Patents

Literature

2531 results about "Colour fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Colour fastness is a term—used in the dyeing of textile materials—that characterizes a material's colour's resistance to fading or running. The term is usually used in the context of clothes. In general, clothing should be tested for colorfastness before using bleach or other cleaning products.

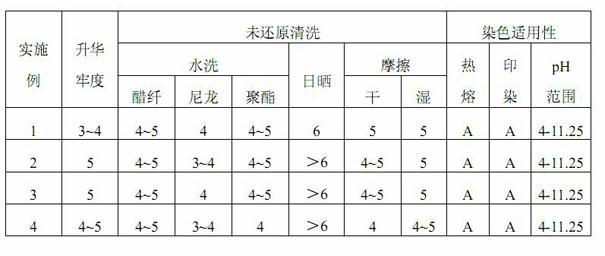

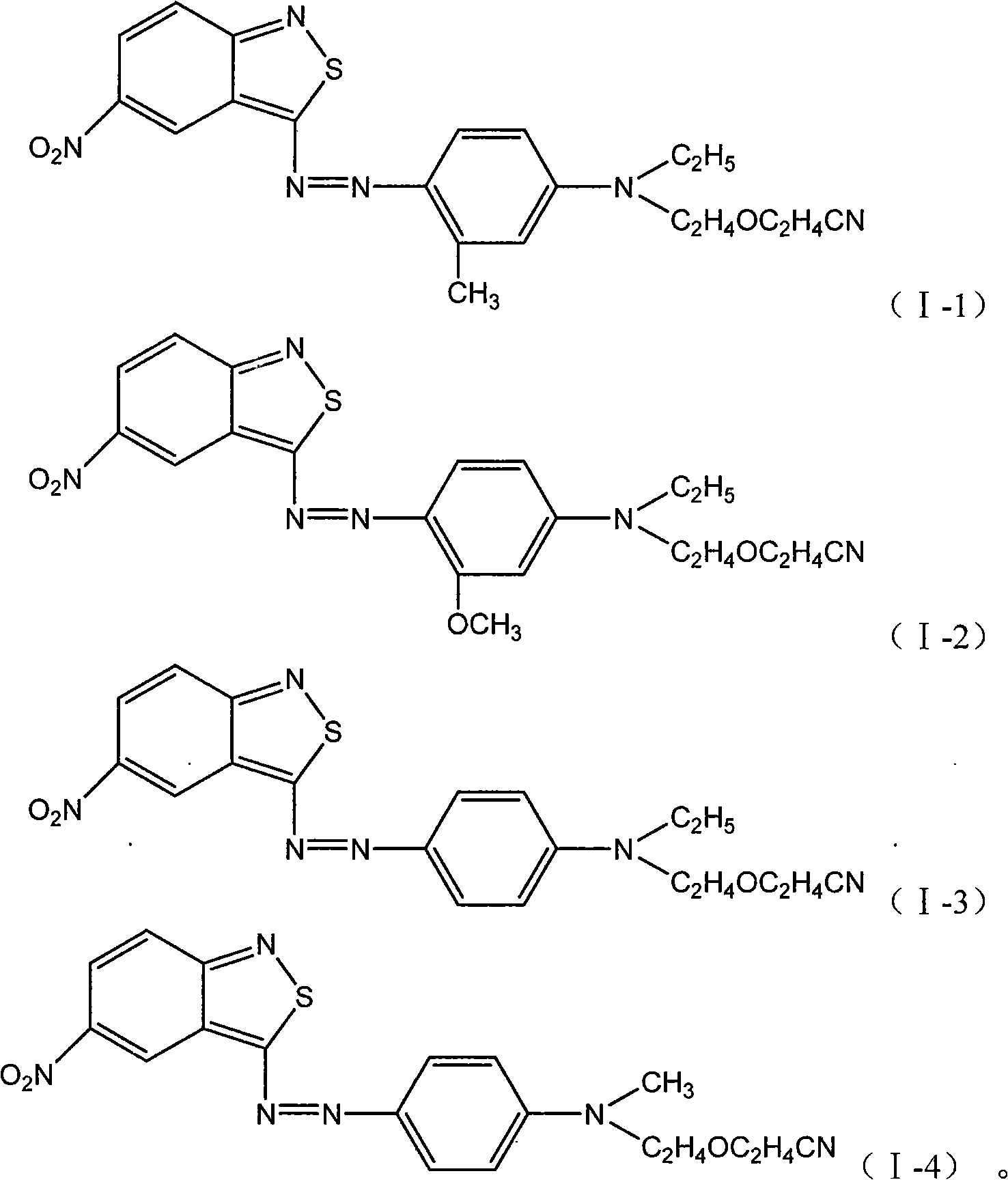

Alkali-resistant disperse dye complex

The invention discloses an alkali-resistant disperse dye complex, and relates to disperse blue BR-based alkali-resistant disperse dye complexes suitable for dyeing in a wide pH range. The complex comprises (1) alkali-resistant disperse dye blue complex, or (2) alkali-resistant disperse dye blue complex, or (3) alkali-resistant disperse dye black complex. The disperse dye complex of the invention has good dispersibility, dyeing stability and good reproducibility, and can effectively avoid the problems of stains, flaws, chromatic aberration and the like caused by dirt such as slurry, oil stain,wax and the like on fibers; and the pH value has wide range during use, dyeing can be performed in the pH range of 4.0 to 11.25, the dyed fabrics have full hue, and the dyed fabrics with predominant color fastness performance such as washing fatness, daylight fastness and the like can be obtained without reduction clearing.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

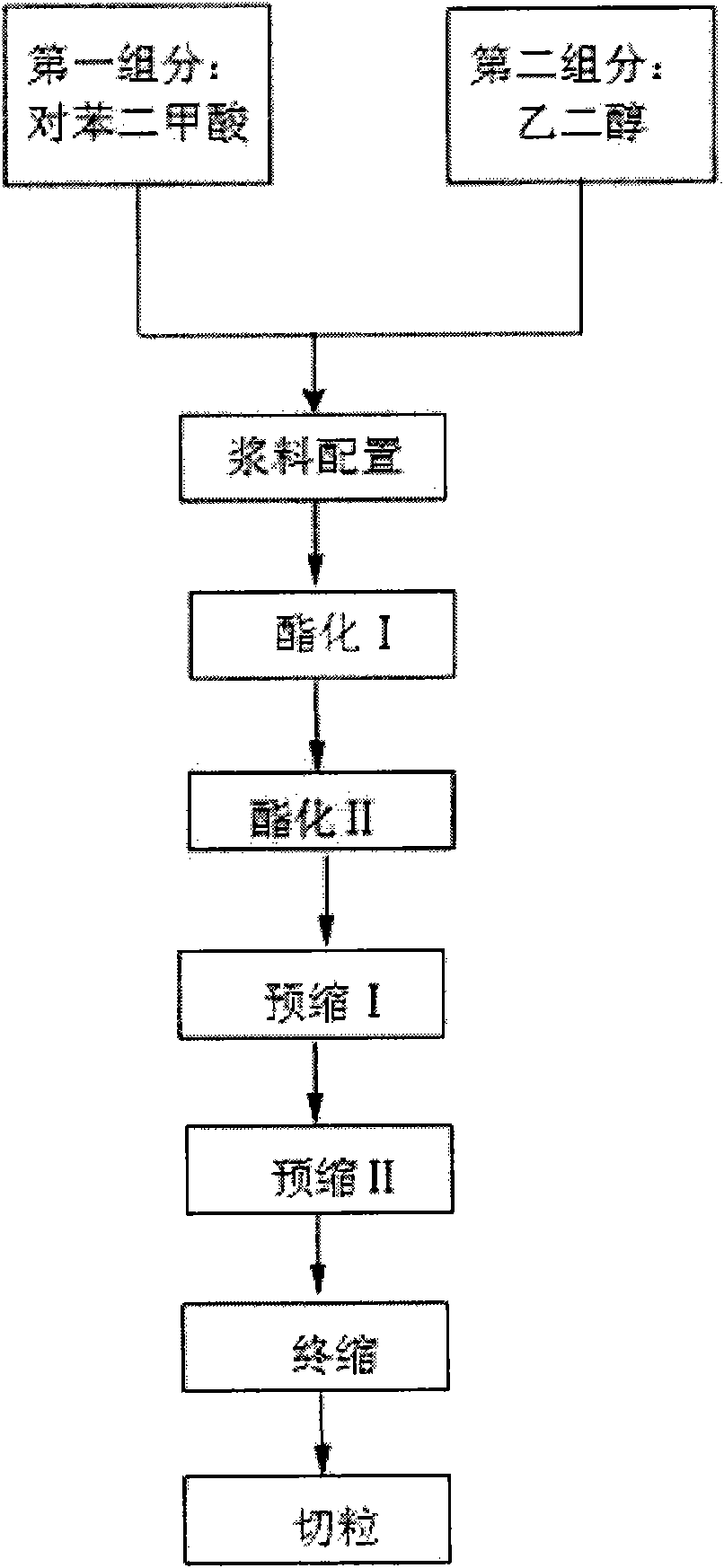

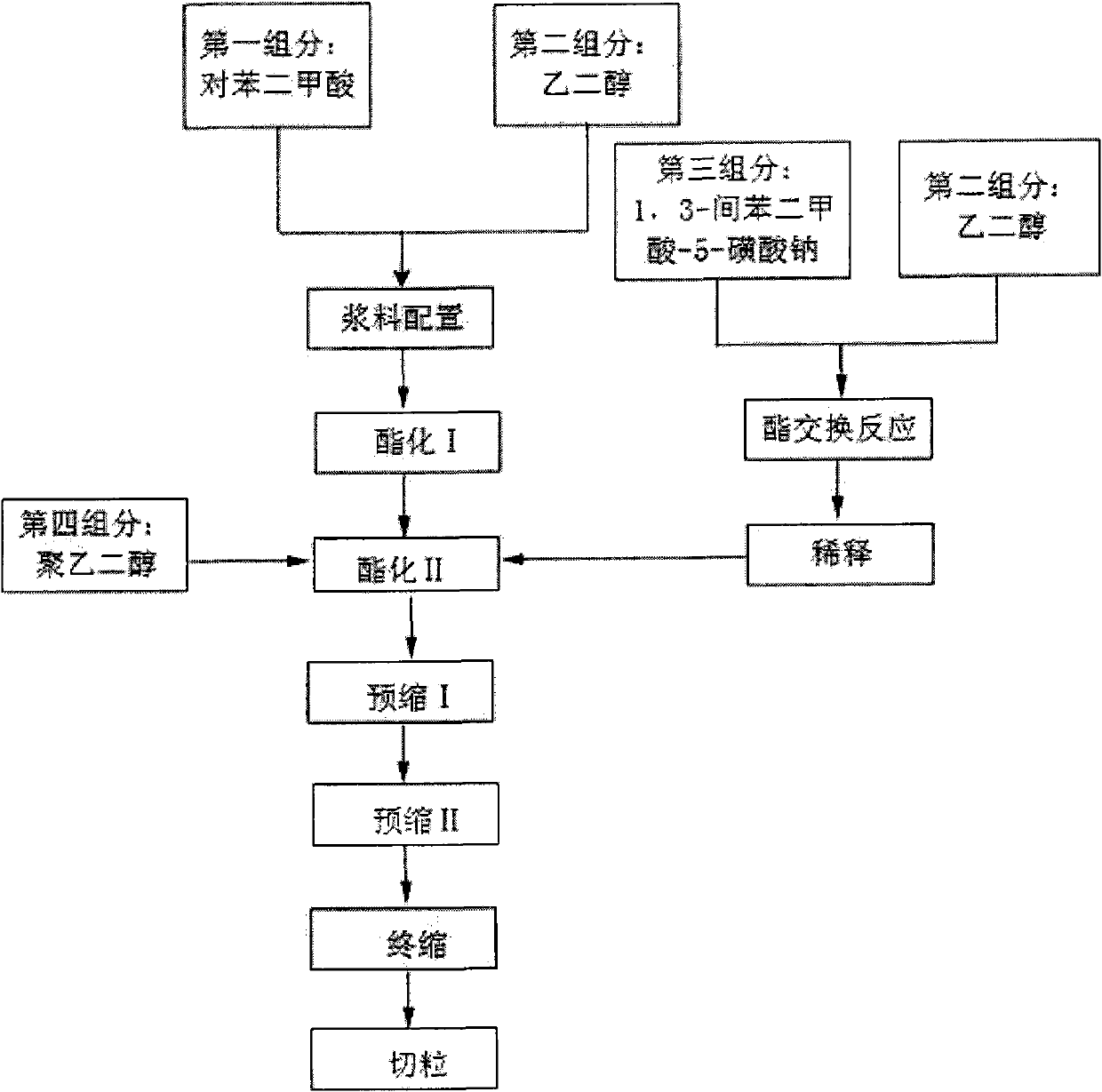

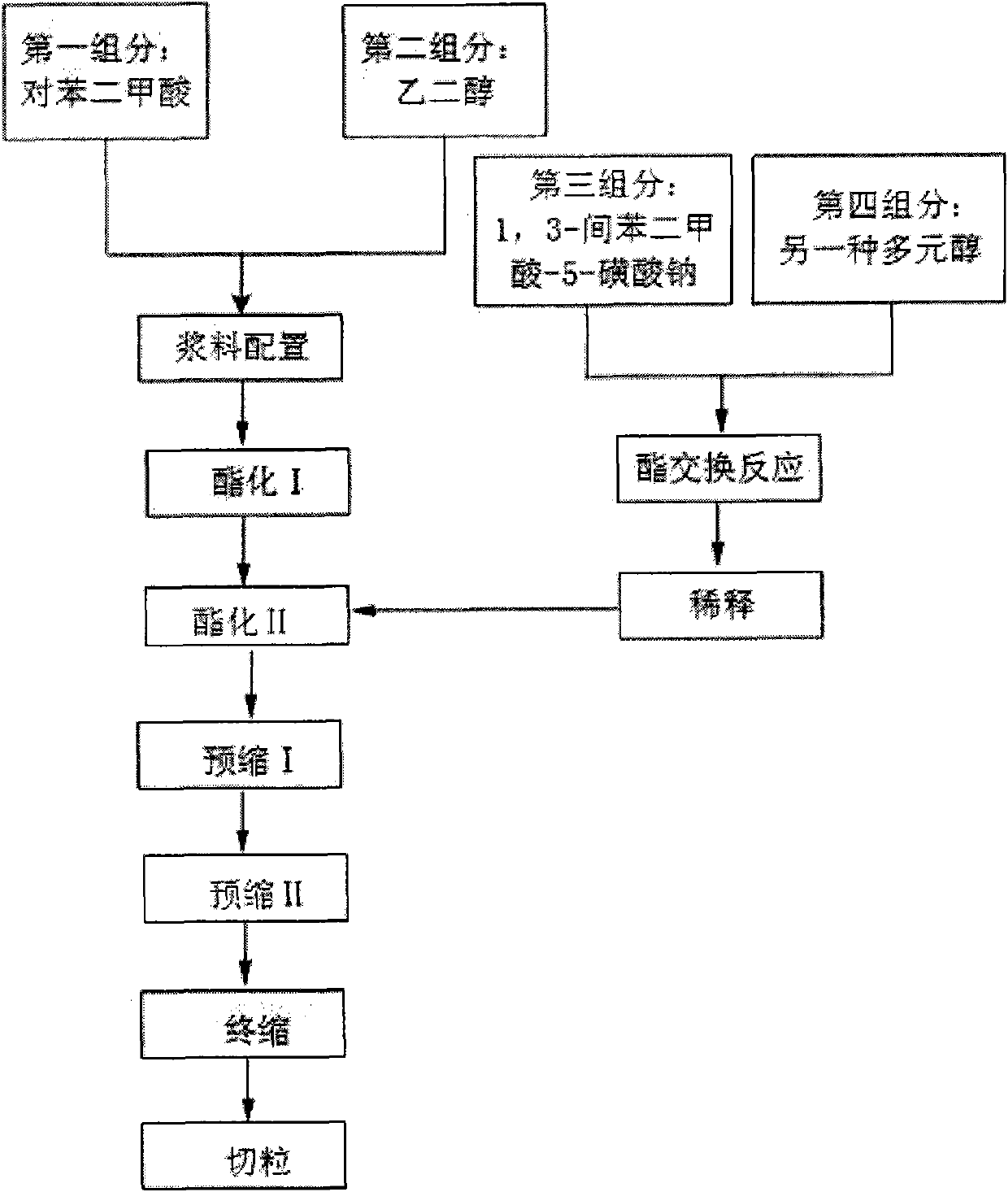

Preparation method of polyol copolyester

InactiveCN102086261AIncrease the chances of participating in a responseAchieve mass ratioDyeing processSlurryPhotochemistry

The invention discloses a preparation method of polyol copolyester. The preparation method comprises the following steps of carrying out slurry preparation, esterifying I, esterifying II, pre-condensing I, pre-condensing II, final condensing and pelletizing on terephthalic acid and glycol. The preparation method also comprises: carrying out ester exchange reaction on 1,3-isophthalic acid-5-sodium sulfonate and another polyol; diluting with the glycol, and then performing the esterifying II. In the preparation method, 1,3-isophthalic acid-5-sodium sulfonate and another polyol react in advance, thereby increasing the reaction probability of another polyol and ensuring that another poyol can reach the required mole ratio in a finished product. The preparation method is mainly applied to production of dye modified polyester by using various dihydric alcohols at normal temperature and normal pressure. The modified polyester is dyed by mainly using anode pigment, the used dye chromatograph is more than that of common polyester, dye-uptake rate can reach above 99%, colour fastness reaches 4-5 grade of European standard, and the color is more flamboyance and beautiful. When filament yarns are subjected to spinning, full-package rate is up to 95%-100%.

