Patents

Literature

84results about How to "Suppresses dimensional changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

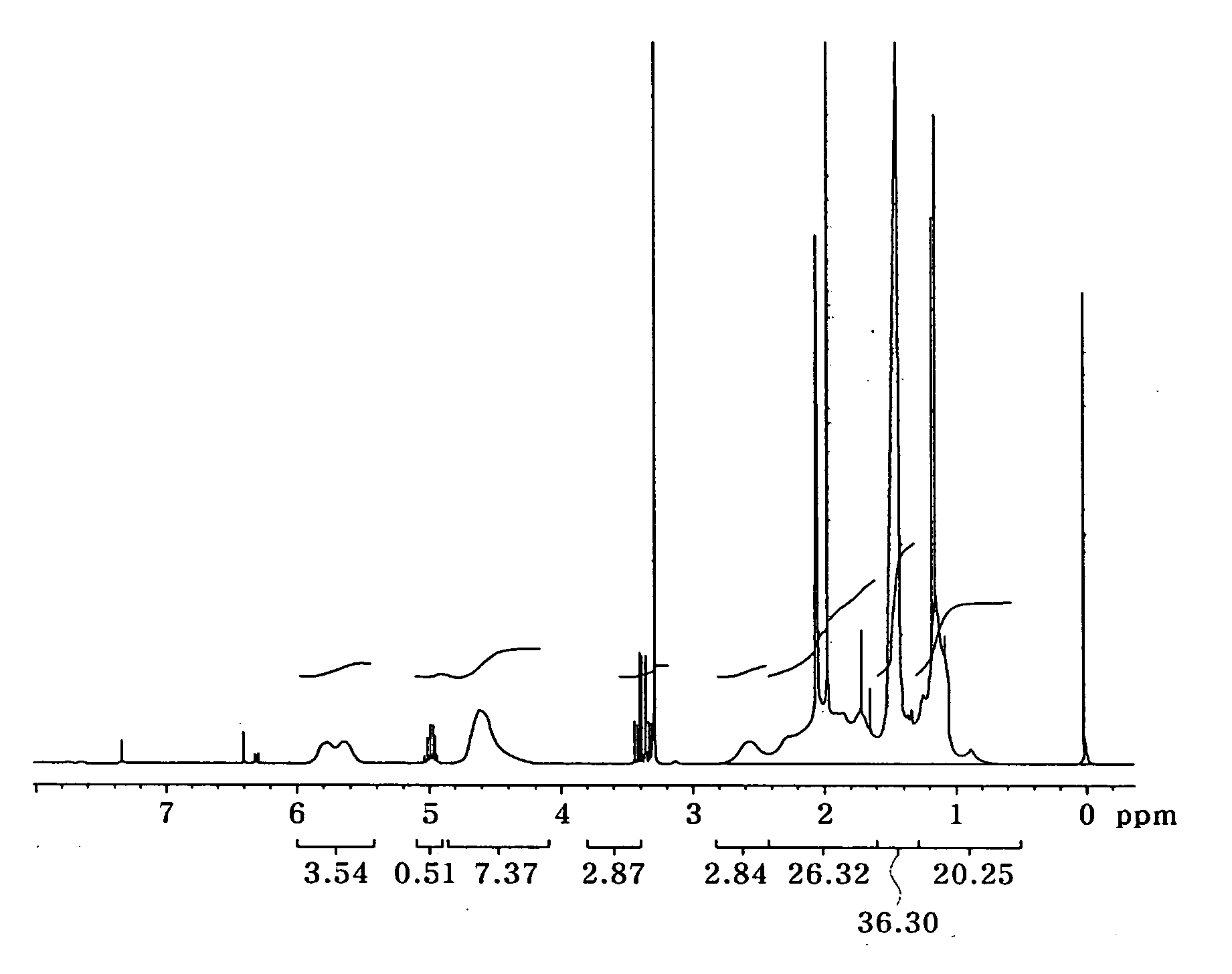

