Patents

Literature

244 results about "Process industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ALSO CALLED: Process Manufacturing, Process Industry. DEFINITION: Manufacturing where a chemical change has taken place. This industry encompasses chemicals, petroleum, coal, textiles and apparel, metal, wood, minerals, paper, printing, publishing, and consumables, such as food, beverages and tobacco.

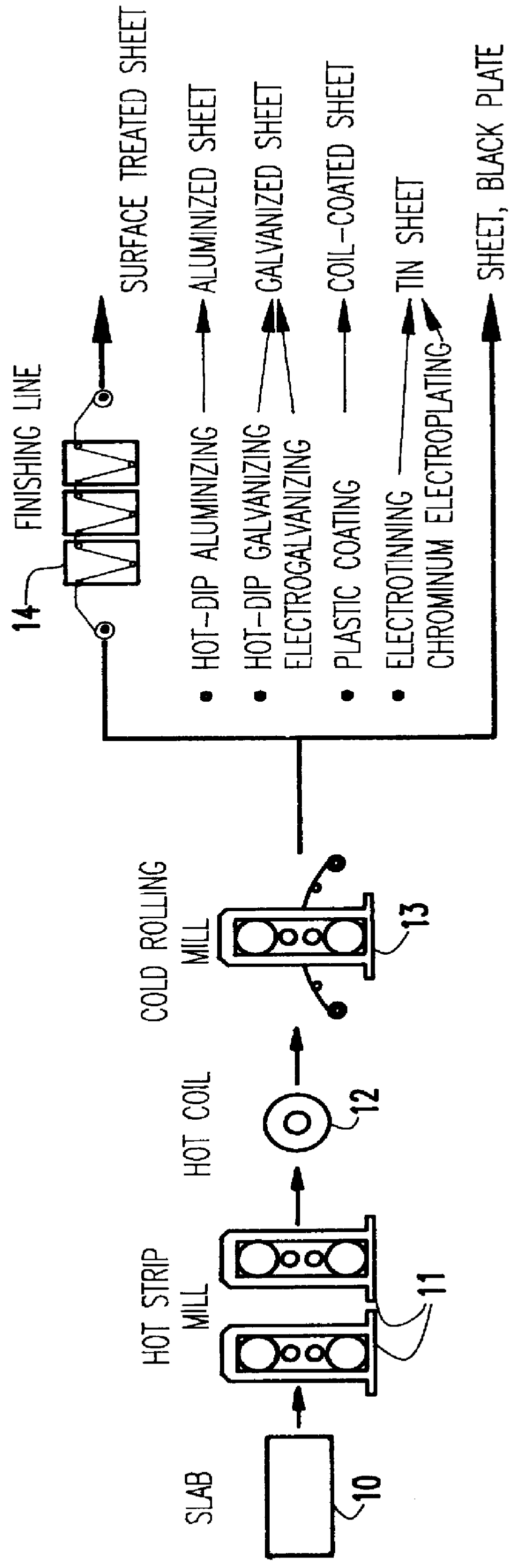

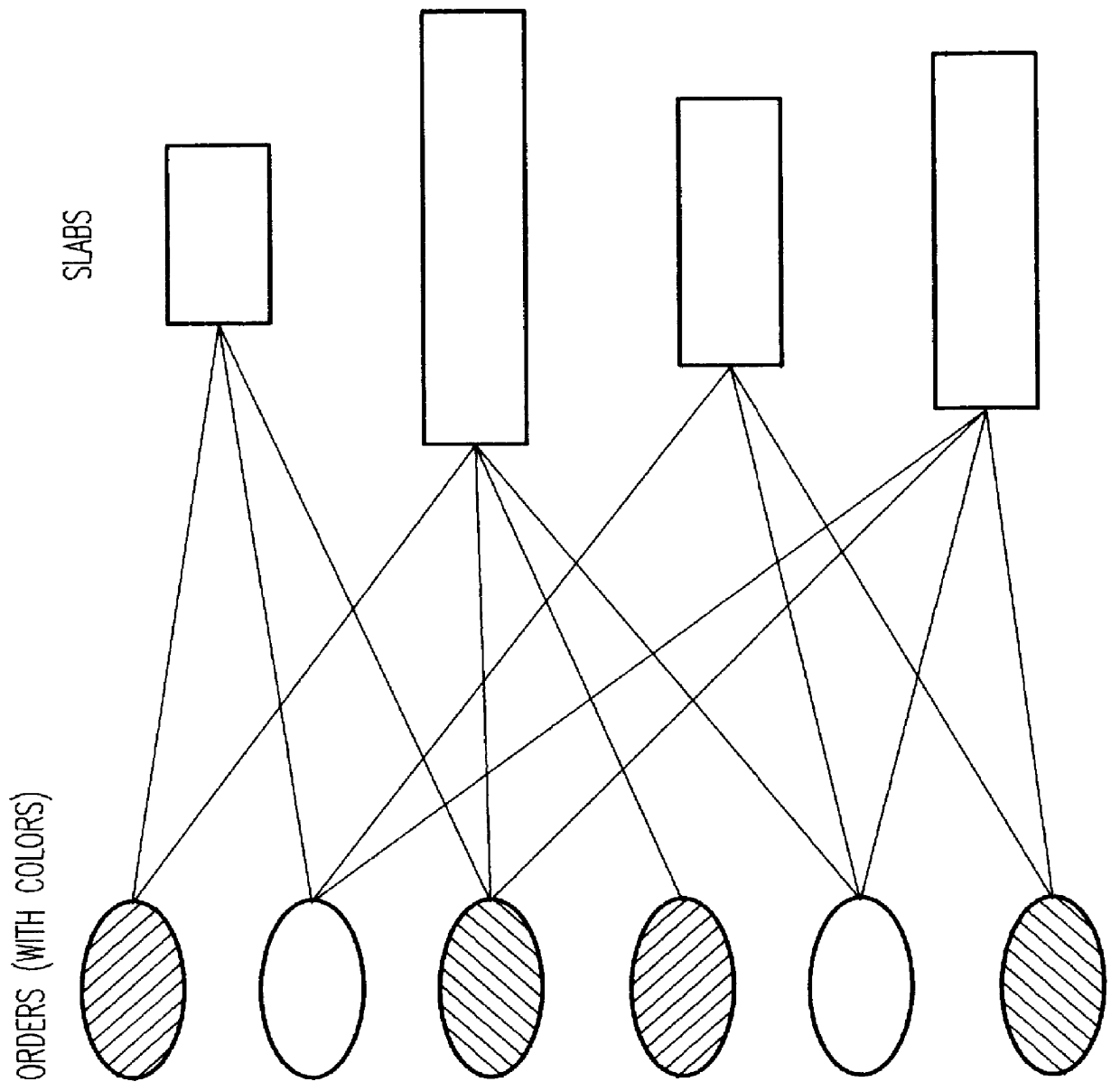

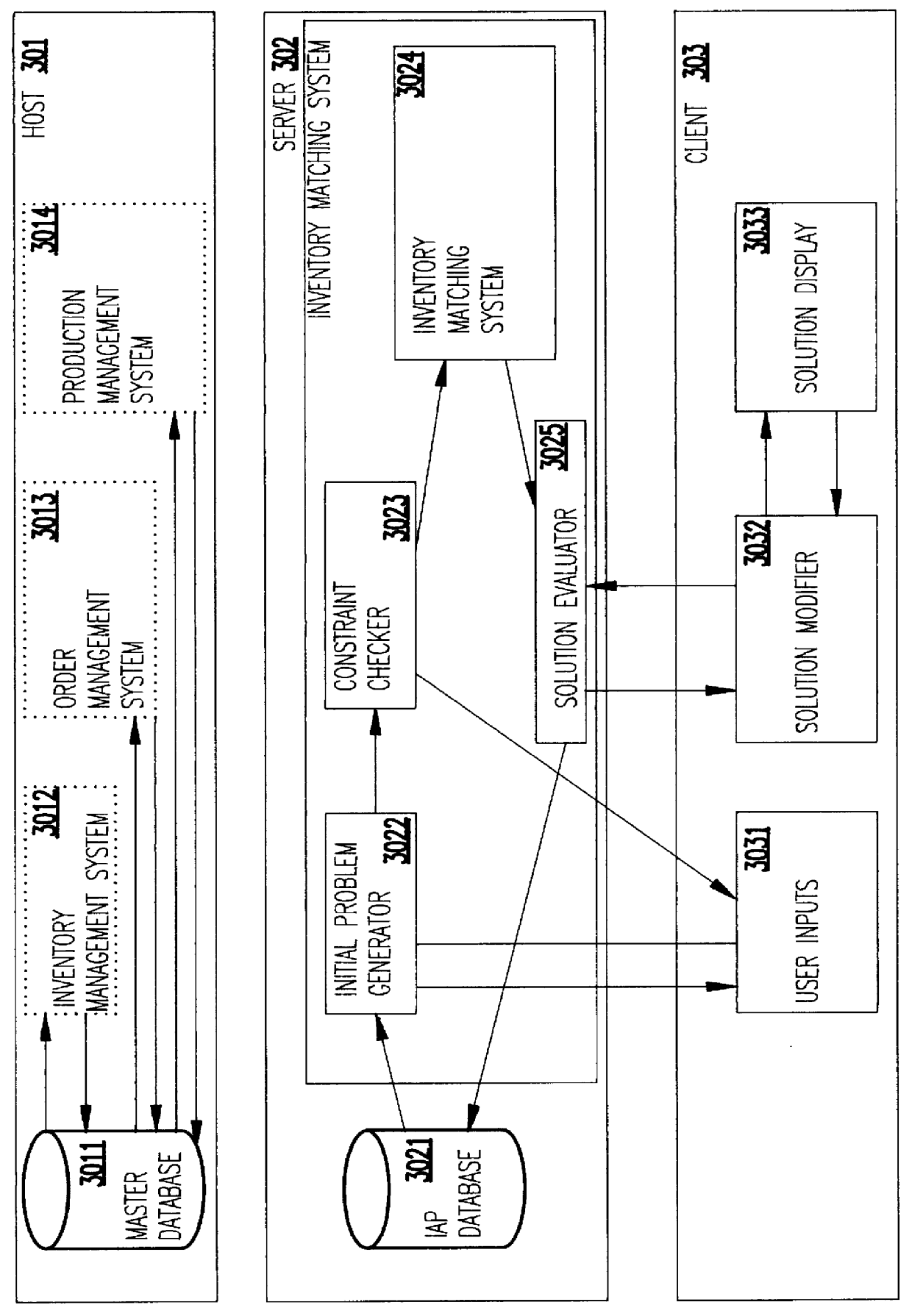

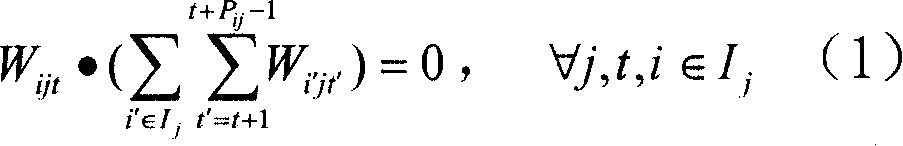

Fast inventory matching algorithm for the process industry

A fast computer implemented method generates near-optimal solutions to the multi-objective inventory matching problem by solving for multiple objectives simultaneously and generating multiple non-dominating solutions. The method implements a multi-assignment backjumping algorithm that consists of three steps. The first step is a rappeling step in which a feasible solution is created by applying Iterative Bipartite Matching and maximum flow algorithm. Near-optimal feasible solutions are stored in a non dominated set. The second step is to use a multi-key sort to identify undesirable matches in a given feasible solution. The third step is backlifting the solution by removing undesirable matches from the feasible solution and places those undesirable matches on a no good set of matches. If the feasible solution is non-dominated, a copy is stored in a non-dominated set. The feasible solution is finally provided as input to the repelling step.

