Patents

Literature

306 results about "Process dynamics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

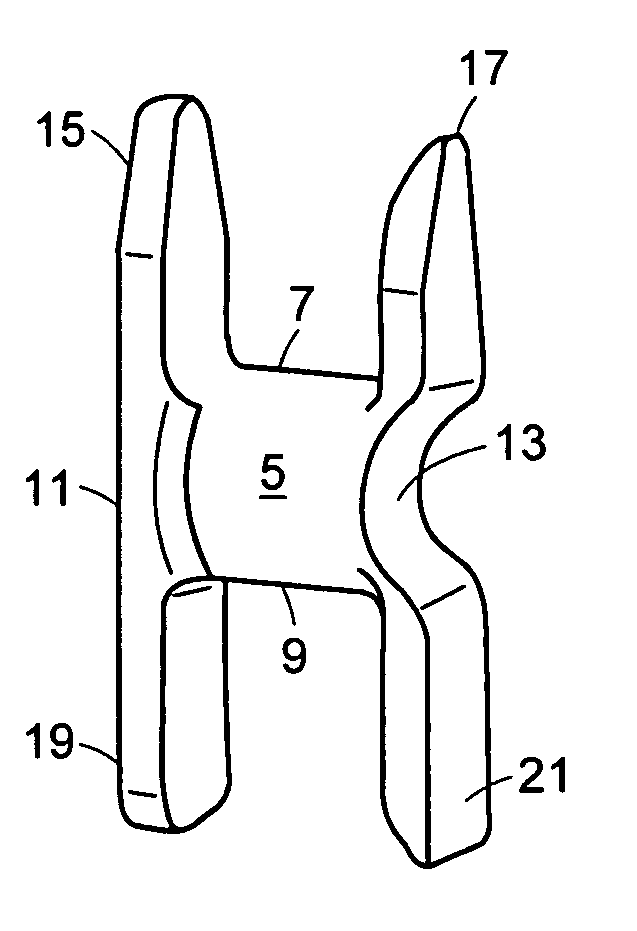

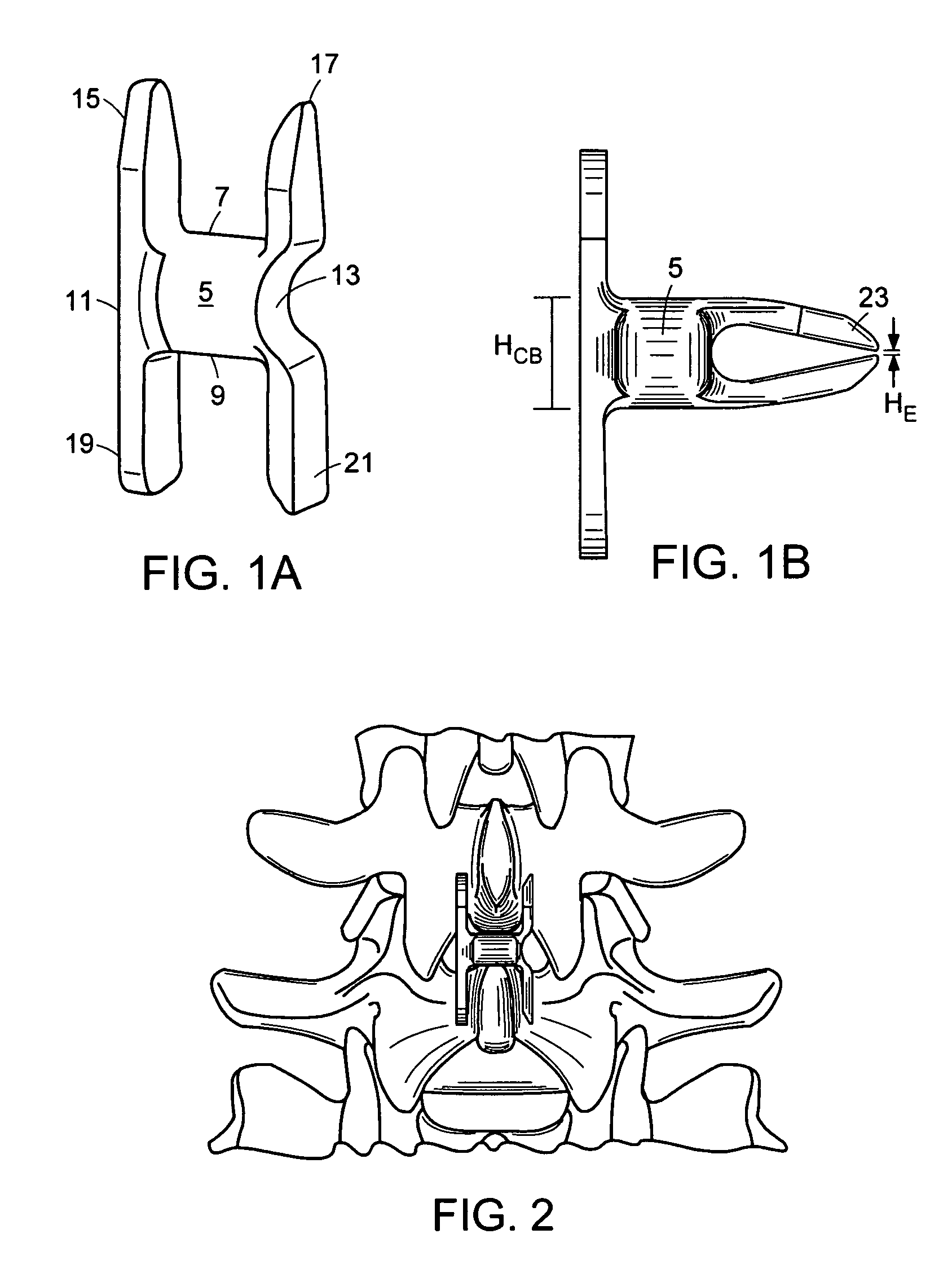

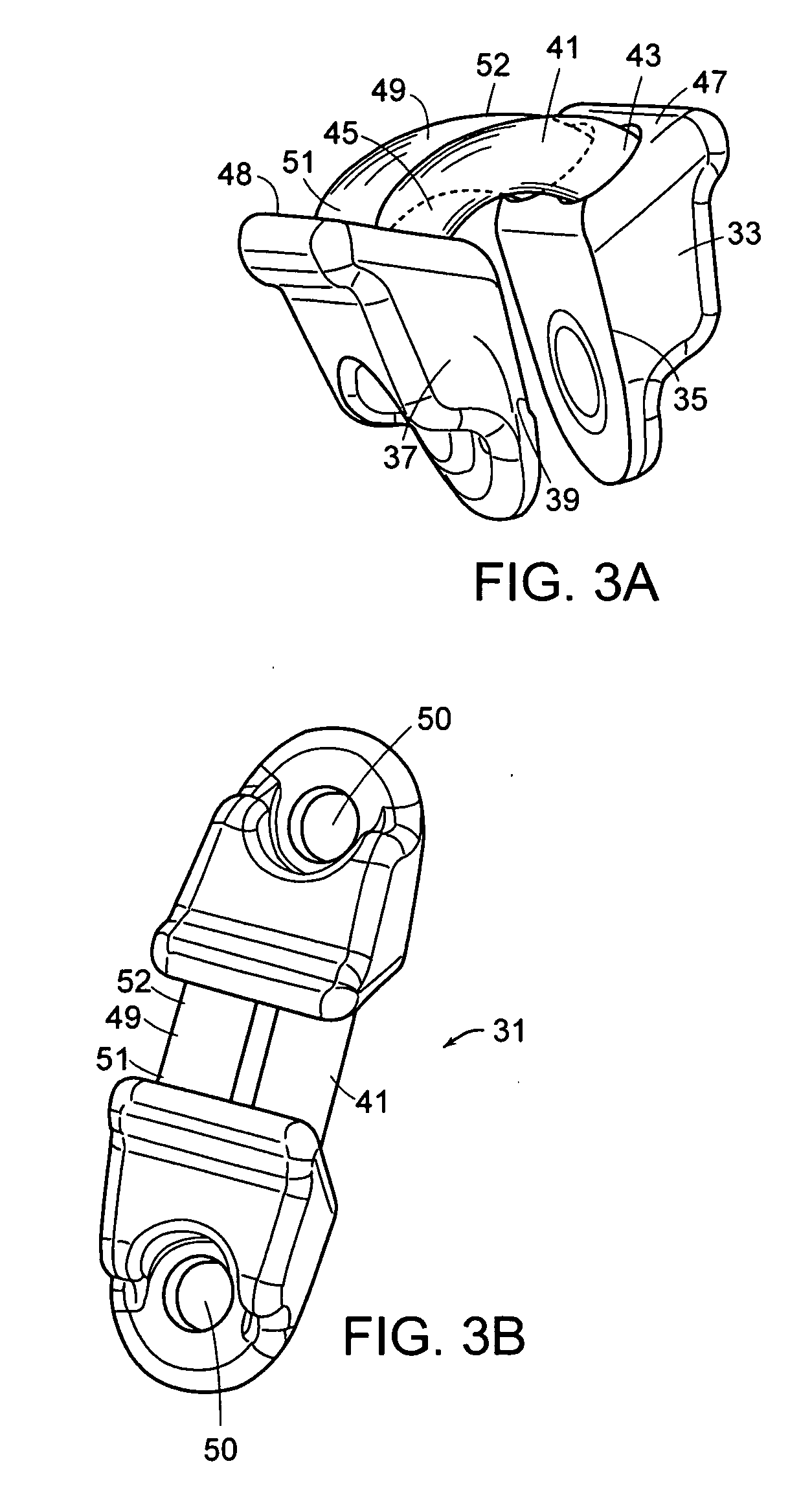

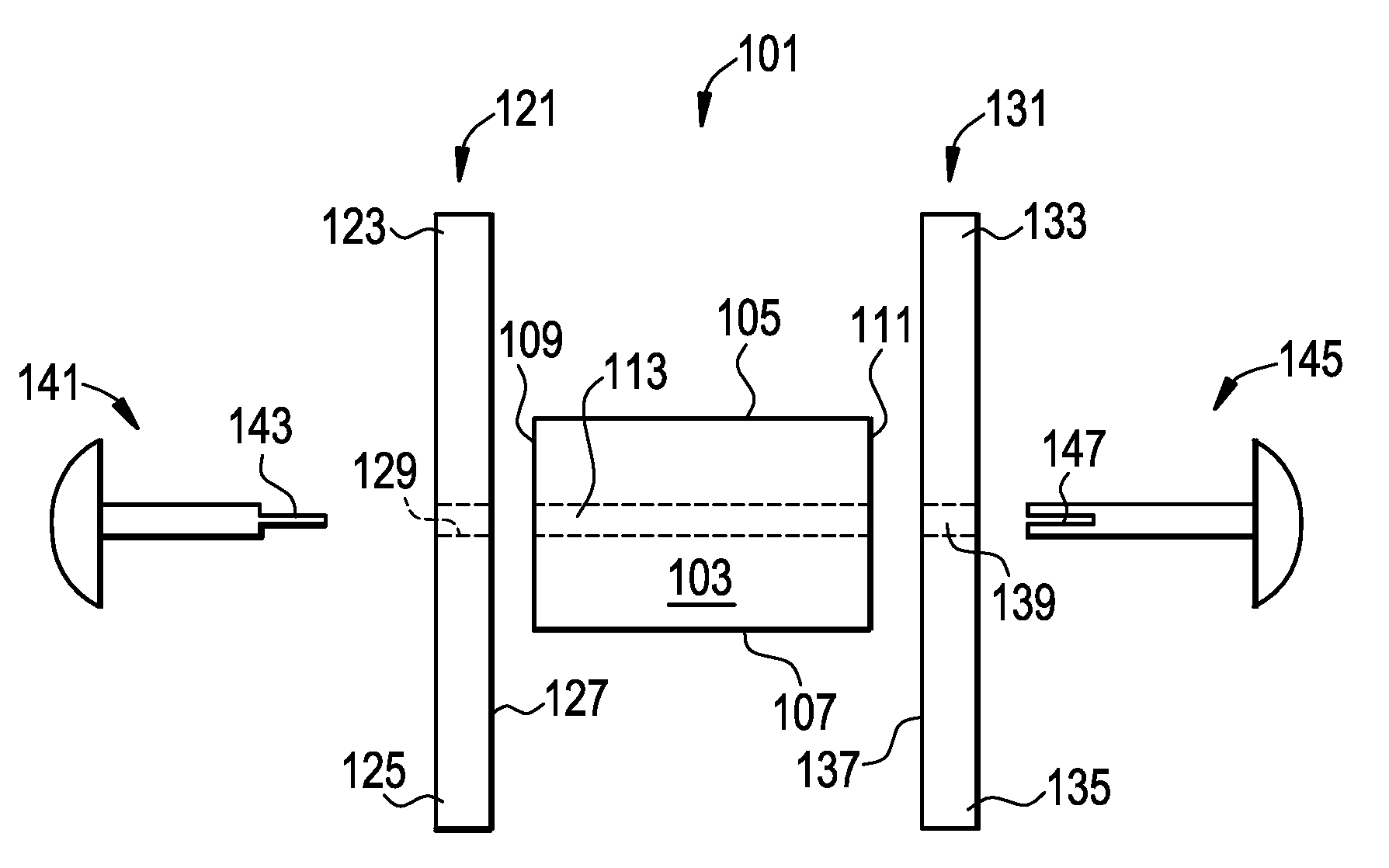

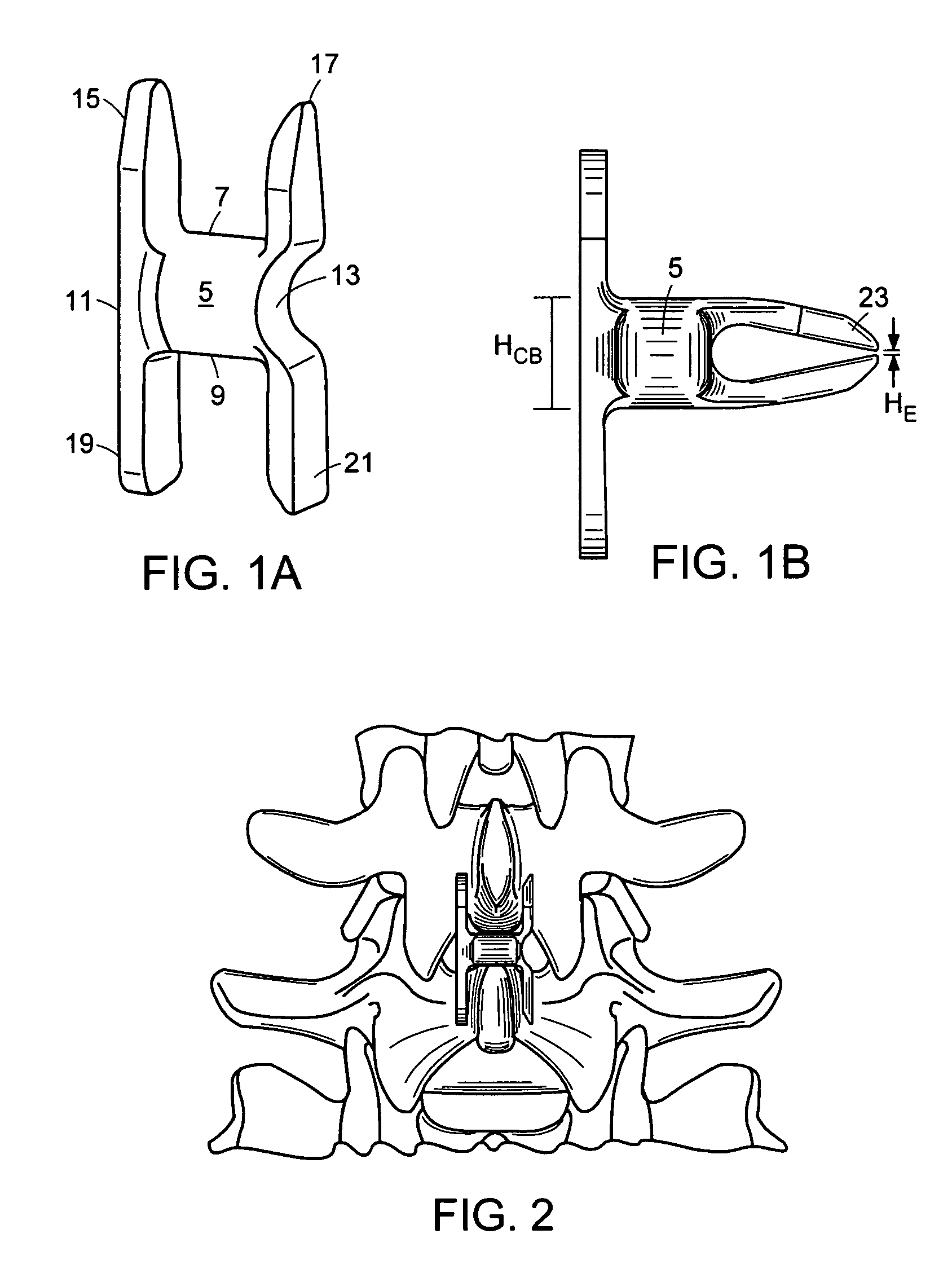

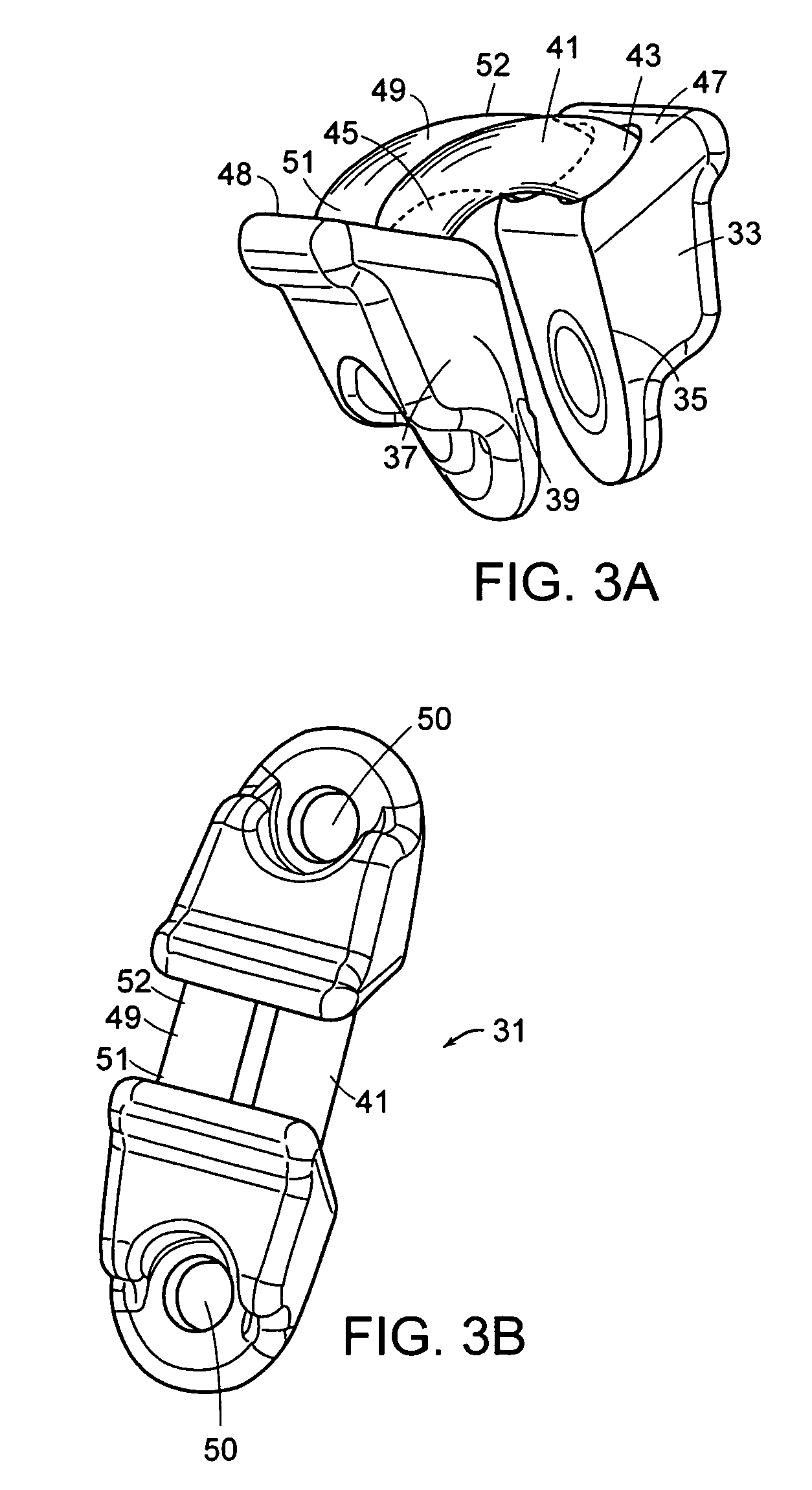

Posterior process dynamic spacer

ActiveUS20050203512A1Gently limiting excessive extensionOrganic chemistryInternal osteosythesisProcess dynamicsMedicine

Owner:DEPUY SPINE INC (US)

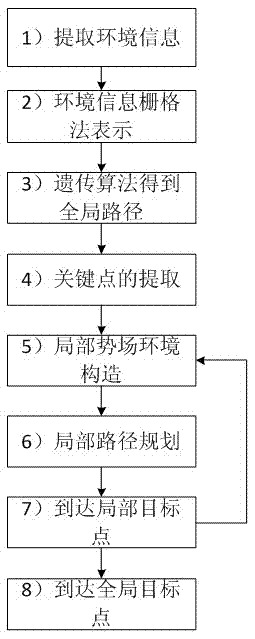

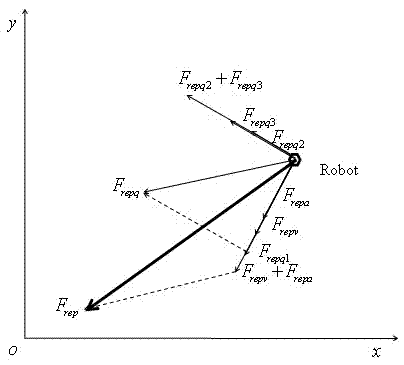

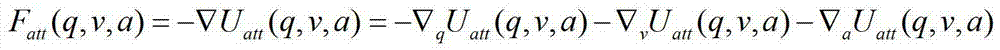

Mixed robot dynamic path planning method

InactiveCN103092204AIncrease flexibilityPosition/course control in two dimensionsGlobal planningProcess dynamics

The invention discloses a mixed robot dynamic path planning method which is capable of being applied on the condition that a part of environment information is known, and unknown dynamic and static obstacles exist at the same time. Aiming at the conditions, the mixed robot dynamic path planning method comprises the following steps: utilizing a genetic algorithm (GA) as a global planning method to obtain global paths, and then conducting local planning by means of an improved artificial potential field method. According to the mixed robot dynamic path planning method, in local planning, speed and acceleration information of a robot and a barrier is considered, and therefore the mixed robot dynamic path planning method has better effects on processing dynamic path planning. In addition, effects of global planning path for local planning are also considered. The mixed robot dynamic path planning method is ease to achieve, robot paths obtained are more optimized, and meanwhile good flexibility is shown in the application.

Owner:ZHEJIANG UNIV

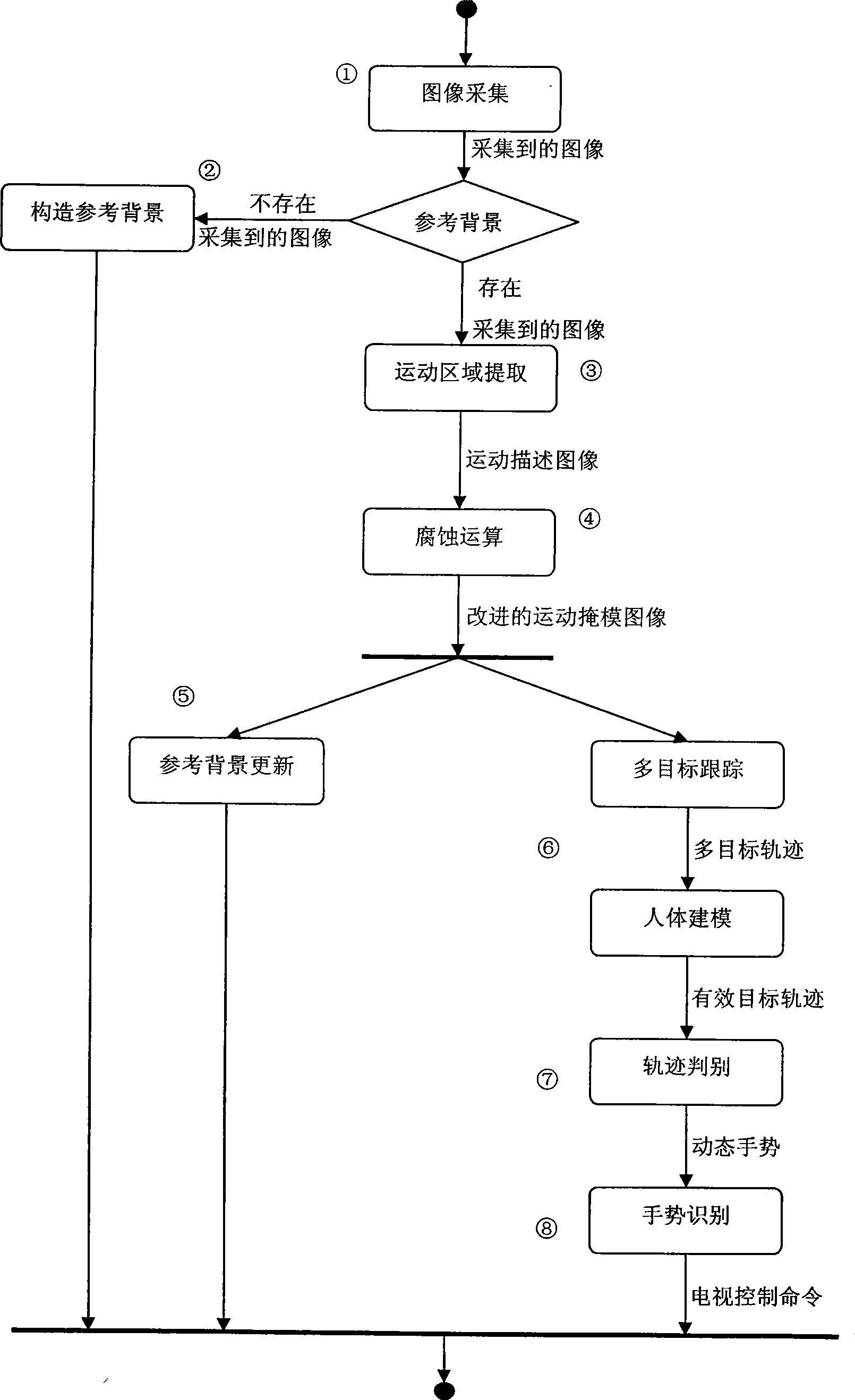

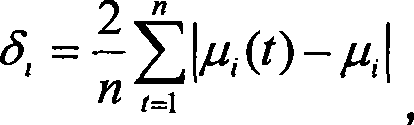

Method for processing dynamic gesture identification signal facing (to)television set control

InactiveCN101437124APerfect remote control methodTelevision system detailsColor television detailsProcess dynamicsRemote control

The invention provides a method for processing a signal by dynamic gesture identification for television control, which relates to a signal processing method which detects motion in an image photographed by a television embedded camera, identifies actions of a hand and converts the action to a television control signal (such as channel switching, volume regulation, more complex menu operation and the like). The method comprises the following steps: acquiring a television user action image by the television built-in camera, analyzing the acquired image to acquire a motion region; extracting information of a hand target from the motion region to generate a track; and determining a command corresponding to the track to generate the television control command. The invention provides a method for controlling the television by a dynamic gesture through positioning the hand without manual assistance, which is to acquire a gesture language through a mode of detecting the motion and constructing a multiple objective body-models, and generate the corresponding television control command. The method provides a more improved mode of remote control for the field of gesture language television. The mode of remote control can significantly promote the development of the television application field.