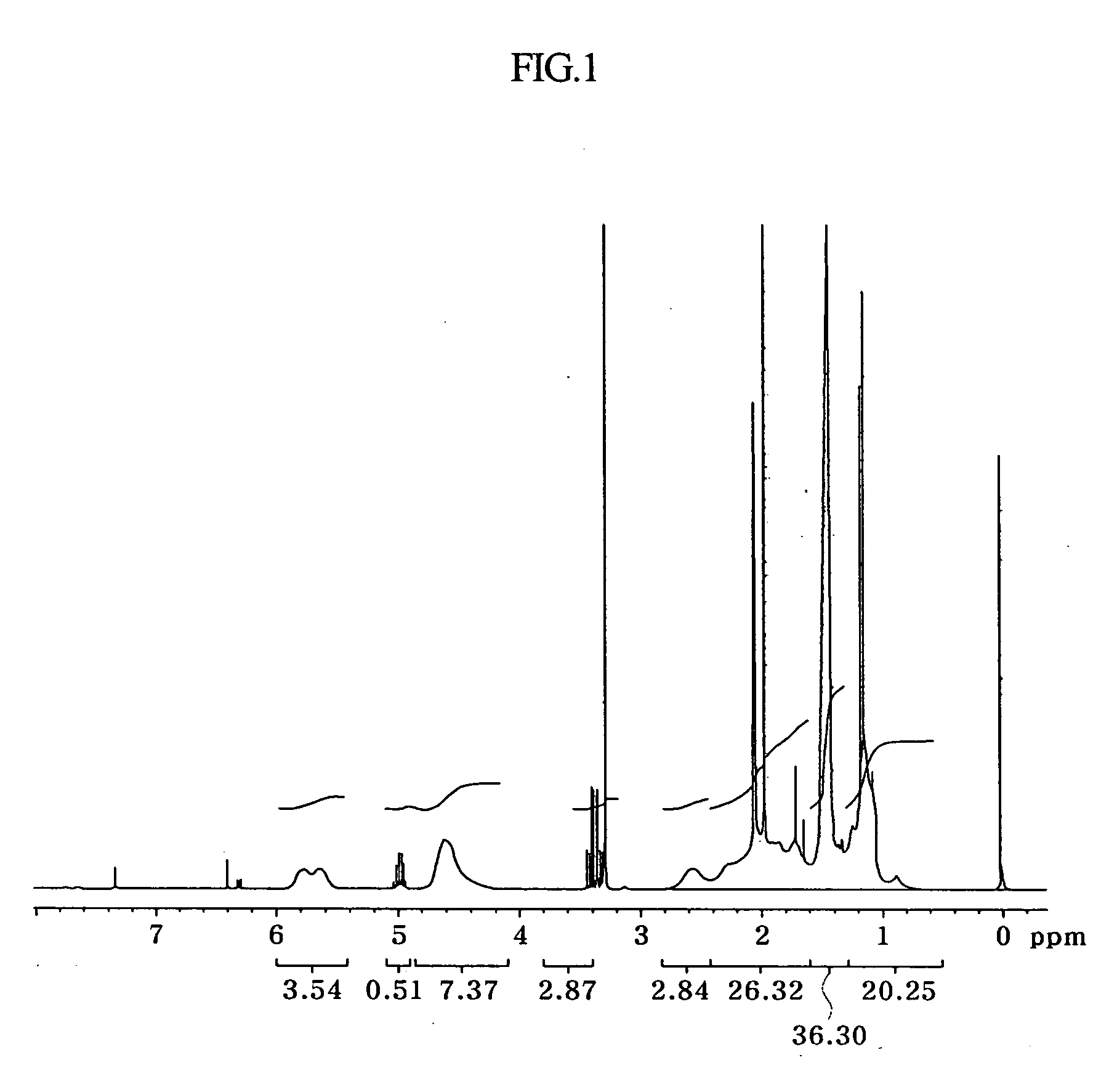

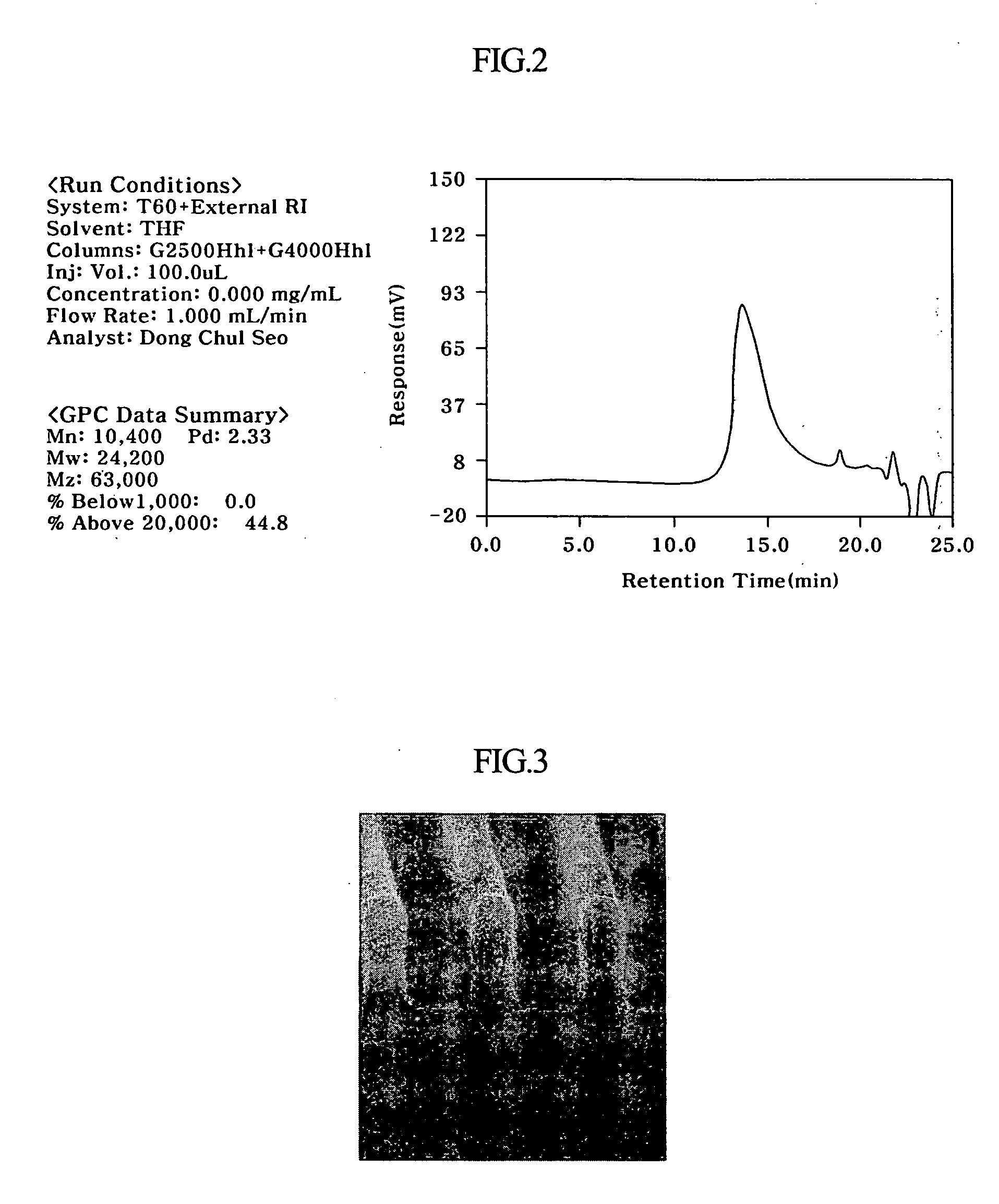

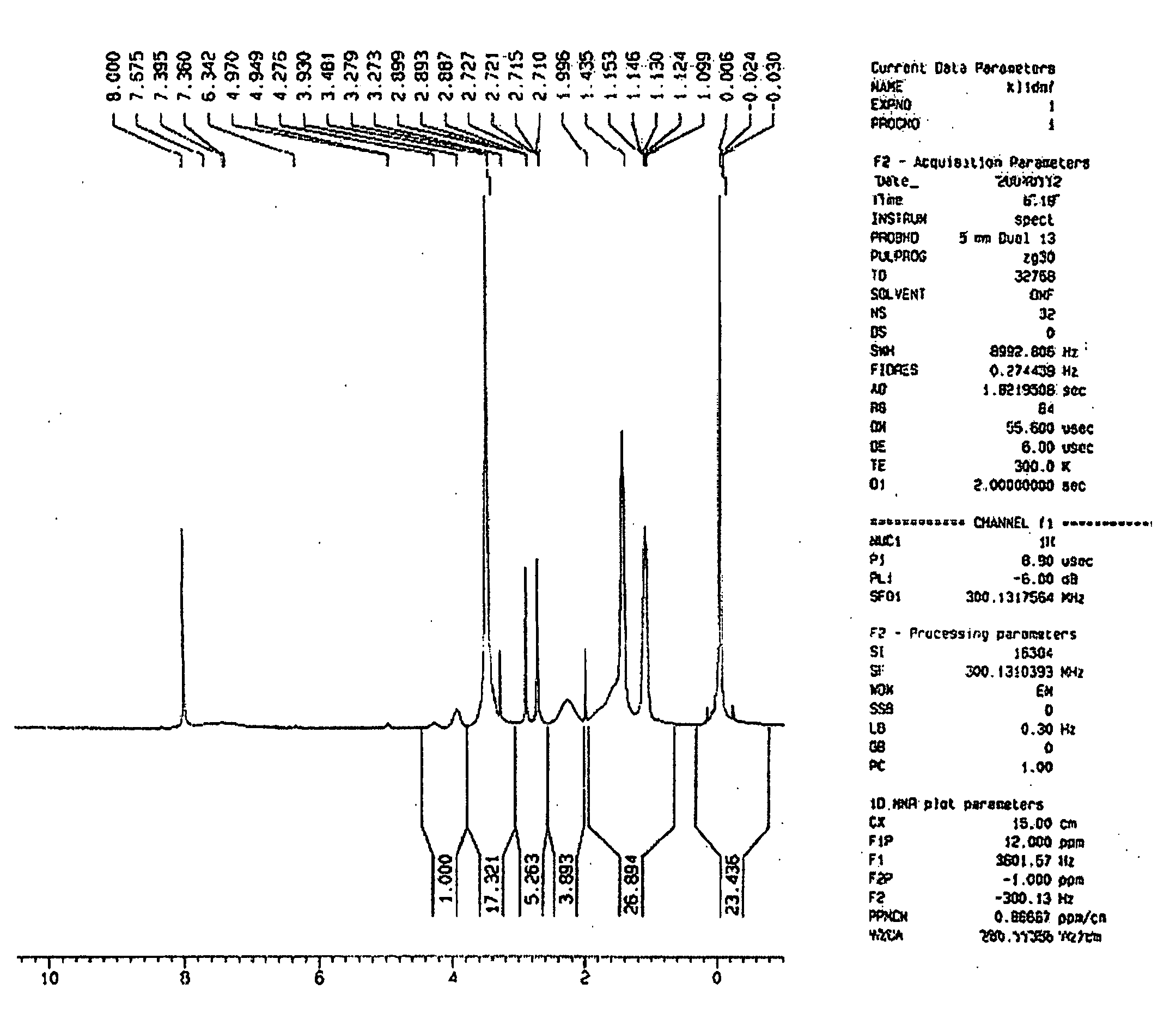