Owner:GOOGLE LLC

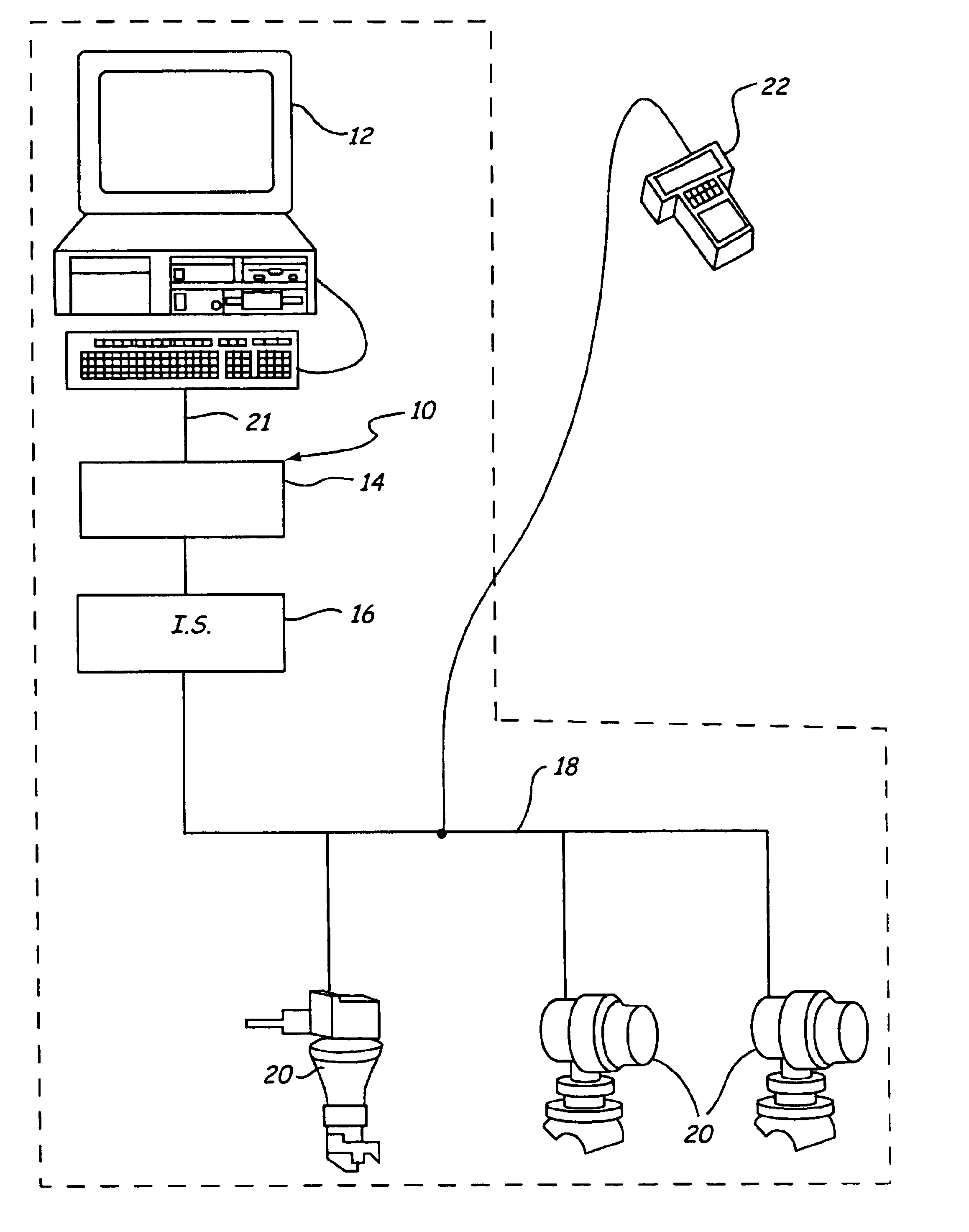

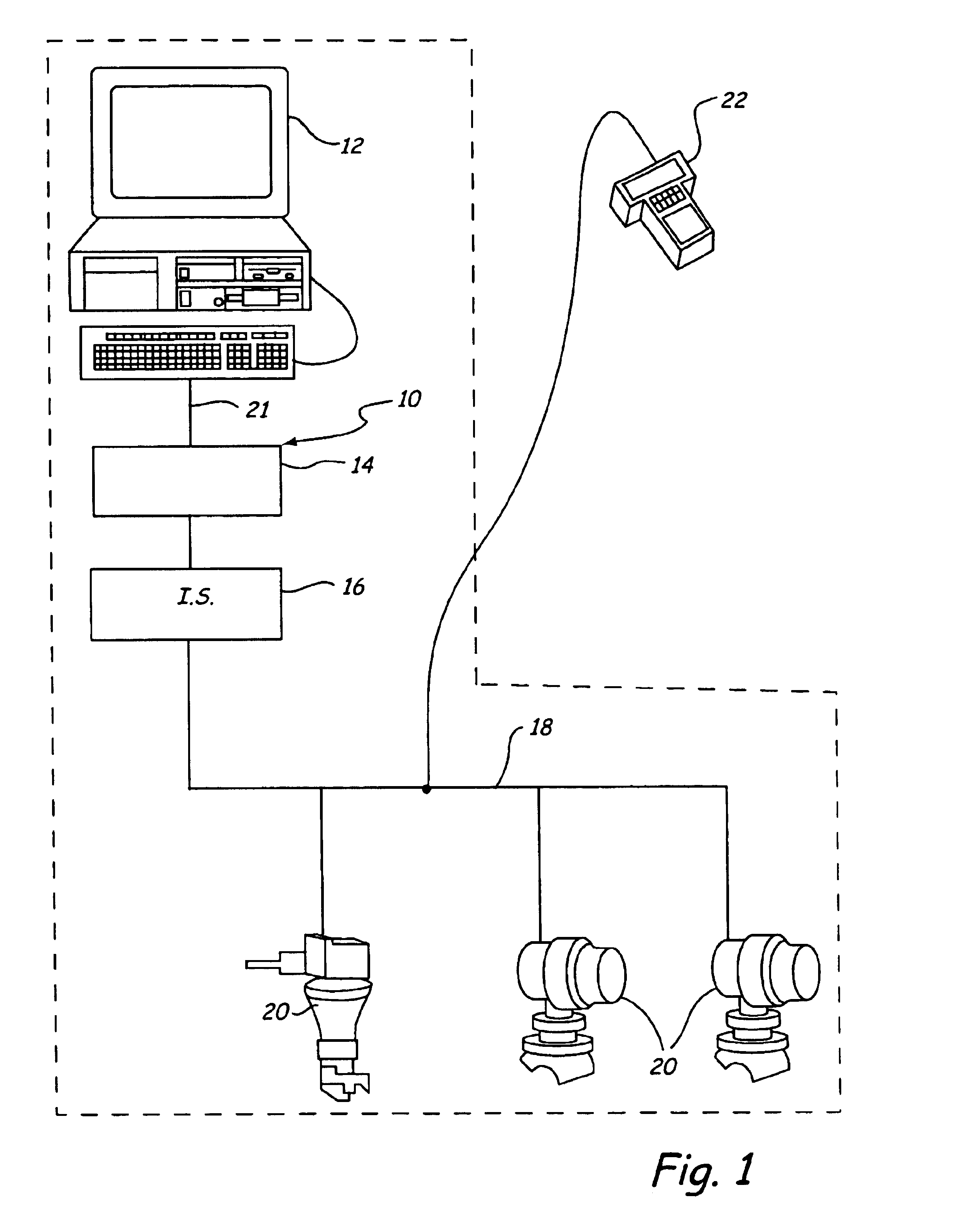

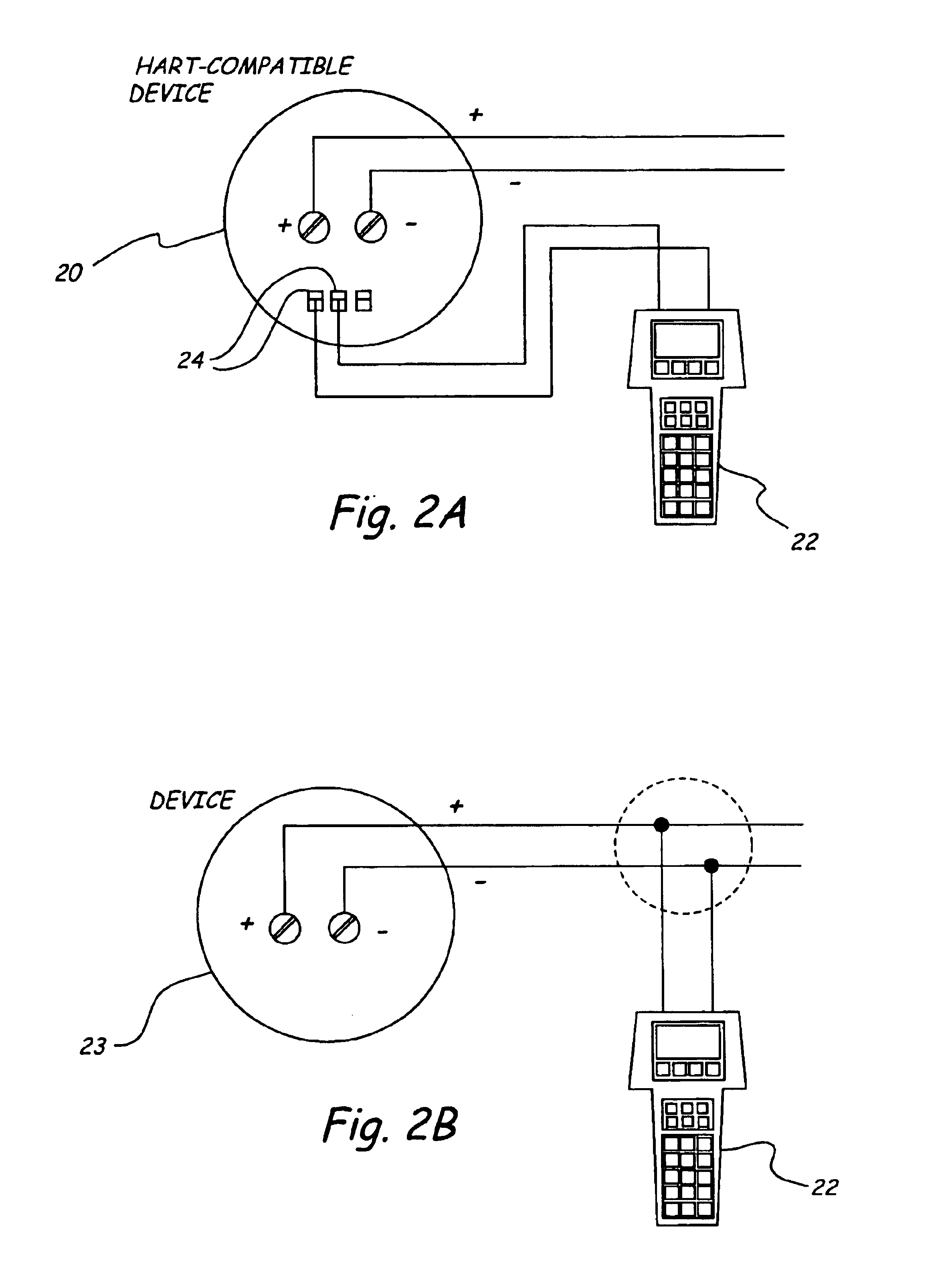

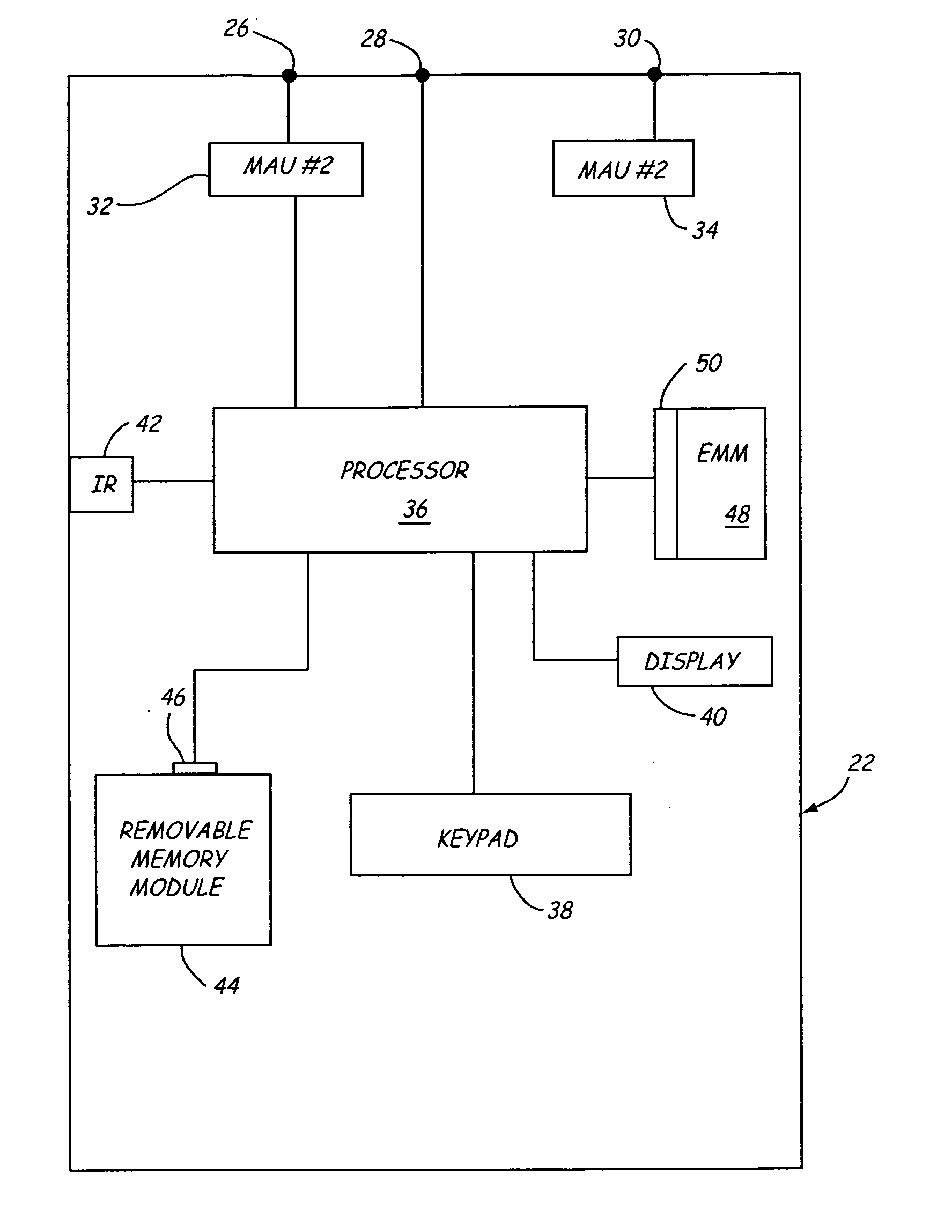

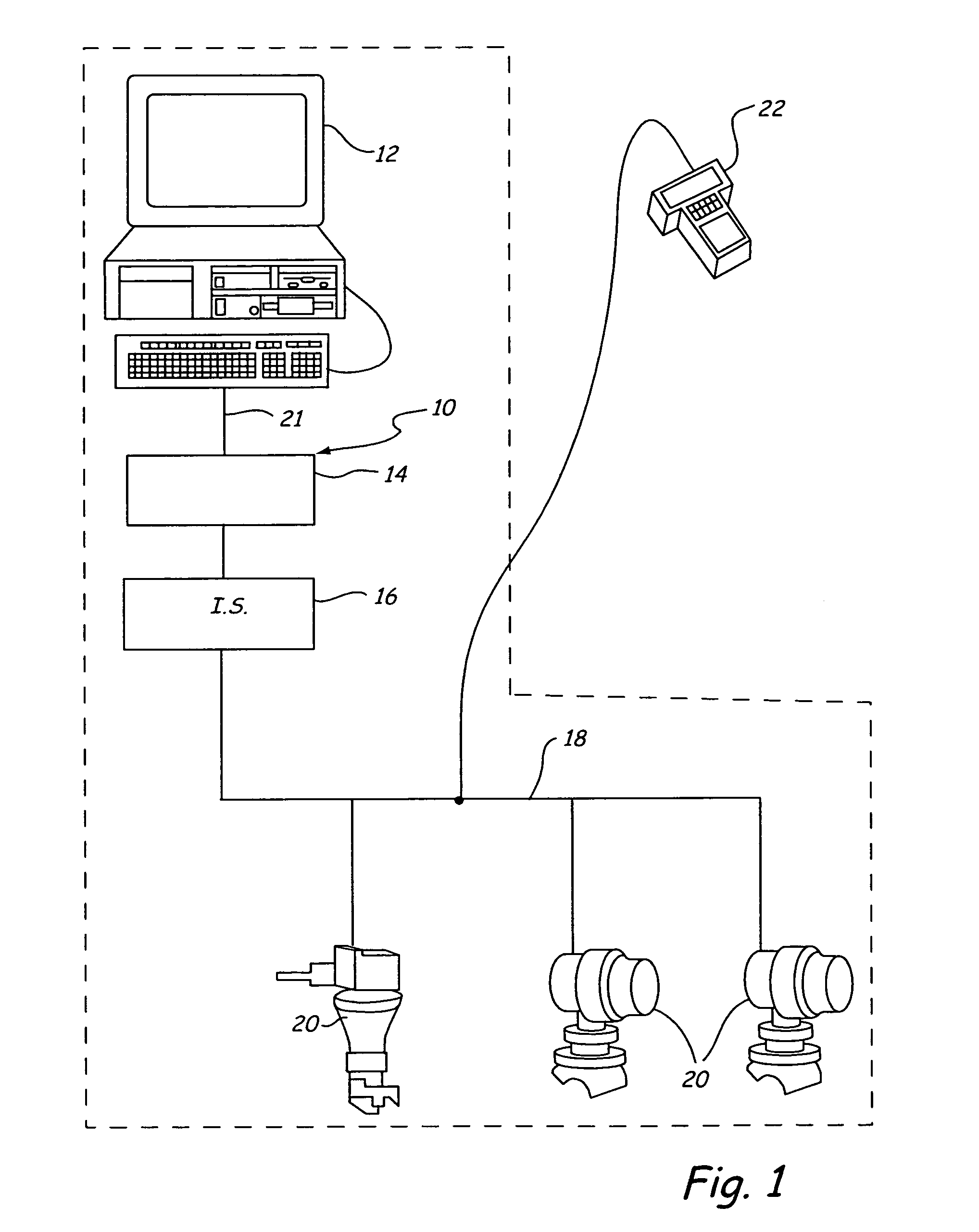

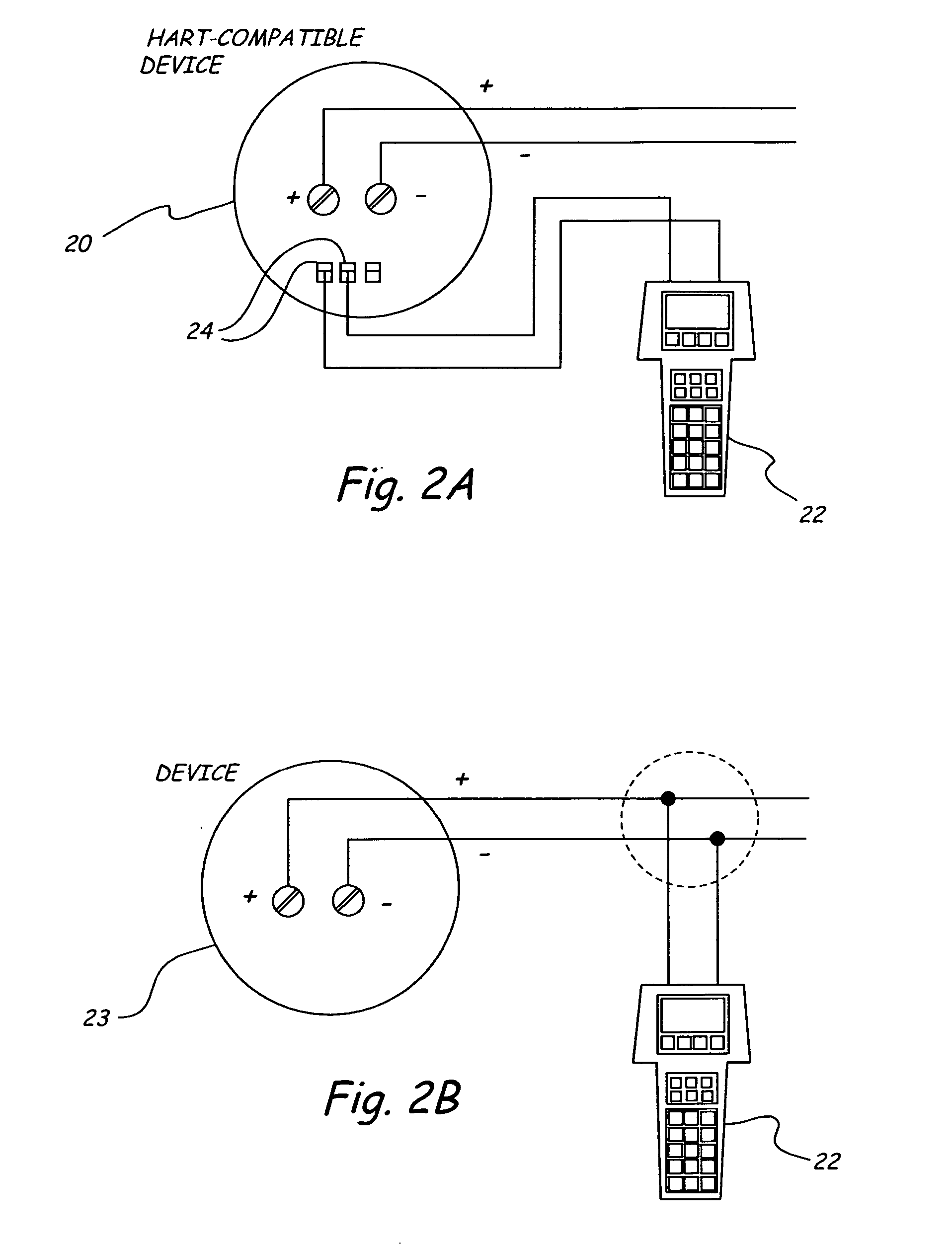

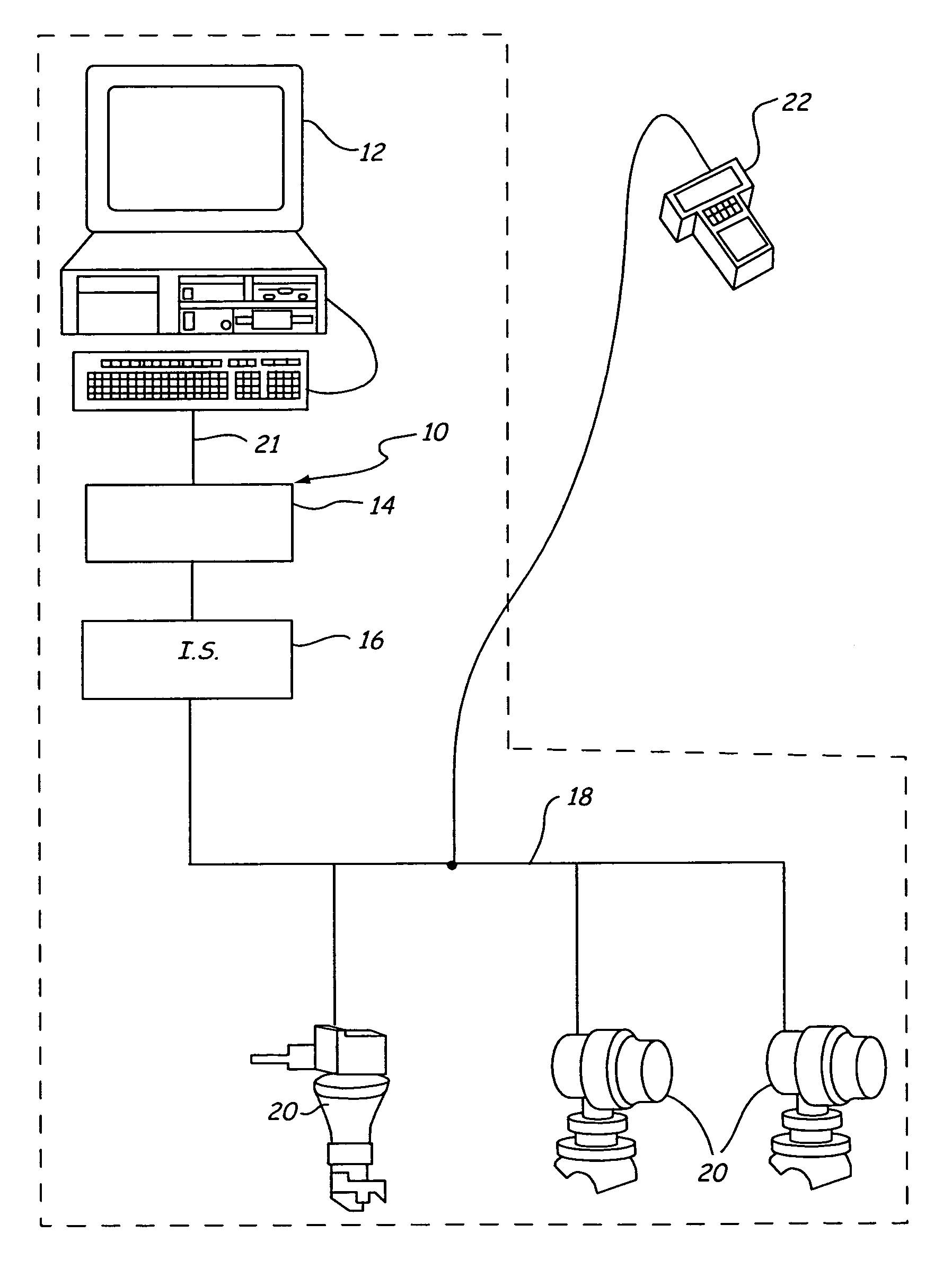

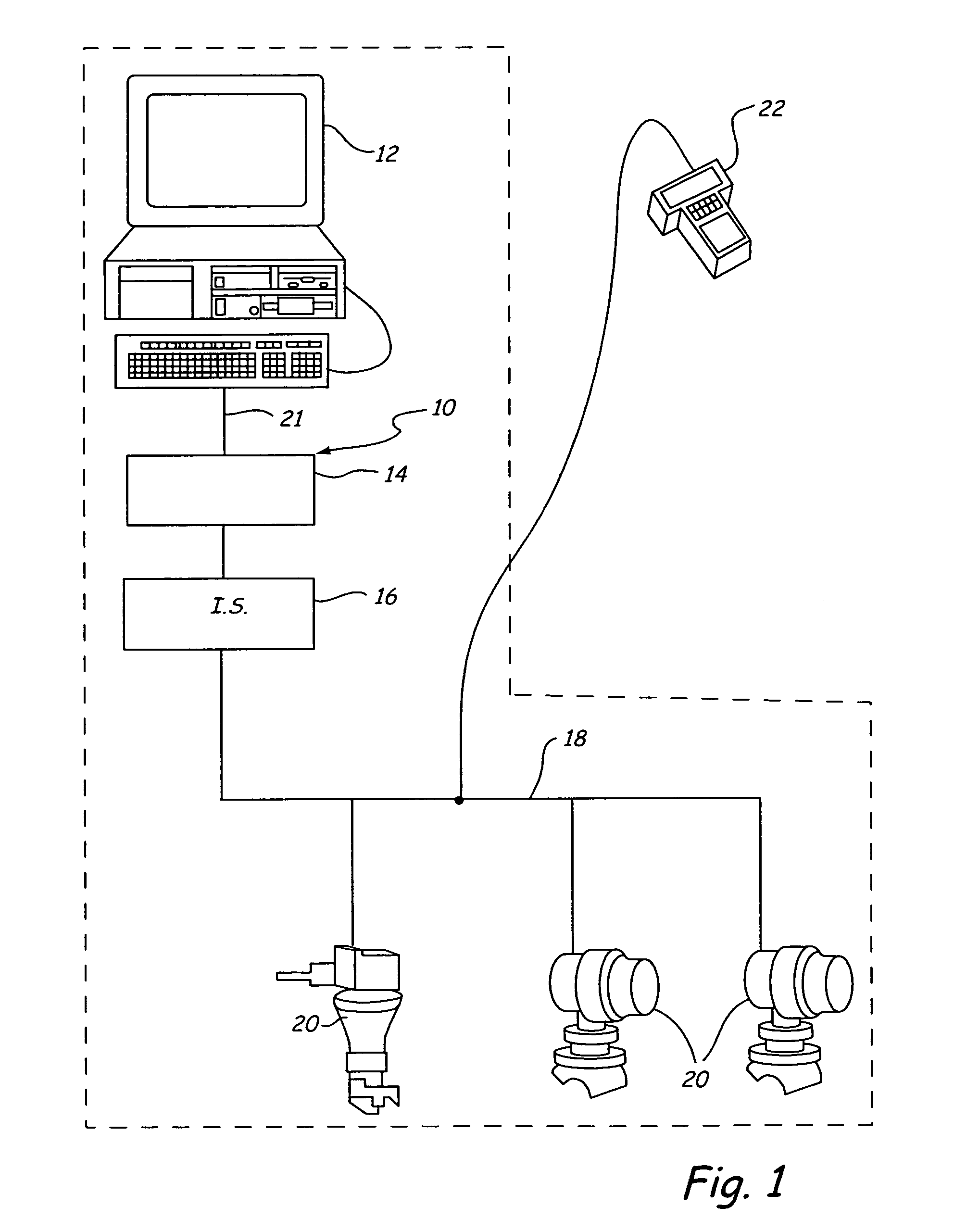

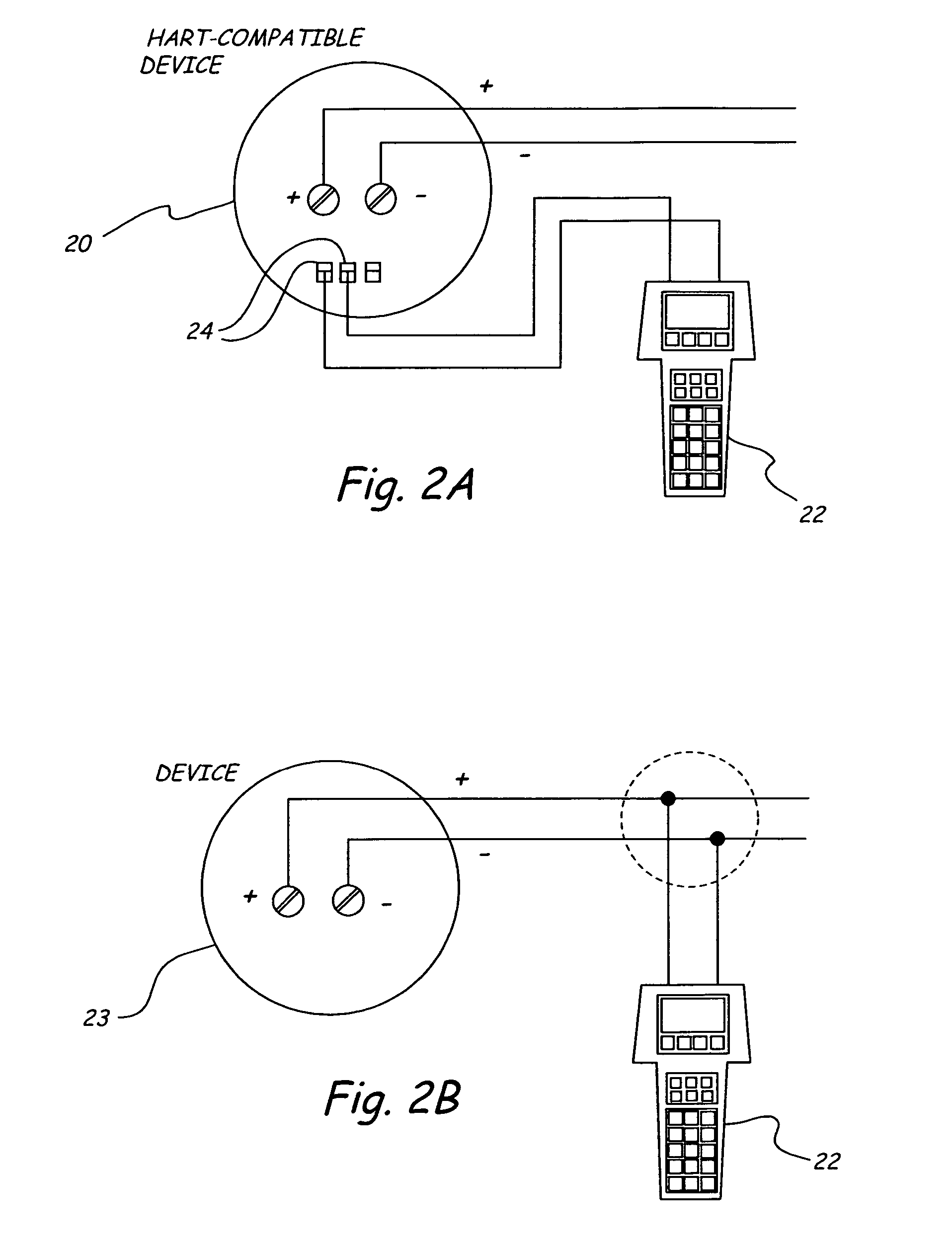

Intrinsically safe field maintenance tool

InactiveUS6889166B2Testing/calibration apparatusElectric testing/monitoringIntrinsic safetyComputer module

An improved intrinsically safe field maintenance tool is provided. The tool is operable with process communication loops in accordance with a plurality of process industry standard protocols. Aspects of the invention include hardware features such as an infrared port; removable memory module; and an expansion memory module. Additional aspects of the invention include protocol-specific diagnostic methods executable with the improved intrinsically safe field maintenance tool.

Owner:ROSEMOUNT INC +1

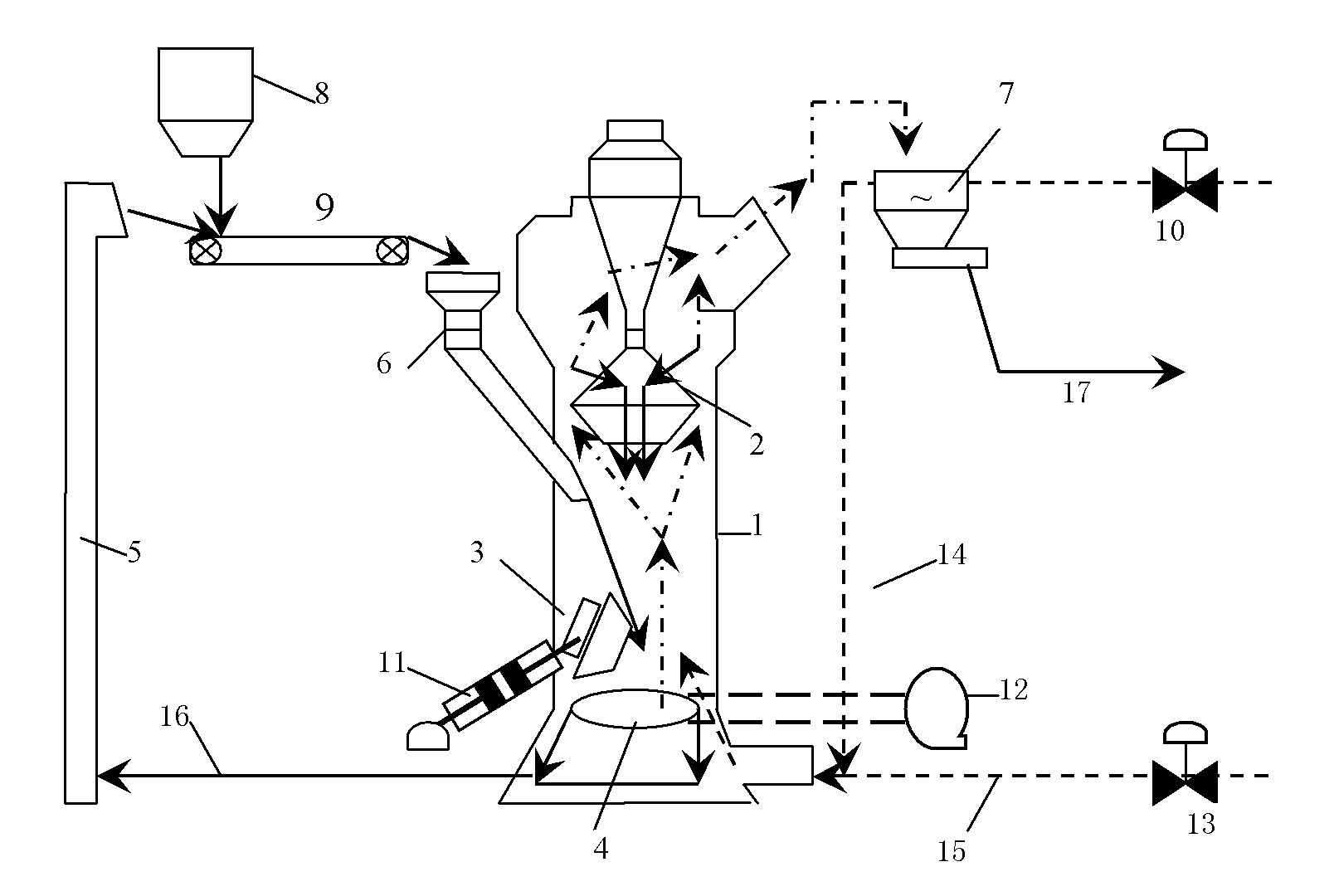

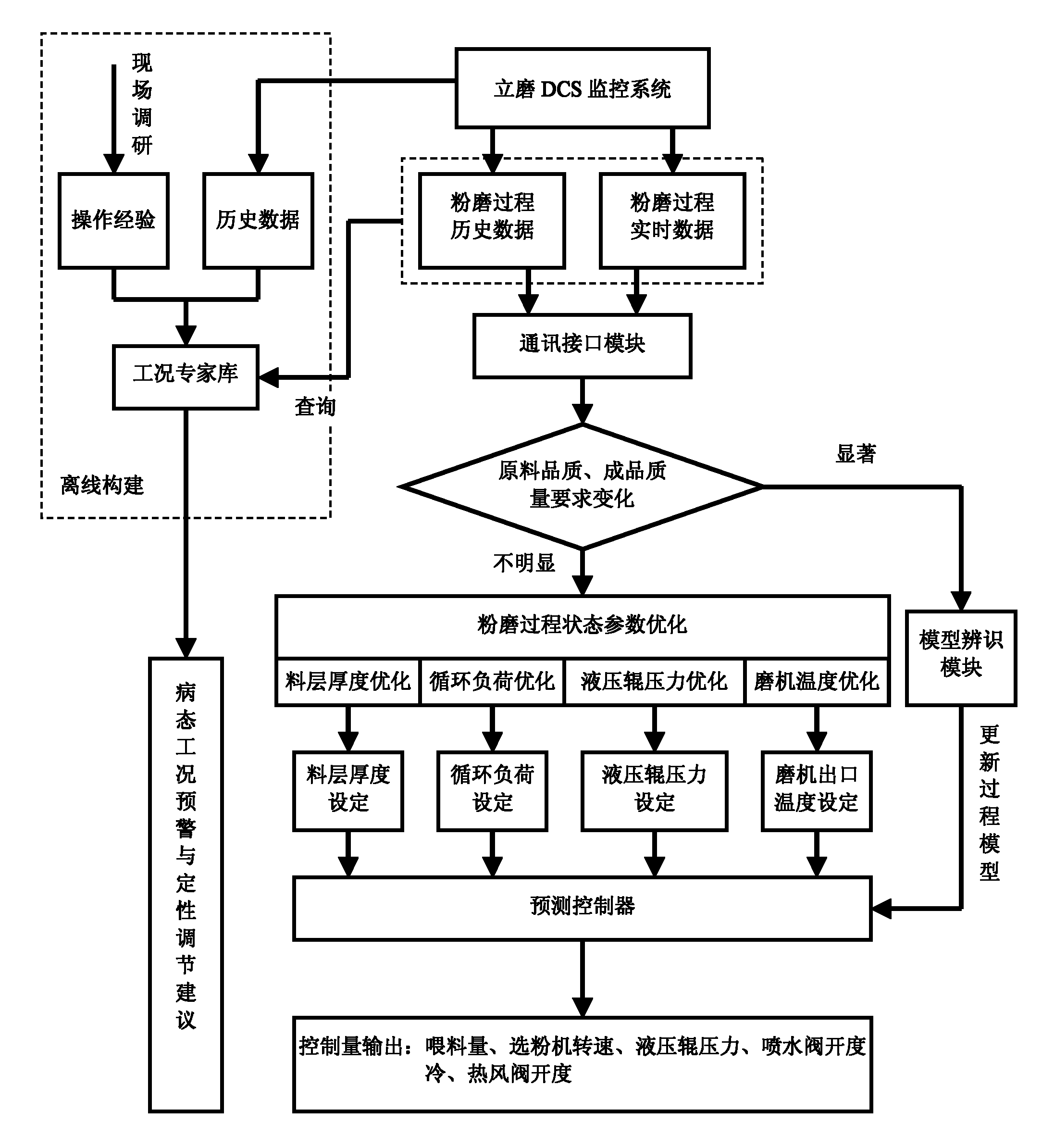

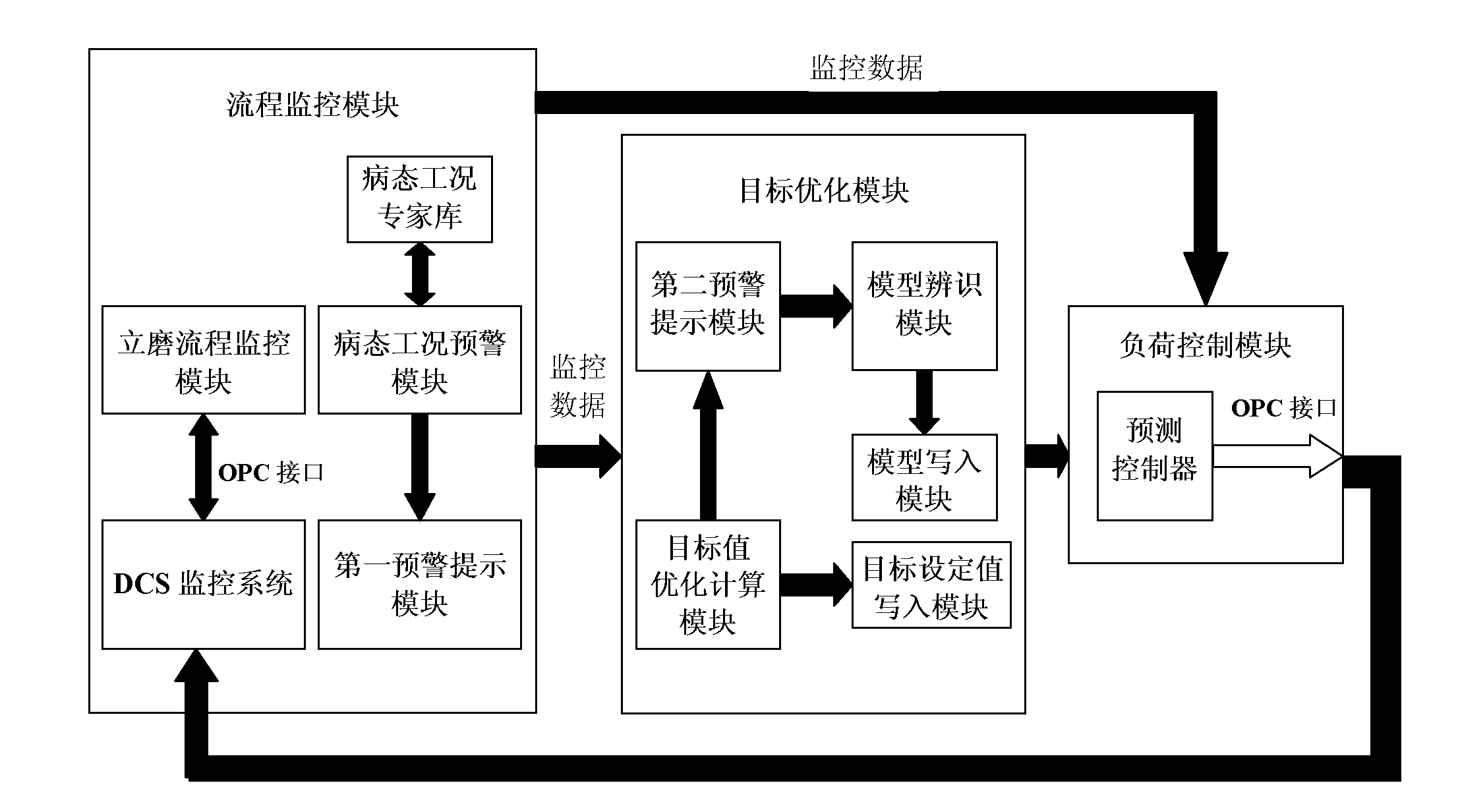

Advanced control method and system for vertical mill based on model identification and predictive control

InactiveCN102151605AIncrease the level of automationQuality improvementCement grindingCement productionMathematical modelOptimal control

The invention relates to raw material grinding in the field of cement process industries, and aims to provide an advanced control method and system for a vertical mill based on model identification and predictive control. The method comprises the following steps of: acquiring real-time data from a distributed control system (DCS) monitoring system; analyzing a variation trend of the operation and technology parameters, and then invoking a pathological working condition expert database for performing trend matching; if a pathological working condition appears, issuing early warning display and giving qualitative adjustment suggestion remind; giving an optimal target set value according to the basic operation condition of the vertical mill and the variation situation of the product quality requirement, and writing into a predictive controller; setting an optimal controlled quantity output according to the optimal target set value, and outputting to the DCS monitoring system to control a field actuator to take action. By adopting the invention, the qualitative adjustment suggestion can be precisely given; a mathematical model of the grinding process of the vertical mill is established and updated in real time; the steady-state error of the control system is reduced; and the grinding process of the vertical mill is instructed, so that the mill can operate stably for long term at a maximum efficiency point, and stable margin is maintained.

Owner:ZHEJIANG UNIV

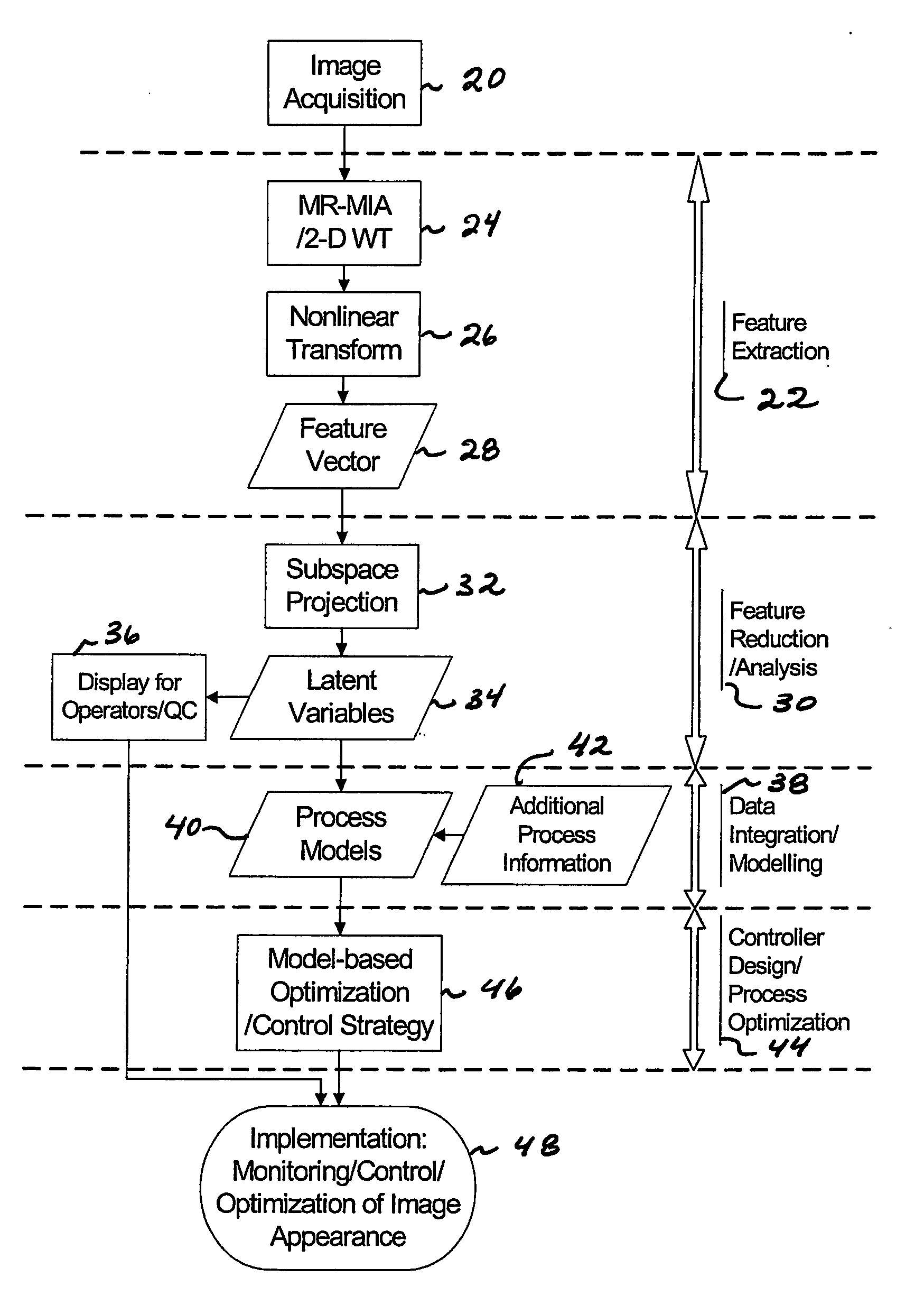

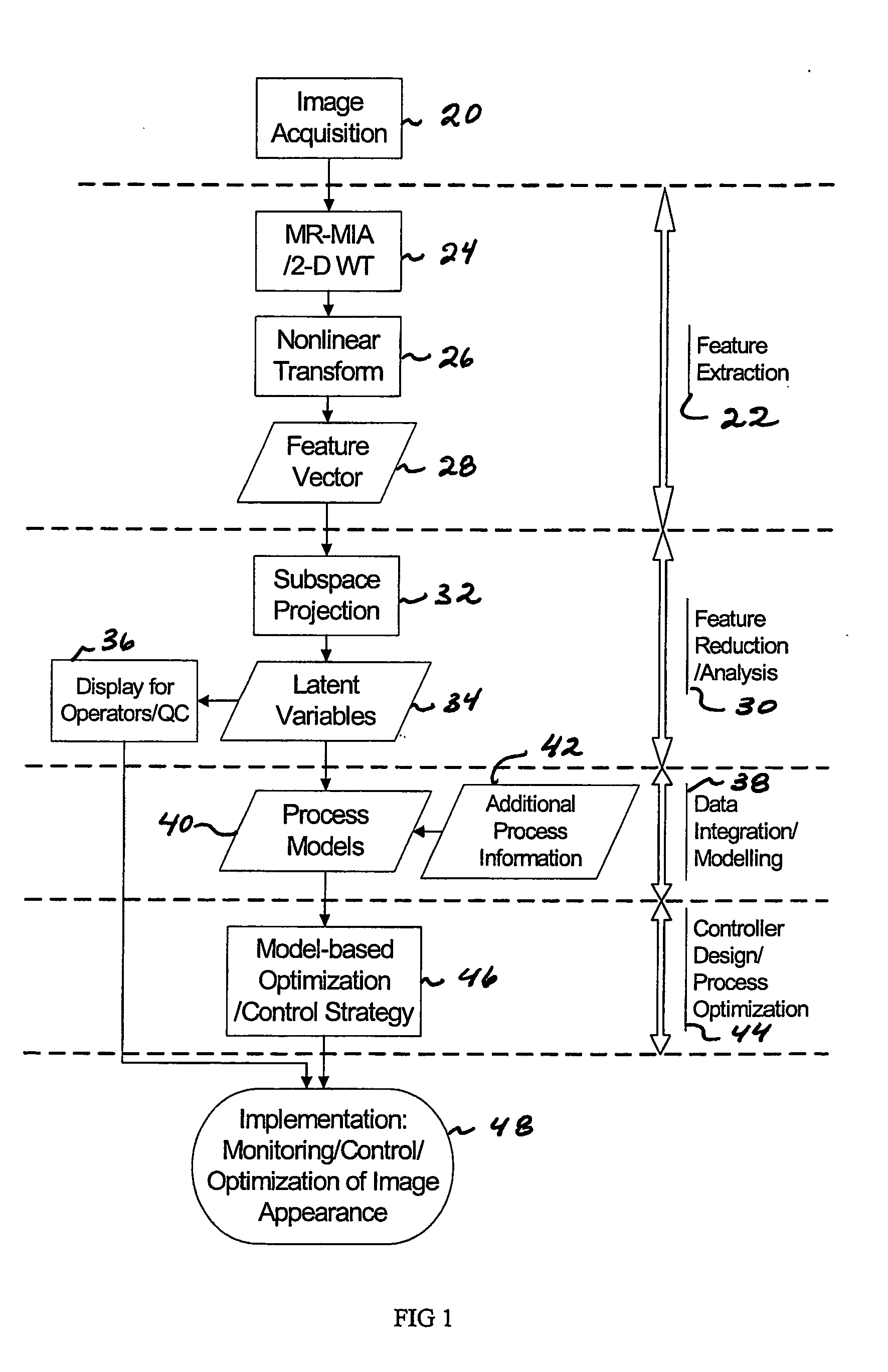

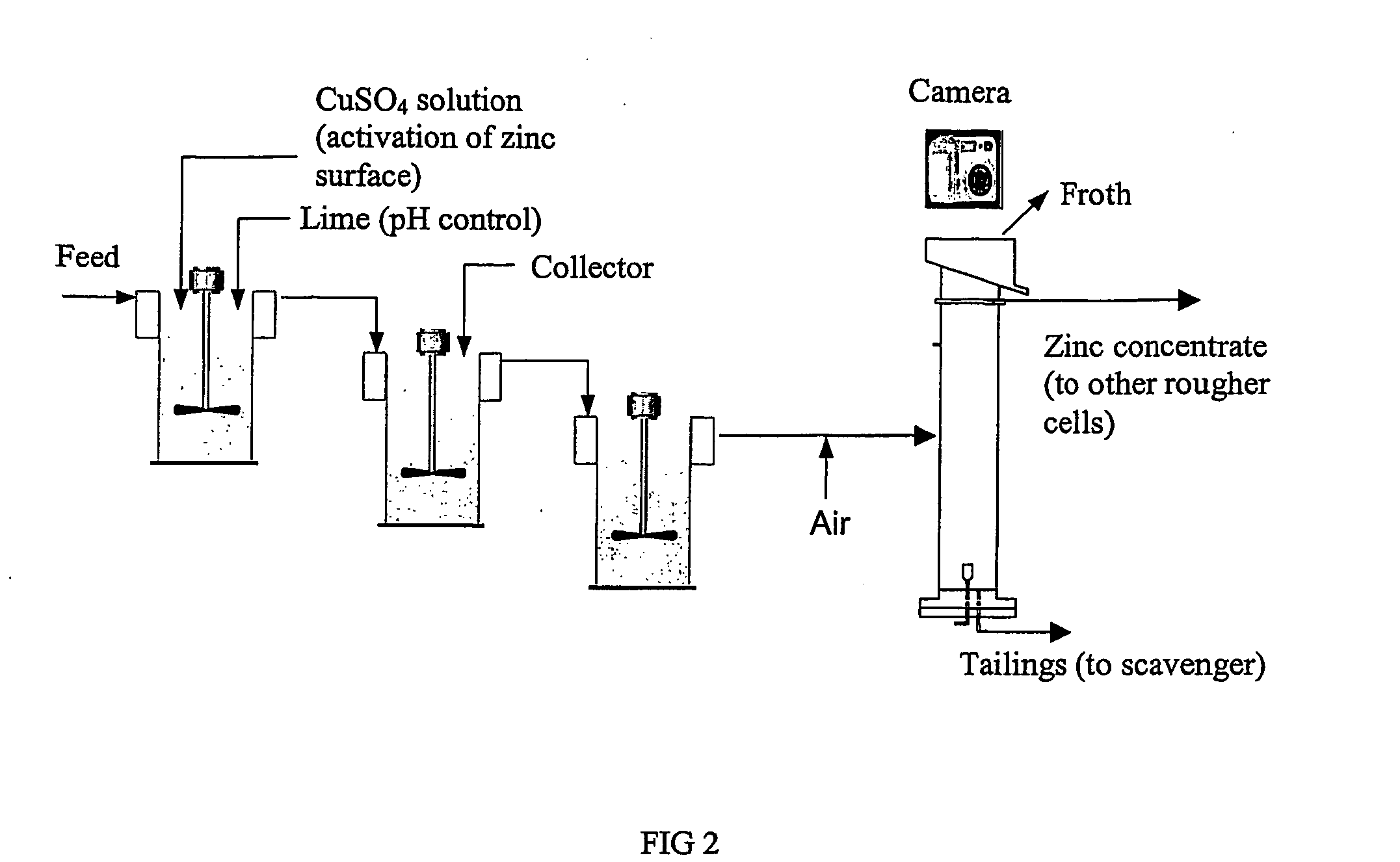

Method For Controlling The Appearance Of Products And Process Performance By Image Analysis

InactiveUS20080013821A1Improve surface qualityImage enhancementImage analysisMachine visionImaging analysis

A new application of machine vision for process industries is proposed. The invention consists of: (1) estimation of visual quality of products, (2) modeling causal relationship between estimated quality and process variables, and (3) optimization of visual quality using the causal model. This invention can handle the stochastic nature in visual appearance of products that process industries provide, which has been a main obstacle for the success of machine vision in process industries. Also, it opens new tasks in machine vision such as modeling and optimization of visual quality of products.

