Advanced control method and system for vertical mill based on model identification and predictive control

A technology of model identification and predictive control, applied in cement grinding, grain processing, cement production, etc., can solve problems such as nonlinearity, large lag, strong coupling, etc., to improve robustness, reduce output energy consumption ratio, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

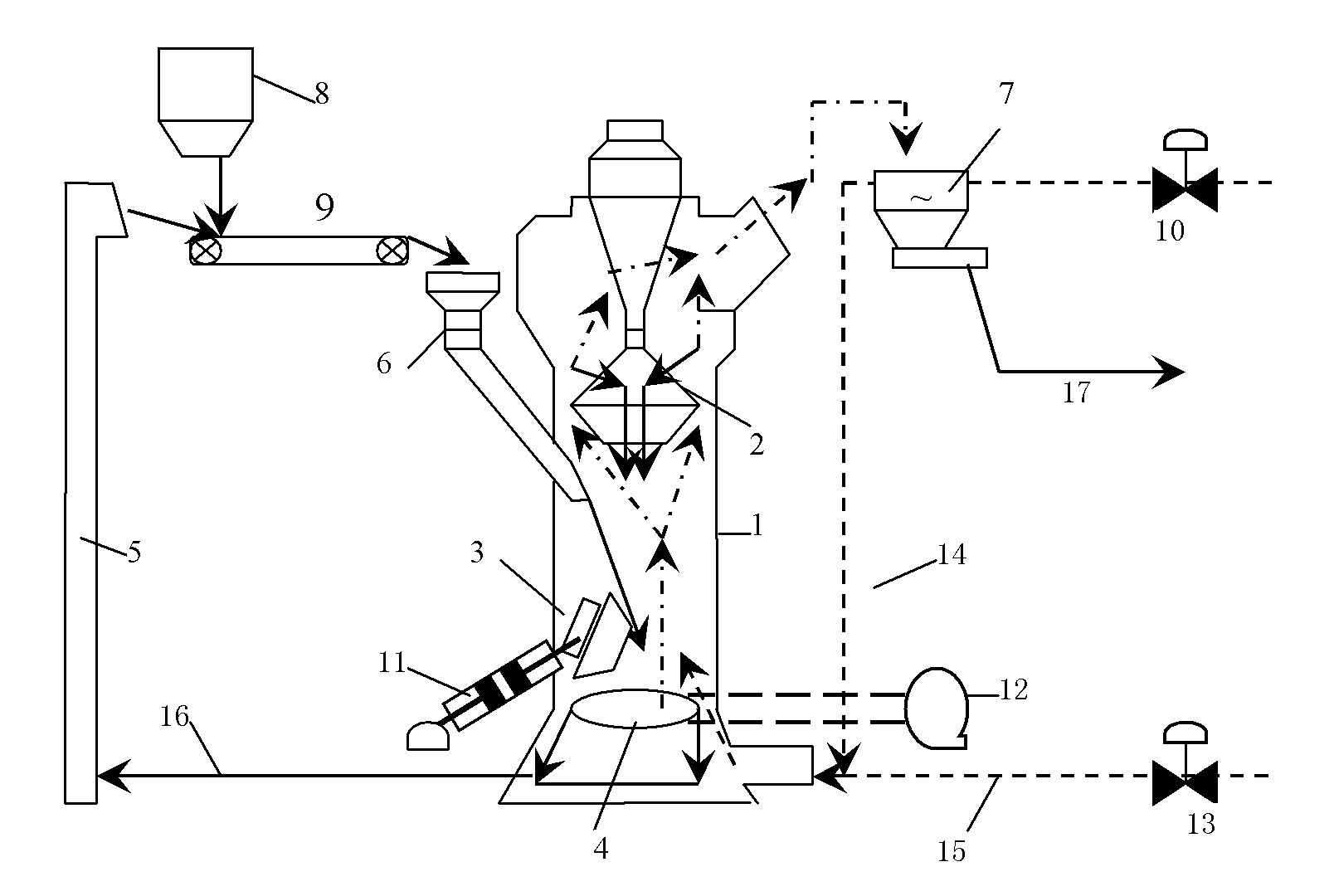

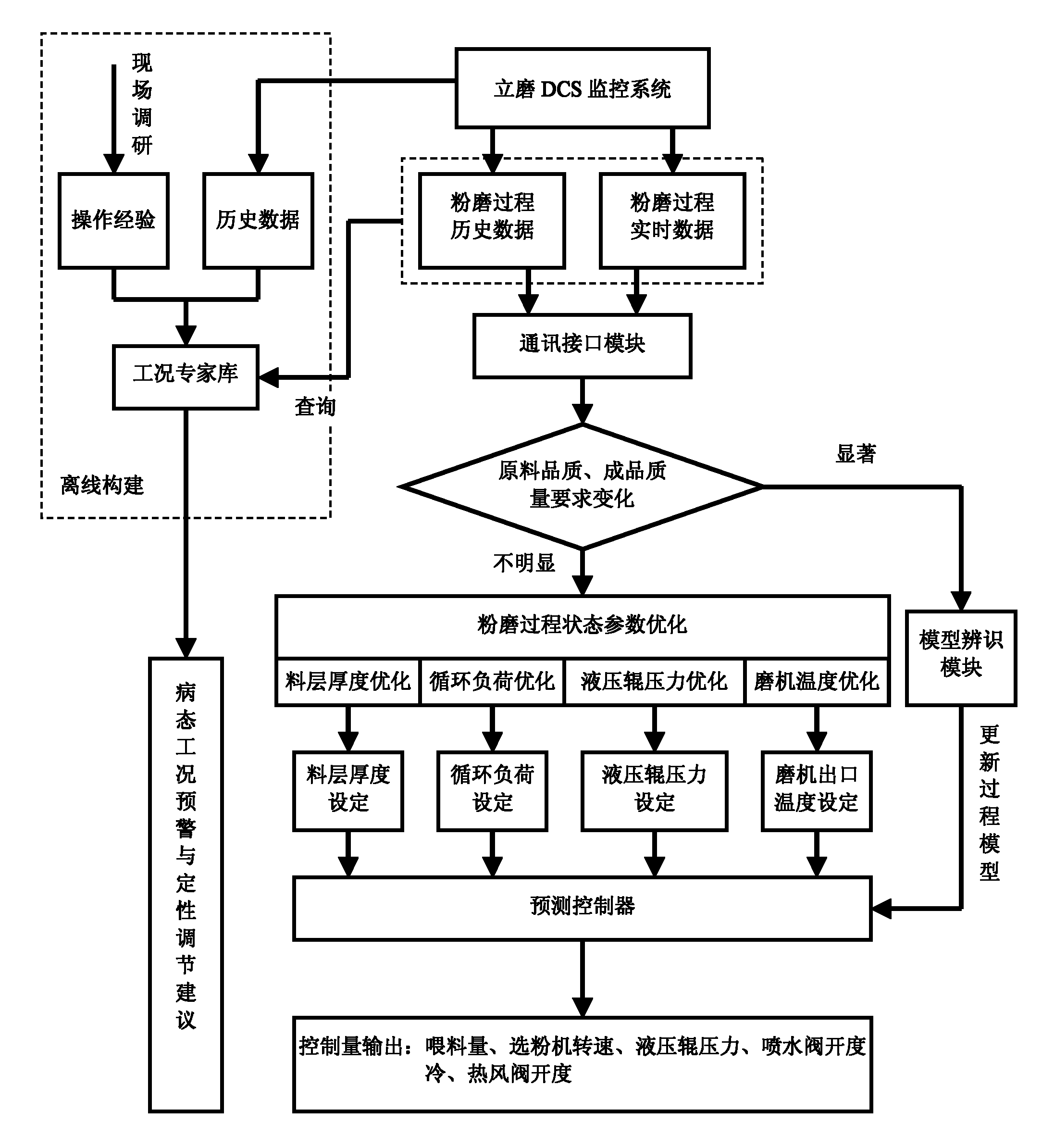

Method used

Image

Examples

