Patents

Literature

2505results about "Radiation-absorbing paints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink-jet inks containing metal nanoparticles

ActiveUS20050078158A1Slow sedimentation rateLow and viscosity gradeMeasurement apparatus componentsConductive materialWater basedNanometre

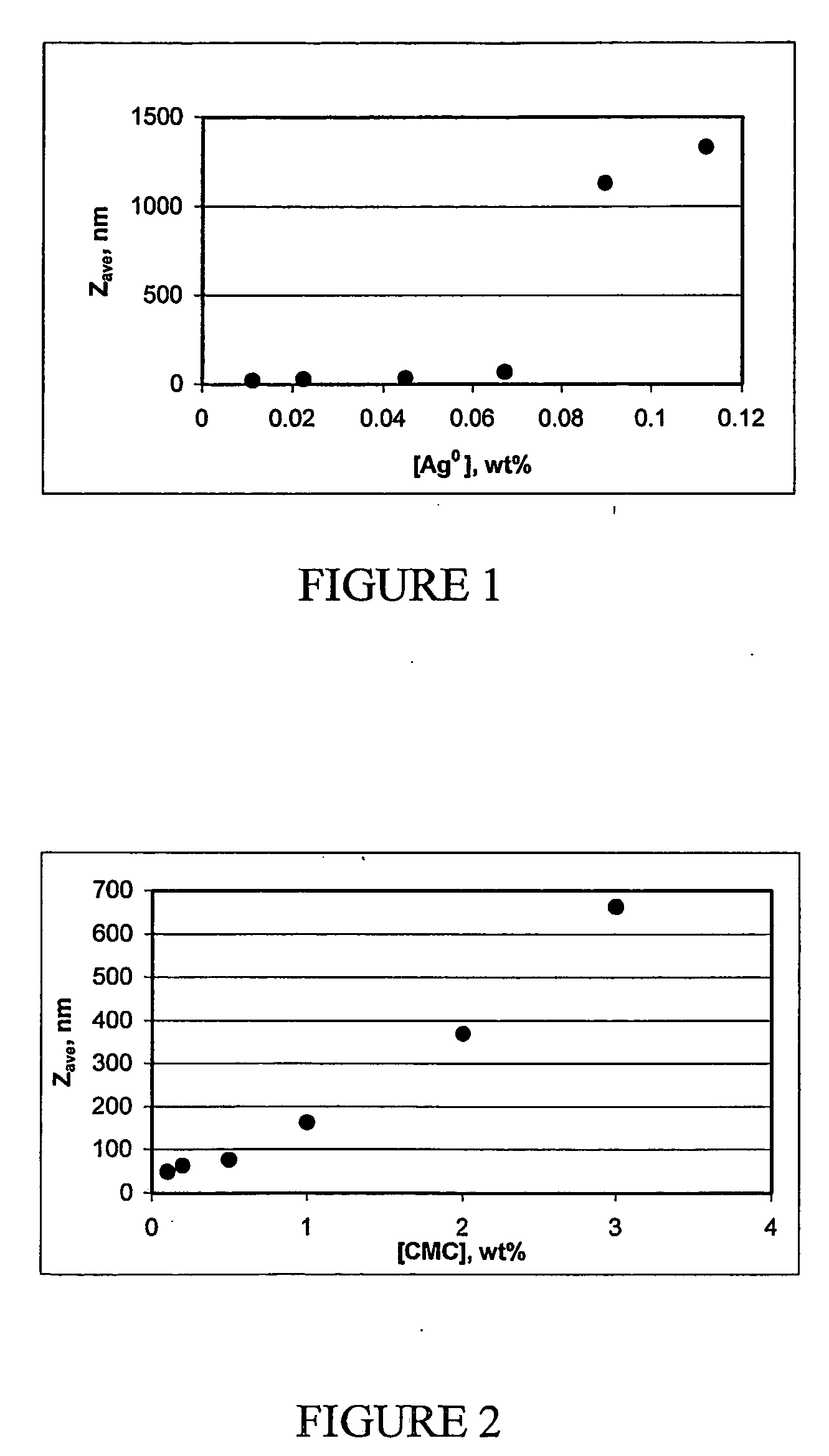

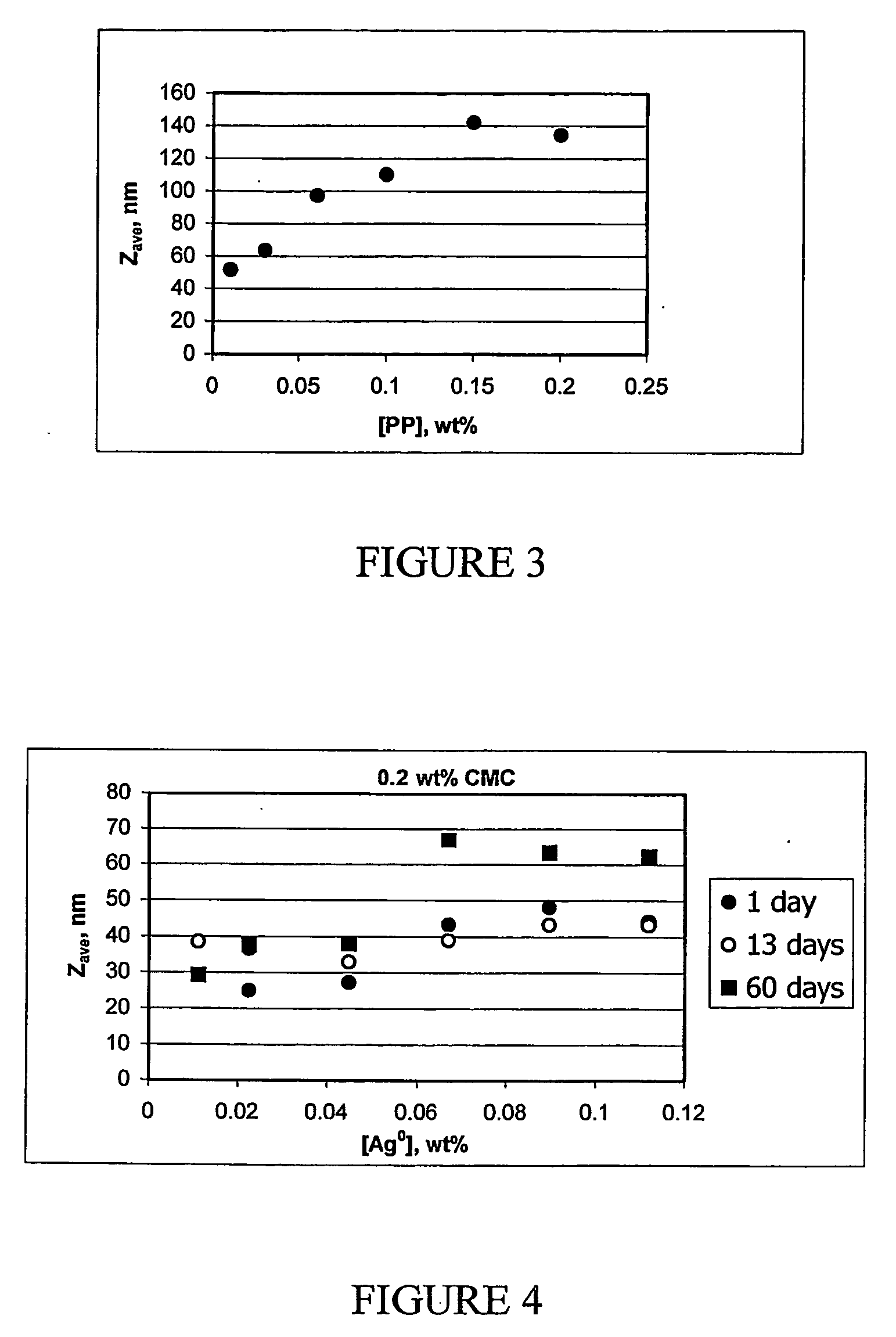

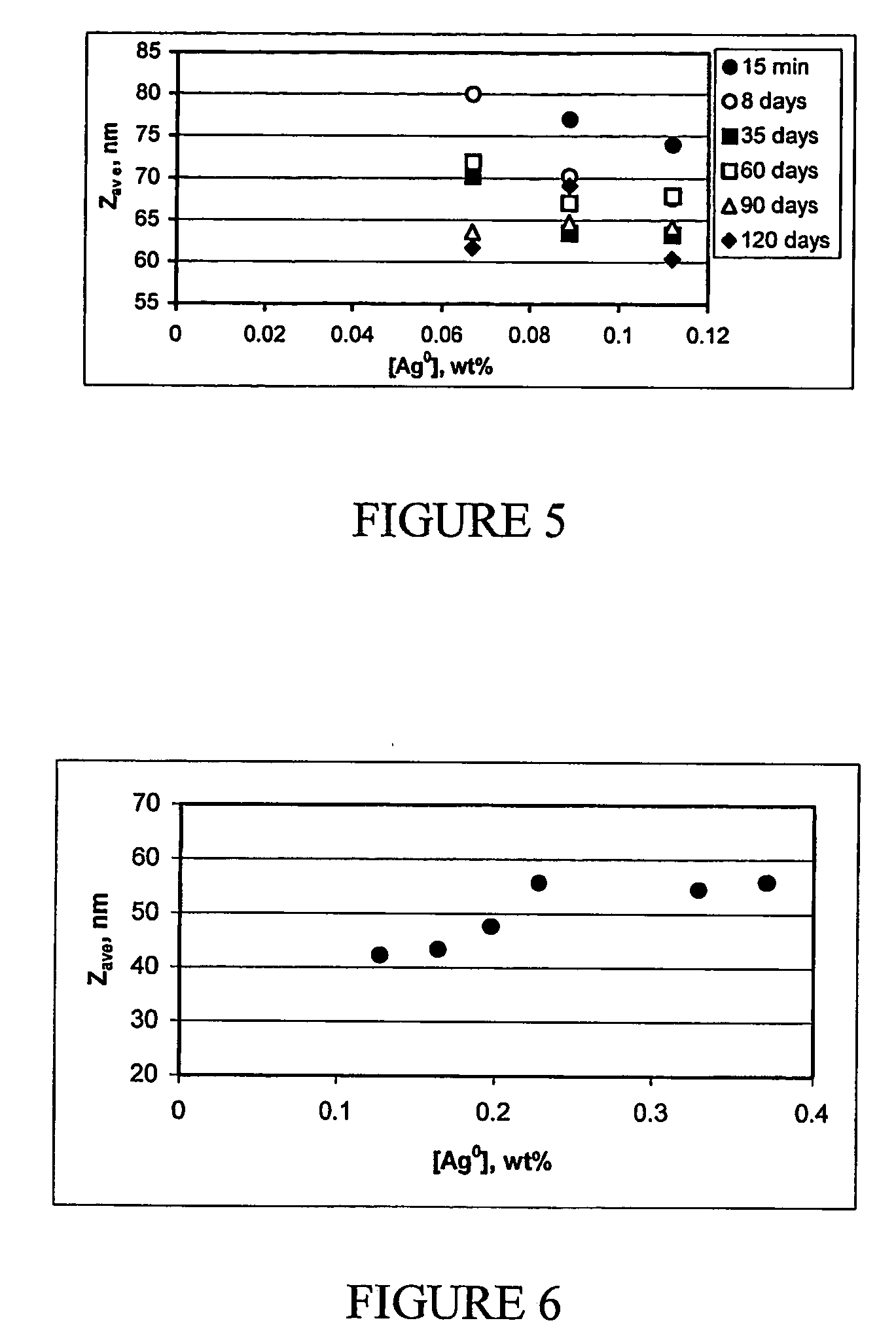

Compositions for use in ink jet printing onto a substrate comprising a water based dispersion including metallic nanoparticles and appropriate stabilizers. Also disclosed are methods for the production of said compositions and methods for their use in ink jet printing onto suitable substrates.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

Infrared shielding material microparticle dispersion infrared shield, process for producing infrared shield material microparticle and infrared shielding material microparticle

ActiveUS20060178254A1Improve featuresEffective shieldingPigmenting treatmentTungsten oxides/hydroxidesArgon atmosphereRoom temperature

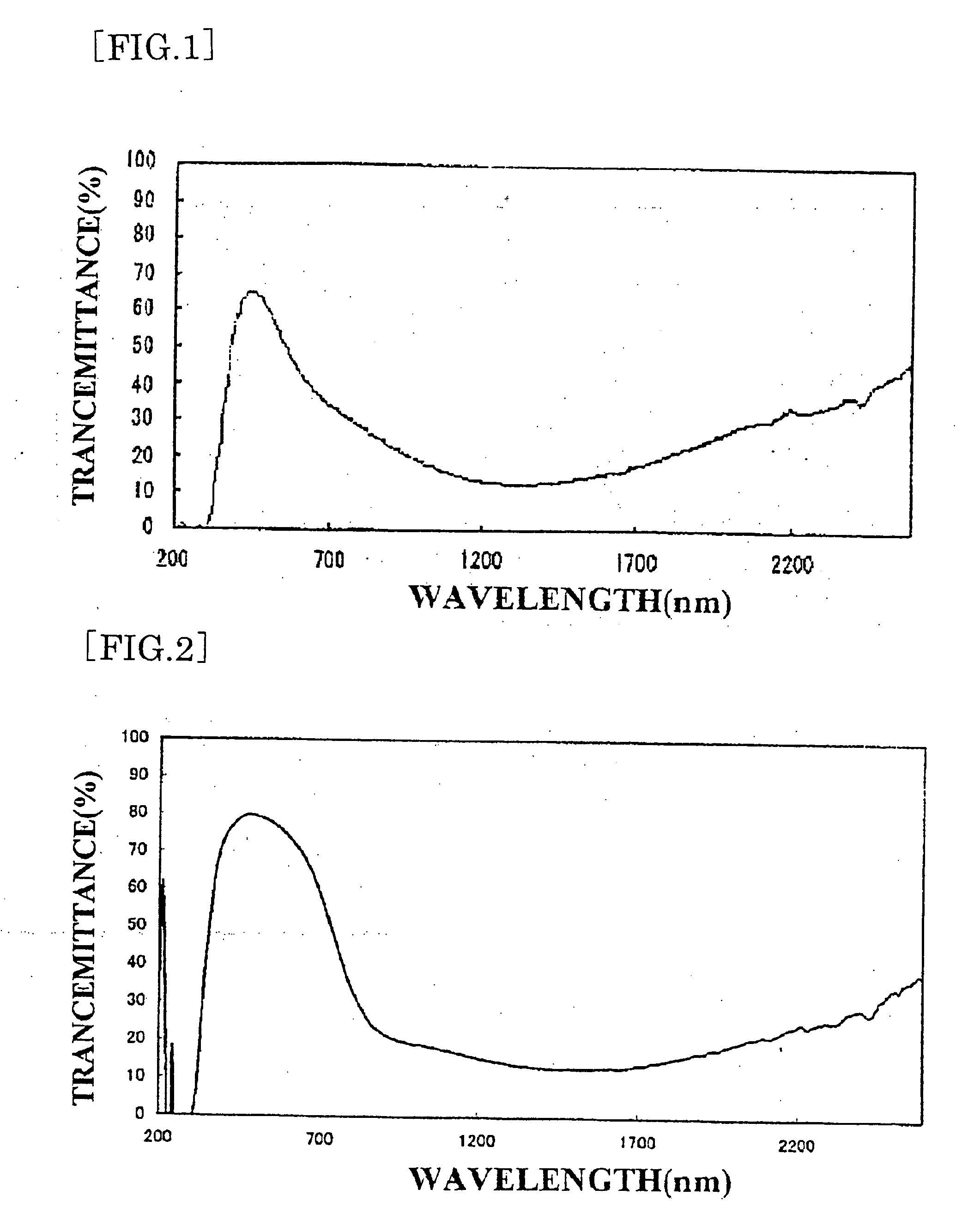

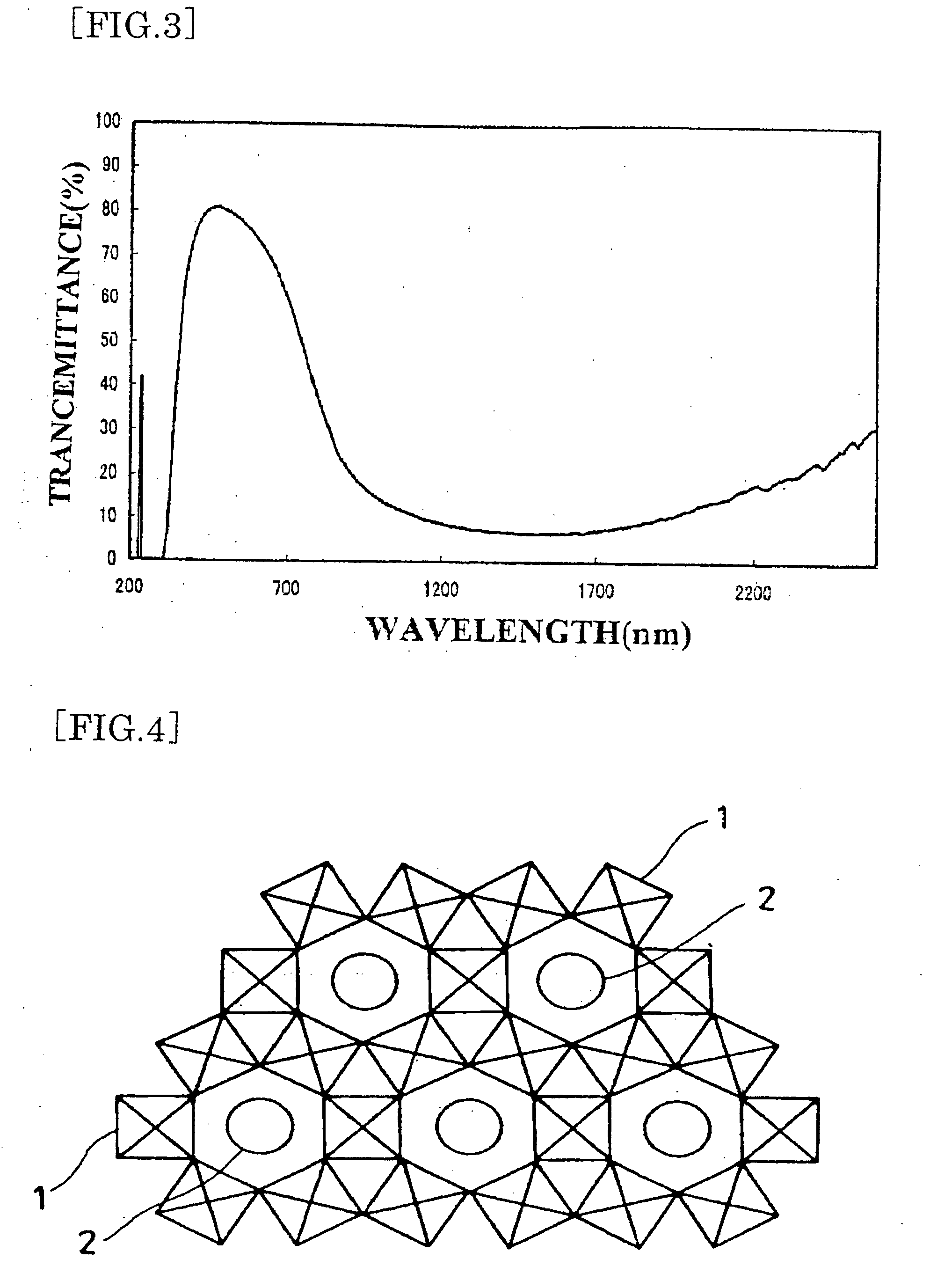

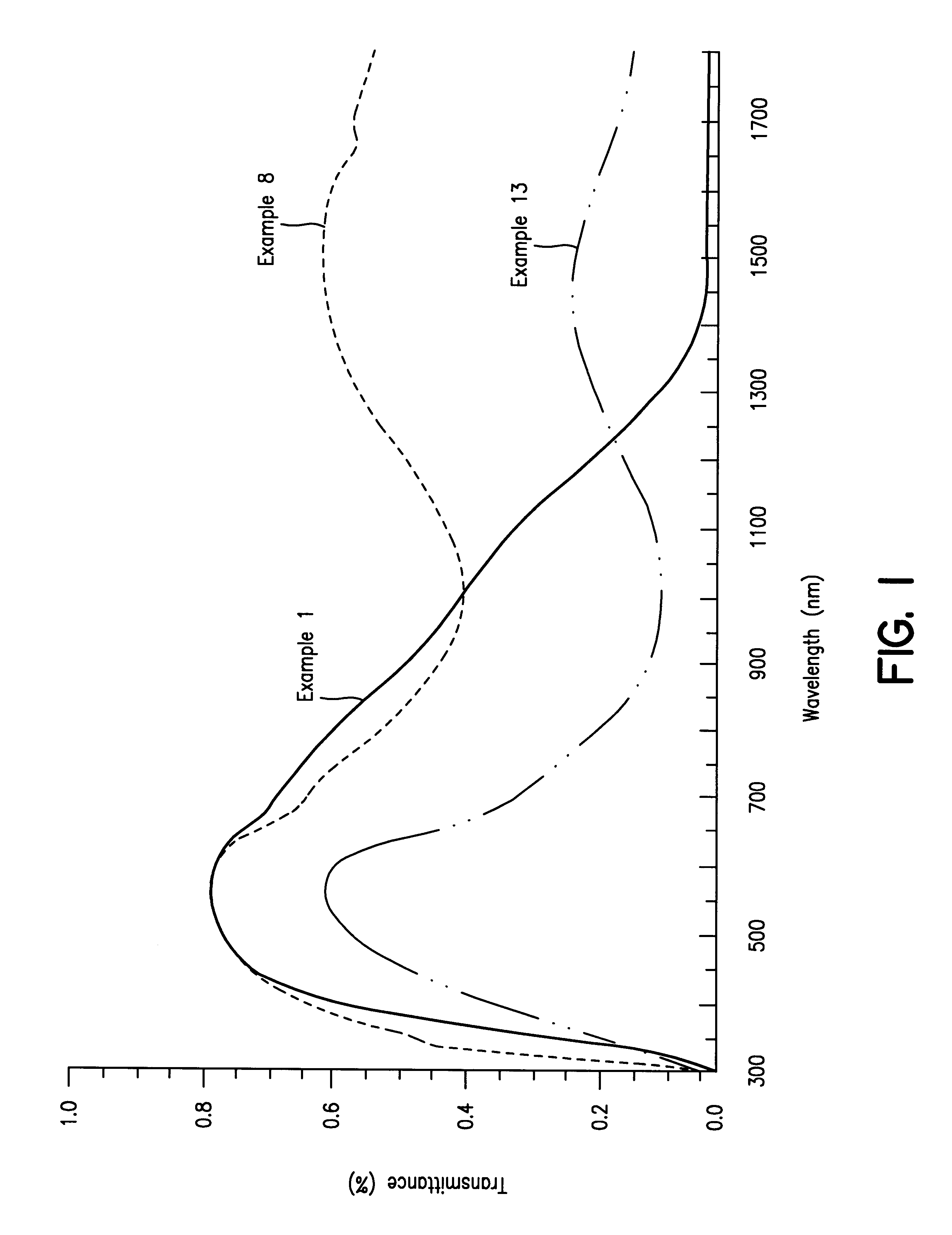

To provide an infrared-shielding body sufficiently transmitting visible rays, having no half-mirror shaped appearance, requiring no large-scale apparatus when forming a film on a substrate, efficiently shutting invisible near-infrared rays with wavelength range of 780 nm or more, while eliminating a heat treatment at high temperature after film formation, and having a spectral characteristic such as transparency with no change of color tone. The starting material, which is a mixture containing a predetermined amount of a tungsten compound, is heated at 550° C. in a reductive atmosphere for 1 hour, then cooled to room temperature once in an argon atmosphere, thus producing powder of W18O49. Then, the powder, the solvent, and the dispersant are mixed, then subjected to dispersion treatment to obtain a dispersion solution. The dispersion solution and a UV-curable hardcoat resin are mixed to obtain a solution of fine particle dispersion of infrared-shielding material. The solution of the fine particle dispersion of infrared-shielding material is applied on a PET resin film to form a film, which is then cured, and an infrared-shielding film having a transmission profile shown in the figure is thereby obtained.

