Patents

Literature

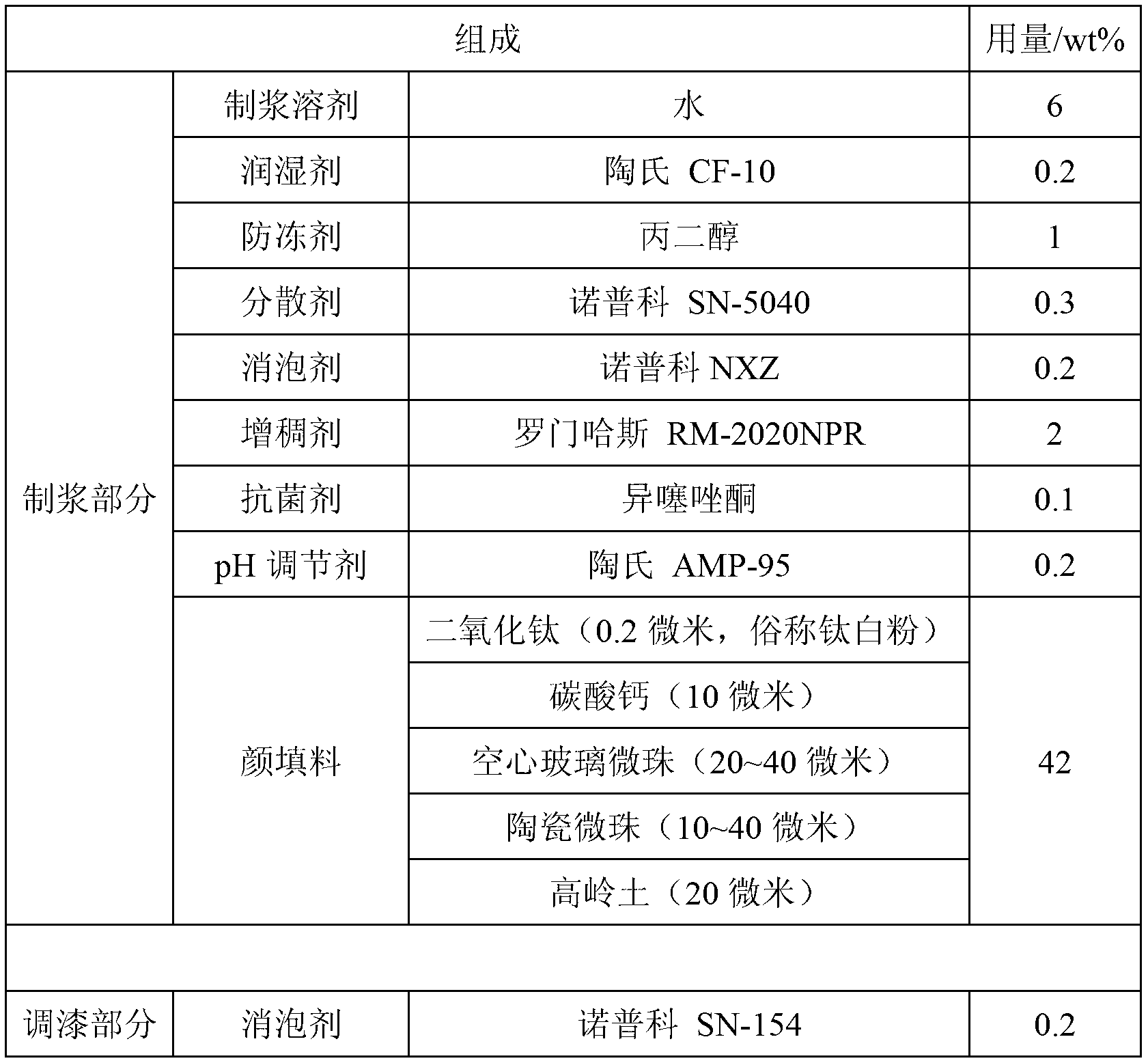

498results about "Thermosensitive paints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

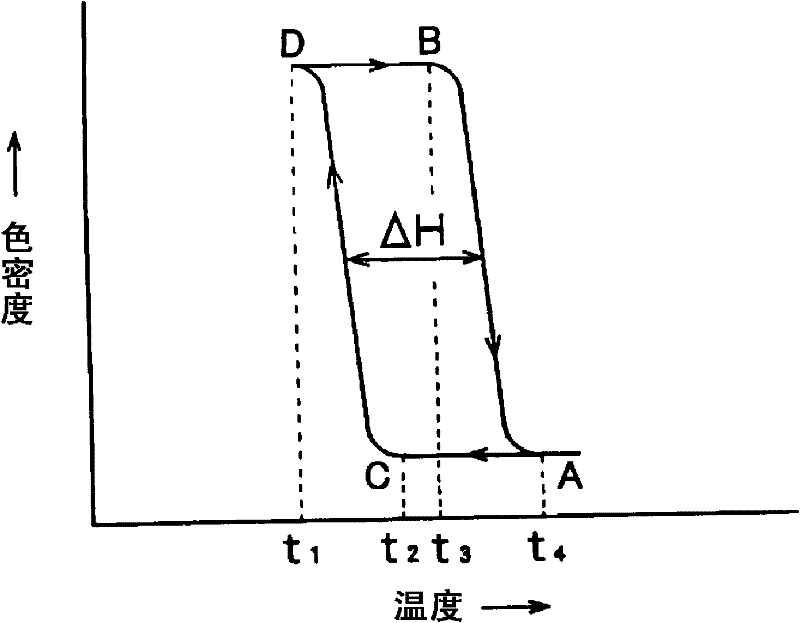

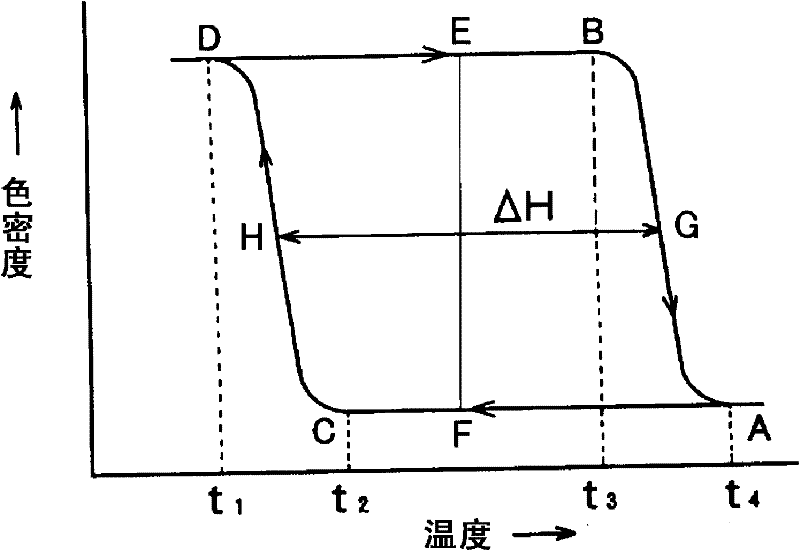

Reversibly thermochromic composition

InactiveUS20140291585A1Improve visibilityGood effectConductive materialPen repairingThermochromismHeat conducting

[Object] To provide a reversibly thermochromic composition free from accidental discoloration by heat conducting from the opposite side writing surface or by self-heating due to quick writing; and also to provide a solid writing material and a writing ink composition comprising that composition.[Means to solve the problem] A reversibly thermochromic composition comprising a combination of: (a) a reversibly thermochromic component capable of being discolored or decolored by heat and (b) a component for controlling heat conducting to the reversibly thermochromic component; and also a solid writing material and a writing ink composition comprising that composition.

Owner:PILOT PEN CO LTD

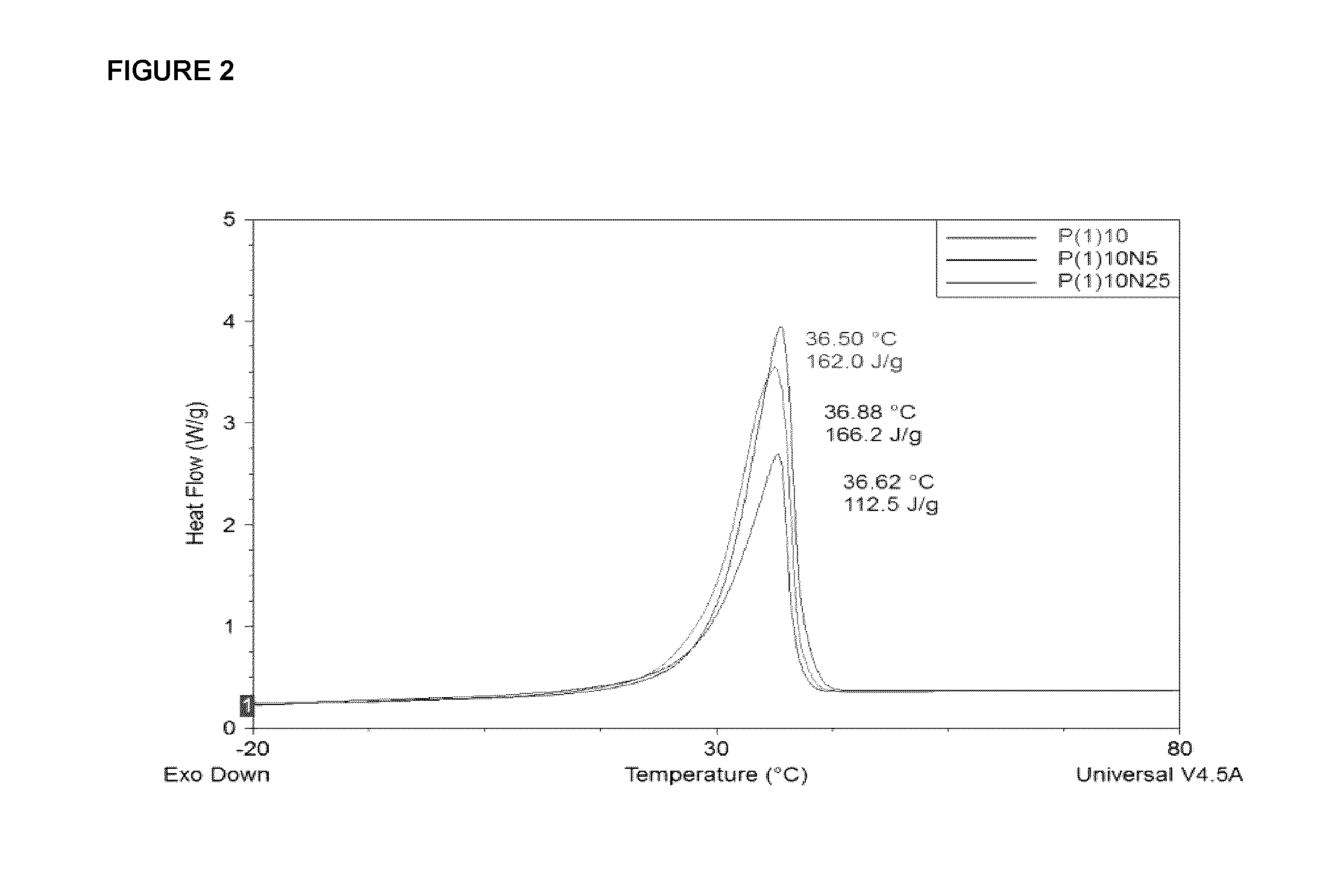

Nanostructured phase change materials for solid state thermal management

ActiveUS20150291868A1Increase heat absorptionMaterial nanotechnologyHeat storage plantsPhase changePhase-change material

Nanostructured phase change materials (PCMs) which are heterogeneous materials having at least two phases, at least one of the phases having at least one of its dimensions in the nanoscale, and comprising a first agent that undergoes an endothermic phase transition at a desired temperature and a second agent that assists in maintaining a nanostructure, are provided. There are also provided methods for manufacturing such PCMs, and applications thereof for providing thermoregulatory coatings and articles containing such coatings for use in a wide range of applications, such as cooling textiles, wipes, packaging, films, walls and building materials.

Owner:BIOASTRA TECH

Solar Heat Responsive Exterior Surface Covering

InactiveUS20080008857A1Improve the overall coefficientRoof improvementRoof covering using flexible materialsThermochromismEngineering

