Patents

Literature

2982results about "Drafting machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

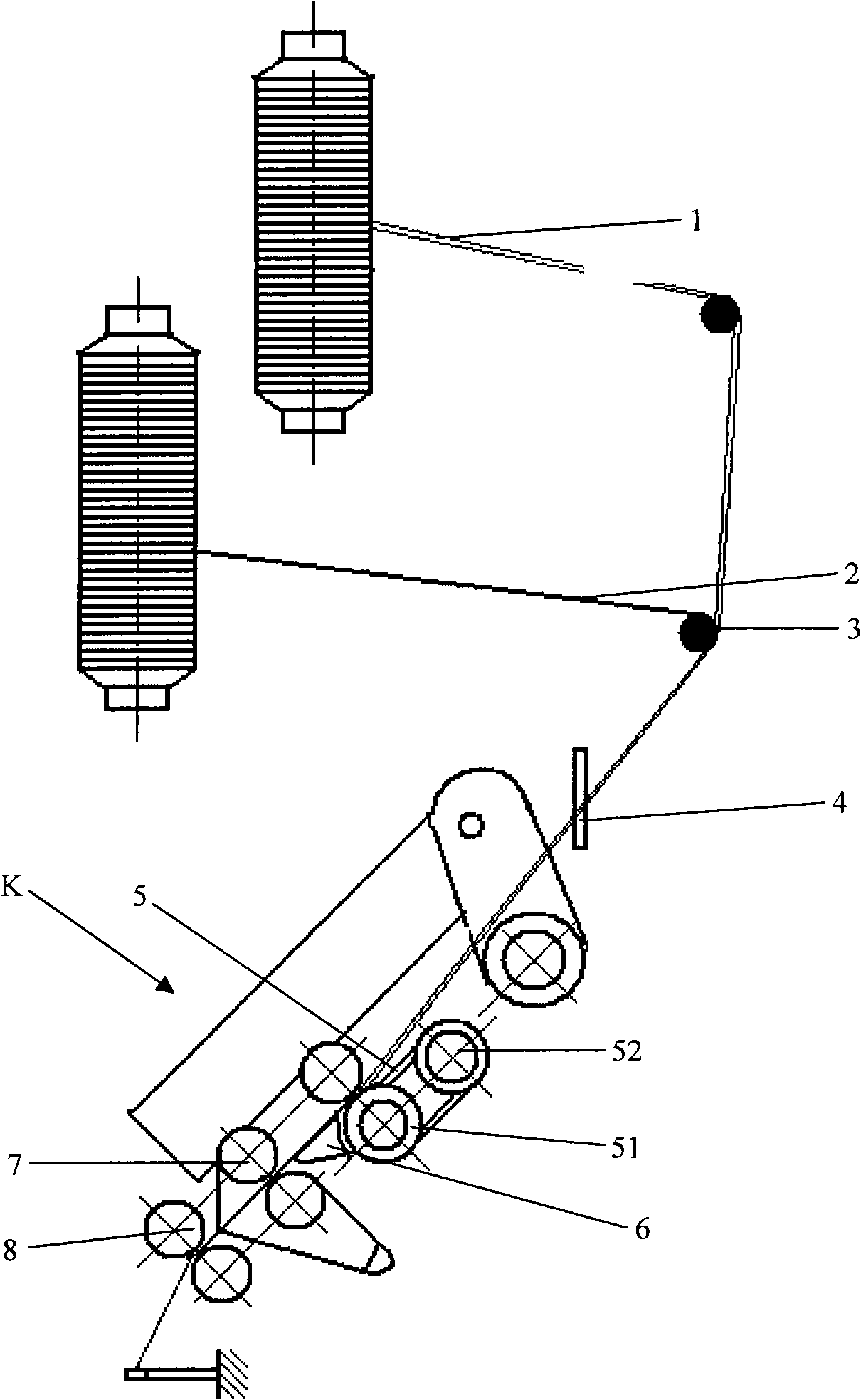

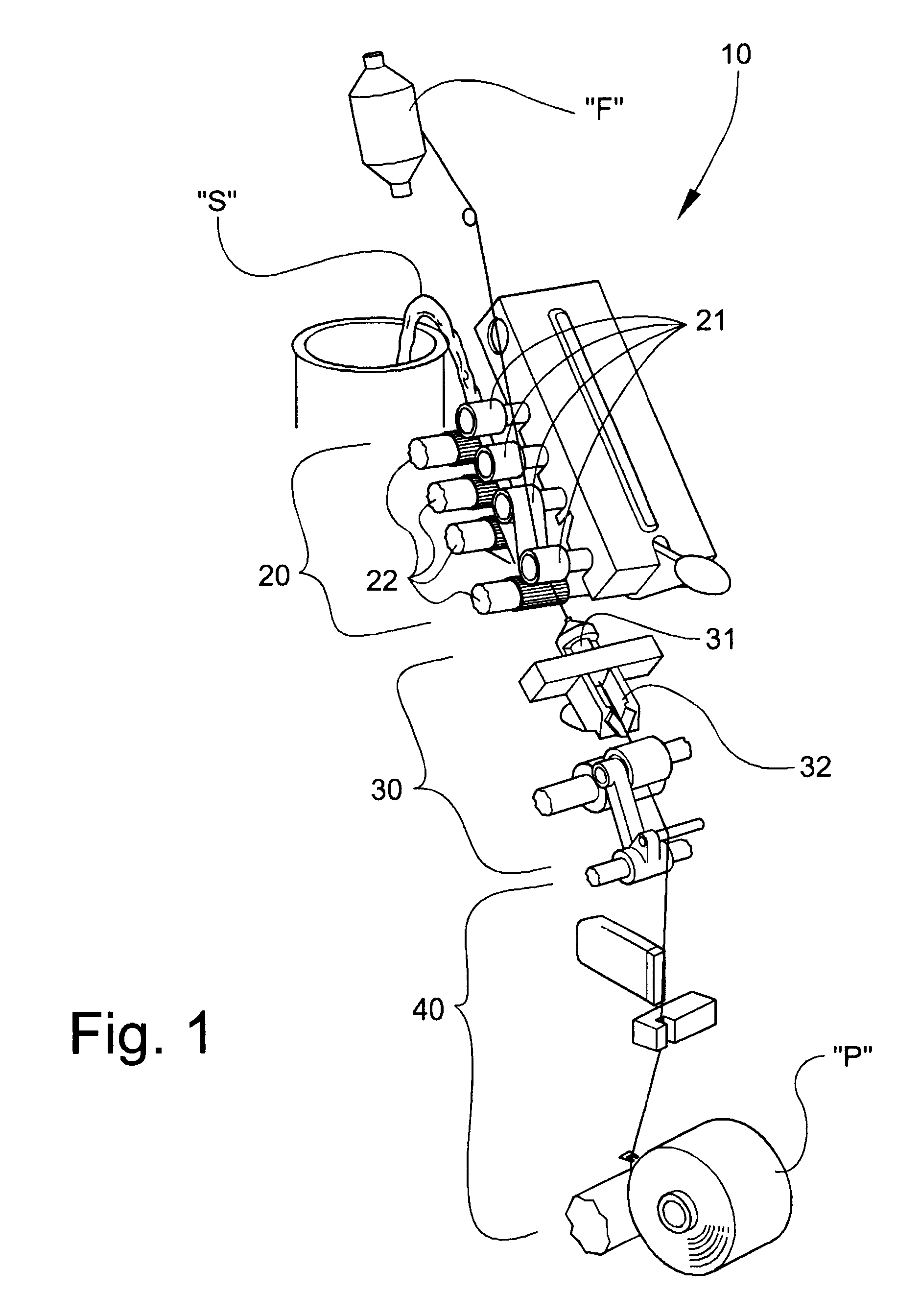

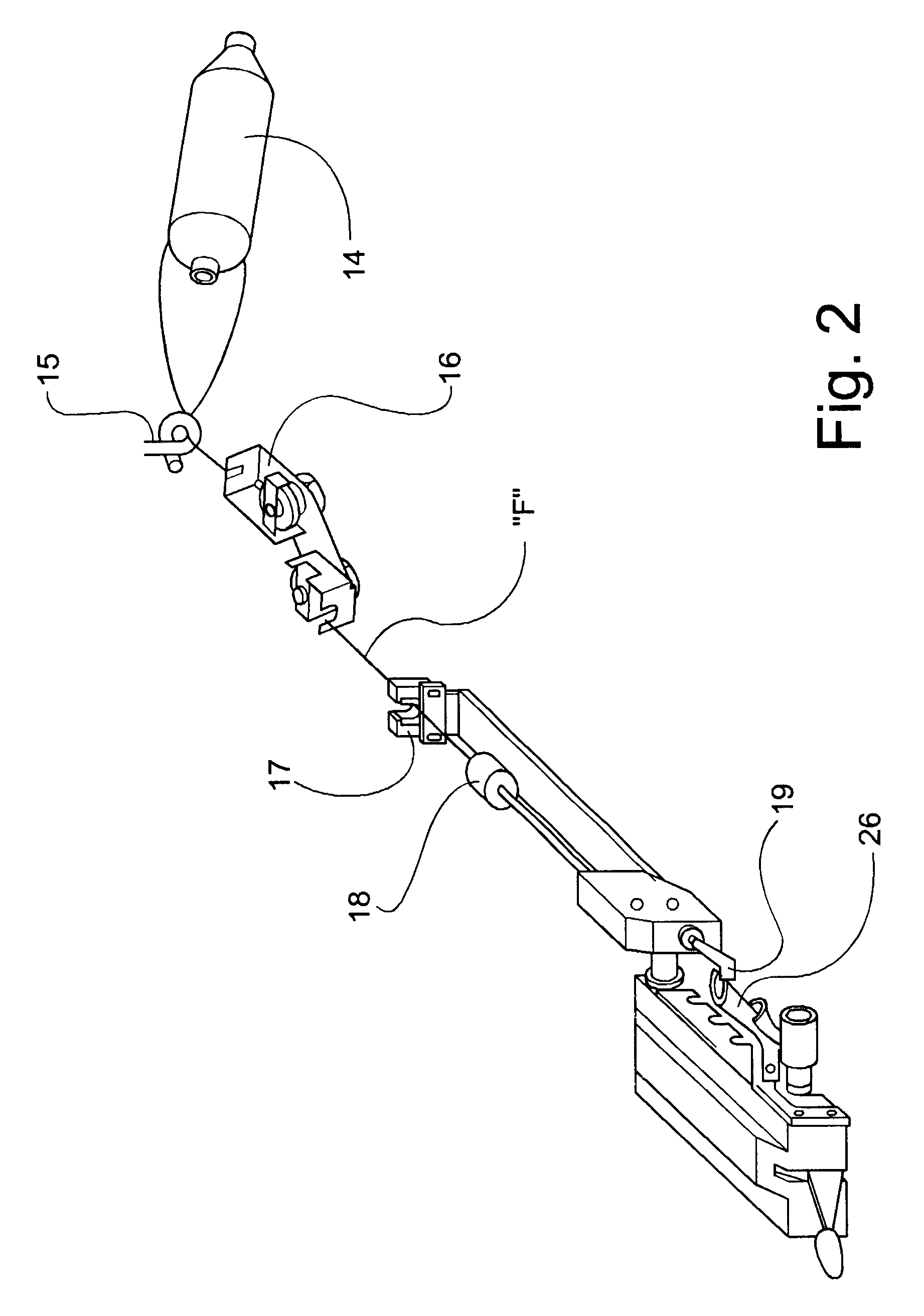

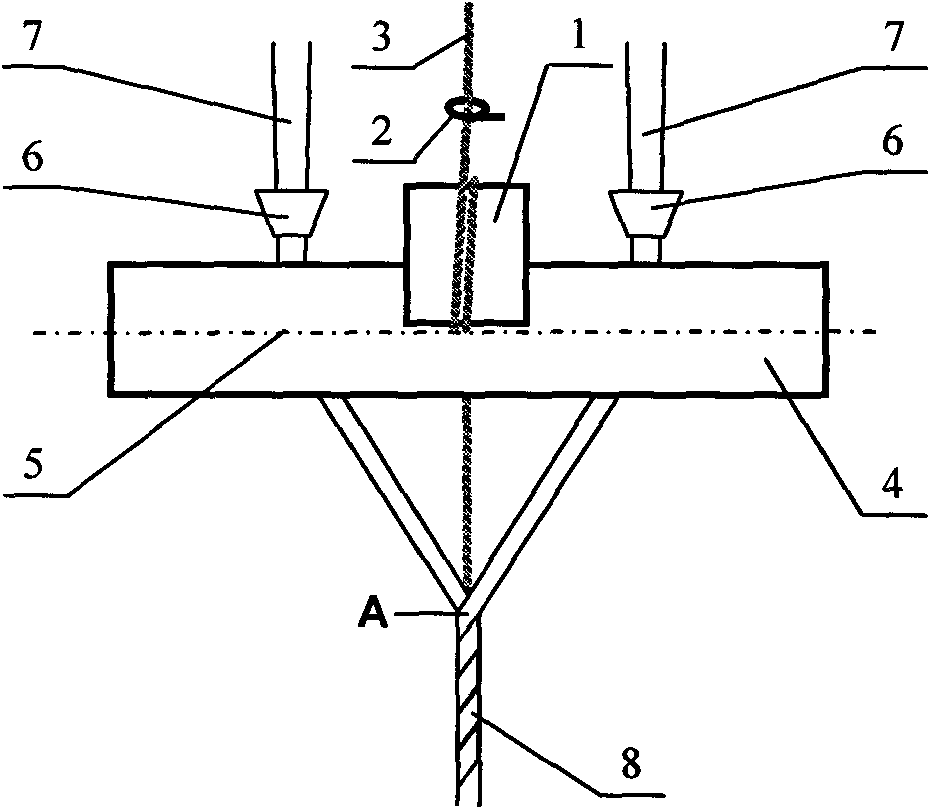

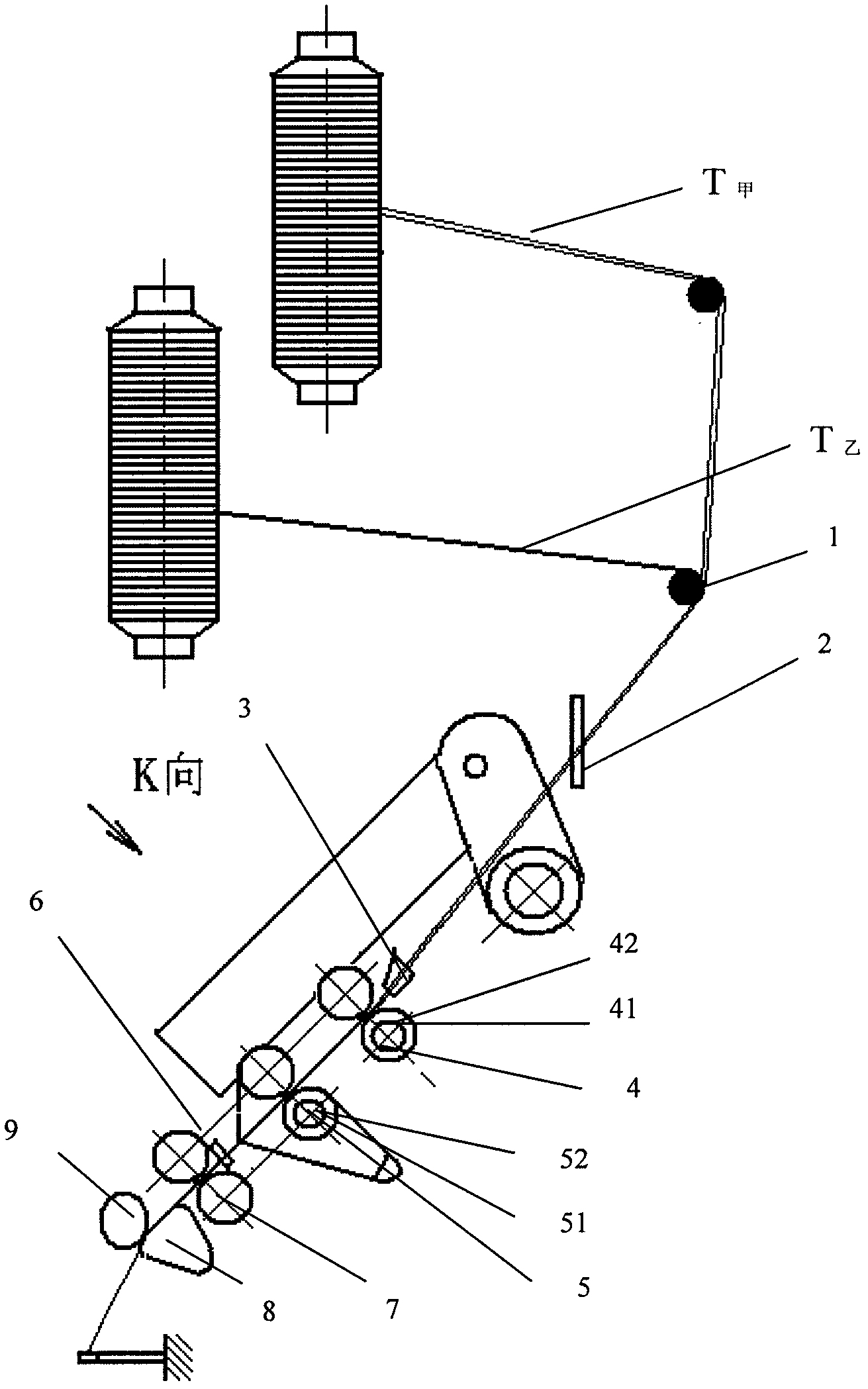

Positioning spinning method of embedded system

InactiveCN101492843ACompact structurePlay a reinforcing roleDrafting machinesContinuous wound-up machinesYarnFiber

Owner:WUHAN TEXTILE UNIV +2

Method and apparatus for making core-spun yarn of steple-fibre covered filament

The present invention is characterized by that on the spinning machine it utilizes addition of a yarn tension control device and simple renovation of guide wheel to spin the invented core-spun composition yarn whose yarn is covered with staple fiber, and its covering rate is high. Said composite core-covered yarn not only has the appearance style, hand property, fluffy property and other advantages of staple fibre, but also possesses the strength and elongation, conformal property and drapping property, etc. of yarn.

Owner:薛元

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

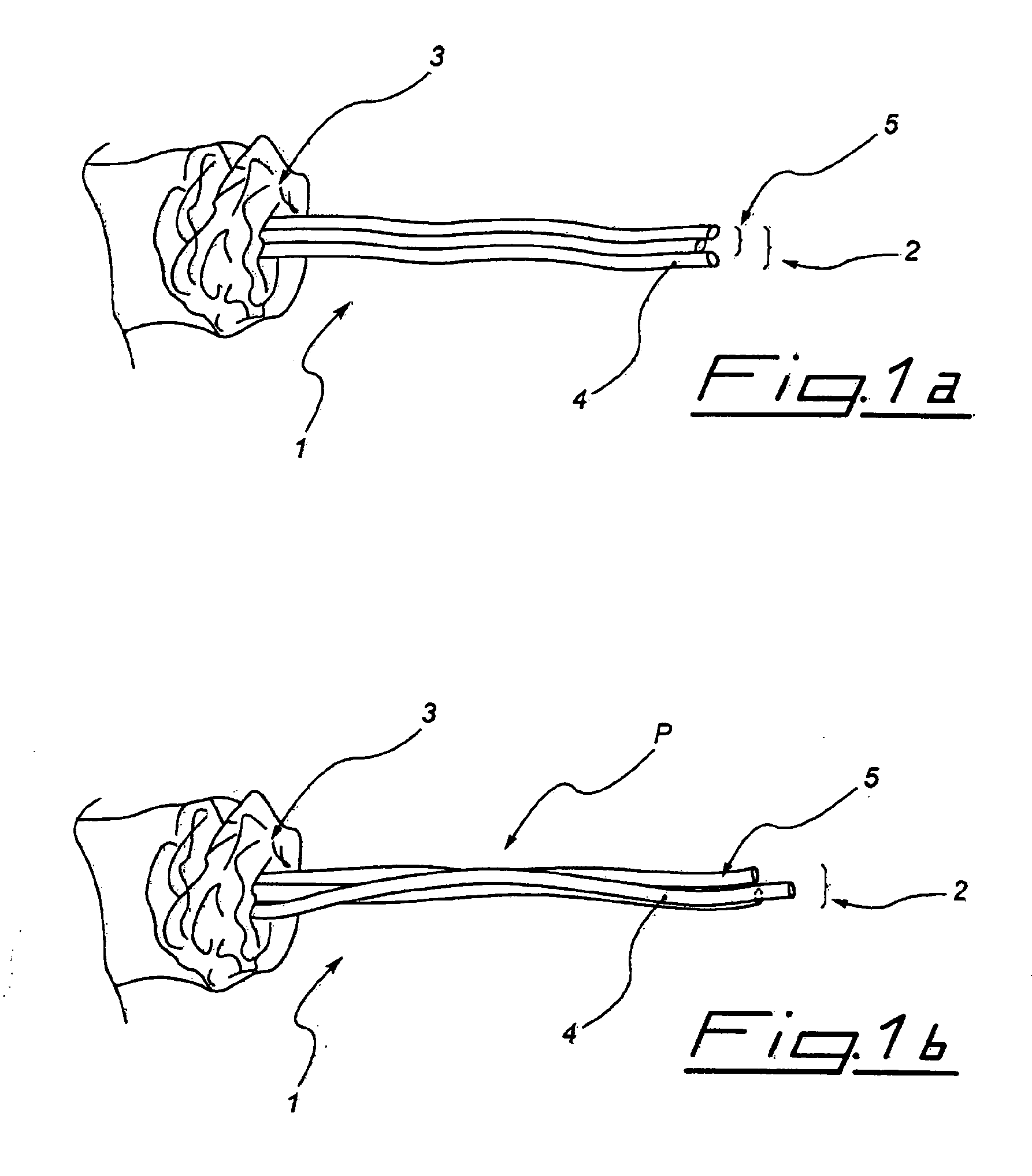

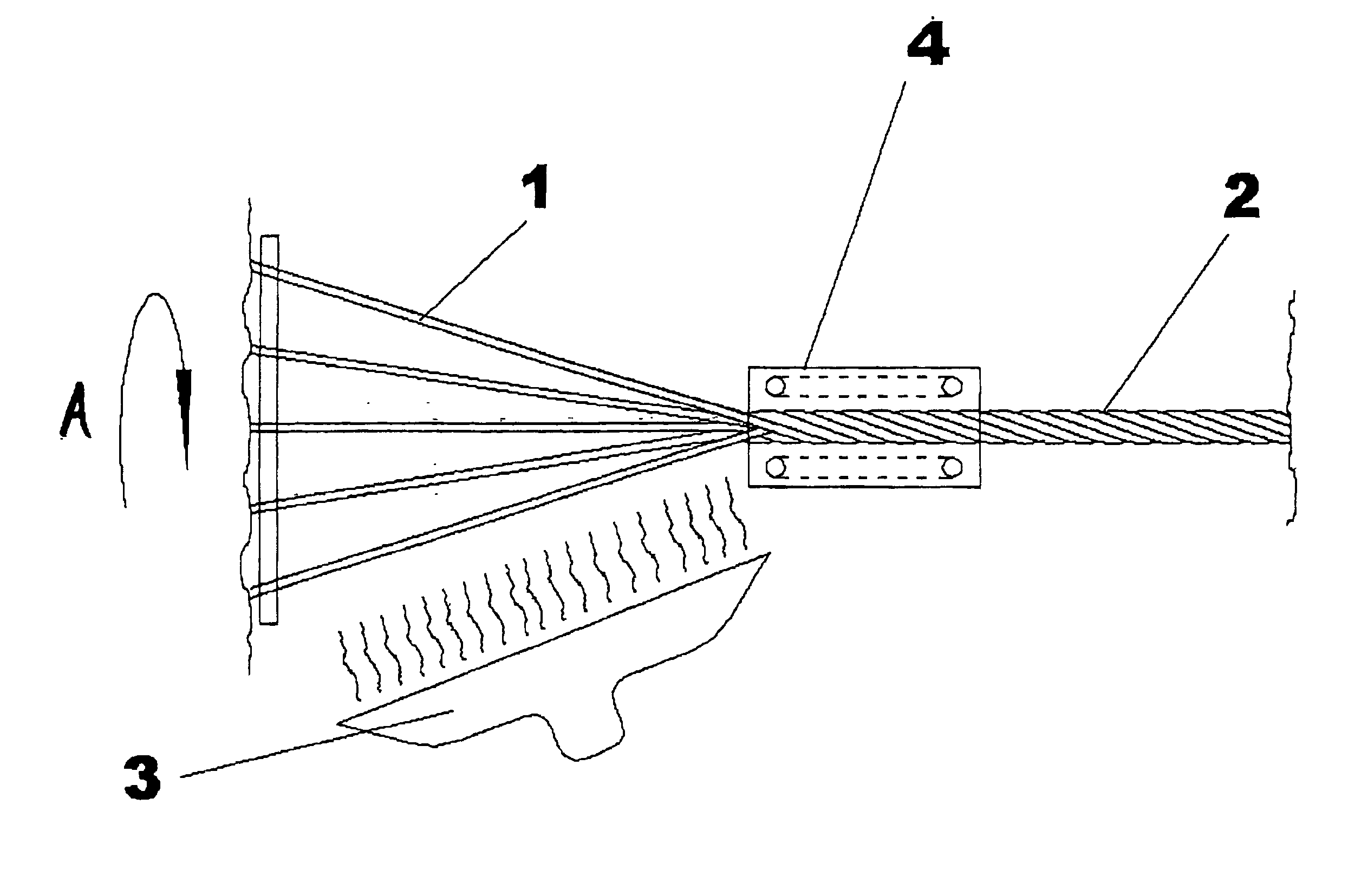

Composite stretch yarn, process and fabric

ActiveUS20130260129A1Increase elasticityGood stretch recoveryDrafting machinesAnimal housingElastomerYarn

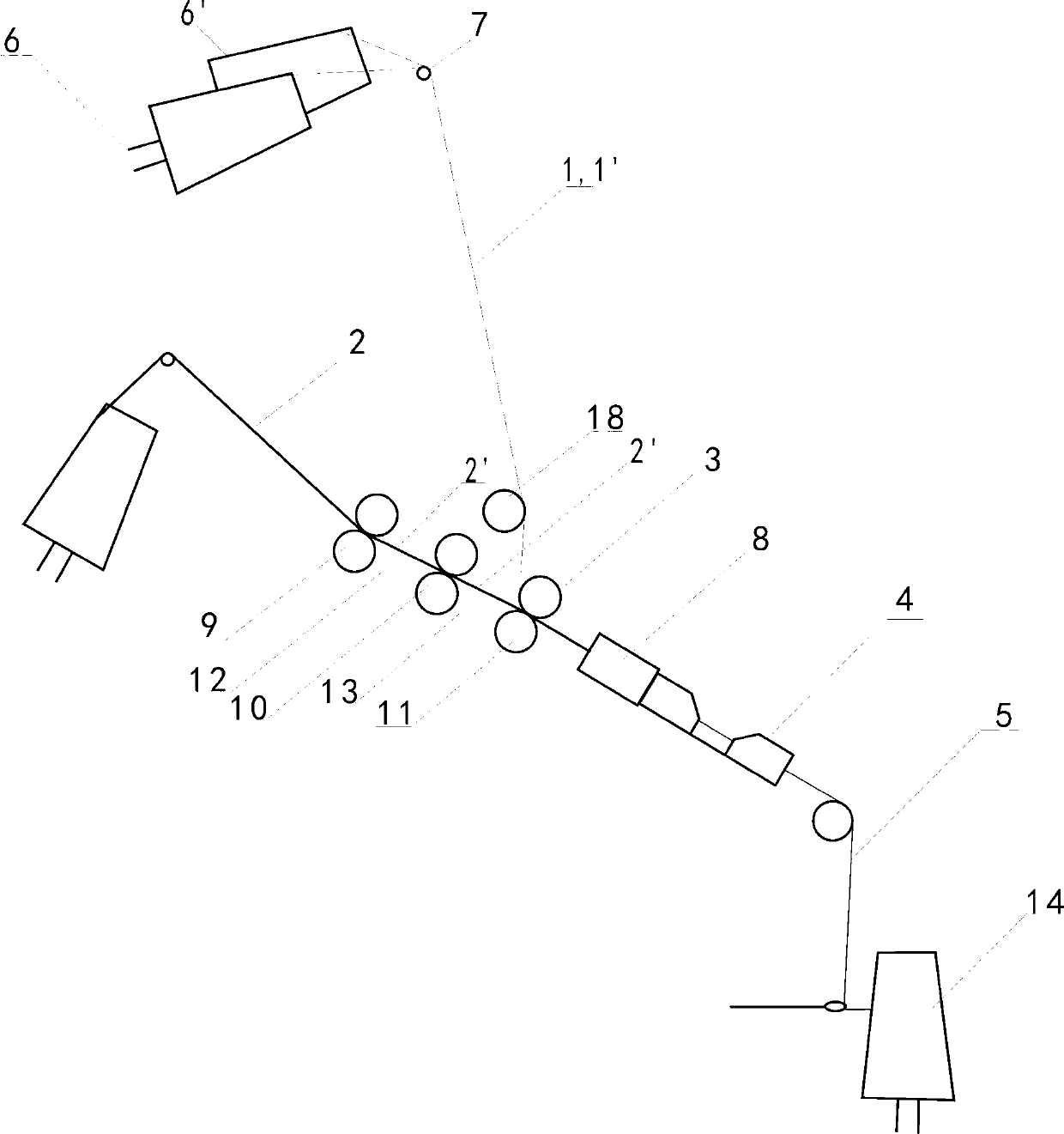

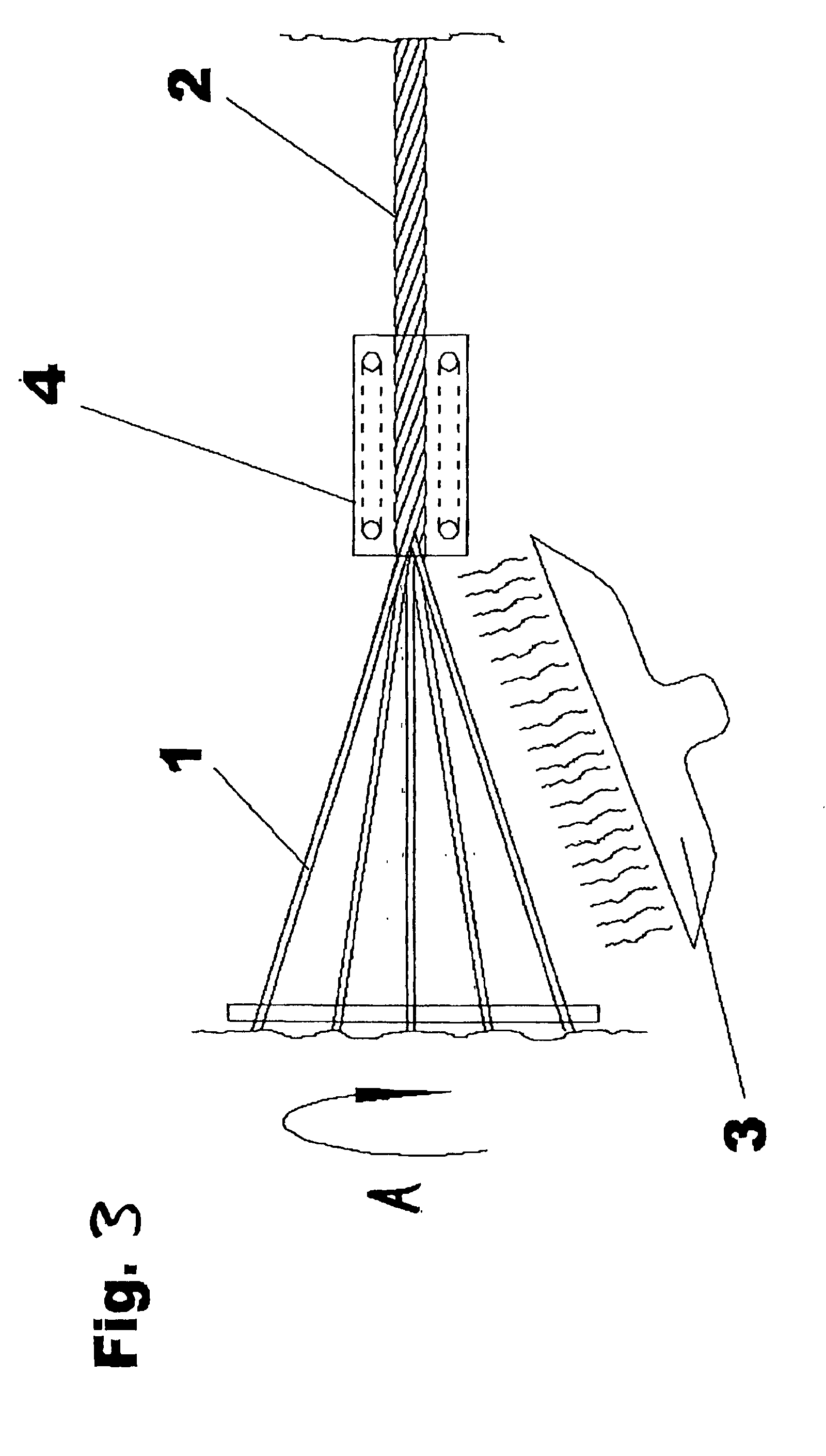

In a stretch yarn (1) comprising a stretchable core (2) covered by an inelastic fibers sheath (3) the stretchable core (2) comprises first and second fibers (4, 5) that have elastic properties, the first fiber (4) is an elastomer and the second fiber (5) is a polyester based (co)polymer, the amount of the second fiber being in the range of 60-90% (w / w) of the total weight of the fibers of the stretchable core (2); the first and second fibers are connected together at least at a plurality of points (P).