Embodiment Construction

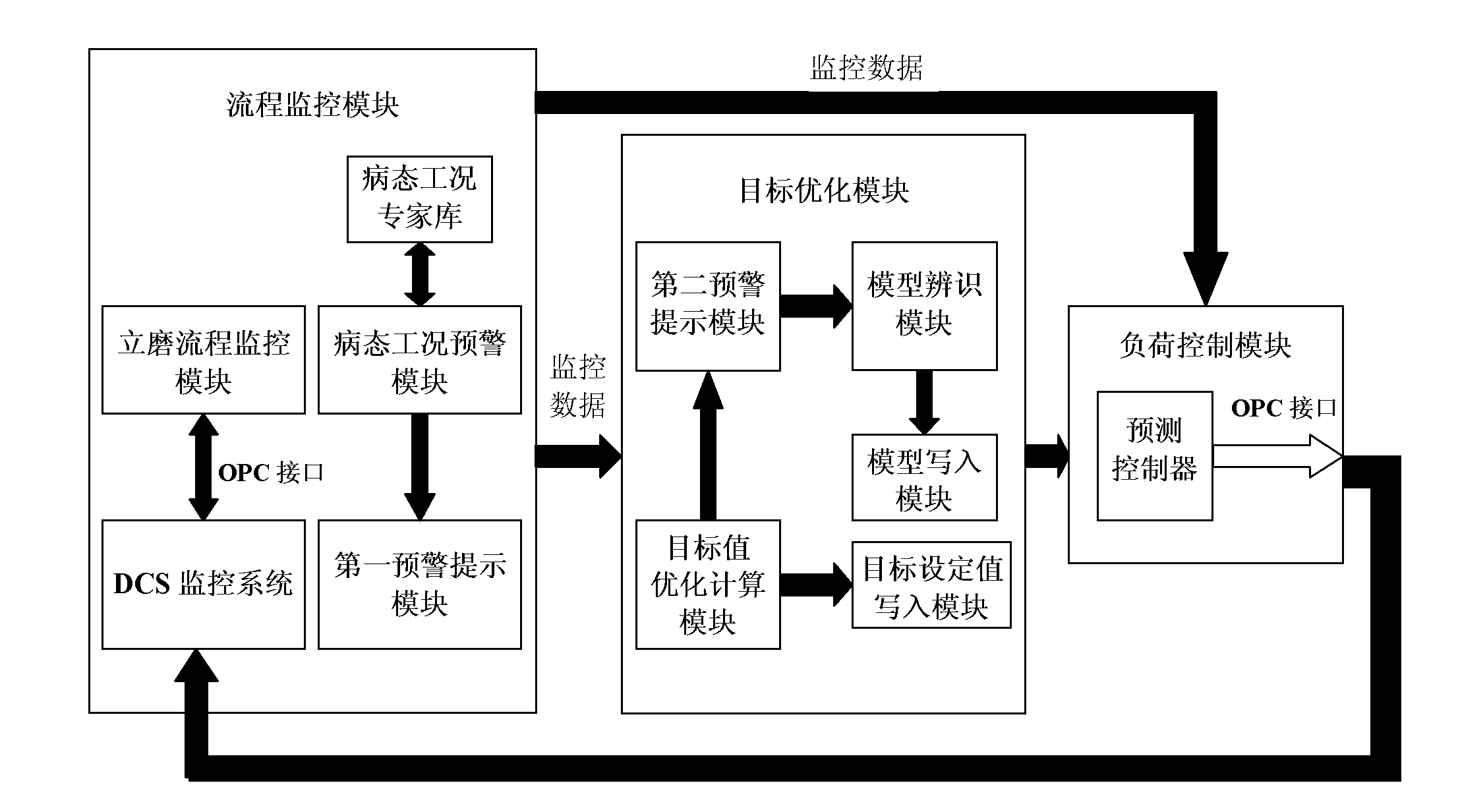

[0039] The present invention has a multi-objective optimization function, and is compatible with static optimization and dynamic optimization, and can obtain the optimal target setting value according to changes in the basic operating conditions of the vertical mill and product quality requirements, and call the online model identification module to re-identify the mathematical model of the grinding process , and update the above optimal target set value and process model to the predictive controller; dynamic optimization refers to the use of predictive control algorithms with rolling error compensation, convex optimization and closed-loop feedback functions to automatically find the target set value Optimum control path to ensure the minimum accumulative value of the control variable change and the fastest approach to the target value.

[0040] In the present invention, the process monitoring module, target optimization module, predictive controller, model identification modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com