Patents

Literature

3877 results about "Rubbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rubbing (frottage) is a reproduction of the texture of a surface created by placing a piece of paper or similar material over the subject and then rubbing the paper with something to deposit marks, most commonly charcoal or pencil, but also various forms of blotted and rolled ink, chalk, wax, and many other substances. For all its simplicity, the technique can be used to produce blur-free images of minuscule elevations and depressions on areas of any size in a way that can hardly be matched by even the most elaborate, state-of-the-art methods. In this way, surface elevations measuring only a few thousandths of a millimeter can be made visible.

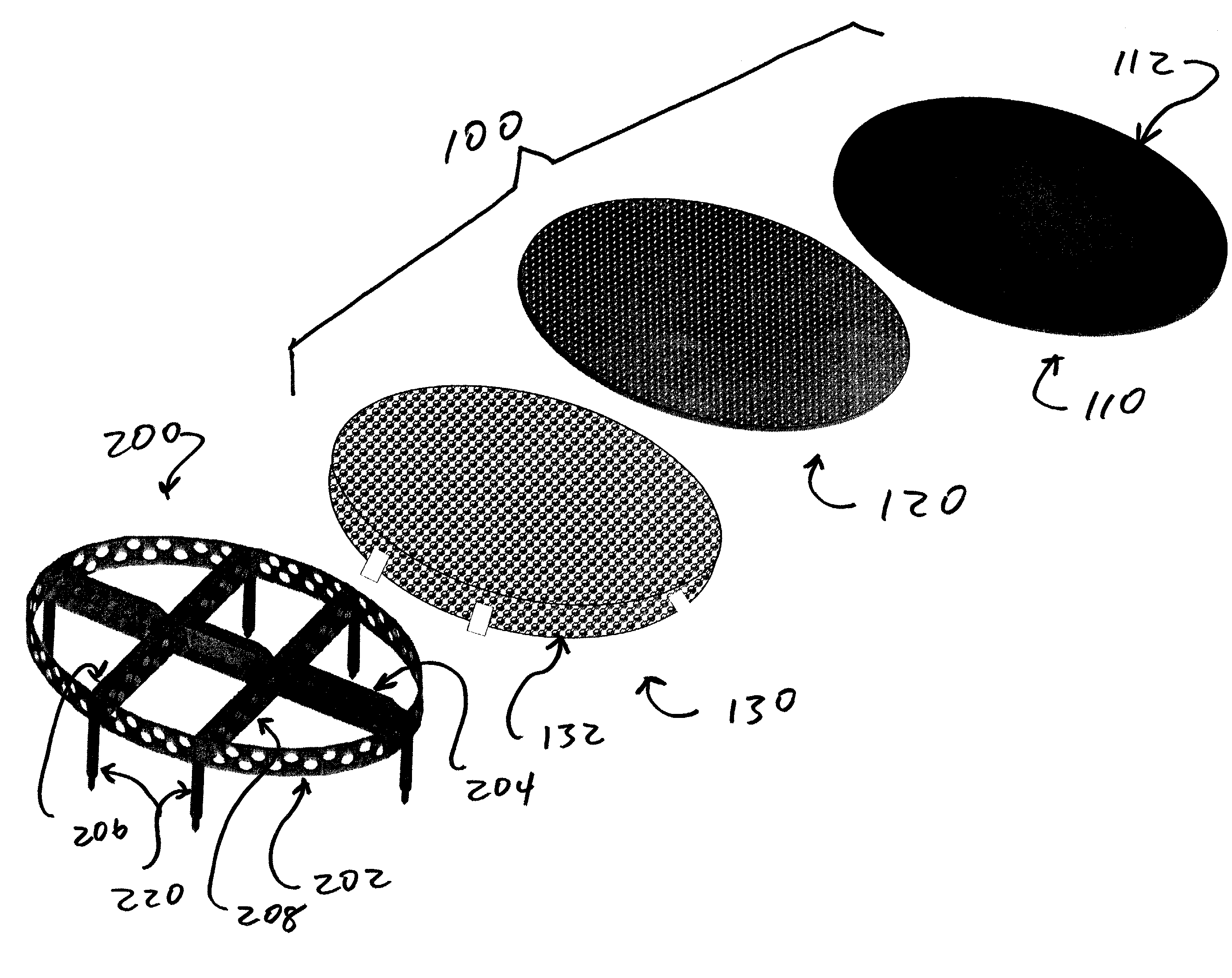

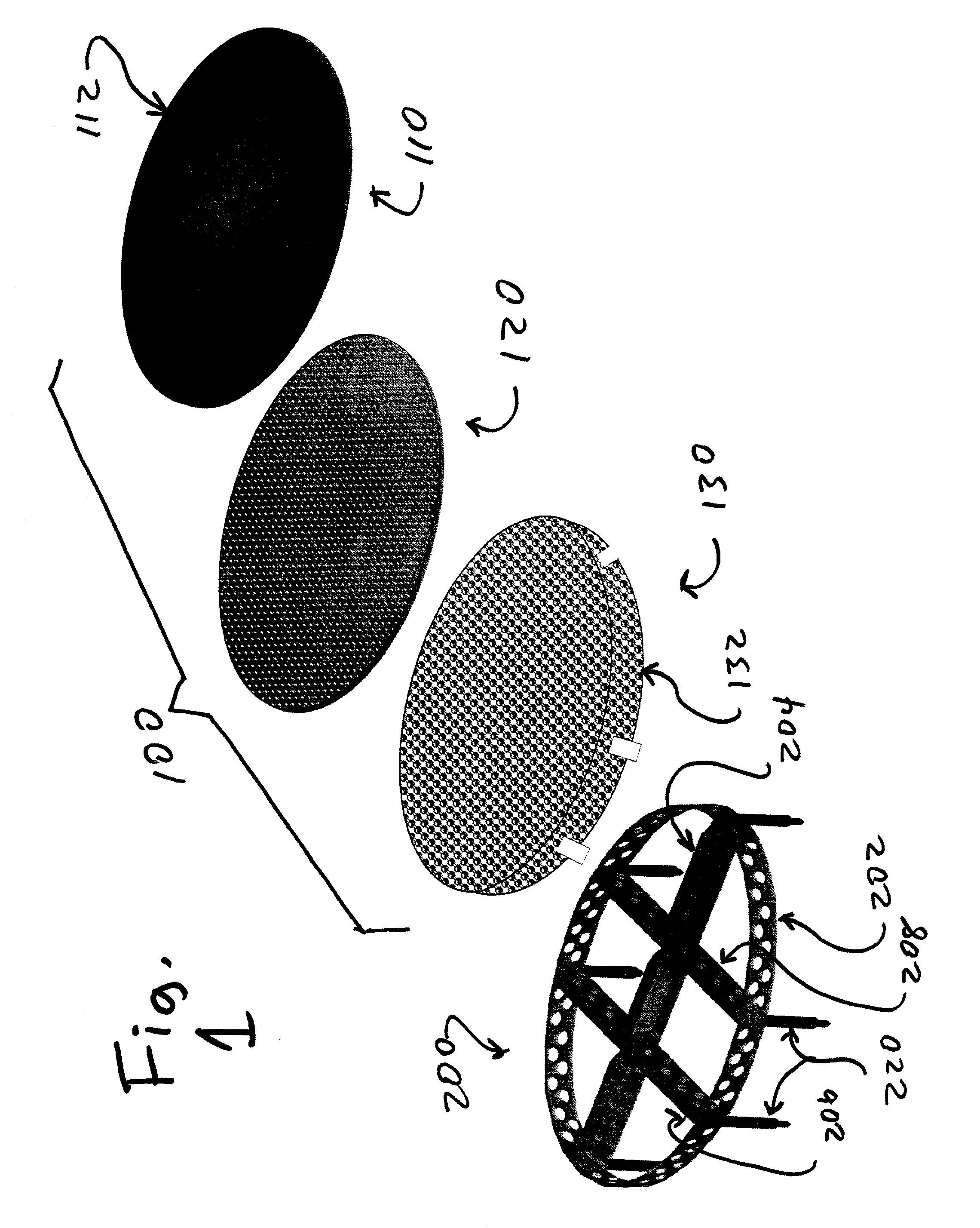

Cartilage repair implant with soft bearing surface and flexible anchoring device

InactiveUS9050192B2Strong and more permanent fixationSoft and bendableJoint implantsHip jointsCartilage repairSurgical implant

A surgical implant for replacing hyaline cartilage in a knee or other articulating synovial joint has an anchoring side on one side of the implant adapted for fixing the implant to one of the bones in the joint, and a bearing surface on the opposite side of the implant for lubricious rubbing and sliding contact with another bone in the joint. The anchoring side can be configured with an irregular surface for tissue ingrowth. The bearing side can include hydrogel. The implant can be rolled up from an original shape and surgically inserted by arthroscopic means, and opens into its original shape when released inside the joint.

Owner:FORMAE

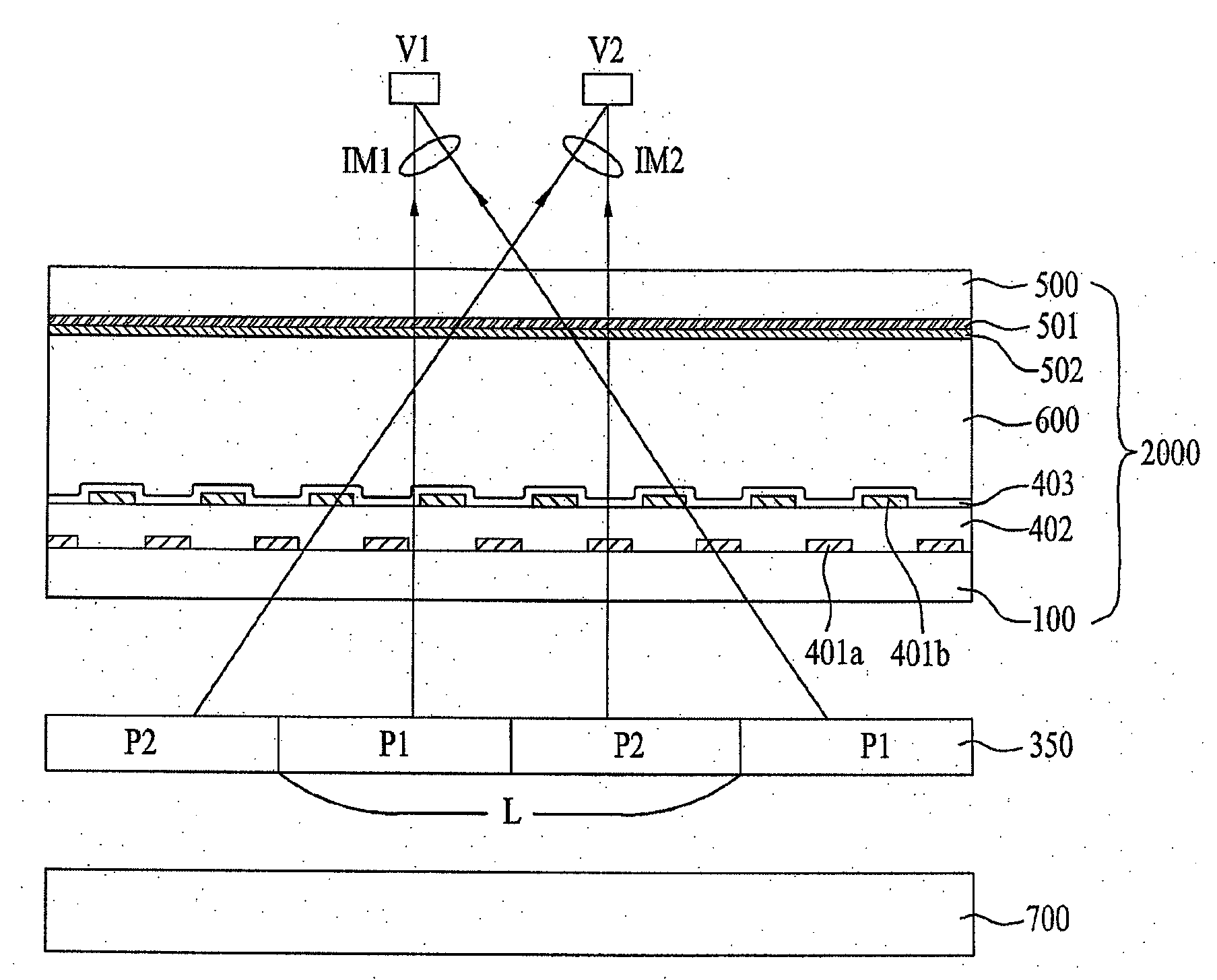

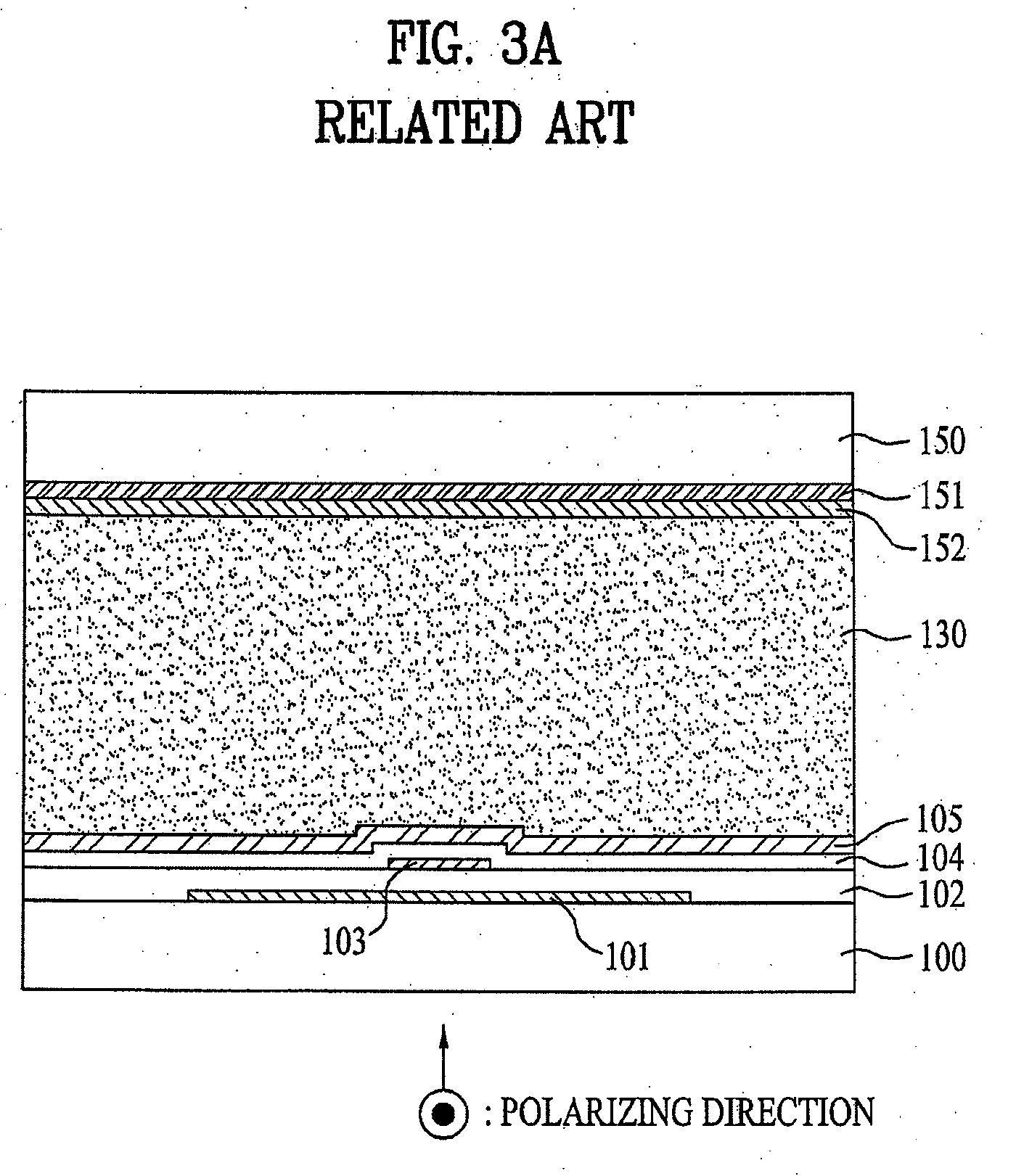

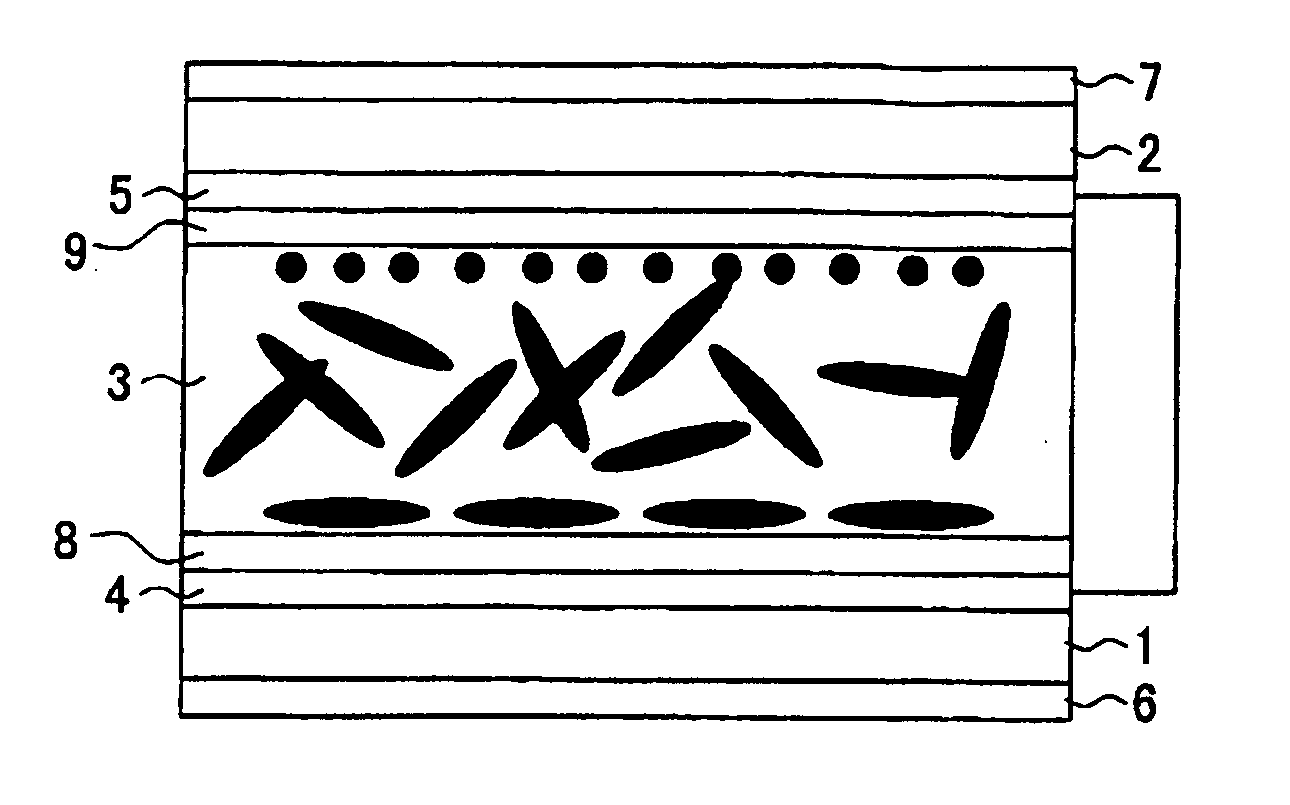

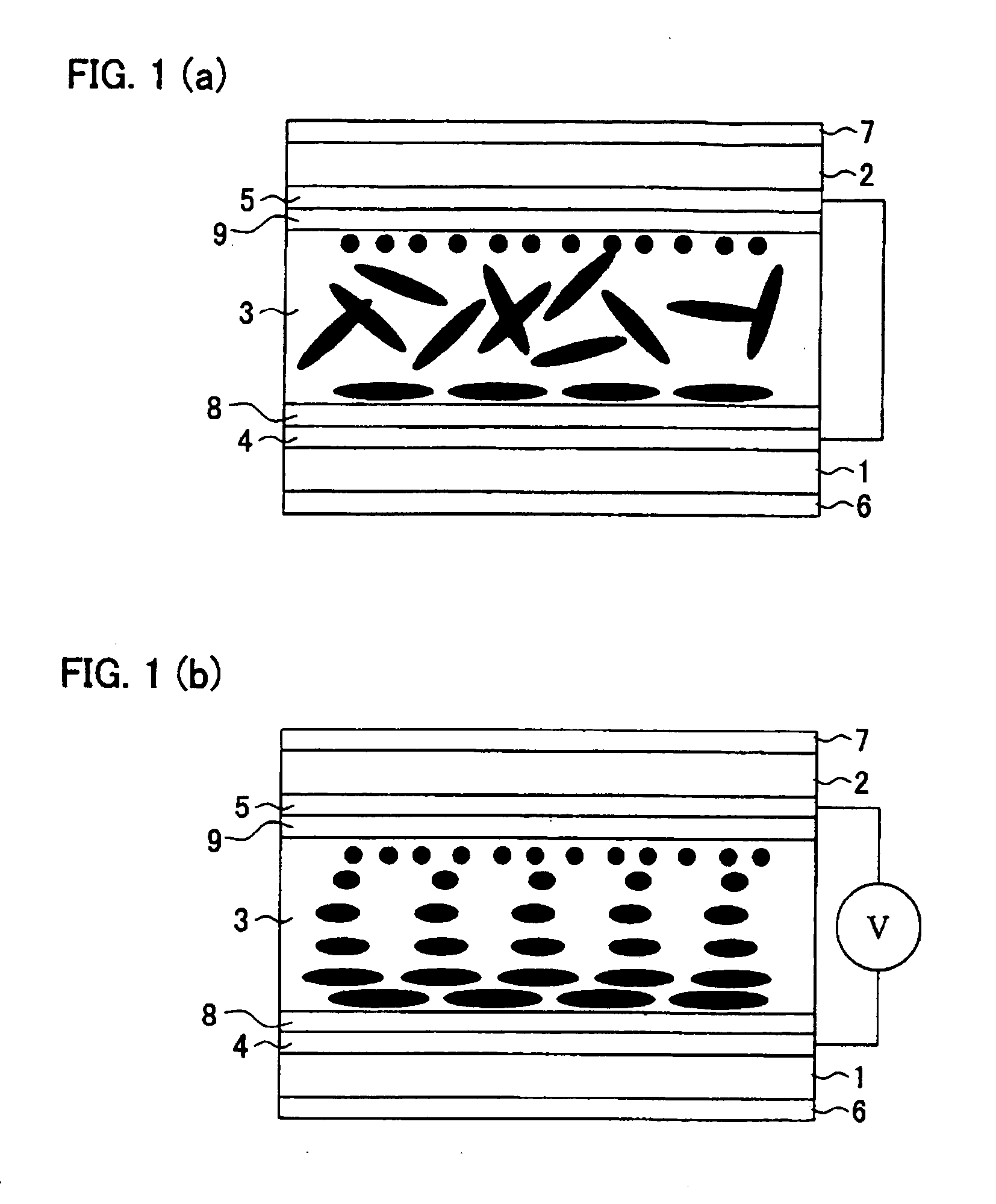

Ferroelectric liquid crystal display and method of manufacturing the same

InactiveUS20020149727A1Increase contrastNon-linear opticsLiquid-crystal displayFerroelectric liquid crystal display

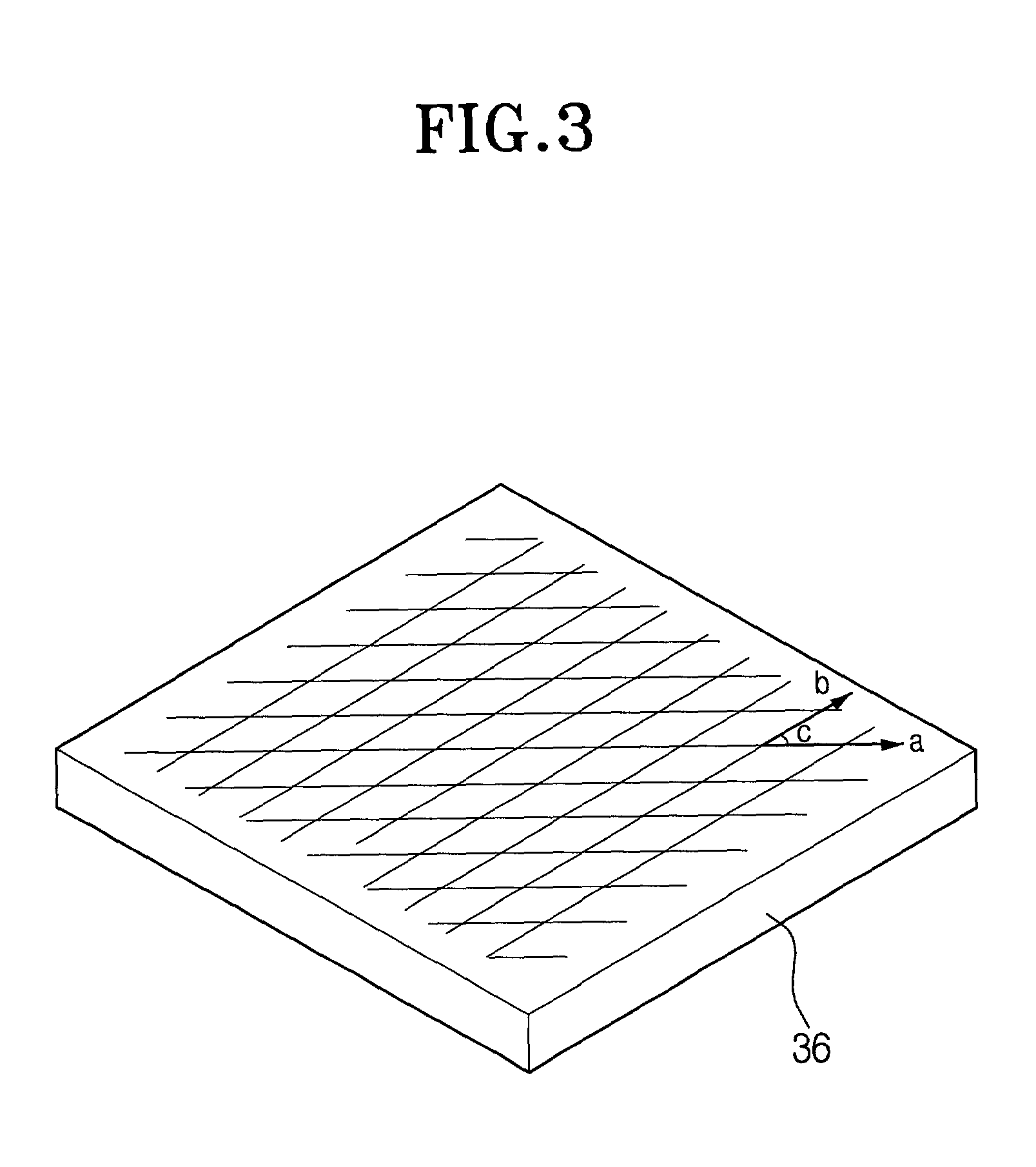

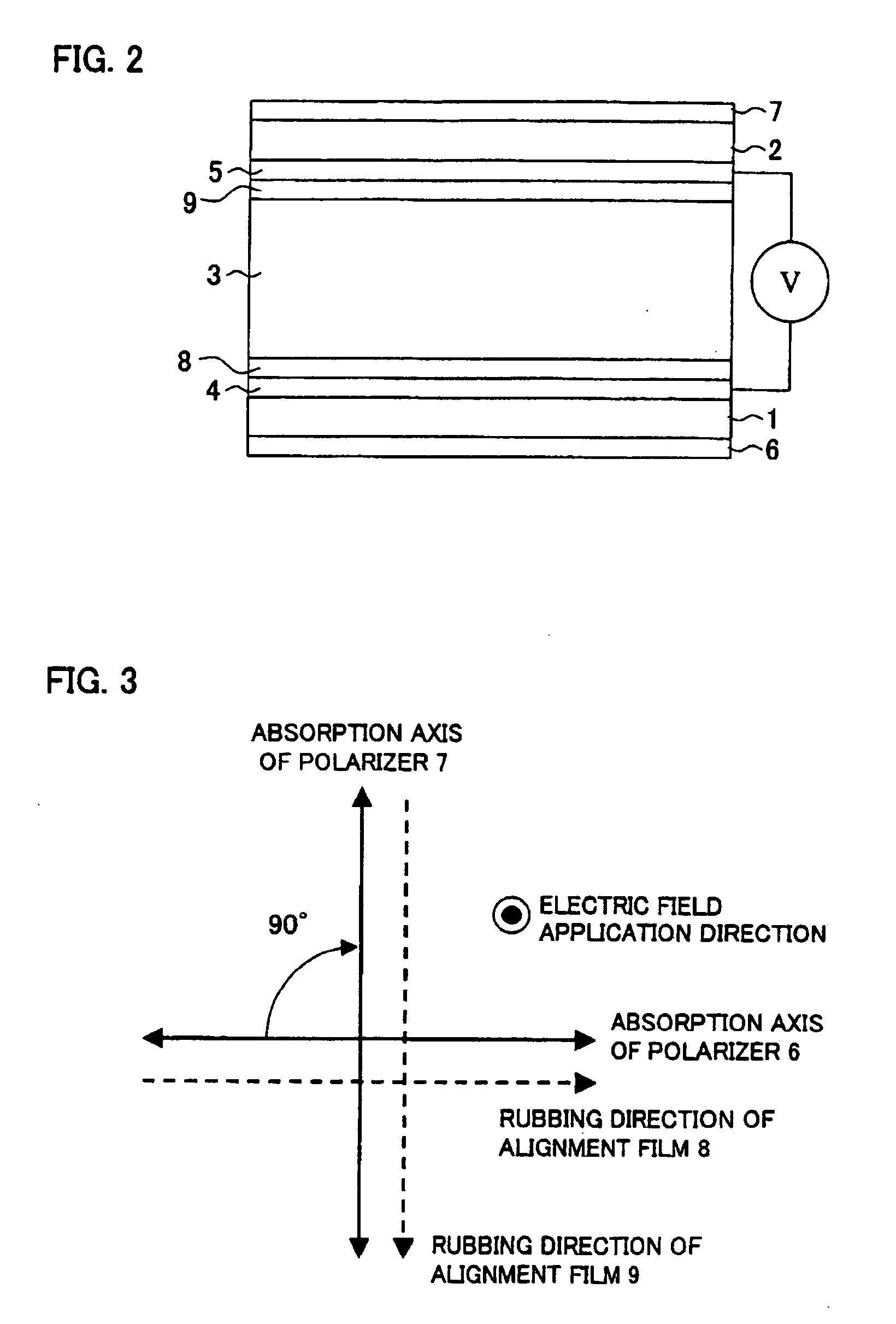

A ferroelectric liquid crystal display including an upper base plate and a lower base plate which are disposed apart from each other at a predetermined distance, electrode layers respectively formed on the upper base plate and the lower base plate facing each other, orientation layers respectively formed on the electrode layers and treated by rubbing in a first rubbing direction and a second rubbing direction which intersect at a predetermined angle, and a liquid crystal layer disposed between the orientation layers and filled with a ferroelectric liquid crystal having a bookshelf structure. Due to the ferroelectric liquid crystal display and the method of manufacturing the same, the ferroelectric liquid crystal of the bookshelf structure can stably twist by the treatment of the orientation such that an afterimage phenomenon is prevented and further a low threshold voltage and a bistability can be obtained.