Owner:SHANGHAI DEFULUN CHEM FIBER

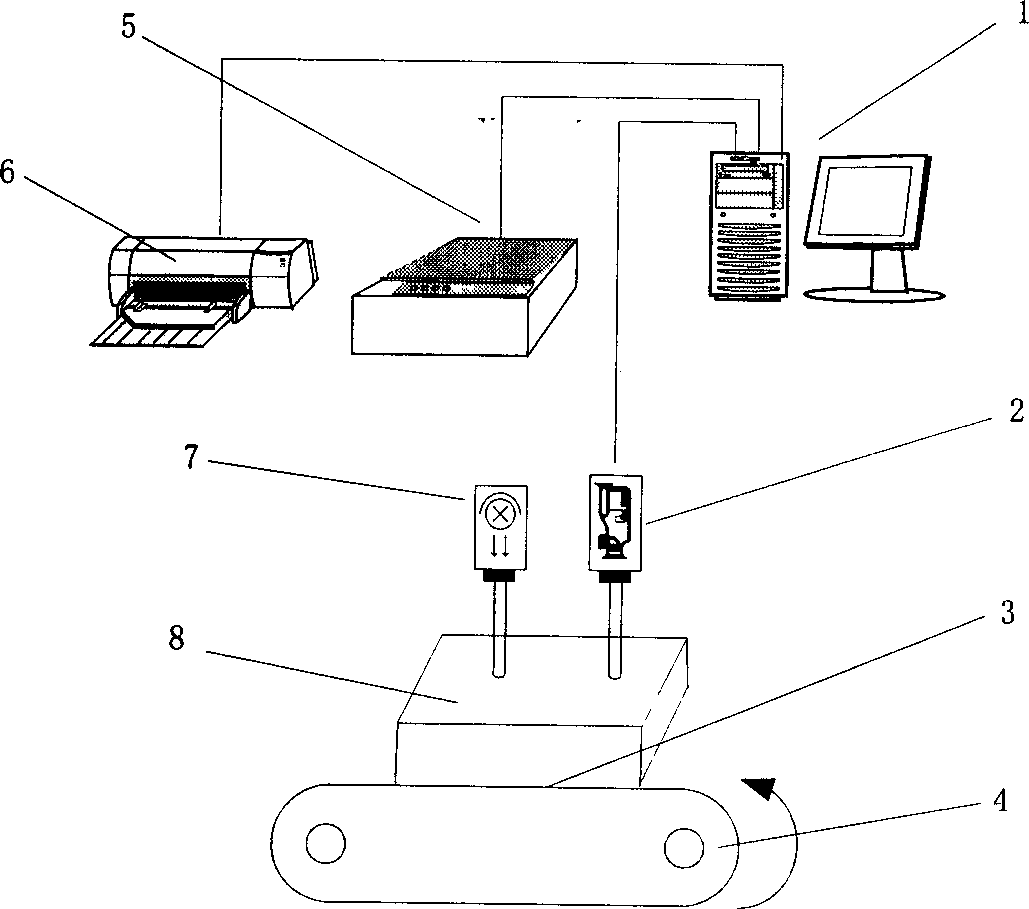

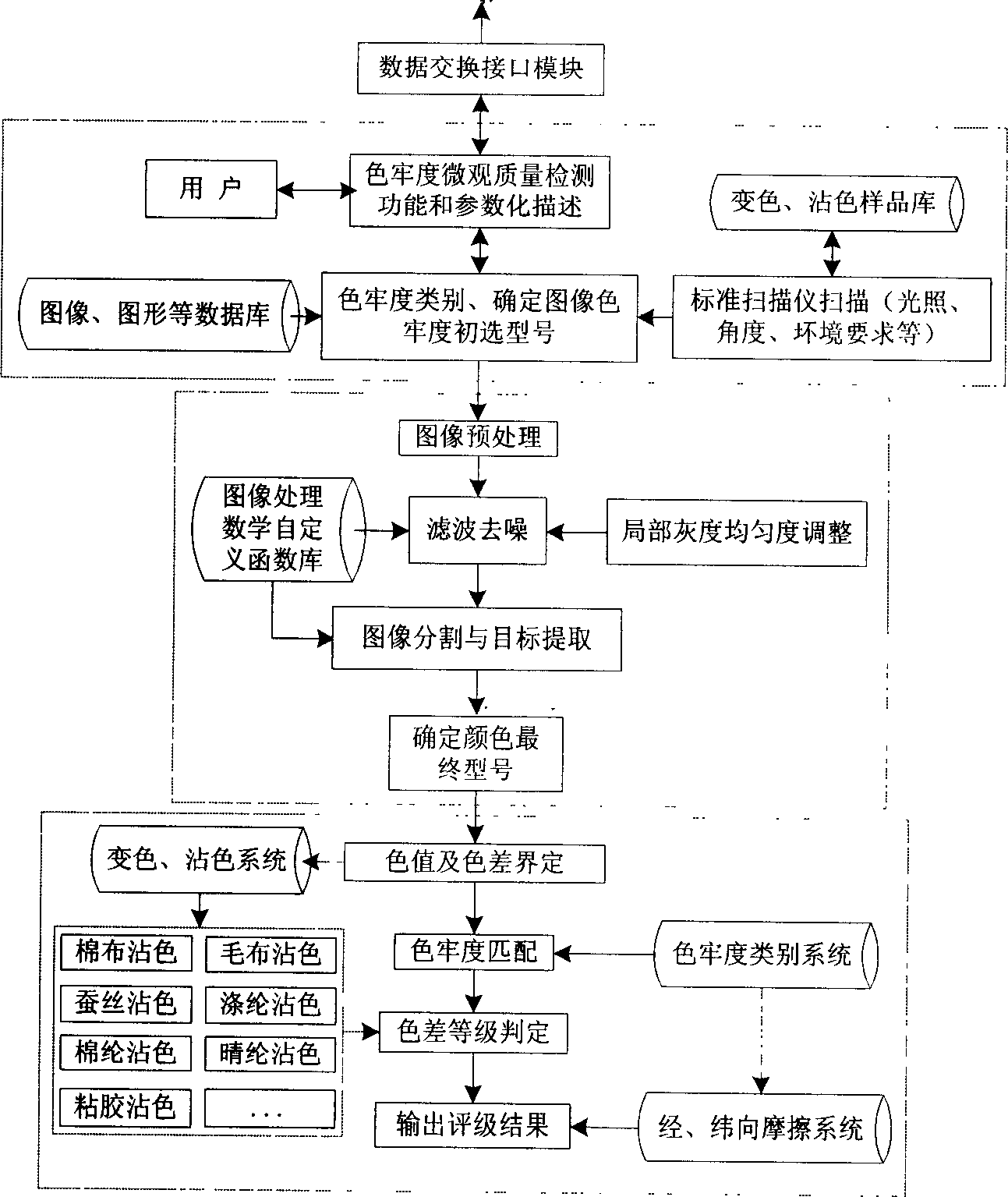

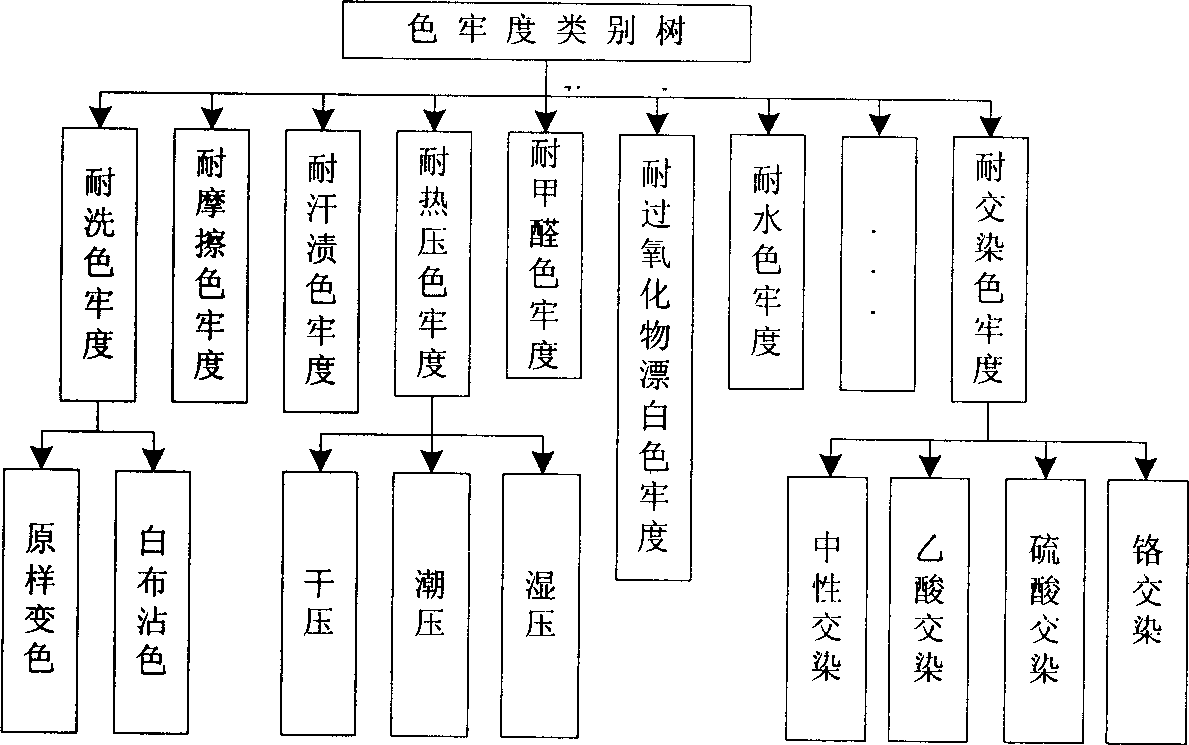

Grade test method and device of textile colour fastness colour difference

InactiveCN1793844AReduce distractionsThe result is accurateTextile testingColor/spectral properties measurementsColour fastnessUltimate tensile strength

A evaluating and testing device of fabric color difference and color fastness is composed of scanner, illuminating system, video camera equipment, image collecting unit and computer for processing and identifying evaluation ¿C test image of fabric color difference and color fastness. The method of evaluating and testing fabric color difference and color fastness is also disclosed.

