Patents

Literature

354 results about "Layer removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

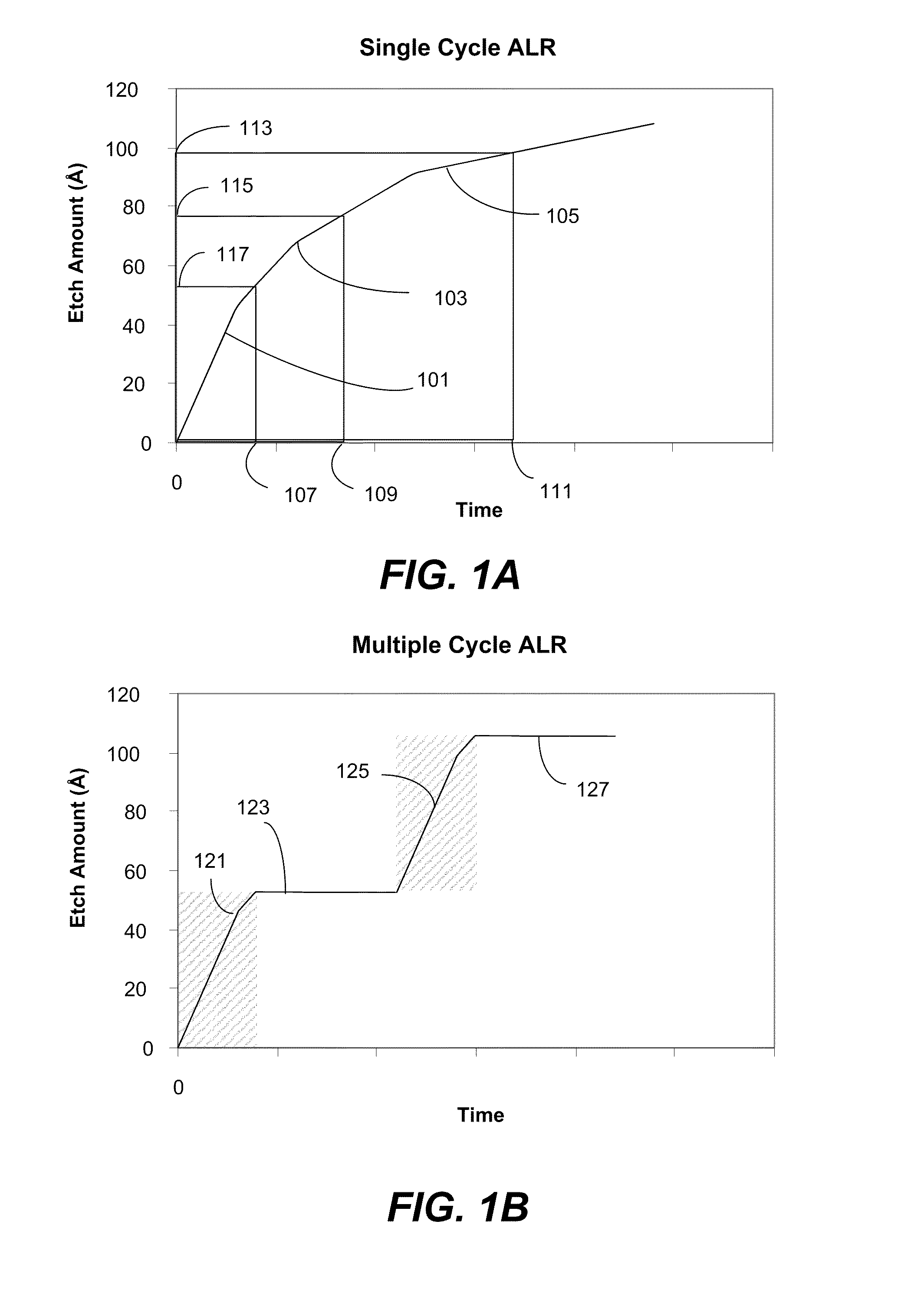

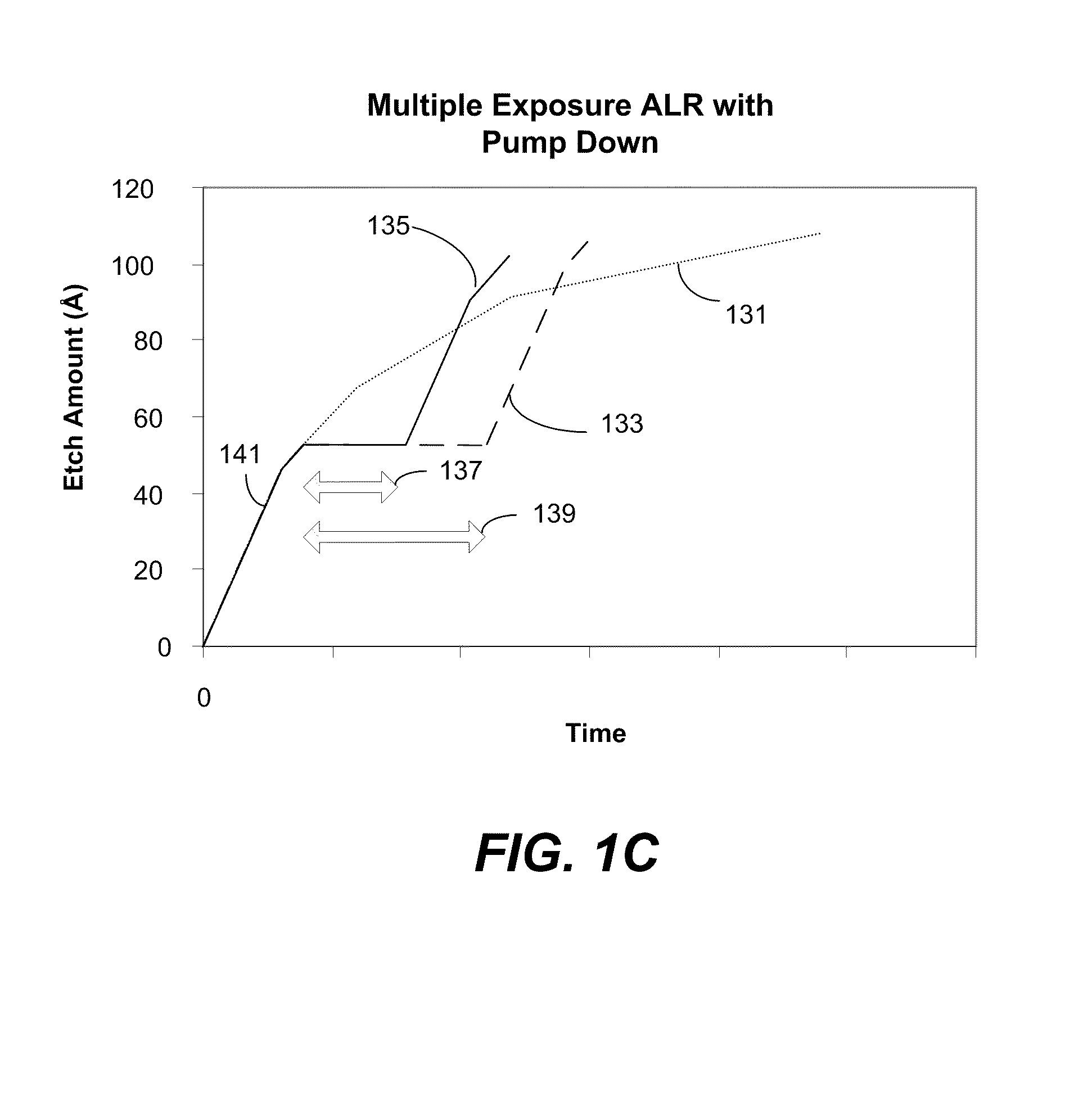

Atomic layer removal process with higher etch amount

InactiveUS8058179B1Easy to controlLimit amount of materialSemiconductor/solid-state device manufacturingSelf limitingLayer removal

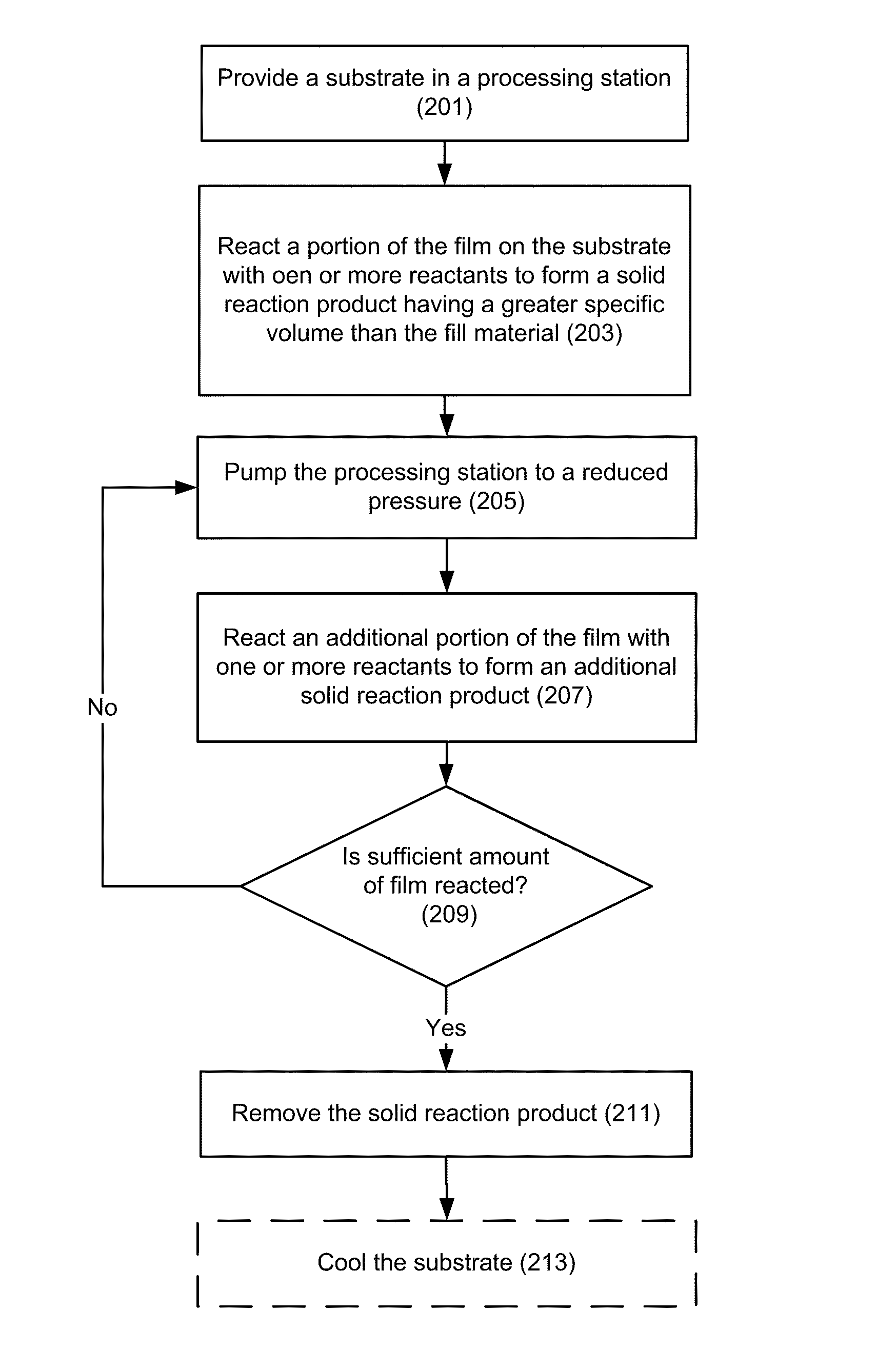

Higher overall etch rate and throughput for atomic layer removal (ALR) is achieved. The reaction is a self-limiting process, thus limiting the total amount of material that may be etched per cycle. By pumping down the process station between reacting operations, the reaction is partially “reset.” A higher overall etch rate is achieved by a multiple exposure with pump down ALR process.

Owner:NOVELLUS SYSTEMS

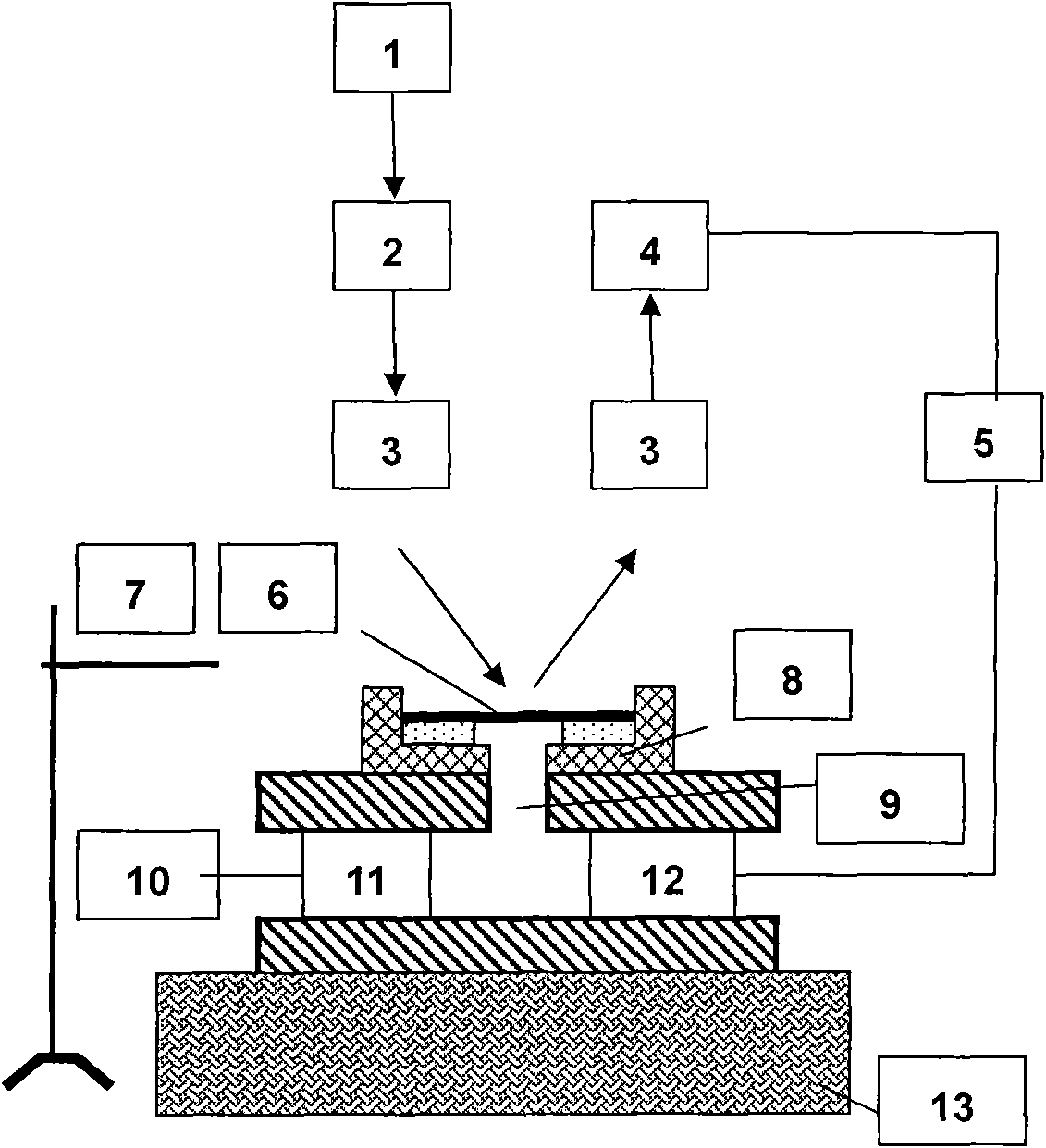

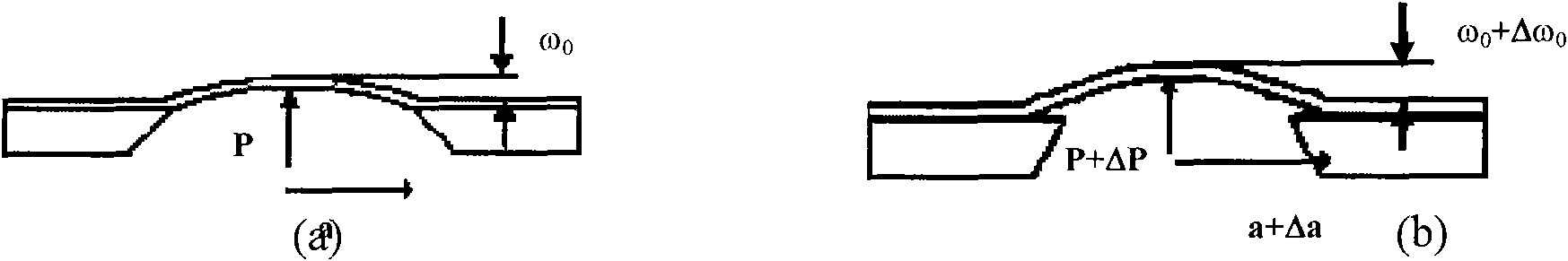

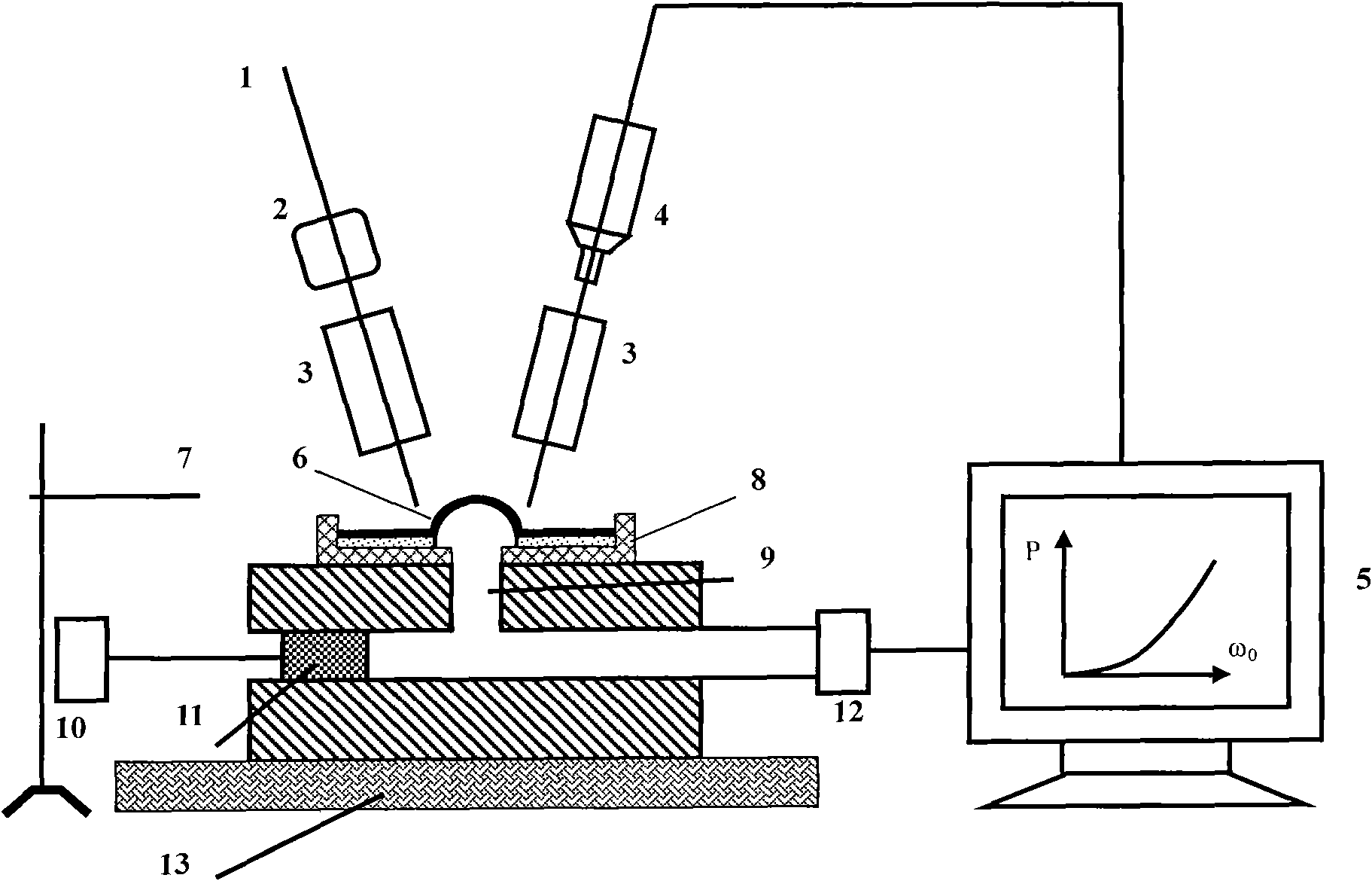

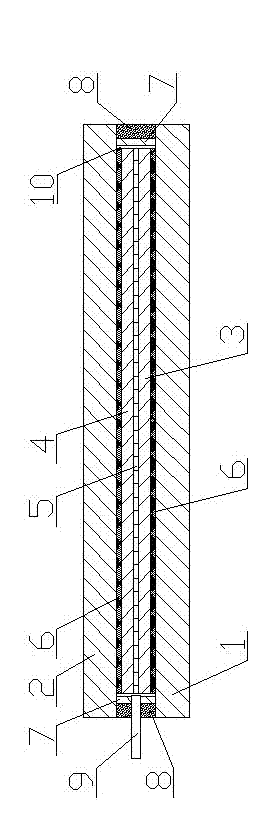

Device for detecting mechanical property of multifunctional film

ActiveCN101788427AHigh measurement accuracyMeasuring field of view can be adjustedMaterial strength using tensile/compressive forcesUsing optical meansElastic plasticSpeckle correlation

The invention discloses a device for detecting the mechanical property of a multifunctional film, comprising a sample stage, a loading mechanism for applying pressure on a film sample, a measuring mechanism for detecting the pressure applied on the film sample and deformation and a computer. The invention uses a digital speckle correlation method (DSCM) to measure film deformation, and combines two mechanical test methods of a bubbling method and a modified layer removal method, thus conveniently, rapidly and accurately measuring a pressure-deformation curve or a corrosion thickness-deformation curve; and mechanical properties of a film and a coating are extracted in terms of a corresponding theoretical model, thus being suitable for detecting the mechanical properties of tool films, decorative films, polymeric films and films of other types in various elastic-plastic systems.

