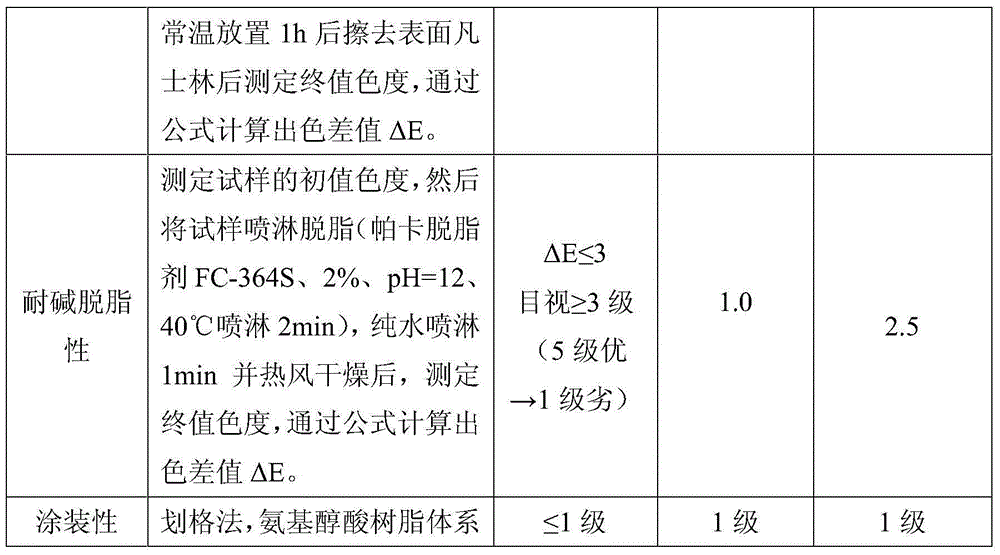

Patents

Literature

1216results about How to "Weather resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

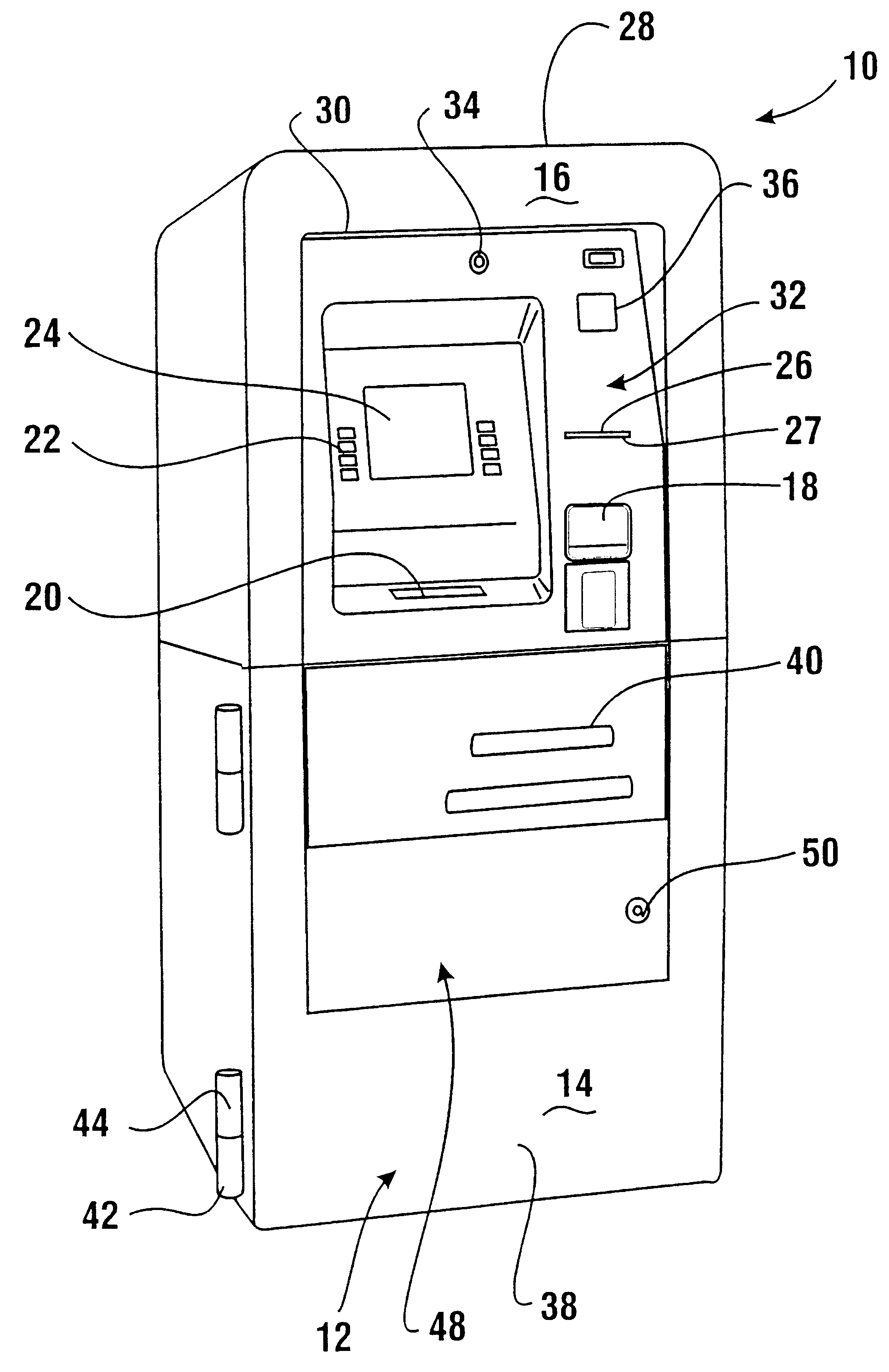

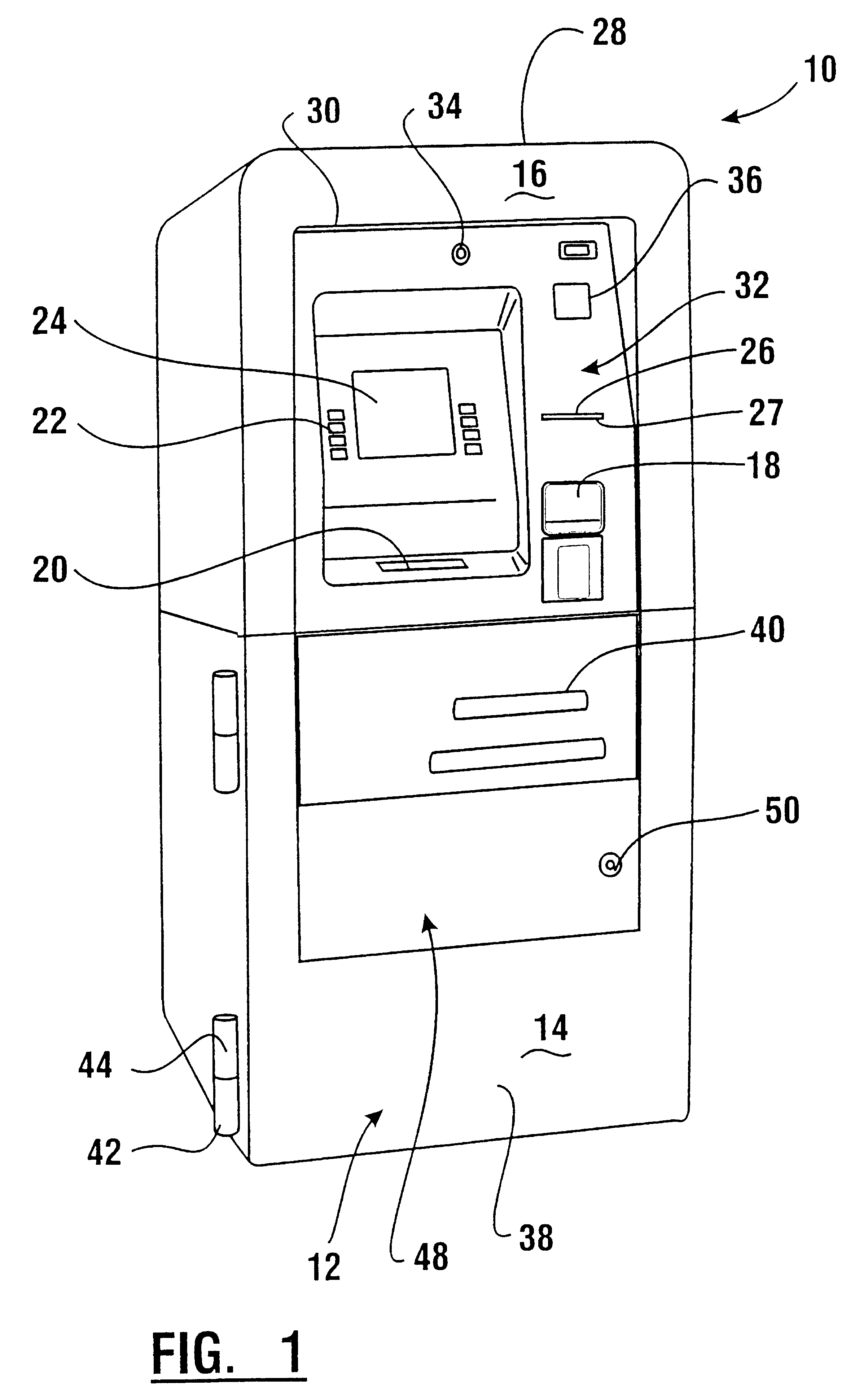

Automated banking machine enclosure

InactiveUS6527172B1Ease of assemblyBroaden accessComplete banking machinesFinanceComputer caseBiomedical engineering

