Patents

Literature

233results about How to "Improve quality indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

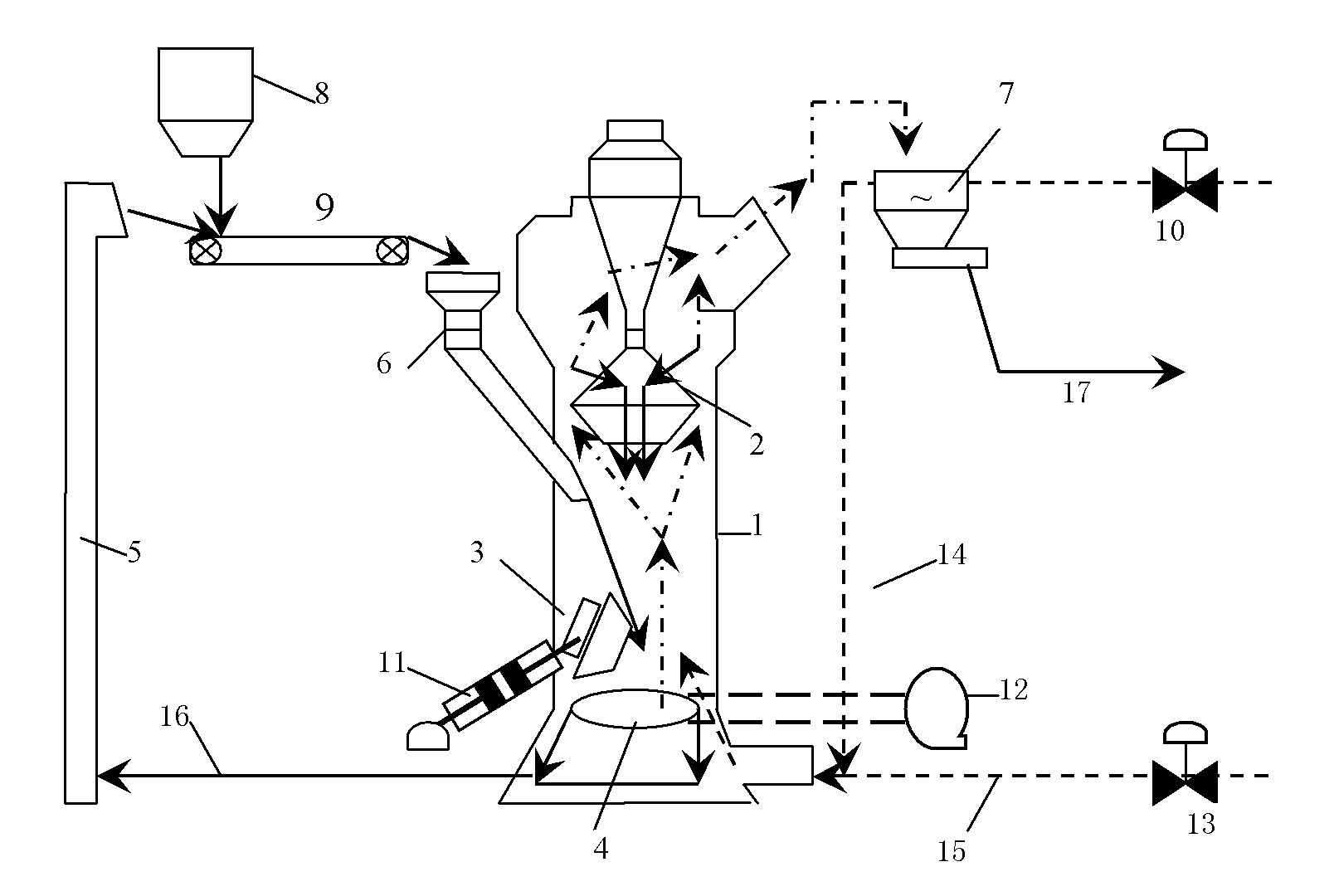

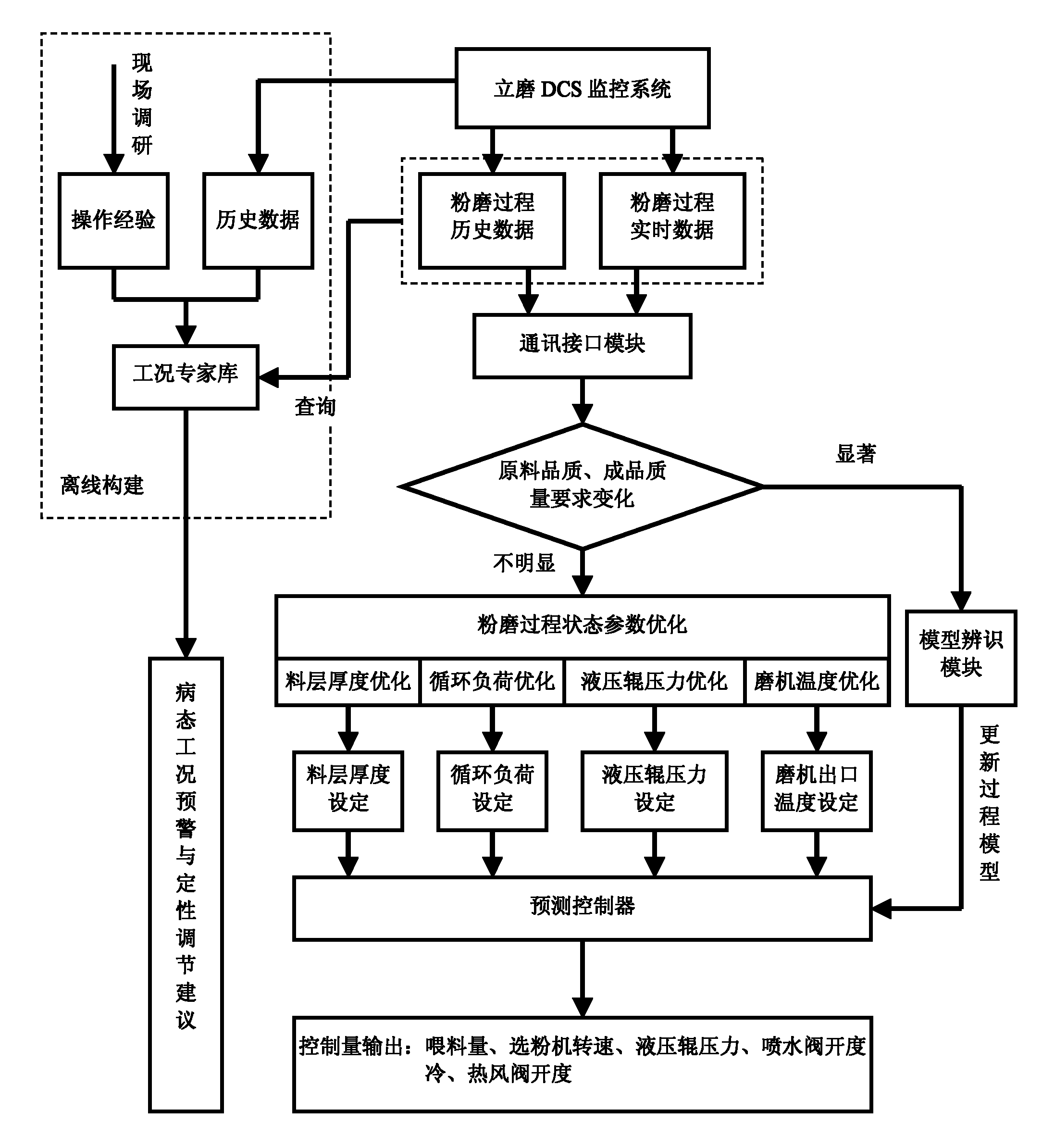

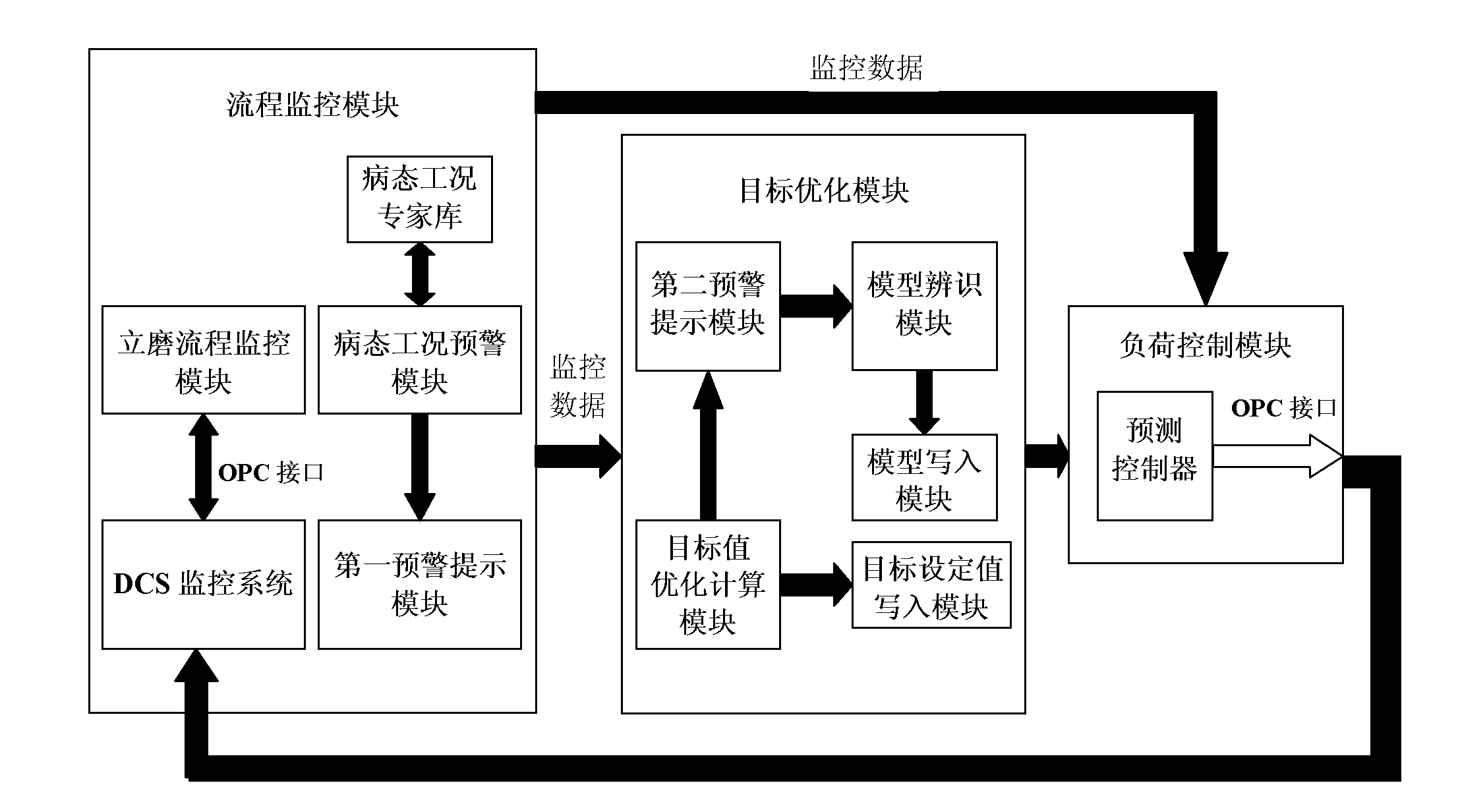

Advanced control method and system for vertical mill based on model identification and predictive control

InactiveCN102151605AIncrease the level of automationQuality improvementCement grindingCement productionMathematical modelOptimal control

The invention relates to raw material grinding in the field of cement process industries, and aims to provide an advanced control method and system for a vertical mill based on model identification and predictive control. The method comprises the following steps of: acquiring real-time data from a distributed control system (DCS) monitoring system; analyzing a variation trend of the operation and technology parameters, and then invoking a pathological working condition expert database for performing trend matching; if a pathological working condition appears, issuing early warning display and giving qualitative adjustment suggestion remind; giving an optimal target set value according to the basic operation condition of the vertical mill and the variation situation of the product quality requirement, and writing into a predictive controller; setting an optimal controlled quantity output according to the optimal target set value, and outputting to the DCS monitoring system to control a field actuator to take action. By adopting the invention, the qualitative adjustment suggestion can be precisely given; a mathematical model of the grinding process of the vertical mill is established and updated in real time; the steady-state error of the control system is reduced; and the grinding process of the vertical mill is instructed, so that the mill can operate stably for long term at a maximum efficiency point, and stable margin is maintained.

Owner:ZHEJIANG UNIV

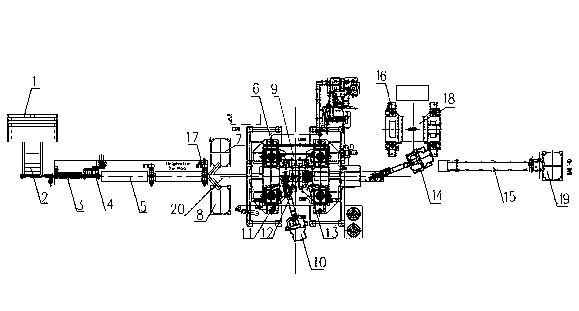

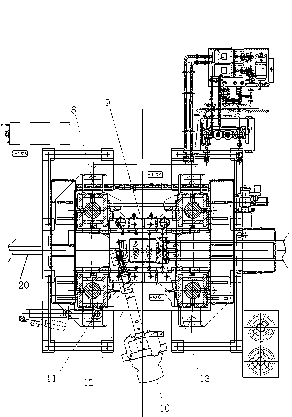

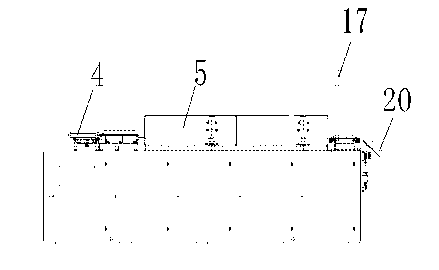

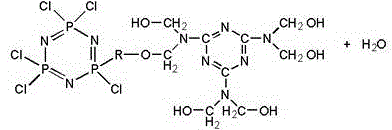

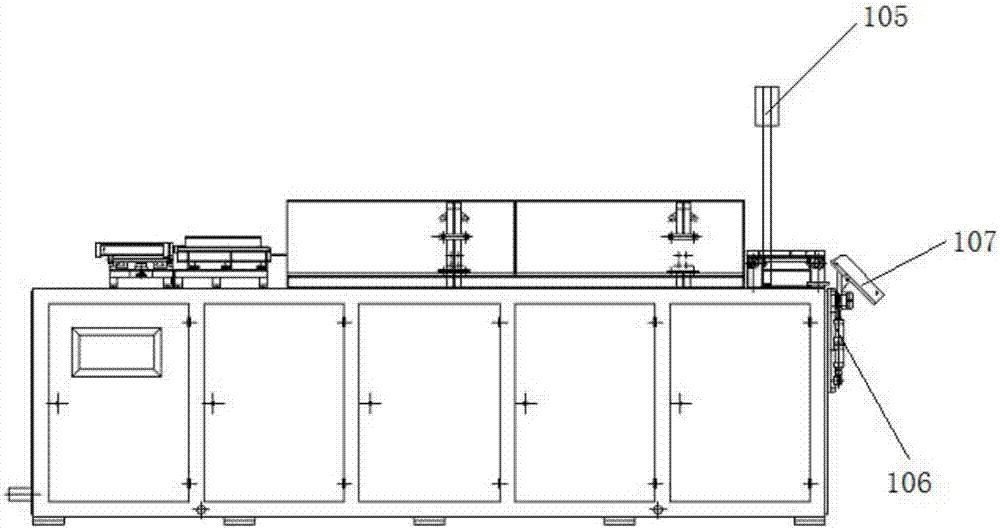

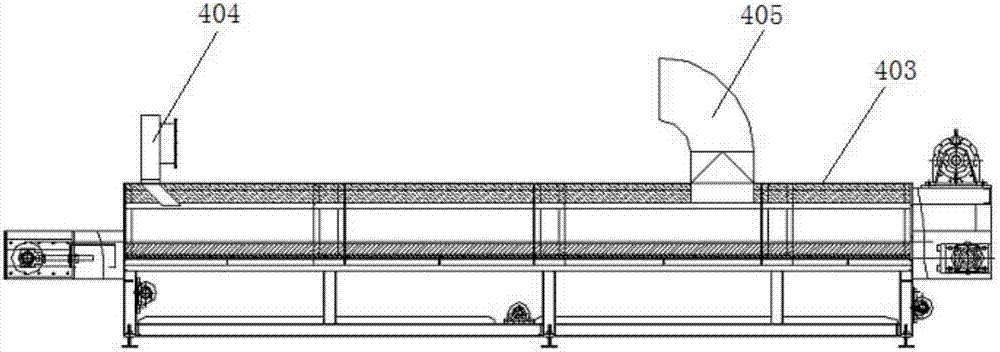

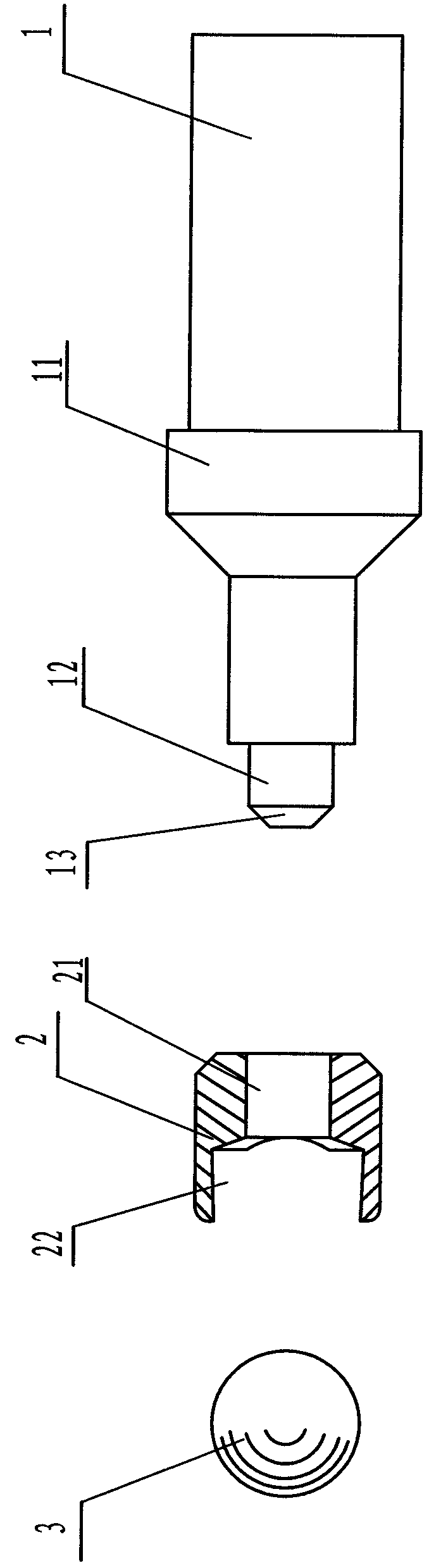

Production device and production technology for non-quenched and tempered steel forge piece automatic forging

