Patents

Literature

46results about How to "Good mixing properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

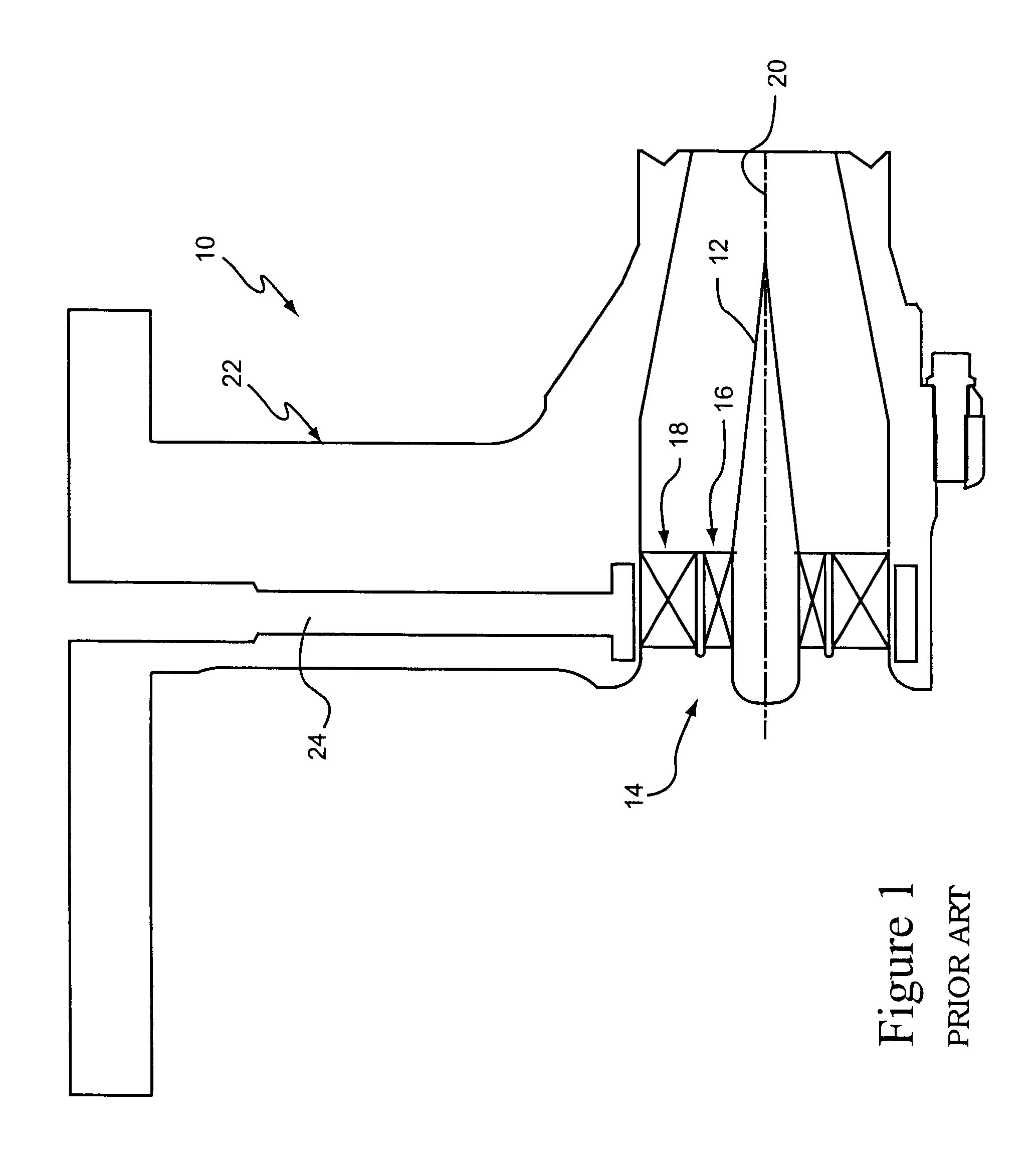

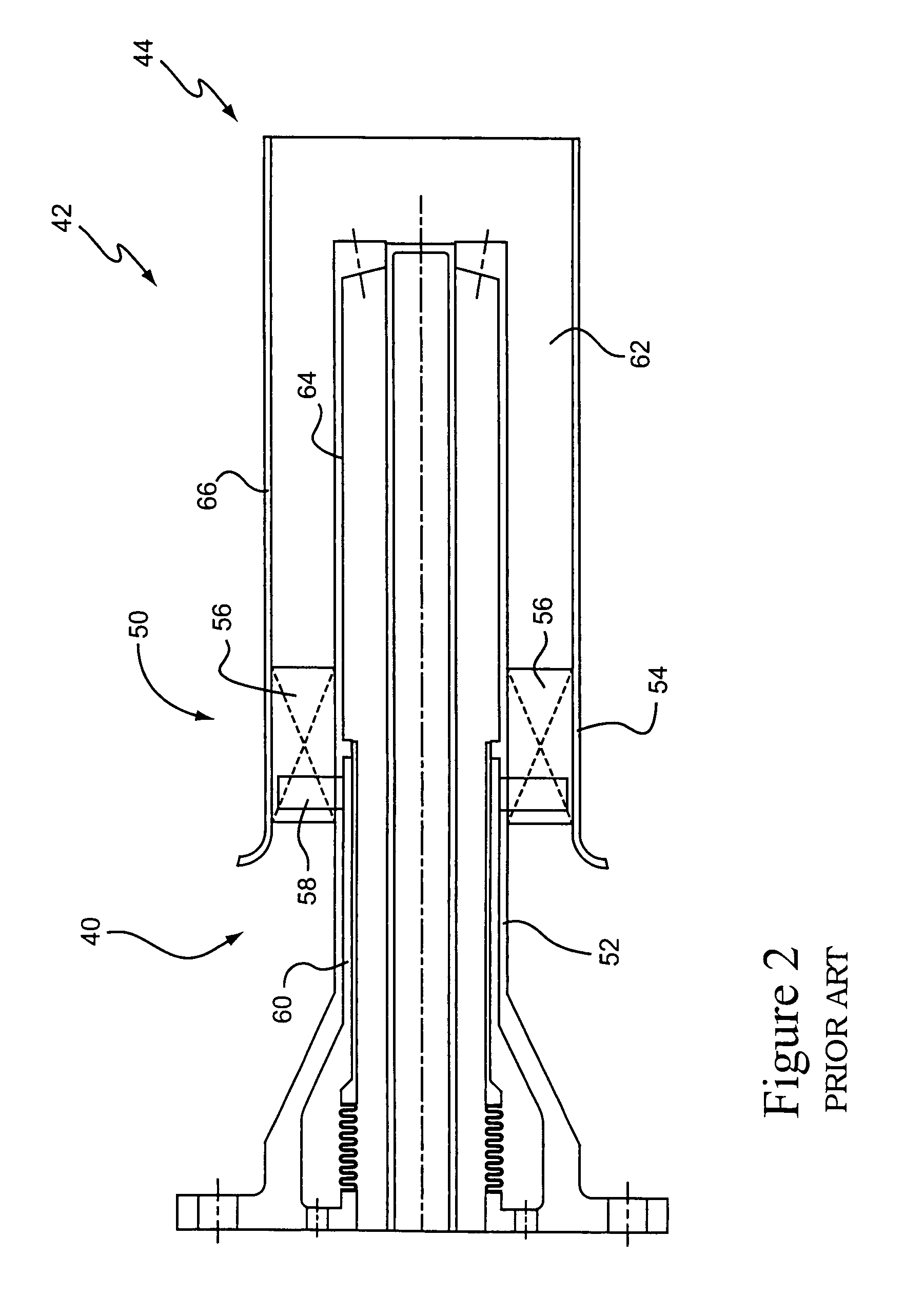

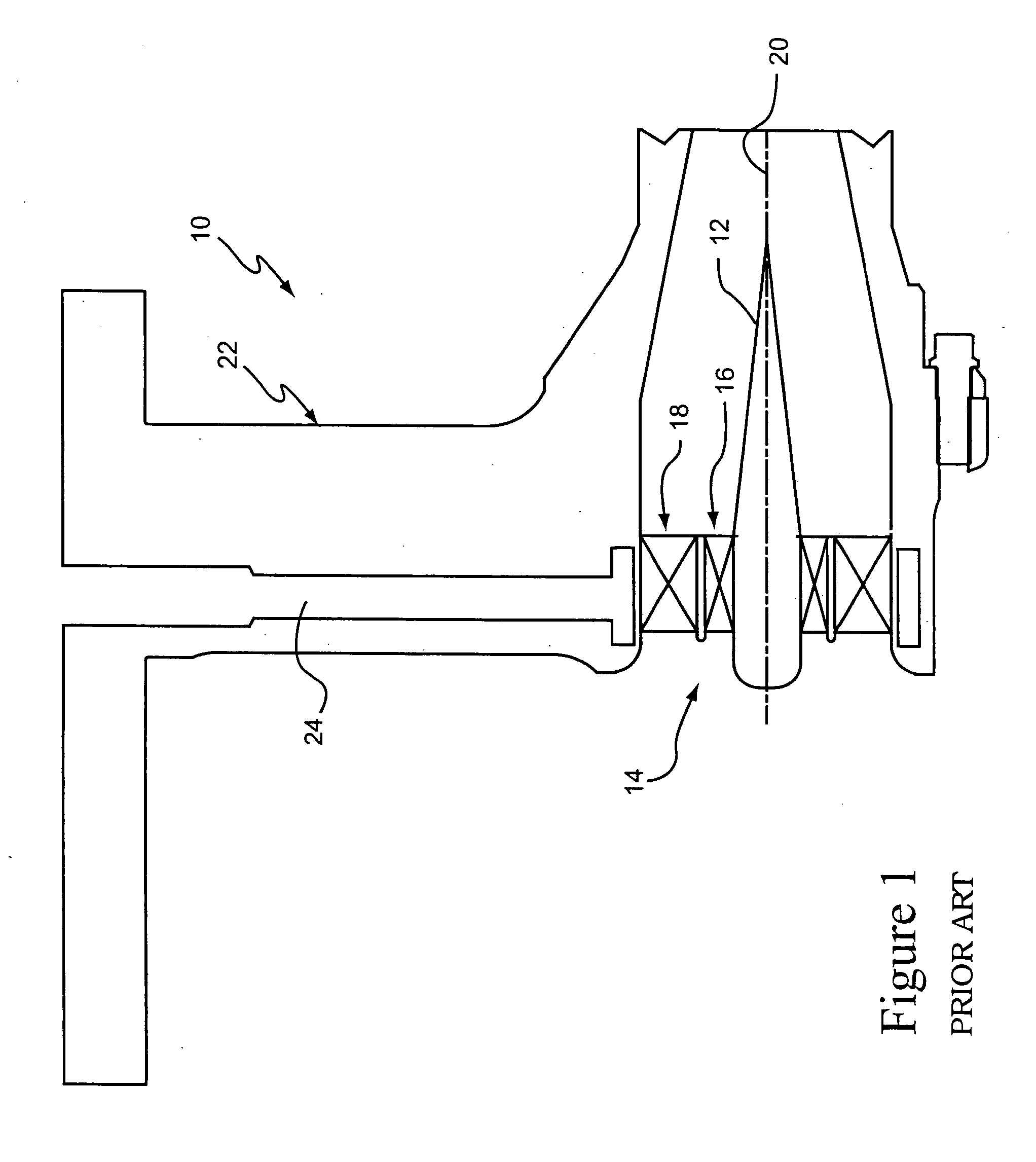

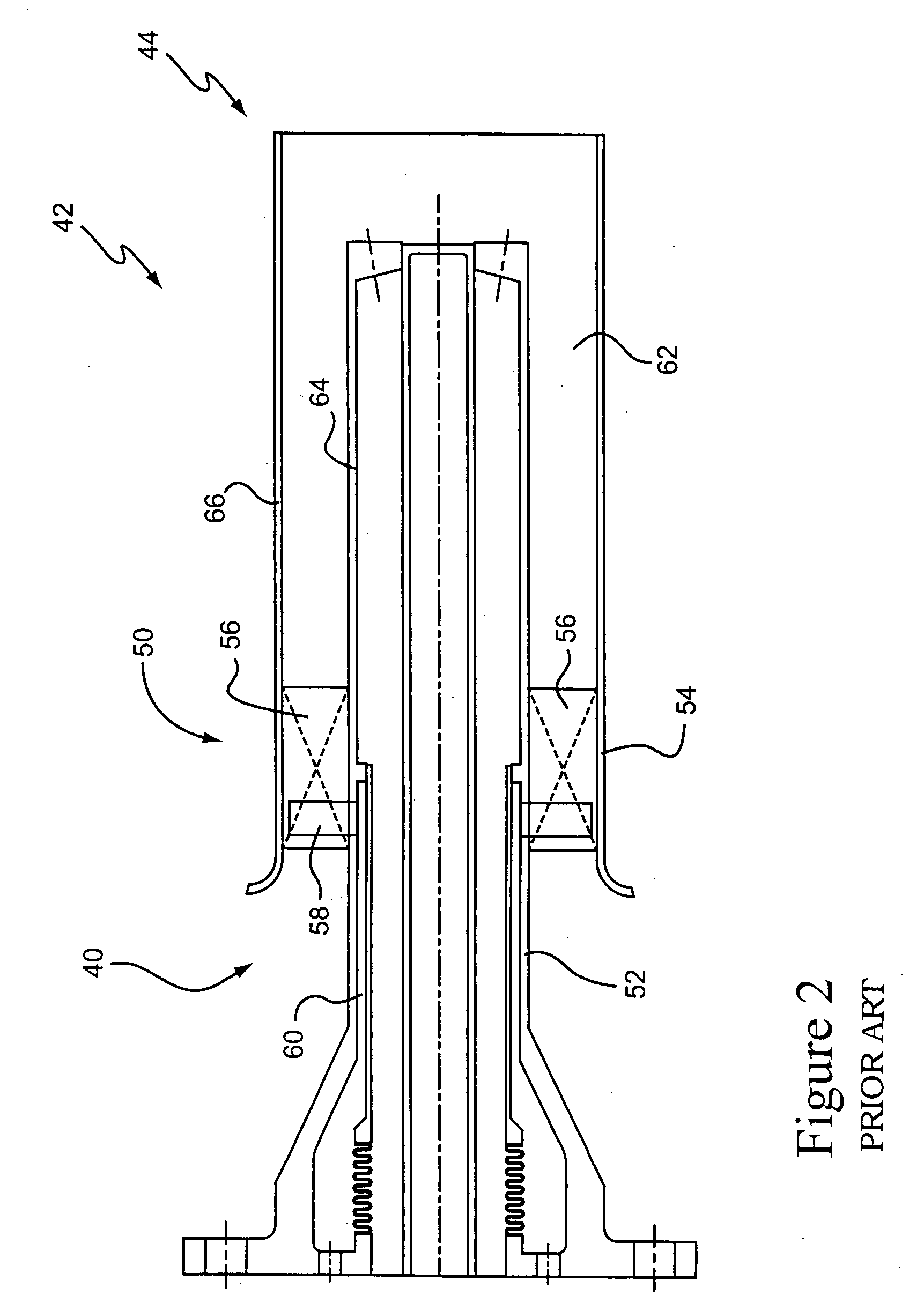

Burner tube and method for mixing air and gas in a gas turbine engine

InactiveUS6993916B2Good mixing propertiesImprove flame stabilityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorGas turbines

Owner:GENERAL ELECTRIC CO

Burner tube and method for mixing air and gas in a gas turbine engine

InactiveUS20050268618A1Improve flame stabilityGood mixing propertiesTurbine/propulsion fuel supply systemsContinuous combustion chamberGas turbinesFuel gas

A hybrid structure that combines characteristics of the DACRS and Swozzle burners to provide the high mixing ability of an axial flowing counter rotating vane swirler with good dynamic flame stability characteristics of a bluff center body.

Owner:GENERAL ELECTRIC CO

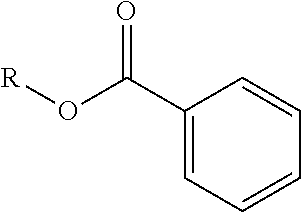

Multi-component peracid generation system

InactiveUS20100086621A1Good storage stabilityGood mixing propertiesInorganic/elemental detergent compounding agentsBiocideDisinfectantCarboxylic acid

Disclosed herein are multi-component peroxycarboxylic acid generation systems for enzymatically producing aqueous formulations of peroxycarboxylic acids suitable for use in, e.g., disinfectant and / or bleaching applications. The multi-component peroxycarboxylic acid generation systems comprise at least one carbohydrate esterase family 7 enzyme having perhydrolytic activity.

Owner:EI DU PONT DE NEMOURS & CO

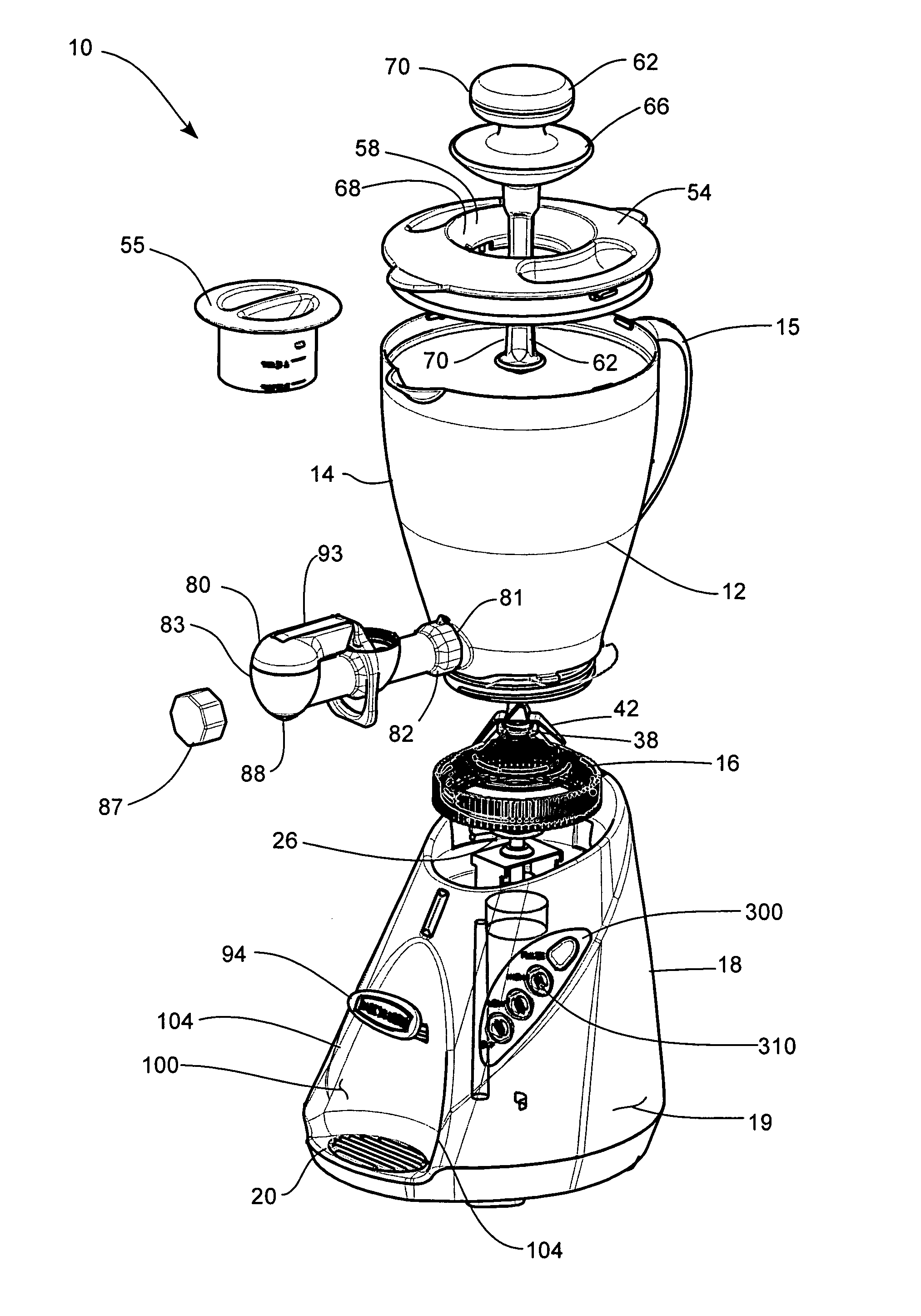

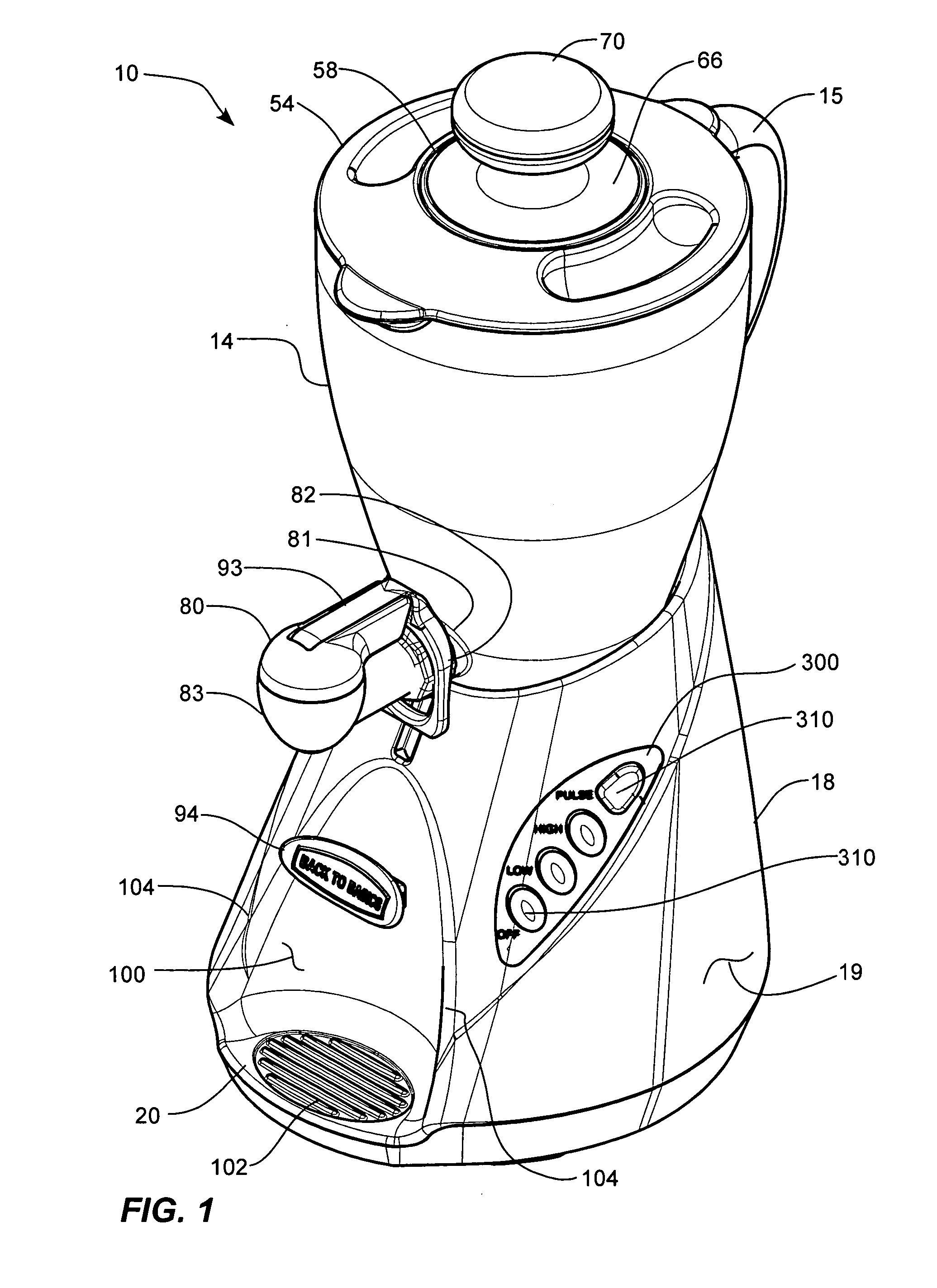

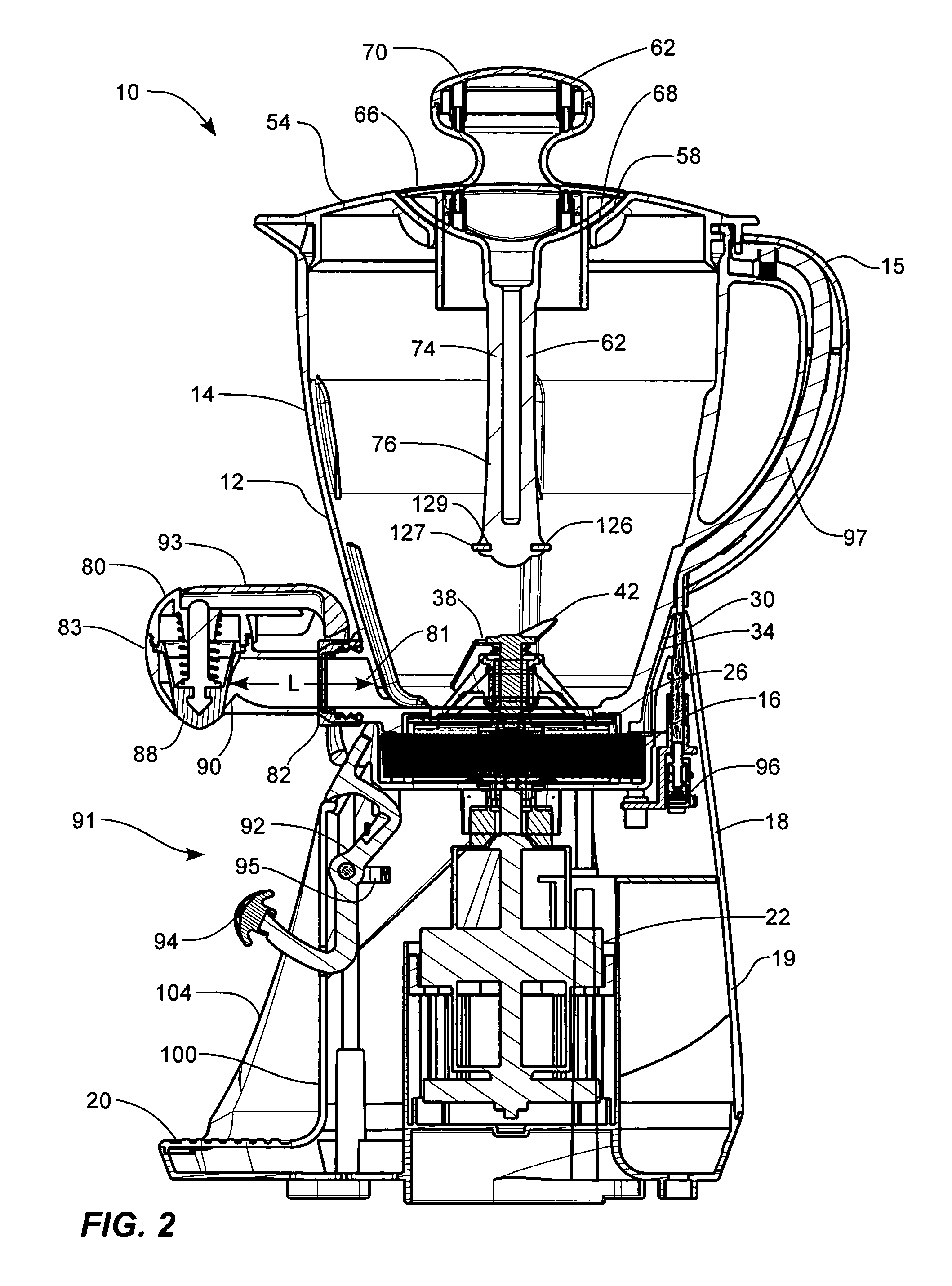

Beverage mixer with spigot and actuator

InactiveUS20070041268A1Optimize allocationImproved dispensing characteristicRotary stirring mixersMixer accessoriesEngineeringActuator

A beverage mixer device with a base including a motor to turn a drive mechanism extending from the base. The beverage mixer includes a container, removably disposable on the base. The container has a mixing assembly rotatably disposed in the container and engagable by the drive mechanism when the container is disposed on the base. The container also includes a spigot operatively coupled to the container to dispense contents of the container. A spigot actuator is carried by the base, and a linkage is operatively coupled to the spigot actuator on the base and the spigot to operate the spigot. The spigot actuator is operatively coupled to the motor such that operation of the linkage actuates the motor to turn the mixing assembly in the container.