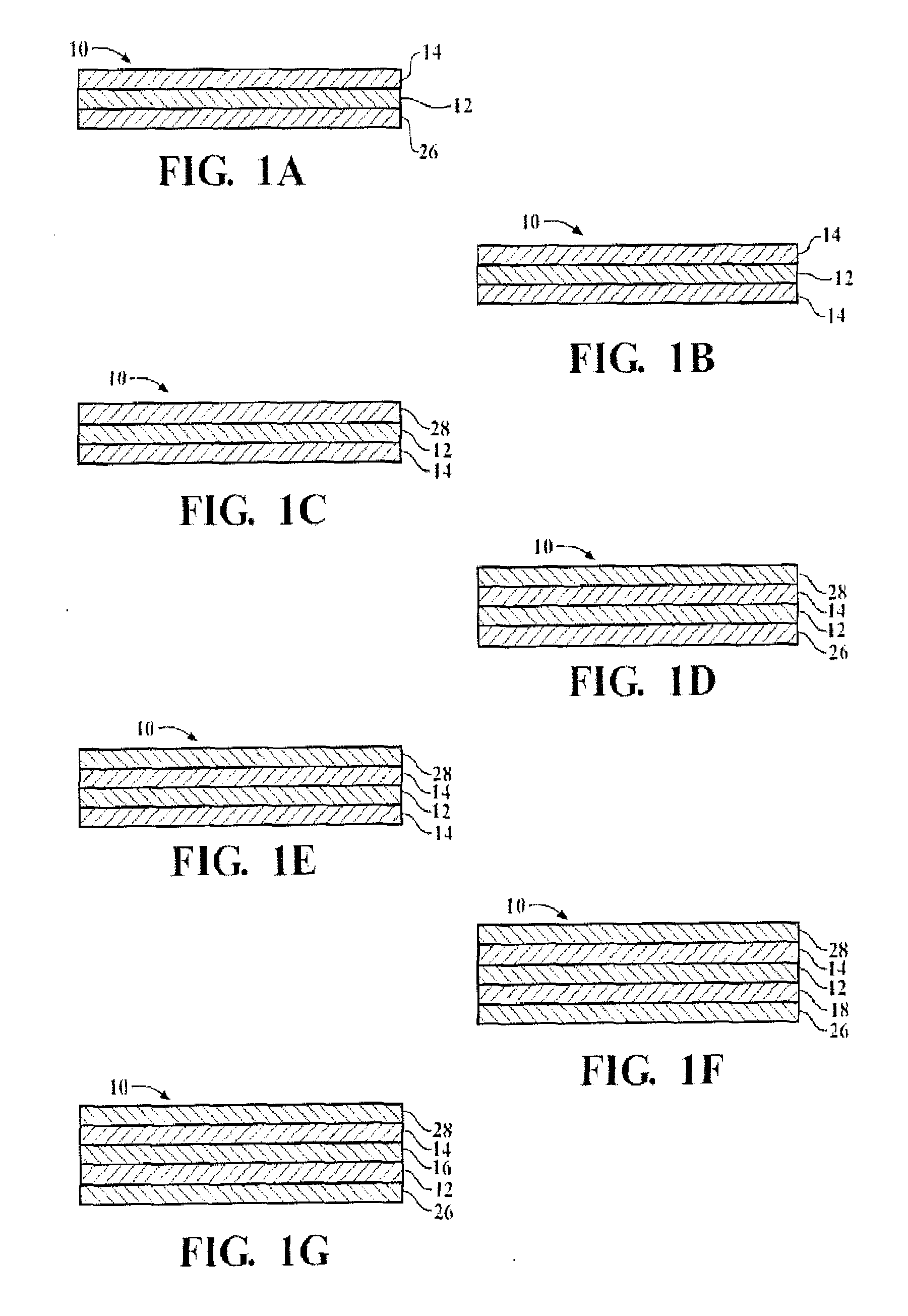

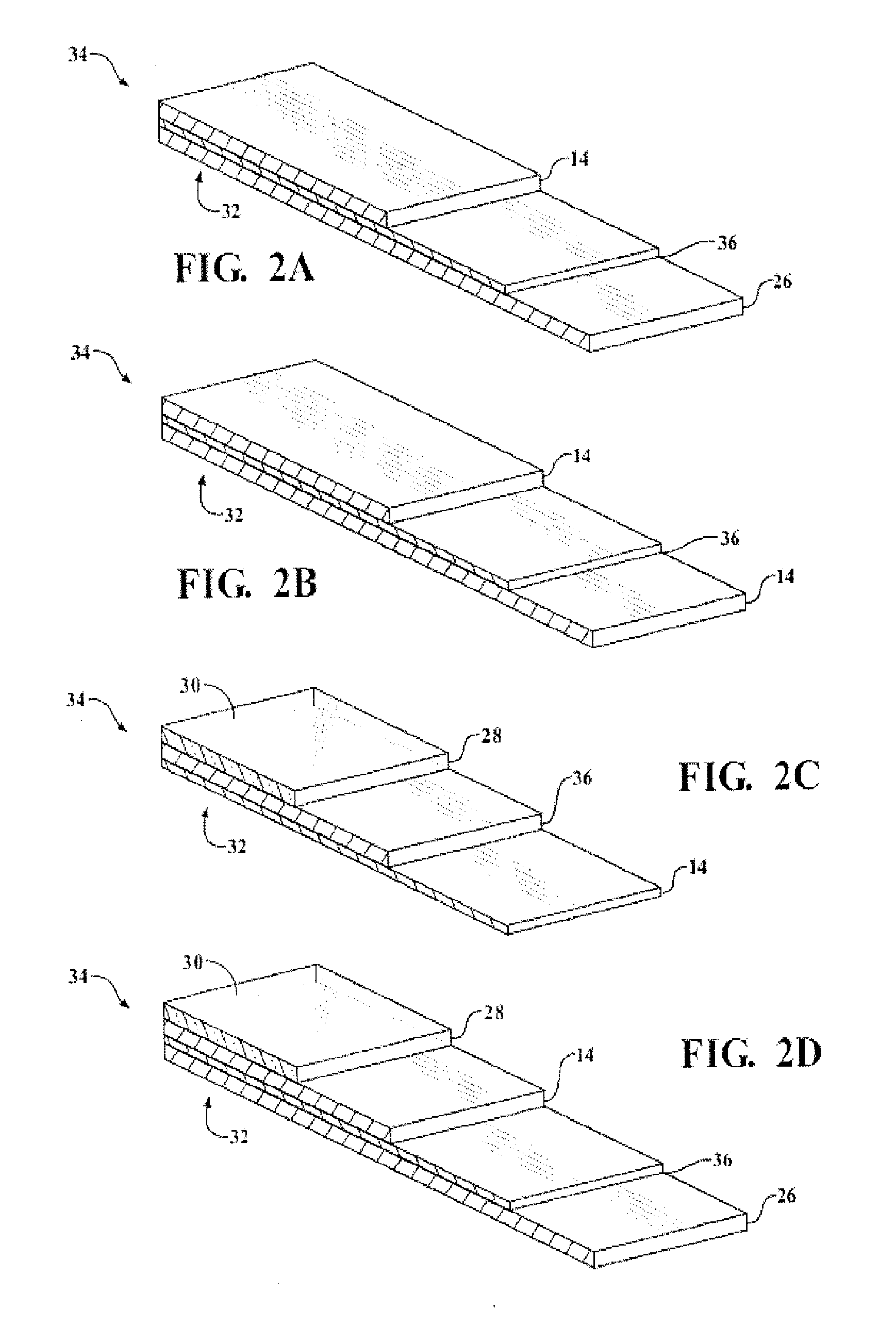

An automated banking machine includes a chest portion (14). Transaction function devices such as an input device (18) and a display screen (24) are supported on the chest portion. A generally one-piece polymer body (28) is operatively engaged relative to the chest portion and extends in generally surrounding relation of the input device and display screen. The body includes at least one opening (30) such that the display screen is visible and the input device is accessible through the body.

Owner:DIEBOLD NIXDORF

High-impact polystyrene blend and preparation thereof

InactiveCN101372548AFlame-retardant high-impact polystyrene blend, environmentally friendlyEnvironmentally friendlyAntioxidantMechanical property

The invention relates to a synthetic material, in particular to a halogen-free flame retardant high impact polystyrene blend and a preparation method thereof. The high impact polystyrene blend comprises high impact polystyrene resin with the mass percent of 35-75%, an inorganic flame retardant with the mass percent of 7-45%, an intumescent flame retardant with the mass percent of 5-20%, a flame retardant synergist with the mass percent of 1-5%, a toughening agent with the mass percent of 10-20%, a coupling agent with the mass percent of 0.5-2.0%, a lubricant with the mass percent of 0.5-3.0% and an antioxidant with the mass percent of 0.2-3.0%. The halogen-free flame retardant high impact polystyrene blend is produced by high-speed premixing and extrusion prilling, and has the advantages of environmental protection, flame retardation, low smoke, weather resistance, good thermal stability and mechanical property, easy machine shaping, etc.

Owner:珠海市远康企业有限公司

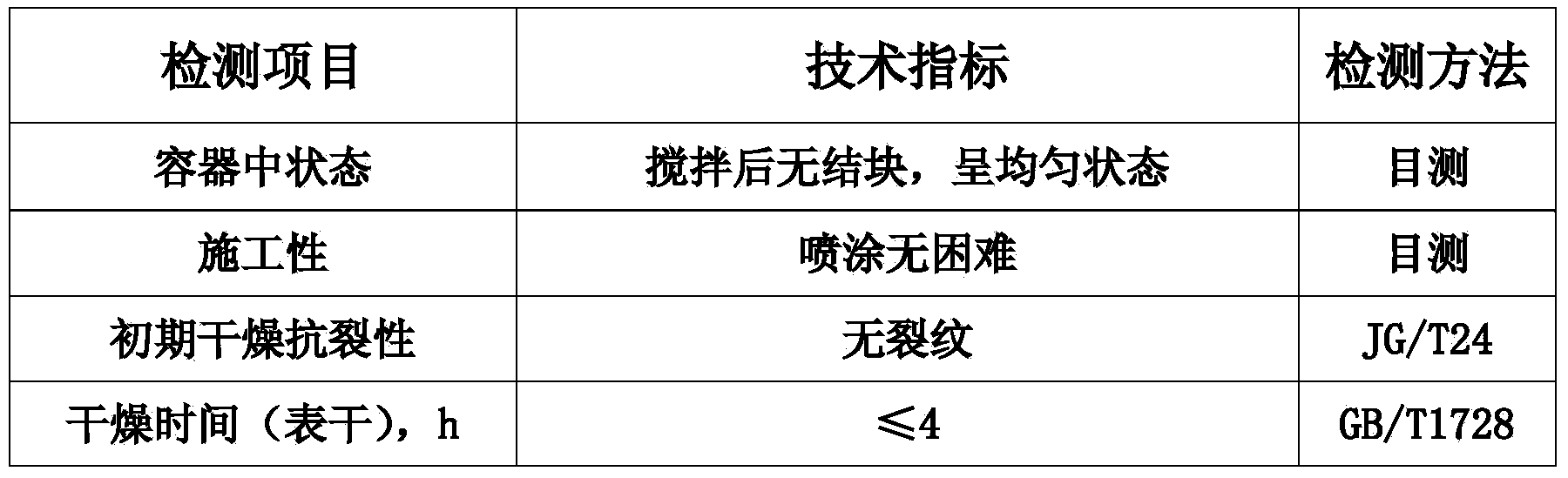

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

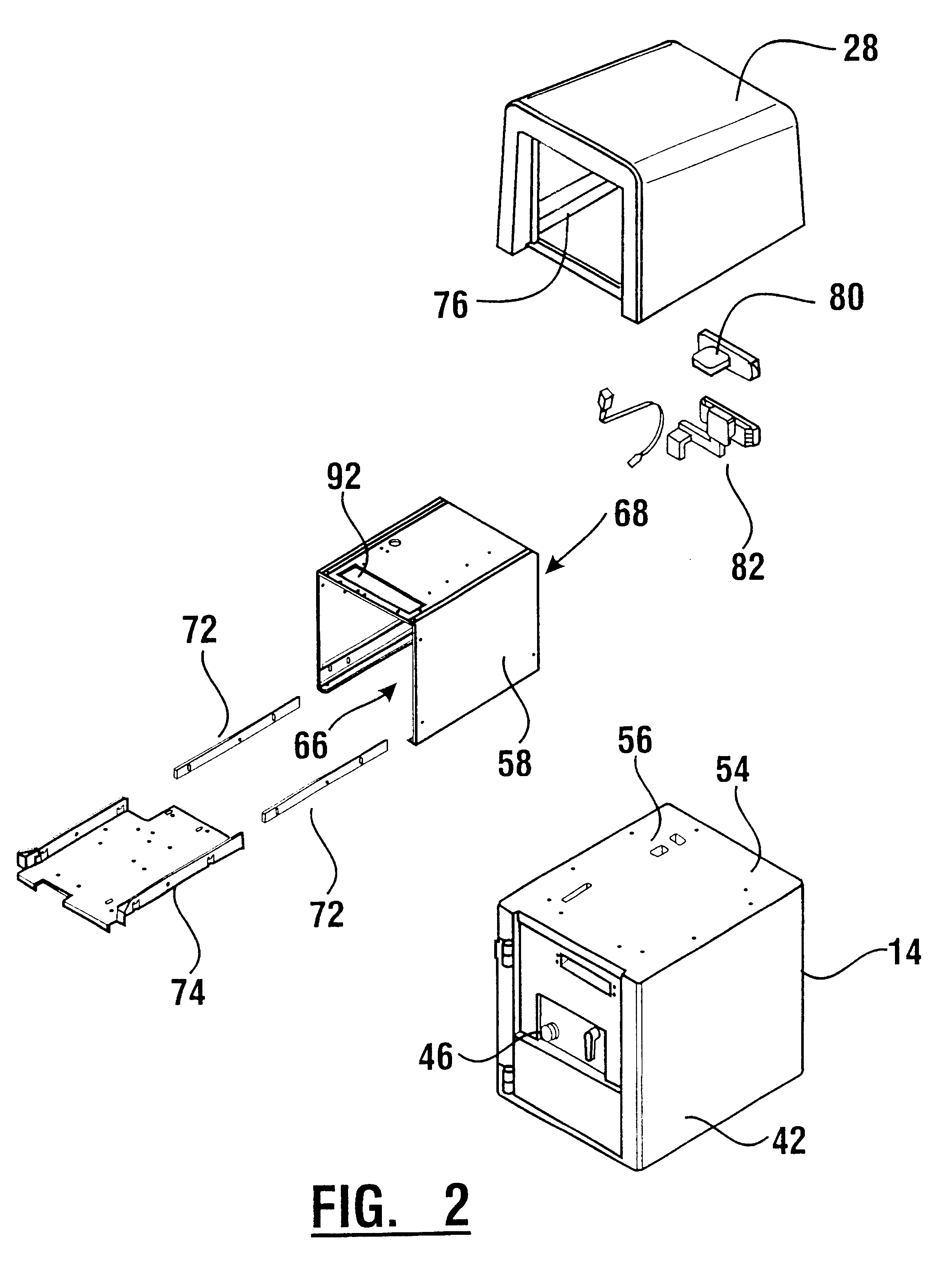

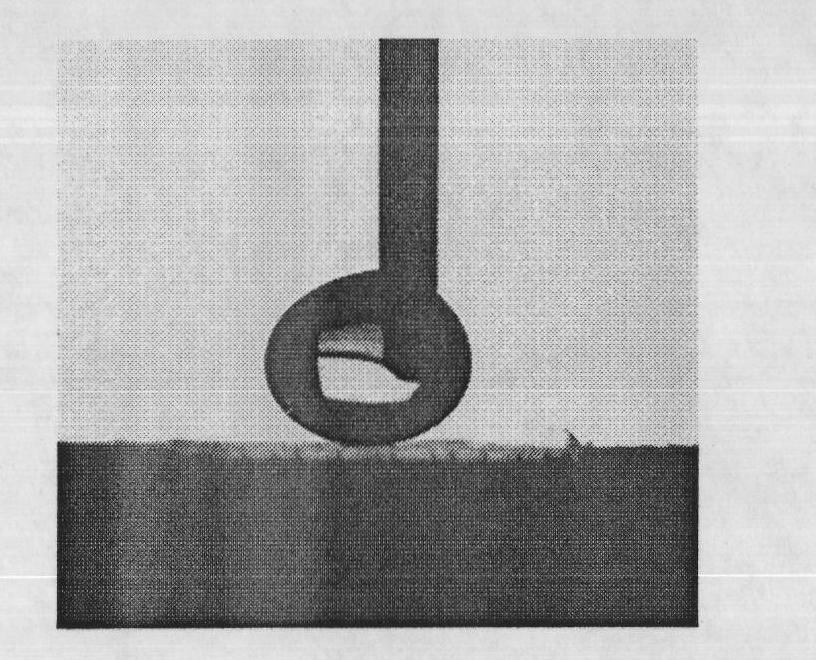

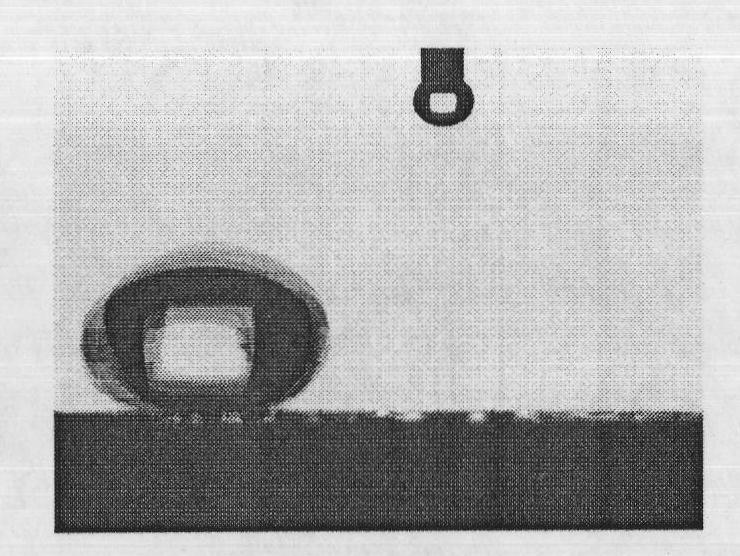

Super-hydrophobic nano-composite coating and preparation method thereof

InactiveCN101845242AExcellent superhydrophobic propertiesAchieve self-cleaning effectCoatingsProcess equipmentHydrophobic polymer

The invention discloses a super-hydrophobic nano-composite coating comprising the following components in percentage by weight: 0.5-10.5 percent of hydrophobic silicon dioxide, 0.2-5.4 percent of hydrophobic polymer material and 86.5-99.3 percent of solvent, wherein a contact angle of a water drop on a membrane surface prepared by the coating is 152-169 degrees, and a rolling angle is 1-9 degrees. When the coating is transparent, the visible light transmission of the membrane prepared from the coating is 80-94 percent. The invention also discloses a preparation method of the super-hydrophobic nano-composite coating. The nano-composite coating not only has excellent super-hydrophobicity and low cost of products, but also can obtain higher transparency by reducing the contents of the hydrophobic silicon dioxide and the hydrophobic polymer material and has simple preparation processing equipment and high production efficiency.

