Patents

Literature

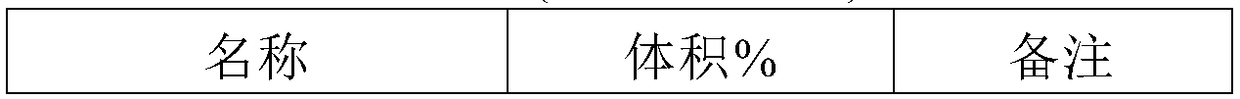

33results about How to "Wide adaptability of raw materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

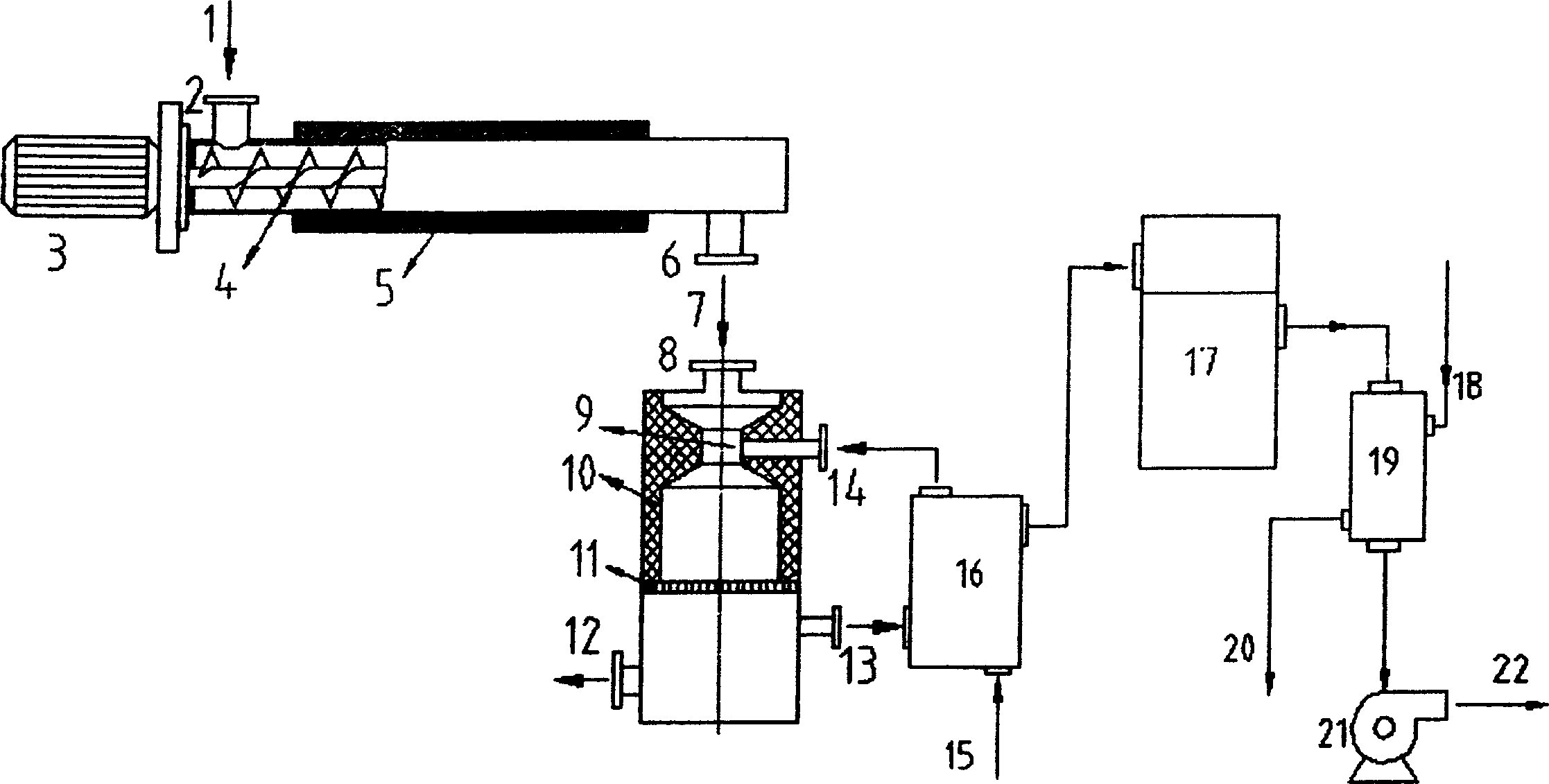

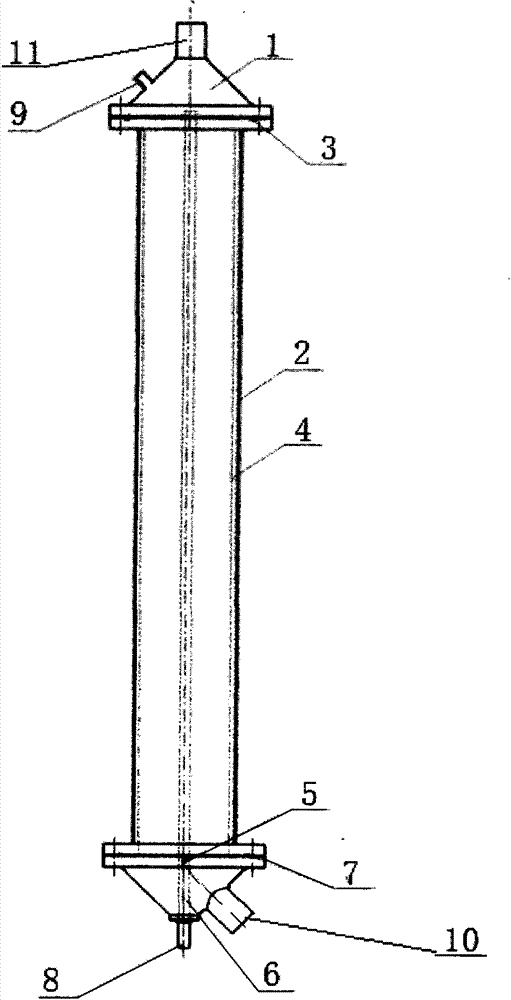

Low-tar biomass gasifying method and apparatus

InactiveCN1710023AWide adaptability of raw materialsSpecial form destructive distillationCarbon layerDecomposition