InactiveCN103230997AEmission reductionImprove electricity efficiencyHandling devicesEngineeringUltimate tensile strength

The invention relates to the technical field of metal hot processing, in particular to the technical field of production device and production technology for non-quenched and tempered steel forge piece automatic forging. The device comprises a forging system, a feeding system and a discharging system, wherein the feeding system is arranged at the front end of the forging system, the discharging system is arranged at the rear end of the forging system, the forging system comprises an electric heating furnace connected with rear part of the feeding system, a forging pressing machine is connected with the rear part of the electric heating furnace, an edge trimmer is connected with the rear part of the discharging system, and the discharging system is connected with the rear part of the edge trimmer. According to the device provided by the invention, defects in the prior art is overcame, the full automatic line technology that the forge piece is heated once and is controlled by one worker is realized, is energy-saving and cost-reducing, labor saving, the outer surface and the inner quality of the forge piece is improved, and the service life is prolonged; as the mechanical property of each part of the forage is close to one anther, the forge piece quality and safety performance are improved, and the non quenched and tempered steel forging piece is high in tensile strength, fatigue strength and machinability.

Owner:ANHUI ANHUANG MACHINERY

Special nutrient solution for strawberry soilless culture and preparation and use method thereof

InactiveCN1621394AImprove quality indicatorsAgriculture gas emission reductionCultivating equipmentsAgricultural scienceTrace element

The present invention belongs to the field of plant cultivation technology, and is nutritious liquid for soil-less cultivation of strawberry and its preparation process and usage. The nutritious liquid contains macro elements N in 259.2-316.8 ppm, P 30.6-37.4 ppm, K 190.8-233.2 ppm, Ca 161.1-196.9 ppm and Mg 55.8-68.2 ppm; and trace elements Fe, Mn, Cu, Zn, B and Mo in certain amounts. The material includes KNO3, CaNO3.4H2O, MgSO4.7H2O, (NH4)24HOP4, NH4NO3, FeEDT4, H3BO3, MnSO4.4H2O, ZnSO4.7H2O, CuSO4.5H2O and NaMoO4.2H2O, and the material is added based on certain calculation. The nutritious liquid is diluted to 1 / 3 to 1 / 2 in different growth stages of strawberry. The present invention provides strawberry with reasonable nutrients to raise its yield and quality.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

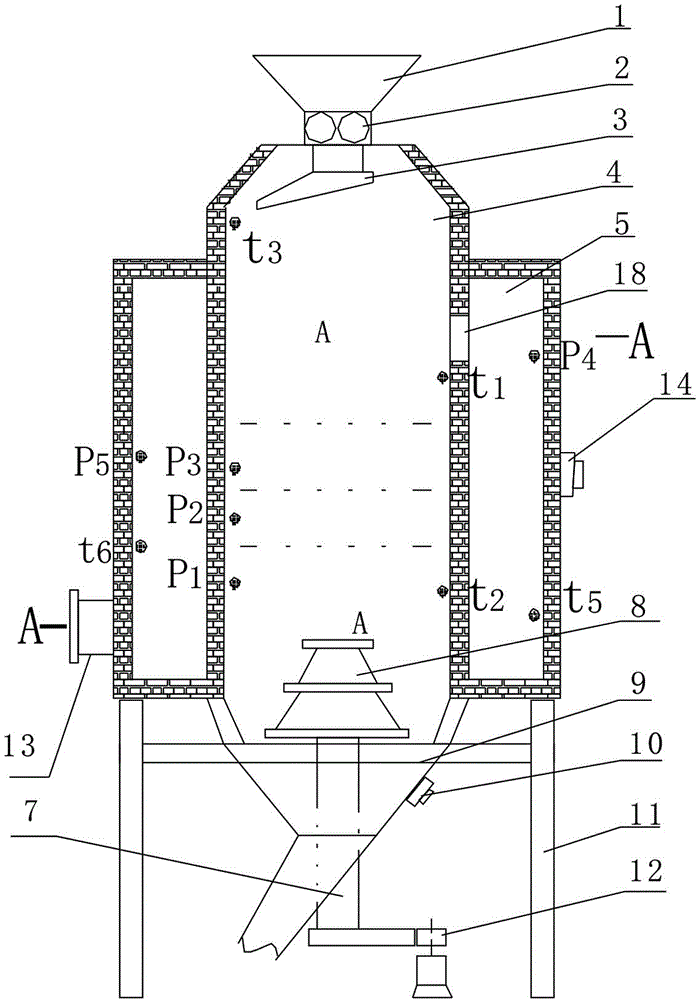

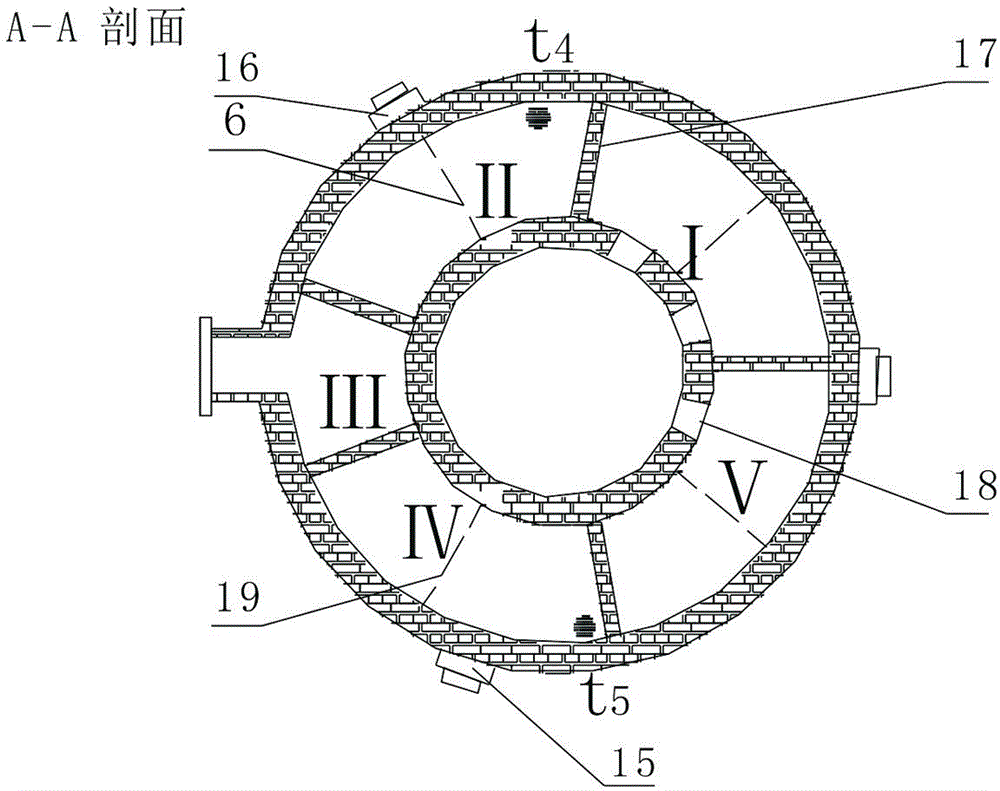

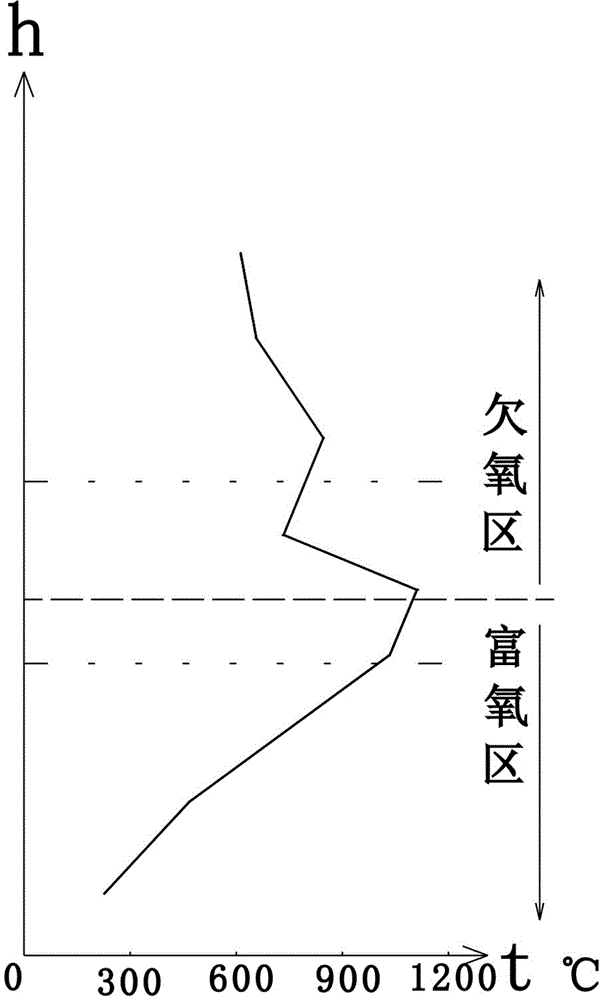

Household garbage pyrolysis combustion furnace and operation process thereof

The invention provides a household garbage pyrolysis combustion furnace which is a vertical sleeve furnace. A furnace body is composed of a cylindrical pyrolysis gasification hearth and a secondary combustion chamber surrounding the hearth. Five isolation walls are arranged in the secondary combustion chamber. The secondary combustion chamber is divided into a secondary combustion hearth I, a secondary combustion hearth II, a secondary combustion hearth III, a secondary combustion hearth IV and a secondary combustion hearth V. The secondary combustion hearth III corresponds to a smoke outlet. The secondary combustion hearth I, the secondary combustion hearth II, the secondary combustion hearth IV and the secondary combustion hearth V are each internally provided with a lattice wall. Each lattice wall is provided with a plurality of smoke flowing through holes with unequal diameters. The outer side in the secondary combustion chamber is further provided with three secondary wind supply systems. The inner side wall of the secondary combustion hearth I and the inner side wall of the secondary combustion hearth V are each provided with a pyrolysis smoke outlet. The smoke flowing state is a layer flow state and a turbulent flow state which are implemented many times to participate in and interfere with secondary wind appropriately, a stable platform is provided for energy conversion of smoke discharged by the pyrolysis gasification process stage and decomposition and purification of harmful substance, and thus the quality index of waste treatment of the discharged smoke is increased greatly.

Owner:YICHANG JIUTIAN ENVIRONMENTAL SCI & TECH

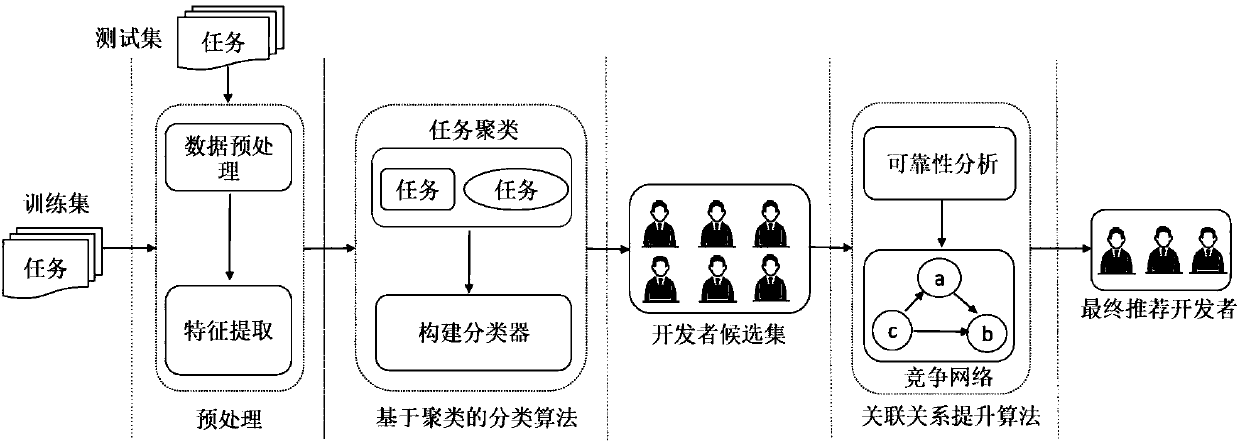

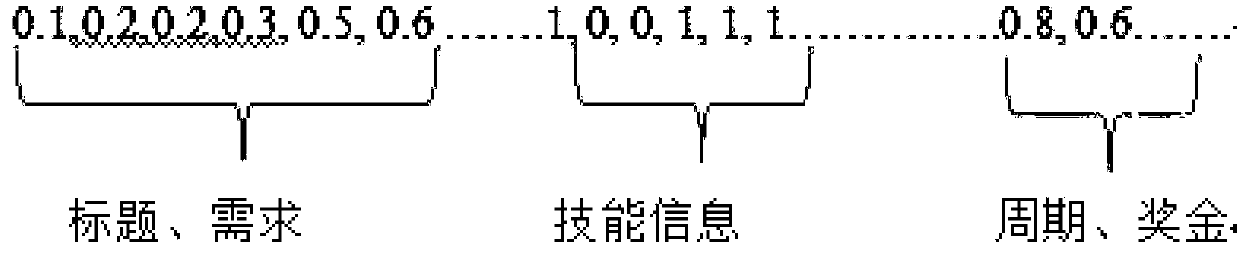

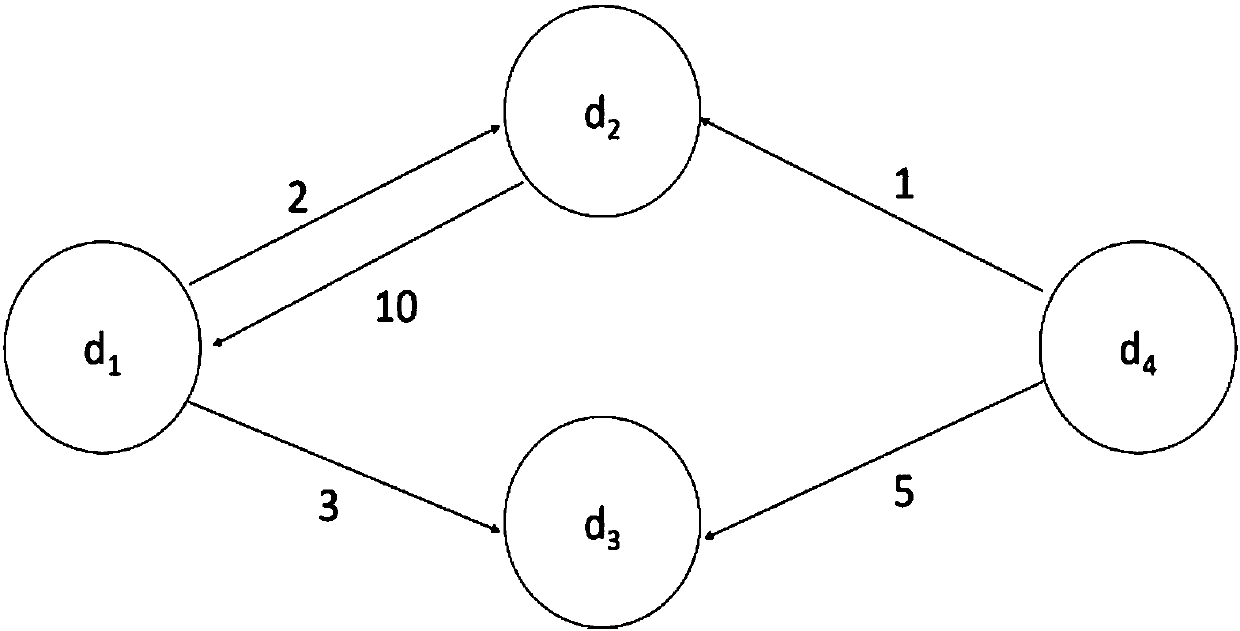

Crowdsourcing software developer recommendation method

ActiveCN107767058AImprove the quality of the finishImprove matchCharacter and pattern recognitionResourcesFeature vectorData set

The invention discloses a crowdsourcing software developer recommendation method. According to the method, first, a dataset is preprocessed, tasks with complete information are selected, and feature information (such as task development time, rewards, demand description, required skills, publishing time and a publishing platform) of the selected tasks are further extracted to construct feature vectors of the tasks; second, the tasks are clustered, and similar tasks are gathered together; third, for a new crowdsourcing task, features of the task are extracted in the same way, cluster tasks similar to the task are obtained, and further developers with high winning percentages serve as a preliminarily-recommended developer candidate set through a machine learning classification algorithm among the similar tasks; and last, the reliability of the developers is calculated in the developer candidate set, part of the developers with low reliability are removed, the incidence relation among thedevelopers is analyzed according to historical task participation conditions of the developers, and a developer competition network is established.

