Preparation method of pigment ink for inkjet printing of non-adhesive textile

An inkjet printing and pigment ink technology, applied in the fields of fine chemicals and material science, can solve problems such as unsatisfactory application effects, and achieve the effects of avoiding unsmooth jetting, little impact on hand feeling, and good color fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

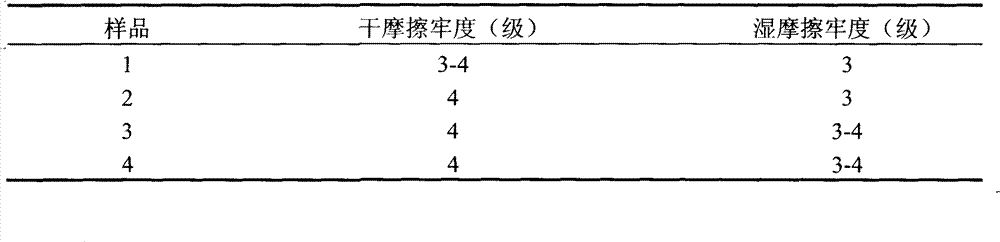

Examples

example 1

[0016] Dissolve 1.5g of allyloxy hydroxypropyl sodium sulfonate in 85.50g of deionized water, adjust the pH to 8.1, add 12g of carbon black to the system at a stirring speed of 600 rpm, stir well and transfer to a sand mill Grind in the machine at a speed of 1800 rpm for 2.0 hours to obtain ultra-fine carbon black, then add 1.00g of methyl methacrylate dropwise, continue grinding for 1.0 hour, take it out and transfer it to a reaction chamber equipped with a stirrer, a thermometer and a condenser Into the container, feed nitrogen, stir, heat up to 65°C, slowly add 0.003g ammonium persulfate dropwise, react for 2.0 hours, take out the reaction solution, and filter it with filter paper with a pore size of 1000nm to obtain ultrafine coated carbon black slurry.

[0017] Weigh 48g of ultra-fine coated carbon black slurry, then add 3g of n-butanol, 4g of isopropanol, 13g of glycerol, 1.2g of Span 40, 0.3g of anilide, and 30.5g of deionized water, and mix evenly with a mixer. Stir fo...

example 2

[0019]Dissolve 3.0g of allyloxynonylphenoxypropanol polyoxyethylene ammonium sulfate into 74.98g of deionized water, adjust the pH to 8.3, and add 20g of C.I. Pigment Blue 15 to the system at a stirring speed of 900 rpm :3, transfer to the sand mill after stirring evenly and grind for 3.5 hours at a speed of 2000 rev / min to obtain superfine C.I. Then transfer to a reactor equipped with a stirrer, a thermometer, and a condenser, feed nitrogen, stir, heat up to 70°C, slowly add 0.02g of sodium persulfate dropwise, and react for 5.0 hours, take out the reaction solution, and use a pore size of 1000nm filter paper to obtain superfine coated C.I. Pigment Blue 15:3 color paste.

[0020] Weigh 40g of superfine coated C.I. Pigment Blue 15:3 color paste, and then add 13g of 1,4-butanediol, 12g of n-propanol, 7g of diethylene glycol, 3.6g of Tween 65, and isothiazolone 0.1 g, 24.3g of deionized water were mixed evenly, stirred for 60 minutes with a stirrer at a rotating speed of 800 rp...

example 3

[0022] Dissolve 6.4g of sodium methacrylate hydroxypropyl sulfonate into 55.55g of deionized water, adjust the pH to 9.0, add 32g of C.I. Pigment Red 105 to the system at a stirring speed of 1500 rpm, stir well and transfer to sand Grind in the mill at a speed of 3000 rpm for 5.0 hours to obtain superfine C.I. Pigment Red 105, then add 2.76g of methyl vinyl ether and 3.00g of acrylonitrile dropwise, continue grinding for 2 hours, take it out and transfer it to a Into the reactor with stirrer, thermometer and condenser, feed nitrogen gas, stir, heat up to 80°C, slowly add 0.29g of azobisisopropylimidazoline hydrochloride dropwise, and react for 9.5 hours, take out the reaction solution, and use Filter through filter paper with a pore size of 1000nm to obtain superfine coated C.I. Pigment Red 105 color paste.

[0023] Weigh 28g of superfine coated C.I. Pigment Red 105 color paste, then add 8g of 1,6-hexanediol, 4g of triethylene glycol, 3g of isopropanol, 2.5g of Triton X-10, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com