Intermittent spinning process and yarn therewith

A technology for spinning yarns and crafts, applied in the field of intermittent spinning and its yarns, which can solve problems such as lack of texture and affecting the wide use of slub yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

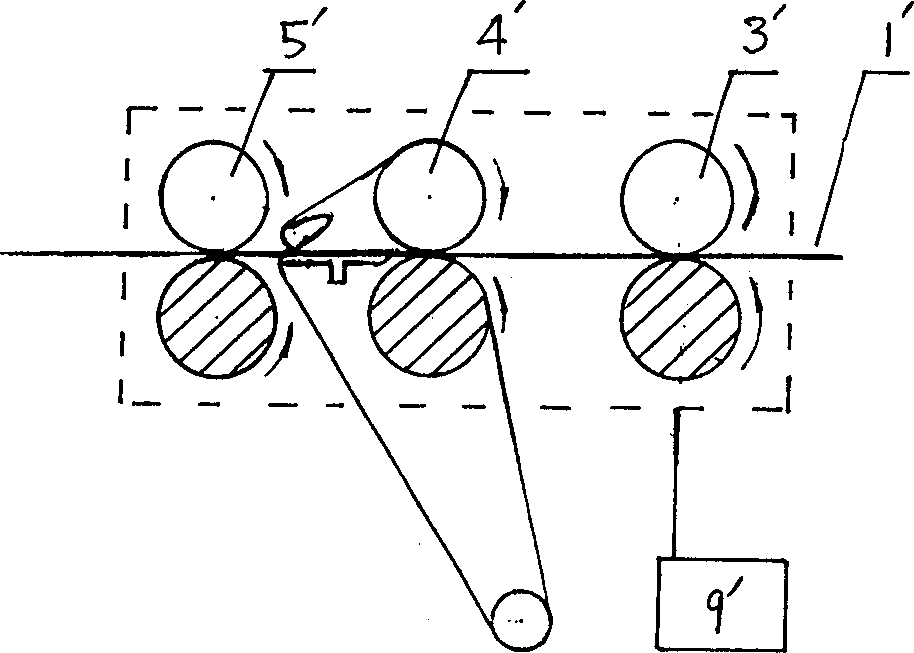

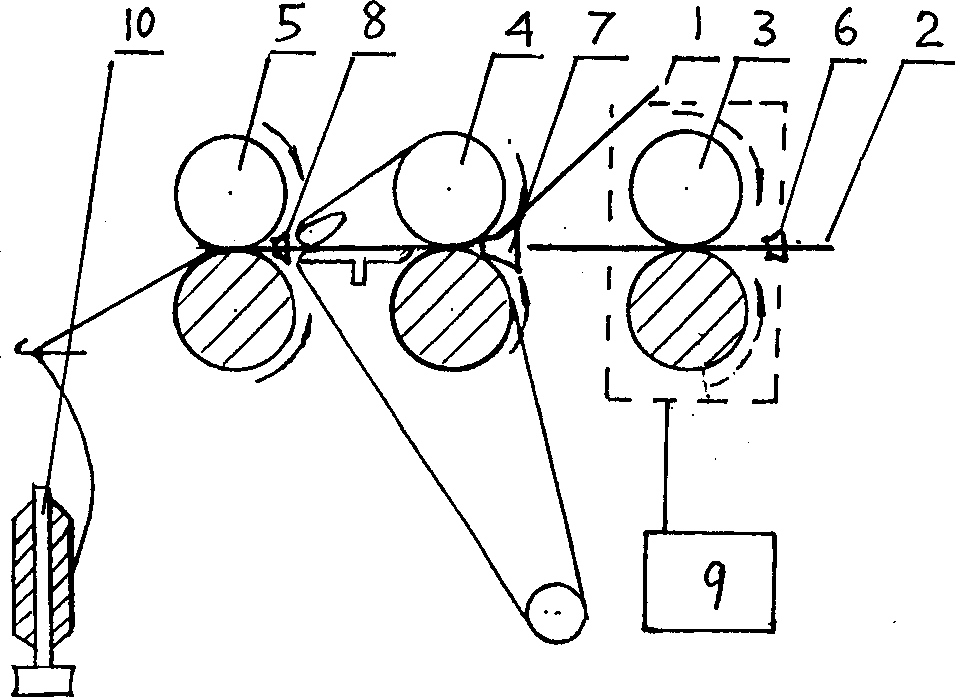

[0012] The intermittent spinning process of the present invention will be further described below in conjunction with the accompanying drawings. See figure 2 , the main fiber bundle 1 adopts T / R65 / 35, quantitative 4g / 10m. The auxiliary fiber bundle 2 is made of black polyester different from the main fiber bundle, and the weight is 5g / 10m; the auxiliary fiber bundle 2 is output intermittently through the bundler 6-feeding roller 3, and merged with the main fiber bundle 1 while entering at a speed of 785mm / min Concentrator 7-rear roller 4 and concentrator 8-front roller 5 are drafted and twisted to obtain intermittently spun yarns, that is, after the continuous main fiber bundle 1 and the intermittent auxiliary fiber bundle 2 are combined, they are passed through a common Yarns drawn and twisted (see image 3 ), and the main fibers and auxiliary fibers in the cross-section of the yarn are roughly uniform (see Figure 4 ). The feeding roller is controlled by the variable pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com