Patents

Literature

1887 results about "Textile processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

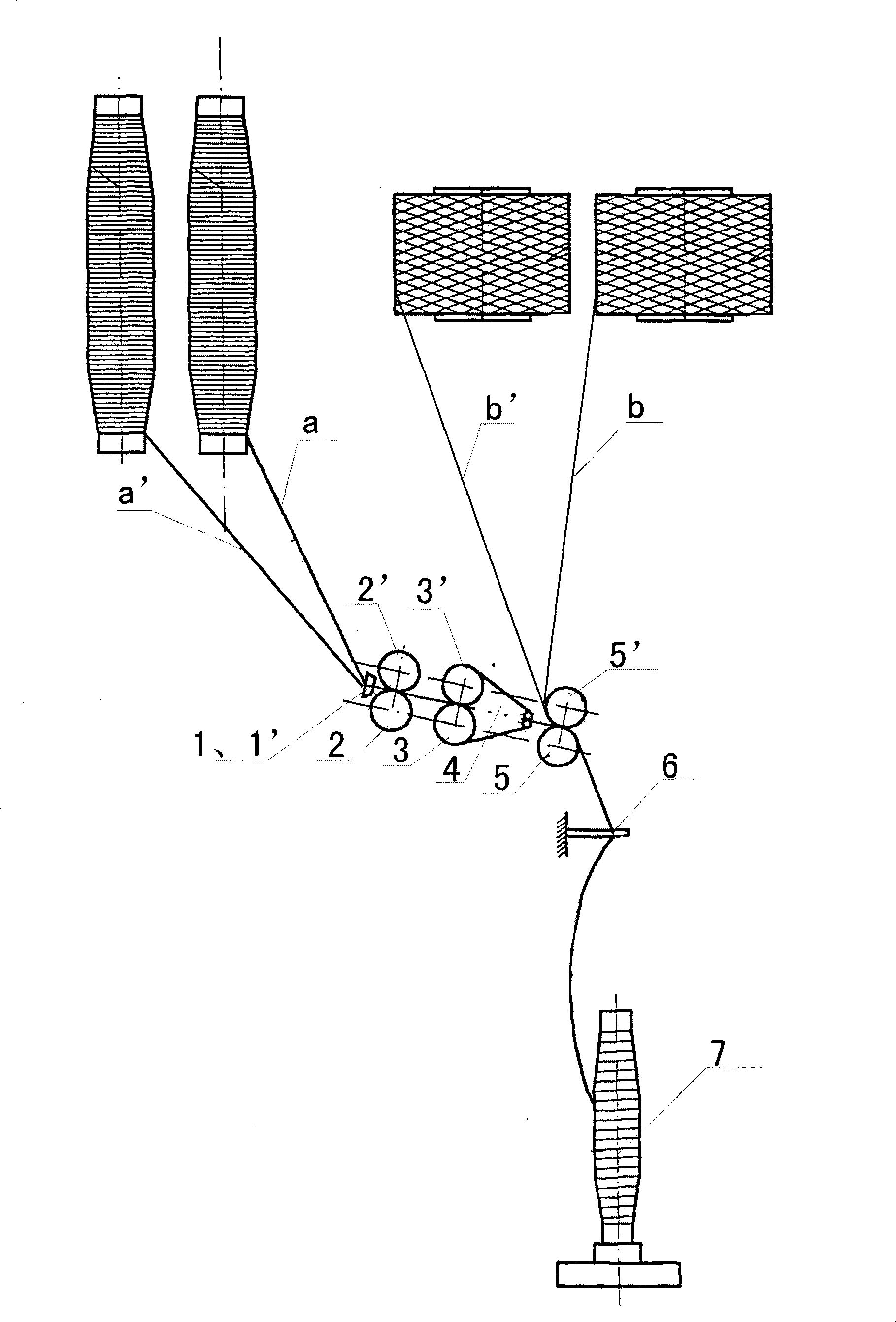

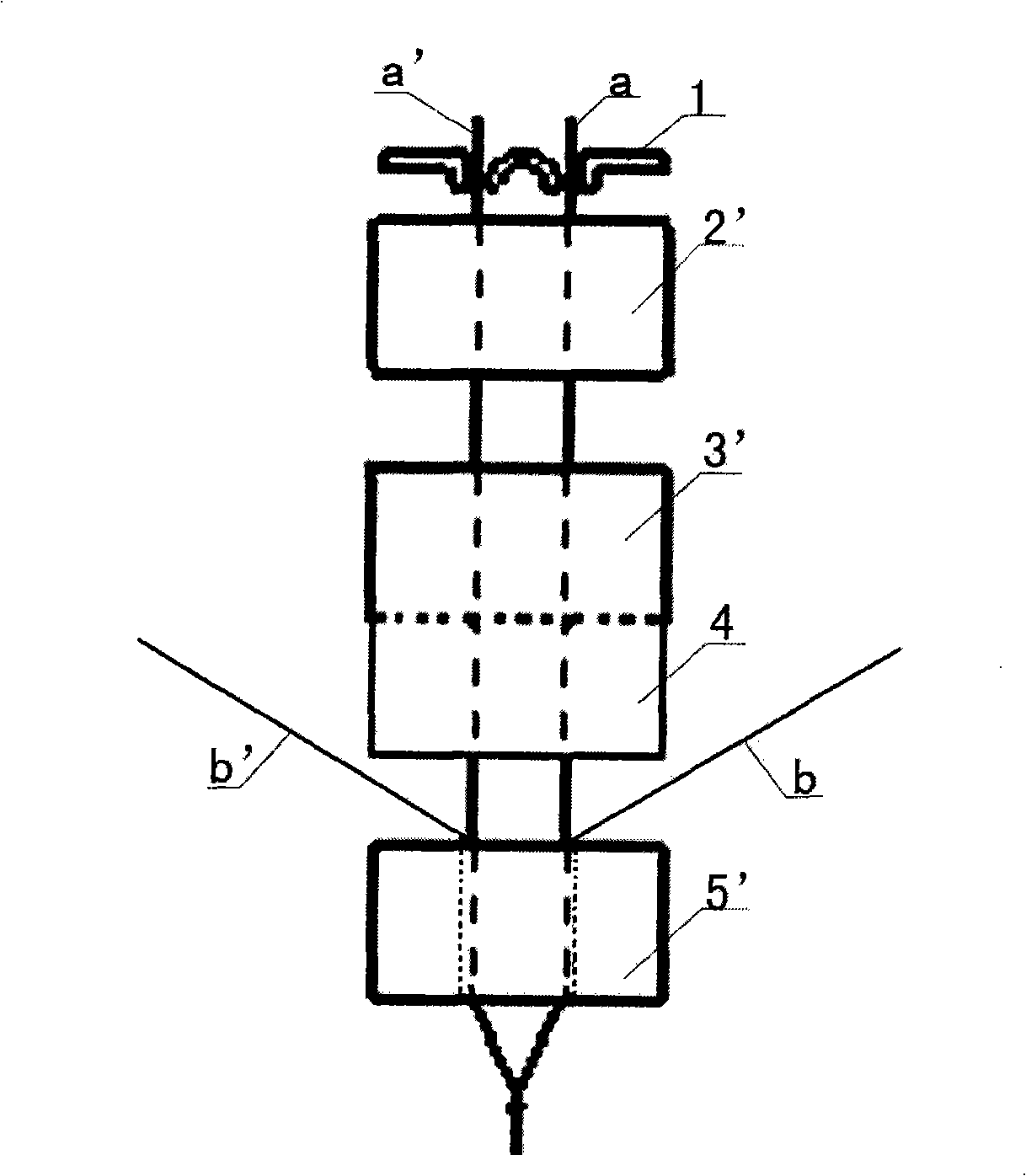

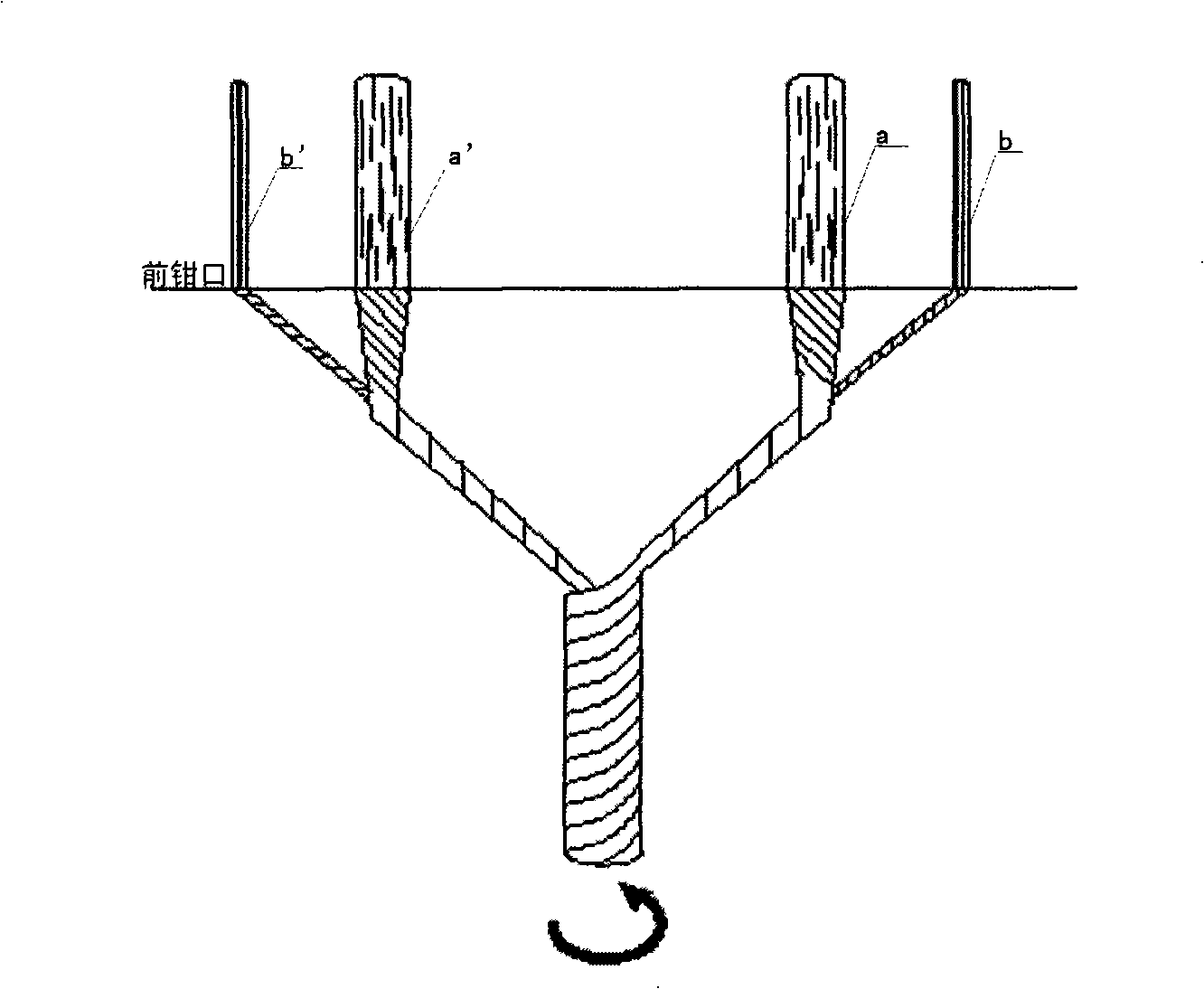

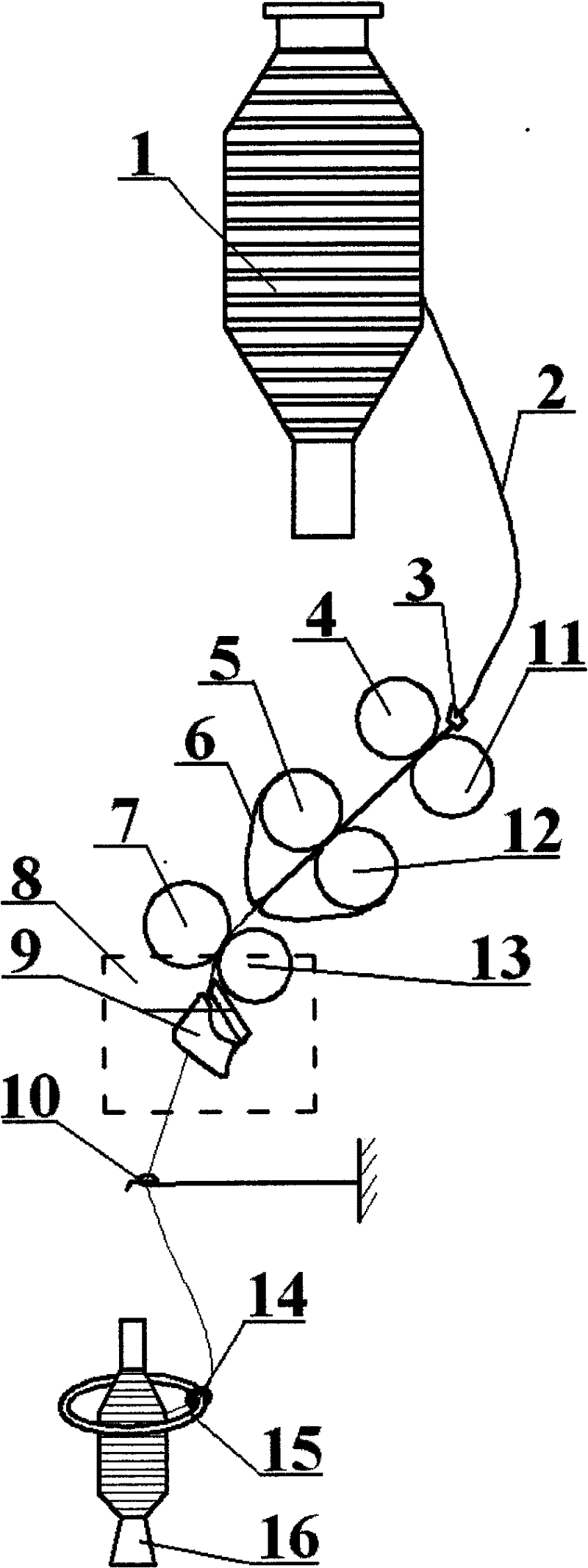

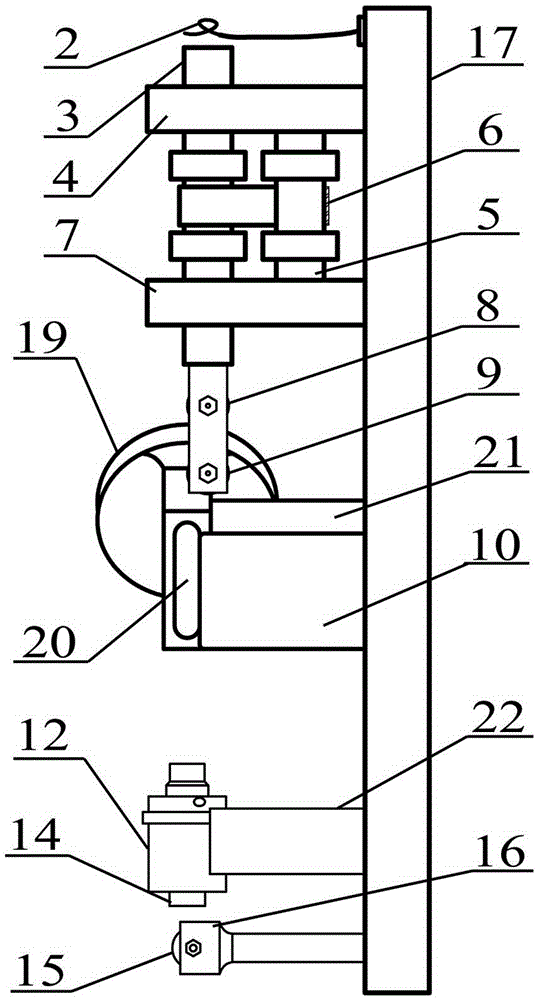

Positioning spinning method of embedded system

InactiveCN101492843ACompact structurePlay a reinforcing roleDrafting machinesContinuous wound-up machinesYarnFiber

Owner:WUHAN TEXTILE UNIV +2

Medical chitosan fibre and preparation method thereof

ActiveCN101250759AHigh molecular weightEnough aminoFilament manufactureArtificial filament washing/dryingAcetic acidBrute force

The invention relates to medical chitosan fiber in the textile processing field and a preparing method thereof, the method for preparing spinning fluid comprises the following steps: arranging the chitosan powder in glacial acetic acid water solution and slowly dissolving by stirring under the condition of controlling temperature and time, wherein the dissolution temperature is 10-30DEG C, the dissolution time is 10-48h, and the stirring speed is 60-180r / min, wherein the chitosan powder occupies 3%-10%, dissolvent glacial acetic acid occupies 1%-5% and the other is water in the spinning raw materials, the chitosan content is more than 99.9% in chitosan fiber, and the chitosan fiber has higher molecular weight, sufficient amido, steady fiber structure, and good antibacterial property, brute force and hygiene security property.