Owner:SICHUAN UNIV

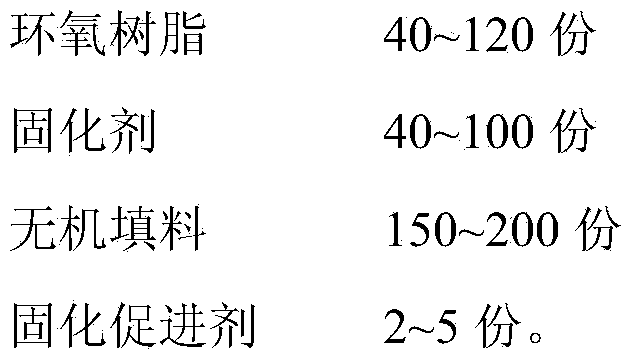

Outdoor electric-insulation modified epoxy resin composition

The invention discloses an outdoor electric-insulation modified epoxy resin composition which comprises an epoxy resin, a curing agent, a curing accelerator and an inorganic filler. The outdoor electric-insulation modified epoxy resin composition has the advantages of high weather resistance, favorable hydrophobicity, high volume resistivity, high tracking resistance, high arc resistance, low thermal expansivity and the like, and can be used for manufacturing suspension insulators for alternating current transmission lines as well as umbrella skirts of cross arms and other outdoor insulation parts. Compared with the silicon rubber umbrella skirt, the umbrella skirt prepared from the composition can prevent birds from damage, resist line walking trampling, avoid shipping damage and the like.

Owner:赛思迈(上海)新材料科技有限公司

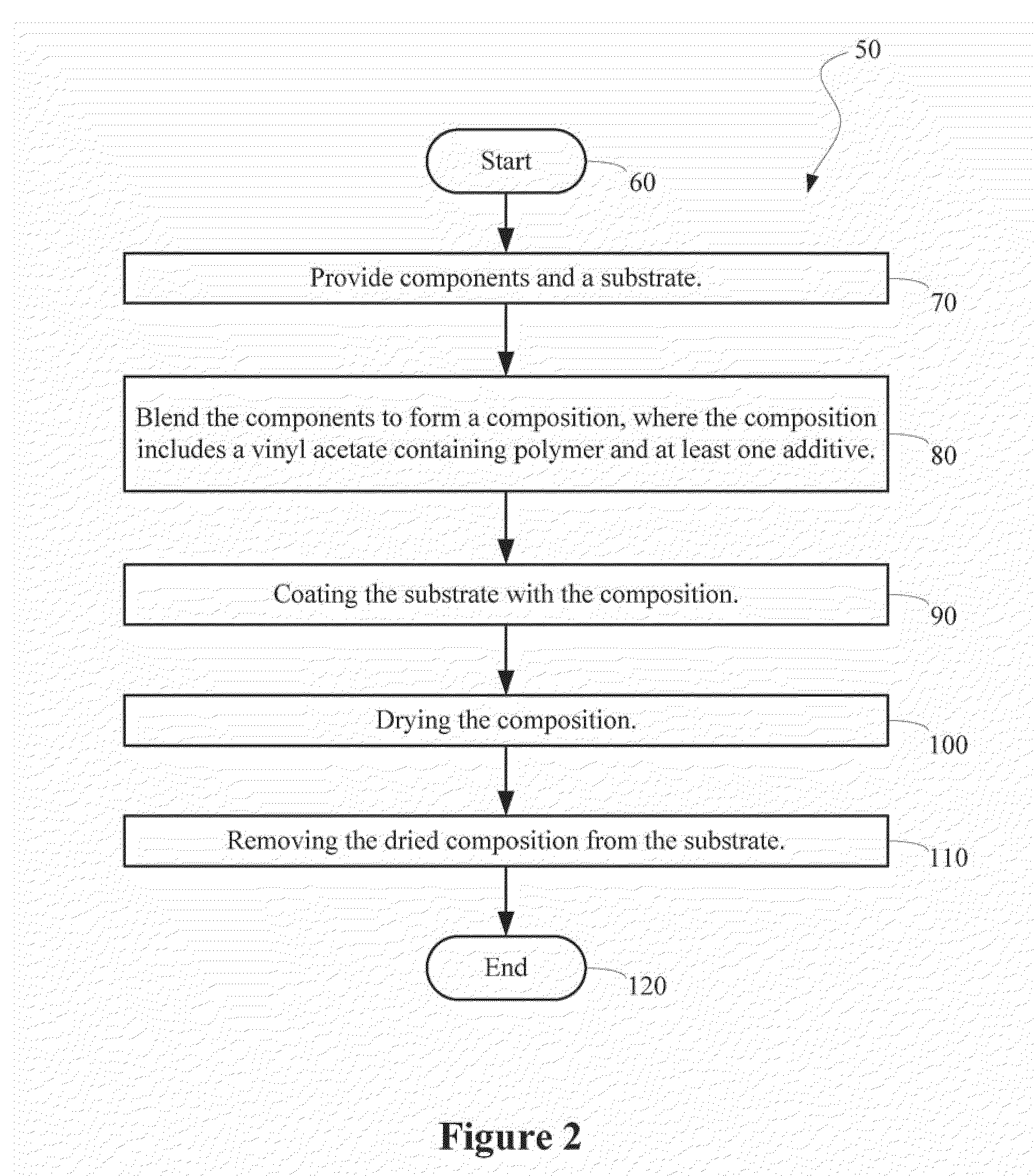

Composition, film and related methods

ActiveUS20100009108A1Easy to printGood colorDuplicating/marking methodsSynthetic resin layered productsUltravioletSolvent

A composition that is configured for use in creating a film. The composition includes a vinyl acetate containing polymer, such as a vinyl acetate ethylene (VAE) copolymer, and at least one additive that is a pigment, a surfactant, a dispersant, a wetting agent, a plasticizer, a defoamer, a coupling agent, a solvent, a UV absorber, a fire retardant, or a light stabilizer.

