Patents

Literature

1879 results about "Hydrogenation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation is a chemical process in which hydrogen gas is bubbled through a liquid oil in the presence of a catalyst, often a reactive metal such as platinum or nickel.

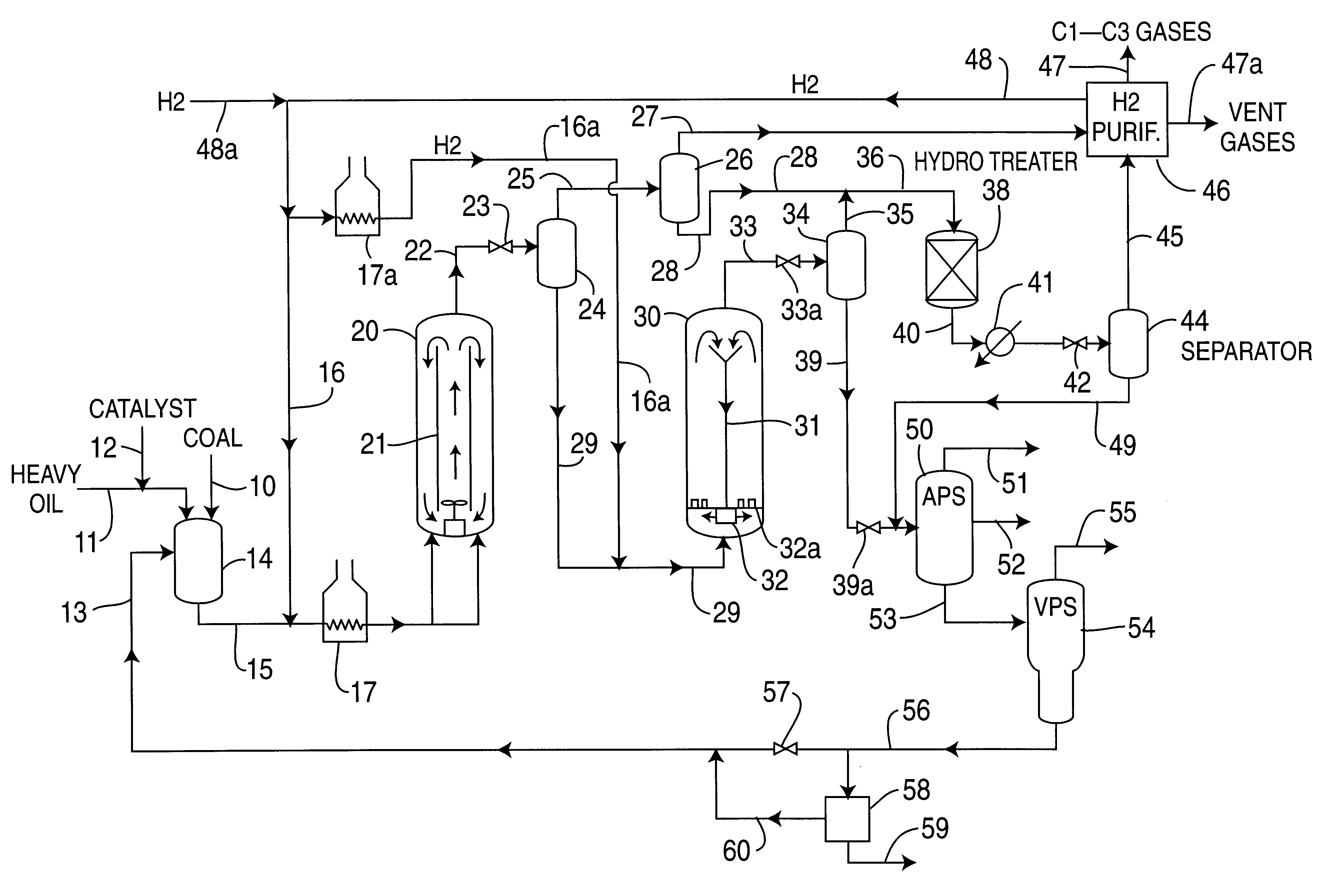

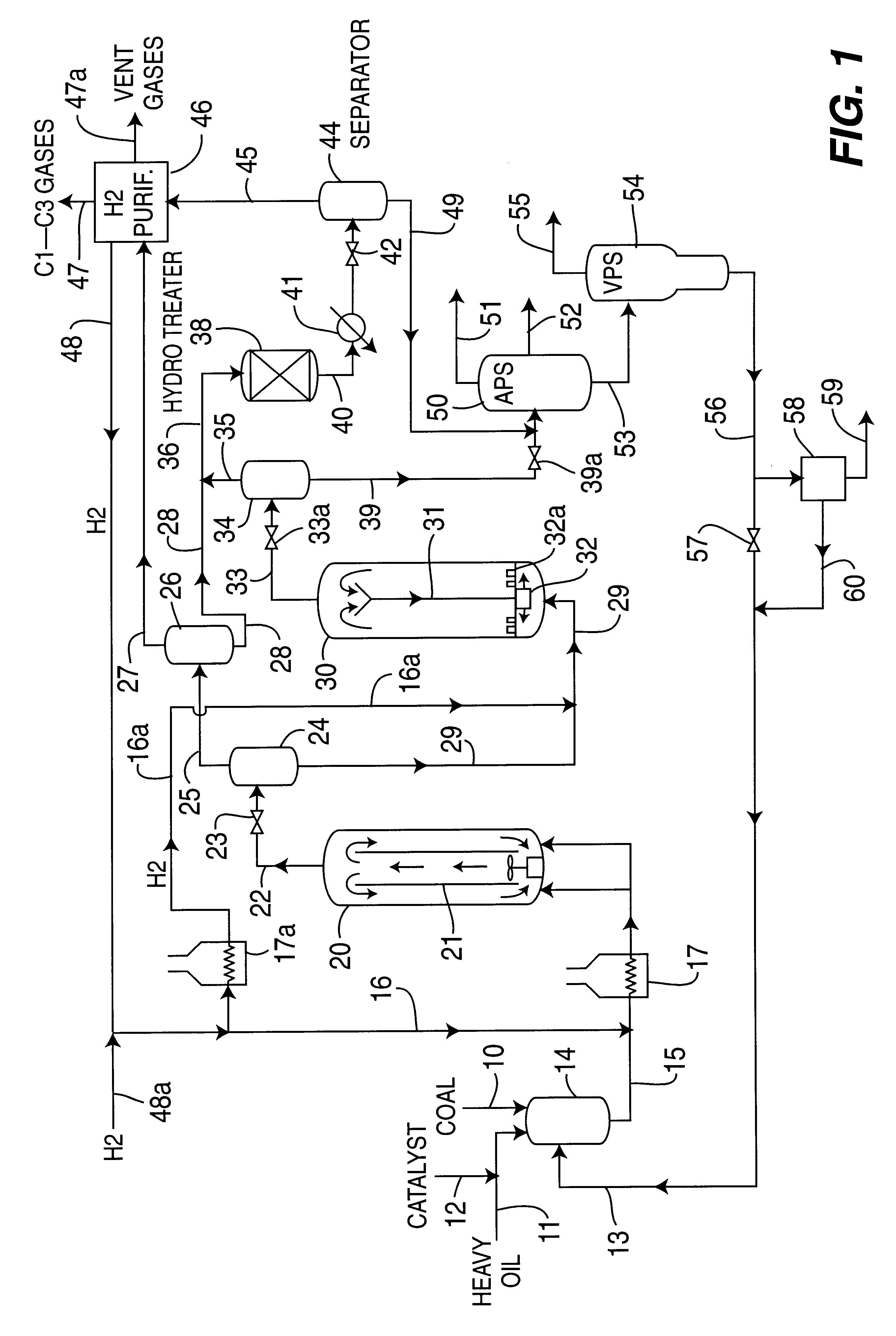

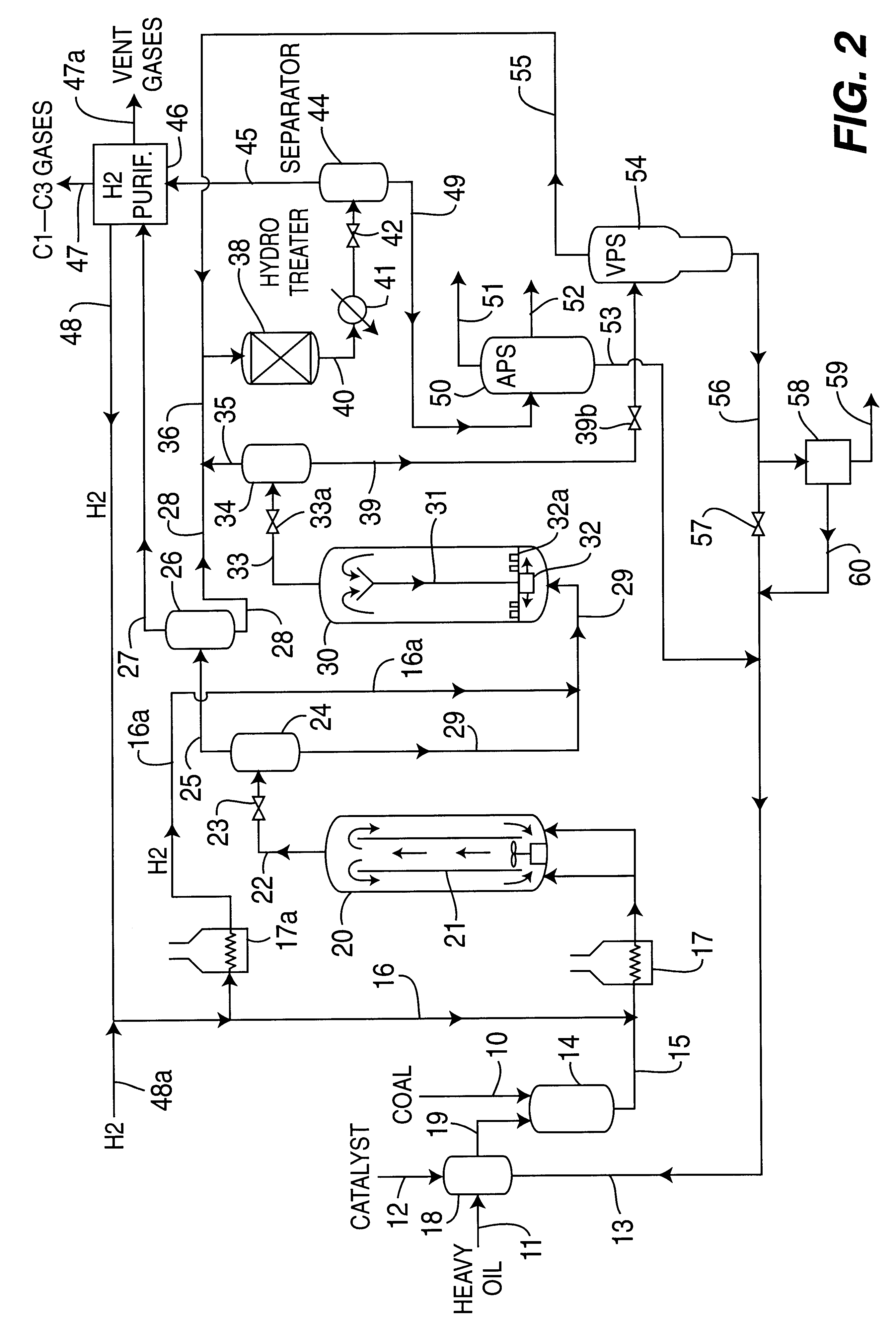

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

Hydrogenation process for hydrocarbon resins

InactiveUS20030150778A1Improve productivityIncrease volumePreparation by oxo-reaction and reductionCatalyst activation/preparationProduction rateHalogen

This invention provides a process for hydrotreating hydrocarbon resins, which process comprises contacting a feedstock comprising a hydrocarbon resin or rosin, under suitable hydrotreating conditions, with a bulk multimetallic catalyst comprised of at least one Group VIII non-noble metal and at least two Group VIB metals and wherein the ratio of Group VIB metal to Group VIII non-noble metal is from about 10:1 to about 1:10. The process accord invention can achieve increased hydrocarbon resin productivity through increase in throughput volumes and effective catalyst lifetimes. The process of the invention is desirably practiced with a bulk catalyst consisting of only the combination of the metal species with the active metal components. The absence of carrier substrates largely removes the possibility of halogen accumulation on substrate surfaces that, in turn, can acidify metal catalysts such that additional, progressive cracking of the hydrocarbon resin molecules occurs.

Owner:EXXONMOBIL CHEM PAT INC

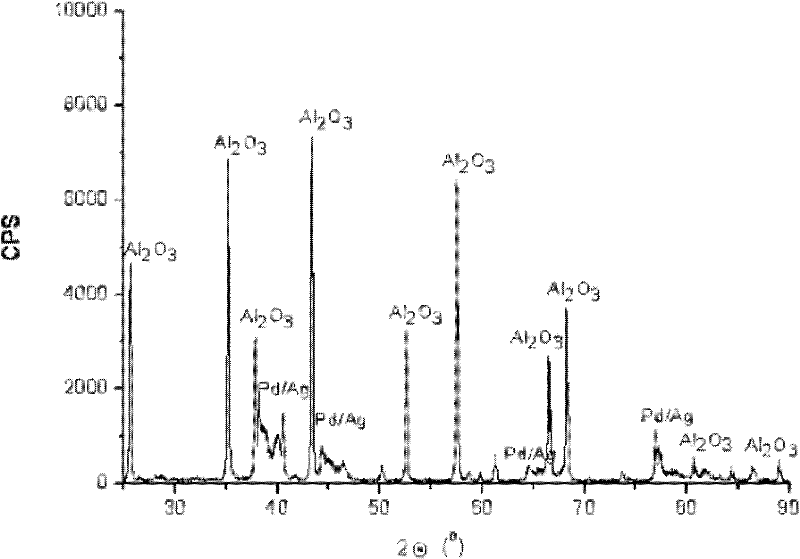

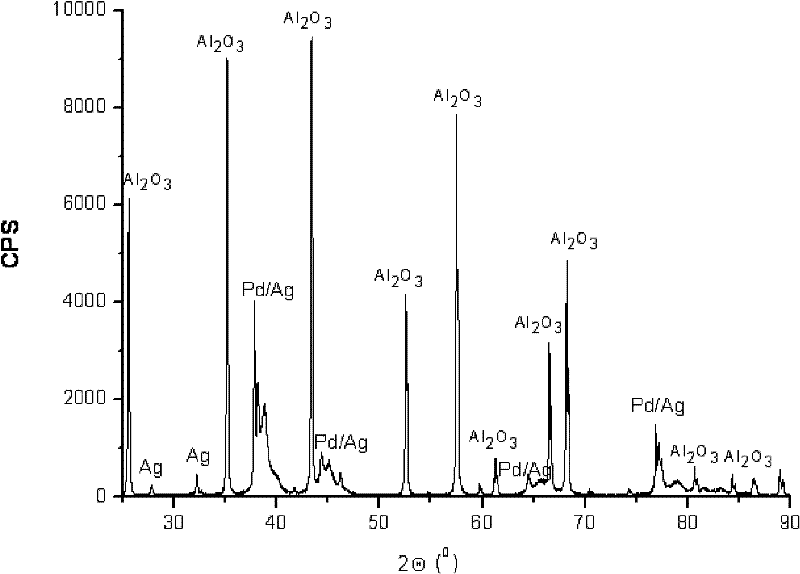

Palladium-silver bimetallic hydrogenation catalyst

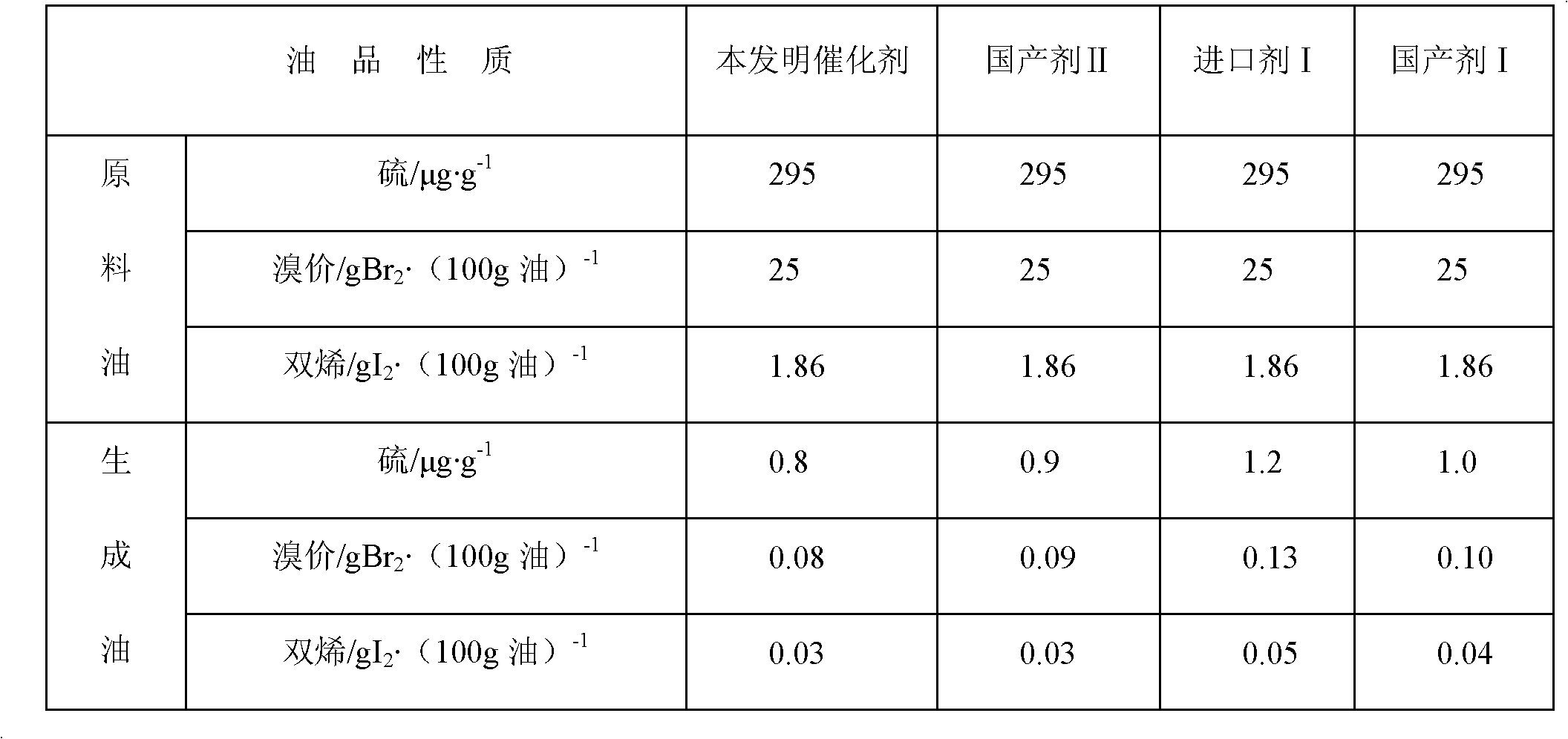

ActiveCN102205243AGood choiceImprove hydrogenation activityHydrocarbon purification/separationHydrocarbonsHydrogenation processSolvation

The invention relates to a palladium-silver bimetallic hydrogenation catalyst, a carrier of which mainly contains Al2O3 and which is characterized by comprising, based on 100% of the catalyst weight, 0.01-0.4% of Pd, 0.02-0.2% of Ag, and has a specific surface area of 1-100m<2> / g. The catalyst is obtained through three steps of: first, preparing a functionalized-high-molecular / Al2O3 precursor, then preparing a Pd-Ag-high-molecular / Al2O3 precursor, and lastly roasting the precursors at 380-550 DEG C for 2-6h. The preparation method overcomes the influences of dipping liquid surface tensionand solvation effect on palladium-silver disperseness, and the prepared catalyst has excellent selectivity. The catalyst of the invention can be applied to selective hydrogenation process of fractions such as C2 and C3, and has a good hydrogenation activity, excellent selectivity and good hydrogenation stability.