Owner:MCMASTER UNIV

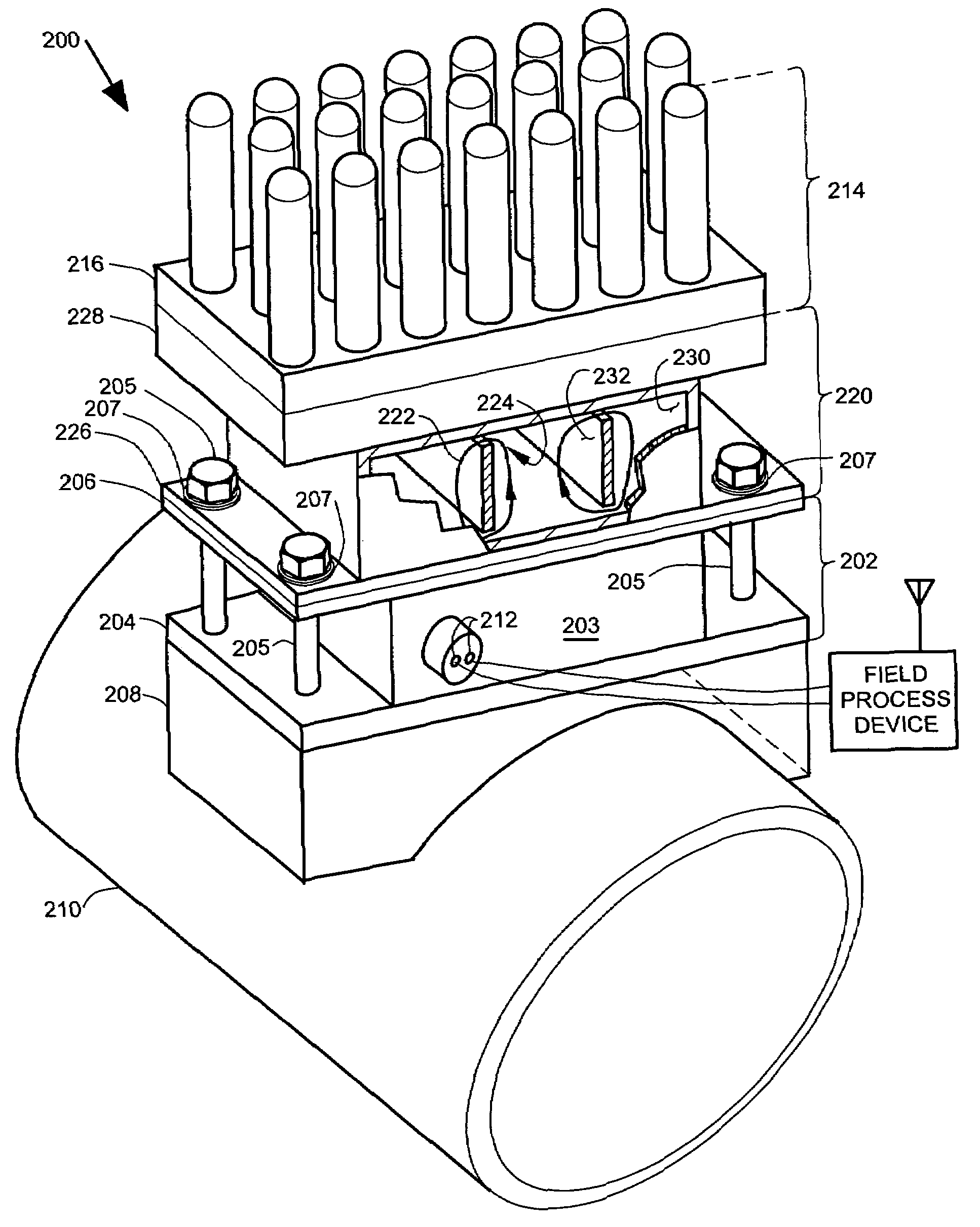

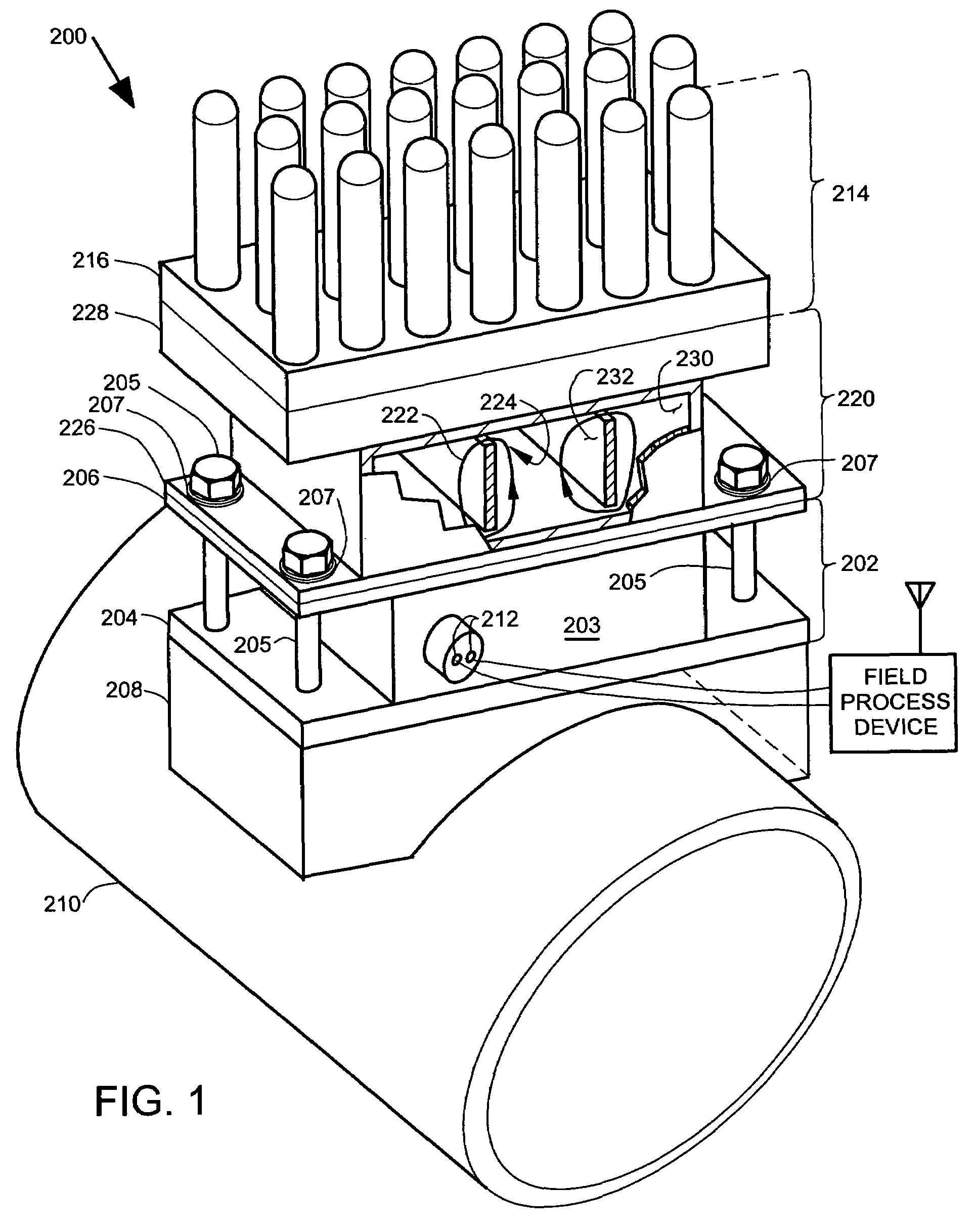

Thermoelectric generator assembly for field process devices

ActiveUS20080083445A1Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentFluid transportHeat flow

A thermoelectric generator assembly includes a thermoelectric generator with hot and cold junction flanges. The hot junction flange includes an adapter shaped for thermally coupling to a process vessel. The thermoelectric generator producing a thermoelectric power output. A heat sink thermally couples to ambient air and has a heat sink flange. A heat pipe assembly includes fluid in a circulation chamber. The circulation chamber has an evaporator flange mounted to the cold junction flange and a condenser flange mounted to the heat sink flange. At least a portion of the fluid transports heat from the evaporator flange to the condenser flange. When a heat pipe assembly on a cold junction flange is used with many of the types of heat flows that are available in process industries, more efficient thermoelectric power generation can be provided in the process industries.

Owner:ROSEMOUNT INC

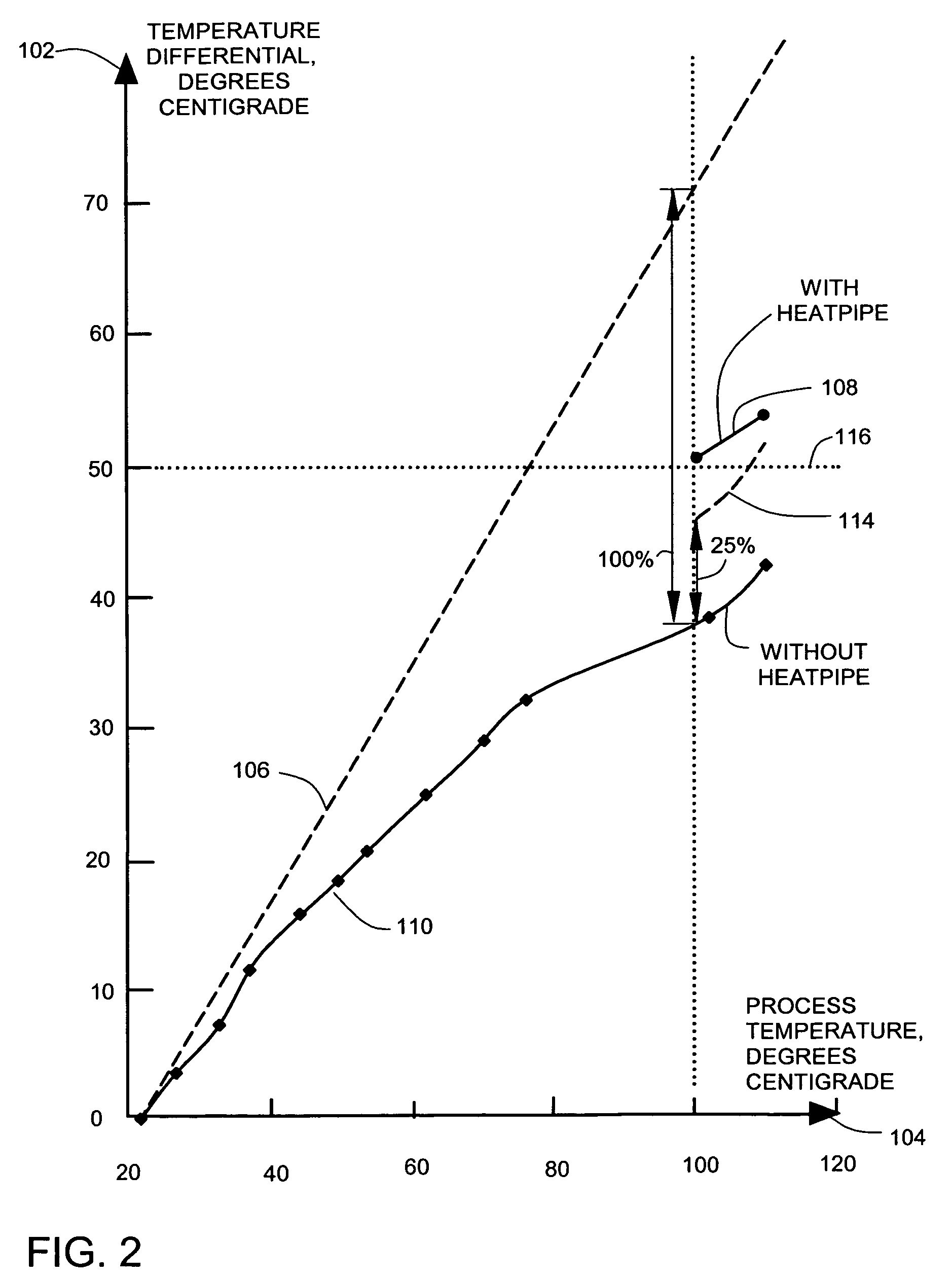

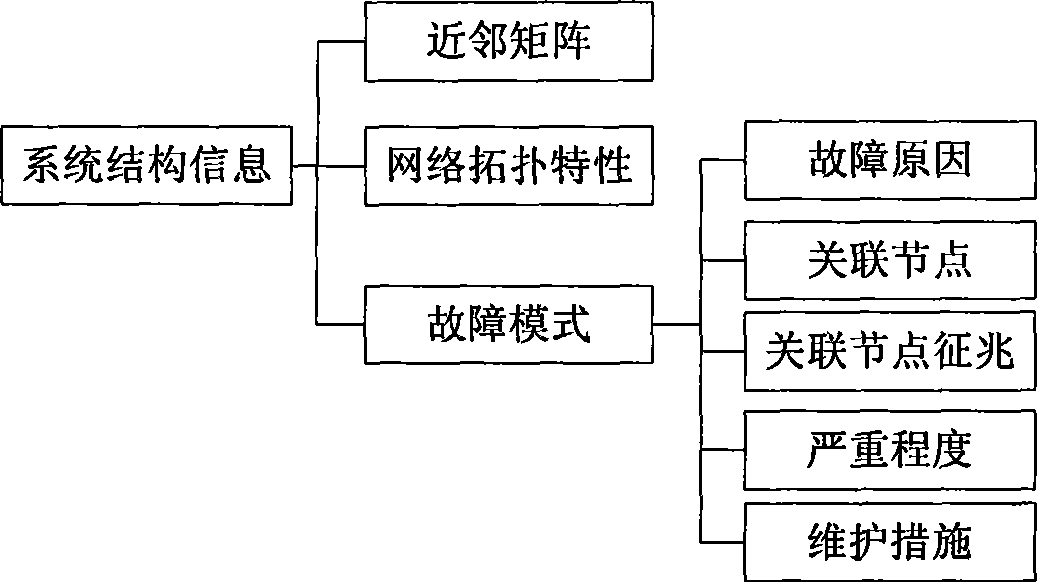

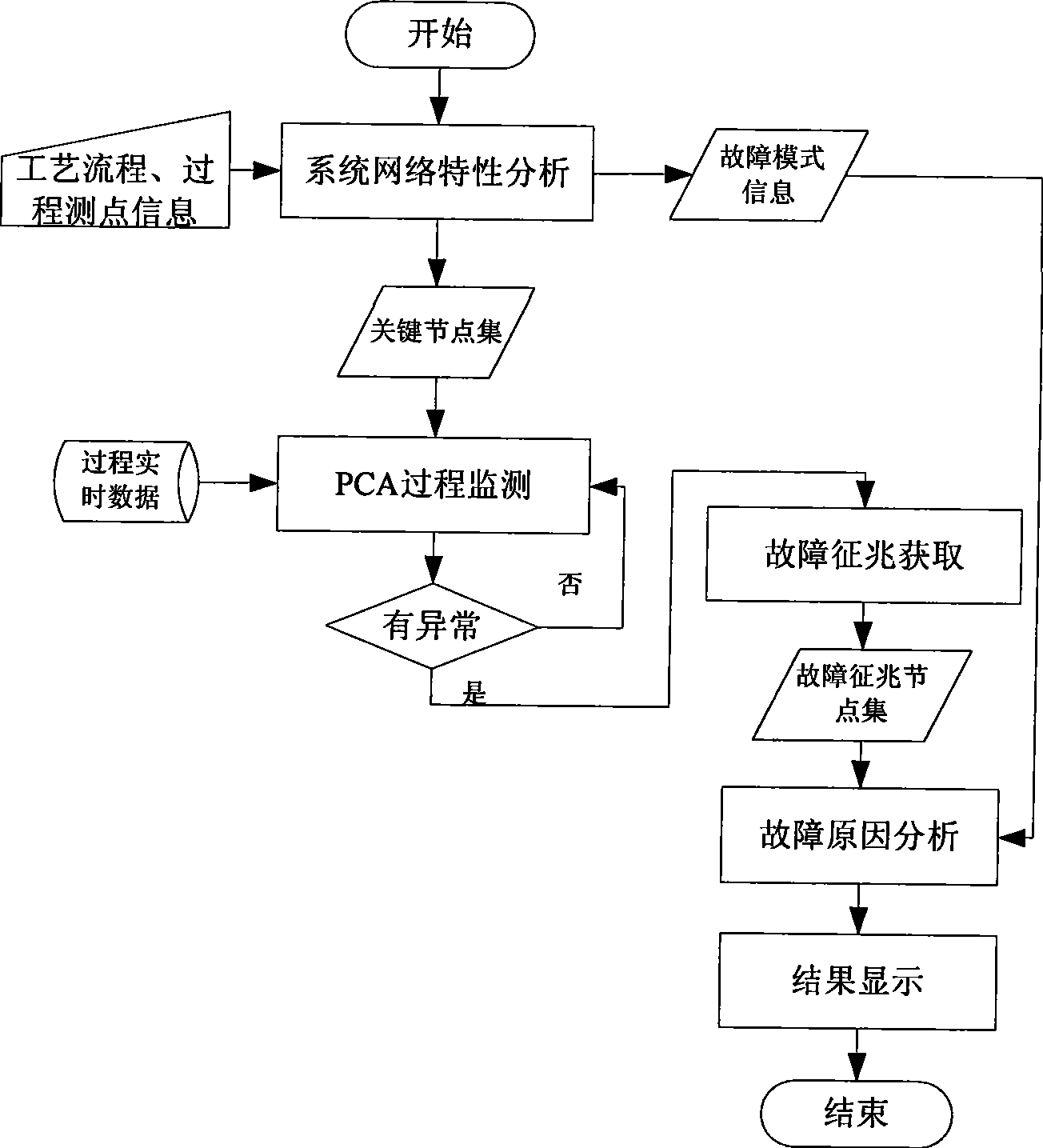

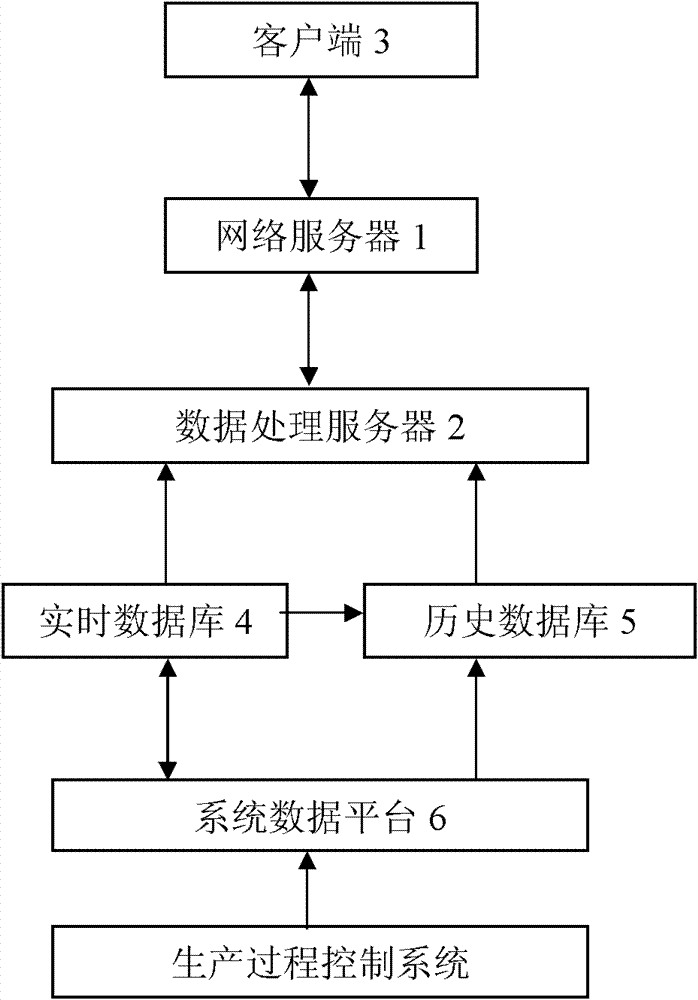

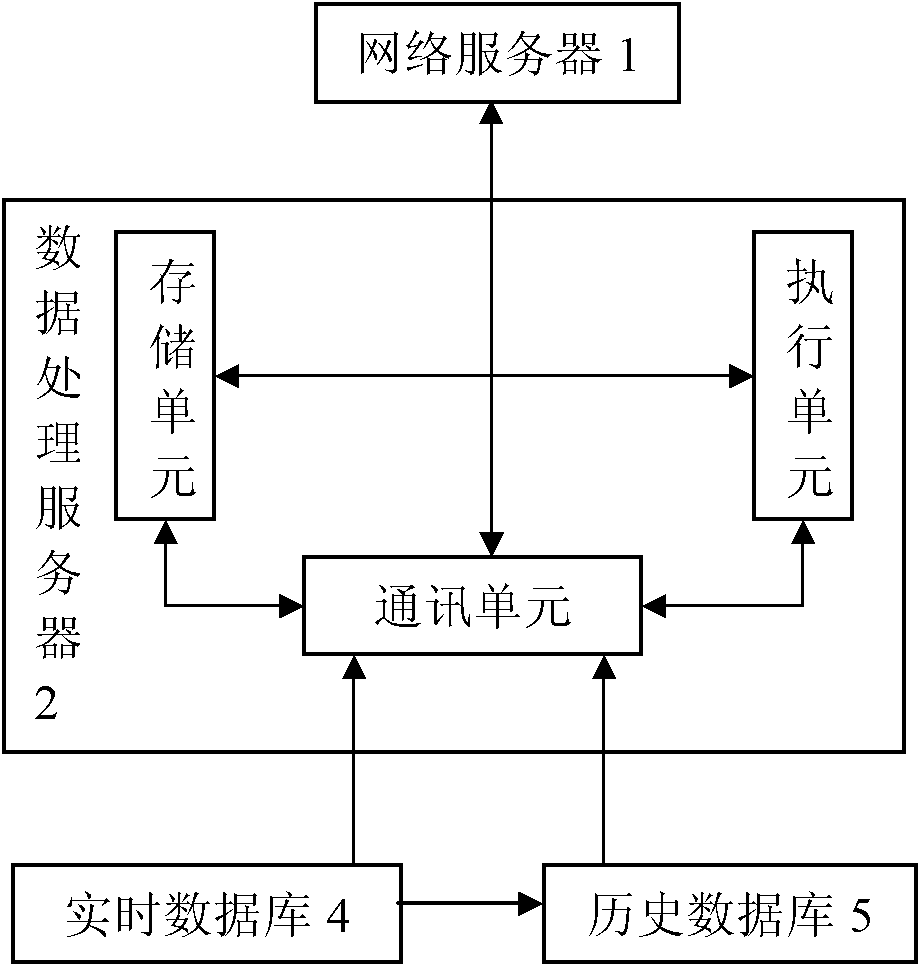

Process fault analysis device of process industry system and method therefor

InactiveCN101446827AEasy to identifyEasy to separateTechnology managementTotal factory controlProcess systemsReal-time data

The invention relates to a process industry system fault analysis device based on complex network theories and a method therefor. The device comprises a system structure information base, a man-machine interaction module, a process data management module, a system network characteristics analysis module and a process fault analysis module. The process fault analysis device and the method provided by the invention can be employed for identifying the key parts of the process system, reducing the process monitoring variables and solving the problem that the selection of monitoring point position depends on people's knowledge or experience; meanwhile, the invention makes the best of real-time data information of the process industry process system, thereby ensuring monitoring over the process fault is more instantaneous and accurate; and the utilization of the system domain knowledge improves the fault recognition and separation capability of the traditional PCA monitoring method.