Owner:JIANGSU UNIV OF SCI & TECH

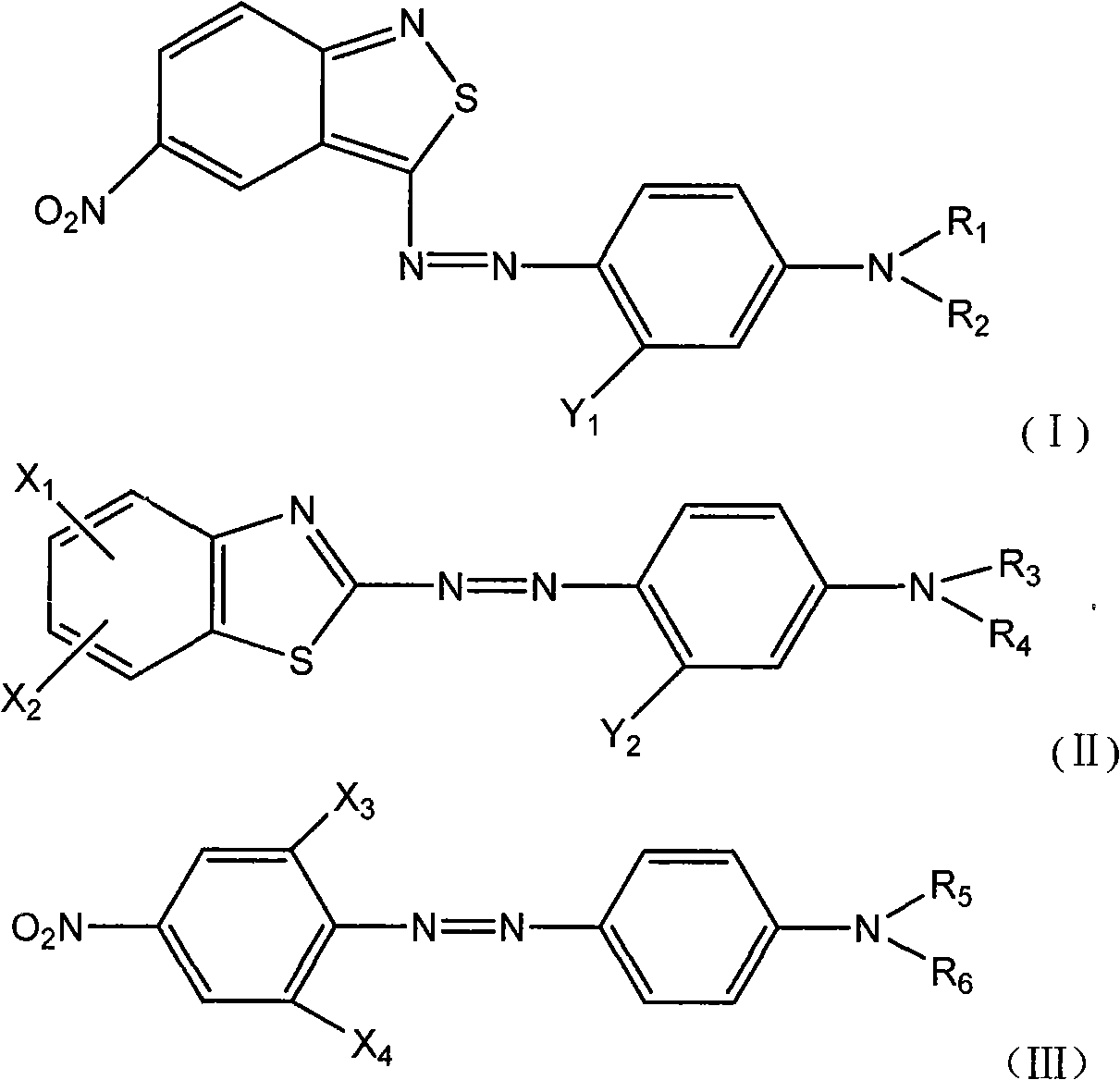

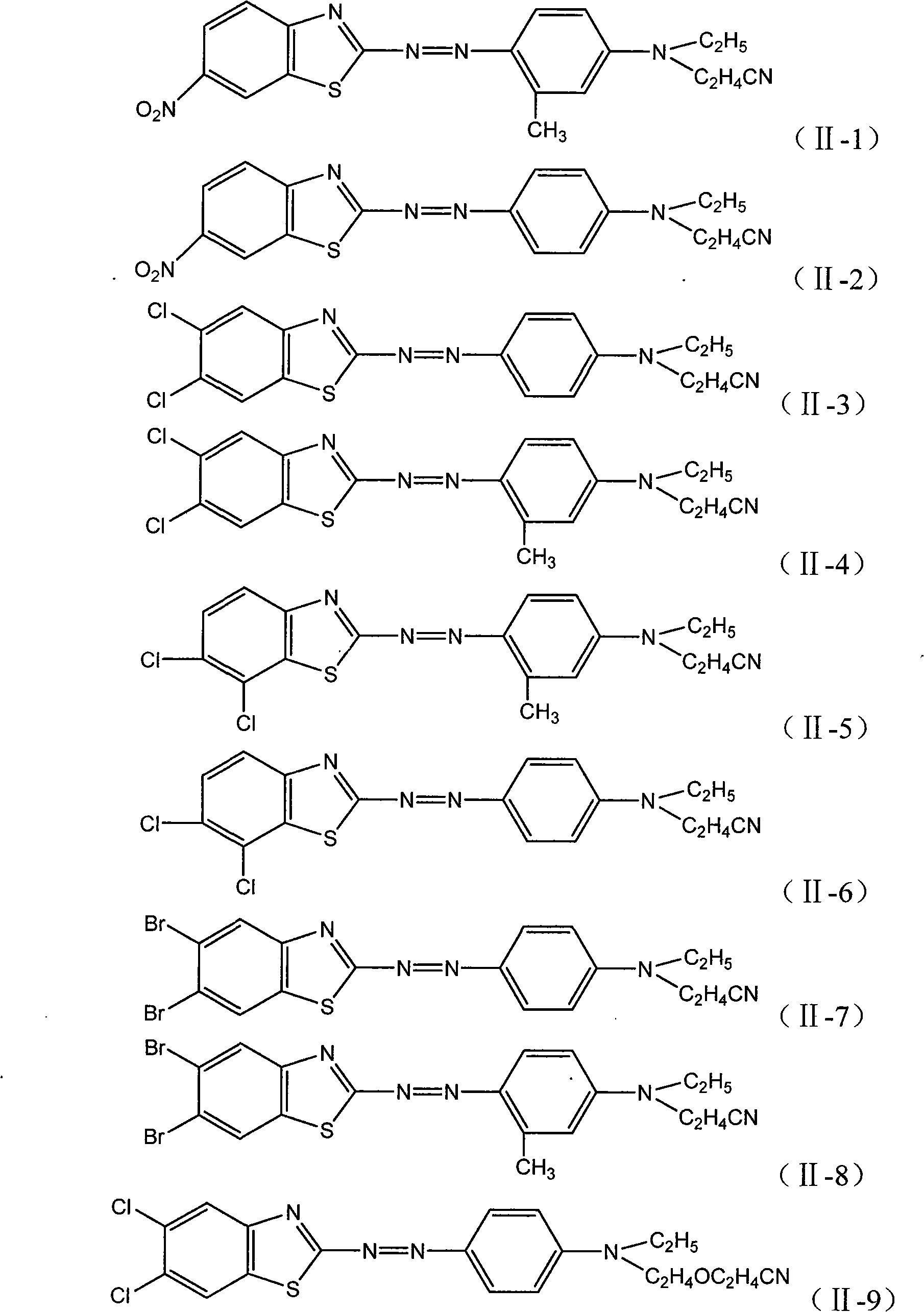

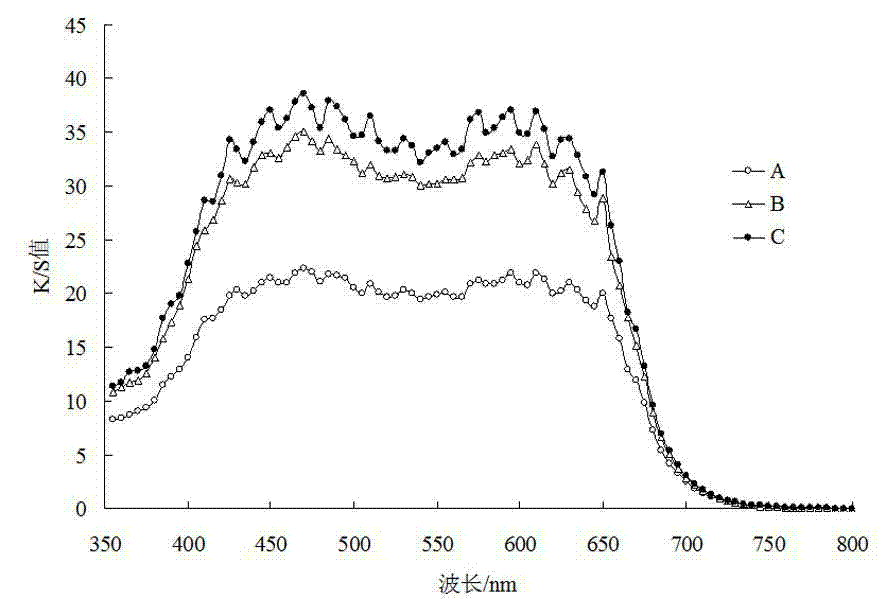

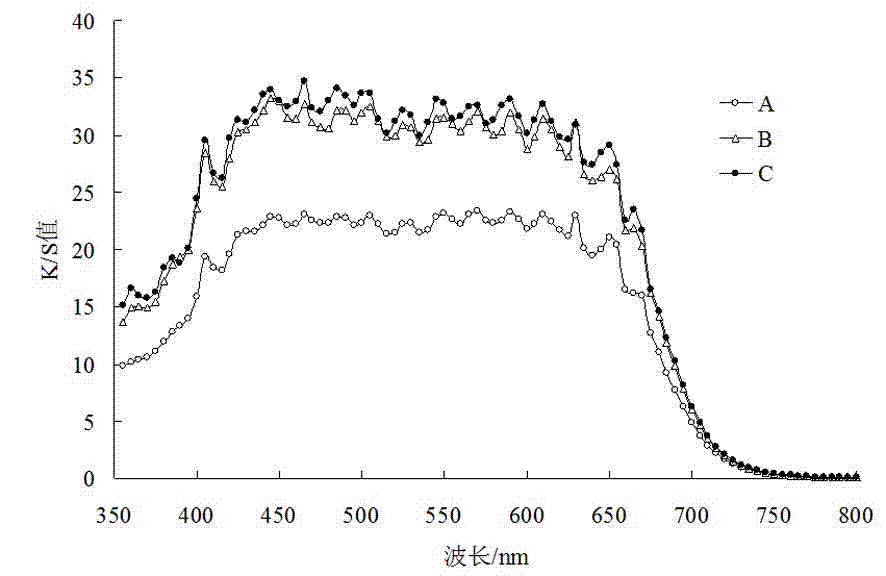

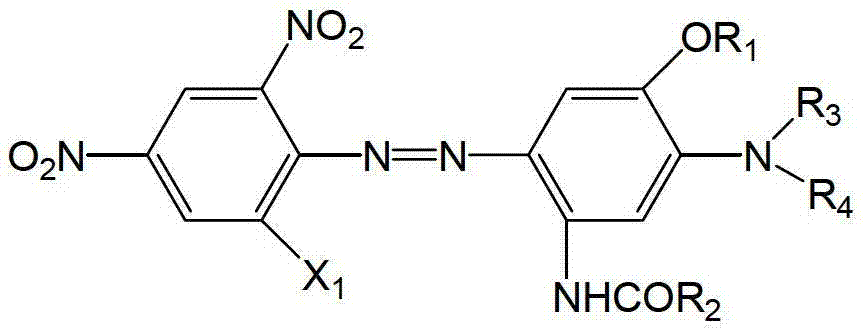

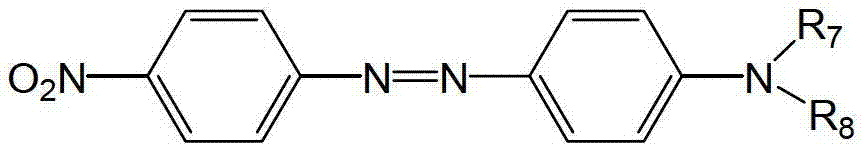

Disperse dye composition suitable for basic dyeing

ActiveCN101649129AAvoid problems such as contaminationGuaranteed stabilityOrganic dyesDyeing processDisperse dyeColour fastness

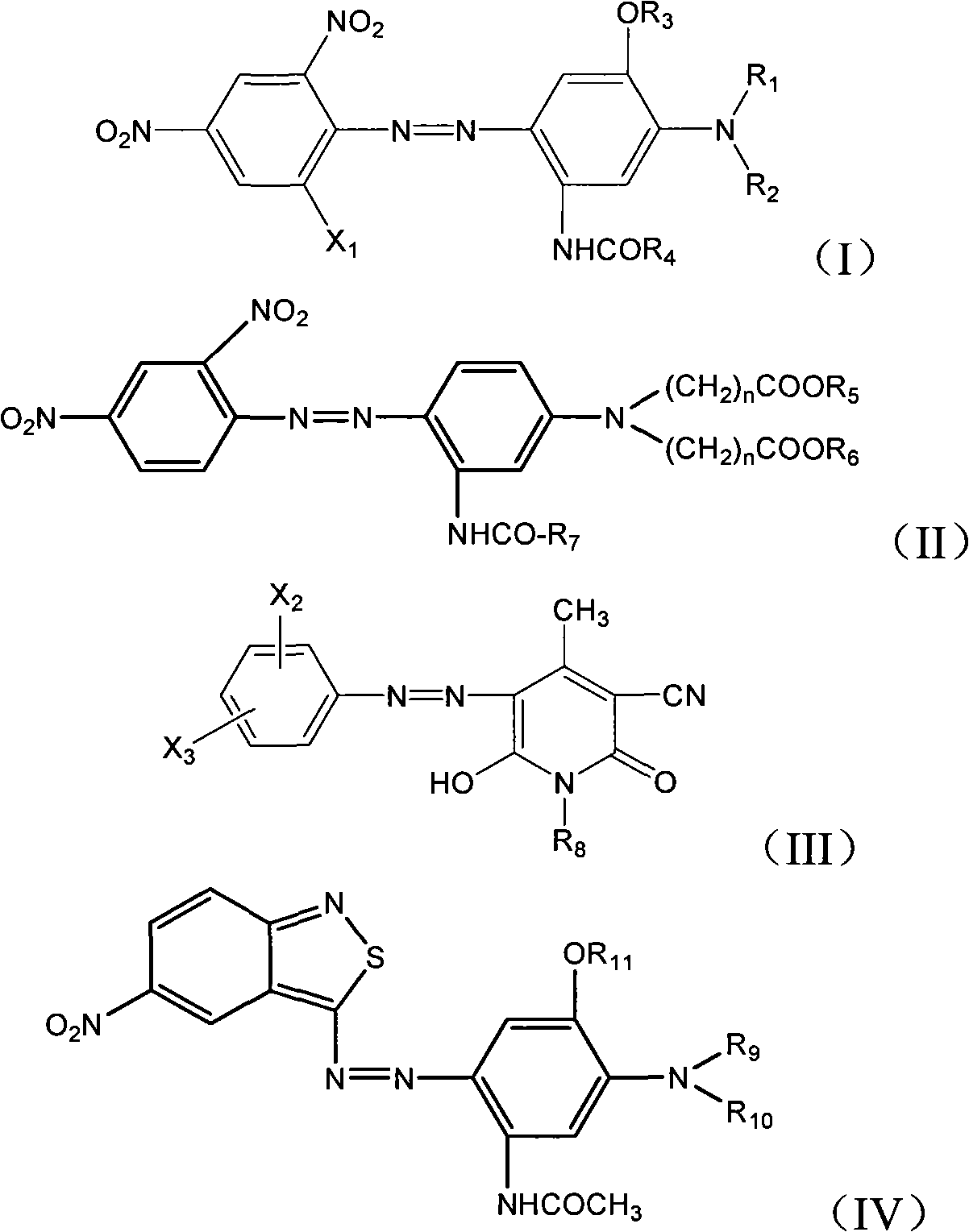

The invention provides a disperse dye composition suitable for basic dyeing, mainly comprising the following raw materials in percentage by weight: 40-95 percent of one or a plurality of blue dyeing components A with a structural formula (I), 1-25 percent of one or a plurality of red dyeing components B with a structural formula (II) and 4-50 percent of one or a plurality of orange dyeing components C with a structural formula (III). The disperse dye composition has a wide dependency range of pH values, and can dye in a pH value ranging from 4.0 to 10; dyed and woven fabrics with predominant color-fastness performance, such as full hues, washing fastness, and the like, can be obtained.

Owner:浙江龙盛染料化工有限公司

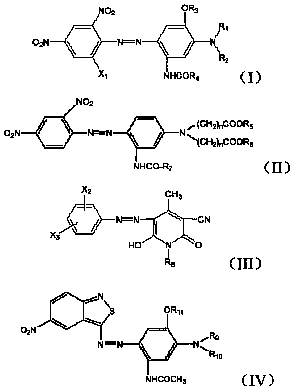

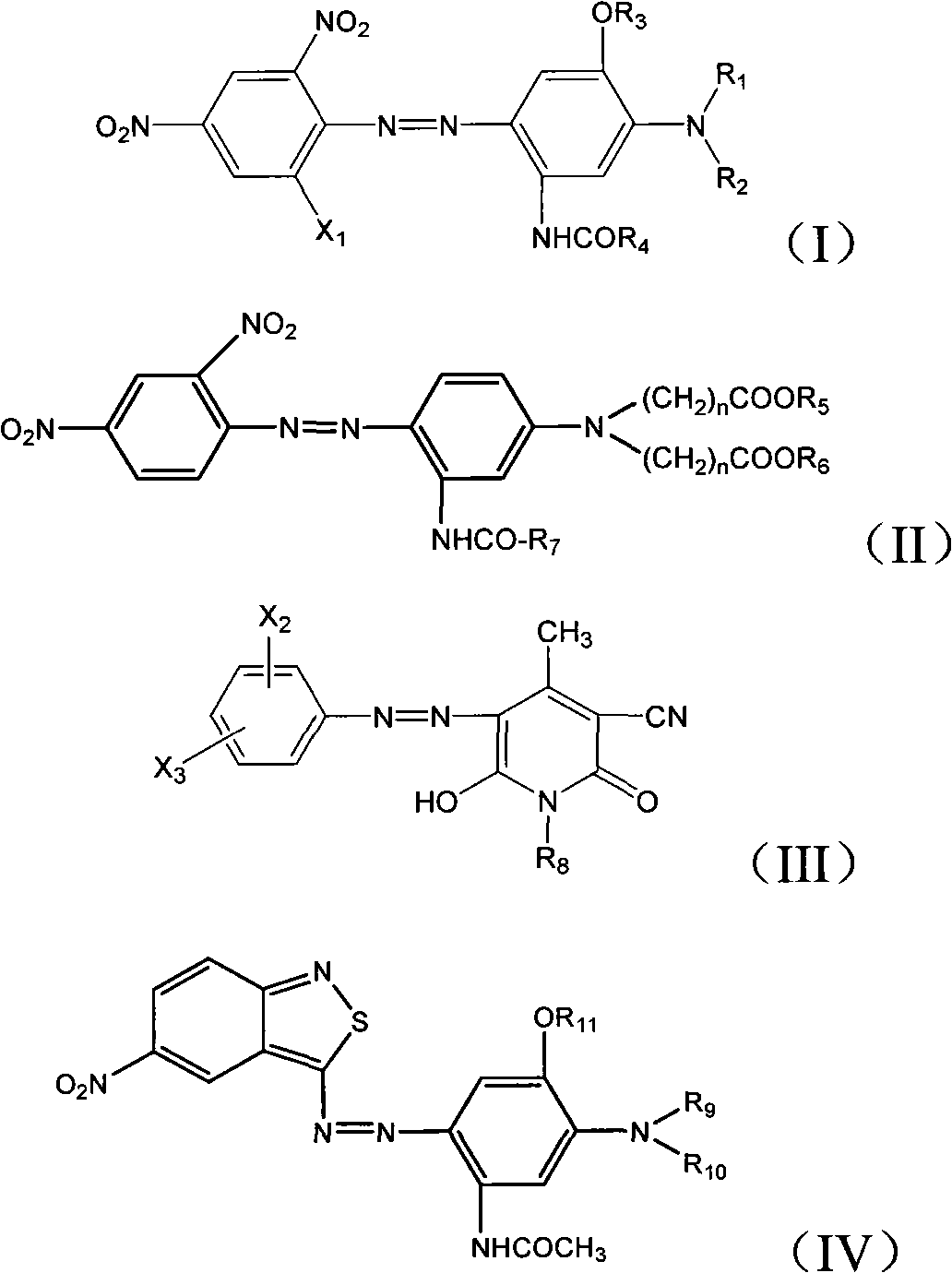

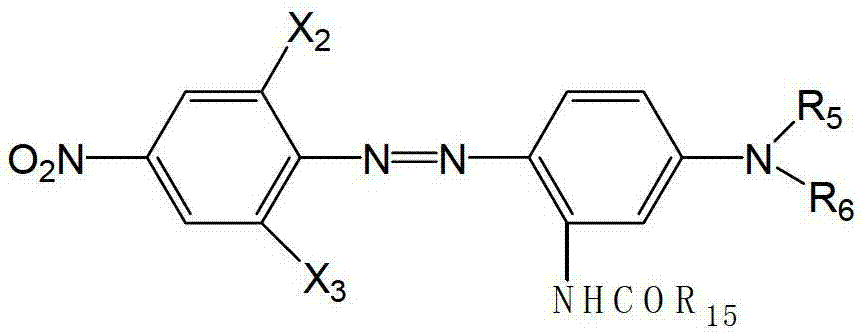

Black disperse dye composition

The invention provides a black disperse dye composition, which mainly comprises: one or more blue components A of which the structure is shown as a formula (I), one or more red components B of which the structure is shown as a formula (II), one or more yellow components C of which the structure is shown as a formula (III) and one or more green components D of which the structure is shown as a formula (IV). Based on the components A, components B, components C and components D, the mass fraction of the components A is 35-85%, the mass fraction of the components B is 1-25%, the mass fraction of the components C is 5-45% and the mass fraction of the components D is 1-35%. When the hydrophobic fiber material is dyed by using the dye prepared from the black disperse dye composition, black fabric with excellent color fastness especially excellent washing fastness after heat treatment can be obtained by adjusting the proportion of different components.