Owner:AVERY DENNISON CORP

Ultraviolet cured coating system

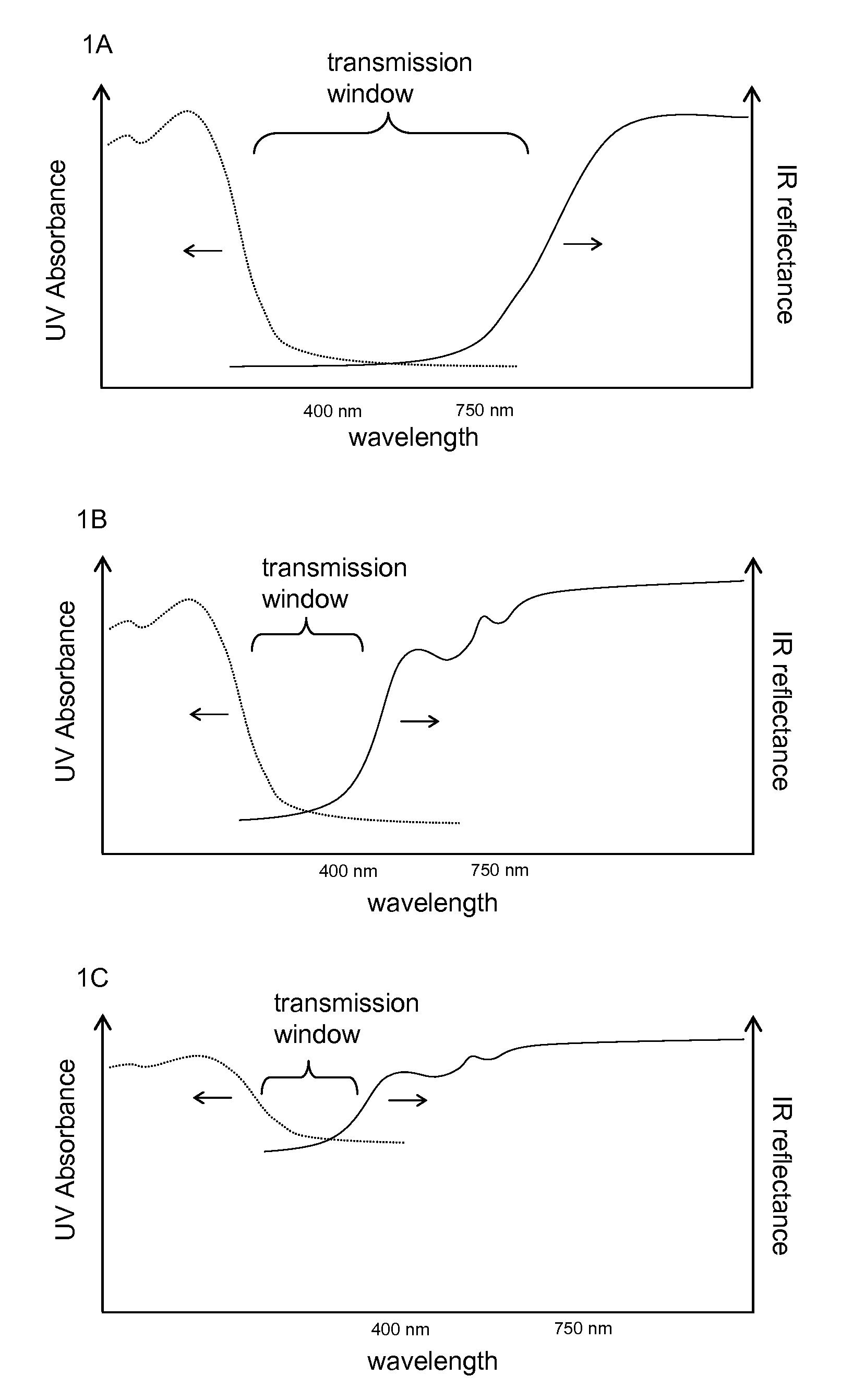

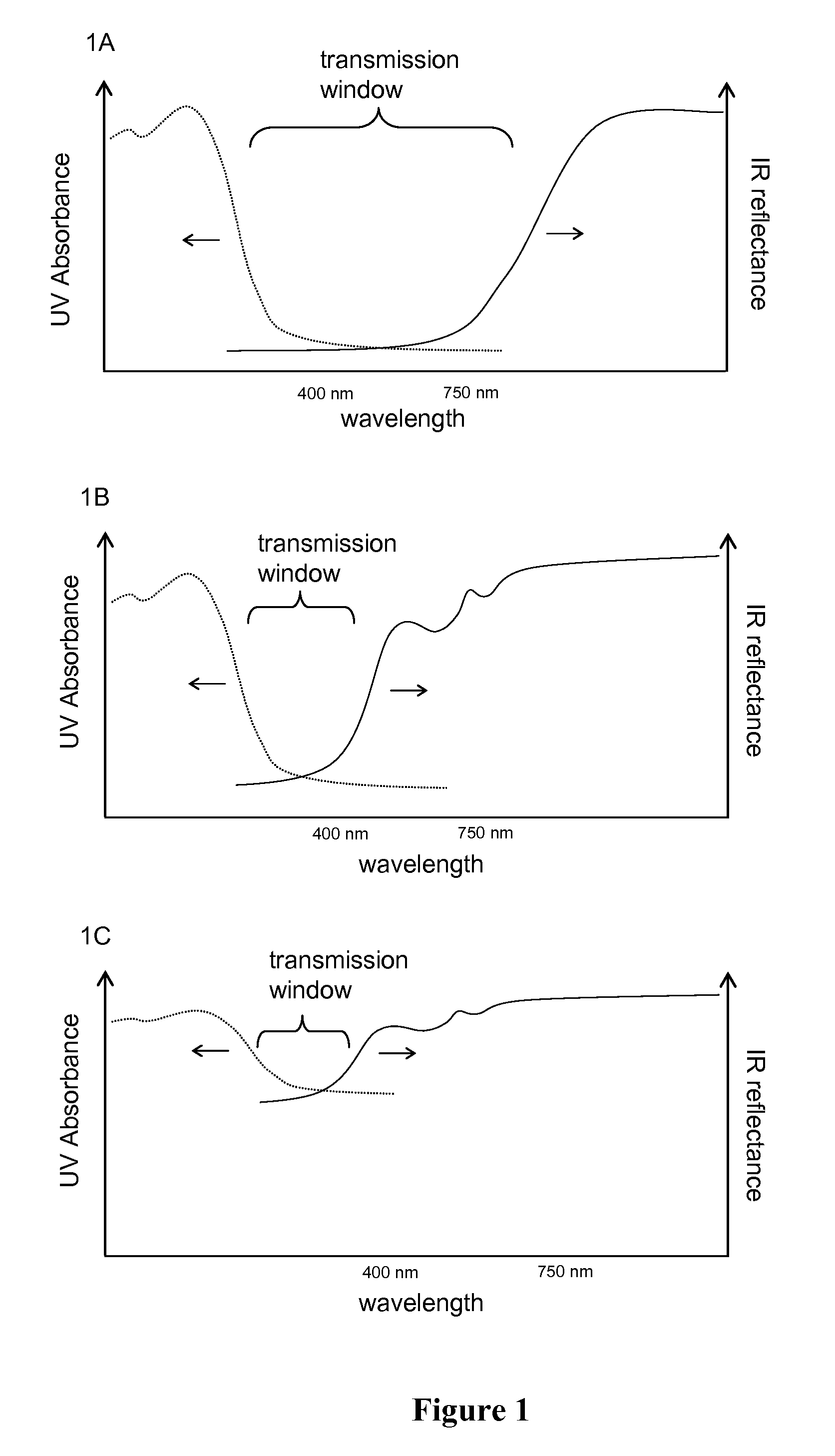

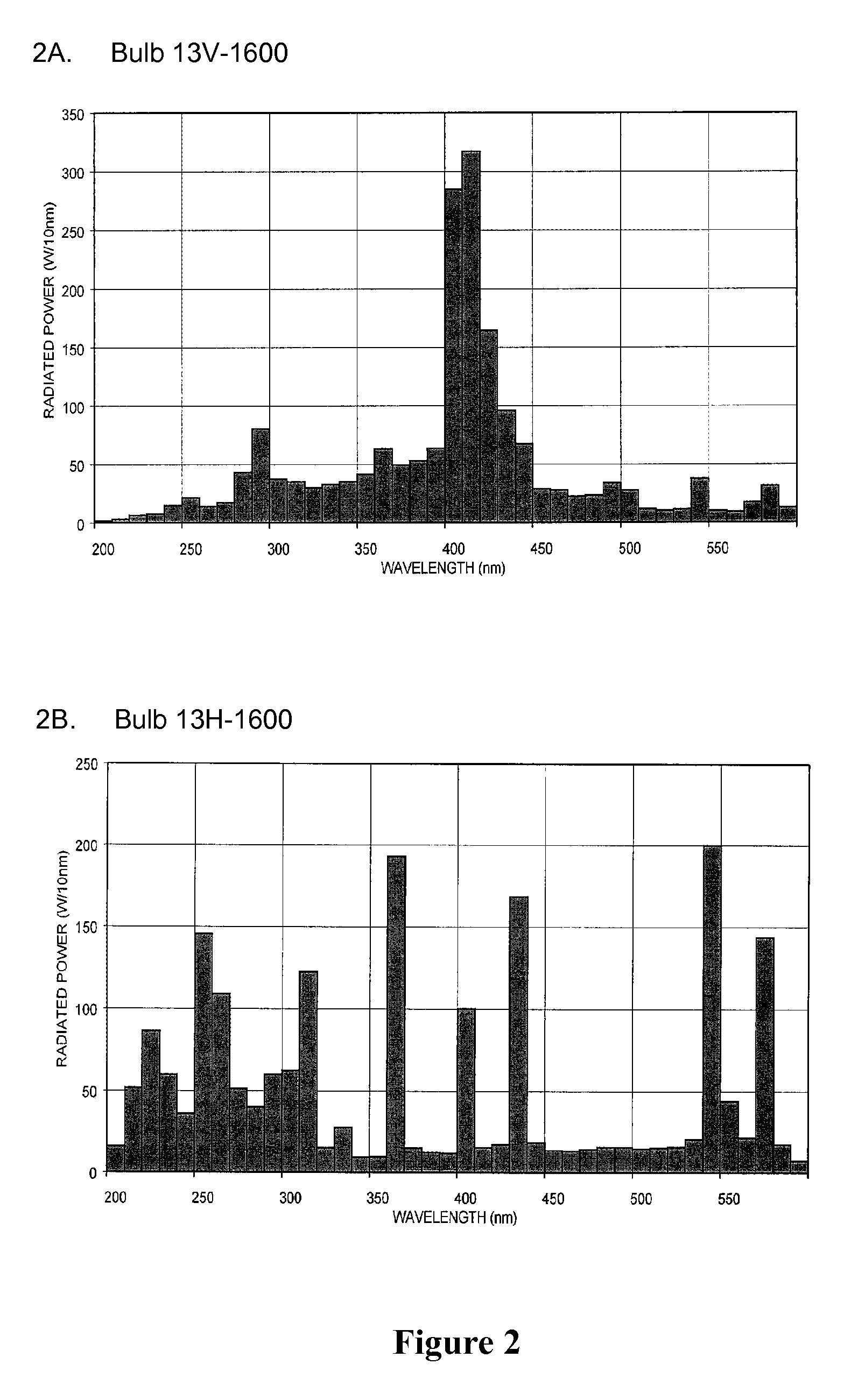

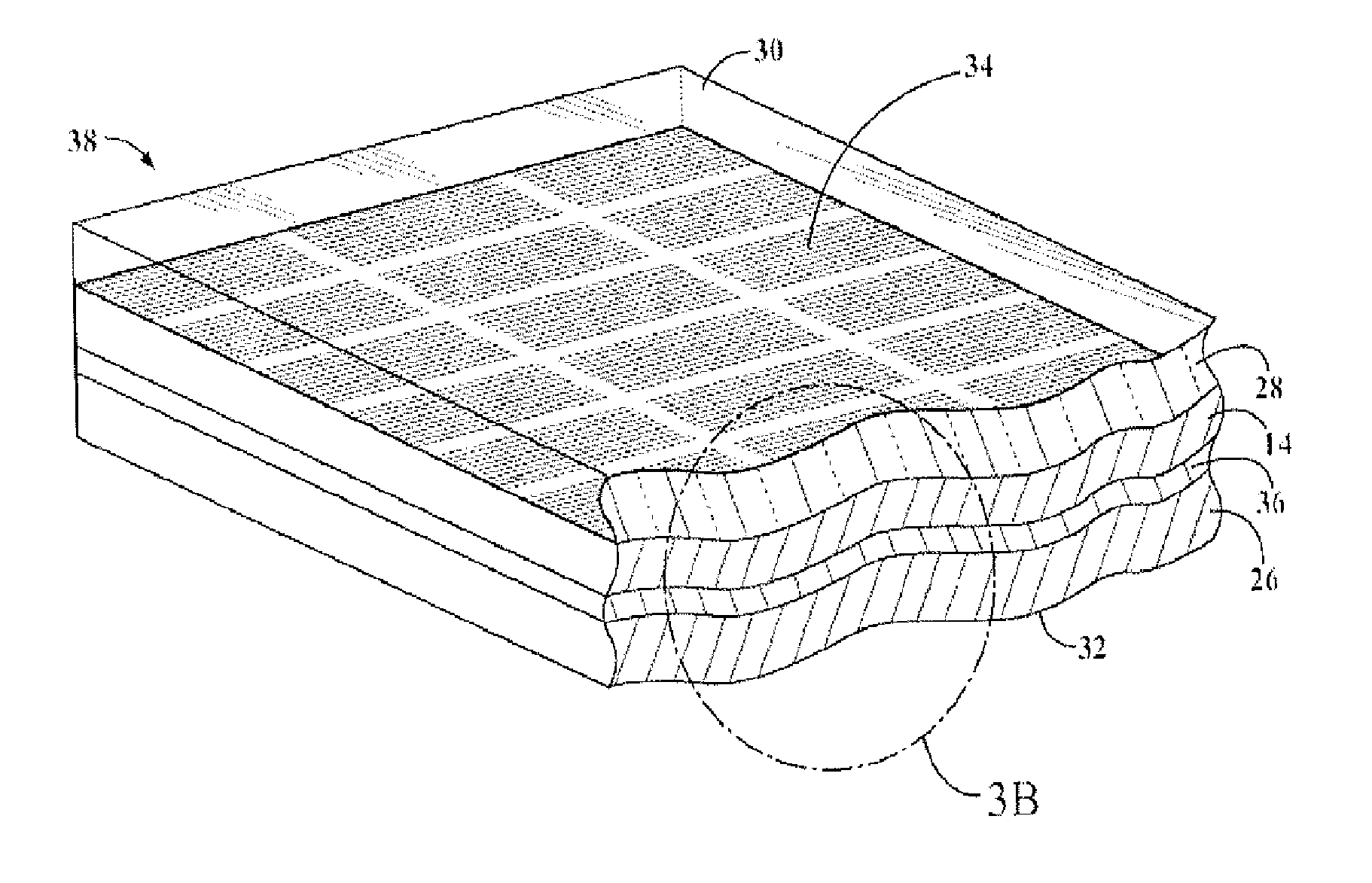

InactiveUS20090188559A1Weather resistantReduce surface temperatureMixing methodsPhotovoltaicsUV curingCoating system

The present invention is directed to ultraviolet cured coating compositions. More specifically, the present invention is directed to urethane / acrylic coating compositions that contain additives for the absorption of ultraviolet radiation and the reflection of infrared radiation and which are UV cured.

Owner:BUILDING SOLUTIONS IP

Organosiloxane block copolymer

ActiveUS20130168727A1High light transmittanceLow costSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceTransmittance

An organosiloxane block copolymer includes 65 to 90 mol % of diorganosiloxane units having the formula R12SiO2 / 2 (I). These diorganosiloxane units are arranged in linear blocks which have an average of from 10 to 400 diorganosiloxane units per linear block. The organosiloxane block copolymer also includes 10 to 35 mol % of siloxane units that have the average formula R2x(OR3)ySiO(4-x-y) / 2 (II). The siloxane units are arranged in nonlinear blocks having at least 2 siloxane units per nonlinear block wherein 0.5≦x≦1.5 and 0≦y≦1. In addition, each R1 is independently a C1 to C10 hydrocarbyl, each R2 is independently an aryl or C4 to C10 hydrocarbyl, at least 50 mol % of R2 are aryl, and each R3 is independently R1 or H. Moreover, the organosiloxane block copolymer has a light transmittance of at least 95%.

Owner:DOW SILICONES CORP

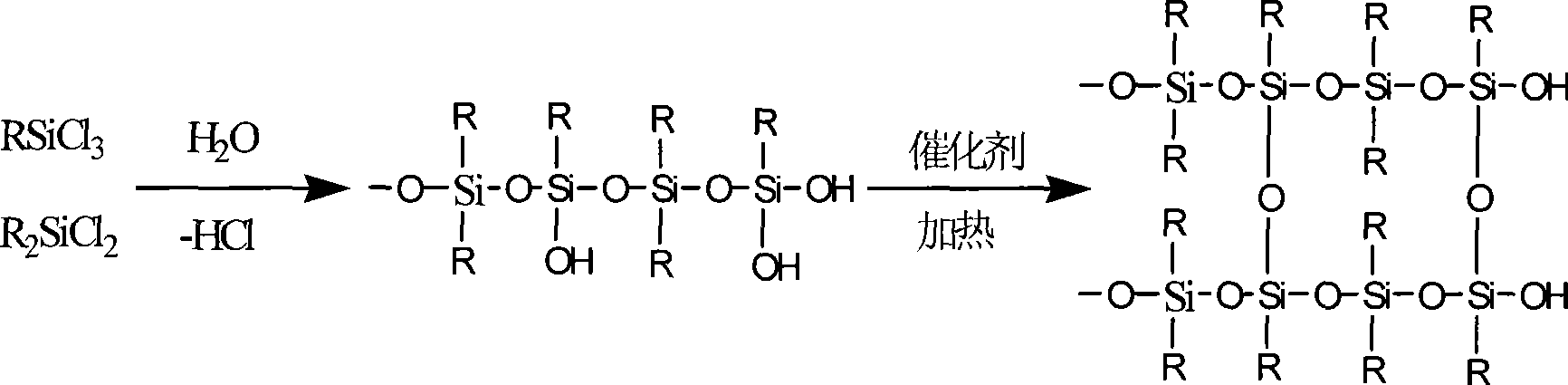

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776AWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

Heat preserving really stone paint and preparation method thereof

The invention discloses a heat preserving really stone paint and a preparation method thereof. The heat preserving really stone paint is prepared from the following components in parts by weight: 150-200 parts of a silicone acrylic emulsion, 450-500 parts of natural colored sand, 150-200 parts of hollow glass beads, 5-8 parts of hydroxyethyl cellulose, 200-250 parts of tap water and 35-50 parts of an auxiliary. By combining the silicone acrylic emulsion, the natural colored sand and the hollow glass beads, the heat preserving really stone paint disclosed by the invention has stabilities such as excellent weather resistance, tarnish resistance, temperature change resistance and ageing resistance and heat preserving performance as well as color diversification. In addition, the preparation method disclosed by the invention does not need grinding. Only dispersion is needed to prepare a product paint, so that the paint is simple in production process.

