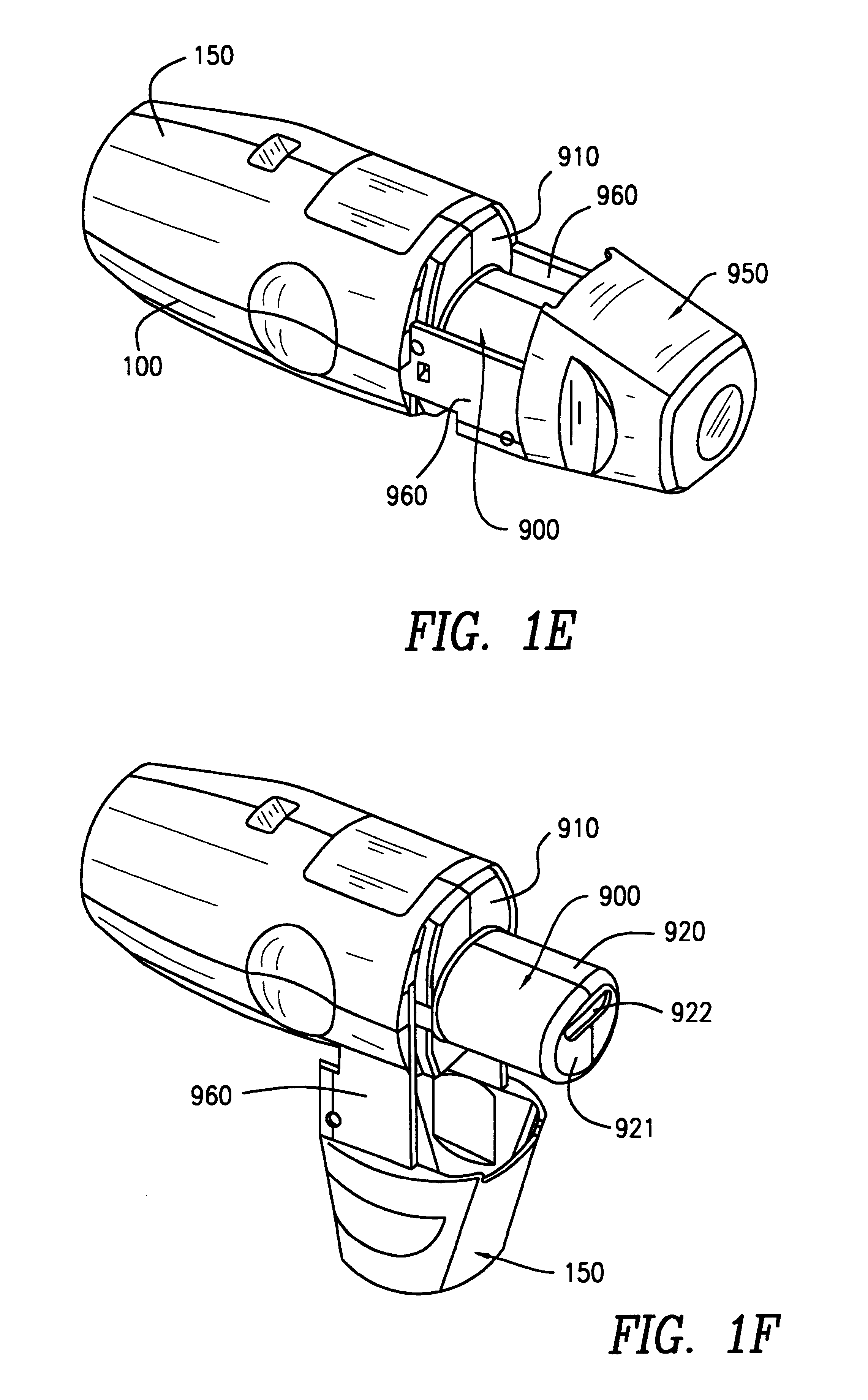

Inhaler for multiple dosed administration of a pharmacological dry powder

InactiveUS6182655B1Avoid possibilityReducing powder flow rateRespiratorsLiquid surface applicatorsMouth pieceEngineering

An inhaler for multiple dosed administration of a pharmacological dry powder consists externally of a housing (100,150) and of a protective cap (950) which can be removed from a special mouthpiece (900) fitted on the housing. Arranged on the inside there are a slide rail (200), a dosing slide (300), a shutter (400), a carriage (500), a funnel arrangement (600), a counter device (700), a valve shield (800) and a valve guide (850). Removal of the protective cap (950) initiates the dosing, with a dose received in the dosing cavity (302) being transported to the mouth-piece (900) by means of the dosing slide (300). Only upon application of a defined minimum intensity of inhalation is the shutter (400) moved by the suctioned valve shield (800), as a result of which the dose is released for inhalation. Completed with an electronic module and a controllable nozzle, all inhalation-relevant data can be recorded and the flow conditions regulated.

