Patents

Literature

496 results about "Desizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desizing is the process of removing the size material from warp yarns after a textile fabric is woven.

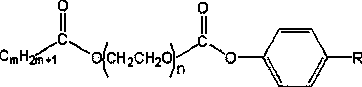

Fabric graft modified full-fixation printing method

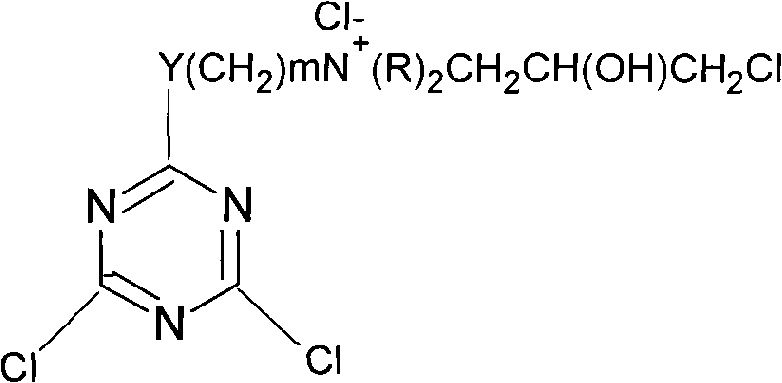

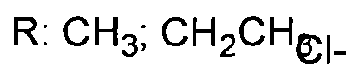

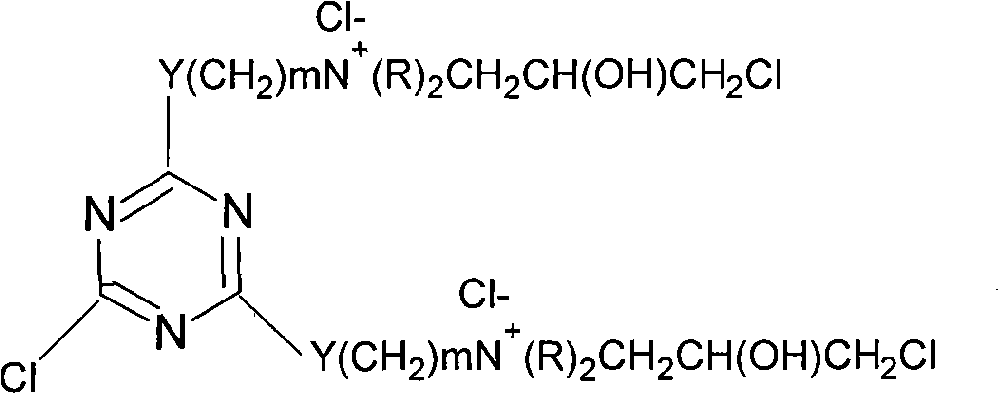

InactiveCN101403185AReduced charge repulsionReduce processing burdenDyeing processVegetal fibresSodium bicarbonateWorking fluid

The invention relates to a whole fixation printing method for the graft modification of textiles, and aims at providing the whole fixation printing method that can promote the dye fixation rate from 70 percent to 80 percent to more than 90 percent to 98 percent. The technical proposal is as follows: 1) the pretreatment of a textile, the textile is treated according to the processes of desizing, boiling, smelting and bleaching; 2) the preparation of the graft modification working fluid, the working fluid comprises 0.1 percent to 10 percent of cationic graft agent, 0.1 percent to 20 percent of alkali agent and 0 percent to 1 percent of penetrating agent, and the rest is water; 3) the treatment of the graft modification, the pretreated textile is put into a dyeing machine, and the graft modification working fluid is added; or the pretreated textile is padded with the graft modification working fluid in a padder; the printing formula of the invention comprises 50 grams of protoplasm, 2 grams to 5 grams of urea, 0.5 gram to 8 grams of dye, 1 gram to 2.5 grams of sodium bicarbonate and 0.5 gram to 1.5 grams of reserve salt, and the rest amount of water in every 100 grams according to weight; and 4) the printing technology, the printing is carried out according to the conventional technology. The whole fixation printing method for the graft modification of the textiles is used in the whole fixation printing.

Owner:ZHEJIANG JIAXIN SILK

Textile printing and dyeing pretreating agent and application thereof

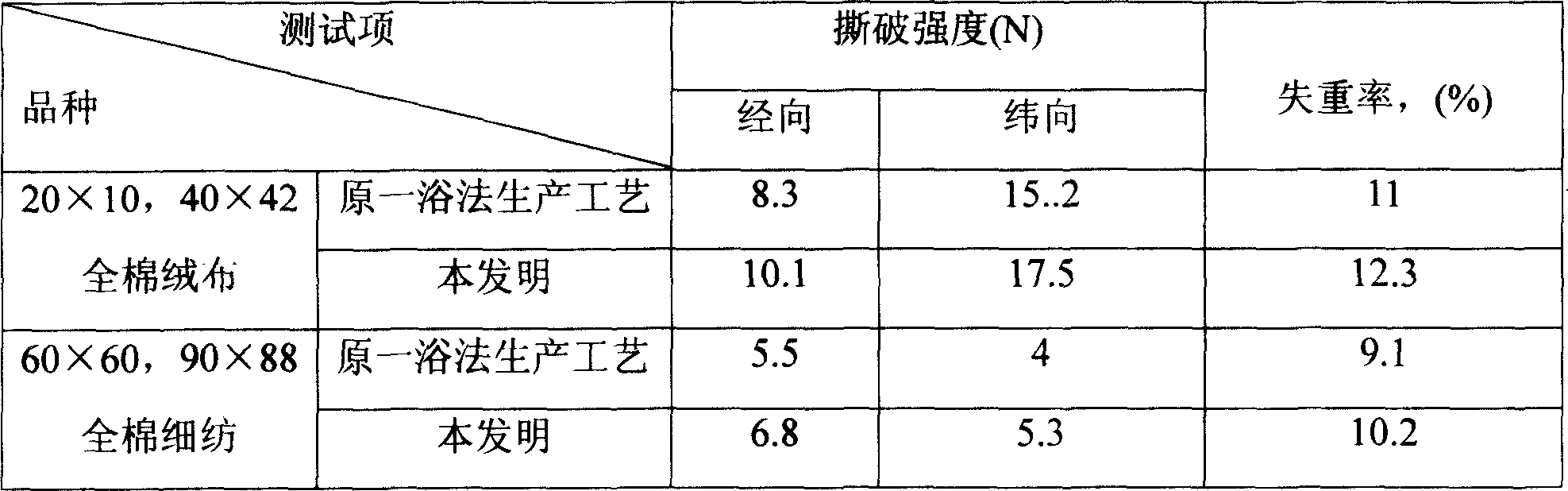

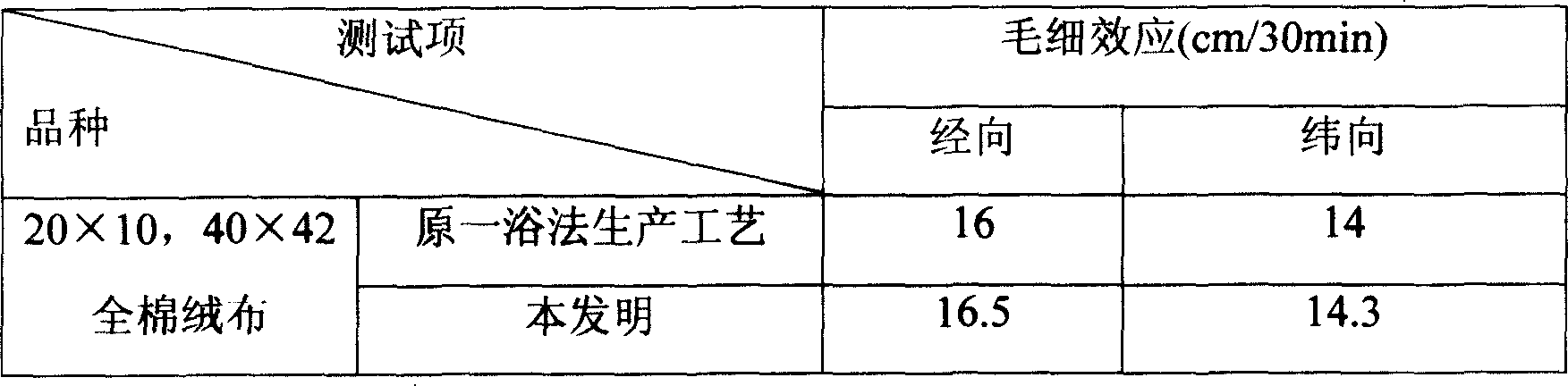

InactiveCN100999869ANo reduction in tear strengthFully desizingBiochemical fibre treatmentTextile printerEngineering

The present invention discloses one kind of pre-treating agent for fabric printing and dyeing and its application. The pre-treating agent includes pre-treating water solution in 40-60 wt% and promoter in 40-60 wt%. The pre-treating agent may be used in the pre-treatment of cotton fabric and blended fabric before printing and dyeing. The cotton fabric and blended fabric treated with the pre-treating agent has full desizing, no degradation in strength and easy printing and dyeing.