Owner:ZHANG ZHOU SAN PAINTS

Poly acrylate composite emulsion for pressure' sensitive adhesive and its preparing and using method

InactiveCN1944479AImprove interface compatibilityUniform particle sizeFilm/foil adhesivesEster polymer adhesivesEmulsionAcrylic acid

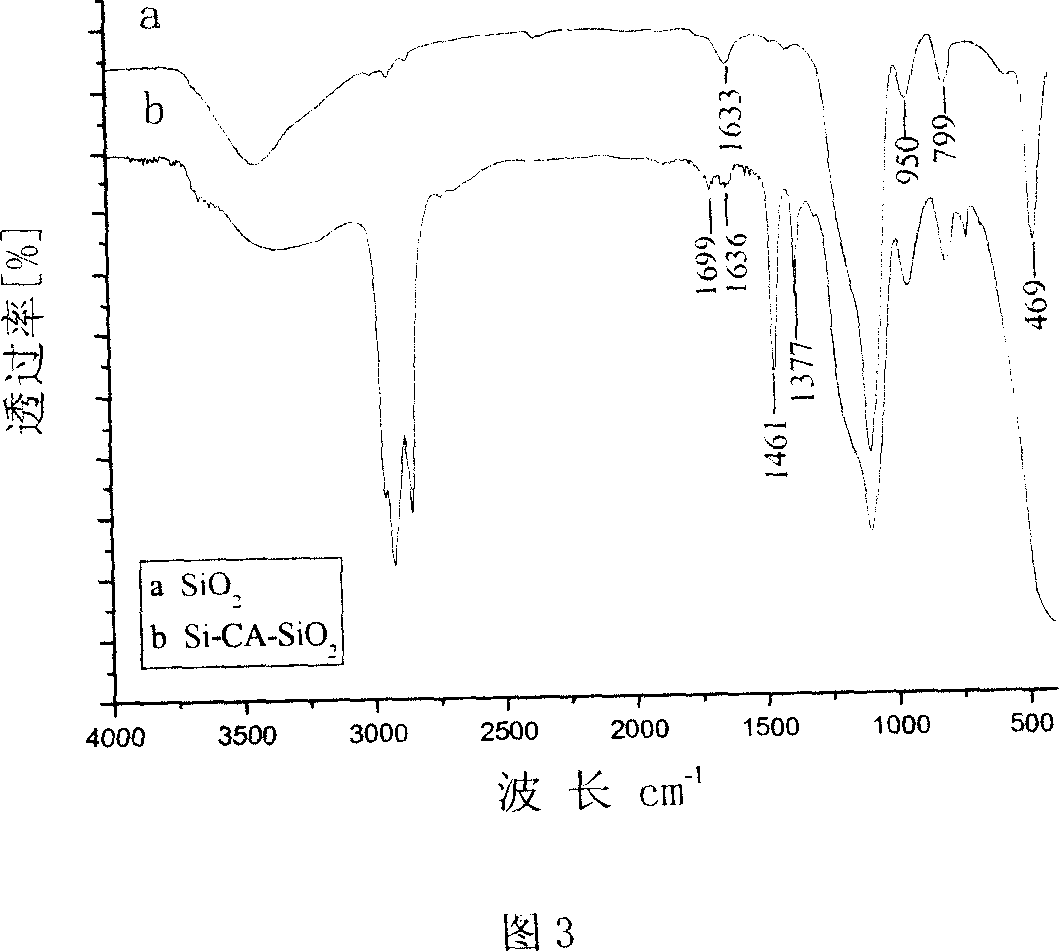

The present invention is composite polyacrylate emulsion for pressure sensitive adhesive and its preparation process and application, and relates to polyacrylate based adhesive. The composite emulsion is one core-shell structure with silane cross-linking agent surface modified nanometer silica as the core and the copolymer of acrylate and acrylic acid as the shell, and has solid content of 30-40 %, viscosity of 1-6 mPa.s, composite emulsion particle size of 250-700 nm and particle size dispersing index of 0.005-0.15. The composite polyacrylate emulsion is prepared through preparing nanometer silica alcohol sol, surface modification of nanometer silica and preparing nanometer silica-polyacrylate composite emulsion. The composite polyacrylate emulsion coating is dried to obtain the pressure sensitive adhesive with high initial adhering performance and cohesive property.

Owner:HEBEI UNIV OF TECH

Manufacturing method of hot bent 3D (Three Dimensional) glass white sheet

InactiveCN106746525AEliminate internal stressFlat surfaceEdge grinding machinesPolishing machinesNumerical controlHeating time

The invention relates to a manufacturing method of a hot bent 3D (Three Dimensional) glass white sheet. The manufacturing method comprises the following steps: (1) cutting a material: cutting a glass white sheet material into a plurality of small glass white sheets with proper sizes; (2) finely engraving: putting the small glass white sheets into a CNC (Computer Numerical Control) fine engraving machine, and punching and grinding edges; (3) cleaning: carrying out cleaning treatment on the glass white sheet by utilizing a glass cleaning machine; (4) carrying out ultrasonic treatment: washing surface residual waste dreg on the surface of the glass white sheet by utilizing an ultrasonic washing machine; (5) hot bending: putting the glass white sheet into a hot bending mold and hotly bending, machining and molding the glass white sheet into a 3D curve surface; (6) tempering: putting the hotly bent glass white sheet into a tempering frame; conveying the tempering frame into a tempering furnace and raising the temperature to 380 DEG C-420 DEG C, wherein the heating time is 4h-8h and the hardness reaches 7H; (7) carrying out plasma spraying: putting the glass white sheet into a fingerprint oil spraying machine and spraying fingerprint oil on a surface through plasmas; baking at a temperature of 140 DEG C-160 DEG C for 25-30 minutes until the fingerprint oil is dried; (8) fitting: fitting release films on upper and lower surfaces of the glass white sheet; and (9) packaging.

Owner:DONGGUAN YUANMEI PRECISION ELECTRONICS CO LTD

Method for applying metal wire-imitated coating film on surface of engineering plastics

ActiveCN102166565AAnti-corrosionWear-resistantCoatingsSpecial surfacesWater savingEngineering plastic

The invention provides a method for applying a metal wire-imitated coating film on the surface of engineering plastics, and relates to a surface treatment method of the engineering plastics. The method for applying the metal wire-imitated coating film on the surface of engineering plastics can improve the function and the quality of a plastic metalized product, can simplify the technology, can reduce the production cost, and is water-saving and environment-friendly without needing any water liquid in the whole technological process. The method comprises the steps of adding dye into plastic master batch, and coloring; cleaning and activating a plastic blank in a drying way; spraying a color coat onto the plastic blank; performing the wire drawing to a work piece so as to obtain the surface with wire drawing veins; cleaning and activating the work piece in a drying way; and spraying finishing paint to the work piece with the wire drawing veins so as to apply the metal wire-imitated coating film on the surface of the engineering plastics.

Owner:XIAMEN RUNNER IND CORP

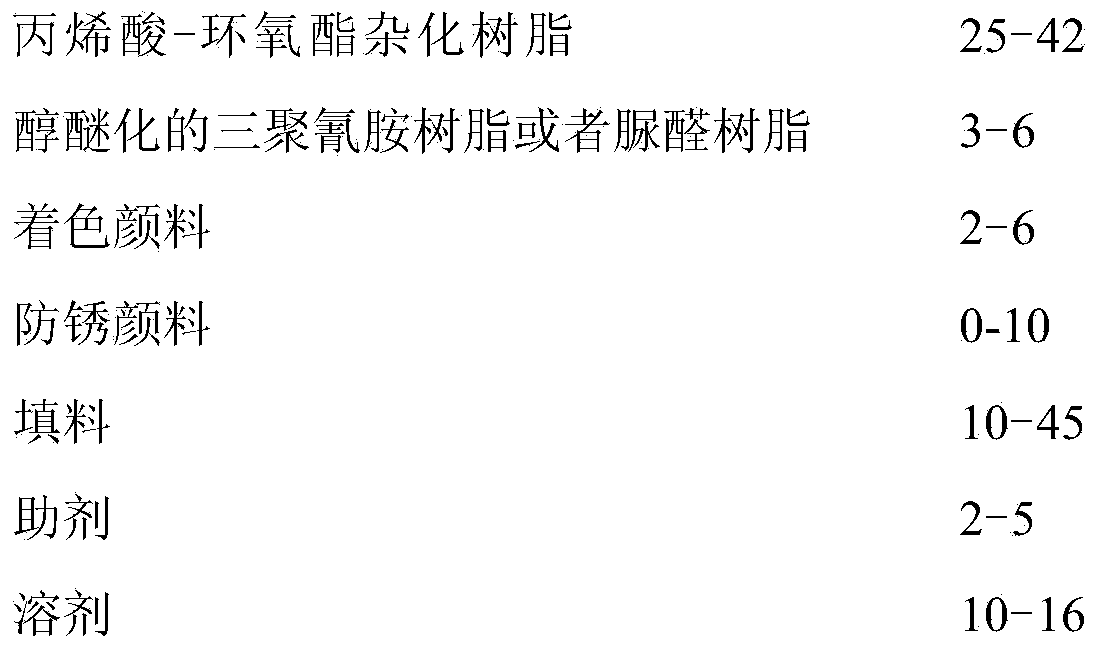

Acrylic acid-epoxy ester hybrid resin and coatings thereof

The invention provides an acrylic acid-epoxy ester hybrid resin. The acrylic acid-epoxy ester hybrid resin is prepared by reacting an epoxy resin and aliphatic acid under the action of a catalyst so as to prepare epoxy ester and then adding acrylic monomers and an initiator under certain conditions. A self-drying type antirust coating can be prepared with the acrylic acid-epoxy ester hybrid resin provided by the invention as a main film forming substance; a dried anticorrosive coating can also be prepared, especially coatings for curtain spraying sliver-coated mirrors, color films and aluminum mirrors; the coatings can meet coating process requirements of a wide-curtain spraying and coating production line with a maximum length of 3 m and are completely dried when baked at a temperature of 130 to 150 DEG C for 5 to 3 min, a film obtained after complete drying has excellent anticorrosion performance, can resist CASS, dampness, dryness and water with a temperature of 60 DEG C for more than 240 h, satisfy requirements of edging and texturing process of a downstream client and do not suffer from edge blackening and corrosion of clad layers.