Owner:SAMSUNG ELECTRONICS CO LTD

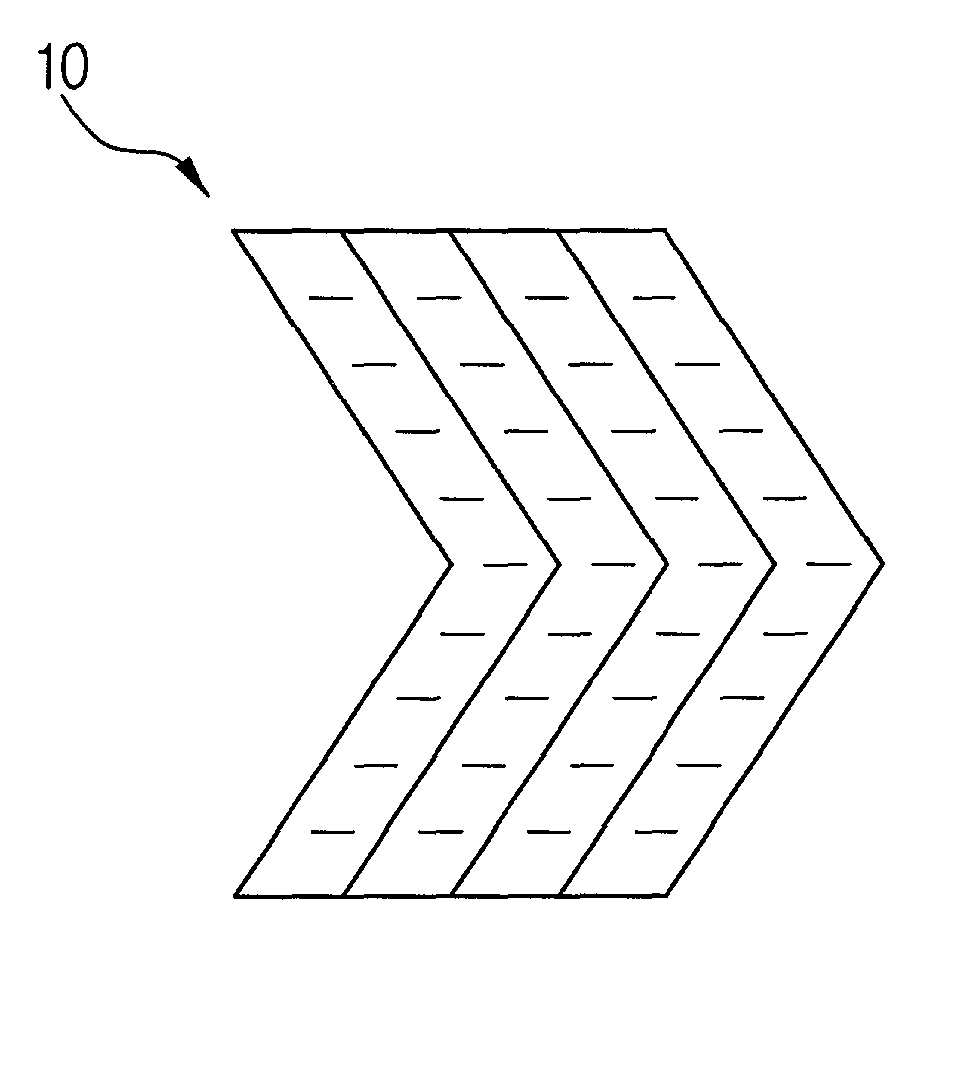

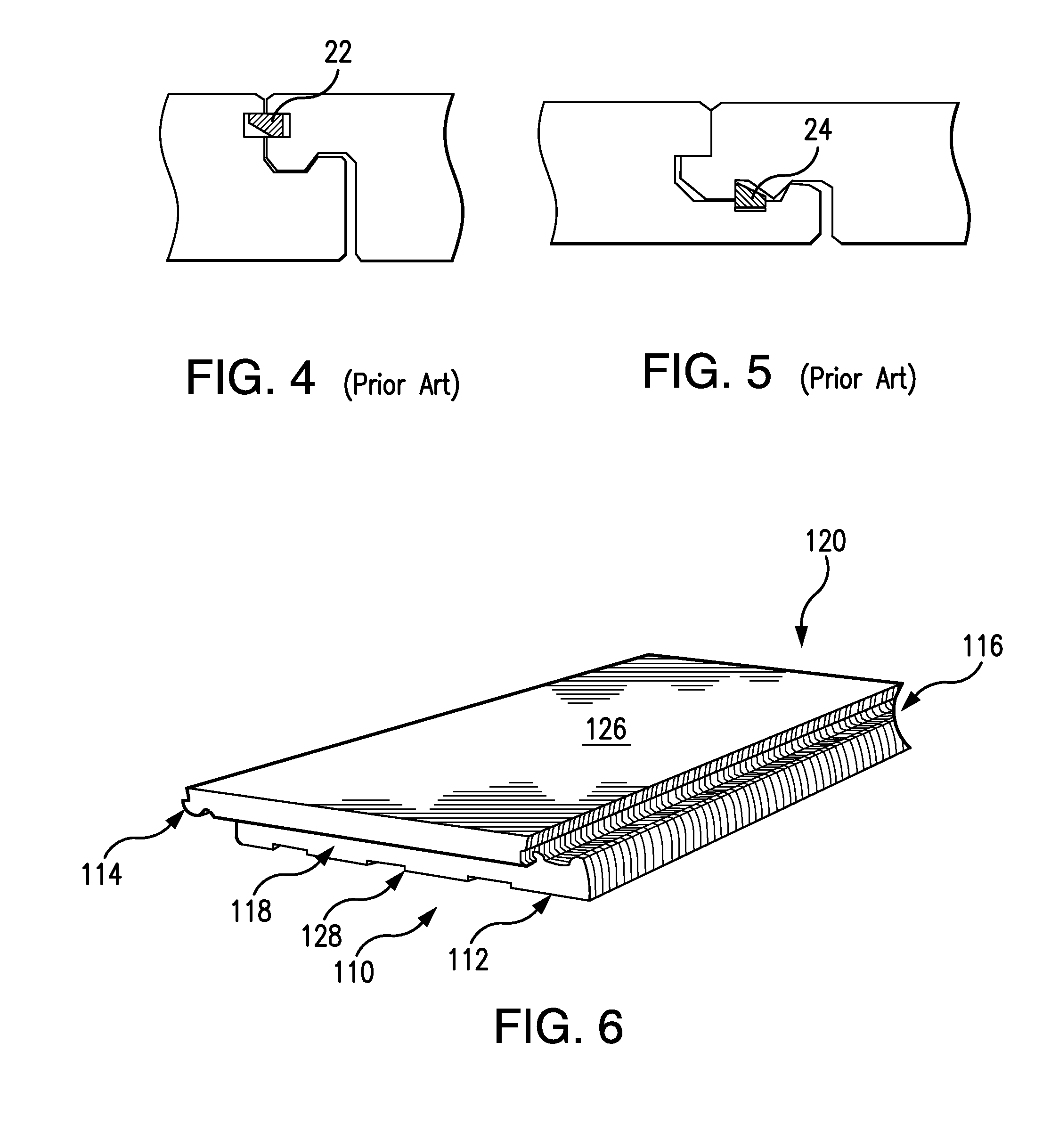

Non-squeaking wood flooring systems and methods

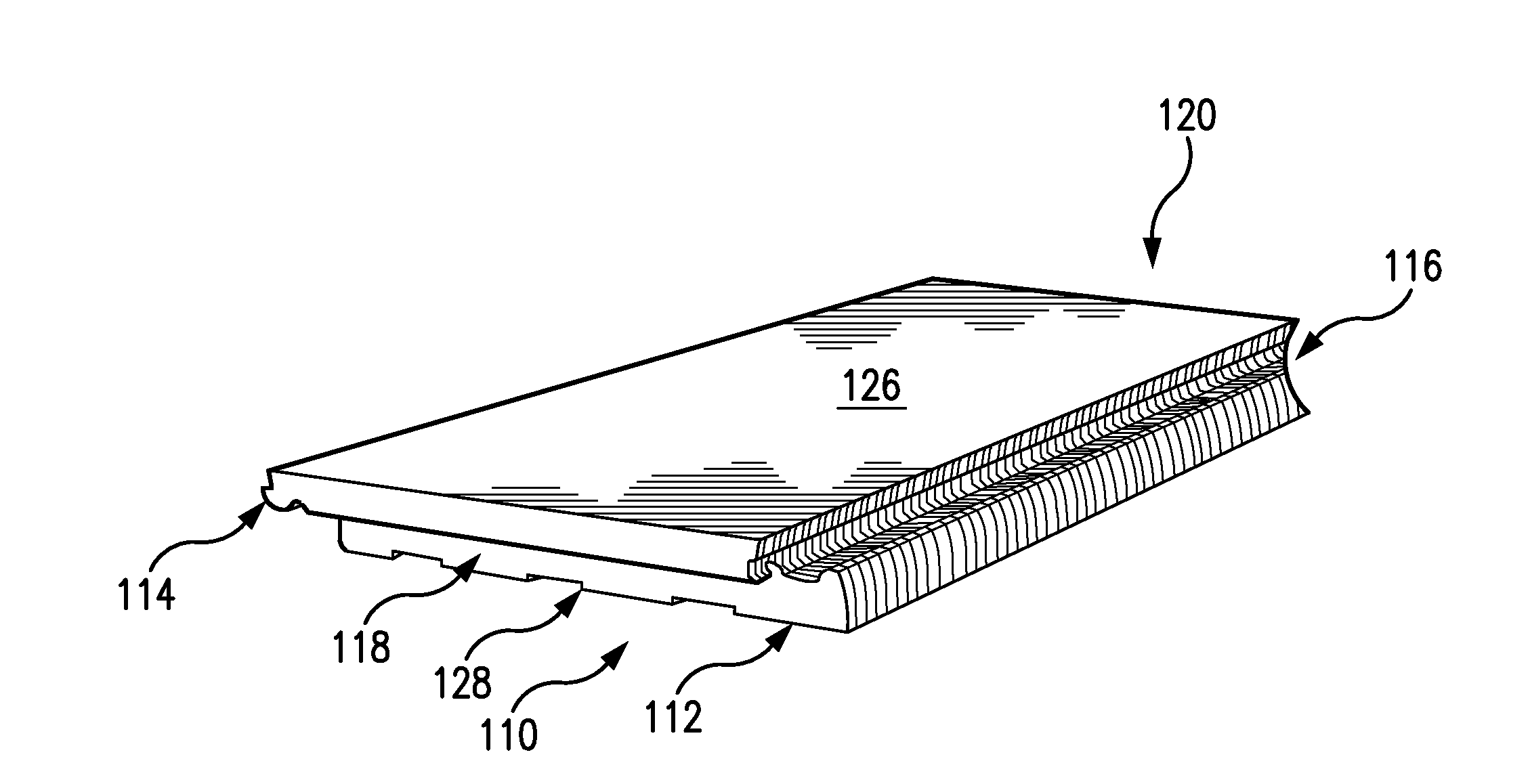

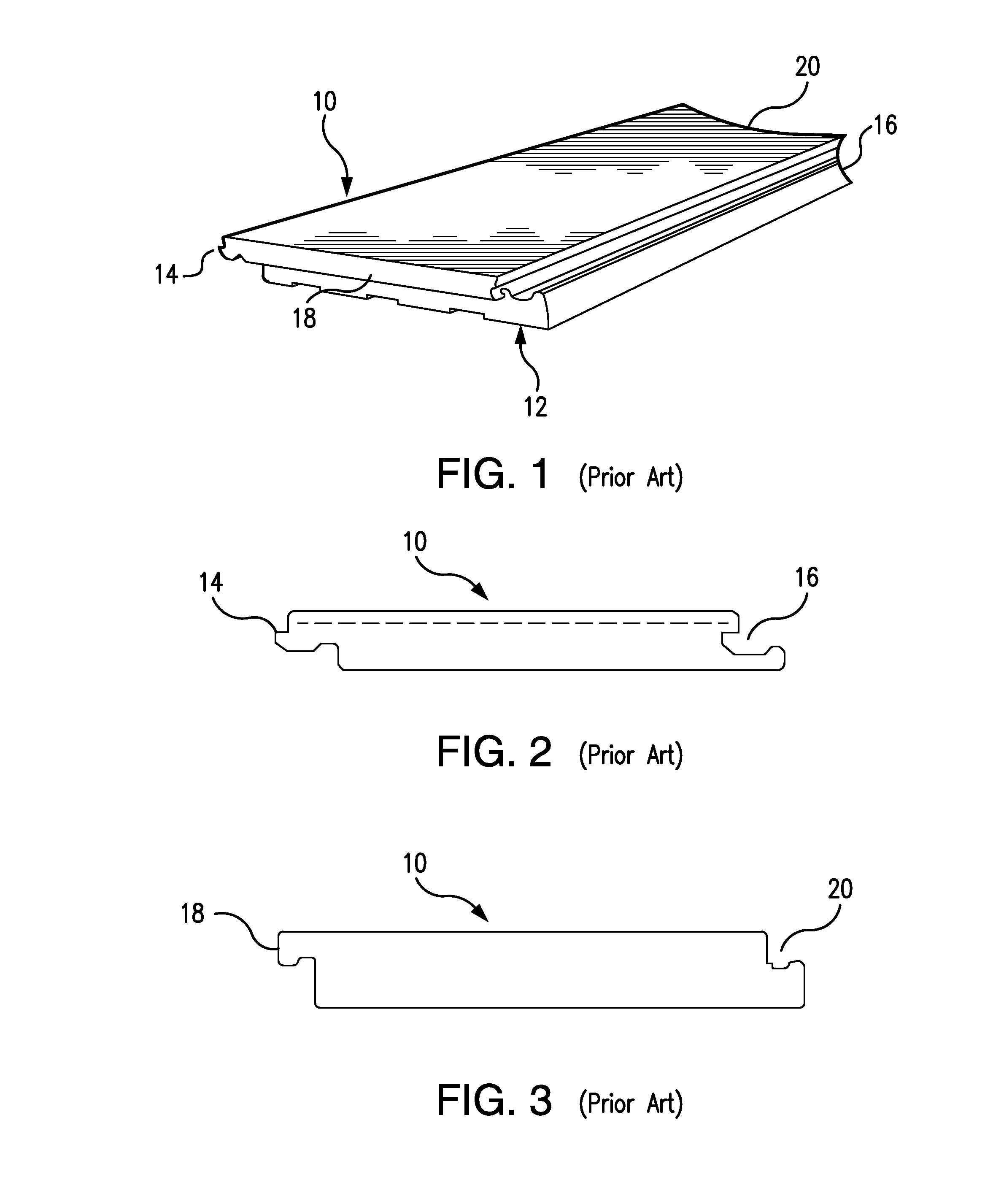

ActiveUS20130008118A1Avoid squeakingAvoid squeaking of the floorboardsFloorsLaminationTectorial membraneEngineering

Wood-based flooring systems with click-type interlocking joint systems include a protective film system covering the contact surfaces of the click system. The protective film system includes one or more sheets of a material with low moisture transmissivity and a low coefficient of friction. In this way, the contact surfaces of the click system are protected against undue humidity absorption and frictional rubbing to thereby avoid squeaking after installation. In some embodiments there are four film sheets covering the entirety of all four click surfaces, in others there is one film sheet covering the entirety of all four click surfaces, in others there is film covering the entirety of only the two longitudinal click surfaces, in others there is film covering the entirety of only the two tongue click surfaces, and in others there is film covering only the contact surfaces of the click surfaces.

Owner:CFL HLDG LTD

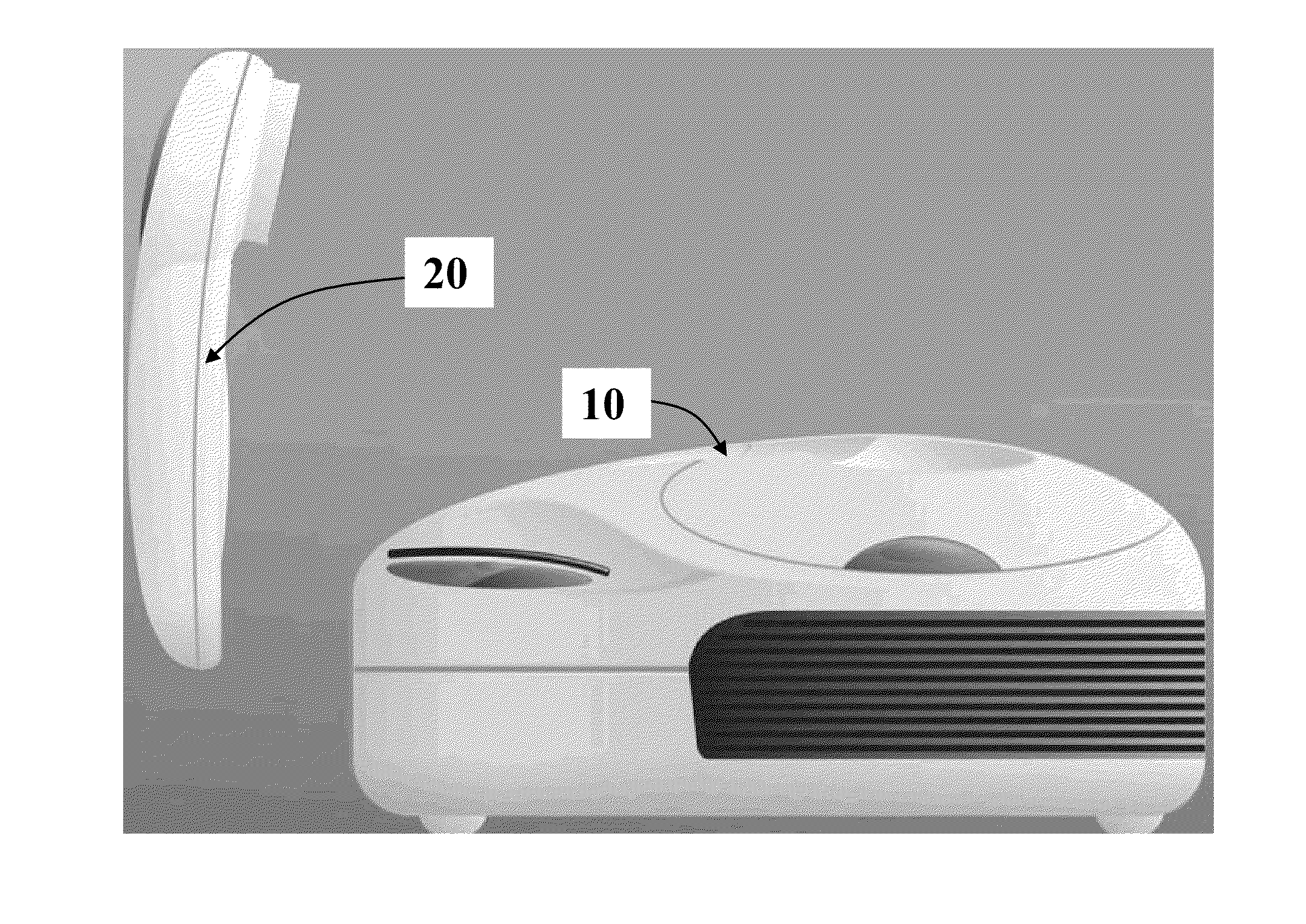

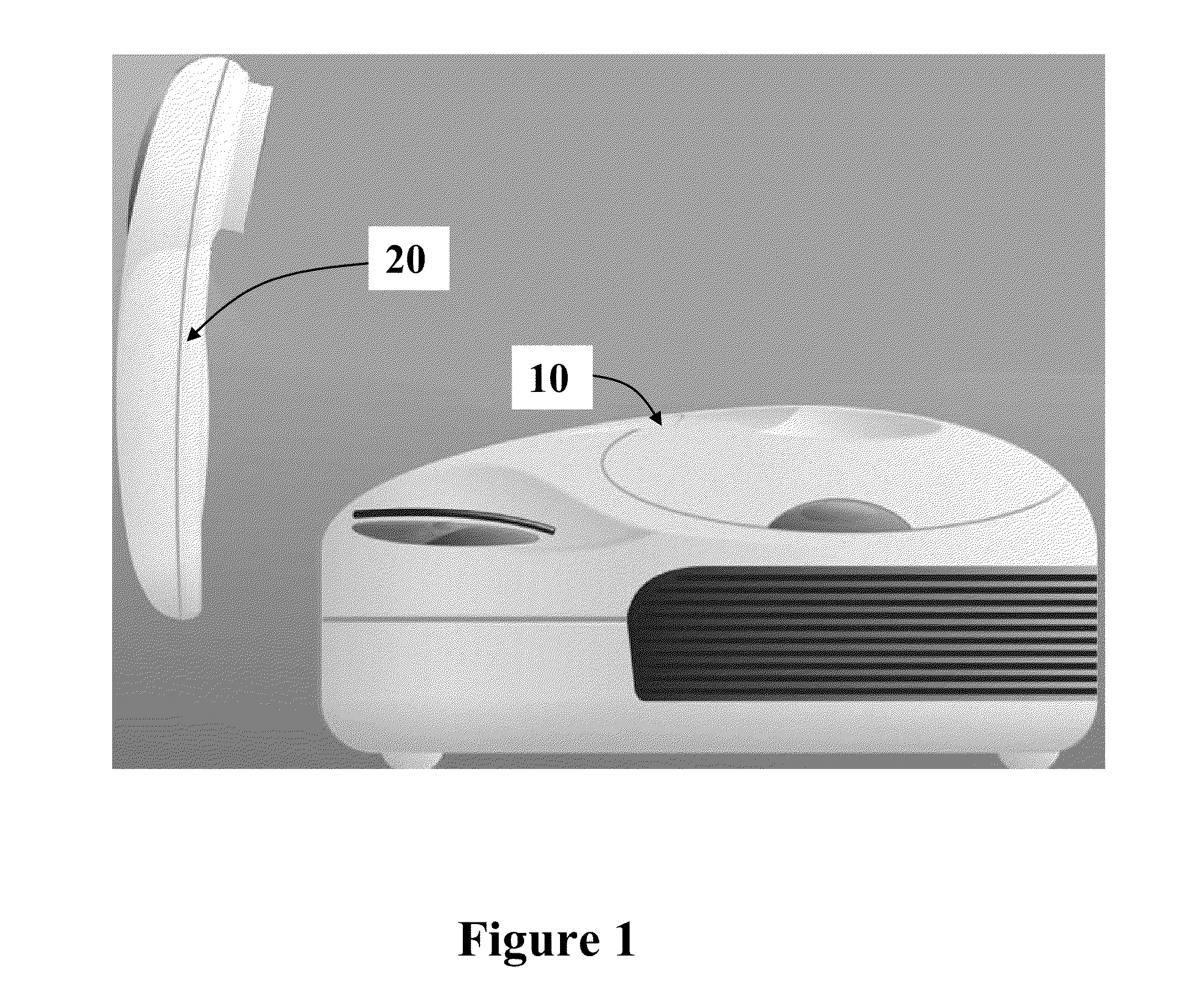

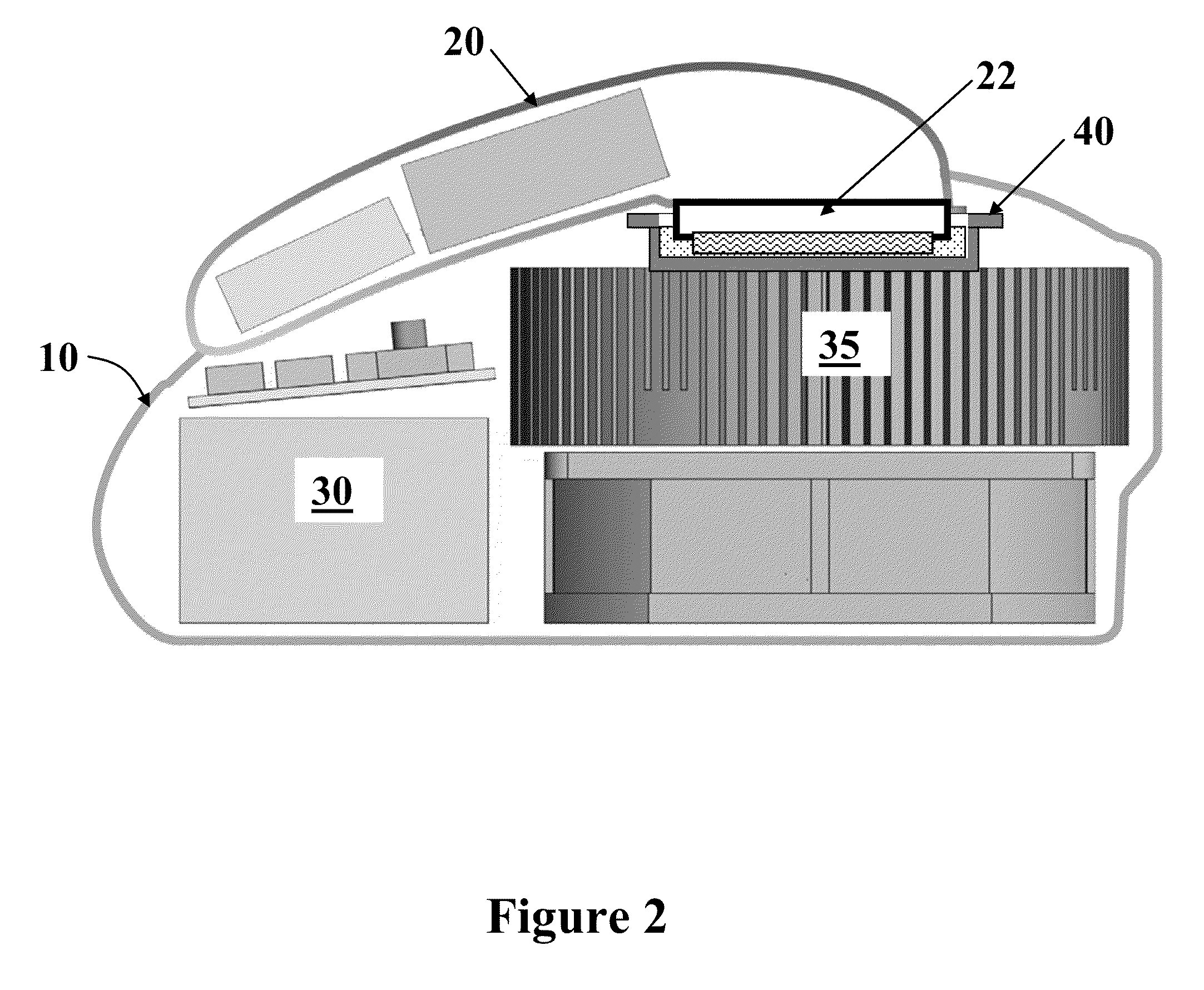

Methods and Apparatus for Personal Care

InactiveUS20100217357A1Effectively cleanseEffectively rejuvenateCosmetic preparationsToilet preparationsEtiologyWrinkle skin