Owner:BEIHANG UNIV

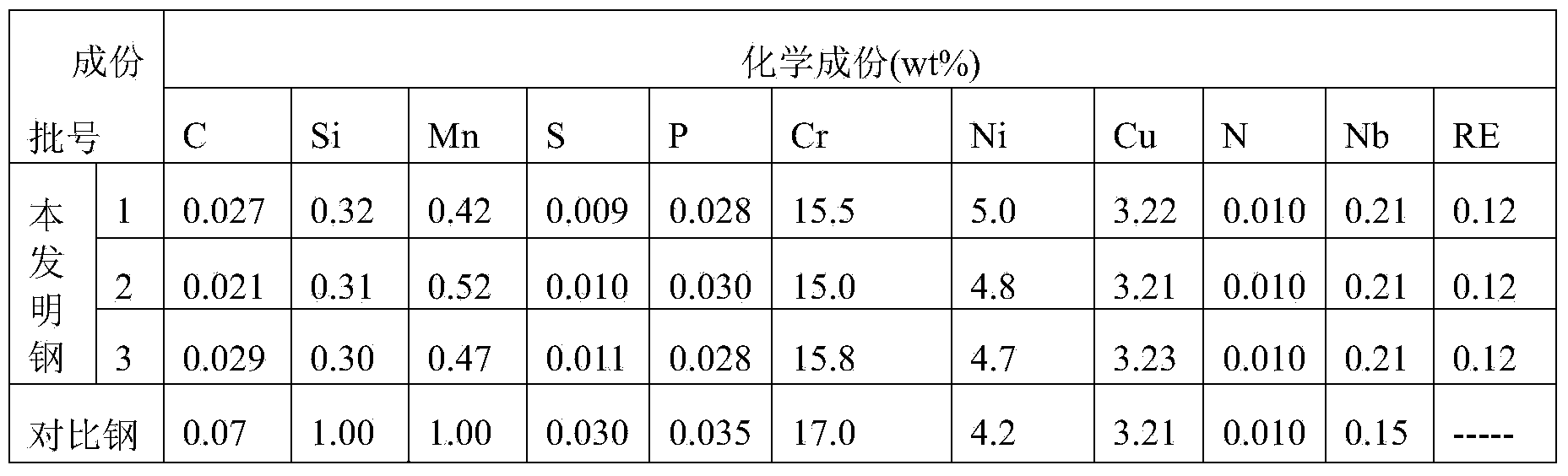

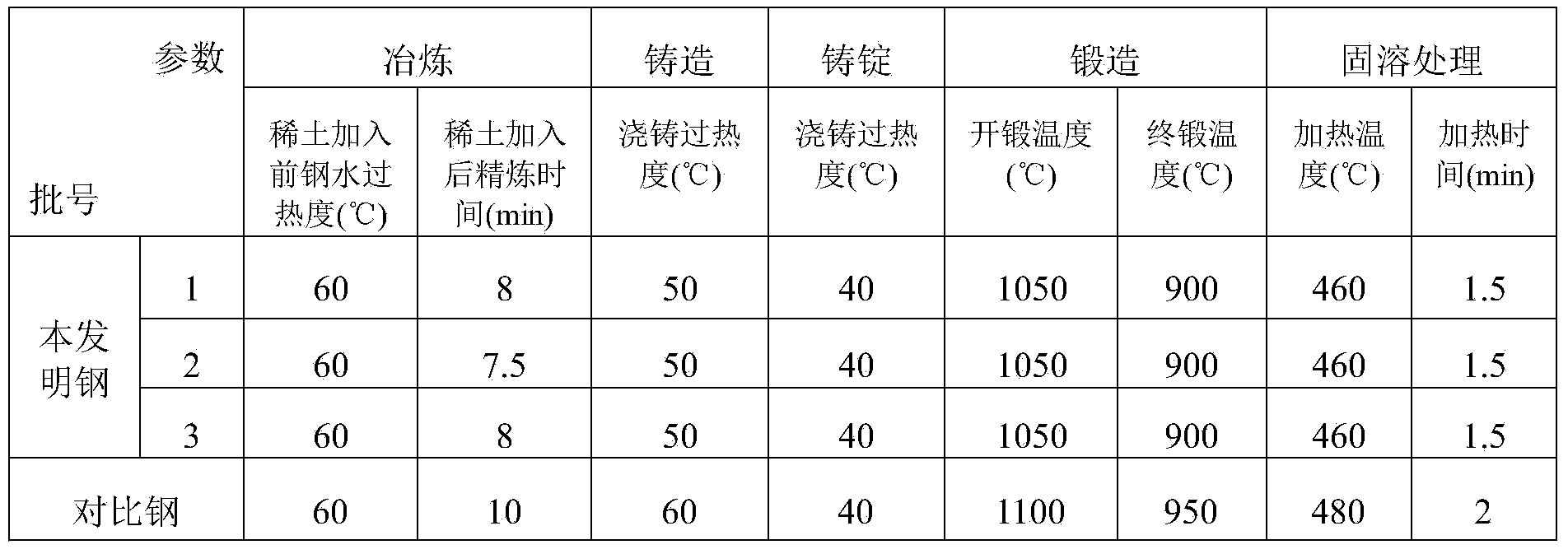

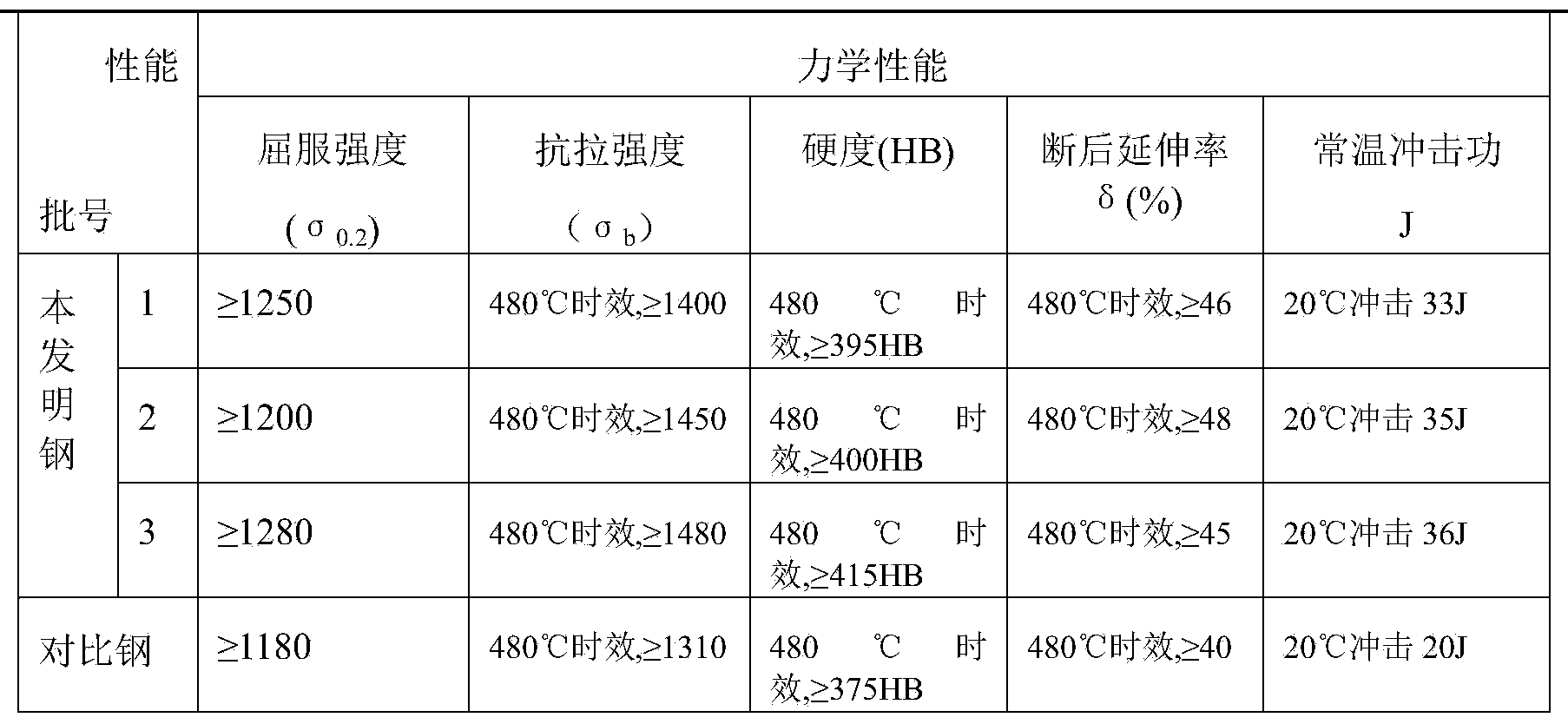

Rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel and preparation method thereof

ActiveCN104328353ARefining solidified tissueImprove performanceSolution treatmentMartensitic stainless steel

The invention discloses rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel is characterized by comprising the following chemical components in percentage by weight: less than or equal to 0.07% of C, less than or equal to 1% of Si, less than or equal to 1% of Mn, less than or equal to 0.035% of P, less than or equal to 0.03% of S, 3.00-5.00% of Ni, 15.5-17.5% of Cr, 3.00-5.00% of Cu, 0.15-0.45% of Nb, 0.05-0.25% of Re and the balance of Fe and belongs to the field of alloy steels. The invention also discloses a preparation method of the rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The preparation method comprises the steps of smelting, casting, carrying out electroslag remelting, casting ingots, forging or rolling, carrying out solution treatment and the like. The rare-earth-type 0Cr17Ni4Cu4Nb special steel, which is disclosed by the invention, as one of precipitation-hardening martensitic stainless steel, has the characteristics of high strength, high hardness, corrosion resistance and the like and is suitable for various technical fields, such as chemical machinery, food machinery, papermaking machinery, aerospace and marine.