Owner:SHENDA NO 2 PRINTING DYEING FINISHING CO LTD SHANGHAI

Full-cotton woven fabric bioenzyme continuous destarch ungumming-bathing pretreatment process

The invention is a kind of fore process of biology enzyme continuous desizing, refinery-washing method for cotton textile, which belongs to textile front process field in printing and dyeing industry. It solves the problem that the water and electricity are consumed in a large amount, and goes against with the environment protection, the process reaches the best process effect. The process carries on boiled water heat process to cotton textile, and then through impregnating biology enzyme liquid, steamed biology enzyme desizing, refinery process water cleaning, then through impregnating hydrogen dioxide bleaching liquid, steaming bleaching process, water cleaning etc. processes. By using the process, the fore process effect is good, the desizing effect is good, the white rate is high, and it has good humidification, small harm to fiber, high quality, soft, the method process the colourity, pH value, COD value to degree far lower than the current process, it reduces the bear of waste water processing, it is advantage to protect the environment, the efficiency is high, the low labour intensity, energy saving, and water saving.

Owner:JIANGNAN UNIV

Dyeing and finishing process of polyolefin elastic fiber fabric coated by polyester cotton filling yarn

InactiveCN101392444AImprove breathabilityGood hygroscopicityBiochemical fibre treatmentSingeingFiberPolyester

The invention provides a dyeing and finishing technology for using polyester cotton warp and weft yarn to warp a polyolefin elastic fiber fabric, and belongs to a processing technology of an elastic fabric. The technology sequentially includes the following steps: turning and sewing of the cloth, shrinking, singeing, desizing, mercerizing, setting, dyeing, after finishing and pre-shrinkage. The dyeing and finishing technology decreases the density of the warp and weft direction during the preliminary treatment before the dyeing of the fabric, and leads the cloth easier to retract, and the width is sufficiently shrunk after the shrinkage, desizing and mercerization process, thus obtaining the cloth has good elastic effect and soft feeling. Compared with the prior art, the fabric has good tensile recovery property, stable and lower washing shrinkage and high temperature resistance, strong acid resistance and strong alkaline resistance, which is favorable for various professional finishing; therefore, the soft dacron-cotton warp and weft elastic fabric with high elasticity, good air permeability and strong moisture absorption property can be obtained.

Owner:HUAFANG

Production method for polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process

ActiveCN104213398AOxygen bleachingTo achieve the purpose of cost reductionMercerising of indefinite length fabricsSingeingDisperse dyeOxygen

The invention a printing and dyeing method, and especially relates to a production method for a polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process. The method comprises the following steps: selecting a sample cloth, carrying out pretreatment desizing, pre-setting a grey, singeing the grey, mercerizing, preparing a complex formulation assistant according to a formula, using the complex formulation assistant according to a ratio, designing a dyeing formula, carrying out jar dyeing on the cloth sample, carrying out hot setting, singeing the obtained color body, washing by water, drying, carrying out oiling setting, carrying out after-finishing calendering, carrying out after-finishing full decatizing, and examining the obtained finished product. The production method for the polyester cotton oxygen bleaching and disperse dyestuff dyeing one bath process has obvious energy saving and emission reduction effects, and the handle elasticity, the color fullness and various quality indexes of fabrics obtained in the invention can meet requirements of different clients.

Owner:ZHEJIANG HANGMIN STOCK

Finishing method of fiber product free of cleaning by detergent

InactiveCN102041685AImprove wettabilityReduce interfacial energyBiochemical fibre treatmentSingeingFiberPre treatment