Owner:PETROCHINA CO LTD

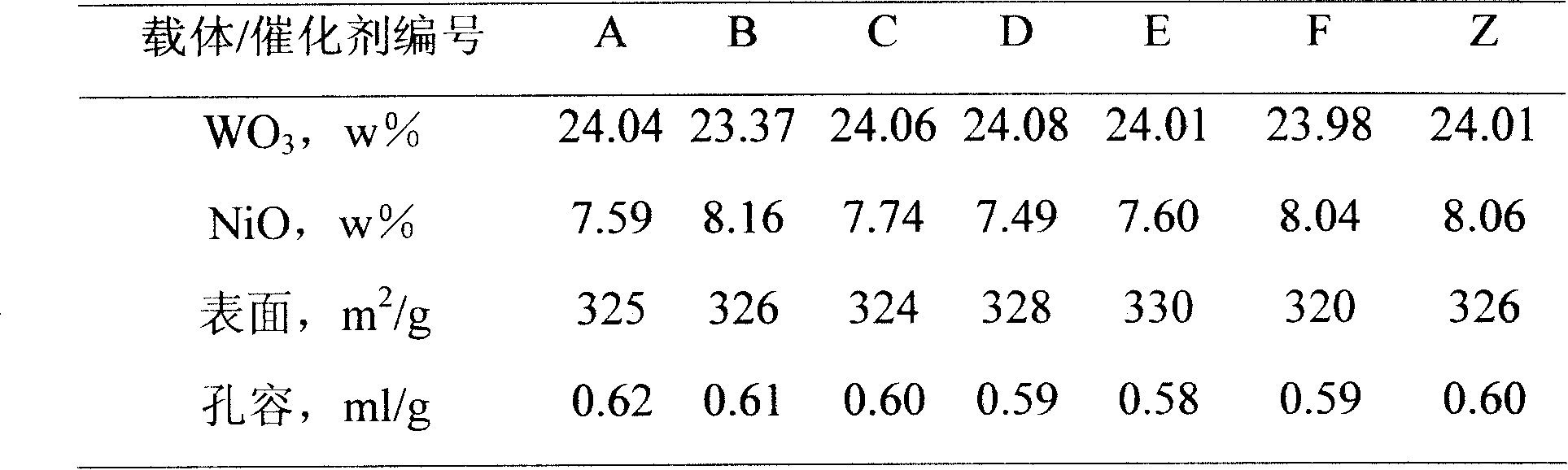

Preparation of hydrogenation catalyst

ActiveCN101172260AEasy to useEvenly dispersedMolecular sieve catalystsCatalyst activation/preparationMolecular sievePolymer science

The invention discloses a preparation method of a hydrogenation catalyst. The final catalyst is prepared by impregnation method or coprecipitation method using a carrier material containing molecular sieve and amorphous silica-alumina. The carrier material is prepared by introducing molecular sieve slurry in the process of forming amorphous silica-alumina gel, which improves the distribution of molecular sieve in the silica-alumina carrier, improves the coordinated catalytic effect of the two carrier materials, and greatly improves the performance of the catalyst. The catalyst prepared by the method of the present invention can be used in various hydrogenation processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation of biochemical derived 1,3 -propanediol

InactiveUS7098368B2Organic compound preparationOxygen compounds purification/separationDownstream processingHydrogenation process

The invention discloses a hydrogenation process for removing impurities and controlling acid for use in downstream processing of biochemically-derived 1,3-propanediol. Preferably, the biochemically-derived 1,3-propanediol, before the contacting, has an initial color and, after the contracting, has a color that is lower than the initial color.

Owner:EI DU PONT DE NEMOURS & CO

Hydrogenation catalysts precuring method and start working method of hydrogenation process

ActiveCN101492607AHigh vulcanization rateHigh sulfur retentionHydrotreatment operations starting-upCatalyst activation/preparationSulfurEconomic benefits

The invention discloses a method for precuring hydrogenation catalyst and a hydrogenation process operation method. During the presulfurization of the catalyst, intake of curing ingredient for partially precuring the catalyst is much more than theoretical sulfur demand of active hydrogenation metal in the catalyst. Precured hydrogenation catalyst and the hydrogenation catalyst which is not precured are mixed or layered in a reactor, and by operation and activation all catalyst is effectively cured. The method of the invention can precure the required catalyst, shorten the production period for precuring the catalyst, reduce the production cost and enhance economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil

ActiveCN102311785AWeak acidSmall grainTreatment with hydrotreatment processesLubricant compositionHydrogenation processBase oil

The invention relates to a method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil. The naphthenic distillate is used as raw material and a one-stage in series hydrogenation process of hydrotreating-hydrodewaxing-hydrofinishing is adopted to produce the lubricating oil basic oil. Ordinary hydrotreating catalysts are filled in the upper part of a hydrotreating reaction area, and hydrotreating catalysts containing modified zeolites are filled in the lower part of the hydrotreating reaction area. The hydrodewaxing and hydrofinishing reaction areas are the same as those of the prior art, and are filled with hydrodewaxing catalysts and hydrofinishing catalysts. Compared with the prior art, the method disclosed by the invention has the advantages that system energy consumption is reduced, the pour point of a product is properly reduced, and the stability of the product is effectively improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of vulcanization type hydrogenation catalyst

ActiveCN101491765AAvoid low loadLoad type high activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsVulcanizationSulfur

The invention relates to a method for preparing a vulcanized hydrogenation catalyst. A catalyst carrier adopts an impregnation method to load hydrogenation metal components; before, after or simultaneously loading the hydrogenation metal components, a vulcanizing agent is introduced, and the use level of the vulcanizing agent is 85 to 150 percent of theoretic sulfur demand of the hydrogenation metal components; and during loading the hydrogenation metal components and introducing the vulcanizing agent, the method comprises at least one step of low-temperature thermal treatment but does not comprise a roasting step. The method overcomes the defects that the conventional oxidation catalyst has high preparation cost, long vulcanizing time and high operating cost. The catalyst prepared by the method is suitable for a hydrogenation process of petroleum fractions, and the hydrogenation activity of the catalyst prepared by the method can reach or exceeds the effect of the conventional catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

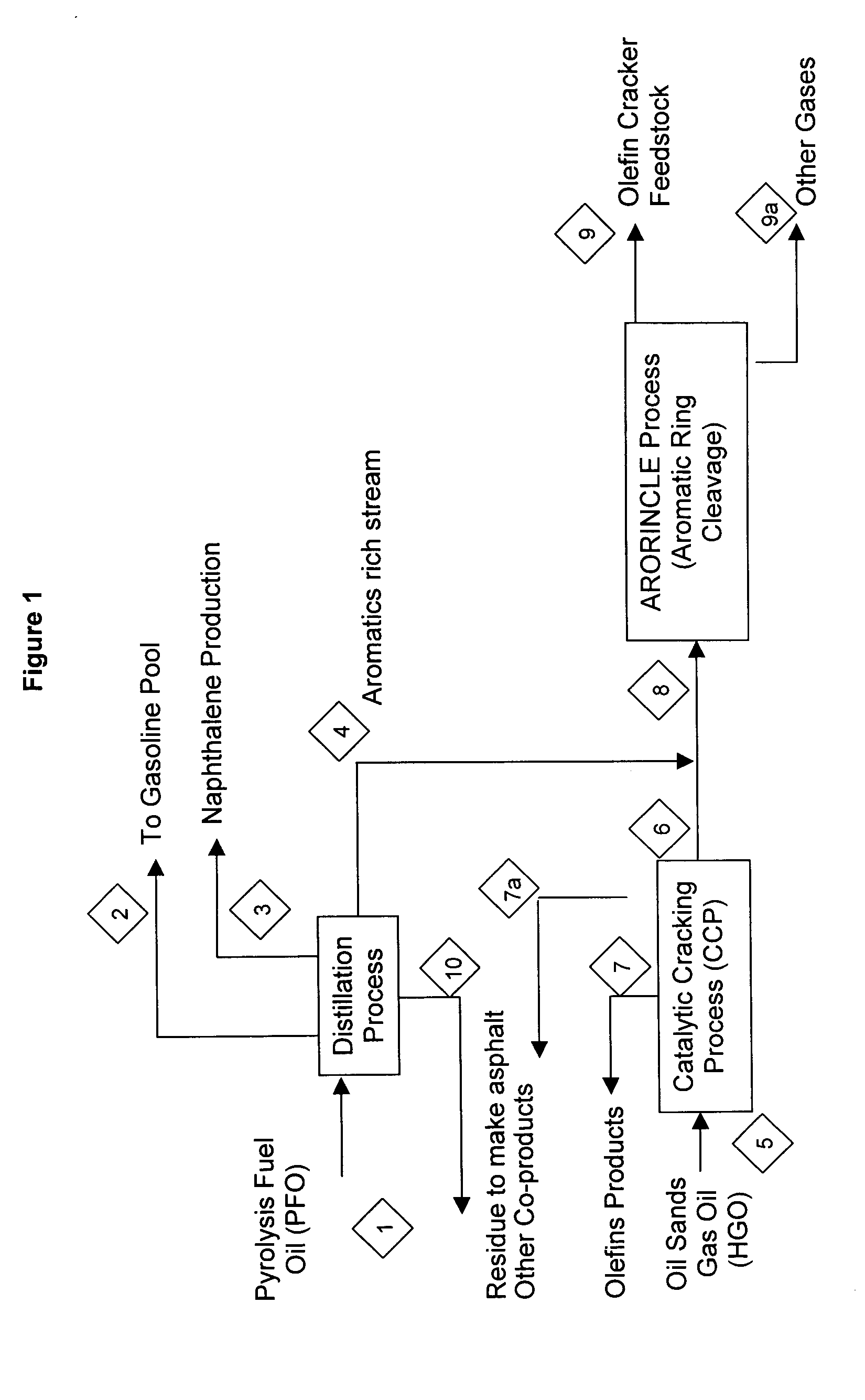

Integrated process to convert heavy oils from oil sands to petrochemical feedstock

ActiveUS20050258073A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyAlkaneFuel oil

An aromatics / naphthalene rich stream obtained by processing heavy gas oil derived from tar sands and cycle oils derived from cracking heavy gas oil may optionally be blended and subjected to a hydrogenation process and a ring opening reaction typically in the presence of a zeolite, alumina, or silica alumina based catalyst which may contain noble metals and or copper or molybdenum to produce paraffinic feedstocks for further chemical processing.