Owner:什邡新工金属材料有限公司

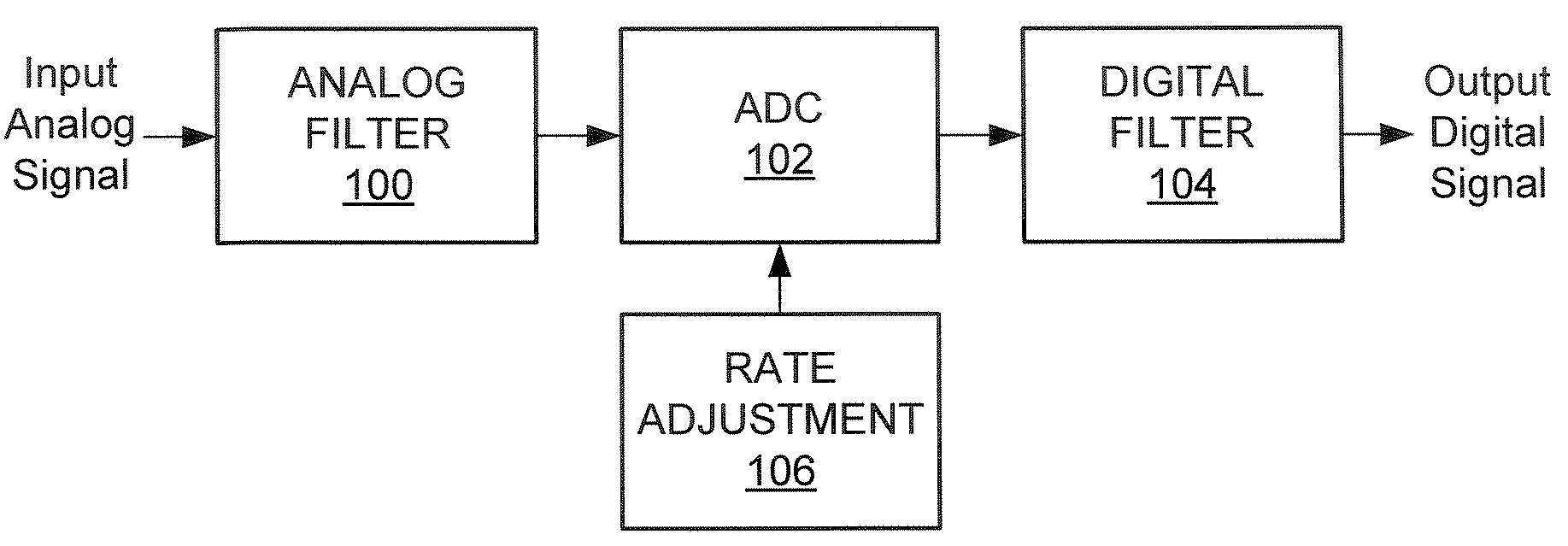

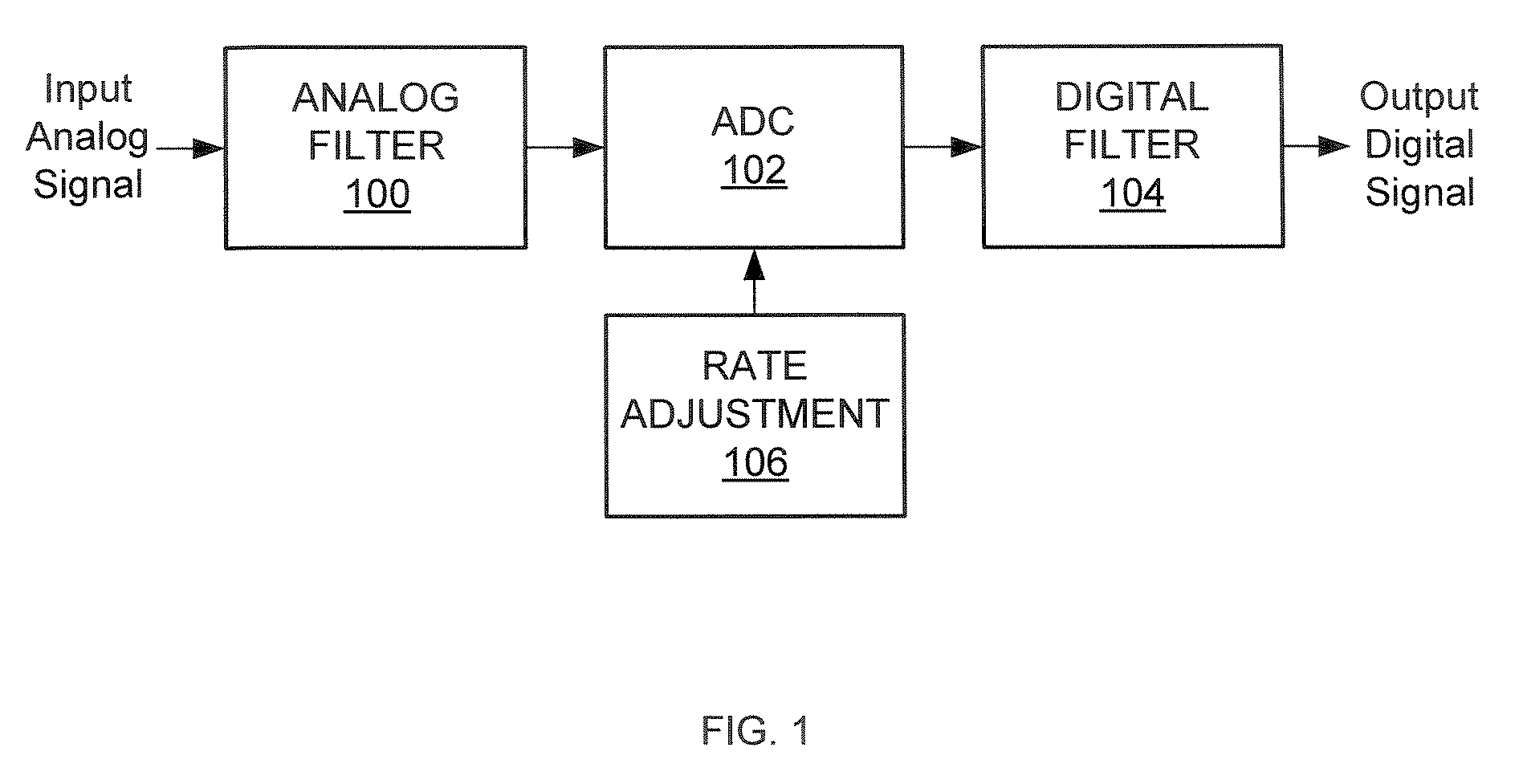

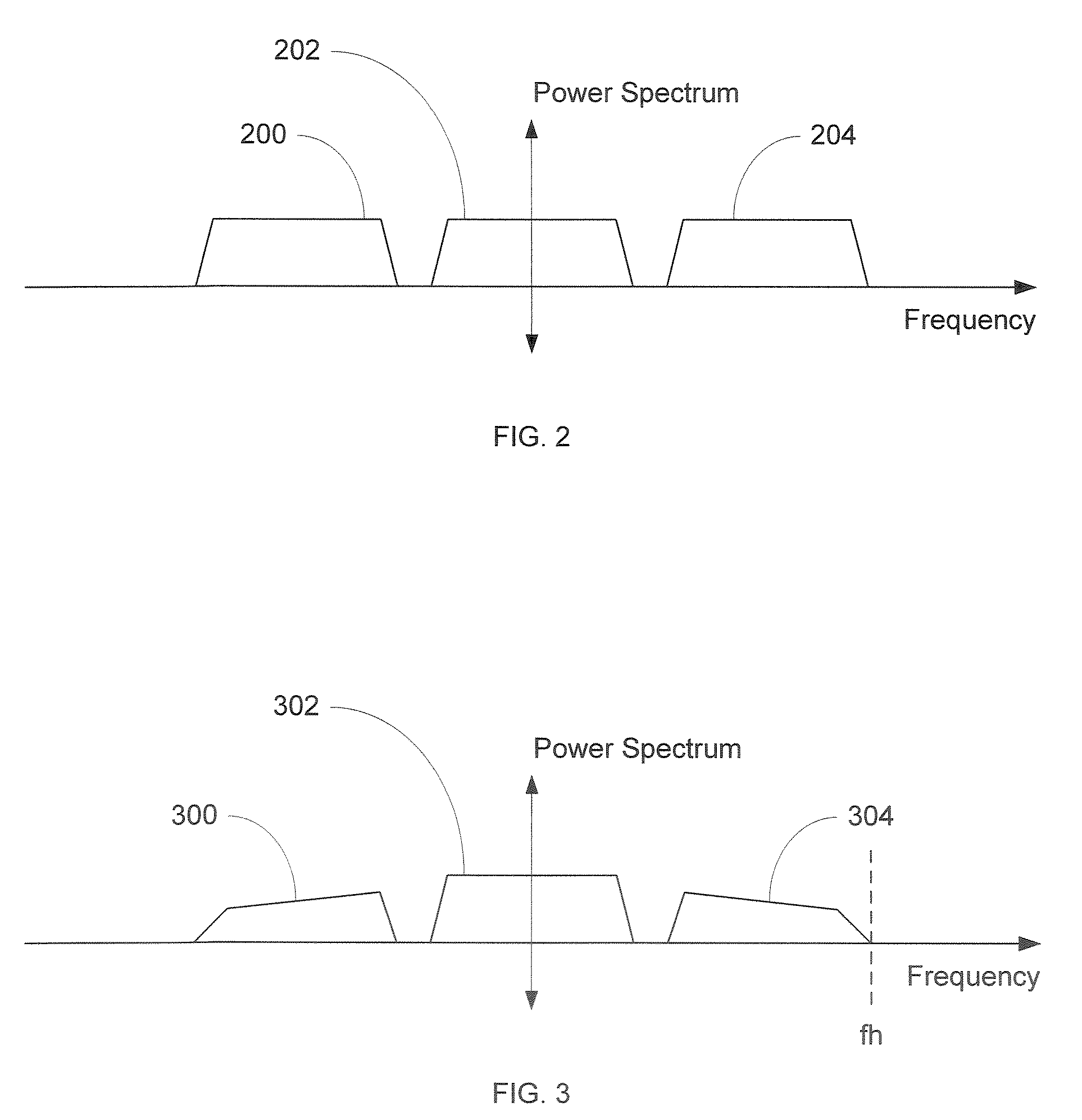

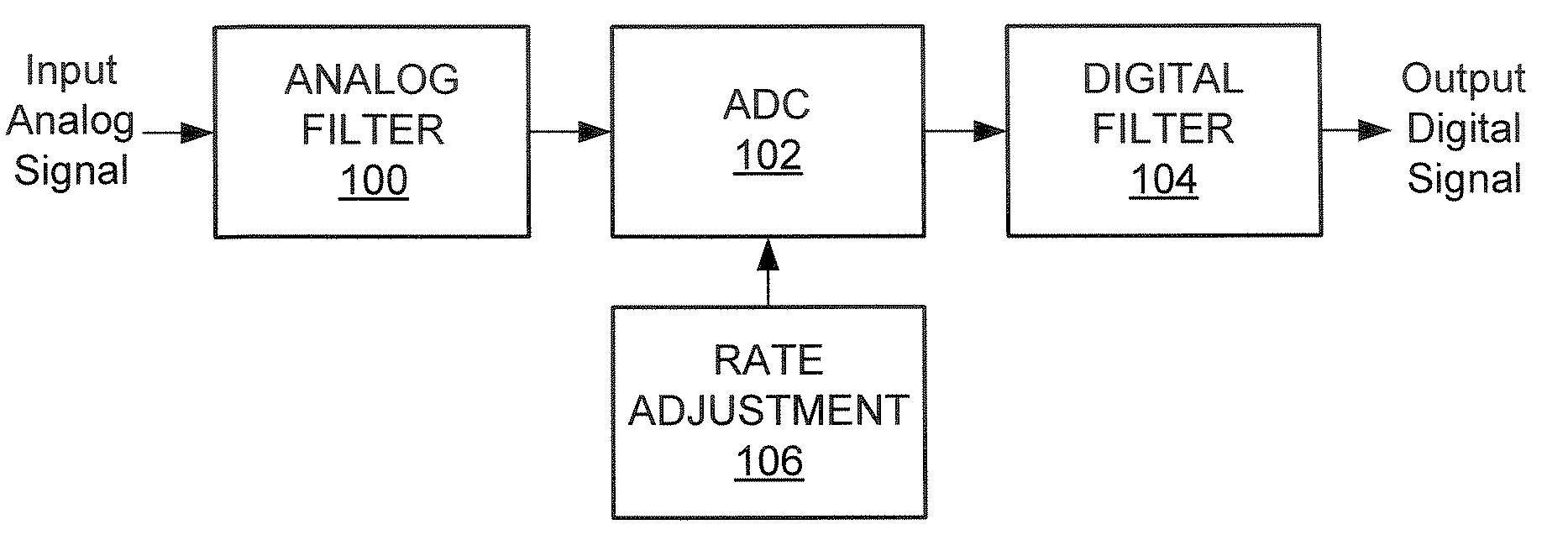

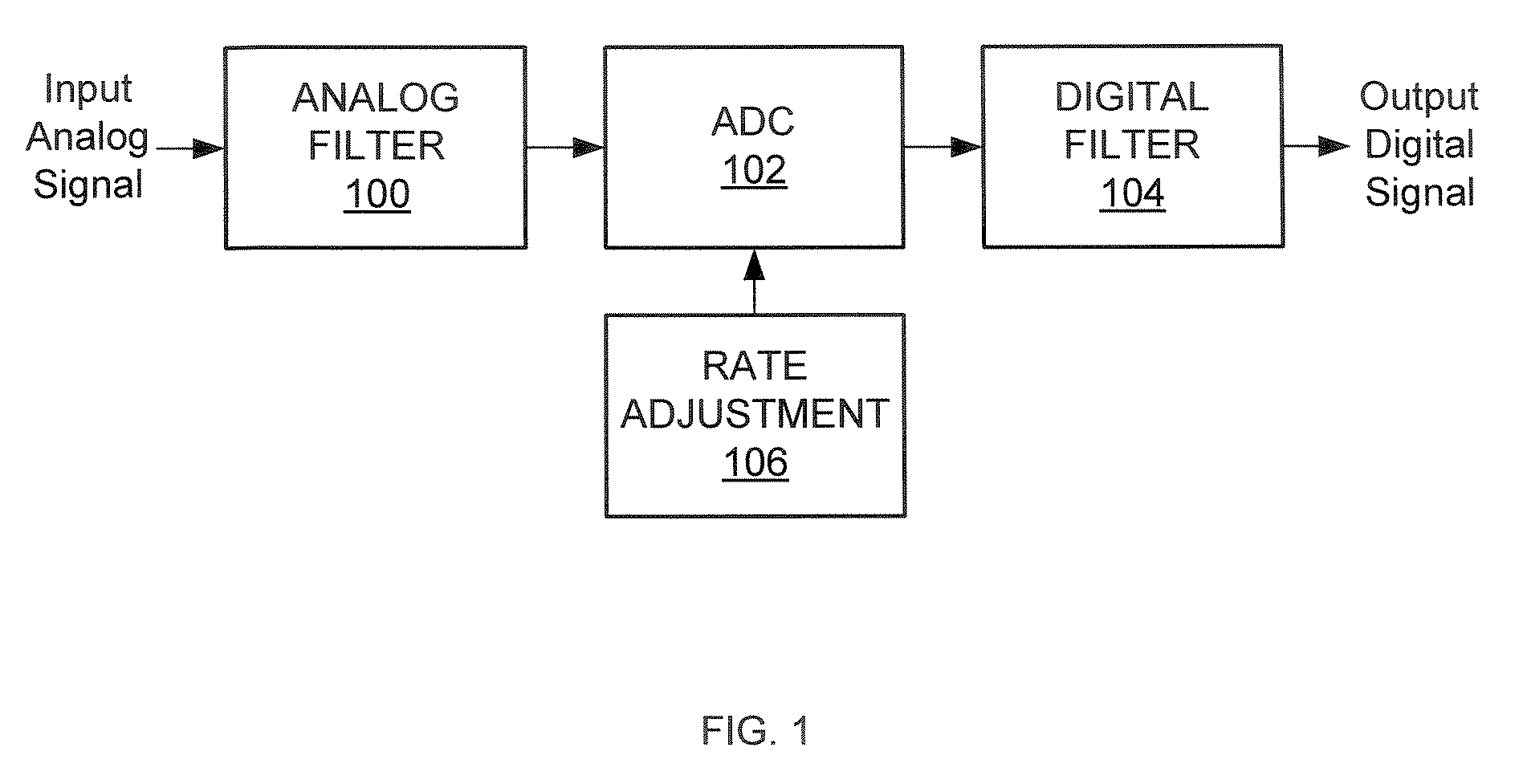

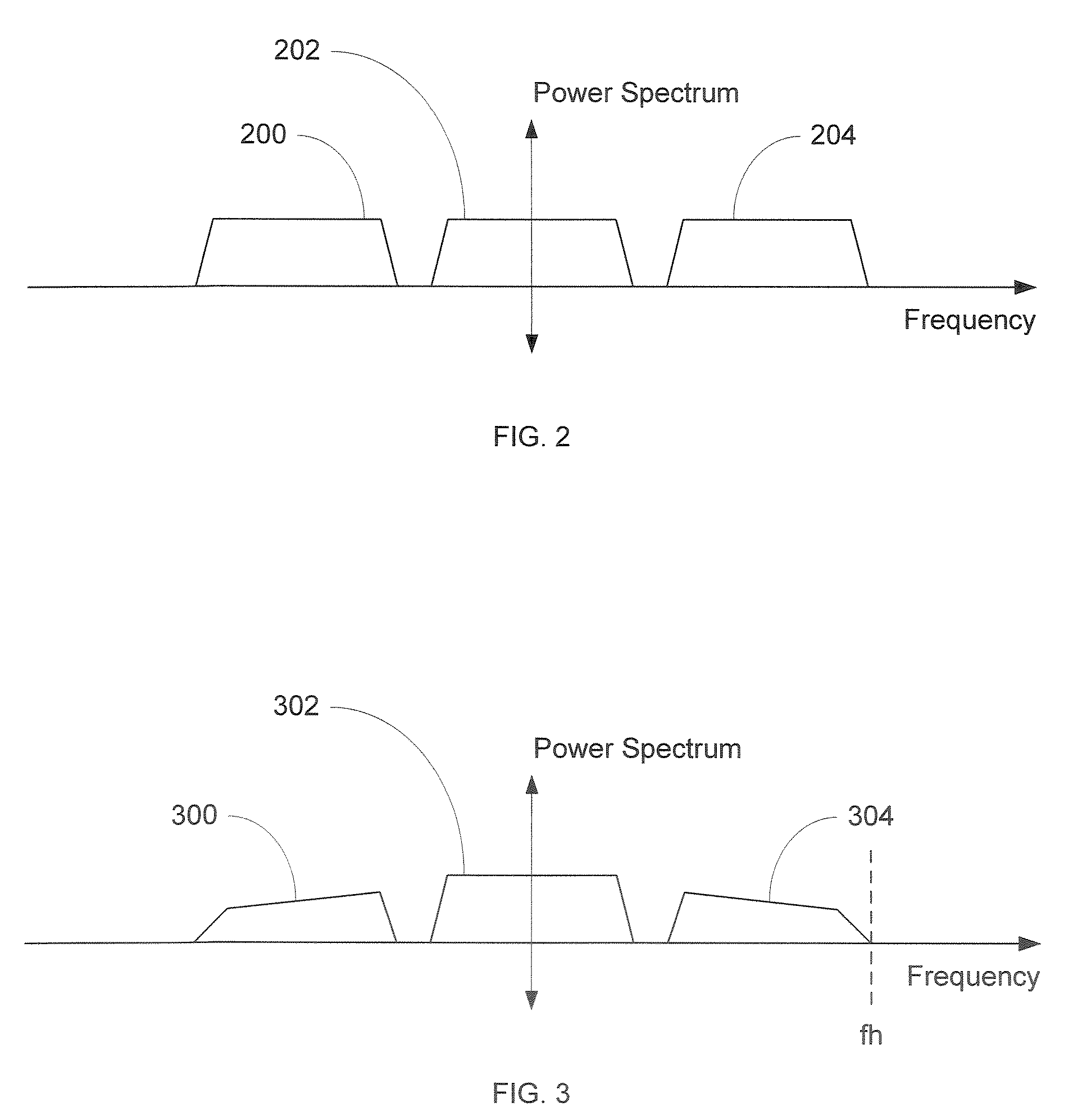

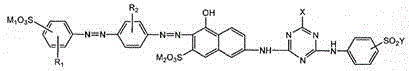

Variable rate analog-to-digital converter

InactiveUS20080238717A1Reduced sampling rate requirementsReduce power consumptionPower saving provisionsElectric signal transmission systemsDigital down converterSignal-to-noise ratio (imaging)