Owner:SAMSUNG ELECTRONICS CHINA R&D CENT +1

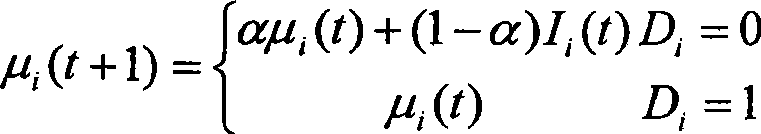

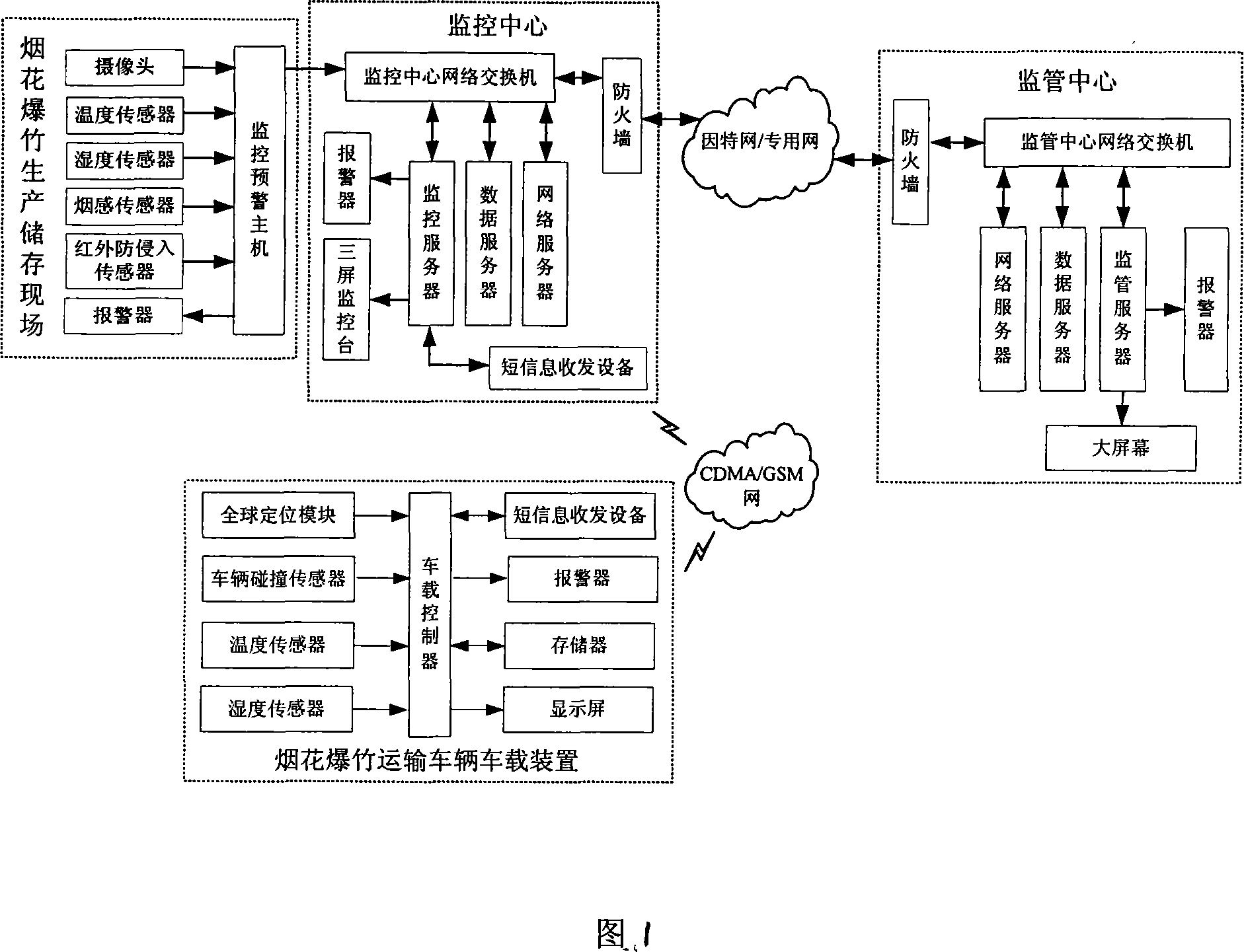

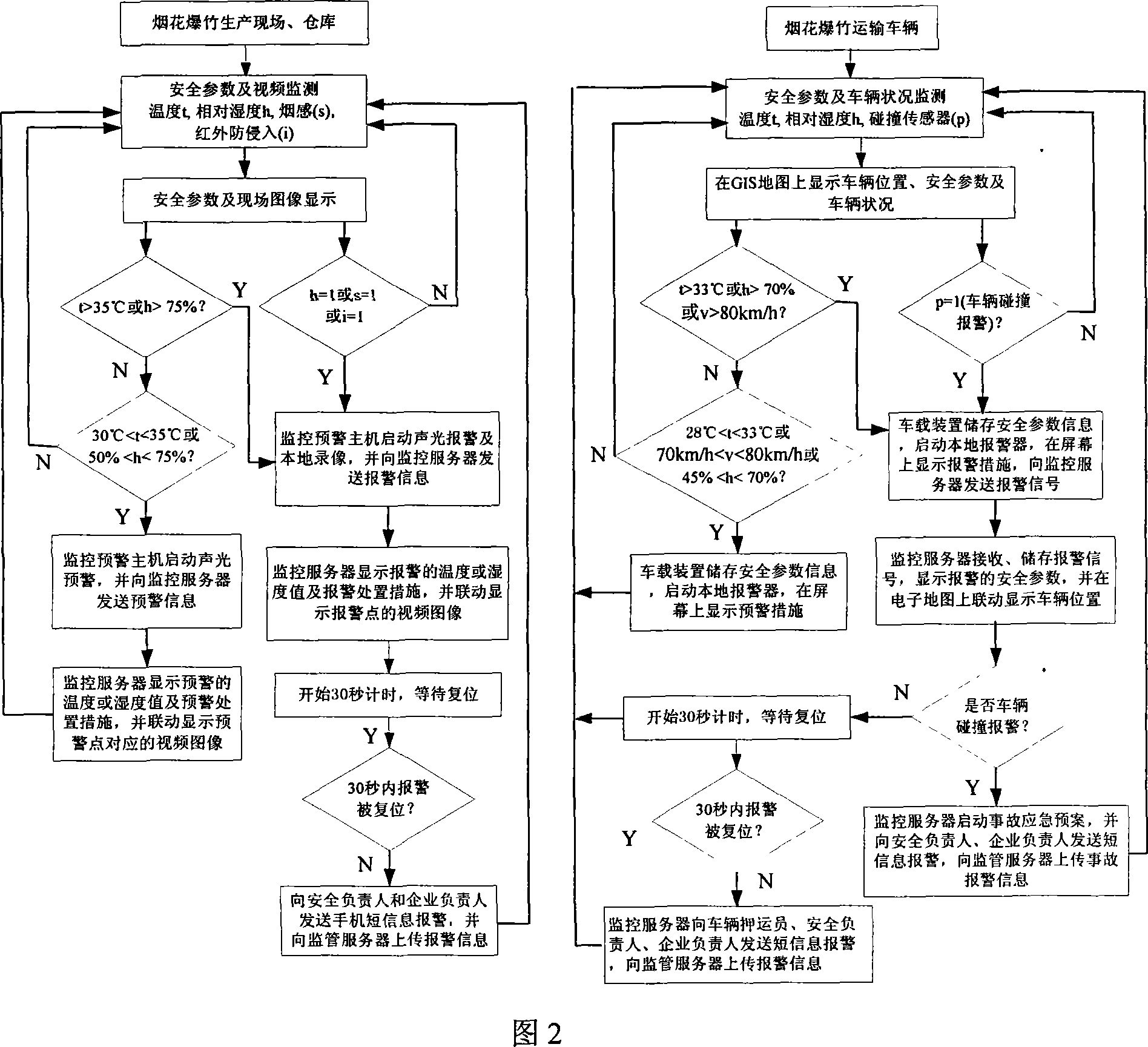

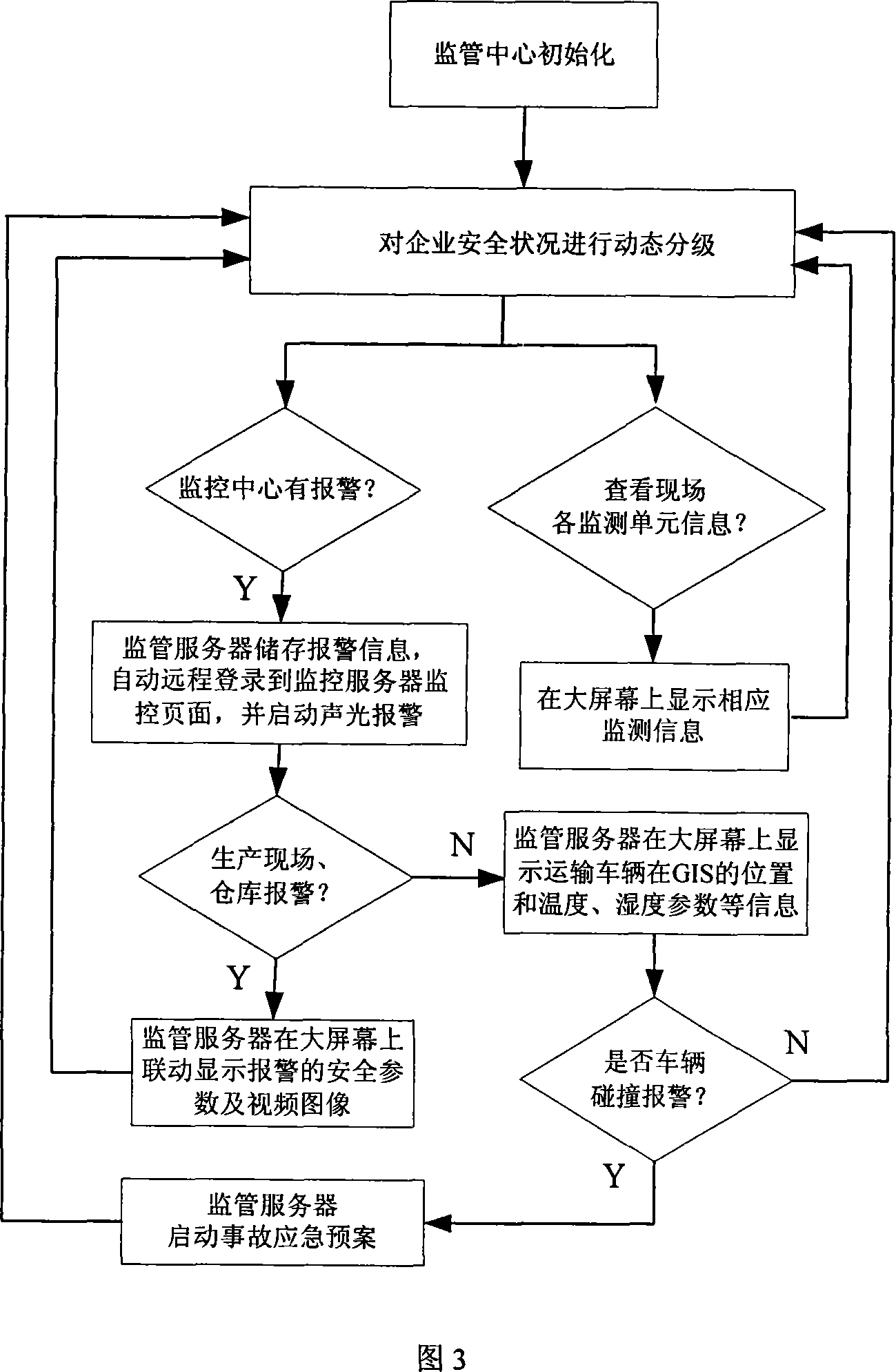

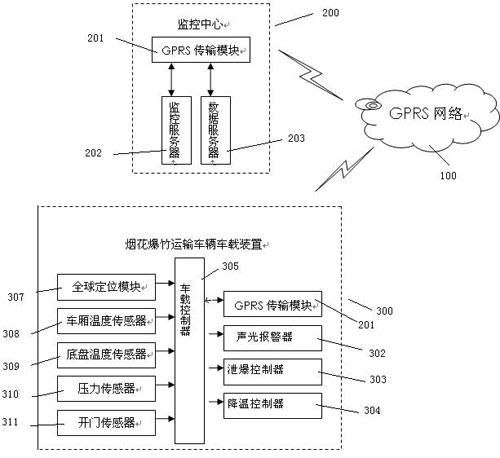

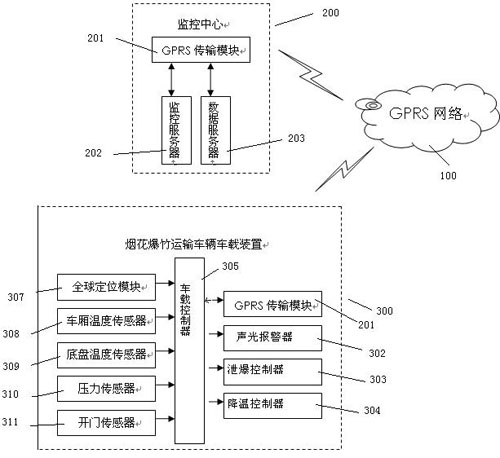

Dynamic monitoring system and method for fireworks and firecracks production storage and transportation process

InactiveCN101067744ARealize hierarchical alarmImprove work efficiencyComputer controlSimulator controlProcess dynamicsStatistical analysis

The invention relates to fireworks and crackers producing, storing, transporting process dynamic monitoring system and method. The method is formed by supervising and monitoring center systems. It includes that real time collecting and dynamically displaying safe parameter and video information for the firework and crackers production field, band and transportation vehicle; dynamically display the safe parameter, position information, speed information for the transportation vehicle; classing early-warning, warning, processing for the safe parameter; statistical analysis for corporation safety condition; searching corporation monitoring information and warning processing; when the transportation happens accident, the monitoring server will start corresponding emergency beforehand. The invention can prevent large malignancy accident from happening in firework and crackers producing, storing, and transporting to protect people life and property better.

Owner:CHINA ACAD OF SAFETY SCI & TECH

Storage mildew-proof and moth-proof packaging hemp cloth and preparation method thereof

InactiveCN102310966APrevent intrusionPrevent mildewBio-packagingBiochemical fibre treatmentProcess dynamicsMildew

The invention provides storage mildew-proof and moth-proof packaging hemp cloth and a preparation method thereof. The hemp cloth comprises green harmless storage protective agent and is prepared by taking common packaging hemp cloth as a material and adding 0.01-10wt% of storage protective agent. The preparation method comprises the following steps of: dissolving the storage protective agent in a solvent to prepare a solution, then impregnating the hemp cloth in the protective agent solution, removing the solution after the hemp cloth sufficiently absorbs the solution, and drying; or dissolving the storage protective agent in the solvent, then uniformly spraying the protective agent solution on the hemp cloth and drying the hemp cloth after the hemp cloth sufficiently absorbs the protective agent solution to prepare the storage mildew-proof and moth-proof packaging hemp cloth. The storage hemp cloth is used for packaging tobaccos or crops, can realize the whole process dynamic and real-time protection of the tobaccos, the crops and the like in purchase, transport and storage processes, protect products from mildew and moths, effectively prevent the mildew and the moths from spreading between bags and prevent the tobaccos, the crops and the like which are soaked by rain water from mildewing. Besides, the invention has an important function for reducing environment pollution and hidden safety danger which are caused by common technologies.

Owner:ZHENGZHOU UNIV

Posterior process dynamic spacer

ActiveUS7763073B2Gently limiting excessive extensionOrganic chemistryInternal osteosythesisProcess dynamicsMedicine

Owner:DEPUY SPINE INC (US)

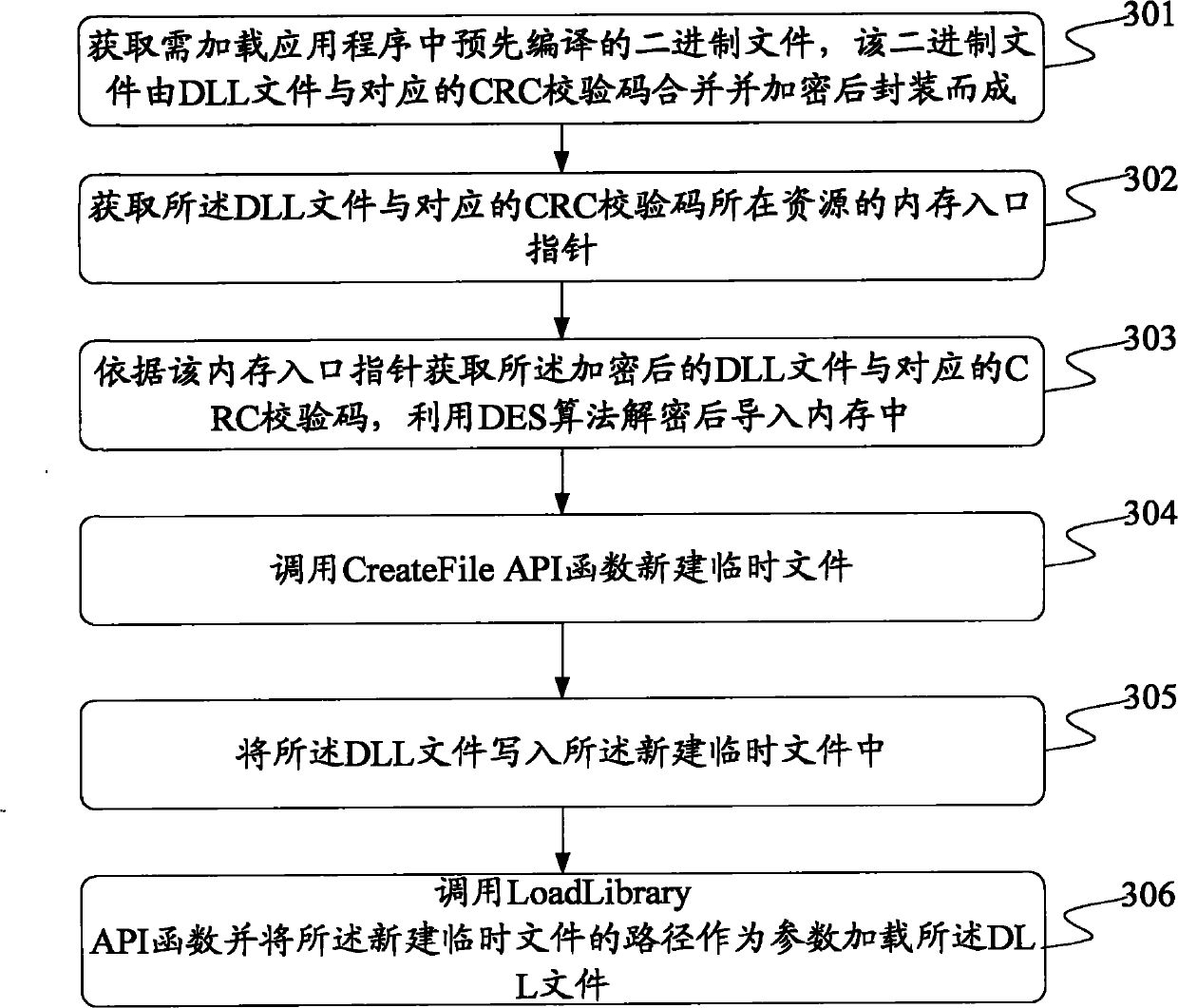

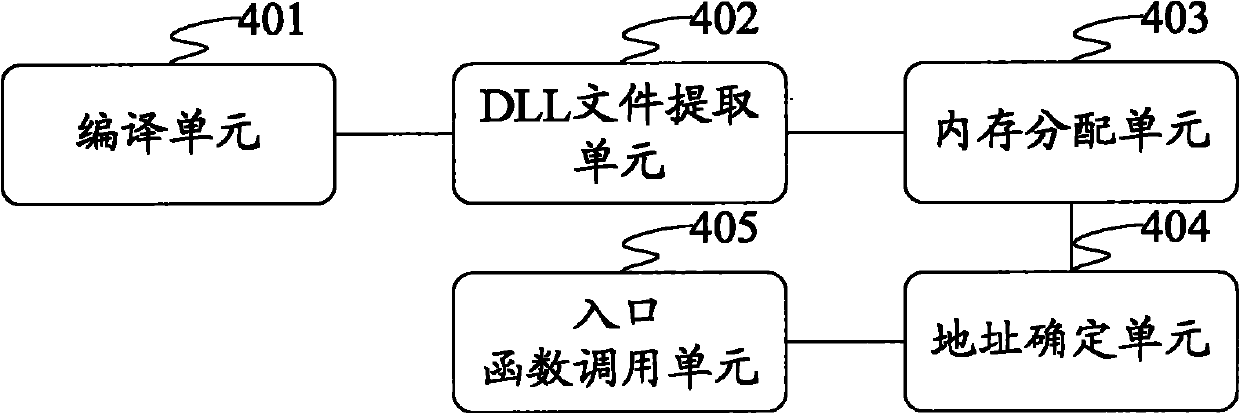

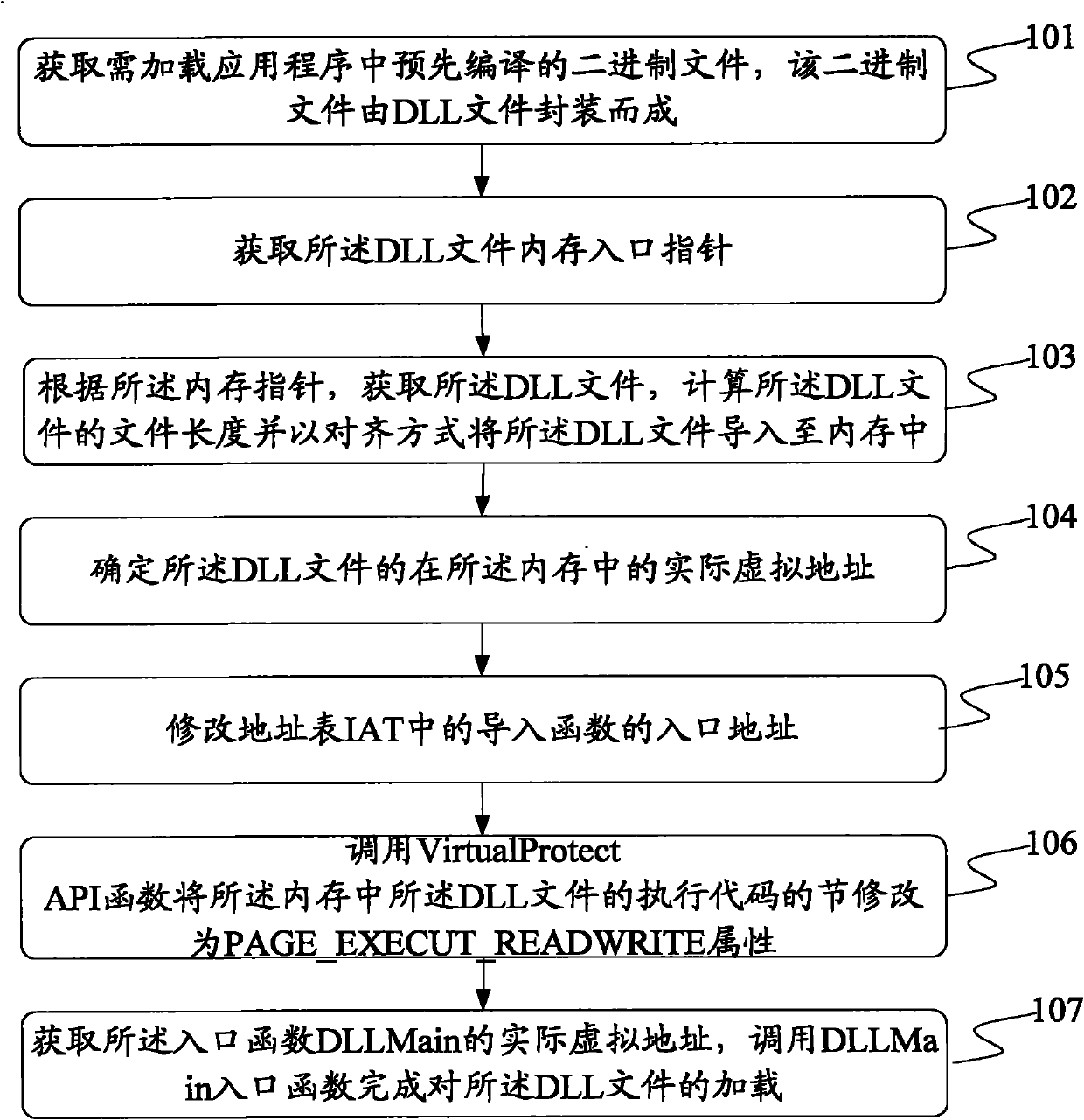

Method and device for processing dynamic link library (DLL) file

ActiveCN101908119AAvoid defectsImplement safe loadingPlatform integrity maintainanceProgram loading/initiatingProcess dynamicsApplication software

The embodiment of the invention discloses a method and a device for processing a dynamic link library (DLL) file. The processing method is characterized in that: the DLL file containing a key code and serving as a resource (specifically a binary resource) is embedded into an application program, wherein the DLL file is not an independent file any more and a cracker cannot easily locate the positions of the key code and the DLL file; and meanwhile, the DLL file is loaded without directly using a Load Library API function any more, the whole loading process is performed in a dynamic loading mode, and the key code of an import function in the DLL file is associated with the actual address of the import function to establish dynamic link by repositioning the actual and virtual addresses of the DLL file and modifying an entry address of the import function in an IAT table so that the cracker has difficulty in judging the time and address of actually loading the DLL file and the technical effect of securely loading the DLL file is achieved.