Owner:SUMITOMO METAL MINING CO LTD

Coating solution for forming a film for cutting off solar radiation and the film formed therefrom

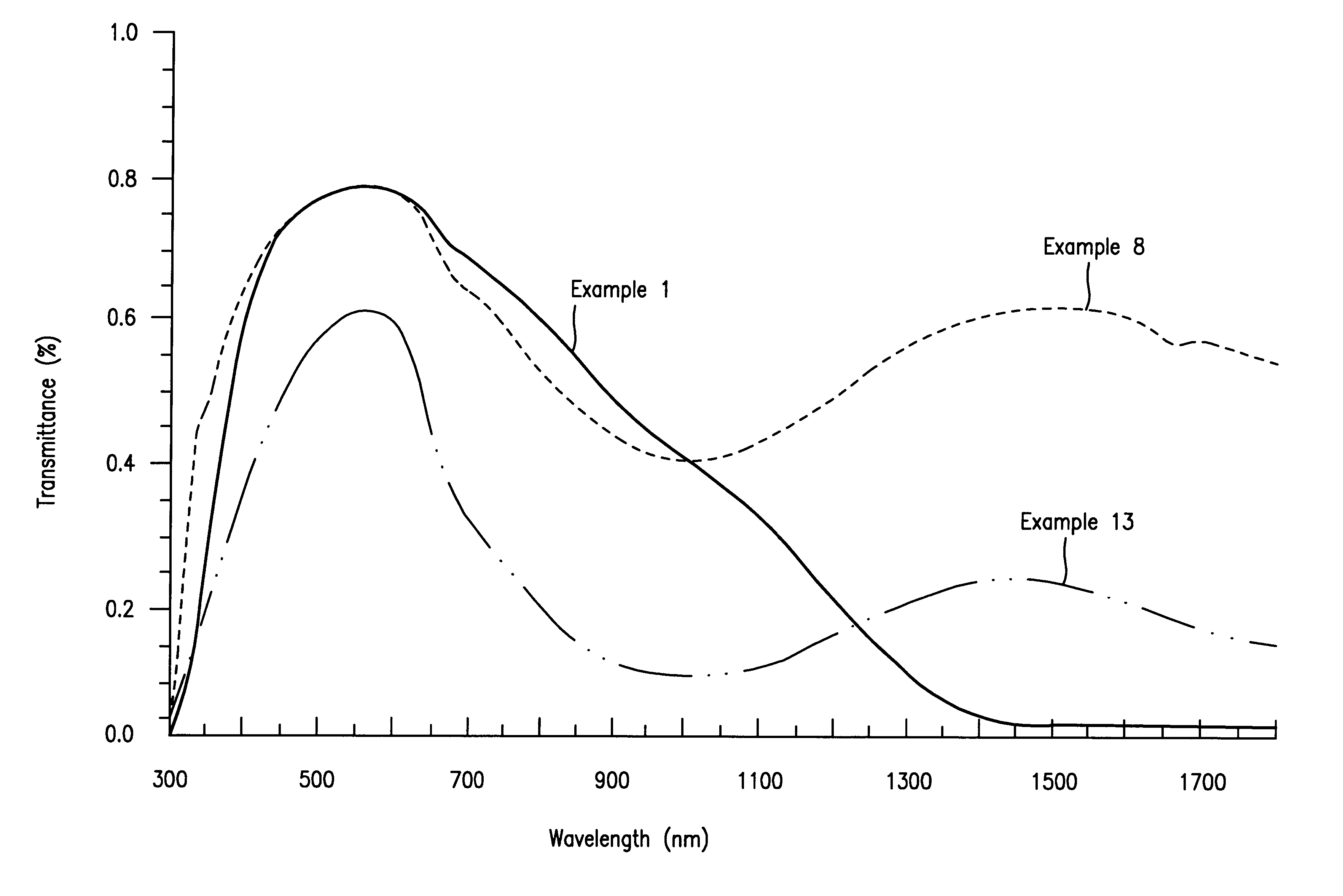

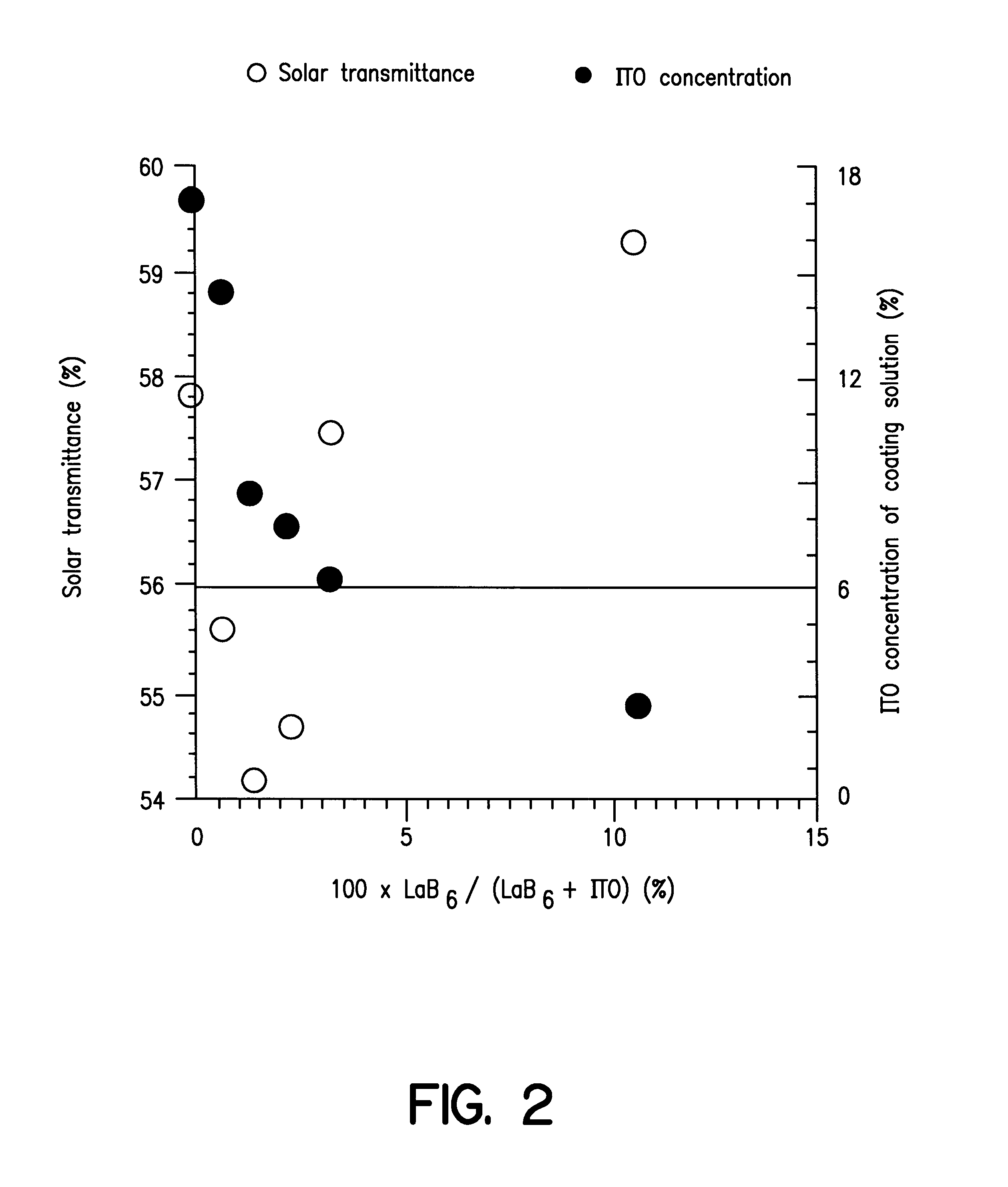

InactiveUS6319613B1Low costReduce heat radiationOther chemical processesSynthetic resin layered productsSurface resistivityNear infrared radiation

A solution for forming a film having a high transmittance and a low reflectivity for visible light, a low transmittance for near infrared radiation, and a surface resistivity of at least 106 ohms / square. It contains fine particles of a hexaboride of Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Th, Dy, Ho, Er, Tm, Yb, Lu, Sr or Ca, and fine particles of ITO or ATO in a weight ratio of from 0.1:99.9 to 90:10. Also disclosed is a film formed on at least one side of a resin film as a base, for cutting off solar heat radiation.

Owner:SUMITOMO METAL MINING CO LTD

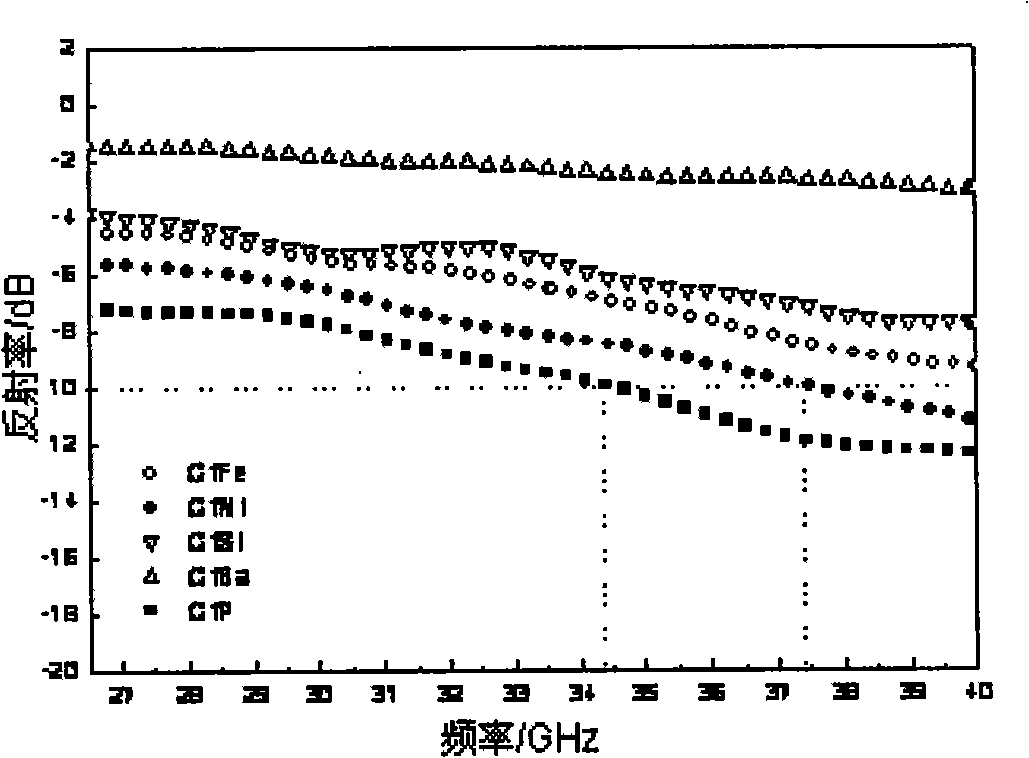

Composite coating electromagnetic shielding paint and composite coating electromagnetic shielding material prepared therefrom

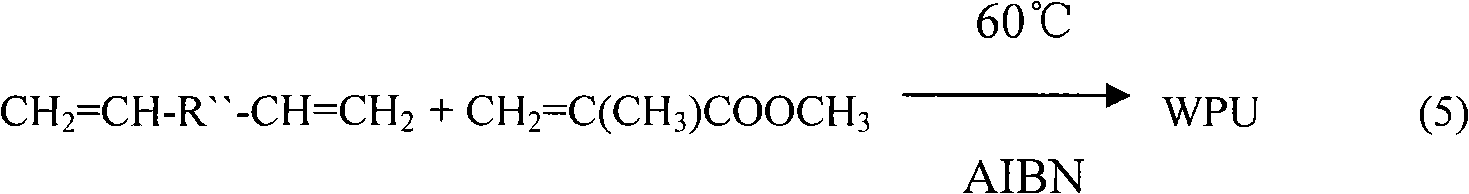

ActiveCN102020899AReduce generationEnsure safetyPolyurea/polyurethane coatingsRadiation-absorbing paintsEmulsionDefoaming Agents

The invention relates to the field of electromagnetic wave shielding, in particular to a composite coating electromagnetic shielding paint and a composite coating electromagnetic shielding material prepared therefrom. The composite coating electromagnetic shielding paint comprises a conducting layer paint with a reflection function and a wave-absorbing layer paint with an absorption function, wherein the reflecting layer paint comprises the components of polymer emulsion, a conducting filler, a coupling agent, a defoaming agent, a wetting agent, a film forming assistant, a thickening agent and water; and the wave-absorbing layer paint comprises the components of polymer emulsion, a wave-absorbing filler, a coupling agent, a defoaming agent, a wetting agent, a film forming assistant, a thickening agent and water. The invention also discloses a composite coating electromagnetic shielding material prepared by coating the paint. The material is prepared by the steps of firstly coating the conducting layer paint on the surface of a base material, drying, then coating the wave-absorbing layer paint and the like. In the invention, the electromagnetic shielding material prepared by using the mode of compounding the wave-absorbing layer with the reflecting layer effectively reduces secondary pollution caused by the reflection of electromagnetic radiation and has wider shielding wave band in comparison to a pure wave absorbing coating; and the use of water emulsion reduces the production of harmful volatile matters and guarantees body safety.

