Patents

Literature

1780 results about "Silk fabric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

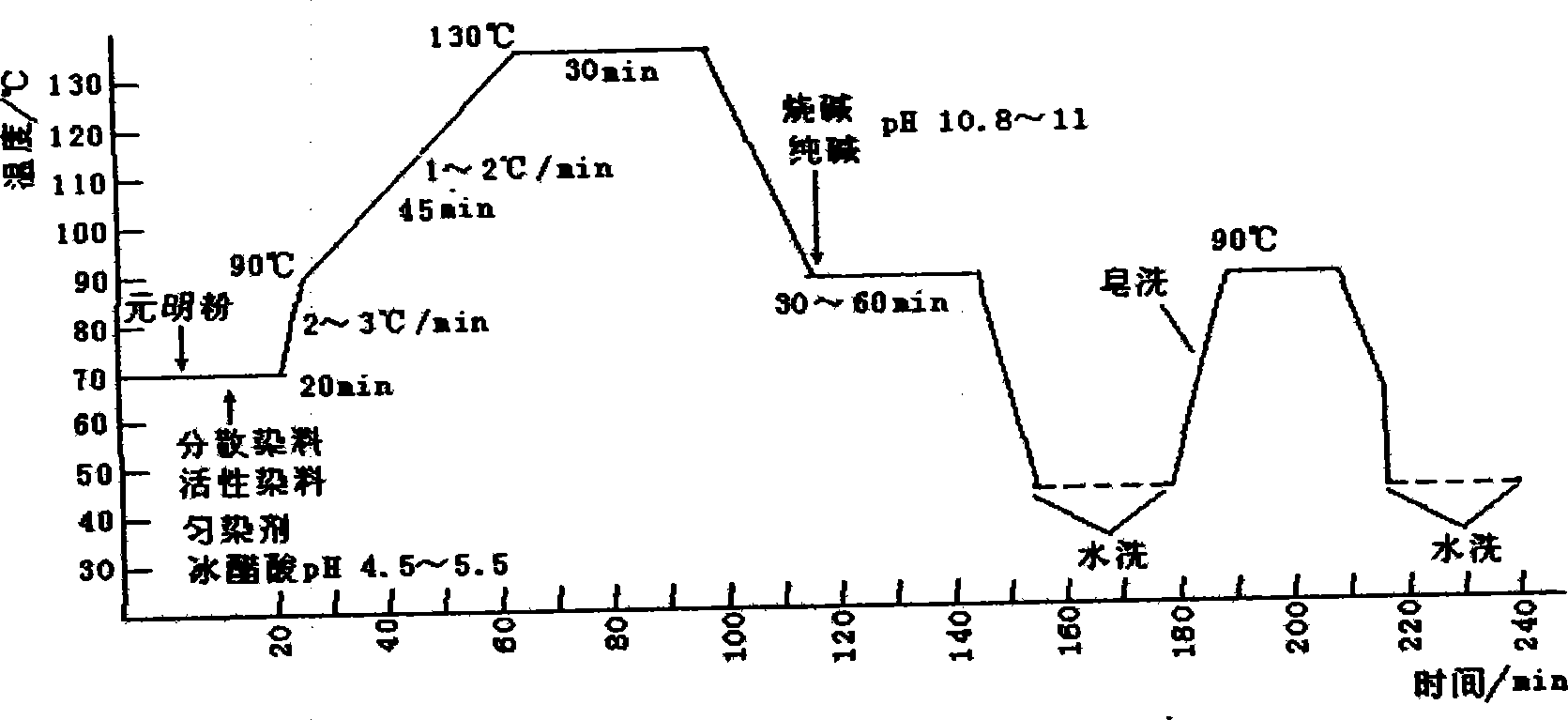

Method for preparing colored fabric containing polylactic acid fiber and silk components

InactiveCN102102268AAvoiding paradoxes of decompositionLow costWeft knittingPolymer sciencePolylactic acid

The invention discloses a method for preparing a colored fabric containing polylactic acid fiber and silk components, which comprises the following steps of: dyeing polylactic acid fibers and silk fibers respectively, and weaving into the colored fabric. By the method, the respective advantages of the polylactic acid fibers and silk are fully exerted, high skin affinity is achieved, the cost of areal silk fabric can be reduced, and the prepared fabric has a wide market prospect.

Owner:HENAN LONGDU BIOLOGY TECH

One-bathing integrated finishing method for real silk fabric by natural extract

InactiveCN101338518AAchieve antibacterialReduce processing stepsDyeing processAnimal fibresEngineeringTextile dyeing

The invention discloses a method for real silk fabric functional finishing, especially relates to a method for one-bath multifunctional finishing of real silk fabric by utilizing natural extract, which pertains to textile dyeing and finishing technical field. The invention includes the following steps: placing real silk fabric in solution with 5-20%(o.w.f) natural extract, liquor ratio of 1:10 to 1:100 and PH value of 2-8, treating for 10-100min; then treating for 10-100min in solution with 3-15%(o.w.f.) metal salt, liquor ratio of 1:10 to 1:100 and PH value of 4-8; after washing, dehydrating and furnace drying, completing one-bath finishing with dyeing, antimicrobial and anti-ultraviolet function to real silk fabric. The invention reduces manufacturing procedure of real silk fabric, has effect of energy-saving and emission-reduction, improves cleaning production of textile processing, is harmless to human body and surroundings, and conforms to ecological textile processing requests.

Owner:SUZHOU UNIV +1

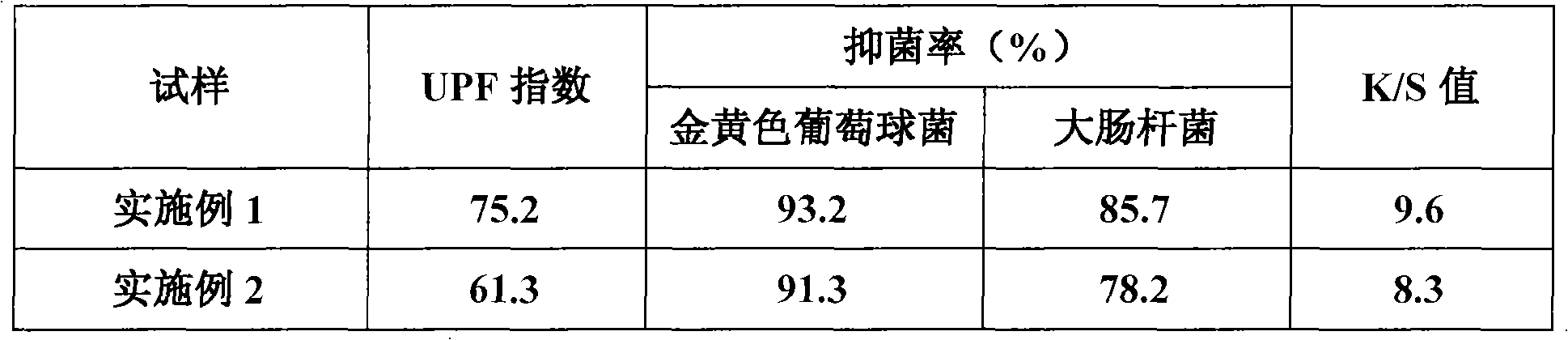

Modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide

ActiveCN102677465AImprove adsorption efficiencyRealize functional fillingLiquid/gas/vapor removalDry-cleaning apparatus for textilesUltravioletEngineering

The invention relates to modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide. The modified tussah silk fabric is prepared by the steps in sequence: weaving the tussah silk fabric by utilizing tussah filament, preparing finishing liquor and finishing tussah silk fabric; and the technical problems that the existing textile materials in the modification technology can not effectively improve the properties that the tussah silk fabric has damage to the environment, is easy to wrinkle, not anti-bacterial and easy to shrink, has poor dyeing property, poor comfortableness and function, and the like can be solved, the comprehensive properties that the tussah silk fabric is anti-wrinkle, soft, anti-bacterial, shrink-proof, self-cleaning and ultraviolet ray-resistant, as well as the adsorption efficiency of dye, and the like can be improved and enhanced, and the tussah silk fabric has the technical benefits of being lower in preparation cost, simple in process, environment-friendly and easy to realize, etc.

Owner:EASTERN LIAONING UNIV

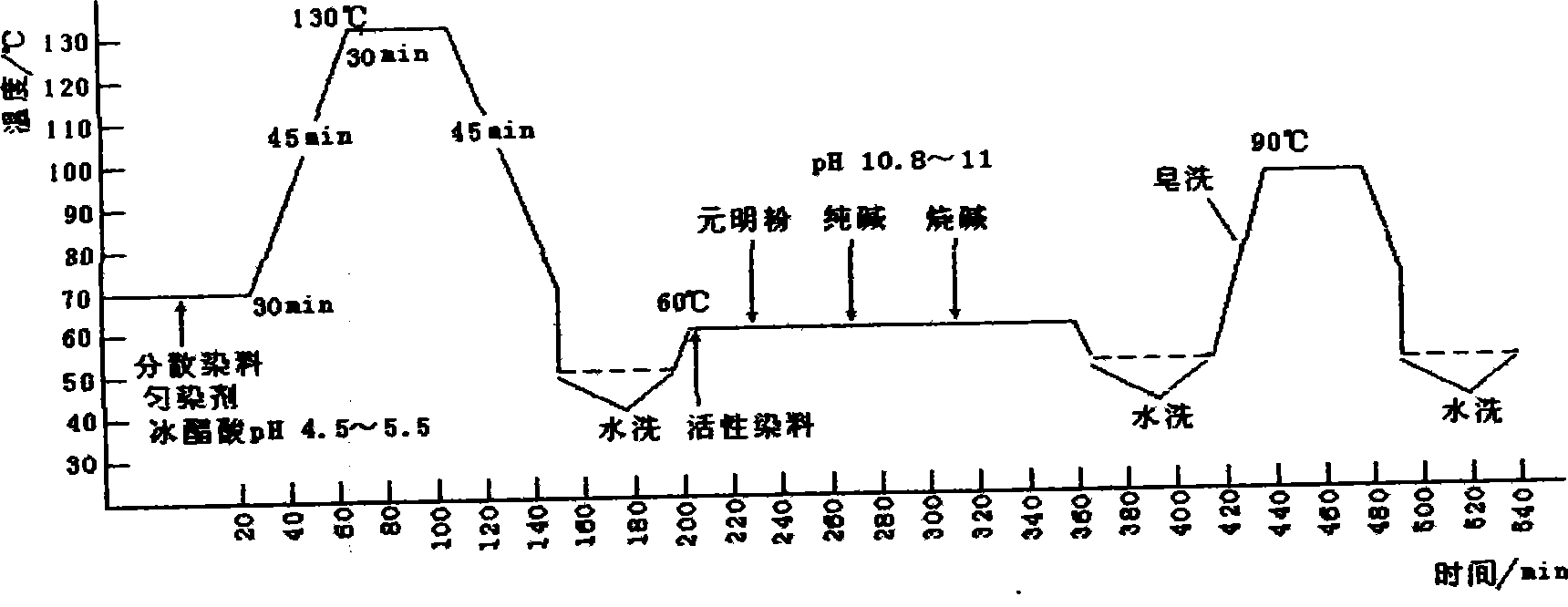

Dyeing and finishing process for sea silk fabric

InactiveCN101413207AStrong damageSoft touchDry-cleaning apparatus for textilesBleaching apparatusFiberTextile printer

The invention discloses a dyeing and finishing technology for seaweed fiber fabrics, which belongs to the technical field of textile printing and dyeing. The dyeing and finishing technology comprises the following steps of pre-treatment, dyeing and after-treatment, wherein pre-treatment adopts the treatment technology of enzyme-deoxidized annealing and bleaching-bath method; and the fabrics are placed into a dye jar with a bath ratio between 1 to 5 and 1 to 30 at a normal temperature, added with an immersing working fluid, heated to a temperature of between 70 and 100 DEG C, bleached, subjected to heat insulation for 30 to 60 minutes, subjected to water scrubbing and standby for dyeing. The dyeing and finishing technology adopts the treatment technology of enzyme-deoxidized annealing and bleaching-bath method; the capillary effect of the fabrics is more than 10.5 centimeters; the brightness reaches more than 82; and the strength loss is less than 10 percent. The dyeing technology of one bath two stage process shortens the processing time for 50 percent, is energy-saving and reduces consumption.