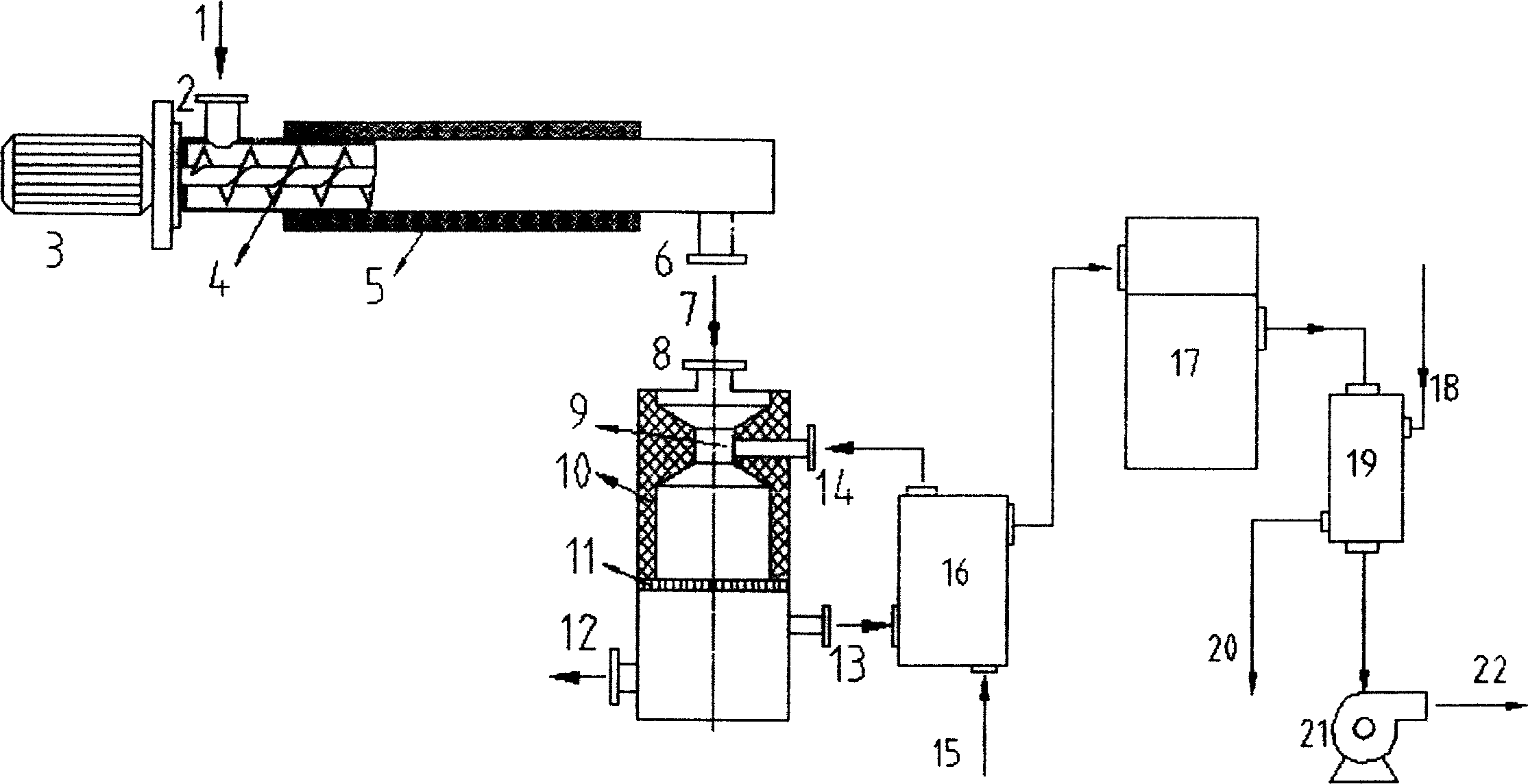

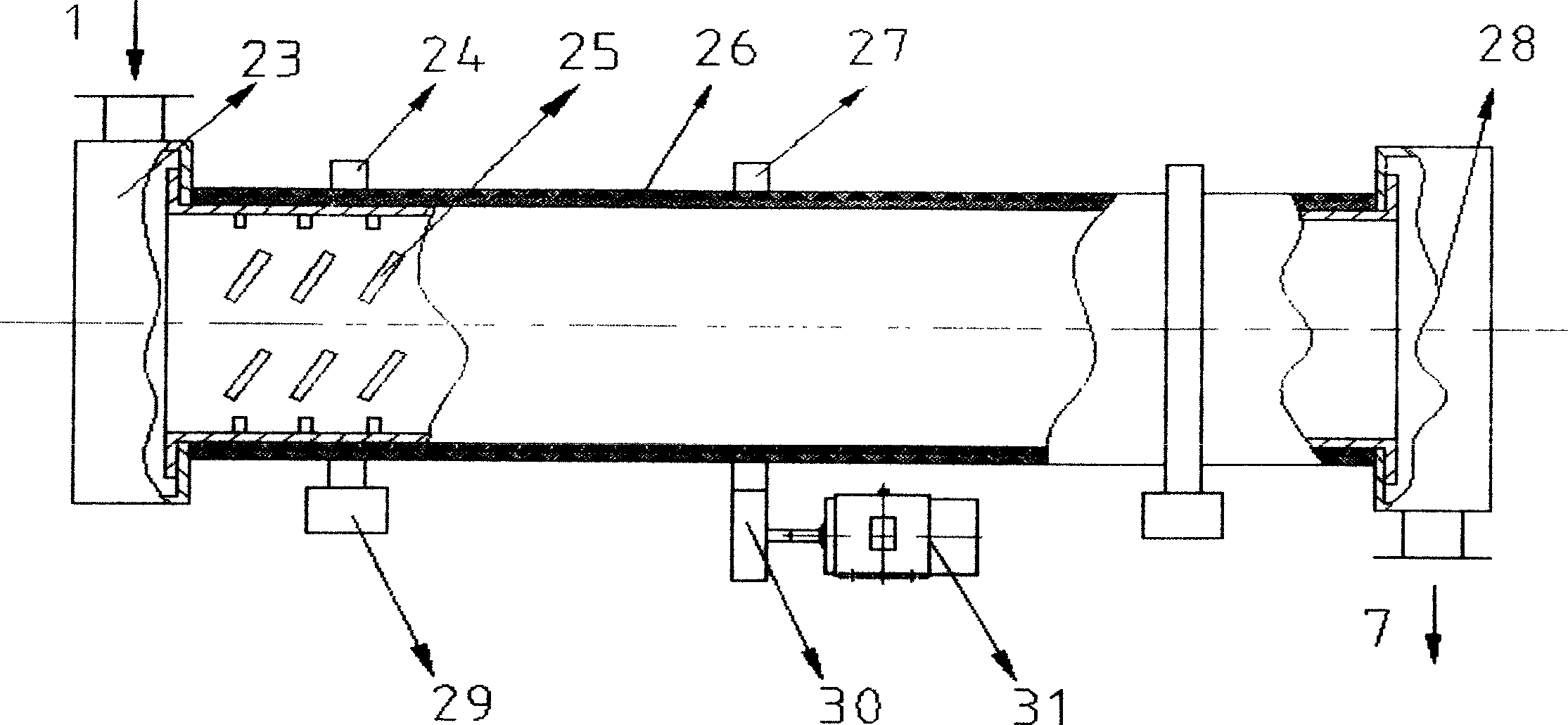

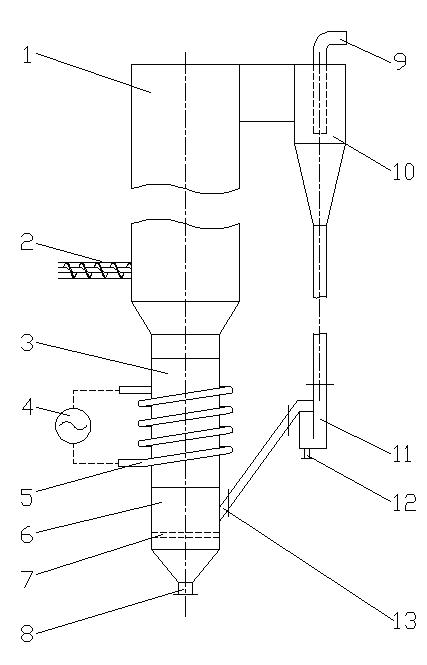

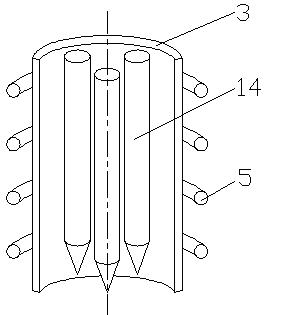

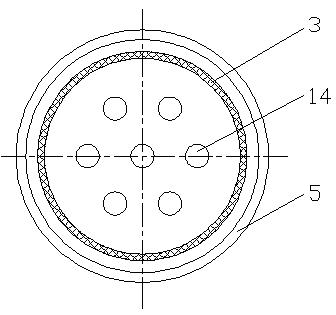

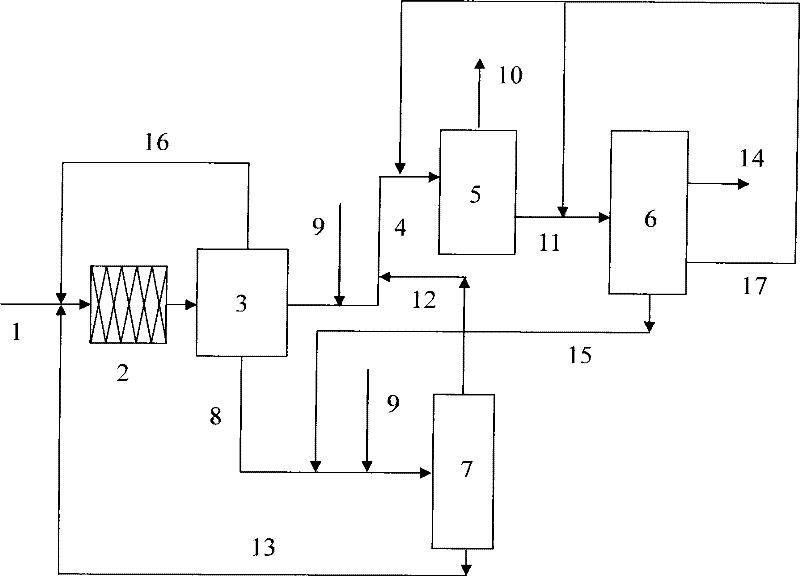

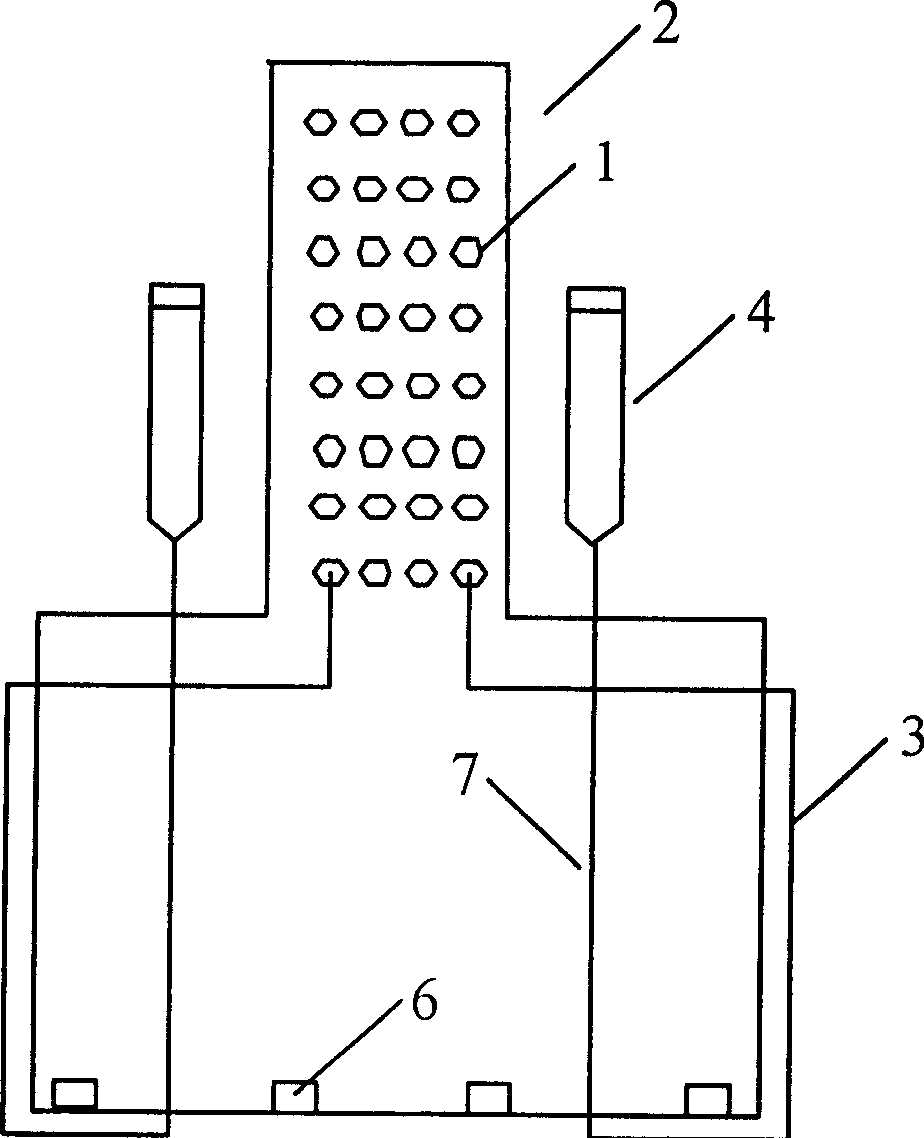

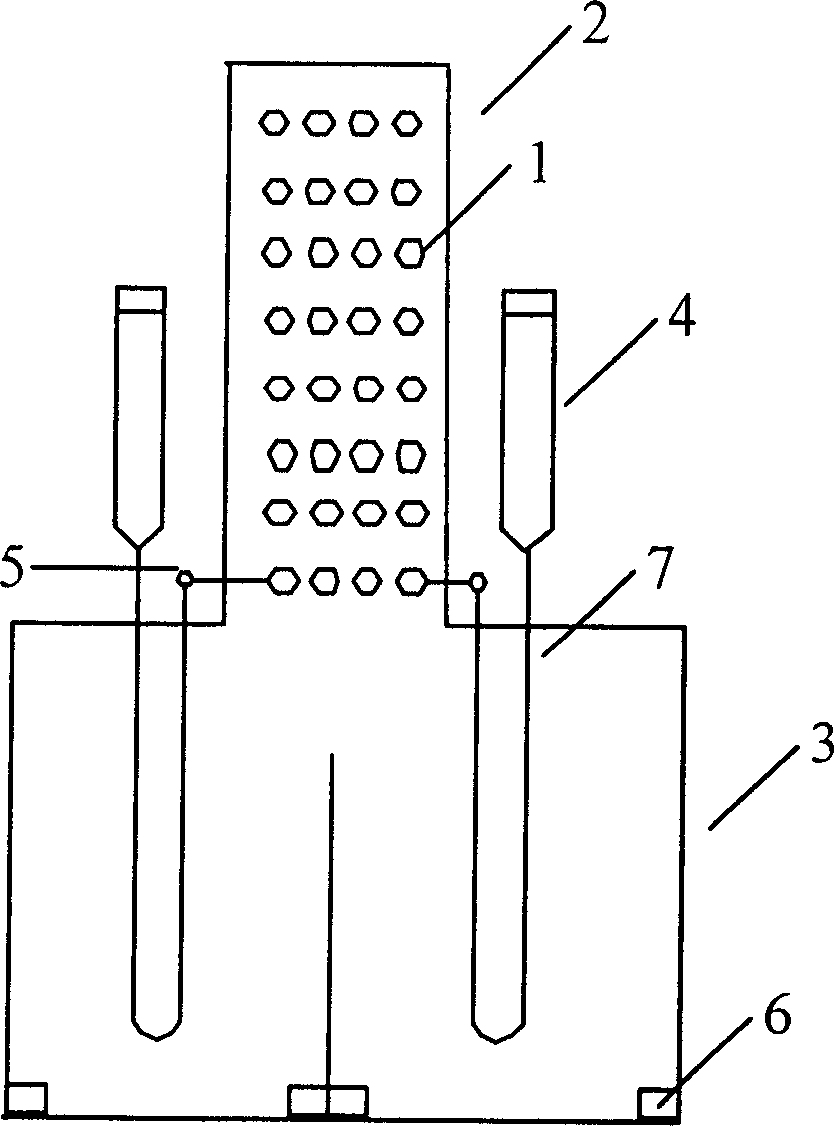

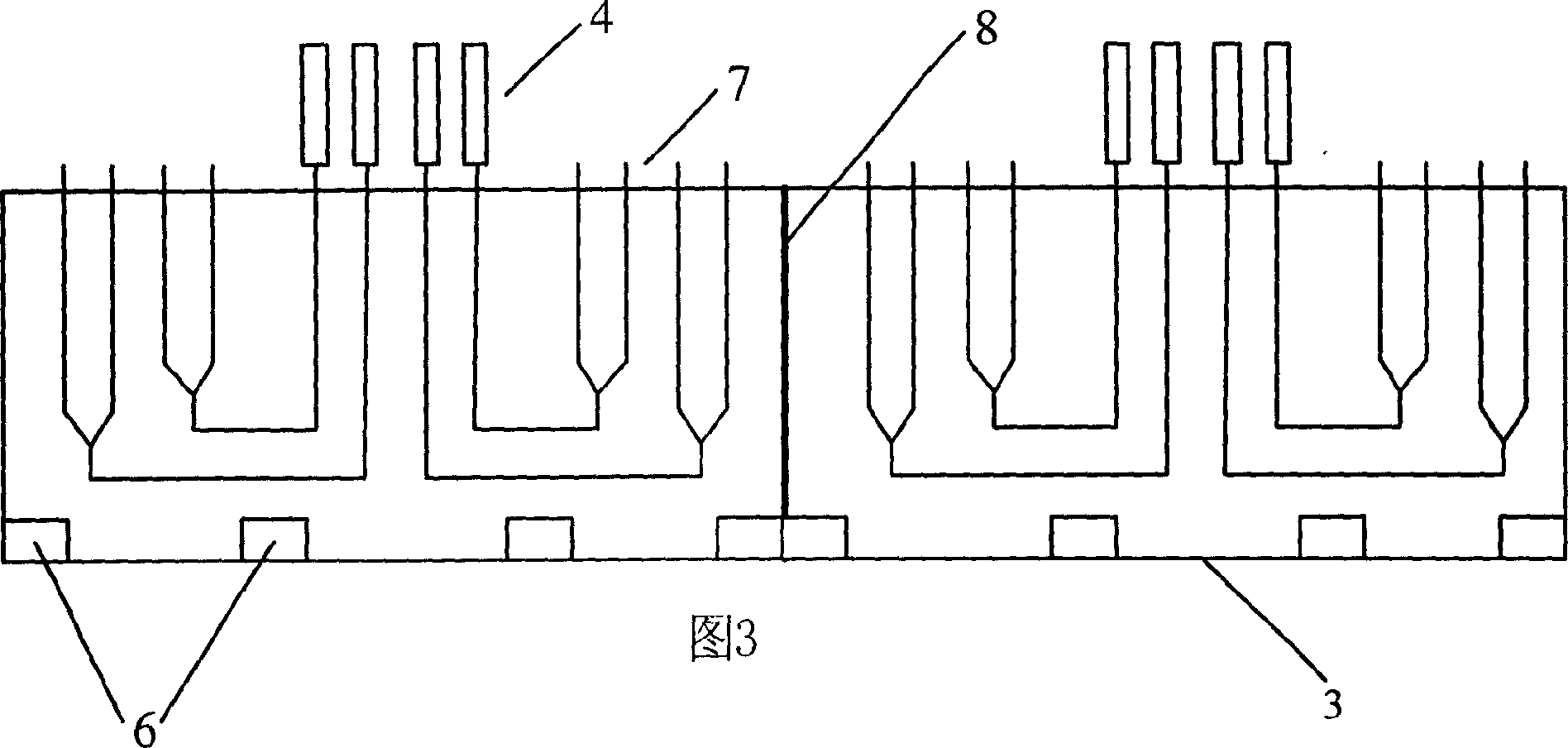

The invention discloses a kind of biomass gasifying method and device. The technology through separating the two courses of solid biomass pyrogenation and decomposition and gasification of the pyrogenation outcome, then transform the biomass into flammable gas of rather low tar content. Firstly send biomass into the pyrogenation reactor, without oxidant in; have pyrogenation reaction at 400 - 650 Deg. C, the pyrogenation outcome including pyrogenation gas and remaining charcoal gets into pyrogenation carburetor, and have incomplete oxidizing combustion reaction with sent oxidant, to form a high temperature of 900 - 1100 Deg. C. At the time, the heavy hydrocarbon substance of tar decomposes into small molecule gas, and the decomposed gas leaves out of the carburetor after having deoxidizing reaction with the nether blazing carbon layer. The high temperature gas is provided for consumers' use after depurated and cooled. The gas produced by the invention has very low tar content, which makes the following depurating equipment simple, won't produce second pollution and makes the raw materials widely used. The produced fuel gas can be used in civil filed and directly used for generating electricity.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

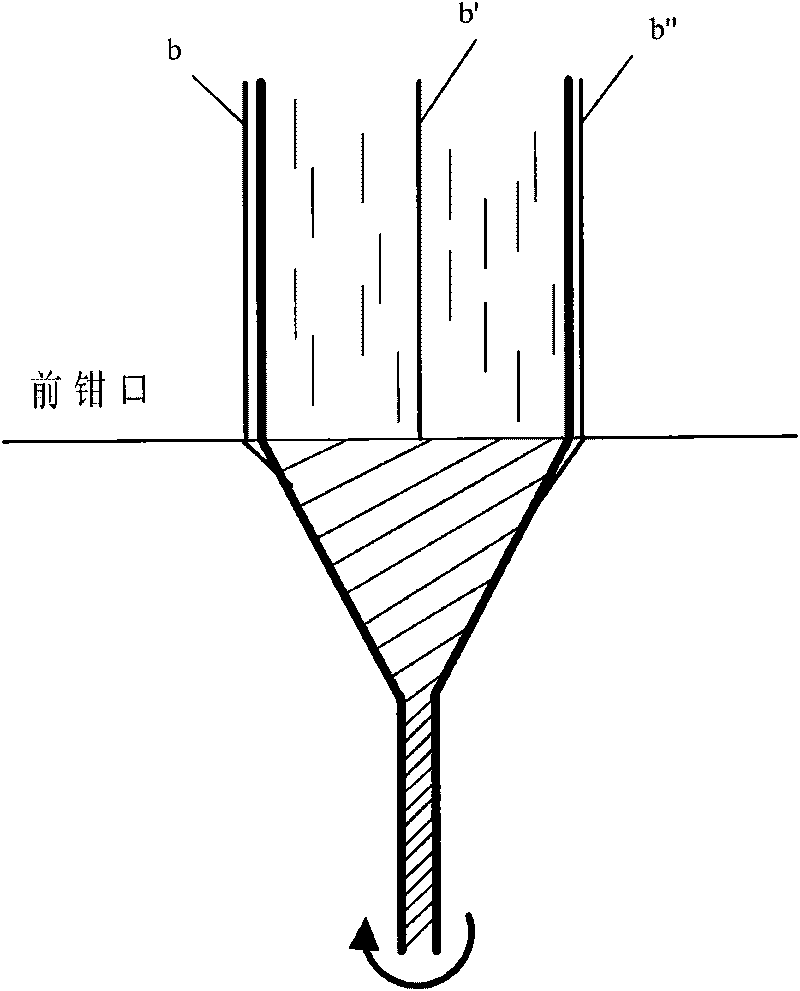

Preparation method of yarn with long and short fiber compound structure

InactiveCN101736469AEasy to transformEasy to operateDrafting machinesContinuous wound-up machinesBobbinCompound structure

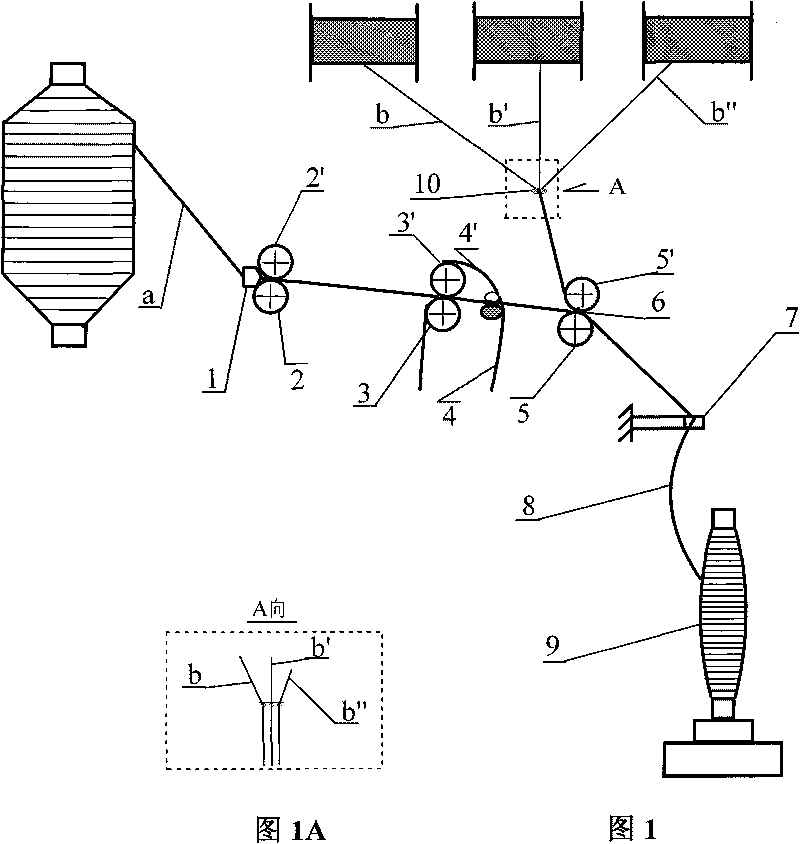

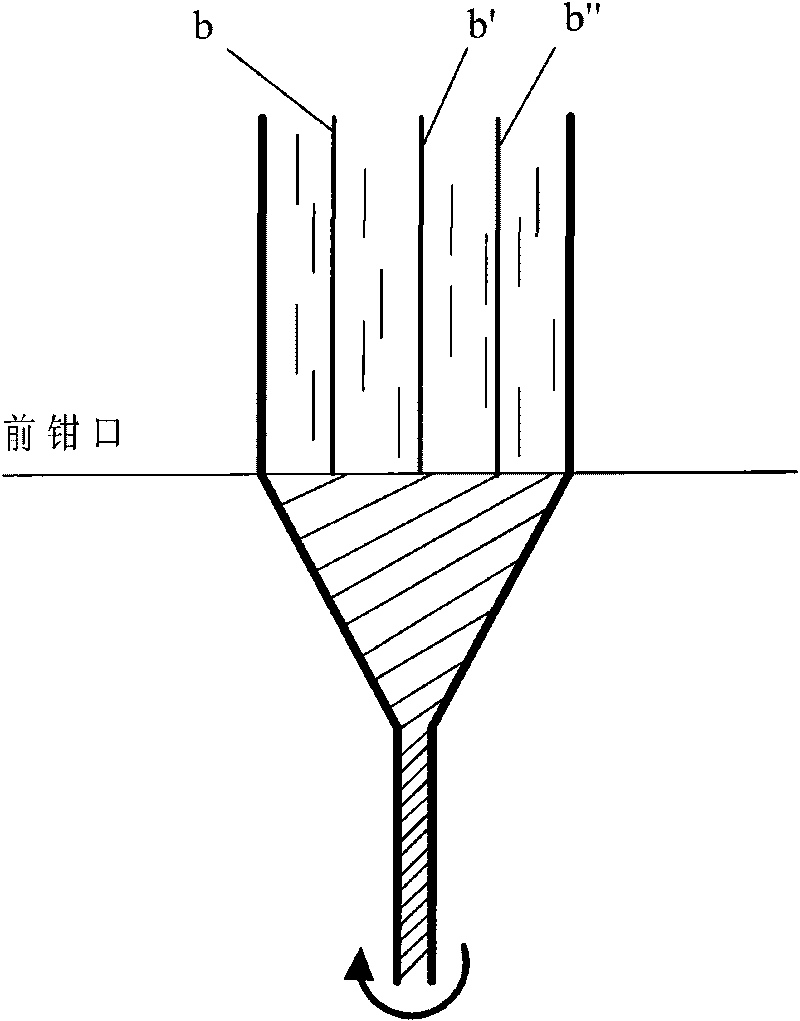

The invention discloses a preparation method of a yarn with a long and short fiber compound structure, belonging to the technical field of textile processing. The preparation method comprises the following steps of: feeding short fiber rove fiber strands unwound from a rove tube into a drafting zone through a yarn-guiding horn for drafting on a drafting mechanism of a ring spinning frame; feeding at least three filaments into a front jaw from the rear end of a front roller at an interval of 0.1-3mm; jointing the filaments and the rove fiber strands at the jaw part; outputting and feeding drafted rove fiber strands and the filaments from the front jaw into a twisting triangular zone; twisting the rove fiber strands and the filaments into the yarn and winding the yarn on a spun yarn bobbin; and forming compound yarns with different structures according to the space among the filaments and the different relative positions of the rove fiber strands. The invention can prepare yarns with a unique internal space structure and an external surface structure on the ring spinning frame, enhances the strength, the wear resistance and the bend resistance of the yarns, has favorable conformality of textures and can achieve the effect of wearing after washing. The invention realizes the preparation of the yarns with special structures and special functions on the traditional spinning equipment.