Owner:NOVA CHEM (INT) SA

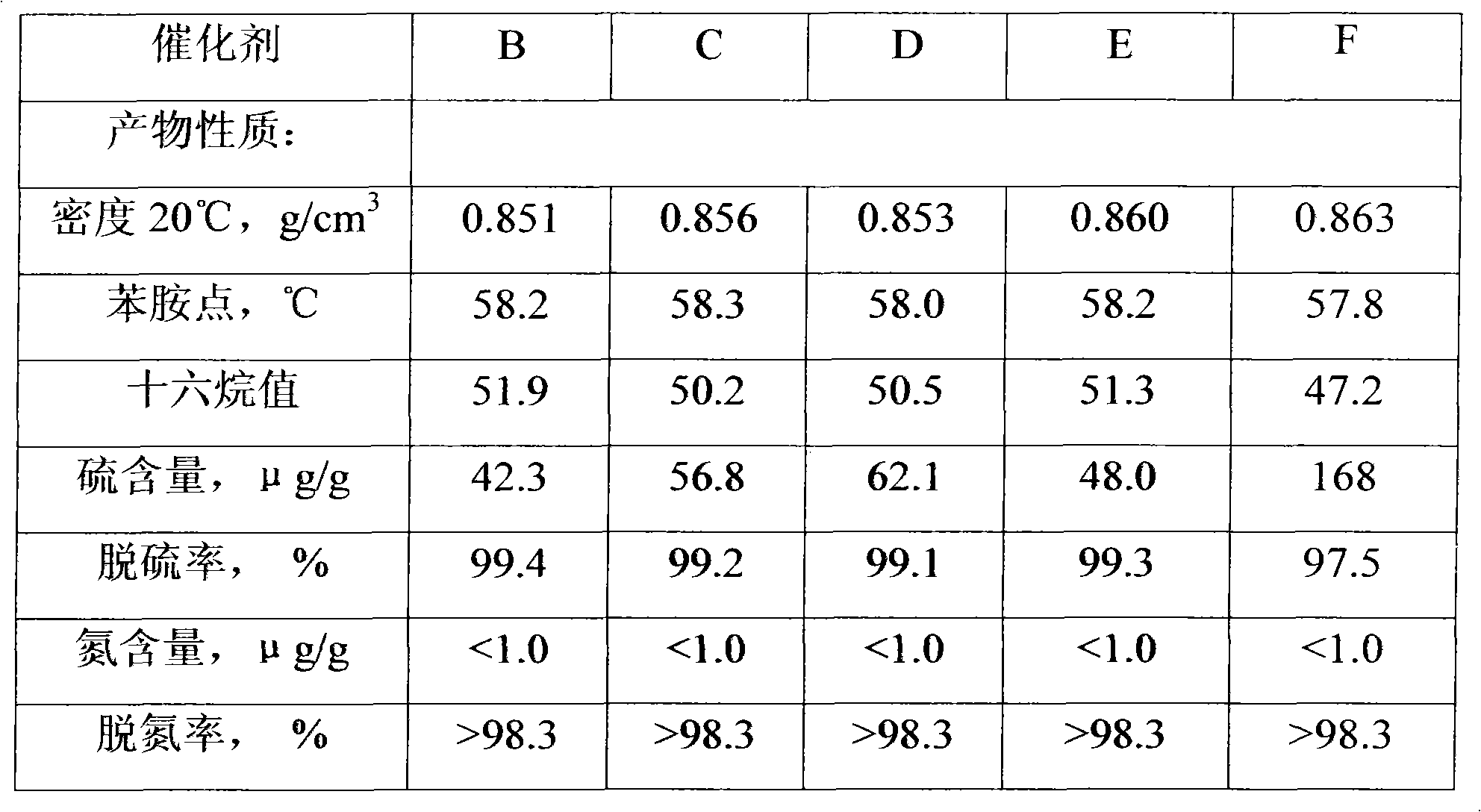

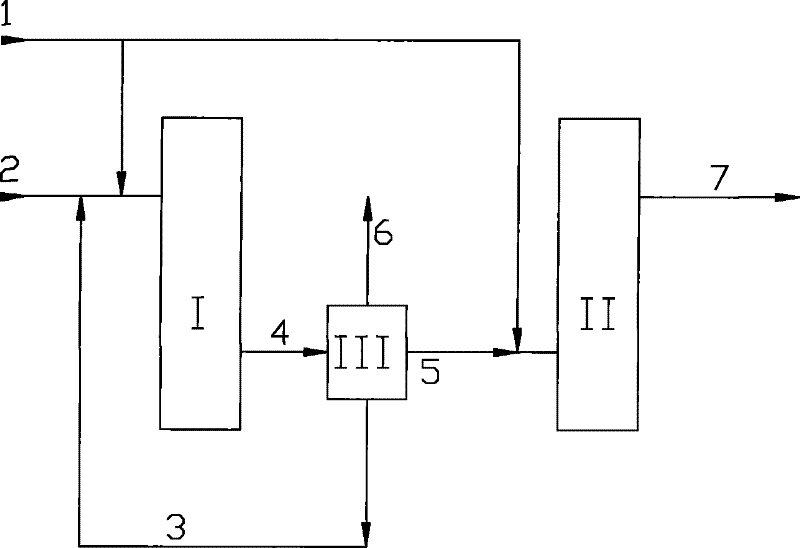

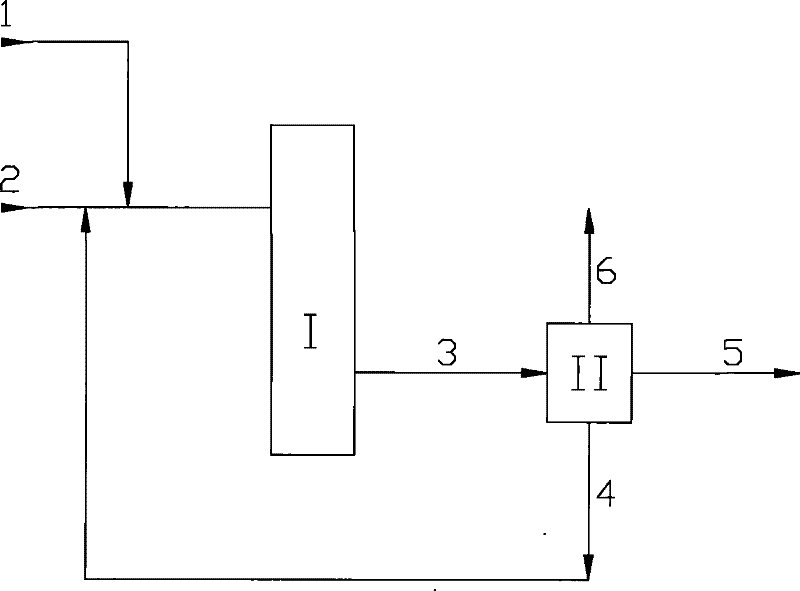

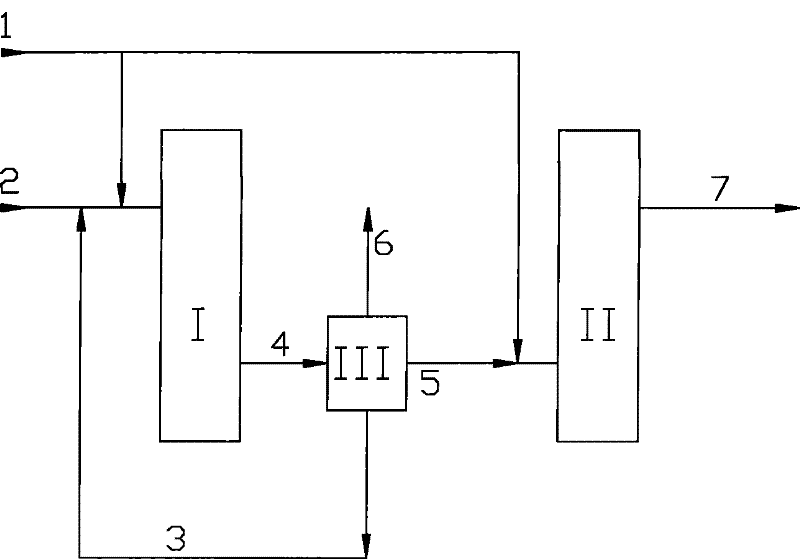

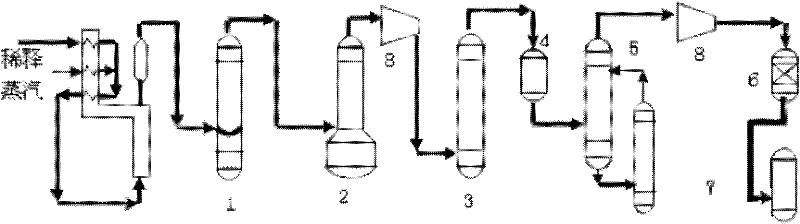

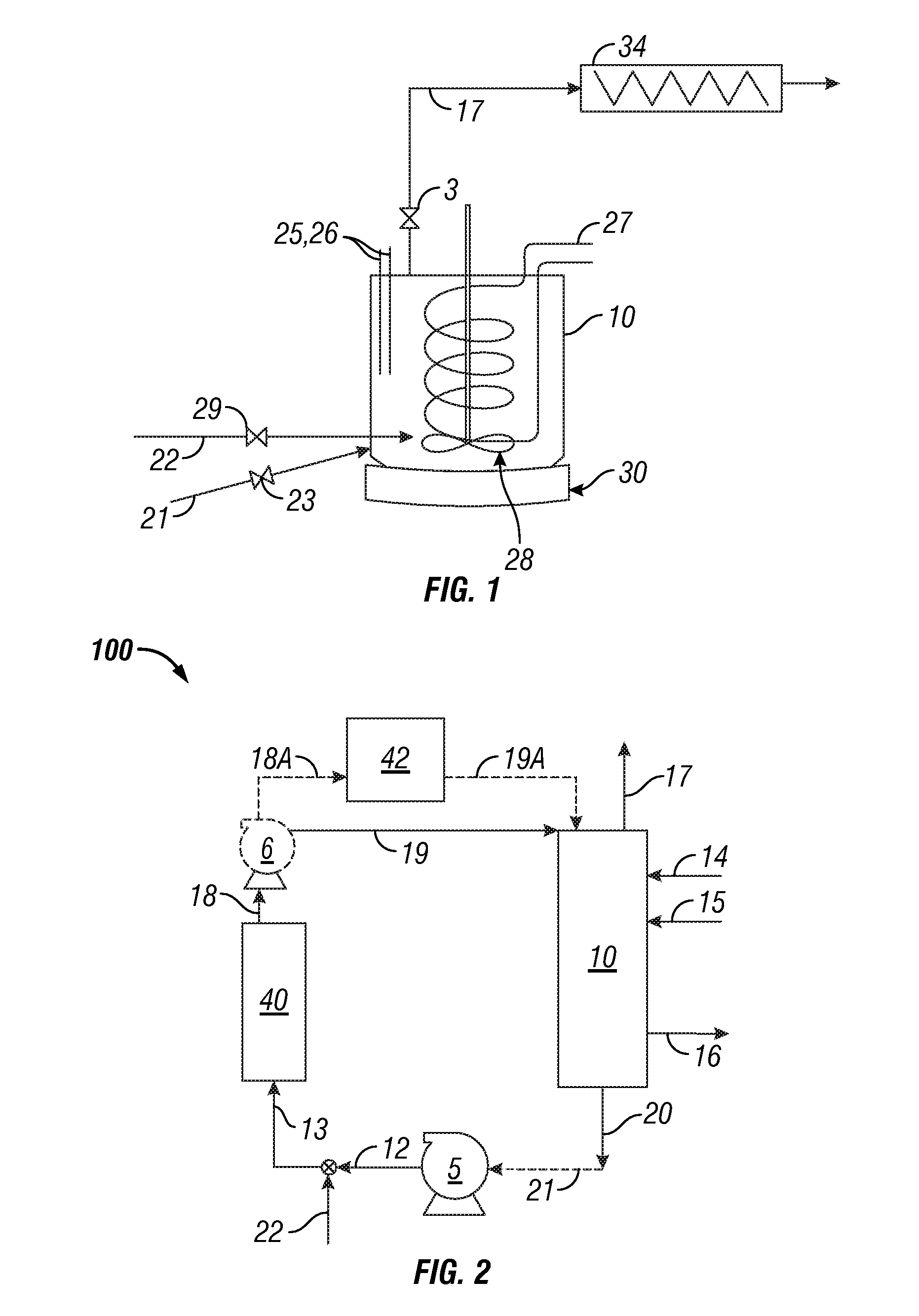

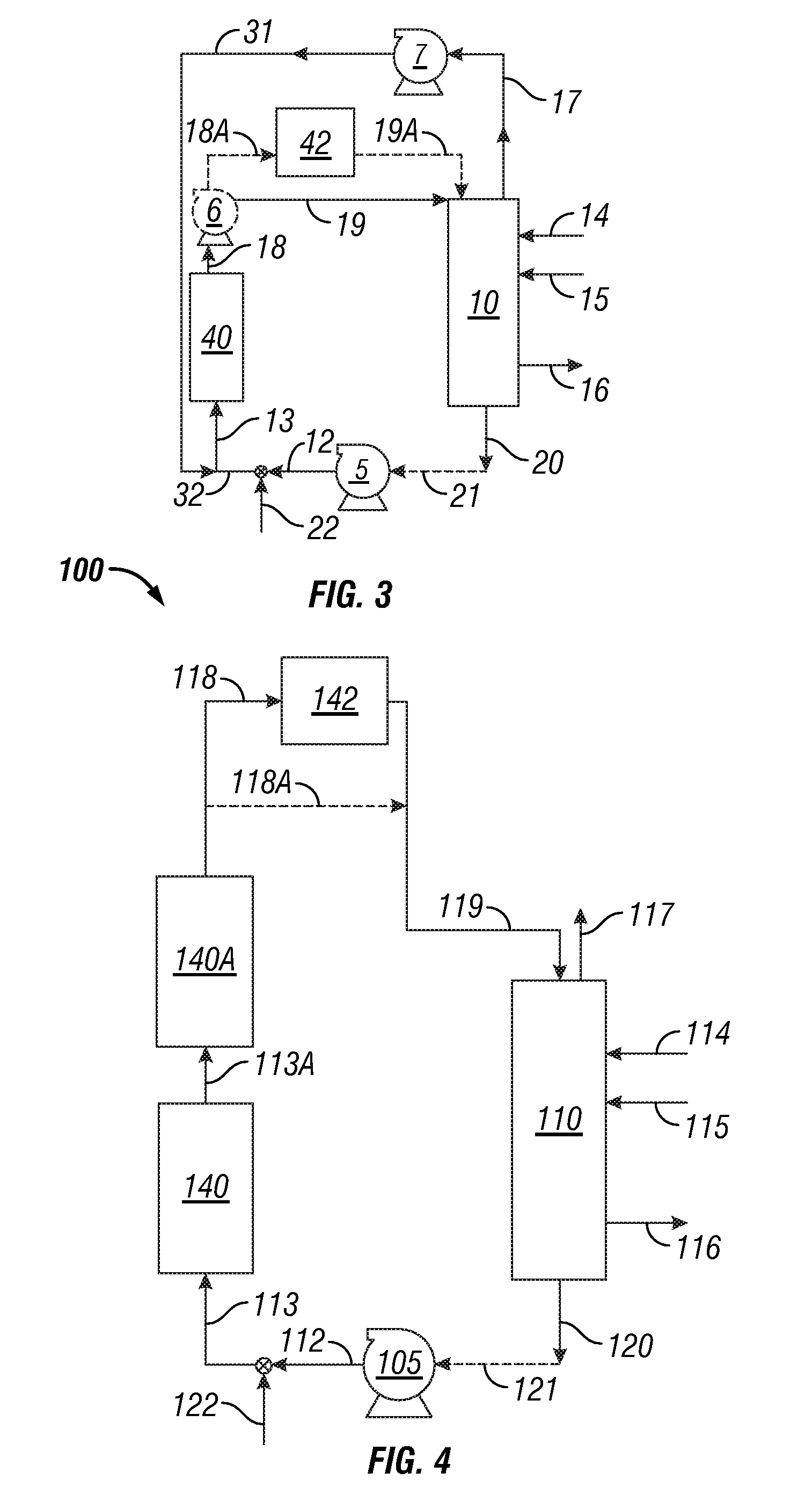

A selective hydrogenation process for C4 stream with high butadiene content

ActiveCN102285859AReasonable useHydrocarbon by hydrogenationHydrocarbon purification/separationHigh concentrationButene

The invention relates to a selective hydrogenation process for a C4 material flow with high concentration of butadiene. The selective hydrogenation process comprises the following steps of: enabling the C4 material flow with the high concentration of butadiene to pass through one or more fixed bed hydrogenation reactors (I) with circulation pipelines, carrying out a selective hydrogenation reaction on the C4 mixture with high concentration of butadiene under the action of a catalyst to remove the butadiene and alkyne and generate butylene, enabling the reactor to pass through a terminal reactor (II) without the circulation pipeline, and further removing the residual butadiene and alkyne from the C4 material flow with the low concentration of butadiene. By utilizing the selective hydrogenation process and the catalyst provided by the invention, the controlled concentration range of the butadiene and the C4 alkyne of the C4 material flow is 5-80wt%, the concentrations of the butadiene and the alkyne of the hydrogenated C4 material flow can be respectively reduced to below 10ppm, the selectivity of the 1-butene generation by the butadiene can be more than 50%, and the butadiene can be taken as the raw material of preparing the 1-butene. According to the selective hydrogenation process disclosed by the invention, the C4 material flow is reasonably utilized.

Owner:CHINA PETROLEUM & CHEM CORP +1

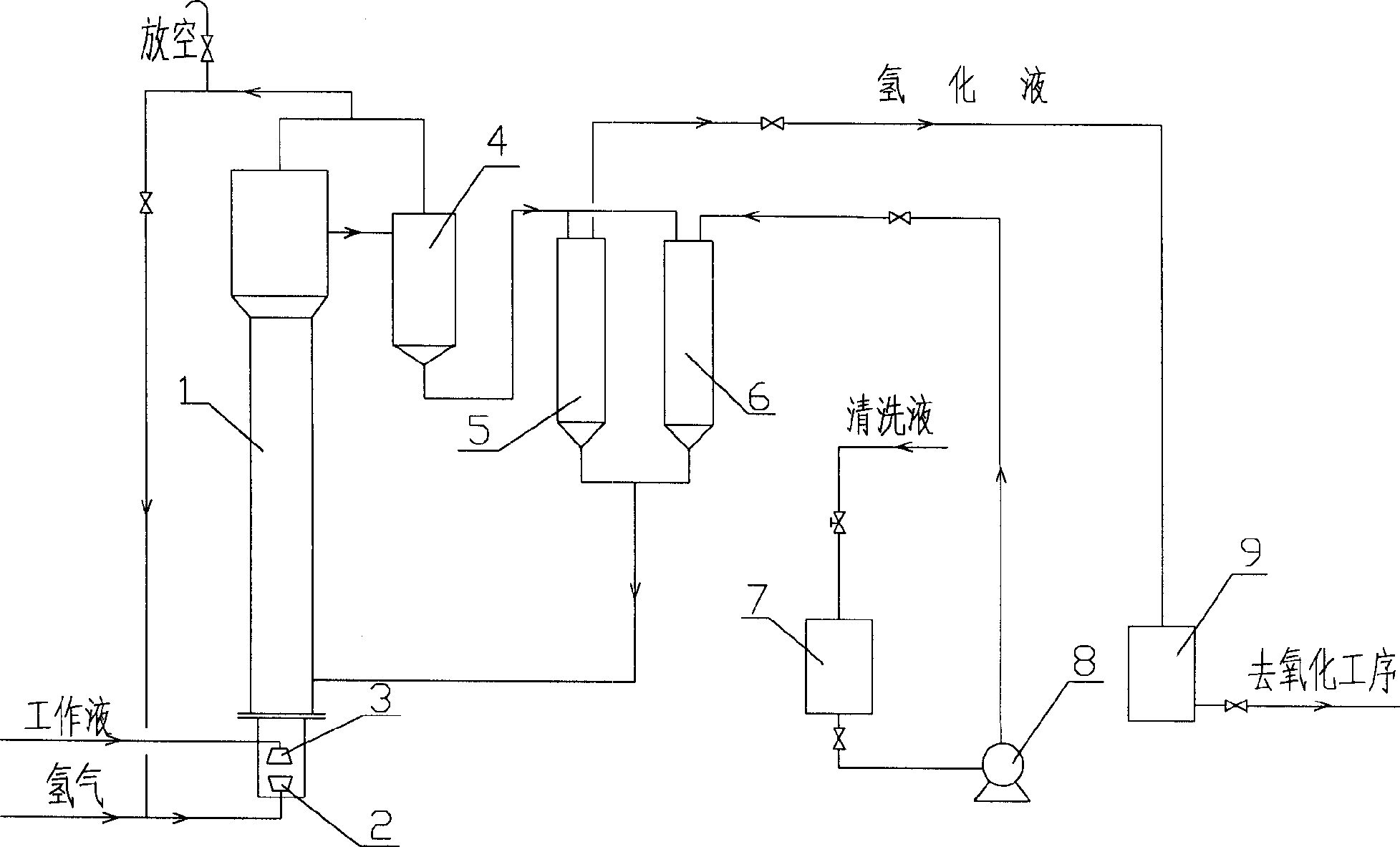

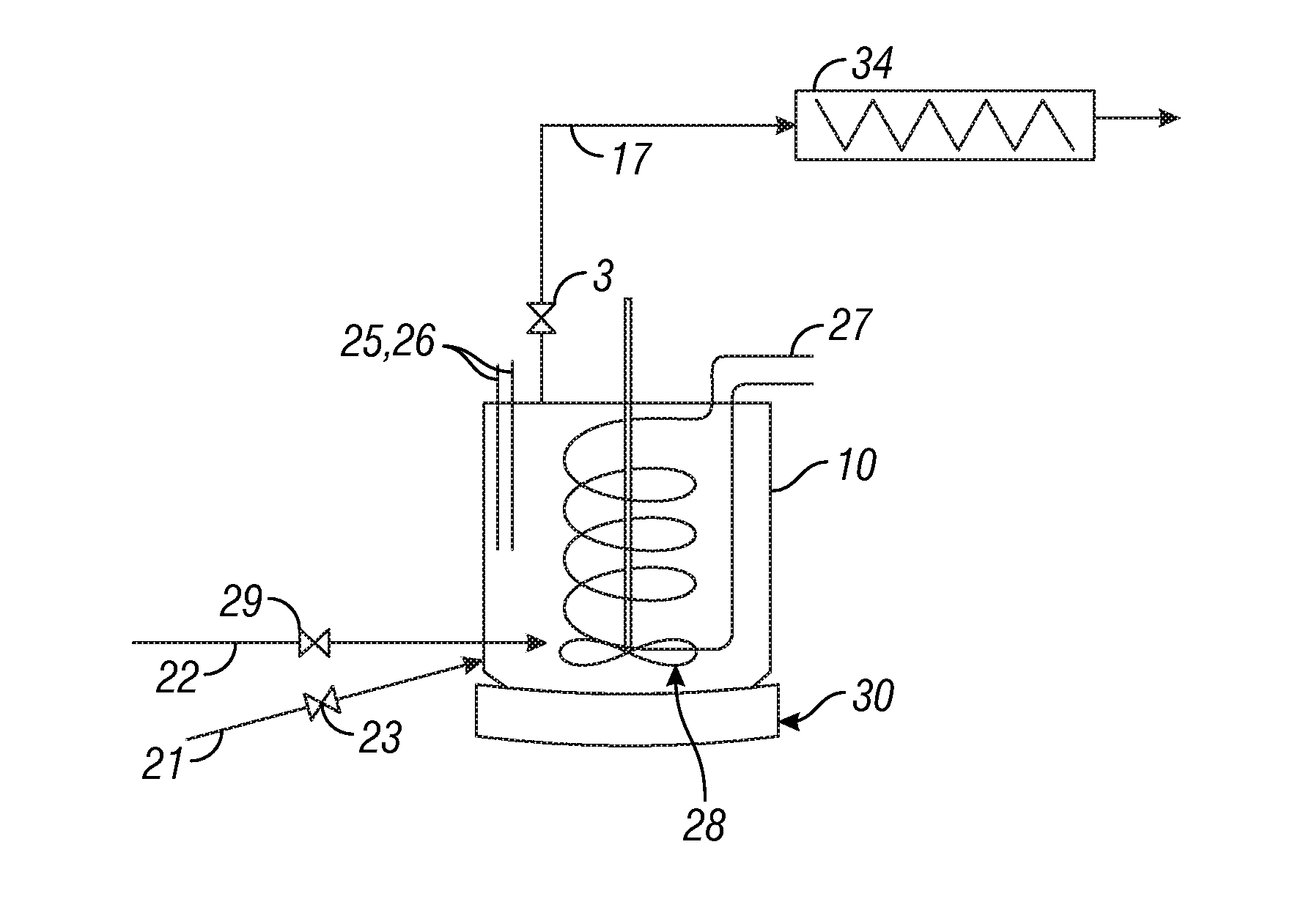

Hydrogenation process of hydrogen peroxide fluidized bed by anthraquinone

InactiveCN1817838AIncrease production capacityReduce differential pressureOrganic chemistryOrganic compound preparationFluidized bedHydrogenation process

A hydrogenation process for producing fluidized bed with hydrogen peroxide by anthraquinone method is carried out by taking empty tower hydrogenation reactor with amplification section on top, moving operating liquid and hydrogen upward at specific speed, floating powdery catalyst in tower body, hydrogenation reacting by free contacting, separating hydrogenated liquid by gas-liquid separating system, filtering by filter system and oxidizing. It has fast hydrogenation speed, low resistance, homogenous distribution and higher utilization rate.

