Patents

Literature

395 results about "Phthalocyanine blue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of phthalocyanine blue. : a blue pigment used chiefly in printing ink especially for outdoor use, in roofing shingles, and in paint for automobiles; the copper derivative of phthalocyanine.

Colorized reflection heat insulation coating and color card thereof

ActiveCN102181217AModulation shortcutHigh Solar ReflectanceReflecting/signal paintsMulticolor effect coatingsHigh reflectivityMaterials science

The invention discloses a colorized reflection heat insulation coating. Carbon black, iron oxide red, organic yellow, phthalocyanine green, phthalocyanine blue, and other conventional common pigments are replaced by the pigments, namely nickel iron chromite black, nickel iron chromite red, cobalt blue, titanium yellow and cobalt green, so that the colorized reflection heat insulation coating can meet the demand of the external wall decoration on colors and has high reflectivity to solar energy and a good heat insulation effect. The invention also provides a color card by which a colorized coating is formed by mixing the nickel iron chromite black, the nickel iron chromite red, the cobalt blue, the titanium yellow and the cobalt green, a user can quickly mix the coating of the corresponding colors according to the pigment formula corresponding to each color in the color card, and the color card is convenient to use.

Owner:NIPPON PAINT GUANGZHOU

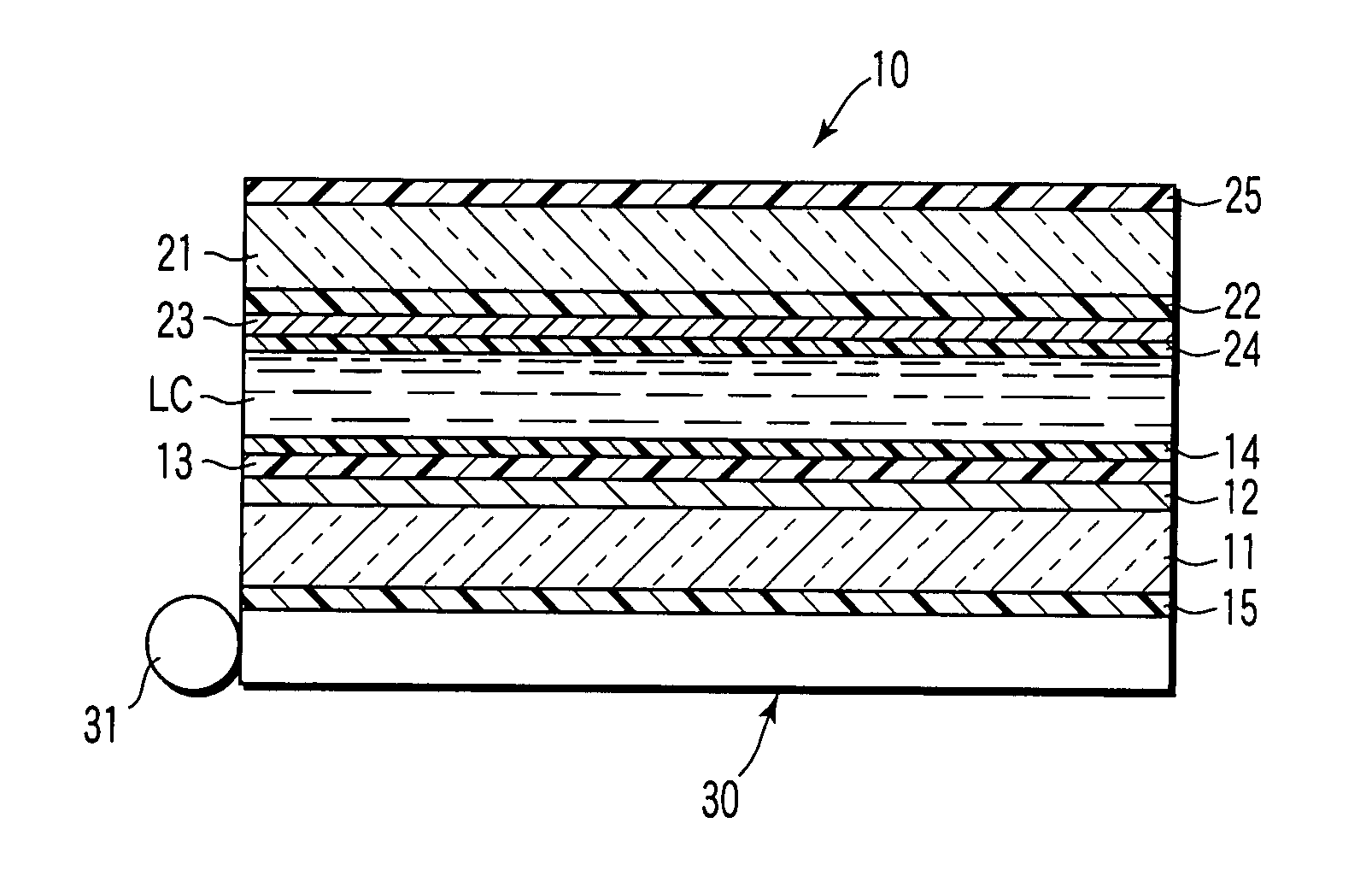

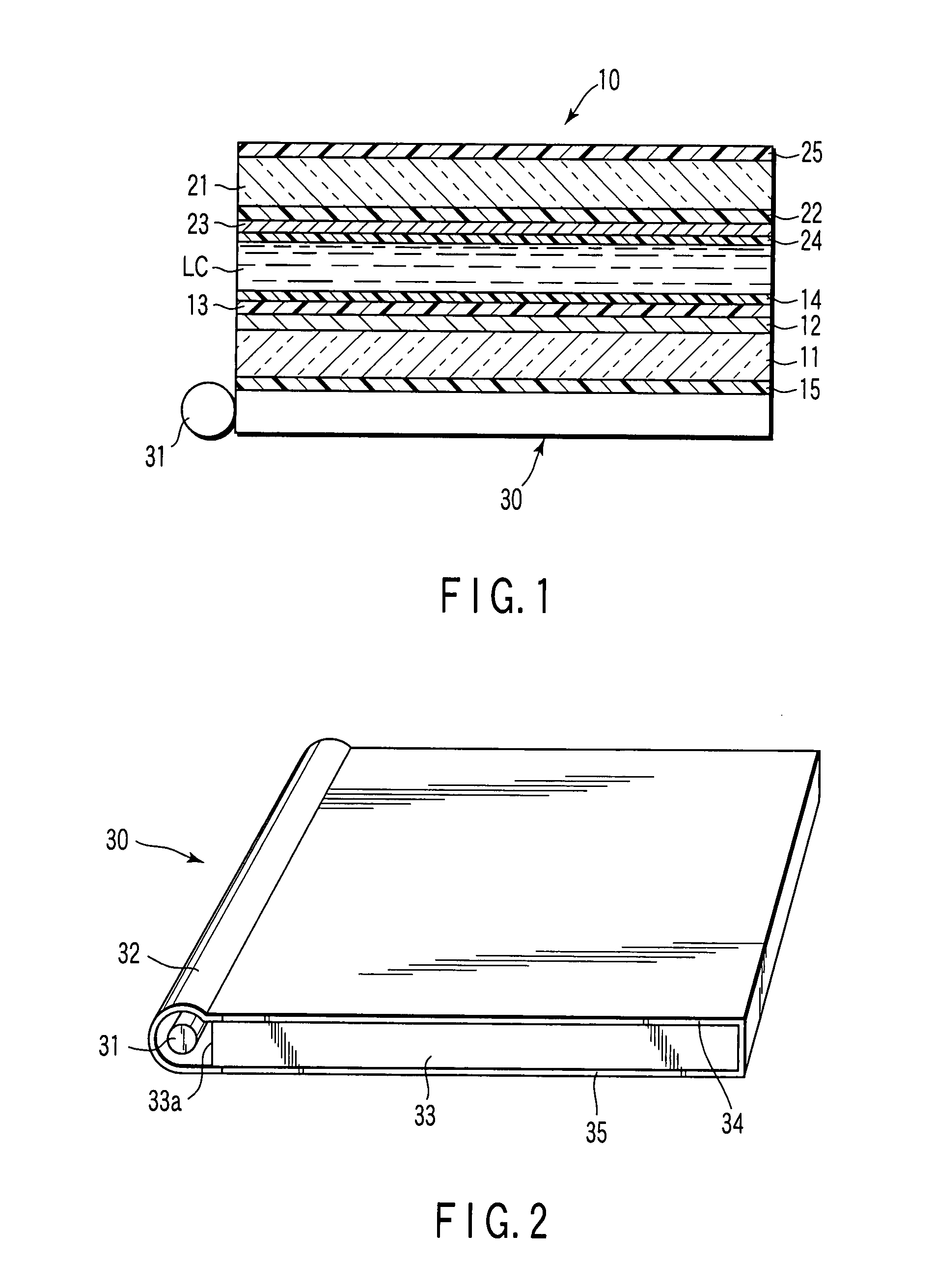

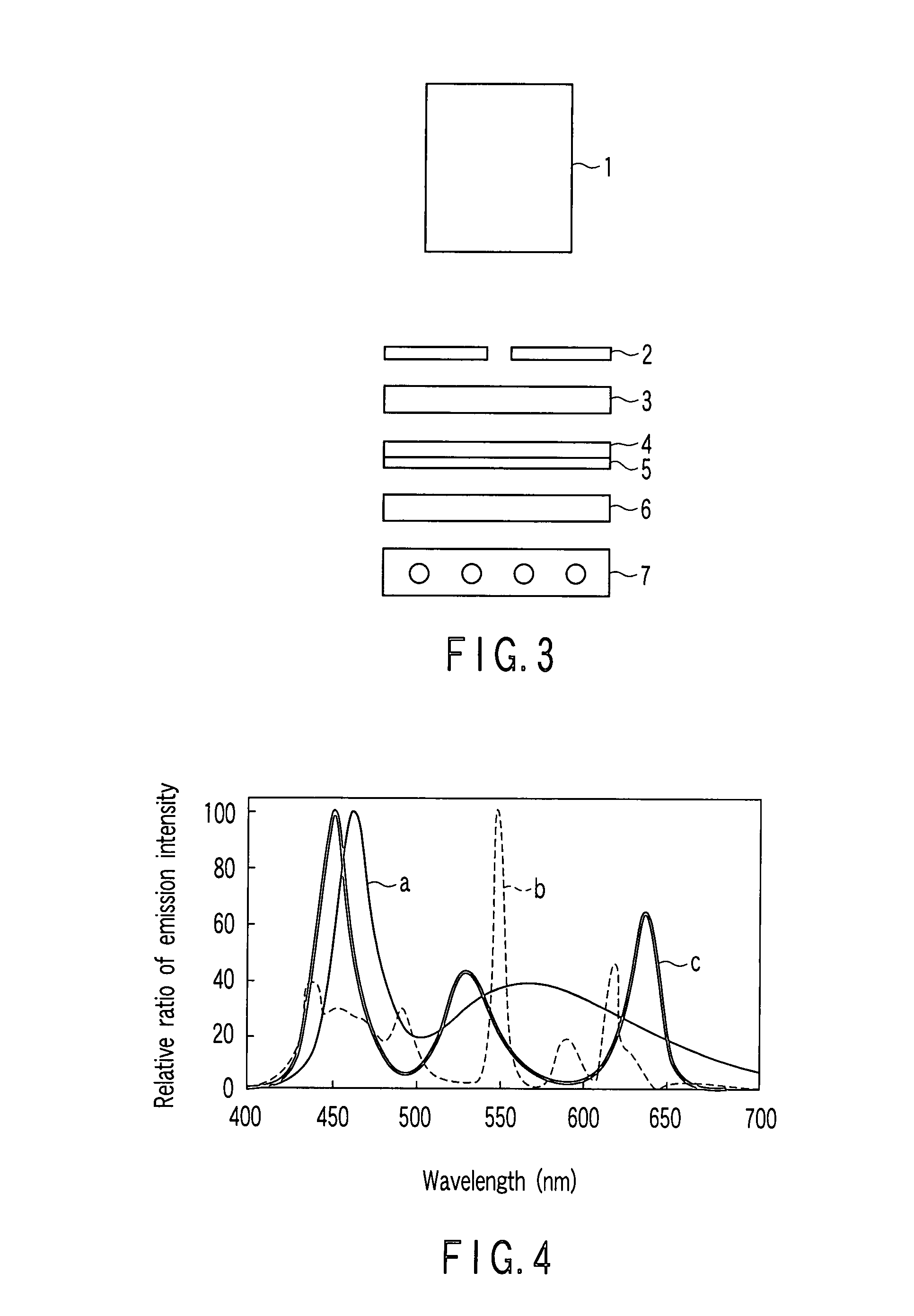

Colored composition for color filters, color filter and liquid crystal display device

InactiveUS20070247565A1Increase contrastGood light fastnessDischarge tube luminescnet screensOptical filtersLiquid-crystal displayAnalytical chemistry

A cyan-colored composition for a color filter contains a phthalocyanine blue pigment comprising either of C.I. Pigment Blue 15:3 and C.I. Pigment Blue 15:4, or both, a phthalocyanine green pigment comprising C.I. Pigment Green 7, and a pigment carrier consisting of a transparent resin, a precursor of the resin or a mixture thereof. A color filter includes a red-colored filter segment, a green-colored filter segment, a blue-colored filter segment, and a cyan-colored filter segment or a yellow-colored filter segment.

