Patents

Literature

5645results about "Bio-packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food Compositions of Microalgal Biomass

InactiveUS20100239712A1Cheaply and efficiently scaleReduce the amount requiredMilk preparationDough treatmentDry weightAdditive ingredient

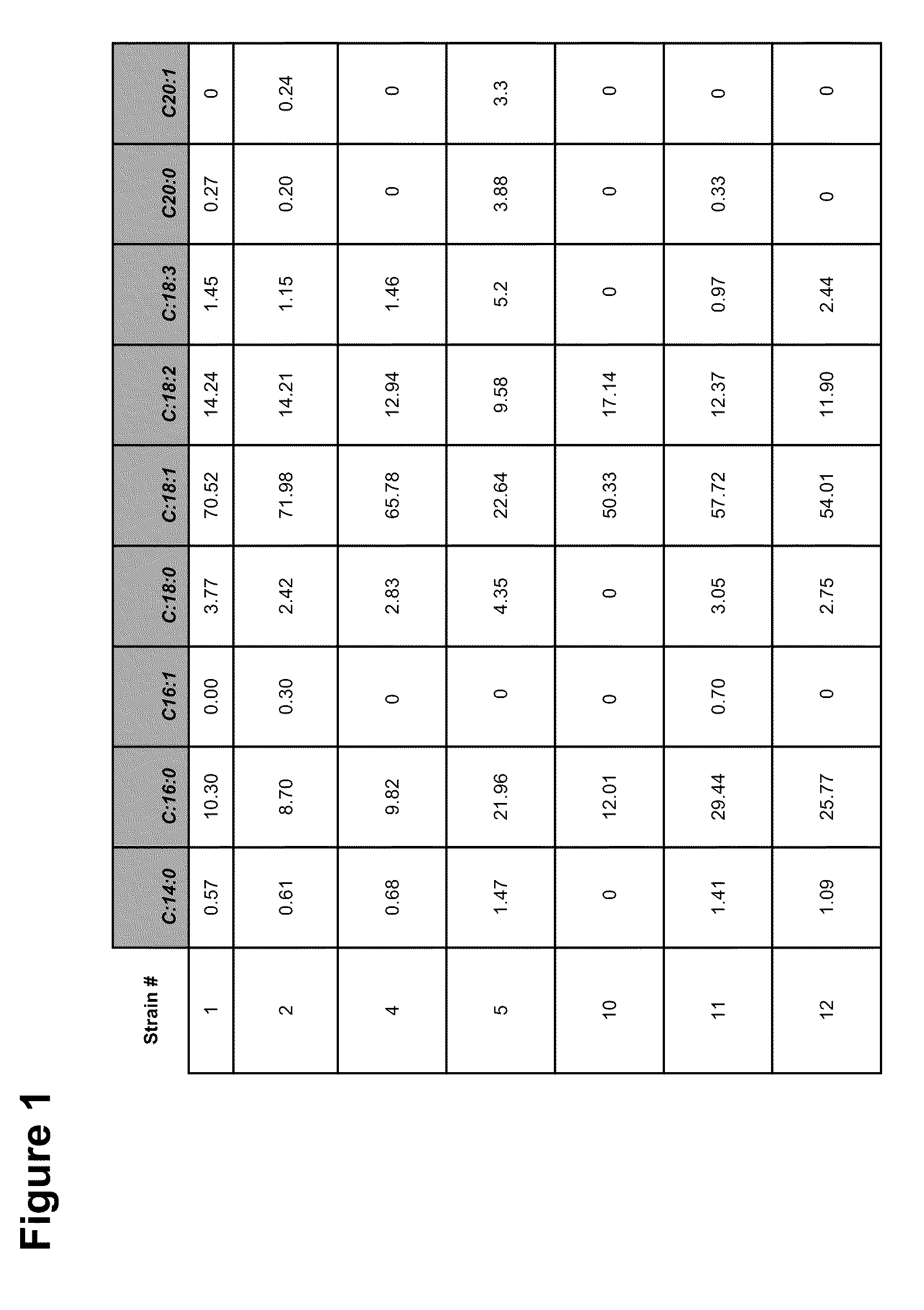

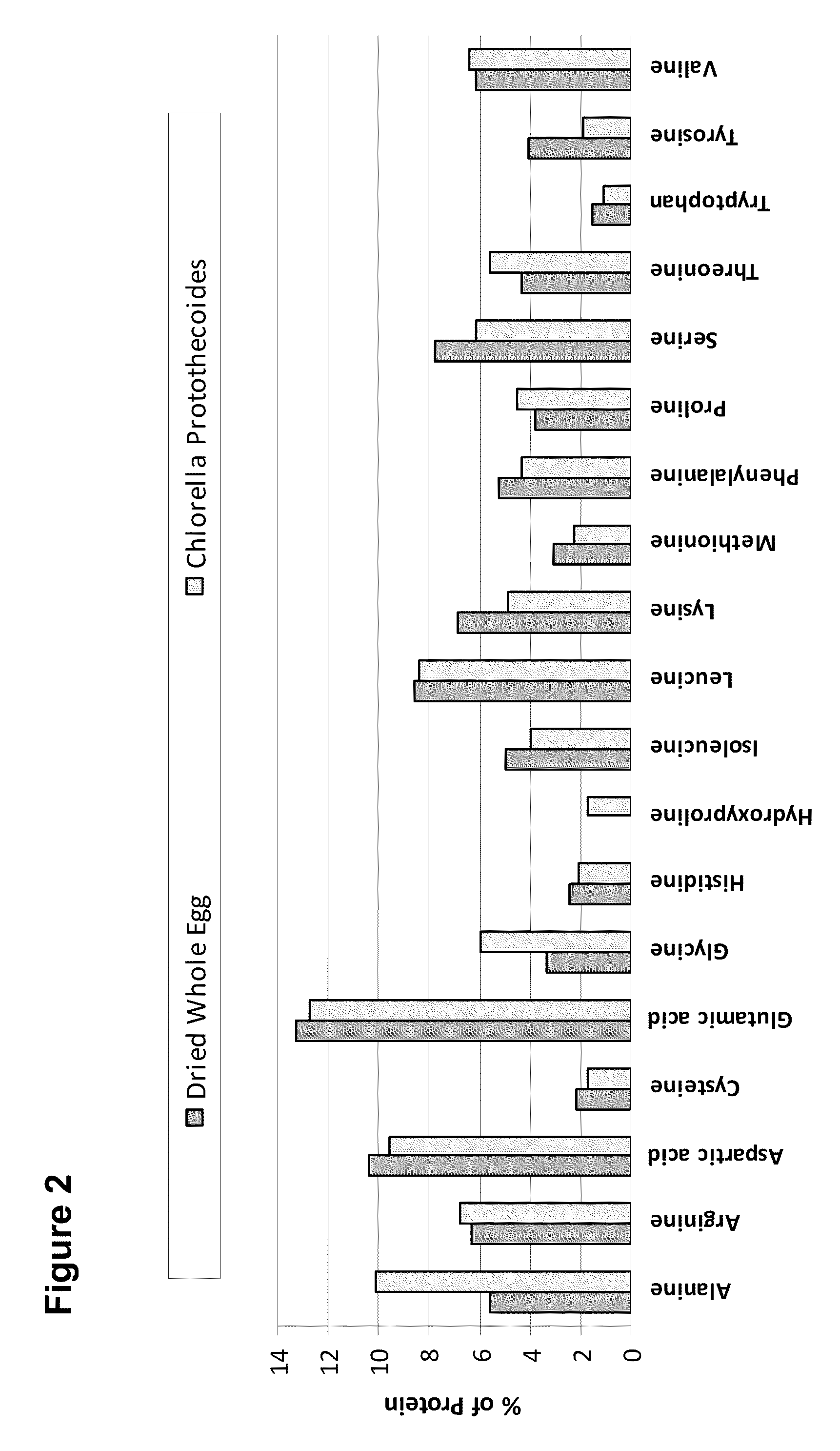

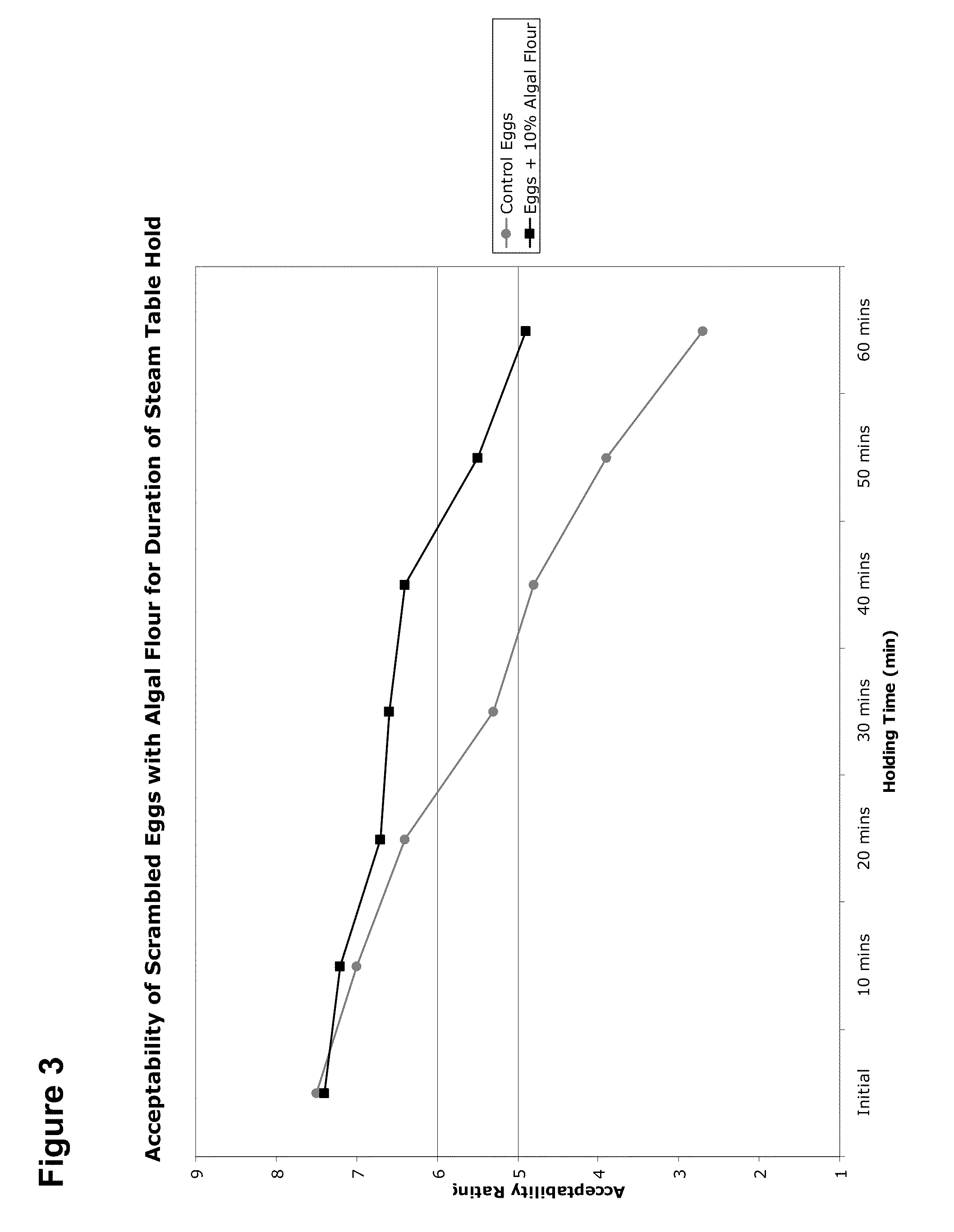

The invention provides algal biomass, algal oil, food compositions comprising microalgal biomass, whole microalgal cells, and / or microalgal oil in combination with one or more other edible ingredients, and methods of making such compositions by combining algal biomass or algal oil with other edible ingredients. In preferred embodiments, the microalgal components are derived from microalgal cultures grown and propagated heterotrophically in which the algal cells comprise at least 10% algal oil by dry weight.