Owner:HISMER BIO TECH

Method for reducing resultant yarn filoplume

The invention relates to a textile processing technology concerning operations after the spinning that can reduce hairiness in finished yarn, and pertains to the technical field of textile processing. The invention provides a hairiness reducer for finished yarn that de-twists and heats on the advancing channel of the yarns, which reduces hairiness of finished yarns by de-twisting, heating, softening and twisting again yarns. The hairiness reducer for finished yarn that de-twists and heats can outstandingly reduce hairiness in finished yarns, and make yarn structure more tight, efficiently avoid the forming of hairiness because the fiber in the yarn stretches out from the yarn surface in subsequent operation. In addition, the hairiness reducer for finished yarn that de-twists and heats can be used on spooling, warping even knitting machines, the reducer consumes low energy, is easy to install and use, and is good for spreading and application widely.

Owner:WUHAN TEXTILE UNIV

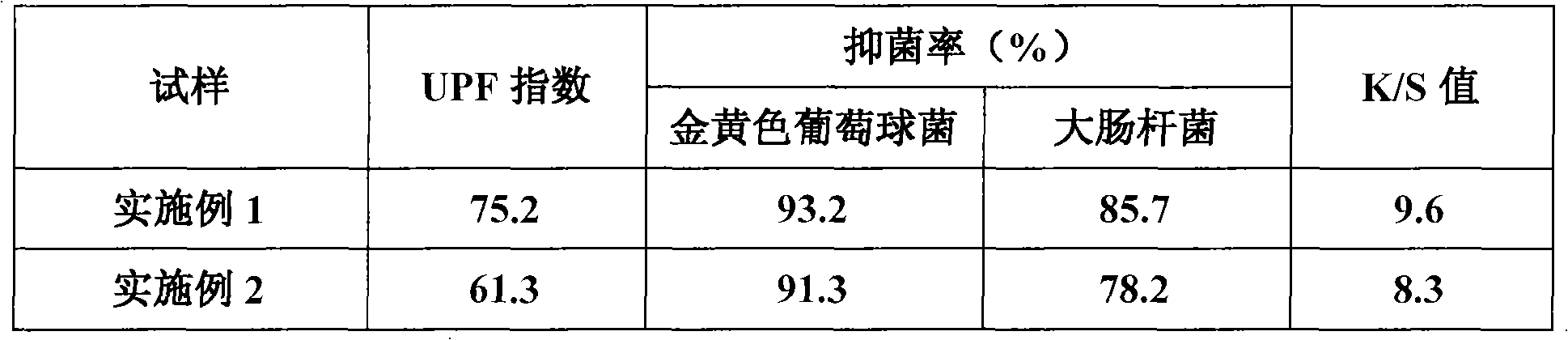

One-bathing integrated finishing method for real silk fabric by natural extract

InactiveCN101338518AAchieve antibacterialReduce processing stepsDyeing processAnimal fibresEngineeringTextile dyeing

The invention discloses a method for real silk fabric functional finishing, especially relates to a method for one-bath multifunctional finishing of real silk fabric by utilizing natural extract, which pertains to textile dyeing and finishing technical field. The invention includes the following steps: placing real silk fabric in solution with 5-20%(o.w.f) natural extract, liquor ratio of 1:10 to 1:100 and PH value of 2-8, treating for 10-100min; then treating for 10-100min in solution with 3-15%(o.w.f.) metal salt, liquor ratio of 1:10 to 1:100 and PH value of 4-8; after washing, dehydrating and furnace drying, completing one-bath finishing with dyeing, antimicrobial and anti-ultraviolet function to real silk fabric. The invention reduces manufacturing procedure of real silk fabric, has effect of energy-saving and emission-reduction, improves cleaning production of textile processing, is harmless to human body and surroundings, and conforms to ecological textile processing requests.

Owner:SUZHOU UNIV +1

Bamboo-carbon viscose fibre and its production

ActiveCN101029420AEvenly dispersedHarm reductionMonocomponent cellulose artificial filamentArtifical filament manufactureViscose fiberFiber strength

A bamboo-carbon viscose fiber and its production are disclosed. It consists of bamboo pulp dregs and nano-bamboo carbon 4-30wt%, the grain size is 75-150nm, final-product fiber strength is 1.7-3.0cN / dtex, extensibility is 9-18%. It adopts viscose coagulation bath composite modifying technology, it has excellent antibacterial, far-infrared health care and deodorization functions. It has better fiber strength and spinning handling property. It's cool, refined and no environmental pollution and can be used for summer clothing production and non-woven industries.

Owner:潍坊欣龙生物材料有限公司

Peppermint composite cellulose fibers and preparation method thereof

ActiveCN104593893AGood antibacterial effectComfortable to wearArtificial filaments from viscosePeppermintsAntibacterial activity

The present invention provides peppermint composite cellulose fibers, which contain 1-12 wt% of a peppermint extract component and 0.5-3 wt% of peppermint odor essential oil slow-release microcapsules, wherein the dry breaking strength of the fibers is 1.0-3.0 cN / dtex, the wet breaking strength of the fibers is 0.8-1.6 cN / dtex, the dry elongation at break is 16-24%, the residual sulfur content is less than or equal to 18 mg / 100 g, the antibacterial activity logarithm value is more than 2.0, and the bactericidal activity logarithm value is more than 0. The peppermint composite cellulose fiber preparation method comprises: peppermint extract adding liquid preparation, degenerated viscose glue preparing, peppermint blending viscose glue preparing, spinning and post-treating, and filament drafting and post-treating so as to obtain the peppermint composite cellulose fibers. The peppermint composite cellulose fibers of the present invention have characteristics of good wearability, textile processability, antibacterial function, bacterial inhibition function, lasting and fresh peppermint aroma, lasting odor, good textile processing performance, and significant antibacterial function.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Regenerated animal micropowder protein cellulose fiber and preparation method thereof

ActiveCN102493020AStrong sense of silkSoft touchConjugated cellulose/protein artificial filamentsArtificial filaments from viscoseViscose fiberTextile processing

The invention discloses a regenerated animal micropowder protein cellulose fiber and a preparation method thereof. The preparation method comprises the following steps of: adding nanoscale animal micropowder protein into a dispersant solution, stirring the mixture uniformly, filtering to obtain 20 to 35 weight percent of animal micropowder protein liquid; preparing viscose by using cellulose pulp as a raw material, adding denaturant in the dissolution step to obtain modified viscose; adding the animal micropowder protein liquid into the modified viscose in a weight ratio of animal micropowder to the finished fiber of (1-30):100, uniformly stirring to obtain animal micropowder compounding viscose; and defoaming and filtering, spinning molding by introducing a coagulating bath, and then drawing filament and performing aftertreatment to obtain the animal micropowder protein viscose fiber. The fabric made of the regenerated animal micropowder protein cellulose fiber is low in density, and is light; the hygroscopicity, the air permeability and the thermal insulating property of the fabric are further improved; the fiber textile processing and wearability are good; and the production process is pollution-free.

Owner:潍坊欣龙生物材料有限公司

Flax material viscose fibre pulp and preparation process of functional fibre thereof

The invention relates to a process technique of producing viscose rayon pulp and functional rayon, and the flow includes: preparing hemp materials -> cutting materials -> screening -> washing materials -> preprocessing -> cooking -> extruding -> breaking -> desanding and concentrating -> chloridizing -> alkali refining -> bleaching -> acid treating -> desanding and concentrating -> making -> dipping -> pressing -> crushing -> ageing -> etiolating -> grinding -> dissolving -> mixing -> prefiltering -> filtering -> defoaming -> filtering -> spinning -> drawing -> cutting off -> after processing -> drying -> packaging. The viscose rayon has the characters: bacteriostasis, smoothness and forcefulness, coolness, fineness, brighness, high dry-wet strength, etc, convenient for spinning and weaving processing and dying and finishing treatment, and the products have natural bacteriostasis function.