Owner:常州市弘可利办公用品有限公司 +1

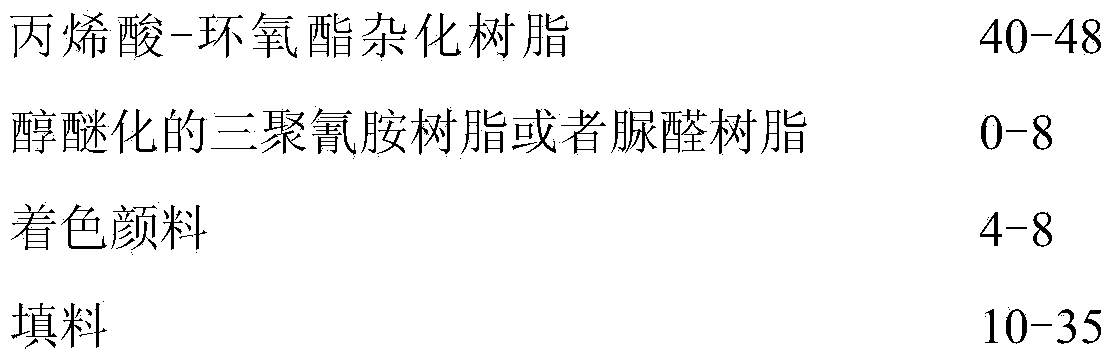

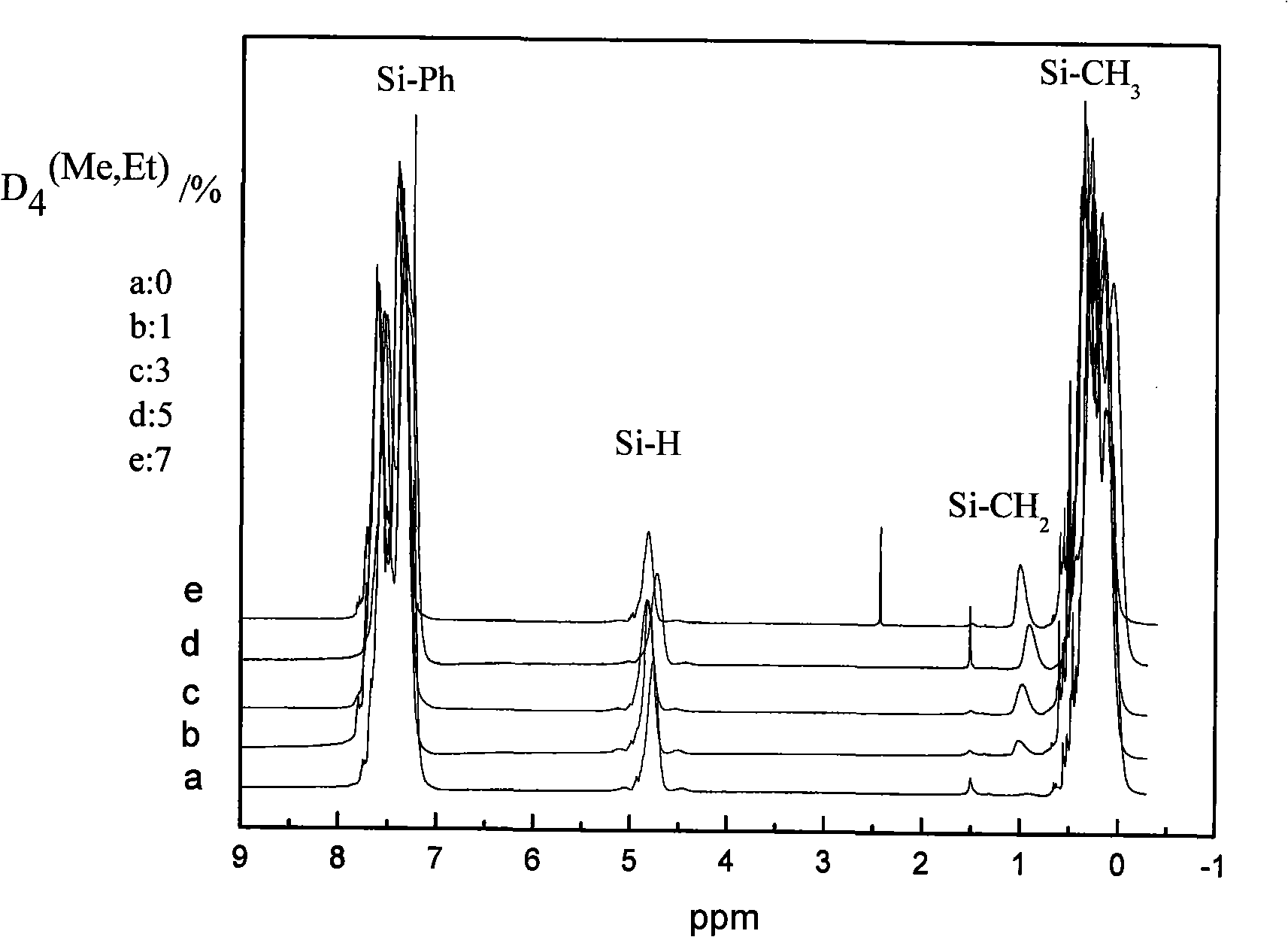

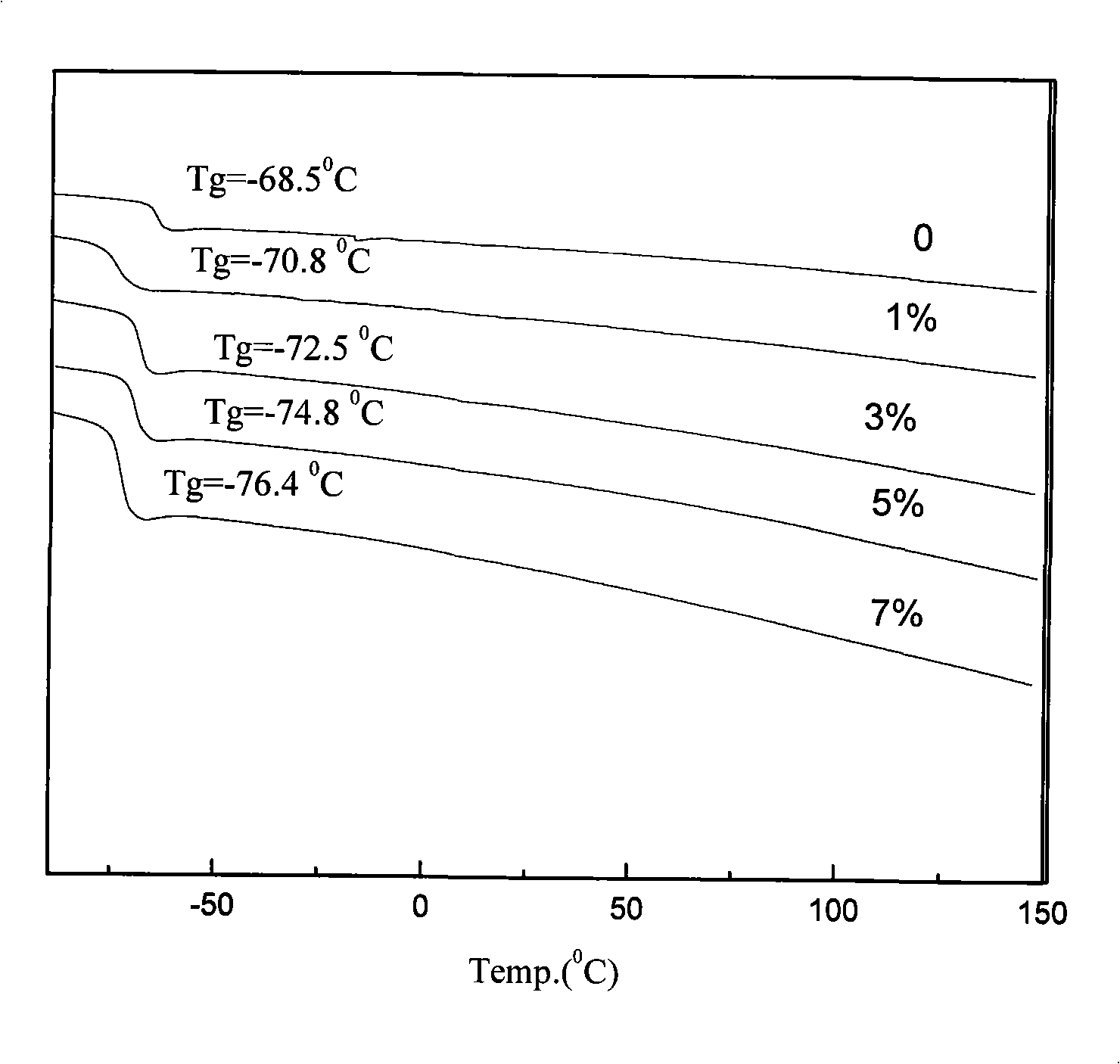

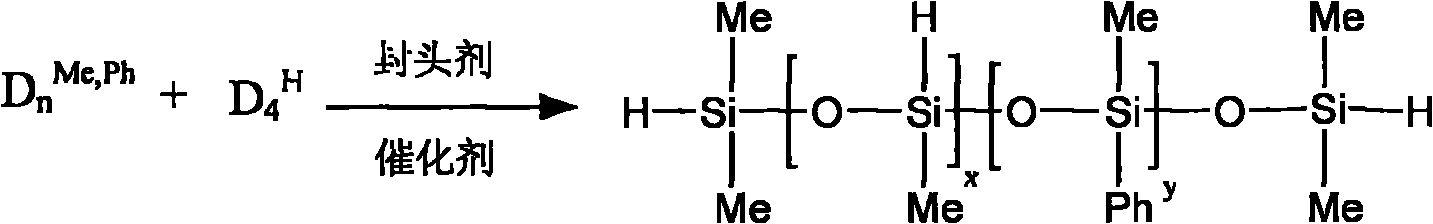

Method for preparing methyl and phenyl hydrogen-containing silicon oil for packaging LED

ActiveCN101289538AHigh refractive indexRadiation resistantChemical recyclingSemiconductor devicesHydrogenRoom temperature

The invention relates to a method for making hydrogen-containing silicone oil, in particular to a method for making methyl phenyl hydrogen-containing silicone oil for the encapsulation of LEDs. The method is characterized in that the methyl-phenyl cyclic siloxane (Dn<Me, Ph>), the tetramethyl tetraethyl cyclic tetra-siloxane (D4<Me, Et>) and hydrocyclotetrasiloxane (D4<H>) are taken as monomers; under the protection of N2, right amount of an end capping agent is added into the monomer mixture to be copolymerized under the action of a catalyst, after the polymerization, the catalyst is filtered and recycled, the low molecular compound of the obtained clear solution is removed in decompression and high temperature conditions, the clear solution without low molecular compound is cooled to the room temperature, and the target product is obtained. The method has the advantages of available raw materials, low cost, moderate conditions, simple technique, simple operation, environmental protection and convenient industrialization. The product made by the method can be widely applied to the enterprises which manufacture and use the LEDs, etc.

Owner:XINYAQIANG SILICON CHEM JIANGSU

Elastic fiber fabric and preparation method thereof

The invention relates to an elastic fiber fabric, in particular to an elastic fiber fabric and a preparation method thereof. Warps and wefts are respectively 150D or75D PTS elastic yarns. The elastic fiber fabric is prepared through the steps of winding, twisting, sectional warping, healding, weaving, blank inspection, unrolling and flattening, pre-shrinking treatment, presetting, dyeing, reduction clearing and finishing. The elastic fiber fabric and a preparation method thereof have the advantages as follows: the structure is simple, the chemical fiber differentiation is promoted, the added value is increased, the preparation steps are scientific and reasonable and conform to the basic state policy of energy conservation and emission reduction, and the fabric feels like nylon, has a bright and pure color, is far lower than spandex in price and is a preferred garment material.

Owner:杭州宏海纺织有限公司 +1

Dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy anticorrosive coating and preparation method thereof

InactiveCN101798484ASolve pollutionNo pollution in the processAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedCross-link

The invention discloses a dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy anticorrosive coating and a preparation method thereof. Compositions of the coating mainly comprise dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy emulsion, anticorrosive pigment and filler, pigment dispersing agent, a film forming aid, a water-based additive, a cross-linking curing agent and deionized water, wherein the dendritic organic-inorganic hybrid water-borne nano polyurethane-epoxy emulsion is prepared by the following steps: prepolymerizing a polyurethane hydrophilic branch; preparing a dendritic polyurethane intermediate product by adopting hyperbranched synthesis technology; inoculating organic-inorganic hybrid into a nano material by adopting a in-situ polymerization; and simultaneously grafting epoxy resin with hydroxyl; and the prepared emulsion is compounded with the anticorrosive pigment and filler and the like to prepare the anticorrosive coating. The anticorrosive coating radically solves the VOC pollution problem of solvent-type anticorrosive coating, and simultaneously solves a series of problems such as poor roughness, weatherability, ageing resistance, alkali resistance and solvent resistance of the conventional water-borne anticorrosive coating.

Owner:SICHUAN UNIV +1

UV-curable elastic polyurethane acrylate emulsion and synthesis method thereof

InactiveCN104558499ASelf-emulsifyingGood flexibilityInksPolyurea/polyurethane coatingsPolyesterEndcapping

The invention discloses UV-curable elastic polyurethane acrylate emulsion and a synthesis method thereof. The synthesis method of the UV-curable elastic polyurethane acrylate emulsion comprises the following steps: carrying out reaction on polyester glycol or polyether glycol, carboxylic acid-containing glycol and diisocyanate to generate a prepolymer, adding an optimized micromolecular chain extender for carrying out chain extension, then adding hydroxy-containing acrylate for carrying out blocking reaction, diluting by virtue of an organic solvent, neutralizing and salifying by adopting organic amine, finally adding deionized water for carrying out hydration, and adding a photoinitiator to obtain the UV-curable elastic polyurethane acrylate emulsion. The UV-curable elastic polyurethane acrylate emulsion is polyurethane blocked by acrylate, and a molecular chain of the UV-curable elastic polyurethane acrylate emulsion is provided with hydrophilic negative ions and double bonds, so that the UV-curable elastic polyurethane acrylate emulsion has self-emulsifying property and photocuring activity; and a cured film formed by carrying out photocuring on the synthesized elastic polyurethane acrylate emulsion has excellent mechanical properties, tensile strength is 21MPa, and elongation is 350%, so that the elastic polyurethane acrylate emulsion can serve as matrix resin of water-based ink and waterborne UV-curable elastic paint.

Owner:HUNAN SUIFENG NEW MATERIAL & TECH DEV

Method for forming a glittering coating film

InactiveUS7166330B2Less feelingUnprecedented variationLayered productsPretreated surfacesWeather resistanceMetal particle

A method for forming a glittering coating film in which after a glittering base coating film is formed on a substrate to be coated by applying thereto a glittering base coating material containing a colloid particle liquid containing noble metal or copper colloid particles, the glittering base coating film is heated or set, and then a clear coating film is formed. By the method, a glittering coating film is provided which has weathering resistance and high gloss, and develops a metal feeling or a coloring metal feeling giving rise to a less feeling of metal particles than by the plating-tone coating film, and superior in design property.

Owner:NIPPON PAINT AUTOMOTIVE COATINGS

Preparation of super-hydrophobic coating with nanocrystalline cellulose/silicon dioxide composite template process

The invention discloses a method for preparing a super-hydrophobic coating with a nanocrystalline cellulose / silicon dioxide (NCC / SiO2) composite template process. The method comprises the following steps: (1) treating microcrystalline cellulose (MCC) with 56% sulfuric acid; (2) performing centrifugal washing; (3) replacing water in an NCC suspension solution with ethanol; (4) grinding for later use; and (5) freezing a sample to subzero 30 DEG C and performing vacuum freeze-drying. The method has the advantages that stearic acid is taken as a modifier and can produce a dehydration reaction with surface -OH of SiO2 / NCC, and stearic acid further introduces hydrophobic -CH3 groups, so that the surface energy of SiO2 / NCC is reduced; and an NCC and SiO2 compound has not only the properties of a biopolymer material but also the properties of an inorganic material such as weather resistance, hardness and the like, can be used for modifying indoor and outdoor coatings, and can play a role in aspects of building floor cleaning, furniture pollution prevention and the like.