Owner:OLYMPUS CORP

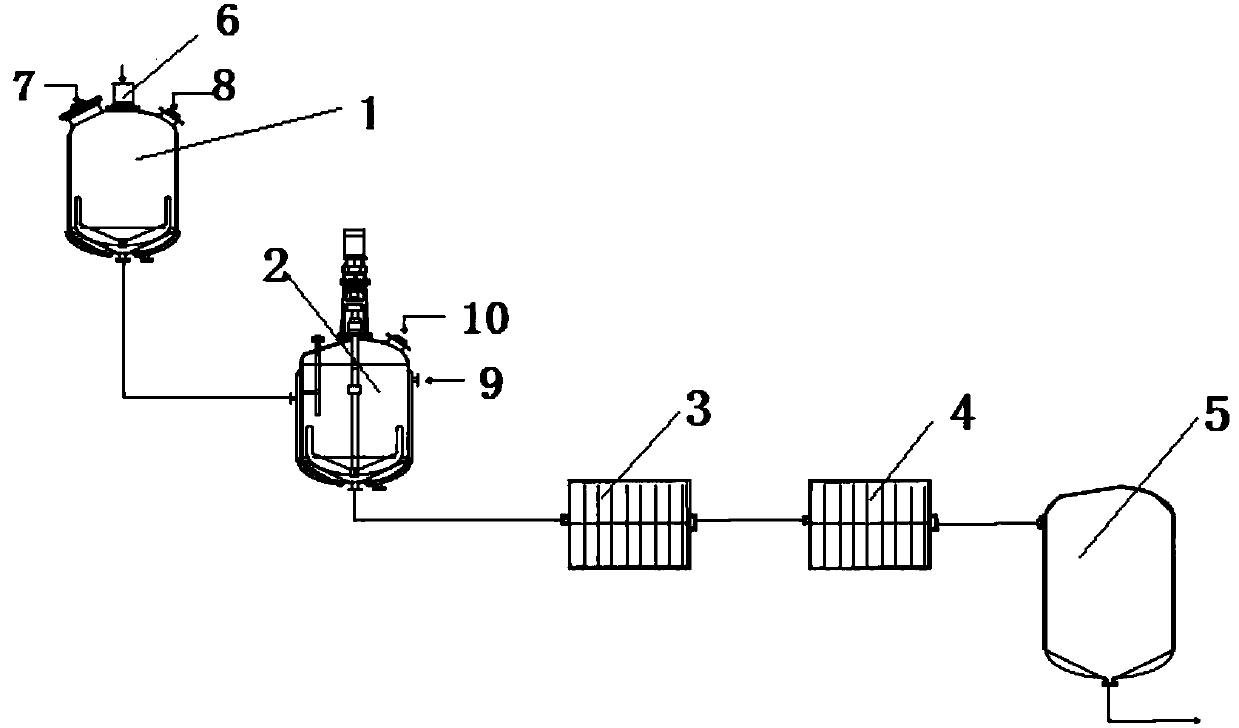

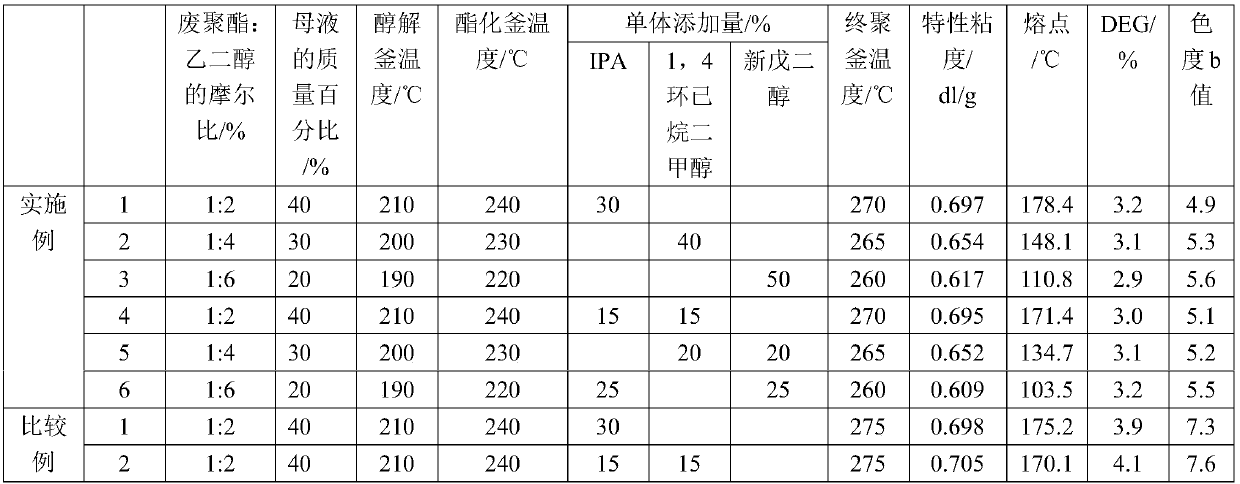

Method for preparing regenerative low-melting-point polyester with waste-polyester alcoholysis method

ActiveCN107652423AImprove alcoholysis efficiencyStabilize the quality of alcoholysis productsPlastic recyclingMonocomponent polyesters artificial filamentIonChemistry

The invention discloses a method for preparing regenerative low-melting-point polyester with a waste-polyester alcoholysis method. The method includes the steps of 1), pretreatment of waste polyester;2), alcoholysis of the waste polyester; 3), quality regulation of esters and adding of one or multiple copolymers of isophthalic acid, 1-4 cyclohexane dimethyl alcohol and neopentyl glycol; 4), polycondensation and slicing preparation, wherein the low-melting-point polyester finally obtained is 0.60-0.70dl / g in intrinsic viscosity, 100-180DEG C in melting point, 3.0+ / -0.3% in content of diglycoland smaller than 6 in chroma value of b. The obtained regenerative low-melting-point polyester is applicable to preparation of cationic-ion dyeable poester filaments and short fiber, and high-value recycling of the waste polyester is realized.

Owner:ZHEJIANG SCI-TECH UNIV

Formaldehyde purification inflaming retarding oriented strand board and manufacturing method thereof

The invention relates to a paint-free decorative overlay fitment board, in particular to a formaldehyde purification inflaming retarding oriented strand board and a manufacturing method thereof, and belongs to the wood processing industry. The formaldehyde purification inflaming retarding oriented strand board comprises a base material layer, an upper surface layer decorative film adhesive layer and a lower surface layer decorative film adhesive layer. The upper surface layer decorative film adhesive layer and / or the lower surface layer decorative film adhesive layer are immersed with an amino resin adhesive solution and a formaldehyde decomposition adhesive solution, the base material layer is an oriented strand board layer, the oriented strand board layer comprises an upper surface layer, a lower surface layer and a core layer shaving layer, wherein the glue mixing wood shavings on the upper and lower surface layers are longitudinally arranged in the fiber direction, the glue mixing wood shavings on the core layer shaving layer are transversely arranged in the fiber direction, an inflaming retarding layer is arranged between the lower surface shaving layer and the core layer shaving layer, and an inflaming retarding layer is arranged between the upper surface shaving layer and the core layer shaving layer. The manufacturing method of the paint-free decorative overlay fitment board comprises the steps of base material sanding, formaldehyde decomposition adhesive solution preparation, decorative film adhesive manufacturing, assembling and pressing and sticking. The formaldehyde purification inflaming retarding oriented strand board is realistic in effect, low in cost and good in formaldehyde purification effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Preparation method of polyester staple fiber

InactiveCN101285218AStable supplyHigh strengthFilament/thread formingMonocomponent polyesters artificial filamentYarnPolymer science

The invention aims to provide a method for preparing polyester staple fiber. The invention is characterized in that the method adopts the process route of directly spinning melt mass to manufacture, and uses purified terephthalic acid (PTA) and ethylene glycol (EG) as raw materials and adds small quantities of mono-pentaerythritol, DEG, antimony trioxide, titanium dioxide and other catalysts, flatting agents and stabilizing agents. The method uses the process flow of five autoclaves polymerization to perform polyreaction so as to receive the melt which is finally spun into tows, and prepares the polyester staple fiber via primary drawing, secondary drawing, 18 roller tension heat setting, third drawing, crimping, relaxation heat setting and cutting. The method has the advantages of stable raw material supply, high product strength, few defects, good crimp, moderate oil applying rate and stable dry-heat shrinkage percentage; products prepared by the method have good spinnability, so that yarn spun by the product is high in each quality index, and produced textile has soft and smooth hand feeling; and the manufacturing cost is lower than chip spinning, so that the marketing competitive power of the products is stronger.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

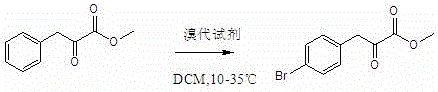

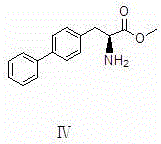

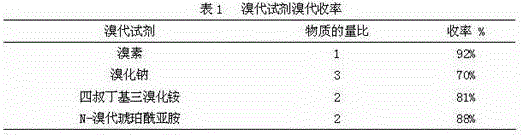

Preparation method of LCZ696 intermediate

ActiveCN105884656AImprove quality indicatorsEasy to get materialsCarbamic acid derivatives preparationOrganic compound preparationPhenylboronic acidEnvironmental resistance

The invention discloses a preparation method of LCZ696 intermediate and relates to the technical field of preparation of an aromatic nucleus compound containing 2 benzene rings and 1 chiral center. The preparation method includes the steps of S1, allowing benzyl magnesium bromide to react with methyl oxalyl chloride to obtain a compound as shown in formula I; S2, allowing the compound as shown in formula I to have a bromination reaction with a bromination reagent to generate a compound as shown in formula II; S3, coupling the compound as shown in formula II with phenylboronic acid to obtain a compound as shown in formula III; S4, performing reductive ammoniation on the compound as shown in formula III to obtain a compound as shown in formula IV; S5, applying Boc to the compound as shown in formula IV to obtain a compound as shown in formula V; S6, performing ester group reduction on the compound as shown in formula V to obtain a compound as shown in formula VI. The preparation method has the advantages that overall raw material consumption is lowered, and product productivity and market competiveness are increased; by the overall process optimization, the reaction of each step can be performed and controlled easily, the use of heavy metal catalysts is reduced and avoided, and accordingly the quality index of the final product is increased, and an economic and environment-friendly process route is developed.

Owner:CANGZHOU SENARY CHEM SCI TEC

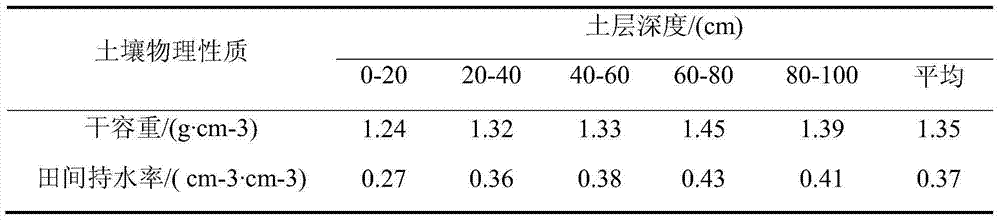

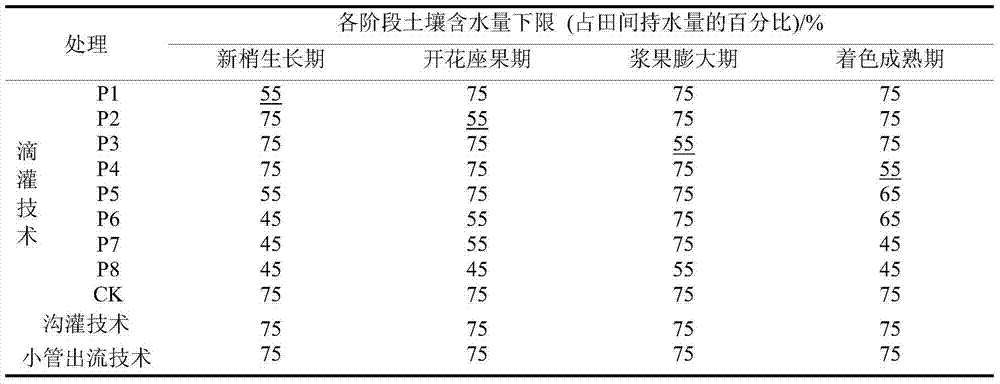

Water-saving high-yield high-quality irrigation method for wine grapes

InactiveCN104838976ACurb the trend of desertificationRelieve ecological pressureClimate change adaptationWatering devicesVitis viniferaEnvironment of Albania

The present invention relates to a water-saving high-yield high-quality irrigation method for wine grapes, and belongs to the technical field of water-saving agricultural irrigation. The irrigation method comprises the following steps: (1) planting grapes in a south-north direction; (2) using single-hedge trellis as grape trellis; (3) distributing drip irrigation zones; (4) dividing the growth period of wine grapes into a shoot growth stage, a flowering and fruit setting stage, a berry expansion stage and a colored and mature stage, and performing timing and quantitative irrigation and fertilization according to the stages. The method provided by the present invention provides the drip irrigation technique of the wine grapes in the Hexi Corridor regions, a high-yield high-quality water-saving efficient scientific irrigation mode for developing the wine grapes is provided for arid desert regions. The method has significances in relieving the imbalance between supply and demand of water resources in the arid desert regions, improving the quality of the wine grapes, improving the ecological environment, and developing the circular economy.

Owner:GANSU AGRI UNIV

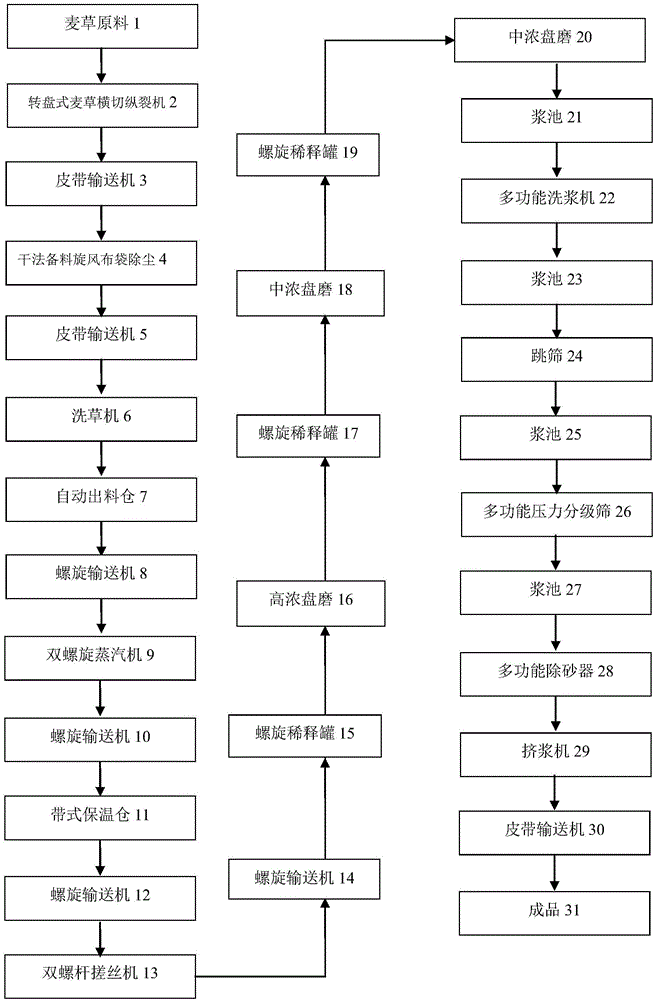

Production process method for novel crop straw environment-friendly material

InactiveCN104631204AHigh strengthDo not damagePretreatment with water/steamFibrous raw materialsHigh concentrationPollution

The invention relates to a production process method for a novel crop straw environment-friendly material. The method comprises the following steps: crushing, drawing and crushing straw raw materials by a rotary table type wheat grass cross-cutting vertical cracking machine; feeding the raw materials into a dry-method stock cyclone cloth bag by a belt conveyor to be subjected to dust removal; conveying the raw materials into a grass washing machine; conveying the raw materials into a double-spiral rotary steam engine, heating and softening; conveying the raw materials into a heat-preservation cabin, carrying out constant-temperature heat preservation and softening; conveying the raw materials into a double-spiral thread-rolling machine, and carrying out thread-rolling treatment; carrying out sub-sectioned grinding treatment on the raw materials by three middle-concentration and high-concentration disc mills in sequence; conveying the ground raw materials into a pulp washing machine; washing and sieving pulp by a jigging sieve pressure sieve; conveying good pulp into a sand removing device, and carrying out sand removing treatment; and finally, conveying the pulp into a pulp extruder to extrude surplus water to obtain a finished product, and conveying the tail pulp into the former link and treating. The production process adopts a pure mechanical treatment machining process and any chemical auxiliary agent is not added into the whole treatment process; and pollution to the environment is not caused and the environment is effectively protected.

Owner:BEIJING JINMENGDI MOLDING TECH DEV

Flat-bottomed trench shallow hole shrinkage method

ActiveCN101634227AIncrease flexibilityGuaranteed stabilityUnderground miningSurface miningMineralogy

The invention belongs to the technical field of underground mining processes, in particular to a flat-bottomed trench shallow hole shrinkage method. The mining process comprises: ore mining from a two-section bord, ore loading by a horizontal trackless forklift and ore removal by transportation equipment, namely pull-bottomed plane and secondary pulverization plane are combined on the same plane till on the same level with transportation plane to form a flat-bottomed trench; the method adopts a bottom trench ore removal mode; the bottom of the bord is a plane; ore on the pull-bottomed plane is a triangular ore pillar; according to the occurrence condition of an orebody and the prior engineering condition, the orientation of the orebody is determined in a horizontal subsection; a horizontal transportation tunnel is dug in an orebody footwall; a cross vein trackless ore removal tunnel is dug towards the orebody in every 25 m to form a cross vein ore removal and vein-following loading transportation mode; the ore removal tunnel selects the vein-following arrangement or the cross vein arrangement of the ore removal tunnel according to the width of the orebody; and the number of the ore removal trench is 1 to 2. The flat-bottomed trench shallow hole shrinkage method improves the operating rate and reduces loss and dilution.