Owner:CERTAINTEED CORP

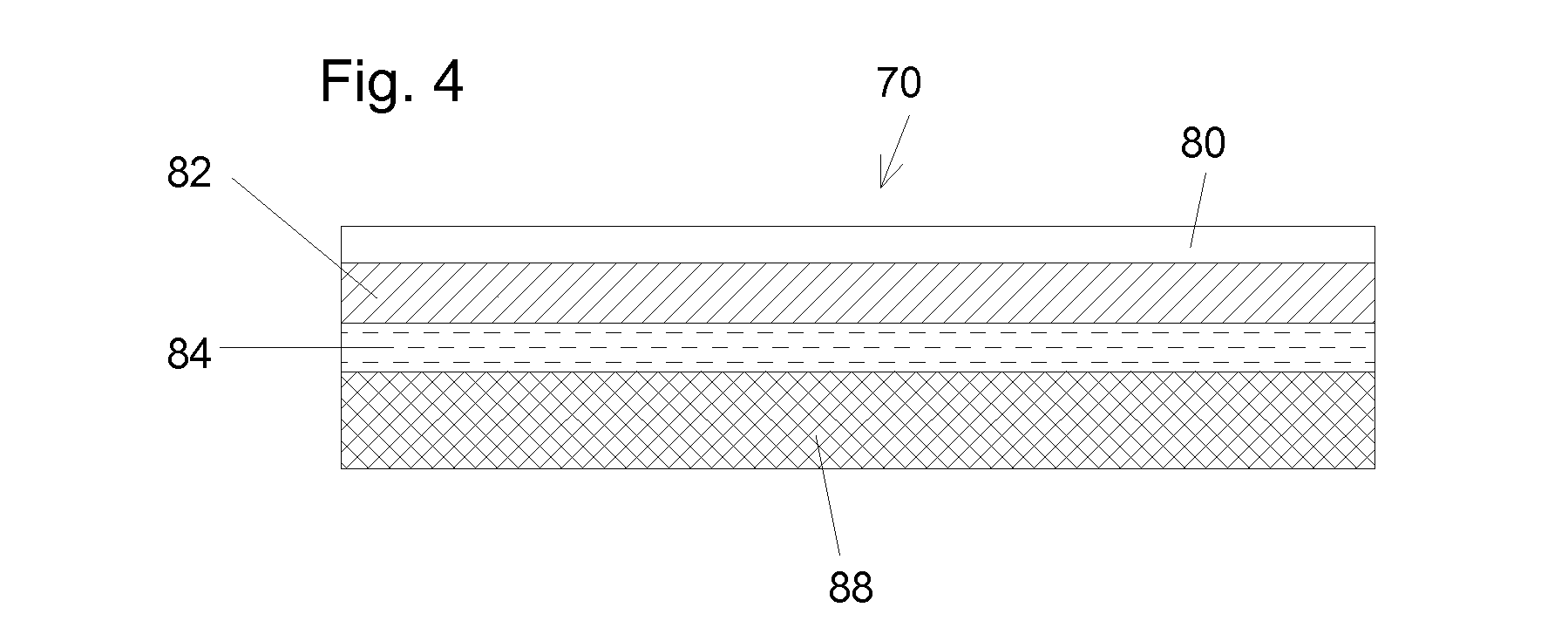

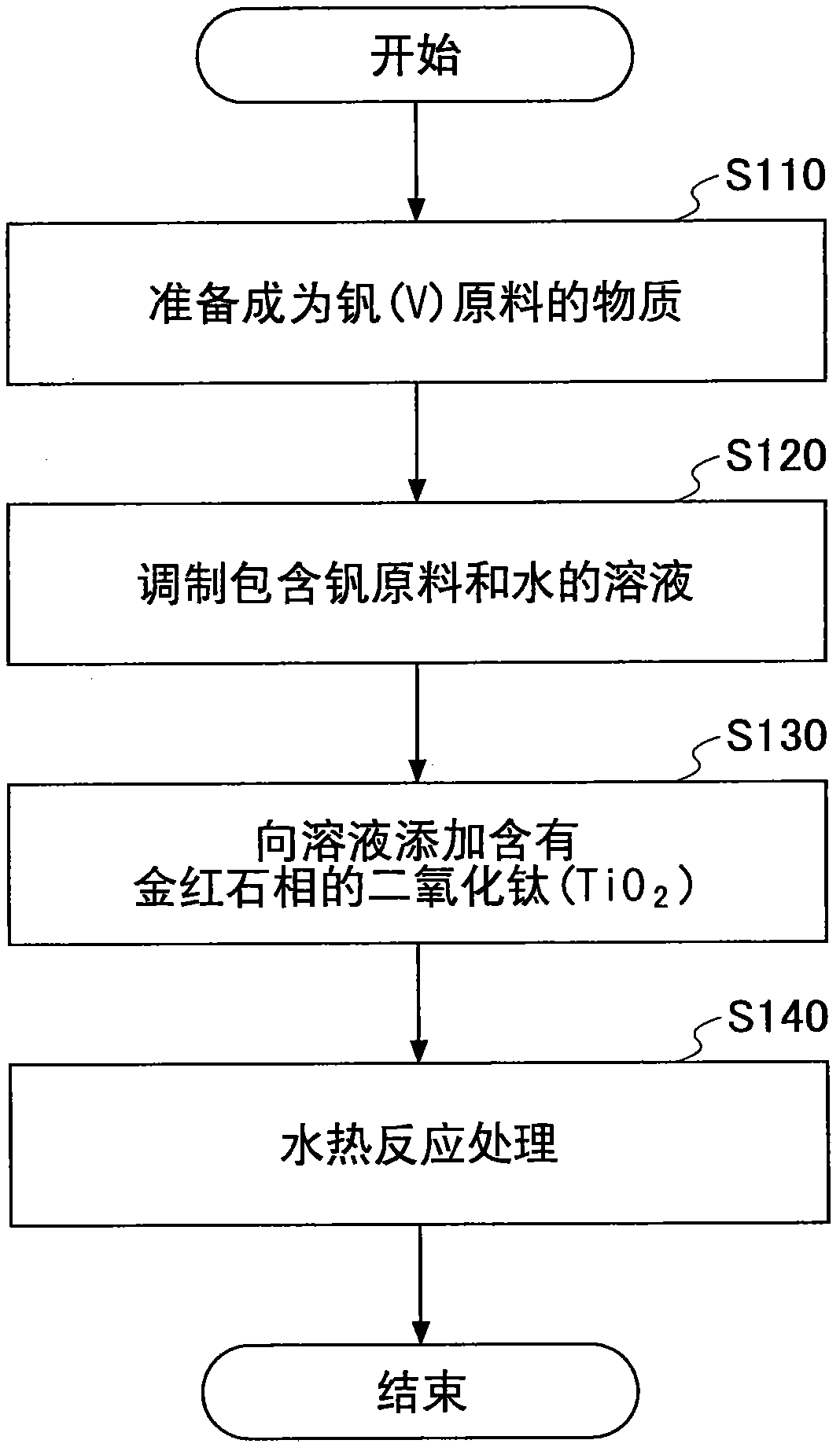

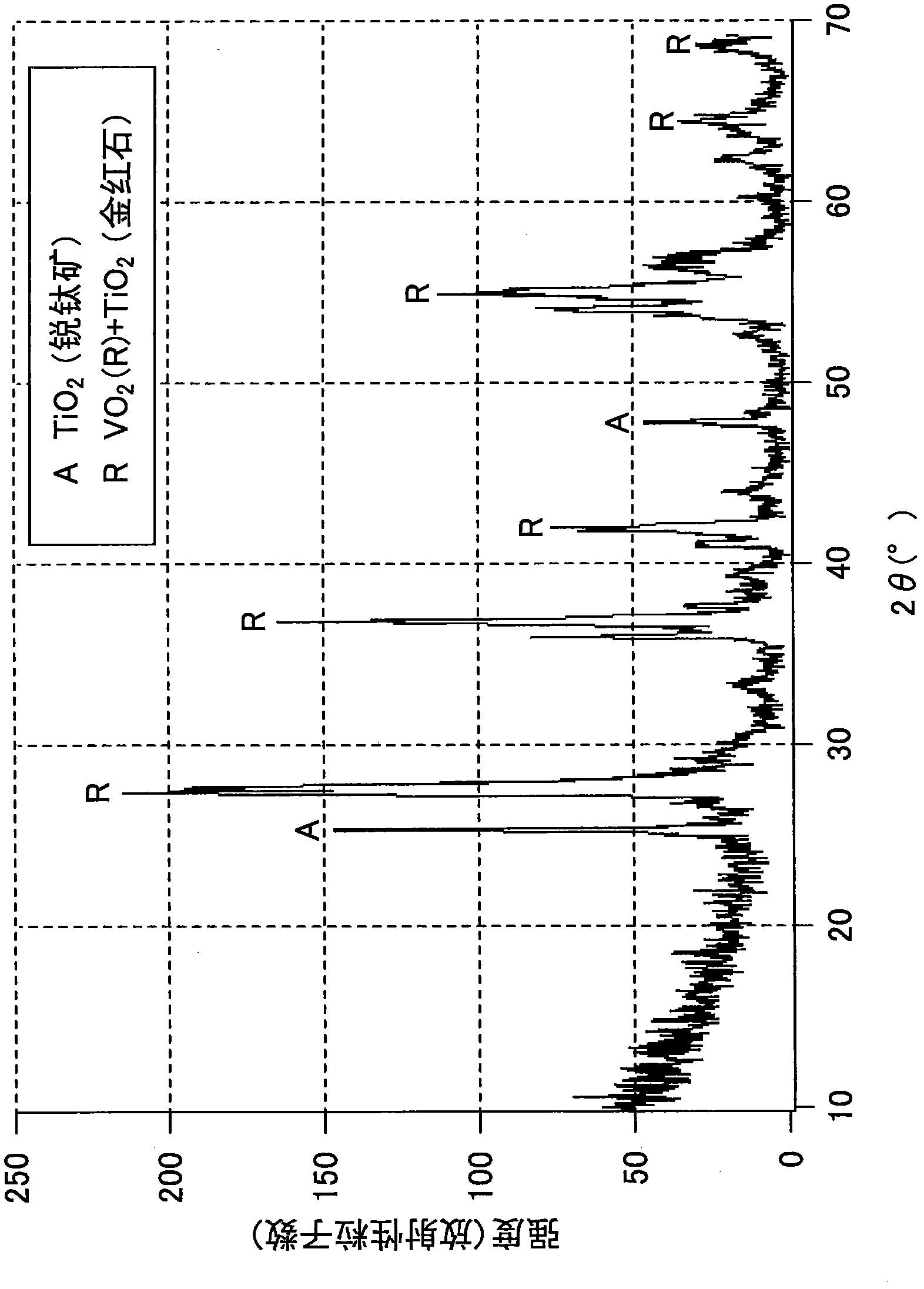

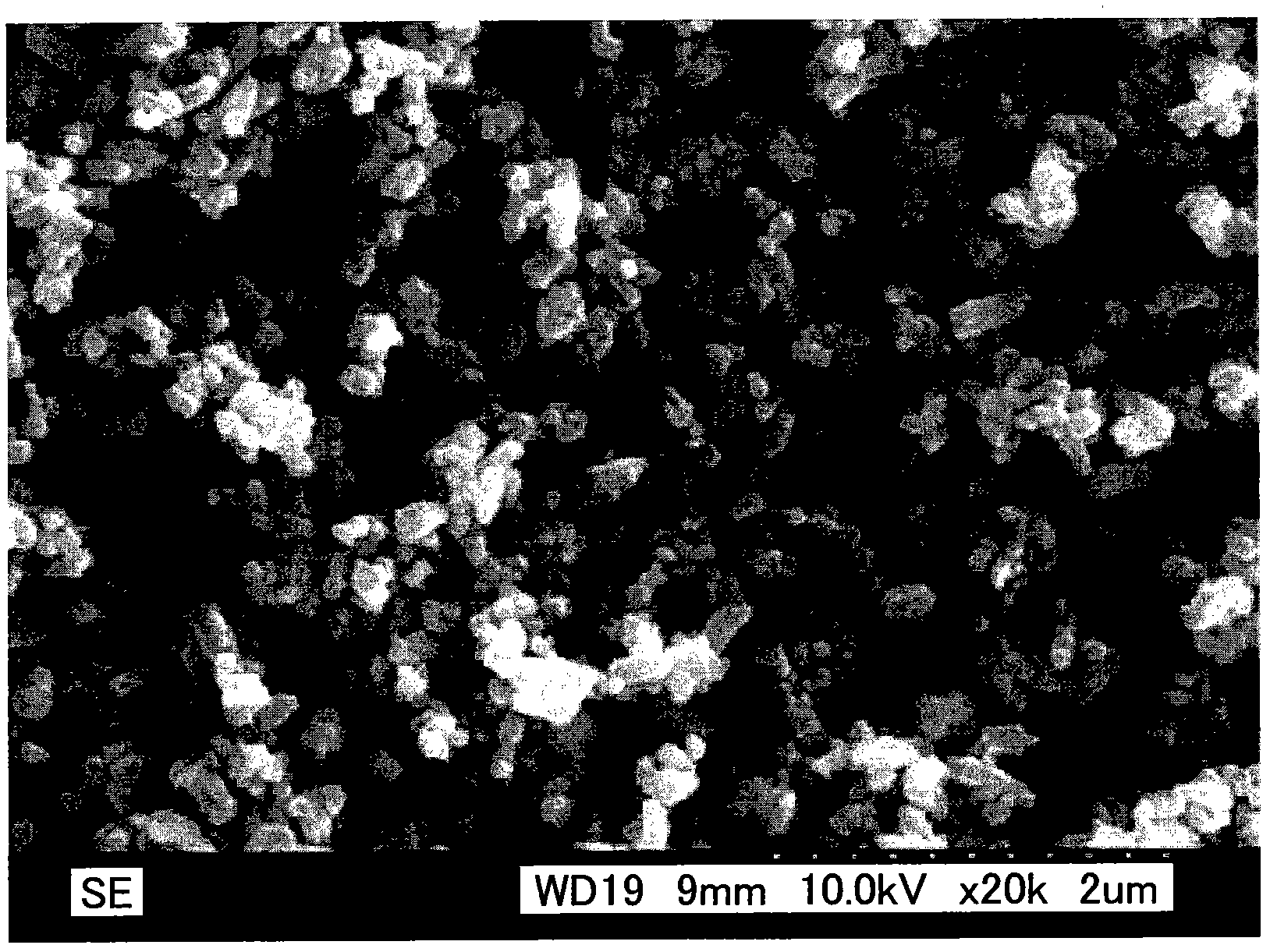

Thermochromic microparticles, dispersions thereof, and manufacturing method thereof, as well as light-modulating coatings, light-modulating films and light-modulating inks

InactiveCN102066261AWith characteristicsGood automatic dimmingMaterial nanotechnologyOther chemical processesVanadium dioxideMicroparticle

Provided are thermochromic microparticles that comprise particles of rutile (R-phase) vanadium dioxide (VO2) and rutile titanium dioxide (TiO2). At least one of the vanadium dioxide (VO2) particles is grown on the titanium dioxide (TiO2) particles so as to be larger than said titanium dioxide (TiO2) particles and in a rod form.

Owner:NAT INST OF ADVANCED IND SCI & TECH

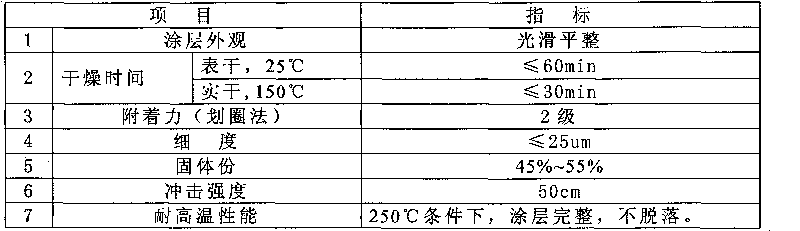

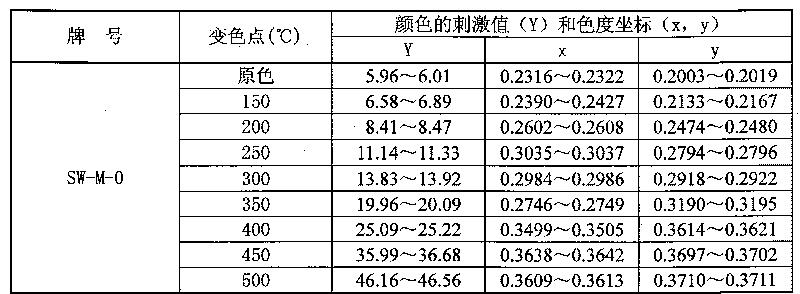

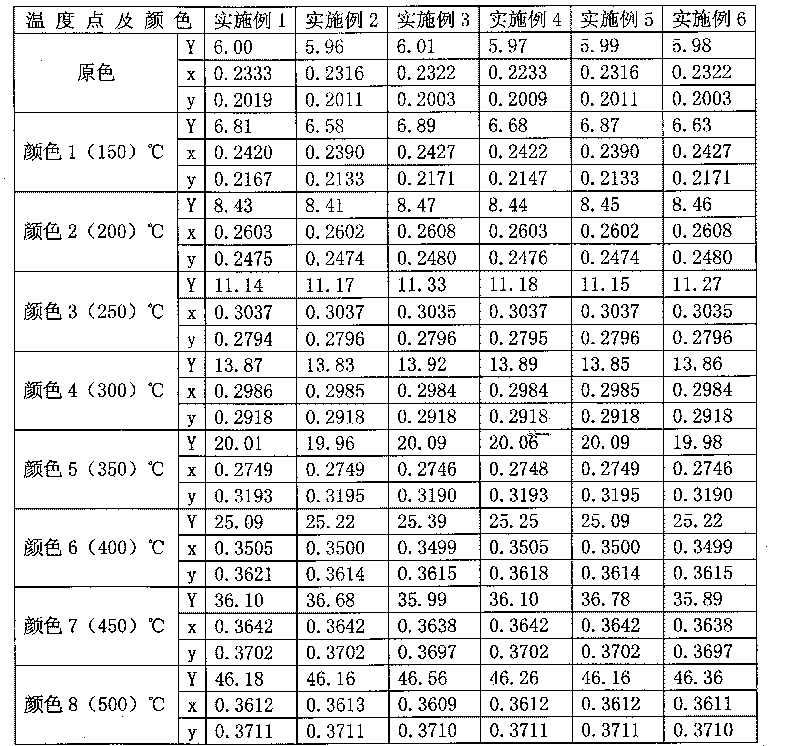

Production method of 150-500 DEG C pleochromatic irreversible thermopaint

InactiveCN101705051AAchieve zero breakthroughReduce the temperature limit of temperature measurementThermometers using physical/chemical changesThermosensitive paintsSolventInorganic pigments

The invention relates to production and detection methods of 150-500 DEG C pleochromatic irreversible thermopaint containing the following components in percentage by mass: 30.0-80.0 percent of base stock, 2.5-8.0 percent of low-temperature organic pigment, 10.0-30.0 percent of low-temperature inorganic pigment, 15.0-5.0 percent of packing and 30.0-50.0 percent of solvents. The 150-500 DEG C pleochromatic irreversible thermopaint is a novel measuring tool with special purpose. The paint is the unique developed product of the low-temperature pleochromatic irreversible thermopaint in China since 1980s, is the effective complement of the traditional varieties of the pleochromatic irreversible thermopaint in China, lowers the temperature measuring limit of the traditional pleochromatic irreversible thermopaint varieties, achieves the zero breakthrough of developing the pleochromatic thermopaint in China to the low temperature direction, and widens the application range of the traditional pleochromatic irreversible thermopaint.

Owner:中昊北方涂料工业研究设计院有限公司

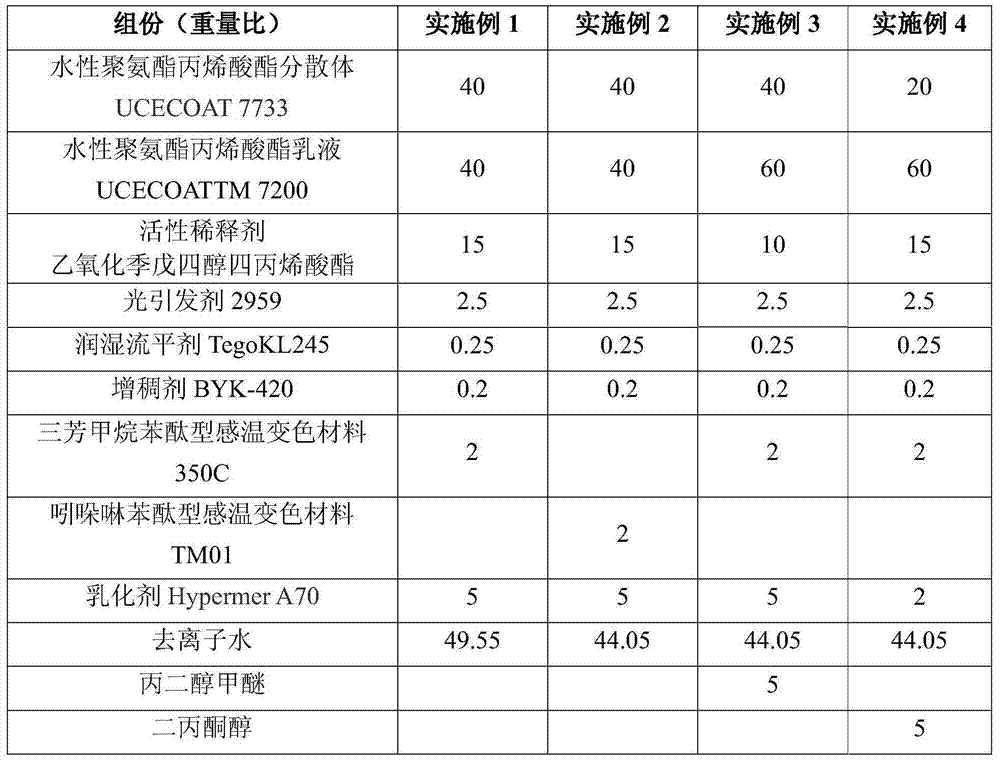

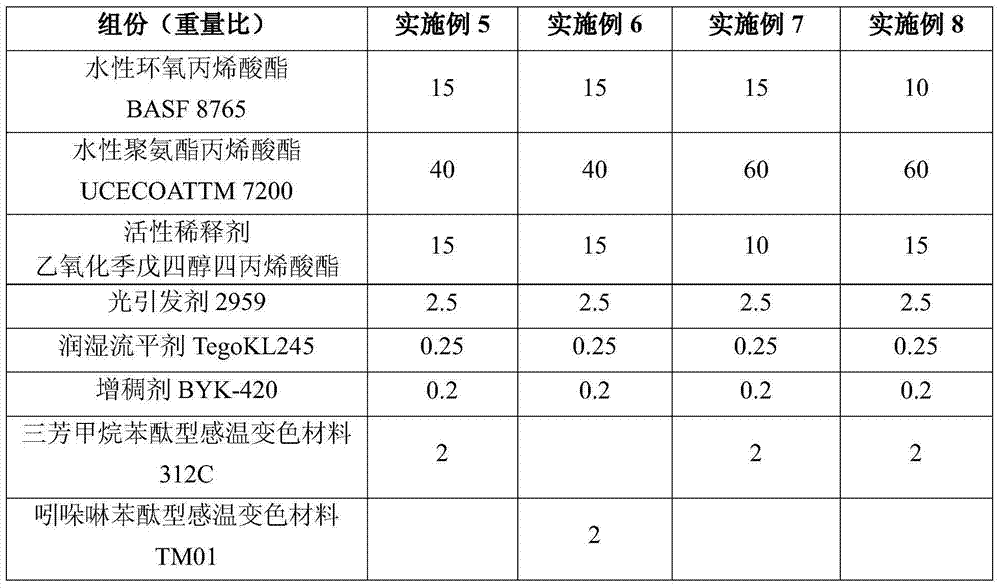

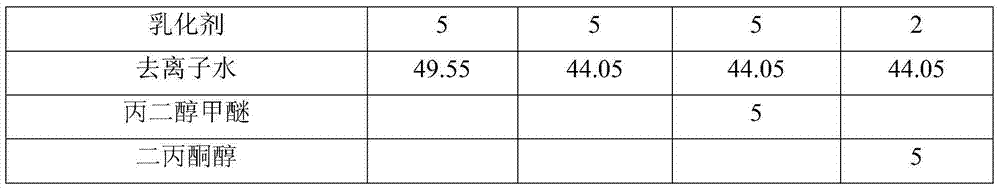

Thermochromic water-based UV coating and preparation method thereof

ActiveCN104497847ASimple preparation processEase of industrial productionPolyurea/polyurethane coatingsThermosensitive paintsWater basedReactive diluent

The invention discloses a thermochromic water-based UV coating which comprises the following components in percentage by mass: 30-60 percent of a water-based resin, 5-25 percent of a reactive diluent, 1-5 percent of a photoinitiator, 0.5-10 percent of a thermochromic material, 0.05-1 percent of a wet flatting agent, 0.05-2 percent of a thickening agent, 0.1-5 percent of an emulsifier, 0.1-2 percent of a defoaming agent, 0-8 percent of a coalescing agent and 25-60 percent of deionized water. The invention also discloses a method for preparing the thermochromic water-based UV coating. According to the thermochromic water-based UV coating provided by the invention, microcapsules do not need to be prepared in advance, the preparation process is simple and convenient, and large-scale industrial production is facilitated.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

Thermochromic coating for metal, glass and ceramic and preparation method thereof

ActiveCN103396730ABright colorImprove ductilityAnti-corrosive paintsPolyurea/polyurethane coatingsWeather resistanceOrganic solvent

The invention relates to the technical field of coatings, and in particular to a thermochromic coating for metal, glass and ceramic and a preparation method thereof. The thermochromic coating comprises the following raw materials in parts by weight: 16-32 parts of polyurethane resin, 6-14 parts of thermosetting acrylic resin, 3-7 parts of fully-methylated amino resin, 16-34 parts of temperature-changing pigments, 0.5-1.5 parts of a levelling agent, 1-3 parts of a defoaming agent, 0.5-1.5 parts of a dispersing agent and 23-45 parts of an organic solvent. A paint film formed by the thermochromic coating disclosed by the invention is level and smooth, bright in colour, good in ductility and flexibility, excellent in adhesive force for various primers and the matrixes of metal, glass, ceramic and the like, excellent in interlayer adhesive force, capable of being re-coated, excellent in flame-retardant and high-temperature-resistant performances, capable of still keeping a high-quality and complete paint film coating in the case that a surface temperature is 200 DEG C, and excellent in acid-base resistance, boiling resistance, solution resistance, weather resistance and corrosion resistance.