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

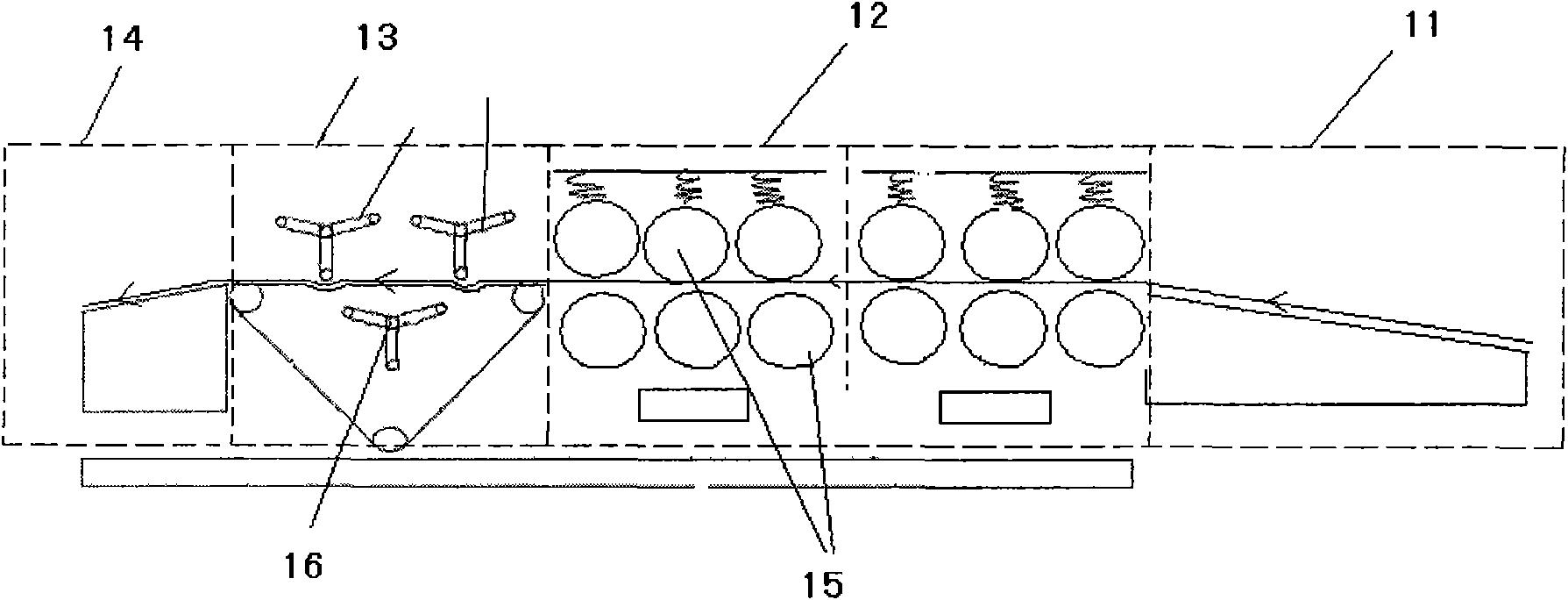

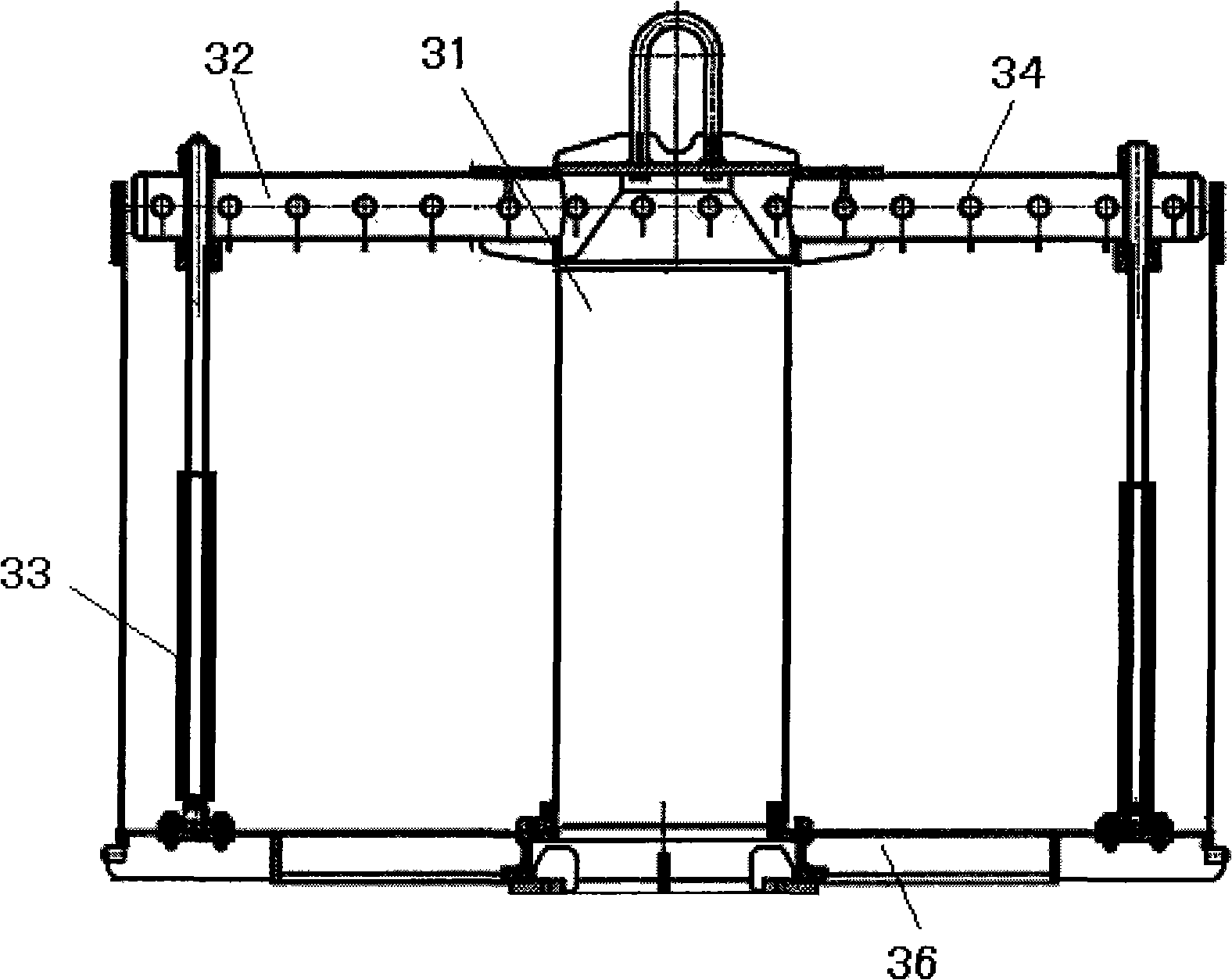

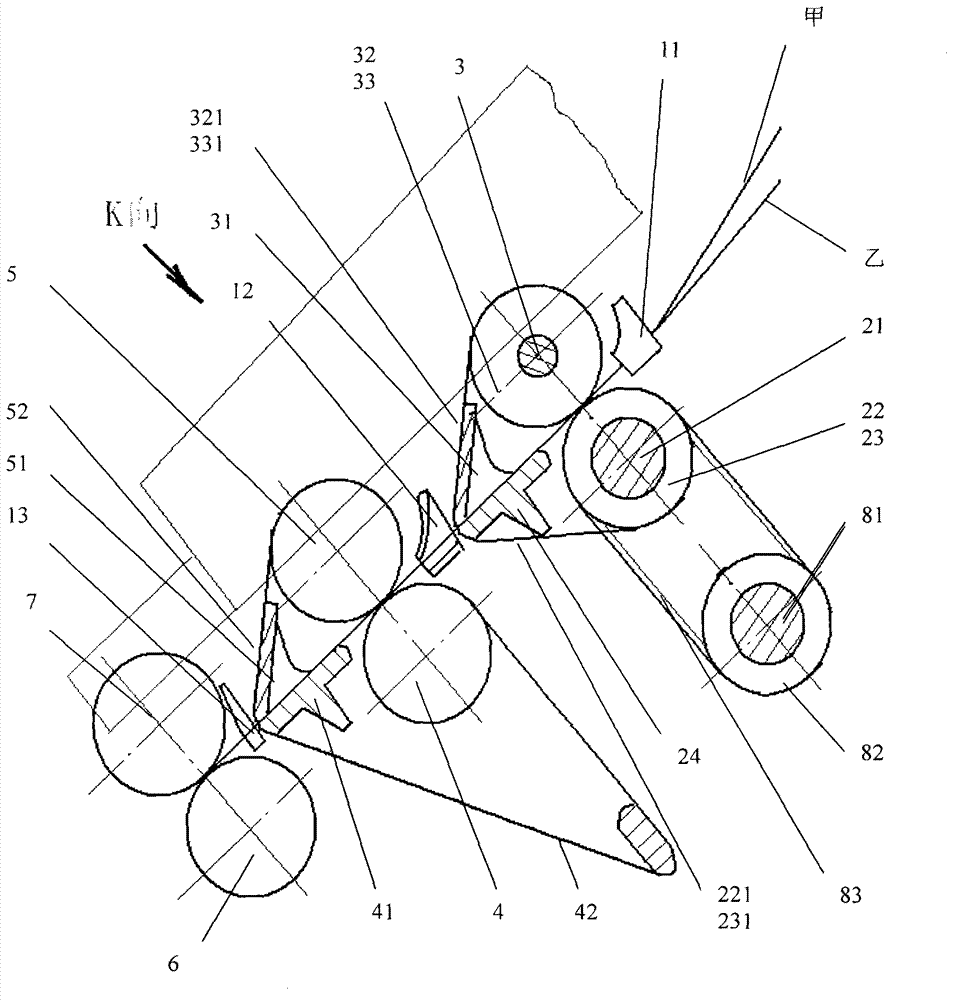

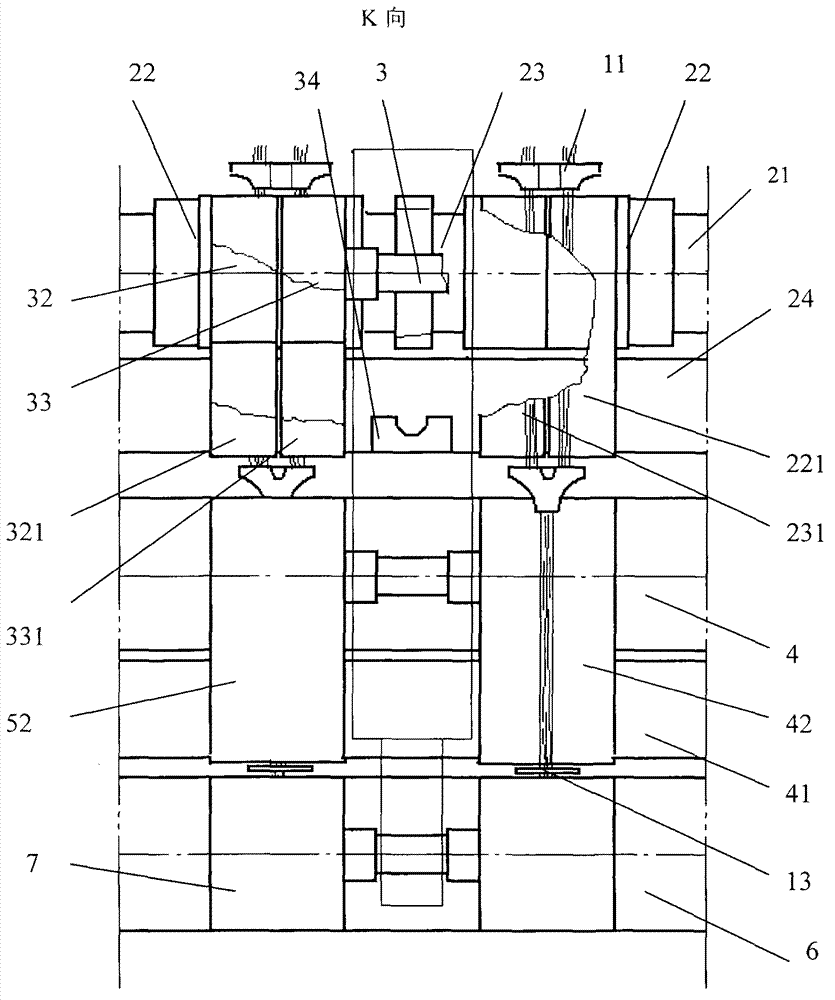

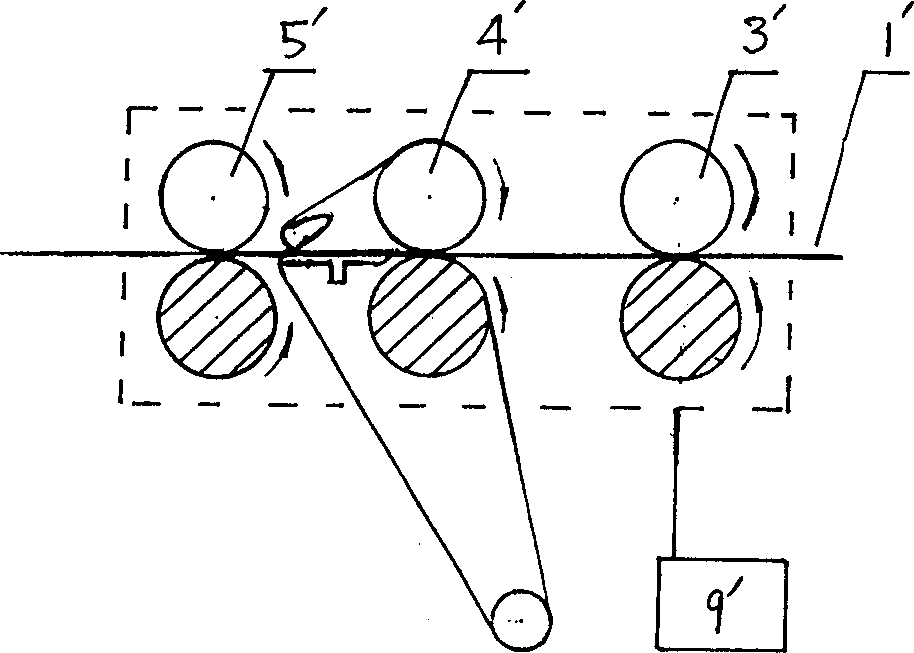

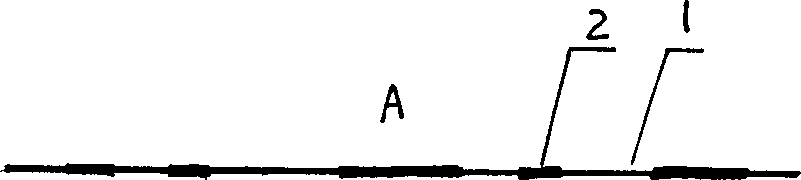

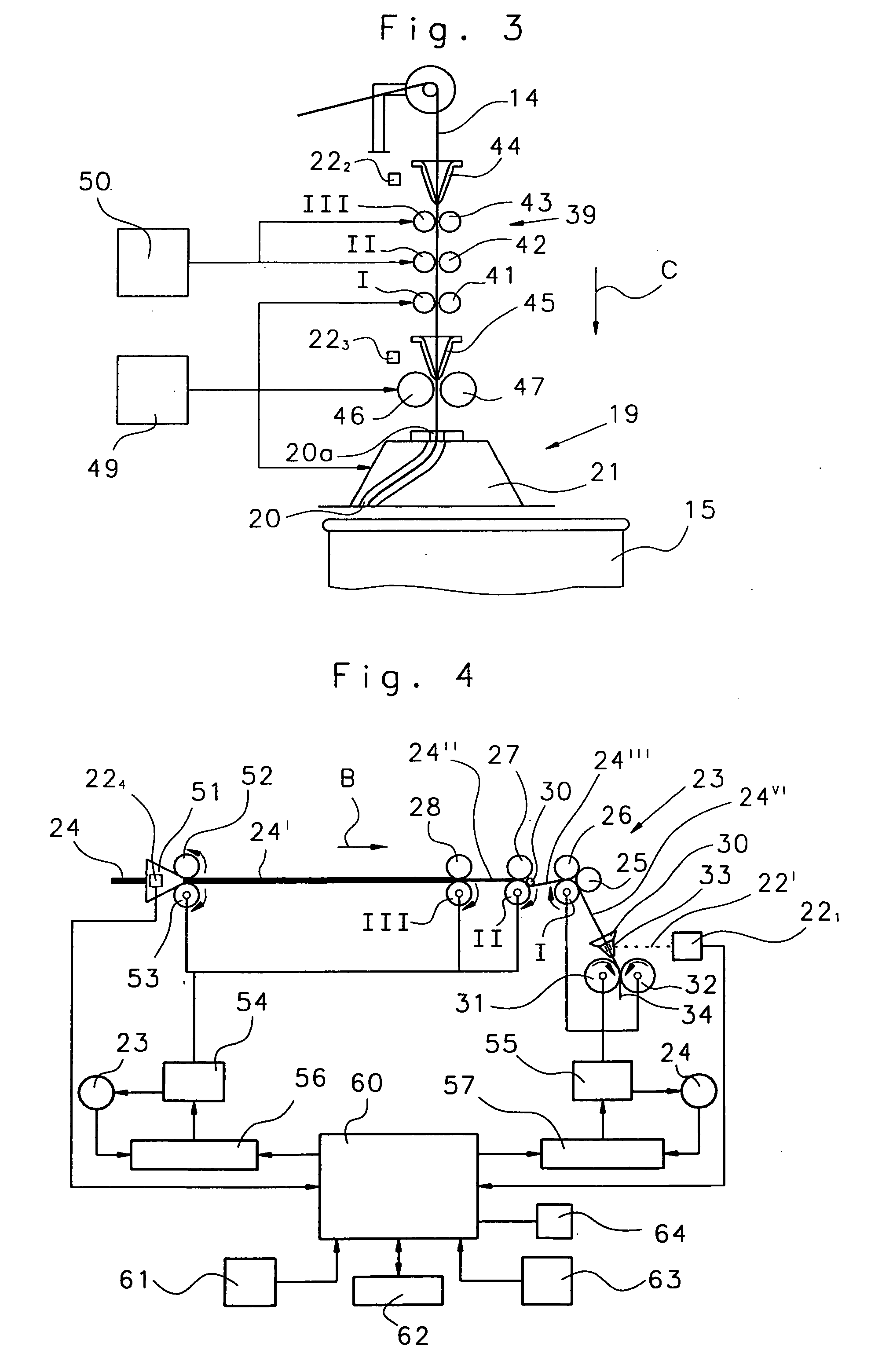

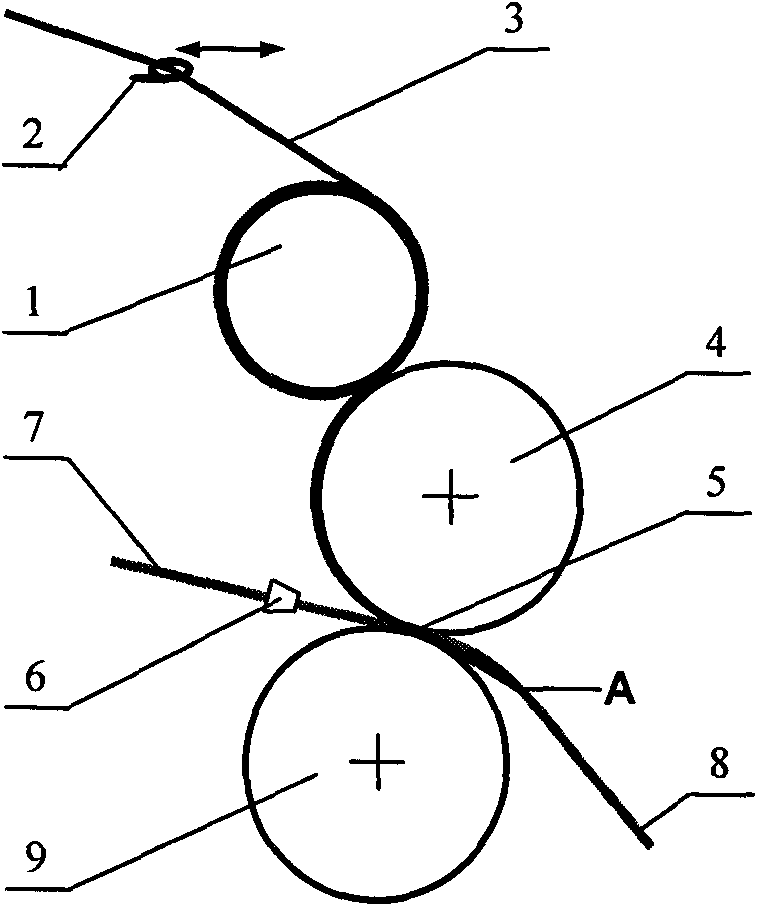

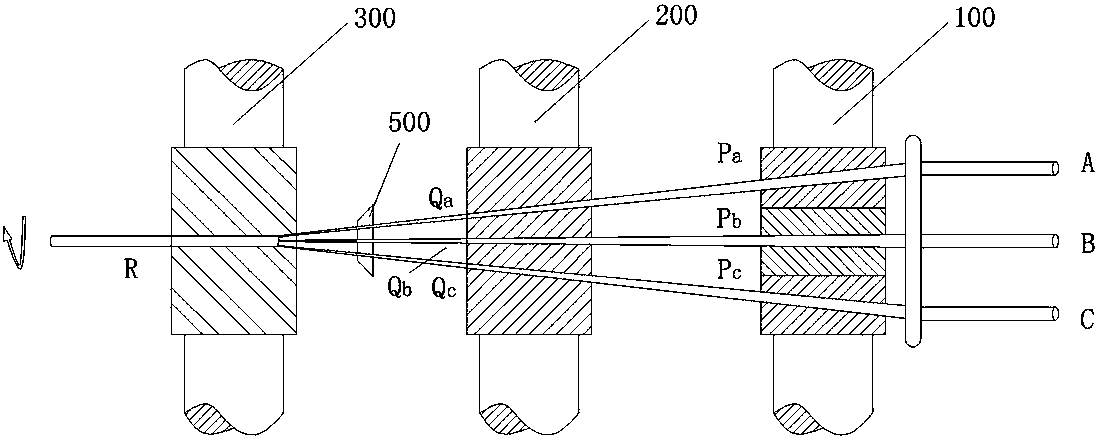

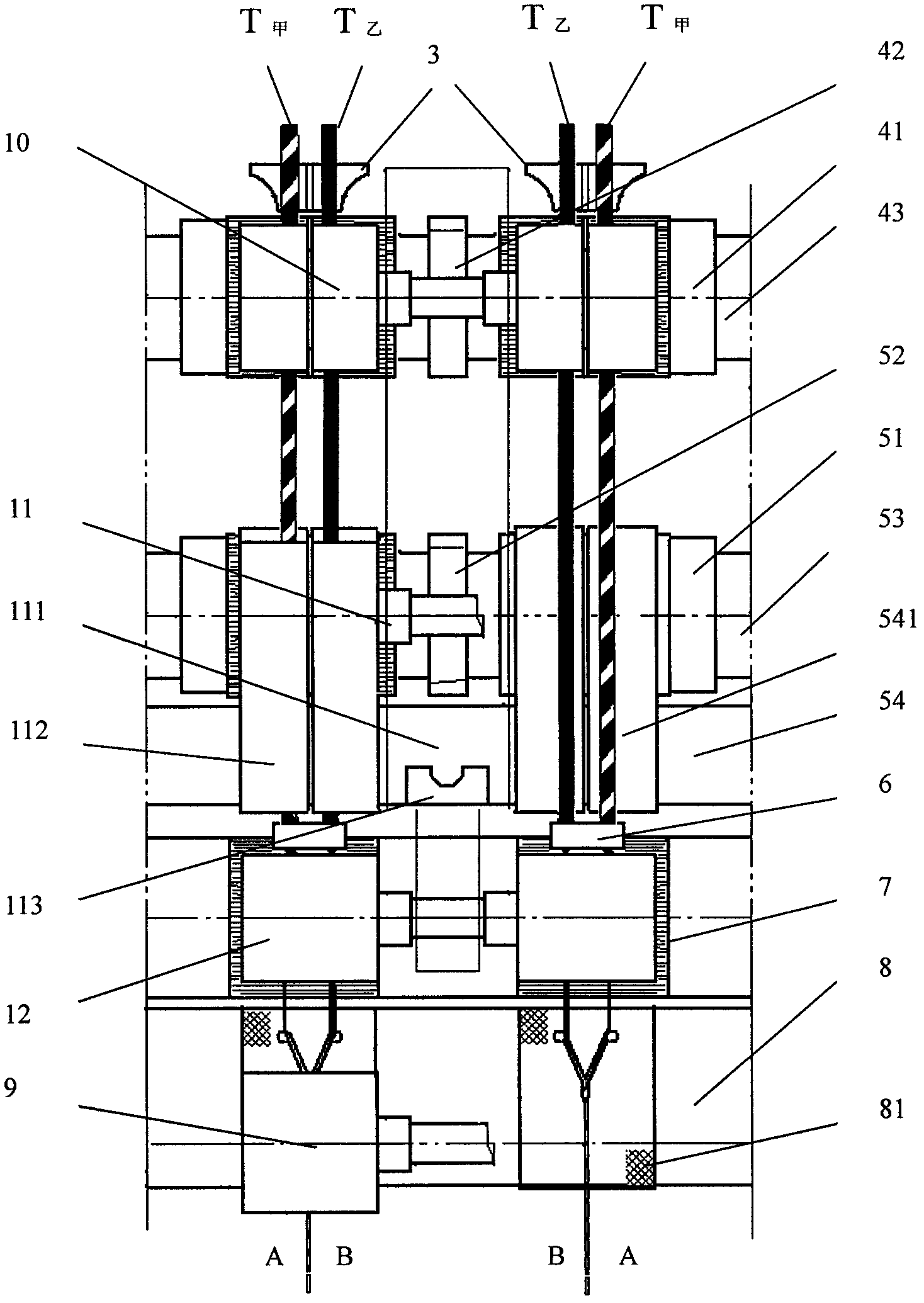

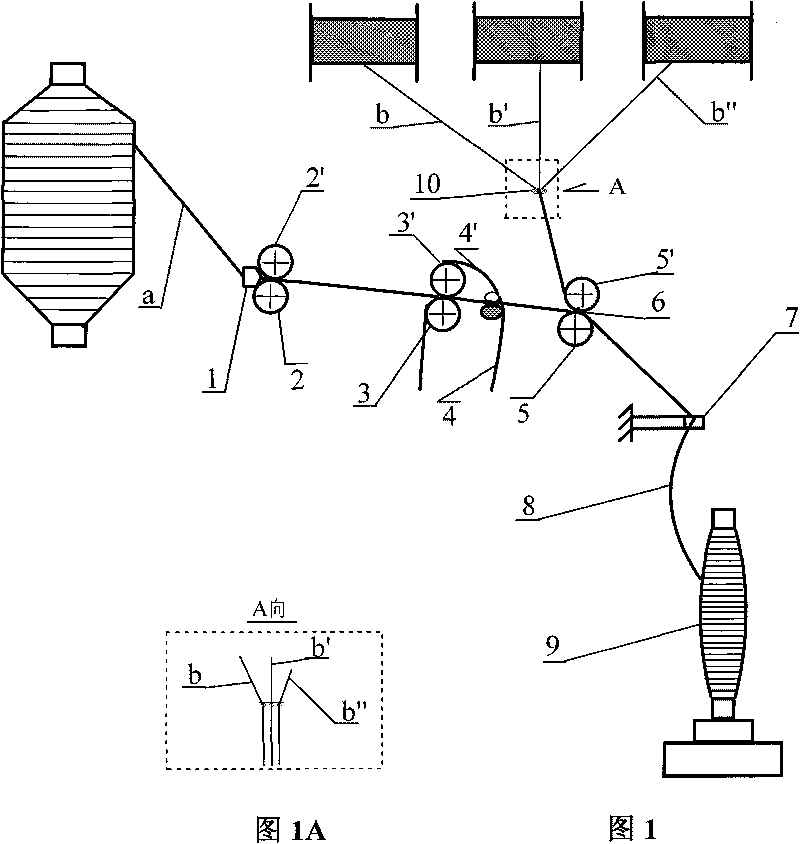

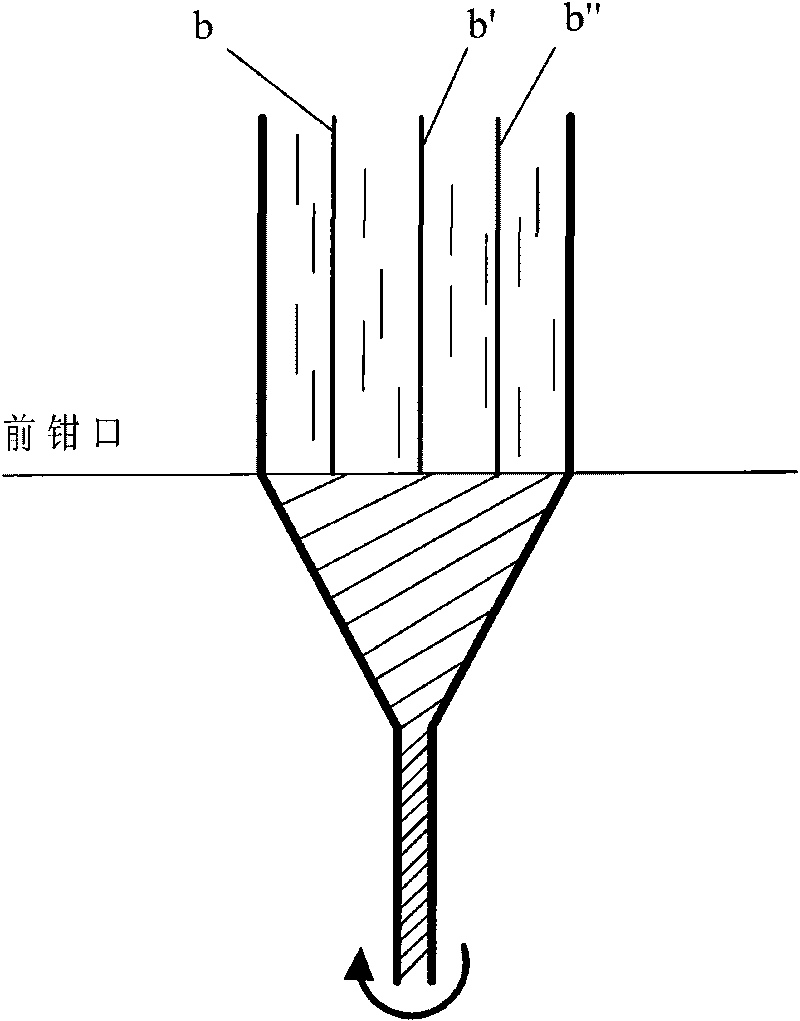

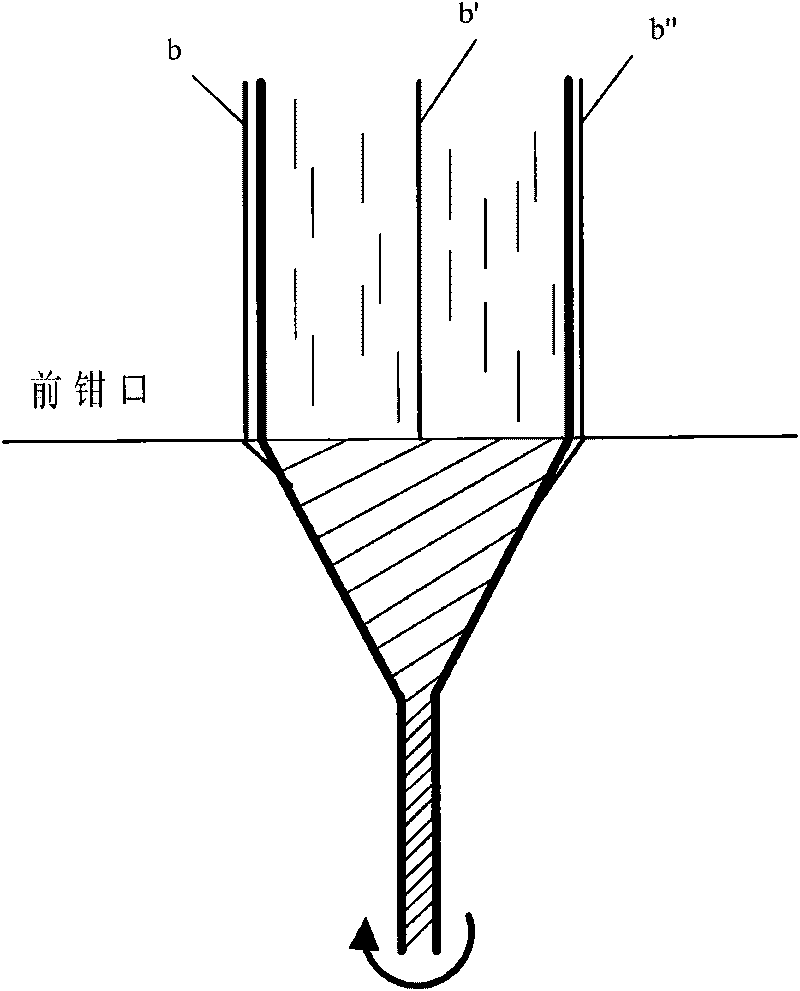

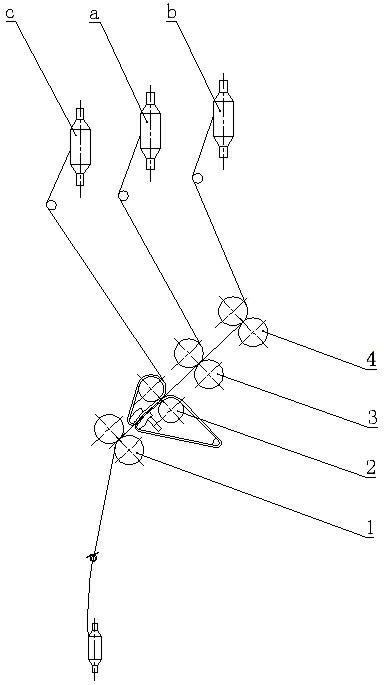

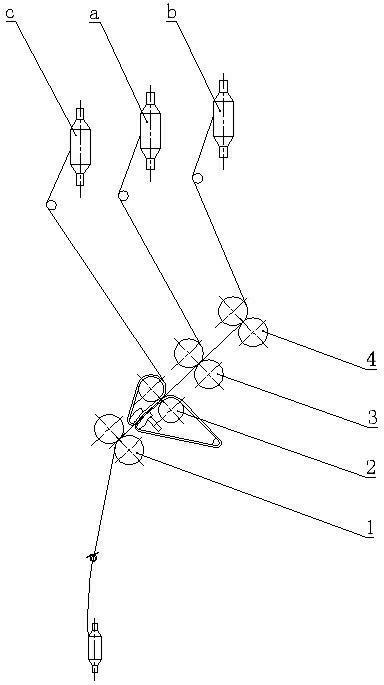

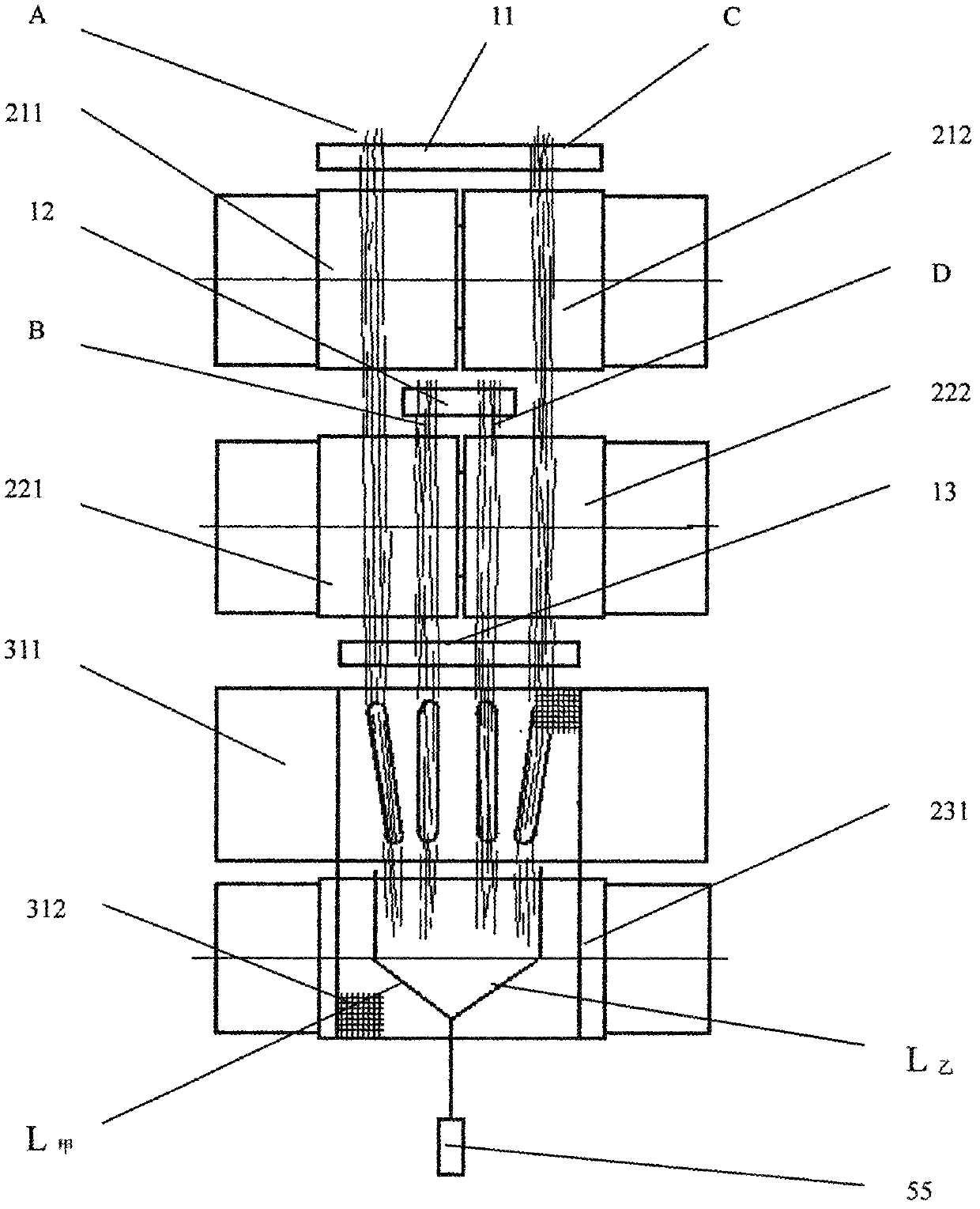

Ring spinning method and device of equi-linear density space dyed yarn

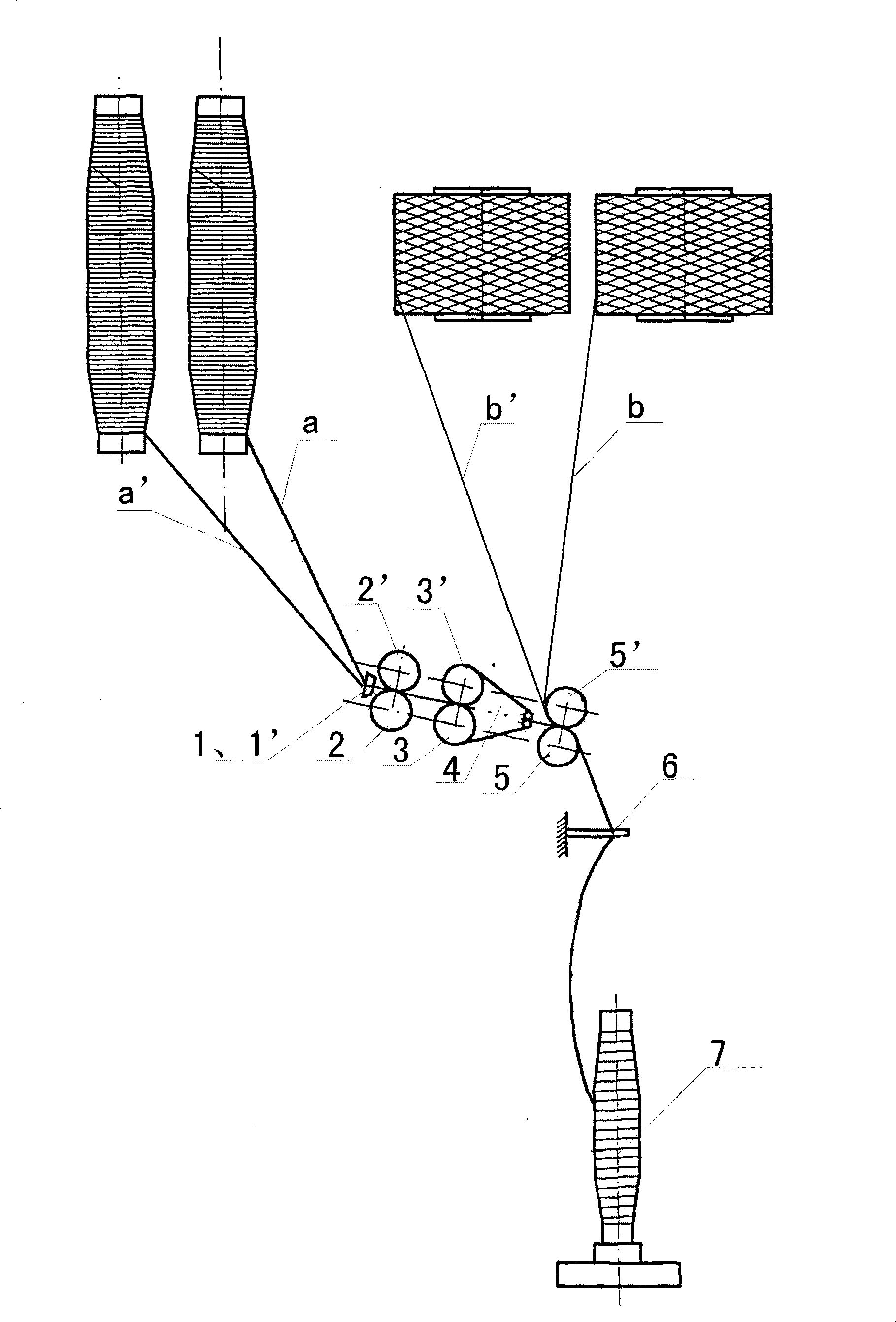

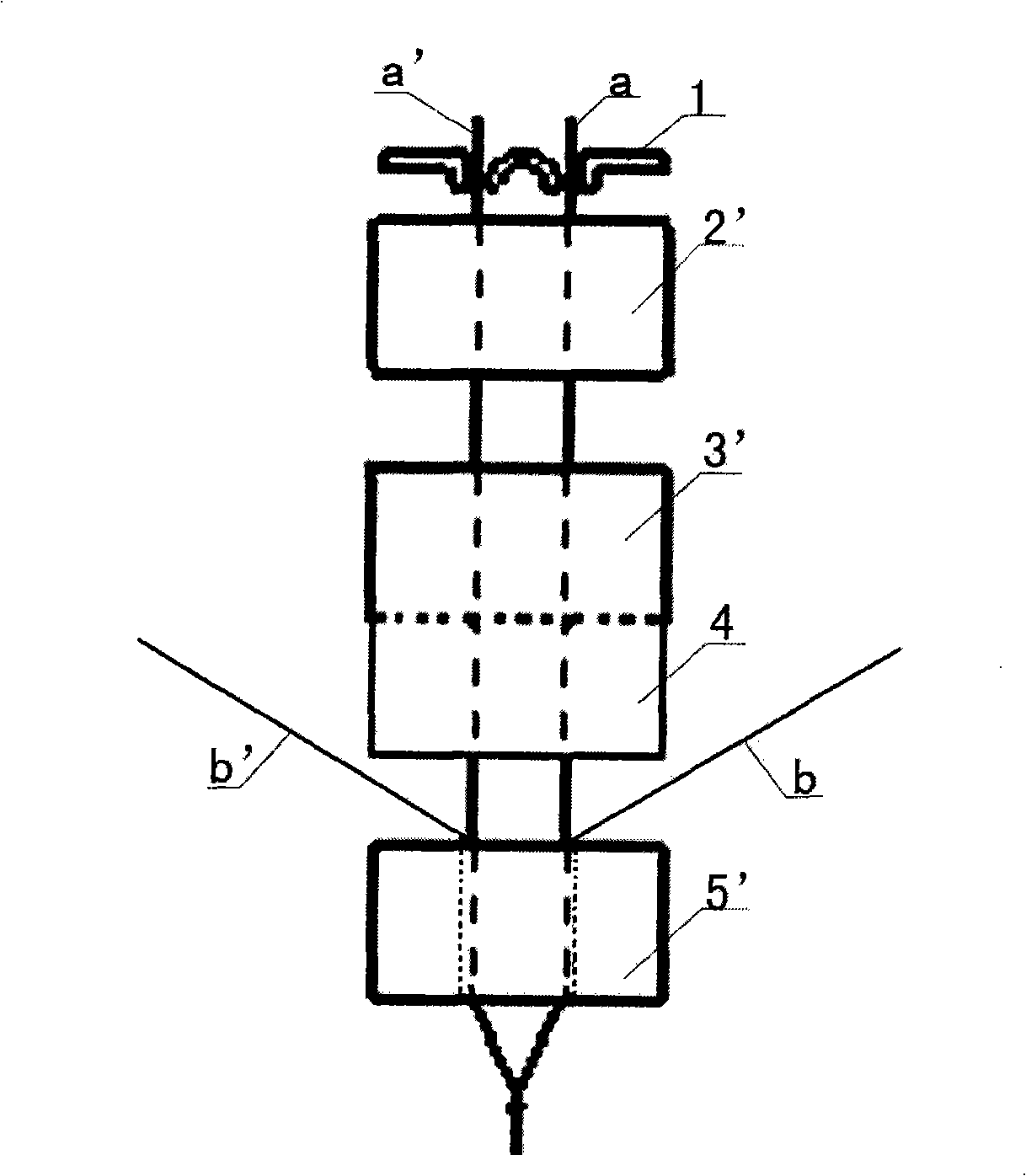

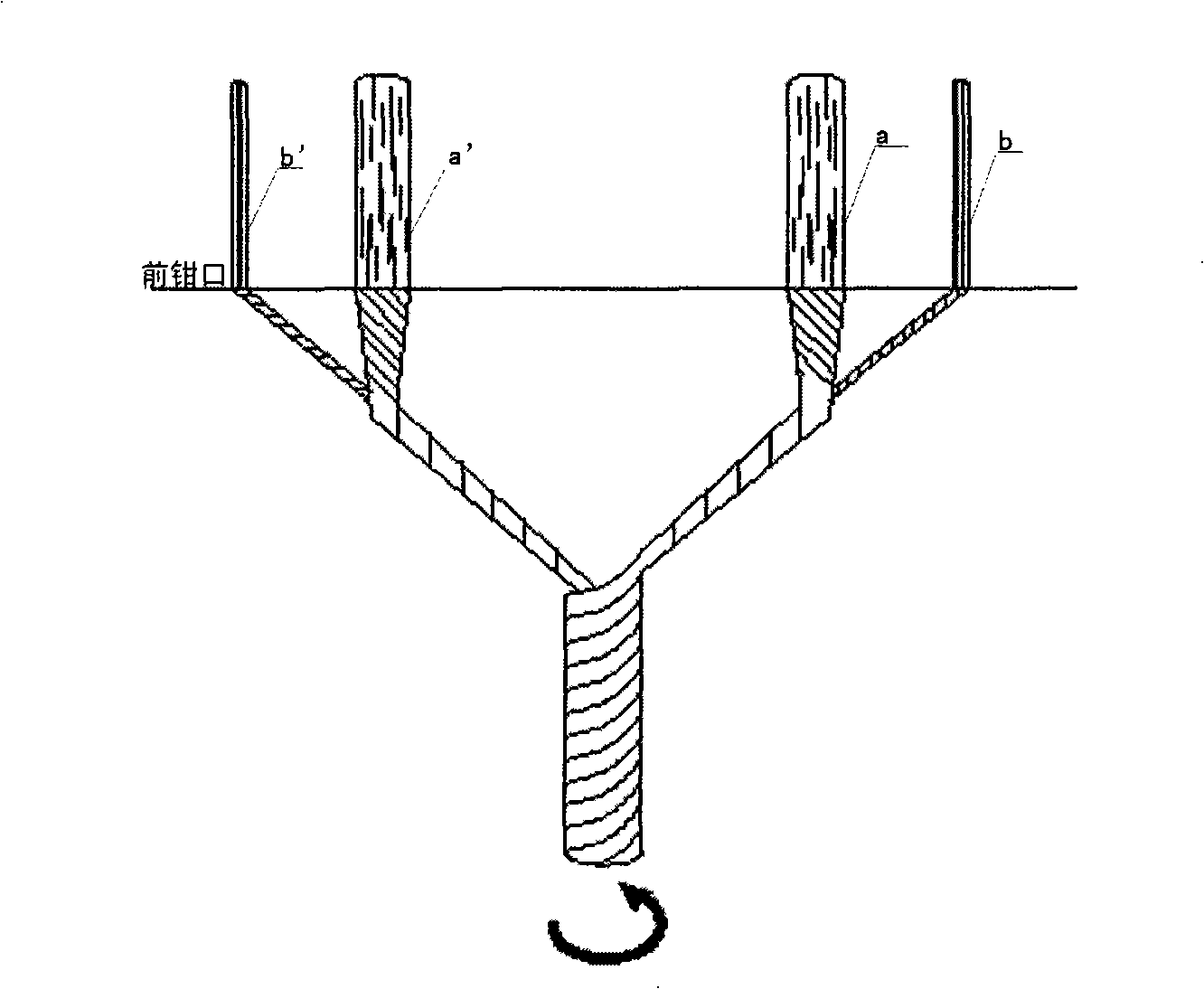

The invention relates to ring spinning method and device of equi-linear density space dyed yarn. The method comprises the following steps of: respectively feeding a fiber strip group (A) with the linear density tex T(A) and a fiber strip group (B) with the linear density tex T(B) into a fixed rear roller and a loop rear roller on a rear roller shaft through yarn guiding rods and grids; and feeding the fiber strip group (A) and the fiber strip group (B) with constant feeding quantity sum into a rear drawing region in any period of time under the process requirement that the feeding speeds of the fiber strip group (A) and the fiber strip group (B) vary with stages by adopting a speed coupling uniform