Owner:LIMING RES INST OF CHEM IND

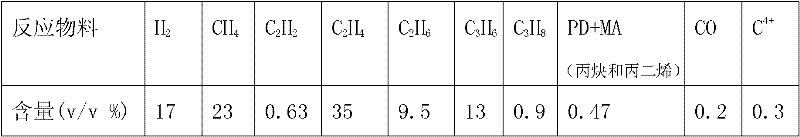

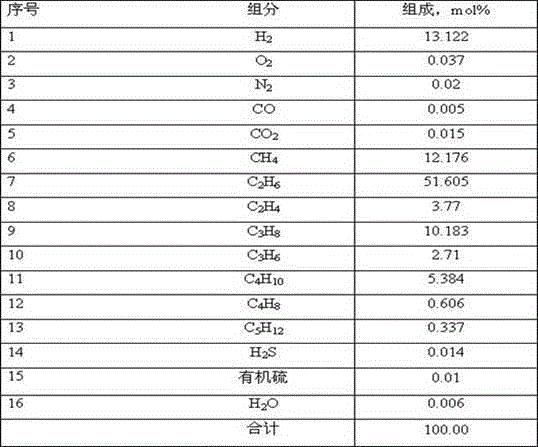

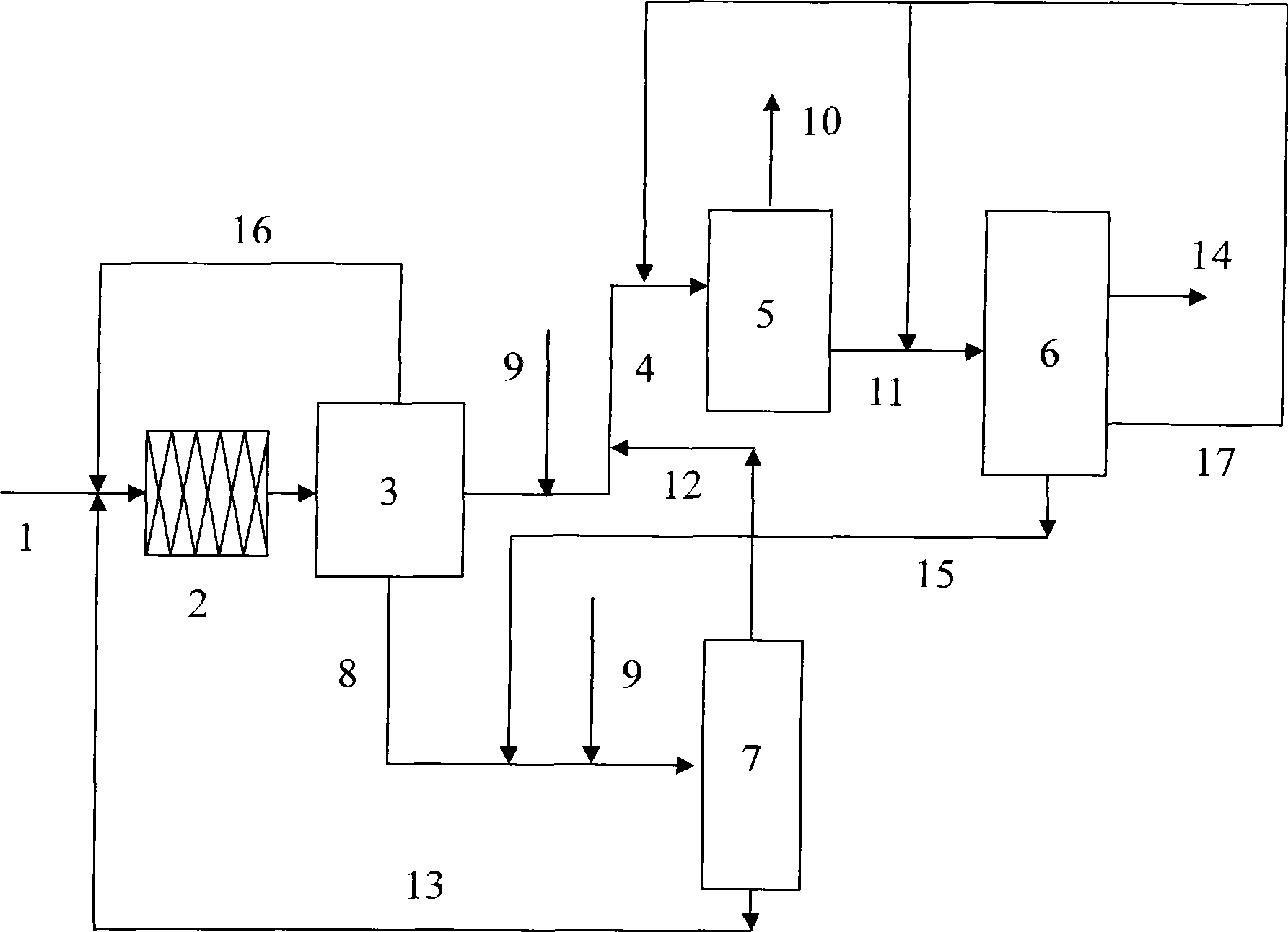

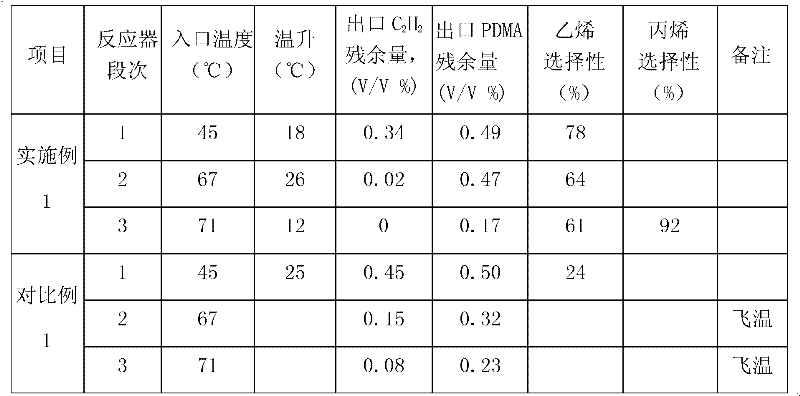

Catalysts grading method for coker dry gas hydrogenation for preparation of ethylene cracking feed

ActiveCN105273756AHigh activityLow costGaseous mixture working upHydrogenation reactionReaction temperature

The invention discloses a catalysts grading method for coker dry gas hydrogenation for preparation of ethylene cracking feed. According to the method, coker dry gas is contacted with a hydrogenation catalyst to carry out a hydrogenation reaction, and olefin in coker dry gas is saturated to further obtain an ethylene cracking feedstock, wherein three hydrogenation reaction zones are successively arranged in a hydrogenation reactor. By reasonable grading of catalysts in different systems, advantages of the respective catalysts during different hydrogenation processes are fully performed. By synergism among the catalysts and by cooperation of reaction temperature gradients of the three hydrogenation reaction zones, activity of the monolithic catalyst is raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite process for treatment of inferior residual oil

ActiveCN101418222AWide adaptability of raw materialsAchieve maximum light weightTreatment with hydrotreatment processesTar working-up by solvent extractionDistillationHydrogenation process

The invention discloses a combined process method for treating inferior residual oil. The method comprises the following steps: a residual oil material enters a solvent deasphalting device to obtain DAO and deoil asphalt; the obtained DAO enters a hydrogenation device of a boiling bed and is treated to obtained a lightweight distillation fraction and hydrogenated tail oil; the hydrogenated tail oil enters a catalytic cracking device and is treated to obtain a lightweight distillation fraction and oil slurry; at least partial oil slurry and the deoil asphalt are mixed, enter a hydrogenation device of a suspension bed and are treated to obtain a lightweight distillation fraction and unconverted tail oil, wherein the unconverted tail oil circularly returns the solvent deasphalting device; and the lightweight distillation fraction and the DAO are mixed and enter the hydrogenation device of the boiling bed. The combined process course organically combines a decarbonization process and a hydrogenation process; and according to different properties of raw materials, a corresponding process and operation condition is adopted so as to maximize conversion of the residual oil material while minimizing equipment investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfuration type catalyst and preparation thereof

InactiveCN101279296AReduce manufacturing costSimple production processCatalyst activation/preparationHydrogenation processThermal treatment

The present invention relates to a sulfide type catalyst and a preparation method thereof, pertaining to the technical field of hydrogenation catalyst preparation. The method provided by the invention uses a dipping method to induce the required categories and quantity of active metals with a sulfide agent induced before, after or simultaneously and then obtains the final sulfide type catalyst by thermal treatment. The method provided by the present invention solves the defects of high preparation cost, long sulfide time and high operation cost of a normal oxidized catalyst. The catalyst prepared by the method of the present invention is suitable for an oil fraction hydrogenation process; therefore, the hydrogenation activity of the prepared catalyst can reach or surpass the effect of the normal catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

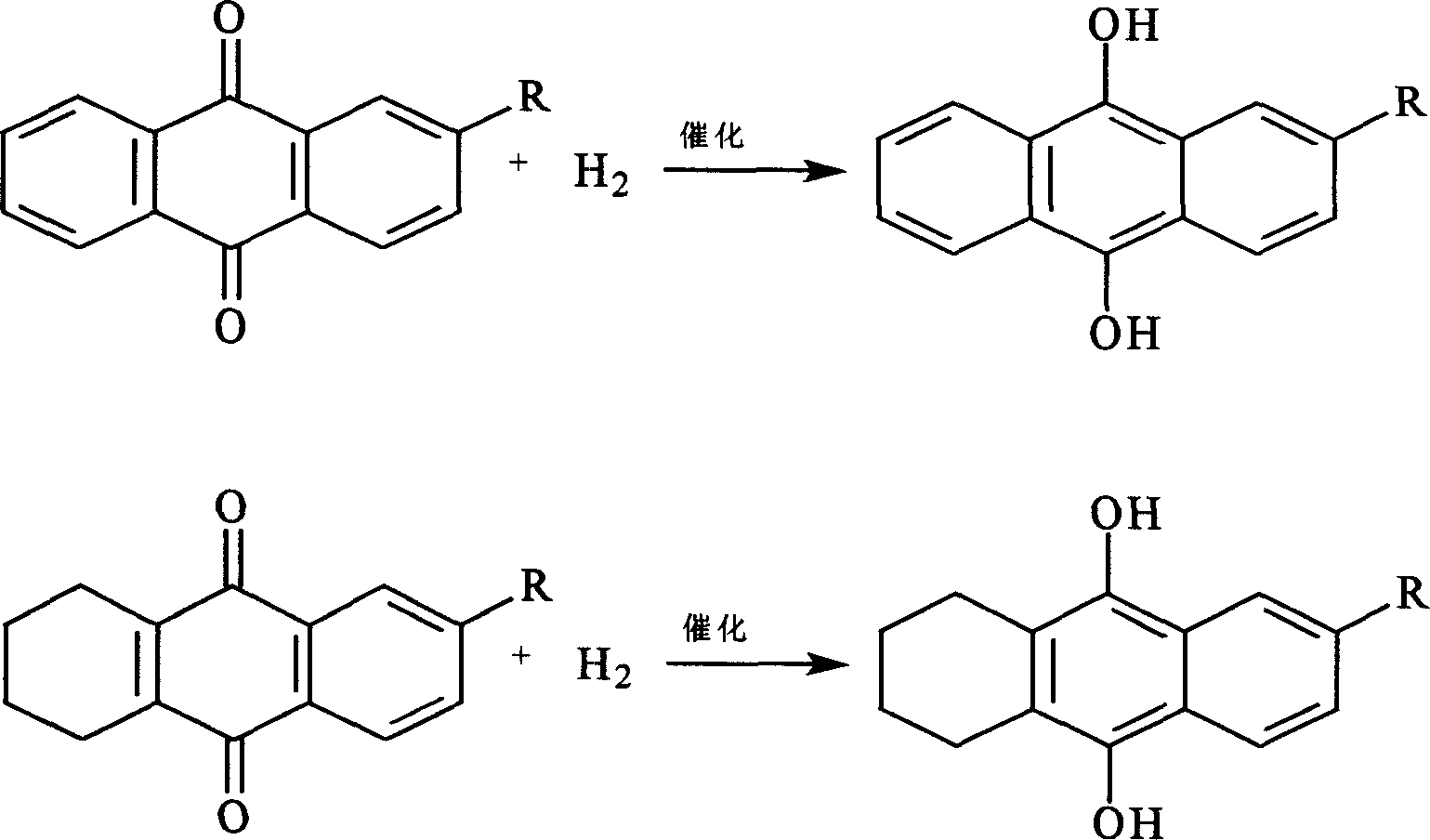

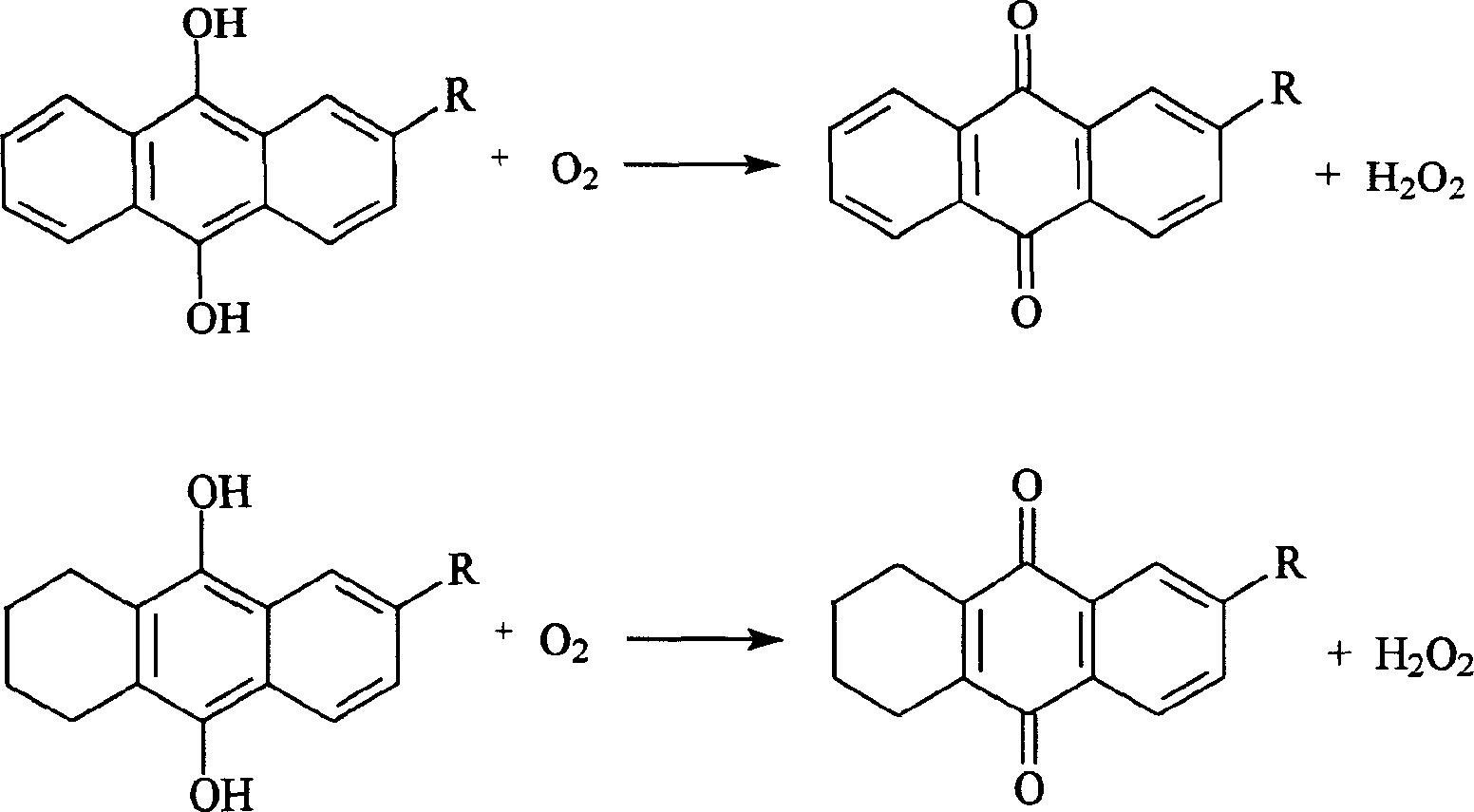

Hydrogenation method for production of hydrogen peroxide by anthraquinone process

InactiveCN102009960AUniform distributionIncrease contact areaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical industryHydrogenation process

The invention discloses a hydrogenation method for production of hydrogen peroxide by the anthraquinone process, belonging to the technical field of chemical industry reaction. The method provided by the invention comprises: dispersing the gaseous phase containing hydrogen into the working solution containing the anthraquinone derivatives to obtain the gas-liquid mixing fluid containing micron bubbles, so that the gas-liquid mixing fluid passes through the pipe reactor filled with the hydrogenation catalyst at the space velocity of 3 to 1000h<-1> to finish the hydrogenation process. In the method provided by the invention, the gas-liquid micro-dispersing process and the static bed catalytic hydrogenation process are directly integrated, so that the interphase mass transfer is strengthened, and the contacts between different reactants and between the reactant and the catalyst are more sufficient and more uniform, thereby enhancing the efficiency and the controllability of the hydrogenation process and improving the economical efficiency and the security of the production of the hydrogen peroxide.

