Patents

Literature

1604results about How to "Avoid hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inherently antimicrobial quaternary amine hydrogel wound dressings

InactiveUS6039940APrevent discolorationAvoid hydrolysisBiocideConductive materialSterile environmentAryl

A composition and method for treating a wound with an inherently antimicrobial dressing. The dressing is a hydrogel containing from about 15 to 95 percent, and preferably from about 61 to 90 percent, by weight of a cationic quaternary amine acrylate polymer prepared by the polymerization of acryloyloxyethyl(or propyl)-trialkyl(or aryl)-substituted ammonium salts or acrylamidoethyl(or propyl)-trialkyl(or aryl)-substituted ammonium salts. The antimicrobial hydrogels are non-irritating to the wound, absorb wound exudate, and, due to the inherently antimicrobial properties, enhance the sterile environment around the wound. The hydrogels have sufficient adhesive properties that loose contact with the wound is assured but can also be removed without leaving any gel residue on the wound. The wound dressings are preferably formed on a substrate, such as a web or patch, for ease in application to and removal from the wound. If desired, additional antimicrobial or other pharmaceutically active agents can also be incorporated into the hydrogel structure.

Owner:AVENT INC

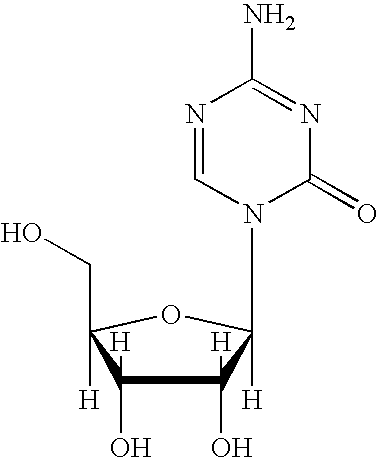

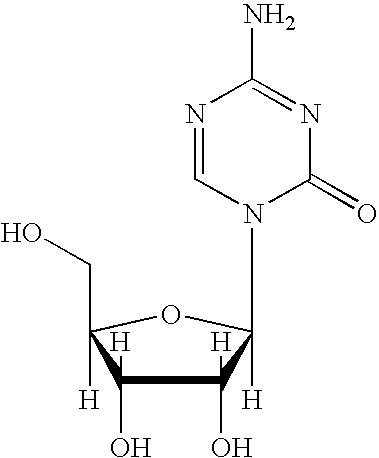

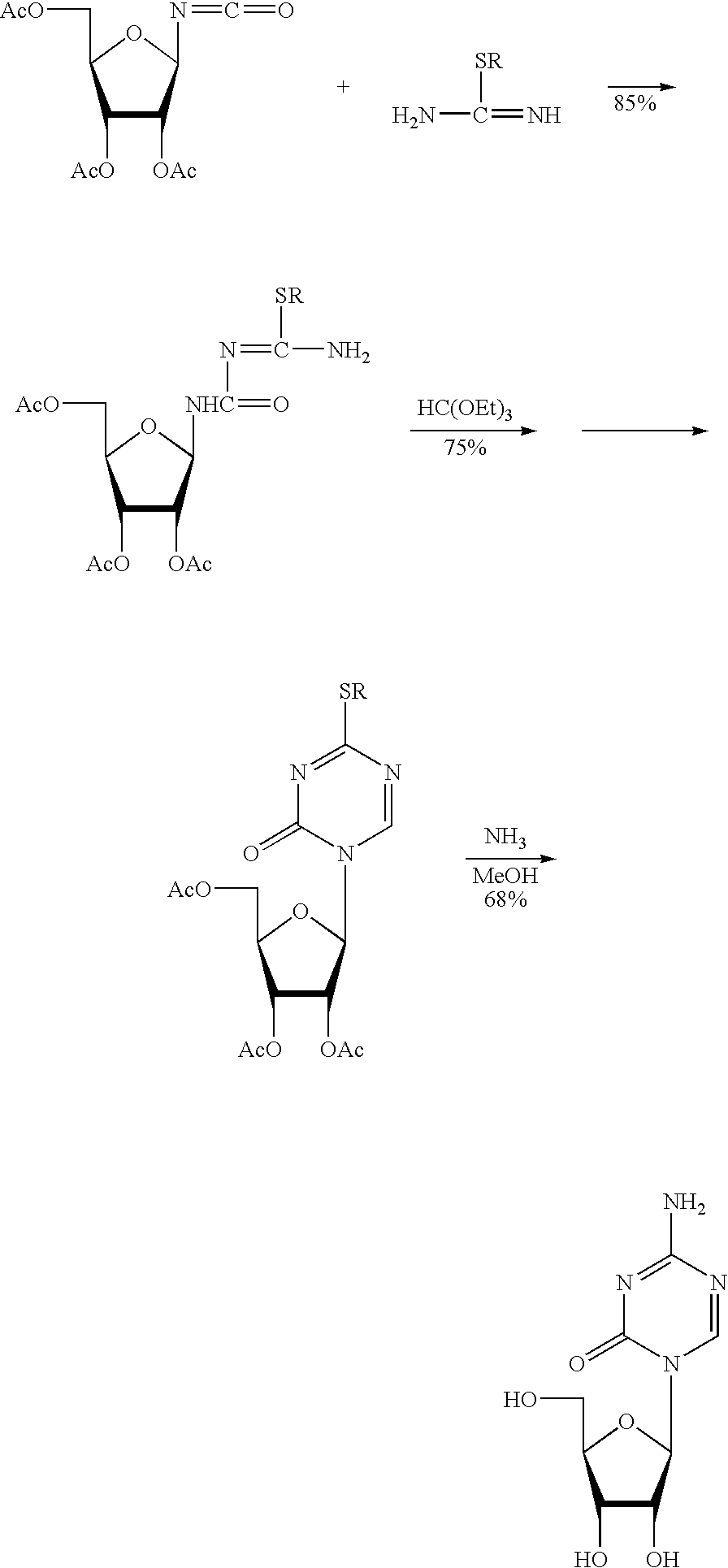

Synthesis of 5-azacytidine

InactiveUS7038038B2Amenable to scale-upAvoiding hydrolysis of the s-triazine ringBiocideSugar derivativesTrimethylsilyl trifluoromethanesulfonateCoupling

The present invention provides a method for the preparation of 5-azacytidine, wherein 5-azacytidine is represented by the structure: The method involves the silylation of 5-azacytosine, followed by the coupling of silylated 5-azacytosine to a protected β-D-ribofuranose derivative. The coupling reaction is catalyzed by trimethylsilyl trifluoromethanesulfonate (TMS-Triflate).

Owner:PHARMION

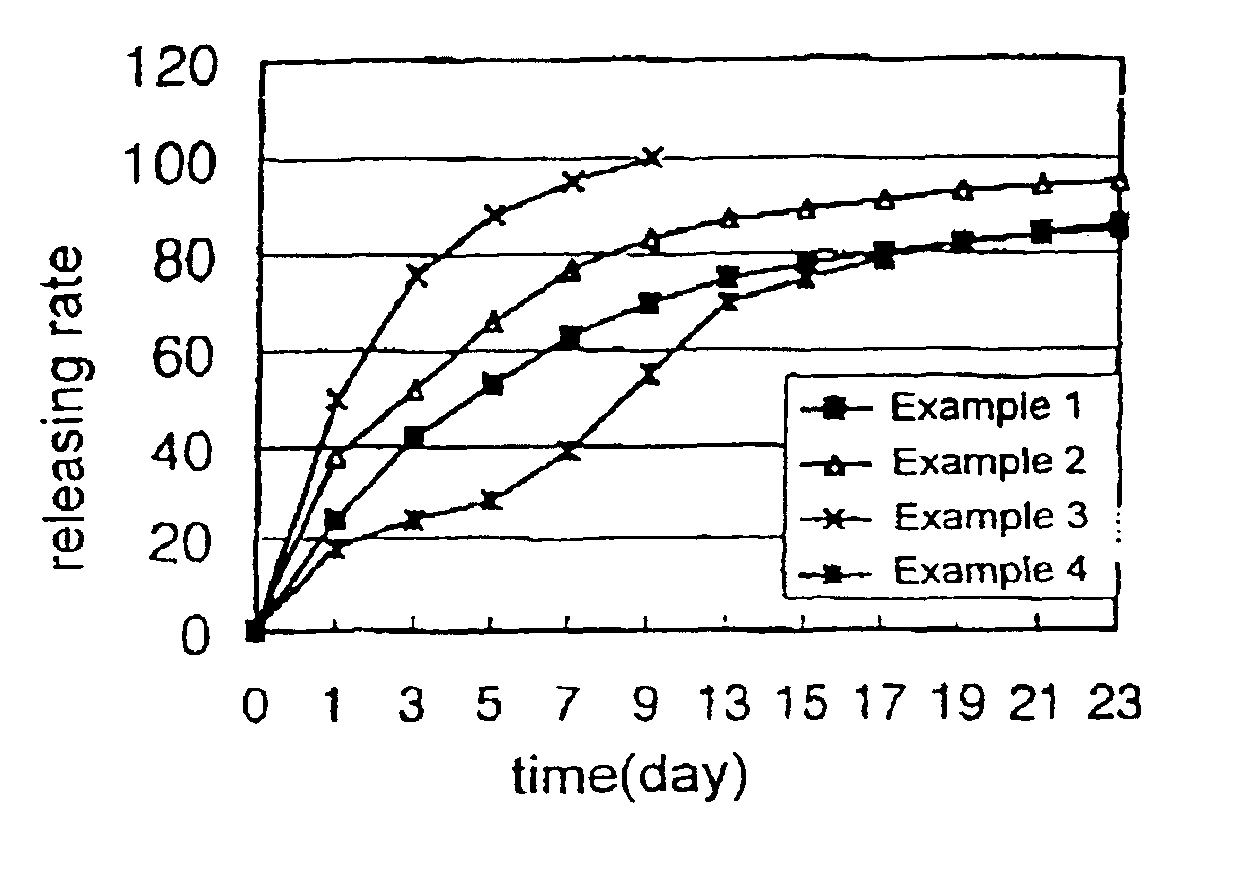

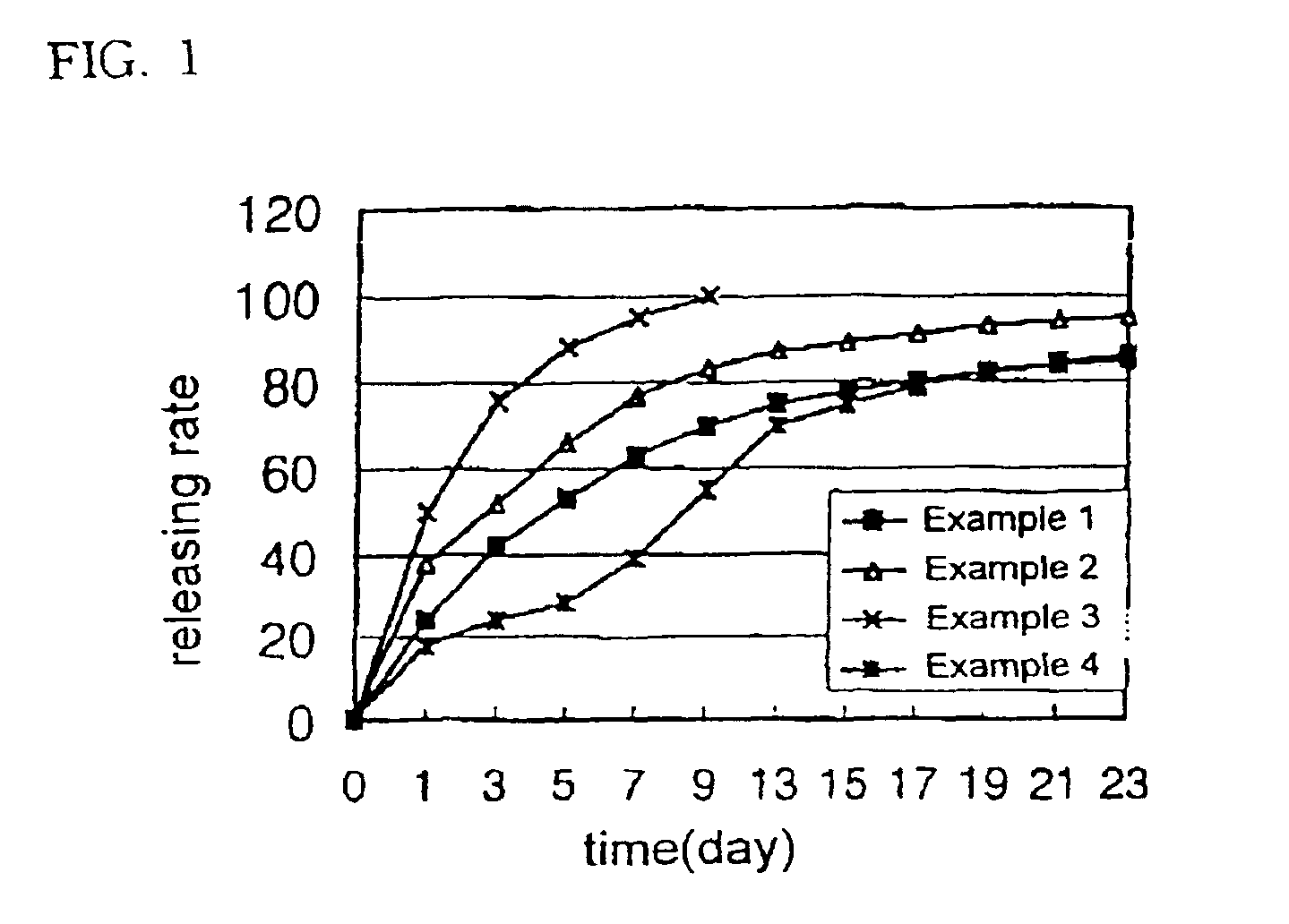

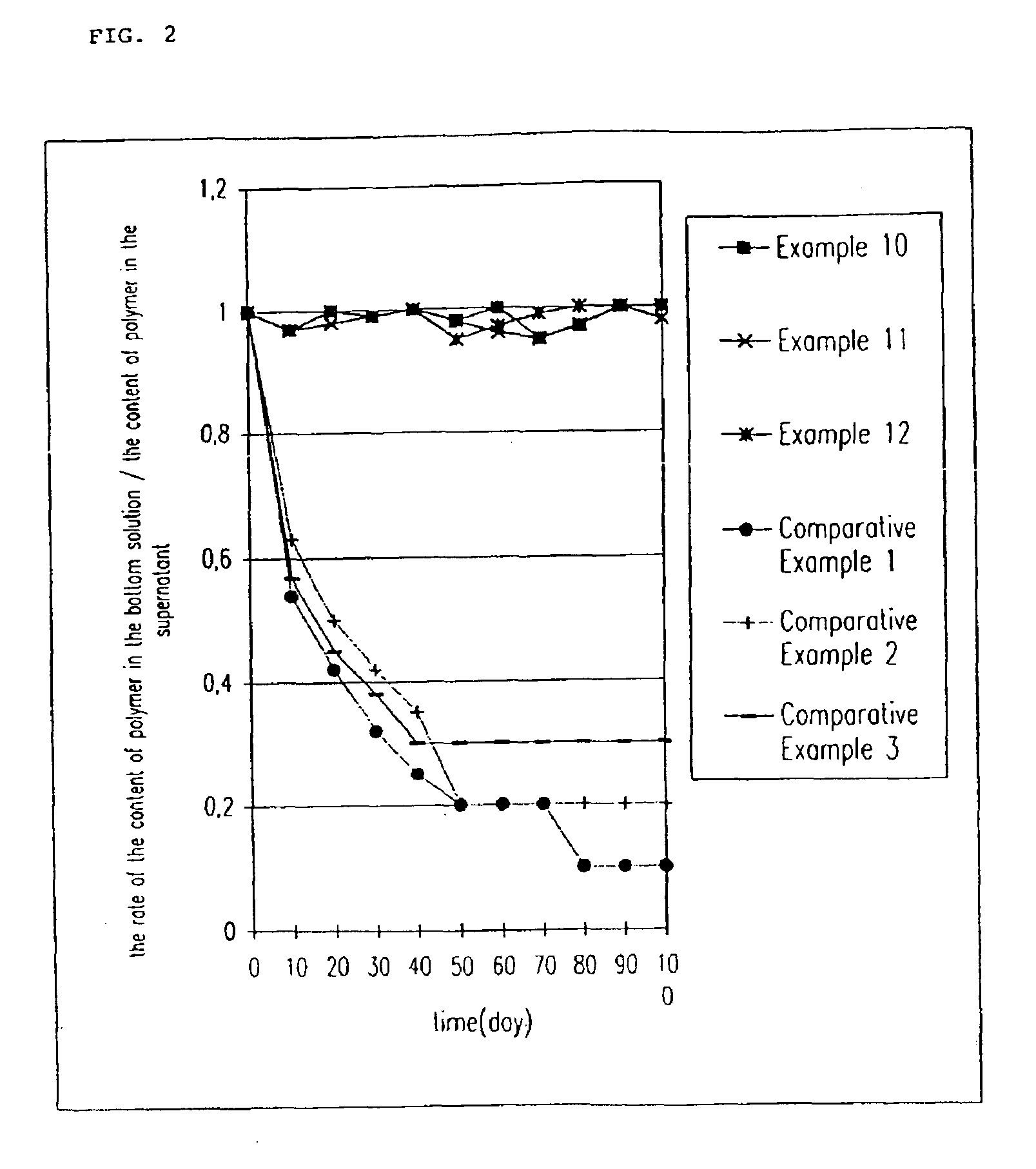

Liquid composition of biodegradable block copolymer for drug delivery system and process for the preparation thereof