Methods, apparatus and systems for personal care, such as treatment of a skin or hair treatment surface, are disclosed. In some embodiments, a base device is configured to thermally modify (heat or cool) an applicator on a hand piece that can then be used to cleanse, treat and / or otherwise rejuvenate the treatment surface. The applicator can be formulated with a smooth or abrasive material that can absorb, be coated with or otherwise take up a variety of materials, such as liquids, lotions, gels or creams, which are suitable for application to the treatment surface. The base device may thermally modify the material that is then coupled to the applicator and applied to the treatment surface during treatment. Application of the applicator at the desired temperature to the treatment surface may, for example, stimulate deeper blood circulation, clear pores, diminishes or removes deep and fine wrinkles, accelerate acne clearing, treat blemished skin, decrease edema and erythema of the skin, and / or reduce puritis of various etiologies. The hand piece may comprise one or more secondary treatment elements, such as LEDs for photoactivation, electrodes for delivery of micro-currents or vibrating elements for rubbing or abraiding, in order to achieve additional activation of the treatment surface and / or of the thermally modified material coupled to the applicator, which may enhance or improve treatment.

Owner:DA SILVA LUIZ B +2

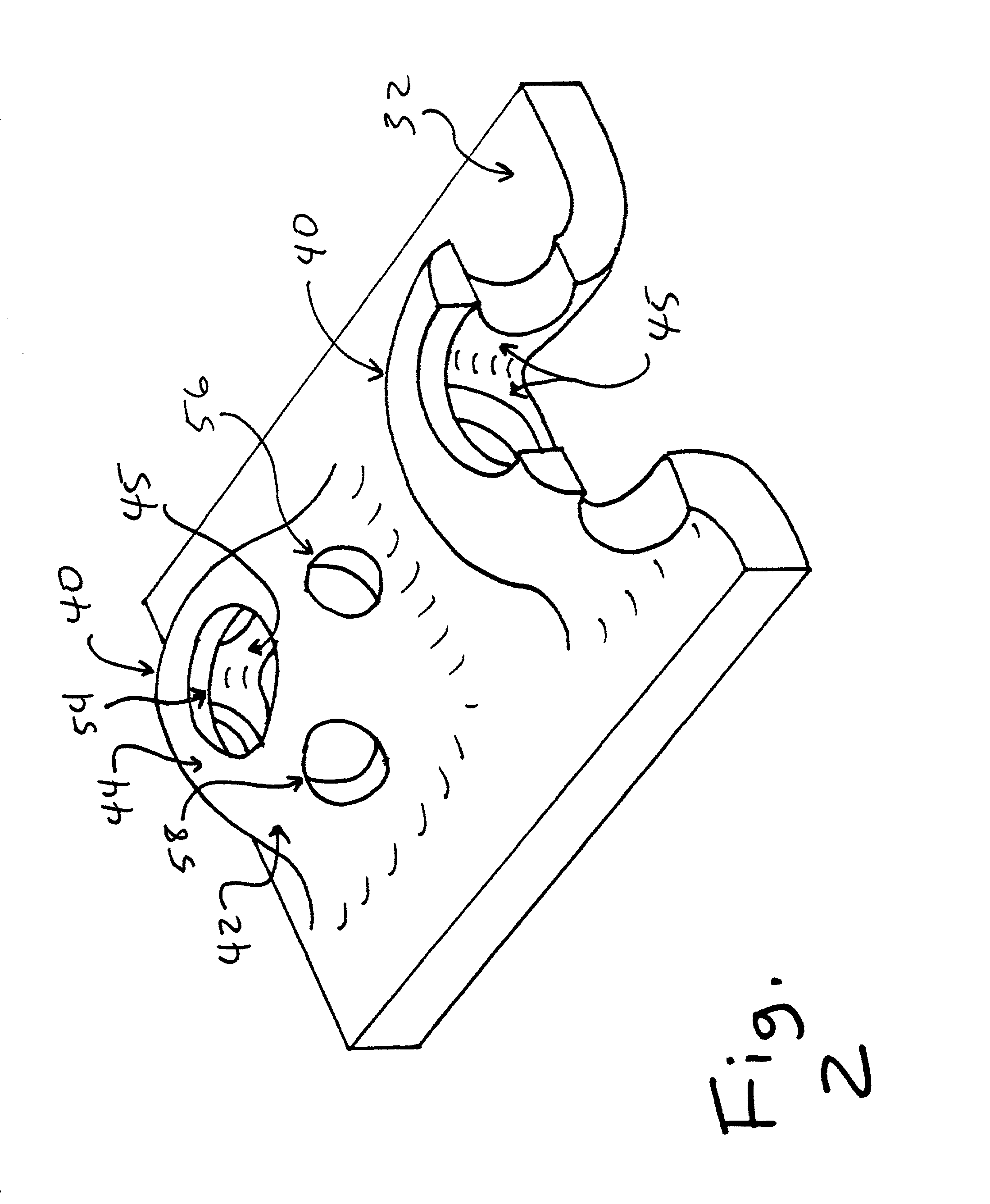

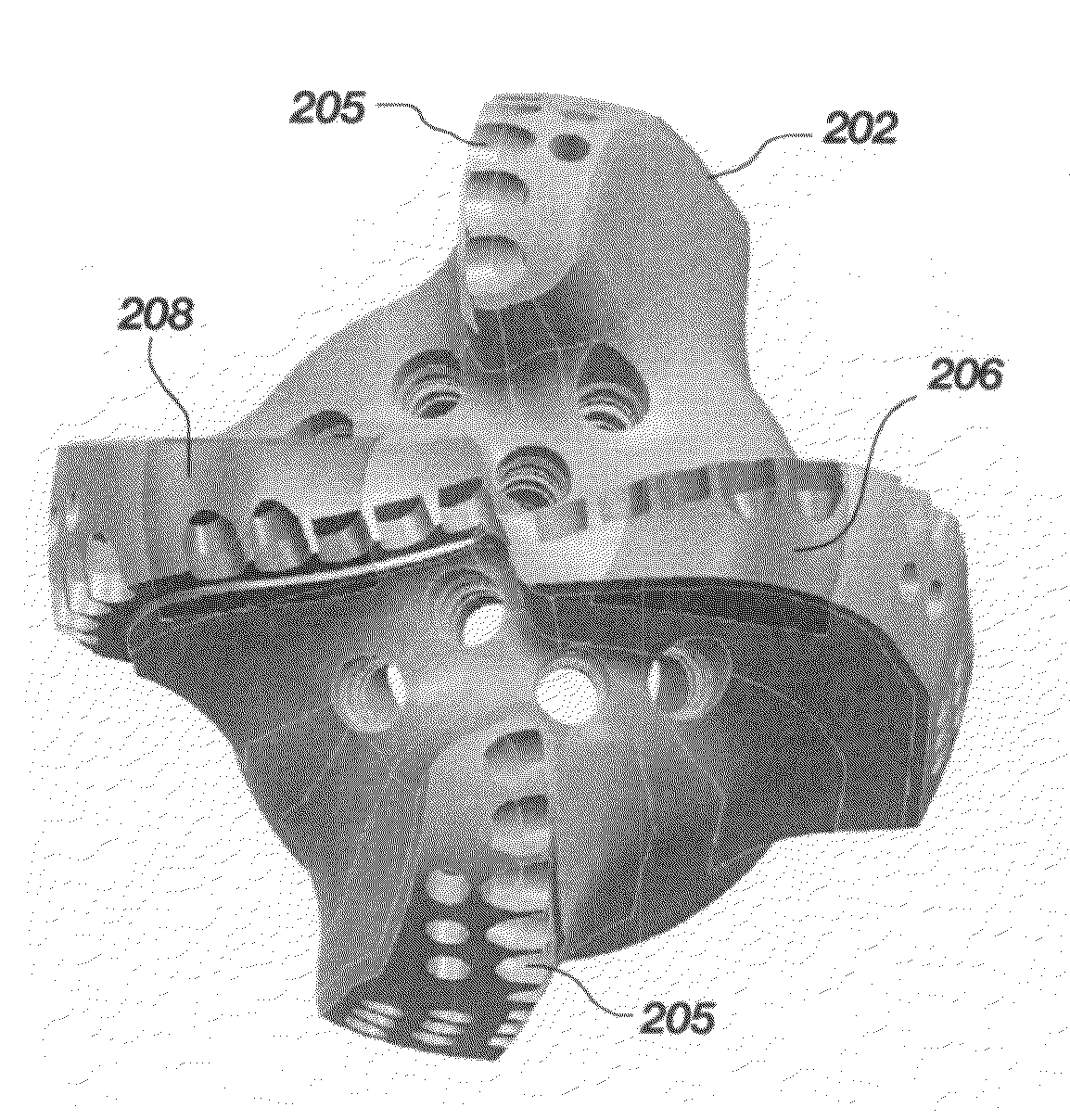

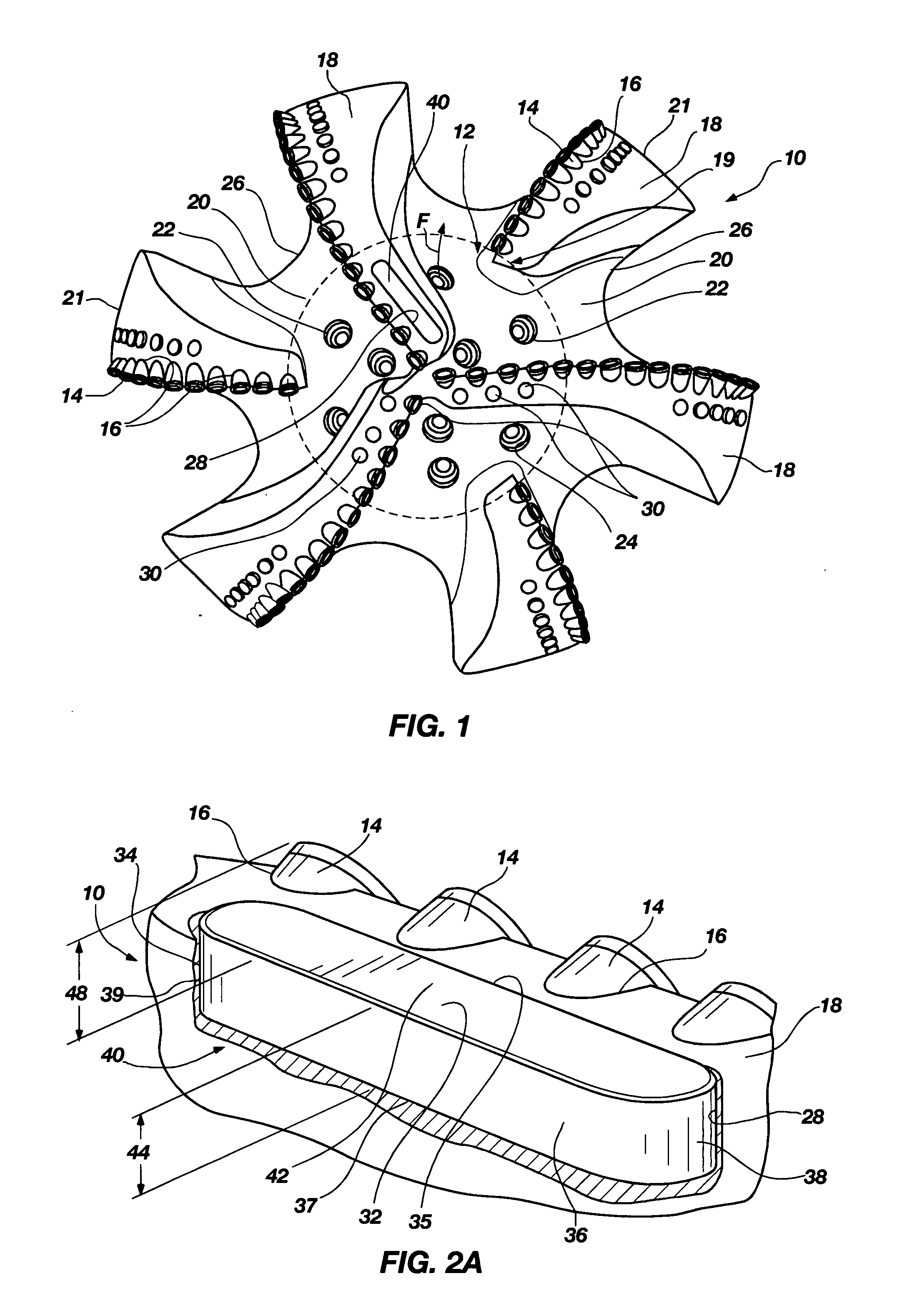

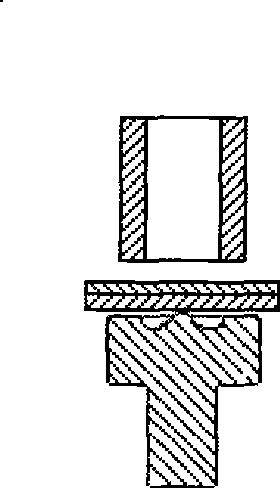

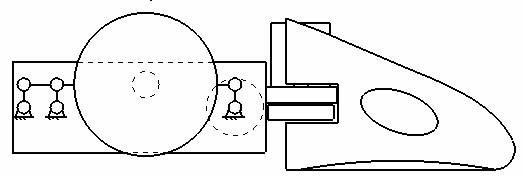

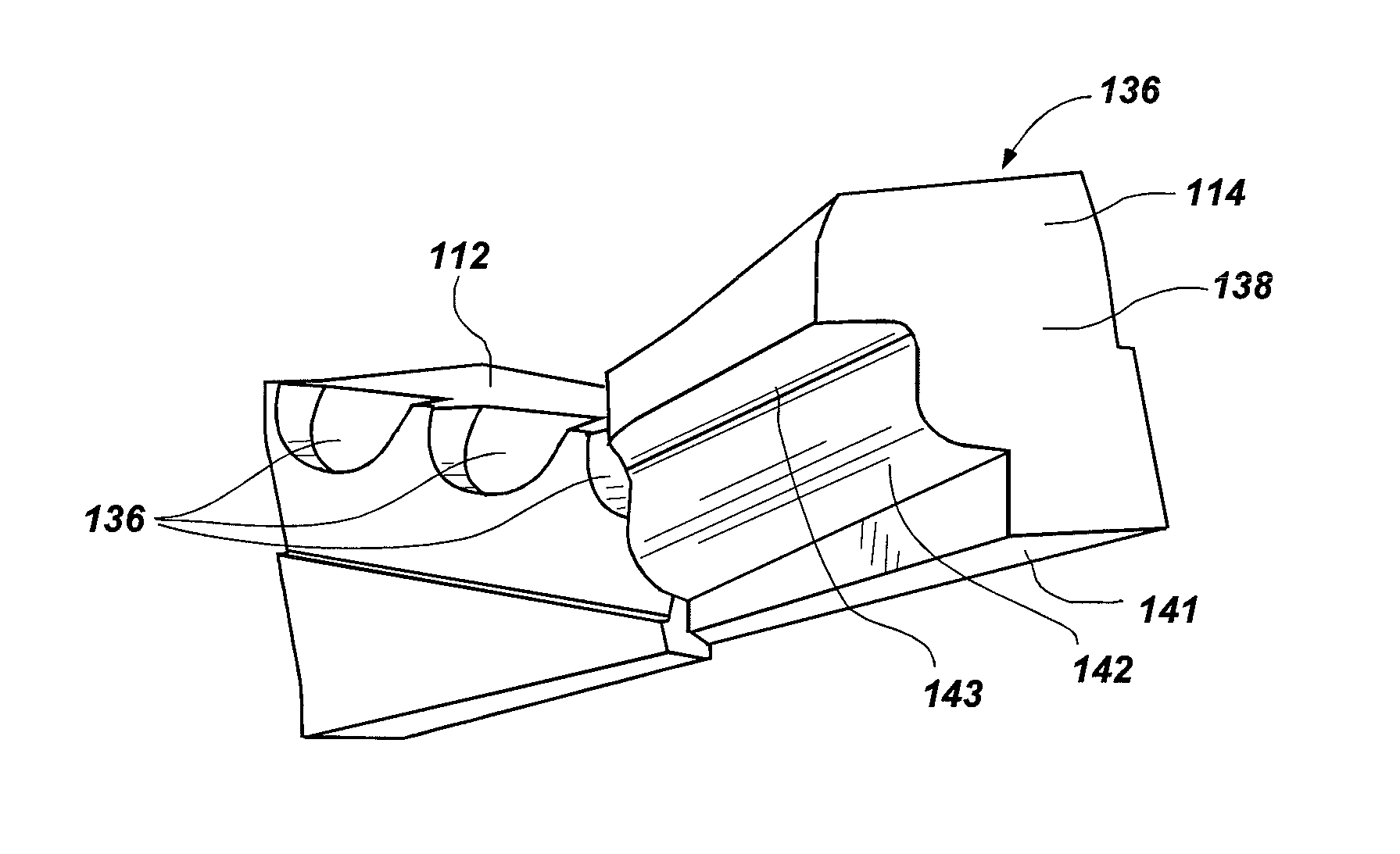

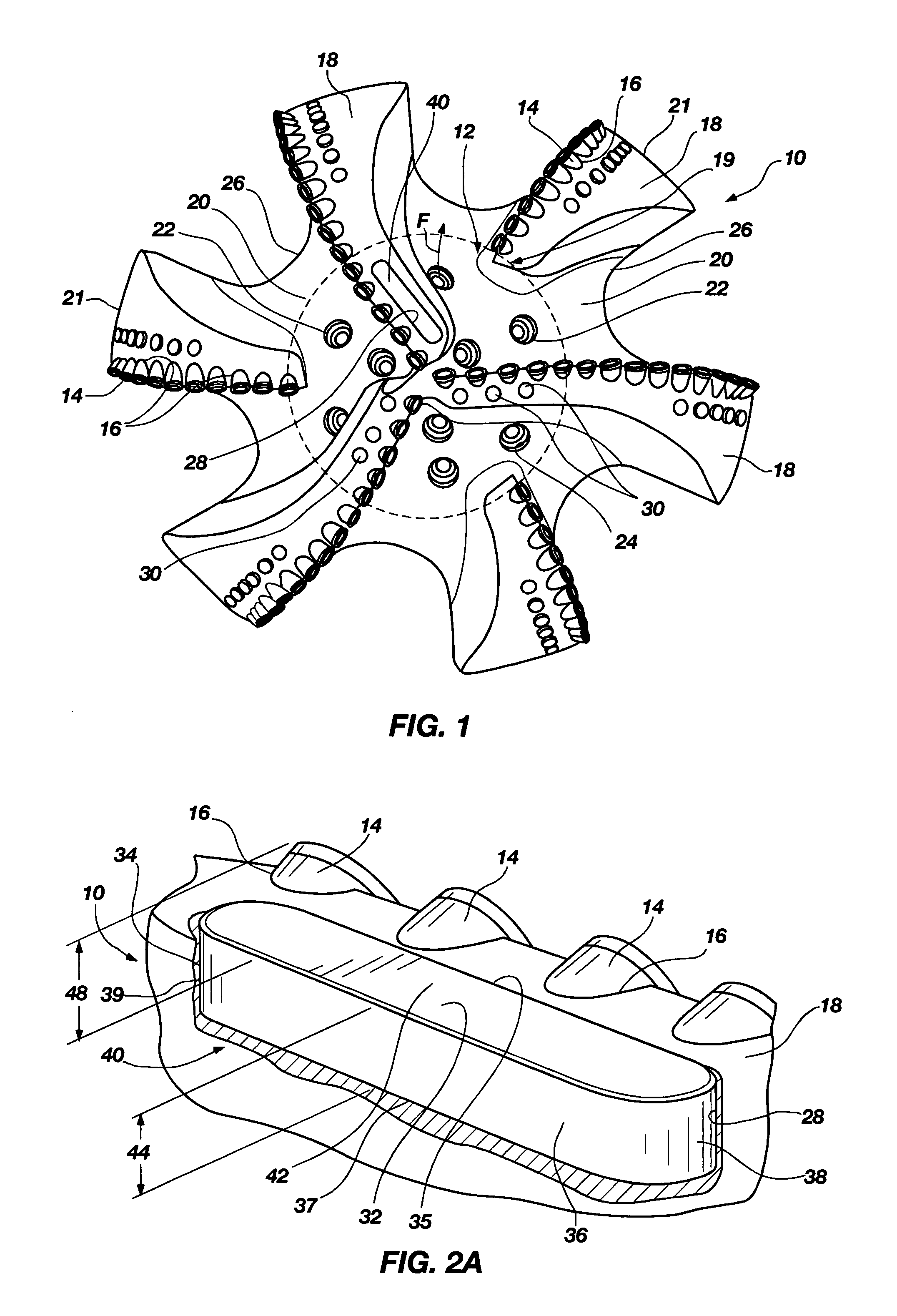

Interchangeable bearing blocks for drill bits, and drill bits including same

ActiveUS20080308321A1Minimize manufacturing tolerance uncertaintyReduce complexityEarth drilling toolsDrill bitsEngineeringRubbing

A bearing block is provided that may be used with a drag bit body or frame to limit depth of cut of cutters on a bit. The bearing block is designed so that it may be interchangeably replaced or repaired without necessitating alteration to a standardized bit frame. The interchangeable bearing block may be used to provide a target depth of cut (TDOC) and / or a selected contact or rubbing area to support weight on bit and limit depth of cut (DOC) for improving drilling performance of a bit. The interchangeable bearing block brings manufacturing selectability by providing a customizable product in terms of depth of cut selection and cutter penetration control for different formations, which is suitable for use with a common bit frame. A rotary drill bit assembly, a unitary cone insert bearing block for a drill bit, and a bit frame are also provided.