Owner:BACK TO BASICS PROD

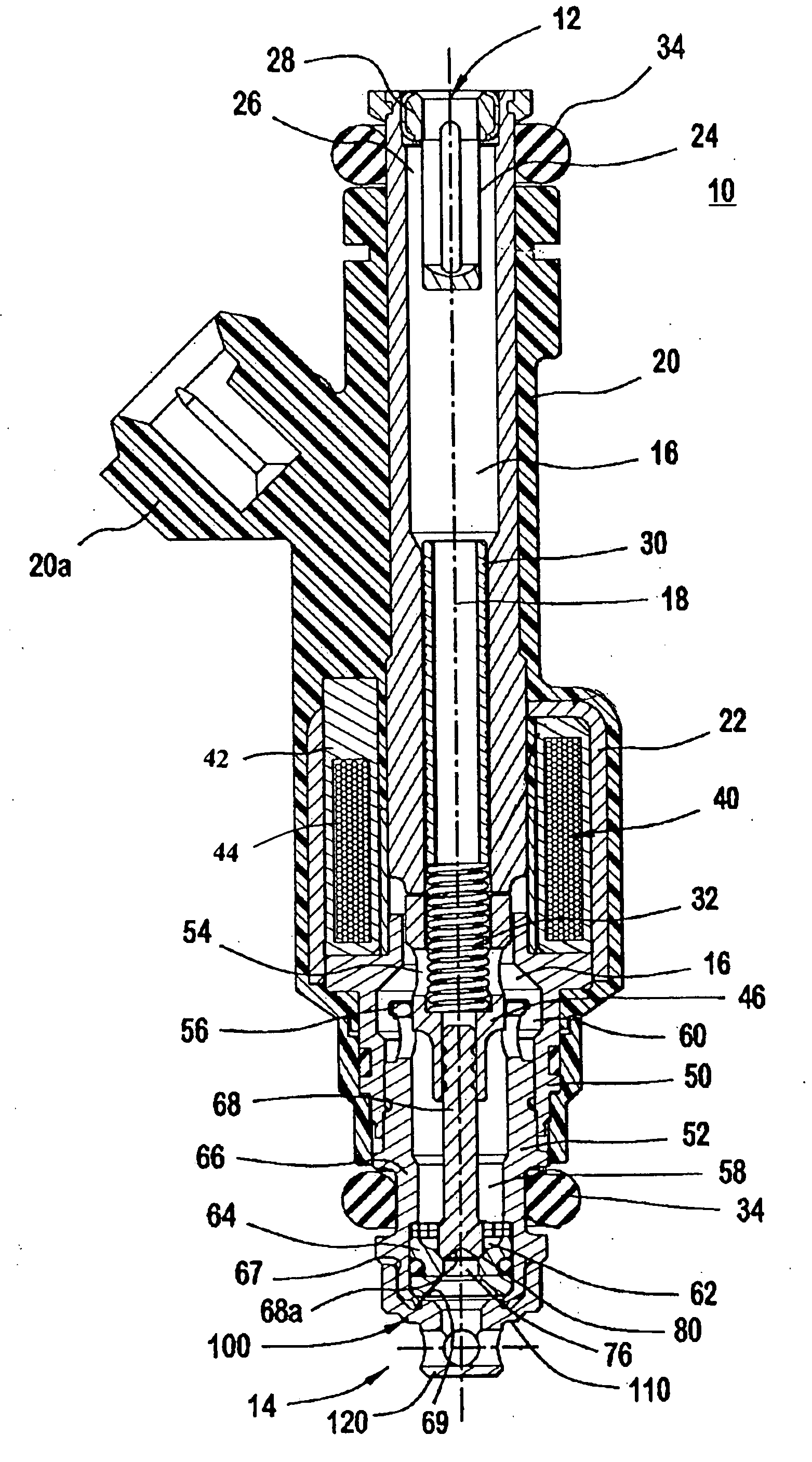

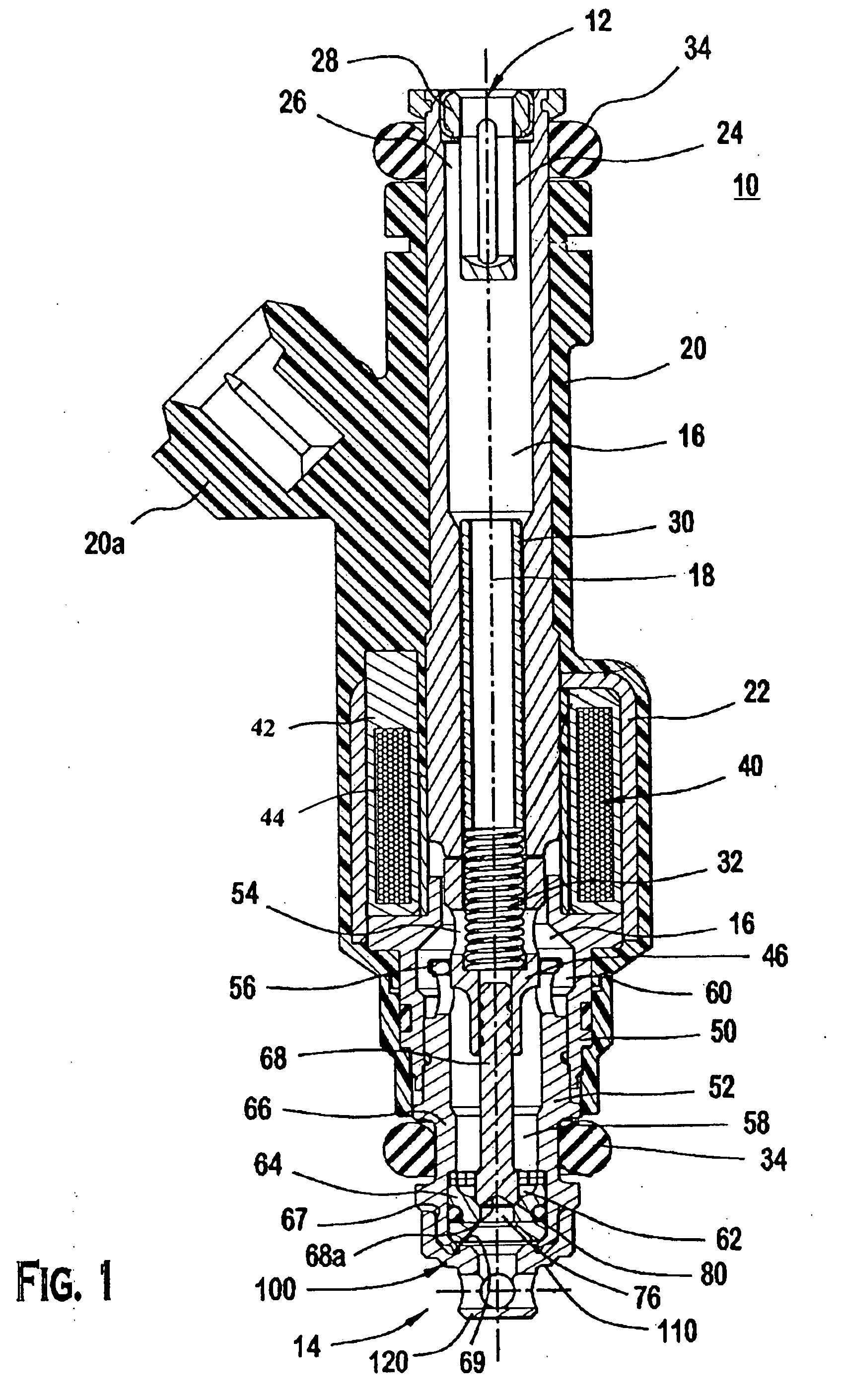

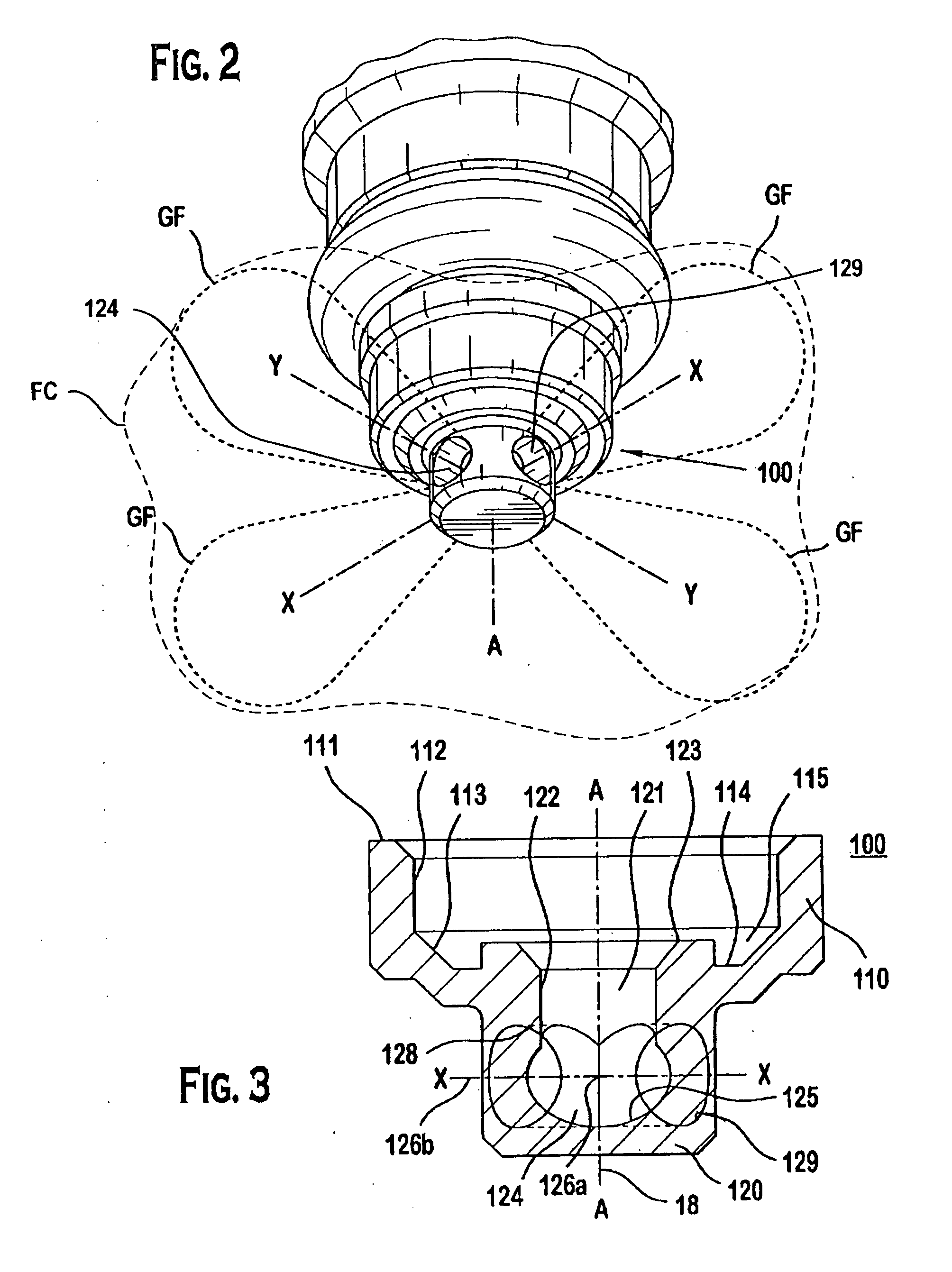

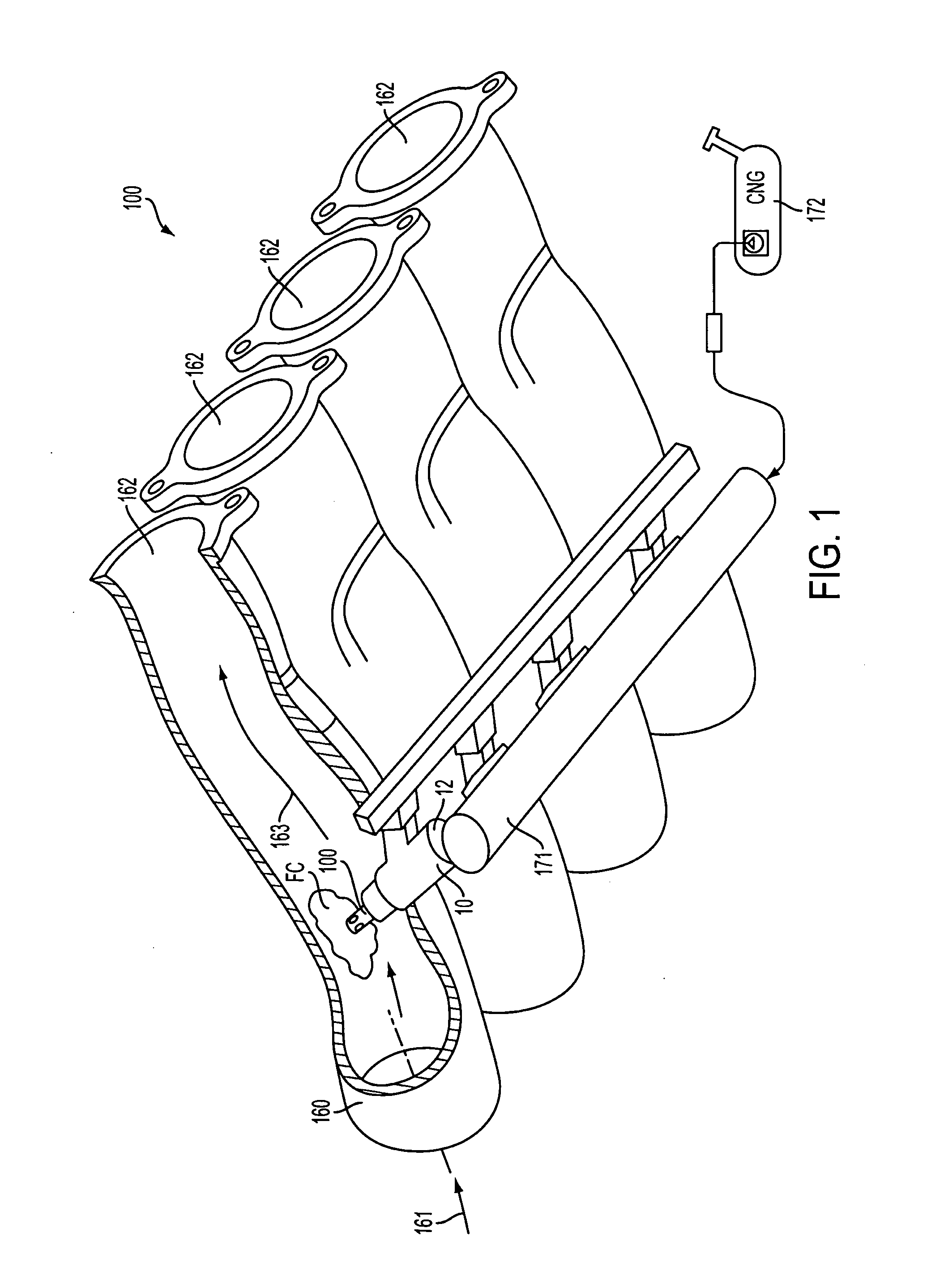

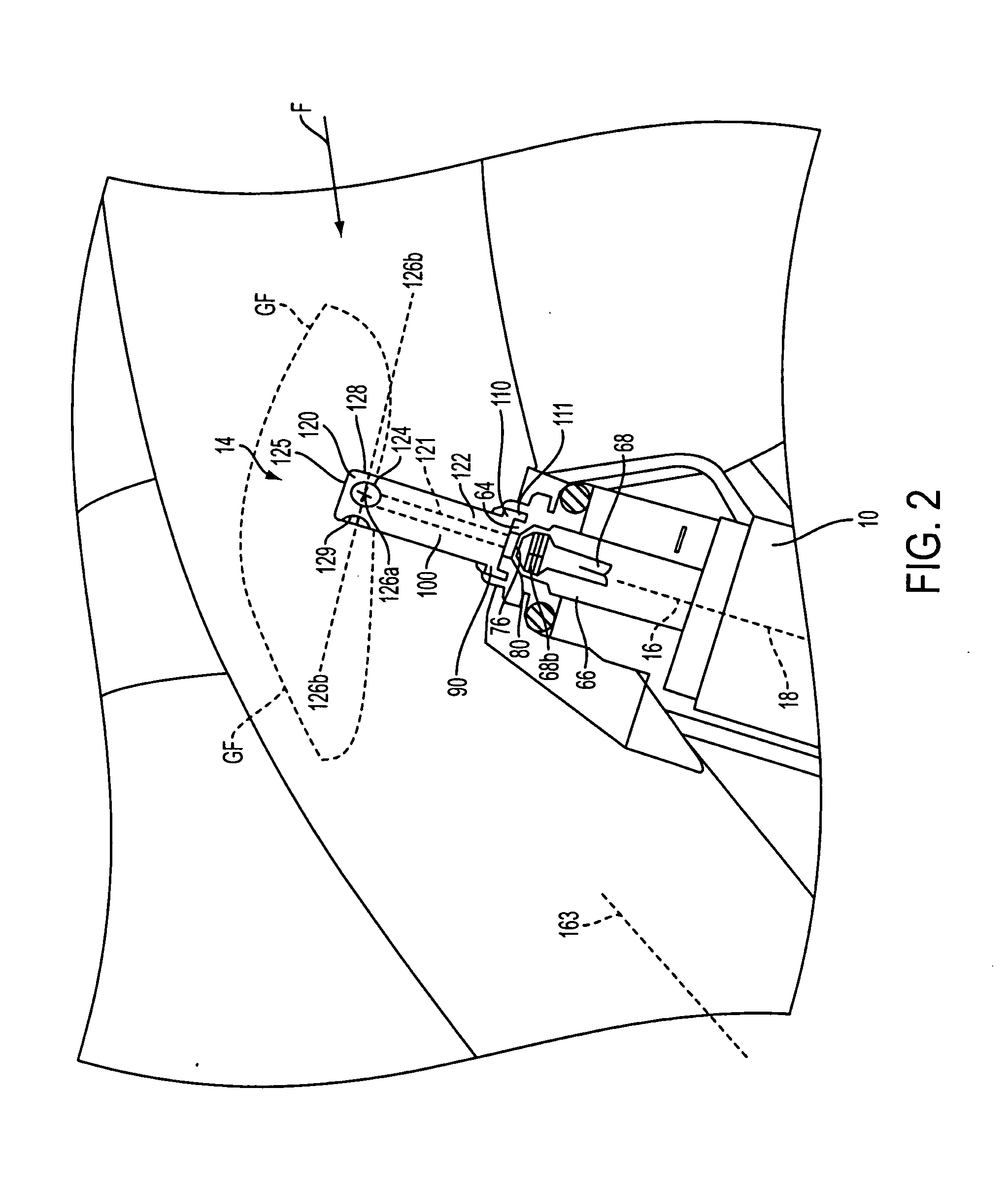

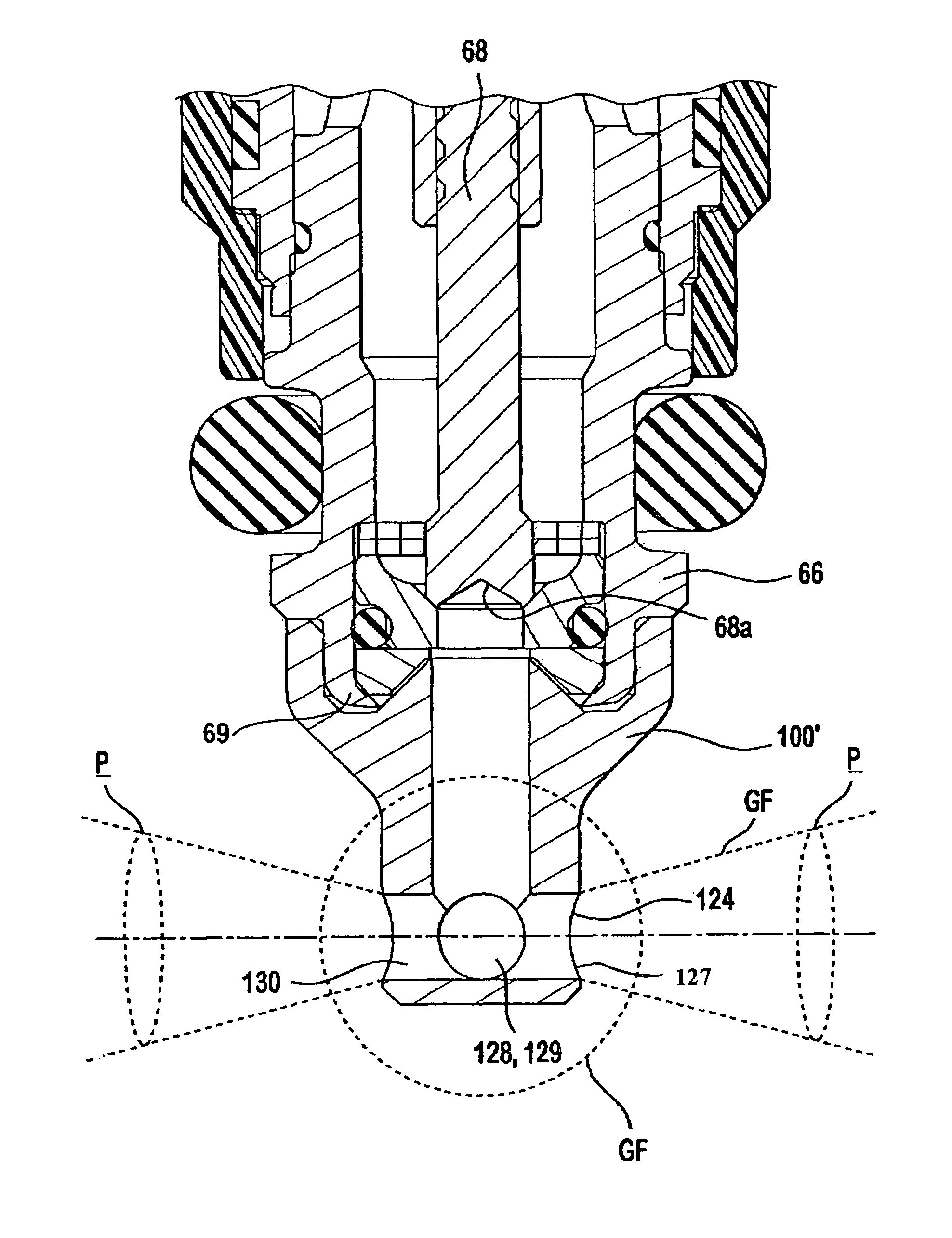

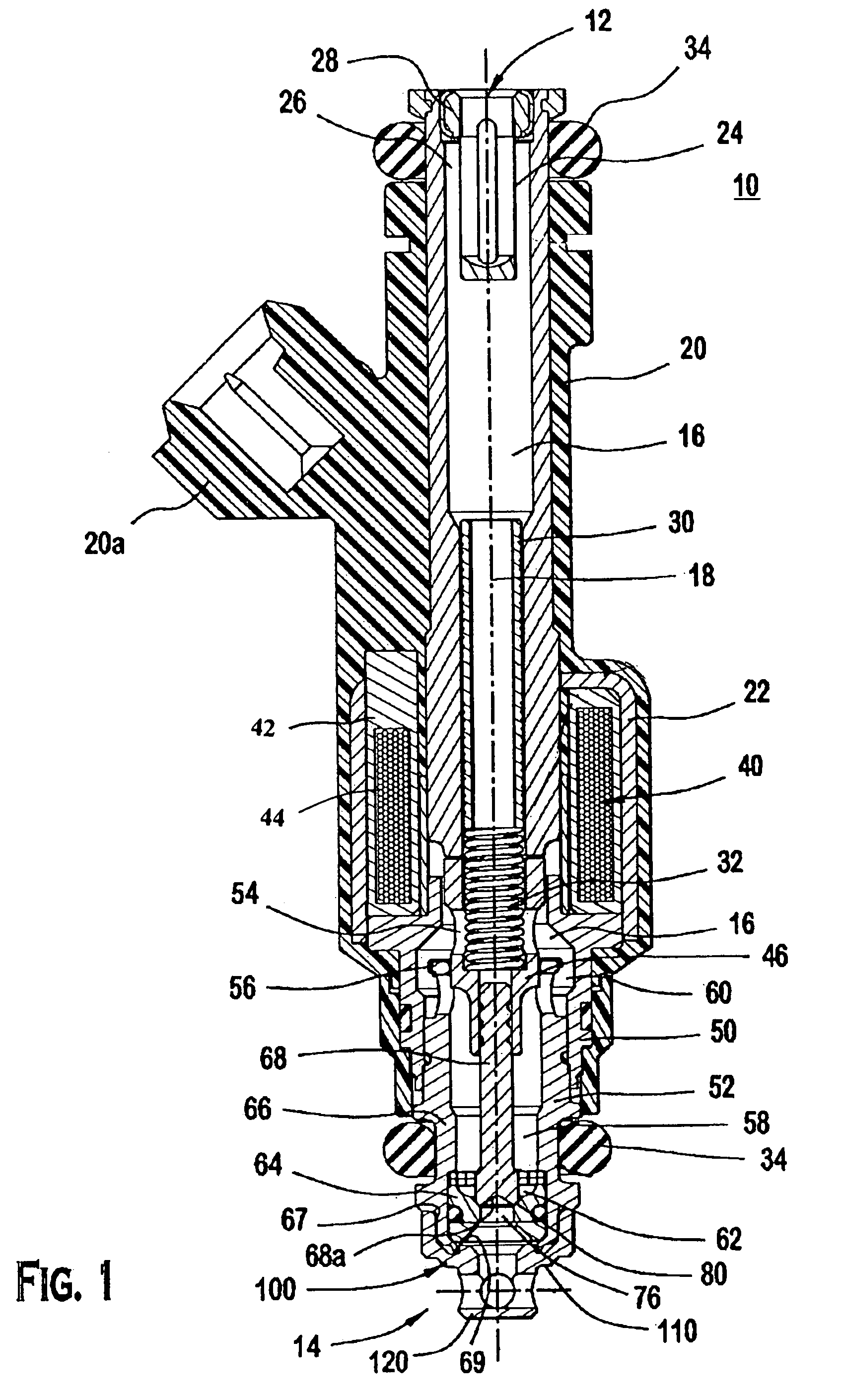

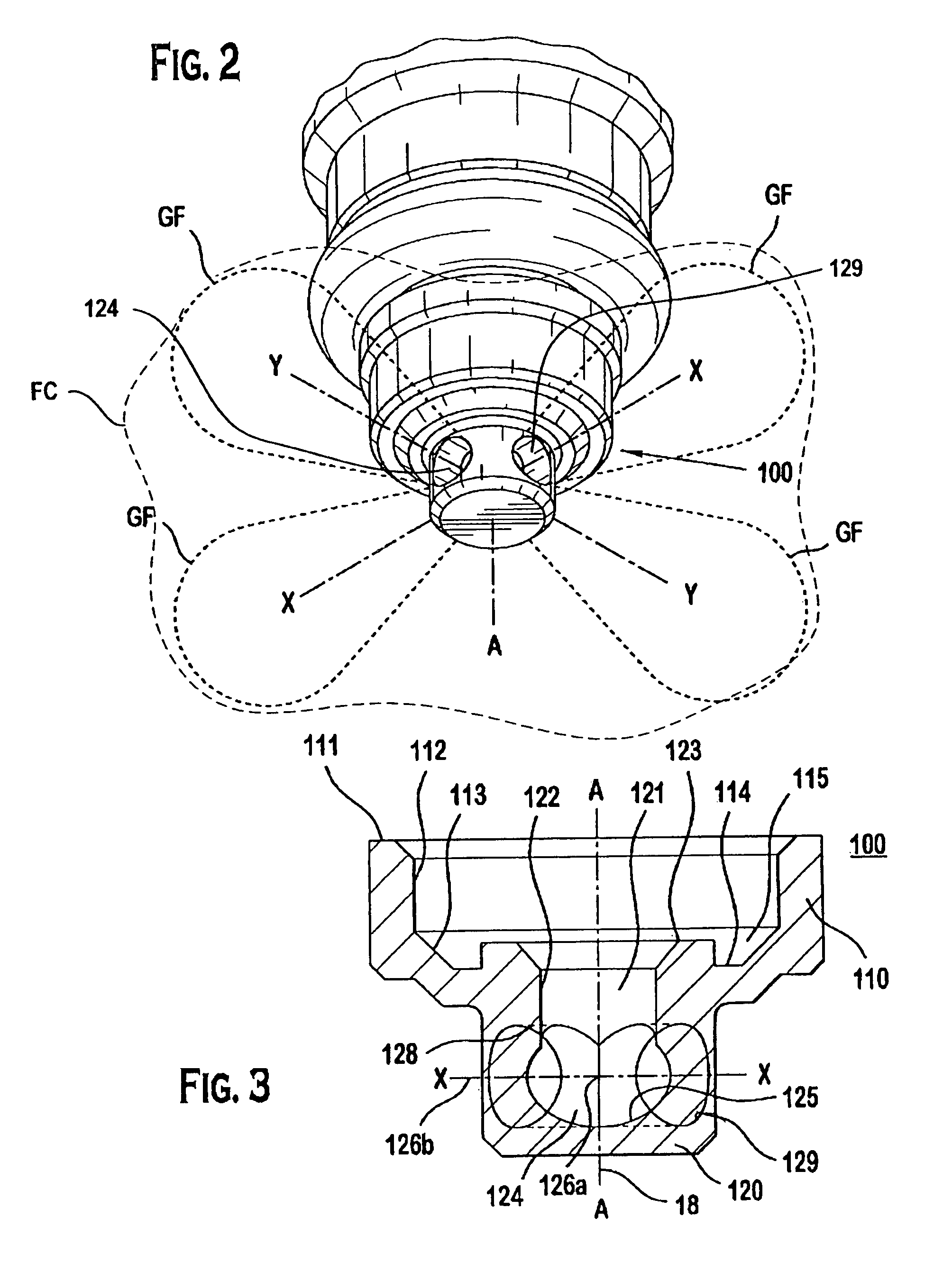

Fuel injector having an external cross-flow nozzle for enhanced compressed natural gas jet spray

InactiveUS20080011887A1Good mixing propertiesImproved gaseous fuel targetingInternal combustion piston enginesFuel supply apparatusCompressed natural gasEngineering

A compressed natural gas fuel injector including a housing, an inlet, an outlet, a seat, a closure member, and an attached nozzle. In a preferred embodiment, the inlet and outlet communicate a flow of gaseous fuel regulated by the closure member. The gaseous fuel passes through the seat, which is coupled to a rim surface of a retainer portion of the attached nozzle, and into a flow passage that further communicates the flow of gaseous fuel into one or more flow channels. The orientation of the flow channels within the attached nozzle greatly affects the discharge pattern and mixing characteristics of the gaseous fuel within an intake manifold. A method of flowing gaseous fuel through the fuel injector is also described.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