Owner:ZHEJIANG GANGLONG WEAVING TECH

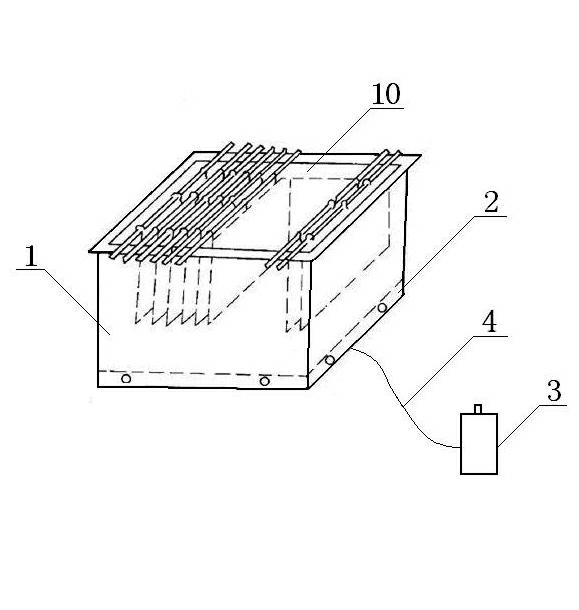

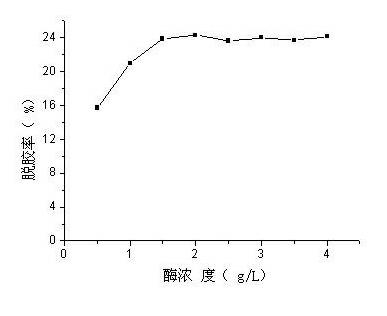

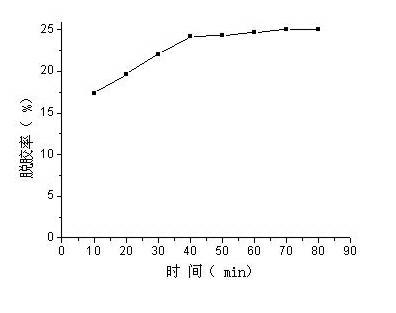

Silk fabric degumming method and apparatus thereof

ActiveCN102605439AShort degumming timeImprove degumming efficiencyDe-gumming silkAlkaline proteasePolymer science

The invention discloses a silk fabric degumming method and a silk fabric degumming apparatus. The invention belongs to the technical field of silk degumming. The method is characterized in that the method comprises the steps that: water with a required volume is injected in a degumming tank according to the weight of silk fabric and a bath ratio of 1:40-50; a pH value of the water is regulated to 8.5-9.5; the water is heated to a temperature of 50-60 DEG C; 1.00-2.50g / L of alkali protease is added into the degumming tank; silk fabric is placed into the tank, and supersonic wave is started, wherein the supersonic wave frequency is 30-80KHz; the supersonic wave treatment is performed for 35-60min, and washing is carried out. According to the invention, factors influencing silk fabric degumming are analyzed, and optimal technical values of alkali protease concentration, degumming time, degumming temperature, pH value, and bath ratio are determined. Also, the degumming apparatus is improved, such that silk fabric degumming time is effectively reduced, and silk fabric degumming efficiency is greatly improved.

Owner:SHAOXING UNIVERSITY

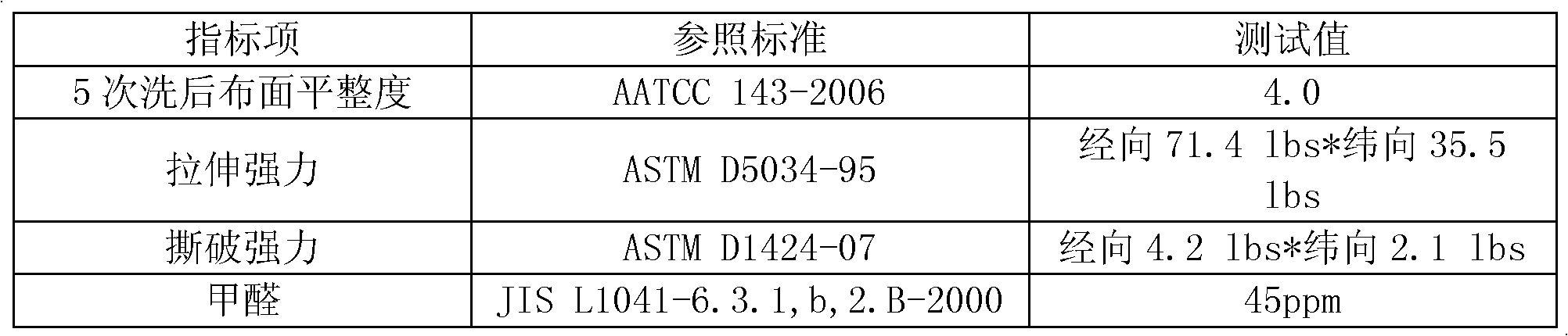

Finishing agent composition for cotton silk fabrics and production method of wash and wear cotton silk shirts

InactiveCN102634984AImprove breathabilityGood hygroscopicityVegetal fibresAnimal fibresEthylene ureaGlyoxal

The invention discloses a finishing agent composition for cotton silk fabrics and a production method of wash and wear cotton silk shirts. The finishing agent composition contains a finishing agent selected from dihydroxyl ethylene urea resin, butanetetracarboxylic acid, propanetricarboxylic acid, citric acid, polymaleic acid, glyoxal and glutaraldehyde, a polyurethane finishing agent and a catalyst. The wash and wear cotton silk shirts produced by the method can simultaneously have such advantages of cotton as good air permeability and strong moisture absorbability and such advantages of silk as good drapability, gloss and outstanding handfeel and can have excellent wash and wear effect while maintaining the peculiar handfeel of the cotton silk fabrics.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

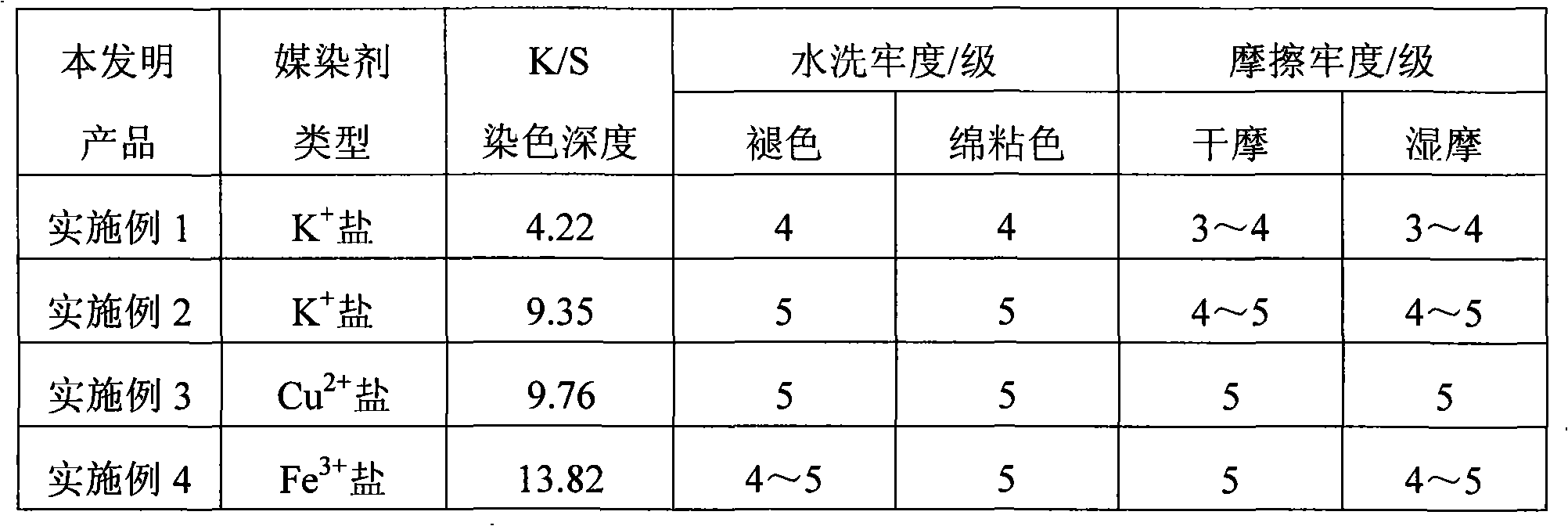

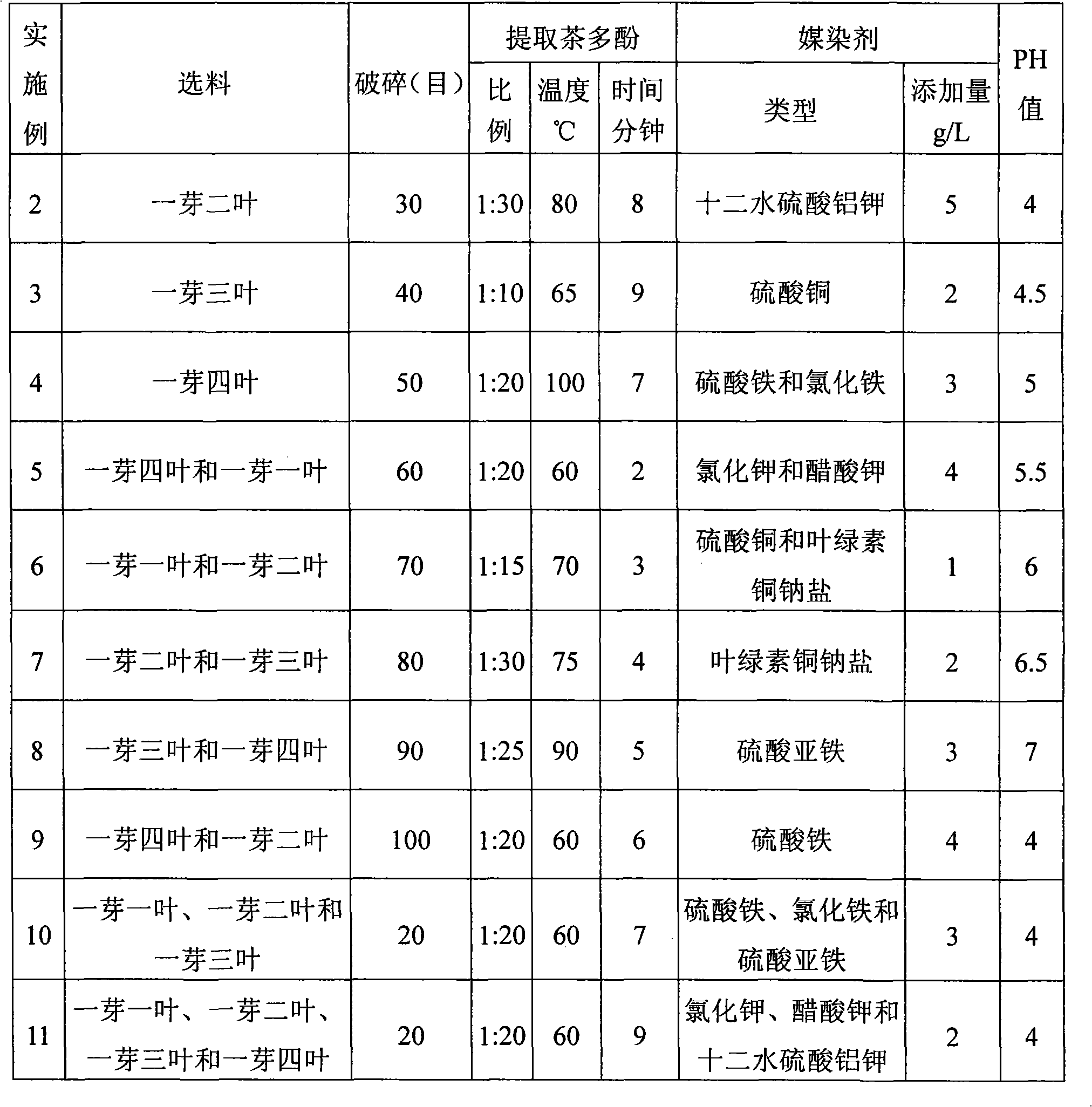

Natural staining agent, preparation thereof and application thereof to silk dyeing

The invention provides a natural coloring agent, which is characterized in that: the fresh tea leaves are used as material to extract tea polyphenol, and then the extraction liquid of the tea polyphenol is added with mordant agent, so as to form the natural coloring agent. As the natural coloring agent has rich color, good dyeing effect, good dyeing fastness (in particular wash fastness), and low production cost, the natural coloring agent has wide application, and strong practicality. The natural coloring agent also provides a preparation method of natural dyeing agent and an application at the aspect of silk fabric dyeing.