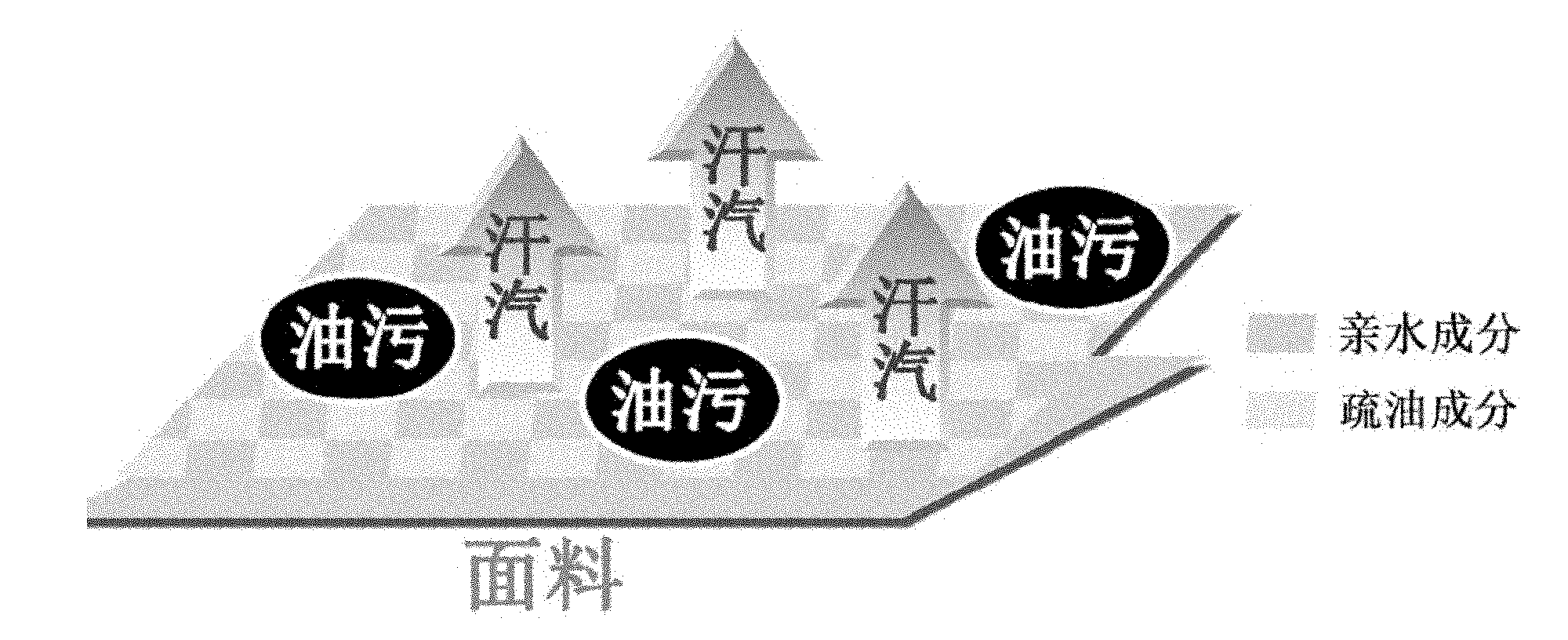

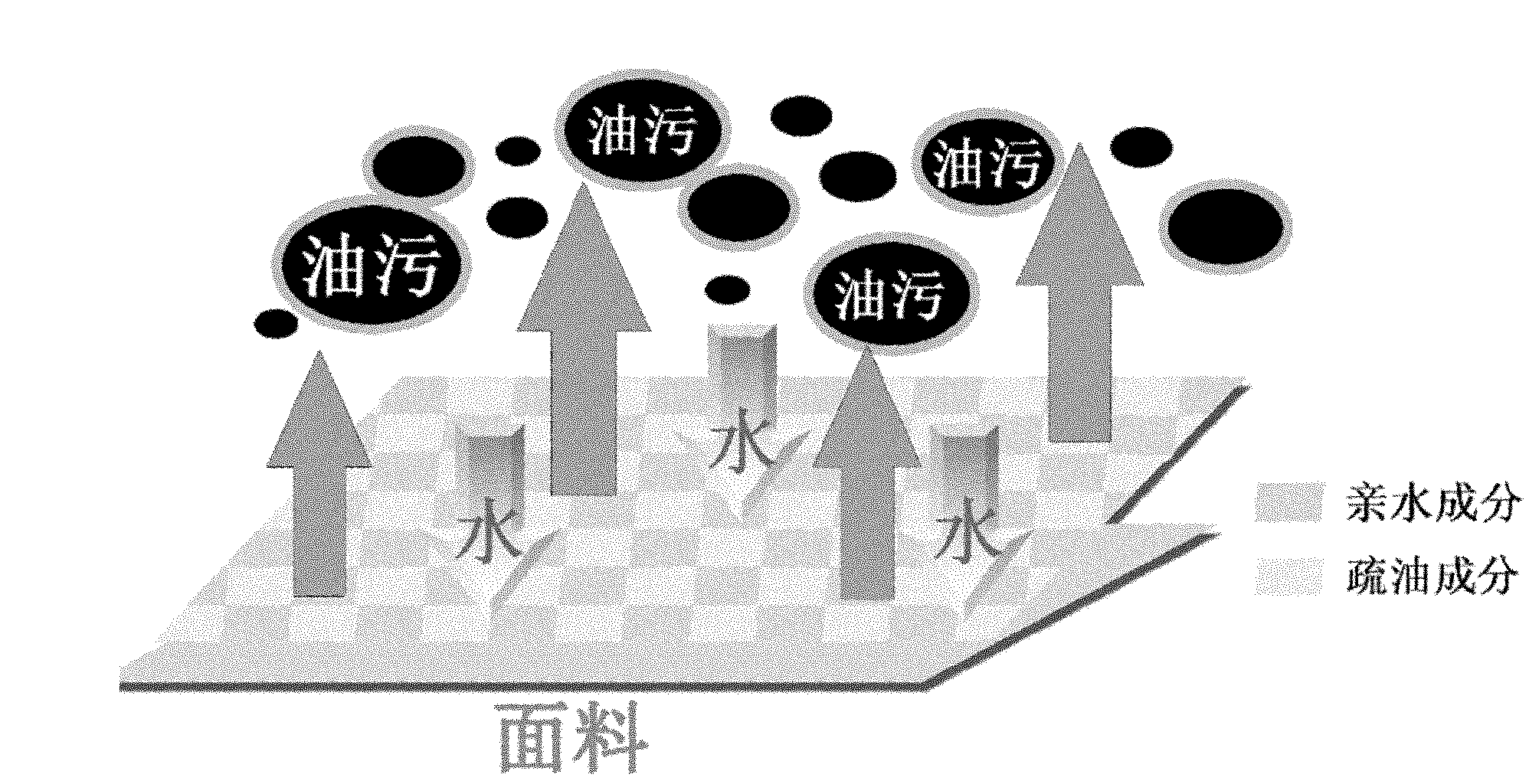

The invention provides a finishing method of a fiber product free of cleaning by a detergent. The technical process comprises singeing, desizing, mercerizing, tentering and preshrinking. The finishing method is characterized in that enzyme piling is added between the singeing and the desizing; a high-efficiency desizing technique is adopted in desizing; liquid ammonia finish and pretreatment are added between the mercerizing and tentering; baking finish is added between the tentering and preshrinking so as to lead the whole technical process to be singeing, enzyme piling, desizing, mercerizing, liquid ammonia finish, pretreatment, tentering, baking and preshrinking. Textiles manufactured by adopting the technique is not cleaned by using the detergent for cleaning, has basically the same cleaning effect with that of cleaning during which the detergent is added, also can not generate secondary dirt in cleaning; and simultaneously, the textile manufactured by using the method has the functions of fouling resistance and easy decontamination, proper oil-proof function, excellent multiple functions of water absorption, air permeability, washing resistance and electrostatic resistance, meets the requirements of people and belongs to an ideal high-grade textile which is energy-saving, environment-friendly and low-carbon.

Owner:LUTAI TEXTILE

Weaving process of hemp towel

InactiveCN101671905ARetain antibacterial health care performanceSoft and comfortableBiochemical fibre treatmentBleaching apparatusRadiation resistantPerspiration

The invention discloses a weaving process of a hemp towel, comprising the steps of cheese winding, warping, weaving and grey cloth post treatment. The rotating speed of a cheese winding grooved drum is 1,200+ / -5r / min; the concentration of caustic soda in desizing boiled bleaching liquor subjected to the grey cloth post treatment is 5ml / L; the concentration of FLOW preliminary treatment agent is 3ml / L; the concentration of hydrogen peroxide is 7.8ml / L; and the temperature of the desizing is 95 DEG C and the boiled bleaching is carried out for 50 minutes. The towel manufactured by the manufacturing process has few filoplume and easy degradation as well as excellent moisture absorbing perspiration performances, natural bacteriostasis and health-care performances reservation of hemp, favorablesoft and comfortable performances, excellent uvioresistant and radiation-resistant performance, high-temperature resistant performance and odor-absorbing and blowdown performances, and is new generation of natural environment-friendly products.

Owner:SUNVIM GROUP

Pre-treating method for cotton fabric by one bath two-step enzyme method

InactiveCN1944784ANo damageImprove wettabilityBiochemical fibre treatmentNatural fibresChemical treatmentAlpha-amylase

The present invention relates to re-compounded enzyme preparation and its application in cotton fabric treatment, and is especially one bath and two step enzyme process for pre-treating cotton fabric. Alkaline pectase, cellulase, alpha-amylase, PVA degrading enzyme, proteinase, lipase, xylanase and sugar oxidase are first re-compounded, and the re-compounded enzyme preparation is then used in the one bath and two step enzyme process for pre-treating cotton fabric. The process includes the first desizing and boiling off step in the treating bath at 55 deg.c and pH 8.0 for 60-90 min, with the sugar oxidase reacting with the desizing product to produce hydrogen peroxide; and the second fabric bleaching step with the enzyme process generated hydrogen peroxide at 95 deg.c and pH 11.0 for 60-120min. The present invention has low power consumption, short technological process and environment friendship, and may be used to replace chemical process.