Owner:SOUTHWEST UNIVERSITY +1

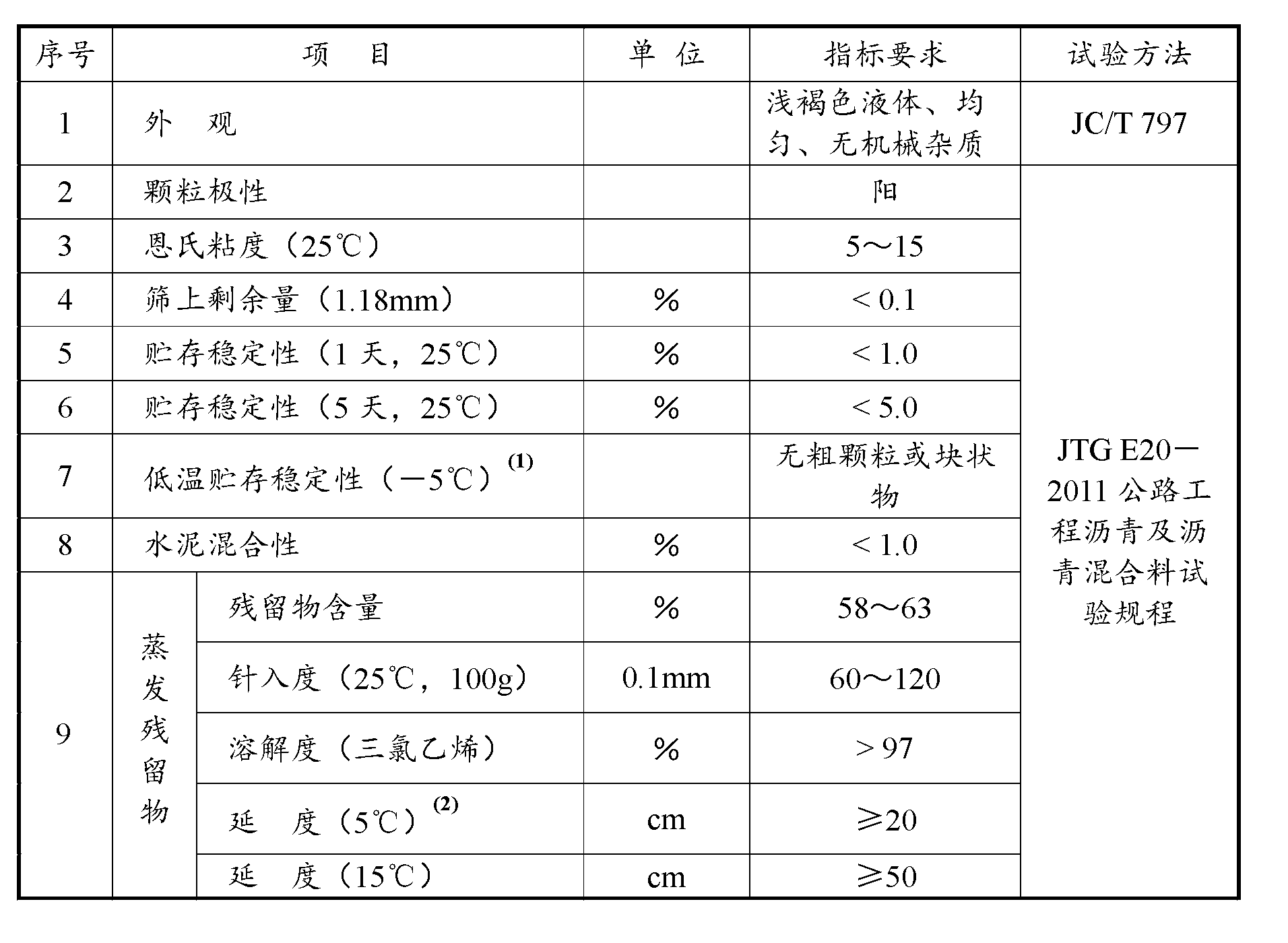

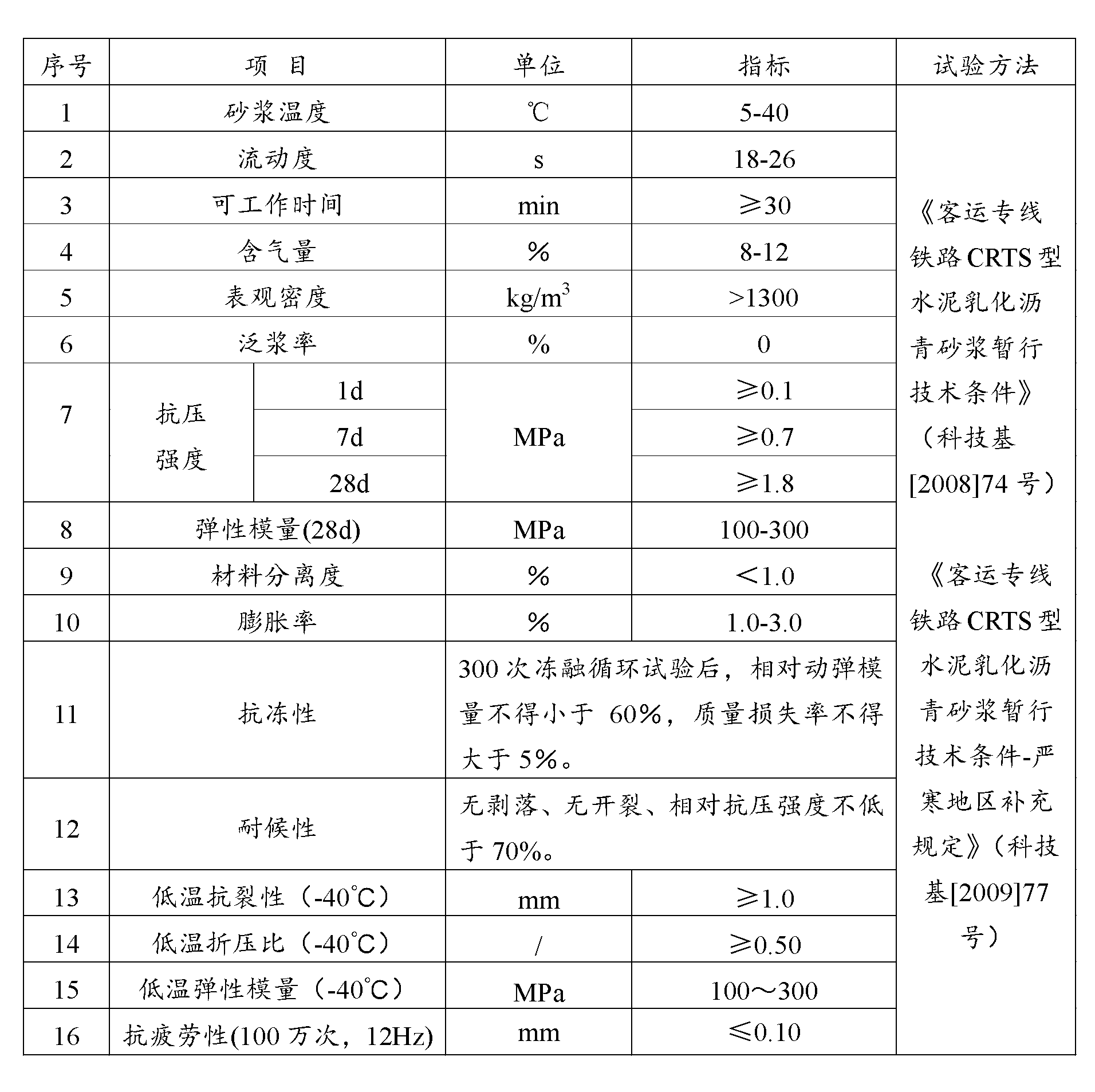

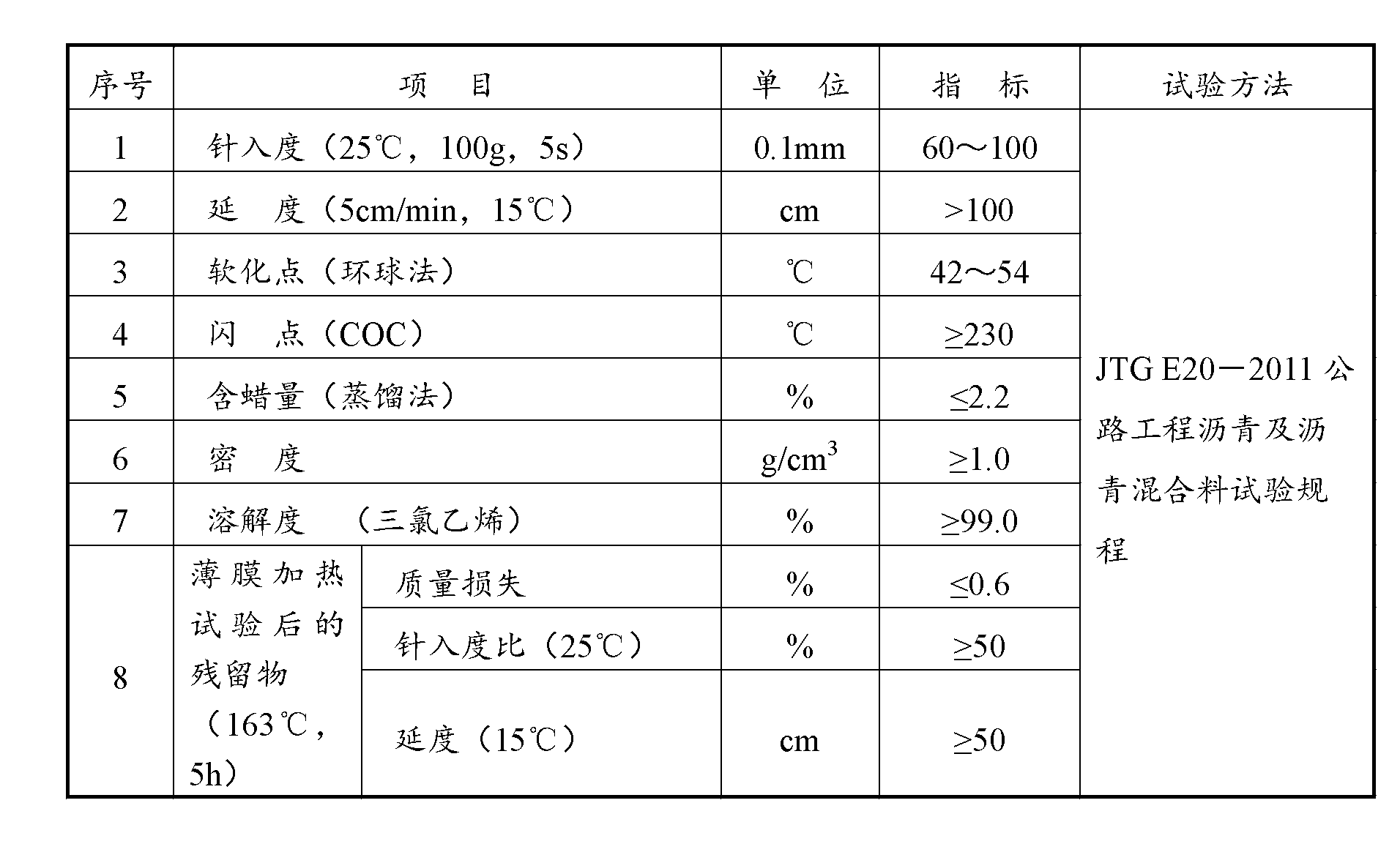

Emulsified asphalt for ballastless slab track in severe cold region and preparation method thereof

InactiveCN103059589AImprove stabilityImprove homogeneityBuilding insulationsAsphaltPassenger transport

The invention provides emulsified asphalt for a ballastless slab track in a severe cold region and a preparation method thereof. The emulsified asphalt comprises the following ingredients by mass portion: 55-65 portions of matrix asphalt or modified asphalt, 35-45 portions of water, 0.1-1.0 portion of stabilizer, 0-1.0 portion of thickening agent, 0-2.0 portions of pH regulator, 0.1-1.5 portions of interfacial modifier, 0.6-1.8 portions of cationic emulsifier, 0.4-1.2 portions of non-ionic emulsifier, 0-1.0 portion of optional amphoteric ionic emulsifier and 0-0.6 portion of mineral emulsifier, wherein the emulsifier amounts to 1.0-4.0 portions. The emulsified asphalt has the advantages of high stability, good thermal adaptability, wide material adaptability, strong adhesive force with aggregate and the like, does not significantly influence the hydration of cement after the emulsified asphalt is mixed with the cement and sand, and is suitable for the ballastless slab track, particularly the ballastless slab tracks of CRTSI type high speed railways, passenger transport lines and interurban railways in the severe cold region.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

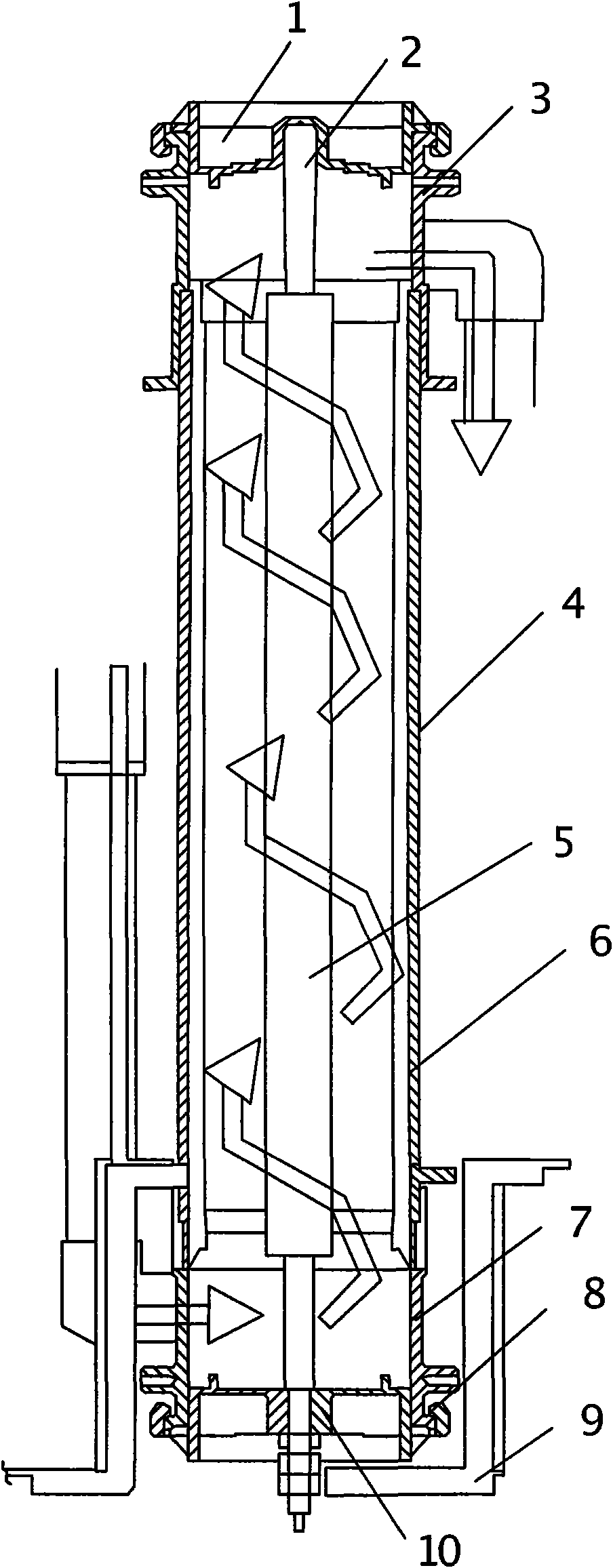

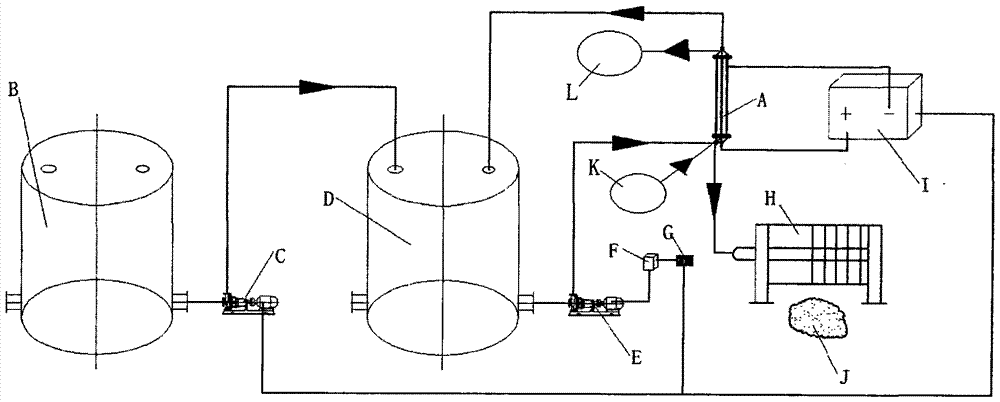

Rotational-flow electrolysis method and device thereof

ActiveCN101886271ASelective electrodepositionWide adaptability of raw materialsPhotography auxillary processesElectrolysisRotational flow

The invention discloses a rotational-flow electrolysis method and a device thereof, which represent new technology for performing selective electrolysis (electrodeposition) on valuable metals and are particularly suitable for performing selective electrolysis (electrodeposition) separation and purification on low-concentration solution, which has complex composition in the metallurgy industry, and stripping heavy metal ions from waste water. Due to the adoption of the technology, the problems of small electrolytic current density, non-uniform current distribution, great difficulty in removing impurities from solution, long process flow, high production cost, low overall efficiency and the like existing in the electrolysis process of conventional flat plate (frame) electrolysis technology (device) can be solved effectively. Moreover, an electrolysis technical solution (device), which has the advantages of high efficiency, reliability, simple process flow, simple and convenient operation and low cost in the presence of complex solution composition, is provided.

Owner:浙江科菲科技股份有限公司

Method for producing functional grease containing rich phytosterin ester from high-acid-value vegetable oil

ActiveCN104178531ARealize the processing effectRealize high-value utilizationFermentationOil and greaseVegetable oil

The invention relates to a method for producing functional grease containing rich phytosterin ester from high-acid-value vegetable oil. The method is characterized by comprising the following steps: (1) addition of reaction raw materials: adding phytosterin, high-acid-value grease and molecular sieve into a reaction kettle, adding 100-200ppm of antioxidant, heating to 45-60 DEG C, stirring and carrying out ultrasonic treatment to obtain a premixture, wherein the mole ratio of the phytosterin to free fatty acids in the high-acid-value grease is 1:1-5:1; (2) enzymatic ester exchange reaction: adding 5-40 g / L lipase into the premixture, and stirring to react at 45-60 DEG C under normal pressure for 6-12 hours; and (3) carrying out after-treatment on the product to obtain the functional grease containing rich phytosterin ester. The method can obviously lower the acid value of the high-acid-value vegetable oil and generate the new functional active component phytosterin ester, and the product is simple for separation and purification; and thus, the method can easily implement large-scale amplification.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Semi-worsted yarn and spinning method thereof

InactiveCN102719953AWide adaptability of raw materialsHigh or low spinning countYarnDyeingEngineering

The invention relates to a semi-worsted yarn and a spinning method thereof. The semi-worsted yarn is formed by blending, by weight, 25-35% of coffee carbon fibers, 25-35% of bamboo carbon fibers and 30-40% of cotton fibers and spinning the same by semi-worsted spinning process. The spinning method sequentially includes a dyeing step, a fiber combining step, a cotton carding step, a drawing step, a roving step, a yarn spinning step and a spooling step. The blended semi-worsted yarn is blended with various fibers. The advantages of each fiber, which are shown by reasonable arrangement of the fibers according to weight proportion, are integrated, and accordingly, basic performance of the yarn is kept while functions of suppressing bacterium breeding, reducing discharge of smelly ammonia and effectively removing peculiar smell of smoke and wine and the like are achieved. Besides, compared with the worsted process, the semi-worsted process is short in procedure. The semi-worsted yarn is looser and softer than worsted yarns and more uniform and lustrous than roving and is high in applicability to raw materials, widely popularized, low in equipment investment and small in occupation space in factories, and the count of the yarn can be adjustable.

Owner:JIANGNAN UNIV +1

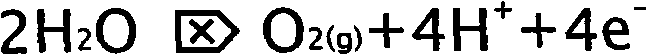

Selective oxygen pressure leaching method for the enrichment of precious metals from high-iron, high-copper and nickel-containing materials

ActiveCN110241310AImprove direct yieldHigh enrichment ratioProcess efficiency improvementAlloyNickel sulfide

The invention belongs to the technical field of nonferrous metallurgy, and particularly relates to a selective oxygen pressure leaching method for the enrichment of precious metals from high-iron, high-copper and nickel-containing materials. The method comprises the following steps of purification and impurity removal, normal-pressure leaching, oxygen-pressure deironing, oxygen-pressure nickel immersion and oxygen-pressure copper immersion. The method is short in technological process and high in direct yield, and can be used for selectively leaching nickel, cobalt, copper and iron and respectively realizing open circuit; and the method is wide in raw material adaptability, suitable for treating various high-iron high-copper nickel-containing materials such as intermediate product low-nickel matte generated in the conventional nickel sulfide ore smelting process, primary alloys, fine grain alloys, cobalt-rich low-nickel matte and cobalt-rich matte, and is remarkable in benefit. The nickel sulfate cobalt sulfate solution obtained by adopting the method is high in the product quality, and the requirements of multi-variety production can be met at the same time; the noble metal can be totally enriched in the oxygen pressure leaching copper slag and can be used as a noble metal concentrate, the direct yield and the enrichment ratio are high, and iron is directly used in a product form; and copper is leached to obtain a copper sulfate solution, and crystallized copper sulfate or electrodeposition copper can be produced.

Owner:SHENZHEN KUNPENG METALLURGY ENG TECH LTD

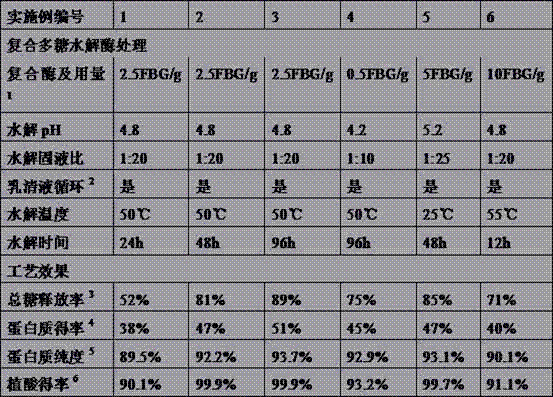

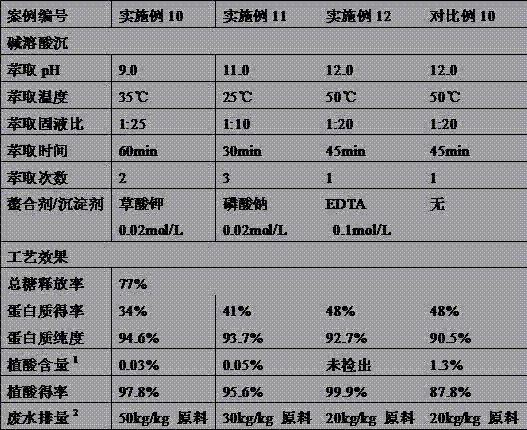

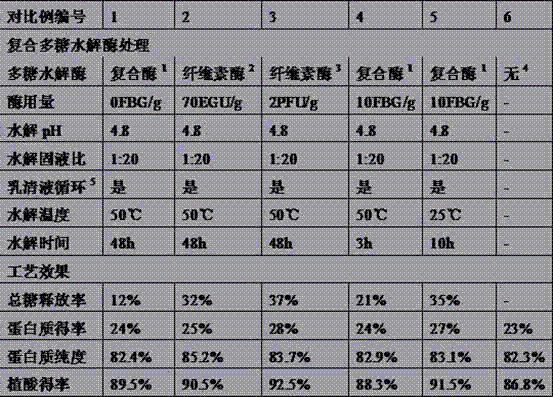

Method for extracting protein and phytic acid from rapeseed meal

InactiveCN102296099AResidue reductionEliminate residueGroup 5/15 element organic compoundsPeptide preparation methodsHydrolysatePolysaccharide Hydrolase

The method for extracting protein and phytic acid from rapeseed cake includes: using a compound of two or more polysaccharide hydrolytic enzymes to hydrolyze the rapeseed cake so that the ratio of the total sugar of the rapeseed cake released into the hydrolyzate liquid phase is greater than 50% ; Adjust the obtained hydrolyzate to pH 3-6 to extract phytic acid, and then separate solid-liquid to obtain phytic acid extract and hydrolyzed cake; use alkaline solution to extract protein in hydrolyzed cake at pH 9-12; use acid precipitation method Or membrane separation method to separate protein from alkaline extract. Improve the extraction efficiency of rapeseed protein and phytic acid, and improve the purity and quality of rapeseed protein products (reduce phytic acid residue).