Owner:ARMY MEDICAL UNIV +1

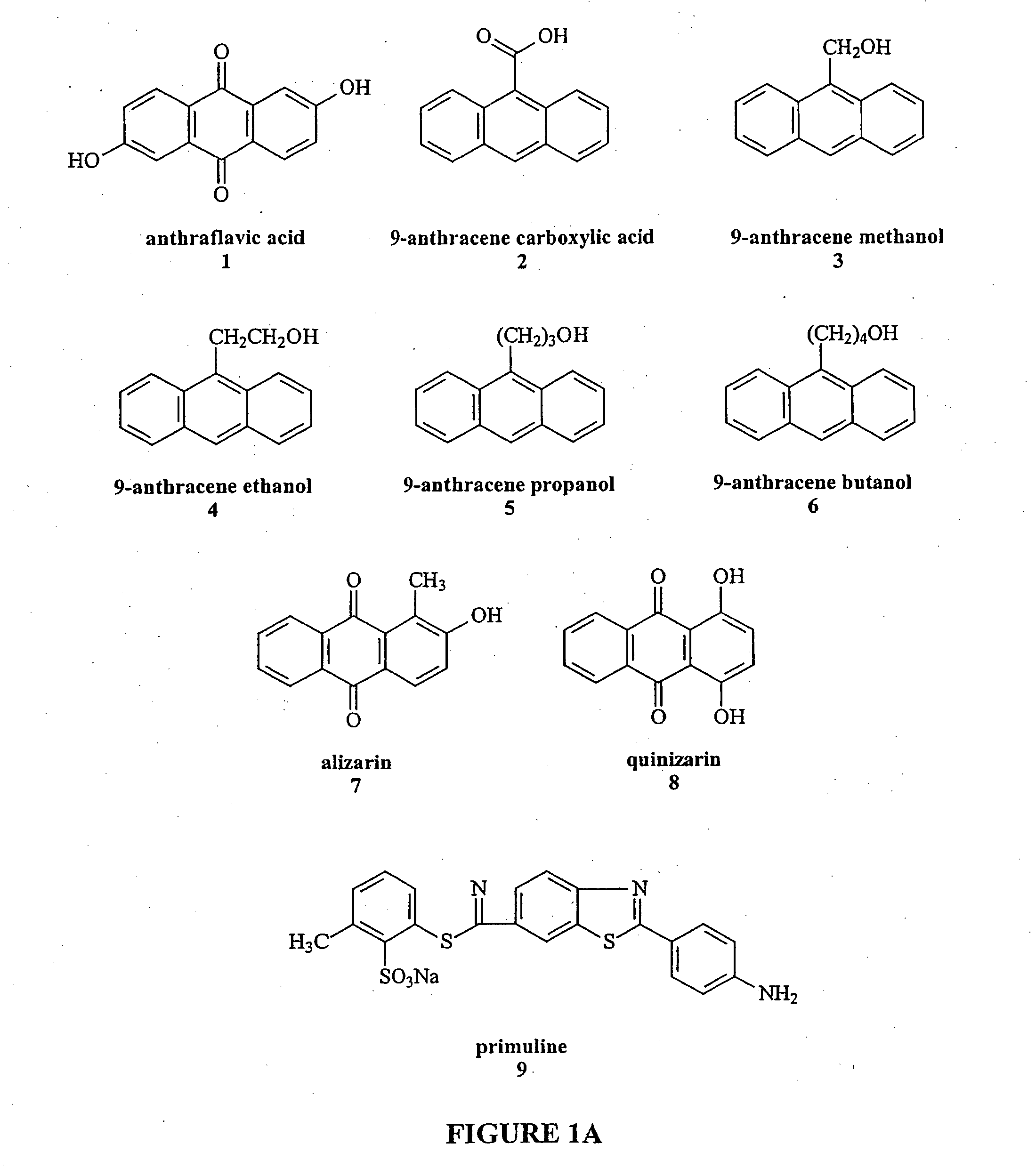

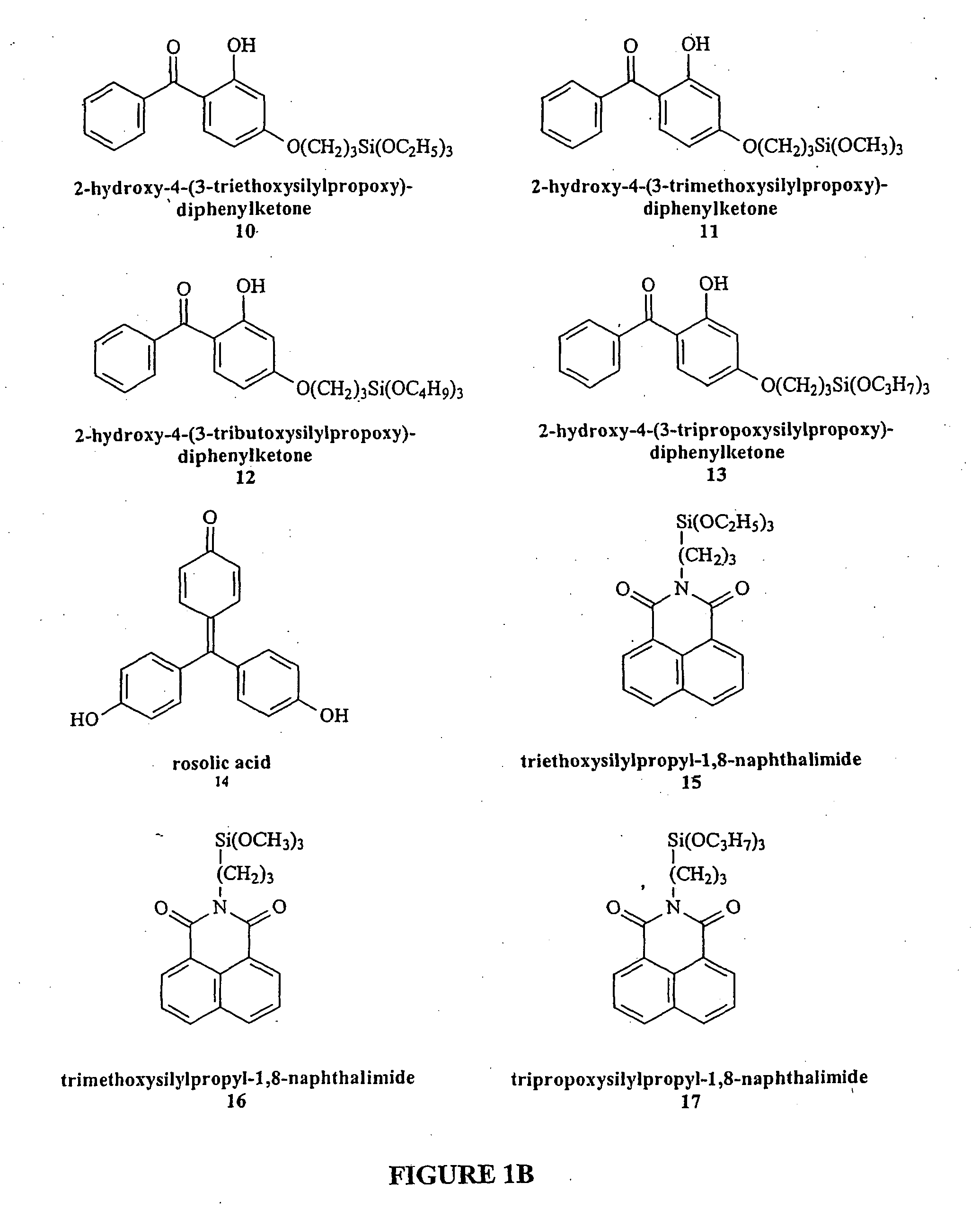

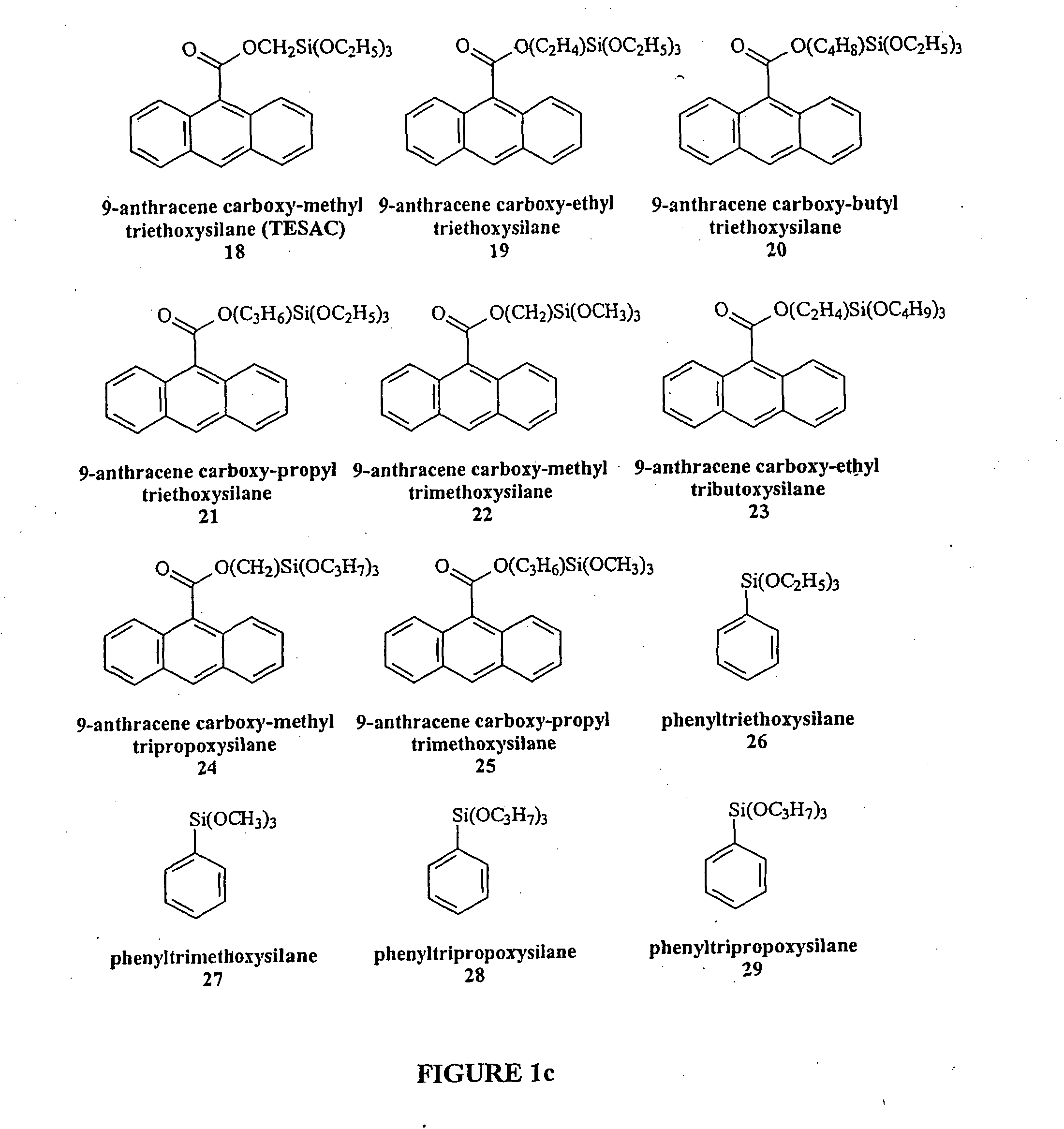

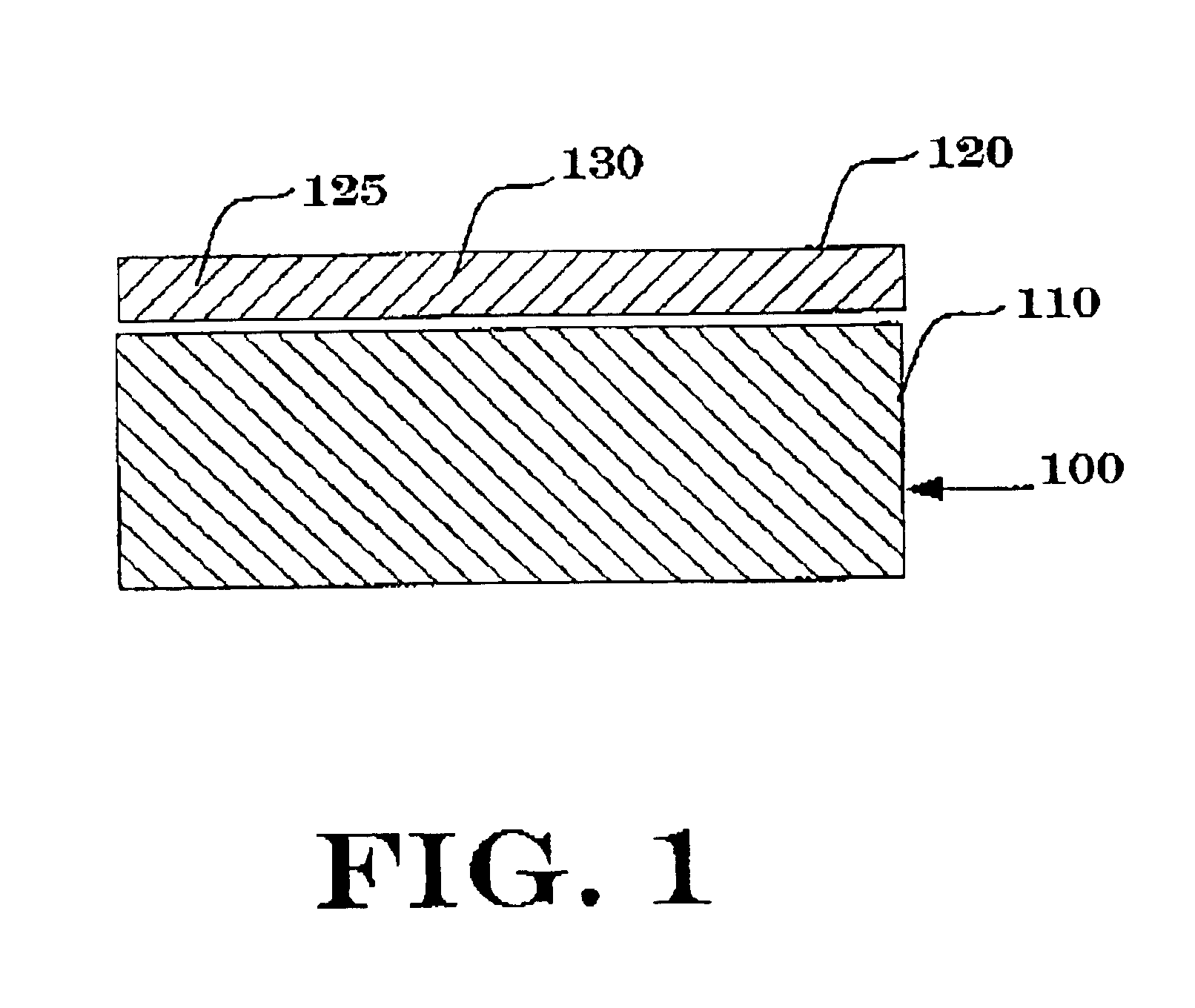

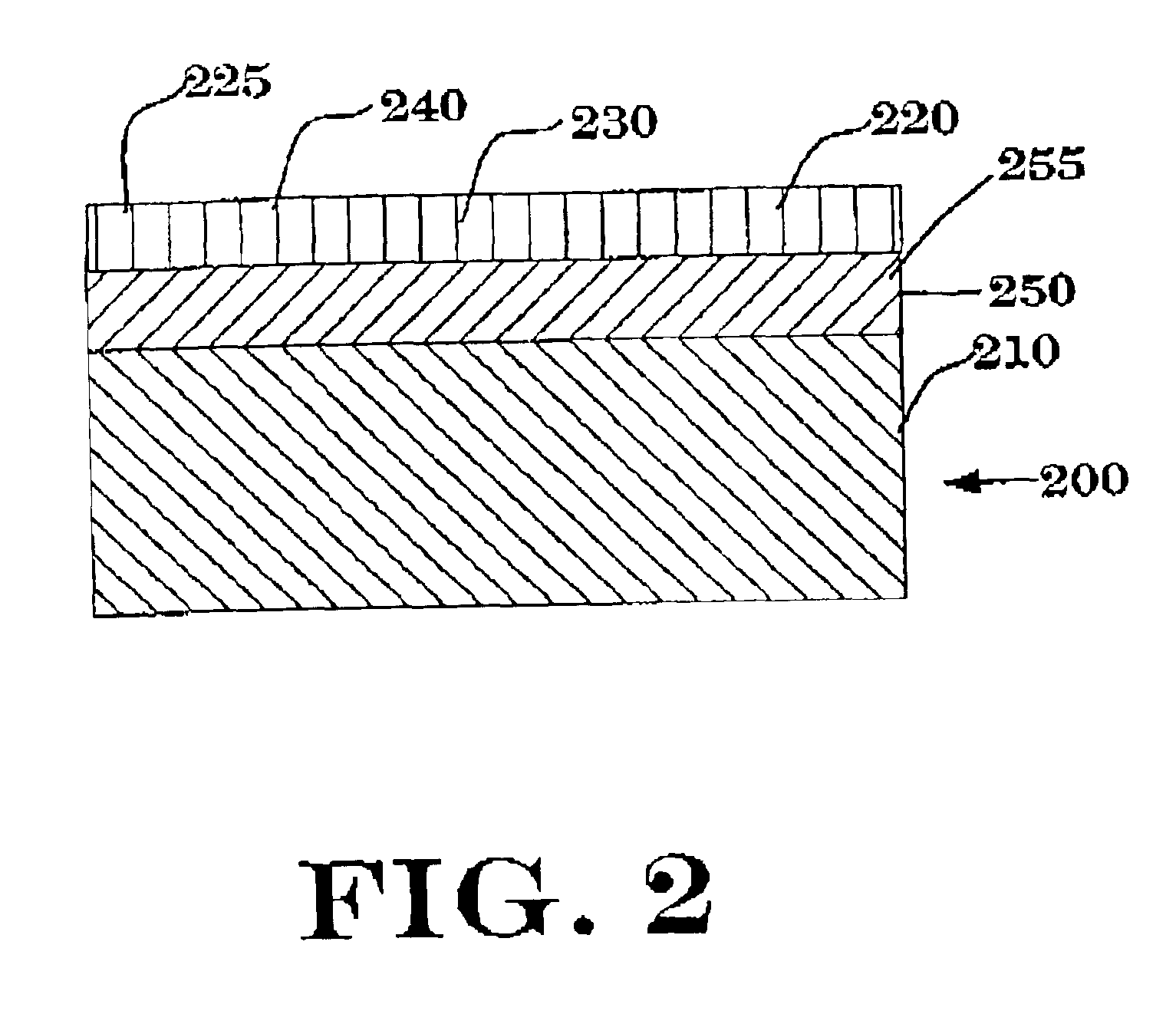

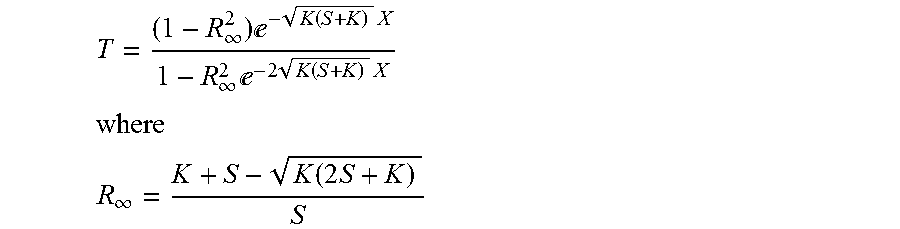

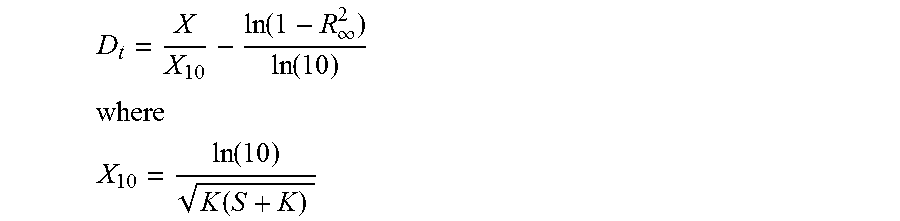

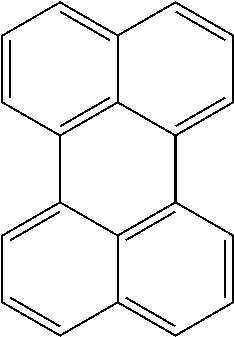

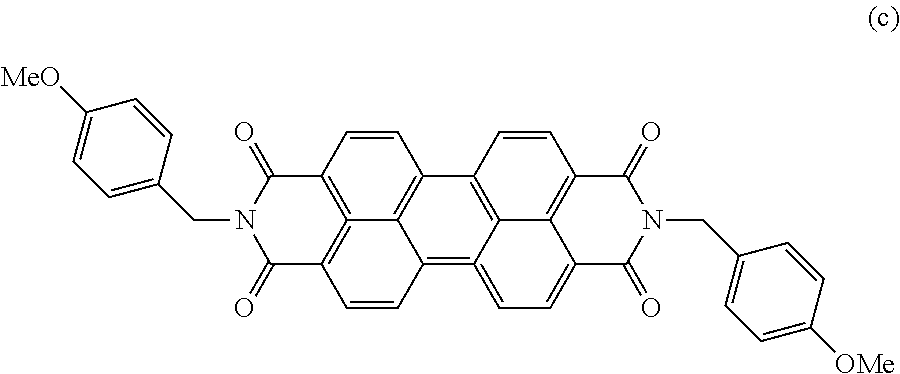

Spin-on anti-reflective coatings for photolithography

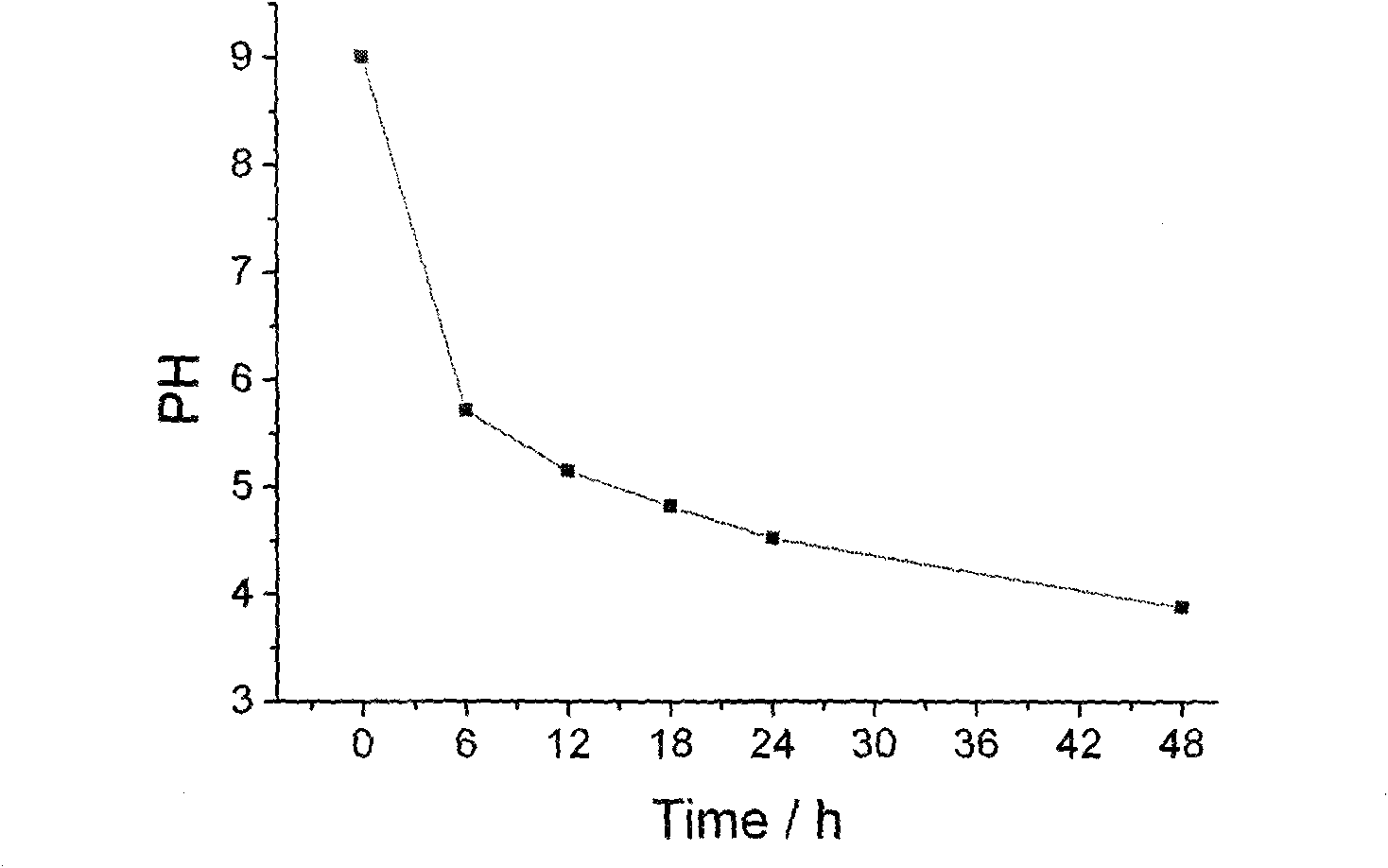

Anti-reflective coating materials for ultraviolet photolithography include at least one absorbing compounds and at least one pH tuning agent that are incorporated into spin-on materials. Suitable absorbing compounds are those that absorb around wavelengths such as 365 nm, 248 nm, 193 nm and 157 nm that may be used in photolithography. Suitable pH tuning agents not only adjust the pH of the final spin-on composition, but also influence the chemical performance and characteristics, mechanical performance and structural makeup of the final spin-on composition that is part of the layered material, electronic component or semiconductor component, such that the final spin-on composition is more compatible with the resist material that is coupled to it. More specifically, the pH tuning agent strong influences the polymeric characteristics, the structural makeup and the spatial orientation that results in increasing the surface properties of the anti-reflective coating for optimal resist performance. In other words, a pH tuning agent that merely adjusts the pH of the spin-on material without influencing the mechanical properties and structural makeup of the spin-on composition or the coupled resist material is not contemplated herein. A method of making absorbing and pH tuned spin-on materials includes combining at least one organic absorbing compound and at least one pH tuning agent with at least one silane reactant during synthesis of the spin-on materials and compositions.