Owner:SHANGYU JINGUAN CHEM IND +2

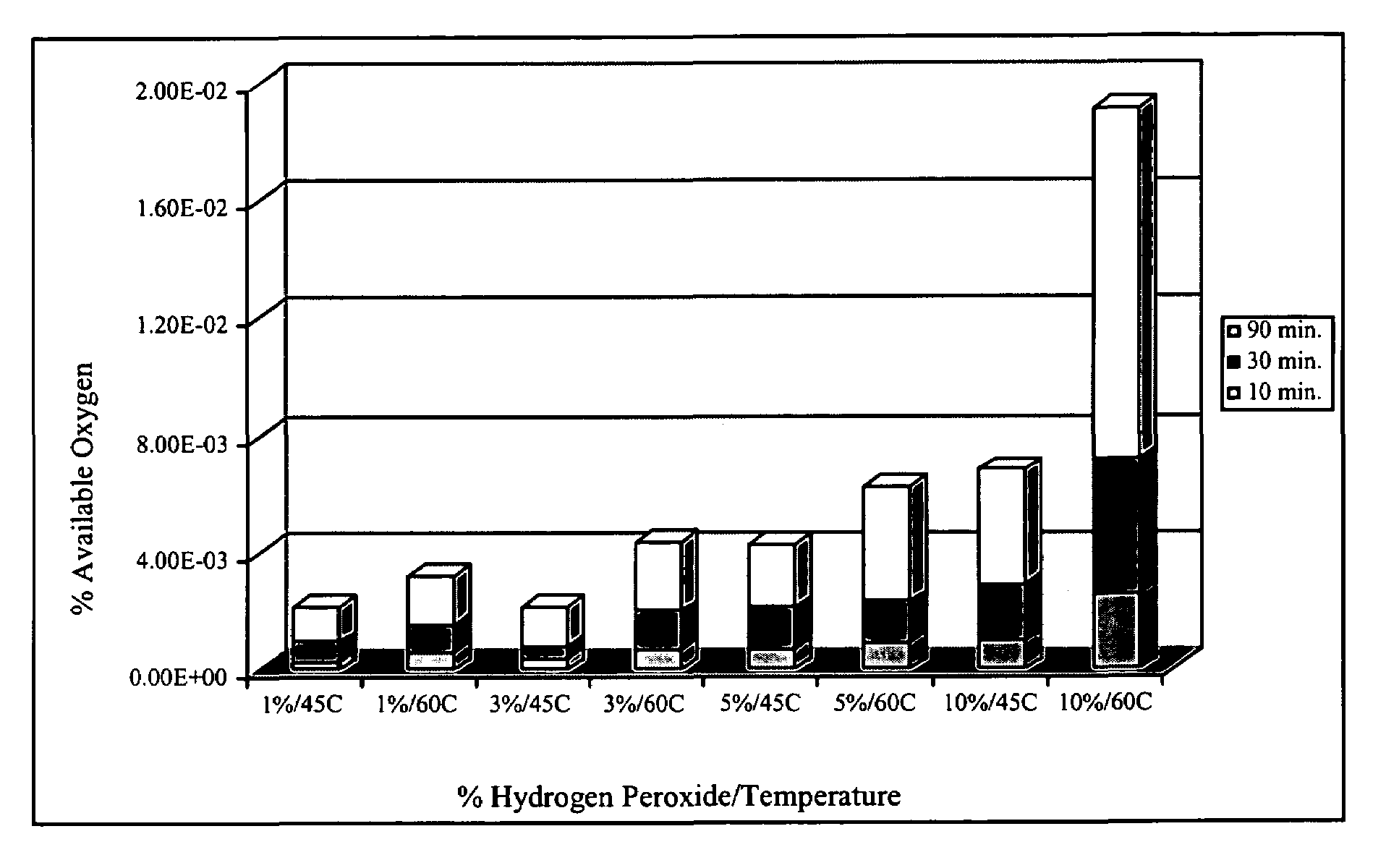

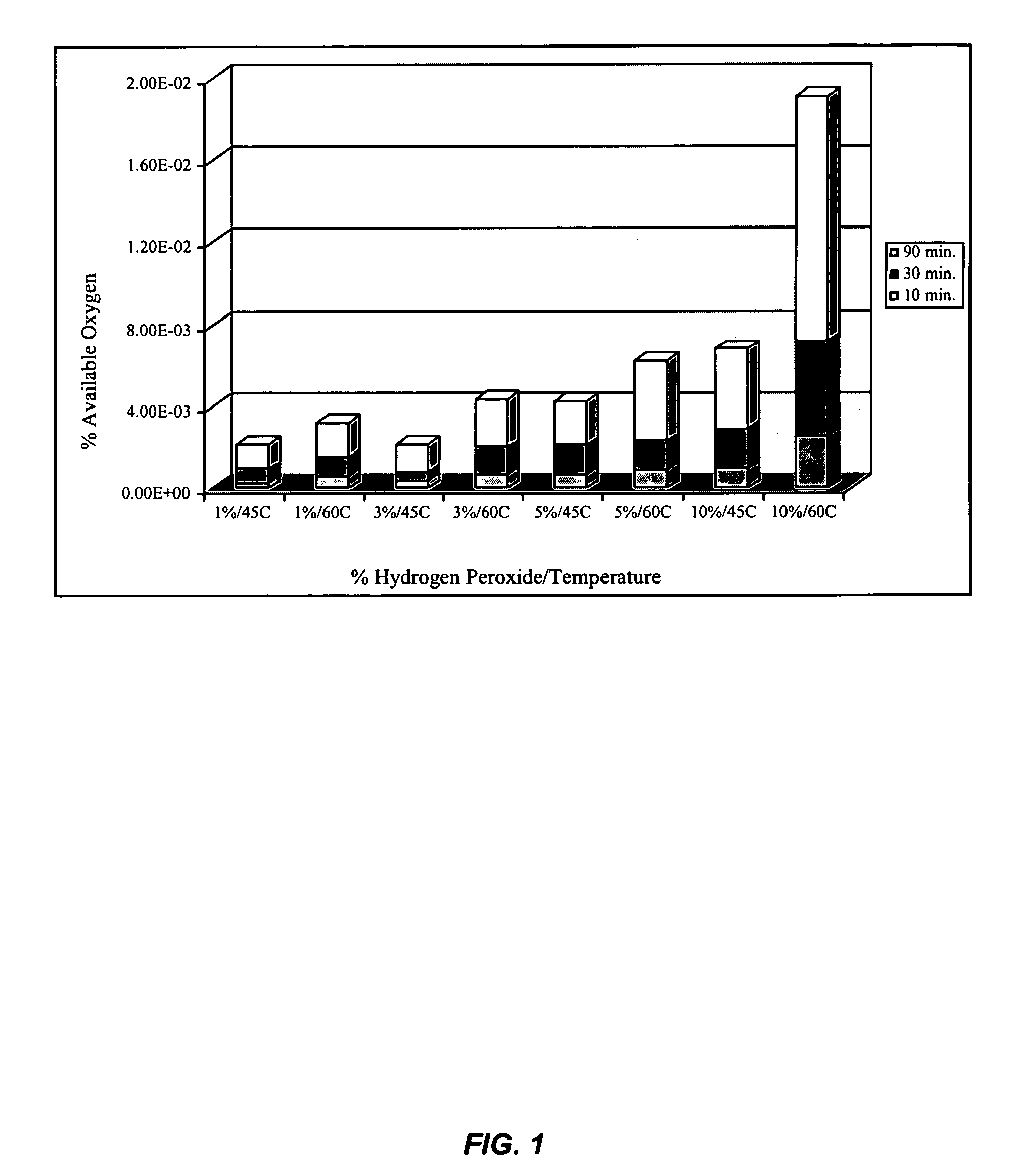

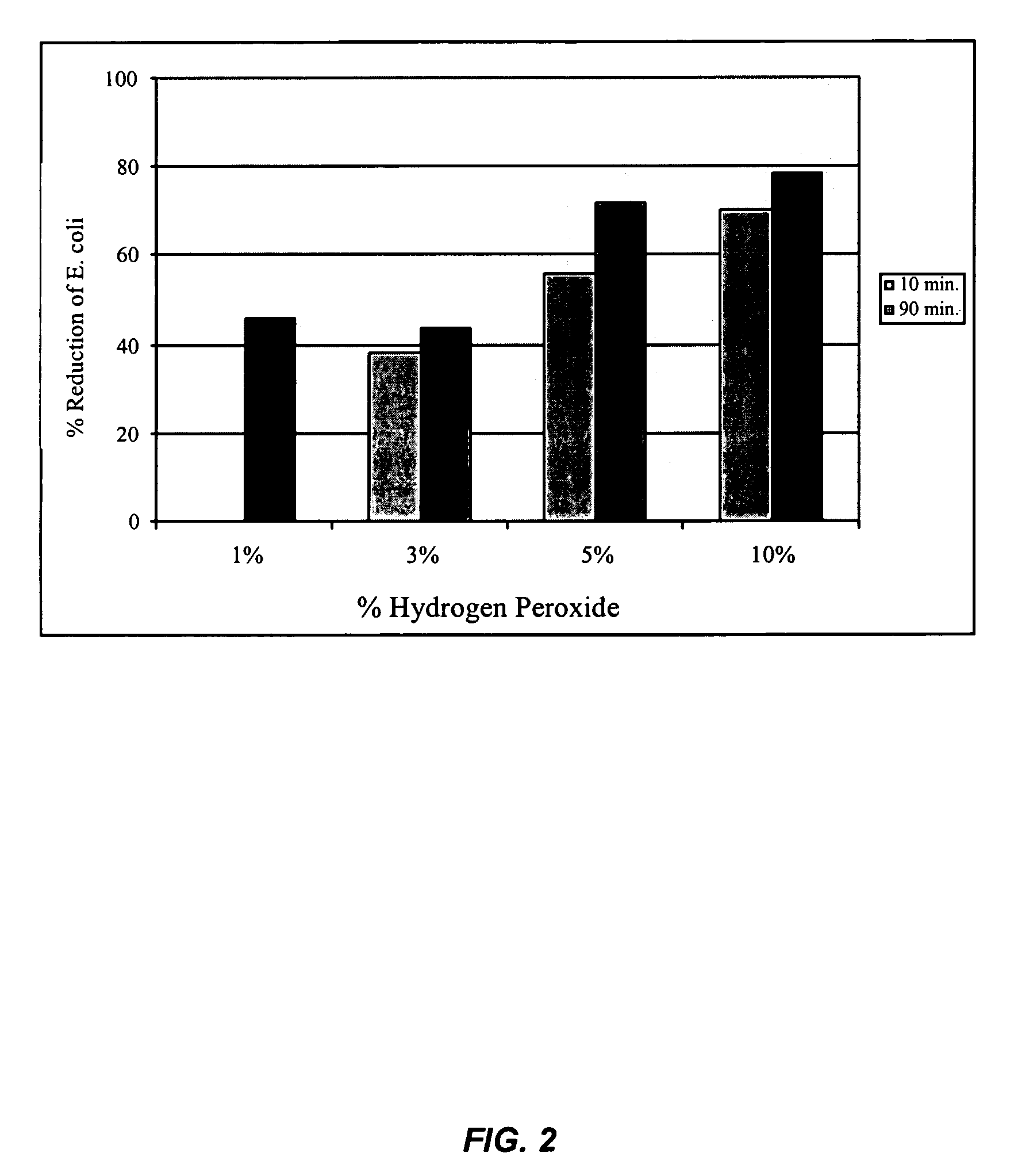

Regenerable antimicrobial polymers and fibers with oxygen bleaches

InactiveUS6962608B1Easy to prepareBroad of biocidal activityLight resistant fibresDetergent compounding agentsFiberColour fastness

The present invention provides durable and regenerable antimicrobial fibers and methods for preparing the same. These fibers have excellent colorfastness and washfastness, and are environmentally friendly. The antimicrobial fibers of this invention are suitable for a variety of purposes, including medical uses, sportswear, and uniforms.

Owner:CALIFORNIA UNIV OF SAN FRANCISCO

Method for increasing inking printing pigment ink color fastness

InactiveCN101100815ADoes not affect jetting performanceResistance to wet and dry frictionDyeing processColour fastnessAlcohol

The invention relates to a method used to increase inking printing dye ink color fastness. It includes the following steps: orderly adding dye color paste, polyhydric alcohol, adhesive, cross linking agent, surface activator in proportion into container; adding water to mix evenly; stirring, filtrating to form super fine dye ink; jet printing on the fabric; drying, baking to fix. The printing film formed by cross linking agent makes the super fine dye particle can tolerate dry wet friction, can increase its color fastness on the fabric without influencing on ink injecting performance.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

High-color-fastness inkjet printing pigment ink and preparation method thereof

ActiveCN104194494AImprove dispersion stabilityImprove rubbing fastnessInksDyeing processTextile printerPolymer science

The invention discloses high-color-fastness inkjet printing pigment ink, which is characterized by comprising superfine coating pigment color paste, a water-soluble cosolvent, a cross-linking agent, a surfactant, a defoaming agent, a bactericide agent, a pH regulator and water, wherein the superfine coating pigment color paste comprises a polymerizable dispersing agent, a pH regulator, a pigment, a monomer, a water-soluble initiator and water. The surface of pigment particles is coated with a polymer through fine emulsion polymerization, so that the dispersion stability of the pigment particles can be improved, and reaction groups capable of bonding with the crosslinking agent can be provided; when the prepared ink is inkjet-printed onto textiles and roasted for fixation, the cross-linking agent and the polymer on the pigment surface are formed into a continuous, compact and smooth printing film on the surfaces of the textiles, so that the rubbing fastness of the inkjet printing ink can be improved, and the hand feeling of the printed textiles can be improved to certain extent.