Owner:ANSTEEL GRP MINING CO LTD

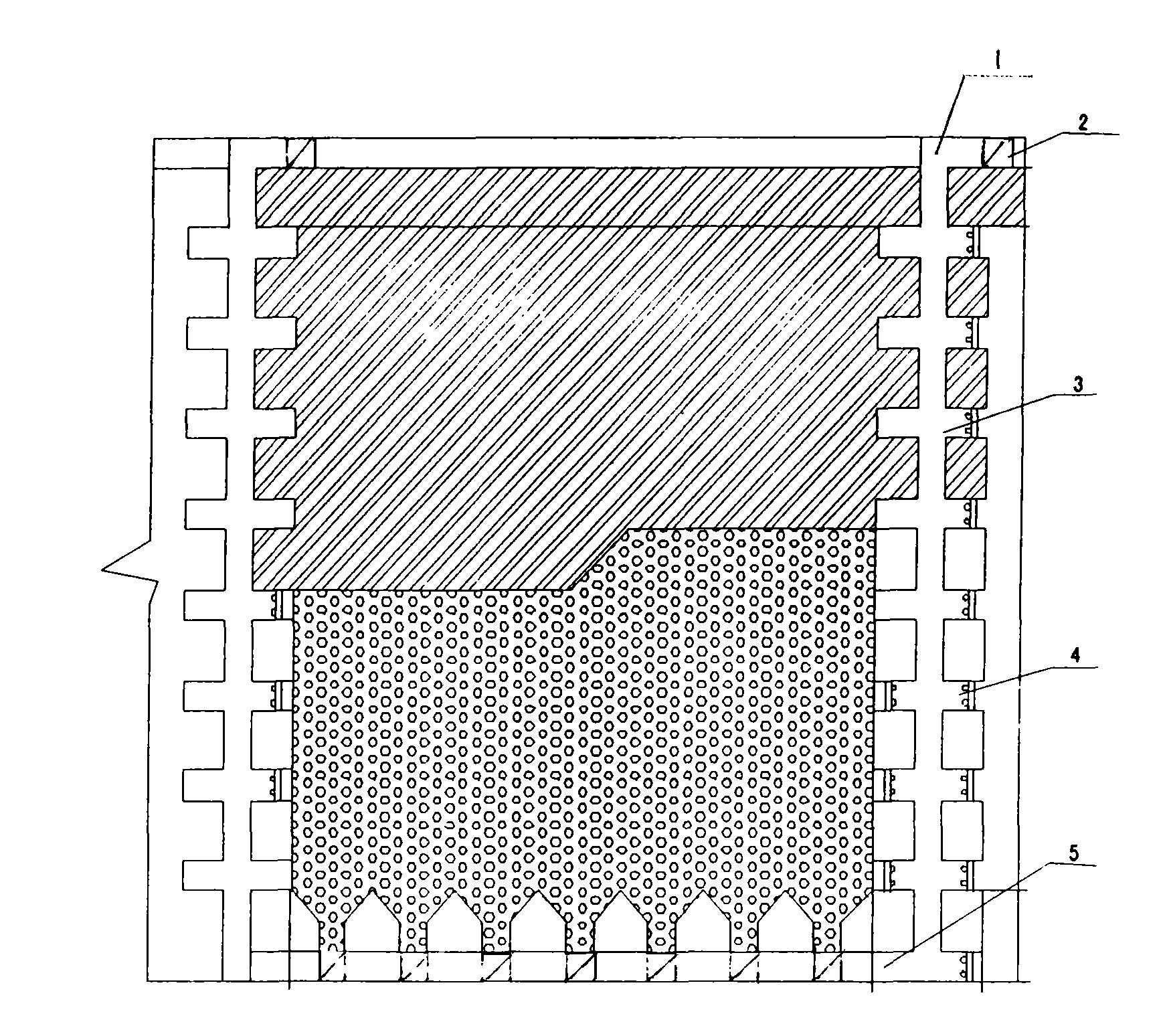

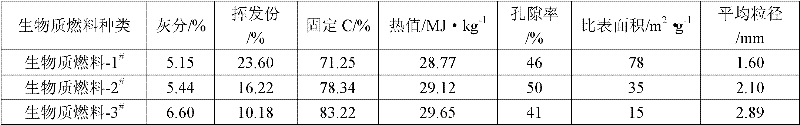

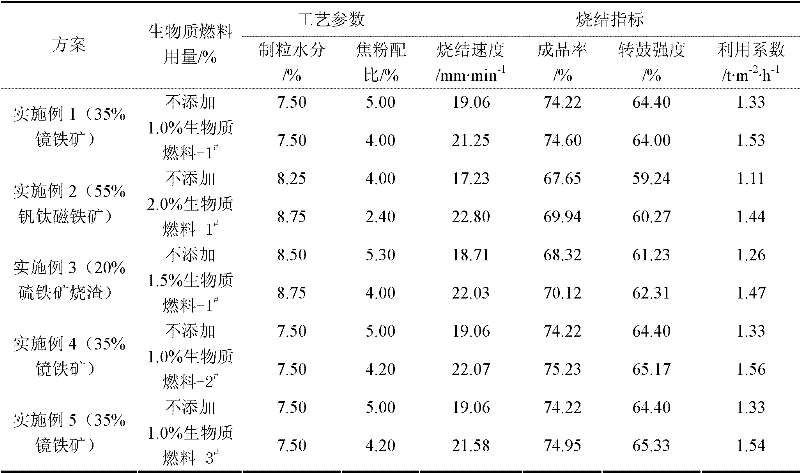

A method of using biomass fuel to strengthen the sintering of refractory iron ore

ActiveCN102296177AMeet the requirements of fast burningMeet caloric requirementsPorosityTitanomagnetite

The invention relates to a method for reinforcing the sintering of iron ores (vanadic titanomagnetite, specularite, secondary iron-containing resources and the like) difficult to pelletize by biomass fuel. By applying the biomass fuel with high burning velocity to the sintering of the iron ores difficult to pelletize, the sintering speed and the utilization coefficient can be improved. The reinforcing method comprises the following steps of: adding 1 to 4 percent of biomass fuel into a sinter mixture containing the iron ores difficult to pelletize, wherein the biomass fuel is required to have 65 to 85 percent of content of fixed carbon, 10 to 25 percent of volatile matter, more than 24 to 30MJ / kg of calorific value, 40 to 60 percent of porosity, 10 to 100m2 / g of specific surface area and 1 to 4mm of average particle size; after weighing the iron ores difficult to pelletize, a flux, sintering return fines and the biomass fuel according to the weight ratio, sufficiently mixing the raw materials and pelletizing; distributing the mixture, igniting and sintering to obtain agglomerates. After the biomass fuel is adopted to reinforce the sintering of the iron ores difficult to pelletize, the sintering speed can be improved by 2 to 5mm / min, the utilization coefficient can be improved by 0.2 to 0.4t / (m2.h) and meanwhile, low intensity variation of an agglomerate revolving drum is ensured.

Owner:CENT SOUTH UNIV

Clarification method of alumina silicate glass melts

InactiveCN102976587AImprove clarification qualityExtended clarification timeGlass furnace apparatusGlass productionChemical treatmentNitrate

The invention discloses a clarification method of alumina silicate glass melts. The method comprises physical treatment and chemical treatment to the alumina silicate glass melts, wherein the physical treatment is to control the air pressure of clarifying parts of the alumina silicate glass melts to 100 to 9*10<4>Pa; and the chemical treatment is to add a composite clarifying agent to the alumina silicate glass mixture, wherein the composite clarifying agent is the composition formed by mixing two or more than two of sulfate or / and nitrate of K, sulfate or / and nitrate of Na and sulfate or / and nitrate of Li with two or more than two of Sn oxide, Sb oxide and Ce oxide. According to the clarification method, the composite clarifying agent is adopted and realizes gradient chemical clarification under different temperatures, so that the clarifying agent in the glass melts can be molten at different temperature ranges during melting, and gas is continuously generated by the glass melts, and the clarifying time of the glass melts is prolonged; and the physical clarifying way under reduced pressure is adopted while the chemical clarifying way is carried out, so that the bubble can be faster generated and overflowed, and the clarifying effect of the high-viscosity alumina silicate glass can be optimized.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

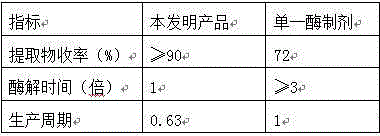

Complex enzyme preparation for extracting effective plant components and method for preparing complex enzyme preparation

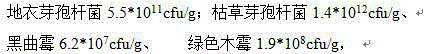

InactiveCN105062990AHigh recovery rateRelease fullyMicroorganism based processesGlycosylasesBacillus licheniformisPectinase

The invention discloses a complex enzyme preparation for extracting effective plant components and a method for preparing the complex enzyme preparation. The complex enzyme preparation comprises components of glycanase, cellulase, pectinase, beta-glucanase and alpha-amylase. The activity of the glycanase is 3000IU / g, the activity of the cellulase is 2000IU / g, the activity of the pectinase is 20000IU / g, the activity of the beta-glucanase is 5000IU / g, and the activity of the alpha-amylase is 3000IU / g. The method for preparing the complex enzyme preparation includes symbiotically cultivating, extracting and concentrating bacillus licheniformis, bacillus subtilis, aspergillus niger and trichoderma viride according to certain proportions, then adding expanded plant protein carriers into the bacillus licheniformis, the bacillus subtilis, the aspergillus niger and the trichoderma viride; spraying mist at low temperatures to obtain the complex enzyme preparation. The complex enzyme preparation and the method have the advantages that the effective component recovery rate of complex enzymes can be increased as compared with a method for individually fermenting and producing various enzymes and then combining the various enzymes with one another, production technologies can be simplified, the production cycle can be shortened, the production cost can be lowered, the production efficiency can be greatly improved, the stability of the activity quality of final products can be guaranteed, and plant extraction complex enzyme production can be industrialized.

Owner:天津科建科技发展有限公司

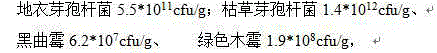

Process for preparing high-purity quartz from vein quartz

The invention discloses a process for preparing high-purity quartz from vein quartz, which comprises the steps of raw vein quartz ore selection, laser fracturing, electromagnetic roasting, water quenching, pulverization and grading, high-gradient magnetic separation, electrostatic separation, impurity removal based on a microwave complexing method, deionized water cleaning and drying. According to the invention, the process flow and structure are reasonable, the technology is advanced, efficient and easy to control, the impurity removal is targeted, high in quality index and favorable in stability; and the high-purity ultrafine quartz material can be used in such high and new technical fields as novel electric light sources, high-insulation sealing, aerospace instruments, war industry technical products, micro electronics, high-grade optical glass, quartz crucible main materials, quartz tubes and quartz rods.