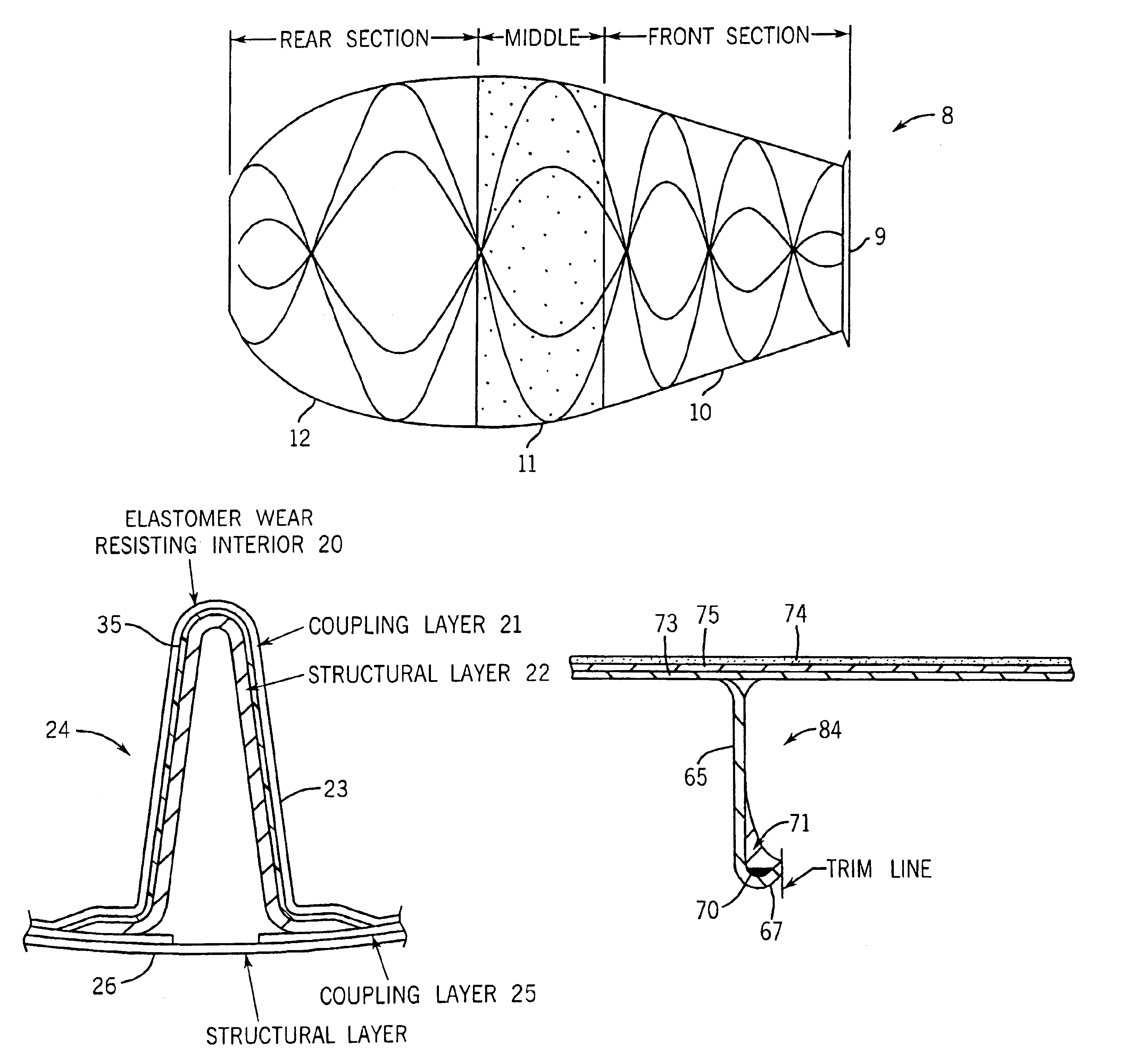

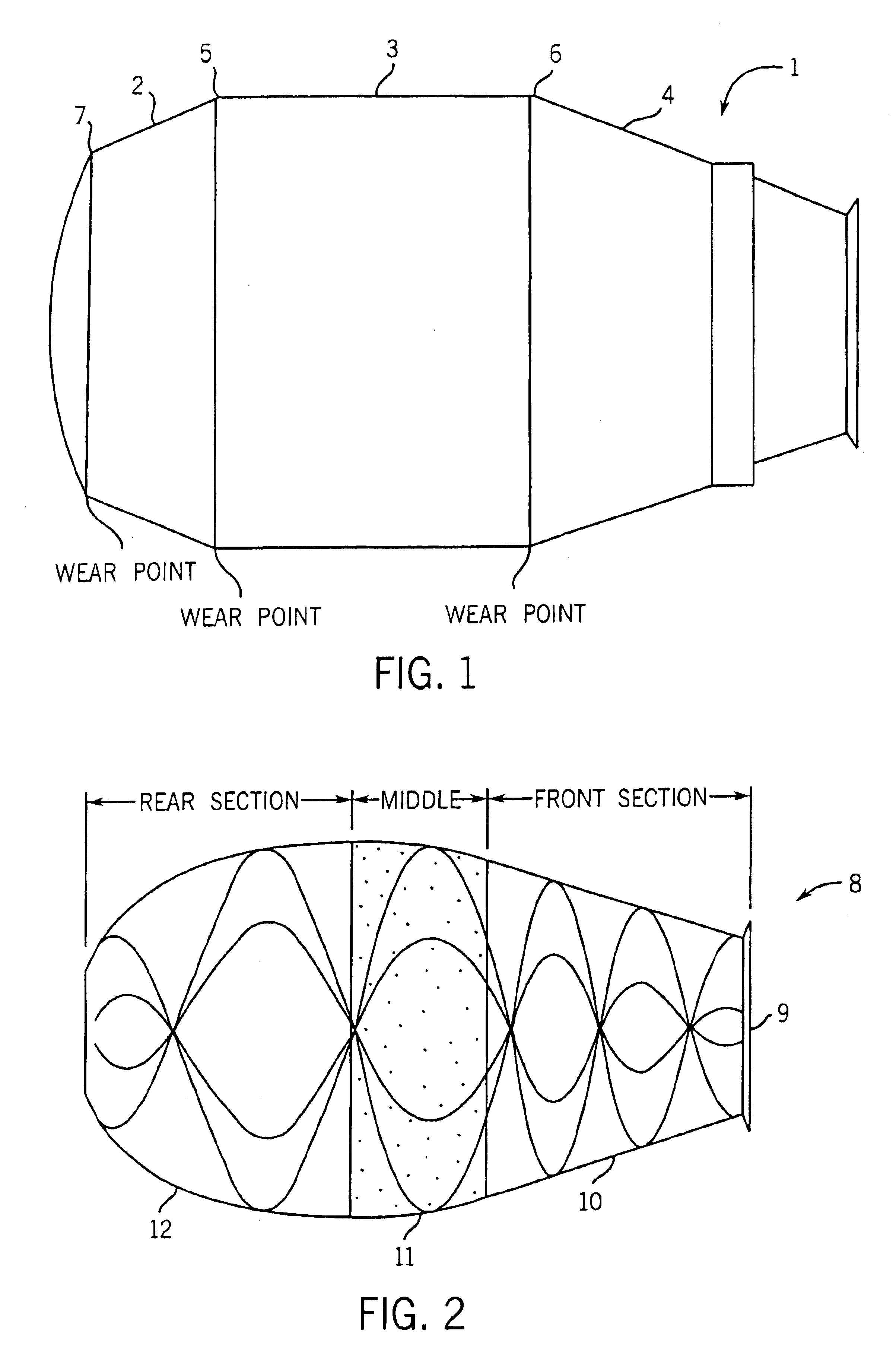

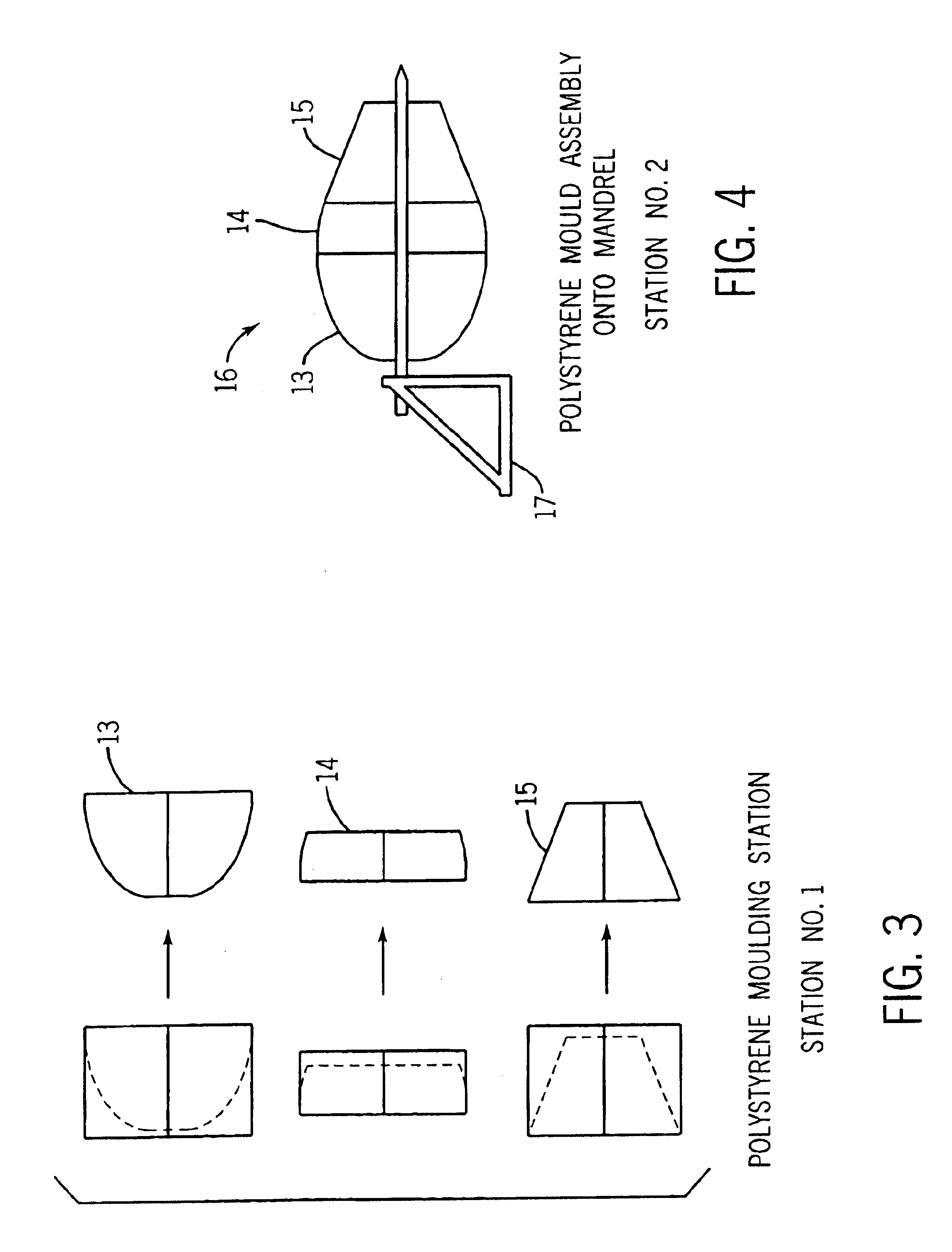

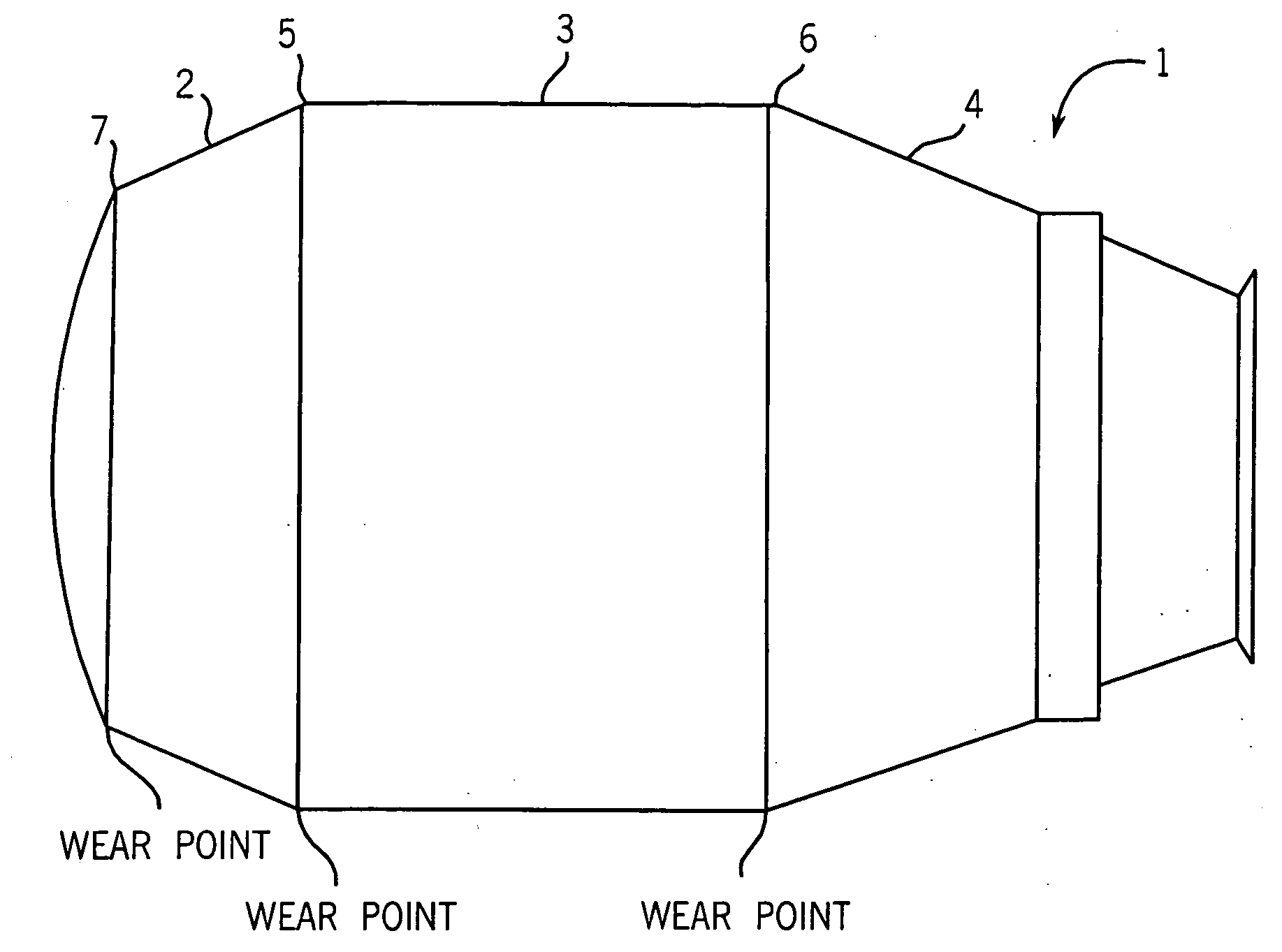

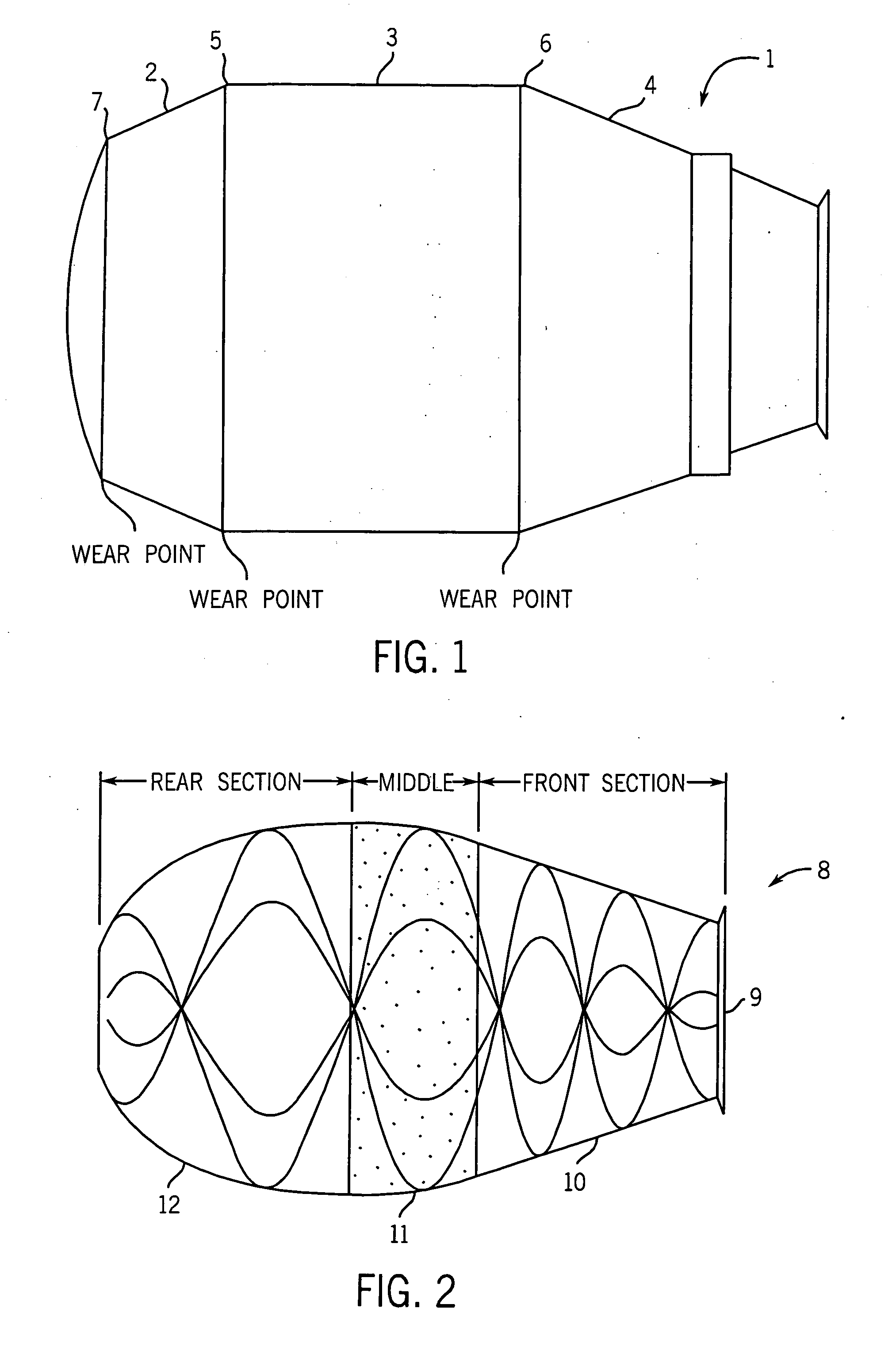

Plastics drum for concrete mixing and methods of manufacture thereof

InactiveUS6902311B1Prolong lifeGood mixing propertiesRotating receptacle mixersButtonsHeavy dutyCivil engineering

A heavy duty rotary concrete mixing drum capable of attachment to a vehicle. The drum comprises a first end which engages a vehicle powered drive assembly which rotates the drum for mixing of said concrete and a second end from which mixed concrete is discharged. The drum is manufactured from at least one layer of plastics material; wherein the drum includes a wall having integral internal formations which promote mixing and discharge of said concrete and an inner surface which promotes mixing of the concrete.

Owner:KHOURI ANTHONY

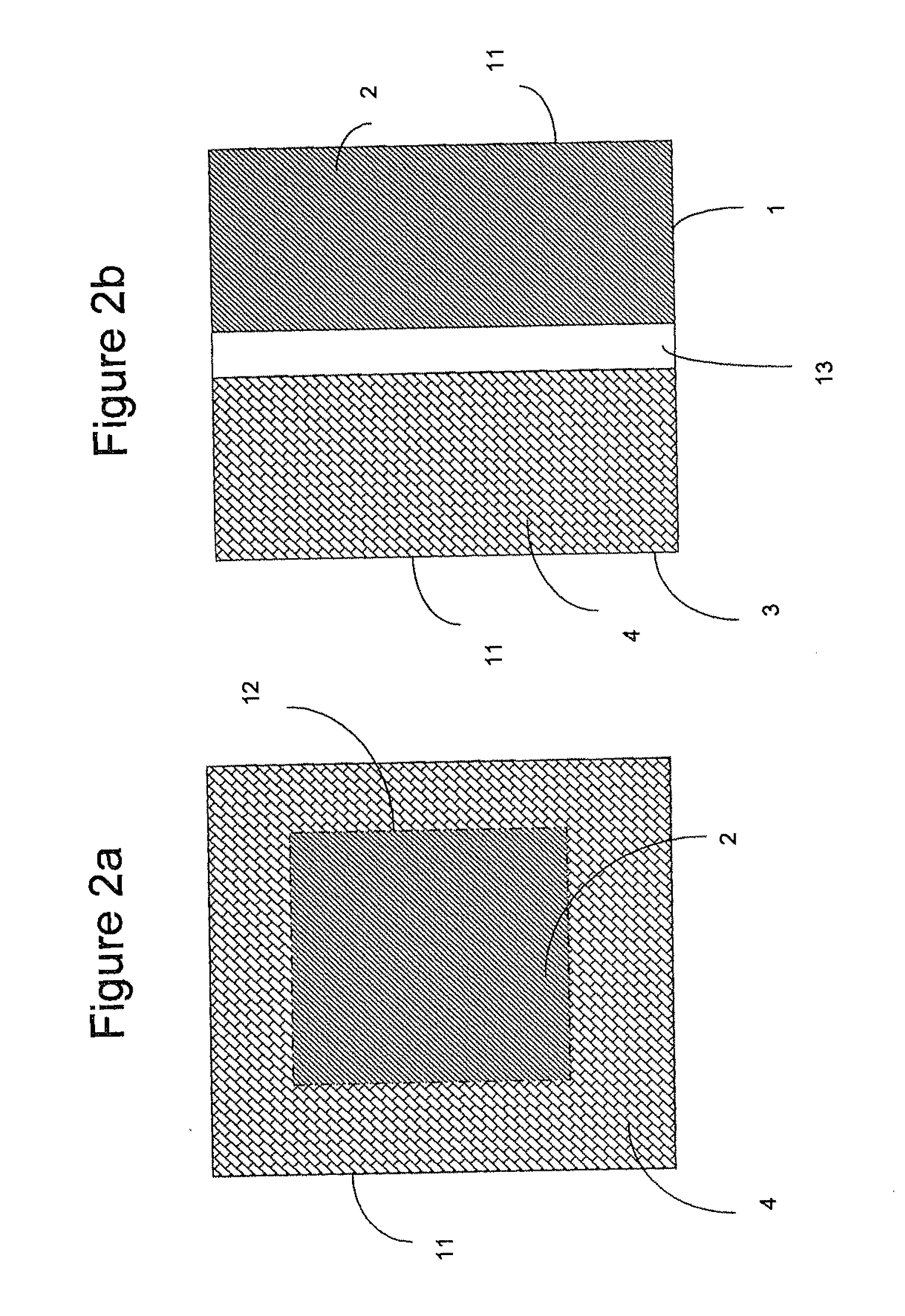

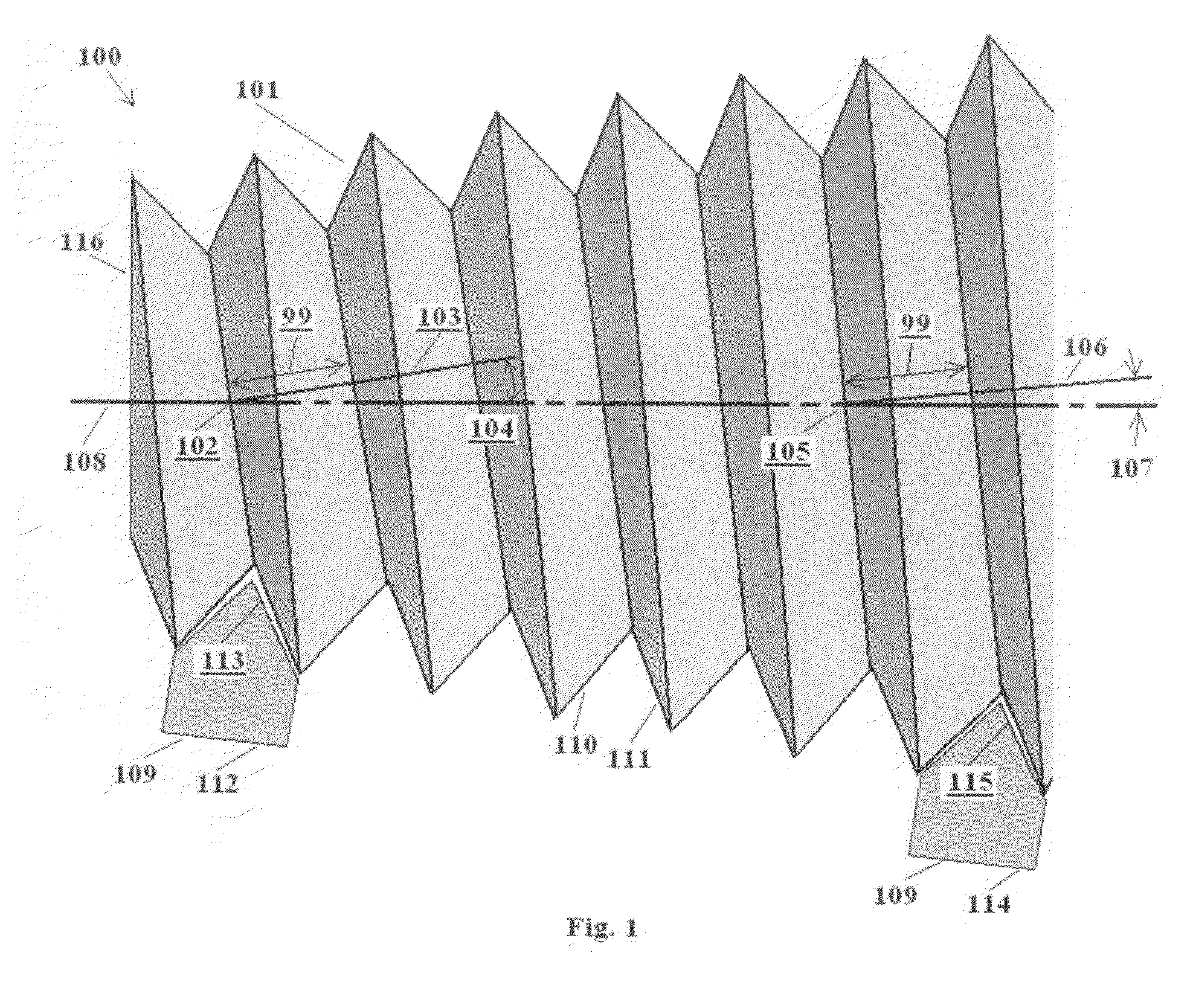

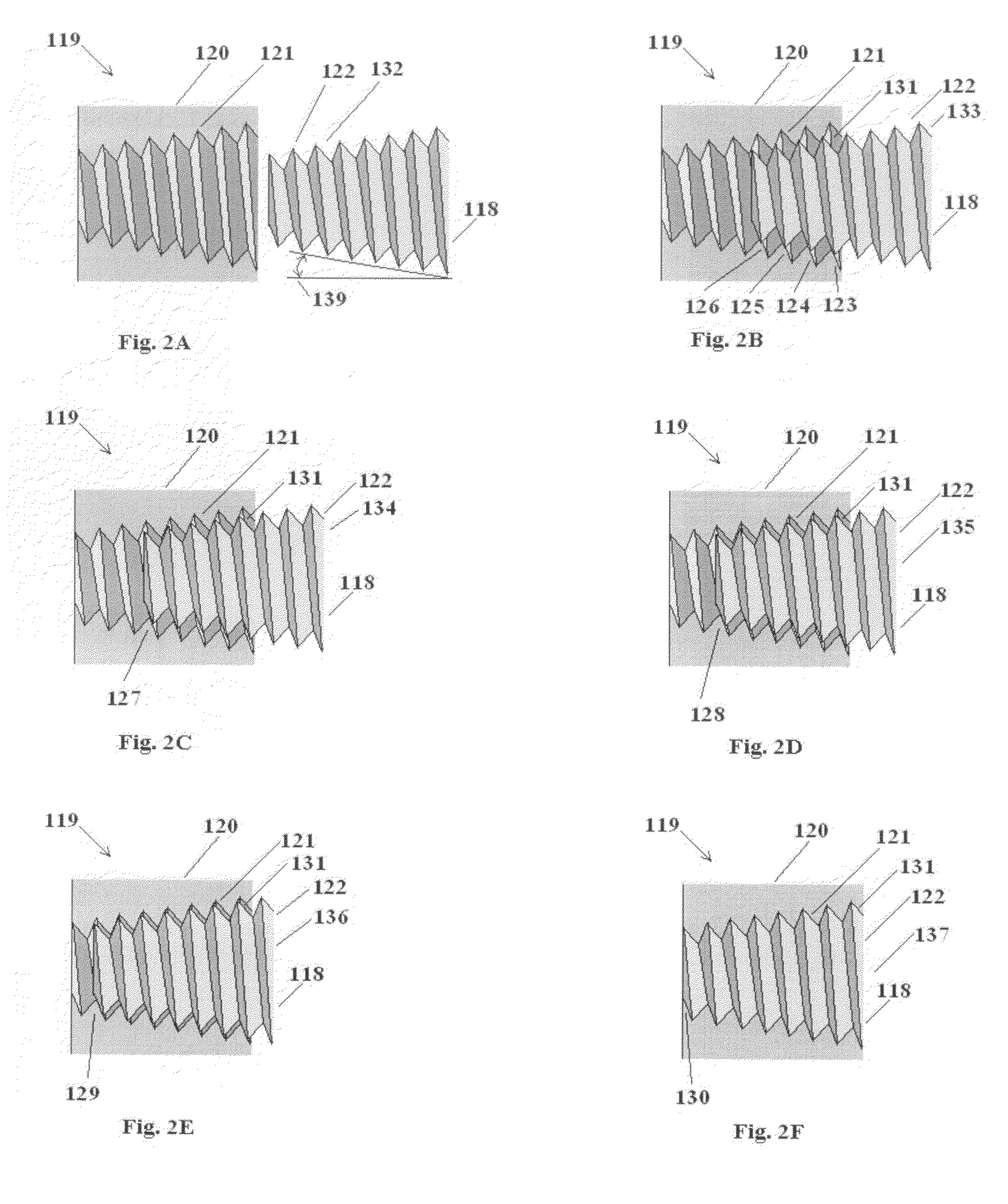

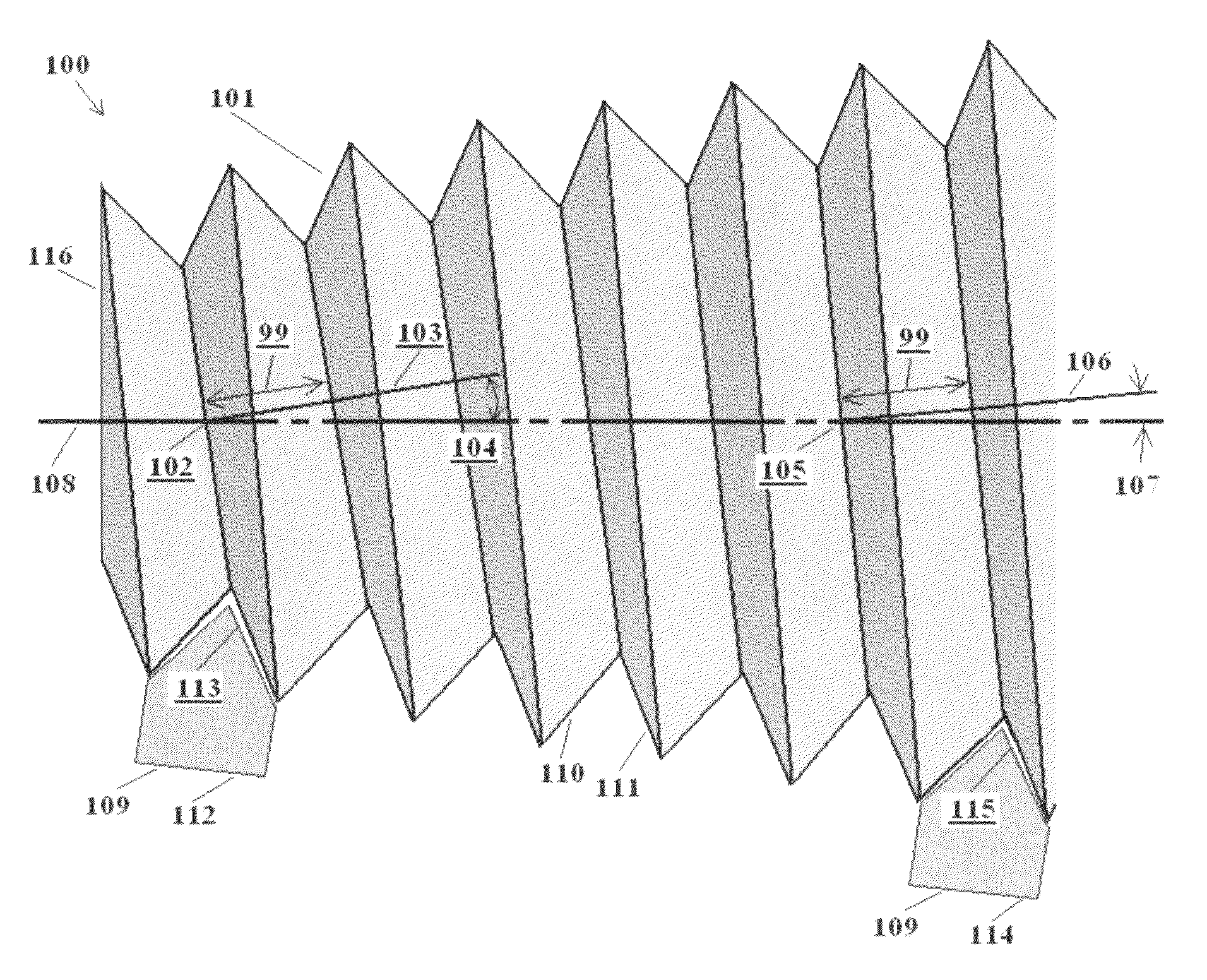

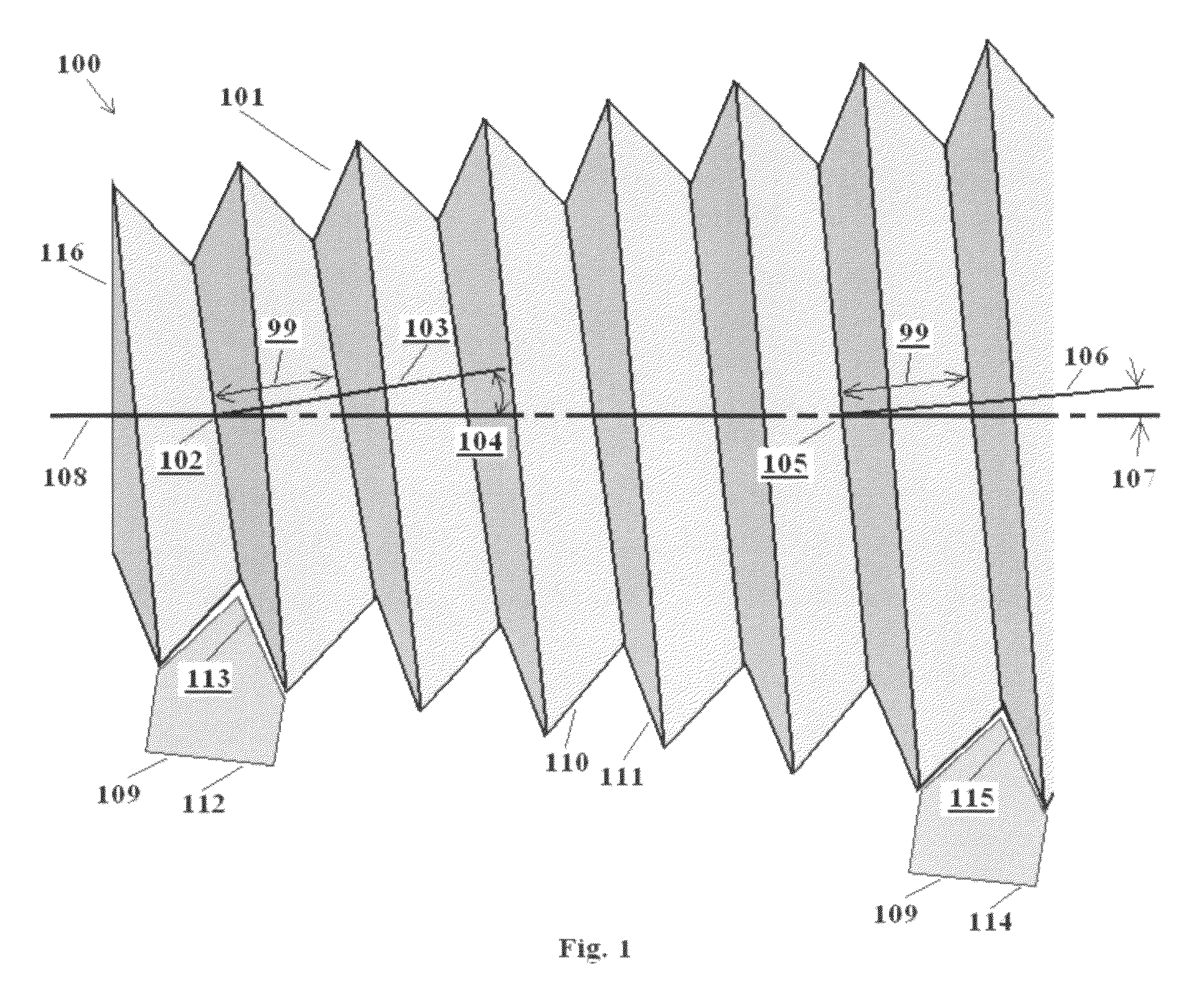

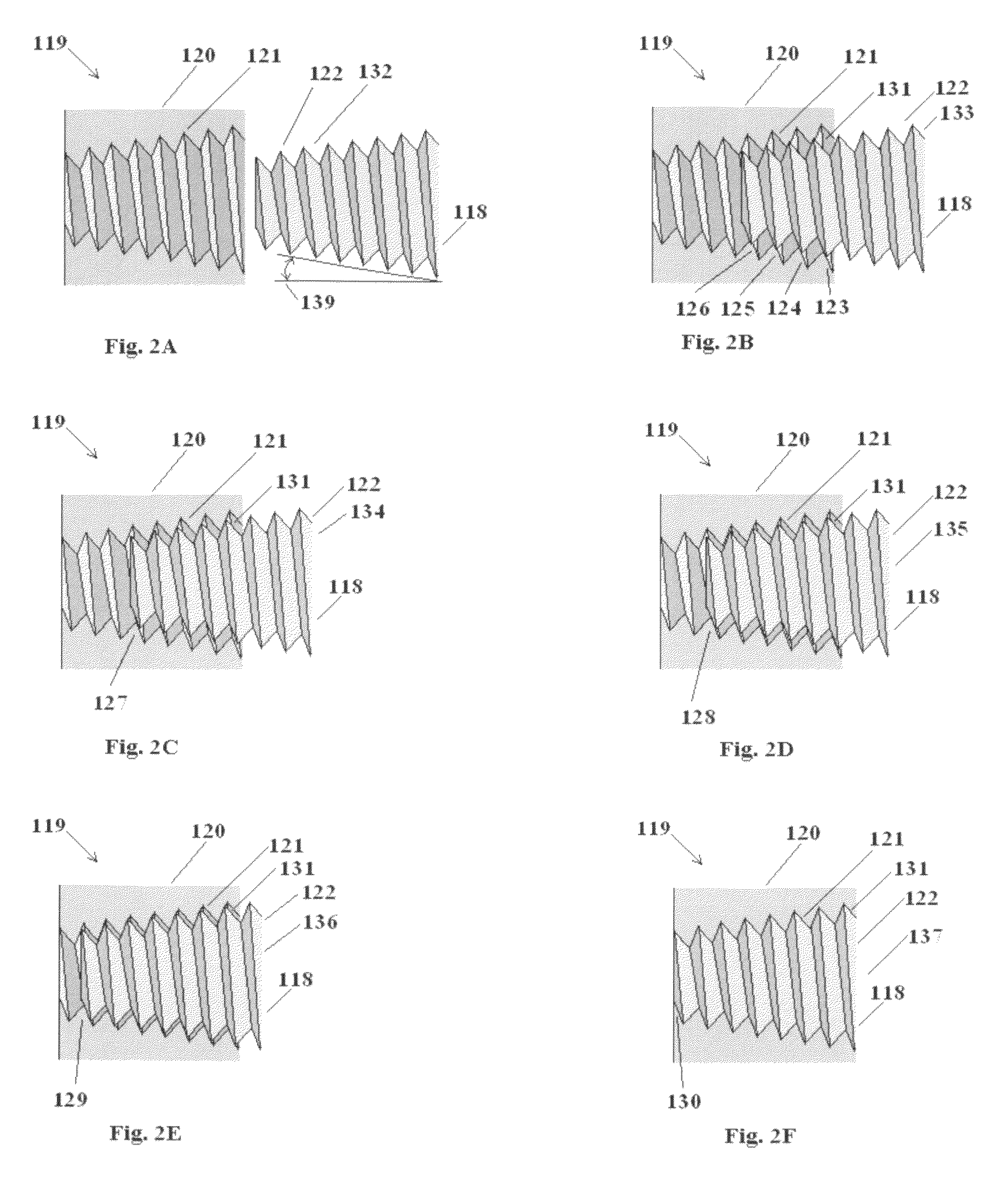

Conic threaded fastener and fastener system

InactiveUS20070009340A1Easy to controlImprove the mixing effectNutsBoltsScrew threadBiomedical engineering

A conic threaded fastener and conic threaded fastener system. The conic threaded fastener includes a body having at least one substantially conic outer surface and at least one conic thread forming a spiral about the substantially conic outer surface of the body. The conic thread forms a plurality of crests and a plurality of roots and the tangential distance between adjacent crests is substantially constant. The conic threaded fastener system includes the conic threaded fastener and a workpiece with an opening having at least one inner conic surface dimensioned to mate with a conic outer surface of the conic threaded fastener.

Owner:VAN COR DALE E

Threaded fastener and fastener system

A threaded fastener and threaded fastener system. The threaded fastener includes a body having at least one outer surface and at least one thread forming a spiral about the outer surface of the body. The thread forms a plurality of crests and a plurality of roots and the tangential distance between adjacent crests is substantially constant. The threaded fastener system includes the threaded fastener and a workpiece with an opening having at least one inner surface dimensioned to mate with outer surface of the threaded fastener.

Owner:VAN COR DALE E

Method for mixing fluids, method for producing particulates, and particulates

InactiveUS20110015416A1Good mixing propertiesAddressing slow performanceFatty acid chemical modificationFlow mixersProcess engineeringMixing zone

A method for mixing fluids that can control mixing characteristics of fluids, a method for producing particulates that can provide desired particulates, and particulates produced thereby are provided. According to an embodiment of the present invention, in a method for mixing at least two kinds of fluids in a microreactor, a first fluid is supplied to a mixing zone through a divided supply passage, and a second fluid is supplied to the mixing zone through a supply passage. A total value of dynamic pressures of the first and second fluids is controlled to mix the first and second fluids in the mixing zone. Then, the mixed fluids are flowed into a micro passage.