Owner:JIANGSU GEMEIGAO DEV CO LTD

Suede artificial leather and production method thereof

ActiveUS7951452B2Excellent color developmentExcellent fastness to lightSynthetic resin layered productsPaper/cardboard layered productsElastomerMechanical property

The suede artificial leather of the present invention comprises a three-dimensional entangled body comprising a superfine fiber having a fineness of 0.2 dtex or less and an elastomeric polymer A, and satisfies the requirements (1) to (4) as specified in the specification. By meeting the requirements, the suede artificial leather acquires excellent color fastness to light and color development in a wide range of colors and a high quality with good suede feeling, surface touch, hand, mechanical properties and color fastness.

Owner:KURARAY CO LTD

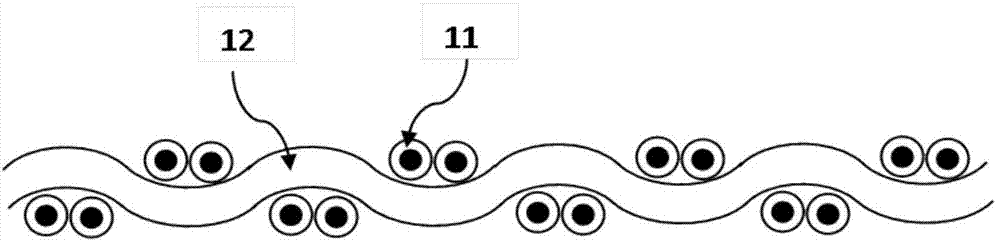

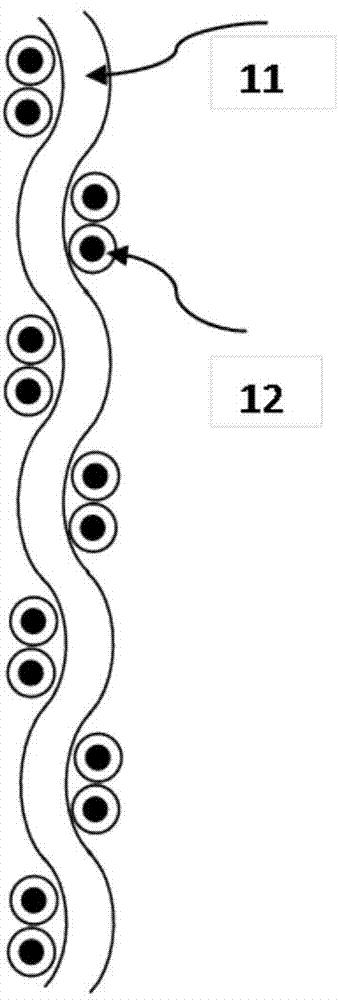

Preparation method of high-imitation cotton printed fabric

InactiveCN103741417AReduce tensionFully swollenSucessive textile treatmentsWoven fabricsPolyesterYarn

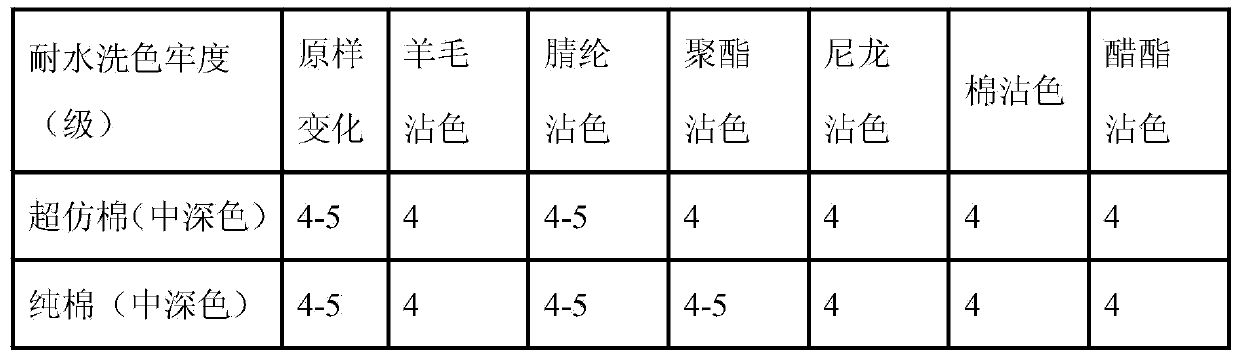

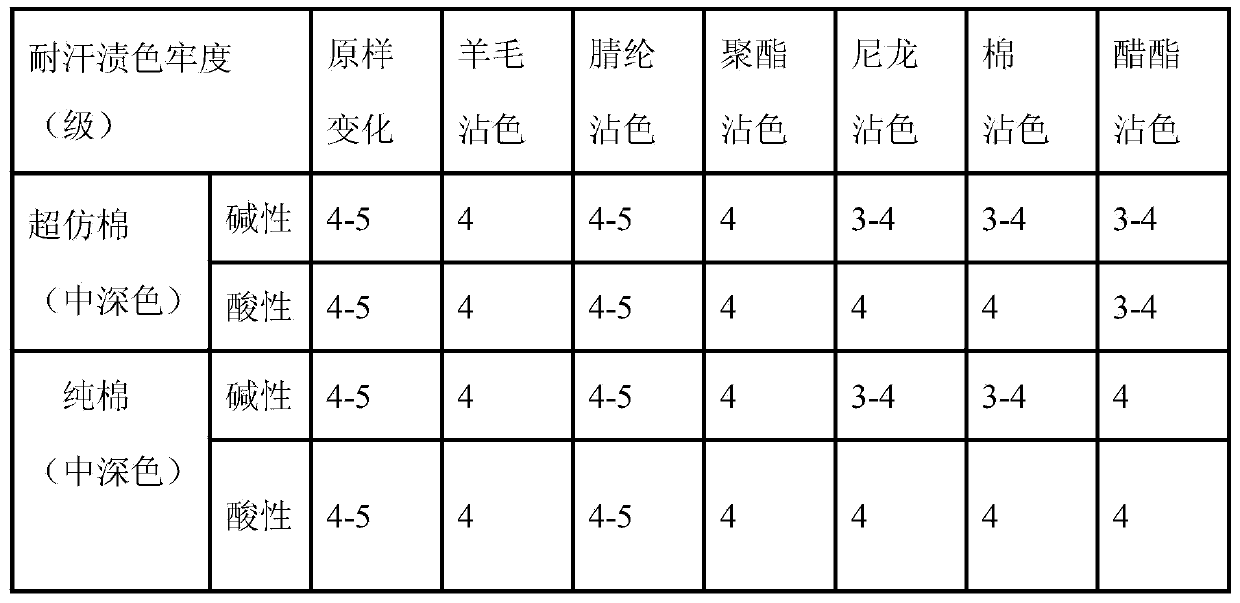

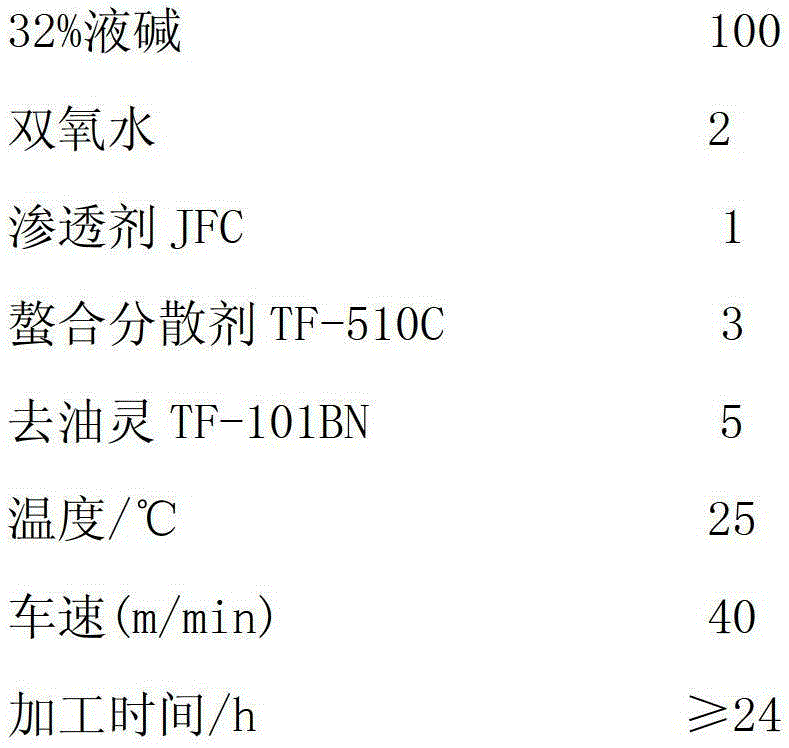

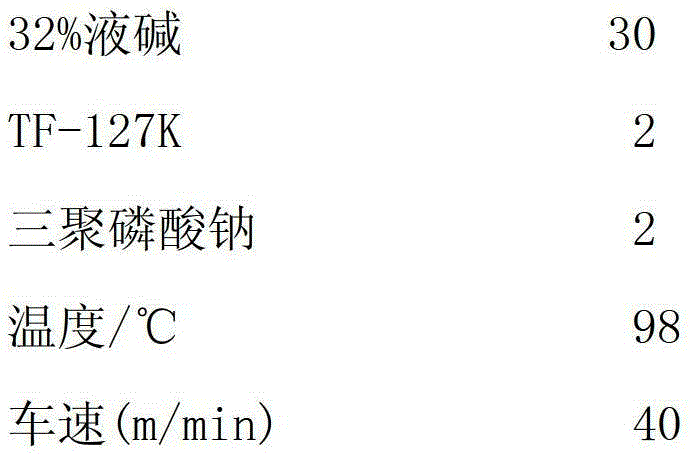

The invention discloses a preparation method of a high-imitation cotton printed fabric. The preparation method comprises the following steps: (1) weaving cloth; (2) sizing and oiling; (3) desizing and refining; (4) reducing alkaline amount; (5) shaping; (6) sanding; (7) printing; (8) post-shaping and drying; and (9) absorbing moisture, sweating and finishing. According to the preparation method, superfine denier fiber is used for weaving; warps and wefts adopt high-fischer yarns; compared with normal polyester cotton fabric, the high-imitation cotton printed fabric s better in moisture absorption and air permeability, and smoother in hand feeling; according the preparation method, raw material selection and structure design are used; and the processes of loosing and desizing, shaping, sanding, padding, absorbing moisture, sweating and finishing are used for preparing the high-imitation cotton printed fabric; the preparation method is simple and practical in process and strong in adaptability; the overall process has the characteristics of obviously saving energy and water; test of performances of colour fastness, strength and anti-static property proves that the high-imitation cotton printed fabric completely achieves the effect of the cotton.

Owner:浙江弘晨印染科技股份有限公司

Production process of peach skin lining

InactiveCN102011299AHatch a delicate and soft styleUnique and innovativeFibre typesDry-cleaning apparatus for textilesPolyesterColour fastness

The invention relates to a production process of peach skin lining without napping, which comprises the following procedures of gray fabric debatching, desizing, alkali deweighting, air cleaning, dyeing, dehydrating and flat setting, wherein the gray fabric is formed by interweaving warp-wise polyester-polyamide composite filaments and across warp polyester-polyamide composite filaments; the alkali deweighting is carried out on an overflow dyeing machine; a used deweighting agent comprises the following components of 14 to 16g / L of NaOH, 0.8 to 1.2g / L of penetrating agent, 1.8 to 2.2g / L of detergent and the balance of water, and the liquor ratio is 1 to 50. Dyeing is carried out by a double-bath process specifically comprising the steps of sequentially dyeing terylene and chinlon. The warp-wise fracture strength of the lining obtained by the invention can reach 980N, the across warp strength is 633N far higher than the standard of GB / T 17253-2008; the dry and wet rubbing fastness of the lining is 4-level, reaching the standard of GB / T 17253-2008. The invention overcomes the defects of uneven dyeing, easy appearance of dyeing defects, poor rubbing color firmness and the like of common peach skin fabrics, and additionally has the advantages of simpler process and lower production cost.

Owner:WUJIANG FUHUA WEAVING

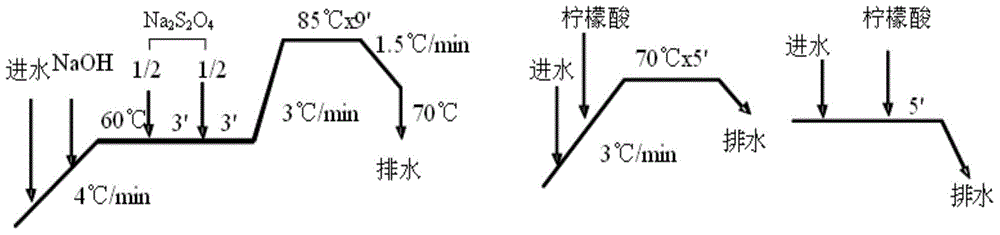

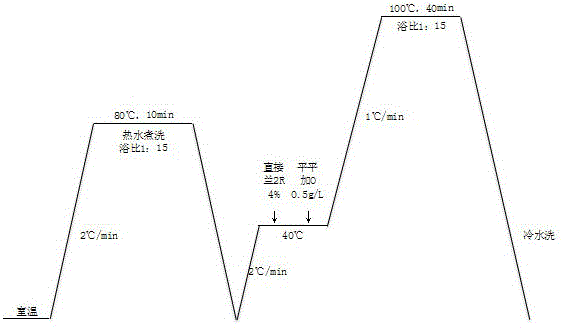

Method for dyeing and finishing polyester-spandex fabric

ActiveCN103147314AHigh color fastnessIncrease elasticityFibre typesHeating/cooling textile fabricsColour fastnessYarn

The invention discloses a method for dyeing and finishing a polyester-spandex fabric. Warp 75D polyester filament and 40D spandex filament twisted yarns and weft 300D polyester filament and 40D spandex filament twisted yarns are used as raw materials. The method comprises the following steps of: pretreating; presetting; dyeing; performing reduction clearing; finishing after thermal setting; and detecting, batching and packaging. The method overcomes the defects in the prior that the polyester-spandex fabric is poor in dyeing reproducibility during dyeing and finishing and poor in color fastness and the elasticity and the strength of the spandex are damaged at high temperature. The polyester-spandex fabric has the characteristics of high strength, good elasticity, stable size, strong feel of fur, full handfeel, mild gloss and good color fastness and is stiff and smooth.

Owner:SHENGHONG GRP CO LTD

Natural vegetable dye textile dyeing and printing technique

InactiveCN101368341AEasy to dyeGood health effectBiochemical fibre treatmentDry-cleaning apparatus for textilesColour fastnessEngineering

The invention relates to a dyeing and printing technique to dye fabrics with natural plant dyestuff, including the following steps: (1) pretreatment, (2) soaping, (3) pre-mordant dyeing, (4), dyeing, (5) washing, (6) post-treatment, (7) washing, and (8) drying. The dyeing and printing technique adopts pollution-free natural plant dye and addition agent and requires no metal mordant during the dyeing process, and the dyeing and printing technique is ecological and produces no harmful gas or volatile substance, so the dyeing and printing technique is nontoxic and is environment-friendly. The product indexes accord with EU Oko-Tex Standard 100 and reach the standard of modern ecological textiles. The dyed fabric has excellent color fastness and good UV screening property. Production shows that the dyeing and printing technique totally satisfies the requirements of industrialized production of fabrics dyed and printed with plant dyestuff. The dyeing and printing technique suits technological development trend and the requirement of the change of consumer product market and has obvious environmental, social and economic benefits.