Owner:TERRAVIA HLDG INC

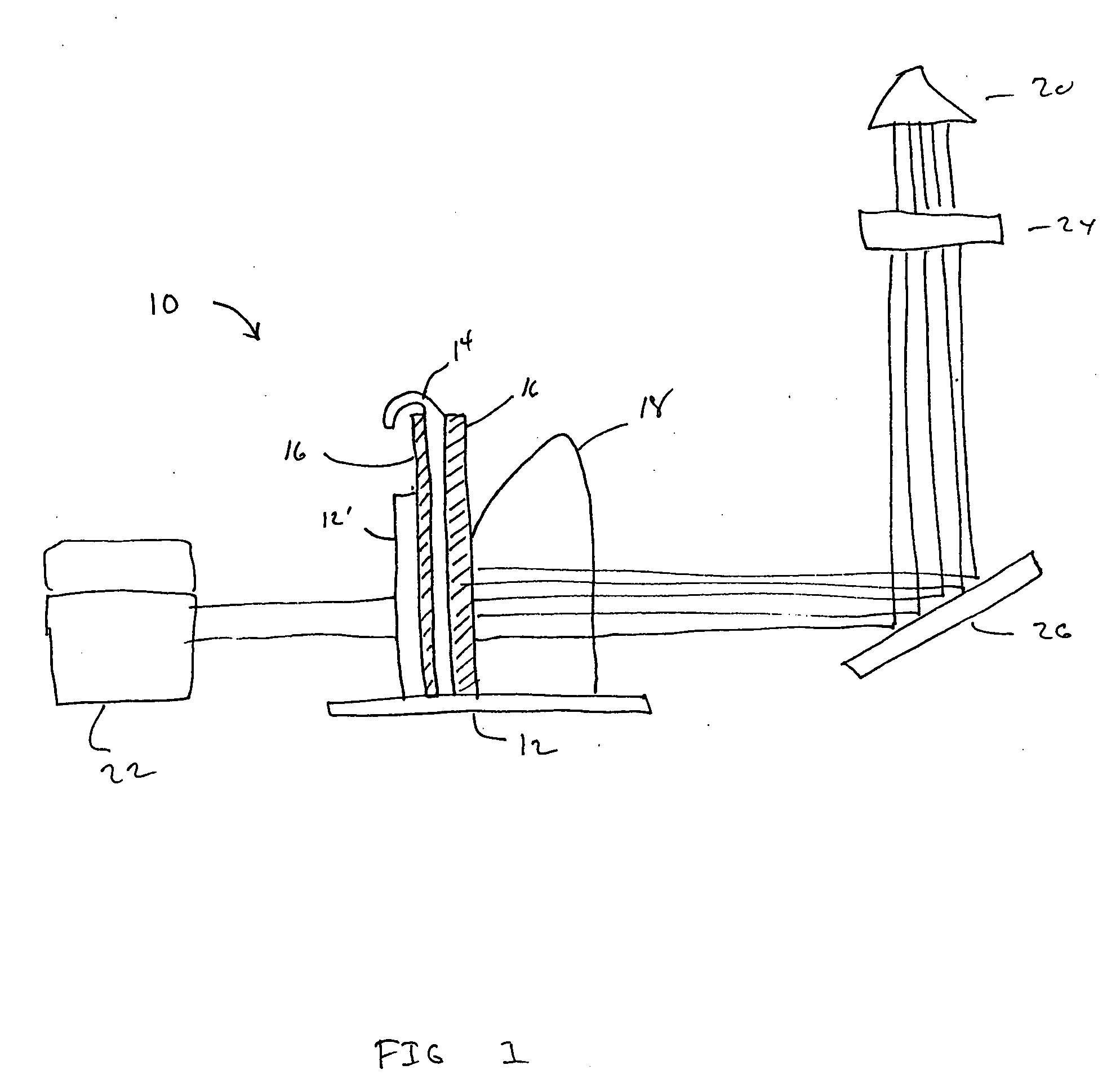

Compositions and methods for manufacturing starch-based compositions

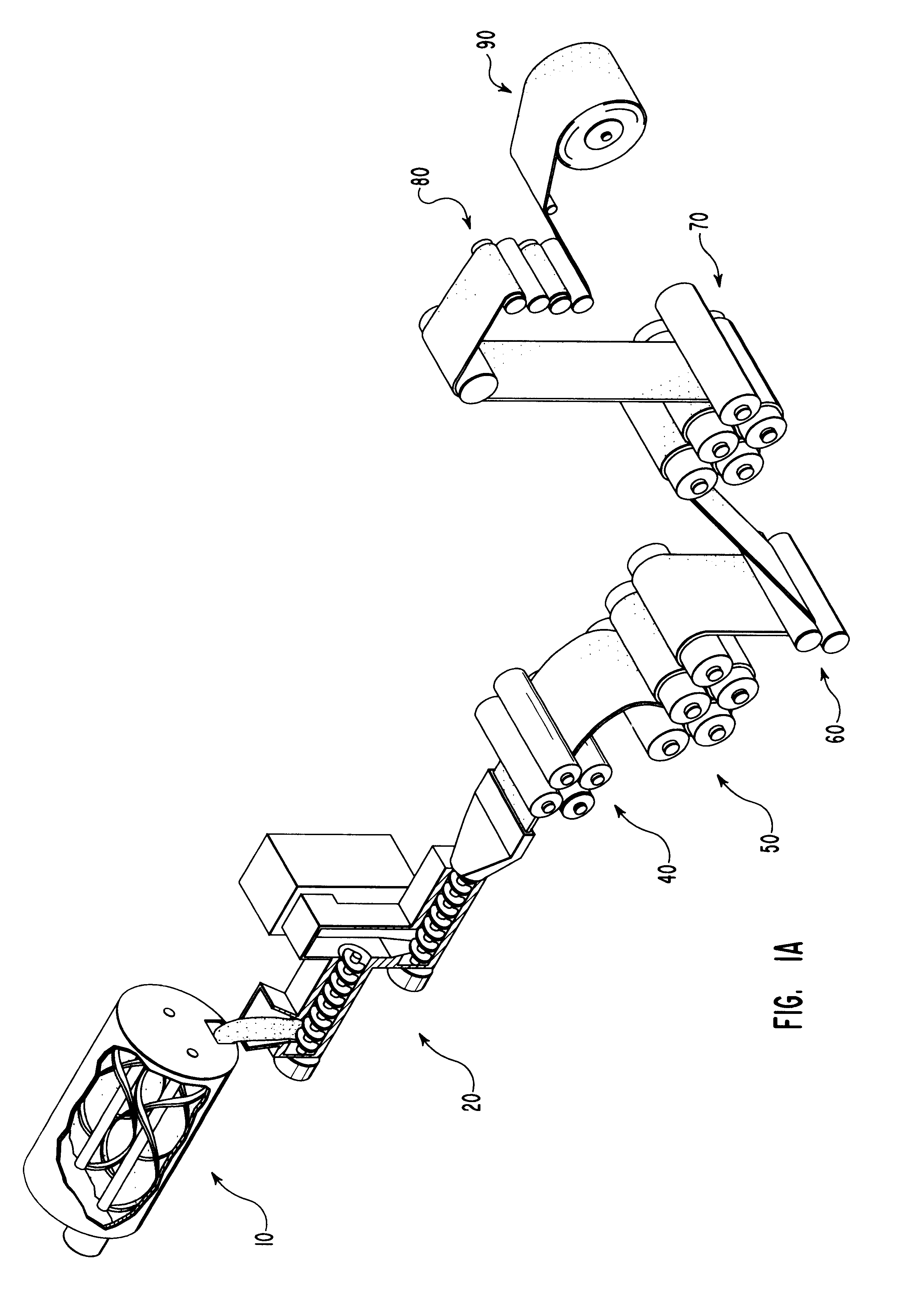

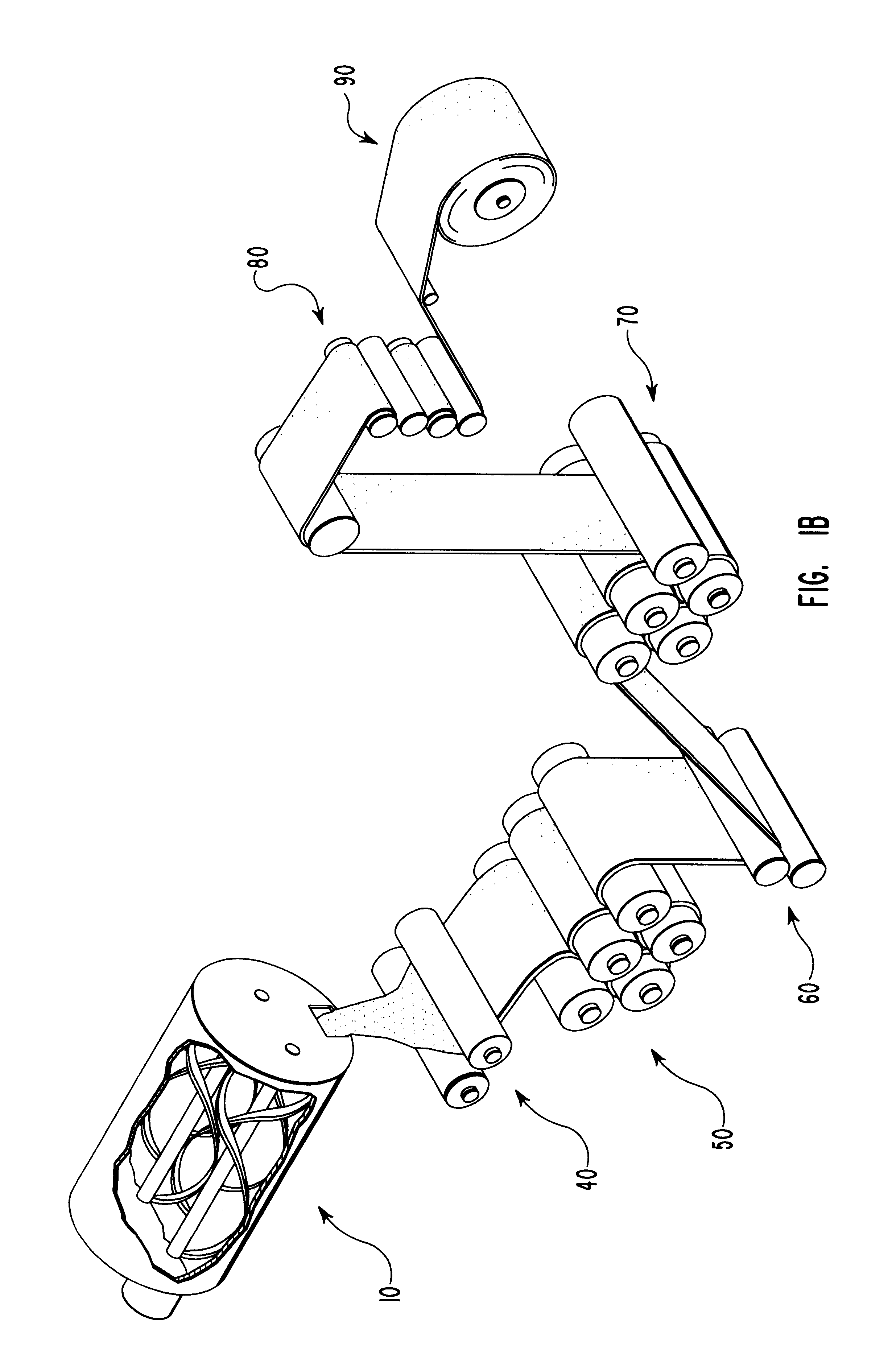

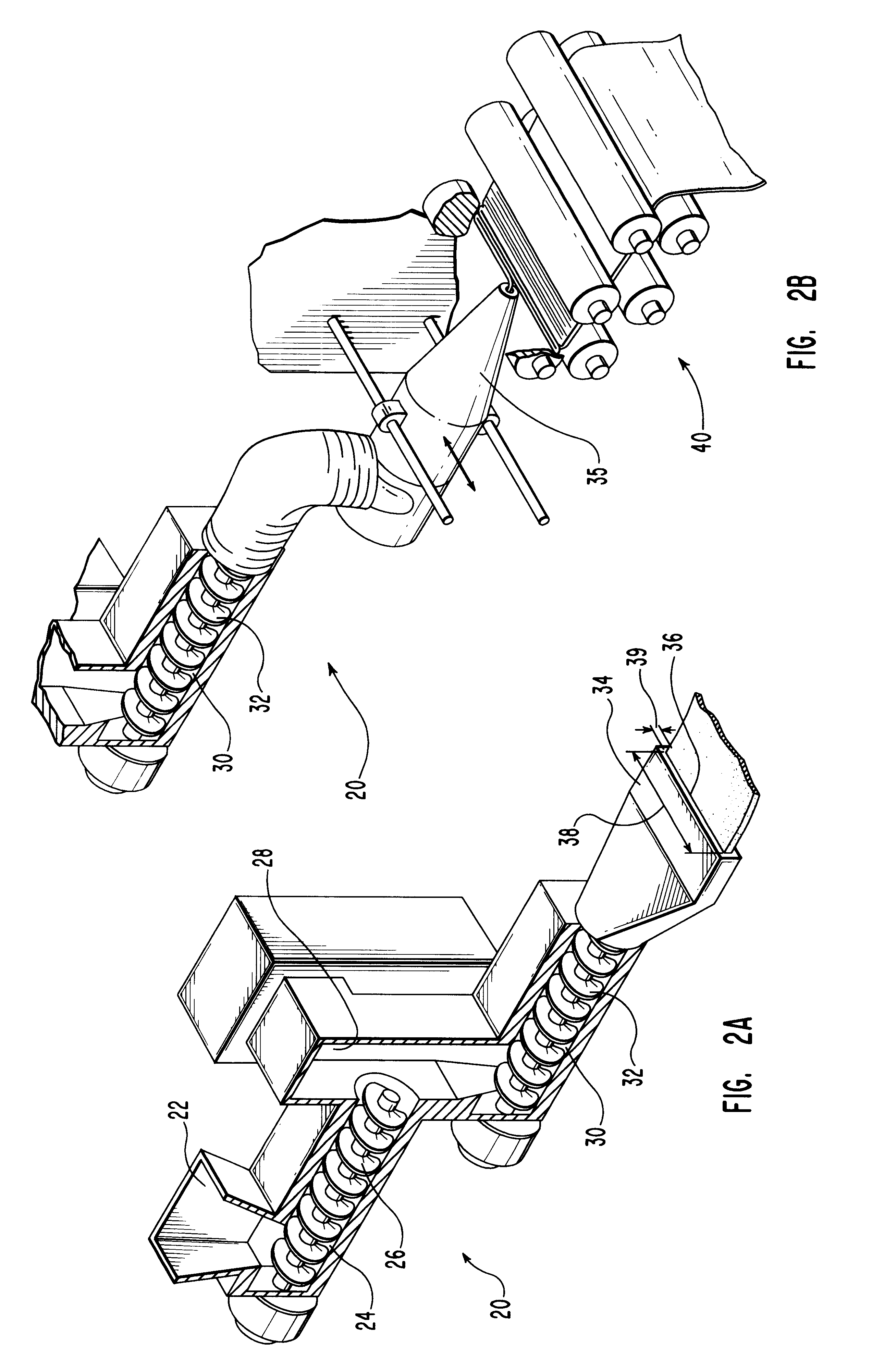

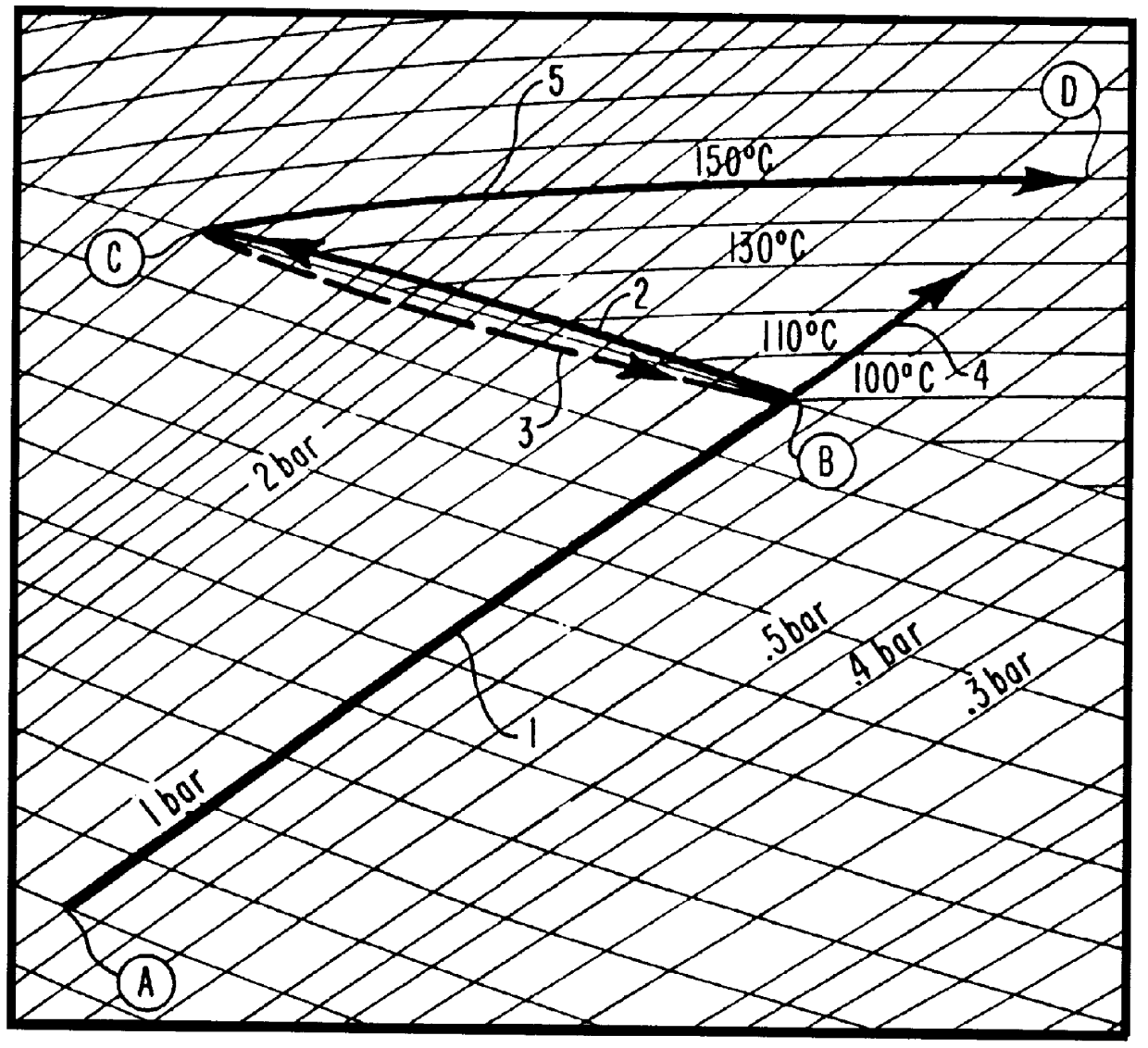

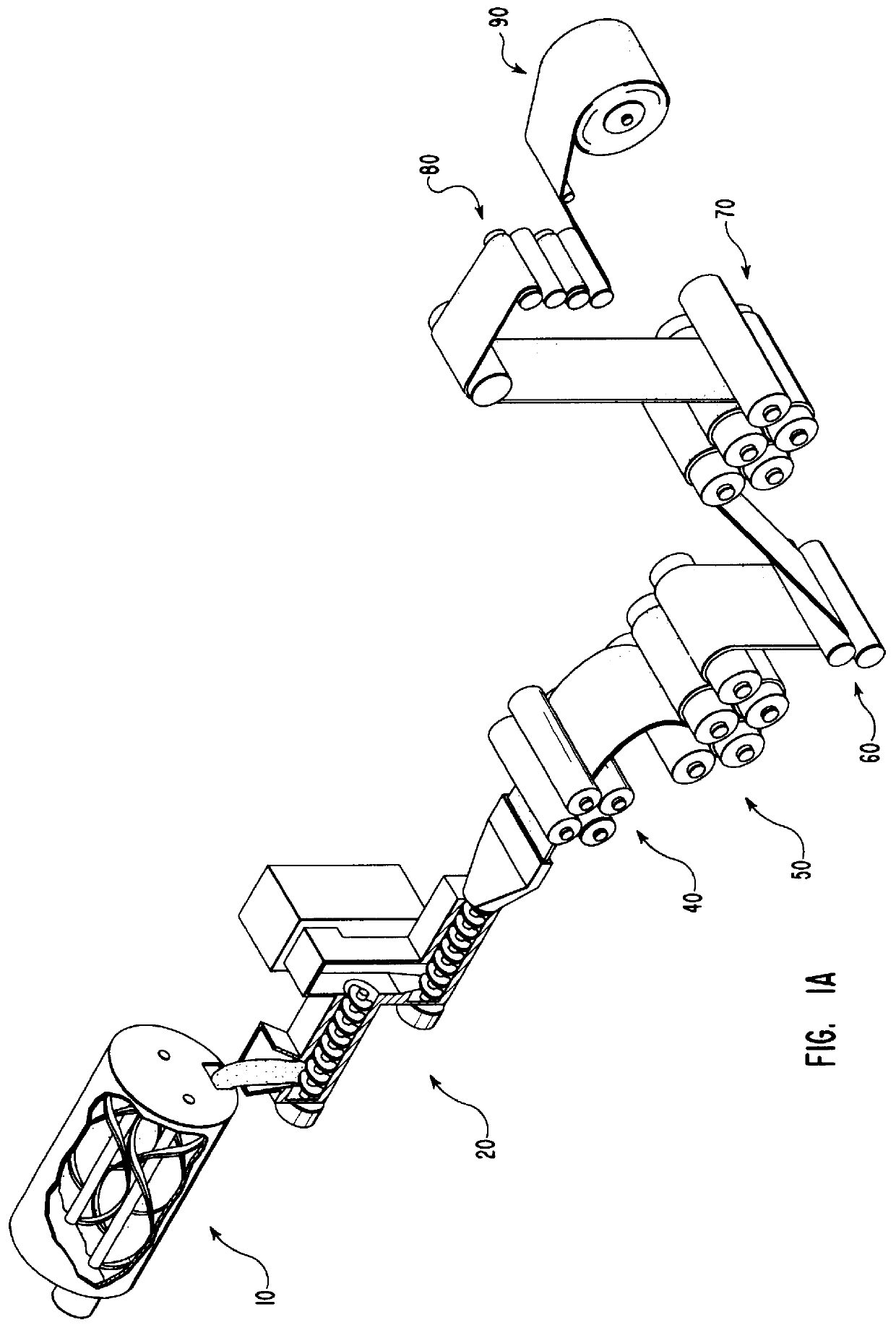

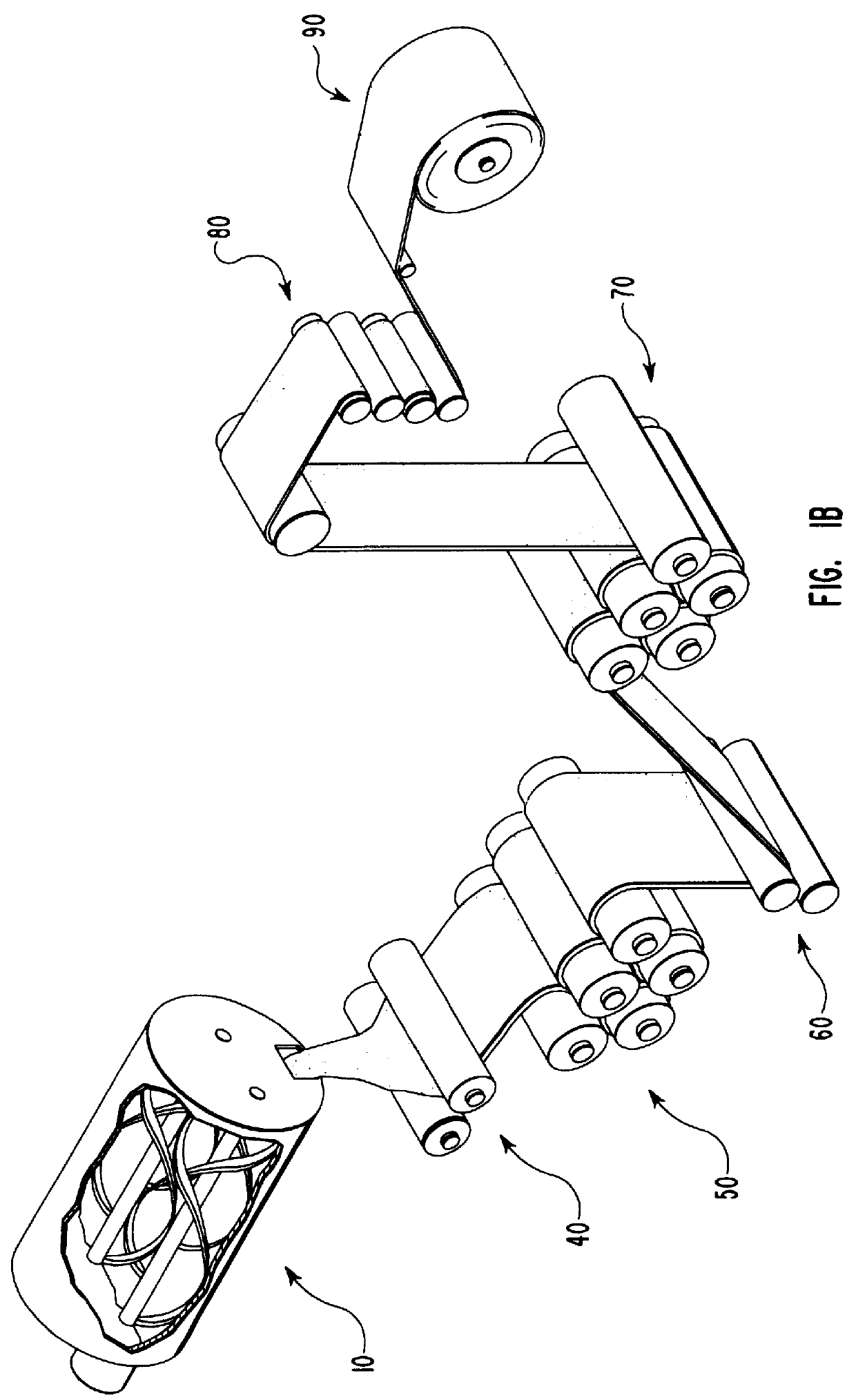

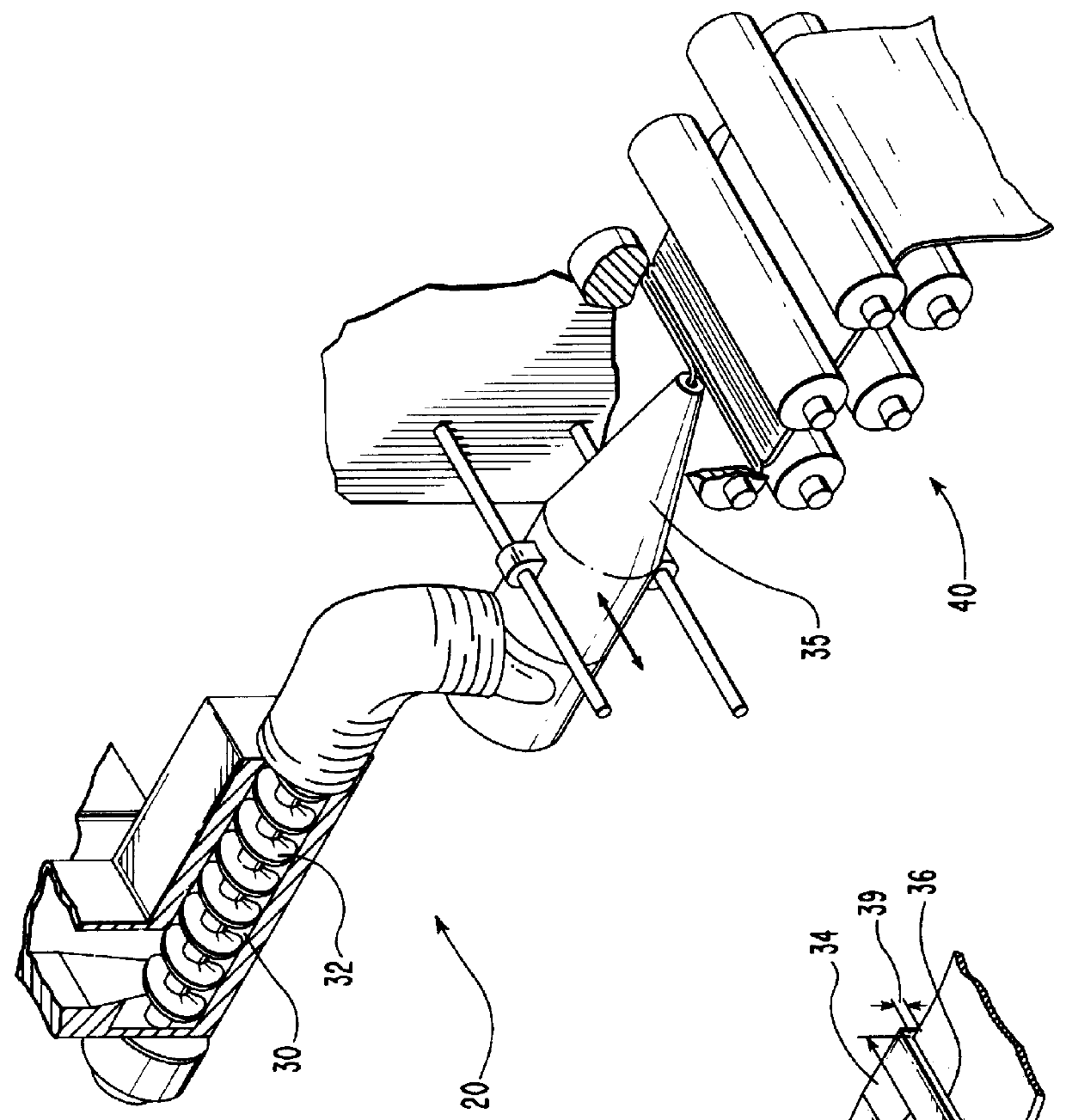

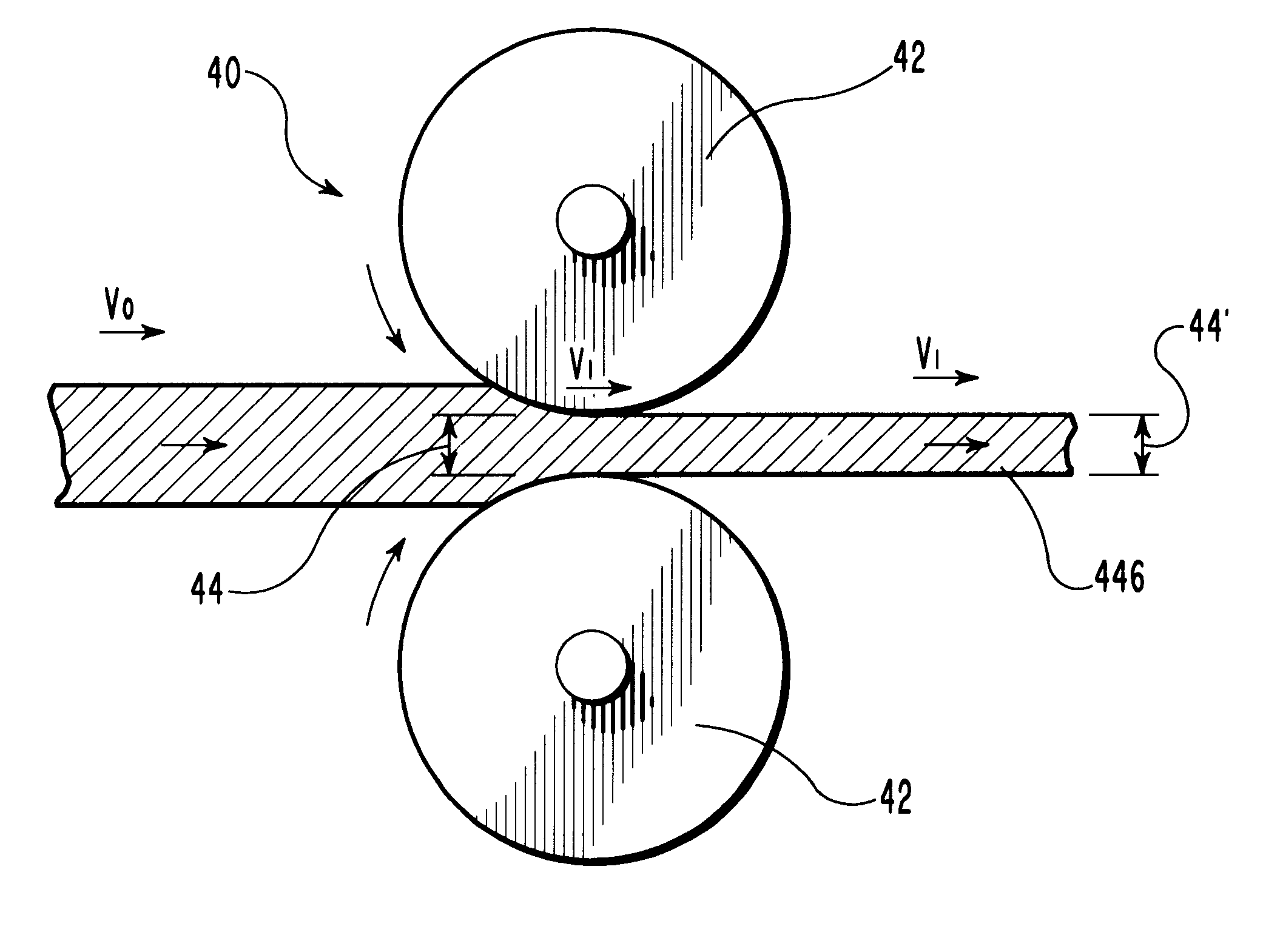

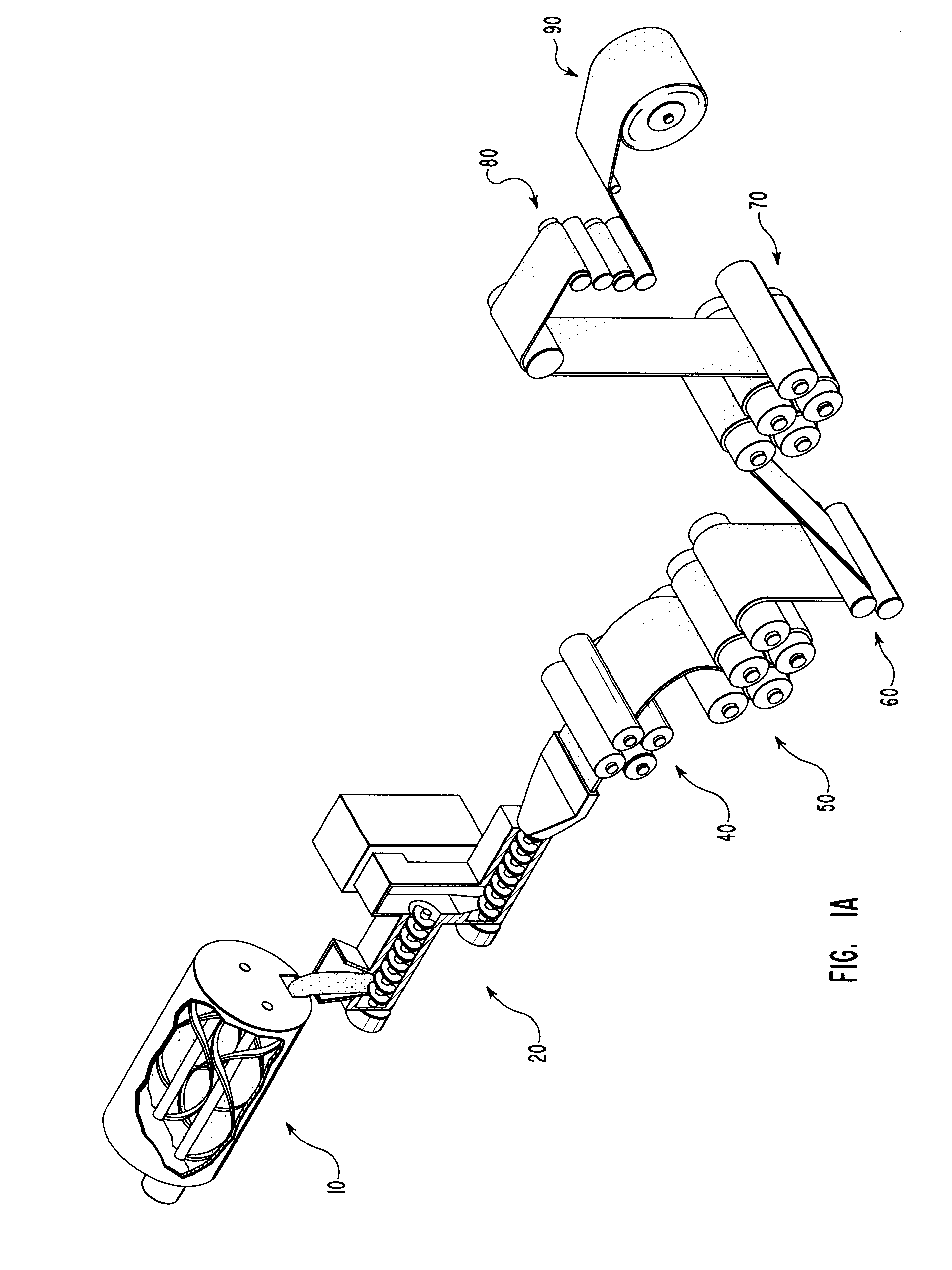

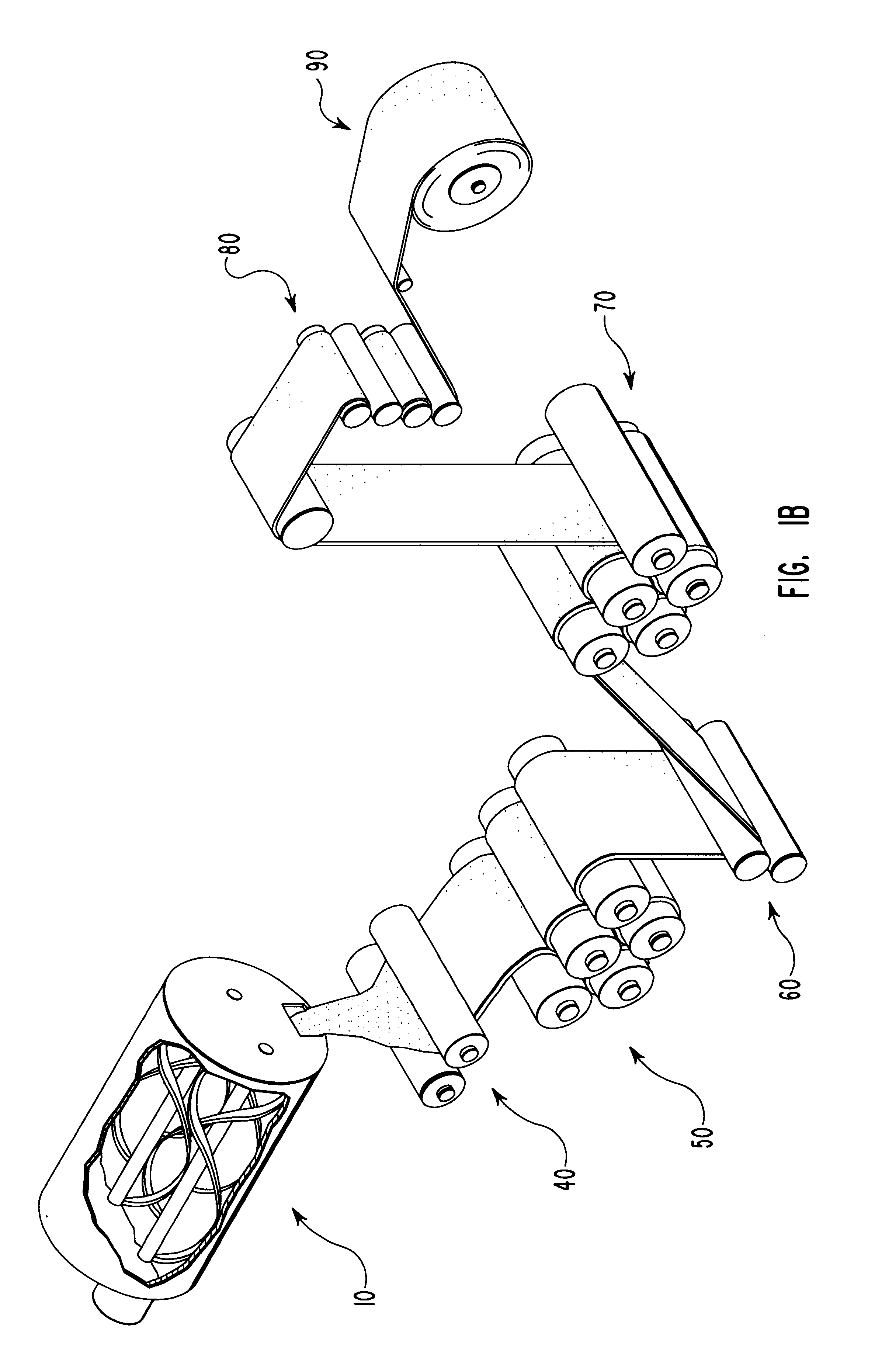

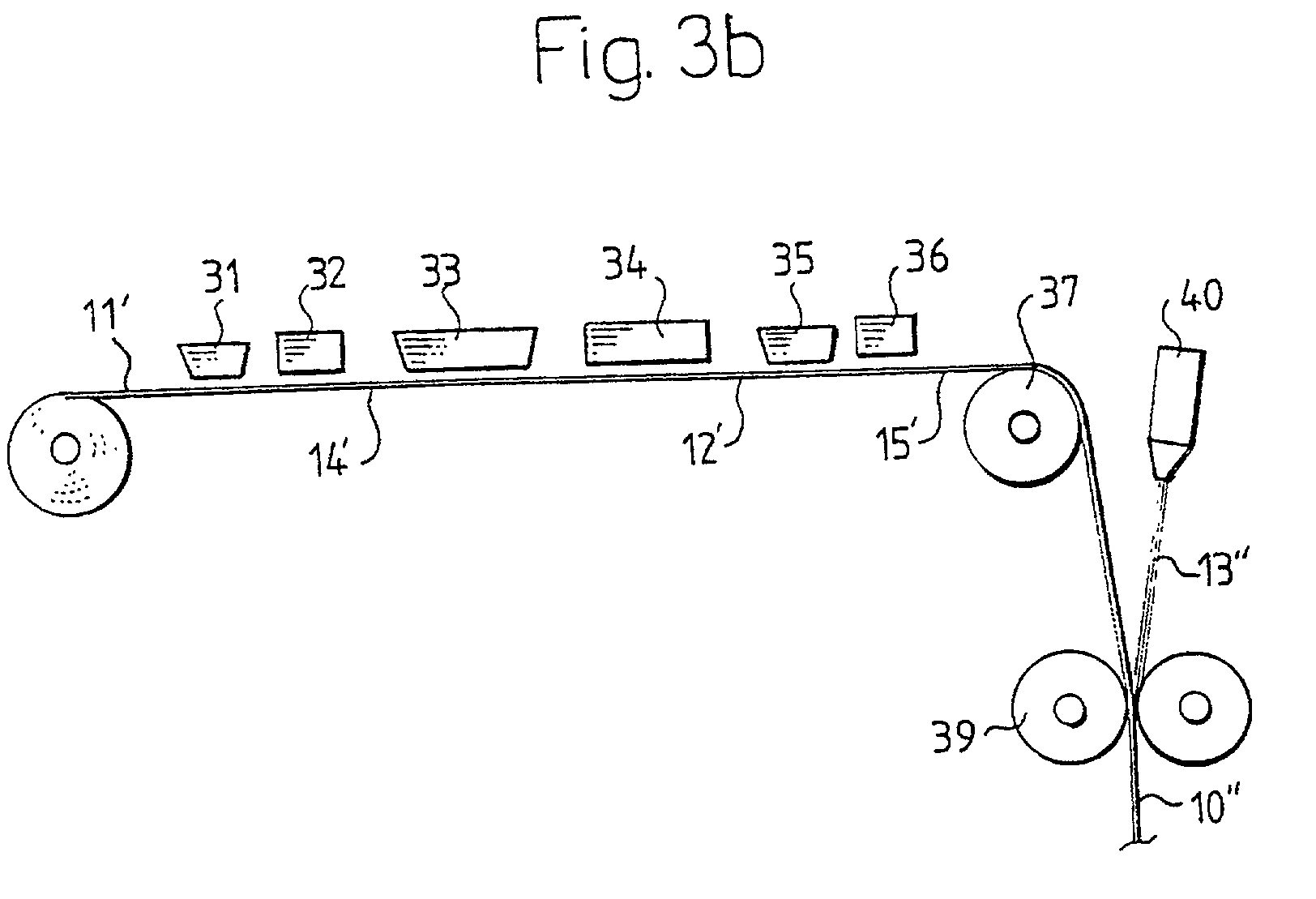

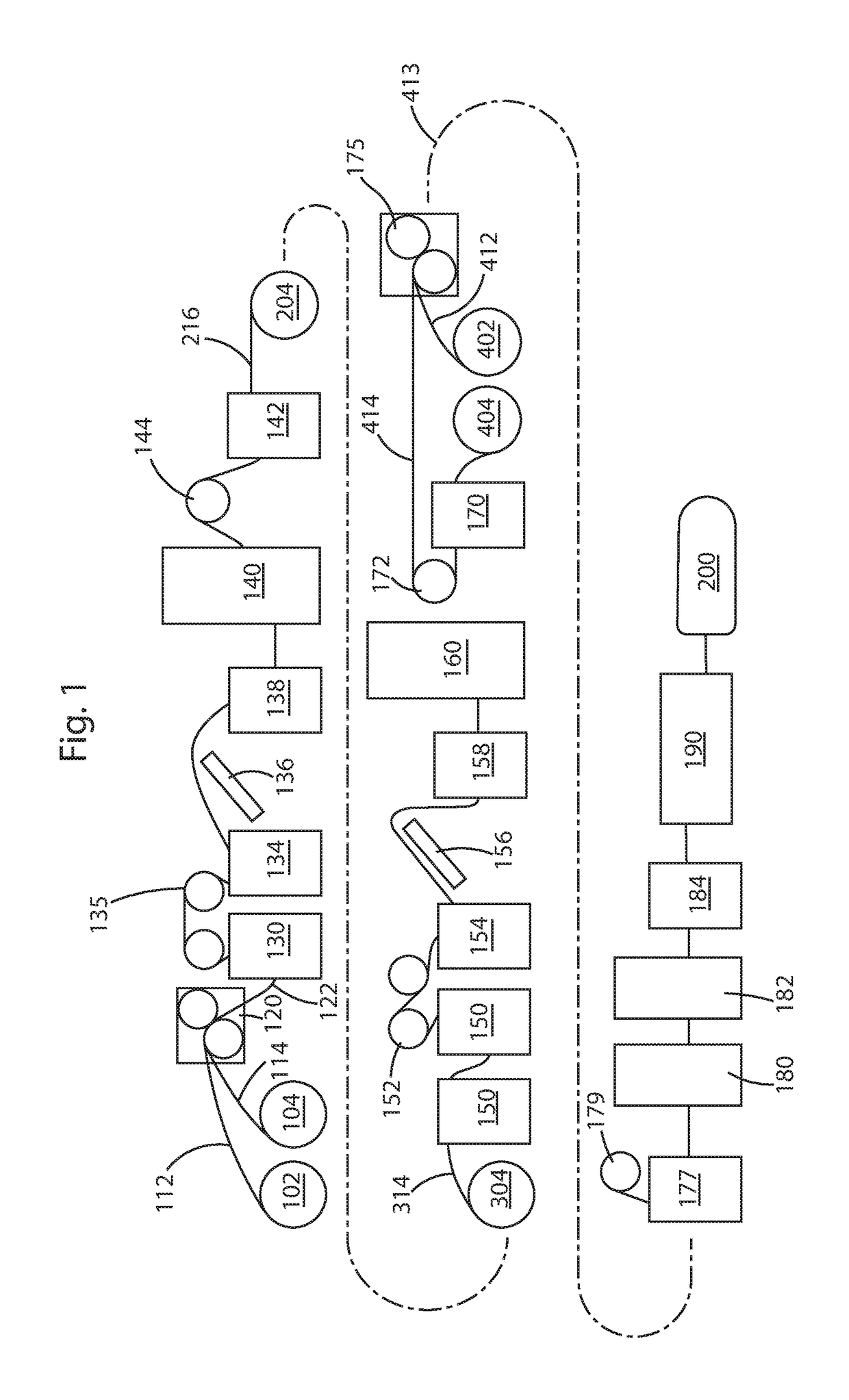

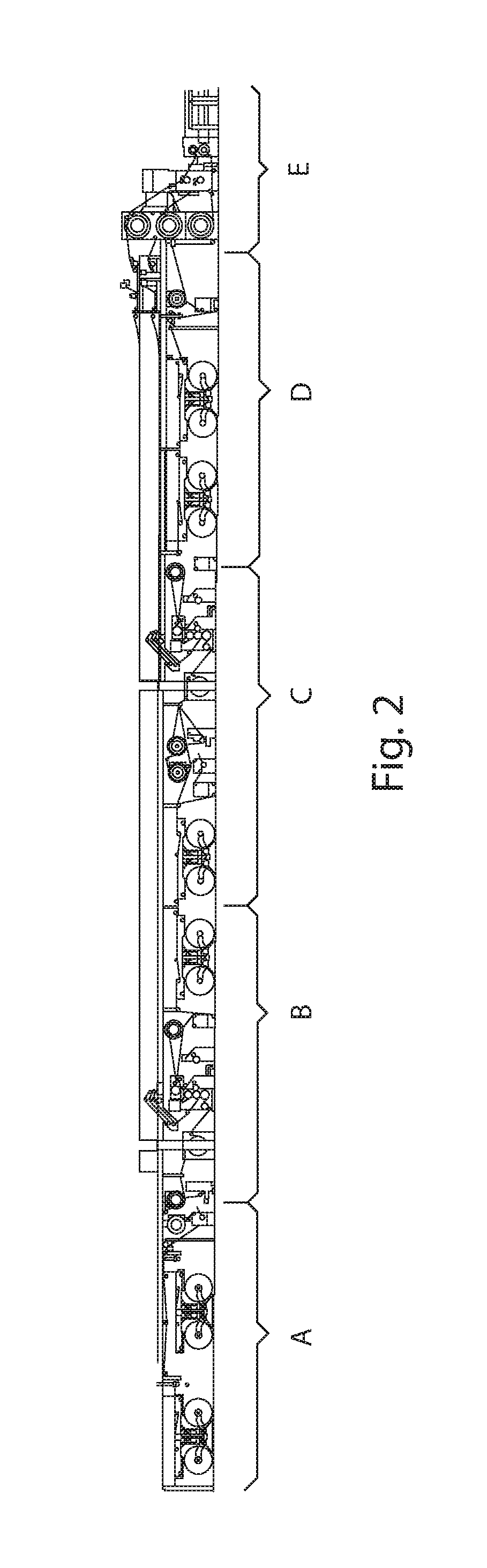

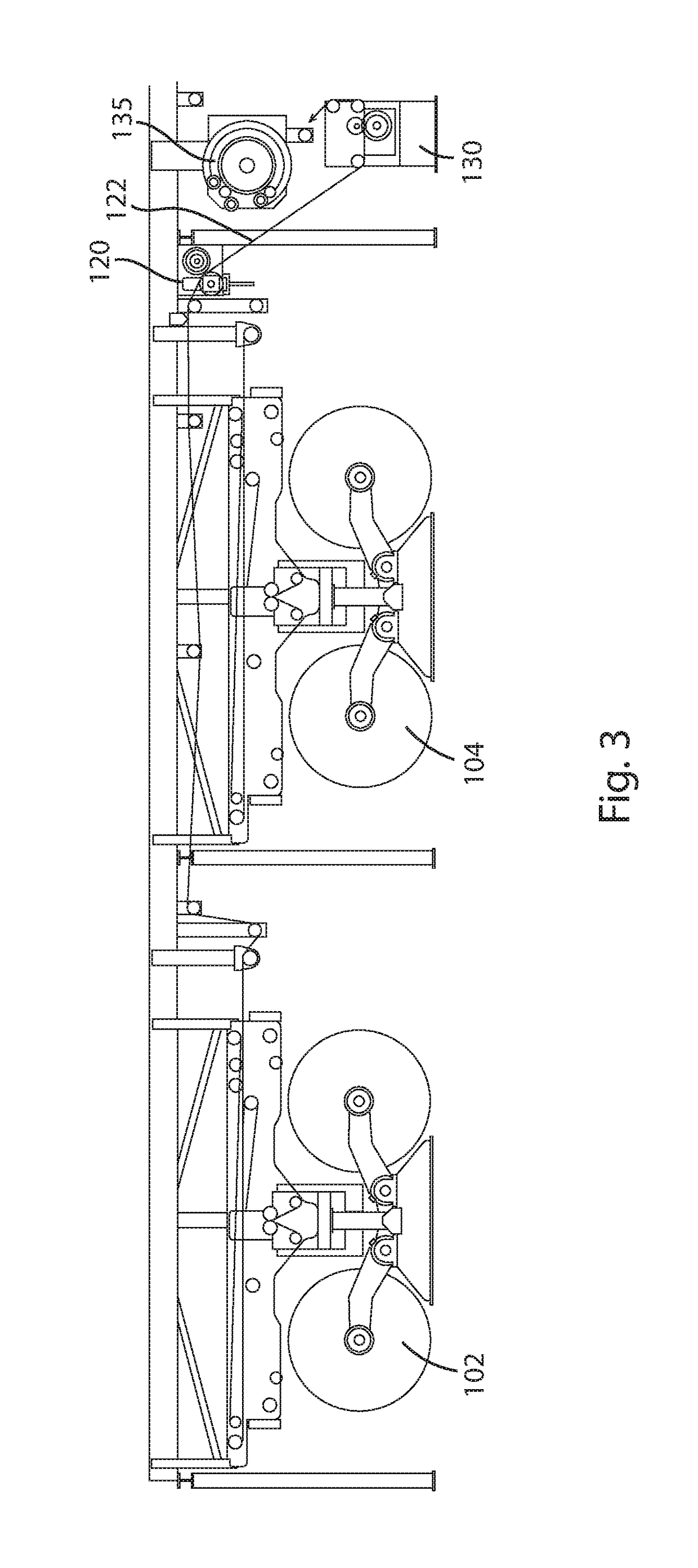

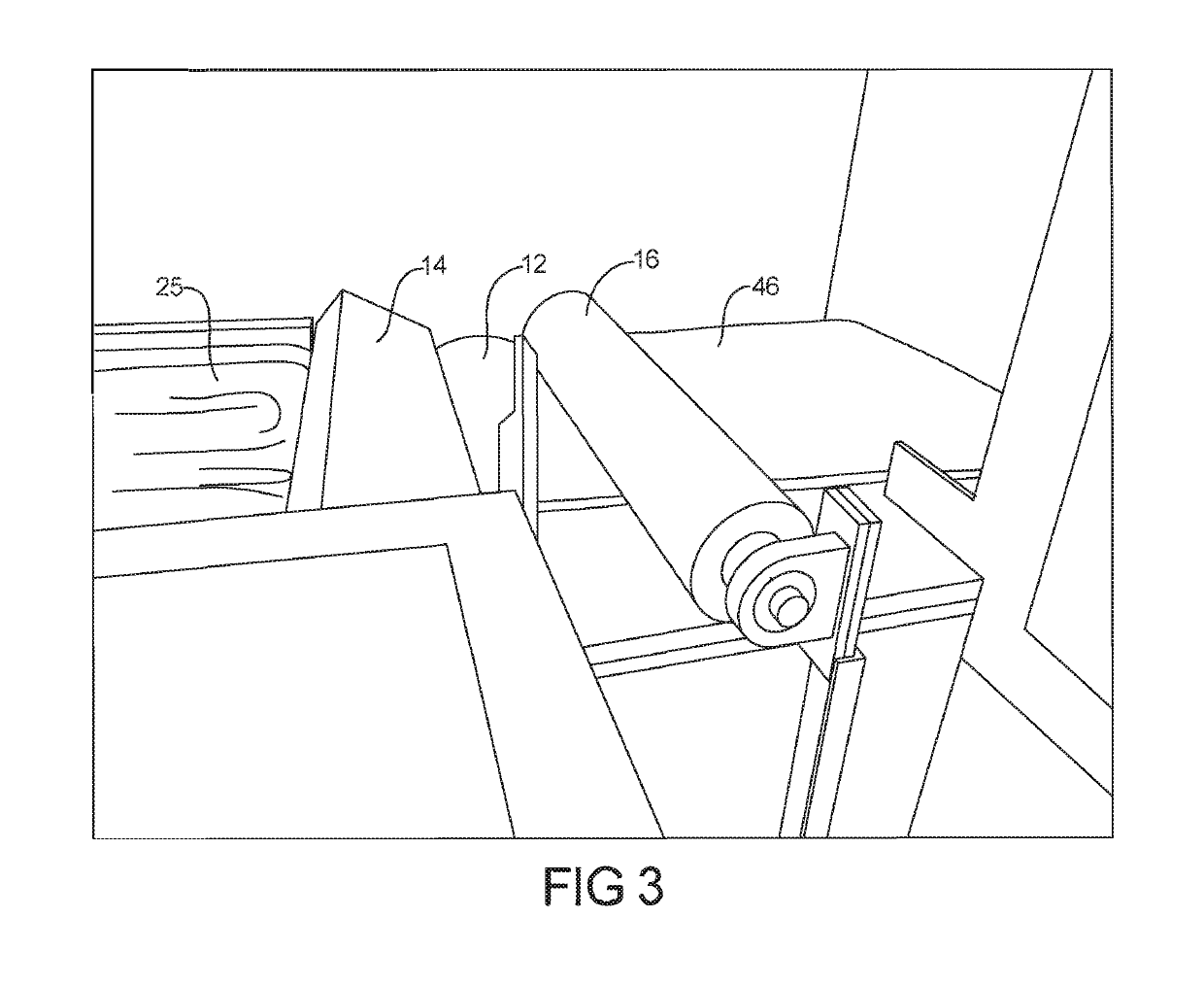

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

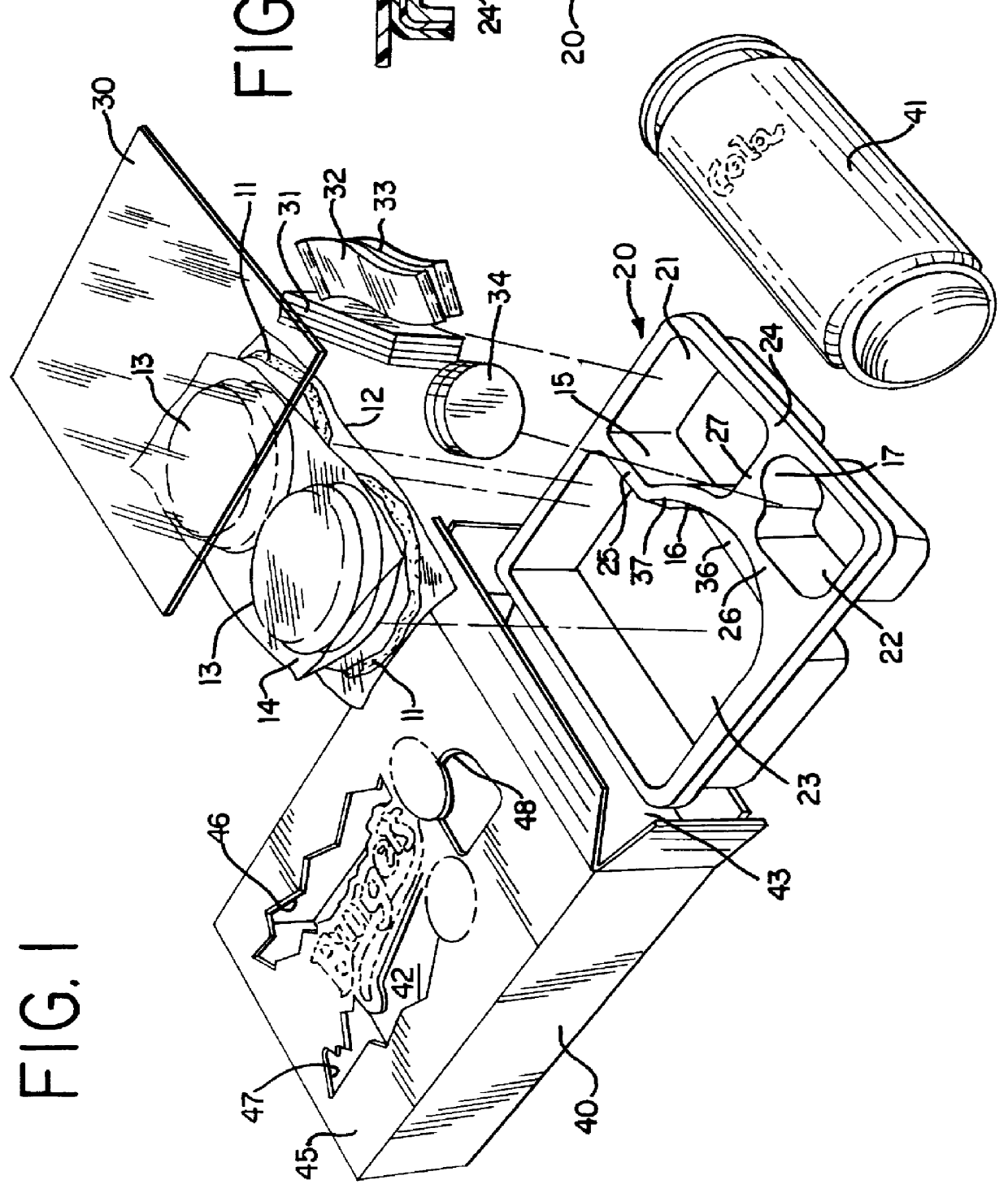

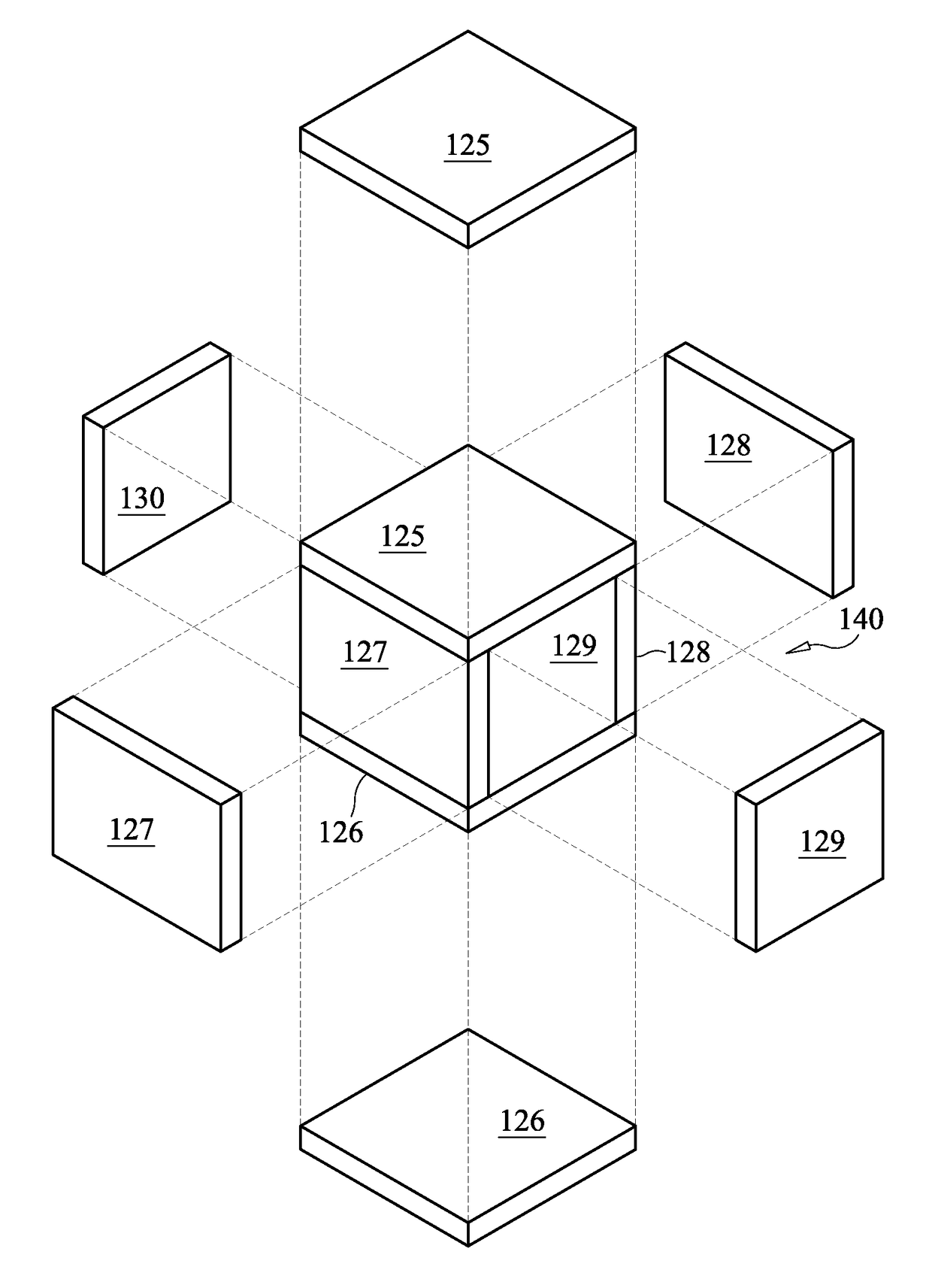

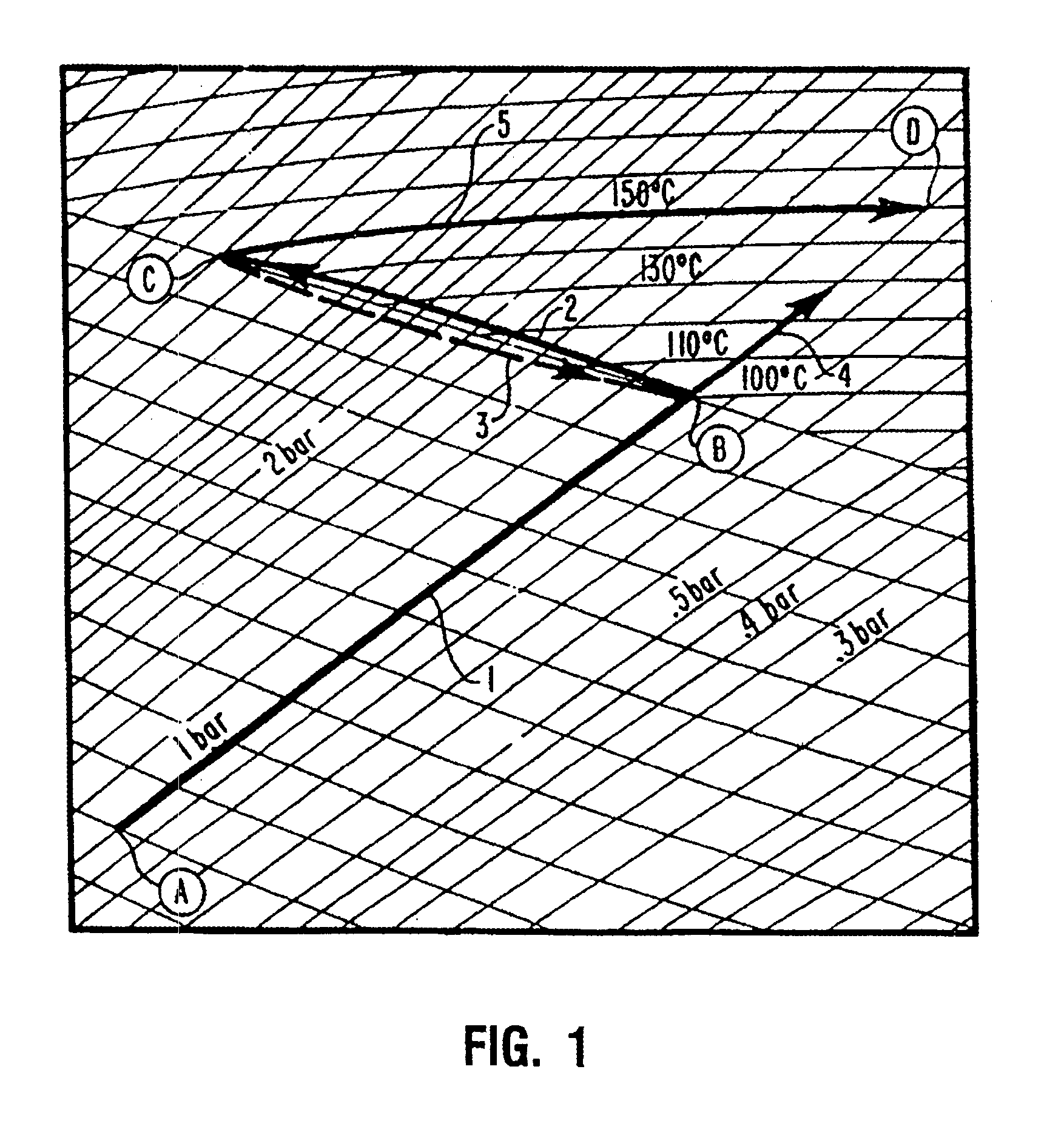