feeding control method. After the strip collection of a strip collector, fiber strips are fed into a middle roller in different drawing ratios, converged in a front drawing region of a spinning machine, drawn and output by a front roller and twisted into equi-linear density space dyed yarn.

Owner:陈伟雄

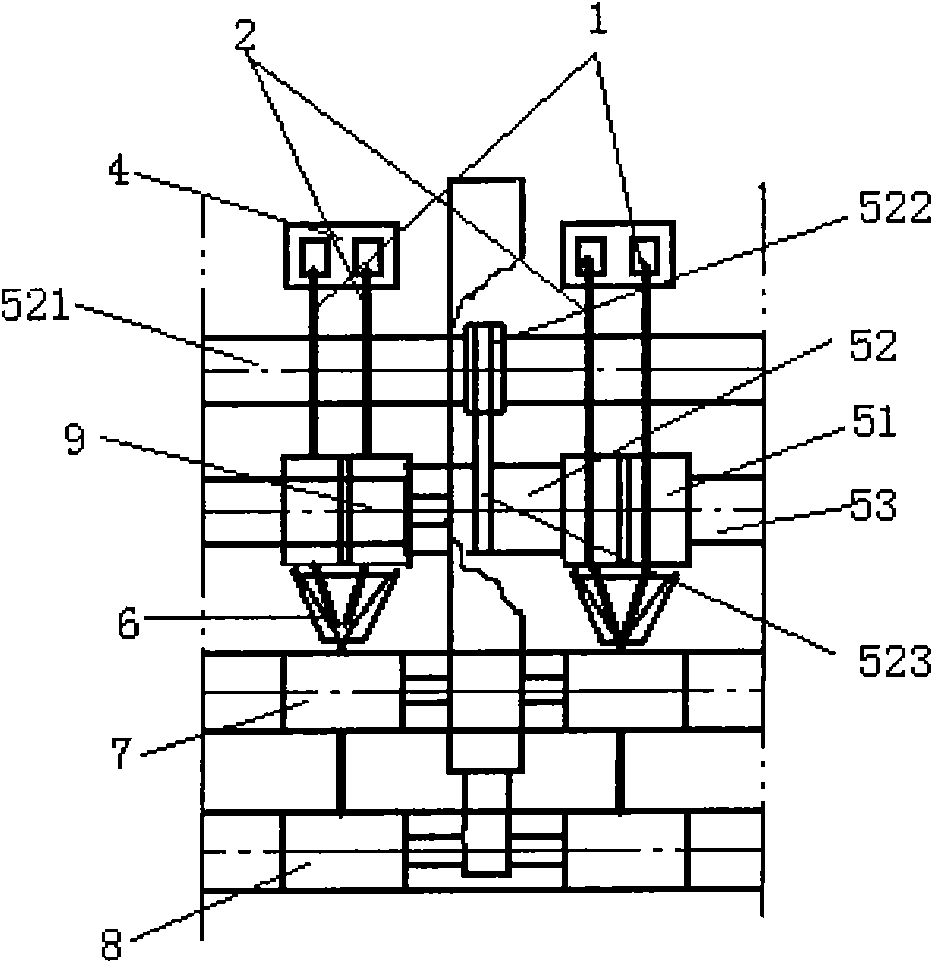

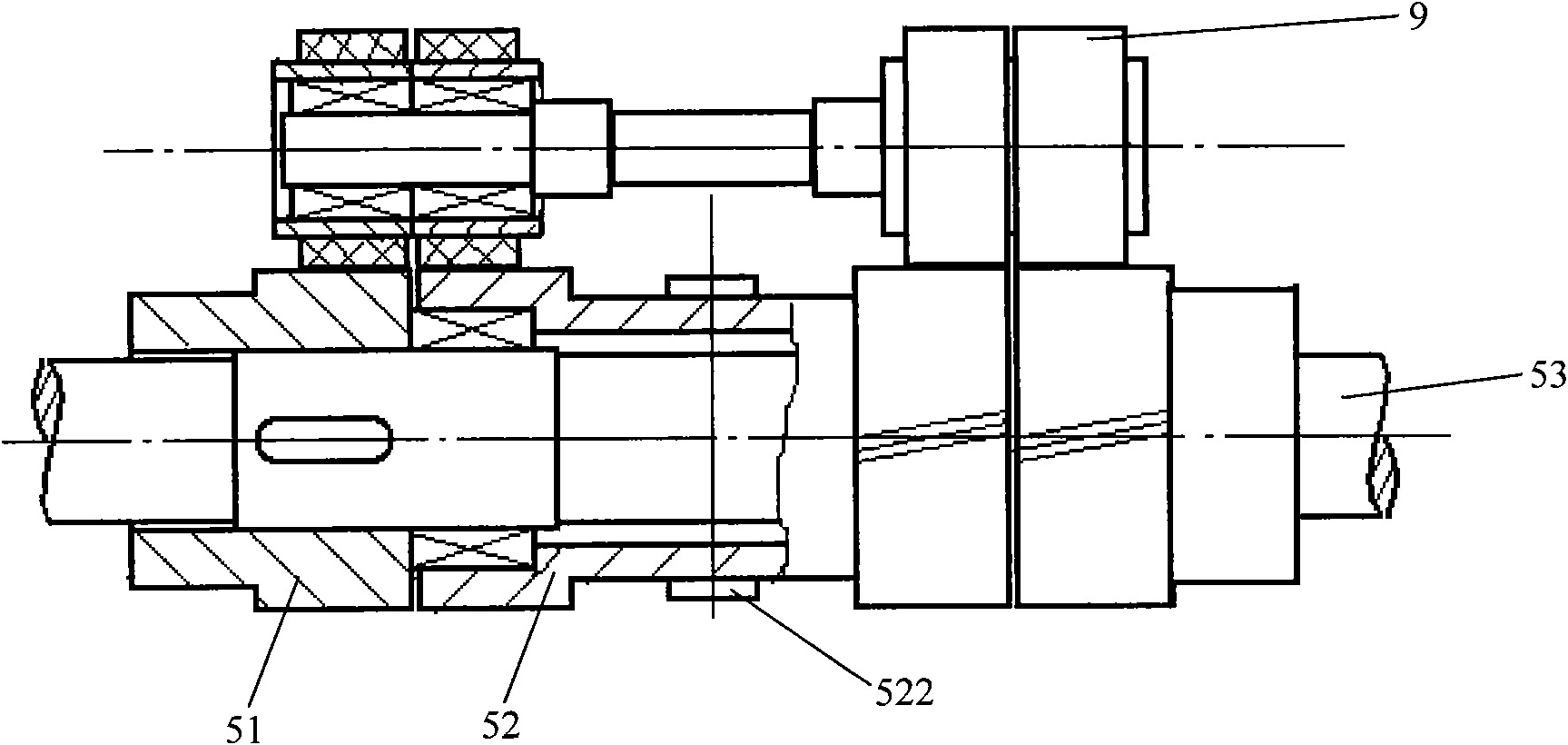

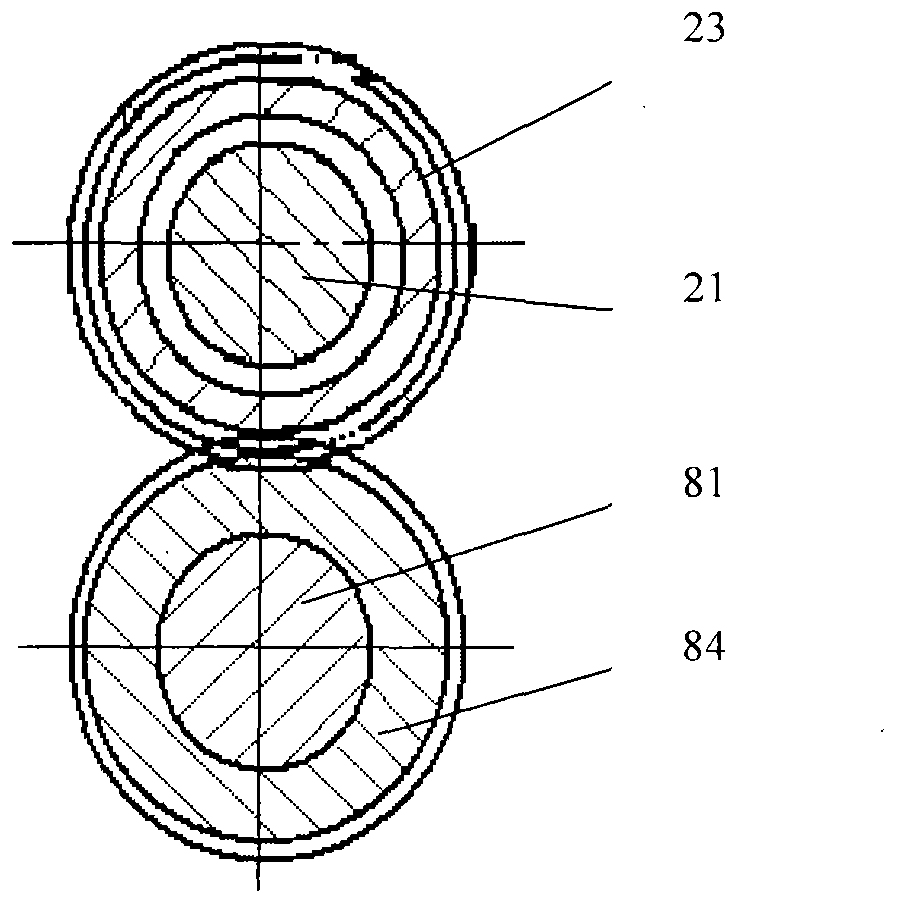

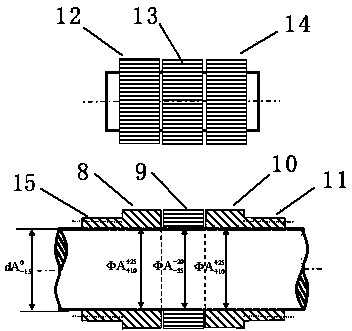

Blending and color mixing device and method based on three-roving coupling drafting twisting system

ActiveCN103556320AAchieve individual controlPrecisely control the mixing ratioDrafting machinesYarnThree degrees of freedom

The invention provides a blending and color mixing device and method based on a three-roving coupling drafting twisting system. The device comprises a drafting and twisting system composed of a rear roller group and a front roller group; the rear roller group comprises a rear stripping roller and a combined roller, and the front roller group comprises a front stripping roller and a front roller. The rear roller group is a combined roller which has three rotation freedom degrees and which is composed of coating three segments of rings with equal outside diameters on one spindle sequentially. The mixing ratio (or the color mixing ratio of roving with different colors) of rovings with different components and operation as required on distributed length on the rovings can be realized by independent control on each part of a drafting mechanism with three freedom degrees, technology is creative, and width of products is increased.