Owner:刘晔

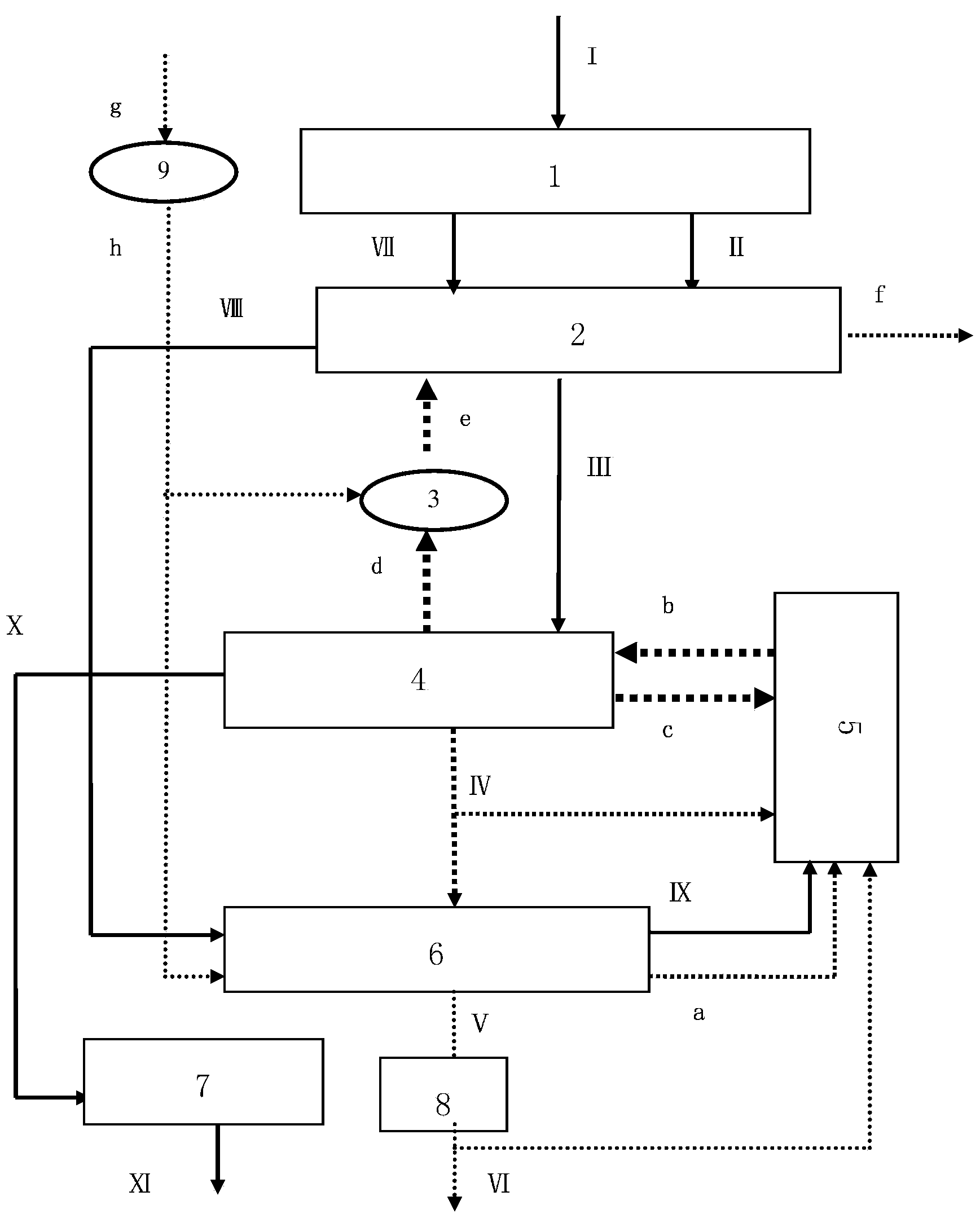

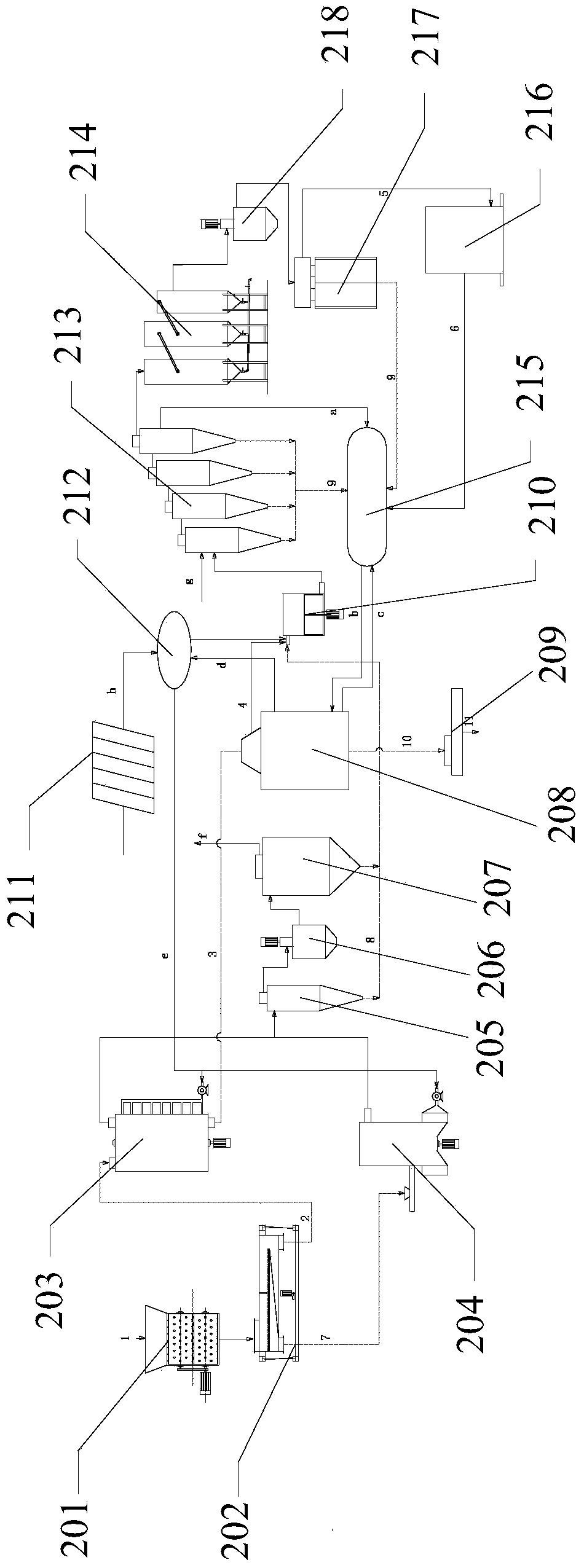

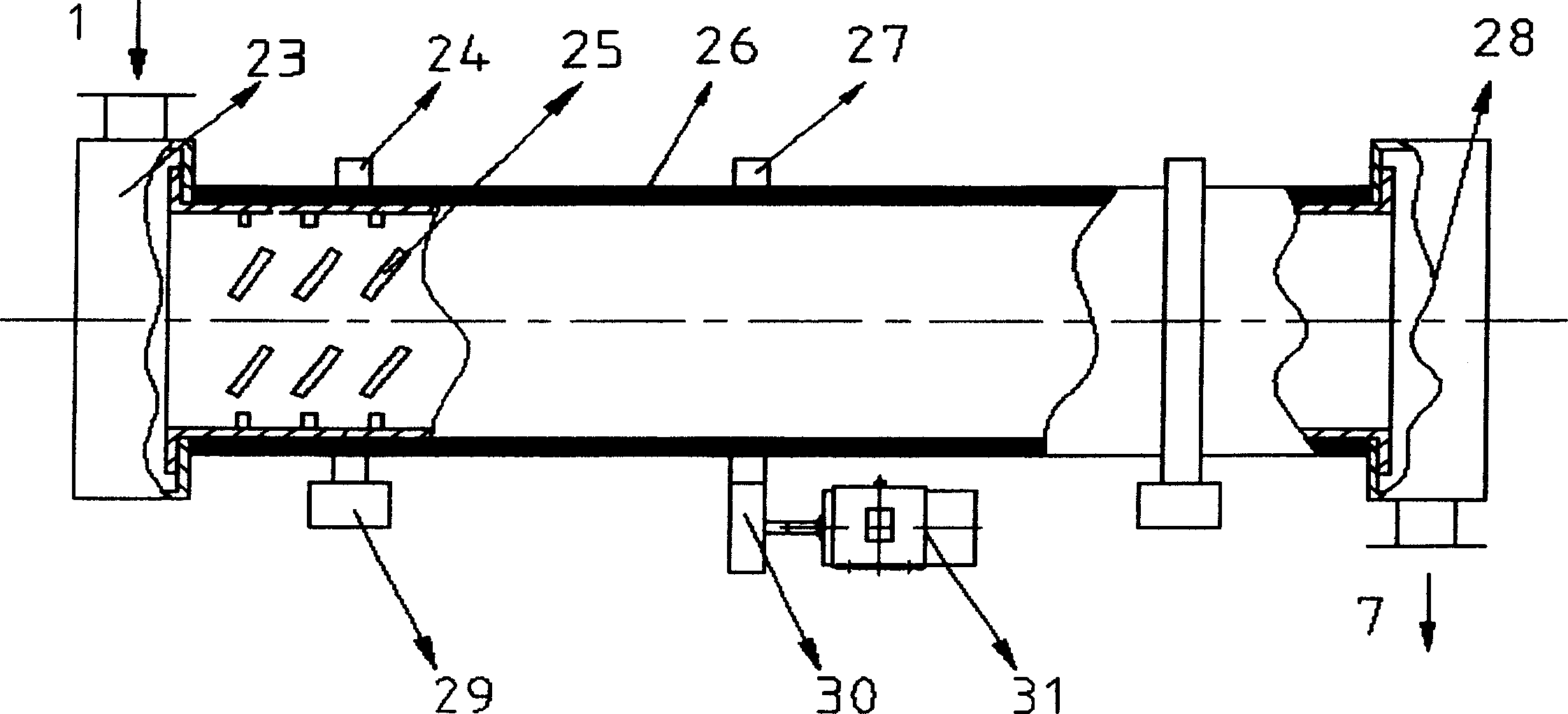

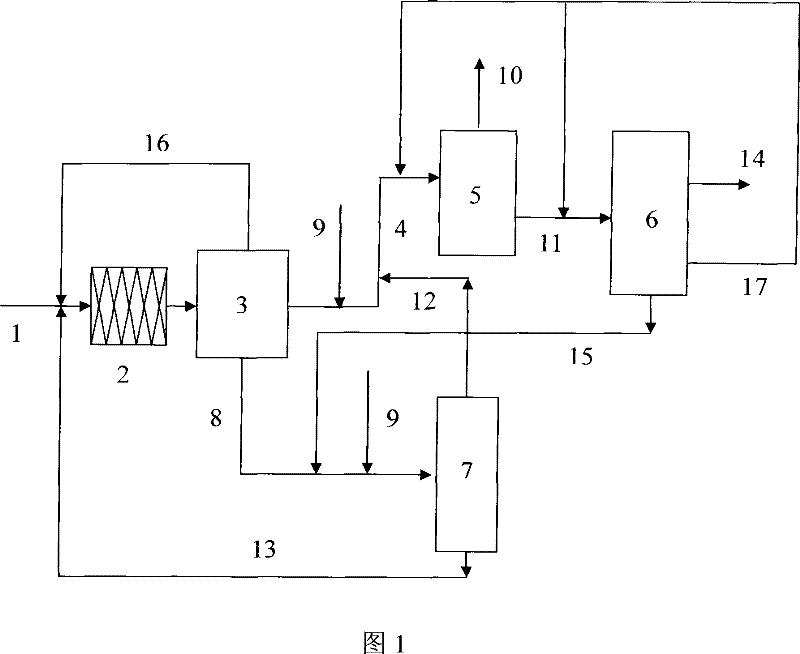

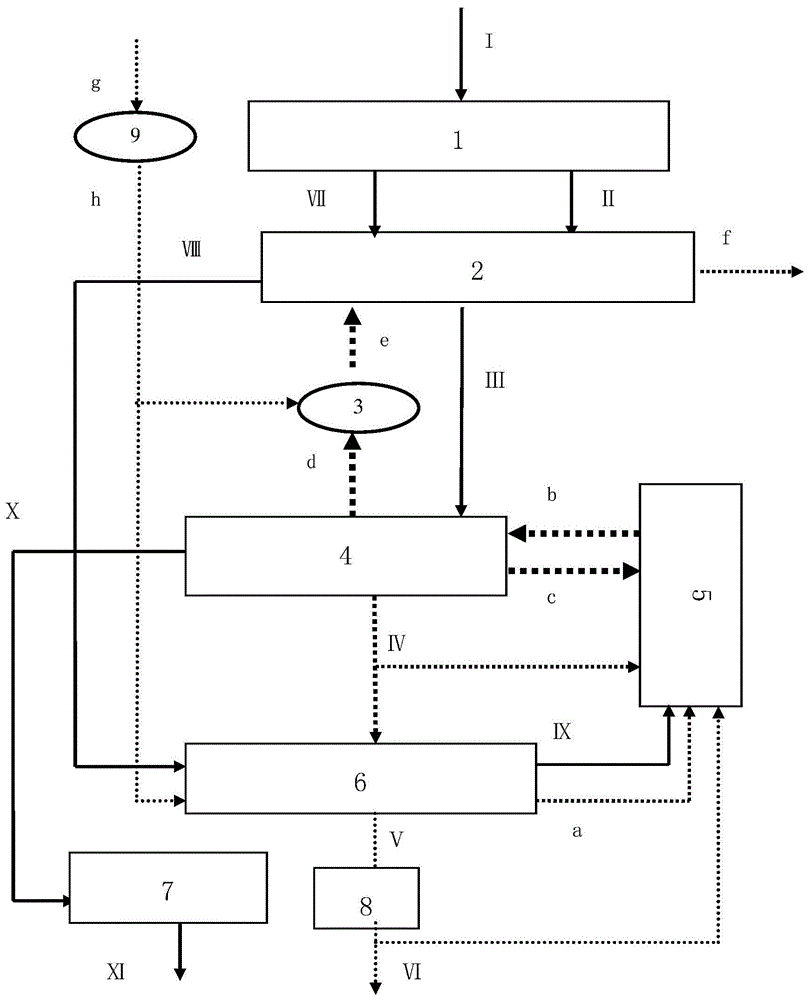

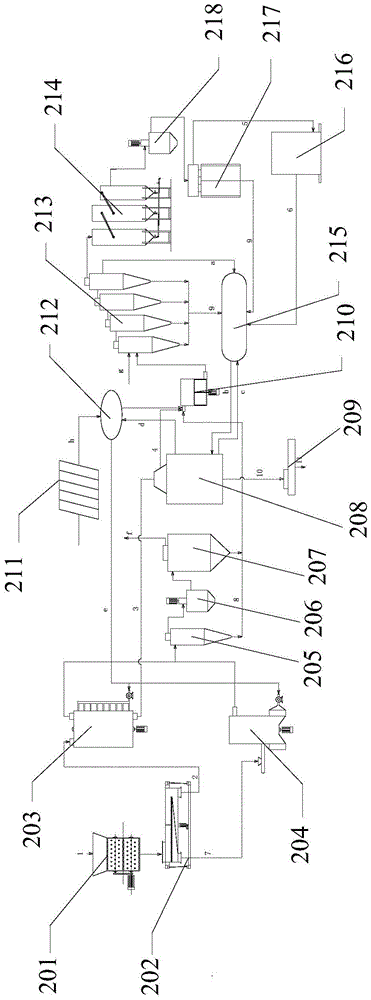

Biomass poly-generation equipment and method of integral pyrolysis-flue gas combined cycle

ActiveCN104293365AReduce aggregate demandImprove utilization efficiencyBiofuelsEnergy inputSolid carbonFlue gas

The invention relates to biomass poly-generation equipment and method for integral pyrolysis-flue gas combined cycle. The biomass poly-generation equipment comprises a pretreatment system, a drying system, a temperature regulation system, an integral pyrolysis furnace, a comprehensive combustion furnace, a fuel gas purification system, a carbon forming system, a gas storage cabinet and a solar collector. In order to solve the problems that the controllability of three processes, namely pyrolysis-pyrolysis gas cracking-solid carbon decoking in the prior art is weak and the integrity is insufficient, the invention provides the biomass poly-generation equipment and method for integral pyrolysis, the three heat absorption processes, namely pyrolysis, pyrolysis gas cracking and solid carbon decoking are completed in regions and segments in the same high temperature environment; the pyrolysis-pyrolysis gas cracking-solid carbon decoking functions are integrated and integral, the reaction process is controllable, fuel gas with a high heat value and such products as high temperature carbon, wood tar, wood vinegar are produced continuously and efficiently. The biomass is fully cracked and the product quality is effectively controlled.