Owner:深圳市鑫太庆科技有限公司

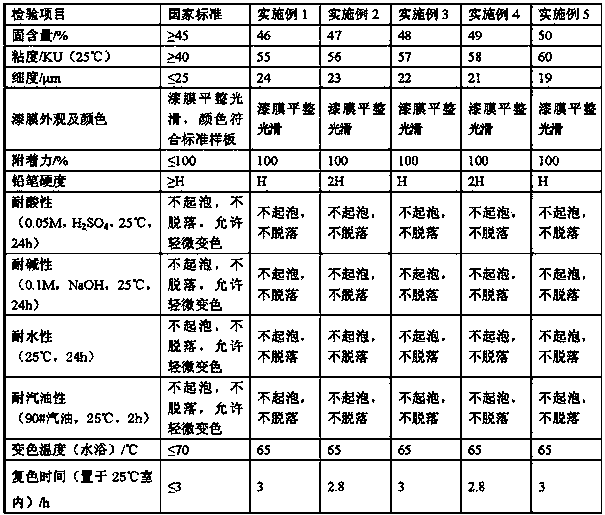

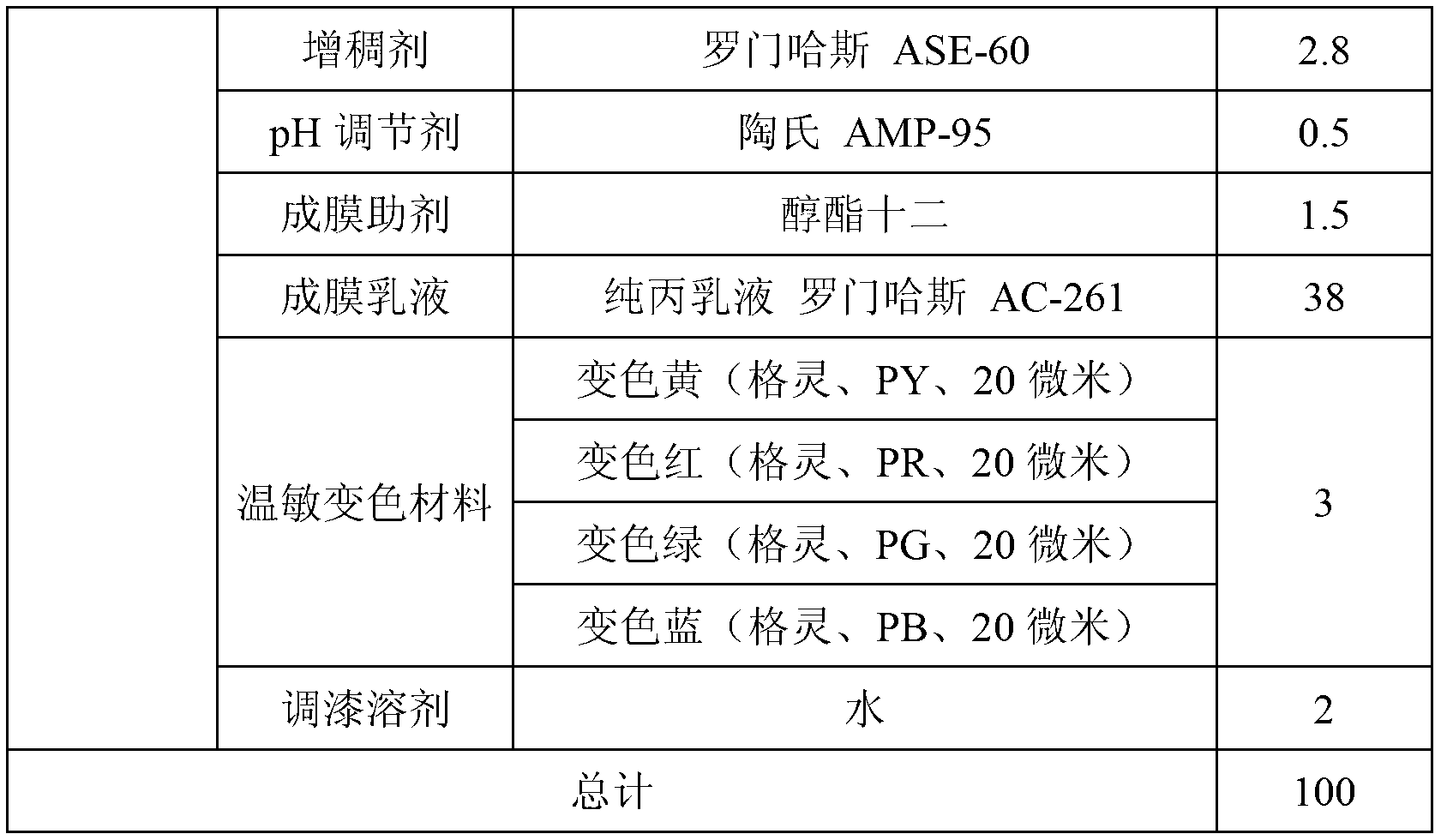

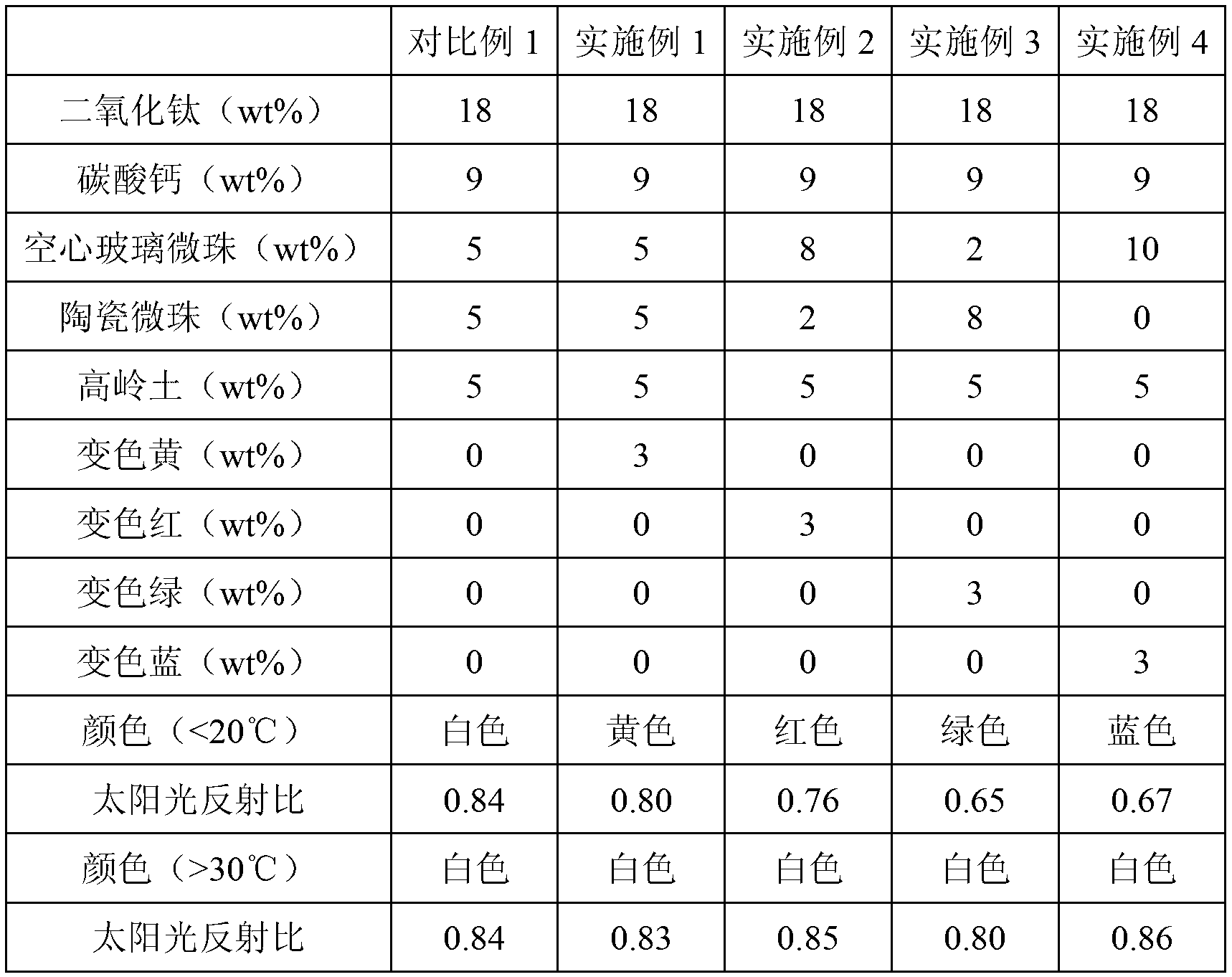

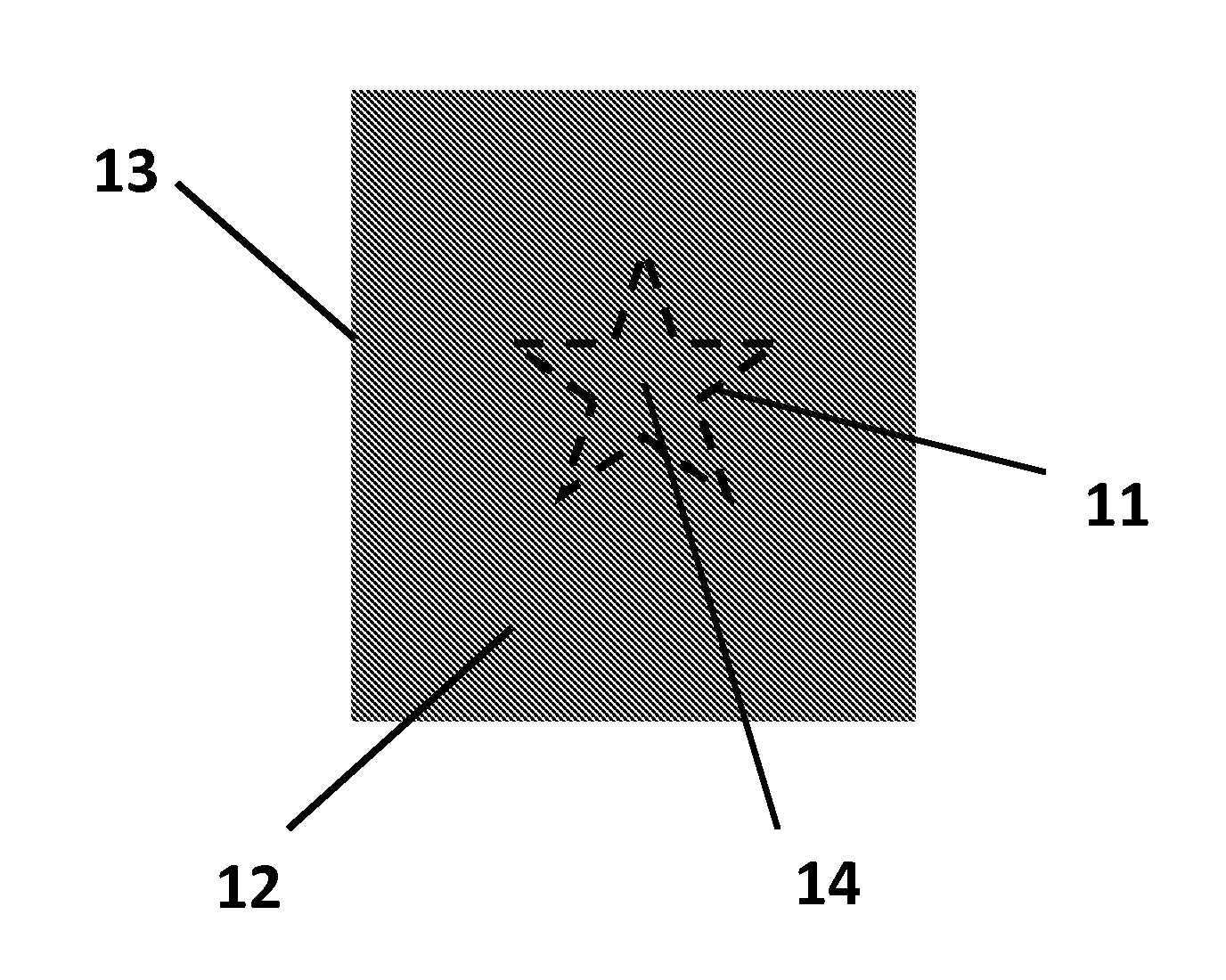

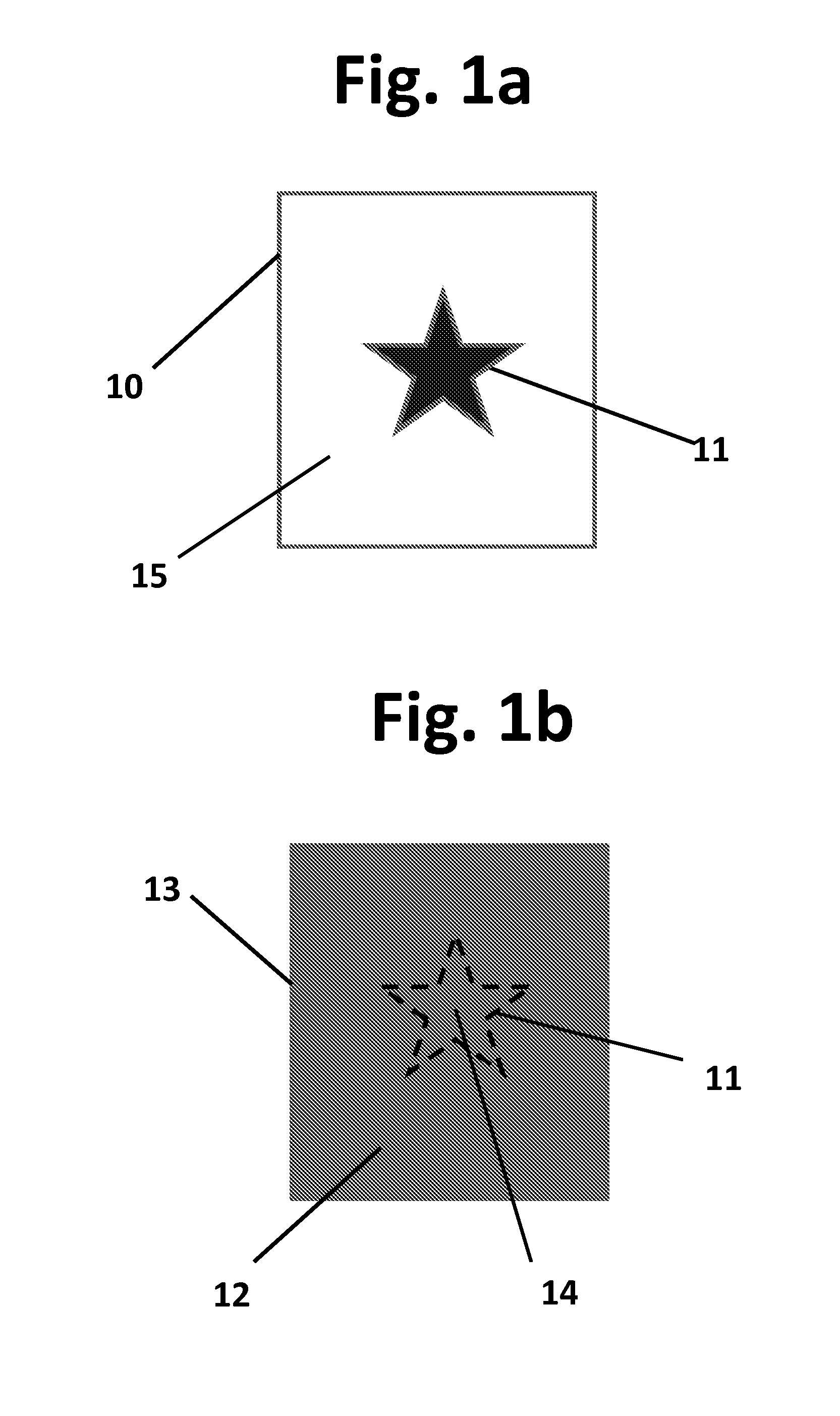

Thermochromic heat insulation coating and preparation method thereof

ActiveCN103214905AImprove the decorative effectReduce the temperaturePolyurea/polyurethane coatingsRadiation-absorbing paintsThermochromismEmulsion

The invention discloses a thermochromic heat insulation coating prepared from the following components in percentage by weight: 32-52% of pigment and filler, 2-10% of pulping solvent, 1-12% of pulping auxiliaries, 30-50% of film forming emulsion, 1-8% of reversible thermochromic material, 1-11.5% of paint mixing auxiliaries and 0-10% of paint mixing solvent. The thermochromic heat insulation coating can be used for achieving the aims of thermochromism, high temperature reflective heat insulation and low temperature heat absorption, and has favorable energy saving and decoration effects. The invention also discloses a preparation method of the thermochromic heat insulation coating. The preparation method comprises the following steps of: grinding the pigment and filler, the pulping solvent and the pulping auxiliaries to obtain a pulping part; stirring the film forming emulsion, the reversible thermochromic material, the paint mixing auxiliaries and the paint mixing solvent to obtain a paint mixing part; and mixing the pulping part and the paint mixing part to prepare the thermochromic heat insulation coating. The method is simple in preparation, easy for realizing large-scale industrial production and better in economic benefit.

Owner:ZHEJIANG UNIV

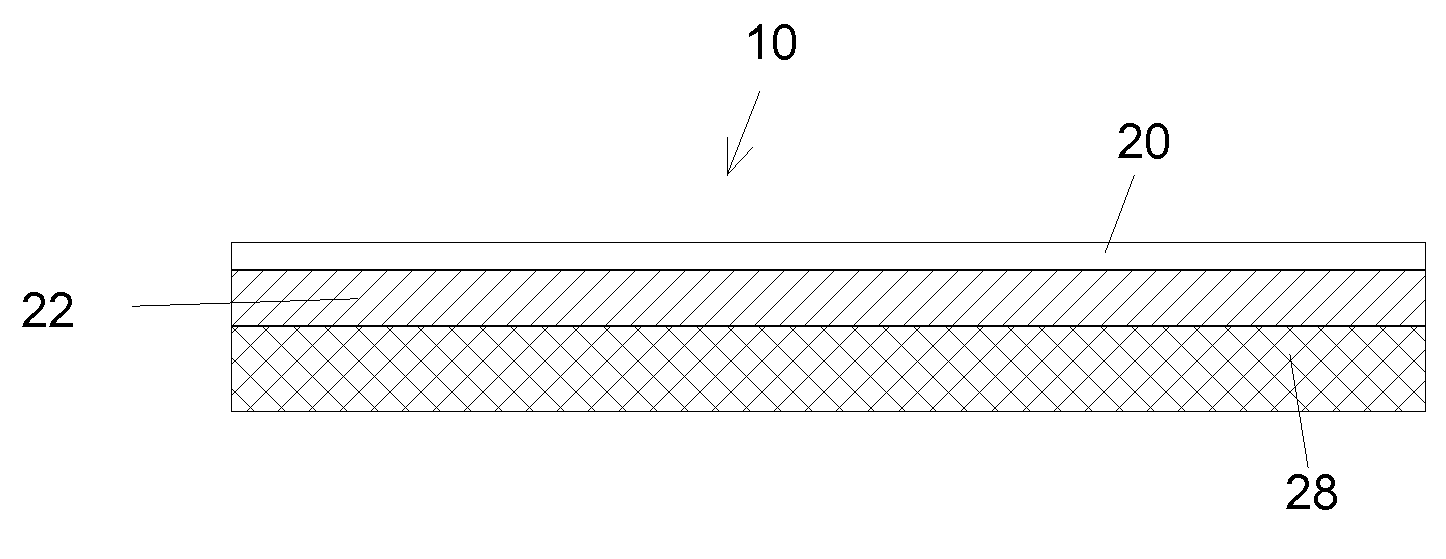

Thermally conductive, corrosion resistant coatings

InactiveUS20140151596A1Polyurea/polyurethane coatingsHeat-exchange elementsPolymer chemistryCorrosion resistant

A thermally conductive, corrosion resistant coating composition for use as a substrate coating. The thermally conductive, corrosion resistant coating composition comprising a waterborne polyurethane polymer, and at least one additive. Other thermally conductive, corrosion resistant coating compositions also comprise thermally conductive particles.

Owner:ENERGYGUARD ATLANTIC

Method of Printing a Conductive Article and Articles Made Thereby

ActiveUS20140050903A1Layered productsNon-conductive material with dispersed conductive materialEngineering

A method of printing articles having variable conductivities, including those having conductivity gradients.