Owner:XI AN JIAOTONG UNIV

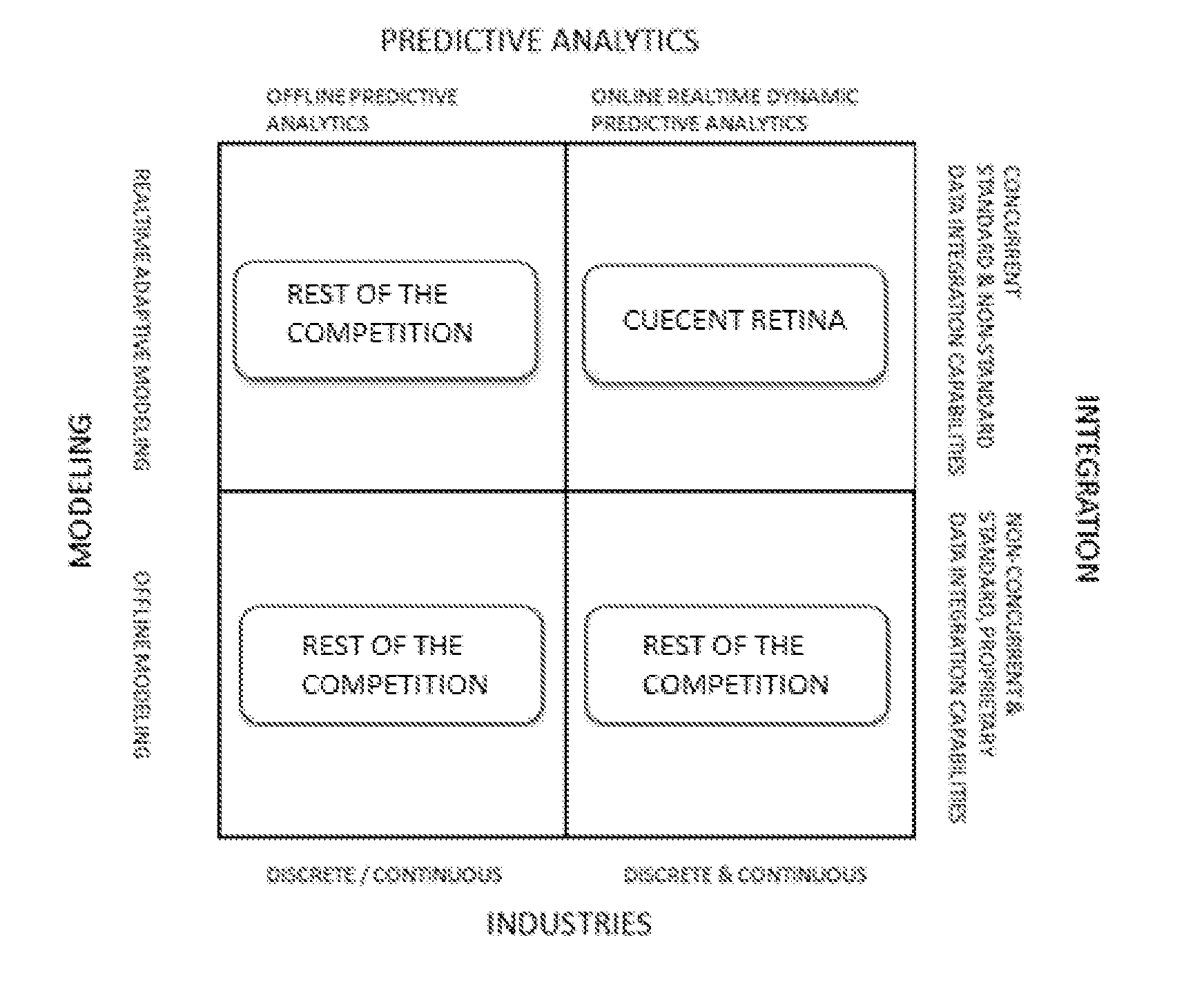

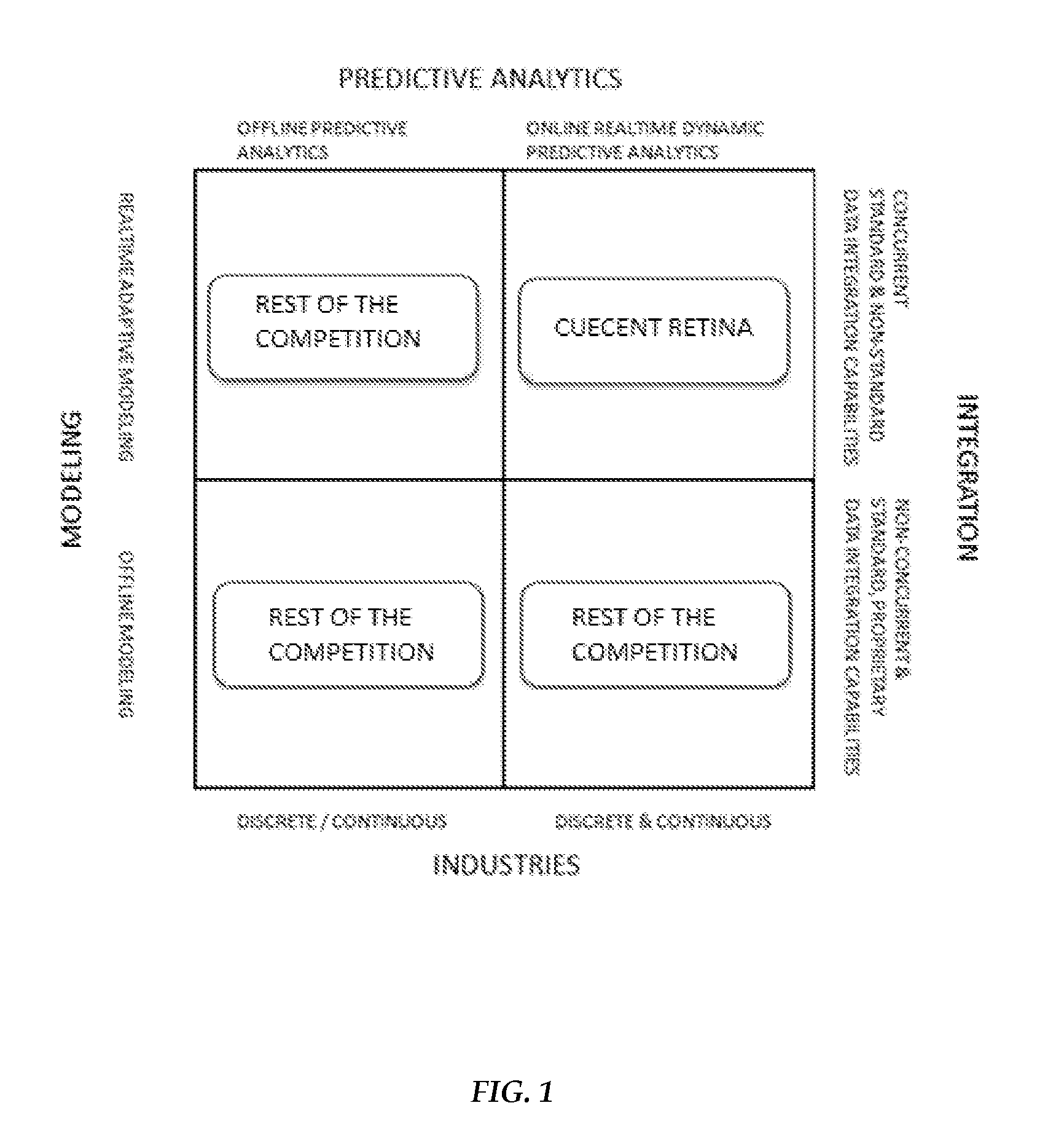

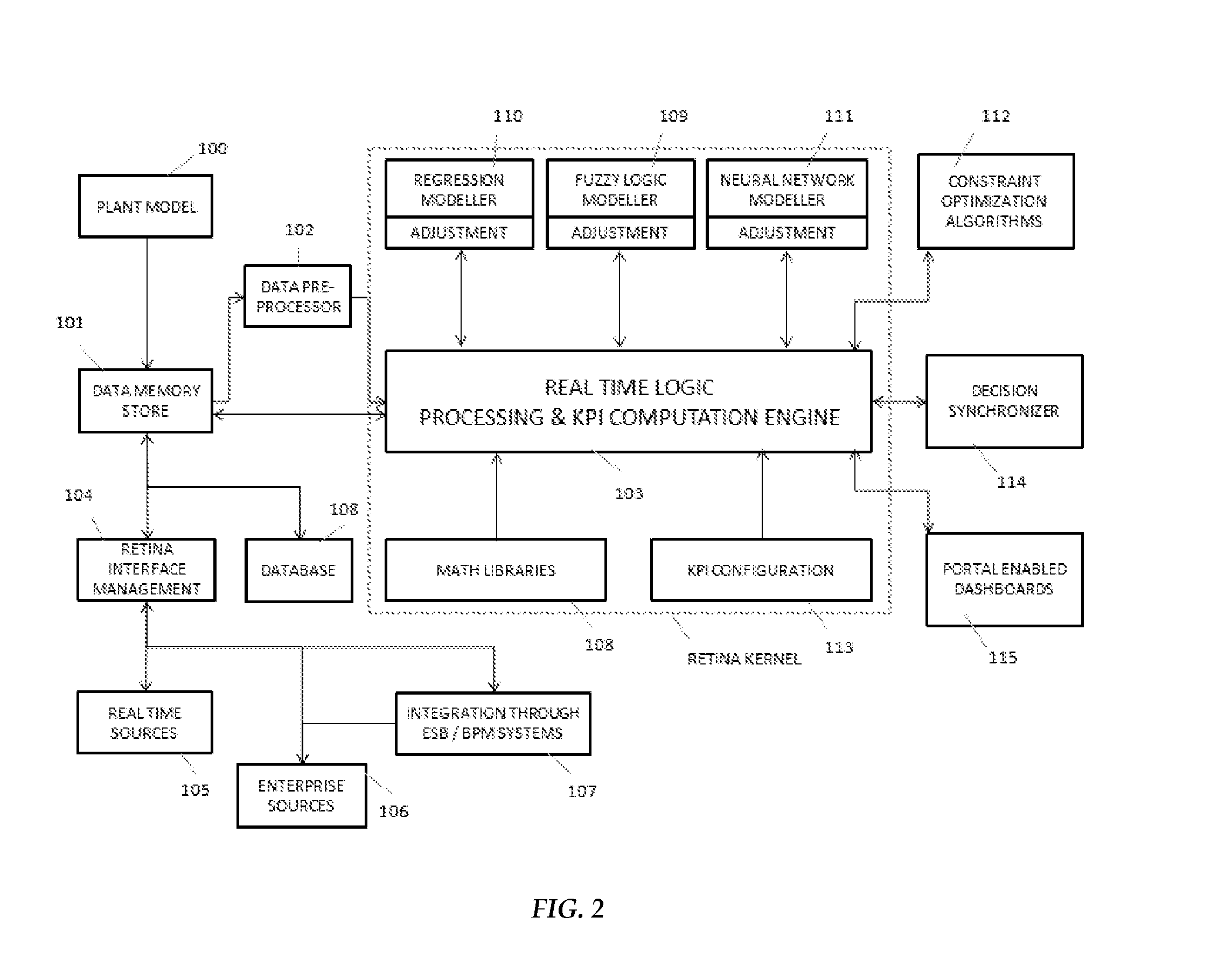

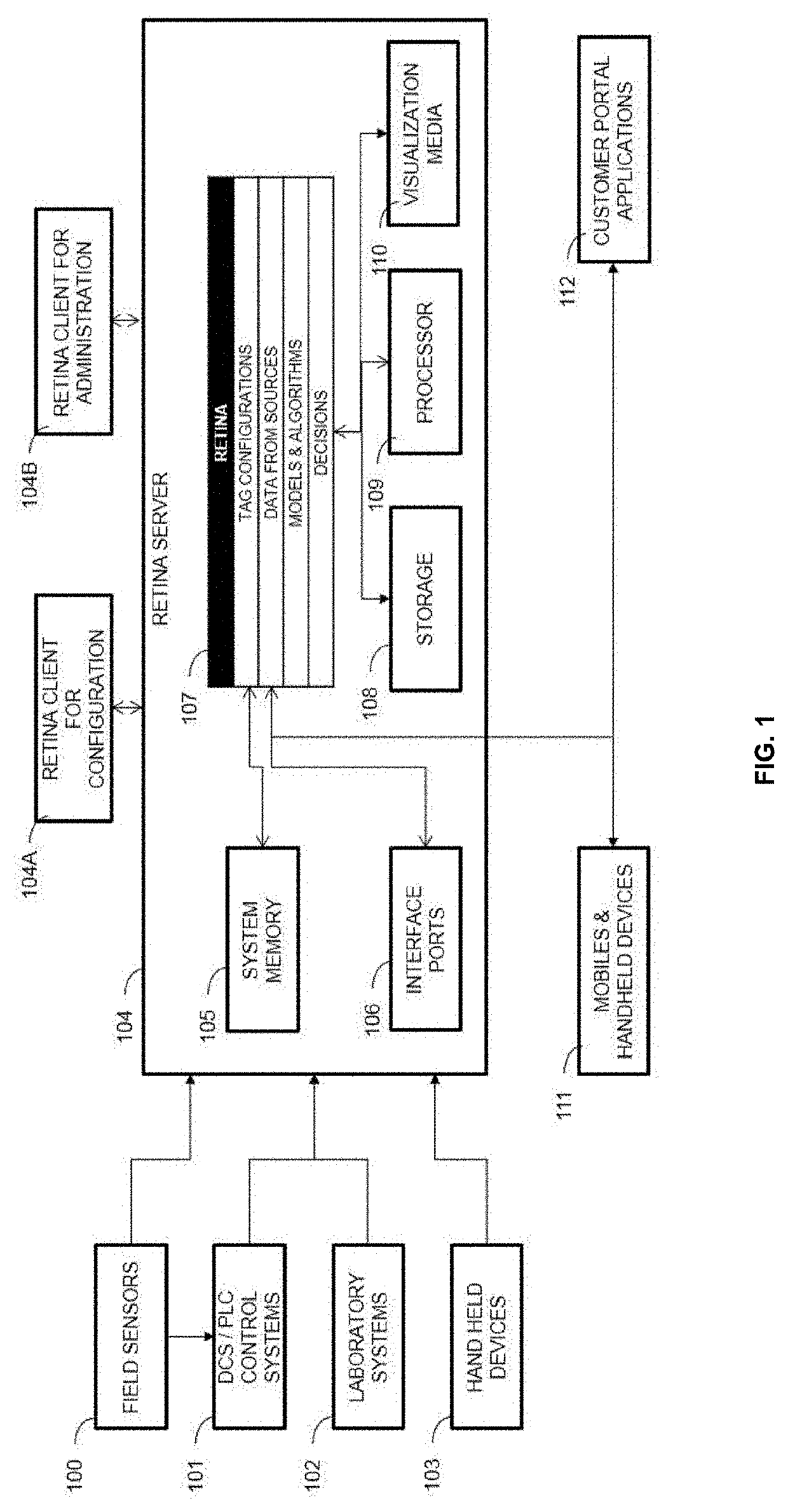

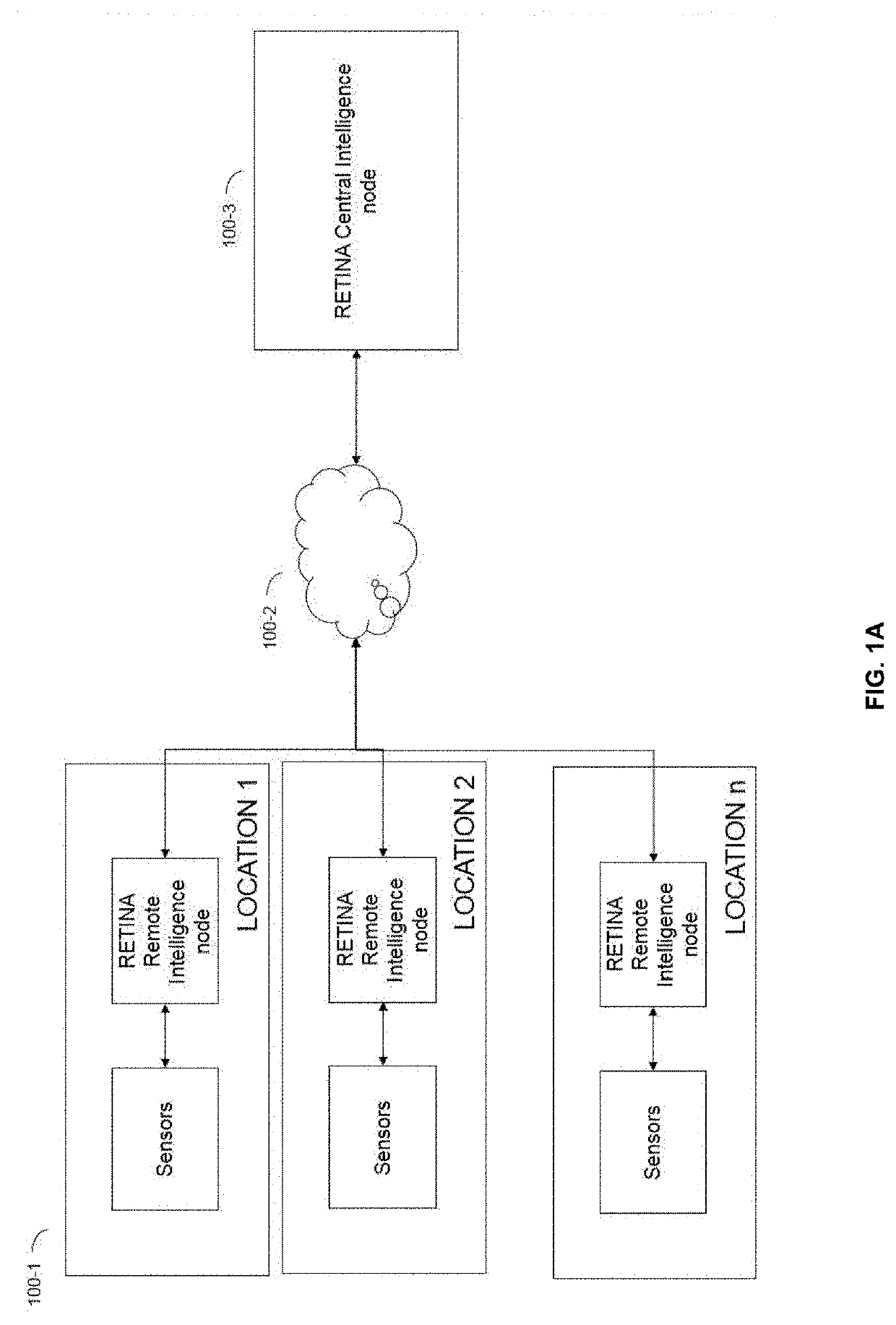

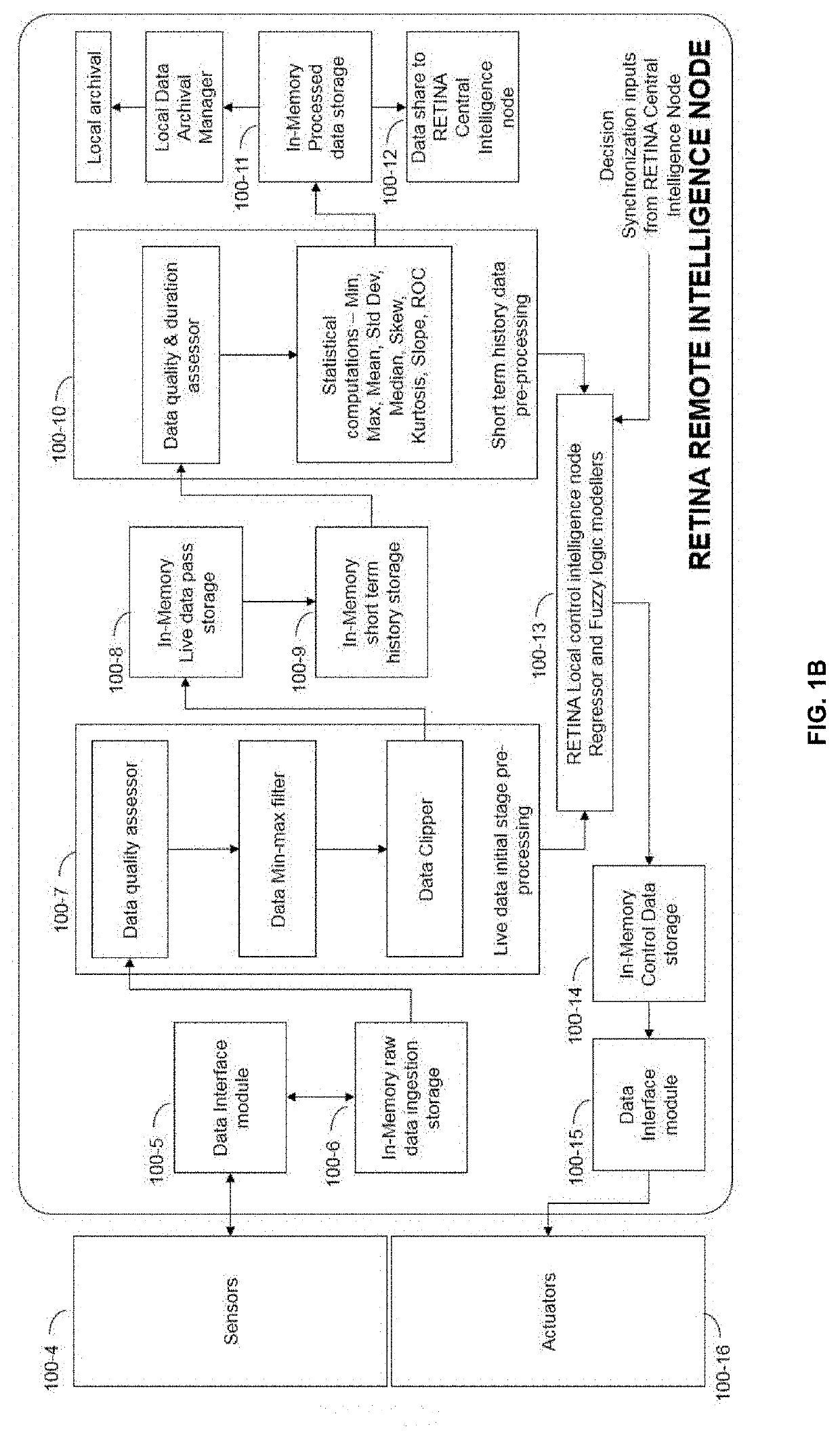

Intelligent Decision Synchronization in Real Time for both Discrete and Continuous Process Industries

A composite technology system RETINA that enables intelligent decision synchronization in real time for continuous, discrete and batch process industries is disclosed. RETINA generates and synchronizes the intelligent decisions that affect the performance and profitability of business operations in real time and helps in analysis that are essential for any successful business operations in any manufacturing industries. RETINA combines the real time integration capability; Predictive analytics capability and adaptive real time process modeling capability to generate intelligent risk-reduced business decisions for continuous, discrete and batch manufacturing processes. RETINA unifies the data from disparate sources or in silos, collates, comprehends and analyses the data, and then convert them into actionable information in real time. Correct decisions are generated, streamlined and shared at the appropriate instant of time with right amount of data to the pertinent personnel to eliminate inefficiencies in operations and performance resulting in tangible profitability.

Owner:BAHWAN CYBERTEK

Field maintenance tool

An improved intrinsically safe field maintenance tool is provided. The tool is operable with process communication loops in accordance with a plurality of process industry standard protocols. Aspects of the invention include hardware features such as an infrared port; removable memory module; and an expansion memory module. Additional aspects of the invention include protocol-specific diagnostic methods executable with the improved intrinsically safe field maintenance tool.

Owner:FISHER-ROSEMOUNT SYST INC

Field maintenance tool

InactiveUS7117122B2Electric testing/monitoringElement comparisonProcess industryProcess communication

An improved field maintenance tool is provided. The tool is operable with process communication loops in accordance with a plurality of process industry standard protocols. Aspects of the invention include hardware features such as an infrared port; removable memory module; and an expansion memory module. Additional aspects of the invention include protocol-specific diagnostic methods executable with the improved field maintenance tool.

Owner:FISHER-ROSEMOUNT SYST INC

A real time dynamic re-dispatching method for production dispatching system in process industry

InactiveCN101261695AIncrease productivityRun in real timeForecastingProgramme total factory controlLogistics managementProgram planning

The invention relates to a real time dynamic rescheduling method used for a process industry production scheduling system, aiming at solving the problems of present domestic process industry enterprises that production planning and dispatching have low efficiency, poor accuracy and real-time capability. The real time monitoring method of the invention includes the establishment of a scheduling-optimization math model and the working-out of a dispatching-optimization plan, the completion of the execution of production dispatching instructions and timely tracking calculation; a rolling optimization method includes the arrangement of dispatching time periods, the calculation of the state changes of various production data from present time to scheduling starting time, the generation of the data files of a target model and the establishment of the scheduling-optimization math model. The method of the invention is characterized by real-time, flexibility and promptness, etc. and can realize the integration of the control, the operation, the planning and the management of production-process and enterprise management to realize the balanced and high-effective production of enterprise logistics, production capability and source, thus enhancing the integral production efficiency of enterprises and reducing the cost of production and stock.

Owner:HANGZHOU DIANZI UNIV

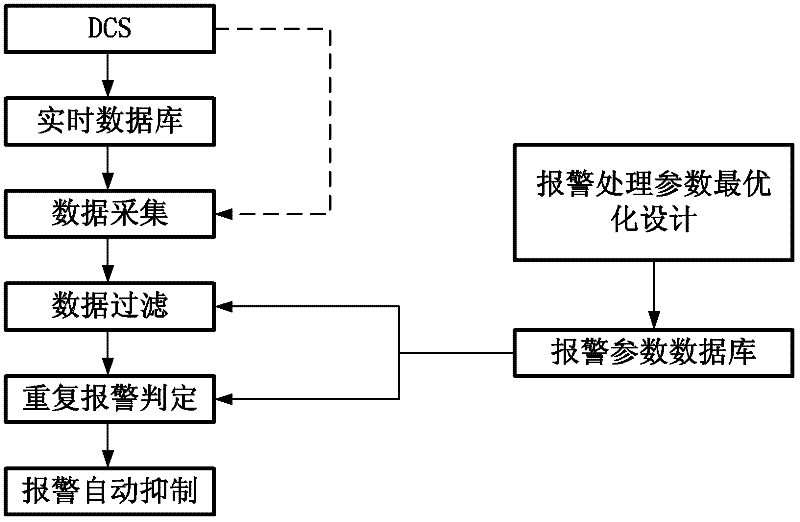

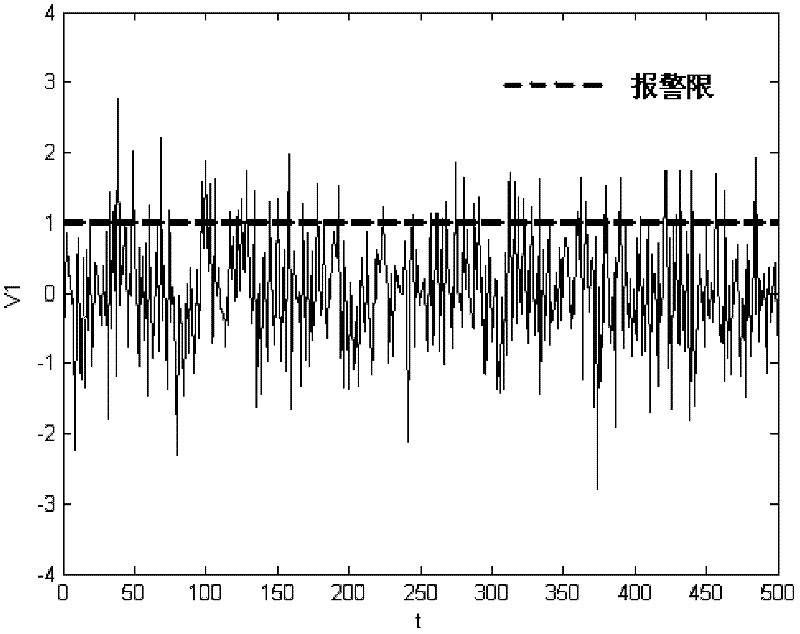

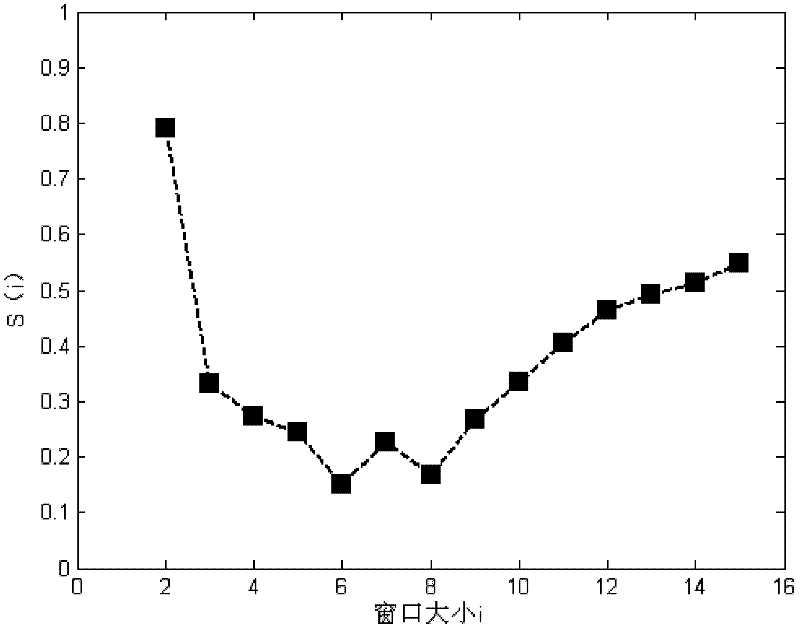

Repeated alarm processing method based on data filtering

ActiveCN102436720AGuaranteed practicalityGuaranteed accuracyAlarmsDistributed control systemProcess industry

The invention discloses a repeated alarm processing method based on data filtering, and belongs to the technical field of alarm management. The method comprises the following steps of: optimally designing variable alarm processing parameters by virtue of variable historical process data, and storing the obtained optimal alarm processing parameters in an alarm parameter database; acquiring real-time process data from a real-time database or a distributed control system (DCS); then obtaining window filtering parameters from the alarm parameter database, and filtering the real-time process data;and finally carrying out repeated alarm judgment on the filtered real-time process data, automatically inhibiting the repeated alarm if the repeated alarm is judged, and otherwise displaying alarm information. The repeated alarm processing method has the beneficial effects that the noise effect in the real-time process data is eliminated, the quantity of occurrence of repeated alarms is reduced and the purpose of alarm management in the process industry is achieved.

Owner:清云智通(北京)科技有限公司

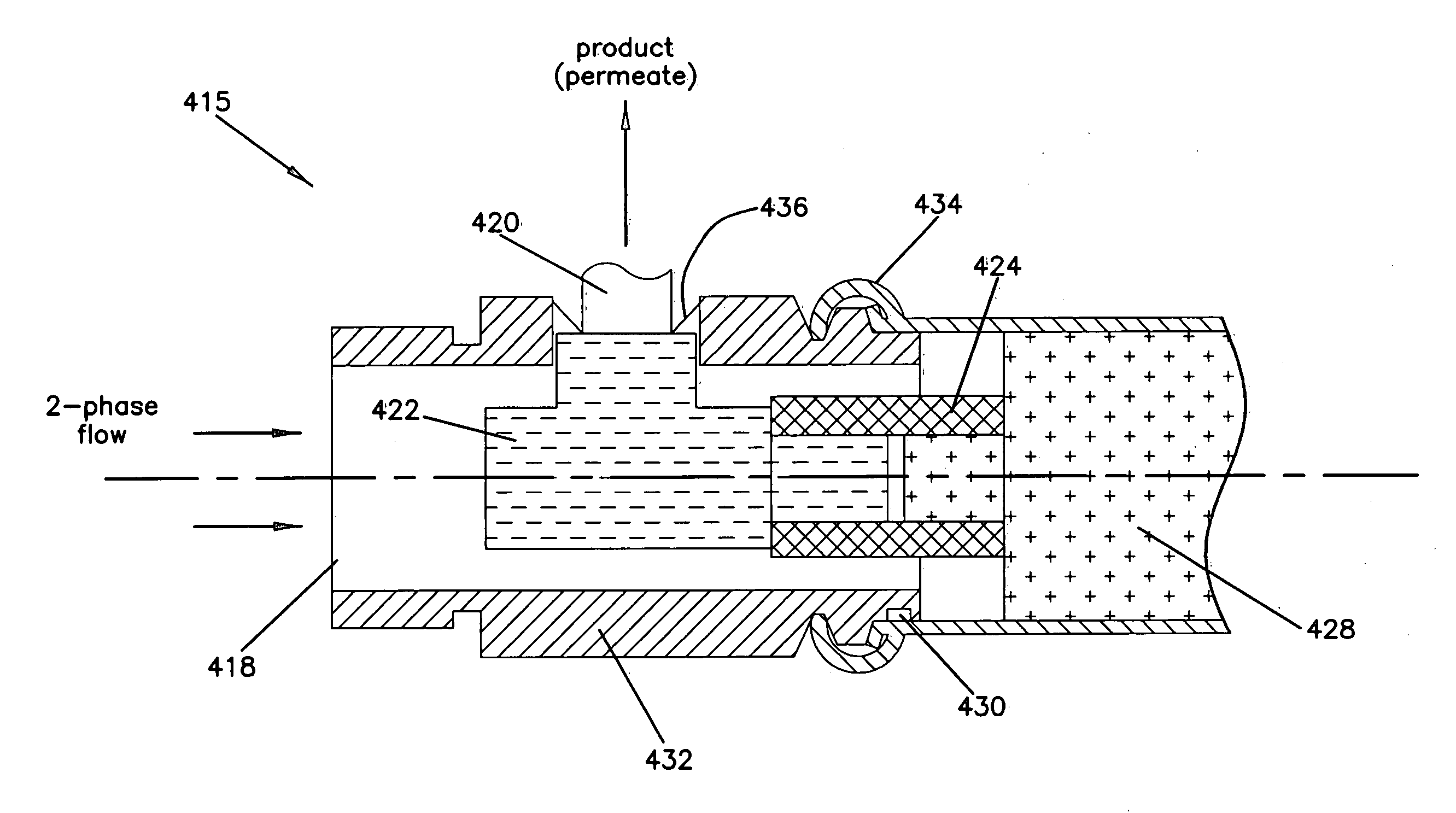

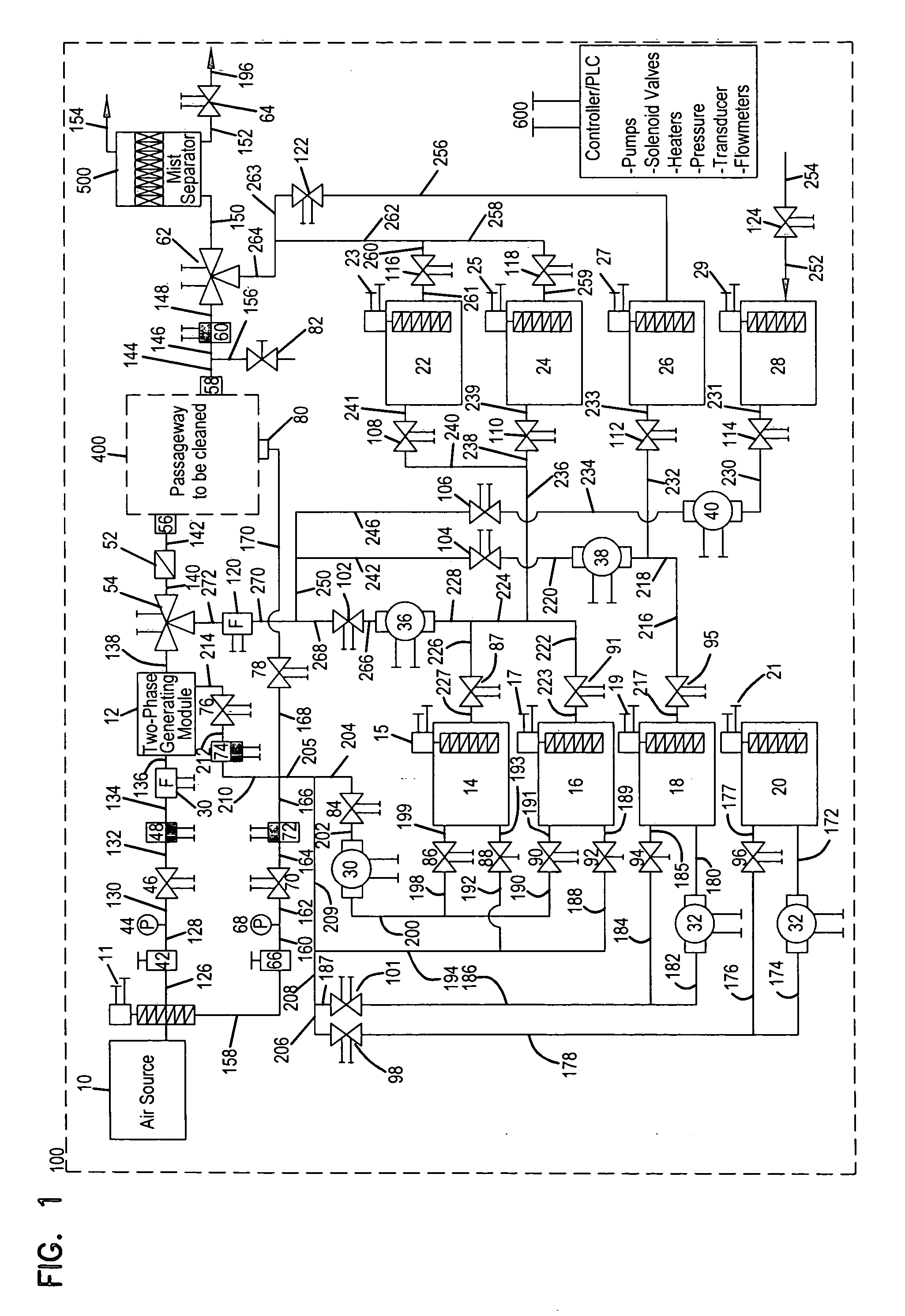

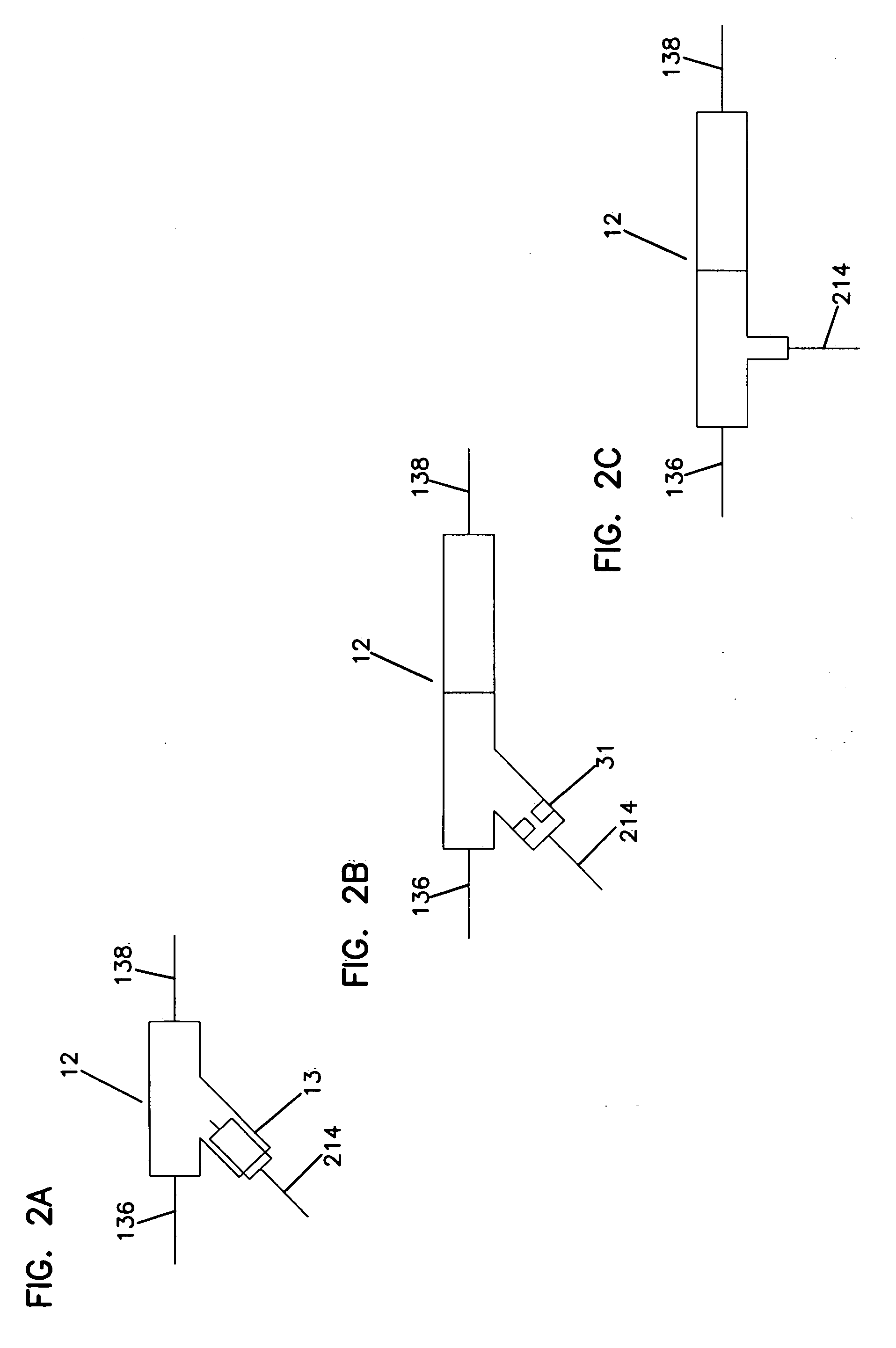

Apparatus and method for cleaning pipelines, tubing and membranes using two-phase flow

InactiveUS20090229632A1Inorganic/elemental detergent compounding agentsDiagnosticsVolumetric Mass DensityProcess industry

An apparatus and method for cleaning passageways and the like with a two-phase mixture of gas under pressure and an aqueous cleaning solution. The two-phase cleaning mixture is generated in a module and is passed out of the module at a predetermined rate that determines droplet size, velocity and droplet density at the pipeline surface to be cleaned. The droplets impact the walls of the passageway to be cleaned, thereby fragmenting, eroding and removing contaminants in said passageway. These are then flushed out of the passageway by the two-phase flow. The flow of cleaning solution can be steady or pulsed. The apparatus and process include a clean-in-place system that is useful in food, beverage, pharmaceutical and similar process industries.