Owner:HONEYWELL INT INC

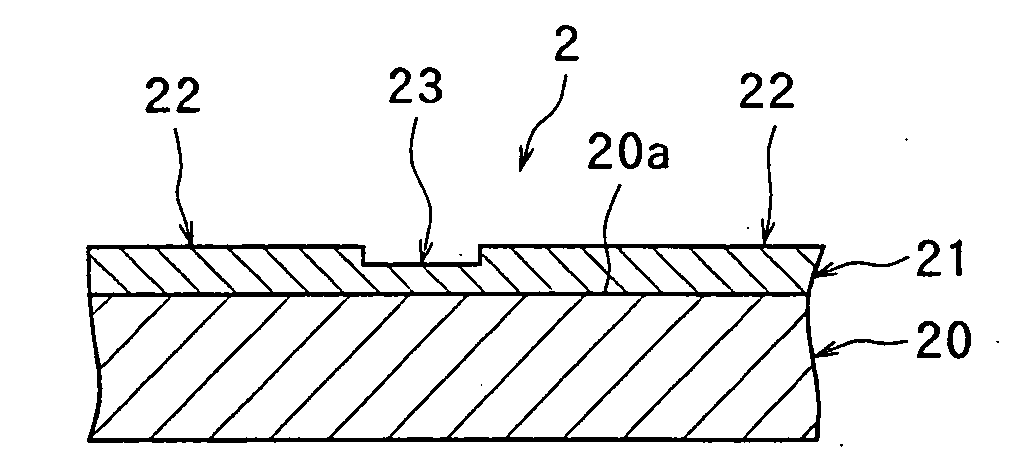

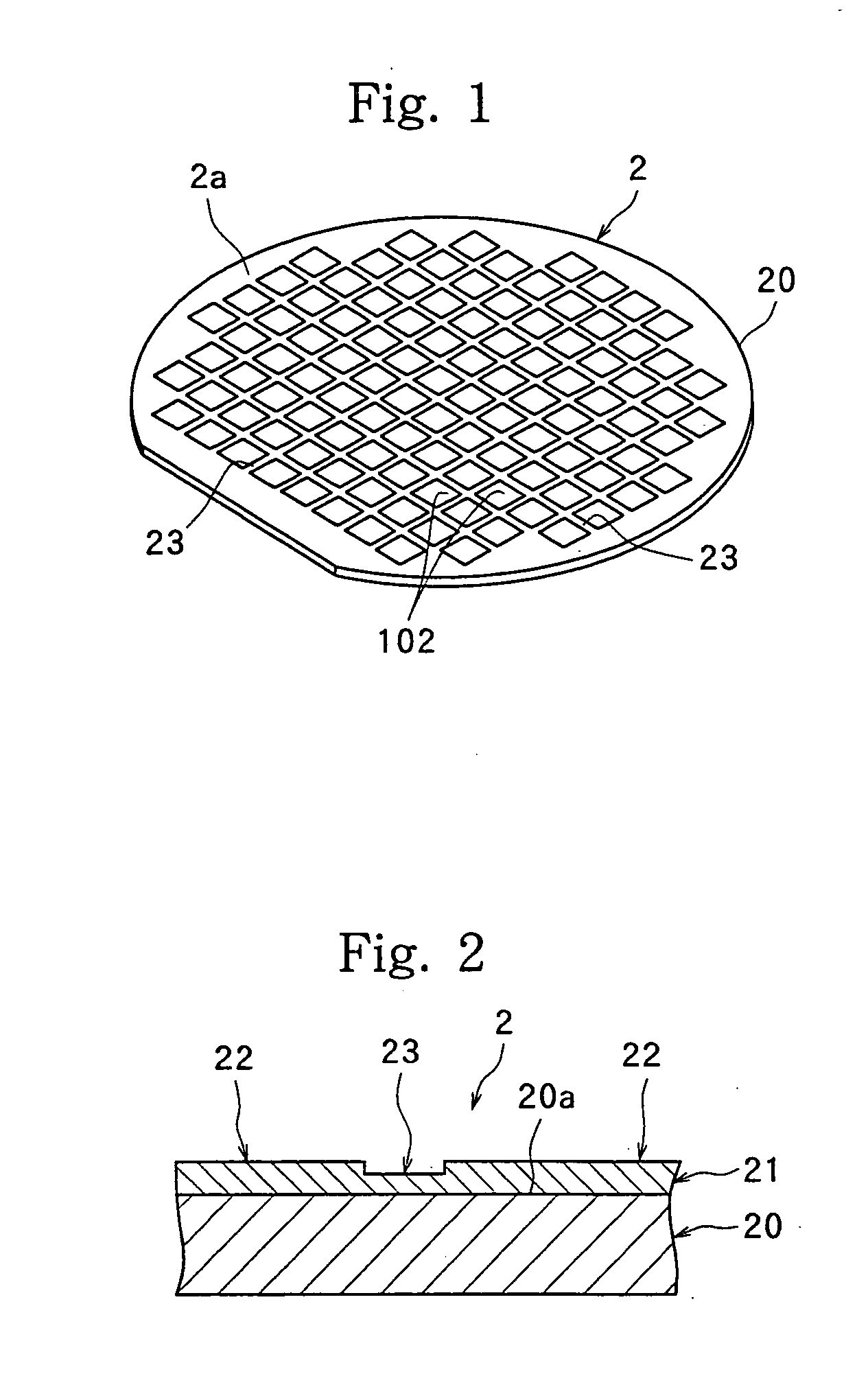

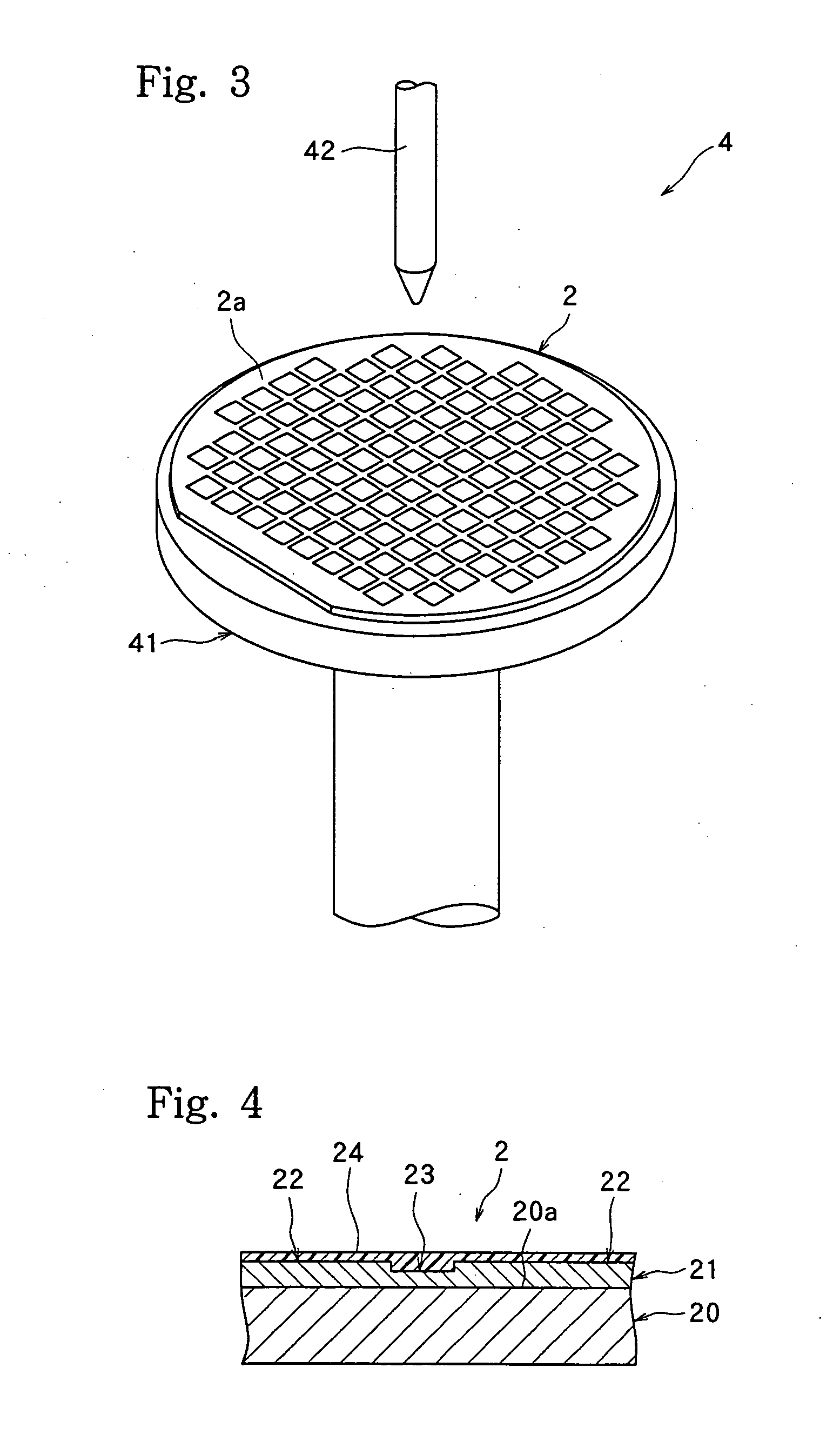

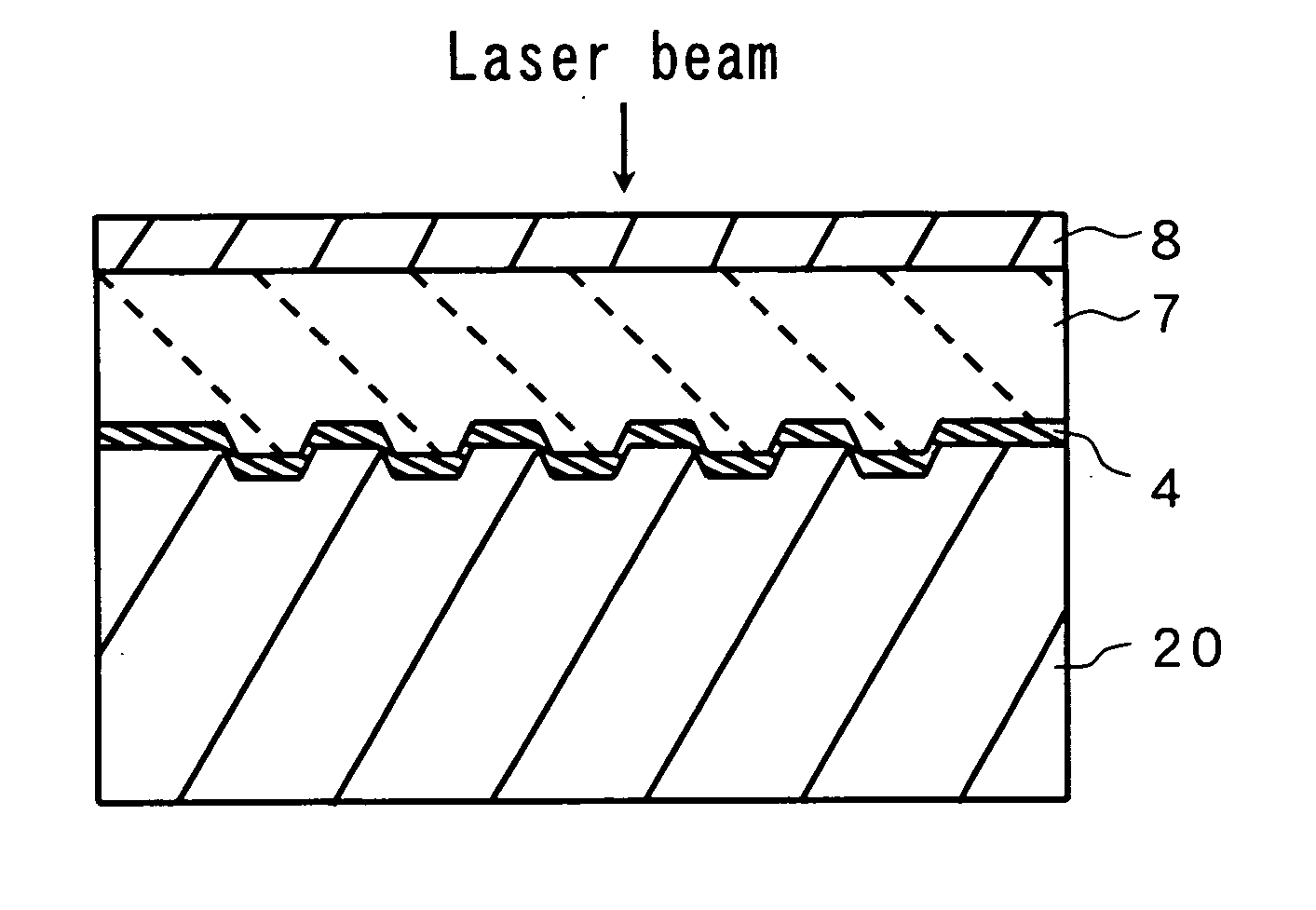

Protective film agent for laser dicing and wafer processing method using the protective film agent

InactiveUS20060105544A1Improve adhesionEffectively preventing deposition of debrisSemiconductor/solid-state device manufacturingRadiation-absorbing paintsUltravioletWafer dicing

A protective film agent for laser dicing according to the present invention comprises a solution having, dissolved therein, a water-soluble resin and at least one laser light absorber selected from the group consisting of a water-soluble dye, a water-soluble coloring matter, and a water-soluble ultraviolet absorber. The protective film agent is coated on a surface of a wafer, which is to be processed, and is then dried to form a protective film. Laser dicing through the protective film produces chips from the wafer. As a result, deposition of debris can be effectively prevented on the entire face of the chips, including their peripheral edge portions.

Owner:TOKYO OHKA KOGYO CO LTD +1

Solar-absorbing coating

ActiveCN102134428AGood weather resistanceGood gloss and color retentionRadiation-absorbing paintsAbsorptanceSolar water

The invention relates to a solar-absorbing coating used for converting solar energy (sunlight) into thermal energy, and provides three kinds of selective solar-absorbing coatings. The coating is prepared from resin, absorbents, extender pigments, addition agents and solvents, and the color of the coating is formed by mixing a plurality of absorbents (pigments); the coating mainly plays the role of converting the solar energy into the thermal energy, and has the certain function of decoration; and the color of the coating is brownish red, bottle green and black, and the absorptance of the coating to sunlight is 0.95, therefore the coating can be used as a heat-absorbing coating for solar water heaters, solar greenhouses and military image decoys.

Owner:西安经建油漆有限责任公司

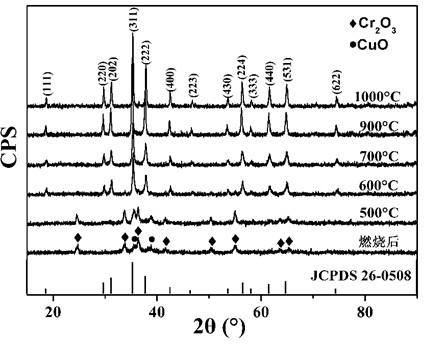

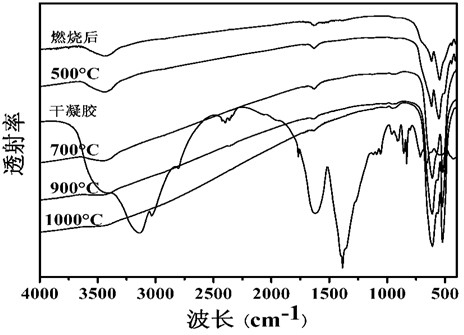

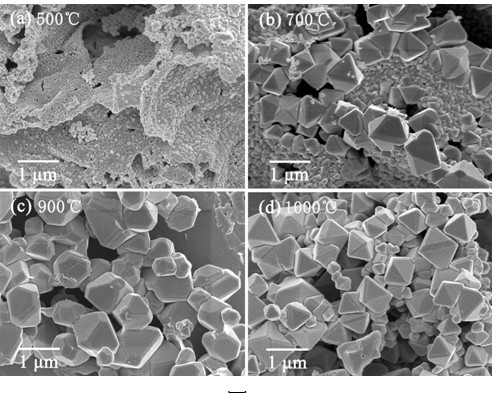

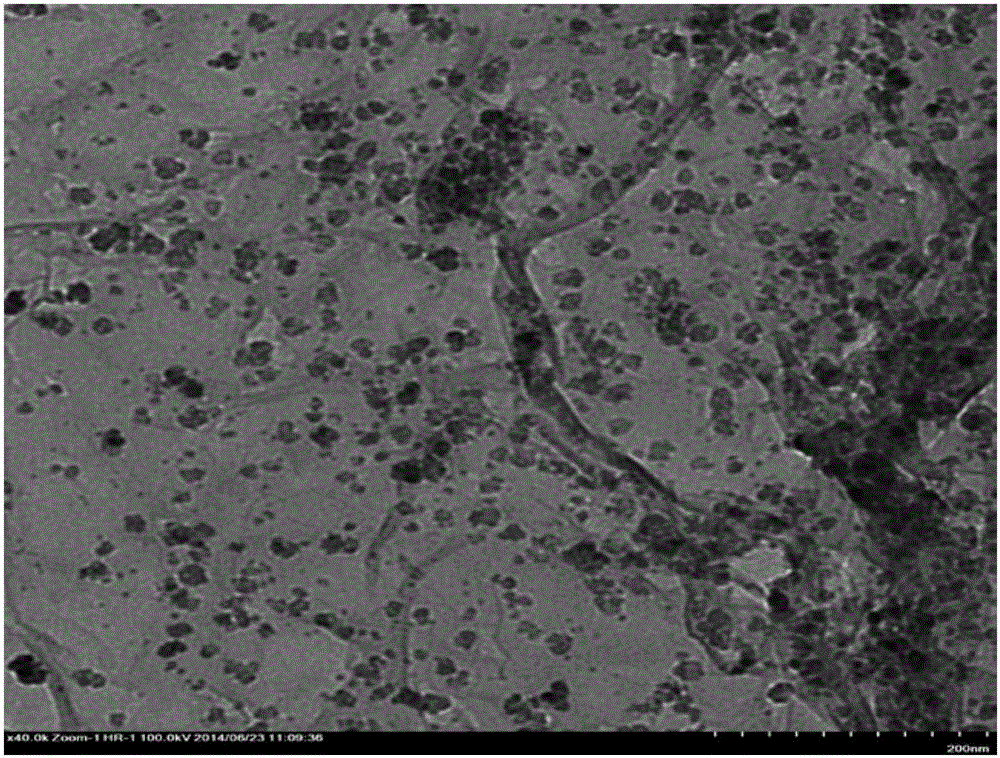

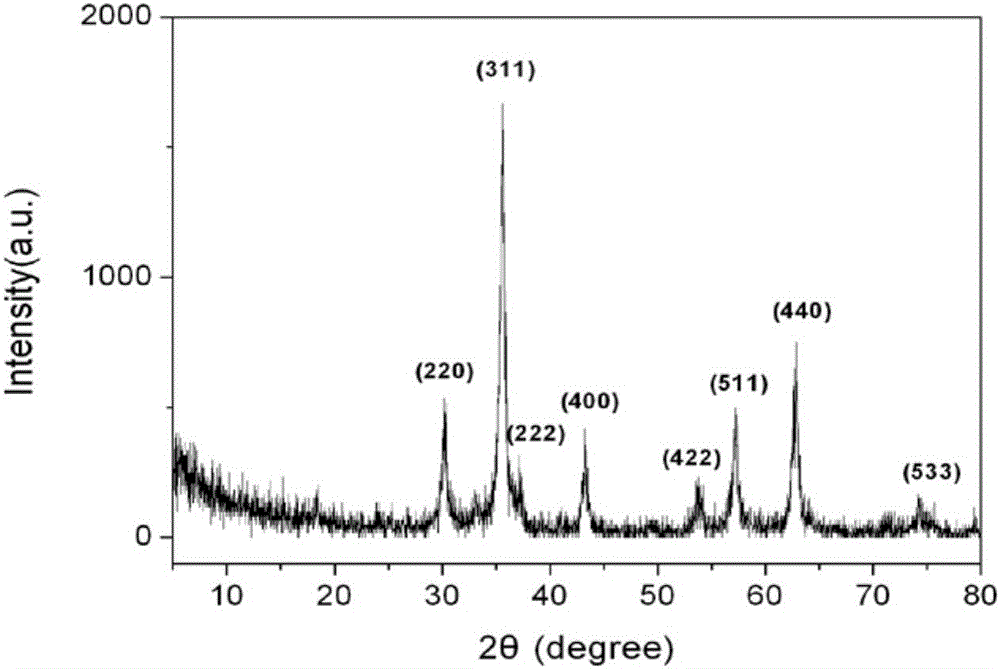

Method for preparing solar selective heat-absorbing coating with spinel pigment as light-absorbing agent

ActiveCN102286243AHigh solar absorption rateLow emissivityPolyurea/polyurethane coatingsRadiation-absorbing paintsSolar absorptancePhotopigment

The invention relates to a method for preparing a solar selective heat absorbing paint by using a spinel type pigment as a light absorbent, which belongs to the field of solar heat utilization. The method comprises the steps of uniformly dispersing a nanoscale spinel type pigment as well as resin, a solvent and auxiliaries by using a ball milling method; and then adding a curing agent to obtain the solar selective heat absorbing paint. It is shown in the experiment that the paint is uniformly coated on a metal substrate by using a spraying method; and the solar selective heat absorbing paint obtained after being cured at room temperature shows higher solar energy absorption rate (0.93-0.95) and lower emissivity (0.18-0.30); and the photothermal conversion efficiency of a solar heat collector can be effectively improved; moreover, the coating has the advantages of good mechanical property, stronger weather resistance and service life of more than 45 years.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Graphene/nano ferrite based water electromagnetic shielding paint and preparation method thereof

ActiveCN105111913AImprove absorbing performanceImprove conductivityPolyurea/polyurethane coatingsRadiation-absorbing paintsFerrite nanoparticlesHazardous substance

The invention discloses a graphene / nano ferrite based water electromagnetic shielding paint and a preparation method thereof. Ferrite nanoparticles are loaded on the surface of graphene to prepare a graphene / ferrite nanocomposite with the electrical conductivity of the graphene and the good magnetic property of the nano ferrite, and then the nanocomposite is combined with a water film-forming resin and other auxiliaries to prepare the green and environment-friendly water electromagnetic shielding paint. The preparation method has the characteristics of being simple to operate, high in practicability, free of hazardous substance, capable of making electromagnetic shielding paints suitable for different frequencies and occasions, good in shielding effect, and the like; the prepared graphene / nano ferrite based water electromagnetic shielding paint has excellent electromagnetic shielding performance, and therefore has good application prospect in the field of electromagnetic shielding paints.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method of detecting wear on a substrate using a fluorescent indicator

InactiveUS6864489B2Quickly and easily determineEasy to implementRadiation pyrometrySpectrum investigationCoated surfaceFluorescence

A method of detecting wear on a substrate including coating a composition that includes a fluorescent compound on the surface of a first substrate, exposing the coated surface to wear, exposing the coated surface to radiation capable of exciting the fluorescent compound, and detecting the presence or absence of fluorescence.

Owner:3M INNOVATIVE PROPERTIES CO

Coating wear indicator

A coating composition includes a material adapted to form a coating; and a material that fluoresces when exposed to U.V. light or the material adapted to form a coating contains a U.V. blocker disposed on a U.V. indicator. A kit containing a U.V. indicator and material adapted to form a coating containing a U.V. blocker. Methods of coating a substrate with the coating compositions are also disclosed.