Owner:JAGOTEC AG

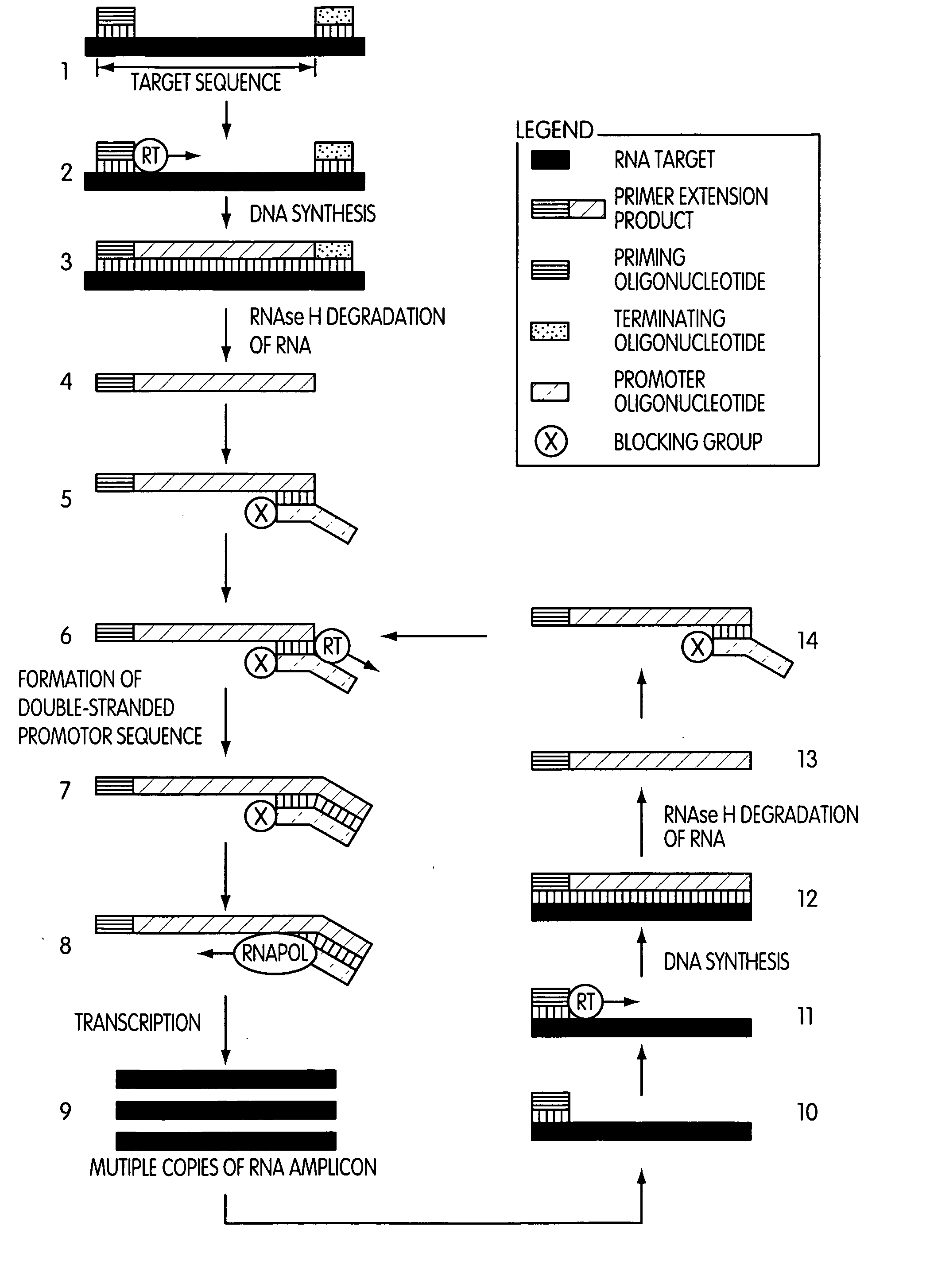

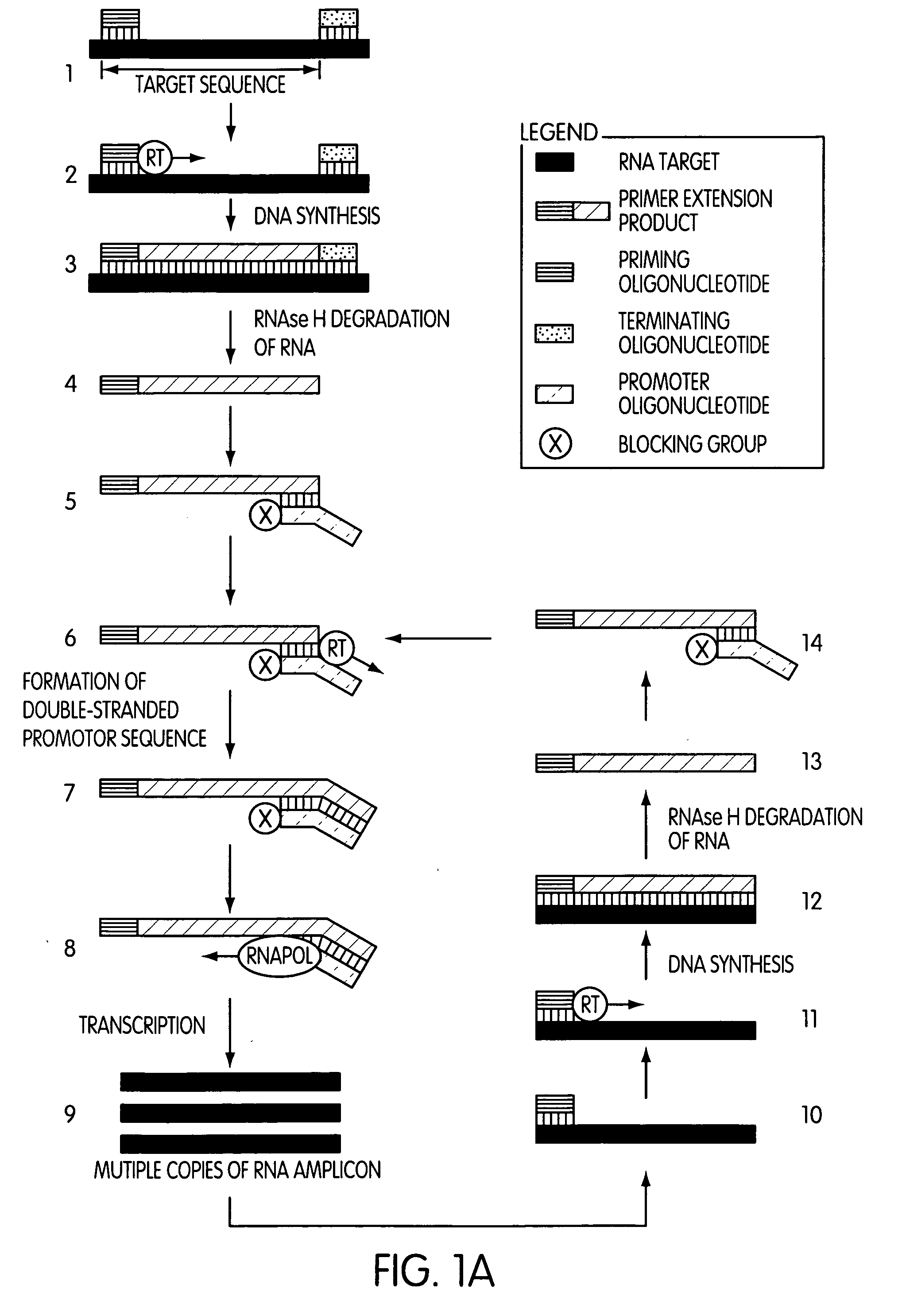

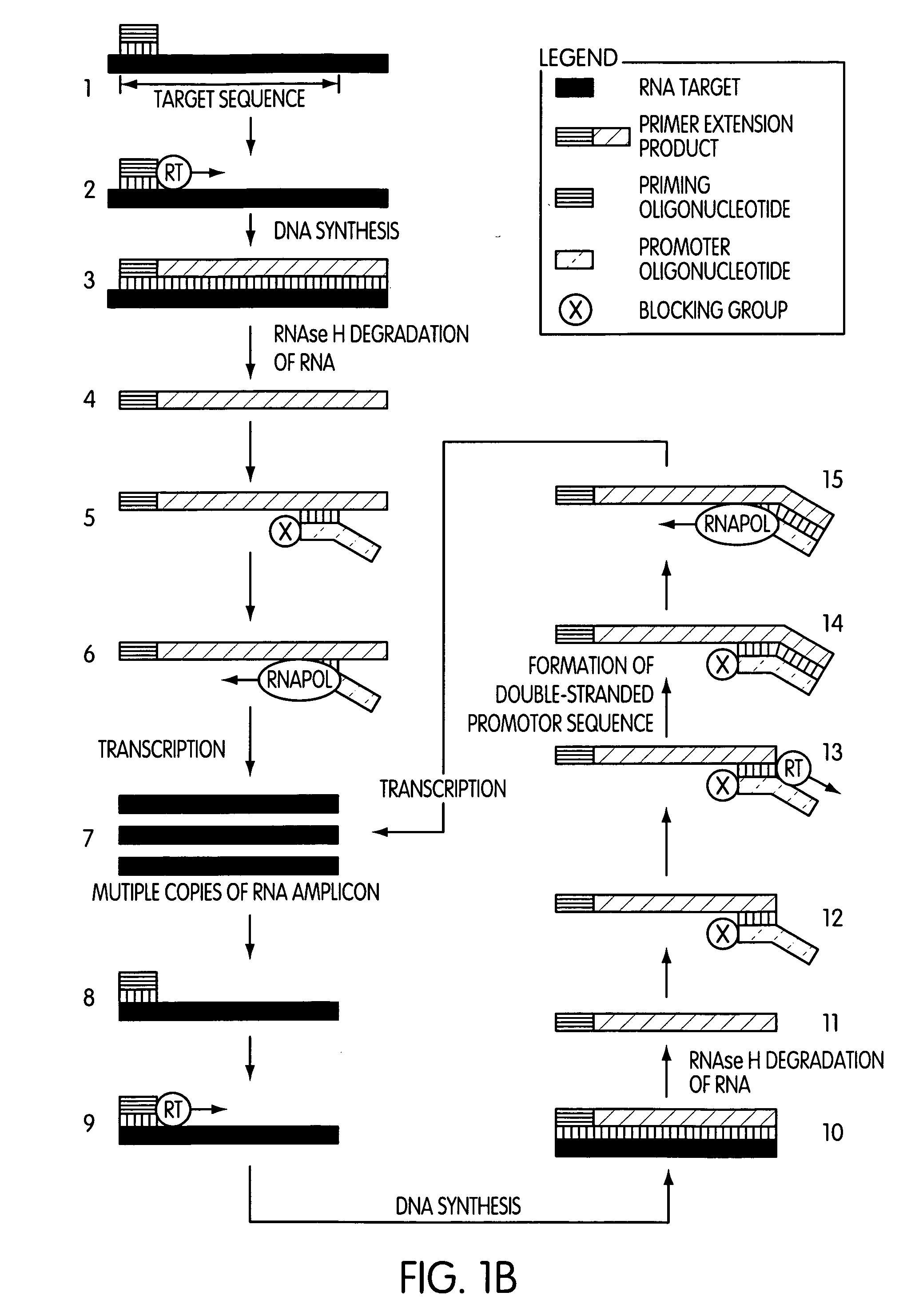

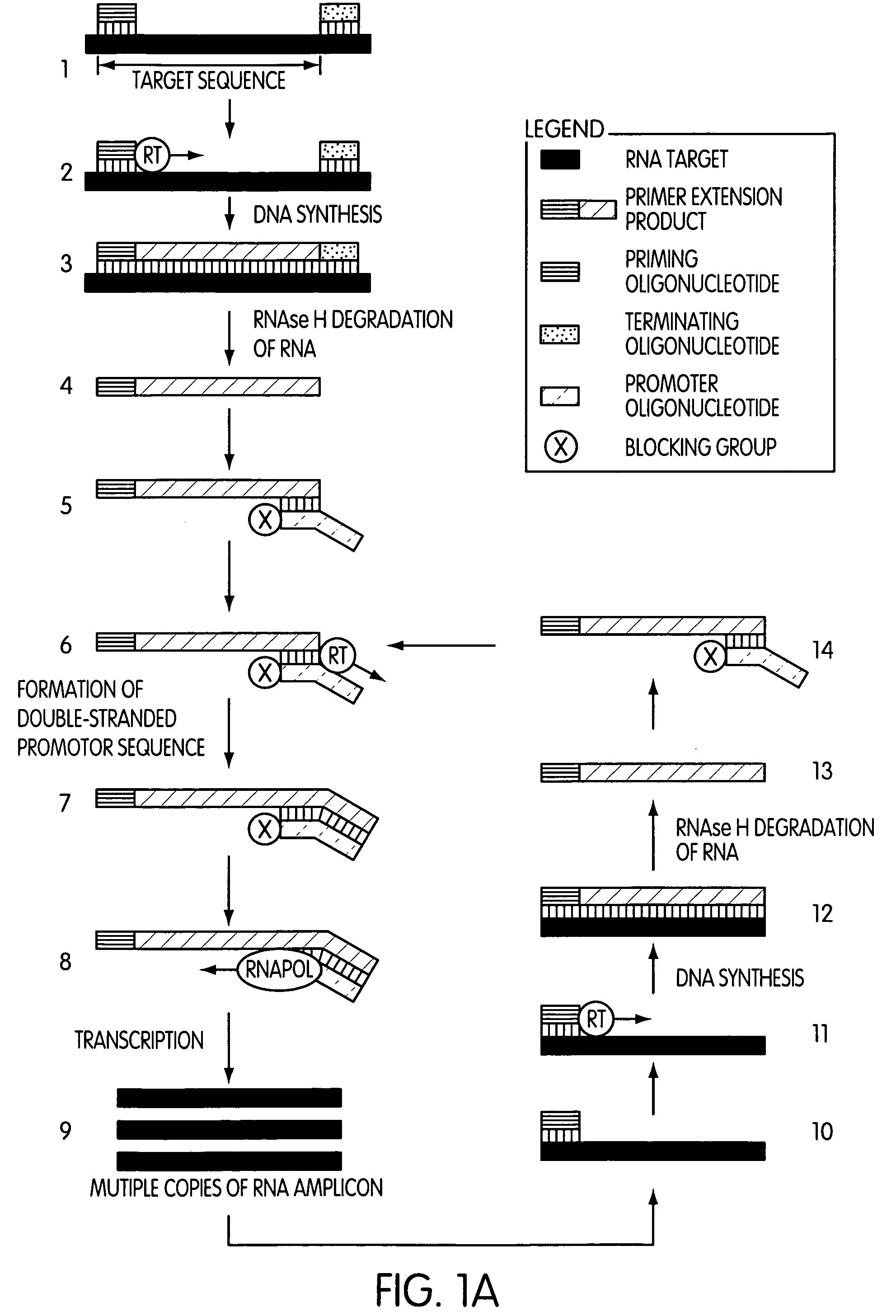

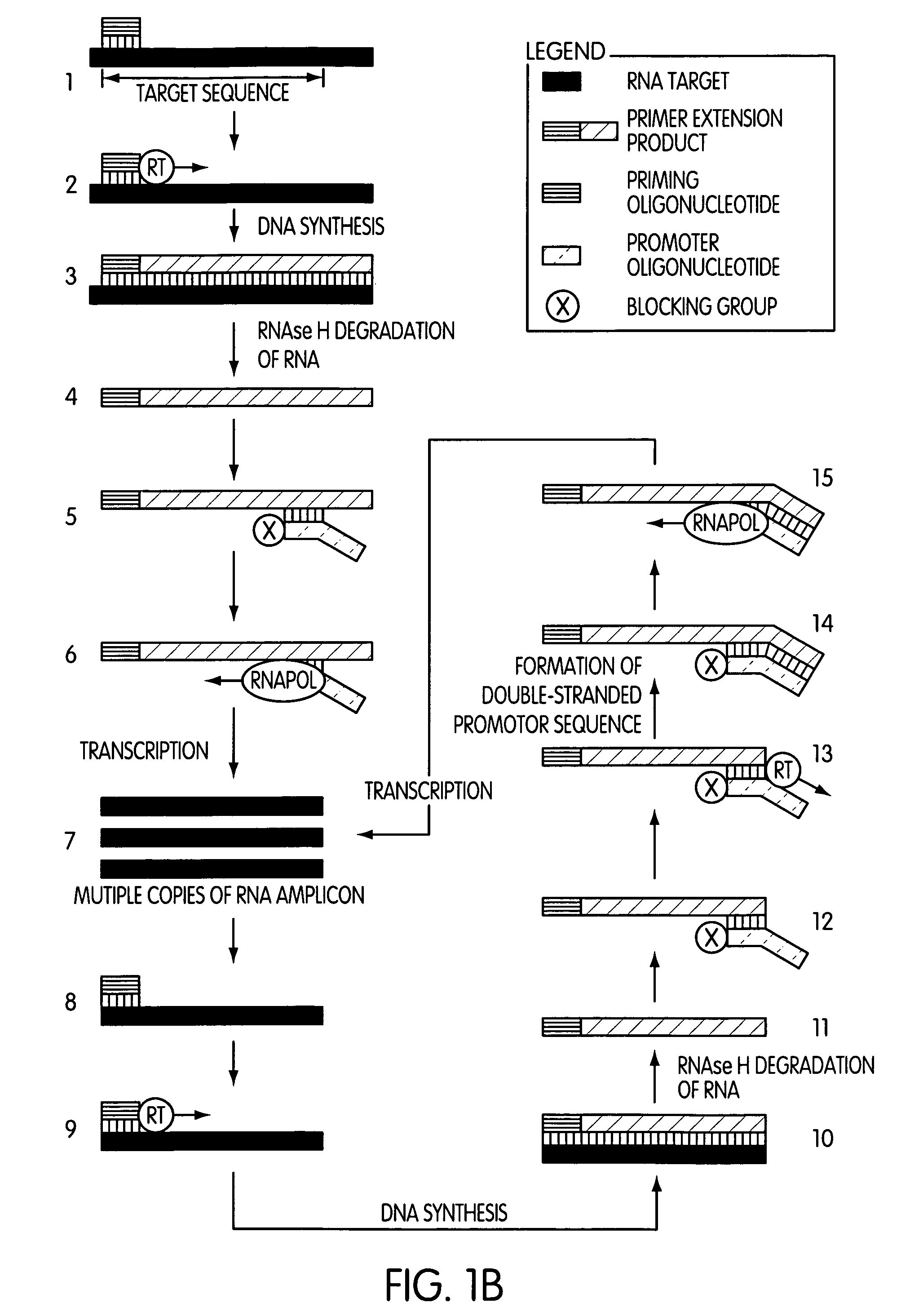

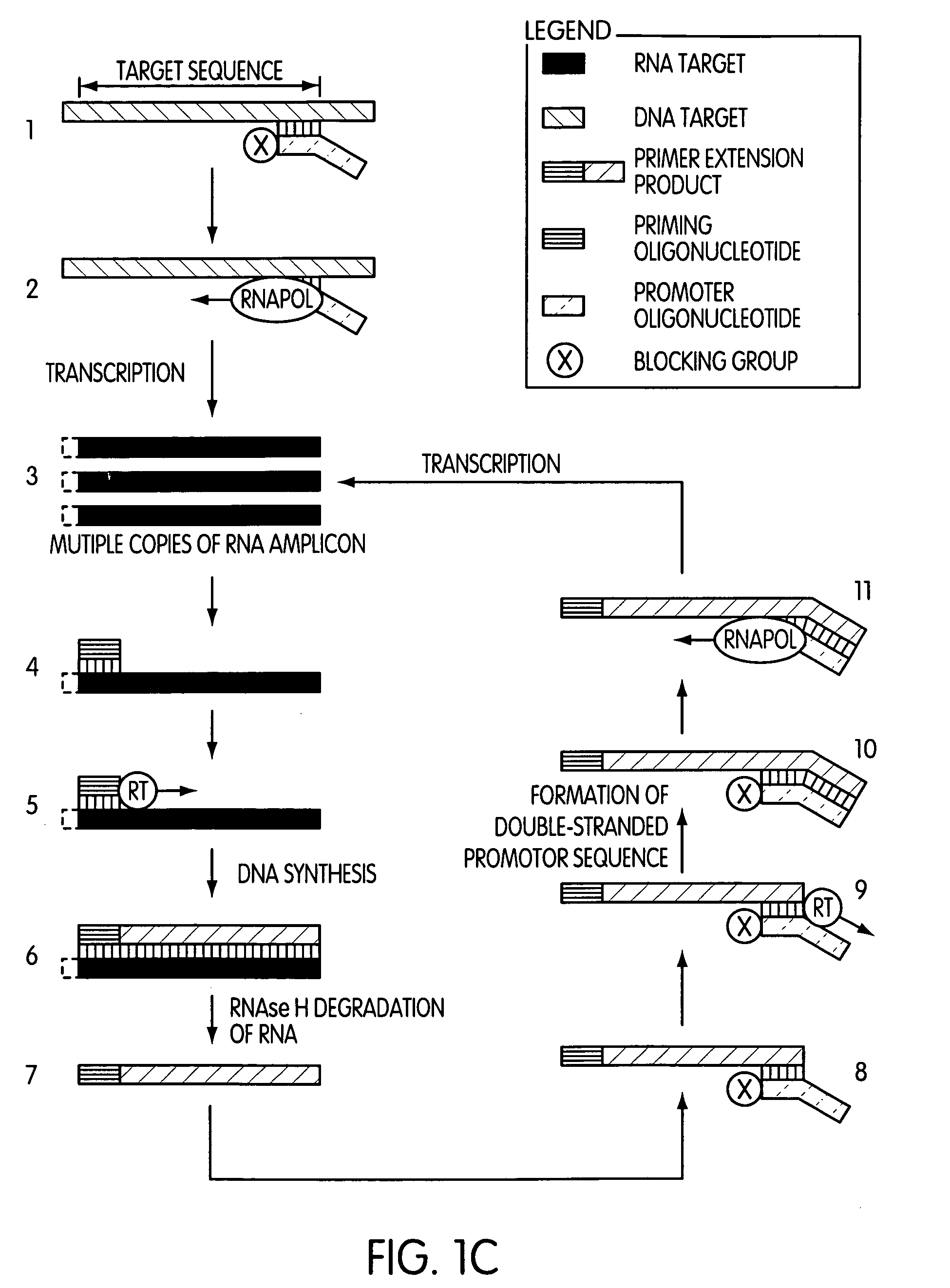

Single-primer nucleic acid amplification methods

ActiveUS20060046265A1Reduce appearanceMinimize emergenceMicrobiological testing/measurementFermentationSide productOligonucleotide

The present invention is directed to novel methods of synthesizing multiple copies of a target nucleic acid sequence which are autocatalytic (i.e., able to cycle automatically without the need to modify reaction conditions such as temperature, pH, or ionic strength and using the product of one cycle in the next one). In particular, the present invention discloses a method of nucleic acid amplification which is robust and efficient, while reducing the appearance of side-products. The method uses only one primer, the “priming oligonucleotide,” a promoter oligonucleotide modified to prevent polymerase extension from its 3′-terminus and, optionally, a means for terminating a primer extension reaction, to amplify RNA or DNA molecules in vitro, while reducing or substantially eliminating the formation of side-products. The method of the present invention minimizes or substantially eliminates the emergence of side-products, thus providing a high level of specificity. Furthermore, the appearance of side-products can complicate the analysis of the amplification reaction by various molecular detection techniques. The present invention minimizes or substantially eliminates this problem, thus providing an enhanced level of sensitivity.

Owner:GEN PROBE INC

Single-primer nucleic acid amplification methods

ActiveUS7374885B2Reduce appearanceHigh levelMicrobiological testing/measurementFermentationNucleotideNucleic acid sequencing

The present invention is directed to novel methods of synthesizing multiple copies of a target nucleic acid sequence which are autocatalytic (i.e., able to cycle automatically without the need to modify reaction conditions such as temperature, pH, or ionic strength and using the product of one cycle in the next one). In particular, the present invention discloses a method of nucleic acid amplification which is robust and efficient, while reducing the appearance of side-products. The method uses only one primer, the “priming oligonucleotide,” a promoter oligonucleotide modified to prevent polymerase extension from its 3′-terminus and, optionally, a means for terminating a primer extension reaction, to amplify RNA or DNA molecules in vitro, while reducing or substantially eliminating the formation of side-products. The method of the present invention minimizes or substantially eliminates the emergence of side-products, thus providing a high level of specificity. Furthermore, the appearance of side-products can complicate the analysis of the amplification reaction by various molecular detection techniques. The present invention minimizes or substantially eliminates this problem, thus providing an enhanced level of sensitivity.

Owner:GEN PROBE INC

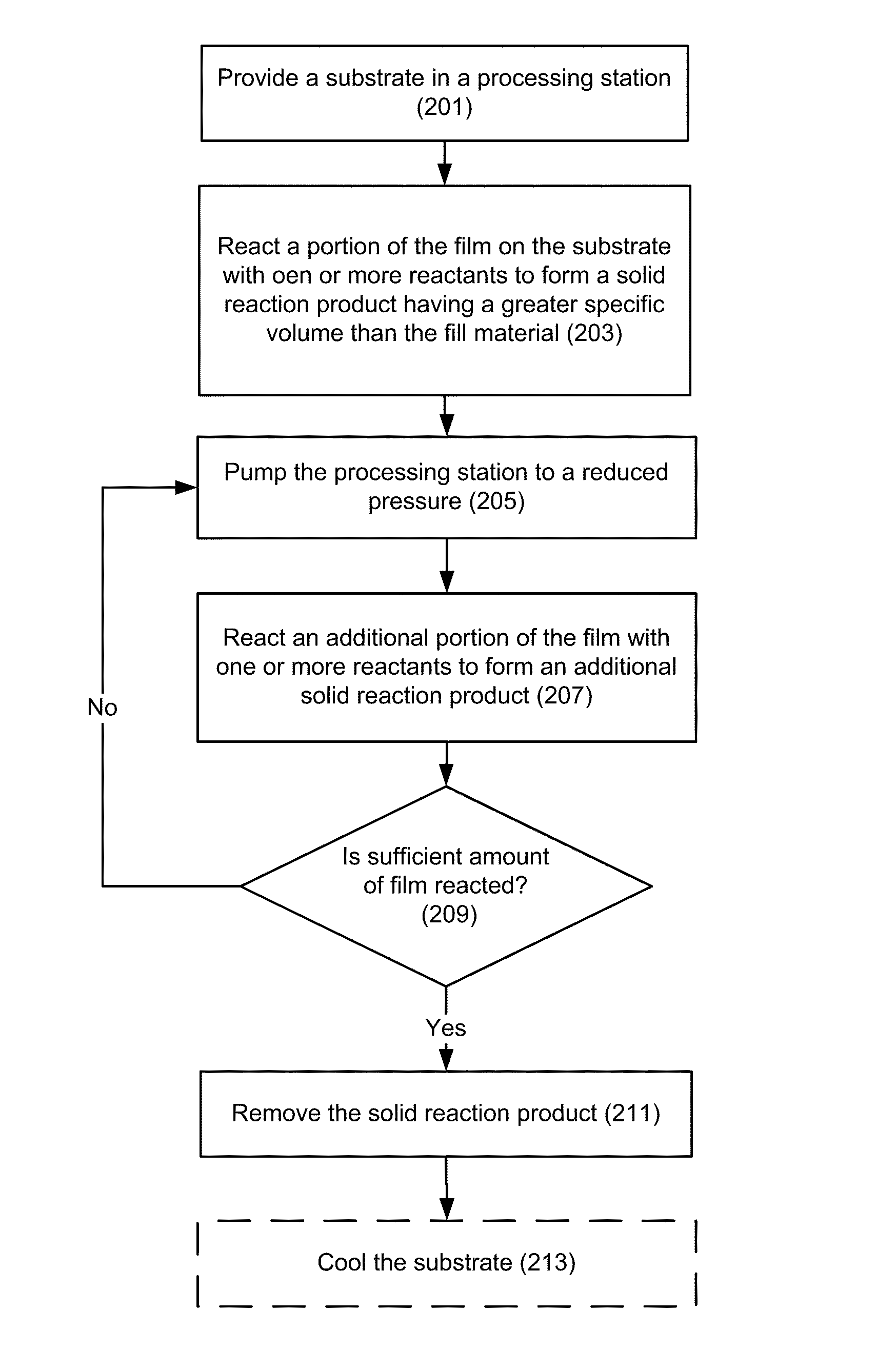

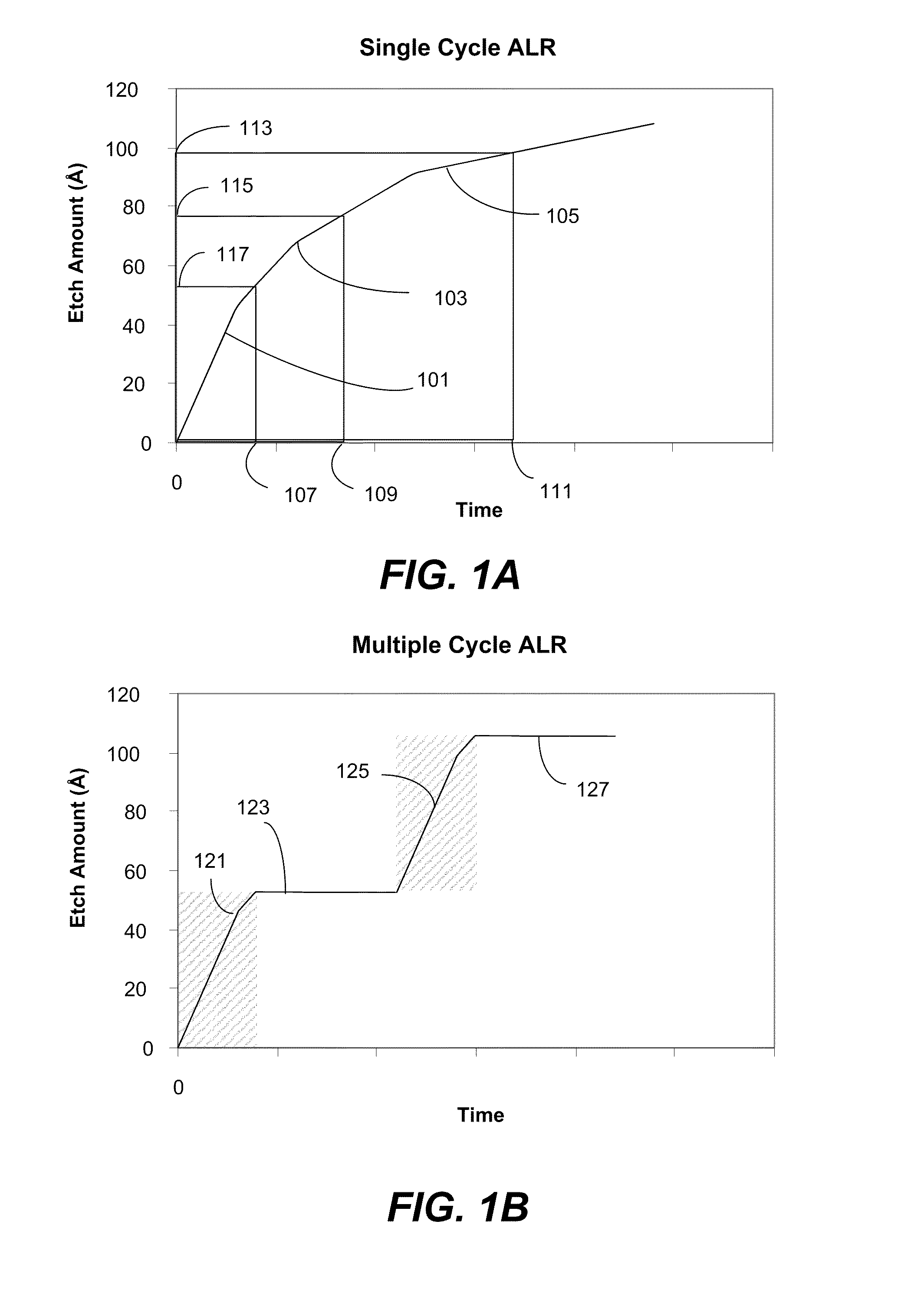

Atomic layer removal process with higher etch amount

InactiveUS8058179B1Easy to controlLimit amount of materialSemiconductor/solid-state device manufacturingSelf limitingLayer removal

Higher overall etch rate and throughput for atomic layer removal (ALR) is achieved. The reaction is a self-limiting process, thus limiting the total amount of material that may be etched per cycle. By pumping down the process station between reacting operations, the reaction is partially “reset.” A higher overall etch rate is achieved by a multiple exposure with pump down ALR process.

Owner:NOVELLUS SYSTEMS

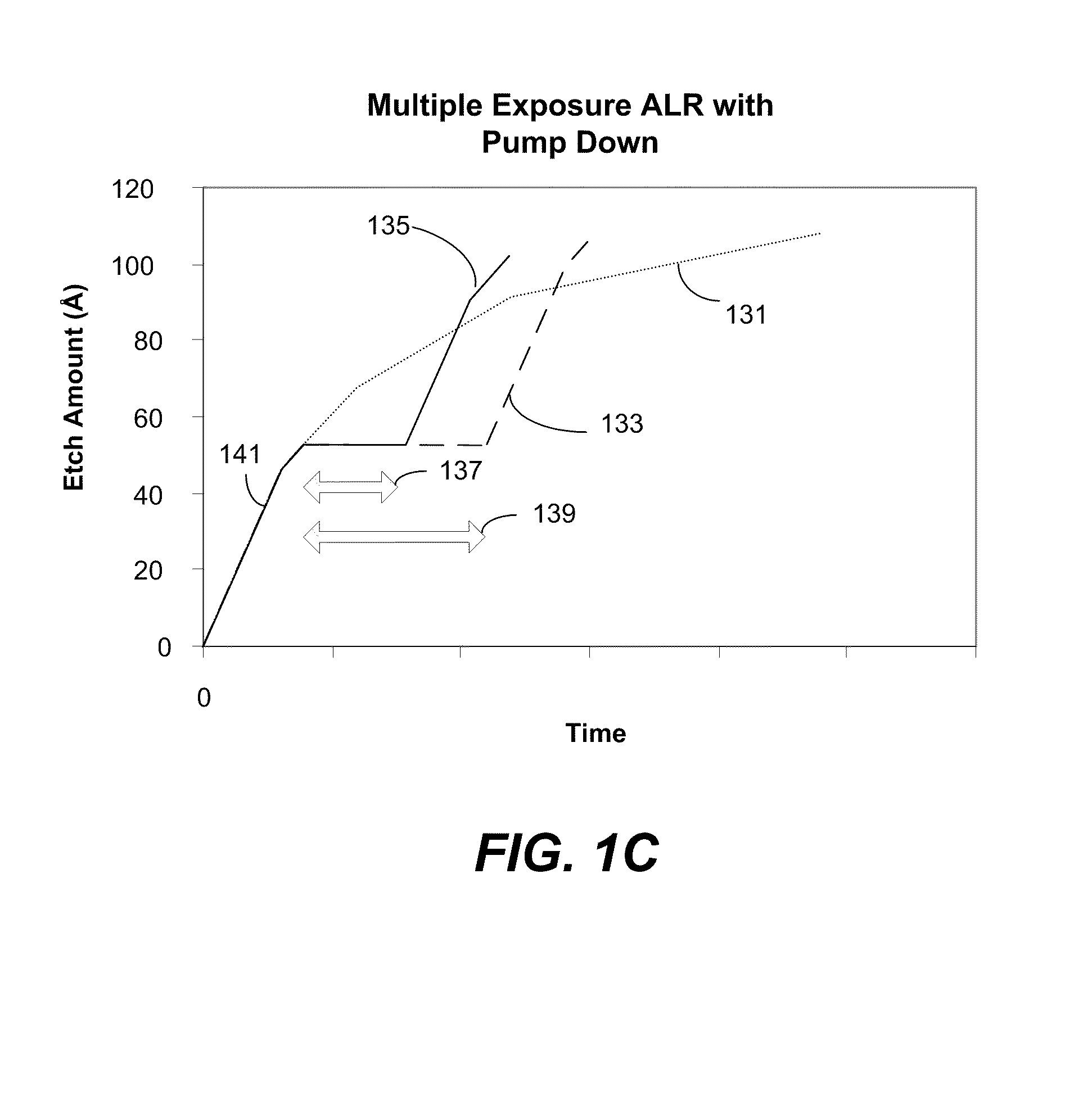

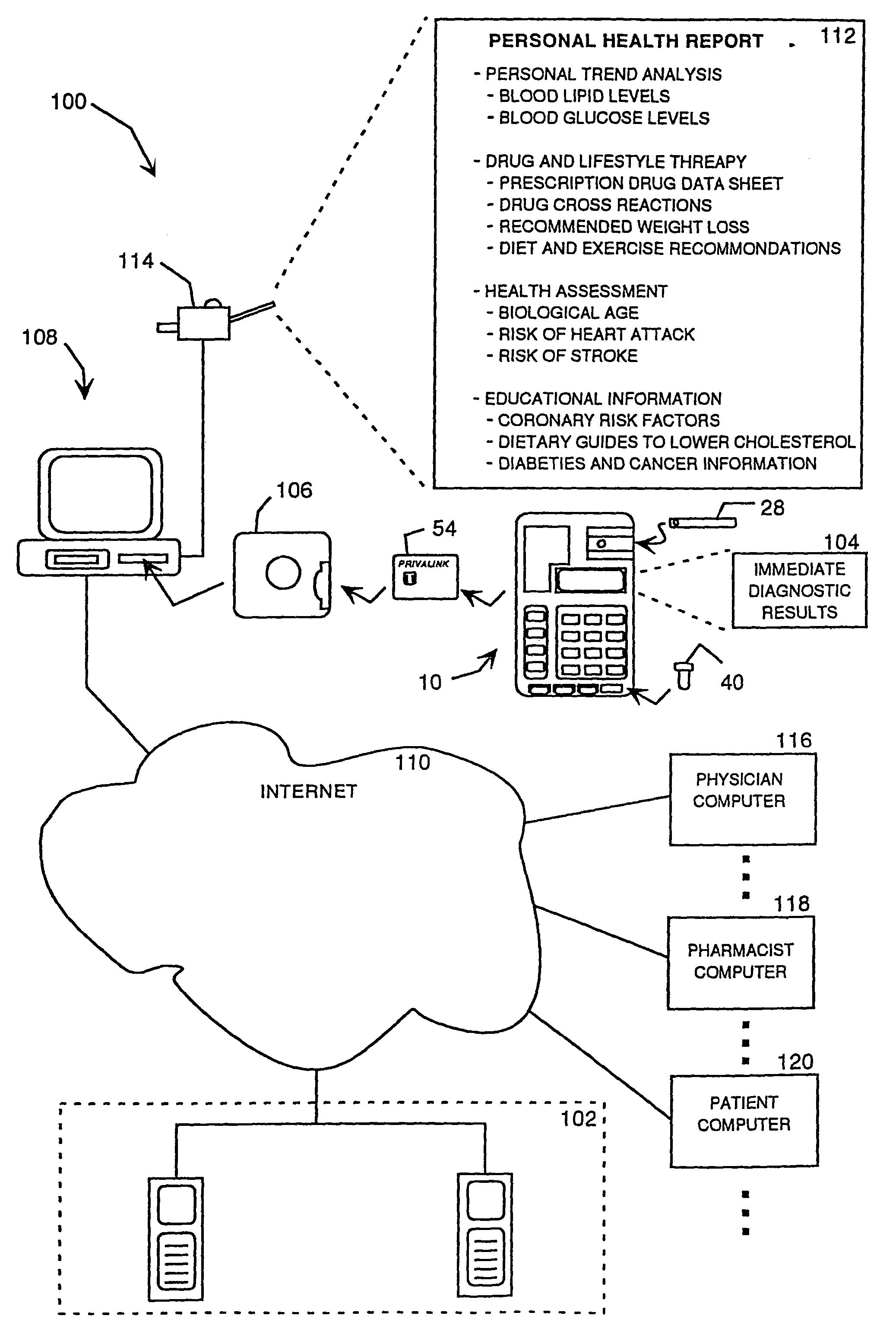

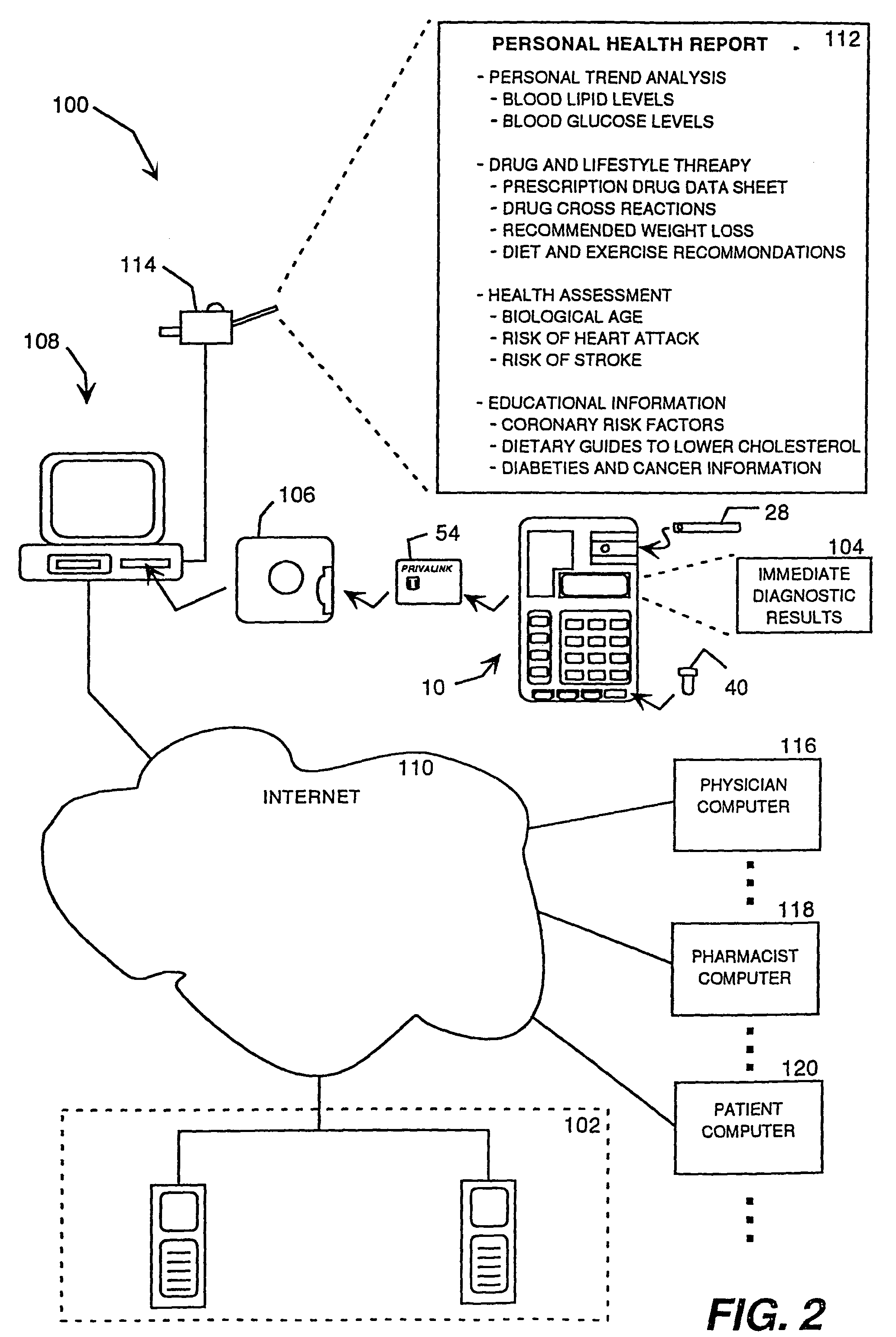

Secure medical records maintenance system

InactiveUS7092891B2Low costReduce inconvenienceBiomass after-treatmentAngiographyMedical recordRemovable media