Owner:OLYMPUS CORP

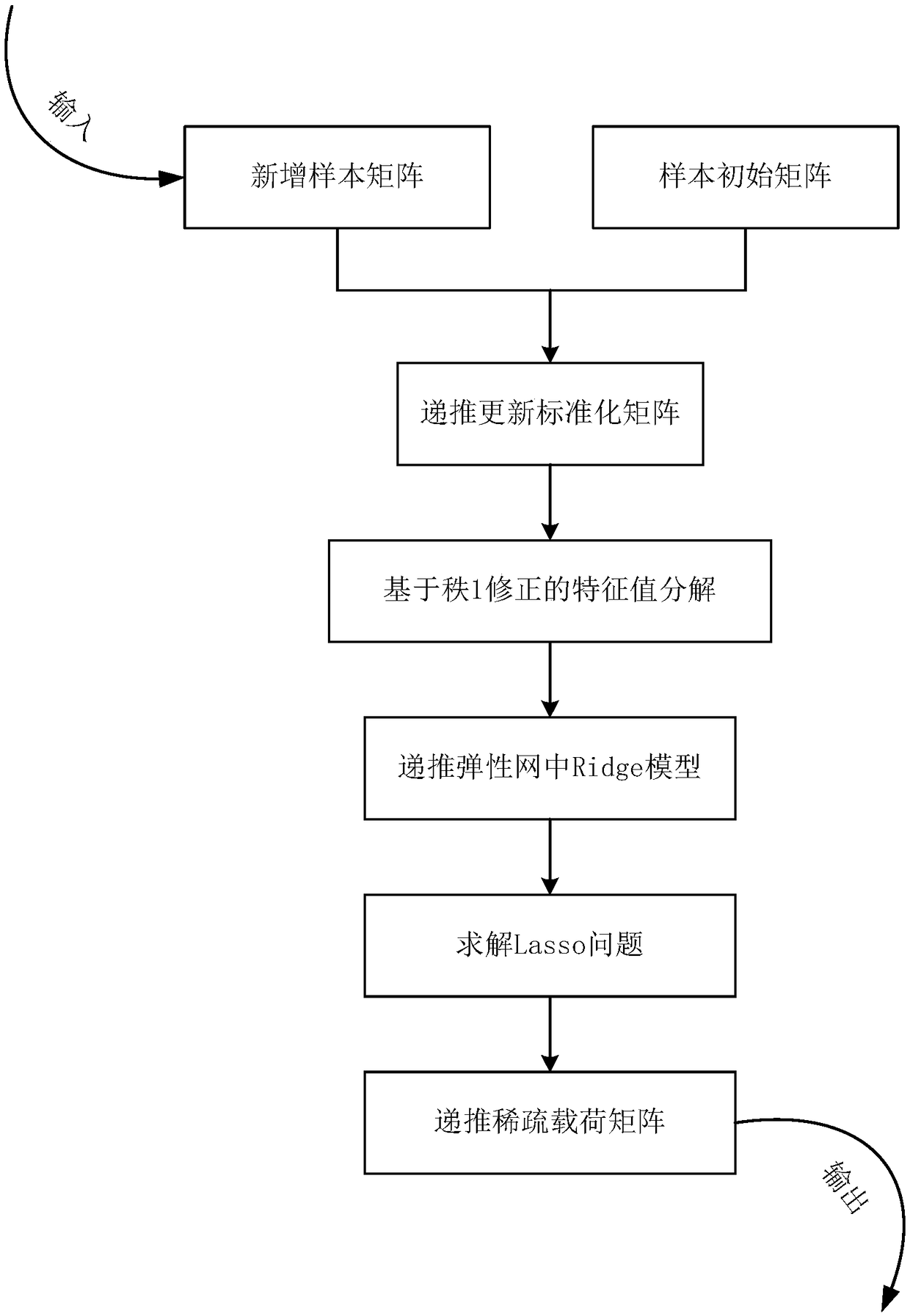

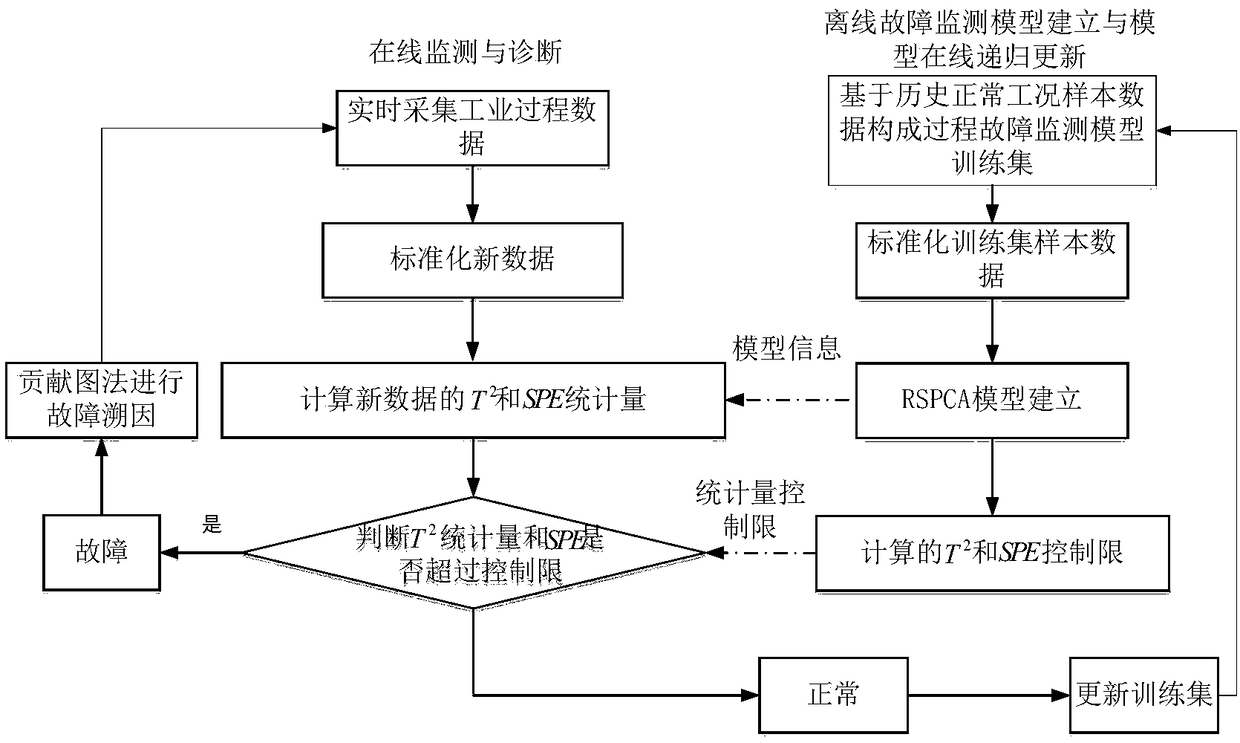

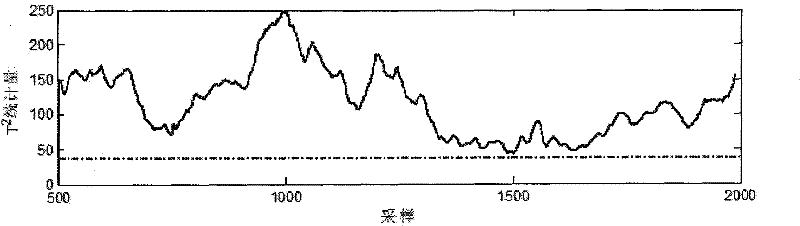

Online self-adaptive fault monitoring and diagnosis method for process industry course

ActiveCN109459993AImprove adaptabilityImplement diagnosticsTotal factory controlProgramme total factory controlComputation complexityPrincipal component analysis

The invention discloses an online self-adaptive working condition monitoring and fault diagnosis method for a process industrial course and belongs to the technical field of fault monitoring and diagnosis of complex industrial courses. The method comprises the following steps of firstly, analyzing historical observation data under a normal working condition, introducing an elastic regression network combining Lasso constraints with Ridge constraints to establish an industrial course fault monitoring model on the basis of sparse principal component analysis, and then obtaining a course controllimit to industrial course fault monitoring statistics; during online monitoring of industrial course faults, adopting an order-1 matrix correcting algorithm for resolving a covariance matrix of the online monitoring data, conducting recursion updating on a load matrix of the sparse monitoring model to obtain the course control limit to the course fault monitoring statistics matched with the working condition, and achieving self-adaptive fault detection in the process industry course; finally, according to the detected faults, adopting a contribution plot method for obtaining specific causes of the faults. By means of the method, the faults of the process industry course with complex and changeable working conditions can be self-adaptively monitored for a long time; the method has the advantages of low calculation complexity, high precision, a low report missing rate and the like.

Owner:HUNAN NORMAL UNIVERSITY

Intelligent Decision Synchronization in Real Time for both Discrete and Continuous Process Industries

ActiveUS20190347590A1Minimizes operation riskReduce operational riskResourcesInformation technology support systemData sourceOil and natural gas

This invention that provides system, method & apparatus for Real Time integration and Analytics (RETINA) to enable proactive decision synchronization in real time in order to minimize the operational risk and maximize the process productivity for process industries such as Oil & Gas Exploration and Fossil fuel power plants is disclosed. RETINA generates and synchronizes the decisions that affect the performance and profitability of business operations in real time and helps in analysis that are essential for any successful business operations. RETINA provides methods and apparatus that combines data from several types of data sources, build models for identifying impending failures, predicting a future state of the process from currently measured process data and provide decision options to business users so that any unwanted opportunity loss such as downtimes or critical equipment failures that are operations risks would be eliminated. RETINA provides methods and apparatus to ensure that correct decisions are taken at the appropriate instant of time with right amount of data to the pertinent personnel to eliminate inefficiencies in operations and performance resulting in tangible profitability.

Owner:DT360 INC

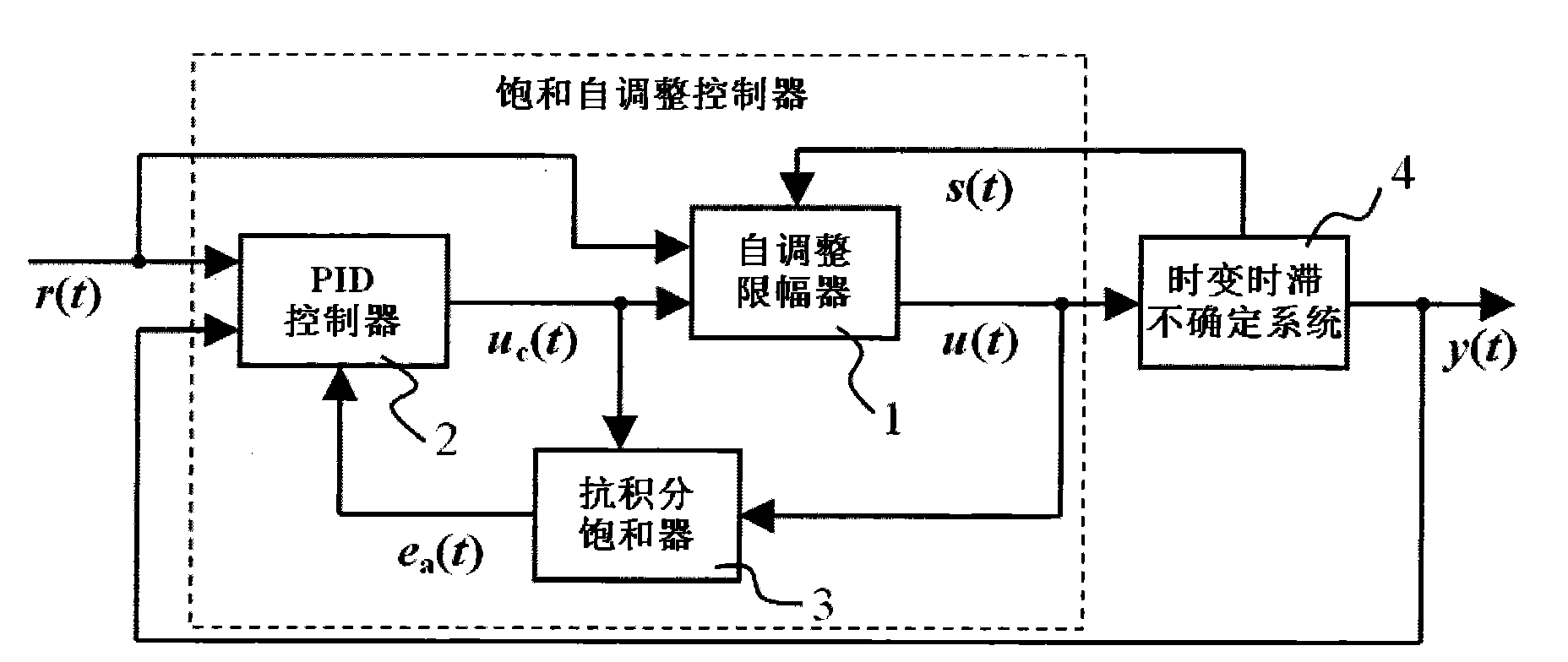

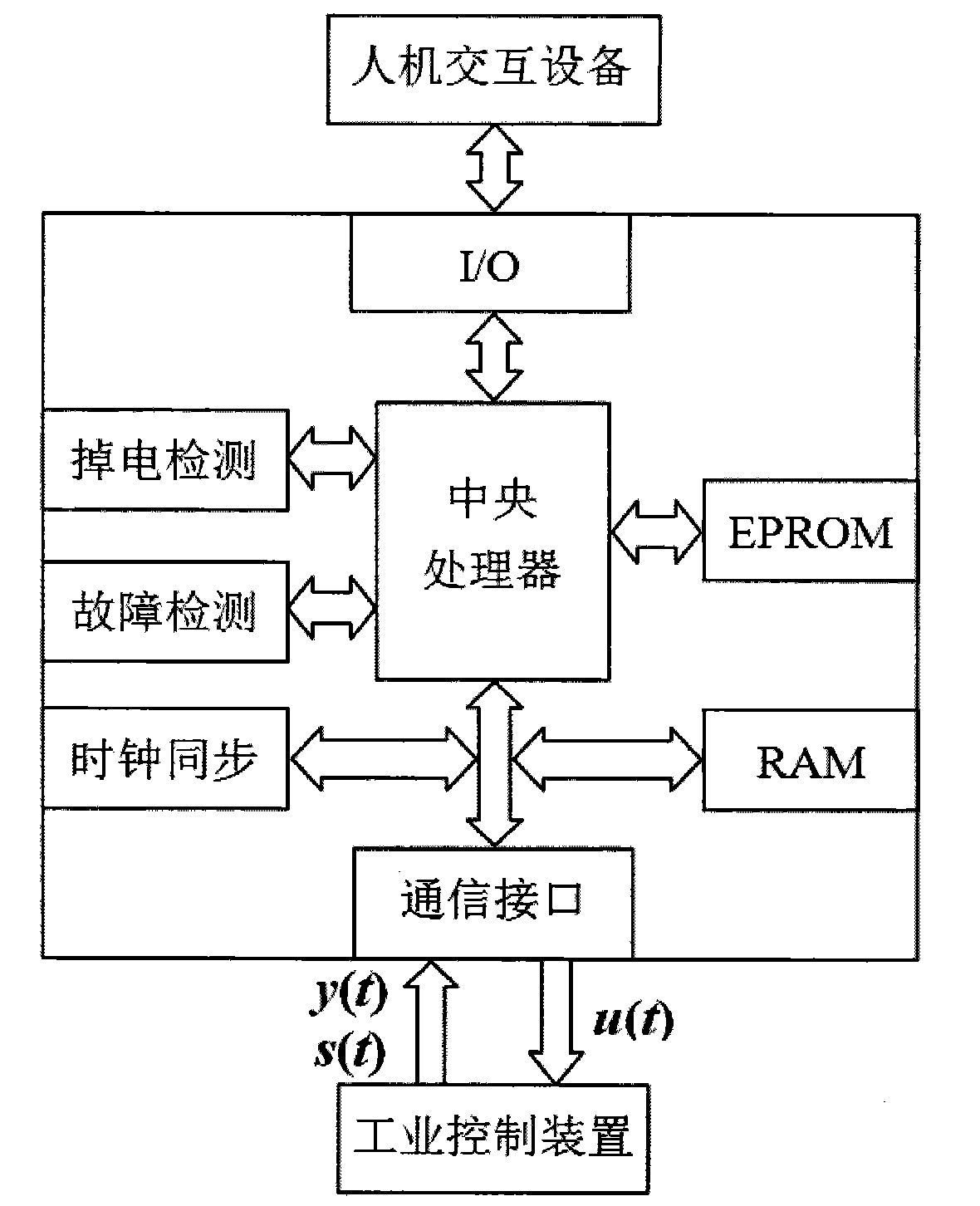

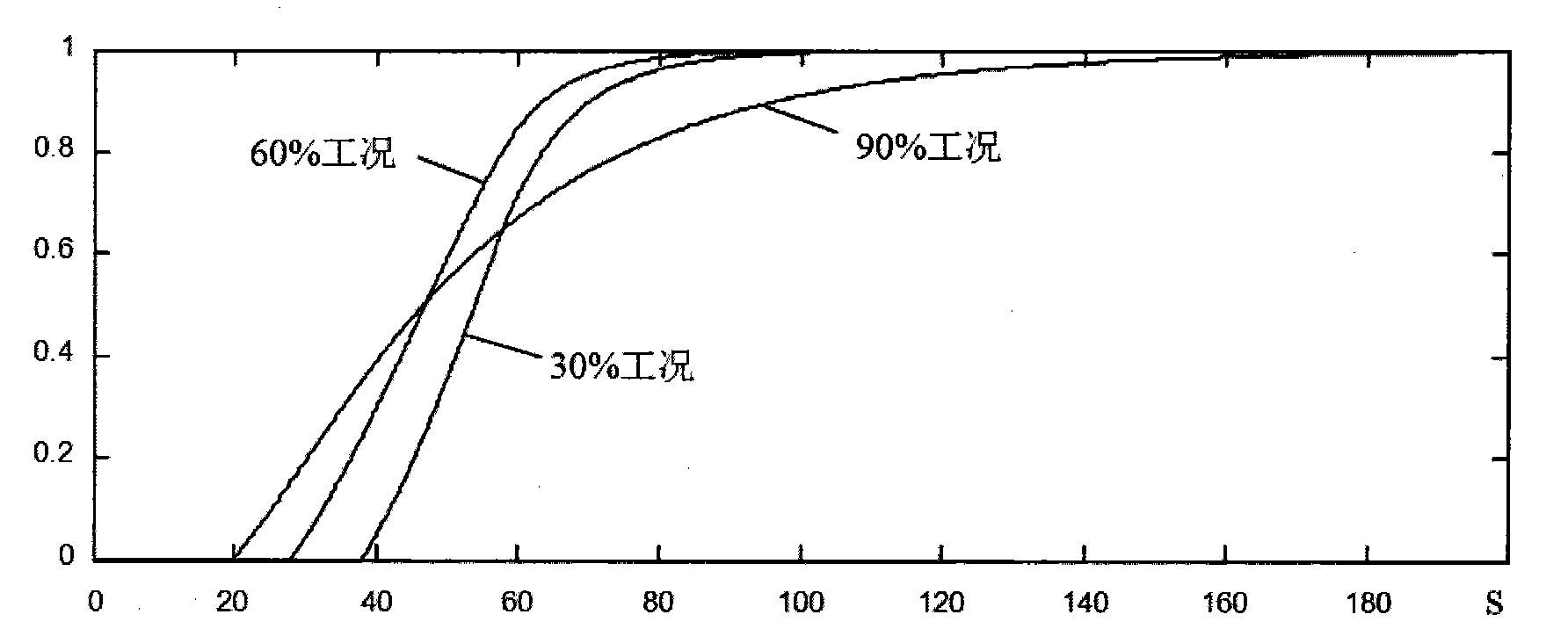

Saturated self-adjusting controller for time-varying delay uncertain system

The invention discloses a saturated self-adjusting controller for a time-varying delay uncertain system. The controller comprises three parts, namely a self-adjusting limiter, a conventional PID controller and an anti-integral saturator, wherein the conventional PID controller generates a control command uc(t) according to the offset of the controlled parameter y(t) and a target value r(t) thereof; the self-adjusting limiter calculates a steady-state gain K of a time-varying delay uncertain object under the corresponding working condition under the driving of a working condition variable s(t), dynamically generates a limiting value according to the K and r(t), timely limits the uc(t) and generates a final control function u(t); and the anti-integral saturator limits the integral function in the PID controller according to the offset of the uc(t) and u(t) in order to solve the possible integral saturation problem. By applying the invention, an engineering technician can conveniently apply effective control to a class of time-varying delay uncertain systems widely present in the process industry on an industrial control system (device) or in the mode of combining a hardware circuit with software programming so as to improve the safety and operating level of the production process.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

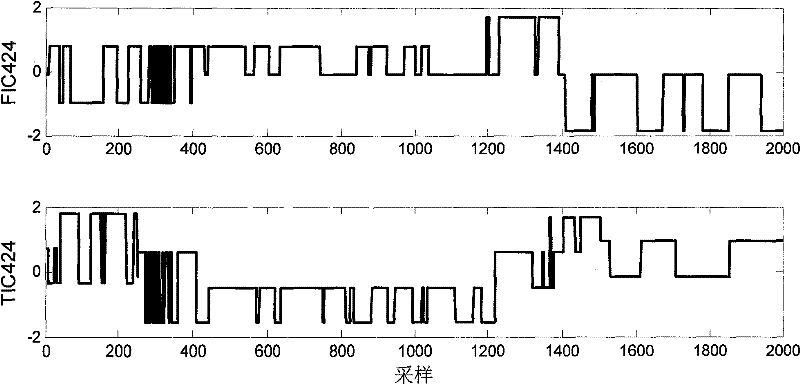

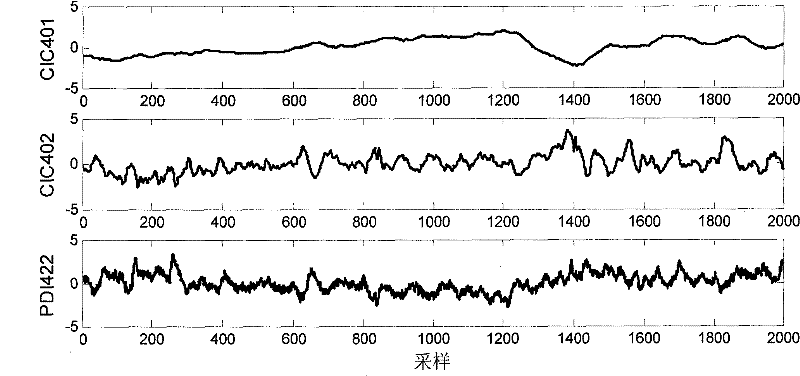

Method for model mismatching detection and positioning of multivariate predictive control system in chemical process

The invention discloses a method for model mismatching detection and positioning of a multivariate predictive control system in a chemical process. By aiming at the typical hierarchical control system in the traditional process industry, the model mismatching detection and positioning is carried out respectively on a multivariate system and all univariate subsystems in the multivariate system. The method comprises the steps of: acquiring residual errors of the multivariate system in a predicative control layer on the basis of an orthogonal projection method, constructing a monitoring statistic computing engine, and acquiring the residual errors, sensitive to process dynamic characteristic variation only, of the univariate system on the basis of an auxiliary variable identification method.In the invention, closed-loop operation data is adopted directly and additional information of the system is not needed; rapid detection and positioning can be made just by utilizing a small amount of data so that fewer disturbances are made to a working condition; and the mismatching information of process models of all univariate subsystems in the multivariate system can be positioned so as to eliminate the influence of the disturbances. By means of the method disclosed by the invention, the accurate model mismatching information can be obtained rapidly at lower cost, the maintenance cost of the predictive control system can be reduced, the service life of the predicative control system can be prolonged and the gain can be improved.

Owner:ZHEJIANG UNIV

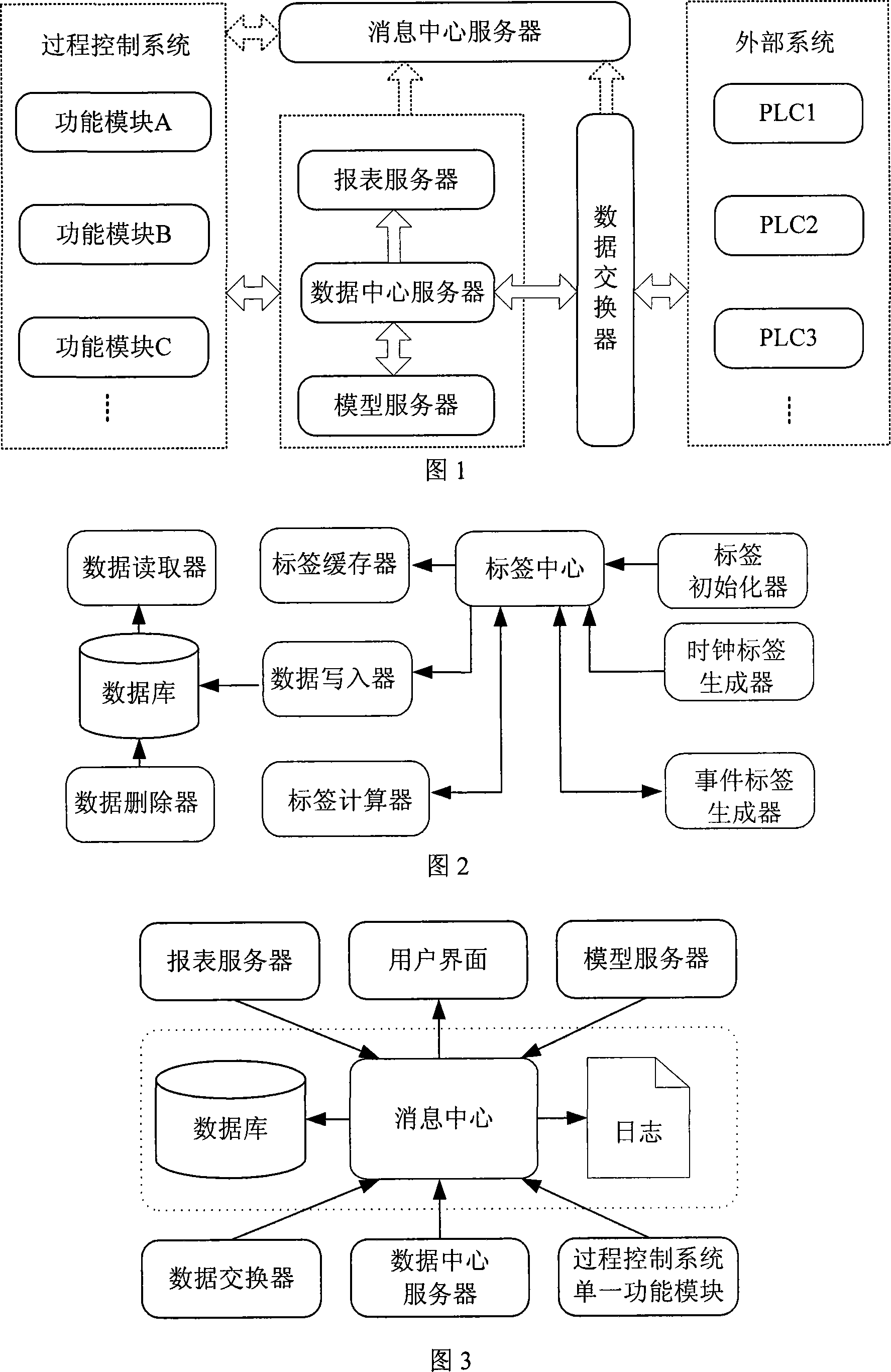

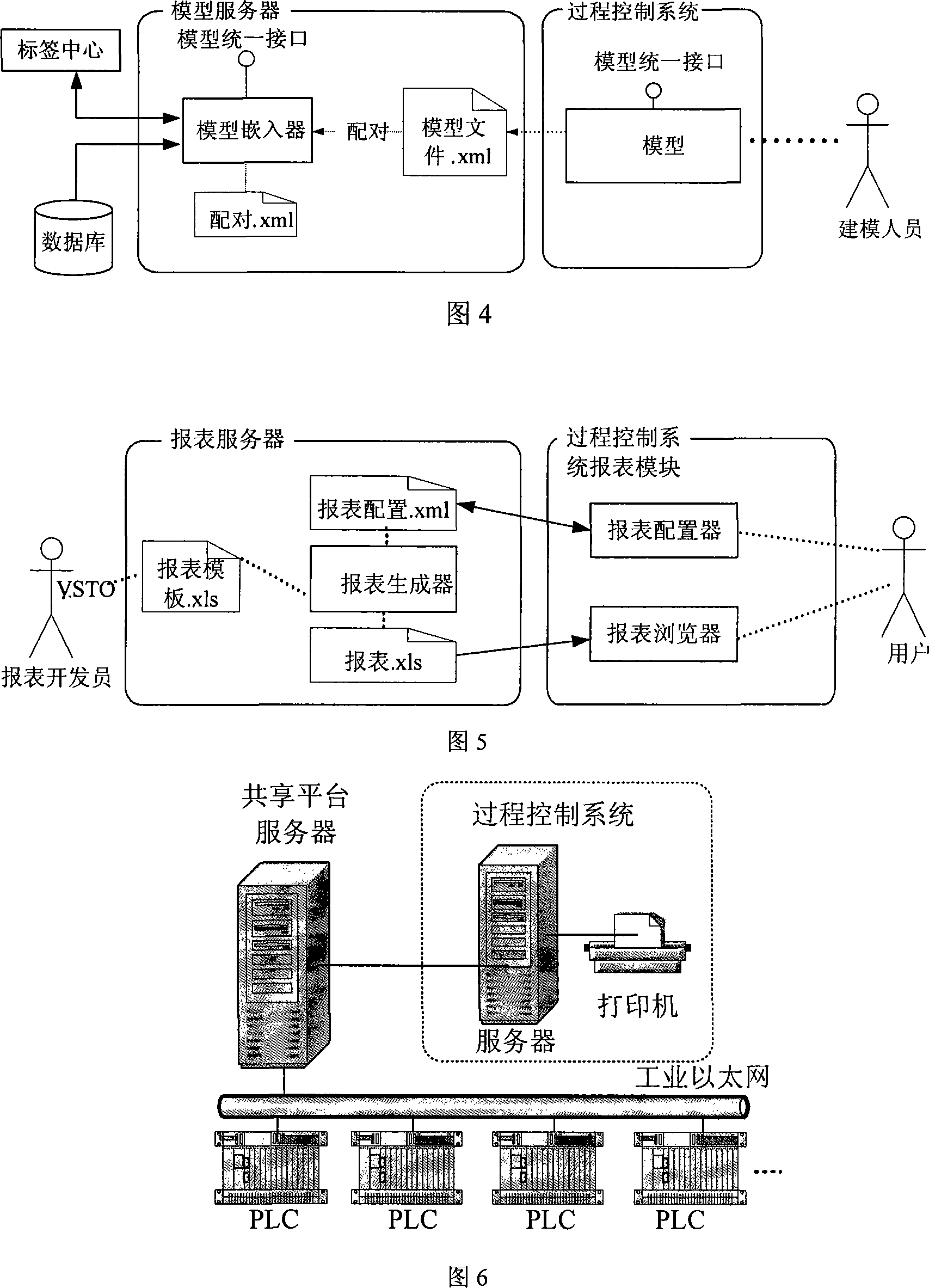

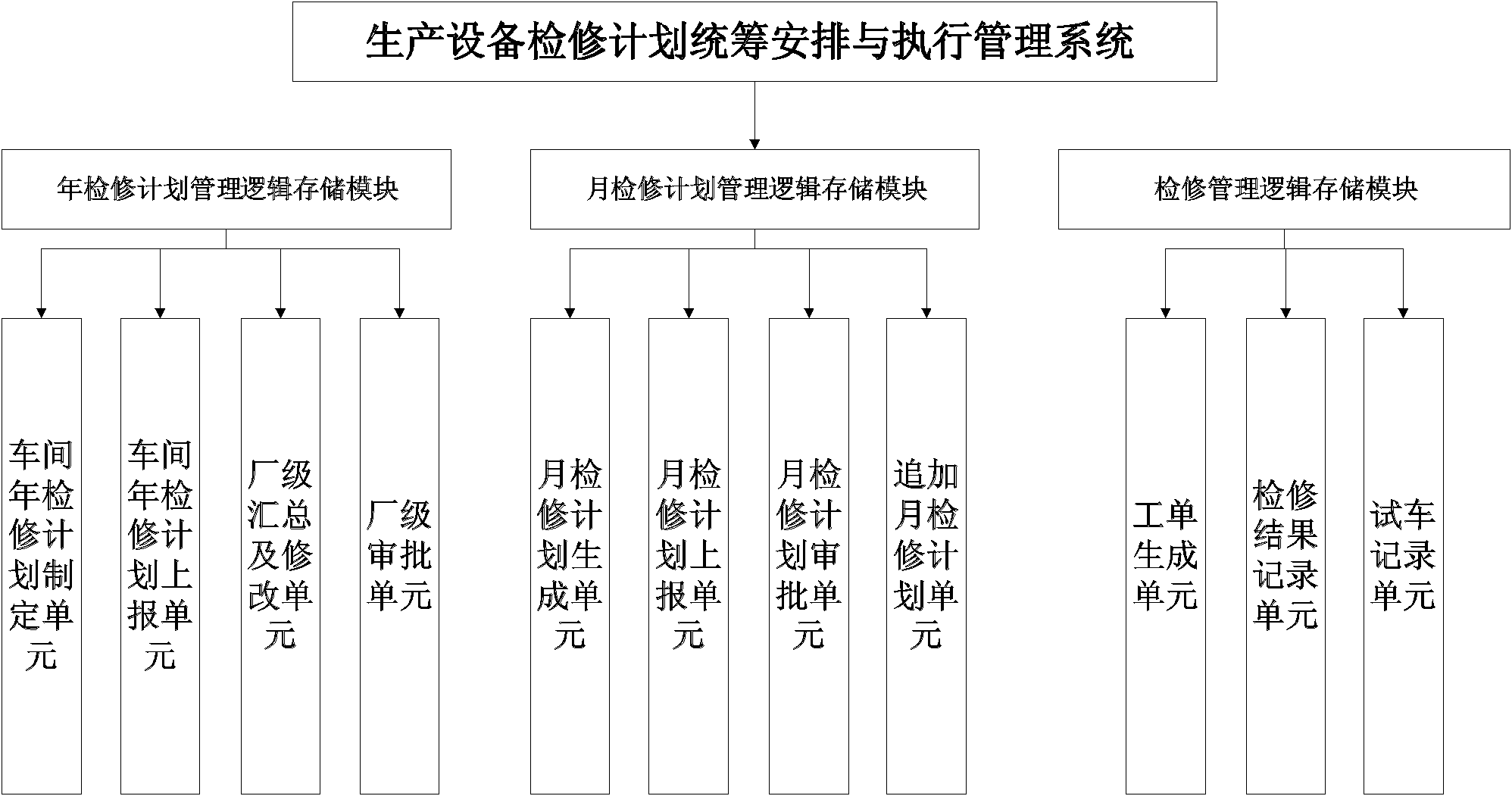

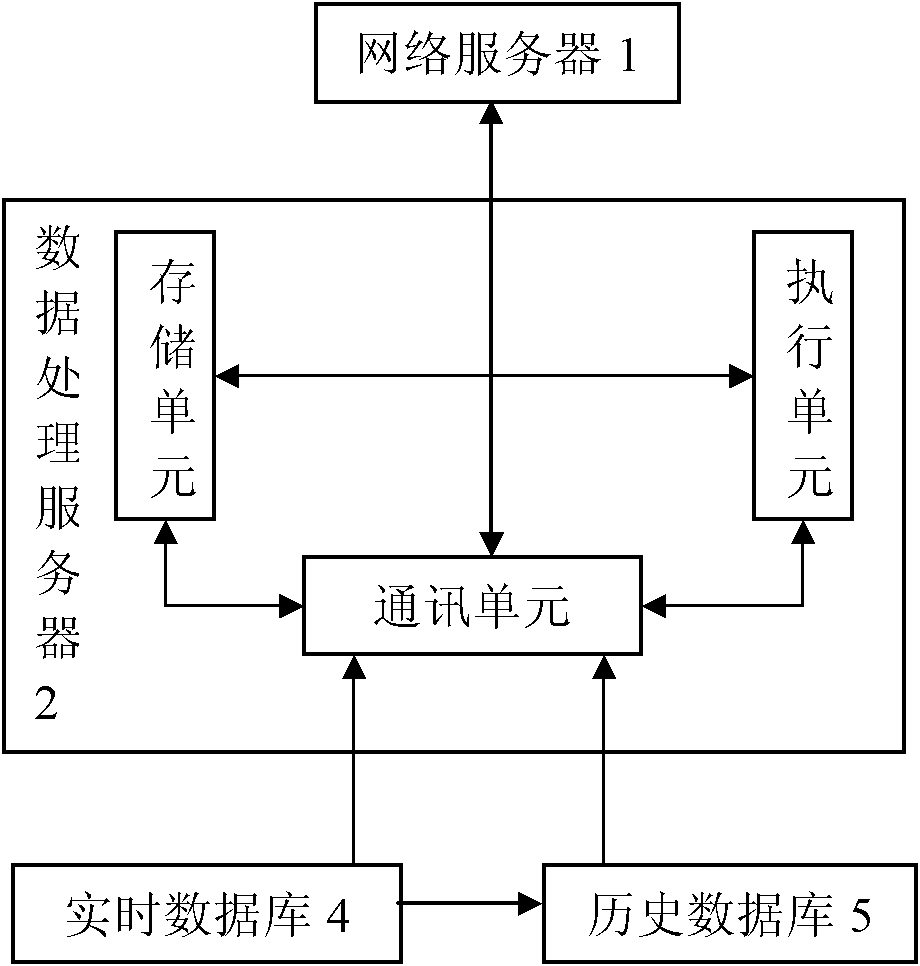

Sharing platform applied to process flow industry process control system

InactiveCN101183263ADecouplingImprove developmentTotal factory controlProgramme total factory controlData streamMessage flow