Owner:ZHEJIANG SUPCON SOFTWARE +1

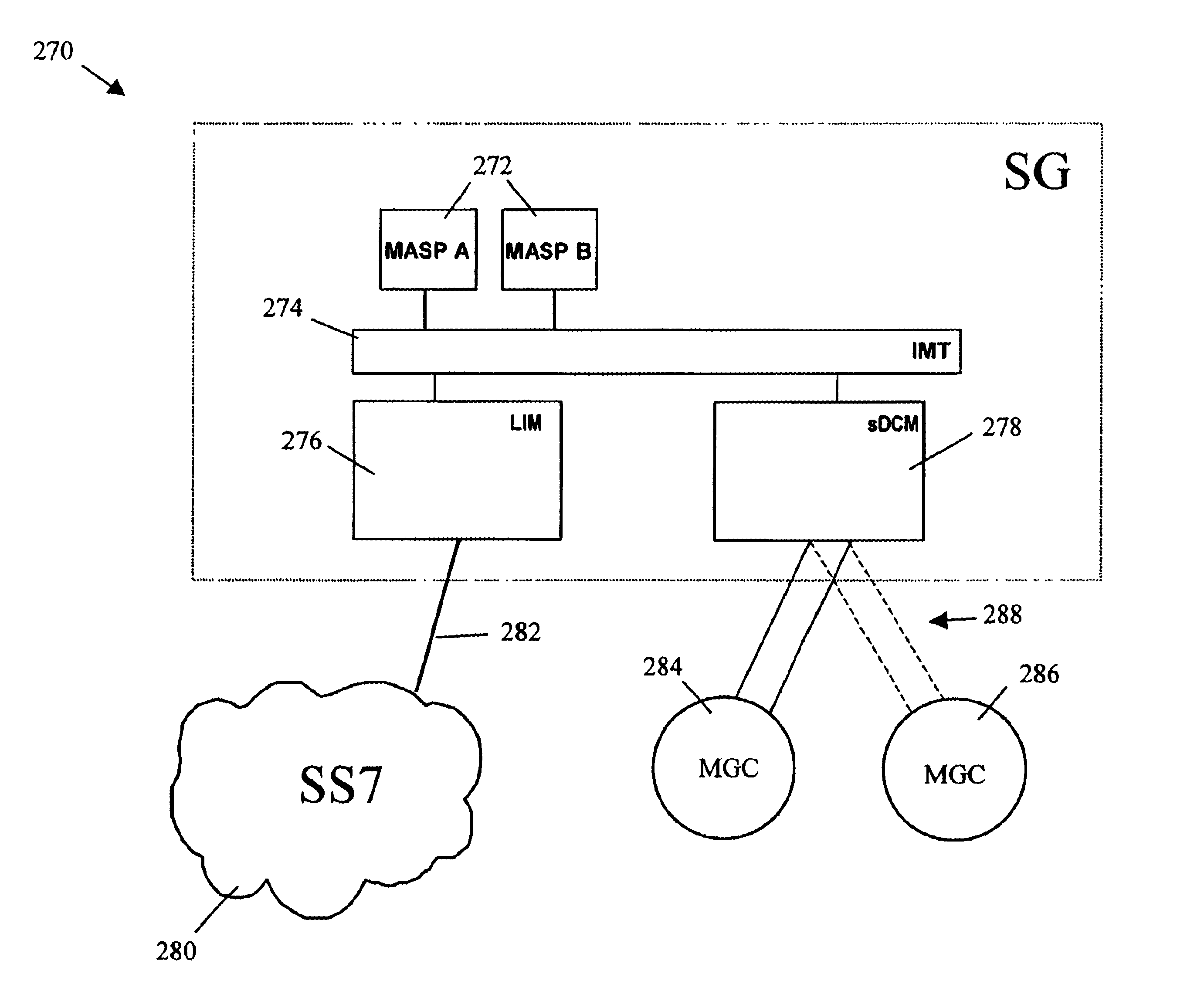

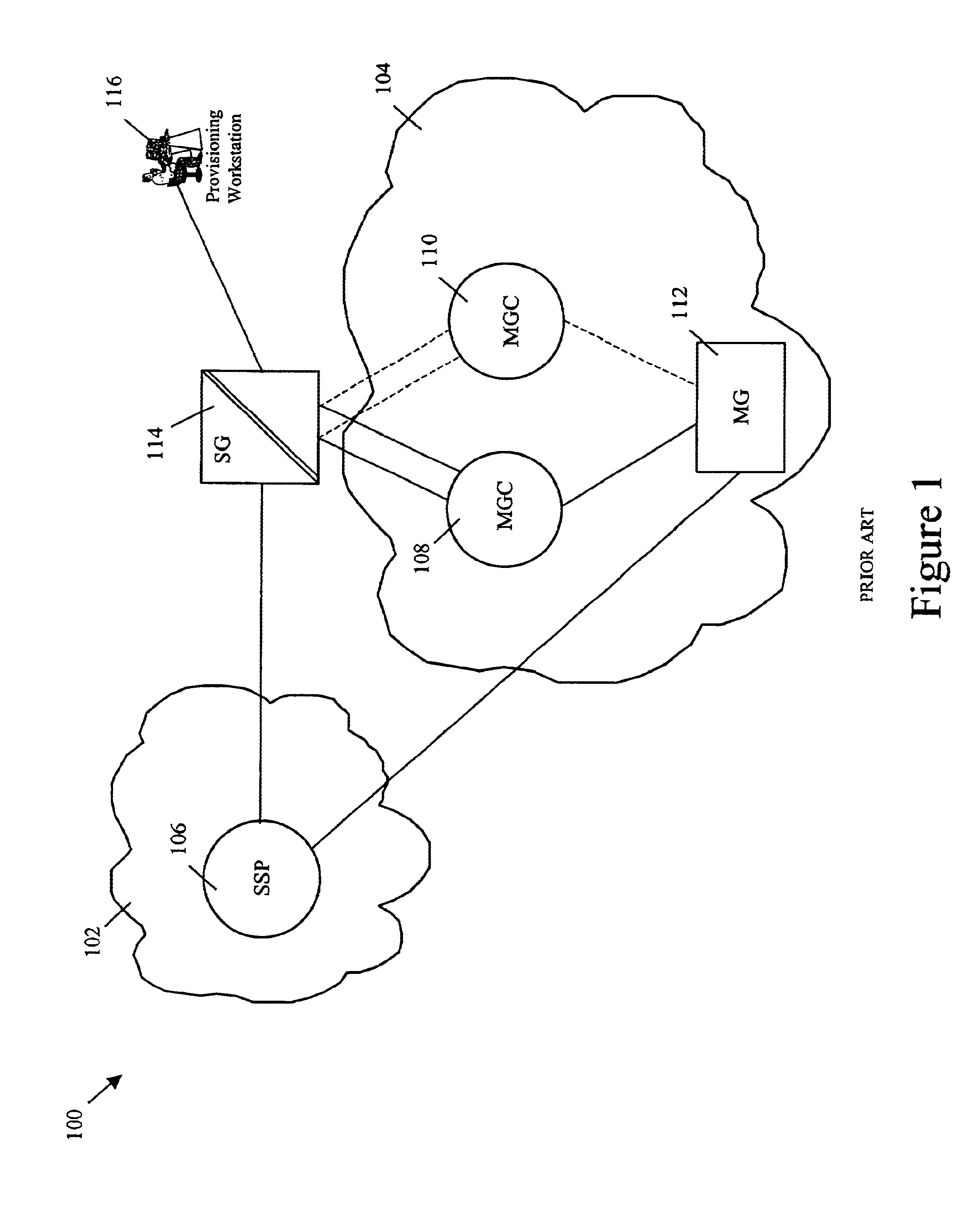

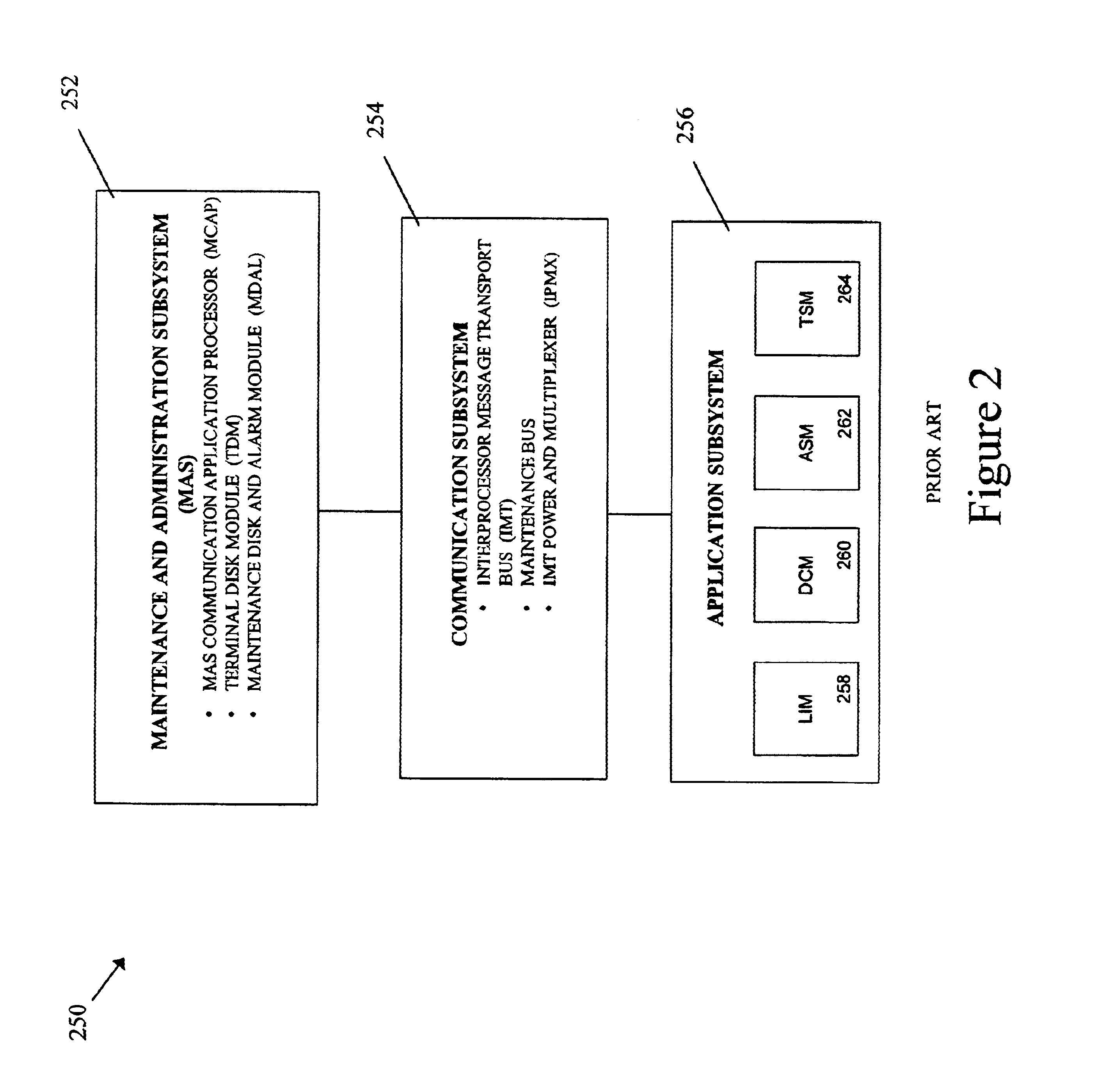

Methods and systems for providing dynamic routing key registration

ActiveUS7113581B2Avoid difficultyFacilitates dynamic self-registrationMultiplex system selection arrangementsInterconnection arrangementsProcess dynamicsTraffic capacity

Disclosed is a communications network element that is capable of routing signaling messages and includes a dynamic routing key registration feature which allows Internet protocol (IP) nodes to automatically register / de-register and subsequently direct traffic towards or away from themselves without the need for manual operator intervention. A signaling gateway routing node includes a self-registering data communication module (sDCM) that is adapted to receive and process dynamic routing key registration messages from associated IP nodes. Such dynamic routing key registration messages may include information that is used to register a new routing key association with a TCP / IP connection, de-register an existing routing key association with the TCP / IP connection, or modify routing key information associated with the TCP / IP connection.

Owner:TEKELEC GLOBAL INC

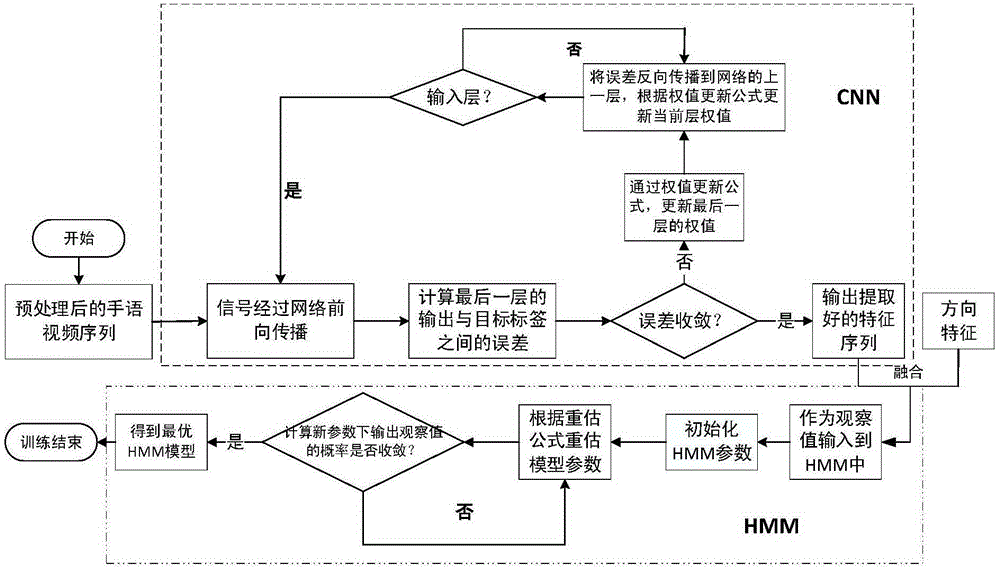

Dynamic gesture recognition method

InactiveCN105205475AImprove accuracyCharacter and pattern recognitionNeural learning methodsProcess dynamicsHide markov model

The invention discloses a dynamic gesture recognition method which can increase the accuracy of dynamic gesture recognition. The method comprises the following steps: (1) pre-processing dynamic gesture data, expanding the dynamic gesture data based on an interval sampling method, and calculating edges of three channels of RGB of expanded dynamic gesture data based on a canny edge detection operator, so as to generate an image with colored edges; (2) extracting a gesture feature sequence based on a convolutional neural network model; (3) carrying out HMM (Hidden Markov Model) training according to the gesture feature sequence extracted in the step (2) and hand direction features, so as to obtain an HMM most approximate to a gesture sample.

Owner:BEIJING UNIV OF TECH

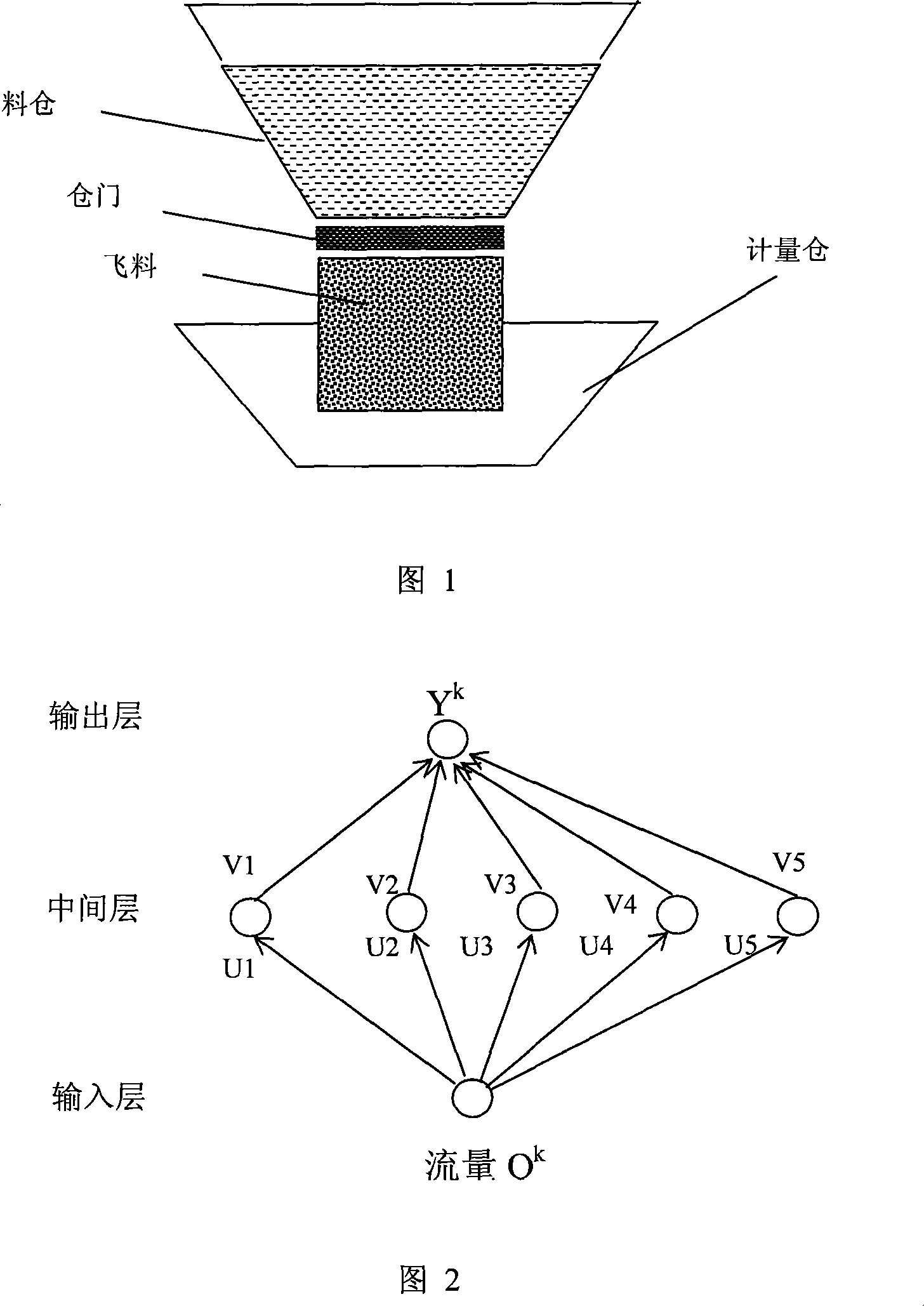

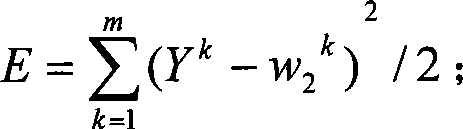

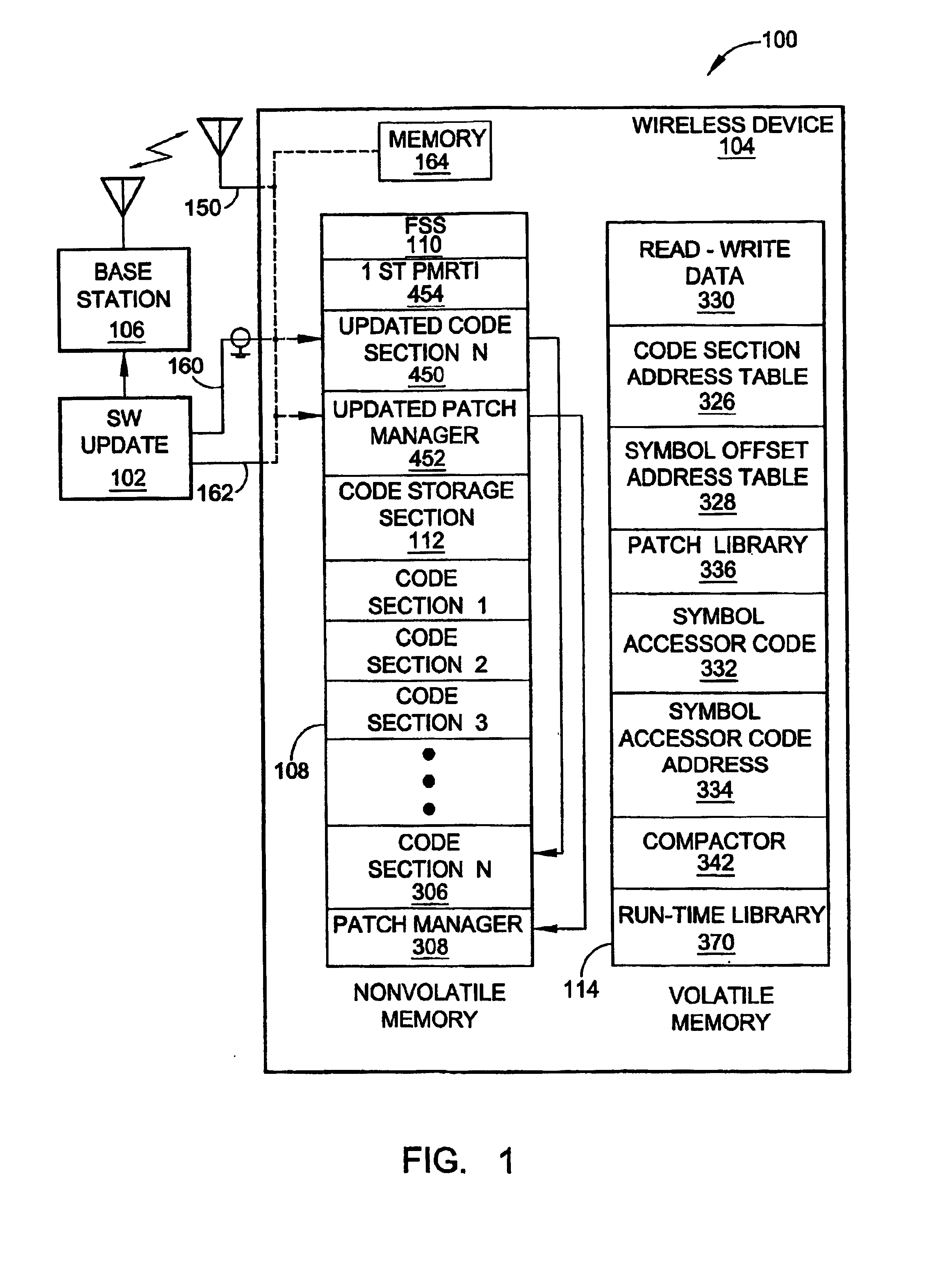

Robust control method for asphalt mixing plant batching error

InactiveCN101226377AImprove batching accuracyImprove control effectMixing operation control apparatusRoads maintainenceProcess dynamicsArtificial neural network model

The invention discloses a robust control method of burden error of pitch concrete stirring device, which comprises first building an input / output artificial neutral network model of three-layer structure, while the input layer has one neuron, the middle layer has five neurons and the output layer has one neuron, processing dynamic prediction and learning. The invention builds the non-linear model of flux and fly ash amount to be compared with a linear model of fixed parameters via continuous learning and adjustment, to adapt the change of external parameters, thereby effectively controlling the burden error of pitch mixture stirring device, reaching +-2% burden error as maximum and improving the burden accuracy of pitch mixture stirring device.