Owner:TSINGHUA UNIV

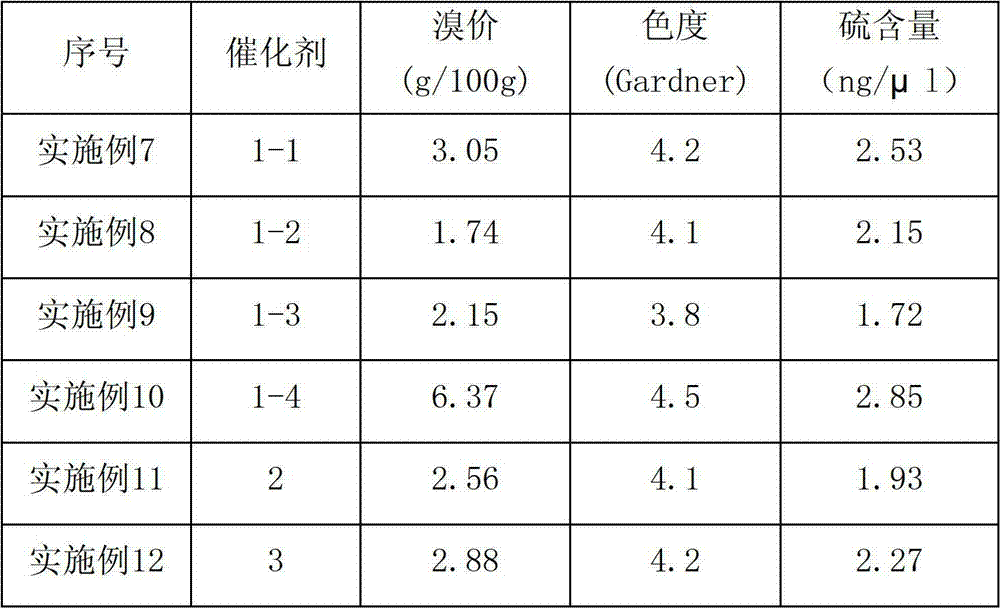

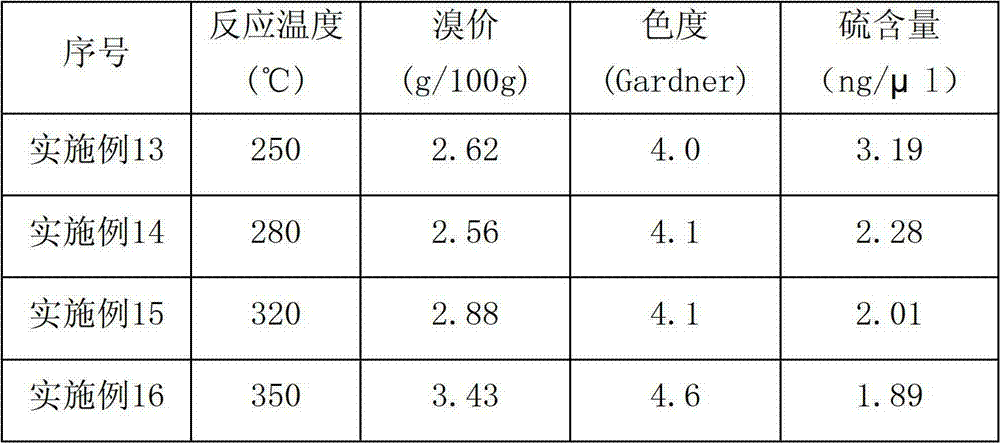

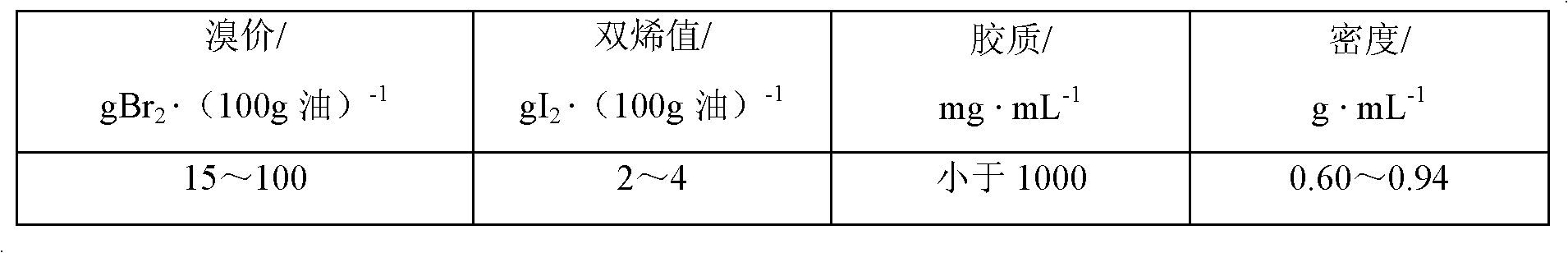

Preparation method for C9 hydrogenation petroleum resin

InactiveCN102924659AWide adaptabilityImprove performanceMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationSolvent

The invention relates to a preparation method for C9 hydrogenation petroleum resin. The C9 hydrogenation petroleum resin is dissolved in organic solvent, and the concentration of the C9 hydrogenation petroleum resin is 5wt %-30wt%. The C9 hydrogenation petroleum resin is filtered to remove undissolved substances, then subjected to a first section of hydrodesulfurization process and a second section of hydrogenation decoloration process, and finally subjected to the process of decompression rectification and solvent recovery to obtain C9 hydrogenation petroleum resin products. The preparation method adopts two-section hydrogenation, improves reaction activity, selectivity and impurity resistant capability, is wide in adaptability of C9 petroleum resin raw materials, and obtains C9 petroleum resin through adoption of thermal polymerization or catalytic polymerization. No matter impurity content in resin solution is high or low, particularly, when sulphur content is high in the resin solution, the two-step hydrogenation process can be carried out through the preparation method, and the C9 hydrogenation petroleum resin with high performance is obtained. Through the first section of hydrodesulfurization, hydrogenation noble metal catalyst in the second section is effectively protected. Service life of catalyst is greatly prolonged. Reaction pressure of the two-section hydrogenation is quite low, and industrial production cost is little.

Owner:CHINA PETROLEUM & CHEM CORP

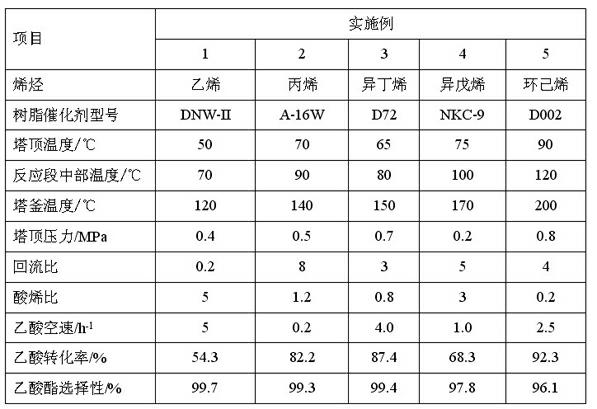

Method for preparing alcohols from olefin

ActiveCN102146019AImprove conversion rateSimple processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidAlcohol

The invention discloses a method for preparing alcohols from olefin. The method comprises an esterification process and a hydrogenation process. The method comprises the following steps of: performing countercurrent contact on olefin and acetic acid in a catalytic distillation tower on the surface of a solid acid catalyst, and synthesizing corresponding acetic ester by catalytic esterification; and then catalytically converting the acetic ester and hydrogen into corresponding alcohols in a fixed bed reactor by using the synthesized acetic ester as a raw material under a copper-containing hydrogenation catalyst and reaction conditions. The method has the characteristics of simple process flow, mild reaction conditions, low energy consumption, high raw material conversion rate and good production selectivity. Moreover, the method for preparing the corresponding alcohols from the olefin can be also used for preparing acetic ester and ethanol products which are wide in application.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Integral catalyst for producing hydrogen dioxide solution as well as preparation and application thereof

InactiveCN101497040AImprove mass transfer efficiencyReduce internal mass transfer resistancePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesCatalyst activation/preparationActive componentHydrogenation reaction

The invention provides a monolithic catalyst for oxydol production and a preparation method thereof. The catalyst uses ceramic monolithic honeycomb or metal monolithic honeycomb as a substrate, one or more of Al2O3, SiO2, CaO, MgO, TiO2, ZrO2, La2O3, CeO2, Fe2O3 and Cr2O3 as a coating material, and noble metal palladium as an active component to be used in an anthraquinone hydrogenation reaction of oxydol production. The monolithic catalyst adopts a preparation method of fractional support so as to effectively control depth of impregnation of the active component. The monolithic catalyst used in the anthraquinone hydrogenation process has the advantages of high activity, good selectivity and 82.21kg (100 percent of H2O2) / mcat.h of space-time yield of the oxydol, which is over 3 times more than a commercial bead catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

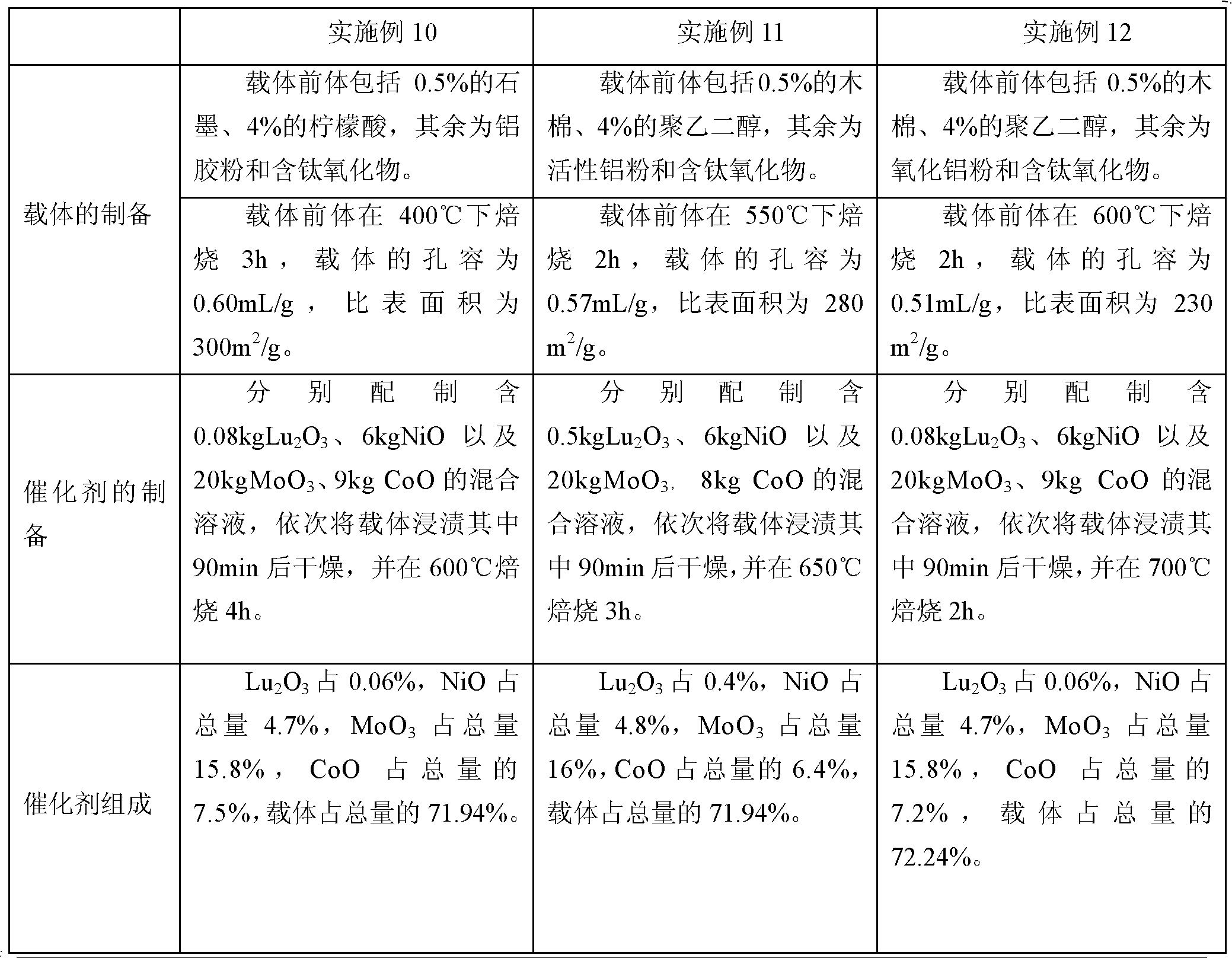

Hydrofining catalyst and preparation method thereof

ActiveCN102861593ALarge hole volumeLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsChemical industryRare-earth element

The invention discloses a hydrofining catalyst and a preparation method thereof, belonging to the field of catalysts used in the petroleum-chemical industry. The hydrofining catalyst disclosed herein comprises a carrier, an active component and an auxiliary agent, wherein the carrier is Ti-modified gamma-alumina, the active component comprises oxides of Mo, Co and Ni, and the auxiliary agent comprises oxides of rare earth. The catalyst is characterized in that: based on 100% of the total weight of the catalyst, Co (measured in CaO) in the active component accounts for 2.0-7.5% of the total weight of the catalyst, Mo (measured in MoO3) in the active component accounts for 4.0-18.0% of the total weight of the catalyst, Ni (measured in NiO) in the active component accounts for 0.2-5.0% of the total weight of the catalyst, the auxiliary agent accounts for 0.05-1.0% of the total weight of the catalyst, and the balance consists of the carrier. According to the invention, the catalyst prepared by the formula and the method disclosed in the invention can carry out hydrogenation on saturated monoolefine while the catalyst is used for carrying out hydrodesulfurization on oils, can be suitable for technical requirements of heavy oriention, changeable sulphur content, and high air speed of hydrogenation liquid for pyrolysis gasoline two-stage hydrogenated raw materials, and simultaneously, the catalyst has the advantages of low activation temperature and low loss of aromatics in the hydrogenation process.

Owner:CHINA PETROLEUM & CHEM CORP

Novel process for preparing xylitol

ActiveCN101823939AIncrease contentImprove qualityIon-exchange process apparatusOrganic compound preparationChromatographic separationDistillation

The invention relates to a novel process for preparing xylitol, which belongs to the technical field of functional sugar alcohol production. Pre-treatment, hydrolysis, neutralization, decoloring, ion exchange, evaporation and concentration and chromatography are carried out to corncob or bagasse and other agricultural waste which contains hemicellulose, high-content xylose solution is collected and distillated, and then continuously hydrogenated, so that the xylose solution is converted into xylitol solution, and finally a xylitol crystal is obtained through refining, concentration, crystallization, centrifugation and drying; the process comprises: corncob-> pre-treatment->hydrolysis->neutralization and decoloring->ion exchange->evaporation and concentration->chromatography->high-content xylose solution collection and distillation-> hydrogenatio->refining->concentration->crystallization->centrifugation->drying->finished crystal xylitol product obtaining. The novel process for preparing xylitol saves a xylose crystallization procedure and a conversion process xylose crystal into sugar, shortens a production procedure, adopts a chromatography technology to improve the content of thexylose solution, facilitates the obtaining of high-content xylitol solution after hydrogenation can prepare the high-grade xylitol product, adopts a continuous hydrogenation process, improves the hydrogenation efficiency, reduces the labor intensity of a worker, and saves the production cost.