Owner:HEBEI JIGAO CHEM FIBER

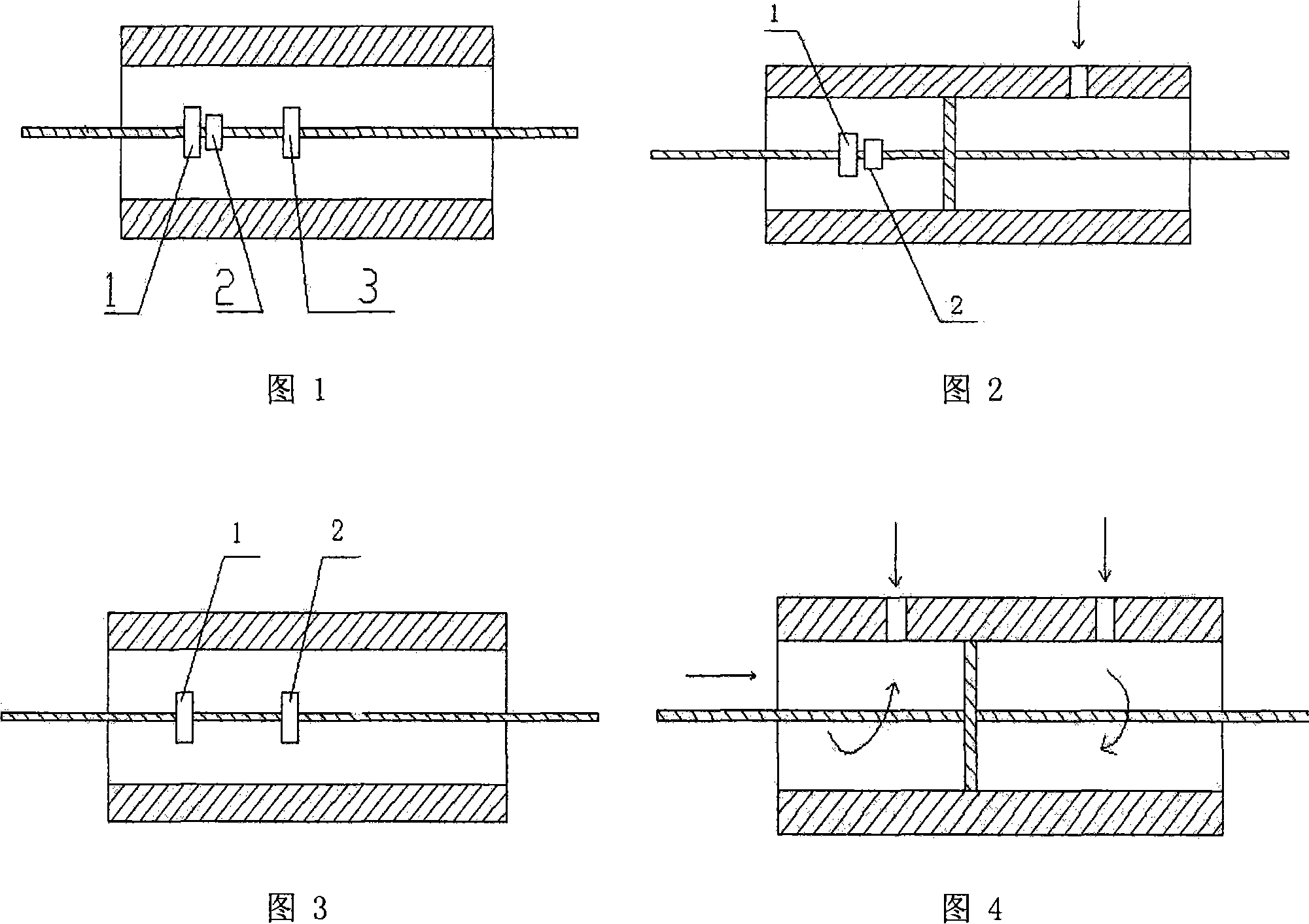

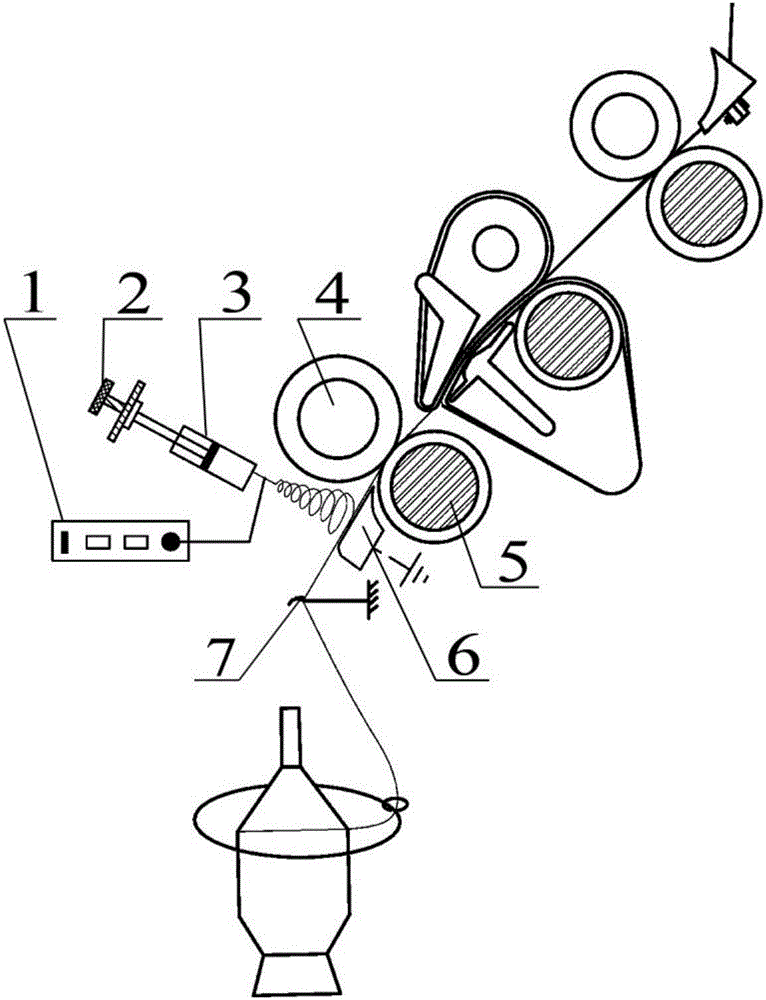

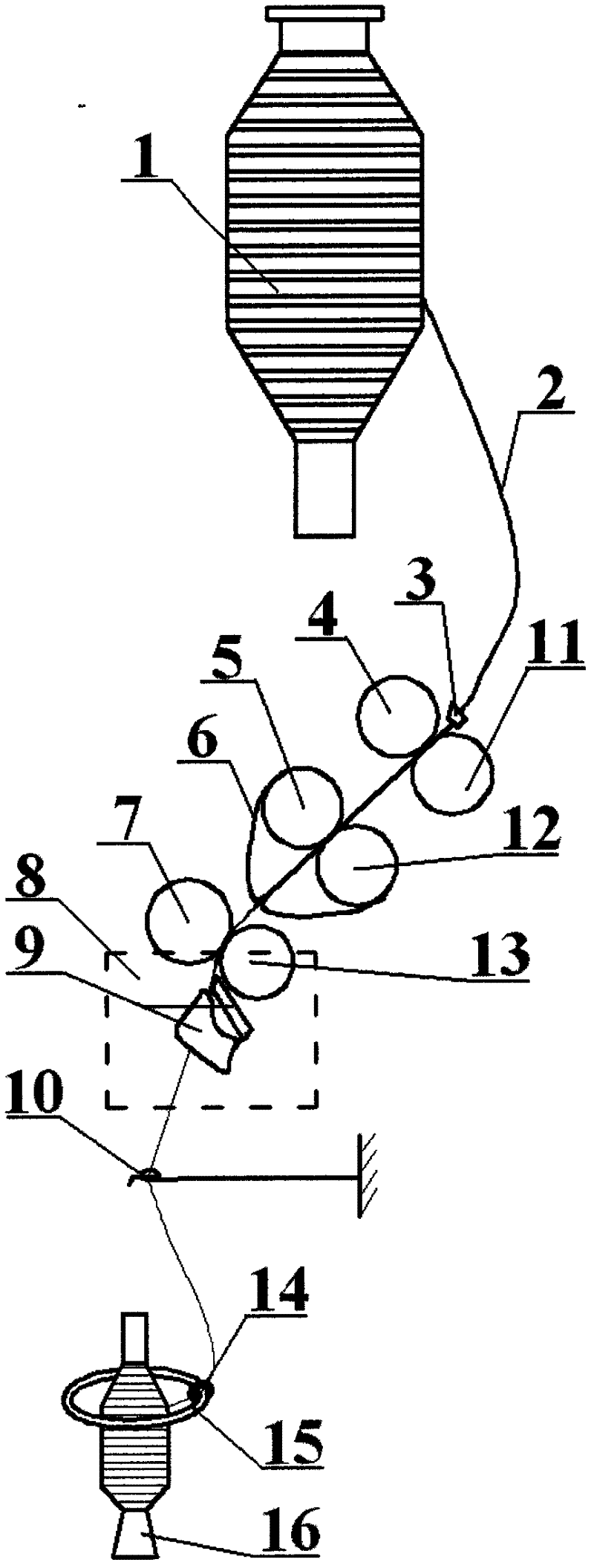

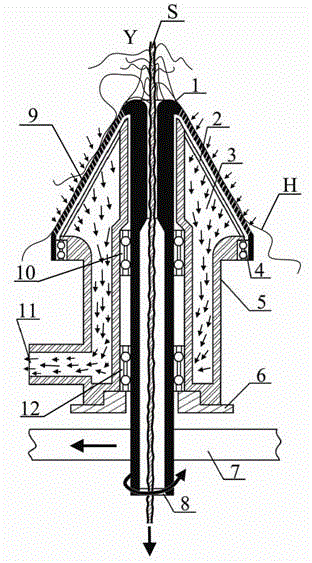

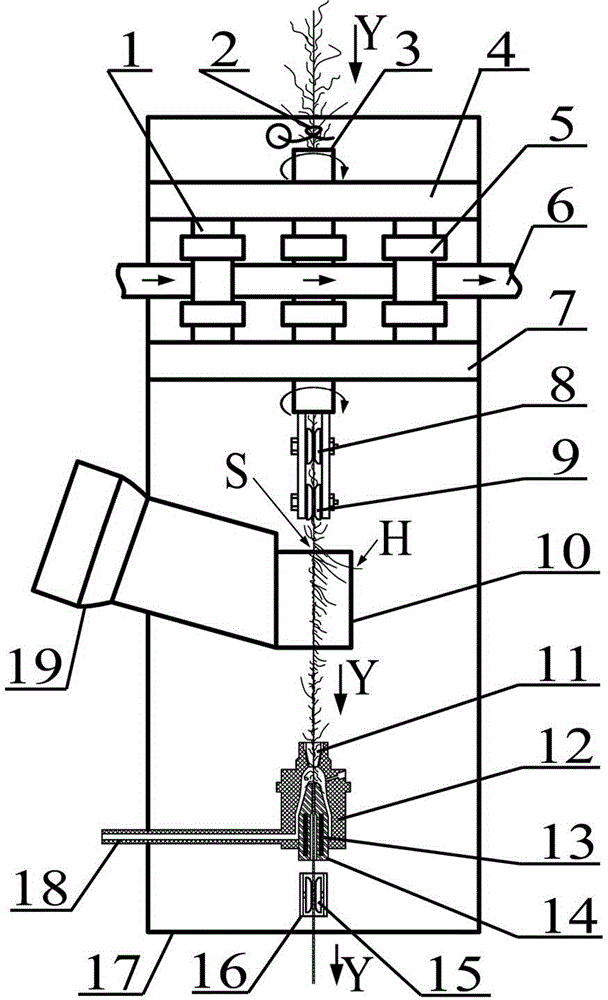

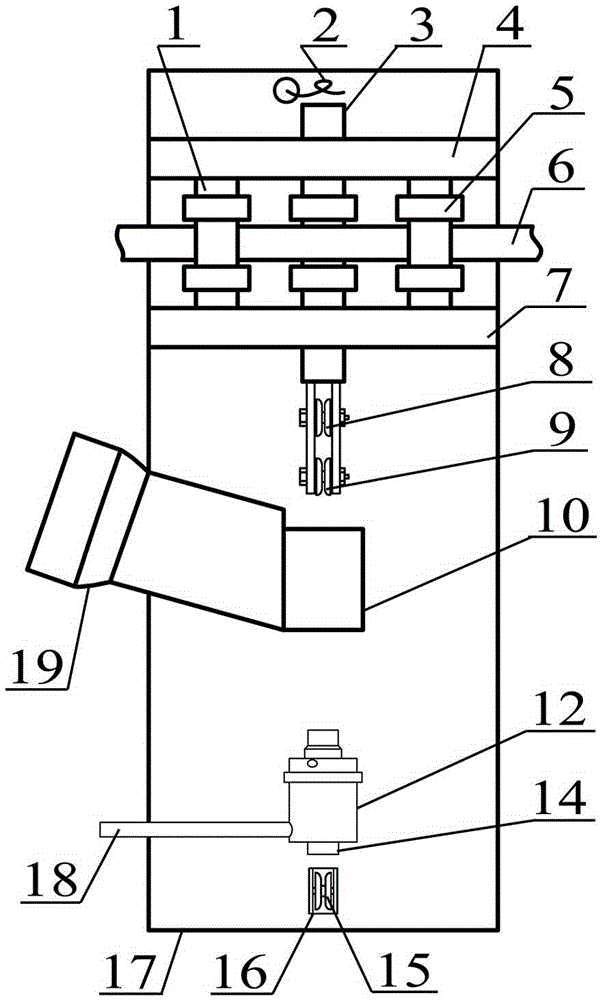

Nano electrostatic spinning and staple fiber ring spinning integrated yarn forming method

The invention relates to a nano electrostatic spinning and staple fiber ring spinning integrated yarn forming method, and belongs to the technical field of textile processing. The method comprises the following steps: arranging an electrostatic spinning apparatus between each yarn guide hook of a ring spinning frame and a front roller jaw formed by a front roller corresponding to the yarn guide hook and a front rubber roll, enabling a receiving surface of the electrostatic spinning apparatus to stay on a same plane with a public tangential surface of a front leather roll and the front roller at the front roller jaw, forming an electrostatic spinning area between an electrostatic spray head and a receiving surface of a receiving plate, and combining and twisting a nano fiber net spun out from the electrostatic spray head and staple fiber strands passing by the receiving surface of the receiving plate. According to the method, the electrostatic spinning and a conventional ring spinning are reasonably integrated, so that the high-speed successful production of nano fiber yarns is guaranteed, the naon fiber net effectively captures exposed fibers and improves the winding tightness, and the yarn forming structure and performance quality of the nano fiber wrapped blended yarns can be greatly improved. Equipment involved in the method is universal, and the operation and the use are convenient.

Owner:WUHAN TEXTILE UNIV

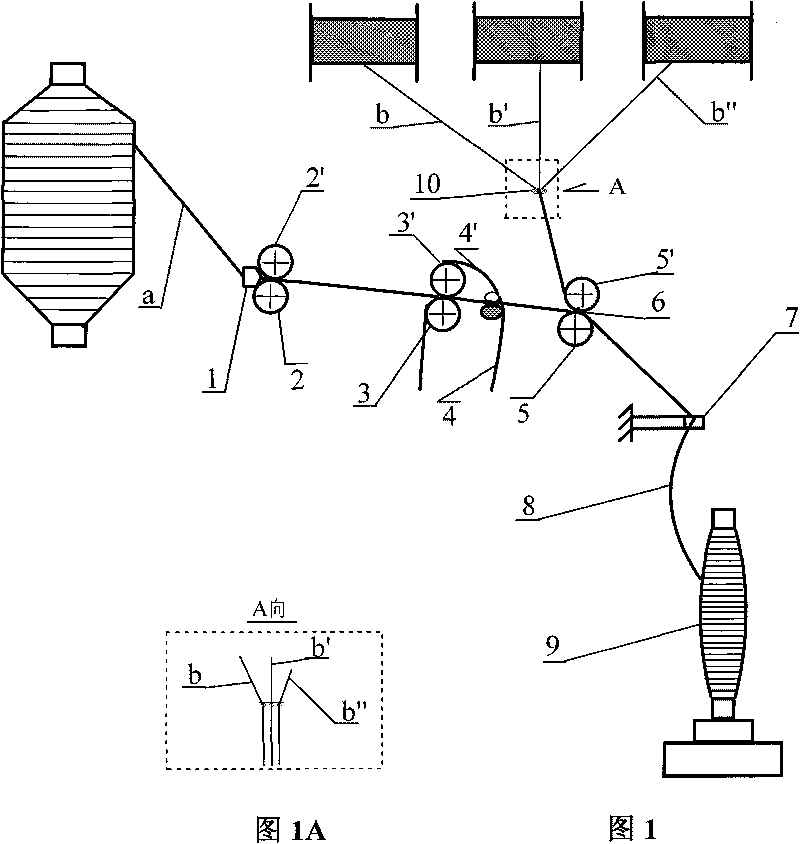

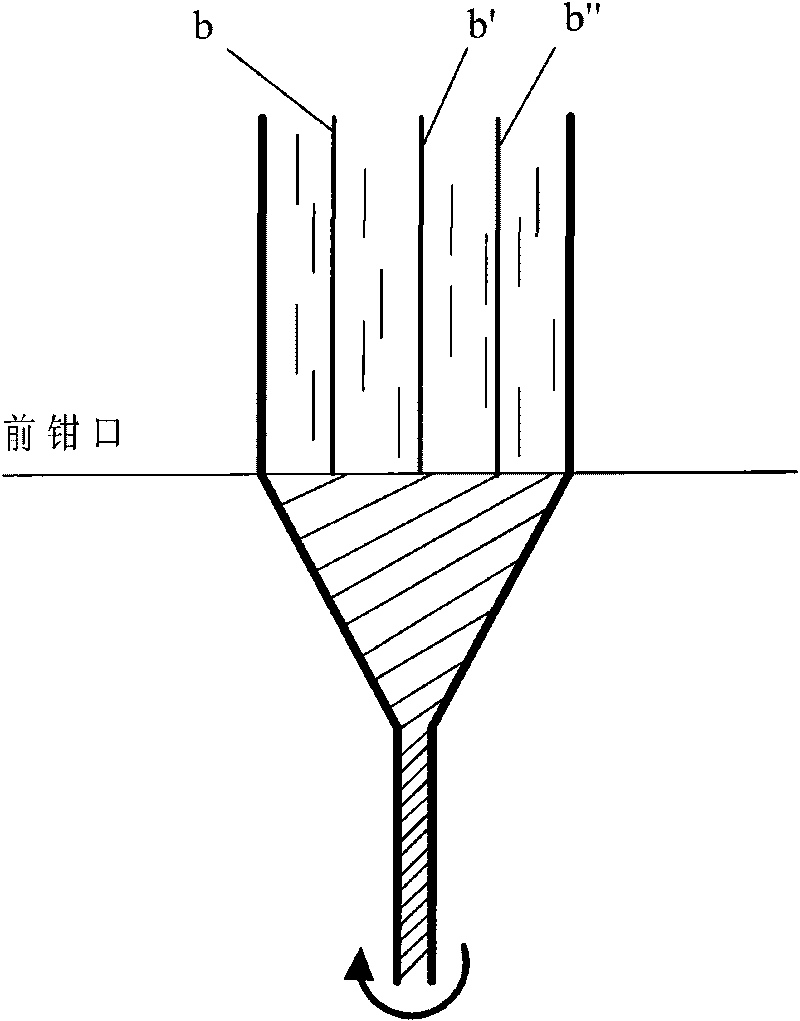

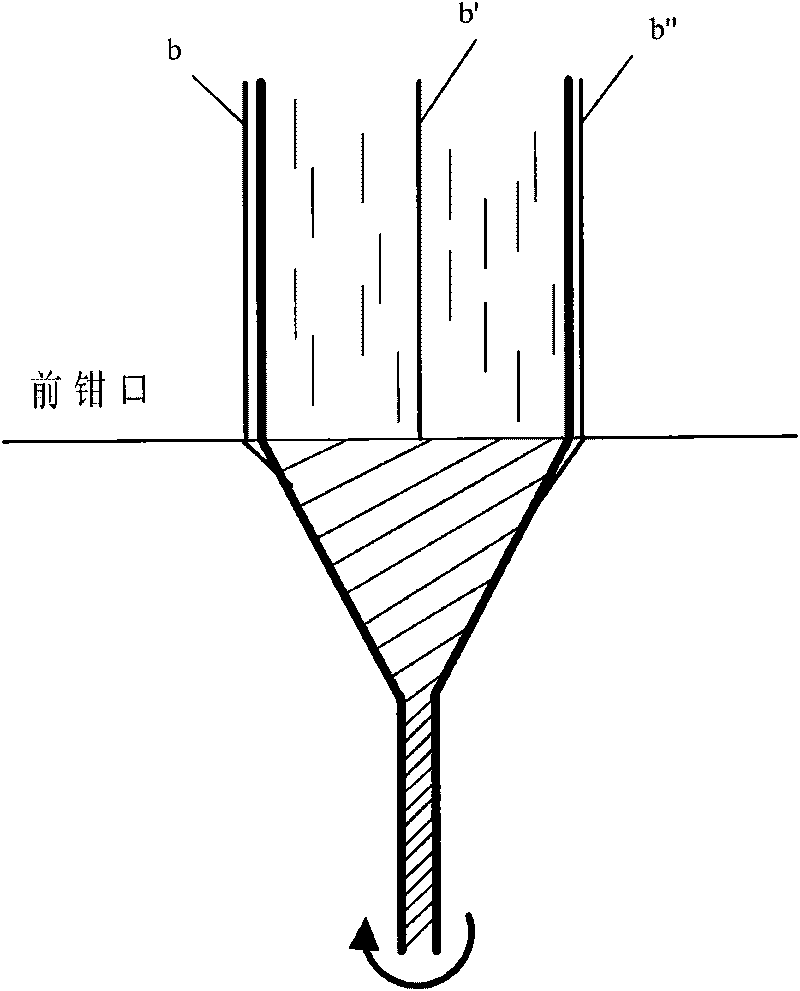

Preparation method of yarn with long and short fiber compound structure

InactiveCN101736469AEasy to transformEasy to operateDrafting machinesContinuous wound-up machinesBobbinCompound structure

The invention discloses a preparation method of a yarn with a long and short fiber compound structure, belonging to the technical field of textile processing. The preparation method comprises the following steps of: feeding short fiber rove fiber strands unwound from a rove tube into a drafting zone through a yarn-guiding horn for drafting on a drafting mechanism of a ring spinning frame; feeding at least three filaments into a front jaw from the rear end of a front roller at an interval of 0.1-3mm; jointing the filaments and the rove fiber strands at the jaw part; outputting and feeding drafted rove fiber strands and the filaments from the front jaw into a twisting triangular zone; twisting the rove fiber strands and the filaments into the yarn and winding the yarn on a spun yarn bobbin; and forming compound yarns with different structures according to the space among the filaments and the different relative positions of the rove fiber strands. The invention can prepare yarns with a unique internal space structure and an external surface structure on the ring spinning frame, enhances the strength, the wear resistance and the bend resistance of the yarns, has favorable conformality of textures and can achieve the effect of wearing after washing. The invention realizes the preparation of the yarns with special structures and special functions on the traditional spinning equipment.

Owner:SOUTHWEST UNIVERSITY +1

Soft and clean spinning method

The invention relates to a soft and clean spinning method which can be used for improving the performances of yarn, especially the performances of yarn hairiness and belongs to the technical field of textile processing. On each drafting mechanism of a ring spinning frame, a roving sliver subjected to drafting is output from a front jaw, and a heat and moisture treatment device is used for performing on-line heat and moisture treatment on the on-line twisted roving slivers which are output from the front jaws and enter into a twisting triangular area. Under the combined action of heat and moisture, bending modulus and rigidity of fiber of the on-line twisted roving slivers are greatly reduced immediately, the softening speed and the degree are greatly improved, soft twisting and yarn forming can be performed on the thicker slivers when the lower modulus and the lower rigidity performance are achieved, and the ends of the fiber are easier to transfer and wind under the action of twisting torsional force and finally twisted into yarn bodies or attached on the surfaces of the slivers, thereby effectively eliminating hair feather in the formed yarn and greatly improving the degree of finish of the surface of the formed yarn. Simultaneously, the residual torque and residual stress of the ring-spun yarn can be reduced, not only can the entanglement phenomenon in the formed yarn be effectively solved, but also the softness of the formed yarn can be improved.