Owner:刘少云

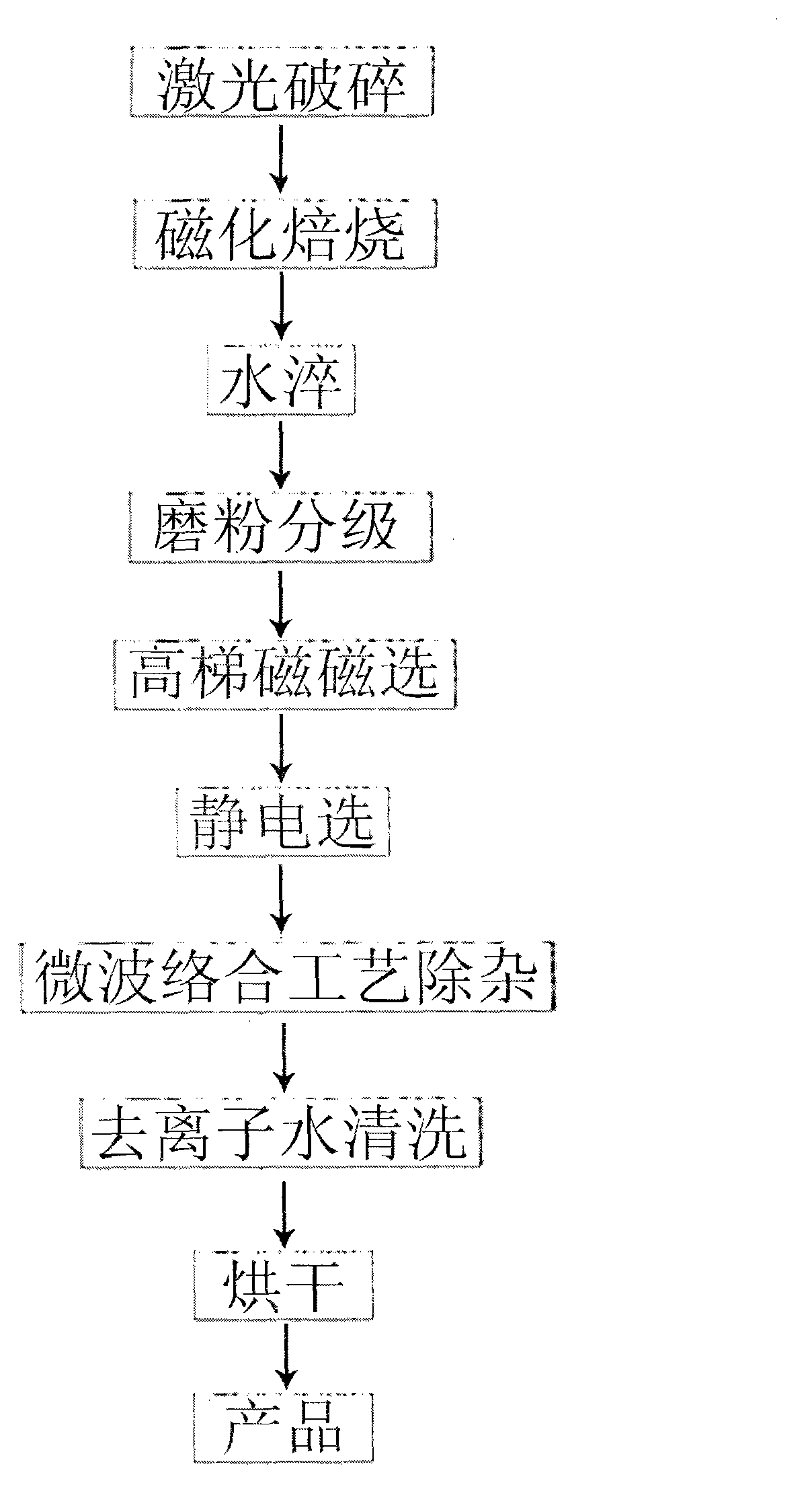

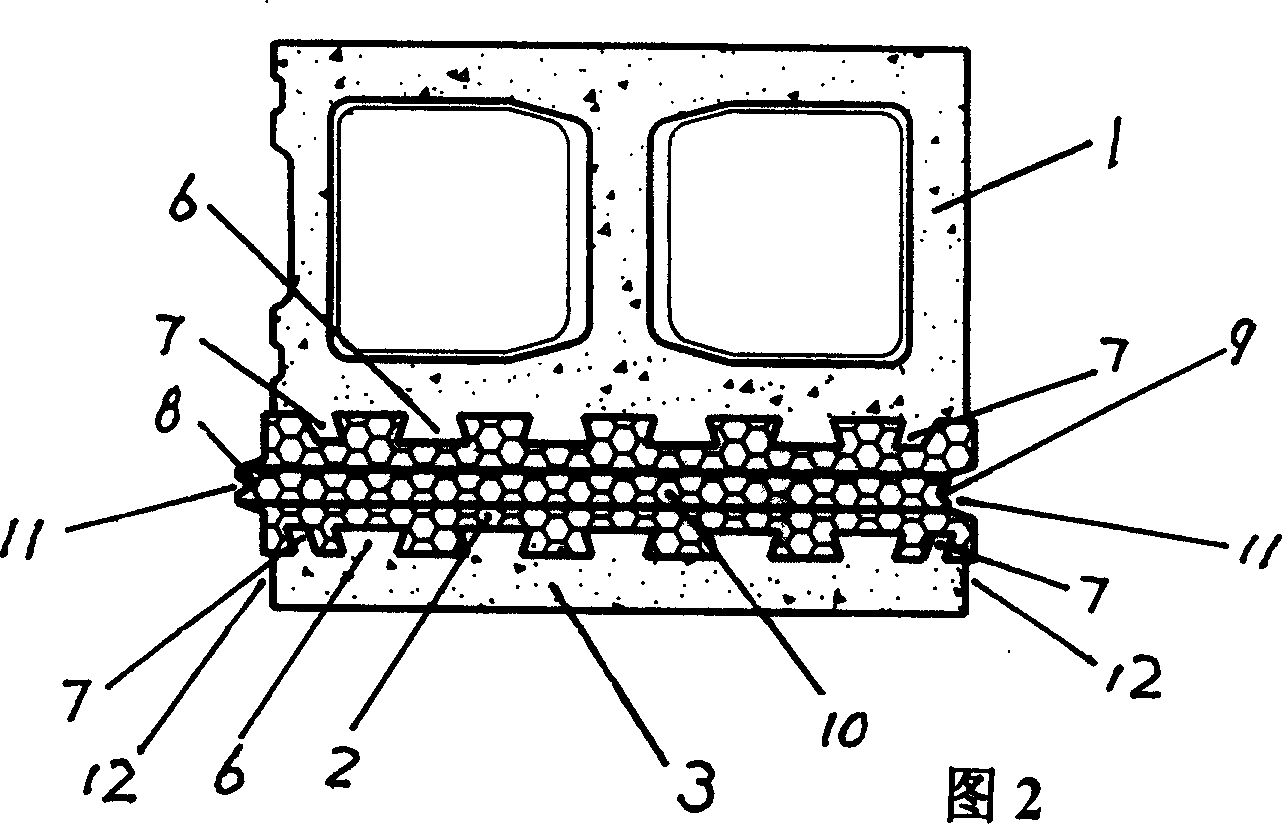

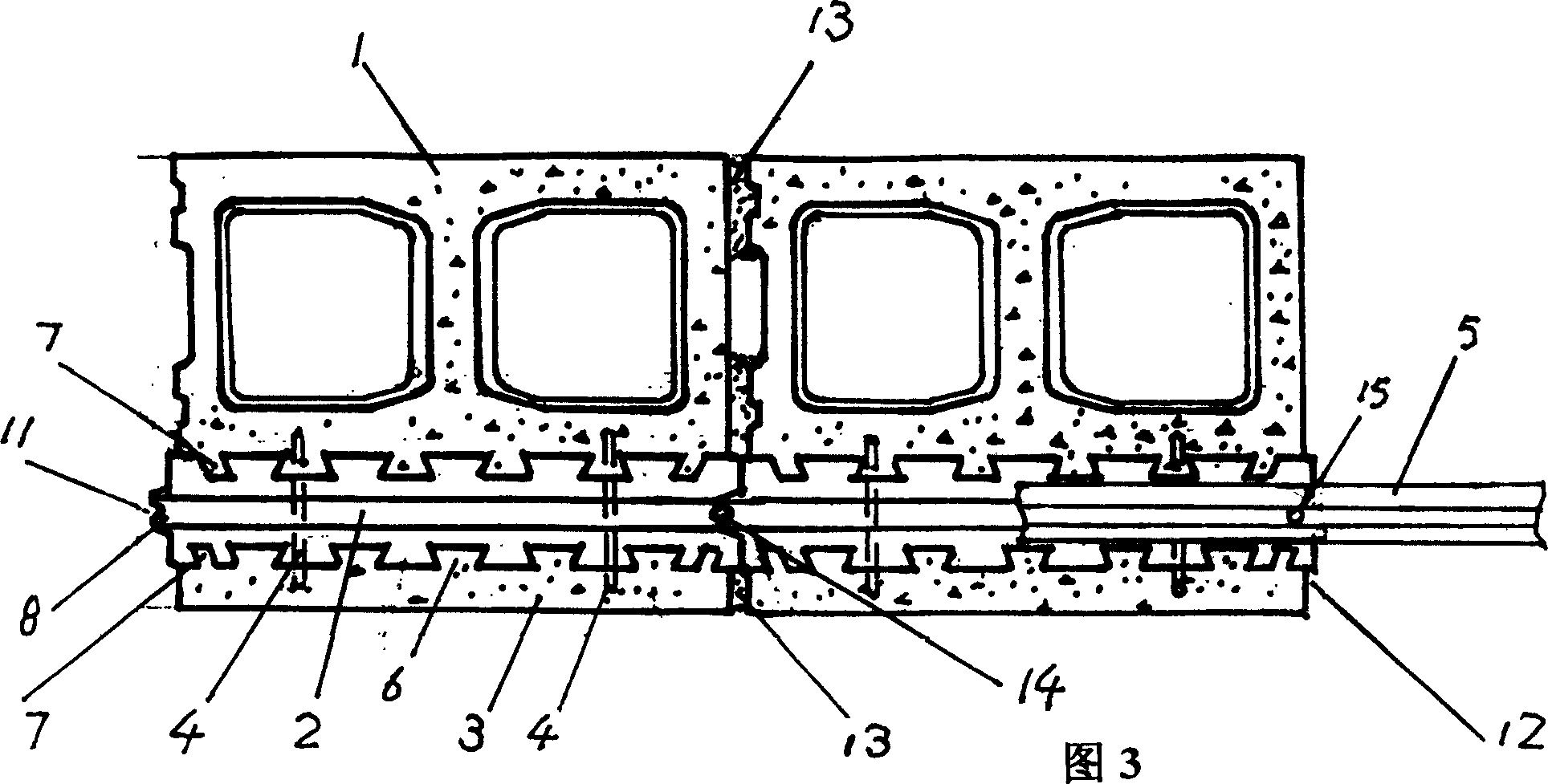

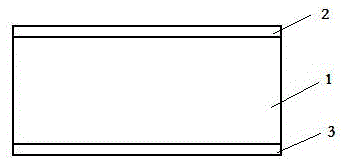

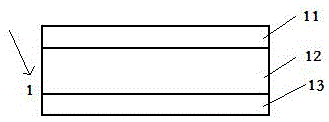

Composite energy saving building blocks and method for making same

InactiveCN1544775ASimple structureImprove insulation effectConstruction materialTectorial membraneSurface layer

The invention relates to a compound energy saving building block and its making method, at present compounded of bearing block, heat-preserving plate, lacing wire, surface layer, and so on. Two ends of the heat-preserving plate are made with inclined anticracking slots, there are air exhaust grooves made on the vertical concave and convex slot, there are cement seam pressure strips on the transverse groove, there are air exhaust holes made on the cement-seam pressure strips, and there are protective films on the lacing wires; and it is made by special techniques of screening antirust low conductive liquor, waterproofing agent and framework material, etc. It has simple and convenient construction, enhances constructing efficiency, has low engineering cost, short working cycle, etc. and it ensures the quality of architectural engineering.

Owner:怀方林

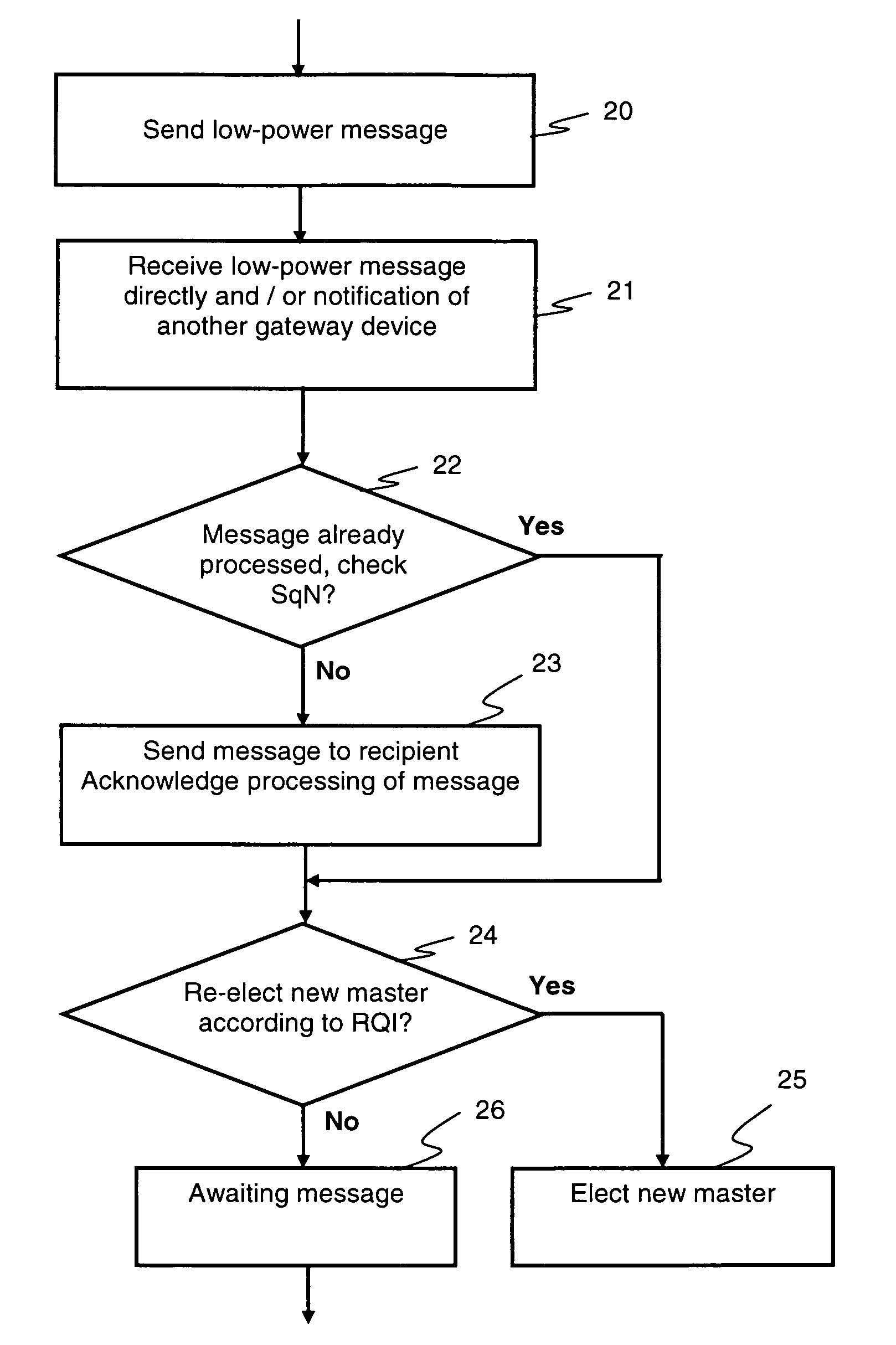

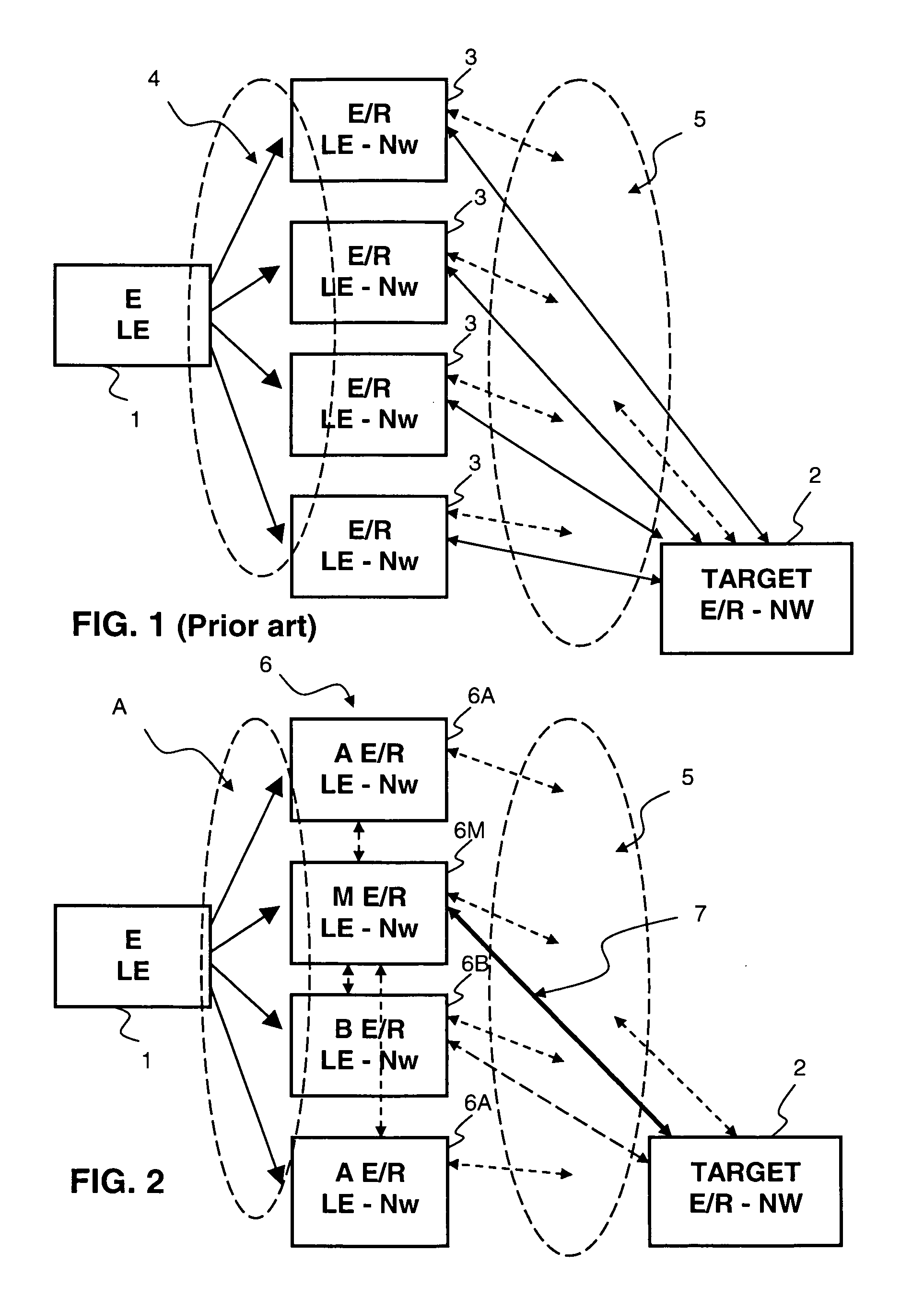

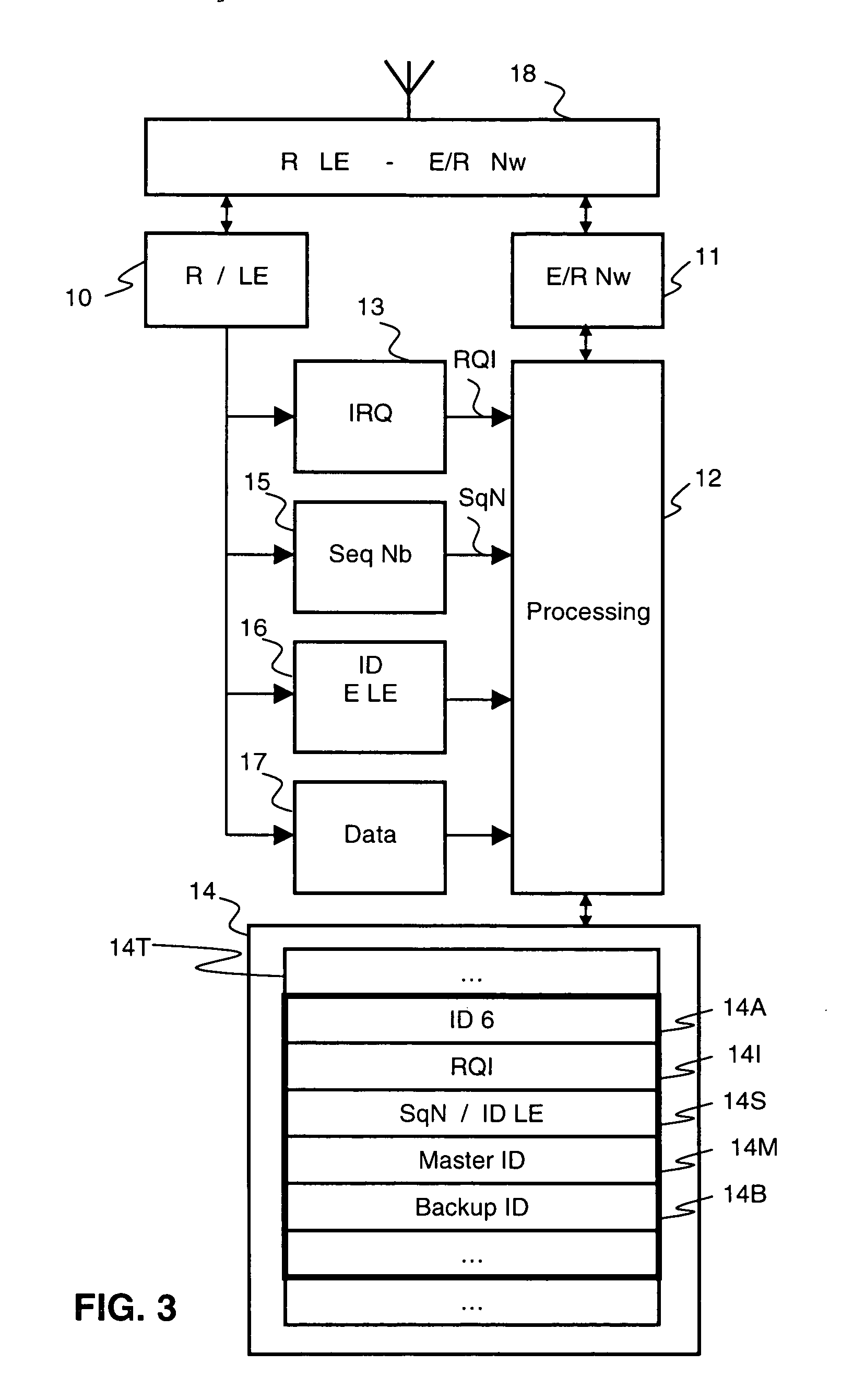

Wireless communication device and method, and system comprising such a method

ActiveUS20110066750A1Improve quality indicatorsEnergy efficient ICTNetwork topologiesCommunication deviceTransmitter

The gateway communication device for wireless communication networks receives messages from a low-power transmitter and communicates with a network. In a system comprising several gateway devices for a low-power transmitter, a master gateway device is defined. Definition of a master gateway device is based on reception quality indicators of the gateway devices situated in said reception zone of messages transmitted by said low-power transmitter. The gateway device having the highest reception quality indicator is selected to be said master gateway device. The communication method also defines a master gateway device in the same way. The master gateway device then selects a backup gateway device to store link tables and in certain cases to act in the place of the master.