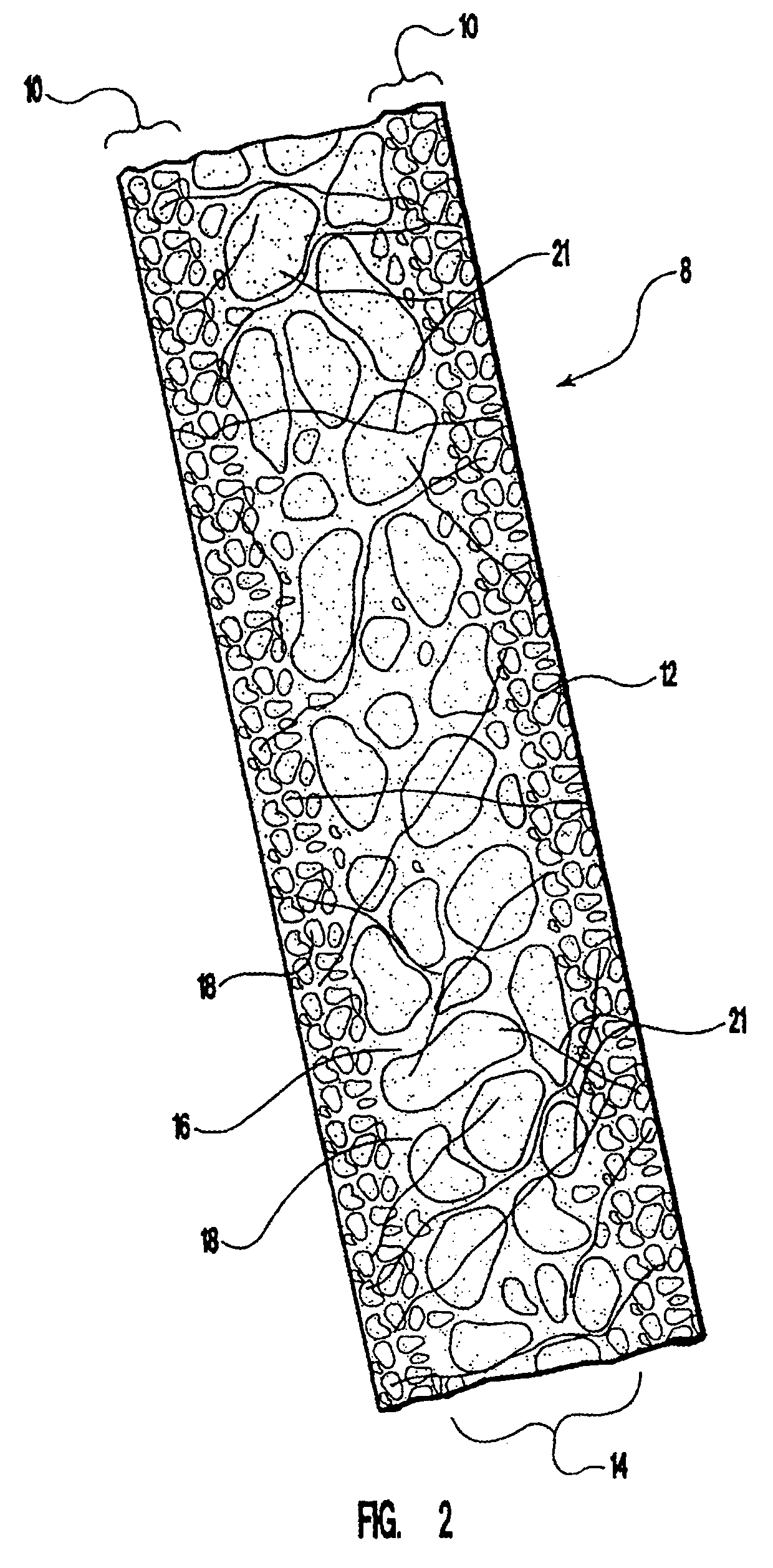

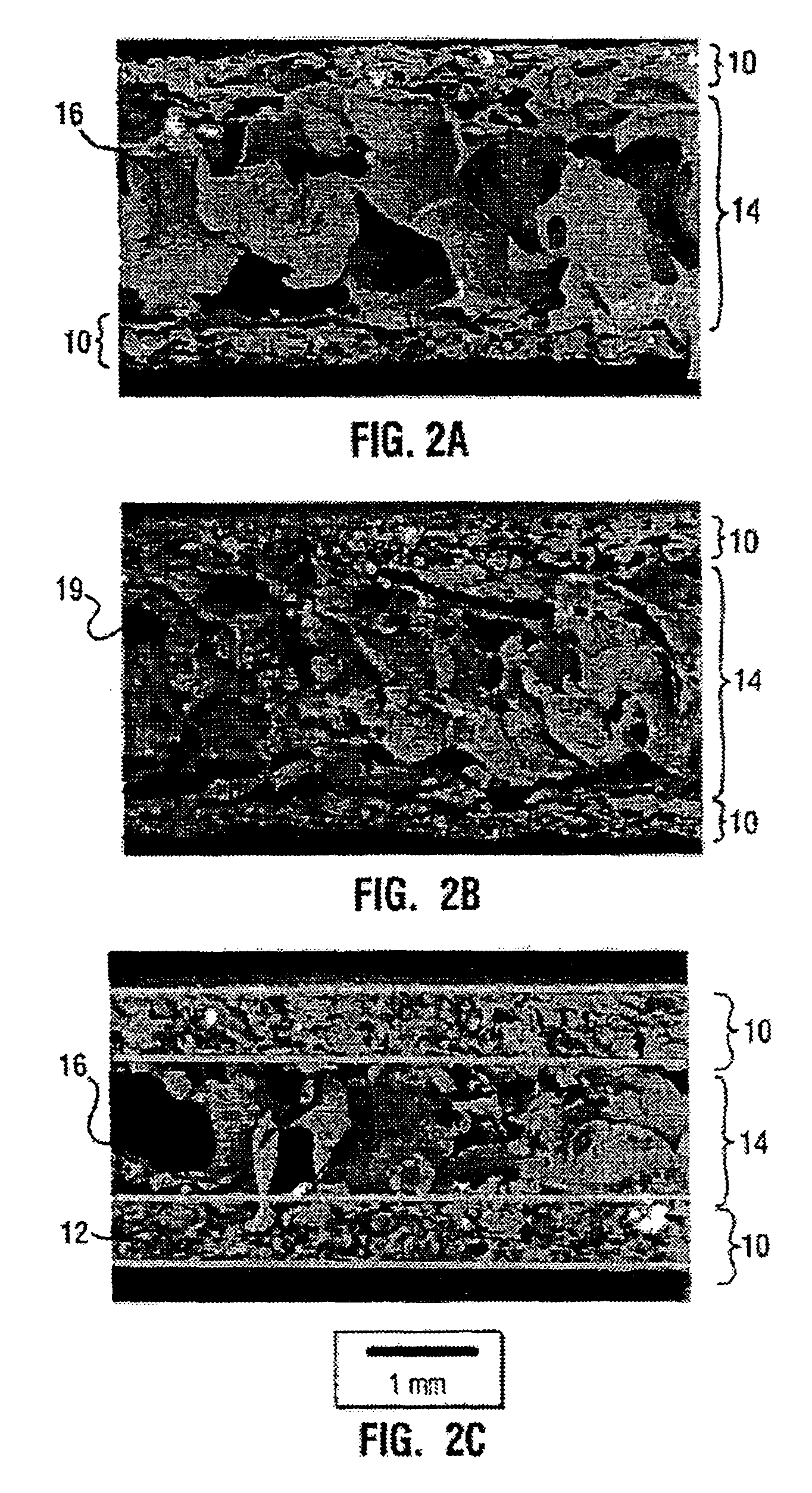

Molded starch-bound containers and other articles having natural and/or synthetic polymer coatings

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a particle packed, highly inorganically filled, cellular matrix are disclosed. Suitable inorganically filled mixtures are prepared by mixing together a starch-based binder, a solvent, inorganic aggregates, and optimal admixtures, e.g., fibers, mold-releasing agents, rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The inorganically filled mixtures have a predetermined viscosity and are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled cellular, structure matrix. The molded articles may be placed in a high humidity chamber to obtain the necessary flexibility for their intended use. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic materials. They have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