Owner:FUJIFILM CORP

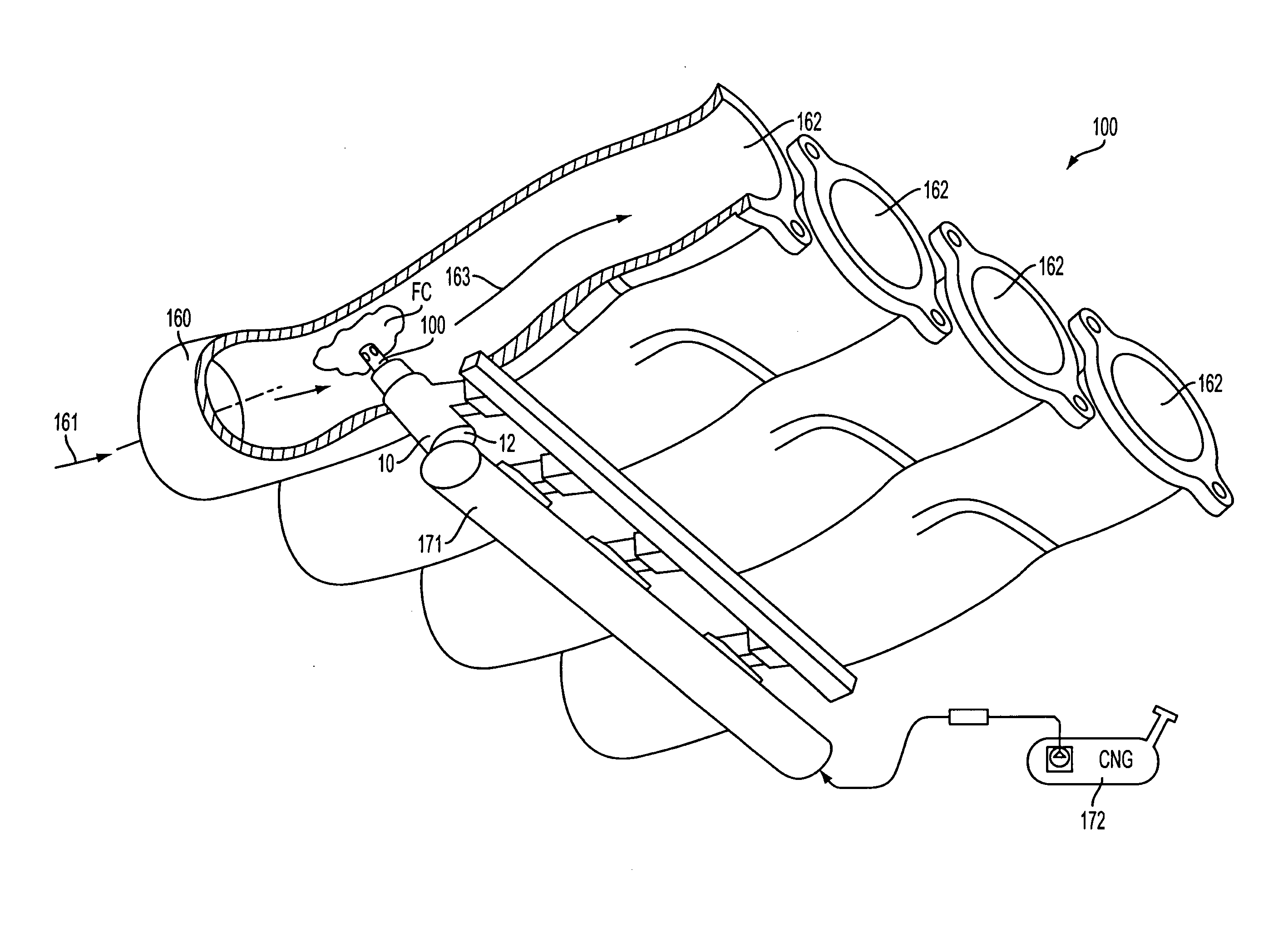

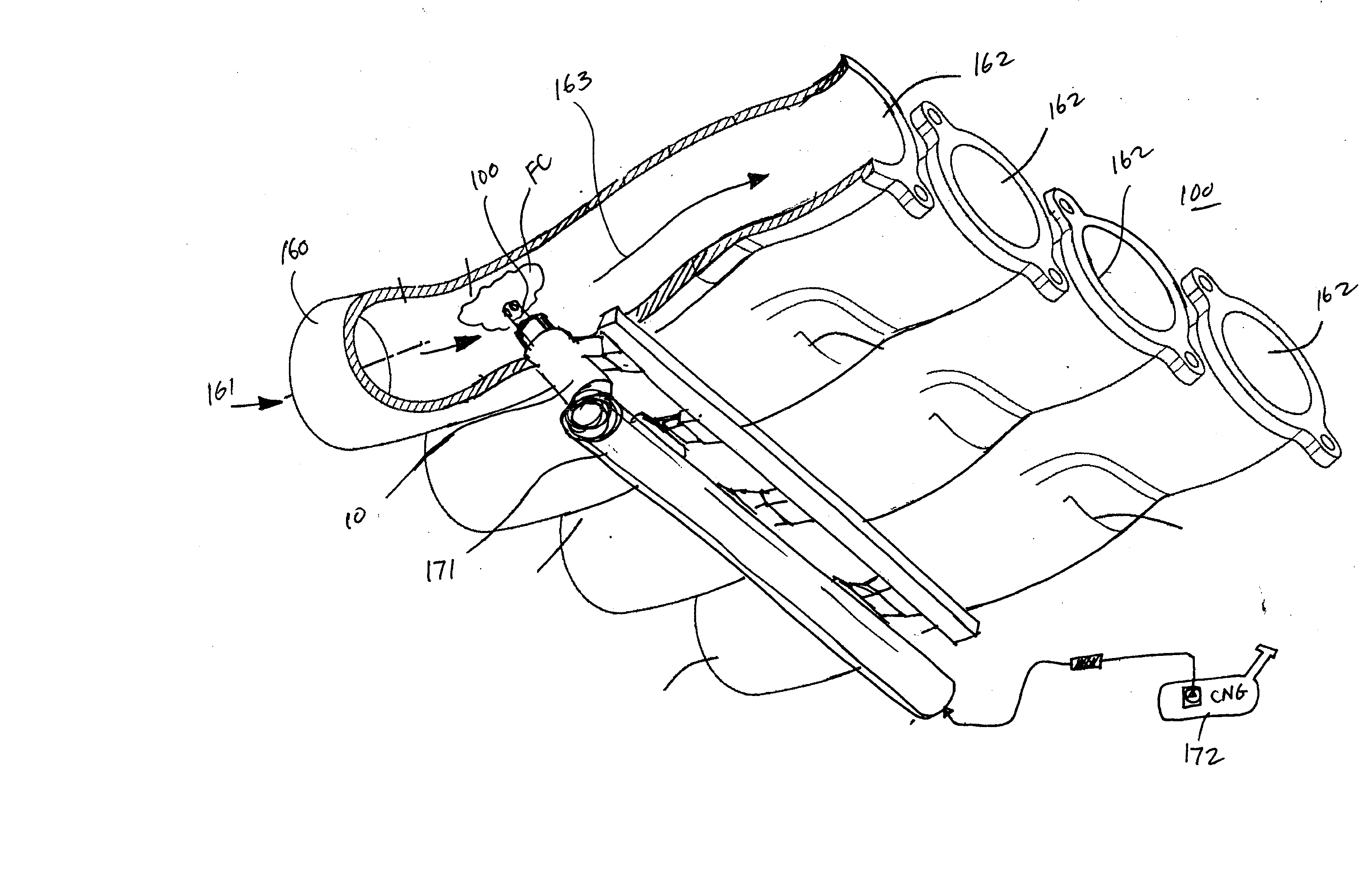

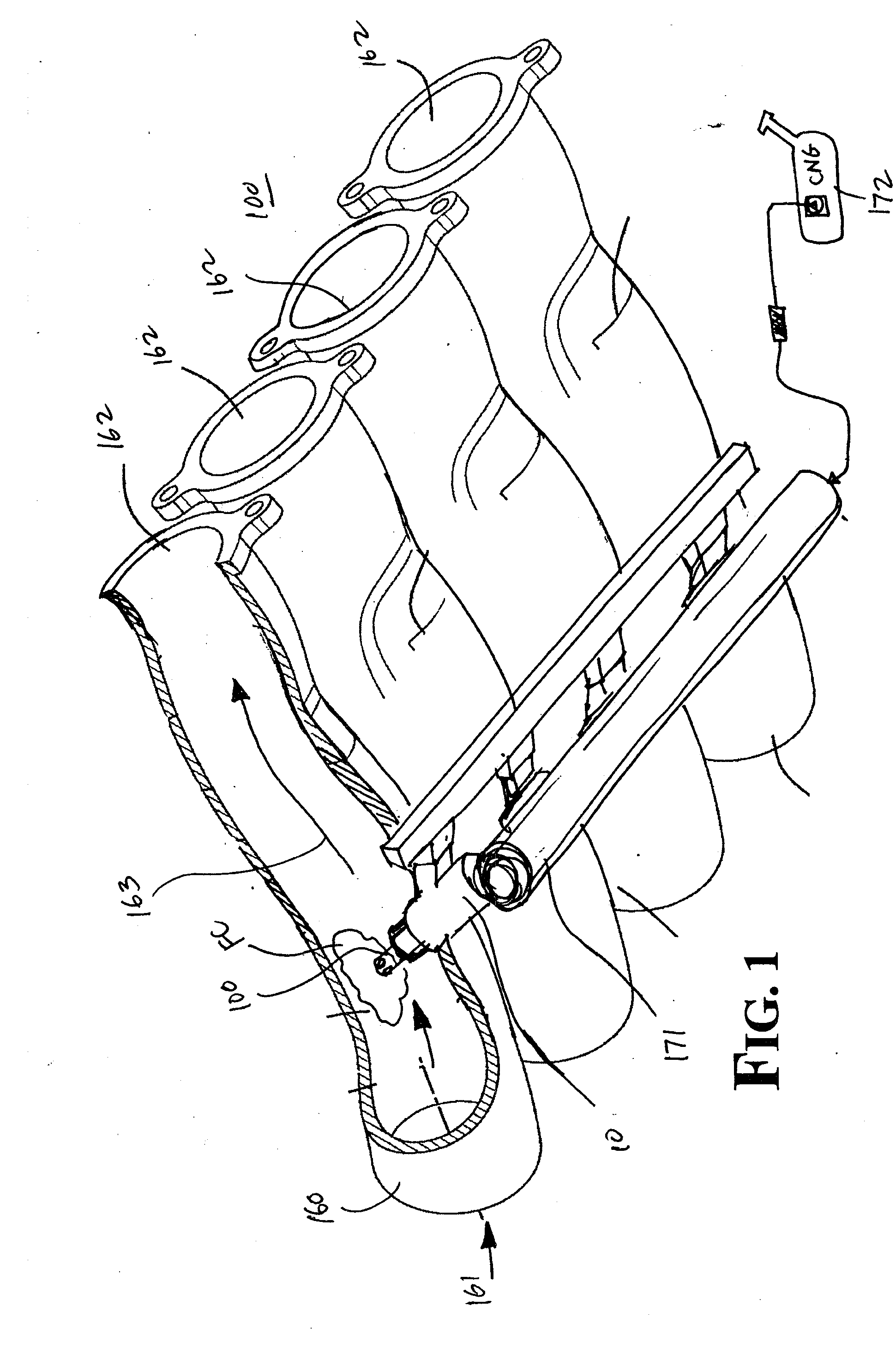

Fuel injection system with cross-flow nozzle for enhanced compressed natural gas jet spray

InactiveUS20080184964A1Improved gaseous fuel targetingImprove the problemInternal combustion piston enginesFuel supply apparatusCompressed natural gasProcess engineering

An intake manifold system including an intake manifold and a compressed natural gas (CNG) fuel injector located between an inlet and an outlet of the intake manifold. The CNG fuel injector includes a housing, an inlet, an outlet, a seat, a closure member, and a nozzle. In a preferred embodiment, the inlet and outlet communicate a flow of gaseous fuel regulated by the closure member. The gaseous fuel passes through the seat, which is secured to a rim surface of a retainer portion of the nozzle, and into a flow passage that further communicates the flow of gaseous fuel into one or more flow channels. The orientation of the flow channels within the nozzle greatly affects the discharge pattern and mixing characteristics of the gaseous fuel within an intake manifold. A method of metering gaseous fuel in an intake manifold having a gaseous fuel supply coupled to a fuel injector is also described.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

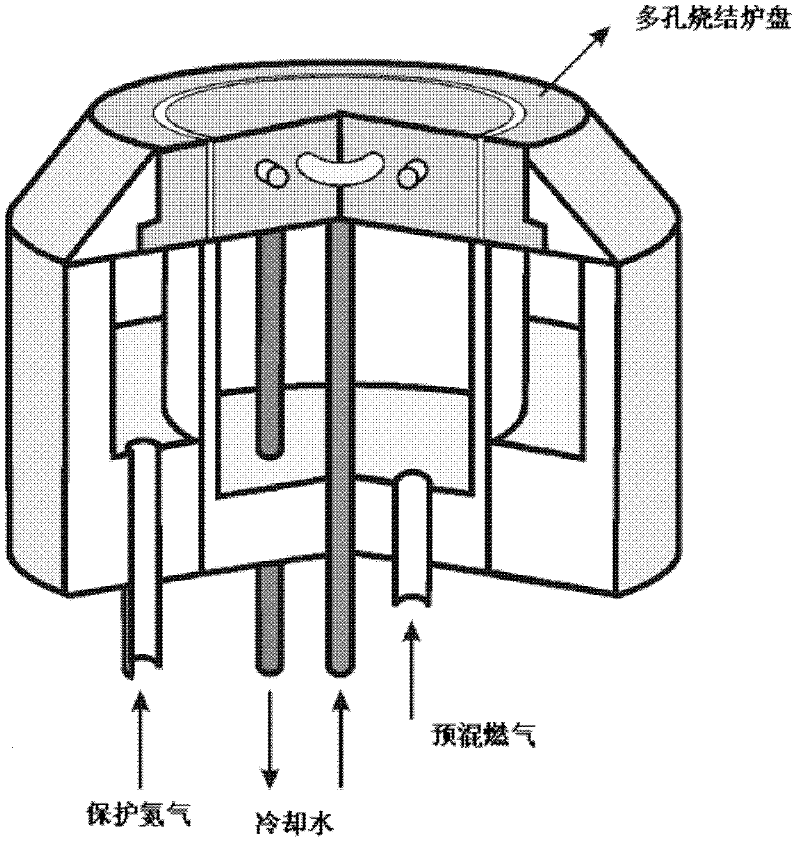

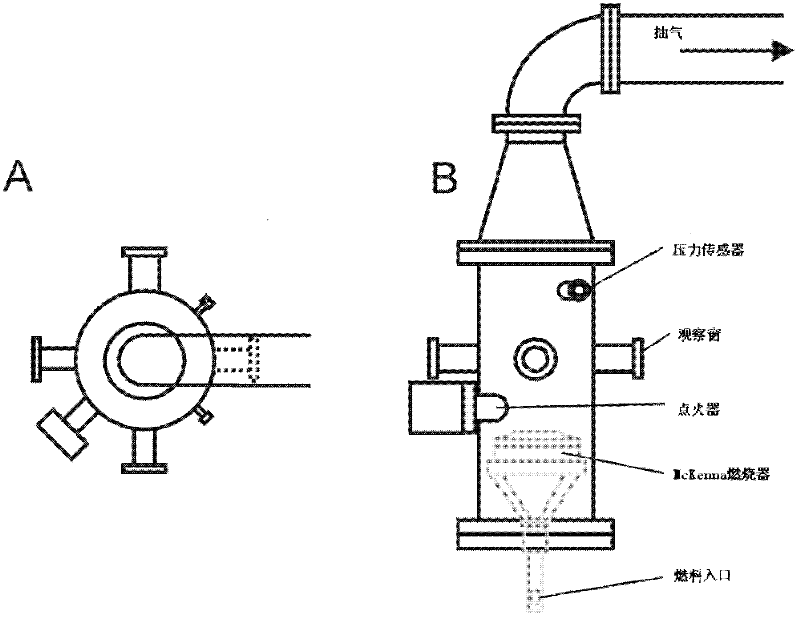

Flat-flamed burner

The invention discloses a flat-flamed burner. The flat-flamed burner comprises such modules as a stove plate (1), a pre-mixing air chamber (2), a protective air chamber (3), an experimental chamber (4), an air exhaust cap (5), a pressure regulator (6), observation window glass (9), a glass sealing cover (10), and the like. The flat-flamed burner is a modularization flat-flamed burner which is compact in structure, convenient in operation, high in safety and reliability, convenient to maintain after the improvement, capable of reducing photometric errors, self-adjustable in pressure and more stable in the generated flat flame. Different modules are designed, and then assembled to a burner of different functions, so that the modularization design method can constantly expand the application range of the flat-flamed burner.

Owner:NAT UNIV OF DEFENSE TECH

Medical stone ceramic product and preparation method thereof

The invention discloses a medical stone ceramic product prepared from the following raw materials in percentage by weight: 41-45% of medical stone powder, 16-20% of potassium feldspar powder, 10-14% of soda feldspar powder, 8-10% of quartz powder and 12-17% of Laiyang soil. The preparation method comprises the following steps: weighing raw materials in percentage by weight, grinding and filtering the raw materials by a sieve with the granularity of 100-150 meshes, and uniformly mixing for later use; grinding the powder in a ball miller for 1-2 hours according to the condition that the ratio of the material to balls to water is 1:2:0.5, filtering mud through a sieve with the granularity of 32-35 meshes, and pugging to obtain a finished mud product; performing slip-casting, demoulding, correcting and grinding, and drying for 12-24 hours; sintering a dried mud blank in a furnace in steps and cooling to obtain the required product. The medical stone ceramic product is reasonable in material proportion and scientific in sintering method, so that the medical stone has improved performance, good air permeability and high plasticity, and the yield is up to 97%; the medical stone is free from toxicity and radiation, and has no change in original property and precipitated trace elements; the medical stone can be prepared into various beautiful new material tea sets, cups and other finished products.

Owner:马仁水

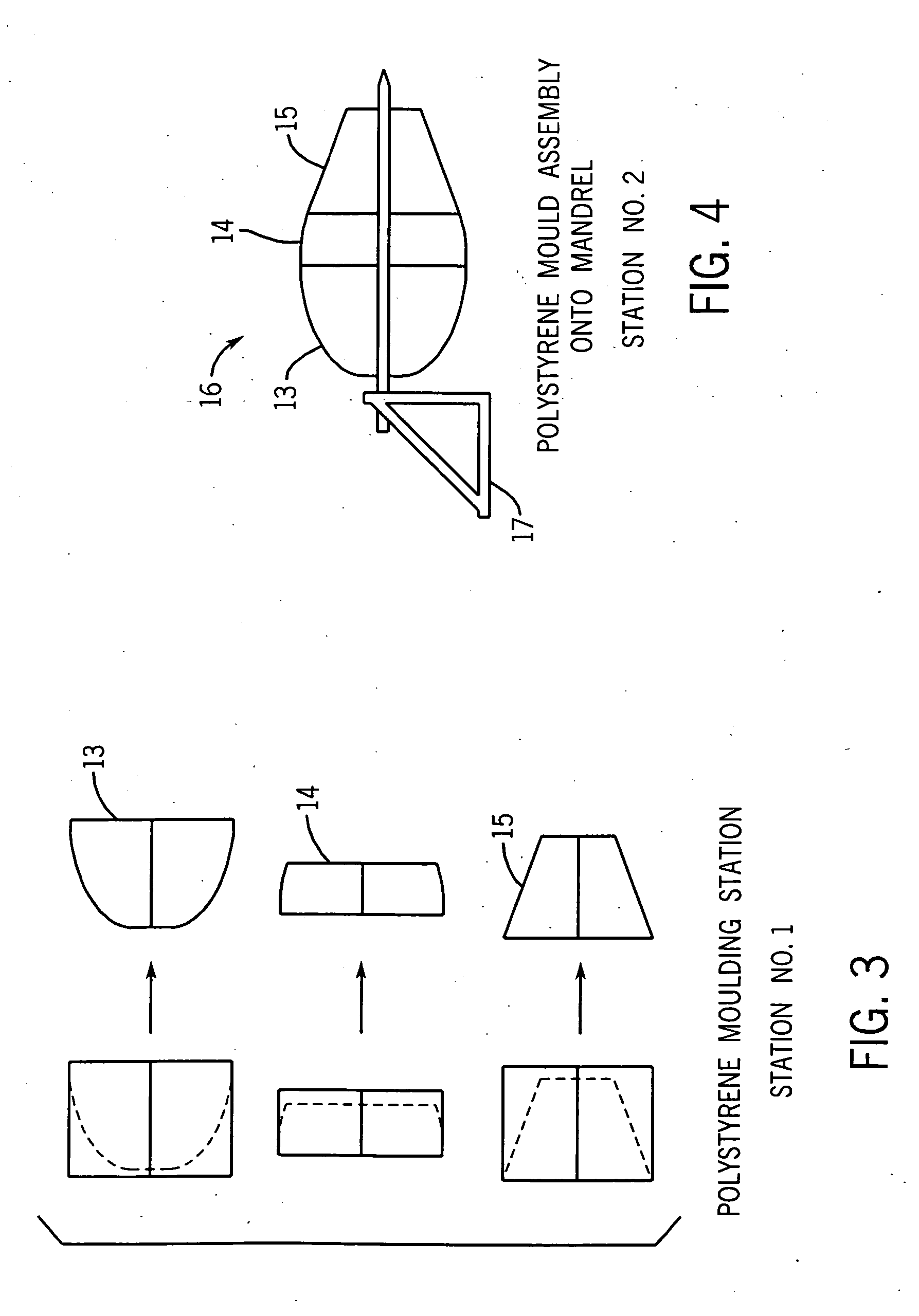

Concrete mixing drum manufacturing method

ActiveUS20050103431A1Prolong lifeGood mixing propertiesRotating receptacle mixersButtonsEngineeringMechanical engineering

A method for making a concrete mixing drum includes forming a first layer of at least one polymeric material having a surface providing at least a portion of a barrel wall of the drum and a spiral mixing blade projecting from the wall on an inner surface of the drum and forming a second layer on the formed first layer.