Owner:TOPPAN PRINTING CO LTD

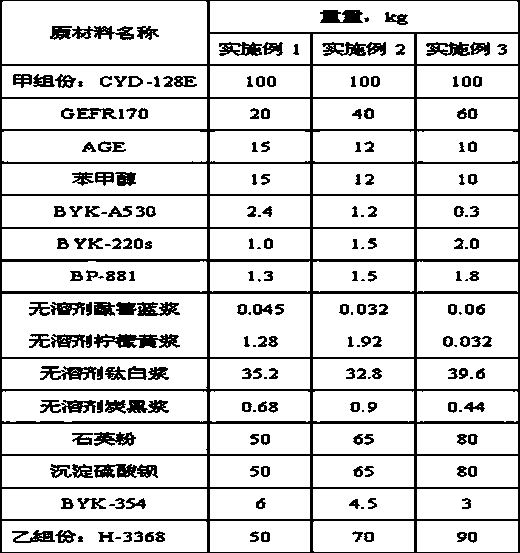

Solvent-free epoxy self-leveling roller coating floor paint and preparation and use method thereof

ActiveCN104250510ALow viscosityHigh viscosityLiquid surface applicatorsEpoxy resin coatingsPolymer scienceSolvent free

The invention relates to a solvent-free epoxy self-leveling roller coating floor paint and a preparation and use method thereof. The paint comprises a low-viscosity epoxy resin compound, an active diluent, an inactive diluent, a defoamer, a leveling agent, a wetting dispersant, a thixotropic additive, a solvent-free phthalocyanine blue pulp, a solvent-free lemon yellow pulp, a solvent-free titanium white pulp, a solvent-free carbon black pulp, quartz powder, precipitated barium sulfate and a modified alicyclic amine curing agent. The preparation and use method comprises the following steps: preparation of various solvent-free individual color pulps, preparation of a component A and use manner; the low-viscosity epoxy resin compound is a compound of bisphenol-A epoxy resin and bisphenol-F epoxy resin, the viscosity of the compounding system is greatly reduced under the condition of no solvents, the viscosity of the solvent-free system is improved, the amount of the active diluents and the inactive diluents is reduced, the physical mechanical performances of coatings are guaranteed and the paint is endowed with excellent levelability, so that the paint disclosed by the invention has roller coating self levelability and excellent construction performance.

Owner:洛阳双瑞防腐工程技术有限公司

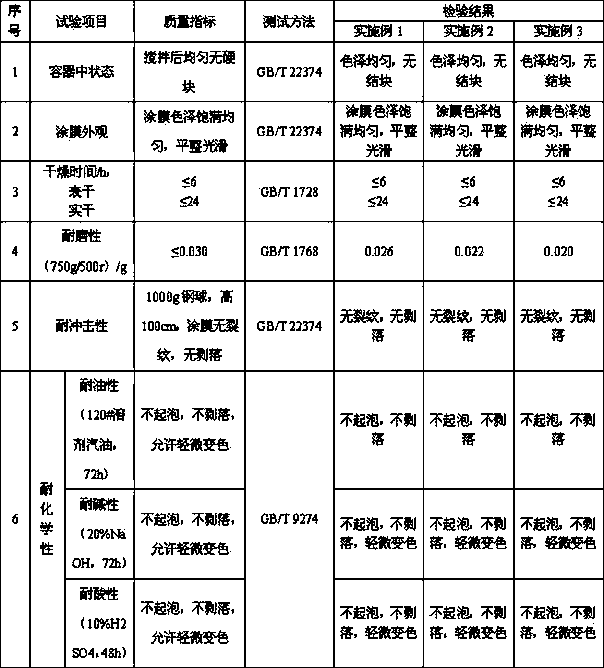

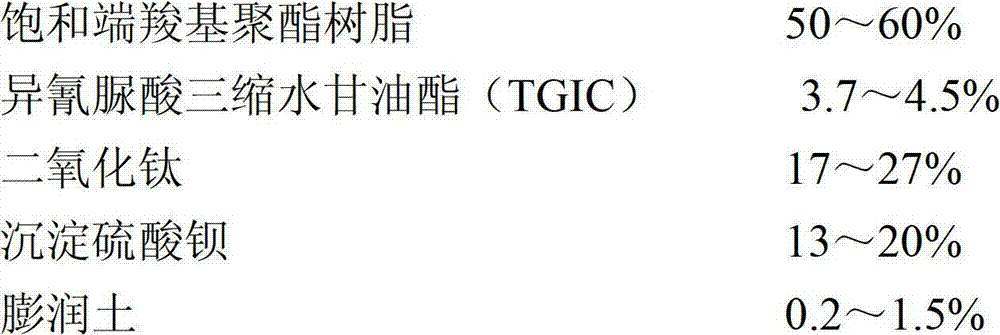

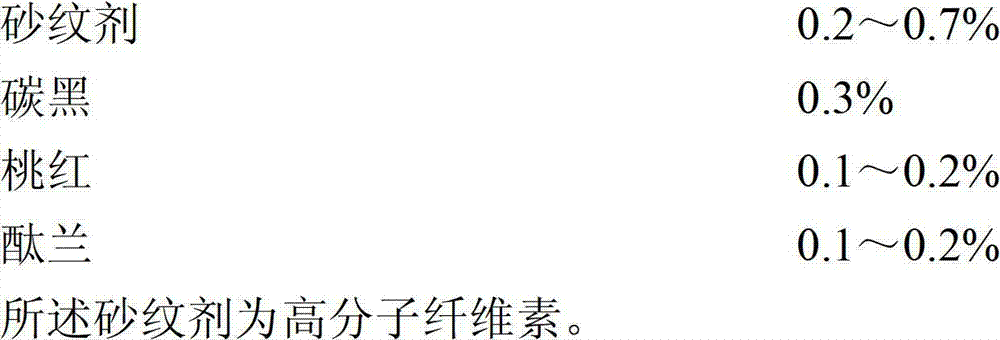

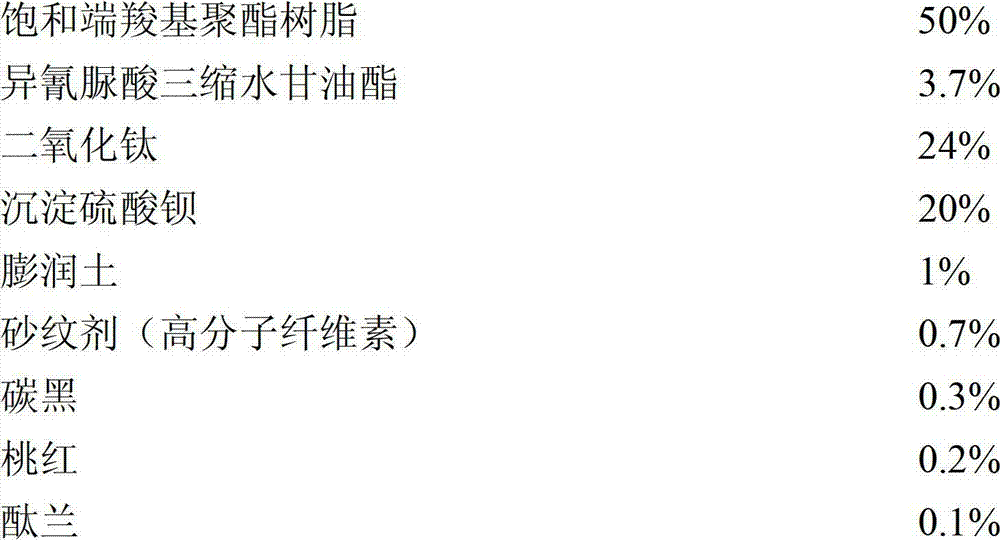

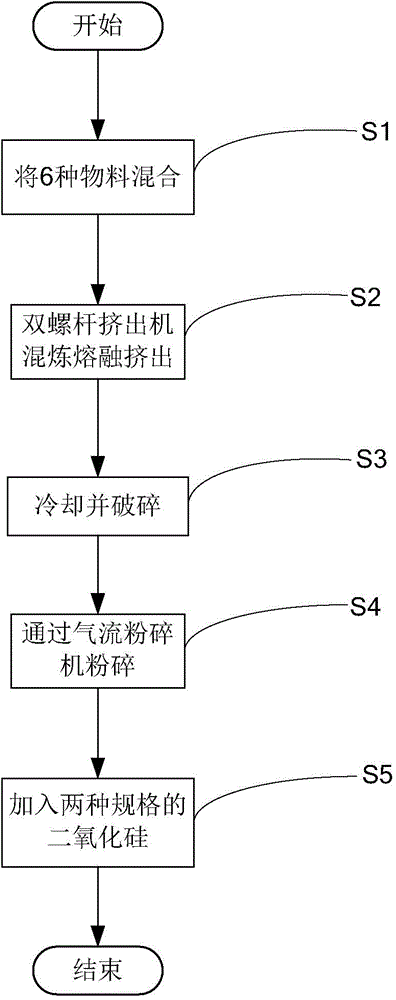

Sand pattern powder coating for aluminum profiles as well as preparation method and application thereof

InactiveCN102775888AFeel smoothNot easy to scratchPowdery paintsPolyester coatingsSodium BentoniteRoom temperature

The invention belongs to the technical field of new materials and discloses a sand pattern powder coating for aluminum profiles as well as a preparation method and application thereof. The coating is prepared from the following raw materials in percentage by weight: 50-60% of saturated carboxyl polyester resin, 3.7-4.5% of triglycidyl isocyanurate, 17-27% of titanium dioxide, 13-20% of precipitated barium sulfate, 0.2-1.5% of bentonite, 0.2-0.7% of sand pattern agent, 0.3% of carbon black, 0.1-0.2% of pink and 0.1-0.2% of phthalocyanine blue. The preparation method comprises the following steps of: putting the raw materials into a mixing cylinder and premixing the raw materials; carrying out melt extrusion on the premixed raw materials and then pressing the materials into flakes; cooling the flakes to room temperature, crushing the flakes and then carrying out fine crushing; and screening the finely crushed materials to obtain the product.

Owner:广东华江粉末科技有限公司

Graphene heat dissipation coating

InactiveCN103468101ASimple preparation processReduce manufacturing costEpoxy resin coatingsArray data structureAcrylic resin

The invention discloses a graphene heat dissipation coating, which is composed of the following components in mass part: 50-80 parts of epoxy acrylic resin, 5-10 parts of graphene, 60-80 parts of water, 10-15 parts of coloring agent, and 20-30 parts of auxiliary agent, wherein the coloring agent is one type or a mixture of multiple types from phthalocyanine blue, azo red and azo blue; the auxiliary agent comprises dispersing agent, defoaming agent, curing agent and adhesion promoter. The graphene heat dissipation coating is simple in preparation process and low in production cost, and can be cured at room temperature. The graphene is adopted as the main heat dissipation medium to provide channels for heat transfer, so that heat release is facilitated. The coating is applied onto the surface of a heat dissipation device, so that the heat dissipation area is increased, the heat dissipation effect is improved, and the characteristics of high efficiency and favorable environment friendliness are achieved.

Owner:SUZHOU AITESI FURTHER MATERIALS CO LTD

Color masterbatch

The invention relates to color masterbatch. The color masterbatch is characterized by comprising, by weight, 75-85% of carriers, 5-6% of additives, 3-5% of dispersing agents, 2-3% of pearl powder, 1-2% of pigments, 1-2% of organic esters and 3-5% of paraffin, wherein the pigments comprise one or the mixture of phthalocyanine red, phthalocyanine blue, phthalocyanine green, sun-proof bright red, macromolecule red, macromolecule yellow, permanent yellow, permanent purple and azo red. The color masterbatch is the indispensable additive for colorization of plastic products, and for PVC products formed in an extrusion mode, the color masterbatch is assorted in variety and color, good in glossiness and high in controllability.