The invention relates to a sharing platform applied to process control systems in process industry, belonging to the technical field of sharing platforms of process control systems, comprising a process control system, a data exchanging machine, a model server, a report server, a data center server, and a message center server. The invention is characterized in that: the process control system is divided into a plurality of single function modules according to system functions; the data exchanging machine enables the data exchange between the PLC in an external system and the data center server; the model server provides model service to the process control system; the report server provides report service to the process control system; the data center server is the transfer station of data streams, which provides data sharing service to the model server, the report server and the process control system; the message center server is the transfer station for massage flows, which receives the messages of the other modules of the sharing platform and the process control system; all the messages can be seen on the user interface of the process control system. The invention has the advantages that: the development process of process control systems in process industry is simplified, and data service, message service, report service and model service are provided to the process control system.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

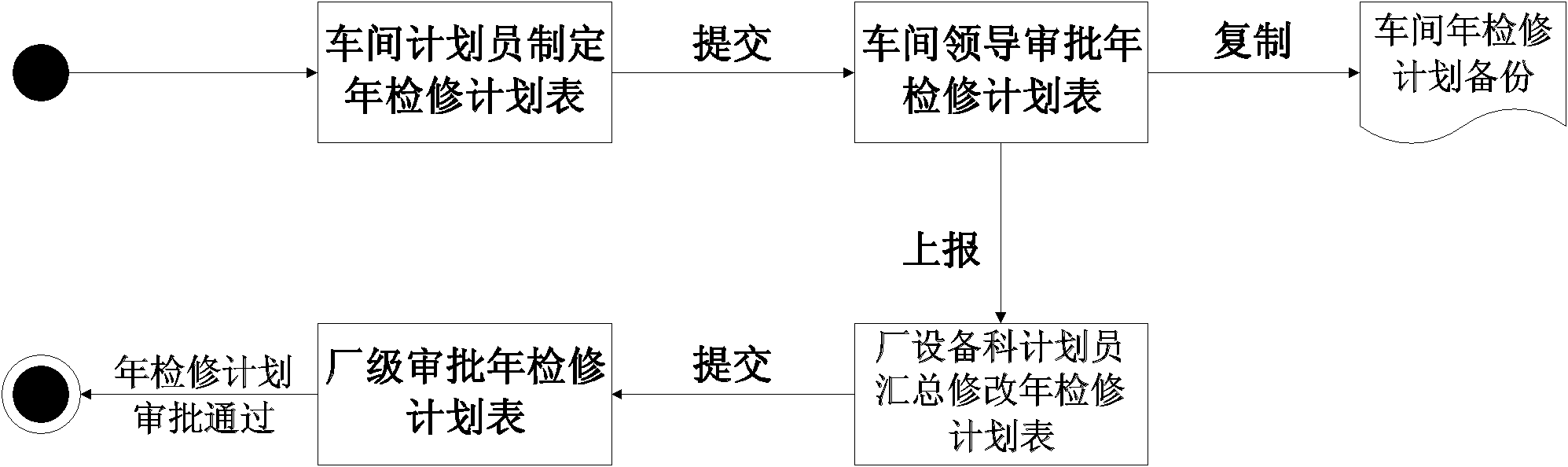

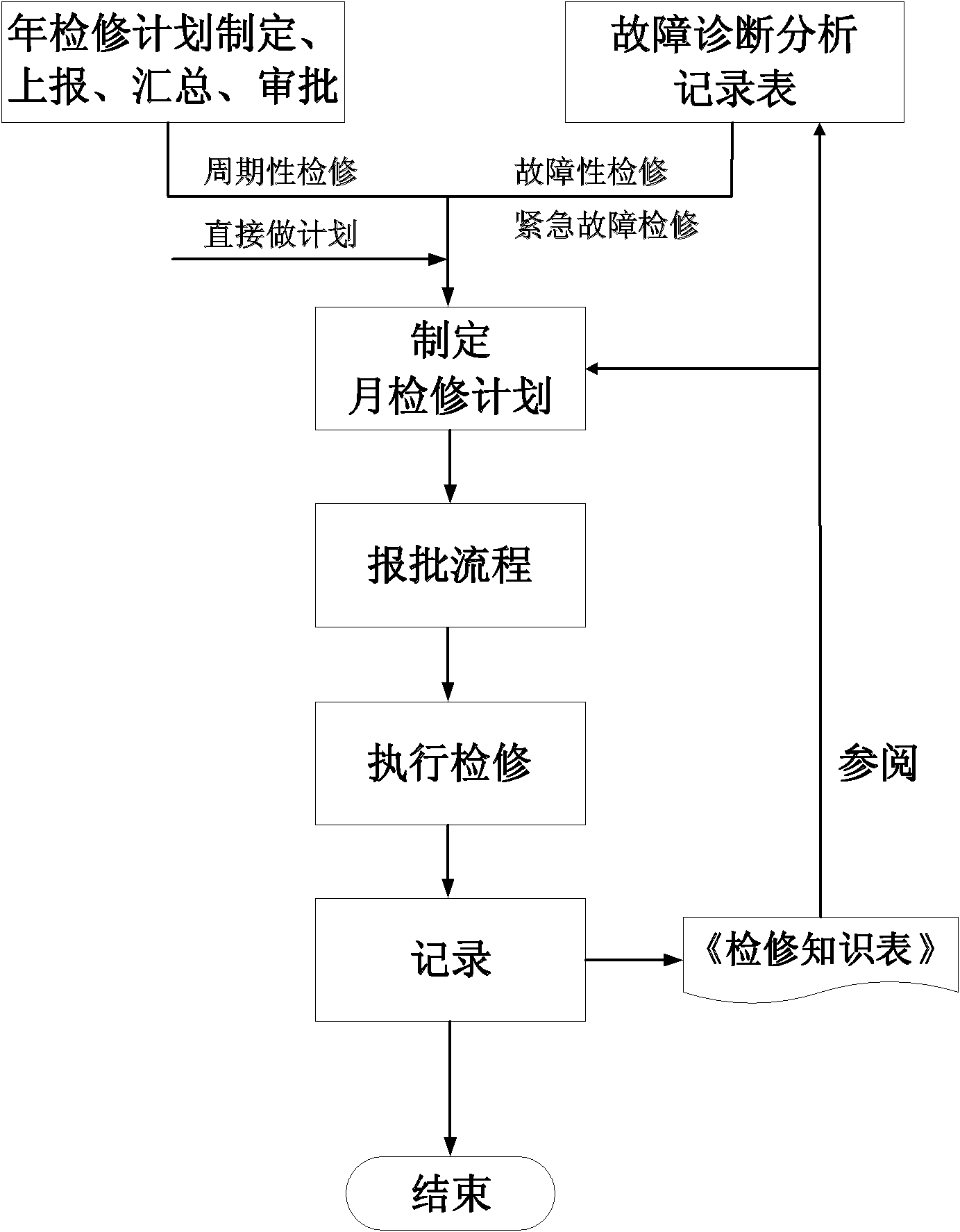

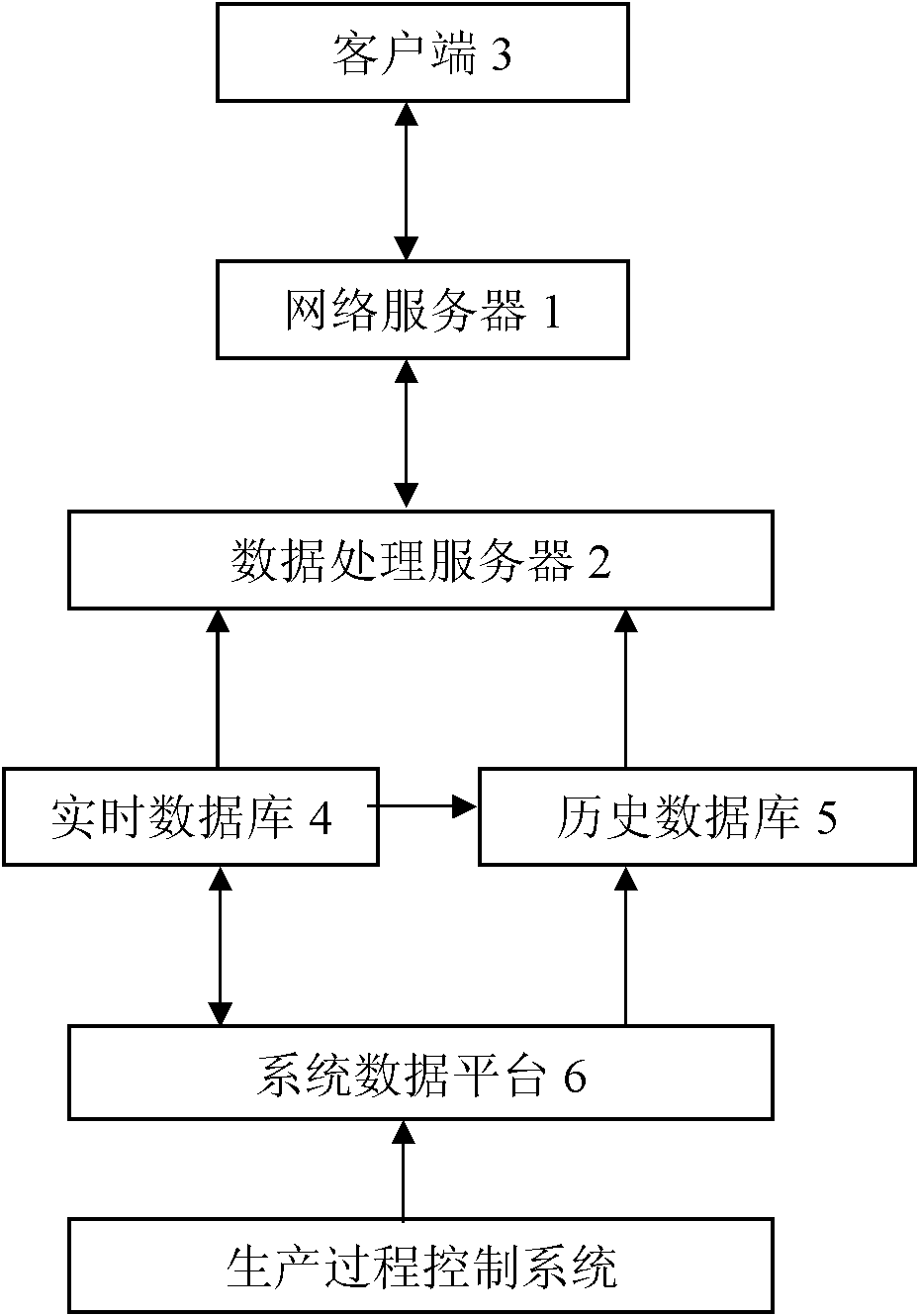

System for comprehensive arrangement and execution management of production equipment maintenance plan

InactiveCN102117444AConvenient queryQuick searchTechnology managementResourcesProgram planningMaintenance management

The invention provides a system for comprehensive arrangement and execution management of a production equipment maintenance plan in the process industry. The system can be used for solving the technical problems of the conventional maintenance plan management mode, such as high complexity, low work efficiency and poor information management. The system provided by the invention is characterized by comprising a network platform consisting of a computer, a server computer and a database application computer, wherein the network platform ensures that an annual maintenance plan management module, a monthly maintenance plan management module and a maintenance management module are mutually connected.

Owner:北京三博中自科技有限公司

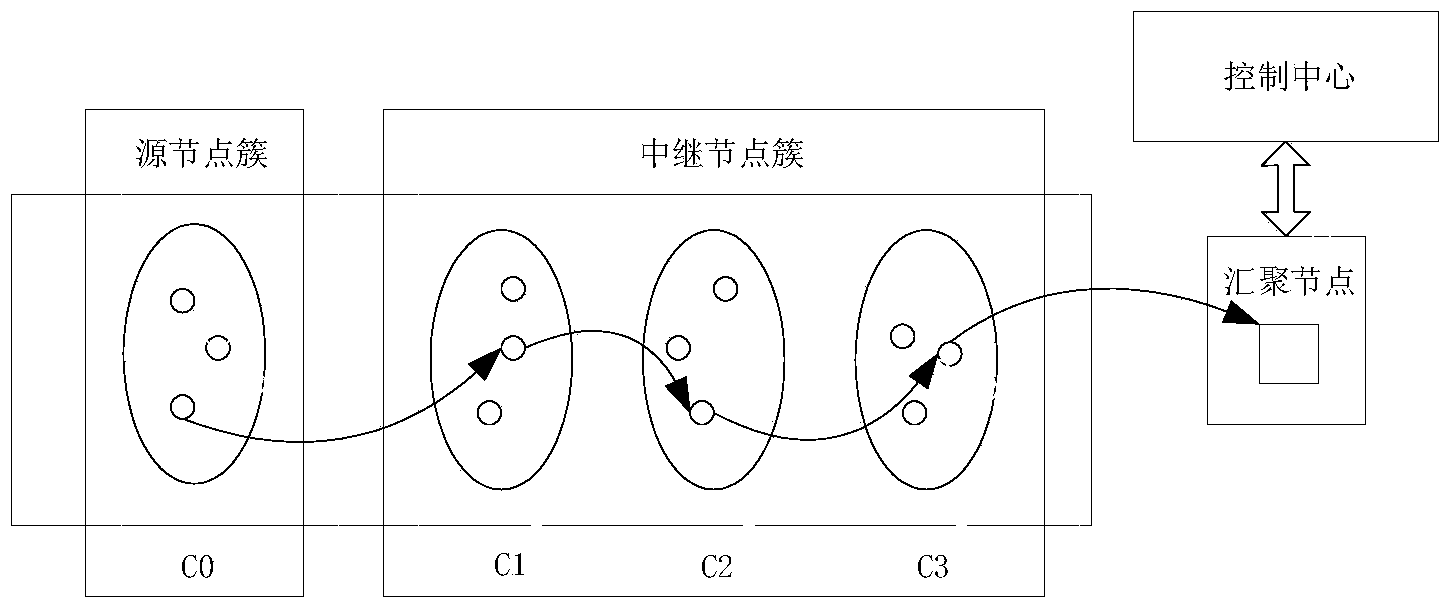

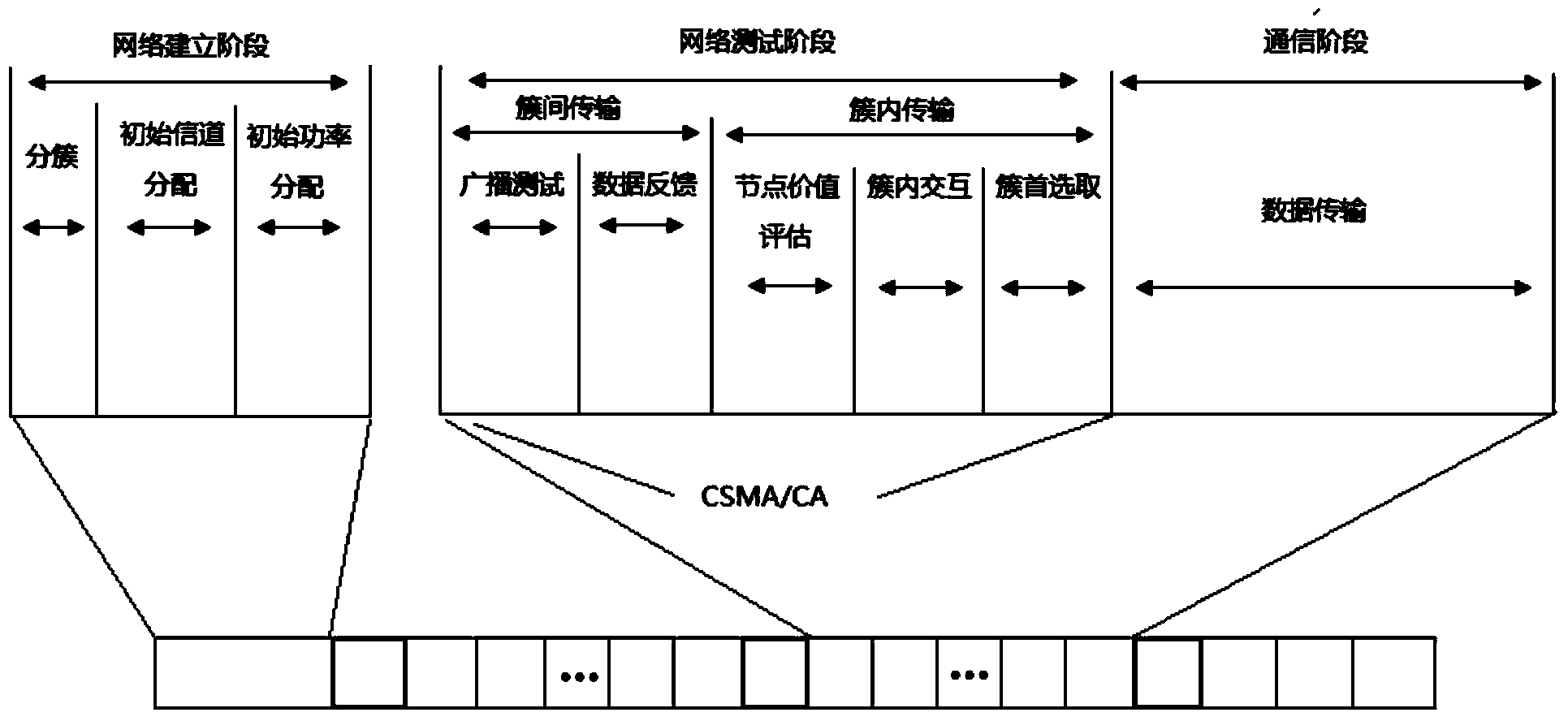

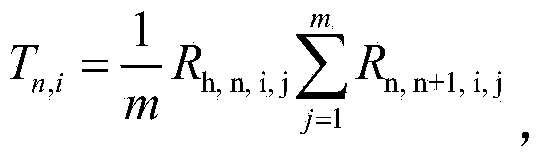

Wireless sensor network system based on dynamic routing and method thereof

InactiveCN103889020AImprove reliabilityCompliant with the process industryNetwork topologiesNode clusteringWireless mesh network

The invention provides a wireless sensor network system based on dynamic routing, wherein the system is used for the industry. The wireless sensor network system based on dynamic routing comprises a source node cluster, a relay node cluster, a sink node and a control center, and a routing link is composed of a cluster head node of the source node cluster, a cluster head node of the relay node cluster and the sink node. In the idle stage of an industrial network, a test is performed on the link to acquire link quality data, the cluster head nodes are selected according to the link quality data, and a routing link is dynamically selected. According to the wireless sensor network system based on dynamic routing and a dynamic routing selecting method of the system, a clustering structure is provided, a work node is divided into multiple modules, and thus the work node can be suitable for characteristics of the process industry. The periodization characteristic of the process industry is considered, the link test is completed in the idle time slot of the process industry, so that the routing link is dynamically selected, and the reliability of sensor network data transmission is improved. A data retransmission mechanism and an emergency mechanism are introduced, and thus sudden change of environment and other problems can be effectively handled.

Owner:SHANGHAI JIAO TONG UNIV

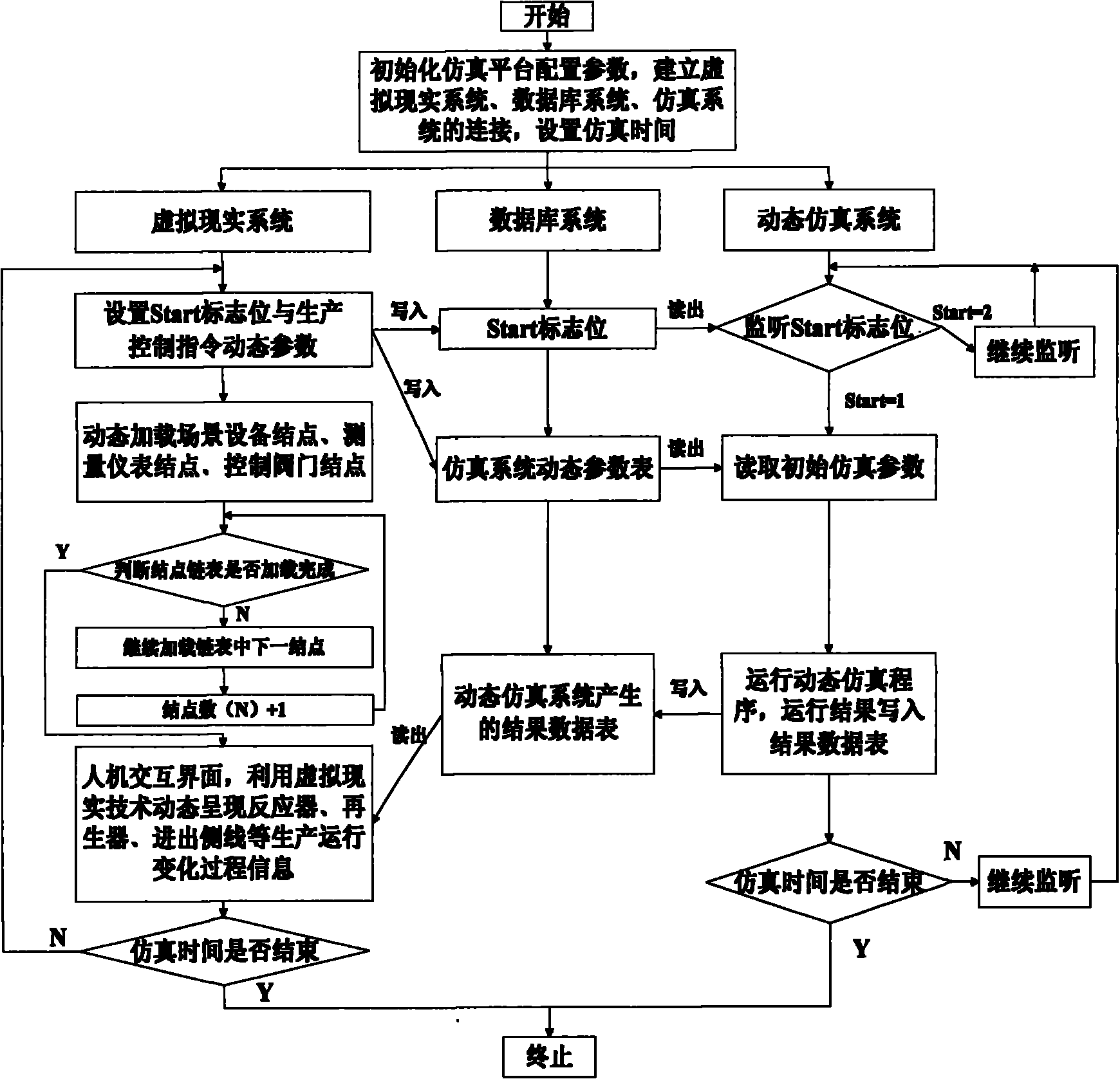

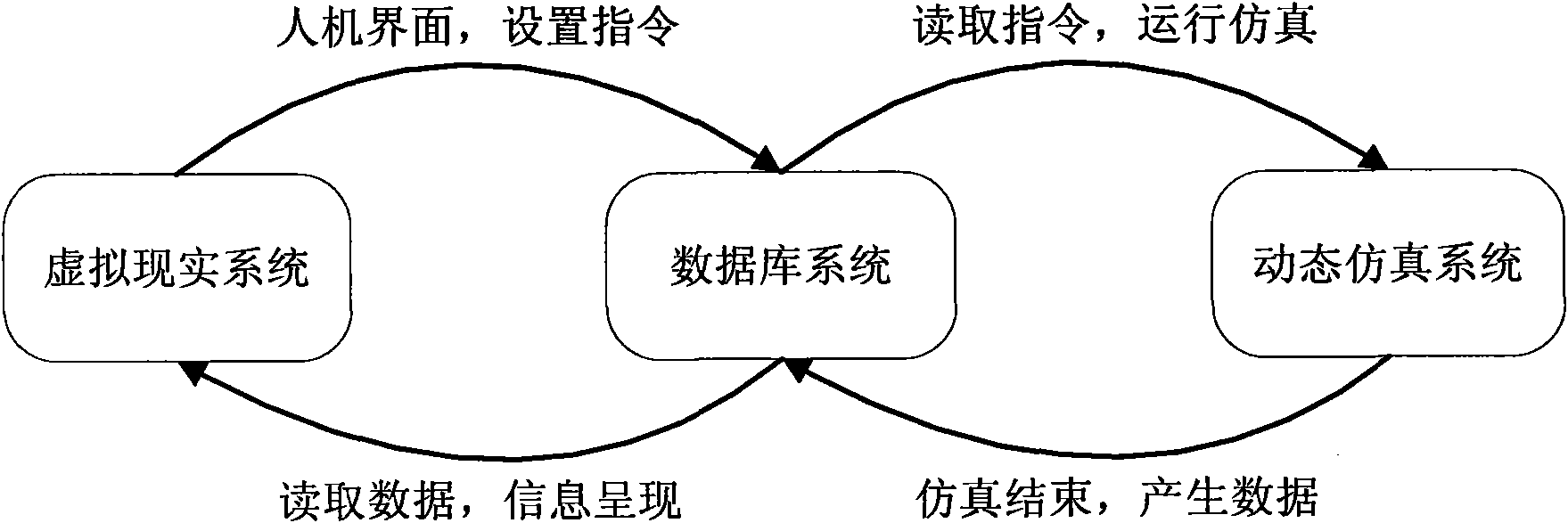

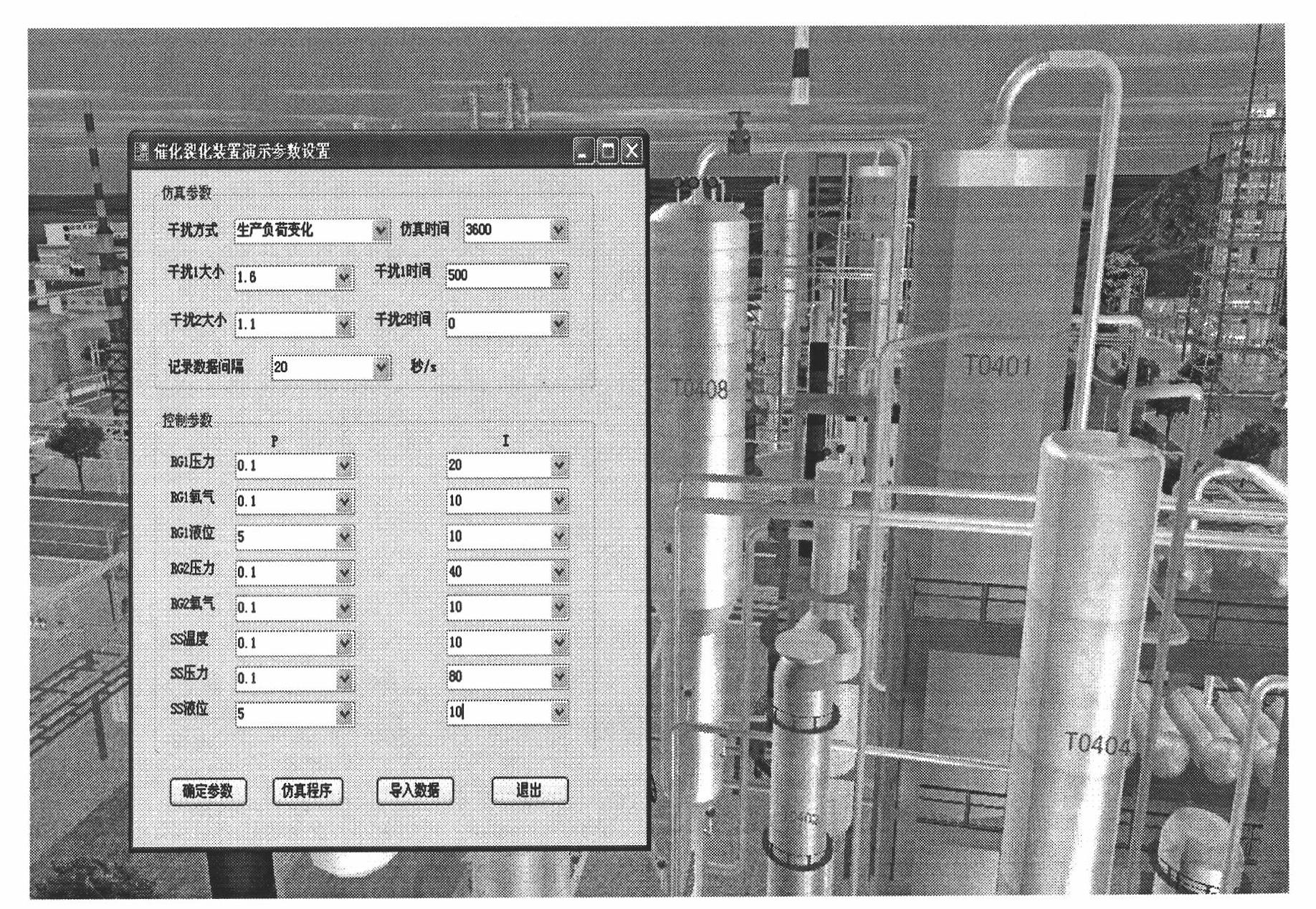

Method for interactive control on key devices in process industry on basis of virtual reality

InactiveCN101872161AEnhanced RealityGet immersiveSpecial data processing applicationsAdaptive controlInformation supportProcess industry

The invention discloses a method for the interactive control on key devices in a process industry on the basis of virtual reality. The method comprises the following steps of: 1) establishing a virtual reality system, a dynamic simulation system and a database system; 2) setting the instructions for operating the key devices and controlling the dynamic parameters in the virtual reality system, writing the instructions into the database system, and monitoring the instructions in the database system by the dynamic simulation system at the same time; 3) when an operation instruction is monitored, reading the initial simulation parameters of the key devices from the database system, carrying out the dynamic simulation and writing the simulation results into the database system; and 4) reading the simulation results from the database system, presenting the changing process of the production data of the key devices in the virtual reality system and carrying out the real-time control. By presenting and controlling the changing process of the production and operation on the basis of the visualization technology, the invention can provide effective information support for users to monitor the production and operation on a real-time basis, help simulate and predict the process control layer in the process industry and improve the benefit of the operation in enterprises.