Owner:KHOURI ANTHONY

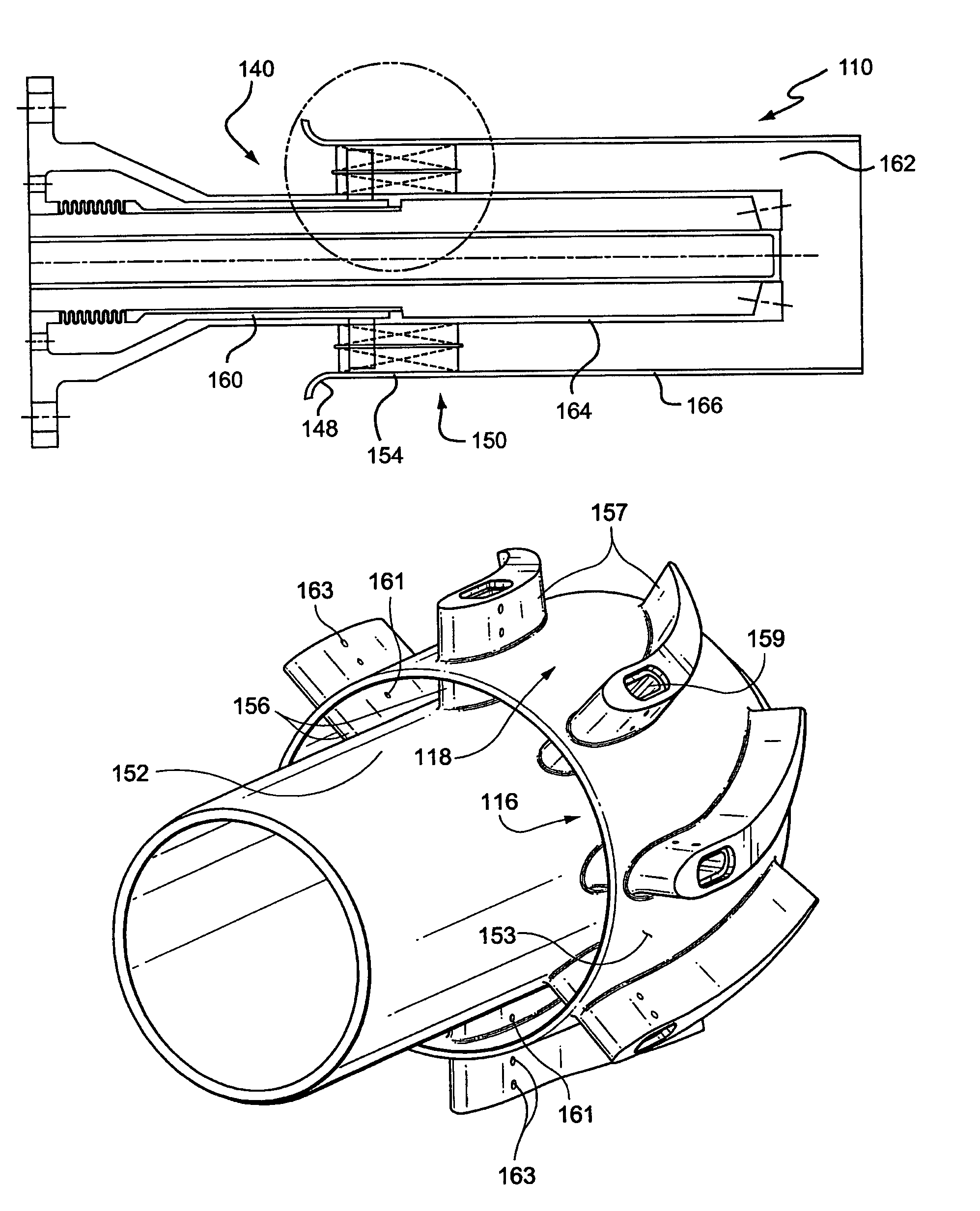

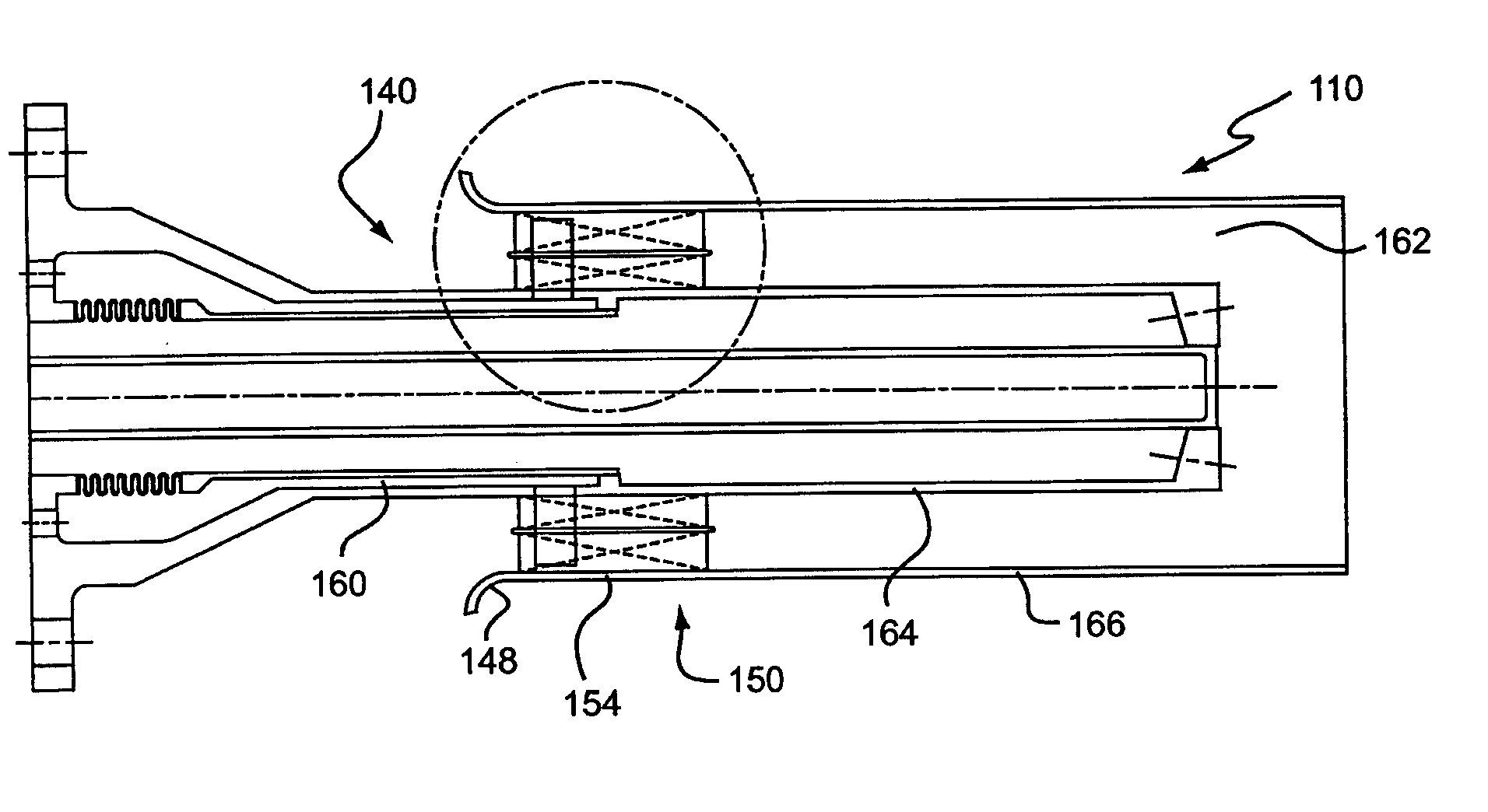

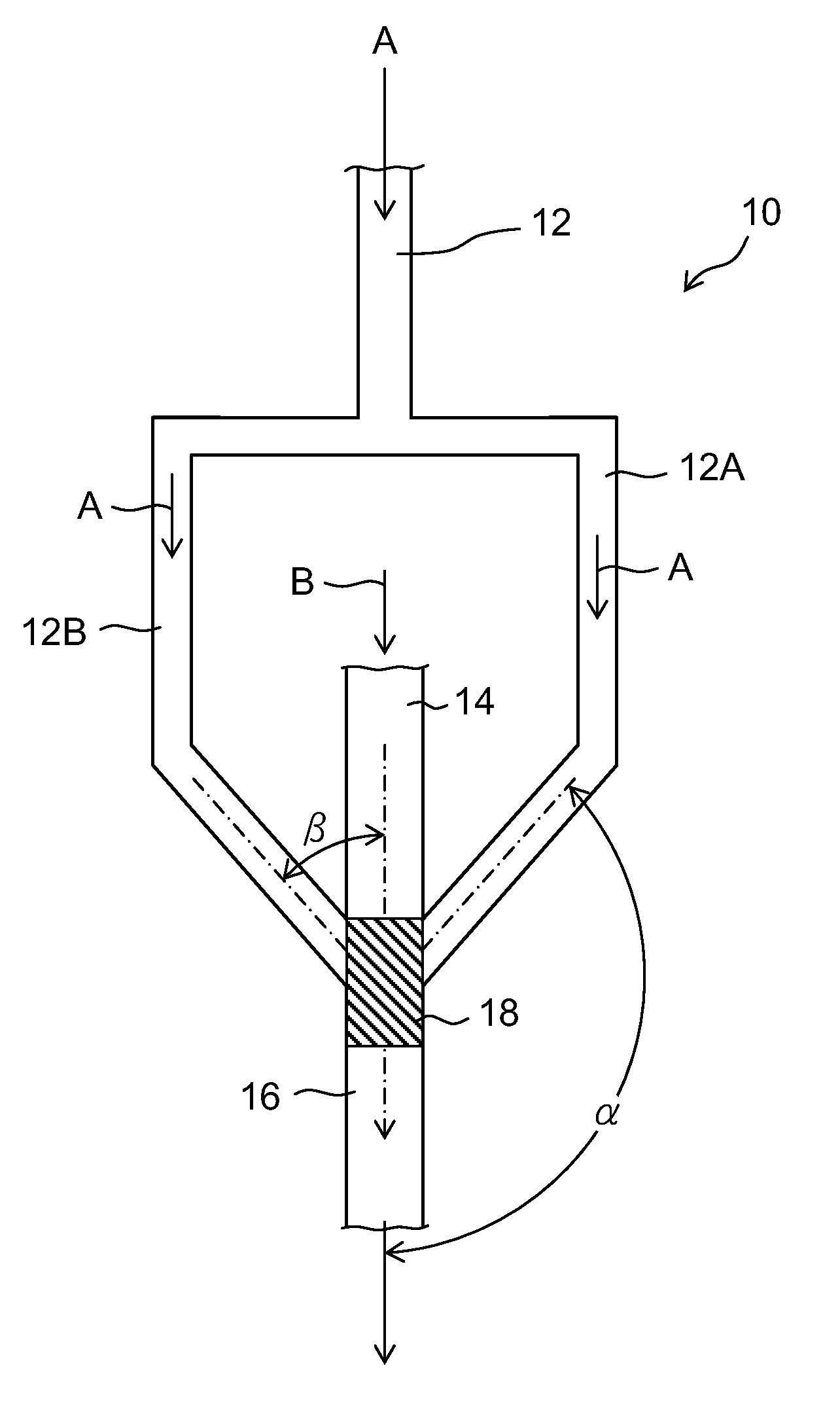

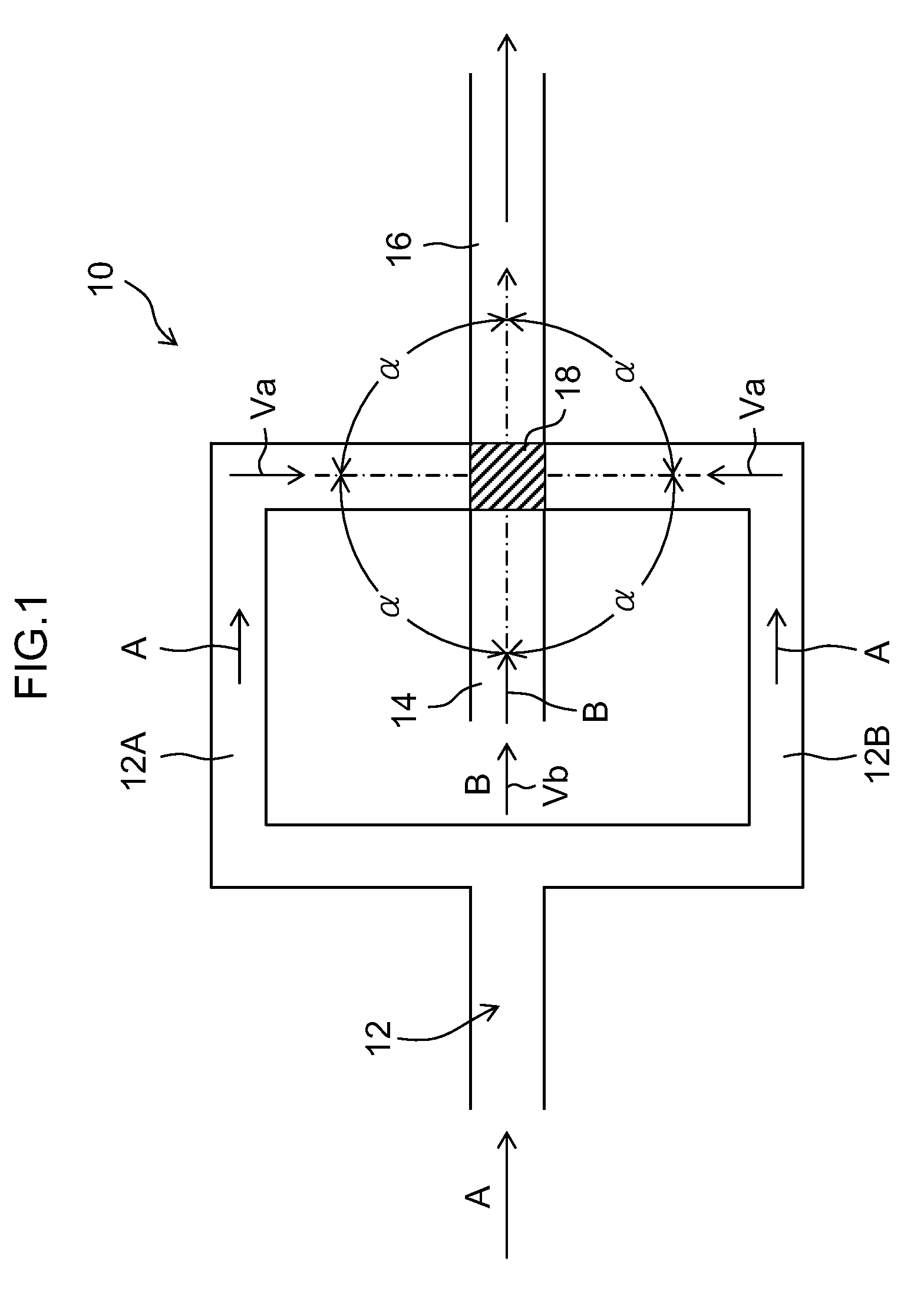

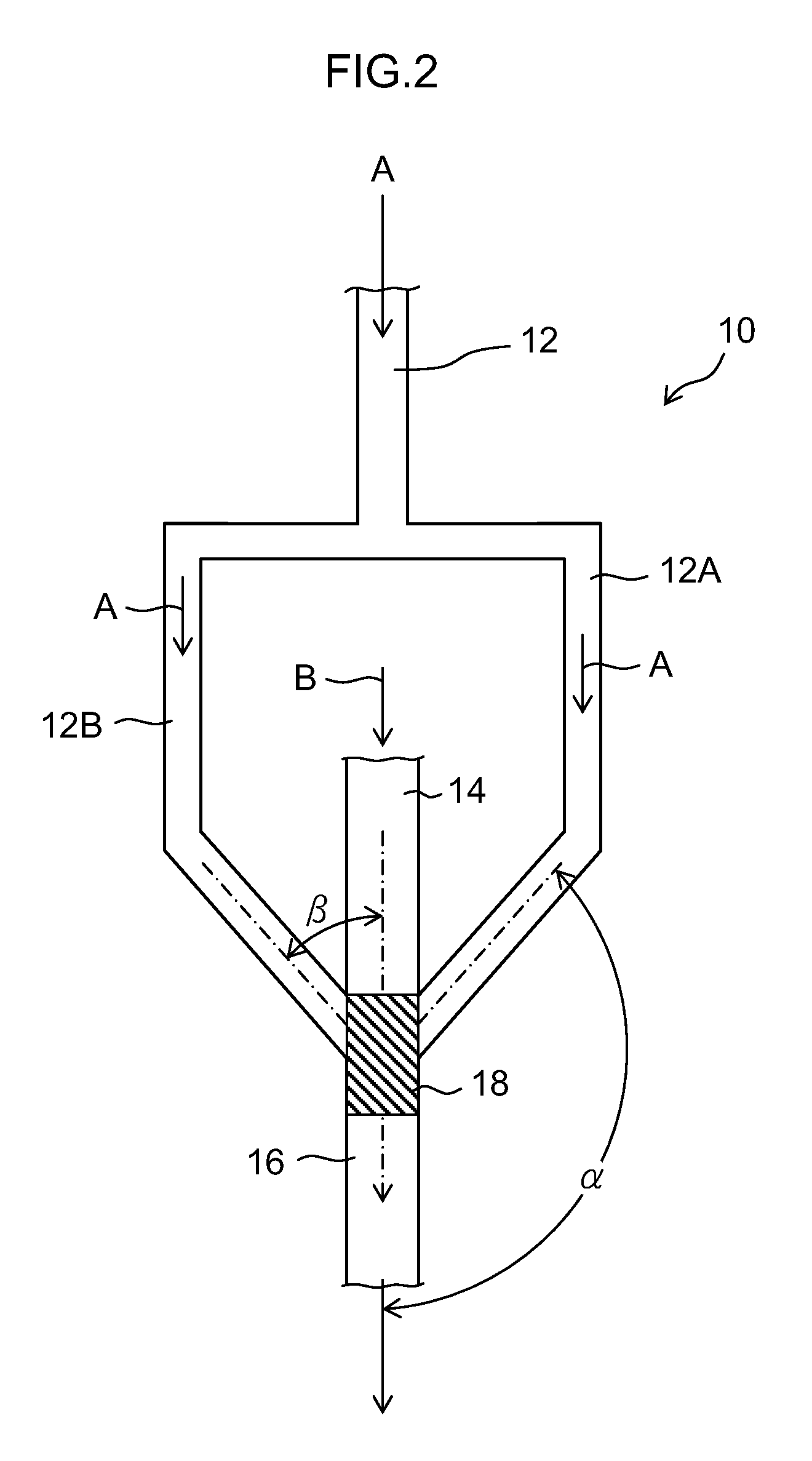

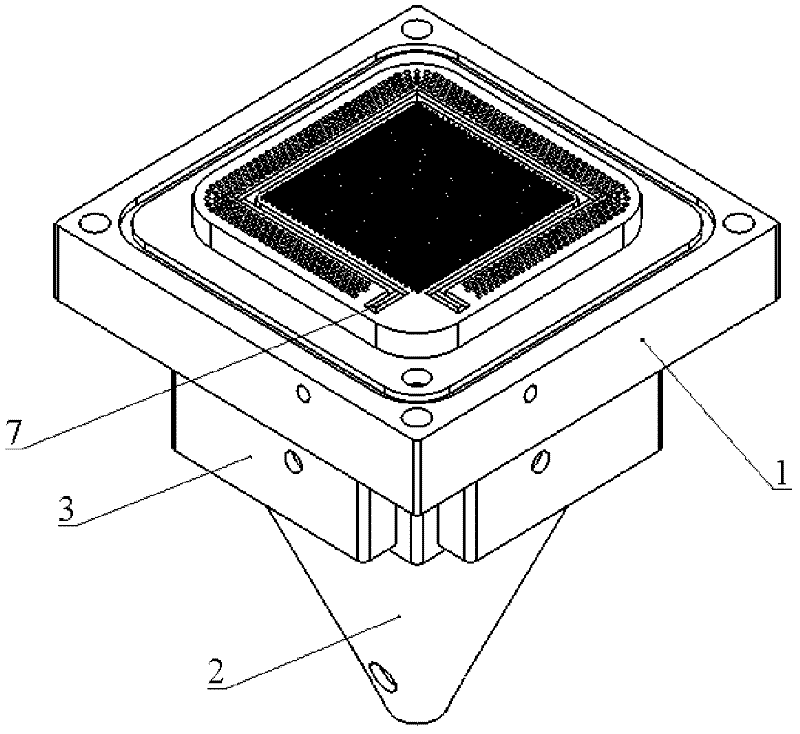

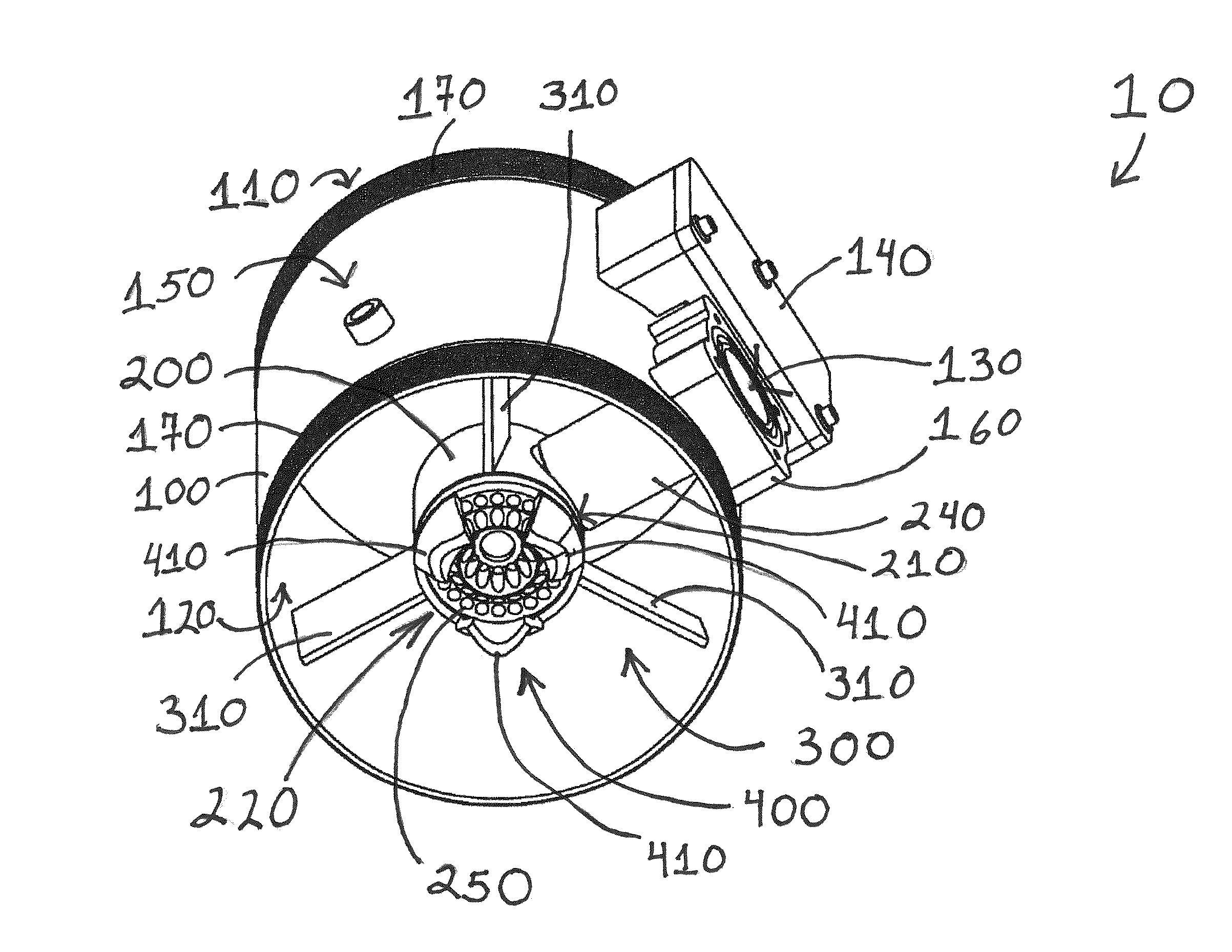

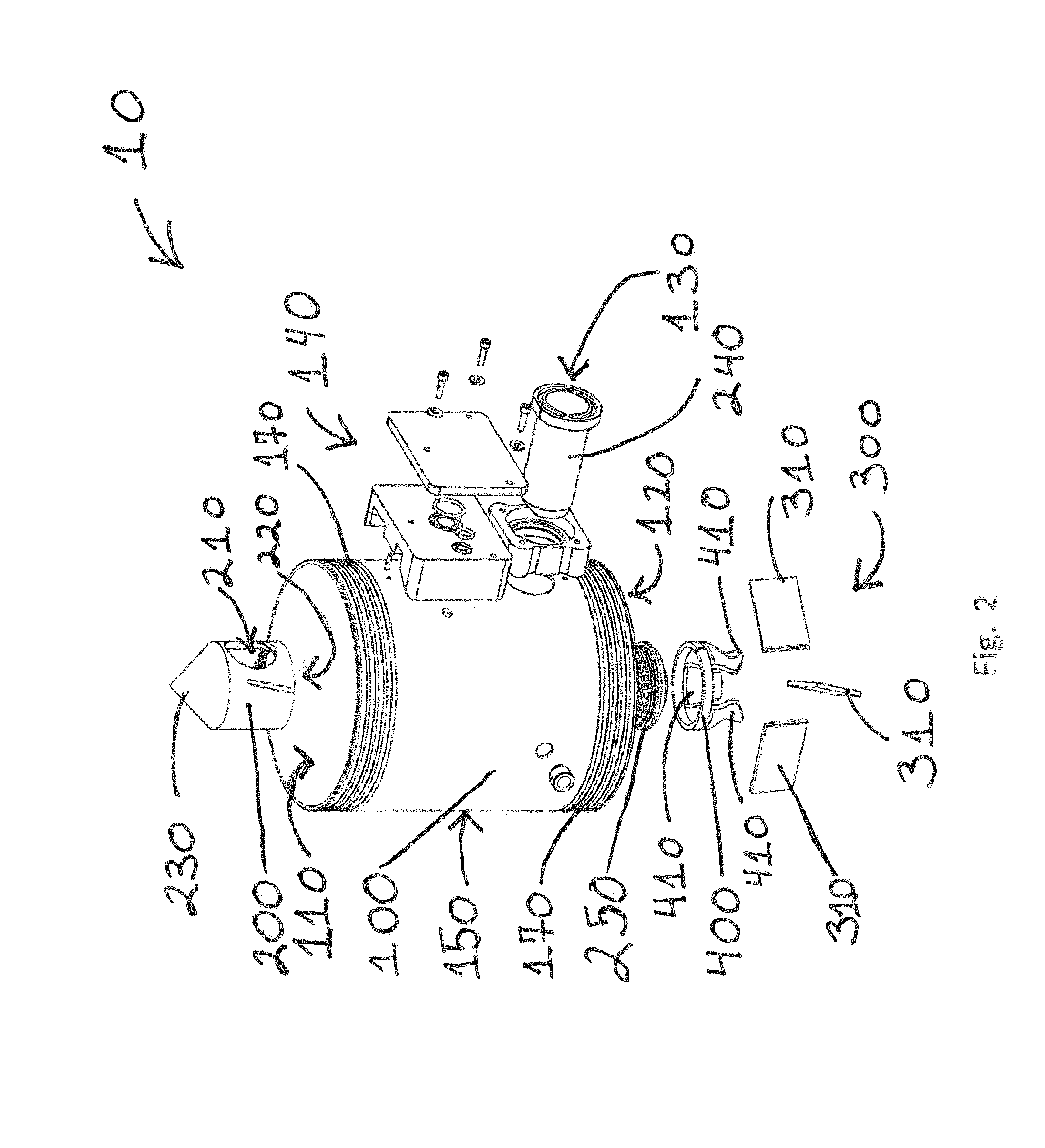

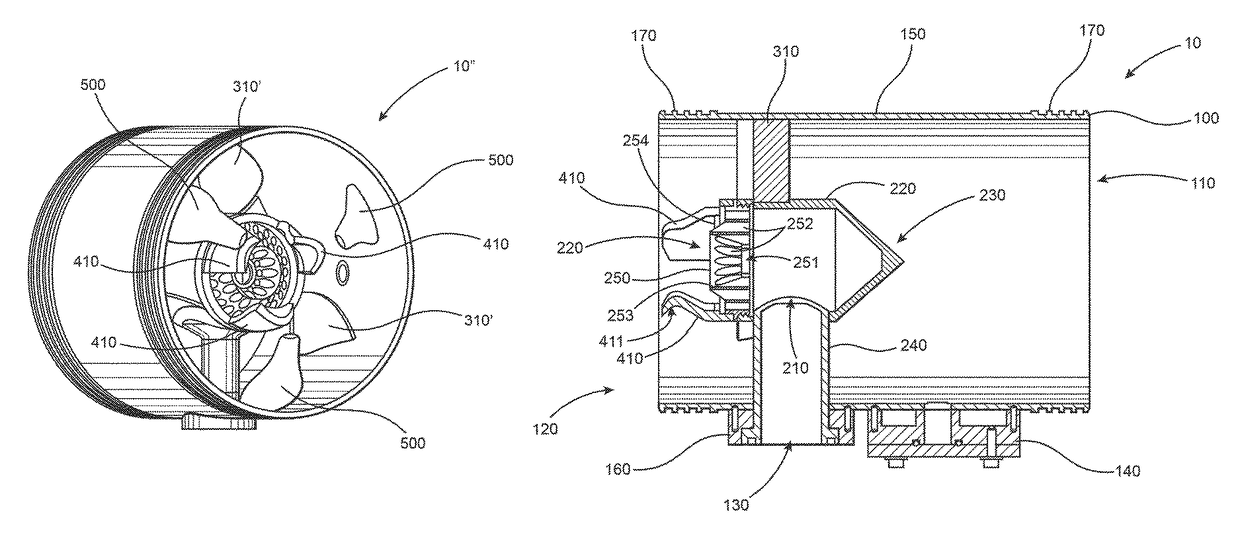

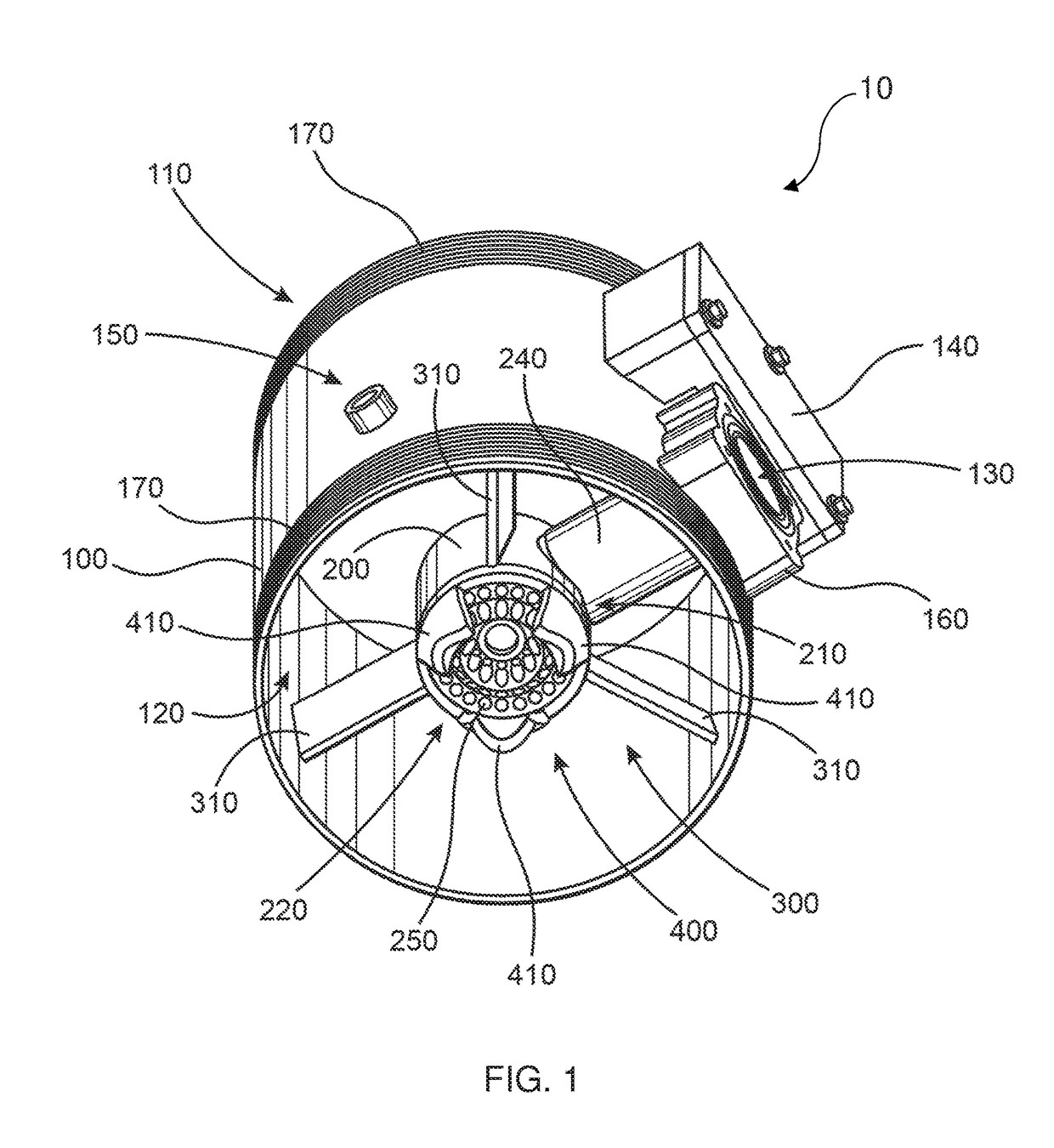

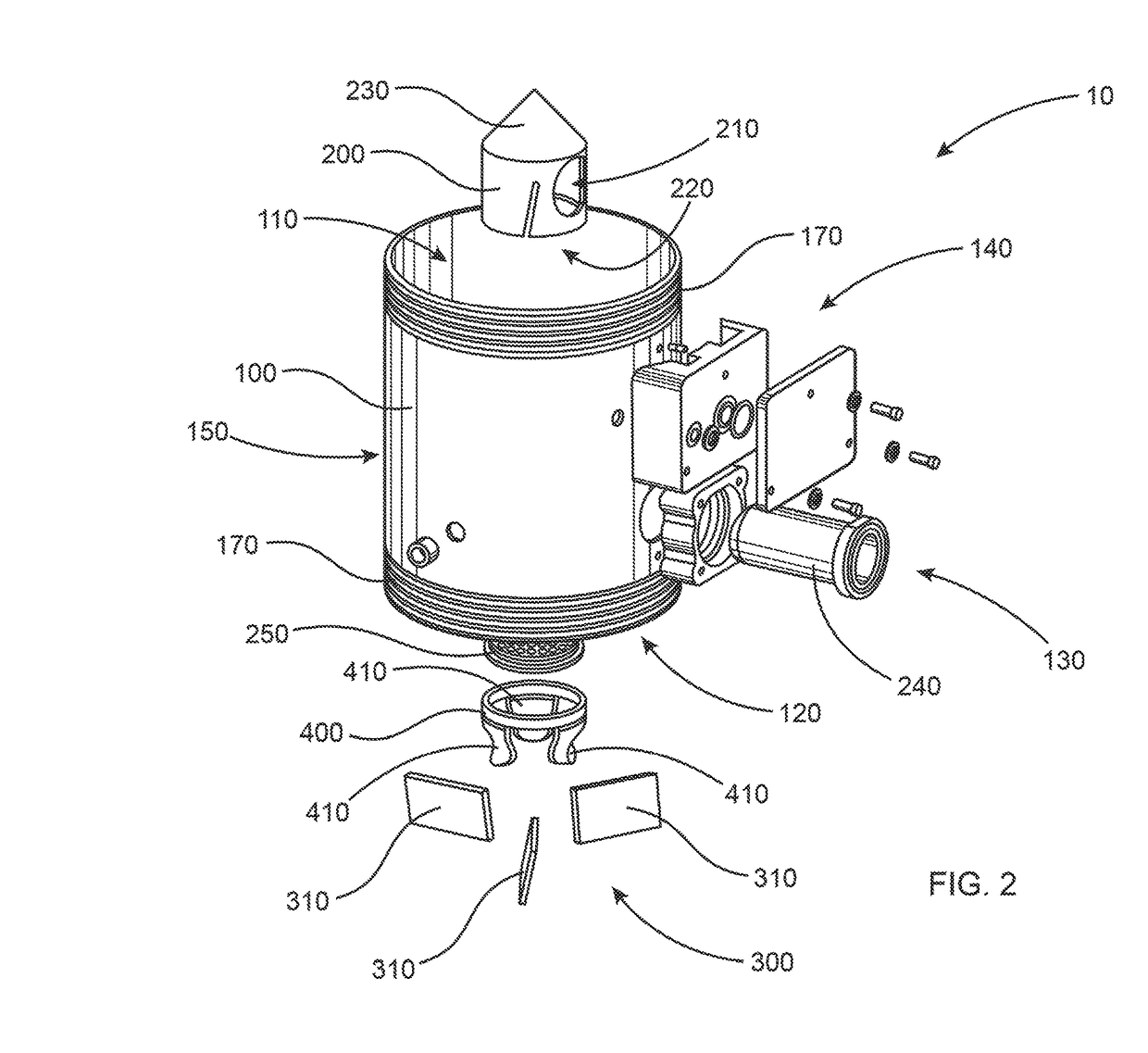

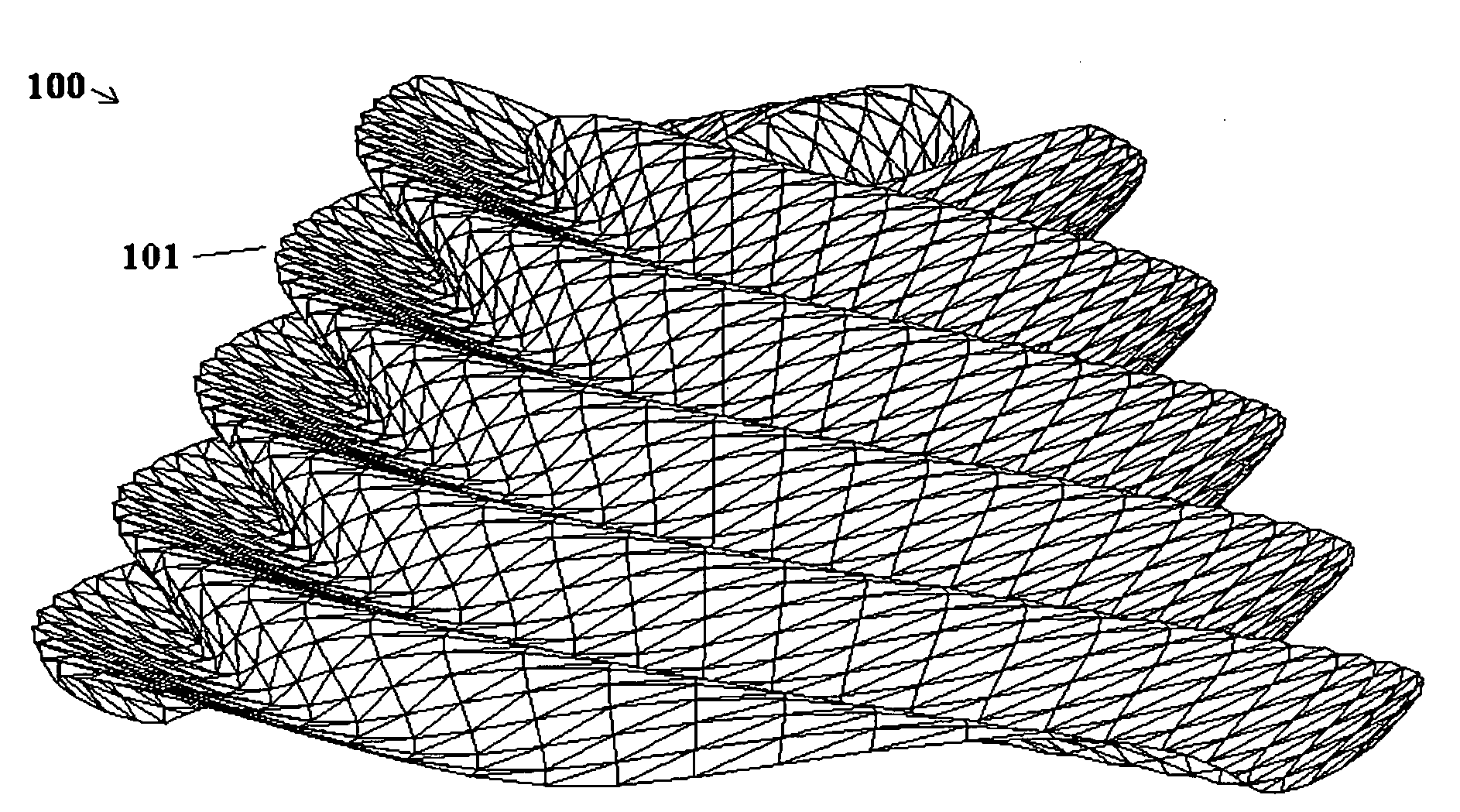

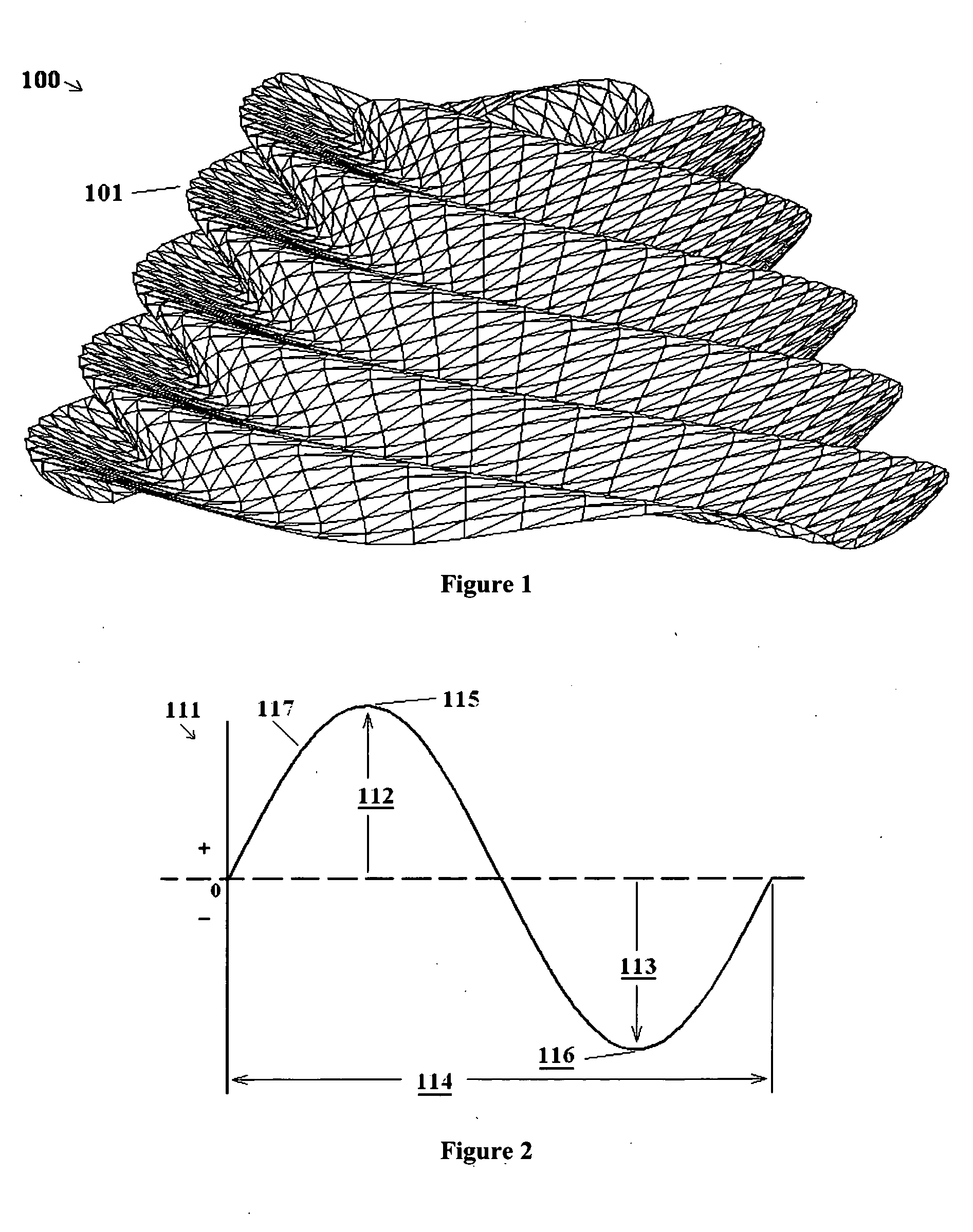

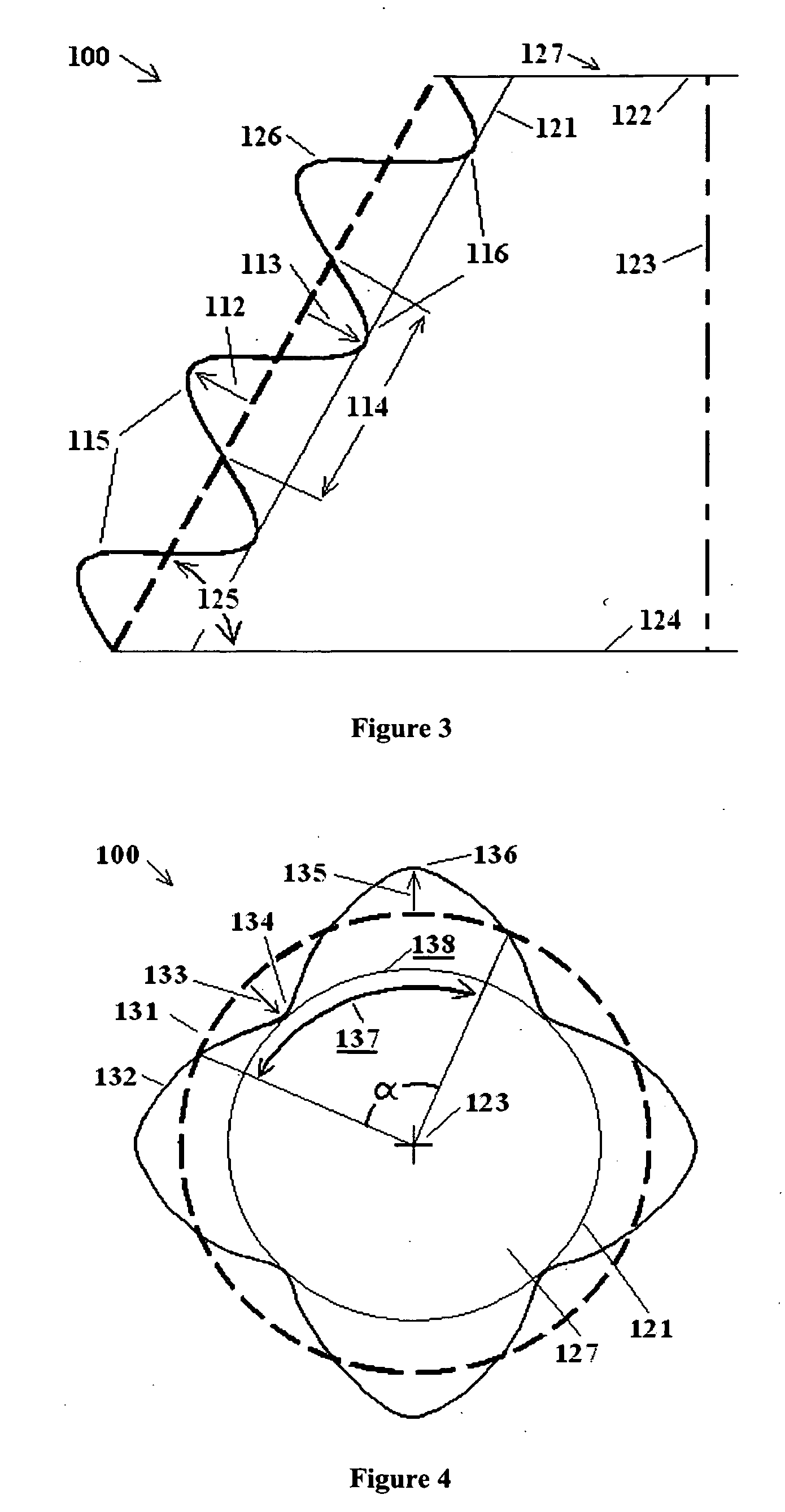

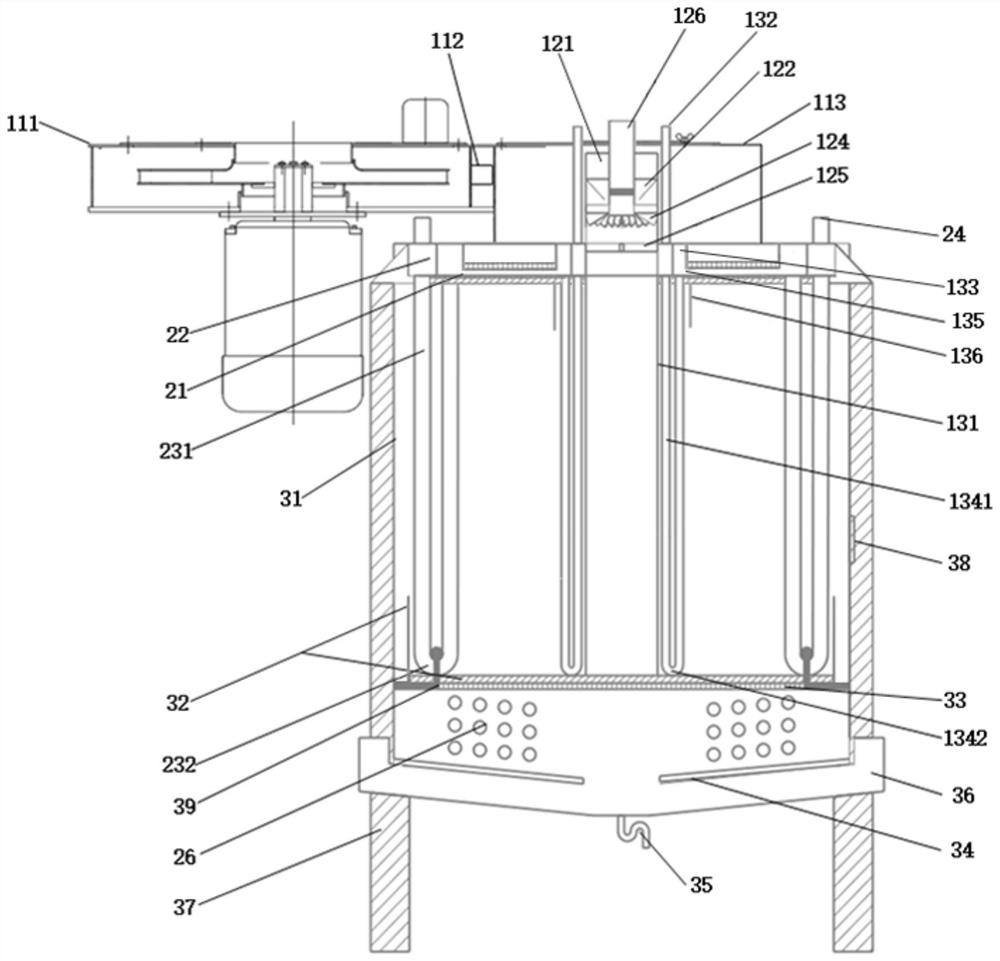

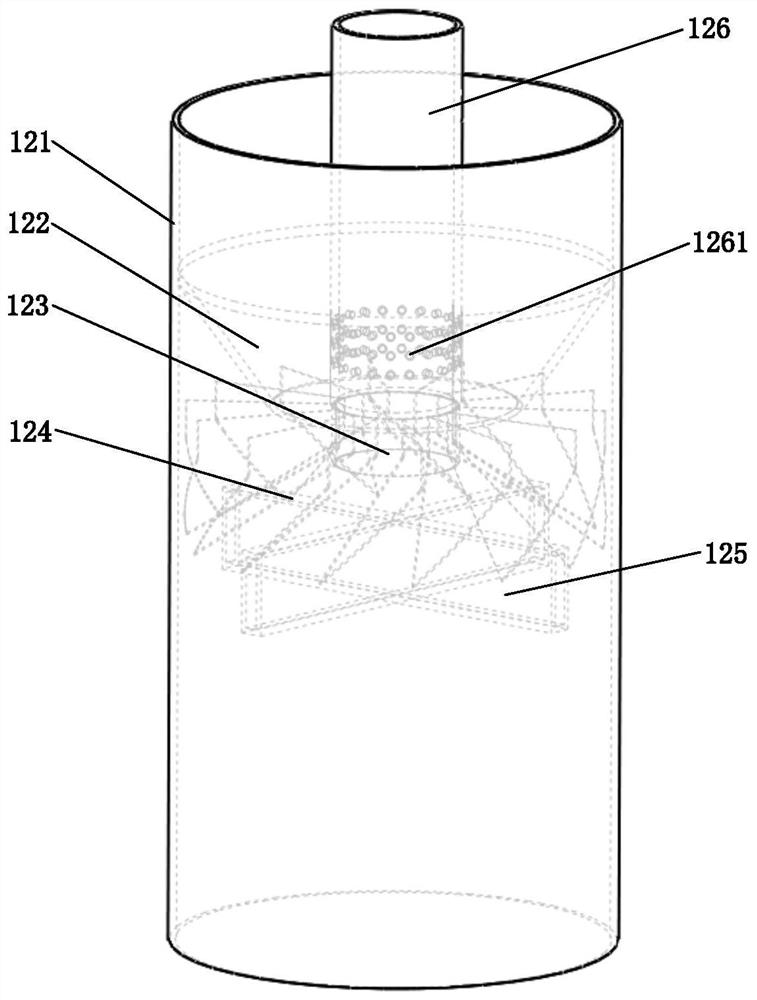

Mixing assembly

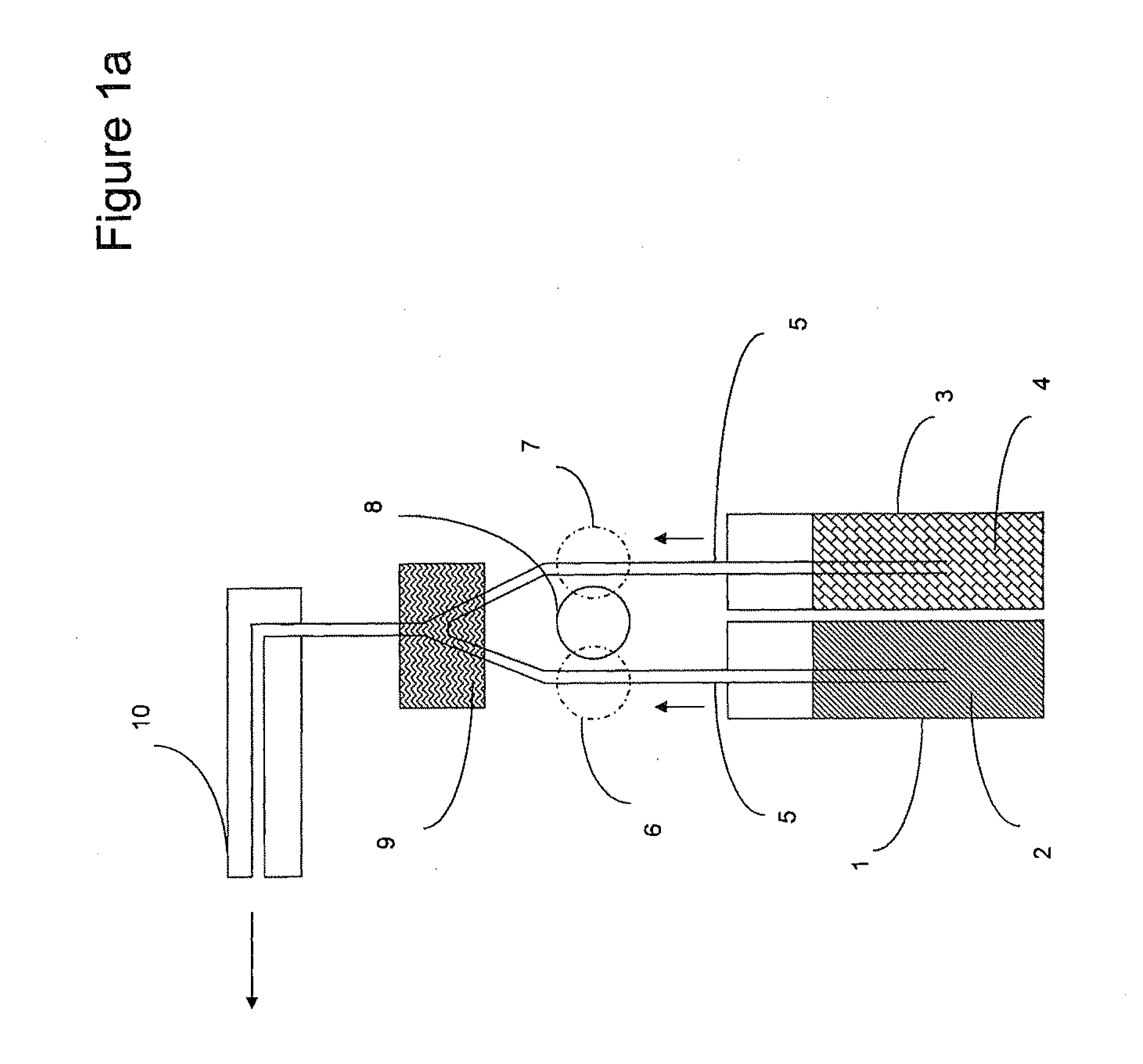

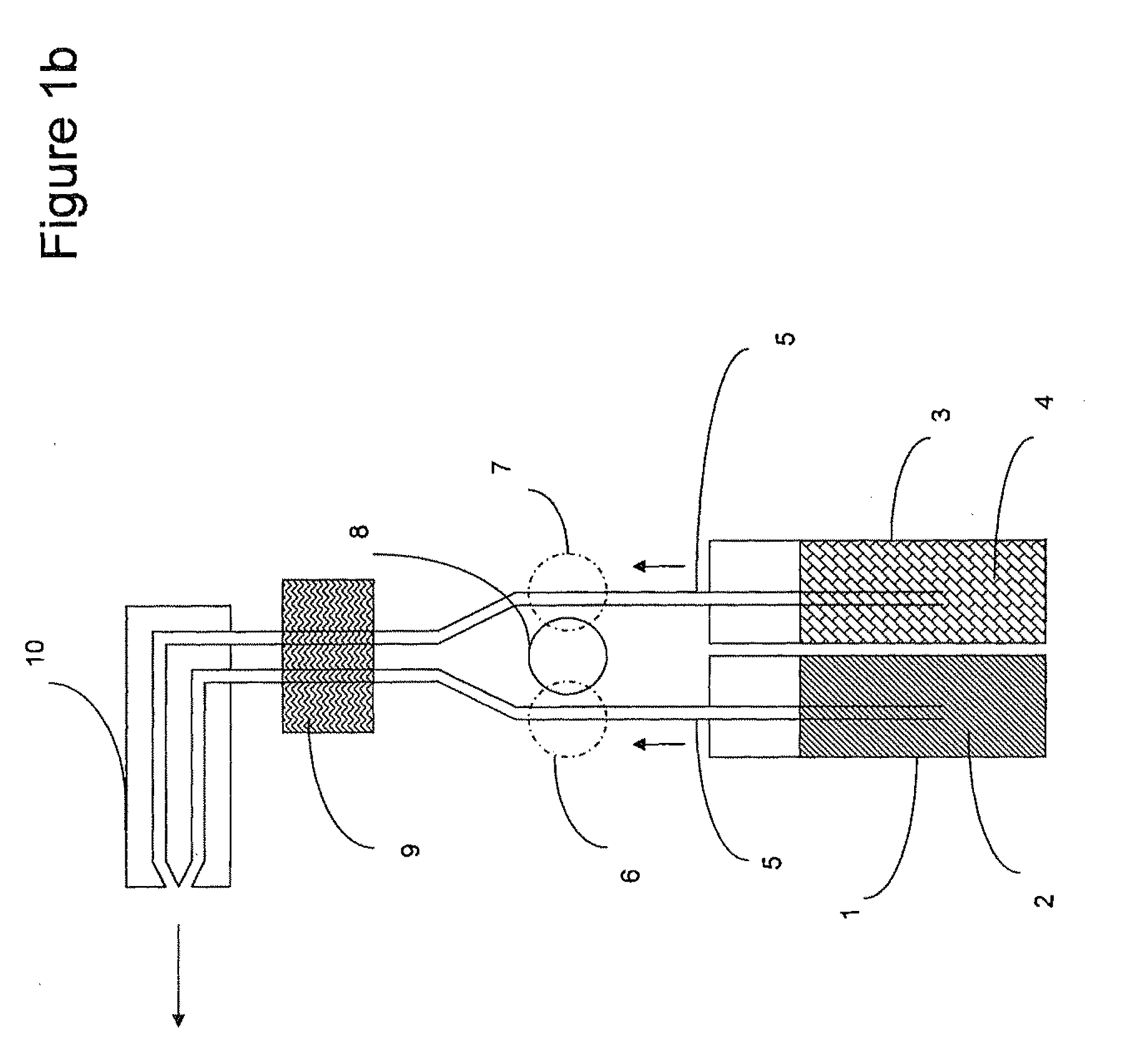

InactiveUS20160195050A1Increased turbulenceGood mixing propertiesInternal combustion piston enginesFlow mixersEngineeringInjector

An embodiment of a mixing assembly for mixing at least two fluids, comprises a housing and an injector body disposed concentrically therein, a vorticing element disposed about the injector body, and a compression element disposed about an outlet of the injector body. The housing is disposed for passage of a first fluid therethrough. The injector body being disposed within the housing and further disposed for the introduction of a second fluid within the flow path of the first fluid.

Owner:GREEN JASON E

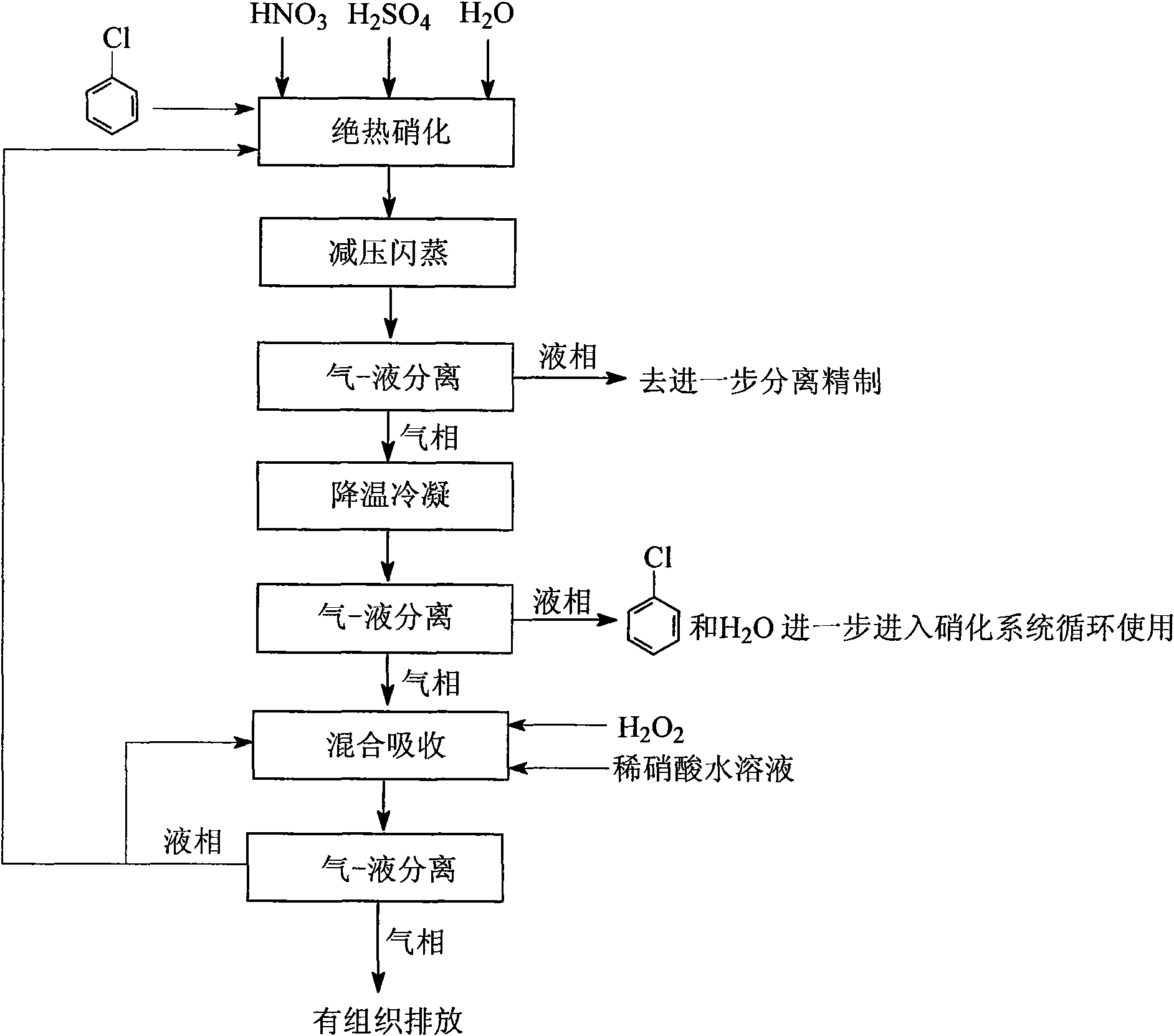

Removal technology of nitrogen oxides generated in chlorobenzene thermal insulation nitration

InactiveCN101607910AFull recoveryIncrease profitOrganic compound preparationDispersed particle separationChlorobenzeneThermal insulation

The invention relates to a removal technology of nitrogen oxides generated in chlorobenzene thermal insulation nitration, comprising the following steps of: (1) thermal insulation nitration; (2) vacuum flashing; (3) gas-liquid separation: nitrochlorobenzene crude products is further treated in liquid phase and gas-phase materials enters a next step; (4) cooling and condensation: condensed materials enter a next step; (5) gas-liquid