Owner:CHUZHOU HONGYUAN SPRAYING

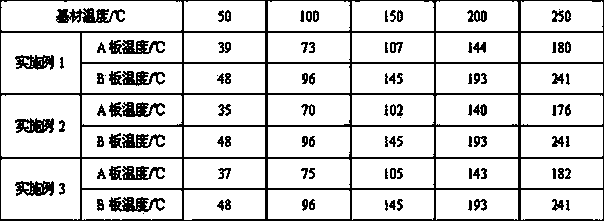

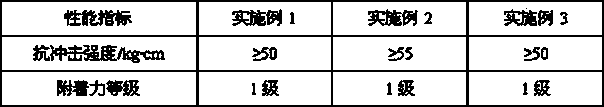

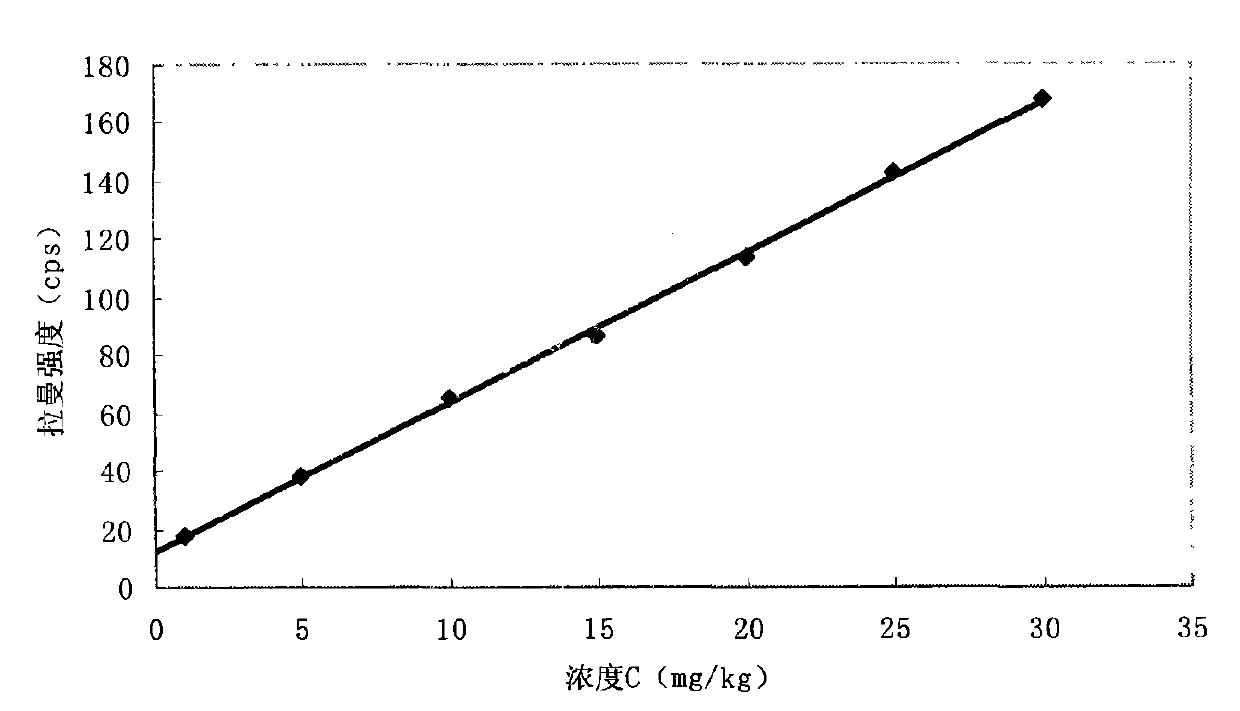

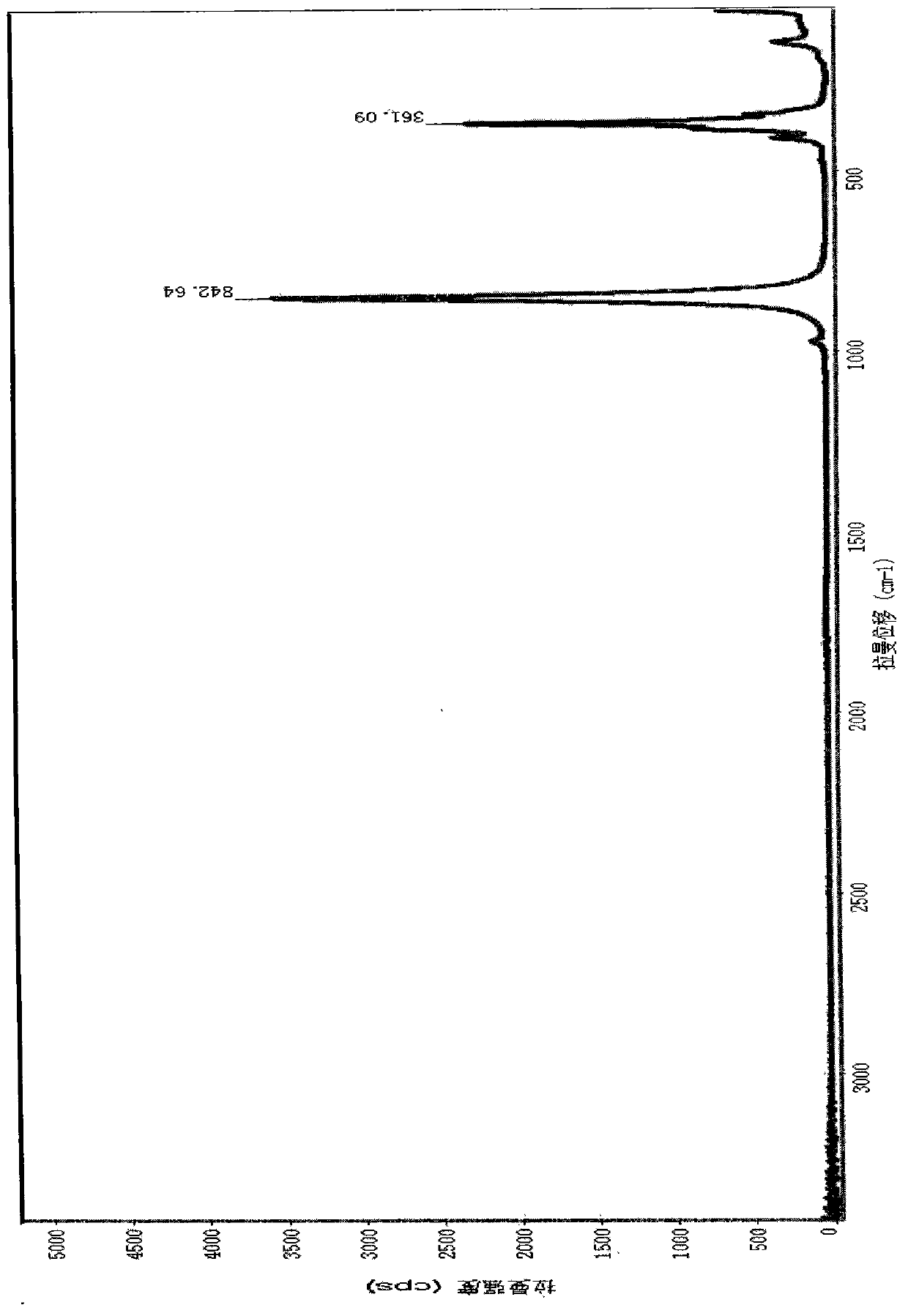

Method for rapidly detecting pigment green in tea through using laser-Raman spectrum technology

ActiveCN102890079ASolve qualitative problemsRapid Qualitative and Quantitative AnalysisRaman scatteringLaser ramanLead chromate yellow

The invention discloses a method for rapidly detecting pigment green in tea through uisng a laser-Raman spectrum technology. The method comprises the following steps of: performing laser-Raman spectrum chart scanning on tea to be detected, and generating any one group of the following three groups of absorption peaks: (1) 2150(+ / -3)cm<-1>, 842(+ / -3)cm<-1>, (2) 1524(+ / -3)cm<-1>, 1339(+ / -3)cm<-1>, 842(+ / -3)cm<-1>, and (3) 2150(+ / -3)cm<-1>, 1524(+ / -3)cm<-1>, 1339(+ / -3)cm<-1>, 842(+ / -3)cm<-1>, so as to obtain a qualitative result of pigment green in the tea, wherein when the first group of characteristic peaks occurs, the pigment green is formed by mixing iron blue and lead chromate yellow; when the second group of characteristic peaks occurs, the pigment green is formed by mixing phthalocyanine blue and lead chromate yellow; and when the third group of characteristic peaks occurs, the pigment green is formed by mixing the iron blue, the phthalocyanine blue and the lead chromate yellow. According to the method, the existence of the pigment green in the tea can be accurately, qualitatively and quantitatively determined.

Owner:江苏省理化测试中心

Method for preparing colorant used in producing color acrylic fibre by mass coloration method

The present invention relates to a preparation method of coloring material for producing colored acrylic fiber by adopting mass coloration process. Said method includes the following steps: mixing pigment, dispersing agent and NaSCN aqueous solution and grinding in ball-grinding machine, in the coloring material the pigment content is 5-25 wt%, the weight ratio of pigment and dispersing agent is 100:3-30, and the ginding time is 0.5-5.0, then the coloring material product can be obtained. The above-mentioned dispersing agent is one compound selected from naphthalenesulfonate formaldehyde condensate, methyl naphthalene sulfonate formaldehyde condensate or benzyl naphthalene sulfonate formaldehyde condensate or mixture of them, and the pigment is carbon black, phthalocyanine blue, iron oxide or ultrasmarine.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Graphene fiber cloth heating chip with physical therapy effect

Disclosed is a graphene fiber cloth heating chip with a physical therapy effect. The graphene fiber cloth heating chip comprises carrier polyester fabrics, an insulating protection layer which comprises a PU layer and phthalo blue insulating ink, a nanometer conductive silver paste layer used for transmitting current, and a graphene heating ink coating layer from the bottom up in sequence; the insulating protection layer subjected to heat treatment is coated with the PU layer; the PU layer is coated with the nanometer conductive silver paste layer; the nanometer conductive silver paste layer is coated with the graphene heating ink coating layer; the graphene heating ink coating layer is coated with the final insulating protection layer; after the obtained product is fully dried and cured, a current is connected; a graphene heating chip which takes the insulating protection layer as the carrier can emit 8-14[mu]m far infrared after the connected current is powered on; and the far infrared and cellular molecules in human body generate thermal resonance to increase the temperature of a subcutaneous deep layer, expand micro vessels, accelerate blood circulation, remove barriers of metabolism, and to achieve the effects of activating cells, strengthening tissues and immunizing organ systems.

