Flat-bottomed trench shallow hole shrinkage method

A shallow-hole ore retention method and cutting ditch technology, which is applied in surface mining, underground mining, special mining, etc., can solve the problems of inability to recover the output ore and mixed rock, the difficulty of ore extraction and recovery, and the loss of ore. The effect of improving quality indicators, increasing production capacity, and reducing rock mixing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

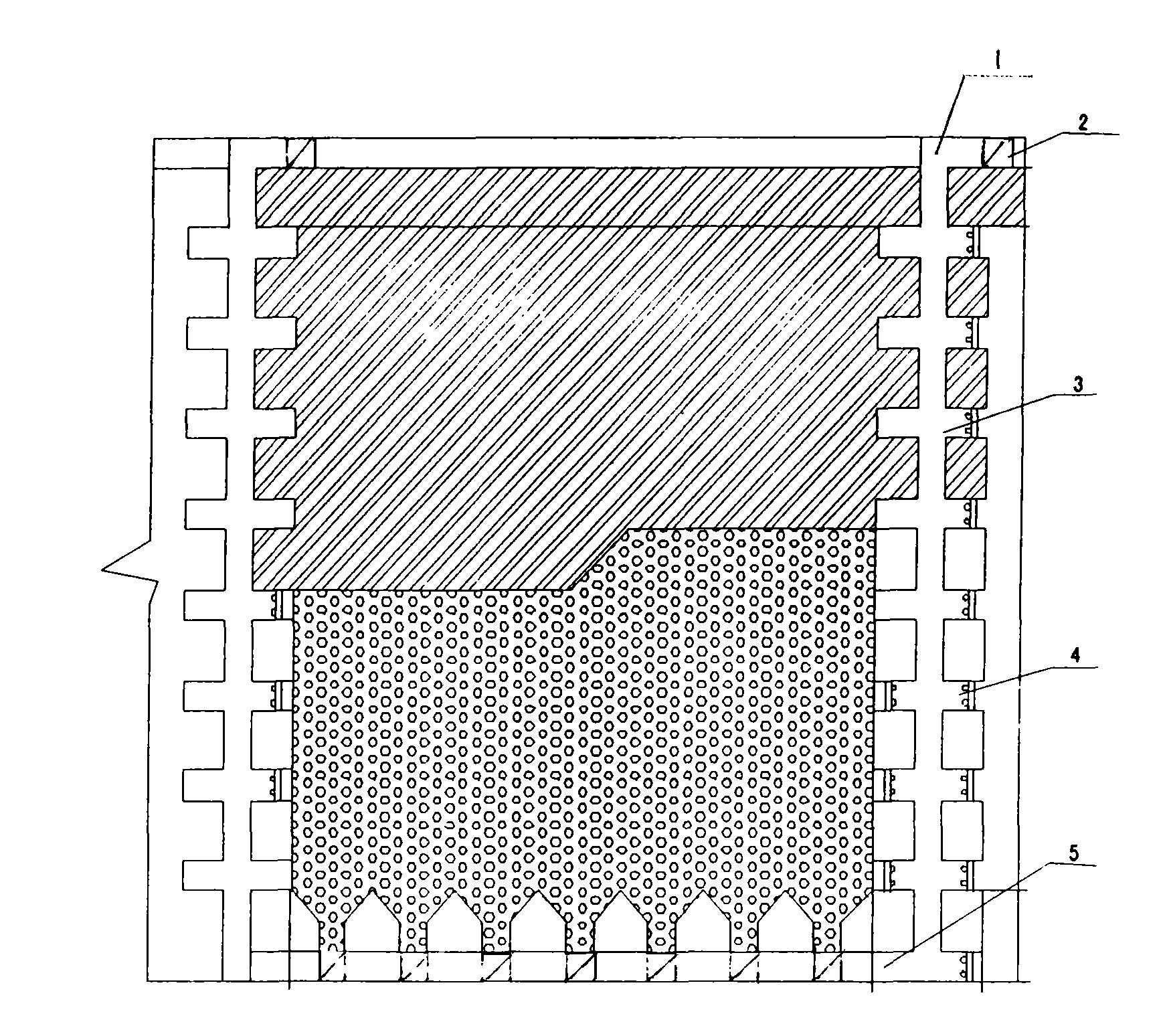

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the method for retaining ore in flat-bottomed trenches and shallow holes of the present invention is characterized in that the mining process is: ore mining in the second section of the mine → loading of ore by a horizontal trackless forklift → ore extraction by transport equipment, that is, pulling the bottom horizontally, secondary The crushing level is merged at the same level until it is at the same level as the transportation level, forming a flat-bottomed ditch. The bottom ditch is adopted to extract ore. According to the occurrence of the ore body and the existing engineering conditions, it is determined to excavate a horizontal transport roadway 1 in the footwall of the ore body along the ore body trend, and excavate a vein-piercing trackless roadway 5 to the ore body at intervals of 25m to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com