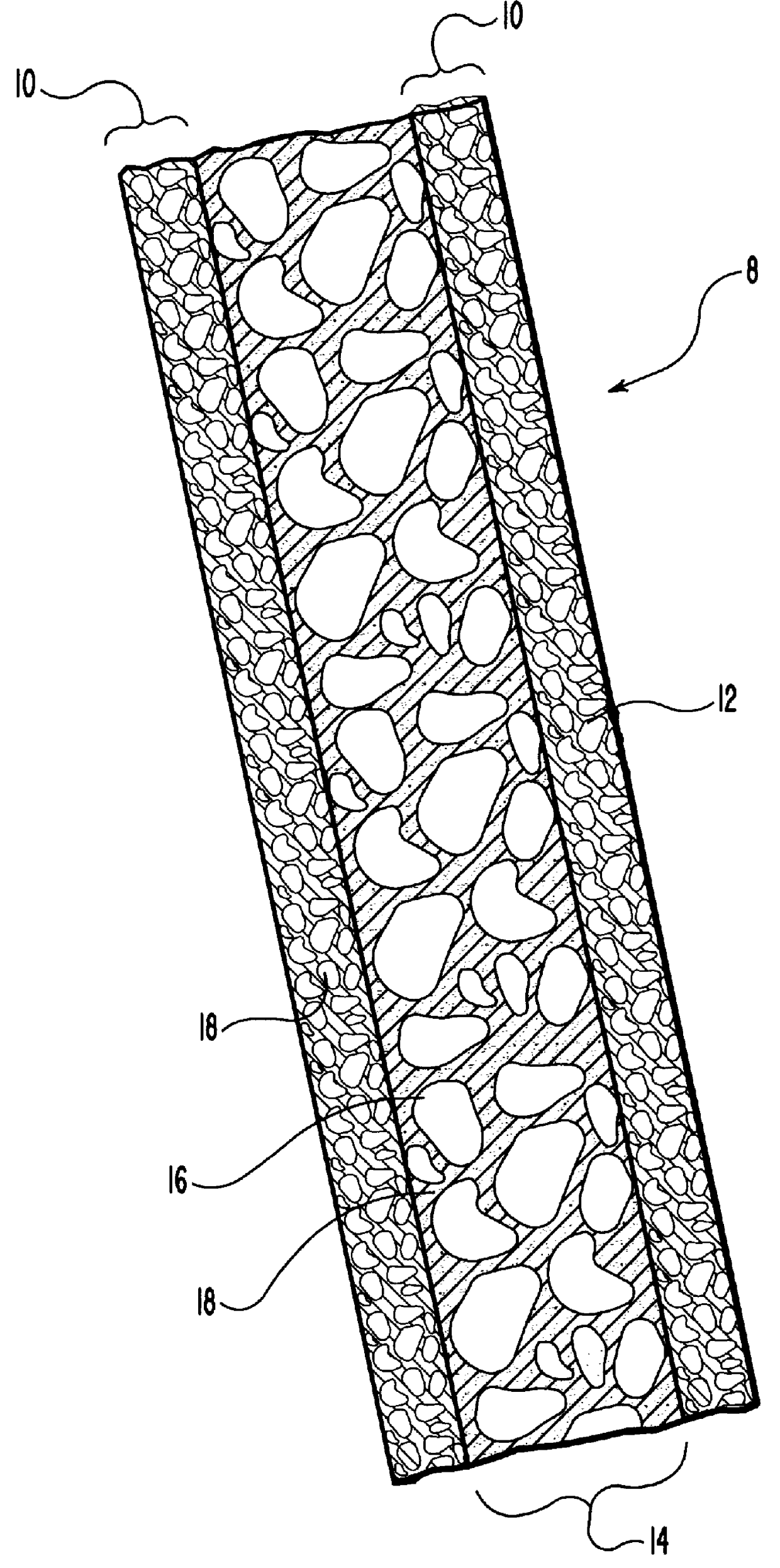

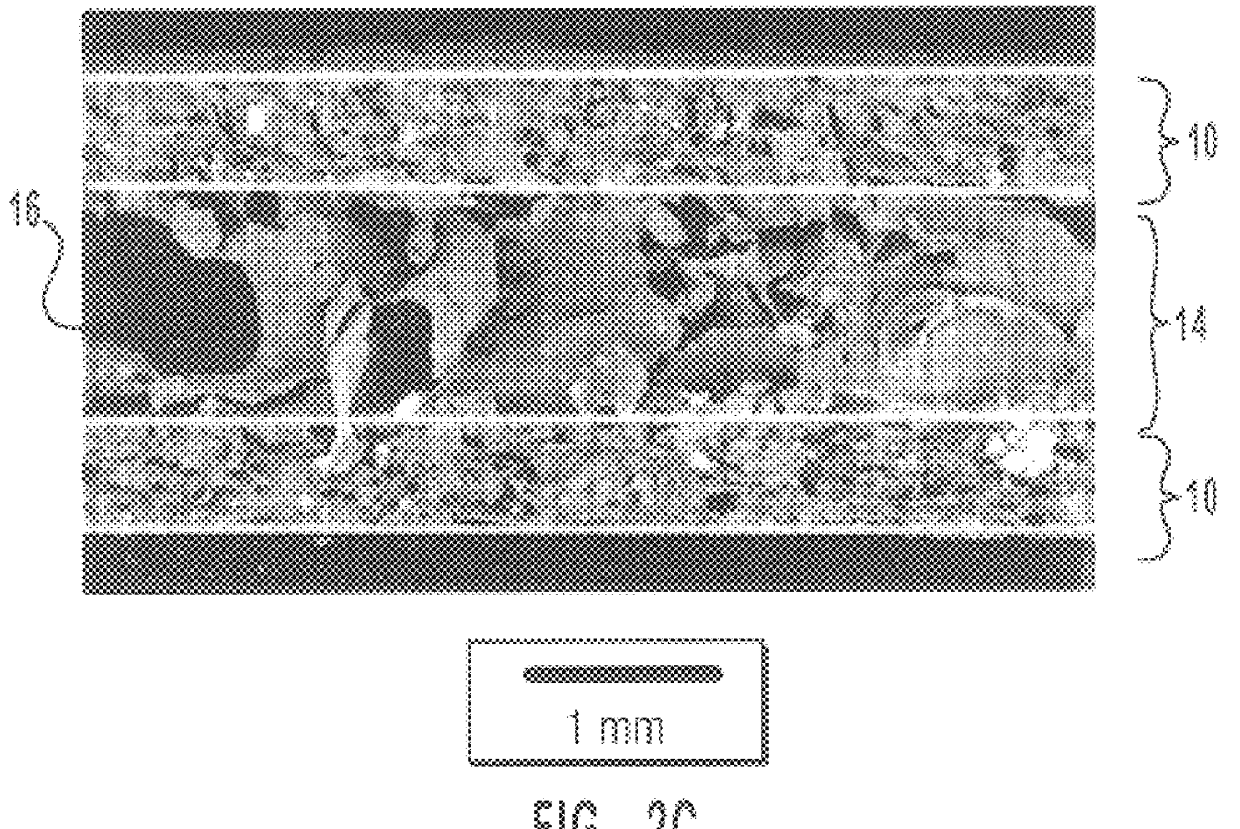

Sheets having a starch-based binding matrix

Compositions and methods for manufacturing sheets having a starch-bound matrix, optionally reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, a cellulosic ether, optionally fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the cellulosic ether to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and cellulosic ether form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

Compositions and methods for manufacturing starch-based sheets

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

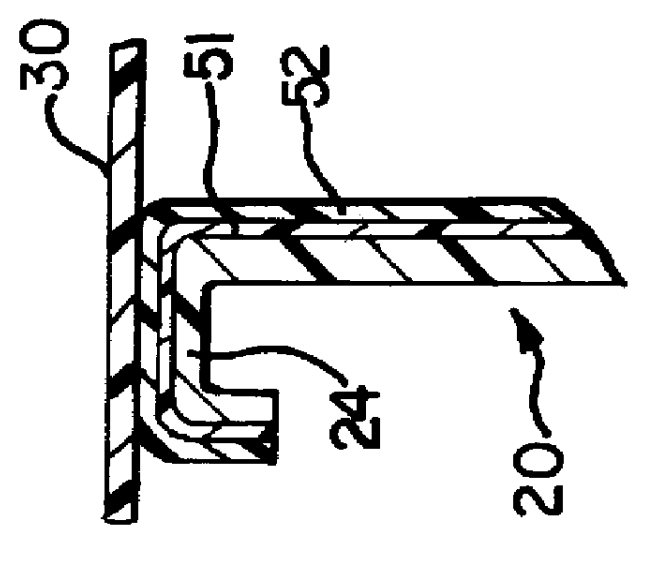

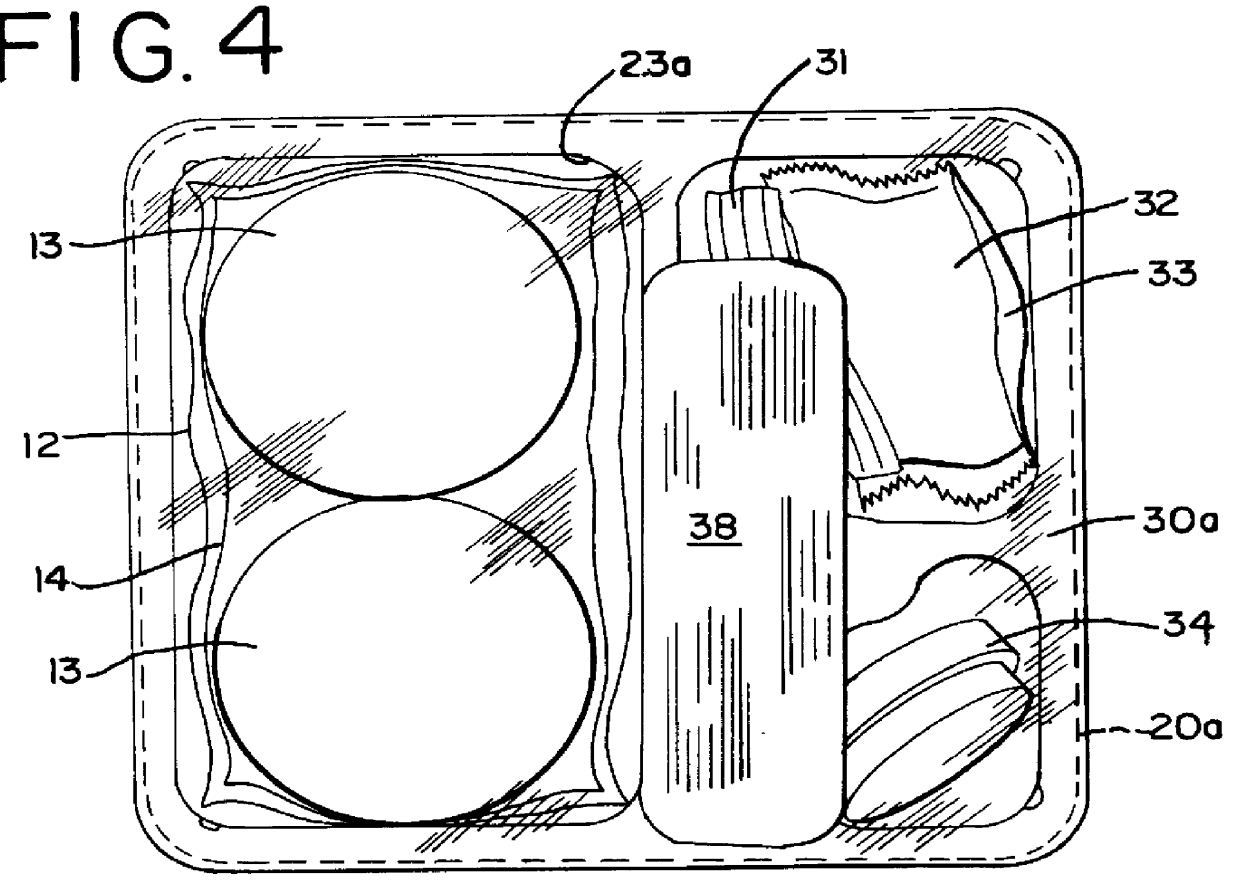

Method of packaging refrigerated meal in a package containing an anti-fog agent

InactiveUS6048558APrevent bucklingAvoid skewDough treatmentBio-packagingExtended timeBiomedical engineering

A packaged meal is provided in the form of a kit arrangement which is formulated and prepared for storage under refrigerated, non-frozen conditions for extended time periods within retail store showcase coolers. The kit includes a compartmentalized, hermetically sealed package, with a refrigerated baked flour-containing component or dough component within an overpouch which is sealed or unsealed and positioned within one of the compartments and being specially formulated to maintain its freshness and retarding staling during extended refrigerated storage within the hermetically sealed package. At least the compartment within which baked component is sealed has an anti-fogging agent component which further assists in maintaining freshness and retarding staling under even refrigerated, non-frozen conditions.

Owner:KRAFT FOODS GRP BRANDS LLC

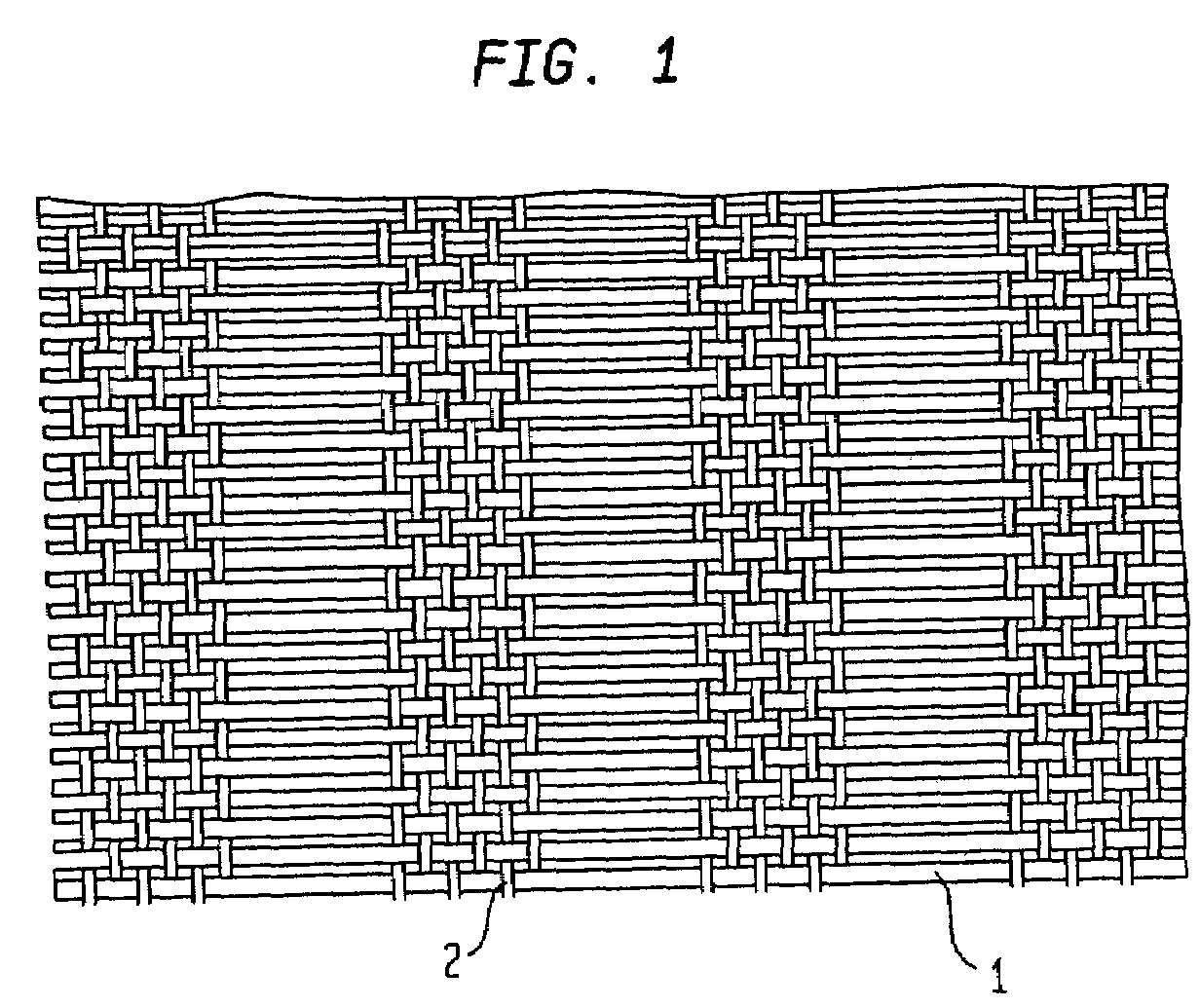

Infusion package

InactiveUS20080095959A1Bio-packagingPedestrian/occupant safety arrangementSynthetic fiberPolylactic acid

The present invention is directed to a material for use in making beverage infusion packages including a plurality of fibers woven with at least one heat-bondable synthetic fiber. Preferably, the fibers are cellulosic fibers such as bamboo and the heat-bondable synthetic fibers are biodegradable fibers, such as polylactides or polylactic acid. The present invention is also directed to beverage infusion packages made from the material and methods of making the infusion package.