Owner:广东新红阳科技有限公司

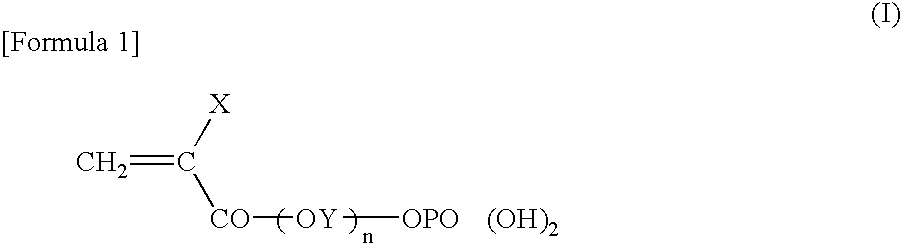

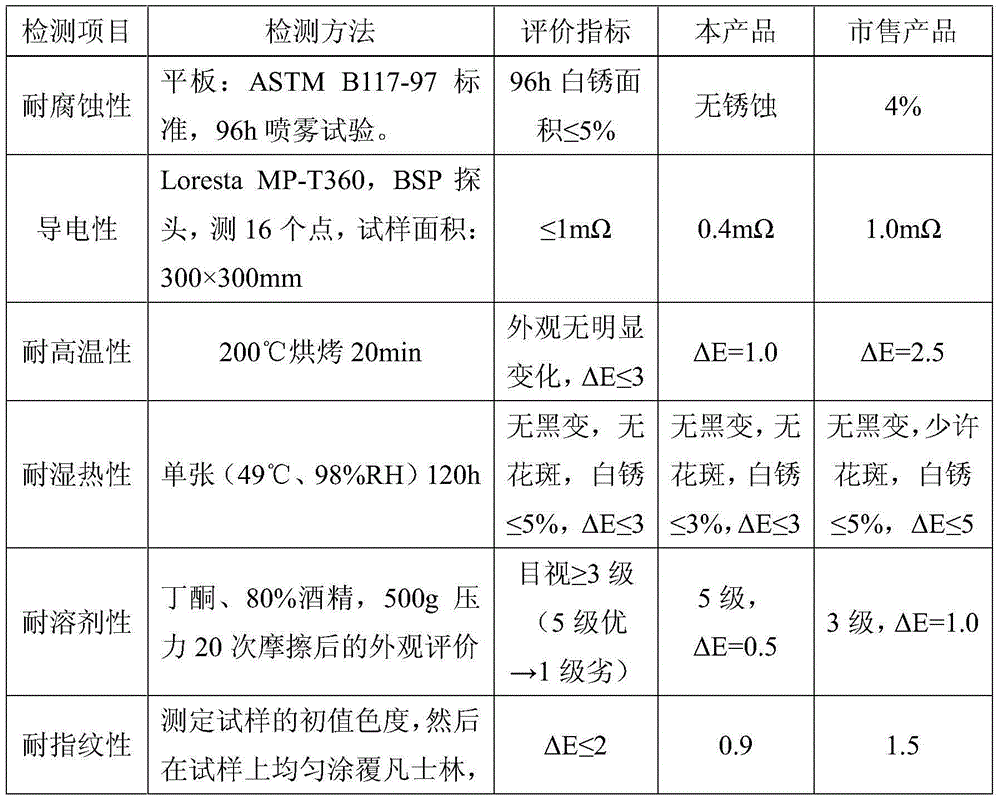

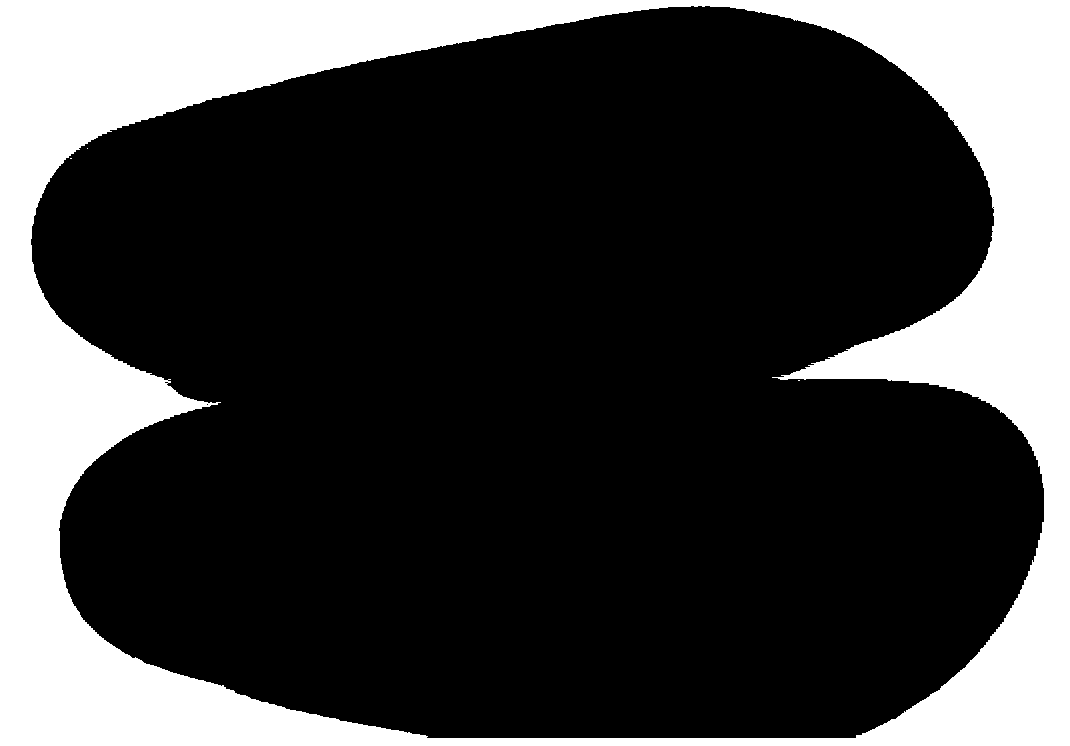

Water-based chromium-free fingerprint-resistant paint for galvanized steel plate

InactiveCN104449154AReduce consumptionWeather resistantAntifouling/underwater paintsPaints with biocidesWater basedPhosphate

The invention discloses water-based chromium-free fingerprint-resistant paint for a galvanized steel plate. The paint comprises raw materials in parts by weight as follows: 30.0-55.0 parts of a fluorine-modified water-based self-crosslinking acrylate emulsion, 0.1-1.5 parts of a neutralizer, 0.5-1.0 part of a silane coupling agent, 0.1-0.2 parts of laurocapram, 0.6-1.0 part of chlorinated paraffin, 4.0-8.0 parts of inorganic sol, 1.5-3.5 parts of metal salt, 0.1-0.3 parts of glycerin, 0.1-0.2 parts of sodium carboxymethylcellulose, 0.1-0.2 parts of polydimethylsiloxane, 1.5-5.5 parts of a cosolvent, 1.0-2.5 parts of aluminium dihydrogen phosphate and 40-50 parts of water; the curing temperature is as low as 40-60 DEG C, and energy consumption is reduced. The fluorine-modified water-based self-crosslinking acrylate emulsion is adopted to enable a film to have weather-resistant, waterproof and self-cleaning performance and the like, the film has a self-repairing function when damaged, and the forming processability is greatly improved. Low VOC (volatile organic compounds) emission is realized, and the problem of chromium passivation pollution is solved.

Owner:HEFEI UNIV OF TECH

Material for rubber forming shoes and preparation method of material

The invention provides a material for rubber forming shoes and a preparation method of the material, relating to a rubber foaming material. The material for the rubber foaming shoes consists of the following raw materials in parts by mass: 100 parts of a main material, 1-5 parts of a vulcanizing agent, 1-4 parts of a vulcanizing adjuvant, 2-5 parts of a foaming agent, 8-15 parts of a plasticizer, 6-20 parts of a filler, 2-6 parts of a lubricant, 0-10 parts of an abrasion-resistant agent, 0.5-2 parts of an antioxidant, and 1.5-3 parts of pigment. The preparation method comprises the following steps of: mixing the raw materials according to the ratio into an internal mixer for mixing until a temperature of rubber is increased to 80-90 DEG C; discharging the mixed materials out the internal mixer, and pelleting through a pelleting machine; placing the pelleted material into an injection molding machine for fusing and vulcanizing; and molding through mould pressing, so as to obtain a product. The cost is low, the preparation method is simple, and the foaming rate and the rigidity are controllable; and the preparation method can be used for producing sandals, high-level beach shoes and the materials of insoles of sneakers, outsoles of leather shoes and the like. The material provided by the invention can replace the conventional shoe foaming material EVA (ethylene-vinyl acetate copolymer); and the defects of poor EVA strength, easiness of deformation, low cost performance and the like can be overcome.

Owner:泉州永悦新材料有限公司

Concrete structure heavy-duty nano composite coating and protection method

The invention relates to a heavy anti-corrosion nano composite coating and a protection method for a concrete structure. The protection method belongs to a method for protecting the reinforced concrete structure. The heavy anti-corrosion nano composite coating for the concrete structure has a three-layer structure and comprises nano modified epoxy sealing coatings, a nano modified epoxy micaceous iron oxide intermediate paint and a nano modified fluorine-containing polyurethane finish or a fluorine-containing polysiloxane finish from inside to outside in turn. By adoption of the nano composite coating protection technology to perform anti-corrosion coating on the concrete structure, the anti-corrosion service life can reach more than 20 years, and the adhesion of the coating can be doubled compared with a common anti-corrosion coating; the coating has better impact resistance, sediment incrustation resistance, weathering resistance and flexibility; and the construction method is simple, and easy to popularize and apply, and has low cost.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

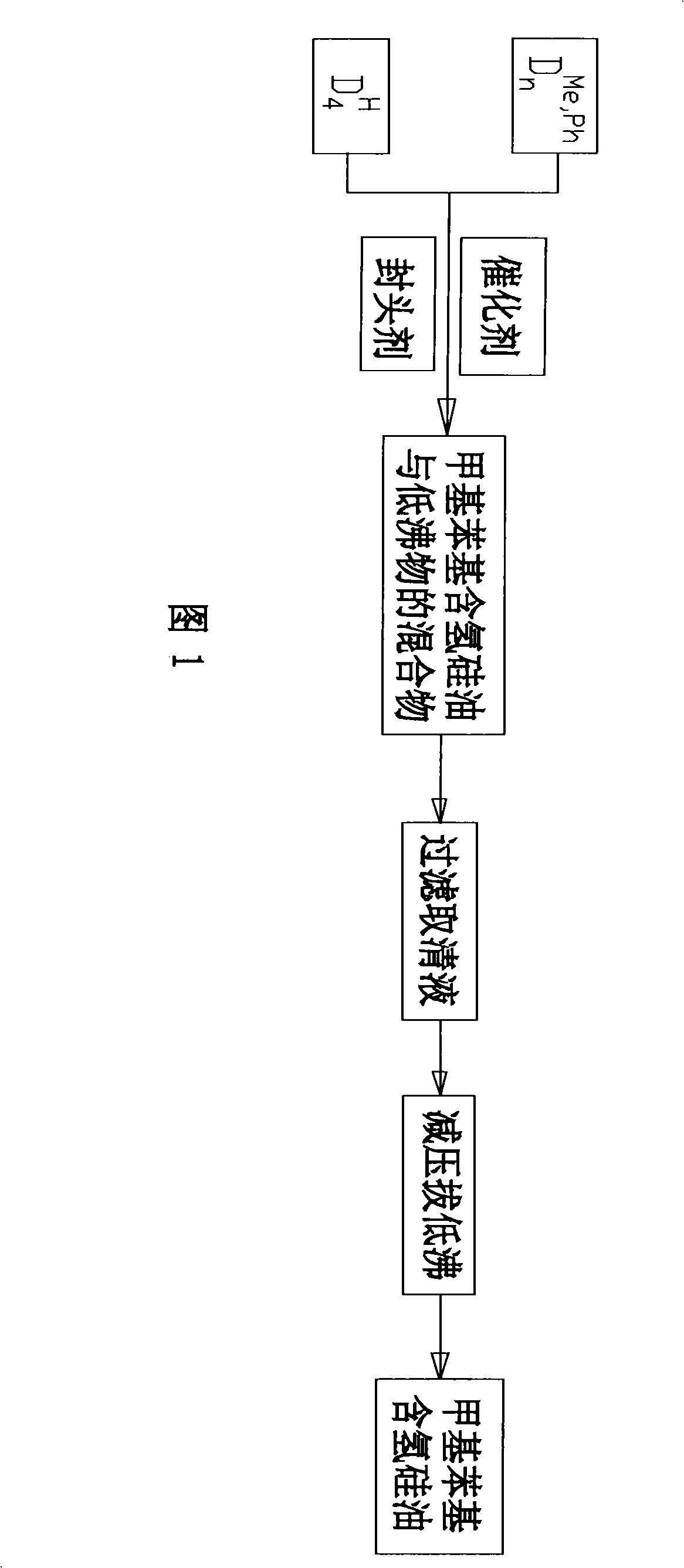

Preparation of methyl phenyl hydrogen-containing silicone oil for LED encapsulation

InactiveCN101328268ALow costMild conditionsOther chemical processesSemiconductor/solid-state device detailsLed packagingChemistry

The invention discloses a method for preparing an organic substance, in particular to a method for preparing methyl phenyl cyclosiloxane for LED packaging. The method takes methyl phenyl cyclic siloxane (Dn<Me, Ph>, n is equal to 3 and 4) and tetramethyl tetrahydric cyclotetrasiloxane (D4<H>) as monomers; under the protection of N2, an end-capping agent is added into the cyclosiloxane monomer which is subjected to pressure reduction and water removal to copolymerize under the action of a catalyst, then the filtration is performed to recover the catalyst, and the a low molecular compound in clear solution is removed under the condition of pressure reduction and high temperature and then is cooled to room temperature to produce a target product. The method has the advantages of easily-obtained raw materials, low cost, mild conditions, simple process, simple and convenient operation, no pollution, and easiness for industrialization. A product prepared by the method has good effect in the packaging process of LEDs.