Owner:CHONGQING ACAD OF AGRI SCI

Preparation method for vegetable tannin dye liquor and application thereof to dyeing aspect of real silk fabric

InactiveCN102321383AEffective resourcesSignificant resource advantagesNatural dyesMordantsBiotechnologyFruit tree

The invention discloses a preparation method for vegetable tannin dye liquor and application thereof to the dyeing aspect of a real silk fabric. The vegetable tannin dye liquor is obtained by extracting larch bark, waxberry bark, black wattle bark, valonia or gallnut serving as a raw material by using acetone or water as an extracting agent or is obtained by extracting a tannin extract product of larch, waxberry, black wattle, valonia or gallnut serving as the raw material by using water as the extracting agent. The vegetable tannin dye liquor prepared by adopting the method or a dye prepared from the dye liquor is applied to dyeing the real silk fabric; the dyeing effect is obvious; the technical problem of low dyeing fastness of a plant dye in the prior art is effectively solved; and an abundant dyeing effect can be achieved by combining a mordanting technology. The raw material selected by the invention is the bark or a byproduct of forest trees and fruit trees which are planted in abundance and are rich in resources; and the dye liquor has obvious resource advantage and broad application prospect.

Owner:SOUTH CHINA AGRI UNIV

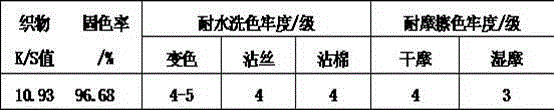

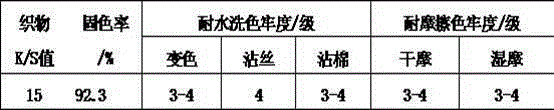

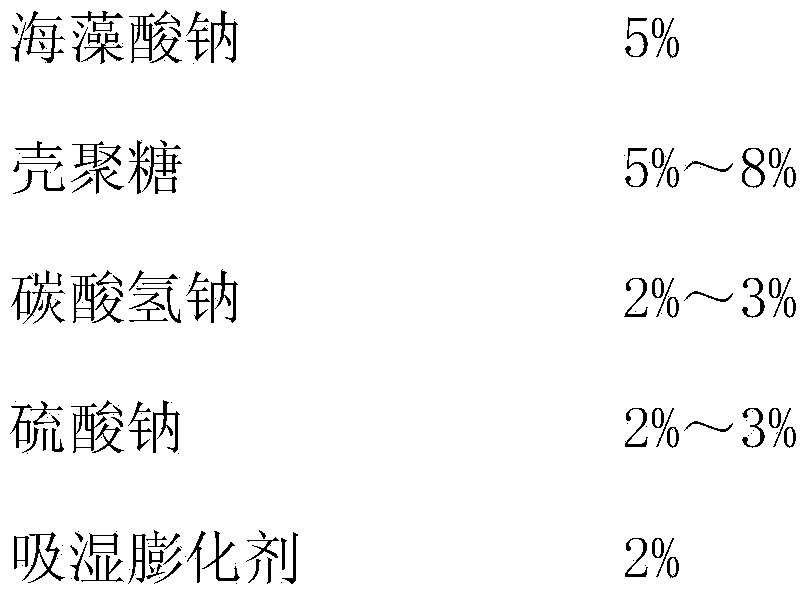

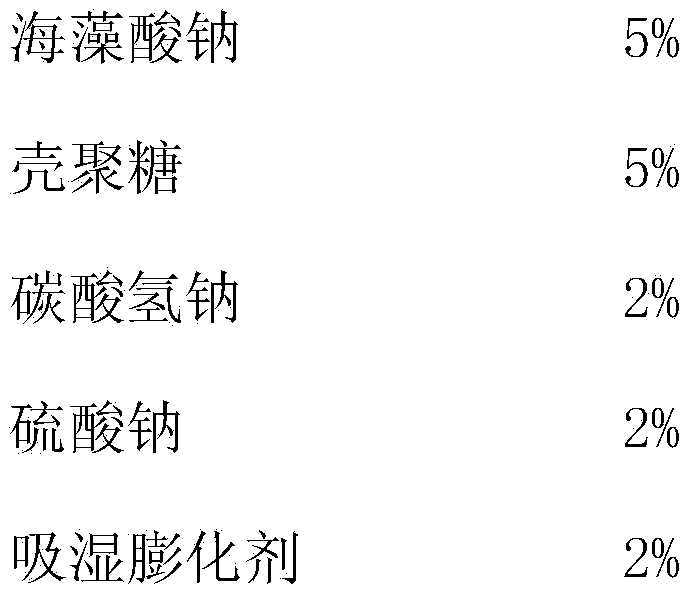

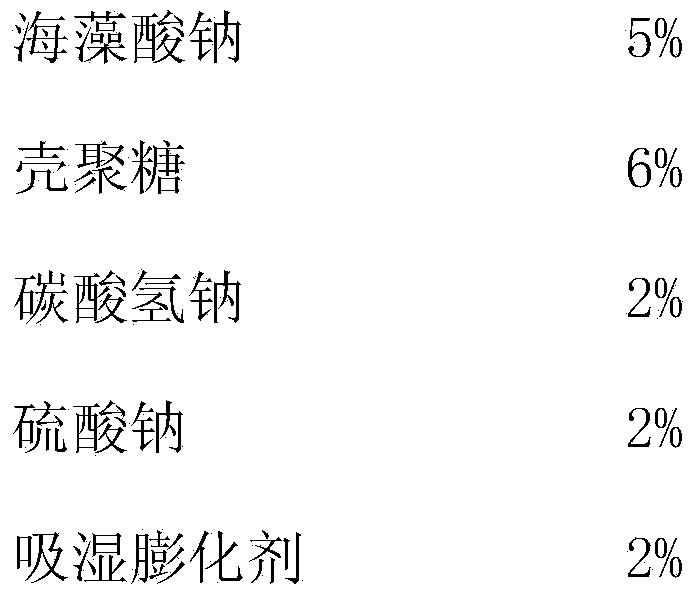

Digital ink-jet printing method of low-urea silk fabric

InactiveCN103952931AReduce dosageReduce the burden onDyeing processAnimal fibresTextile printerSewage treatment

The invention relates to a digital ink-jet printing method of a low-urea silk fabric. The method comprises the following steps: firstly, carrying out a single-sided sizing pre-treatment on the silk fabric which is degummed and stentered by a sizing machine containing slurries such as a quaternary ammonium salt cationic modifier, guar gum and a low-urea wet absorption swelling agent; then, drying the fabric by an infrared drier at high frequency; then, jet-printing and steaming and fixing by regenerated active dye base ink; and finally, soaping by modified tea saponin, washing and drying to realize digital ink-jet printing of the low-urea silk fabric. According to the method provided by the invention, the silk fabric has good K / S value, fixation rate and wet-processing fastness, the use level of urea is reduced by 70-80%, and meanwhile, the utilization ratio of the active dye ink is increased, and finally, the burden of sewage treatment is alleviated. The method provided by the invention is a clean production method which satisfies the environmental requirement.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Technique for dyeing silk face fabric by vegetable dye

InactiveCN101148827AAvoid damageImprove color uniformityDyeing processLiquid/gas/vapor textile treatmentDye absorptionAcetic acid

The present invention is technological process of dyeing silk fabric with vegetable dye and belongs to the field of fabric producing technology. The technological process includes the following steps: degumming silk fabric biologically with enzyme, flushing with cold water, and winding; dyeing the degummed silk fabric through adding acetic acid to regulate pH value, adding neutral phosphate and mordant, adding tea lutein as vegetable dye and heating; cold water washing, soaping, hot water washing, cold water washing, stoving, pre-shrinking to set breadth, and winding or packing. The dyeing process has high dyeing homogeneity, high stability and less damage to silk fabric.

Owner:无锡汇罗新材料科技有限公司

Anti-creasing anti-bacterial anti-violet composite function silk fabric and its preparation method

The invention discloses a silk face material with compound functions of anti-wrinkle, antibiotic and anti-ultraviolet and the production method, which processes the product through the steps of processing silk nanometer anti-wrinkle, antibiotic and anti-violet finish and finishing the silk fabric, wherein the invention uses waste silk as material, which is helpful of resource regeneration; the waste silk belongs to natural green product and the silk face material with the compound functions of anti-wrinkle, anti-biotic and anti-ultraviolet meets the requirements of twenty-first century that the fabric functions should be oriented to develop based on comfort, cleanness and safety and cater for the consumption concept of green, health and fashion with easy process and low cost. The product passes the test with good anti-wrinkle, anti-biotic and anti-ultraviolet functions.

Owner:TAIZHOU JIEFENG CAP IND

Silk afterfinishing compound softening agent and preparation method

The invention relates to a silk afterfinishing compound softening agent and a preparation method. The softening agent is nontoxic, nonirritating, very low in yellowing possibility, good in re-wettability, biodegradable, and completely harmless to an environment. The method comprises the steps that required water temperature is selected between 0 DEG C and 100 DEG C according to used different quaternization raw materials; 1-30% of ester quaternary ammonium salt is added to water, and stirred; and then 1-30% of hydrophilic amino silicone oil is added and stirred uniformly after ester quaternary ammonium salt is completely dissolved or dispersed in the water and forms a uniform white viscous emulsion. The softening agent has the advantages that 1, the softening agent adopts raw animal or plant synthetic chemicals as main components of the softening agent, and is completely nontoxic, nonirritating, very low in yellowing possibility, and good in re-wettability, and 2, the softening agent is biodegradable and completely harmless to the environment, and is an ideal silk fabric afterfinishing softening agent.