separation: the nitrochlorobenzene and water are further treated and utilized in liquid phase, and gas-phase materials enter a next step; (6) mixed absorption: nitric acid aqueous solution and hydrogen peroxide aqueous solution absorb nitrogen oxides from exhaust gas; and (7) gas-liquid separation: the gas-phase materials are discharged after the nitrogen oxides therein achieve the standard in content, the batching of mixed acid and recycling of absorption liquid are conducted in liquid phase. The technology has the advantages of high utilization of materials, less three wastes and easy industrial implementation.

Owner:YANGZHOU UNIV

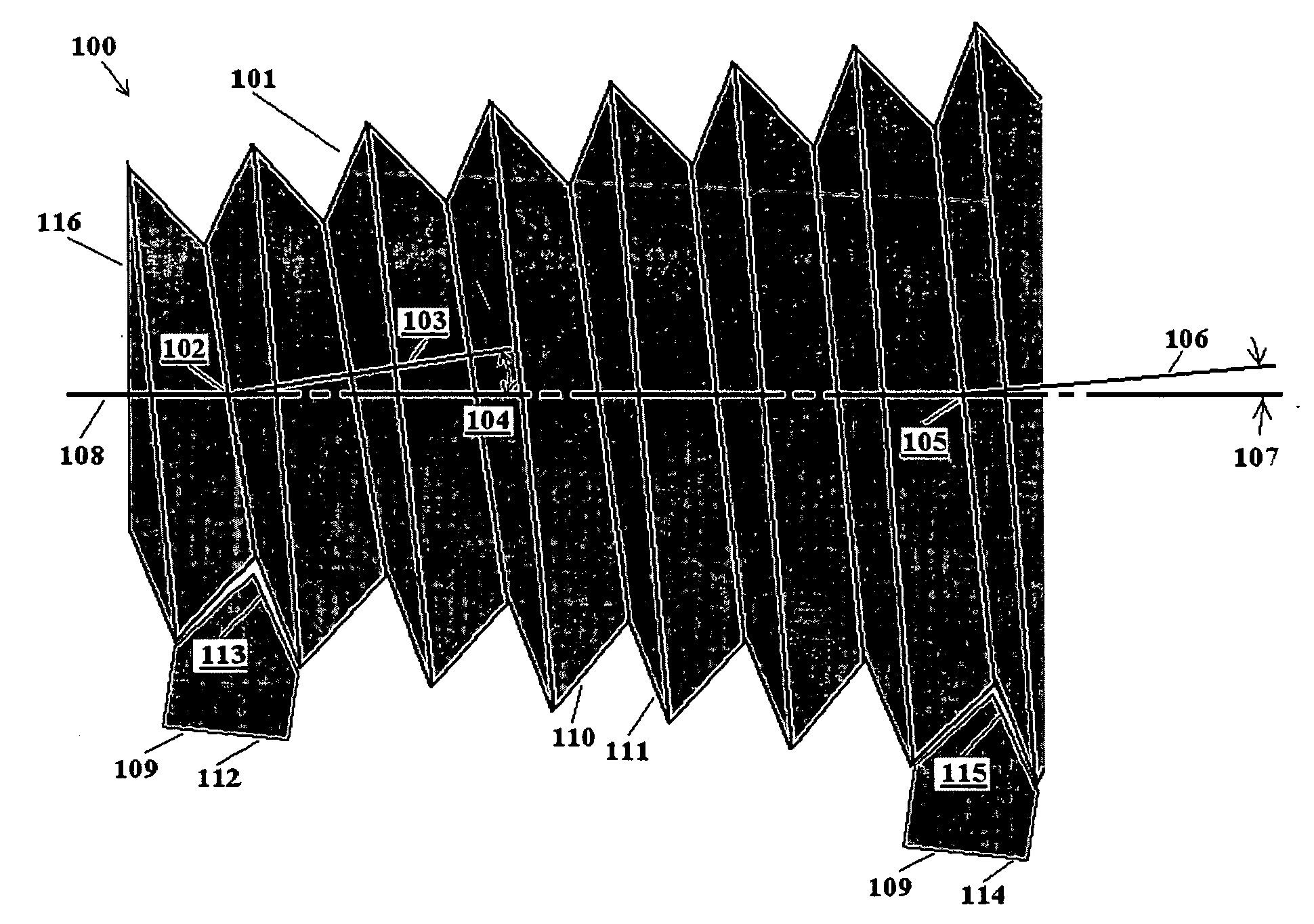

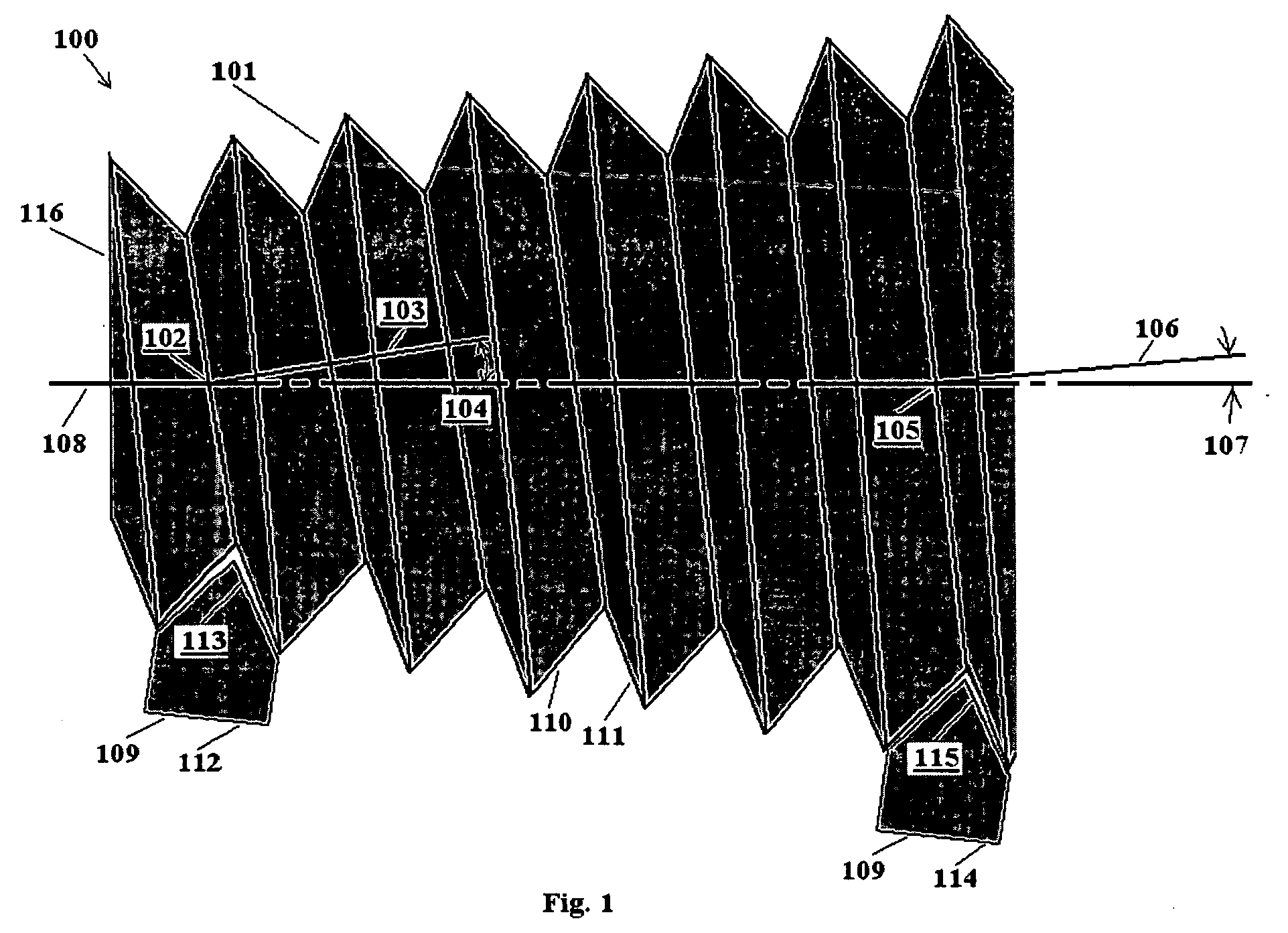

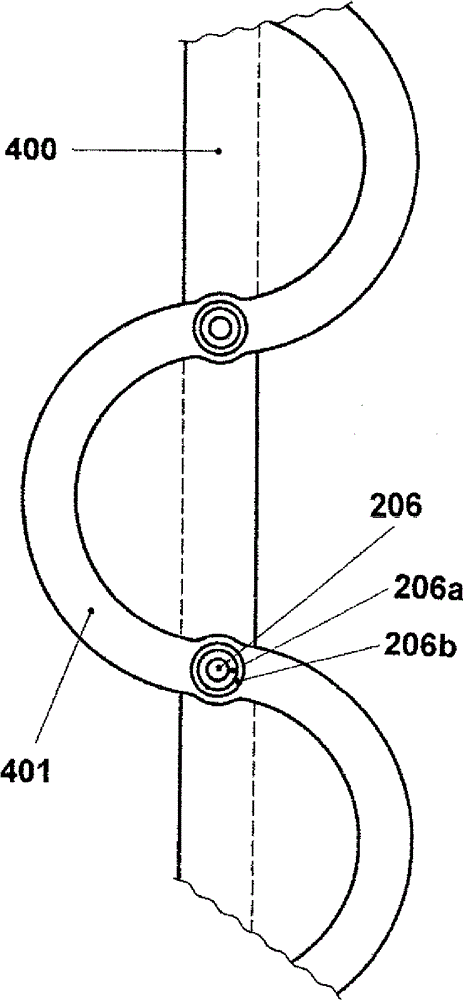

Reheat burner arrangement

ActiveCN103776060AQuick mixAchieve outer diameterContinuous combustion chamberEngine manufactureAnnular ductCombustion chamber

Reheat burner arrangement comprising a center body, an annular duct with a cross-section area, an intermediate fuel injection plane located along the center body and being actively connected to the cross section area of the annular duct, wherein the center body is located upstream of a combustion chamber, wherein the structure of the reheat burner arrangement is defined by various parameters and the structure of the reheat burner arrangement is defined by various dependencies.

Owner:ANSALDO ENERGIA SWITZERLAND AG

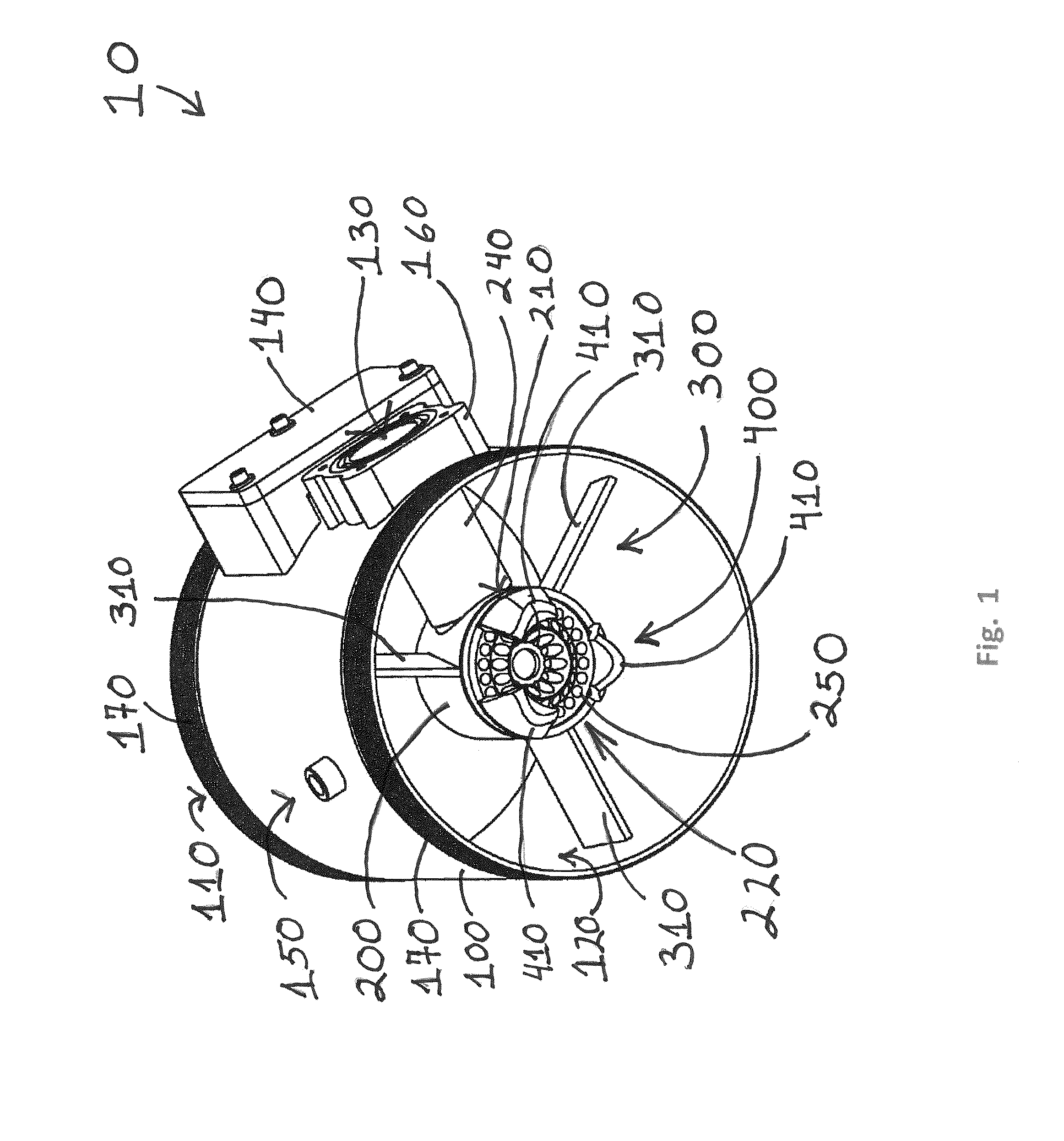

Mixing assembly

InactiveUS9885318B2Increase chaotic mixing characteristicImprove the mixing effectInternal combustion piston enginesFlow mixersEngineeringInjector

An embodiment of a mixing assembly for mixing at least two fluids, comprises a housing and an injector body disposed concentrically therein, a vorticing element disposed about the injector body, and a compression element disposed about an outlet of the injector body. The housing is disposed for passage of a first fluid therethrough. The injector body being disposed within the housing and further disposed for the introduction of a second fluid within the flow path of the first fluid.