Owner:ZHEJIANG UNIV

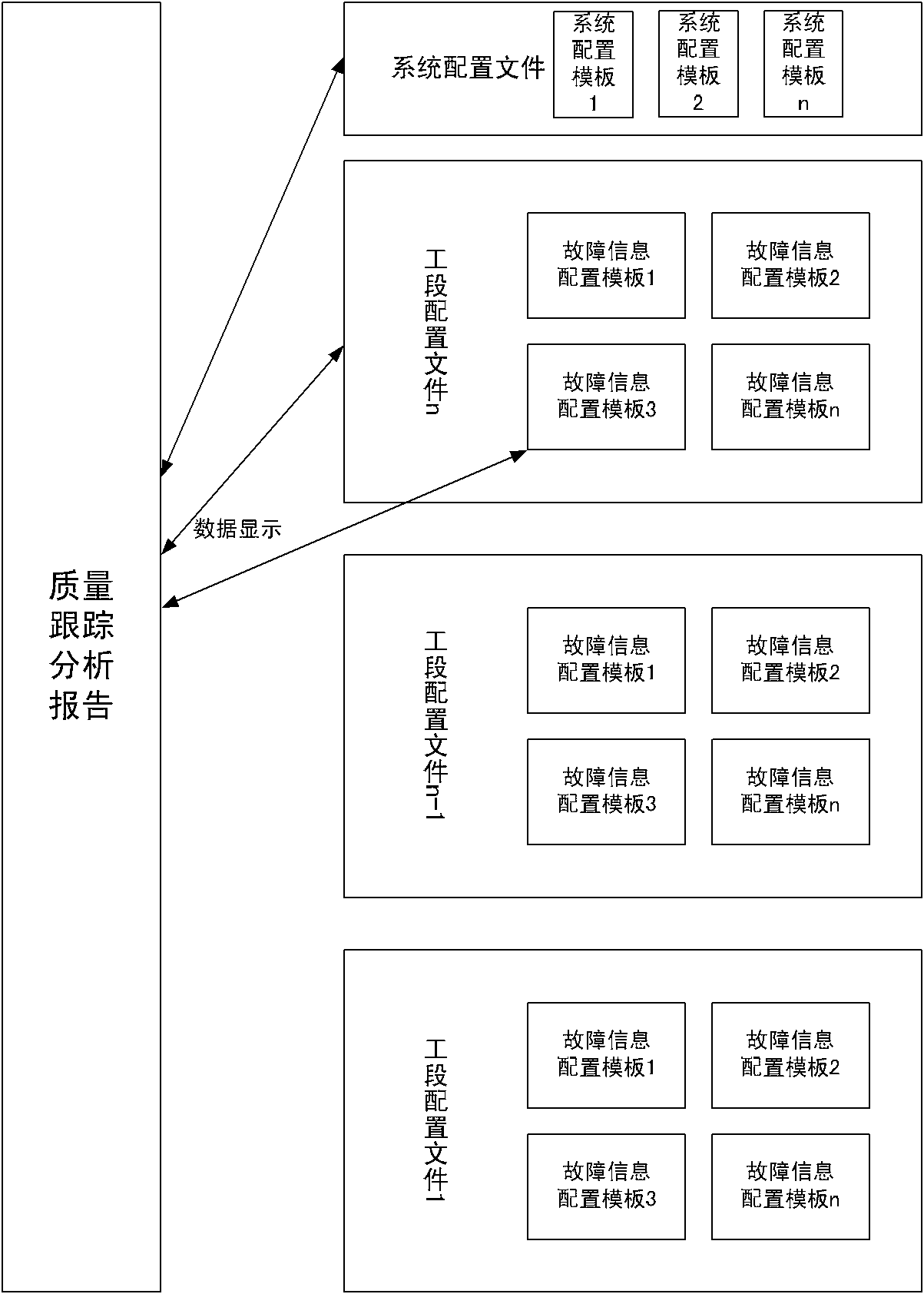

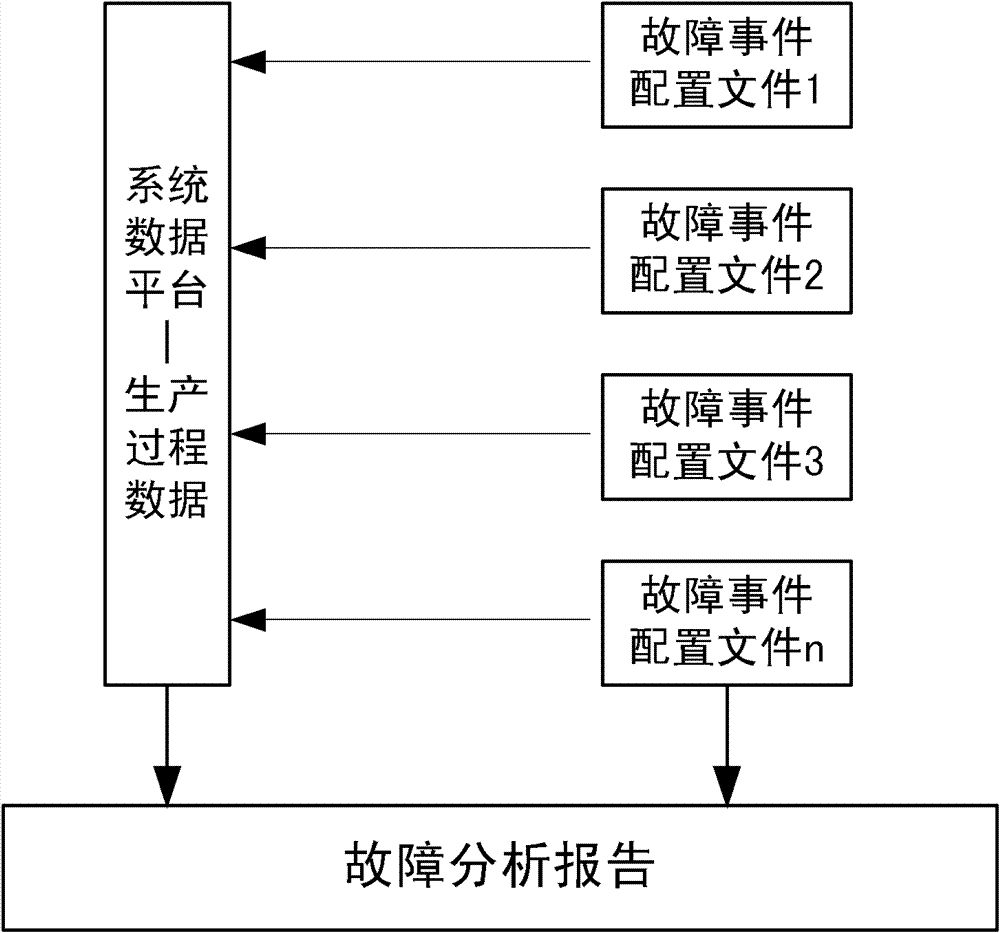

Method and system for tracking quality of products in flow industry

InactiveCN102654907AQuick searchImprove the search for factors affecting product qualityInstrumentsProcess industryManufacturing engineering

The invention discloses a method and a system for tracking the quality of products in a flow industry. Failure events, for example, the index of material components is unqualified, important process parameters are abnormal, important equipment fails to run and production operation does not meet the requirement are automatically triggered, tracked and searched during production of products when the products are finally detected to be unqualified or the products are detected to be unqualified in the middle working section during production of the products through a preset product production process flow, and the failure events are timely showed to a monitor, so that the factor of searching the influence on the quality of the products is increased, and production can be commanded effectively.

Owner:北京三博中自科技有限公司

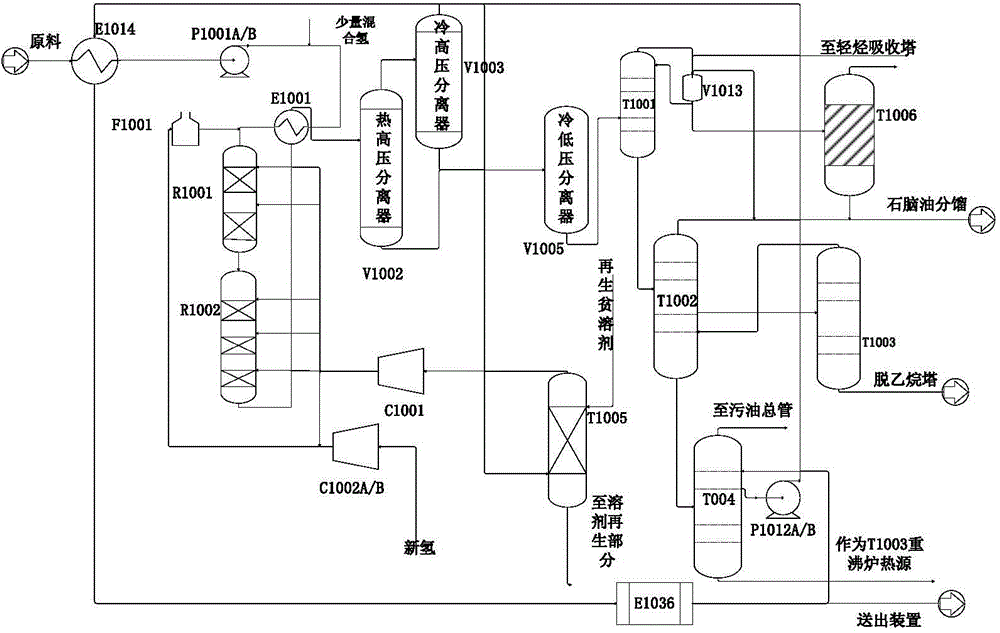

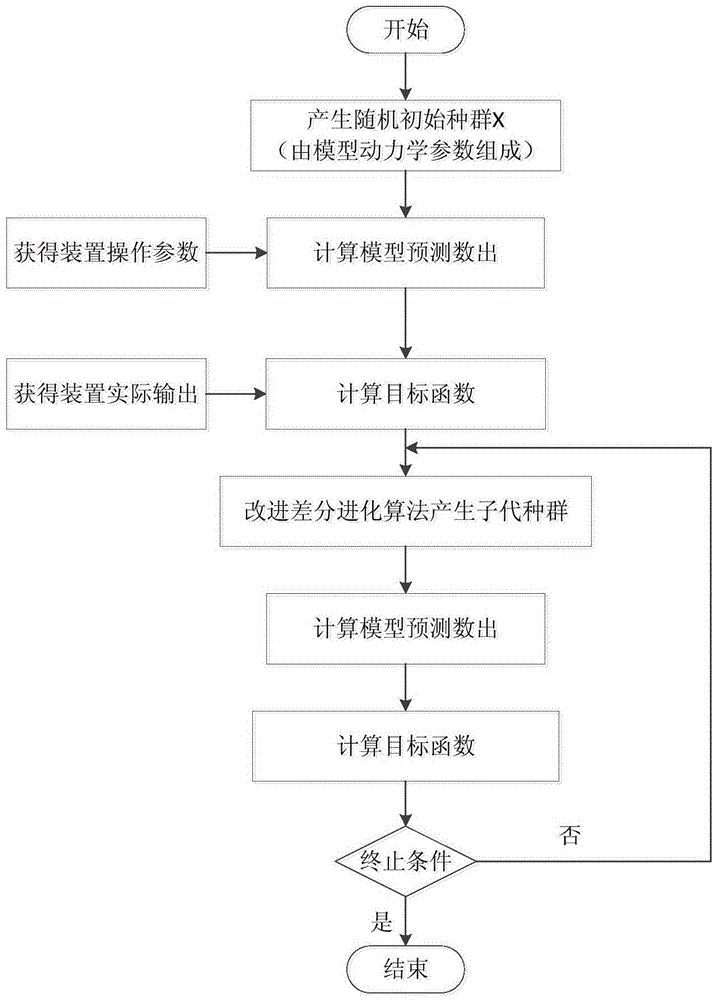

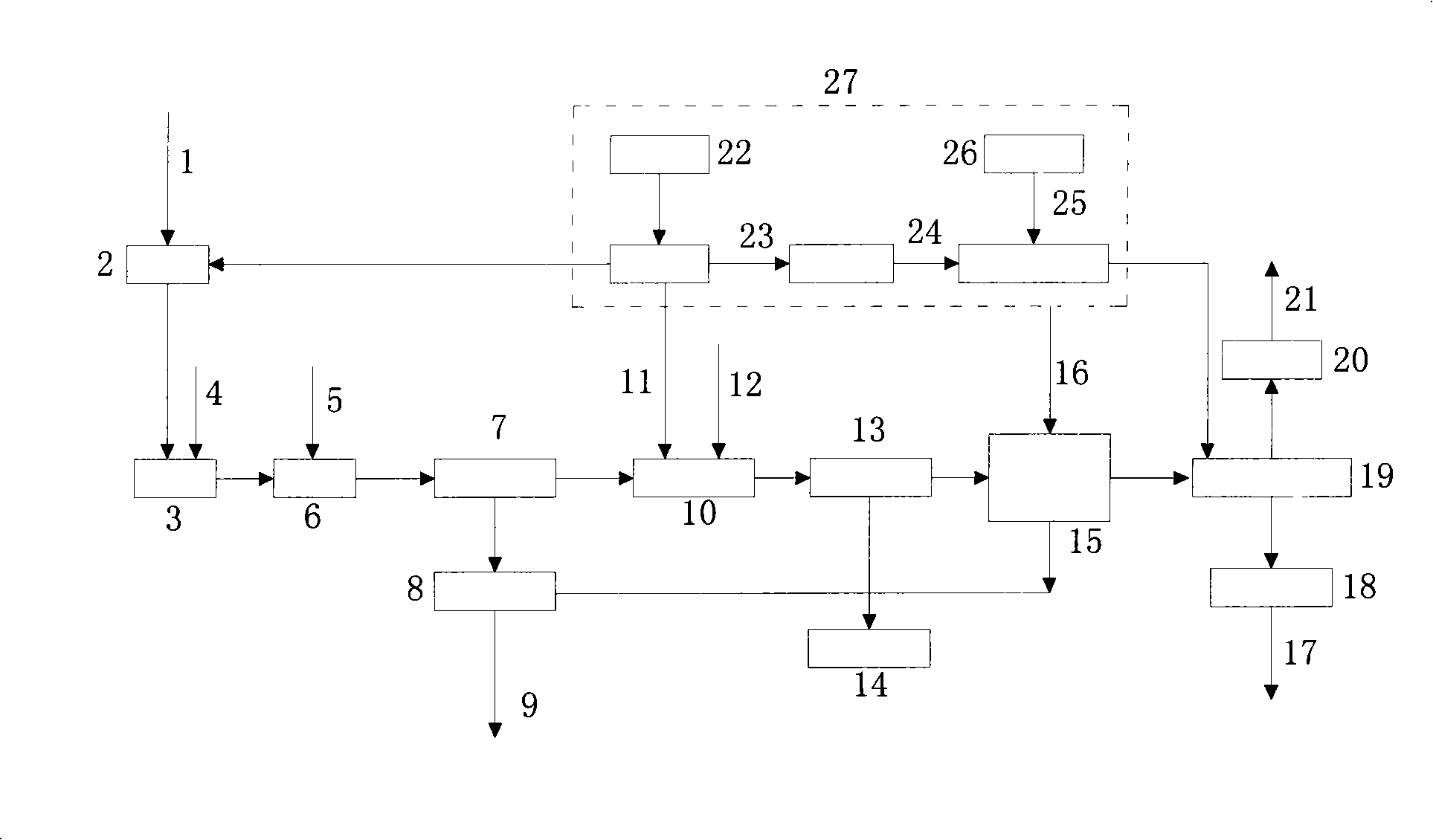

Real-time yield prediction method for hydrocracking device

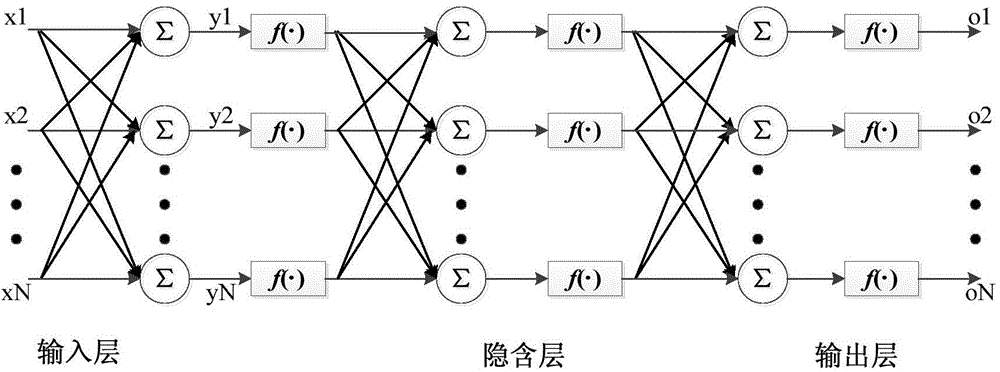

ActiveCN104804761AAchieving real-time predictionReal-time acquisitionBiological neural network modelsHydrocarbon oil crackingReaction temperatureOperant conditioning

The invention discloses a real-time yield prediction method for a hydrocracking device. Field real-time data are processed with a data reconciliation technology, and hydrocracking reaction kinetics parameters are corrected in real time in combination with an improved differential evolution algorithm, so that a mechanism model can accurately describe the actual running condition of the device. On the basis of the corrected model, effects caused by key operation / process conditions such as the raw material density, the sulfur content, the nitrogen content, the reaction temperature, the pressure, the hydrogen-to-oil volume ratio and the like on hydrocracked products are analyzed. Piecewise linearization is performed according to the effect trend, a linear equation is solved, corresponding Delta-Base yield data are acquired, the operation condition is associated with the Delta-Base data with a neutral network modeling technology, a yield surrogate model is established, the yield data calculation speed is increased, real-time prediction of the yield of products of the hydrocracking device is realized, and theoretical support is provided for establishing an accurate plan optimization PIMS (process industry modeling system) model.

Owner:EAST CHINA UNIV OF SCI & TECH

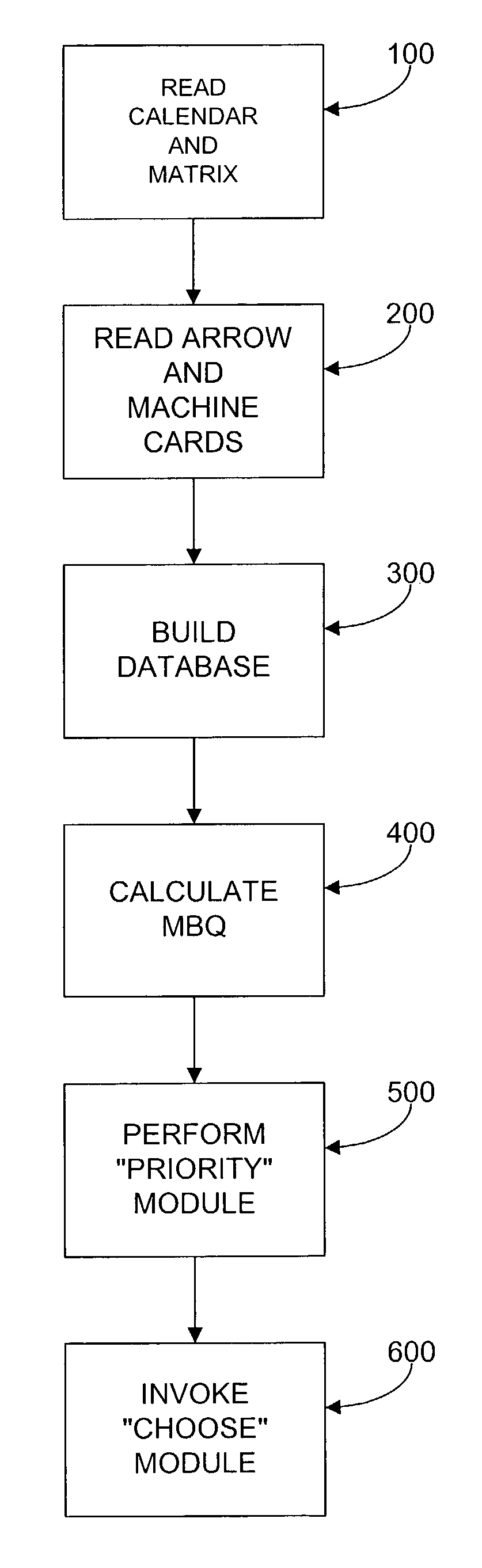

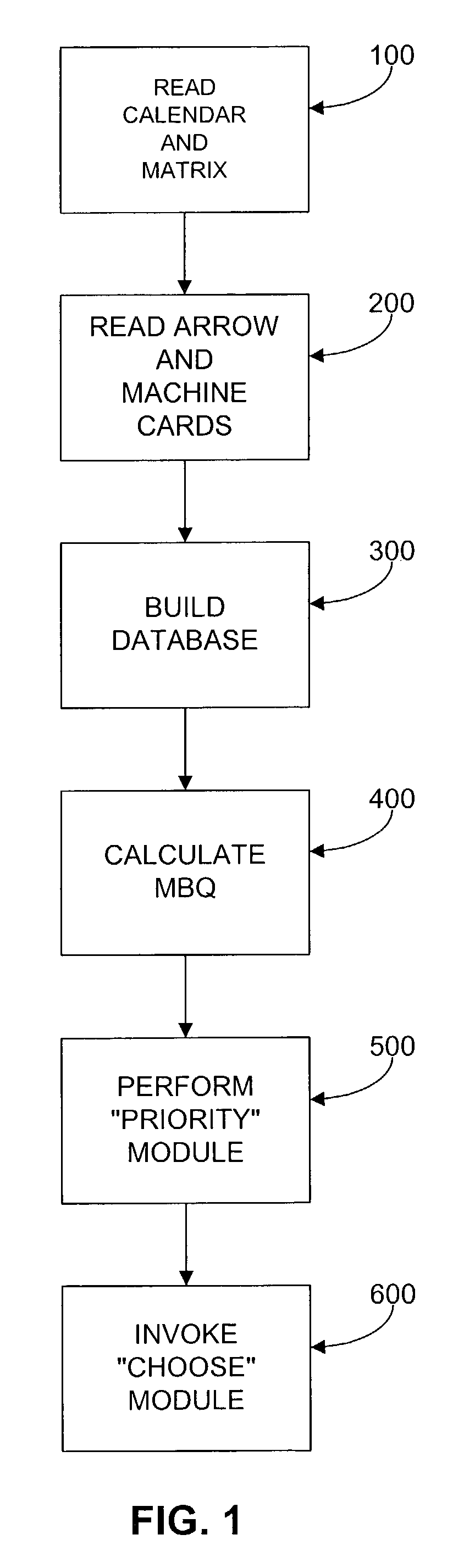

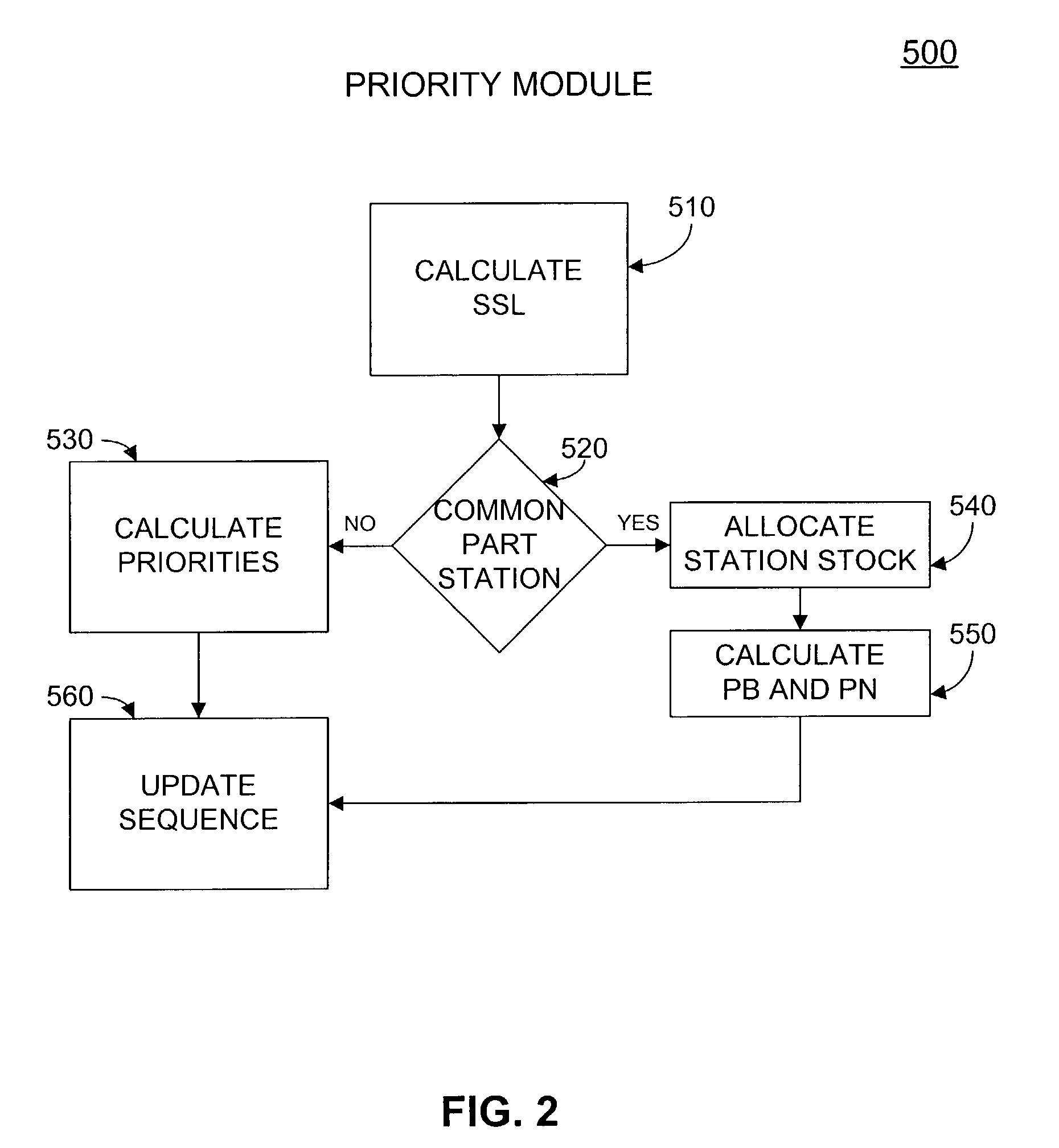

Constraint-based production planning and scheduling

ActiveUS7860737B2Increase capacitySimple materialForecastingMultiprogramming arrangementsProgram planningProcess industry

The present invention is a constraint-based planning tool that specifically addresses the needs of complex discrete and process industries by providing a computationally efficient method and system for fulfillment of customer orders in a supply chain. By comprehensively synchronizing and optimizing the flow of materials through the enterprise, the present invention creates a feasible plan for manufacturing operations that simultaneously optimizes both material and capacity constraints by planning and scheduling multiple customer orders, planning for use the various resources located in remote locations needed to fulfill such orders, and scheduling the used resources for replenishment at appropriate times so that the resources meet the needs of the orders.

Owner:BLUE YONDER GRP INC

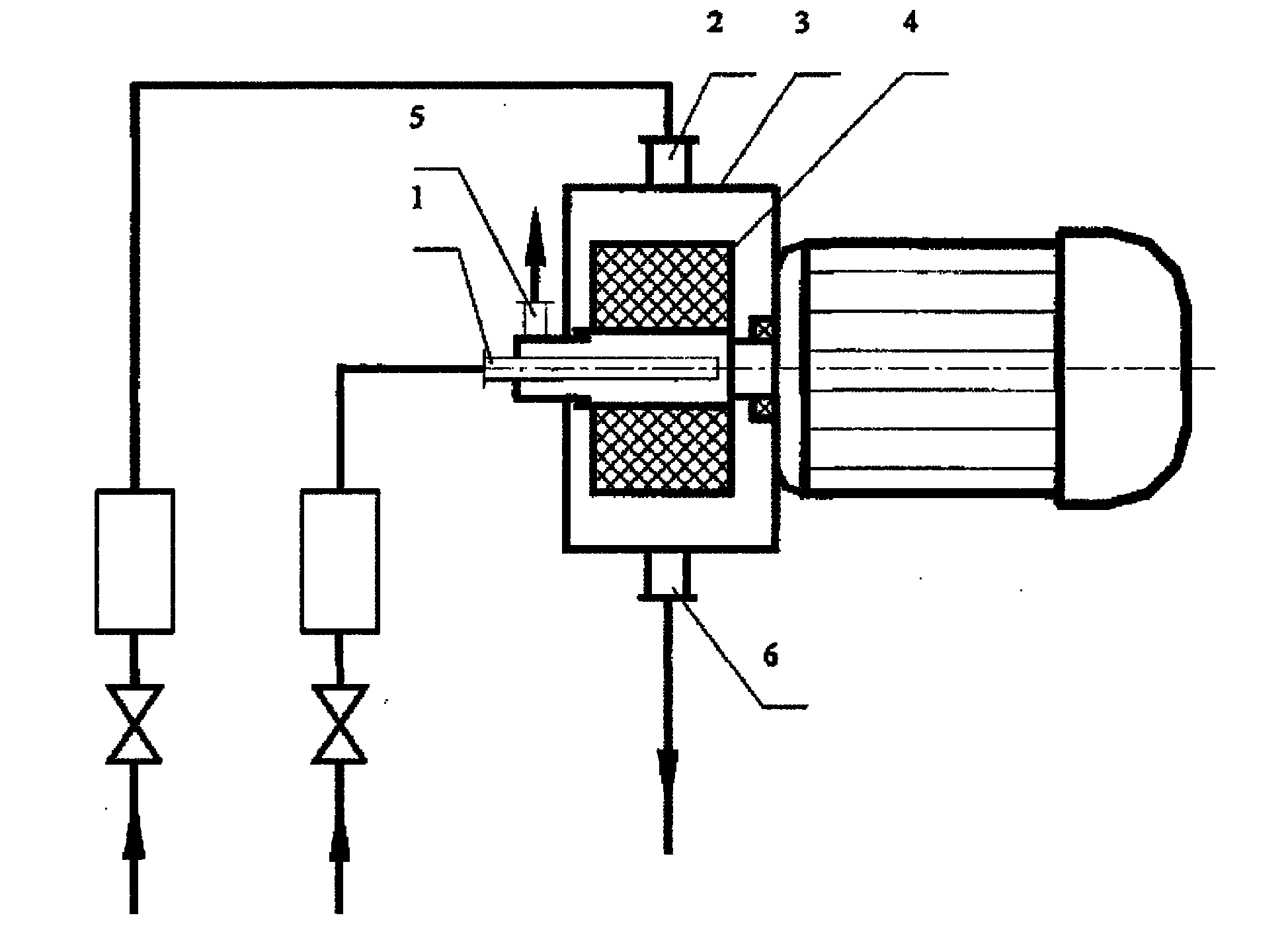

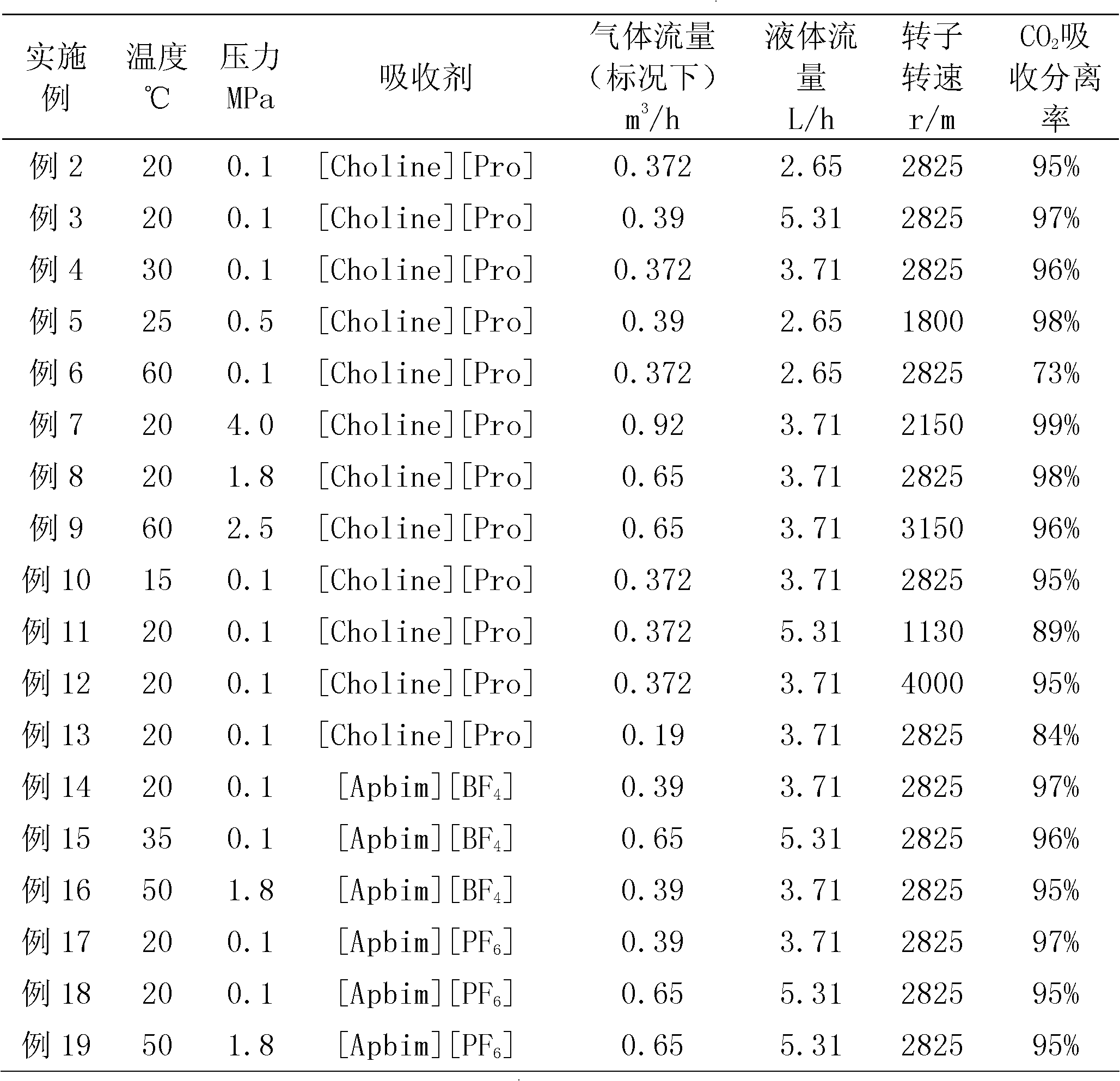

Novel method for capturing and separating carbon dioxide

ActiveCN102580462AEffective separation and captureLess investmentProductsReagentsGas to liquidsProcess industry

The invention discloses a novel method for capturing and separating carbon dioxide, which is applicable to capturing and separating CO2 from tail gas in gas purification, emission reduction of greenhouse gas and process industry and from oil field gas. According to the method, with a high-gravity rotating bed as a rotator and ionic liquid as an absorbent, the absorbent and a mixed gas containing CO2 are in countercurrent or cross-current contact in the high-gravity rotating bed to capture CO2, and the volume-flow ratio of gas to liquid is (50-500):1; the rotating speed of the high-gravity rotating bed is 100-400 rpm; the absorbent is the ionic liquid including amino functional groups or mixture thereof; the pressure in absorption is 0.1-4.0 MPa and the temperature is 15-60 DEG C; and the removal rate of CO2 in raw gas can reach more than 95% (volume). The novel method disclosed by the invention has the advantages of low investment of equipment, small occupied area, low energy consumption, environment friendliness and no corrosion to equipment and the like.