Owner:殷大卫

Method for producing differential terylene color yarns

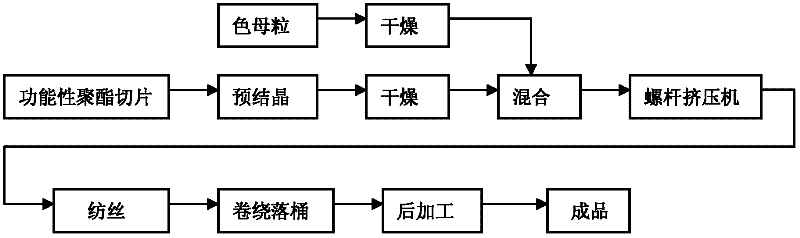

InactiveCN102392317AReduce pollutionHigh fastnessFilament forming substance formingMelt spinning methodsYarnPolyester

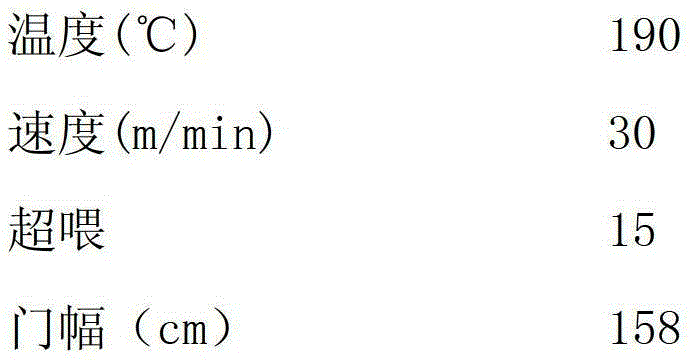

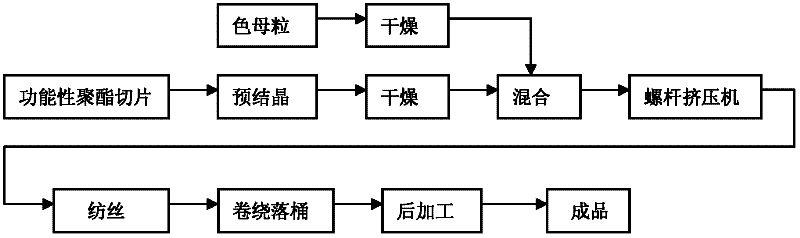

The invention discloses a method for producing differential terylene color yarns. The method comprises the following steps of: pre-crystallizing a functional polyester chip at the temperature of between 144 and 146 DEG C for 20 to 60 minutes, and drying at the temperature of between 149 and 151 DEG C for 4 to 6 hours, so that the moisture content of the dried functional polyester chip is less than or equal to 17 ppm; and drying masterbatches for 1 to 2 hours, mixing the dried masterbatches and the dried functional polyester chip fully, adding the mixture into a screw extrusion spinning machine, spinning by using a spinneret plate of the screw extrusion spinning machine, winding and dropping into a bucket, and processing to obtain the differential terylene color yarns. In the method, the masterbatches are added into the functional polyester chip to be spun into the color yarns, the masterbatches and the functional polyester chip are mixed uniformly in a mode of dynamic mixing or static mixing in a screw extruder, and the color yarns are produced through the spinneret plate. By the method, the color fastness and stability of the products are improved, the production cost is reduced, and environmental pollution is reduced.

Owner:ZHEJIANG SANZHI TEXTILES

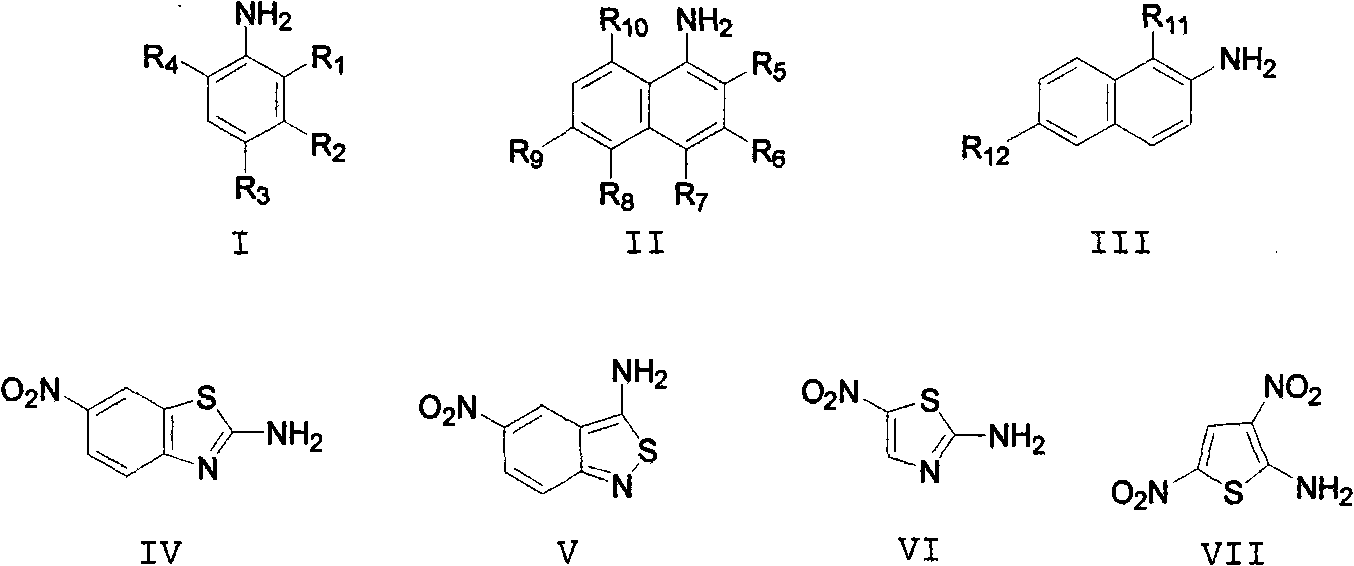

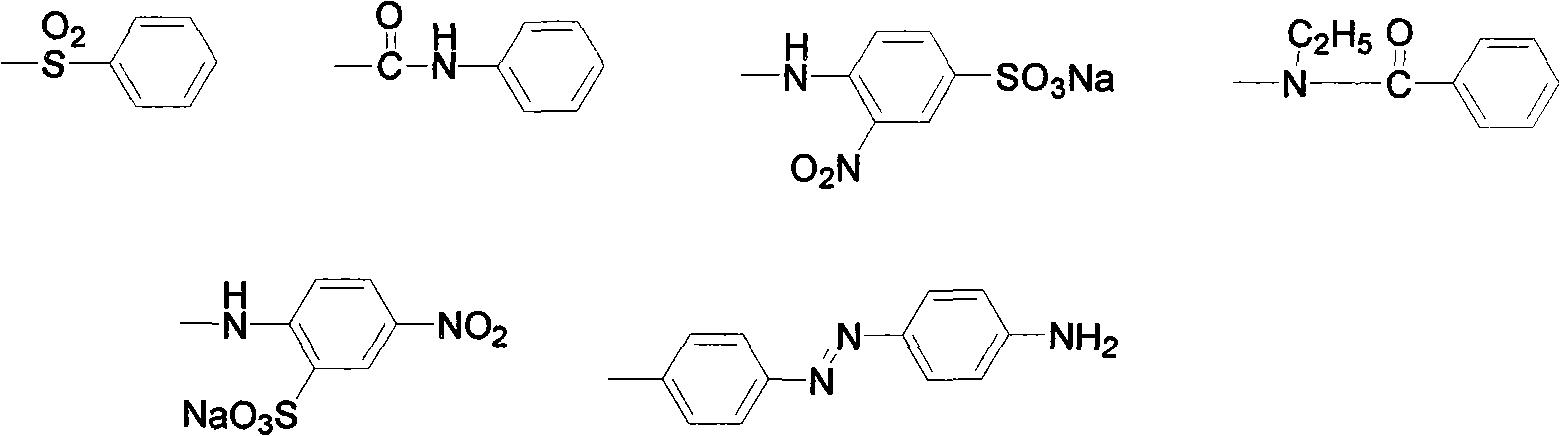

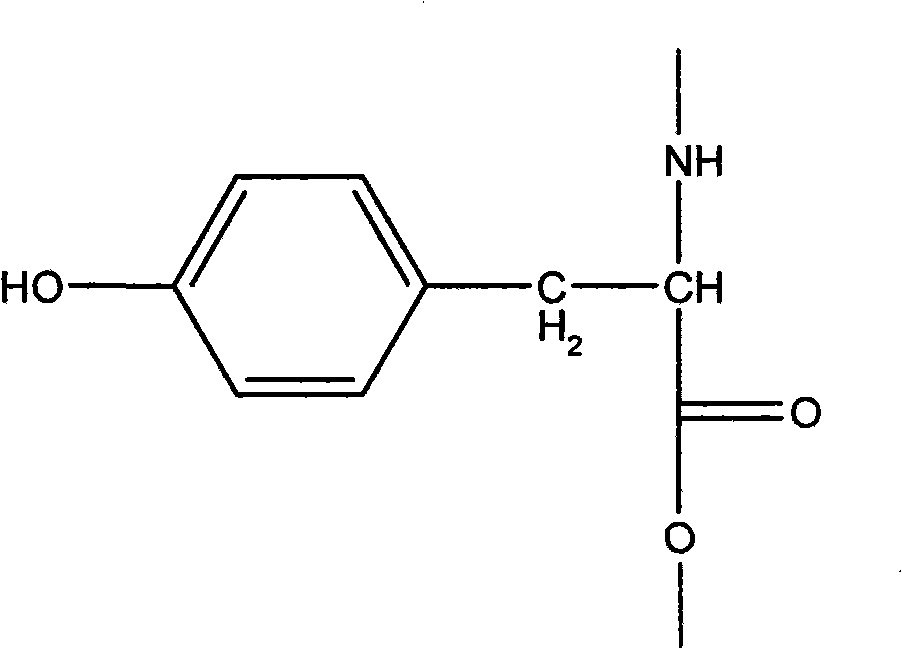

Dyeing method of protein material

The invention discloses a dyeing method of protein material. Arylamine compound is diazotized and then is directly coupled with tyrosine segment in protein molecule, so as to generate coloured substance containing azo bond; dosage of arylamine compound is equivalent to 0.1-5% of weight of protein material, and dyeing bath ratio is 1:20-100. Arylamine compound is taken as colour base and diazotized and then is directly coupled with tyrosine segment in protein molecule, and coloured substance connected with main chain by covalent bond in protein molecule, thus realizing dyeing on protein material and obtaining various colours by selecting arylamine colour bases in different structures. The dyeing method has the advantages of low energy consumption, less pollution and high colour fastness. The protein fiber fabric obtained by the method has higher wet-processing fastness; and the dyed protein powder also has higher fastness. The invention also provides a new dyeing method for protein material.

Owner:ZHEJIANG SCI-TECH UNIV

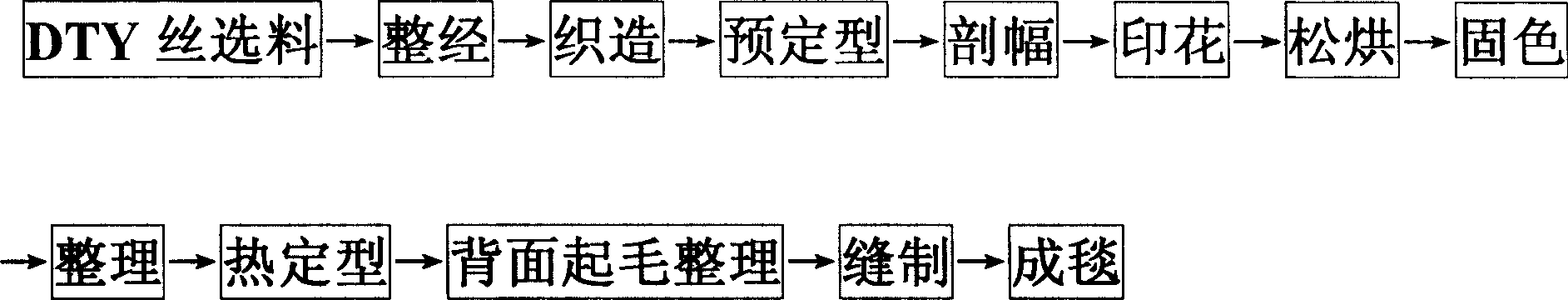

Process of machining full terylene ultrafine fiber coral fleece blanket

InactiveCN101016675ALongitudinal vertical stabilityHigh color fastnessWarp knittingHeating/cooling textile fabricsPolyesterColour fastness

The invention relates to a method for processing polyester ultra-fine fiber coral blanket comprises a DTY material selection, a warping process, a weaving process, a pre-shaping process, a cutting process, a printing process, a loosening drying process, a color fixing process, a finishing process, a thermal shaping process, a back furring finishing process, a sewing process, and final product outlet. The pre-shaping process comprises that pre-shaping the blank cloth in weaving process at high temperature before the cutting process. And the invention has the advantages that the invention can assure the contract homogeneity of blank fiber and stabilize the longitudinal verticality, to obtain better smooth, water adsorption and thermal insulation functions, and the invention can save cost, reduce SS degree of printed pollutant, and can improve the color stability of fabric.

Owner:常熟市锦绣经纬编有限公司

Preparation method of moisture-absorbing, sweat-permeable and anti-crease fabric

ActiveCN101949092AComfortable and breathableImprove wrinkle resistanceDyeing processWoven fabricsFiberColour fastness

The invention relates to a preparation method of a moisture-absorbing, sweat-permeable and anti-crease fabric, which comprises the following steps: weaving combed long stapled cotton and terylen fibers with grooves of a special shape into a base fabric by warp and weft interwaving based on a certain ratio, and enduing the fabric with the soft and air-permeable natural texture and permanent moisture-absorbing, sweat-permeable and anti-crease functions based on the physical structures of the raw materials; and dyeing the base fabric at high pressure and high temperature, carrying out a post-treatment on the fabric with a finishing liquid mixed according to a ratio of a special formula, and chemically finishing to enable the fabric to have high color fastness and feel soft and comfortable while having the moisture-absorbing, sweat-permeable and anti-crease functions. Thus, the invention meets the requirements for the moisture-absorbing, sweat-permeable and anti-crease fabric in the market, especially the requirements for outdoor clothes such as police uniforms, sports wears and the like.

Owner:江苏恒润盛鑫纺织实业有限公司

Cation hybrid collosol and method for improving clearness and fastness of decoration printing

InactiveCN101117769AFeel goodImprove anti-seepage performanceFibre treatmentDyeing processTextile printerColour fastness

The present invention relates to a cation hybrid sol and a firm for increasing clarity and firmness of textile printing, which belongs to the textile chemical industry field. The present invention is characterized in that solvent, cation compound, precursors and deionized water are added into a reaction vessel in turn, after being agitated and evenly mixed, catalyst is added into the mixture, and agitated under room temperature and cation hybrid sol is obtained. After diluting the cation hybrid sol and deionized water as per specified ratio, a textile is padded and finished in the sol, and the finished textile is dried. The present invention can improve the anti-bleeding performance of the ink color printing of the textile; and clarity, depth and vividness of color of the ink color printing products are increased; paint / pigment on the textile can be fixed, meanwhile, the combined effect of the cation hybrid sol and paint / pigment make aggregation for fixation of the paint / pigment, and color firmness of the textile color printing is increased.