InactiveUS6916788B2Rule out the possibilityAvoid hydrolysisAntibacterial agentsOrganic active ingredientsPolyethylene glycolWater soluble

The present invention relates to a liquid polymeric composition capable of forming a physiologically active substance-containing implant when it is injected into a living body and a method of preparation thereof. The composition comprises a water-soluble biocompatible liquid polyethylene glycol derivative, a biodegradable block copolymer which is insoluble in water but soluble in the water-soluble biocompatible liquid polyethylene glycol derivative and a physiologically active substance.

Owner:SAMYANG BIOPHARMLS CORP

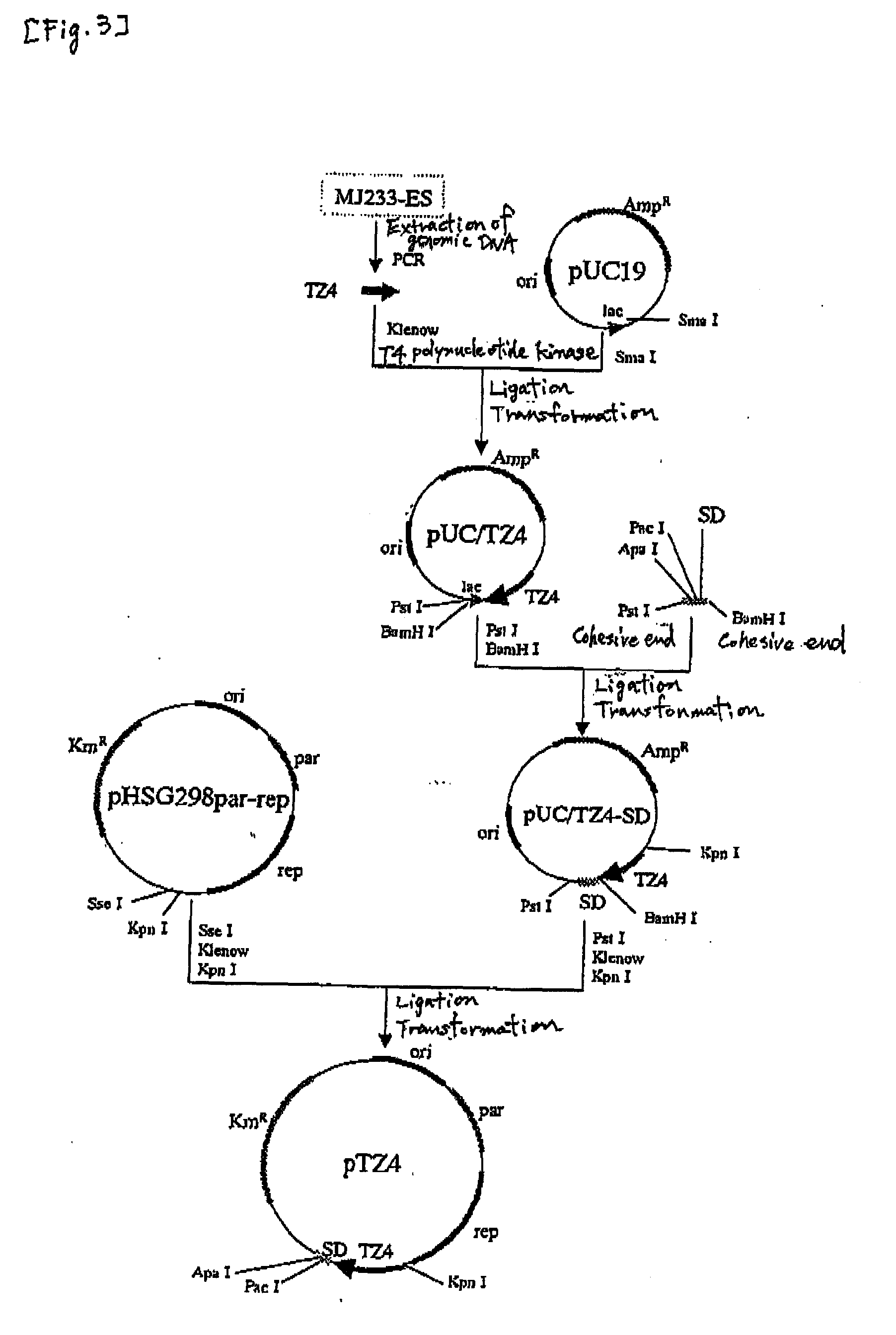

Polyester derived from biomass resources and method for production thereof

ActiveUS20090171037A1Reduce deteriorationStable supplyBio-packagingMicroorganism based processesPolyesterDiol

The present invention provides a resin capable of contributing greatly to solve environmental problems and problems related to exhaustion of fossil fuel resources and having physical properties suited for practical use.The polyester according to the present invention has a diol and a dicarboxylic acid as constituent components and has an amount of terminal acid of 50 equivalents / metric ton or less.