Owner:ZEP IP HLDG LLC

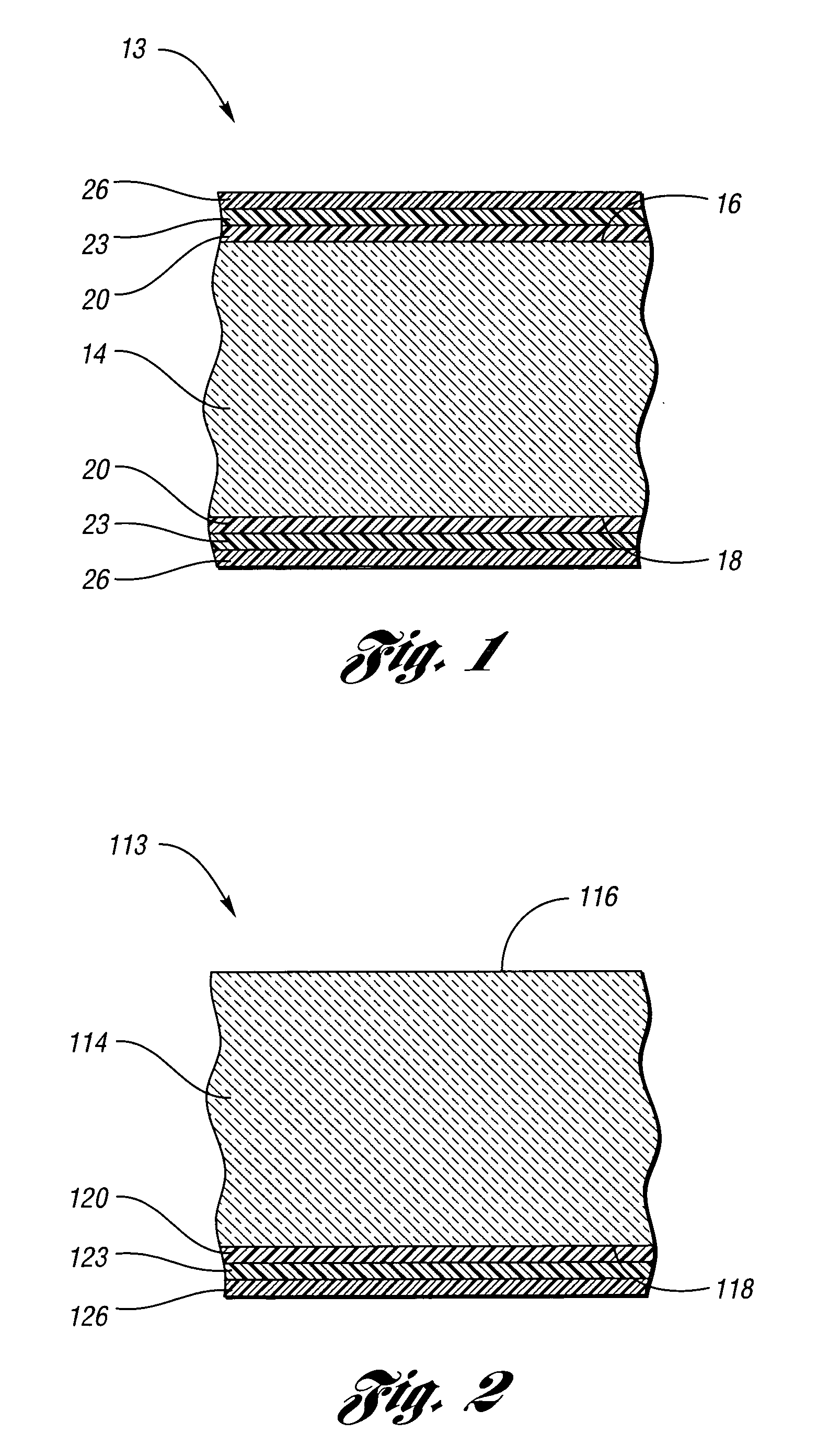

Light blocking articles having opacifying layers

ActiveUS20150234098A1Increased durabilityIncrease flexibilityDiffusing elementsSynthetic resin layered productsClear LayerVitrification

A light-blocking article is designed to be lightweight but effective to block most incident actinic radiation and can be designed into fabrics, curtains, and other materials. Such an article has an opacifying layer that is capable of blocking predetermined electromagnetic radiation. The article contains (a) porous particles comprising a continuous polymeric binder and pores within the continuous polymeric binder, the porous particles having a glass transition temperature of at least 25° C. and a mode particle size of at least 2 μm and up to and including 50 μm. The article also contains an opacifying colorant that absorbs the predetermined electromagnetic radiation (such as within 400 nm to 700 nm), in an amount of at least 0.001 weight % based on the total dry weight of the opacifying layer, and a matrix polymer in which the porous particles and opacifying colorant are dispersed.

Owner:EASTMAN KODAK CO

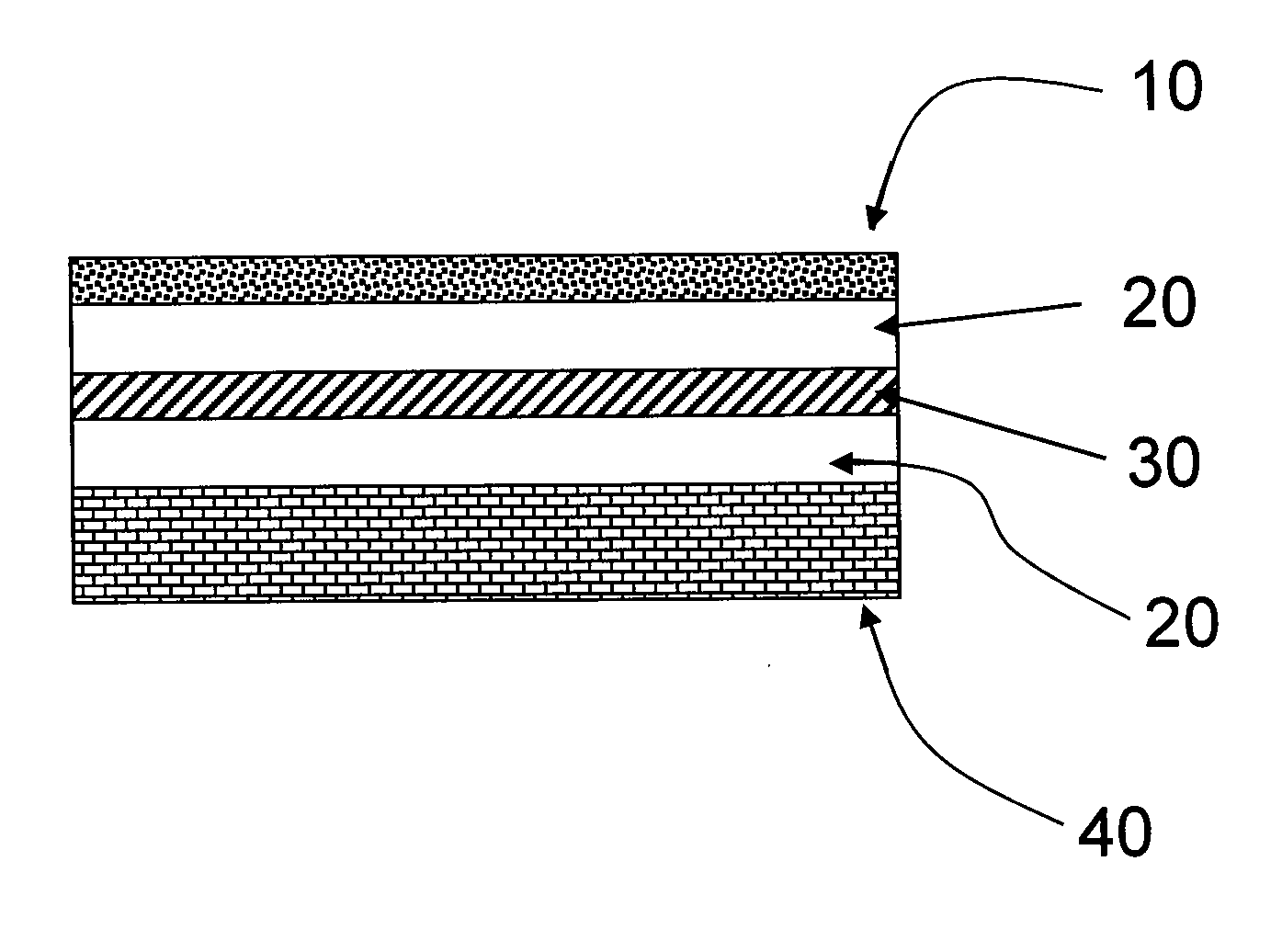

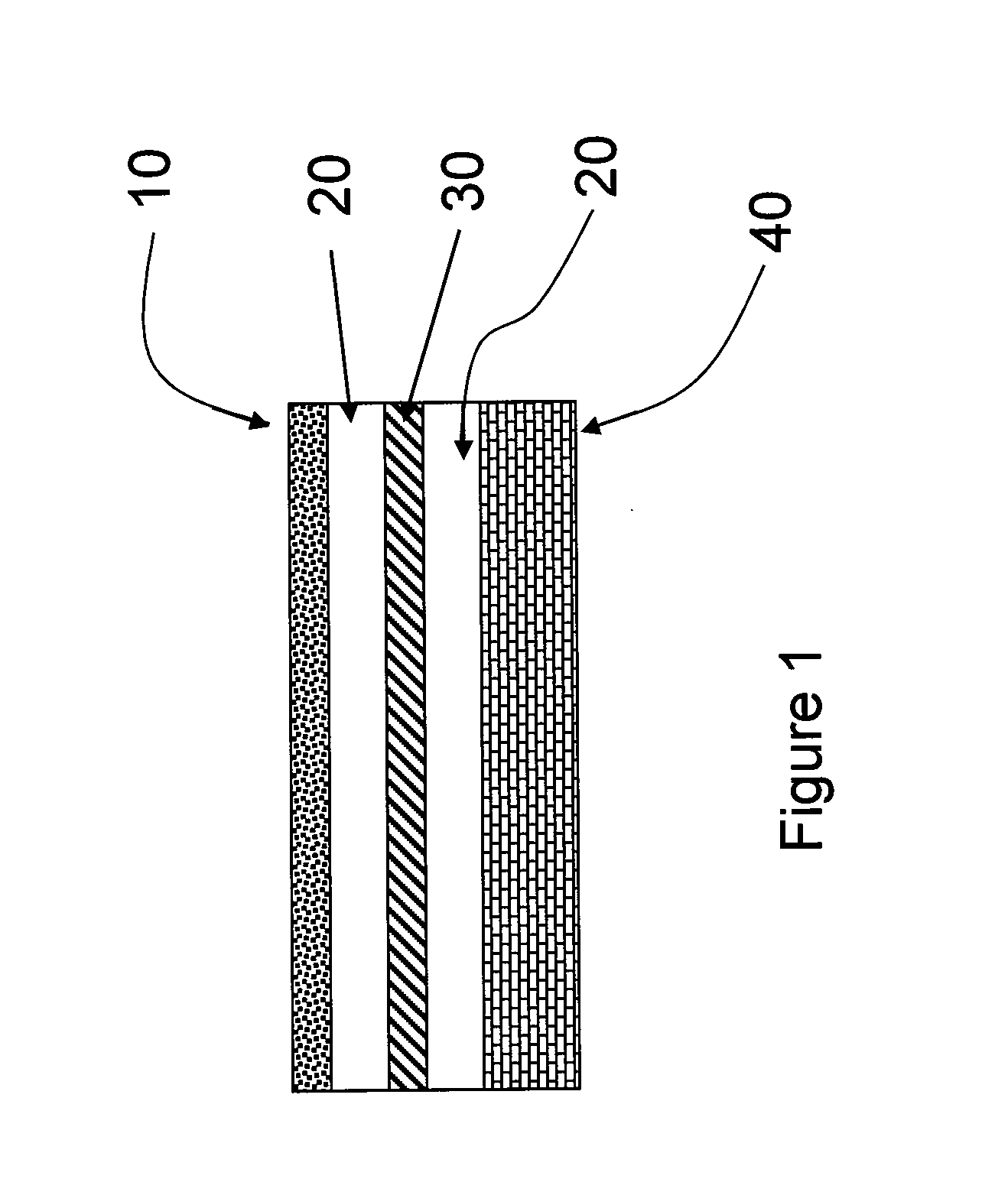

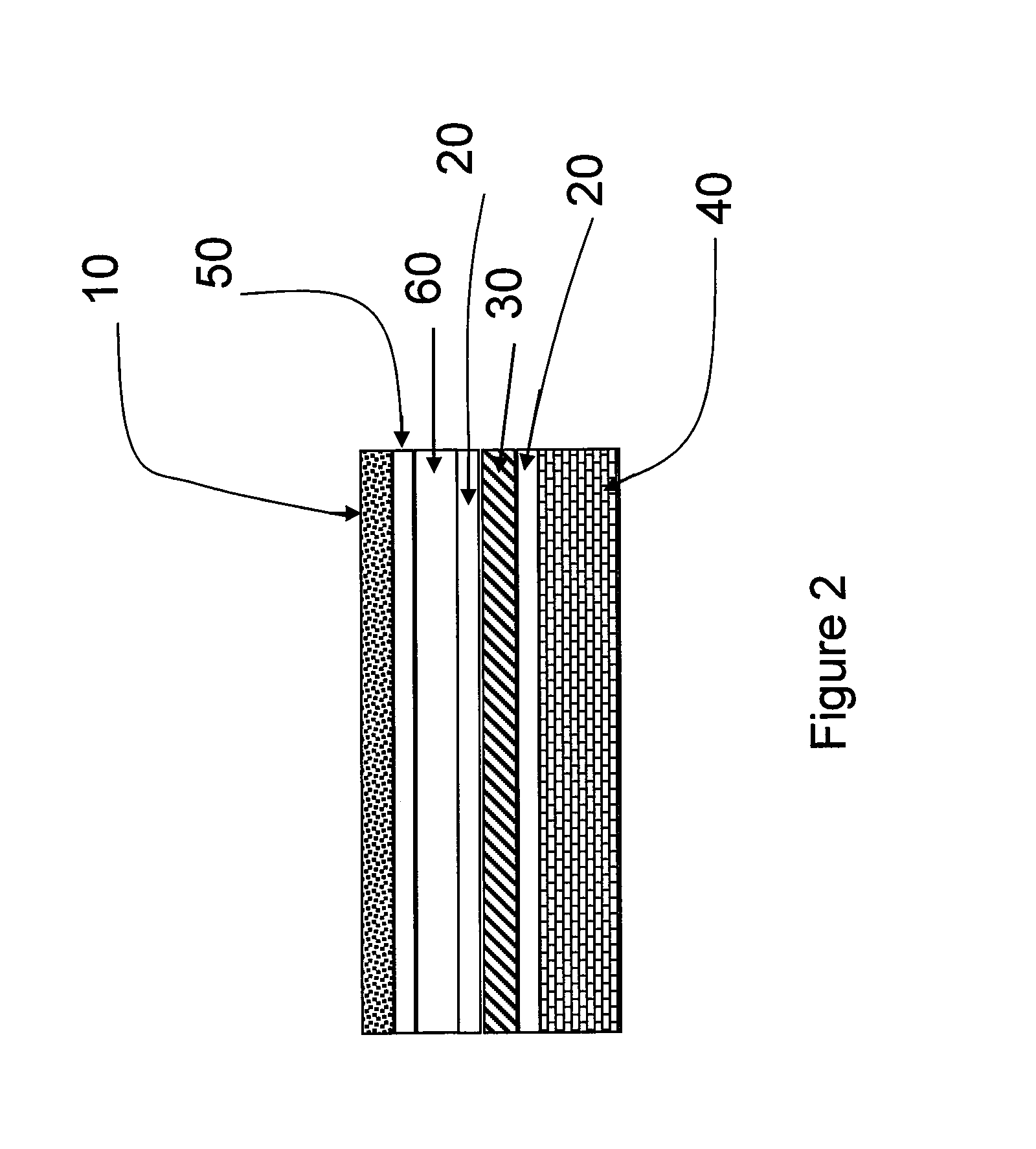

High friction coating formulations and systems and coated articles thereof exhibiting radar signature reduction and methods of providing the same

InactiveUS20090226673A1Improve featuresImprove securityRadiation/particle handlingPretreated surfacesParticulatesCoating system

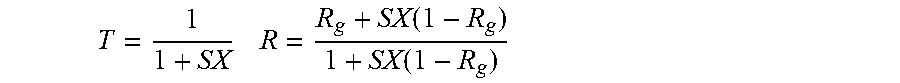

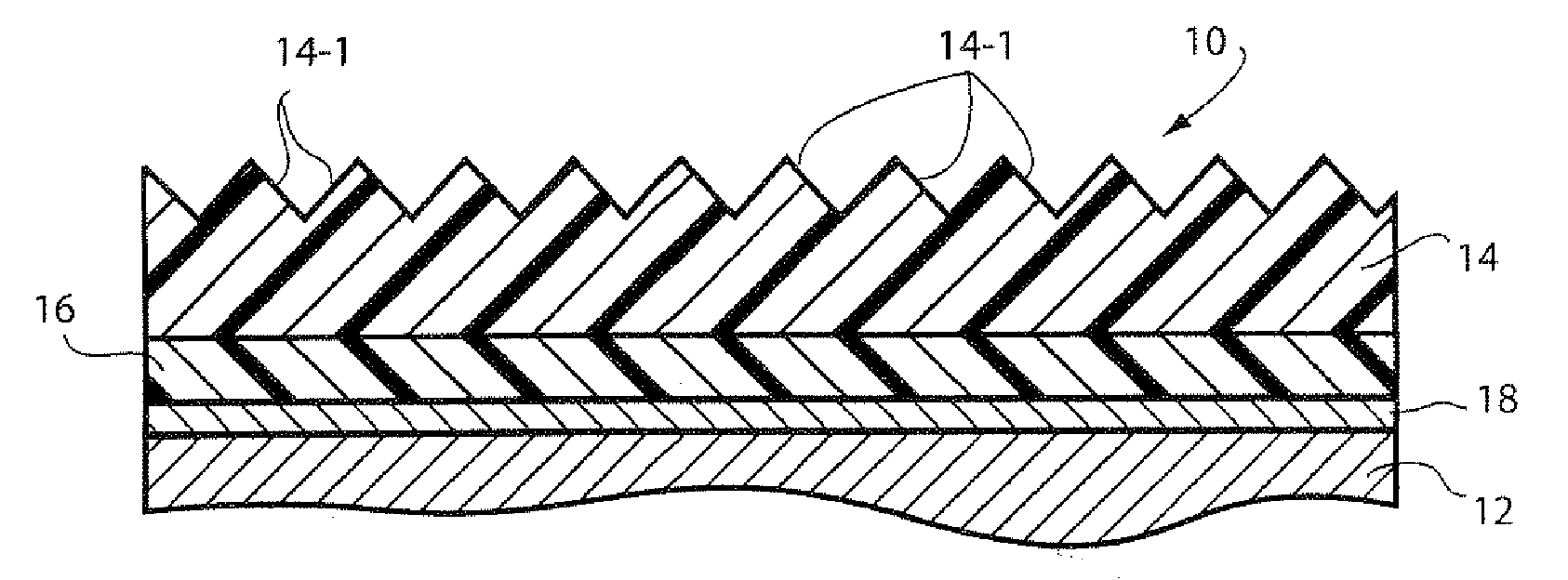

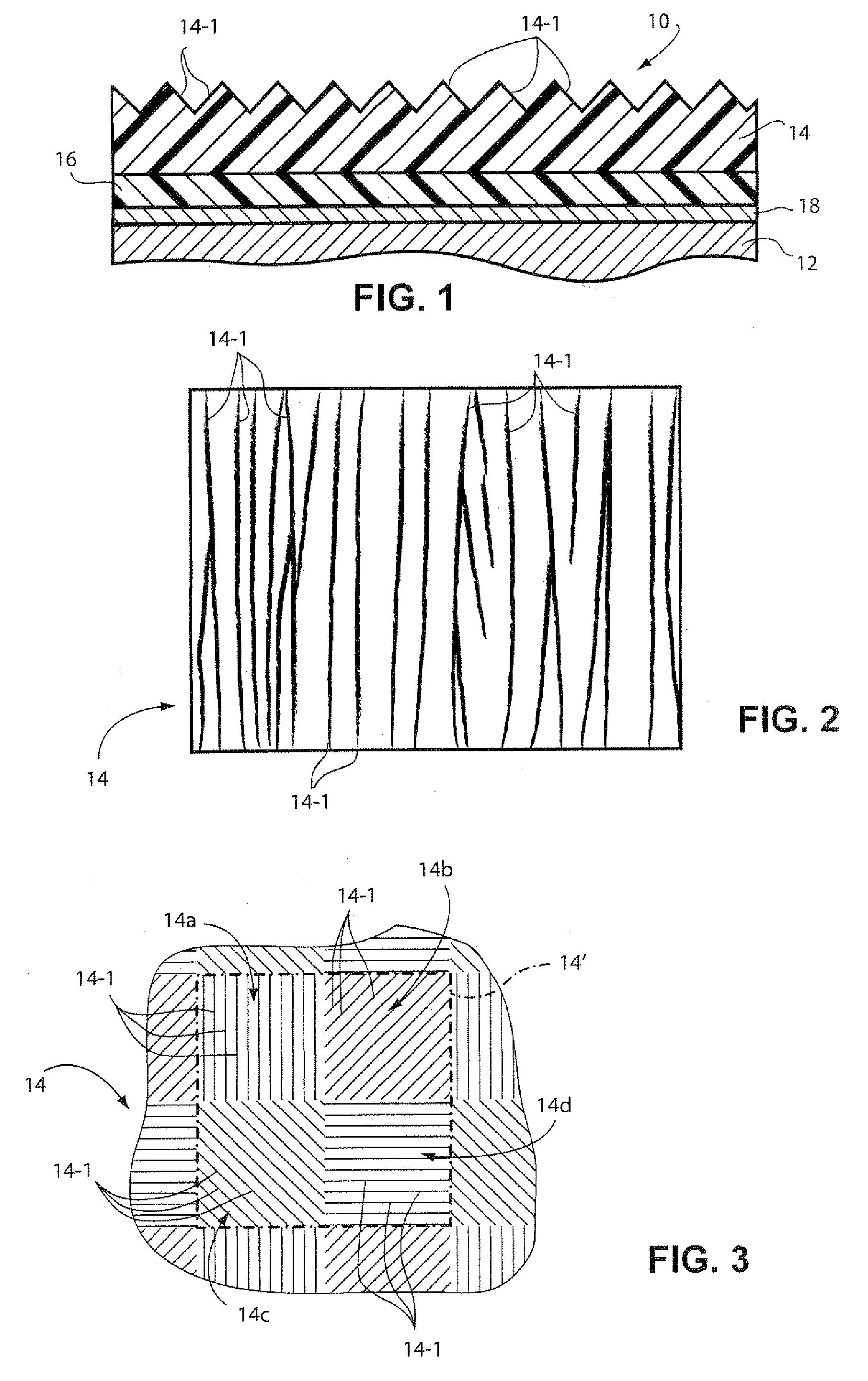

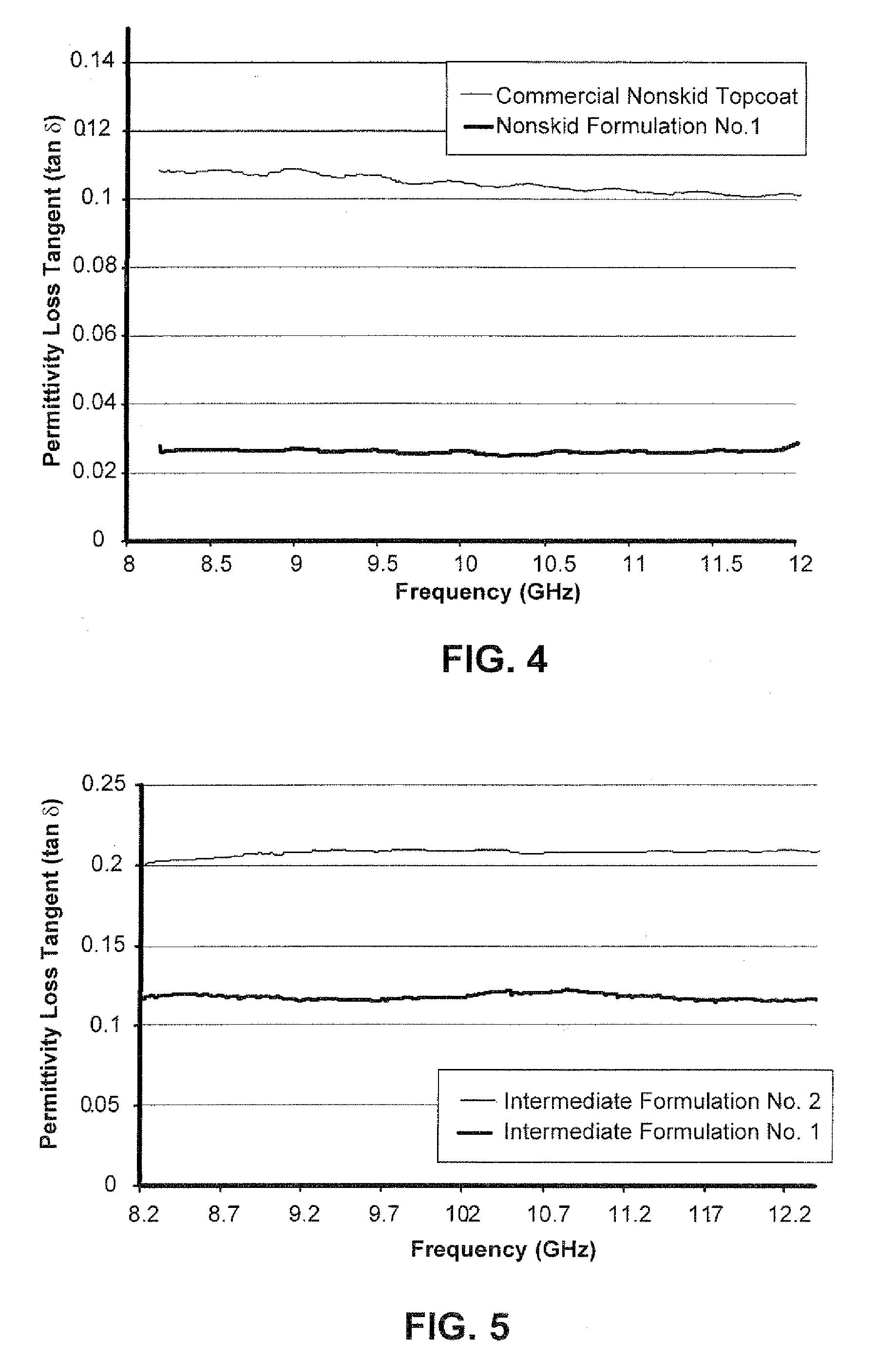

High friction and radar attenuating coating formulations are provided and include a resin matrix, a particulate friction additive dispersed in the resin matrix in an amount sufficient to achieve a minimum coefficient of friction according to MIL-PRF-24667B(SH), and a particulate dielectric filler dispersed in the resin matrix in an amount sufficient to achieve a permitivitty (∈′) of less than about 10 and a loss tangent (tan δ) of less than about 0.05. A substrate surface may be coated with the coating formulation so as to provide a topcoat layer thereon. The topcoat layer may thus be applied directly onto the substrate surface. Alternatively, the coating formulation is present as a topcoat layer component of a coating system on the substrate which further comprises an intermediate layer interposed between the topcoat layer and a surface of the substrate and / or a primer layer coated directly onto the surface of a substrate between the topcoat layer and the substrate. In some embodiments, the coating formulation is applied so as to form a series of substantially parallel ridges having a predetermined directional orientation. In certain preferred embodiments, the coating formulation is applied to a block area on the substrate surface comprised of plural areal regions, wherein the directional orientation of the substantially parallel ridges of one areal region are angularly biased with respect to the directional orientation of the substantially parallel ridges of an adjacent areal region.