Owner:WUHAN TEXTILE UNIV

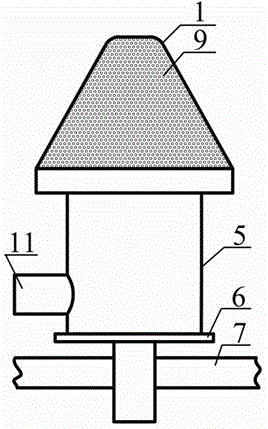

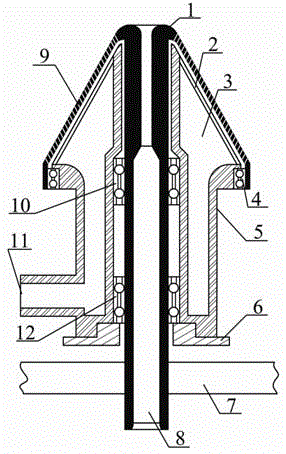

Method of improving yarn surface structure in positive holding rotation mode

The invention relates to a method of improving a yarn surface structure in a positive holding rotation mode and belongs to the technical field of textile processing. According to the method, a front central positioning yarn guide hook, a holding rotation type yarn hairiness reducing device and a rear central positioning yarn guide hook are arranged on the operation path of each yarn in sequence, wherein each yarn enters the holding rotation type yarn hairiness reducing device through the front central positioning yarn guide hook; the trunk of the yarn enters the center of a yarn channel and keeps a tensioning straightening state, the surface hairiness of the yarn is subjected to a negative pressure air draft effect, the hairiness is absorbed on the outer surface of a conical housing and synchronously rotates along with the conical housing, and meanwhile, at the inlet of the yarn channel, the hairiness continues tightly winding the operating yarn trunk, and the smooth densifying treatment is realized on the yarn surface structure. The method is wide in applicable range and can be used for processing various yarns; the holding rotation type yarn hairiness reducing device is reasonable in structure and convenient to operate.

Owner:WUHAN TEXTILE UNIV

Fire-retardant cellulose reinforced plastic composite material and preparation method thereof

InactiveCN101885871AReduce smoke productionImprove flame retardant performancePolymer sciencePolyvinyl chloride

The invention discloses a fire-retardant cellulose reinforced plastic composite material and a preparation method thereof. The composite material is characterized by comprising 100 parts of thermoplastic high polymer and 20 to 50 parts of cellulosic material in part by weight, wherein at least one of the thermoplastic high polymer or the cellulosic material is a material after fire-retardant modification; the thermoplastic high polymer is polyethylene, polypropylene, polyvinyl chloride or polystyrene; and the cellulosic material is one of or a mixture of more than two of the following materials in a mass ratio: wood flour, bamboo powder, wheat straw powder, corn straw powder, bran or rice chaff of which the grain size is 50 to 400 meshes, and cellulose fibers having no textile processing value. The preparation method comprises the following steps of: firstly, performing corresponding fire-retardant modification on the thermoplastic high polymer or / and the cellulosic material; secondly, uniformly mixing the thermoplastic high polymer and the cellulosic material by using a screw extruder; thirdly, extruding the mixture out after fusion; and finally, performing compression molding forming.

Owner:TIANJIN POLYTECHNIC UNIV

Protein and alginate composite fiber and manufacturing method thereof

InactiveCN101654813AConjugated cellulose/protein artificial filamentsAlginate artificial filamentsFiberTextile processing

The invention relates to a protein and alginate composite fiber which is a regenerated protein composite fiber containing 5-90% of natural protein and 10-95% of natural alginate. The protein and alginate composite fiber is manufactured by the technological processes of raw liquid preparation, wet spinning, crosslink finishing and the like. The protein and alginate composite fiber has good hydroscopic property, antistatic property, dyeing property and flame resistance, can be completely degraded biologically, is a real green ecological textile material, has soft and smooth hand feel, is suitable for spinning and processing underclothes, articles for bedrooms, articles for health care and the like, and is suitable for manufacturing hairline for wigs because of good flame resistance.

Owner:陈福库

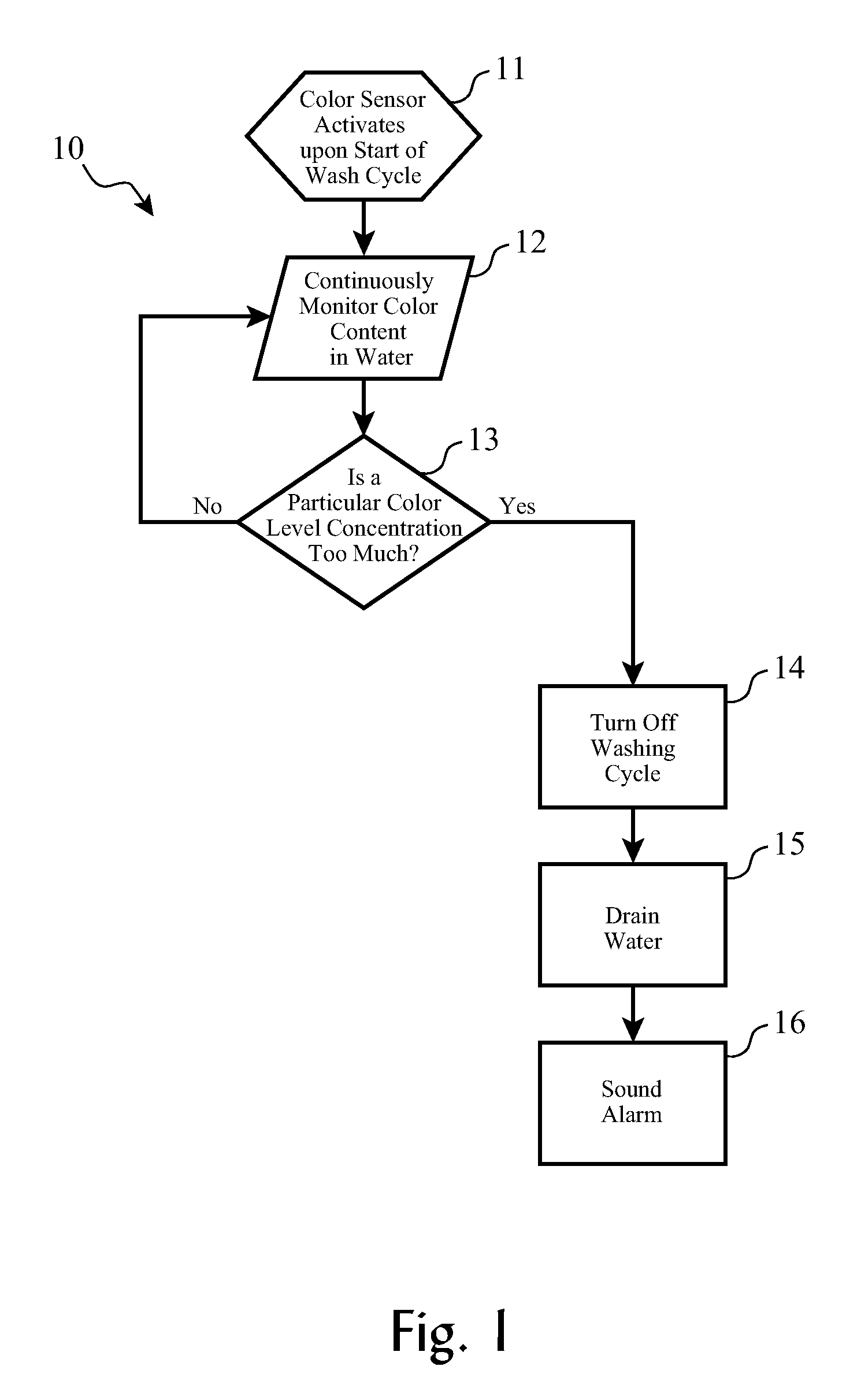

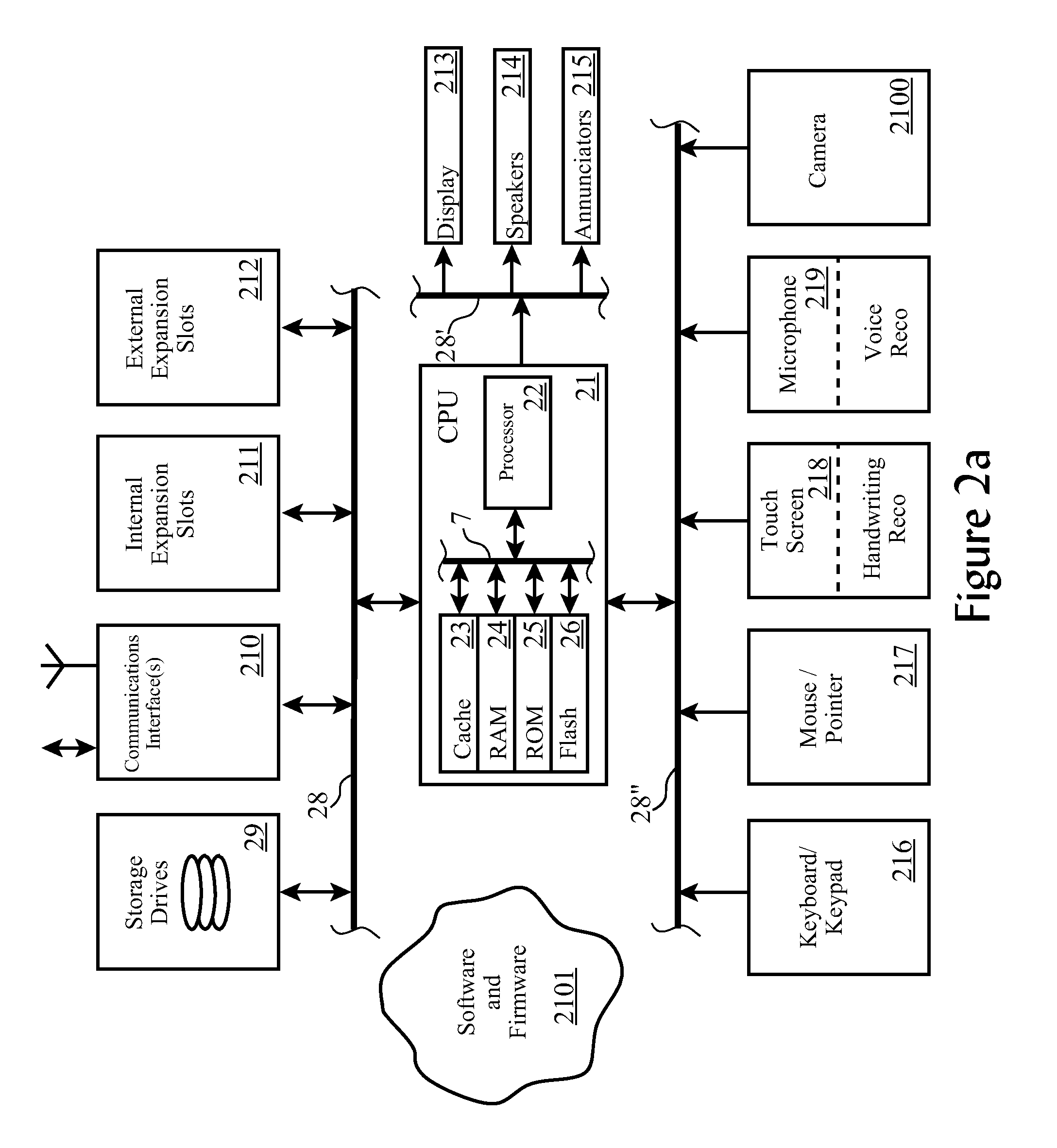

User interface for color transfer control in textile processing equipment

InactiveUS8108063B2Reduce, stop, or minimize damage caused by color bleedOptimizationSafety arrangmentsSynthetic resin layered productsScavengerDisplay device

Owner:INT BUSINESS MASCH CORP

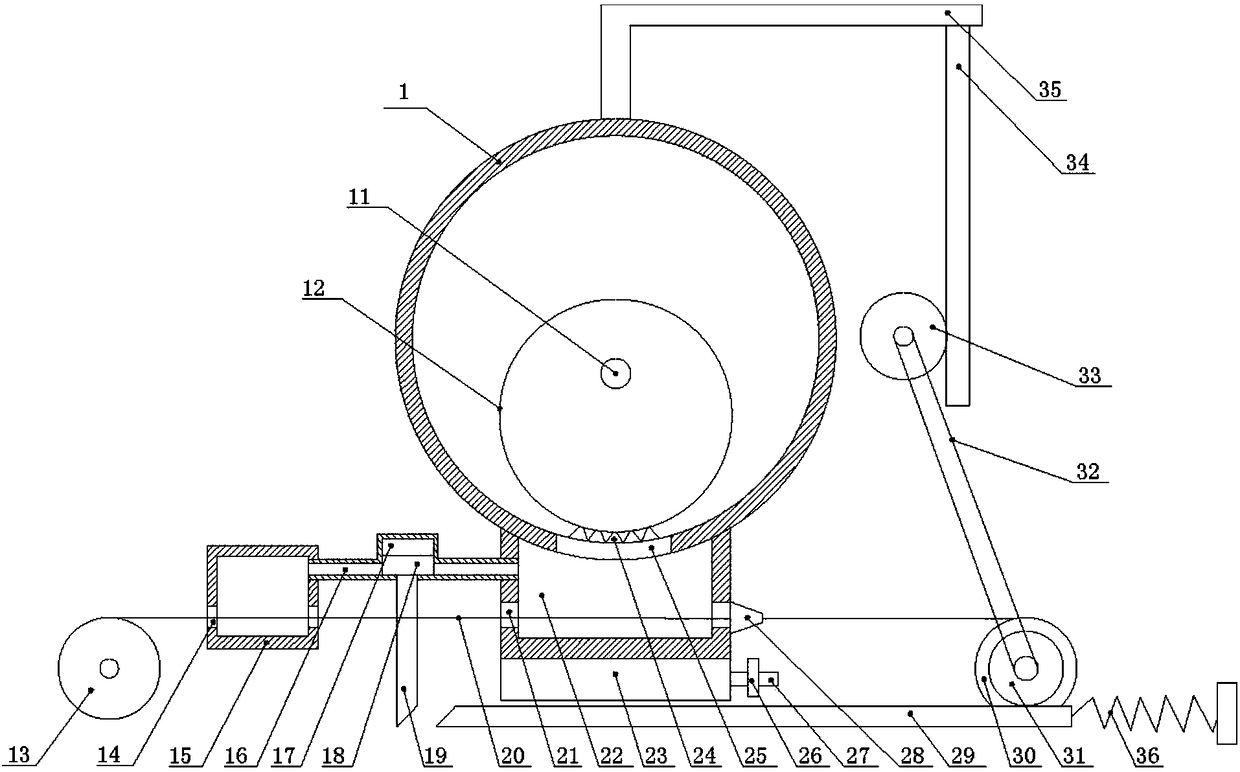

Textile yarn waxing device

The invention relates to the technical field of textile processing, in particular to a textile yarn waxing device. The textile yarn waxing device comprises a rotary drum. A rotary shaft is arranged inthe rotary drum. The rotary shaft is arranged under the axis of the rotary drum and is parallel to the axis of the rotary drum. A wax block is eccentrically arranged on the rotary shaft. A scraper isarranged at the bottom of the rotary drum and can make contact with the wax block. A wax melting box is arranged below the scraper. First through holes allowing yarns to pass through are symmetrically formed in the side walls of the wax melting box. A pay-off roller and a take-up roller are arranged on the two sides of the wax melting box correspondingly. A gear is arranged above the take-up roller. A transmission part is connected between the gear and the take-up roller. A first rack is vertically engaged with one side of the gear. A support is connected with one end of the first rack and connected with the rotary shaft. The problems that in the prior art, yarns are waxed unevenly, and wax blocks are wasted seriously can be solved.