Owner:GREEN JASON E

Bladder rubber and its preparation method

A bladder rubber and its preparation method are provided. The bladder rubber contains brominated butyl rubber 45-60, carbon black 20-30, talcum powder 5-15, oil material 1-5, anti-aging agent 1-2, and vulcanizing agent 1-3 wt%. The inventive bladder rubber has performances of butyl rubber and active bromine, effectively improves gas tightness of bladder, accelerates vulcanizing speed, ensures adhesion property, and improves service life of bladder.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

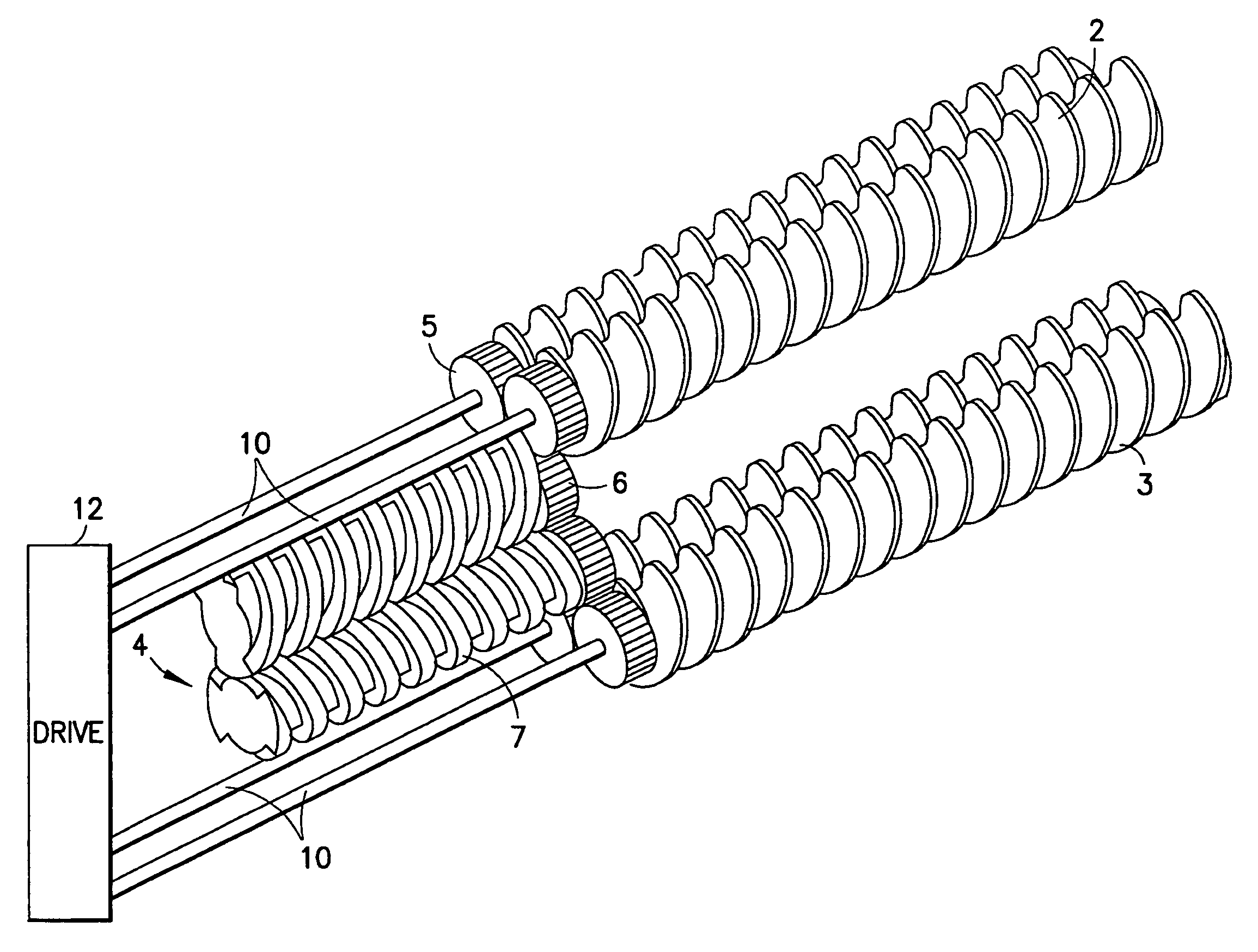

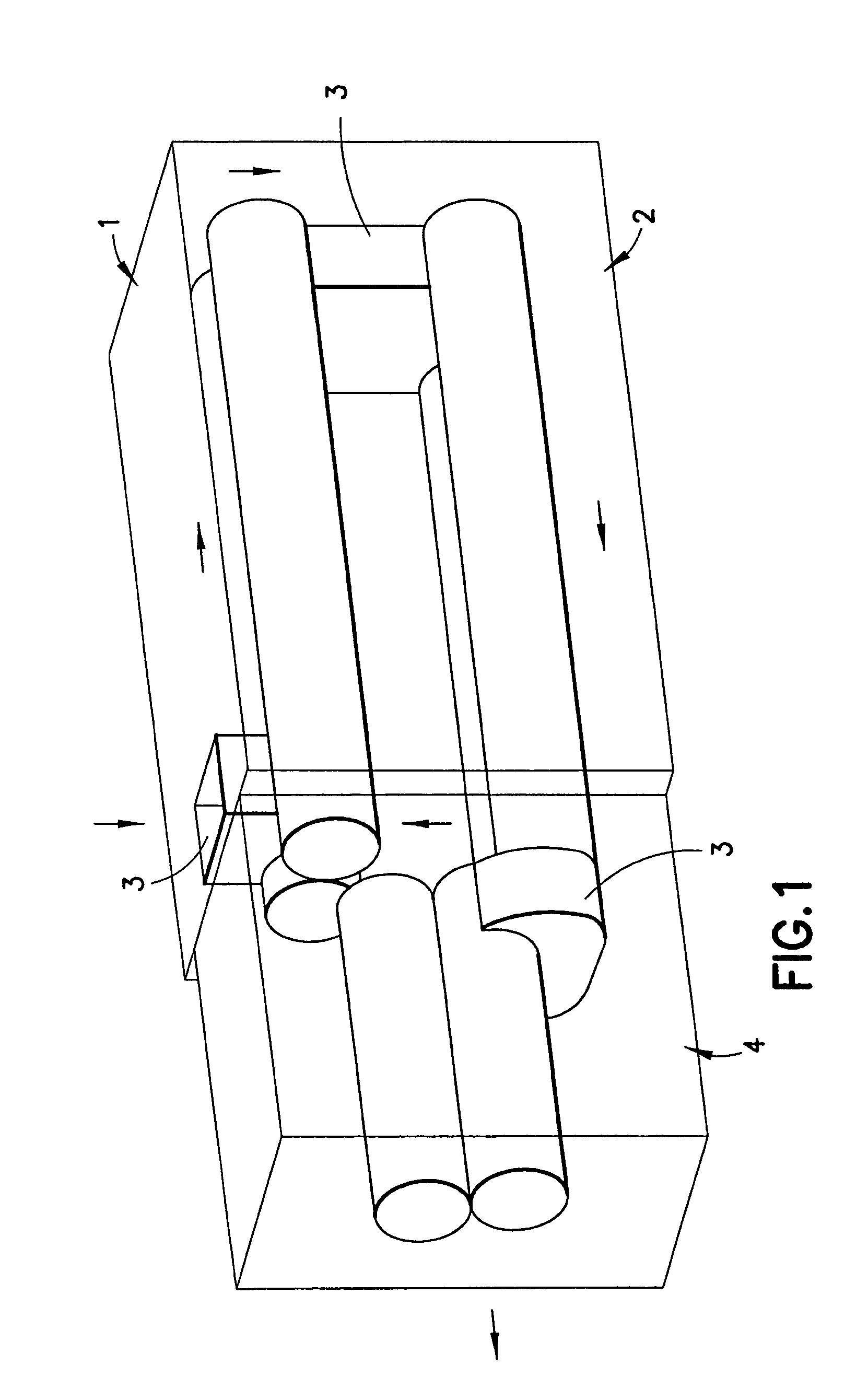

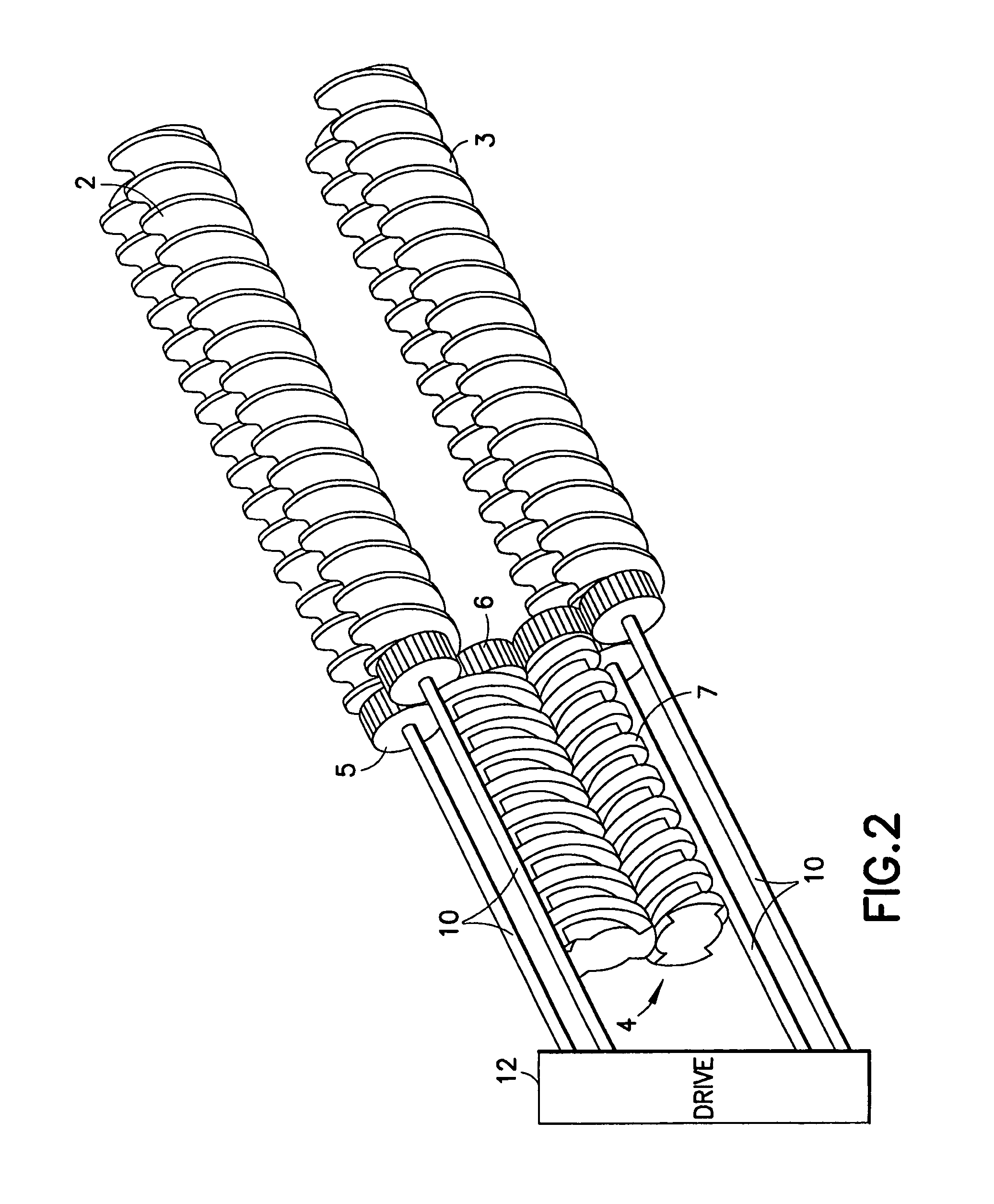

Multiple extruder configuration

InactiveUS7017732B2High mean residence timeHigh torqueRotary stirring mixersMixing/kneading with horizontally-mounted toolsBiomedical engineeringTwin screw extruder

The invention concerns a multiple-extruder configuration in which two co-rotating twin-screw extruders and a counter-rotating twin screw extruder are connected to each other with respect to the flow of material.

Owner:BERSTORFF GMBH

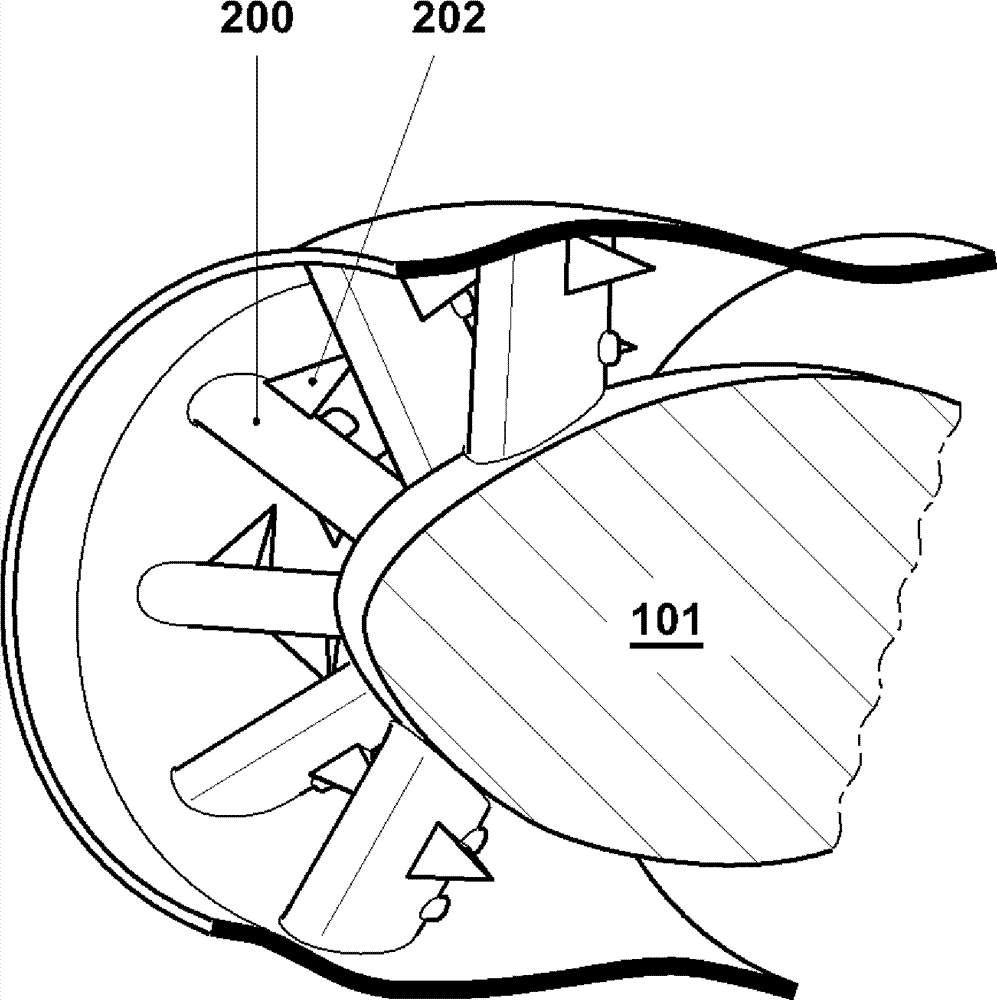

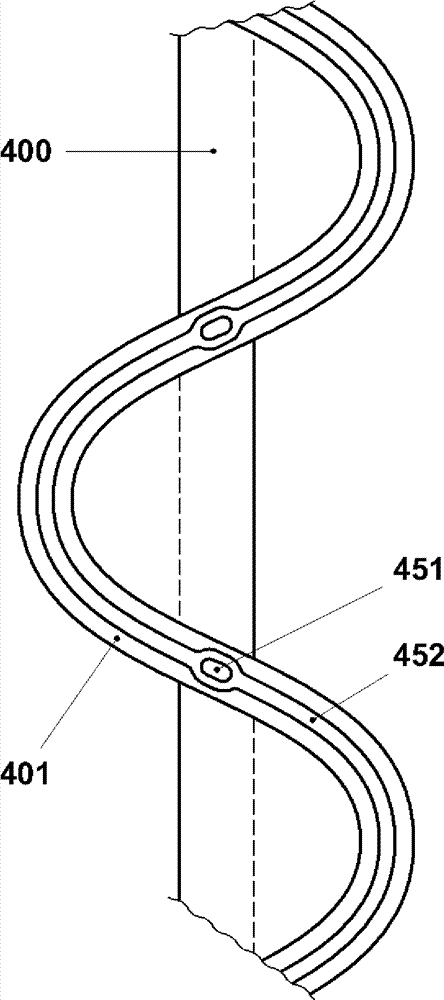

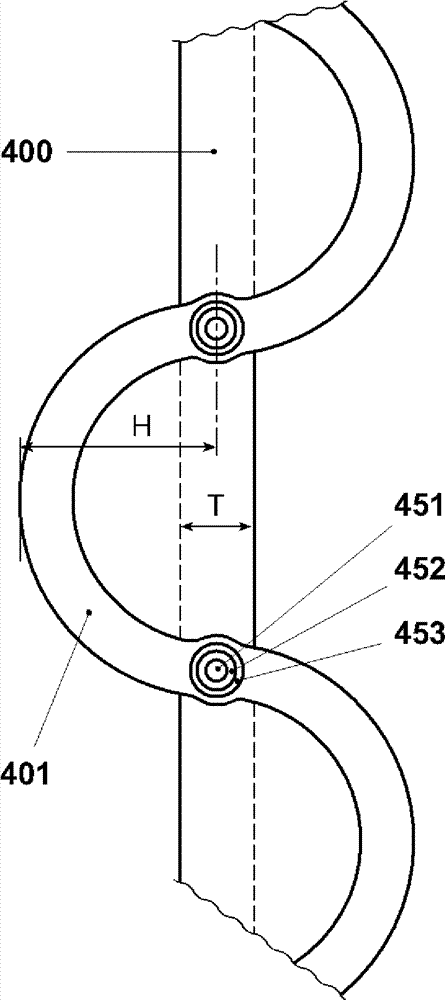

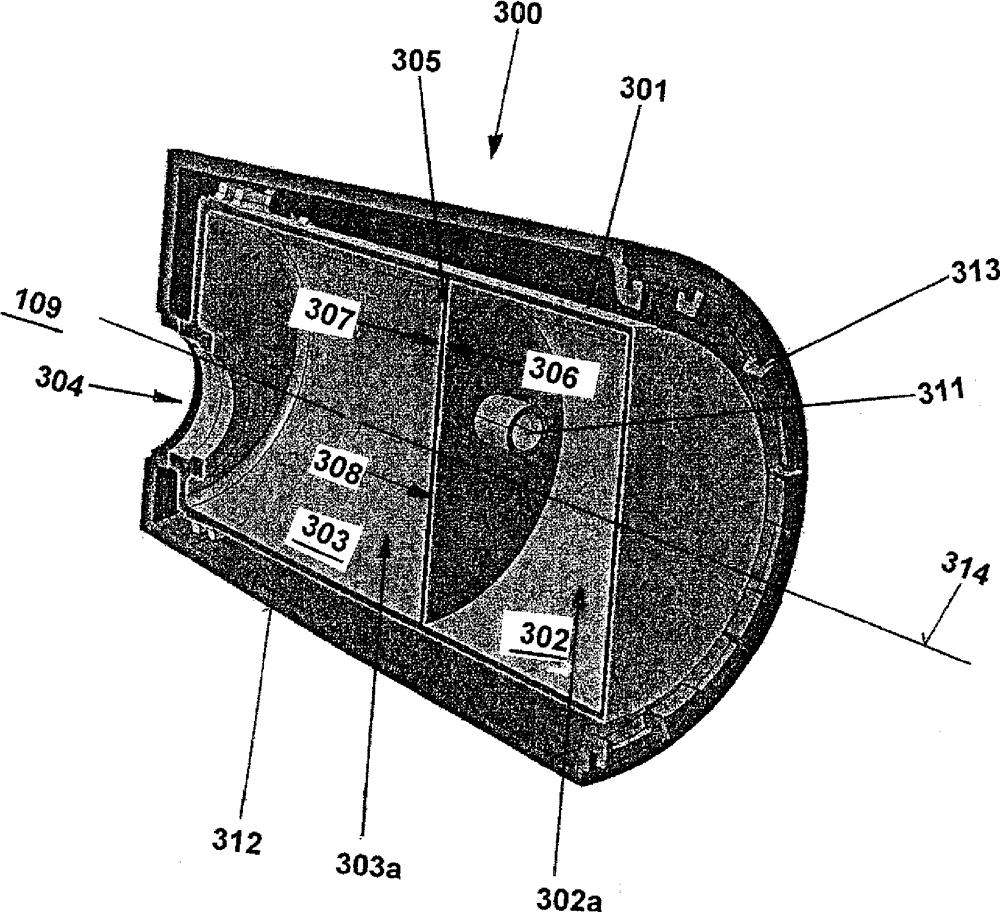

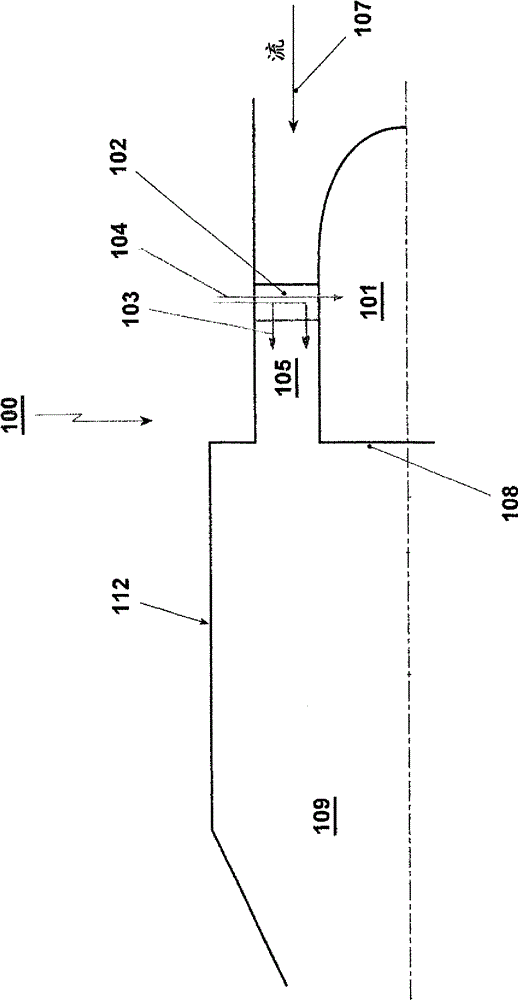

Burner arrangement and method for operating a burner arrangement

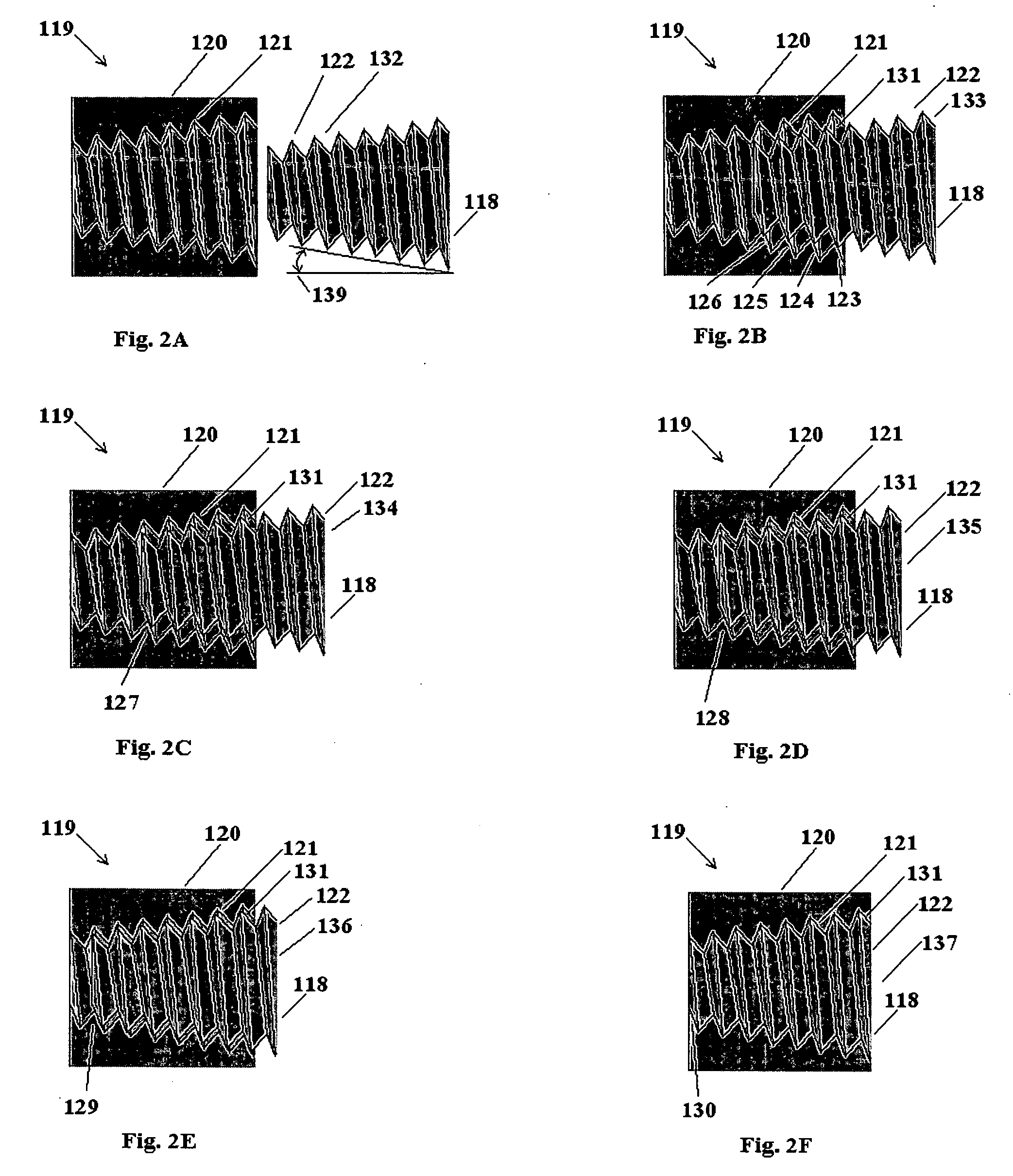

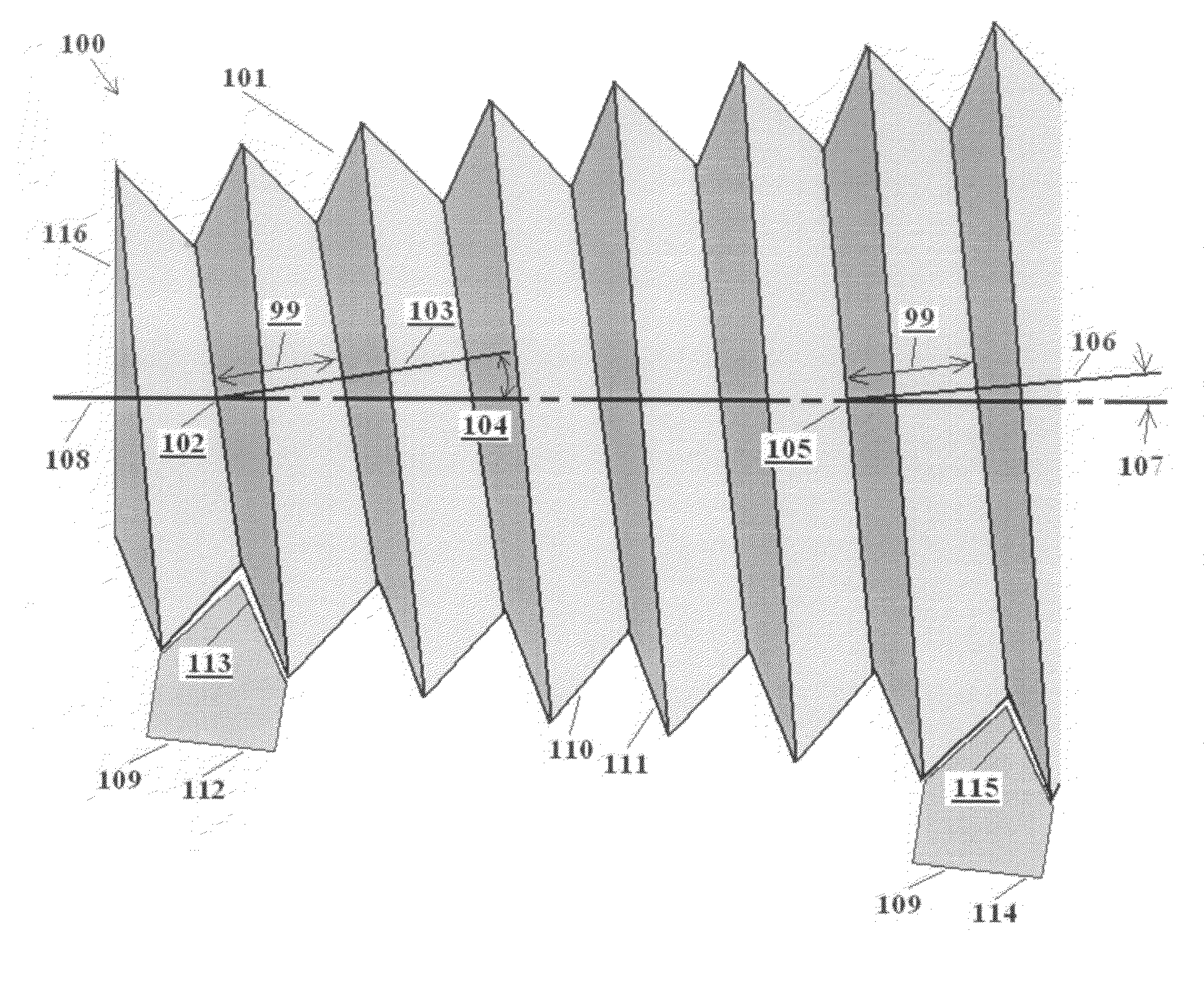

ActiveCN104373961AGood mixing propertiesReduce sizeBurnersContinuous combustion chamberAnnular ductCombustion chamber

Second stage can annular burner arrangement of a sequential gas turbine comprising: a combustion zone; a center body (101) burner, located upstream of the combustion zone, and having an annular duct with a mixing zone having a cross section area; intermediate lobes (102) which are arranged with respect to the center body (101) burner as bond-bridge in circumferential direction, perpendicular or quasi-perpendicular and in longitudinal or quasi-longitudinal direction to the main mass flow, and which are actively connected to the cross section area of the mixing zone. Cooling air (104) is guided through a number of pipes within the lobes (102) to the center body and cools beforehand at least the front section (201) of the center body (101) based on impingement cooling (203). Subsequently, the impingement cooling air cools the middle face (204) and back face (202) of the center body (101) based on convective and / or effusion cooling (205). At least the back face (202) of the center body includes on the inside at least one damper (300).

Owner:ANSALDO ENERGIA SWITZERLAND AG

Threaded fastener and fastener system

A threaded fastener and threaded fastener system. The threaded fastener includes a body having at least one outer surface and at least one thread forming a spiral about the outer surface of the body. The thread forms a plurality of crests and a plurality of roots and the tangential distance between adjacent crests is substantially constant. The threaded fastener system includes the threaded fastener and a workpiece with an opening having at least one inner surface dimensioned to mate with outer surface of the threaded fastener.

Owner:VAN COR DALE E

Adhesive composition

ActiveUS20180320036A1Improve stabilityGood mixing propertiesNatural rubber adhesivesNon-macromolecular adhesive additivesWater basedAdhesive

The present invention is in the field of an improved adhesive composition, use of said composition and products comprising said composition. The adhesive composition may be a one component and a two component adhesive, each component typically comprising various ingredients. The present adhesives are water-based dispersions.

Owner:STRONGBOND BV

Threaded fastener and fastener system

A wave threaded fastener and system. A wave thread extends from the outer surface of the body and is made up of a profile wave and a lateral wave. The profile wave includes a plurality of profile crests and profile roots defining a plurality of profile thread widths. The lateral wave includes at least one lateral crest and at least one lateral root defining at least one wave period. Each wave period forms a period arc having a period arc angle and the sum of all period arc angles about the lateral Wave equals three hundred and sixty degrees. Each of the profile crests and roots are aligned with corresponding lateral crests and roots and the wave thread travels one profile thread width per each period arc traveled.