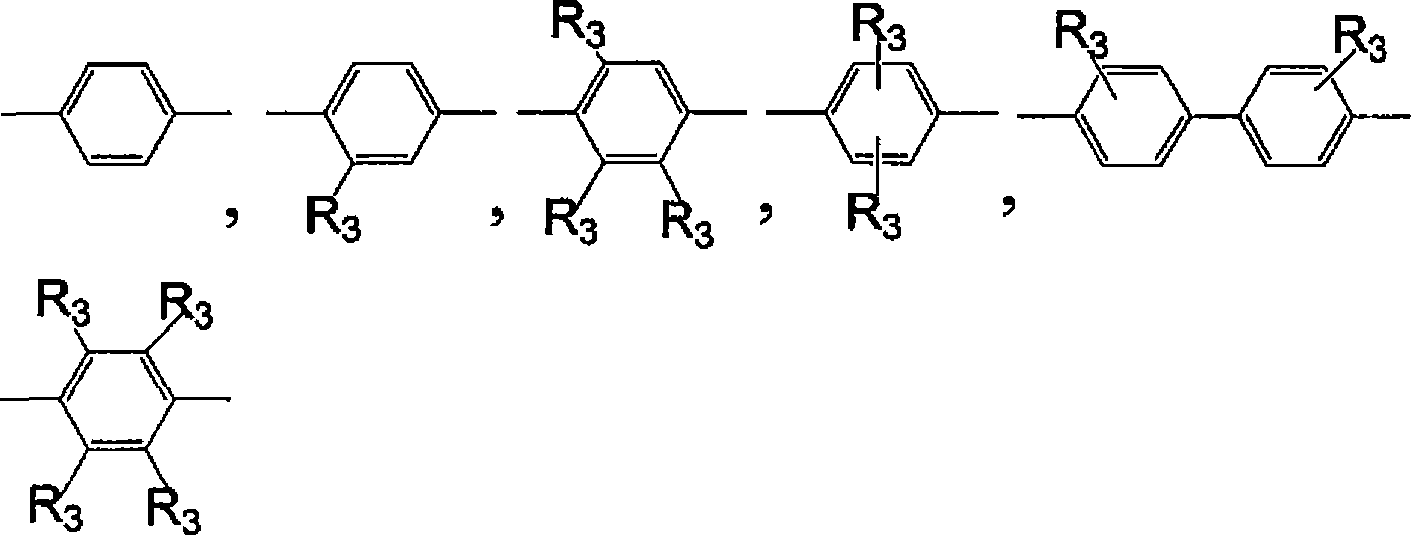

Top ARC polymers, method of preparation thereof and top ARC compositions comprising the same

ActiveUS20050239296A1Minimize scattered reflectionSuppresses dimensional changesPhotosensitive materialsSemiconductor/solid-state device manufacturingAnti-reflective coatingHydrogen