Owner:XIANGTAN UNIV

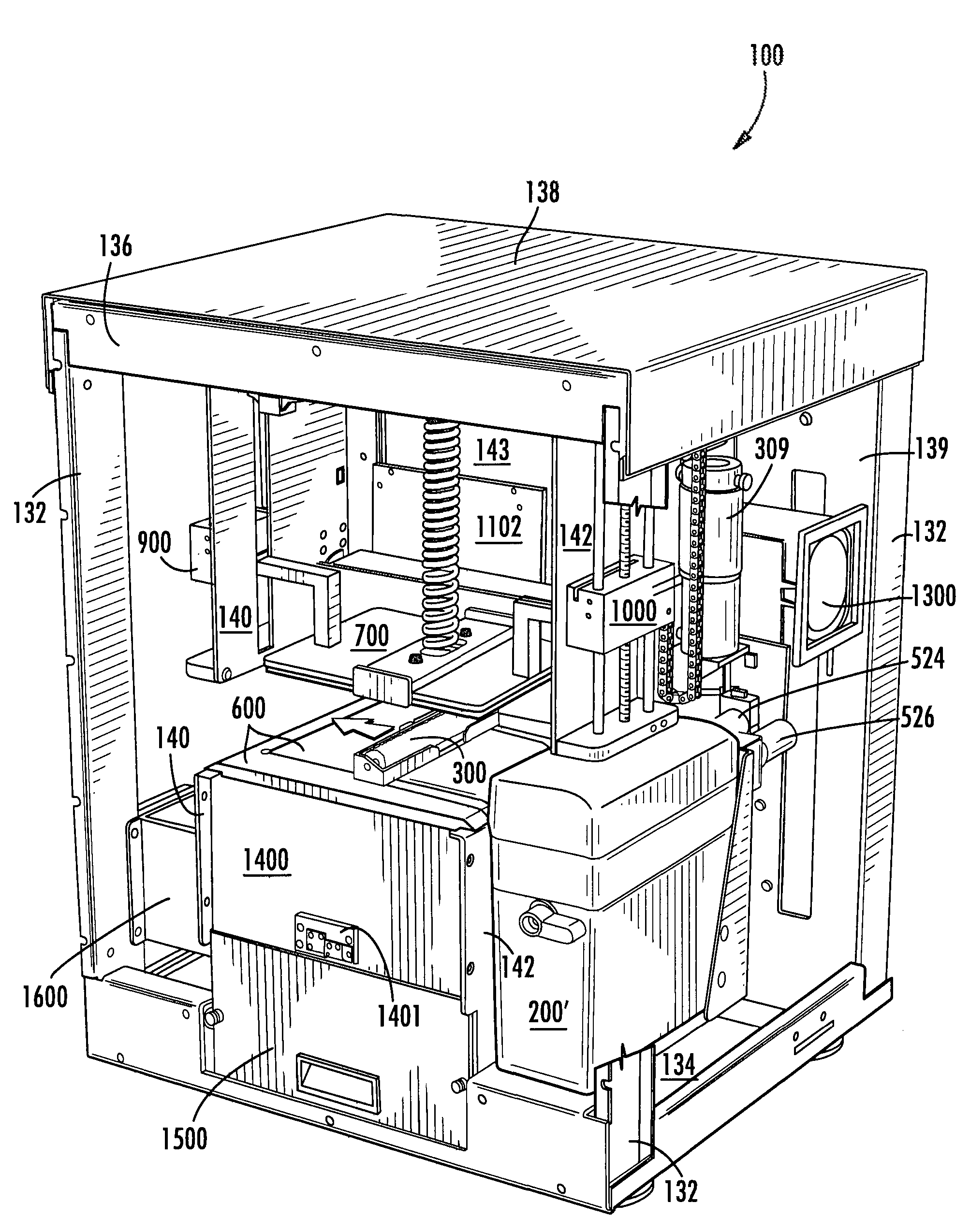

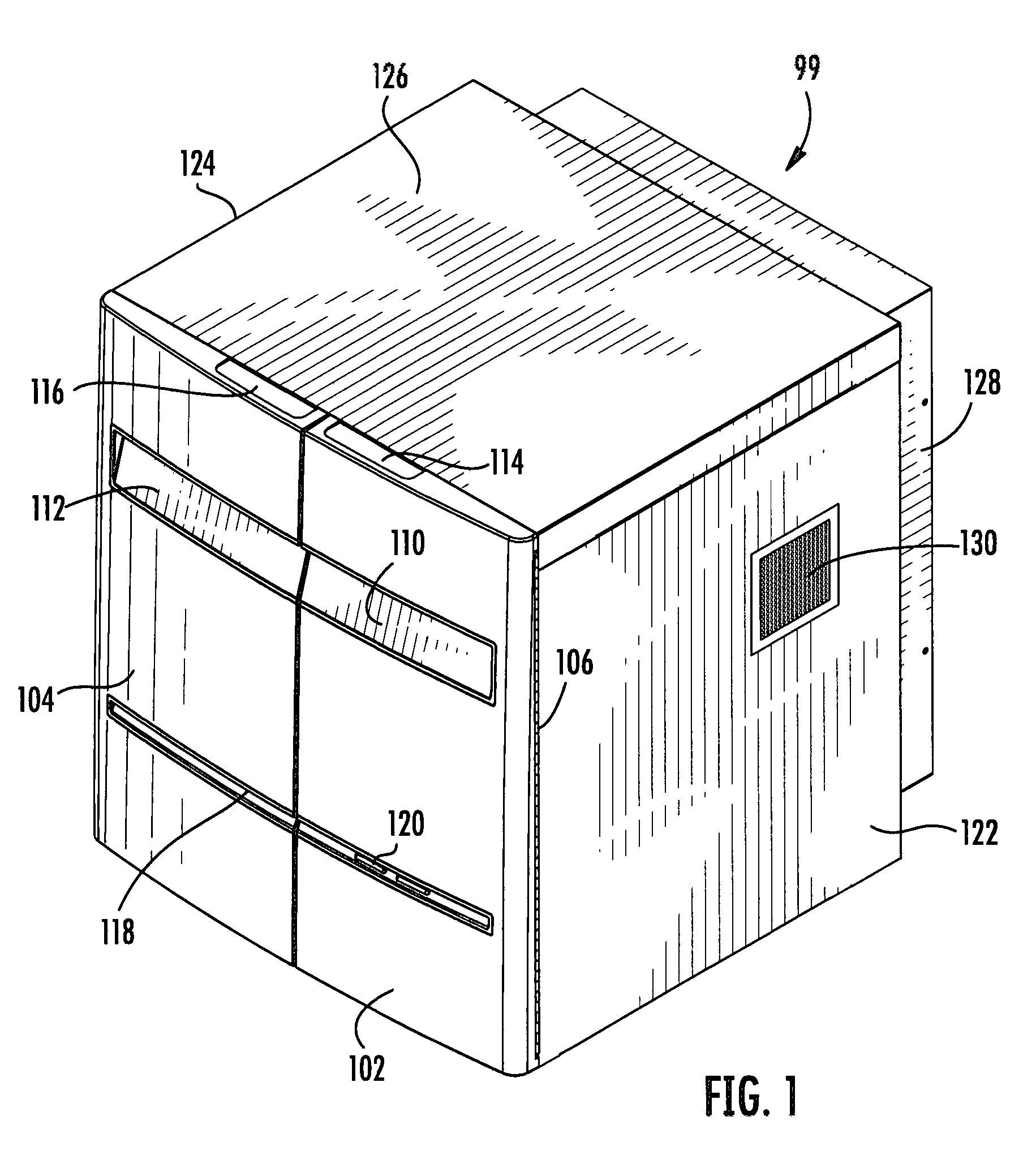

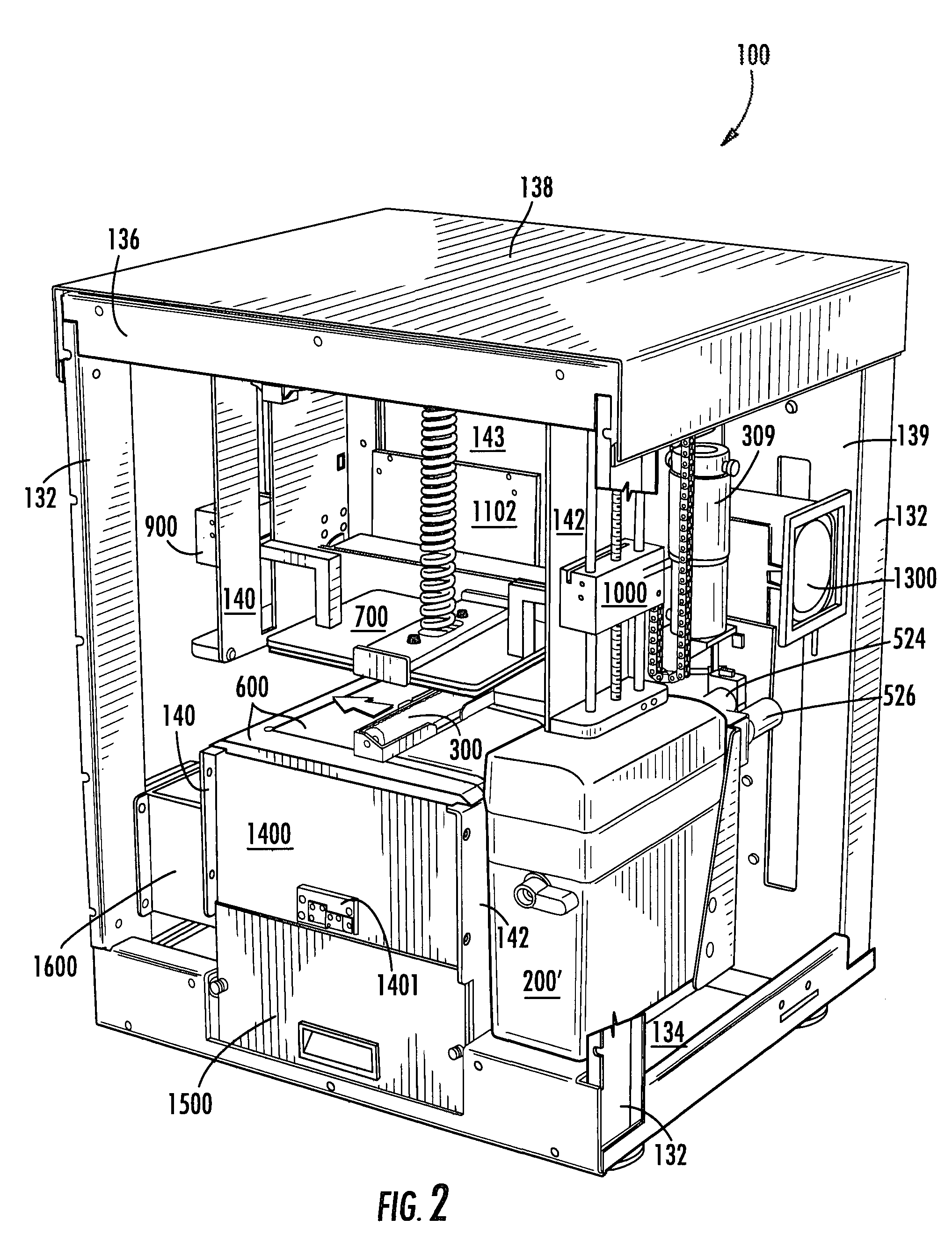

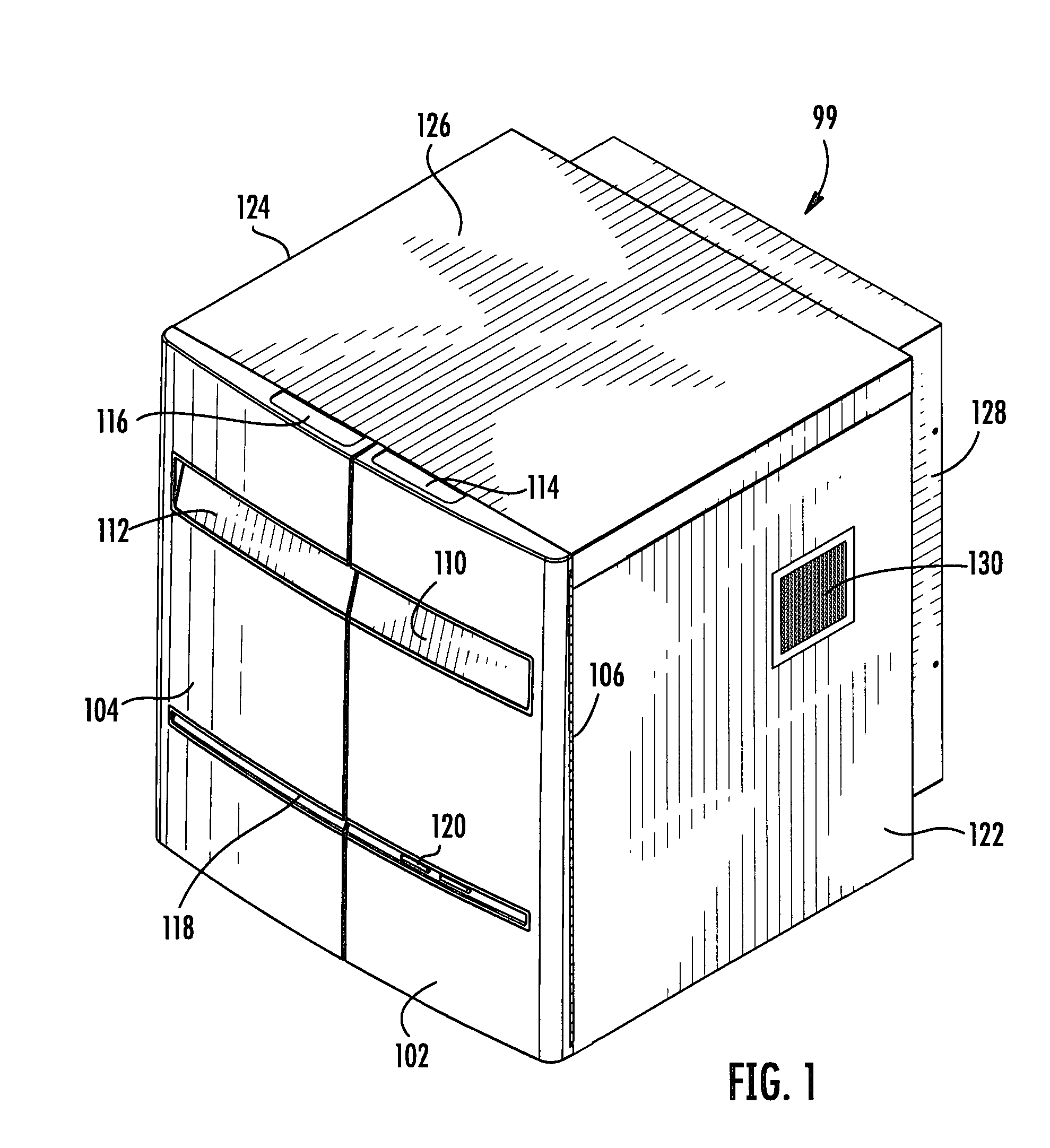

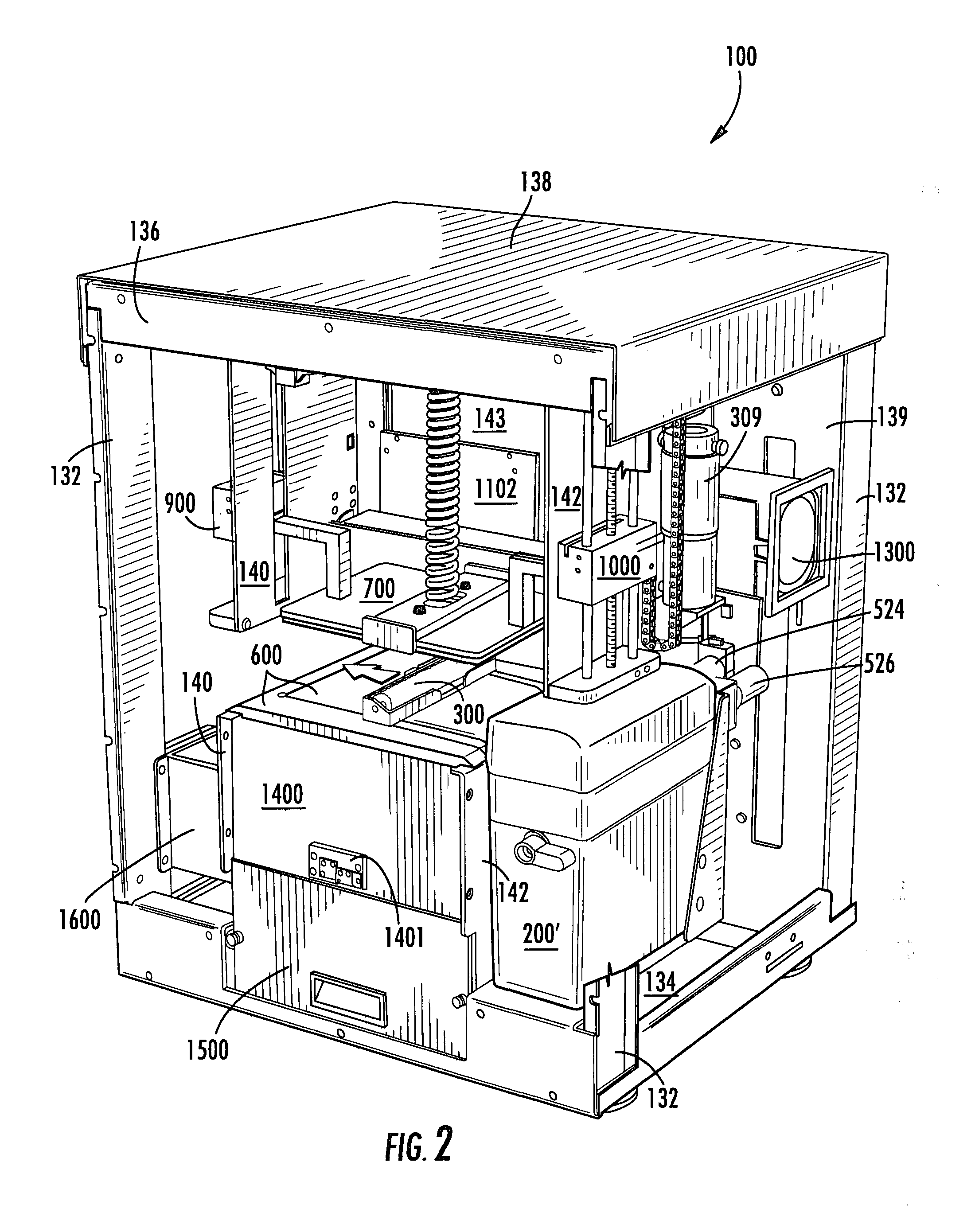

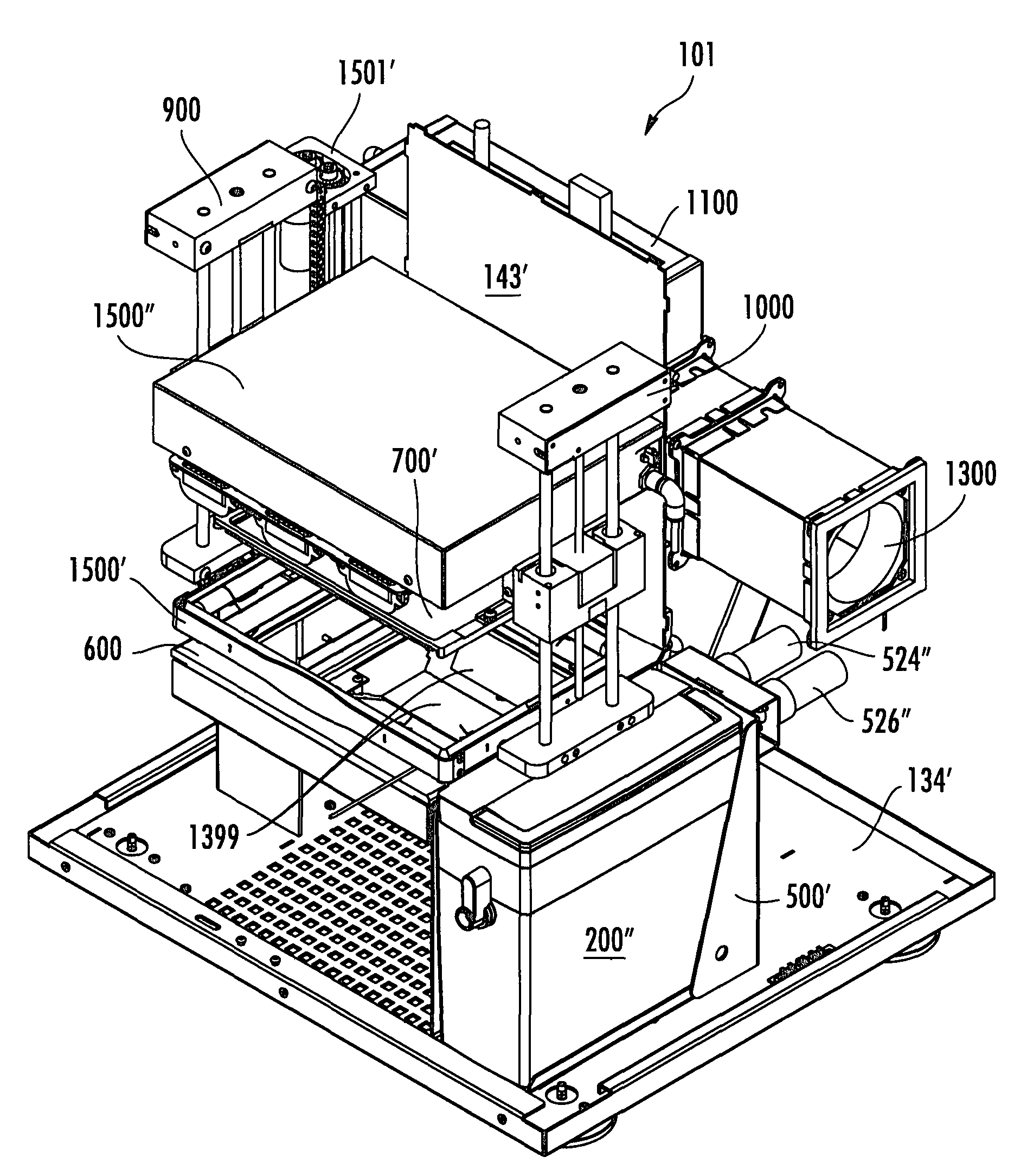

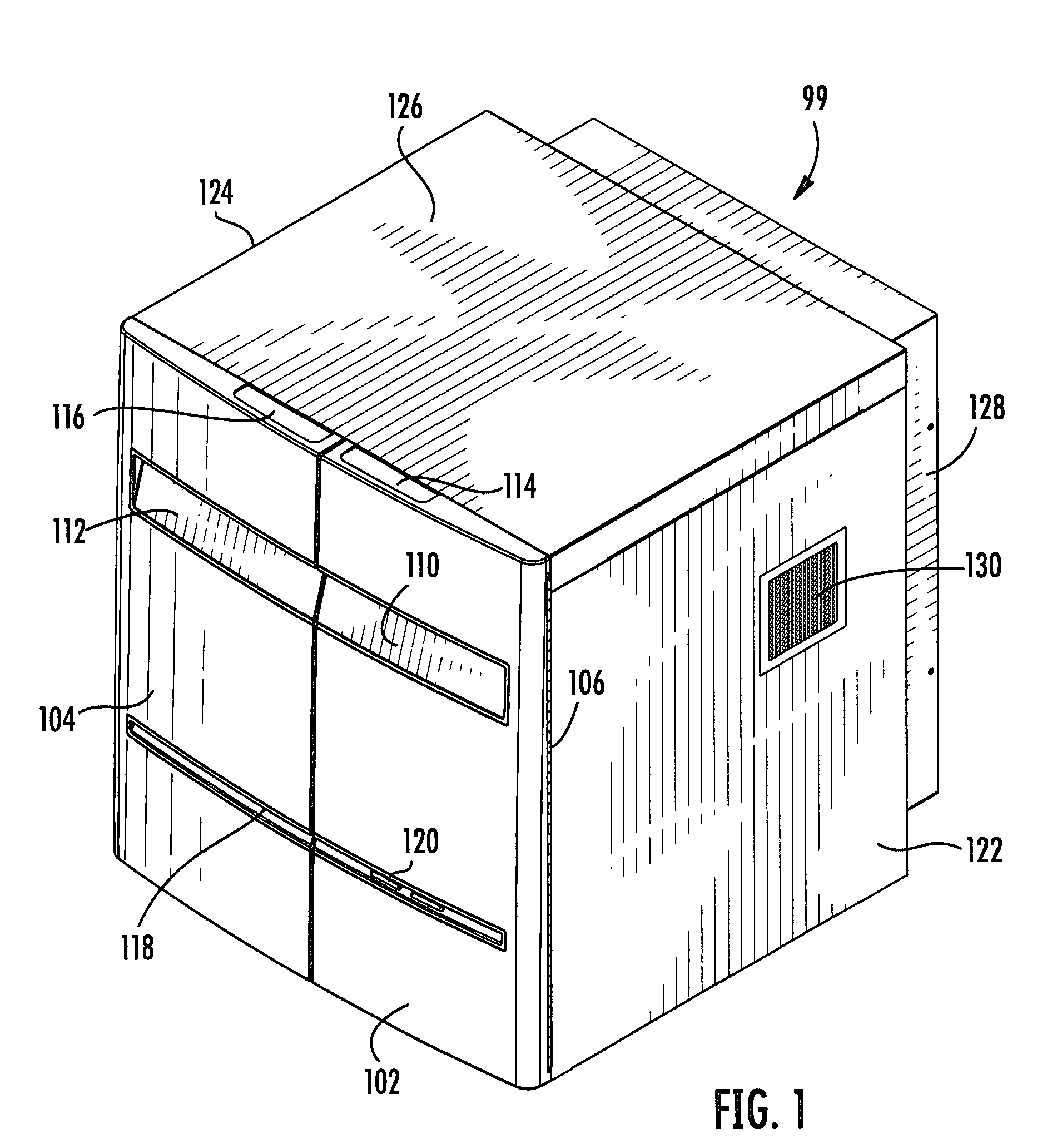

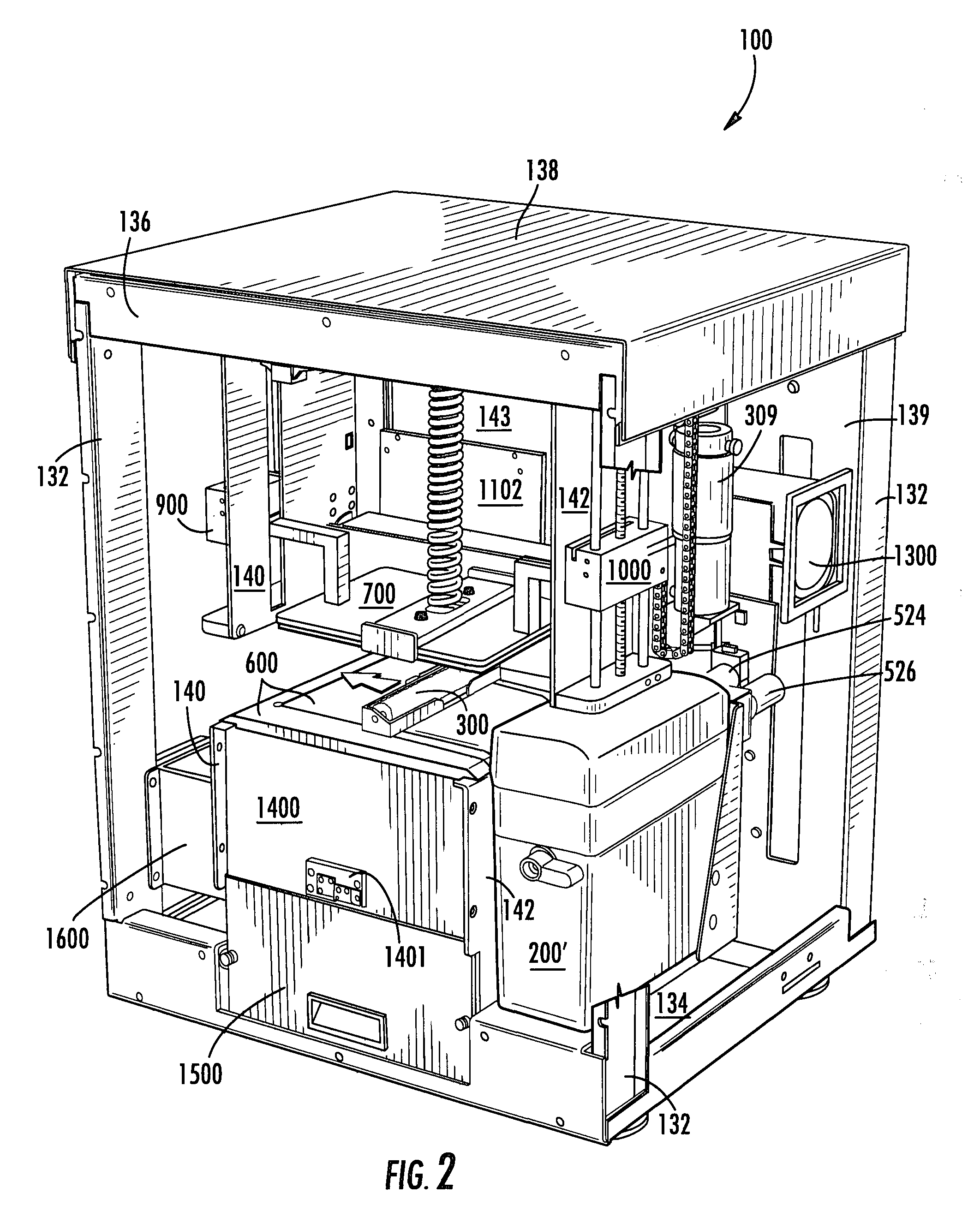

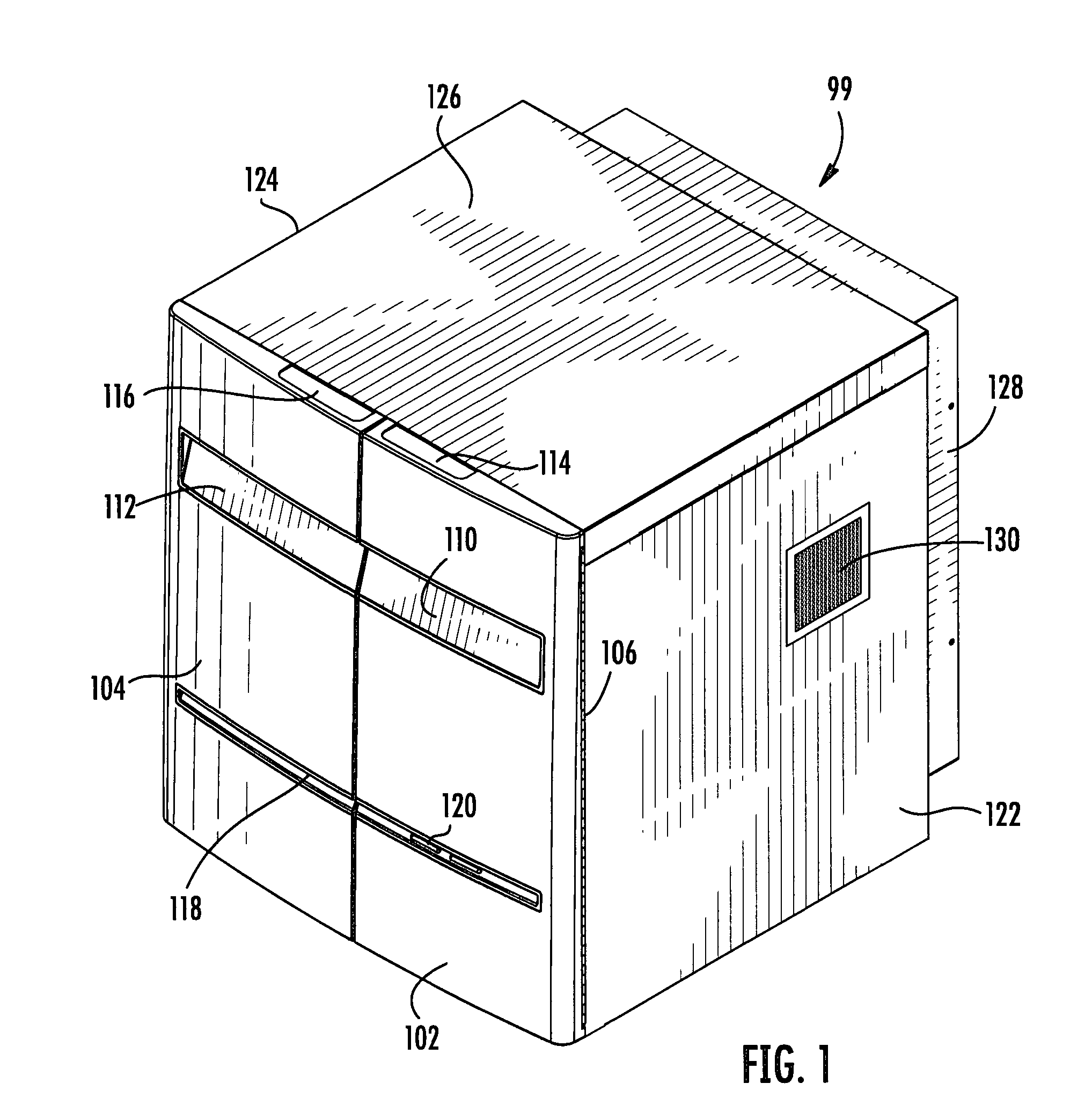

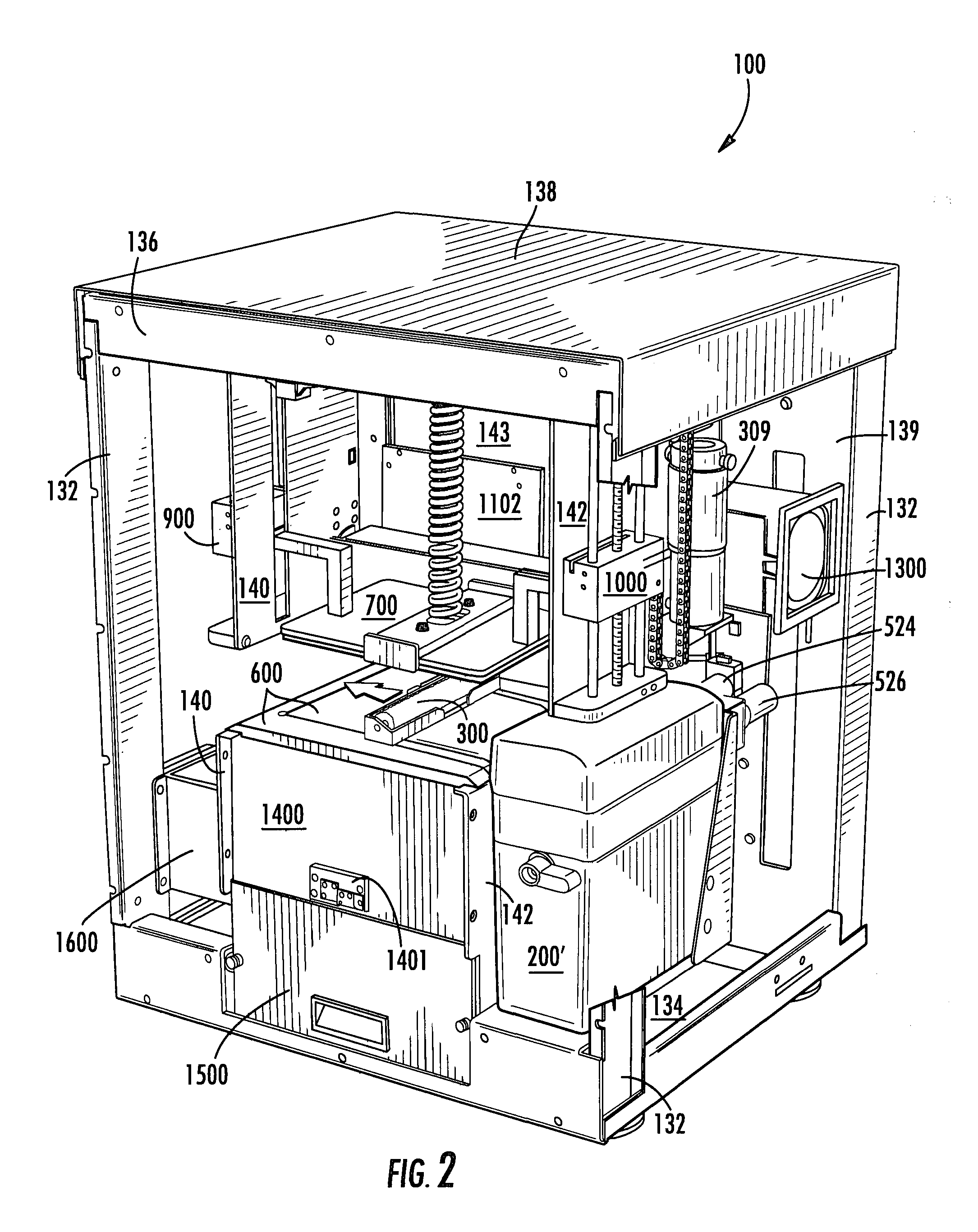