A secure medical records maintenance system including a first server that stores patient identification information indexed by patient identification numbers (PINs) and a second server that stores patient medical data indexed by medical record identification numbers. For security purposes, the medical data maintained in the second remote server cannot be correlated to the associated patient identification information maintained in the first server based on the information contained in the servers. A correlation table uniquely associating each medical record identification number with a particular one of the patient identification numbers is used to allow correlation of the databases. The correlation table for a particular patient typically resides on a patient's removable memory storage device (smartcard). The correlation table for a practaioner's patients may also reside on the practitioner's computer, which is associated with the licensed medical practitioner having an assigned professional registration number

Owner:ORANGEHOOK INC

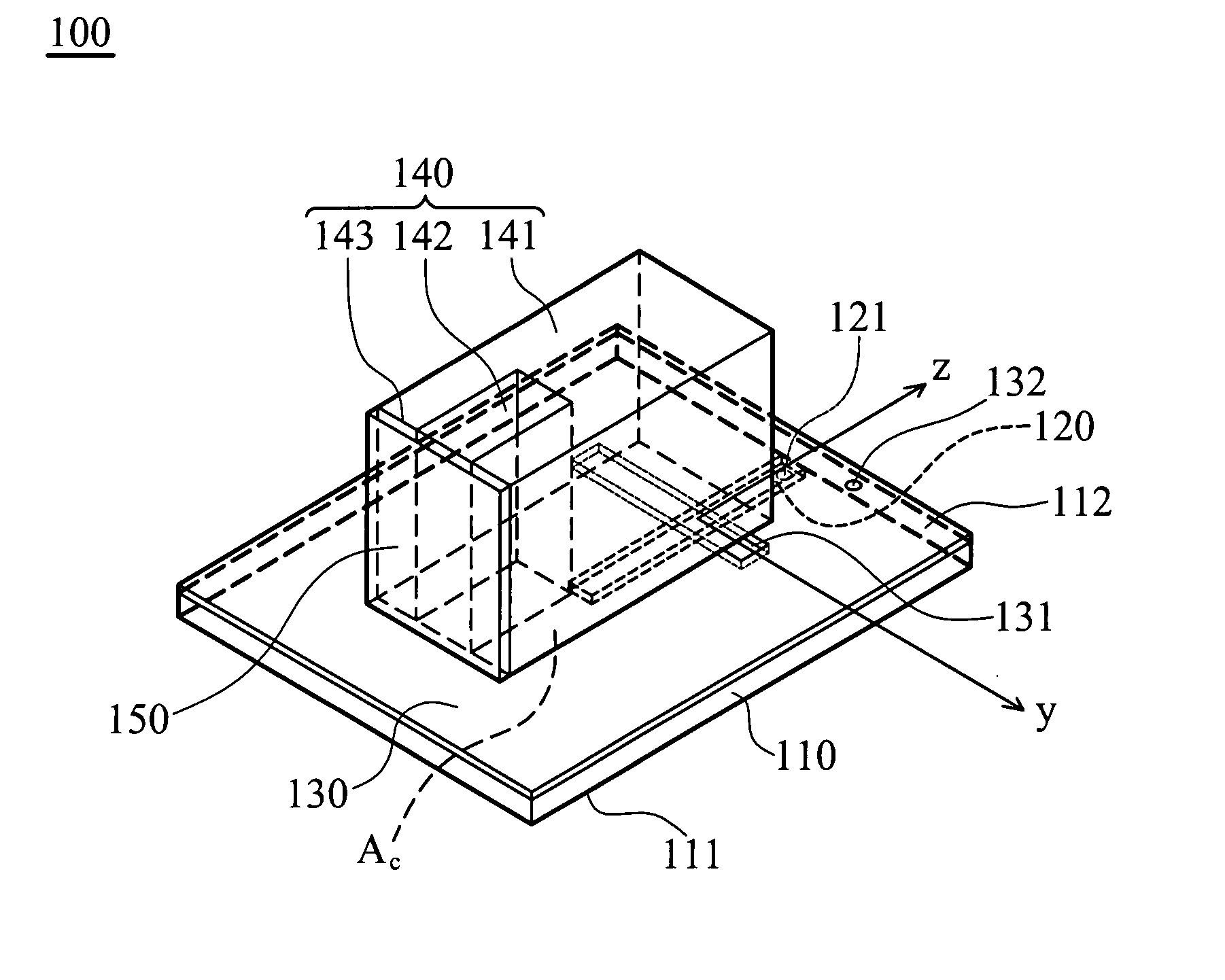

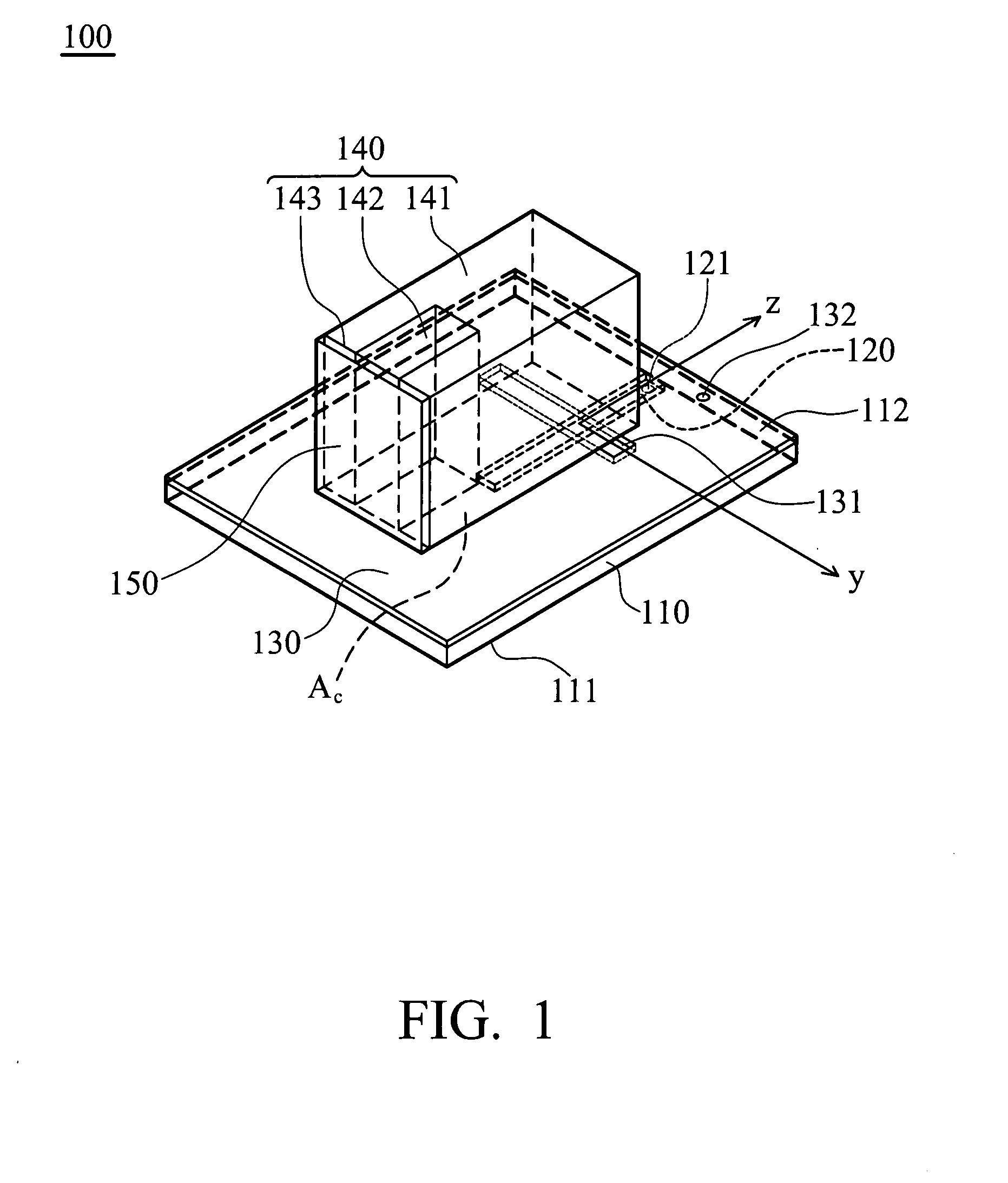

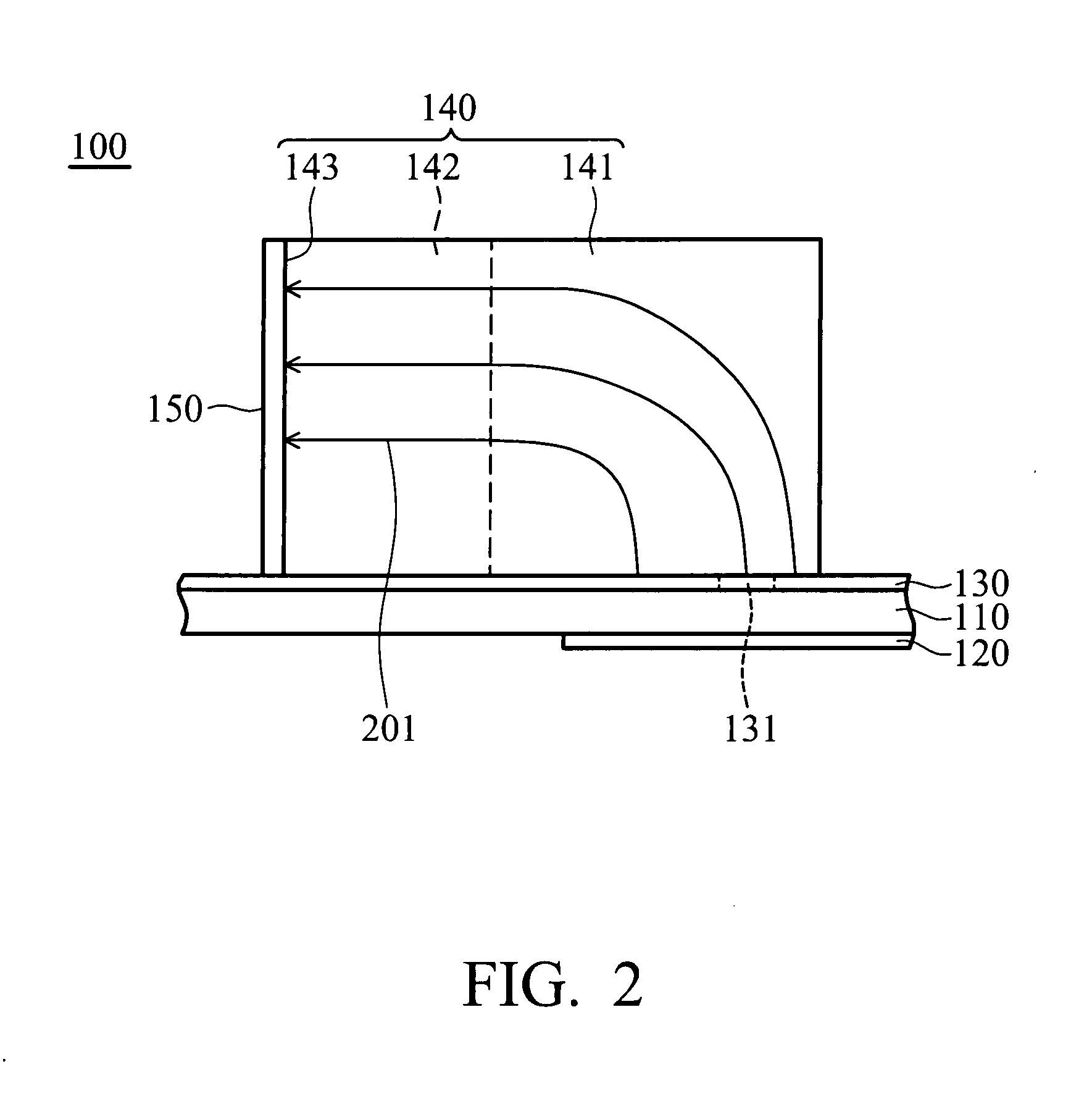

Wideband dielectric resonator antenna

InactiveUS20080278378A1Easy to manufactureReduces attrition rateSimultaneous aerial operationsRadiating elements structural formsDielectric resonator antennaGround plane

Owner:NAT TAIWAN UNIV

Method for forming silicon nitride film selectively on sidewalls of trenches

ActiveUS20190057857A1Low densityPlasma-enhanced chemical vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingChemical resistance

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing the sidewall portion of the film by wet etching which removes the sidewall portion of the film more predominantly than the top / bottom portion according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

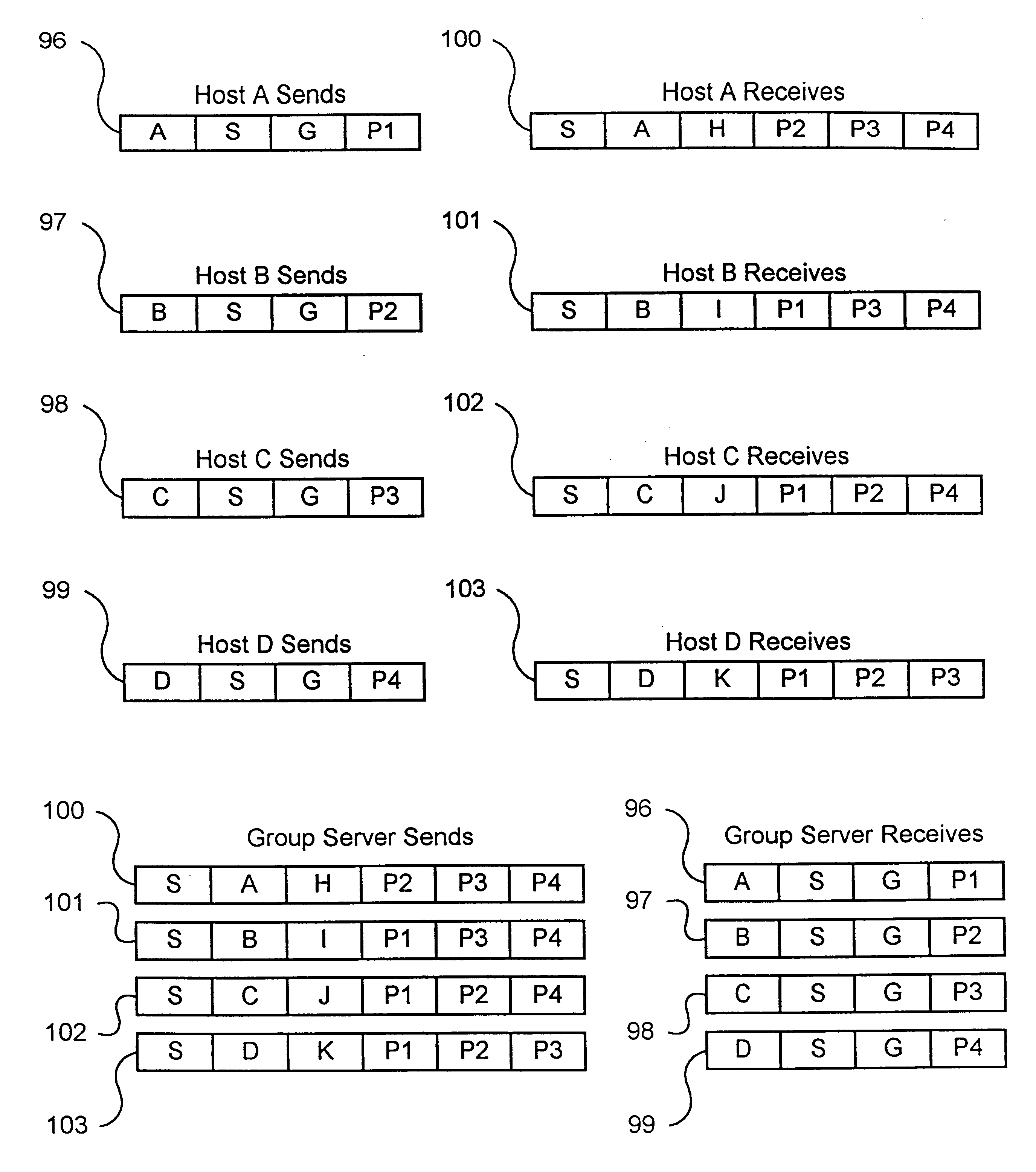

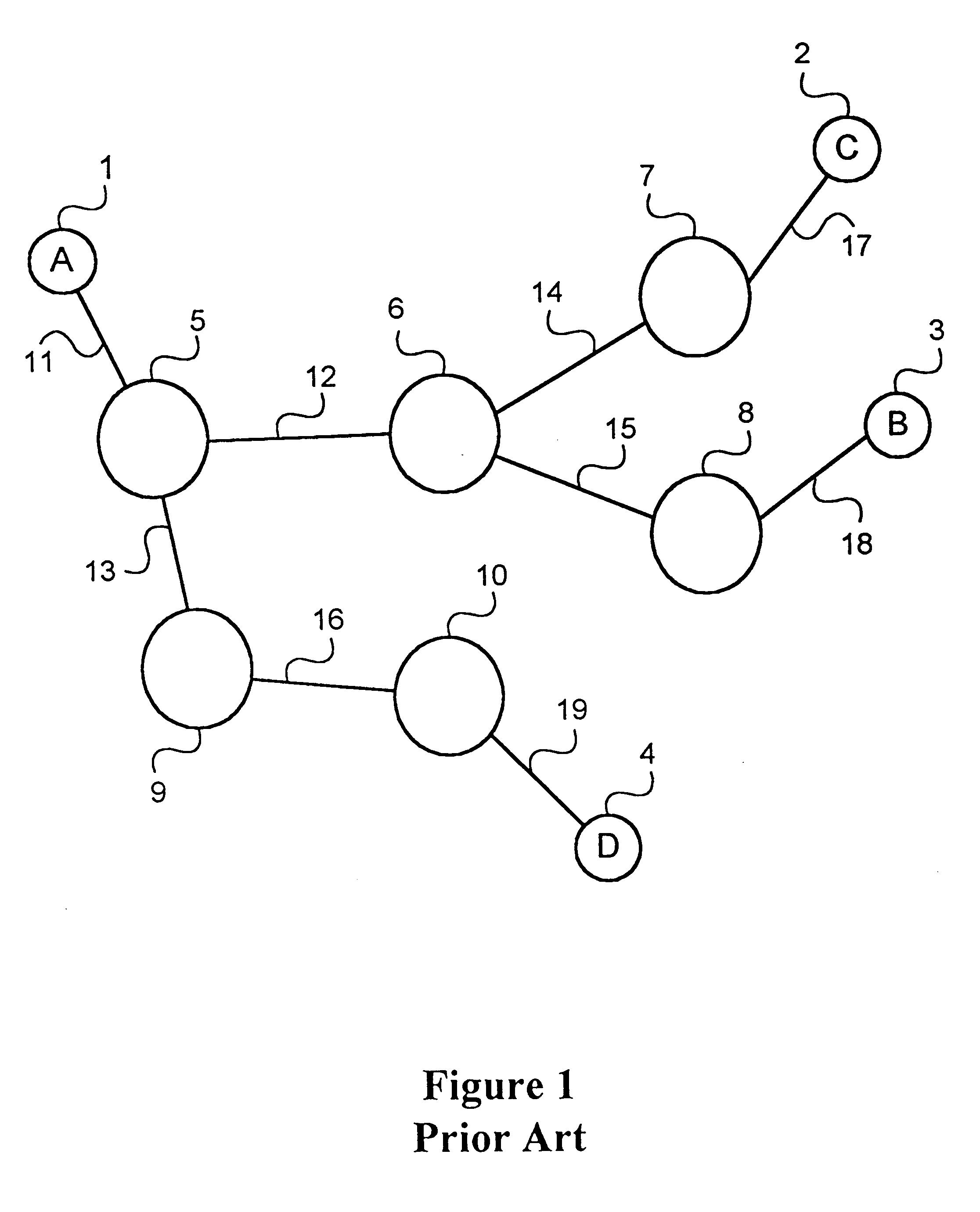

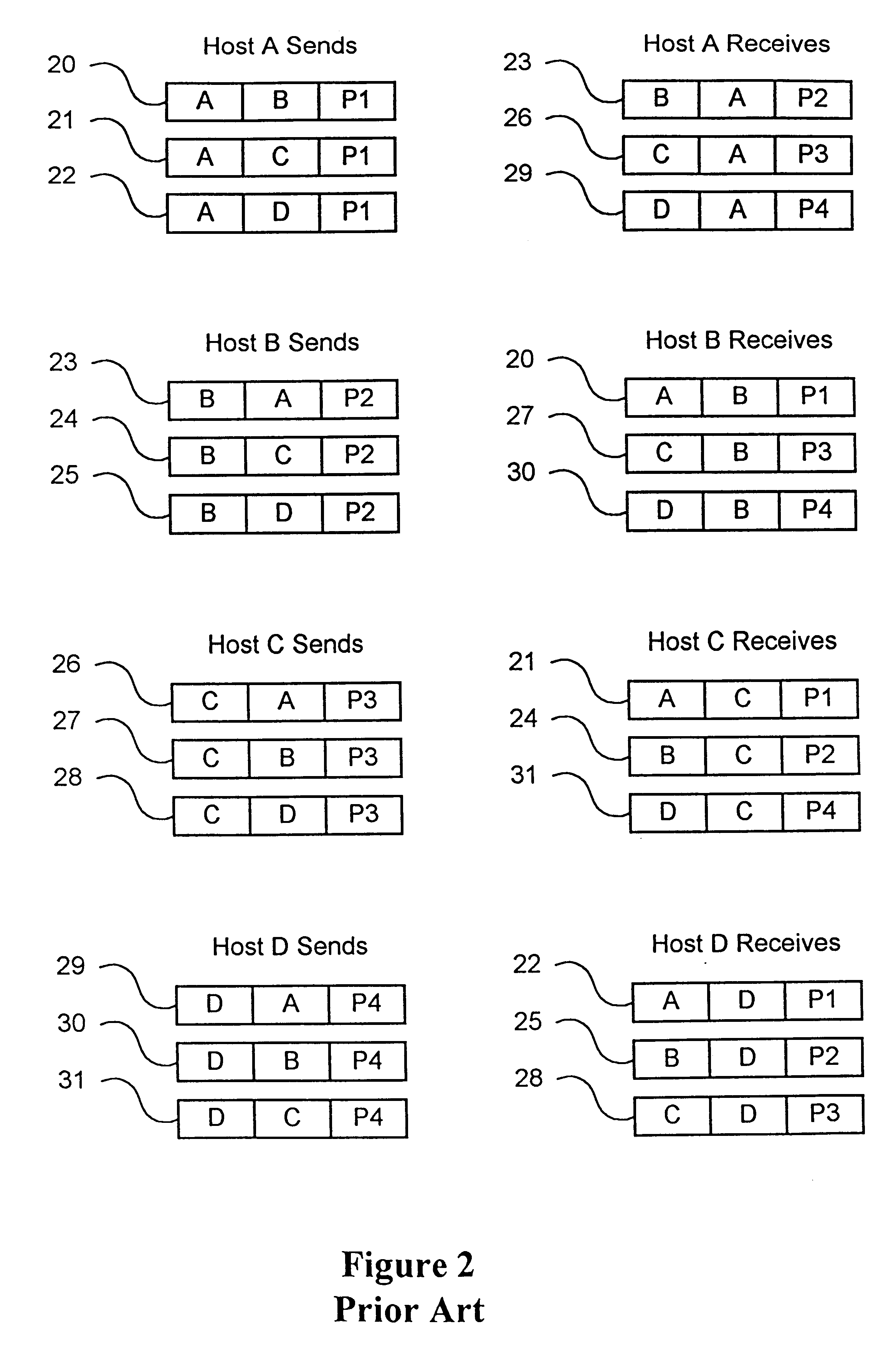

Server-group messaging system for interactive applications

InactiveUS6226686B1Reduce rateLower latencySpecial service provision for substationMultiple digital computer combinationsTraffic capacityNetwork link

A method for deploying interactive applications over a network containing host computers and group messaging servers is disclosed. The method operates in a conventional unicast network architecture comprised of conventional network links and unicast gateways and routers. The hosts send messages containing destination group addresses by unicast to the group messaging servers. The group addresses select message groups maintained by the group messaging servers. For each message group, the group messaging servers also maintain a list of all of the hosts that are members of the particular group. In its most simple implementation, the method consists of the group server receiving a message from a host containing a destination group address. Using the group address, the group messaging server then selects a message group which lists all of the host members of the group which are the targets of messages to the group. The group messaging server then forwards the message to each of the target hosts. In an interactive application, many messages will be arriving at the group server close to one another in time. Rather than simply forward each message to its targeted hosts, the group messaging server aggregates the contents of each of messages received during a specified time period and then sends an aggregated message to the targeted hosts. The time period can be defined in a number of ways. This method reduces the message traffic between hosts in a networked interactive application and contributes to reducing the latency in the communications between the hosts.