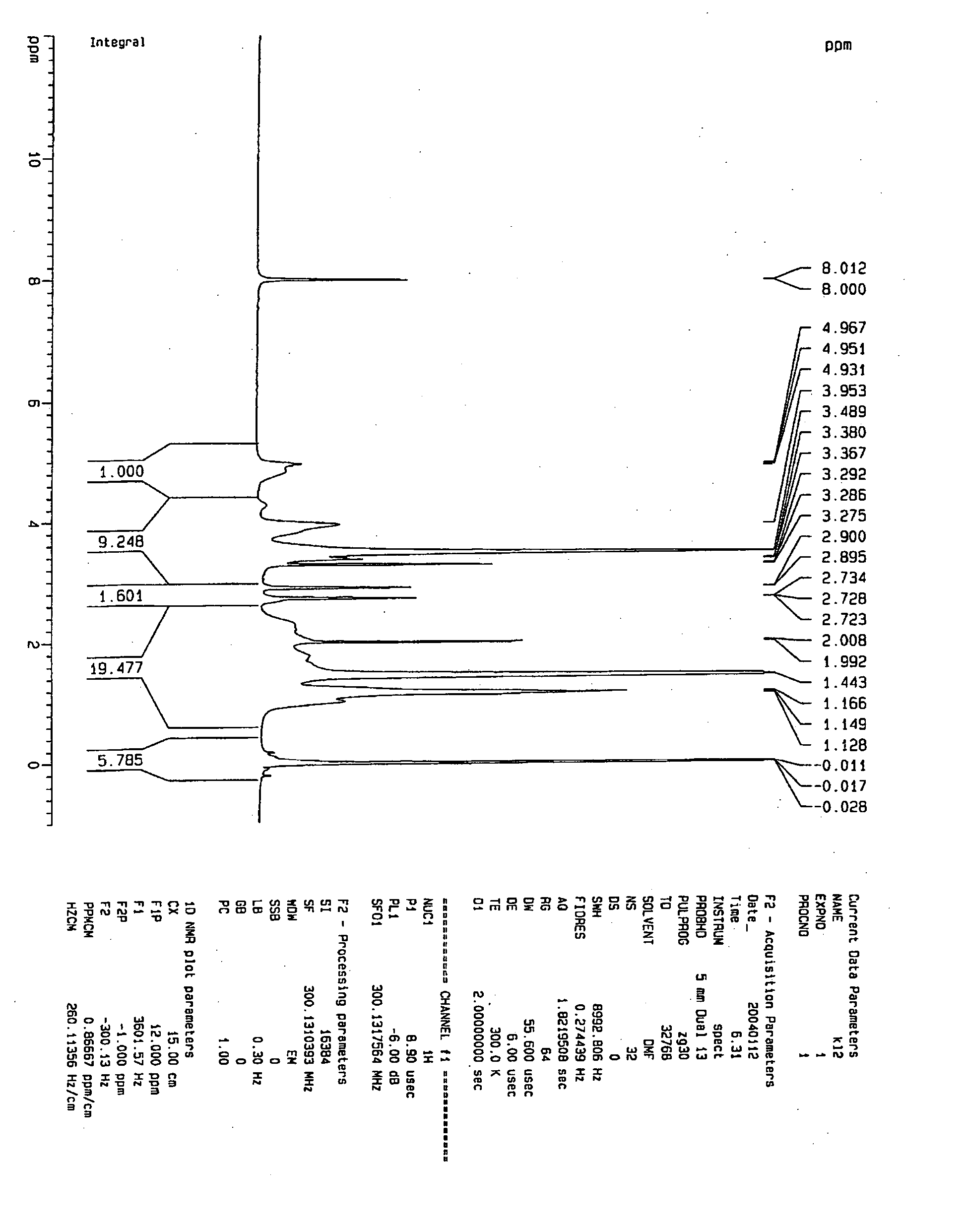