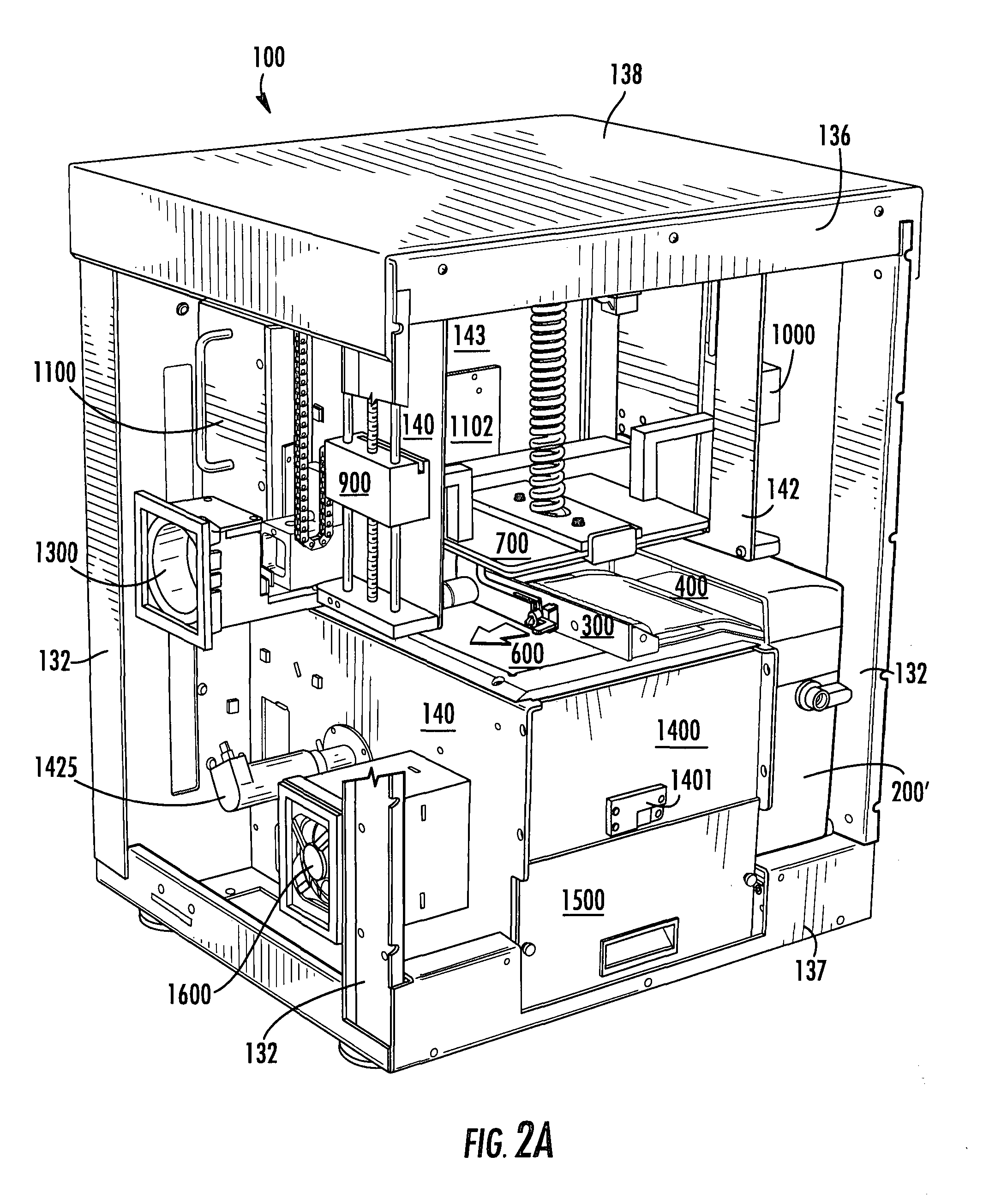

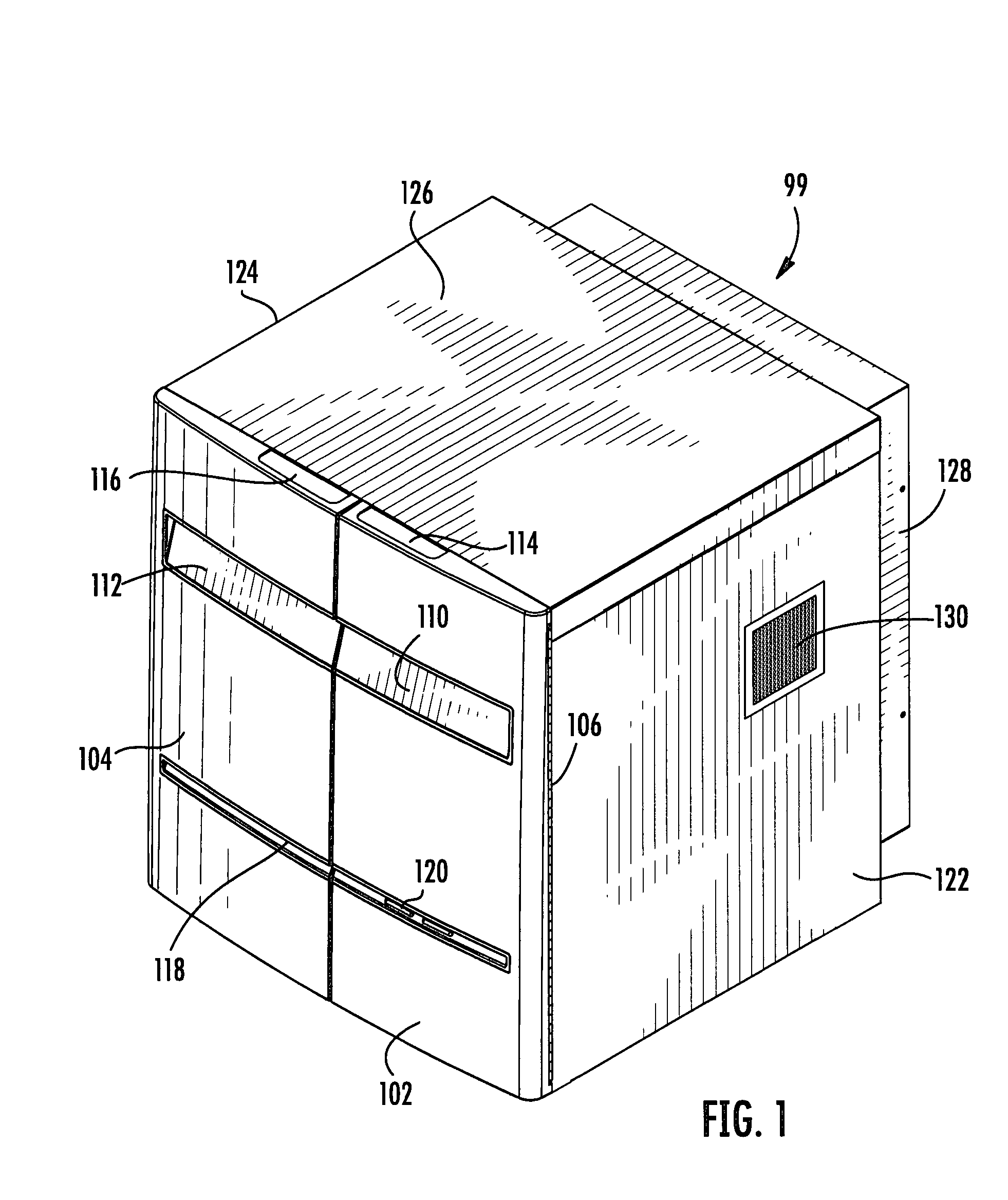

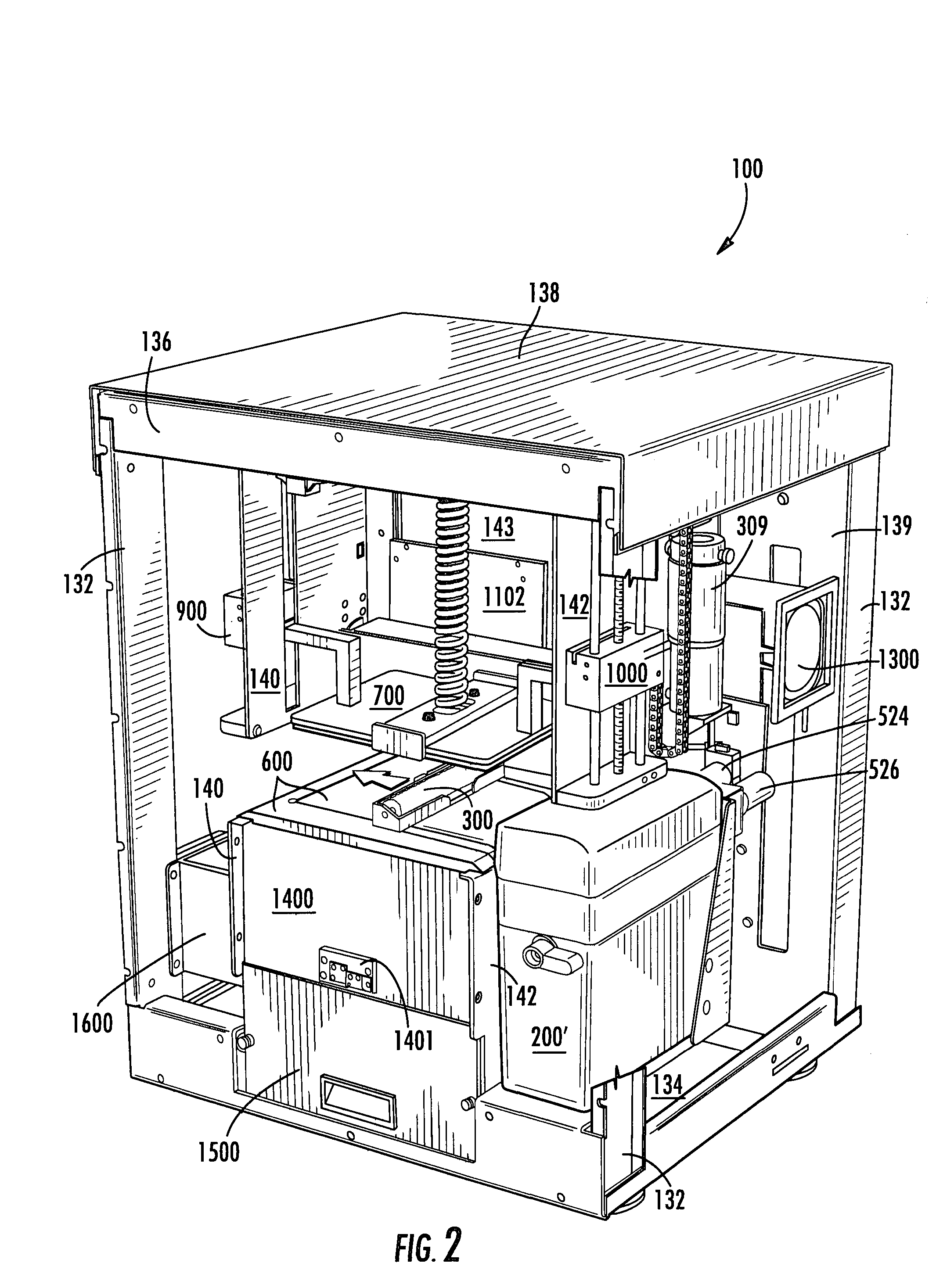

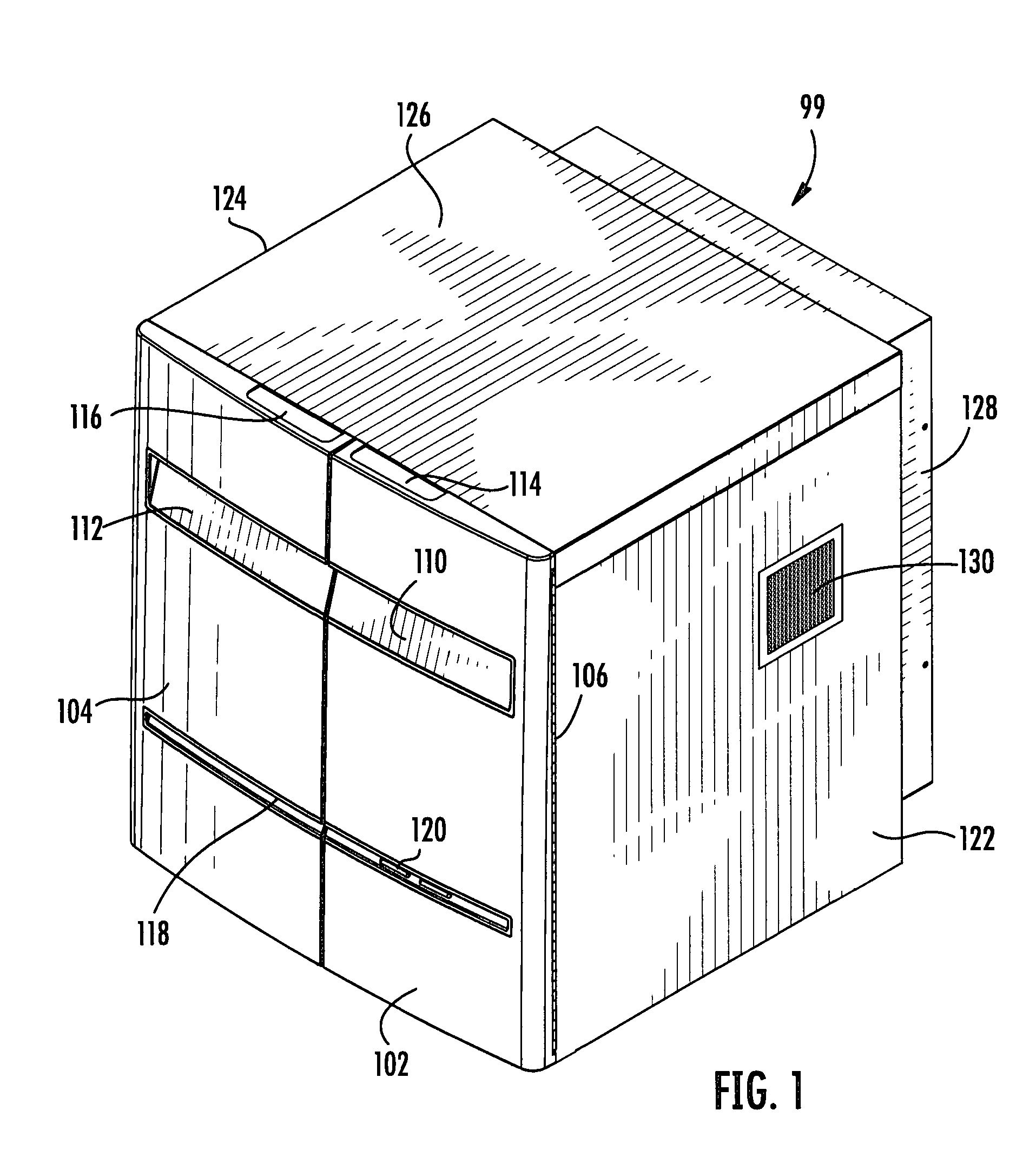

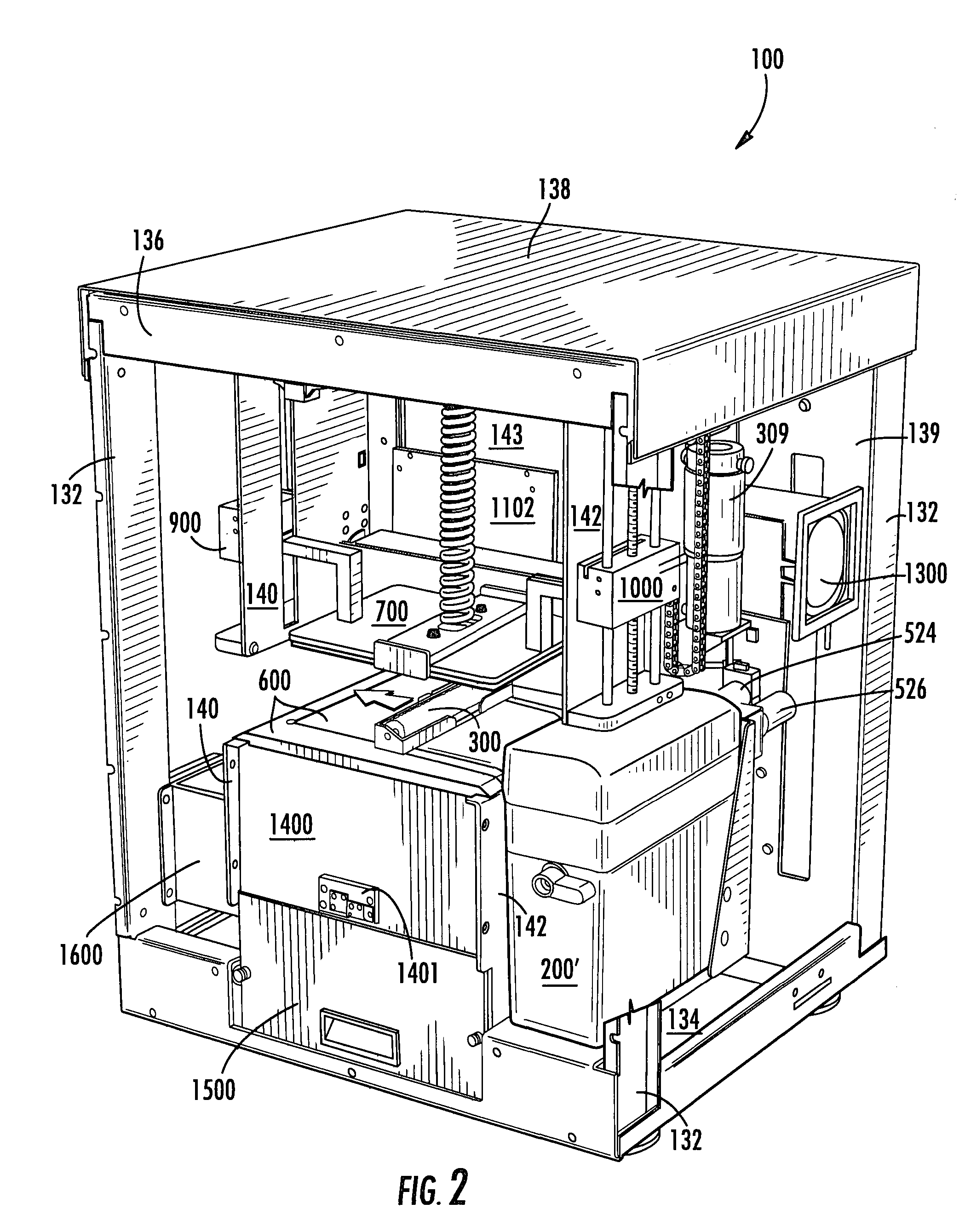

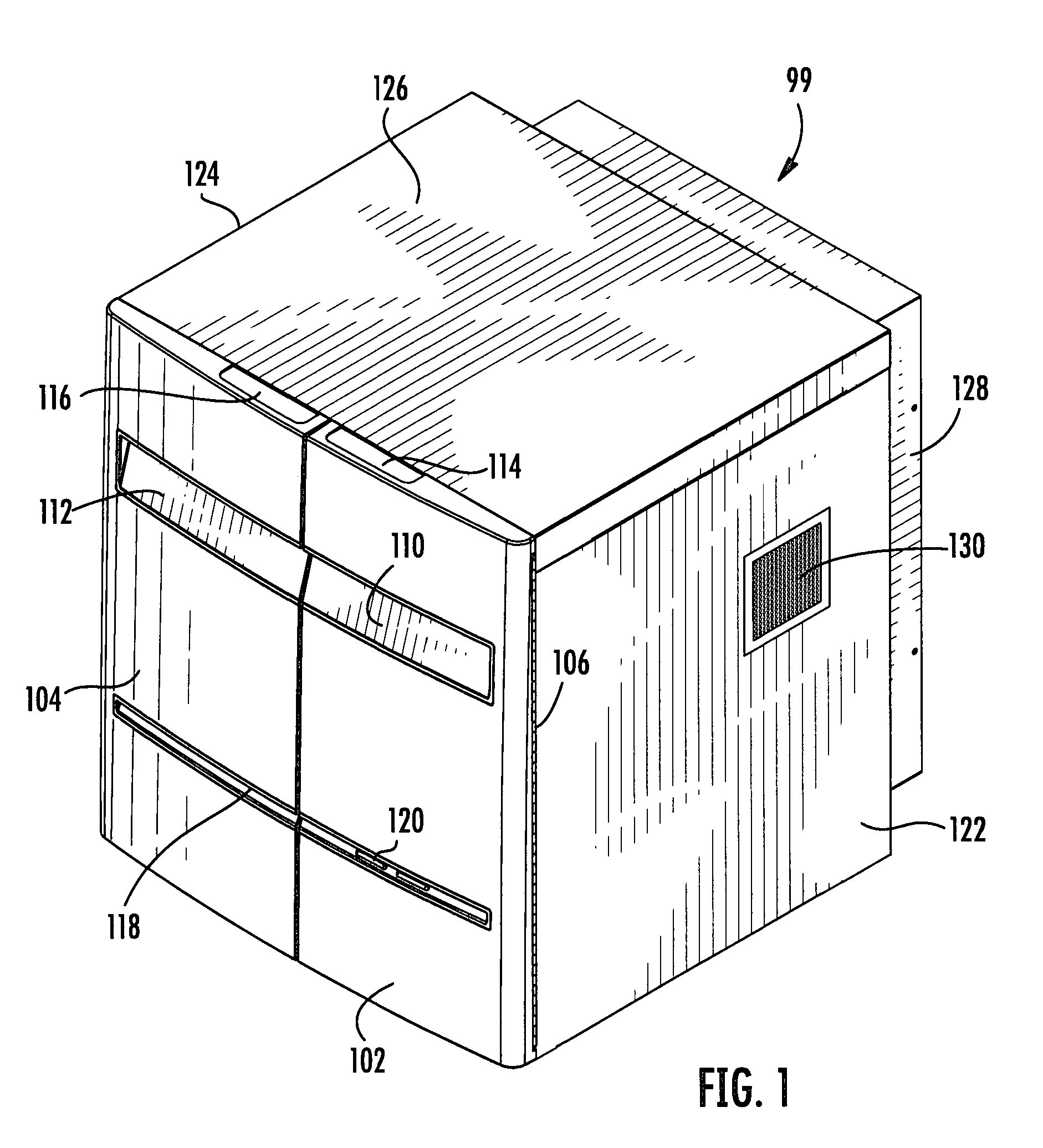

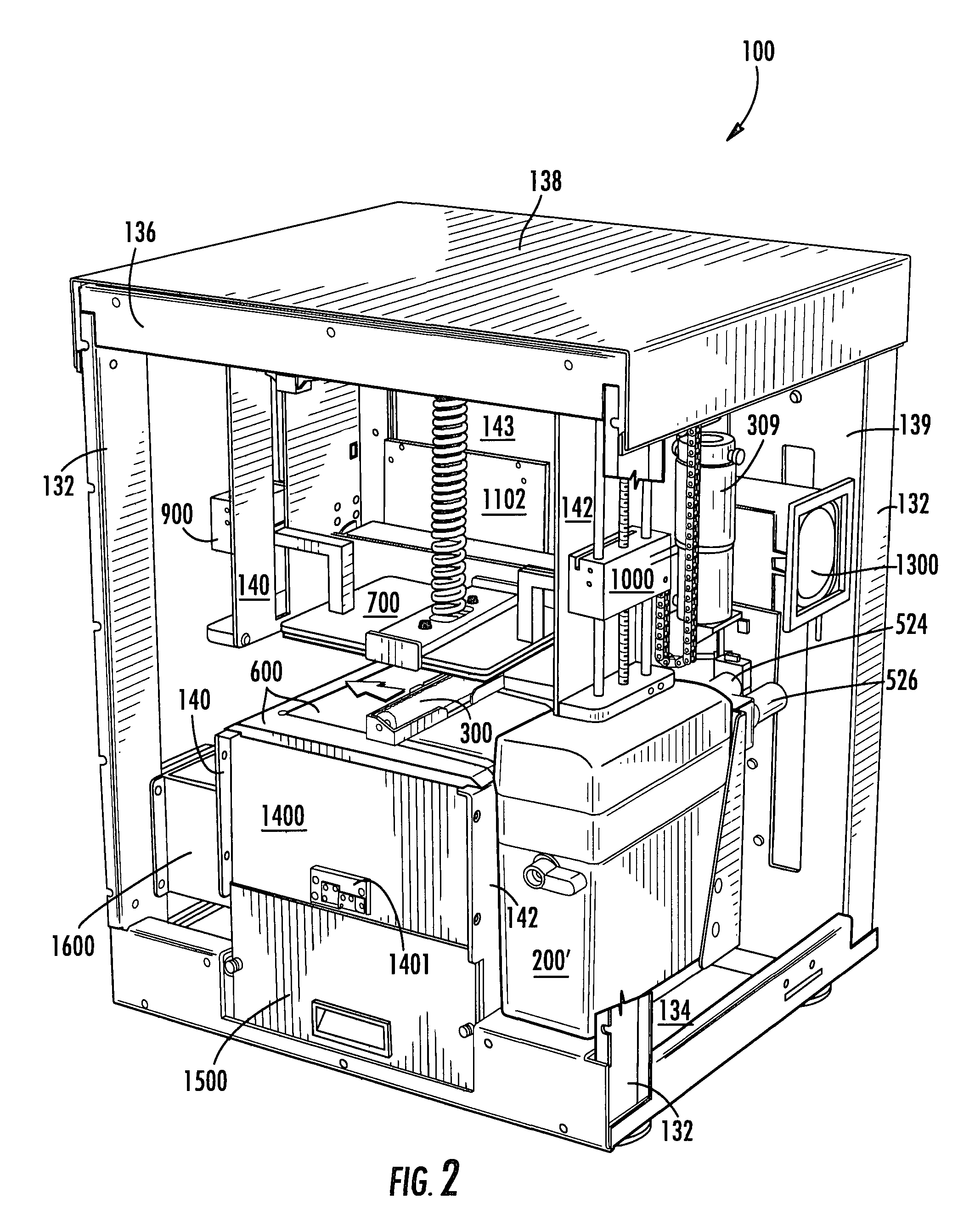

Solid imaging apparatus and method

ActiveUS7614866B2Reduce viscosityImprove bindingLiquid surface applicatorsConfectioneryAir entrainmentHigh intensity