Owner:JIANGNAN UNIV

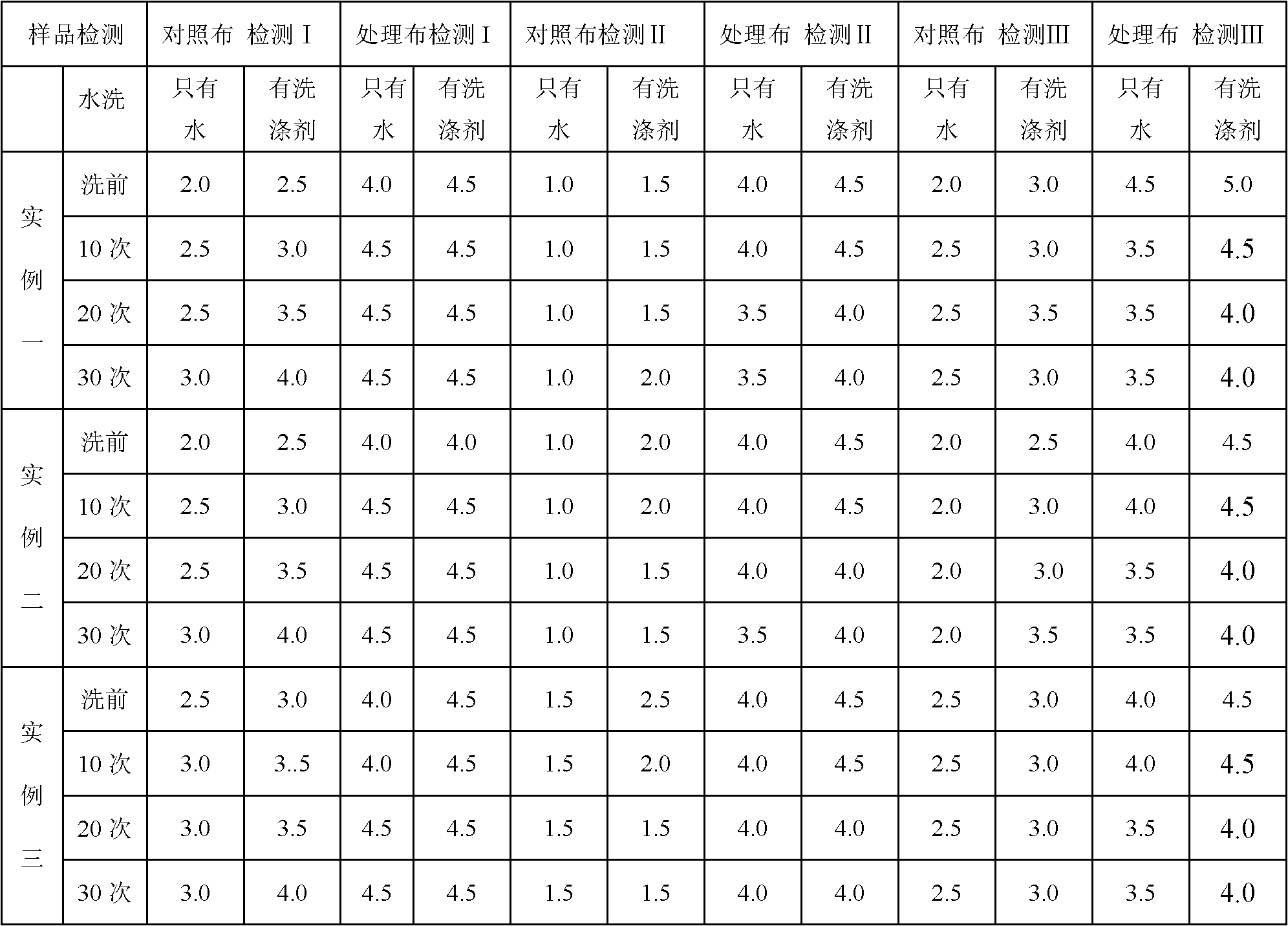

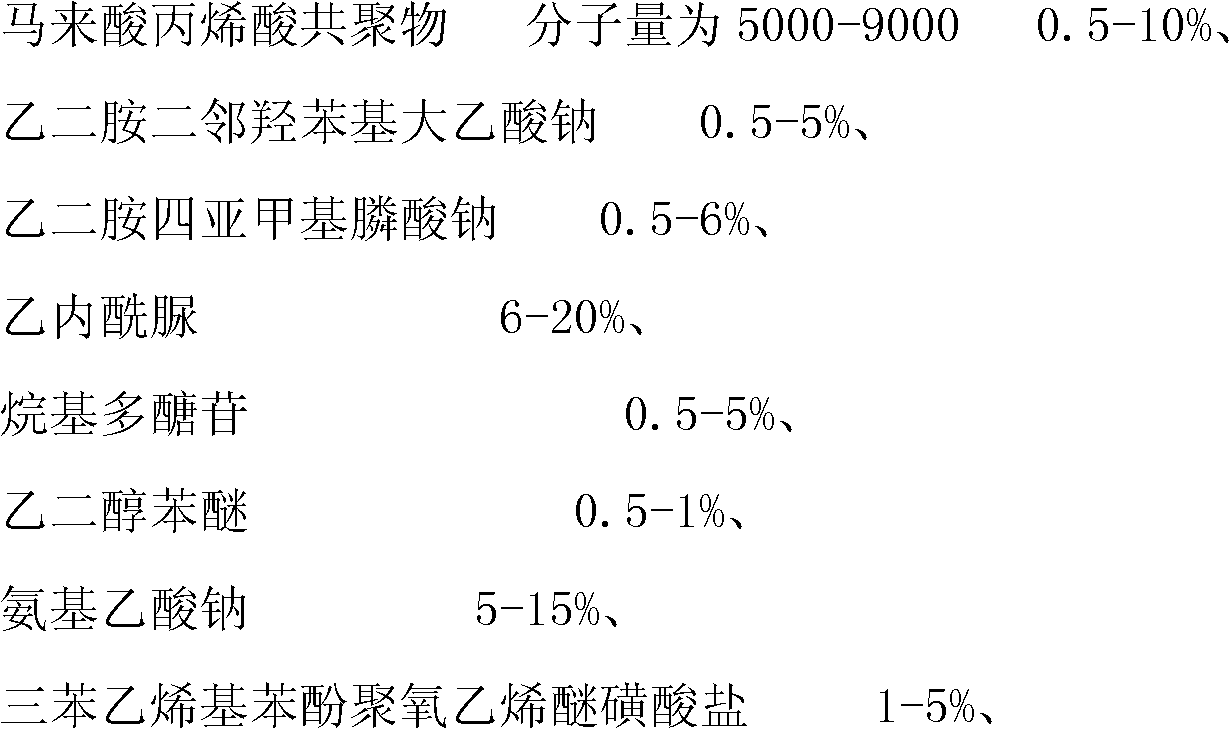

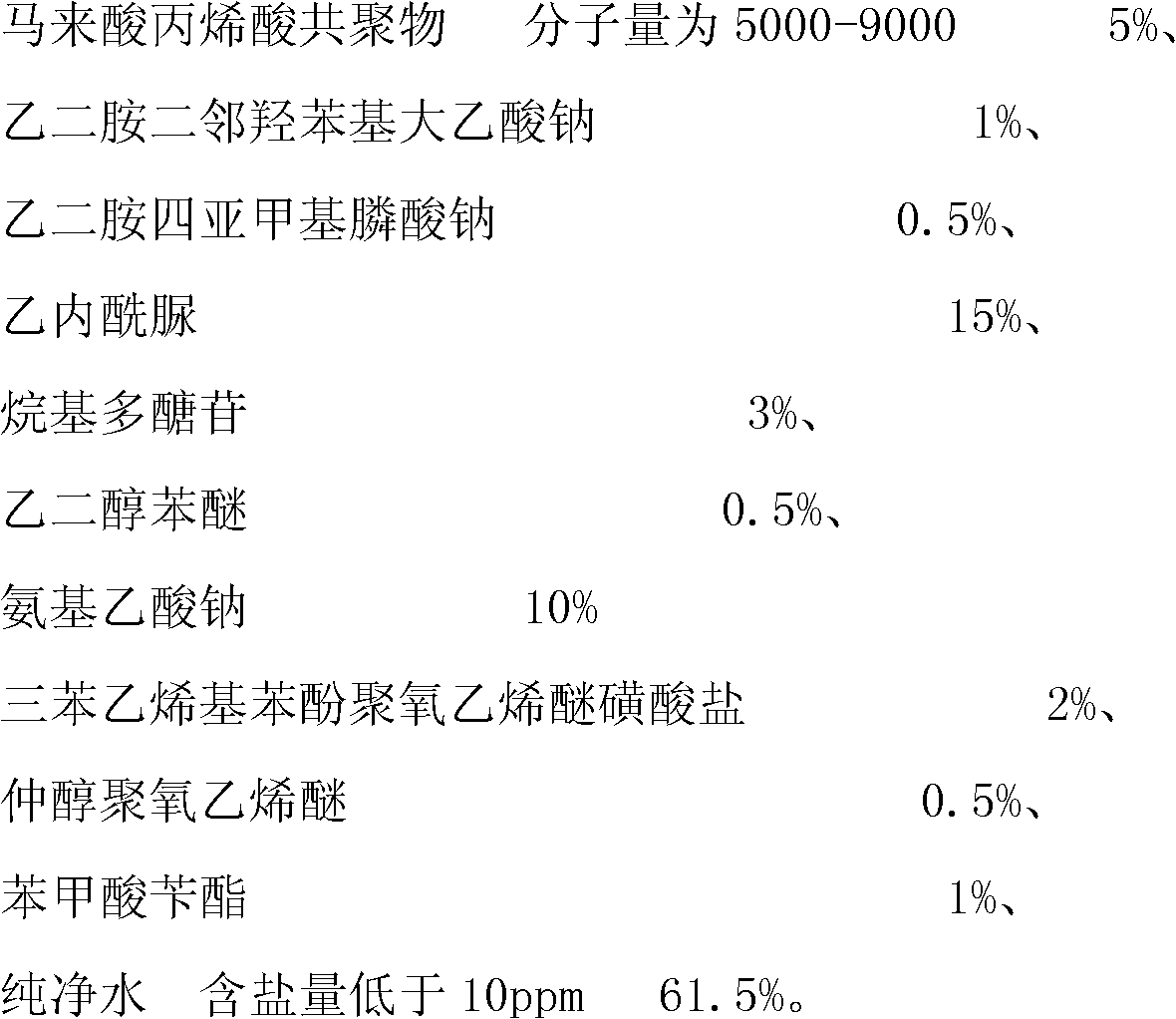

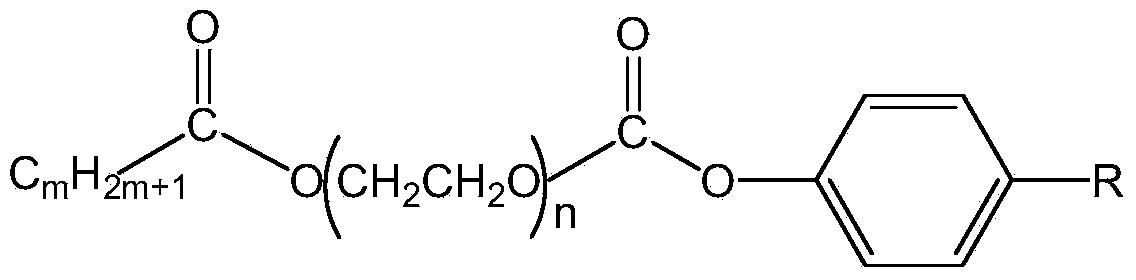

Short-process low-temperature dyeing aid and preparation method thereof

ActiveCN102619101AEliminate reduction cleaning processLower dyeing temperatureDyeing processYarnPolyester

The invention relates to the field of dyeing, in particular to a short-process low-temperature dyeing aid and a preparation method thereof. The short-process low-temperature dyeing aid is characterized by mainly comprising the following components in percentage by weight: maleic acid acrylic copolymer, sodium ethylene diamine di-orthohydroxyphenyl aceticacid (EDDHA), ethylene diamine tetra sodium, hydantoin, alkyl polysaccharide, ethylene glycol phenylate, sodium glycinate, tristyrylphenol ethoxylates sulfonate, secondary alcohol polyoxyethylene ether, benzyl benzoate and the like. Compared with the prior art, the aid and the method have the advantages that the conventional pretreatment and dyeing processing mode of polyester and blended (yarns) fabrics is thoroughly changed, namely pretreatment processes of the yarns and the fabrics which comprise a yarn and knitwear oil removing process, a woven fabric desizing process, a slight decrement process, a polyester / cotton fabric bleaching treatment process and other processes are combined with a dyeing process to form a one bath treatment process; and the dyeing temperature of one bath dyeing is reduced, reduction clearing processes of most of dyed fabrics are eliminated, water is saved by more than 60 percent, and electricity is saved by more than 30 percent.

Owner:杭州彩润科技有限公司

TR cloth desizing refining and dispersed dyeing-bath dyeing production method

ActiveCN104213349ALittle power lossShade effect is smallSingeingDyeing processDisperse dyeProduct inspection

The invention provides a dyeing method, and particularly relates to a TR cloth desizing refining and dispersed dyeing-bath dyeing production method. The method is performed according to the following steps comprising sample cloth selection, blank cloth pre-shaping, white cloth singeing, compound auxiliary agent recipe design, preparation and dosage determining, dyeing recipe design, piece cloth jar dyeing, drying and shaping, color cloth singeing, water washing and drying, oiling and shaping, after finishing calendaring, after finishing decator steaming and finished product inspection. The TR cloth desizing refining and dispersed dyeing-bath dyeing production method has the advantages that the energy-saving and emission reduction effects are obvious, in addition, the hand feeling of fabrics after the production and the processing is soft, full color and luster can be realized, and the like. Various internal indexes such as the quality can meet requirements of different customers.