Owner:VAN COR DALE E

Fuel injector having an external cross-flow nozzle for enhanced compressed natural gas jet spray

InactiveUS7481381B2Improved gaseous fuel targetingImprove the problemInternal combustion piston enginesFuel supply apparatusCompressed natural gasProduct gas

Owner:CONTINENTAL AUTOMOTIVE SYST INC

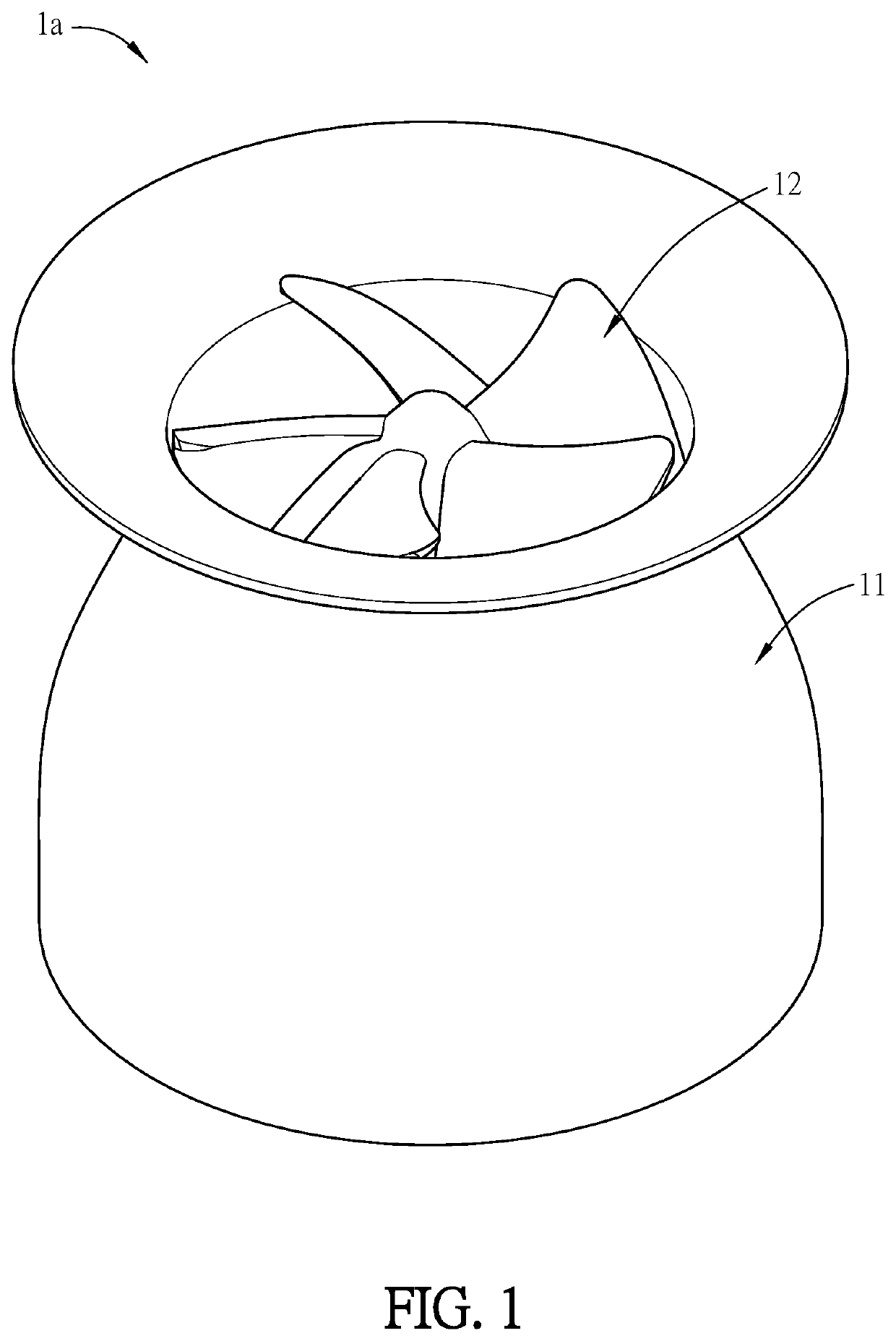

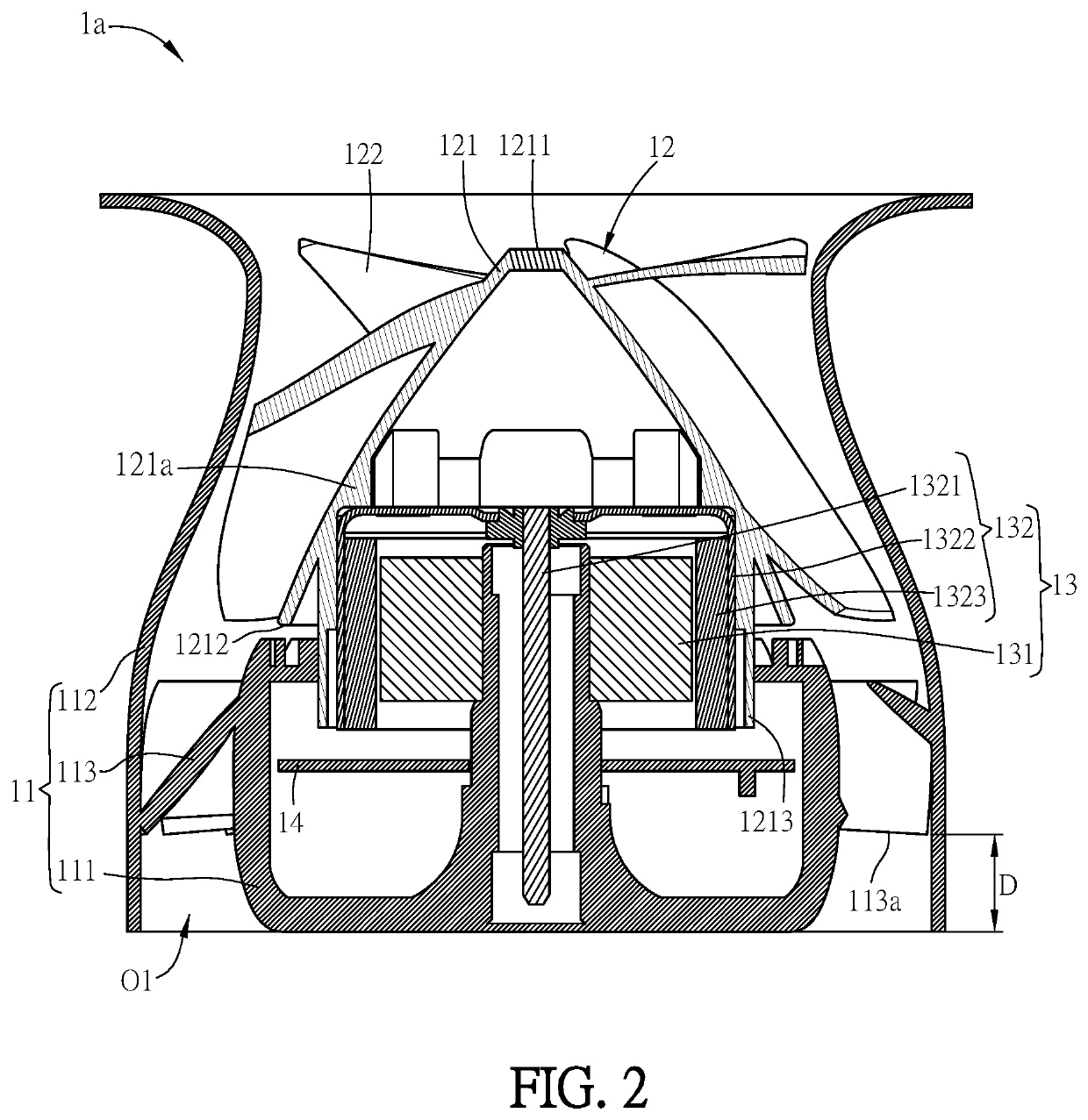

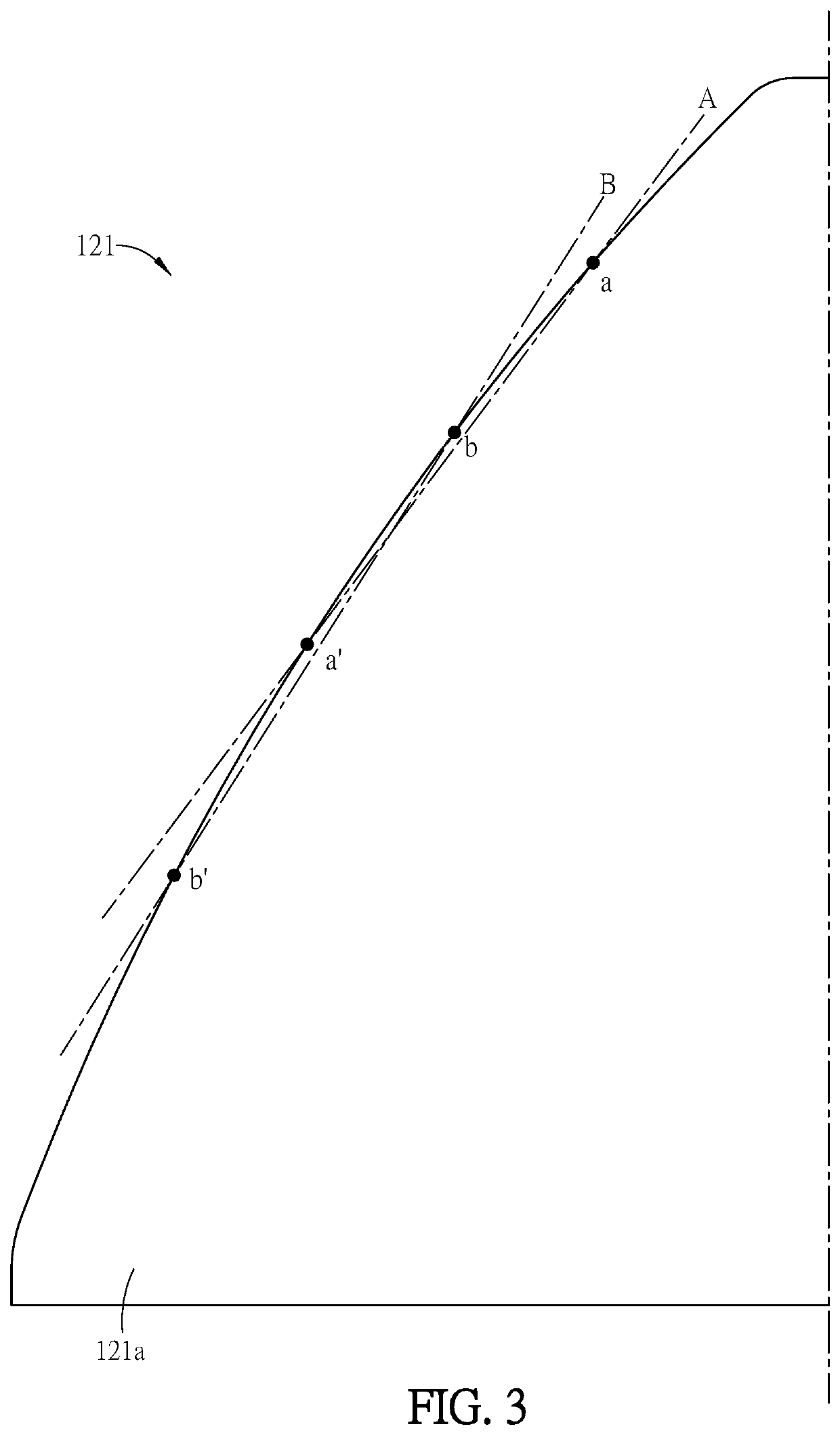

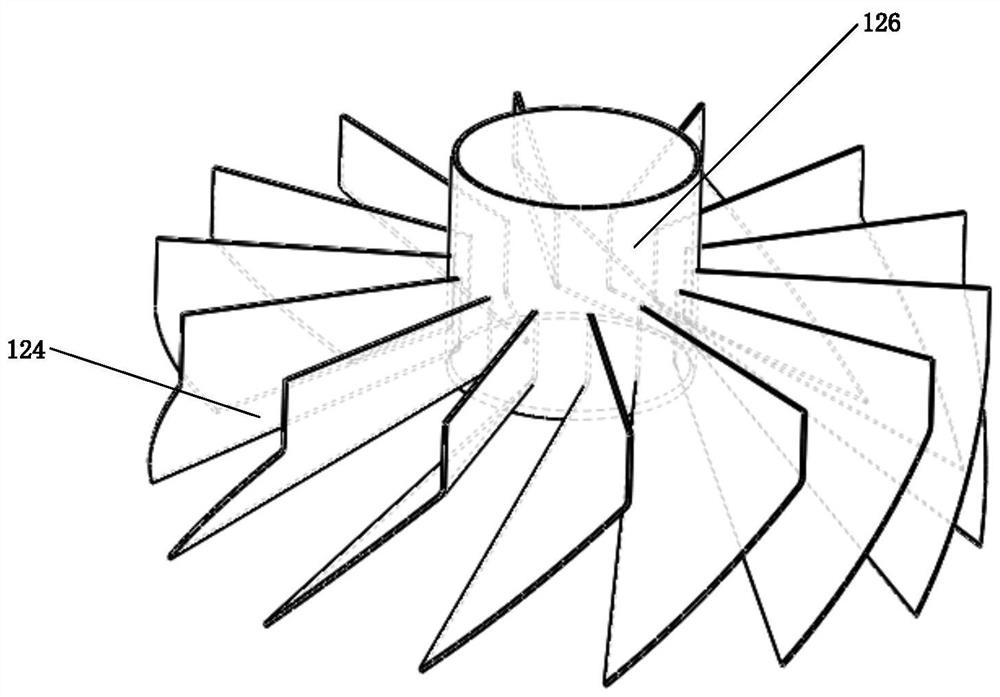

Fan

ActiveUS20200124051A1Enhance fan characteristic of fanExtended service lifePump componentsPump installationsImpellerClassical mechanics

A fan includes a frame, an impeller and a motor. The frame includes a base, a frame housing and a plurality of static blades. The frame housing includes an outlet. The static blades are disposed around the outer periphery of the base and connect between the base and the frame housing. A distance is provided between the outlet and the ends of the static blades located adjacent to the outlet, and the static blades are not protruding from the outlet. The impeller includes a hub and a plurality of rotor blades. The hub has a curved surface. The slopes of the straight lines connecting any two points on the curved surface are not equal. The rotor blades are disposed around the outer periphery of the hub. The motor is disposed on the base, and connects with and drives the impeller to rotate.

Owner:DELTA ELECTRONICS INC

Fuel injection system with cross-flow nozzle for enhanced compressed natural gas jet spray

InactiveUS20080041343A1Improve mixing characteristicImproved gaseous fuel targetingInternal combustion piston enginesFuel supply apparatusInjectorFuel supply

An intake manifold system including an intake manifold and a compressed natural gas (CNG) fuel injector located between an inlet and an outlet of the intake manifold. The CNG fuel injector includes a housing, an inlet, an outlet, a seat, a closure member, and a nozzle. In a preferred embodiment, the inlet and outlet communicate a flow of gaseous fuel regulated by the closure member. The gaseous fuel passes through the seat, which is secured to a rim surface of a retainer portion of the nozzle, and into a flow passage that further communicates the flow of gaseous fuel into one or more flow channels. The orientation of the flow channels within the nozzle greatly affects the discharge pattern and mixing characteristics of the gaseous fuel within an intake manifold. A method of metering gaseous fuel in an intake manifold having a gaseous fuel supply coupled to a fuel injector is also described.

Owner:SIEMENS VDO AUTOMOTIVE CORP +1

Full-premixing water-cooling gas boiler with U-shaped pipe structure

ActiveCN112460568AFlame stabilizationUniform flow and heat transferSteam generation using pressureWater heatersFlue gasEngineering

The invention discloses a full-premixing water-cooling gas boiler with a U-shaped pipe structure. The full-premixing water-cooling gas boiler comprises a water-cooling combustor and a water-cooling heat exchanger which are coaxially arranged, a premixer and a water-cooling combustion head are arranged in the water-cooling combustor, a water outlet of the water-cooling combustor is in communicationwith a water inlet of the water-cooling heat exchanger, and the premixer is in communication with a gas inlet of the water-cooling combustion head; the water-cooling combustion head comprises combustion head water-cooling tube bundles and a combustion head upper header, the combustion head upper header is nested inside and outside, and the two ends of each combustion head water-cooling tube bundle are in communication with the combustion head upper header on the inner side and the combustion head upper header on the outer side respectively; a water inlet of the combustion head upper header isin communication with boiler feed water, and a single water cooling tube of each water cooling tube bundle is U-shaped; a flow equalizing pore plate is arranged on the inner side of the water-coolingcombustion head, and an ignition gun is arranged on the outer side of the water-cooling combustion head; and flue gas flows out of the water-cooling combustion head, then uniformly flows to each water-cooling tube bundle in the water-cooling heat exchanger, then flows downwards to a dew containing disc from a gap between an outer-ring water-cooling tube bundle and the boiler wall and is discharged through a chimney, so that the heat exchange capacity is greatly improved, and the safe and stable operation of the boiler is facilitated.

Owner:XI AN JIAOTONG UNIV

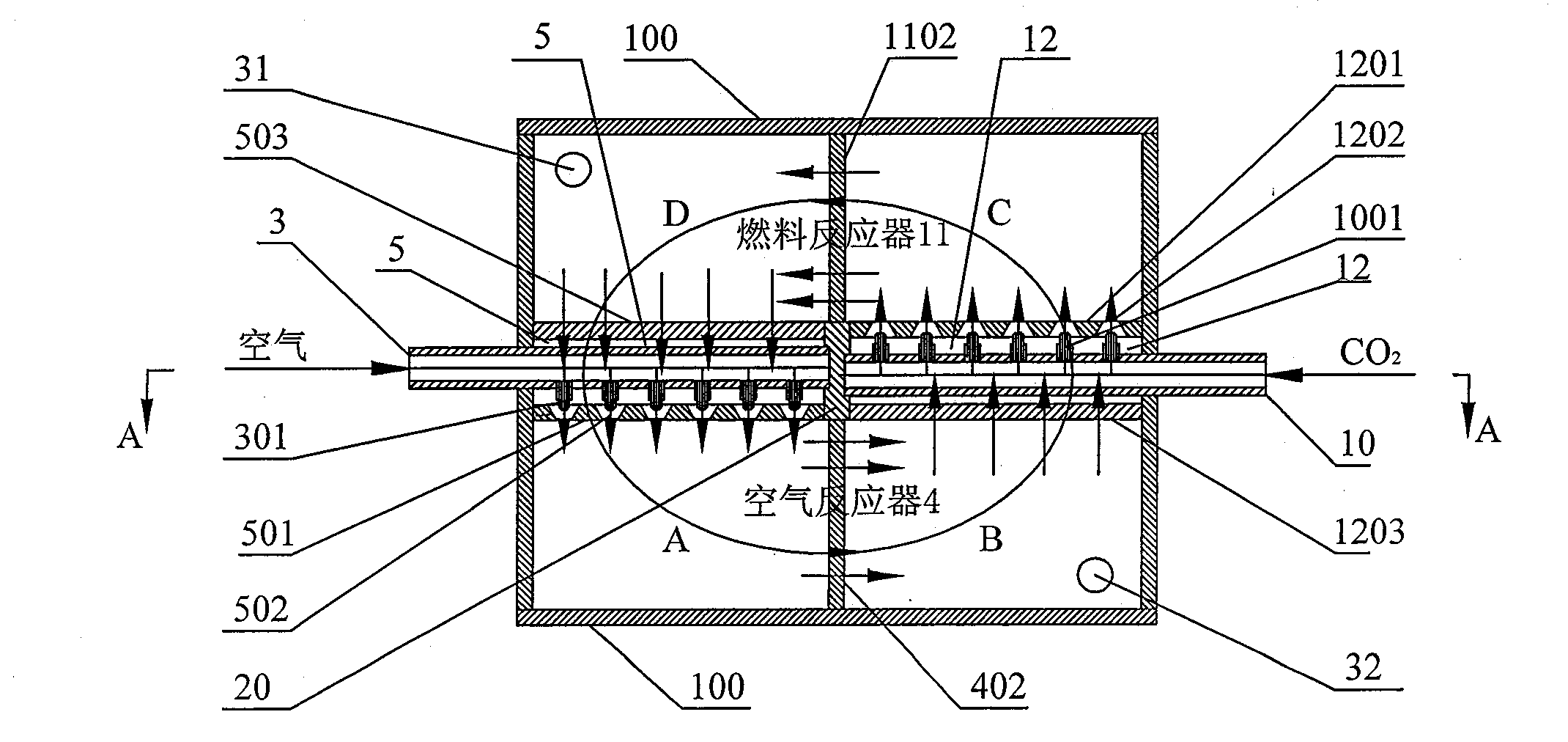

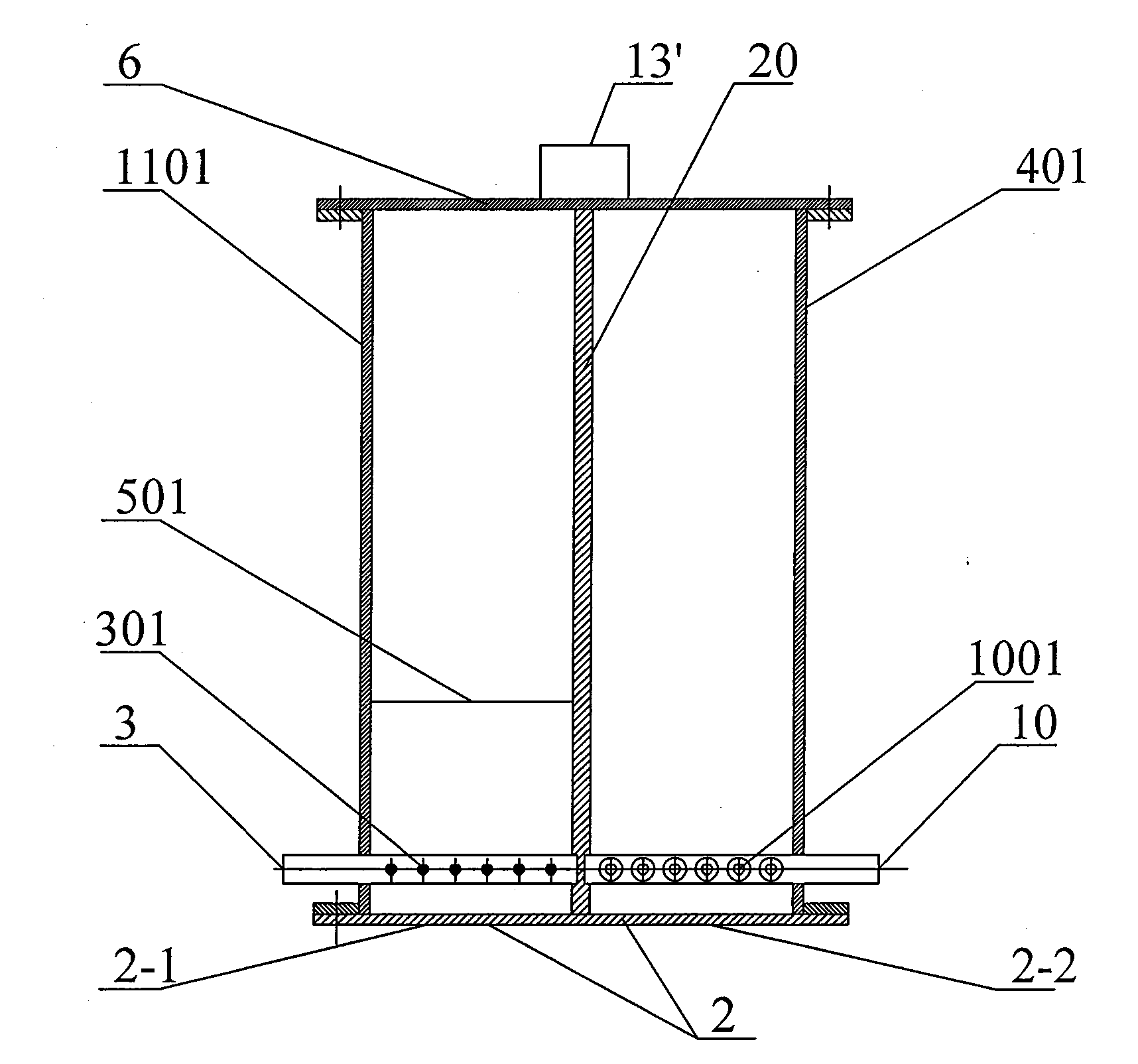

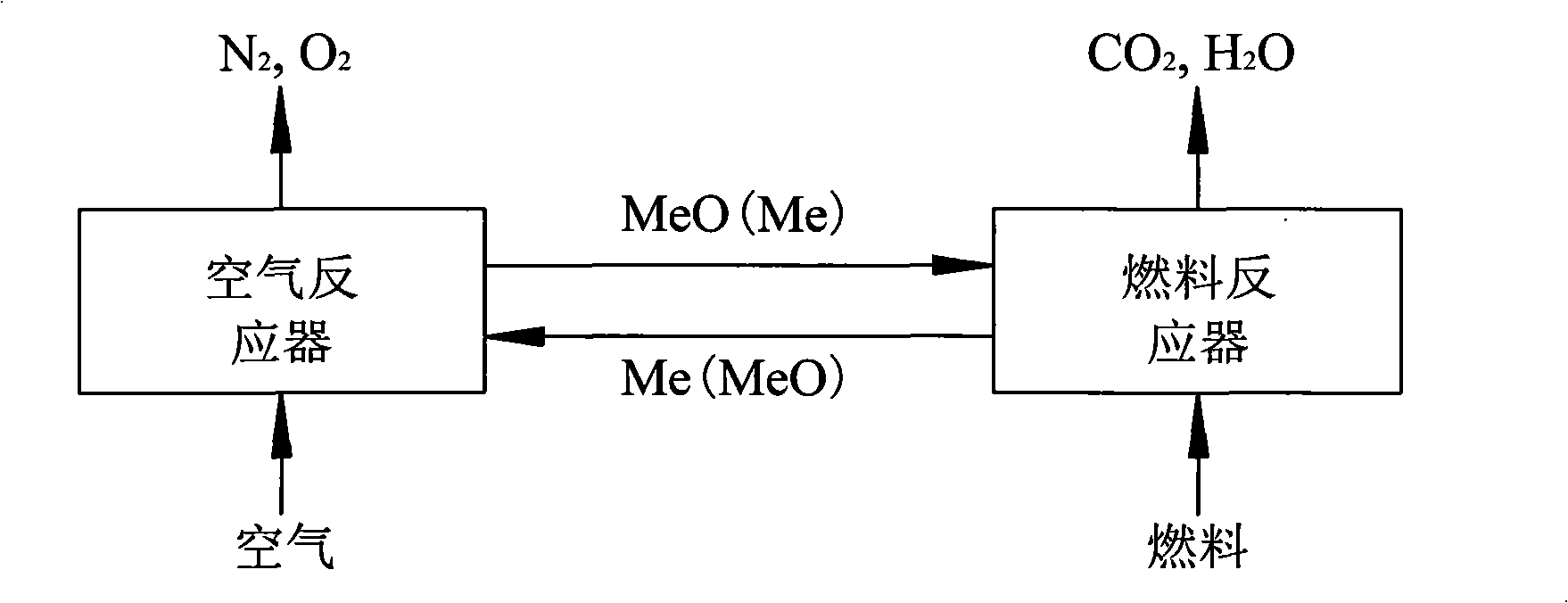

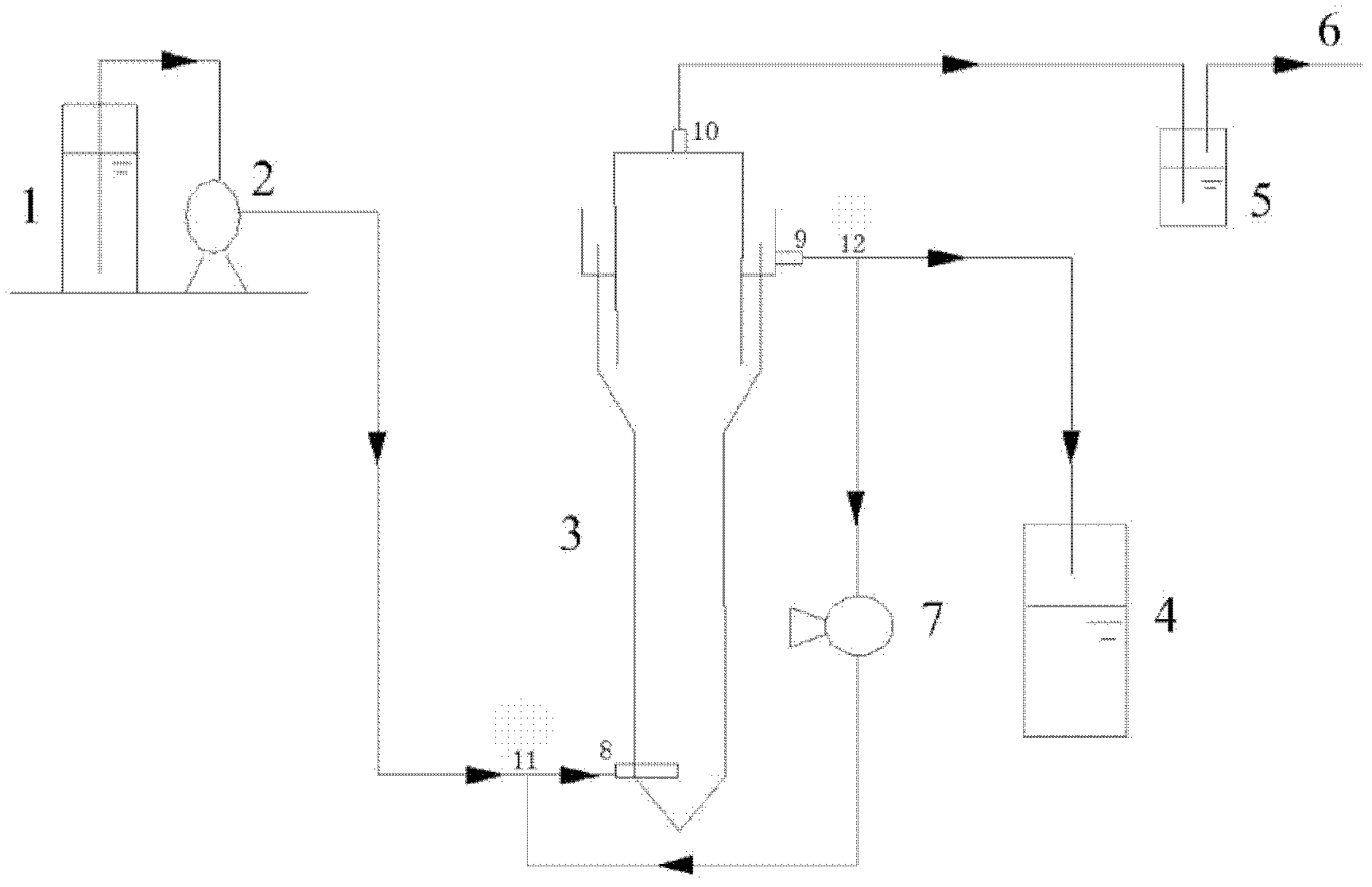

Horizontal circulation and parallel fluidization chemical looping combustion device

InactiveCN101576253BSimple structureEasy to operateFluidized bed combustionIndirect carbon-dioxide mitigationRetention timeFlue gas

The invention discloses a horizontal circulation and parallel fluidization chemical looping combustion device, which comprises a combustion cylinder, wherein the bottom of the combustion cylinder is agrid plate. A boundary of the grid plate is oppositely and horizontally provided with two nozzle tubes, and set directions of nozzles of the two nozzle tubes are opposite; two closed partition wallsare connected into a whole by a transverse closed partition wall to form a Z shape, a cylinder of a fluidized bed combustion device is longitudinally divided into two completely independent and closedfluidized bed reactors, and the top of each fluidized bed reactor is provided with a high-temperature flue gas outlet respectively; plunger area dwarf partition walls, the closed partition walls andthe transverse closed partition wall form two plunger areas together; and overflow dwarf partition walls are arranged from both ends of the transverse closed partition wall to the side wall of the cylinder of the fluidized bed combustion device. The device realizes the integration of an air reactor and a fuel reactor, strengthens transverse mixing characteristics of particles in a fluidized bed, prolongs the retention time of the particles and fuel, avoids the phenomenon of 'short circuit' of an oxygen carrier, solves the problem of gas leakage between the air reactor and the fuel reactor, andimproves the combustion reaction efficiency.

Owner:NANJING NORMAL UNIVERSITY

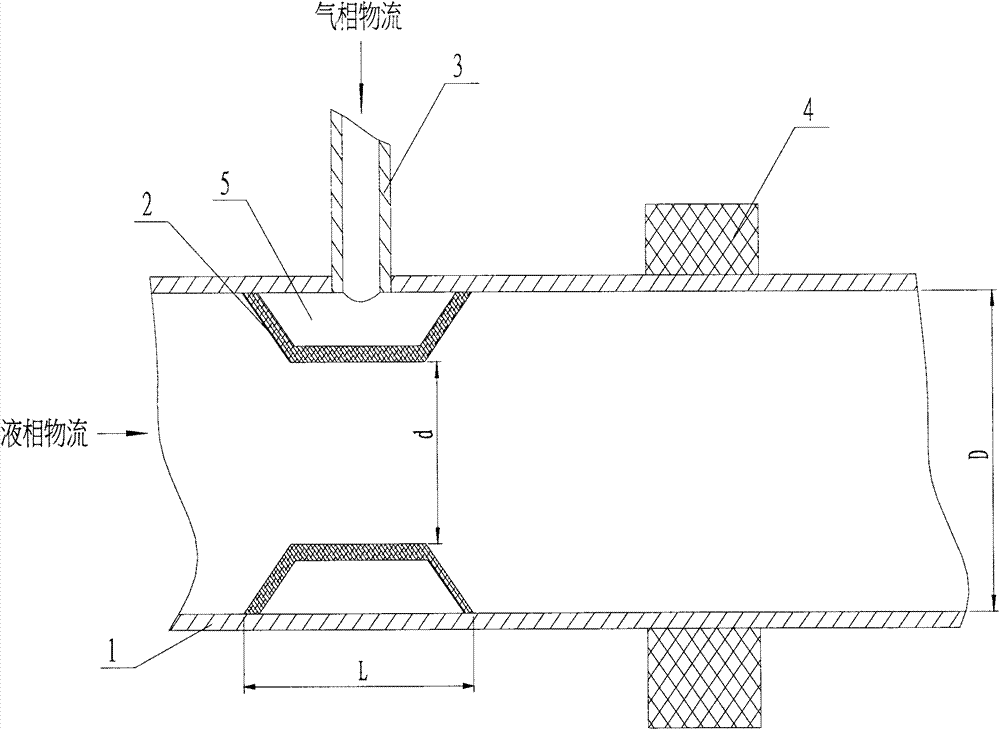

A Microbubble Generator for Strengthening Hydrogenation Process

ActiveCN104874315BSmall pressure dropSimple structureMixing methodsMixersHydrogenation processEngineering

The invention discloses a microbubble generator for intensifying hydrogenation process, which is mainly composed of a main pipe, a Venturi pipe, an intake pipe and an ultrasonic generator; the Venturi pipe and the main pipe are coaxially arranged and welded on the inner wall of the main pipe, An independent annular air intake space is formed between the outer wall of the Venturi tube and the inner wall of the main body tube. The air intake tube is welded on the outer wall of the main body tube and communicates with the annular air intake space. The Venturi tube is made of microporous materials. The air inlet pipe, the annular air inlet space and the micropores of the Venturi tube together form a gas channel, and the inner wall of the Venturi tube and the inner wall of the main tube together form a gas-liquid channel; the ultrasonic generator is installed on the outer wall of the main tube and is located in the venturi tube downstream. By adopting the invention, the hydrogenation efficiency can be improved, and deep and efficient hydrogenation treatment or hydrocracking of oil products can be realized.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

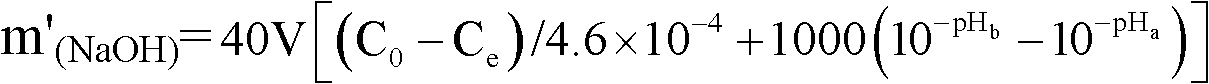

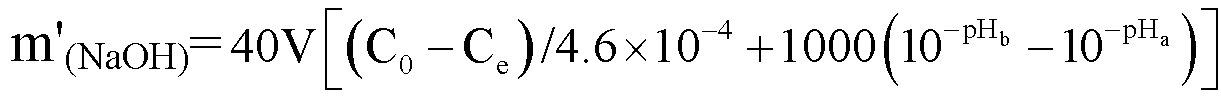

Method for quickly remitting inhibition of nitrite in anaerobic ammonium oxidation

ActiveCN102583729BAvoid large fluctuations in pHThorough responseTreatment with anaerobic digestion processesPeristaltic pumpSulfamic acid

The invention discloses a method for quickly remitting inhibition of nitrite in anaerobic ammonium oxidation. The method provided by the invention comprises the steps of: when a concentration of nitrite nitrogen is more than 100mg / L in a reactor body, stopping water entering the anaerobic ammonium oxidation reactor, starting a reflux peristaltic pump, adding a sulfamic acid solution and a sodium hydroxide solution in a water outlet of the anaerobic ammonium oxidation reactor in sequence, performing a reflux reaction for 2-3min, repeatedly adding the sulfamic acid solution and the sodium hydroxide solution alternately in the water outlet of the anaerobic ammonium oxidation reactor in sequence and performing the reflux reaction for 2-3min each time, keeping the circulation until the added sulfamic acid and the sodium hydroxide reach a required input quantity under a condition that the concentration of the nitrite nitrogen is less than 20mg / L and a pH value is at a range of 7.8-8.3 in the anaerobic ammonium oxidation reactor, then stopping the reflex reaction, and starting a water entering peristaltic pump. The method disclosed by the invention can remit the inhibition of the nitrite in the anaerobic ammonium oxidation in a short time, so as to save resources and ensure the high activity of anaerobic ammonium oxidizing bacteria; and the method is simple and convenient to implement and reduces the cost of infrastructure.

Owner:HANGZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com