Owner:THE REPUBLIC OF TEA

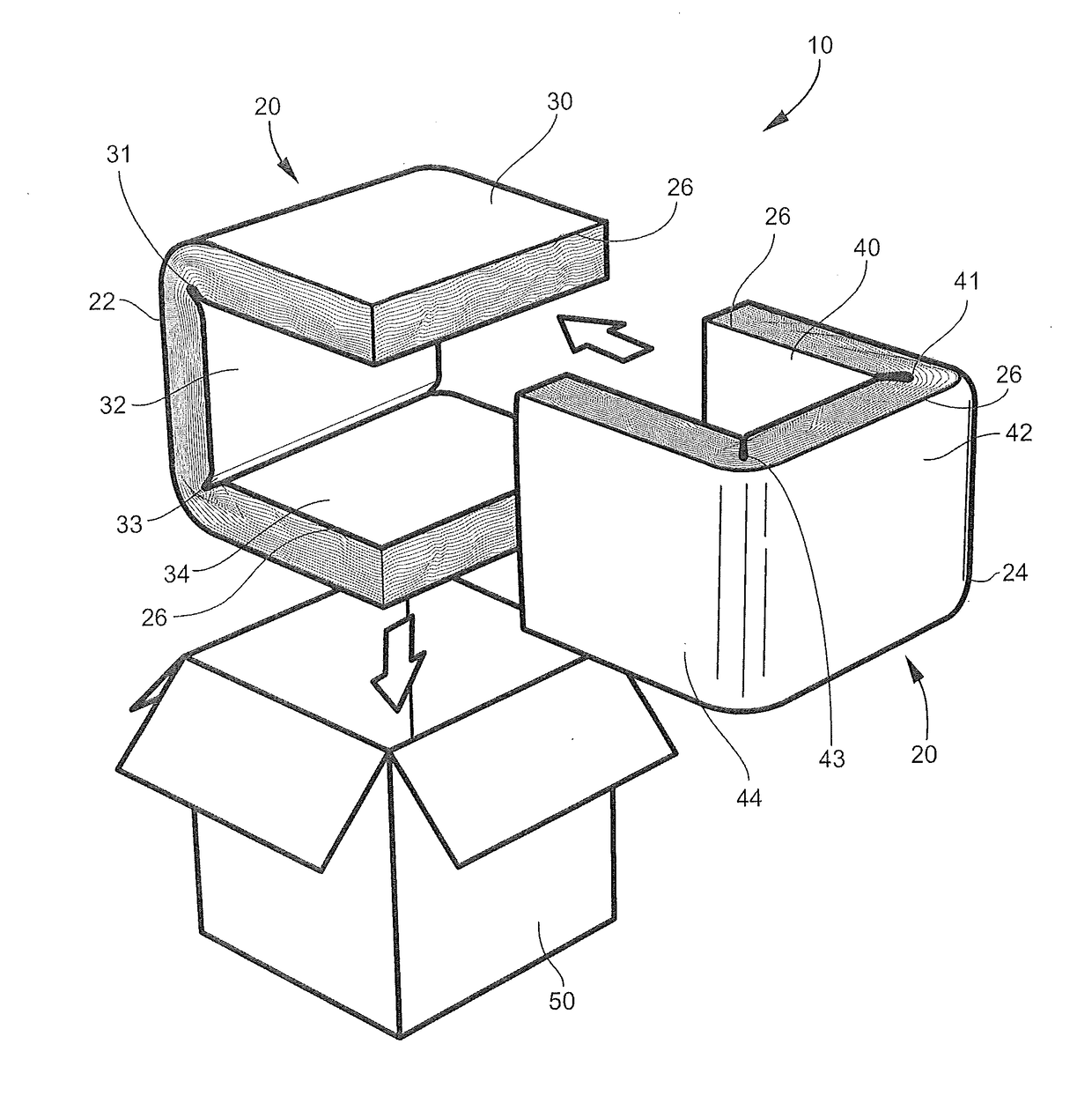

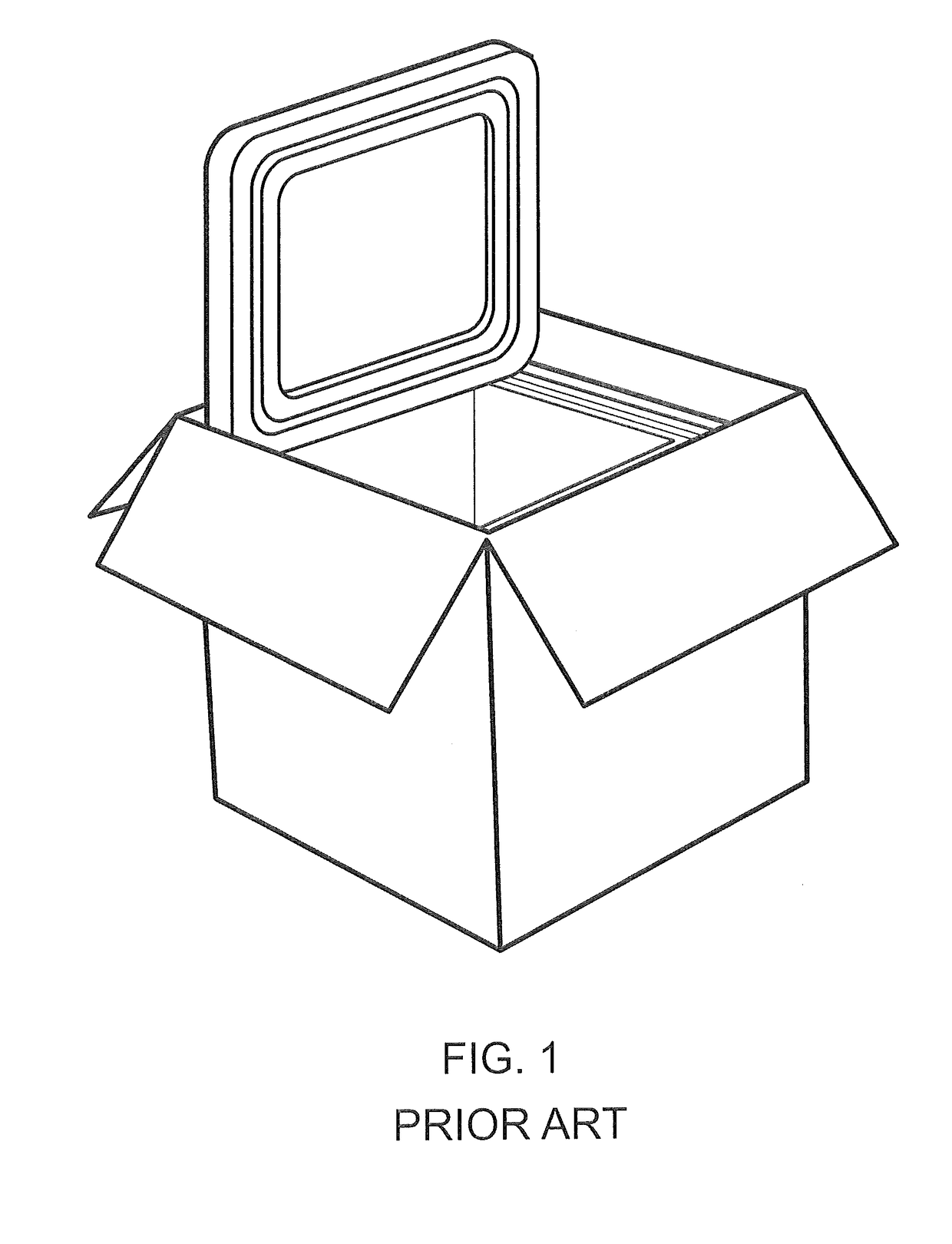

Cellulose based recyclable container

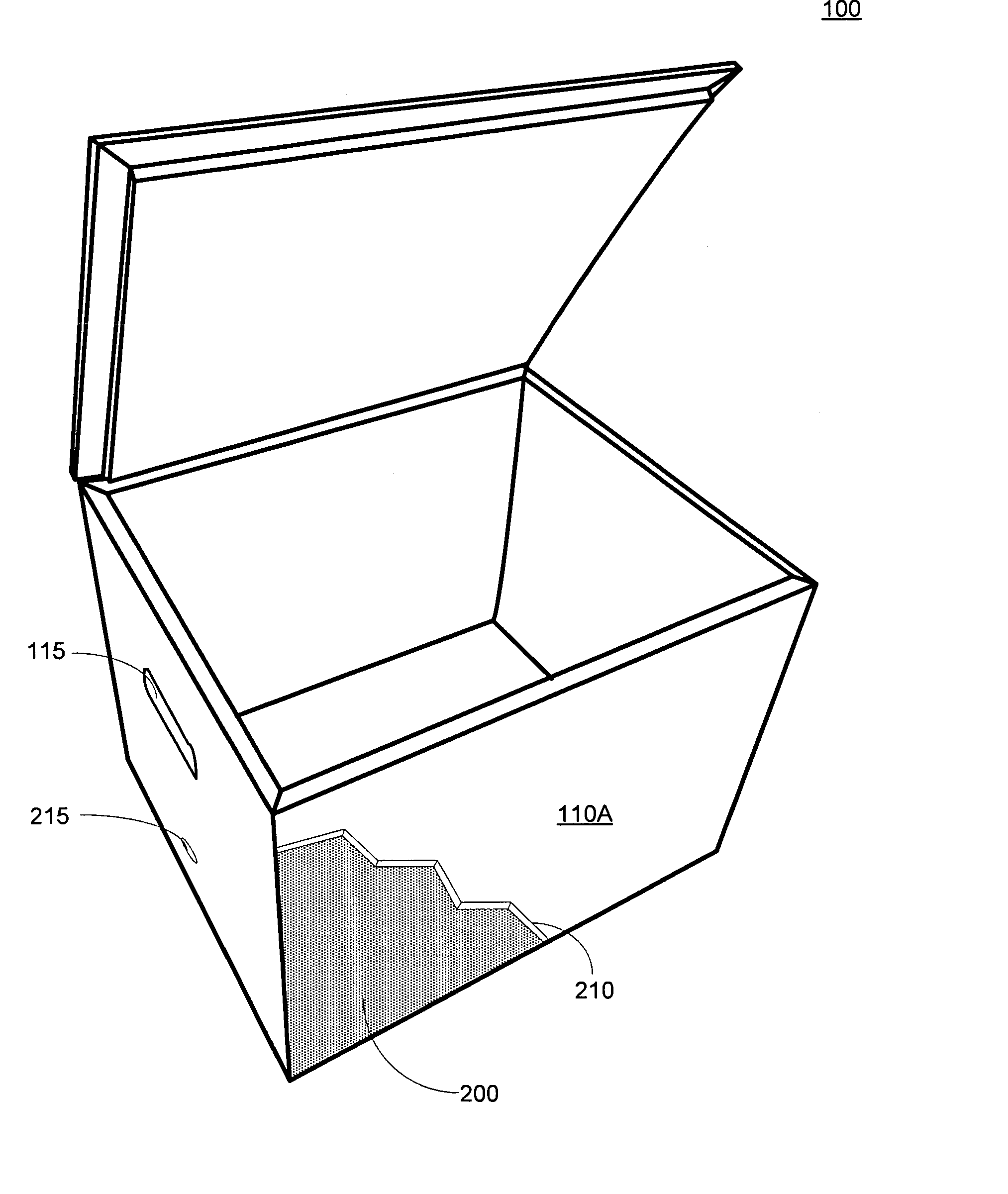

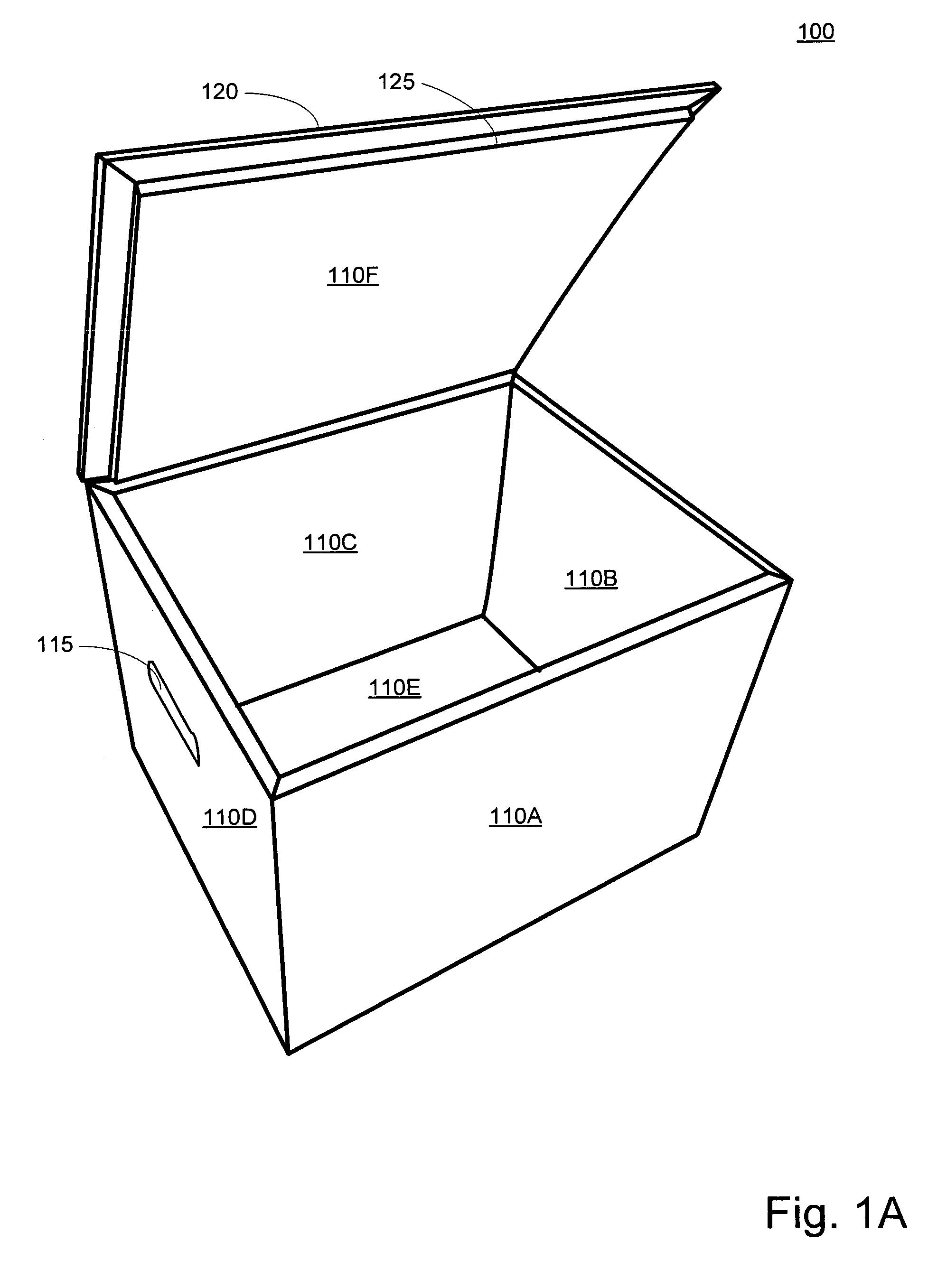

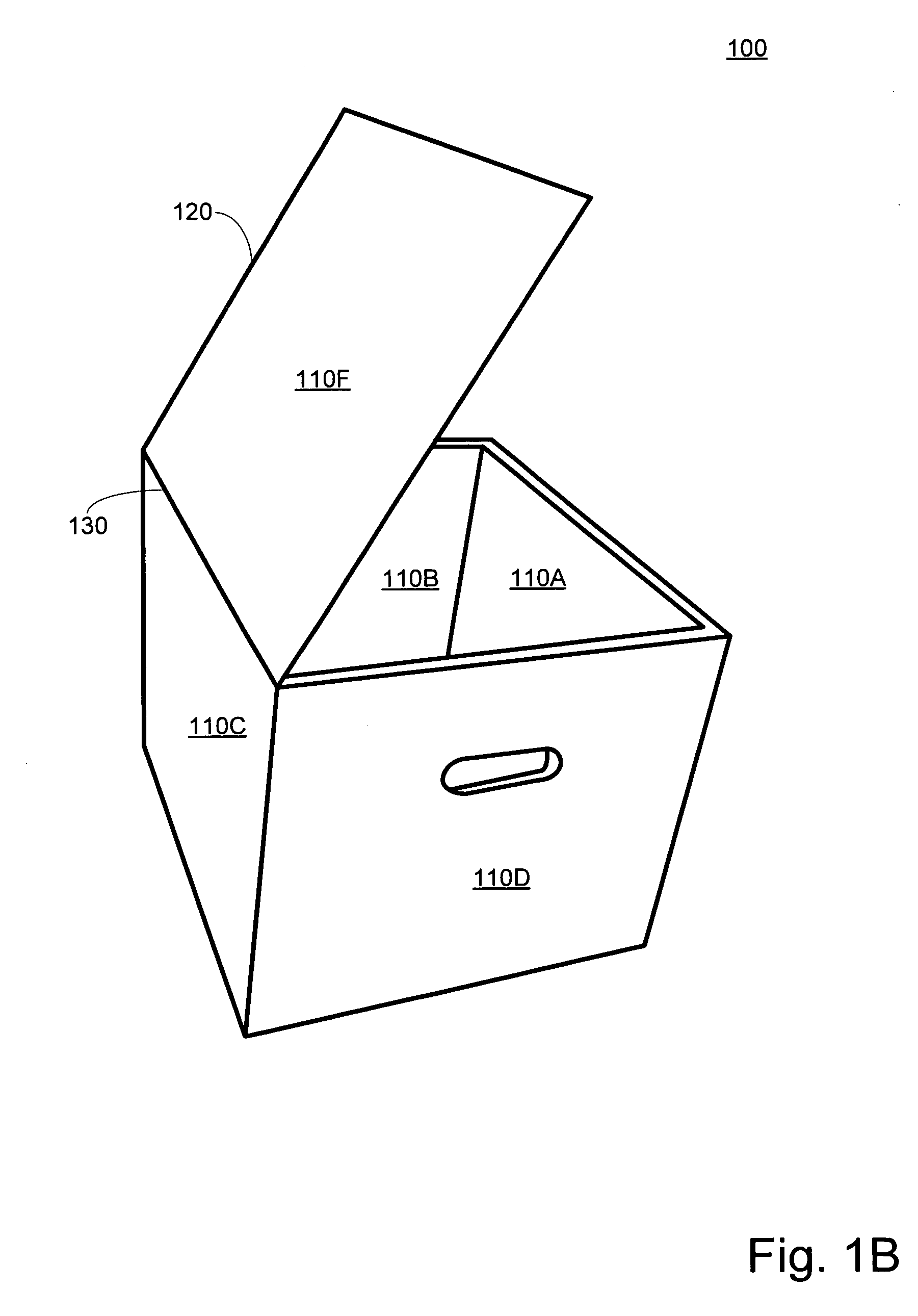

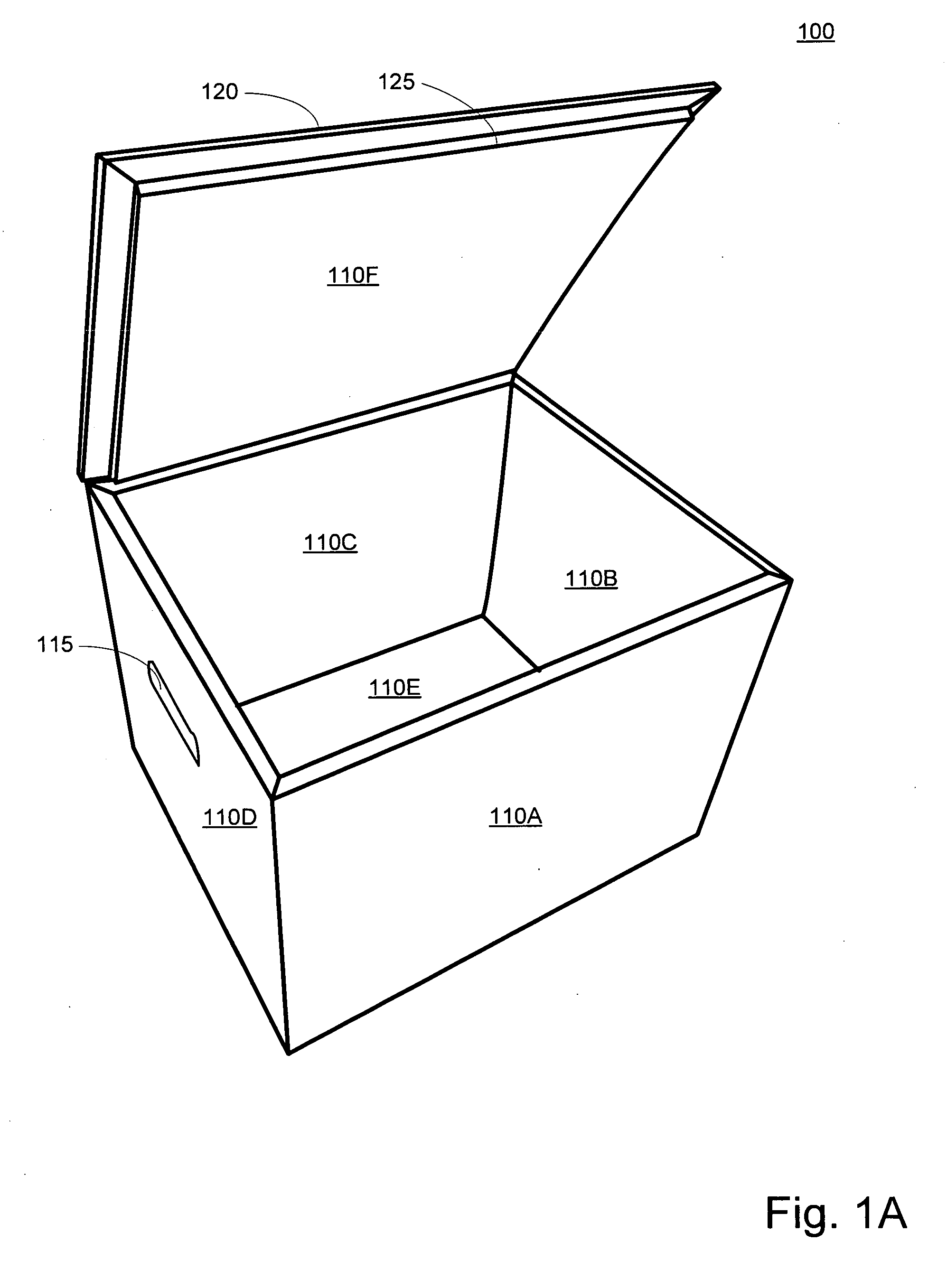

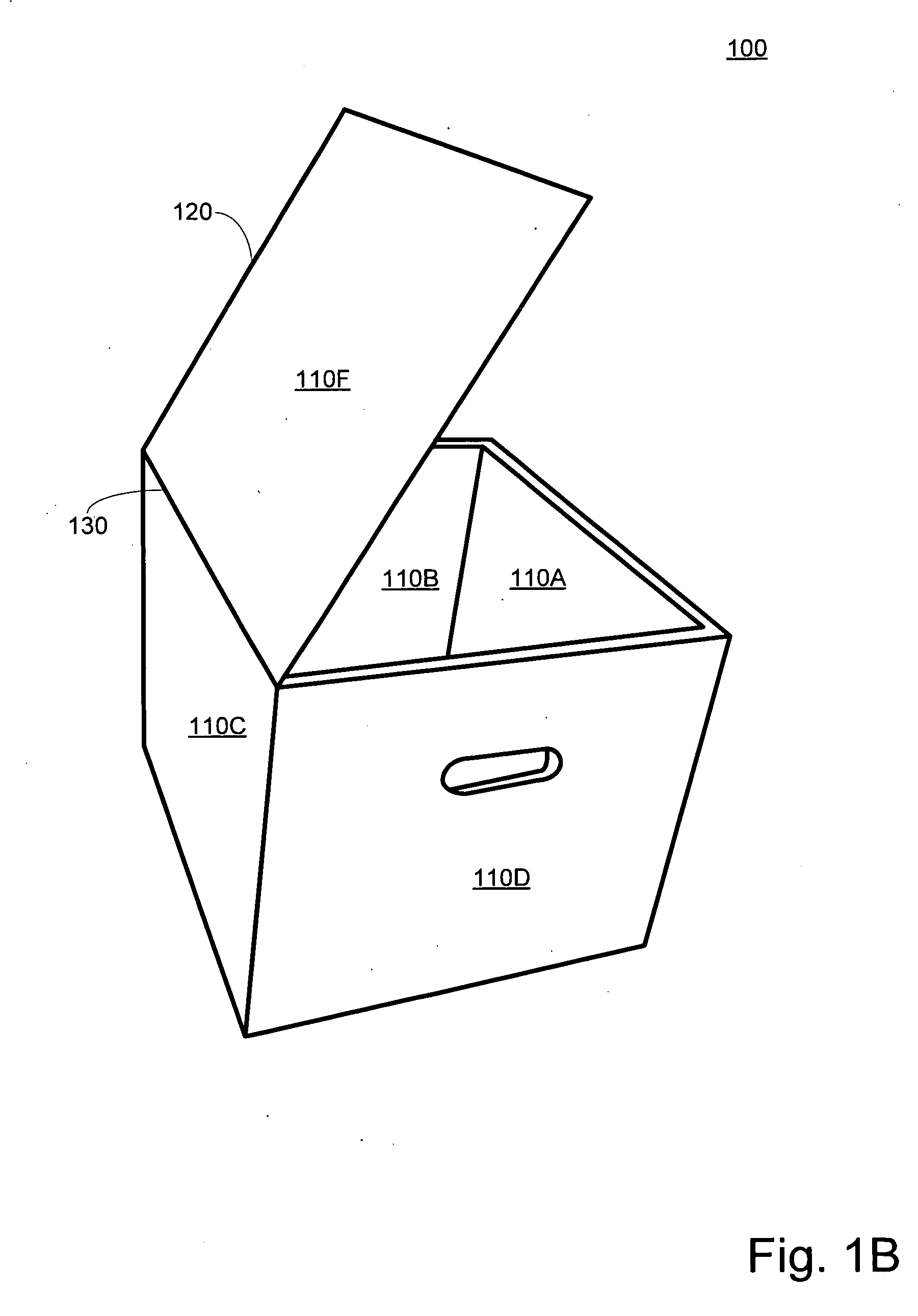

ActiveUS8365943B2Easy constructionEasy maintenanceDomestic cooling apparatusBio-packagingCelluloseNatural fiber

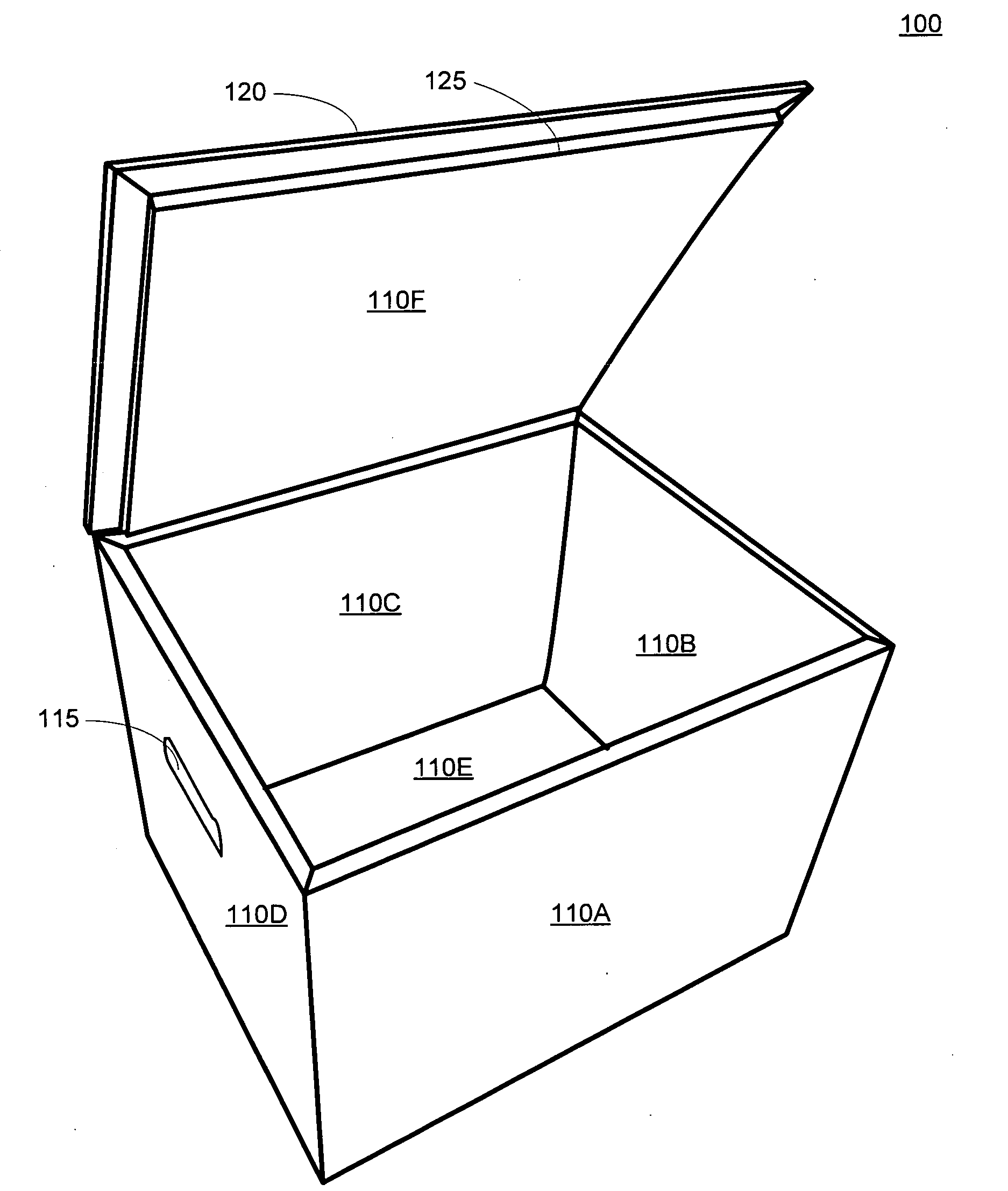

Disclosed is a portable cooler device comprised of recyclable materials. Some embodiments of the device comprise components constructed entirely of, or substantially of, cellulose. Other embodiments may be comprised of recyclable materials not classified as cellulose such as, but not limited to, cotton, bamboo, hemp, or other natural fibers. The specific percentages of recycled and / or recyclable content are not limiting factors for the invention; however, most embodiments have consistent materials of construction such that the entire device may be recycled in a single recycling process without the need for deconstruction. Further, if not recycled, embodiments are operable to biodegrade within a reasonable amount of time when exposed to the elements in a landfill. Typical embodiments are comprised of an inner shell, an outer shell having an integrally hinged lid, and pressed cellulose insulating boards sandwiched between the shells.