Owner:BEIJING UNIV OF CHEM TECH

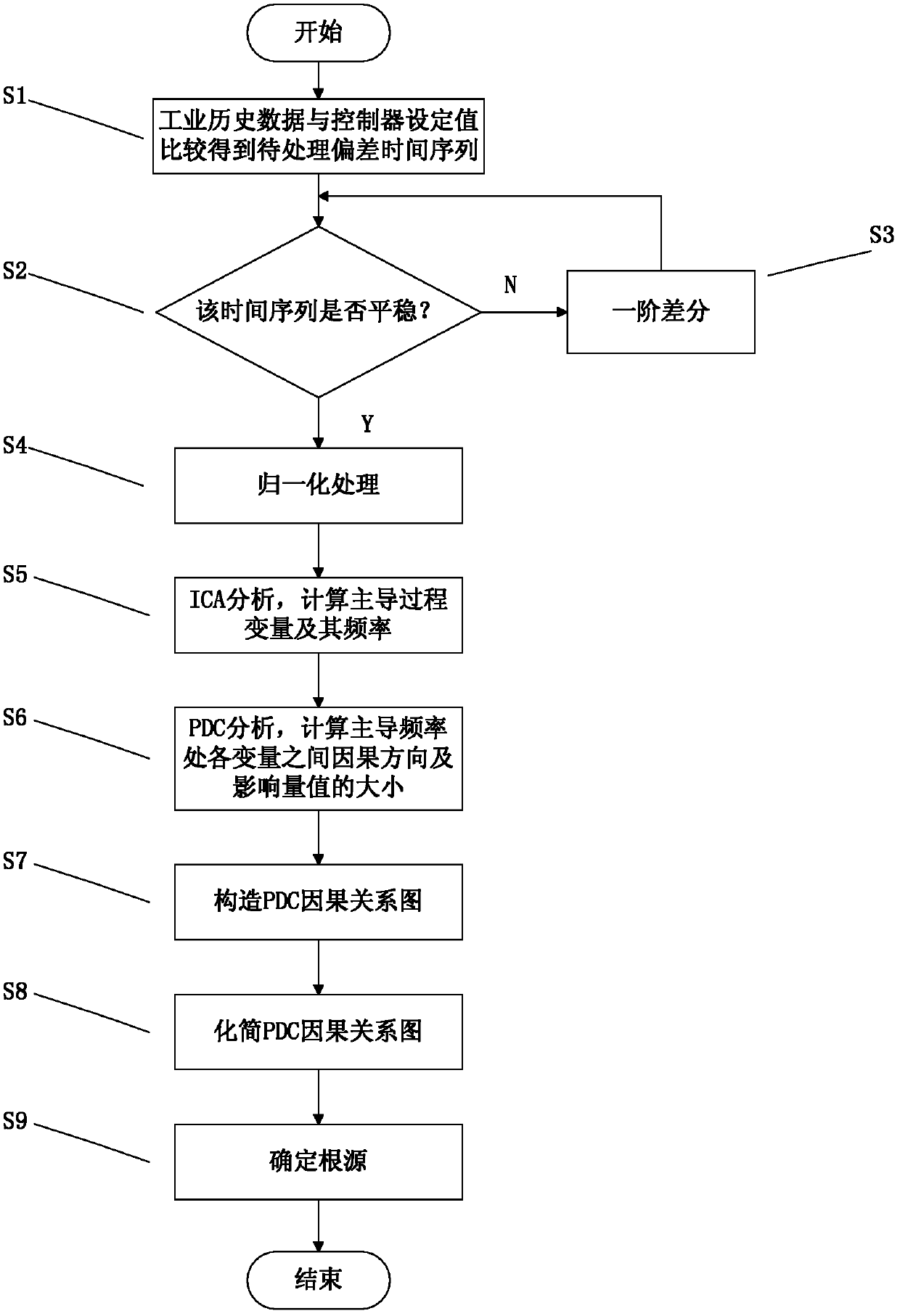

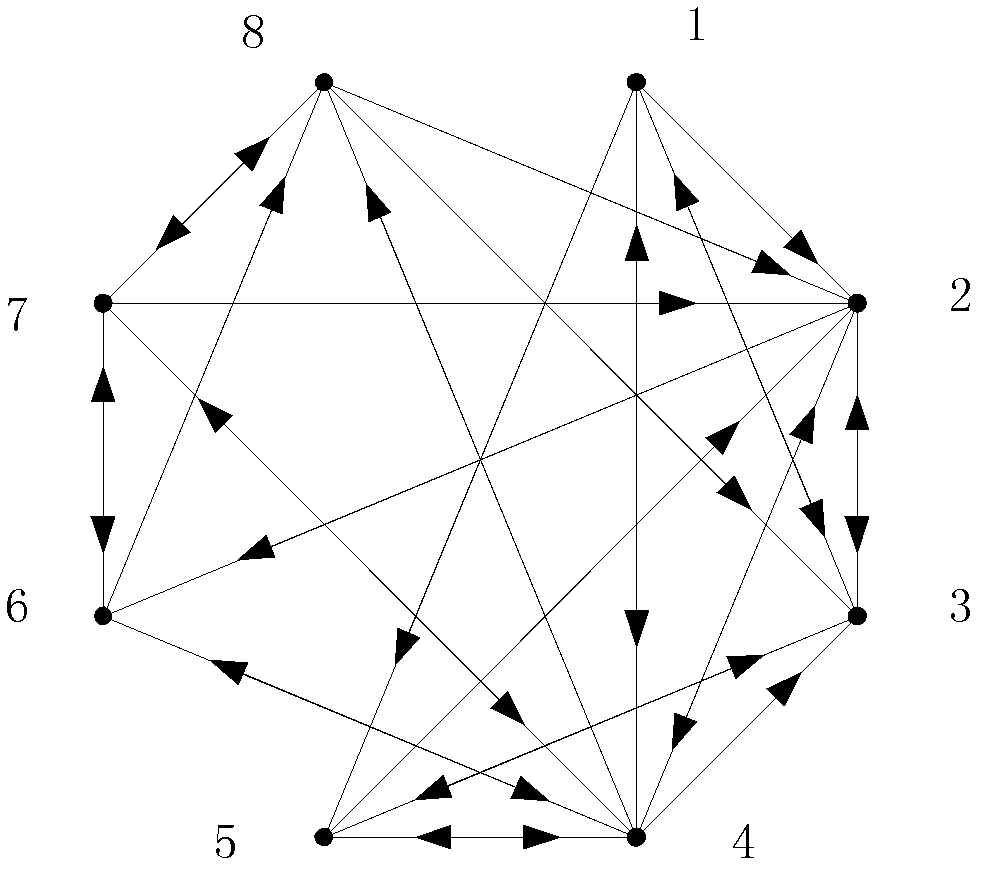

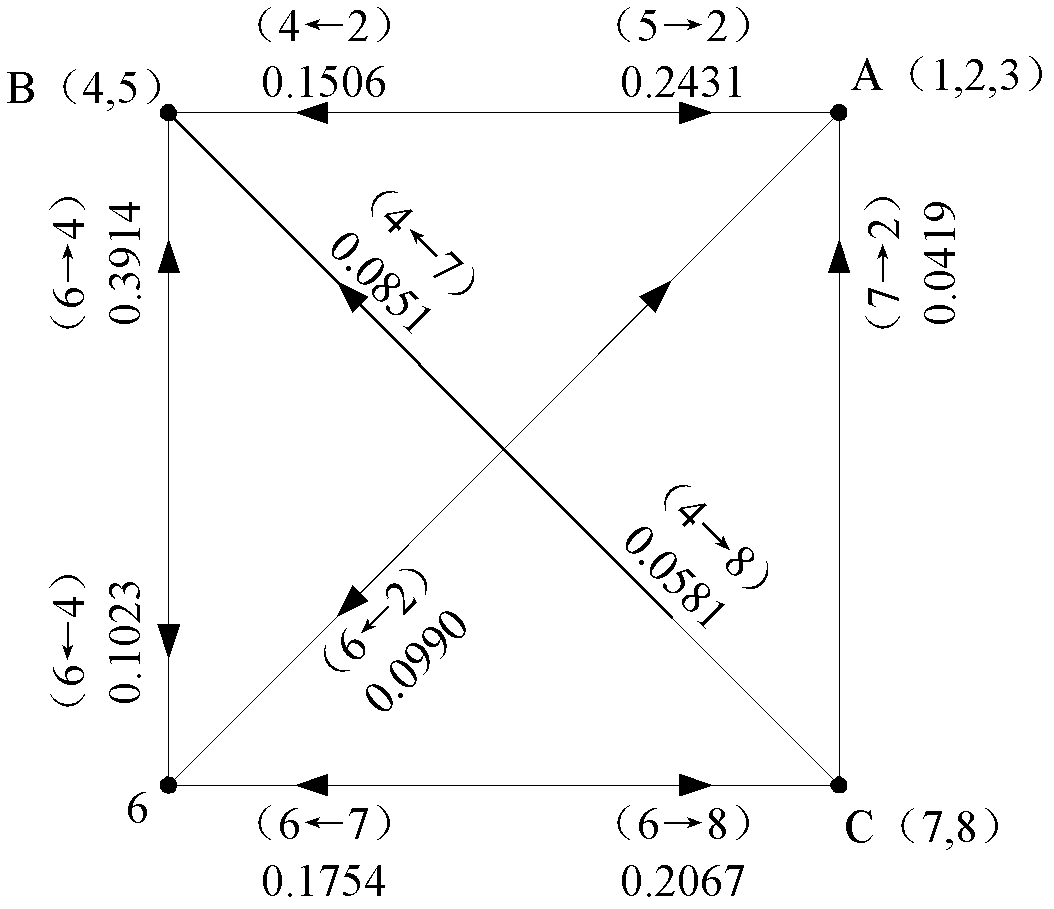

Fluctuation source localization method of multi-loop oscillation of novel process industry

InactiveCN102520708AImprove product qualityElectric testing/monitoringMulti loop controlDecomposition

The invention relates to a fluctuation source localization method of multi-loop oscillation of a novel process industry. According to the method, a frequency domain independent component analysis (ICA) is employed to carry out independent component decomposition on industry historical process data; a variable quantity that plays a leading role in fluctuation oscillation and a dominant frequency can be screened; a local directed coherence analysis is carried out on the screened data; and a cause-and-effect relationship graph is used to visually express a cause-and-effect relationship between loop variables, so that a propagation path of a fluctuation interference can be characterized; process priori knowledge is used to simplify the cause-and-effect relationship graph as well as a threshold automatic searching mode is utilized to filter a secondary cause-and-effect relationship branch, so that a main propagation path of fluctuation is obtained and thus a fluctuation source is localized and identified. Compared with the prior art, the technology employed in the invention enables the method to have the following beneficial effects: a signal analysis on a frequency domain is utilized to reveal an essential attribute of oscillation of a multi-loop control system, so that a fluctuation source of the oscillation is determined; and thus, it is beneficial for a factory engineer to carry out follow-up maintenance and repairing work of a fault circuit.

Owner:EAST CHINA UNIV OF SCI & TECH

Searching methd and system for reasons of fault event in process industry

ActiveCN102768511AAuto searchQuick searchTotal factory controlProgramme total factory controlProcess industryFault occurrence

The invention relates to a searching method and system for reasons of a fault event in the process industry. According to the invention, a basic reason resulting in the fault event is automatically searched and sought according to logic and / or time sequence relationship between pre-set fault events and the fault event, and then the basic reason is presented to a monitor to facilitate the monitor to guide the production more effectively.

Owner:中广核智能科技(深圳)有限责任公司

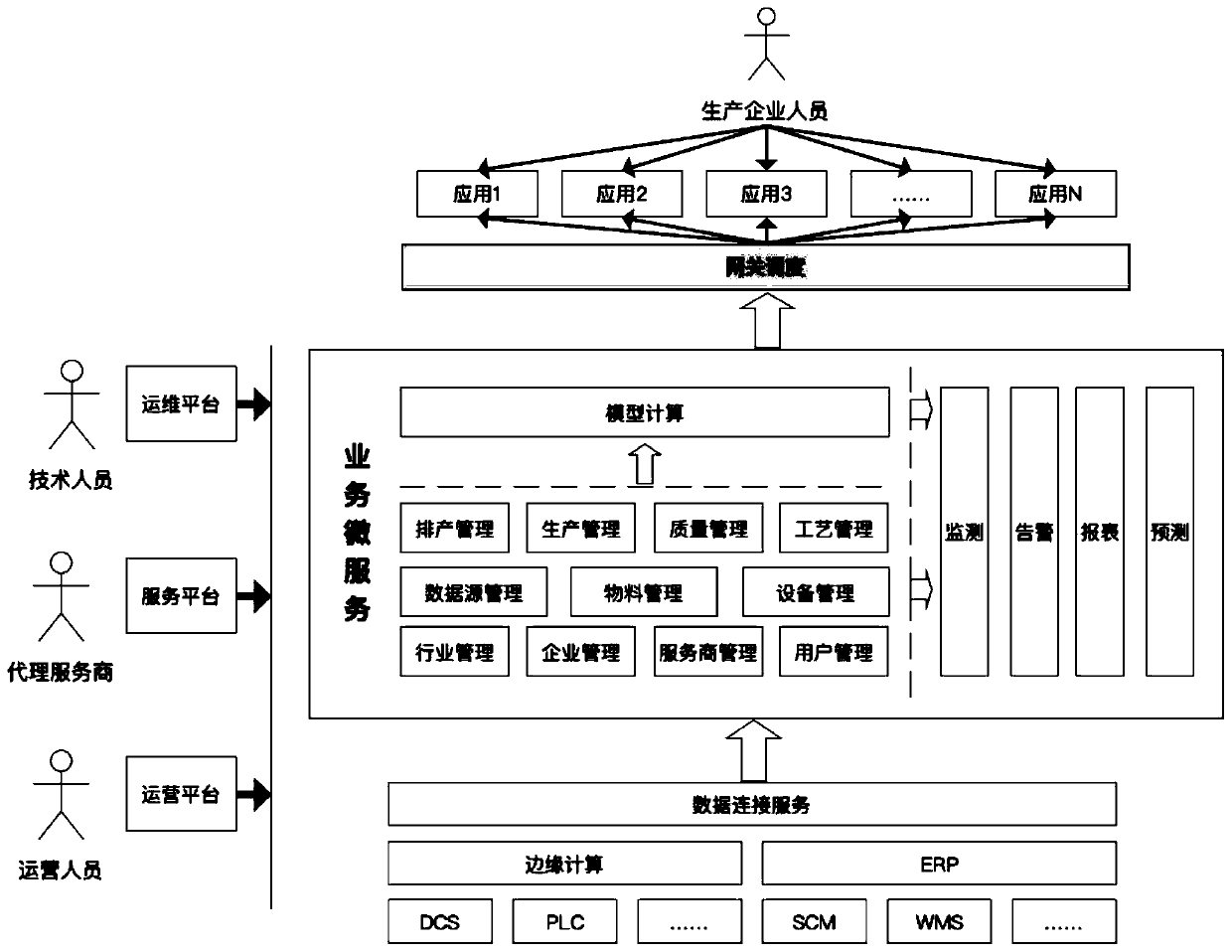

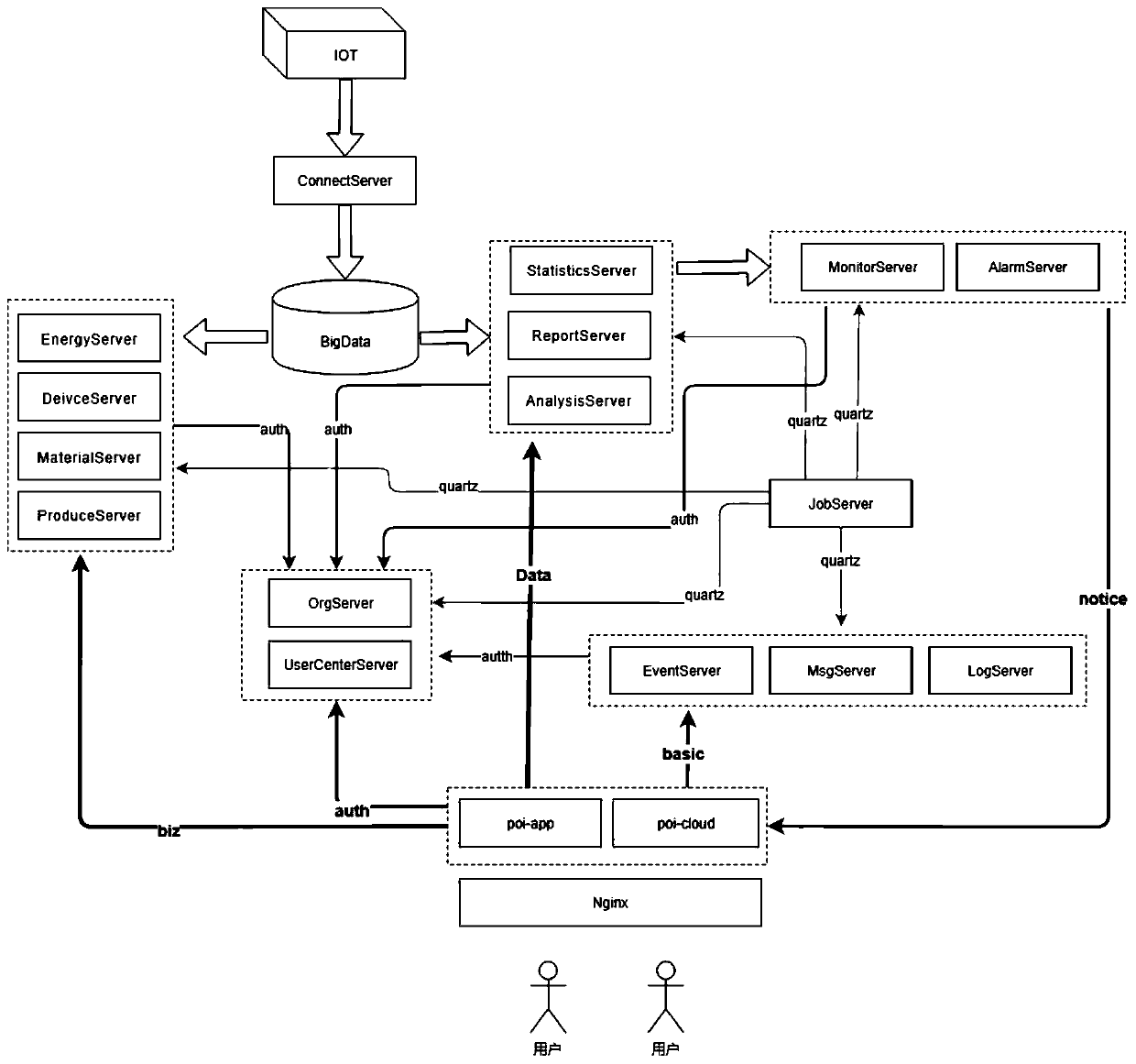

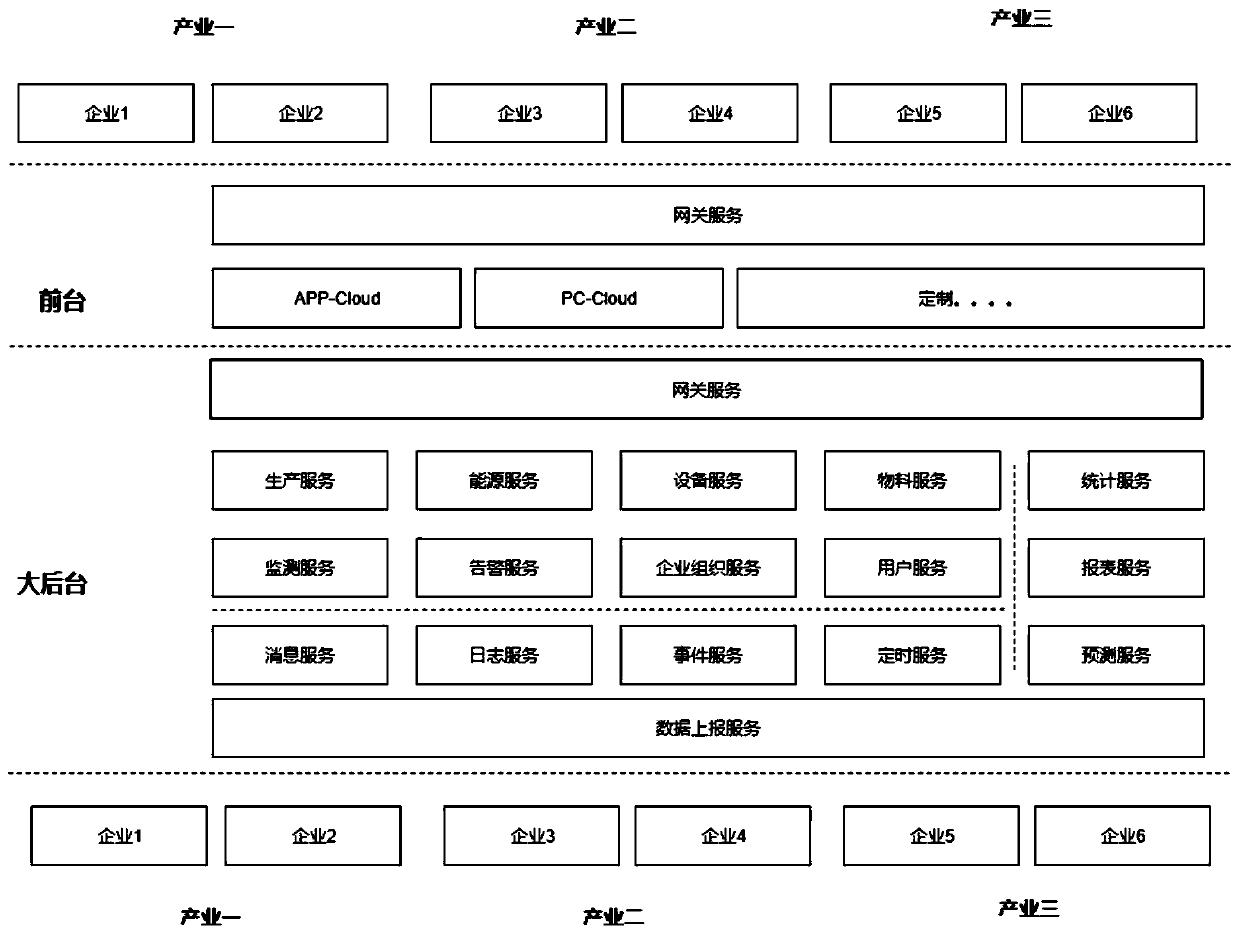

Micro-service architecture of process industry datamation operation platform

ActiveCN111178782ASolve the problem of MES service rigidityRegain service scalabilityResourcesManufacturing computing systemsDomain modelDatafication

The embodiment of the invention provides a micro-service architecture of a process industry datamation operation platform. The micro-service architecture comprises a micro-service business architecture and a micro-service technology architecture, wherein the N micro-services are realized by abstracting a whole process industrial model through a high-cohesion low-coupling design mode and DDD domainmodel abstraction, N is greater than 1; the implementation of the high cohesion and low coupling design mode is abstracted through a DDD tactical mode, each domain defines a model, logic and an interface of the domain, relationships among the models are distinguished through UML, and the models with close relationships are placed in the same domain. According to the embodiment of the invention, the problem of MES service rigidity of the traditional process industry is solved, the service expansibility is obtained again, and a comprehensive and reasonable datamation operation platform can be constructed.

Owner:广州博依特智能信息科技有限公司

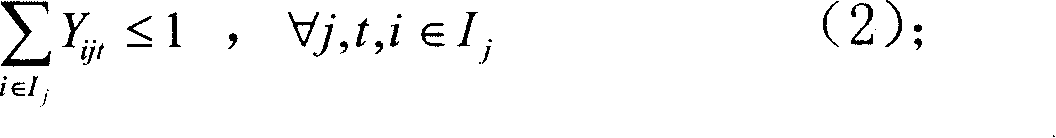

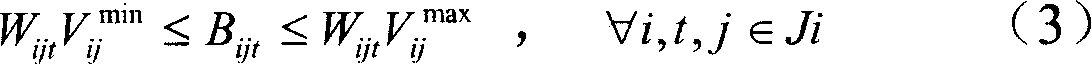

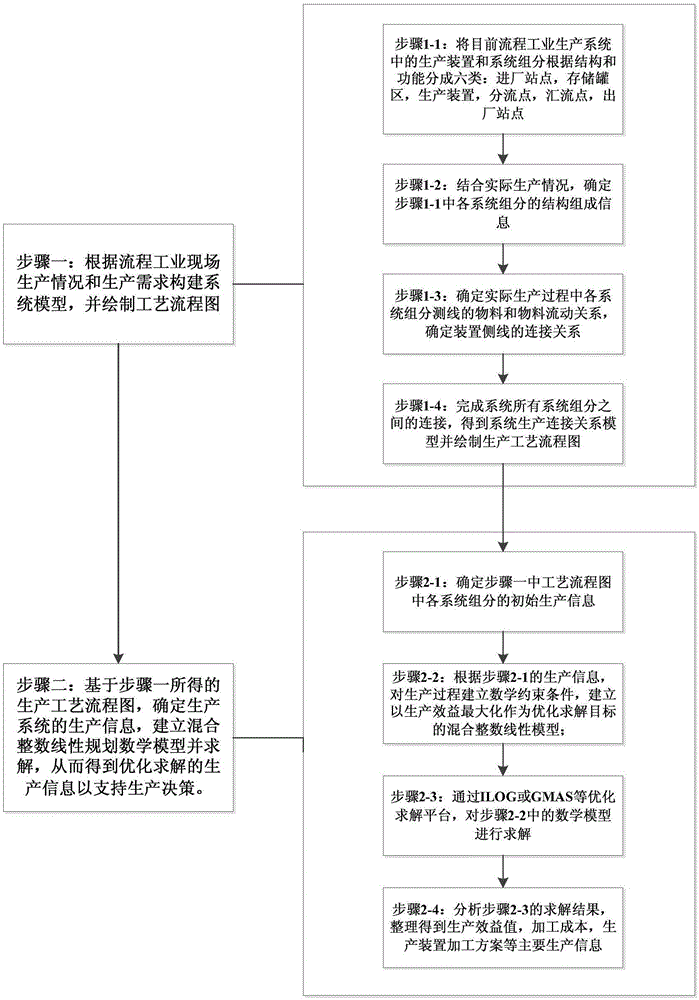

Control method of process industry production system

InactiveCN105096008AConvenient structureMaximize production efficiencyForecastingLogisticsLogistics managementEngineering

The invention discloses a control method of a process industry production system. The control method comprises the following steps: according to the site production situation and the production requirements of the process industry production system, constructing a system model, and drawing a production technological process chart; on the basis of the production technological process chart, determining the production information of the production system, and establishing a target function based on mixed integer linear programming; and taking system production benefit maximization as an optimization object to carry out optimization solution on the target function, and obtaining optimal production information used for controlling the process industry production system. The invention provides a feasible control method of the process industry production system, the control method realizes the combination of the unified modeling and the logistics optimization of the process industry production system, is effective and universal and can provide effective reference information for a production plan of the process industry for controlling.

Owner:ZHEJIANG UNIV

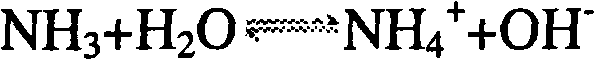

Method for processing industry high-concentration ammonia nitrogen wastewater

InactiveCN101293683ASpeed up stripping rateImprove stripping efficiencyWater contaminantsWater/sewage treatment by degassingHigh concentrationProcess industry

The invention relates to a method for dealing with industrial high concentration ammonia nitrogen wastewater, which is characterized in that the method consists of deamination agent and a deamination reactor. The deamination agent is a composite catalyst using cellulose derivatives as main agent and a plurality of activators as assistant agents, and comprises a plurality of free radicals and active radicals. The deamination agent can destroy the binding force of water molecules and NH3 molecules, and under the condition that the PH value is 10.5 to 11, the deamination agent leads the NH3 molecules to get rid of the influence of water molecules and exist in the form of free ammonia, and therefore the NH3 molecules are easily released from water. The deamination reactor is a multi-stage continuous aeration air stripping pool and each pool is provided with an aeration device and an ammonia eduction tube. The high concentration ammonia nitrogen wastewater comes into each grade aeration pool from the first pool and is deaminased in each grade aeration pool, and the gas ammonia timely educes the air stripping system by the ammonia eduction tube, and the partially deaminased wastewater sequentially flows into the next grade aeration air stripping pool from the upper grade aeration air stripping pool to continuously carry out aeration air stripping a plurality of times.

Owner:杨惠琼

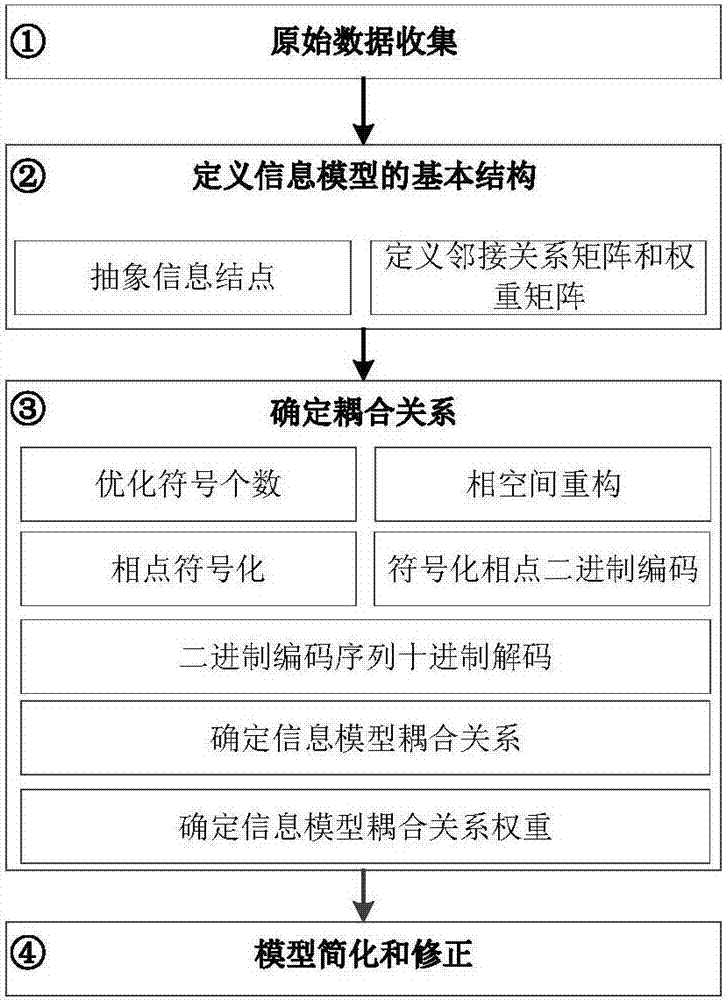

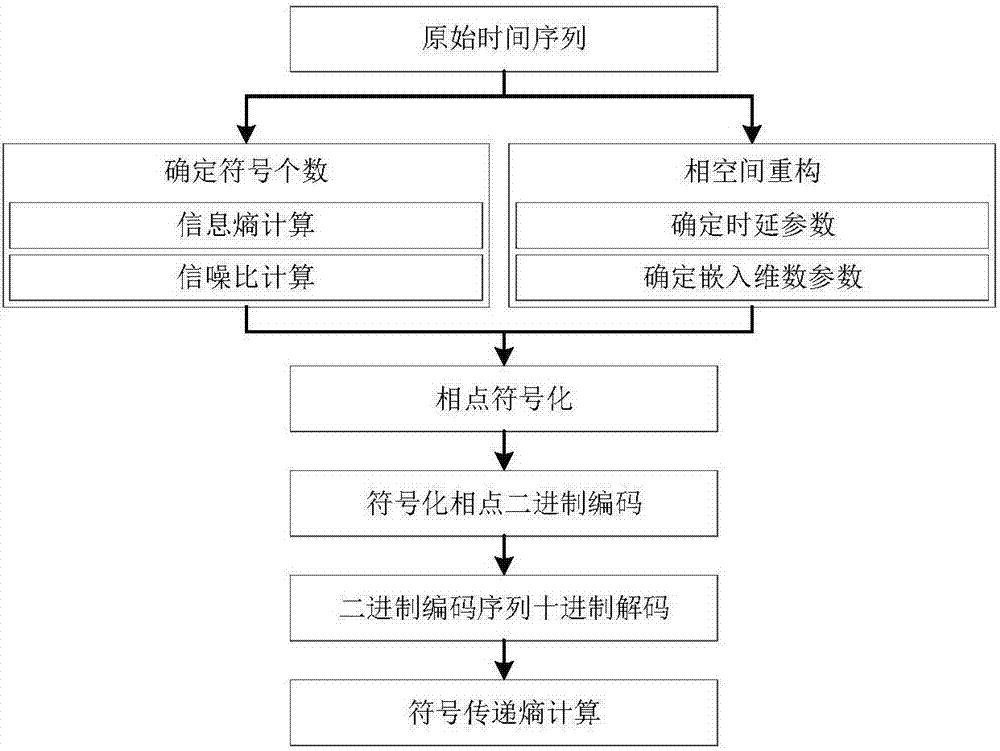

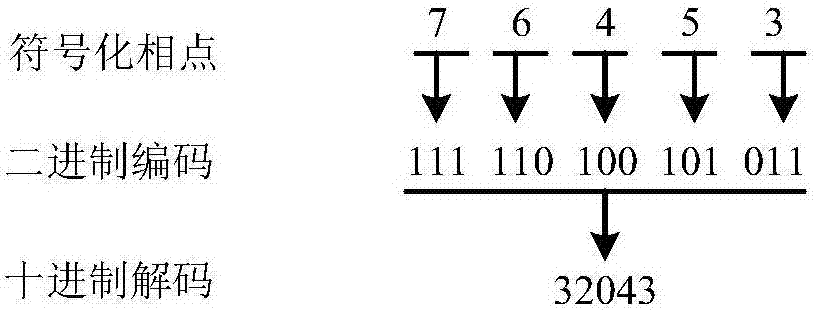

Data-driven information modeling method for complex electromechanical system in process industry

InactiveCN107292061AOptimize the symbolization processAchieve integrationDesign optimisation/simulationSpecial data processing applicationsCouplingProcess industry

The invention discloses a data-driven information modeling method for a complex electromechanical system in the process industry. The data-driven information modeling method for the complex electromechanical system in the process industry is employed. The overall modeling process does not need prior knowledge of physical topology. In the modeling process, an information flow relationship is taken as a reference for analyses of coupling relations among different functional components of the system. By taking the anti-noise property and information loss into full consideration, a symbolization process of the system for monitoring time sequences is optimized. By binary coding and decimal decoding of symbolized phase points, the integration between the symbolization process with automated analyses and calculations is achieved. Therefore, the difficulty in building an information model of the complex electromechanical system in the process industry based on monitored data under the noise condition is resolved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com