Owner:BAKER HUGHES INC

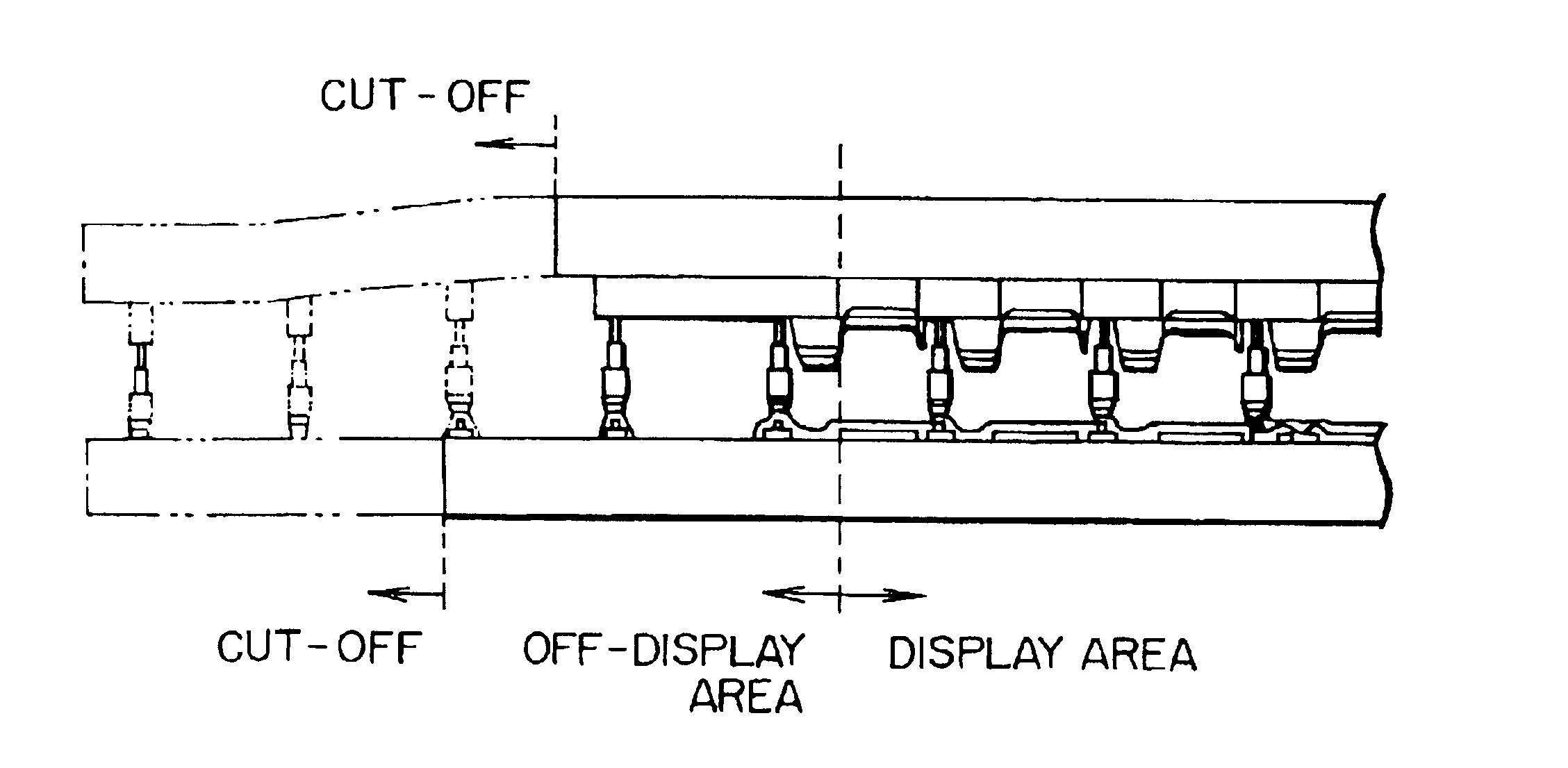

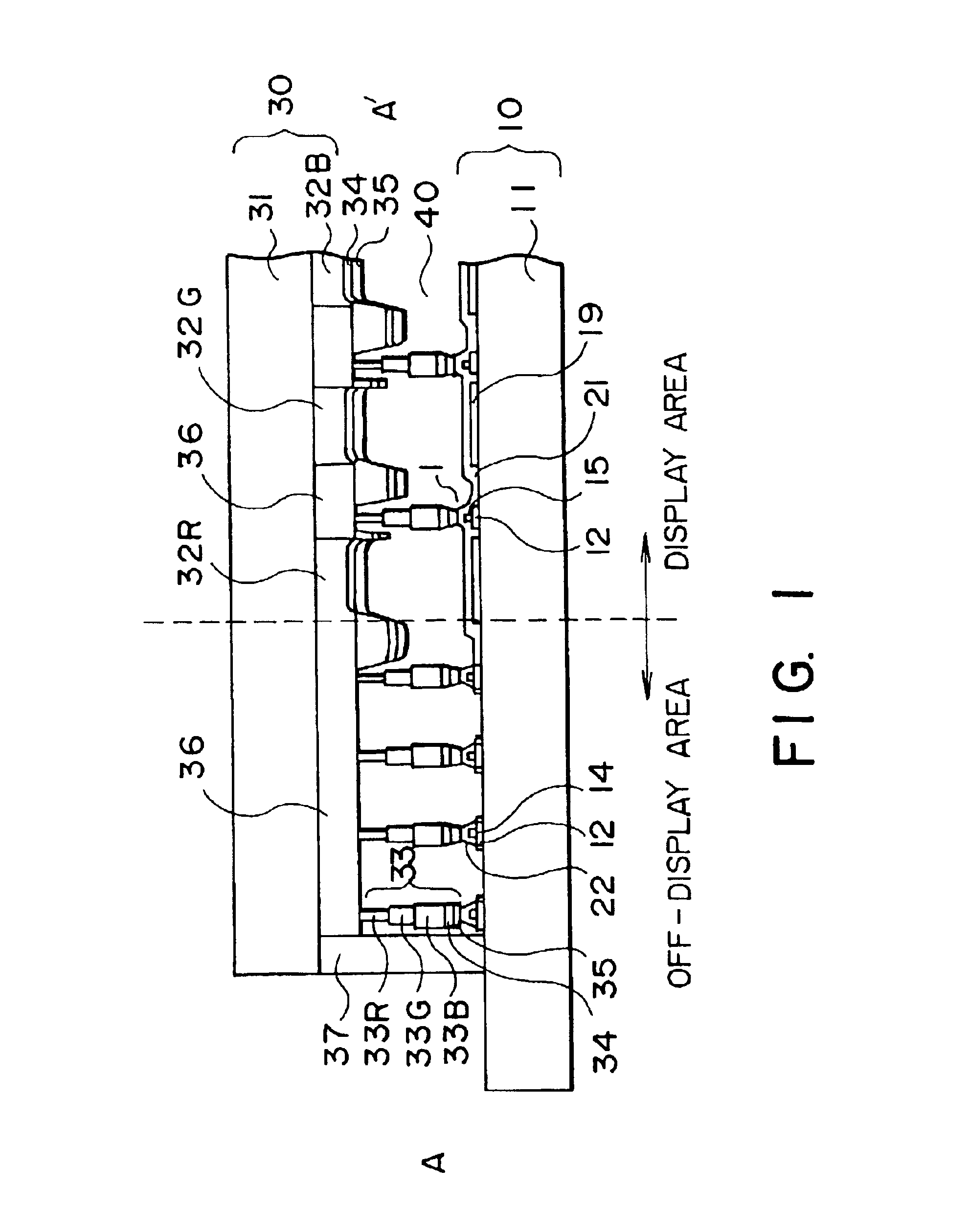

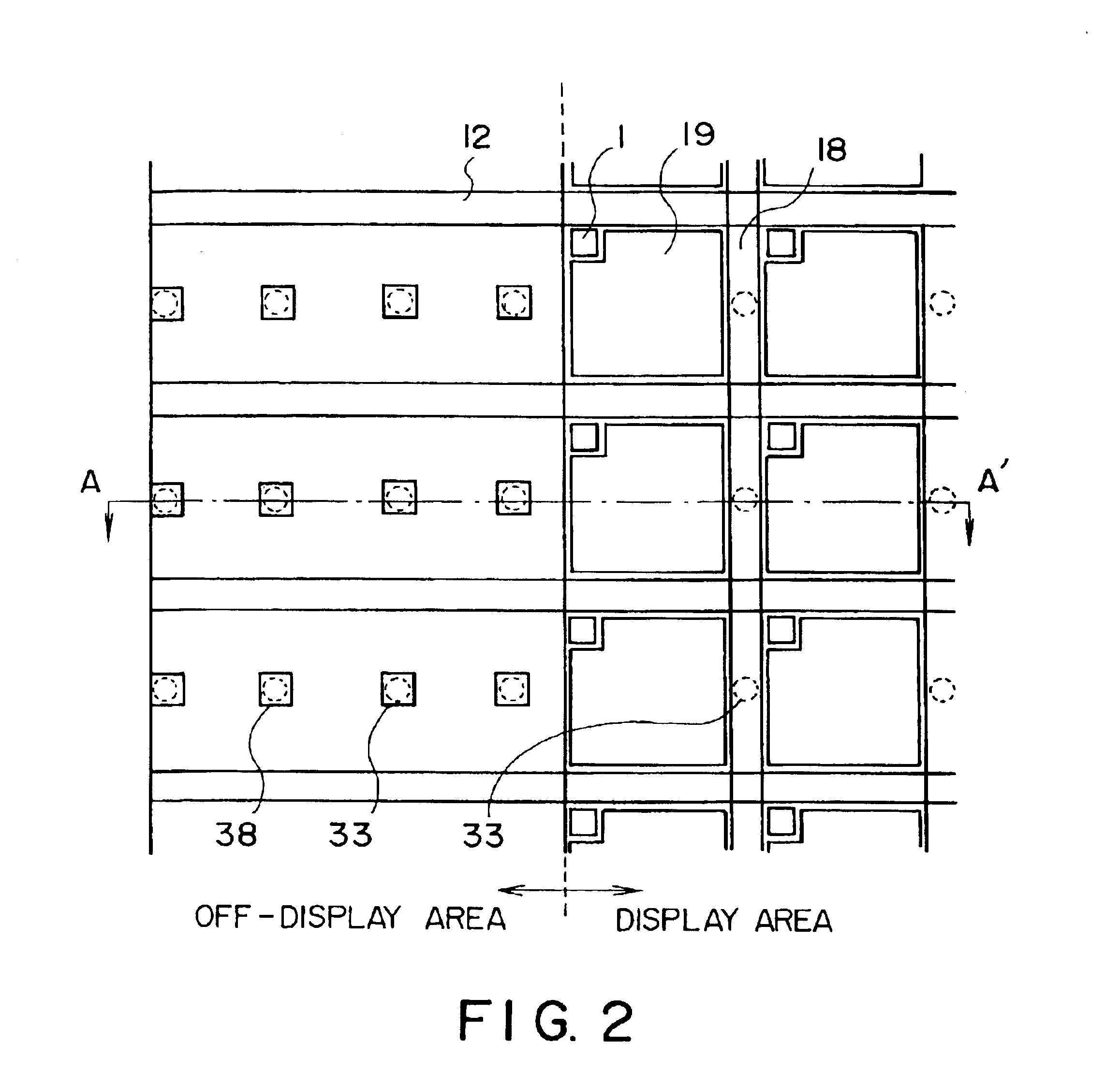

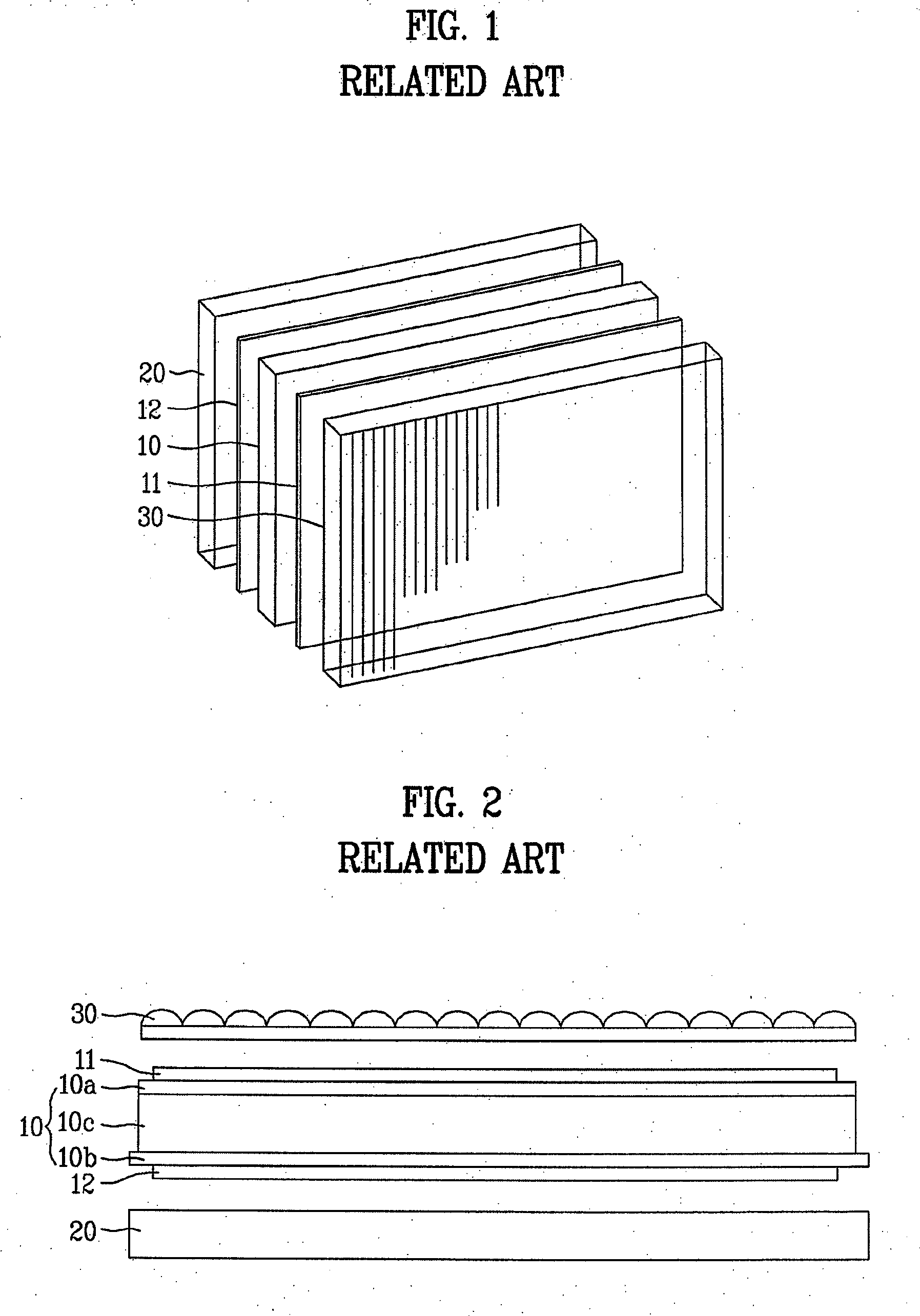

Liquid crystal display device

InactiveUS6888608B2Reduce the number of stepsReduce in quantityNon-linear opticsLiquid-crystal displayEngineering

A improved liquid crystal display device including two substrates each having transparent electrode thereon disposed in parallel while keeping a predetermined gap by means of pillar-shaped spacers and a liquid crystal held between said first and second substrates is proposed. In the liquid crystal display device, density or volume of the number of the pillar-shaped spacers provided in the off-display area is higher than those of a density of the number of said pillar-shaped spacers provided in the display area. This change is made continuously or stepwise along areas. The spacers are preferably disposed so that a contact area between the spacer and a rubbing cloth during the rubbing process is minimized, or so that an orientation defective area caused starting from the spacer does not extend into the pixel area, or so that a plurality of spacers are disposed along a flow of liquid crystal from filling port into the gap between the first and second substrate.

Owner:AU OPTRONICS CORP

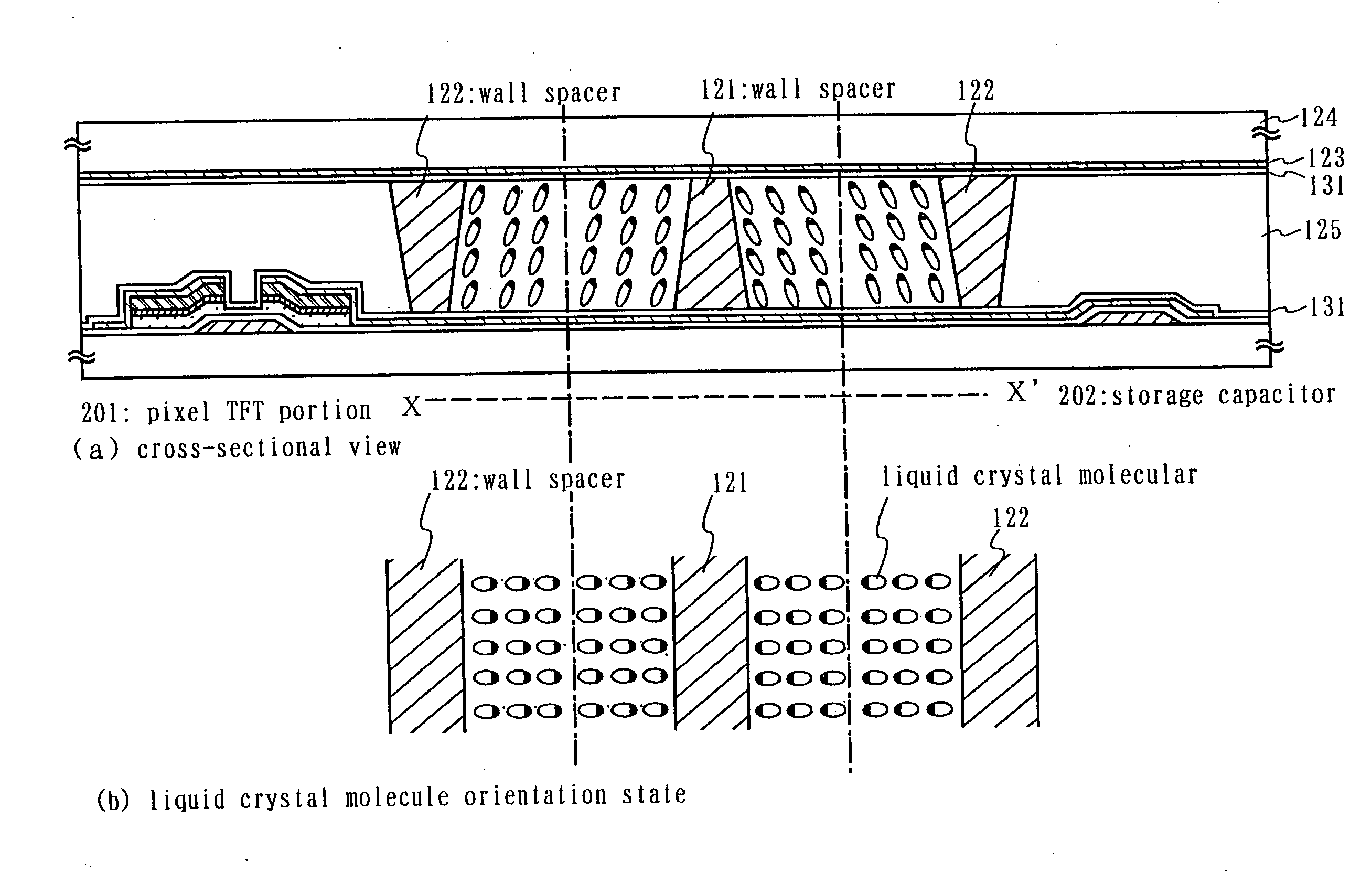

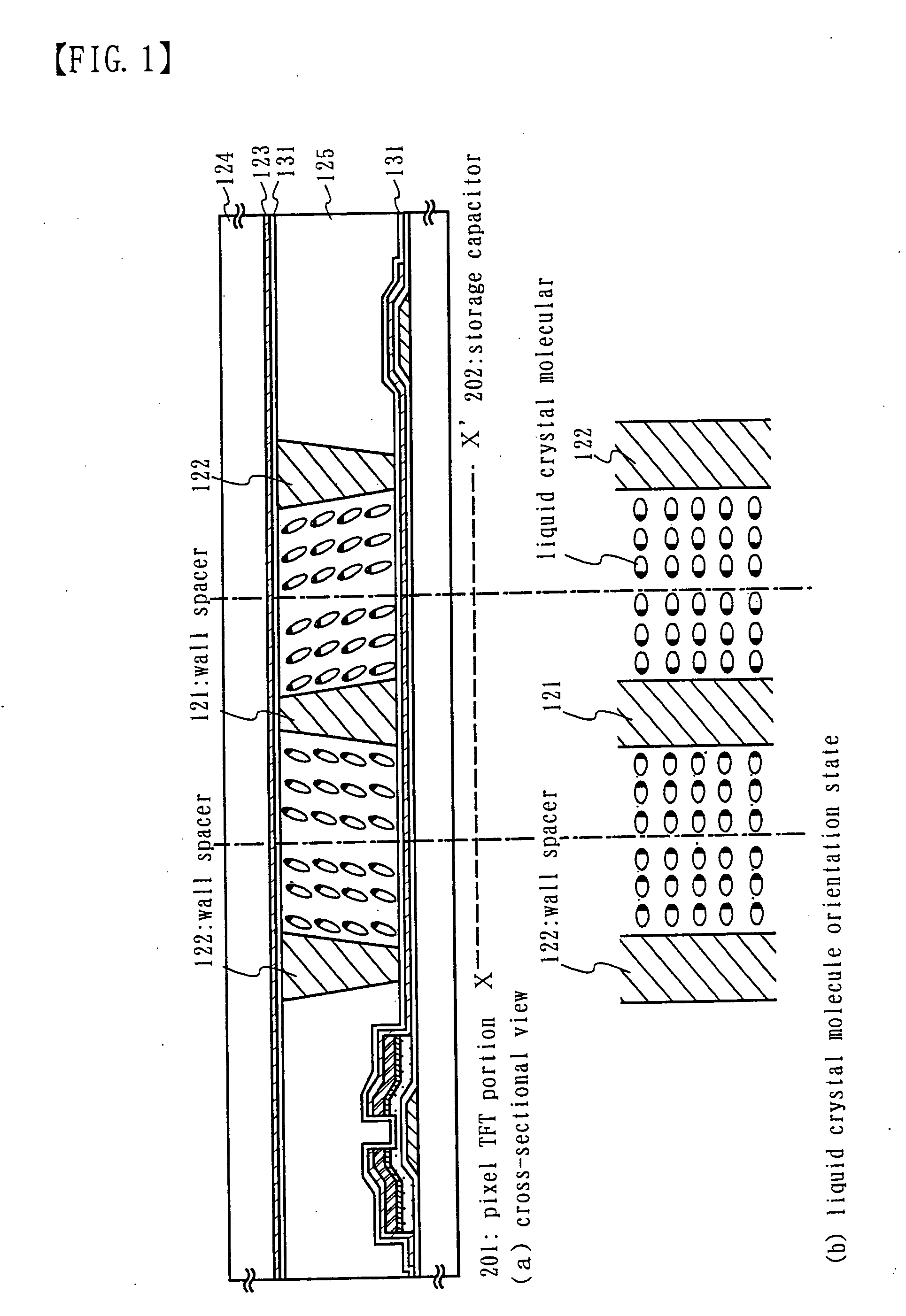

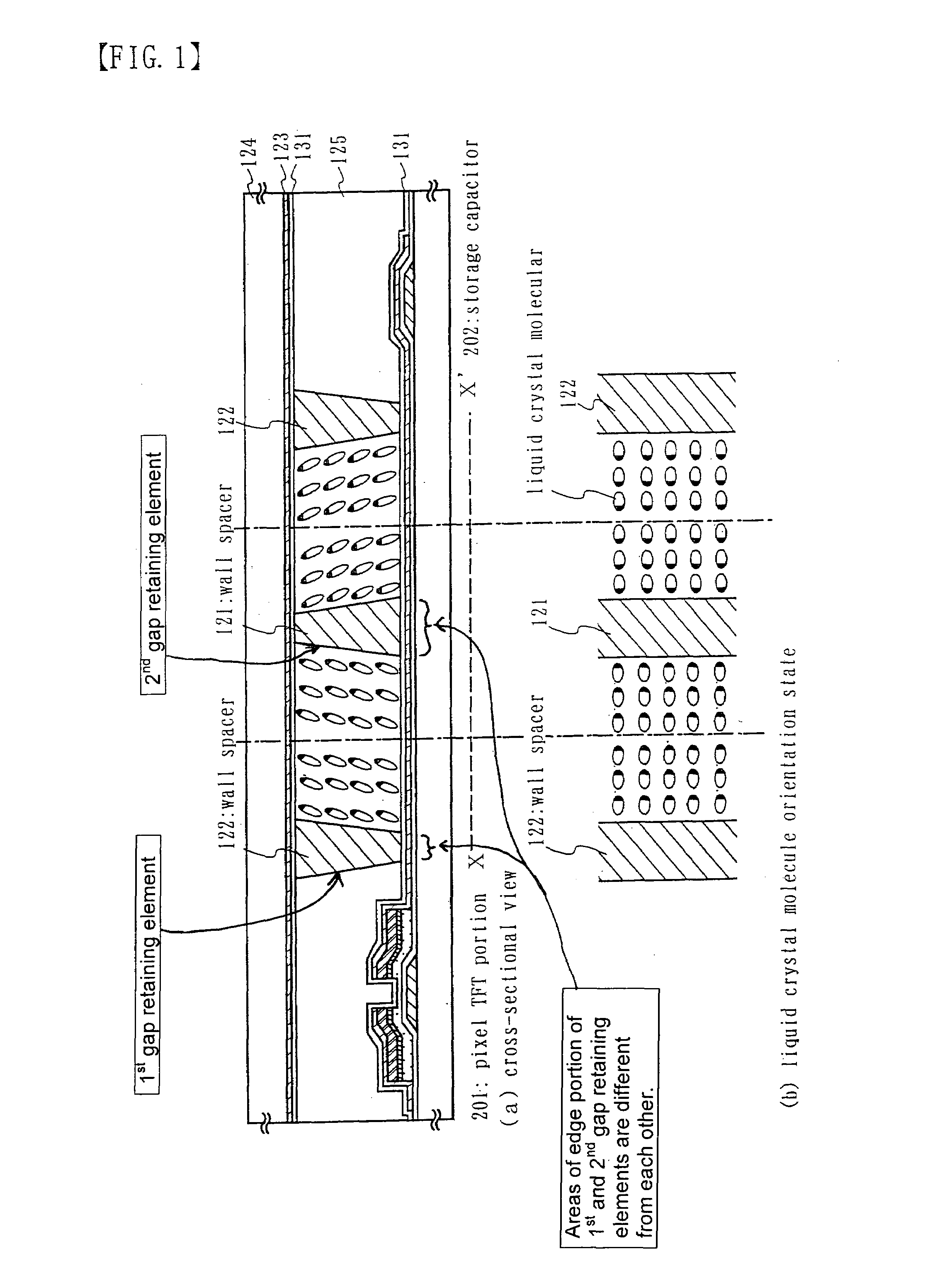

Liquid crystal display device and manufacturing method thereof

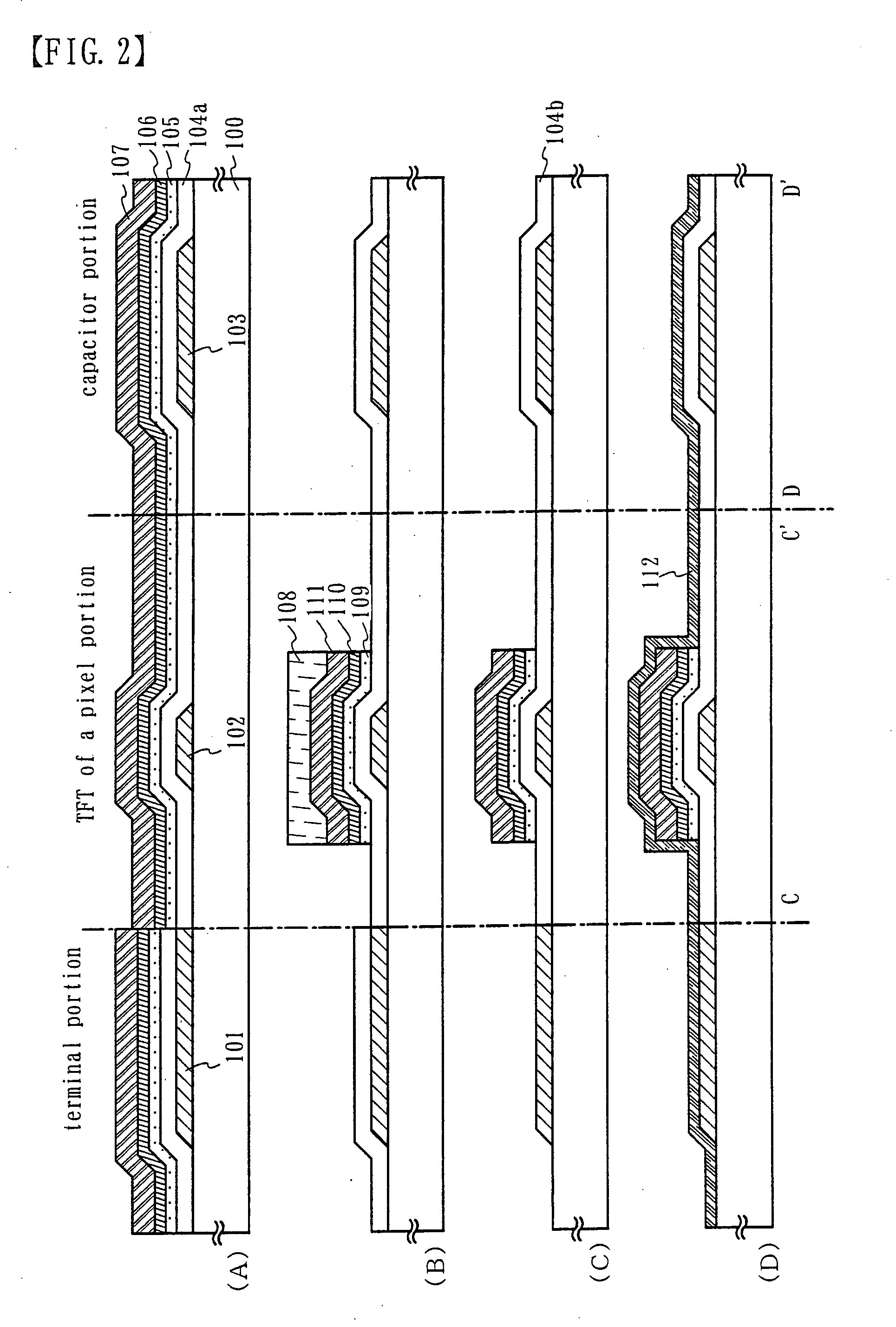

InactiveUS20070146568A1Improve productivityIncrease productionTransistorDevices for pressing relfex pointsActive matrixEngineering

An electro-optical device typified by an active matrix type liquid crystal display device, is manufactured by cutting a rubbing process, and in addition, a reduction in the manufacturing cost and an improvement in the yield are realized by reducing the number of process steps to manufacture a TFT. By forming a pixel TFT portion having a reverse stagger type n-channel TFT, and a storage capacitor, by performing three photolithography steps using three photomasks, and in addition, by having a uniform cell gap by forming wall-like spacers by performing one photolithography step, without performing a rubbing process, a multi-domain perpendicular orientation type liquid crystal display device having a wide viewing angle display, and in which a switching direction of the liquid crystal molecules is controlled, can be realized.