Owner:ZHEJIANG HSDP SILK TECH

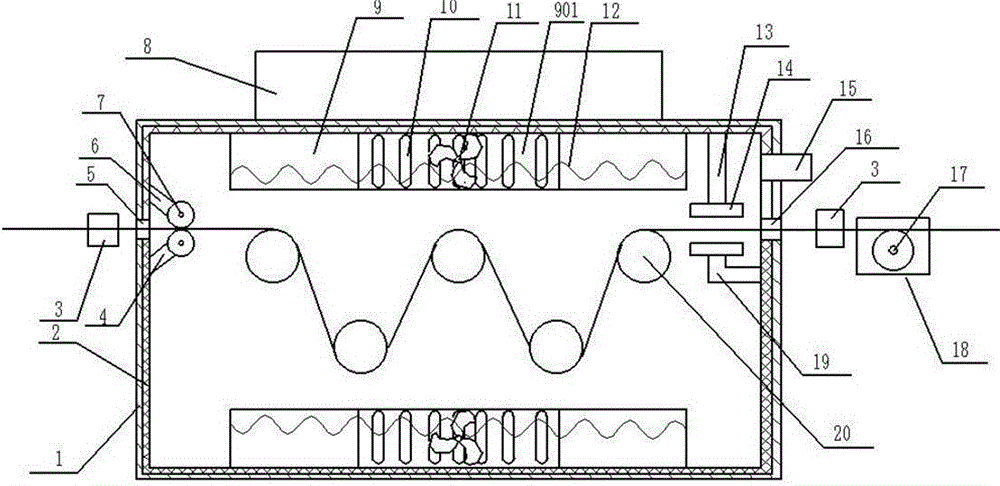

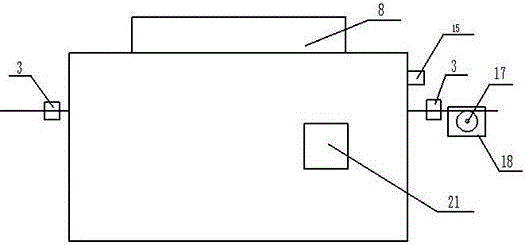

Silk fabric drying device

InactiveCN106766786AQuality improvementAvoid knotsDrying gas arrangementsDrying machines with progressive movementsElectricityInductor

The invention relates to the textile technical field, in particular to a silk fabric drying device. The silk fabric drying device comprises a box body, wherein a control box is arranged on the top of the box body, and a charge hole, a discharge hole, an exhaust fan interface and a traction roller are arranged on the side wall of the control box; a first heating deice is arranged in the charge hole; a second heating device, a guide roller and a temperature sensor are arranged in the box body; a humidity inductor is further arranged outside the charge hole and the discharge hole; the traction roller is arranged outside the discharge hole, and is connected with a traction motor; the traction motor is electrically connected with the control box; a control main board is arranged inside the control box; the control box is electrically connected with a touch display screen; the touch display screen is arranged on a front panel of the box body for receiving a user operation order, so that temperature setting is realized on the heating device; after the temperature sensor senses the temperature in the box body, the corresponding temperature value is directly displayed through the touch display screen; and after the humidity sensor senses material humidity information, the corresponding humidity value is directly displayed through the touch display screen.

Owner:ANHUI SHAWOSI CLOTHING CO LTD

One-way wet-guide quick-drying real silk facing material

InactiveCN101270524ADistinct silk styleSpeed up moisture transferFilament/thread formingWoven fabricsMoisture absorptionEngineering

The invention relates to a unidirectional wicking fast-drying true silk fabric which is characterized in that the front surface of the fabric is two first or three first twill-weave; the back surface corresponding to the front surface is one second or one third twill-weave; the material of the front surface adopts silk with the specification of 15 to111dtex; the material of the back surface adopts ultrathin denier wicking fast-drying terylene DTY long thread with the single thread density of 0.2 to 0.8dtex; the section of the long thread is crisscross; the invention adopts a embedded weaving method for weaving and manufacture. The surface of the fabric obviously assumes the styles of true silk which has fleshy and soft hand feelings as well as excellent moisture absorption and ventilation properties. As the wicking fast-drying terylener is adopted as the back surface of the fabric, the excellent fast-drying property thereof can quicken the wicking speed of the true silk fiber on the front surface after absorbing moisture and simultaneously can not go so far to reveal the defects of hard hand feeling, easy pilling and generating static of the terylener.

Owner:SUZHOU HUACHOU TECH

Biological enzyme process antibacterial and anti-wrinkle finishing method of silk fabric

InactiveCN102677475AHigh catalytic efficiencyReduce dosageBiochemical fibre treatmentAnimal fibresCooking & bakingCatalytic oxidation

The invention discloses a biological enzyme process antibacterial and anti-wrinkle finishing method of a silk fabric, belongs to the field of a textile biotechnology, and aims to overcome the defects of high baking temperature, high probability of damage of silk fibers and reduced whiteness in real silk antibacterial and anti-wrinkle treatment of the conventional chemical method and realize enzyme-promoted antibacterial and anti-wrinkle functional modification of a real silk fabric. According to the method, a chitosan natural finishing agent with a primary amine structure is grafted to the surface of the silk fiber by utilizing the catalytic oxidation effect of tyrosinase, so that the antibacterial and anti-wrinkle effects of the silk fabric are improved. The process flow comprises the following steps of: pre-treating the silk fabric; catalyzing grafting modification treatment of chitosan by the tyrosinase; washing; and drying. Through the silk fabric treated by the invention, the antibacterial performance is improved, the wrinkle recovery performance is improved, and the mechanical property and the dyeing performance of the fabric are also improved. Compared with the conventional chemical method, the method has the advantages of adoption of the tyrosinase process for catalysis of the antibacterial and anti-wrinkle treatment process of the real silk, low energy consumption, high efficiency, less pollution and contribution to environmental protection.

Owner:FOSHAN CITY HANHAI YANBU SISTER FLOWER UNDERWEAR

Production method for enabling pure mulberry silk fabric to have natural elasticity style in weft direction

ActiveCN101634097AWeft stress balance and stabilityGuaranteed uniformityLiquid/gas/vapor removalHeating/cooling textile fabricsFiberMoisture absorption

The invention discloses a production method for enabling a pure mulberry silk fabric to have a natural elasticity style in a weft direction. The technological processes sequentially comprise blank silk weaving, preprocessing, cooked smelting, bleaching, water washing, pickling, dewatering or squeezing, coiling, baking stentering and check mounting, wherein the cooked smelting comprises primary smelting and secondary smelting. The baking stentering comprises the following steps: firstly, carrying out baking shaping on a wool carpet finishing machine and then at least carrying out stentering processing for more than two times on a stentering machine. The technological processes of the blank cloth weaving comprise the selection of wefts, the selection of the twisting degree and the twisting direction of the wefts and the twisting direction arrangement of weft combination. Because the pure mulberry silk fabric does not depend on elastic fibre, such as urethane elastic fibre and the like, and adopts blank silk woven by super-strong twisting real silk wefts to carry out the methods of degumming, stentering, shaping and processing so as to enable a pure real silk fabric to obtain better weft direction elasticity and excellent elastic restoring force, the fabric is not easy to crack and has relatively flexible hand feel and good moisture absorption and air permeability, and a dress article made by the fabric shapes the body and has convenient movement, good form retention, small dimensional change rate and small seam slippage.

Owner:DALI SILK ZHEJIANG

Silk broadcloth thermal transfer printing method

ActiveCN101148828ARealize the perfect processSolve the problem of washing fastnessDyeing processState of artWinding machine

The present invention relates to fabric treating technology, and is especially hot transfer printing process for silk fabric with high color vividness and high color fastness. The technological scheme includes the following steps: inputting pattern into a computer and printing the pattern on transfer paper with one ink jet printer; padding silk fabric with pre-treating agent in a padding and winding machine and in padding rate of 100 %; stoving silk fabric at the temperature from room temperature to 150 deg.c; setting the transfer paper with pattern on the surface of silk fabric; heating to 180-220 deg.c and pressurizing in a transfer printing machine for 20-35; and stripping the transfer paper from the silk fabric.

Owner:HANGZHOU WENSLI SILK CULTURE

High counts and high density down-proof fabric production method

The invention discloses a manufacturing method of high count and high density down-proof cloth. The cloth of the invention is made from a long-staple cotton combed yarn after procedures of warping, sizing, reeding, air-jet weaving, cloth inspecting, finishing, packing and stocking, etc. The sized yarn is made from mixed slurry of PVA and etherifying starch and sized by double-clip-double-nip and high temperature sizing; the weaving adopts the air-jet weaving and the ratio of a weft tension peak value and weft tension strength is controlled to be less than or equal to 55 percent. The invention is characterized by simple operation, easy control, high production efficiency and product quality, high cloth quality of produced products, smooth, even and clean cloth surface, soft and fine texture, erect and smooth hand feeling, special high moisture absorption and discharging performance, and the invention resembles to imitating the style of silk fabric, which is beneficial for improving downstream processing procedure and processing quality.

Owner:丁宏利

Method for treating recycled printing and dyeing sewage

InactiveCN101613167ACOO reductionWater/sewage treatment by irradiationTreatment with aerobic and anaerobic processesFiberTreatment effect

The invention discloses a method for treating recycled printing and dyeing sewage, which is applicable to the treatment and reutilization of sewage of printing and dyeing of fabrics such as wool fabrics, silk fabrics, cotton, linen, chemical fiber fabrics and the like. The method aims to overcome the disadvantages of sewage treatment of the prior printing and dyeing mills and ensure that the sewage reaches the national discharge standard of water pollutants for dyeing and finishing. The method adopts treatment technology of physicochemical-biochemical, precipitation and filtration, which comprises the following process flow: the sewage, a collecting basin, an anaerobic tank, an aerobic tan, a dosing tank, a sedimentation tank, a filter tank, and the discharge or recycling of water which achieves the standard. In addition, complex enzyme is also added; the complex enzyme has a catalytic function, and can strengthen the activation of microorganisms; the method has good treatment effect on the sewage; and the adding of the complex enzyme can strengthen the activity of the microorganisms, improve the effect of sewage treatment, can also save electric energy, reduce the loss of medicaments, and save the cost. The sewage is recycled after the filtration through a microstrainer, which saves the resource, reduces the cost once again, and truly achieves the aims of energy conservation and discharge reduction.

Owner:东莞市明珠染整实业有限公司

Digital printing process for real silk fabric

The invention provides a digital printing process for a real silk fabric. The digital printing process comprises the following steps: carrying out low-temperature plasma treatment on the real silk fabric, padding a pretreatment solution, drying, carrying out inkjet printing, drying, carrying out dry heat color fixation, washing by cold water, washing by warm water, washing by soap, washing by warm water, and drying, wherein the pretreatment solution subjected to padding comprises the following components: 5-10 g / L of sodium alginate, 30-50 g / L of sodium hydrogen carbonate, 30-50 g / L of urea and 5-15 g / L of a de-foaming agent. By virtue of the process, the digital printing color yield of the mulberry silk fabric is increased, the digital printing color depth on a textile is increased, and the color difference between a pattern on the textile and an electronic pattern is reduced; the real silk fabric is high in color fastness, and multiple washing experiments prove that the real silk fabric still cannot fade and lose color even in a severe experimental environment.

