Thermosensitive chromotropic material and manufacturing method and application thereof

A heat-sensitive discoloration and manufacturing technology, applied in heat-sensitive coatings, applications, household appliances, etc., can solve the difficulty of precise control of discoloration temperature, and achieve the effect of reducing material costs and broadening the range of choices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

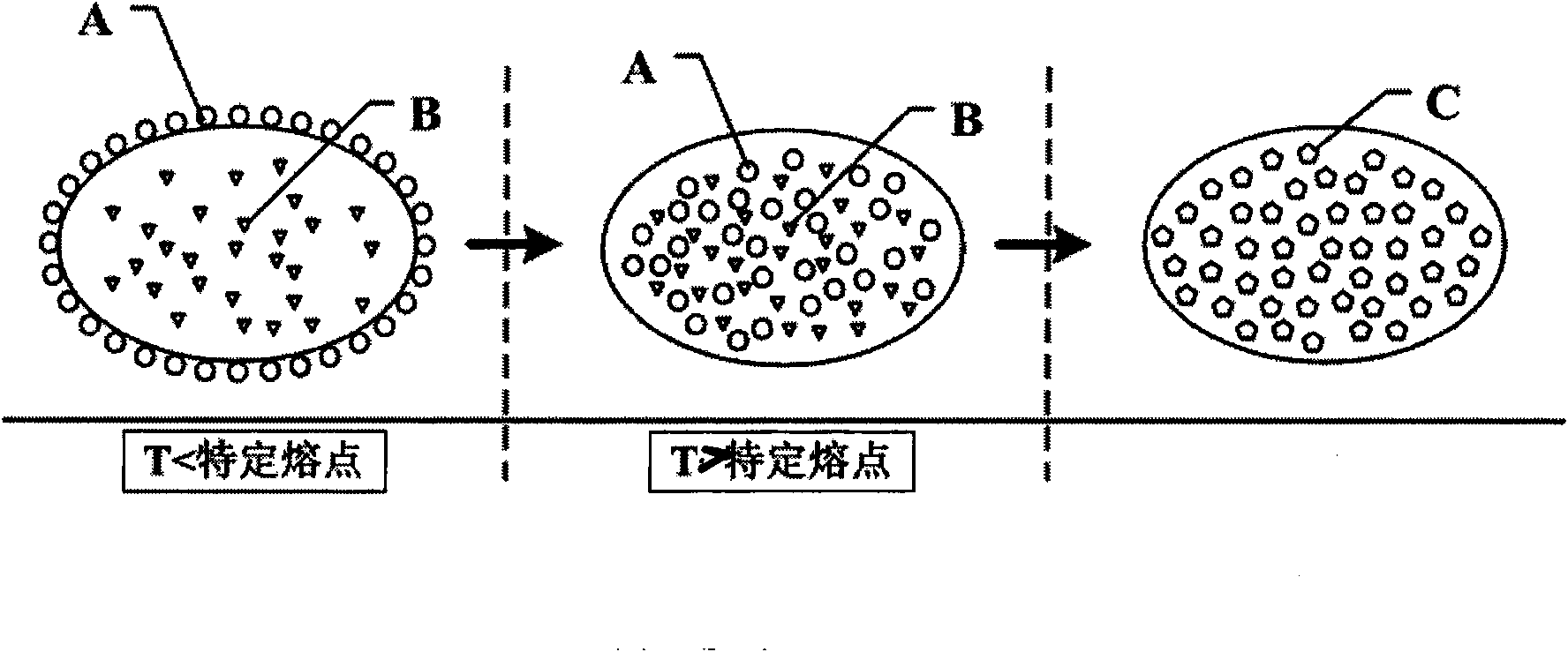

[0030] The invention provides a novel thermosensitive material capable of controlling discoloration reaction by material phase transition to realize irreversible thermosensitive discoloration in any temperature range and a preparation method thereof. The design principle is: separate the temperature sensitive function from the discoloration function, which is undertaken by two kinds of materials, and coordinate the functions of the two materials by designing an intelligent material structure, so as to realize irreversible thermal discoloration at low temperature, and broaden the possibilities of discoloration temperature and discoloration mode. The selection range can meet the different needs of practical applications.

[0031] The heat-sensitive color-changing material can realize one color-changing reaction or multiple color-changing reactions under different temperature conditions according to different structural features. Its representative structural features can be unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com