Owner:武汉海德天物新材料有限公司

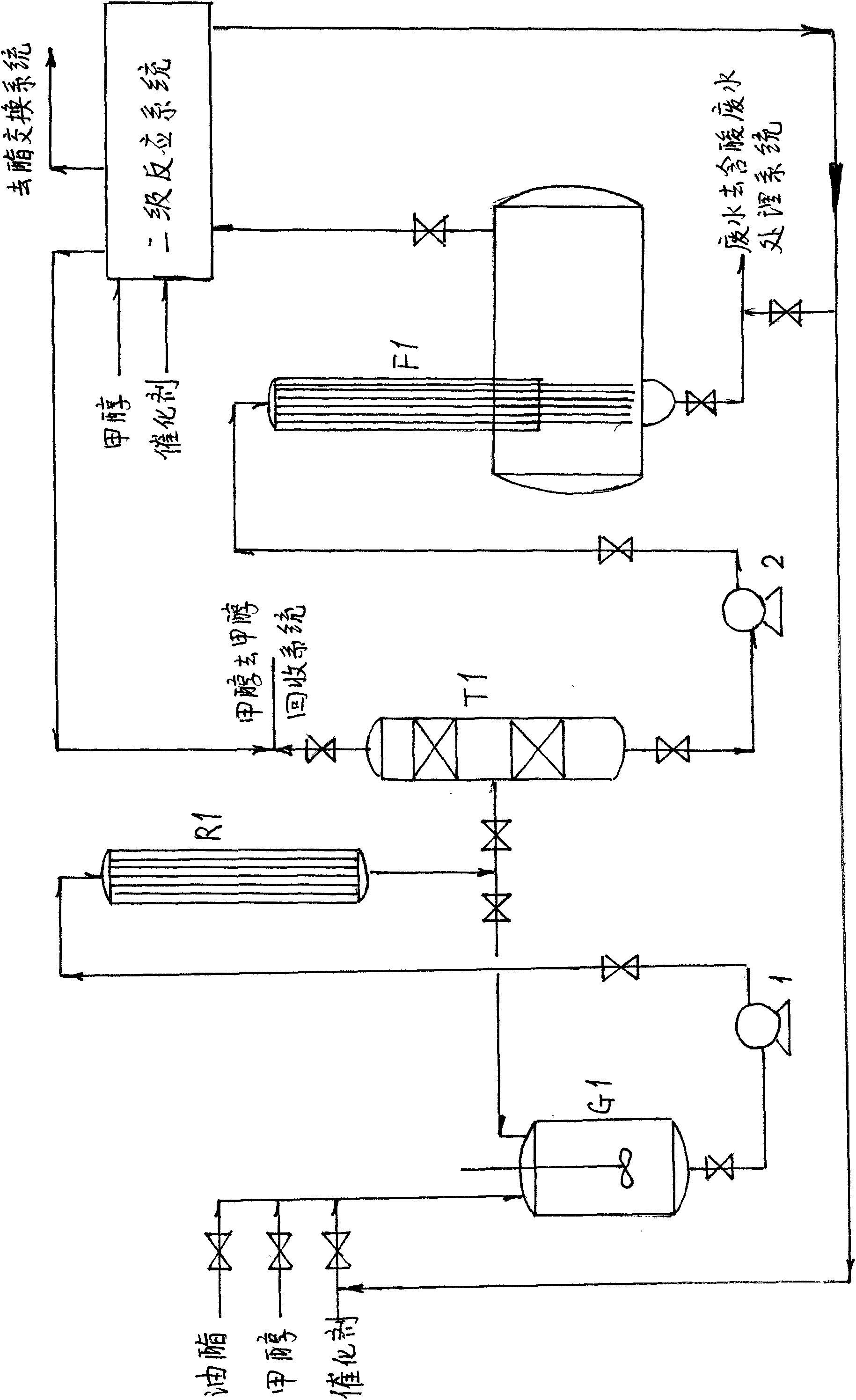

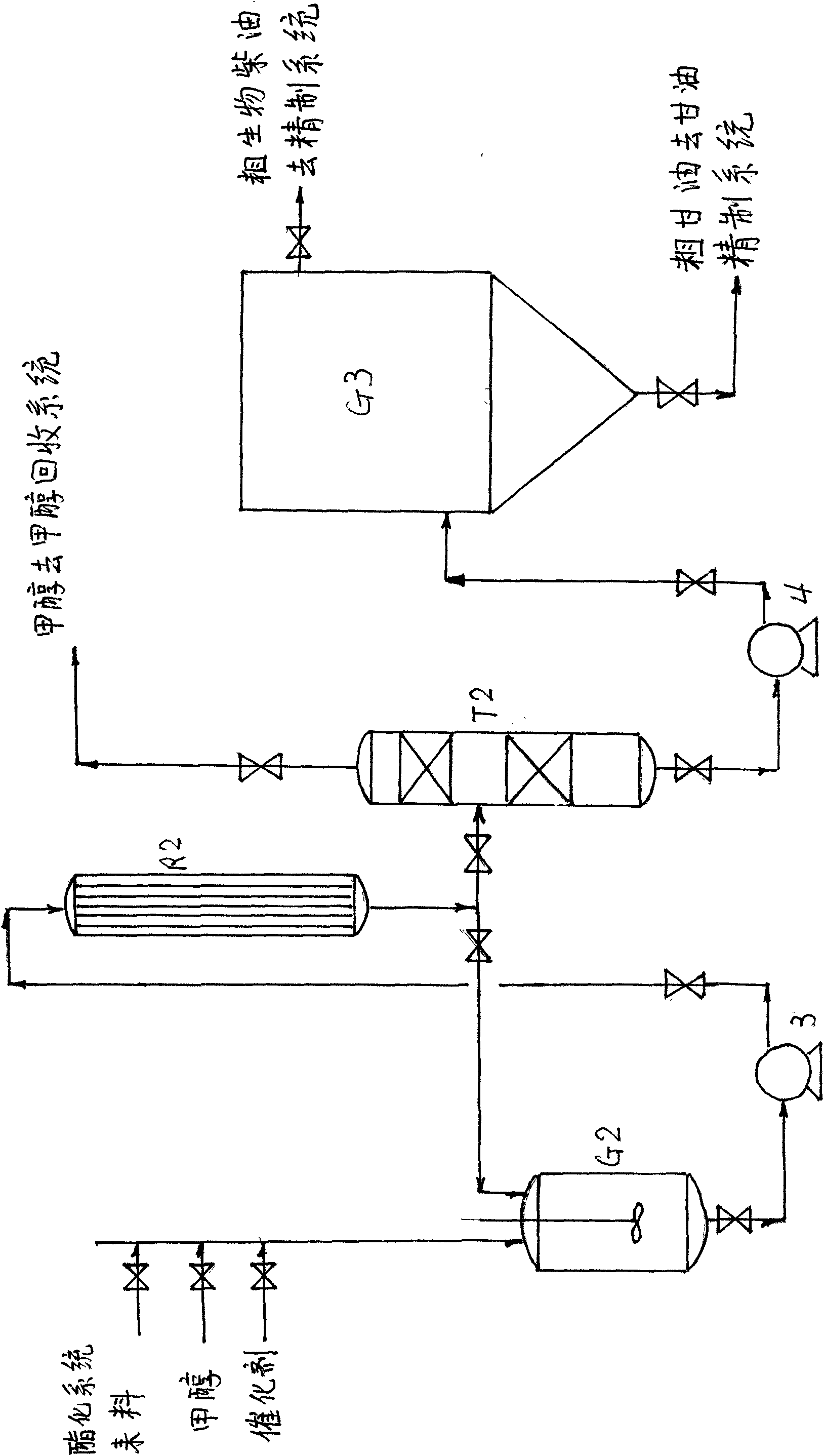

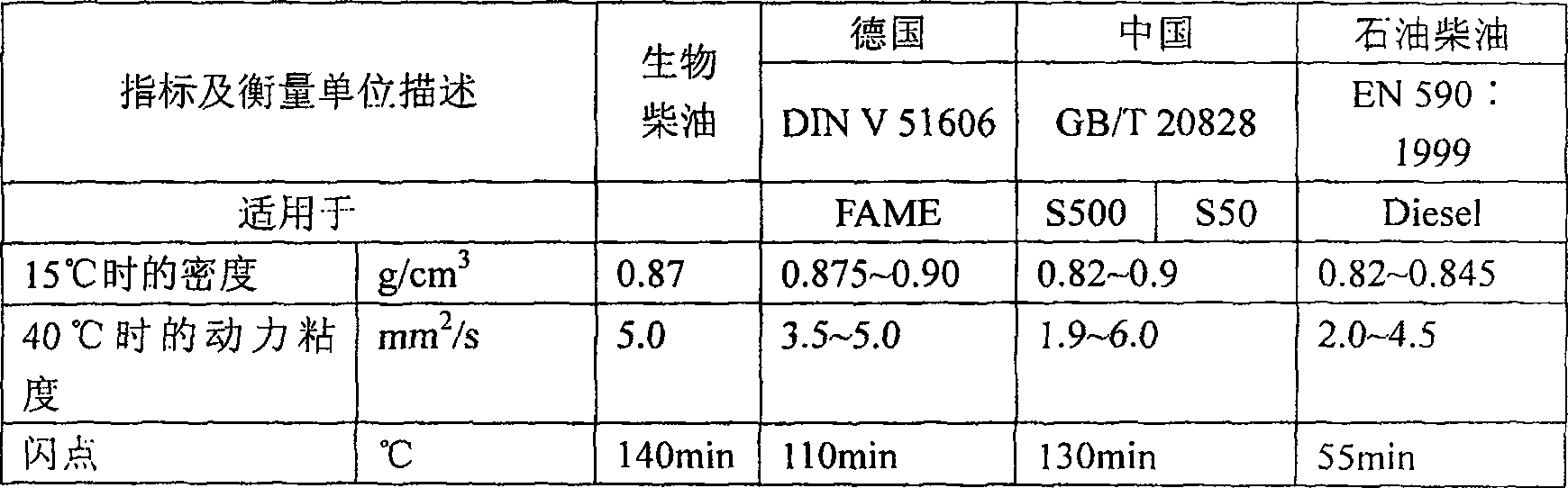

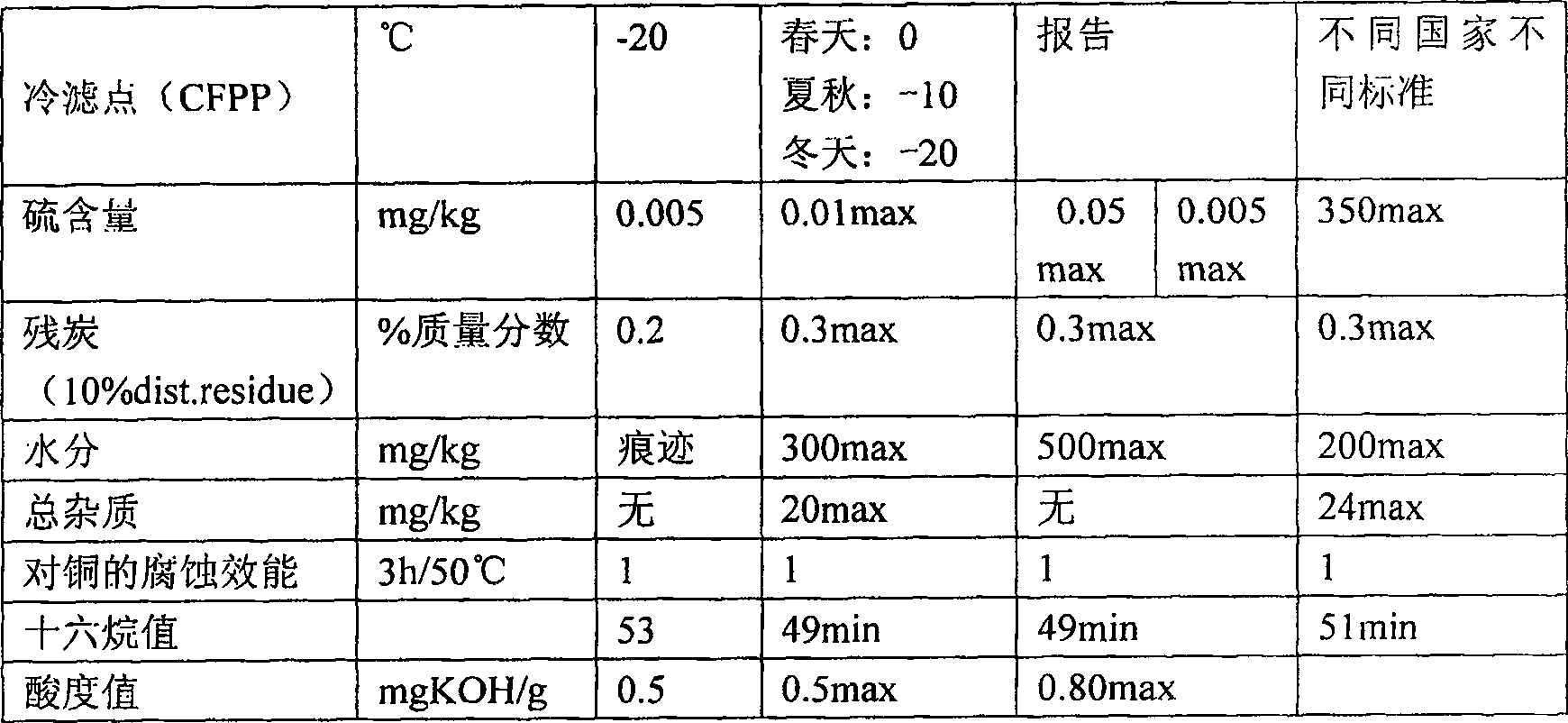

Continuous esterification and ester exchange process used for producing biodiesel

InactiveCN101781610AMeet production requirementsWide adaptability of raw materialsFatty acid esterificationBiofuelsFiberGlycerol

The invention relates to a continuous esterification and ester exchange process used for producing biodiesel, which comprises the following steps of: continuously delivering high-acid value oil, carbinol and an acid catalyst to an esterification mixing tank G1, stirring and mixing and then pumping into an esterification fibrous membrane reactor R1 by a pump B1; after reaction, entering a carbinol-removing tower T1 to remove carbinol; pumping carbinol-removed materials into a fibrous membrane water knockout vessel F1 by a pump B2; after acid-contained wastewater is separated out, delivering to a secondary reaction system; completely repeating the processes in the secondary reaction system after the carbinol and the acid catalyst are supplemented; delivering water-knocked out materials to an ester exchange system; delivering the materials from an esterification system and the carbinol and the acid catalyst to an ester exchange mixing tank G2; stirring and mixing and then pumping into an ester exchange fibrous membrane reactor R2 by a pump B3; entering a carbinol-removing tower T2 after the ester exchange reaction to steam off the carbinol; pumping the carbinol-removed materials into a setting tank G3 by a pump 4; and then settling and separating glycerol to obtain biodiesel. Since the fibrous membrane high-efficiency mass transfer reactor is used by the process, the speed of generating fatty acid methyl ester is greatly increased.

Owner:刘宽 +3

Method and catalyst for producing biological diesel oil by high-acid value grease

InactiveCN101074391AHigh yieldIncrease production speedFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsTetrachlorideBiodiesel

A composite catalyst for biological diesel-oil by high-acidity grease is carried out by mixing methyl sulfonic acid with tin tetrachloride and concentrated sulfuric acid in proportion of 1:1:1, and esterification reacting by composite catalyst 2.5-3% at 58-63 degree for 3.5-4 hrs to convert waste grease into biological diesel-oil. It's fast, has gentle reactive condition, higher recovery rate and better quality.

Owner:青岛福瑞斯生物能源科技开发有限公司

Low-tar biomass gasifying method and apparatus

InactiveCN1272404CWide adaptability of raw materialsSpecial form destructive distillationCarbon layerDecomposition

The invention discloses a kind of biomass gasifying method and device. The technology through separating the two courses of solid biomass pyrogenation and decomposition and gasification of the pyrogenation outcome, then transform the biomass into flammable gas of rather low tar content. Firstly send biomass into the pyrogenation reactor, without oxidant in; have pyrogenation reaction at 400 - 650 Deg. C, the pyrogenation outcome including pyrogenation gas and remaining charcoal gets into pyrogenation carburetor, and have incomplete oxidizing combustion reaction with sent oxidant, to form a high temperature of 900 - 1100 Deg. C. At the time, the heavy hydrocarbon substance of tar decomposes into small molecule gas, and the decomposed gas leaves out of the carburetor after having deoxidizing reaction with the nether blazing carbon layer. The high temperature gas is provided for consumers' use after depurated and cooled. The gas produced by the invention has very low tar content, which makes the following depurating equipment simple, won't produce second pollution and makes the raw materials widely used. The produced fuel gas can be used in civil filed and directly used for generating electricity.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