Owner:PALTALK HLDG +1

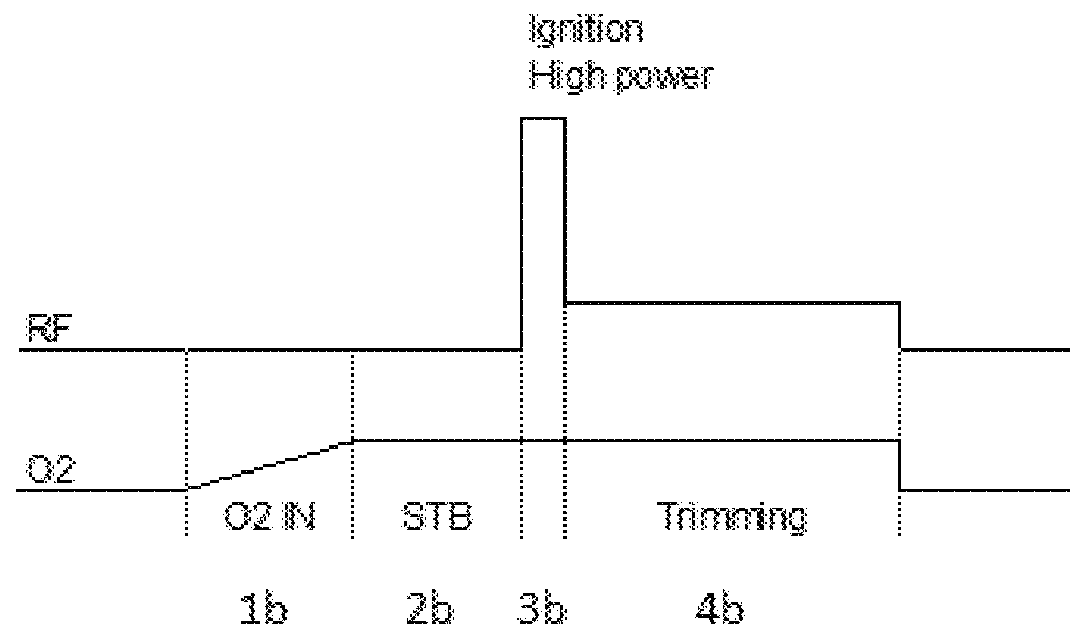

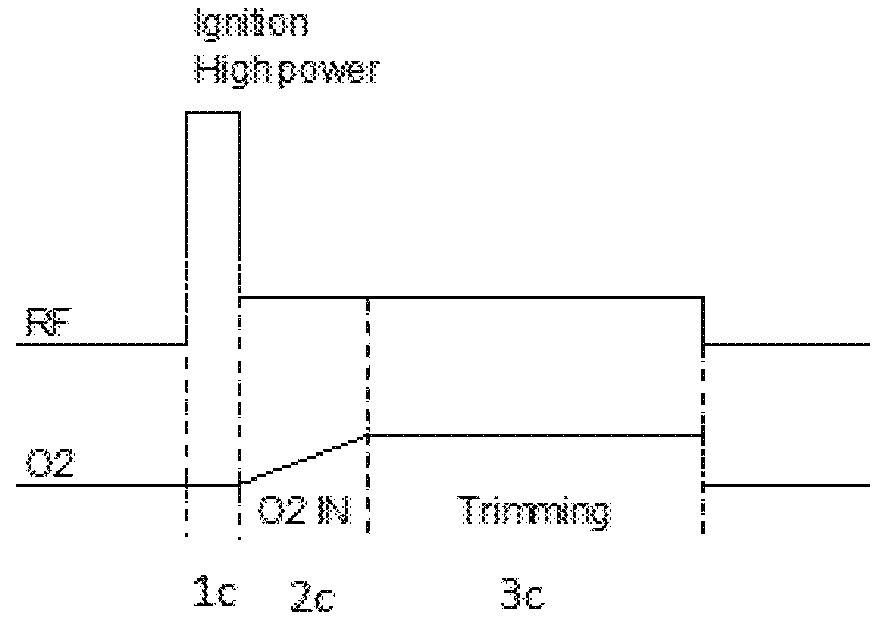

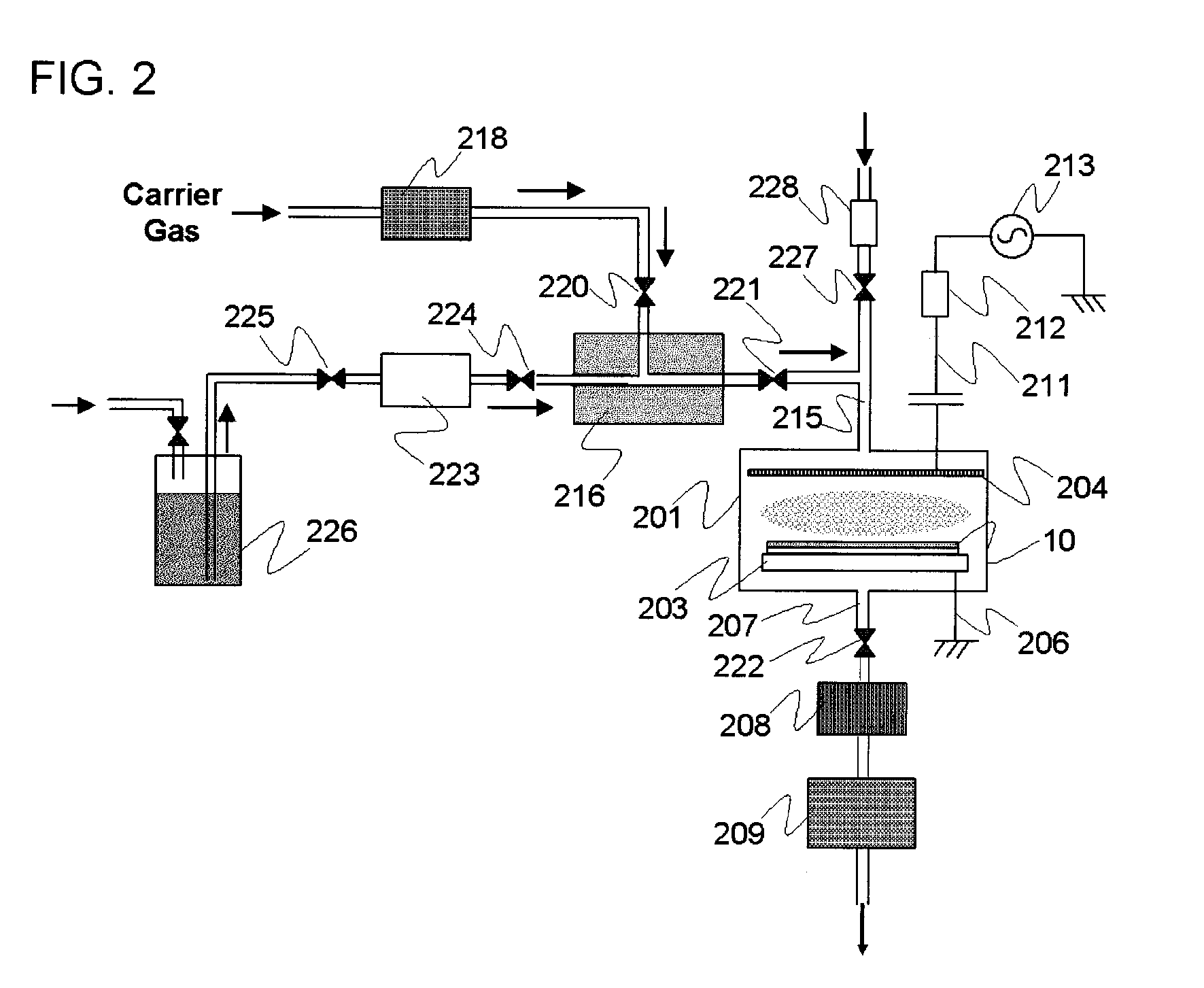

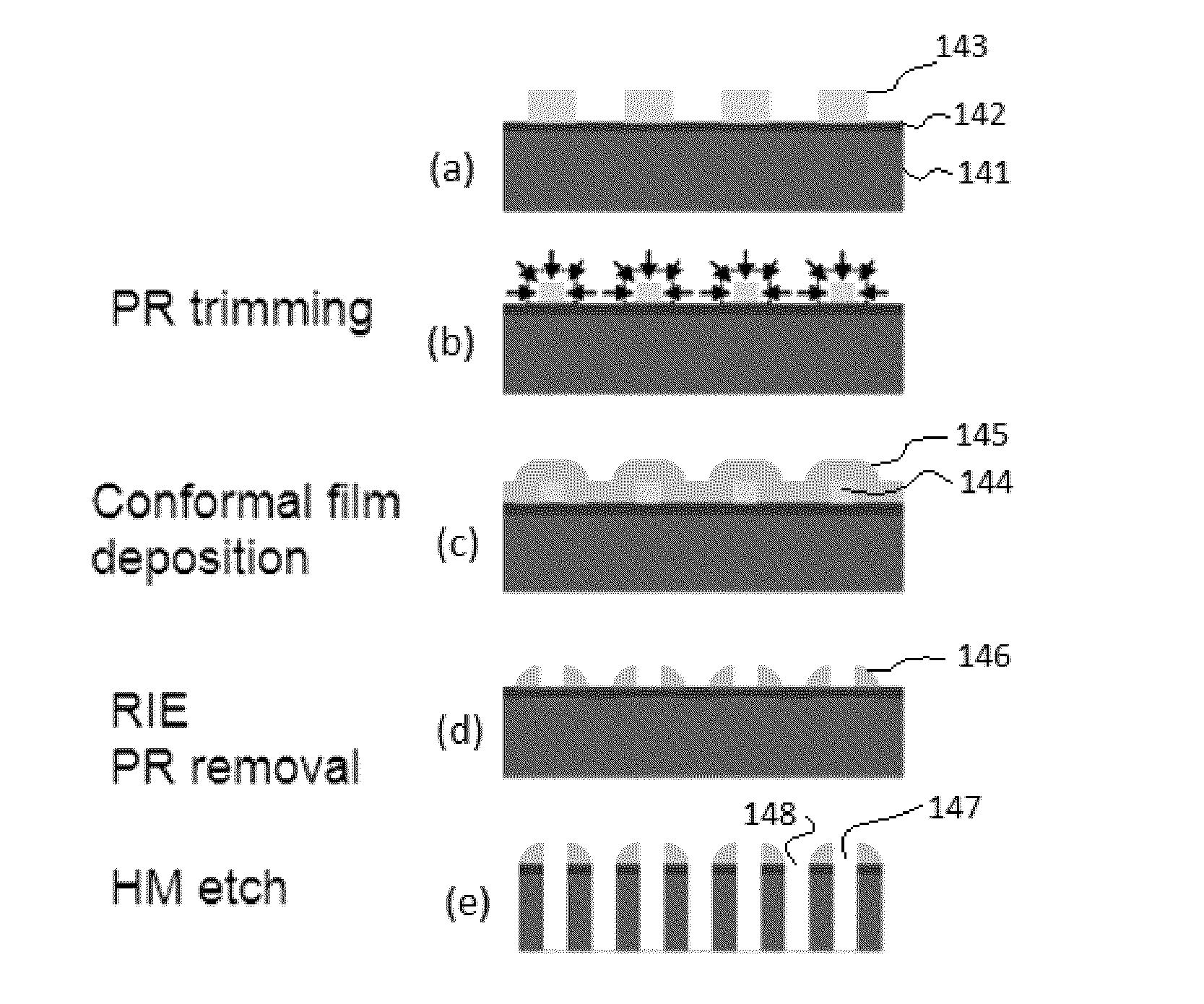

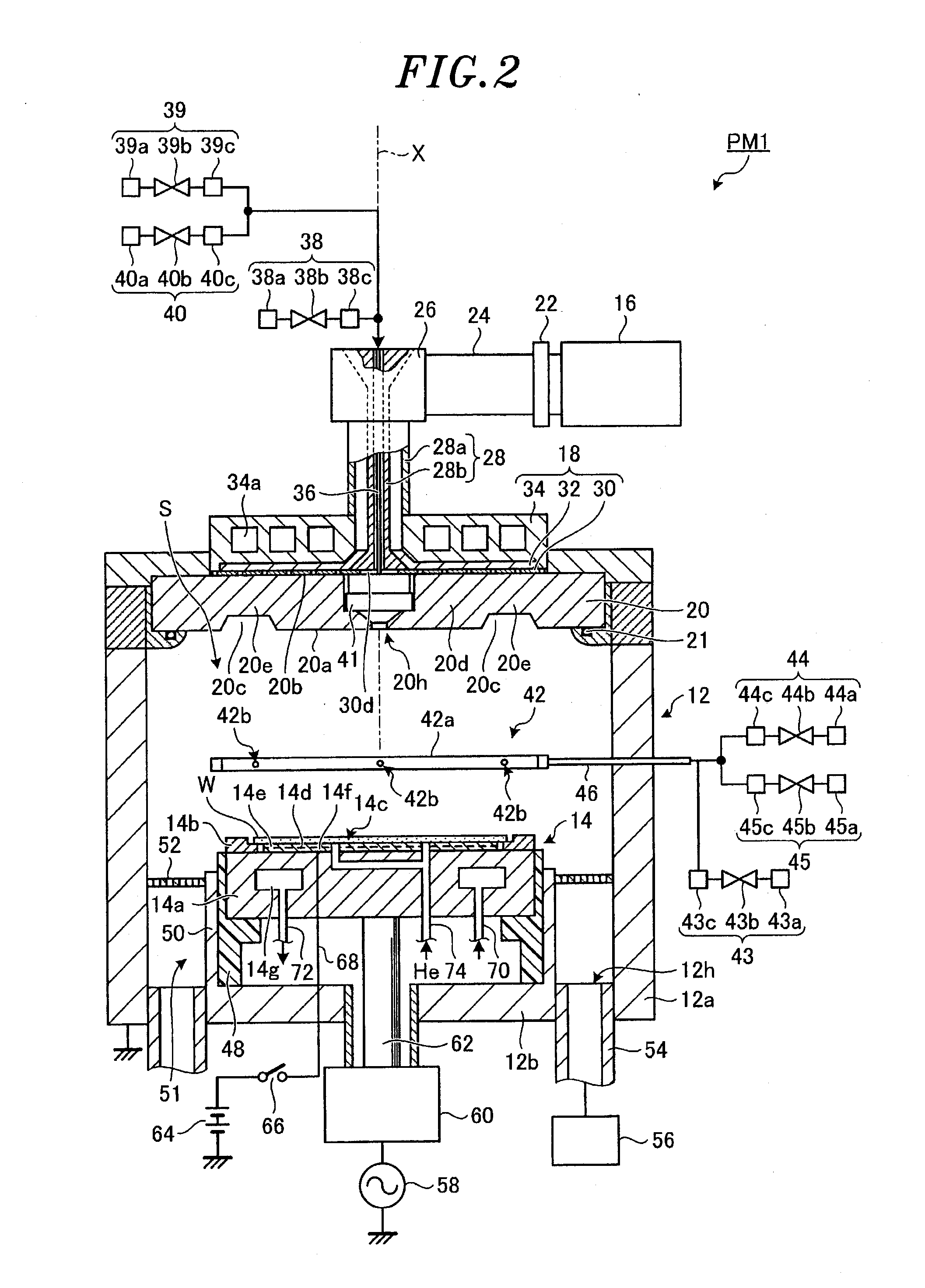

Method For Trimming Carbon-Containing Film At Reduced Trimming Rate

ActiveUS20150118846A1Reduce trimming rateReducing trimming rateElectric discharge tubesSemiconductor/solid-state device manufacturingNoble gasNitrogen

A method for trimming a carbon-containing film includes: (i) providing a substrate having a carbon-containing film formed thereon; (ii) supplying a trimming gas and a rare gas to the reaction space, which trimming gas includes an oxygen-containing gas; and (iii) applying RF power between the electrodes to generate a plasma using the trimming gas and the rare gas and to thereby trim the carbon-containing film while controlling a trimming rate at 55 nm / min or less as a function of at least one parameter selected from the group consisting of a flow rate of an oxygen-containing gas, a flow rate of nitrogen-containing gas to be added to the oxygen-containing gas, pressure in the reaction space, RF power, a duty cycle of RF power, a distance between the electrodes, and a temperature of a susceptor on which the substrate is placed.