Owner:JIAXING UNIV

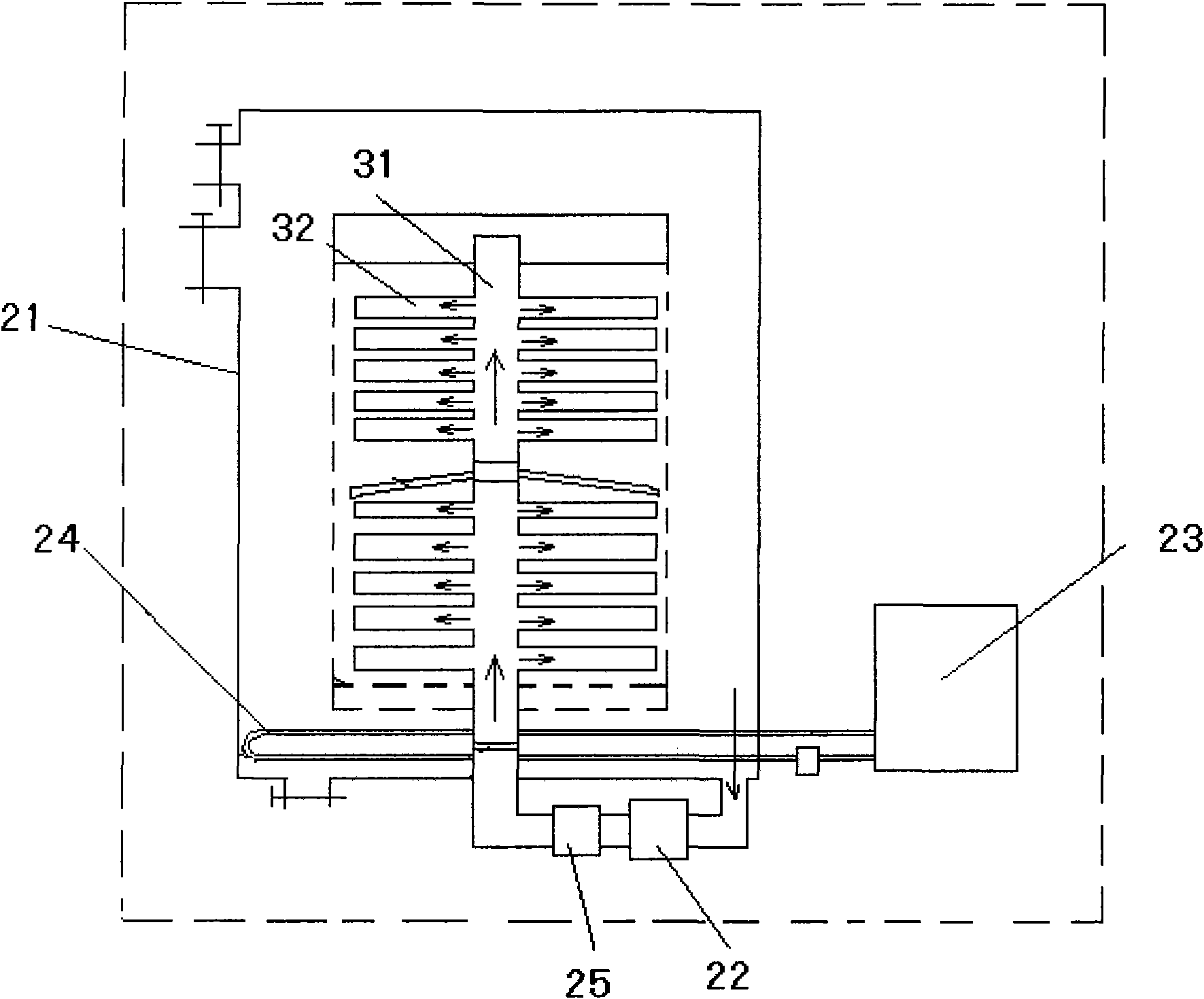

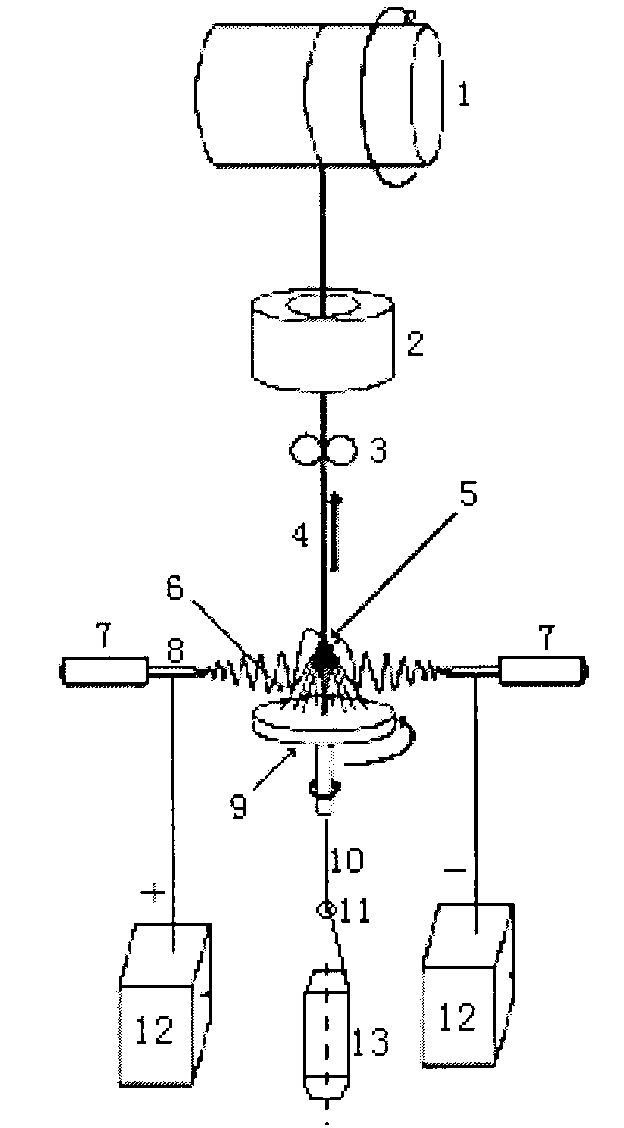

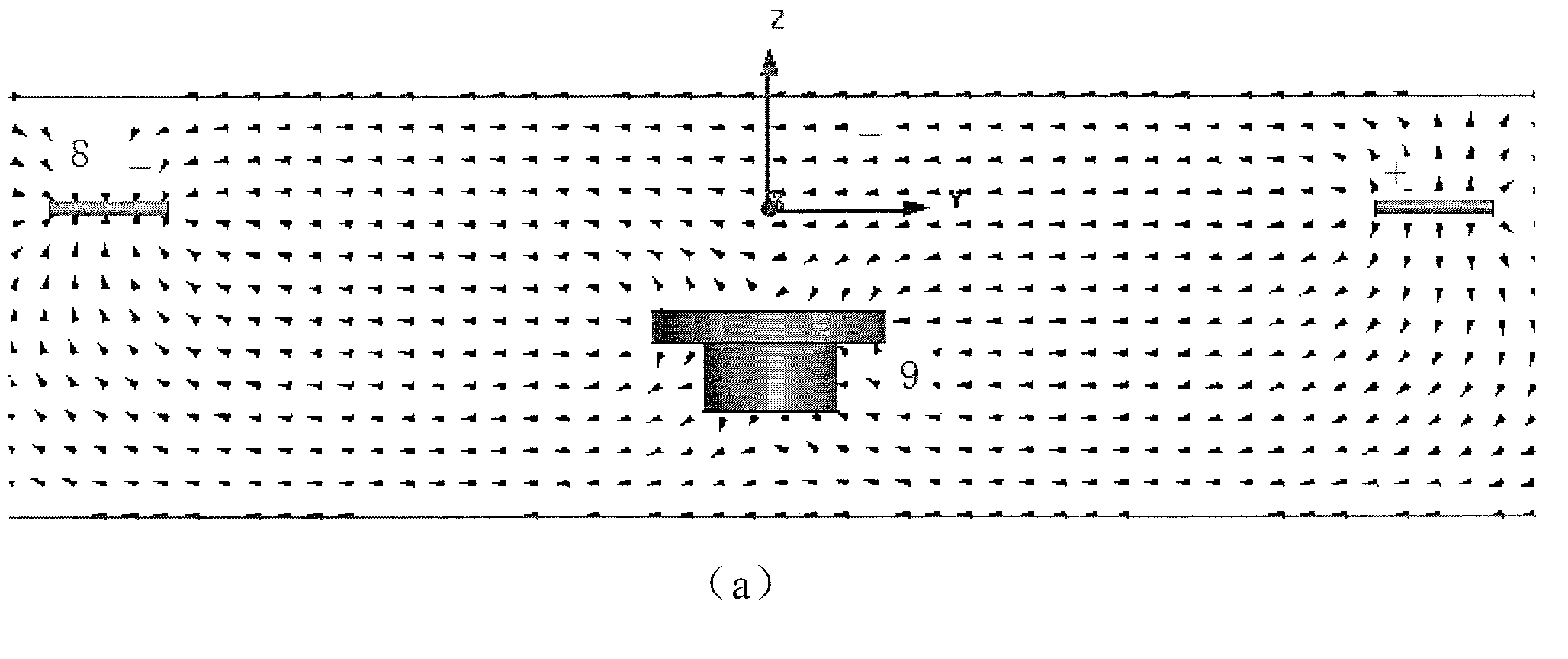

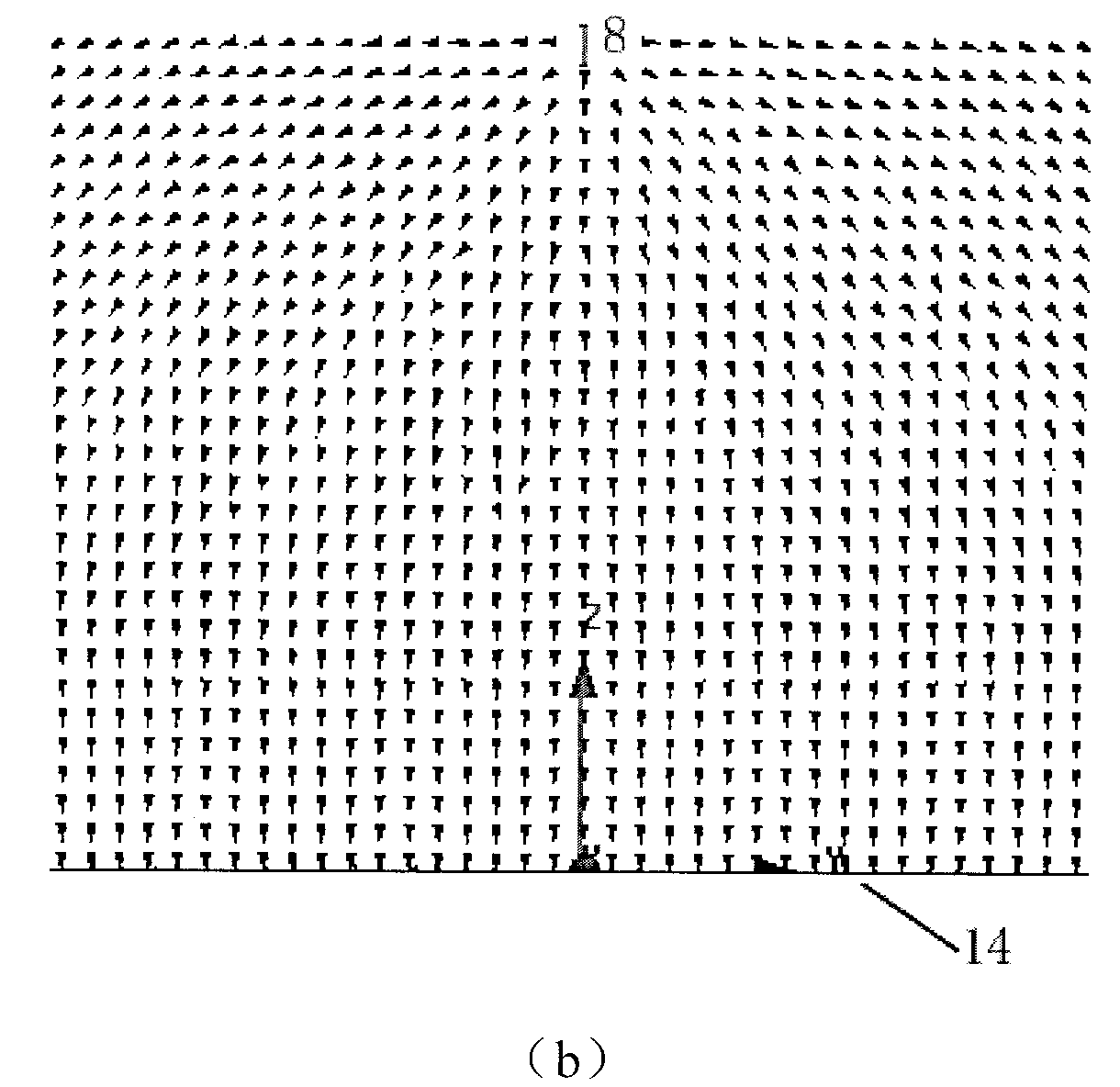

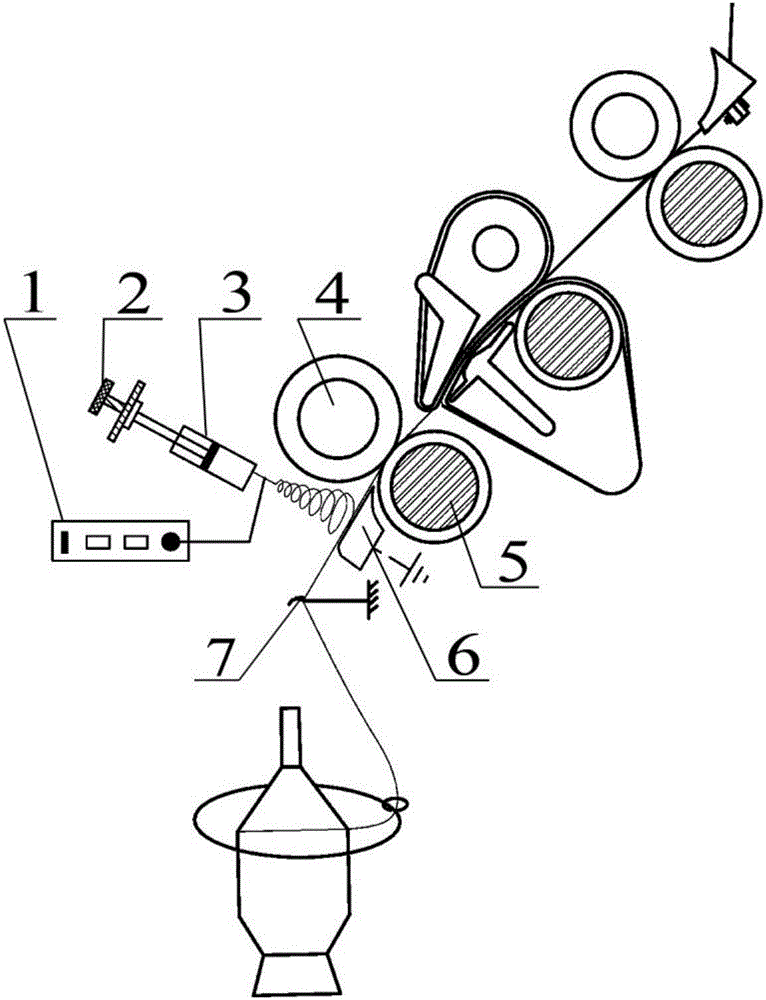

Orientation electro-spinning nanometer fiber spinning method and device thereof

InactiveCN103132194AHigh degree of axial orientationSuppress spinning instabilityDrafting machinesFilament/thread formingBobbinEngineering

The invention discloses an orientation electro-spinning nanometer fiber spinning method and a device thereof. A metal shower nozzle which exerts positive and negative high pressure is adopted to spin two strands of nanometer fibers with opposite charges, an electric field line of a spinning electric field, relative to a common spinning electric field, is straight, stability of spinning is effectively restrained, and the spinning nanometer fibers are straight. Two strands of the fibers surround the yarn tail and form a cone-shaped twisting trigonum on the upper portion of a metal twisting machine, and enable the nanometer fibers to be further oriented and twisted to form yarn through electric field force, tractive force of the yarn and acting force of the metal twisting force. The spinning nanometer fiber yarn is conducted heat shaping through a heat processing device under certain tensile force, degree of orientation of the nanometer fibers along the axial direction of the yarn, breaking force and yarn levelness are further improved, and the yarn after shaped is collected by a winding bobbin. The device can achieve the aim that orientation nanometer fiber yarn can be continuously prepared, is simple in device, convenient to operate, and good in resultant yarn continuity, yarn breaking strength and yarn levelness, and not only can spin pure nanometer fiber yarn, but also can spin nanometer fibers / filament core composite yarn. The orientation nanometer fiber spinning method and the device thereof have important application value in the fields, such as a biomedical field and a sensor field.

Owner:杨恩龙 +1

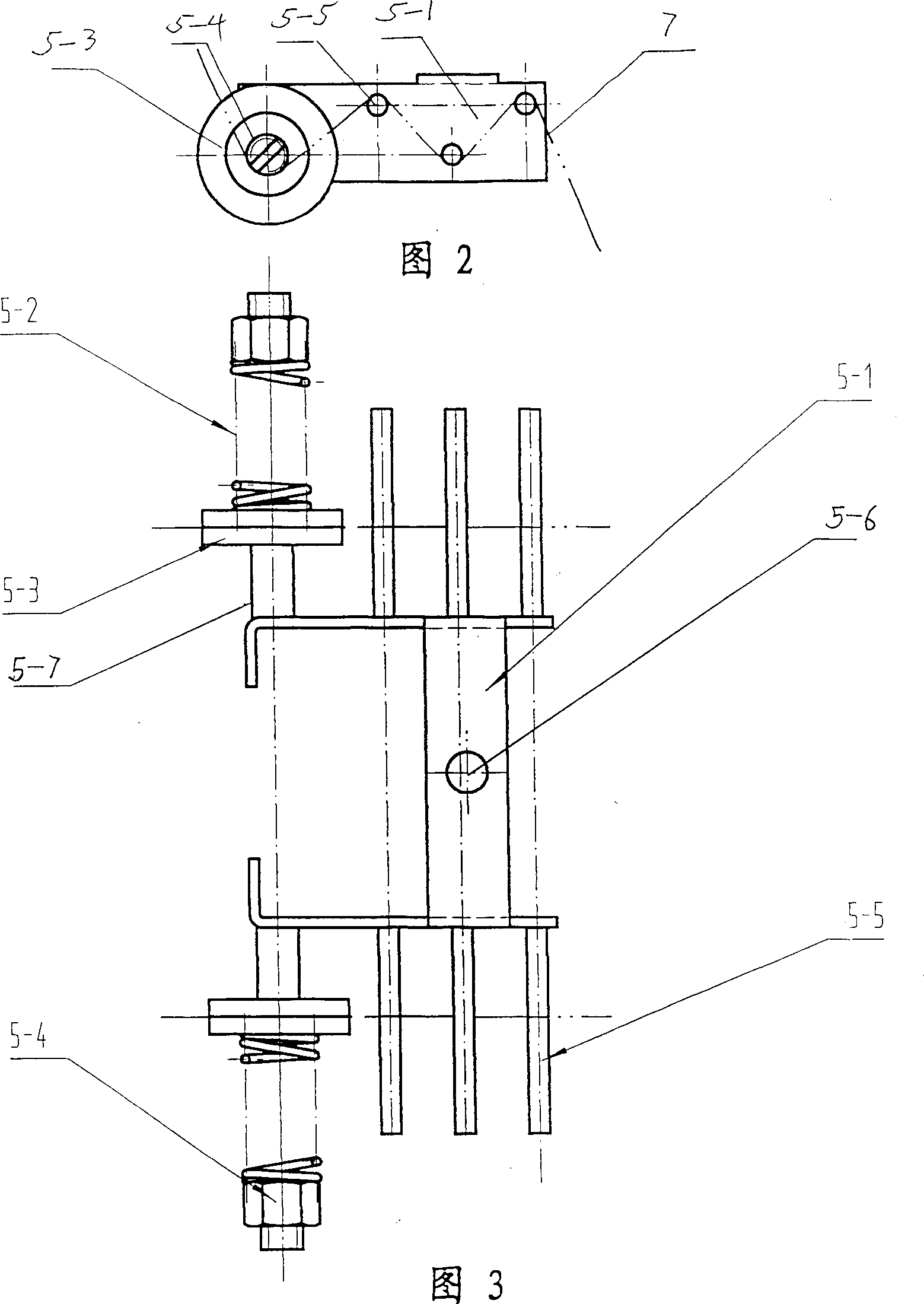

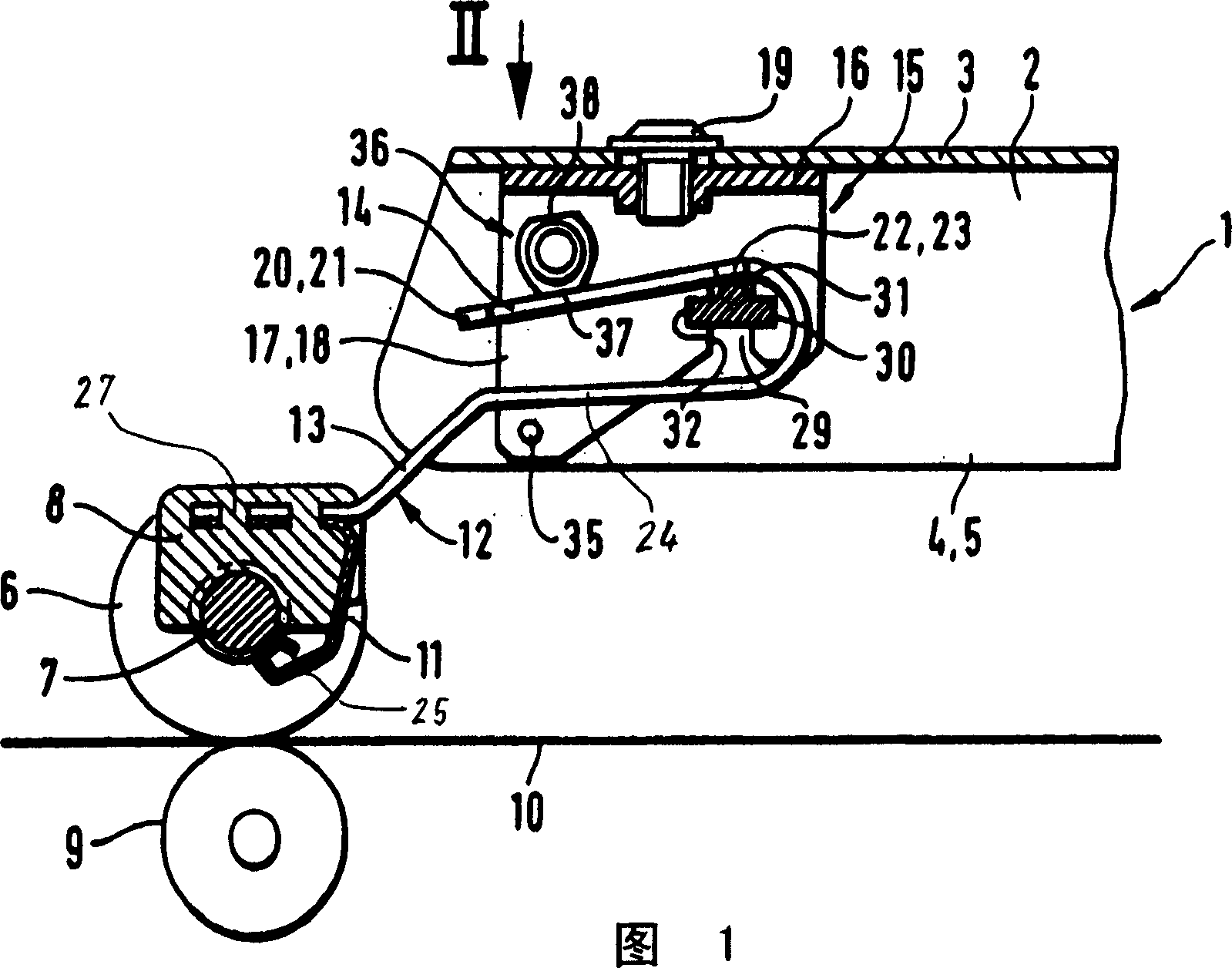

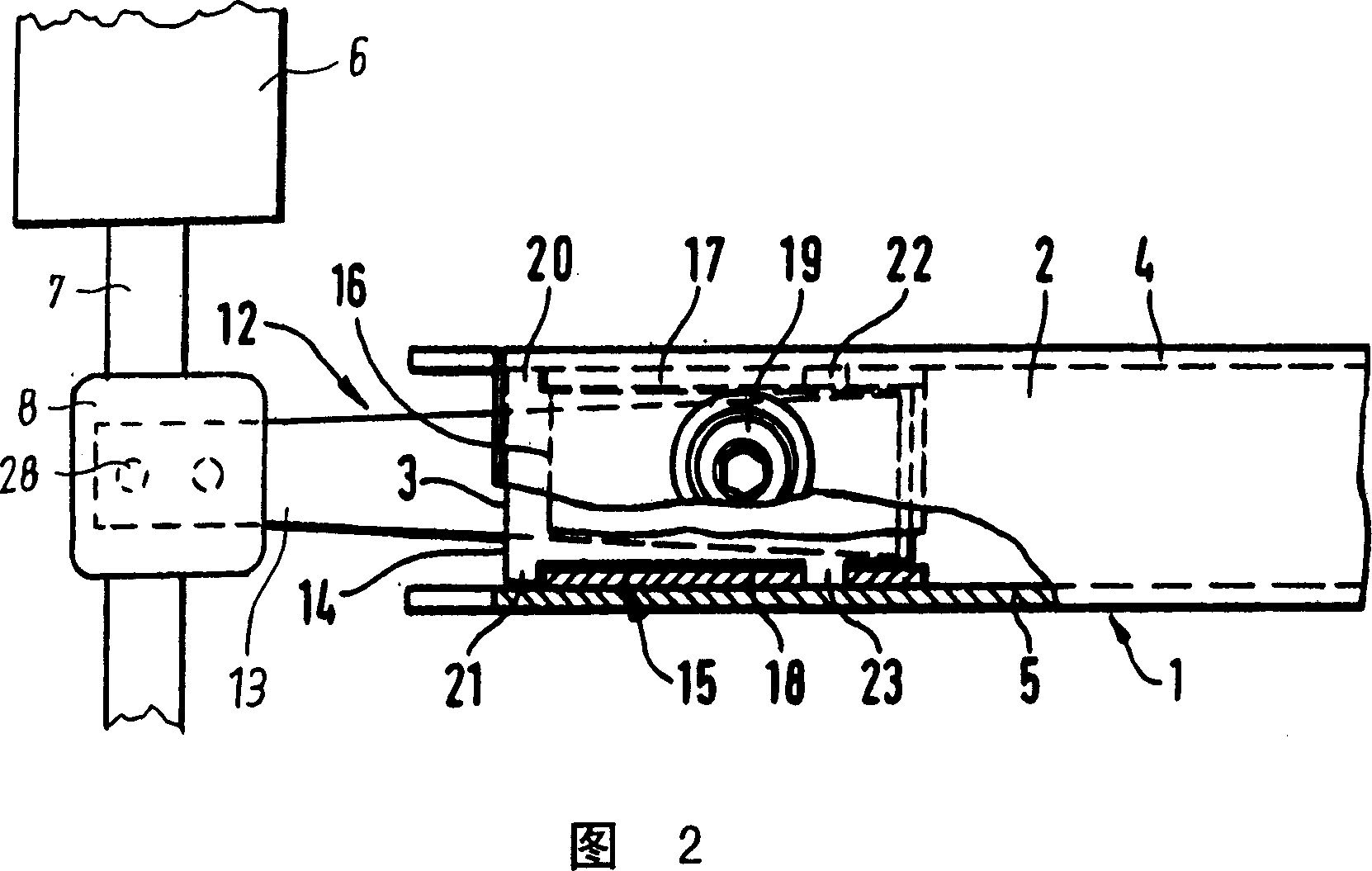

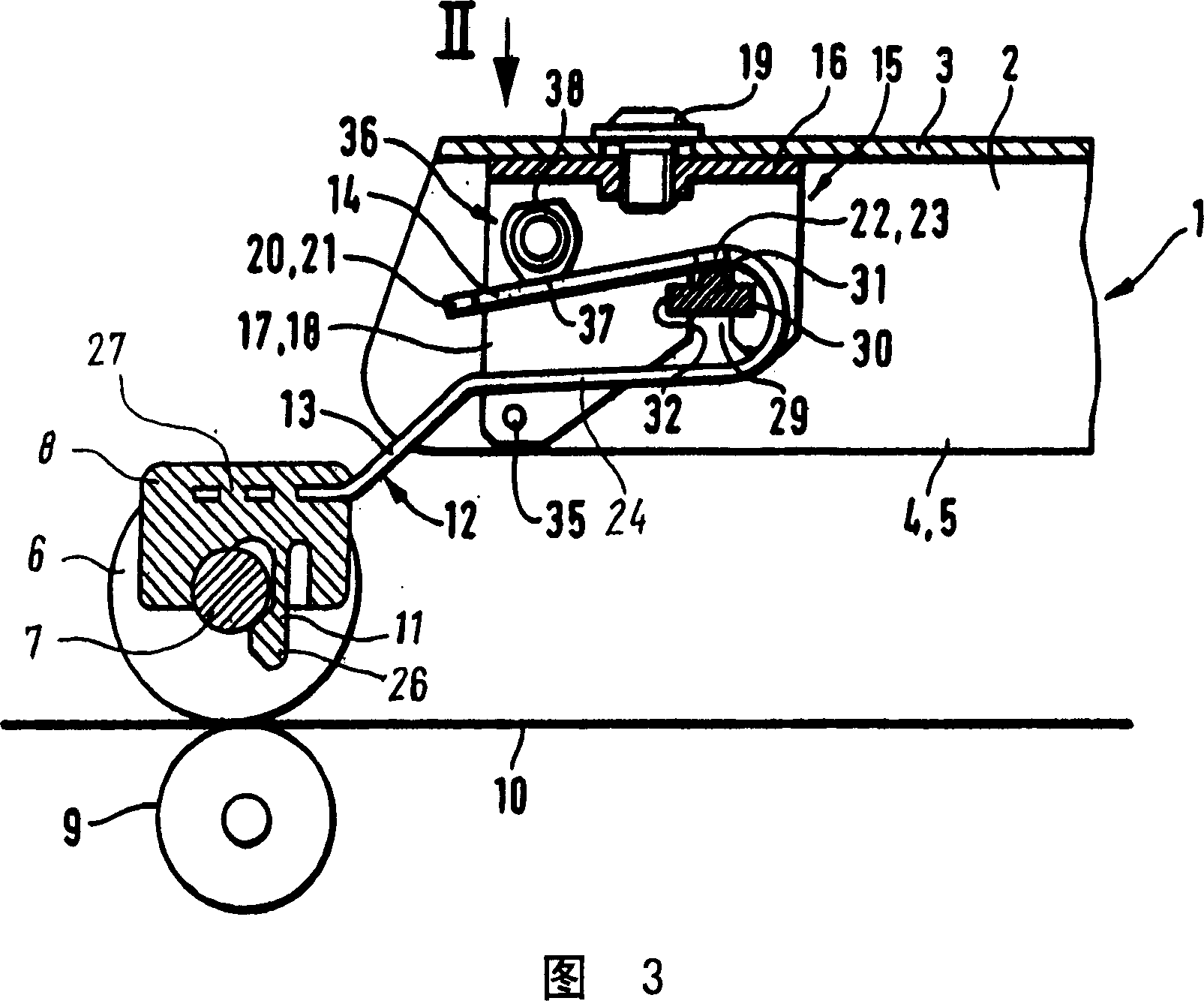

Pressing roller holder for stretching structure

The invention relates to a pressure roller support for fixing double pressure rollers in a drafting mechanism, which comprises a spring for pressing the double pressure rollers and a fixing frame for the double pressure roller shafts. The holder is a die-cast or injection-molded part, wherein the holder is cast onto the spring. Furthermore, the invention relates to a method for producing the pressure roller support, in which the spring is inserted into the mold at least in a partial region so that the holder is connected to the spring during the casting process.

