Reactive dye ecological dyeing method of silk fabrics

A reactive dye and ecological dyeing technology, applied in the dyeing and finishing field, can solve the problems of high salt content and alkalinity, low dye utilization rate, high chroma, etc., and achieve the effects of convenient operation, improved dye fixation rate, and saving dyeing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 (C.I. Reactive Red 195):

[0030] 1. Dyeing formula:

[0031] Reactive dye (C.I. Reactive Red 195): 2% (o.w.f);

[0032] Silk fabric weight: 1g;

[0033]Mass ratio of reactive dye to decamethylcyclopentasiloxane (D5): 1:30;

[0034] Squeezing rate: 160%;

[0035] Sodium bicarbonate concentration: 40g / l;

[0036] 2. Dyeing process:

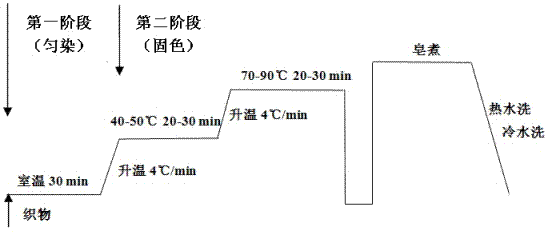

[0037] (1) Level dyeing: According to the ratio, reactive dyes and decamethylcyclopentasiloxane (D5) are mixed to prepare reactive dyes / D5 suspension dispersions, and silk fabrics are padded in sodium bicarbonate solution, with 160% padding The liquid rate is placed in the reactive dye / D5 suspension dispersion at room temperature for 30 minutes;

[0038] (2) Color fixation: raise the temperature of the mixture system obtained in step (1) to 50°C, keep it warm for 20 minutes, then raise the temperature to 85°C, keep it warm for 20 minutes, the heating rate for both times is 4°C / min; take out the silk fabric , soaped, rinsed...

Embodiment 2

[0043] Example 2 (Anoxin Yellow L-H):

[0044] 1. Dyeing formula:

[0045] Reactive dye (Annuosu Yellow L-H): 2% (o.w.f);

[0046] Silk fabric weight: 1g;

[0047] Mass ratio of reactive dye to decamethylcyclopentasiloxane (D5): 1:20;

[0048] Squeezing rate: 160%;

[0049] Sodium bicarbonate concentration: 30g / l;

[0050] 2. Dyeing process: The above dyeing formula is used, and the specific process is the same as in Example 1, except that in the color fixing step, the mixture system obtained in step (1) is heated to 50°C, kept for 20 minutes, and then heated to 70°C. ℃, keep warm for 30 minutes.

[0051] 3. See Table 3 and Table 4 for the performance test of the dyed silk fabric and the comparison results with the conventional water bath dyeing method.

[0052]

Embodiment 3

[0053] Example 3 (Annosol Red L-H):

[0054] 1. Dyeing formula:

[0055] Reactive dye (Annosal Red L-H): 2% (o.w.f);

[0056] Fabric weight: 1g;

[0057] Mass ratio of reactive dye to decamethylcyclopentasiloxane (D5): 1:50;

[0058] Squeezing rate: 200%;

[0059] Sodium bicarbonate concentration: 80g / l;

[0060] 2. Dyeing process: The above dyeing formula is used, and the specific process is the same as in Example 1, except that in the color fixing step, the mixture system obtained in step (1) is heated to 50°C, kept for 20 minutes, and then heated to 70°C. ℃, keep warm for 20 minutes.

[0061] 3. See Table 5 and Table 6 for the performance test of the dyed silk fabric and the comparison results with the conventional water bath dyeing method.

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com