Owner:3D SYST INC

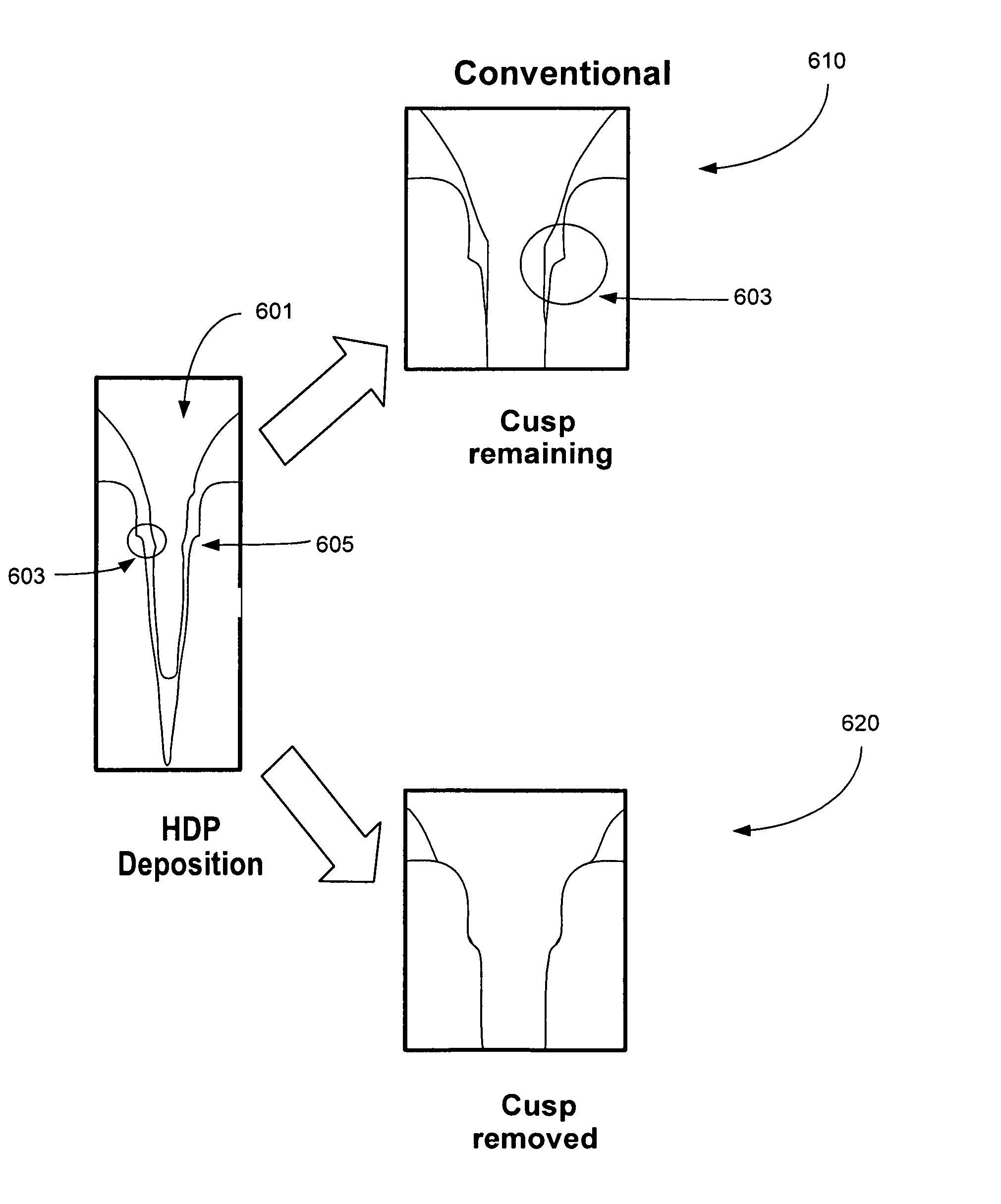

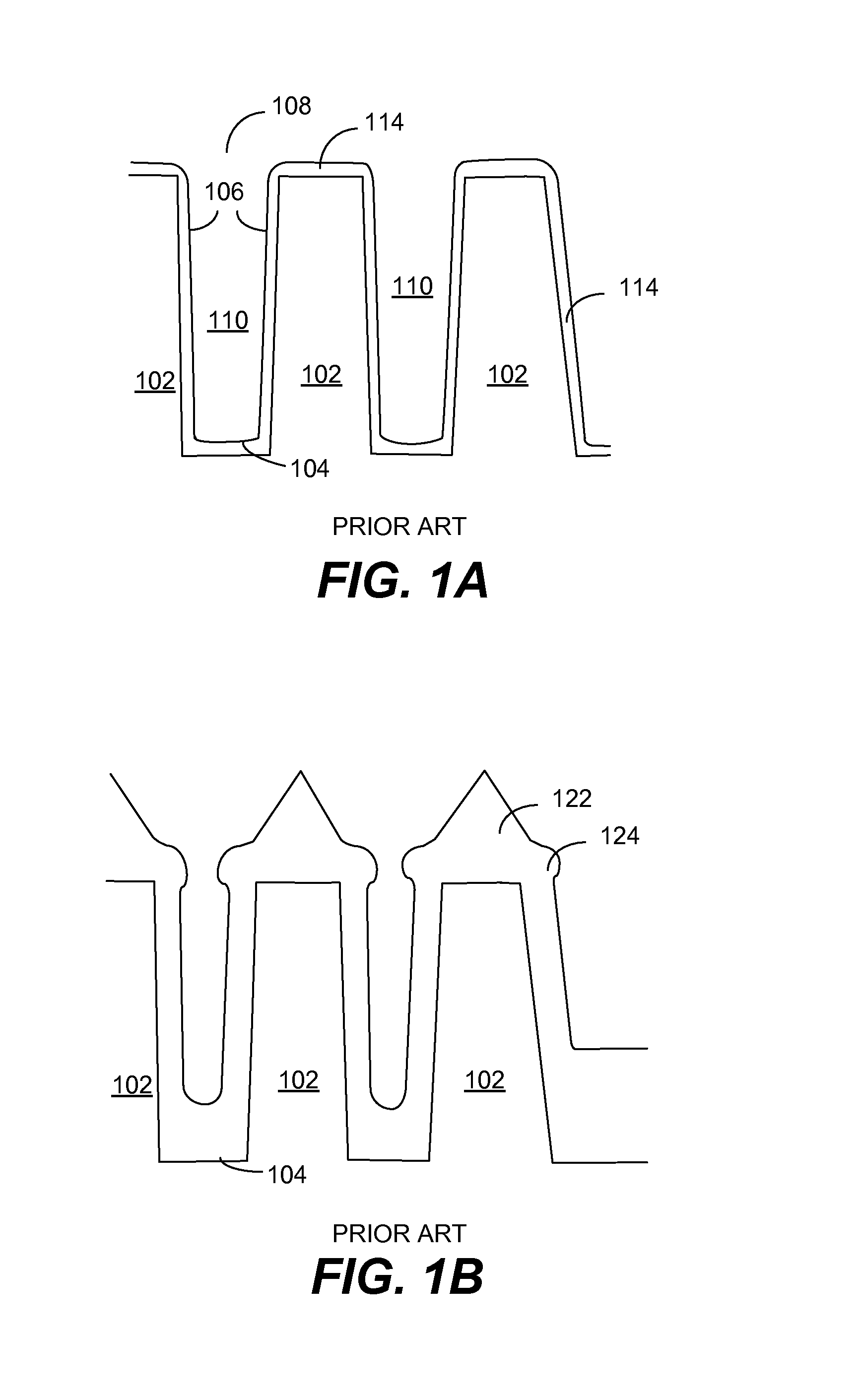

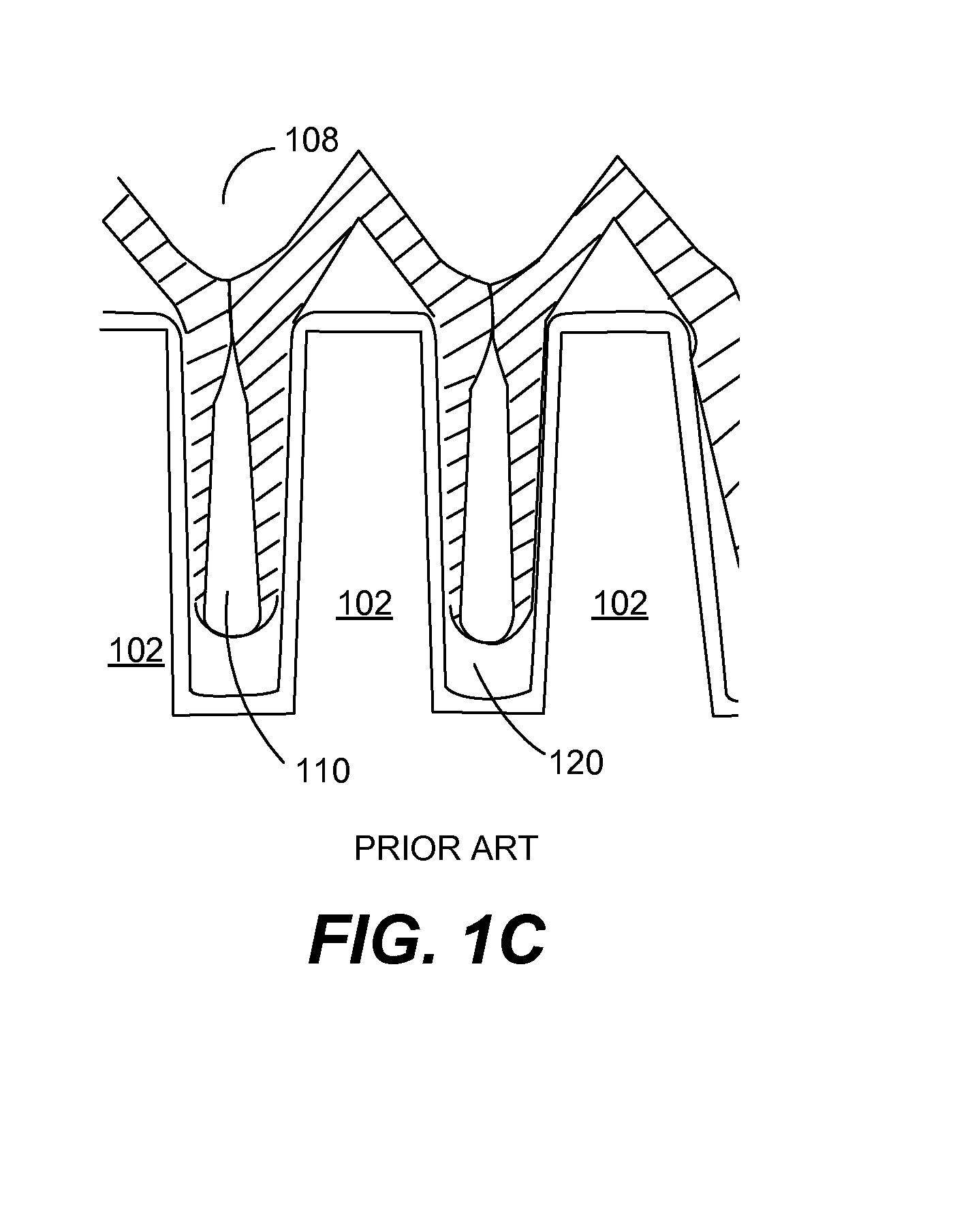

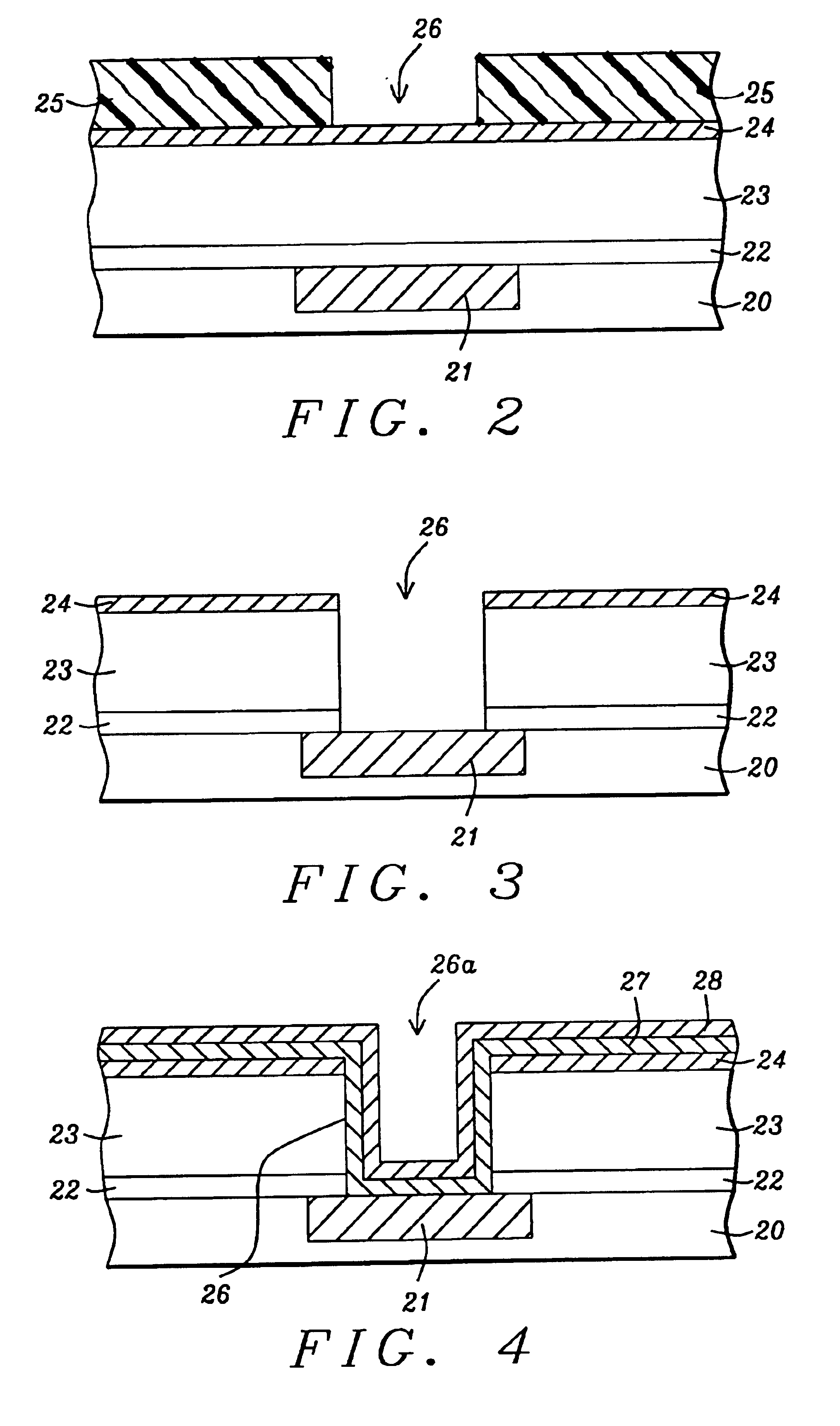

Atomic layer removal for high aspect ratio gapfill

Owner:NOVELLUS SYSTEMS

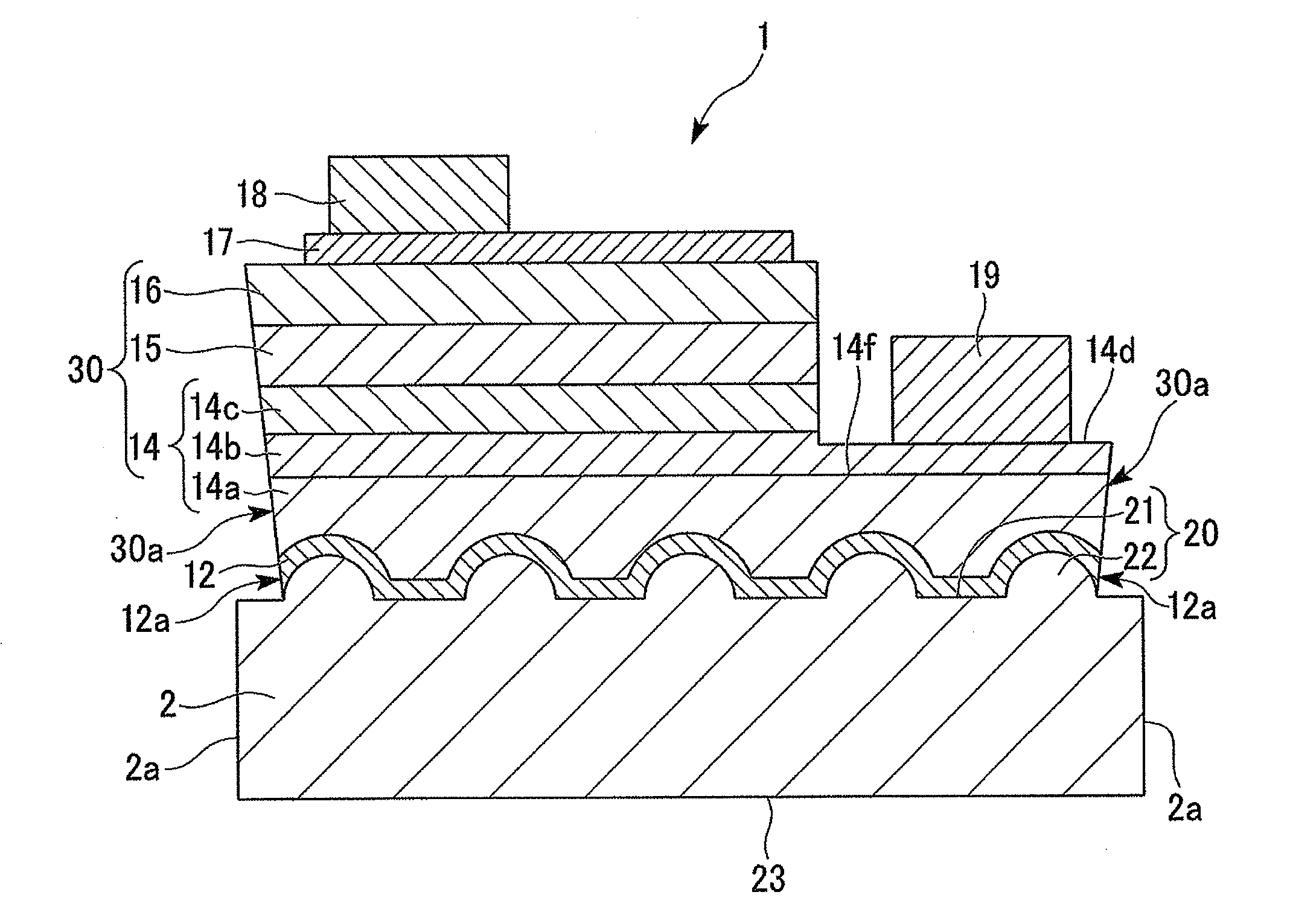

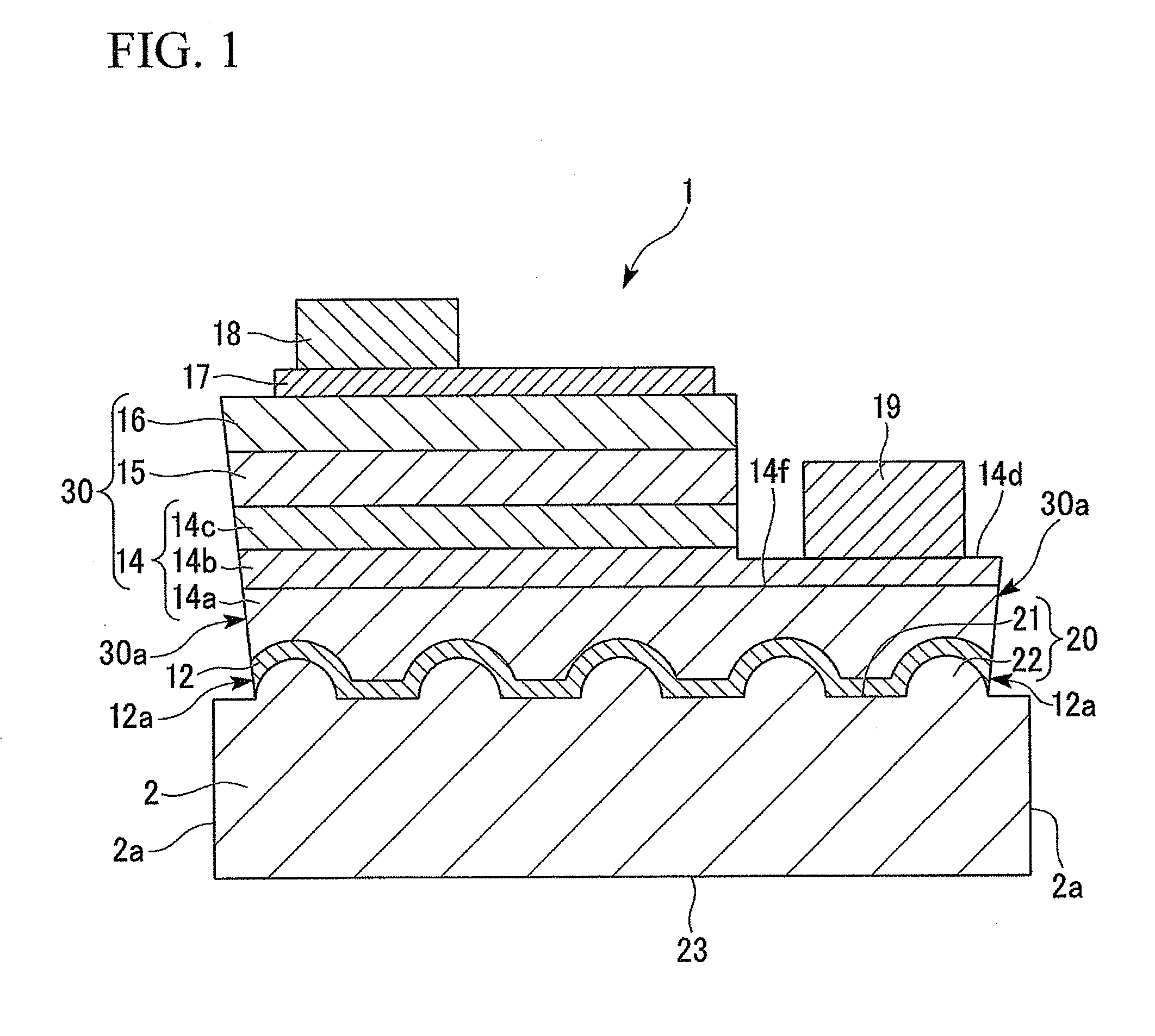

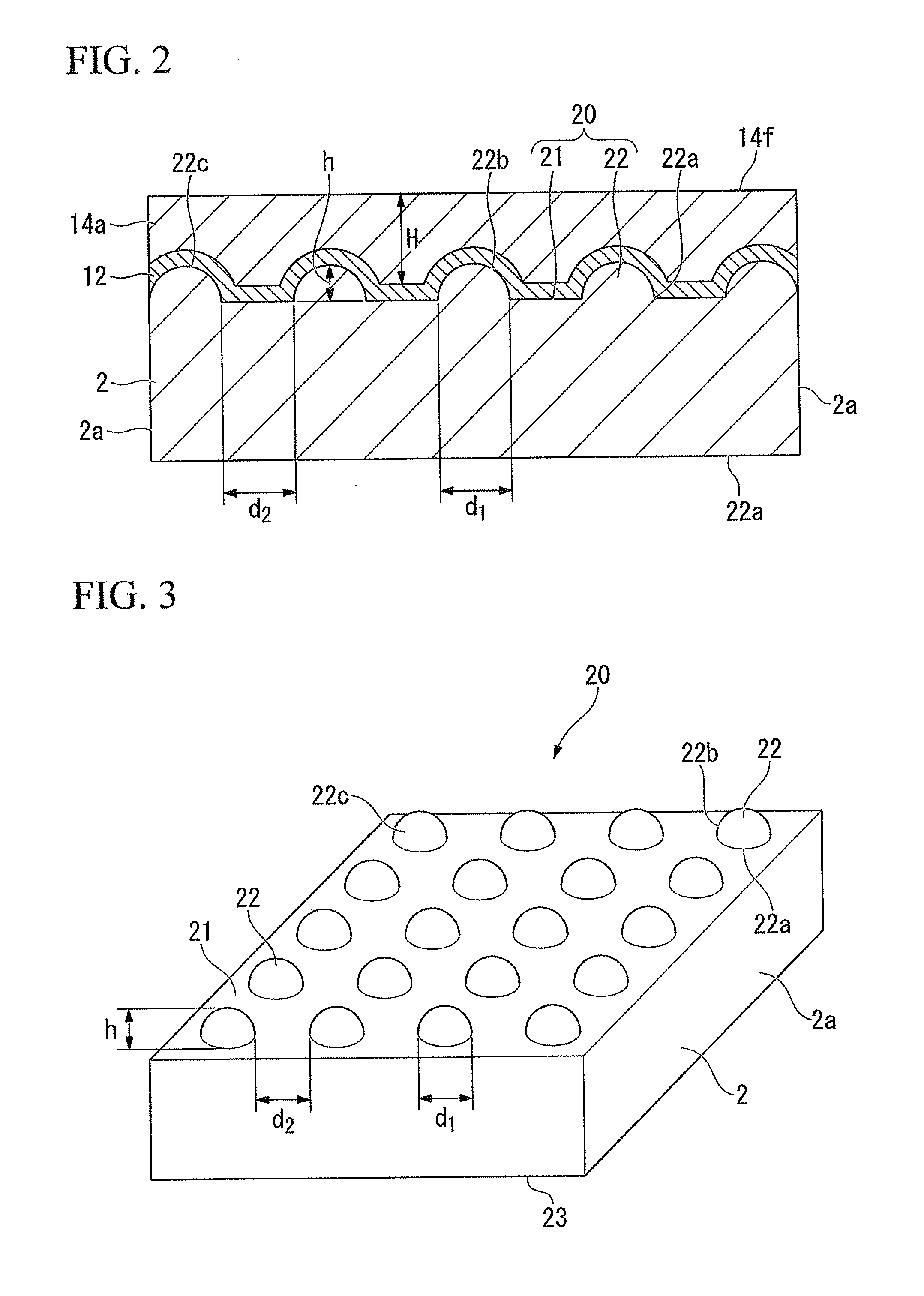

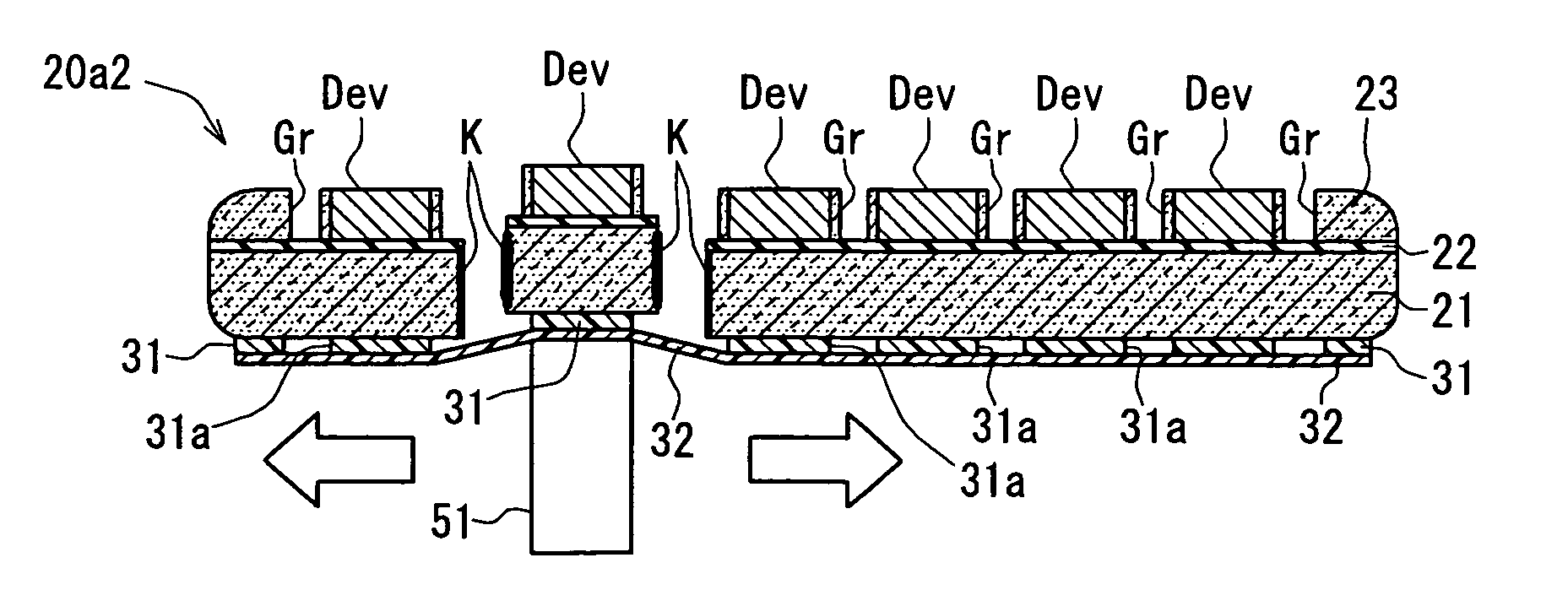

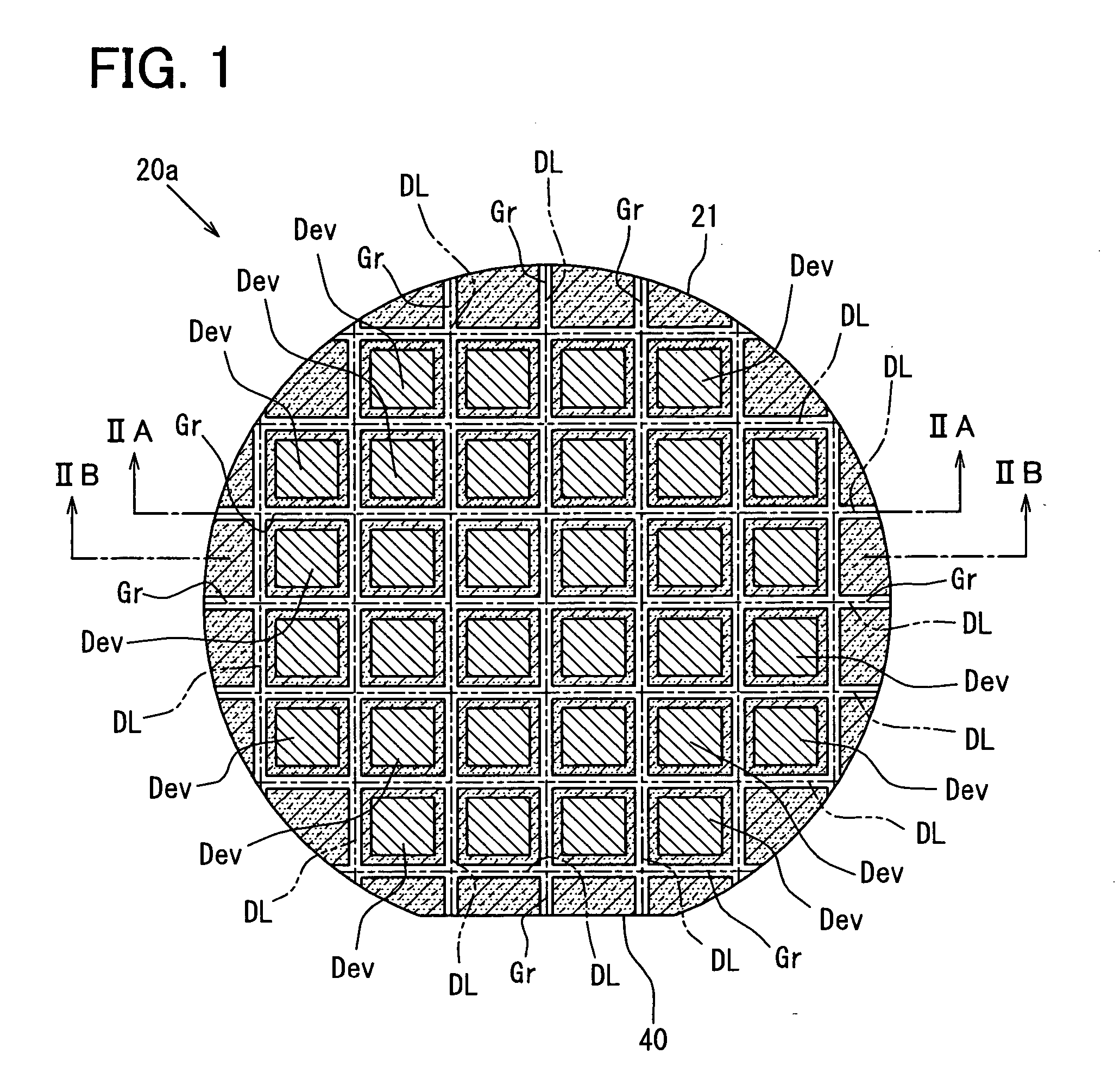

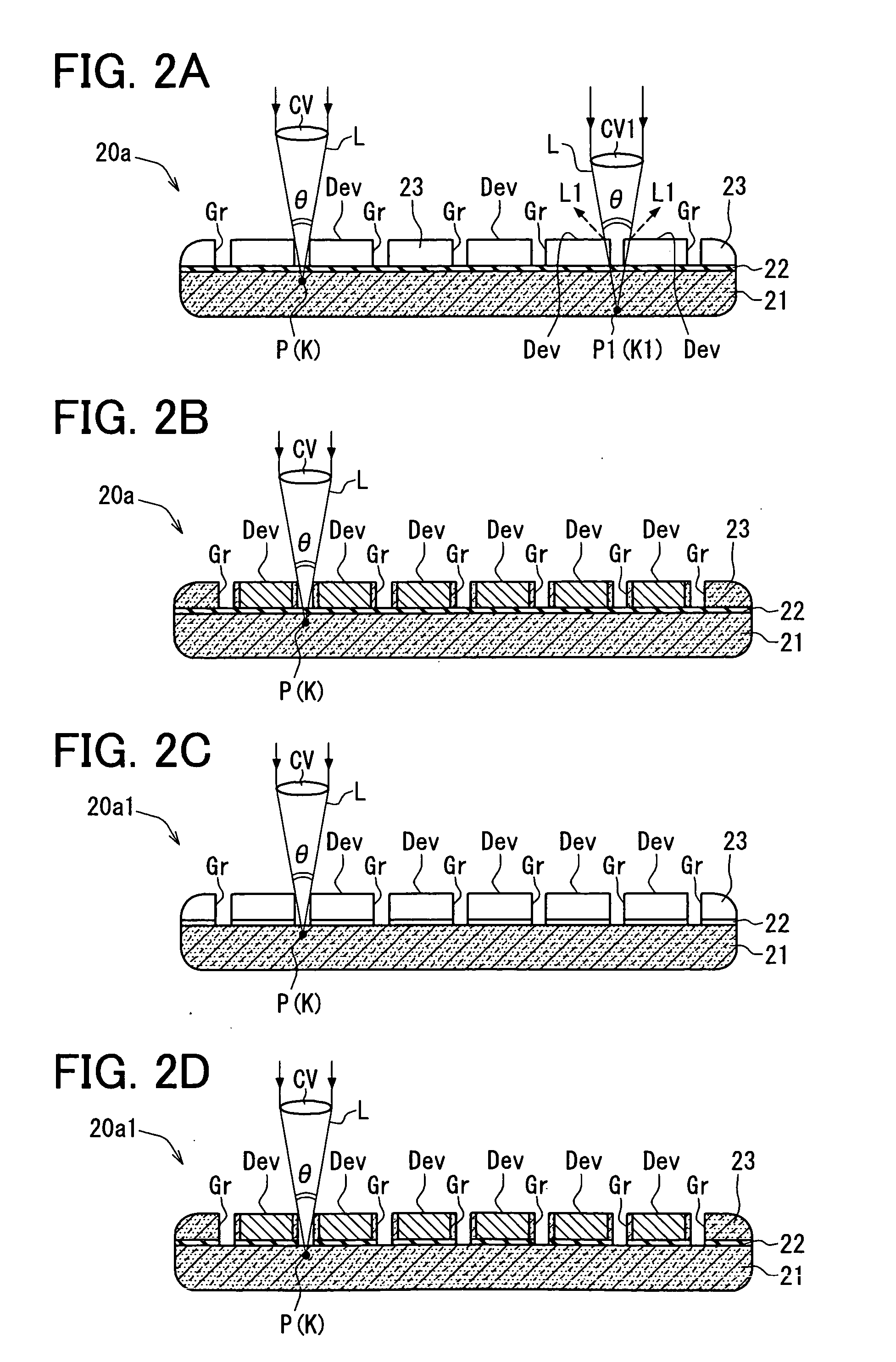

Method of manufacturing group-iii nitride semiconductor light-emitting device, and group-iii nitride semiconductor light-emitting device, and lamp

ActiveUS20110062479A1Reduce thicknessWithout lowering device characteristicSolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencyRough surface

Provided are a method of manufacturing a group-III nitride semiconductor light-emitting device in which a light-emitting device excellent in the internal quantum efficiency and the light extraction efficiency can be obtained, a group-III nitride semiconductor light-emitting device and a lamp. Included are an epitaxial step of forming a semiconductor layer (30) so as to a main surface (20) of a substrate (2), a masking step of forming a protective film on the semiconductor layer (30), a semiconductor layer removal step of removing the protective film and the semiconductor layer (30) by laser irradiation to expose the substrate (2), a grinding step of reducing the thickness of the substrate (2), a polishing step of polishing the substrate (2), a laser processing step of providing processing marks to the inside of the substrate (2), a division step of creating a plurality of light-emitting devices (1) while forming a division surface of the substrate (2) to have a rough surface.

Owner:TOYODA GOSEI CO LTD

Build pad, solid image build, and method for building build supports

InactiveUS20080170112A1Less post-build cleaningLess curing3D object support structuresPrintingAir entrainmentEngineering

A solid imaging apparatus is provided that includes a replaceable cartridge containing a source of build material and an extendable and retractable flexible transport film for transporting the build material layer-by-layer from the cartridge to the surface of a build in an image plane. An operator using the device needs merely to remove a spent cartridge and replace it with a fresh cartridge to continue solid imaging virtually uninterrupted. The apparatus also includes the capability of withdrawing and inserting an imager without the operator having to perform a separate alignment step. A brush attached to the transport film and forming part of the cartridge provides for intra-layer removal of excess uncured build material. If desired, the apparatus can produce a fully reacted build. A high intensity UV source cures the build between layers. An injection molded build pad is designed to hold a build in an inverted position for improving the build. The invention also provides for tilting the build elevator to reduce air entrainment and for releasing the build from the image plane.

Owner:3D SYST INC

Brush assembly for removal of excess uncured build material

InactiveUS20080181977A1Less post-build cleaningLess curingFrozen sweetsConfectioneryAir entrainmentHigh intensity

A solid imaging apparatus is provided that includes a replaceable cartridge containing a source of build material and an extendable and retractable flexible transport film for transporting the build material layer-by-layer from the cartridge to the surface of a build in an image plane. An operator using the device needs merely to remove a spent cartridge and replace it with a fresh cartridge to continue solid imaging virtually uninterrupted. The apparatus also includes the capability of withdrawing and inserting an imager without the operator having to perform a separate alignment step. A brush attached to the transport film and forming part of the cartridge provides for intra-layer removal of excess uncured build material. If desired, the apparatus can produce a fully reacted build. A high intensity UV source cures the build between layers. An injection molded build pad is designed to hold a build in an inverted position for improving the build. The invention also provides for tilting the build elevator to reduce air entrainment and for releasing the build from the image plane.

Owner:3D SYST INC

Elevator and method for tilting solid image build platform for reducing air entrainment and for build release

ActiveUS20080179787A1Reduce viscosityImprove bindingMouldsConfectioneryAir entrainmentHigh intensity

A solid imaging apparatus is provided that includes a replaceable cartridge containing a source of build material and an extendable and retractable flexible transport film for transporting the build material layer-by-layer from the cartridge to the surface of a build in an image plane. An operator using the device needs merely to remove a spent cartridge and replace it with a fresh cartridge to continue solid imaging virtually uninterrupted. The apparatus also includes the capability of withdrawing and inserting an imager without the operator having to perform a separate alignment step. A brush attached to the transport film and forming part of the cartridge provides for intra-layer removal of excess uncured build material. If desired, the apparatus can produce a fully reacted build. A high intensity UV source cures the build between layers. An injection molded build pad is designed to hold a build in an inverted position for improving the build. The invention also provides for tilting the build elevator to reduce air entrainment and for releasing the build from the image plane.

Owner:3D SYST INC

Imager and method for consistent repeatable alignment in a solid imaging apparatus

ActiveUS20080231731A1Less post-build cleaningLess curingTelevision system detailsAdditive manufacturing apparatusAir entrainmentEngineering

A solid imaging apparatus is provided that includes a replaceable cartridge containing a source of build material and an extendable and retractable flexible transport film for transporting the build material layer-by-layer from the cartridge to the surface of a build in an image plane. An operator using the device needs merely to remove a spent cartridge and replace it with a fresh cartridge to continue solid imaging virtually uninterrupted. The apparatus also includes the capability of withdrawing and inserting an imager without the operator having to perform a separate alignment step. A brush attached to the transport film and forming part of the cartridge provides for intra-layer removal of excess uncured build material. If desired, the apparatus can produce a fully reacted build. A high intensity UV source cures the build between layers. An injection molded build pad is designed to hold a build in an inverted position for improving the build. The invention also provides for tilting the build elevator to reduce air entrainment and for releasing the build from the image plane.