Owner:NINGBO WENZE TEXTILE CO LTD

Preparation method of textile function finishing agent

The invention relates to a preparation method of a textile nano-function finishing agent which is used for producing antibacterial, anti-odor, health care and skin care functional textiles and mainly contains inorganic nano-material. The preparation method comprises the following steps: dispersing the inorganic nano-material in water solution of a surfactant under stirring condition, continuously stirring to form fluid type colloid, further adding auxiliary components, and continuously uniformly stirring to prepare the nano-function finishing agent, wherein the inorganic nano-material is nano-zinc oxide, nano-titanium dioxide or mixture of nano-zinc oxide and nano-titanium dioxide, the content of the inorganic nano-material is 0.02%-35% by weight of the finishing agent, the balance is the auxiliary components, and the total amount of a prepared product is 100% by weight. The prepared nano-function finishing agent can be used for processing textile raw material through the process steps of immersing, rolling, parching and baking or direct spray-coating, thereby enabling the textile raw material to have antibacterial, anti-odor, health care and skin care functions and being further used for preparing the textiles. The method is simple in production process, reasonable in raw materials and formula and good in product performances, thereby being an ideal textile processing technology for disease prevention and health care.

Owner:马飞

Preparation method of fibroin blending regenerated cellulose fiber

ActiveCN102851777AImprove stabilityHigh chemical activityConjugated cellulose/protein artificial filamentsArtificial filaments from viscoseCross-linkAdhesive

The invention discloses a preparation method of fibroin blending regenerated cellulose fiber, comprising the steps of (1) degumming, swelling, drying and smashing the silk offcuts to obtain a fibroin powder with grain size of 0.1-0.5 micrometers; (2) dispersing the fibroin powder with sodium hydroxide solution, adding the dispersing agent and the cross-linking agent aliphatic acid alkylolamides to obtain the fibroin dispersion mother solution; and (3) blending the fibroin dispersion mother solution with the cellulose adhesive to obtain the blended adhesive, and carrying out spinning molding and post processing to obtain the fibroin blending regenerated cellulose fiber. According to the preparation method provided by the invention, the loss amount of the protein in the preparation process is low, the content of protein in the produced fibroin blending regenerated cellulose fiber is high, the production cost is low, the strength of the fibroin blending regenerated cellulose fiber is high; and the preparation method is easy for industrial production, improves the textile processing performance of the fibroin blending regenerated cellulose fiber and broadens the application range of the fibroin blending regenerated cellulose fiber.

Owner:湖州珠力纳米材料科技开发有限公司

Flame-retardant viscose fiber and preparation method thereof

InactiveCN102505169AGood textile processing performanceReduce usageArtificial filaments from viscoseWet spinning methodsCellulosePolymer science

The invention discloses flame-retardant viscose fiber and a preparation method thereof. The flame-retardant viscose fiber mainly comprises the following components in percentage by weight: 20 to 55 percent of polysilicic acid (based on SiO2), 0.5 to 10 percent of pyrophosphoric acid ester and 40 to 70 percent of cellulose. The preparation method comprises the following steps of: (1) adding a solution of sodium metasilicate and a solution of pyrophosphoric acid ester into a yellowed cellulose viscose solution respectively, and uniformly mixing the sodium metasilicate, the pyrophosphoric acid ester and cellulose viscose to obtain a flame-retardant spinning viscose solution; (2) performing spinning molding on the flame-retardant spinning viscose solution in coagulating bath containing sulfuric acid, zinc sulfate and sodium sulfate to obtain as-spun fiber; and (3) after-treating the as-spun fiber, namely washing, desulfurizing, applying oil and drying to obtain the flame-retardant viscose fiber. The synergistic effect of silicon and phosphorus flame retardants greatly improves the flame-retardant effect and high temperature resistance of flame-retardant fiber and the textile processing performance of fabrics.

Owner:阜宁澳洋科技有限责任公司

Folium isatidis cellulose fiber having antiviral, antibacterial and skin-care functions and preparation method thereof

InactiveCN105603556AEasy to takeGood textile processabilityArtificial filaments from viscoseWet spinning methodsSodium CaseinateEngineering

The invention discloses a folium isatidis cellulose fiber having antiviral, antibacterial and skin-care functions and a preparation method thereof. The folium isatidis cellulose fiber contains, by weight, 2.0-8.0 parts of folium isatidis extract, 2.0-8.0 parts of sodium caseinate, 2-30 parts of porous starch and 2-50 parts of protein. The preparation method includes the following steps that 1, preparation of folium isatidis extract-sodium caseinate compound microcapsules, 2 preparation of a blended spinning stock solution and 3 spinning and post-processing. Compared with conventional viscose fibers, the influenza A virus inactivation rate of the fiber is 82.0% or above, the herpes virus inactivation rate is 84.0% or above, a bacteriostatic activity value is greater than or equal to 2.0, a bactericidal activity value is greater than or equal to 0.2, a variety of amino acids and trace elements are contained in the fiber, the fiber has good skin-care and health-care functions, the physical index of the product can meet the requirements of GB / T14463-2008 viscose staple fiber first-grade products, and the fiber has good wearability and textile processing performance.

Owner:单大伟

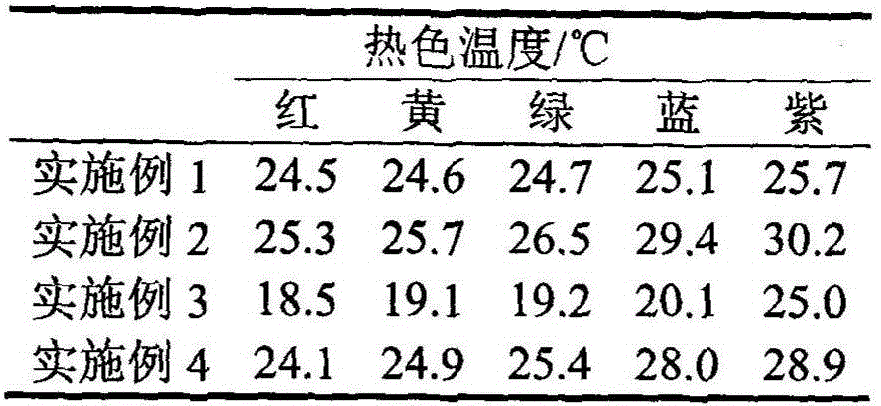

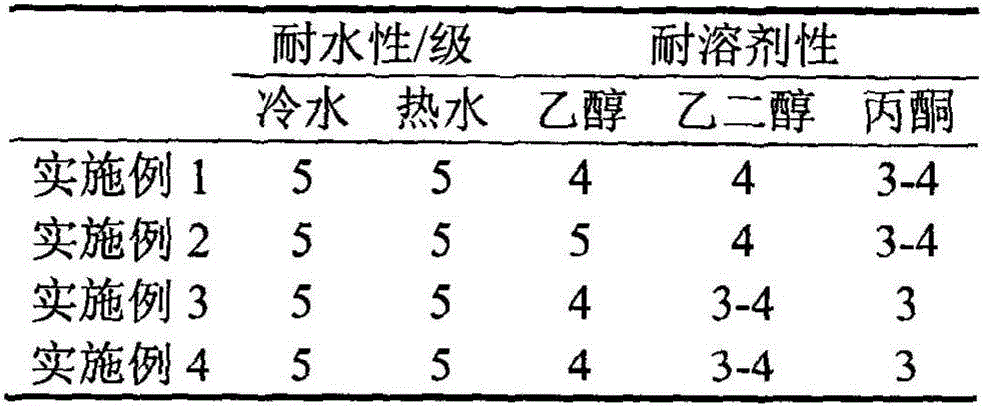

Preparation method of liquid crystal microcapsule for textile printing

ActiveCN106749871ASmall particle sizeNarrow particle size distributionLiquid crystal compositionsDyeing processCrystallographyTextile printer

The invention discloses a preparation method of a liquid crystal microcapsule for textile printing, and belongs to the technical field of fine chemical engineering and material science. The liquid crystal microcapsule suitable for textile printing is prepared through the emulsion polymerization. The shell structure of the obtained liquid crystal microcapsule can protect liquid crystal, improve water resistance and solvent resistance of the liquid crystal and can take participation in film forming, the color of the liquid crystal microcapsule is bright and varied, the original color property can still be kept after textile processing and treatment, and the liquid crystal microcapsule can better meet requirements of textiles and can meet the requirements of people for clothes personalization and diversity.