Owner:LUNA INNOVATIONS

Lightweight acoustical paint and preparation method thereof

The present invention discloses one kind of light sound absorbing paint and its preparation process. The paint consists of acrylate emulsion of average grain size of 0.15-0.5 micron as the adhesive, open-pored expanded perlite as light aggregate, pigment, stuffing and assistants combined together. It is prepared through pre-mixing, dispersing grinding and blending via fast stirring. It has low density, non-toxicity, no smell, environment friendship, simple production, simple application, coating of 1-5 mm thickness, average sound absorbing coefficient higher than 0.4 and other advantages, and is suitable for use in household, meeting room, concert hall, theater, etc.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

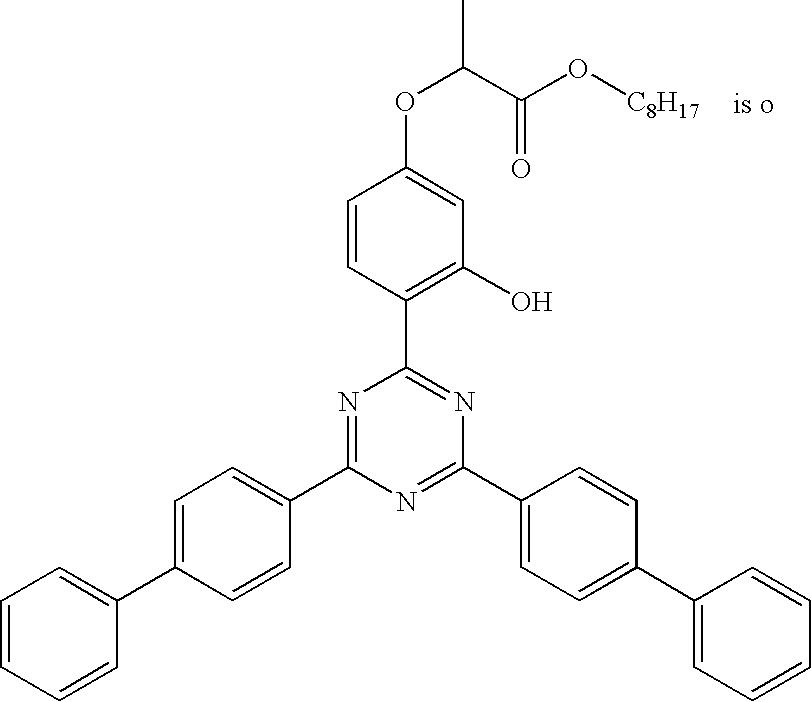

Outdoor weatherable photopolymerizable coatings

InactiveUS6974850B2Prolong lifeLimited solubilityOrganic chemistryLayered productsBenzeneBenzotriazole

Plastic articles can be coated with polymerizable compositions containing a vinyl-functional crosslinkable film former, a large amount of benzotriazole and a copolymerizable monomer that solubilizes the benzotriazole. The cured compositions help protect the article from UV exposure and other weathering effects.

Owner:3M INNOVATIVE PROPERTIES CO

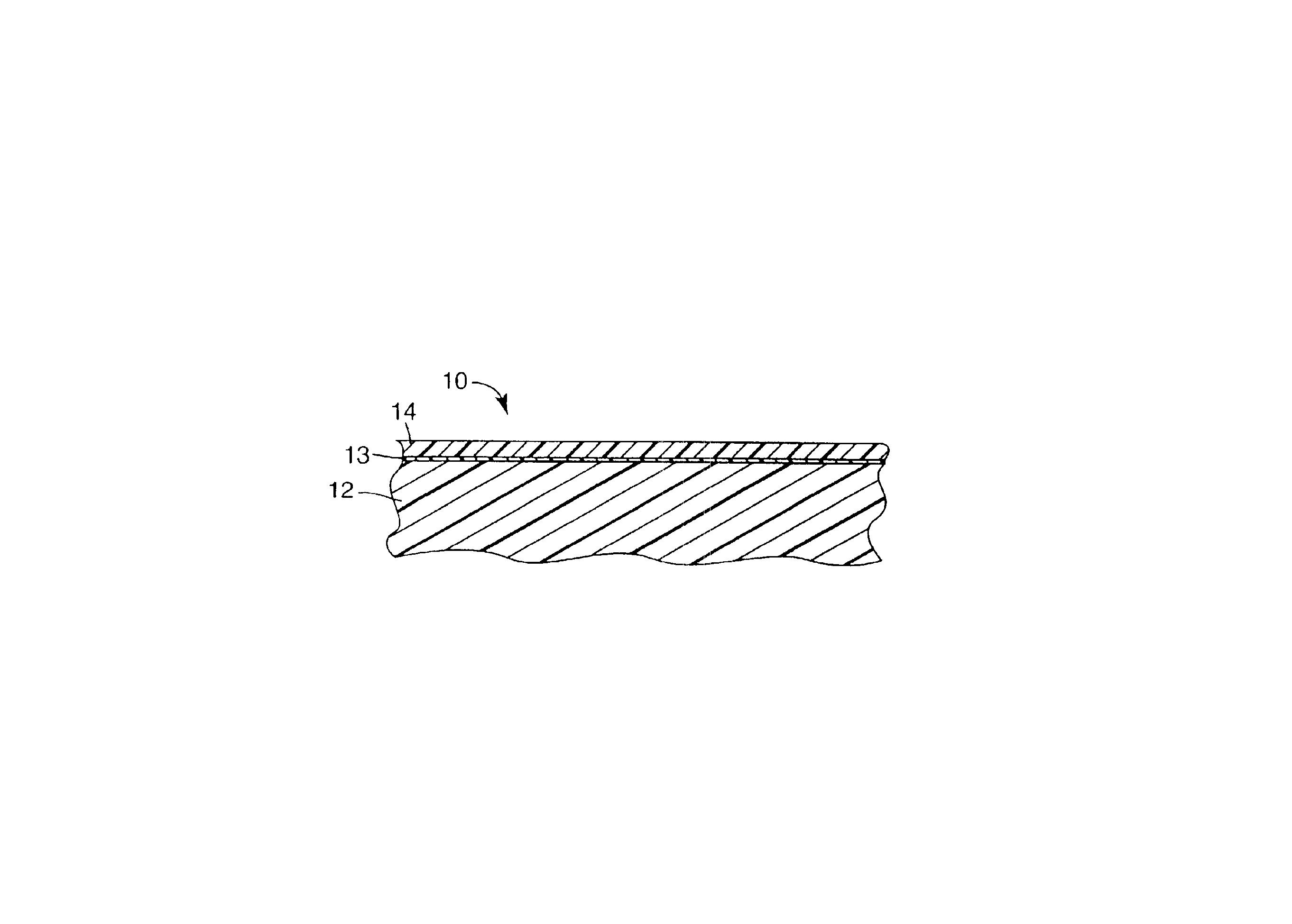

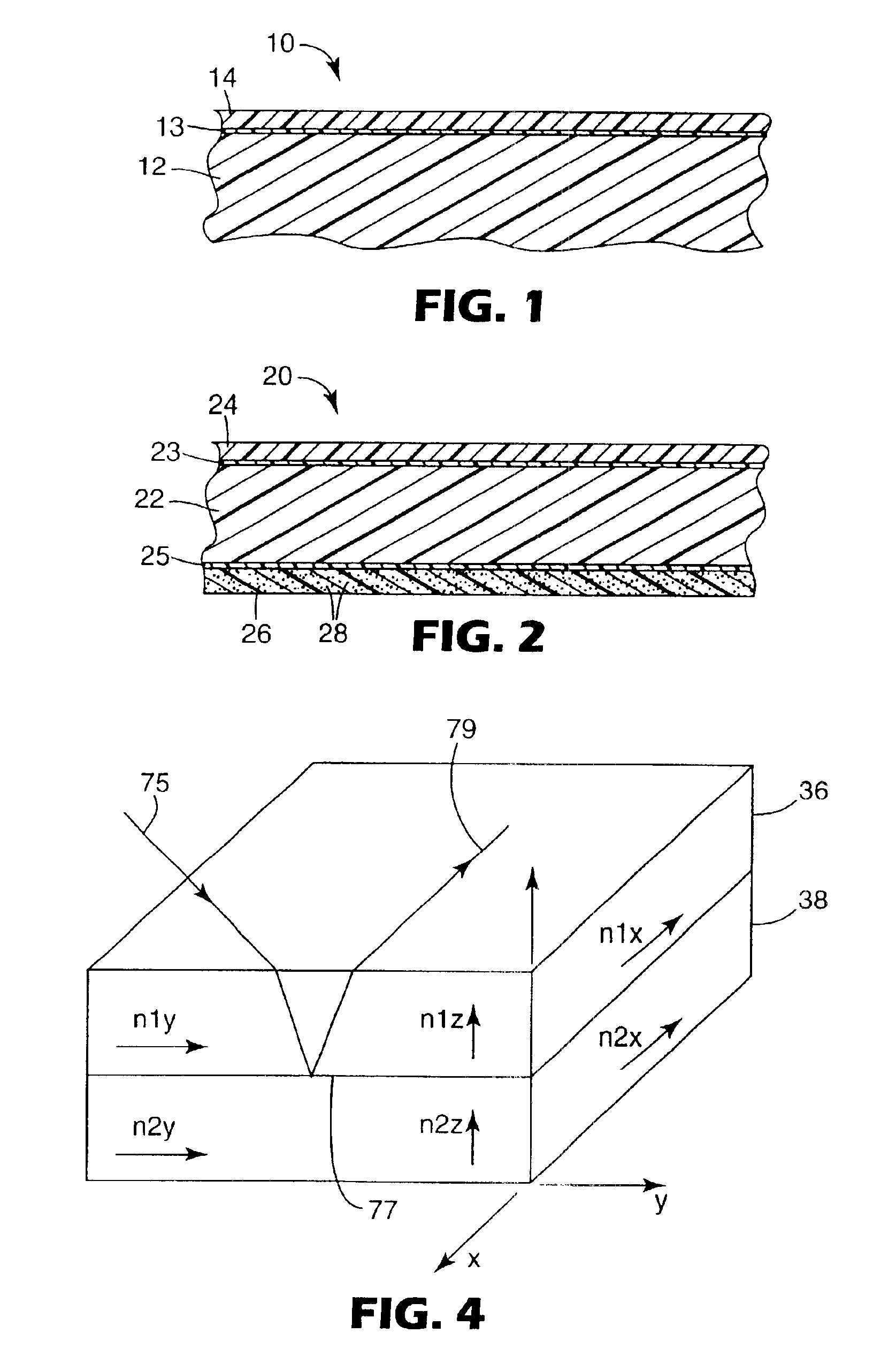

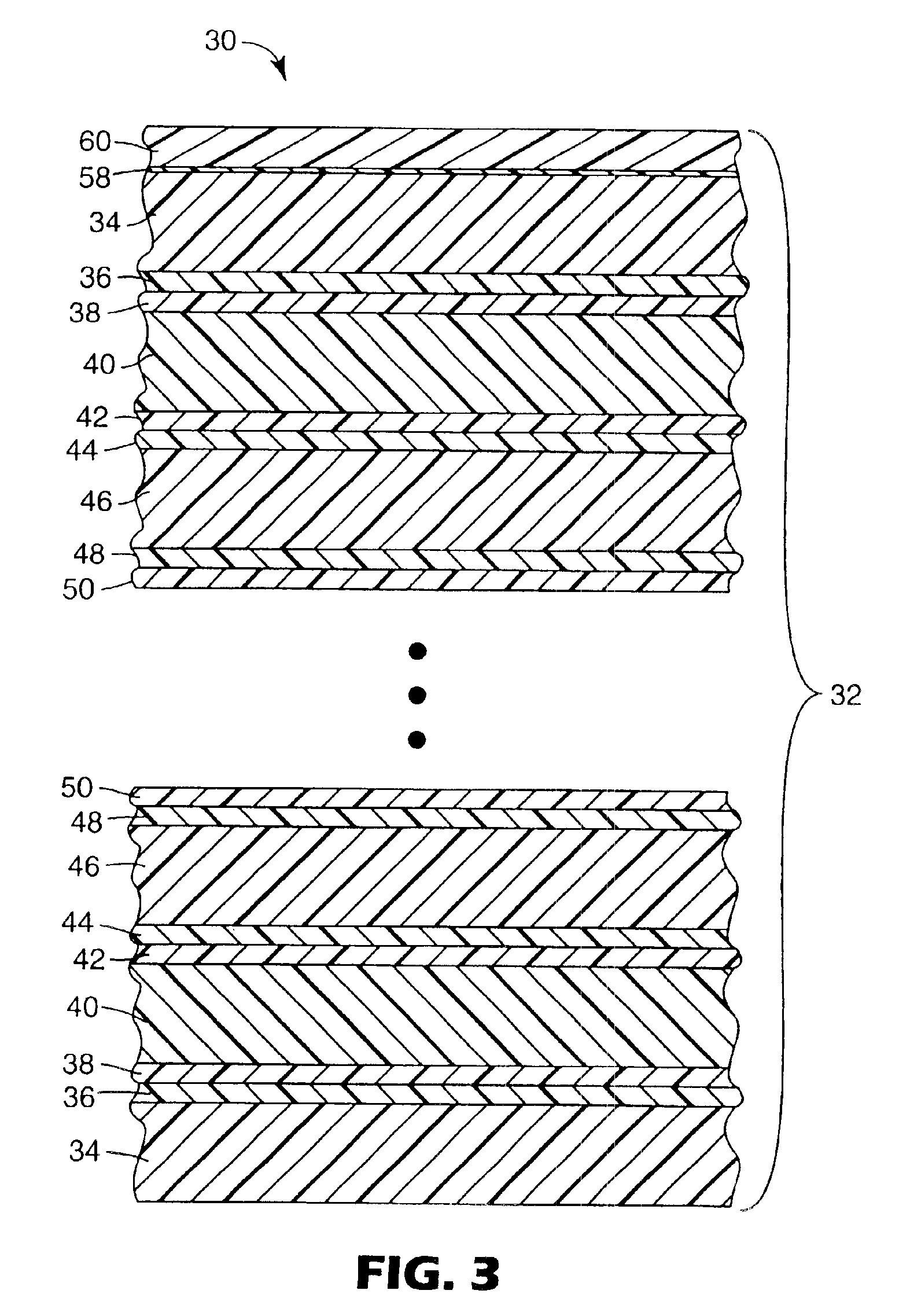

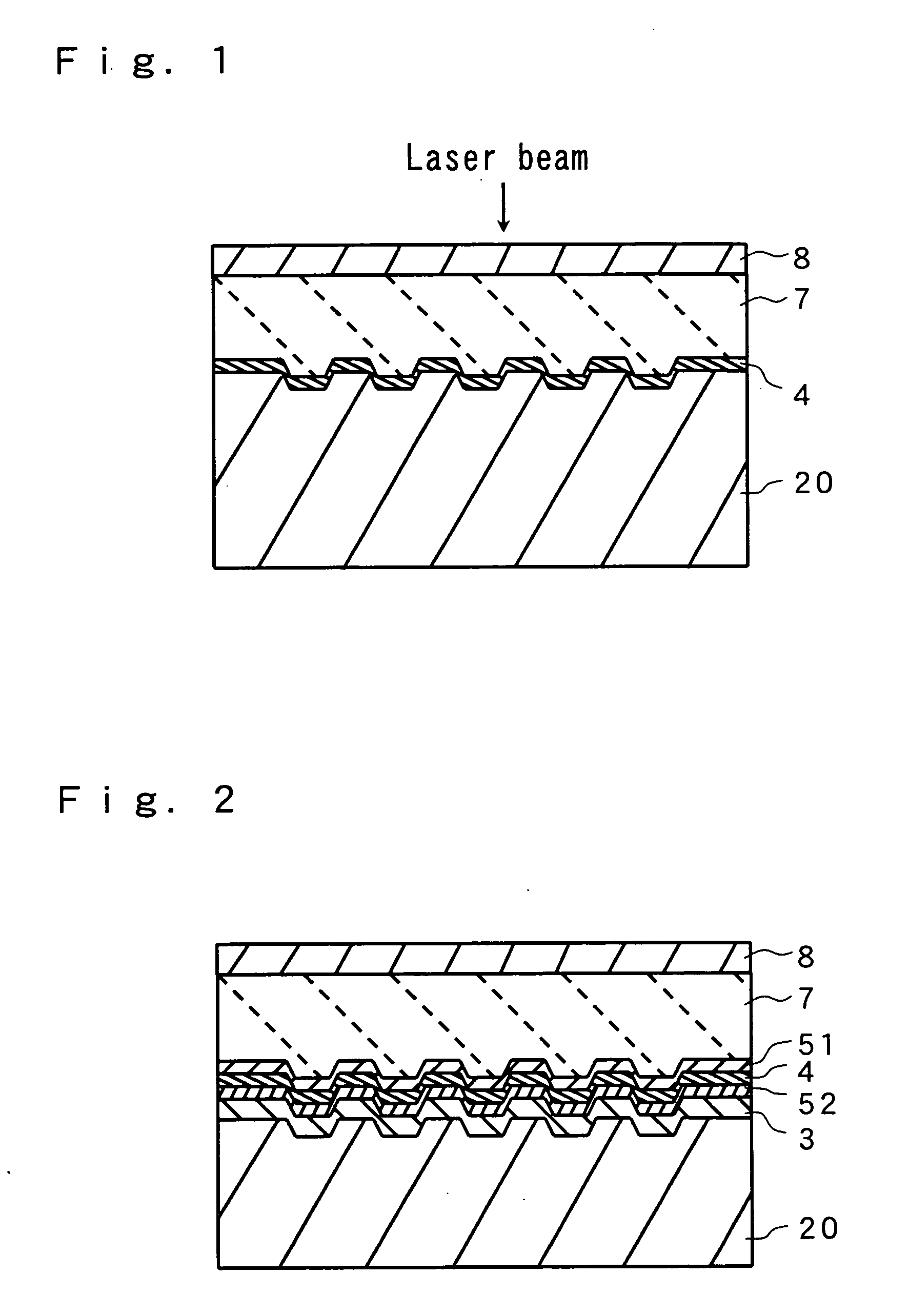

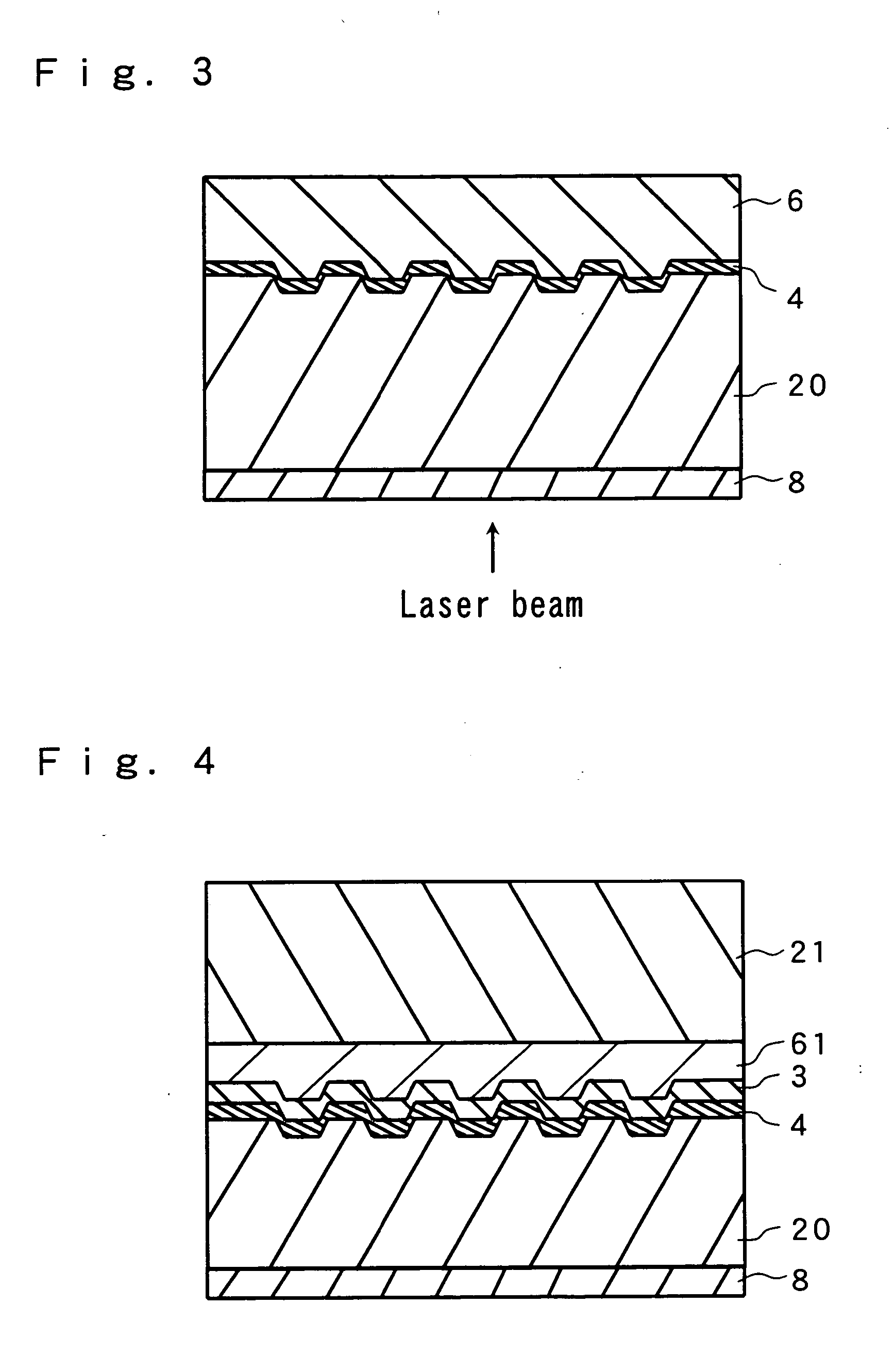

Hard coat agent composition and optical information medium using the same

ActiveUS20050072336A1Reduce coefficient of frictionImprove scratch resistanceMaterial nanotechnologyNon-macromolecular adhesive additivesReflective layerRecording layer