Owner:MITSUBISHI CHEM CORP

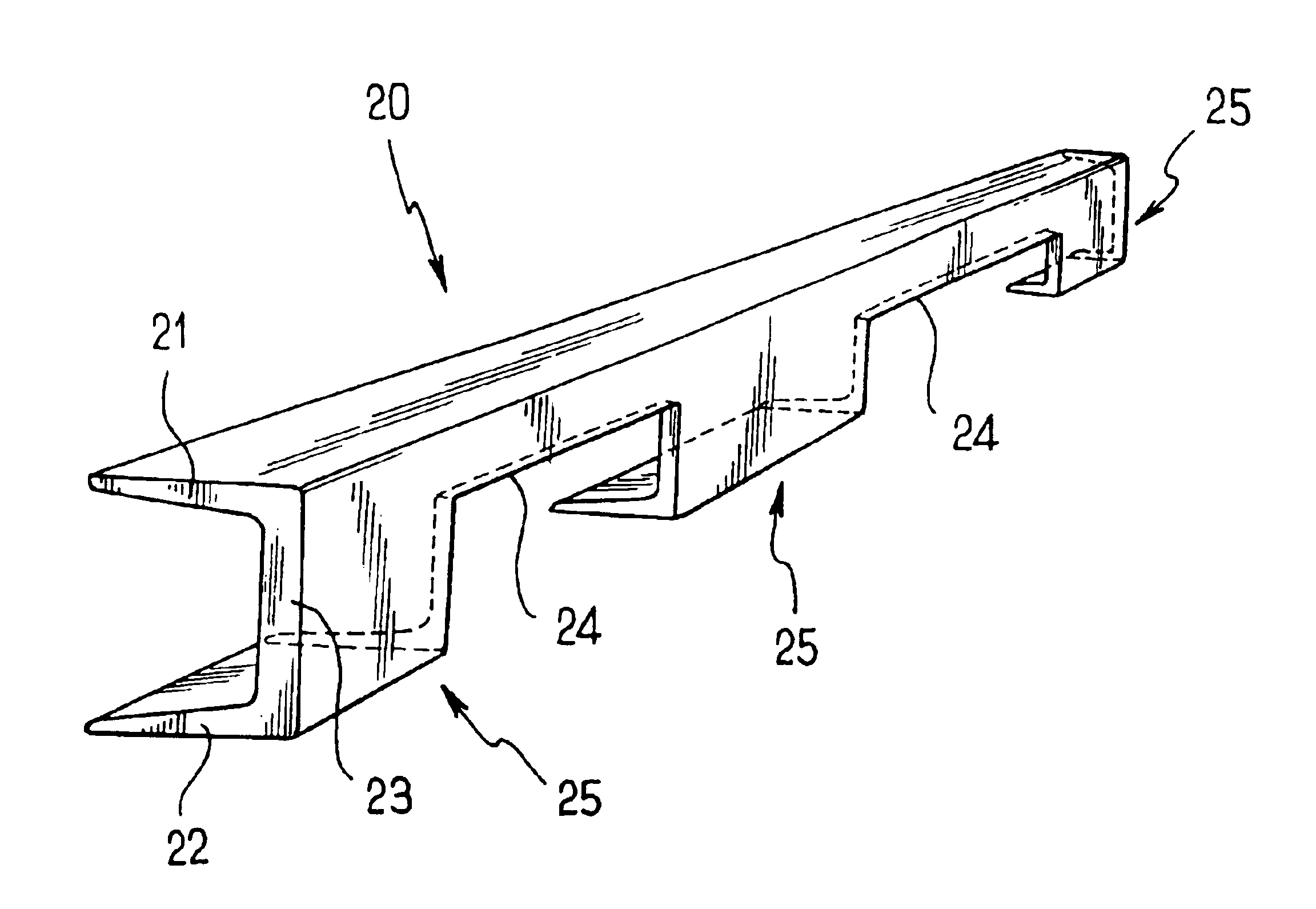

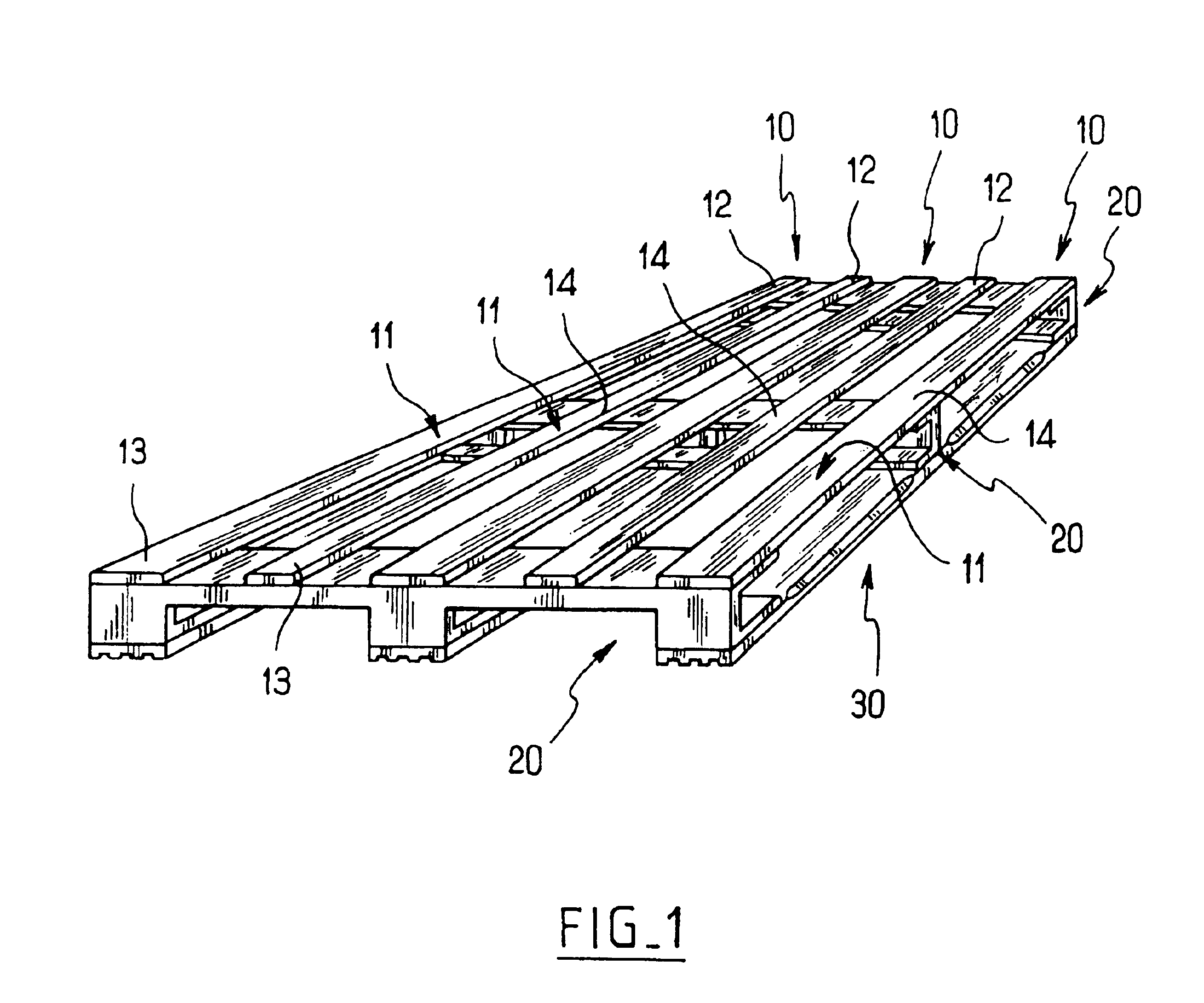

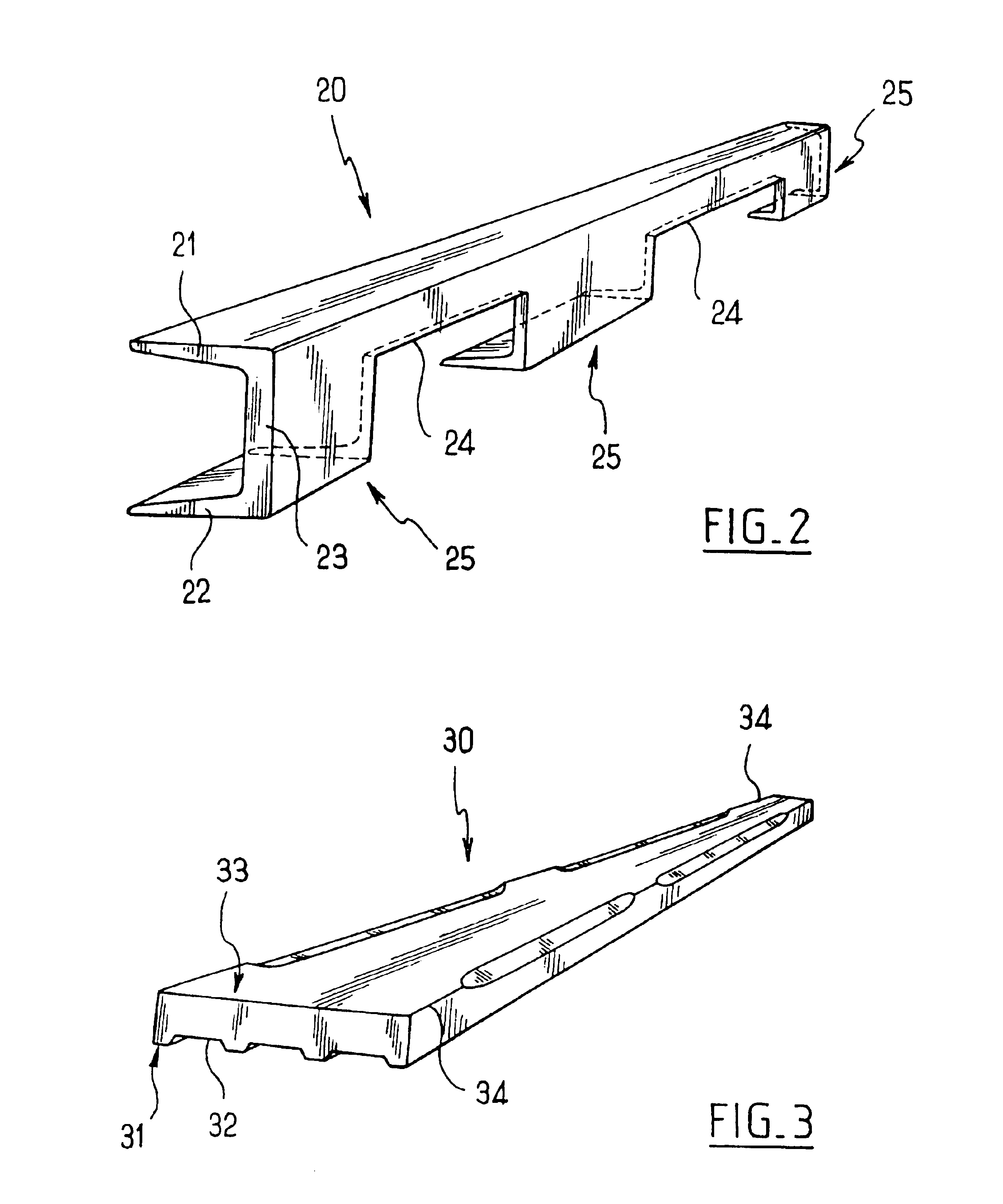

Part made of recycled thermoplastic material, a corresponding method of manufacture, and a pallet comprising at least one bar of this type

InactiveUS6780500B2Improve featuresSatisfactory characteristicSynthetic resin layered productsPlastic recyclingPolyethylene terephthalateEngineering

Owner:DUMOUCHEL CATHERINE +1

Acrylic amide modified graft copolymer, preparation method and application thereof

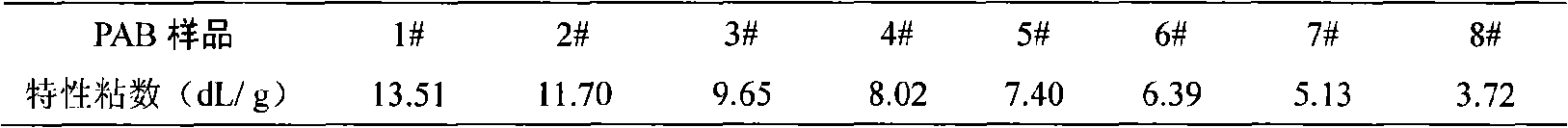

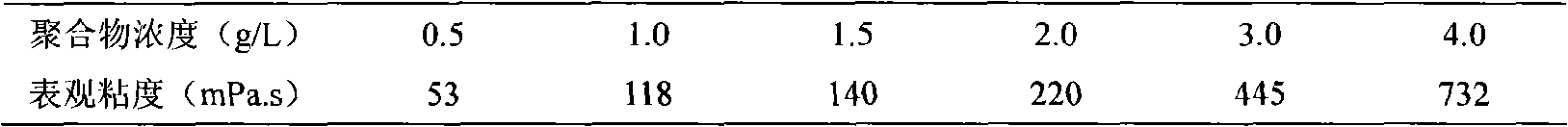

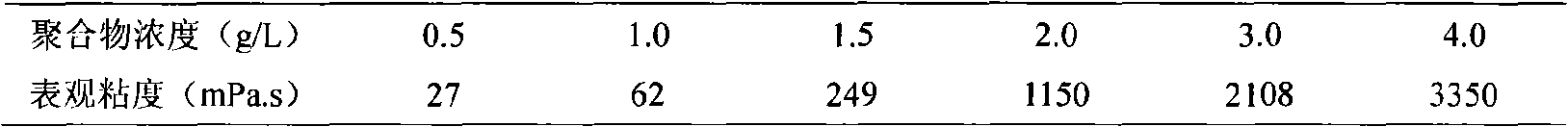

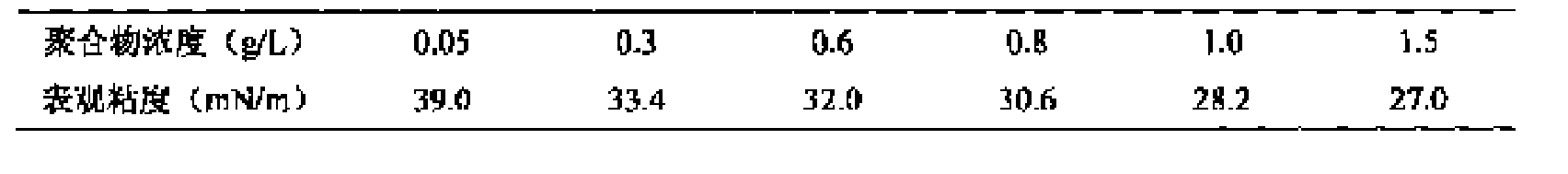

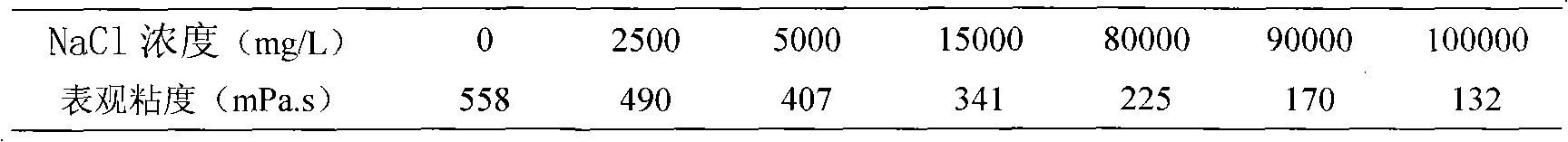

The invention discloses an acrylamide modified graft copolymer and a preparation method and usage thereof. The invention is characterized in that 20 parts of acrylamide, 1-20 anionic monomer and / or cationic monomer, 0.1-15 macromonomer, 0.05-10 ionic lyophobic monomer and 50-1000 deionized water are added into a three-necked reaction bottle, the pH value is adjusted to be 3-9, N2 is introduced for 30min, then 0.002-0.5 part of initiator persulfate is added at 30-75 DEG C, the reaction lasts 8-36h, then copolymer PAB is obtained, and finally water is used for dilution to obtain strong PAB solution. During polymerization, no surfactant is used, and the macromonomer with a long chain and the ionic lyophobic monomer with intermolecular association function are introduced into the copolymer PAB, so the capabilities of cooperative tackification and salt-resistance between the rigid conformation of a molecular chain and the intermolecular association can be played optimally, the PAB exhibits unique solution property and has higher colloidal viscosity in high saline solution than in fresh water, and the PAB obtains the capabilities of tackification, salt resistance, low surface tension and strong molecular association and can be used for the oil-displacing acrylamide modified graft copolymer. The copolymer is prepared into water solution with mass concentration of 0.2-3.0g / L and surfactant concentration of 0.01-2 mmol / L, then the water solution is added into a mixing vessel by a stirring device, and then a polymer oil-displacing agent with tackification, salt resistance and cutting resistance is obtained. The PAB has the functions of both a tackifier and a macromolecule surfactant. The copolymer PAB is prepared into water solution which has mass concentration of 0.05-7%, so the macromolecule surfactant with excellent surface activeness can be obtained and then applicable to an emulsifier, an emulsion splitter, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

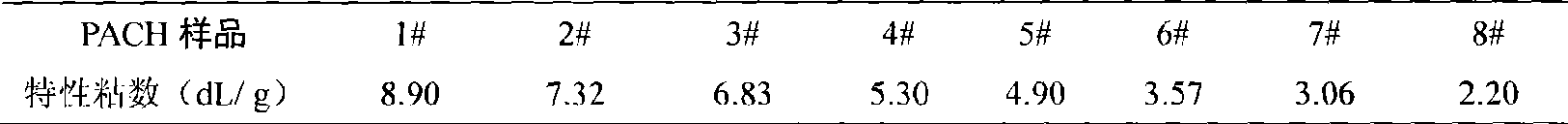

Non-linear associating water-soluble quadripolymer, and preparation and use thereof

InactiveCN101463116AImprove rigidityHigh temperature resistanceTransportation and packagingMixingIonChemistry

The invention discloses a non-linear associated water soluble quadripolymer as well as a preparation method and use thereof, comprising: adding 20 parts of acrylamide, 1-20 parts of nionic monomer or / and cationic monomer, 0.1-15 parts of macromonomer, 0.05-10 parts of hydrophobic monomer, 0.1-50 parts of surfactant and 60-1000 parts of deionized water to a three-necked reaction flask, adjusting the pH to be 3-9, adding 0.002-1 part of initiator (persulphate) at 30-75 DEG C after introducing N2 for 30min, reacting for 8-36h to obtain the quadripolymer PACH, diluting with water, and obtaining concentrated PACH solution. The macromonomer with a long chain and the hydrophobic monomer with a molecular association function are simultaneously introduced in a copolymer PACH, which can obtain the best synergistic viscosifying between rigid conformation of a molecular chain and molecular association and salt resistance. The non-linear associated water soluble quadripolymer is obtained. The copolymer is prepared into aqueous solution with the mass concentration of 0.2-3g / l and the surfactant concentration of 0.01-2mmol / l, added to a mixing vessel with a stirring device and evenly stirred at the room temperature to obtain a viscosified, salt-resistant and shear-resistant polymer oil displacement agent. The PACH has dual functions of a viscosifier and a high molecular surfactant; minute amount of a low molecular surfactant is added to the PACH solution, thus improving the apparent viscosity of the solution, reducing the surface tension of solution and the water-oil interfacial tension, and being beneficial to improving the crude oil recovery ratio. A copolymer PABE is prepared into the aqueous solution with the mass concentration of 0.05-7% to obtain high molecular surfactant with excellent surface activity, and the high molecular surfactant is used as an emulsifier, a demulsifier, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

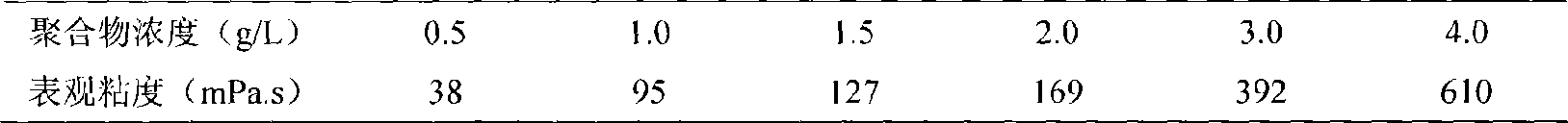

Flame-retardant resin composition

InactiveUS7205346B2Satisfied levelAvoid hydrolysisPlastic/resin/waxes insulatorsDyeing processUreaFire retardant

A flame-retardant resin composition comprises a thermoplastic resin; a flame retardant comprising a phosphorus-containing compound (A), a aromatic resin (B), and at least one flame-retardant auxiliary (C) selected from a nitrogen-containing compound and a metal salt of an inorganic acid; and at least one stabilizer auxiliary (D) selected from a compound having a functional group reactive to an active hydrogen atom and a water-repellent compound. The phosphorus-containing compound may be a phosphoric ester. The aromatic resin may be a polyphenylene sulfide-series resin or a polyphenylene oxide-series resin. The nitrogen-containing compound is a salt of an amino group-containing triazine compound with an oxygen acid, a salt of an amino group-containing triazine compound with a hydroxyl group-containing triazine compound, a polyphosphoric acid amide, a cyclic urea compound, or others. The present invention provides a flame-retardant resin composition which has been flame-retarded without using a halogen-containing flame retardant.

Owner:POLYPLASTICS CO LTD

Method for producing paper pulp, lignins, sugars and acetic acid by frantionation of lignocellulosic vegetable material in formic/acetic acid medium

InactiveUS7402224B1Low hydrationPromote dissociationWashing/displacing pulp-treating liquorsDigestersVegetable materialChemistry

A method for producing paper pulp from a lignocellulosie vegetable raw material. The method includes contacting the raw material with a mixture of formic acid and acetic acid (in an amount more than 5 wt. % of the mixture) at a temperature and for a suitable reaction time, the whole being performed at room temperature. The paper pulp is separated from the organic phase and optionally bleached with ozone. The organic phase is treated to enable the recycling of the formic and acetic acids and the extraction of lignins, sugars and excess acetic acid.

Owner:CIE IND DE LA MATIERE VEGETALE

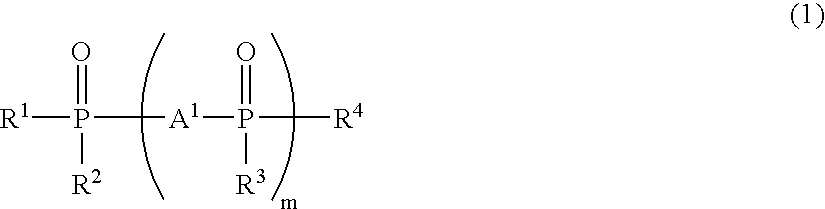

Method for low-temperature atmosphere-pressure hydrothermal synthesis of stephanoporate metal-organic framework

InactiveCN101429209AFully contactedQuality improvementCadmium organic compoundsZinc organic compoundsMetal-organic frameworkChemistry

The invention discloses a method for hydrothermally synthesizing a porous metal-organic framework under low temperature and normal pressure, which comprises the following steps: 1) bivalent transition metal salt is put into proper amount of distilled water to be dissolved; 2) a multidentate organic ligand is put into proper amount of distilled water, and ammonia (30 percent, W / W) is added into the solution until the organic ligand is dissolved; 3) solutions obtained in step 1) and step 2) are mixed, and diluted by the distilled water; 4) the solution obtained in step 3) reacts for 4 to 24h at a temperature of between 80 and 100 DEG C, and is naturally cooled to room temperature at an environmental temperature to obtain an MOF crystal product; and 5) the MOF crystal product obtained in step 4) is filtered, MOF crystals are colleted and washed by the distilled water and absolute ethyl alcohol respectively, and the product is obtained after the natural drying. By performing a hydrothermal reaction in an ammonia solution, the method has mild conditions needed by the synthesis, less energy consumption and time consumption, and does not need a voltage resistant reactor. Therefore, the method is simpler and has lower cost; and a porous crystal material obtained by the synthesis has potential application value in the fields of gas separation, gas storage and heterogeneous catalysis.