Owner:ZHEJIANG HANGMIN STOCK

Manufacturing process for chinlon filament high-strength wear-resistant fabric having strong cotton touch feeling

ActiveCN105350152AImprove the shortcomings of insufficient wear resistanceKeep the touchFibre typesHeating/cooling textile fabricsYarnWear resistant

The invention discloses a manufacturing process for a chinlon filament high-strength wear-resistant fabric having a strong cotton touch feeling. The chinlon filament high-strength wear-resistant fabric having a strong cotton touch feeling is manufactured through steps of yarn selecting, sectional warping, sizing, re-beaming, weaving, desizing and washing, dyeing, centralizing, water-sprinkling and setting, calendaring, plastic dropping and the like. According to the invention, throwing, weaving, dyeing and finishing steps are designed in the manufacturing process for the chinlon filament high-strength wear-resistant fabric having a strong cotton touch feeling, so that a problem that a pure cotton fabric is lack of wear resistance is solved, the cotton touch feeling is remained to the largest extent, and therefore the fabric has a good touch feeling, is soft in texture and is high in wearability. The fabric having a strong cotton touch feeling and manufactured through the process can undergo more than 100000 times of wear-resistant tests carried out based on a Martindale method mentioned in the GB / T21196.2-2007(9KPA).

Owner:HUAMAO (XIAMEN) WEAVING DYEING & FINISHING CO LTD

Full-cotton woven fabric amylase, pectinase, proteinase continuous padding-decatizing pretreatment process

The invention refers to a kind of process for cotton textile starch enzyme, pectinase, prolease continuous desizing, refinement prepreocess, it belongs to textile front process field in printing and dyeing industry. It solves the technology problem that the effect of cotton textile biology enzyme continuous steam front process is not good, and it optimizes the process effect. The invention uses three-steps method front process of carry on cotton textile impregnating desizing enzyme liquid, steaming and washing with water, then carry on impregnating biology refinery liquid, steaming, enzyme eliminating, water washing, finally carry on impregnating hydrogen peroxide solution bleaching liquid, steaming and washing with water. The effect is good, the harm does to the fiber is small, the quality of textile is high, the product is soft, the method process the colourity, pH value, COD value to degree far lower than the current process, it reduces the bear of waste water processing, it is advantage to protect the environment, the efficiency is high, the low labour intensity, energy saving, and water saving.

Owner:JIANGNAN UNIV

Cotton-like lining cloth and production process thereof

The invention relates to cotton-like lining cloth which is formed by blending viscose fibre / polyester staple fiber blended yarn serving as warp yarn and functional polyester filament serving as weft yarn, wherein the functional polyester filament can absorb and discharge moisture. In addition, a production process of the cotton-like lining cloth is further related. The production process includes the following steps: 1, warp yarn selection; 2 weft yarn selection; 3, weaving; 4, overflow desizing and bleaching processing or overflow desizing and bath dyeing processing; 5, dehydration; 6, scotching; 7, sizing; 8, coating calendaring; 9, perching volume classification; and 10, laboratory sample detection.

Owner:CPL NEW MATERIAL TECH CO LTD

Novel sizing agent for sizing terylene or terylene staple fiber

The invention provides a novel sizing agent for sizing terylene or terylene staple fiber. The novel sizing agent comprises the following components in parts by mass: 35 to 40 parts of polyving akohol, 35 to 40 parts of potato starch, 45 to 55 parts of phosphate starch, 10 to 20 parts of crylic acid, 0.5 to 1.5 parts of wax sheets, 1 to 2 parts of antistatic agent and 1 to 2 parts of softening agent. The novel sizing agent has the advantages of easy desizing, stable viscosity, no pollution and low material cost and is beneficial to large-scale production.

Owner:WANG TAI CHINA

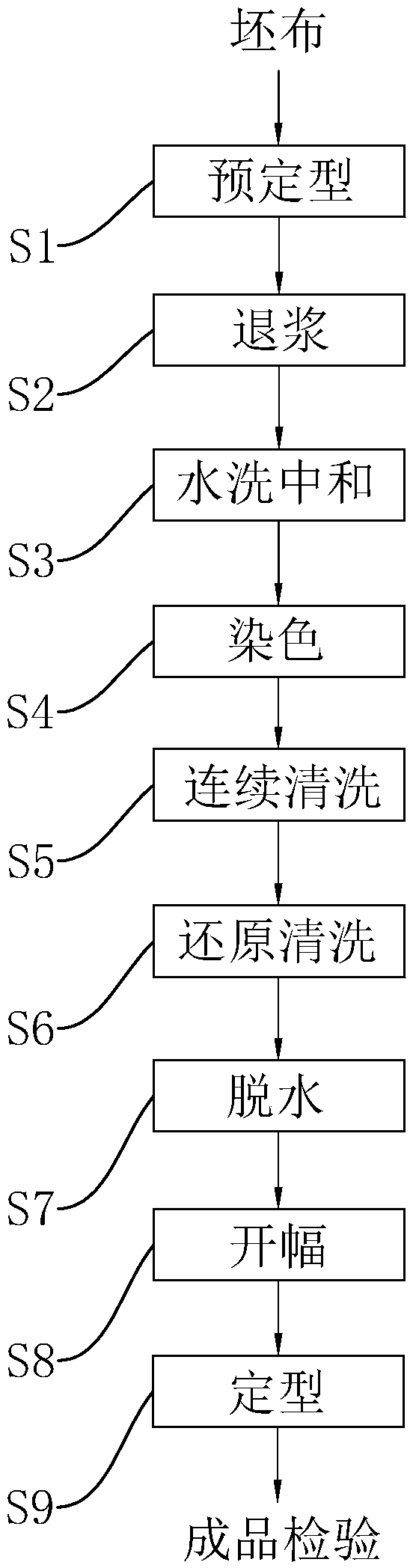

Dyeing technology of polyester knitted fabric

InactiveCN109267382AGood water solubilityPrevent subsidenceDry-cleaning apparatus for textilesDyeing processPolyesterSolubility

The invention relates to the technical field of textile processing, and discloses a dyeing technology of a polyester knitted fabric. The dyeing technology comprises the following steps: performing S1presetting, S2 desizing, S3 neutralization with washing, S4 dyeing, S5 continuous cleaning, S7 dehydration, S8 scutching and S9 setting on a grey fabric, wherein a used dye in S4 dyeing is prepared from the following substances in percentage by mass: 5-10 percent of monoazo dye, 3-7 percent of sodium lignosulfonate, 3-7 percent of OP-10, 15-25 percent of levelling agent, 1-3 percent of acetic acidand 48-73 percent of water. In the dyeing technology, by adding the sodium lignosulfonate and the OP-10 as dyeing auxiliaries in the dye, the monoazo dye has good water solubility; and meanwhile, theOP-10 enables the monoazo dye to be wet and prevents molecules in the monoazo dye from coagulation and then sedimentation, so that the polyester fabric is higher in colour fastness after being dyed,and the colour and lustre of the dyed polyester fabric are more lasting under the natural environment of exposing to sun and wind.

Owner:绍兴华星丝织印染有限公司

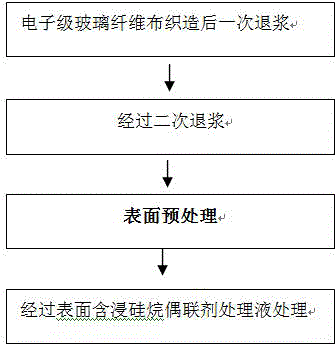

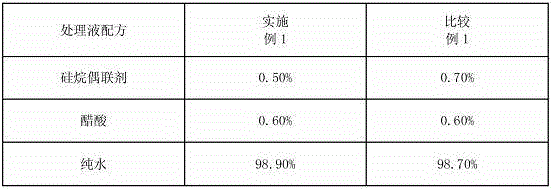

Electronic grade glass fiber cloth surface treating agent and method

ActiveCN103556461ARapid infiltrationImprove heat resistanceFibre treatmentSynthetic resin layered productsGlass fiberPolymer science