Owner:SHIJIAZHUANG HEXI APPL TRADING

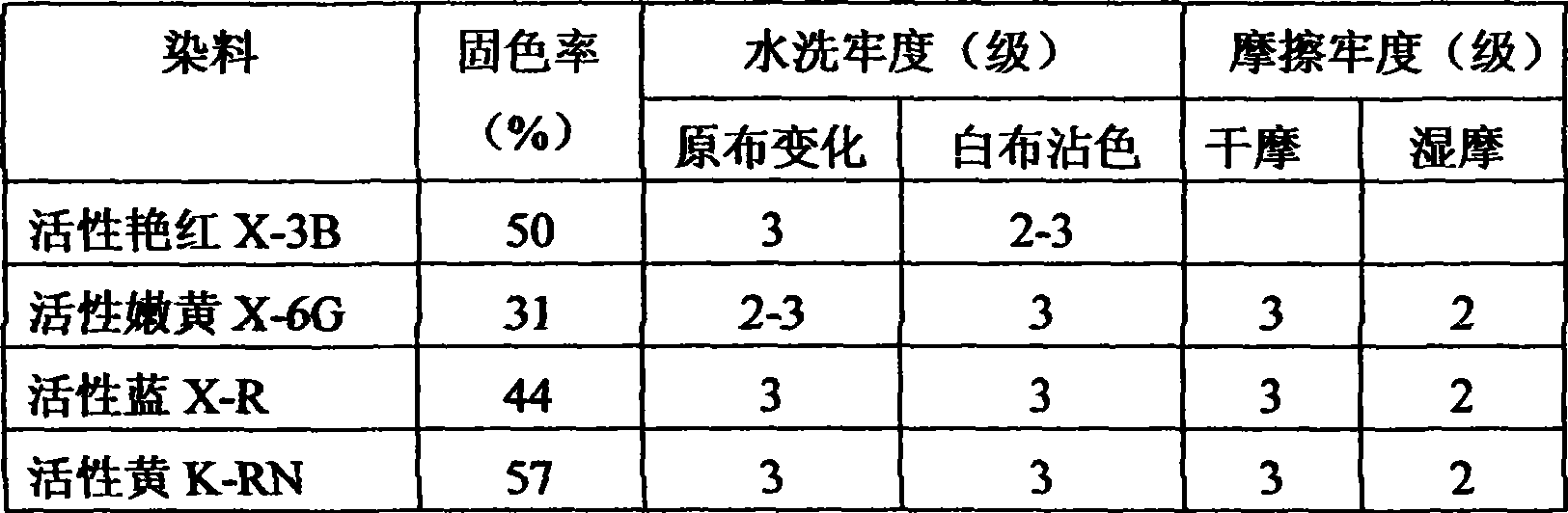

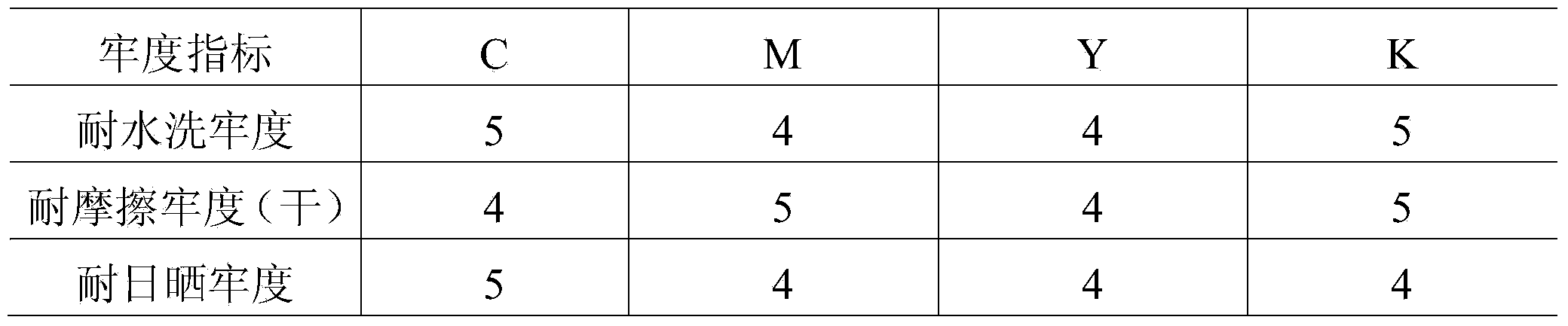

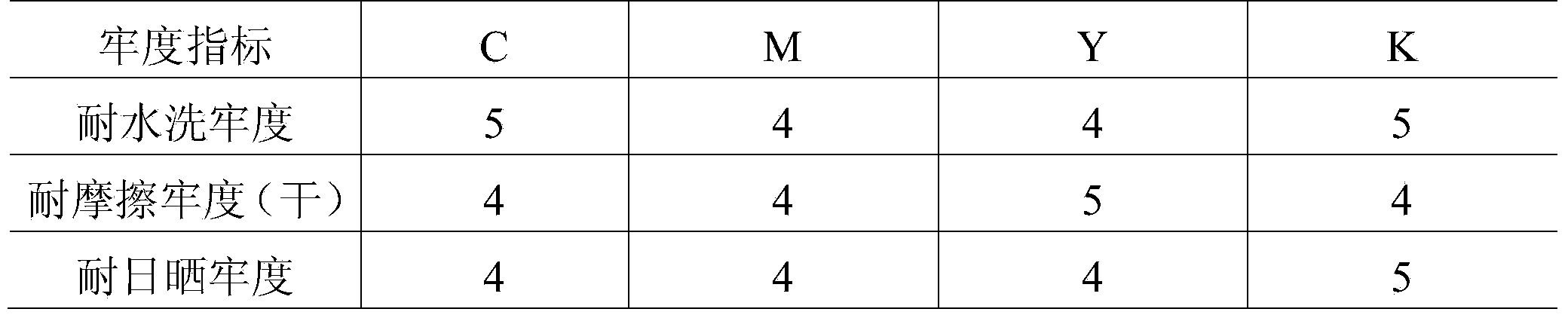

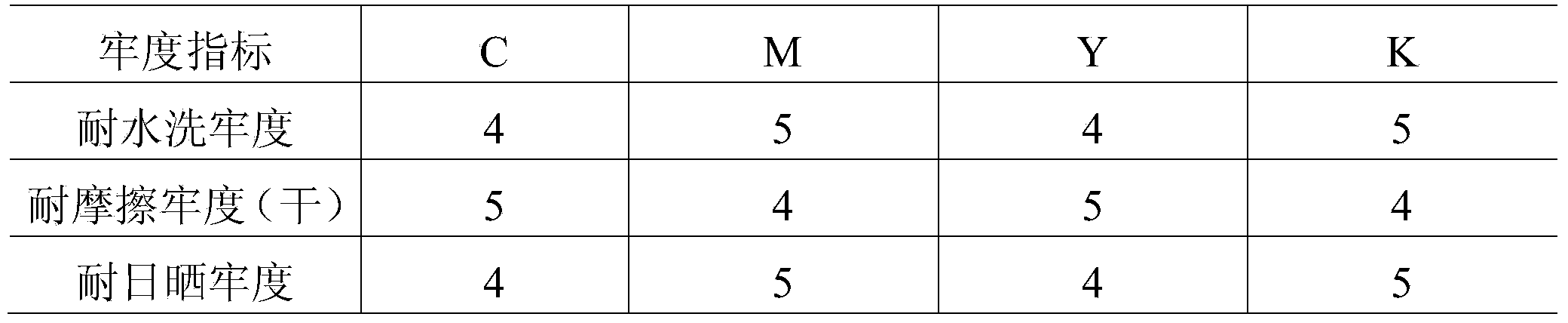

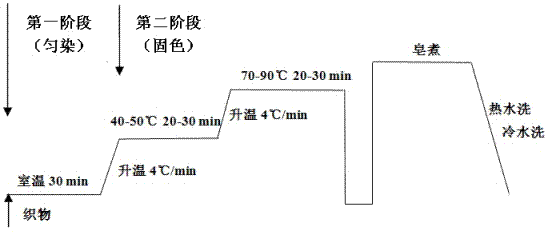

Reactive dye ecological dyeing method of silk fabrics

InactiveCN102767099ASave water for dyeingEasy to operateDyeing processSodium bicarbonateSodium Bicarbonate Solution

The invention provides a reactive dye ecological dyeing method of silk fabrics, which comprises the following steps of: (1) even dyeing: using reactive dye and decamethyl cyclopenta siloxane (D5) according to the mass ratio of 1:10 to 50 to prepare a reactive dye / D5 suspending dispersed liquid; padding the silk fabrics in 30 to 90 g / l of sodium bicarbonate solution; and dyeing the silk fabrics in the reactive dye / D5 suspending dispersed liquid with the rolling liquid rate of 160 to 200% at room temperature for 25 to 35 minutes, wherein the rolling liquid rate is used for ensuring even dyeing of the silk fabrics; and (2) color fixing: heating a mixture system obtained from the step (1) to 40 to 50 DEG C, and keeping the temperature for 20 to 30 minutes; then heating to 70 to 90 DEG C, and keeping the temperature for 20 to 30 minutes; and taking the silk fabrics out, and performing soap boiling. In the process of dyeing provided by the invention, an electrolyte is not added for dyeing acceleration, the dyeing rate of the dye is close to 100%, the fixing rate is higher than that of traditional bath dyeing, and the fastness of the fabrics is good after dyeing. Because the electrolyte is not needed for dyeing acceleration, the burden of treating dyeing waste water is effectively reduced, and the ecological environment is protected.