Owner:SCHNEIDER ELECTRIC IND SAS

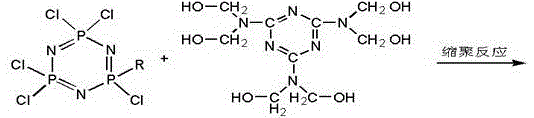

Flame-retardant oriented strand board

ActiveCN105619565ASolving Diversity Matching ProblemsWell-Matched SynergiesWood treatment detailsWood veneer joiningChlorideEngineering

The invention relates to boards, in particular to a flame-retardant oriented strand board. The flame-retardant oriented strand board comprises a core layer oriented four-layer laying flame-retardant strand layer and facing layers which are pressed and glued to the upper surface and the lower surface of the core layer oriented four-layer laying flame-retardant strand layer correspondingly. A fire retardant in the flame-retardant strand layer is a magnesium-aluminum nano layered double metal hydroxide fire retardant. The fire retardant comprises, by molar mass, 1-5 parts of magnesium chloride, 0.5-1.2 parts of aluminum chloride, 0.5-1 part of sodium hydroxide and 0.6-1.3 parts of sodium carbonate. The facing layers are made of anyone of decorative paper, veneer or engineered veneer. When the facing layers are made of the decorative paper, balancing layers are further pressed and glued between the core layer oriented four-layer laying flame-retardant strand layer and the facing layers. The engineered veneer with the required thickness is formed by slicing functional engineered wood. The flame-retardant strand layer is vivid in decoration effect, low in cost and good in formaldehyde purifying effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Full-automatic non-quenched-and-tempered steel forge piece production line

ActiveCN107442726AEmission reductionImprove electricity efficiencyForging/hammering/pressing machinesForging press drivesProduction linePunching

The invention discloses a full-automatic non-quenched-and-tempered steel forge piece production line. The production line comprises heating equipment, forging equipment, edge cutting and punching equipment, a cooling temperature control conveying chain, a finished product box and a programmable control system which are sequentially connected. According to the production line, a forge piece is heated at a time, continuous and automatic machining of multiple processes including upsetting, pre-forging molding, final forging molding, edge cutting, punching, heat treatment and the like is achieved, all machining processes need to be operated by one person, and the beneficial effects of being high in production efficiency and good in product quality are achieved.

Owner:CHONGQING VOCATIONAL INST OF ENG +1

Preparation method for pharmaceutic adjuvant--magnesium stearate

InactiveCN103193614AImprove quality indicatorsThe production process conditions are easy to controlCarboxylic acid salt preparationSodium stearateMagnesium stearate

The invention provides a preparation method for a pharmaceutic adjuvant--magnesium stearate. The preparation method comprises the following two steps: step 1, subjecting stearic acid and sodium hydroxide to a saponification reaction; and step 2, reacting sodium stearate produced by stearic acid and sodium hydroxide with magnesium sulfate so as to produce the magnesium stearate. The pharmaceutic adjuvant magnesium stearate produced by using the method provided by the invention has stable quality indexes, and in particular, the content of MgO accords with requirements prescribed in Chinese Pharmacopoeia (2010 edition); production process conditions are easily controllable, and the produced magnesium stearate has a good color.

Owner:郑桂富

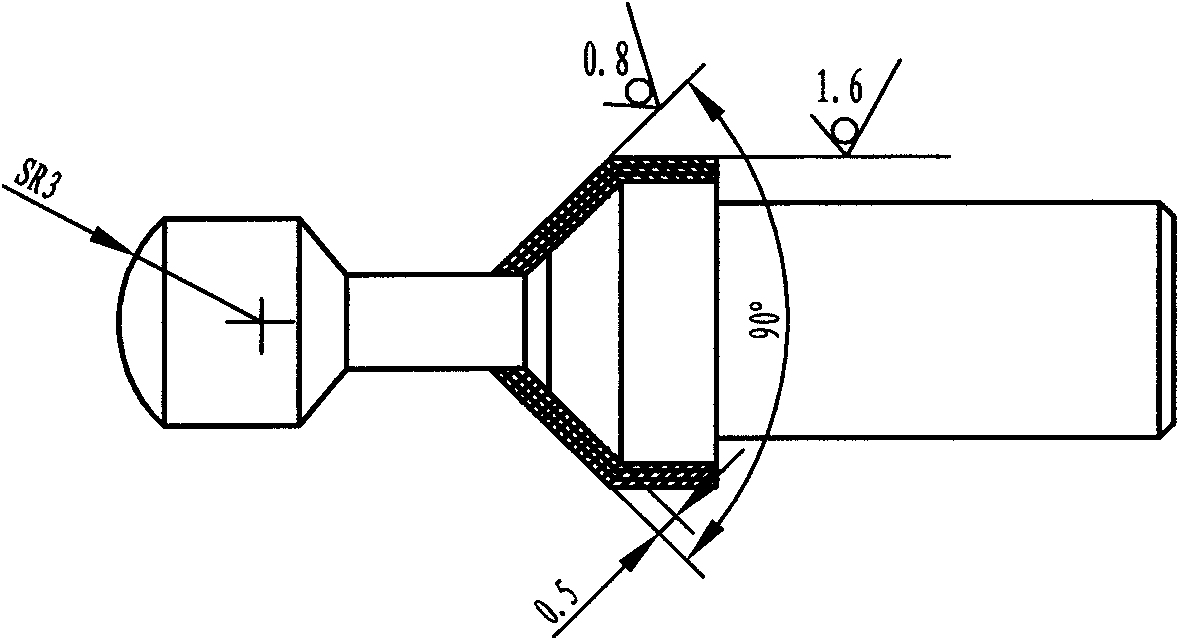

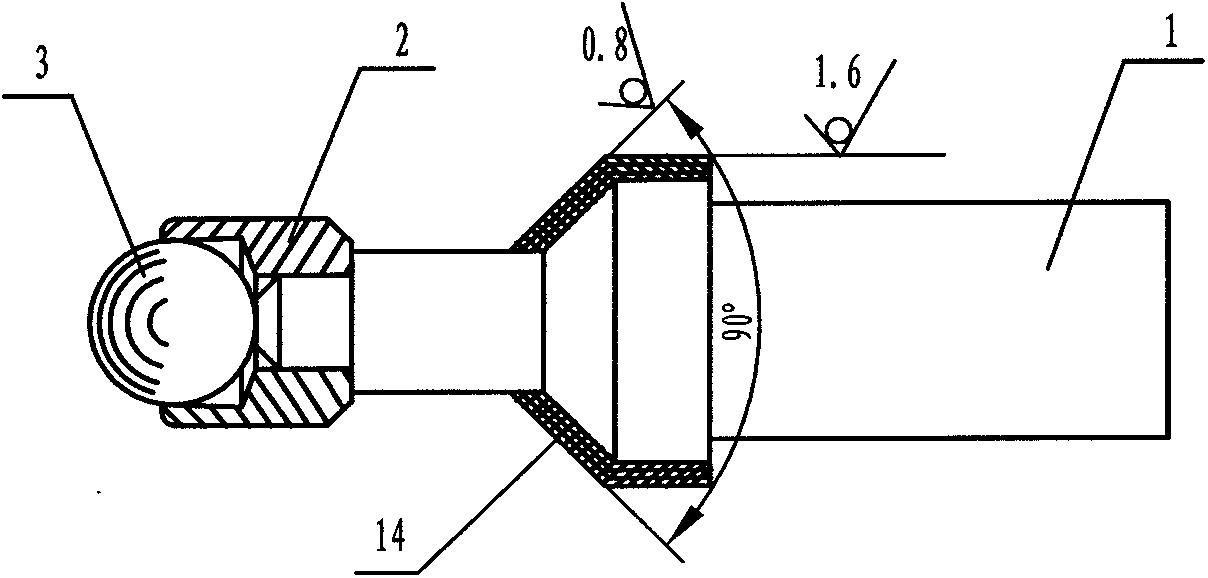

Main valve element of precise pressure reducing valve and production technology

ActiveCN103433704AImprove quality indicatorsSimple processing technologyValve arrangementsInterference fitBall bearing

The invention discloses a main valve element of a precise pressure reducing valve. The main valve element of the precise pressure reducing valve comprises a valve rod, a connecting sleeve and a steel ball. A connection section is turned on the end portion of the valve rod. A conical bearing shoulder is turned on the neck portion of the connection section. A shoulder-shaped step is turned in the middle of the valve rod. A nitrile rubber layer is vulcanized on the shoulder-shaped step. A connection through hole is turned in one end of the connecting sleeve, the end with the connection through hole is connected to the connection section of the valve rod in a pressing mode through interference fit, a bearing hole with the small end portion and a swallow-tail section is turned in the other end of the connecting sleeve, and the steel ball is pressed into the bearing hole through interference fit. The steel ball is a steel ball for a ball bearing. According to the structure of the main valve element, the production technology is simplified and various technical requirements of the main valve element are met.

Owner:ZHEJIANG BLCH PNEUMATIC SCI & TECH

Method for producing glucose bulk drug for injection by using rice

ActiveCN102703547AHigh biological potencyImprove saccharification puritySugar derivativesFermentationIon exchangeChemistry

The invention provides a method for producing a glucose bulk drug for injection by using rice. The method comprises the following steps of: soaking and defibrination, size mixing, liquefaction and slag removal, saccharification, primary decoloration and filtration, secondary decoloration and filtration, ion exchange, concentration and refining, primary crystallization, primary centrifugation, sugar solution, sugar concentration and decoloration, secondary sugar boiling and crystallization, secondary centrifugation, drying, packaging and the like. The method has the following advantages: (1), a two-time crystallization process is adopted, the quality is high, and a filtration speed is quick; (2), the problem that a raw material for producing an injection glucose in the south does not existis solved by using the rice as the raw material, and the blank of the production of a crystalline glucose in the south is filled; (3), the crystalline glucose produced by using the rice as the raw material has low-irritability in absorption property and is high in biological value; and (4), a breeding fermentation problem in a production procedure is solved successfully, the sugar concentration and the filtration are added, the quality of a finished product is greatly improved, and the clarity and the filtration speed of the product are guaranteed. The continuous feed and the continuous discharge can be carried out; the crystallization and fermentation contamination is stopped; the quality can be guaranteed; and the continuous production is guaranteed.

Owner:北京佳沃臻诚科技有限公司

Formaldehyde purification plate and preparation method thereof

ActiveCN105014752ALow costGood effectSynthetic resin layered productsLaminationSurface layerDecomposition

The present invention relates to a paint-free decorative furniture plate and particularly relates to a formaldehyde decomposition (purification) function plate and a preparation method thereof. The plate comprises a substrate layer and an upper surface layer decorative film paper layer and a lower surface layer decorative film paper layer which are respectively pressed and glued to the upper surface and the lower surface of the substrate layer. The gram weight of the upper surface layer decorative film paper layer or the lower surface layer decorative film paper layer is 60 to 150 grams per square meter. The upper surface layer decorative film paper layer and / or the lower surface layer decorative film paper layer is decorative paper which is impregnated with an amino resin solution and a formaldehyde decomposition solution, the thickness of the decorative paper is 0.08 to 0.12 mm, the thickness of the substrate layer is 2.5 to 25mm, and the substrate layer is an oriented strand board layer. The preparation method comprises the steps of (a) substrate sanding, (b) formaldehyde decomposition solution modulation, (c) decorative film paper manufacture, (d) assembly and (e) pressing. The formaldehyde purification plate has the advantages of lifelike decoration effect, low cost and good formaldehyde purification effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Variable rate analog-to-digital converter

InactiveUS7492293B2Low sampling rateReduce power consumptionPower saving provisionsElectric signal transmission systemsDigital down converterSignal-to-noise ratio (imaging)

An analog-to-digital converter can use a variable sampling rate. By using a variable sampling rate analog-to-digital converter and an anti-aliasing filter lower sampling rates, and accordingly, generally lower power consumption may be achieved. For example, a lower sampling rate can be used when it is determined that no undesirable signals are present and a higher sampling period can be used when an undesirable signal is present. Determining the presence of an undesired signal can be based on signal-to-noise ratio, over-sampling, bit error rate, using a detector, etc. An undesirable signal can be any signal that is close in frequency to a signal of interest or a signal farther away in frequency that has a relatively high amplitude. Sampling rate can be varied in a binary fashion, stepwise, continuously, etc.

Owner:OLYMPUS CORP

Black fruit health-care yellow rice wine and production technology thereof

The invention relates to a black fruit health-care yellow rice wine and a production technology thereof. The black fruit health-care yellow rice wine is prepared by immersing black fruits into yellow rice wine as a raw material wine. The black fruit health-care yellow rice wine comprises: by weight, 50 to 100 parts of yellow rice wine, 5 to 10 parts of black wolfberry, 5 to 10 parts of dark plum, 2 to 8 parts of black mulberry, 5 to 15 parts of black date, 5 to 15 parts of black grape and 5 to 10 parts of blackcurrant. The production technology comprises the following steps of raw material screening, batching, immersion, blending and product finishing. The black fruit health-care yellow rice wine has a strong fruit fragrance, a mellow, fresh and smooth state, and effects of clearing away heat and toxins, promoting the production of body fluid to quench thirst, promoting digestion, preventing aging and resisting debility.

Owner:黄金洪

Preparation method of functional type engineered wood

ActiveCN105563586AWear-resistantWeather-resistantRadiation/waves wood treatmentWood treatment detailsStainingManufacturing technology

The invention relates to a furniture plate and in particular to a preparation method of a functional type engineered wood. The preparation method comprises the following steps: rotary cutting or slicing to prepare a blank veneer, and shearing the blank veneer into a needed size to obtain an A veneer; soaking the A veneer in a ternary compound solution prepared from a biomass nano cellulose solubilizer, a flame retardant and acid dyes, and carrying out treatments including toughening, flame retarding and dyeing to obtain a B veneer, wherein the ternary compound solution is prepared from the biomass nano cellulose solubilizer, the flame retardant and the acid dyes of a bis-azo compound according to the mass ratio to be 1:(25-40):(100-300) in a compounding manner; and adding a formaldehyde decomposition powder in a modified MUF adhesive, uniformly stirring, and carrying out dispensing, assembling, cold pressing and sawing on the B veneer to obtain a finished product. With the interface controlling design, the biomass nanotechnology and the synergistic compounding technology, the preparation method effectively solves the diversified matching problem of the flame retardant, a staining reagent and the adhesive, and realizes one material with multiple functions of the reconstituted decorative lumber manufacturing technology.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

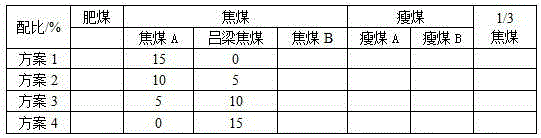

Method for carrying out coal source development by comprehensively applying coal petrography indexes

ActiveCN104449778AExpand the scope of selectionOptimize coal blending structureCoke ovensPhysicsProcess engineering

The invention relates to a method for carrying out coal source development by comprehensively applying coal petrography indexes. The method comprises the following steps of: I, carrying out coal petrography analysis on a new coal type, and judging coal as a single coal type when reflectivity standard deviation is less than 0.10; II, analyzing the coal quality indexes on the coal, and comparing ash content, volatile content, sulfur content, a caking index G value and a colloidal layer thickness Y value with those of a coal type which is in use; III, evaluating the coking property of the new coal type by using an experimental coke oven, and comparing with a substituted coal type, wherein coke strength indexes include M40, M10, CRI and CSR; IV, substituting the new coal type for the coal type which is in use according to the proportion of 4%-18%, and experimenting two coal blending schemes by using two experimental coke furnaces, wherein the coke strength indexes include M40, M10, CRI and CSR; V, trying to use the new coal type on an industrial 7.63 m coke furnace, and inspecting the coke strength indexes including M40, M10, CRI and CSR. The method disclosed by the invention can be used for partially or wholly substituting the coal resource which is in use so as to widen the selecting range of the coal resource.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com