Owner:NANJING UNIV OF SCI & TECH +1

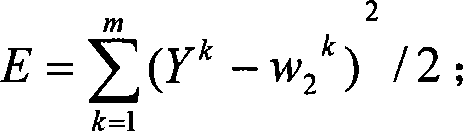

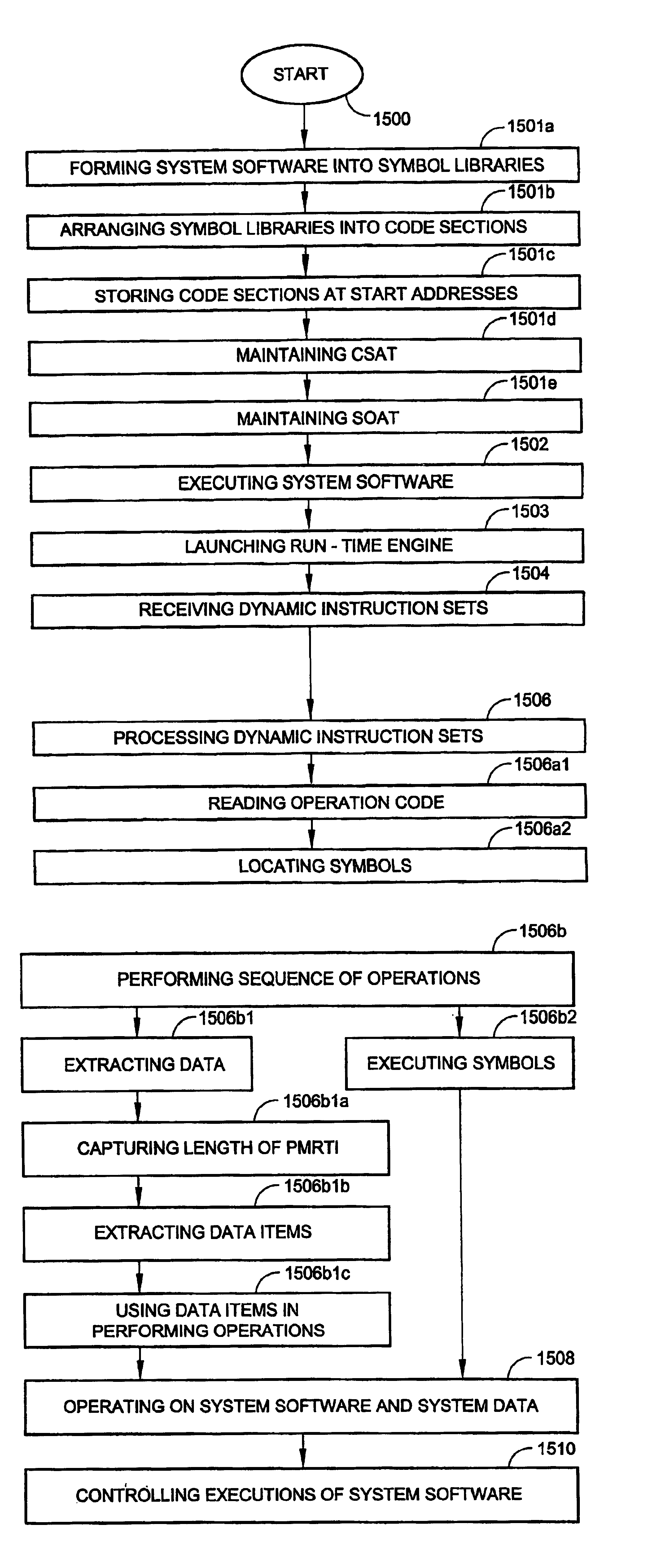

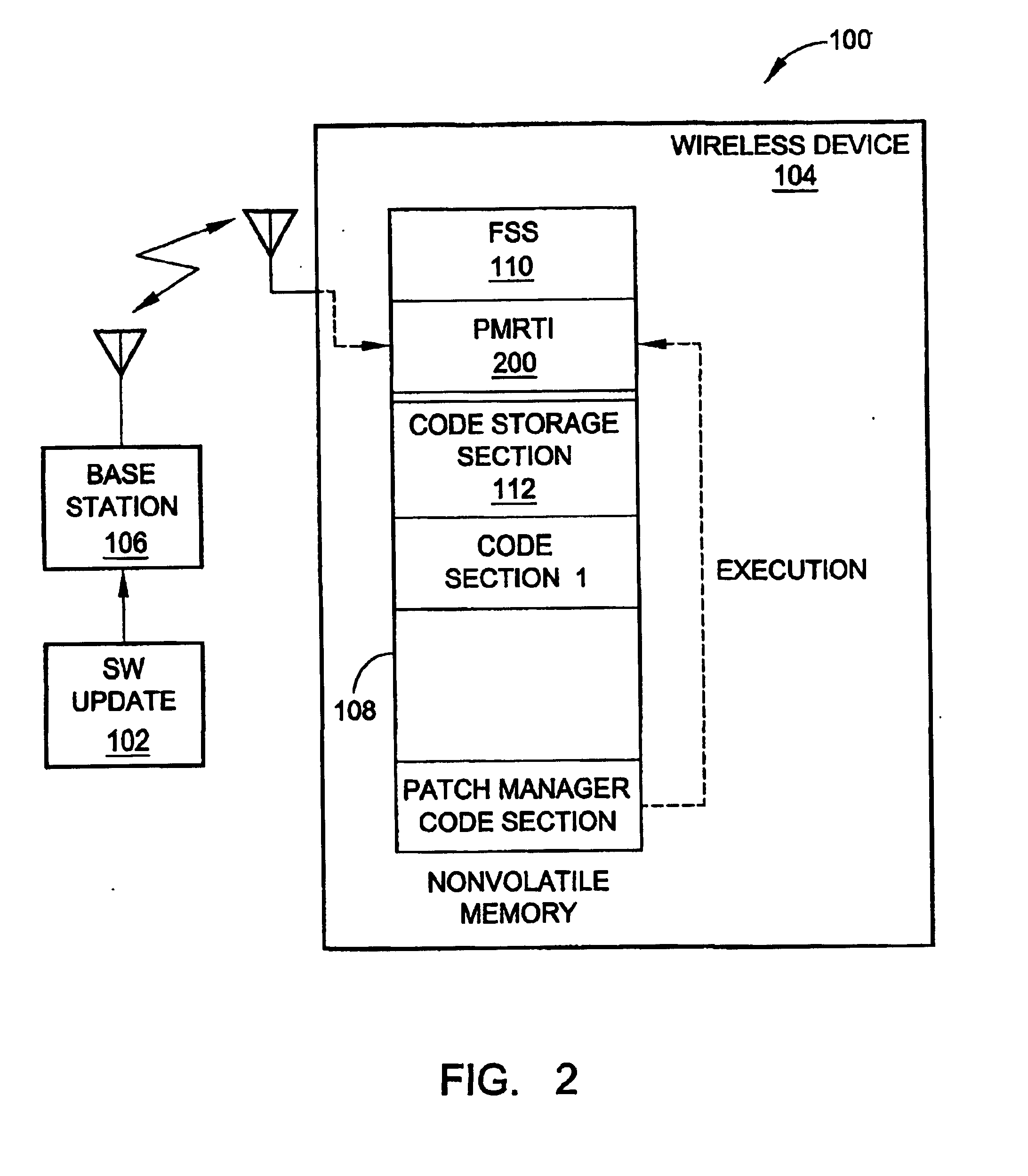

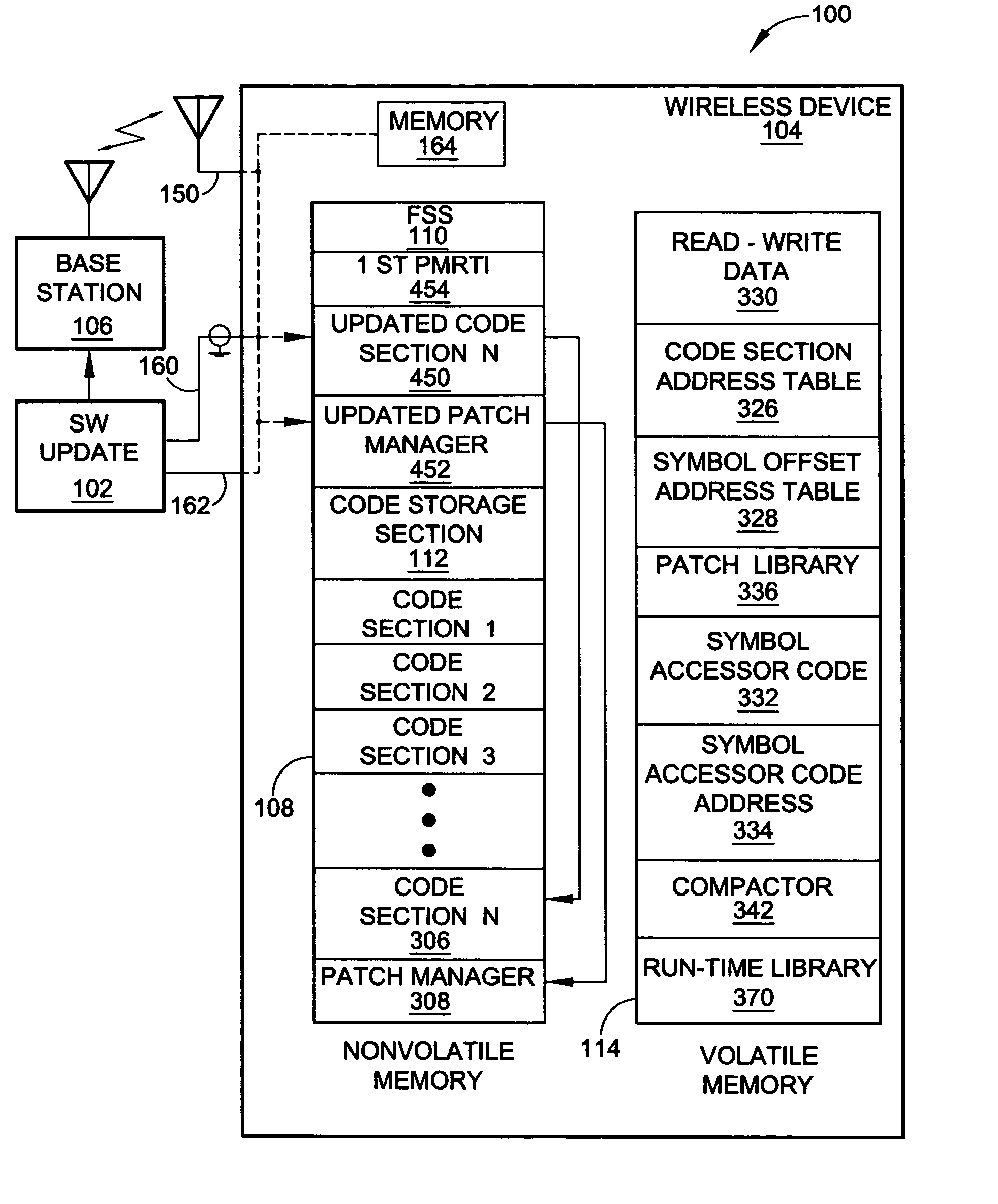

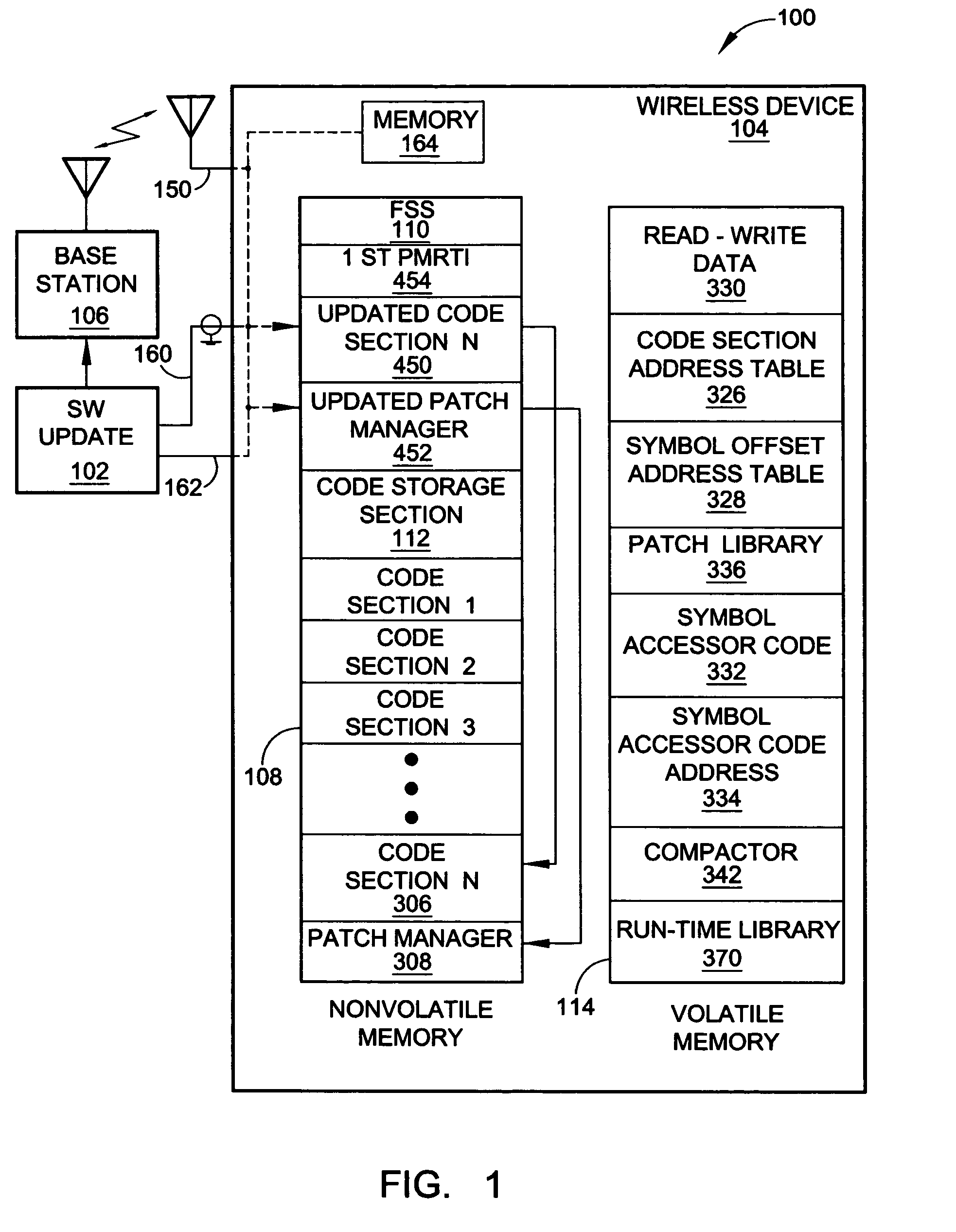

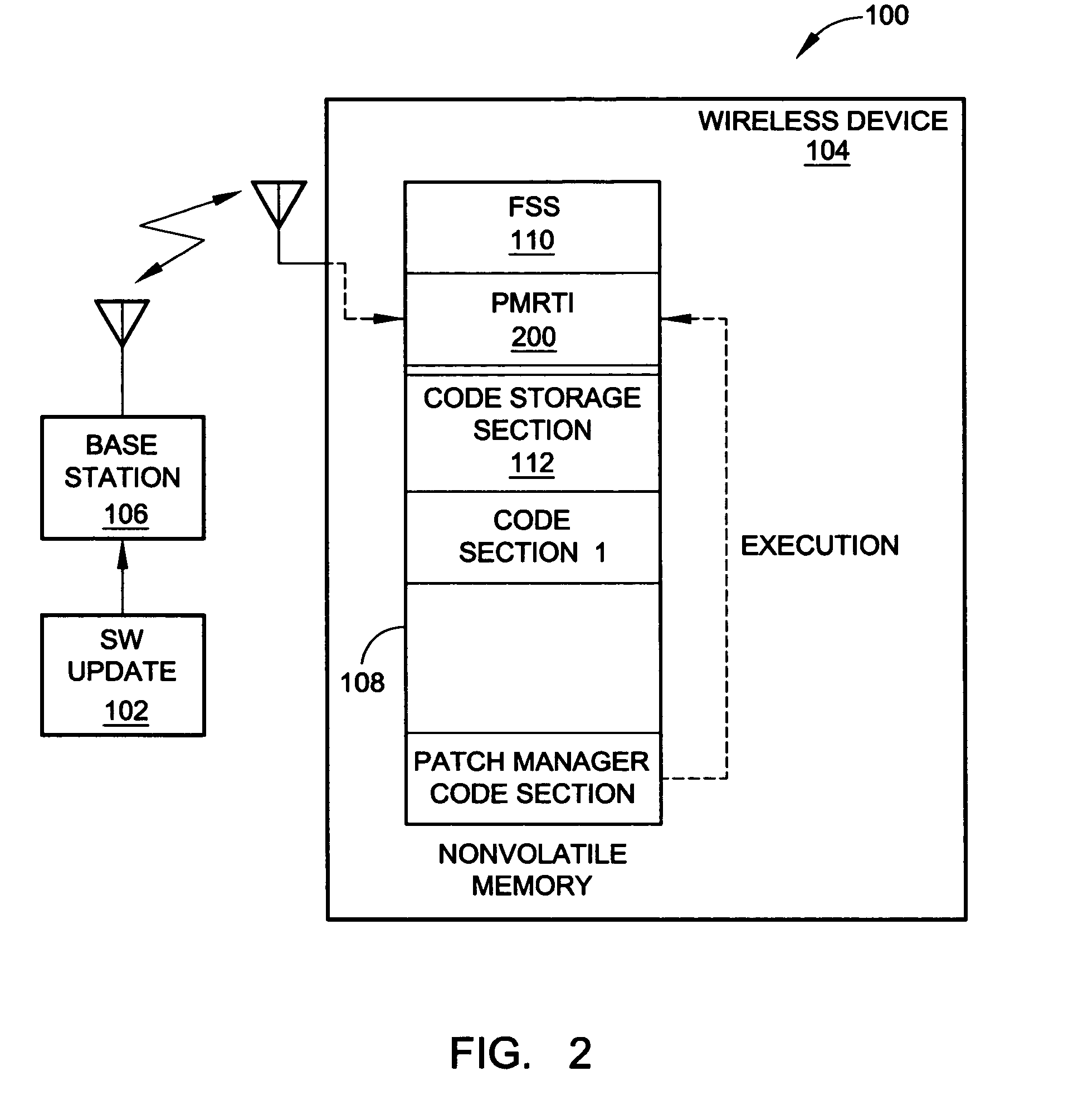

System and method for field diagnosis of wireless communications device system software

InactiveUS6918108B2User identity/authority verificationInterprogram communicationProcess dynamicsFile system

A system and method are provided for field diagnosing system software in a wireless communications device. The method comprises: executing system software; launching a run-time engine; receiving patch manager run time instructions (PMRTI), including dynamic instruction sets and new code sections, in a file system section nonvolatile memory; and, processing dynamic instruction sets to field diagnose the system software. Processing the dynamic instruction sets includes: executing the diagnosis instruction sets with the system software to collect data; analyzing the collected data; and, in response to analyzing the collected data, operating on system data and system software. The method further comprises: following the operating on the system software and system data, executing the system software.

Owner:KYOCERA CORP

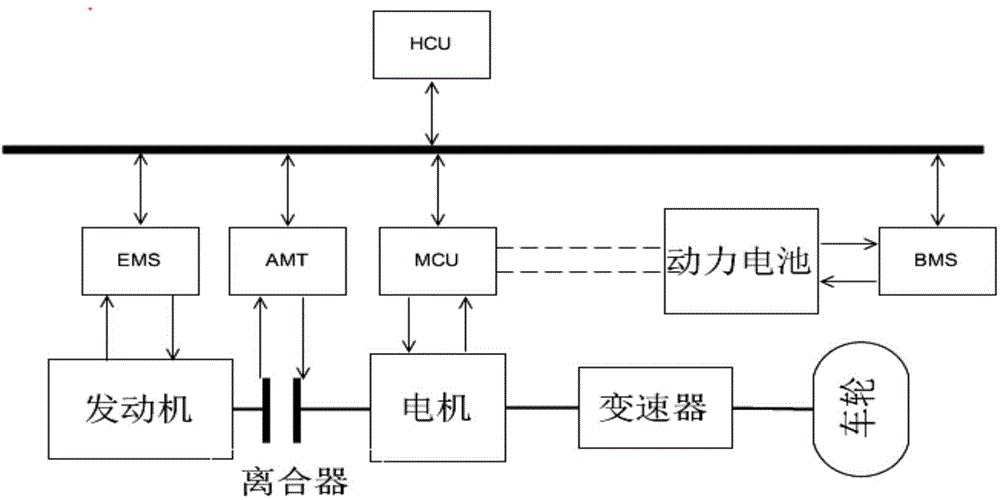

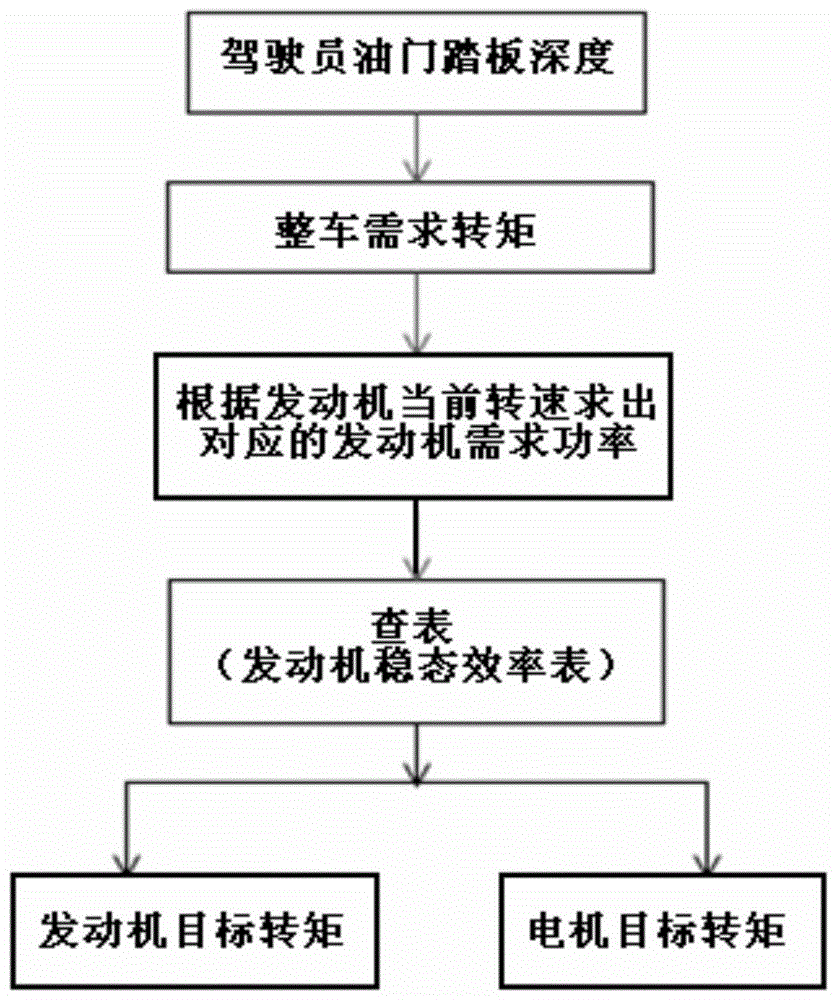

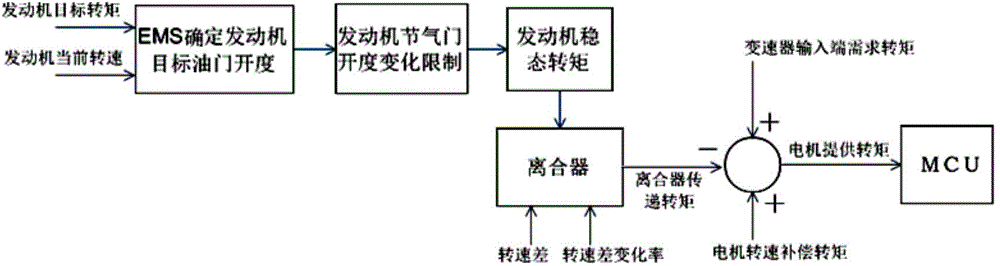

Hybrid electric vehicle work mode switching process dynamic coordination control method

ActiveCN104670221AReduce dynamic processImprove ride comfortHybrid vehiclesDriver input parametersProcess dynamicsElectric vehicle

The invention discloses a hybrid electric vehicle working mode switching process dynamic coordination control method. Accelerator pedal depth is acquired by an EMS (engine management system) to obtain required vehicle torque, and an HCU (vehicle control unit) can select a work mode under a current working condition to work according to the required vehicle torque or the actual working condition; by controlling change rate from engine throttle percentage to target throttle percentage, the engaging speed of a clutch is reasonably controlled according to speed differences of an engine and a motor, insufficient dynamic output torque of the engine is offset by the quick response ability and the characteristic of accuracy torque control of the motor, and output torques of the motor and the engine are coordinated and allocated in the mode switching process. According to the technical scheme, the torque output of a hybrid power system is controlled, so as to reduce the dynamic process of the engine; oil consumption is reduced, so as to improve the economical efficiency; great fluctuation of the required vehicle torque is not generated in the mode switching process, so as to improve vehicle riding comfort; wear of the clutch is reduced, so as to ensure power transmission smoothness.

Owner:奇瑞新能源汽车股份有限公司

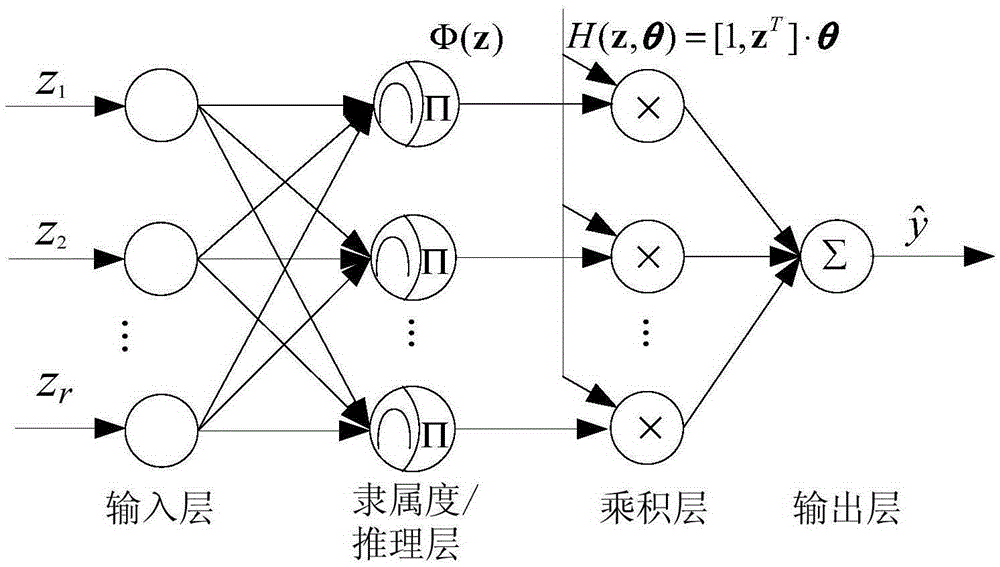

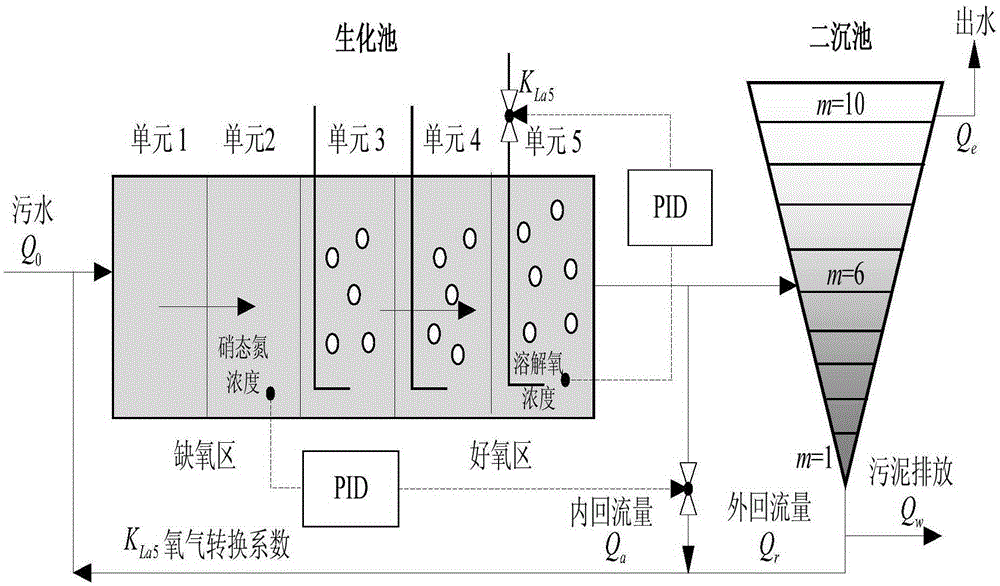

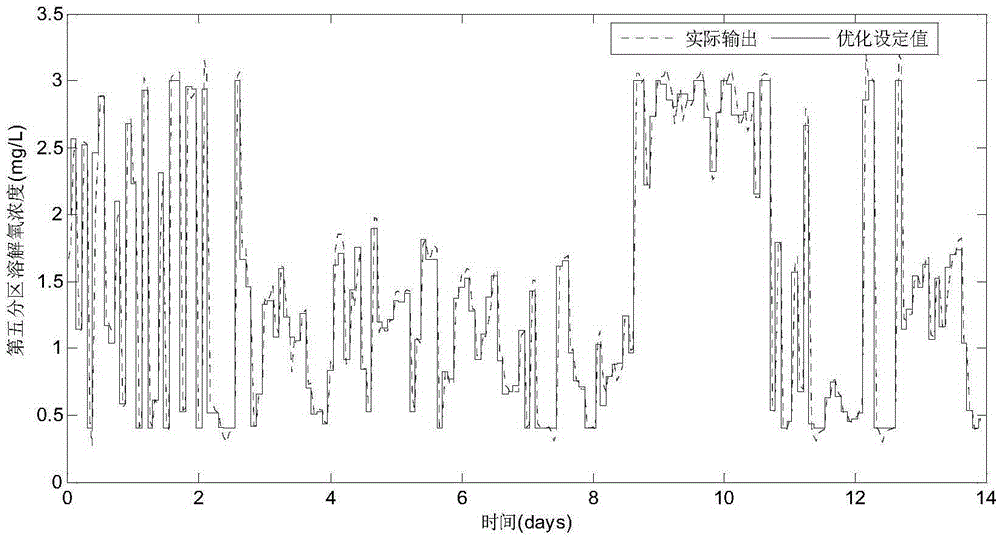

Sewage processing process dynamic multi-target optimization control method

ActiveCN105404151AHigh energy consumptionImprove water quality indicatorsAdaptive controlProcess dynamicsNerve network

The invention discloses a sewage processing process dynamic multi-target optimization control method, belongs to the field of water research and also belongs to the field of intelligent control, for simultaneously optimizing energy consumption and water quality indexes under the condition that the water quality reaches the standard. First of all, a sewage processing process multi-target optimization model is constructed through a nerve network online modeling method for solving the problem of lack of accurate mathematic description between an optimization variable and a performance index; secondly, based on the established optimization model, a Pareto optimal solution of the problem is obtained through a multi-target optimization algorithm, and according to decision information, one satisfactory optimization solution is determined from a Pareto solution set, i.e., optimization set values of a dissolved oxygen concentration and a nitrate nitrogen concentration; and finally, a bottom controller realizes a tracking task of the optimization set value. The method provided by the invention can effectively reduce the energy consumption and the operation cost of a sewage processing process under the condition that the water quality reaches the standard.

Owner:BEIJING UNIV OF TECH

System and method for the management of wireless communications device system software downloads in the field

A system and method are provided for managing system software download operations in a wireless communications device. The method comprises: executing system software; launching a run-time engine; processing dynamic instruction sets; and, in response to processing the dynamic instruction sets, managing the downloading of system software updates received via an airlink interface using management functions selected from the group including recovery status monitoring, back up, compacting, and update ordering.

Owner:KYOCERA CORP

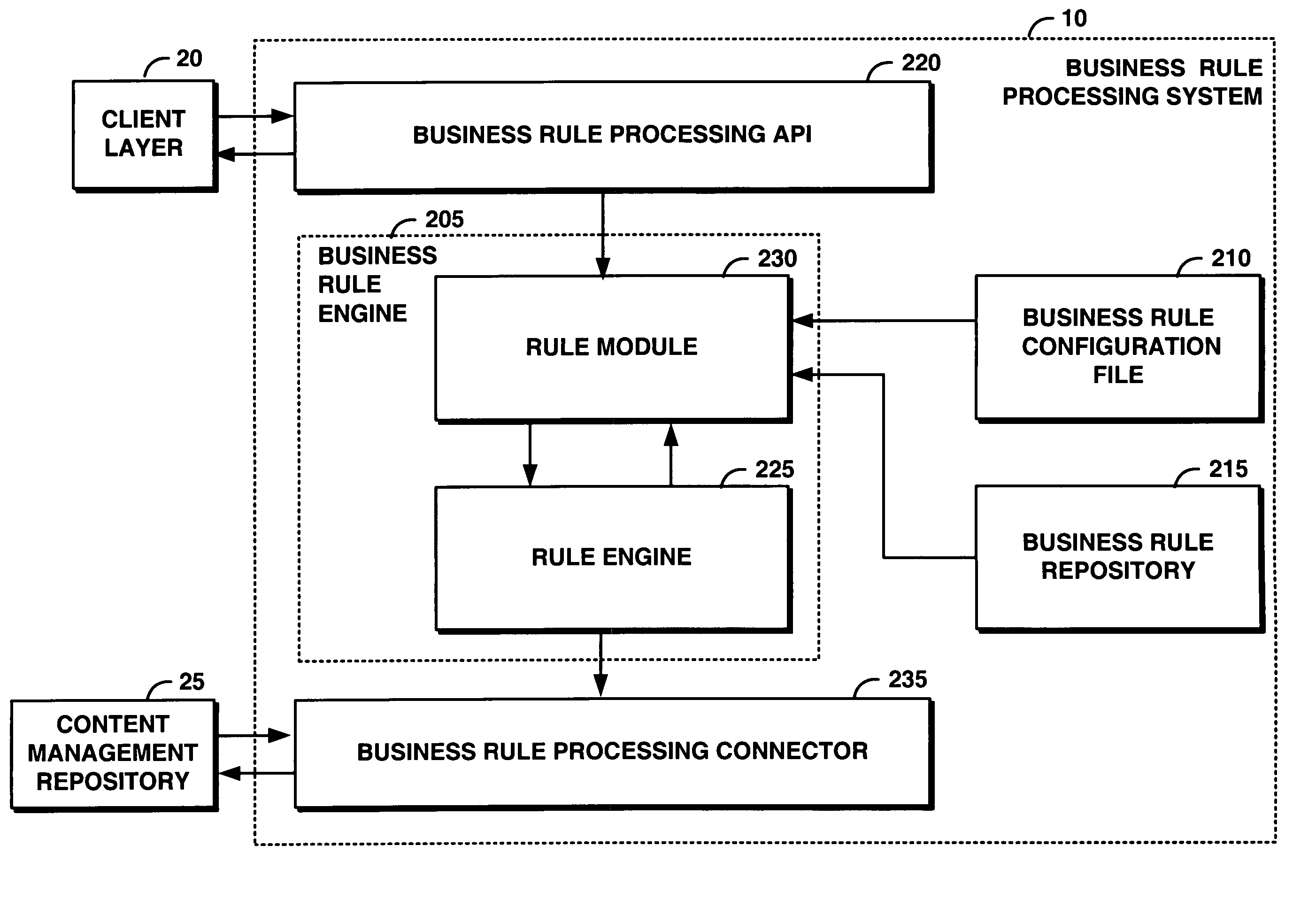

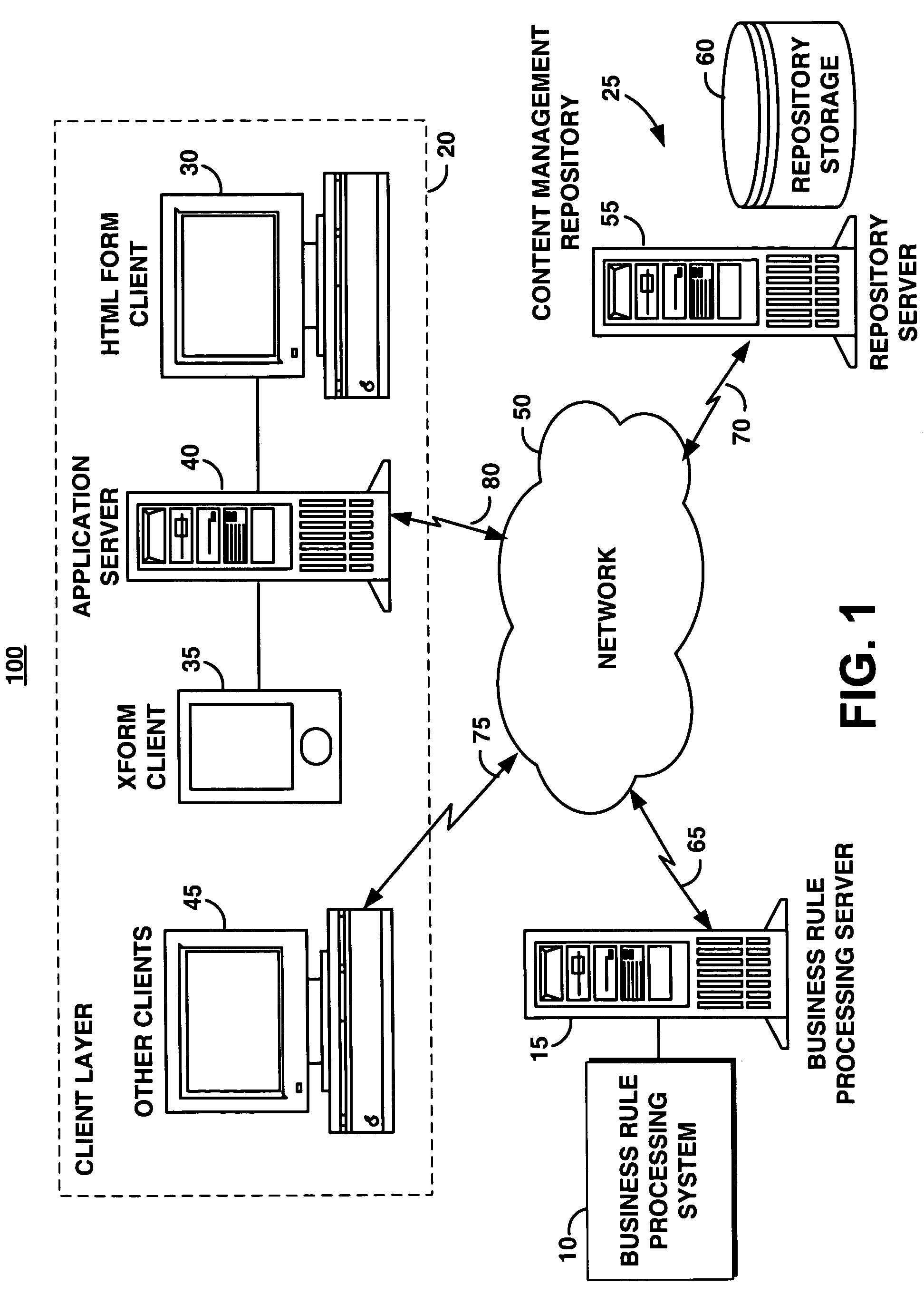

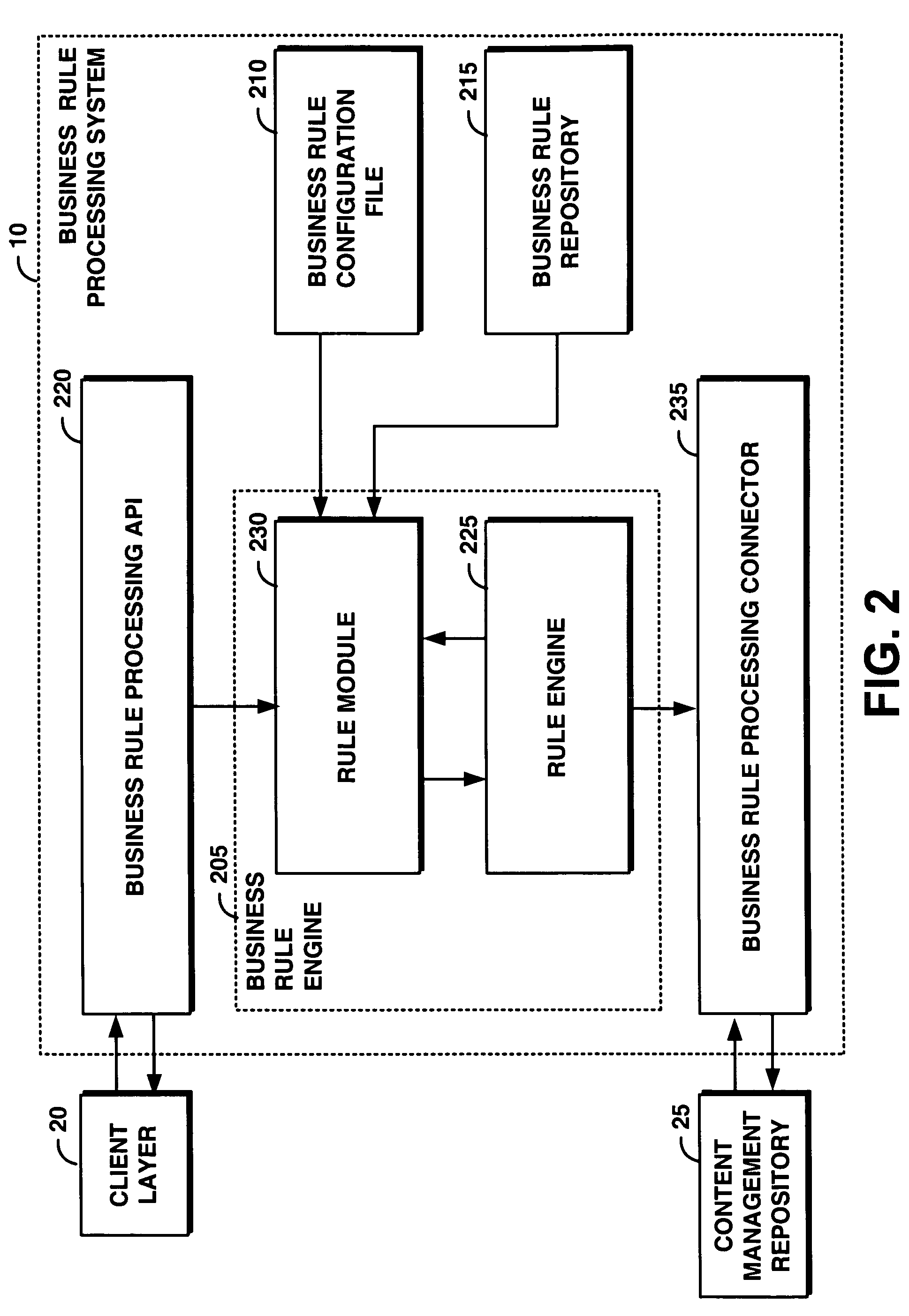

Automatically processing dynamic business rules in a content management system

ActiveUS8140362B2Reduce developmentReduce maintenanceOffice automationKnowledge representationProcess dynamicsContent management