Owner:ZHEJIANG SCI-TECH UNIV

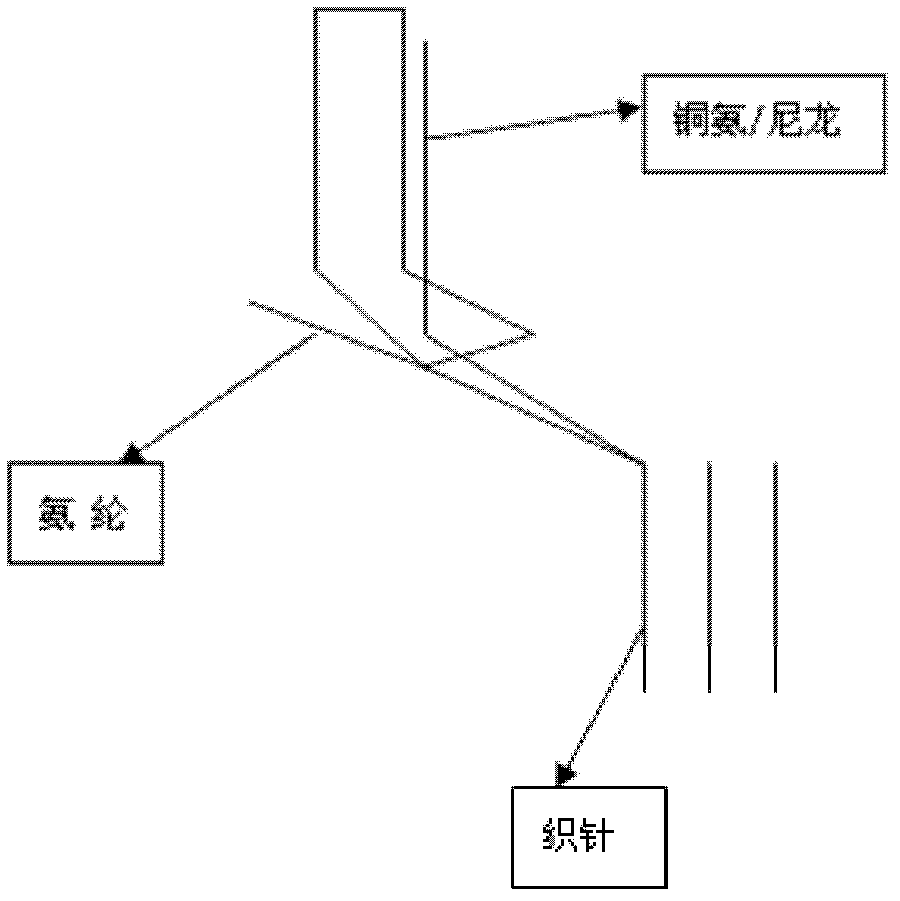

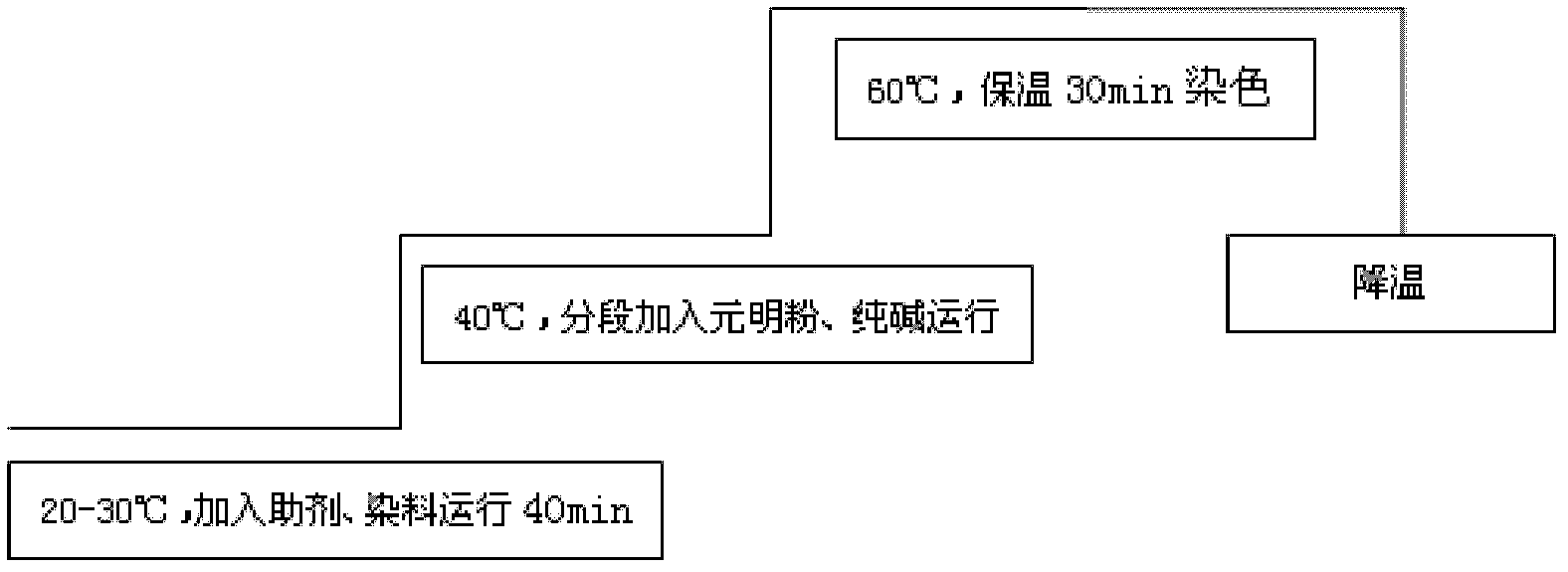

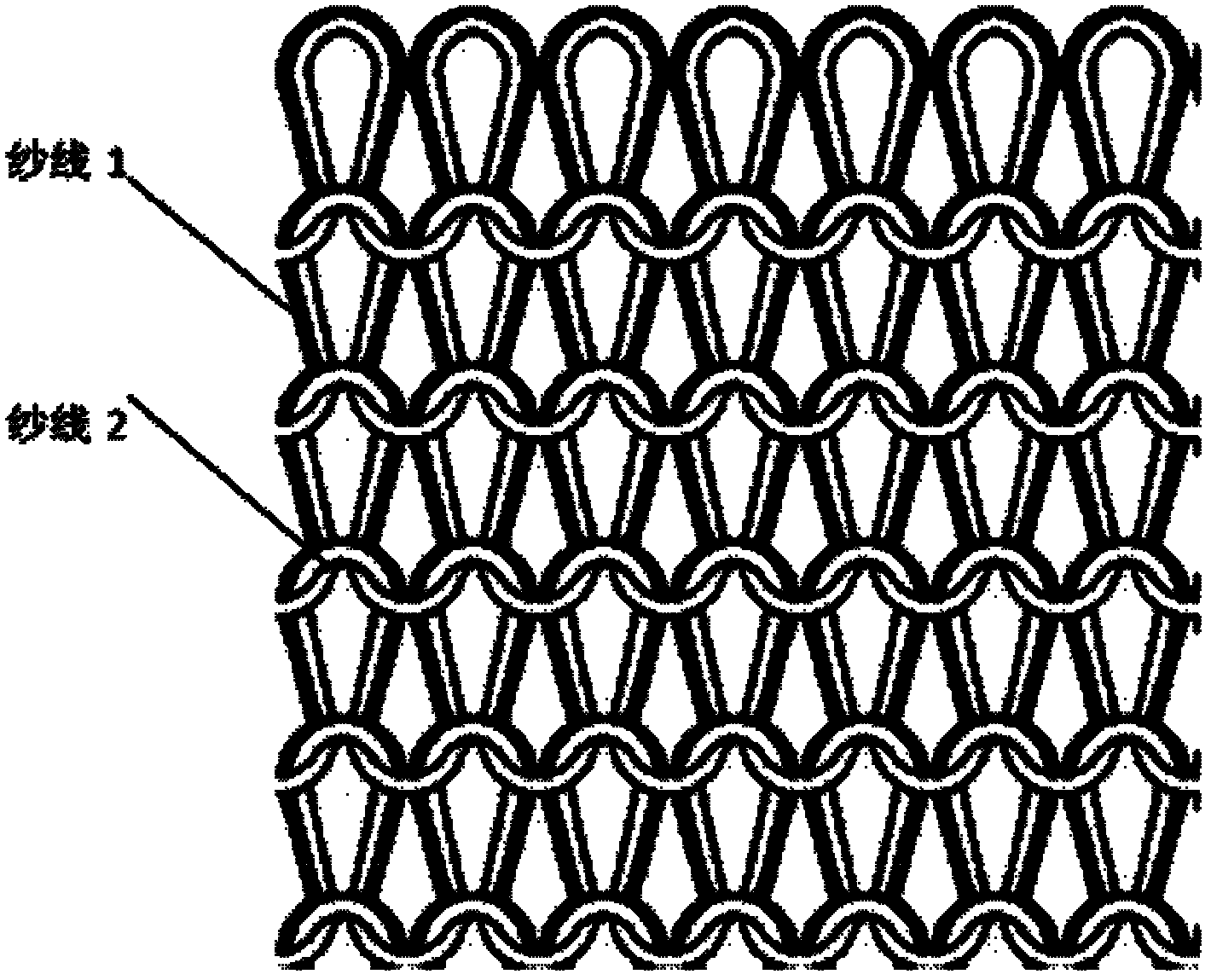

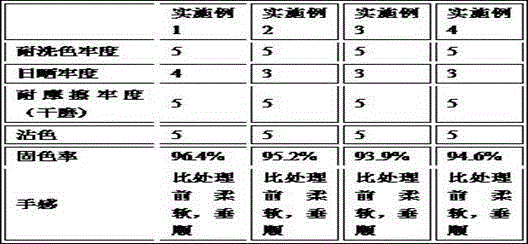

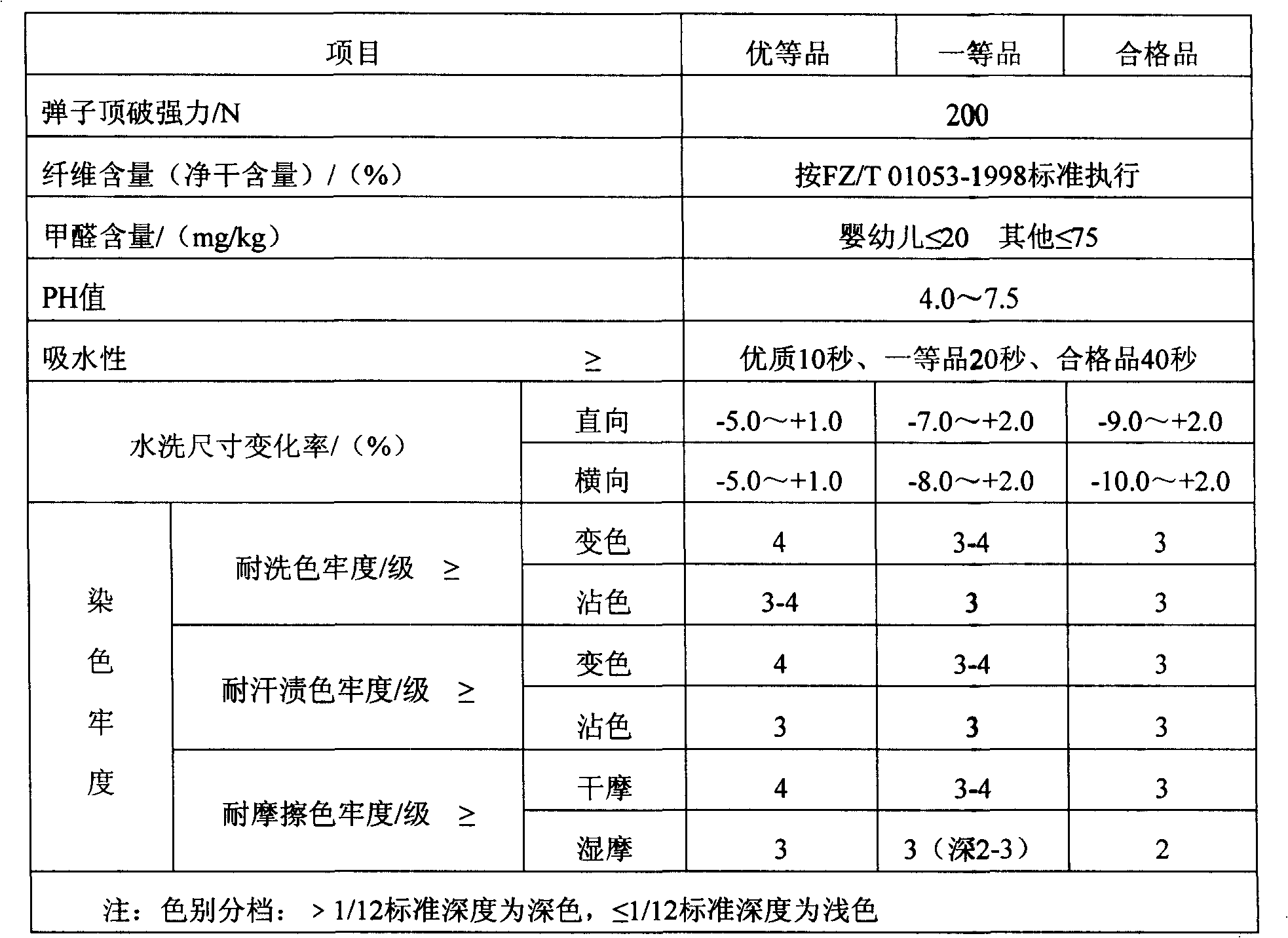

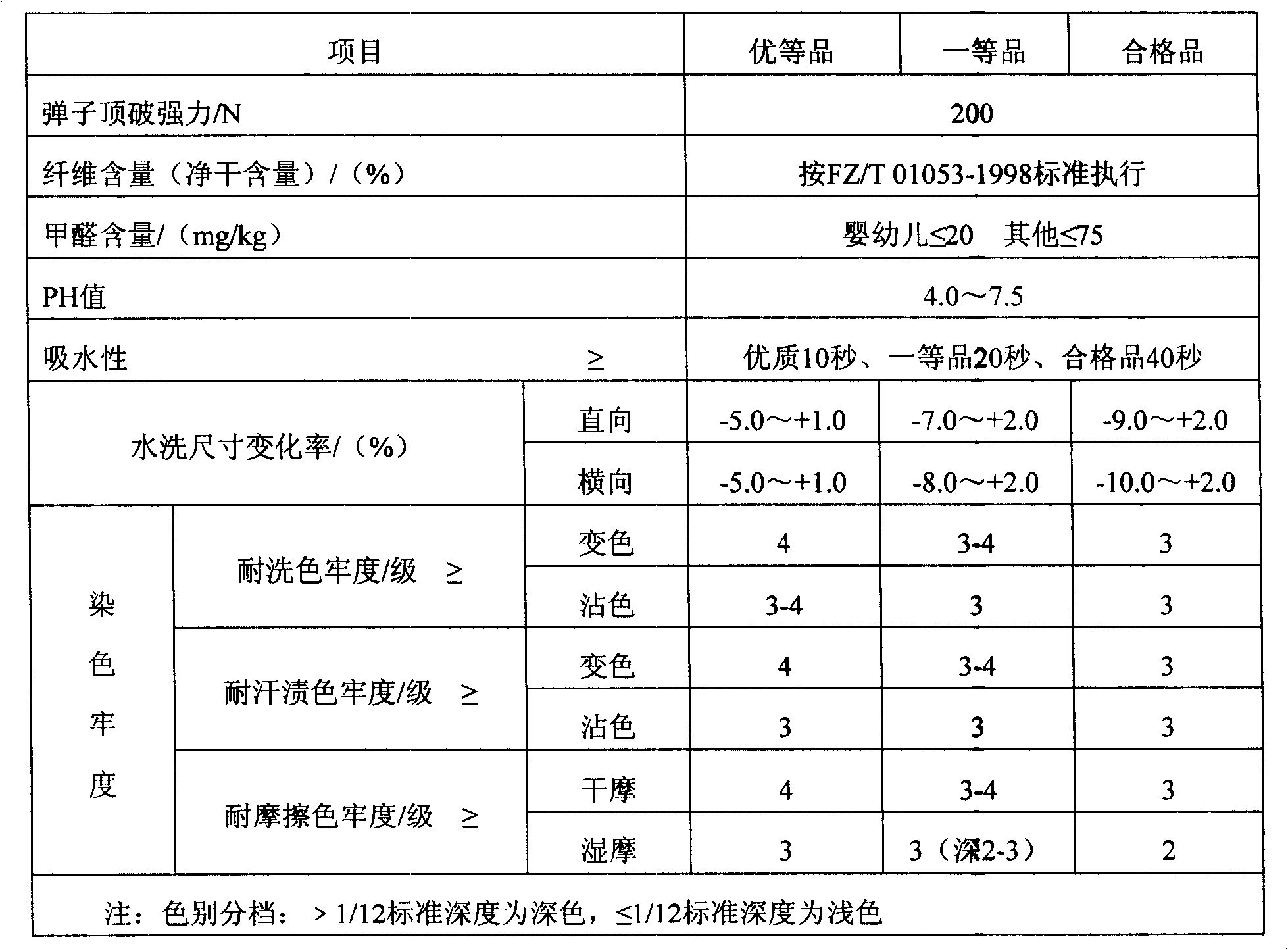

Imitated silk high-elasticity knitted underwear fabric and preparation method thereof

ActiveCN102631030AControl flatnessGuaranteed weightWeft knittingBleaching apparatusYarnBursting strength

The invention relates to imitated silk high-elasticity knitted underwear fabric and a preparation method thereof. The fabric is formed by interweaving fine-denier copper ammonia / nylon bi-component filament and spandex yarn, wherein the fine-denier copper ammonia / nylon bi-component filament is located on the front of the fabric and completely covers the spandex yarn. The preparation method comprises the following steps of: sequential weaving, fabric pre-sizing, pretreatment, copper ammonia dyeing, aftertreatment, nylon dyeing, soaping, soft finish, dehydration and re-sizing. The imitated silk high-elasticity knitted underwear fabric provided by the invention has smooth handfeel, brightness, full appearance, soft handfeel, antibacterial property, comfort and the like; the problems of low bursting strength and insufficient elasticity of the single copper ammonium imitated silk fabric are solved; and the problems of non-uniform blend dyeing of copper ammonium and chemical fiber, color yellowing and rough cloth cover are solved.