Owner:JIANGNAN UNIV

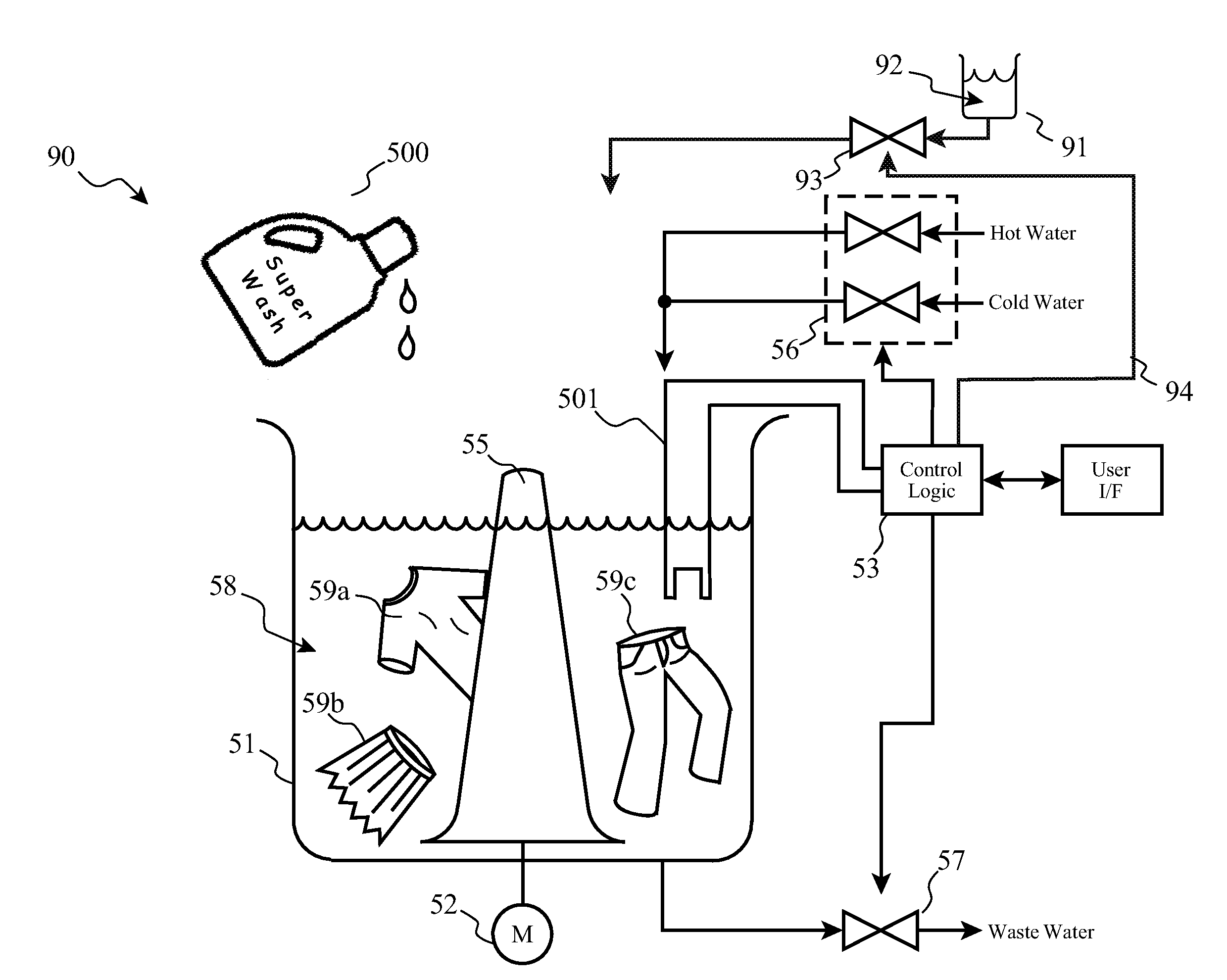

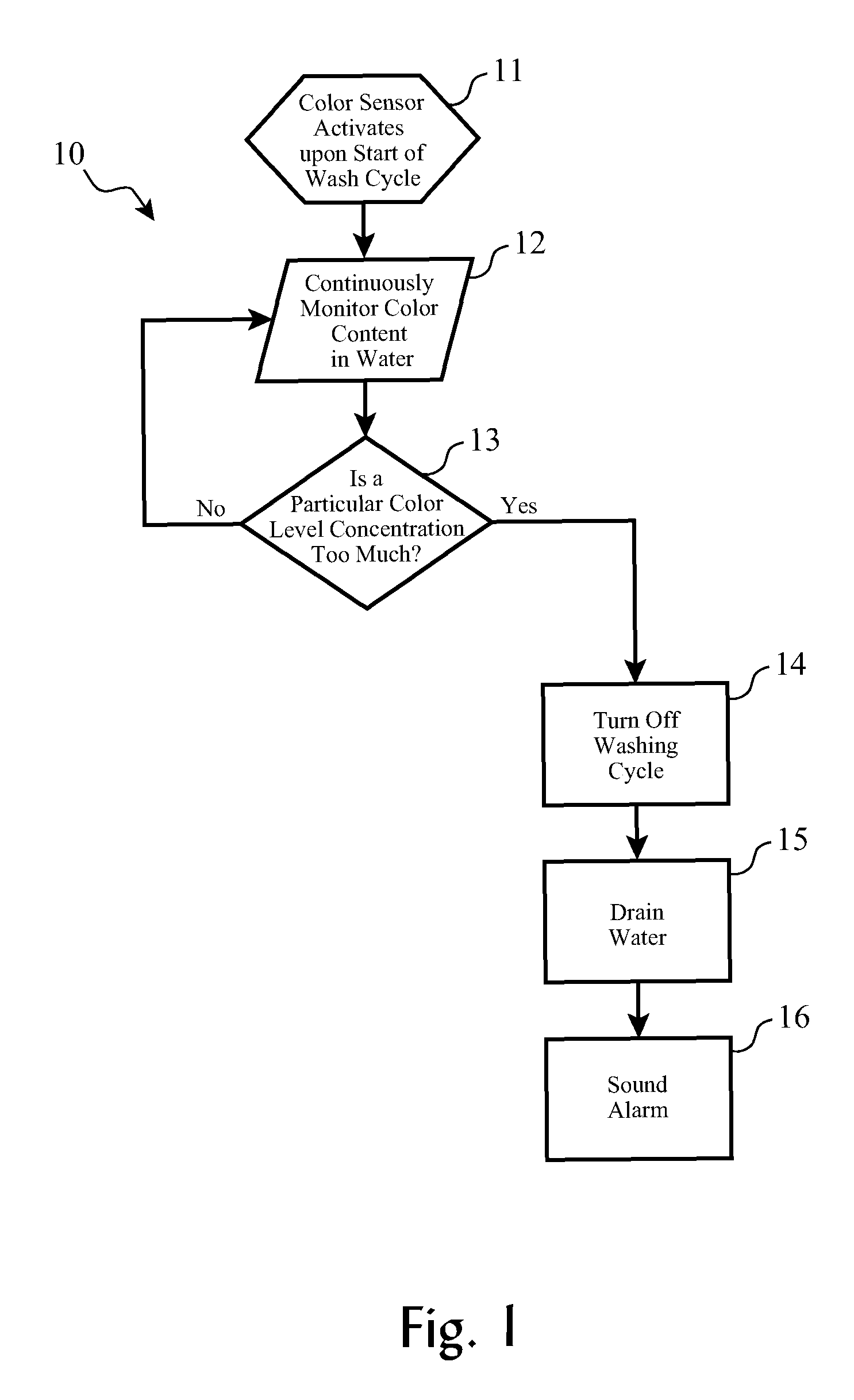

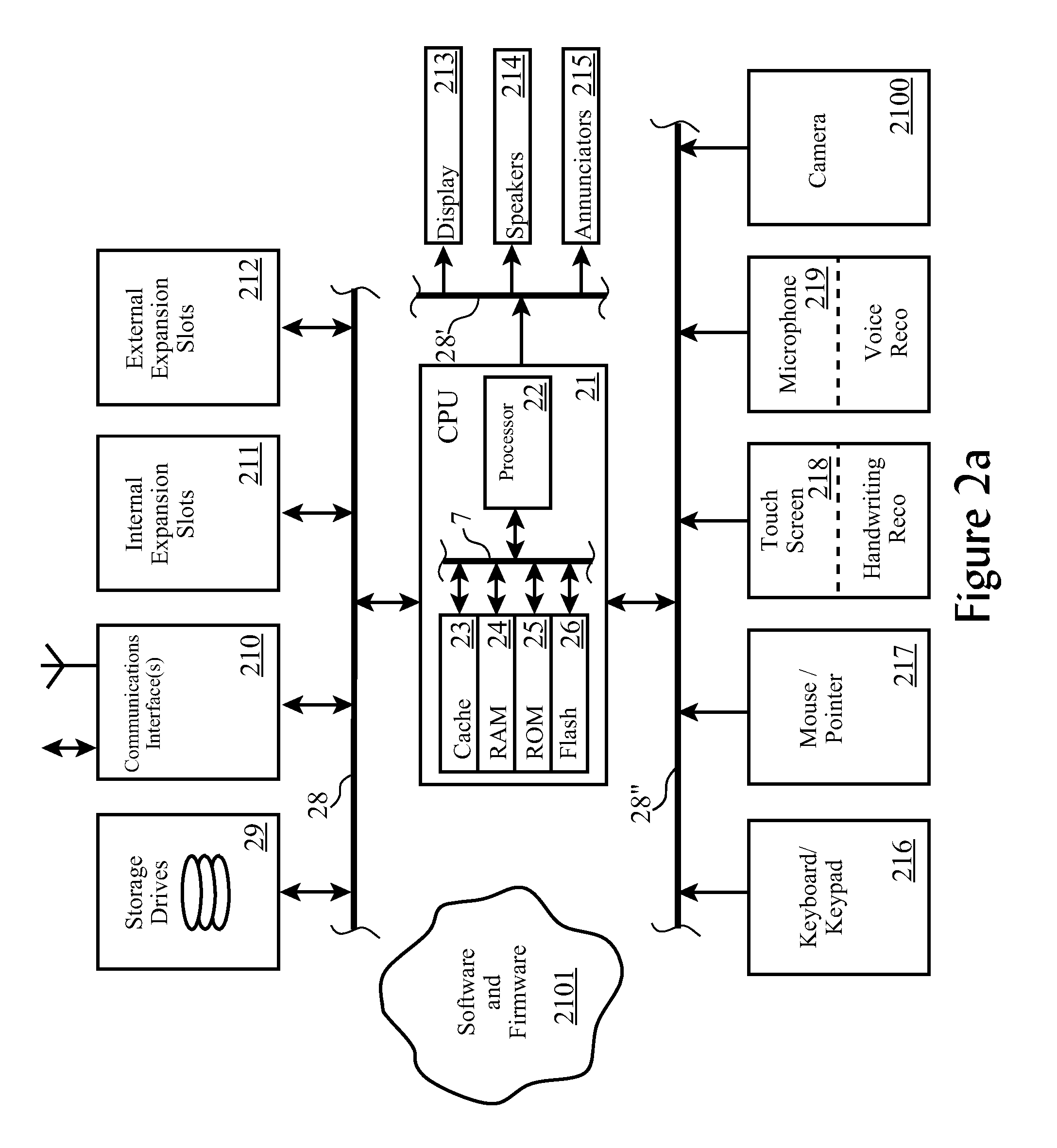

User interface for color transfer control in textile processing equipment

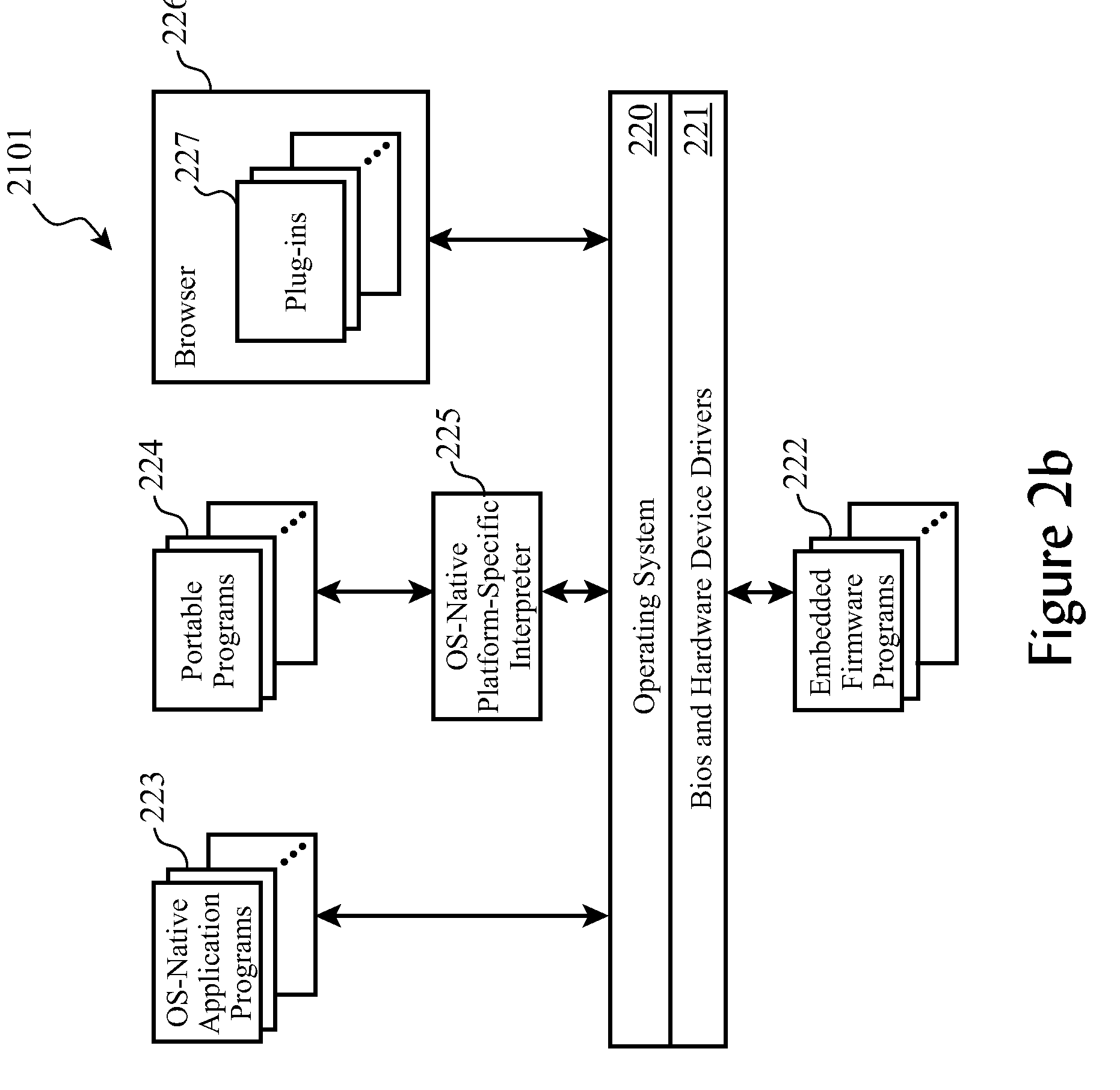

InactiveUS20080003904A1OptimizationEasy to useSafety arrangmentsSynthetic resin layered productsDisplay deviceHuman–computer interaction

A system, method, and computer-readable medium encoded with software for allowing a user to configure controls of dye transfer in a dying machine or washing machine, including a user display having a user-operable selection device, a first dialog with primary color level indicators for setting a threshold to trigger a dye transfer control action, and threshold adjustment controls, and a second dialog having one or more control action enablers for enabling one or more control actions to be taken upon detection of a color reaching the threshold.

Owner:IBM CORP

Novel electromagnetic shielding textile fabric and preparation method thereof

InactiveCN104727139ASimple preparation processLow costPhysical treatmentVacuum evaporation coatingFiberHeat conducting

The invention discloses novel electromagnetic shielding textile fabric and its preparation method and belongs to the field of textile processing. By a magnetron sputtering technology, nano-silver, nano-copper and nanometer titania particles are respectively sputtered onto a fabric base material to form an uniform nanocomposite film so as to obtain the electromagnetic shielding fabric. The electromagnetic shielding fabric for children's garments has advantages of simple preparation technology, low cost, high binding strength of the film and the base material, uniformly and compactly distributed film, strong adhesive force and no environmental pollution, and has excellent electrical conductivity and electromagnetic shielding performance. Resistance can be less than 10 omega / cm, SE value reaches about 28dB, and more than 99% of electromagnetic wave is shielded. By means of rapid heat-conducting property of metal, the fiber fabric can have effects of regulating body temperature and making the winter warm and the summer cool. In addition, the fabric feels very soft and has excellent resistance to water washing.

Owner:JIANGNAN UNIV +1

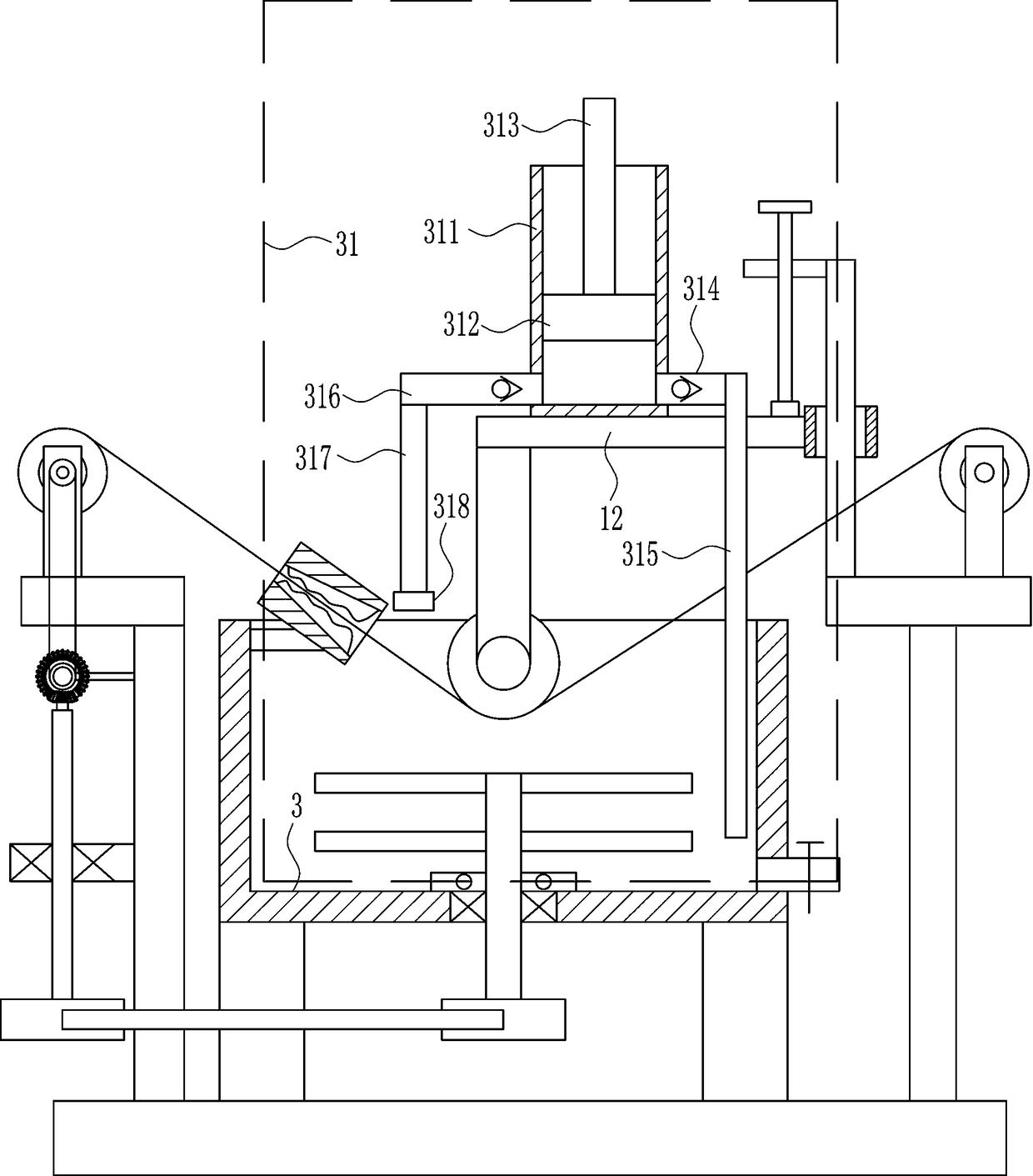

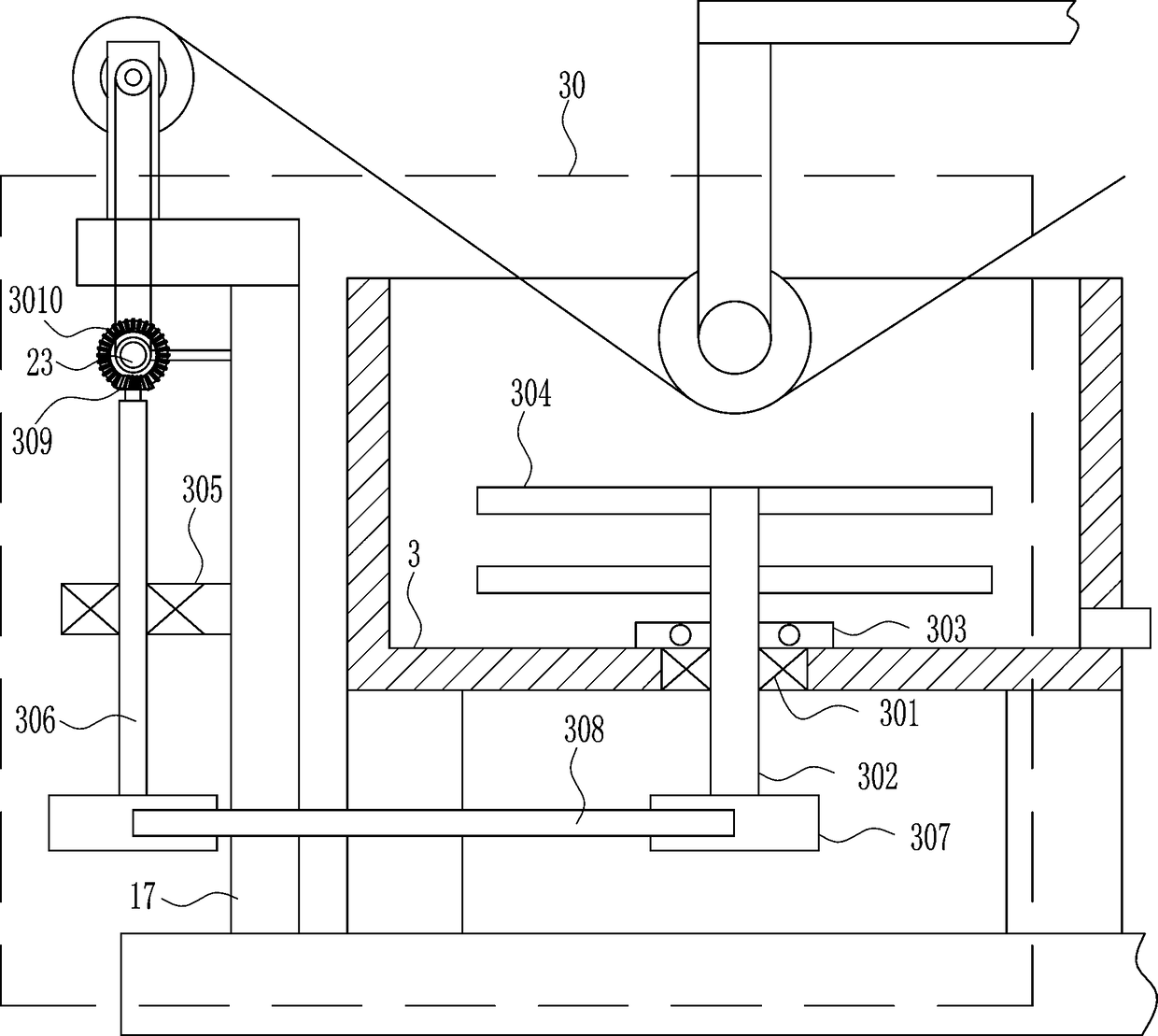

Textile fabric dyeing equipment

ActiveCN108277594AAvoid color inconsistenciesNo precipitationLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsEngineeringSediment

The invention relates to textile processing equipment, in particular to textile fabric dyeing equipment. The to-be-solved technical problem is to provide the textile fabric dyeing equipment capable ofstirring dye, so that no sediment occurs in the dye, the fabric is dyed uniformly, the upper and lower layers of the fabric both can be dyed with the dye at same depth in a dyeing process. In order to solve the above technical problem, the invention provides the textile fabric dyeing equipment, the textile fabric dyeing equipment comprises a bottom plate, brackets, a dye box, a discharging tube,a valve, a first supporting plate, a first mounting plate, a first connecting rod, and a first sleeve wheel, a guiding rail, a guiding sleeve, a second connecting rod and the like, wherein the left and right sides of the bottom plate both are connected to the brackets, and the dye box is connected between the upper ends of the brackets. According to the textile fabric dyeing equipment, the effectsthat the dye is stirred, so that no sediment occurs in the dye, the fabric is dyed uniformly, and the upper and lower layers of the fabric both can be dyed with the dye at same depth in the dyeing process are achieved.