Owner:ASM IP HLDG BV

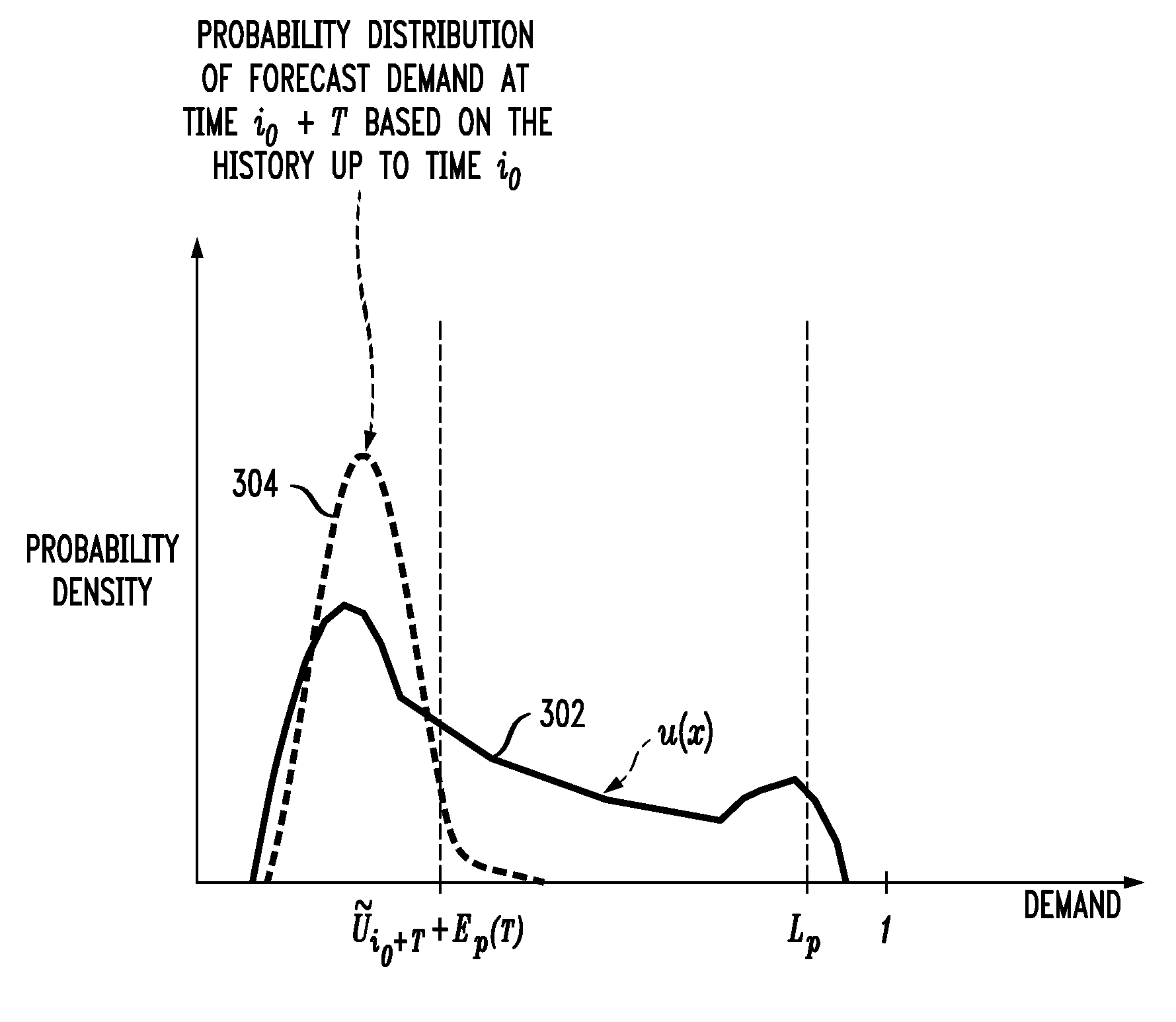

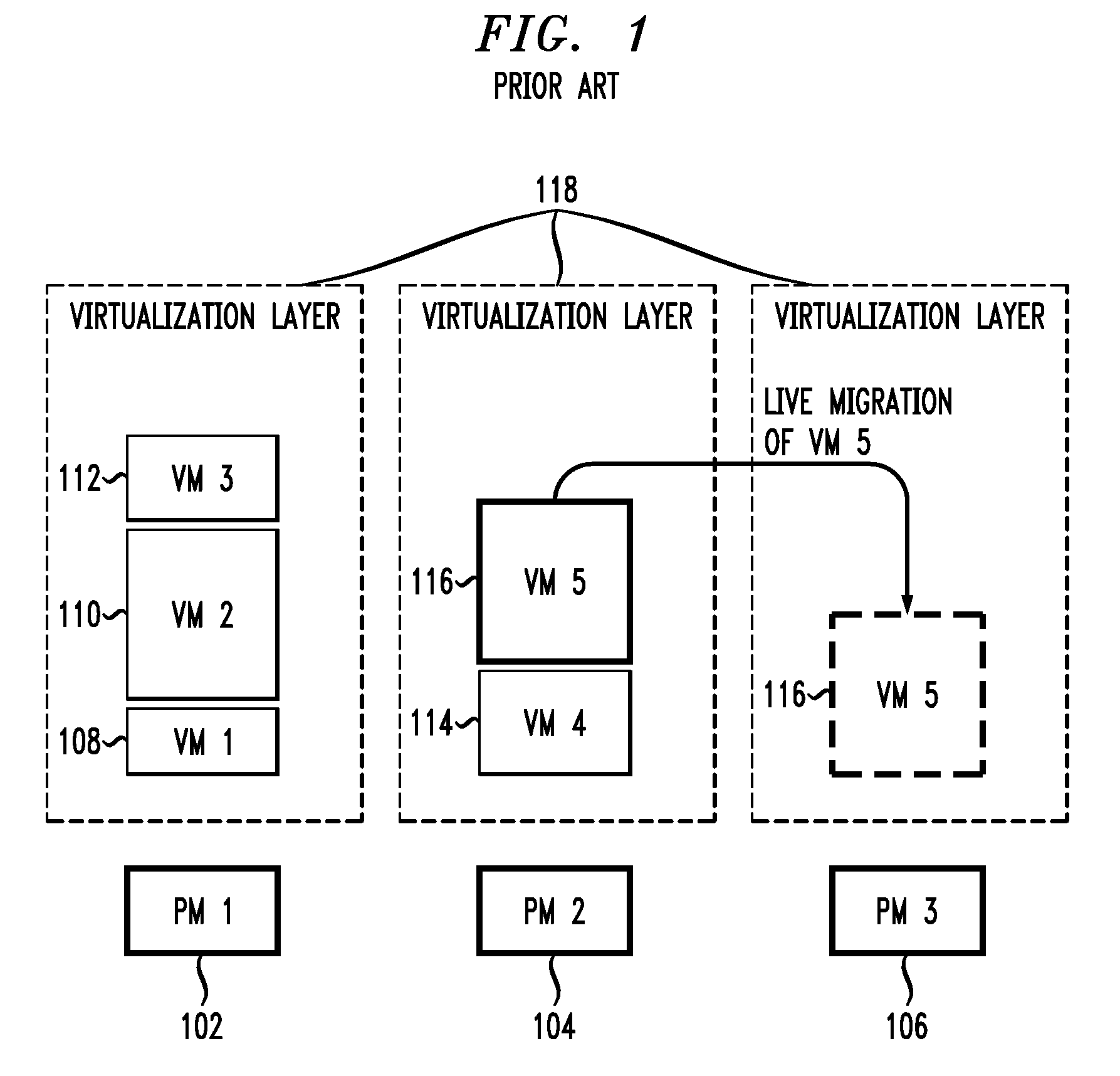

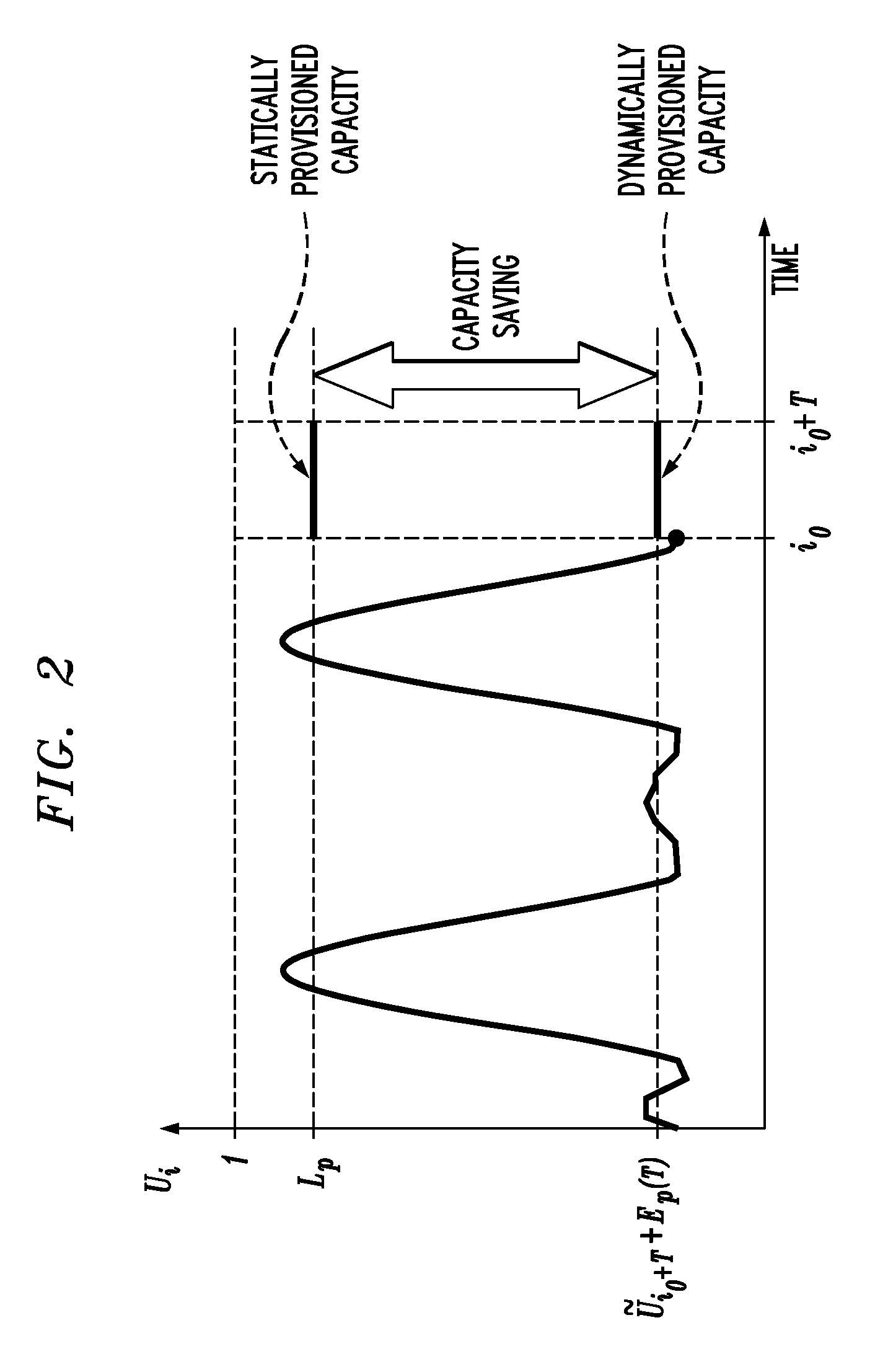

DYNAMIC PLACEMENT OF VIRTUAL MACHINES FOR MANAGING VIOLATIONS OF SERVICE LEVEL AGREEMENTS (SLAs)

InactiveUS20080295096A1Reduce the amount requiredReducing of rate of serviceForecastingMultiprogramming arrangementsService-level agreementBusiness forecasting

Historical data is measured for a computer server system. Future demand for service in the computer server system is forecast based on the historical data, and the mapping of virtual machines to physical machines is updated based on the forecast of the future demand. Measurement, forecasting, and placement modules can be employed.

