Preparing technology for color master batches

A technology for preparation process and color masterbatch, which is applied in the field of color masterbatch and its preparation process, can solve problems such as cold resistance, weather resistance, heat resistance, etc., achieve heat resistance and cold resistance maintenance, strengthen anti-aging performance, The effect of better mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

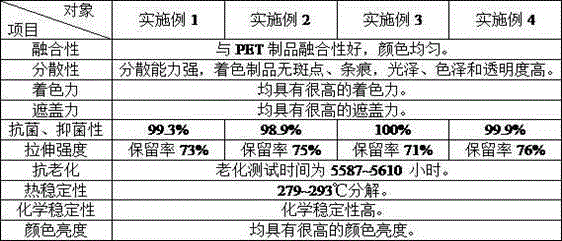

Examples

Embodiment 1

[0033] A kind of masterbatch preparation process, its preparation steps are as follows:

[0034] S1, carrier grinding: 10 parts of polyolefin, 8 parts of polyethylene terephthalate, and 5 parts of polyamide resin are mixed to obtain a mixed carrier, and 20 parts of the mixed carrier and water are mixed at a mass ratio of 8:5 and then ground. Grinding time is 30~40min, standby; The polyethylene terephthalate is polyethylene terephthalate, polybutylene terephthalate or polyethylene terephthalate;

[0035] S2. Pigment grinding: 5 parts of coloring material and water are mixed according to the mass ratio of 8:5, put into a grinder and grind for 30 minutes, and then set aside; the toners are phthalocyanine red, phthalocyanine blue, and phthalocyanine green , one of Sunfast Scarlet, Macromolecular Red, Macromolecular Yellow, Permanent Yellow, Permanent Violet, and Azo Red;

[0036] S3. Grinding of ingredients: after mixing 5 parts of dispersant and 1 part of glycidyl glycidyl ester...

Embodiment 2

[0044] A kind of masterbatch preparation process, its preparation steps are as follows:

[0045] S1, carrier grinding: 13 parts of polyolefin, 10 parts of polyethylene terephthalate, and 8 parts of polyamide resin are mixed to obtain a mixed carrier, and 40 parts of the mixed carrier is mixed with water at a mass ratio of 8:5 and then ground. Grinding time is 30~40min, standby; The polyethylene terephthalate is polyethylene terephthalate, polybutylene terephthalate or polyethylene terephthalate;

[0046] S2. Color grinding: mix 10 parts of color with water in a mass ratio of 8:5, put it into a grinder for grinding for 30 minutes, and set aside; the color powders are phthalocyanine red, phthalocyanine blue, and phthalocyanine green , one of Sunfast Scarlet, Macromolecular Red, Macromolecular Yellow, Permanent Yellow, Permanent Violet, and Azo Red;

[0047] S3, batching grinding: After mixing 10 parts of dispersant and 3 parts of epoxy fatty ester, mix with water in a mass rati...

Embodiment 3

[0055] A kind of masterbatch preparation process, its preparation steps are as follows:

[0056] S1, carrier grinding: 16 parts of polyolefin, 13 parts of polyethylene terephthalate, and 12 parts of polyamide resin are mixed to obtain a mixed carrier, and 60 parts of the mixed carrier is mixed with water at a mass ratio of 8:5 and then ground. Grinding time is 30~40min, standby; The polyethylene terephthalate is polyethylene terephthalate, polybutylene terephthalate or polyethylene terephthalate;

[0057] S2. Color grinding: mix 20 parts of color with water in a mass ratio of 8:5, put it into a grinder for grinding for 30 minutes, and set aside; the color powders are phthalocyanine red, phthalocyanine blue, and phthalocyanine green , one of Sunfast Scarlet, Macromolecular Red, Macromolecular Yellow, Permanent Yellow, Permanent Violet, and Azo Red;

[0058] S3. Grinding of ingredients: after mixing 20 parts of dispersant and 6 parts of calcium stearate, they are mixed with wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com