The present invention provides a hard coat agent composition that is useful for forming a hard coat layer with excellent anti-staining properties and lubricity, as well as superior scratch resistance and abrasion resistance, on the surfaces of various articles. The present invention also provides an optical information medium using the above hard coat agent composition. A hard coat agent composition comprising a fluorine-containing polyether compound (A) comprising an active energy ray-reactive group, and a curable compound (B) comprising two, or three or more active energy ray-polymerizable groups within each molecule. An optical information medium comprising a film element composed of one or more layers including at least a recording layer (4) or a reflective layer, on a supporting substrate (20), wherein at least one of the supporting substrate (20)-side surface and the film element-side surface is formed of a hard coat layer (8) comprising a cured product of the hard coat agent composition.

Owner:TDK CORPARATION

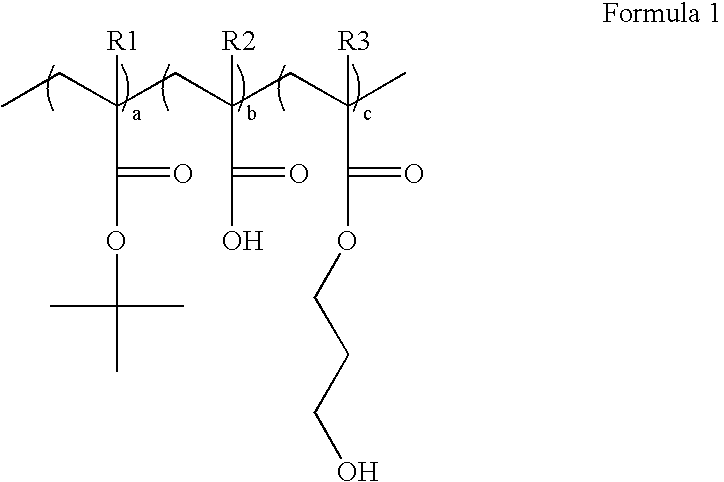

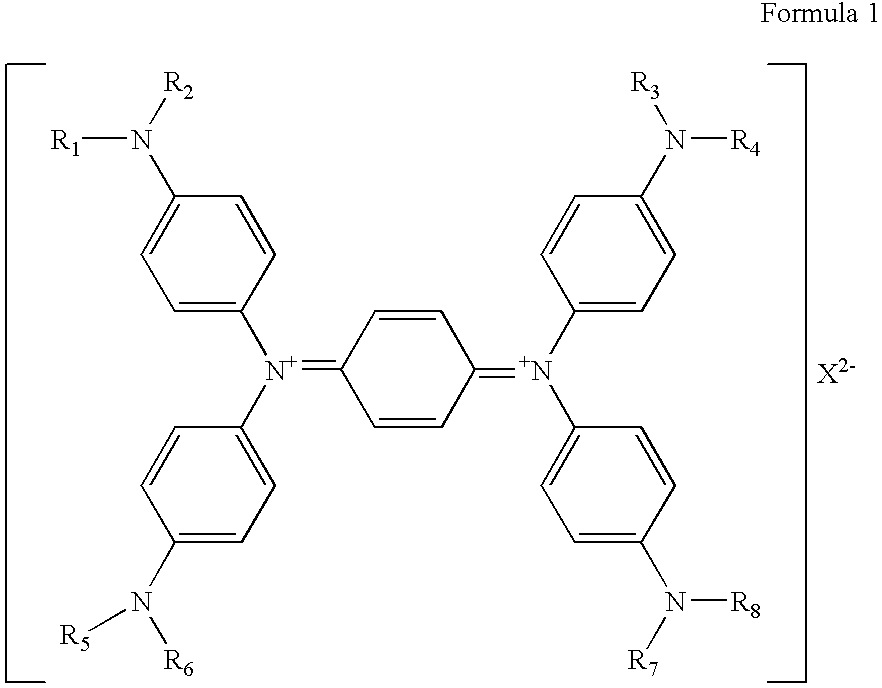

Top ARC polymers, method of preparation thereof and top ARC compositions comprising the same

ActiveUS20050239296A1Minimize scattered reflectionSuppresses dimensional changesPhotosensitive materialsSemiconductor/solid-state device manufacturingAnti-reflective coatingHydrogen

Disclosed herein are a top anti-reflective coating polymer used in a photolithography process, a method for preparing the anti-reflective coating polymer, and an anti-reflective coating composition comprising the anti-reflective coating polymer. The disclosed top anti-reflective coating polymer is used in immersion lithography for the fabrication of a sub-50 nm semiconductor device. The top anti-reflective coating polymer is represented by Formula 1 below: wherein R1, R2 and R3 are independently hydrogen or a methyl group; and a, b and c represent the mole fraction of each monomer, and are in the range between 0.05 and 0.9. The top anti-reflective coating formed using the anti-reflective coating polymer is not soluble in water and can be applied to immersion lithography using water as a medium for a light source. Since the disclosed top anti-reflective coating can reduce the reflectance from an underlayer, the uniformity of CD is improved, thus enabling the formation of an ultrafine pattern.

Owner:SK HYNIX INC

Foamed aqueous composition

ActiveUS9469738B1Minimize exposureEliminates sewingCurtain accessoriesRadiation-absorbing paintsPorous substrateFluorescence

Foamable aqueous compositions can be used to form light-blocking and light-colored foamed, opacifying elements with one or more dry foamed layers. The compositions contain: (a) 0.05 to 20 weight % of porous particles comprising a continuous polymeric phase and a first set of discrete pores, the porous particles having a mode particle size of 2 to 50 μm; (b) at least 20 weight % of a binder material (that can be curable); (c) 0.1 to 30 weight % of one or more additives including dispersants, plasticizers, inorganic or organic pigments or dyes, thickeners, flame retardants, biocides, fungicides, optical brighteners, tinting colorants, metal flakes, and inorganic or organic fillers; (d) water; and (e) at least 0.001 weight % of an opacifying colorant different from (c), which opacifying colorant absorbs electromagnetic radiation. The foamable aqueous composition can be aerated, disposed on a porous substrate, dried, and crushed on that porous substrate.

Owner:EASTMAN KODAK CO

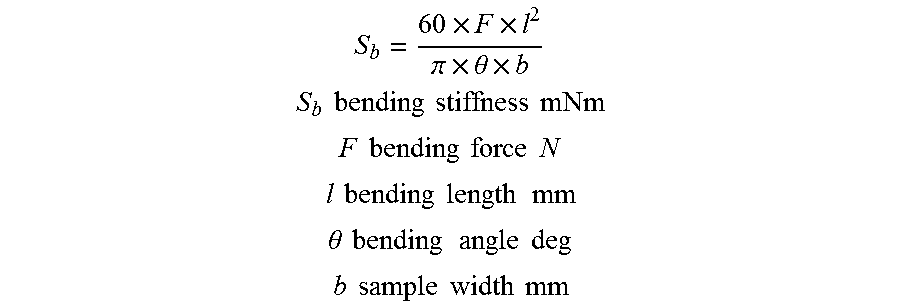

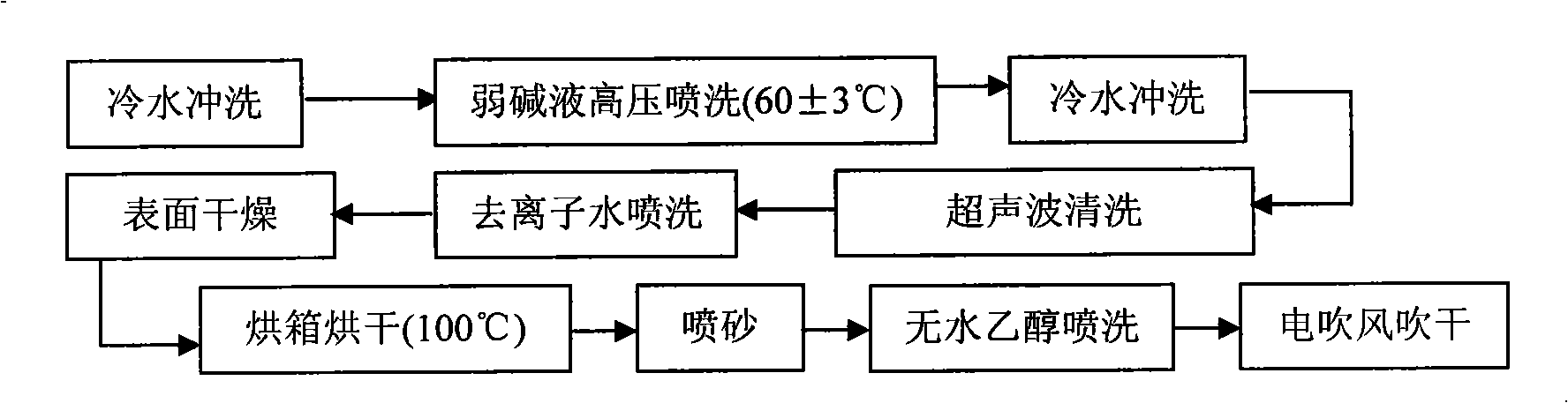

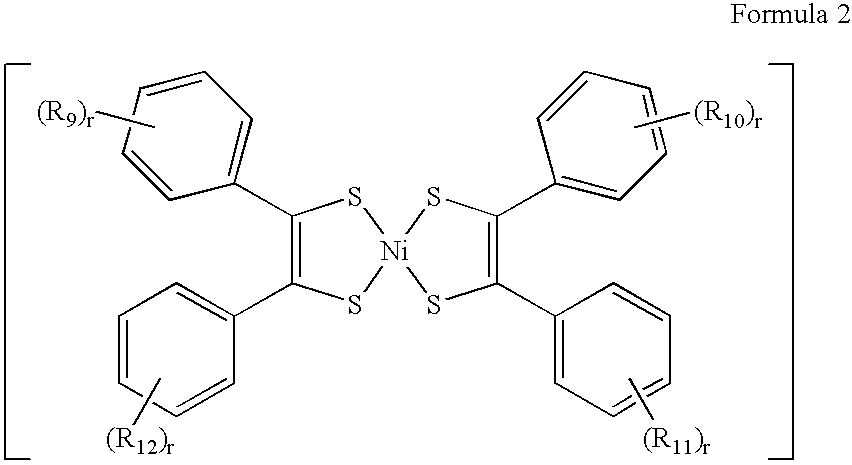

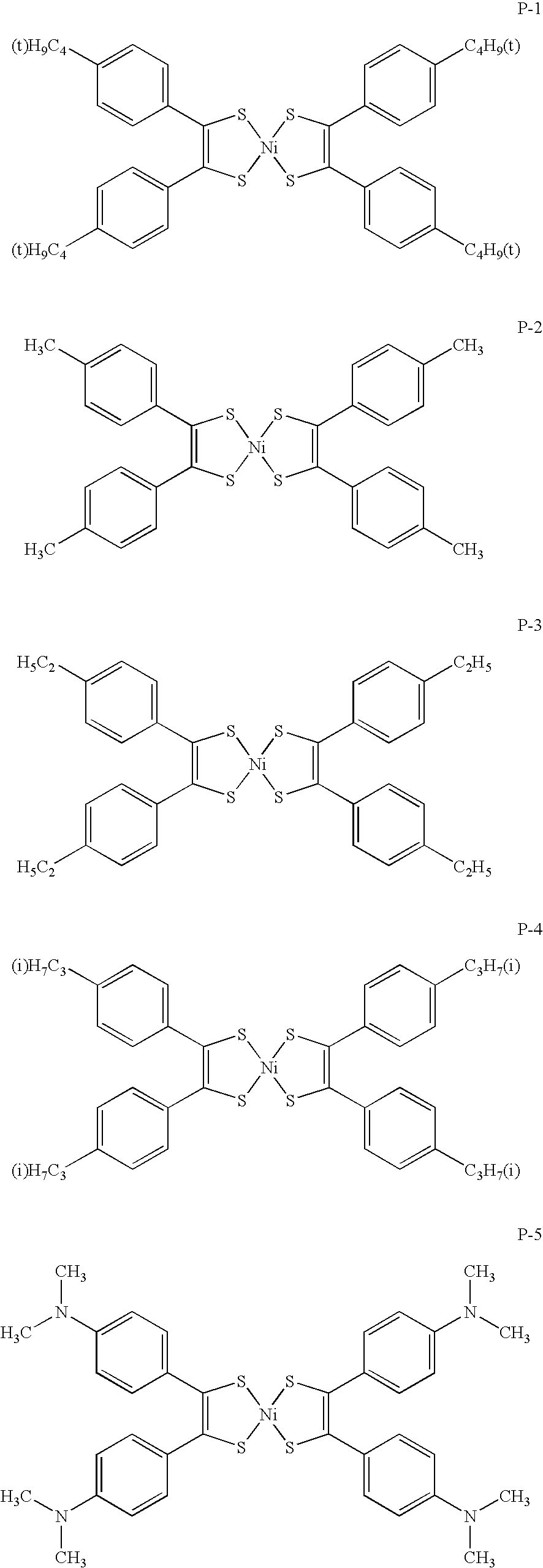

Preparation of foam aluminum alloy base wave-absorbing material

InactiveCN101259463AHigh porosityGood mechanical propertiesPretreated surfacesRadiation-absorbing paintsDegreasingAluminium alloy

The invention discloses a preparation method for a foam aluminum alloy-based wave absorbing material and includes the steps of a surface pretreatment of the foam aluminum alloy material, a preparation of wave absorbing agent material and a spraying of the foam aluminum alloy material; the preparation method of the invention is characterized in that the foam aluminum alloy material through degreasing and sand spraying treatments is took as a basic body, and a single wave absorbing material or compound wave absorbing materials are coated on the surface of the basic body to prepare a foam aluminum alloy-based absorbing material of single wave absorbing agent or foam aluminum alloy-based absorbing material of compound wave absorbing agent. The product of the invention provides a new thought for a development of wave absorbing material, and a new field for the popularization and application of foam metal materials and establishes theory and technique foundations for the developing of porous material-based wave absorbing materials.

Owner:NORTHEASTERN UNIV

Near-infrared ray absorbing material and production method of the same

InactiveUS20070054216A1Promote absorptionImprove efficiencyPhotosensitive materialsPhotomechanical apparatusInfraredLength wave

A method of producing a near-infrared ray absorbing material comprising the steps of: applying a coating liquid of a near-infrared ray absorbing layer comprising a near-infrared ray absorbing dye and a latex onto a support to form a coated layer; and drying the coated layer by heat to form a near-infrared ray absorbing layer, wherein the near-infrared ray absorbing layer absorbs not less than 60% of a total amount of near-infrared rays having wavelengths of 800 to 1000 nm.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Polycarbonate system having enhanced weatherability and method of making same

InactiveUS20070104956A1Enhanced abrasion resistance and ultraviolet resistance featureGood weather resistanceSynthetic resin layered productsVehicle componentsExtinctionUltraviolet

A polycarbonate system having enhanced weatherability is disclosed. The polycarbonate system comprises a substrate comprising a first surface and a second surface, a primer disposed on the first surface of the substrate, and a top coat disposed on the primer on the first surface for abrasion resistance. At least one of the primer and the top coat comprises an ultraviolet absorber in a solvent for ultraviolet absorption, the ultraviolet absorber having an extinction coefficient of ≧45,000 L-mol−1 cm−1 at λ=325 nm.

Owner:EXATEC LLC

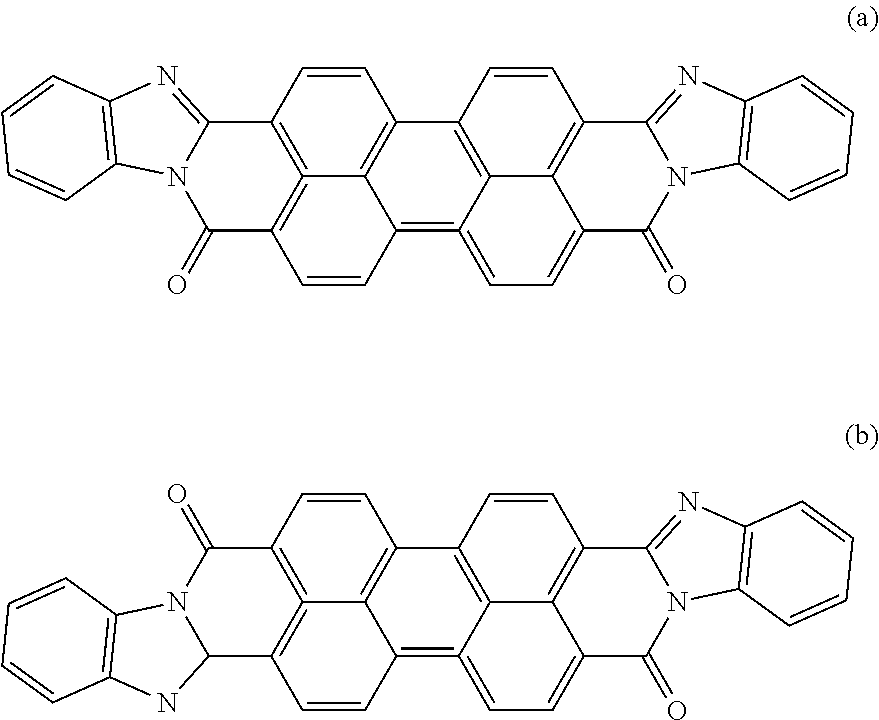

Coating compositions that transmit infrared radiation and exhibit color stability and related coating systems

ActiveUS20120308724A1High blacknessRadiation-absorbing paintsElectrostatic spraying apparatusCoating systemPigment

A coating composition suitable for producing coatings that are transparent to infrared radiation and can exhibit color stability, such as a jet black color. The coating compositions include a first tint having a low haze and a second tint having a high haze. The tints include visibly absorbing infrared transparent pigments.