Owner:RECYCOOL

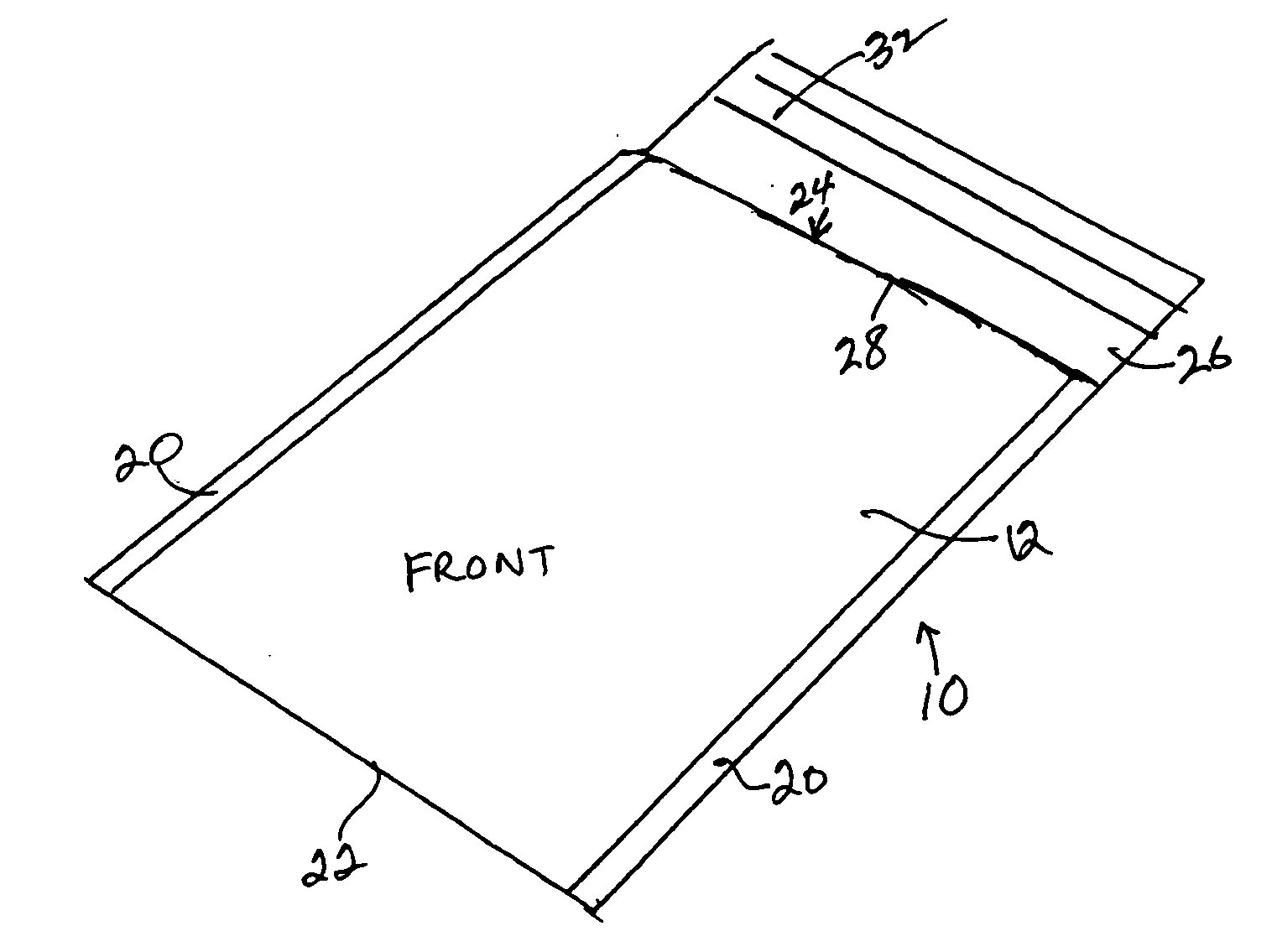

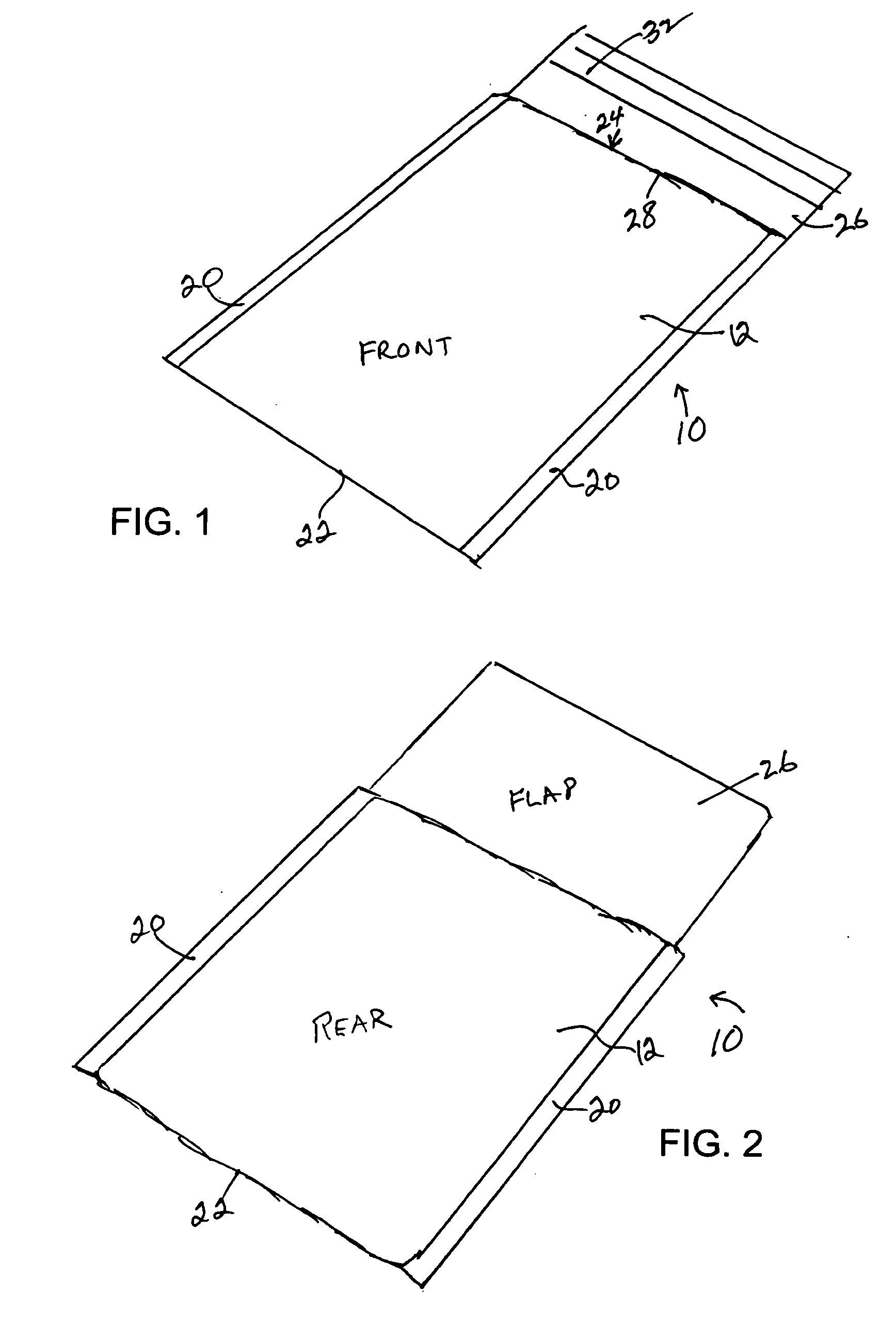

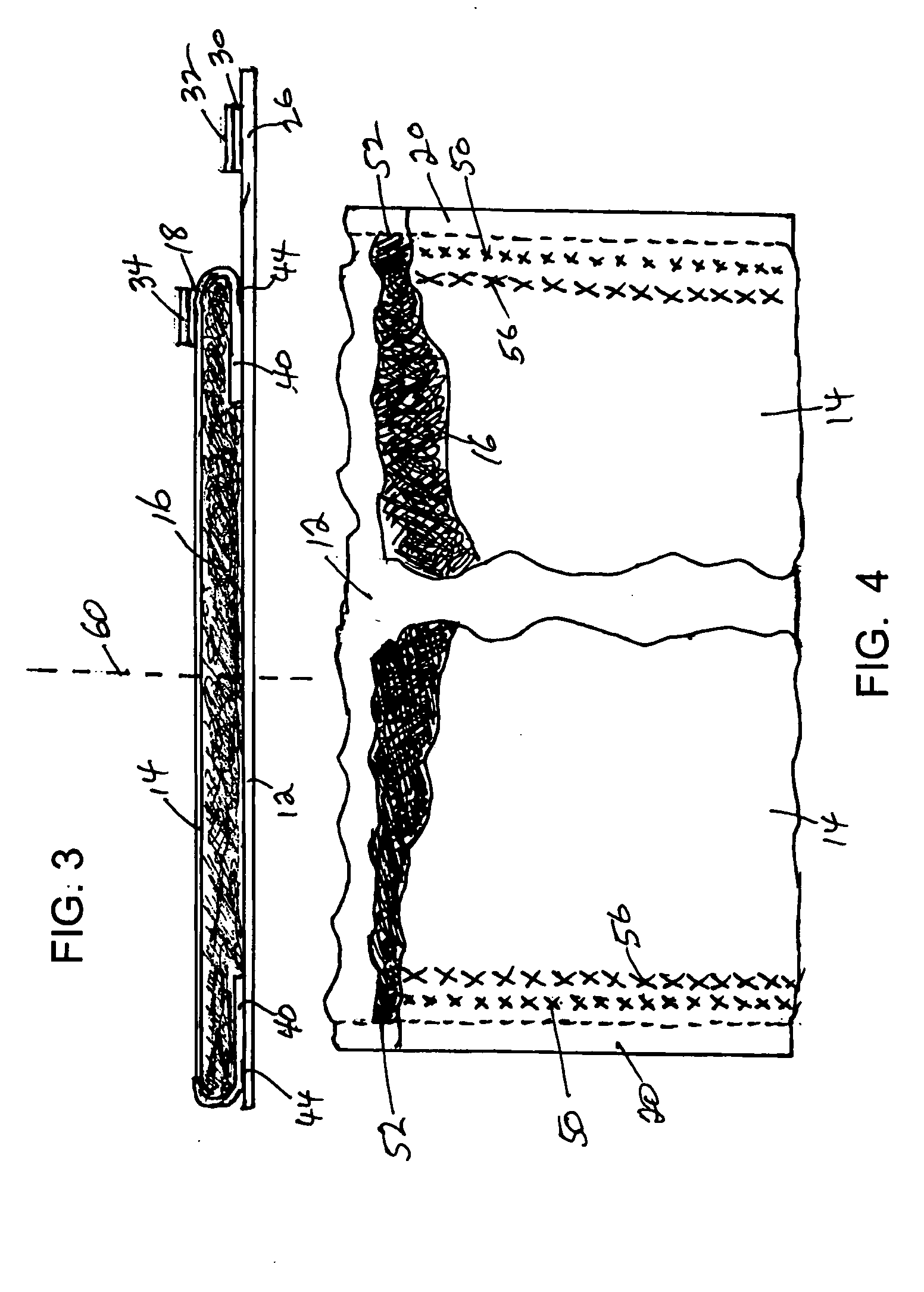

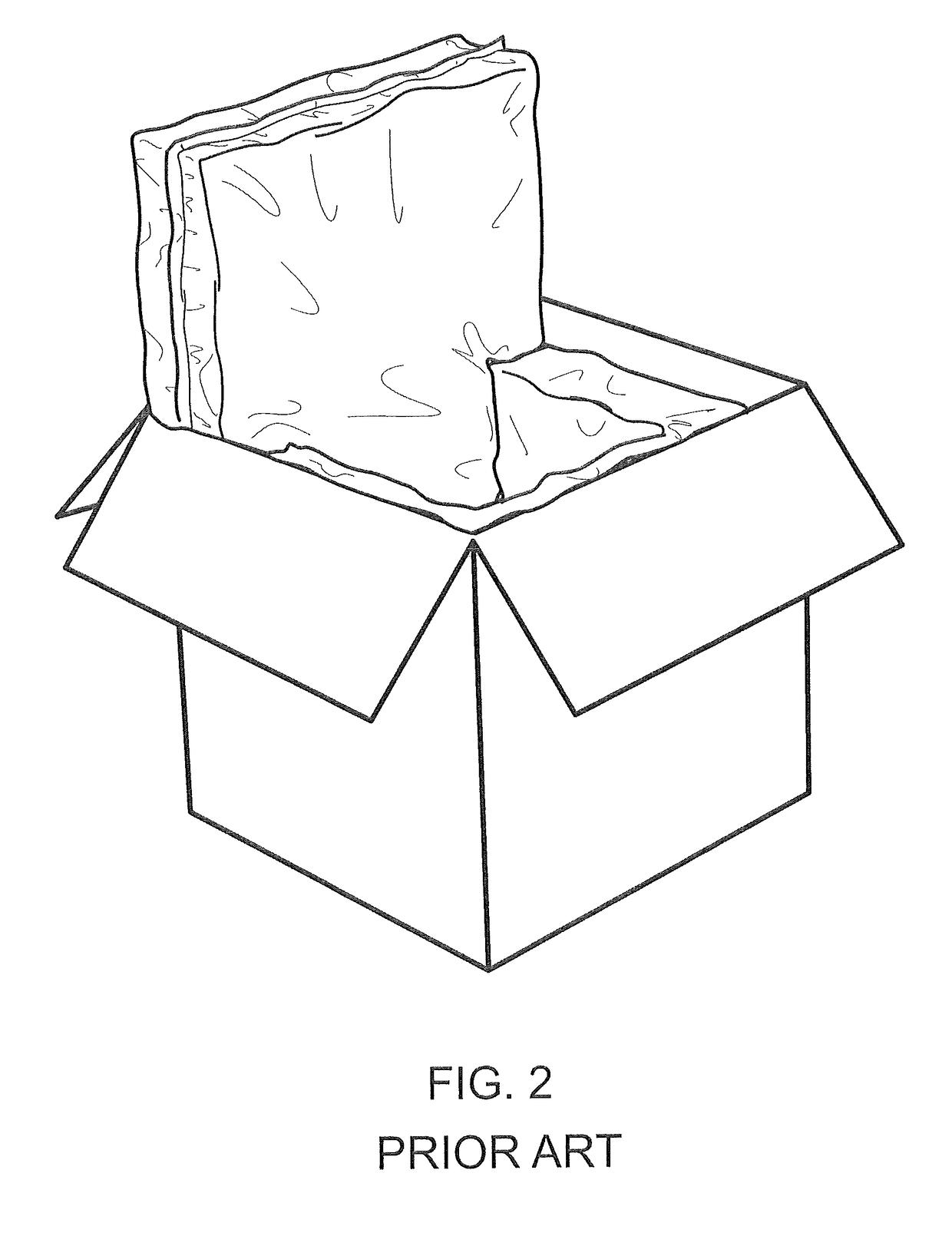

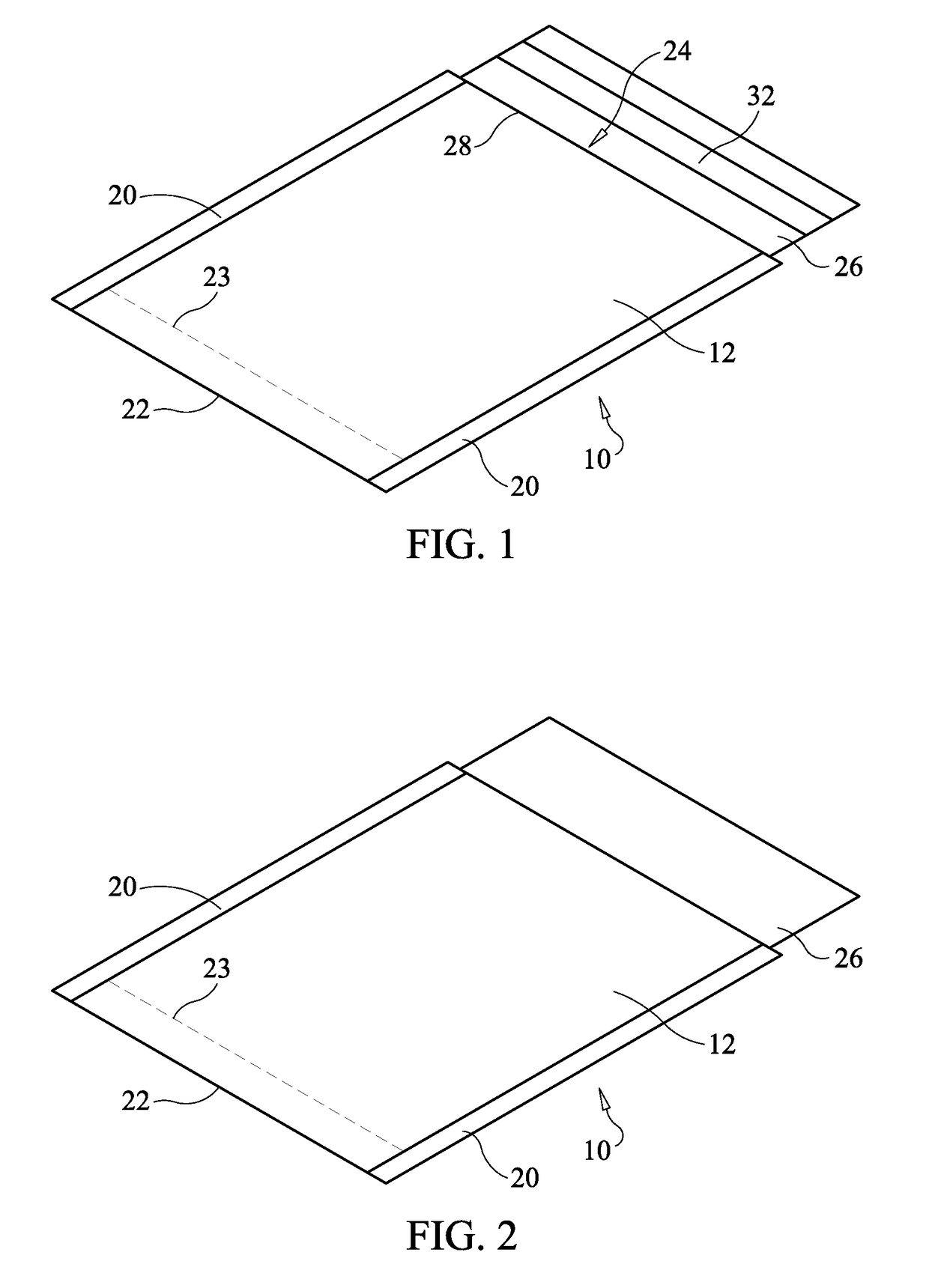

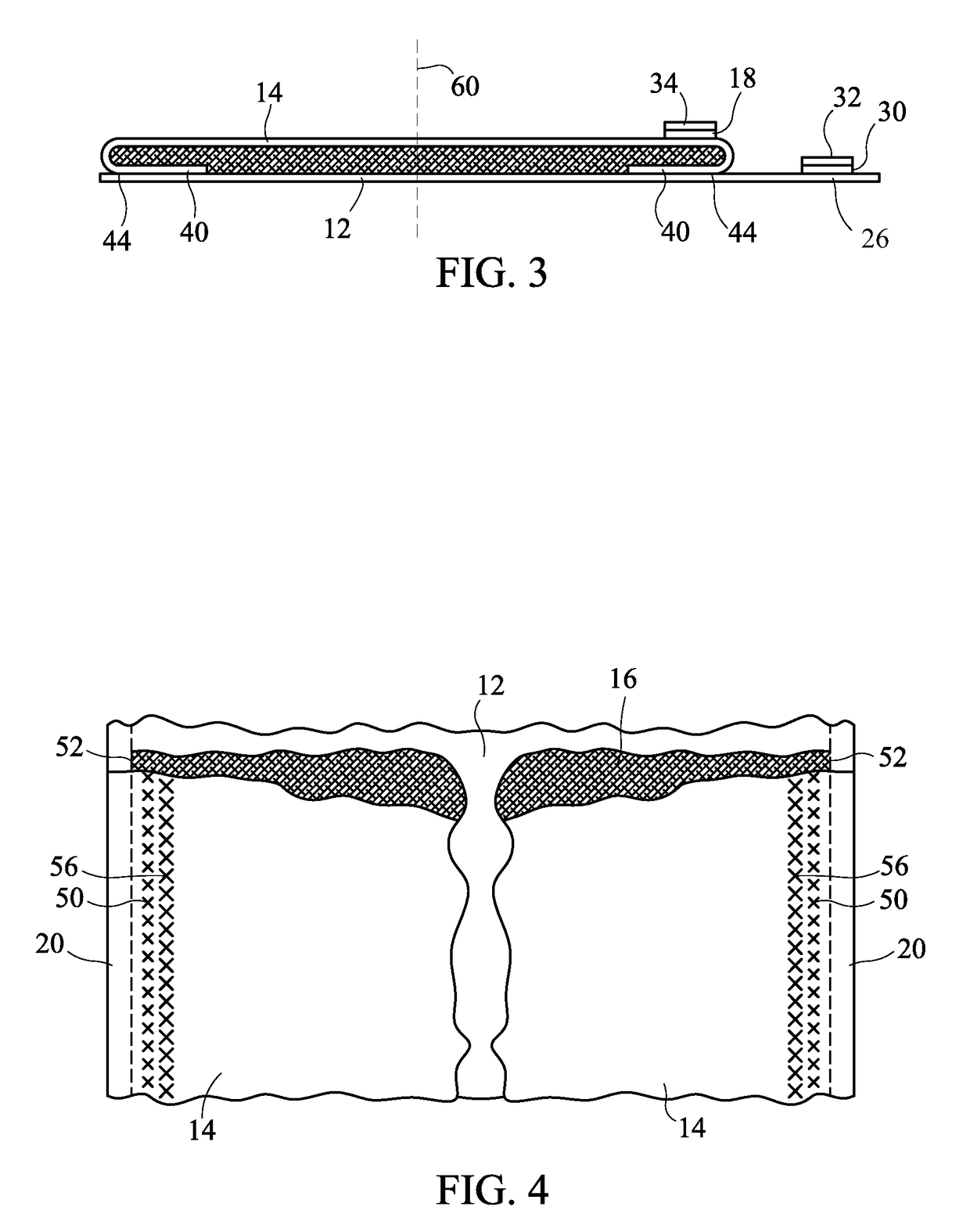

"green" temperature- controlled mailer

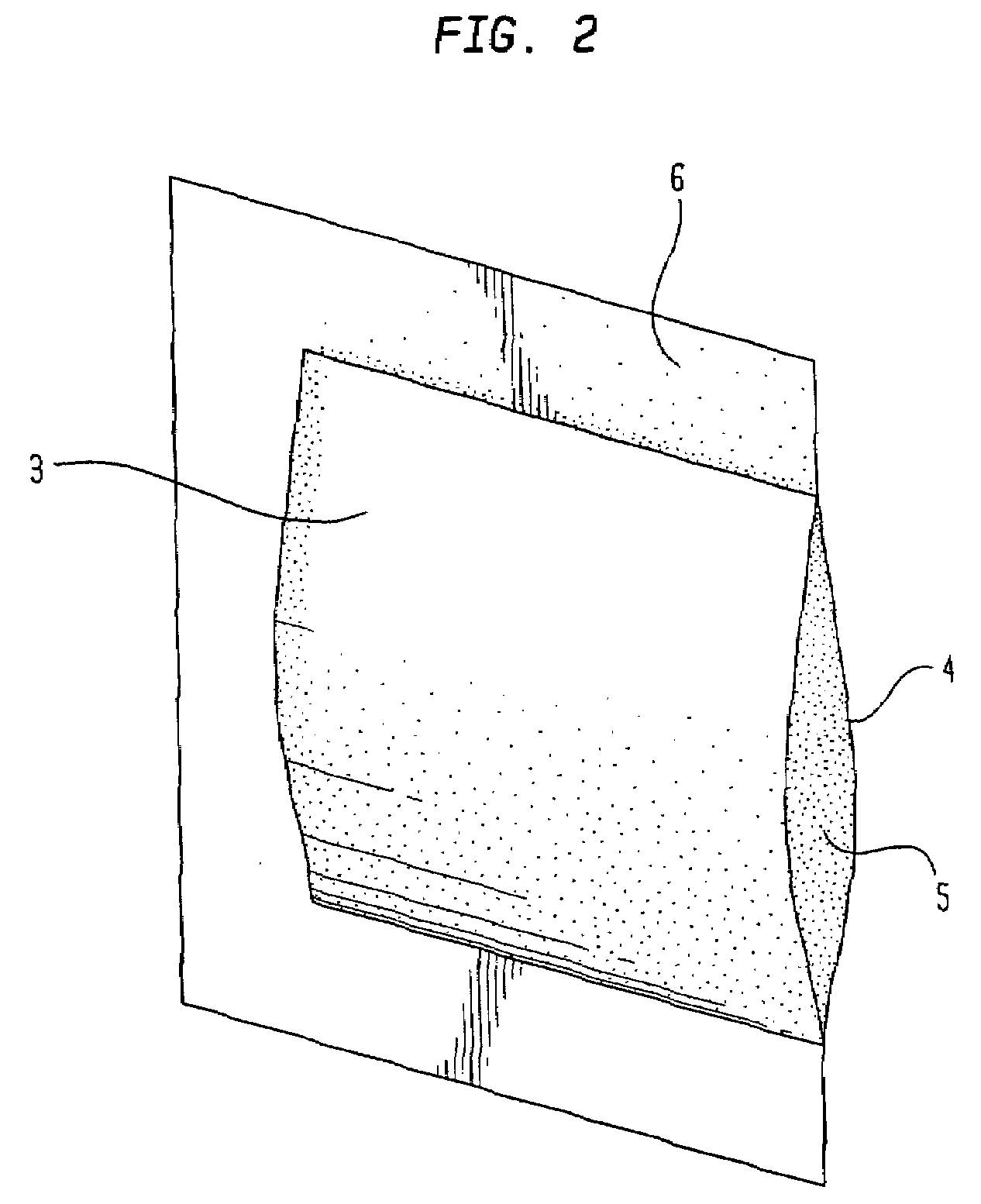

A mailer has an outer, longitudinally extending, biodegradable film with lateral edges folded on itself to form a pocket having an opening and sealable by a flap. An assembly is composed of an inner, longitudinally extending, biodegradable film having lateral edges and a longitudinal extending pad composed of textile cuttings and microbial and super-absorbent powders. The inner film extends longitudinally around the pad and is attached to the pad. The assembly is positioned in the pocket with the inner film being sealed to the outer film adjacent the opening to the pocket trapping the pad between the outer and inner films. Sealing tape is mounted on the inner film adjacent to the pocket to seal the pocket closed. The lateral edges of both the outer and inner films, which extend laterally beyond the pad, are heat sealed together.

Owner:MILLER DRAYTON

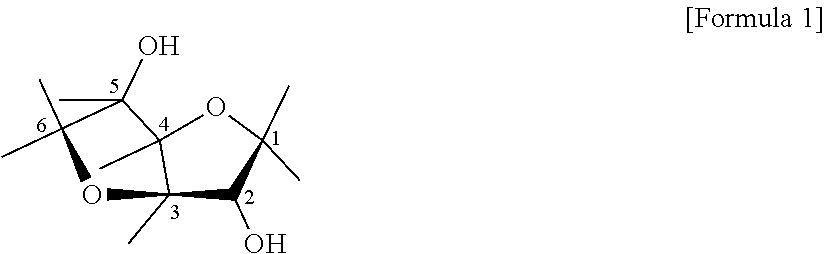

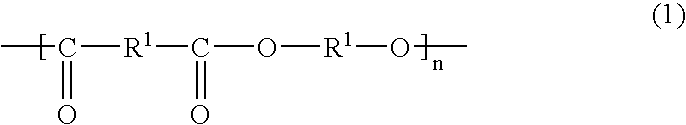

Polyester resin and method for preparing the same

InactiveUS20120177854A1Superior heat-resistanceHigh impact strengthBio-packagingSynthetic resin layered productsCyclohexanedimethanolDiol

A polyester resin copolymerized with isosorbide and 1,4-cyclohexane dimethanol and having an improved impact strength, and a method for preparing the same are disclosed. The copolymerized polyester resin has an alternating structure of acid moieties which are derived from acid components and diol moieties which are derived from diol components, wherein the acid components comprise terephthalic acid, and the diol components comprise (i) 5˜99 mol % of 1,4-cyclohexanedimethanol and (ii) 1˜60 mol % of isosorbide with respect to the total diol components.

Owner:SK CHEM CO LTD

Renewably sourced films and methods of forming same

Mono- and multi-layer films having film layers at least partially formed from a polymer (A) wherein polymer (A) is at least partially derived from a renewable resource such that the mono- or multi-layer film has a bio-based content of about 10% to about 100% using ASTM D6866-10, method B. Methods of forming high biocontent mono- and multi-layer films are also provided.

Owner:THE PROCTER & GAMBLE COMPANY

Cellulose based recyclable container

ActiveUS20100258574A1Easy constructionEasy maintenanceDomestic cooling apparatusBio-packagingCelluloseLitter

Disclosed is a portable cooler device comprised of recyclable materials. Some embodiments of the device comprise components constructed entirely of, or substantially of, cellulose. Other embodiments may be comprised of recyclable materials not classified as cellulose such as, but not limited to, cotton, bamboo, hemp, or other natural fibers. The specific percentages of recycled and / or recyclable content are not limiting factors for the invention; however, most embodiments have consistent materials of construction such that the entire device may be recycled in a single recycling process without the need for deconstruction. Further, if not recycled, embodiments are operable to biodegrade within a reasonable amount of time when exposed to the elements in a landfill. Typical embodiments are comprised of an inner shell, an outer shell having an integrally hinged lid, and pressed cellulose insulating boards sandwiched between the shells.

Owner:RECYCOOL

Biodegradable or compostable containers

The present invention provides an improved method and materials for forming biodegradable containers that can hold food products in dry, damp or wet conditions and provides the biodegradable containers prepared according to the disclosed process. The containers are produced through the use of a pre-gelled starch suspension that is unique in its ability to form hydrated gels and to maintain this gel structure in the presence of many other types of materials and at low temperatures.

Owner:NEW ICE LTD

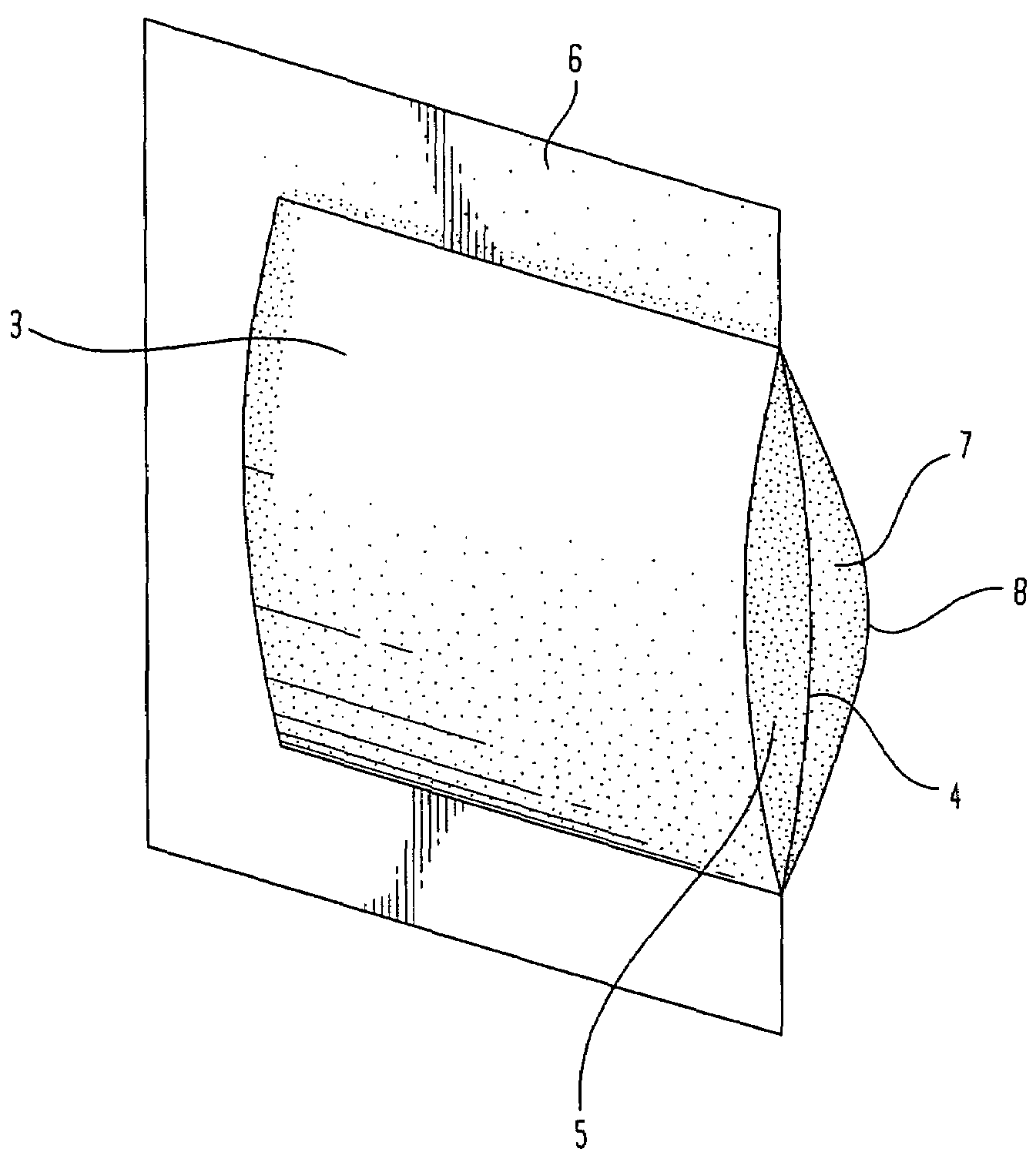

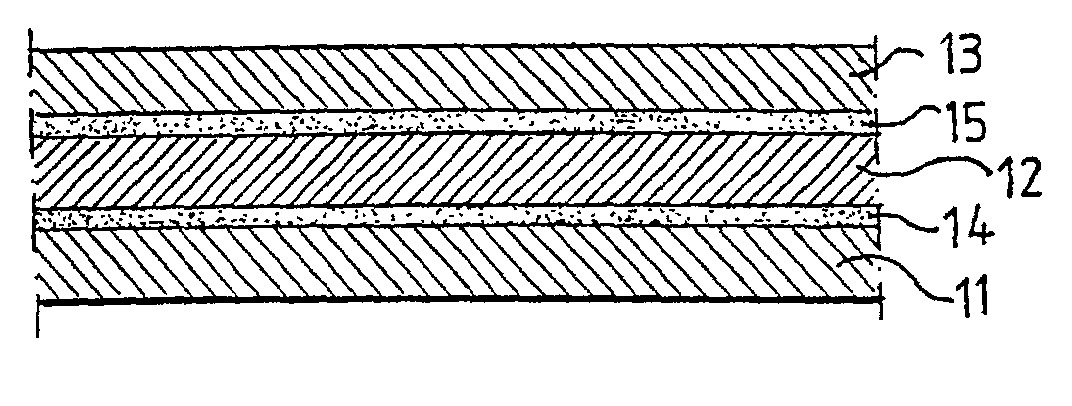

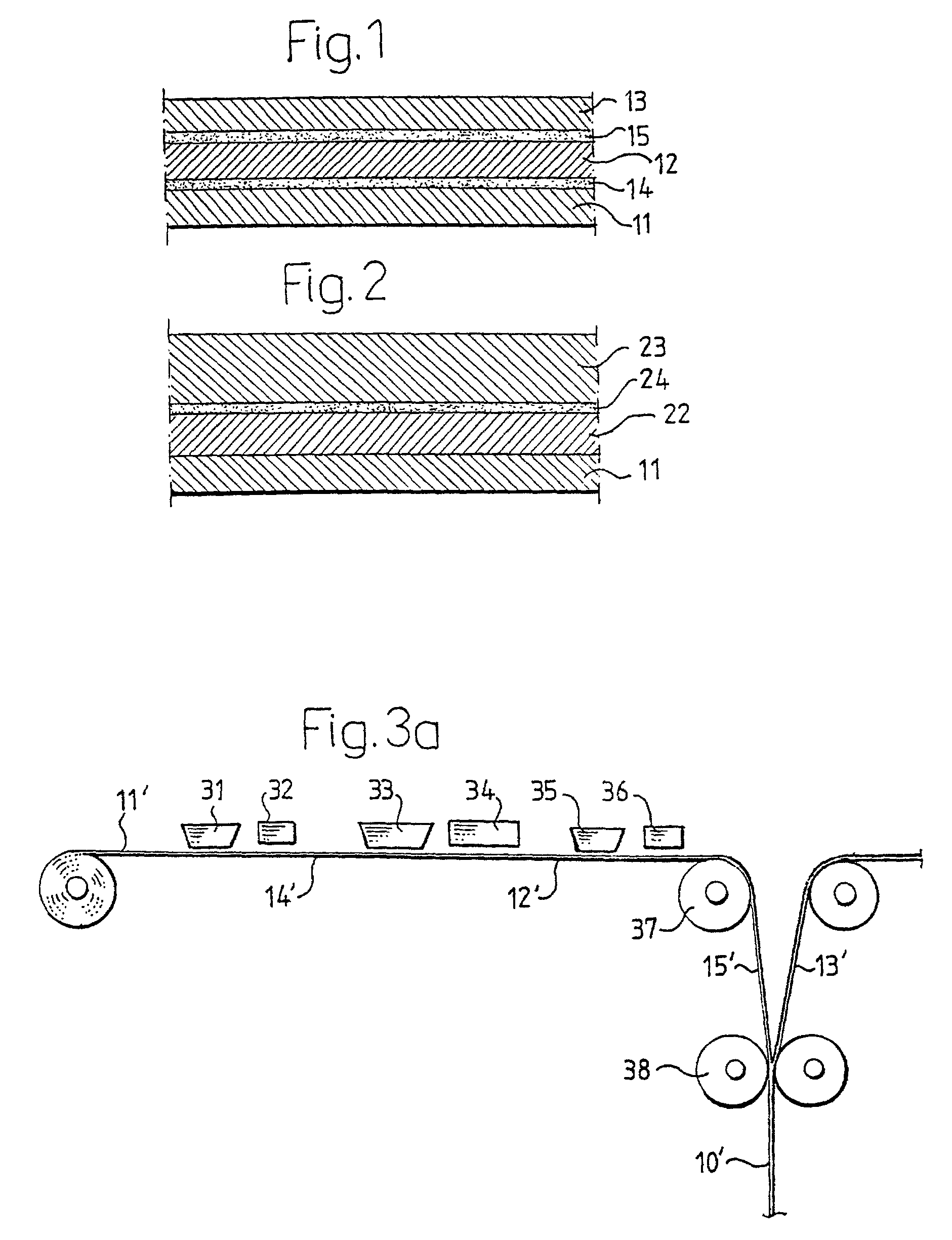

Biodegradable packaging laminate, a method of producing the packaging laminate, and packaging containers produced from the packaging laminate

InactiveUS20020127358A1Improve adhesionExcellent gas barrier performanceAdhesive processesLiquid surface applicatorsLactideBiopolymer

Packaging laminate for packages for liquid foods having excellent liquid and oxygen gas barrier properties in which all included layers are biodegradable. The packaging laminate includes at least one liquidtight layer (11, 13) of homo or copolymers of monomers selected from a group consisting of lactic acid, glycol acid, lactide, glycolide, hydroxy butyric acid, hydroxy valeric acid, hydroxy caproic acid, valerolactone, butyrolactone and caprolactone, as well as an oxygen gas barrier layer (12) of ethylene vinyl alcohol, polyvinyl alcohol, starch or starch derivatives. The oxygen gas barrier layer is preferably applied by a dispersion coating process. The layers may be laminated directly to one another or indirectly by means of interjacent adhesive layers. The packaging laminate may also include a core layer of, for example, paper or paperboard, or a biopolymer. The invention also realises a method of producing the biodegradable packaging laminate according to the invention.

Owner:TETRA LAVAL HLDG & FINANCE SA

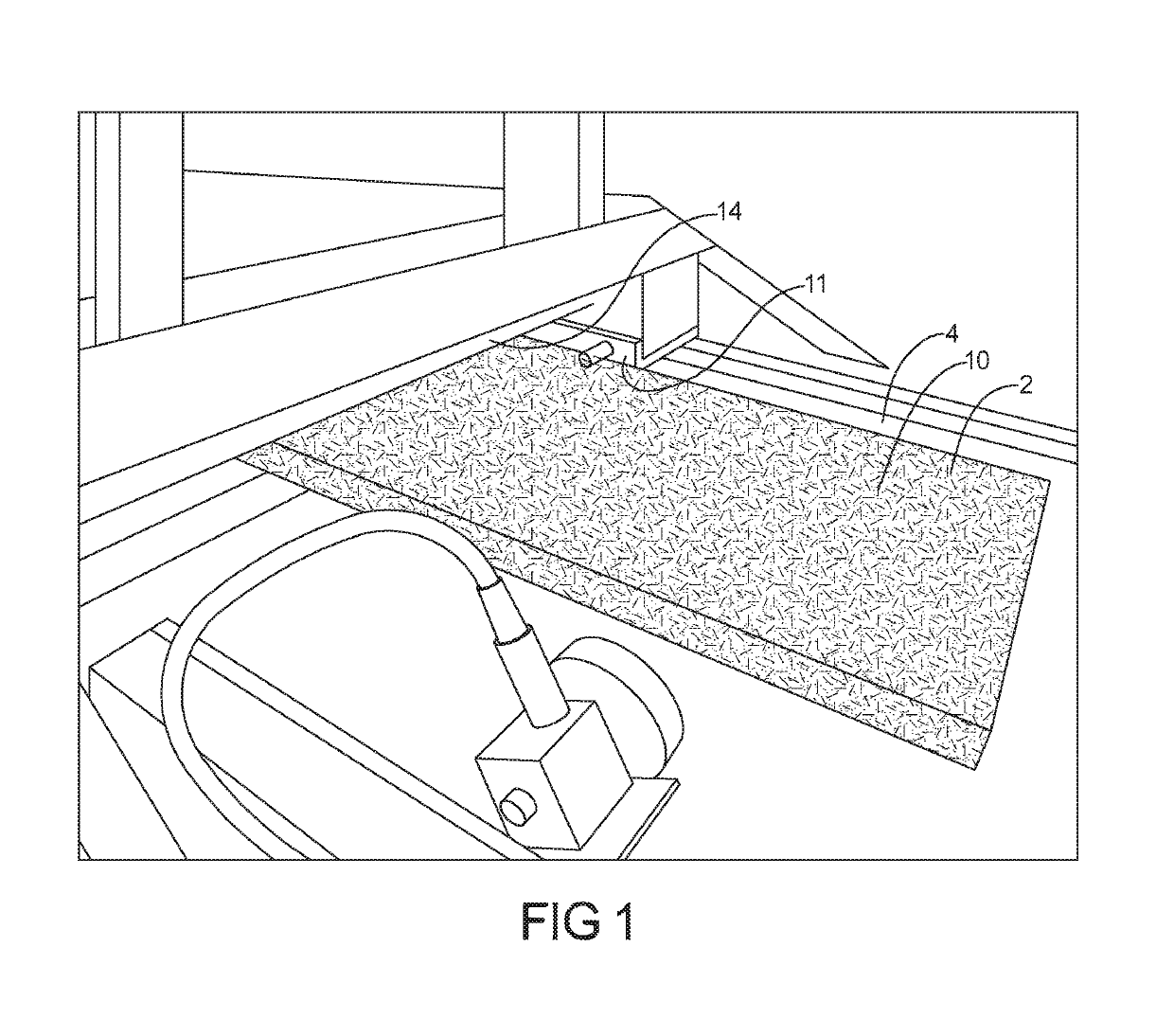

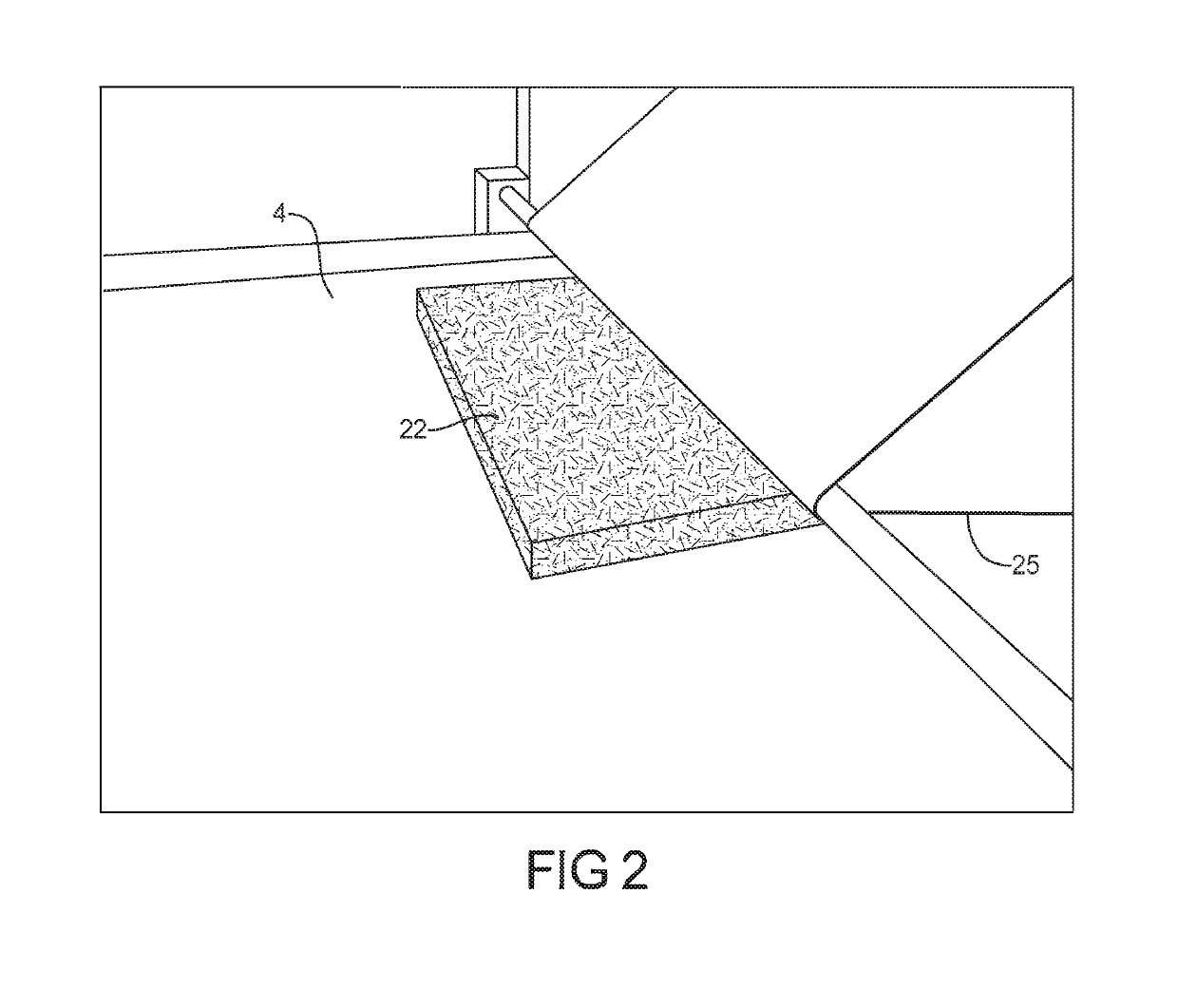

Insulated container

ActiveUS20170334622A1Efficient and economically manufacturedMinimize negative impactWrappersBoxes/cartons making machineryInsulation layerIsolation layer

An insulated container may include a rigid container surrounding an insulation layer formed from a post-industrial, pre-consumer card waste. The insulation layer may be characterized by a lack of any wrapping material. The insulation layer may be manufactured using a variety of converting processes including, carding, airlay, and needle punch to form a non-woven material for providing consistent density throughout the insulation layer. The insulation layer may include a natural fiber lamination layer on an outer surface of the insulation layer. The insulation layer may be biodegradable in an anaerobic environment.