Owner:SERVICENOW INC

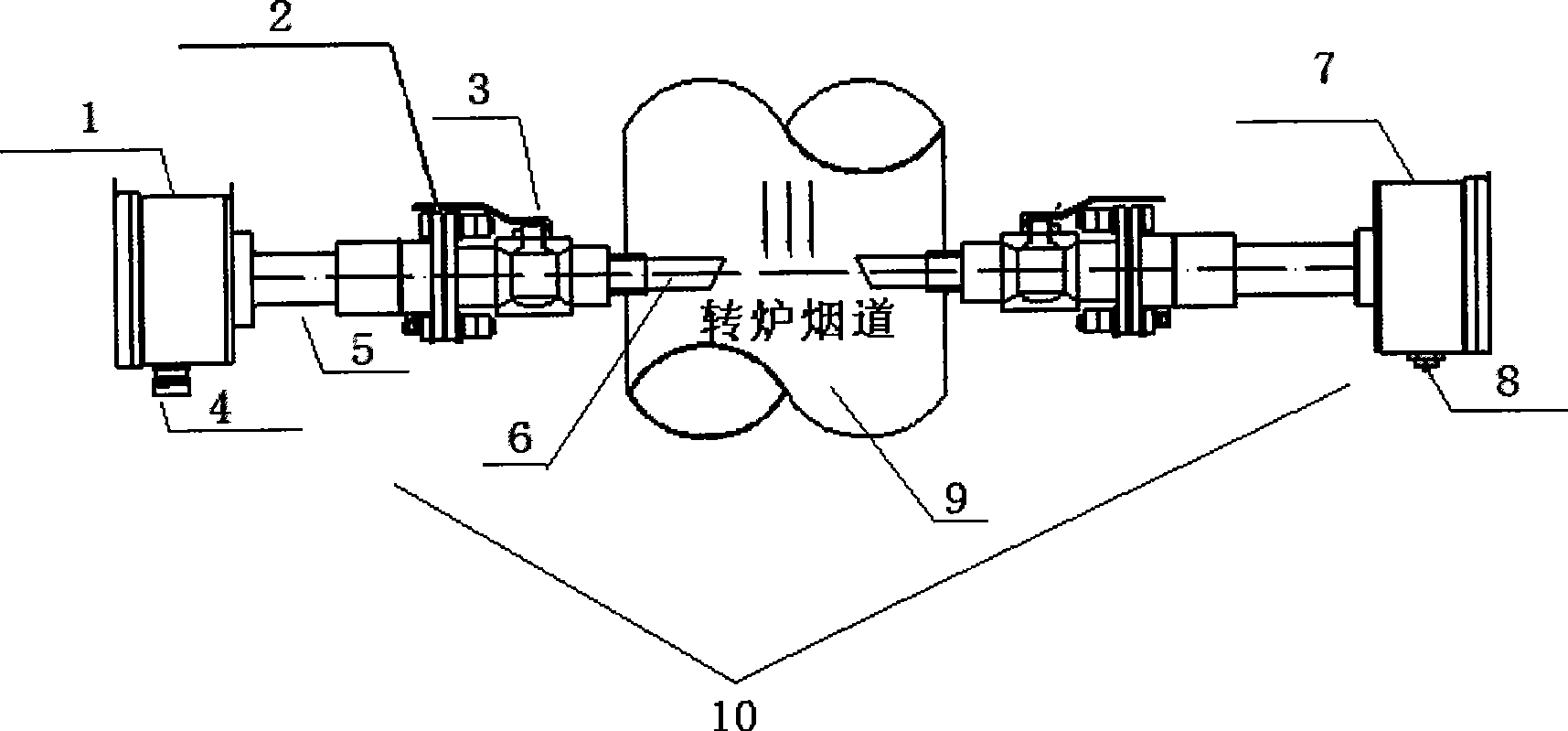

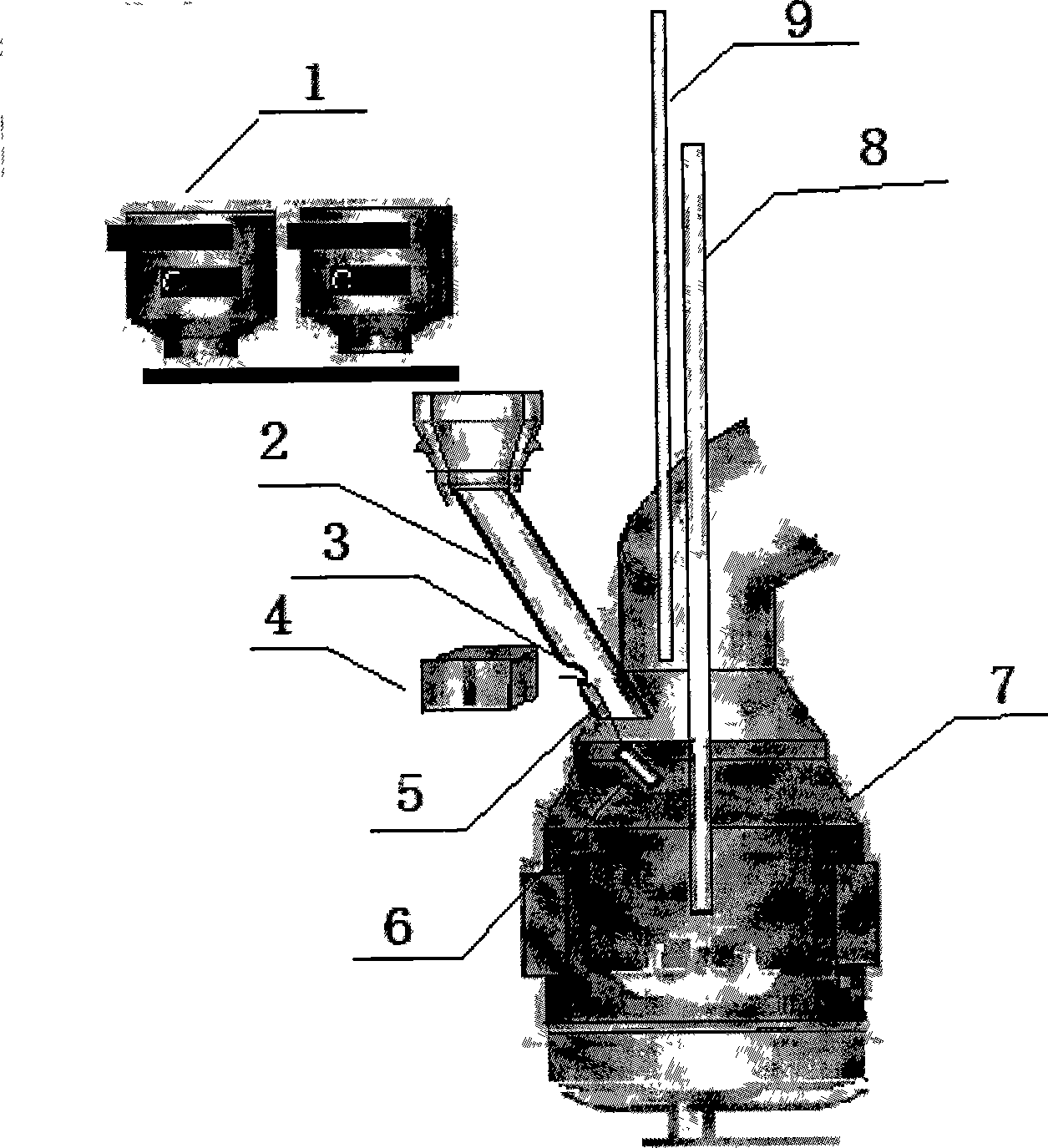

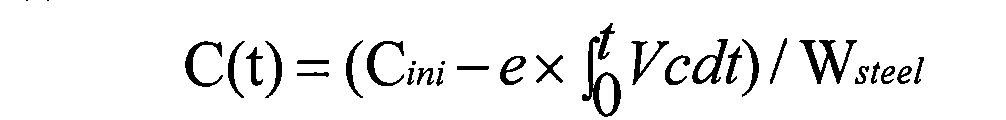

Whole process dynamic monitoring method for converter steel melting

ActiveCN101476014AHigh precisionQuality improvementProgramme controlComputer controlSteelmakingProcess dynamics

The invention pertaining to the field of metallurgy and steel-making technology provides a convertor steelmaking whole-course dynamic monitoring method. The whole-course dynamic control of the convertor steelmaking can be realized by adopting a laser gas analyzer and a stock bin port bombing technology, molten steel component and temperature are forecasted continuously and detected dynamically, and the convertor is assisted to perform the end point judgment. The method comprises steps of using a network of computer to monitor the information of charging, jetting and the like; using the laser gas analyzer as the gas signal acquiring and analyzing device in the convertor smelting process; using the bombing device installed at the stock bin port to performing head ejecting to detect information of molten steel component, temperature and the like; acquired parameters are all transferred through the network of computer; the computer continuously forecasts the parameters of molten steel component, temperature and the like by utilizing the above parameters and a built-in control model, and displays the parameters and provides guidance on the user interface.The invention has advantages that the whole-course feedback signals can be obtained, a whole-course dynamic control of the convertor smelting can be realized, variation of temperature and molten steel component can be forecasted continuously, the size of the convertor capability is not limited, and the convertor has characteristics of simple structure, convenient maintenance, small investment and low rate of fault.

Owner:北京北科麦思科自动化工程技术有限公司

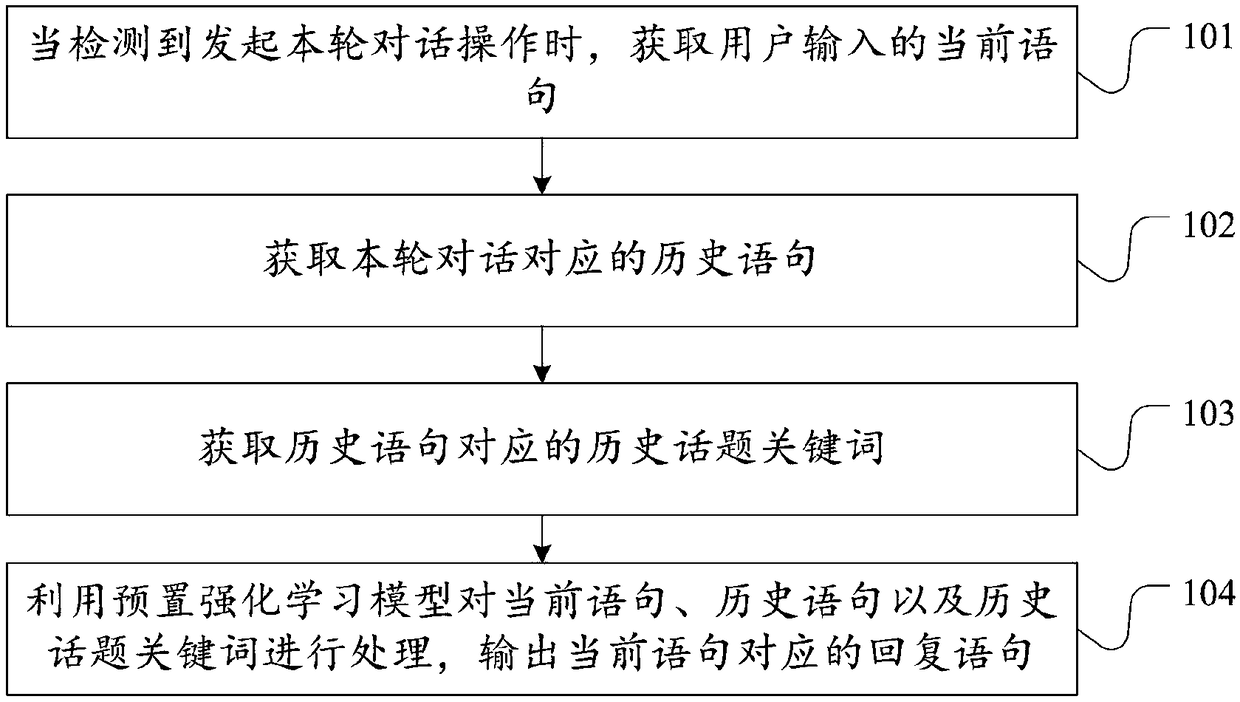

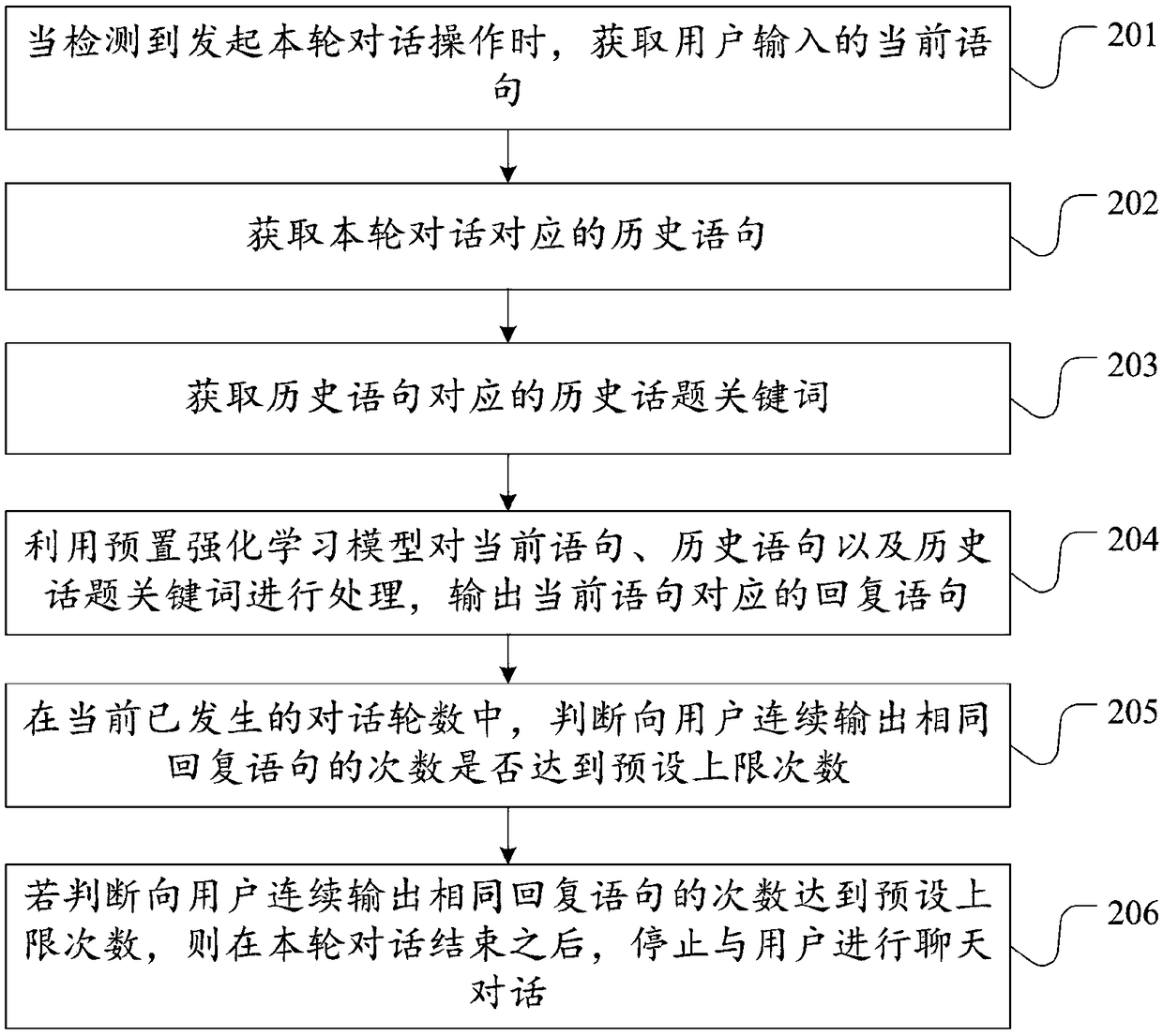

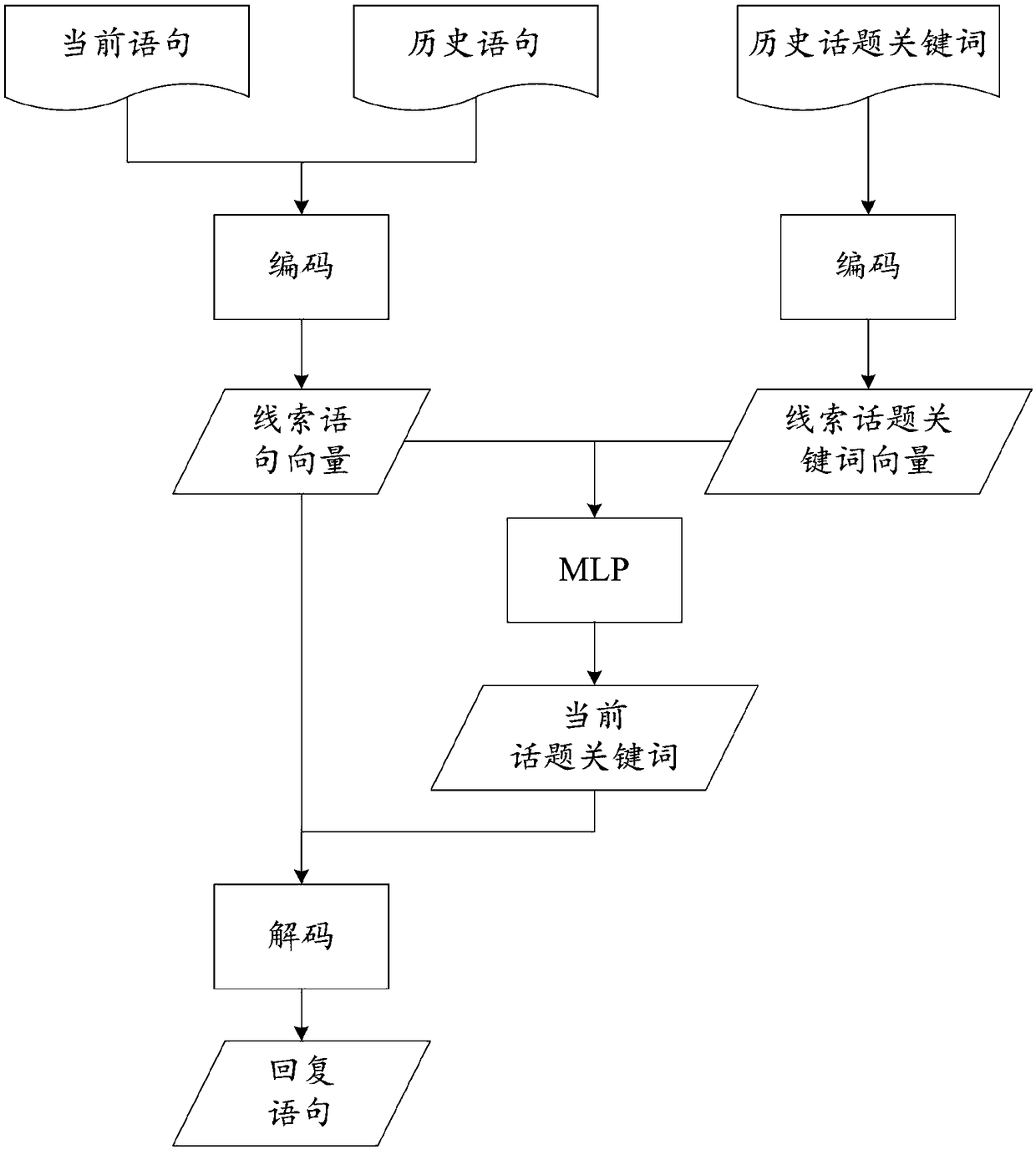

Method and device for conducting multi-round conversation based on topic keyword guidance

ActiveCN109086329AImprove chat performanceIncreased number of dialogue roundsSpecial data processing applicationsProcess dynamicsUser input

The embodiment of the invention discloses a method and a device for conducting multi-round dialogue based on topic keyword guidance, which relate to the technical field of natural language processing,and can enable the machine side to output richer, more diverse and more interesting replies to increase the number of conversation turns. A main technical proposal of that embodiment of the inventionis as follow: when the operation of initiating the current round of dialogue is detected, the current sentence input by the user being obtained; a round of dialogue referring to a chat dialogue between the user and the machine; acquiring a history statement corresponding to the current round of dialogues, wherein the history statement refers to a chat conversation between the user and the machinebefore the current round of dialogues; acquiring a history topic keyword corresponding to the history statement; a preset reinforcement learning model being used to process the current statement, thehistorical statement and the historical topic keywords, and output a reply statement corresponding to the current statement. The embodiment of the invention is mainly applied to process dynamic man-machine multi-round dialogue.