Owner:HANGZHOU NORMAL UNIVERSITY

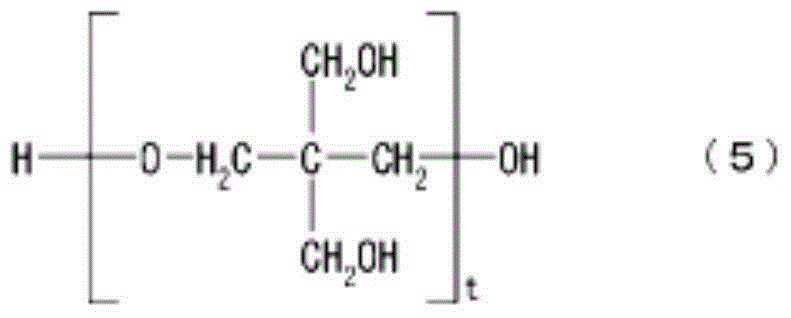

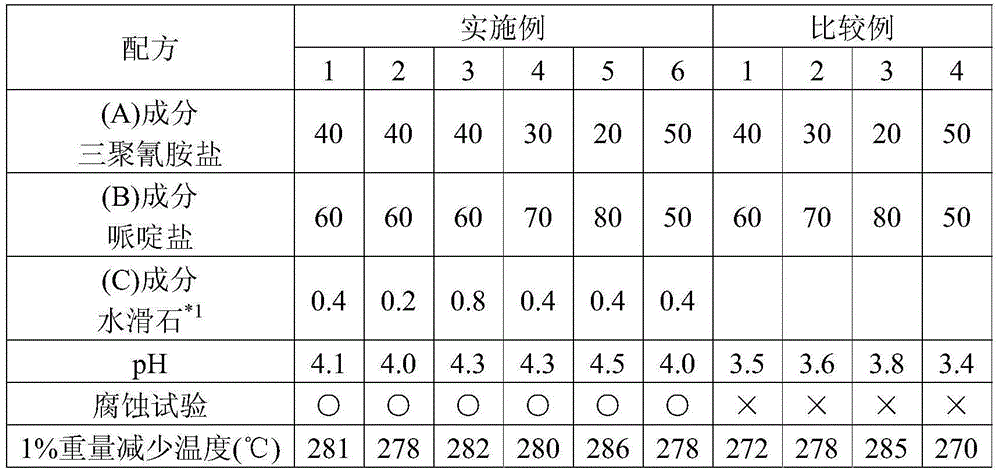

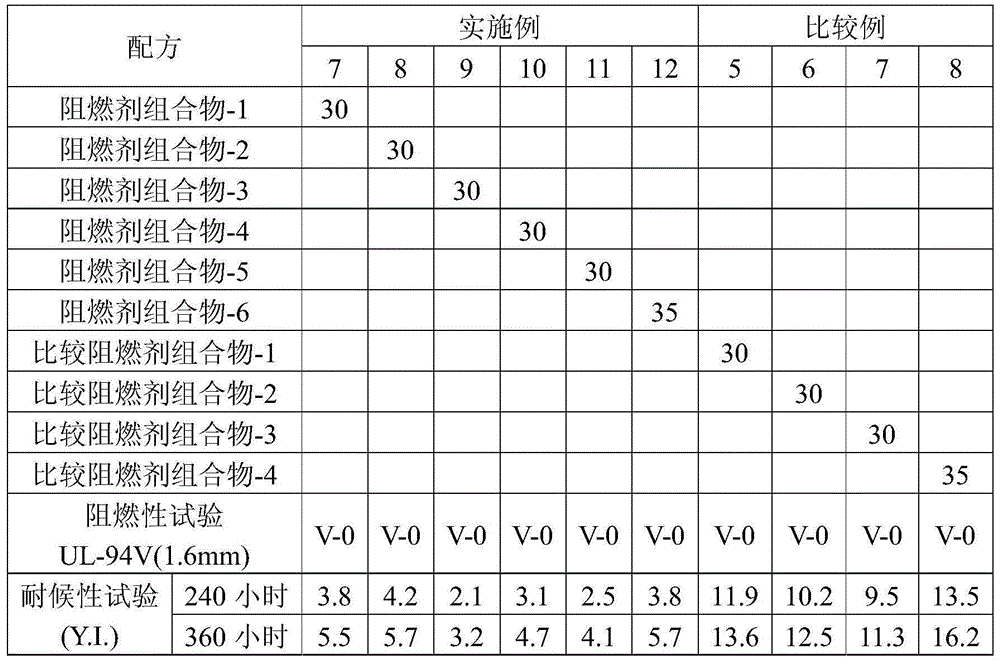

Flame-retardant composition and flame-retardant synthetic resin composition

InactiveCN105209576AImprove heat resistanceImprove flame retardant performanceFireproof paintsMelamine phosphateHeat resistance

The present invention provides a flame-retardant composition having excellent heat resistance and reduced risk of corroding processing equipment during resin compounding, specifically a flame-retardant composition containing 20-50 parts by mass of component (A), 50-80 parts by mass of component (B) (where the total of component (A) and component (B) is 100 parts by mass), and 0.01-5 parts by mass of component (C). Component (A): one or more melamine salts selected from melamine orthophosphate, melamine pyrophosphate, melamine polyphosphate, and mixtures containing two or more of these melamine salts. Component (B): one or more piperazine salts selected from piperazine orthophosphate, piperazine pyrophosphate, piperazine polyphosphate, and mixtures containing two or more of these piperazine salts. Component (C): hydrotalcite compound.

Owner:ADEKA CORP

Wet paved/pre-paved polymer self-adhesive waterproofing rolled material and preparation method thereof

InactiveCN102454226AExtended service lifeWeather resistantUnderground chambersRoof covering using flexible materialsPolymer resinCompound (substance)

The invention provides a wet paved / pre-paved polymer self-adhesive waterproofing rolled material which comprises a modified asphalt self-adhesive layer. The modified bitumen self-adhesive layer contains petroleum asphalt, modifier, softener, tackifier and filler. The wet paved / pre-paved polymer self-adhesive waterproofing rolled material which is prepared from the by taking a polymer resin layer as a base has a long use life, stable chemical properties and excellent waterproof effect, wherein the modified asphalt self-adhesive layer is prepared through single side or double side adhering.

Owner:沈阳蓝光科技发展有限公司

Heat-conducting and wave-absorbing rubber material and preparation method thereof

InactiveCN106751910AHigh temperature resistantLow temperature resistanceHeat-exchange elementsCross-linkRubber material

The invention discloses a heat-conducting and wave-absorbing rubber material and a preparation method thereof. The heat-conducting and wave-absorbing rubber material is prepared from the following substances in parts by weight: 100 parts of a rubber matrix, 50-600 parts of heat-conducting powder, 50-400 parts of wave-absorbing powder, 0-2 parts of a release agent and 0.5-2 parts of a cross-linking agent. The heat-conducting and wave-absorbing rubber material has the properties of high temperature resistance, low temperature resistance, high voltage resistance, ozone aging resistance, radiation resistance, weather resistance, physiologically inert property, high permeability and solvent resistance, and especially has outstanding high temperature resistance, so that the possibility is provided for preparation of the heat-conducting and wave-absorbing material; the heat-conducting and wave-absorbing rubber material can be directly applied between a heat dissipation room and a metal housing, and heat energy can be effectively exported; and meanwhile, the heat-conducting and wave-absorbing rubber material has electromagnetic shielding and electromagnetic noise wave absorbing properties, so that a good solving scheme is provided for electronic communication products in heat conduction and electromagnetic shielding.

Owner:DALIAN DONGSHIN MICROWAVE TECH

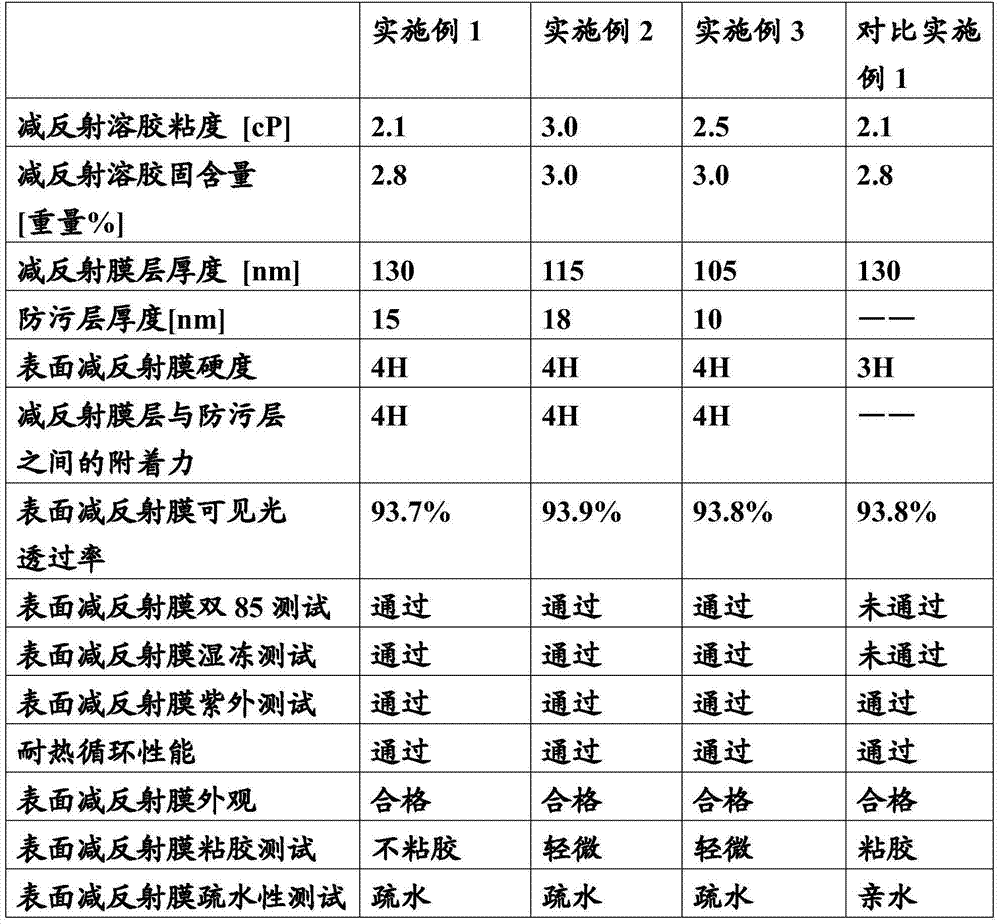

Anti-reflection glass substrate as well as preparation method and application thereof

The invention relates to a preparation method of an anti-reflection glass substrate. The preparation method comprises the following steps: a, preparing an anti-reflection sol, namely, acidizing silica sol, adding orthosilicate to react with deionized water to form sol, then adding an organic solvent, stirring, sealing and ageing; adding a coalescing agent in the aged sol and controlling a dry chemical additive, and stirring to obtain the anti-reflection sol; b, coating, namely, applying the anti-reflection sol in the step a on the surface of a glass substrate to form a glass substrate with an anti-reflection coating; c, tempering, namely, tempering the glass substrate prepared by the step b to form an anti-reflection film layer; and d, spreading an anti-fouling solution, namely, applying the anti-fouling solution above the film layer of the glass substrate treated in the step c to form an anti-fouling layer. The invention further relates to an anti-reflection glass substrate prepared by adopting the method disclosed by the invention, and an application of the anti-reflection glass substrate.

Owner:HENAN ANCAI HI-TECH

Water-borne perfluoroalkyl fluorocarbon emulsion, water-borne cable anti-icing paint containing same and preparation method thereof

ActiveCN101798366AImprove stabilityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesCelluloseEmulsifying wax

The invention relates to a water-borne cable anti-icing paint containing water-borne perfluoroalkyl fluorocarbon emulsion, which comprises the following raw materials in percentage by weight: 58 to 62 percent of aqueous perfluoroalkyl fluorocarbon emulsion, 1.5 to 2.5 percent of water-borne polytetrafluoroethylene emulsifying wax, 15 to 20 percent of water-borne color paste, 0.1 to 0.5 percent of pH regulator, 1 to 2 percent of amino resin cross-linking agent or water-borne polyurethane cross-linking agent, 0.1 to 0.2 percent of antiseptic preservative, 1 to 1.2 percent of cellulose and the balance of deionized water, wherein the water-borne color paste is the mixture of the water-borne color paste with one color or the water-borne color paste with more than two colors. The water-borne cable anti-icing paint of the invention is big in water repellent angle, low in surface energy, excellent in water repellent and oil repellent properties, safe and environment-friendly, can firmly adhere to the surface of a cable in a low temperature and cold environment and is obvious in anti-icing function.

Owner:CHANGZHOU GUANGHUI CHEM

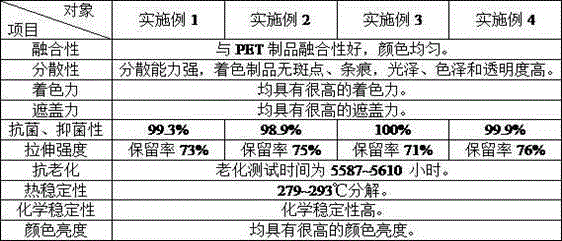

Preparing technology for color master batches

The invention relates to the technical fields of color master batches and preparing technologies thereof, in particular to a preparing technology for color master batches, and particularly discloses a preparing technology for color master batches for high-speed spinning fibers. The preparing technology includes the steps of carrier grinding, coloring material grinding, matched material grinding, assistant grinding, mixed grinding, high-speed grinding, extrusion prilling and drying. The color master batches prepared with the technology can be easily mixed with PET product plastic, and the even coloring effect can be achieved. Dispersibility, coloring strength and covering power are improved, weather resistance, acid resistance, heat resistance and cold resistance are achieved, the chemical stability of pigment is kept, and the color master batches are more environmentally friendly and healthier in the use process.

Owner:JIEDONG PARIS WANZHU SHAHUA TEXTILES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com