Owner:MASCHINENFABRIK RIETER AG

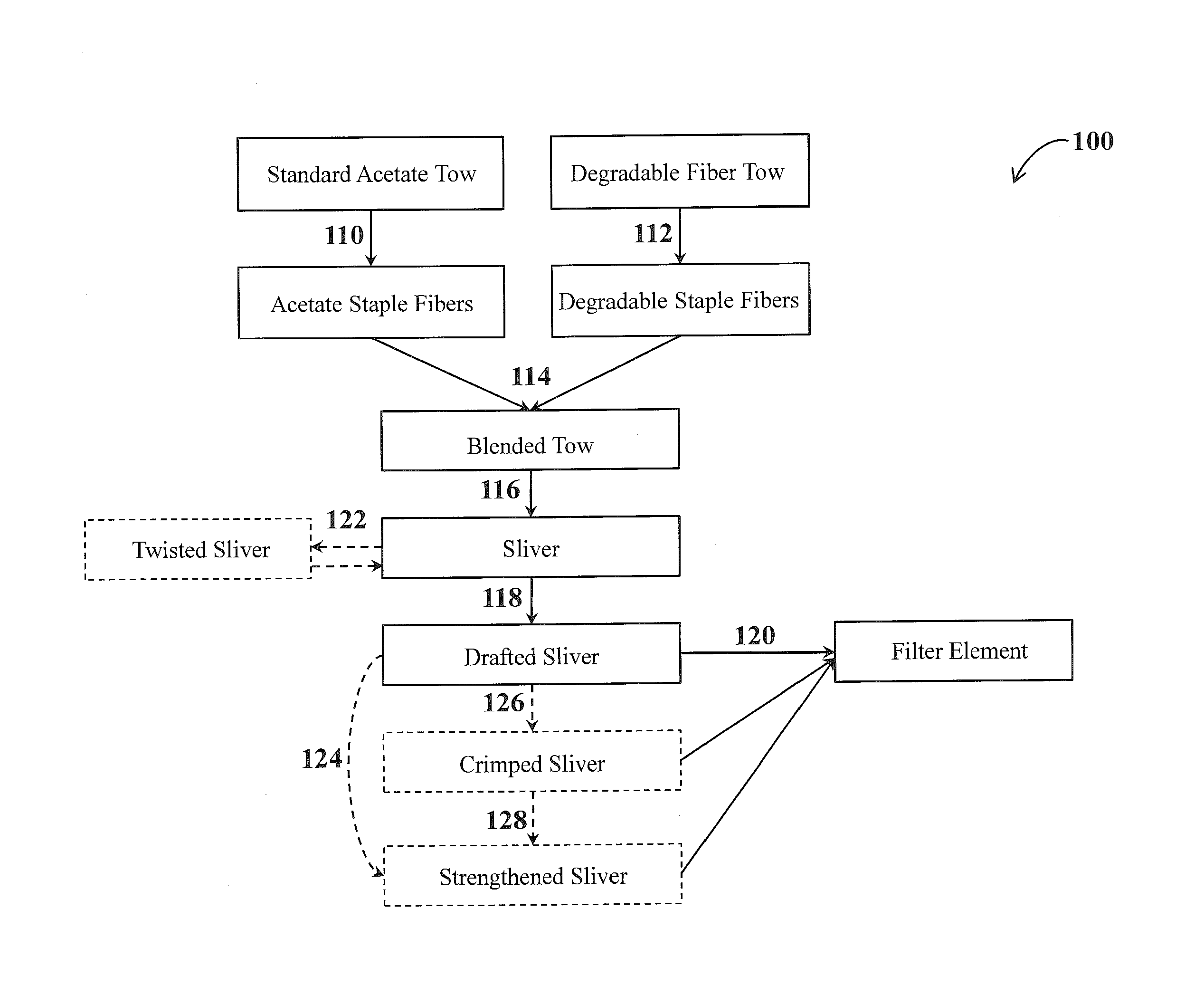

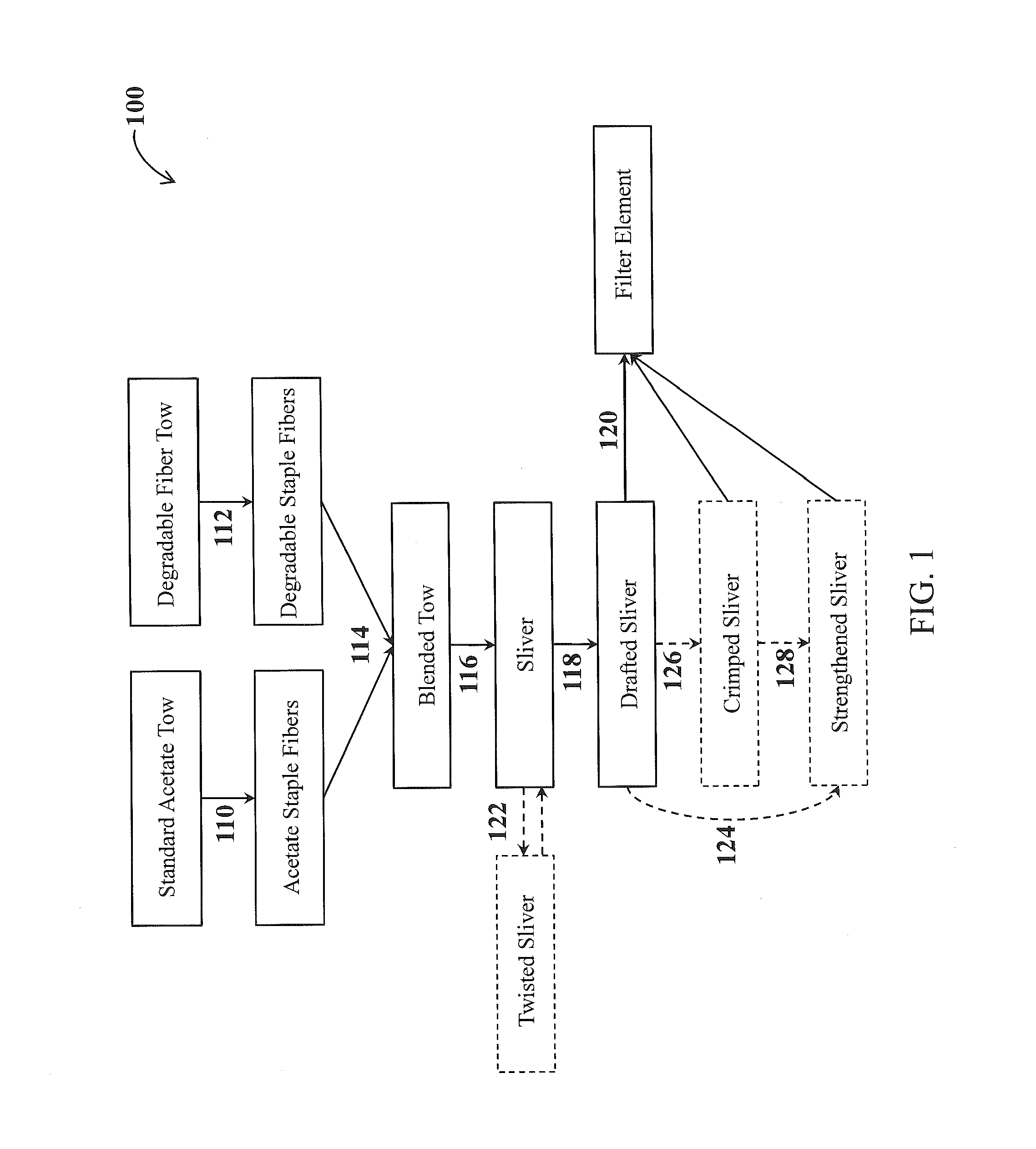

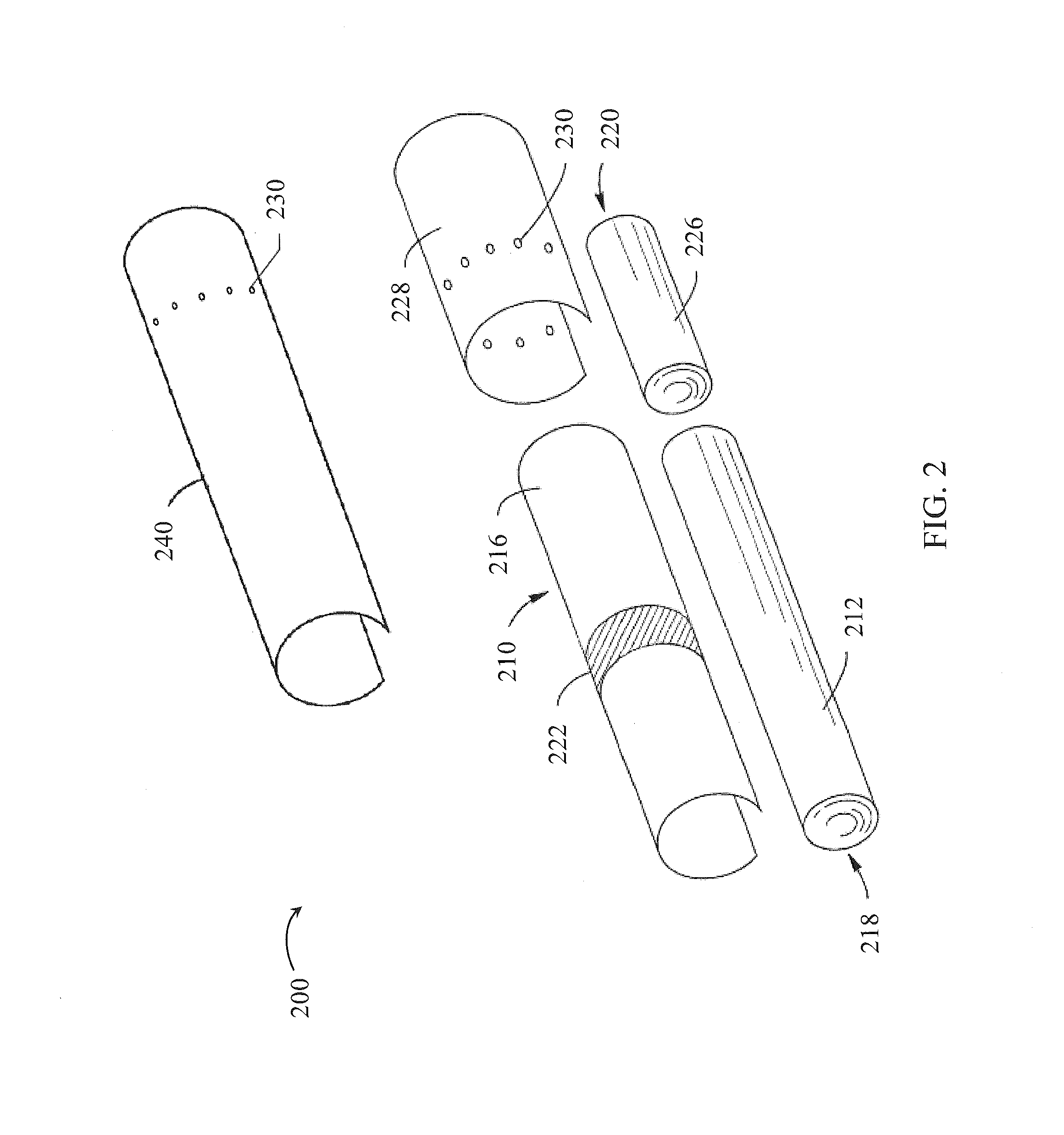

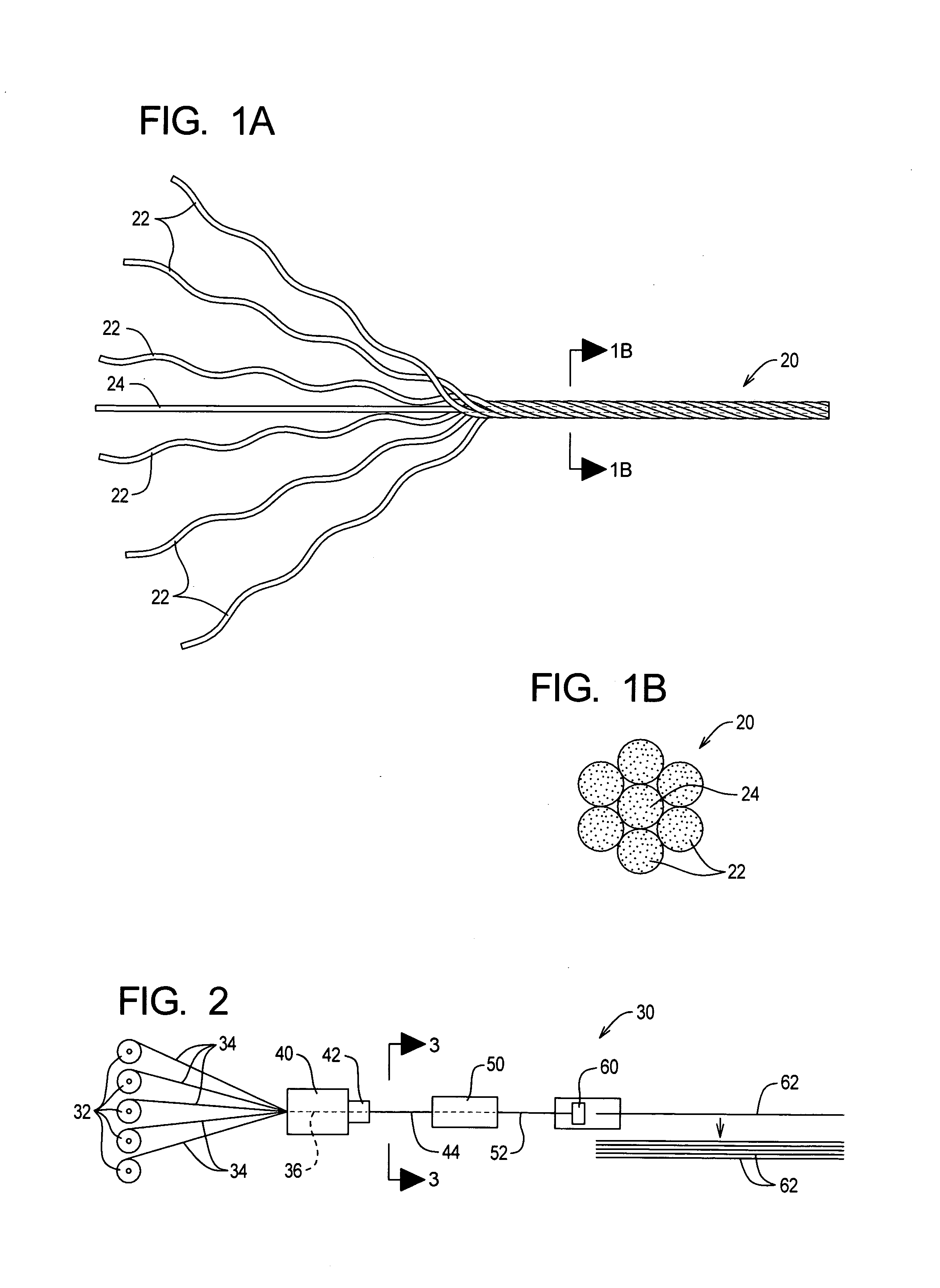

Mixed fiber sliver for use in the manufacture of cigarette filter elements

Smoking articles including filter elements formed from two or more fibrous inputs with different physical properties are provided. The two or more fibrous inputs are provided in the form of staple fibers, which are at least partially entangled with each other to form a mixed fiber sliver. The mixed fiber sliver includes a first plurality of cellulose acetate staple fibers blended with a second plurality of staple fibers comprising a polymeric material different from the first plurality of staple fibers, such as staple fibers of a degradable polymeric material. The entangled fibers of the mixed fiber sliver may be sufficiently separated from one another such that blooming operations typically required in filter element production may not be necessary prior to incorporating the mixed fiber sliver into a filter element. Related methods, apparatuses and mixed fiber products are also provided by the disclosure.

Owner:R J REYNOLDS TOBACCO COMPANY

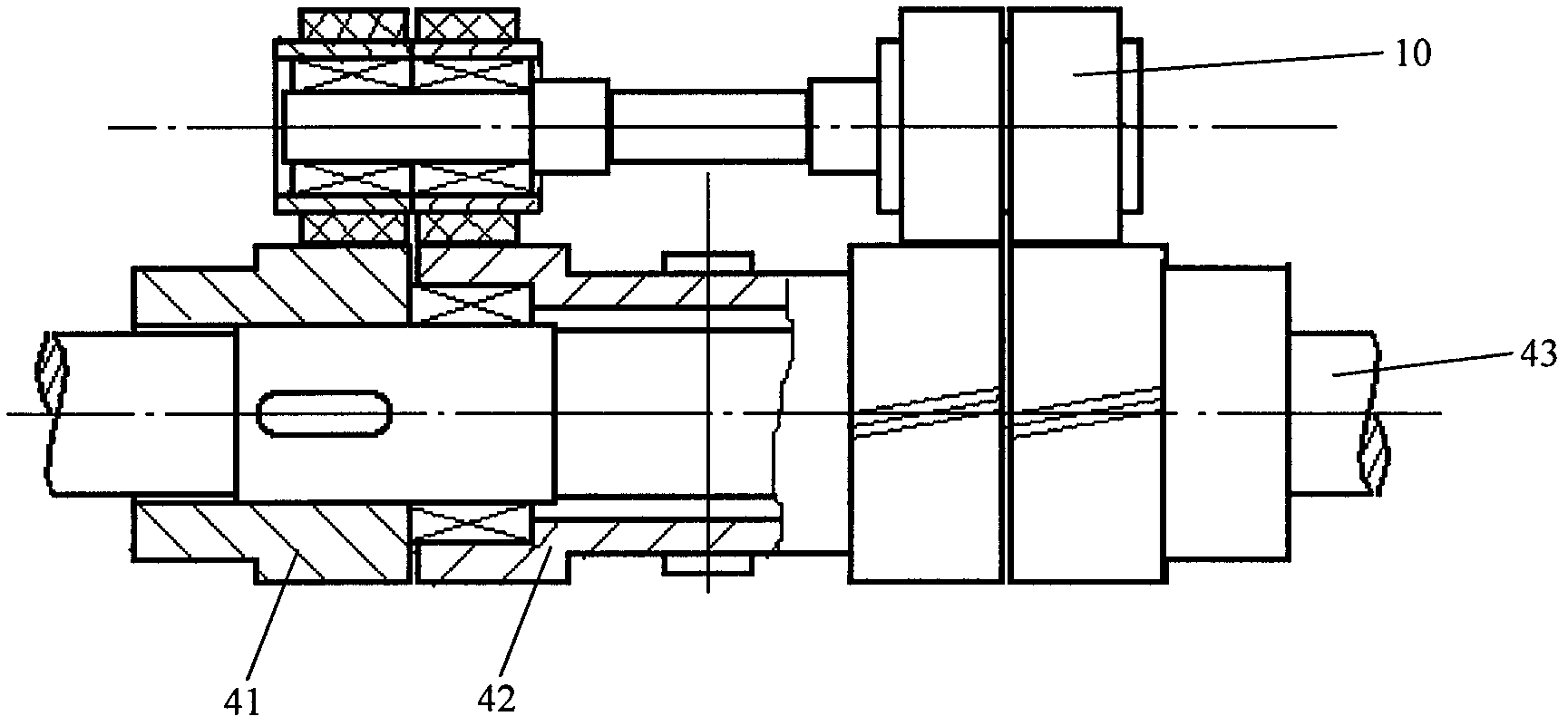

Method for spinning section-color yarns and drafting mechanism for spinning

The invention discloses a method for spinning section-color yarns and a drafting mechanism for spinning. At the rear drafting area of the drafting mechanism, leather rings are used for guiding and controlling yarns, namely a group of upper leather rings and a group of lower leather rings are used for controlling two groups of fiber fringes respectively, so for the rear drafting area of the drafting mechanism, the capacity of controlling free fibers is improved, when the drafting ratio at the rear area is changed greatly in sections, the stability of drafting of each sectional process is kept, and evenness and a sectional color effect of section-color resultant yarns are ensured. In the respect of product process design, the drafting ratio of the rear area is increased, and the transition length of the two groups of fibers between every two sections is shortened.

Owner:陈伟雄

Intermittent spinning process and yarn therewith

The present invention relates to spinning technology of facy yarn, it is characterized in that the auxiliary fiber bundle enters the rollers and intermittently comes out, then combines with main fiber bundle and at the samd time enter into back and front rollers, it is drawed and twisted to form product. The incoming rollers are controlled by programmable controller to make the auxiliary fiber bundle intemittently comes in, thereby obtain intermittent spinning yarn which is combined with main fiber bundle to obtain fancy yarn. Advantages: smooth and gradation feedling of cloth surface, infinite change of contrast chroma etc.

Owner:HANGZHOU NO 2 COTTON YARN

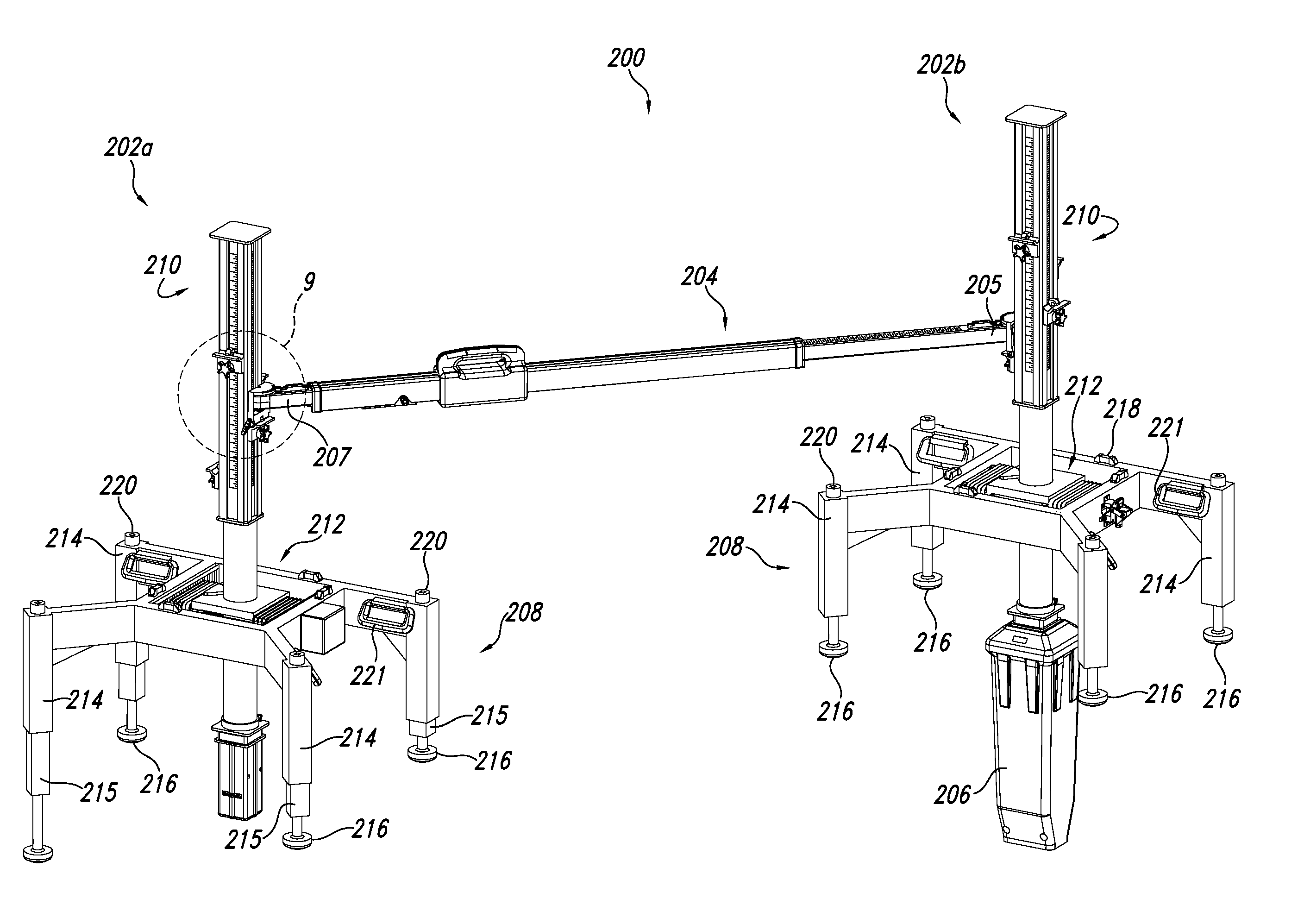

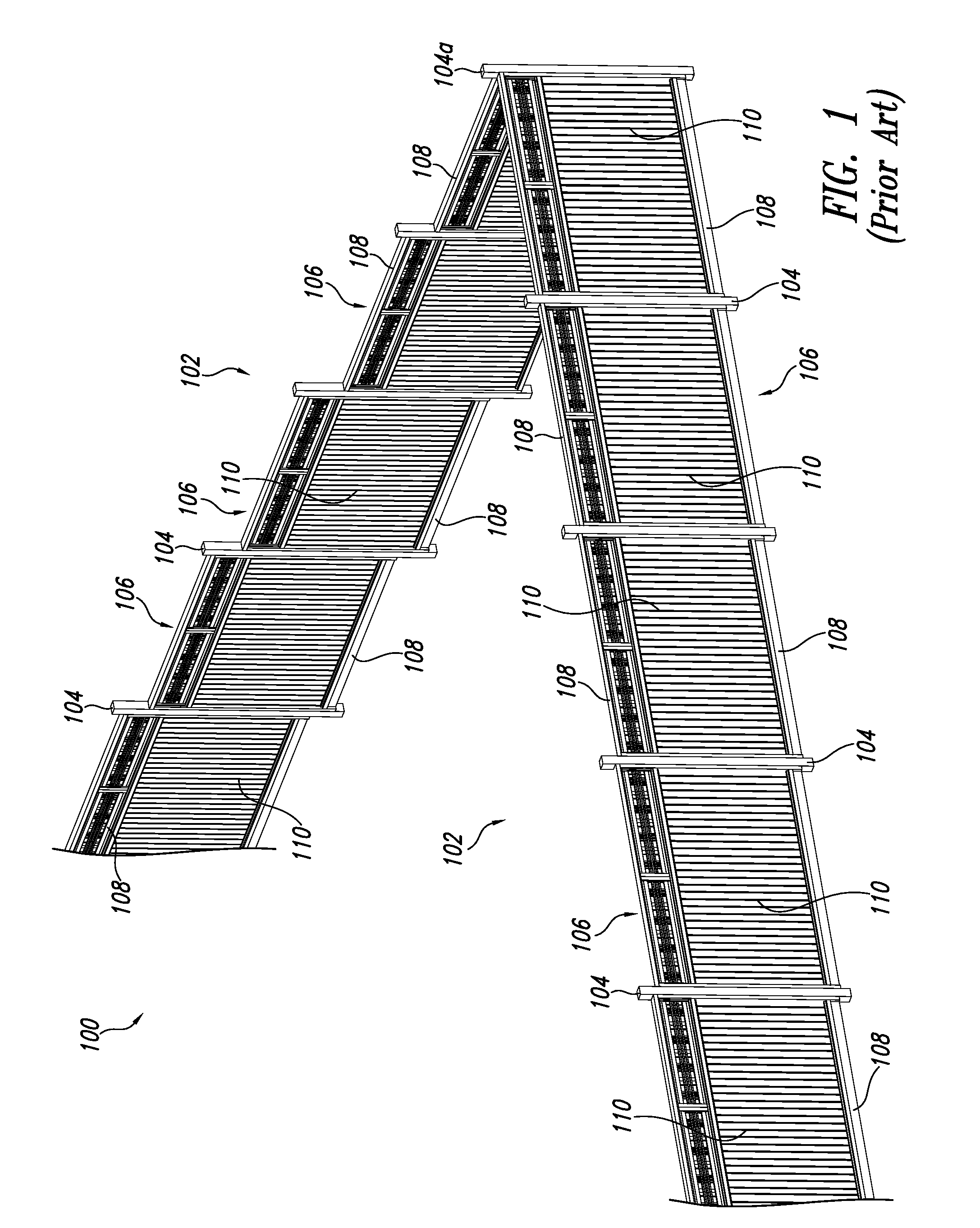

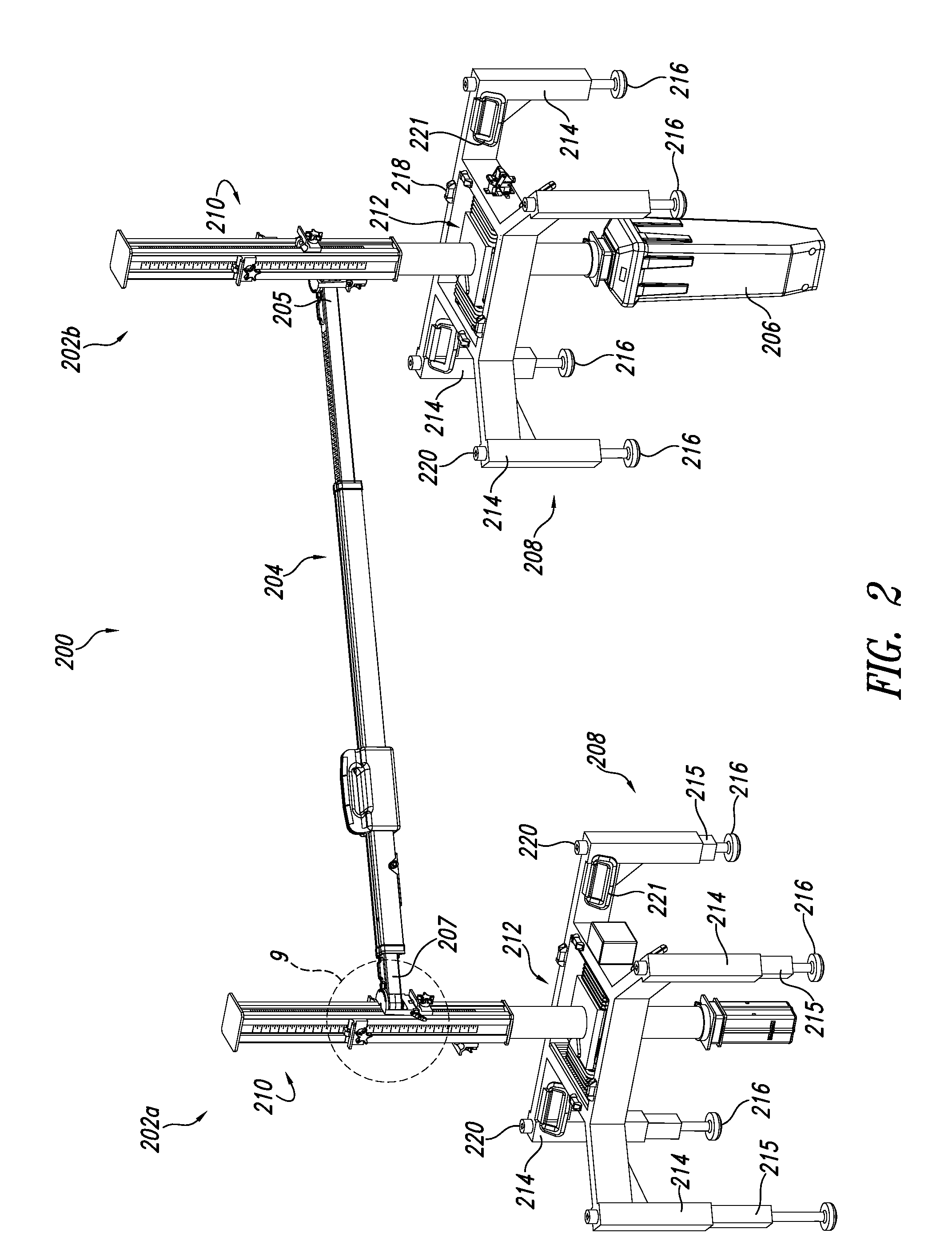

Post sleeve positioning apparatus and method

ActiveUS7861434B2Inhibition of translationAngles/taper measurementsRecording apparatusEngineeringVertical axis

A post sleeve installation device includes a standing structure, a structure coupled to the standing structure and configured to support a post sleeve below the standing structure, and a mechanism configured to enable selective translation of the support structure in three axes and rotation around a vertical axis. Locks are provided to lock the post sleeve at a selected position and orientation relative to the standing structure. A beam extending from one installation device to another measures or controls the relative spacing, orientation, and elevation of associated post sleeves, and related data is collected for off-site manufacture of fence panels. Additionally, a repository is provided, to which the data is transmitted for retention, and from which the data can be retrieved for manufacture of replacement fence panels.

Owner:KNUDSEN N ERIC

Composite, break-resistant sewing thread and method

InactiveUS6405519B1Improve fracture resistanceReduce tensionDrafting machinesContinuous wound-up machinesFiberYarn

A composite, break-resistant sewing thread having a core of continuous multi-filament, non-stretch high-tenacity synthetic yarn and a cover of drafted staple fibers air-jet twisted around and covering the core for protecting the core from heat and friction during a sewing operation. The yarn is plied.

Owner:BURKE MILLS

Apparatus on a spinning preparation machine for ascertaining the mass and/or fluctuations in the mass of a fibre material

InactiveUS20060260100A1Improved and accurate measurementSmall dimensionSafety devices for fibre treatmentMeasurement devicesEngineeringDistance sensors

In an apparatus on a spinning preparation machine, for example a flat card, roller card, draw frame, combing machine or the like, for ascertaining the mass and / or fluctuations in the mass of a fibre material, for example at least one fibre sliver, fibre web or the like, of cotton, synthetic fibres or the like, the fibre material is scanned mechanically by a feeler element the excursions of which are converted into electrical signals. In order to facilitate improved and more accurate measurement of the fibre in a way that is simple in terms of structure and installation, a contactless distance sensor is provided for detecting the position of the feeler element, the sensor being a sensor that measures distance using transmitted waves, and is connected to an electronic evaluating device.