Owner:CHONGQING UNIV

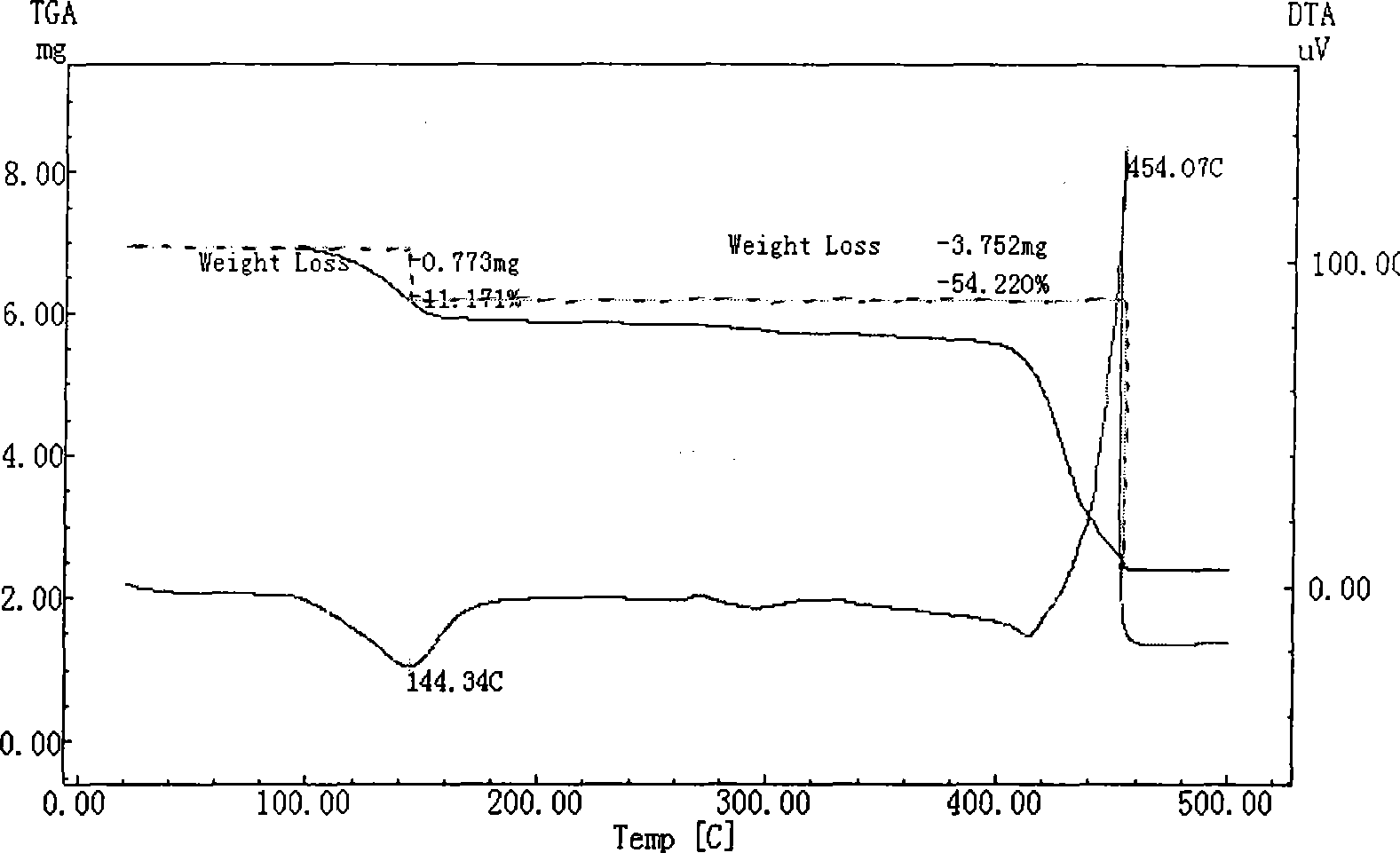

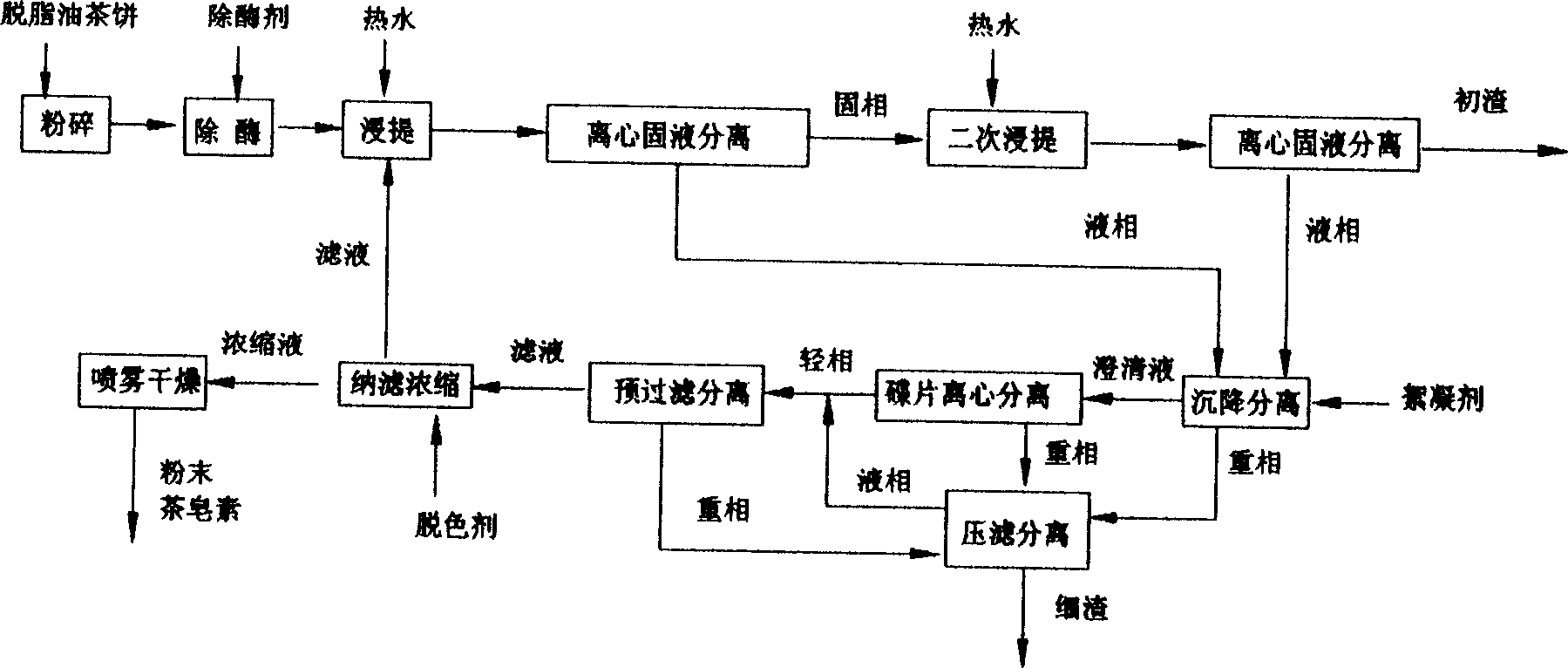

Production process for extracting tea saponin from tea-oil tree cake by using water as dissoluent

InactiveCN1754883AAvoid hydrolysisEfficient removalSugar derivativesGlycosidesChemical treatmentCamellia oleifera

The preparation method to extract tea saponin from oil meal, which comprises smashing, removing enzyme, leaching with hot mixing to boost infiltration capacity, centrifugal solid-liquid separating to add flocculant, deposition separating, disc centrifugal separating for cleaning solution, prefiltration separating for flocculation deposition, nano-membrane concentrating, and spray drying. Wherein, using chemical treatment to inhibit and eliminate hydrolase activity before leaching. This invention is simple and low cost with yield more than 70% and 80% purity.

Owner:NANHUA UNIV

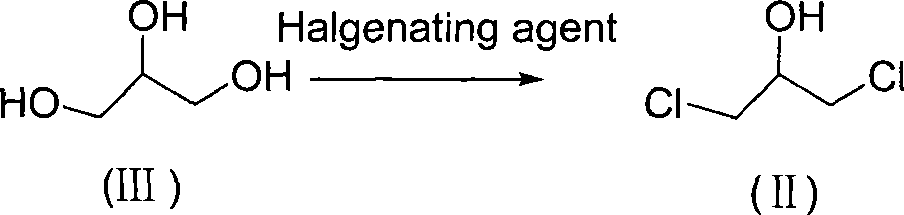

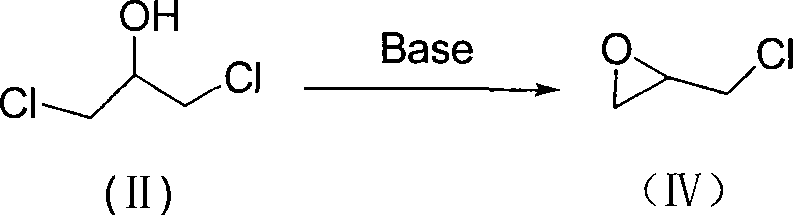

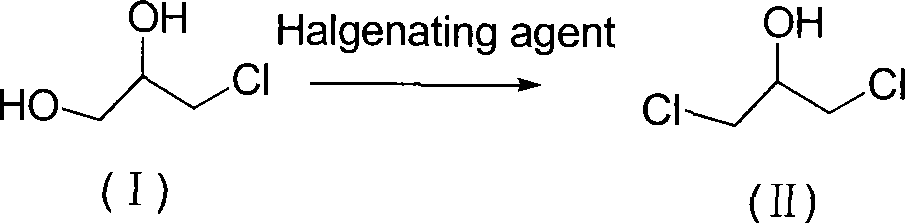

Method for synthesizing epichlorohydrin

The invention relates to a synthesis method of epichlorohydrin, which is a reclaim utilization method of R-3-chloro-1, 2-propanediol during the separation and the preparation of S-epichlorohydrin by utilizing the dynamics of epichlorohydrin and a utilization method of utilizing glycerin which is the byproduct in the production of biodiesel. The R-3-chloro-1, 2-propanediol is reacted with chlorinating agent with the catalysis of the acid catalyst to generate the 1, 3-dichloro propanol, the obtained 1,3-dichloro propanol is reacted with alkali to generate the epichlorohydrin; the glycerin is reacted with the chlorinating agent with the catalysis of the acid catalyst to generate the 1,3-dichloro propanol, and the obtained 1,3-dichloro propanol is reacted with alkali to generate the epichlorohydrin. The synthesis method of the invention is simple, which can effectively convert the highly toxic waste R-3-chloro-1, 2-propanediol and the crude glycerin into the epichlorohydrin, the yield is high, the production cost is low, the environment pollution is reduced, so the synthesis method is an ideal method for industrialization reclaiming and utilization of R-3-chloro-1, 2-propanediol and the crude glycerin.

Owner:WUHAN UNIV OF TECH

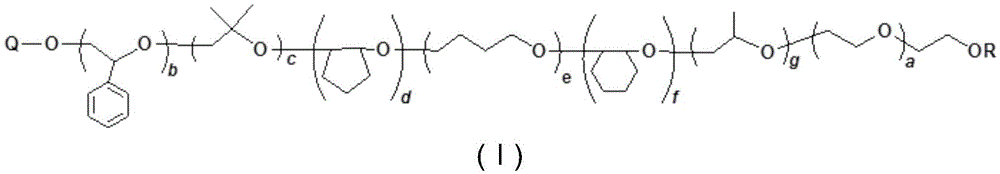

Preparation method and application of polycarboxylate superplasticizer containing phosphate groups

ActiveCN105601839AAvoid hydrolysisGuarantee the effect of graftingChemical recyclingOrganic solventPhosphate

The invention provides a preparation method and application of a polycarboxylate superplasticizer containing phosphate groups. The preparation method can overcome the defect that due to the chain transfer effect of the phosphate groups, the structure and molecular weight of the superplasticizer can not be accurately controlled. The preparation method includes the steps that firstly, unsaturated polyether macromonomers and unsaturated anhydride are subjected to a solution copolymerization reaction in an organic solvent to obtain a polycarboxylate superplasticizer prepolymer; then, the polycarboxylate superplasticizer prepolymer is subjected to phosphorylation modification to obtain the polycarboxylate superplasticizer, wherein the unsaturated polyether macromonomers do not contain OH, phosphorylation modification refers to that anhydride groups in the polycarboxylate superplasticizer prepolymer and a phosphorylation reagent are subjected to an amidation reaction to obtain the polycarboxylate superplasticizer containing the phosphate groups, molecules of the phosphorylation reagent contain one or more phosphate groups and amino capable of participating in the amidation reaction, and the molar ratio of unsaturated anhydride participating in the solution copolymerization reaction to the phosphorylation reagent is 1:(0.01-0.5).

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Method for covering silicon dioxide film on aluminate series long afterglow fluorescent powder surface

InactiveCN1371957AImprove water resistanceHigh initial brightnessLuminescent compositionsWater bathsAluminate

The ethyl metasilicate is dissolved in ethyl alcohol and deionized water, heated in hot water bath with 50-90 deg.c to hydrolyze solution into transparent ethyl metasilicate sol; the long-persistencephosphor powder is immersed in the ethyl metasilicate sol, heated to 50-100 deg.c, the sol can be completely changed into gel; the covered mixture is placed in oven, oven-dried at 50-100 deg.c, and the over-dried covered powder is placed in sintering furnace, heat-insulated for 1-5 hr, at 300-500 deg.c and cooled so as to implement said invention which can obviously raise water-resisting propertyof long-persistence phosphor powder.