Owner:PPG IND OHIO INC

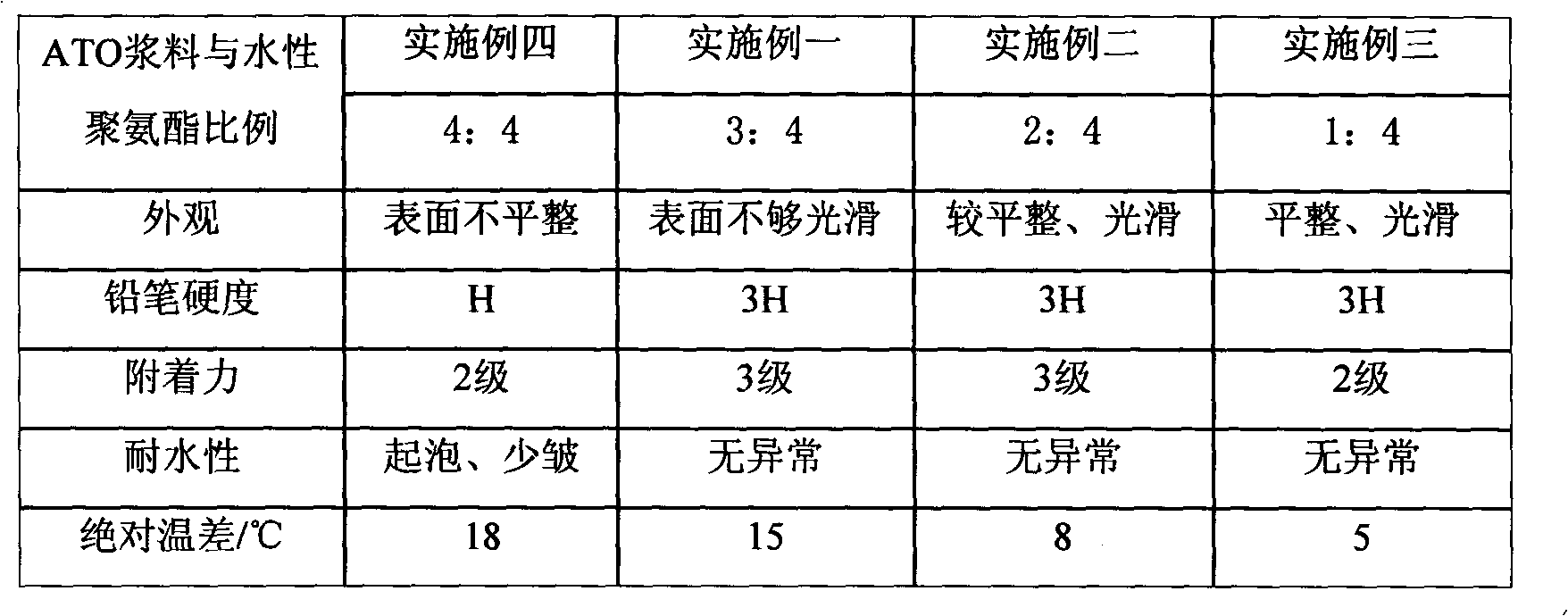

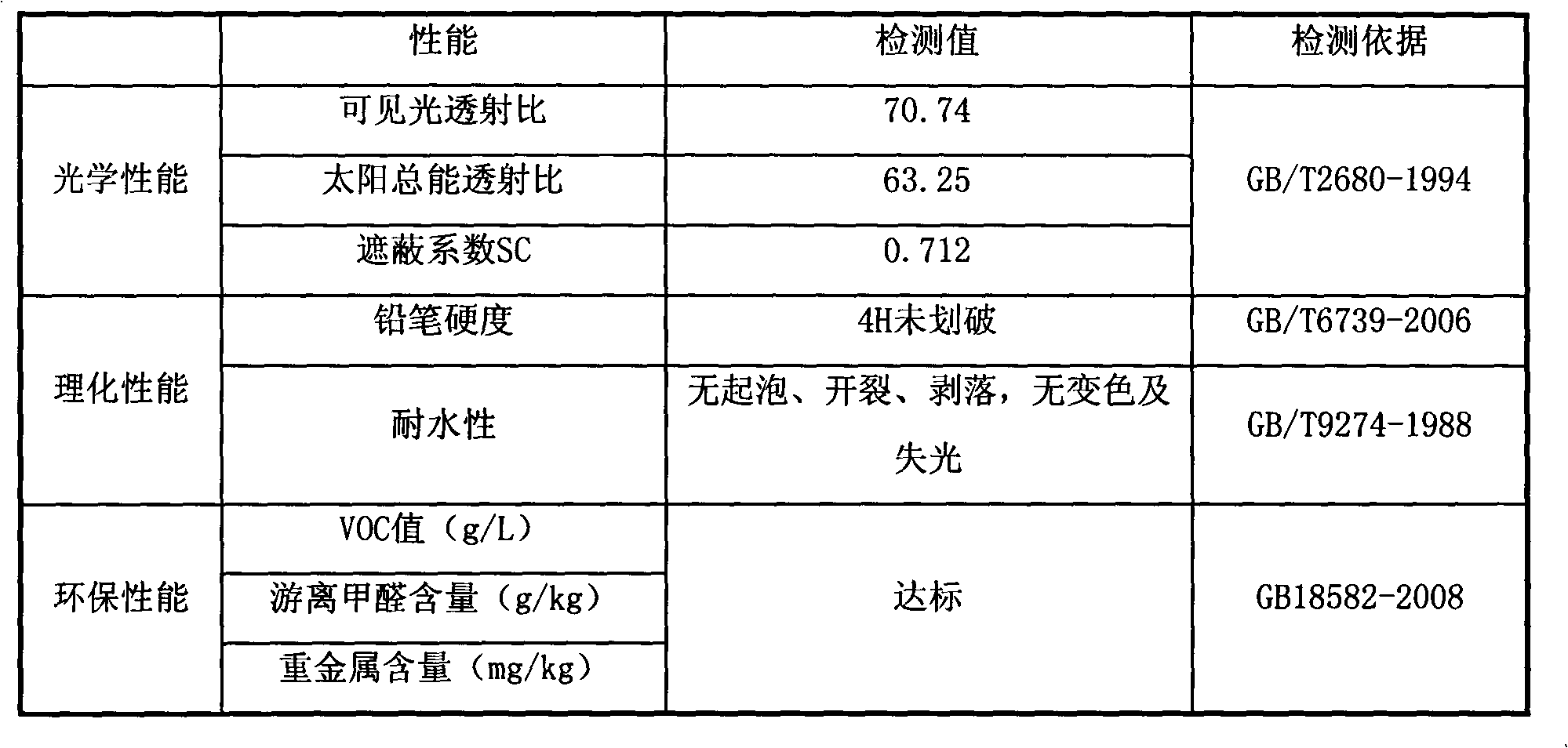

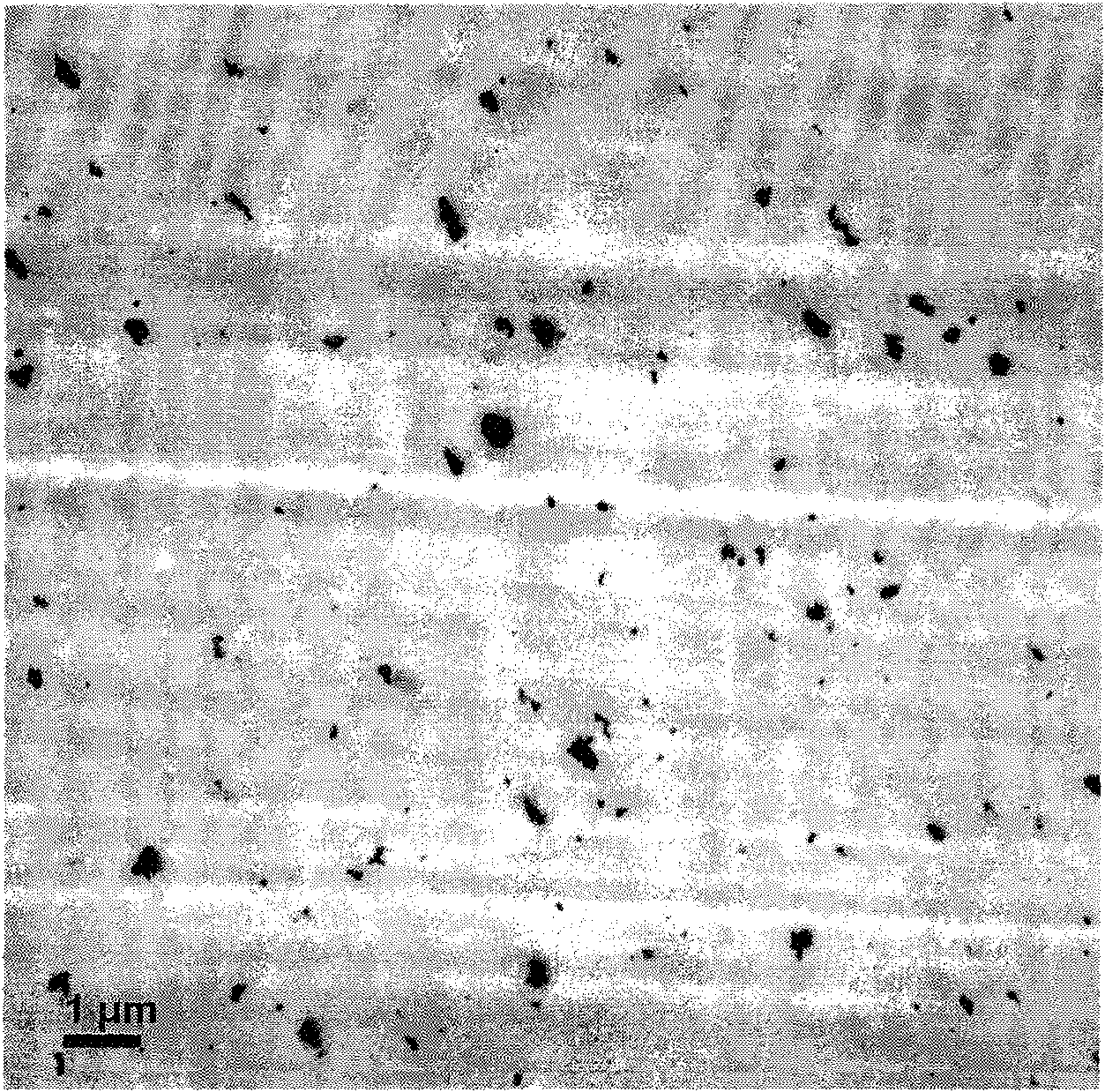

Nano-glass heat insulation paint and preparation method thereof

ActiveCN101885943AHigh visible light transmittanceLow costPolyurea/polyurethane coatingsRadiation-absorbing paintsSlurryAntimony tin oxide

The invention discloses a nano-glass heat insulation paint and a preparation method thereof, belonging to the field of paint. The paint comprises component A and component B, wherein the polyalcohol component A is formed by mixing waterborne polyurethane and nano antimony tin oxide slurry according to the mass ratio of 4: 1-1: 1; curing agent is isocyanate curing agent; the mass ratio between thecomponent A and the component B is 10: 1; in the polyalcohol component A, the nano antimony tin oxide slurry is prepared by taking mixture of nano antimony tin oxide, water and absolute ethyl alcohol(mixing according to the volume ratio of 1: 1), and polymer anion dispersing agent as raw materials, and has the solid content of 20%; and the nano-glass heat insulation paint is prepared by taking the waterborne polyurethane, the nano antimony tin oxide slurry, the water, adhesive force accelerating agent, wetting agent, flatting agent, thickening agent, defoaming agent and the isocyanate curingagent as raw materials. The invention has the advantages of simple paint preparation, low cost, good heat insulation property, being environment-friendly and safe, and the like.

Owner:FIRST NEW MATERIAL TECH DEV

Titania fluorocarbon nano-coating and preparation thereof

The invention relates to a nano titanium dioxide fluorine-carbon coating in the technical field of nono, and a preparation method thereof. The coating comprises the following compositions by weight percentage: 2 to 6 percent of nano titanium dioxide, 80 to 90 percent of fluorine-carbon base material, 5 to 10 percent of curing agent and 2 to 10 percent of coating thinner. The preparation method comprises the following steps: 1, according to weight percentage, 2 to 6 percent of nano titanium dioxide particle is weighed and added into the 2 to 10 percent of coating thinner so as to be evenly mixed through ultrasonic dispersion; and 2, the mixture is added with the 80 to 90 percent of fluorine-carbon base material and the 5 to 10 percent of curing agent orderly and is evenly stirred to be made into coating mother solution. In addition, the nano titanium dioxide is rutile-type nano titanium dioxide particle modified by silane coupling agent KH-570. The nano titanium dioxide fluorine-carbon coating can effectively improve the dispersing performance of nano particle in the coating and the UV aging resistance of the coating.

Owner:SHANGHAI JIAO TONG UNIV

Water-soluble nano camouflage paint and preparation method thereof

ActiveCN103642361AEliminate hazardsPolyurea/polyurethane coatingsRadiation-absorbing paintsOrganic solventAnti freezing

The invention discloses water-soluble nano camouflage paint and a preparation method thereof, belonging to the technical field of wave-absorption paint. The water-soluble nano camouflage paint is prepared from the following components in percent by mass: 20%-60% of water-soluble resin, 2%-6% of a silane coupling agent, 24%-40% of wave-absorbing particles, 1.5%-2.0% of a protective agent, 2%-4% of an emulsifier, 4%-6% of an anti-freezing agent, 0.1%-0.5% of a defoaming agent and the balance of deionized water. According to the invention, the water-soluble resin is used as a carrier of components such as a film forming matter and a wave-absorption material and the deionized water is used as a diluent, so that harms of an organic solvent in the camouflage paint on a human body and an environment are completely avoided, and therefore, the water-soluble nano camouflage paint is environment-friendly type paint in true sense.

Owner:BEIJING XINLI MACHINERY

Water-based nano heat insulating coating used for glass and preparation method thereof

InactiveCN101538444AGood heat insulationHigh transparencyPolyurea/polyurethane coatingsRadiation-absorbing paintsWater basedWeather resistance

The invention belongs to the technical field of nano coatings, and particularly relates to a water-based nano heat insulating coating used for glass. The water-based nano heat insulating self-cleaning coating used for glass consists of the following components by weight: 45-55 portions of high molecular resin, 5-15 portions of nano ATO slurry, 0.1-1 portion of crosslinking agent, 0.1-0.8 portion of ultraviolet absorber and 5-10 portions of ethanol. The invention aims at overcoming the disadvantages in the prior art, and provides a heat insulating coating used for glass which has excellent heat insulating performance and transparency, weather resistance, simple and feasible production process, convenient construction and low production cost and a preparation method thereof.

Owner:ZHEJIANG TIANYUAN ENERGY TECH

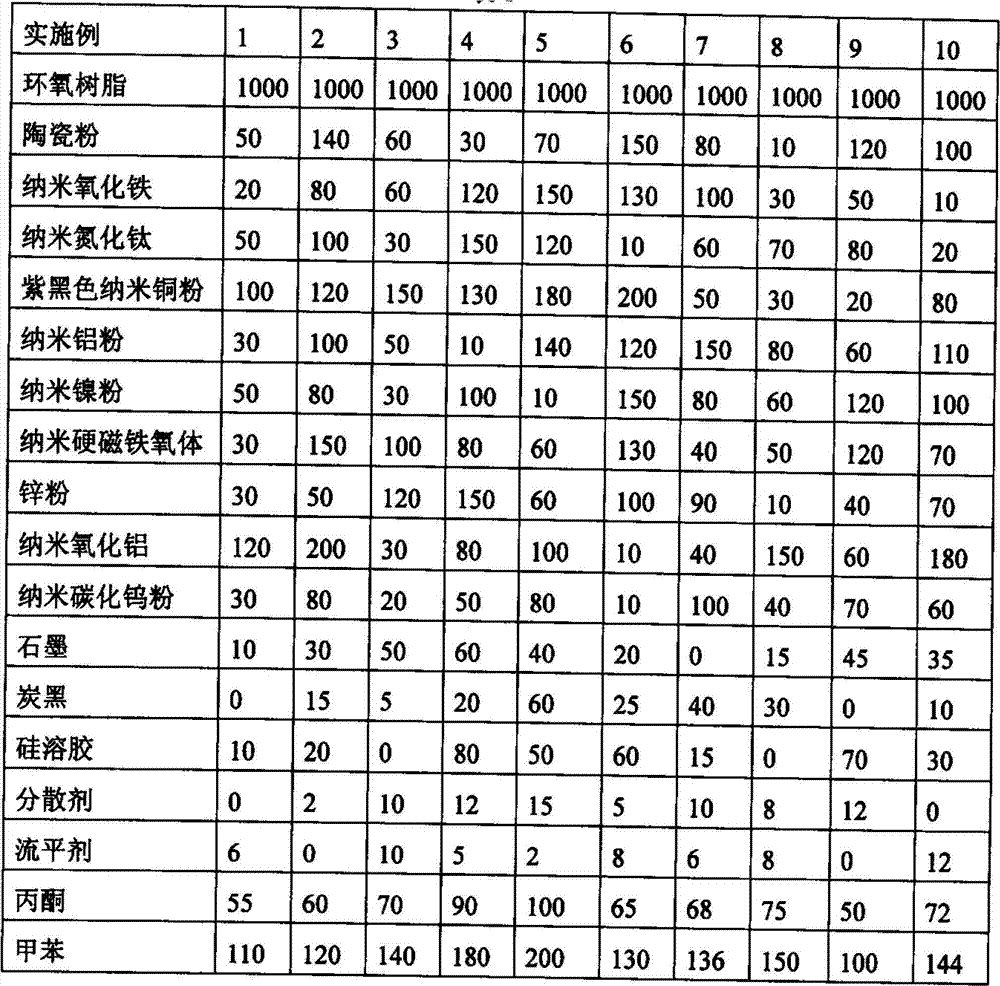

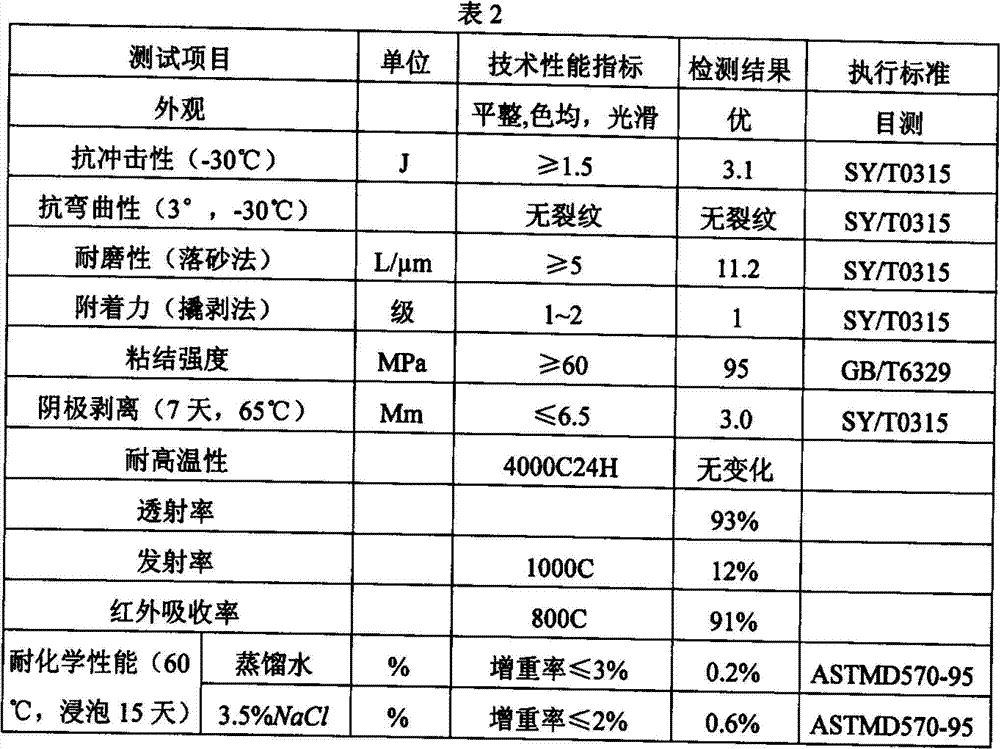

Solar heat absorbing paint and manufacturing method thereof

InactiveCN103589275APromote absorptionImprove corrosion resistanceRadiation-absorbing paintsEpoxy resin coatingsEpoxyHigh absorption

A solar heat absorbing paint is prepared by mixing a nano magnetic powder, a variety of nano metal powders, a ceramic powder, epoxy resin and a variety of additives. The paint provided by the invention is prepared by evenly mixing and stirring the components in the formula at room temperature. The production process is simple, convenient, economical and environment-friendly. The paint provided by the invention can be used individually; and a coating of the paint has high absorption rate, high thermal conductivity, low radiation, high temperature resistance, high stability, strong adhesion, compactness and stability. The paint is ideal for solar energy absorption, can be widely used as the heat absorbing coating for solar collector, and absolutely can substitute the existing expensive solar energy absorption coating.

Owner:上海陆亿新能源有限公司

UV blocking fluoropolymer film

InactiveUS20110297228A1Balancing interactionDifficult to balanceProtective equipmentSynthetic resin layered productsPolymer scienceLight energy

The invention describes a polymer that is composed of a fluoropolymer modified with a UV absorber. The UV absorber is grafted to the polymeric backbone of the fluoropolymer. Optionally, a HALS can also be grated to the polymeric backbone of the fluoropolymer. Incorporation or the absorber or stabilizer helps to reduce degradation of underlying layers such as an encapsulant while still allowing useful light energy to pass through the layers to a device, such as a photovoltaic device.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

Water-based interior wall thermal insulation nano coating

InactiveCN101948652ALow toxicitySimple preparation processRadiation-absorbing paintsWater basedThermal insulation

The invention provides a water-based interior wall thermal insulation nano coating, belonging to the technical field of environment-friendly water-based building energy conservation coating. The coating comprises the following components by weight percentage: 20-40% of emulsion, 20-35% of pigment filler, 5-15% of thermal insulation function material, 0.1-1% of thickening agent, 0.5-2.5% of wetting and dispersing agent, 0.1-0.6% of defoaming agent, 0.4-2.5% of anti-creaming agent, and the balance water. Due to containing no organic matters with large volatility, the coating in the invention has little toxicity and is favor to environment protection. The adopted pigment filler in the invention is nano-level or superfine magnesium carbonate or magnesium silicate, thus greatly improving the surface area of the pigment, and increasing gaps among coating particles by a large margin, thereby enhancing the thermal separation property of the coating. The water-based interior wall thermal insulation nano coating provided in the invention has obvious radiative thermal insulation and separation type thermal insulation effects, and has simple preparation process and wide application.

Owner:CHINA MCC17 GRP

Aqueous self-cleaning transparent heat-insulated nano-dope capable of fully shielding infrared ray and ultraviolet ray

InactiveCN102732108AStrong hardnessHardness can reach 2H level, strong adhesionRadiation-absorbing paintsReflecting/signal paintsPhotochemistryFluorocarbon Resins

The invention relates to an aqueous self-cleaning transparent heat-insulated nano-dope capable of fully shielding infrared ray and ultraviolet ray and a preparation method. The dope comprises the following components in percentage by weight: 30%-70% of film-forming resin, 5%-30% of nano-ATO dispersion, 1%-10% of nano-LaB6 dispersion, 1%-15% of nano-WO3 dispersion, 5%-15% of co-solvent, 2%-10% of film-forming assistant, 0.5%-5.0% of assistant and 5%-25% of deionized water. The preparation method comprises the following steps of: dropping the nano-ATO dispersion, the nano-LaB6 dispersion and the nano-WO3 dispersion into aqueous fluorocarbon resin while stirring, stirring for 30-40 min, orderly adding antifoaming agent, wetting agent, the film-forming assistant, thickening agent and accelerating agent, stirring the solution to obtain the self-cleaning transparent thermal-insulation nano-dope. The dope is applied to the surfaces of cement, an automotive glass and a building glass, has self-cleaning function, can fully shield the infrared ray and ultraviolet ray and has obvious thermal-insulation performance.

Owner:惠州市彩田化工实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com