Owner:SEMICON ENERGY LAB CO LTD

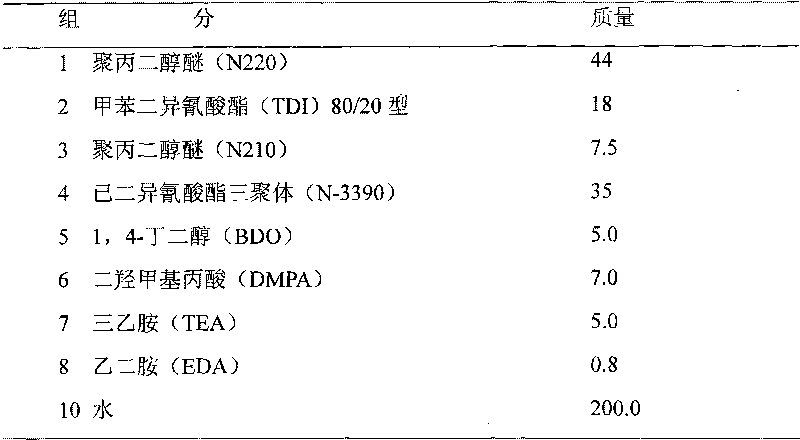

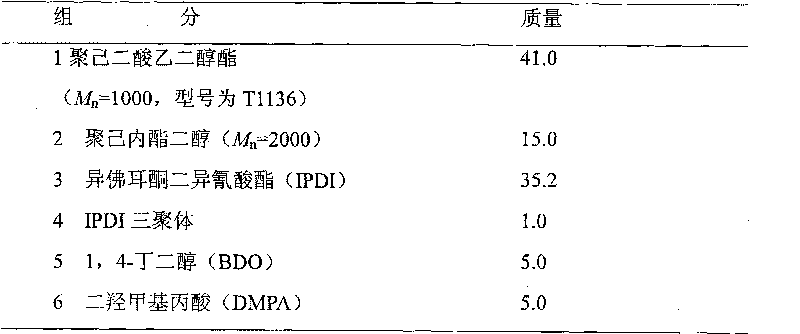

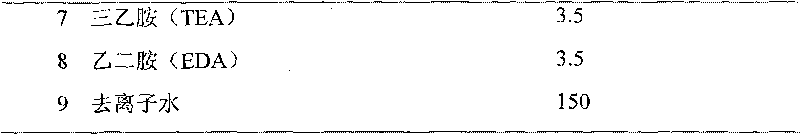

Preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents

InactiveCN101696262ASimple processEasy to operatePolyurea/polyurethane coatingsLeather surface finishingPolyesterSolvent

The invention discloses a preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents. The preparation method comprises the following steps of: carrying out prepolymerization reaction by using polyester polyol, vulcabond monomer and a polyisocyanate curing agent; reacting with a hydrophilic chain-extending agent and a micro-molecule chain-extending agent to obtain polyurethane prepolymer containing hydrophilic groups (carboxyl or sulfonic groups) and isocyanate(NCO)-terminated groups; neutralizing the polymer into salt, and then dispersing the salt into water; and preparing the modified polyurethane aqueous dispersions of the polyisocyanate curing agents by the chain extending of a polyamine chain-extending agent. The modified polyurethane aqueous dispersions of the polyisocyanate curing agents have self-crosslinking function at room temperature, and the self-crosslinking density is over 85%. Compared with non-modified polyurethane aqueous dispersions prepared under the same condition, the modified polyurethane aqueous dispersions have superior film forming property, water resistance, alcohol resistance, pollution resistance, cold resistance, dry / wet rubbing resistance and chemical solvent resistance; and coating films have especially high drying speed, high hardness increment speed and high final hardness.

Owner:SOUTH CHINA UNIV OF TECH

Topical Pharmaceutical Foam Composition

InactiveUS20120128598A1Reduce intensityMinimizing the skin sensitizing reactionsAntibacterial agentsAntimycoticsAlcohol freeMedicine

Owner:PRECISION DERMATOLOGY

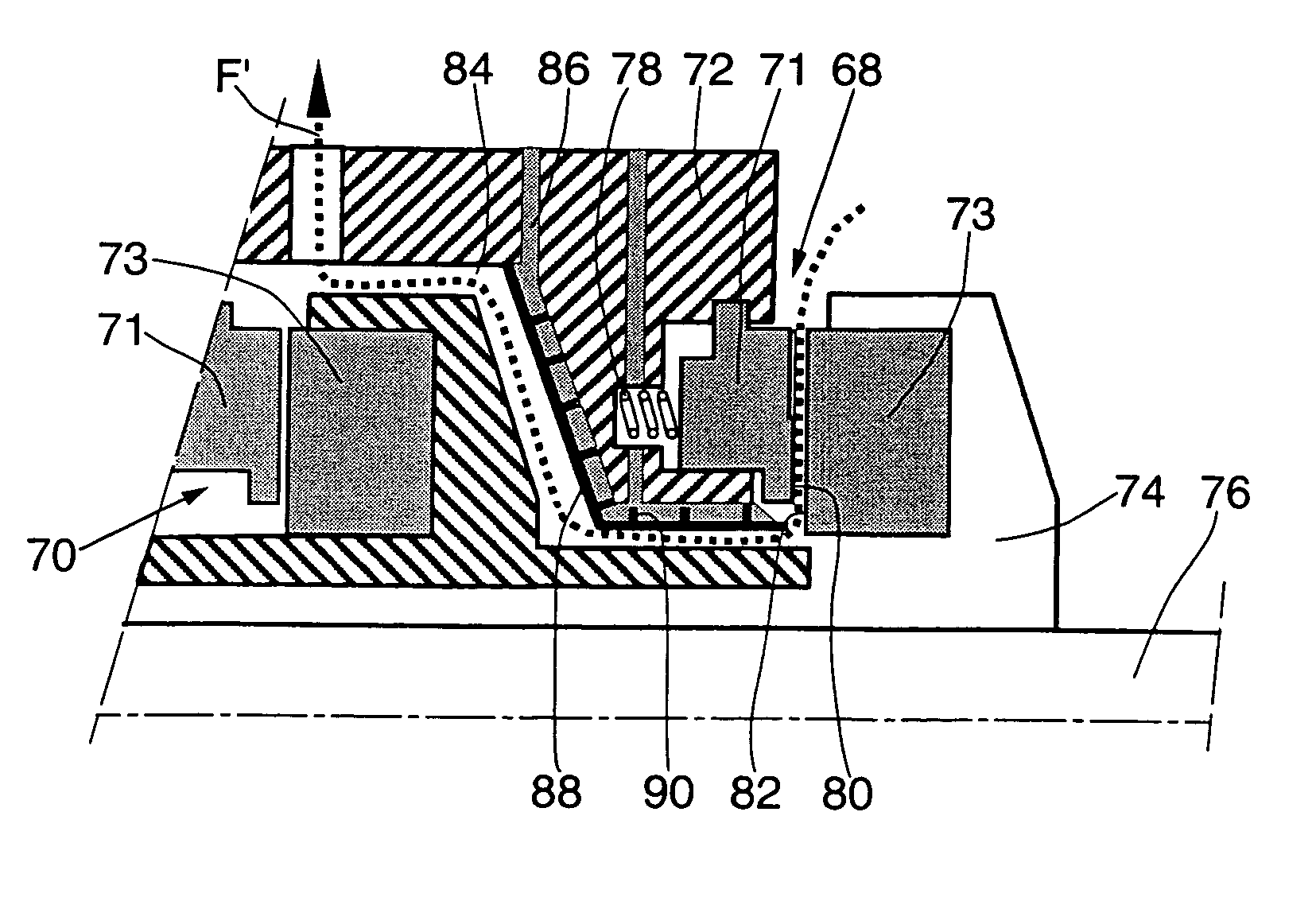

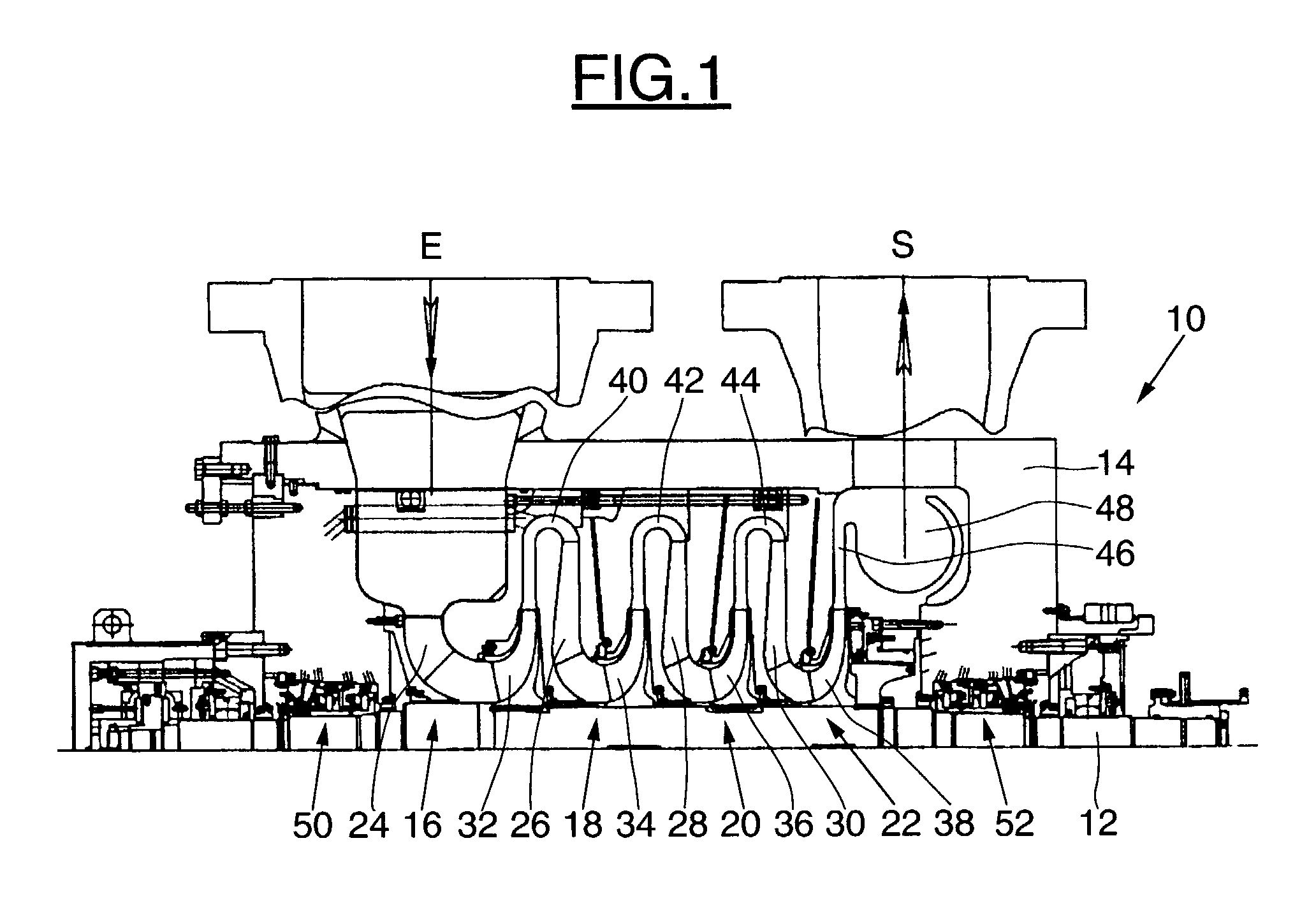

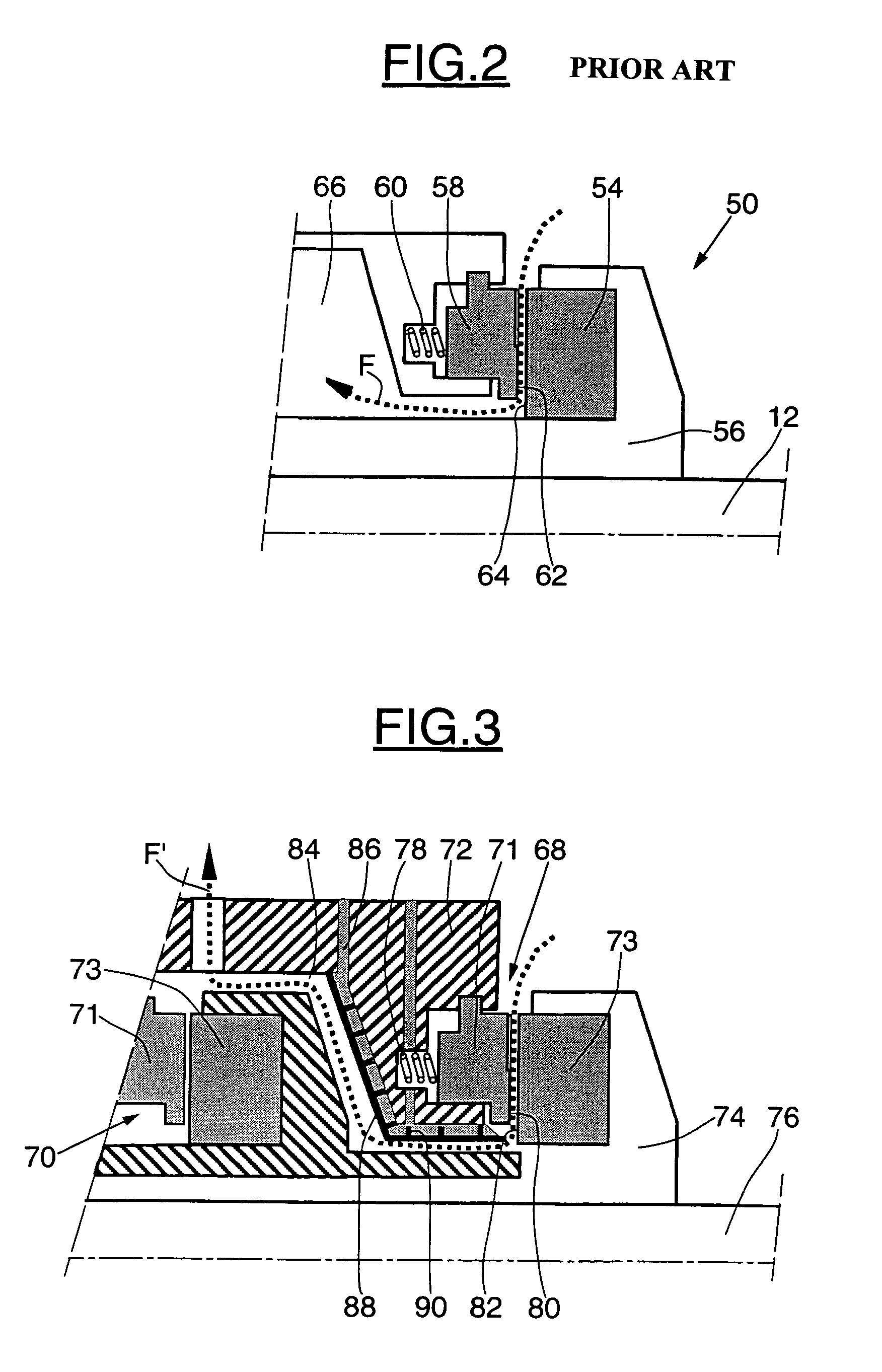

Seal for a compressor and centrifugal compressor equipped with such a seal

A seal for a rotary compressor comprises a casing, at least one assembly having a rotating seal face ring which rotates as one with a sleeve intended to be mounted on a shaft of the compressor and of a stationary seal face ring mounted on the casing, the seal face rings being urged to press against one another via their rubbing face. The seal design further incorporates fluid circulation for heating leaks of compressible fluid conveyed by the compressor that occur between the seal face rings, this fluid circulation being formed in the casing and extending at least partially downstream of the seal face rings with respect to the direction of flow of the fluid stream.

Owner:THERMODYN

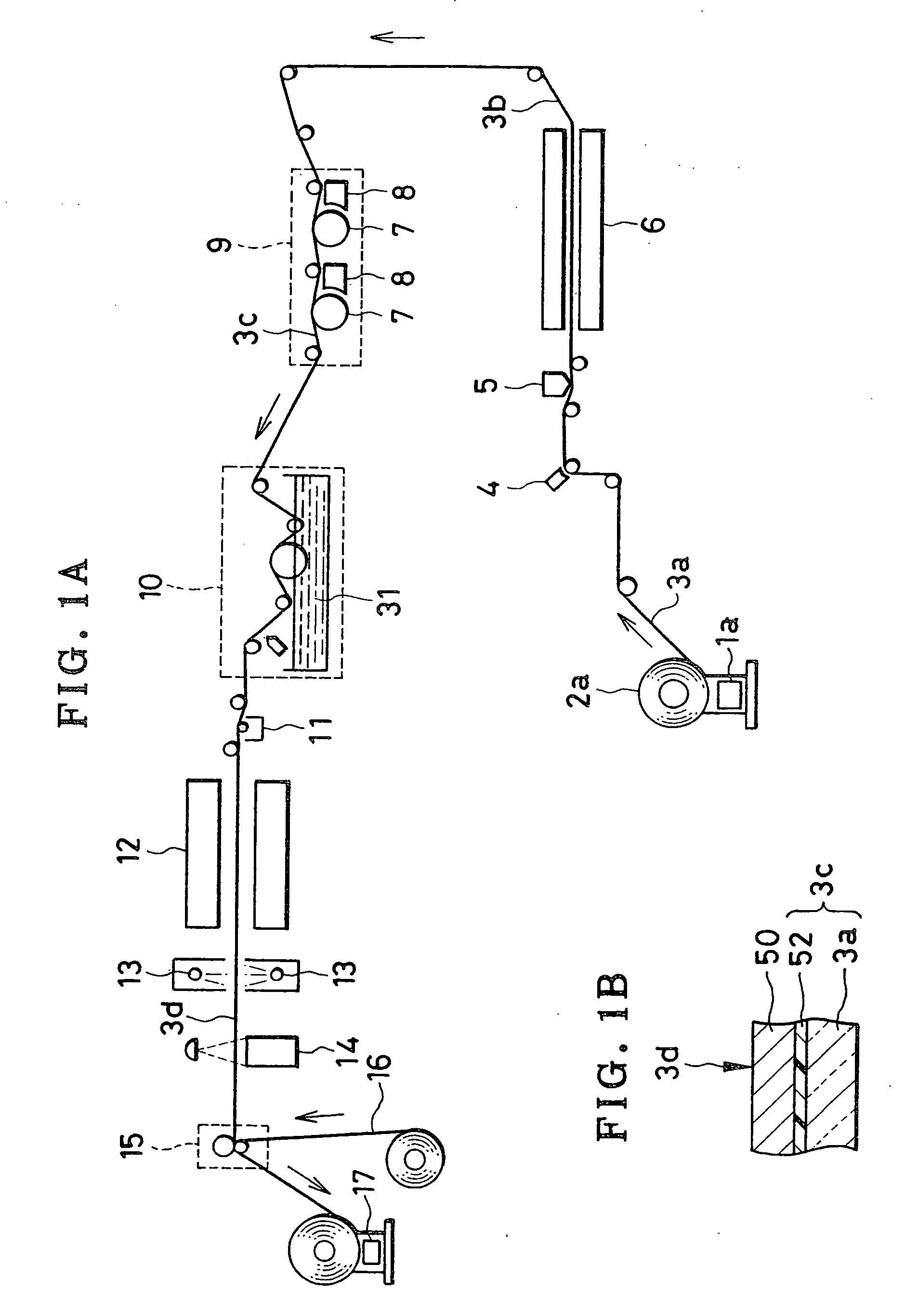

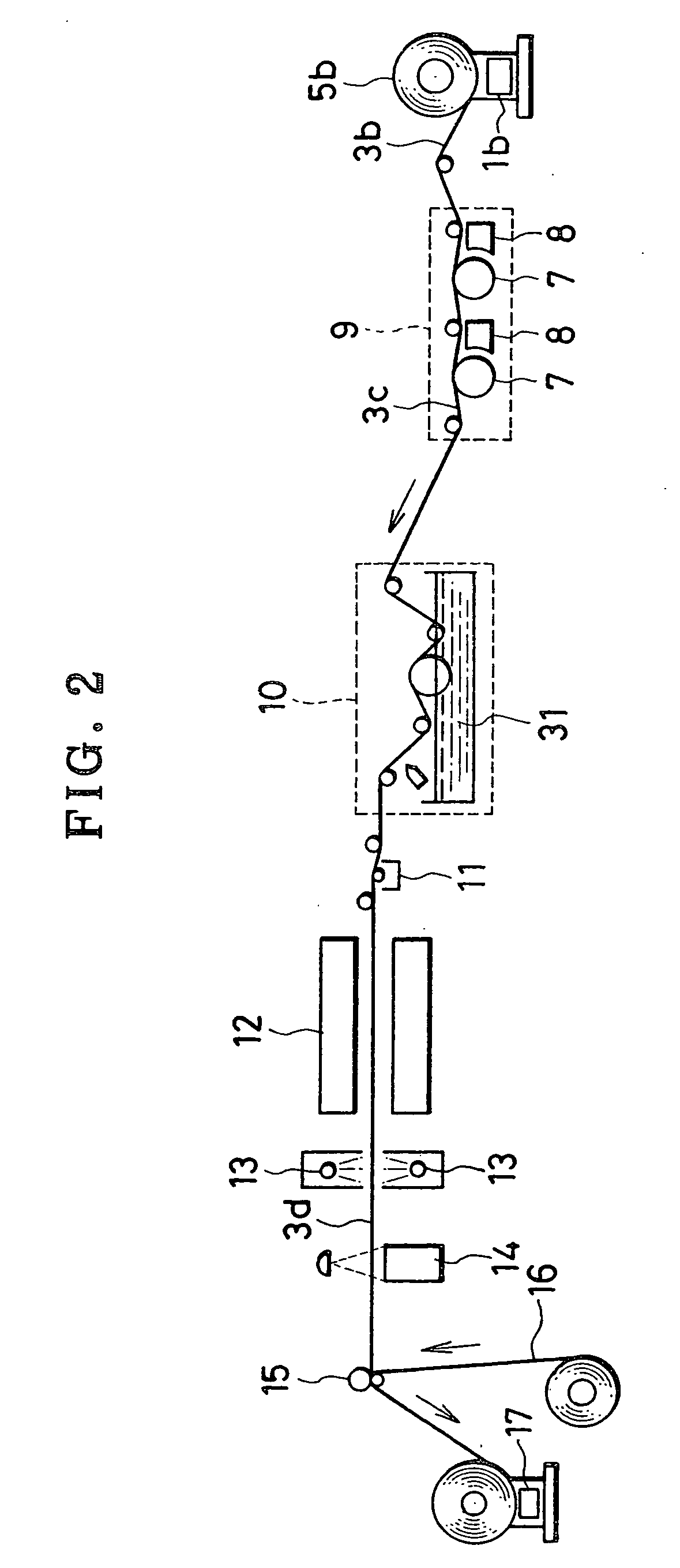

Optical compensatory sheet producing method and apparatus, thermal treating method and apparatus, and dust removing method and apparatus

InactiveUS20060177587A1Increase contrastGood colorLighting and heating apparatusPretreated surfacesLiquid crystallineEngineering

An optical compensatory sheet producing apparatus produces an optical compensatory sheet having a liquid crystal layer. In the apparatus, a rubbing unit is supplied with resin film having a first layer including resin, and subjects the first layer to a rubbing process, so as to form an orientation layer. A dust remover removes dust from the orientation layer by use of liquid such as perfluorocarbon, to which the orientation layer is insoluble. A liquid crystal layer coater is disposed downstream from the dust remover, for coating the orientation layer with coating liquid including liquid crystalline compound, so that the liquid crystal layer is formed.