Owner:JIANGNAN UNIV

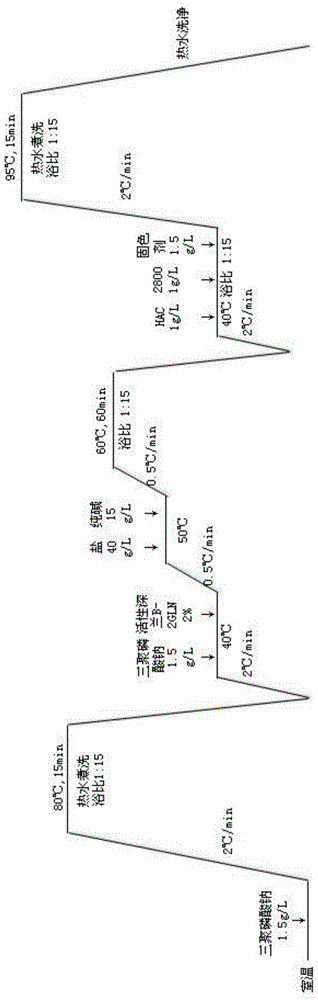

Method for dyeing modified cellulose fiber fabric on rhubarb and curcuma longa dyes

InactiveCN101349020AHigh fixation rateStable color fastnessDyeing processVegetal fibresHigh rateCellulose fiber

The invention provides a method for dyeing a modified cellulose fiber textile by a rhubarb and turmeric dye. The method comprises the following: 1. a step of modifying a quaternary ammonium group of the cellulose fiber textile, in which a modifying agent with a concentration of 50 to 60 g / l and sodium hydrate with a concentration of 12 to 18g / l react for 40 to 60 minutes at a temperature of between 64 and 75 DEG C, the bath ratio is 1:30; in the post treatment after the modification, the fiber textile is washed by hot water at a temperature of between 40 and 50 DEG C for 10 minutes, is washed by cold water, is prickled by HAC with a concentration of 2 to 3g / l for 2 minutes, is washed by water to be neutral and is dried; 2. a step of preparing the dye solution by the sodium hydrate extracting agent with a concentration of 15 to 45g / l; and 3. a step in which the modified cellulose fiber textile is dyed, washed by water and dried directly by the dyeing technique and is washed by soap, washed by water and dried. The technique is simple and easy to implement, does not need the mordanting and the fixation processes and the like, has high rate of dye-uptake, good dye quality and the friction resisting color fastness and the colorfastness to washing up to more than three grades, is nontoxic, does not pollute the environment, and has low cost, and remarkable economic benefits and environmental benefits.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Preparation method and application of chitosan-natural plant pigment macromolecular dye solution

ActiveCN104087020AImprove adsorption capacityAchieve purificationOrganic dyesDyeing processColour fastnessCellulose fiber

The invention belongs to the field of new materials, and particularly relates to a preparation method and application of a chitosan-natural plant pigment macromolecular dye solution. The preparation method comprises the following steps: firstly purifying a natural plant dye by utilizing the electrostatic attraction and the intermolecular force between the amido of chitosan and a negative ion natural plant pigment to obtain a chitosan-natural plant pigment macromolecular dye; and then preparing the chitosan-natural plant pigment macromolecular dye into a dye solution for textile coloration. Compared with the original natural plant dye, the obtained chitosan-natural plant pigment macromolecular dye has heavier molecular weight and has very high coloring capacity on natural fibers, such as cotton, hemp, silk and fur, because the chitosan has high affinity with cellulose fibers and protein fibers; a dyed fabric obtained by the chitosan-natural plant pigment macromolecular dye solution not only has deep color, but also has good color fastness.

Owner:临泉县嘉鸿装饰工程有限公司

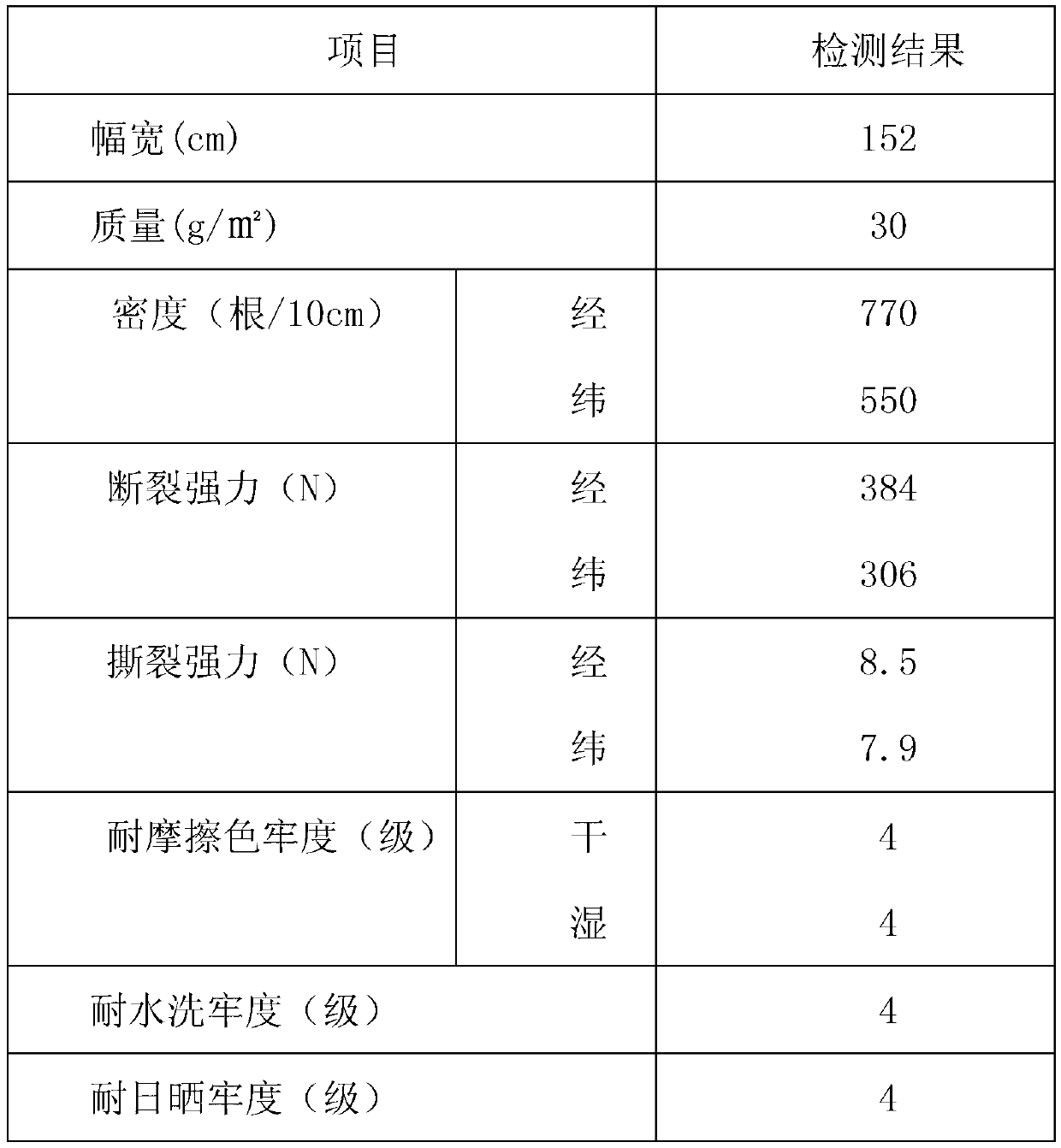

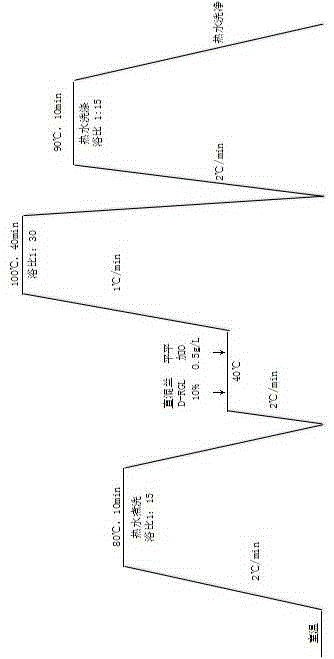

Dyeing and finishing method of superfine denier nylon fabric

ActiveCN103132349AHave affinityReduce initial dyeing speedFibre typesDry-cleaning apparatus for textilesCooking & bakingColour fastness

The invention discloses a dyeing and finishing method of superfine denier nylon fabric, belongs to the field of processing on the superfine denier nylon fabric, and aims at solving the problems that dyeing defect and uneven dyeing of the superfine denier nylon fabric are easily generated in the dyeing process. The method disclosed by the invention comprises the steps of: cold heaping, open-width desizing, pre-setting, dyeing, performing fixation, baking and molding a finished product. An anionic leveling agent disclosed by the invention has affinity on nylon, and can generate an unexpectedly dyeing effect on the fiber together with anionic dye. Thus, the initial dyeing speed of the dye is reduced, so as to achieve a uniform dyeing effect; and the fold resistance of the fabric is improved when the craping style of the fabric is kept by presetting the desized fabric. By using the dyeing and finishing method, the dyeing process is even, the color and the luster are good, the colour fastness is good, and the like; and the dyeing defect can not be generated, and the fabric processed by using the method accords with the requirements of superior products specified by the standard of GB / T17253-2008 'synthetic filament yarn fabric'.

Owner:SHENGHONG GRP CO LTD

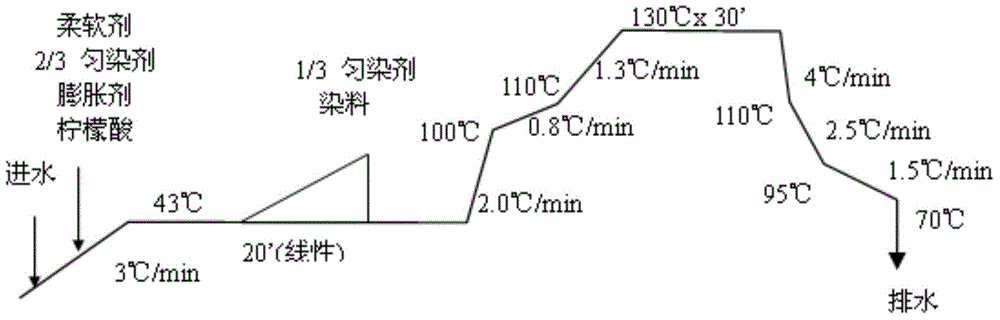

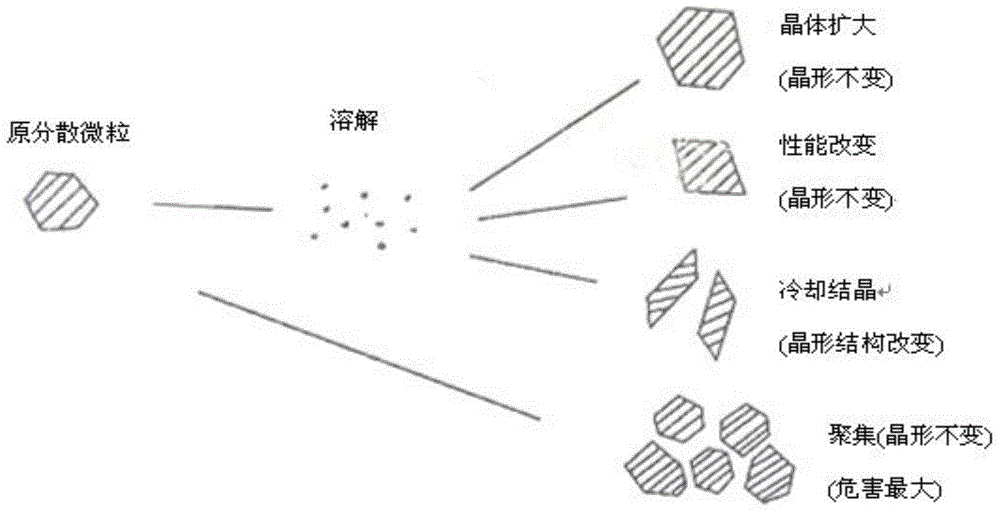

Method for dyeing superfine terylene fabric

ActiveCN104878618AGuaranteed color fastnessImprove dye uptakeDyeing processDisperse dyeColour fastness

The invention discloses a method for dyeing a superfine terylene fabric. The method comprises the following dyeing steps: adding a softening agent, part of a leveling agent, and an expansive agent into the soppy superfine terylene fabric to prepare a working solution; adding a pH regulator to regulate the pH value of the working solution to 3.5-4.0; heating the working solution with the adjusted pH value to 43 DEG C, and adding disperse dye and the residual leveling agent to prepare a dye liquor; carrying out heating and dyeing. The method aims at dyeing of a brightly colored superfine terylene fabric, and has the advantages the softening agent, the leveling agent and the expansive agent are added simultaneously, and the pH value of the dye liquor is regulated to 3.5-4.0, so that poor leveling property, uneven dyeing and other quality problems existing in a low-bath-ratio dyeing process can be solved; moreover, the dye-uptake rate of the disperse dye can be improved, secondary aggregation of the disperse dye in a high-temperature descending process is prevented, all color fastness indices of the superfine terylene fabric exceed 4-level, the dyeing property is improved, and the dyeing effect is ideal; the method further has the advantages of being environment-friendly and low in energy consumption.