Owner:FOSHAN SHUNDE SANBEI ELECTRONICS CO LTD

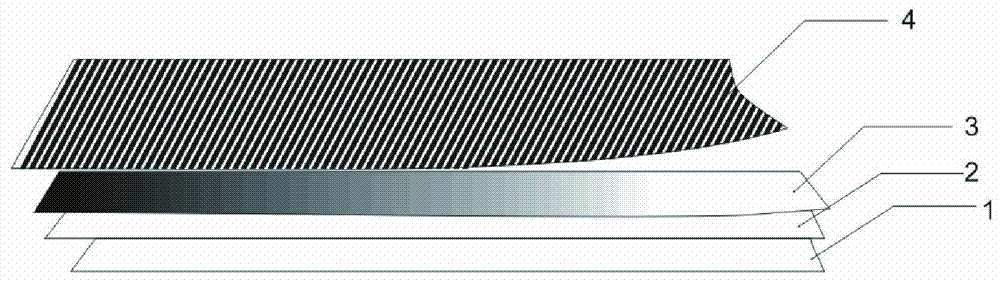

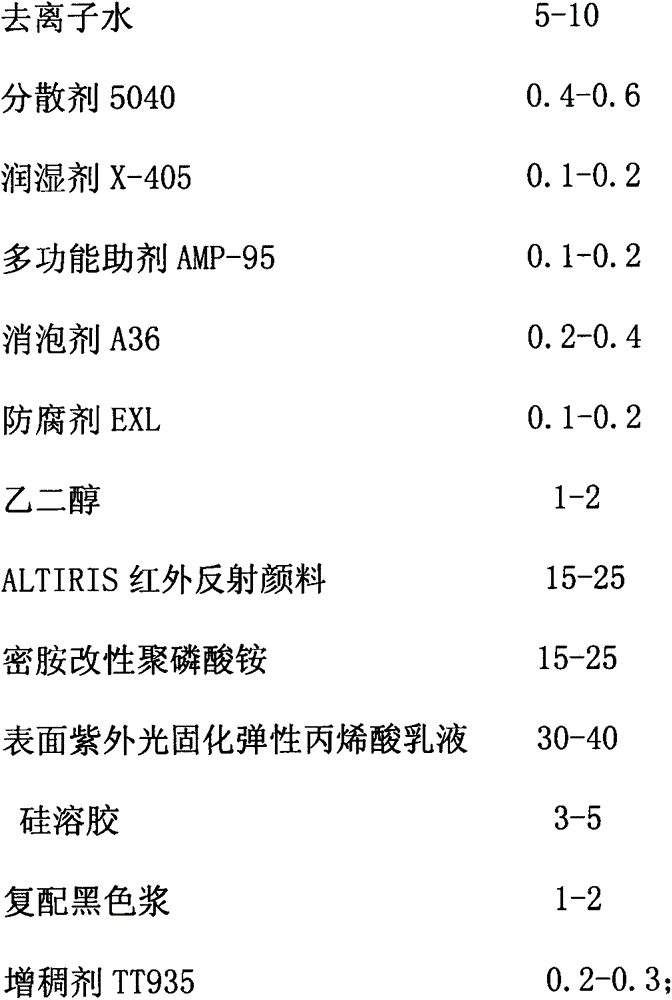

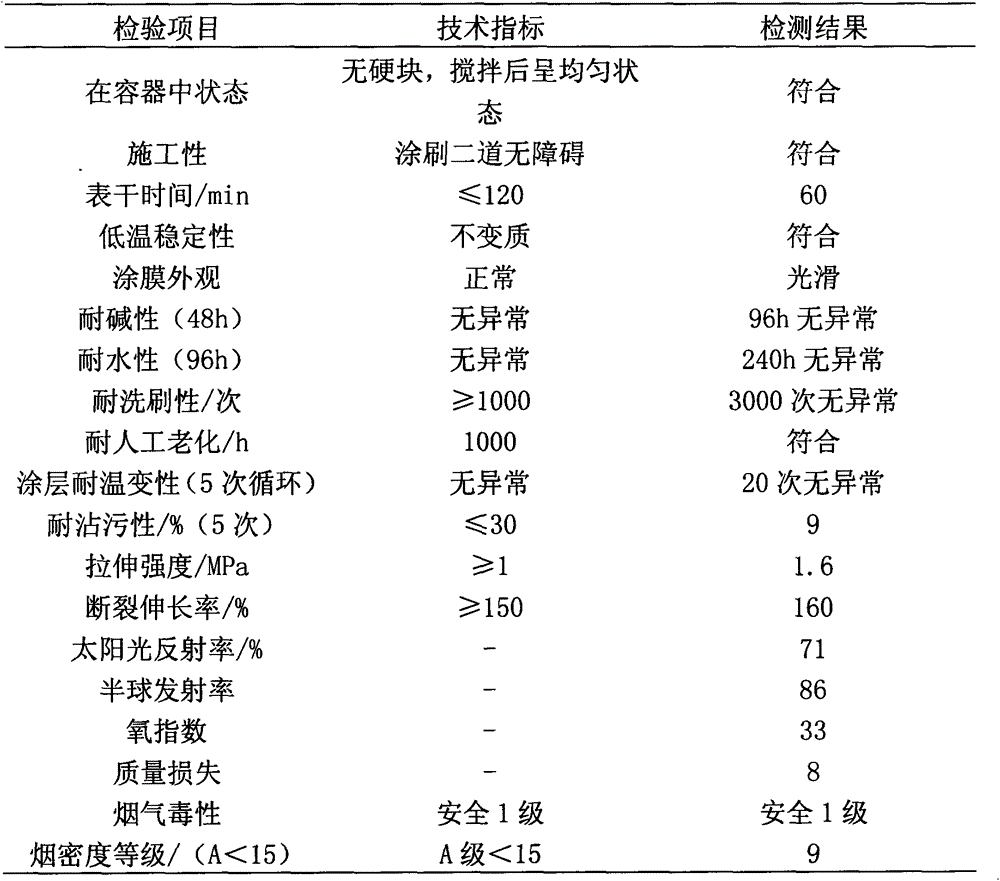

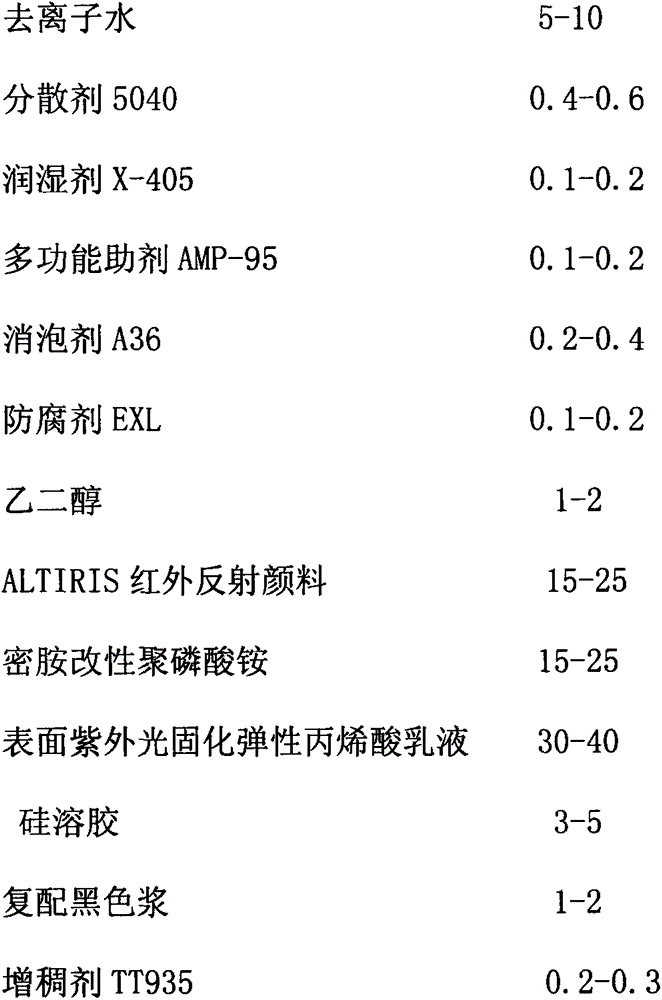

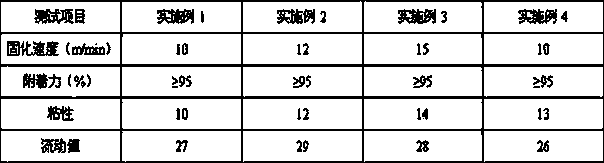

Grey heat-insulation flame-retardant external wall paint

InactiveCN103146275AElastic and crack-resistantWith fire performanceFireproof paintsReflecting/signal paintsPolymer scienceCrack resistance

The invention discloses a grey heat-insulation flame-retardant external wall paint. A surface ultraviolet-curing elastic acrylic emulsion and modified silica sol are compounded to obtain a film forming material, an ALTIRIS infrared reflection pigment is used as a white pigment, a compound black color paste is used as a coloring pigment, and melamine-modified ammonium polyphosphate is used as a flame retardant; and under the cooperation of deionized water and multiple assistants, dispersion, grinding, blending, and color matching are carried out to prepare the grey heat-insulation flame-retardant external wall paint. The compound black color paste is prepared by the following steps: compounding iron oxide red, titanium-chrome yellow and phthalocyanine blue into a black pigment, mixing with a proper amount of deionized water, dispersing agent, wetting agent and defoaming agent, dispersing and grinding. The invention has the characteristics of grey color, high solar reflection factor, cracking resistance due to high elasticity, heat insulation and control, flame retardancy and fire resistance, is suitable to be sprayed as a veneer paint for EPS, XPS and polyurethane hard foamed external wall external-thermal-insulation systems, and has wide popularization prospects.

Owner:BEIJING GUOTAI RUIHUA DIATOMS APPL TECH

Environment-friendly waterless offset ink

The invention discloses environment-friendly waterless offset ink which comprises the following raw materials in parts by weight: 40-50 parts of polymerized rosin resin, 5-15 parts of an adhesive, 10-25 parts of refined linseed oil, 6-15 parts of a photoinitiator, 10-15 parts of phthalocyanine blue, 0.5-5 parts of an antiwear agent, 1-3 parts of a neutralizing agent and 0.1-2 parts of an addition agent, wherein the photoinitiator is one or a mixture of several of a cracking type initiator 907, BP (benzophenone) and triaryl iodonium salt, is one of important components of a photocuring adhesive, and plays a decisive role in the curing speed. The obtained ink is good in resin rheological property; a connecting material is higher in cohesive energy; the obtained ink is good in flowing property; the curing speed is not less than 10 m / min; and the ink is good in printing quality, clean and pollution-free.

Owner:苏州凹凸彩印厂

Liquid pressure transfer ink, liquid pressure transfer film, liquid pressure transfer article and liquid pressure transfer method

InactiveUS6551392B1Effectively prevent disarrangementEffectively prevent blurringLayered productsDecorative surface effectsWeather resistanceColor printing

A pattern-transferring film having a print pattern provided on an upper surface thereof is floated on a liquid surface within a transferring bath and an objective body is immersed into a liquid within the transferring bath together with the pattern transferring film under a liquid pressure so as to transfer the print pattern onto the objective body. An ink set of at least blue, yellow and red inks is used for printing the pattern on the pattern-transferring film. Each of the printing inks comprises at least a resin ingredient and a pigment including color pigments. The color pigment for the blue ink is a phthalocyanine blue, the color pigment for the yellow ink is an isoindolinone yellow and the color pigment for the red ink is a quinacridone red. The ink set may include one or both of a white ink and a black ink. The color pigment for the white ink is a titanium white and the color pigment for the black ink is a carbon black. All the five color printing inks have a weather resistance of more than 3000 hours on a weather resistance test by a JIS based sunshine weather meter and therefore a color tone of the transferred pattern obtained by using these printing inks is balanced and the pattern transferred article having such a transferred pattern has the same weather resistance, which causes the article to have its life span maintained.

Owner:TAICA

Powdered ink for laser blueprint machine and manufacturing method of powdered ink

The invention provides powdered ink for a laser blueprint machine. The powdered ink consists of the following components in percentage by weight: 60-80 percent of a polyester resin, 10-30 percent of a styrene acrylic acid resin, 1-10 percent of phthalocyanine blue, 0.1-4 percent of phthalocyanine red, 2-5 percent of a release agent and 1-3 percent of a charge control agent. The glass transition temperature Tg of the polyester resin is 40-55 DEG C, and the softening temperature T1 / 2 of the polyester resin is 80-110 DEG C; and the glass transition temperature Tg of the styrene acrylic acid resin is 50-70 DEG C, and the softening temperature T1 / 2 of the styrene acrylic acid resin is 120-140 DEG C. The powdered ink provided by the invention is excellent in performance, firm in fixation and double image-free in the fixation process, the fixation temperature is low, and the energy consumption is reduced.

Owner:ICMI CHINA

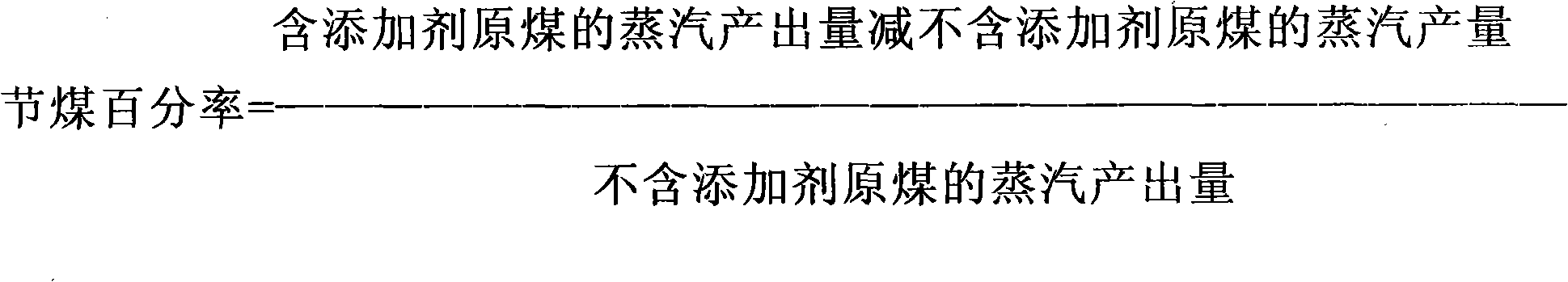

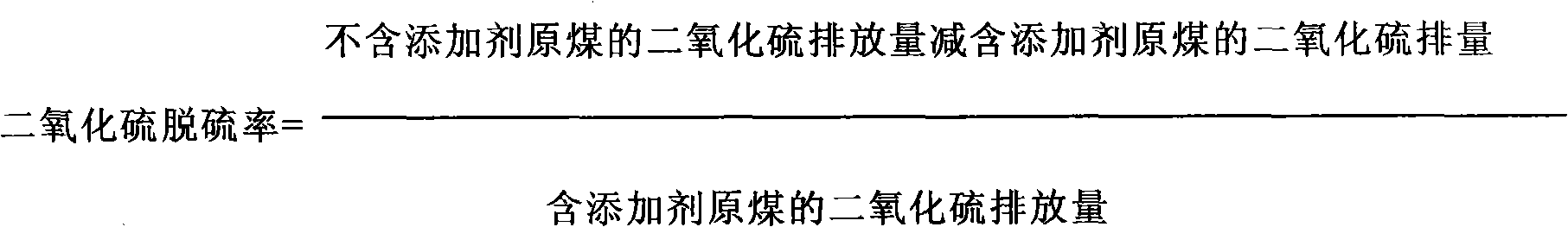

Fire coal energy-saving additive

InactiveCN101265429ALower ignition pointSpeed up the burning processSolid fuelsFurnace temperatureChemical reaction