Owner:LETTOW JOHN S +2

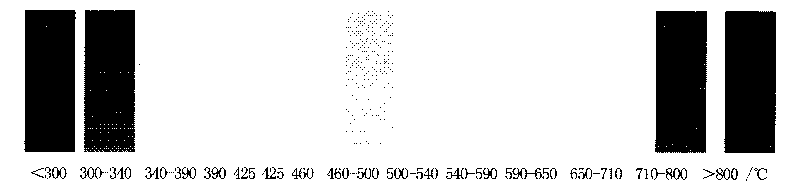

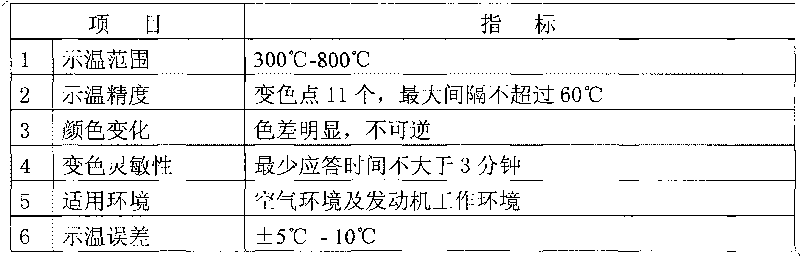

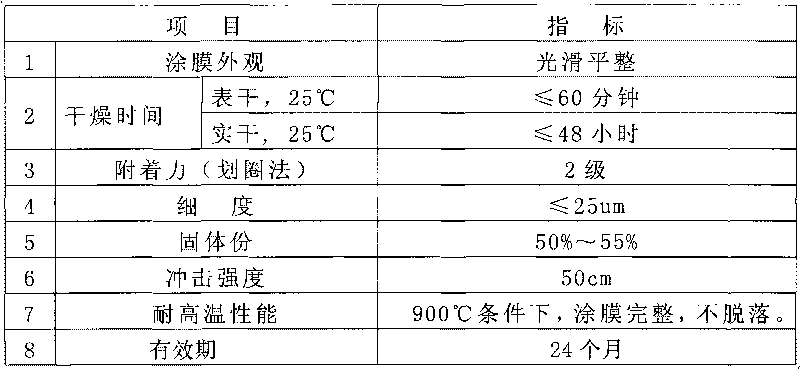

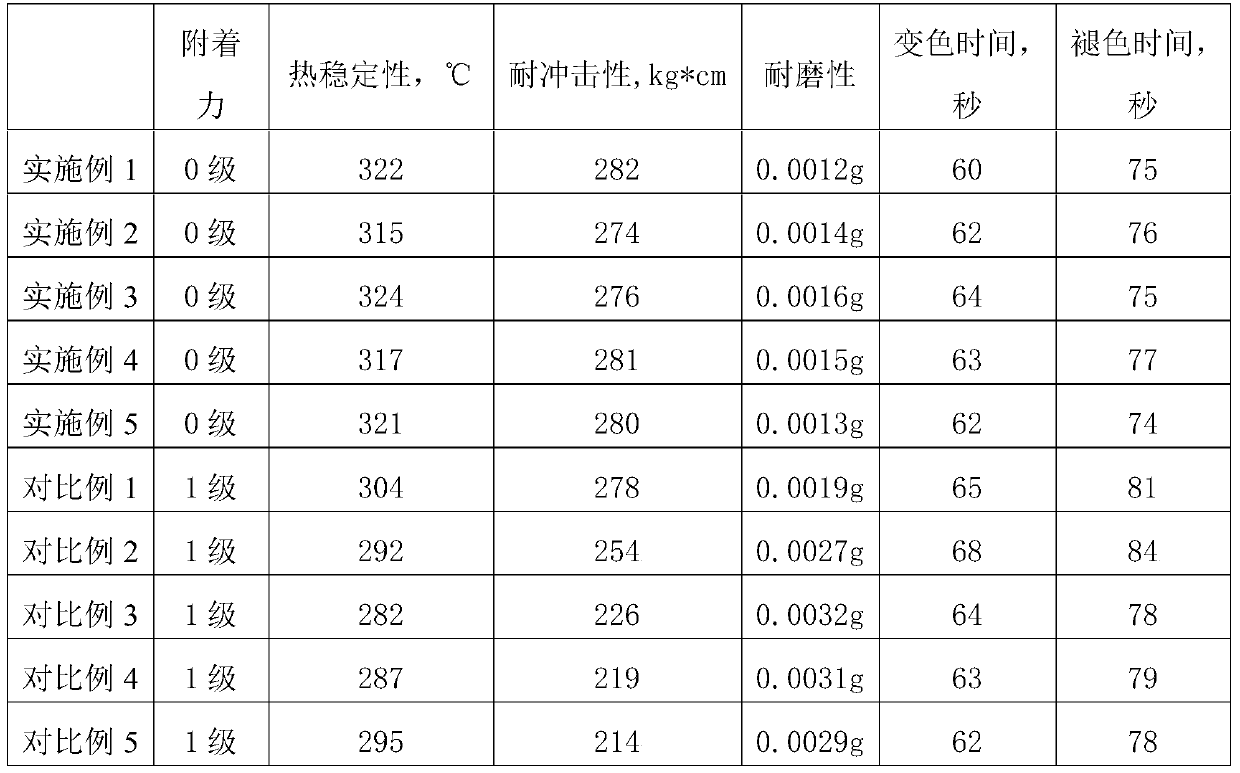

300 DEG C-800 DEG C pleochromatic irreversible thermopaint

The invention relates to 300 DEG C-800 DEG C pleochromatic irreversible thermopaint, comprising organosilicon modified epoxy resin, a phthalocyanine organic pigment, a compound type thermochromic pigment, padding, an assistant, a curing agent and a solvent, wherein the organosilicon modified epoxy resin is used as a base material. The pleochromatic irreversible thermopaint is mainly used for dynamic operating parts and the temperature measurement of large-area temperature fields, and has the advantages of good paint storage stability, convenient use, good mechanical property of a paint film, sensitive discoloration, obvious chromatism, high precision, and the like.

Owner:中昊北方涂料工业研究设计院有限公司

Flame retardant adhesive composition, and adhesive sheet, coverlay film and flexible copper-clad laminate using same

InactiveUS20050196619A1Excellent characteristicsExcellent retardancyNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyCopper

Provided is a flame retardant adhesive composition including (A) a halogen-free epoxy resin, (B) a thermoplastic resin and / or a synthetic rubber, (C) a curing agent, (D) a curing accelerator, and (E) a phosphorus-containing filler. Also provided are an adhesive sheet, a coverlay film, and a flexible copper-clad laminate prepared using such a composition. A cured product yielded by curing the composition, as well as the adhesive sheet, the coverlay film, and the flexible copper-clad laminate display excellent flame retardancy and electrical characteristics (anti-migration properties).

Owner:SHIN ETSU CHEM IND CO LTD

Thermochromic ceramic coating material and coating

ActiveCN103113766ASimple preparation processLow costThermosensitive paintsChange colorCeramic coating

The invention relates to a thermochromic ceramic coating material. The coating material is characterized by comprising the following components in parts by weight: 100 parts of silica sol, 50-100 parts of organosilane, 0.3-1 part of catalyst and 15-45 parts of inorganic thermochromic powder or 5-35 parts of organic thermochromic powder. The thermochromic ceramic coating is characterized by comprising a base coat which is made from the thermochromic ceramic coating material and a transparent finishing coat which is coated on a base coat surface. The thermochromic ceramic coating material provided by the invention is simple in preparation technology, low in cost and convenient to coat; the produced thermochromic ceramic coating has good hot and cold hardness and wear resistance and can change color according to temperature variation; and moreover, the using temperature of the organic thermochromic powder can be increased and can be normally used at 240 DEG C for 30 minutes.

Owner:INNOTEK TECH CHINA

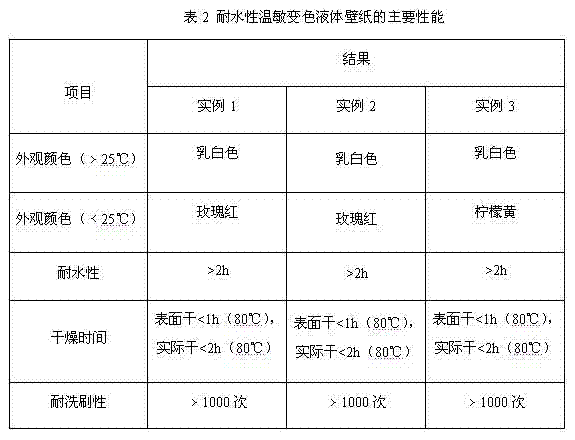

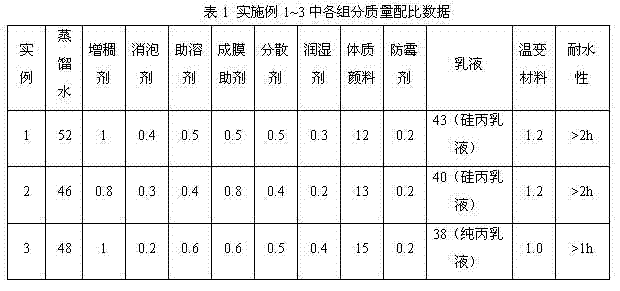

Water-resistance thermosensitive color-changing liquid wall paper and preparation method thereof

InactiveCN102199388AImprove water resistanceImprove stabilityThermosensitive paintsPolymer scienceSolvent

The invention discloses a water-resistance thermosensitive color-changing liquid wall paper and a preparation method thereof. In the liquid wall paper, a temperature-changing material is used as a main color-changing material, and a silicone-acrylate emulsion is used as a main film-forming substance. The liquid wall paper also comprises distilled water, a cosolvent, a film-forming agent, a thickener, a defoamer, a dispersing agent, a wetting agent, an extender pigment and a mildew preventive component. In the water-resistance thermosensitive color-changing liquid wall paper, organic silicon modified acrylic emulsion is used as the film-forming component, thereby improving the water resistance, stability, heat resistance and film-forming ability of the wall paper; and the organic silicon modified acrylate emulsion prepared by a seed emulsion polymerization method has a good stability and small emulsion particles, the contamination resistance of the prepared paint is good, and the formed adhesive film has excellent water resistance and contamination resistance self-cleaning property and excellent atmosphere resistance ageing property and is suitable for inner walls of a building.

Owner:GUANGDONG UNIV OF TECH

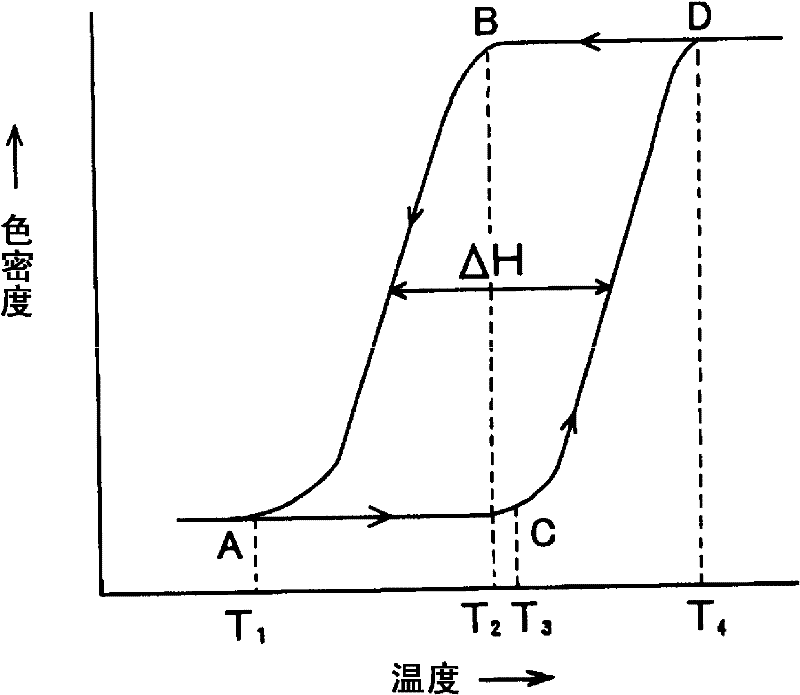

Reversibly thermochromic aqueous ink composition, and writing instrument and writing instrument set each utilizing same

ActiveCN102575123ASuppresses lighteningInhibit deepeningErasing devicesWriting connectorsSimple Organic CompoundsOrganic solvent

A reversibly thermochromic aqueous ink composition comprising water, a water-soluble organic solvent, a reversibly thermochromic microcapsule pigment, a comb-shaped polymeric dispersant having a carboxyl group in a side chain thereof, a nitrogen- and sulfur-containing organic compound, and a water-soluble resin, wherein a reversibly thermochromic composition comprising (A) an electron-donating color-developing organic compound, (B) an electron-accepting compound and (C) a reaction medium that determines the temperature at which the color-developing reaction between the components (A) and (B) occurs is encapsulated in the reversibly thermochromic microcapsule pigment; a writing instrument produced using the ink composition; and a writing instrument set comprising the writing instrument and a friction body.

Owner:THE PILOT INK CO LTD +1

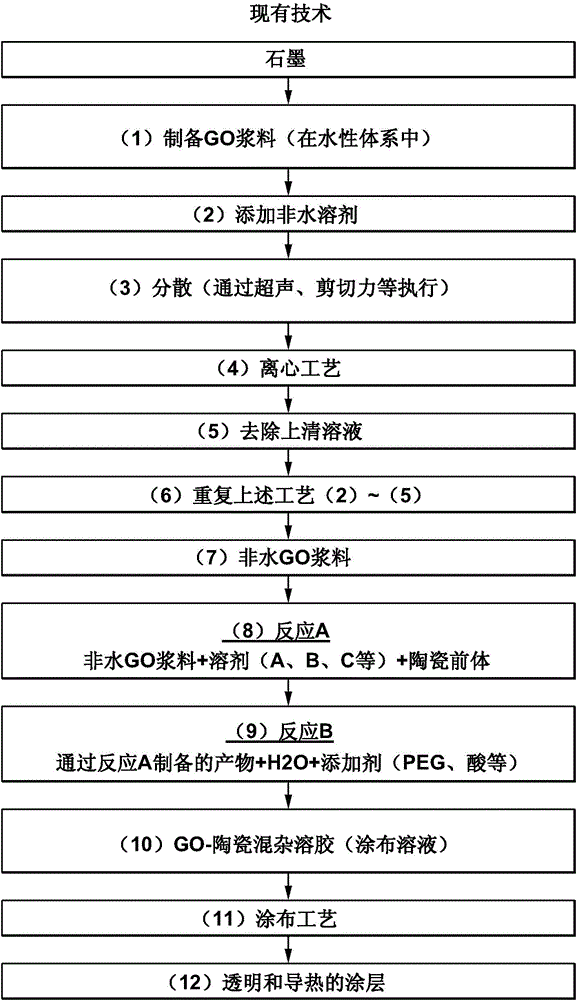

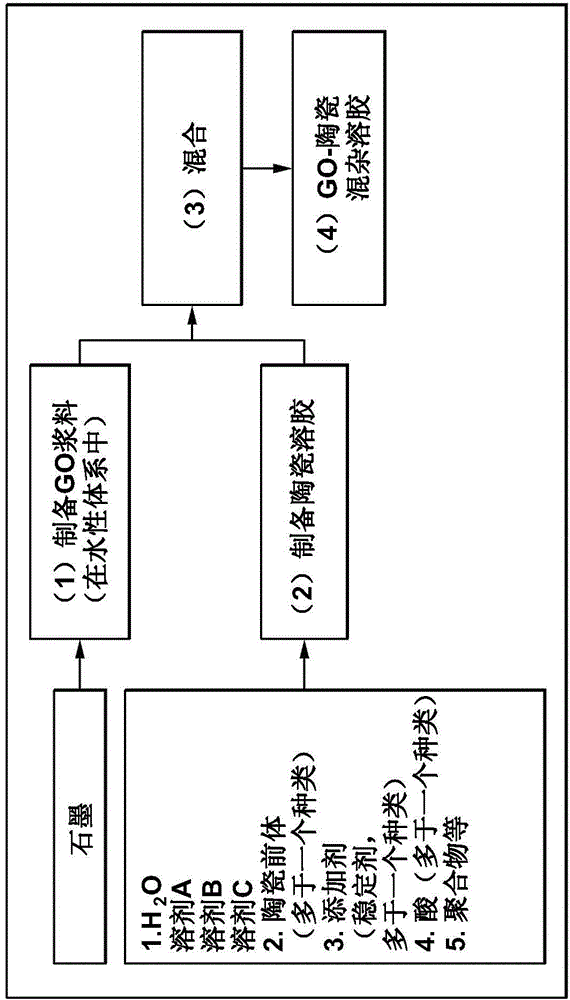

Graphene oxide-ceramic hybrid coating layer, and method for preparing the same

A graphene oxide-ceramic hybrid coating layer formed from a graphene oxide-ceramic hybrid sol solution that includes graphene oxide (GO) and a ceramic sol and a method of preparing the coating layer are provided. A content of graphene oxide in the graphene oxide-ceramic hybrid coating layer is about 0.002 to about 3.0 wt % based on the total weight of the graphene oxide-ceramic hybrid coating layer.