Owner:FUJIFILM CORP

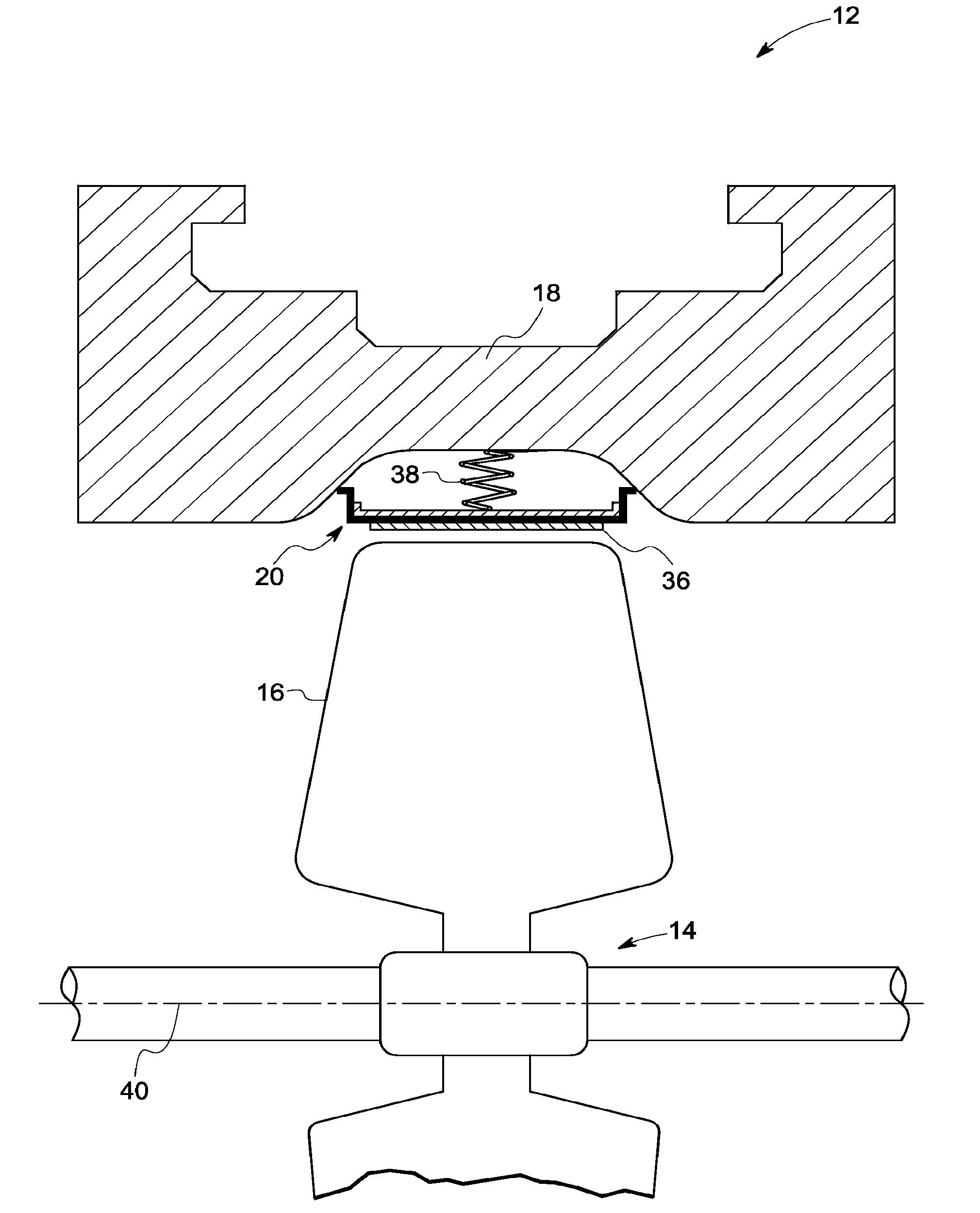

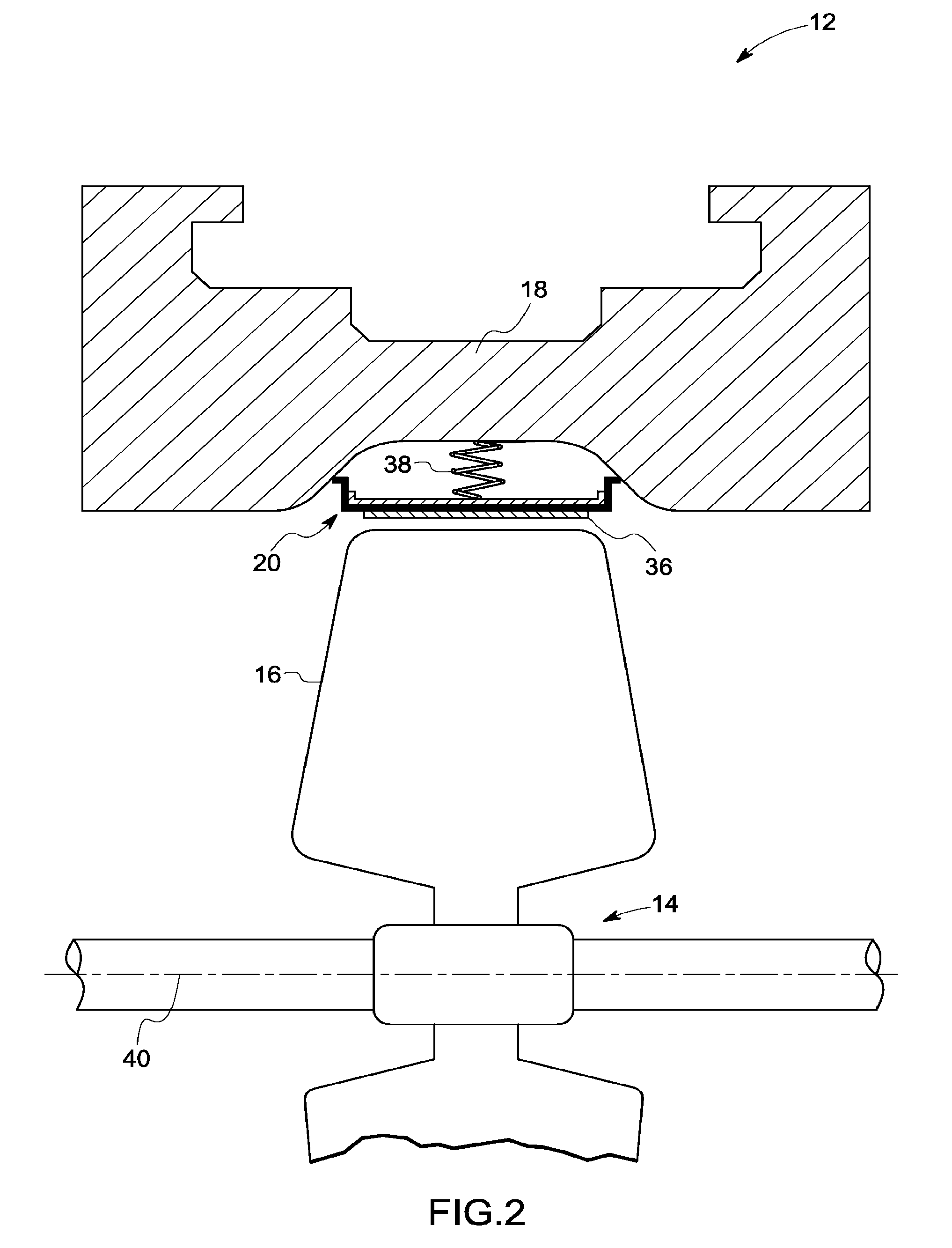

Sealing device and method for turbomachinery

A compliant seal for use between rotating blades and a static shroud surrounding the rotating blades in a steam or gas turbine is disclosed. The seal includes a tip surface, substantially resistant to wear due to rubbing by the tip of the rotating blades, and an elastic biasing member, comprising a biasing element. The wear-resistant surface is thus biased against the tips of the rotating blades to seal a gas path between the rotating blades and the static shroud.

Owner:GENERAL ELECTRIC CO

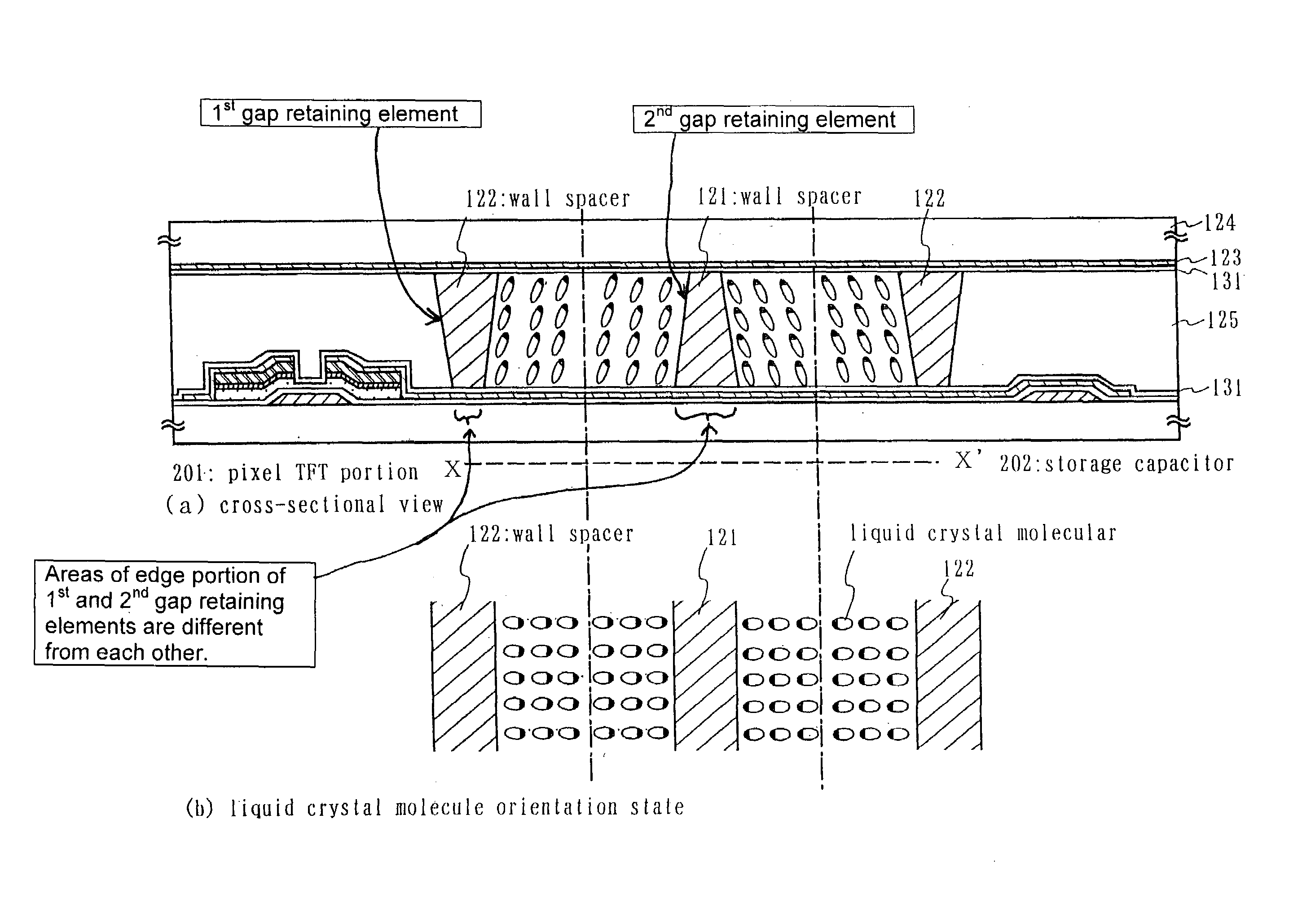

Liquid crystal display device and manfacturing method thereof

InactiveUS7714975B1High production costImprove productivityTransistorDevices for pressing relfex pointsActive matrixEngineering

An electro-optical device typified by an active matrix type liquid crystal display device, is manufactured by cutting a rubbing process, and in addition, a reduction in the manufacturing cost and an improvement in the yield are realized by reducing the number of process steps to manufacture a TFT.By forming a pixel TFT portion having a reverse stagger type n-channel TFT, and a storage capacitor, by performing three photolithography steps using three photomasks, and in addition, by having a uniform cell gap by forming wall-like spacers by performing one photolithography step, without performing a rubbing process, a multi-domain perpendicular orientation type liquid crystal display device having a wide viewing angle display, and in which a switching direction of the liquid crystal molecules is controlled, can be realized.

Owner:SEMICON ENERGY LAB CO LTD

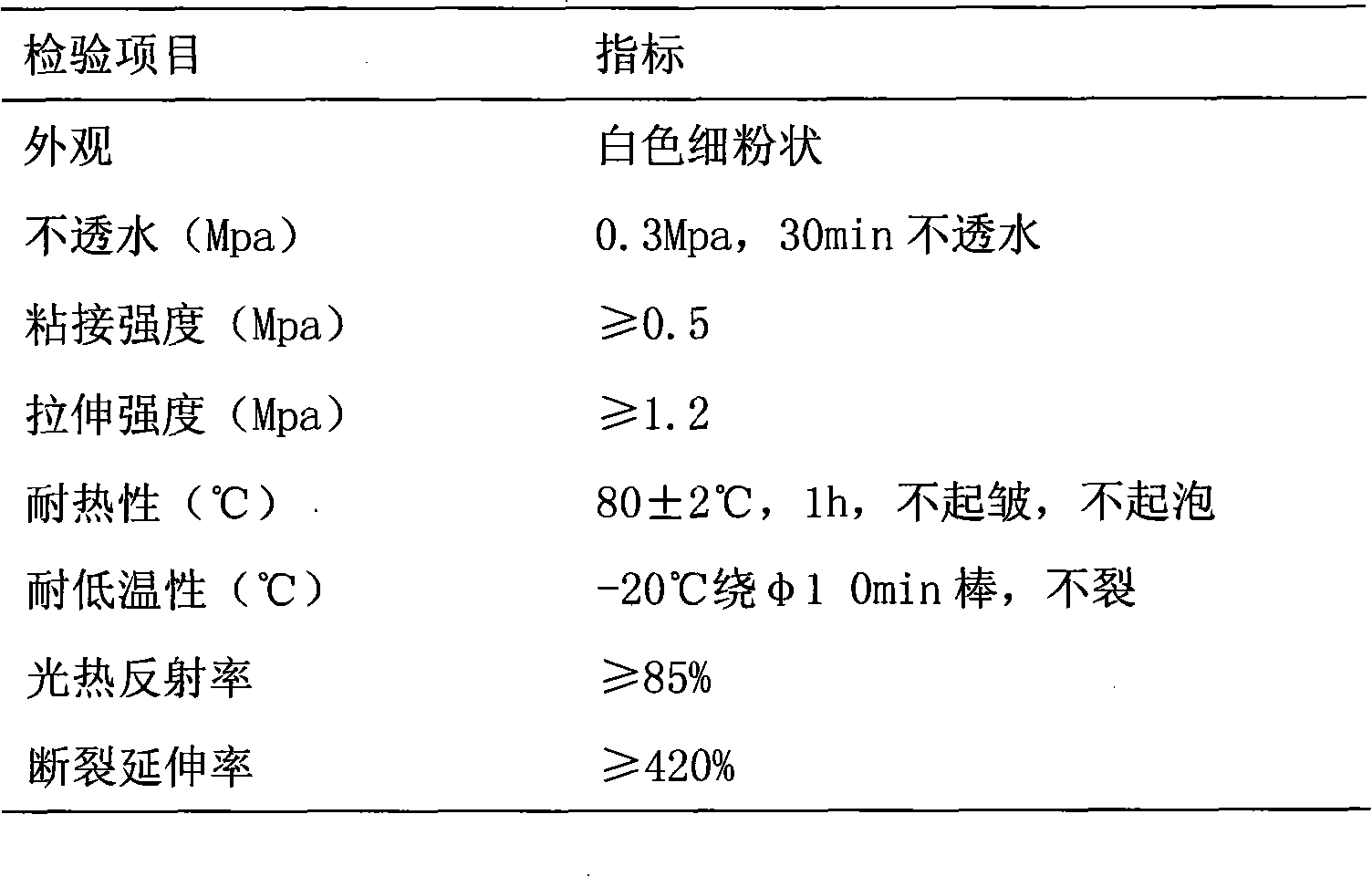

Dry-type heat-insulating waterproof coating

InactiveCN101648794AGood heat insulation and waterproof effectImprove waterproof performancePliabilityTalc

The invention relates to a dry-type heat-insulating waterproof coating which comprises the following raw materials in percentage by weight: 0-5.5 dispersible polymer powder, 10-20 hollow filling beads, 5-20 sepiolite powder, 5-10 mica powder, 5-30 heavy calcium carbonate powder, 5-15 light calcium carbonate powder, 0.5-1.5 rutile titanium dioxide, 10-20 talc powder and 10-40 white cement. A coat formed by the coating of the invention has favorable heat-insulating waterproof effect (lowers indoor temperature by 4-20 DEG C) and excellent flexibility, impermeability, weathering resistance and bonding strength to a substrate as well as high strength, good brightness, uniform luster, smooth and tender touch feeling, waterproof washing and rubbing, and the like. The dry-type coating has the advantages of simple production process, convenient transportation, long storage time, convenient construction, and the like, no toxicity or pollution, environment-friendly trend suitability, low cost, low VOC and high performance, thereby becoming a new-generation building coating product.

Owner:吕海涛

Contact lens solution

InactiveUS20050074467A1Safe for eyeSuppresses the adhesion of a large amount of polylysineSpectales/gogglesOrganic detergent compounding agentsPhosphoric acidNitrogen

A liquid formulation for contact lenses which comprises polylysine, polyphosphoric acid and / or salt thereof as a substance for suppressing the adhesion of polylysine to a contact lens, nitrogen-containing organic anti-microbial agent excluding polylysine and water. Contact lenses can be cleaned, disinfected and stored simply by soaking them in the liquid formulation without cleaning by digital rubbing or without rinsing before they are worn in eyes.

Owner:OPHTECS CORP

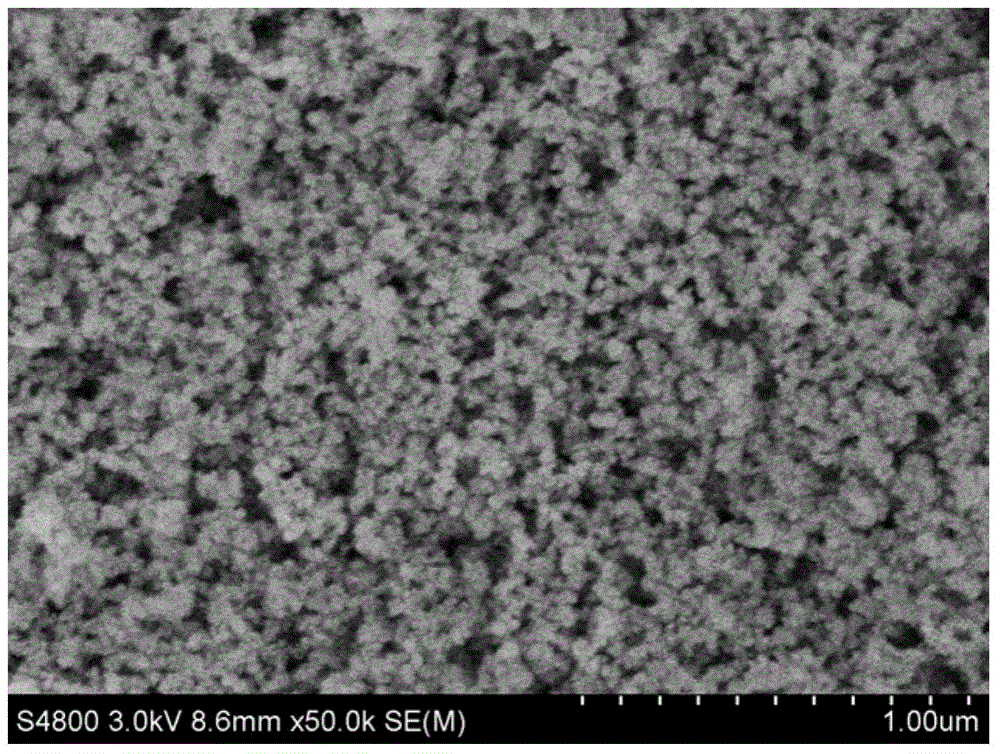

Transparent super-hydrophobic coating material and method for preparing transparent super-hydrophobic coating by transparent super-hydrophobic coating material

ActiveCN104449357AEasy to prepareDoes not damage surface propertiesPolyurea/polyurethane coatingsSpecial surfacesMicro nanoGas phase

The invention discloses a transparent super-hydrophobic coating material. The raw materials of the transparent super-hydrophobic coating material comprise gas-phase silica nano-particle dispersion liquid which consists of gas-phase silica nano-particles and a solvent, and a hydrophobic treating agent. The invention further discloses a preparation method of a transparent super-hydrophobic coating; a coating of a micro-nano structure is prepared by rubbing and coating a substrate with the gas-phase silica nano-particle dispersion liquid, and then the coating is subjected to surface hydrophobization treatment by the hydrophobic treating agent to obtain the transparent super-hydrophobic coating. According to the super-hydrophobic coating material provided by the invention, hydrophobization treatment manners can be changed flexibly according to the difference of coated substrates; the method for preparing the super-hydrophobic coating has low requirement on equipment; the using cost is extremely low; the method is simple; the coating application is convenient; a large-area high-efficiency super-hydrophobic coating can be prepared; the prepared super-hydrophobic has excellent super-hydrophobicity, high transparency, droplet impact resistance, temperature and pH stability, durability, and repeated rubbing and coating capacity, and can be applied to almost all currently known solid surfaces.

Owner:ZHEJIANG UNIV

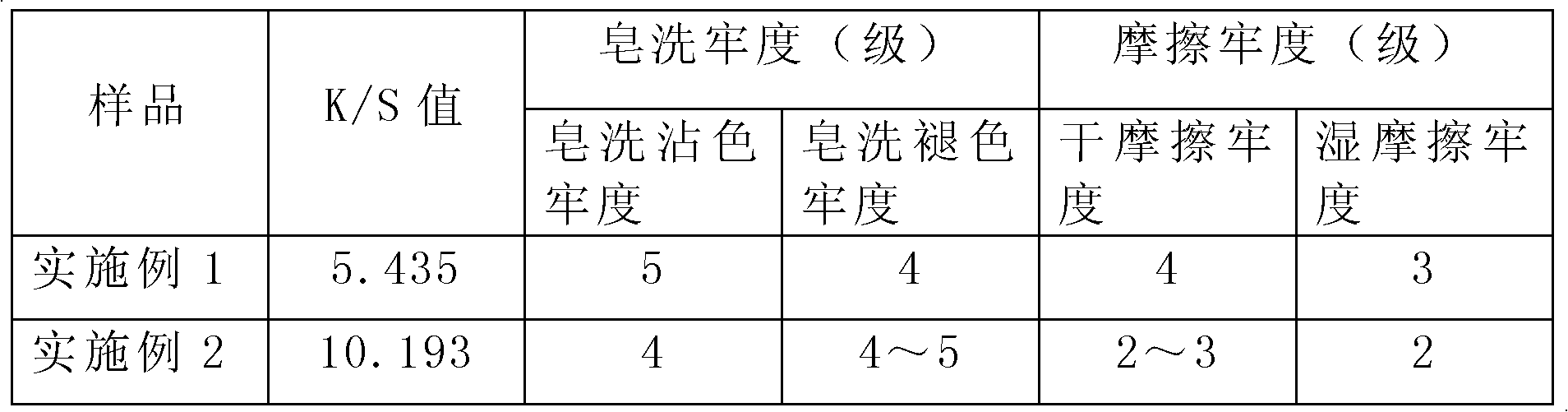

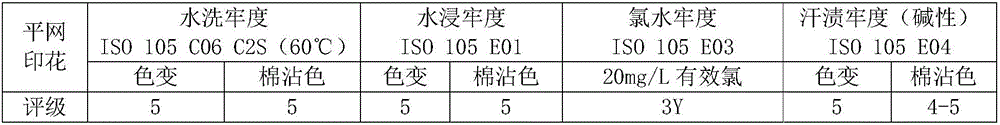

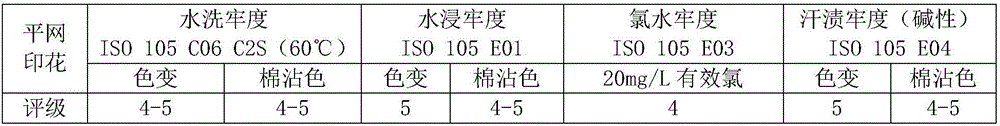

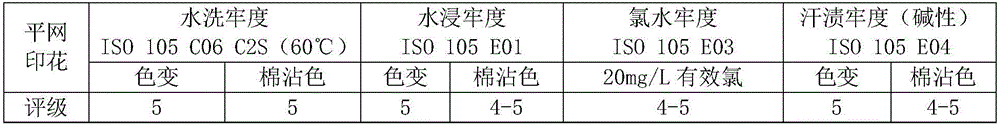

Method of dyeing fabric by using dye

ActiveCN102535194ASoft touchImprove washing fastnessBiochemical fibre treatmentDry-cleaning apparatus for textilesTextile printerEngineering

The invention provides a method for dyeing fabric by using a dye, belonging to the technical field of textile printing and dyeing and aiming to the solve the problems of complex process, low dyeing rate, poor dyeing uniformity and poor color fastness and hand feel of dyed fabric of the existing method for dyeing the fabric by using the dye. The method comprises the following steps of: desizing the fabric, scouring, bleaching and mercerizing; adding the dye, a cationic modifier, a leveling agent, a dispersant, an alkaline reagent and a wet rubbing fastness enhancer to water, and mixing uniformly to prepare a dyeing solution; soaking the fabric into the dyeing solution, and controlling temperature and liquor ratio to dye; steaming the dyed fabric for colour fixation, washing by water and drying to finish dyeing the fabric by using the dye. The method for dyeing the fabric by using the dye is simple, ensures the high dyeing rate and the uniform dyeing, and ensures that the dyed fabric has good washing fastness and rubbing fastness and a soft feel.

Owner:台州东海翔染整有限公司

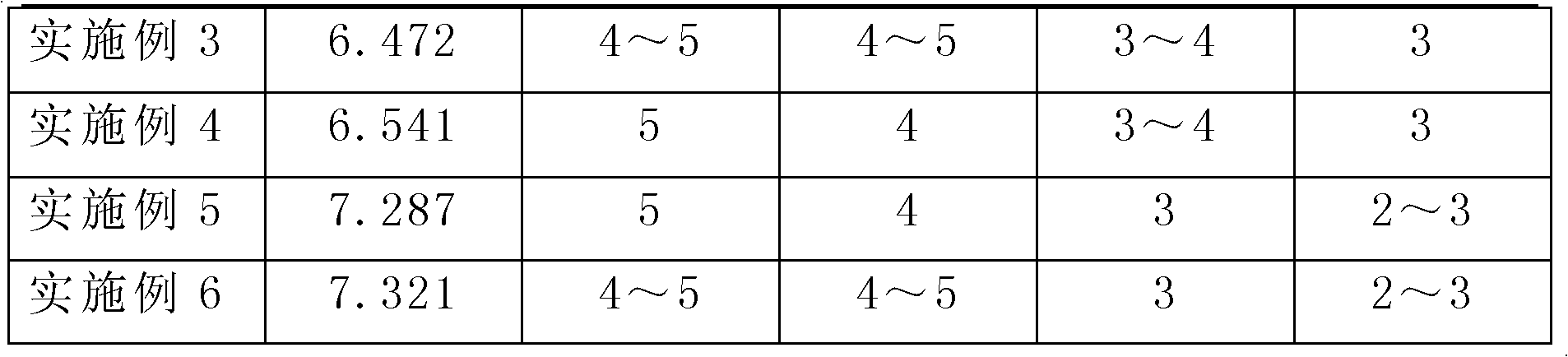

Electrically-driven liquid crystal lens and stereoscopic display device using the same

An electrically-driven liquid crystal lens wherein an electrode is defined with a vertical or horizontal rubbing direction, achieving an improved lens profile effect, and a stereoscopic display device using the same are disclosed. The liquid crystal lens includes first and second substrates arranged opposite each other and each including a plurality of lens regions, a plurality of first electrodes formed on the first substrate to correspond to the respective lens regions while being spaced apart from one another, to which voltages gradually increasing from the center to the edge of each lens region are applied, a second electrode formed over the entire surface of the second substrate, a first alignment film formed over the entire surface of the first substrate including the first electrodes and having an alignment direction parallel to or perpendicular to a longitudinal direction of the first electrodes, a second alignment film formed on the second electrode and having an anti-parallel alignment direction relative to the first alignment film, and a liquid crystal layer filled between the first substrate and the second substrate.

Owner:LG DISPLAY CO LTD

Liquid composition for making pigment fixed, ink set, method for producing ink jet recorded matter on fabric and ink jet recorded matter on fabric

InactiveUS20090226678A1Improve wear resistanceGood dry-cleanabilityLayered productsDecorative surface effectsHigh resistanceColor intensity

There are provided a liquid composition for making pigment fixed having a high resistance to rubbing and a good dry-cleanability; an ink set including the liquid composition for making pigment fixed and an ink composition excellent in terms of color intensity, discharge stability, and adhesiveness; and a method for producing ink-jet-recorded matter on a fabric having a high resistance to rubbing and good dry-cleanability using the liquid composition for making pigment fixed and the ink composition.The liquid composition for making pigment fixed according to the present invention contains at least a reactant and polymer fine particles synthesized from an alkyl (meth)acrylate and / or cyclic alkyl (meth)acrylate, the glass transition temperature and acid value of the liquid composition being equal to or lower than −10° C. and equal to or lower than 100 mg KOH / g, respectively.