Owner:NINGBO DAQIAN TEXTILE

Silk digital ink-jet printing method

InactiveCN105002762ANo dischargeNo pollutionDyeing processAnimal fibresTextile printerPolymer science

The invention discloses a novel silk digital ink-jet printing method. The novel silk digital ink-jet printing method comprises carrying out fabric pre-treatment: heating a silk fabric to a temperature of 30-35 DEG C for pre-treatment, carrying out sizing on the pre-treated silk fabric by a sizing machine at a sizing temperature of 50-60 DEG C, carrying out drying at a drying temperature of 80-95 DEG C by an infrared drying device, making a file, carrying out ink-jet printing by a digital ink-jet printing device and carrying out dye fixation under saturated vapor at a temperature of 60-65 DEG C for 10-15min. The silk digital ink-jet printing method improves printing effects and color fastness, is free of special treatment on ink, does not need a high heating temperature, produces small damage to the fabric and realizes good hand feeling.

Owner:浙江宝石蝶围巾有限公司

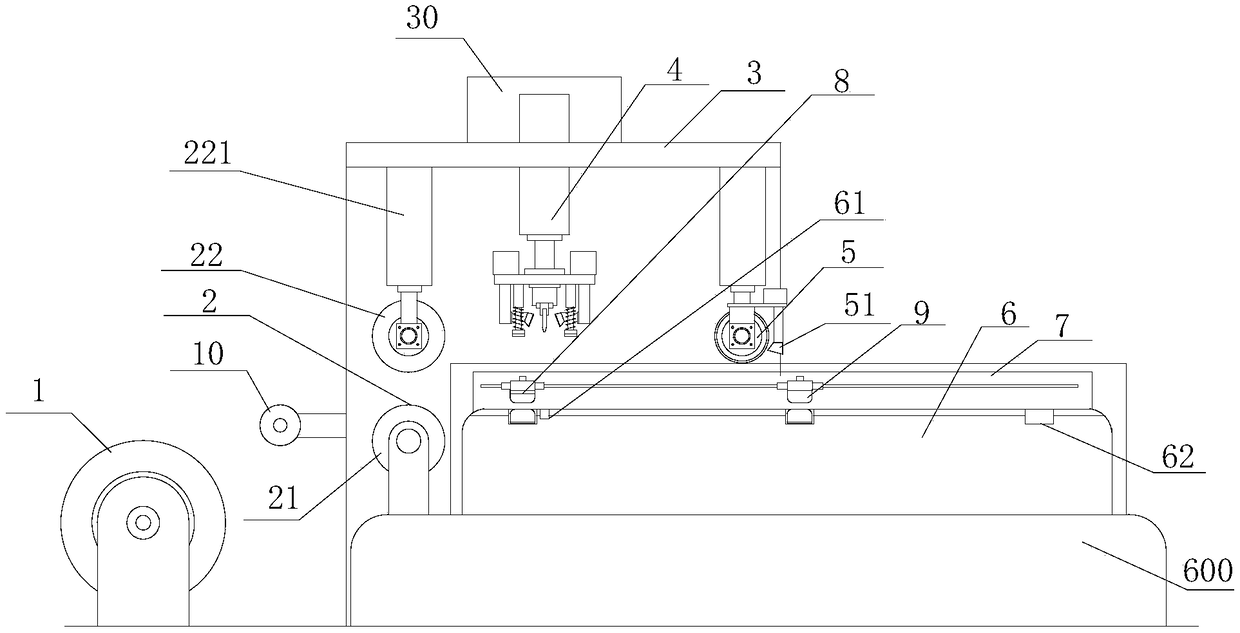

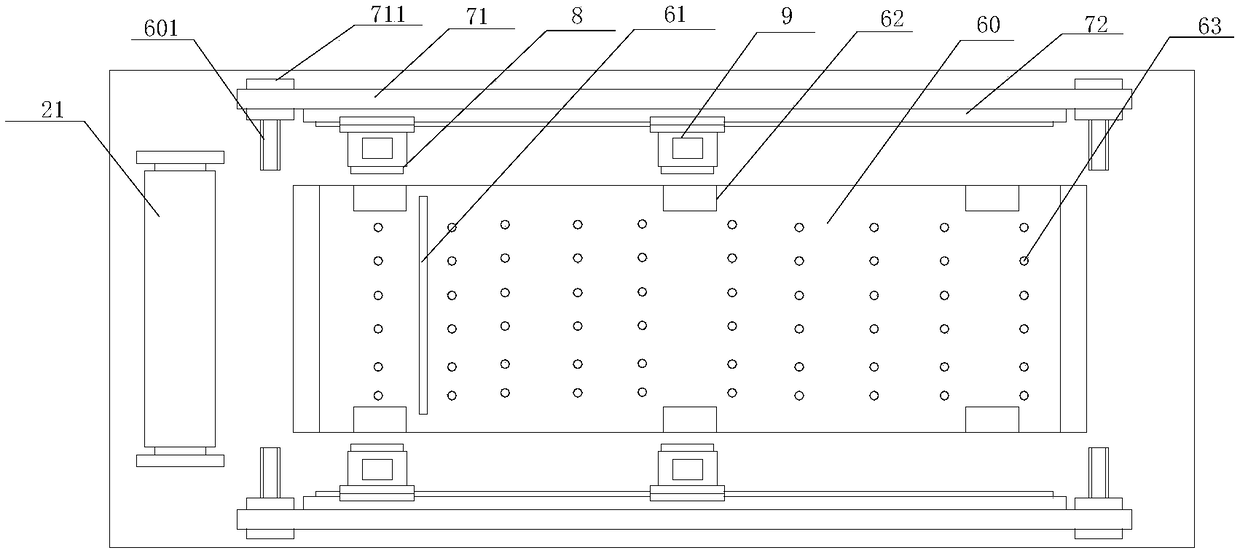

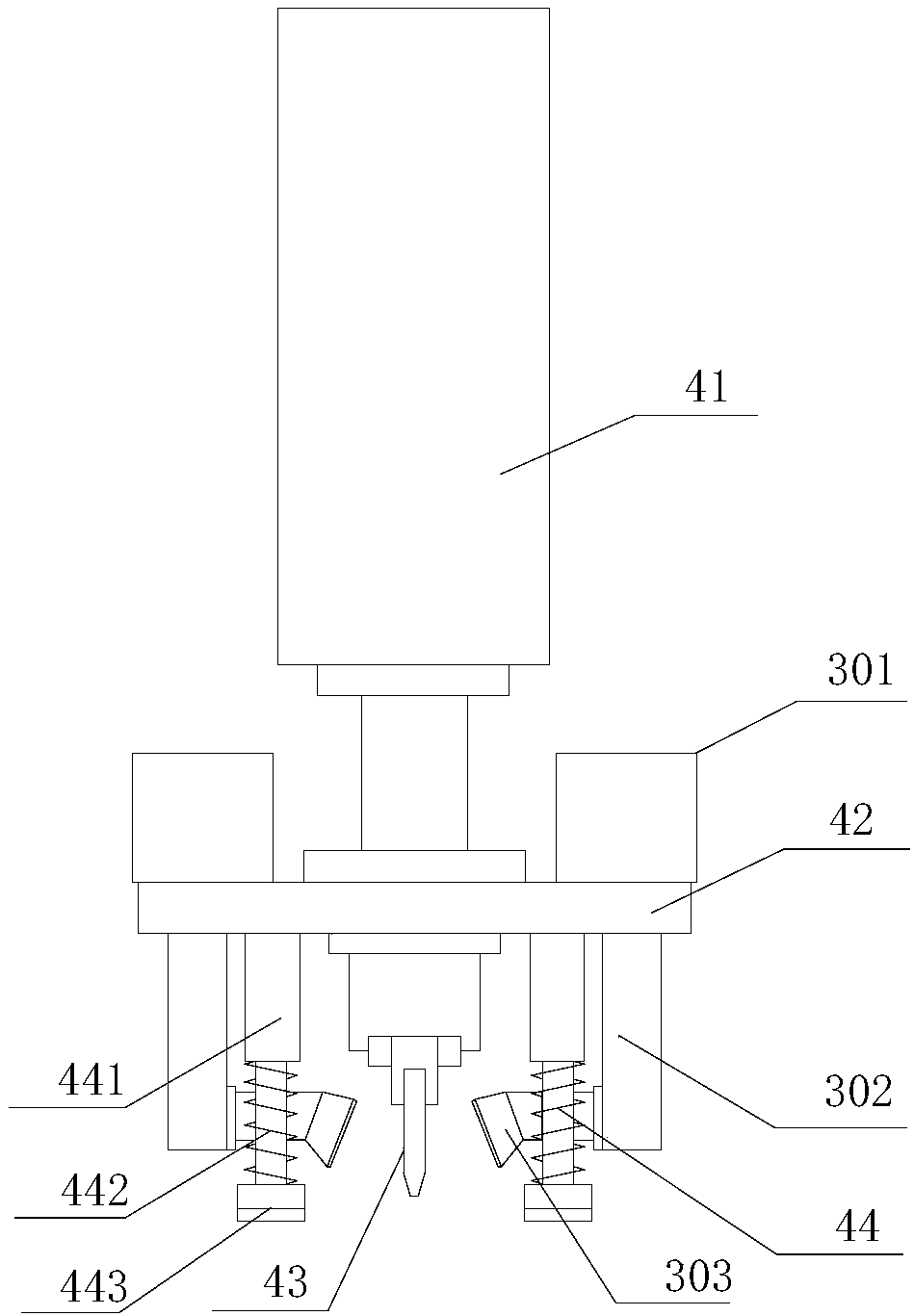

Silk fabric cutting device

PendingCN108867015AReduce intensitySuction in timeSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention discloses a silk fabric cutting device which comprises an unwinding mechanism, a feeding conveying roller mechanism, an installation supporting frame, a cutting device, a brush roller mechanism, a machine frame, a feeding walking seat, a first cloth feeding mechanism and a second cloth feeding mechanism, wherein a guiding roller assembly is arranged between the unwinding mechanism and the feeding conveying roller mechanism, the cutting device is arranged on the installation supporting frame through a second lifting air cylinder, the cutting device is arranged between the feedingconveying roller mechanism and the brush roller mechanism, a cutter assembly is arranged on the cutting device, the cutter assembly is matched with a cutter groove, a lifting installation seat is arranged on the feeding walking seat, and the first cloth feeding mechanism and the second cloth feeding mechanism are arranged on the lifting installation seat. As the conveying roller mechanism and thecloth feeding mechanisms are matched, the end of cloth to be cut can be tightly clamped to be conveyed in a fixed point mode after once cutting, so that the labor intensity is reduced; a dust collection cover can suck waste chips which are generated in a cutting process in time, so that the comfortableness of production environment is improved.