Owner:TSINGHUA UNIV

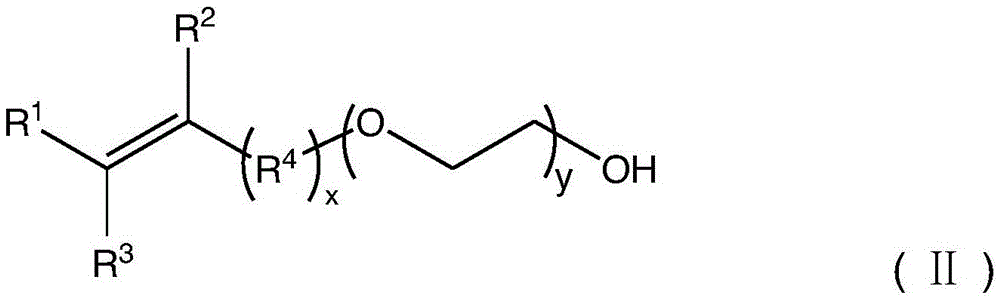

Comb-typed amphiphilic water-soluble co-polymer, method for preparing same and use

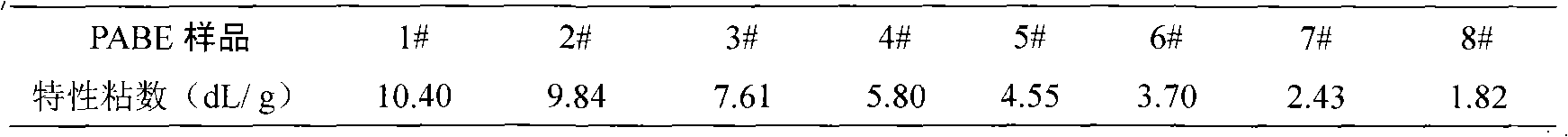

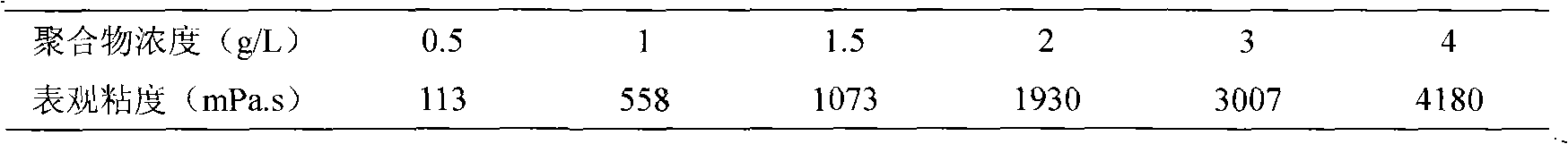

The invention discloses a comb-type amphipathicity water-solubility multipolymer and a method for making the same as well as an application. The method is characterized in that: 20 portions of acrylamide, 0.1 to 10 portions of negative ion monomer, 0.5 to 15 portions of at least one of the surface activity macromolecular monomer 4-vinyl benzyl alkylphenol polyoxyethylene ether or / and allyl alkylphenol polyoxyethylene ether and 30 to 600 portions of deionized water are added into a three-necked reaction bulb, the pH value of the solution is adjusted to between 4 and 9, N2 is introduced into the solution for 30 minutes, 0.002 to 0.3 portion of evocating agent sulphate is added at the temperature of between 30 and 70 DEG C to react 12 to 36 hours in order to prepare PABE which is diluted by water to obtain the PABE strong solution; the comb-type amphipathicity water-solubility multipolymer which can viscosify, has salt resistance and the low surface tension as well as the molecular association ability and can be used for the fuel scavenge. The multipolymer is prepared into a water solution with a mass concentration between 0.3 and 3g / L and a surface active agent concentration between 0.01 and 2mmol / L, the water solution is added into a blending container with a stirring device and is stirred evenly at room temperature so that the polymer oil-displacing agent which can viscosify and shear-resistant and has excellent anti-aging performance in a hyperhaline state and at the temperature of 70 DEG C. The PABE has the double function of a tackifier and a macromolecule surfactant. Infinitesimal low molecular surface active reagent is added into the PABE solution, thereby evidently increasing the apparent viscosity of the solution, reducing the surface tension and the oil-water boundary tension of the solution and contributing to improving the recovery ratio.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method for dyeing textile by dye liquor prepared by mutually dissolving organic solvent and water

The invention relates to a method for dyeing textile by dye liquor prepared by mutually dissolving organic solvent and water and belongs to the technical field of textile printing and dyeing processing. The dye liquor applies organic solvent soluble in water and lower than water in boiling point, and dye is soluble in water and insoluble in organic solvent, so that effective liquor ratio is lowered, distribution coefficient of dye on fiber is changed, and dye uptake is of dye is increased. Adding the organic solvent allows boiling point of the dye liquor to reduce, energy is saved, water consumption in dyeing process is greatly reduced, the organic solvent can be recycled and reused, and discharge of waste liquor is reduced. The dyeing process includes performing twice-soaking and twice-rolling accelerant solution to textile, and solid accelerant is prevented from being precipitated out at a great amount by being added in dyeing process. The method is low in water consumption, utilization rate of dye is increased, energy consumption is low, the organic solvent can be recycled and reused, and cleaning and dyeing are achieved simultaneously.

Owner:WUHAN TEXTILE UNIV

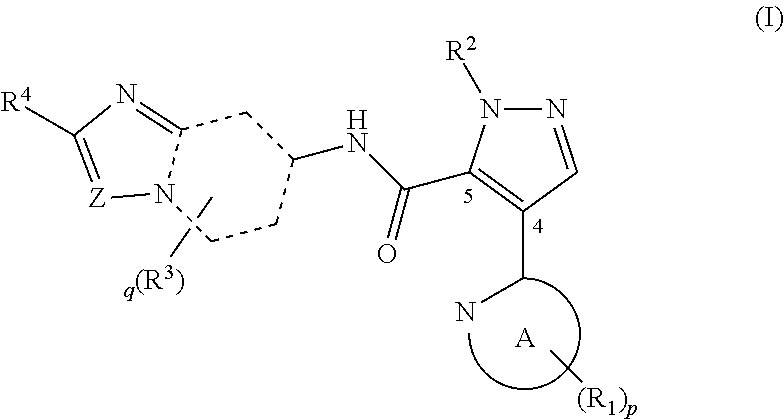

Novel pyrazole derivative

It has been desired to develop a pharmaceutical composition, which is used in agents for preventing and / or treating various diseases related to PDE10 (e.g. mental disorder and neurodegenerative disorder). The present invention provides: compounds having PDE10 inhibitory effect, in particular, compounds having a 4-heteroarylpyrazole-5-carboxylic acid amide structure represented by the following formula (I), or their pharmaceutically acceptable salts, or their solvates; pharmaceutical compositions comprising, as active ingredients, the compounds, or their pharmaceutically acceptable salts, or their solvates; and medical use of the compounds, or their pharmaceutically acceptable salts, or their solvates.

Owner:MOCHIDA PHARM CO LTD

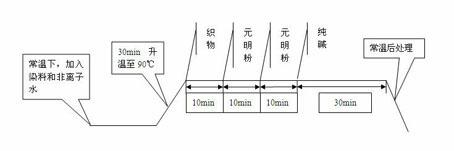

Processing method of salt-free dyeing through activated dye

InactiveCN102899929AIncrease the adsorption rateImprove adsorption capacityDyeing processInorganic saltsOrganic solvent

The invention relates to a processing method of salt-free dyeing through activated dye, which includes the steps of: (1), acid pickling and enzyme washing of cotton fabric after the pretreatment of scouring and bleaching; (2) mixing water with organic solvent at volume ratio of (1:4)-(1:9) to form a mixed solution, and then adjusting the pH value of the mixed solution; and (3)dyeing the pretreated cotton fabric in 20-30 DEG C activated dye by using the mixed solution, then carrying out water scrubbing, acid pickling, soaping, hot-water scrubbing, color fixing and softening on the dyed cotton fabric, and finally recovering the solvent. With the processing method, the adsorption rate and the equilibrium adsorption amount of the activated dye are improved, and environmental and ecological problems caused when large quantity of inorganic salt is used are completely solved. In the dyeing process, the input of inorganic salt is omitted, so the operational techniques and the labor intensity in the dyeing process are effectively simplified and the production cost is reduced. Through a solvent recovery system, the solvent contained in the dyeing residue of the hydrosolvent is recovered for cycle use. Therefore, the recovery and the recycling of the resource are realized, the production cost is saved and the pollution to the environment is alleviated.

Owner:DONGHUA UNIV +1

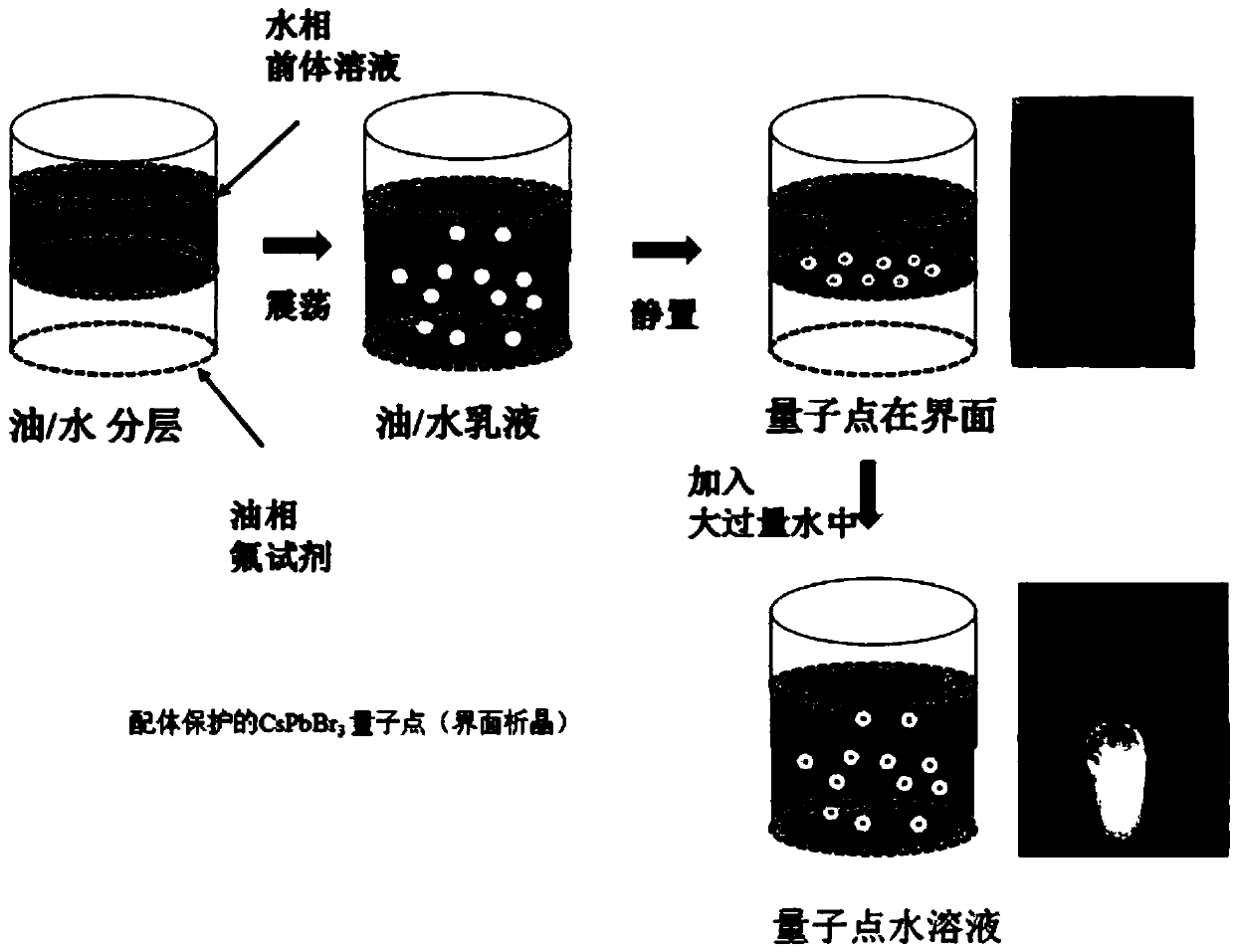

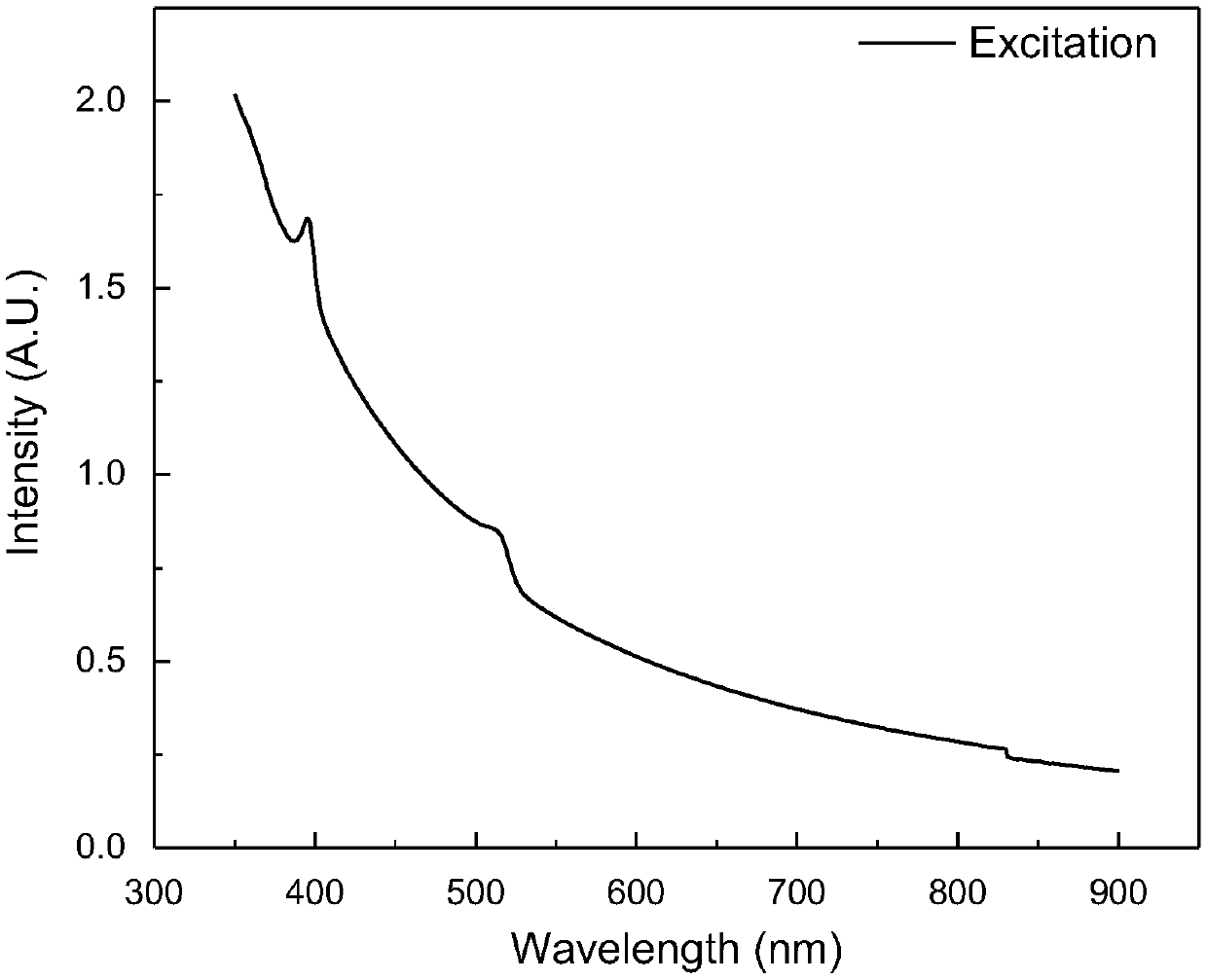

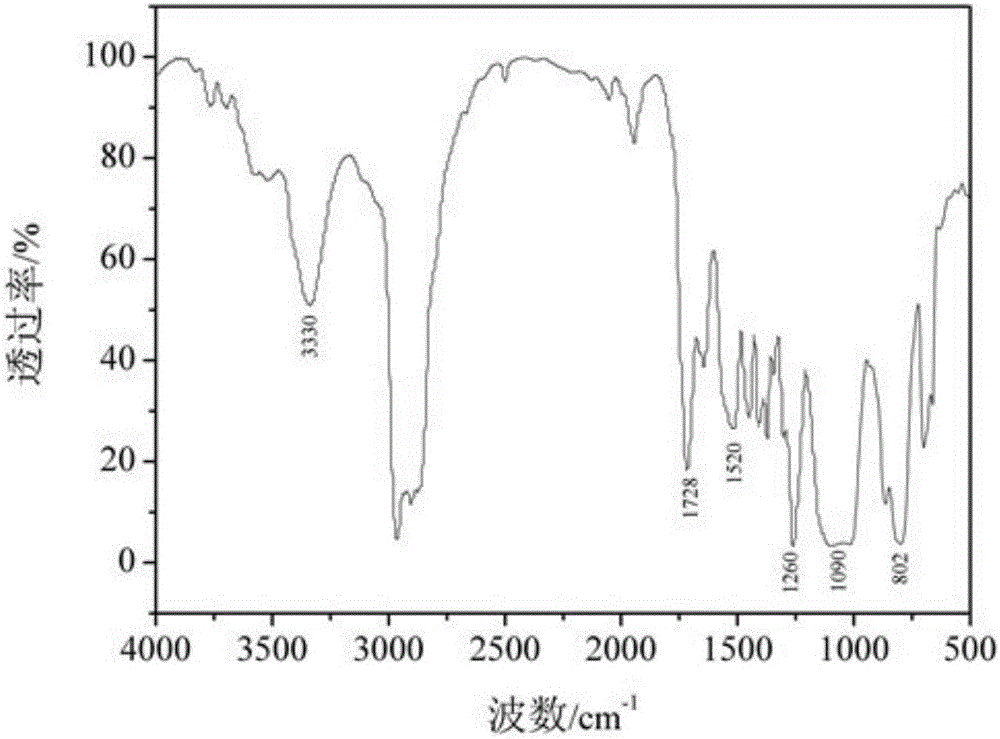

Preparation method of metal halide perovskite quantum dots

ActiveCN107603614ASmall sizeFluorescence stabilizationNanotechnologyLuminescent compositionsEmulsionLiquid state