Owner:SEIKO EPSON CORP

Dyeing and coating integrated dye dyeing and printing paste-shaped compound and application thereof

ActiveCN105970671AGuaranteed high sublimationGuaranteed wet rubbing fastnessDyeing processDisperse dyeHigh concentration

The invention relates to a textile dyeing and printing technique and specifically relates to a dyeing and coating integrated dye dyeing and printing paste-shaped compound for a hydrophobic textile material and an application thereof. The dye dyeing and printing paste-shaped compound is composed of 1-25% of dyeing and printing concentrated paste, 0.5-10% of thickening agents, 0.05-3% of pH modifiers and 62-98.45% of water. The paste-shaped compound provided by the invention is used for dyeing and printing the hydrophobic textile material and has the advantages of dye dyeing and printing and pigment dyeing and printing; the high sublimation, washing and dry and humid rubbing fastness are ensured while the color is bright and the hand feeling is soft; the generation of high concentration waste water in the traditional disperse dyeing and printing processes is avoided; and therefore, the dyeing and coating integrated dye dyeing and printing paste-shaped compound is a clean and environment-friendly dye dyeing and printing product.

Owner:SHENYANG RES INST OF CHEM IND

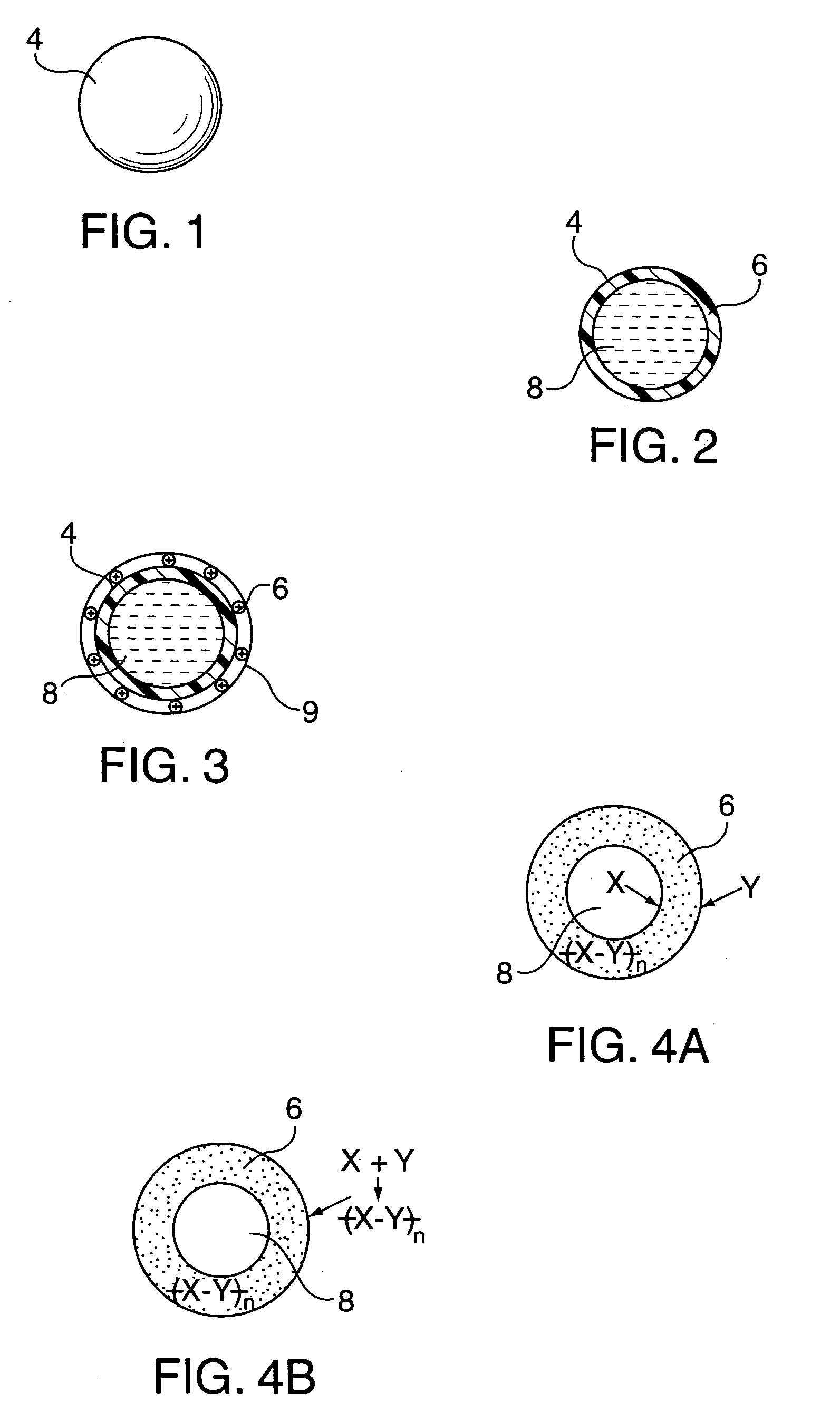

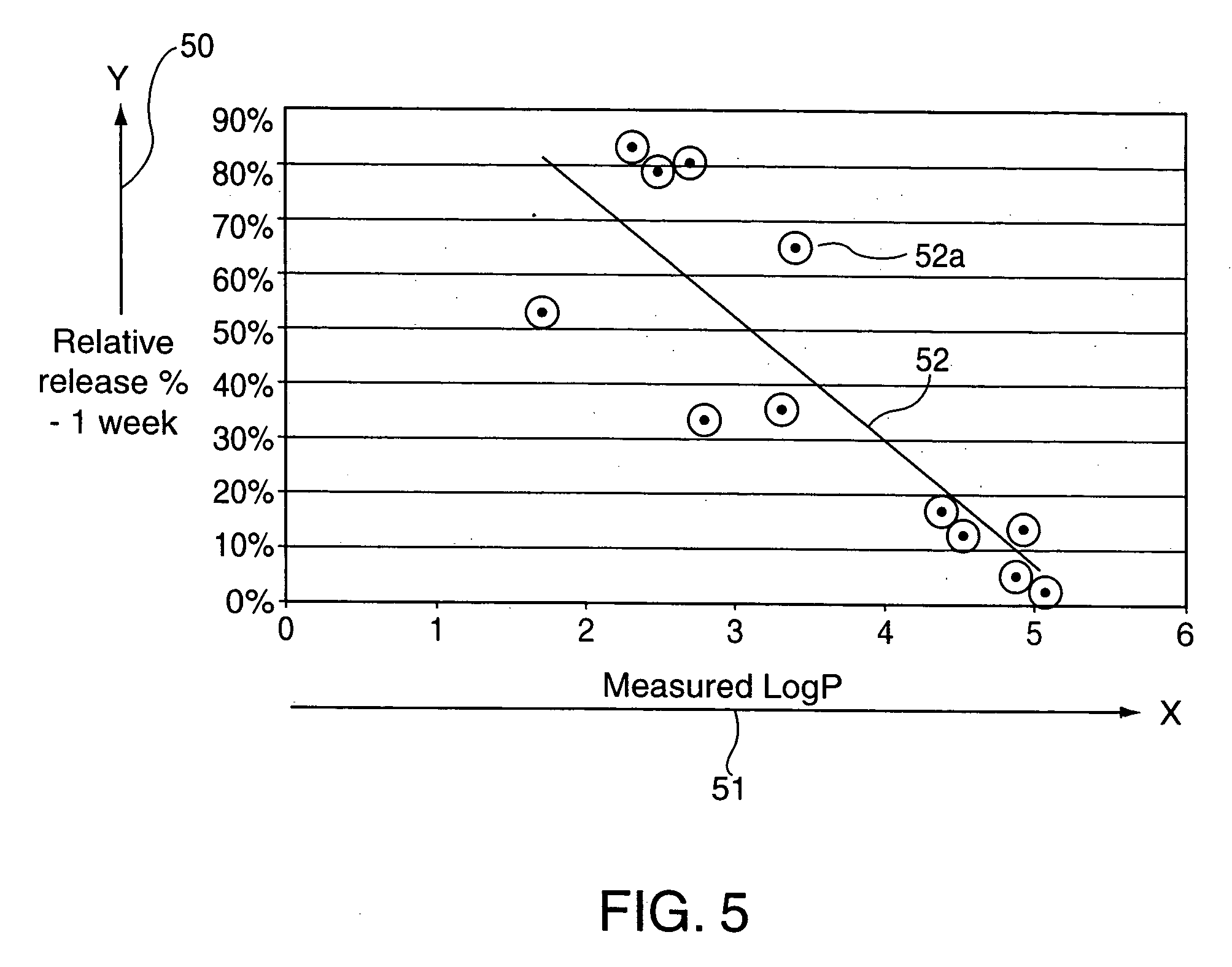

Skin and hair treatment composition and process for using same resulting in controllably-releasable fragrance and/or malodour counteractant evolution

InactiveUS20050226900A1Reducing aromaReducing headspace concentrationCosmetic preparationsHair cosmeticsControlled releaseFlavor

Described is a human epidermal and / or human hair treatment composition of (i) fragrance and / or malodour counteractant and (ii) fragrance- and / or malodour counteractant-compatible solvent-containing microcapsules provided in a suspension gel or emulsion. Also described is a method for delivery of fragrance and beneficial agents to the human epidermal surface area region treatment and / or human hair treatment wherein the microcapsules remain on the human epidermis and / or on the hair follicles for a substantial period of time subsequent to their application and the microcapsules are ruptured over a period of time, thereby effecting both an initial delivery of fragrance and beneficial agent subsequent to rubbing, and, in addition, a controlled release of fragrance and beneficial agents into to the treated human epidermis and / or hair follicles.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Waterbased pigment type ink-jet printing ink and preparation method and application thereof

The invention relates to waterbased pigment type ink-jet printing ink and a preparation method and application thereof. The ink comprises the following components by weight percent: 5.0-25.0% of pigment paste, 0.2-2.0% of surfactant, 2.0-15.0% of fabric adhesive, 5.0-35.0% of moisturizer, 0.5-3.0% of pH regulator, 0.1-0.5% of antibacterial agent and the balance of deionized water. The preparationmethod is as follows: mixing and stirring the components and filtering. The application method comprises the following steps: the waterbased pigment type ink-jet printing inks with four basic colors are respectively filled in the ink boxes of an ink-jet printing machine, a computer is used to print the required colors and patterns on fabric, and then the fabric is baked for fixation. The ink-jet printing ink has good storage stability and printing fluency and high washing fastness and rubbing fastness; and the preparation method and application method have simple processes and good application prospects.

Owner:上海英威喷墨科技有限公司 +1

Agitating friction riveting device and riveting method

InactiveCN101468421AA new method of high-quality point-to-fix connectionA New Method for Efficient Point-to-Fix ConnectionWelding/soldering/cutting articlesNon-electric welding apparatusEngineeringRubbing

The invention relates to a fixedly-connecting technique for board points, in particular to a stirring, rubbing and riveting device and a riveting method. The device comprises a driving rod, a rivet II and a rigidity pad, wherein the driving rod which can be matched with the rivet II and drive the rivet II to rotate is arranged above the rivet; the rigidity pad is arranged below the rivet II; the driving rod is matched with the rivet II; and a board is arranged between the rivet II and the rigidity pad. The method comprises: firstly, aligning the rigidity pad and the driving rod; secondly, placing the connected board and the rivet II in sequence, lifting the driving rod down, making the driving rod matched with the rivet II completely, and starting the driving rod to drive the rivet II to rotate synchronously; heating and softening the local of the connected board under the action of the pressure and rubbing heat, making a local material of the connected board fully flow under the action of the rubbing heat and mechanical stir along with continual rotating and down-moving of the rivet II; and filling a groove II on the rigidity pad and a rivet neck space of the rivet II to realize metallurgical bonding of the rivet II and the board and complete stirring, rubbing and riveting joints.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

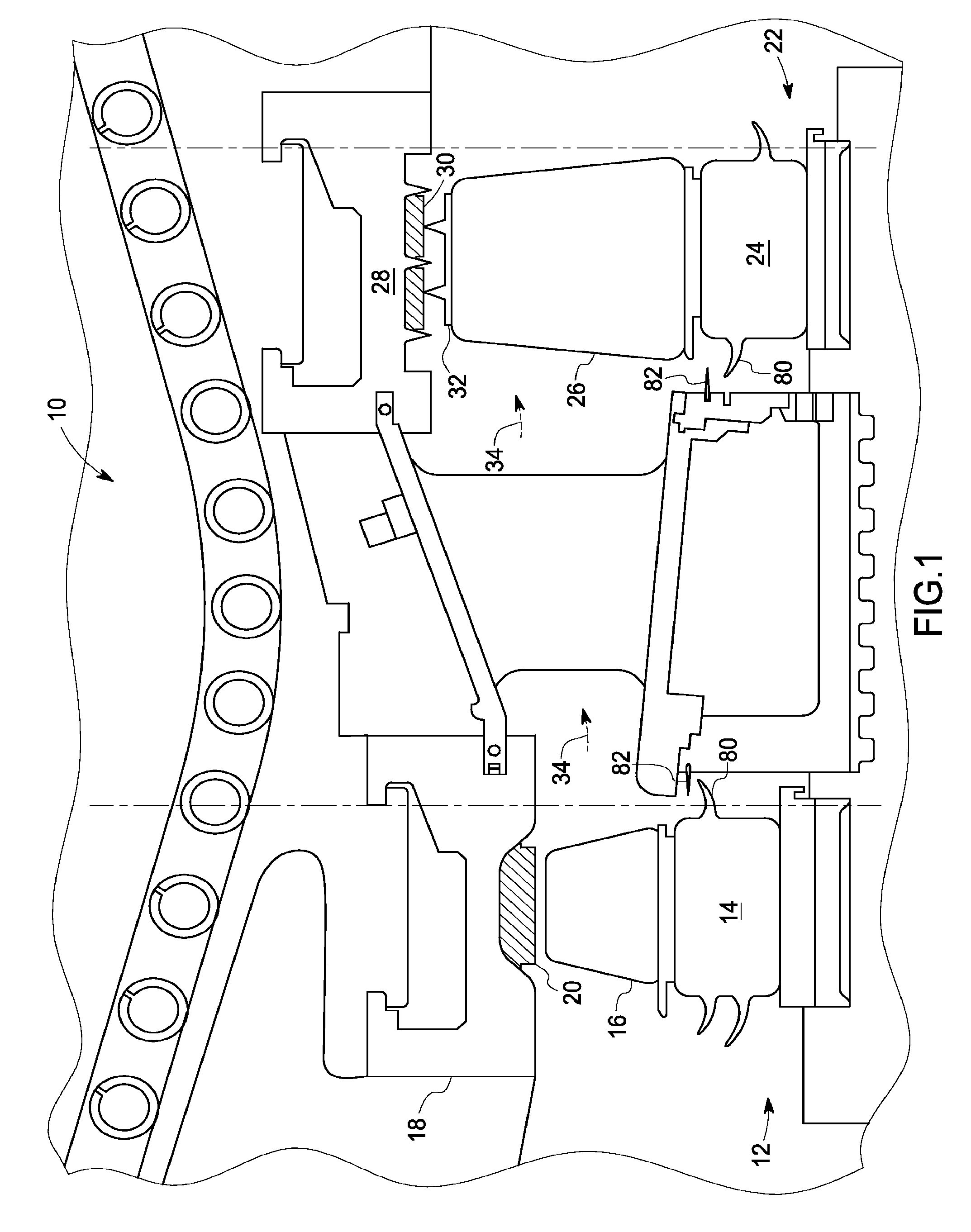

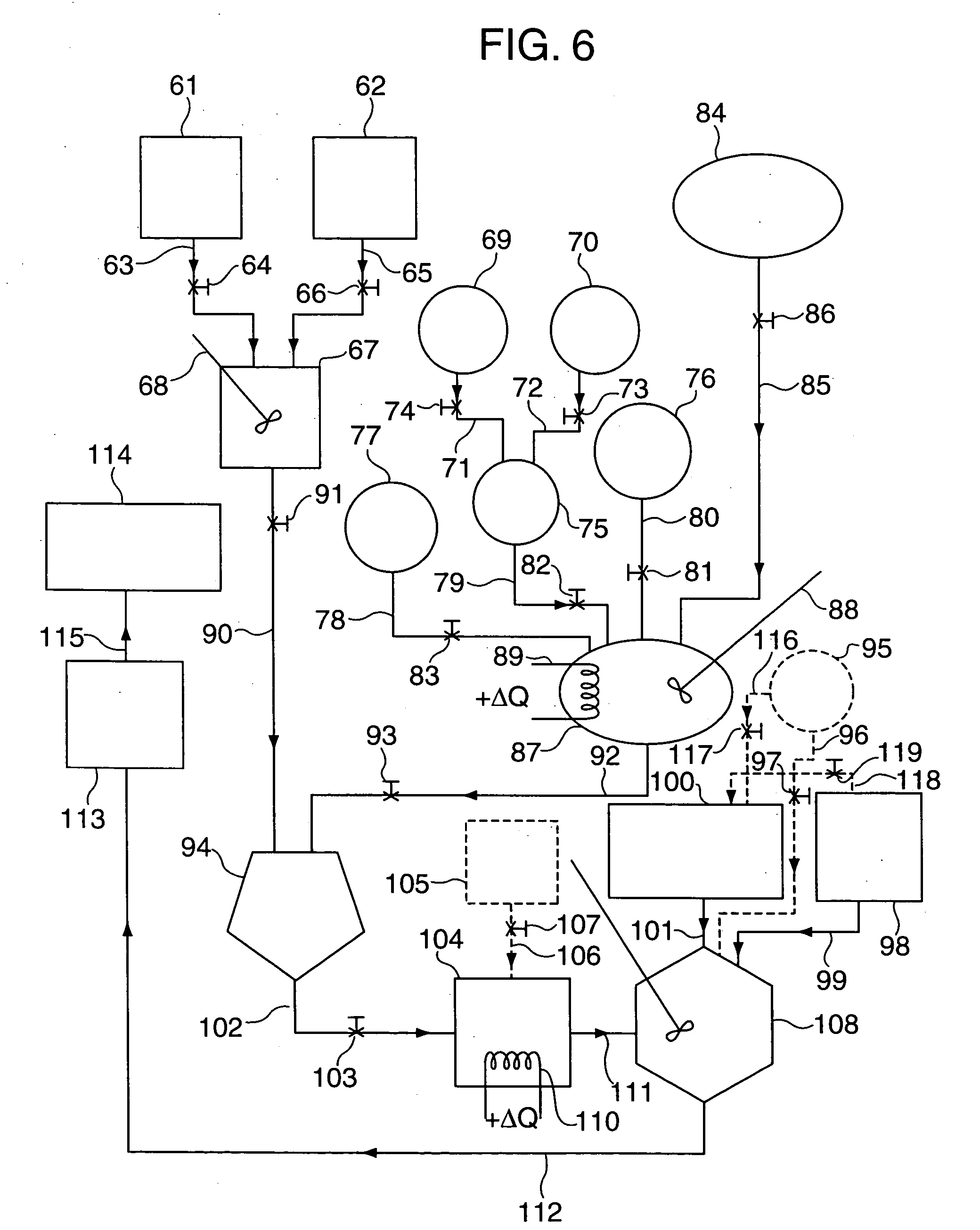

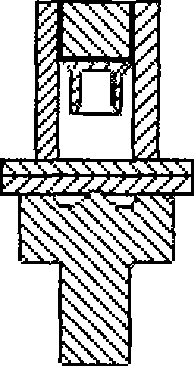

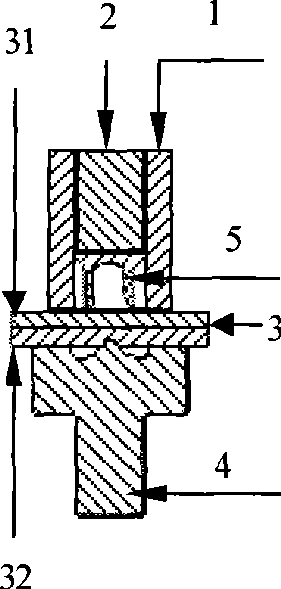

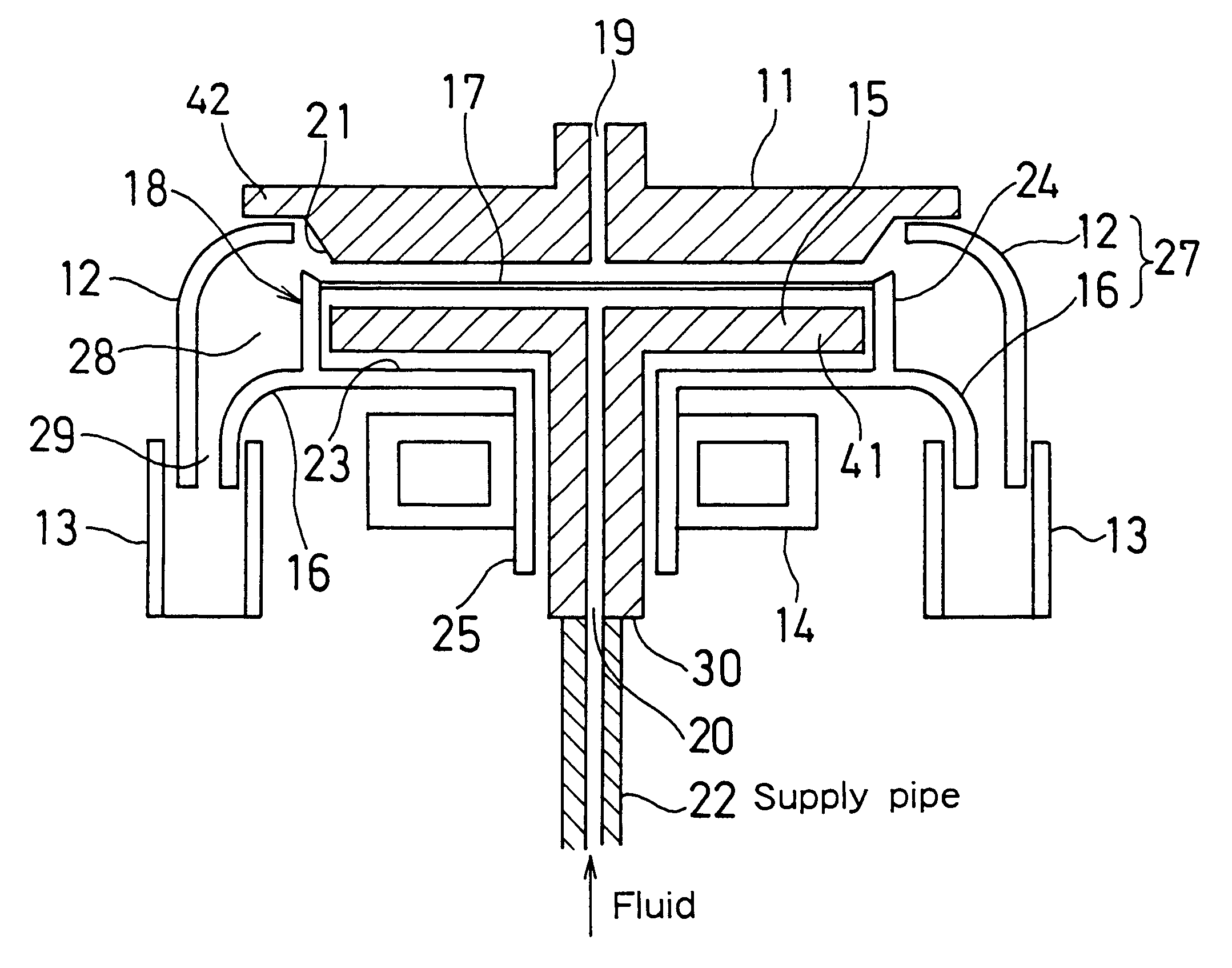

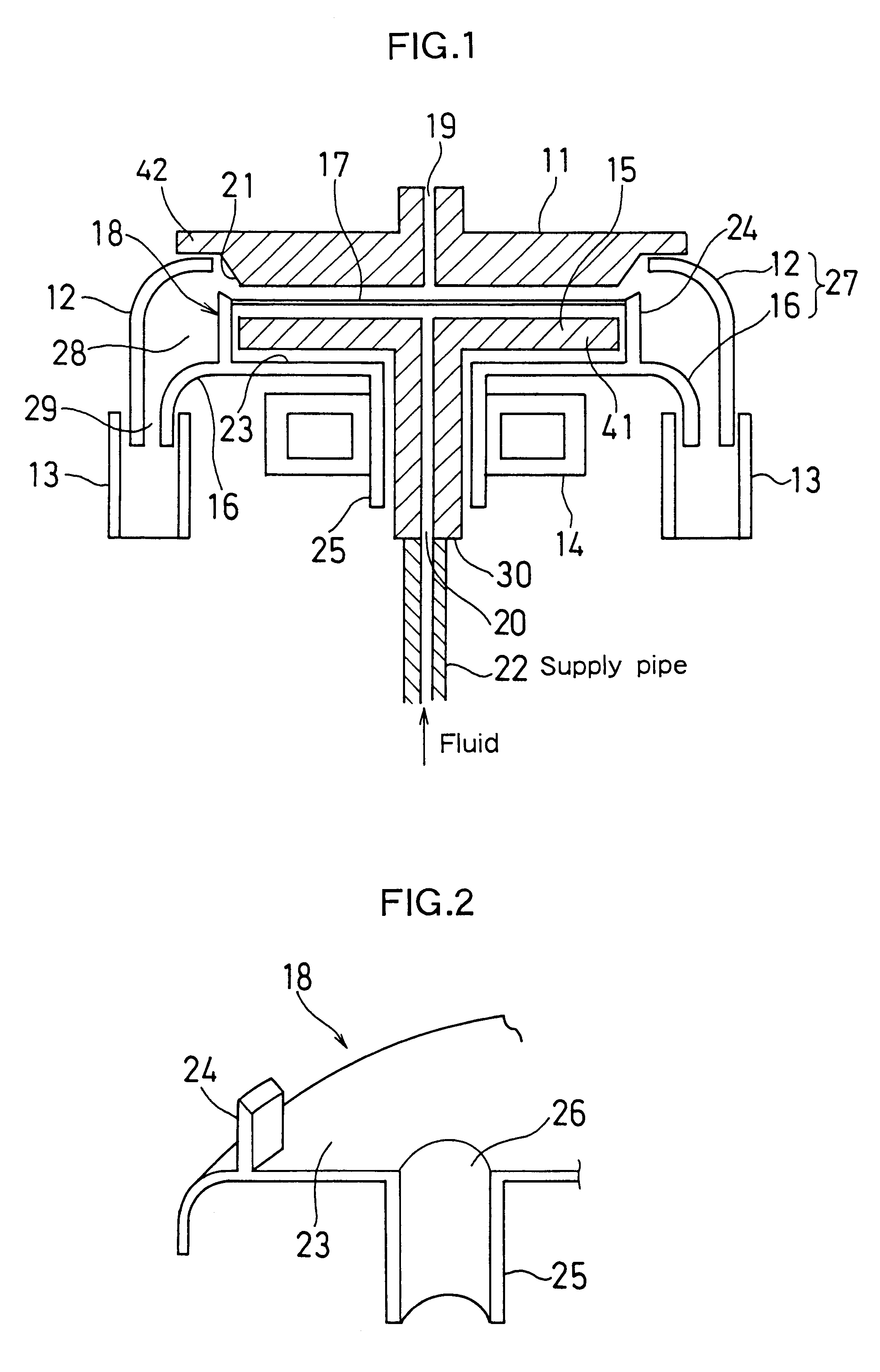

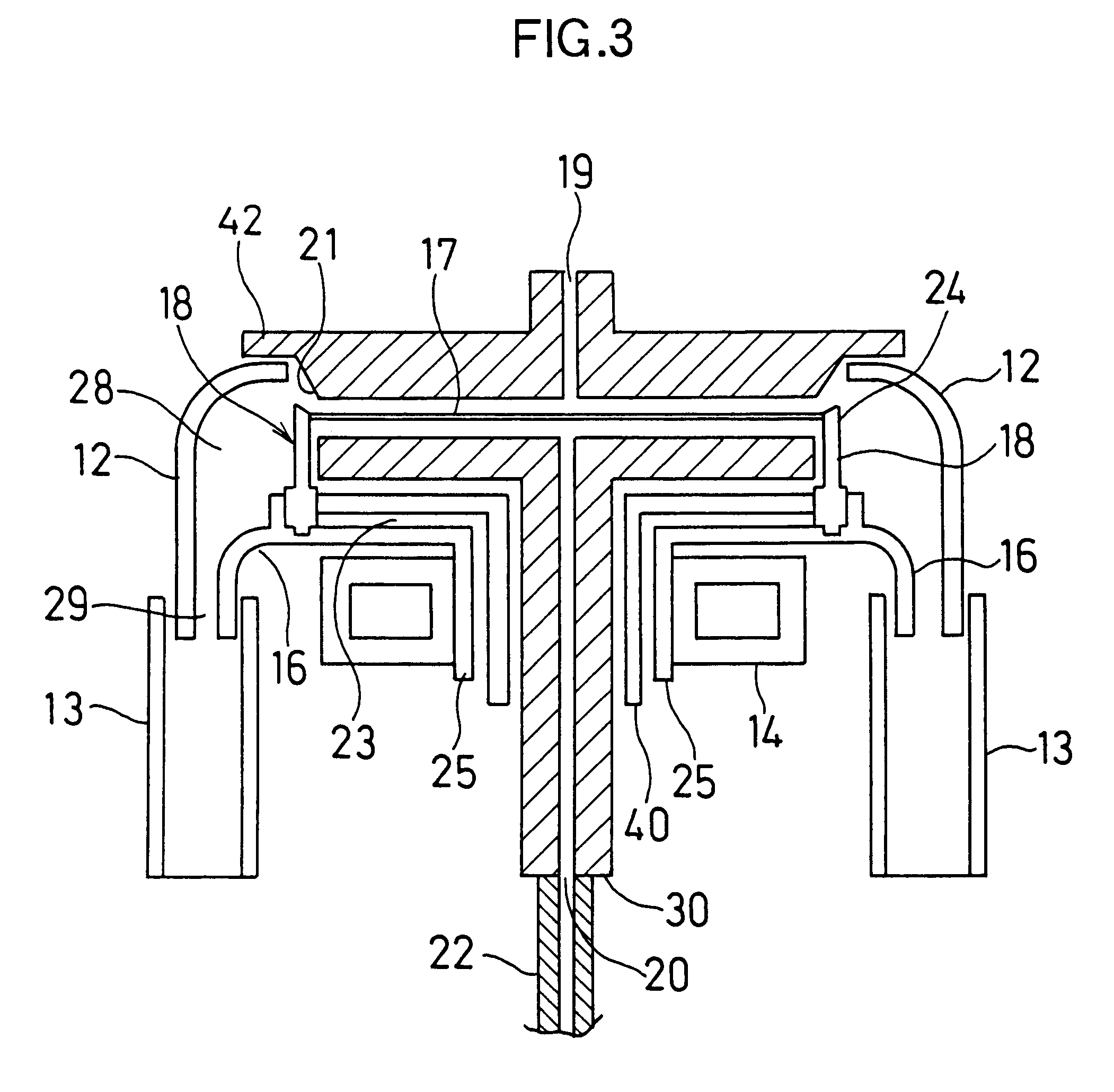

Fluid processing apparatus

InactiveUS6431190B1Electrostatic cleaningSemiconductor/solid-state device manufacturingEngineeringRubbing