Owner:TRUETZSCHLER GMBH & CO KG

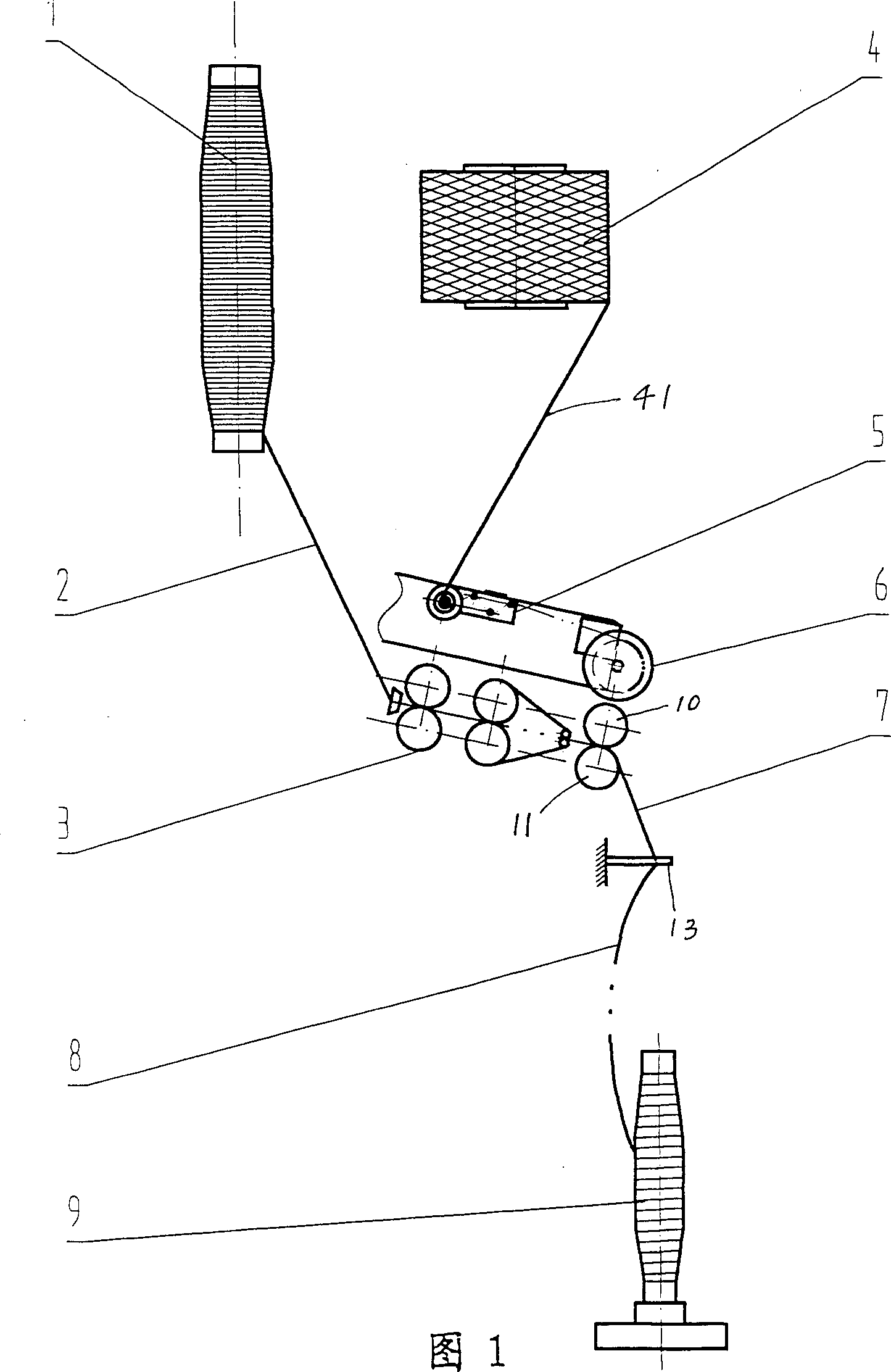

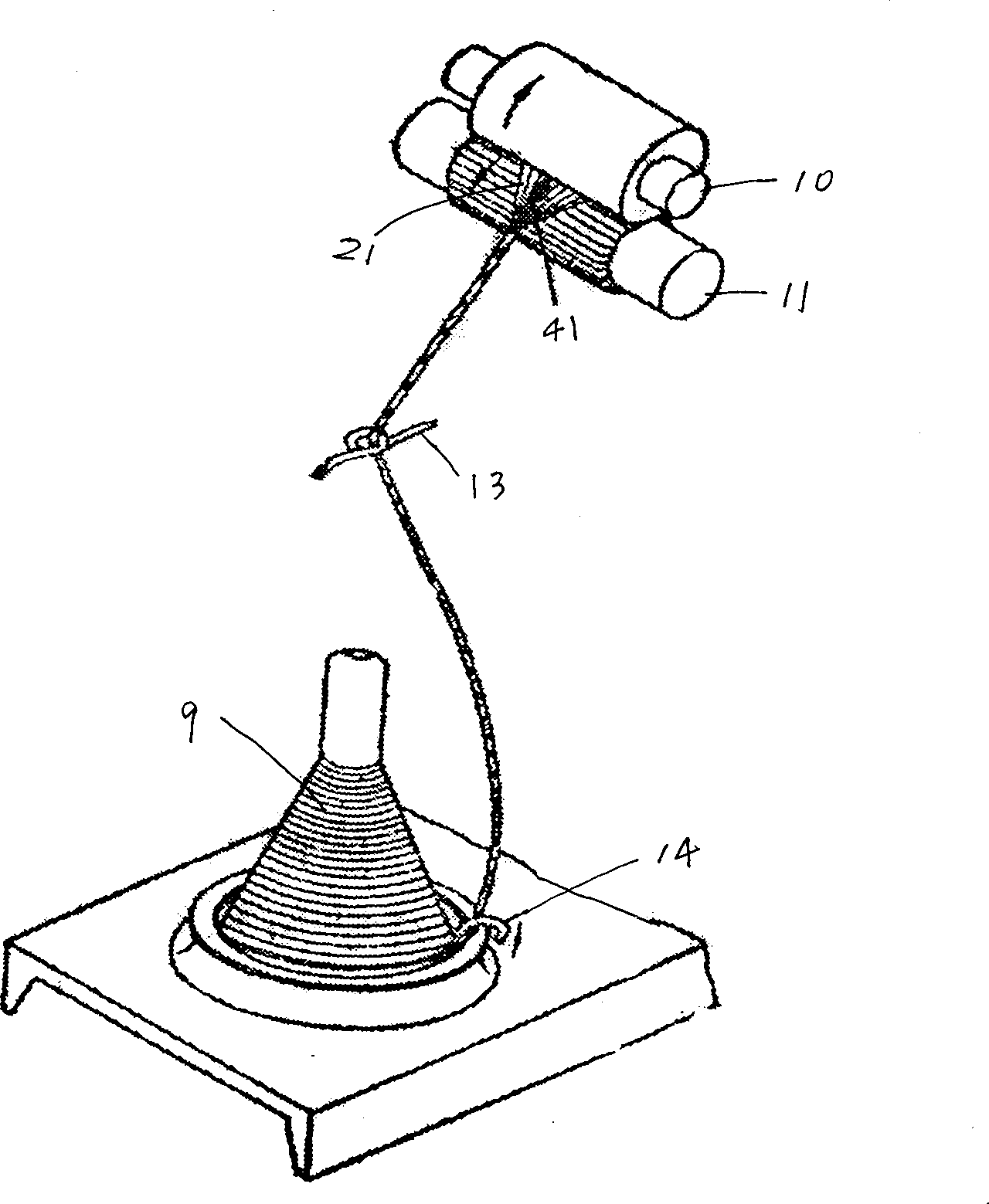

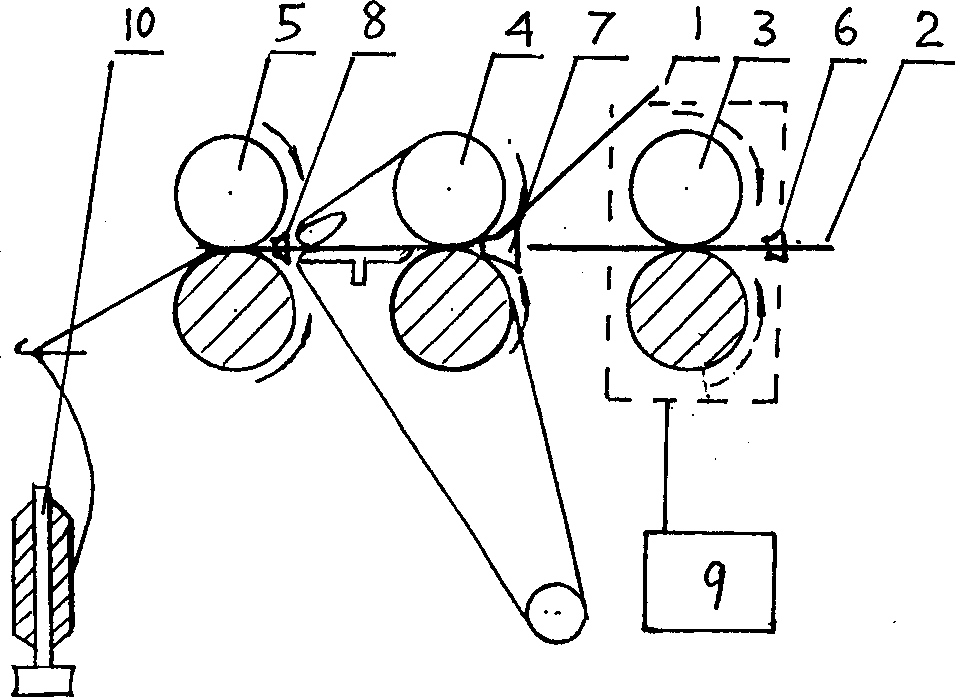

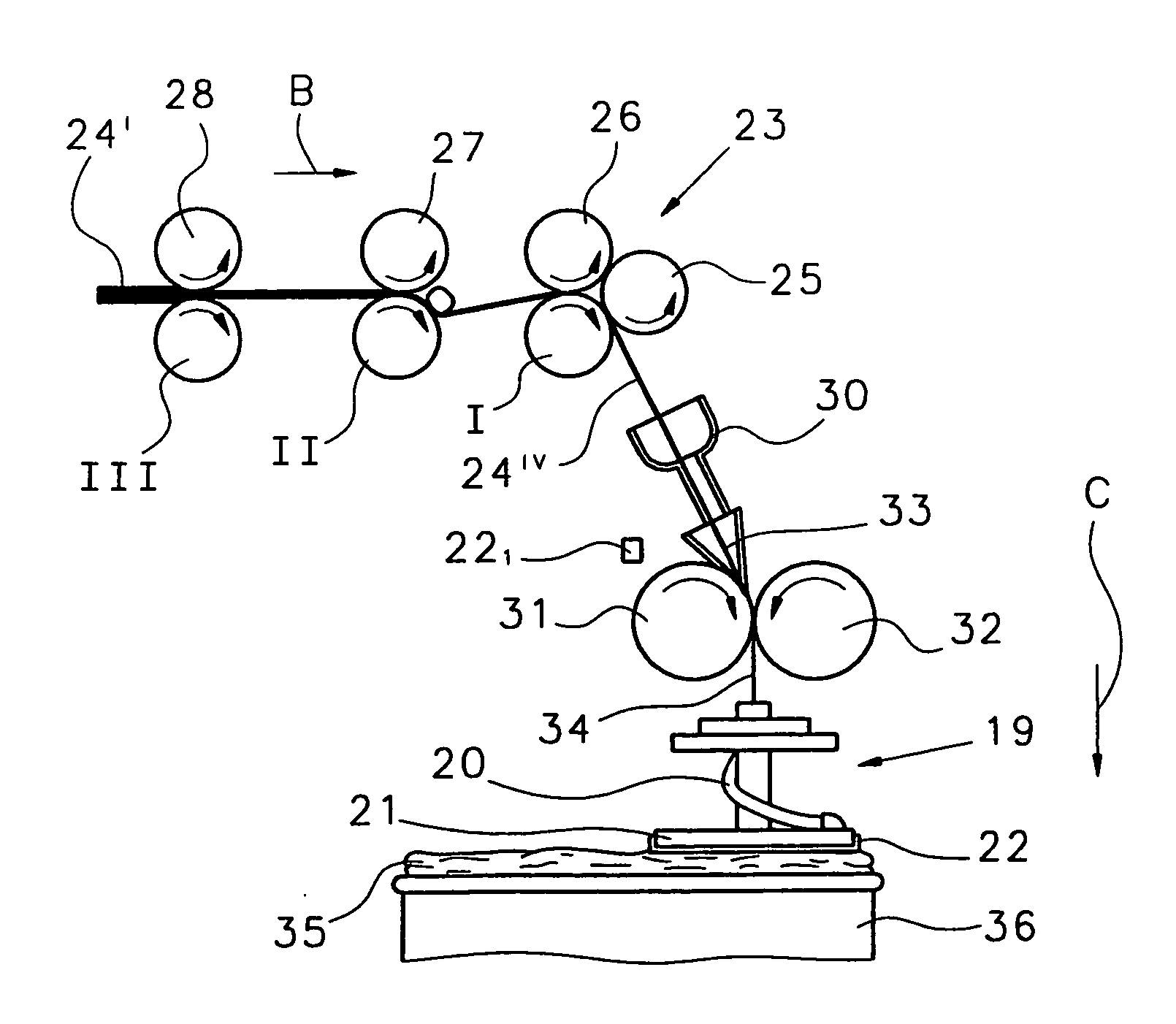

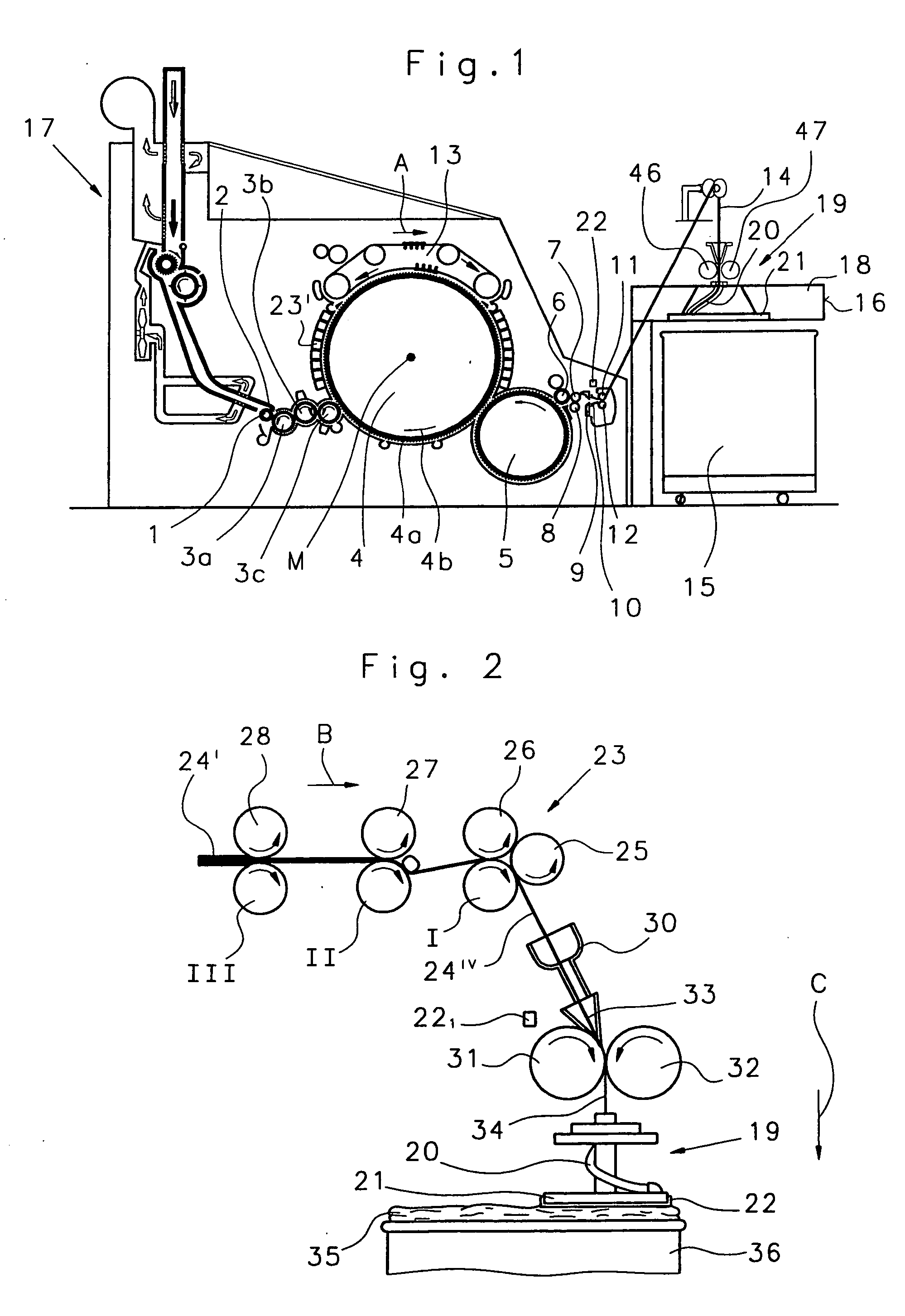

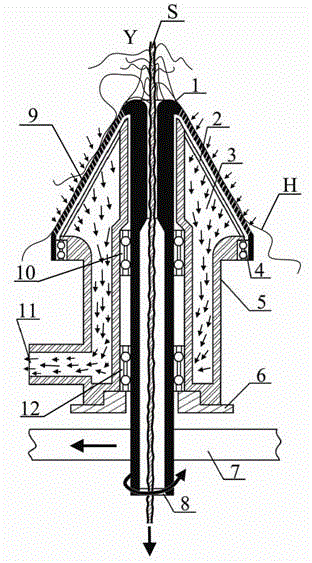

Nano electrostatic spinning and staple fiber ring spinning integrated yarn forming method

The invention relates to a nano electrostatic spinning and staple fiber ring spinning integrated yarn forming method, and belongs to the technical field of textile processing. The method comprises the following steps: arranging an electrostatic spinning apparatus between each yarn guide hook of a ring spinning frame and a front roller jaw formed by a front roller corresponding to the yarn guide hook and a front rubber roll, enabling a receiving surface of the electrostatic spinning apparatus to stay on a same plane with a public tangential surface of a front leather roll and the front roller at the front roller jaw, forming an electrostatic spinning area between an electrostatic spray head and a receiving surface of a receiving plate, and combining and twisting a nano fiber net spun out from the electrostatic spray head and staple fiber strands passing by the receiving surface of the receiving plate. According to the method, the electrostatic spinning and a conventional ring spinning are reasonably integrated, so that the high-speed successful production of nano fiber yarns is guaranteed, the naon fiber net effectively captures exposed fibers and improves the winding tightness, and the yarn forming structure and performance quality of the nano fiber wrapped blended yarns can be greatly improved. Equipment involved in the method is universal, and the operation and the use are convenient.

Owner:WUHAN TEXTILE UNIV

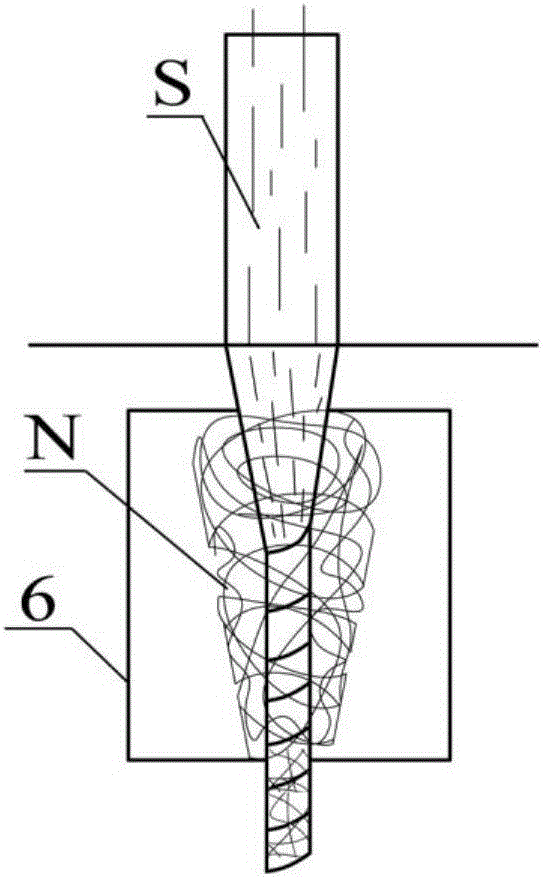

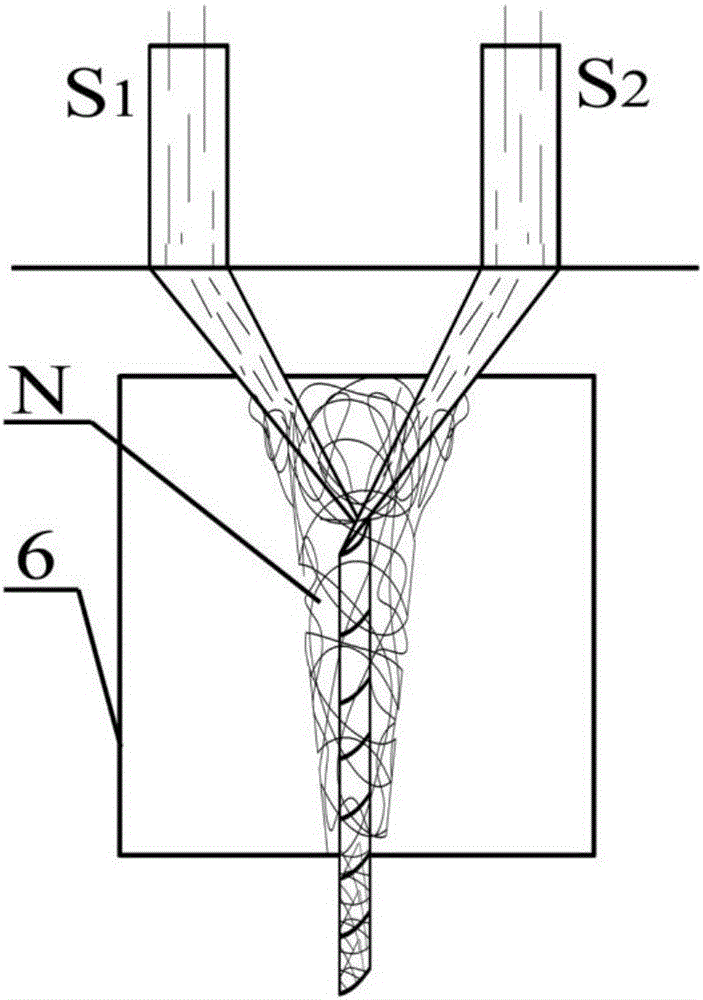

Three-axis symmetrical composite spinning process and equipment for high-elasticity composite yarn

The invention relates to a three-axis symmetrical composite spinning process and equipment for a high-elasticity composite yarn and belongs to the technical field of multi-axis composite spinning. The three-axis symmetrical composite spinning process for the high-elasticity composite yarn is characterized in that: a holding roller capable of controlling the tensile force is arranged above a front roller of the common ring spinning machine, so that a stretch yarn passing around is centrally fed into the jaw of the front roller under the isostension condition; short fiber strips on two sides of the stretch yarn are rounded by a buncher and then are fed into the jaw of the front roller symmetrically and synchronously; and after the stretch yarn and the two short fiber strips go out of the jaw of the front roller, the stretch yarn and the two short fiber strips are converged under the twisting action to form the high-elasticity composite yarn with the stretch yarn arranged inside and the short fiber strips wrapped outside. By the process, the high-elasticity composite yarn can be effectively obtained and the absolute elasticity elongation rate is 30 to 95 percent. By the process and the equipment thereof, the technical problem that the elasticity of the yarn can be improved, but the high-elasticity composite yarn cannot be obtained at present can be solved.

Owner:WUHAN TEXTILE UNIV

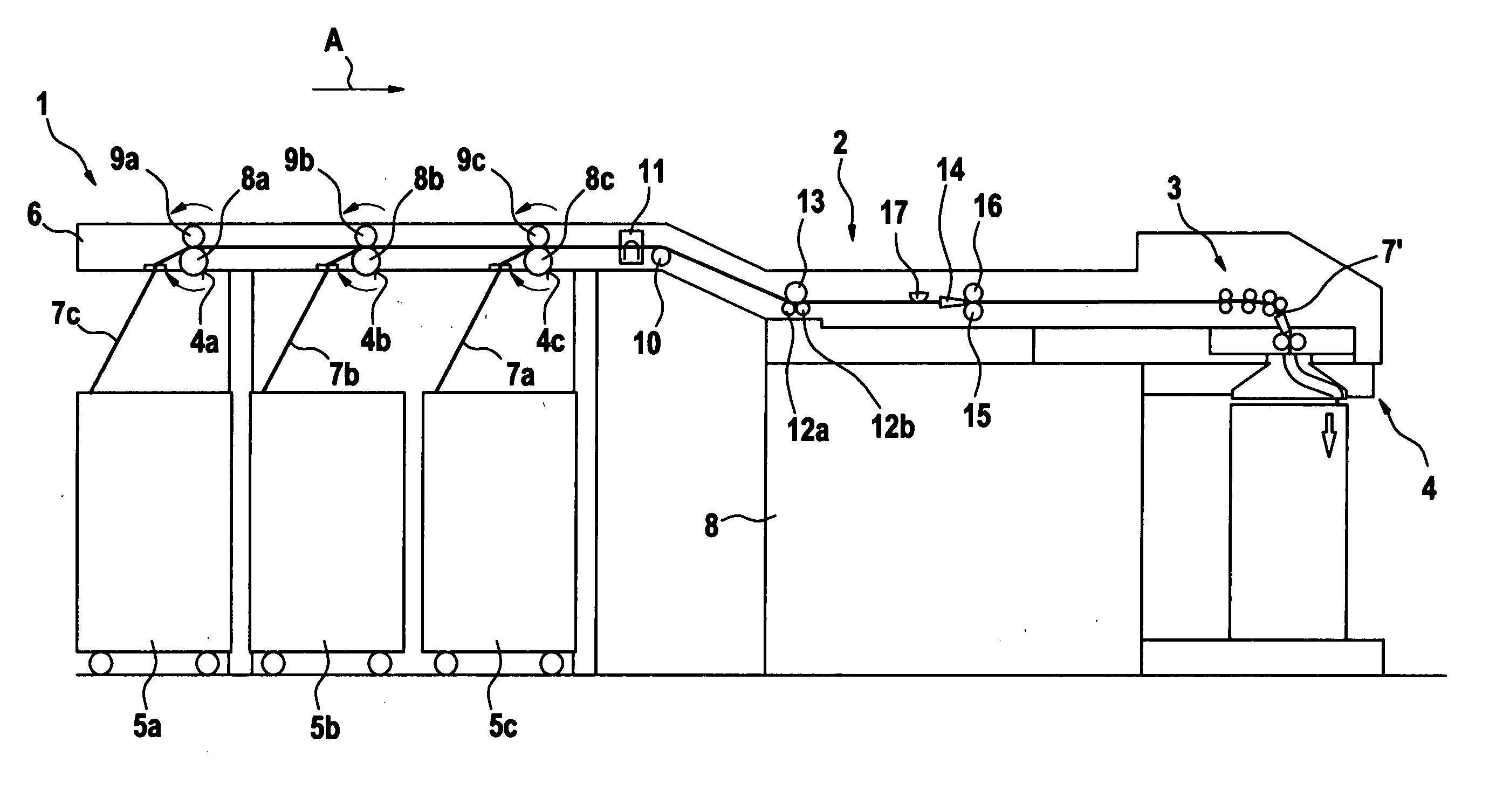

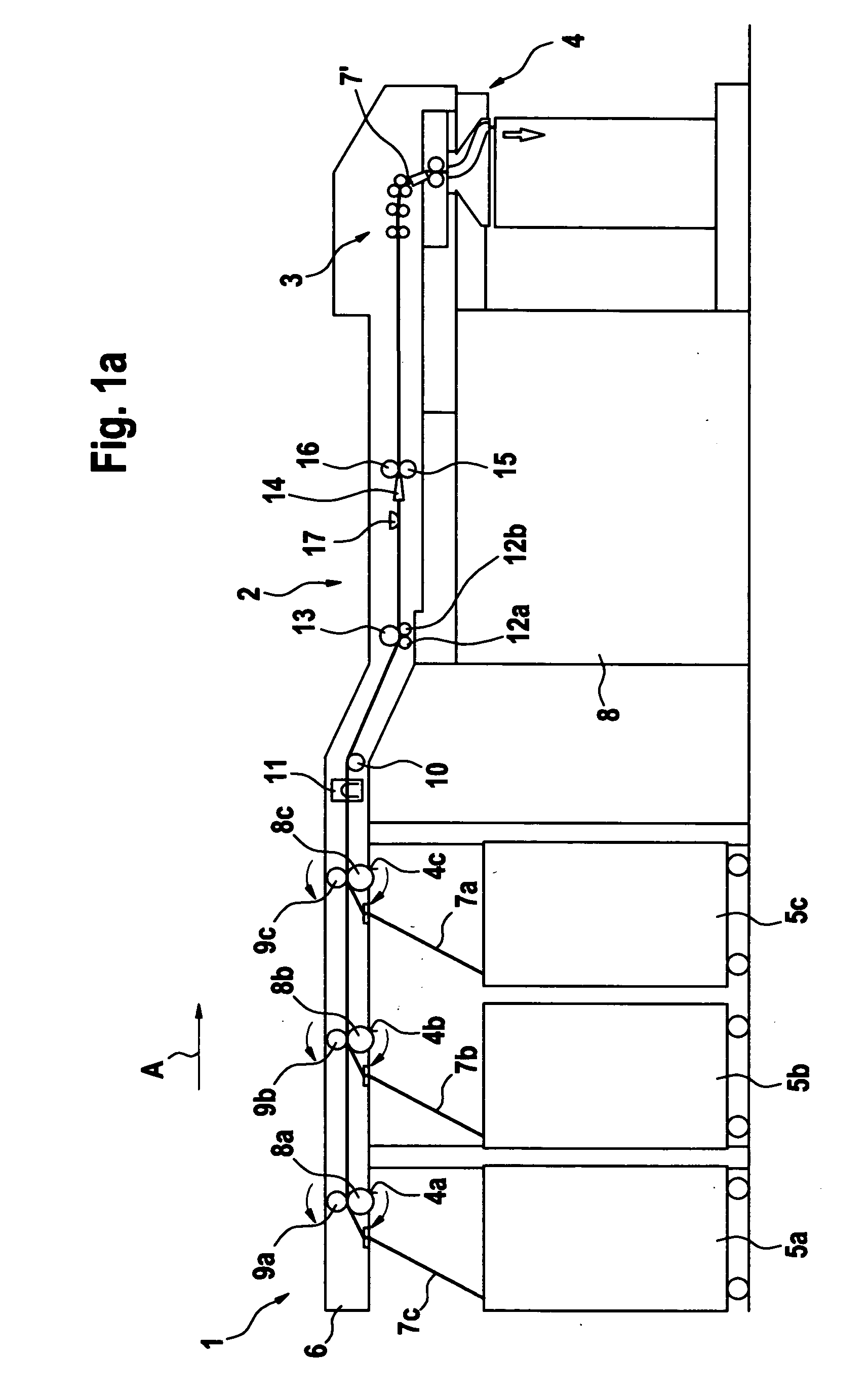

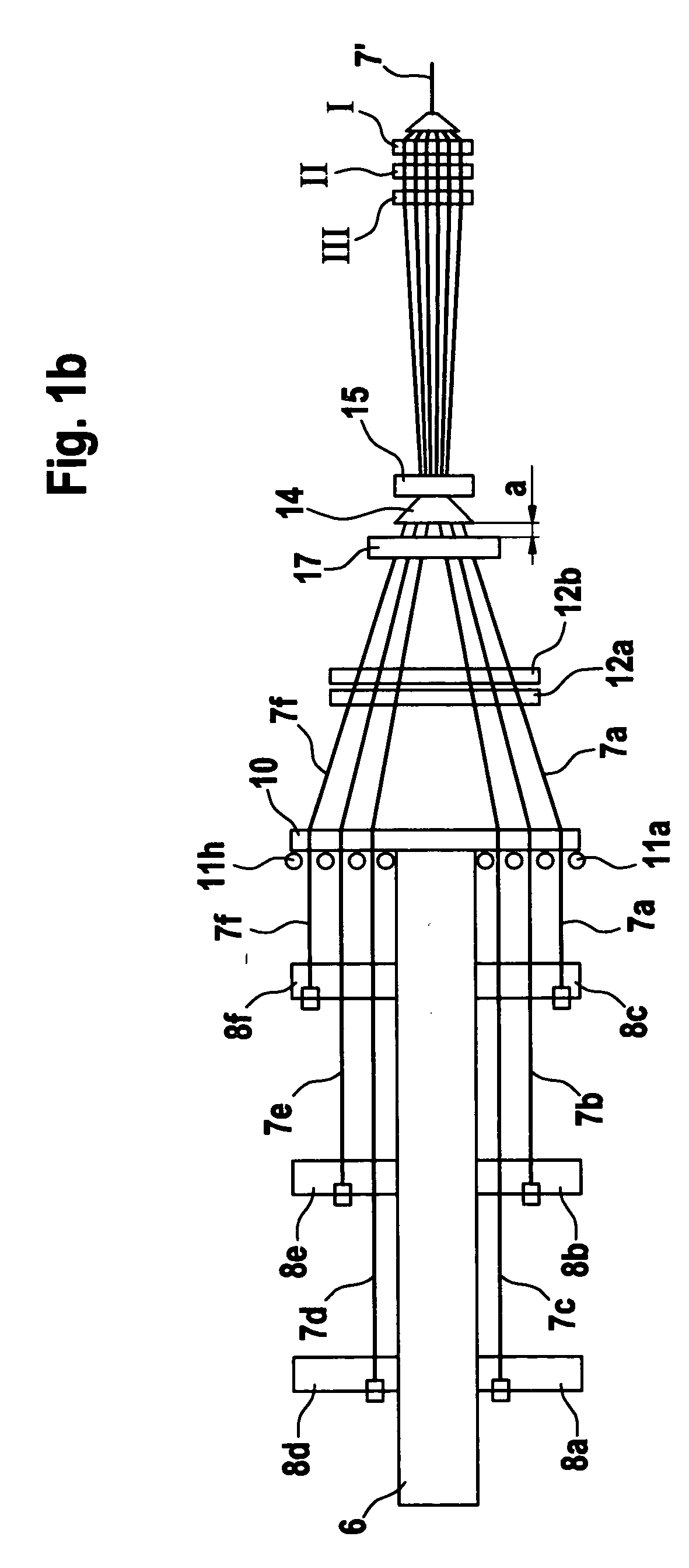

Apparatus at a draw frame for supplying fibre slivers to a drawing mechanism comprising at least two pairs of rollers

Owner:TRUETZSCHLER GMBH & CO KG

Processing method of double-component elastic spandex core-spun yarn

The invention discloses a processing method of a double-component elastic spandex core-spun yarn, comprising raw materials, production steps and production process improvement thereof, wherein the raw materials include a first elastic spandex filament, a second elastic spandex filament and wrapping yarn; the second elastic spandex filament is half of the first elastic spandex filament in diameter, and the two elastic spandex filaments differ in traction multiple; and the wrapping yarn is a short fiber; the production steps include: rolling the comparatively thick wrapping yarn into the form of a flat strip; before entering into a spinning room, guiding both the elastic spandex filaments as double cores to the middle of the flat-strip shaped wrapping yarn; folding the flat-strip shaped wrapping yarn by taking the double cores as a fold line, and covering the double cores on the fold line in the flat-strip shaped wrapping yarn; feeding the double cores and the folded flat-strip-shaped wrapping yarn into the spinning room, and stretching and twisting in an 8-shaped form to form the double-component elastic spandex core-spun yarn. The product is elastic and free from the feeling of being too tight on the body, and overcomes the shortcoming of being insufficient in elasticity or too tight.

Owner:徐州时代纺织有限公司

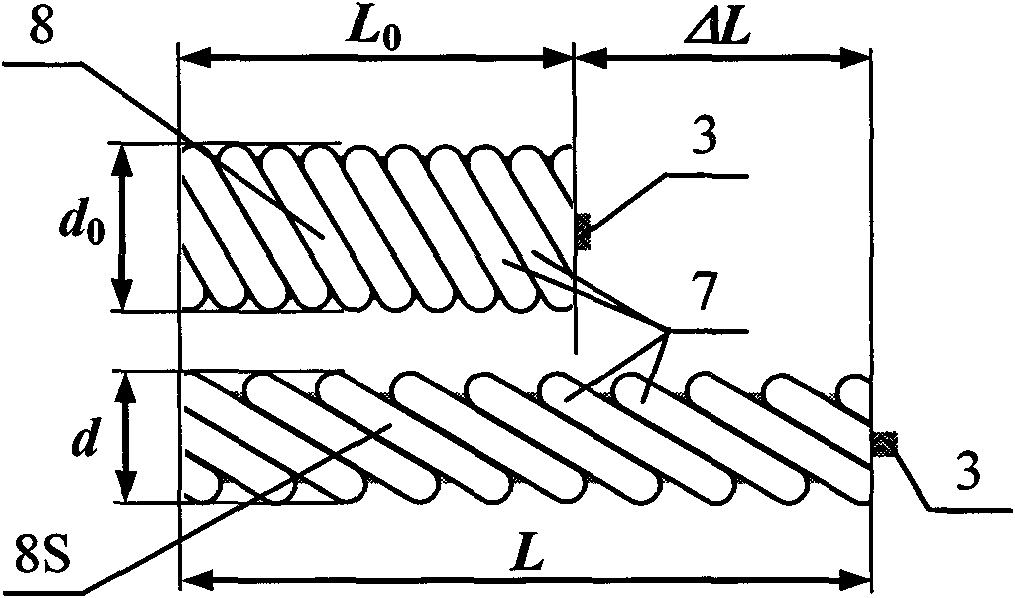

Method for producing colorful yarns by blending tricolor rough yarns and colorful yarns prepared through method

The invention discloses a method for producing colorful yarns by blending tricolor rough yarns. The method includes the steps that three rings of a back roller of a tricolor yarn coupling and drafting system independently rotate, and the sum of the surface linear speeds of the three rings of the back roller is maintained to be a constant or the sum of the drafting multiples of the three colored rough yarns is maintained to be a constant, and then the colorful yarns with uniform thickness and random colors can be obtained, wherein the three rings of the back roller are embedded into a mandrel. Compared with the prior art, the produced colorful yarns are richer in color, and the method is simple and practical.

Owner:JIAXING UNIV

Section coloured yarn and its spinning device and spinning method

A segmentally colored yarn is disclosed, which features that in has different colors longitudinally. Its spinning apparatus features that a feed roller behind the third roller, a controller and a driver are additionally used. Its spinning method features that the draft in the primary draft region for the first group of fibres is formed by the fourth roller, the third roller, and the first and the second apron rollers of spinning frame, and the draft in the primary draft region for the second group of fibres is formed by the fourth roller, the third roller, and the first roller and the second apron roller of spinning frame.

Owner:上海日舒棉纺织厂

Ring spun sectional-color yarn and preparing method and device thereof

InactiveCN102560759AAchieve reproductionAccurately control segment color lengthDrafting machinesFiberYarn

A ring spun sectional-color yarn preparing method includes: feeding a first group of fiber strips and a second group of fiber strips with yarn density tex of Tst and Tnd into two back rollers and two middle rollers pairwise from a yarn guide rod, a splitting grate and a distance separation bell mouth, controlling rotation speed of the middle rollers by stages through a computer program controller, feeding the fiber strips to the front rollers while keeping the sum of feeding of the first group and the second group of the fiber strips constant, aggregating loosened small fiber strips of the group A and the group B drafted and output from the front rollers under the guide action of air after passing a Y-shaped guide groove on the surface of a negative-pressure suction aggregation pipe, outputting the aggregated fiber strips to a guide rubber roller and twisting the same to be sectional-color yarns with identical yarn density.