Owner:嘉兴市永泰五金塑料有限责任公司

Super-smooth warping method of yarns with many drafted fibers

ActiveCN105274695AAvoid gatheringWrap tightlyWarping machinesOther manufacturing equipments/toolsFiberYarn

The invention relates to a super-smooth warping method of yarns with many drafted fibers and belongs to the textile processing technical field. According to the method of the invention, on each yarn warping mechanism of a warping machine, a false twisting device is adopted to make the trunk of a yarn rotate; a drafted fiber directional stretching device is adopted to directionally eject steam flows so as to directionally stretch the drafted fibers of the yarn, so that some of the drafted fibers of the yarn forwards and orderly wrap the trunk of the yarn, and therefore, the drafted fibers can be prevented from being entangled to from neps when randomly or vertically winding the trunk of the yarn; a drafted fiber vortex wrapping device is adopted to reversely wrap the other drafted fibers of the yarn on the trunk of the yarn, so that the other drafted fibers of the yarn and the forwards and orderly wrapped drafted fibers can be closely tangled in a cross manner; and therefore, progressive complete wrapping and cross tight wrapping of the drafted fibers of the yarns can be realized, and winding tightness and firmness of the drafted fibers can be greatly increased, and the problem of series rebound of the drafted fibers of the yarns in a warping procedure and subsequent procedures of warping can be solved, and super-smooth warping of the yarns with many drafted fibers can be realized. The device of the invention has the advantages of reasonable structure and convenient operation.

Owner:WUHAN TEXTILE UNIV

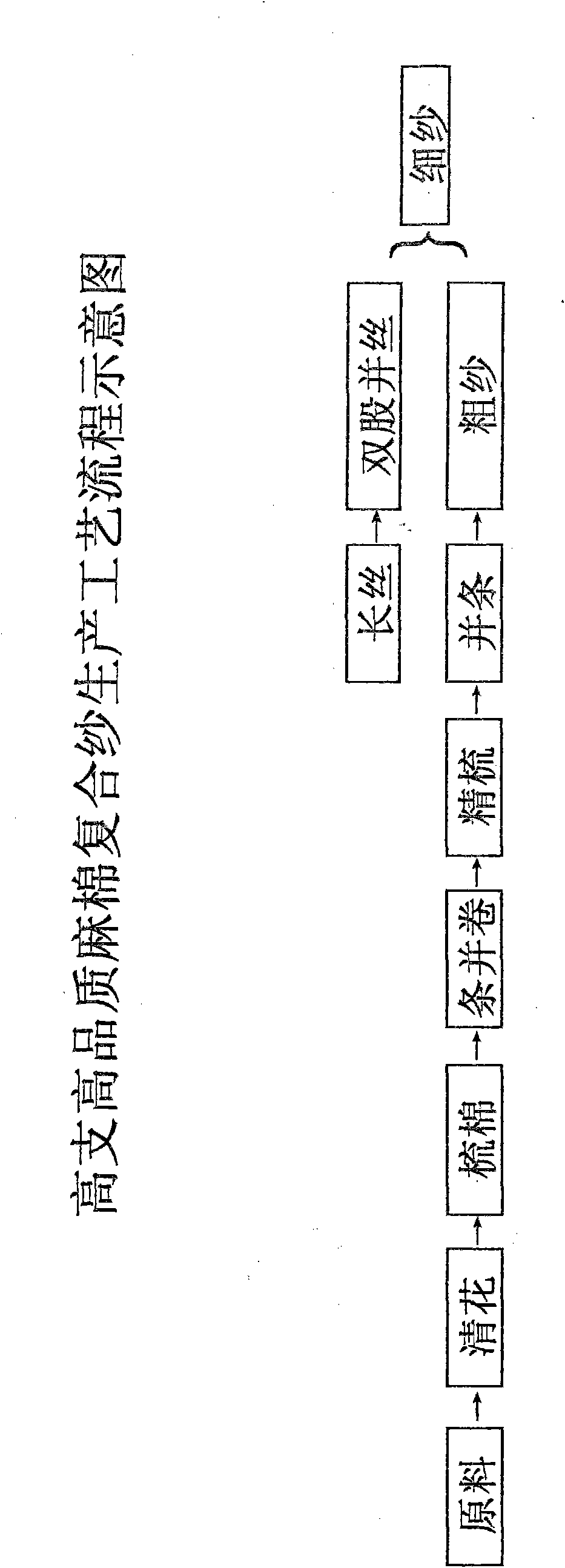

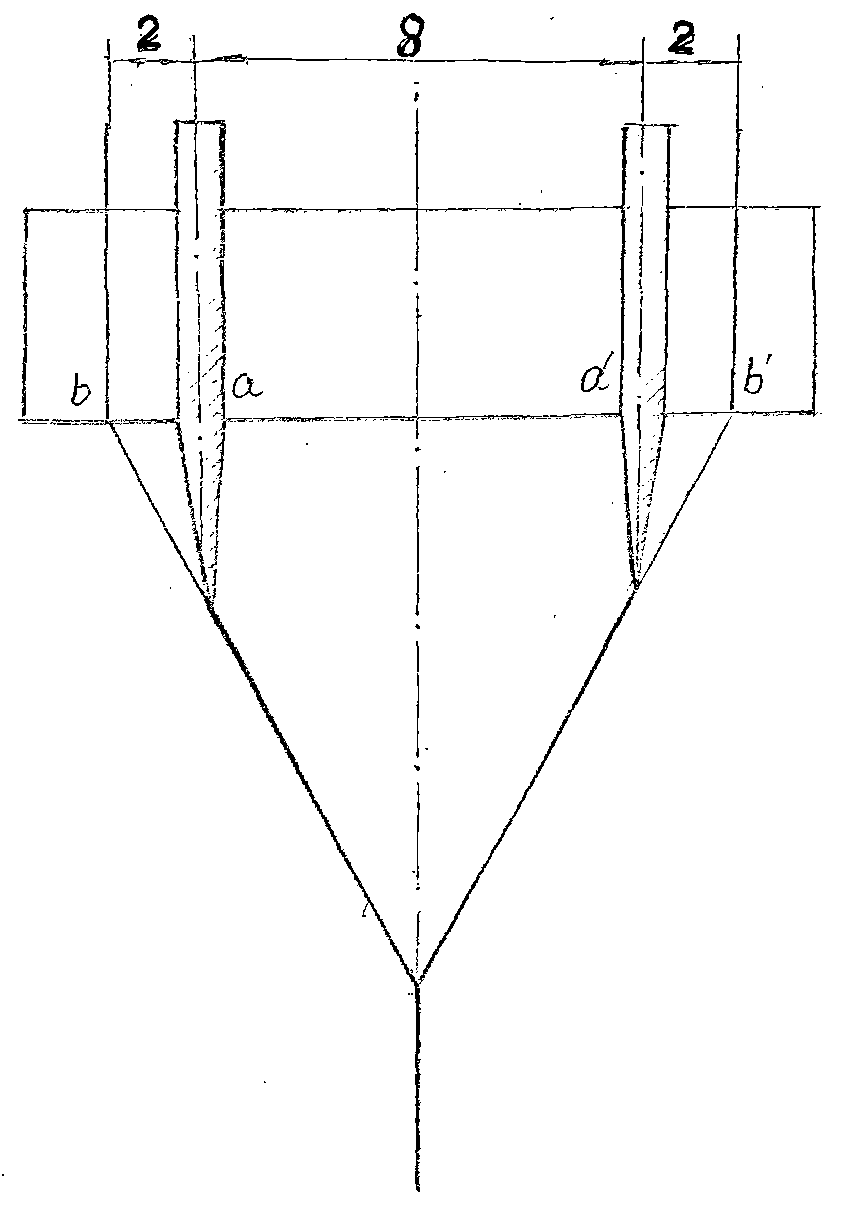

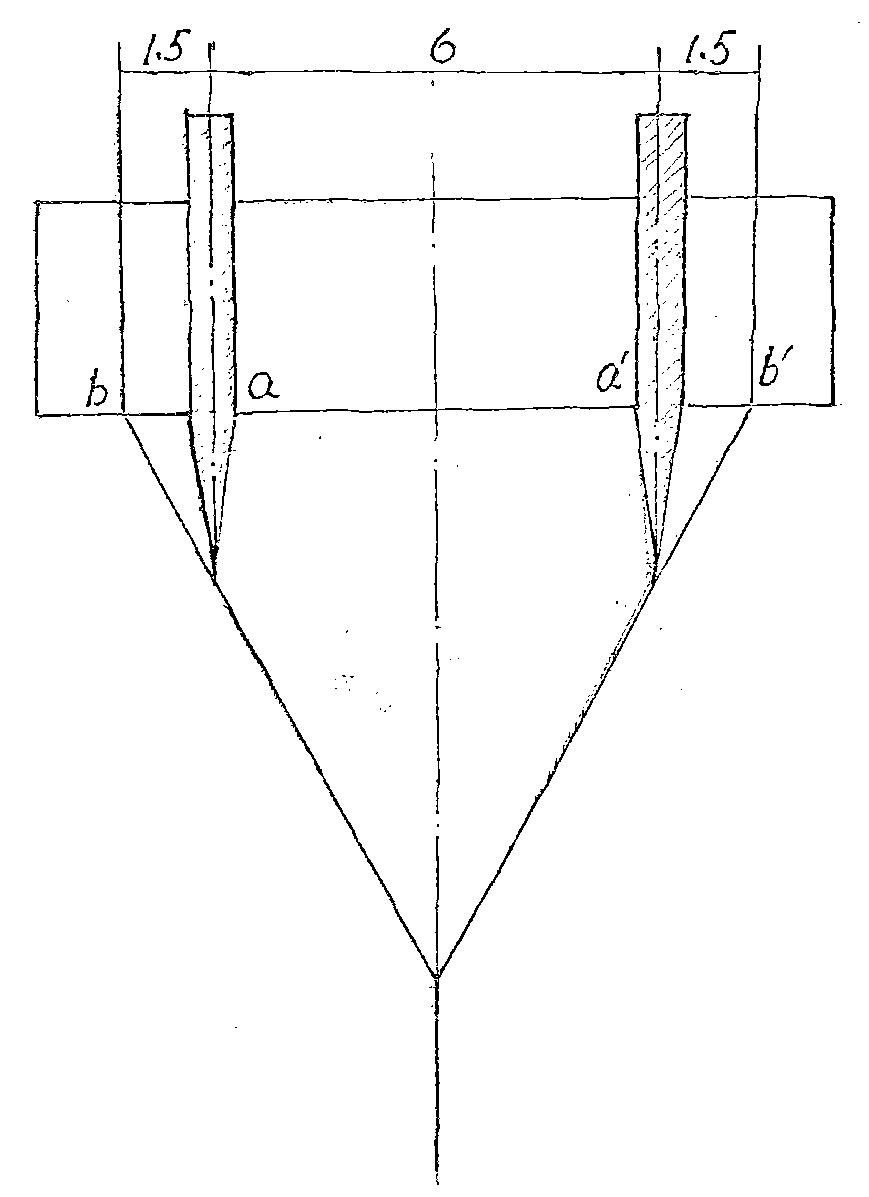

Technology for processing embedded high count high-quality ramie cotton blending yarns

The invention discloses technology for processing embedded high count high-quality ramie cotton blending yarns, and relates to the technical field of textile processing. The technology comprises filament double-strand doubling technology, jute fiber roving processing technology, and spinning technology, wherein the spinning technology comprises the steps of: forming four yarn components by two filaments and two jute fiber rough yarns; using an embedded spinning technology principle and a double-strand filament cake (barrel) phase difference unwinding method; and using a double-strand filament positioning wire-leading feeding device on a traditional spinning machine to spin the high count high-quality ramie cotton blending yarns. The multi-component different-structure high count high-quality ramie cotton blending yarns can be spun on the traditional spinning machine, and the defects that the jute fiber has poor cohesive force, poor fiber length uniformity, short fiber, high yarn hairness, and difficulty in spinning high count yarns are overcome. Therefore, the composite yarns have the advantages of compact structure, excellent yarn hairness, brute force and yarn levelness, meet the requirement on high-grade shell fabrics, and expand the development space of linen textiles. The technology is applied to the field of processing all blending yarns in the spinning industry.