The invention discloses a preparation method of metal halide perovskite quantum dots. The method is characterized in that a liquid state hydrophobic fluorine-containing reagent and a precursor aqueoussolution used for preparing a metal halide perovskite material are mixed to obtain an emulsion, the metal halide perovskite quantum dots are synthesized in the emulsion, the surface of the metal halide perovskite quantum dots are tightly coated with the hydrophobic fluorine-containing reagent, so that the metal halide perovskite quantum dots which can dispersed in an aqueous solution as a singleparticle state are obtained. Through key integral process flow design and each technological step improvement for the preparation method, compared with the prior art, the problem of poor stability ofCsPbX3 quantum dots can be effectively solved, and the CsPbX3 metal halide perovskite quantum dots prepared by the invention have good dispersibility.

Owner:HUAZHONG UNIV OF SCI & TECH

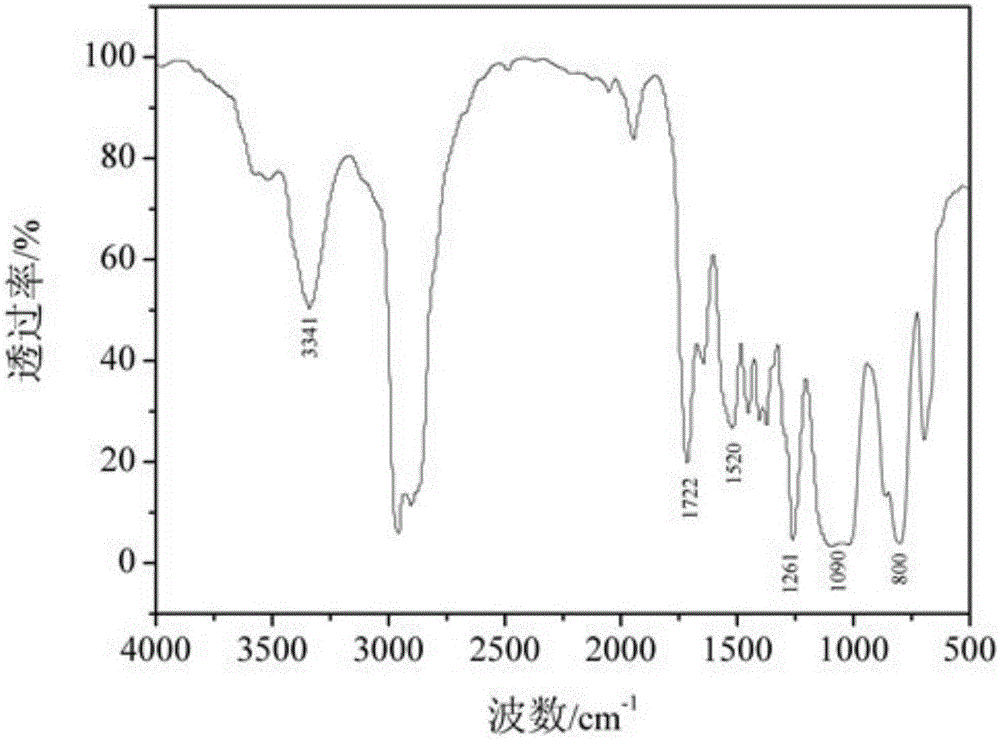

Organosilicone modification polyurethane color fixing agent and preparation method thereof

The invention relates to a textile color fixing agent, and in particular to an organosilicone modification polyurethane color fixing agent and a preparation method thereof. The organosilicone modification polyurethane color fixing agent is synthesized from end hydroxyl polysiloxane, polypropylene glycol (PPG), isophorone diisocyanate (IPDI), N-methyl diethanol amine, trimethylolpropane (TMP), acetone, glacial acetic acid and methyl ethyl ketoxime as raw materials. As trimethylolpropane is adopted as a chain extender, a synthesized polyurethane prepolymer has multiple branch chains, and the cross-linking property and the filming property in curing can be improved; as methyl ethyl ketoxime is adopted to seal the end, sufficient active groups can be maintained for the prepolymer to react with active groups on a fabric and dye in high temperature baking, the color fastness and the washing fastness of the fabric can be improved, and meanwhile due to introduction of a polysiloxane chain segment, the softness of the settled fabric can be improved.

Owner:HANGZHOU MEIGAO HUAYI CHEM

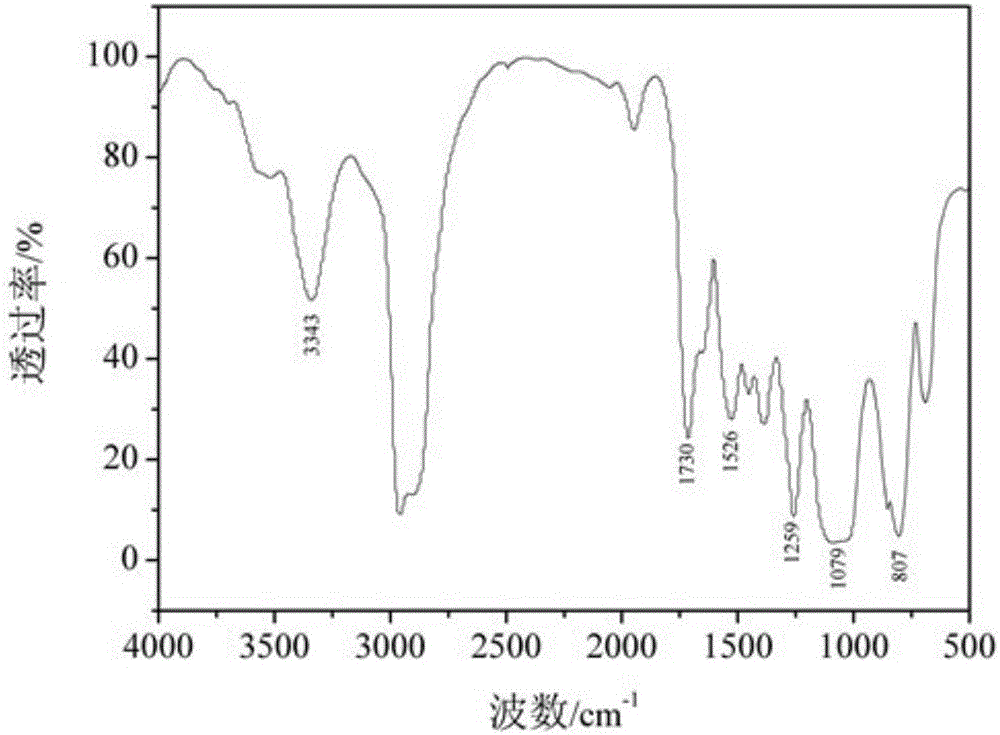

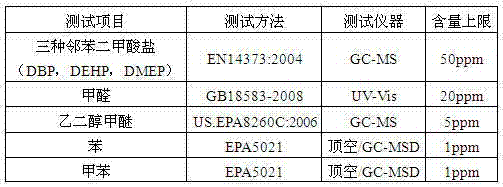

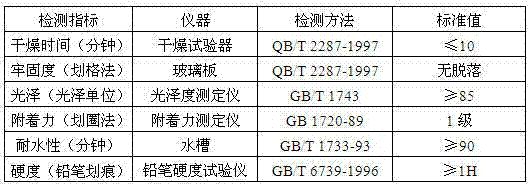

Preparation method of alkyd resin

InactiveCN102408551AImprove adhesionFullnessCosmetic preparationsToilet preparationsPolymer scienceNitrocellulose

The invention relates to a preparation method of alkyd resin. The preparation method comprises the following specific steps: (1) adding neopentyl glycol, trihydroxymethyl propane, phthalic anhydride, hydrogenated phthalic anhydride and antioxidant to a reaction container, and heating to carry out melt esterification on the materials at the temperature of 200-240 DEG C; (2) when esterification is carried out to an acid value being 40-45 mgKOH / g, cooling to 120-160 DEG C, and adding short-chain synthetic fatty acid and an aliphatic hydrocarbon solvent; (3) heating to carry out reflux esterification at the temperature of 180-200 DEG C, and diluting with acetic acid ester organic solvent when the acid value is smaller than or equal to 8 mgKOH / g; and (4) cooling to 100 DEG C and filtering to obtain alkyd resin. The paint prepared from the alkyd resin obtained in the invention and nitrocellulose has the characteristics of rapid drying, high hardness, good fullness, good adhesion force, and good water resistance.

Owner:JIANGSU SANMU GROUP CORPORATION

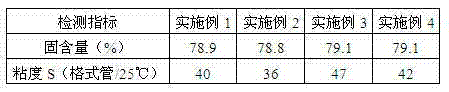

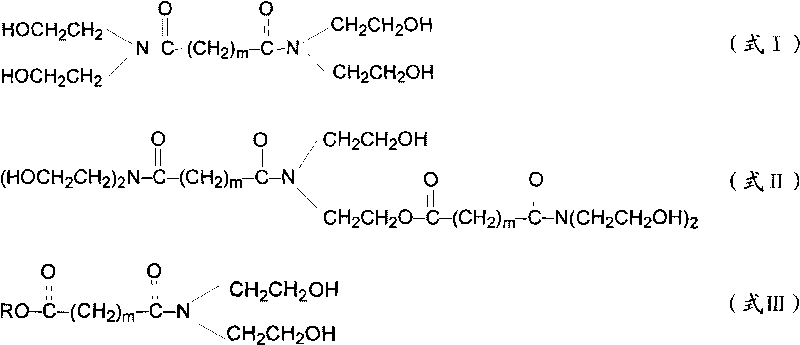

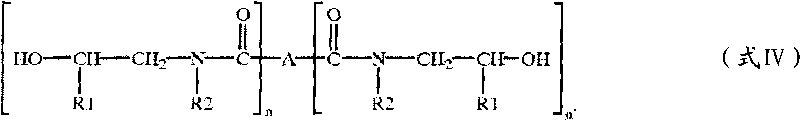

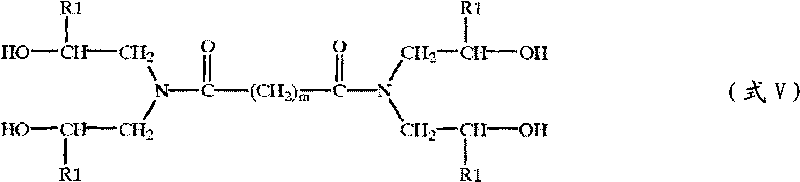

Production technology of beta-hydroxyalkylamide

ActiveCN101704762AAvoid hydrolysisHigh purityOrganic compound preparationCarboxylic acid amides preparationDistillationAminolysis

The invention discloses a production technology of beta-hydroxyalkylamide. The method comprises the following steps: taking carboxylic acid alkyl ester and excessive beta-alkanolamine as raw materials, conducting aminolysis reaction while heating and stirring, then adding volatile acid to break alkali catalyst, further raising temperature, constantly removing byproducts and the unreacted beta-alkanolamine by adopting the combination of bubbling and sweeping by inert gas and the reduced pressure distillation process, and then emptying, cooling and grinding to directly obtain a high-purity beta-hydroxyalkylamide powder product. The production technology purifies products by replacing the traditional organic solvent crystallization technology with the combination of bubbling and sweeping by the inert gas and the reduced pressure distillation process, needs not to add acetone, methanol and other organic solvents and can not only obtain the high-purity beta-hydroxyalkylamide product, but also avoid the consumption of crystallized solvent and the pollution thereof to the environment, thus being a novel production technology with low material consumption and low pollution.