Owner:MOBVOI INFORMATION TECH CO LTD

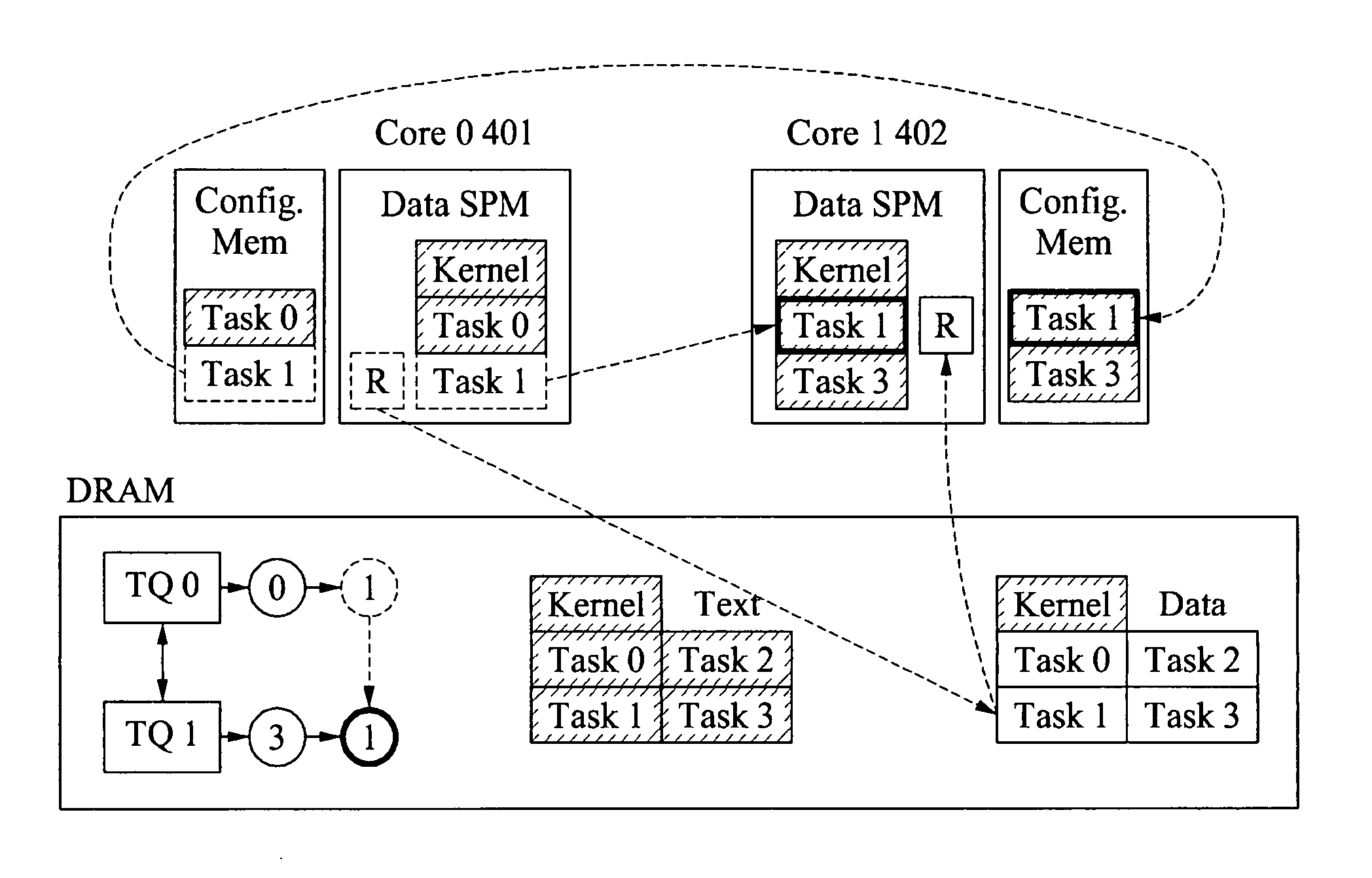

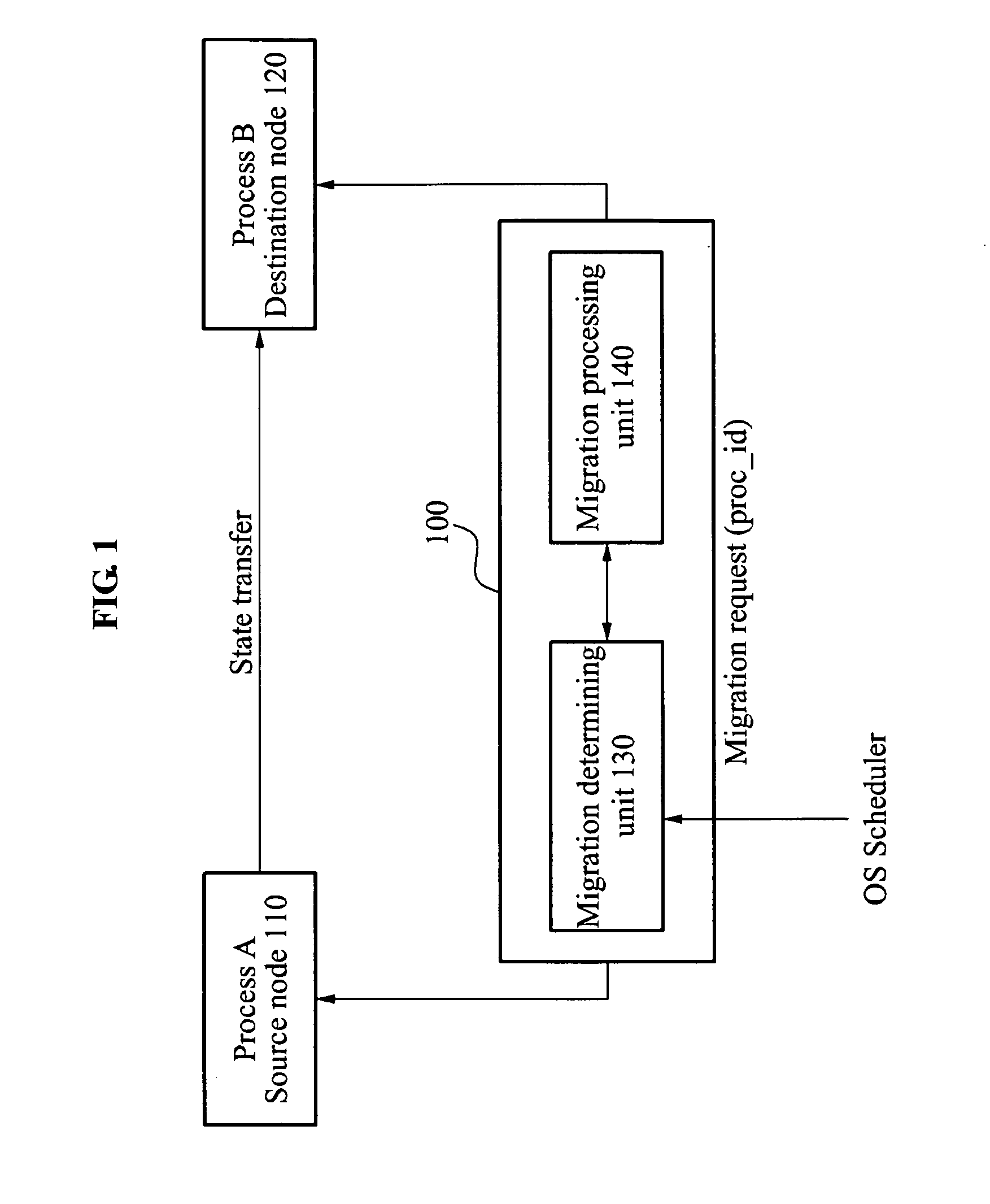

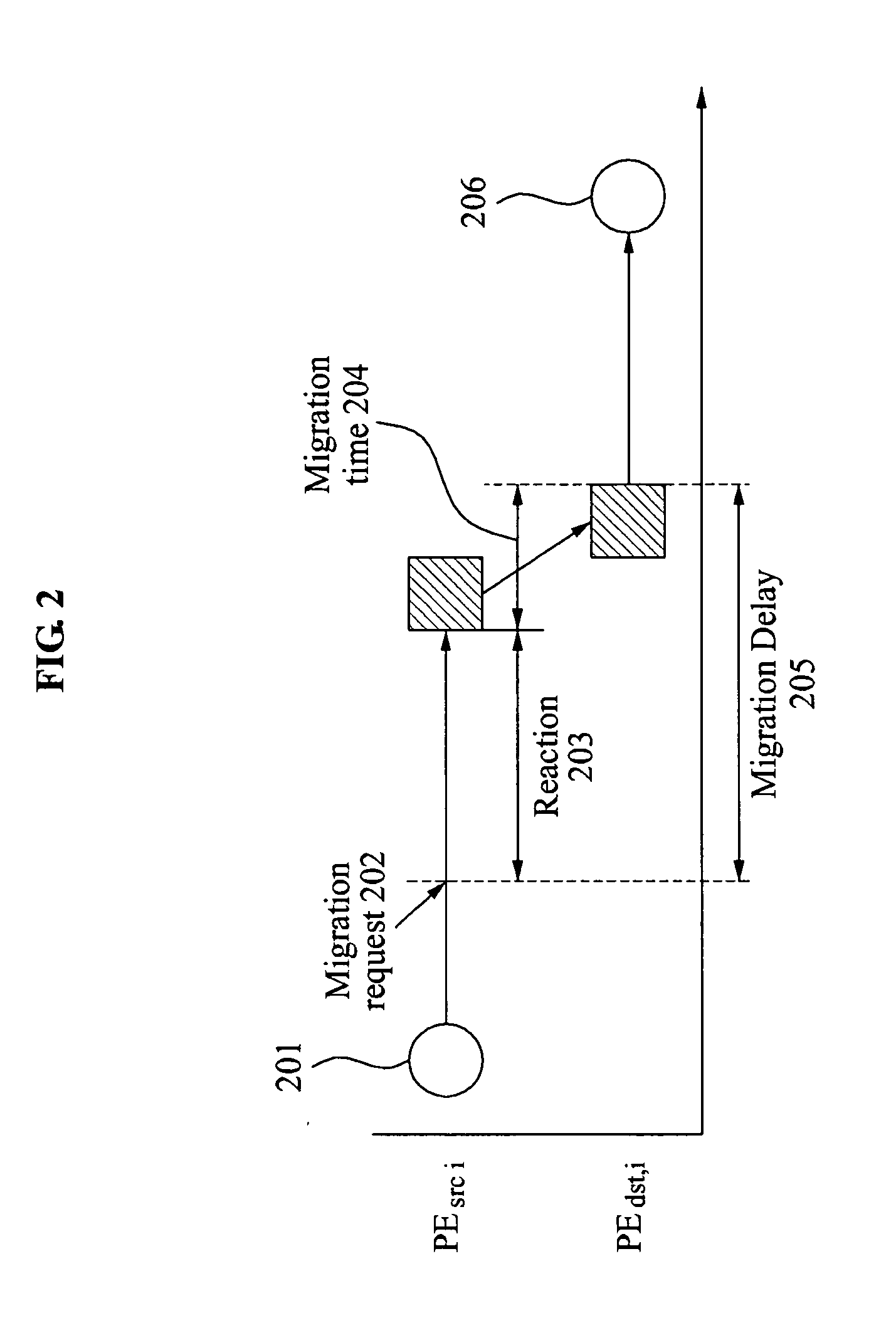

System and method for dynamic task migration on multiprocessor system

A multiprocessor system and a migration method of the multiprocessor system are provided. The multiprocessor system may process dynamic data and static data of a task to be operated in another memory or another processor without converting pointers, in a distributed memory environment and in a multiprocessor environment having a local memory, so that dynamic task migration may be realized.

Owner:SAMSUNG ELECTRONICS CO LTD

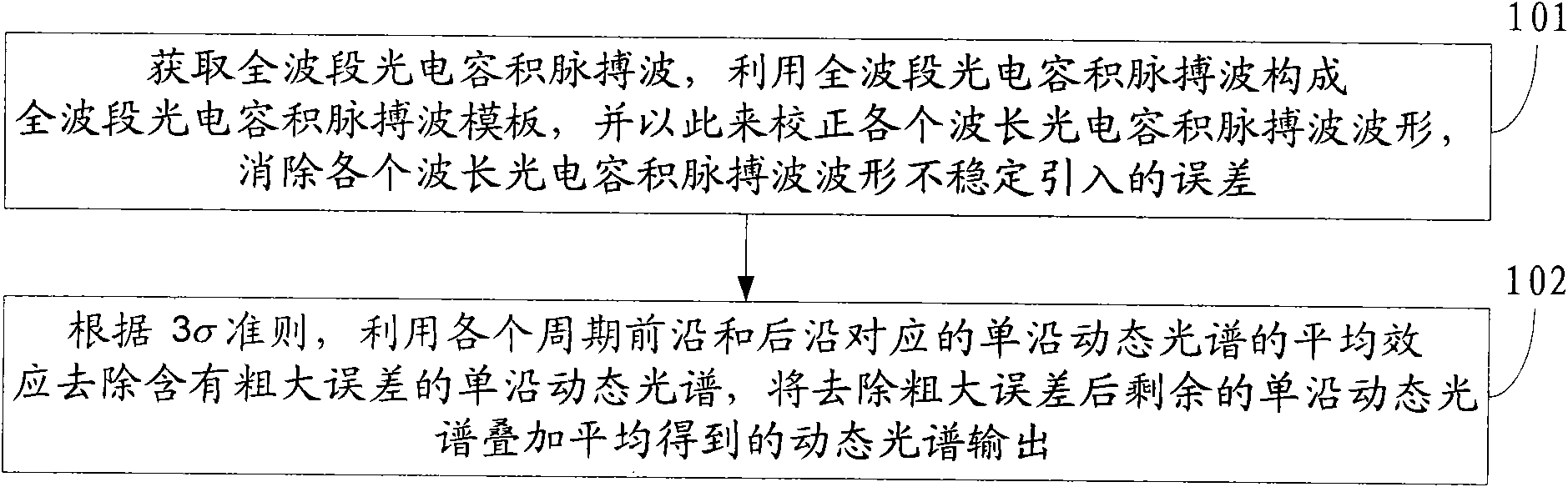

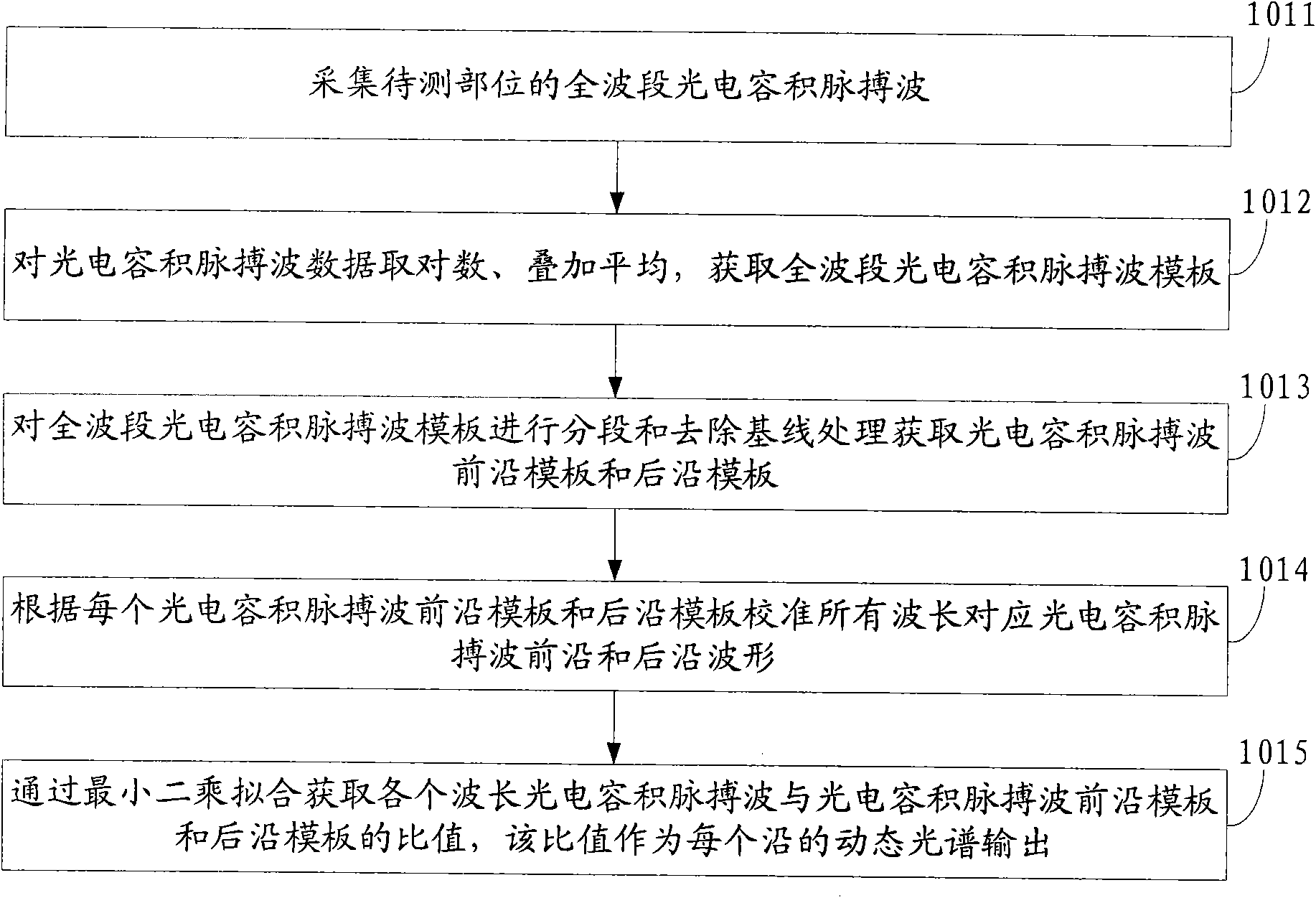

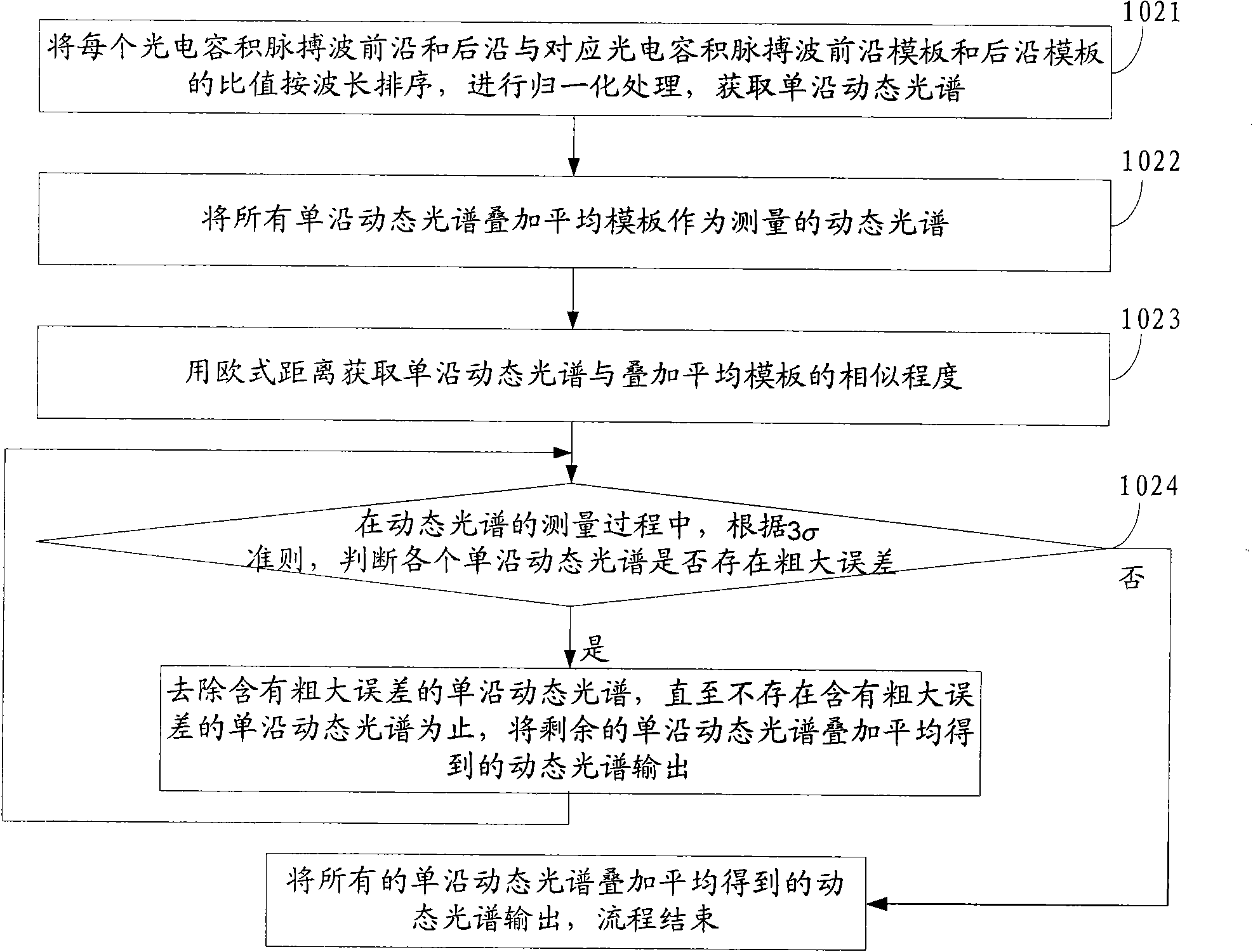

Method for processing dynamic spectral data based on single-edge extraction

InactiveCN101912256AImprove accuracyImprove signal-to-noise ratioCatheterDiagnostic recording/measuringProcess dynamicsEdge extraction

The invention discloses a method for processing dynamic spectral data based on single-edge extraction, and relates to the field of spectral analysis technology. The method comprises the following steps of: acquiring the all-band photoplethysmographic pulse wave; acquiring an all-band photoplethysmographic pulse wave template by using the all-band photoplethysmographic pulse wave and correcting the waveform of the photoplethysmographic pulse wave with each wavelength so as to eliminate the error introduced by the instability of the waveform of the photoplethysmographic pulse wave with each wavelength; removing single-edge dynamic spectrum comprising gross error by using the average effect of single-edge dynamic spectrums corresponding to a front edge and a rear edge of each pulse period according to a 3sigma rule; and superposing the remaining single-edge dynamic spectrums after the removal of the gross error to obtain dynamic spectral output. The method fully utilizes the acquired spectral data, improves the accuracy of the waveform of the photoplethysmographic pulse wave within each wavelength and each period, has higher accuracy, obviously improves the measurement speed, effectively improves the dynamic spectral signal-to-noise ratio and improves the accuracy of dynamic spectral method-based noninvasive blood component detection.

Owner:TIANJIN UNIV

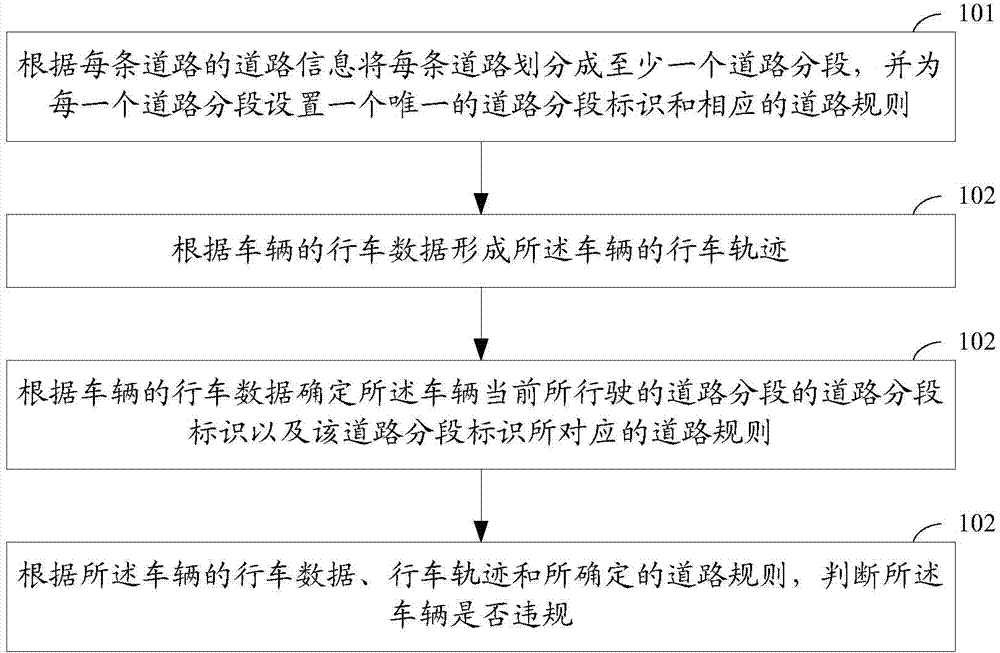

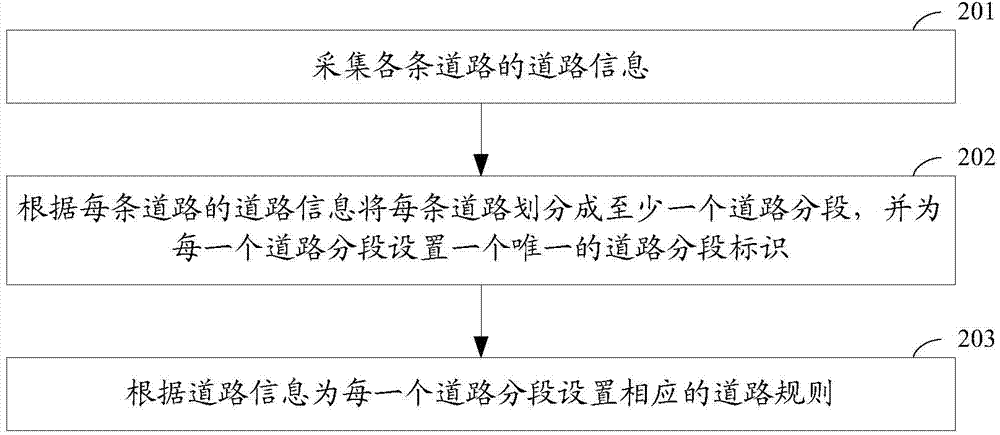

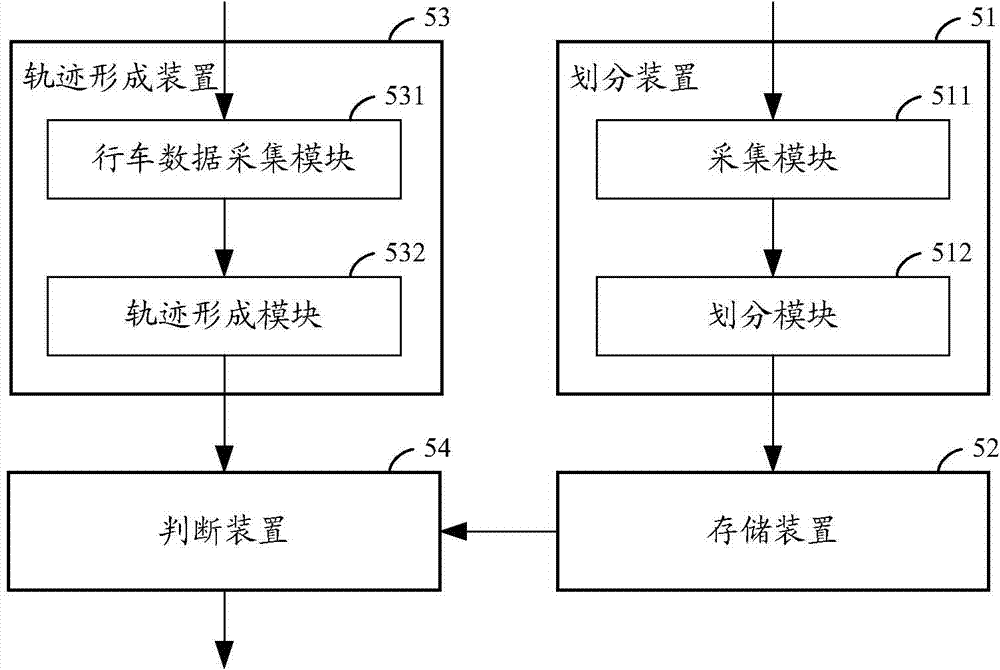

Method and system for monitoring vehicle

InactiveCN104751628AImprove managementGood time complexityDetection of traffic movementProcess dynamicsEngineering

The invention provides a method and a system for monitoring a vehicle. The method comprises the steps of dividing each road into at least one road section according to the road information of each road and setting a unique road section identification and a corresponding road role for each road section, forming the running trajectory of the vehicle according to the running data of the vehicle, determining the road section identification of the road section on which the vehicle runs at present and the road rule corresponding to the road section identification according to the running data of the vehicle, and determining whether the vehicle gets out of the line according to the running data and the running trajectory of the vehicle and the road rule determined. The method is capable of performing whole-process dynamic real-time monitoring on the motor vehicles.

Owner:CHINA MOBILE COMM GRP CO LTD

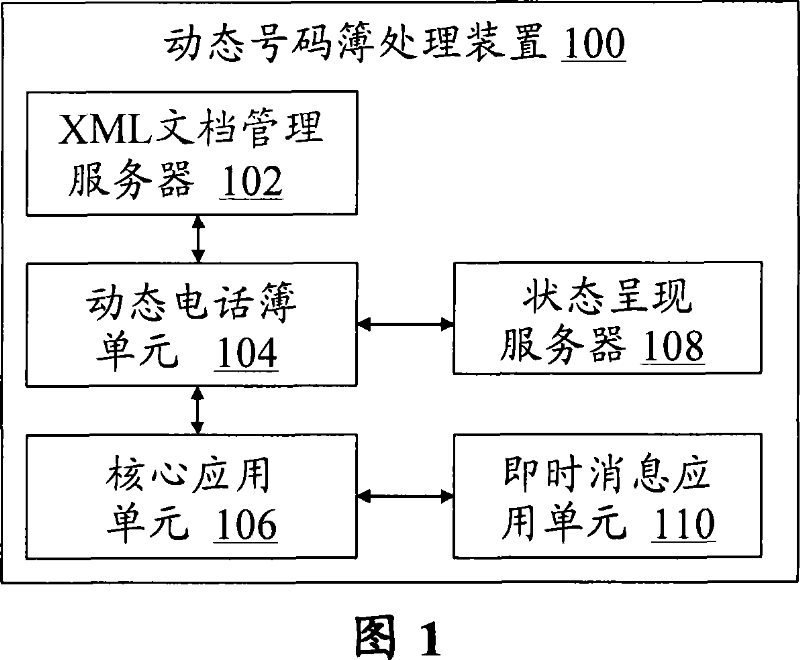

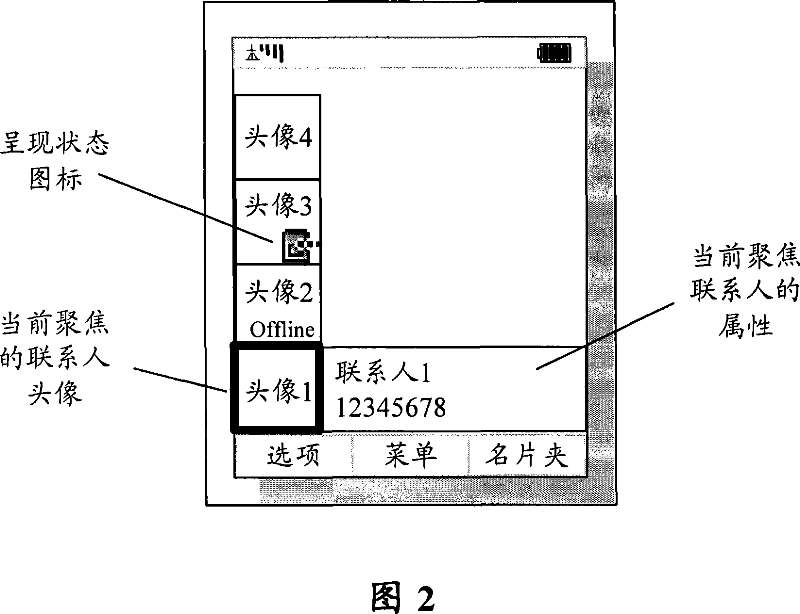

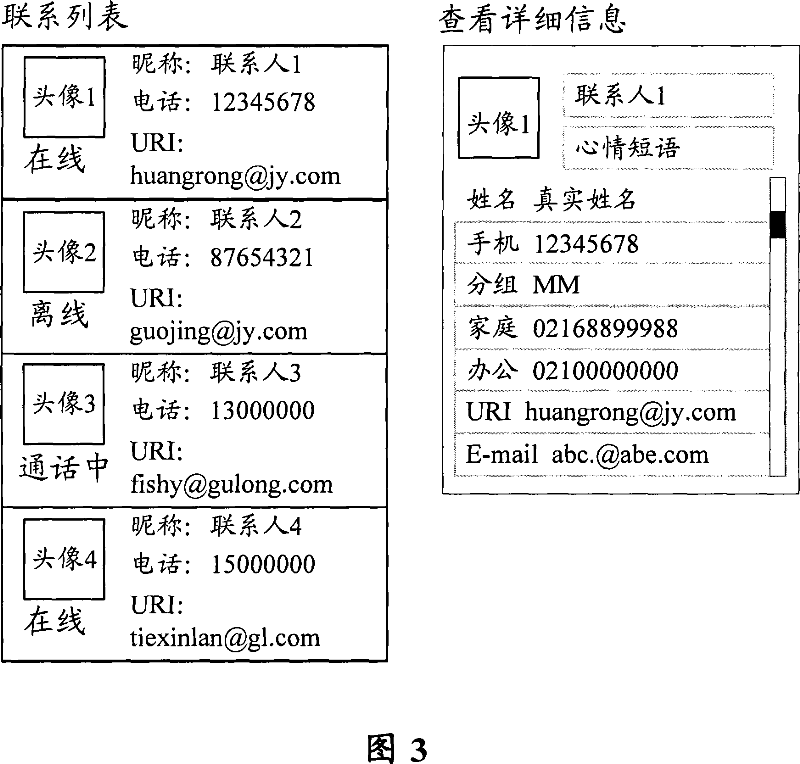

Apparatus and method for processing dynamic number book of mobile terminal

InactiveCN101039485AImprove intuitivenessImprove practicalityRadio/inductive link selection arrangementsSubstation equipmentProcess dynamicsUniform resource identifier

The present invention discloses a dynamic telephone directory processing device for the mobile terminals, including: a XML document management server for managing thecontact lists and contact information of the mobile terminals; a dynamic telephone directory unit, runing in the background in the circumstances that mobile terminals are open, for obtaining the contact lists and detailed contact information from the XML document management server, and displaying the detailed contact information; a core application unit, for obtaining the summary of contact information from the dynamic telephone directory unit, and displaying the contact sign on the stand interface of the mobile terminal; a state showing server, for monitoring the online state of the contact, and noticing the telephone directory unit when the contact's online state changes; and an instant message application unit, for notifying the uniform resource identifiers of the instant message sending part to the core application unit, or receiving the uniform resource identifiers of the instant message receiving part from modules from the core application unit, and carrying out related processing to the instant message.