Owner:FUTASTE PHARM CO LTD

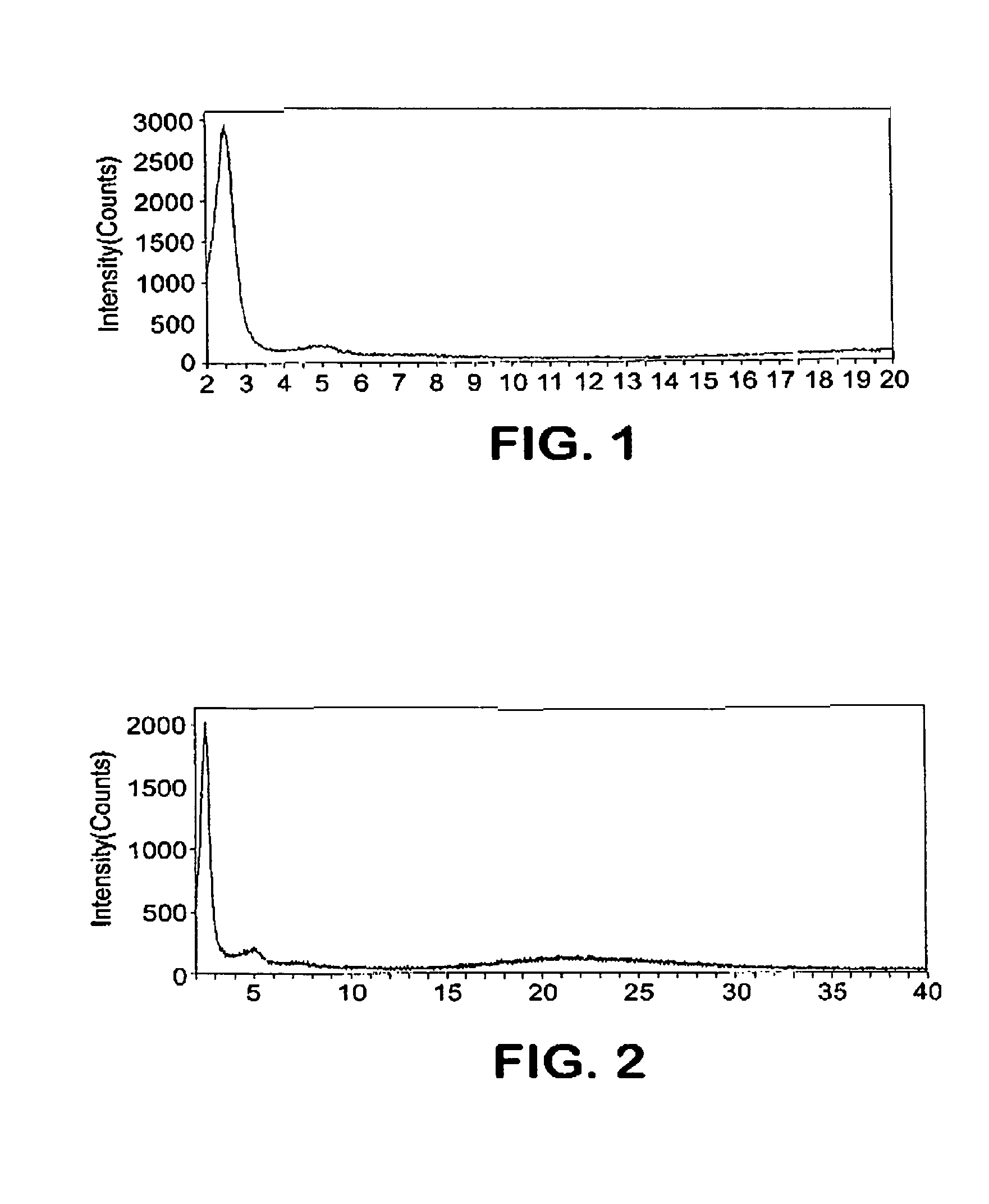

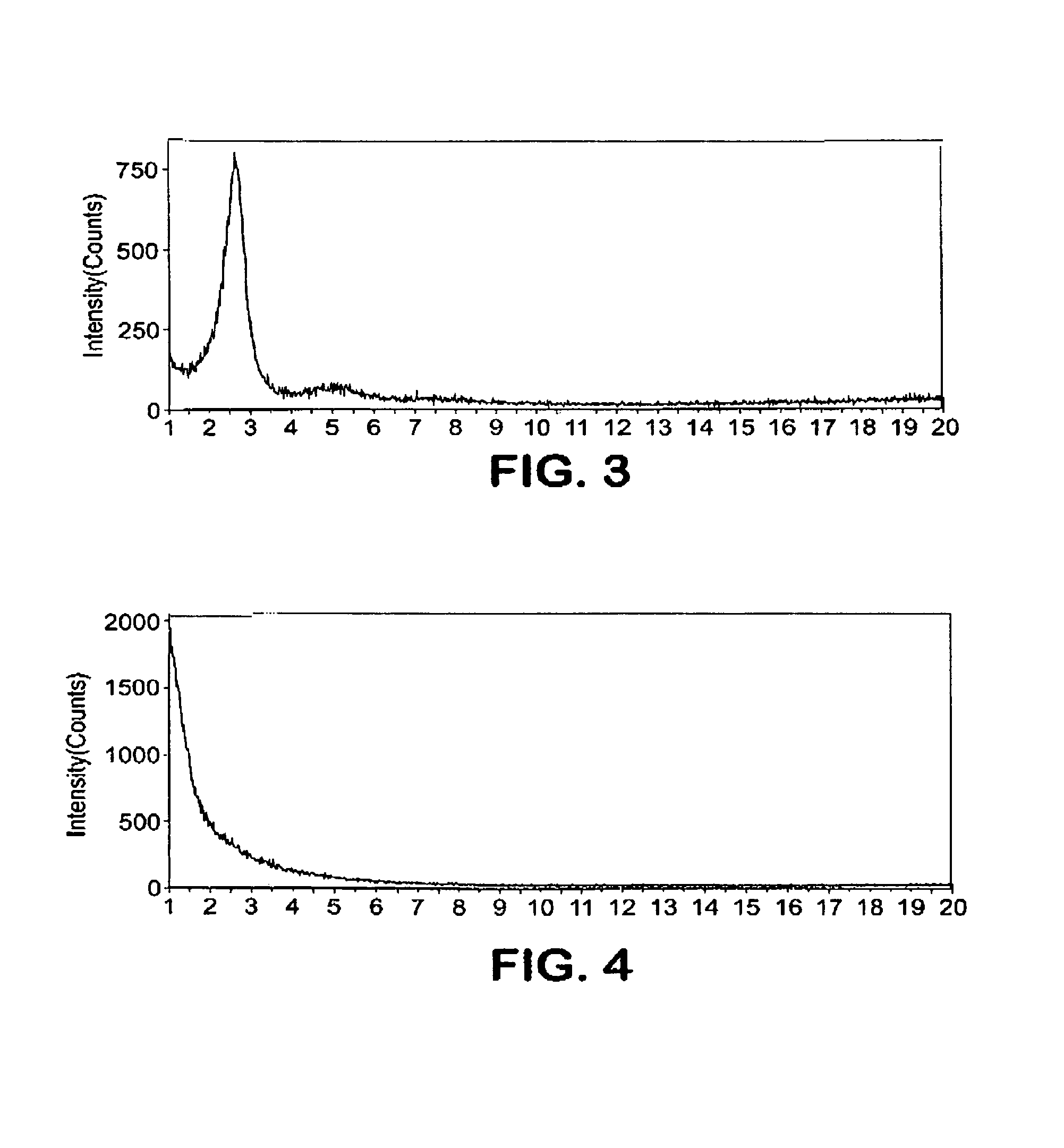

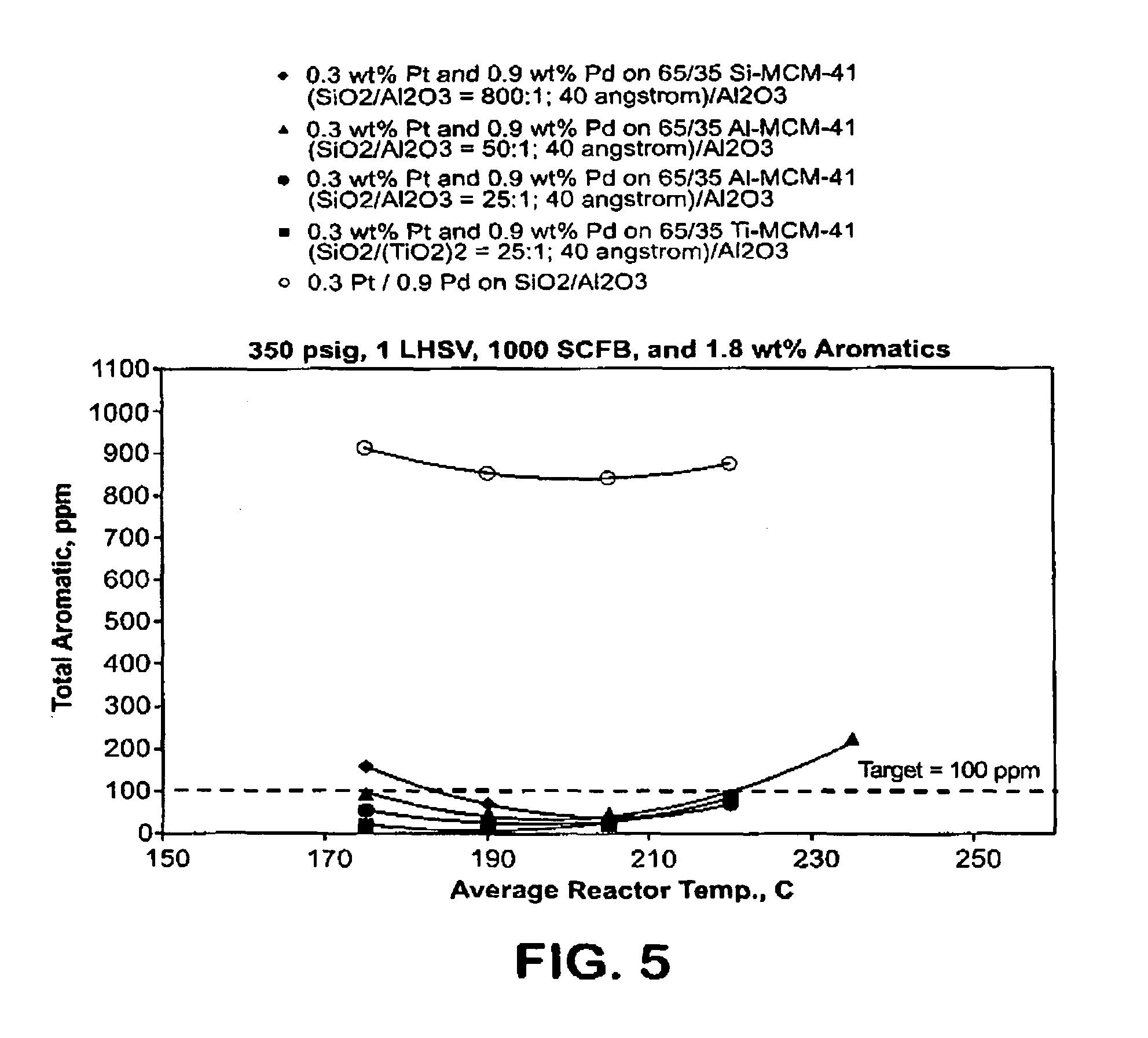

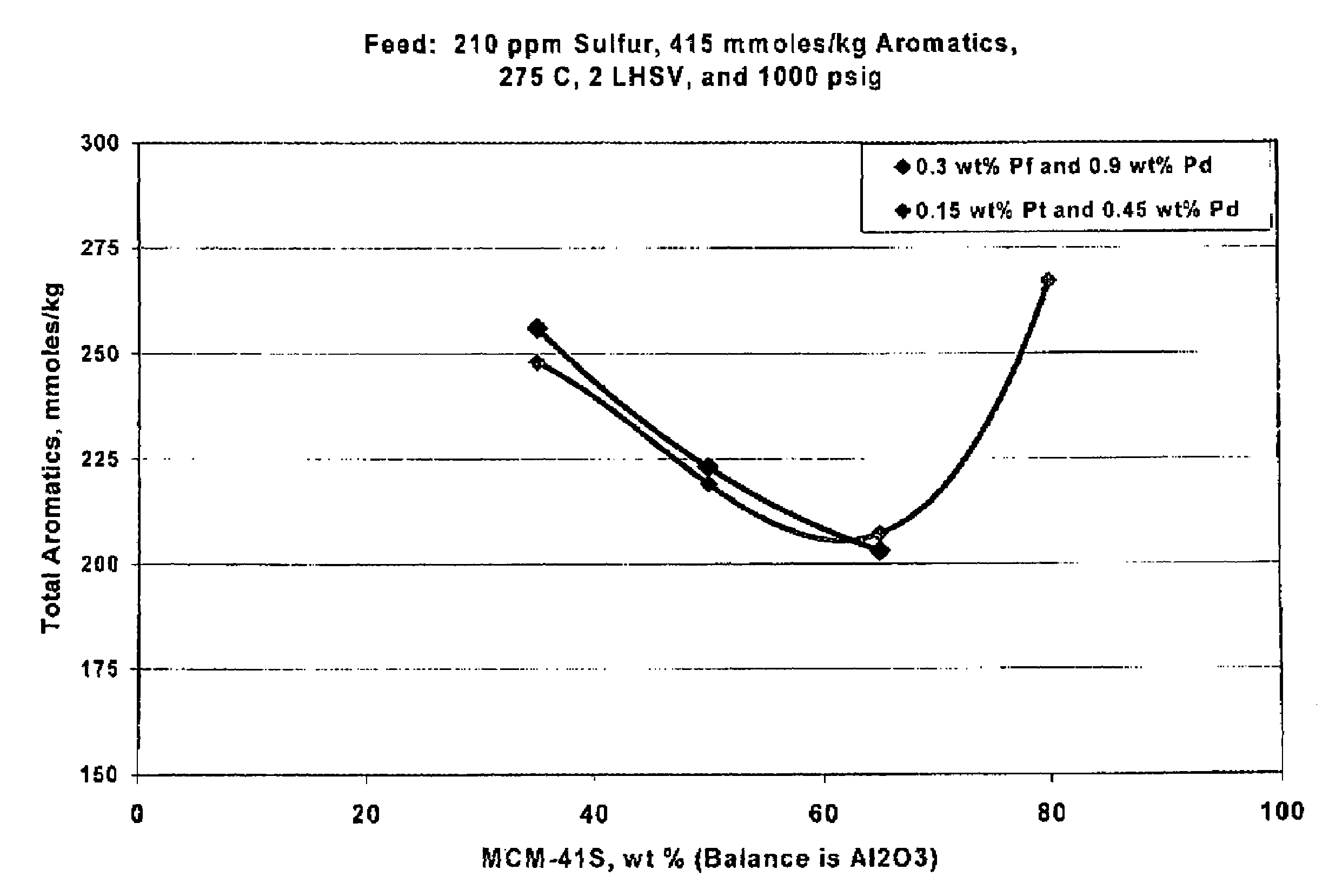

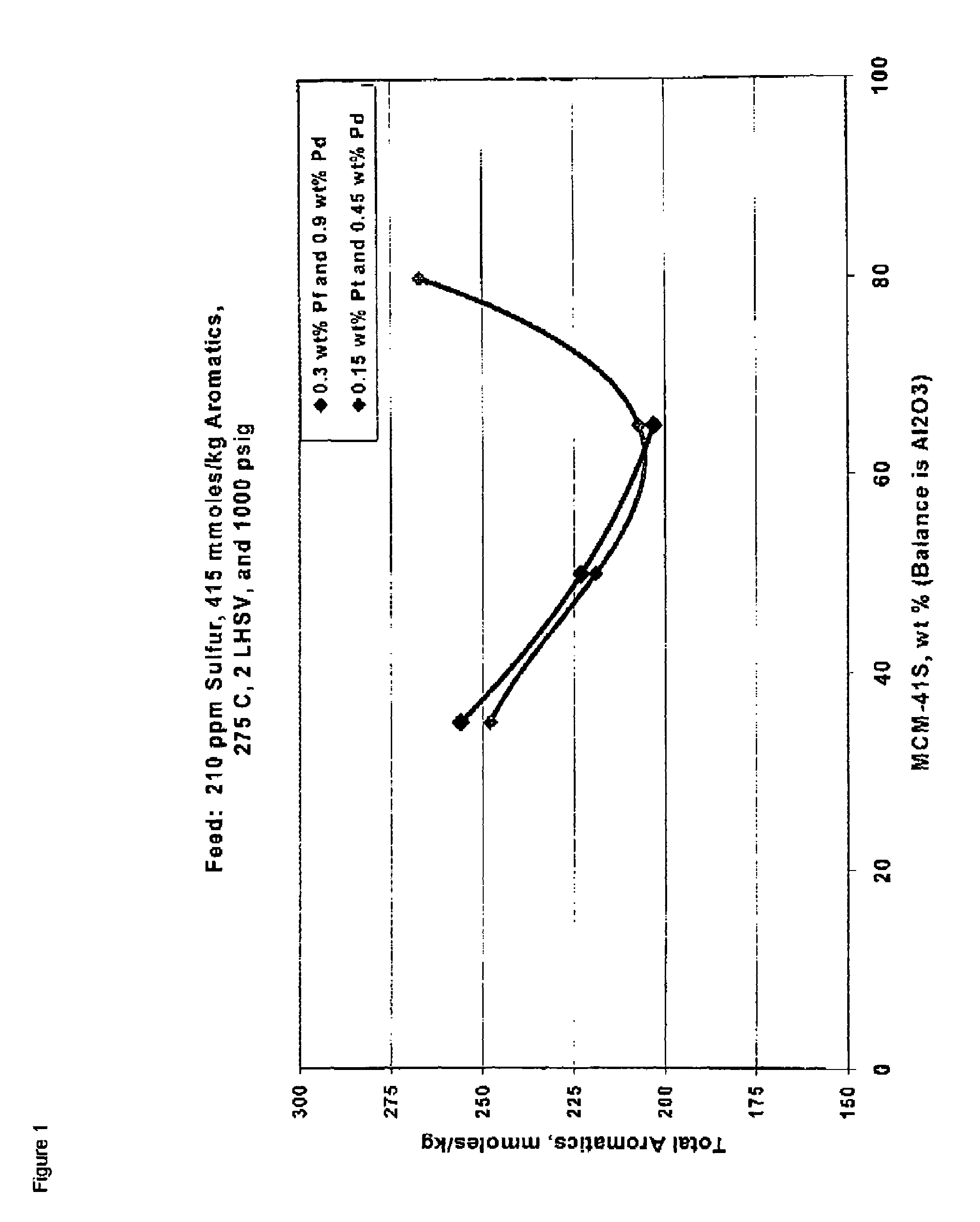

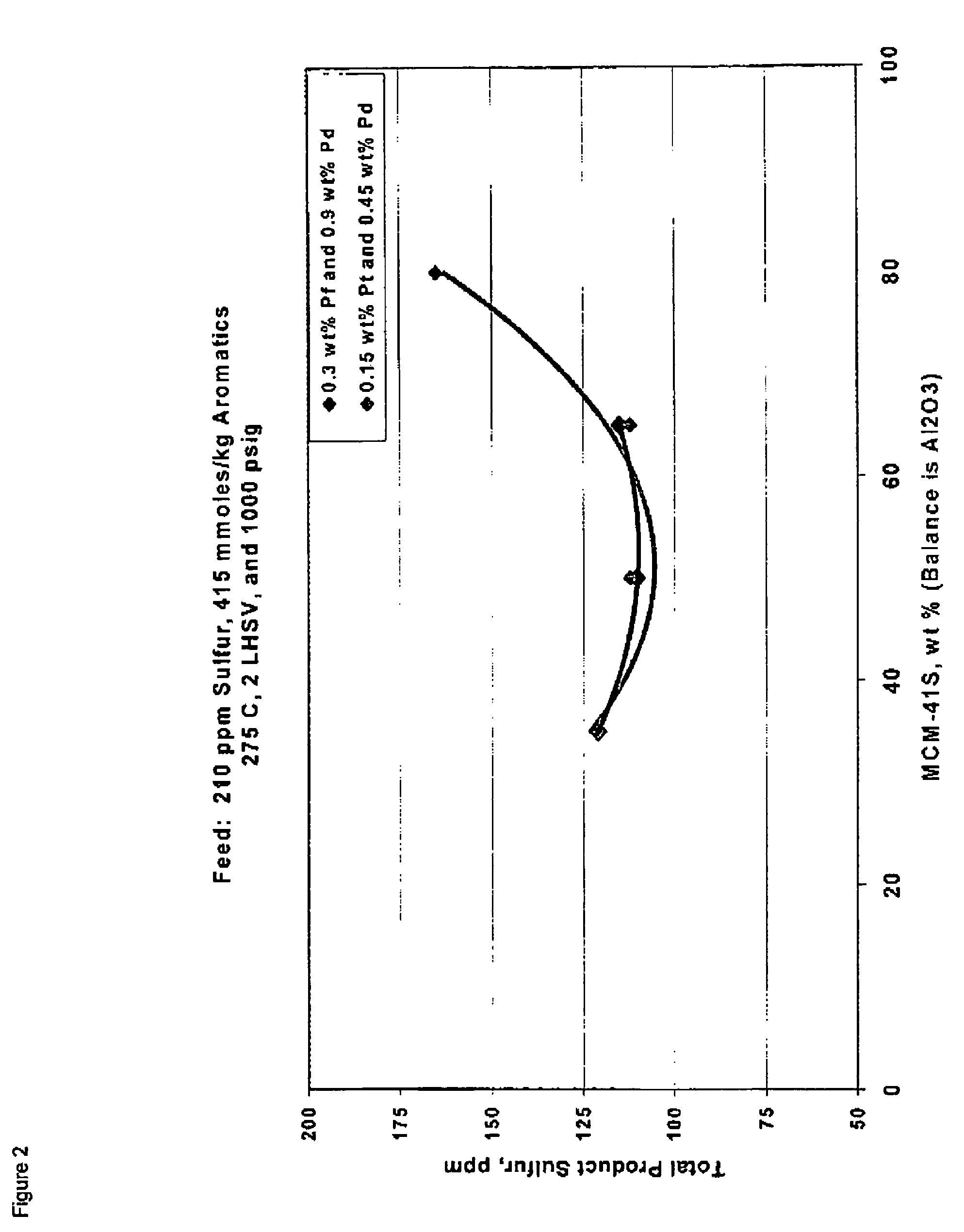

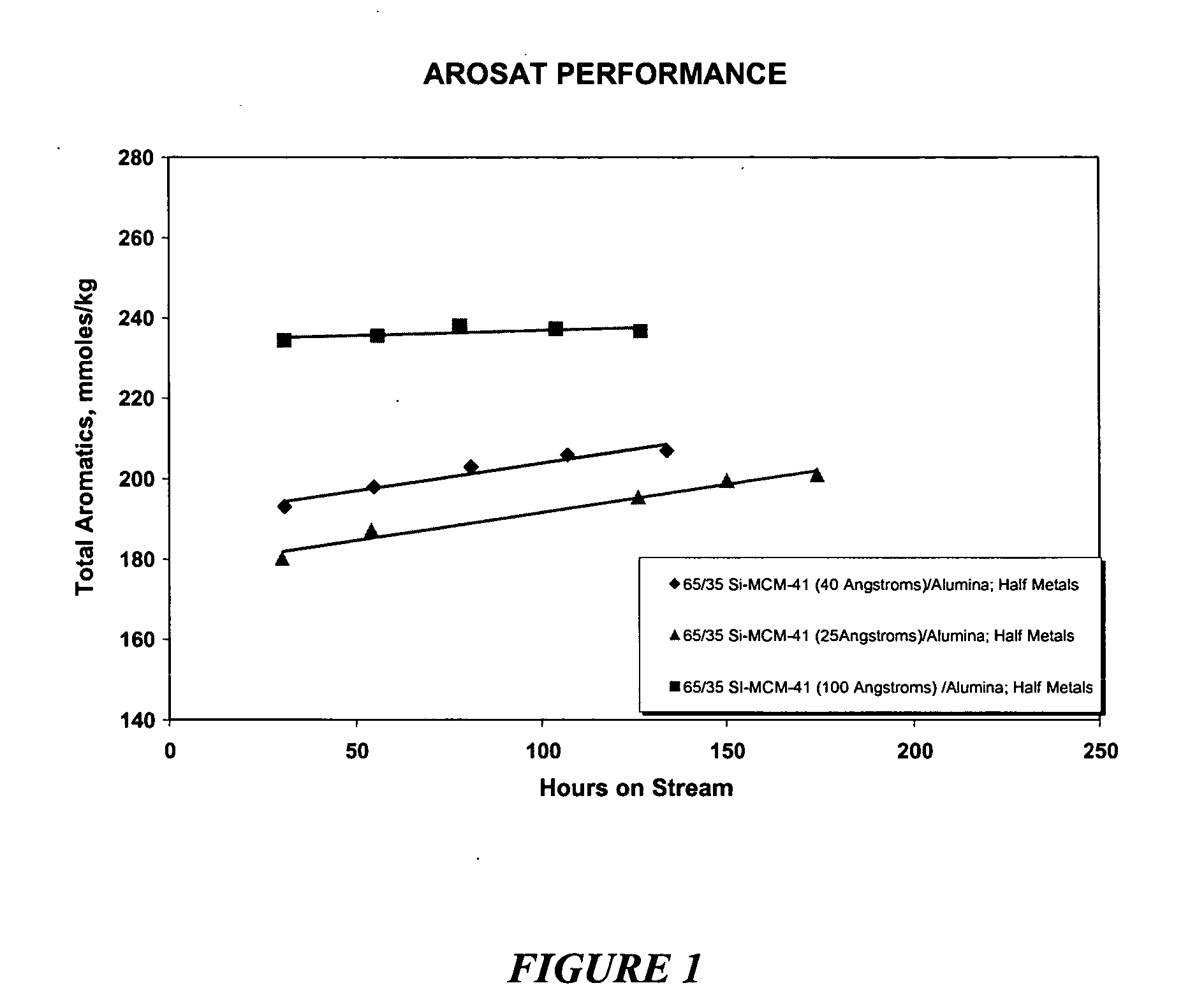

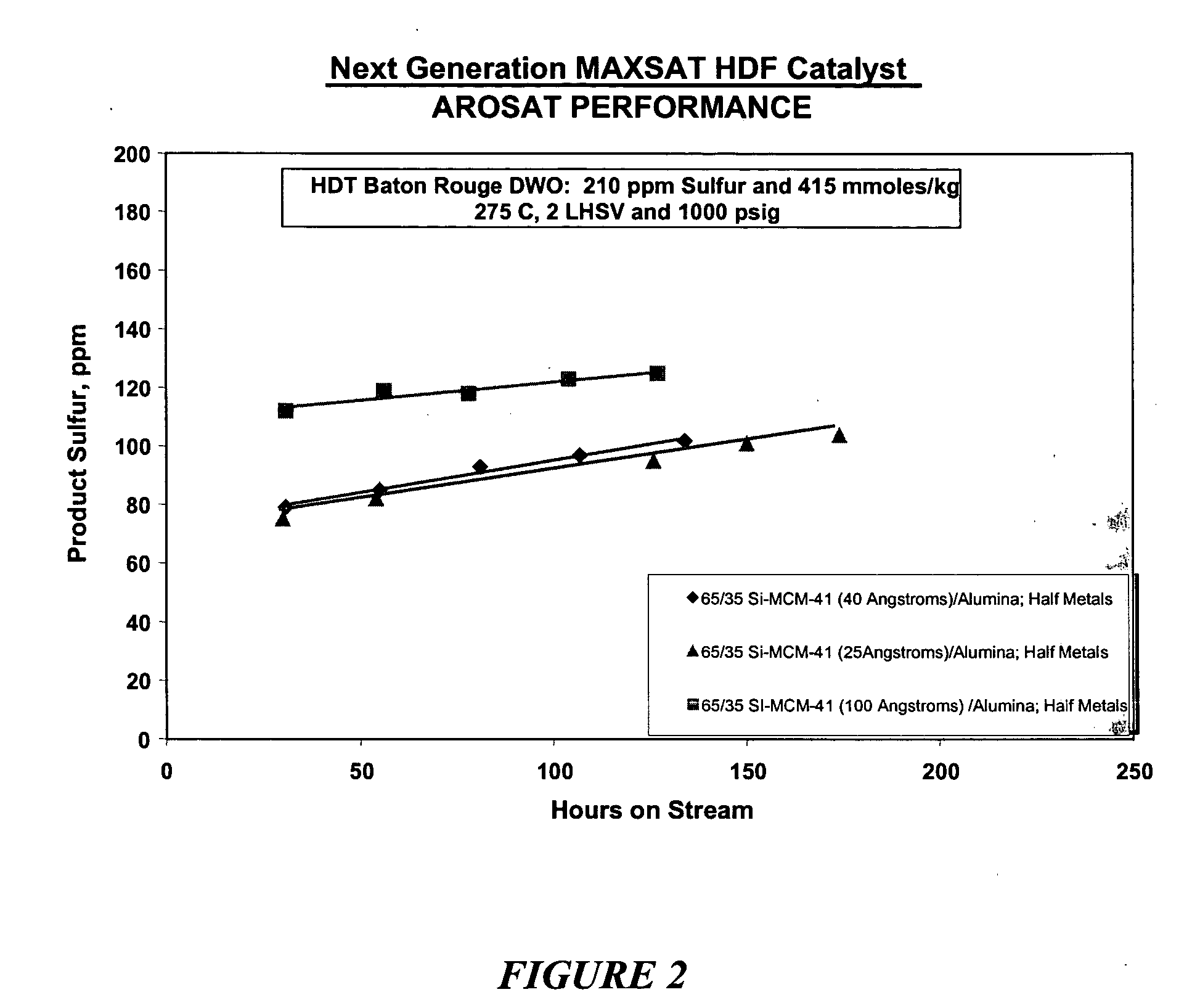

Aromatic hydrogenation process

ActiveUS8425762B2Molecular sieve catalystsTreatment with hydrotreatment processesHydrogenation processMCM-41

Owner:EXXON RES & ENG CO

Process to hydrogenate aromatics present in lube oil boiling range feedstreams

ActiveUS7682502B2Molecular sieve catalystsHydrocarbon by hydrogenationHydrogenation processPore diameter

An improved hydrogenation process for lube oil boiling range feedstreams utilizing a catalyst comprising at least one Group VIII noble metal selected from Pt, Pd, and mixtures thereof having an average pore diameter of about 15 to less than about 40 Å.

Owner:EXXON RES & ENG CO

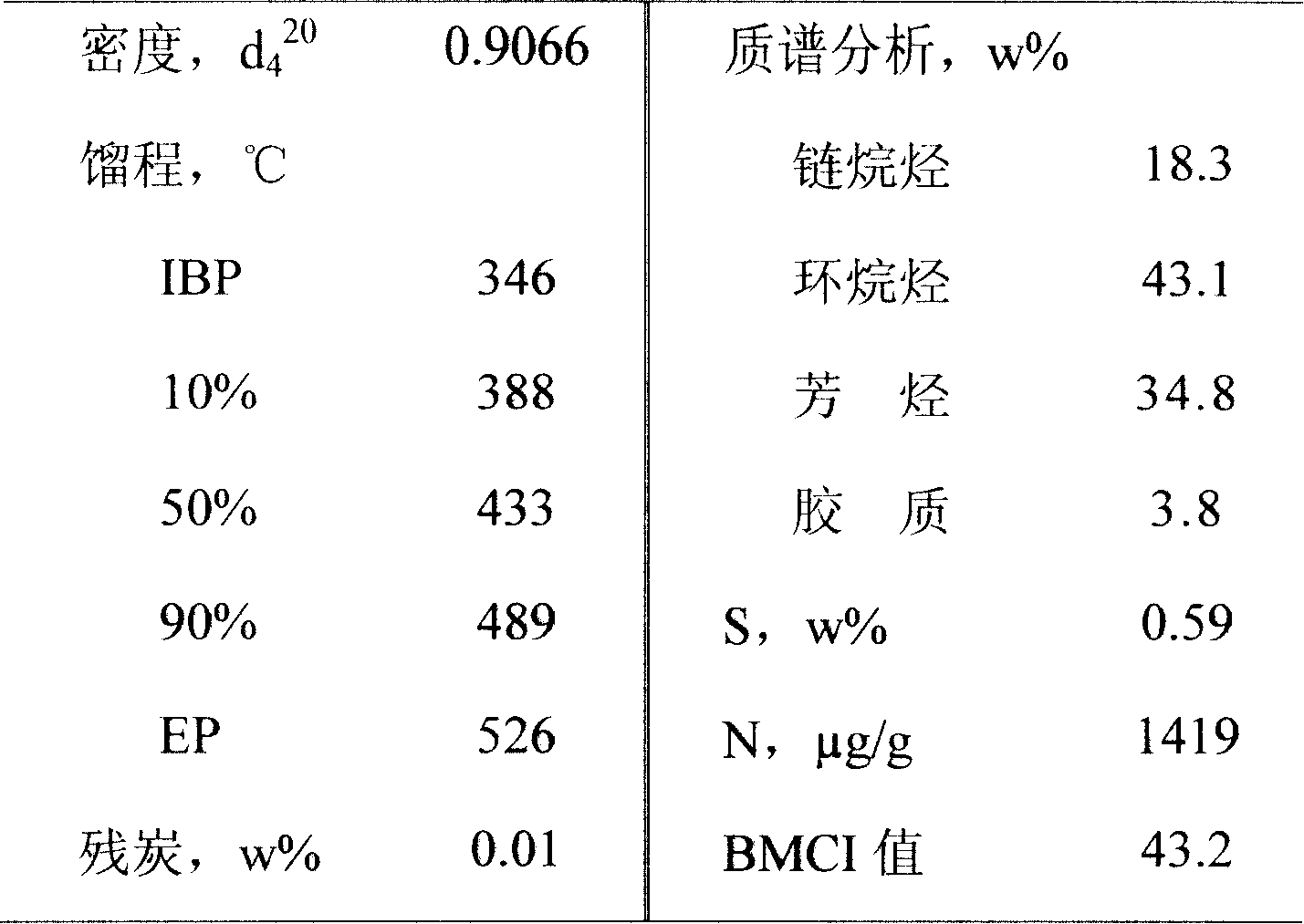

Production method for extra high voltage transformer oil