Owner:六安捷通达新材料有限公司

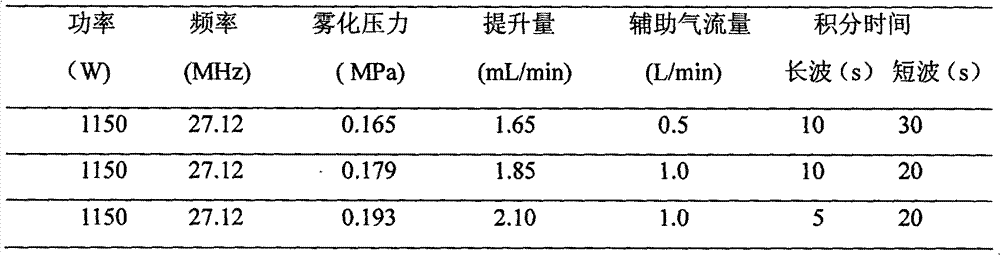

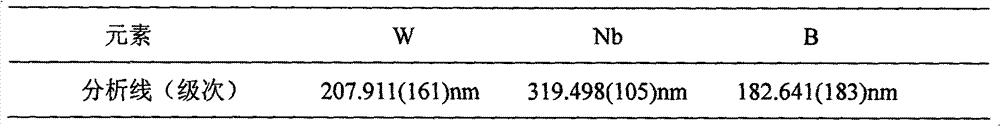

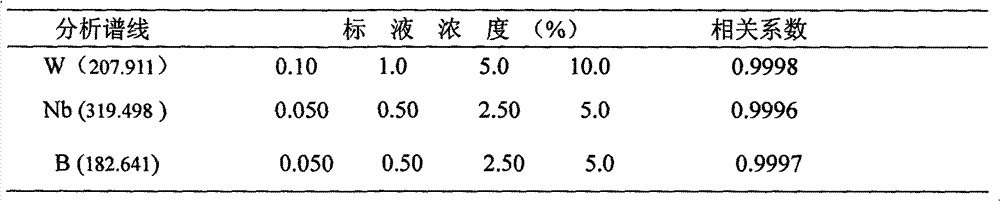

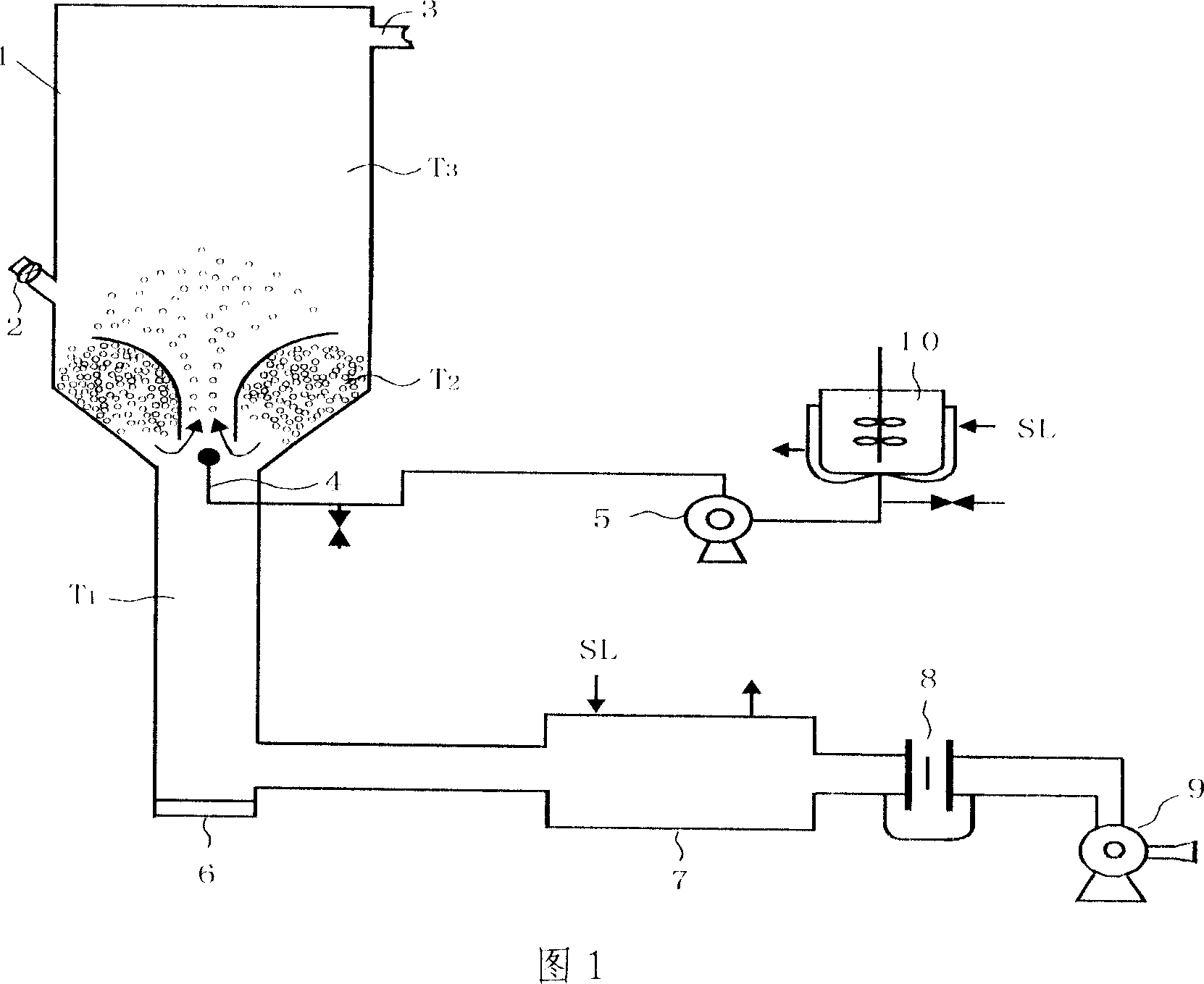

Method for determining niobium element content in ferroniobium

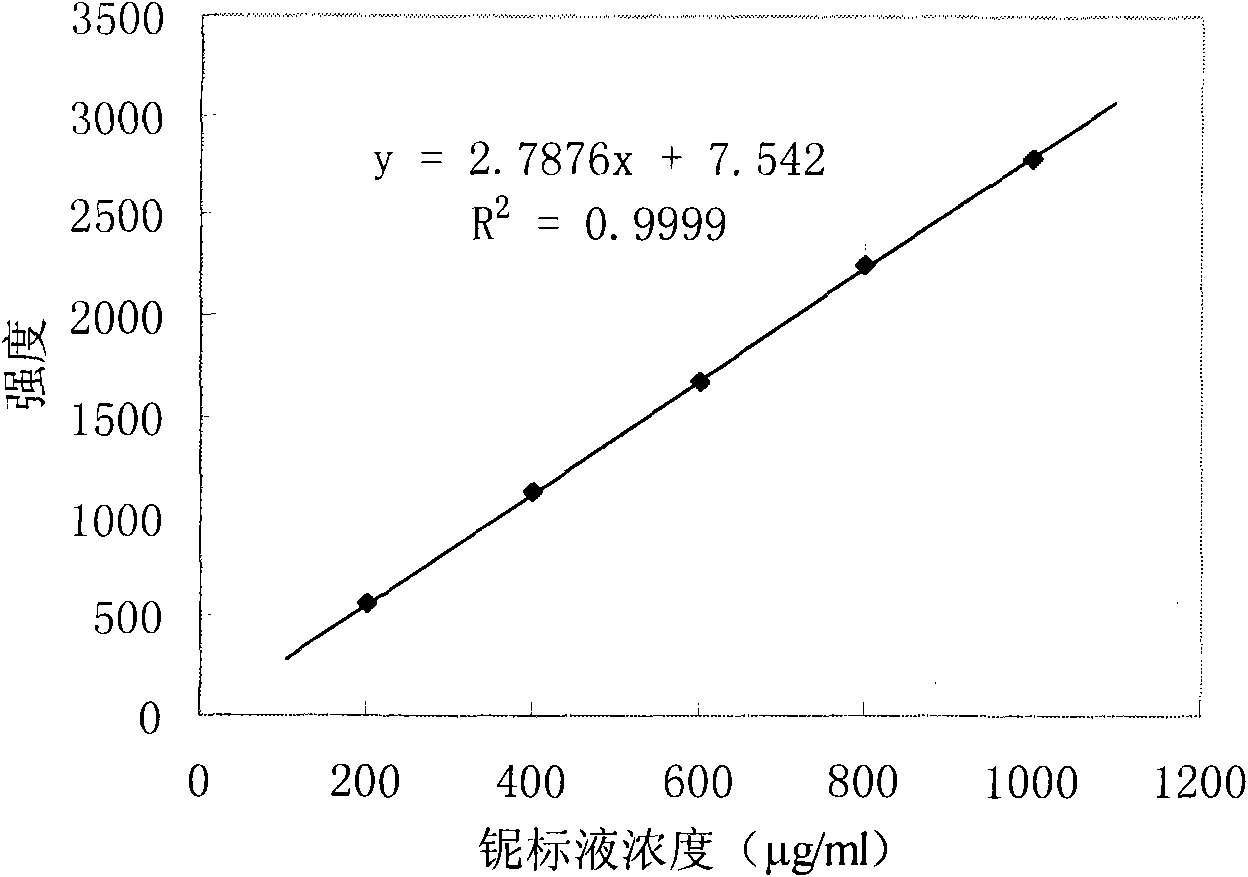

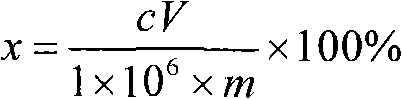

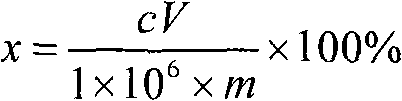

InactiveCN101609048AAvoid hydrolysisBreak down completelyAnalysis by thermal excitationPretreatment methodNiobium

The invention relates to a method for determining niobium element content in ferroniobium, which comprises the following steps: a sample is weighted and put in a polytetrafluoroethylene beaker and deionized water is added for humidifying the sample; hydrofluoric acid and nitric acid are added into the sample, and then are heated so that the sample is slowly dissolved; after the sample is completely dissolved, the breaker is taken down and cooled; after the sample is cooled to room temperature, the volume is metered; reagent blank without the sample is adopted, and then standard solution of niobium element with different volumes is added, and finally deionized water is added and the volume is metered; spectral line strength of niobium element in standard solution is determined under the working condition of a setting inductively coupled plasma atomic emission spectrometer and a working curve is drawn; the spectral line strength of niobium element in ferroniobium sample solution to be determined is determined, and then a computer automatically determines the concentration of niobium element in sample solution according to the working curve. The method mainly solves problems of long operational process, narrow measuring range and the like, determines appropriate sample processing methods and analytic conditions of instruments, and realizes effectively, rapidly and accurately measuring niobium element in ferroniobium.

Owner:武钢集团有限公司

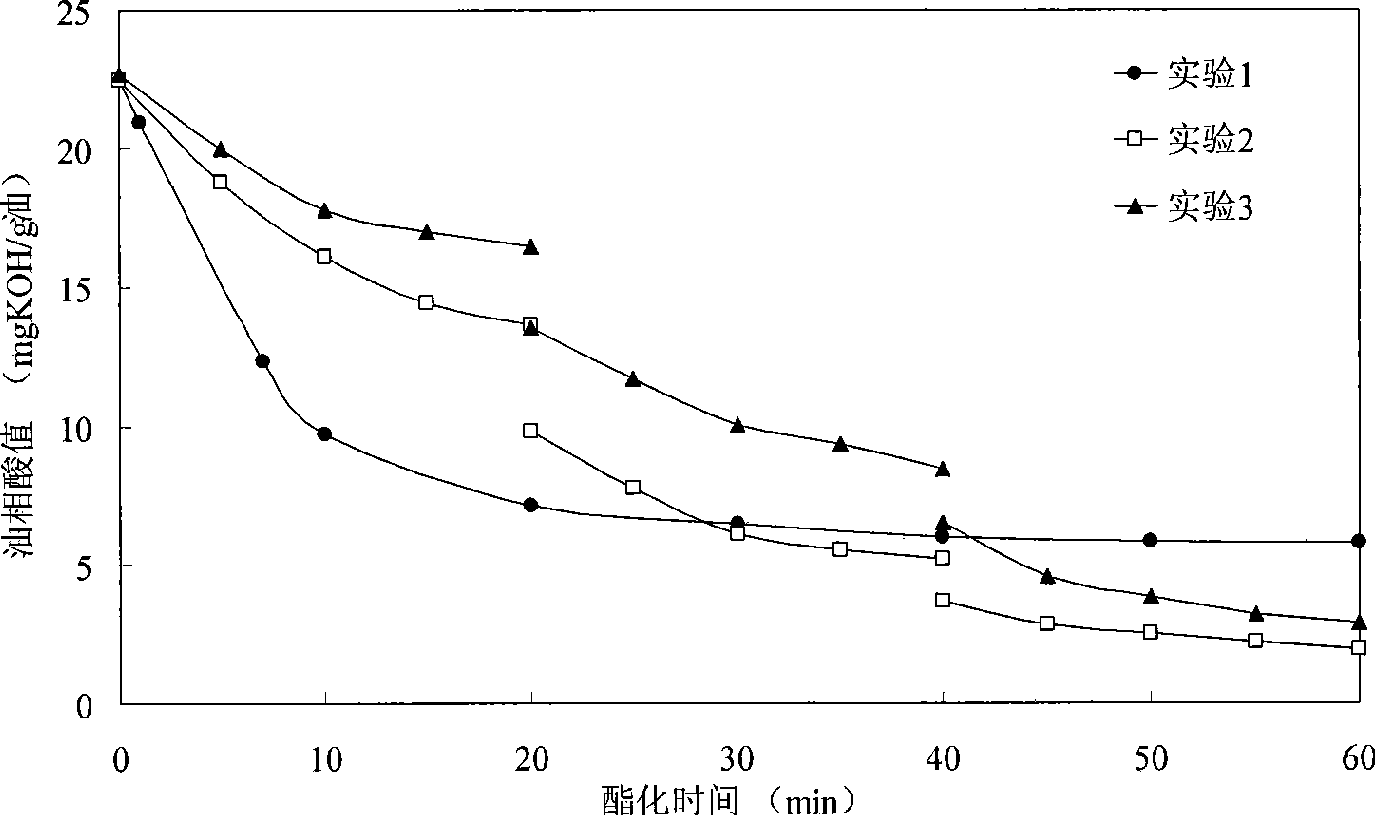

Method for preparing biodiesel by utilizing stratified and graded esterified deacidification of high acid value oil

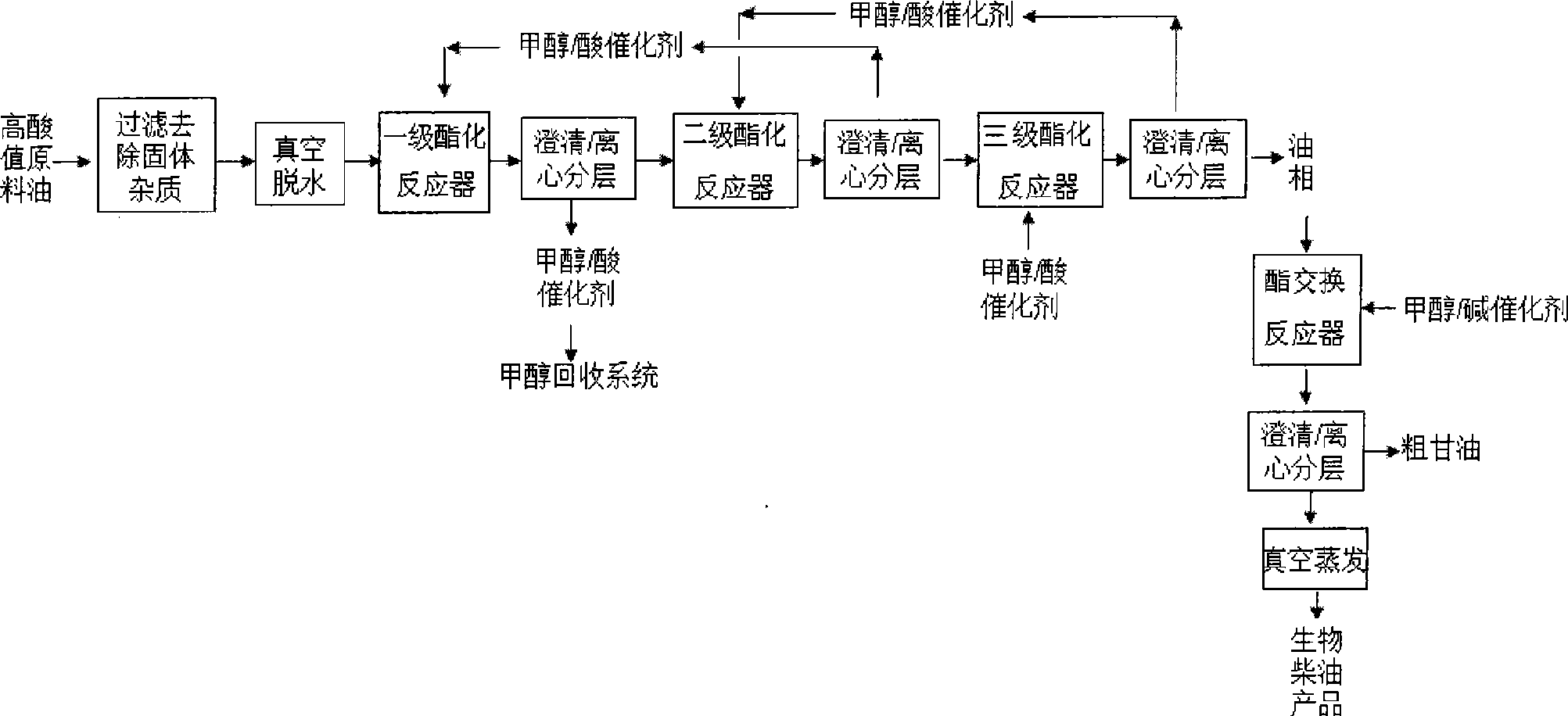

InactiveCN101445742AHigh reaction conversion rateNot easy to carbonizeBiofuelsLiquid hydrocarbon mixture productionOil and greaseFiltration

The invention provides a method utilizing high acid value oil as raw material for preparing biodiesel. Various animal and vegetable oil, the acid value of which is larger than 3.0mg KOH / g oil, oilstock, soapstock and acidic oil in a vegetable oil refining process, various food waste oil (restaurant waste oil, hogwash oil, trench waste oil, and the like) and various waste animal oil in industrial processing (waste animal oil in leather processing, waste animal oil in slaughtering process, and the like) are used as raw materials to obtain biodiesel products by filtration for removing solid impurities, vacuum dehydration, stratified graded acid catalytic esterification, alkali catalytic transesterification and vacuum distillation. The method utilizing the high acid value oil as the raw material for preparing the biodiesel has the beneficial effect that the production process can be applied to raw materials with different acid values to produce biodiesel products with high purity by changing the operational series of the stratified graded acid catalytic esterification reaction and has the advantages of simple process, low energy consumption, high conversion rate and small device. And continuous production can be realized.