Owner:ZTE CORP

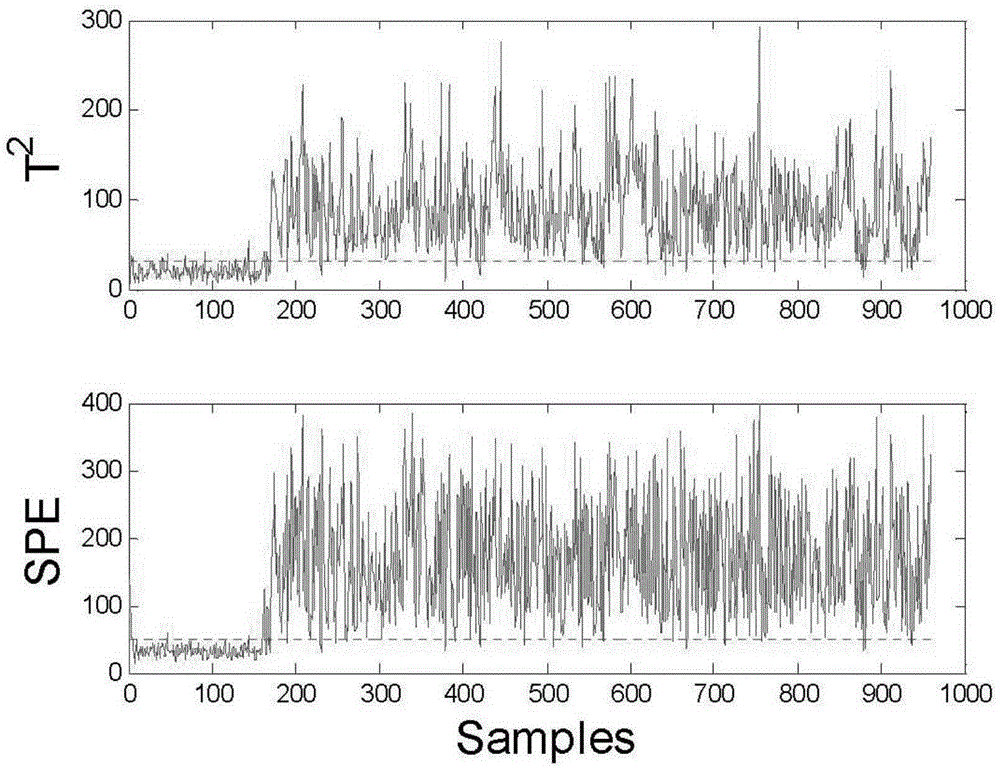

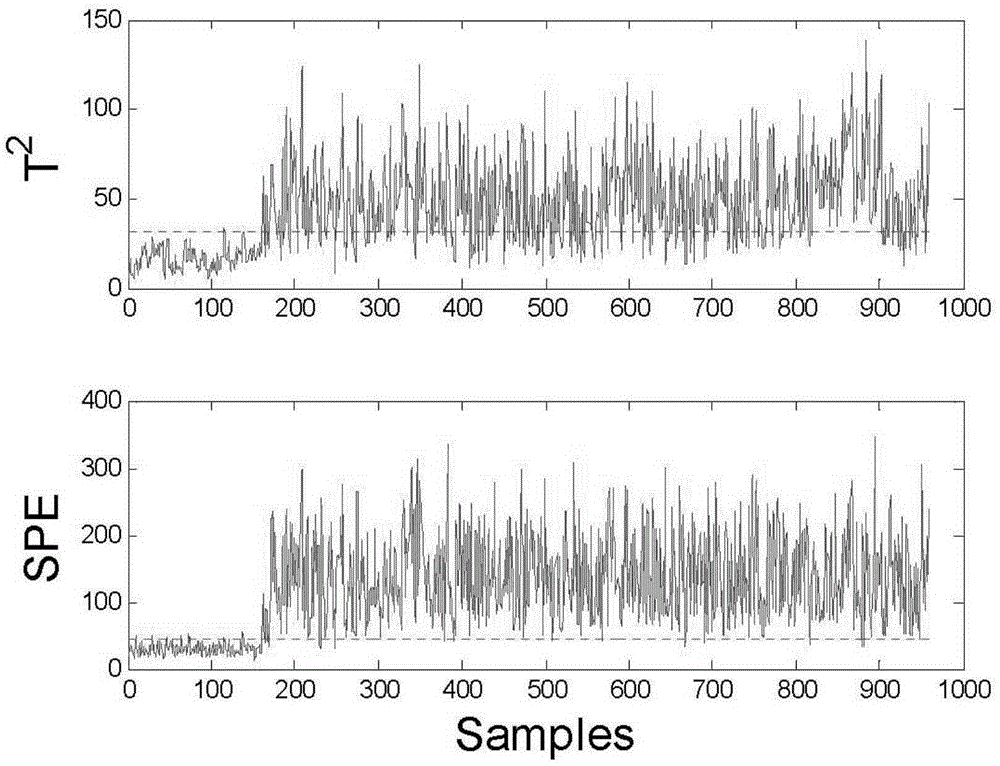

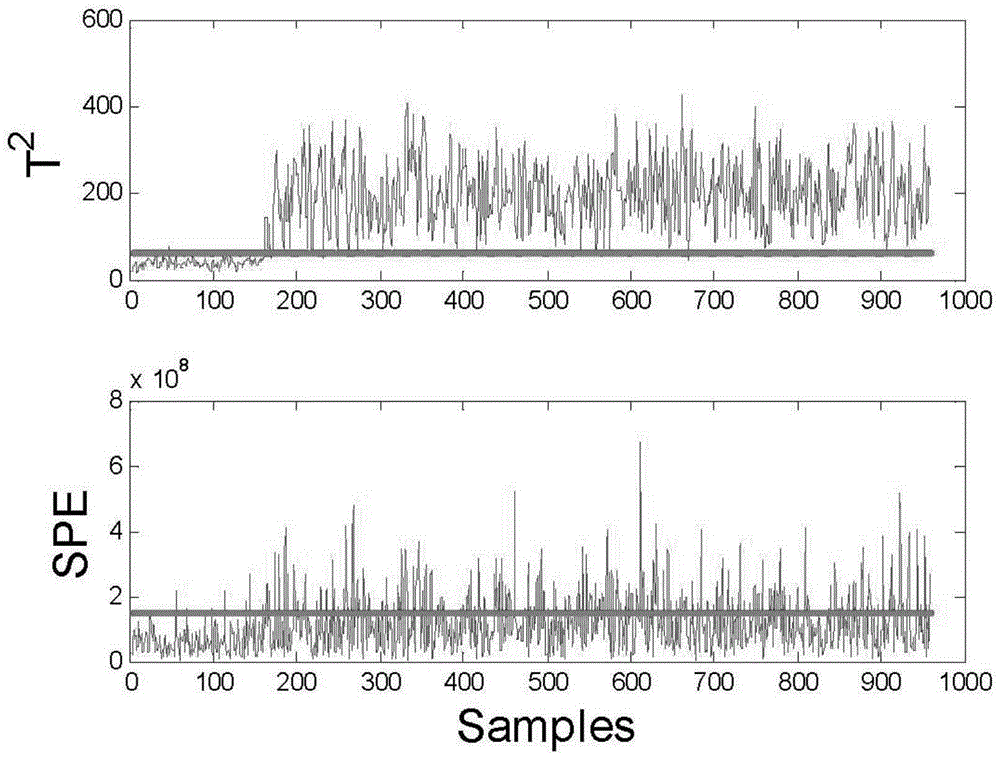

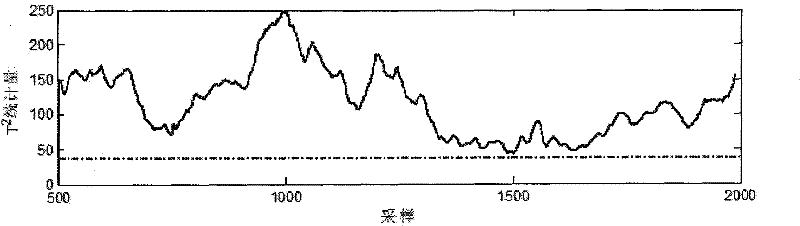

Industrial process fault detection method based on autoregression dynamic hidden variable model

InactiveCN105404280AEasy to detectFacilitates automated implementationProgramme controlElectric testing/monitoringExpectation–maximization algorithmProcess dynamics

The invention relates to an industrial process fault detection method based on an autoregression dynamic hidden variable model. According to the method, by use of data at a normal operation state in an industrial process, a dynamical process model with universality is established, and the model predicts a model structure through a Kalman filter and a smoother and an expectation maximization algorithm, such that dynamical and static coupling relation of industrial data can be effectively extracted; and then, based on dynamic and static noise of the dynamic model, a corresponding monitoring statistical amount is constructed, and a final fault detection result is obtained. Compared with other existing methods, the method provided by the invention can greatly improve the effects of industrial process dynamic modeling and fault detection, reduces the false alarm rate and the missed alarm rate of faults, improves the monitoring performance to a quite large degree, enhances the understanding capability and the operation confidence of process operators for the process and better facilitates automation implementation of the industrial process.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

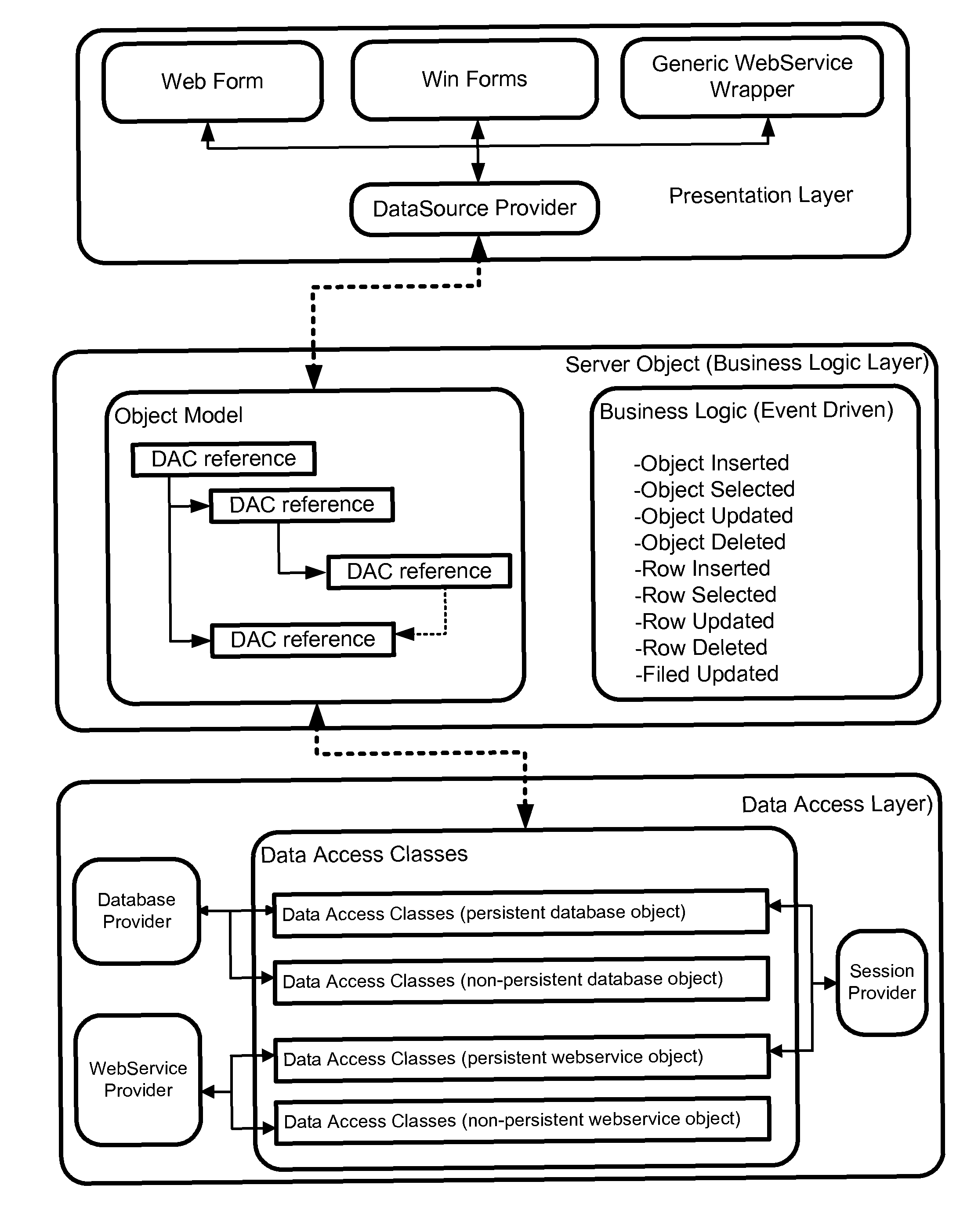

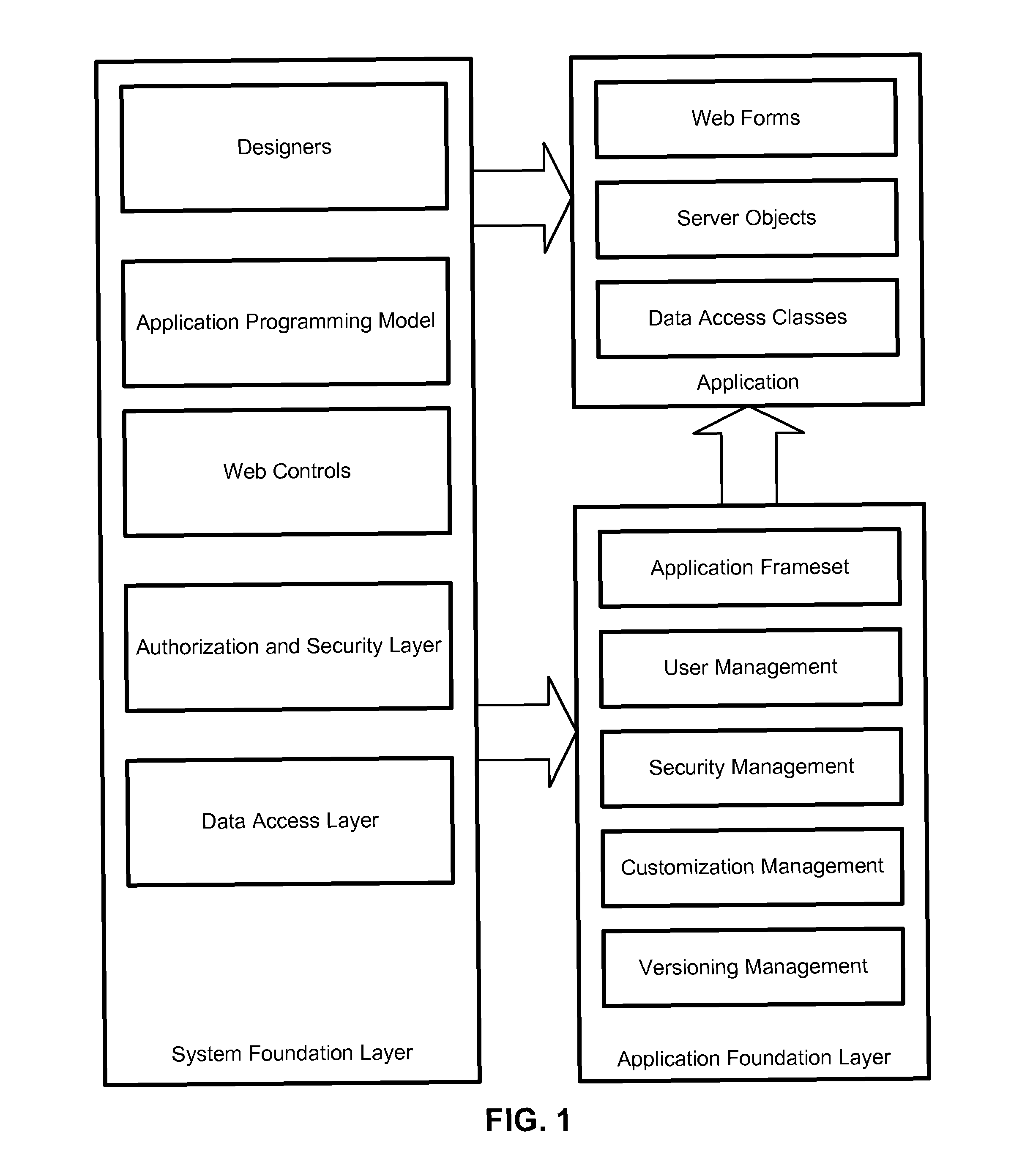

System and method for managing web-based forms and dynamic content of website

ActiveUS8181156B1Requiring controlRequires minimizationWebsite content managementSpecial data processing applicationsProcess dynamicsWeb site

Managing dynamic content of a website, including creating static content assigned to dynamic content of the website, with unmodifiable scripts; creating an active content for processing dynamic content, with hidden elements and elements with only visual marks representation; transmitting the static content to a user; selecting references to the active content within the static content; requesting description of the active content from a server; transmitting the active content to the user; displaying the active content; editing dynamic content and visual representations of data requested by user; representing a first document form generated from an HTML representation of server data and unmodifiable scripts, and which includes the elements; generating a request for data needed for a current visualization of the form; generating a second related data representation of another form; delivering second related data representation for display in browser; storing content of the website on server and making it publicly available.

Owner:CLOUDBLUE LLC

Method for model mismatching detection and positioning of multivariate predictive control system in chemical process

The invention discloses a method for model mismatching detection and positioning of a multivariate predictive control system in a chemical process. By aiming at the typical hierarchical control system in the traditional process industry, the model mismatching detection and positioning is carried out respectively on a multivariate system and all univariate subsystems in the multivariate system. The method comprises the steps of: acquiring residual errors of the multivariate system in a predicative control layer on the basis of an orthogonal projection method, constructing a monitoring statistic computing engine, and acquiring the residual errors, sensitive to process dynamic characteristic variation only, of the univariate system on the basis of an auxiliary variable identification method.In the invention, closed-loop operation data is adopted directly and additional information of the system is not needed; rapid detection and positioning can be made just by utilizing a small amount of data so that fewer disturbances are made to a working condition; and the mismatching information of process models of all univariate subsystems in the multivariate system can be positioned so as to eliminate the influence of the disturbances. By means of the method disclosed by the invention, the accurate model mismatching information can be obtained rapidly at lower cost, the maintenance cost of the predictive control system can be reduced, the service life of the predicative control system can be prolonged and the gain can be improved.

Owner:ZHEJIANG UNIV

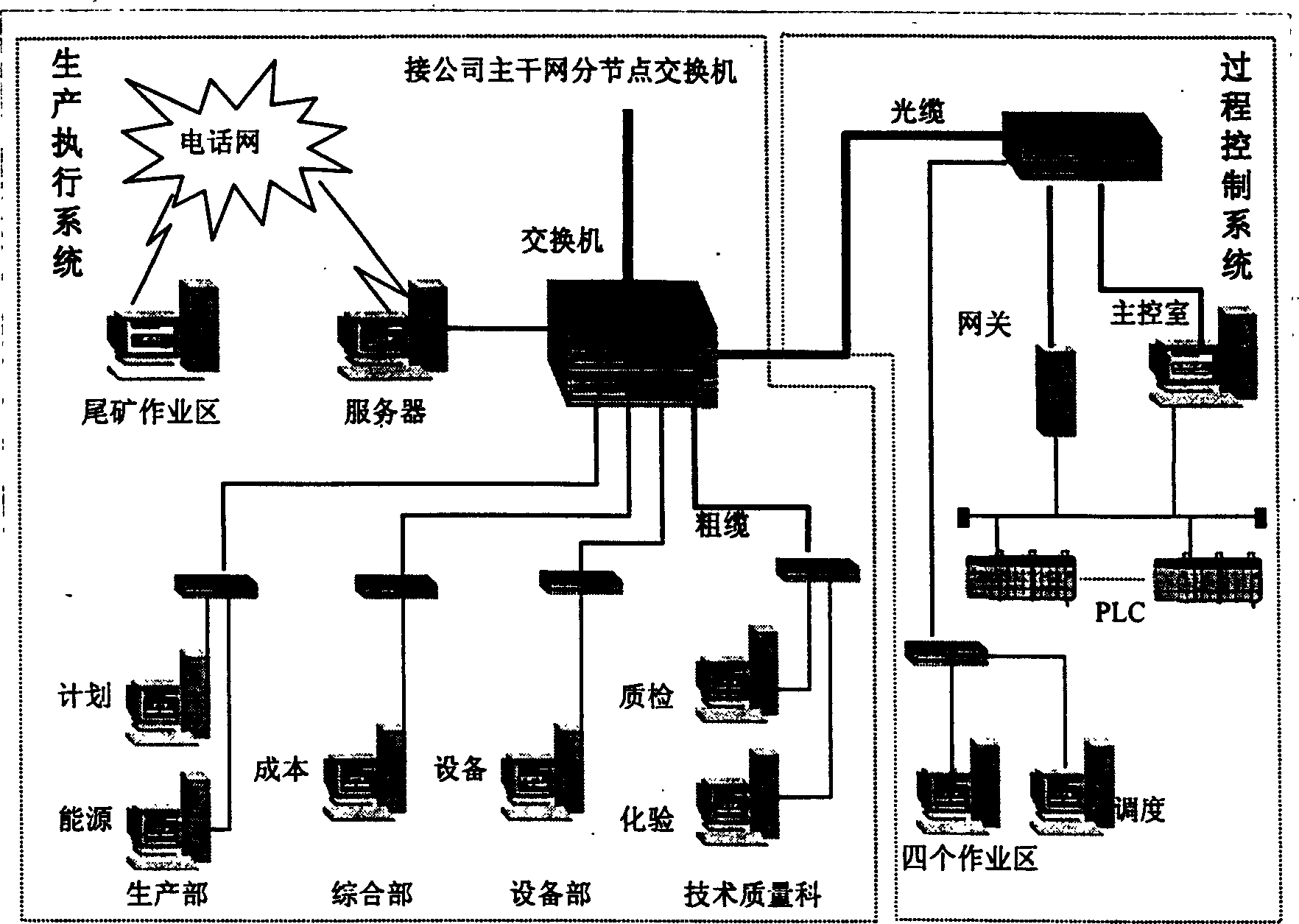

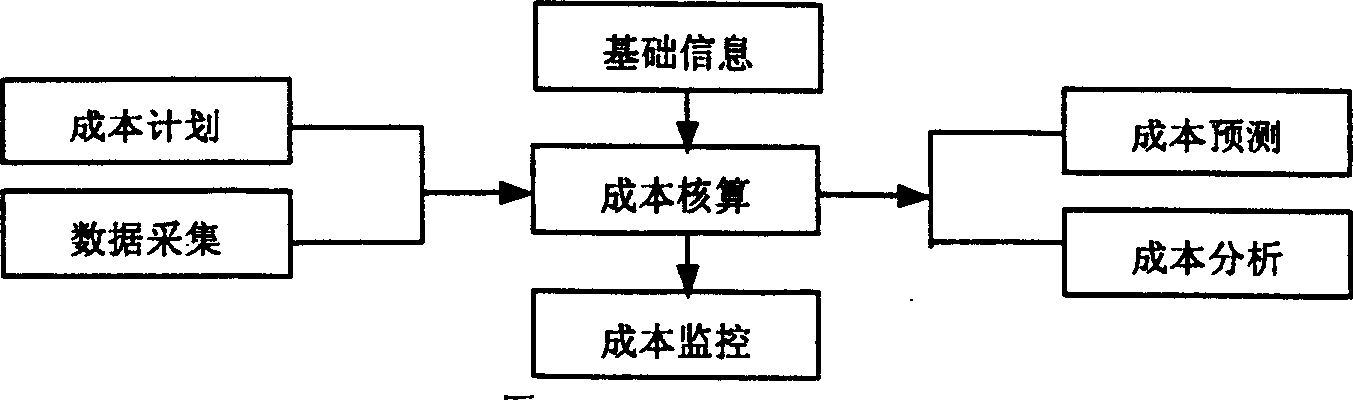

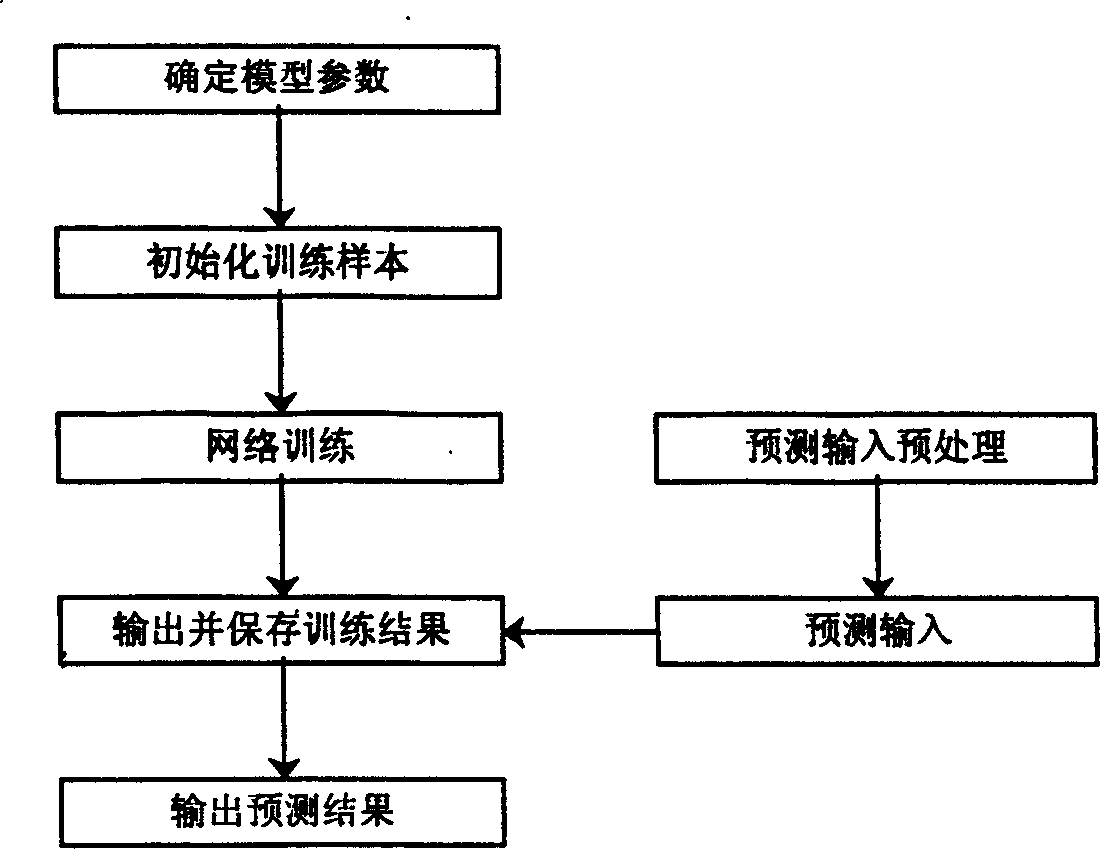

Metallurgy production process dynamic cost control method based on neural network

InactiveCN1542658ALow costBiological neural network modelsSpecial data processing applicationsProcess dynamicsNerve network

The present invention is dynamic cost controlling method for metallurgical production process under network environment and by means of concentrated and distributed control technology, dynamic cost management technology, intelligent nerve network technology, etc. The system structure consists of hardware system and software system, the hardware system includes exchanger, server, user terminals, dynamic data acquisition system, control network and enterprise network, and the software system includes application platform software, data base, information collection and interface software. The key algorithm in dynamic cost control software package utilizes nerve network in dynamic cost prediction and analysis. The present invention can lower production cost of production enterprise.