Owner:IBM CORP

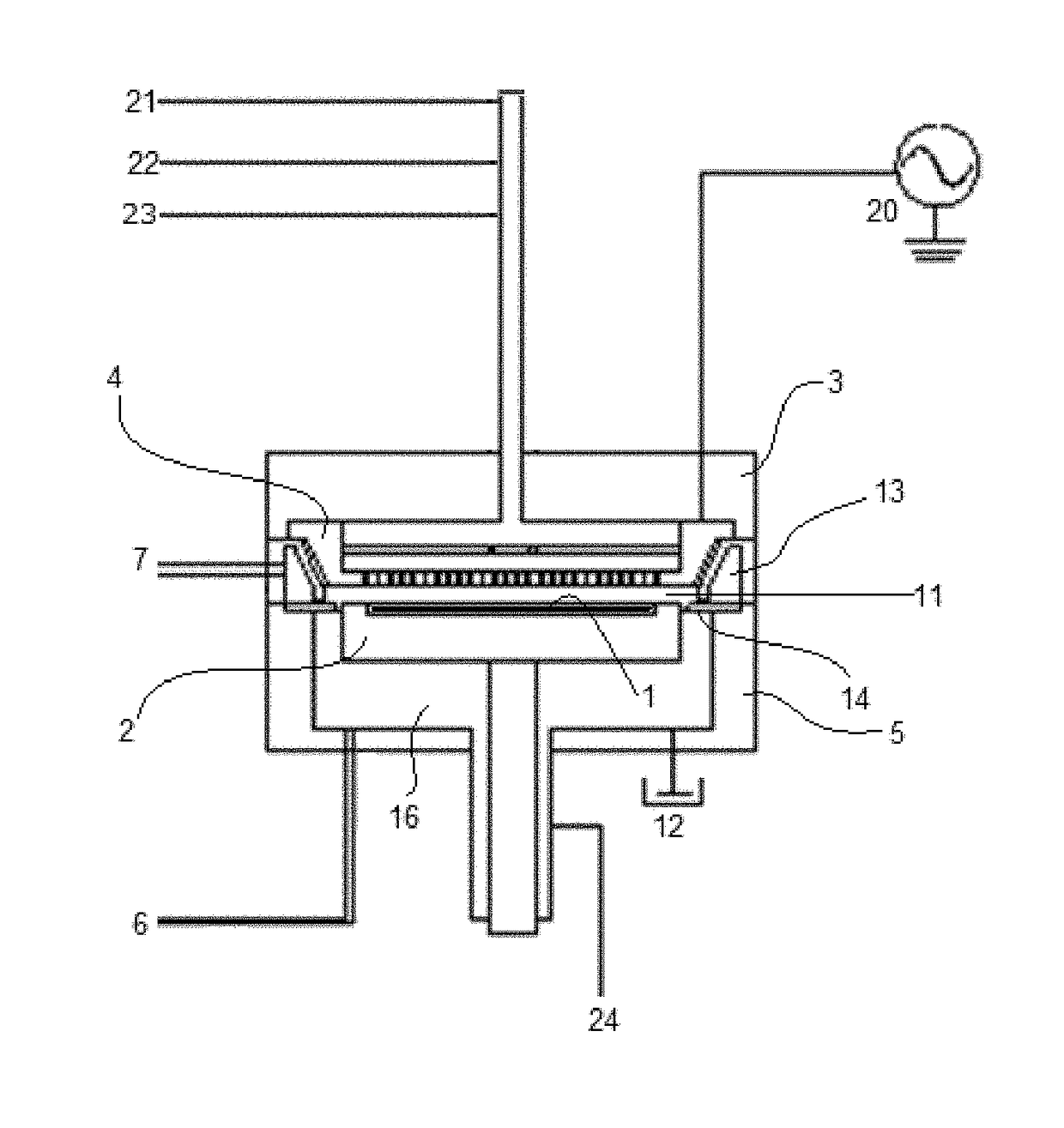

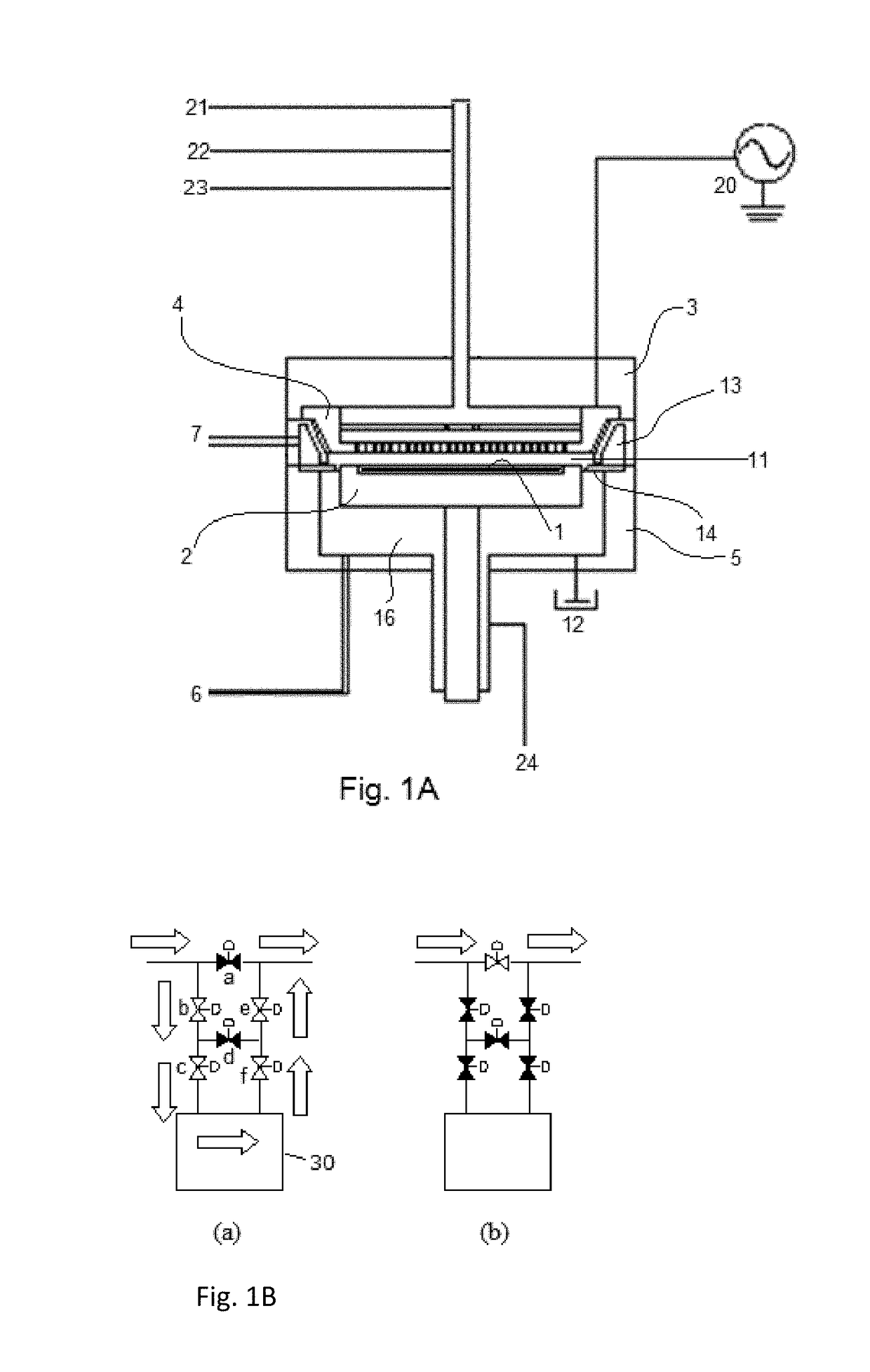

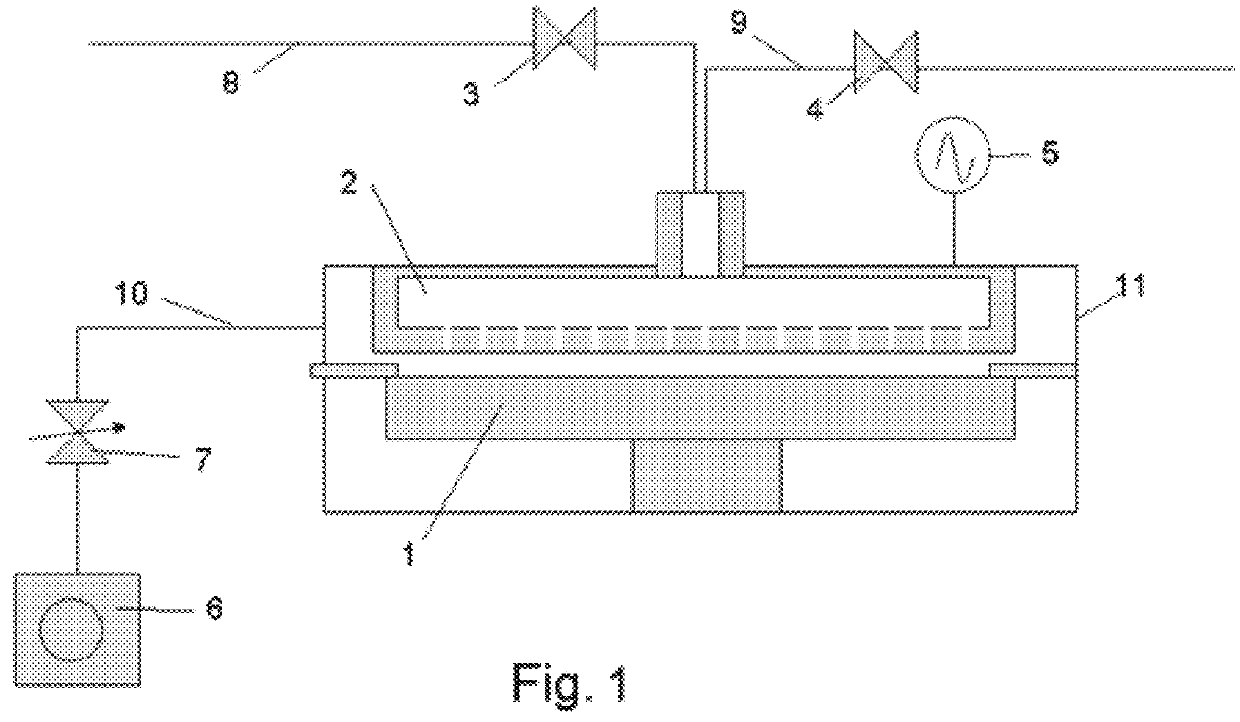

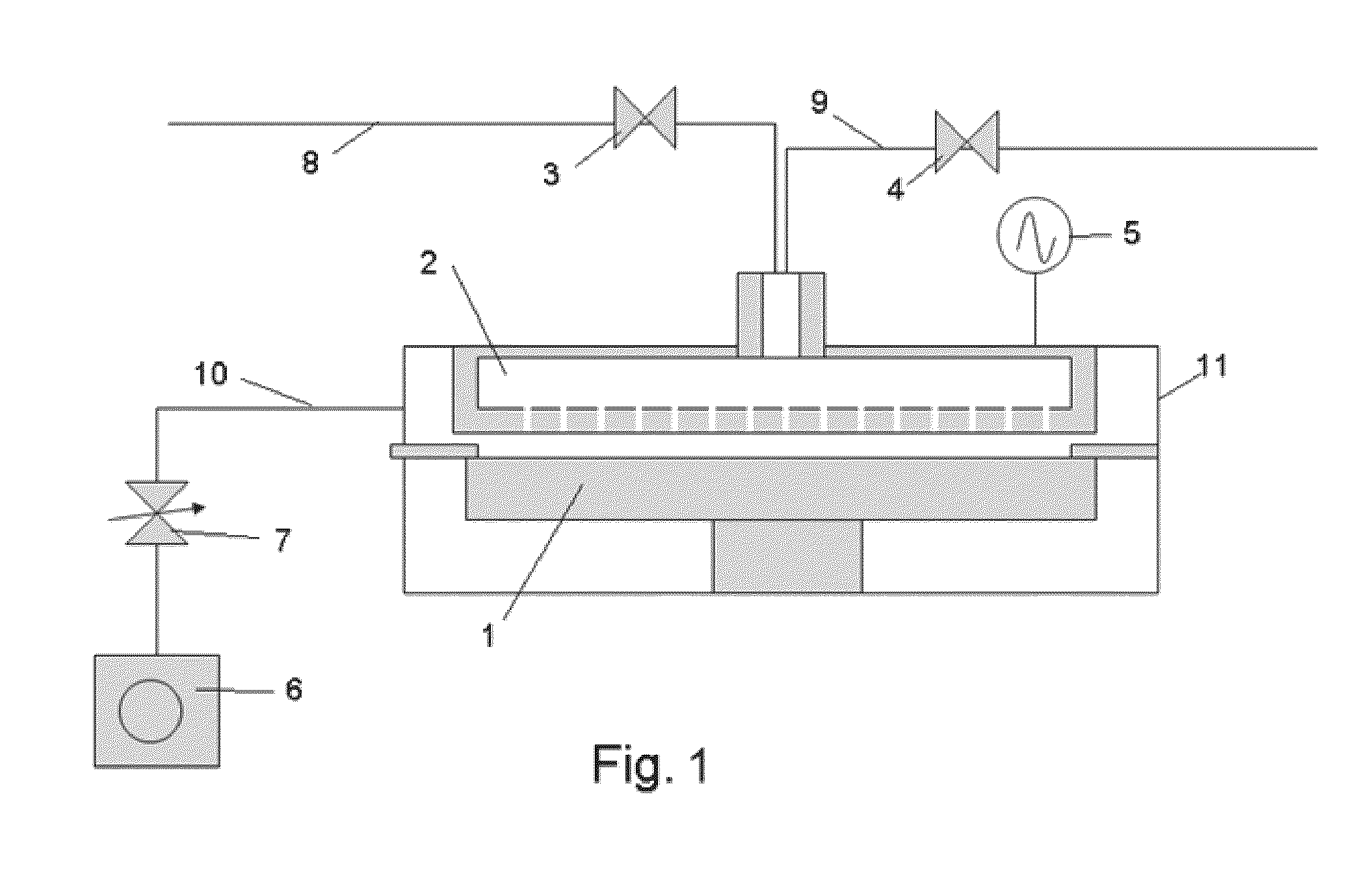

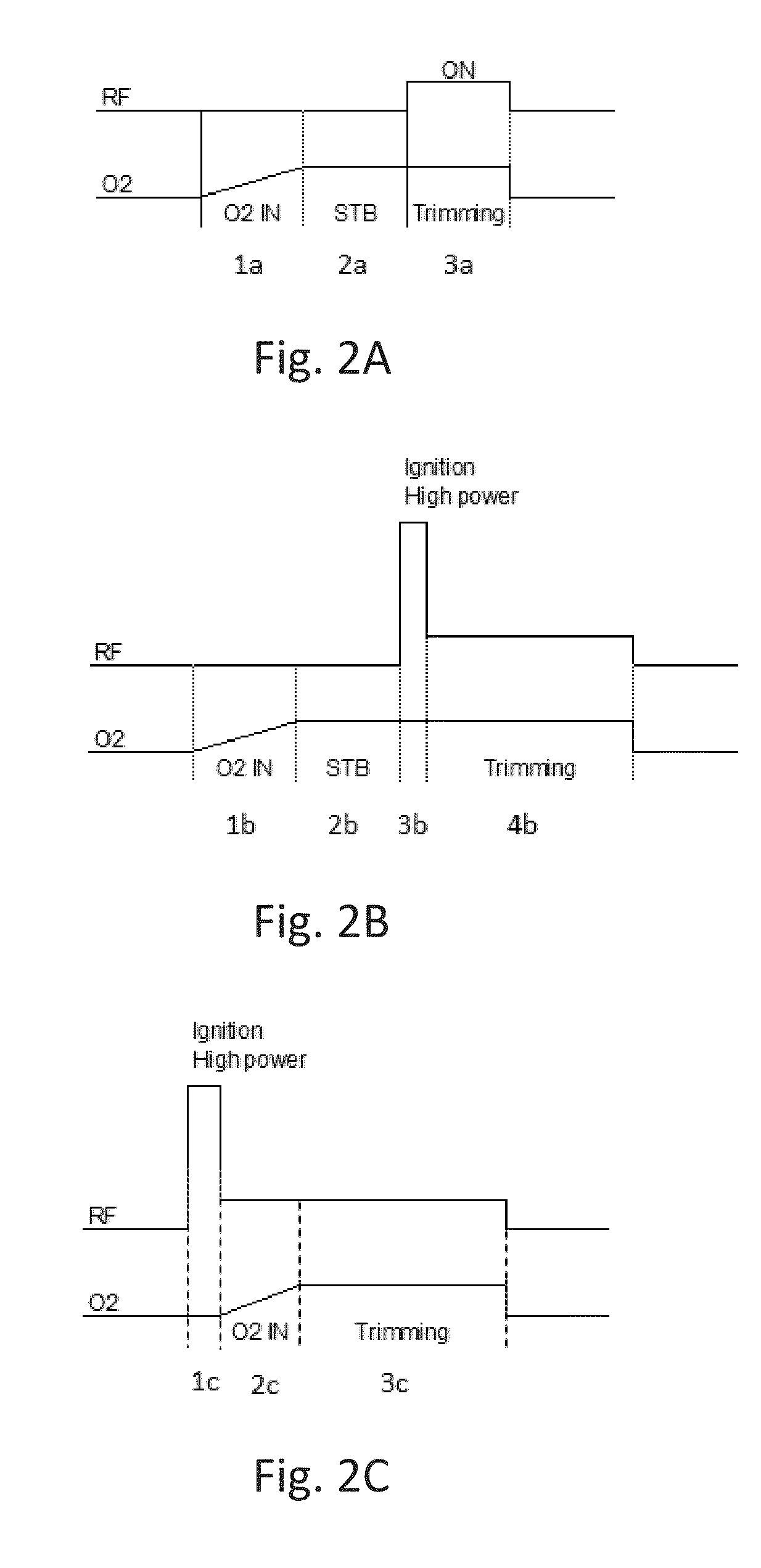

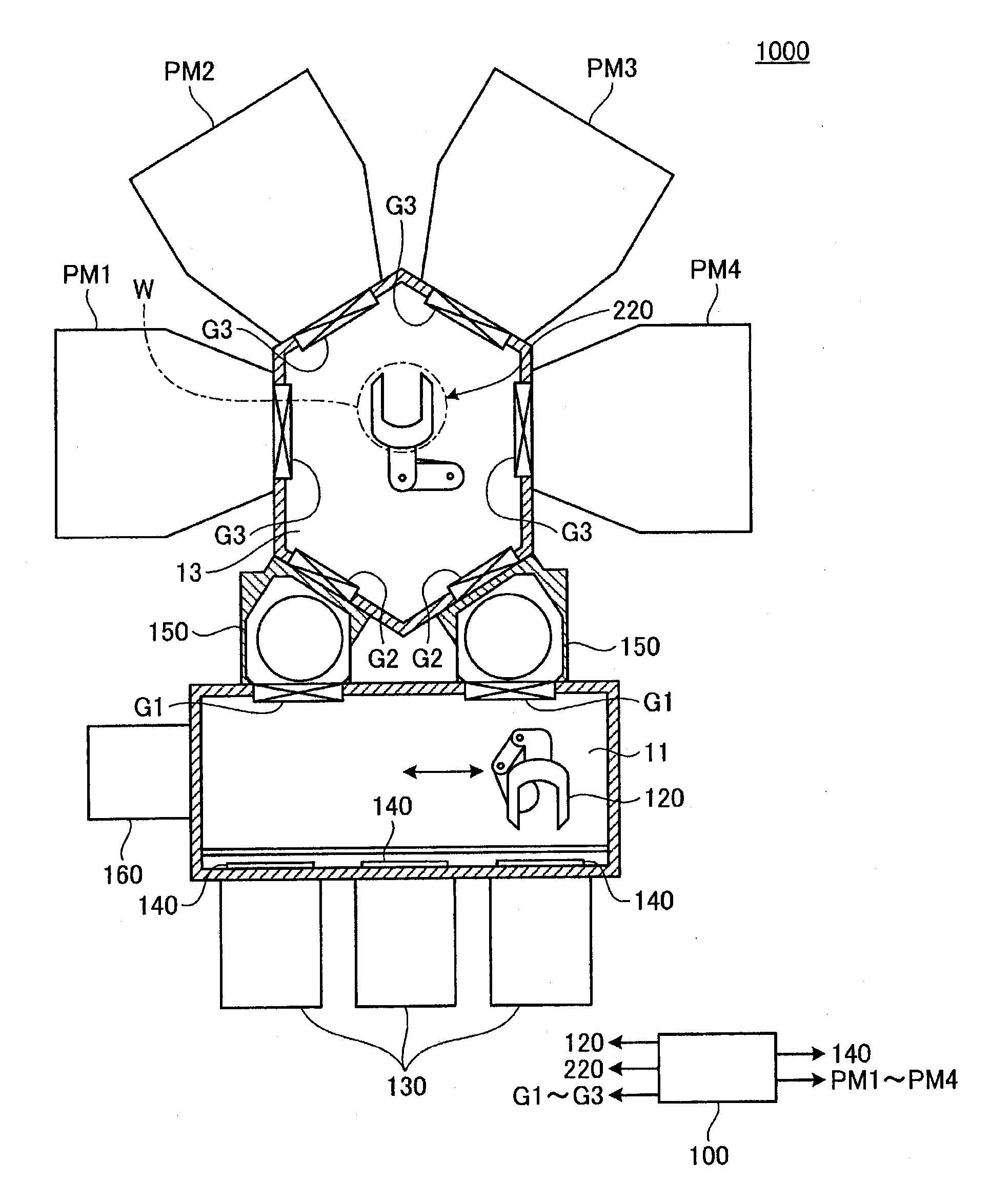

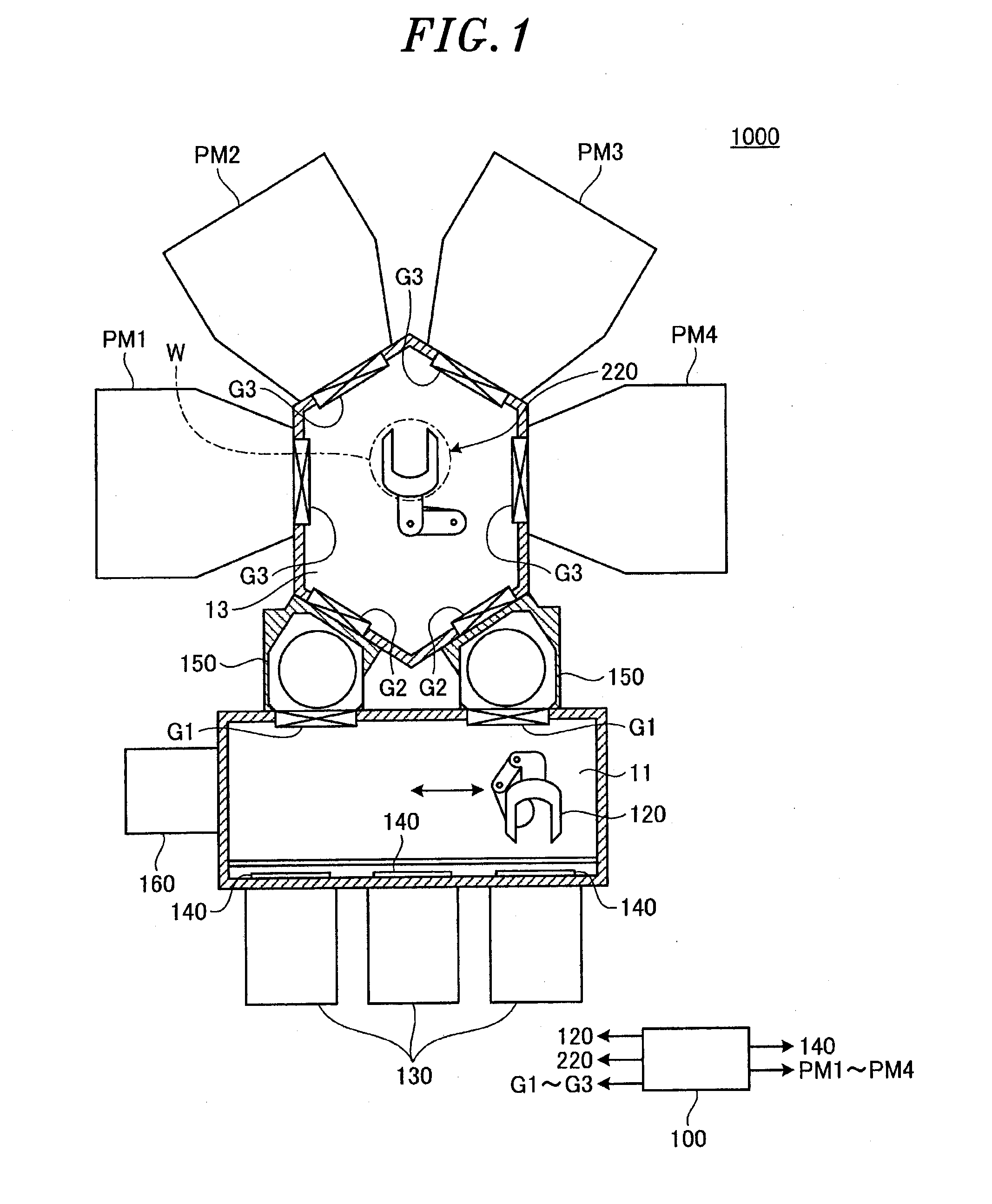

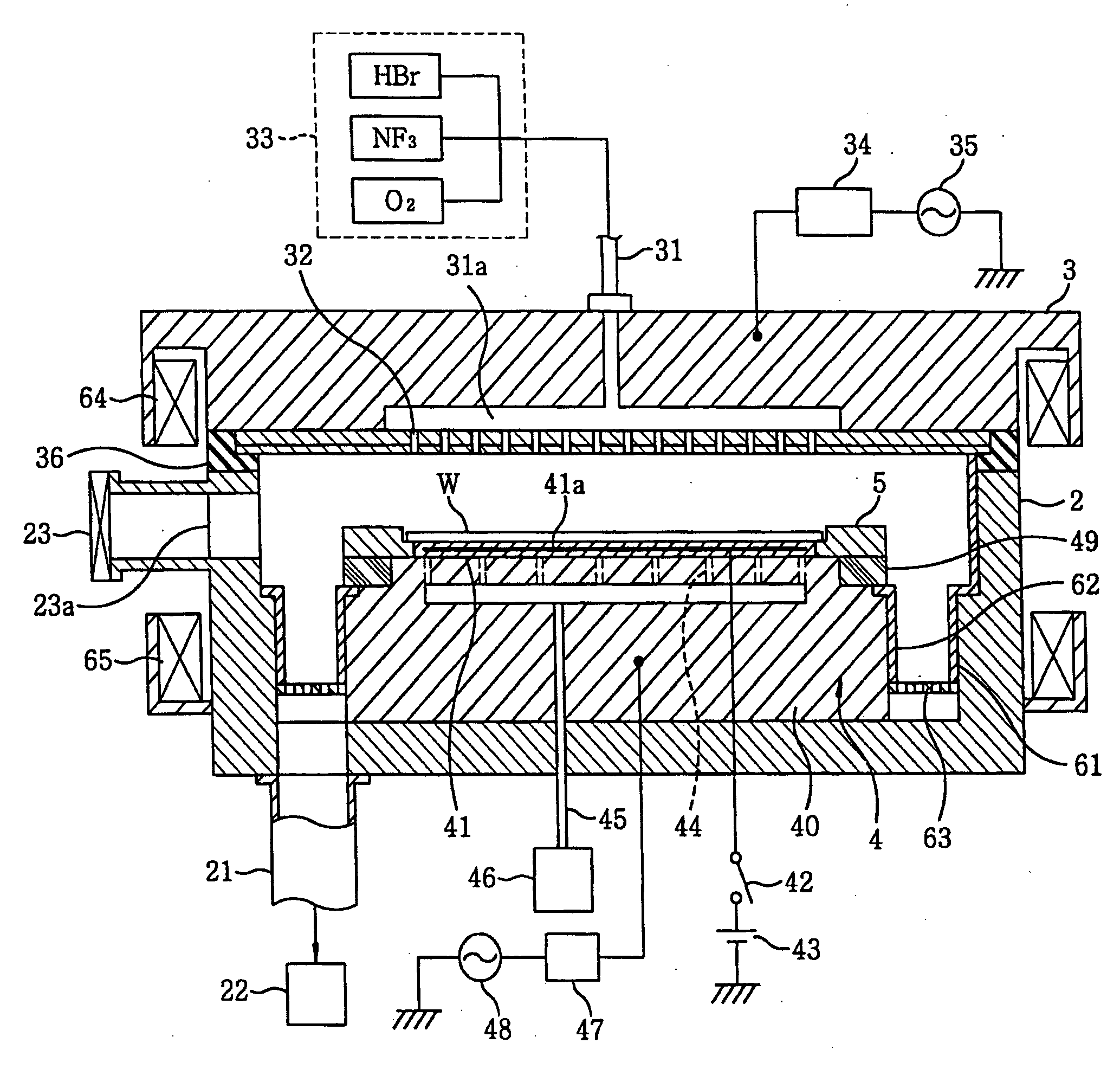

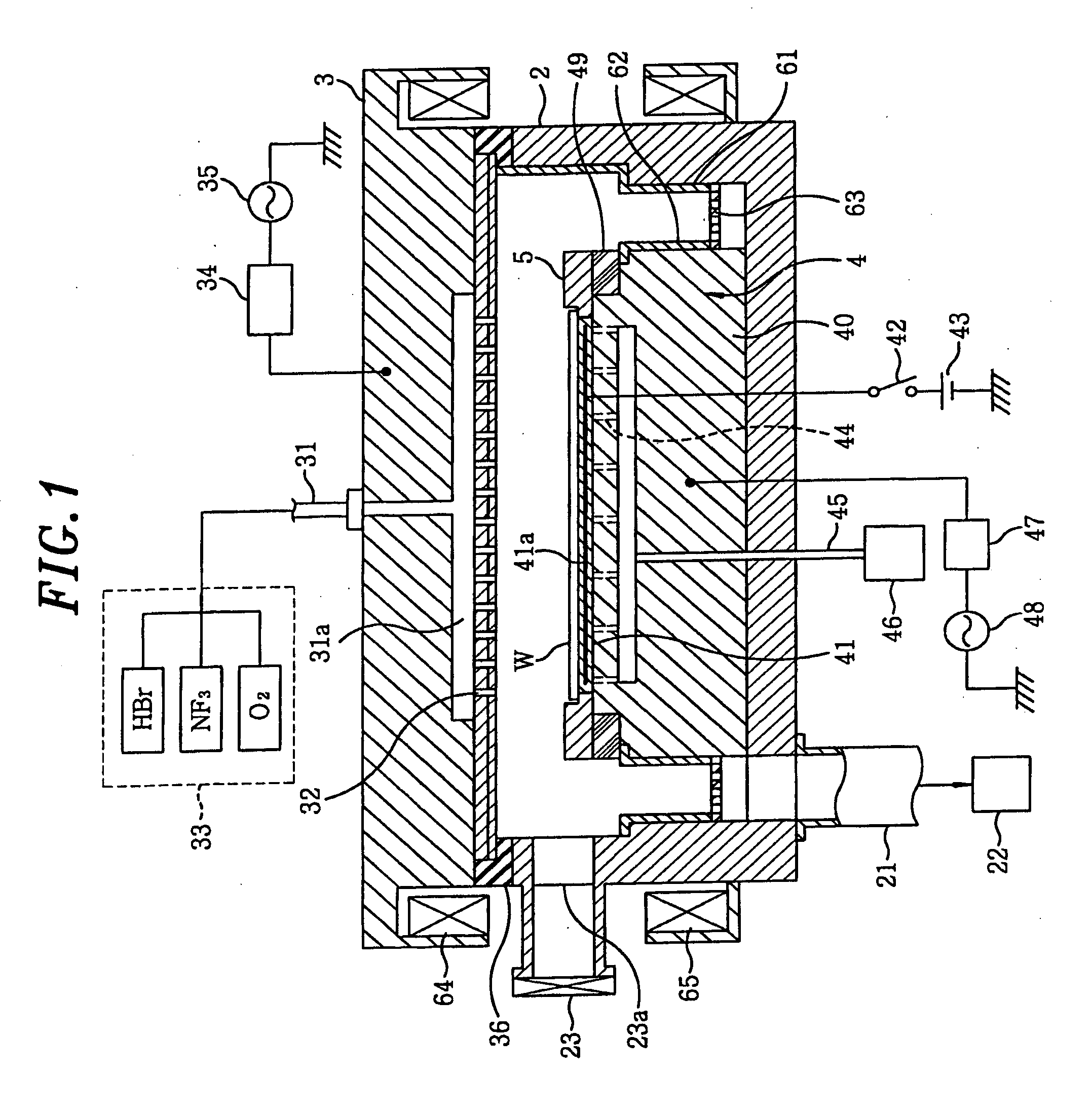

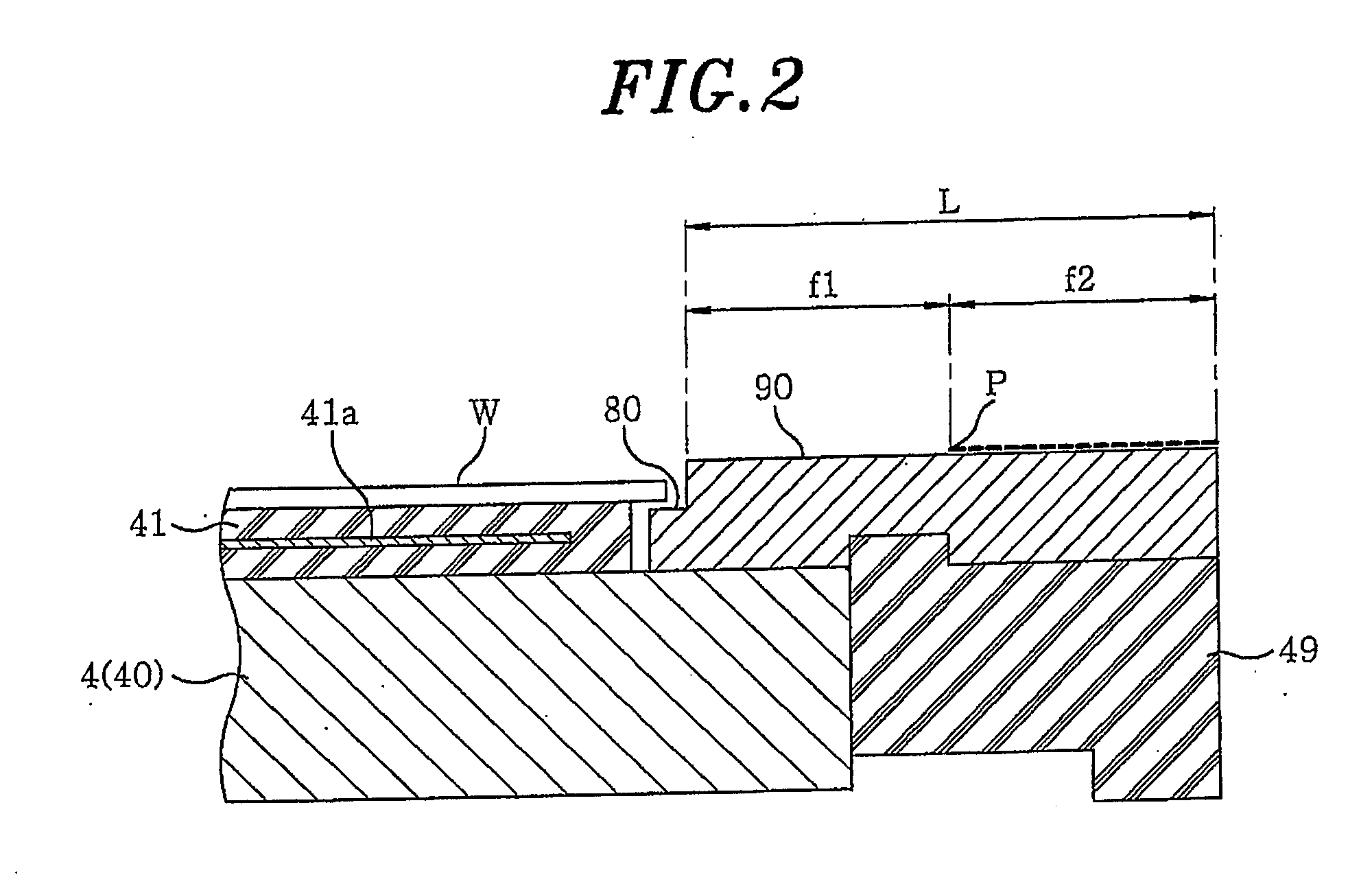

Plasma processing device and plasma processing method

ActiveUS20150064923A1Reduce rateReduce throughputElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringElectromagnetic shielding

A plasma processing device includes a processing chamber defining a plasma processing space and a stage for mounting thereon a target substrate in the processing chamber. The plasma processing device further includes a gas supply mechanism for introducing a processing gas into the plasma processing space, a plasma generation mechanism for supplying electromagnetic energy into the plasma processing space, and a control unit configured to, if a command to start a plasma process for the target substrate mounted on a substrate carry-in stage is issued, perform a warm-up process for supplying the processing gas into the plasma processing space by the gas supply mechanism and supplying the electromagnetic energy by the plasma generation mechanism in a state where no target substrate is mounted on the stage.