Owner:ZHEJIANG UNIV OF TECH

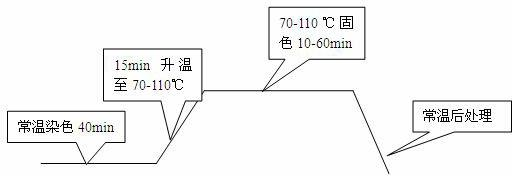

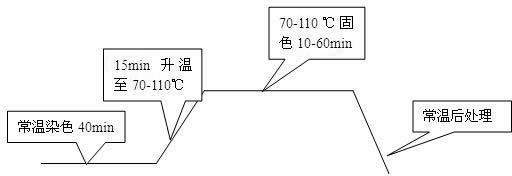

Dyeing process of pure cotton fabric

The invention discloses a dyeing process of a pure cotton fabric, which comprises the following steps: a. taking one mass part of pure cotton fabric to be dyed; b. grinding a powdery reactive dye occupying 2-8% of the total mass of the fabric in a ball grinding mill for 2h, adding ethanol and grinding for 1h, wherein the mass of ethanol is nine times of that of the powdery reactive dye; c. adding decamethylcyclopentasiloxane, high-speed cutting for 5min at a rotating speed of 600r / min, and preparing a powdery reactive dye / decamethylcyclopentasiloxane suspension system, wherein the mass of the decamethylcyclopentasiloxane is 50 times of the total mass of the fabric; d. pretreating the pure cotton fabric to be dyed in an alkali solution of 1-130g / L so as to enable the pure cotton fabric tofully swell, and controlling the fabric liquid carrying rate to be 100-220% through a rolling machine; and e. immersing the treated fabric into the powdery reactive dye / decamethylcyclopentasiloxane suspension system, dyeing for 40min at normal temperature, slowly rising the temperature to 70-110 DEG C within 15min, fixing color for 10-60 min at the temperature of 70-110 DEG C, and finally reducing the temperature to the normal temperature to finish dyeing. The dyeing process disclosed by the invention has the advantages of high dyeing fixation rate, environmental-protection and no pollution.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

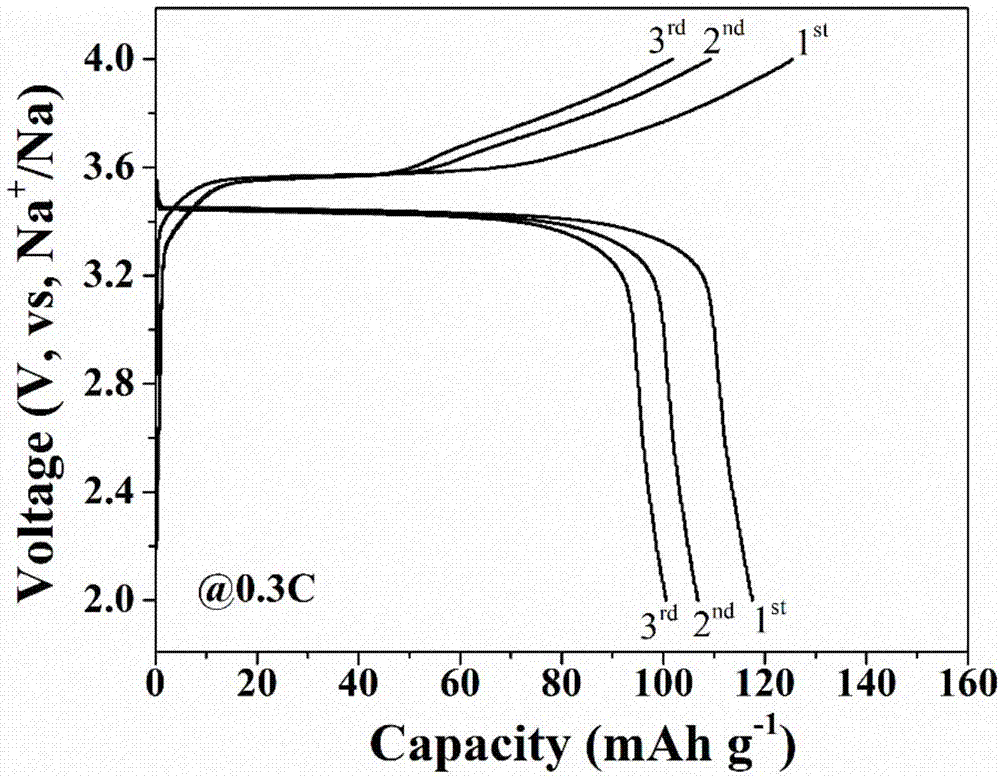

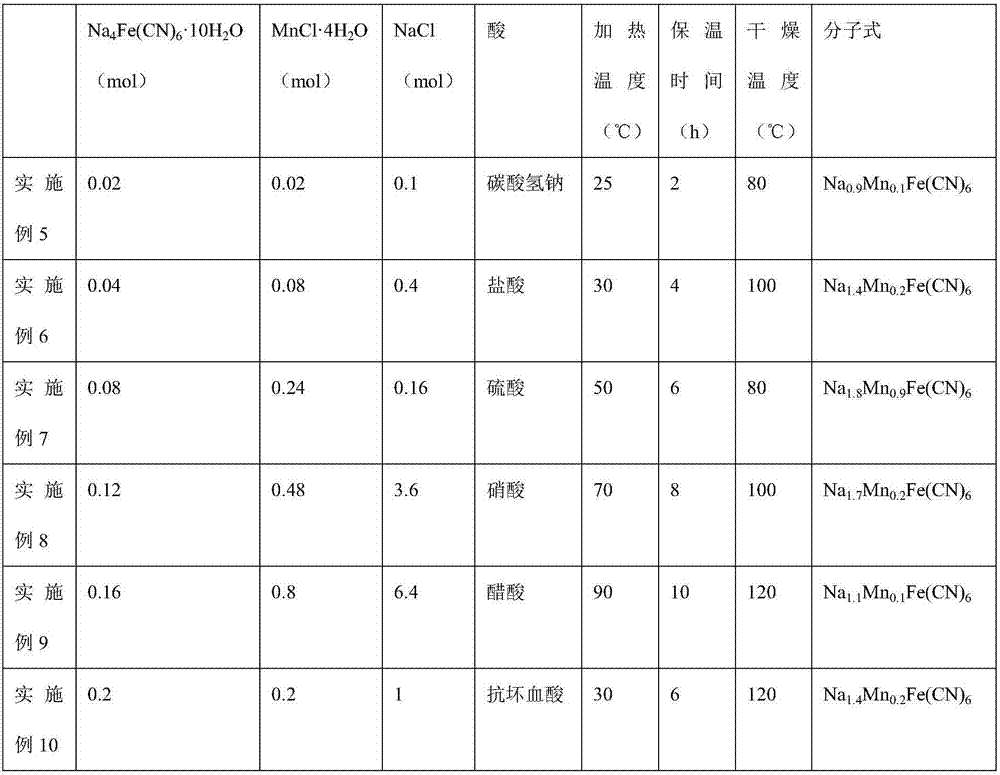

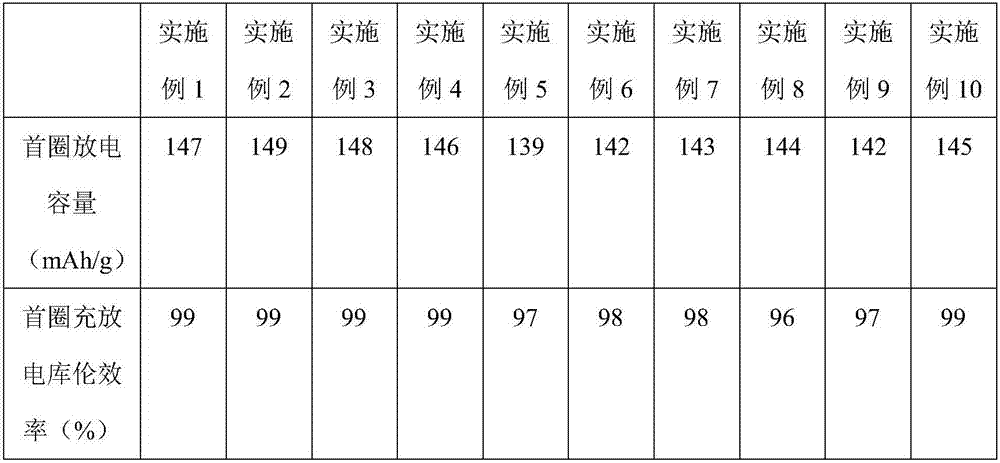

Method for preparing Prussian blue positive electrode material, and sodium ion battery

InactiveCN107364875AAvoid hydrolysisHigh specific capacityIron cyanidesCell electrodesHigh sodiumSodium-ion battery

The invention discloses a method for preparing a Prussian blue positive electrode material, and a sodium ion battery, wherein the molecular formula of the Prussian blue positive electrode material is Na2-xMyFe(CN)6, x is more than o 0 and is less than 2, y is more than 0 and is less than 1, and M is a transition metal. The preparation method comprises: adding a Na4Fe(CN)6 solution into a solution 2 containing the salt solution of M, a sodium salt and a pH value adjusting agent in a dropwise manner, maintain the pH value of the mixed solution at 6-7, and heating for a certain time in a protection atmosphere to obtain the Prussian blue positive electrode material. According to the present invention, the method has characteristics of simple process, easy control and continuous and scale production, and can be used for preparing the high sodium content Prussian blue positive electrode material; and the prepared Prussian blue positive electrode material as the sodium ion battery positive electrode material can improve the specific capacity of the battery, can reduce the polarization in the battery charging and discharging process, and has wide application prospects in the field of electric energy storage in the power grid.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Oil-in-oil nonaqueous microemulsion used as medicine carrier and its medicine prepn

ActiveCN101019833AEasy to manufactureExpand the range of speciesBiocideAnthropod material medical ingredientsControlled releaseWater insoluble

The present invention discloses oil-in-oil nonaqueous microemulsion used as medicine carrier and its medicine preparation. The oil-in-oil nonaqueous microemulsion consists of oil phase I, oil phase II, surfactant and co-surfactant, and can dissolve water insoluble medicines to prepare microemulsion. The nonaqueous microemulsion has the advantages of no hydrolysis and long effective period, slow or controlled release of medicine, nanometer level dispersion of water insoluble medicine and obviously raised bioavailability. For example, the present invention can obtain bioavailability of puerarin microemulsion and puerarin sol as high as 40.41 % and 52.68 % separately.

Owner:HEFEI LIFEON PHARMA

Method for simultaneously determining W, B and Nb in high-alloy deposited metal

ActiveCN102954958AIntensity automatically determinedAvoid hydrolysisPreparing sample for investigationAnalysis by thermal excitationAlloySolvent

The invention discloses a method for simultaneously determining W, B and Nb in a high-alloy deposited metal. The method comprises the following steps: placing a high-alloy deposited metal sample in a mixed acid solvent comprising hydrochloric acid, nitric acid and hydrofluoric acid, digesting through utilizing a microwave digestion instrument to prepare a W, B and Nb simultaneously-dissolved solution to be tested, selecting the optical analytic spectral lines of all elements according to the matrix of the sample and the composition of coexistence elements, determining a spectral interference correcting method, preparing a group of standard solutions having concentrations from the low to the high through a coupling method of a matrix close to the sample matrix, introducing the standard solutions to ICP-AES (inductively coupled plasma-atomic emission spectrometer) under optimized apparatus working parameters, drawing a working curve according to the concentrations and the intensities of elements to be tested, introducing the sample solution to the ICP-AES, testing to obtain the intensities to be tested, and determining the contents of W, B and Nb in the sample solution according to the working curve. The method has the advantages of less reagent application amounts, reduction of the pollution of chemical reagents to the environment, and effective satisfying of the practical needs of the scientific research and the production.

Owner:ANGANG STEEL CO LTD

Slow release, long-acting urea manure and technique of manufacturing the same

InactiveCN101108781AFully functionExtend the fertilizer periodAgriculture gas emission reductionUrea compound fertilisersOrganic solventFluidized bed

The invention relates to the nitrogen manure, in particular to the slow-release and long-effect urea fertilizer coating a layer of biochemical inhibitor on the urea surface and the preparation process. The fertilizer components are the urea, the biochemical inhibitor, the bond and the organic solvent. The process is that: the levitated solution mixed with the biochemical inhibitor, the bond and the organic solvent is sprayed and coated on the surface of the molding urea granule under the fluidized state through a fluidized bed to gain the slow-release urea fertilizer. The fertilizer of the invention makes full play of the functions and effects of two biochemical inhibitors, makes the fertilizer effect period prolonged obviously and realizes that once basal nitrogen fertilizer application can meet the requirement of whole growing seasons on the nitrogen. The agricultural production saves labor and time with low production cost and friendly environment. For the secondary processing of the urea, the preparation process of the invention has simple operation and easy realization and can carry out industrial production on a large scale.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Preparation method of maca extractive

ActiveCN103040896AConvenient inactivation treatmentDestructive activitySexual disorderFood preparationOral medicationRoom temperature

The invention provides a preparation method of a maca extractive. The method comprises the steps that maca powder is placed into a microwave dryer, heated to 50-60 DEG C for 15-25min, and cooled to a room temperature; enzyme deactivation treatment is conducted; enzyme activity is destroyed; glucosinolate hydrolysis is prevented; backflow extraction is conducted; water is added to an extractive; the extractive is stirred, stands and is precipitated; supernatant liquid is separated and concentrated; beta-cyclodextrin is added; stirring is conducted for 50-70min; the extractive is embedded; volatilization of glucosinolate is prevented; vacuum drying is conducted; and the maca extractive is obtained. The method can effectively prevent hydrolysis of an available component, namely glucosinolate, in maca, and in particular can effectively prevent volatilization of glucosinolate as the extractive is embedded at normal temperature and pressure; the component is reserved to the greatest extent for improving an effect; a stimulation feel during oral administration is reduced; and the dosage is reduced.

Owner:云南润苍生科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com