Owner:HYUNDAI MOTOR CO LTD +1

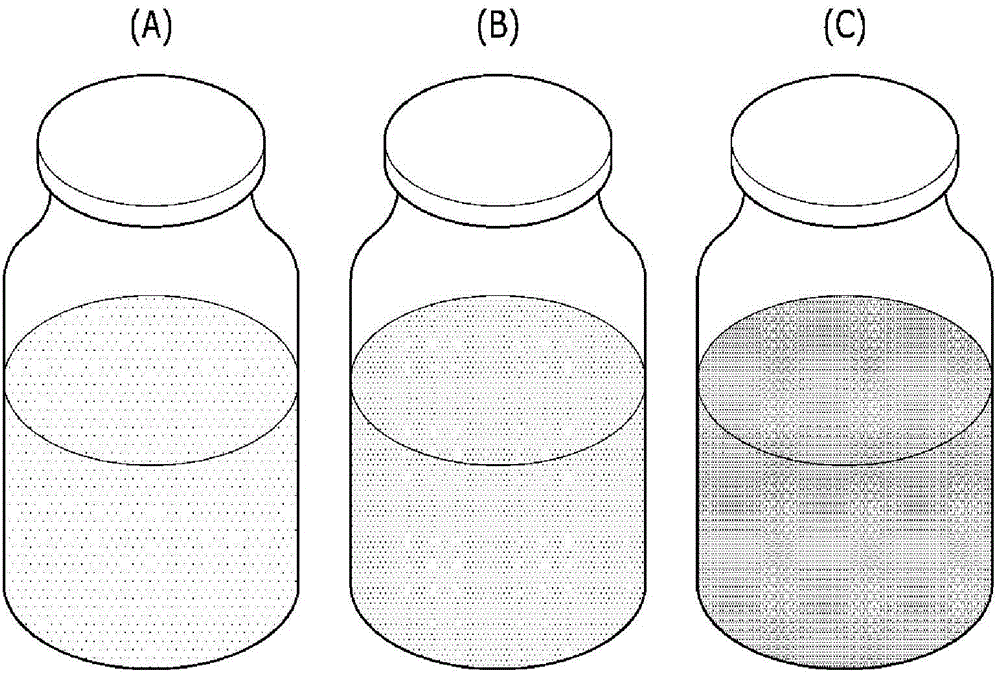

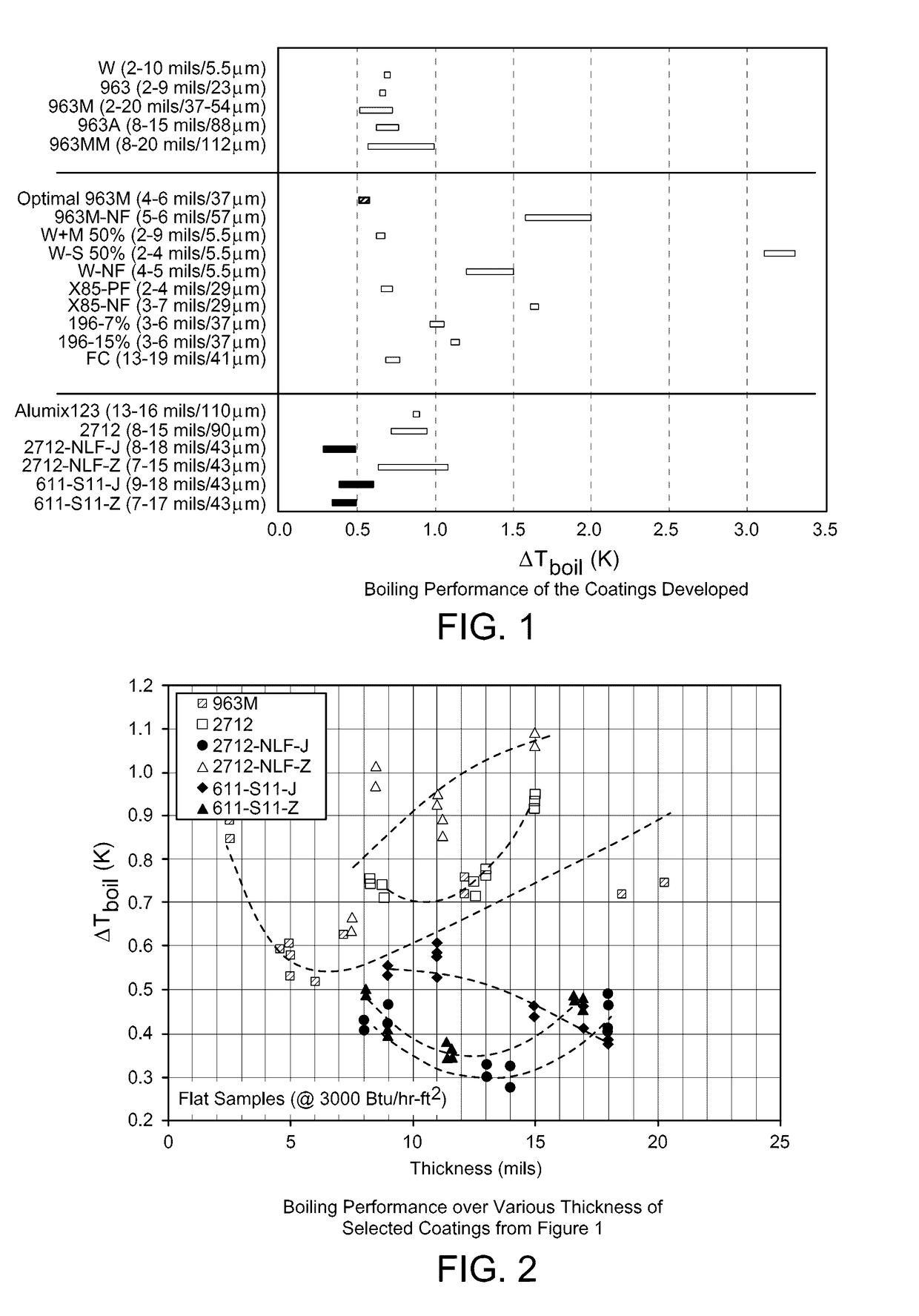

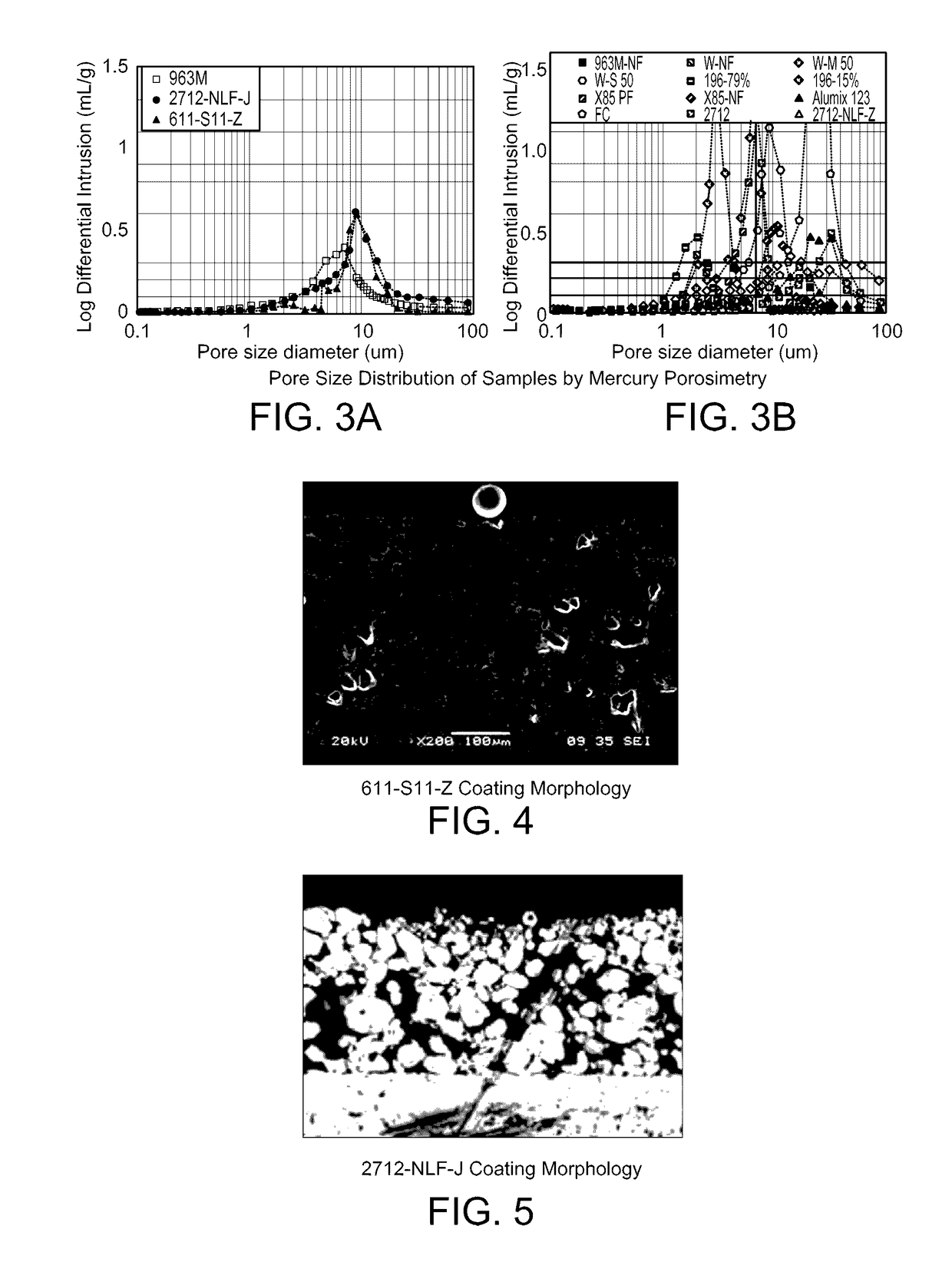

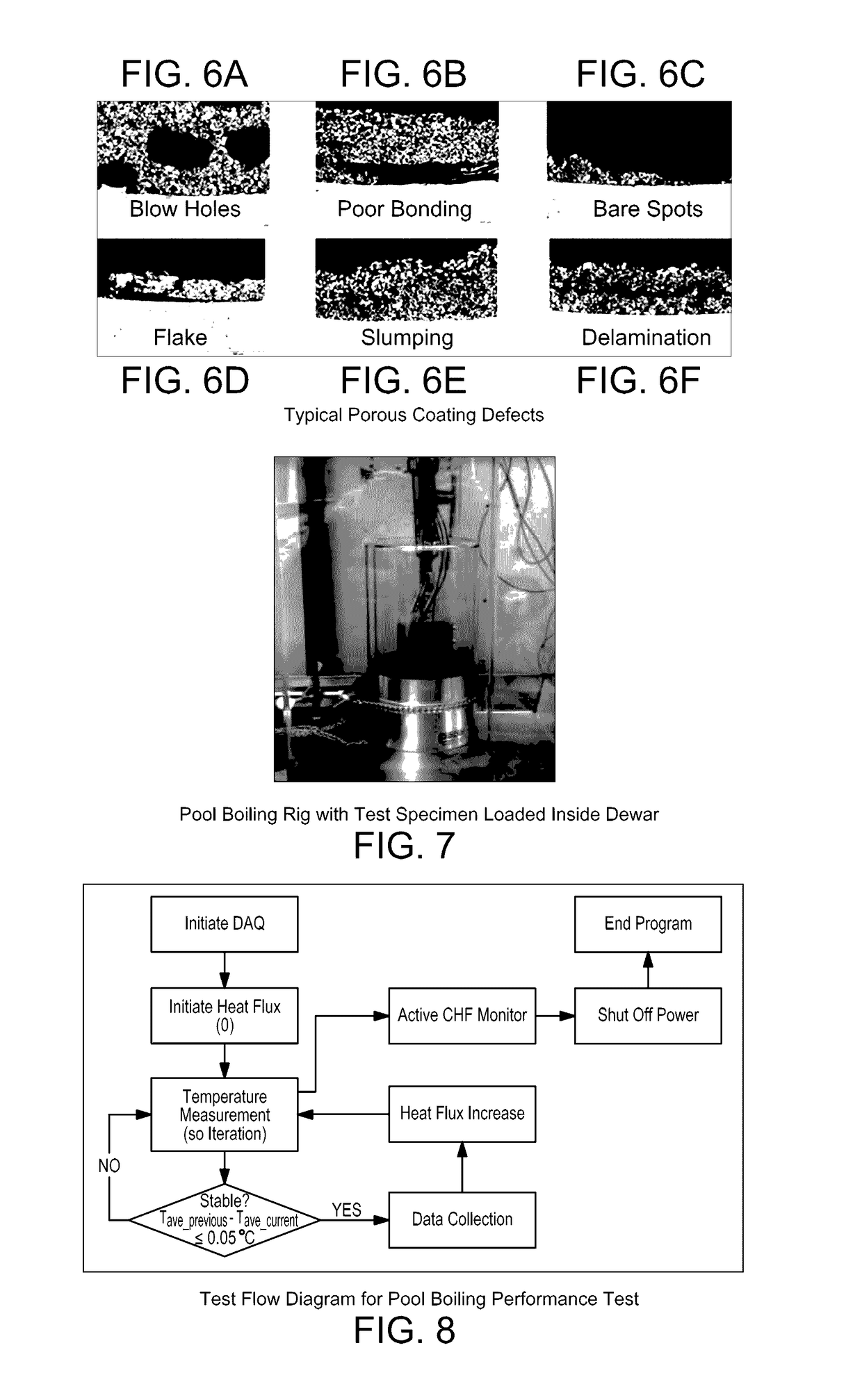

Porous coatings

ActiveUS20170108148A1Chemical industryMetallic material coating processesPorous coatingAir separation

A porous metallic coating is provided. The coating is characterized by a combination of optimized properties that improve coating performance, as measured by heat transfer efficiency. The porous coating has optimal ranges for properties such as porosity, particle size and thickness, and has particular applicability in boiling heat transfer applications as part of an air separations unit. The porous coatings are derived from slurry-based formulations that include a mixture of metallic particles, a binder and a solvent.

Owner:PRAXAIR TECH INC

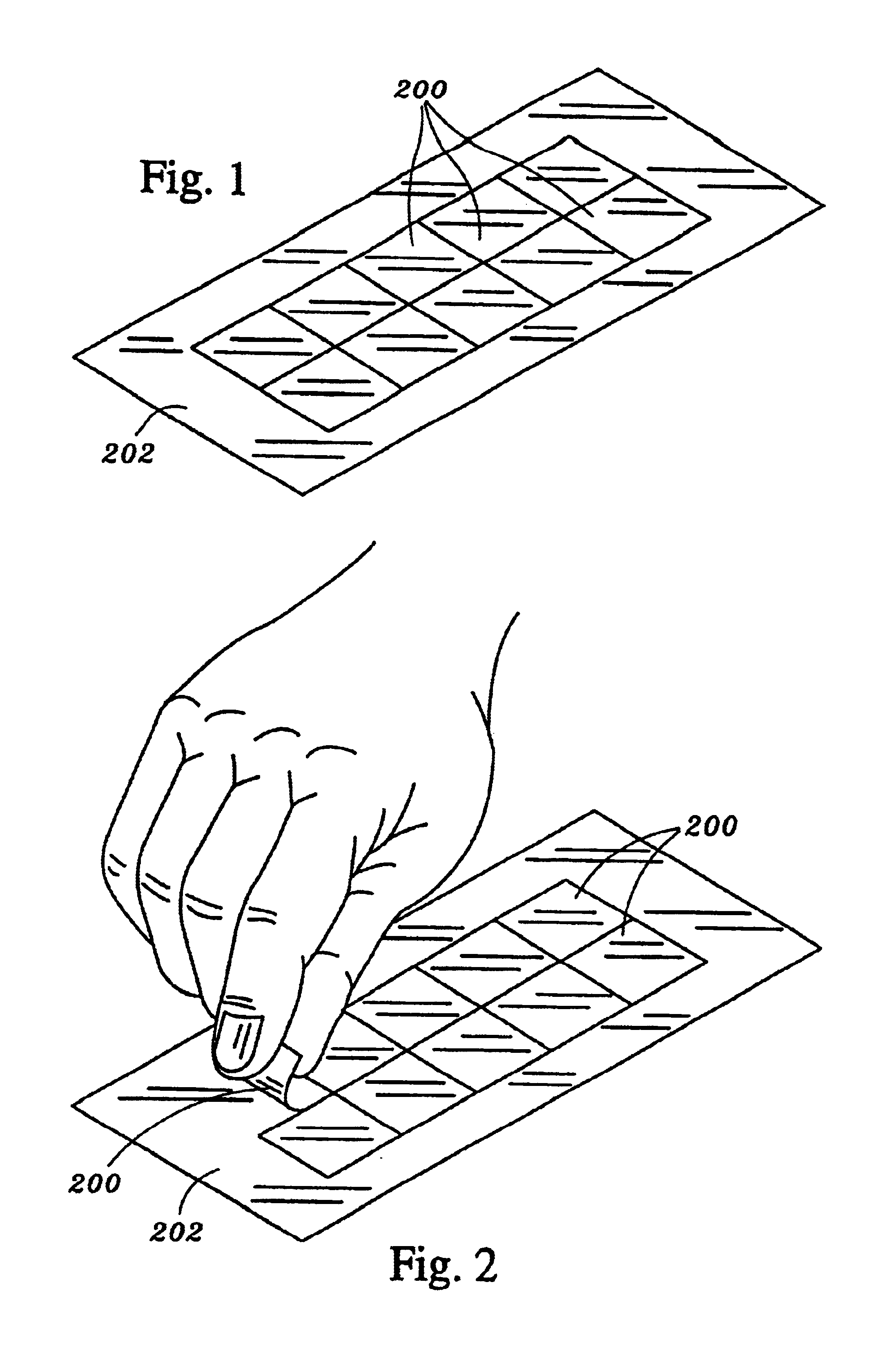

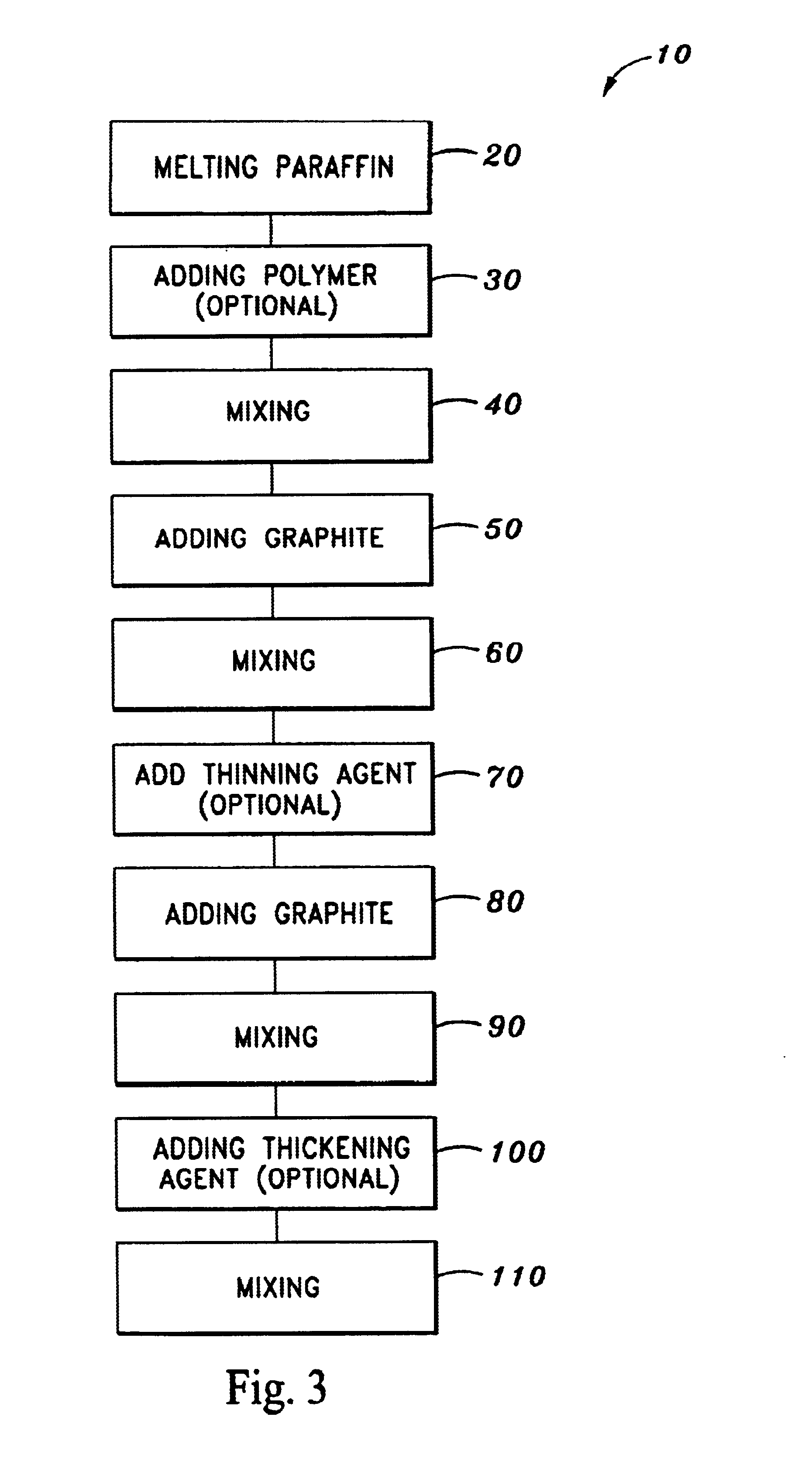

Phase change thermal interface composition having induced bonding property

InactiveUS6869642B2Easy to packEasy to shipSemiconductor/solid-state device detailsSolid-state devicesParaffin waxRoom temperature

An improved, more durable heat conductive composition for transferring heat from a heat-dissipating component to a heat dissipater and method of producing the same. The composition preferably comprises a base consisting of paraffin and, optionally, paraffin and petrolatun having electrically-conductive particles suspended therein, which preferably include graphite diamond, or elemental metals such as silver. In the preferred embodiment, the composition further includes a resin polymer to increase durability. The composition is formulated to be solid in the range of normal room temperatures, but liquify once subjected to temperatures just below the range at which heat generating electronic semi conductor devices typically operate. The present invention further comprises processes for packaging the compositions of the present invention, as well as applying the heat conductive composition to an interface between a heat-dissipating component and a heat sink.