The invention relates to a coal-fired energy-saving additive, which comprises the following components and contents (weight percentage): 6 to 16 percent of phthalocyanine blue; 5 to 20 percent of porphyrin; 12 to 19 percent of tween 60; 3 to 9 percent of iron oxide; 3 to 12 percent of magnesium oxide; 2 to 18 percent of manganese carbonate; 2 to 10 percent of calcium oxide; 6 to 12 percent of sodium chloride; 2 to 11 percent of potassium nitrate; 2 to 8 percent of sodium nitrate; 5 to 13 percent of potassium permanganate; 1 to 16 percent of sodium hydrate; 3 to 10 percent of sodium dodecyl benzene sulfonate; 8 to 11 percent of sodium heametaphosphate; 3 to 9 percent of trisodium phosphate; 3 to 13 percent of vermiculite; 7 to 16 percent of terrae rare. The additive solves the quick ignition of the coal during the combustion process, has the effect of the cracking gasification strong combustion supporting, improves the flame to heighten and enlarge the flame, and enables the radiation to be intensified; the adding of the coal-fired energy-saving additive can increase the furnace temperature to be more than 200 DEG C; the utilization of the coal-fired energy-saving additive can ensure the accumulative carbon on a boiler tank and a tube wall in a boiler to automatically drop off through chemical reactions and physical reactions, thereby improving the thermal efficiency, saving the energy and reducing the pollution.

Owner:陈汉明

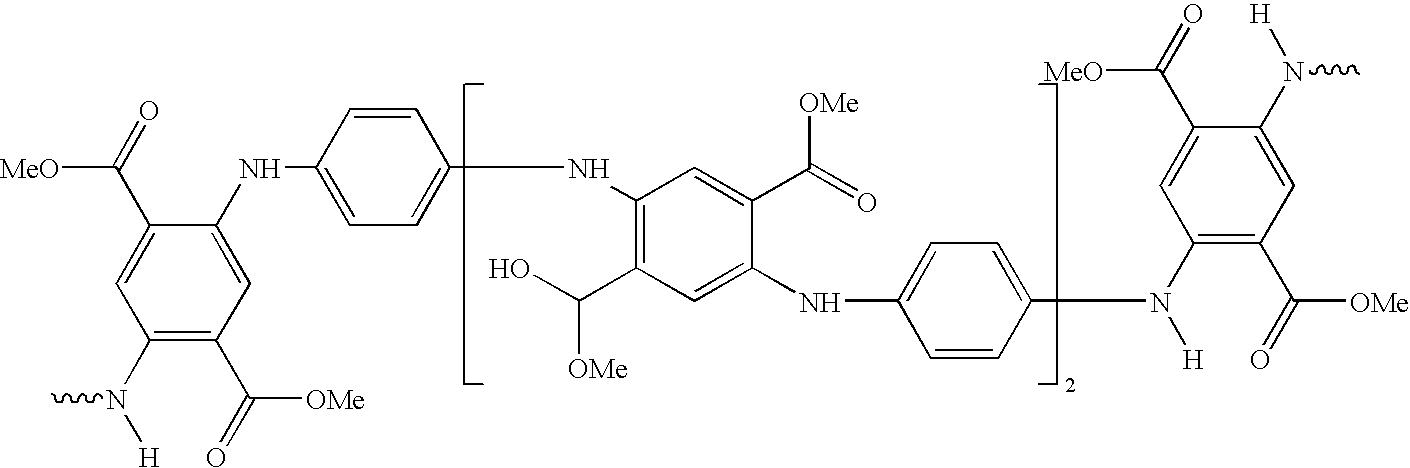

Copper phthalocyanine blue pigment composition and water borne dispersion thereof

Phthalocyanine blue pigments and pigment dispersions for water-borne inks and coatings are described. The pigments are produced by dry milling phthalocyanine blue and a polymeric dispersant, optionally with inorganic fillers and other additives, to obtain a material with improved coloristic, rheological, and stability properties. The resulting activated crude is then processed directly into water-based pigment dispersion with additives and / or surfactants to facilitate conversion to pigmentary form while maintaining the desirable green and clean shade.

Owner:SUN CHEM CORP

Pigment color paste for PU (polyurethane) artificial leather

InactiveCN101942248ARetain cost advantageOvercoming a large amountTextiles and paperPigment pastesMicrometerTitanium

The invention relates to a pigment color paste for PU (polyurethane) artificial leather, which adopts dimethylbenzene as a regulating solvent and polyurethane resin as a pigment vector to be prepared into resin liquid components, and triethanolamine as a dispersing agent, light calcium carbonate as stuffing and titanium white, carbon black, phthalocyanine blue, phthalocyanine blue red and everbrightfastyellow as color developing pigments. The invention can ensure that the stuffing and one of the pigments is blended with the resin liquid components, and the dispersing agent is added to be fully stirred and then grinded by a three-roller grinder, and the fineness is between 3 to 5 micrometers.

Owner:王文庭

High acid-resistant environment coil steel coating

ActiveCN101781512ALow costImprove protectionAnti-corrosive paintsEpoxy resin coatingsCyclohexanoneStrontium

The invention relates to a high poaching-resistance and high acid-resistance coil steel coating and preparation thereof, particularly to the preparation of a polyester finish paint and an epoxy primer, which belongs to the technical field of coatings. A high acid-resistant environment coil steel coating is provided with a finish paint and a primer, wherein the finish paint is prepared from titanium white, phthalocyanine blue, polyester resin, amino resin, a catalyst, an adhesion promoter and a thinner; and the primer is prepared from high molecular epoxy resin, low molecular epoxy resin, normal butanol, cyclohexanone, strontium yellow, titanium white, kaolin, amino resin and xylene, and the finish paint and the primer are used after matched packaging.

Owner:NIPPON PAINT GUANGZHOU

PVC (polyvinyl chloride) diamante shower curtain and preparation method thereof

ActiveCN104194217AReduce forceLower glass transition temperatureFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of plastic shower curtains and particularly relates to a PVC (polyvinyl chloride) diamante shower curtain and a preparation method thereof. The PVC diamante shower curtain comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 40-60 parts of a plasticizer, 5-10 parts of a thermal stabilizer, 0.05-0.5 part of a flame retardant, 0.1-0.2 part of an anti-ultraviolet agent and 0.01-0.02 part of phthalocyanine blue. The preparation method for the PVC diamante shower curtain comprises the following steps: preparing raw materials, stirring at a high speed, carrying out primary plastification, carrying out secondary plastification, filtering in a hierarchical manner, calendaring molding and cooling rolling. The shower curtain disclosed by the invention is flame-resistant, insulated, alkaline-resistant, acid-resistant, waterproof, corrosion-resistant, tensile-resistant, ageing-resistant, antistatic, clear in grain pattern, and good in 3D (three dimensional) steric effect. And the preparation method of the PVC diamante shower curtain is simple in process, convenient to operate and control, stable in quality, high in production efficiency and capable of being applied to large-scale industrial production.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Developer and its preparing method

The present invention relates to developer and is especially a kind of developer for electrostatic printer and facsimile equipment and its preparation process. The developer is prepared with carbon black 75-90 portions, resin 50-55 portions, polypropylene wax 10-20 portions, charged agent 6-8 portions, SiO2 1-1.5 portions, phthalocyanine blue 0.5-1 portions, azo dye 0.5-1 portions and zinc stearate 5-12 portions, and through mixing, extruding, crushing, sieving and other steps. It has high flowability and great charging amount, and may be used to produce black and clear file and picture copy without back grey.

Owner:周学良

Polyethylene composition having reduced warpage in molded articles

ActiveUS20110201729A1Reduced warpage to molded articlesReduce warpageOrganic dyesPolymer scienceTalc

Disclosed is a colored high density polyethylene composition. The composition comprises a high density polyethylene, phthalocyanine blue, and talc. The composition exhibits reduced warpage in molded articles compared to those which do not contain talc. The composition is useful for injection molding and many other applications where a blue color is needed and low warpage is desired.

Owner:EQUSR CHEM LP

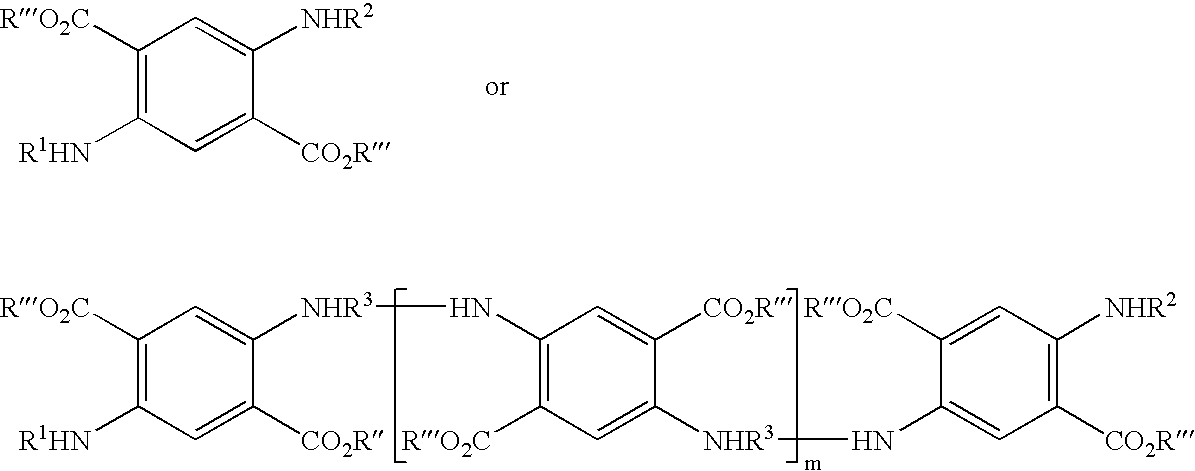

Pigment composition containing phthalocyanine blue 15:2 and preparation method thereof

InactiveCN108192385AImprove heat resistanceExcellent anti-flocculation performancePorphines/azaporphinesPhthalocyanineHeat treated

The invention belongs to the technical filed of phthalocyanine blue pigment preparation, and particularly relates to a pigment composition containing phthalocyanine blue 15:2 and a preparation methodthereof. The pigment composition is prepared from the following ingredients including phthalocyanine blue 15:0, copper phthalocyanine chloro derivatives and copper phthalocyanine sulfonation derivatives. According to the preparation method, the copper phthalocyanine chloro derivatives, the phthalocyanine blue 15:0 and the copper phthalocyanine sulfonation derivatives are subjected to mixing and pulping and are then subjected to heat treatment at 78 to 85 DEG C; water is added for temperature lowering; press filtering, water washing and drying are performed; a solid is obtained through filtering; a finished product is obtained. The pigment composition and the preparation method provided by the invention achieve the goals of crystallization resistance, color fastness, flocculation resistanceand system viscosity reduction. The prepared phthalocyanine blue pigment has the advantages of high transparency, high coloring intensity, high flowability, high heat resistance and high weather resistance, and can be widely applicable to the fields of printing, paint, ink and weaving.