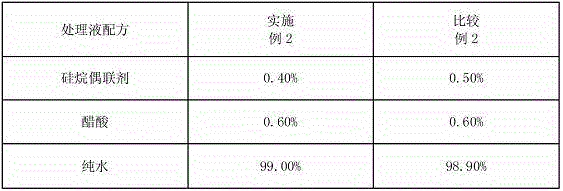

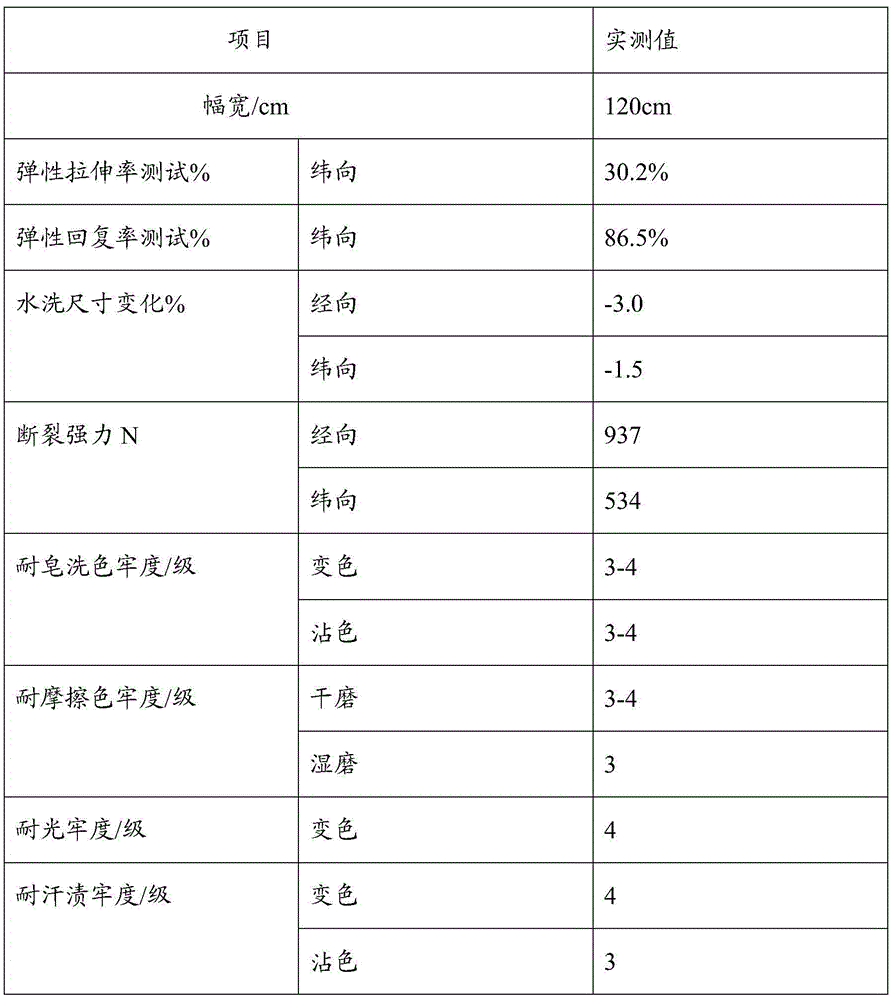

An electronic grade glass fiber cloth surface treating agent and a method relate to surface treatment technology of insulation reinforced material electronic grade glass fibre cloth applied to printed circuit boards. The method comprises that: desized electronic grade glass fibre cloth subjected to two-time desizing is sent for pretreatment, specifically a silane coupling agent pretreatment fluid with a weight percent of 0.03%-0.1% is employed for spraying processing on the cloth surface, and then the electronic grade glass fibre cloth enters an immersion trough for immersion processing by the silicane coupling agent treating agent provided by the invention. The formula of the silane coupling agent treating agent comprises: 0.03%-0.50% by weight of the silane coupling agent (with a general formula Y(CH2)nSiX3), 0.1%-1.7% of acetic acid, and the balance deionized water. The electronic grade glass fiber cloth surface treating agent is economical and efficient; and the electronic grade glass fiber cloth, which is produced by combining the electronic grade glass fiber cloth surface treating agent and the pretreatment technology, possesses the advantages of high heat resistance, ion migration resistance, relatively fast resin wetability and the like.

Owner:SHANGHAI GRACE FABRIC

Desizing pretreatment method for high-density nylon fabric

InactiveCN103132305ASoft and uniform forceAvoid damageFibre typesDry-cleaning apparatus for textilesFiberHigh density

The invention discloses a desizing pretreatment method for high-density nylon fabric. The desizing pretreatment method comprises two steps including a cold heaping procedure, and an efficient open-width desizing and washing procedure, wherein a working solution used in the cold heaping procedure comprises the components of caustic soda liquid, a degreaser TF-115C, and a four-in-one refining agent TF-170 which are processed for 30-39 hours under the conditions that the liquid containing rate is 28-31% and the temperature is 22-25 DEG C; and a working solution used in the efficient open-width desizing and washing procedure comprises the components of an oxidation desizing agent TF-127K, a sequestering agent TF-133A, a degreaser TF-126 and caustic soda liquid, and the open-width desizing and washing can be carried out under the conditions that the temperature is 96-100 DEG C and the machine speed is 75-83m / min. The desizing pretreatment method has the advantages that the treatment can be carried out at normal temperature by a reasonable design and allocation of each auxiliary component of the working solution in the cold heaping and desizing washing procedures; the damage to fiber is small; the dyeing reproducibility and the primary success rate can be obviously improved; and the technical problems of high energy consumption, large loss of the fabric, and difficult guarantee on subsequent dyeing quality caused by an unreasonable pretreatment process of the common nylon fabric are well solved.

Owner:SHENGHONG GRP CO LTD

High-count bamboo-fibril fabric. and dyeing-finishing technological method thereof

The present ivnention relates to a high-count bamboo fibril fabric dyeing and finishing process includes the following steps: using the blended yarn made of bamboo fibril and its carrier water-soluble fibre in which the content of bamboo fibril is 60-74% and water-soluble fibre content is 26-40% and weaving them into gray goods, then making said gray goods undergo the process of after-finishing process to remove water-soluble fibre to obtain the invented high-count bamboo fibril fabric. Its concrete dyeing and finishing process includes the procedures: fabric-turning and sewing-up, singeing, desizing and boiling, primary bleaching, merceizing, re-bleaching, biological treatment, softening and spreading and pre-shrinking.

Owner:ZHUZHOU XUESONG FLAX IND

Dyeing and finishing technology for cotton/viscose ammonia multi-fiber stretch fabric employing bio-enzyme low-temperature treatment

ActiveCN105544227ASoft touchFluffyMercerising of indefinite length fabricsTextile storage in wounded formTextile printerRoom temperature

The invention belongs to the technical field of textile printing and dyeing, and in particular relates to a dyeing and finishing technology for a cotton / viscose ammonia multi-fiber stretch fabric employing bio-enzyme low-temperature treatment. The dyeing and finishing technology comprises a pretreatment technology, a dyeing technology and a post-finishing technology. According to the printing and dyeing method for a cotton / viscose stretch fabric, room-temperature stacked desizing is carried out by a biologic desizing enzyme; and an efficient refining agent is selected, so that various pretreatment indexes are effectively improved; soft and fluffy hand feeling of the cotton / viscose stretch fabric is achieved; energy conservation and emission reduction are achieved through low-temperature desizing; potential drapes in the fabric processing process are eliminated; and smooth production of the dyeing procedure is facilitated. A light-colored fabric is dyed from pad dyeing, and a dark fabric is subjected to cold pad-batch dyeing, so that an improvement of various color fastness indexes is met; dyeing process parameters are optimized; and uniform and full dying material quality is obtained. A softening agent is preferably adopted in fabric post-finishing, so that the hydrophilicity of the fabric is achieved; and the wearing comfort of the fabric is achieved.

Owner:HUAFANG

Printing anti-sliding process for ultrathin full-cotton wrinkle fabric

ActiveCN103061105AEnsure complete removalGuaranteed uniformityBiochemical fibre treatmentSingeingColour fastnessTextile printer

The invention discloses a printing anti-sliding process for an ultrathin full-cotton wrinkle fabric, which belongs to the field of printing and dyeing processes. The invention aims to provide the printing anti-sliding process for the ultrathin full-cotton wrinkle fabric with soft handle, a high strength retention rate, perfect print register and good seam slippage. The process comprises the following steps: singeing, loose desizing, bleaching and wrinkling, printing, ageing, loose wrinkle recovery and washing and anti-sliding finishing. With the process provided by the invention, uniformity during dyeing can be guaranteed, the fabric is allowed to have good seam slippage performance and a good printing effect, softness and color fastness of the fabric are guaranteed, and uniform wrinkling is realized.

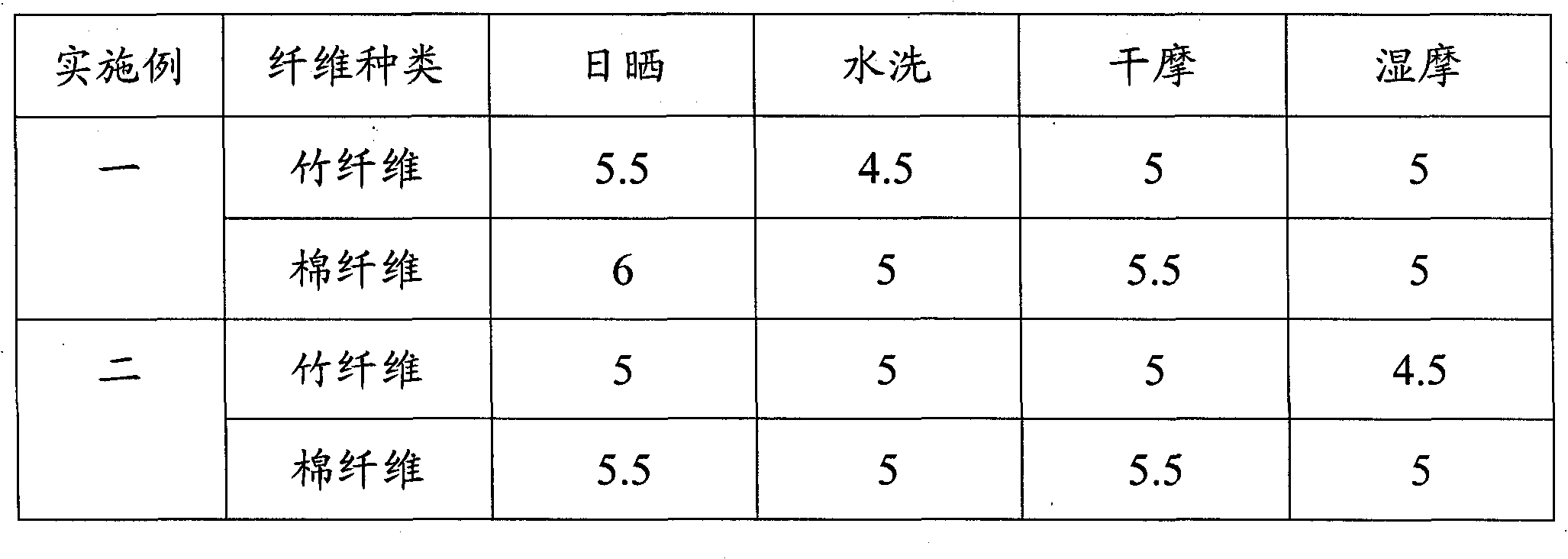

Dyeing process of bamboo-cotton fiber blended fabric

InactiveCN102433782AShort processReduce processBiochemical fibre treatmentBleaching apparatusCotton fibreProcess conditions