Owner:3D SYST INC

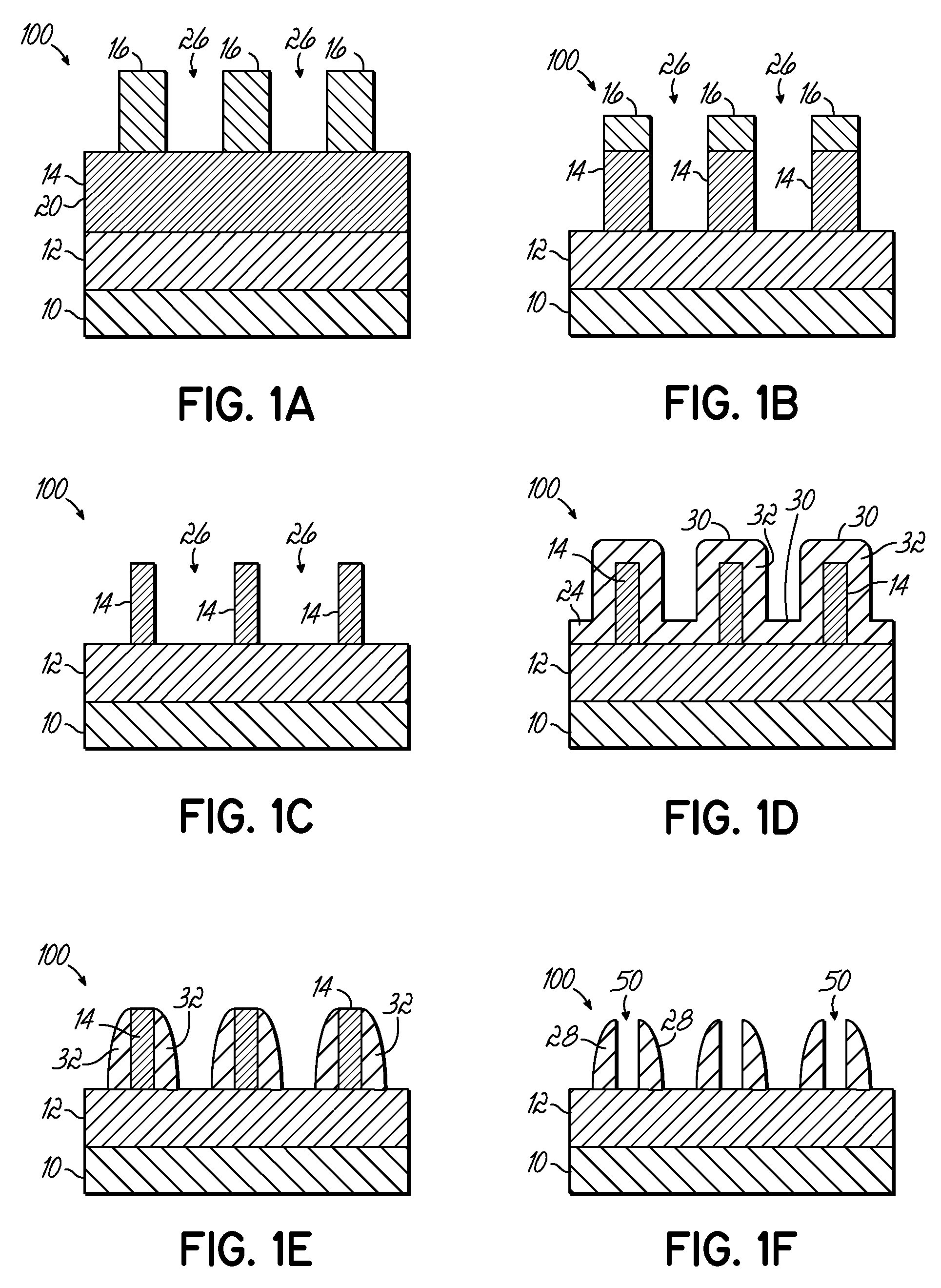

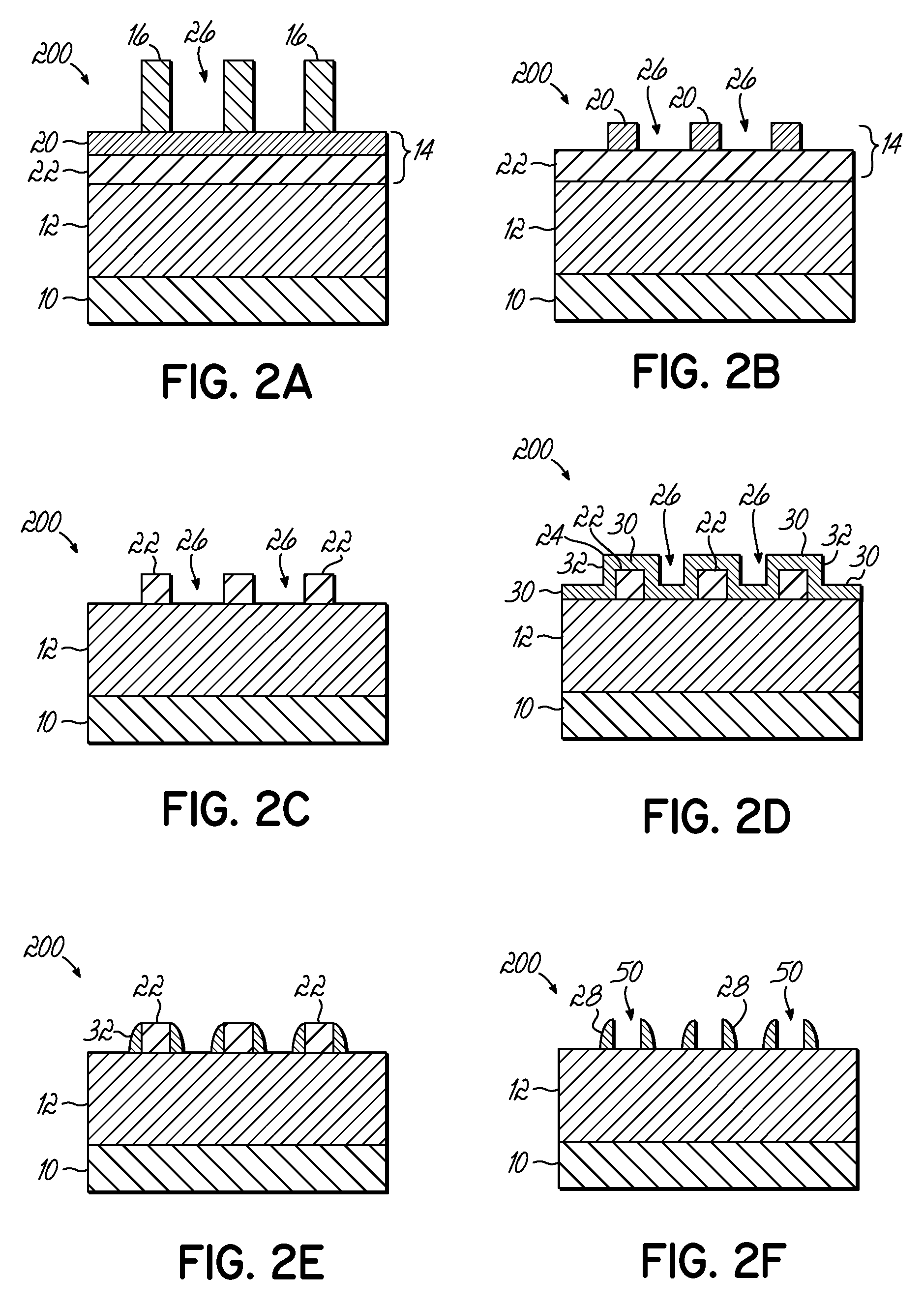

Method of double patterning using sacrificial structure

InactiveUS20090311634A1Semiconductor/solid-state device manufacturingOriginals for photomechanical treatmentResistLayer removal

A method of patterning a thin film on a substrate is described. The method includes forming a sacrificial structure over the thin film, and forming a photo-resist layer over the sacrificial structure. The sacrificial structure has anti-reflective properties, comprises silicon and is capable of withstanding the photo-resist layer removal process and the stress induced during the spacer layer deposition. Thereafter, an image pattern is formed in one or both of the sacrificial structure or the photo-resist layer. A spacer layer is then conformally deposited over the pattern. The spacer layer is etched back to remove horizontal portions while substantially leaving vertical portions. The remaining photo-resist and / or sacrificial structure that is not overlaid with the etched-back spacer layer is removed leaving spacers that are utilized to transfer another pattern to the thin film.

Owner:TOKYO ELECTRON LTD

Preparation method of titanium-steel single-sided composite board

ActiveCN102773254AReasonable process designLow requirements for welding conditionsMetal rolling arrangementsLayer removalTechnical design

The invention discloses a preparation method of a titanium-steel single-sided composite board, comprising the following processing steps of: (1) respectively selecting two titanium plates with same size and two steel plates with same size and carrying out rust and oxide layer removal treatment on the surfaces of the plates; (2) assembling to form multiple layers of symmetrical combined blank sequentially including a steel plate, a transition layer, a titanium plate, a parting agent, a titanium plate, a transition layer and a steel plate, wherein a gap exists between the periphery of the titanium plate and a barrier strip in the combined blank; (3) compressing the combined blank and respectively welding the barrier strip with a first steel plate and a second steel plate to form a closed cavity among the first steel plate, the second steel plate and the barrier strip, drilling holes in the barrier strip and welding a steel tube in the holes, and communicating the steel tube and the closed cavity; (4) conveying the combined blank into a heating furnace to heat and vacuumizing; (5) sealing the outer end of the steel tube and then conveying the combined blank into a rolling mill; and (6) cutting the combined blank after rolling to obtain the titanium-steel single-sided composite board. The preparation method disclosed by the invention is rational in technical design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