Owner:滨海康益医药化工有限公司

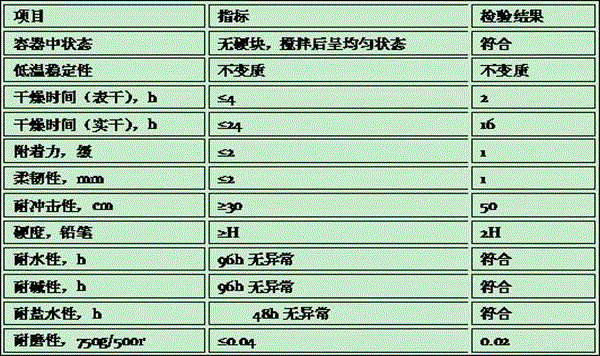

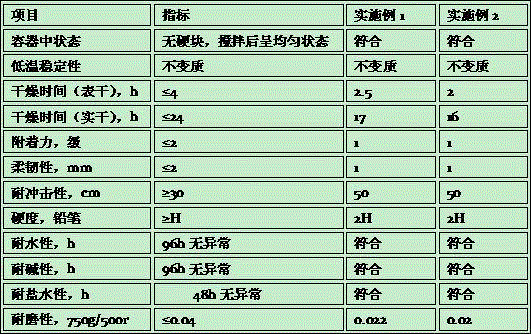

Novel water-based epoxy floor paint and preparation technique thereof

InactiveCN106675314AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsWater basedBound property

The invention relates to a novel water-based epoxy floor paint and a preparation technique thereof. The invention is characterized in that the novel water-based epoxy floor paint is composed of a component A and a component B. The component A is prepared from the following raw materials in parts by mass: 80 parts of water-based epoxy resin and 20 parts of reactive diluent. The component B is prepared from the following raw materials in parts by mass: 20-25 parts of water-based epoxy curing agent, 25-35 parts of deionized water, 0.2-0.6 part of RS610 wetting and dispersing agent, 0.3-0.5 part of DF681F defoaming agent, 0.5-1 part of scratch-resistant aid, 0.2-0.4 part of A401 alkali swelling thickener, 4-6 parts of titanium white, 2-3 parts of BGS phthalocyanine blue, 1-1.5 parts of 801 strontium chrome yellow, 10-15 parts of light calcium carbonate, 20-25 parts of precipitated barium sulfate and 10-15 parts of ultrafine talcum powder. By using water as the dispersion medium, the floor paint is free of volatile organic solvents (such as methylbenzene and xylene), so that abundant resources are saved, the fire hazard during construction is eliminated, the atmosphere pollution is lowered, and the working environment conditions are improved; and the coating has high adhesion and high binding property for most substrates.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

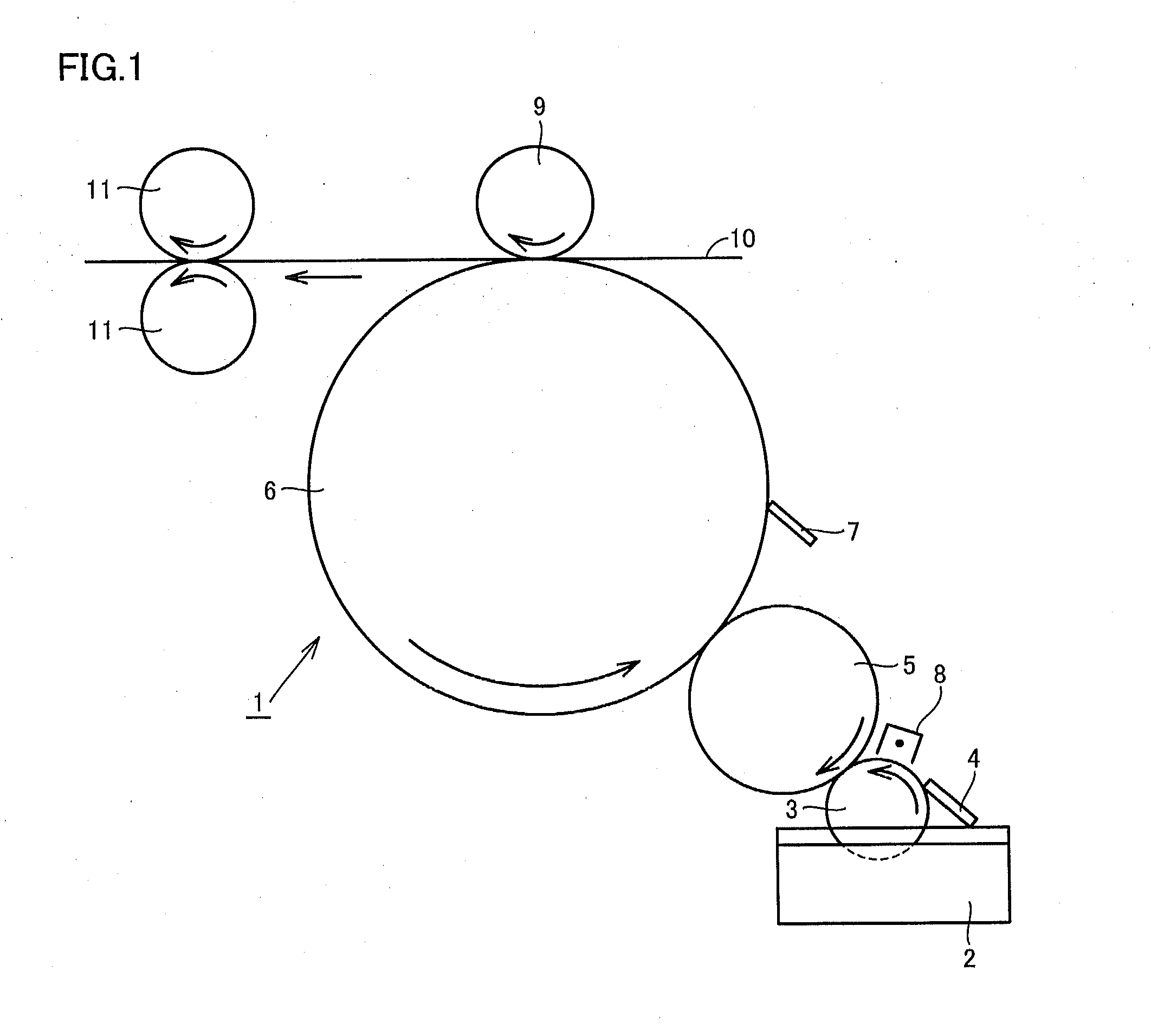

Liquid developer

A liquid developer of the present invention includes a toner particle and an insulating liquid, the toner particle including a resin and a pigment, the resin including a polyester resin, the pigment including a first pigment, a second pigment, and a third pigment, the first pigment being a carbon black, 10 to 25 mass % of the first pigment being included in the toner particle, the second pigment being nigrosine, 3 to 15 mass % of the second pigment being included in the toner particle, the third pigment being at least one organic pigment selected from a group consisting of a phthalocyanine blue pigment, a phthalocyanine green pigment, a carmine-based pigment, a naphthol-based pigment, a quinacridon-based pigment, an azo-based pigment, a benzimidazolone-based pigment, and an isoindoline-based pigment, 5 to 20 mass % of the third pigment being included in the toner particle.

Owner:KONICA MINOLTA INC

Method for preparing colorant used in mass coloration of acrylic fibre spinning

The preparation method of colouring material for mass coloration process in spinning of acrylic fibre includes the following steps: mixing pigment, dispersing agent and NaSCN aqueous solution and grinding by means of ball-grinding machine. In the colouring material the pigment content is 5-25 wt%, the weight ratio of pigment and dispersing agent is 100:3-30, and the grinding time is 0.5-5.0 hr., then the colouring material can be obtained. The above-mentioned dispersing agent is one compound selected from alkyl-polyoxyethylene ether, alkylphenol ethoxylates, trimethyl stearamide chloride or hexadecyltrimethylamine bromide or their mixture, and the pigment is cabron, black, phthalocyanine blue, iron oxide or ultramarine generally.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