Owner:LOCTITE

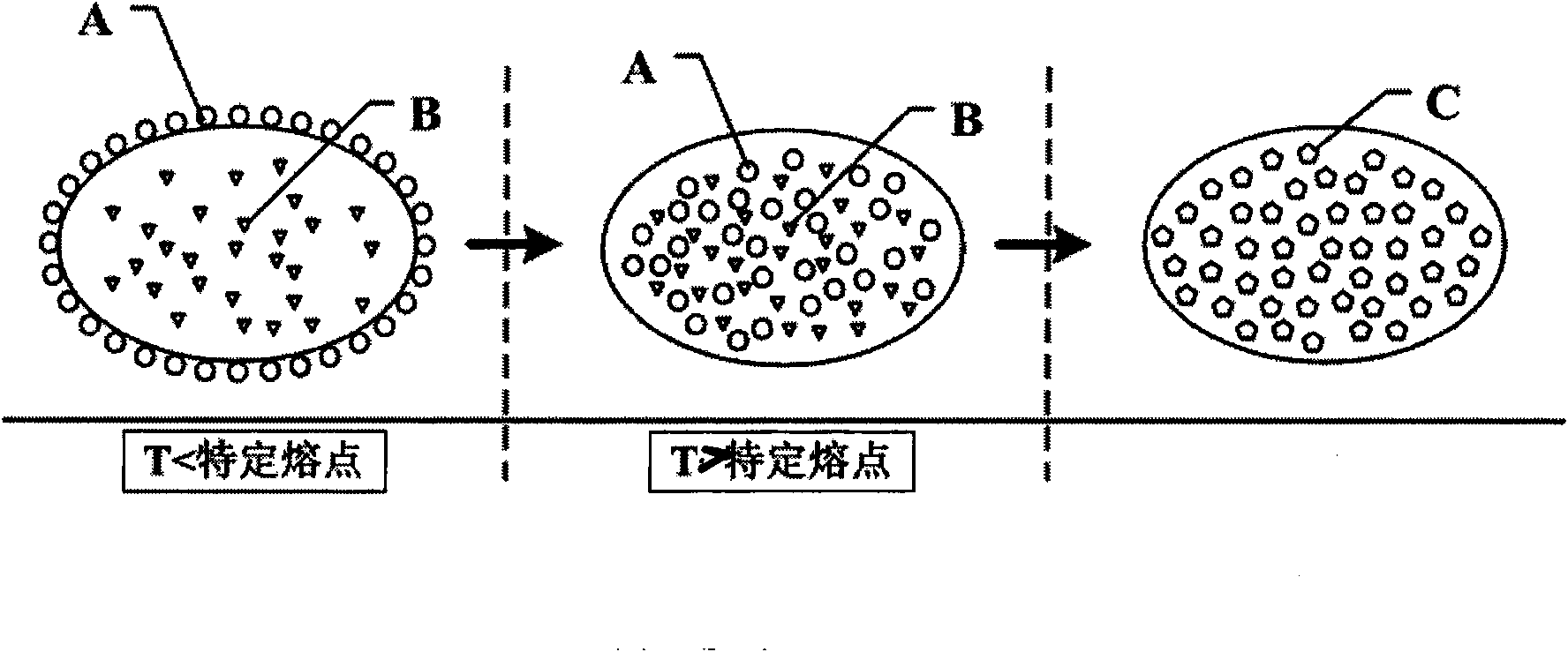

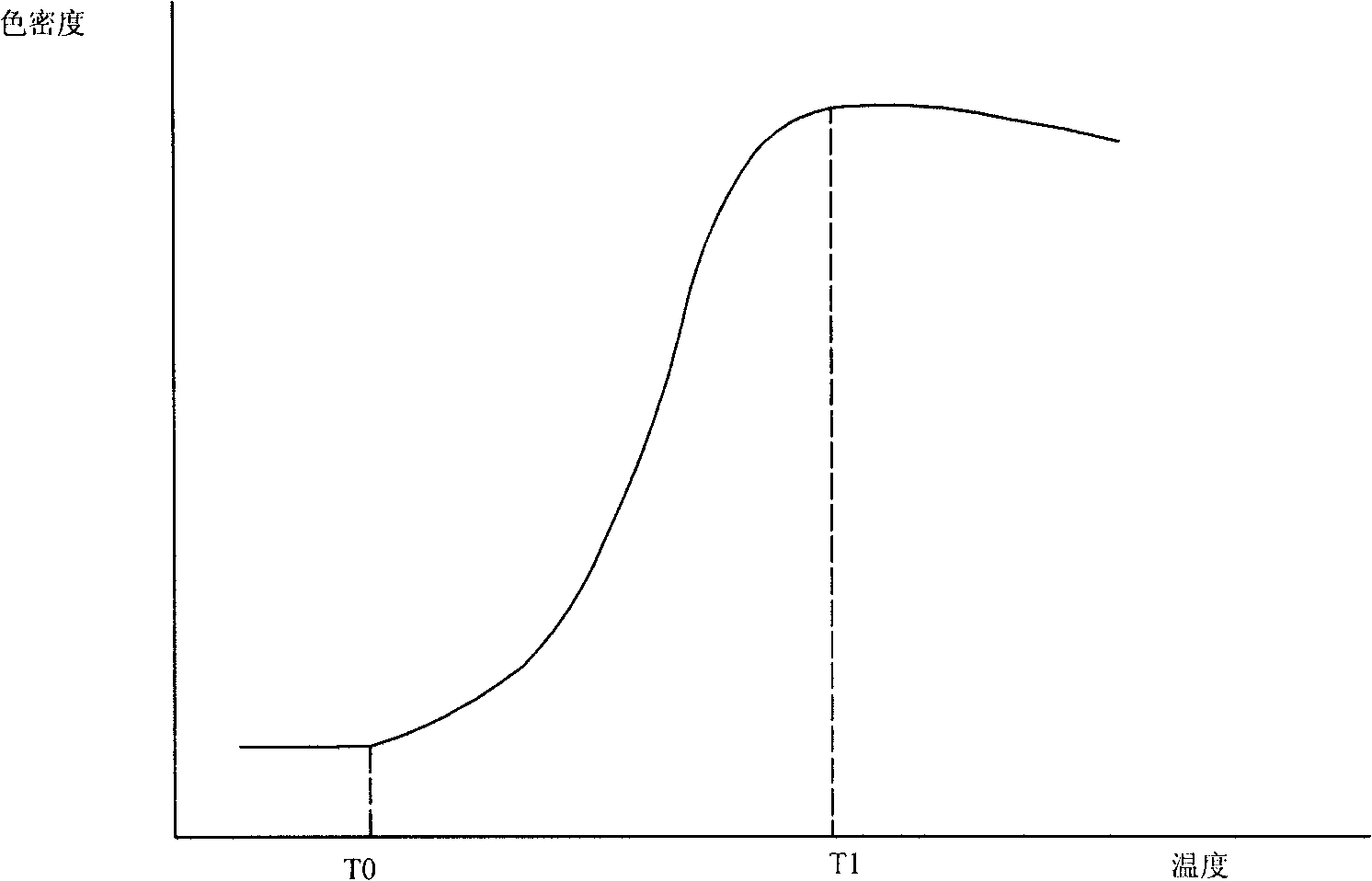

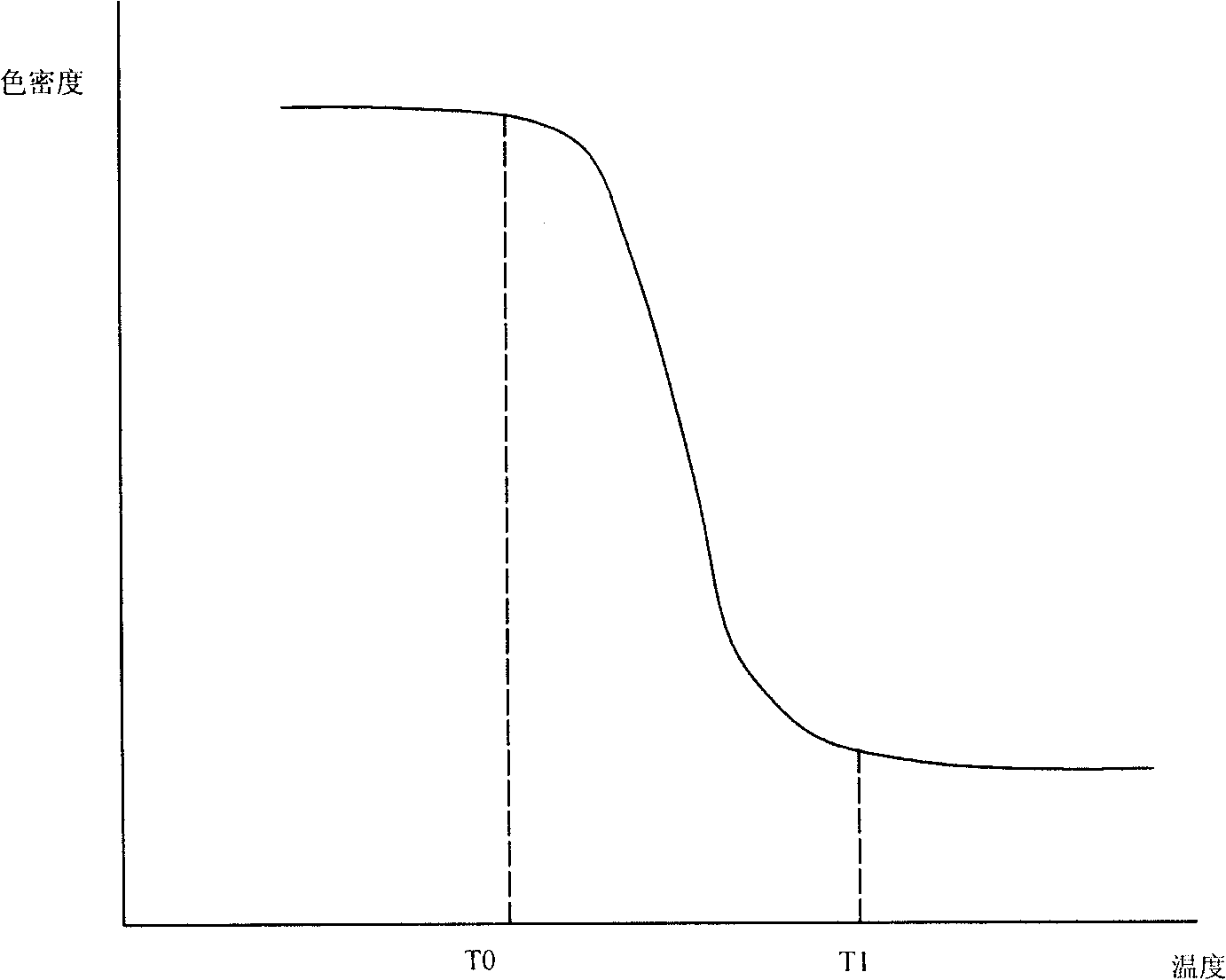

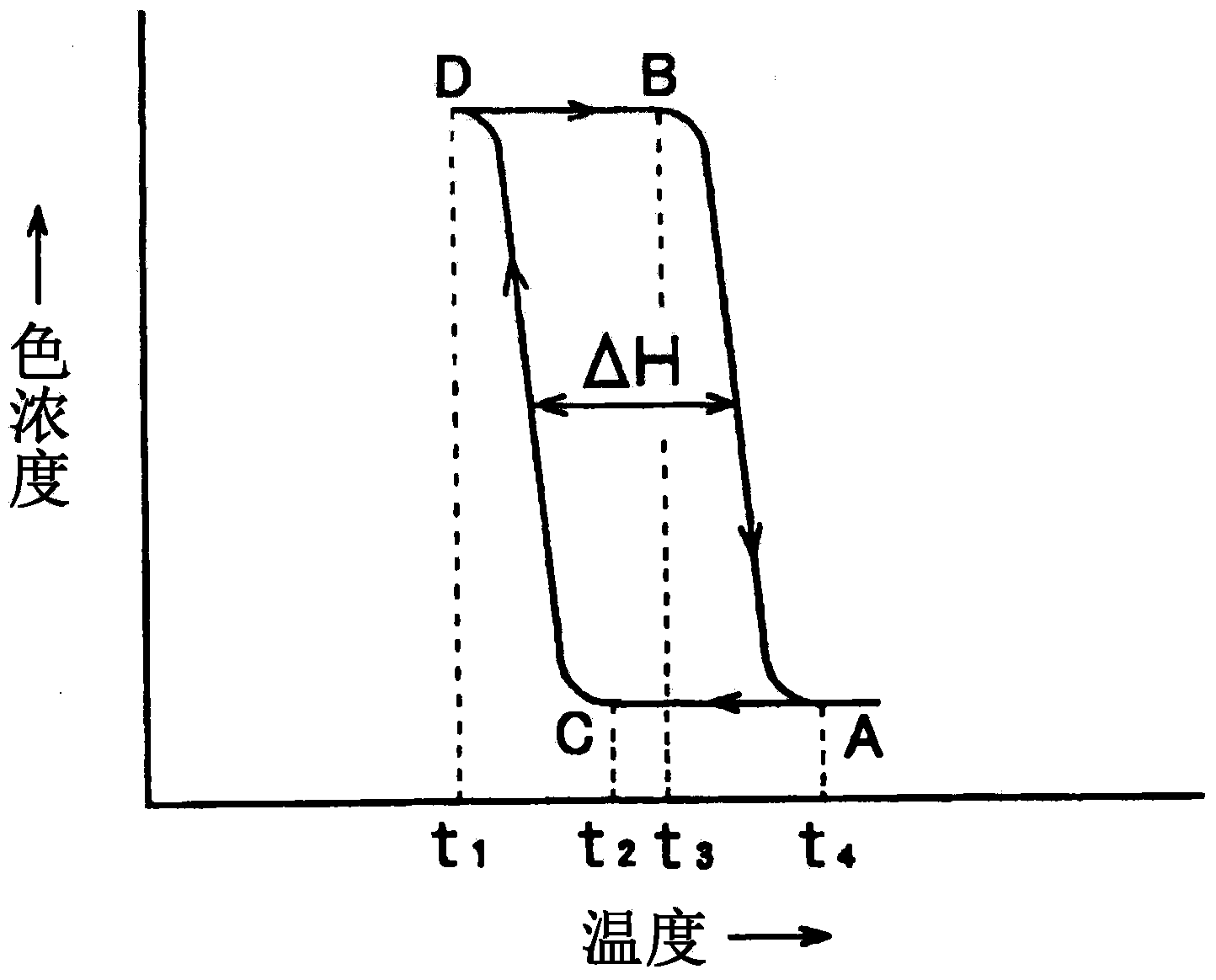

Thermosensitive chromotropic material and manufacturing method and application thereof

The invention provides a chromotropic material using material phase transition control chromotropic reaction for realizing irreversible thermosensitive discoloration, and a manufacturing method and anapplication thereof, which is characterized in that a temperature-sensitive function and a chromotropic function are separated and respectively born by two materials, and the functions of the two materials are coordinated through designing a solidified carrier material structure with a specific melting point, realizing low temperature irreversible thermosensitive discoloration, enlarging the optional range of chromotropic temperature and chromotropic modes, and satisfying the different demands of practical application. The concrete method comprises the following steps: dissolving one of reactants of a chromotropic reaction into a material with the specific melting point by using the solid-liquid phase transition process of the material, solidifying into powder or grains, and then mixing with the other reactant of the chromotropic reaction to manufacture the irreversible thermosensitive chromotropic material. The invention has the principle that when the temperature of the mixture increases to be above a solidification point, the material dissolved with the chromotropic reactant is melted, and the reactant is released to react with the other reactant through contact to generate products with different colors.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Temperature-changeable microcapsule coating and preparation method thereof

InactiveCN104910714AWide temperature range of discolorationAvoid defects where discoloration cannot be achievedConjugated diene hydrocarbon coatingsStarch coatingsPhenolphthaleinAdhesive

The invention discloses a temperature-changeable microcapsule coating which comprises the following components in parts by mass: 20-50 parts of temperature-changeable microcapsules, 2-8 parts of a spacing agent, 2-10 parts of an adhesive and 100-250 parts of water, wherein each temperature-changeable microcapsule comprises a core material and a capsule wall coating the core material; the core material comprises a solvent, a color former and a color developing agent; and the color former is a phenolphthalein or fluoran compound containing a lactonic ring structure. The temperature-changeable microcapsule coating disclosed by the invention is relatively wide in color changing temperature range, and can be subjected to color changing reaction in a temperature range of 30-80 DEG C, and urea is added during the preparation of microcapsule powder to absorb formaldehyde in a capsule wall material, so that the maximization of the material utilization rate is realized, and the surrounding environment is protected.