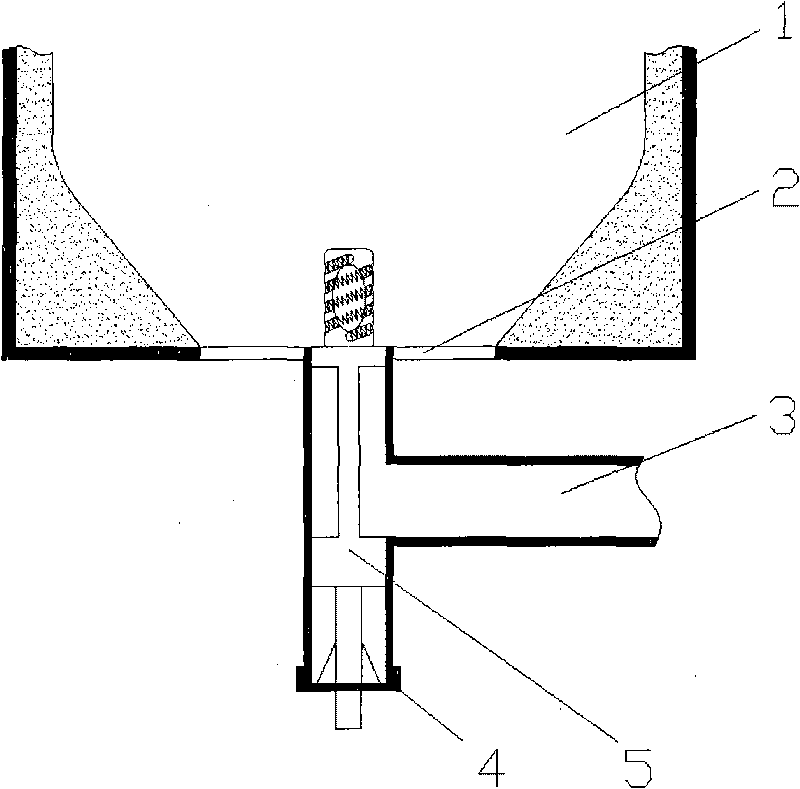

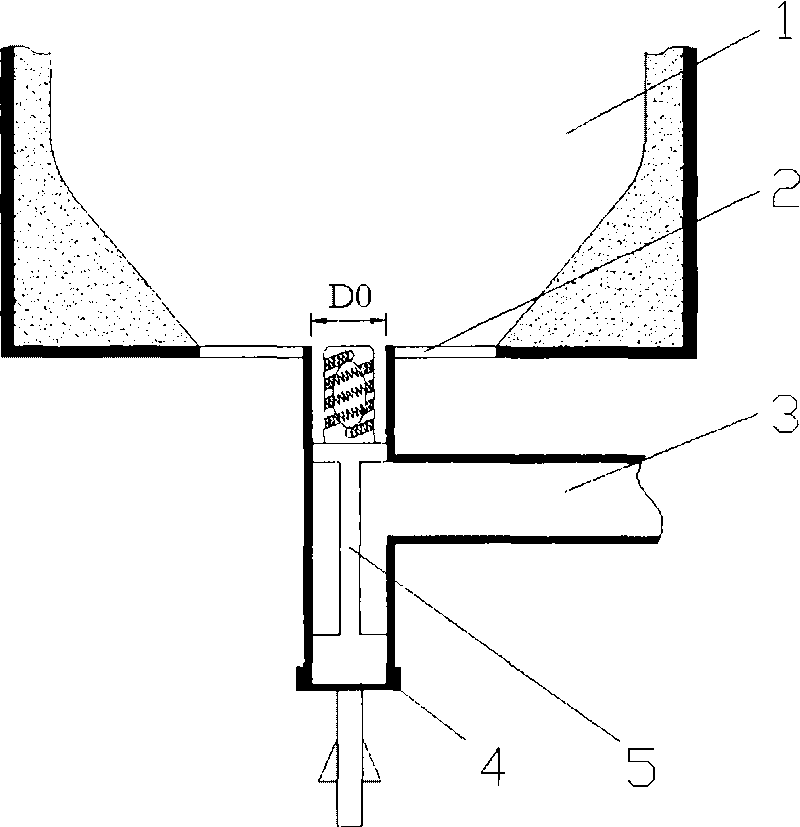

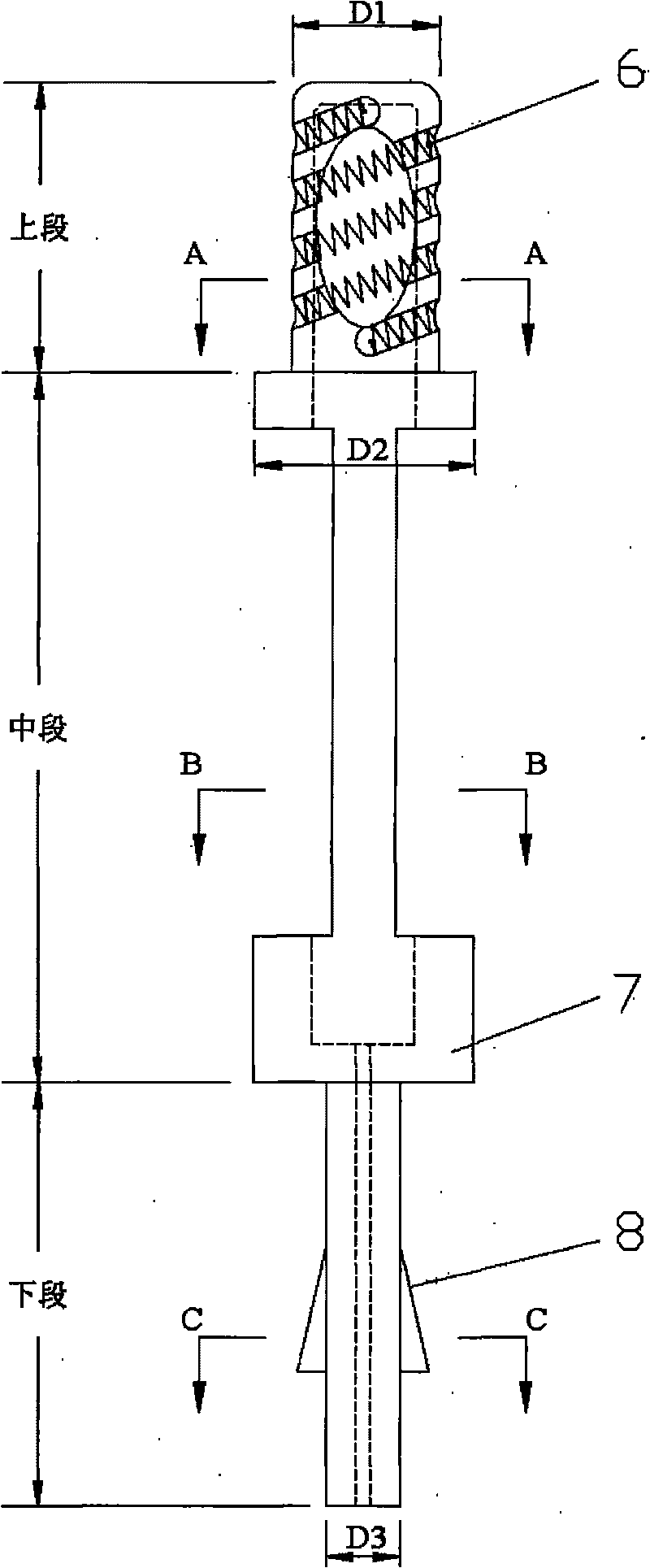

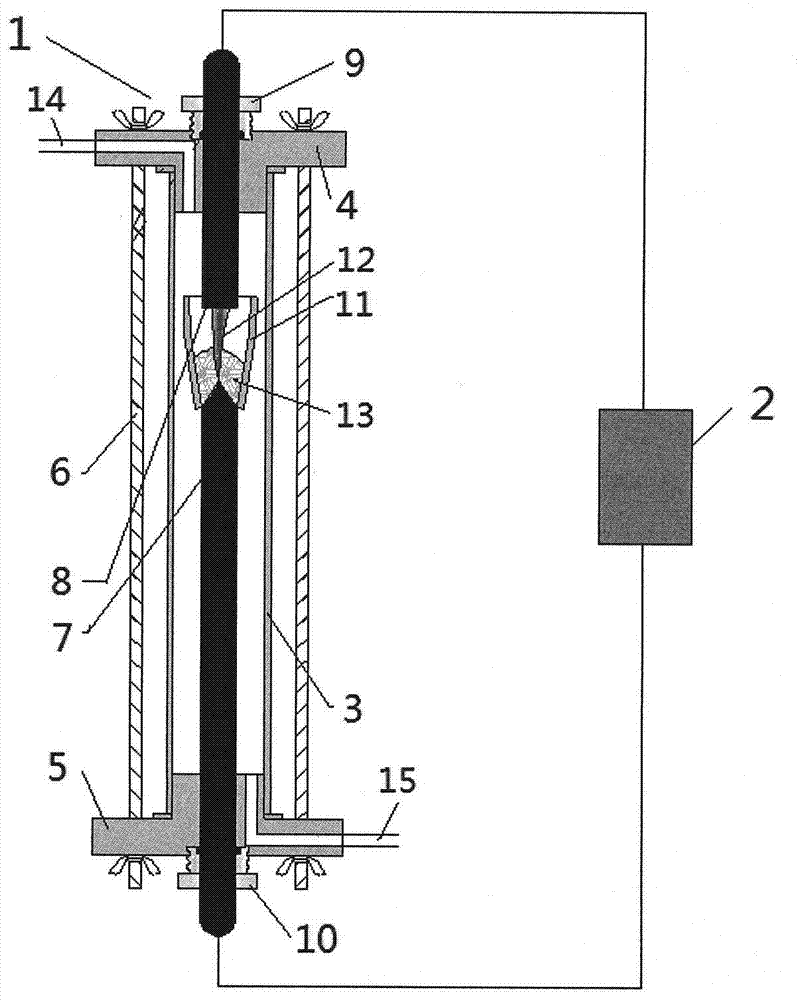

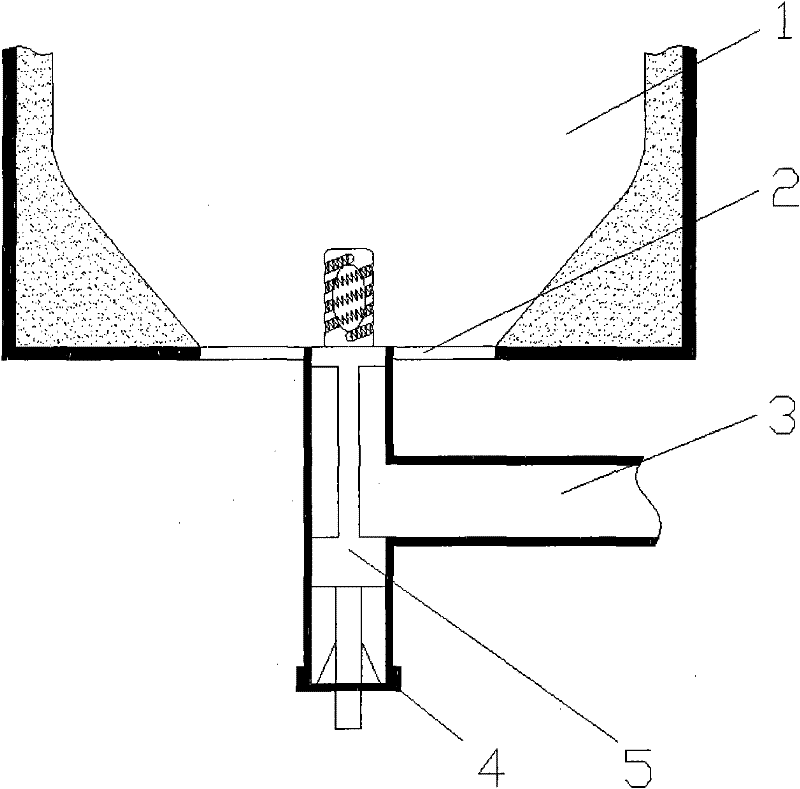

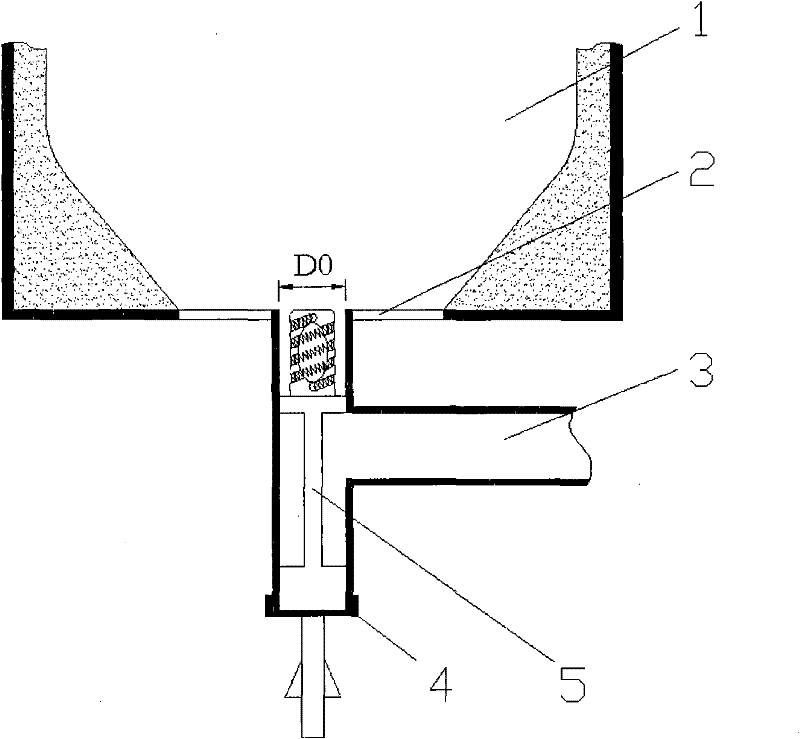

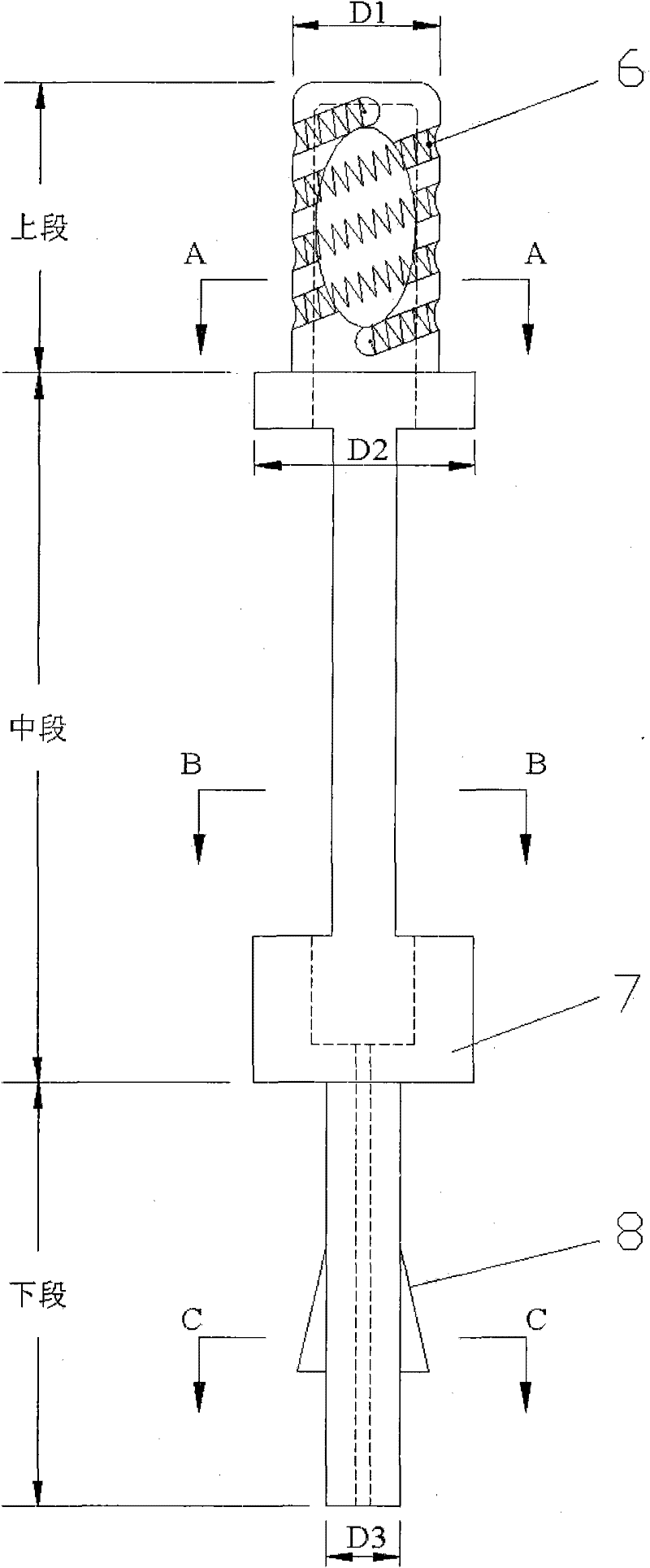

Ignition device for biomass gasification furnace and using method thereof

InactiveCN101726002APromote combustionImprove ignition success rateIncandescent ignitionCombustible gas productionElectricityEngineering

The invention relates to an ignition device for a biomass gasification furnace and a using method thereof. In the device, an ignition bar formed by a heating wire and a ceramic tube element is vertically arranged in a three-way inlet tube of the biomass gasification furnace; the upper end of the ceramic tube element wound with the heating wire is positioned above a grate; the biomass gasification furnace are filled by granular biomass materials and compacted; the biomass materials are closely contacted with the heating wires; after the ignition bar is electrified, the biomass materials at the periphery of the ignition bar is directly heated; a draught fan is opened after 10 to 20 seconds of heating, air is introduced to the bottom of the gasification furnace from the lateral side of the upper section of the ignition bar; the power supply of the ignition bar is closed after the electrification lasts for 10 to 20 seconds; and the ignition bar is twitched downwards and is rotated to ensure that the ignition bar is retracted inside the three-way inlet tube, the ignition bar is separated from the biomass material subjected to high-temperature gasification reaction with the ignition bar, and the air is introduced into the biomass gasification furnace from clearance between the upper end of the ignition bar and the inlet tube to maintain constant performance of the gasification reaction. The ignition device has the advantages of high success rate of ignition, short ignition time, simple and convenient operation and safe use.

Owner:JIANGSU UNIV +1

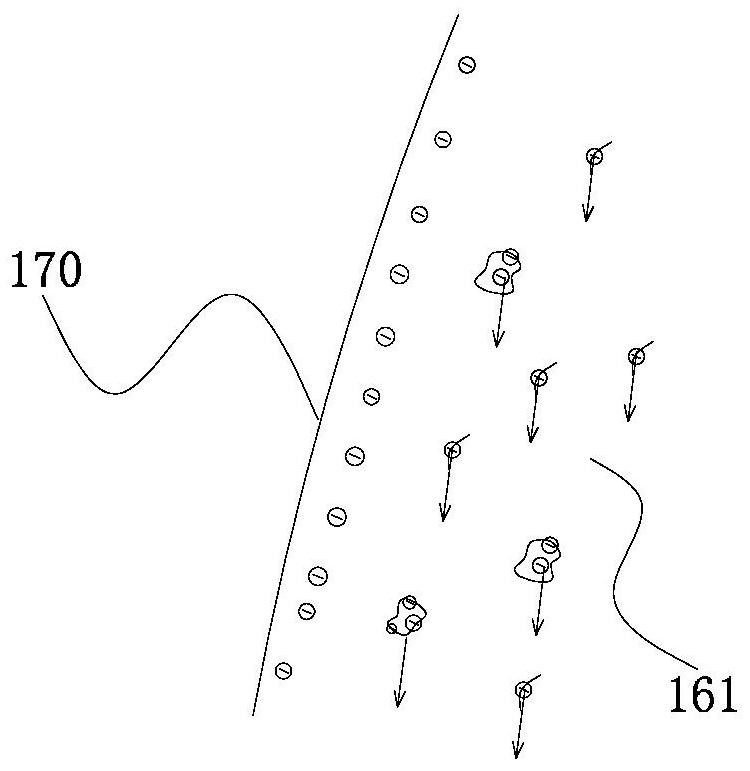

Circulating fluidized bed reactor for preparing hydrogen by gasifying biomass

InactiveCN101885472AWide adaptability of raw materialsSimple structureHydrogen productionDistributorCyclonic spray scrubber

The invention provides a circulating fluidized bed reactor for preparing hydrogen by gasifying biomass. The reactor comprises a reactor shell, a cyclone dust collector and a material returning device, wherein the reactor shell consists of a reactor upper shell, a cylindrical furnace lining and a reactor lower shell, the top part of the reactor upper shell is connected with the cyclone dust collector, the lower end of the reactor upper shell is provided with a biomass charging port, and the bottom part of reactor upper shell is muff coupled with the cylindrical furnace lining; an induction heating device is suspended in the cylindrical furnace lining, and an electric induction coil is wound outside the cylindrical furnace lining and connected with a heating power supply; the bottom part of the cylindrical furnace lining is muff coupled with the reactor lower shell, air distributors are arranged in the reactor lower shell, the bottom part of the reactor lower shell is provided with a vapor charging port, and a material returning port is arranged above the air distributors; and the bottom part of the cyclone dust collector is connected with the material returning device, the material returning device is connected with the material returning port, and the bottom part of the material returning device is provided with a material returning vapor charging port. The circulating fluidized bed reactor has the advantages of uniform heating, energy conservation and environmental protection, continuous operation, simple structure and the like, and can produce the hydrogen-enriched synthetic gas by pyrolysis of biomass materials such as stalks, rice hulls and sawdust.

Owner:ZHENJIANG DANTU TIANLONG CHEM

Complex acid catalyst for producing biodiesel from acidified oil and production method of biodiesel

InactiveCN101955850AImprove conversion rateWide adaptability of raw materialsFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsPhosphoric acidEconomic benefits

The invention discloses a complex acid catalyst for producing biodiesel from acidified oil and a production method of the biodiesel. The method comprises the complex acid catalyst which comprises concentrated sulfuric acid, concentrated phosphoric acid and linear alkylbenzene sulfonic acid, and the method comprises the following steps: mixing the concentrated sulfuric acid, the concentrated phosphoric acid and the linear alkylbenzene sulfonic acid according to the weight ratio of 2-4: 1: 1; and dissolving the complex acid catalyst in methanol, adding into a reaction kettle, producing refined fatty acid methyl ester, namely the biodiesel, through three steps. The method for producing the biodiesel from the acidified oil by utilizing the complex acid catalyst has simple process, strong operability, low production energy consumption, high conversion rate of the biodiesel and improved economic benefits.

Owner:上海绿铭环保科技股份有限公司

Composite process for treatment of inferior residual oil

ActiveCN101418222BWide adaptability of raw materialsAchieve maximum light weightTreatment with hydrotreatment processesTar working-up by solvent extractionDistillationHydrogenation process

The invention discloses a combined process method for treating inferior residual oil. The method comprises the following steps: a residual oil material enters a solvent deasphalting device to obtain DAO and deoil asphalt; the obtained DAO enters a hydrogenation device of a boiling bed and is treated to obtained a lightweight distillation fraction and hydrogenated tail oil; the hydrogenated tail oil enters a catalytic cracking device and is treated to obtain a lightweight distillation fraction and oil slurry; at least partial oil slurry and the deoil asphalt are mixed, enter a hydrogenation device of a suspension bed and are treated to obtain a lightweight distillation fraction and unconverted tail oil, wherein the unconverted tail oil circularly returns the solvent deasphalting device; and the lightweight distillation fraction and the DAO are mixed and enter the hydrogenation device of the boiling bed. The combined process course organically combines a decarbonization process and a hydrogenation process; and according to different properties of raw materials, a corresponding process and operation condition is adopted so as to maximize conversion of the residual oil material while minimizing equipment investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

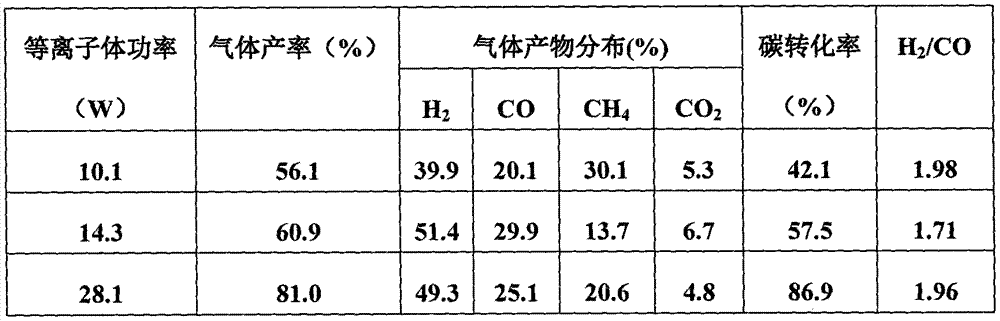

Device for preparing synthetic gas by virtue of non-thermal arc plasma pyrolysis of coal

InactiveCN104498067AEasy to produceEfficient productionSpecial form destructive distillationSolid carbonHigh energy

The invention discloses a device for preparing synthetic gas by virtue of non-thermal arc plasma pyrolysis of coal. The device comprises a non-thermal arc plasma reactor and a high-voltage power supply for supplying power to the plasma reactor, wherein the non-thermal arc plasma reactor mainly comprises a quartz container, an upper polytetrafluoroethylene flange, a lower polytetrafluoroethylene flange, a tip graphite electrode, a flat graphite electrode and a ceramic crucible. Coal is crushed and loaded into the plasma reactor, a carrier gas is introduced, the high-voltage power supply is started and thus the plasma reactor begins to work; the carrier gas between the electrodes is broken down and ionized by virtue the high voltage to form non-thermal arc plasma and coal in the plasma region is subjected to pyrolysis reaction under the actions of high-energy electrons, free radical active substances and an electric field to produce solid carbon residues and hydrogen-enriched synthetic gas. By the device, the process for preparing synthetic gas from coal can be completed according to the actual requirements and the device has the characteristics of wide adaptability of raw materials and low investment cost and can be used in production of chemical synthetic gas and civil fuel gas, industrial furnace kiln fuel gas and power generation fuel gas.