The invention discloses a dyeing process of a bamboo-cotton fiber blended fabric. The process comprises the six steps of enzyme desizing and scouring, singeing, oxygen bleaching, dehairing enzyme finishing, dyeing and postprocessing. The dyeing process has short flow and few working procedures. Through precisely selecting a working solution desizing, scouring and padding prescription and a working solution oxygen bleaching and padding prescription, precisely controlling the process conditions of desizing and scouring as well as oxygen bleaching and reasonably selecting a dyeing and color fixing postprocessing process, the color fastness of the bamboo-cotton fiber blended fabric is improved, the consistency of the fastnesses of bamboo fiber and cotton fiber is kept, and the service life of the blended fabric is prolonged.

Owner:无锡市联盛印染有限公司

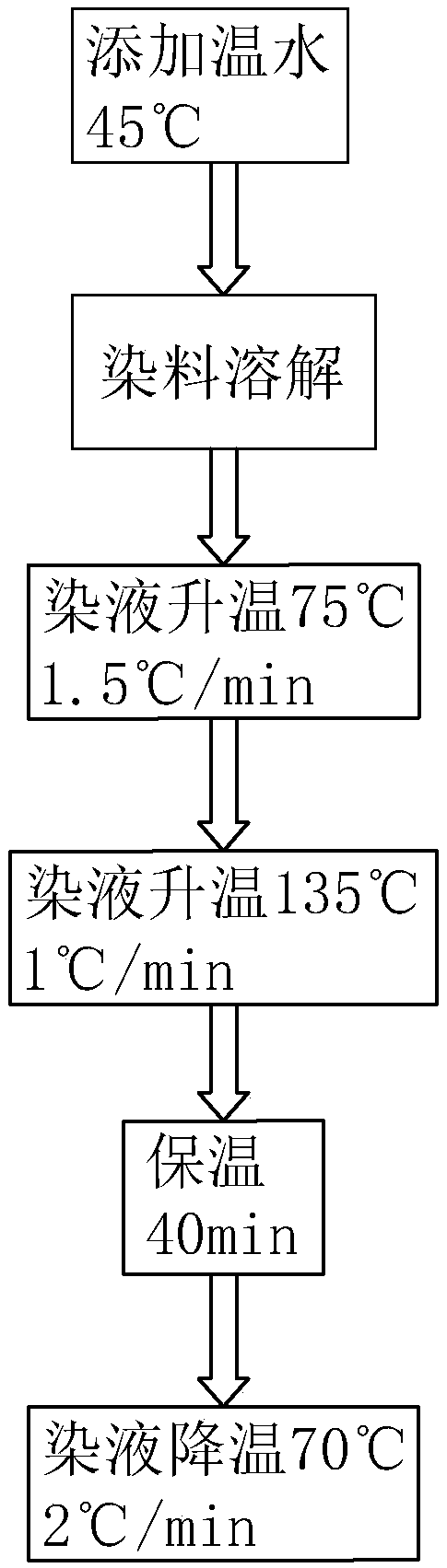

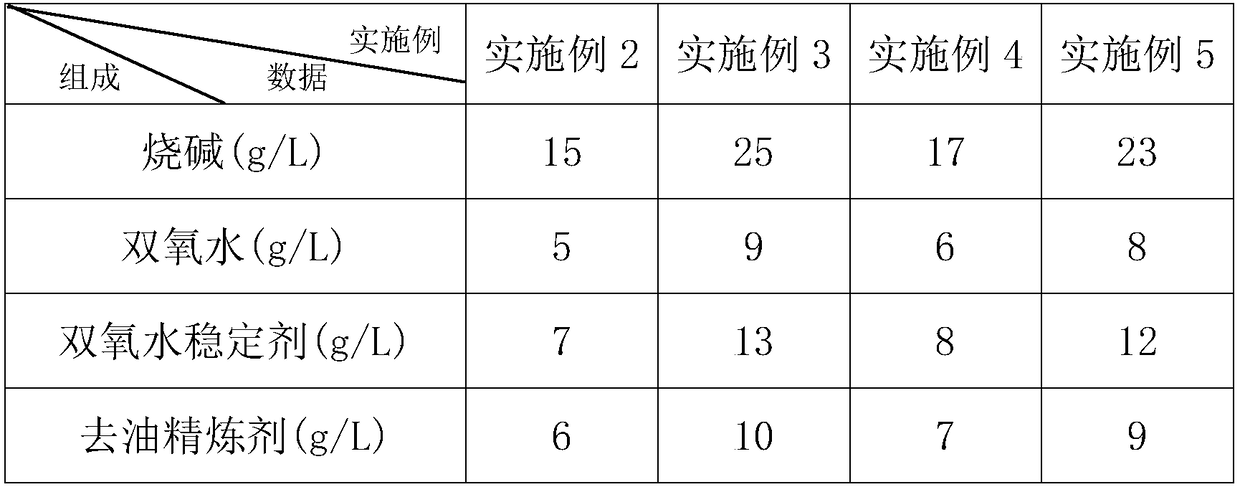

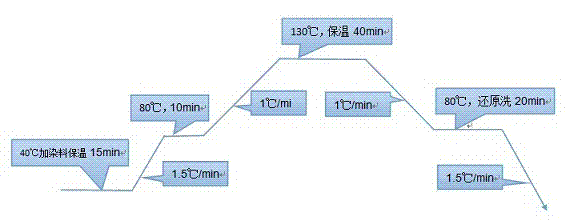

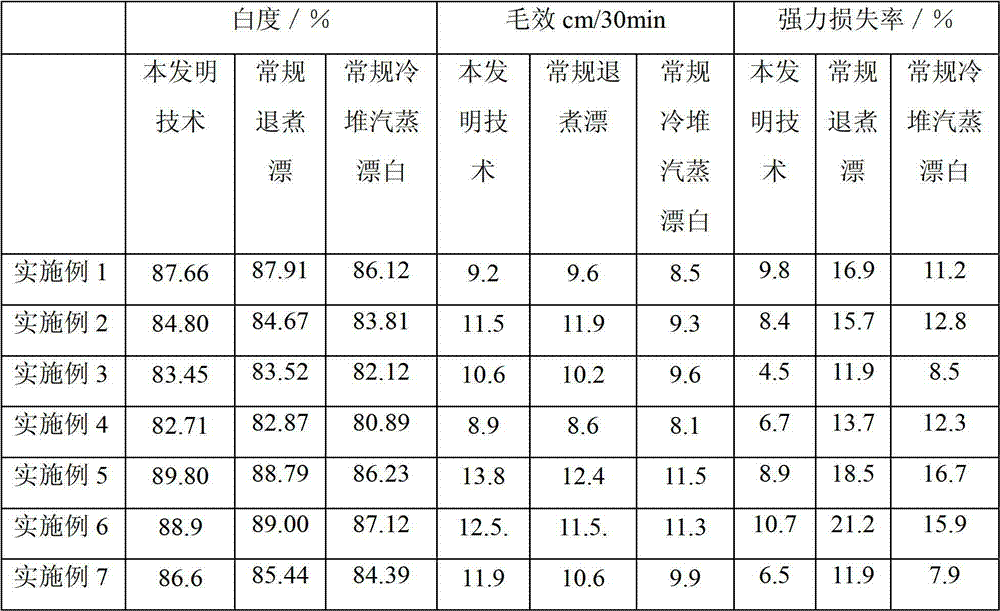

Desizing, boiling, bleaching and dyeing alkaline single bath dyeing method and adjuvant composition used thereby

InactiveCN101440581AIncrease productivityDry-cleaning apparatus for textilesBleaching apparatusAdjuvantSewage

The invention discloses a one alkaline bath dyeing method integrating desizing, cloth refining, bleaching and dyeing. The method comprises: (a) a step of raw material mixing, during which an auxiliary composition is added with stirring at 40 DEG C and dye is added with stirring five minutes later; (b) a step of integrated desizing, cloth refining, bleaching and dyeing, in which 1 to 3 heat-preservation stages are set according to fabric type, the dyeing temperature is 130 DEG C, the total time is kept within 30 to 60 minutes according to the fabric type, and the rate of temperature rise is adjusted within a range from 1 to 2DEG C / min; (c) a step of cooling to 70 DEG C and discharging sewage after dyeing and adding a washing agent for washing; and (d) a step of water washing. The invention also discloses an auxiliary composition used by the method. The auxiliary composition comprises an auxiliary agent for desizing, cloth refining and bleaching and an accelerating agent, wherein the auxiliary agent for desizing, cloth refining and bleaching is a surfactant compound of which the principle component is sodium persulfate, and the accelerating agent is a surfactant compound of which the principle component is 14,16-polyoxyethylene alkyl ether. The invention is applicable to dacron and has the advantages of simple processing, high quality, high efficiency, low pollution and so on.