Owner:陈伟雄

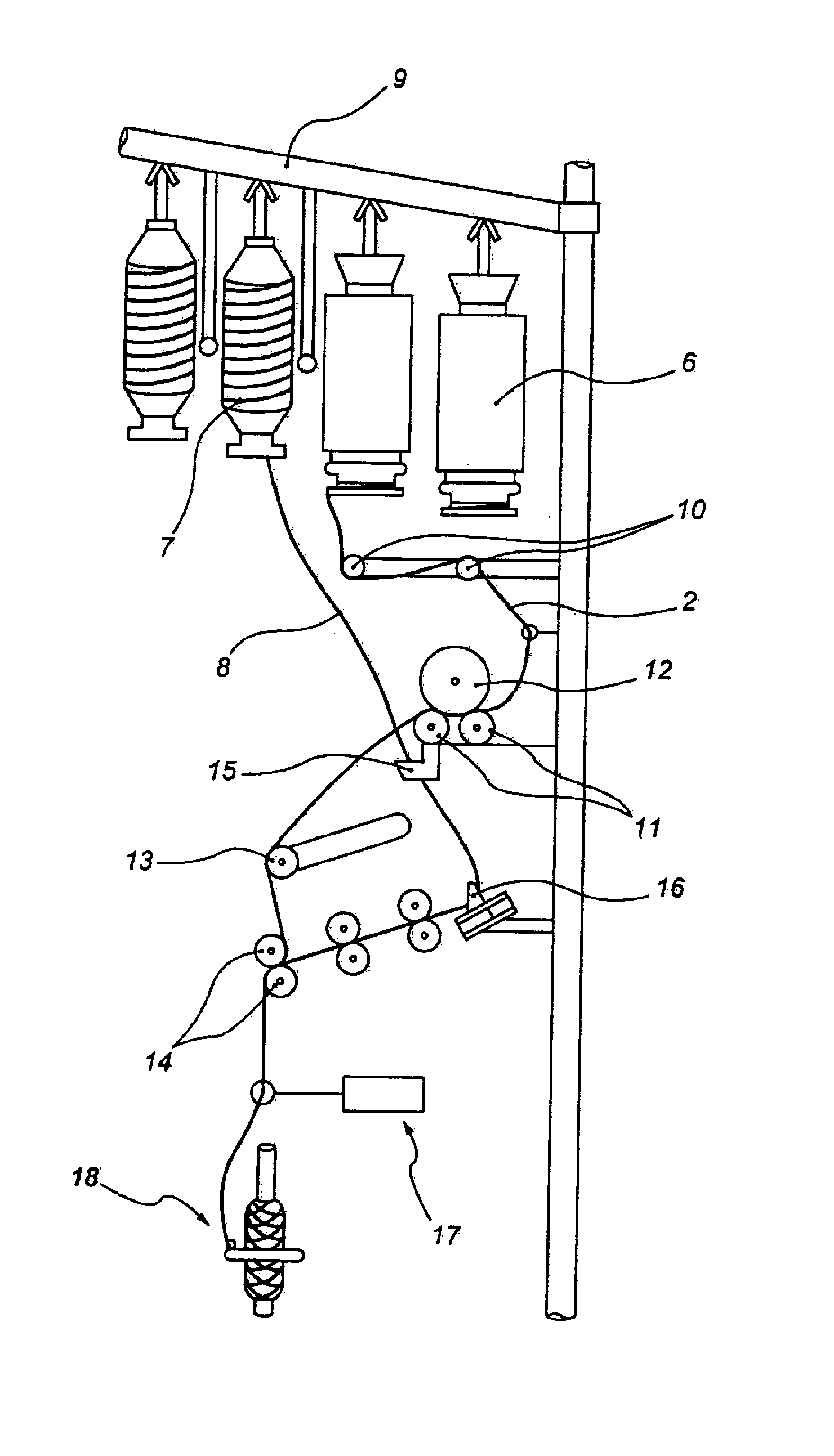

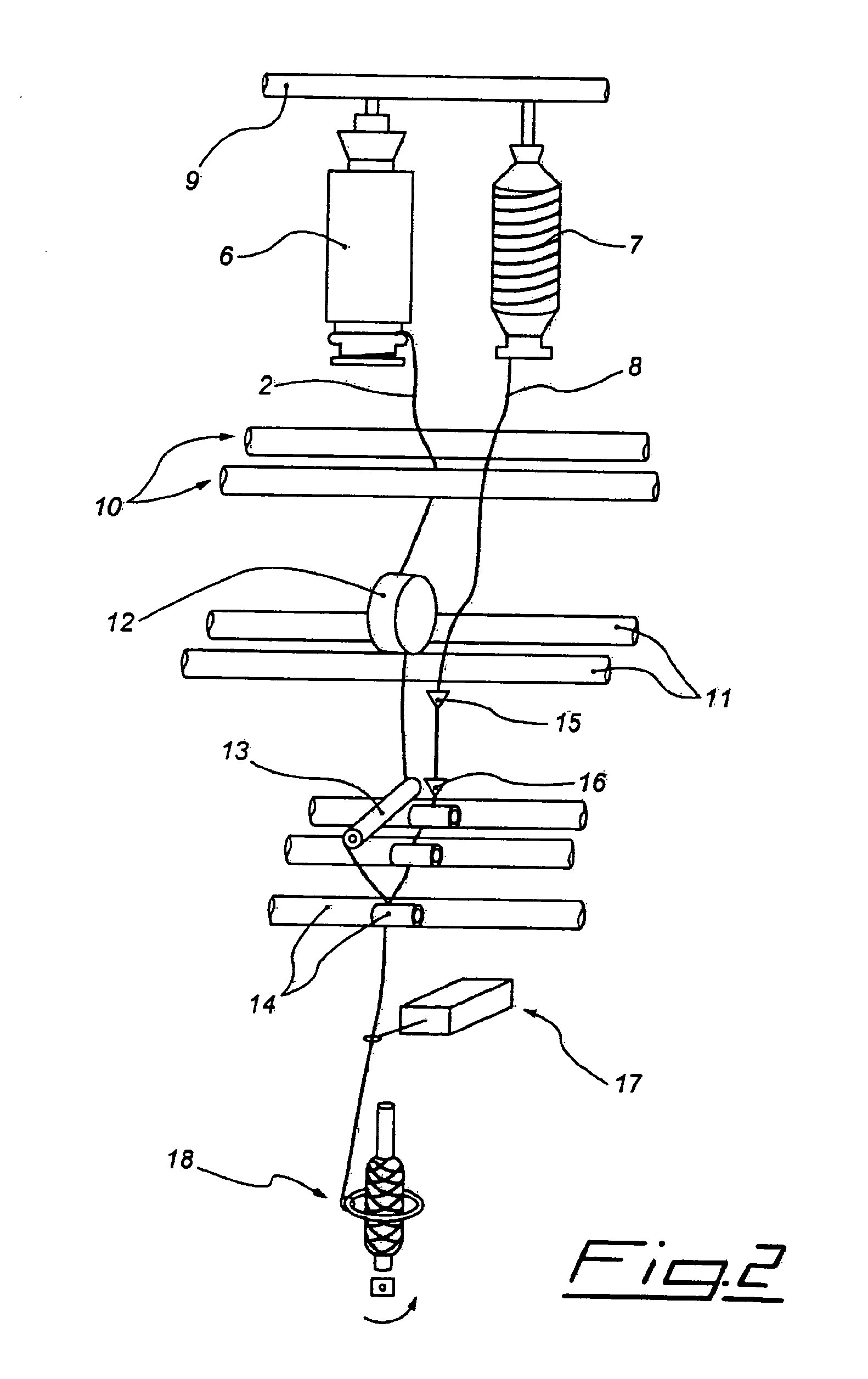

Preparation method of yarn with long and short fiber compound structure

InactiveCN101736469AEasy to transformEasy to operateDrafting machinesContinuous wound-up machinesBobbinCompound structure

The invention discloses a preparation method of a yarn with a long and short fiber compound structure, belonging to the technical field of textile processing. The preparation method comprises the following steps of: feeding short fiber rove fiber strands unwound from a rove tube into a drafting zone through a yarn-guiding horn for drafting on a drafting mechanism of a ring spinning frame; feeding at least three filaments into a front jaw from the rear end of a front roller at an interval of 0.1-3mm; jointing the filaments and the rove fiber strands at the jaw part; outputting and feeding drafted rove fiber strands and the filaments from the front jaw into a twisting triangular zone; twisting the rove fiber strands and the filaments into the yarn and winding the yarn on a spun yarn bobbin; and forming compound yarns with different structures according to the space among the filaments and the different relative positions of the rove fiber strands. The invention can prepare yarns with a unique internal space structure and an external surface structure on the ring spinning frame, enhances the strength, the wear resistance and the bend resistance of the yarns, has favorable conformality of textures and can achieve the effect of wearing after washing. The invention realizes the preparation of the yarns with special structures and special functions on the traditional spinning equipment.

Owner:SOUTHWEST UNIVERSITY +1

Method and apparatus for manufacturing slalom false twisting on ring yarn

InactiveCN101643948AHigh strengthThe contact angle can be adjustedDrafting machinesContinuous wound-up machinesFiberYarn

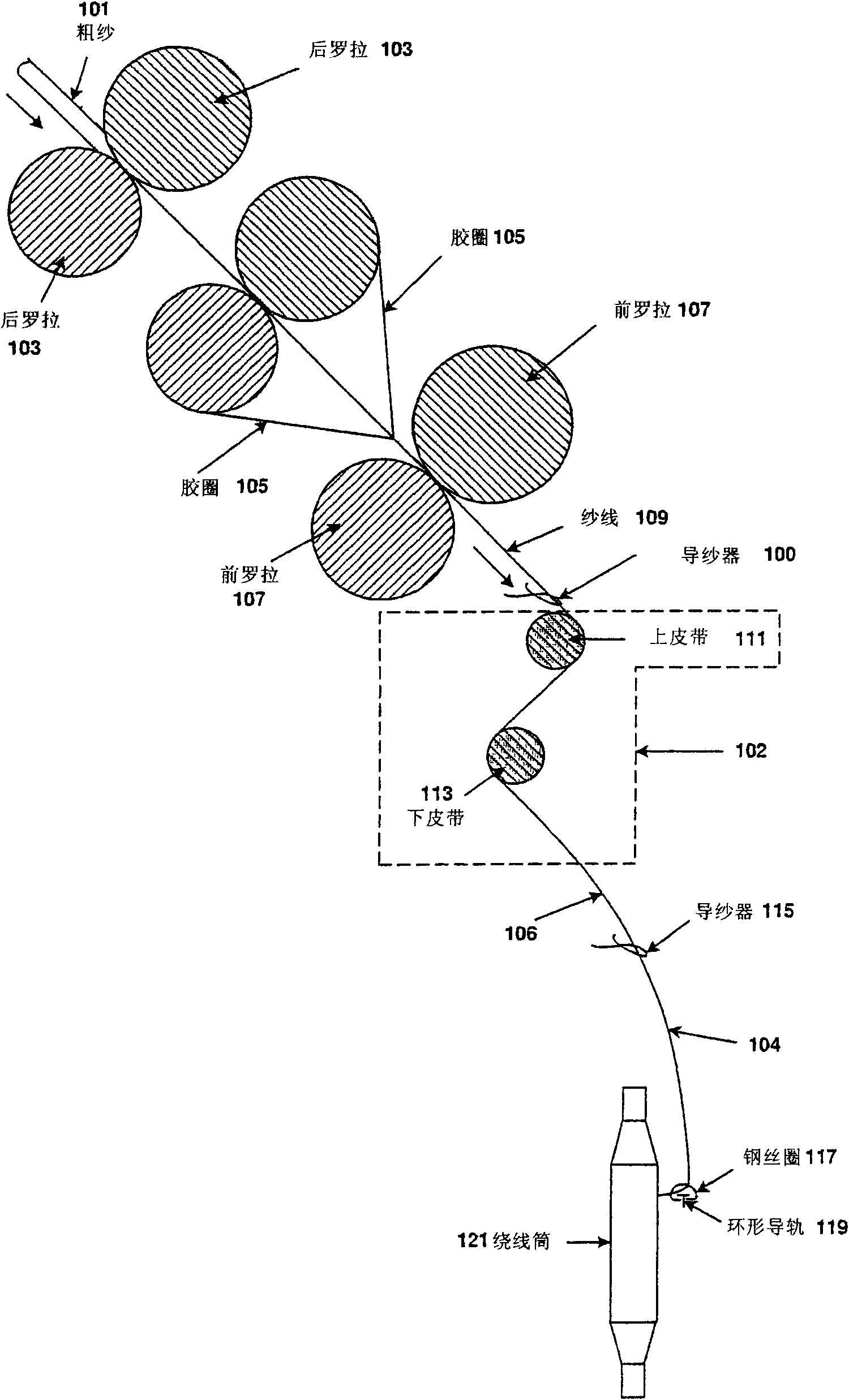

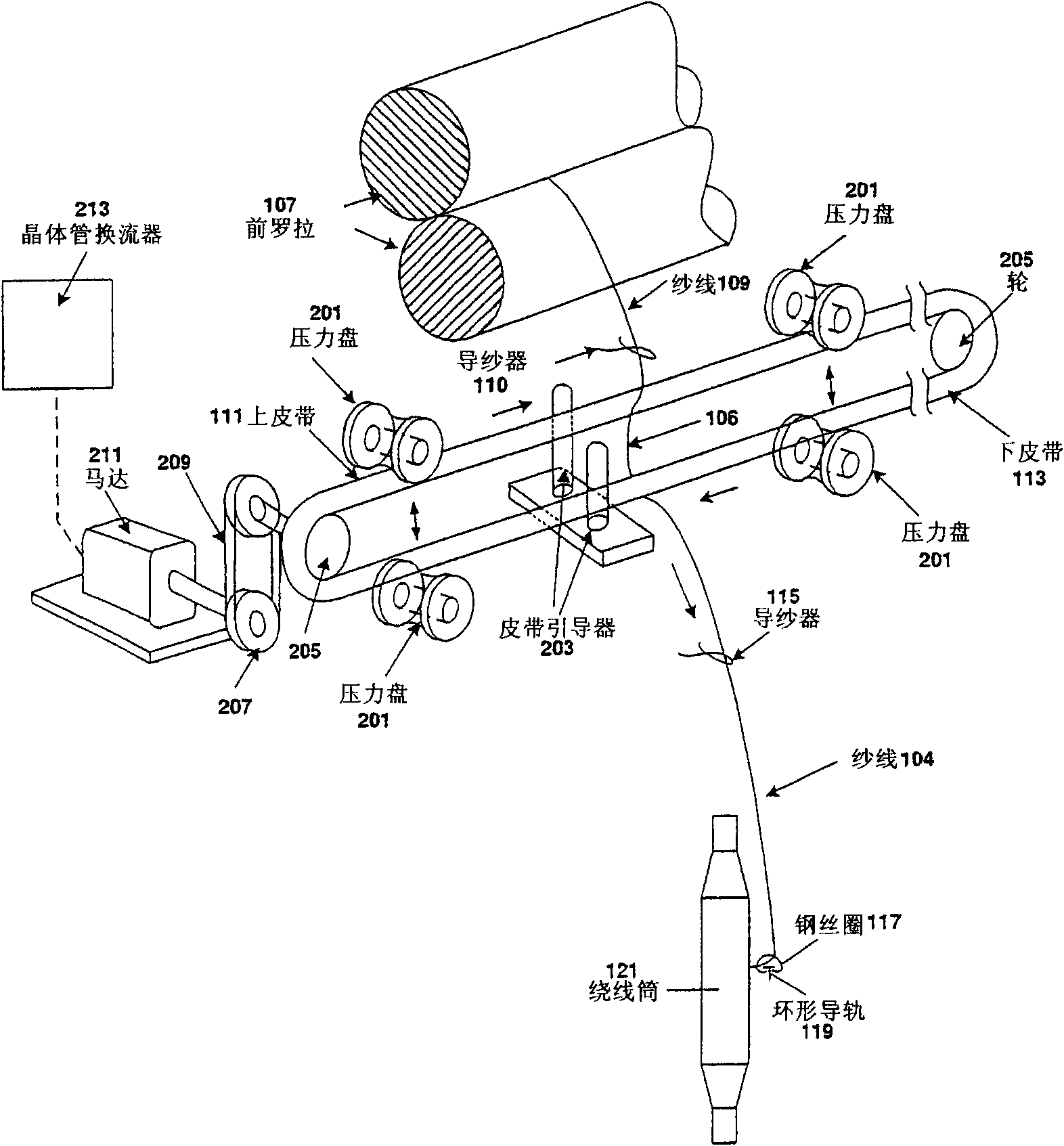

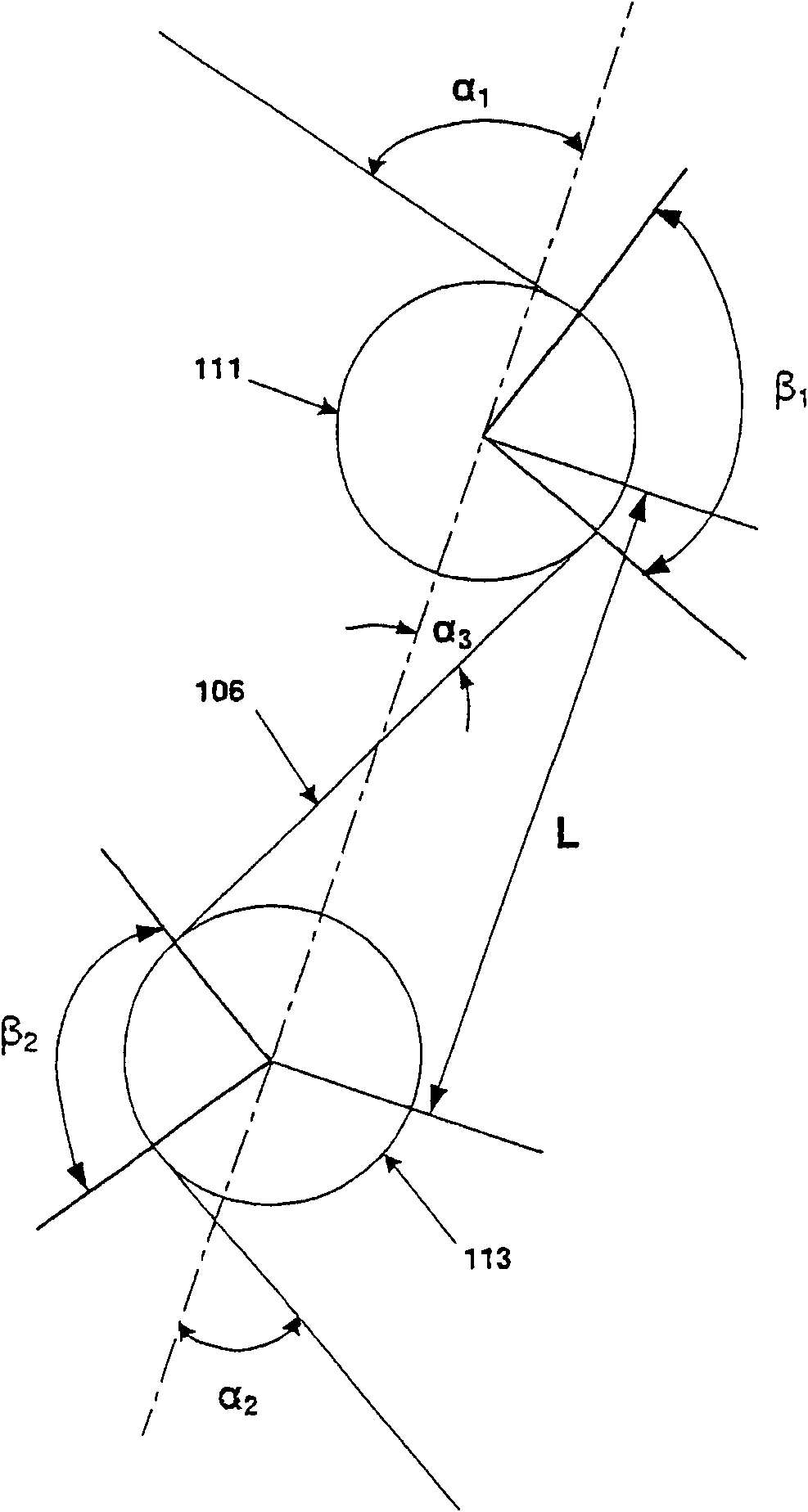

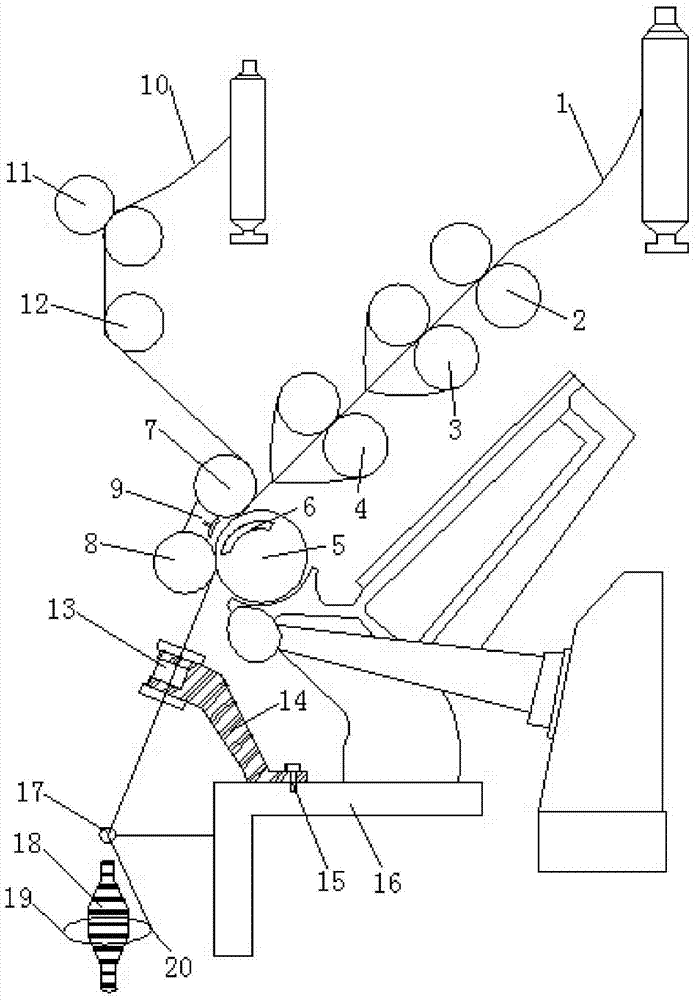

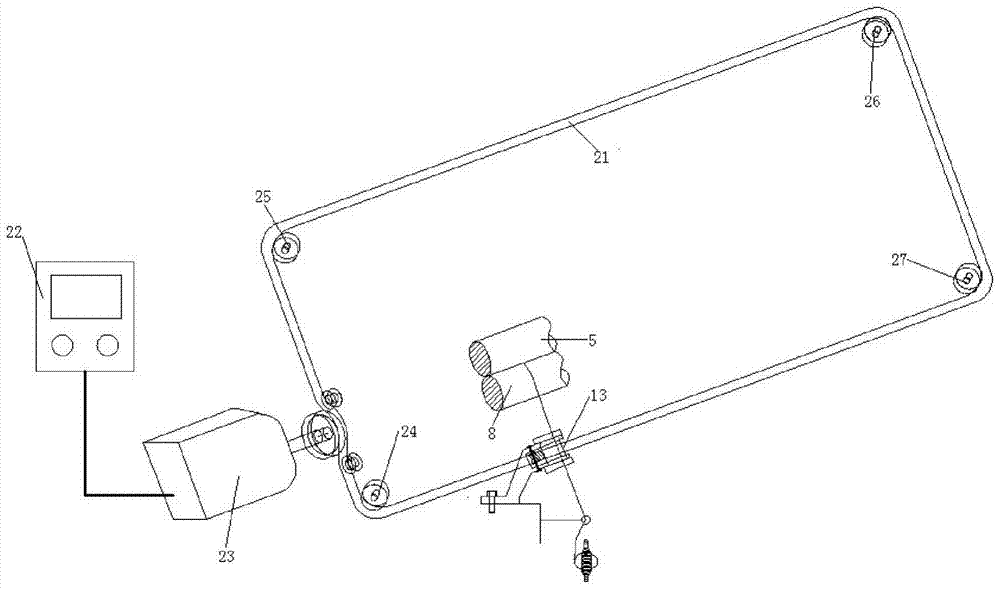

A process and apparatus for manufacturing a singles ring yarn, which utilizes double belts (111,113) as a false twist device and incorporates it in a conventional ring spinning machine for producing asingles ring yarn. In this process, double-belts are applied, and thus two twisting points, instead of one twisting point, are applied for the false twisting of the yarn, which improves the false twist efficiency. Accordingly, the ratio of the velocity of the belt to the delivery speed of the yarn is controlled and the wrapping angle of the yarn on the belts is adjusted in order to obtain the desired property of the final singles ring yarn. The process can enhance the strength of fiber strand at the spinning triangle and thus ensure that yarns are spun in normal conditions at a low twist multiplier, which is unable to be obtained by a conventional ring spinning machine.

Owner:THE HONG KONG POLYTECHNIC UNIV

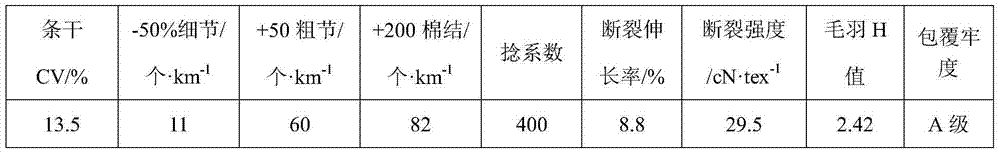

Low-twist, high-strength and little-fuzz yarn production method and yarn

The invention discloses a low-twist, high-strength and little-fuzz yarn production method and yarn. The method includes the opening picking process, the cotton carding process, the fine carding process, the drawing process, the roving process and the yarn spinning process. A larger-diameter and narrow-groove negative pressure hollow roller and a corresponding air draft assembly are adopted for the method, and therefore generated fuzz can be effectively reduced; under the condition that a mechanical friction twist device is adopted in the yarn spinning segment to reduce the twist coefficient by 15-30%, the single yarn strength is kept unchanged, polyester filament yarn serves as core silk so that the kind adaptability of the yarn can be effectively improved, the yarn strength is enhanced, the rotating direction of the twist device is opposite to that of a spindle, the twist stopping effect can occur, the width of a twisting triangular area is increased, the wrapping effect of core yarn is favorable for being improved, and a foundation is laid for developing fabric with good soft comfort. The low-twist, high-strength and little-fuzz yarn is produced with the method. Under the condition that the designed twist coefficient is reduced by 16-28%, compared with a normal designed twist coefficient, the strength is improved by 3-5%, resultant yarn is 3mm or longer, and the harmful fuzz is reduced by 80-95% compared with harmful fuzz in ring spun yarn.

Owner:WUJIANG JINGYI SPECIAL FIBER

Method for producing multicolor composite slub or satin color yarn series, shell fabric and yarn

The invention discloses a method for producing a multicolor composite yarn. The method includes that a roller device is added to a spinning frame, the process is adjusted, and a clearance motion is formed between the added roller and a prior middle roller, so that a prior two colored yarn of a component of a yarn is changed, and the multicolor composite yarn is obtained. The yarn and the shell fabric which is produced by the yarn have the advantages that the yarn and the shell fabric are multicoloured and extremely suitable for the current market of diversified demands, and the cloth has various colors.

Owner:RUGAO CITY DINGYAN TEXTILE

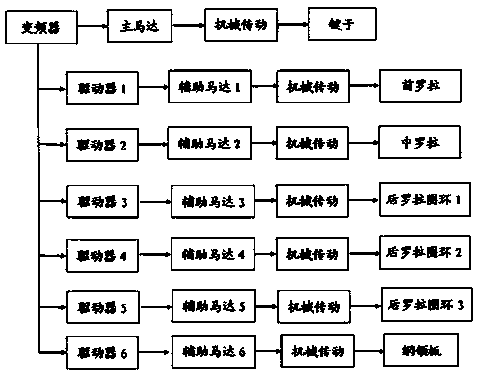

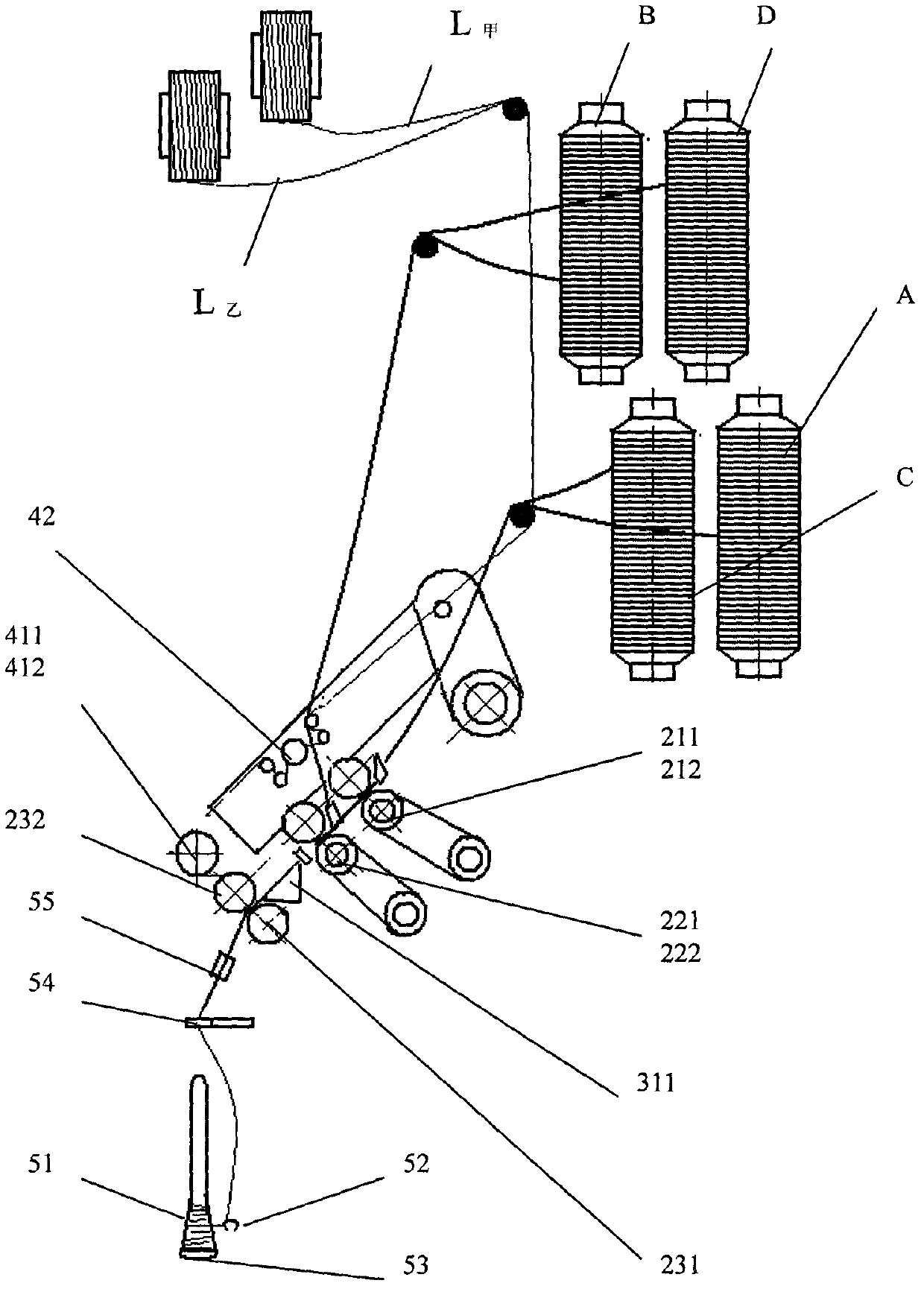

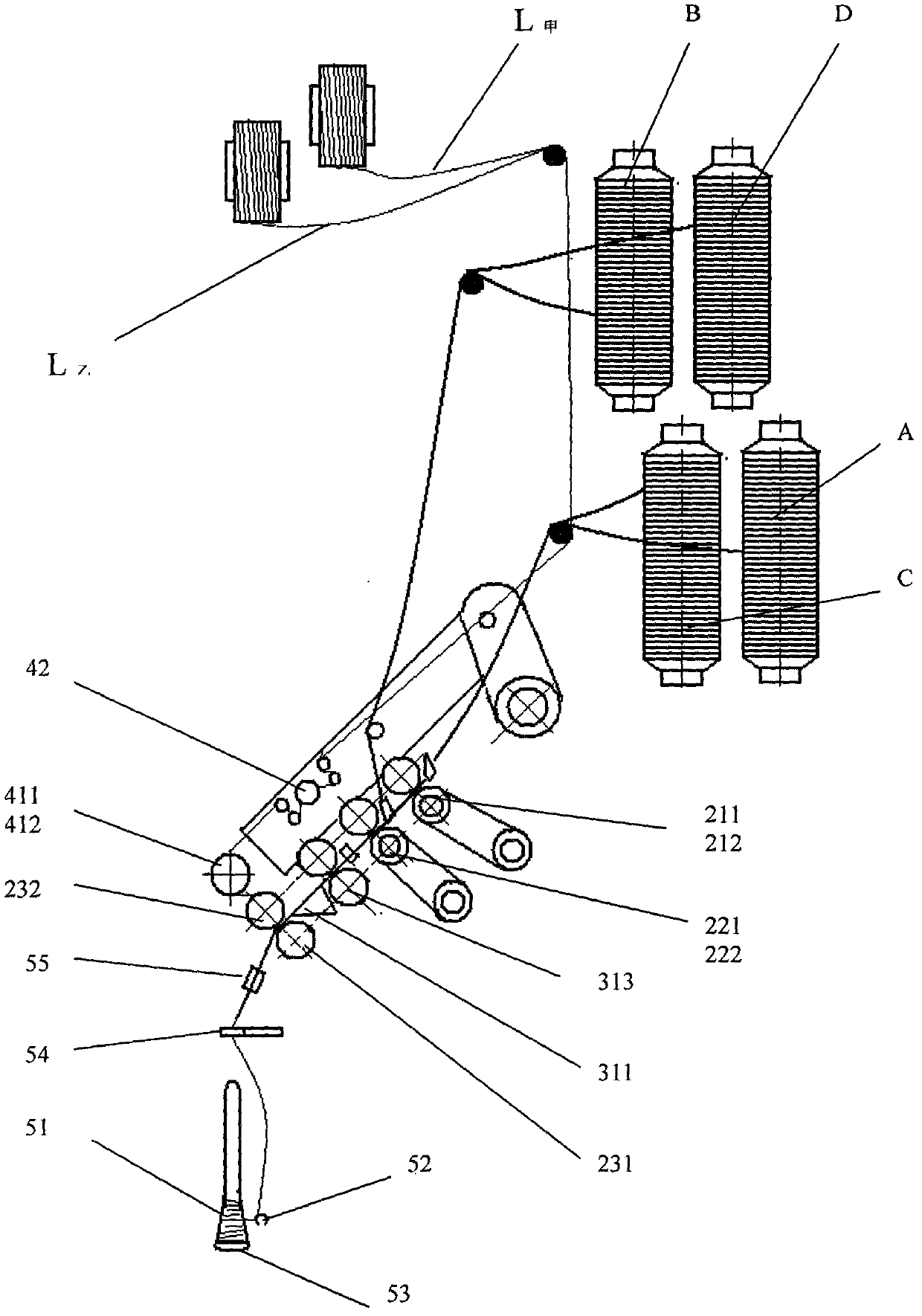

Multi-color embedding type section colorful spinning method, and device and product thereof

ActiveCN103276485ARealize segmented feedingRealize independent feedingDrafting machinesYarnEngineeringAbnormal shaped

The invention provides a multi-color embedding type section colorful spinning method, and a device and a product thereof. Four feeding rollers which are driven by servo motors in an independent mode are utilized to form a drawing area with a front roller, a negative pressure special-shaped pipe, a grid ring and a grid ring transmission roller in the drawing area constitute a negative pressure holding and sliding moving mechanism of roving, the feeding rollers are controlled through a computer program controller, and interval feeding and drawing of four roving filters are achieved. By means of twisting of two filament yarns and self rotation in a twisting process, various filter strips which are output in a sectioned mode are twisted into co-mingled yarns, and multi-color embedding type section colorful spinning is achieved.