Owner:TOKYO ELECTRON LTD

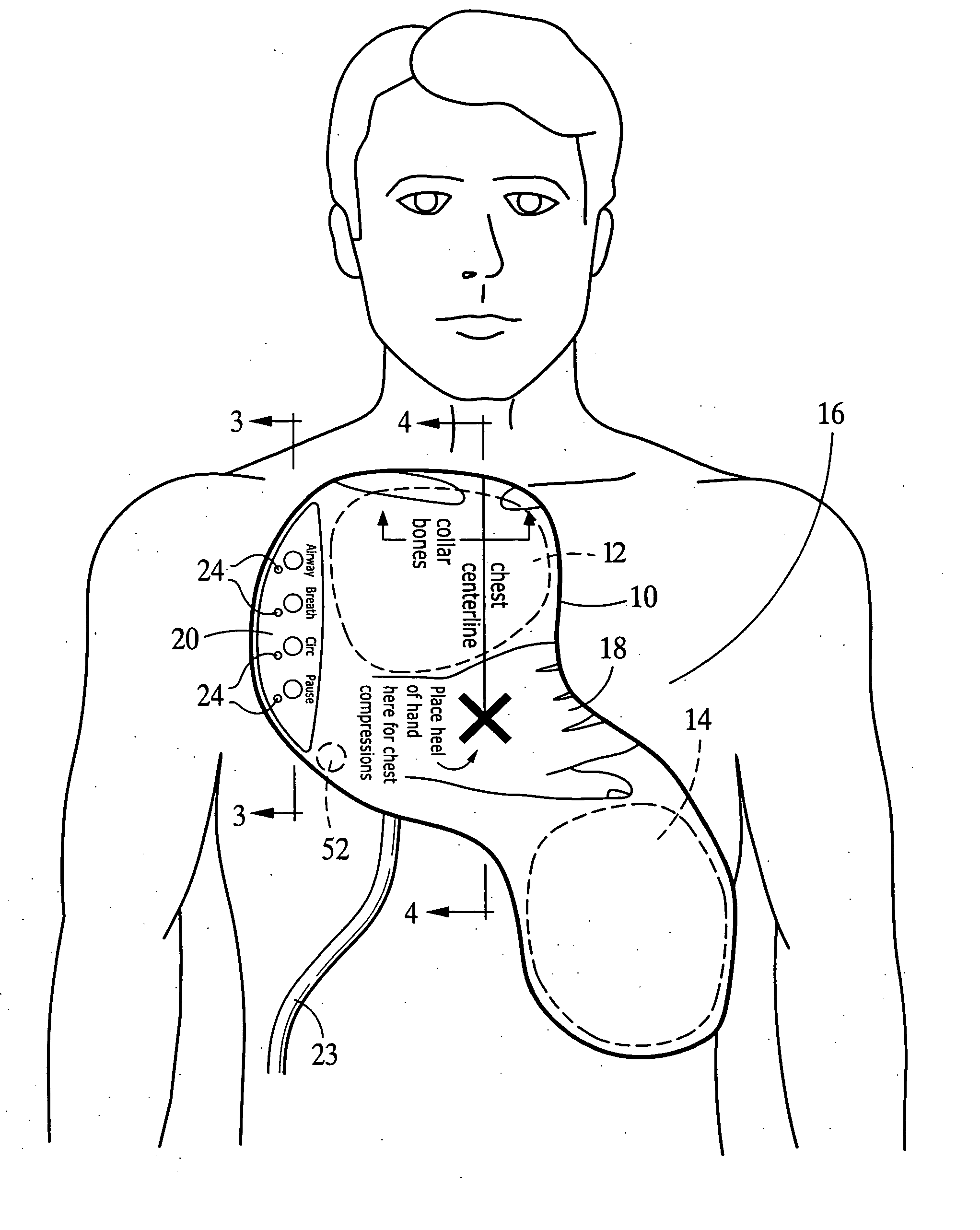

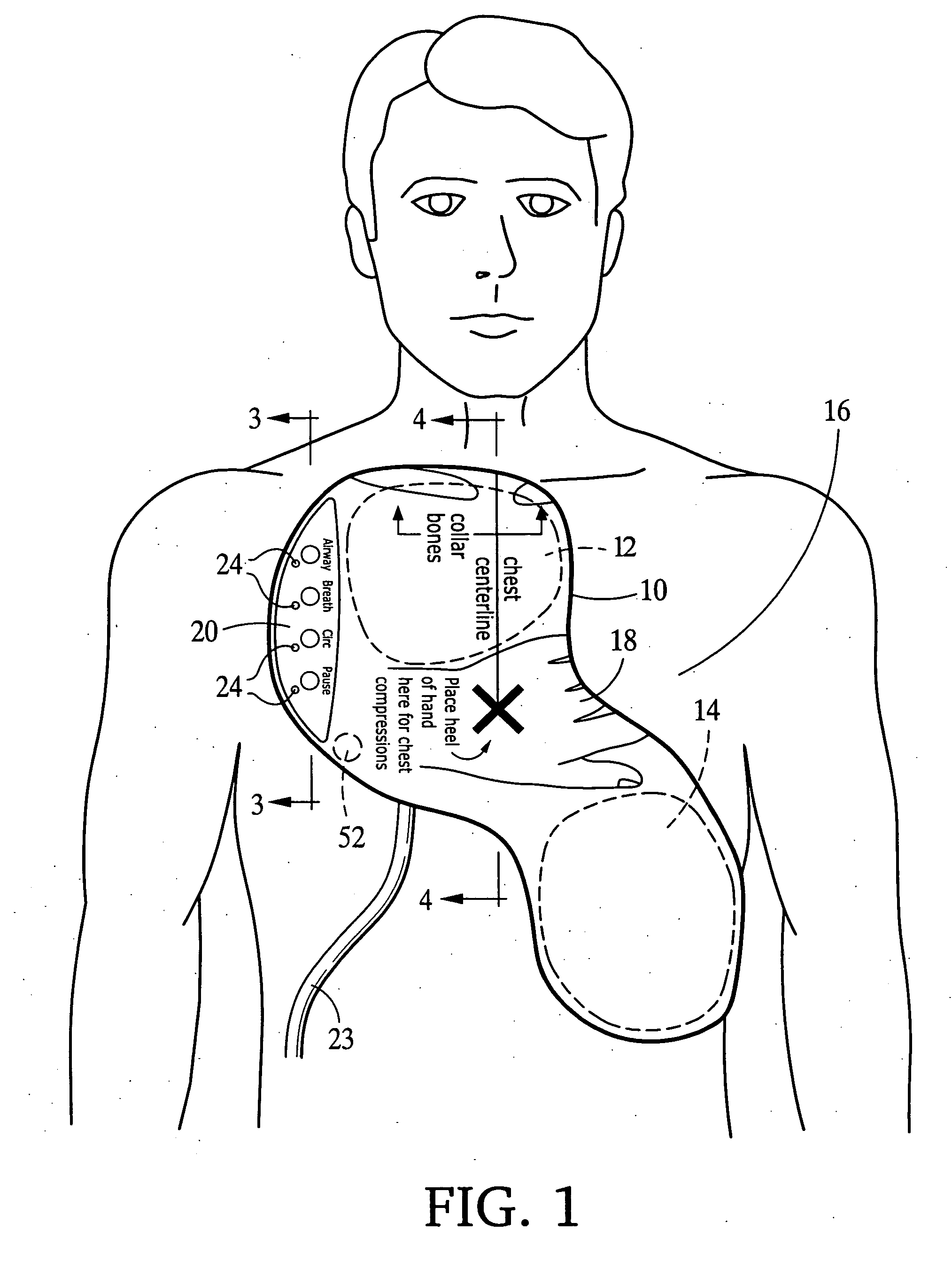

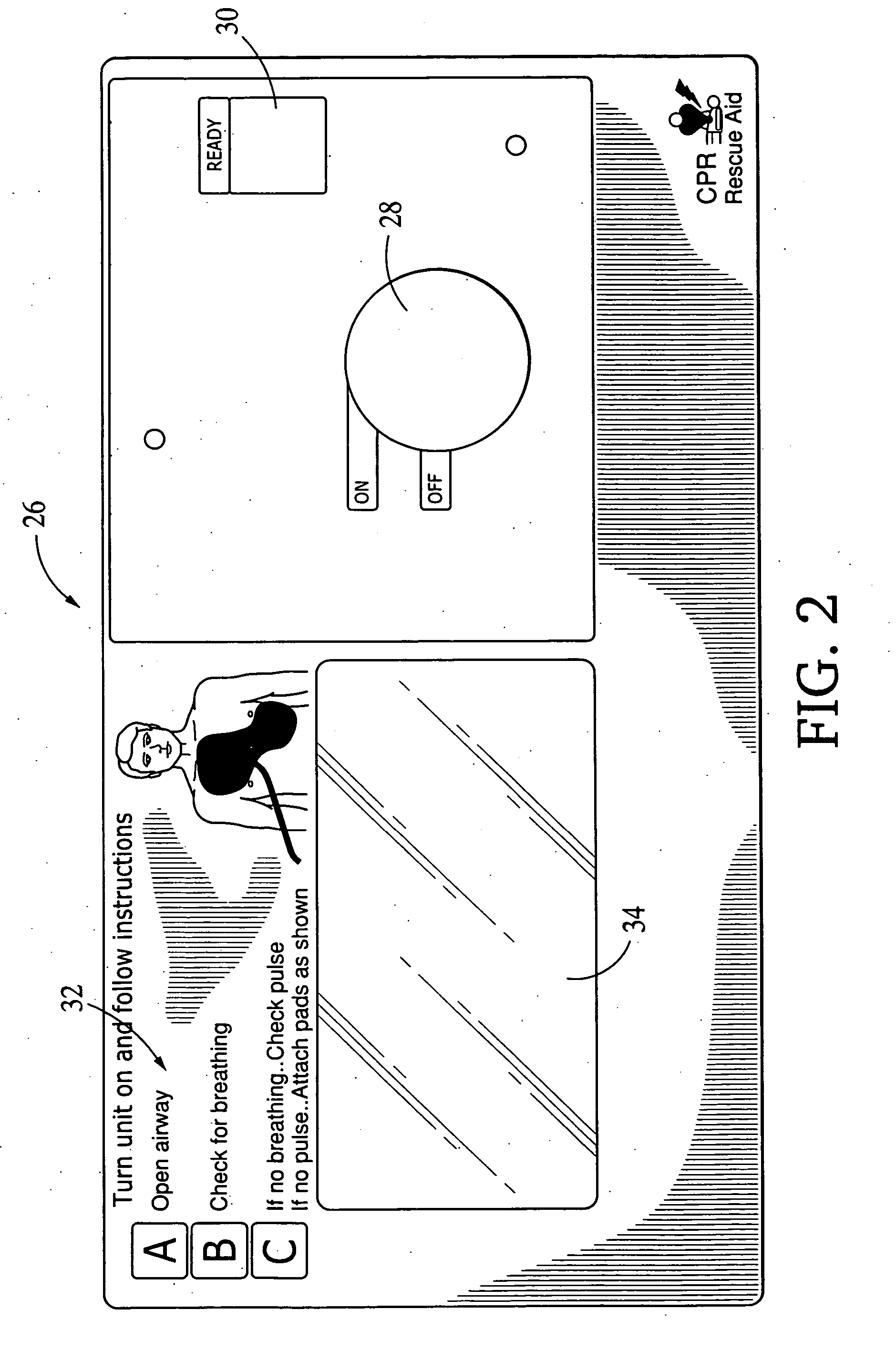

Integrated resuscitation

InactiveUS20050131465A1Widely distributedLow costHeart defibrillatorsStethoscopeElectricityElectrical connection

A resuscitation system for use by a rescuer for resuscitating a patient, comprising at least two high-voltage defibrillation electrodes, a first electrical unit comprising circuitry for providing resuscitation prompts to the rescuer, a second electrical unit separate from the first unit and comprising circuitry for providing defibrillation pulses to the electrodes, and circuitry for providing at least one electrical connection between the first and second units. In another aspect, at least two electrical therapy electrodes adapted to be worn by the patient for extended periods of time, circuitry for monitoring the ECG of the patient, an activity sensor adapted to be worn by the patient and capable of providing an output from which the patient's current activity can be estimated, and at least one processor configured for estimating the patient's current activity by analyzing the output of the activity sensor, analyzing the ECG of the patient, and determining whether electrical therapy should be delivered to the electrodes.

Owner:ZOLL MEDICAL CORPORATION

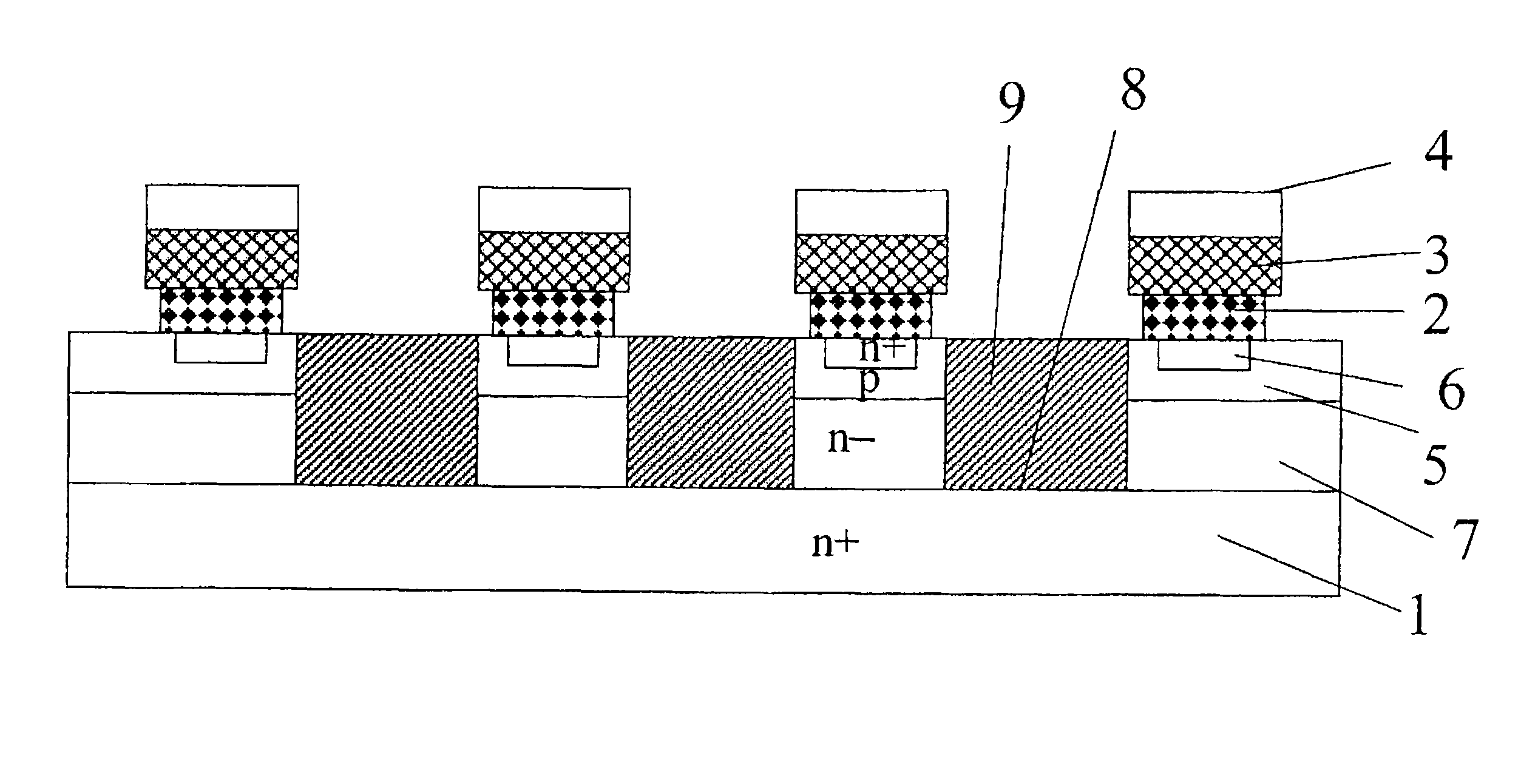

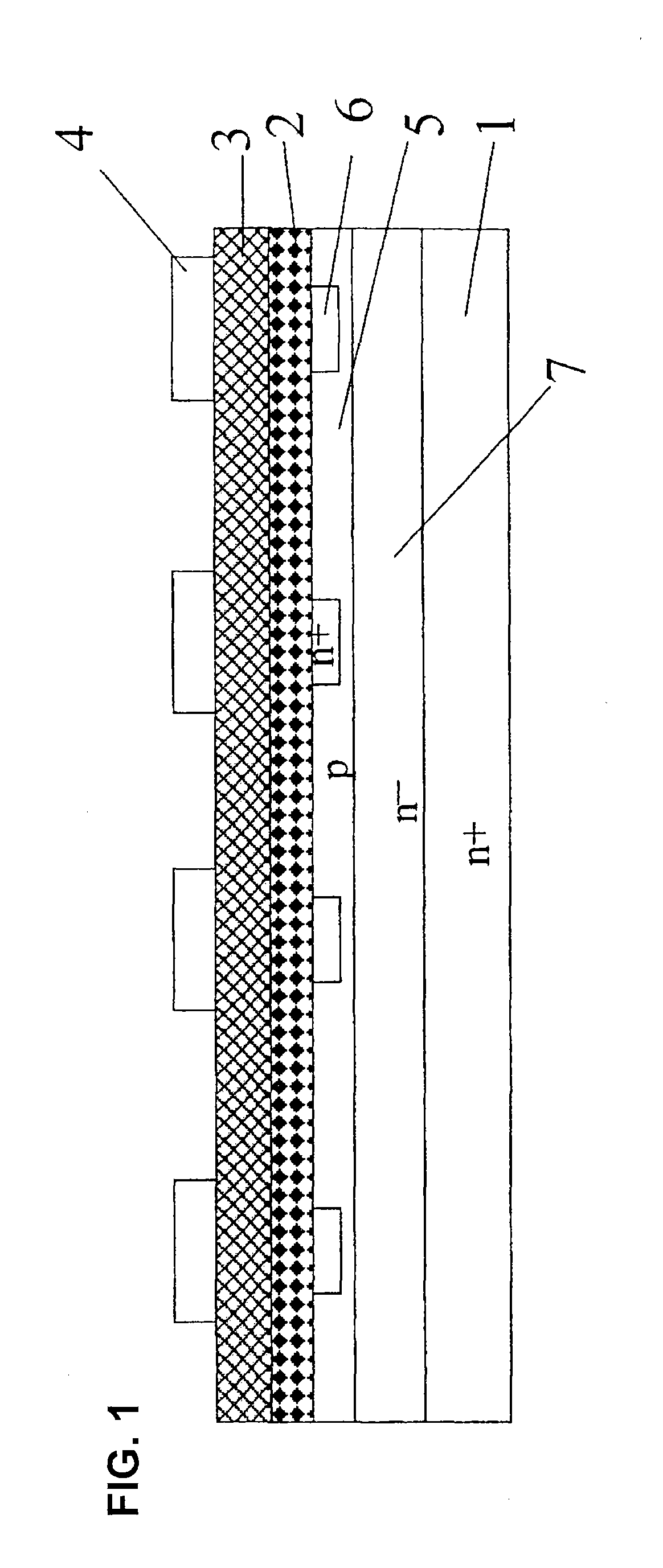

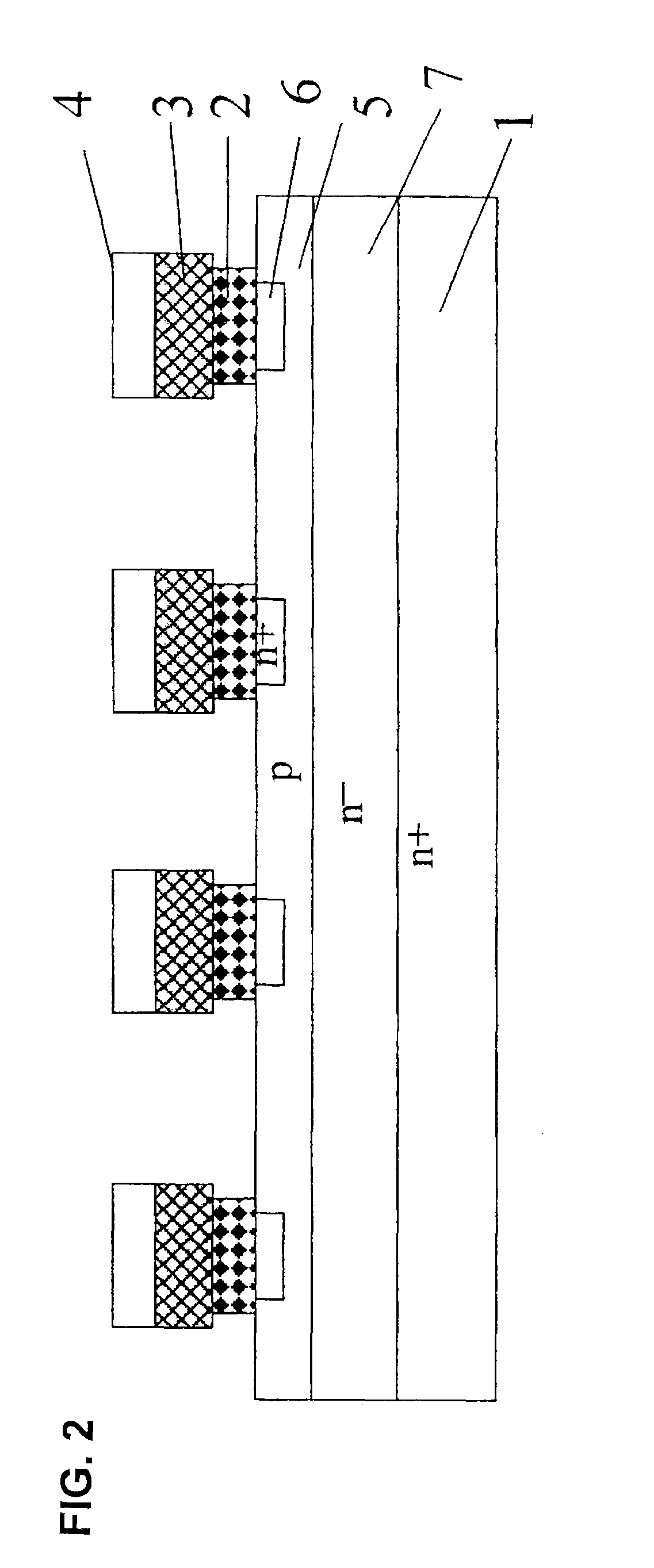

Manufacturing method of a silicon carbide semiconductor device

InactiveUS8071482B2Smooth curveImprove breakdown voltageSemiconductor/solid-state device detailsSolid-state devicesSemiconductorDry etching

A manufacturing method for a silicon carbide semiconductor device is disclosed. It includes an etching method in which an Al film and Ni film are laid on an SiC wafer in this order and wet-etched, whereby a two-layer etching mask is formed in which Ni film portions overhang Al film portions. Mesa grooves are formed by dry etching by using this etching mask.

Owner:FUJI ELECTRIC CO LTD

Focus ring, plasma etching apparatus and plasma etching method

ActiveUS20090255902A1Improve etching effectAccurate storageElectric discharge tubesDecorative surface effectsSusceptorSurface roughness

In a plasma etching apparatus for performing a plasma etching on a surface of a substrate mounted on a susceptor in a processing vessel, a focus ring is installed to surround the substrate and has a first region at an inner side on a surface thereof, in which an average surface roughness is small such that a reaction product produced during an etching processing is not captured to be deposited, and a second region at an outer side from the first region, in which an average surface roughness is large such that a reaction product produced during the etching process is captured to be deposited. A boundary between the first and the second region is a part where an etching amount is relatively significantly changed compared to other parts while the focus ring is equipped in the plasma etching apparatus and the plasma etching is performed on the substrate.