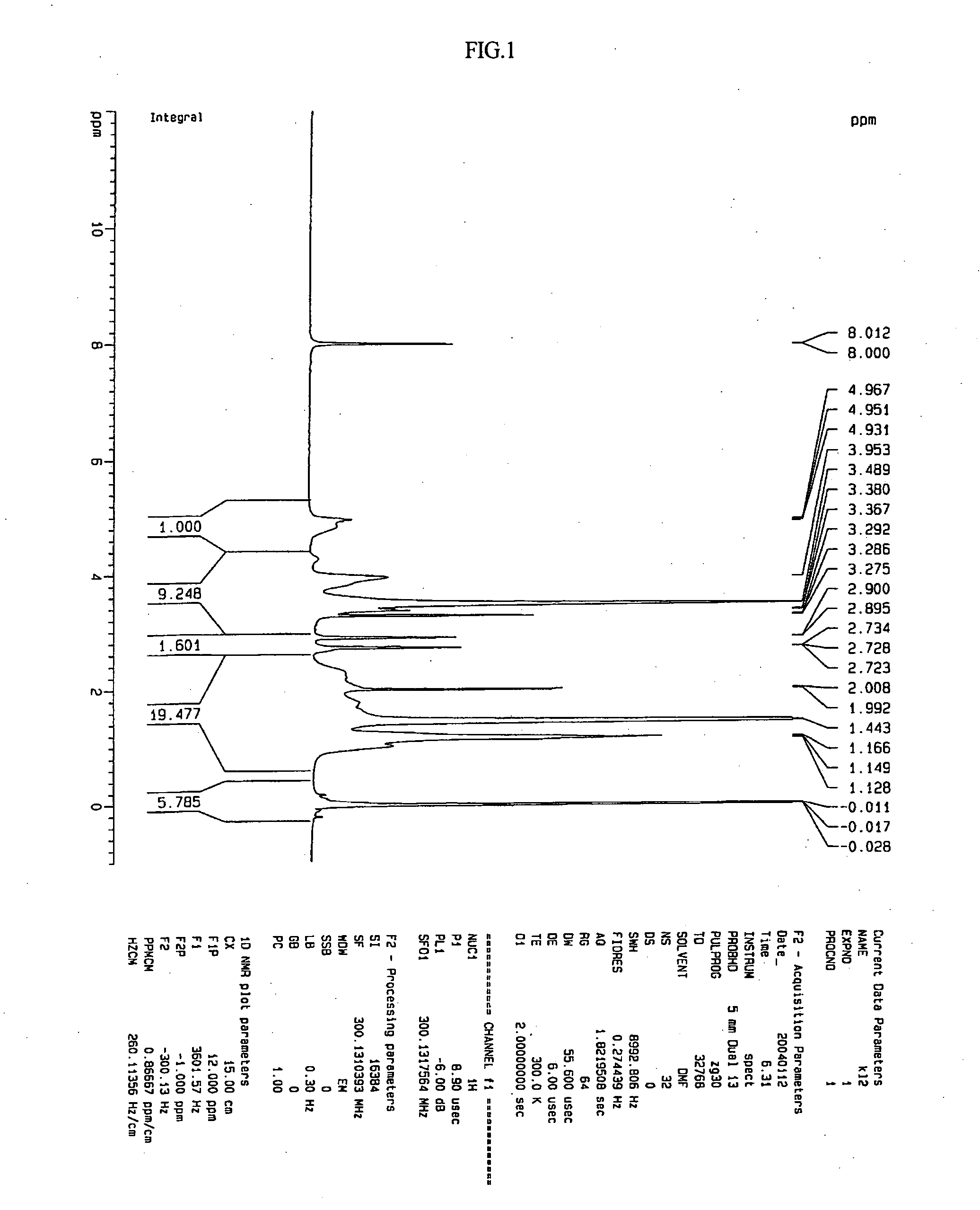

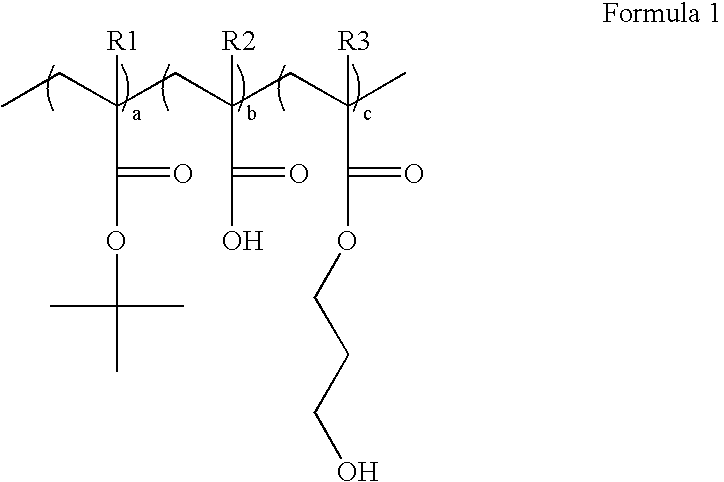