Owner:海安市春华线业有限公司

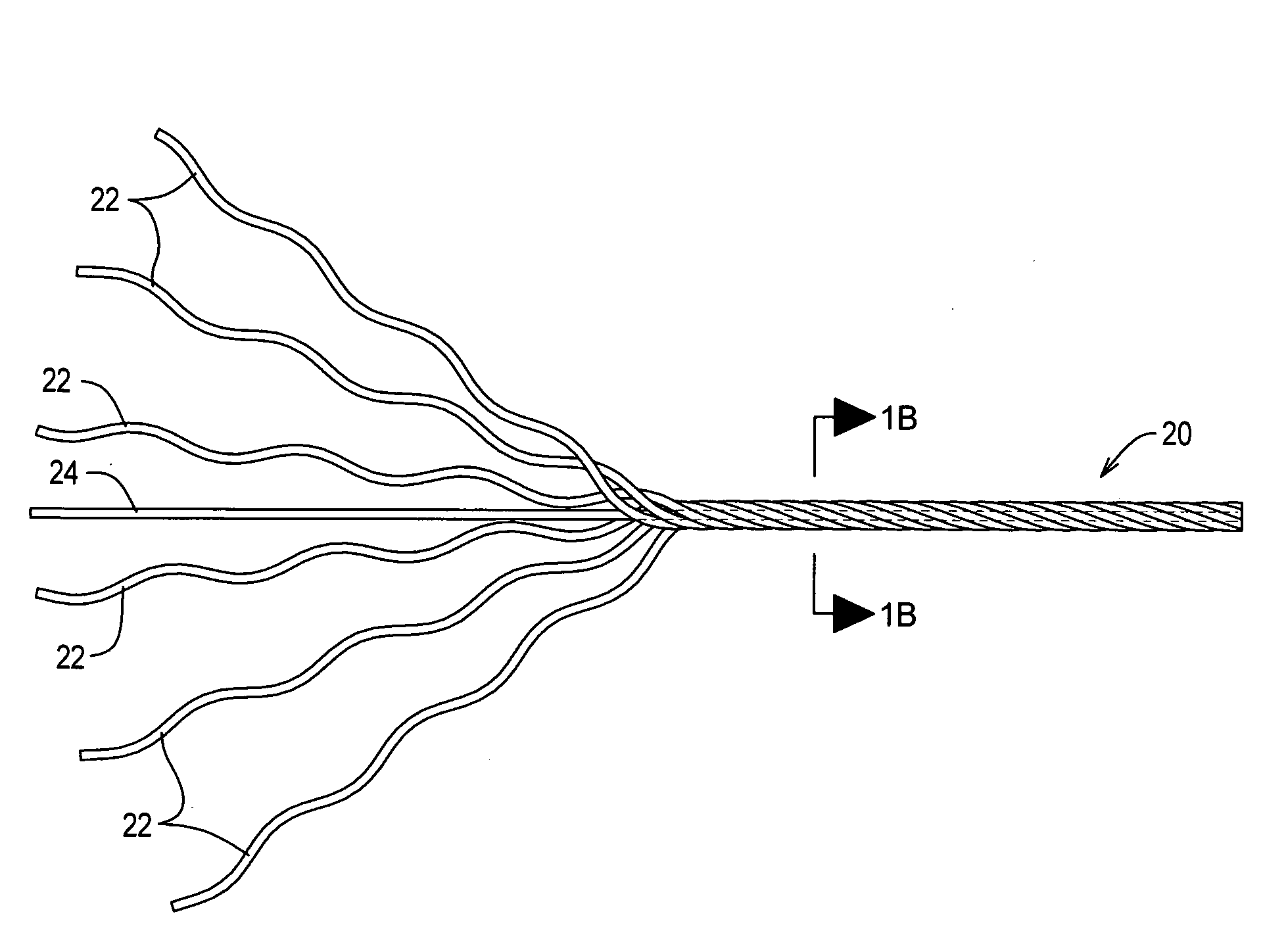

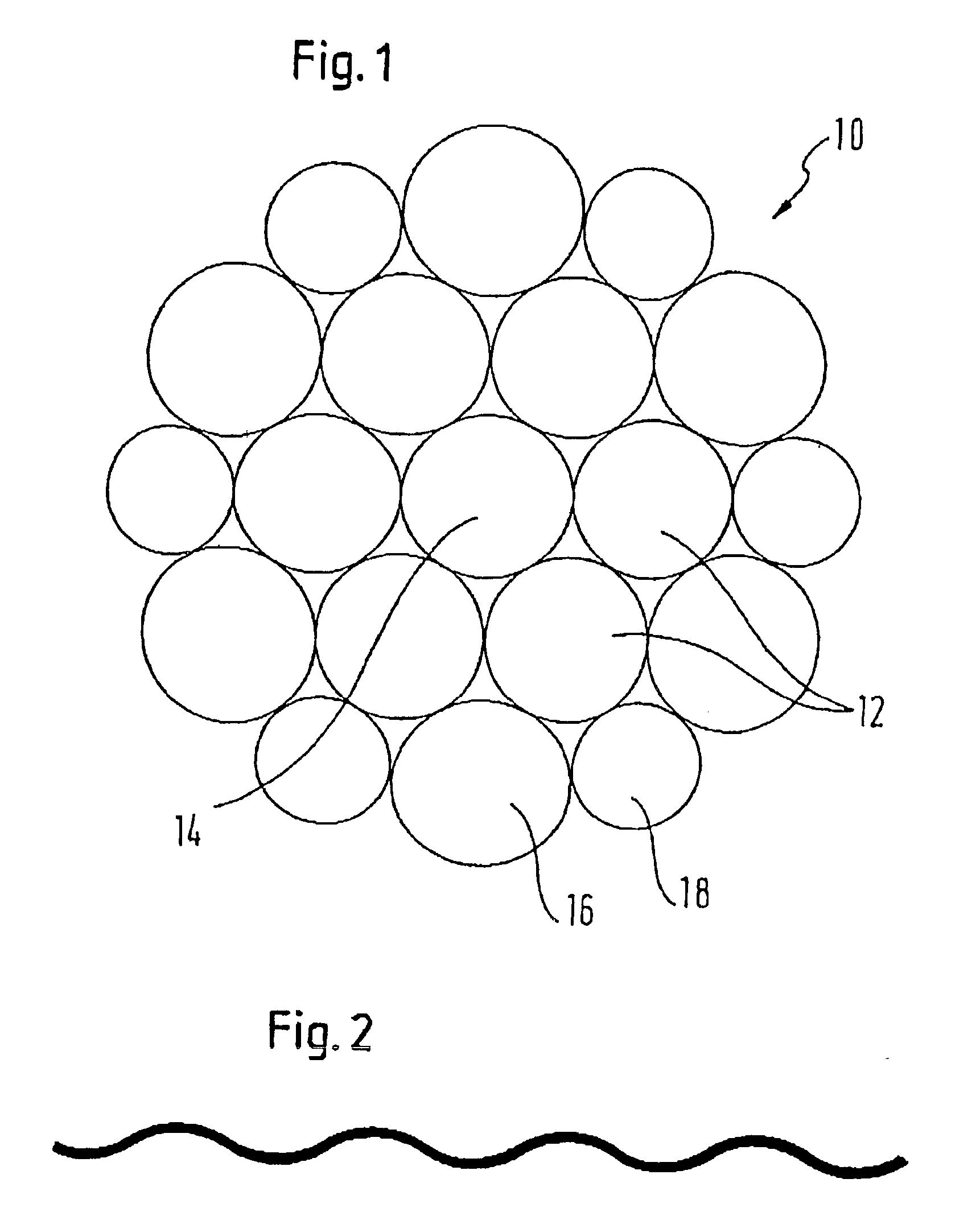

Composite rope structures and systems and methods for making composite rope structures

A rope structure comprising a plurality of formed composite strands. Each of the formed composite strands comprises fiber material and matrix material. The fiber material within the matrix material is twisted. The shapes of the plurality of formed composite strands are predetermined to facilitate combination of the plurality of composite strands into the rope structure.

Owner:SAMSON ROPE TECH

Method of improving yarn surface structure in positive holding rotation mode

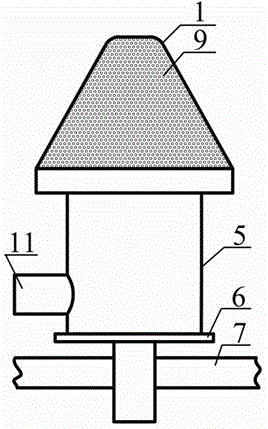

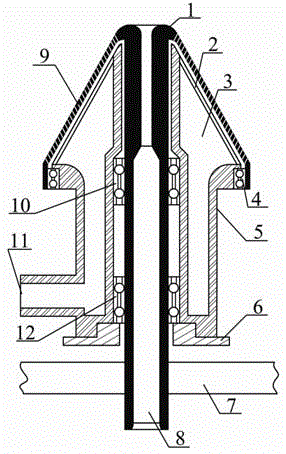

The invention relates to a method of improving a yarn surface structure in a positive holding rotation mode and belongs to the technical field of textile processing. According to the method, a front central positioning yarn guide hook, a holding rotation type yarn hairiness reducing device and a rear central positioning yarn guide hook are arranged on the operation path of each yarn in sequence, wherein each yarn enters the holding rotation type yarn hairiness reducing device through the front central positioning yarn guide hook; the trunk of the yarn enters the center of a yarn channel and keeps a tensioning straightening state, the surface hairiness of the yarn is subjected to a negative pressure air draft effect, the hairiness is absorbed on the outer surface of a conical housing and synchronously rotates along with the conical housing, and meanwhile, at the inlet of the yarn channel, the hairiness continues tightly winding the operating yarn trunk, and the smooth densifying treatment is realized on the yarn surface structure. The method is wide in applicable range and can be used for processing various yarns; the holding rotation type yarn hairiness reducing device is reasonable in structure and convenient to operate.

Owner:WUHAN TEXTILE UNIV

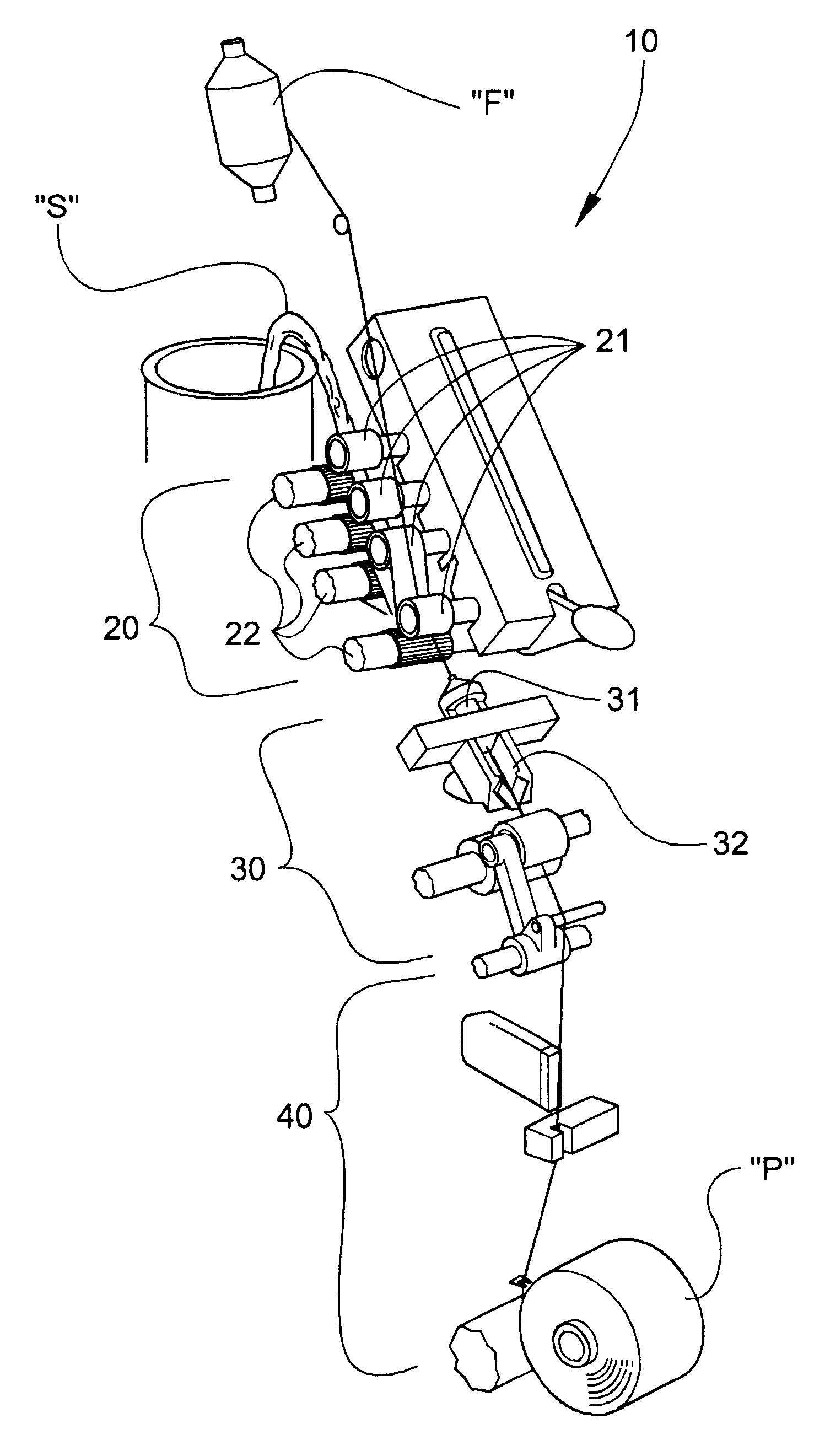

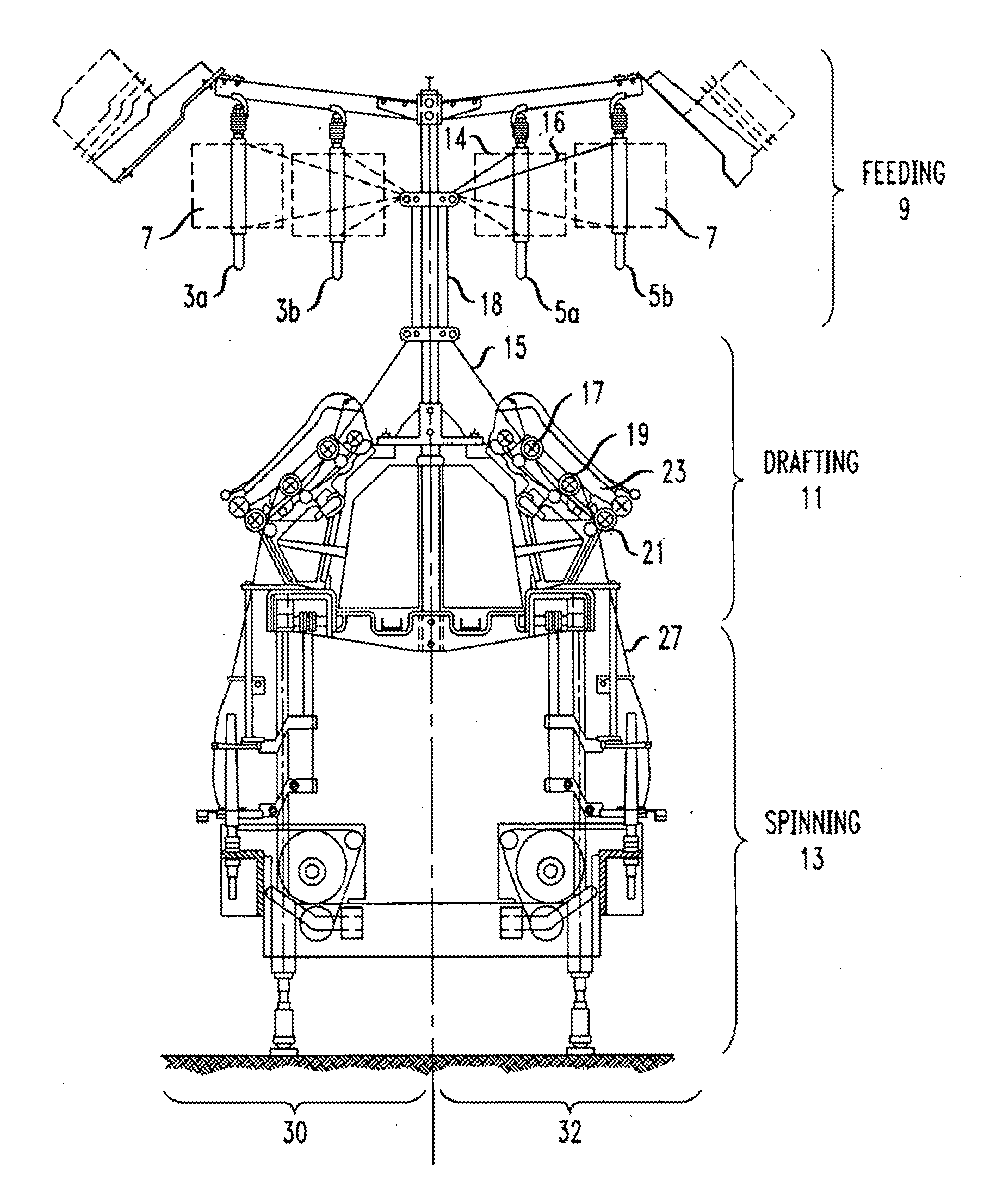

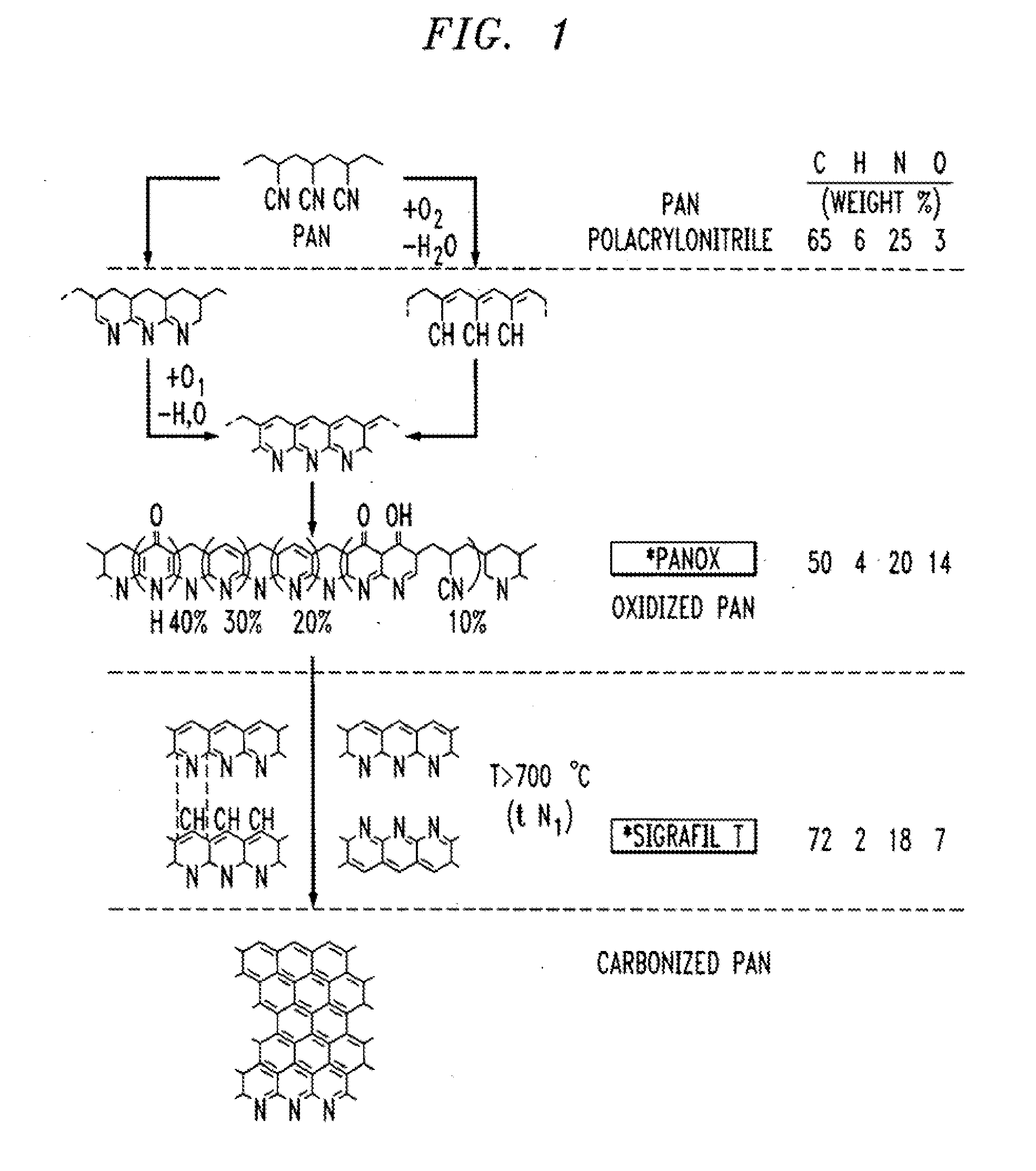

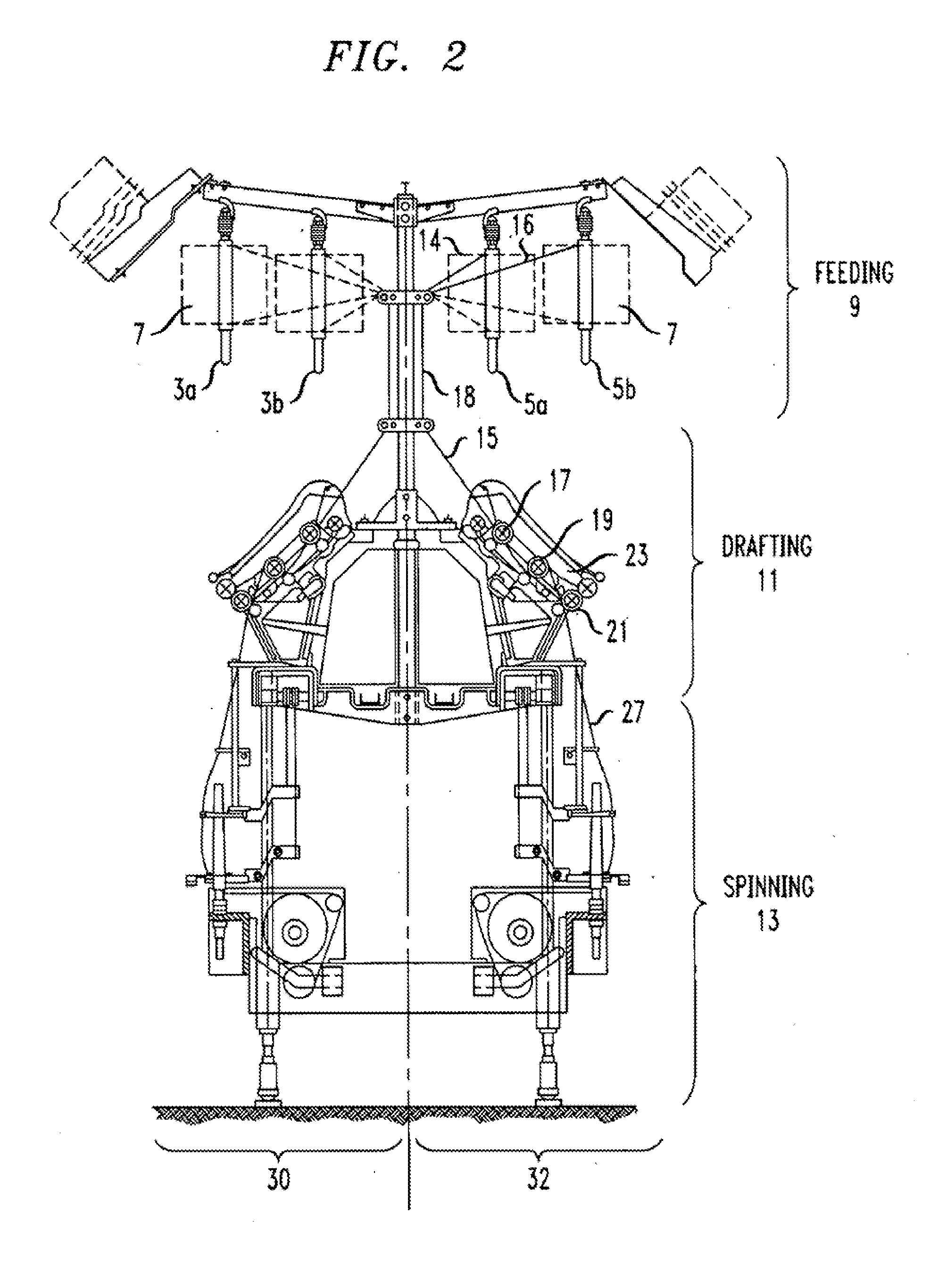

Fire retardant compositions and methods and apparatuses for making the same

An apparatus for producing a textile product generally includes a feeding section for providing a starting material to facilitate producing a textile product derived from the starting material; a drafting section operably coupled to the feeding section for gripping, pulling, stretching and breaking at least one strand of the starting material into at least one continuous and cohesive network of an intermediate product; and a spinning section operably coupled to the drafting section for winding and twisting the at least one continuous and cohesive network of an intermediate product onto a removable receiving member to form the textile product; the feeding section, the drafting section, and the spinning section are configured to form the textile product in a continuous operation.

Owner:LORICA INT

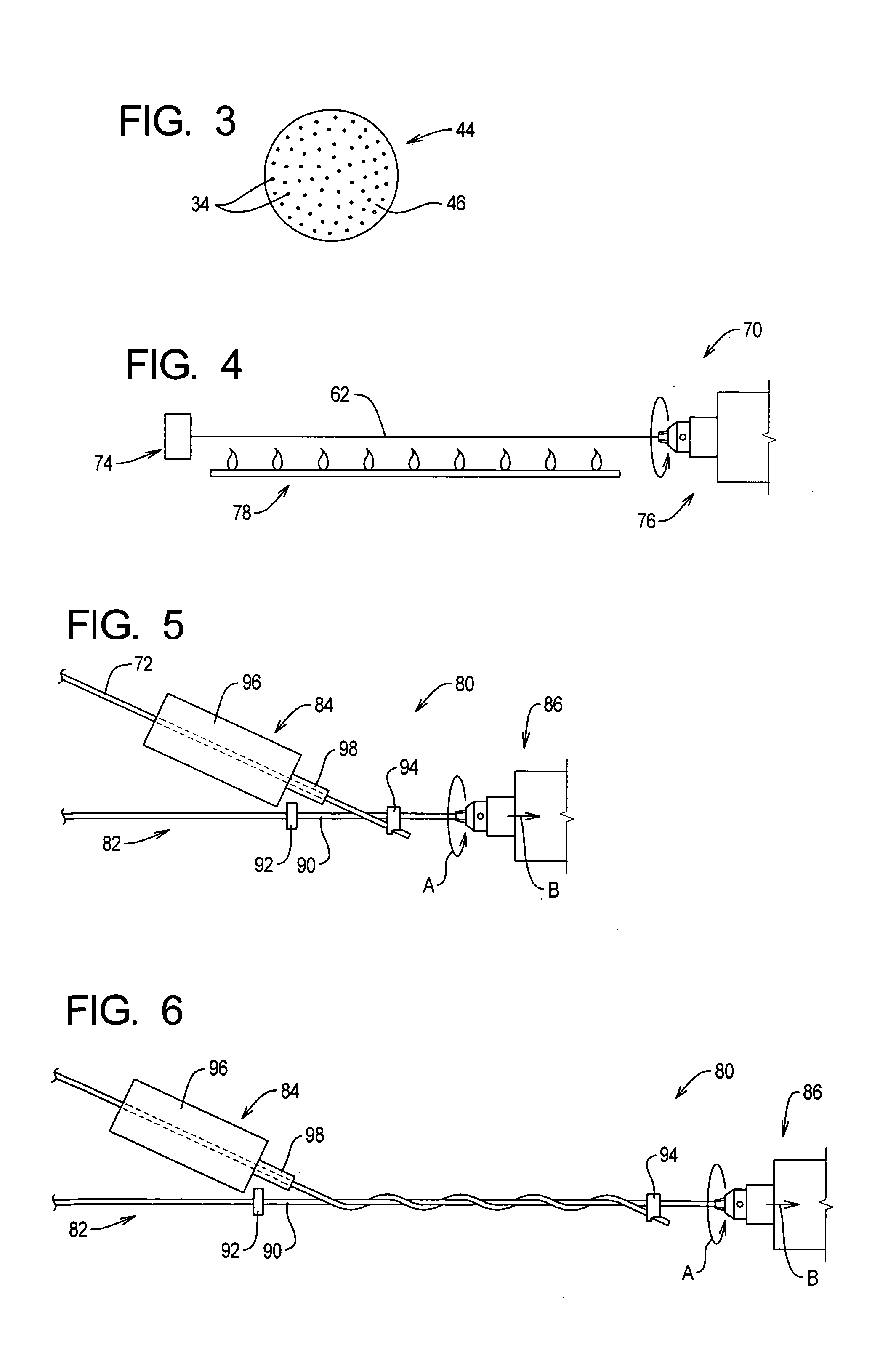

Method and stranding device for producing a cable or a cable element

A method for producing a cable or cable element from individual elements is provided. The method comprises heating the individual elements before or during a stranding process until they are at least close to plastification and cooling the individual elements to a solidification temperature of a plastic. A cable or cable element comprising individual elements that are twisted together to form the cable is also disclosed. The individual elements are heated either before or during a stranding process until they are at least close to plastification, and are subsequently cooled to a solidification temperature of the plastic until they leave a stranding machine. A stranding device for the production of a cable or cable element from individual elements is also disclosed. The stranding device comprises a heating device which acts on the individual elements and a cooling device located downstream of the heating device in a direction of processing.

Owner:DE REGT GERMANY

Popular searches

Liquid/gas/vapor treatment of definite length materials Textile treatment by spraying/projecting Mechanical fibre separation Liquid/gas/vapor fibres/slivers/rovings treatment Bacteriological retting Fibre treatment to obtain bast fibre Thin material handling Fencing Measurement arrangements for variable Mechanical clearance measurements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com