Owner:TOKYO ELECTRON LTD

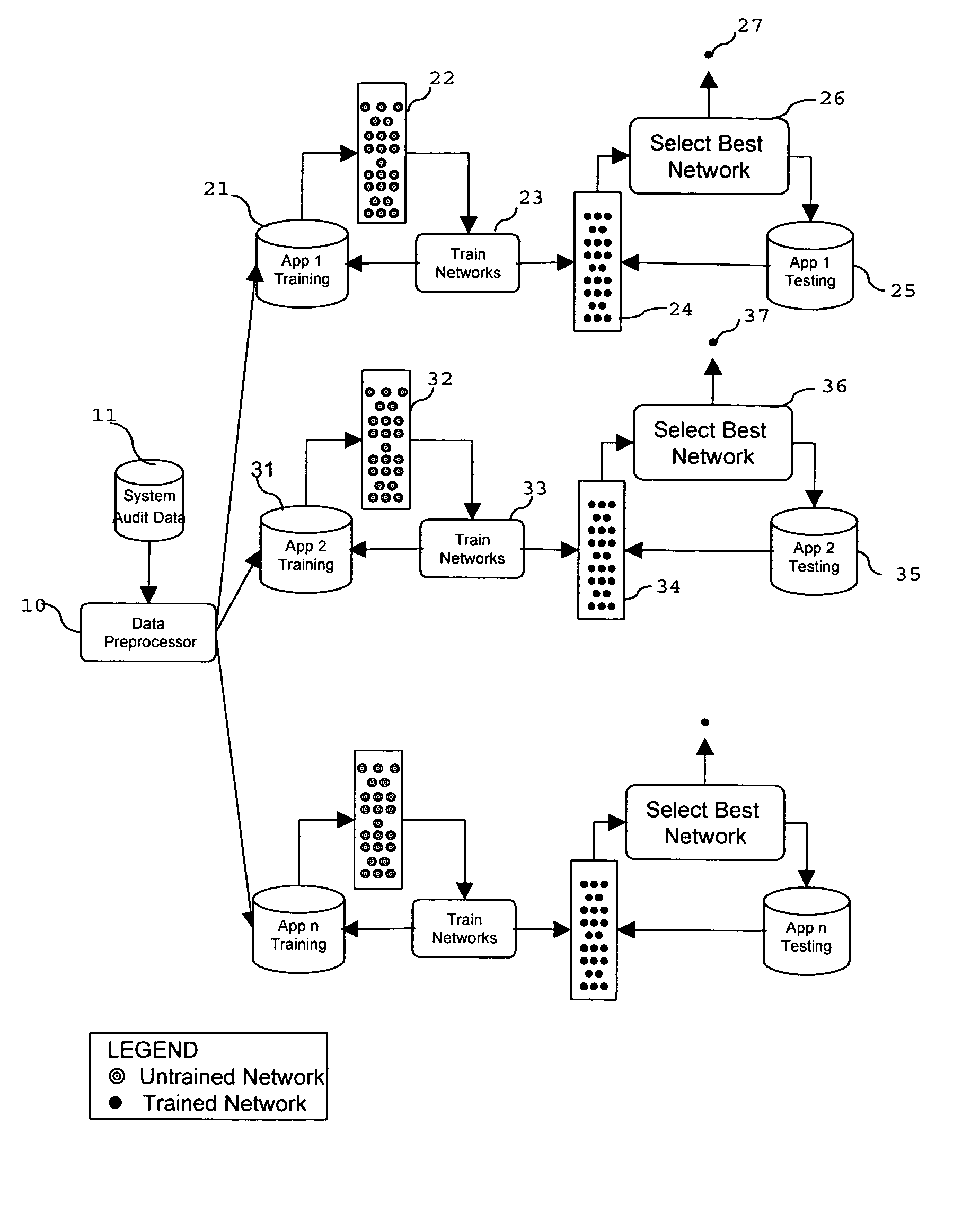

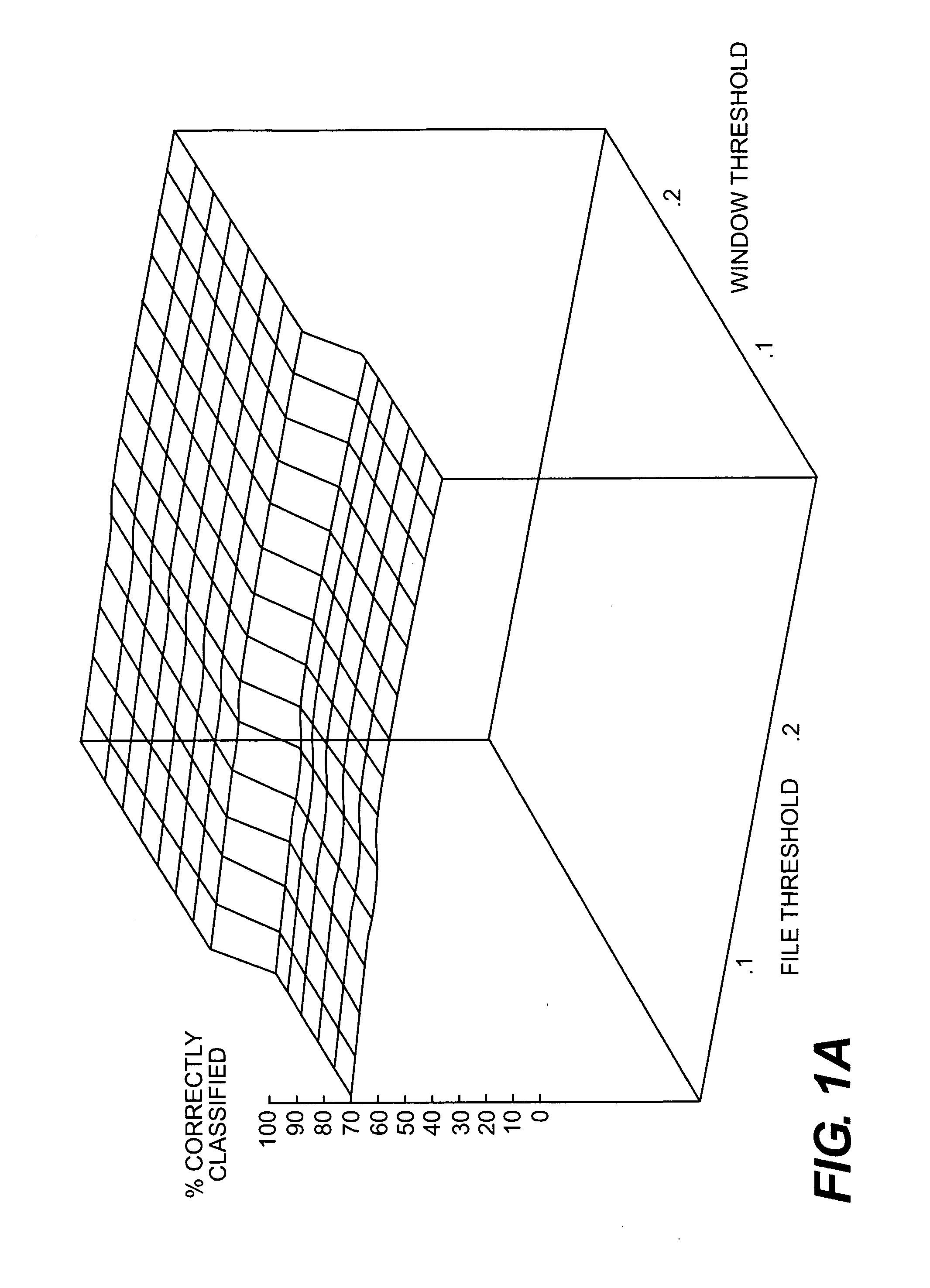

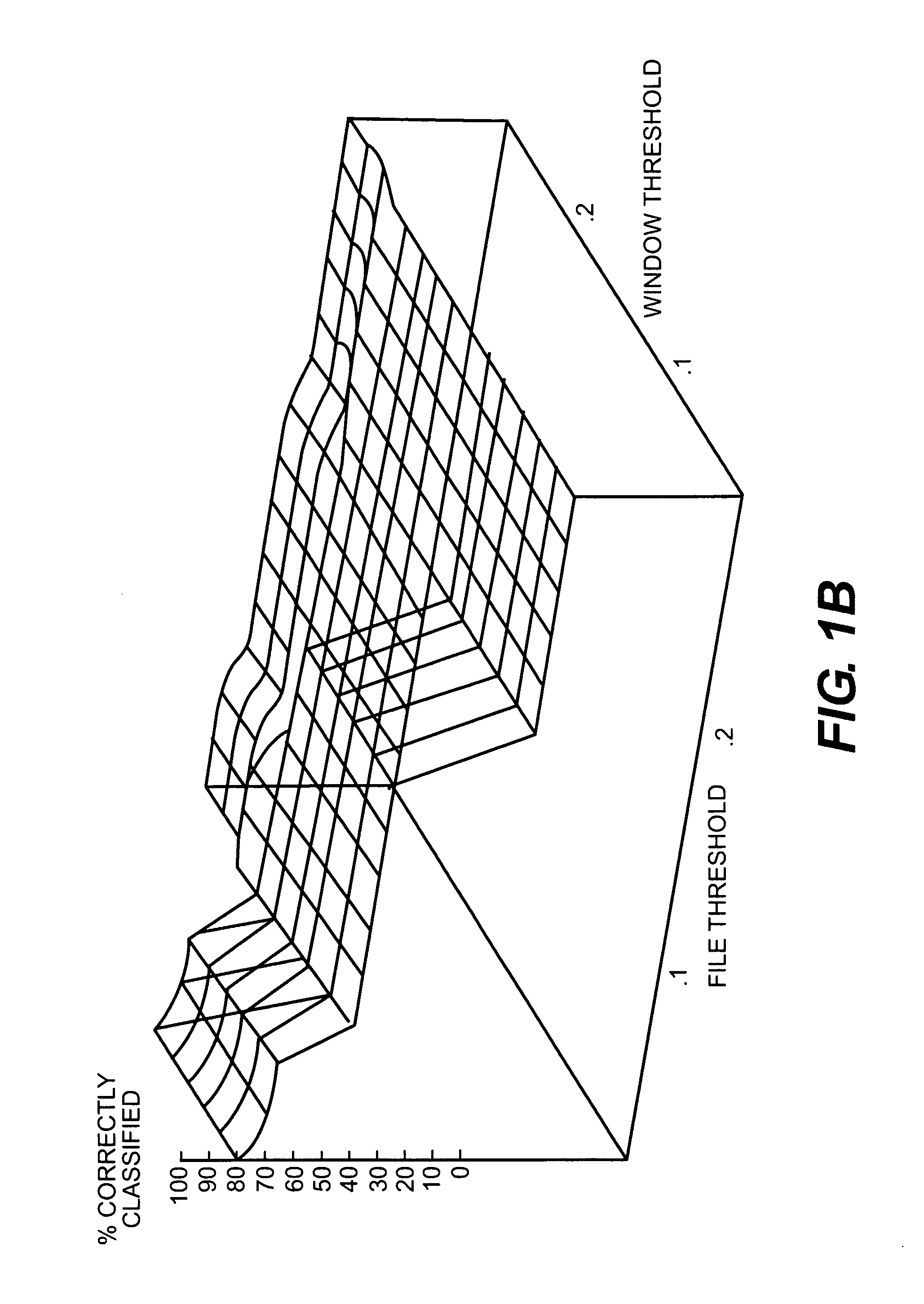

Computer intrusion detection system and method based on application monitoring

InactiveUS7181768B1Reduced false positive falseReduce false negative rateMemory loss protectionError detection/correctionNerve networkPrediction algorithms

An intrusion detection system (IDS) that uses application monitors for detecting application-based attacks against computer systems. The IDS implements application monitors in the form of a software program to learn and monitor the behavior of system programs in order to detect attacks against computer hosts. The application monitors implement machine learning algorithms to provide a mechanism for learning from previously observed behavior in order to recognize future attacks that it has not seen before. The application monitors include temporal locality algorithms to increased the accuracy of the IDS. The IDS of the present invention may comprise a string-matching program, a neural network, or a time series prediction algorithm for learning normal application behavior and for detecting anomalies.

Owner:SYNOPSYS INC

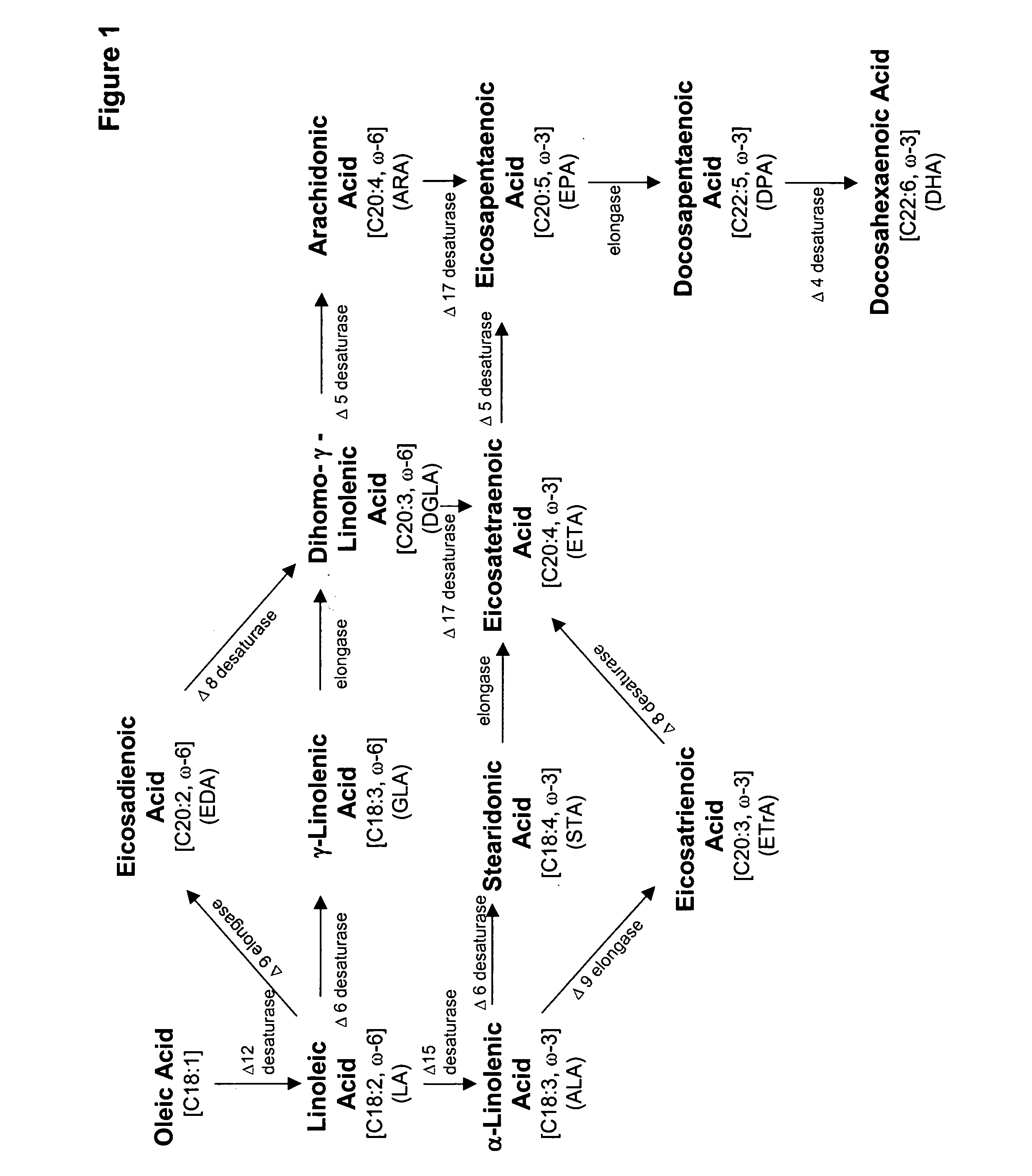

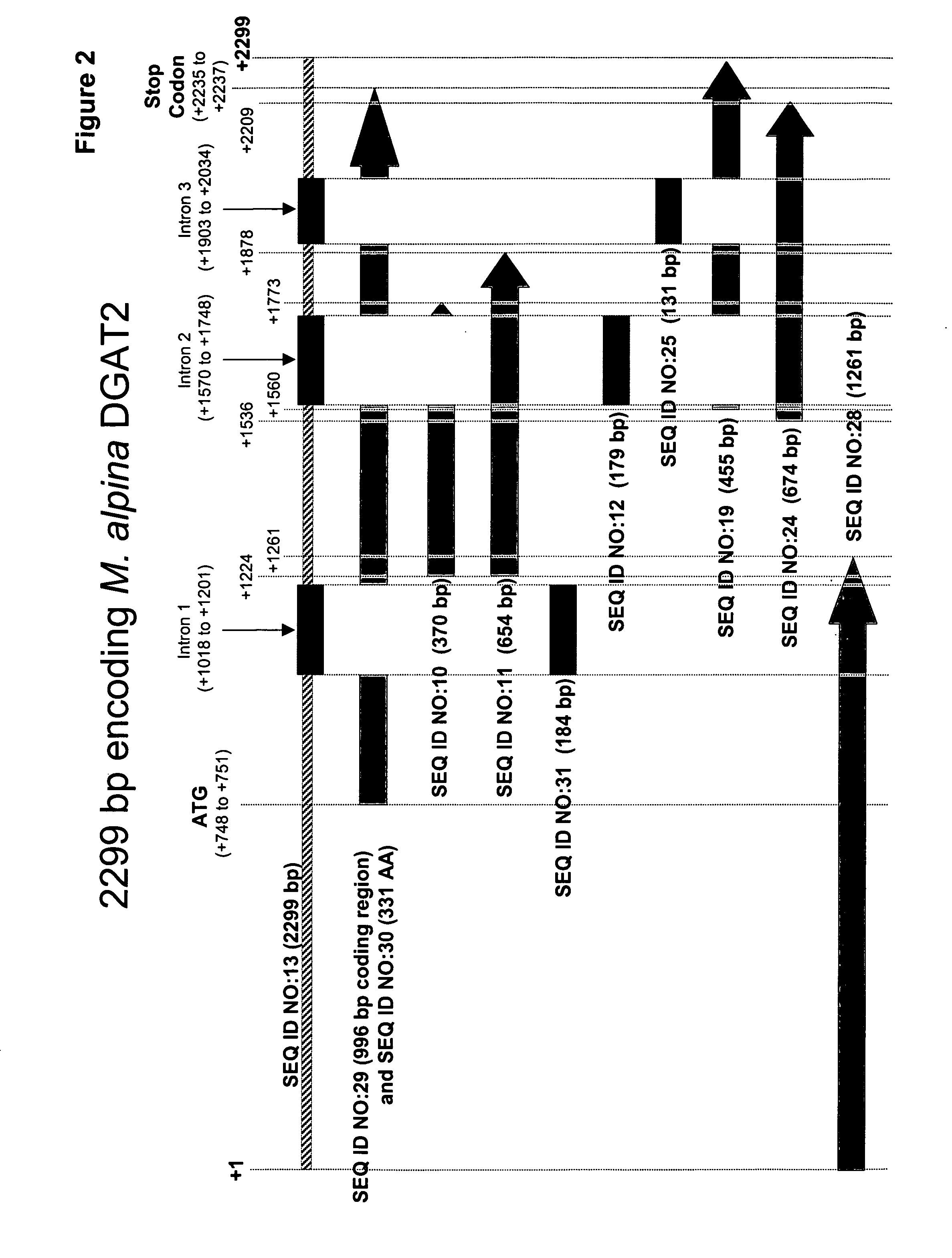

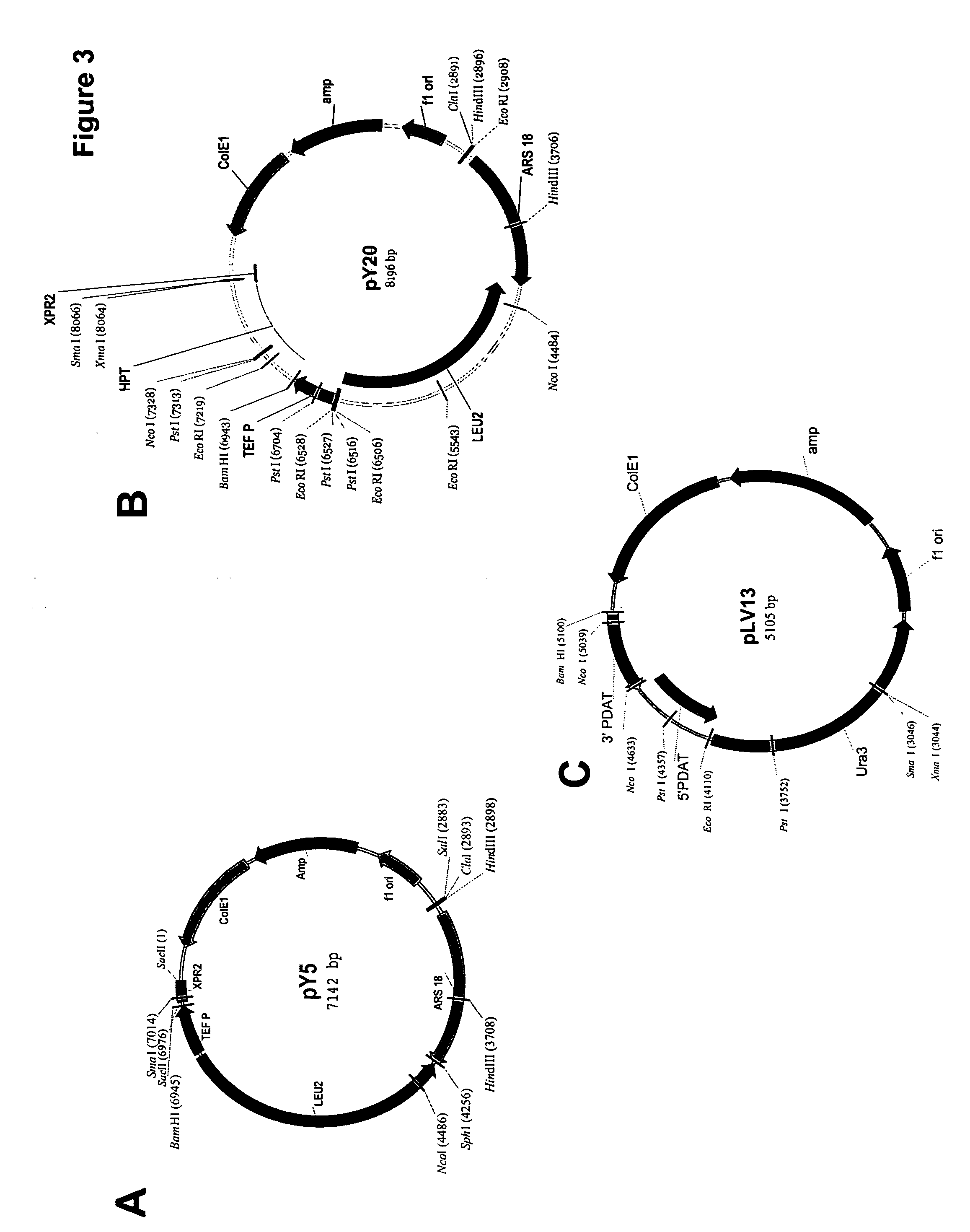

Acyltransferase regulation to increase the percent of polyunsaturated fatty acids in total lipids and oils of oleaginous organisms

InactiveUS20060094088A1Reduced activityOil rate can be reducedFungiSugar derivativesBiotechnologyPDAT enzyme

Methods to increase the percent of polyunsaturated fatty acids (PUFAs) within the total lipids and oils of PUFA-producing oleaginous organisms are provided herein, by regulating the activity of specific acyltransferases. Specifically, since oil biosynthesis is expected to compete with polyunsaturation during oleaginy, it is possible to reduce or inactivate the activity of an organism's DAG ATs (e.g., phospholipid:diacylglycerol acyltransferase (PDAT) and / or diacylglycerol acyltransferase 1 (DGAT1) and / or diacylglycerol acyltransferase 2 (DGAT2)) to thereby reduce the overall rate of oil biosynthesis while concomitantly increasing the percent of PUFAs that are incorporated into the lipid and oil fractions. The teachings herein will thereby enable one to engineer a wide variety of oleaginous organisms to produce oils with very specific fatty acid compositions.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com