The invention provides a method for preparing super- voltage transformer oil. It comprises following steps: making naphthenic base oil contact with hydrogenation treatment catalyst and hydrogenation refining catalyst in sequence under hydrogenation process condition; said hydrogenation treatment catalyst contains a thermal- resistant inorganic oxidant carrier and cobalt and / or nickel, molybdenum and / or tungsten and fluoride or phosphorus that loaded on said carrier, the total airspeed of said naphthenic base oil is 0.2- 1 h-1, and the relative airspeed of hydrogenation treatment catalyst is 0.3- 1.2 h-1, the relative airspeed of hydrogenation refining catalyst is 0.3- 2h-1.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation process for the preparation of 1,2-diols

ActiveUS7615671B2Effectively hydrogenatedOrganic compound preparationOxygen compounds preparation by reductionGlycolic acidRuthenium

Disclosed is a process for the preparation of 1,2-glycols by hydrogenation of 1,2-dioxygenated organic compounds in the presence of a catalyst composition comprising a ruthenium compound, a trivalent phosphorus compound selected from 1,1,1-tris(diarylphosphinomethyl)alkyl or substituted alkyl, and a promoter selected from Lewis acids, protic acids having an ionization constant (Ki) of 5×10−3 or greater, and onium salts. The process is useful for the hydrogenation of glycolic acid or derivatives thereof to ethylene glycol.