Owner:NANCHANG TIM RITT IND

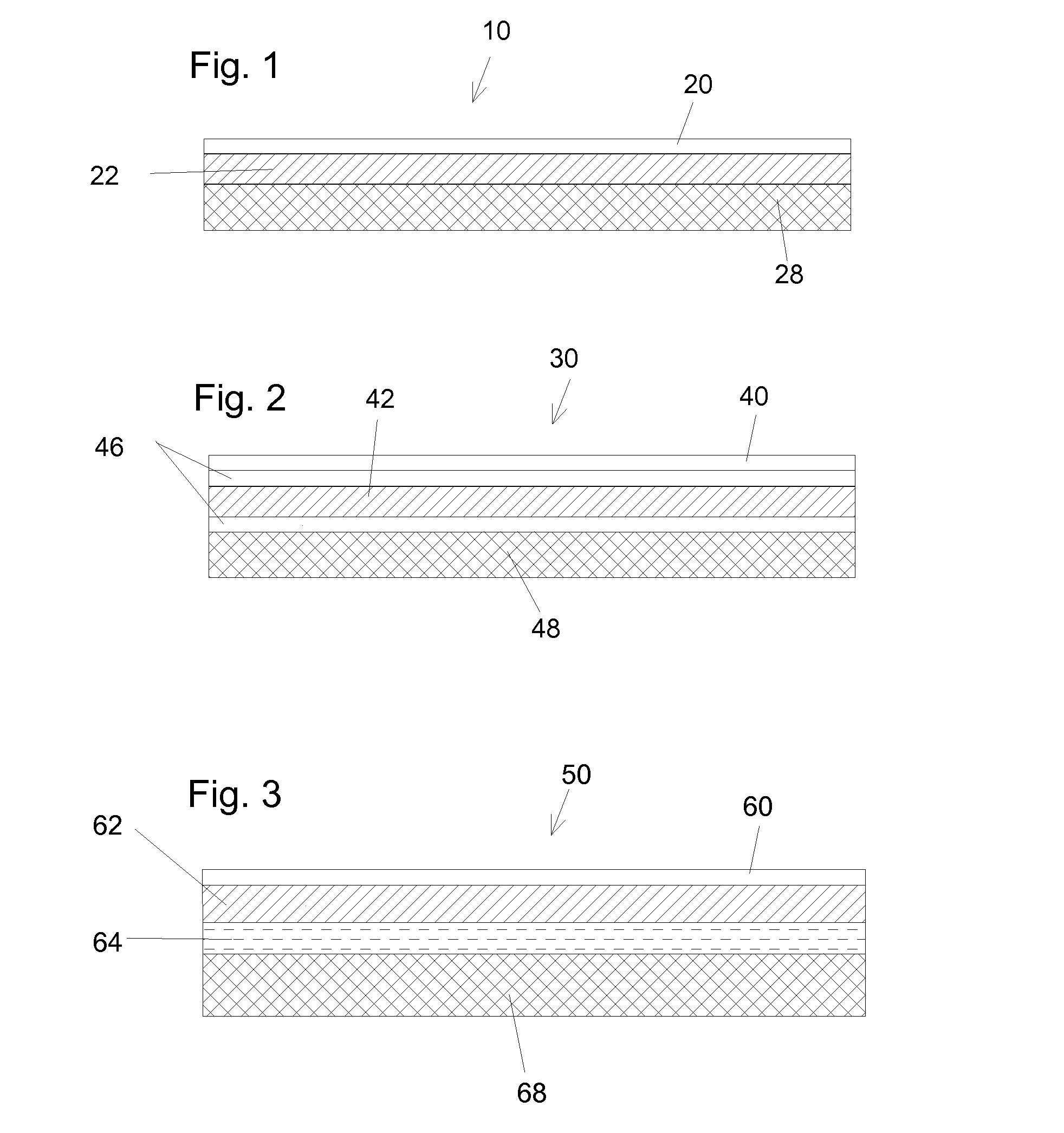

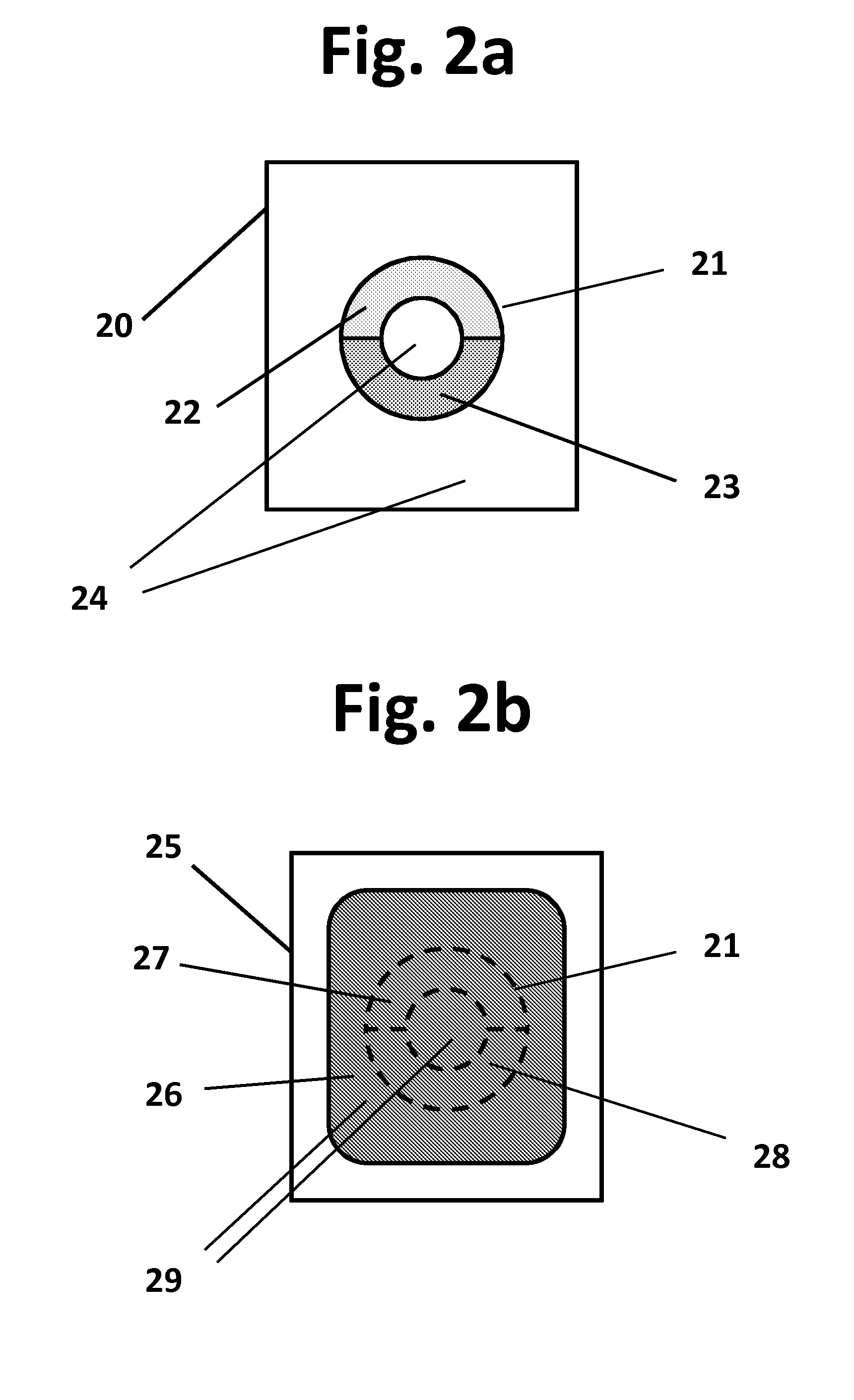

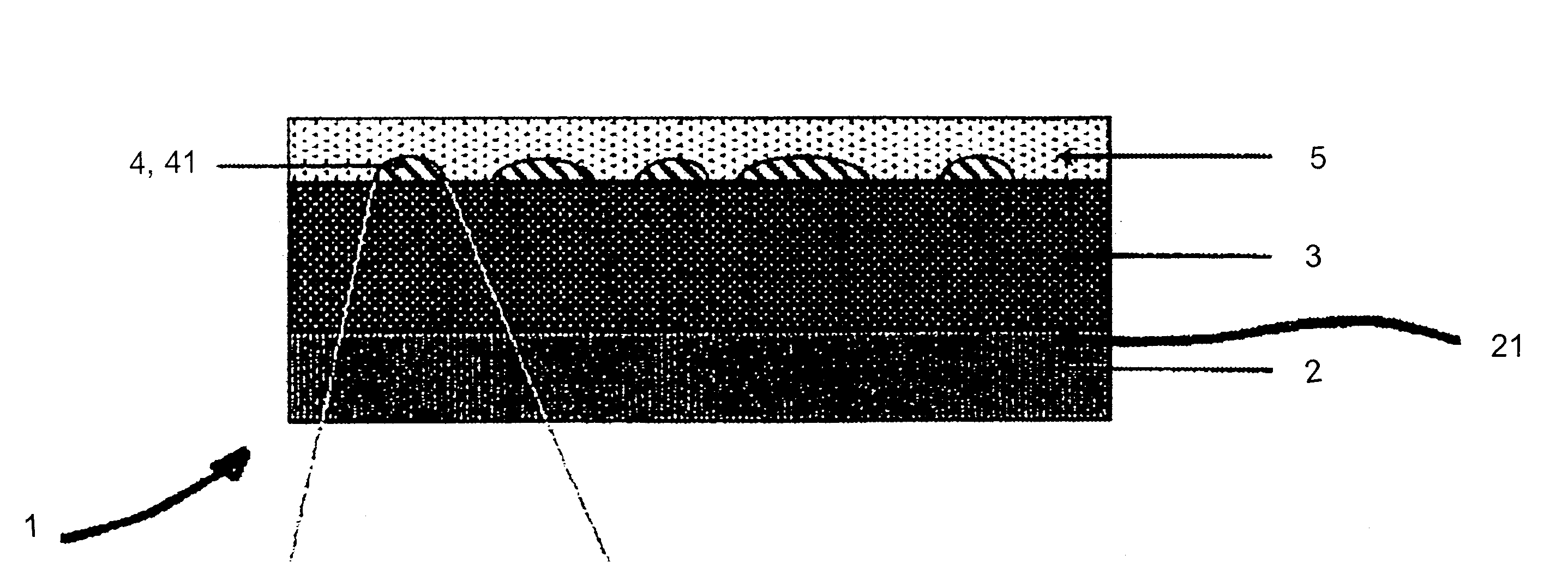

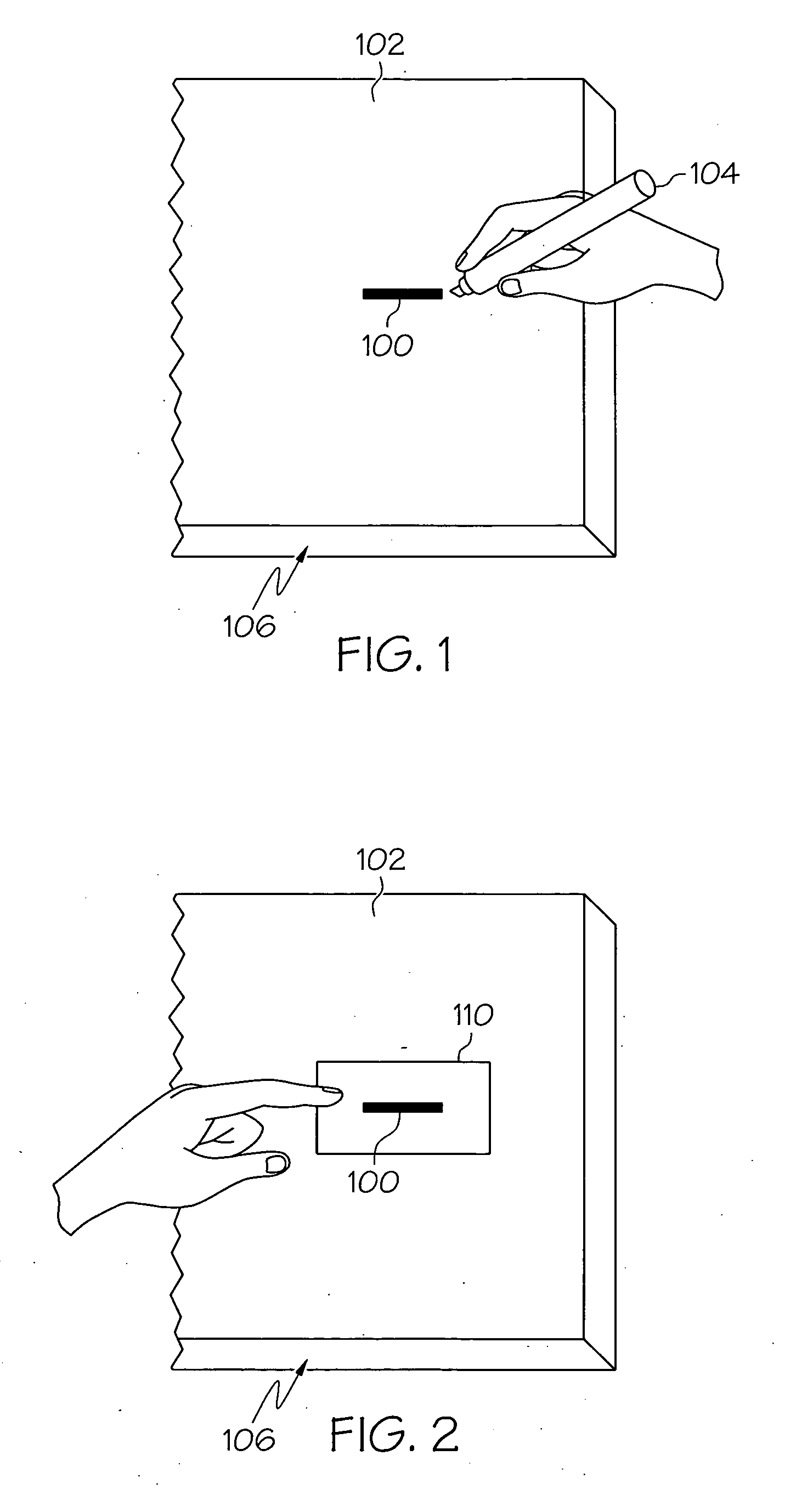

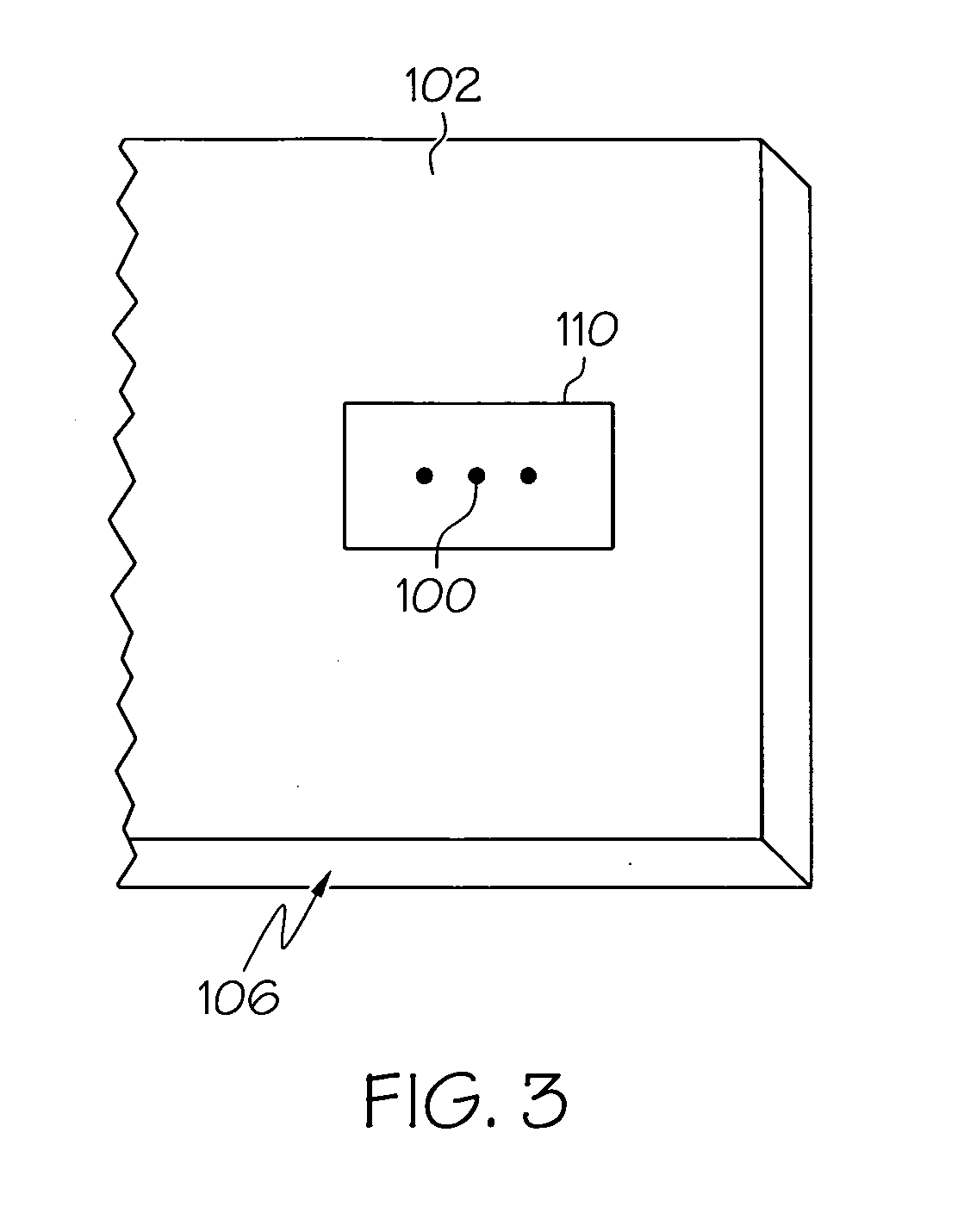

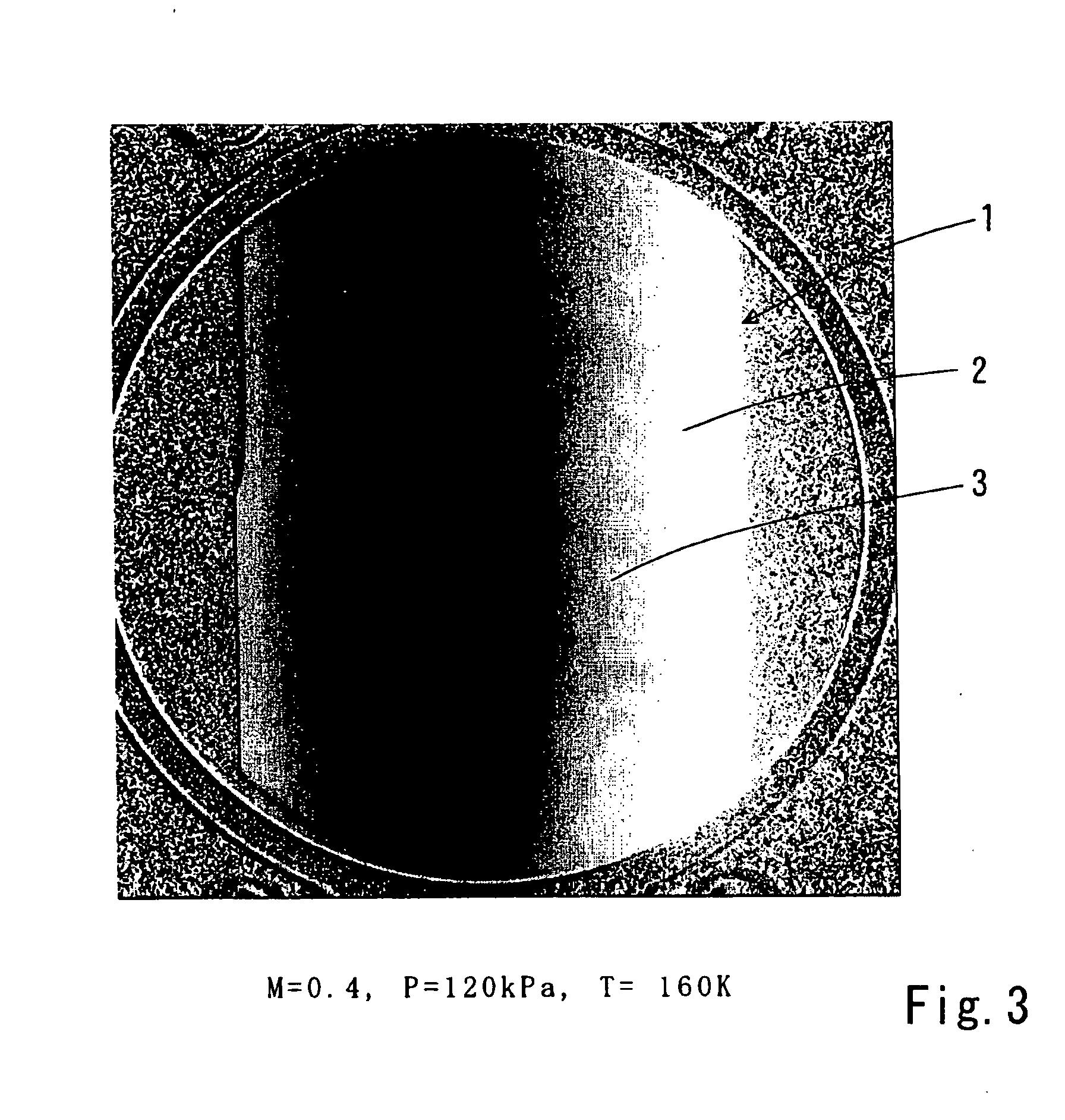

Heating Article Including Coloured Heat Indicator with Improved Visability and Precision

ActiveUS20120052265A1Improved visibility and precisionResistant to high-temperaturesCooking-vessel materialsLayered productsThermochromismSemiconductor

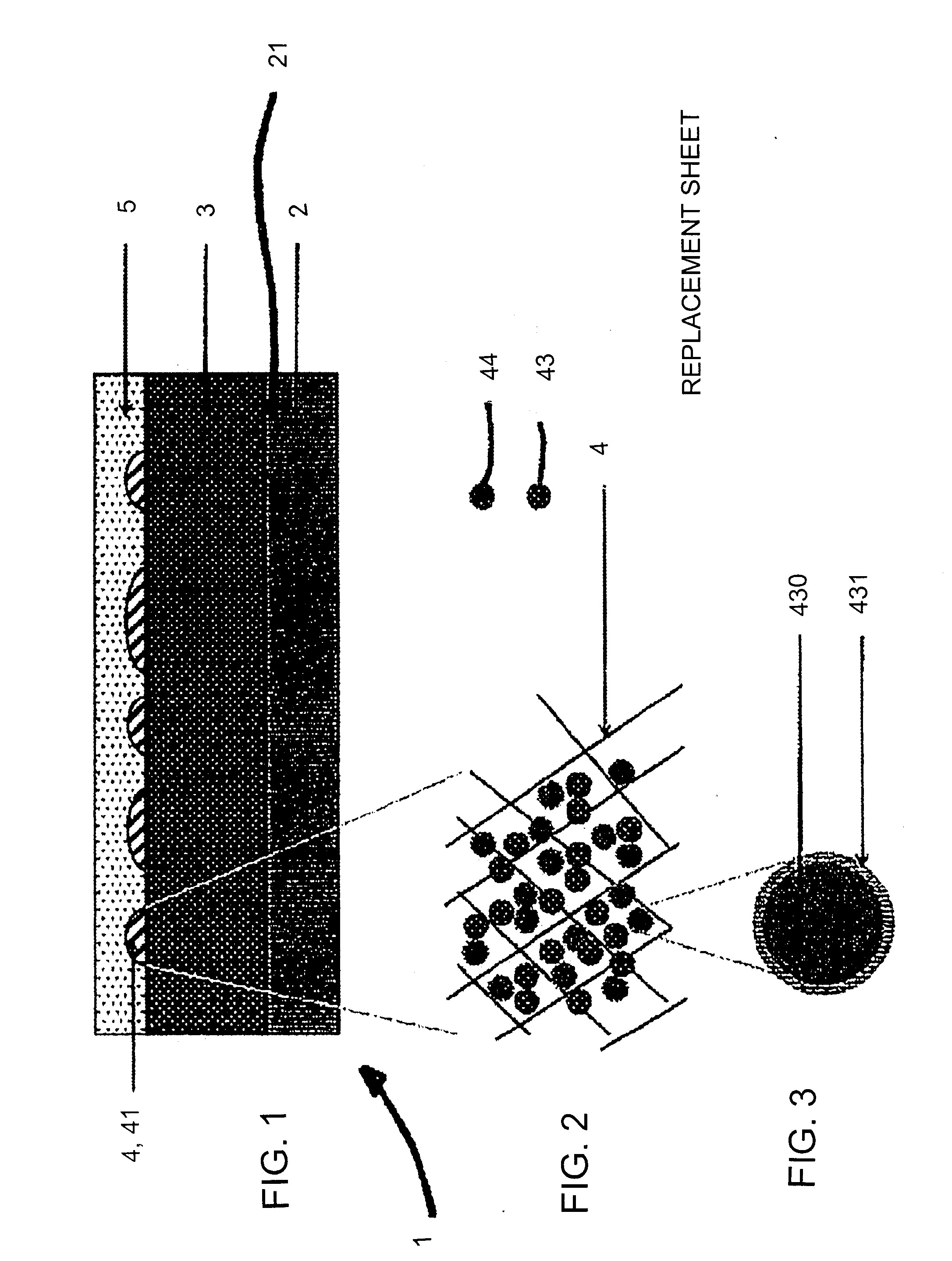

This invention relates to a heating article (1) comprising a substrate (2) of which one of the surfaces (21) is equipped with a design (4), in the form of a coating layer with at least one pattern (41, 42), which comprises a thermochromic pigment composition with at least one SC thermochromic pigment that is lipid-sensitive under heat. According to the invention, the thermochromic pigment composition includes at least one thermostable pigment and composite pigment grains (43), which each include a core (430) including the semiconducting thermochromic pigment, and a solid, transparent and continuous envelope (431), formed by a mineral or organomineral material. The thermochromic pigment composition shows a reversible change in colour in a thermal colour-change area with an amplitude of no more than 40° C. within the range of variation of said temperature T1 of use.