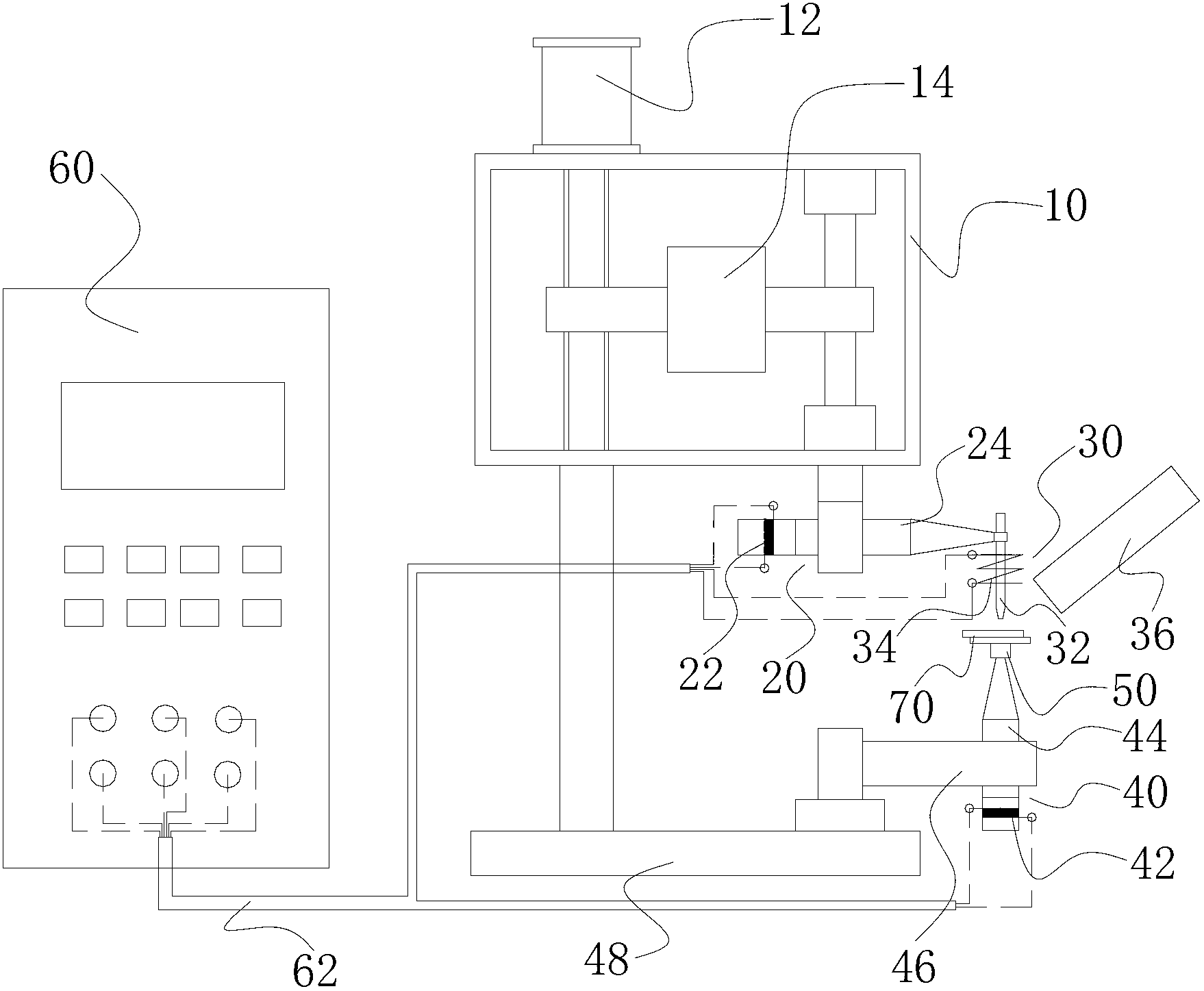

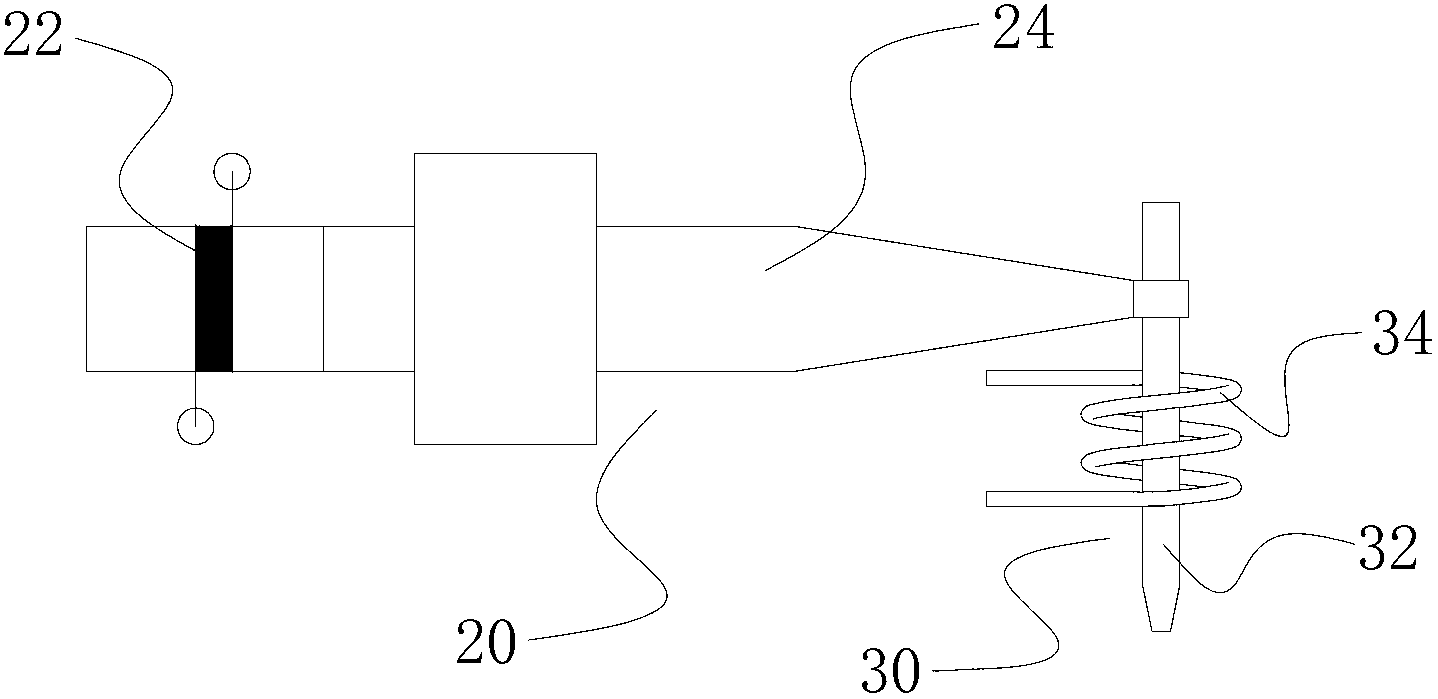

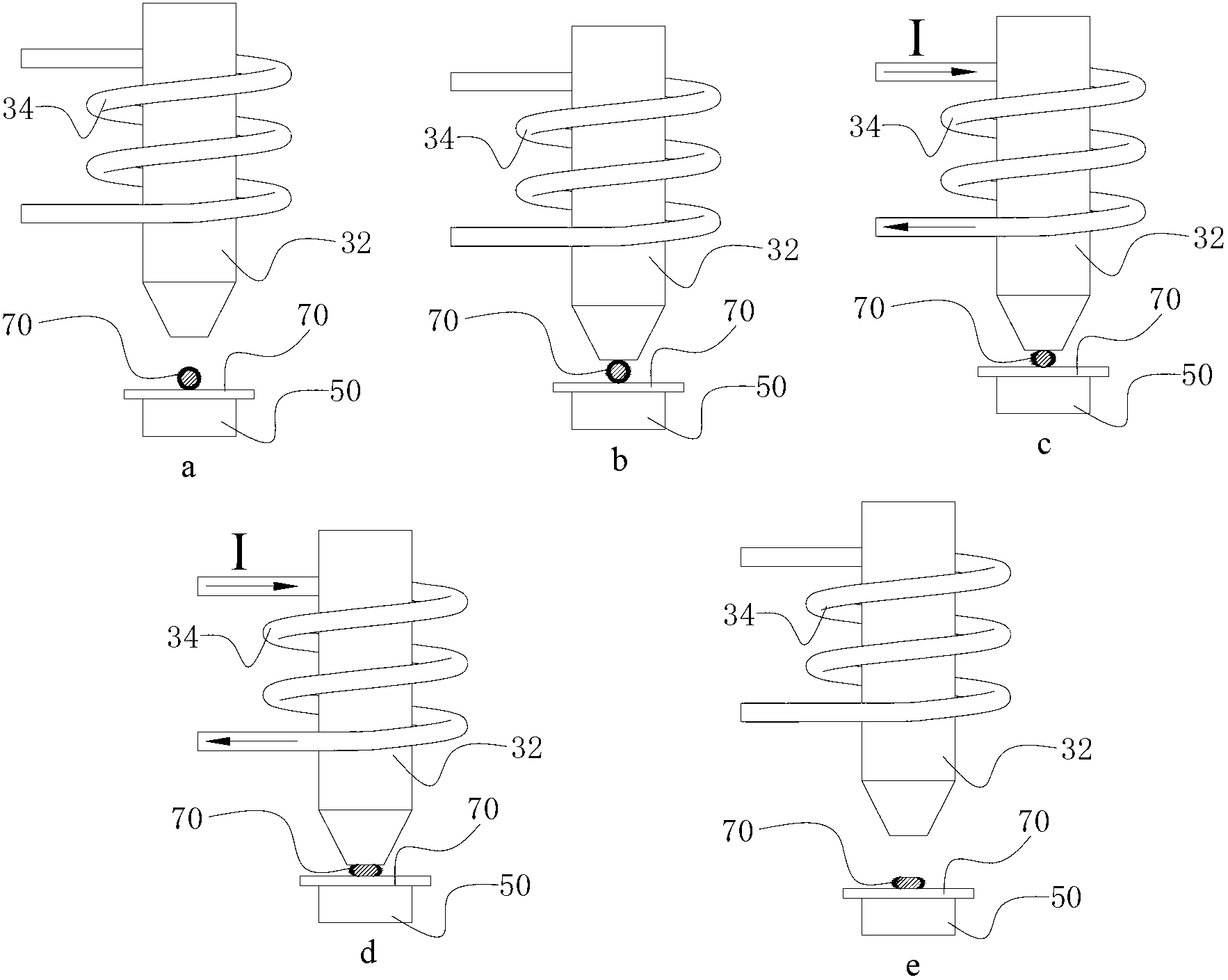

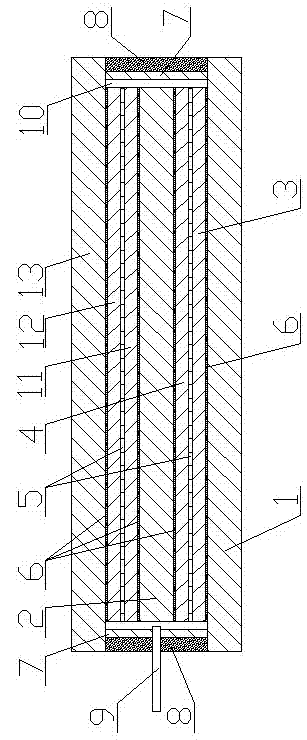

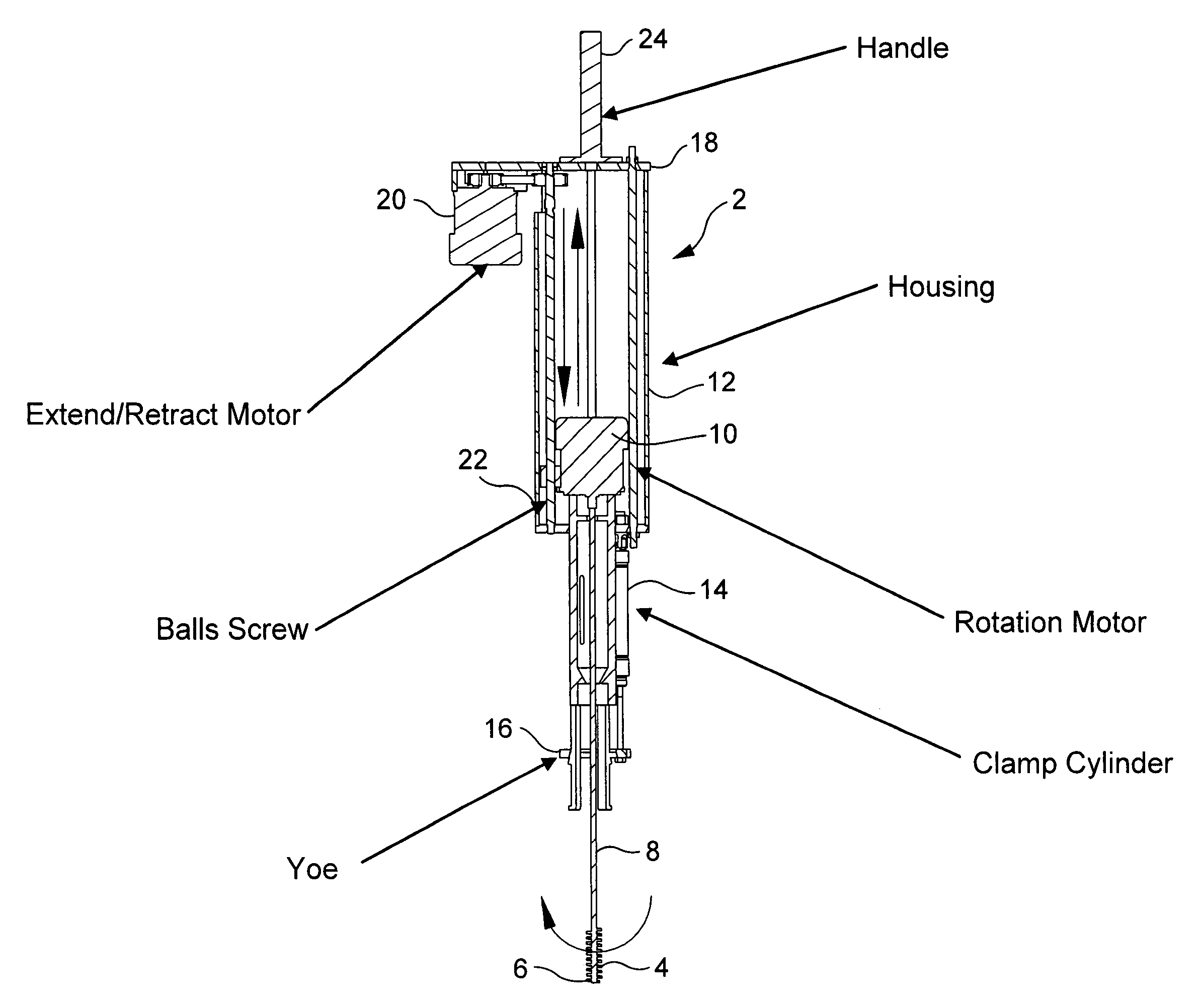

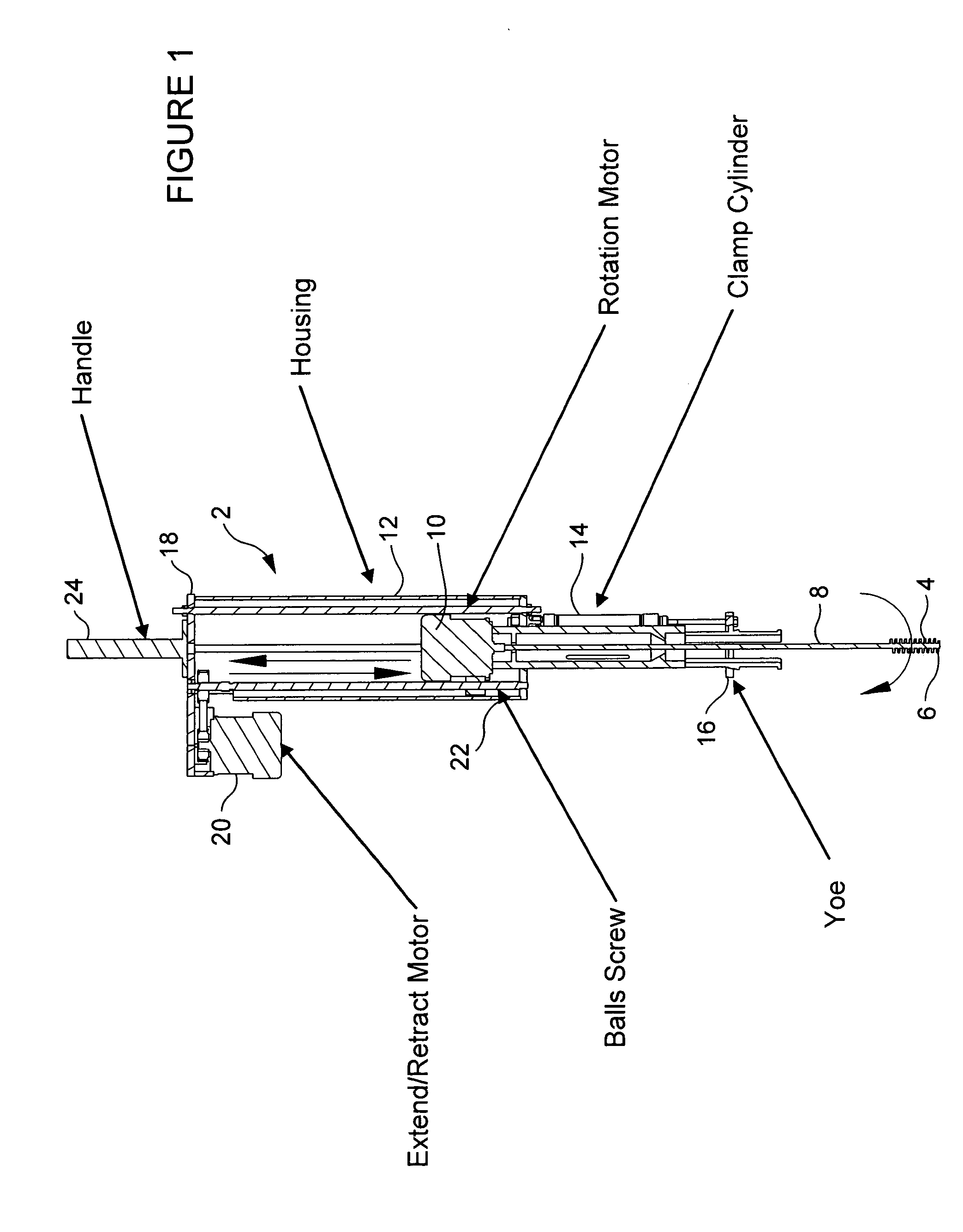

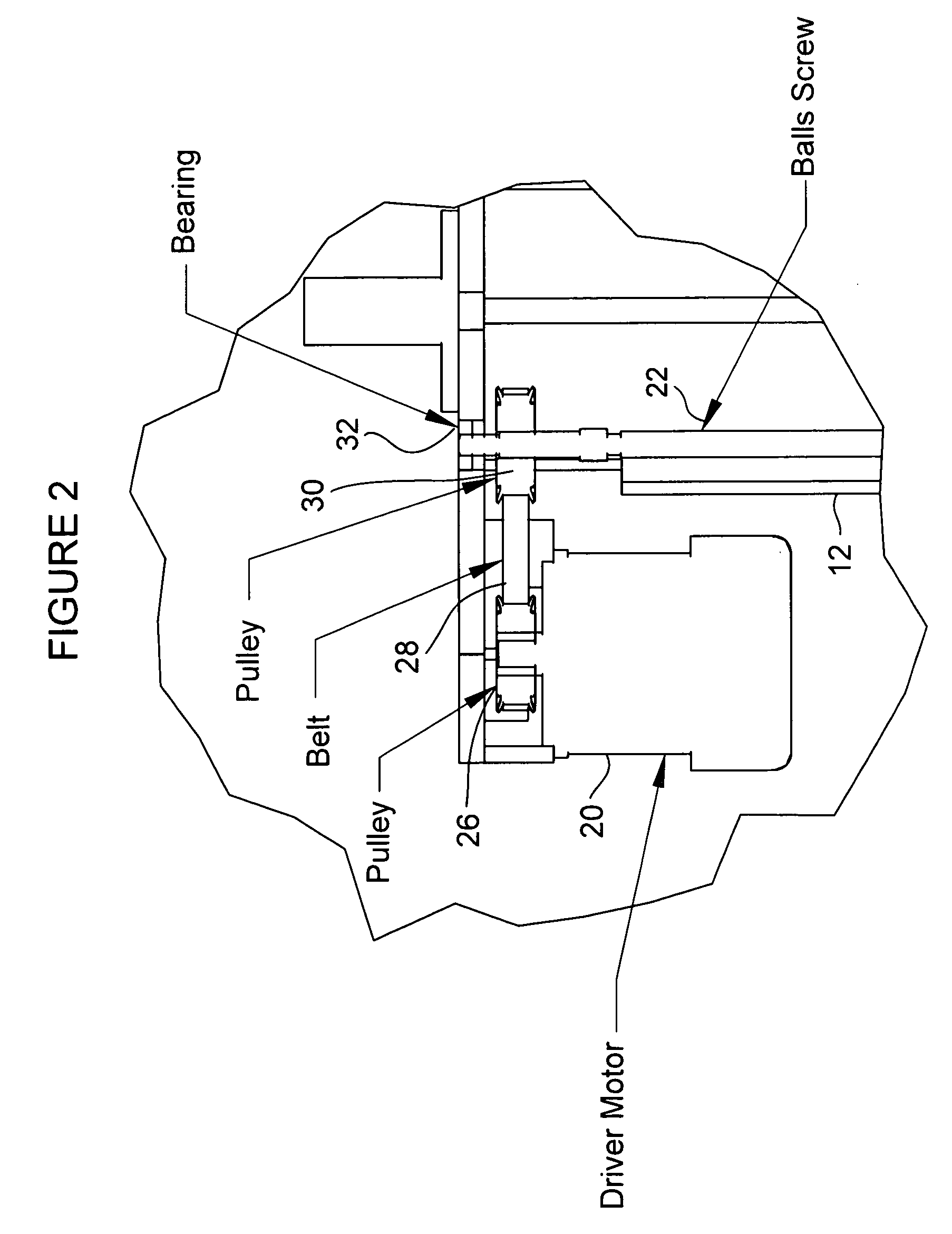

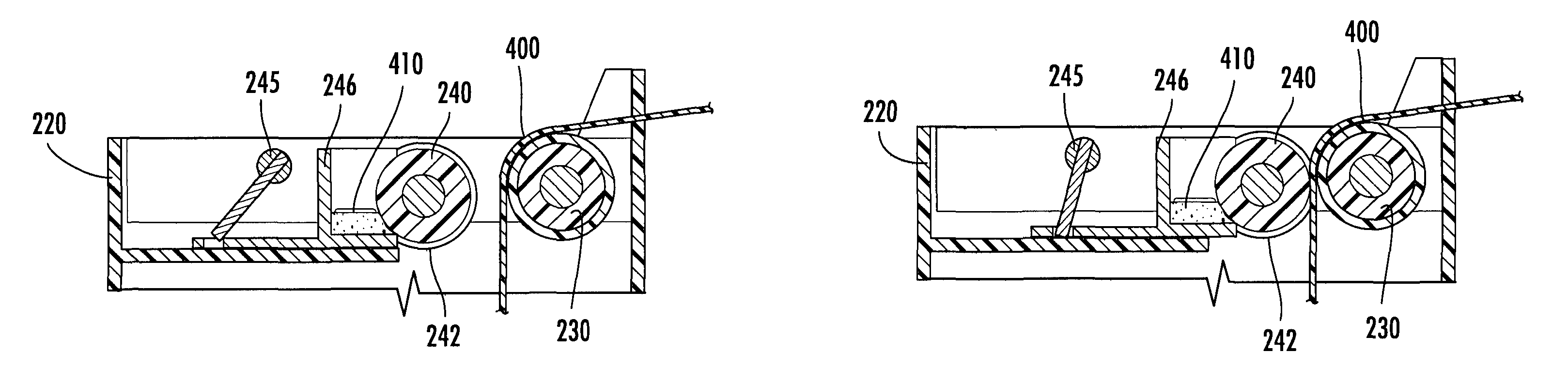

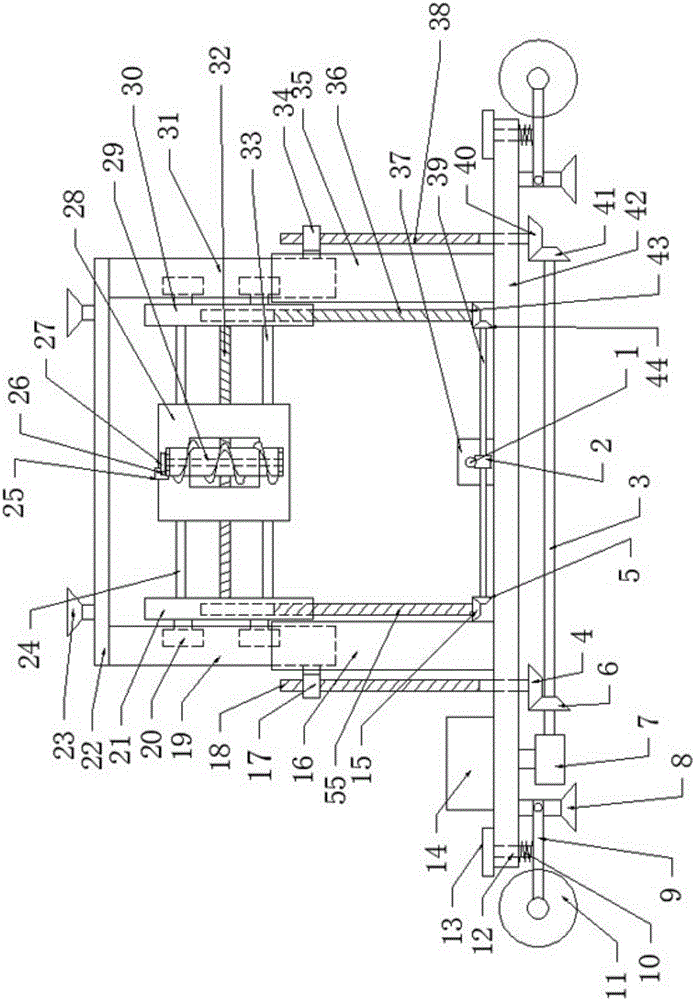

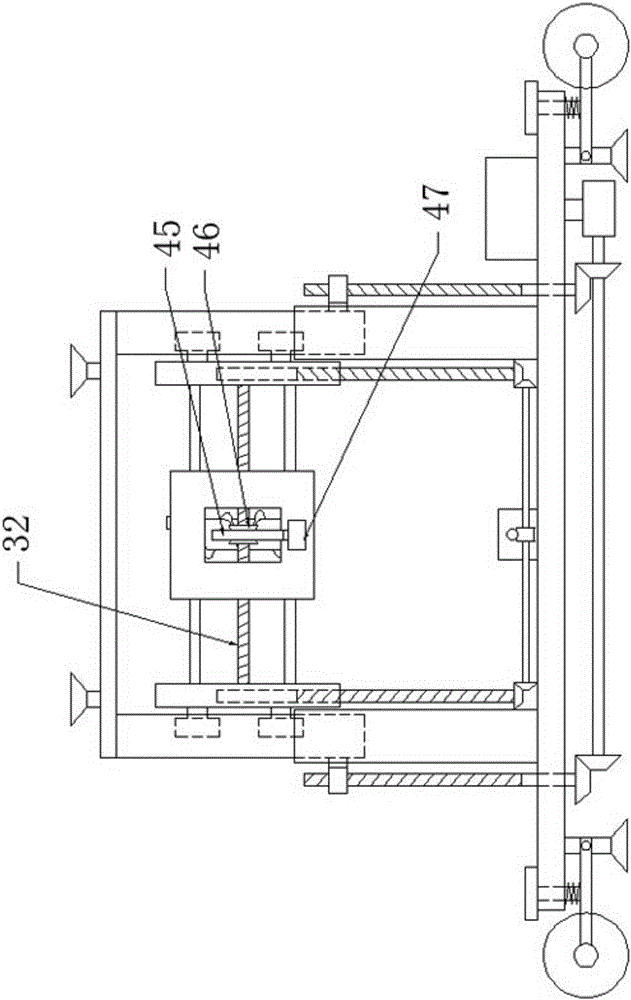

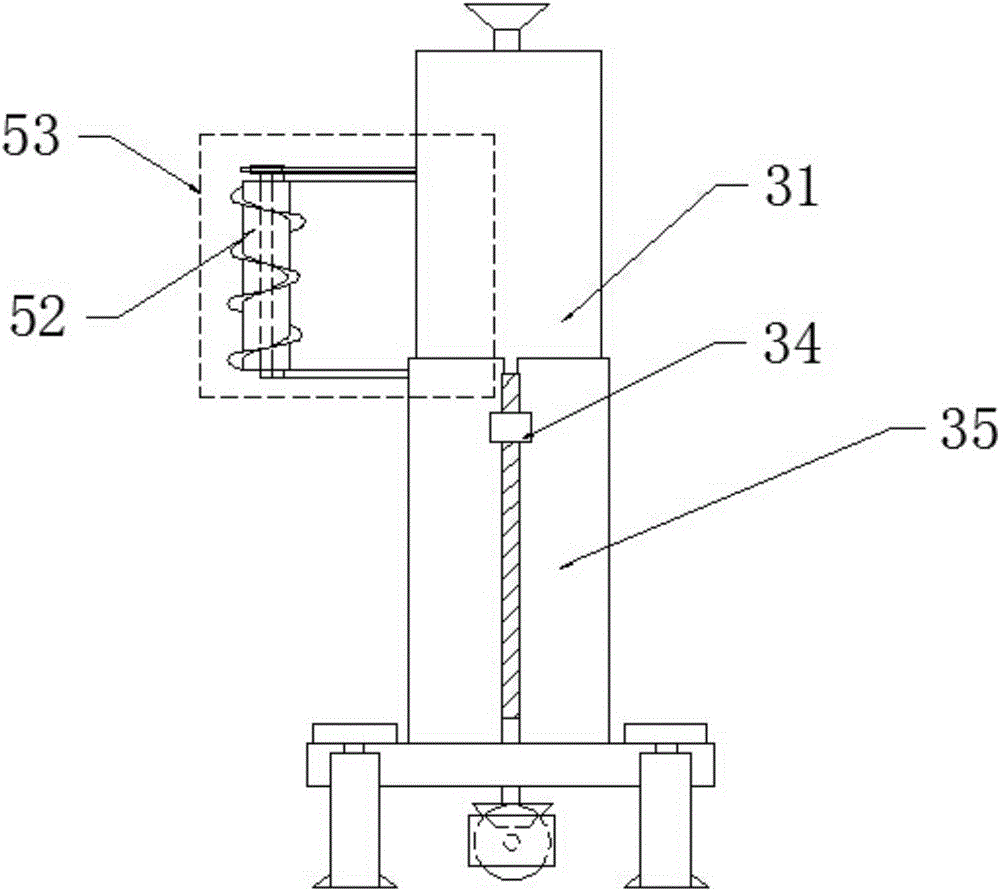

Double-ultrasonic-high-frequency induction combined precision micro-connection device and method

InactiveCN103071910AAvoid problems such as incomplete removalRealize one-sided weldingNon-electric welding apparatusUltrasonic vibrationEngineering

The invention discloses a double-ultrasonic-high-frequency induction combined precision micro-connection device, which comprises a rack, a driving mechanism, a transmission mechanism, an upper ultrasonic vibration system, a high-frequency induction self-heating device, a lower ultrasonic vibration system, a workbench and a power supply, wherein the driving mechanism and the transmission mechanism are arranged on the rack; the upper ultrasonic vibration system is connected with the transmission mechanism; the high-frequency induction self-heating device is connected with the output end of the upper ultrasonic vibration system; the lower ultrasonic vibration system is arranged below the upper ultrasonic vibration system; the workbench is arranged above the lower ultrasonic vibration system; and the upper ultrasonic vibration system, the high-frequency induction self-heating device and the lower ultrasonic vibration system are connected with the power supply. According to the device, dual-ultrasonic vibration and heat energy are combined, so that the phenomenon that a workpiece to be connected is fused or damaged by over-temperature when only the heat energy is used is avoided, the problems of high unsoldering rate and incomplete insulating layer removal of ordinary ultrasonic hot pressure welding are also solved, the working efficiency is improved, and the production cost is lowered. In addition, the invention also discloses a method for performing double-ultrasonic-high-frequency induction combined precision micro-connection by adopting the device.

Owner:GUANGDONG UNIV OF TECH

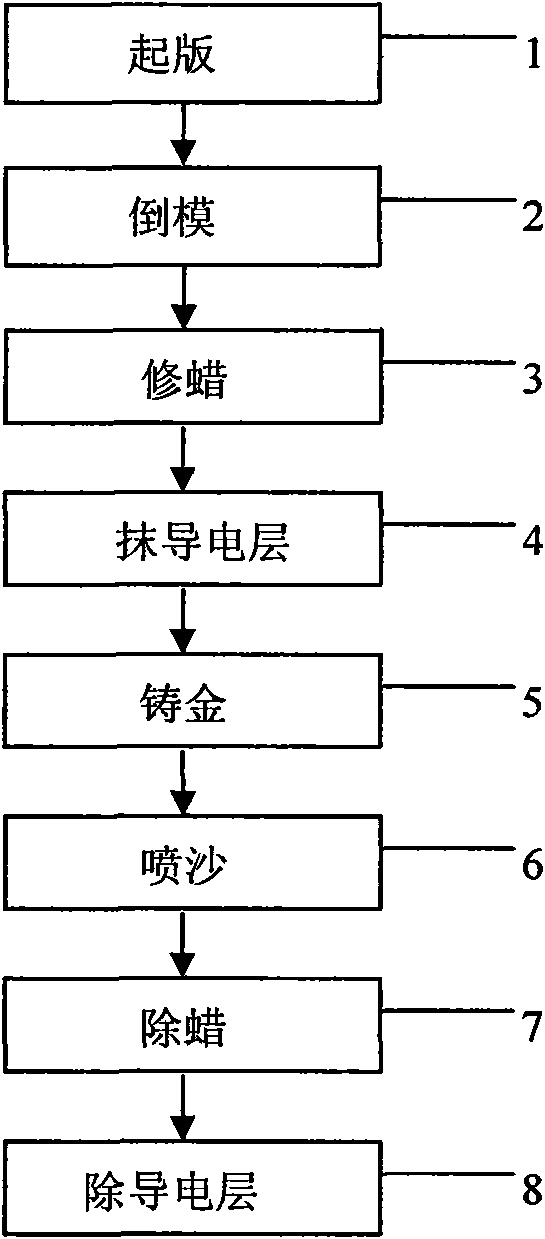

Method for electroforming hard gold product

InactiveCN101560676AIncrease in sizeHigh hardnessElectroforming processesChemical structurePotassium

The invention relates to a method for electroforming hard gold products. The method comprises the following steps: template picking, mould pouring, wax repairing and electric conducting layer coating are carried out to obtain a wax mould of a gold product to be processed, and a layer of electric conductive oil is coated on the surface of the wax mould; and a titanium net is taken as anode in the gold electroforming step, the wax mould coated with the electric conductive oil is put in an electrotyping bath as cathode, the electroforming solution is put in the electrotyping bath and includes sulfurous acid gold potassium, ammonium sulfite and potassium citrate, wherein the sulfurous acid gold potassium is combined with the ammonium sulfite, a trivalent gold ion is reduced into a univalent gold ion, the univalent gold ion generates close crystal grains, the close crystal grains are combined through the potassium citrate to form complexing gold through PH buffer solution, the gold is deposited on the wax mould to form a casting gold layer, and the half-finished product is prepared; and the wax film in the half-finished product and the electric conductive layer are removed in the wax removal step and the electric conductive layer removal step to obtain the finished product. The volume and the hardness of the gold product are changed by using the variation of the chemical structure of the gold ion, so that the hardness, the volume and the toughness of the gold product meet the standards simultaneously.

Owner:武汉金凰珠宝股份有限公司

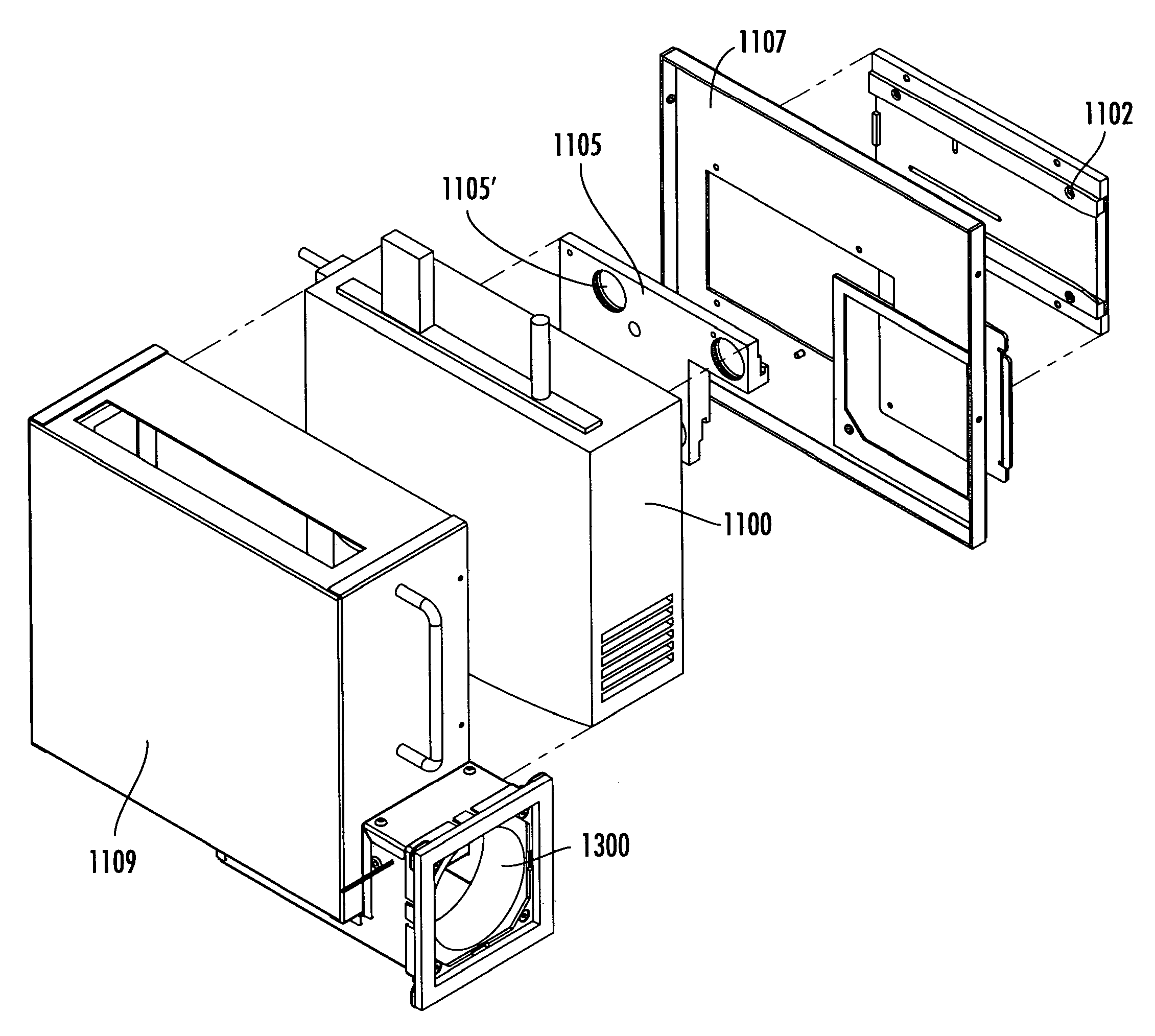

Imager and method for consistent repeatable alignment in a solid imaging apparatus

ActiveUS8221671B2Reduce viscosityImprove bindingTelevision system detailsAdditive manufacturing apparatusAir entrainmentHigh intensity

A solid imaging apparatus is provided that includes a replaceable cartridge containing a source of build material and an extendable and retractable flexible transport film for transporting the build material layer-by-layer from the cartridge to the surface of a build in an image plane. An operator using the device needs merely to remove a spent cartridge and replace it with a fresh cartridge to continue solid imaging virtually uninterrupted. The apparatus also includes the capability of withdrawing and inserting an imager without the operator having to perform a separate alignment step. A brush attached to the transport film and forming part of the cartridge provides for intra-layer removal of excess uncured build material. If desired, the apparatus can produce a fully reacted build. A high intensity UV source cures the build between layers. An injection molded build pad is designed to hold a build in an inverted position for improving the build. The invention also provides for tilting the build elevator to reduce air entrainment and for releasing the build from the image plane.

Owner:3D SYST INC

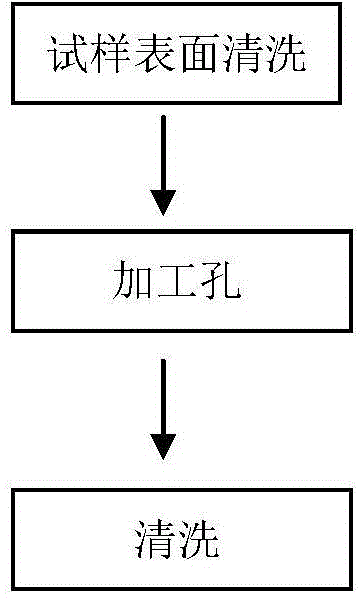

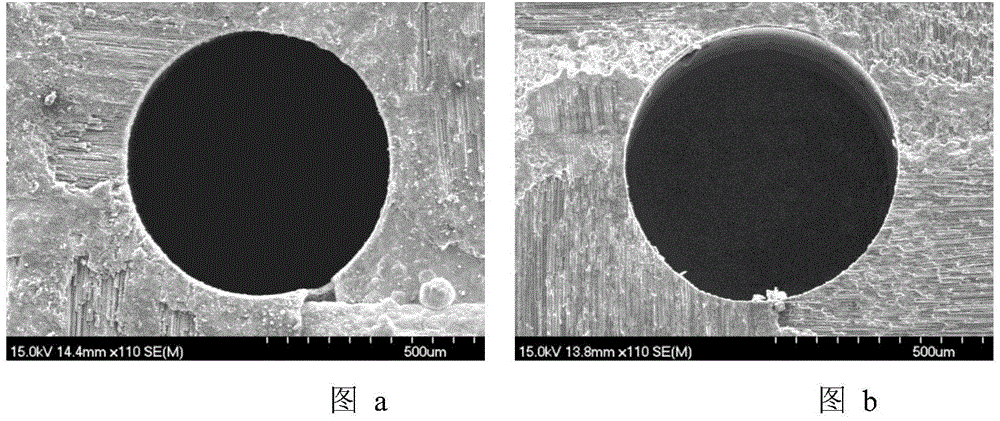

Method for machining micro holes in ceramic matrix composite through femtosecond lasers

ActiveCN104607808AHigh peak powerShort pulse widthWelding/soldering/cutting articlesLaser beam welding apparatusWavelengthLayer removal

The invention relates to a method for machining micro holes in a ceramic matrix composite through femtosecond lasers. According to the method, the silicon carbide ceramic matrix composite sample is placed on a working table and machined layer by layer in a spiral line mode through the femtosecond lasers or machined in a linear scanning mode, wherein the thickness of the sample is smaller than 3 mm; in the micro-machining process, the wave length of femtosecond laser machining ranges from 400 nm-1500 nm, the pulse width ranges from 80 fs to 500 fs, the output power of the lasers is determined according to the requirements of micro-machining and ranges from 20 mW to 20 W, and the repetition frequency of the lasers is determined according to the requirements of micro-machining and ranges from 50 K to 25 MHz; the sample is machined in a layer-by-layer removal mode, wherein the rotation speed of a machining head is 2400 rev / s. In the machining process, the method has the advantages that machining damage is small, and because material around the damage region is still in a cold state after machining, the heat effect is small; machining precision is high, energy of the femtosecond lasers is in Gaussian distribution, absorption and action of the energy in the machining process are limited within the size of which the focus center is quite small, and the machining dimension is expressed from a micro form to a sub-micro form.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

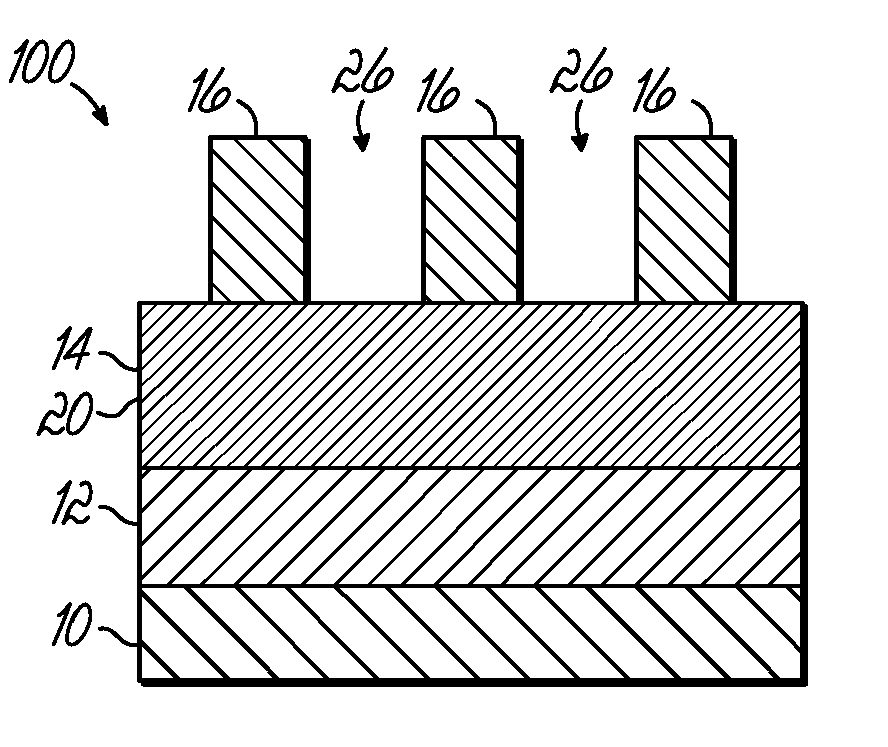

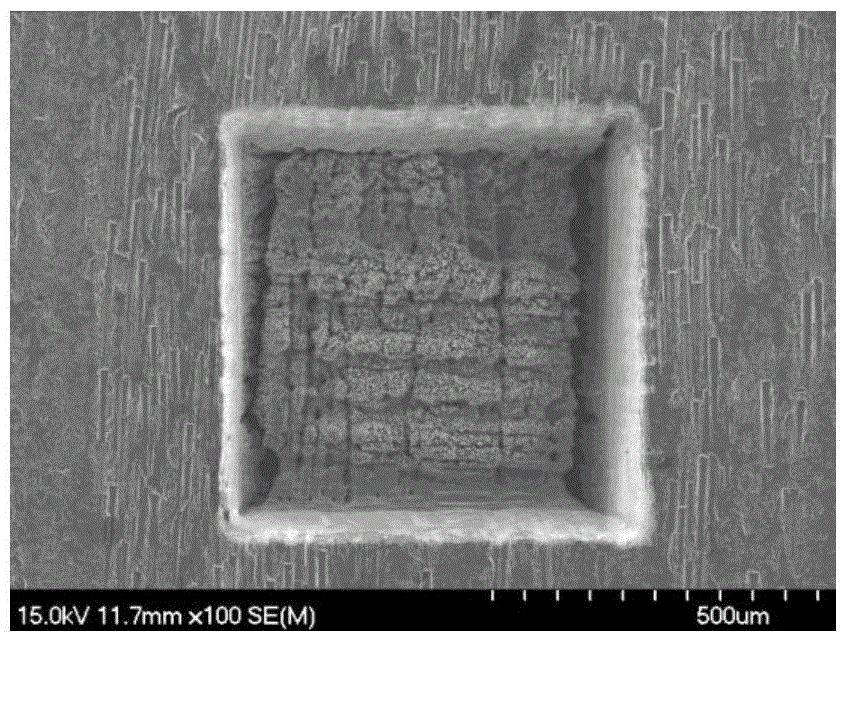

Semiconductor wafer having multiple semiconductor elements and method for dicing the same

InactiveUS20060220183A1High yieldQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesRefractive indexLight beam

A semiconductor wafer includes: a first layer having a first refraction index; a second layer having a second refraction index, which is different from the first refraction index; a plurality of semiconductor elements; and a layer removal region. The semiconductor elements are capable of being separated each other by irradiating a laser beam on the first layer along with a cutting line. The laser beam irradiation provides a modified region in the first layer so that the semiconductor elements are capable of being separated by a crack generated in the modified region. The layer removal region is provided such that the second layer in the layer removal region is removed from the wafer.

Owner:DENSO CORP

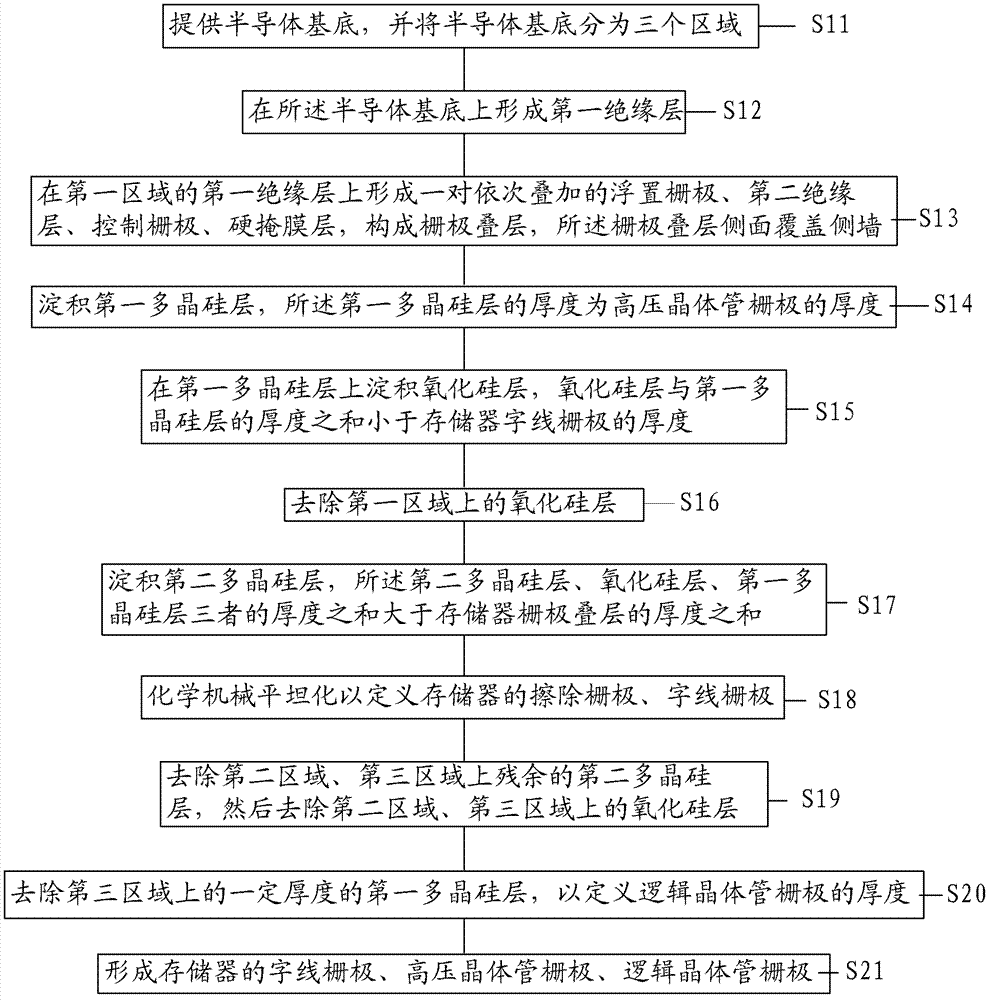

Separate gate type flash memory of embedded logic circuit and fabricating method thereof

ActiveCN102956554AHigh densitySimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingEtchingHigh voltage transistors

The invention provides a fabricating method of a separate gate type flash memory of an embedded logic circuit. Compared with a forming method of a single separate gate type flash memory, the separate gate type flash memory, a high voltage transistor and a logic transistor can be simultaneously fabricated on one integrated circuit by five techniques of primary silicon oxide deposition, primary polycrystalline silicon deposition, secondary etching and primary silicon oxide layer removal, therefore, the densities of the three elements are increased, the integration degree is high, the operation speed is faster, and the integrated chip is smaller, so that the cost of each integrated chip is reduced, and the application is more extensive. Furthermore, in the forming process of the separate gate type flash memory of embedded logic circuit, the grids of the high voltage transistor and the logic transistor have few defects to meet the quality demands of the grids. Correspondingly, the invention further provides a separate gate type flash memory of the embedded logic circuit.

Owner:SEMICON MFG INT (SHANGHAI) CORP

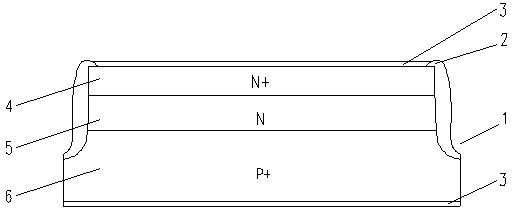

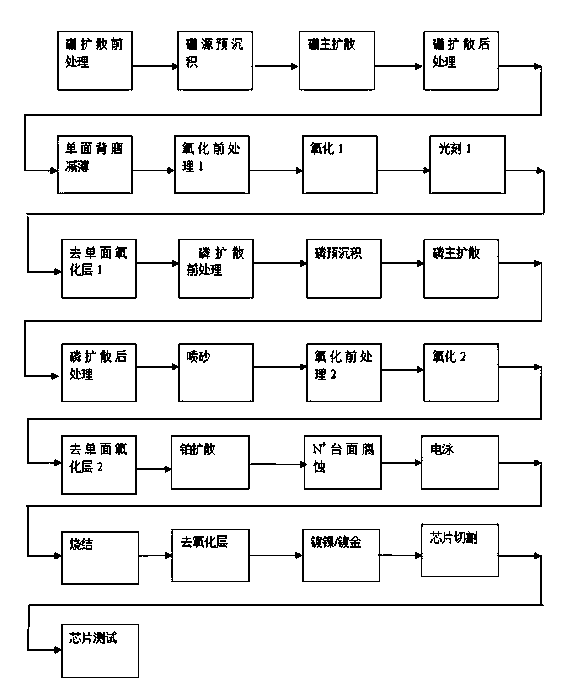

Fast recovery diode FRD chip and production process for same

ActiveCN104201102AImprove anti-surge performanceImprove flatnessSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingLayer removal

The invention relates to a fast recovery diode FRD chip and a production process for the same. The process comprises the following steps of: diffusion pre-treatment, boron source pre-deposition, boron source main diffusion, diffusion after-treatment, single-surface back grinding thinning, oxidation pre-treatment, oxidation, photoetching, single-surface oxide layer removal, phosphorus source pre-deposition, phosphorus diffusion, sand blasting, platinum diffusion, N + surface mesa etching, electrophoresis, sintering, oxide layer removal, nickel plating, gold plating and chip cutting, wherein the structure of the obtained chip is P+-N-N+ type. According to the process, the uniformity of the reverse recovery time of the fast recovery diode is improved and controllability is improved, meanwhile, voltage drop is reduced, leakage current is reduced, and voltage-proof stability is improved; the contradiction of mutual condition among the reverse voltage, the positive voltage, the reverse recovery time and the leakage current of the fast recovery diode is solved to enable the various parameters to achieve the optimal matching, thus improving the reliability and switching characteristic of the diode, and reducing power consumption. The fast recovery diode disclosed by the invention breaks through the technical bottleneck of the traditional fast recovery diodes.