Owner:HUBEI TIANHUA RAMIE TEXTILE CO LTD

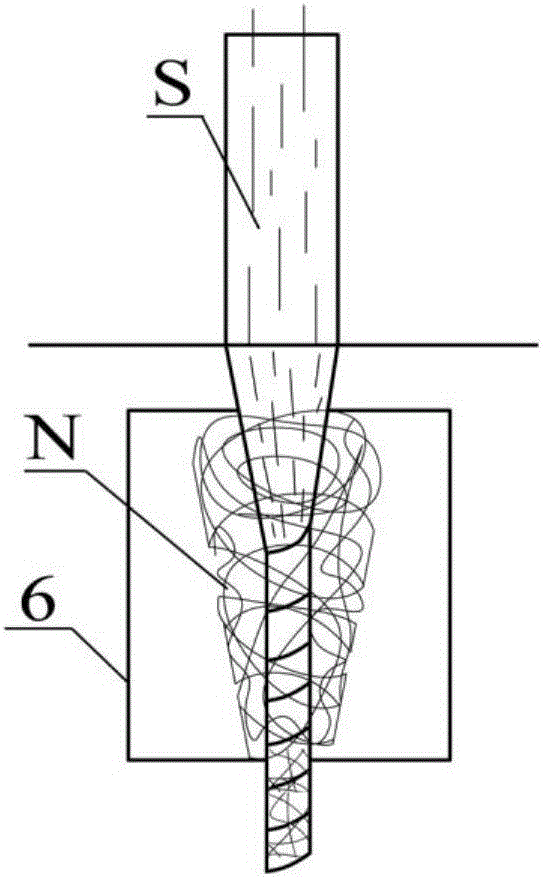

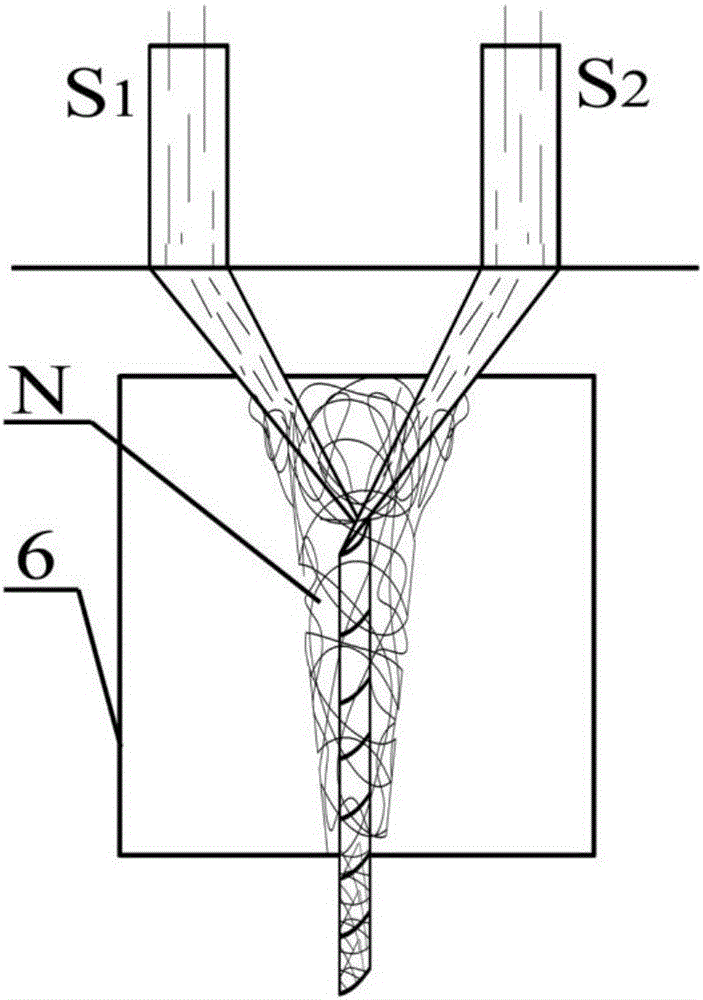

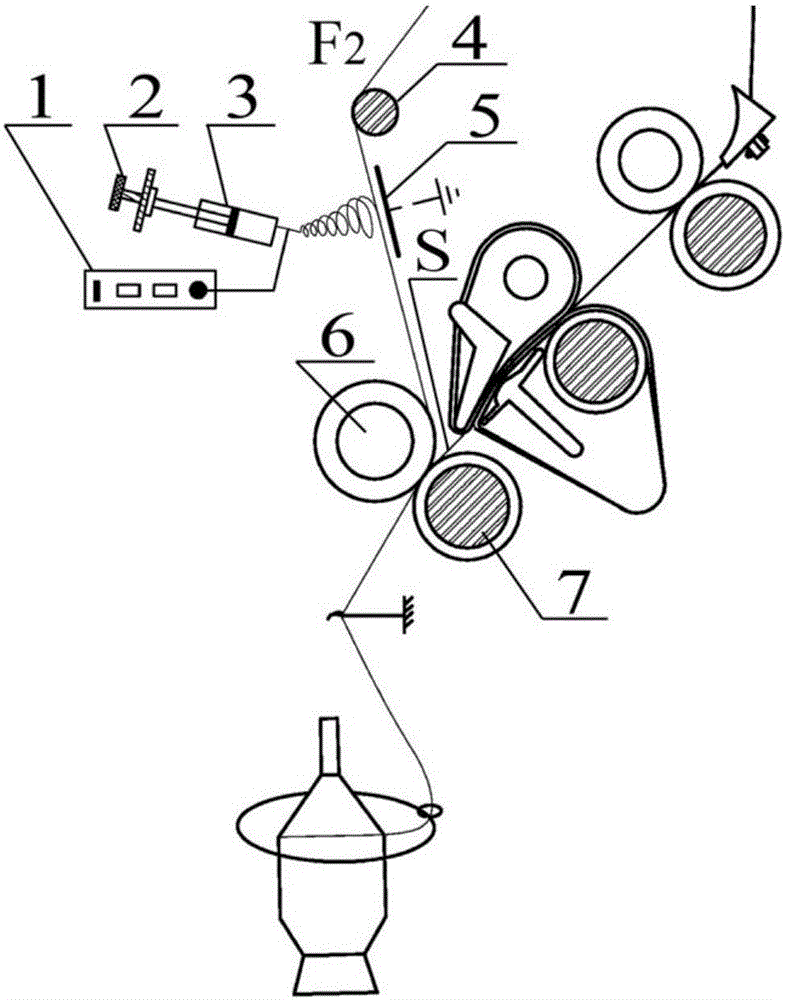

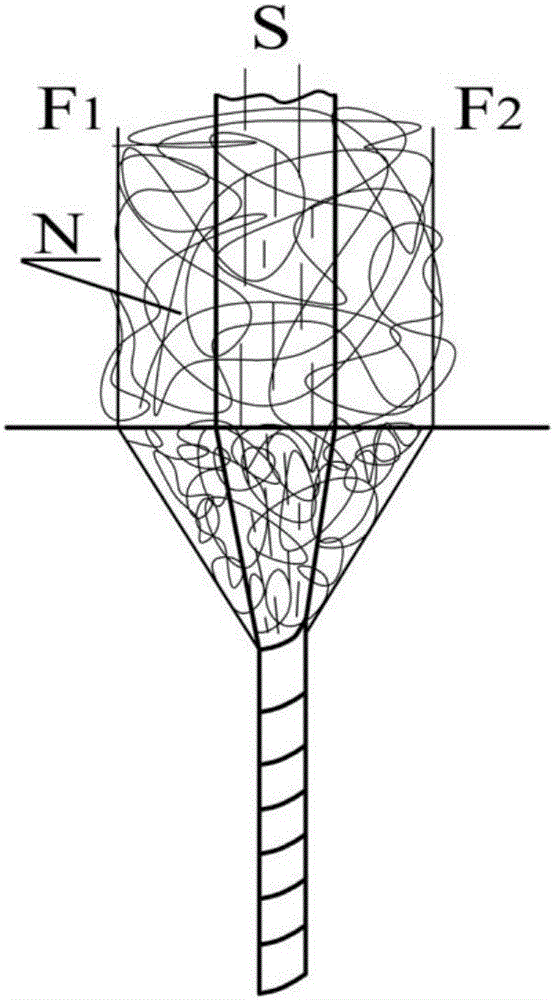

Filament ring spinning composite spinning method of nano-microscale reinforced fiber

ActiveCN106480556AHigh strengthImprove structural stabilityFilament/thread formingDrafting machinesElectrospinningNanofiber

The invention relates to a filament ring spinning composite spinning method of nano-microscale reinforced fiber, and belongs to the technical field of textile processing. The method applies the placement of an electrostatic spinning device between a front roller and a guide roller of a ring spinner, wherein an electrostatic ejection area is formed between the electrostatic spinning nozzle of the electrostatic spinning device and a receiving surface of a receiving plate, thus making the electrostatic spinning nozzle continuously eject the nano-fiber through the guide roller to the filaments F1 and F2 located at a roller nip to form a nano-fiber web. The nano-fiber web at the nano-fiber web makes contact simultaneously with the filaments and short staple stripes inner fibers, thus increasing the attachment between fibers in the filament ring spinning composite yarns, and solving the problems that in the normal composite spinning, the filament and the short staples are prone to sliding and have low attachment. Essentially speaking the method organically combines the nano-spinning and the normal filament ring spinning composite spinning, overcomes the problem of low strength of the pure nano-fiber resultant yarn, and guarantees the fast and smooth production of the nano-microscale fiber blended yarns.

Owner:WUHAN TEXTILE UNIV

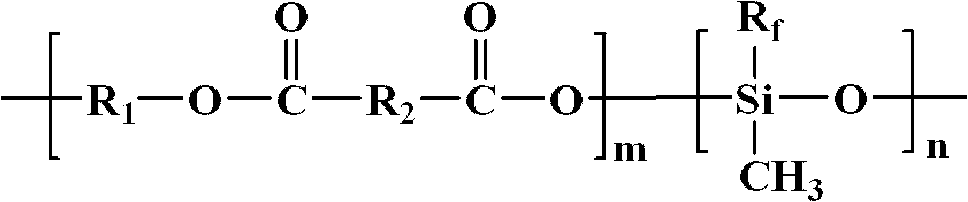

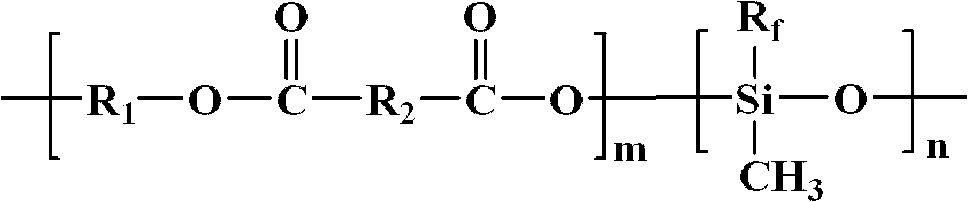

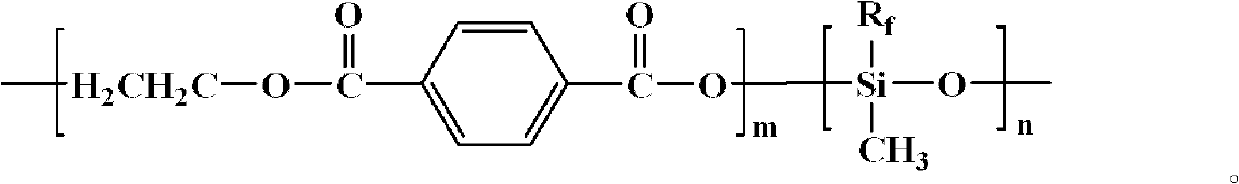

Hydrophobic modified polyester and preparation method thereof

The invention provides hydrophobic modified polyester, with a structural formula, wherein R1 and R2 are respectively C2-C8 alkyl, aryl or cycloalkyl, Rf is C1-C20 fluoroalkyl, n ranges from 6 to 141, m is 42-104. The preparation method of the polyester is as follows: mixing of dibasic acid, dibasic alcohol and a catalyst or mixing of dibasic ester, dibasic alcohol and a catalyst or mixing of oligomer of dibasic acid and dibasic alcohol, dibasic alcohol and a catalyst, and polyreaction under the temperature of 140-300 DEG C and the vacuum degree of 5-150Pa until the expected degree of polymerization is realized, thereby obtaining the hydrophobic modified polyester. The modified polyester has low surface energy and excellent hydrophobic properties, and is suitable for both spinning and textile processing.

Owner:CHINESE TEXTILE ACAD

Extraction method of bamboo shoot case fibre for spinning

InactiveCN101117731ASimple processLow costVegetable materialBacteriological rettingChemical treatmentPre treatment

The present invention relates to a method for extracting spinning fiber from bamboo shoot shells. The extracting method of spinning fiber from bamboo shoot shells is characterized in that the present invention comprises the following steps: firstly, pretreatment: cutting the bamboo shoot shells into pieces 20-100mm long; storing the pieces in a sealed environment and adjusting the humidity to control the moisture regain rate at 6 percent -10 percent; secondly, degumming treatment: using one or combination of any two or three of steam explosion treating method, microbial treating method and chemical treating method for degummed bamboo shoot shell fiber; thirdly, post-treatment: a, oil feeding: adding wool oil to the degummed bamboo shoot shell fiber, the wool oil being 1-2 percent of the degummed bamboo shoot shell fiber in weight; b, drying: controlling the temperature of the drying oven at 60-80 DEG C; c, fiber dispersing: obtaining spinning bamboo shoot shell fiber. The present invention has the advantages of simple process and low cost and, applied to textile processing, can take full use of bamboo shoot shell resources and protect the environment.

Owner:WUHAN TEXTILE UNIV

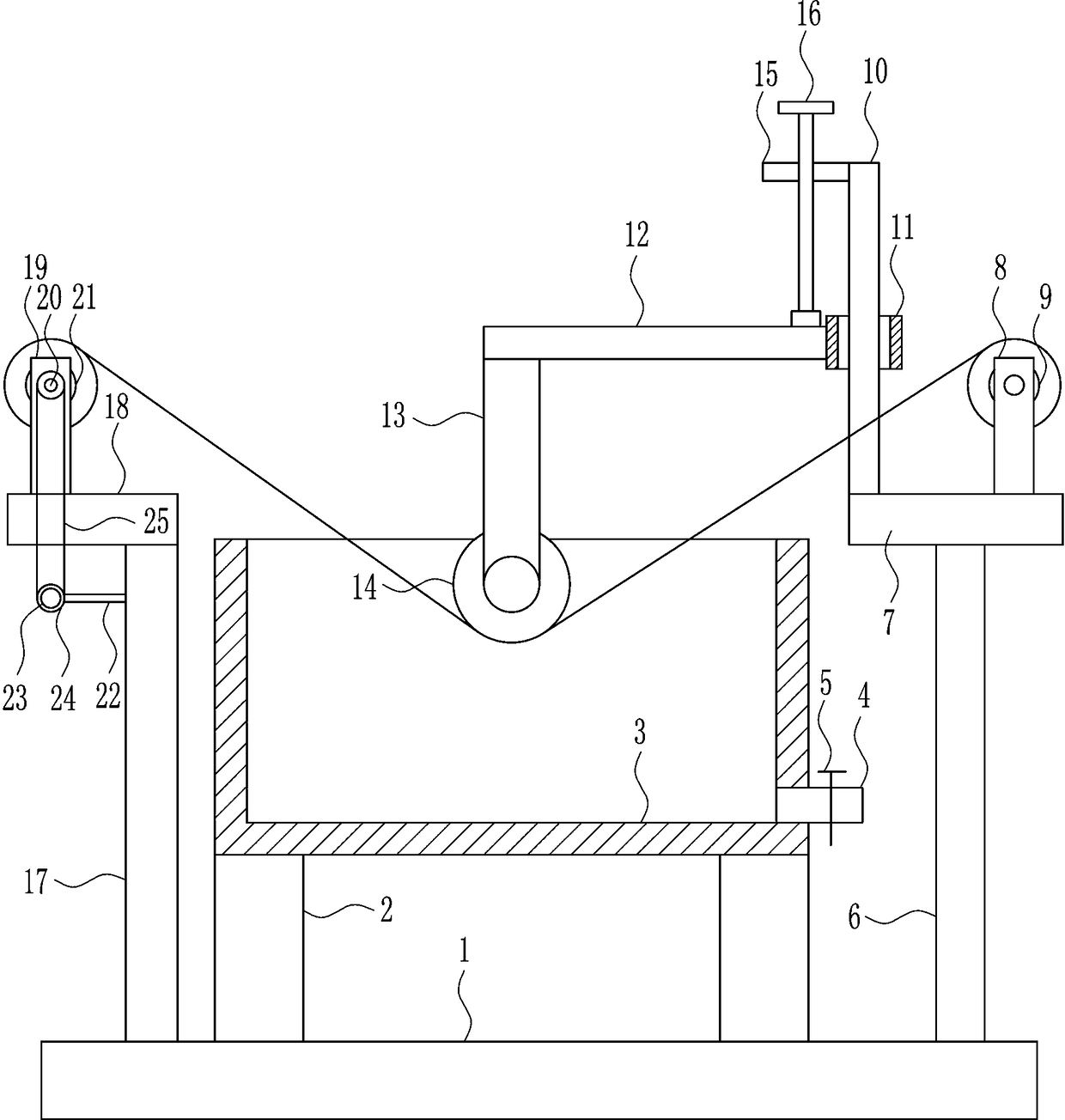

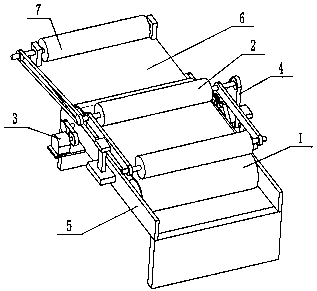

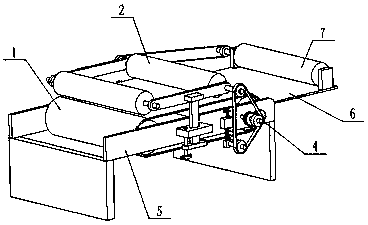

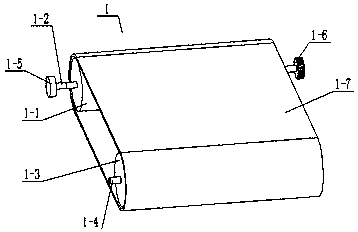

Cloth clipping and conveying device for textile processing

InactiveCN108221345AImprove work efficiencyImprove delivery capacitySevering textilesArticle deliveryMechanical engineeringTextile processing

The invention relates to the field of textile processing and particularly relates to a cloth clipping and conveying device for textile processing. The cloth clipping and conveying device comprises a cloth conveying mechanism, a cloth pressing roll lifting mechanism, a driving mechanism, a tension transmission mechanism, a stander, a clipping table and a cloth discharging roll mechanism, wherein the cloth conveying mechanism is connected to the inner side of the stander; the cloth pressing roll lifting mechanism is arranged at the upper end of the cloth conveying mechanism, and two sides of thebottom end of the cloth pressing roll lifting mechanism are respectively connected to the middles of two ends of the stander; the driving mechanism is fixedly connected to the left end of the standerand is connected with the cloth conveying mechanism; and the tension transmission mechanism is fixedly connected to the right end of the stander, and the cloth conveying mechanism is connected to thecloth pressing roll lifting mechanism through the tension transmission mechanism. According to the invention, the cloth conveying mechanism and the cloth pressing roll lifting mechanism are arrangedin the cloth clipping and conveying device, so that the cloth can be clamped and conveyed effectively, and the distance between the cloth conveying mechanism and the cloth pressing roll lifting mechanism can be adjusted, so as to be suitable for conveying cloth of different thickness.

Owner:佛山市冠康隆纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com