Owner:AIRLITE PLASTICS

Polyester derived from biomass resources and method for production thereof

ActiveUS20090171037A1Reduce deteriorationStable supplyBio-packagingMicroorganism based processesPolyesterDiol

The present invention provides a resin capable of contributing greatly to solve environmental problems and problems related to exhaustion of fossil fuel resources and having physical properties suited for practical use.The polyester according to the present invention has a diol and a dicarboxylic acid as constituent components and has an amount of terminal acid of 50 equivalents / metric ton or less.

Owner:MITSUBISHI CHEM CORP

“Green” temperature-controlled mailer

ActiveUS9738420B2Avoid pollutionPrevent tamperingWrappersDomestic cooling apparatusTemperature controlAnti-Microbial Agents

A mailer has an outer, longitudinally extending, biodegradable film with lateral edges folded on itself to form a pocket having an opening and sealable by a flap. An assembly is composed of an inner, longitudinally extending, biodegradable film having lateral edges and a longitudinal extending pad composed of textile cuttings and microbial and superabsorbent powders. The inner film extends longitudinally around the pad and is attached to the pad. The assembly is positioned in the pocket with the inner film being sealed to the outer film adjacent the opening to the pocket trapping the pad between the outer and inner films. Sealing tape is mounted on the inner film adjacent to the pocket to seal the pocket closed. The lateral edges of both the outer and inner films, which extend laterally beyond the pad, are heat sealed together. A container has an outer box an inner insulative layer. The insulative layer is made from flocked textiles and is mixable with absorbatives and antimicrobials.

Owner:MILLER DRAYTON GRANVILLE

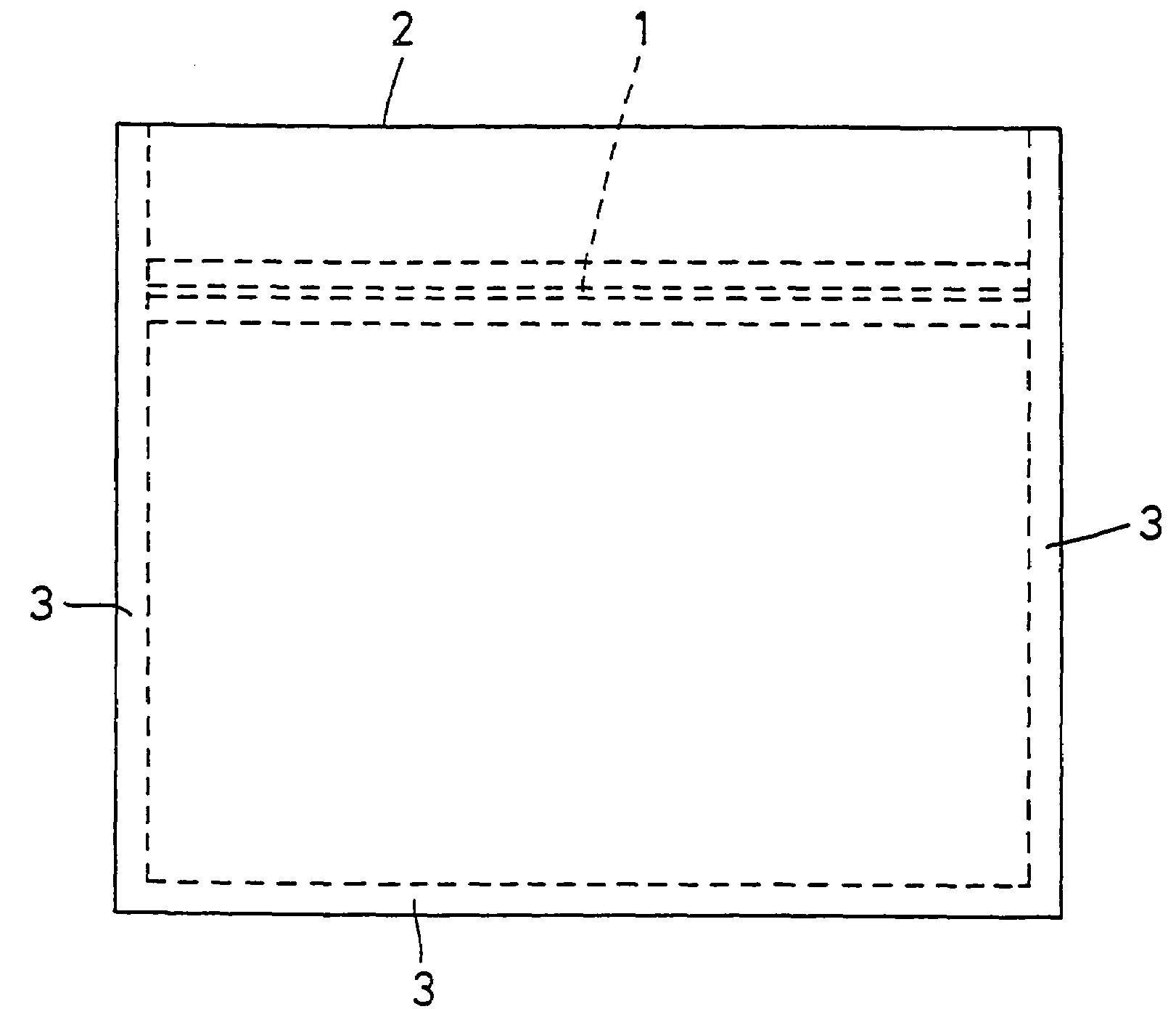

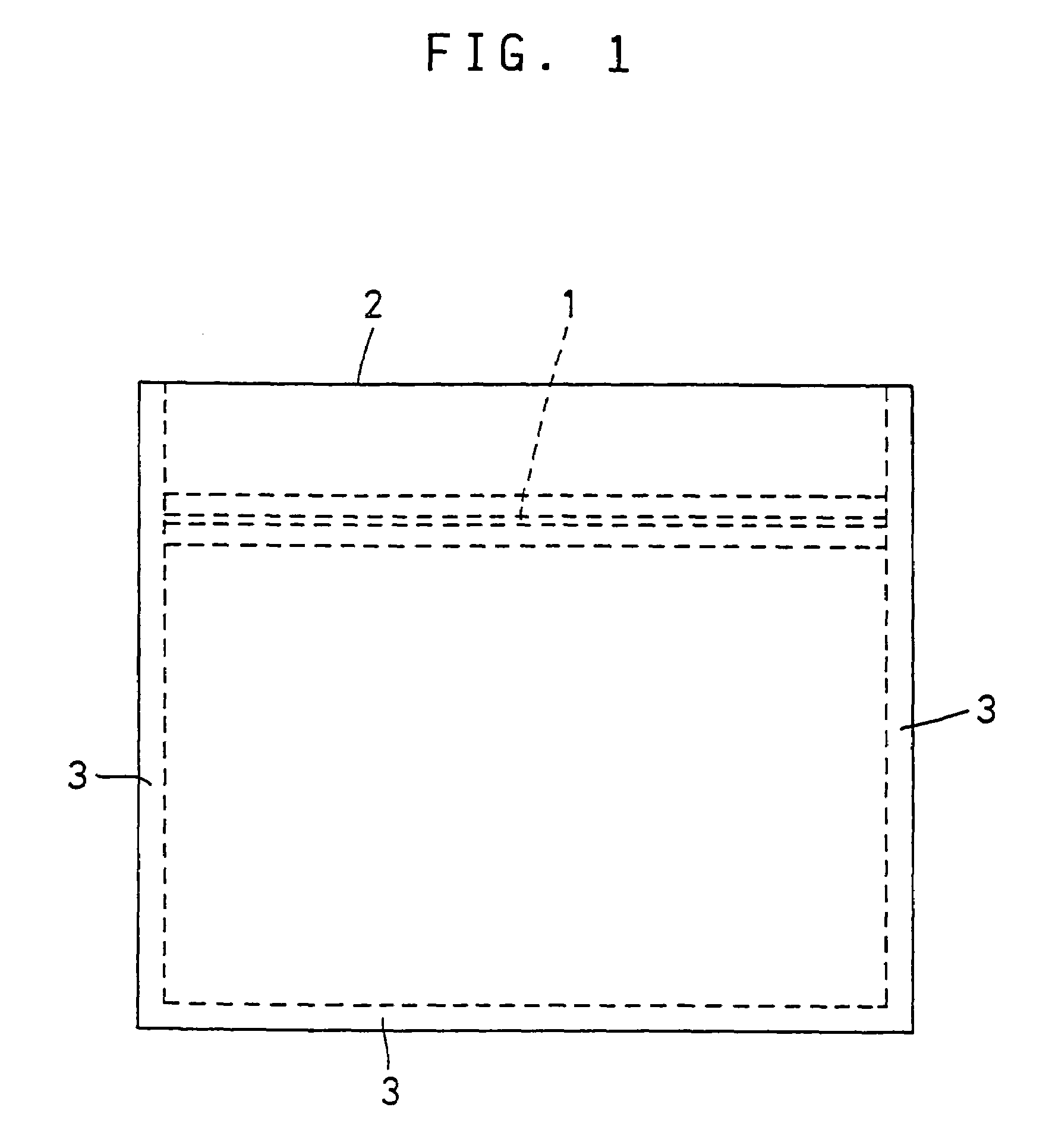

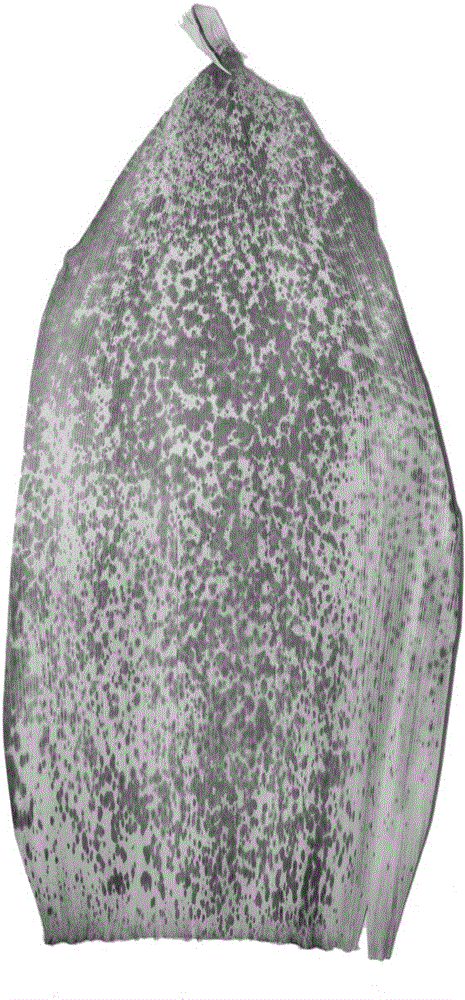

Biodegradable bag

The present invention provides a biodegradable bag which can be heat-sealed at low temperature, does not develop corrugation, has transparency, and has degradability in the natural environment. Laminates including a biaxially oriented film of which the major component is a polylactic acid-family polymer, and a film of which the major component is an aliphatic polyester having a predetermined structure are heat-sealed so that the biaxially oriented film of which the major component is the polylactic acid-family polymer will be an outer layer.

Owner:MITSUBISHI CHEM CORP

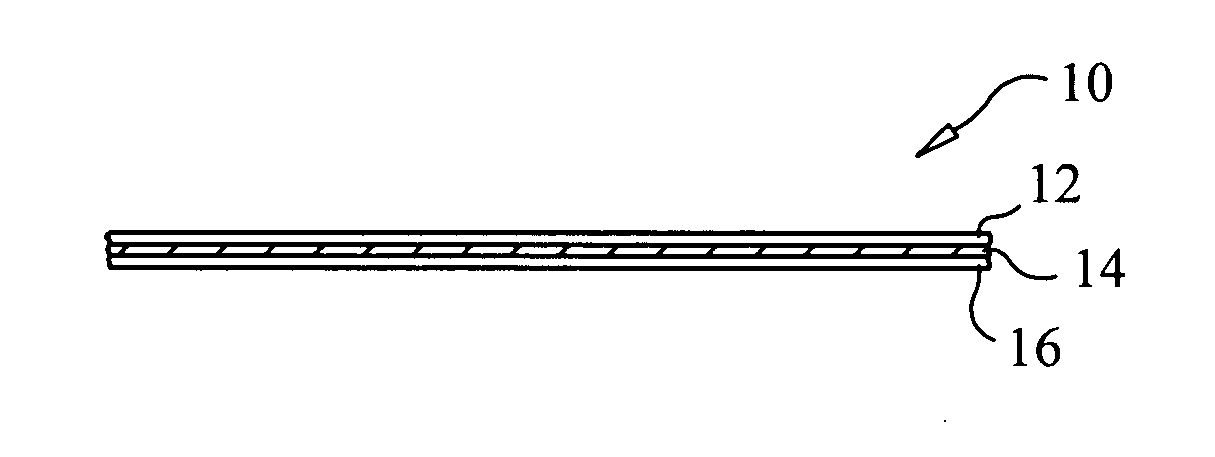

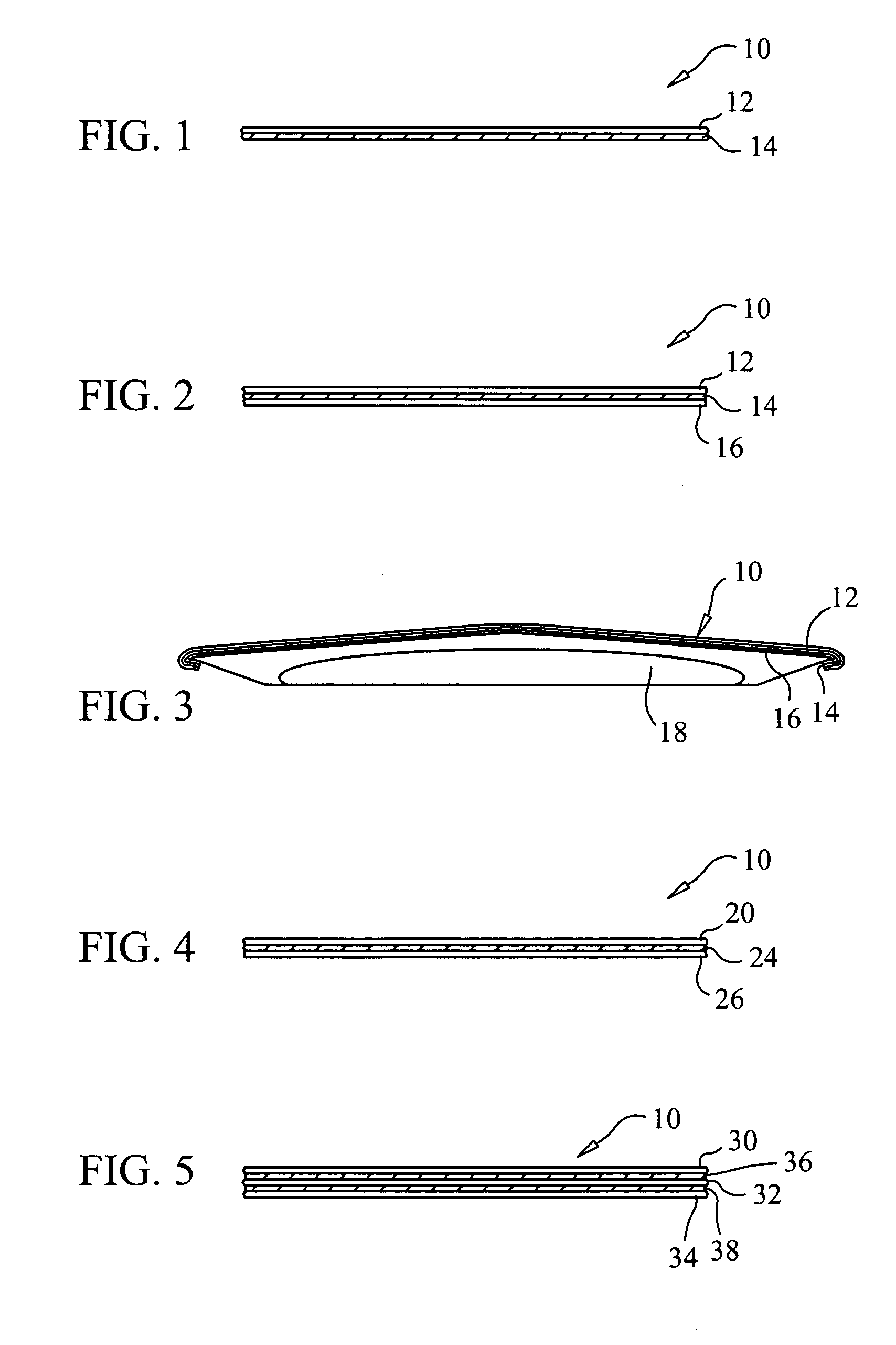

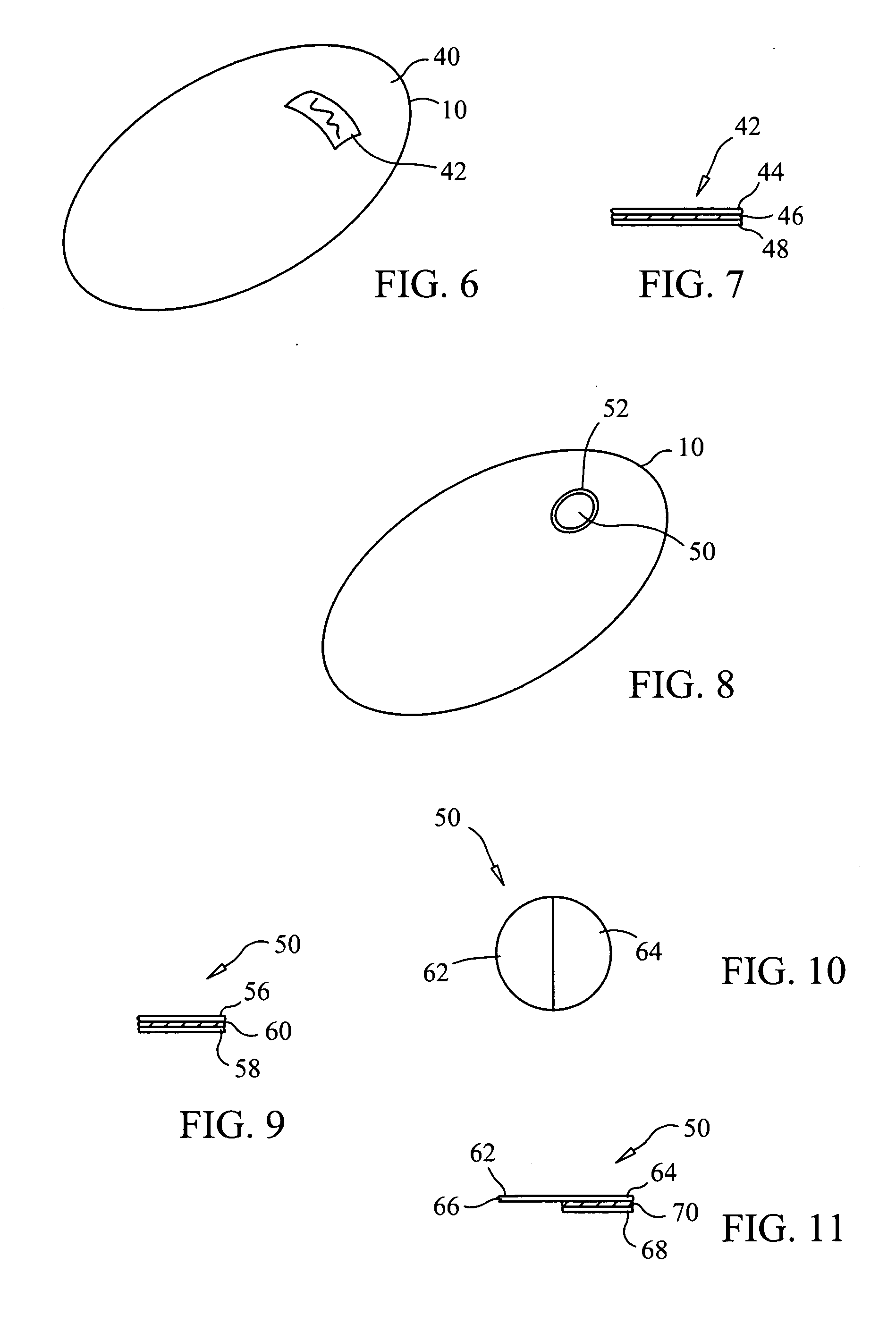

Biodegradable packaging material

The present invention provides a biodegradable packaging material useable for indicating the expiration of the shelf-life of the goods enclosed therein. For example, the packaging material of the present invention is used to enclose perishable foods, medicines, medical devices, medical instruments, medical implant, or other such limited shelf-life goods.

Owner:P TECH

Storage mildew-proof and moth-proof packaging hemp cloth and preparation method thereof

InactiveCN102310966APrevent intrusionPrevent mildewBio-packagingBiochemical fibre treatmentProcess dynamicsMildew

The invention provides storage mildew-proof and moth-proof packaging hemp cloth and a preparation method thereof. The hemp cloth comprises green harmless storage protective agent and is prepared by taking common packaging hemp cloth as a material and adding 0.01-10wt% of storage protective agent. The preparation method comprises the following steps of: dissolving the storage protective agent in a solvent to prepare a solution, then impregnating the hemp cloth in the protective agent solution, removing the solution after the hemp cloth sufficiently absorbs the solution, and drying; or dissolving the storage protective agent in the solvent, then uniformly spraying the protective agent solution on the hemp cloth and drying the hemp cloth after the hemp cloth sufficiently absorbs the protective agent solution to prepare the storage mildew-proof and moth-proof packaging hemp cloth. The storage hemp cloth is used for packaging tobaccos or crops, can realize the whole process dynamic and real-time protection of the tobaccos, the crops and the like in purchase, transport and storage processes, protect products from mildew and moths, effectively prevent the mildew and the moths from spreading between bags and prevent the tobaccos, the crops and the like which are soaked by rain water from mildewing. Besides, the invention has an important function for reducing environment pollution and hidden safety danger which are caused by common technologies.

Owner:ZHENGZHOU UNIV

Laminated moisture resistant poultry box and process

InactiveUS10226909B2Easily biodegradableEasy to re-pulp and recyclePackage recyclingMechanical working/deformationMechanical engineeringMoisture

A moisture resistant poultry box having a composite structure with a fluted paper medium, a top backing board assembly secured to one side of the fluted medium and a bottom backing board assembly secured to the other side of the fluted medium. The backing board assemblies and the fluted medium are impregnated with a hydrogenated triglyceride, and each backing board assembly has PET film glued thereto covering an outside surface to provide moisture resistant recyclable poultry box so that it has a Cobb value ranging between about 0 to about 1.

Owner:INDEVCO NORTH AMERICA INC

Bamboo shoot clothing packaging box and production process thereof

The invention relates to a packaging box, in particular to a bamboo shoot clothing packaging box which is formed by adopting bamboo shoot clothing (commonly called bamboo shoot shells, bamboo shells and indocalamus shells) made of moso bamboos (phyllostachys pubescens), phyllostachys parvifolia, dendrocalamus latiflorus, phyllostachys praecox, fargesia utilis, overlord bamboos and the like as raw materials (give priority to the moso bamboos) and processing through the processes of raw material purchasing and storage, rinsing, harmless treatment (insect control, mildew prevention, fiber softening, color development and mercerization), washing, drying, flattening, cutting, gluing (glue spraying or blanching and gluing), collage (blanching and collage), polishing, laser printing, inspecting, warehousing and the like. The bamboo shoot clothing packaging box has the main characteristics of moisture absorption and mildew prevention, insect control and corrosion resistance, stain repellence and scale prevention, is an ideal preferred package of tea leaves, tobaccos, food, instruments, jewelry and other products and has very extensive purpose; meanwhile, the bamboo shoot clothing packaging box is fashionable and attractive in appearance, realizes low carbon and environmental protection, is durable and fully embodies the change of wastes into valuables; moreover, a new high-quality laying and decoration material and a processing technology can be provided for the packaging industry in China.

Owner:CHIBI JIAXIANG BAMBOO SHOOT DEV

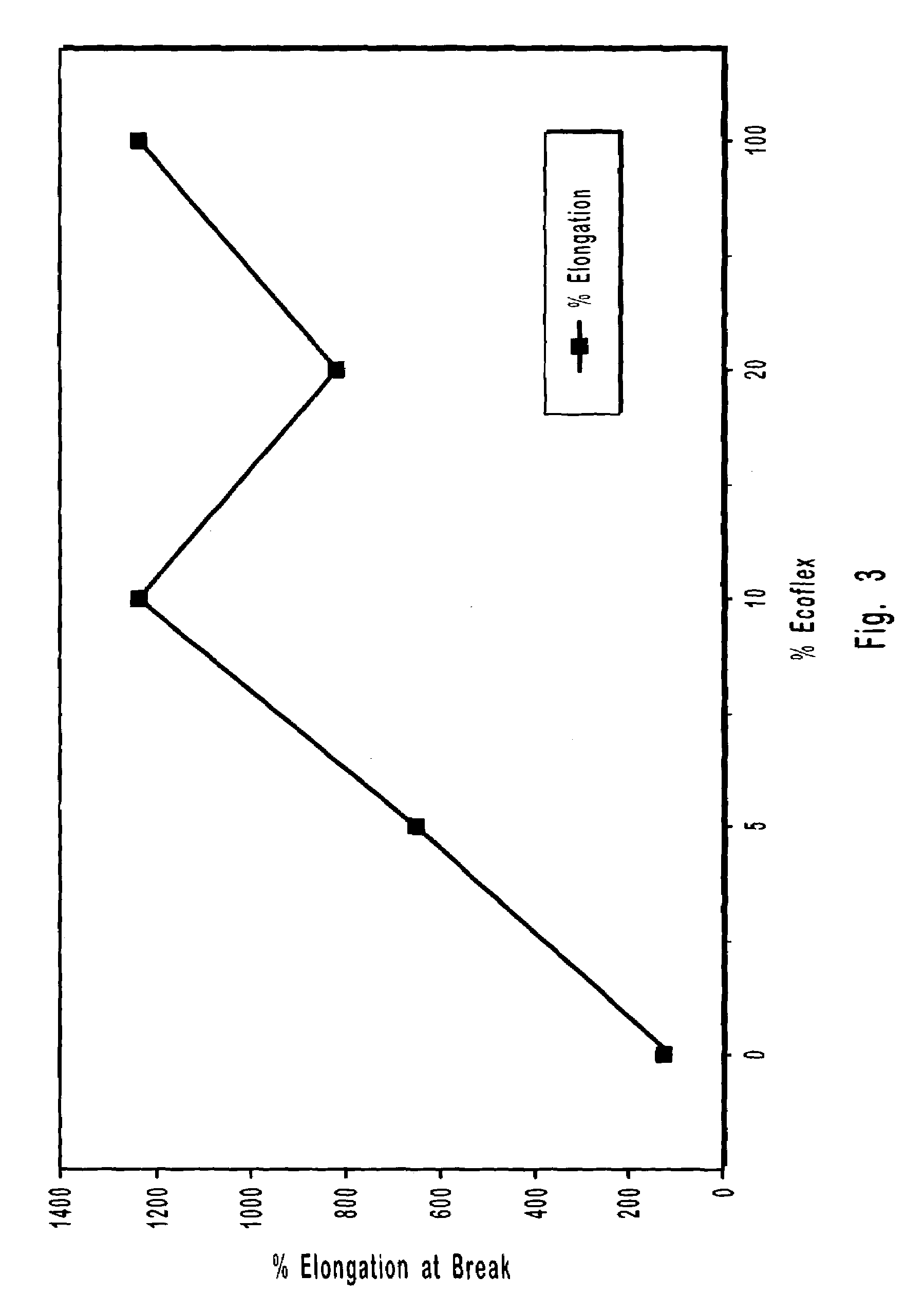

Fibrous sheets coated or impregnated with biodegradable polymers or polymers blends

ActiveUS7172814B2High glass transition temperatureImprove the crystallization processBio-packagingPaper coatingPolymer scienceBiopolymer

Fibrous sheets are coated or impregnated with a biodegradable composition to render the sheets more resistant to penetration by liquids. Biodegradable polymer blends suitable for use in coating or impregnating a fibrous sheet can be manufactured from at least one “hard” biodegradable polymer and at least one “soft” biodegradable polymer. “Hard” biopolymers typically have a glass transition temperature of at least about 10° C. “Soft” biodegradable polymers typically have a glass transition temperature less than about 0° C. Another useful biodegradable polymer composition includes one or more biodegradable polymers and sufficient inorganic filler so as to render the treated sheet microwaveable. The biodegradable polymer compositions are especially well-suited for coating or impregnating paper sheets, e.g., 12–15 lb / 3000 ft2 tissue paper to yield food wraps. Food wraps will typically be manufactured to have good “dead-fold” properties so as to remain in a wrapped position and not spring back to an “unwrapped” form.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

Specialty beverage infusion package

InactiveUS20050136155A1High tensile strengthShort sink timeFlexible coversWrappersEngineeringThermoplastic polymer

The present invention provides an infusion beverage package having a good balance of properties including, being biodegradable, good tensile strength and a short infusion times, while being transparent enough so as to enable a user of the package to see the contained infusion beverage precursor within the package before infusing the package into water. The infusion beverage package of the present invention is prepared from a porous web derived from a biodegradable thermoplastic polymer, wherein the package has a transparency of at least about 30%, a tensile strength of at least about 2N / 15 mm, and an infusion time of less than about 20 seconds. In addition, the seal strength of the package is at least 2N / 15 mm.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Compositions for manufacturing fiber-reinforced, starch-bound articles having a foamed cellular matrix

InactiveUSRE39339E1Avoid lack of toughnessHigh strengthClosure lidsSolid waste managementPolymer sciencePaperboard

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a fiber-reinforced, starch-bound cellular matrix. Suitable mixtures used to form the articles are prepared by first preparing a viscous preblended mixture comprising water, a gelatinized starch-based binder, and fibers having an average length greater than about 2 mm. The highly viscous preblended mixture effectively transfers the shearing forces of the mixer to the fibers. The final moldable mixture is then prepared by mixing into the preblended mixture the remaining starch-based binder, water, and other desired admixtures, e.g., mold-releasing agents, inorganic filler rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The moldable mixtures are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled foamed structural matrix. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic-based materials and have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

Repulpable container

A repulpable insulated container assembly having a container formed of paper such as corrugated cardboard or varying paper materials and defining an interior; and a repulpable insert placed within the interior of the container and formed of a first paper layer; and a paper fiber pad coupled to the first paper layer.