Owner:SUZHOU QILAN POWER ELECTRONICS

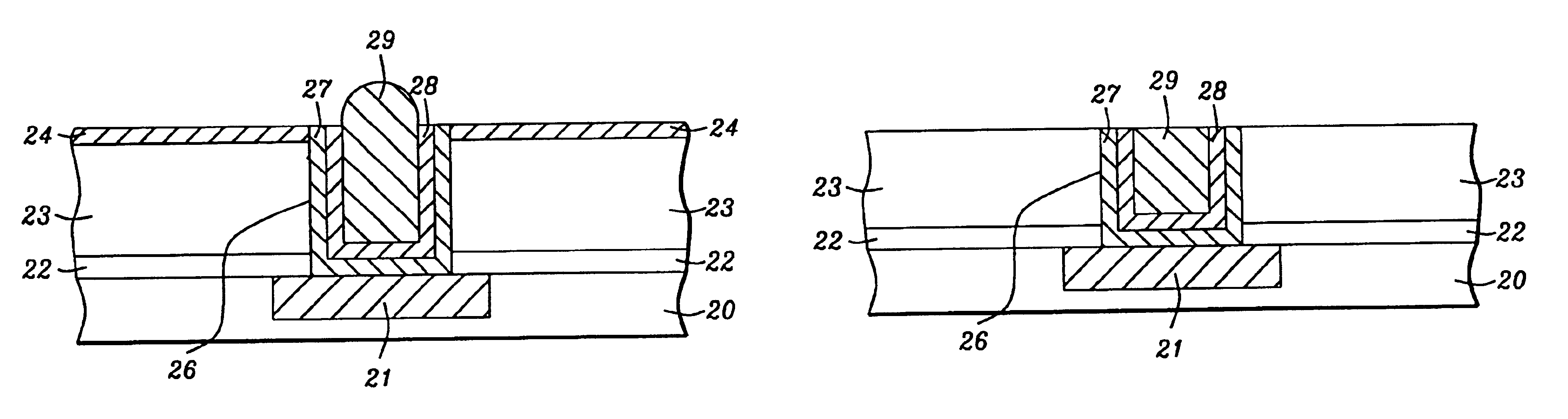

Method of selectively making copper using plating technology

InactiveUS6841466B1Improve uniformitySimple methodSemiconductor/solid-state device manufacturingResistCopper interconnect

A method of forming a more uniform copper interconnect layer is described. A dielectric layer, electroconductive (EC) layer, and a photoresist layer are sequentially deposited on a substrate. An opening in the photoresist is etched through the dielectric layer while the EC layer serves as a hard mask. Following deposition of a diffusion barrier layer and copper seed layer on the EC layer and in the opening, the copper seed layer is removed above the EC layer by a first CMP step. The EC layer serves as a CMP stop to protect the dielectric layer and provides a more uniform surface for subsequent steps. Copper is selectively deposited on the seed layer within the opening. A second CMP step lowers the copper layer to be coplanar with the dielectric layer and removes the EC layer. The resulting copper interconnect layer has a more uniform thickness and surface for improved performance.

Owner:TAIWAN SEMICON MFG CO LTD

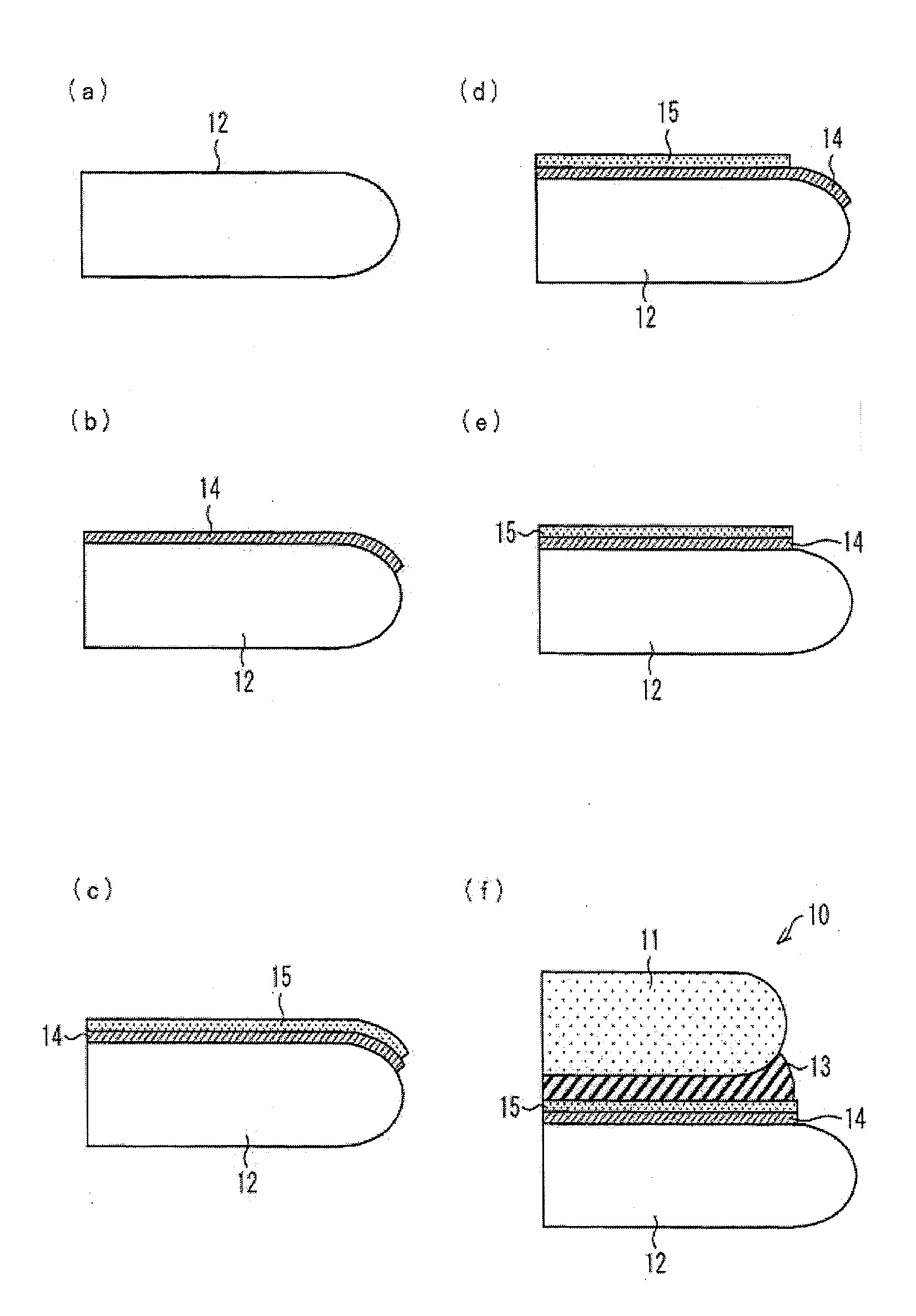

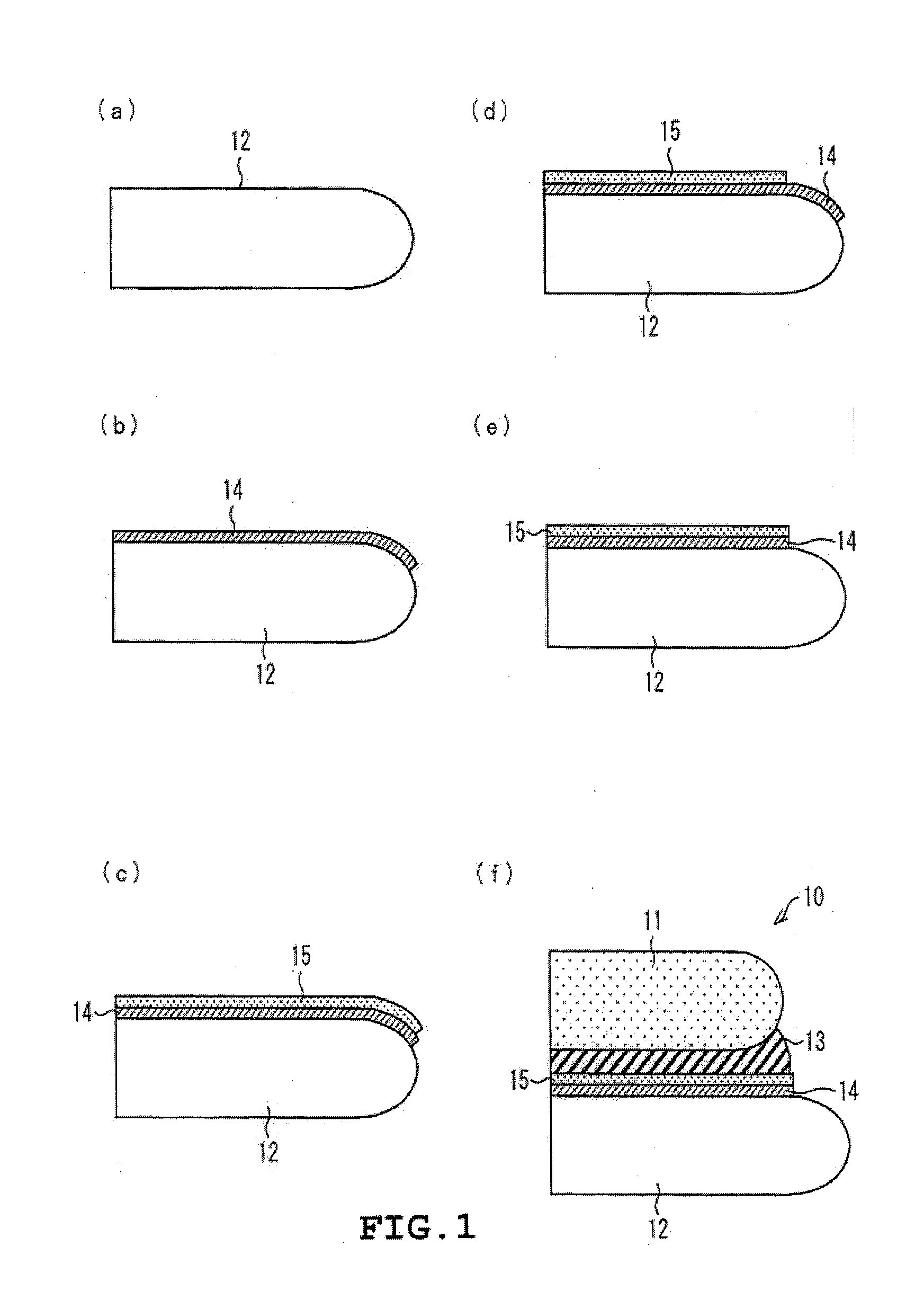

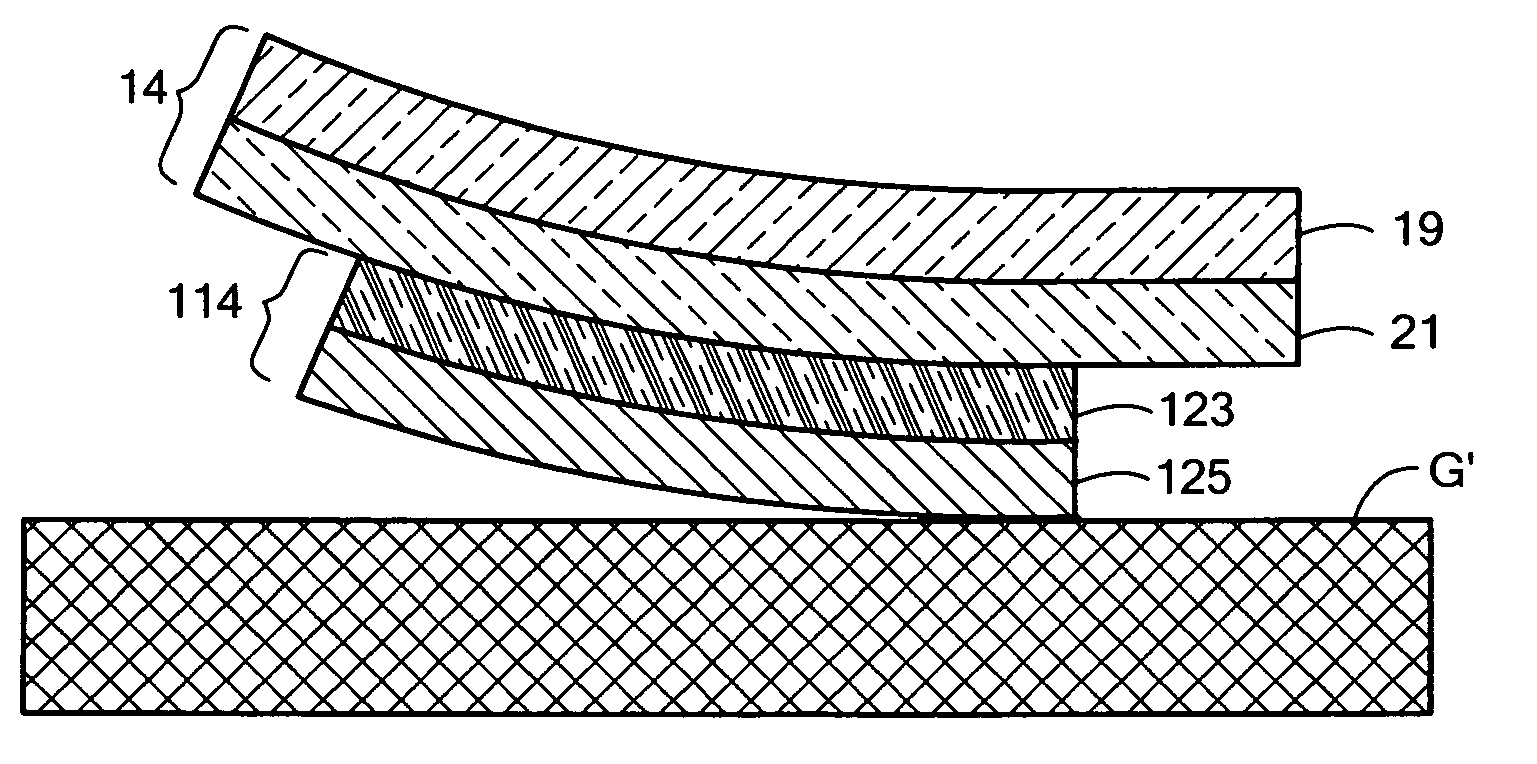

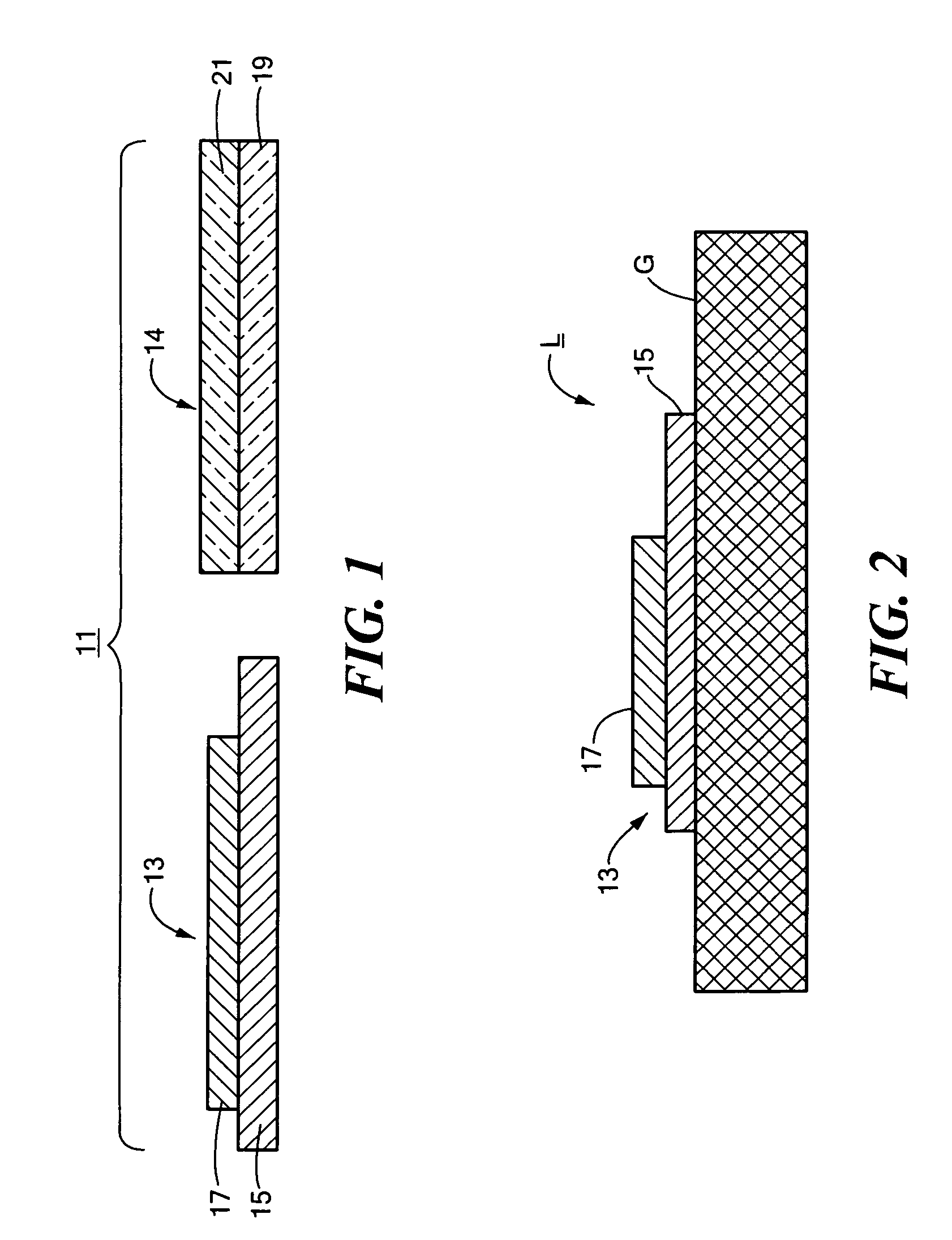

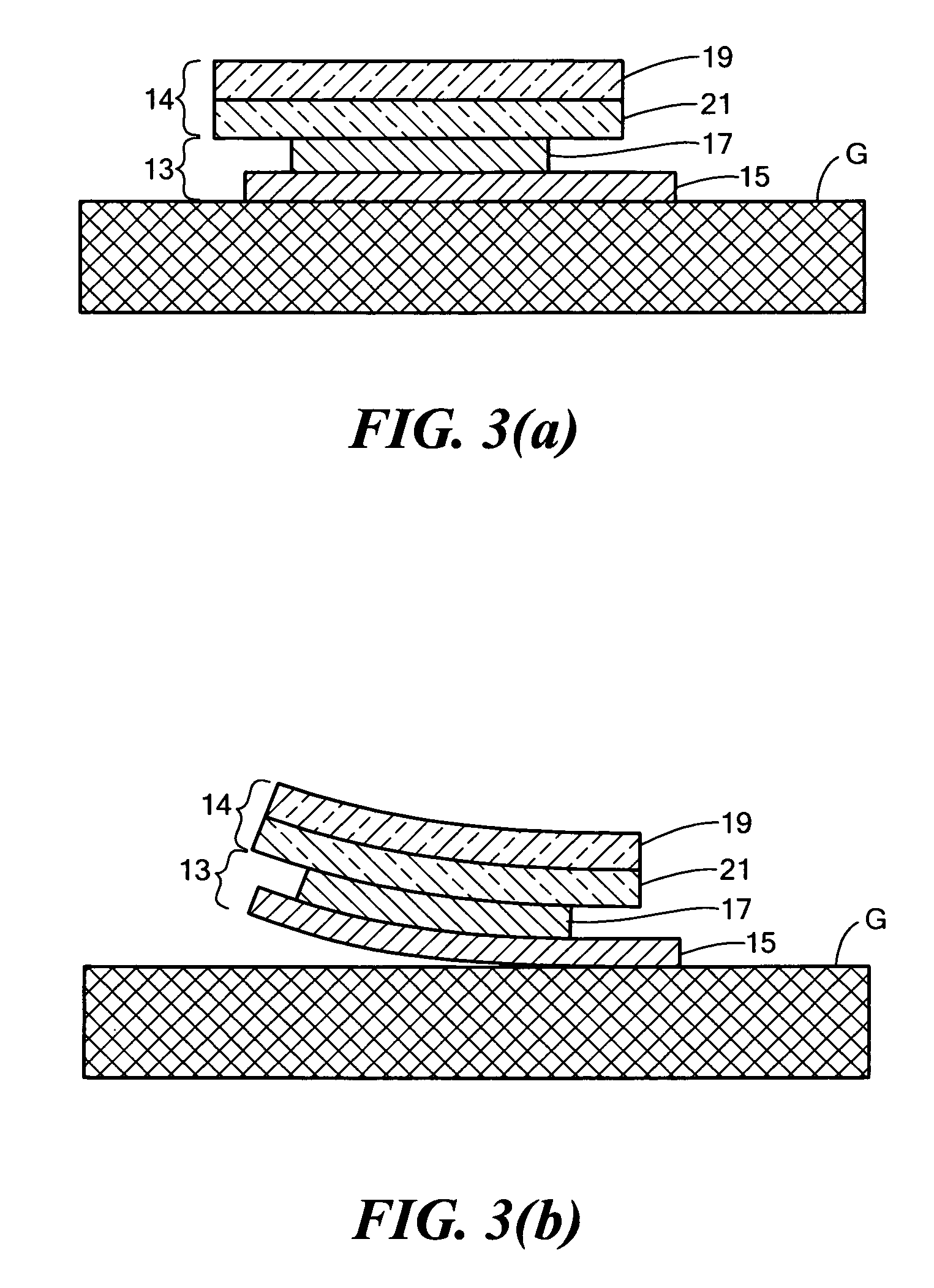

Method for forming laminate

InactiveUS20140151328A1Sufficient protectionLamination ancillary operationsDecorative surface effectsEngineeringLayer removal

A release layer is adequately protected by a protective layer when a laminate is subjected to a desired treatment. A method for forming a laminate 10 includes a protective layer forming step of forming a protective layer 15 for covering a face that is a surface of a release layer 14 and which is not adhered to a support plate 12 and not superimposed at least on an adhesive layer 13; and a protective layer removal step of removing a portion of the protective layer 15, which is exposed at the time of forming the laminate 10.

Owner:TOKYO OHKA KOGYO CO LTD

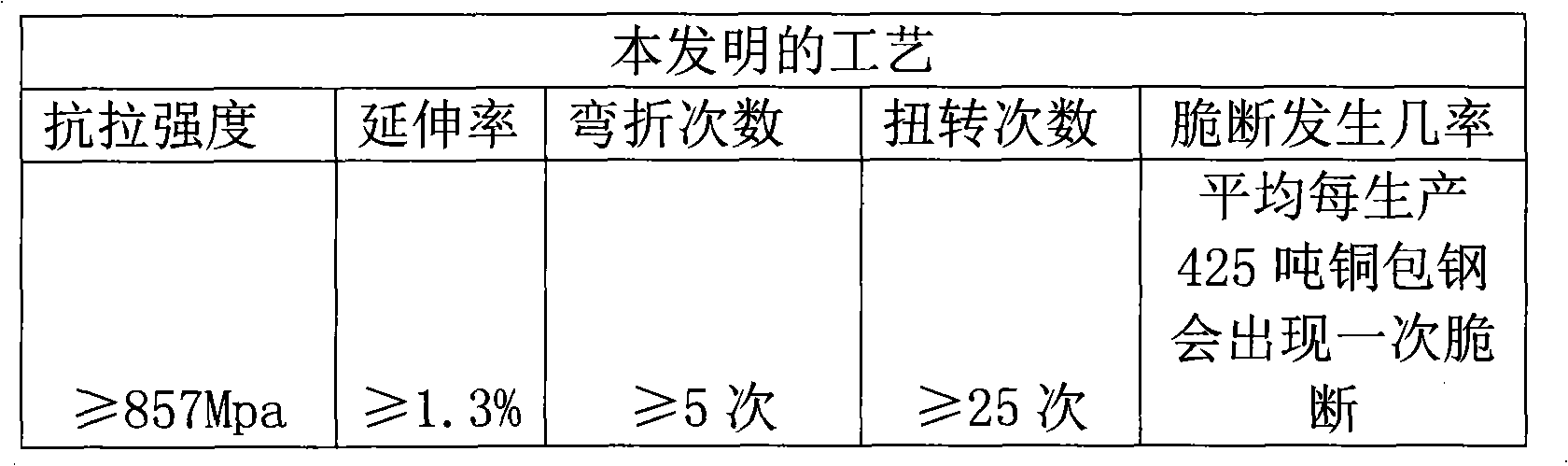

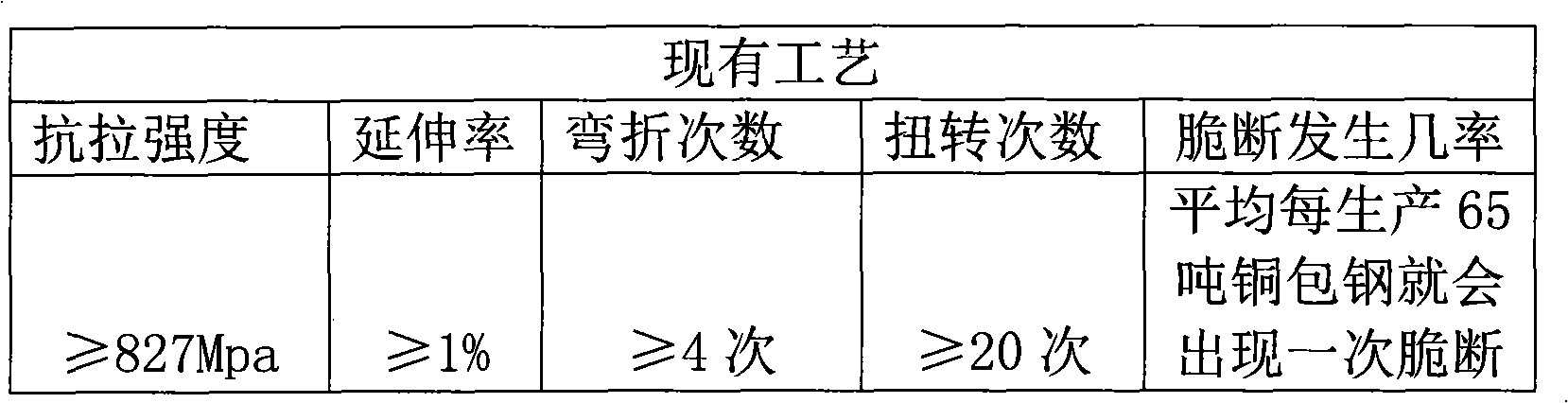

Technique for producing high-strength copper covered steel conductor for coaxial cable inner core wire

ActiveCN101303923AEliminate internal stressHigh tensile strengthMetal/alloy conductorsCable/conductor manufactureCoaxial cableElectrolysis

The invention relates to a high-strength copper-clad steel conductor. A production technique of a high-strength copper-clad steel conductor used for an inner core wire of a coaxial cable is characterized by comprising the following steps: rough drawing, medium temperature tempering, oxide layer removal, fine drawing, treatment before electro-deposition, acid electrolysis, washing, pretreatment of electro-deposition, washing, thick treatment of the electro-deposition, washing, oxidation protection, drying, tank wire drawing, washing, oxidation protection, drying and collecting lines and tray filling. Physical properties such as tensile strength, elongation, small reduction of area and bending times of the high-strength copper-clad steel conductor produced by the technique are enhanced.

Owner:ZHEJIANG PUJIANG BAICHUAN IND

Manufacturing method of titanium-steel-titanium two-sided composite plate

ActiveCN102773670AReasonable process designLow requirements for welding conditionsSheet steelTitanium

The invention discloses a manufacturing method of a titanium-steel-titanium two-sided composite plate. The manufacturing method comprises the following processing steps: (1) four titanium plates with the same dimension and three steel plates with the same dimension are selected respectively, and rust and oxide layer removal processing is performed on the surfaces of the titanium plates and the steel plates; (2) a multilayer combination blank with three layers of steel plates, four layers of titanium plates and four layers of transition layers is formed through assembly, and gaps are arranged between the peripheries of the titanium plates and barrier strips in the combination blank; (3) the combination blank is pressed tightly and enables the barrier strips to be welded to a first steel plate and a third steel plate so as to enable the first steel plate, the second steel plate and the inner portions of the barrier strips to form a closed cavity, holes are drilled on the barrier strips, steel tubes are welded in the holes, and the steel tubes are communicated with the closed cavity; (4) the combination blank is sent to a heating furnace to be heated and vacuumized; (5) the combination blank is sent to a rolling mill to be rolled after the outer ends of the steel tubes are sealed; and (6) one titanium-steel-titanium two-sided composite plate and two titanium-steel single-sided composite plates are obtained by slitting the combination blank after the combination blank is rolled. The manufacturing method of the titanium-steel-titanium two-sided composite plate is reasonable in design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