Owner:SUN YAT SEN UNIV

Biomass polygeneration equipment and method for integral pyrolysis-flue gas combined cycle

ActiveCN104293365BReduce aggregate demandImprove utilization efficiencyBiofuelsEnergy inputSolid carbonFlue gas

The invention relates to biomass poly-generation equipment and method for integral pyrolysis-flue gas combined cycle. The biomass poly-generation equipment comprises a pretreatment system, a drying system, a temperature regulation system, an integral pyrolysis furnace, a comprehensive combustion furnace, a fuel gas purification system, a carbon forming system, a gas storage cabinet and a solar collector. In order to solve the problems that the controllability of three processes, namely pyrolysis-pyrolysis gas cracking-solid carbon decoking in the prior art is weak and the integrity is insufficient, the invention provides the biomass poly-generation equipment and method for integral pyrolysis, the three heat absorption processes, namely pyrolysis, pyrolysis gas cracking and solid carbon decoking are completed in regions and segments in the same high temperature environment; the pyrolysis-pyrolysis gas cracking-solid carbon decoking functions are integrated and integral, the reaction process is controllable, fuel gas with a high heat value and such products as high temperature carbon, wood tar, wood vinegar are produced continuously and efficiently. The biomass is fully cracked and the product quality is effectively controlled.

Owner:武汉海德天物新材料有限公司

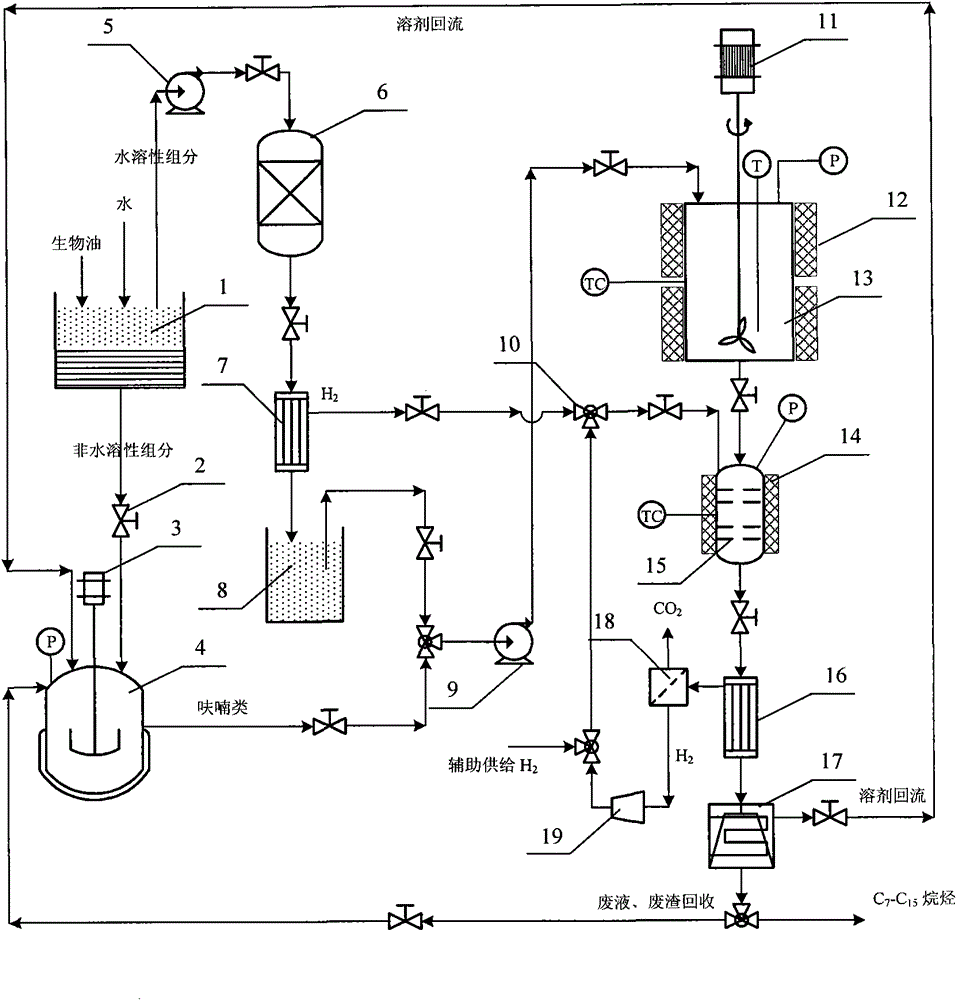

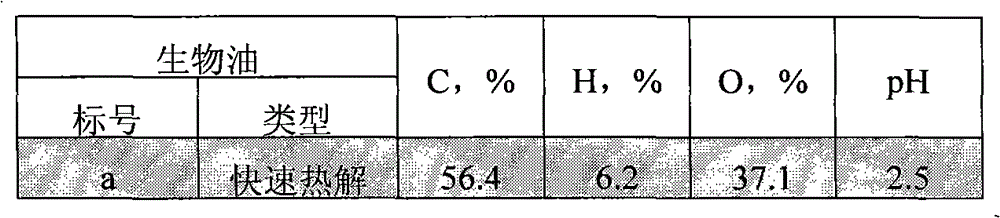

Method for preparing liquid alkane fuel by upgrading bio-oil in aqueous phase catalytic mode

ActiveCN101870881BReduce cokingHigh recovery rateLiquid hydrocarbon mixture productionBio-feedstockAlkaneDesorption

The invention provides a method for preparing liquid alkane fuel by upgrading bio-oil in an aqueous phase catalytic mode. The method comprises the following steps of: 1) pretreating the bio-oil to obtain a water-soluble component and a water-insoluble component; 2) performing a pressurized acid hydrolysis process on a furan compound of the water-insoluble component to prepare the furan compound; 3) performing a reforming and hydrogen production reaction on the water-soluble component; 4) mixing the furan compound with a liquid-phase product separated from the step 3) to perform an aldol condensation reaction to increase carbon chains; and 5) performing a hydrogenation and dehydration reaction on an aldol condensation product to obtain liquid linear alkane. The method has the advantages that: an upgrading process, which is performed in a double-phase system, can effectively contribute to the desorption of an intermediate product from the surface of a catalyst and the mass transfer of an upgraded product, and can reduce the risk of carbon deposition on the surface of the catalyst; the quality of oil obtained by the method is high; the energy density and the energy grade of the bio-oil are improved greatly; and the liquid alkane fuel can be obtained from all kinds of bio-oil so as to partially substitute for the conventional widely-used fossil gasoline and diesel oil fuel.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A kind of ionic liquid type polyoxometalate catalyst and its preparation method and application

ActiveCN110201712BEfficient enrichmentSatisfy multi-level step-by-step conversionOrganic chemistryOrganic compound preparationPhosphomolybdic acidPtru catalyst

The invention discloses an ionic liquid type polyoxometalate catalyst, the structural formula is [MIMPS] n h 6‑n P 2 Mo 18 O 62 , where n=1‑6, by adding phosphomolybdic acid H 6 P 2 Mo 18 O 62 Dissolve in distilled water, then add 1‑(3‑sulfonic acid group) propyl‑3‑methylimidazole to obtain a mixed solution, age the mixed solution at room temperature, prepare through suction filtration, washing, and drying, used for Catalyzes the conversion of biomass straw into phenolic compounds, xylose and glucose.

Owner:NORTHEAST NORMAL UNIVERSITY

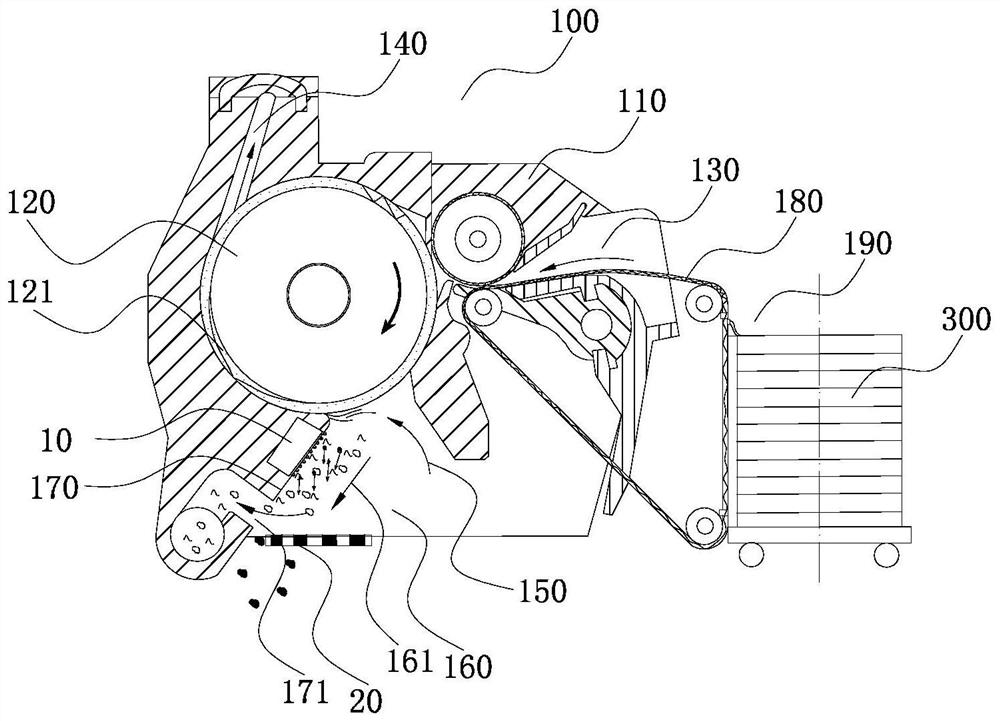

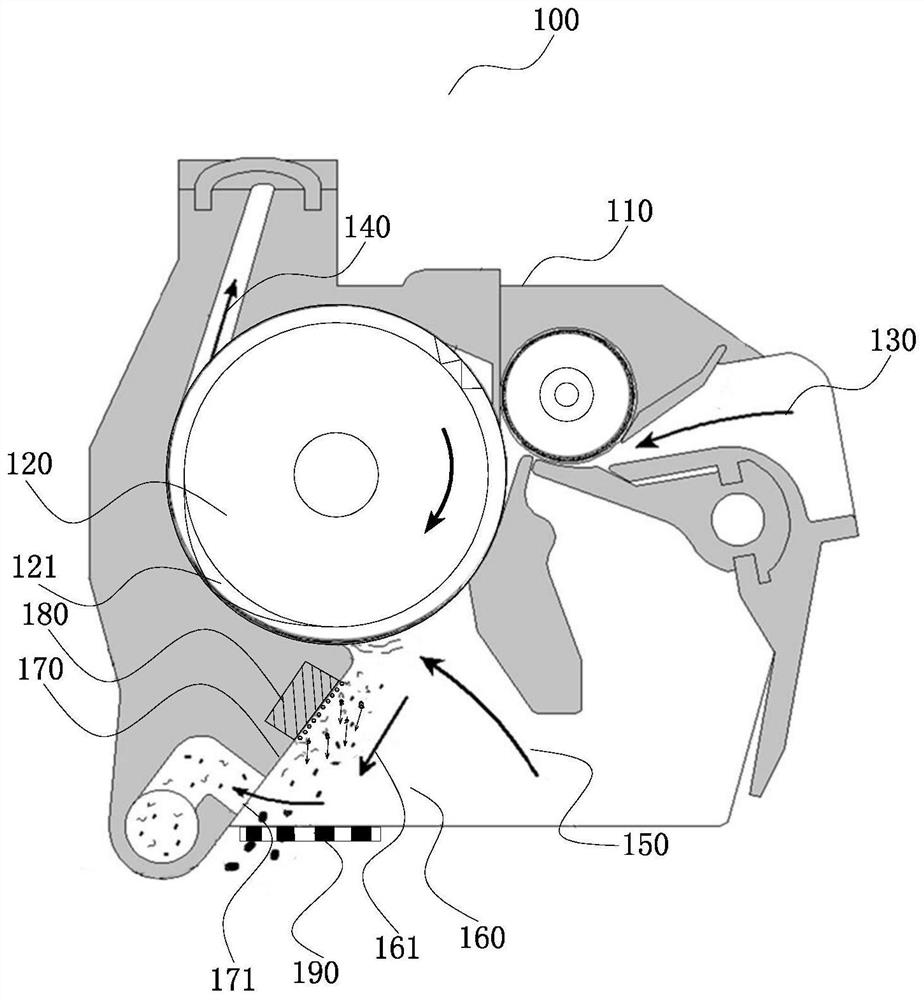

Intelligent spinning device and system of rotor spinning machine

ActiveCN114687015ARealize artificial intelligence sortingTaking into account the effect of decontaminationTextile disintegration and recoveryContinuous wound-up machinesSpinningPhysics

The invention provides an intelligent spinning device and system of a rotor spinning machine, and relates to the technical field of intelligent spinning equipment. The intelligent spinning device comprises a cotton sliver feeding mechanism and an impurity discharging and carding mechanism. A charge release area and a traction area are arranged in an impurity removal area of a carding cavity, a charge adsorption instruction is triggered when cotton sliver impurities are detected to be light impurities through an impurity detector, so that the light impurities passing through the charge release area are electrified, the electrified impurities are pulled to move through the traction area, and the electrified impurities are sucked away by an impurity suction opening when passing through the impurity suction opening; the sliver feeding mechanism comprises a sliver guide device and a feeding roller, a sliver self-transmission mechanism is arranged corresponding to the sliver feeding mechanism, and the sliver self-transmission mechanism comprises an outer circulation traction structure which is connected with an inner circulation traction structure of the can conveying mechanism to form a closed-loop sliver conveying structure so as to convey slivers on the cans into a channel of the sliver guide device. Intelligent impurity removal based on the cotton sliver impurity type is achieved, and meanwhile automation, continuity and intelligence of spinning equipment are improved.

Owner:苏州多道自动化科技有限公司

An electrolysis system based on a fully sealed selective powder electrolysis device

ActiveCN104357881BWide adaptability of raw materialsSpiritual diversityElectrodesCurrent distributionEngineering

The present invention relates to an electrolysis system based on a fully sealed selective powder electrolysis device, which includes a fully sealed selective powder electrolysis device (A) and an auxiliary device, wherein the auxiliary device includes a catholyte storage tank (B), Solution delivery pump (C), solution circulation tank (D), solution circulation pump (E), silicon rectifier DC power supply (I), compressed air tank (K) and waste gas collection tank (L). The electrolysis system can effectively improve the traditional flat (frame) electrolysis device in the electrolysis process of low electrolytic current density, uneven current distribution, difficulty in removing impurities from the solution, long process flow, high production cost, poor collection of products, and overall Low efficiency and other problems can be electrolyzed under complex solution components, and it is efficient, reliable, simple in process flow, easy to operate, and low in cost.

Owner:江苏万途思睿环境科技有限公司

Ignition device for biomass gasification furnace and using method thereof

InactiveCN101726002BPromote combustionImprove ignition success rateIncandescent ignitionCombustible gas productionElectricityEngineering