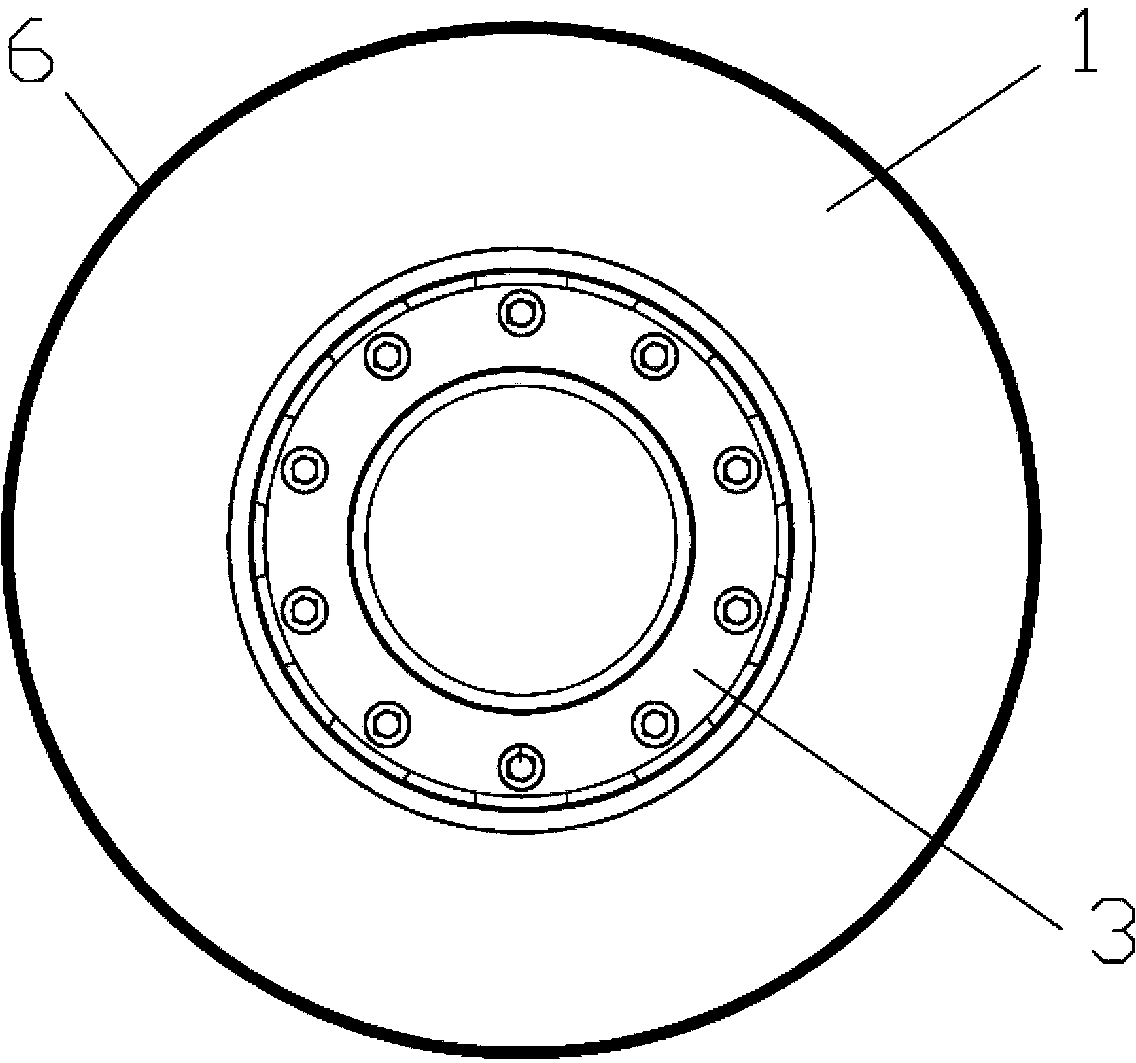

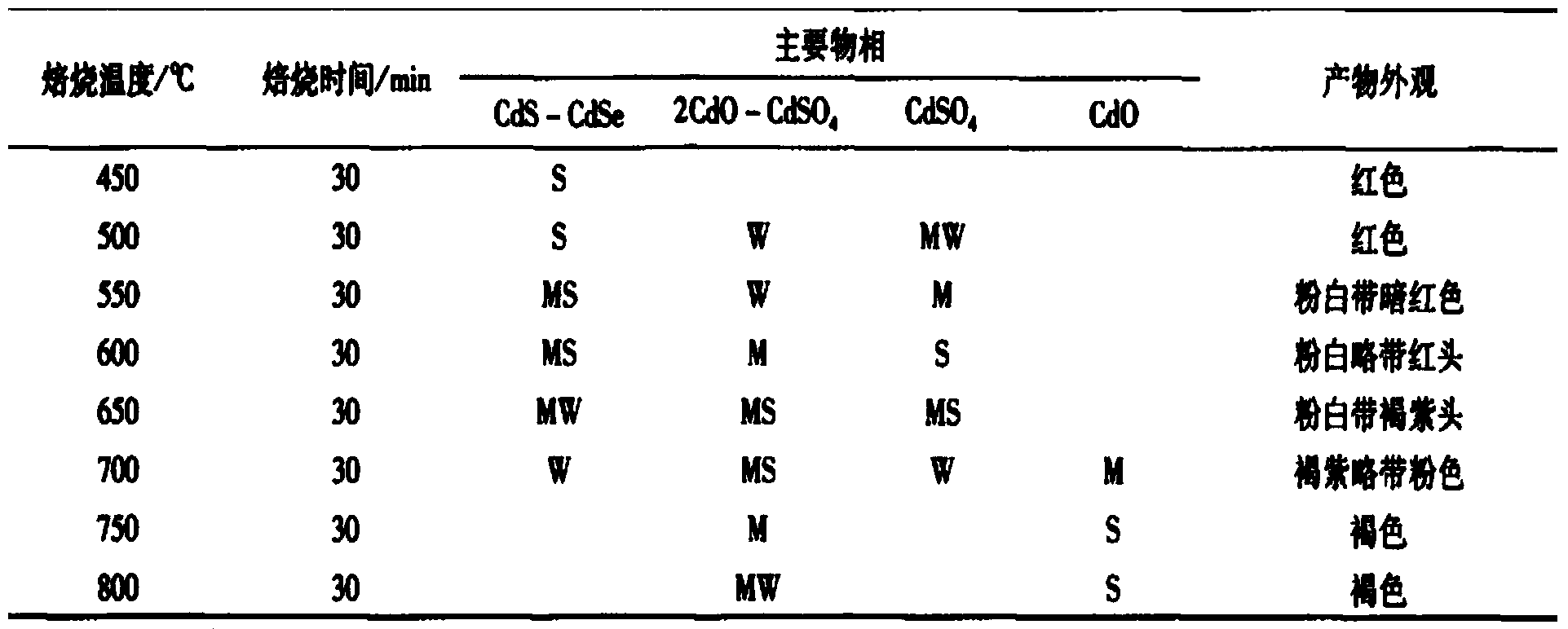

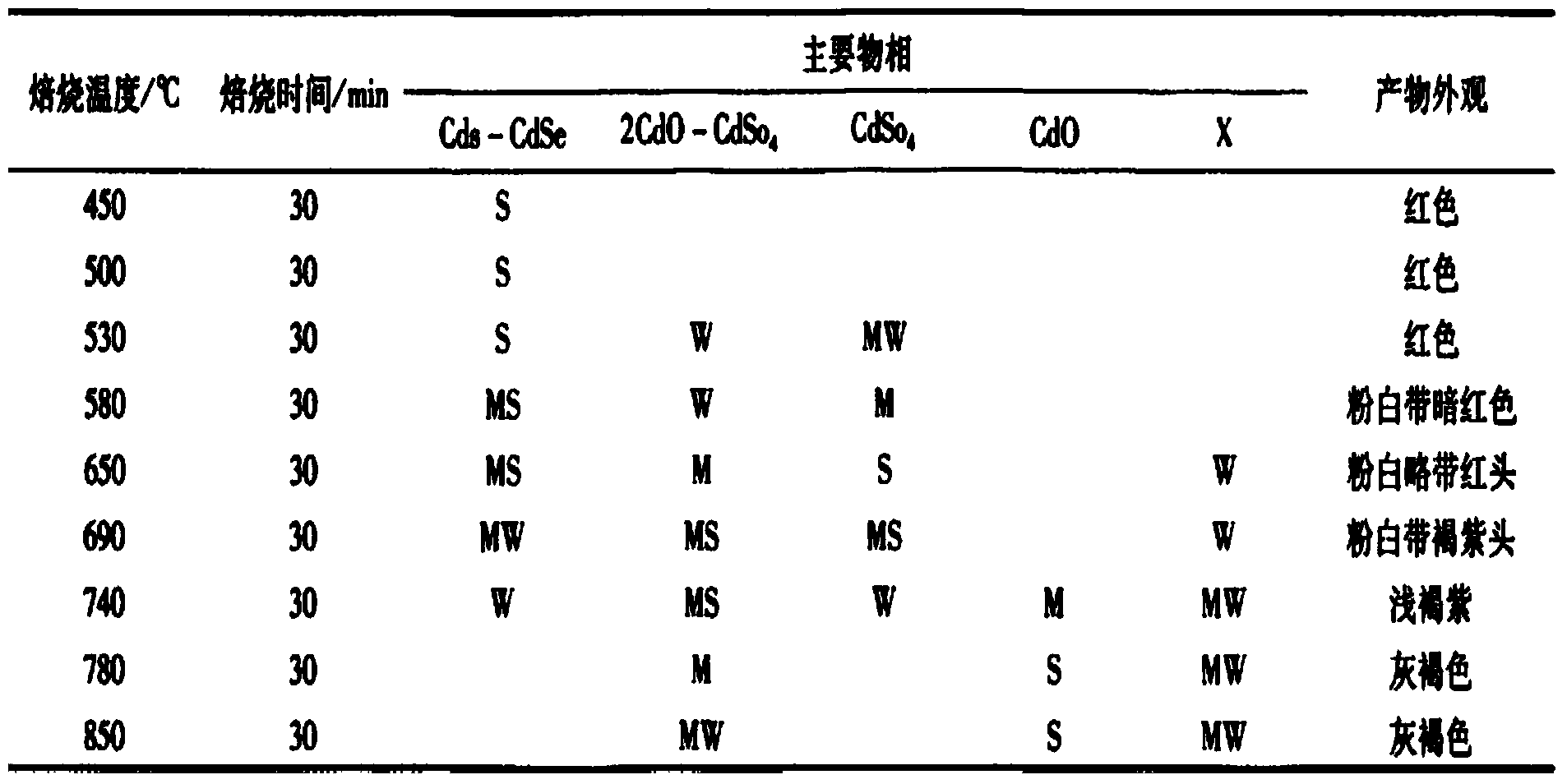

Irreversible temperature indicating paint for brake discs and preparation method thereof

InactiveCN103911069AKnow the maximum temperatureTimely detection of overheating hazardsThermosensitive paintsEngineeringColor changes

The invention provides an irreversible temperature indicating paint for brake discs and a preparation method thereof. The irreversible temperature indicating paint contains the following components by mass: 40-45% of a binder; 5-6% of a phthalocyanine blue pigment; 16-22% of cadmium yellow and cadmium red pigments (1:3); 6-10% of a filler; and 20-30% of dimethylbenzene. By providing the irreversible temperature indicating paint with specific components to brake discs, the brake discs can have multiple color change preset temperatures in the range of 150DEG C-700DEG C, thus facilitating visual understanding of a maximum temperature reached in the temperature range in a braking process of the brake discs. Also, the paint has good high temperature resistance, can ensure a coating not to fall off in the 150-700DEG C, thus being conducive to timely finding of overheat hidden troubles during working of the brake discs and guaranteeing driving safety. The irreversible temperature indicating paint provided by the invention is especially suitable for train brake discs.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