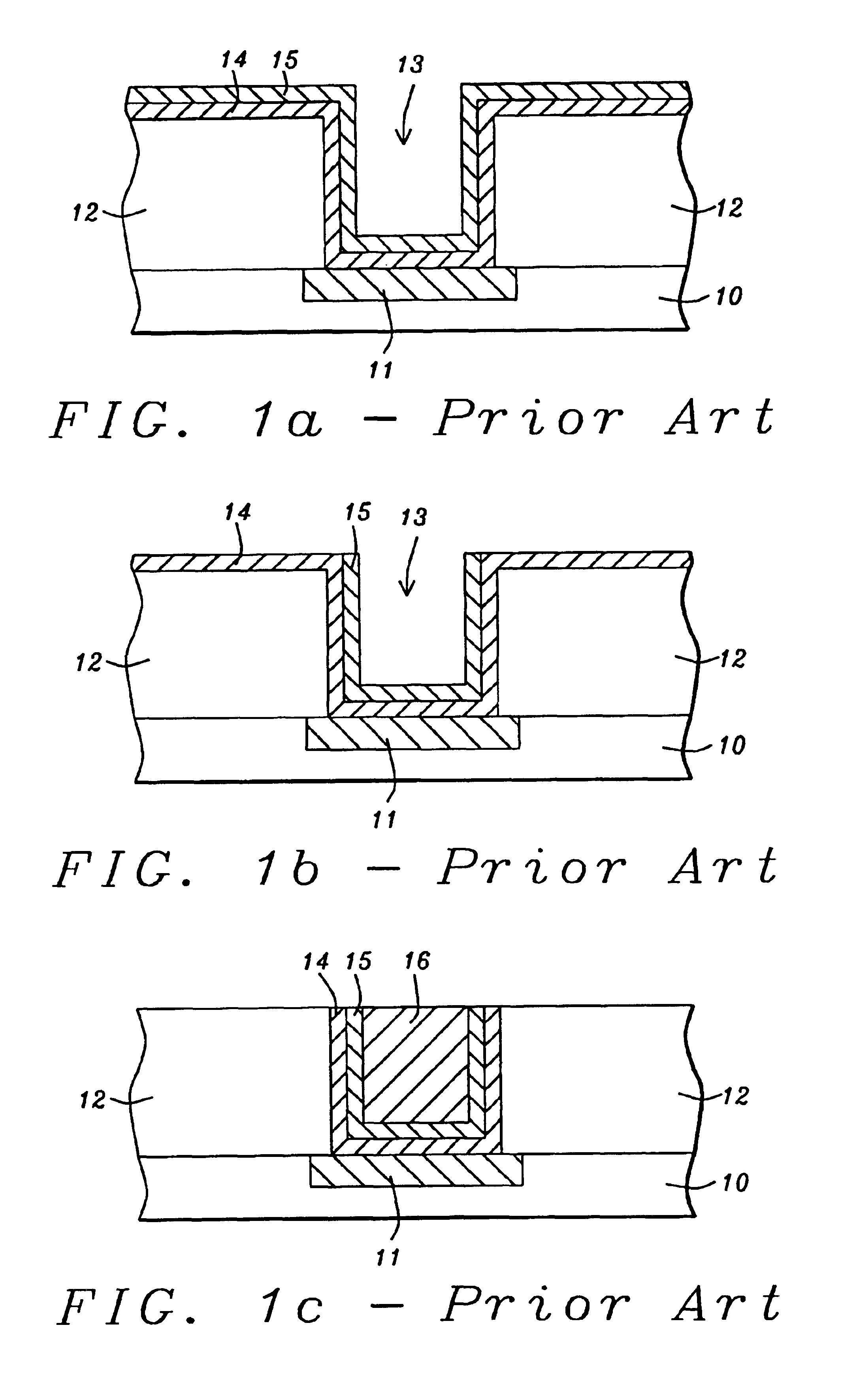

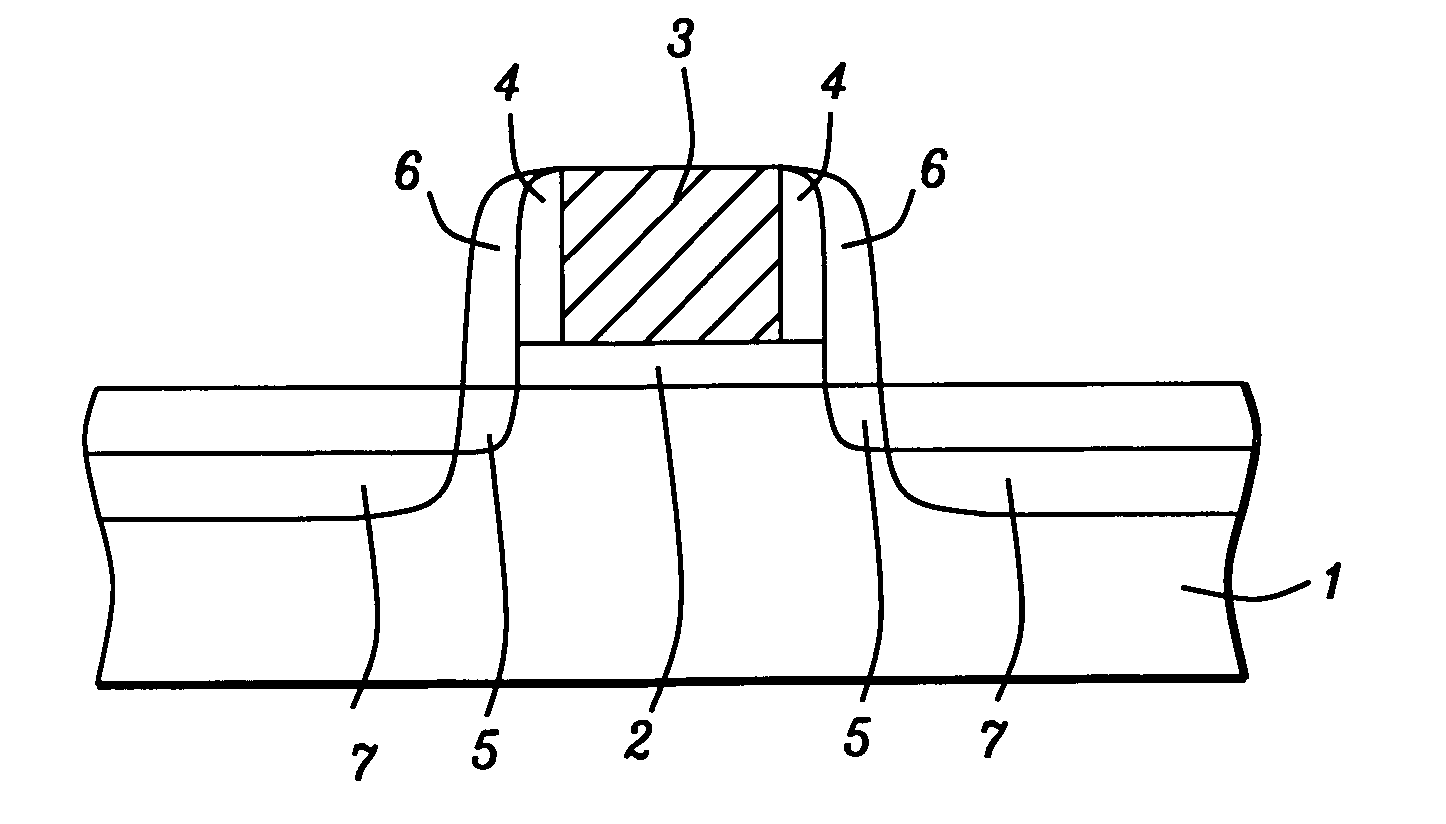

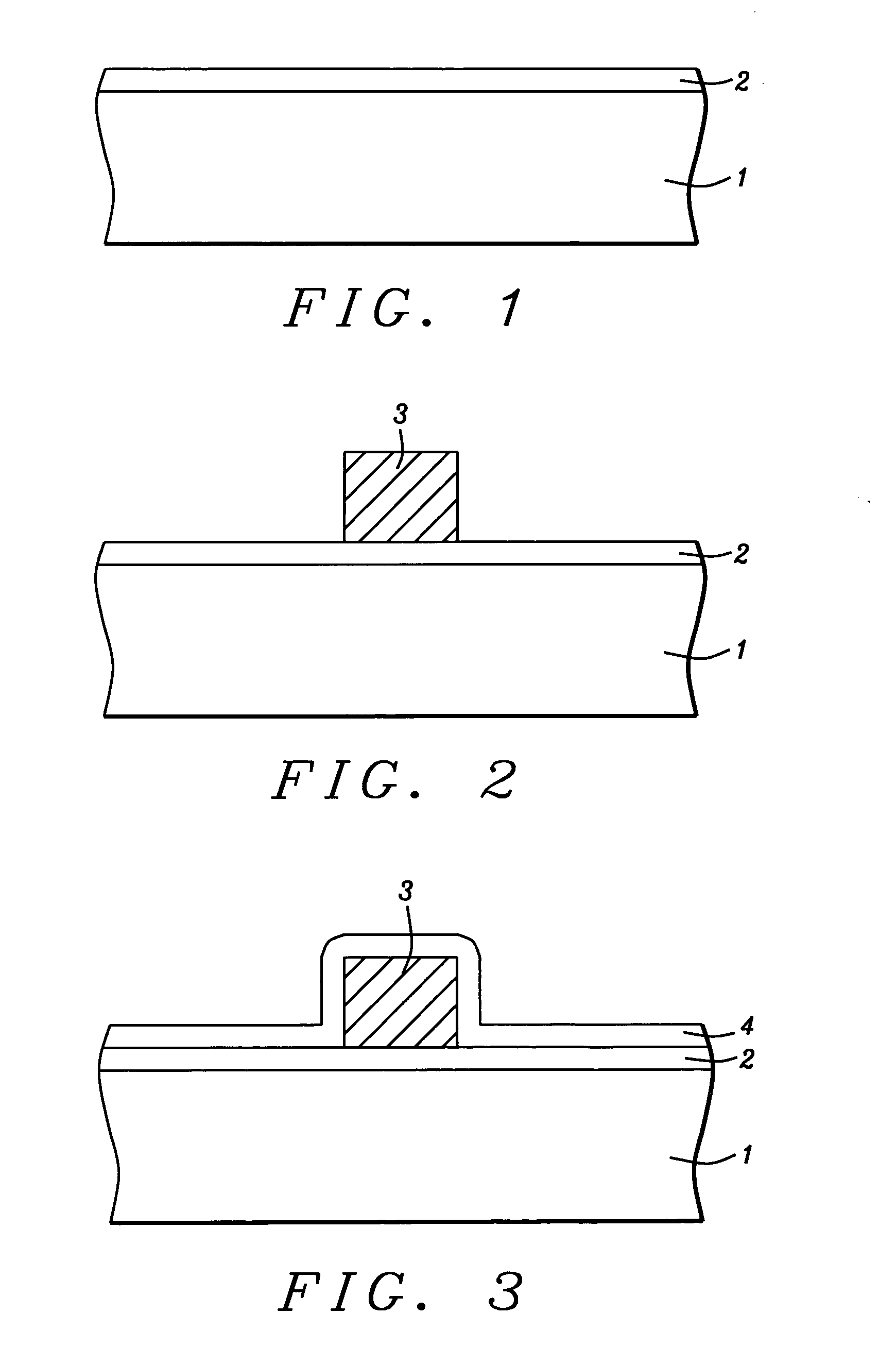

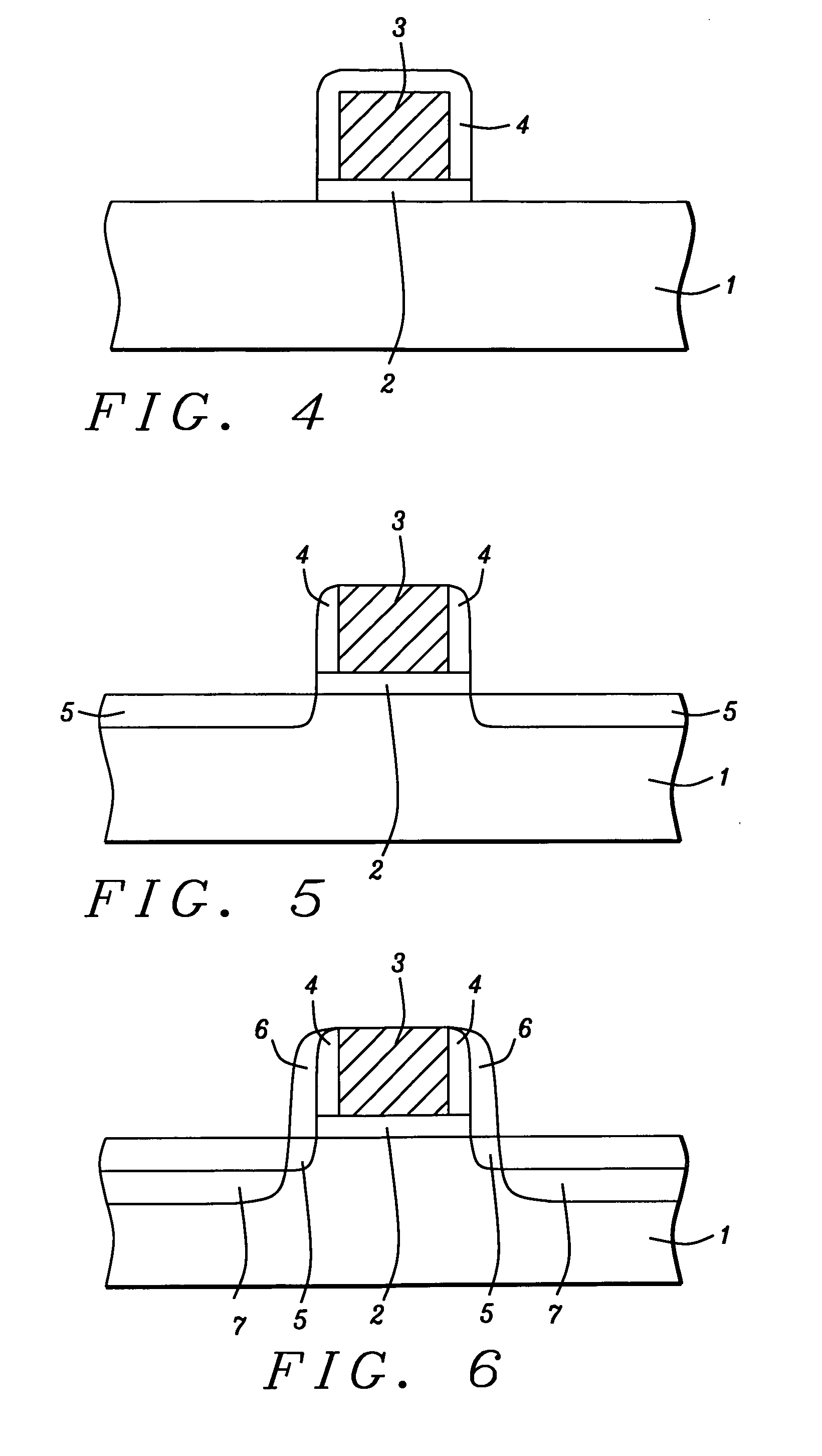

Method of forming a semiconductor device with a high dielectric constant material and an offset spacer

InactiveUS20050121733A1Minimize fabrication stepTransistorSemiconductor/solid-state device manufacturingMOSFETDevice material

A process sequence for forming a MOSFET device featuring a high k gate insulator layer, wherein the use of the high k gate insulator layer requires no additional photolithographic procedures, has been developed. After deposition of a high k gate insulator layer followed by the definition of an overlying conductive gate structure, an insulator layer is deposited. An anisotropic dry etch procedure is then employed to first define offset insulator spacers on the sides of the conductive gate structure, then to selectively remove the unwanted portions of the high k gate insulator layer. The use of the high k gate insulator layer provides a thin gate insulator layer with less risk of leakage when compared to counterpart gate insulator layers such as silicon dioxide, while the integration of the definition of the offset insulator spacer step and of the high k gate layer removal procedure, results in fabrication cost savings.

Owner:TAIWAN SEMICON MFG CO LTD

Mitigation of stress corrosion and fatigue by surface conditioning

InactiveUS20090029631A1Reduce tensile stressEdge grinding machinesGrinding machine componentsBristleSurface conditions

Method and apparatus for surface conditioning a metal surface typically having irregular surface contours, by rubbing the metal surface with a surface conditioning device having a plurality of bristles which contact the metal surface during the rubbing and effect tensile stress reduction or degraded layer removal in the metal surface.

Owner:GENERAL ELECTRIC CO

A novel method of diffused layer removal on the single surface

InactiveCN101217173AImprove conversion efficiencySimple processFinal product manufactureSemiconductor devicesLayer removalProtection layer

The invention provides a novel method for removing a diffusion layer on a single surface, the method is that a front surface on an N-type single crystal silicon wafer substrate is firstly formed with an N<PLUS> layer by phosphorus diffusion, a silicon nitride thin film protection layer is deposited at the front surface, and a back surface uses the strong base corrosion for removing the back surface diffusion layer; the invention can significantly improve the conversion efficiency of an N-type single crystal silicon solar cell and reduce the cost, the process is simple, the operation is convenient; the invention is applicable to large-scale production, particularly simplifies the technology of removing the back N-type diffusion layer, thus greatly improving production efficiency.

Owner:NINGBO ULICA SOLAR SCIENCE & TECHNOLOGY CO LTD

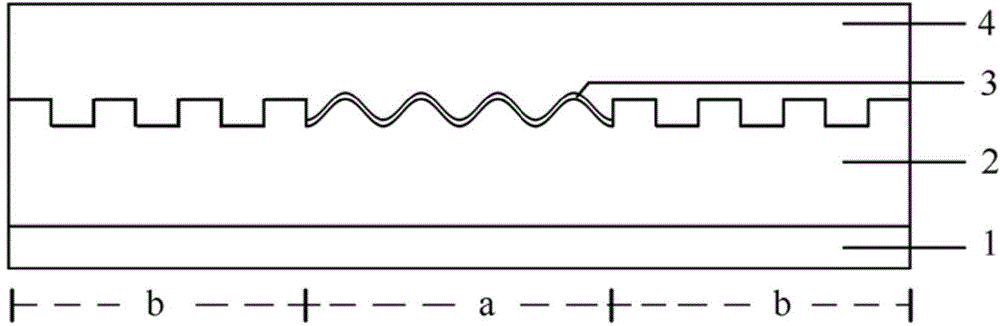

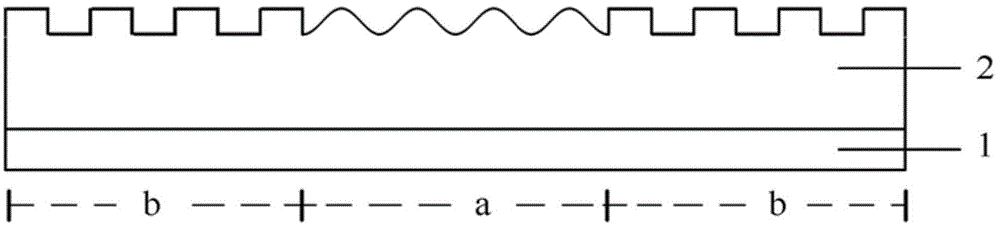

Optical anti-counterfeiting element and manufacturing method thereof

The invention discloses an optical anti-counterfeiting element and a manufacturing method thereof. The method comprises the steps that a fluctuating structural layer (2) is formed on a base material (1), and the fluctuating structural layer (2) at least comprises a first area and a second area, wherein the first area is of a first fluctuating structure, and the second area is adjacent to the first area and is of a second fluctuating structure; the second fluctuating structure is provided with a side wall, wherein the included angle formed between the plane of the base material (1) and the side wall is larger than 45 degrees, and the depth-to-width ratio of the second fluctuating structure is smaller than 0.3; a clad layer (3) is formed on the fluctuating structural layer (2); and the clad layer (3) is arranged in the clad layer removal environment till the clad layer (3) on the second area is stripped from the fluctuating structural layer (2).

Owner:ZHONGCHAO SPECIAL SECURITY TECH +1

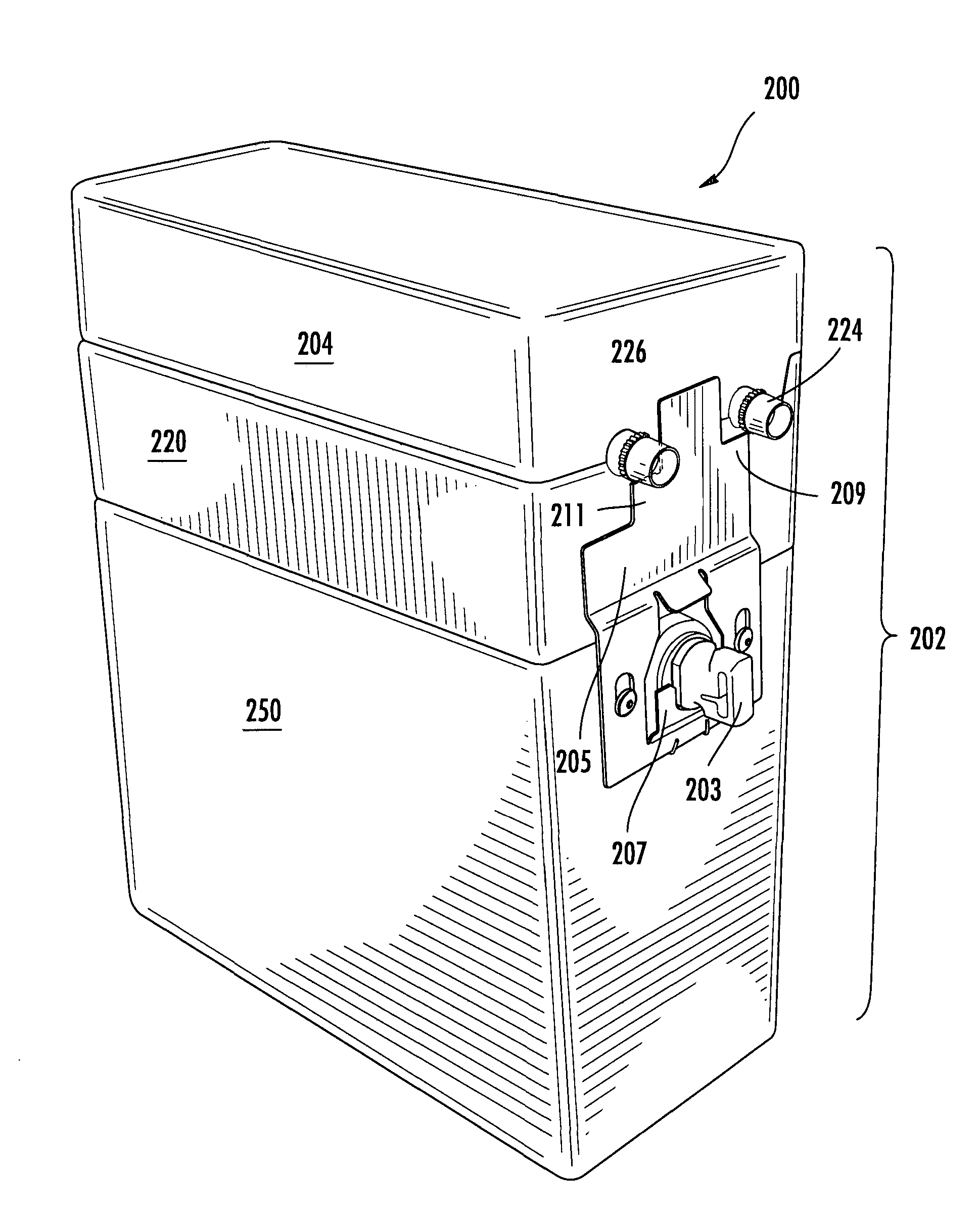

Cartridge for solid imaging apparatus and method

ActiveUS8105066B2Reduce viscosityImprove bindingLiquid surface applicatorsInking apparatusAir entrainmentHigh intensity

A solid imaging apparatus is provided that includes a replaceable cartridge containing a source of build material and an extendable and retractable flexible transport film for transporting the build material layer-by-layer from the cartridge to the surface of a build in an image plane. An operator using the device needs merely to remove a spent cartridge and replace it with a fresh cartridge to continue solid imaging virtually uninterrupted. The apparatus also includes the capability of withdrawing and inserting an imager without the operator having to perform a separate alignment step. A brush attached to the transport film and forming part of the cartridge provides for intra-layer removal of excess uncured build material. If desired, the apparatus can produce a fully reacted build. A high intensity UV source cures the build between layers. An injection molded build pad is designed to hold a build in an inverted position for improving the build. The invention also provides for tilting the build elevator to reduce air entrainment and for releasing the build from the image plane.

Owner:3D SYST INC

Label assembly and method of using the same to label articles durably yet removably

Owner:AVERY DENNISON CORP

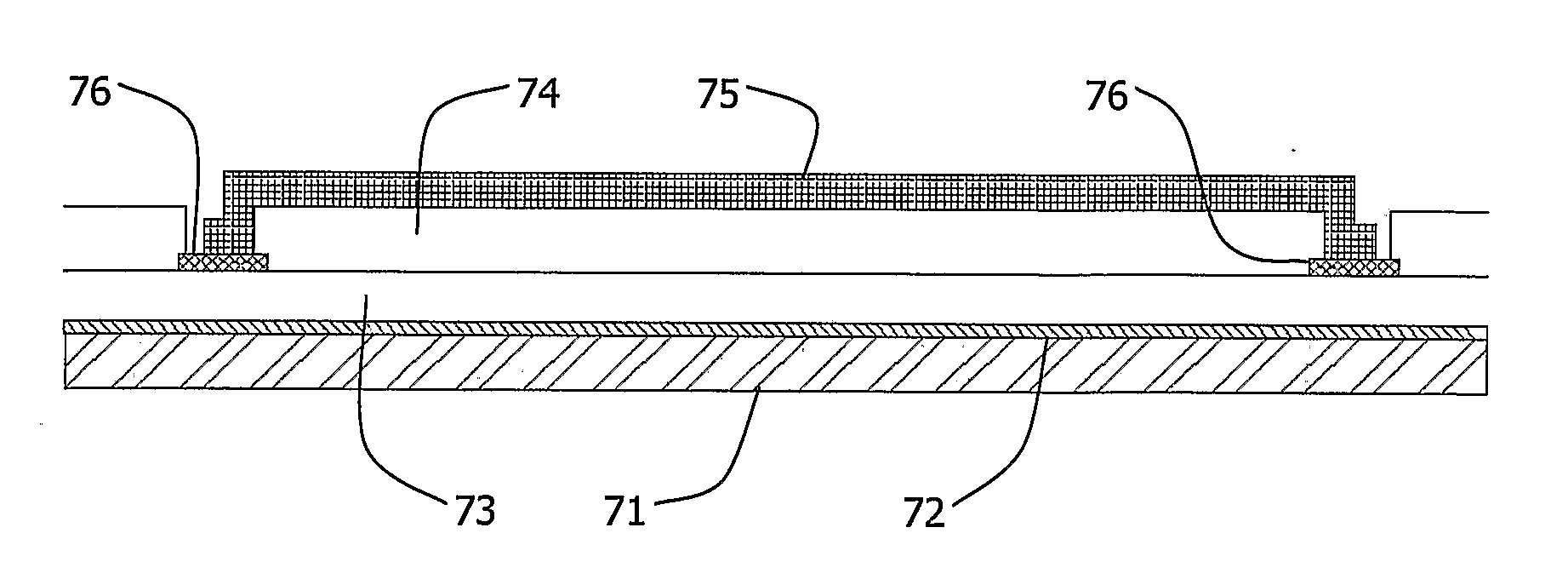

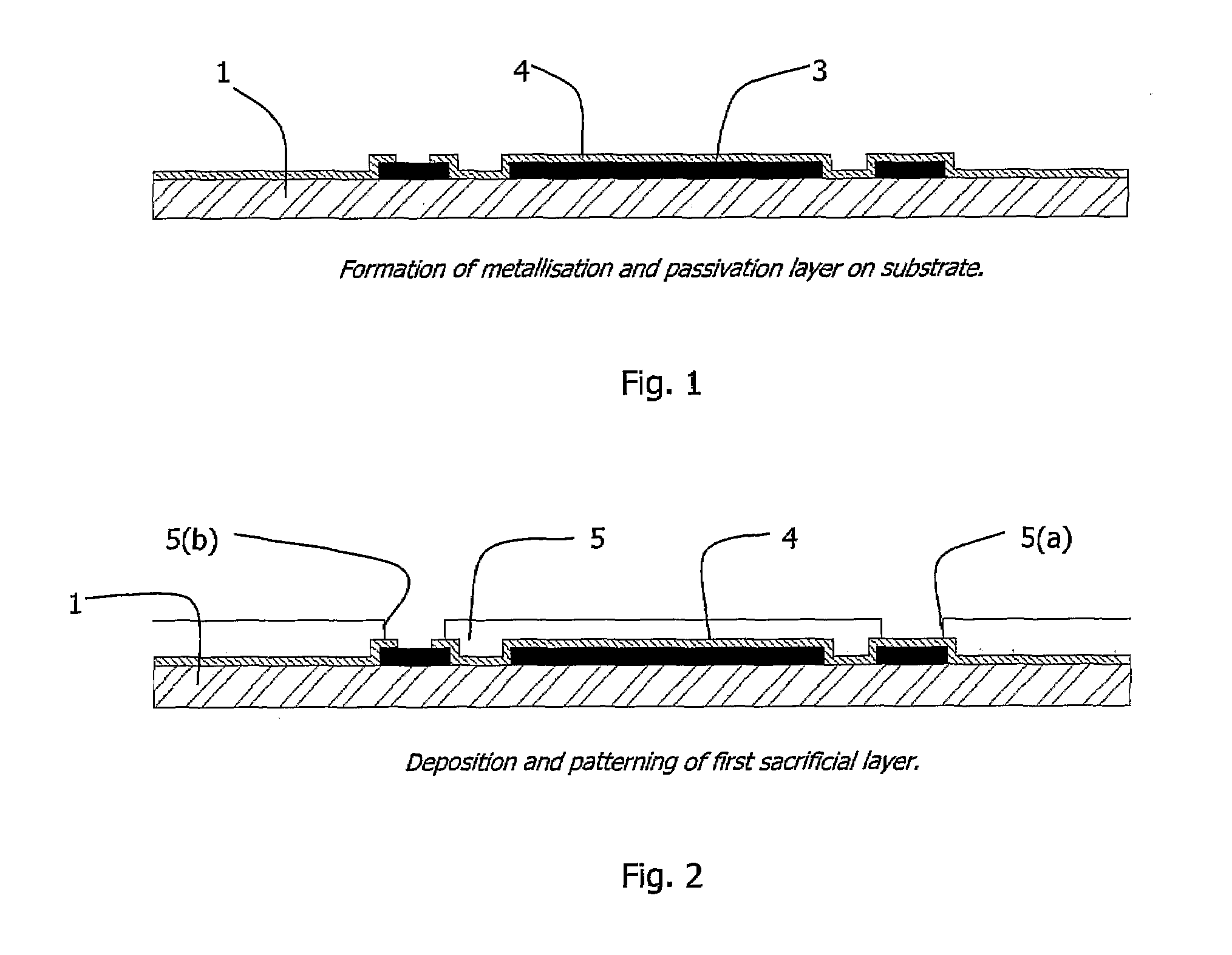

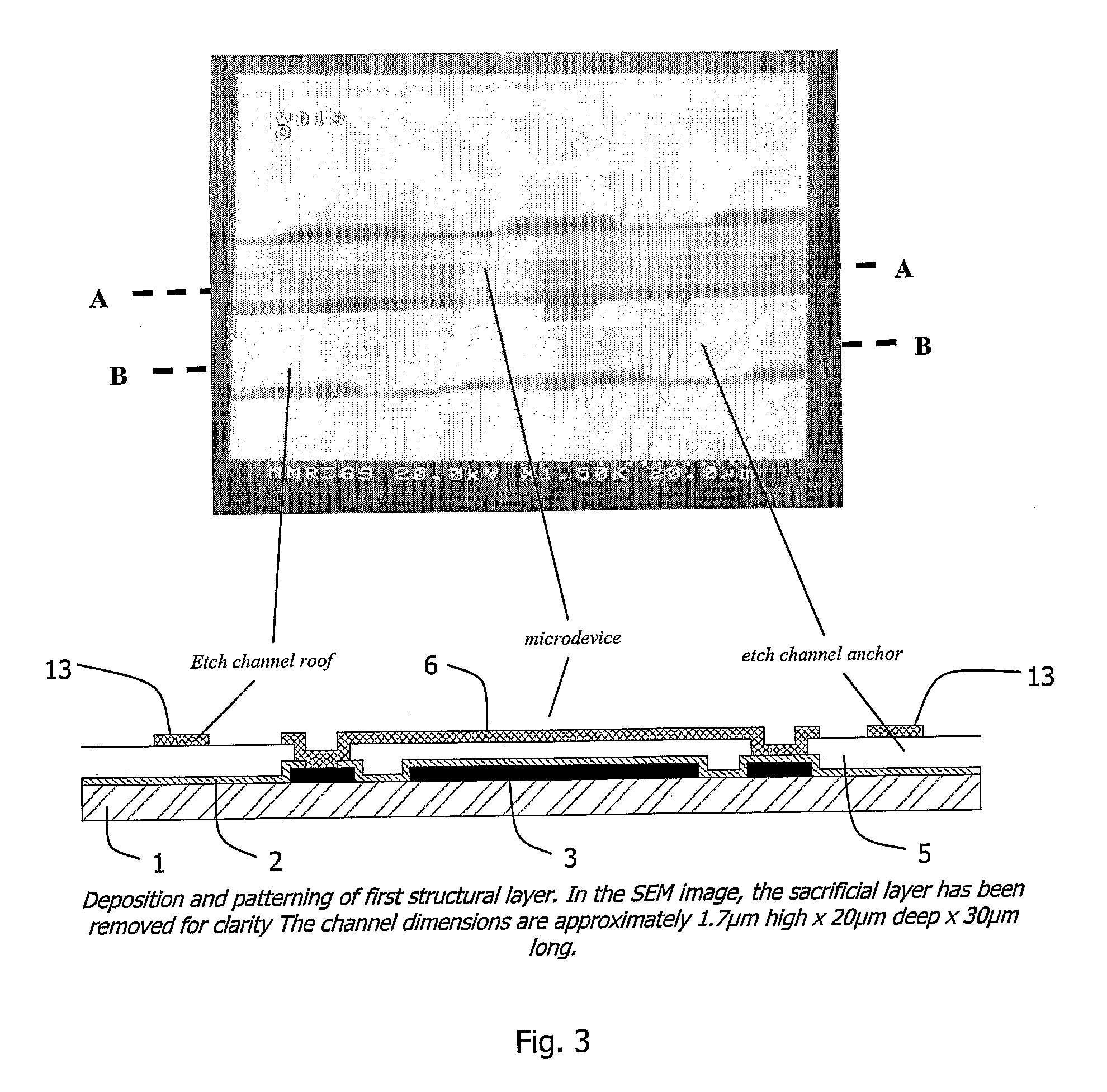

Packaging of Micro Devices

InactiveUS20080145976A1Decreasing channel heightReduce the overall heightSemiconductor/solid-state device manufacturingForming microstructural systemsOxygen plasmaThin layer

A silicon wafer is used as a substrate (1). A thin layer of metal is deposited and etched to form device metallisation (3), including electrodes and bondpads. A passivation layer (4) of silicon nitride is patterned to open access points to the metal. A lower sacrificial layer (5) is formed from polyimide and is patterned (at 5(a) and 5(b)) to open anchor regions for a device and for bridges that will define lateral etch channels for package evacuation. Structural materials that form a MEMS device (6) and bridges (13) are then deposited and patterned. The bridges (13) are patterned simultaneously with the device 6 on the lower sacrificial layer (5). An upper sacrificial layer (7) is then deposited over the device (6) and the lower sacrificial layer (5) and is patterned to open anchor regions (8) for an encapsulation layer (10). Both sacrificial layers are then simultaneously removed in an oxygen plasma ash through lateral etc channels (15). This step leaves a hollow and empty shell, inside which the MEMS device (6) is present. The device (6) is free to move after sacrificial layer removal and has clearance both above and below. The etch channels (15) are sealed by a sealant (40) applied over the encapsulant layer.

Owner:UNIV COLLEGE CORK NAT UNIV OF IRELAND CORK

Equipment with functions of cleaning and full-automatic wall outer layer removal

The invention relates to equipment with functions of cleaning and full-automatic wall outer layer removal. The equipment comprises a bottom plate and a top plate, wherein support seats are arranged on the bottom plate and the top plate, a telescopic device is mounted between the bottom plate and the top plate and comprises telescopic rods I mounted on the bottom plate, and telescopic rods II capable of moving up and down relative to the telescopic rods I are mounted on the telescopic rods I and connected with a power drive device I; connecting pillars capable of sliding relative to the telescopic rods II are arranged on the telescopic rods II and connected with a power drive device II, a screw rod I and guide rods are fixedly mounted on the connecting pillars, the screw rod I is connected with a power drive device III, a fixing support plate is arranged on the guide rods, a concentric shaft is mounted on the fixing support plate and connected with a power drive device IV, and a blade or a cleaning material is mounted on the concentric shaft. The equipment has multiple functions and can vertically move up and down and can horizontally move, and the work effect is greatly improved.

Owner:袁宁婧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com