Owner:浙江华越丝绸制品有限公司

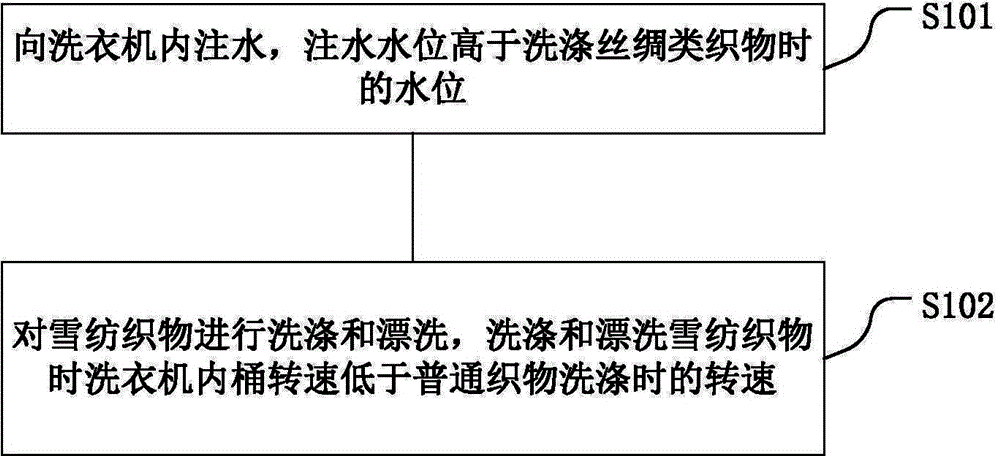

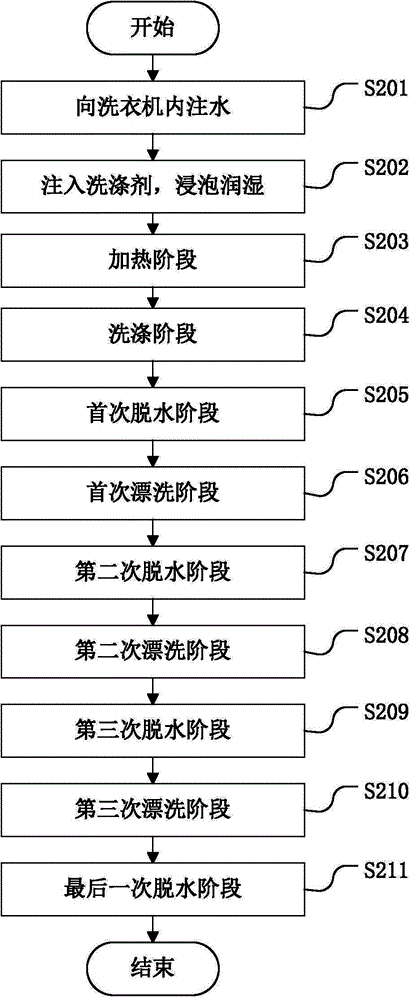

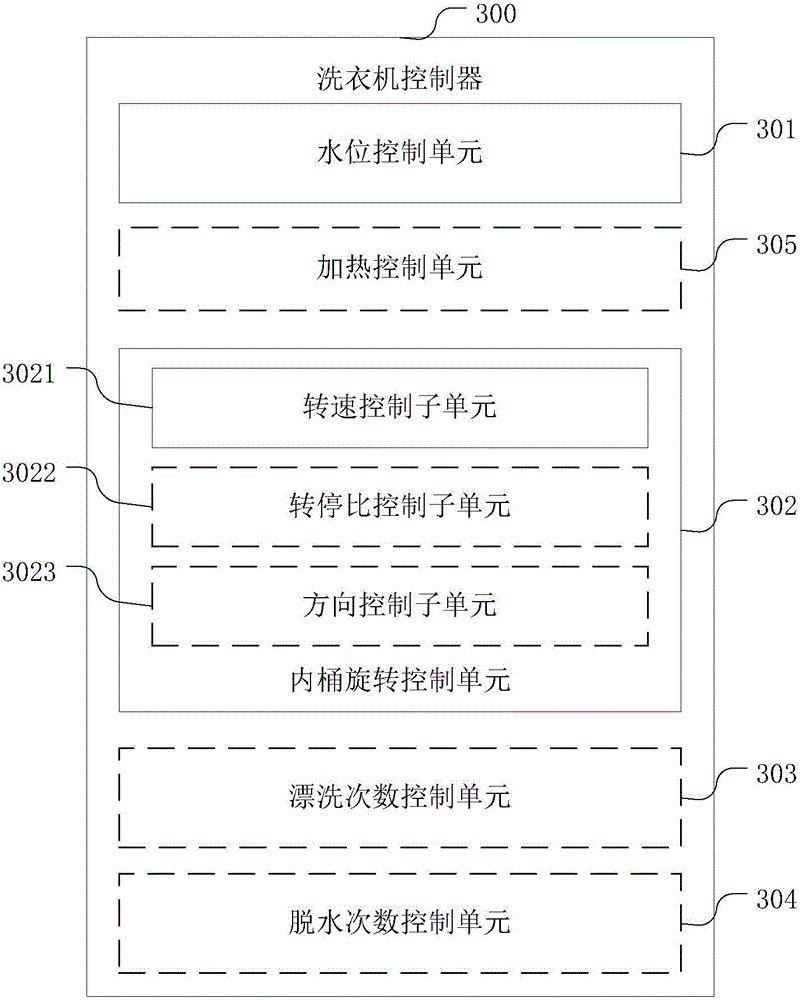

Washing machine, method for washing chiffon fabric and washing machine controller

ActiveCN104674502AAvoid the problem of not being easy to cleanImprove cleanlinessControl devices for washing apparatusTextiles and paperProcess engineeringWater level

Provided are a washing machine, a method for washing chiffon fabric and a washing machine controller. The method includes injecting water in the washing machine to achieve the water level higher than the level for washing silk fabric; washing and rinsing the chiffon fabric with the rotating speed of an inner barrel of the washing machine lower than the rotating speed used when common fabric is washed. By means of the method, the washing machine and the washing machine controller, the ideal washing effect can be achieved under the condition that the chiffon fabric is well protected, users are relieved from hand washing of chiffon fabric, and the requirement of the user for adopting the washing machine to wash the chiffon fabric is well met.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

Method for dyeing silk broadcloth by using plant dye solution extracted from lily

InactiveCN102587153ASafe to takeIncrease added valueDry-cleaning apparatus for textilesNatural dyesFiltrationPollen

The invention discloses a method for dyeing silk broadcloth by using the pollen of lily as a natural dye and belongs to the technical field of textile dyeing and finishing. The method comprises the following steps of: soaking fresh or dried dark-red lily pistil, heating and performing suction-filtration to obtain a dye solution; adding silk broadcloth fabric which is refined, and dyeing the silk broadcloth fabric; and adding different mordants for mordanting and thus obtaining silk fabric with different colors. The method has the advantages of low cost, simple process, high performance, high additional value, non-allergic and non-carcinogenic to skin, and the like; raw materials are inexpensive, easy to get, and reproducible; and taking of dyeing products is safe. Particularly, by taking plant ash as a mordant, pollution is avoided. The method is environment-friendly and energy-saving, and clothes which are made of fabric dyed by using the method are natural, environment-friendly and nonirritating to the skin.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Terylene superfine warp-knitting soft and cleaning silk face fabric and production method thereof

InactiveCN101289779AUnique styleSoft touchWarp knittingHeating/cooling textile fabricsPolyesterHigh density

The invention discloses polyester ultrafine tricot soft silk fabrics and a method for producing the same. The invention is characterized in that: the polyester ultrafine tricot soft silk fabrics are prepared by adoption of 0.5 to 0.56 dtex of polyester silk or polyester-nylon composite silk as raw materials of chenille yarns and adoption of 75 to 150 D of polyester as bottom silk, wherein, the weight percent of the polyester silk or the polyester-nylon composite silk is between 55 and 75 percent and the weight percent of 75 to 150 D of the polyester is between 25 and 45 percent. The fabrics are unique in style and reach the appearance style of soft silk; the products have soft feel, high flexibility, high water absorptivity and oil absorption ability, high density and high specific surface area, can meet the demand of cleaning high-grade products, are green and environment-friendly and do not contain substances which are harmful to the human body. Simultaneously, the products have few production procedures, short period, high efficiency and high qualification rate.

Owner:SHANGHAI JINLE TEXTILE DECORATIONS

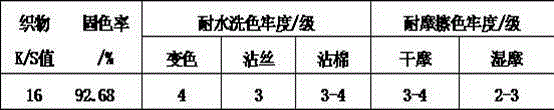

Environment-friendly silk printing method

ActiveCN104233825AIncrease profitGood K/S valueBiochemical fibre treatmentDyeing processEngineeringPaper document

The invention discloses an environment-friendly silk printing method, which comprises the following steps: (1) performing enzyme pretreatment on a fabric, namely putting the silk fabric subjected to degumming and tentering into an enzyme solution for pretreatment; (2) performing sizing; (3) drying; (4) making a document, wherein jet printing is generated by color card software, and ink for the jet printing is regenerative reactive dye-based ink; (5) performing jet printing; (6) steaming and drying; (7) washing, namely washing with cold water, then soaping, and washing with cold water again; and (8) performing tentering drying.

Owner:CHANGXING GUOYUAN PRINTING & DYEING

Method for detecting ancient argillic silk fabric on basis of immunoblotting

ActiveCN107389641AReduce lossesGuaranteed accuracyFluorescence/phosphorescenceFluorescenceGel electrophoresis

The invention relates to the field of cultural relic detection and discloses a method for detecting ancient argillic silk fabric on the basis of immunoblotting. The method comprises steps as follows: firstly, a silk secondary antibody marked with fluorescent carbon points is prepared, a modern silk sample and an ancient argillic silk fabric sample are hydrolyzed with an ionic liquid and PM13-alkaline protease step by step, a protein extraction solution is obtained and subjected to dialysis, purification and SDS-PAGE gel electrophoresis, an obtained protein band is transferred to a PVDF (polyvinylidene fluoride) film and subjected to incubation with a silk first antibody and the silk secondary antibody marked with the fluorescent carbon points, an immunofluorescence band can be observed in a gel imaging system, and the type of ancient silk is identified. The consumption of chemical reagents is low, the reaction is mild, and the method is environment-friendly and harmless; during detection for the ancient silk fabric, the method has the characteristics of being low in sample consumption, direct, rapid and high in sensitivity.

Owner:ZHEJIANG SCI-TECH UNIV

Non-ironing processing method of ready-made real silk cotton shirt

The invention aims at providing a non-ironing processing method of a ready-made real silk cotton shirt, which is environmentally friendly, high in cloth smoothness and lasting in anti-wrinkling finishing effect, and belongs to the technical field of application of dyeing and finishing in textile industry. Different from the existing traditional non-ironing dyeing and finishing process of cotton and silk fabrics, the process of combining liquid ammonia finishing with no ironing of ready-made garment is adopted by the invention, namely, the process comprises the following steps: firstly, performing liquid ammonia mercerizing treatment on the real silk cotton fabric; and then performing dipping, dehydration predrying, ironing, high-temperature baking and the like on the ready-made shirt during the finishing of anti-wrinkling polybasic carboxylic acid non-aldehyde resins. The real silk cotton shirt processed by the method is low in shrinkage rate, good in appearance gloss and wrinkle resilience and low in fabric strength descending. Thus, the defects that fibers are easy to damage, non-ironing performance in short joints is poor and the shirt is difficult to sew in the conventional non-ironing processing are overcome. The surface smoothness and the finishing effect durability of the processed ready-made real silk cotton shirt are improved.

Owner:NANTONG XINLAI SILK GARMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com