Owner:SEB SA

Temperature-sensing color-changing material and application thereof in electric kettle

InactiveCN101538427AAvoid breakingPracticalCooking vesselsThermosensitive paintsChange colorEngineering

The invention relates to a temperature-sensing color-changing material which comprises a film-forming substrate, a pigment which changes color along with the change of temperature and a color-changing additive, and the weight percentage of each component is as follows: the film-forming substrate is 75-78 percent, the pigment which changes the color along with the change of the temperature is 20-23 percent and the additive is 1-23 percent. The temperature-sensing color-changing material is applied onto an outer wall of an electric kettle, and the electric kettle can display different colors according to different temperatures during the heating process. The invention provides the temperature-sensing color-changing material which is difficult to damage an outer shell and strong in practicality during the use and the electric kettle with the temperature display function.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

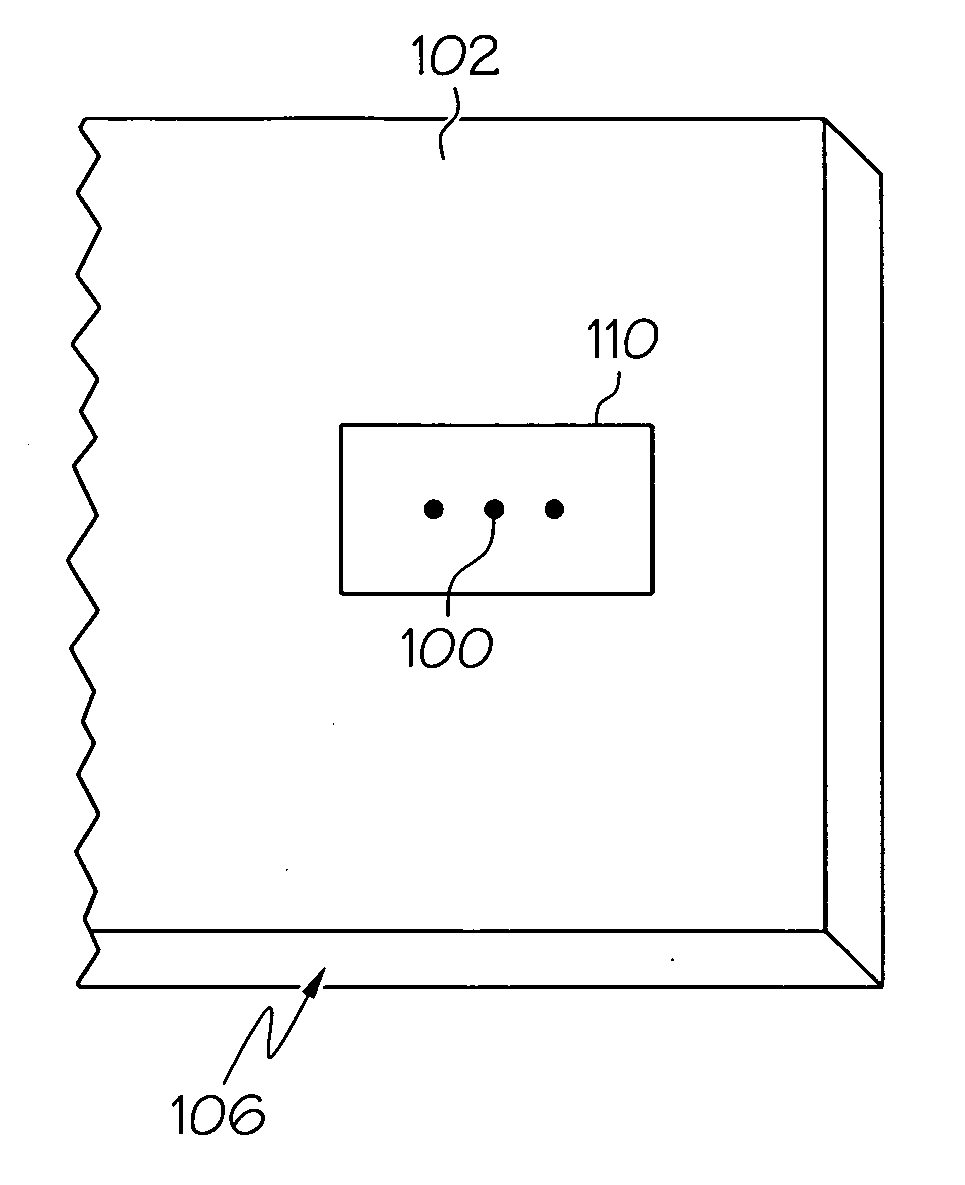

Method of sensing high surface temperatures in an aircraft

InactiveUS20080144699A1Simple methodThermometer detailsThermometers using physical/chemical changesEngineeringHigh surface

A method of sensing high surface temperatures in aircraft applications is provided. The method includes the steps of applying a temperature indicator material on a surface an object in which monitoring exposure to high temperatures is sought. The temperature indicator material is reactive to a pre-determined temperature threshold. The temperature indicator material is next covered with a heat resistant film to protect the material during exposure to operating temperatures and deleterious environmental conditions. An identified visible change in the temperature indicator material provides confirmation of exposure of the surface of the object to temperatures in excess of the pre-determined temperature threshold.

Owner:HONEYWELL INT INC

Ceramic Coating with Scratch Resistance and Thermal Conduction Properties

Provided is a ceramic coating intended to be applied on a metal support and having the form of at least a continuous film having a thickness between 2 and 100 μm, this coating comprising a matrix including at least a metal polyalkoxide and wherein are dispersed particles whereof the diameter ranges between 0.01 and 50 μm, said particles being from a material having a thermal conductivity equal to or higher than 10 W·m−1·K−1 and a bulk density of at the most 3.9 g / cm3. Also provided is an article, for example culinary, comprising such a coating and its method of manufacture.

Owner:SEB SA

Thermosensitive decolorable ink composition

InactiveUS8616797B2Readily be decoloredImprove the heating effectErasing devicesDuplicating/marking methodsLeuco dyeHue

In order to provide a thermosensitive decolorable ink composition which can readily be decolored with simple heating by rubbing and the like without using a microcapsule and is not developed again in color even after stored at very low temperature (−50° C. or lower) and which is excellent in stability with passage of time and has a vivid hue intensity, the above thermosensitive decolorable ink composition is provided with a constitution in which it contains as a colorant, color developing particles comprising at least a leuco dye, a developer and a crystalline substance and in which it further contains a decolorant comprising an amorphous resin.

Owner:MITSUBISHI PENCIL CO LTD

Thermochromic coating and thermochromic container

InactiveCN106928794ARich color variationSimple preparation processDrinking vesselsThermosensitive paintsWater basedThermochromism

The invention discloses a thermochromic coating and a thermochromic container. The thermochromic coating is prepared from the following raw materials in parts by mass: 100 parts of water-based resin, 10 to 50 parts of a thermochromic toner, 10 to 50 parts of a common toner, 0.5 to 0.9 part of a dispersing agent, 0.5 to 1 part of a defoaming agent, 1.5 to 2.5 parts of an adhesion promoter and 20 to 50 parts of water. The thermochromic container comprises a container body, a thermochromic layer arranged on the surface of the container body, and a transparent protective layer arranged on the thermochromic layer; the thermochromic layer is obtained by drying and curing the thermochromic coating; the transparent protective layer is obtained by drying and curing a transparent coating. The thermochromic coating and the thermochromic container are rich in color change; diversified patterns are arranged on the container; a preparation process is simple; the thermochromic layer and the container body are closely combined and difficult to fall off; furthermore, the transparent protective layer is arranged on the outermost layer of the container, so that the durability of the color and the pattern on the surface of the container can be guaranteed.

Owner:广州市昌成陶瓷有限公司

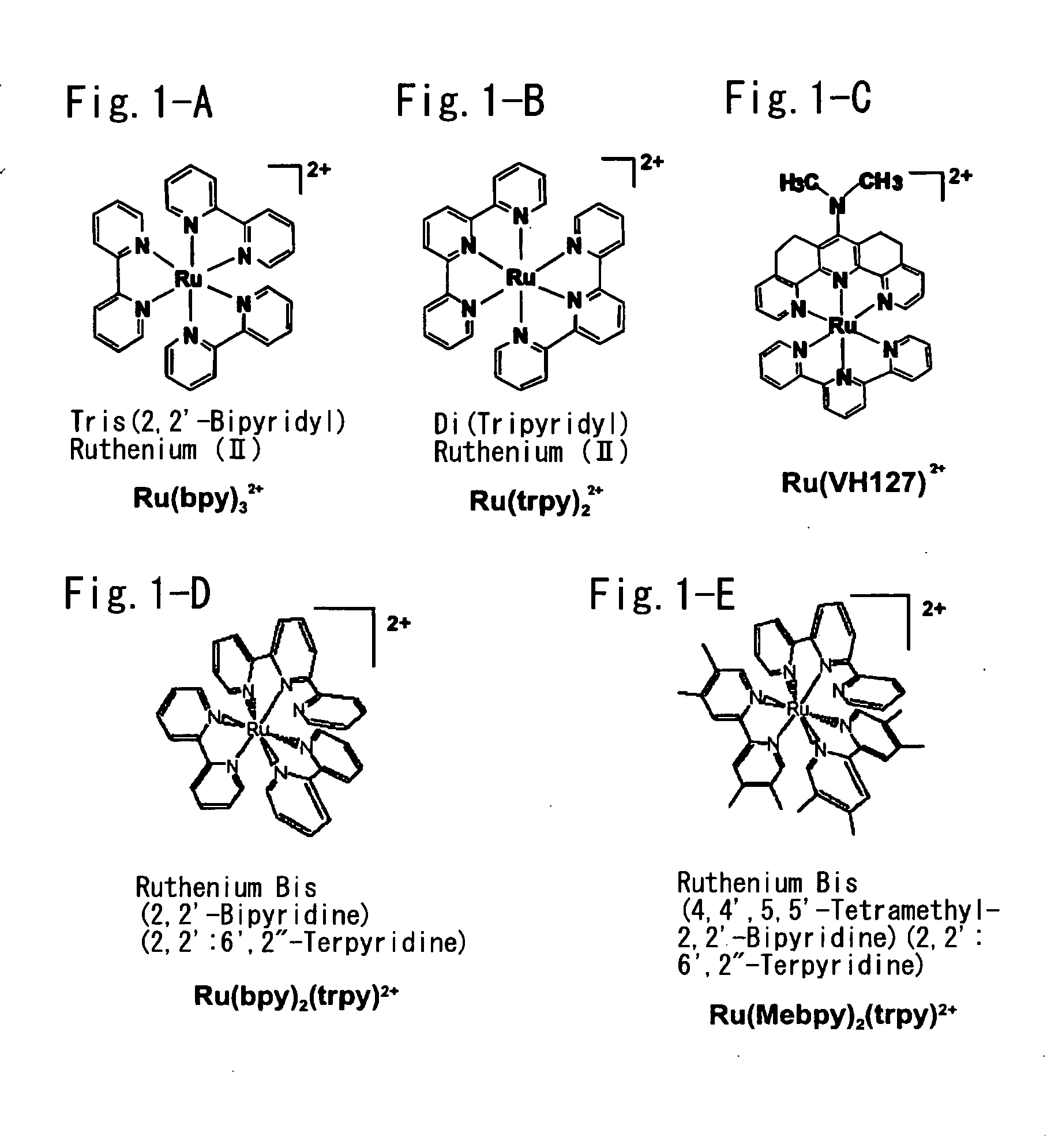

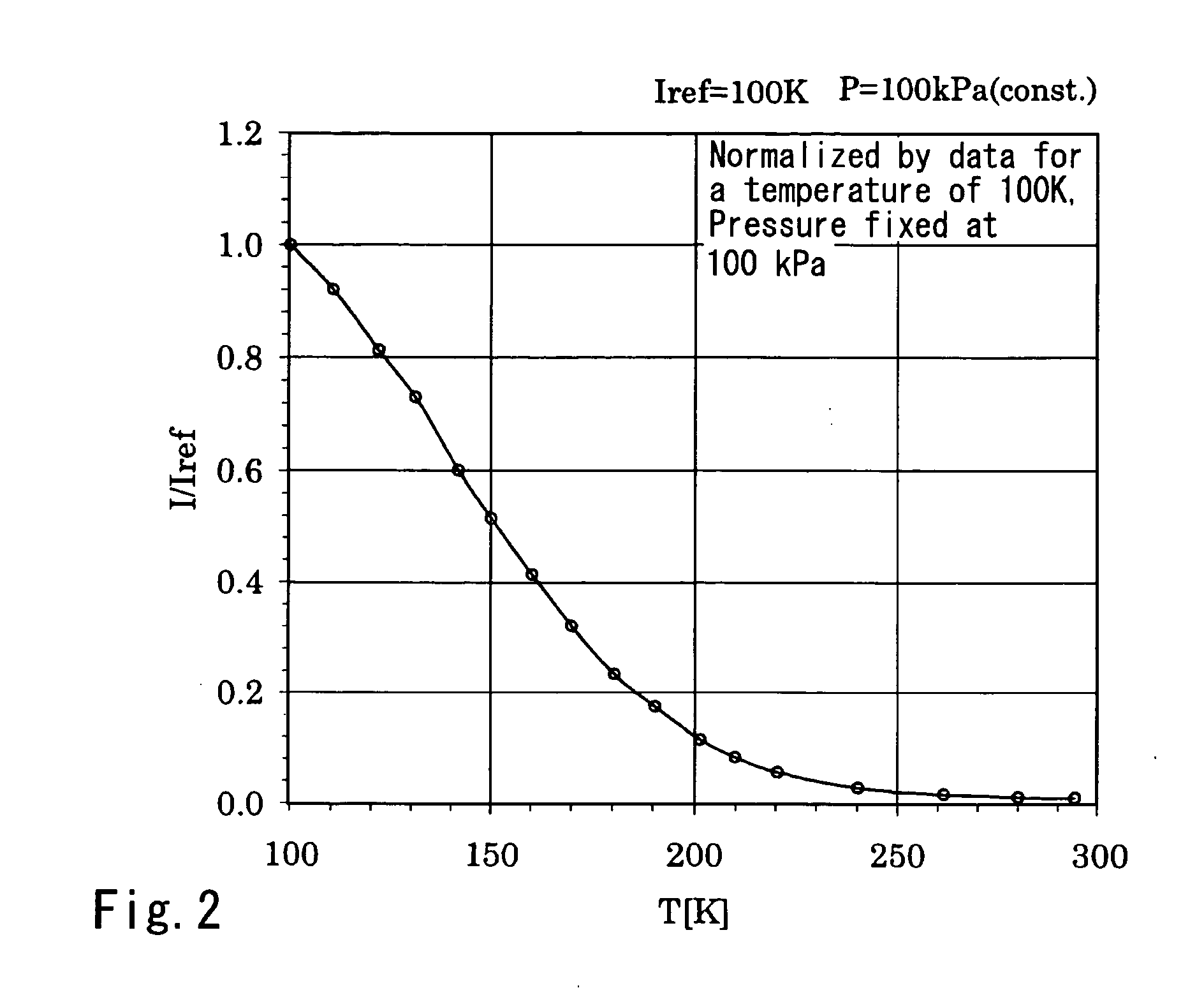

Temperature sensitive paint for low-temperature use

InactiveUS20050040368A1High luminous intensityLarge variation in light emission intensityAnalysis using chemical indicatorsLuminescent paintsSolubilityLuminous intensity

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

Nonstick coating containing graphene material, and preparation method thereof

ActiveCN110358442ASensitive over-temperature reminder effectReversible over-temperature reminder effectFireproof paintsCooking-vessel materialsFatty alcoholAmmonium sulfate

The invention discloses a nonstick coating containing a graphene material. The nonstick coating is formed by a bottom layer and a surface layer; the bottom layer comprises, by weight, 50-90 parts of apolytetrafluoroethylene / polysulfone blend, 0.5-2 parts modified graphene oxide, 1-5 parts of a thermochromic pigment, 0.8-1.2 parts of modified silicon carbide whiskers, 1.5-3 parts of an additive and 15-35 parts of deionized water; and the surface layer comprises, by weight, 35-75 parts of polytetrafluoroethylene resin, 1.5-5 parts of modified calcium carbonate whiskers, 3-8 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 5-10 parts maleic anhydride and 35-60 parts deionized water. Different raw material components of the bottom layer and the surface layer are reasonably combined, so the obtained nonstick coating has the advantages of good over-temperature prompting function, facilitation of control of the cooking heat, excellent high temperature wear resistance, and prolongation of the service life of a nonstick pan.

Owner:宁波市金象厨具有限公司

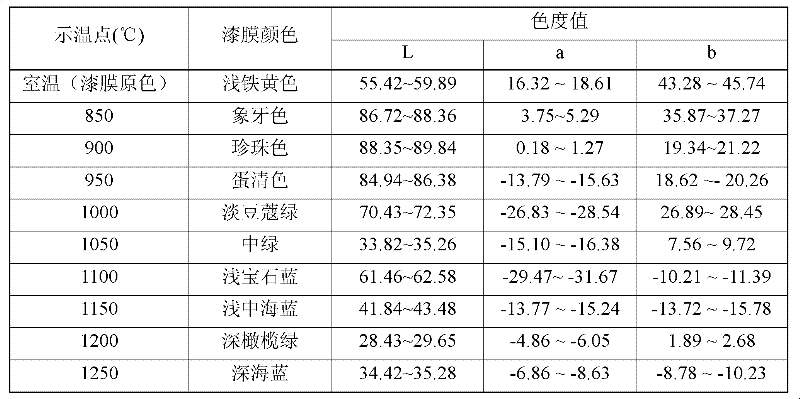

800DEG C-1250DEG C multi color-changing irreversible thermopaint

ActiveCN102492362AGood physical and mechanical propertiesSensitive to discolorationThermometers using mean/integrated valuesThermometers using physical/chemical changesAdhesiveDiluent

The invention discloses a 800DEG C-1250DEG C multi color-changing irreversible thermopaint, which is prepared by taking epoxy modified organic silicon resin as an adhesive and a high temperature resisting yellow pigment for underpainting, and adding a cobalt pigment, a silicate filling material, part of metal carbonates and a diluent. The paint is mainly used for temperature measurement of dynamic operating parts and large-area temperature fields, and a painted film has the characteristics of good physical and mechanical properties, sensitive color change, obvious color difference and high precision, etc.

Owner:中昊北方涂料工业研究设计院有限公司

Reversibly thermochromic composition

InactiveCN103998569AImprove visibilityGood effectErasing devicesPen repairingHeat conductingOrganic chemistry

[Object] To provide a reversibly thermochromic composition free from accidental discoloration by heat conducting from the opposite side writing surface or by self-heating due to quick writing; and also to provide a solid writing material and a writing ink composition comprising that composition. [Means to solve the problem] A reversibly thermochromic composition comprising a combination of: (a) a reversibly thermochromic component capable of being discolored or decolored by heat and (b) a component for controlling heat conducting to the reversibly thermochromic component; and also a solid writing material and a writing ink composition comprising that composition.

Owner:PILOT PEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com