Owner:NORTHEASTERN UNIV

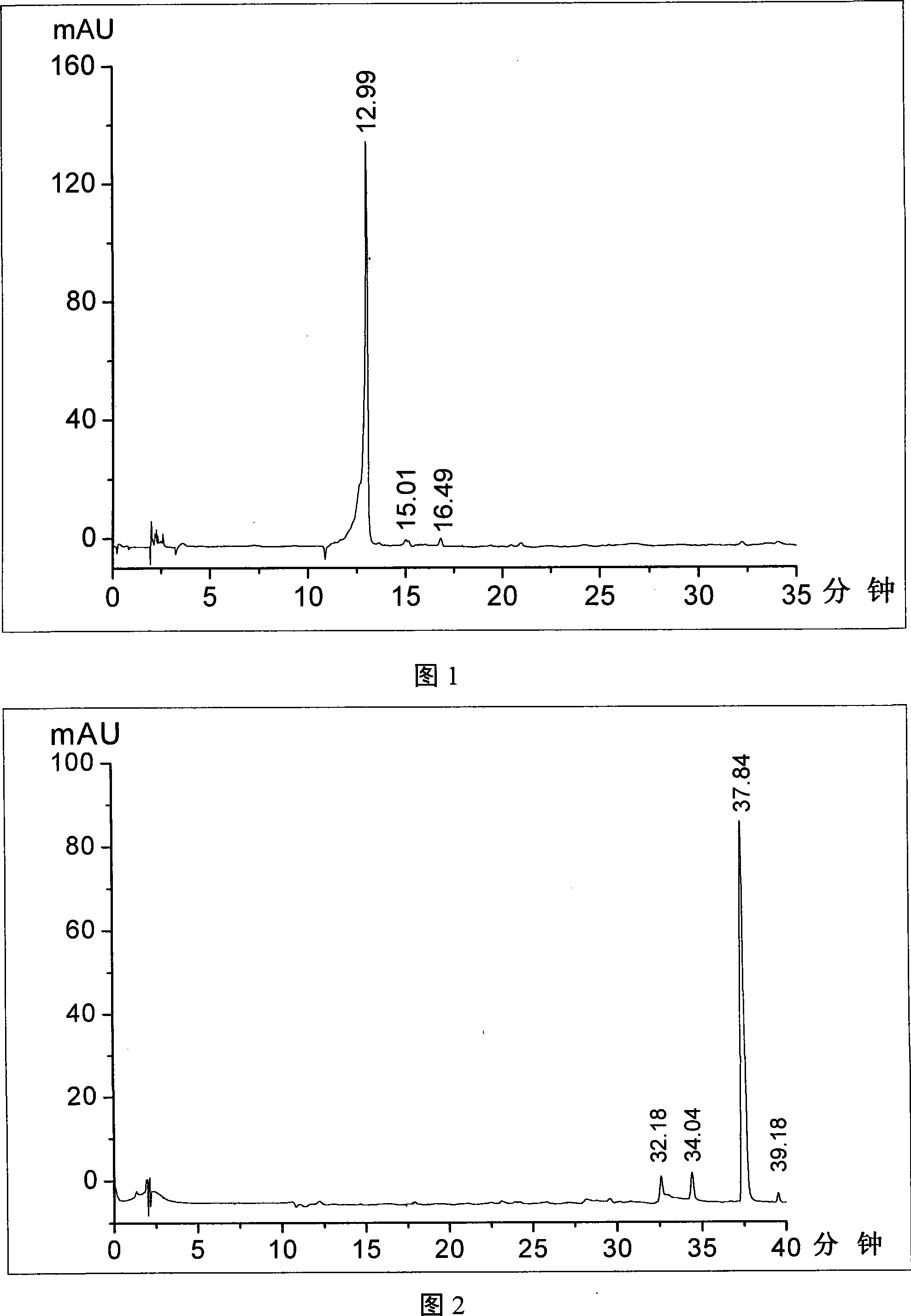

Method for separating and purifying salvianolic acid from red sage root liquid extract by one step

InactiveCN101186572ACarboxylic compound separation/purificationPlant ingredientsProcess dynamicsSalvianolic acid B

The invention relates to a method for furthering separating and purifying salvianolic acid from Danshen extract fluid, which comprises that prepares, breaks and extracts Danshen via water solution, acidifies extract to adjust pH and adds salt to process post-treatment, processes dynamic continuous adsorption and elution on the treated extract at chromatography column stuffed with resin adsorbent, elutes via water, collects and concentrates eluent, elutes via gradient ethanol solution, segmented collects and concentrates eluent, and dries the concentrates solution to obtain product. The invention can simply, effectively and quickly separate and purify various salvianolic acids, wherein test on different salvianolic acid products shows that the highest yields of tanshinol, alkannic acid, rosmarinic acid, salvianolic acid A and salvianolic acid B are 35. 55%, 70.65%, 99.27%, 82.78%, and 89.34%, and relative highest purities are 95.32%, 65.05%, 29.40%, 33.93%, and 82.35%, which are near or higher than the result of purification on the goal of single component.

Owner:TIANJIN UNIV

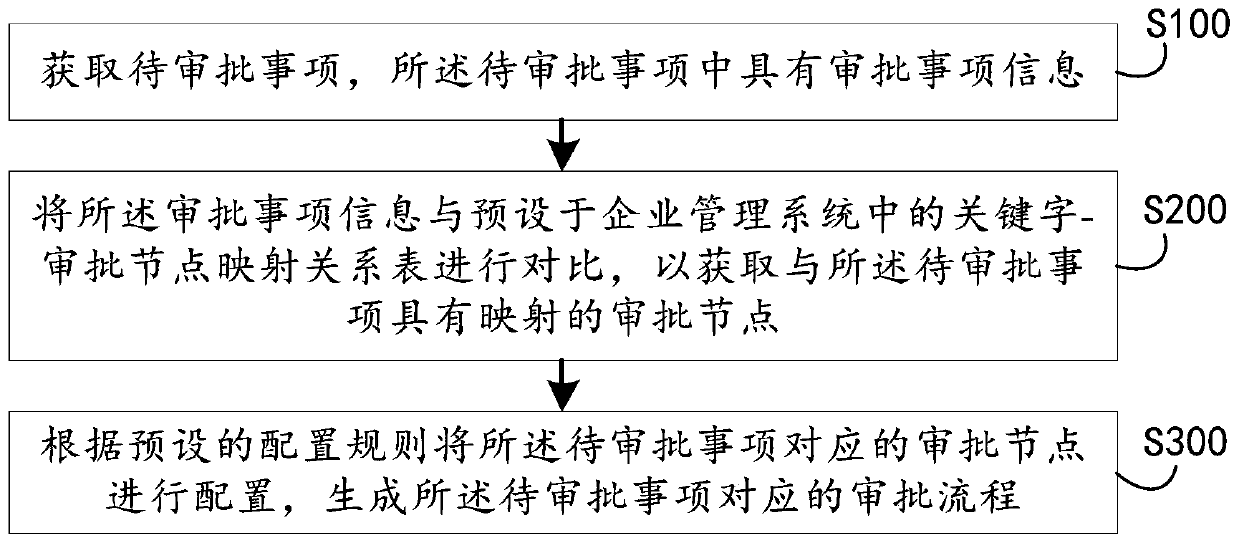

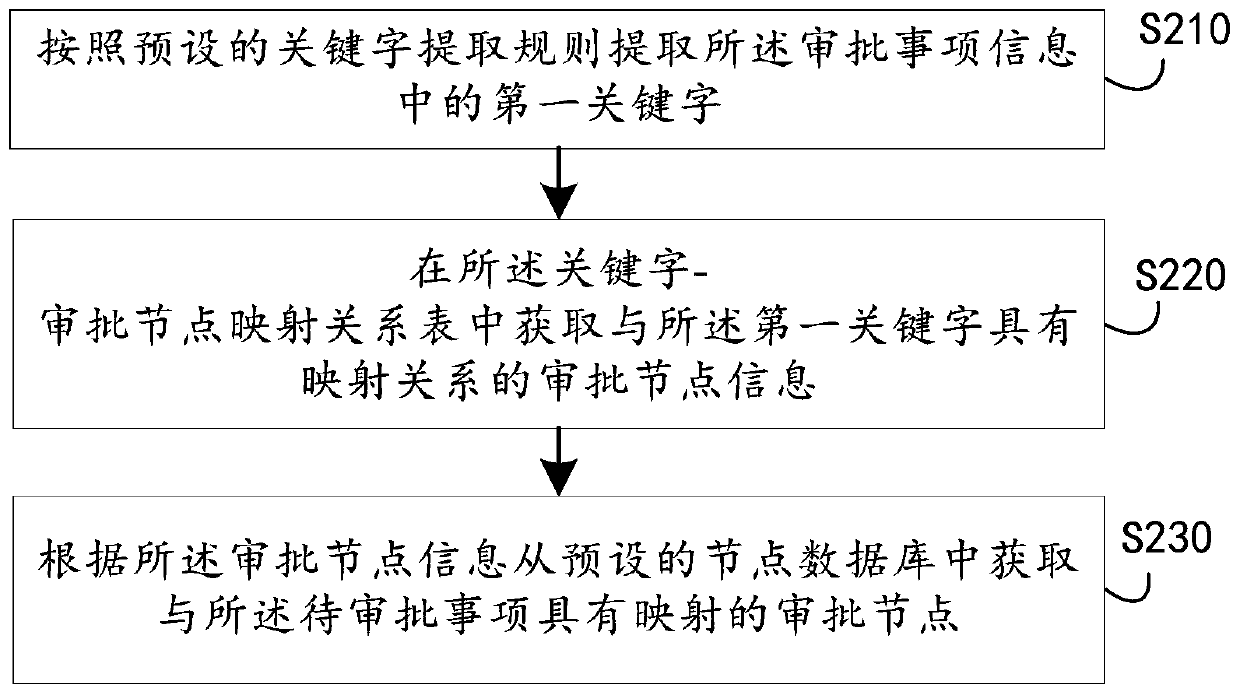

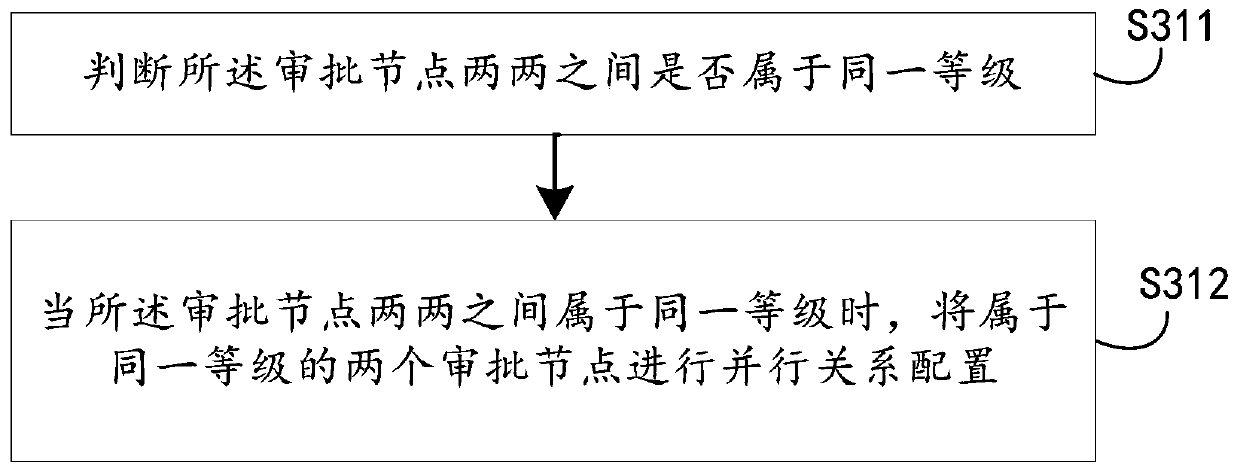

Examination and approval process dynamic configuration method and device, computer equipment and storage medium

PendingCN109784829AFlexible configurationImprove general performanceOffice automationFile replicationProcess dynamics

The invention discloses an approval process dynamic configuration method and device, computer equipment and a storage medium. The method comprises: acquiring a to-be-approved item, wherein the to-be-approved item contains approval item information; comparing the approval item information and a keyword-approval node mapping relation table preset in an enterprise management system to obtain an approval node having mapping with the to-be-approved item; And configuring the approval node corresponding to the to-be-approved item according to a preset configuration rule, and generating an approval process corresponding to the to-be-approved item. As the approval process corresponding to the to-be-approved item is dynamically generated according to the approval item information, the method has thecharacteristics of flexible configuration, wide application scene, high universality and the like. The approval node can also be set to be an approval node group with a plurality of sub-nodes, circulation between the nodes and the node group and circulation between the node group and the node group are supported, and the efficiency of file replication and the efficiency of related workers can beimproved.

Owner:PING AN TECH (SHENZHEN) CO LTD

Fireworks and crackers transport process dynamic-monitoring and supervision system and method

InactiveCN101943895AGuarantee the safety of lifeGuarantee property securityProgramme controlComputer controlProcess dynamicsTime response

The invention aims to provide a fireworks and crackers transport process dynamic-monitoring and supervision system and a fireworks and crackers transport process dynamic-monitoring and supervision method, which are used for acquiring and processing the safety parameter, speed and position information of a fireworks and crackers transport vehicle and performing pre-warning and alarming on fireworks and crackers transport accidents to prevent and reduce the fireworks and crackers transport accidents. Compared with the prior art, the system and the method have the advantages of dynamically monitoring and supervising the fireworks and crackers transport vehicle in the whole process to realize safety monitoring and pre-warning, the tracking of the whole transport process and the real-time response and emergency linkage processing of emergencies in the fireworks and crackers transport process, providing timely and accurate information and data support for the emergency response of an administration section, preventing serious and extraordinarily serious terrible accidents in the fireworks and crackers transport process and better ensuring the safety of lives and property of people.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

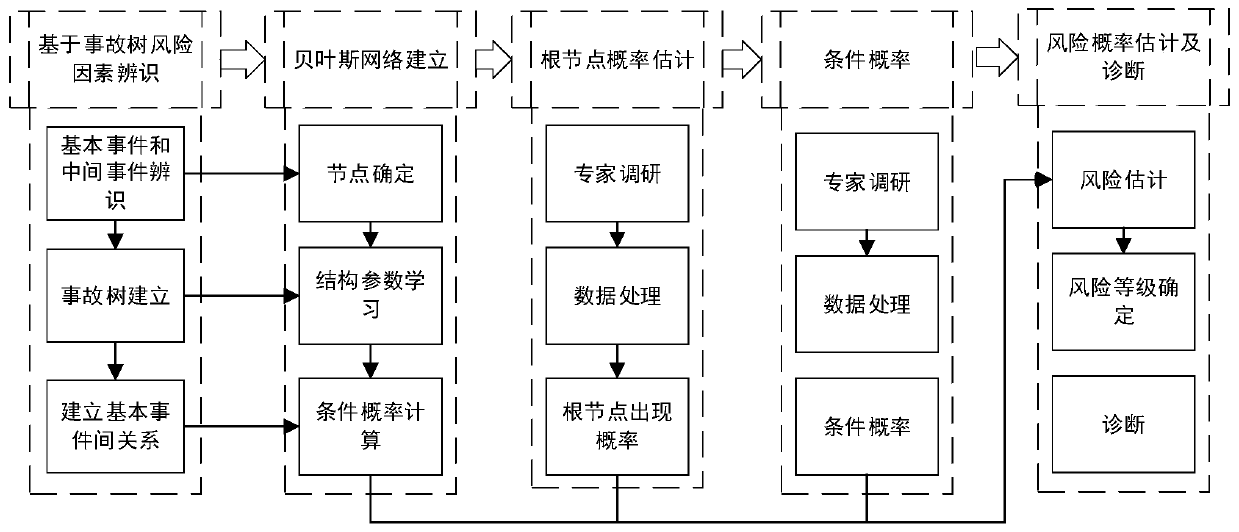

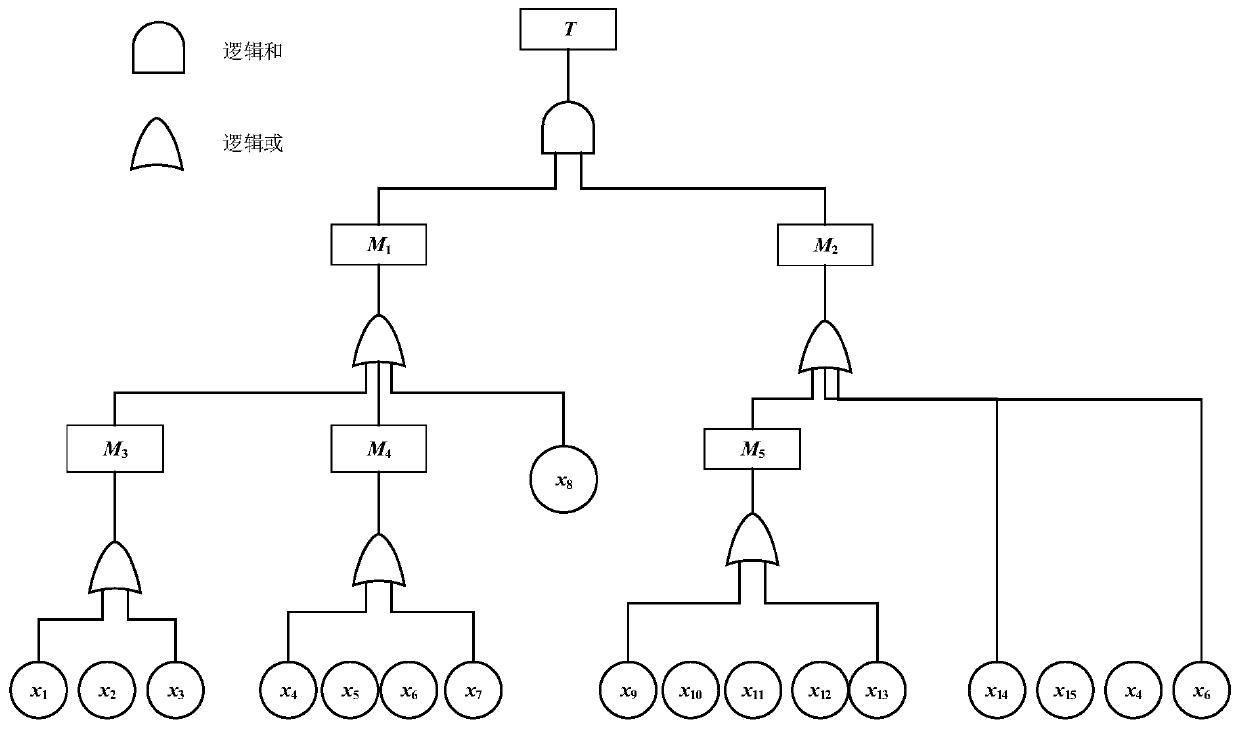

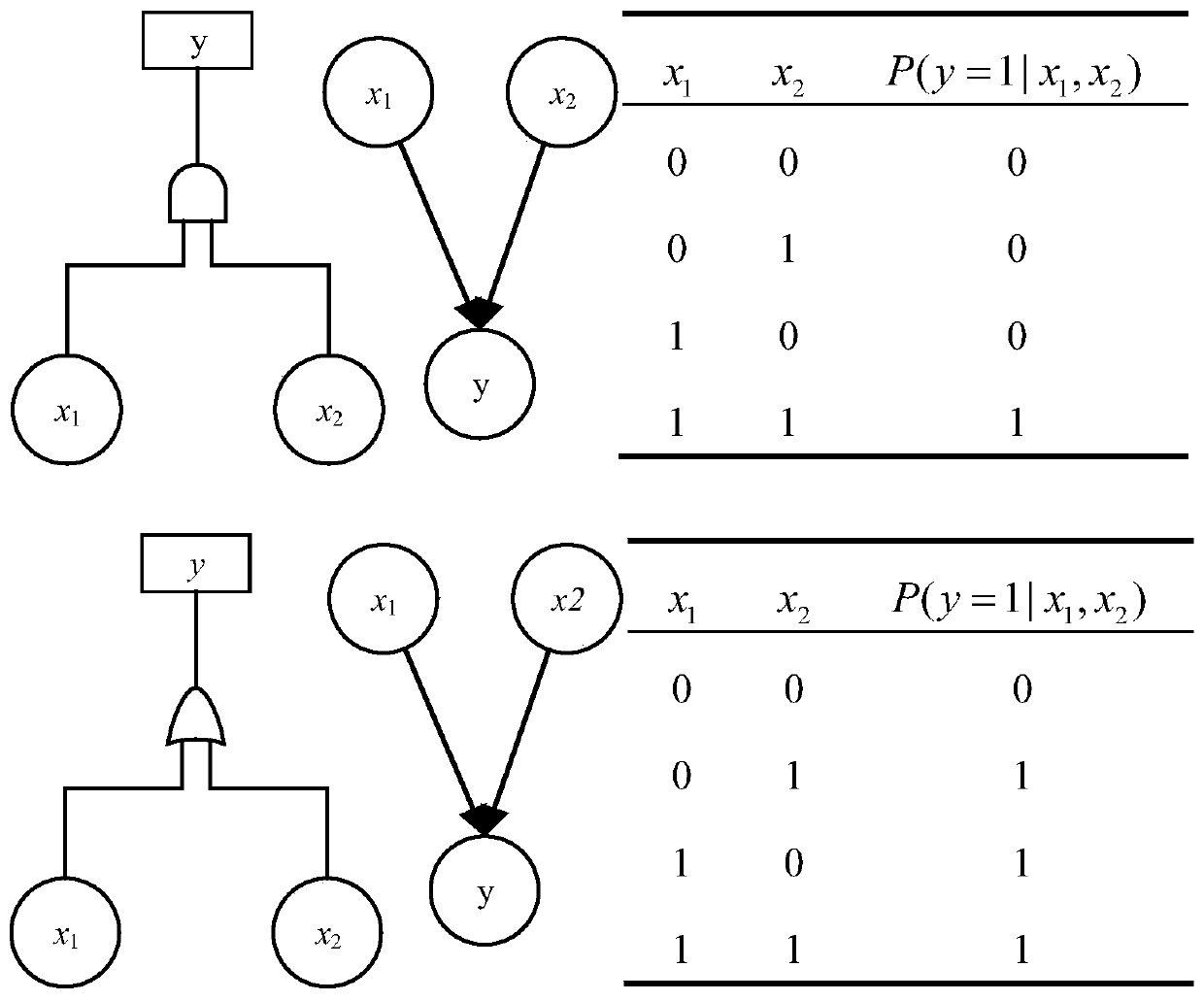

Tunnel risk evaluation method based on fuzzy polymorphic Bayesian network

InactiveCN110059963AReduce subjectivityImprove Risk PredictionCharacter and pattern recognitionResourcesInformatizationProcess dynamics

The invention discloses a tunnel risk evaluation method based on a fuzzy polymorphic Bayesian network. The invention provides an investigation method combining a confidence index, a weight index and aprobability interval based on expert judgment. According to the method, a tunnel risk accident tree is constructed according to an existing tunnel accident case, a basic event of a tunnel risk accident and the occurrence probability of each factor under the current technical level are obtained, and a polymorphic Bayesian network is constructed by the accident tree. The probability obtained by expert investigation and the probability obtained by case accidents are processed by a subjective and objective method to obtain a conditional probability, so that a polymorphic fuzzy Bayesian network conditional probability construction method and a tunnel risk probability calculation method are provided. According to the method, the subjectivity of risk factor identification can be reduced, the risk prediction accuracy is improved, informatization management and whole-process dynamic evaluation of underground engineering construction are realized, and the construction safety is ensured.

Owner:BEIJING JIAOTONG UNIV

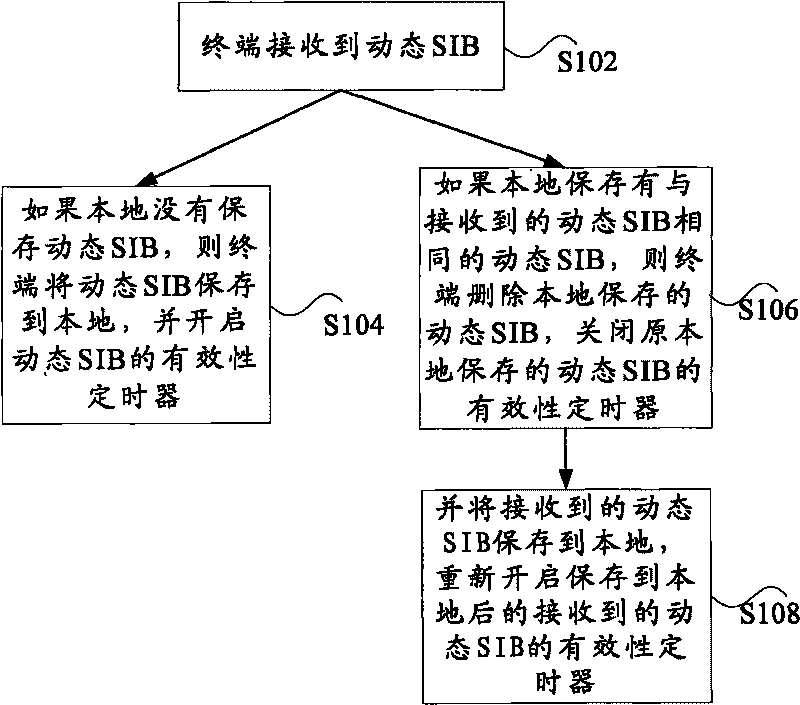

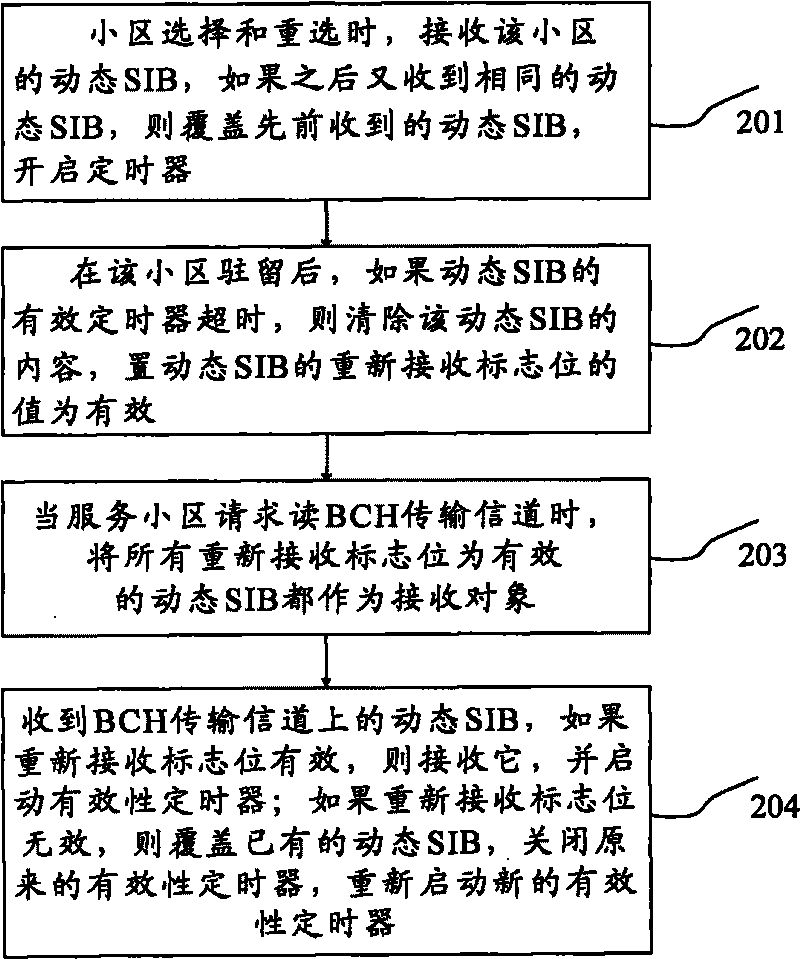

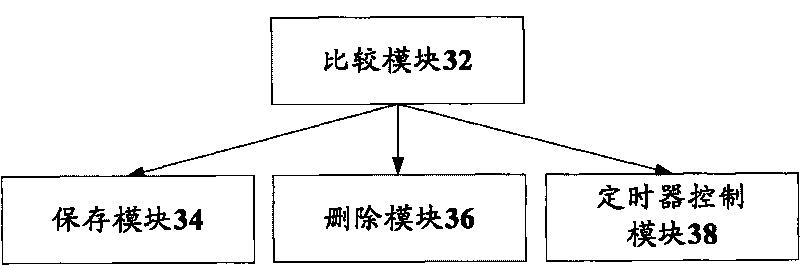

Method and device for processing dynamic system message block

ActiveCN101697614AReduce the number of updatesReduce overheadEnergy efficient ICTAssess restrictionProcess dynamicsTransmission channel

The invention discloses method and device for processing a dynamic system message block. The method comprises the following steps: after a terminal receives dynamic SIB, if the local does not store the dynamic SIB, storing the dynamic SIB to the local by the terminal and starting a validity timer of the dynamic SIB; if the local stores dynamic SIB same with the received dynamic SIB, deleting the local-storing dynamic SIB by the terminal, closing the validity timer of the original local-storing dynamic SIB, storing the received dynamic SIB to the local, and opening the validity timer of the received dynamic SIB after being stored in the local. The updating frequencies of the dynamic SIB are reduced and the expenses for UE to frequently read a BCH transmission channel are decreased, further reducing the power consumption of UE.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com