Owner:JIANGSU UNIV +1

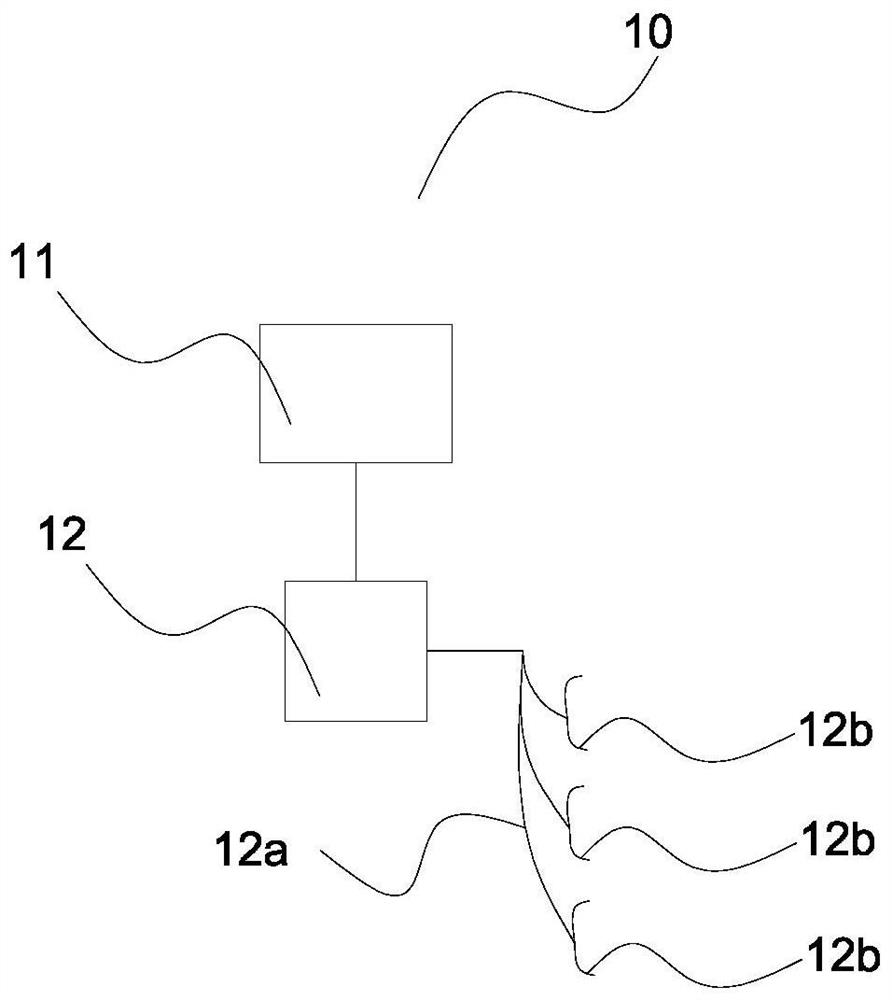

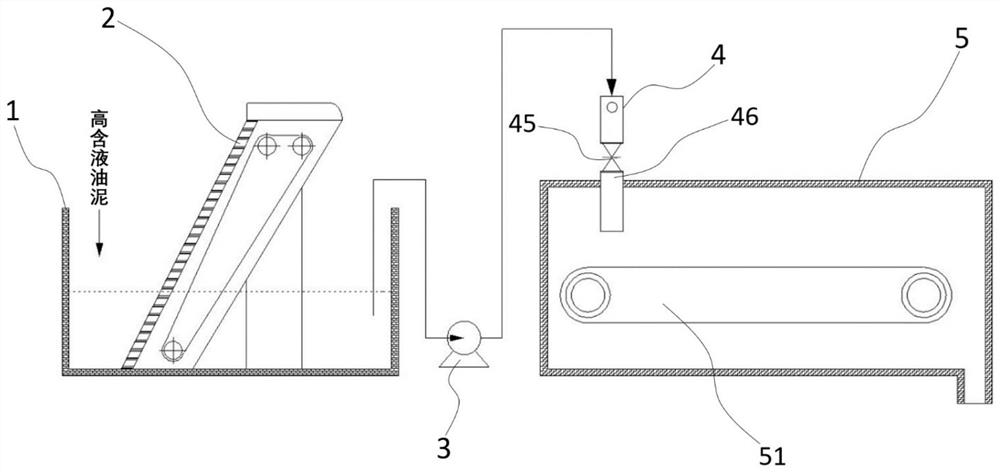

High-liquid-content oil sludge distributed feeding pyrolysis device

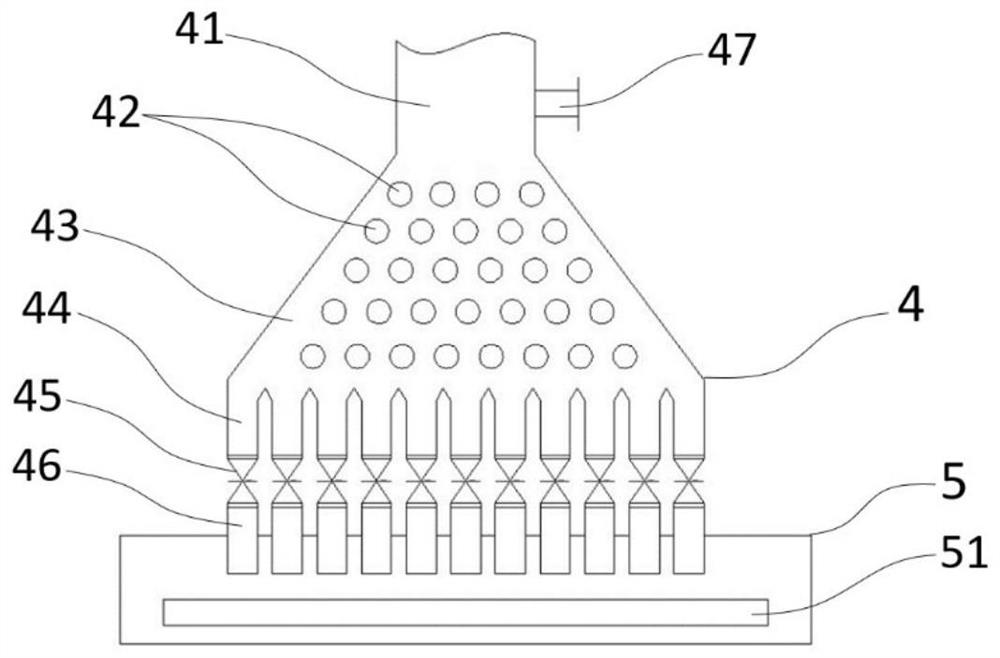

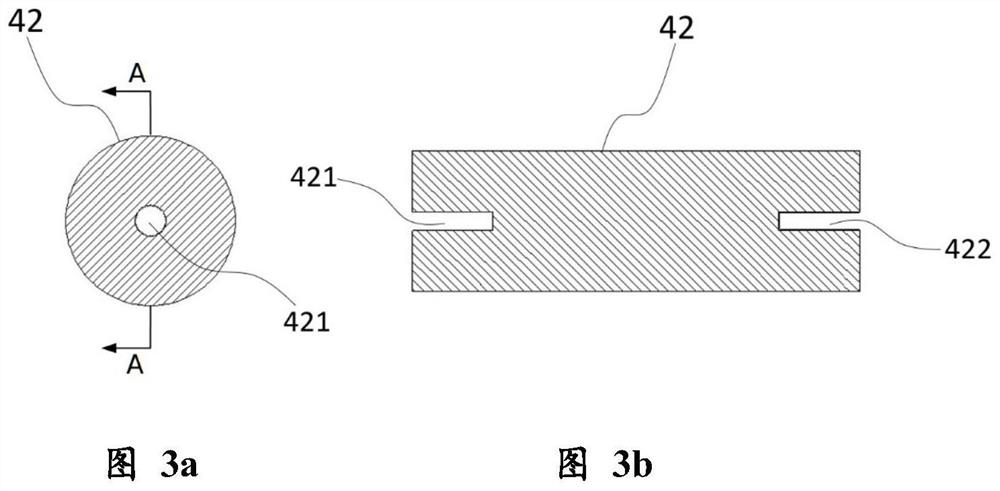

ActiveCN112830654ASimple structureEasy to operateWaste water treatment from quariesSludge treatment by pyrolysisProcess engineeringOil sludge

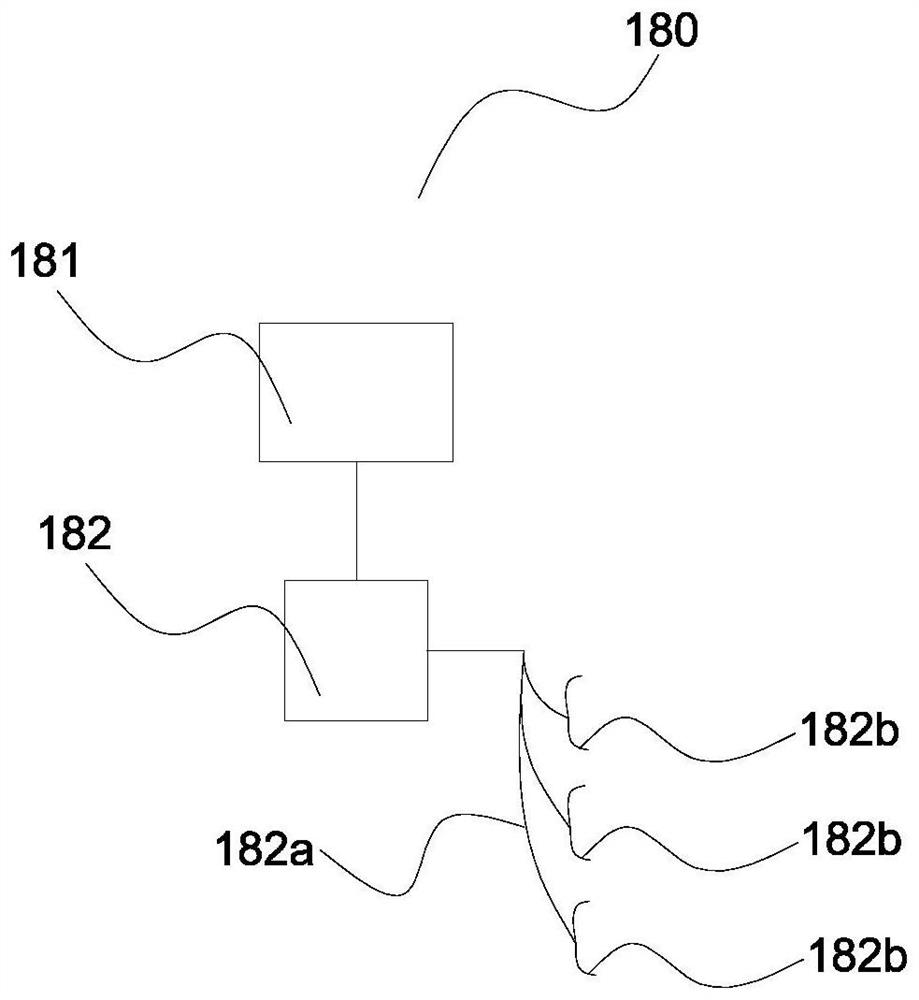

The embodiment of the invention provides a high-liquid-content oil sludge distributed feeding pyrolysis device. The high-liquid-content oil sludge distributed feeding pyrolysis device comprises an oil sludge storage tank, a grating, an oil pump, a distributed feeding device and a chain plate type pyrolysis device, wherein the distributed feeding device comprises an oil sludge main pipe, a distributed material distributor, a material distribution chamber, an oil sludge branch pipe, an electromagnetic valve, an oil sludge discharge pipe and a purging opening. When the device runs, oil sludge is fed into the oil sludge storage tank from the outside, large impurities are filtered out through the grating, the filtered high-liquid-content oil sludge is conveyed to the oil sludge main pipe through the oil pump, enters the material distribution chamber, is uniformly distributed under the action of the distributed material distributors and enters the oil sludge branch pipes, and by controlling the opening and closing states of the electromagnetic valves, the distribution form of the oil sludge entering the chain plate type pyrolysis device is controlled. The high-liquid-content oil sludge distributed feeding pyrolysis device is exquisite in design and easy to operate, uniform feeding of the high-liquid-content oil sludge in pyrolysis can be achieved, the pyrolysis efficiency is effectively improved, and wide raw material adaptability can be achieved by adjusting the distribution structure of the distributed feeder.

Owner:北京博霖环境科技有限公司

Method for extracting nickel with pressure leaching of non-metal high nickel sulfonium material

ActiveCN101195858BDoes not cause enrichmentWide adaptability of raw materialsProcess efficiency improvementSulfate radicalsSlag

The invention relates to a nickel extracting method through the pressurized leaching of non metallization high content nickel matte material. The invention is characterized in that the two-stage atmospheric pressure leaching process and the two-stage pressurized leaching process are adopted to extract nickel through the pressurized leaching of the non metallization high content nickel matte material. By adopting the method of the invention, the leaching rate of nickel and cobalt is larger than 98 percent, the noble metal is completely concentrated in leached slag, the sulfur of the high content nickel matte is oxidized into sulfate radical to enter the solution, the pour solution of nickel sulphate and cobalt sulphate is obtained after the one stage pressurized leaching solution is processed through the one stage atmospheric pressure leaching and purifying. Copper is mainly delivered into the two-stage pressurized leaching solution. Iron and noble metal are concentrated in the two-stage pressurized leached slag. The process has the advantages that the process is simple, highly efficient and environment friendly, and the adaptability of the raw material is wide. The invention is suitable for the treatment of albata alloy, and through adjusting the relative technical parameter, the invention is suitable for selectively leaching and segregating nickel, copper and noble metal fromnon metallization high content nickel matte with various grades.

Owner:JINCHUAN GROUP LIMITED

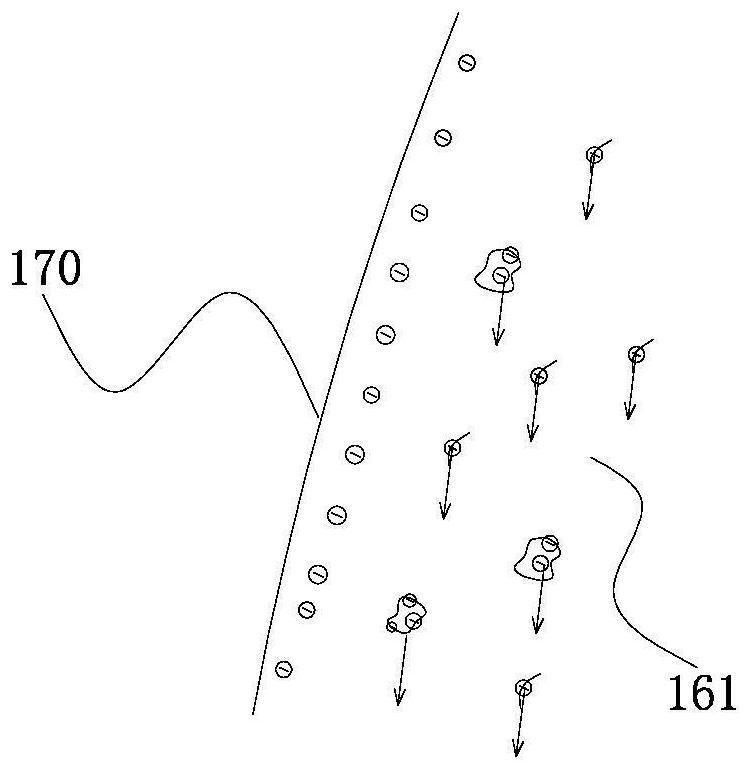

Rotor spinning machine double-impurity-discharging carding device combined with charge balance and application

ActiveCN113652783AReduce or eliminate rollbackHigh yarn yieldTextile disintegration and recoveryContinuous wound-up machinesFiberEngineering

The invention provides a rotor spinning machine double-impurity-discharging carding device combined with charge balance and application, and relates to the technical field of spinning equipment. The double-impurity-discharging carding device comprises an air supplementing channel and a carding cavity impurity discharging area which are arranged corresponding to the lower portion of a carding cavity; an impurity stripping channel inclining downwards is formed in the lower portion of a carding roller through an impurity stripping surface; the impurity stripping channel comprises an effective fiber area, a coiling back suction area and a free impurity falling area; impurities in the coiling back suction area are discharged through an impurity suction opening in the impurity stripping surface; and a charge release area and a traction area are arranged corresponding to the coiling back suction area; the charge release area enables impurities in the coiling back suction area to be electrified by releasing net charge substances, the traction area adsorbs the electrified impurities to move towards the traction area, and the electrified impurities are sucked and discharged when passing through an impurity suction port. Free impurity falling and precise impurity absorption are organically combined, the charge release area and the traction area are used for assisting precise impurity absorption, and the device has the advantages of being wide in raw material adaptability, good in yarn forming quality consistency and low in energy consumption.

Owner:苏州多道自动化科技有限公司

Multi radiation reqion pyrolyzer and its use

InactiveCN1219024CIncrease production capacityWide adaptability of raw materialsThermal non-catalytic crackingPetroleumCracking reaction

A cracking furnace for the crack reaction of petroleum hydrocarbon features that its radiating segment includes n radiating regions isolated by furnace walls, which use a common convection segment, and the bottom burners are uniformly arranged at both sides of furnace wall. Its advantages are uniform heating, high heat transfer efficiency, and high productivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and catalyst for producing biological diesel oil by high-acid value grease

InactiveCN100526427CHigh yieldIncrease production speedFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsOil and greaseBiodiesel

A composite catalyst for biological diesel-oil by high-acidity grease is carried out by mixing methyl sulfonic acid with tin tetrachloride and concentrated sulfuric acid in proportion of 1:1:1, and esterification reacting by composite catalyst 2.5-3% at 58-63 degree for 3.5-4 hrs to convert waste grease into biological diesel-oil. It's fast, has gentle reactive condition, higher recovery rate and better quality.

Owner:青岛福瑞斯生物能源科技开发有限公司

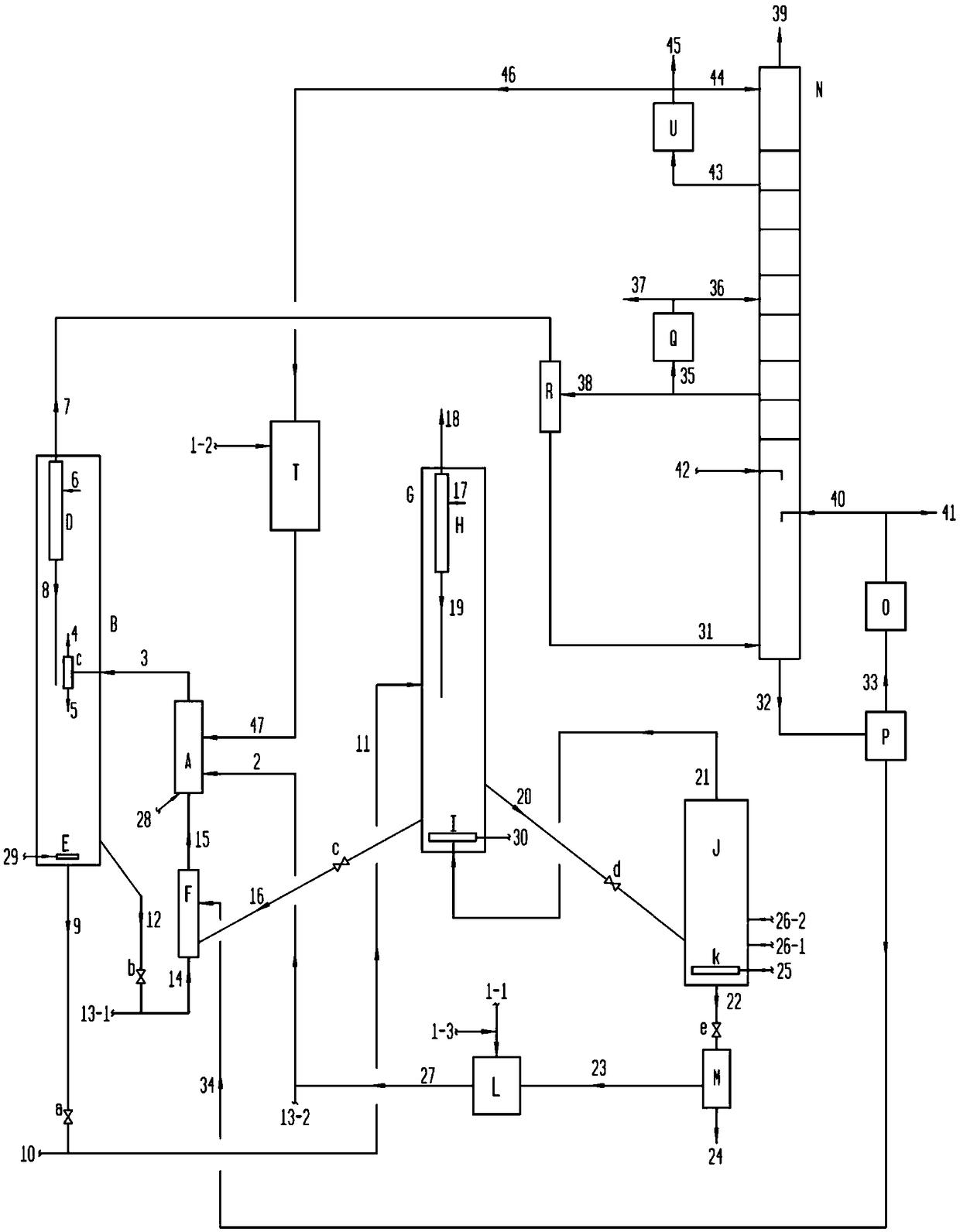

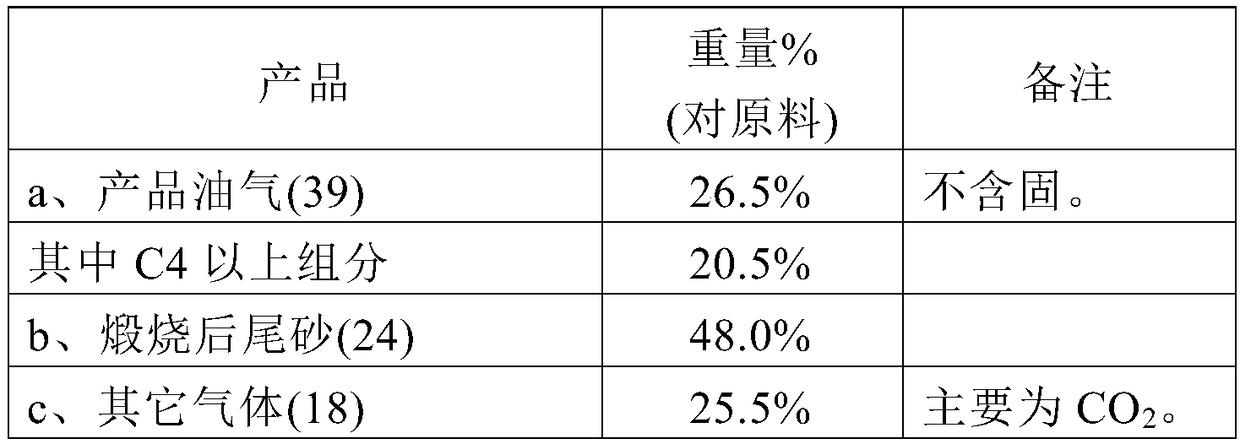

Method and device for comprehensively utilizing oil sand and oil sludge

PendingCN109385288ASolve the problem of high viscosity and difficult solid feedingRapid lysisLiquid hydrocarbon mixture productionSpecial form destructive distillationResource basedOil sludge

The invention discloses a method and a device for comprehensively utilizing oil sand and oil sludge. Specifically, the processing device comprises crushing equipment (L), premixing equipment (T), a dry distillation reactor (A), a prereactor (F), a settler (B), a heater (G), a calciner (J), a heat collector (M), a quenching device (R), a scrubber (N), a liquid-solid separator (P), a heavy oil heatexchanger (O), a middle extraction oil heat exchanger (Q) and an upper extraction oil heat exchanger (U), and the specific connection details are shown in the description. The processing method has the advantages of wide raw material adaptability, good product quality, good energy utilization, environmental friendliness and the like by clean and efficient processing on the oil sand and the oil sludge and harmless and recycling treatment on tailings, and an efficient, clean, resource-based and harmless processing line is provided for treatment of the oil sand and the oil sludge.

Owner:上海博申工程技术有限公司

A method for producing functional oil rich in phytosterol esters by utilizing high acid value vegetable oil

ActiveCN104178531BRealize the processing effectIncrease profitFermentationOil and greaseVegetable oil

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com