Owner:PRATT RETAIL SPECIALTIES LLC

Matte biaxially oriented polylactic acid film

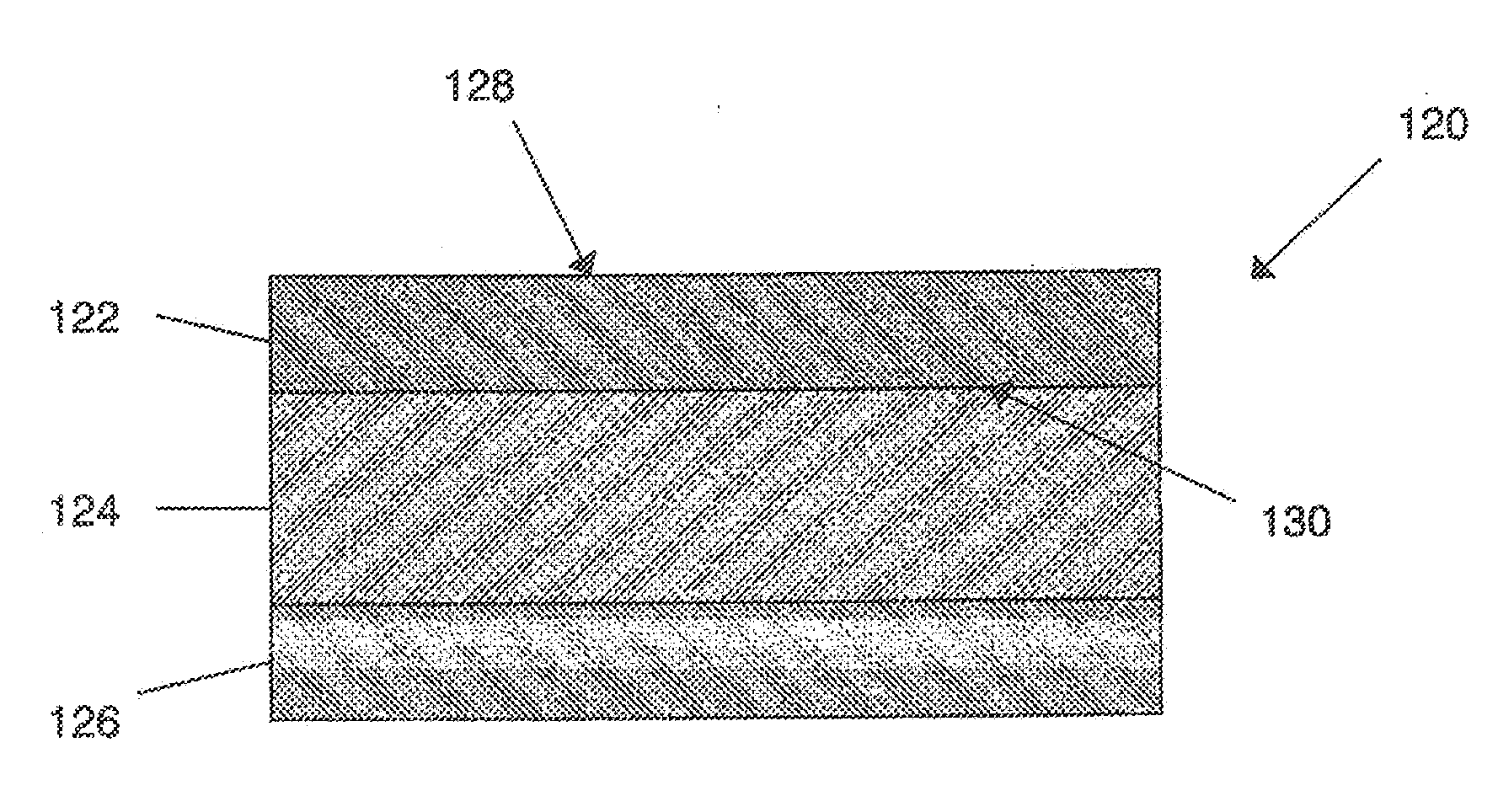

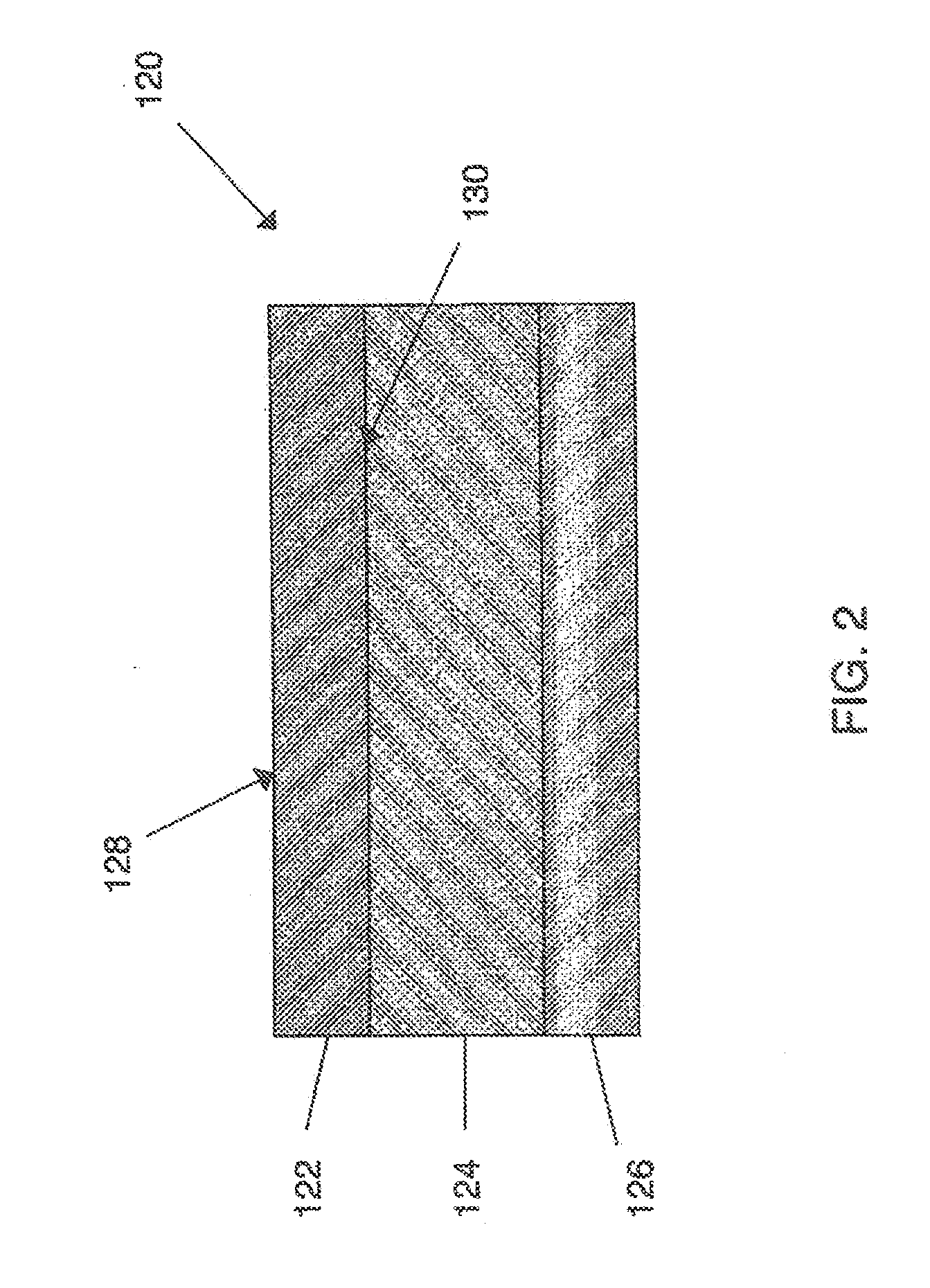

ActiveUS20100009208A1Minimize thermal shrinkage effectReduce internal stressBio-packagingSynthetic resin layered productsPolyolefinPolymer chemistry

A biaxially oriented laminate film including a core layer including a blend of crystalline polylactic acid polymer and a minority amount of polyolefin with a compatibilizing resin which is biaxially oriented such that a matte or opaque appearance is obtained. The laminate film may further have additional layers such as a heat sealable layer disposed on one side of the core layer including an amorphous polylactic acid resin and / or a polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Modified polylactic acid material and preparation method and application thereof

The invention provides a modified polylactic acid material and a preparation method and application thereof. The modified polylactic acid material comprises the following raw materials in part by weight: 40 to 70 parts of polylactic acid, 10 to 20 parts of thermoplastic polyester elastomer, 10 to 20 parts of plasticizer and 10 to 20 parts of organic or inorganic filler, wherein the thermoplastic polyester elastomer is polyester thermoplastic polyurethane; the plasticizer is one or two of tributyl acetocitrate, epoxidized soybean oil, propylene glycol polyester adipate or dioctyl maleate; and the organic or inorganic filler is one or more of starch, talcum powder, calcium carbonate, mica, montmorillonite, clay or titanium dioxide. The modified polylactic acid material has the advantages of improving the flexibility of a polylactic acid material and reducing the cost of a biodegradable material. A mechanical performance test shows that in the modified polylactic acid material, the tensile strength is 15 to 70 MPa and the fracture tensile rate is 20 to 38 percent.

Owner:江苏天仁生物材料有限公司

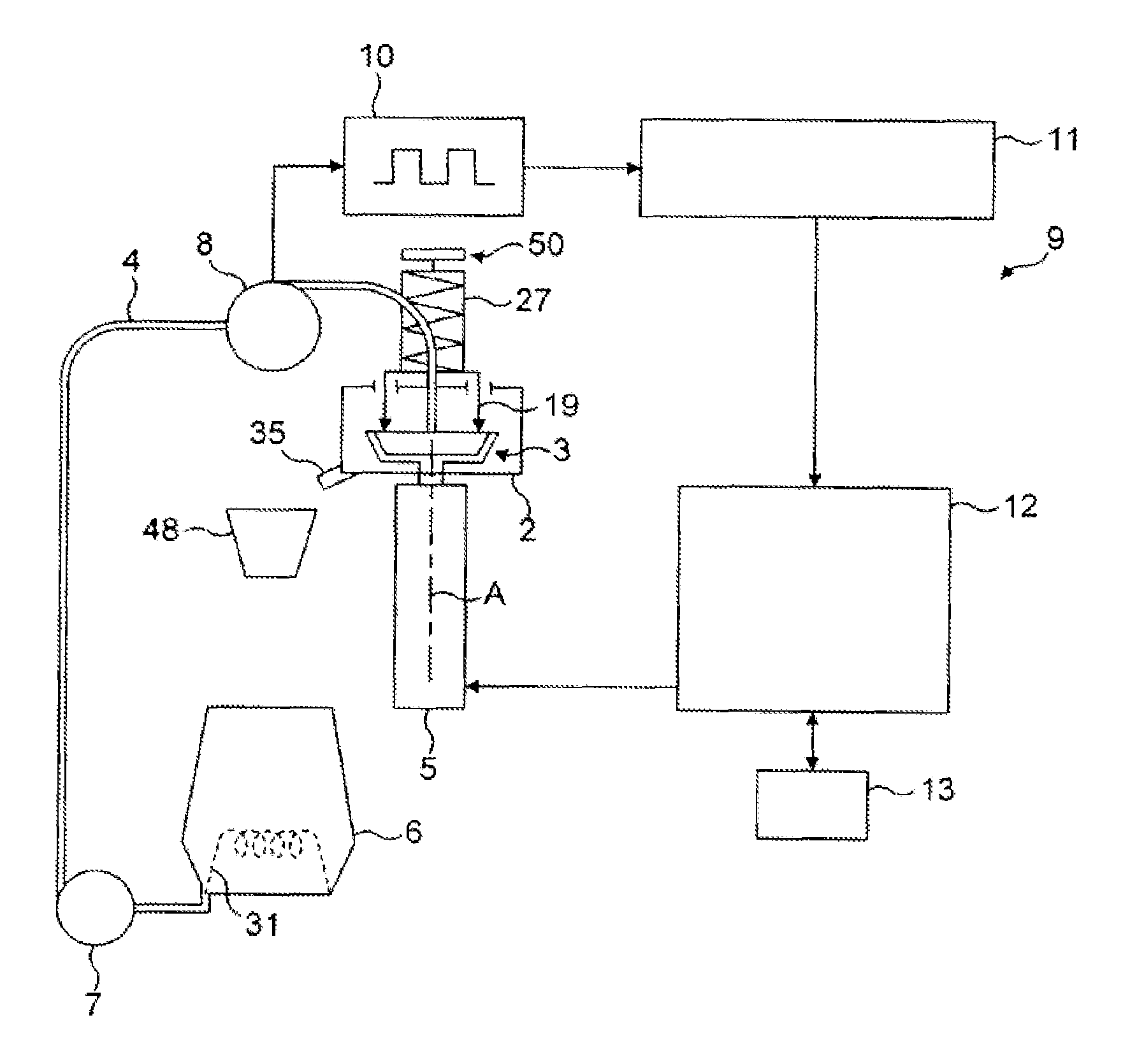

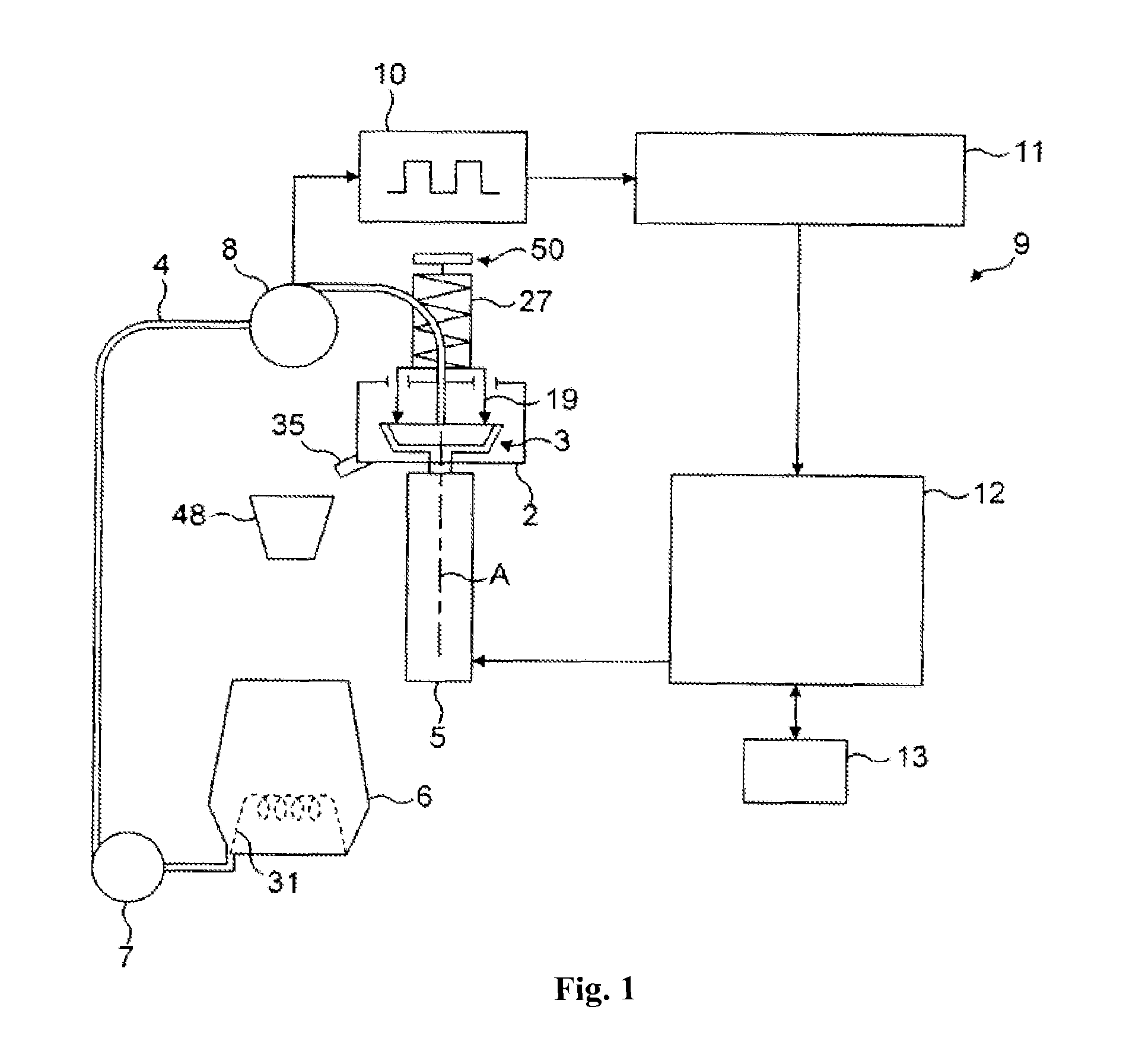

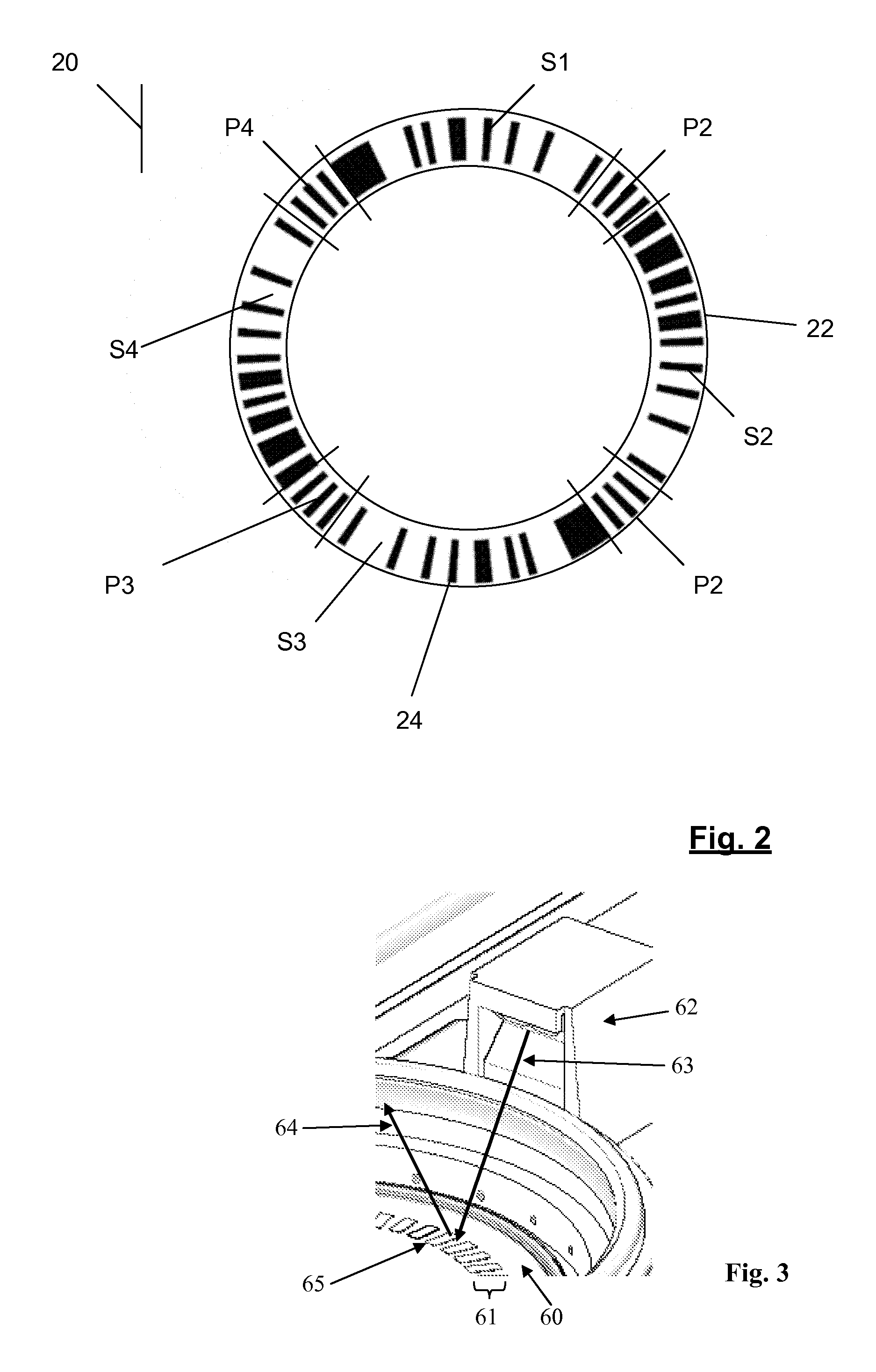

Support and capsule for preparing a beverage by centrifugation, system and method for preparing a beverage by centrifugation

InactiveUS20130064929A1OptimizationIncrease the areaContainer decorationsLevel indicationsCentrifugationBiomedical engineering

Support (20) adapted to be associated with, or part of a capsule (7) for the preparation of a beverage, comprising a section on which at least one sequence of symbols (24) is represented so as that each symbol is sequentially readable, by a reading arrangement of an external device, while the capsule is driven in rotation along an axis of rotation, each sequence coding a set of information related to the capsule.

Owner:NESTEC SA

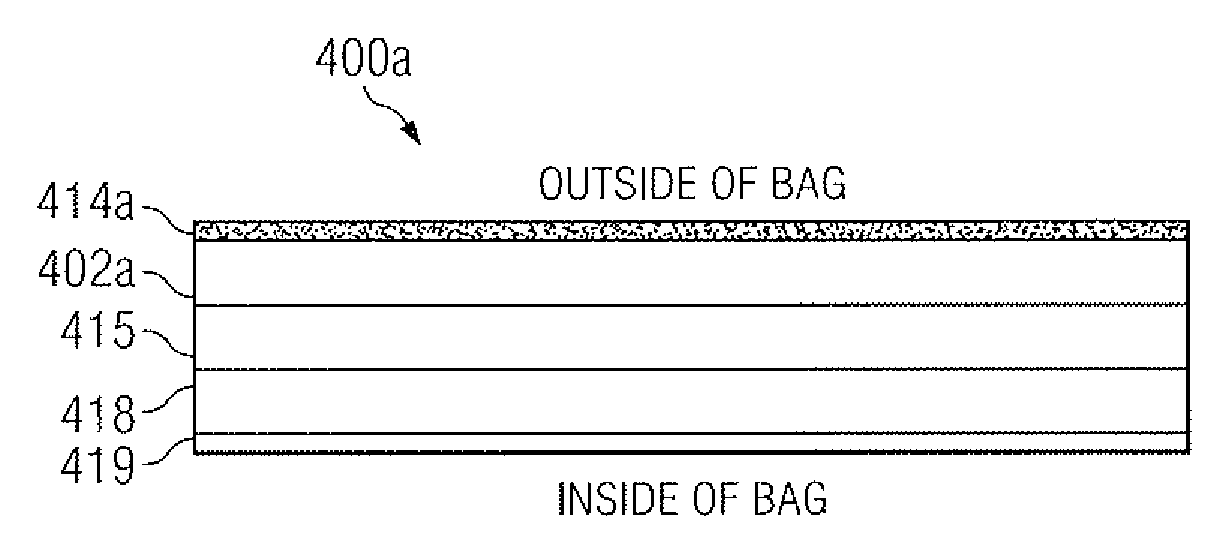

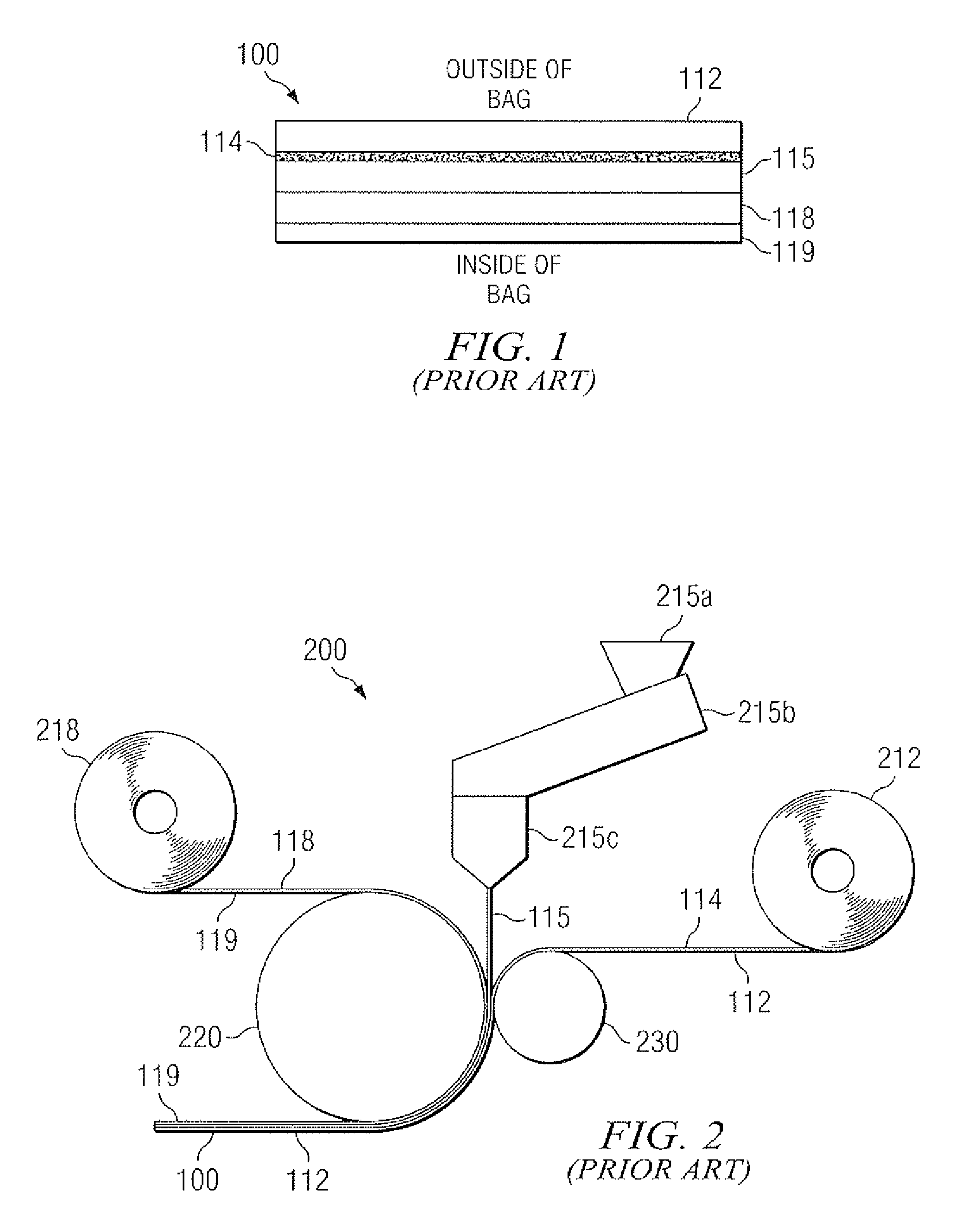

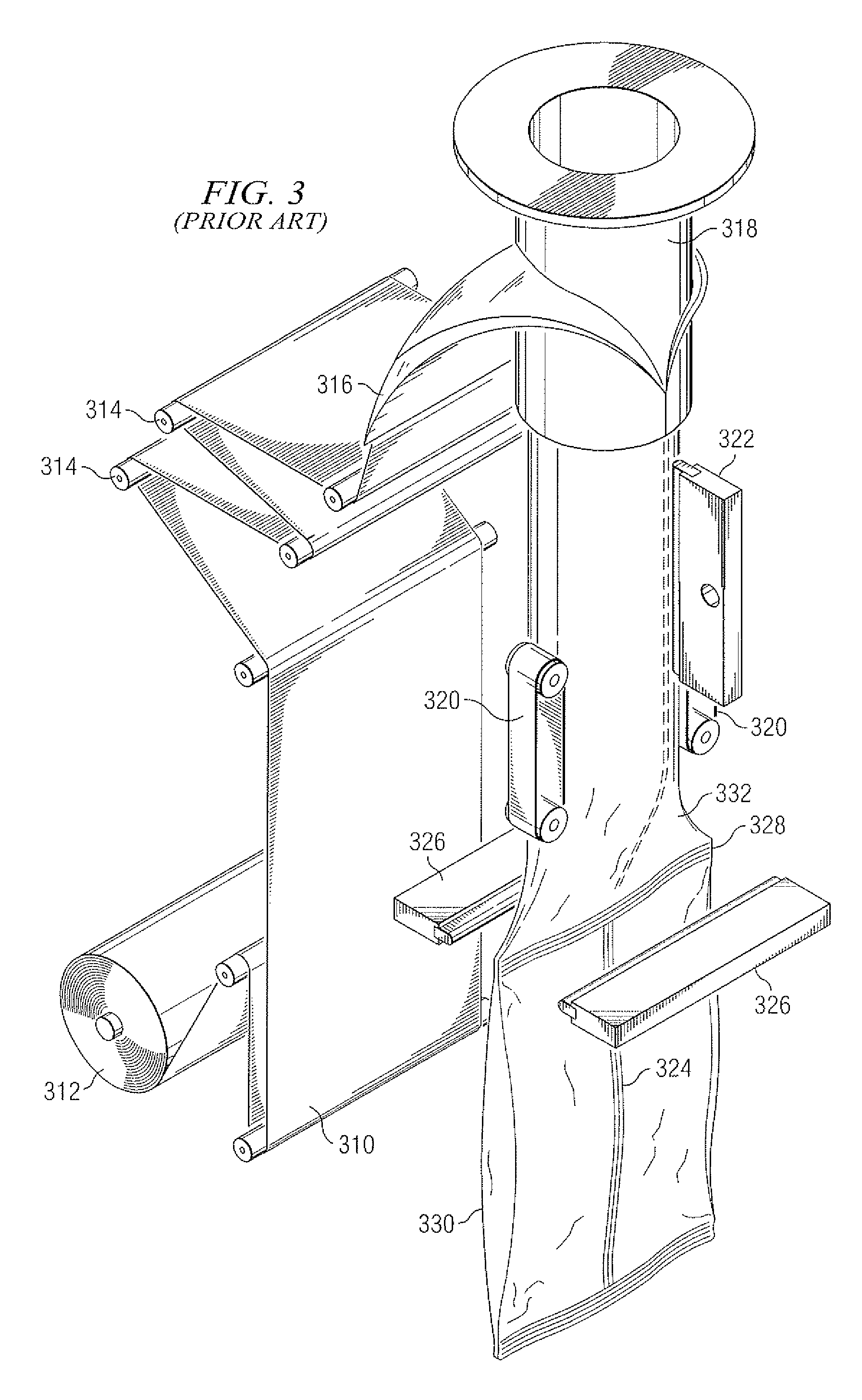

Environmentally-Friendly Multi-Layer Flexible Film Having Barrier Properties

A multi-layer film with barrier properties having two or more layers made from a bio-based film is disclosed. In one aspect, the print web comprises a bio-based film. In one aspect, the barrier web comprises a bio-based film. In one aspect, a bio-based adhesive adheres the print web to the barrier web. The bio-based film can include paper, PCR, polylactide or polyhydroxy-alkanoate. Unlike prior art petroleum-based films, the bio-based film of the present invention is made from a renewable resource and is biodegradable.

Owner:FRITO LAY NORTH AMERICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com