Owner:EASTMAN CHEM CO

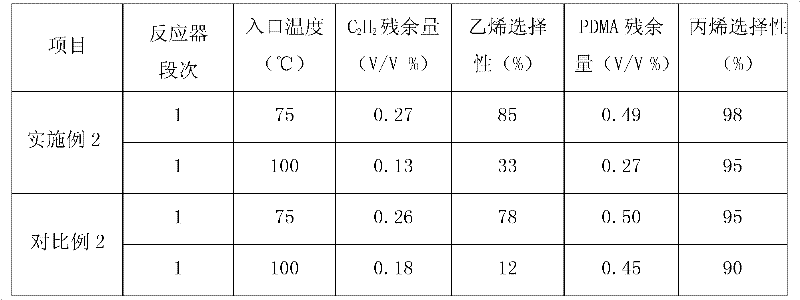

Selective hydrogenation method for C2 fraction

ActiveCN102199067ASelective distinctionGuaranteed hydrogenation qualifiedHydrocarbon purification/separationHydrocarbonsPolymer metalHydrogenation reaction

The invention relates to a selective hydrogenation method for C2 fraction, which employs a front-end hydrogenation process method of front-end depropanization. The selective hydrogenation method is characterized in that a Pd-Ag catalyst is loaded in a heat-insulation bed reactor, wherein the Pd-Ag catalyst contains Al2O3 used as a carrier, and the contents of Pd and Ag are 0.010-0.4% and 0.02-0.2% respectively if assumed that the weight percentage of the catalyst is 100%, and the Pd-Ag catalyst has a specific surface area of 1-20 m<2> / g and a pore volume of 0.1-0.35 mL / g; during the preparation process of the catalyst, an organic polymer metal complex is formed; and the reaction conditions are as follows: the inlet temperature of the used heat-insulation bed reactor is 45-100 DEG C, the reaction pressure is 3.5-4.5 MPa, and the volume airspeed of gas is 3500-25000 h<-1>. Using the method provided by the invention, the improvement of selectivity facilitates the operation of hydrogenation reaction and excessive hydrogenation is not easy to occur; moreover, at high reaction temperature, the catalyst has good activity, and alkyne leakage is not easy to occur.

Owner:PETROCHINA CO LTD

Process to hydrogenate aromatics present in lube oil boiling range feedstreams

ActiveUS20060070917A1Molecular sieve catalystsHydrocarbon by hydrogenationHydrogenation processPore diameter

An improved hydrogenation process for lube oil boiling range feedstreams utilizing a catalyst comprising at least one Group VIII noble metal selected from Pt, Pd, and mixtures thereof having an average pore diameter of about 15 to less than about 40 Å.

Owner:EXXON RES & ENG CO

Process and catalyst for production of low trans fat-containing triglycerides

InactiveUS20080161588A1Improve product appearanceImprove textureFatty acid hydrogenationFatty acids production/refiningVegetable oilHydrogenation process

Hydrogenated vegetable oil exhibiting superior thermal stability and containing reduced levels of saturates and trans fatty acids are produced using an activated hydrogenation catalyst and / or an improved hydrogenation process incorporating high shear. The use of a high shear mechanical device incorporated into the hydrogenation process as a reactor device is shown to be capable of enabling reactions that would normally not be feasible under a given set of reaction pressure and temperature conditions. For example, the hydrogenation process described herein enables a reduction of hydrogenation time, and operation at lower temperatures than current processes. The resulting hydrogenated vegetable oil is particularly useful in frying, confectionery baking, and other applications where a product with a low trans fat content or higher thermal stability is desirable. The hydrogenated oil produced may comprise less than 10 weight % of trans fatty acids with less than 5 weight % of linolenic acid (C18:3).

Owner:HRD CORP

Hydrogenation process for producing catalytically cracked material

ActiveCN101020843AImprove processing depthExpand sourceRefining to eliminate hetero atomsHydrogenation processResidual oil

The hydrogenation process for producing catalytically cracked material includes the successive contacting and reaction of the mixture of material oil and hydrogen with hydrogenation protecting agent, residual oil hydrogenating and demetallizing agent and residual oil hydrogenating and desulfurizing agent, cooling the reaction resultants, and separating obtain hydrogen-rich liquid and gas products. The catalyst includes hydrogenation protecting agent in 2-10 vol%, residual oil hydrogenating and demetallizing agent in 5-70 vol%, and residual oil hydrogenating and desulfurizing agent 20-93 vol%. The present invention makes it possible to produce high quality catalytically cracked material via adding residual oil in 5-50 wt% into gas oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supported ruthenium catalyst and preparation method thereof

InactiveCN102476052ALow costEasy to prepareOrganic reductionMolecular sieve catalystsAlkaline earth metalSecondary component

The invention discloses a supported ruthenium catalyst and a preparation method thereof. The preparation method is characterized in that the preparation method comprises the following steps: 1, preprocessing a carrier with a soluble alkaline earth metal salt, wherein the mass of the soluble alkaline earth metal salt accounts for 0.1-20% of the mass of the carrier; and 2, dipping the alkaline earth metal salt processed carrier with a material which comprises a primary active component metallic ruthenium and an assisted catalytic component comprising one or several of Ni, Co, Pd and Pt, wherein the mass of the primary component metallic ruthenium accounts for 0.1-5% of the carrier, and the mass of the secondary component comprising one or several of Ni, Co, Pd and Pt accounts for 0.01-5% of the mass of the carrier. The catalyst of the invention is mainly applied to the selective hydrogenation process of an aromatic ring of an aromatic compound, wherein the aromatic ring of the aromatic compound has at least one alkyl group, one ester group, one hydroxyl group or an amino group and also has at least one C1-8 alkyl group. Compared with catalysts prepared with the prior art, the catalyst of the invention has the advantages of low cost, simple preparation method, high activity, good selectivity, high safety in the operation of the aromatic ring hydrogenation, realization of the operation of the aromatic ring hydrogenation under a low pressure, and good economy.

Owner:CHINA PETROLEUM & CHEM CORP +1

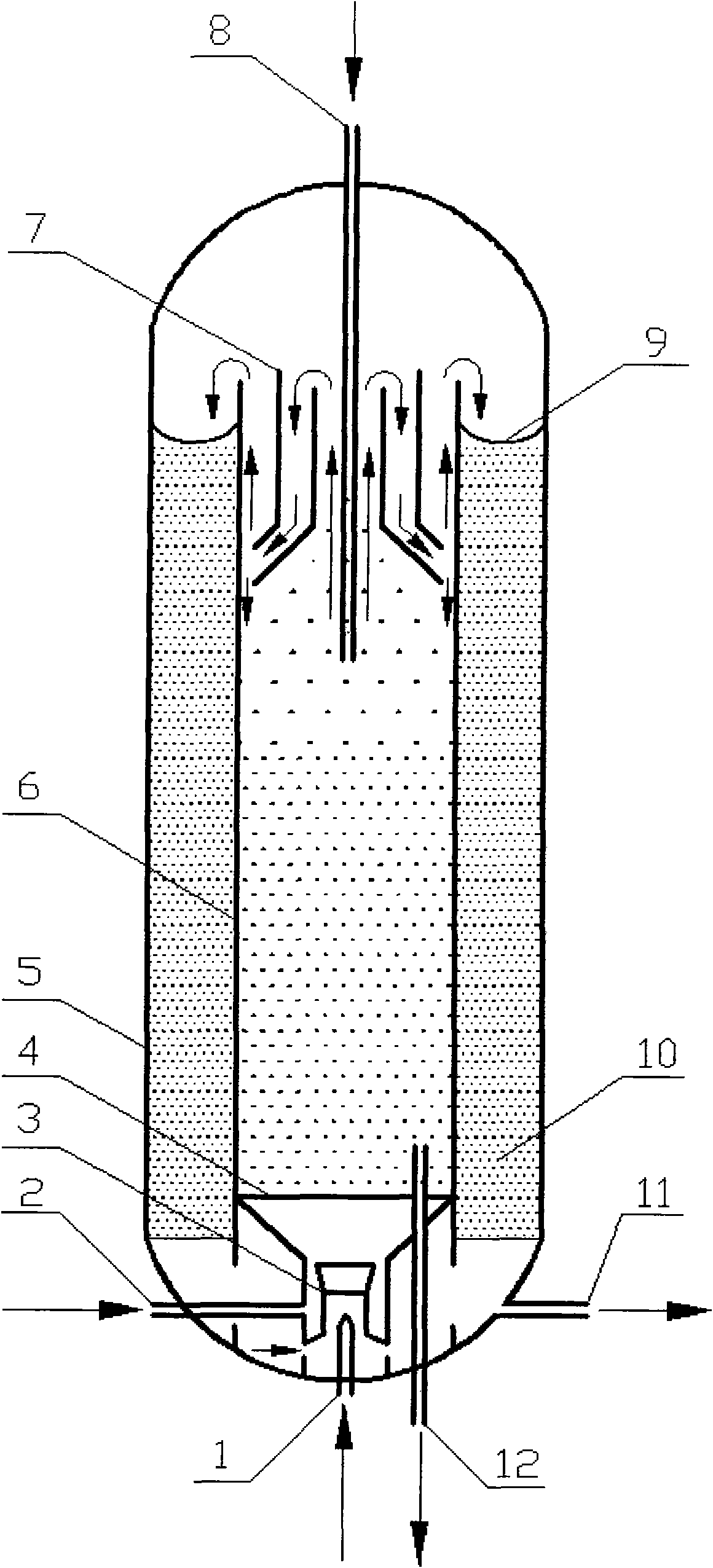

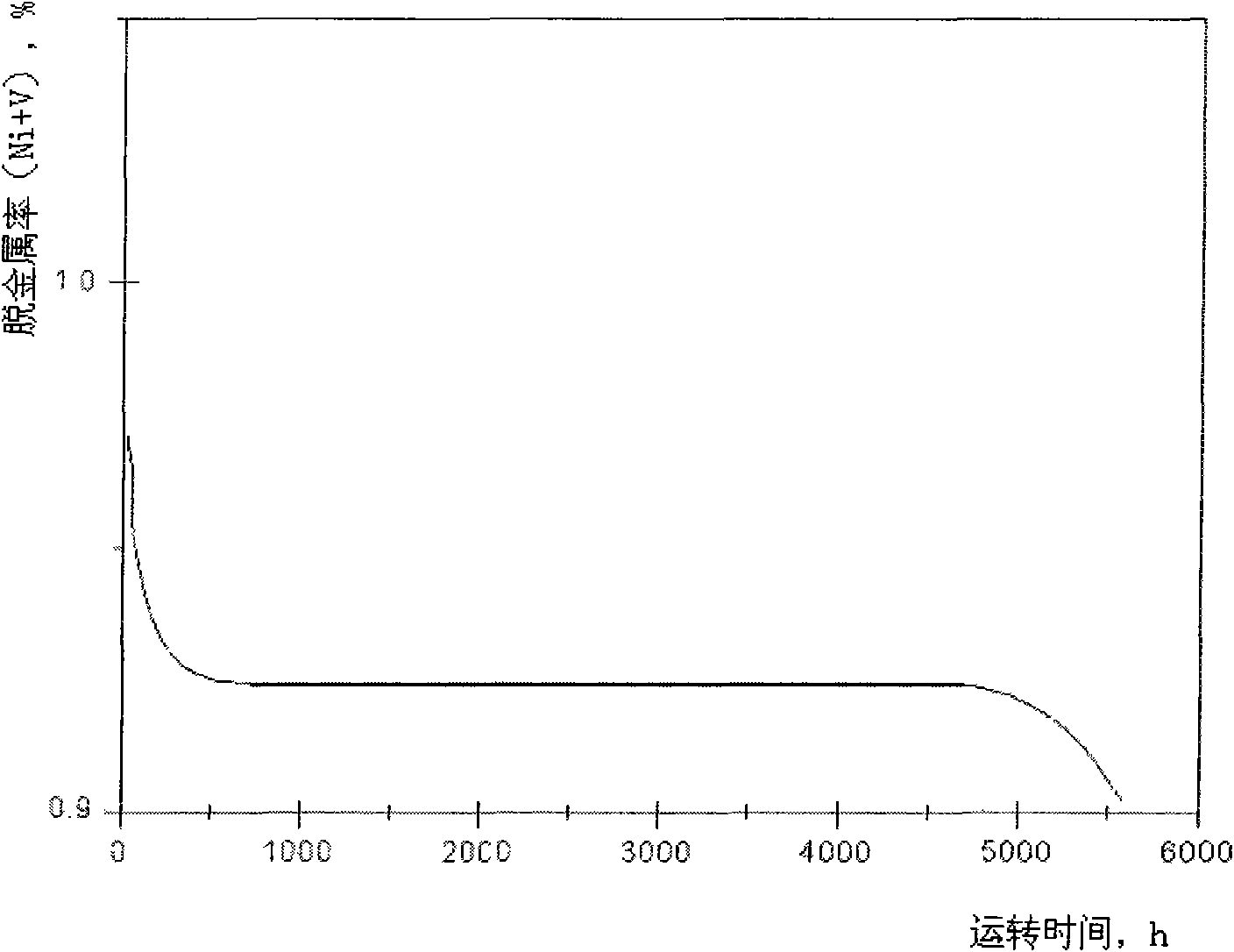

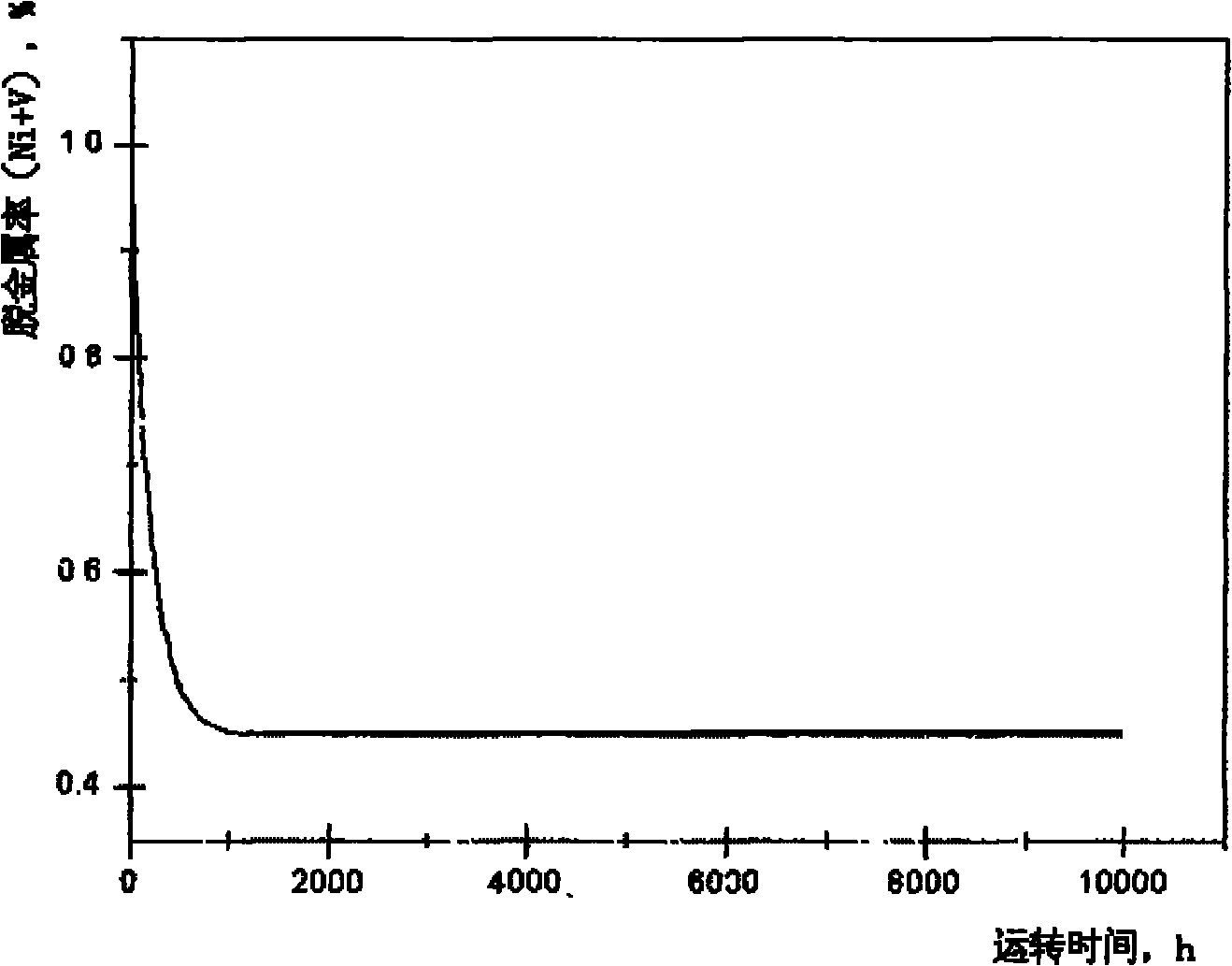

Heavy oil hydroprocessing method and reactor

ActiveCN101942325AImprove adaptabilityGreat operating flexibilityChemical/physical processesHydrocarbon oils treatmentHydrogenation reactionFluidized bed

The invention discloses a heavy oil hydroprocessing method and an internal loop reactor used by the method. In the heavy oil hydroprocessing method of the invention, the internal loop reactor is internally divided into two reaction segments, namely a fluidized bed reaction segment in a sleeve and a fixed bed reaction segment of a loop gap, and the mixture of heavy oil and hydrogen gas enters the reactor from the bottom and passes through the fluidized bed reaction segment first to undergo hydrogenation in the presence of a fluidized bed catalyst; and the catalyst is separated from the mixtureafter the reaction by a separator arranged on the upper part of the sleeve, and gas and liquid continuously go downwards to enter the fixed bed reaction segment of the loop gap to further undergo thehydrogenation in the presence of a fixed bed catalyst. The method has the combined characteristics of the fluidized bed and fixed bed hydrogenation processes, is well adapted to inferior raw materialoil with high metal and high asphaltene content and can realize the long-period stable operation of the device under the condition of achieving a high conversion rate and a high impurity removal rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com