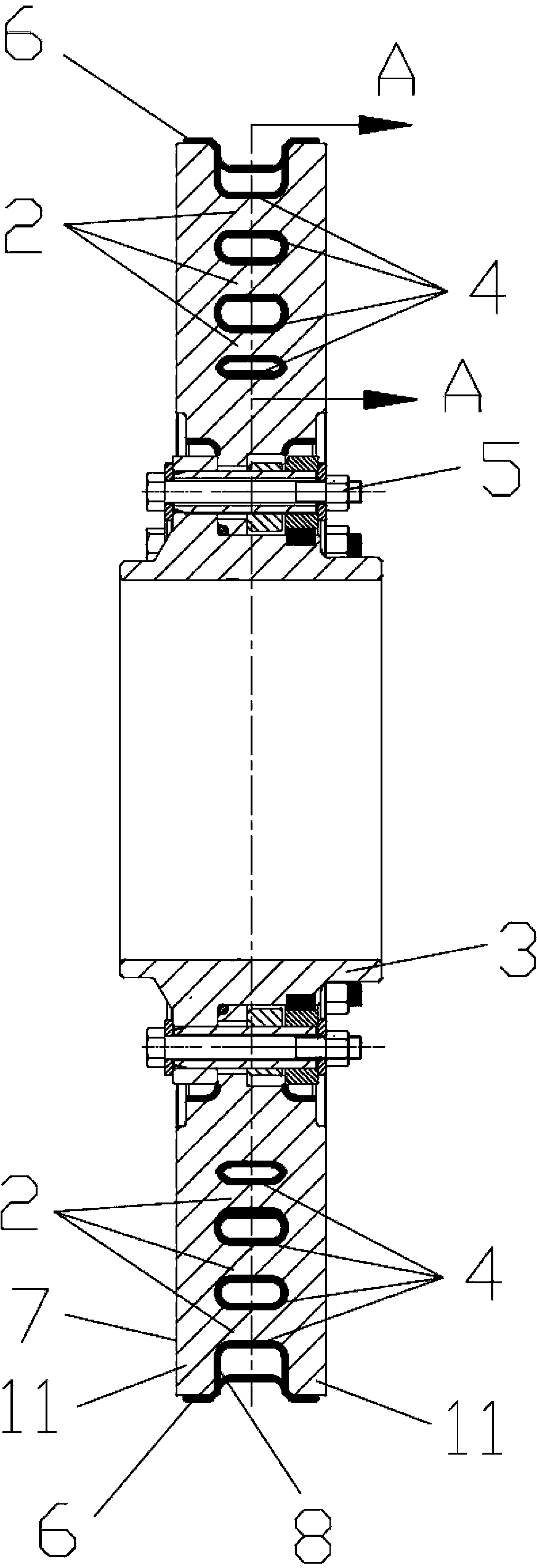

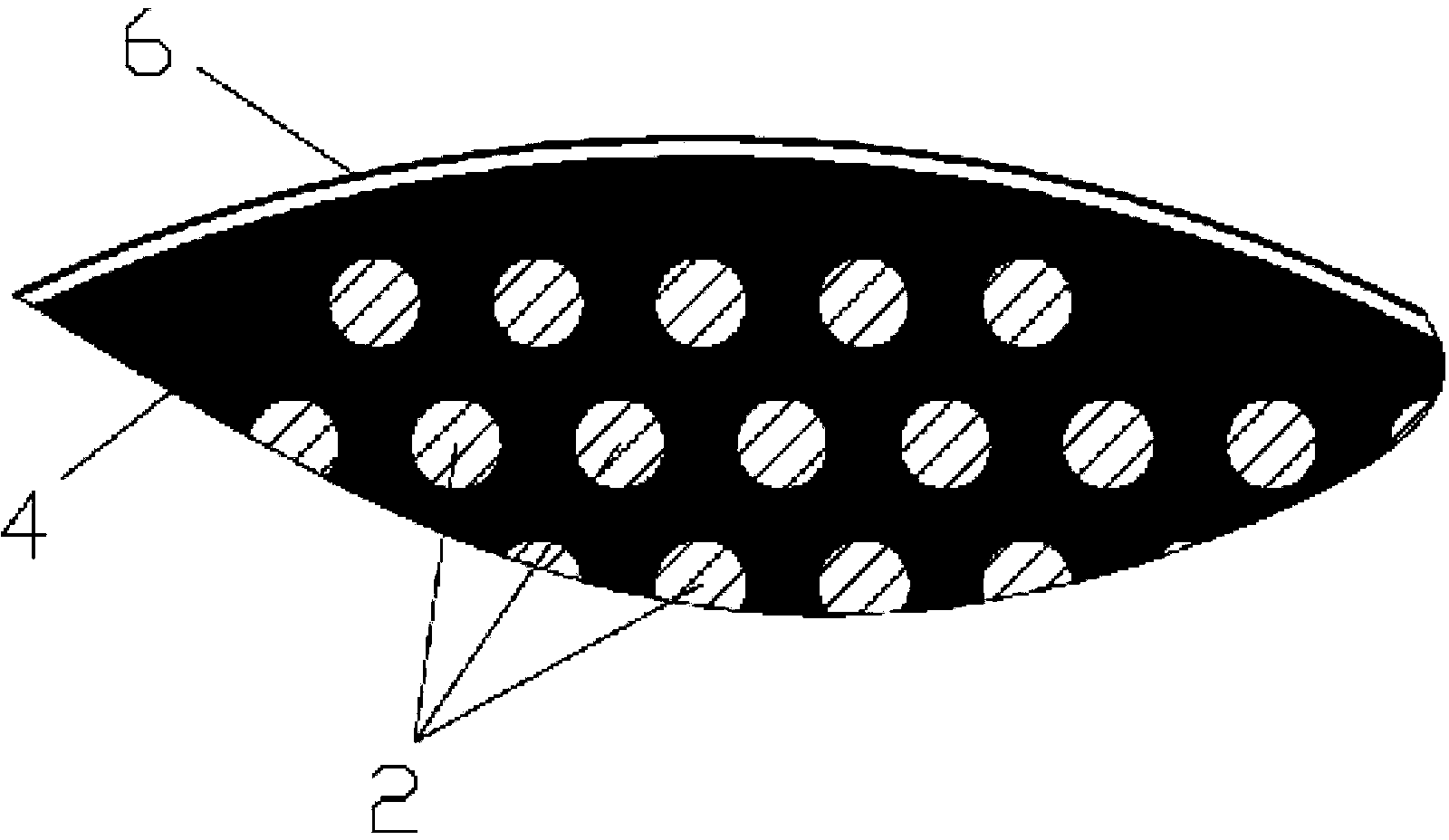

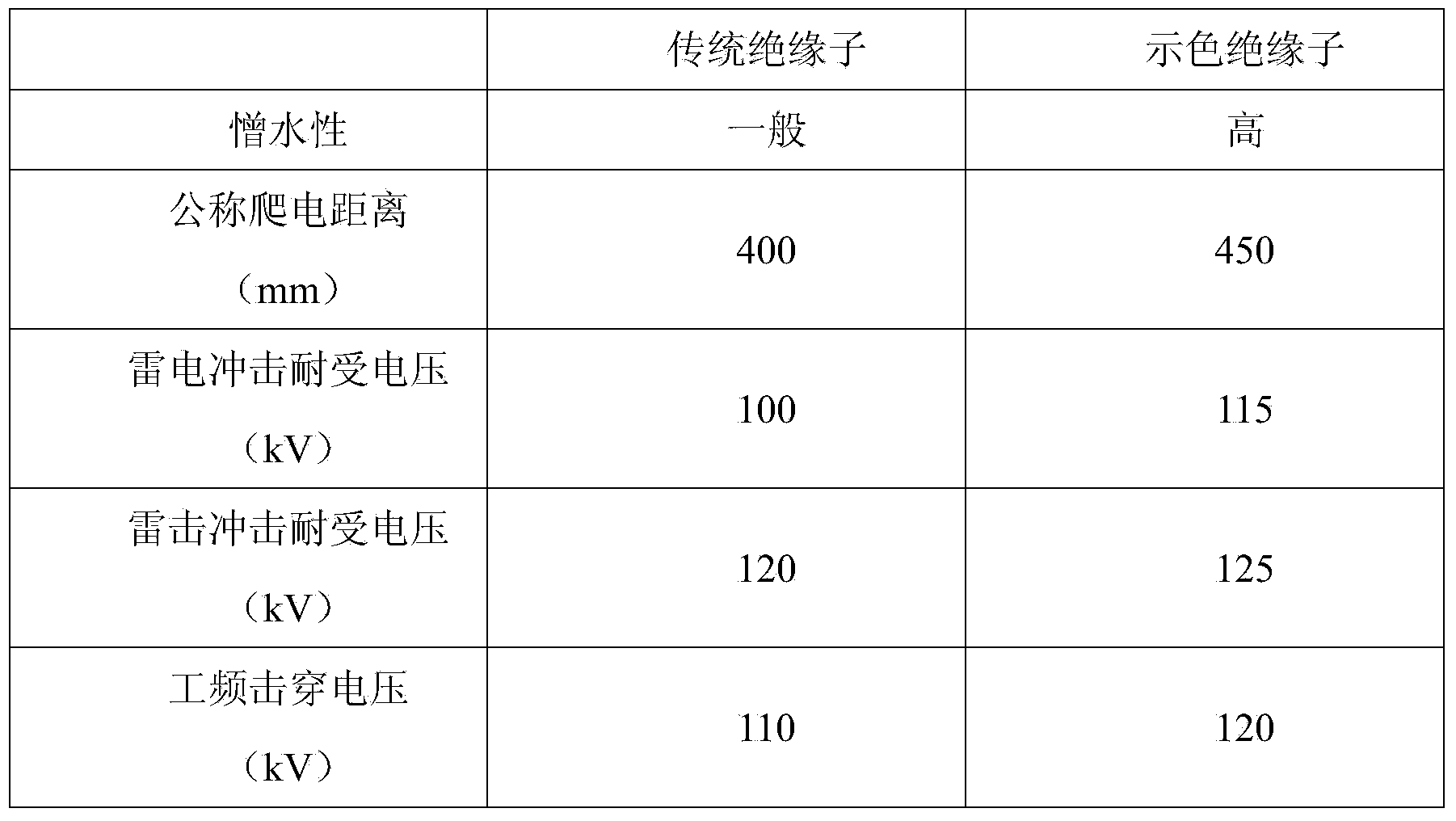

Visual allochroic insulator coating and preparation method thereof

InactiveCN103709936AReduce labor intensityEasy maintenanceInsulatorsThermosensitive paintsLead carbonateSilicon rubber

The invention discloses a visual allochroic insulator coating and a preparation method thereof. The visual allochroic insulator coating is prepared from the following raw materials in parts by weight: 40-50 parts of silicon rubber, 4-7 parts of phthalocyanine blue, 1-6 parts of calcium carbonate, 0.1-1.0 part of lead carbonate, 1-3 parts of talcum powder, 15-20 parts of cadmium red, 10-15 parts of greenish orchid, 1-3 parts of titanium dioxide, 1-5 parts of barium metaborate, 1-3 parts of dispersing assistant and 1-3 parts of binder. By using a visual rubber insulator containing the visual allochroic insulator coating disclosed by the invention, the flashover position can be obviously seen under the condition of not climbing on the rod, and the flashover origin can be judged.

Owner:BEIJING DINGYI TONGYUAN SCI & TECH DEV CO LTD

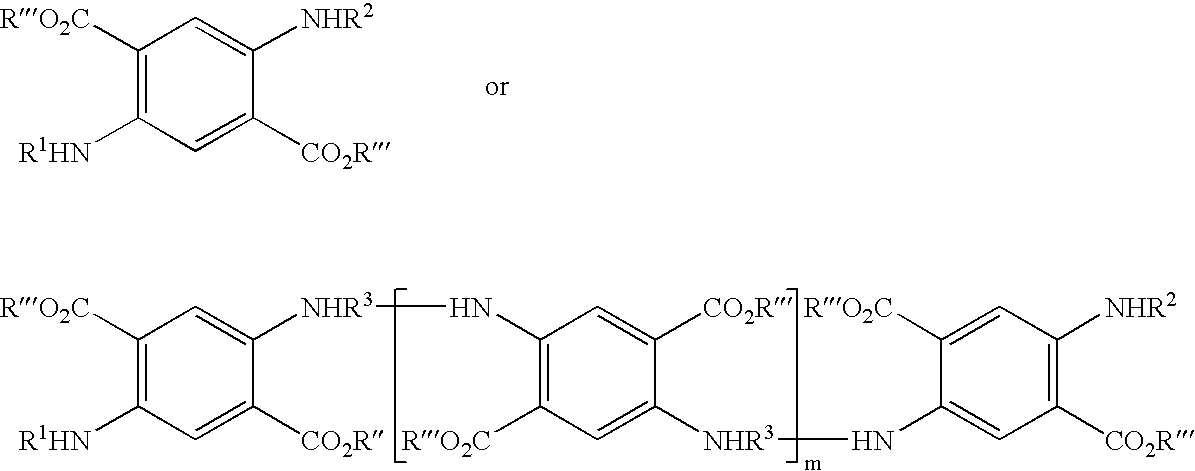

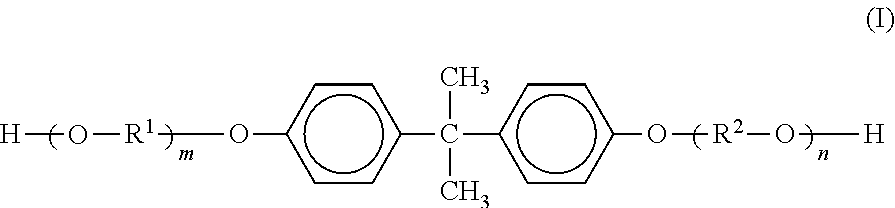

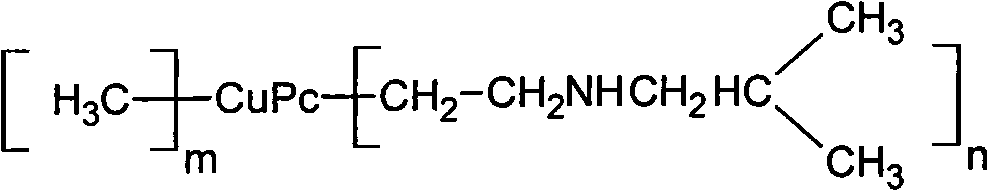

Production method of phthalocyanine blue 15:4 for toluene ink

InactiveCN101880467AReduce the impactShort production processInksPorphines/azaporphinesColor intensityToluene

The invention discloses a production method of phthalocyanine blue 15:4 for toluene ink, wherein crude copper phthalocyanine has the purity of over 98.5% and the free copper of less than 1000ppm, and in an expression of a copper phthalocyanine derivative, m arranges between 0.2 to 1.8, n arranges between 0.5 to 0.9; the crude copper phthalocyanine is placed into grinding equipment to be ball milled, then a magnetic filter is utilized to separate iron generated during the ball milling process, and phthalocyanine blue 15:4 is prepared. The method has the notable characteristics of short production process, low cost and small influence on environment; and compared with the pigment prepared by the traditional method, the phthalocyanine blue 15:4 pigment for the toluene ink, which is produced by the method, is the same with the color and the color intensity of the toluene ink, and obviously improves the viscosity, luster and transparency.

Owner:SHUANGLE CHEM PIGMENT YANGZHOU CITY

Preparation method of fertilizer colorant and application method thereof

The invention relates to a preparation method of a fertilizer colorant and an application method thereof. The preparation method comprises the following steps of: respectively dissolving water-soluble dyes such as bright red, rose red, acid blue, brilliant blue, golden yellow or lemon yellow into water; respectively adding 1-3% dispersing agent; stirring and respectively preparing into red inner colorant, blue inner colorant and yellow inner colorant for later use; respectively dissolving oil-soluble dyes such as lithol red, toluidine red, phthalocyanine blue, transparent blue, benzidine yellow or fluorescence yellow into base oil dissolvent; respectively adding the 1-3% dispersing agent; stirring and respectively preparing into red outer colorant, blue outer colorant and yellow outer colorant; directly stirring and blending the inner colorants and fertilizer raw materials; and spraying the outer colorants, so that the fertilizer is evenly colored. The preparation method can prepare the colored fertilizer which can not discolor under the functions of strong acid, strong base, strong reductant, strong oxygenant and microbe, and has the characteristics of small use amount of the colorant, stable coloration, low cost, pure color, good appearance, wide adaptability, high safety, good performance and the like.

Owner:广东新绿源化工有限公司

High-temperature-resistant epoxy powder coating for corrosion prevention of pipeline

InactiveCN104497799AGood coating performanceImprove bindingAnti-corrosive paintsPowdery paintsFirming agentPolypropylene

The invention relates to a high-temperature-resistant epoxy powder coating for corrosion prevention of a pipeline. The high-temperature-resistant epoxy powder coating comprises the following raw material components in percentage by weight: 50-60% of modified phenolic epoxy resin, 3-4% of toughened resin, 3-4% of a curing agent, 30-40% of a filler, 1-2% of pigments and 1-2% of additives. The epoxy value of the modified phenolic epoxy resin is 0.2-0.3eq / 100g, and the softening point is 65-75 DEG C; the toughened resin is solid epoxy resin modified by nitrile butadiene rubber; the curing agent is an imidazole curing agent or a modified phenolic curing agent; the filler is titanium dioxide, wollastonite powder, mica powder, barite powder or several types thereof; the pigments comprise phthalocyanine blue and iron oxide yellow; and the additives comprise more of an acrylic acid leveling agent, a benzoin defoaming agent, a fumed silica thixotropic agent and dimethylimidazole. As a bottom-layer coating of a 3PE (polyethylene) / 3PP (polypropylene) anti-corrosion coating, the high-temperature-resistant epoxy powder coating can still keep good binding force at the temperature of 120 DEG C and further ensure that the 3PE / 3PP anti-corrosion coating can still keep stable coating performance at the temperature of 120 DEG C.

Owner:SHANGHAI HILONG PETROCHEM RES INST +2

Gypsum mold oil composition

ActiveCN102925252AExtended service lifeMeet the use requirementsAdditivesMicrocrystalline waxLanolin

The invention provides a gypsum mold oil composition. The gypsum mold oil composition comprises 0.2-0.5wt% of lanolin magnesium soap, 3.0-6.0wt% of microcrystalline wax, 3.0-5.0wt% of rosin, 20-30wt% of solvent oil, 0.5-0.6wt% of phthalocyanine blue BGS, and the balance base oil. The gypsum mold oil composition is developed according to the technological characteristics of gypsum molds used in the ceramic production, can satisfy use requirements of molds for ceramic production by like enterprises, and enables the service lives of the gypsum molds to be prolonged by above 20%. The gypsum mold oil composition has the advantages of reasonable compatibility of product raw materials, simple preparation method, wide application range, and easily available raw materials.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com