Owner:PACIFIC (PANYU) TEXTILES LTD

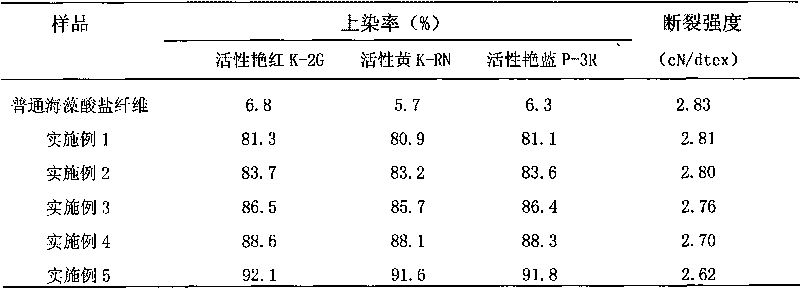

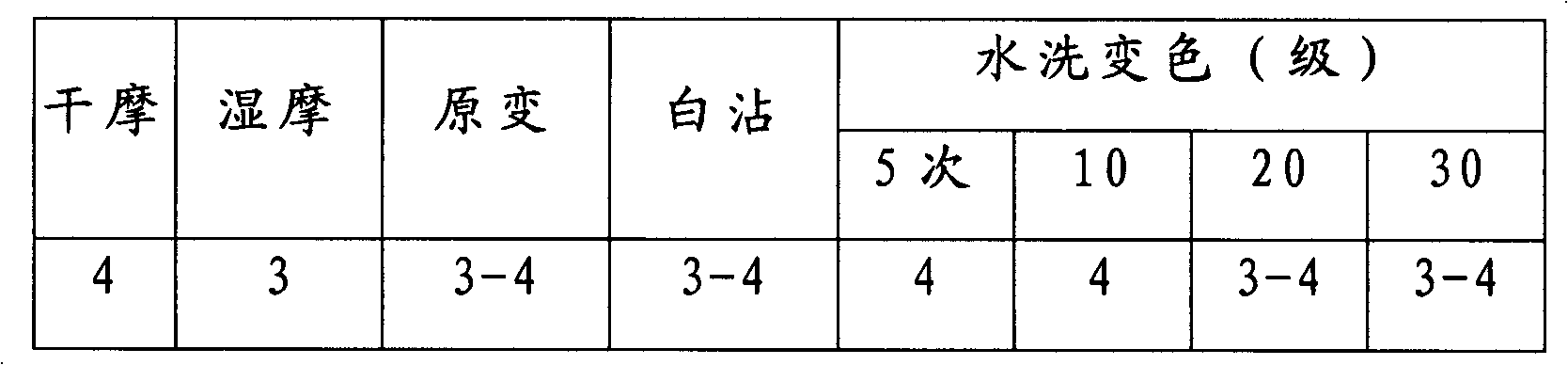

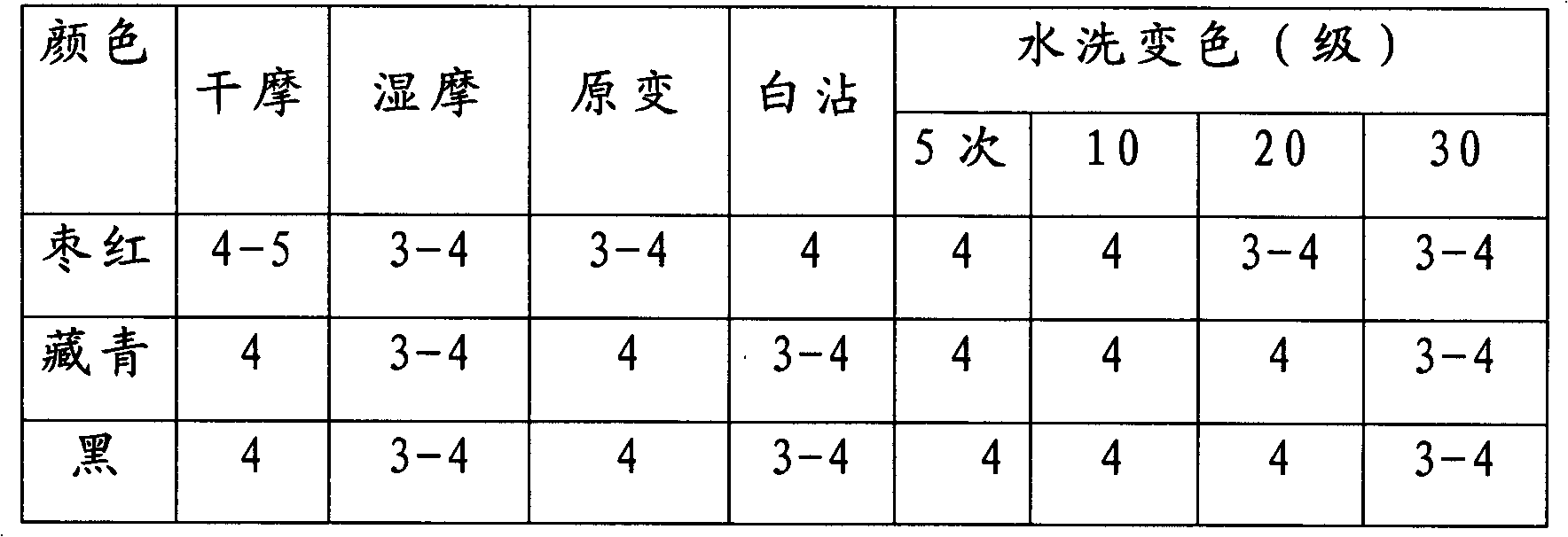

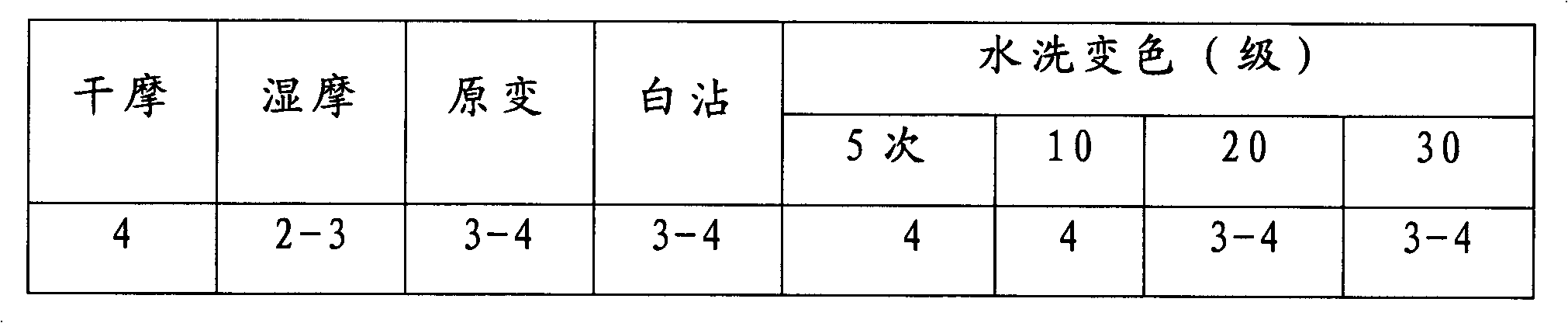

Manufacturing method of stainable alginate fibers

ActiveCN101736440AAchieve dyeingMeet diverse needsAlginate artificial filamentsWet spinning methodsColour fastnessState of art

The invention disclose a manufacturing method of stainable alginate fibers, which comprises the following steps of: adding a water-soluble dendrimers compound into a alginate fiber spinning solution, and solidifying, drafting, water washing and post-processing by adopting wet spinning equipment and technology to obtain the alginate fibers with excellent staining property, wherein the content of dendrimers in the alginate fibers is 1-10 percent. Compared with a traditional alginate fiber production technology, the invention has the advantages that the prepared alginate fibers can be applied to direct dyes and active dyes under a salt-free condition to realize staining and have higher dye uptake rate which generally reaches above 80 percent and is 10-15 times that of the alginate fibers produced by the traditional technology. In addition, the alginate fibers prepared by the invention has better color fastness and particularly excellent wet-processing fastness which reaches above grade 4.

Owner:QINGDAO TIANYI GROUP

Dyeing and finishing process of washing colorfastness for a plurality of times of deep color pure cotton fabric

InactiveCN101634113AReduce water consumptionIncrease profitDyeing processColour fastnessProcess engineering

The invention relates to a dyeing and finishing processing method in the printing and dyeing production field, in particular to a dyeing and finishing process of washing colorfastness for a plurality of times of a deep color pure cotton fabric. The process comprises the following steps: carrying out reactive dyeing on the pure cotton fabric by a cold pad-batch color-fixing method by stacking under normal temperature, selecting a reactive dye for cold pad-batch dyeing so as to improve the fixation rate and properties such as compatibility, levelling property, alkali resistance and the like, padding a washing colorfastness promoter, and optimizing the cold pad-batch dyeing process to meet the requirement that the fabric has the washing colorfastness for a plurality of times.

Owner:HUAFANG

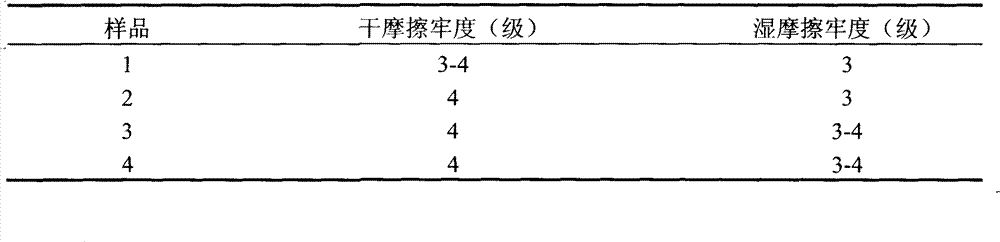

Capability verification sample for detection of textile color fastness to rubbing and preparation method thereof

InactiveCN104007061AEvenly dyedEasy to preparePreparing sample for investigationUsing mechanical meansColour fastnessRubbing

The invention discloses a capability verification sample for detection of textile color fastness to rubbing and a preparation method thereof. The capability verification sample is prepared by reactive dye or direct dye-based dying of pure cotton woven plain or twill bleached grey cloth. A test according to GB / T3920-2008 textile color fastness and color fastness to rubbing proves that color fastness to dry rubbing and color fastness to wet rubbing are in a range of 2-5 level, the existing daily detection range of color fastness to rubbing in the textile and clothing field is covered, and capability evaluation of different laboratory detection projects or laboratory quality control use is realized. The preparation method of the capability verification sample has simple processes, a high yield and high practicality. The capability verification sample can be stored and transported at a normal temperature and has uniformity and stability according with the CNAS-GL03 capability verification sample uniformity and stability evaluation guide requirements.

Owner:INSPECTION & QUARANTINE TECH CENT OF CHONGQING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

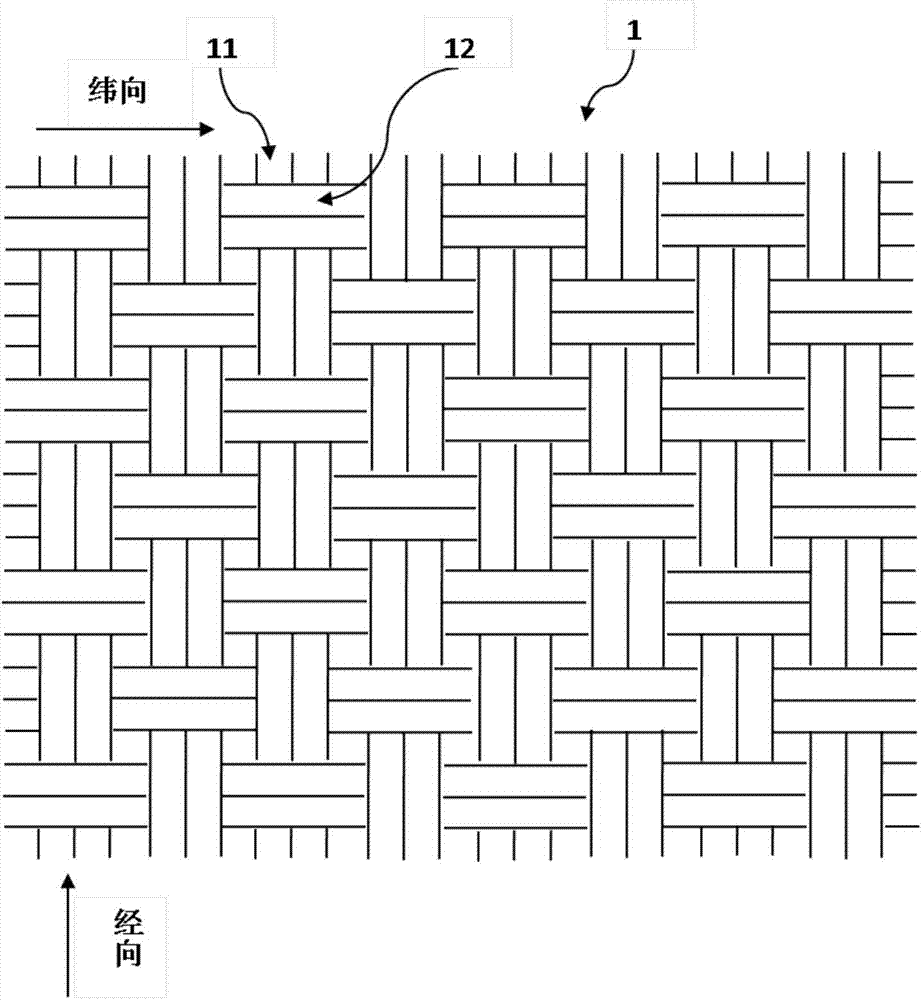

Sun-shading composite material with extinction and high flame-retardant effects

The invention discloses a sun-shading composite material with extinction and high flame-retardant effects. The composite material is a fabric comprising warps and wefts, wherein the fabric is woven by covering threads, rectangular or square gaps are left among the wefts, and the porosity of the composite material is 2-5%; the covering threads are made of a polyvinyl chloride composite material coating the surfaces of polyester fibers, the polyvinyl chloride composite material has the extinction and high flame-retardant effects and the covering threads are 0.3-0.5mm in diameter. The invention also provides a preparation method of the composite material. The sun-shading composite material has the characteristics of sunshading, ultraviolet ray resistance, inflaming retarding, high color fastness and the like of similar sun-shading composite materials, and also has the advantages of low glossiness, glare control, softness, comfort for eyes, fine and smooth handfeel and good breathability, and therefore, the sun-shading composite material can be well applied to the fields of leisure, fashion and individuation.

Owner:NINGBO XIANFENG NEW MATERIAL

Deepening agent and preparation method thereof, as well as method for improving color fastness of dyeing textiles

InactiveCN103614910AImprove bindingAvoid yellowingFibre treatmentDyeing processOrganosiliconColour fastness

The invention discloses a deepening agent and a preparation method thereof, as well as a method for improving the color fastness of dyeing textiles. The deepening agent consists of amino organic silicon, ternary copolymerized organosilicon, alkyl ketene, an emulsifier and water. Deepened textiles finished by the deepening agent have good deep color property and high color fastness. In addition, the preparation method of the deepening agent and a finishing processing method of the textiles are low in production cost, simple to operate and applicable in the field of finishing of dyeing textiles.

Owner:ZHEJIANG QUEPING TEXTILE CHEM

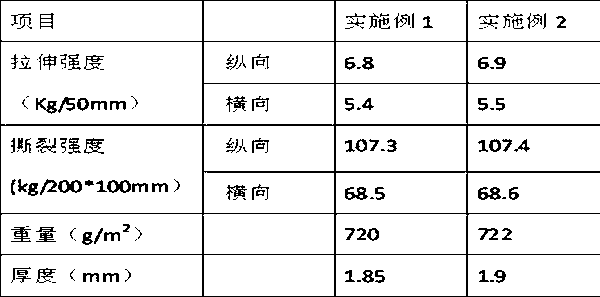

High-strength terylene microfiber needling fabric

ActiveCN103057219ALow costReduce water consumptionFibre typesTwo or more solvent application treatmentColour fastnessPolymer science

The invention relates to high-strength terylene microfiber needling fabric and belongs to the technical field of needling non-woven cloth. The high-strength terylene microfiber needling fabric is prepared by the following steps: performing non-woven double carding and double lapping on island type island short fiber to obtain double-layer cotton web; clamping base cloth which is obtained by using polyester filament yarn through a hydraulic loom in the middle of the double-layer cotton web; performing non-woven needling to obtain composite base cloth; starching; performing polyurethane (PU) resin impregnation; performing alkali reducing splitting; dyeing; drying; and performing double-sided sanding, wherein the polyester filament yarn is 68 to 75 D, the fineness of the island type island short fiber is 1 to 3 D, the island type island short fiber contains 37 islands and has the length of 38 to 51 mm, and the sea / island ratio is 30 / 70. The high-strength terylene microfiber needling fabric is low in dye cost and water consumption, uniform in dyeing, bright in color and luster, and high in color fastness and air permeability, enhances the stretching resistance, and takes both leather feeling and fluff feeling into consideration.

Owner:ZHEJIANG MEISHENG NEW MATERIALS CO LTD

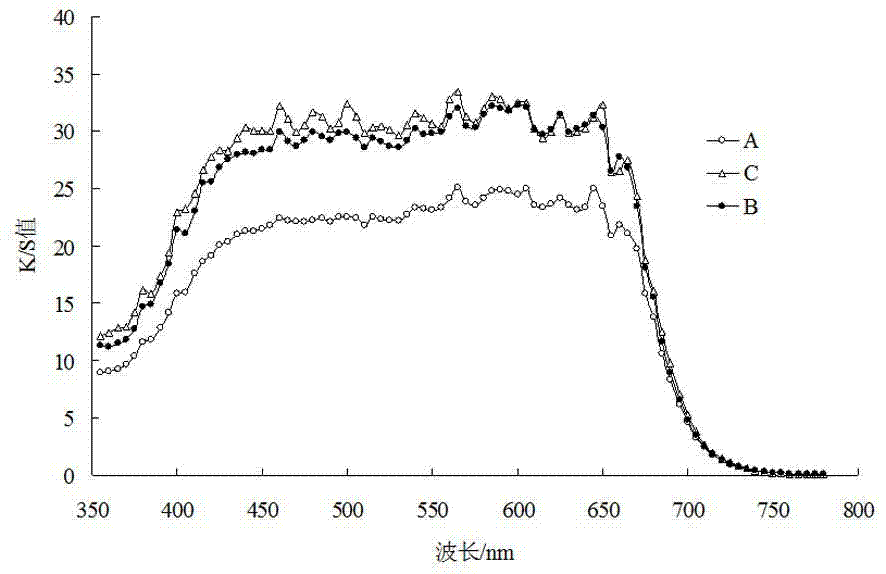

Composition of blue to black disperse dyes

The invention provides a composition of blue to black disperse dyes. The dyes mainly comprise the ingredients in parts by mass of 20-85 parts of at least one component A of which the structure is shown in the formula (I), 5-50 parts of at least one component B of which the structure is shown in the formula (II), and 1-55 parts of at least one component C of which the structure is shown in the formula (III). The composition of the disperse dyes disclosed by the invention can supply and dye in a micro-pelletized liquid state, a paste state or a powder state which is dried by a spray drying process and the like, and a granular state after being commercialized. When the composition of the disperse dyes disclosed by the invention dyes the hydrophobic fiber materials, each dye performance and the color fastness are excellent; and the blue to black fabrics (I), (II) and (III) can be obtained by adjusting the ratio of different components.

Owner:ZHEJIANG LONGSHENG GROUP

Preparation method of pigment ink for inkjet printing of non-adhesive textile

InactiveCN102926224AGood storage stabilityLittle impact on hand feelingDyeing processColour fastnessAdhesive

The invention discloses a preparation method of pigment ink for inkjet printing of a non-adhesive textile, and belongs to the technical field of fine chemical engineering and material science. Different from the conventional ink for inkjet printing, the ink is obtained by adopting ultrafine coated pigment color paste obtained by a miniemulsion polymerization method as a coloring agent, adding substances such as a water-soluble cosolvent, a surface active agent and deionized water, stirring, mixing and filtering. The ink does not contain the adhesive, has the advantages of small particle diameter, high storage stability and good jetting smoothness and the like; and the inkjet printed textile prepared by the ink has the advantages of good color fastness and color brightness and good hand feel.

Owner:JIANGNAN UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com