Owner:SHENGHONG GRP CO LTD

Preparation method for multicolour section linnet

The invention relates to linnet, particularly to a preparation method for multicolour section linnet. The preparation method comprises the following steps: spinning of linnet yarn, beaming in batches, slashing and combing bobbins, drafting and denting, weaving, desizing and refining, dying, heat shaping, calendering and full decatizing. The multicolour section linnet prepared with the preparation method has the multicolor effect, is smooth in hand feeling, ventilate, moisture conductive, and excellent in elasticity.

Owner:富丽达集团控股有限公司

Method for preparing composite modified starch

The invention discloses a method for preparing composite modified starch. The method comprises the following steps: 1) slurrying a raw material, namely a natural starch, and adjusting pH value of the natural starch by caustic alkali; 2) adding an oxidizing agent into the starch slurry to carry out oxidation modification treatment; 3) filtering, washing and drying the starch slurry into a powdered semi-finished product for standby; 4) spraying a catalyst and composite phosphate into the semi-finished product to carry out dry modification treatment; and 5) cooling the semi-finished product to a temperature of between 25 and 35 DEG C, adjusting the pH value of the semi-finished product to 6-8 to carry out secondary drying, and crushing the product to obtain a finished product. The product obtained by the method greatly improves dispersibility of the starch slurry, can be easily stewed with stable slurry, cannot be frozen, can completely replace the chemical synthetic slurry to size pure coarse cotton and medium yarns, and can replace the synthetic slurry in large scale to size high grade cotton yarns and union yarns, thereby greatly reducing yarn sizing cost, facilitating desizing, and contributing to environment-friendly waste water treatment.

Owner:GUANGDONG HUIMEI STARCH SCI & TECH

Silk floss colored woven fabric preparation method

InactiveCN101187176ABright colorSoft touchDry-cleaning apparatus for textilesBleaching apparatusYarnEngineering

The invention discloses a process for preparing silk-cotton colored fabric, which comprises: cotton yarn dyeing, silk dyeing, weaving in the gripper loom, cotton yarn desizing, silk degumming and bleaching. The silk-cotton colored fabric made through the process is a colored fabric woven by warp thread cotton and weft thread silk, wherein although the silk content is about 15 % of the fabric, the fabric has a more bright color and a soft hand feeling, humidity and air ventilation and comfort compared with the traditional pure cotton colored cloth and at the same time has lower price and is easier for finishing, thereby the fabric is widely welcomed by the consumers. Besides, the process for preparation has a reasonable design.

Owner:TIANJIN TF SUNNY GARMENT

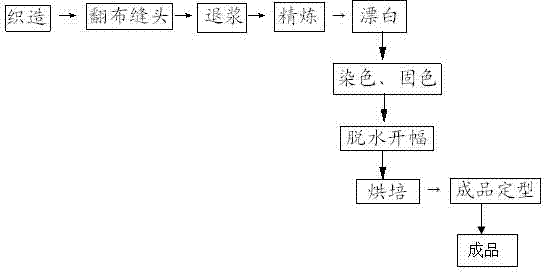

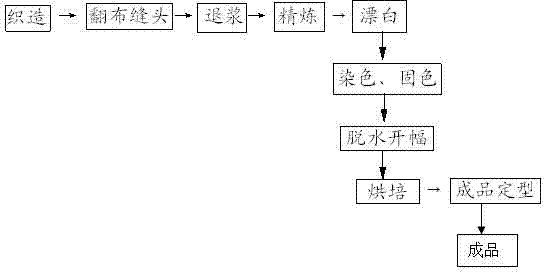

Antibacterial fabric and processing method thereof

InactiveCN102477640ASoft textureGood warmth retentionBiochemical fibre treatmentBleaching apparatusMicroorganismCarbon fibers

The invention relates to an antibacterial fabric and a processing method thereof. The fabric comprises the following raw materials in percentage: 10%-30% nano bamboo charcoal fiber, 10%-30% of nano silver fiber and 40%-80% of terylene fiber. The fabric has the processing processes of weaving, cloth turning and end stitching, desizing, refining, bleaching, dyeing, color fixing, dewatering scotching, baking and finished product sizing. In the antibacterial fabric and the processing method thereof disclosed by the invention, through reasonable material selection and careful process arrangement, the fabric has a flexible texture, a good warm keeping effect and ideal permeability and hygroscopicity, and more important, the fabric has a special antibacterial effect and can kill bacteria, moulds, spores, fungi and other microorganisms contacted with the fabric.

Owner:CHANGSHU JINDE KNITTING

Antibacterial, deodorant and moisture-absorbing child bed sheet shell fabric and production technology thereof

The invention discloses antibacterial, deodorant and moisture-absorbing child bed sheet shell fabric. The shell fabric is formed by weaving weft yarn and warp yarn by the ratio of 1:2 in a twilled mode, wherein the warp yarn is formed by blending super-absorbent hollow polyester fibers and bamboo pulp fibers by the ratio of 1:1, and lycra fibers are adopted as the weft yarn. The production technology includes the steps of weaving, singeing, desizing, oxygen bleaching, pretreating, dyeing, soaping, mercerizing, tentering and shaping, preshrinking and detecting. The antibacterial, deodorant and moisture-absorbing child bed sheet shell fabric absorbs water, dries quickly and is breathable, moisture permeable, uvioresistant, antibacterial, deodorant and resistant to acid, alkaline, sweat, dry cleaning and abrasion, and service life is prolonged.

Owner:南通梭子纺织科技有限公司

One-bath low-temperature desizing, refining and bleaching pretreatment method of cotton woven fabric

ActiveCN104233826AShort process flowAvoid strong damageBiochemical fibre treatmentBleaching apparatusPretreatment methodDesizing

The invention discloses a one-bath low-temperature desizing, refining and bleaching pretreatment method of cotton woven fabric. The method comprises the steps of adding 1-5g / L of bio-enzyme for desizing, 3-8g / L of bio-enzyme for refining, 2-6g / L of hydrogen peroxide, 1-4g / L of a bleach activator, 2-6g / L of a chelating agent and 0.5-4g / L of an auxiliary agent into a one-bath system, adjusting the pH value to 6.0-7.5, putting the fabric into a dye bath according to the bath ratio of 1: (10-100), heating up to 50-70 DEG C at the speed of 0.5-2 DEG C / minute, carrying out heat preservation for 40-120 minutes, finally, washing the fabric with water, and drying or airing. The bio-enzyme for desizing, the bio-enzyme for refining and the bleach activator are added into a pretreatment system of the cotton woven fabric, so that the processes of desizing, refining and bleaching of the cotton woven fabric can be carried out in one bath at a low temperature, the strength damage to the fabric is avoided, the technological process of the dyeing and finishing pretreatment of the cotton woven fabric can be shortened, the energy consumption is reduced, and the production efficiency is increased.

Owner:HENAN INST OF ENG

Polyester taslan fabric moisture absorbing and sweat releasing dyeing and finishing process

InactiveCN104762837AFully absorbedGuaranteed fastnessSucessive textile treatmentsHeating/cooling textile fabricsPolyesterPulp and paper industry

The invention discloses a polyester taslan fabric moisture absorbing and sweat releasing dyeing and finishing process. The production process includes: cold stacking, open-width desizing, in-cylinder finishing scouring, overflow dyeing, reducing cleaning, finishing, cylinder discharge, dehydration width opening, and shaping. Specifically, the finishing adopts moisture absorbing and sweat releasing, overflow washing is conducted after reducing cleaning, and a moisture absorbing and sweat releasing assistant is added after washing the fabric surface clean to carry out finishing. The process ensures sufficient textile desizing, makes the capillary effect of the taslan fabric reach the best state, so that the textile can fully absorb the moisture absorbing and sweat releasing assistant to enhance the moisture absorbing and sweat releasing effect, and the fabric can be resistant to washing. The process avoids or reduces the generation of watermark problem, and has very good practical effect.

Owner:WUJIANG FUHUA WEAVING

Non-steaming cold pad-batch process of all-cotton or polyester-cotton fabric

ActiveCN102817240AAvoid damageHigh energy consumptionBiochemical fibre treatmentDry-cleaning apparatus for textilesPolyesterProcess engineering

The invention discloses a non-steaming cold pad-batch process of all-cotton or polyester-cotton fabric. The non-steaming cold pad-batch process includes the steps of firstly, padding the all-cotton or polyester-cotton fabric in desizing, refining and bleaching-bathing liquid which is aqueous solution of alkaline agents, additives, Wantefu PLA (polylactic acid) and 100% hydrogen peroxide; secondly, using a rolling machine to roll the fabric padded in the step 1, and batching up after wrapping; and thirdly, washing and drying the fabric batched in the step 2. The non-steaming cold pad-batch process provides moderate conditions, production time is shortened evidently, fabric damage is reduced, energy consumption is lowered, efficiency is improved, treatment of printing and dyeing wastewater is facilitated, and the treated fabric is better than that treated by the traditional cold batch process in terms of impurity removal, wettability and whiteness.

Owner:BEIJING CTA TEX CHEM

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com