To carry out very clean and low-cost fluid processing on both the front and rear surfaces of an object to be processed without generating rubbing particles and without leakage of fluid. A retention member for the object to be processed 18 that retains the object to be processed 17 and a rear shielding plate 15 that prevents the rear surface of the object to be processed from becoming contaminated by excessive fluid flow are mechanically separated. The rear shielding plate 15 is fixed in like manner to a front shielding plate 11, only the retention member for the object to be processed 18 is allowed to rotate making it possible to rigidly connect a supply pipe 22 (that supplies fluid through the rear shielding plate 15) to the rear shielding plate 15. Further, a circulation system is provided that collects fluid which underwent front surface processing in a collection tube 13, circulates that fluid and then supplies it to the rear surface of the object to be processed from a supply pipe.

Owner:KOKUSA ELECTRIC CO LTD

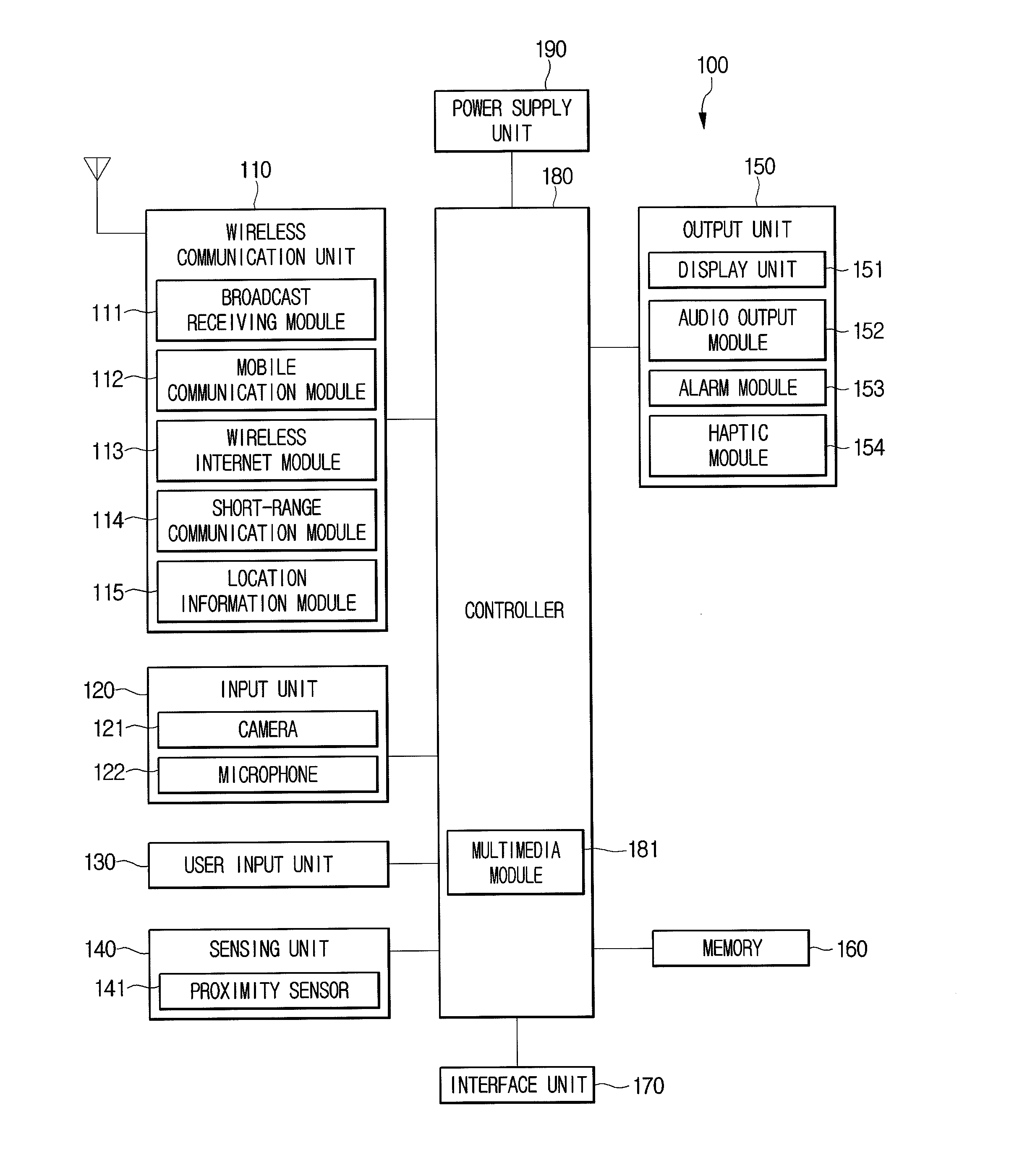

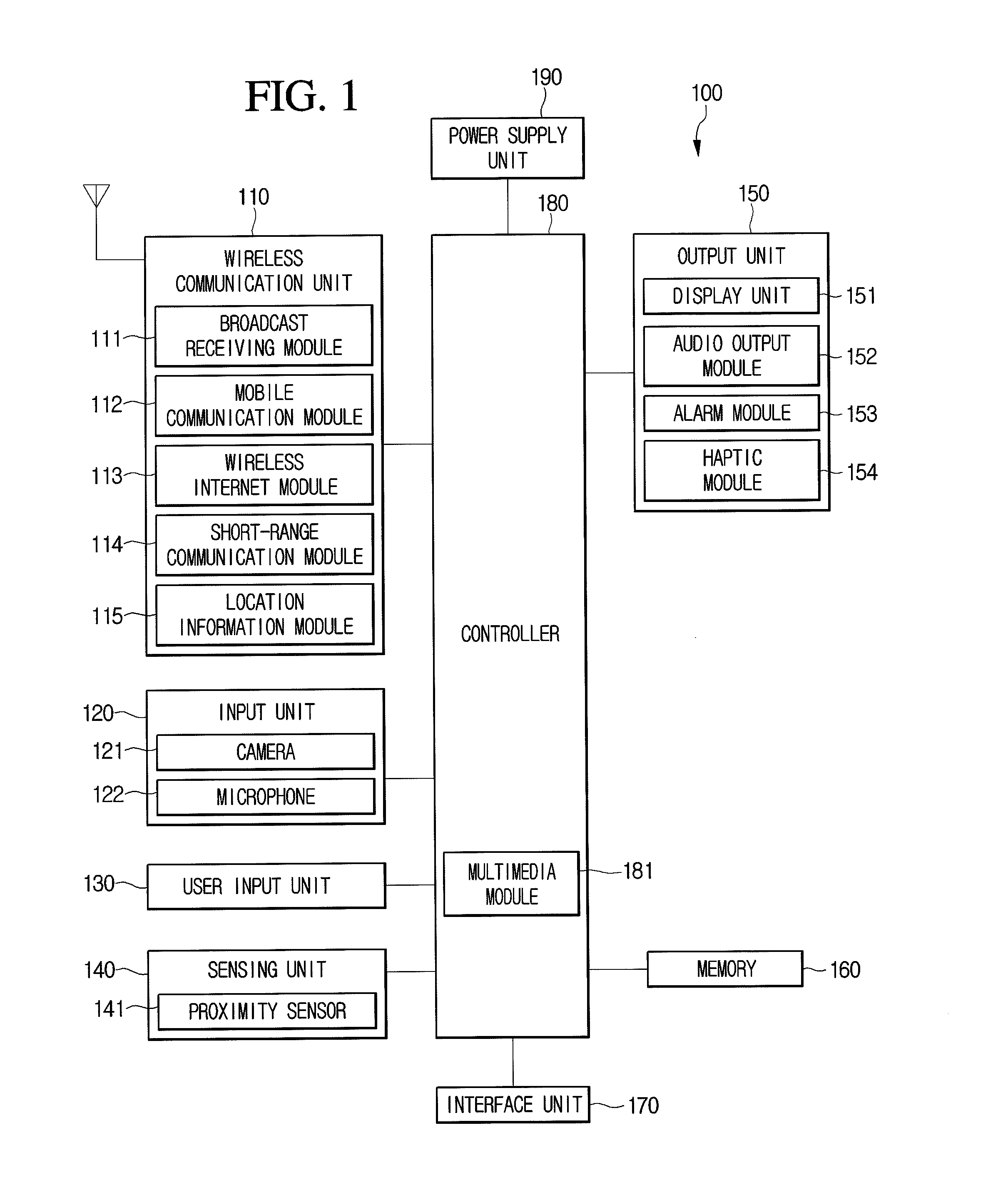

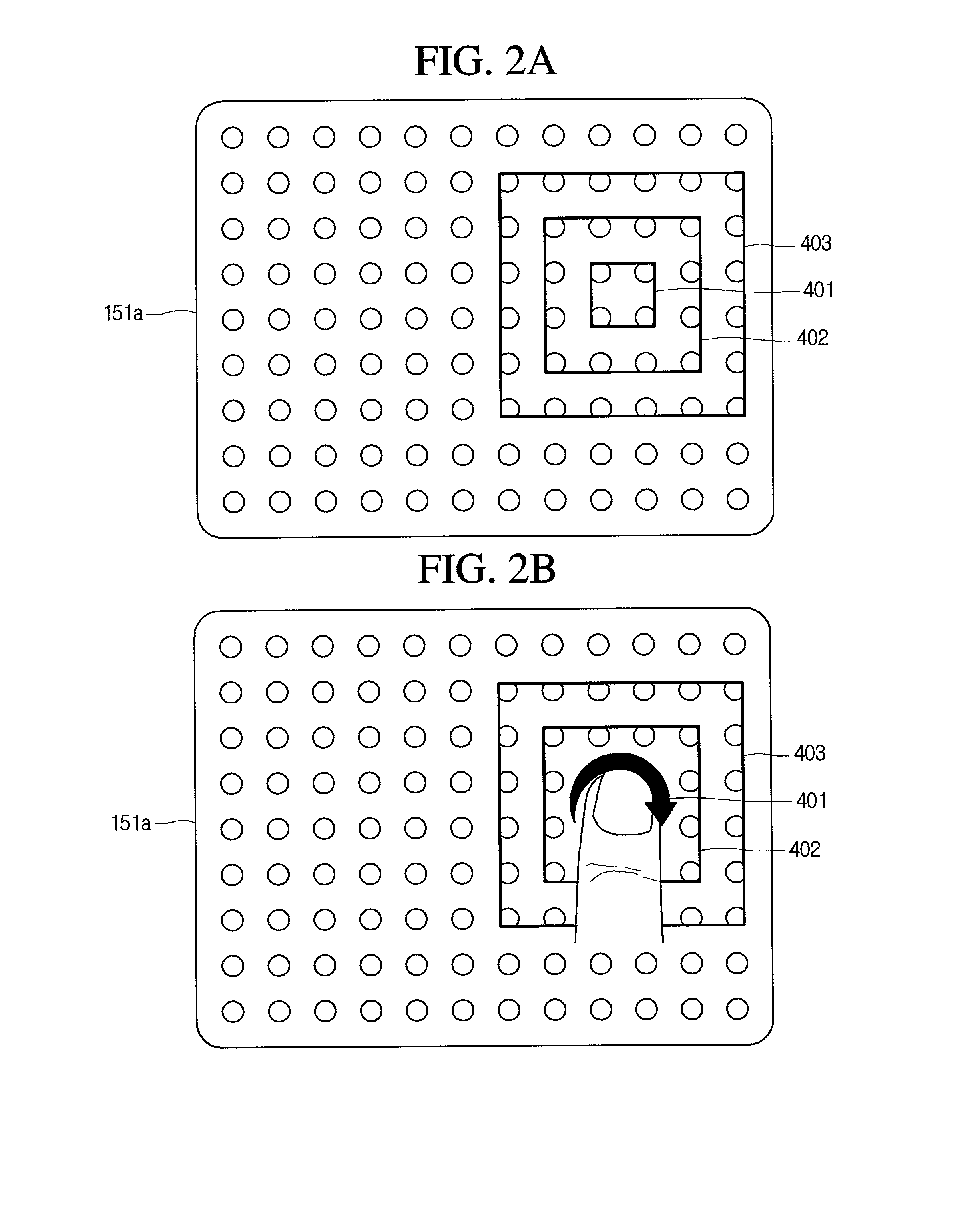

Terminal and operating method thereof

A method of controlling a terminal, and which includes obtaining a rubbing touch input rubbing a partial area of a touch screen of the terminal; executing an intelligent agent providing a function or operation of the terminal based on the received rubbing touch input; and performing a function corresponding to an object displayed in the partial area based on the executed intelligent agent.

Owner:LG ELECTRONICS INC

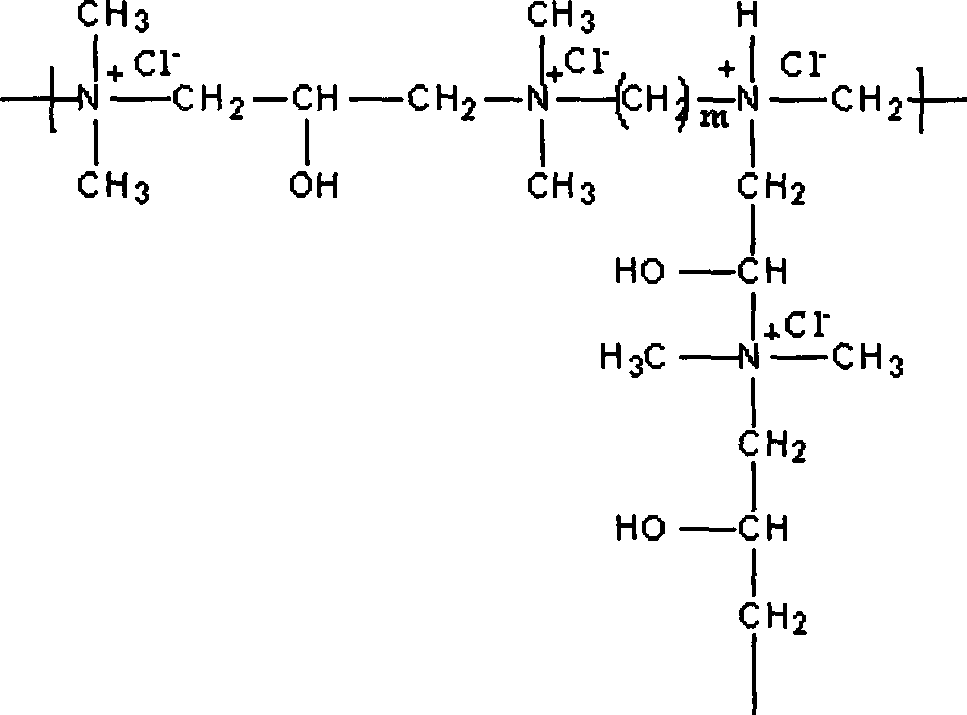

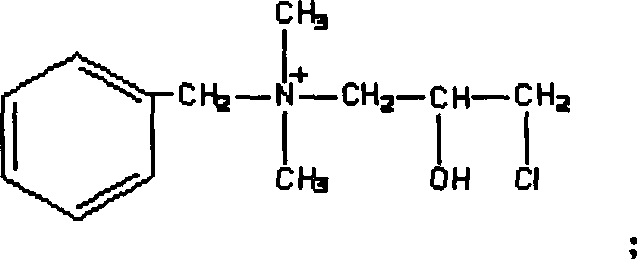

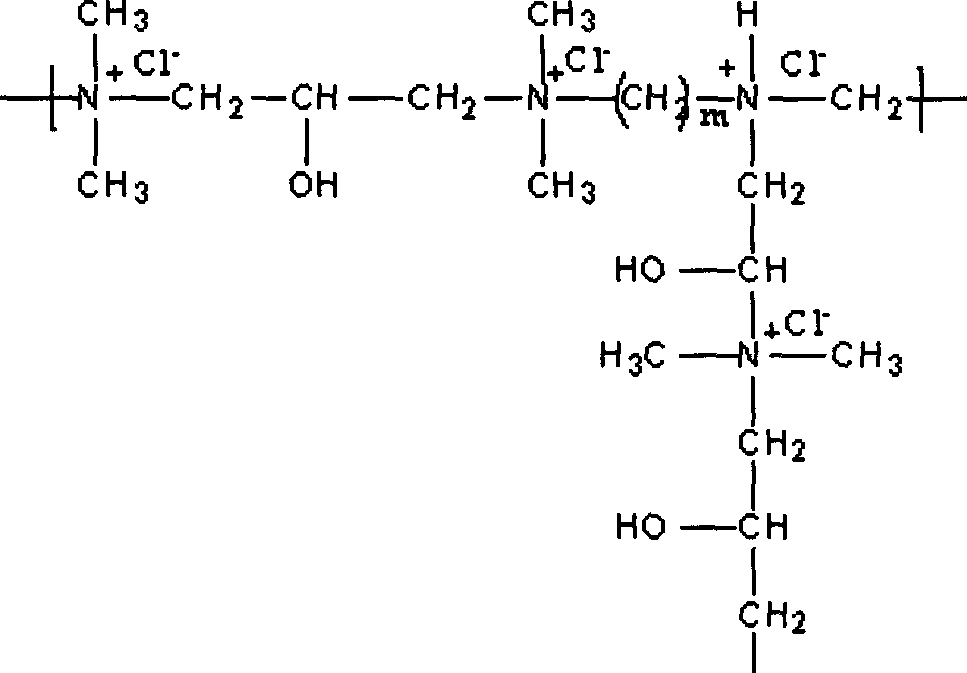

Ecological low-salt dyeing and finishing agent for reactive dyes and preparation method and applications thereof

The invention discloses an ecological low-salt dyeing and finishing agent for reactive dyes, which comprises a crosslinking cationic modifier A and a branched cationic modifier B, wherein the weight ratio of the crosslinking cationic modifier A to the branched cationic modifier B is (30-50): 50. The ecological low-salt dyeing and finishing agent for reactive dyes disclosed by the invention has the advantages that in the process of treating cotton fibers by using the crosslinking cationic modifier and the branched cationic modifier, the inner portions and surfaces of the fibers can be modified through cationization, therefore, the utilization rate of reactive dyes can be improved, and the dye-uptake rate and fixation rate of cotton fabrics are significantly higher than those in conventional dyeing; salt-free low-alkali dyeing even salt-free alkali-free dyeing can be achieved, and dyeing wastewater can be recycled for secondary utilization; and the color fastness to washing and the color fastness to rubbing are consistent with those of conventional cotton fabrics.

Owner:南通曙光染织有限公司

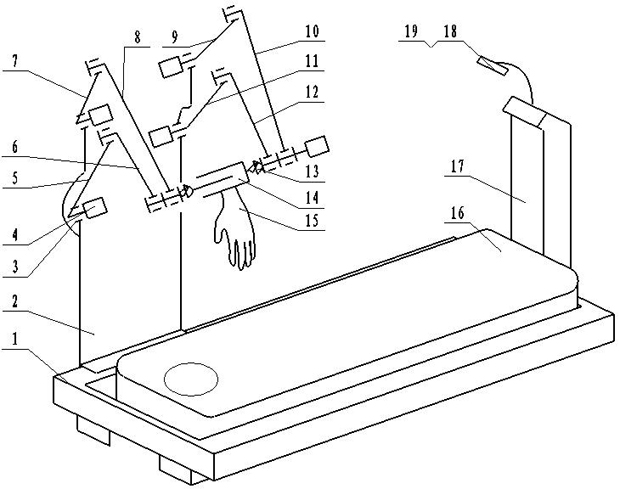

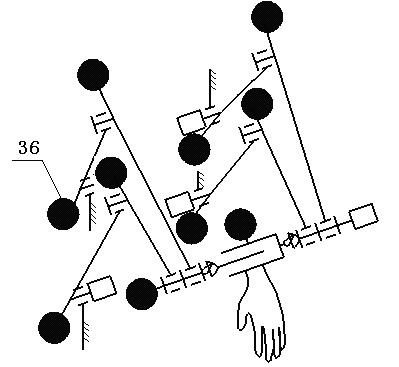

Chinese massage robot

InactiveCN102058466ALarge space for exerciseSimple structureDevices for pressing relfex pointsVibration massageMedicineMassage

The invention discloses a Chinese massage robot, relating to the field of Chinese massage mechanical and automatic devices. The Chinese massage robot is characterized by comprising a bed body (16), a spatial six degrees of freedom main body mechanism and a massage hand (15) and can realize a palm-rubbing technique, a scrubbing method, a pushing manipulation, a wiping manipulation, a pressing manipulation, a pointing method, a finger-nail pressing method, a clapping method, a striking method, a rebounding method, a rolling method, a palm-kneading method, a finger-kneading method, a tremble manipulation, a shaking manipulation, a holding method, a kneading method, a plucking method, a pushing method, a twisting method, a pulling and turning method, a stretching method and other general single-hand and dual-hand massage methods. The invention has the advantages of simple structure, high rigidity, small size, light weight, low cost, large motion space, sensitive and quick action, favorable decoupling, real-time and dynamic response characteristics of system control, and the like.

Owner:扬中中科维康智能科技有限公司

Display element and display device

InactiveUS20050185125A1Increase contrastReduce colorPillowsStatic indicating devicesLiquid crystallineNegative type

On one of surfaces of each substrate, an electrode is provided. Then, alignment films, which have been subjected to rubbing treatment, are provided on the respective electrodes so that the alignment films covers the respective electrodes. Moreover, on the other one of the surfaces of each substrate, a polarizer is provided so that its absorption axial direction matches with a rubbing direction of the corresponding alignment film. The substrates face each other so that the rubbing directions of the alignment films respectively provided on the substrates cross each other perpendicularly. A medium having a negative type liquid crystalline property is sealed between the substrates so as to form a material layer. In this way, it is possible to improve contrast and to alleviate coloring phenomenon in a display element in which transmittance is changed by controlling orientational order of molecules.

Owner:SHARP KK

Interchangeable bearing blocks for drill bits, and drill bits including same

ActiveUS7814997B2Reduce complexityReduce inventory quantityDrill bitsDrilling rodsEngineeringRubbing

A bearing block is provided that may be used with a drag bit body or frame to limit depth of cut of cutters on a bit. The bearing block is designed so that it may be interchangeably replaced or repaired without necessitating alteration to a standardized bit frame. The interchangeable bearing block may be used to provide a target depth of cut (TDOC) and / or a selected contact or rubbing area to support weight on bit and limit depth of cut (DOC) for improving drilling performance of a bit. The interchangeable bearing block brings manufacturing selectability by providing a customizable product in terms of depth of cut selection and cutter penetration control for different formations, which is suitable for use with a common bit frame. A rotary drill bit assembly, a unitary cone insert bearing block for a drill bit, and a bit frame are also provided.

Owner:BAKER HUGHES HLDG LLC

Production of coating fabrics with high-peneration and waterproofing functions

InactiveCN1940174AImprove waterproof performanceGood moisture permeabilityTextiles and paperSocial benefitsOrganic solvent

This invention was a public high permeability high waterproof coating fabrics manufacturing methods, including polyurethane polymer, an organic solvent, allocation of water, as agent, crosslinking agents, other agents, water mixed into a fabric coating agents will be made of fabric coated with the coating in uniform as coating on the fabric, Fabric coating agent had dried occasion of the coating for drying processing steps. The invention manufactured coated fabric is not only an excellent waterproof and good moisture permeability but also has good rubbing sex and the feeling of fullness soft features. Product hydrostatic pressure 5000mm H2O over Al permeability to 8000g / m2 . 24hr above Tolerance washing and rubbing. Such coated fabric has broad prospects for sales, which can be used to produce rainwear, breathable, ski clothes, cool suits. Have greater economic and social benefits.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com