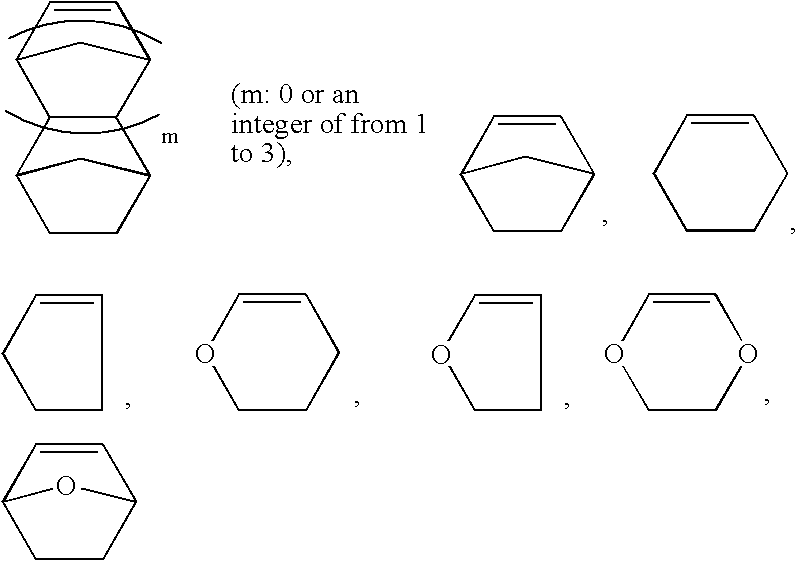

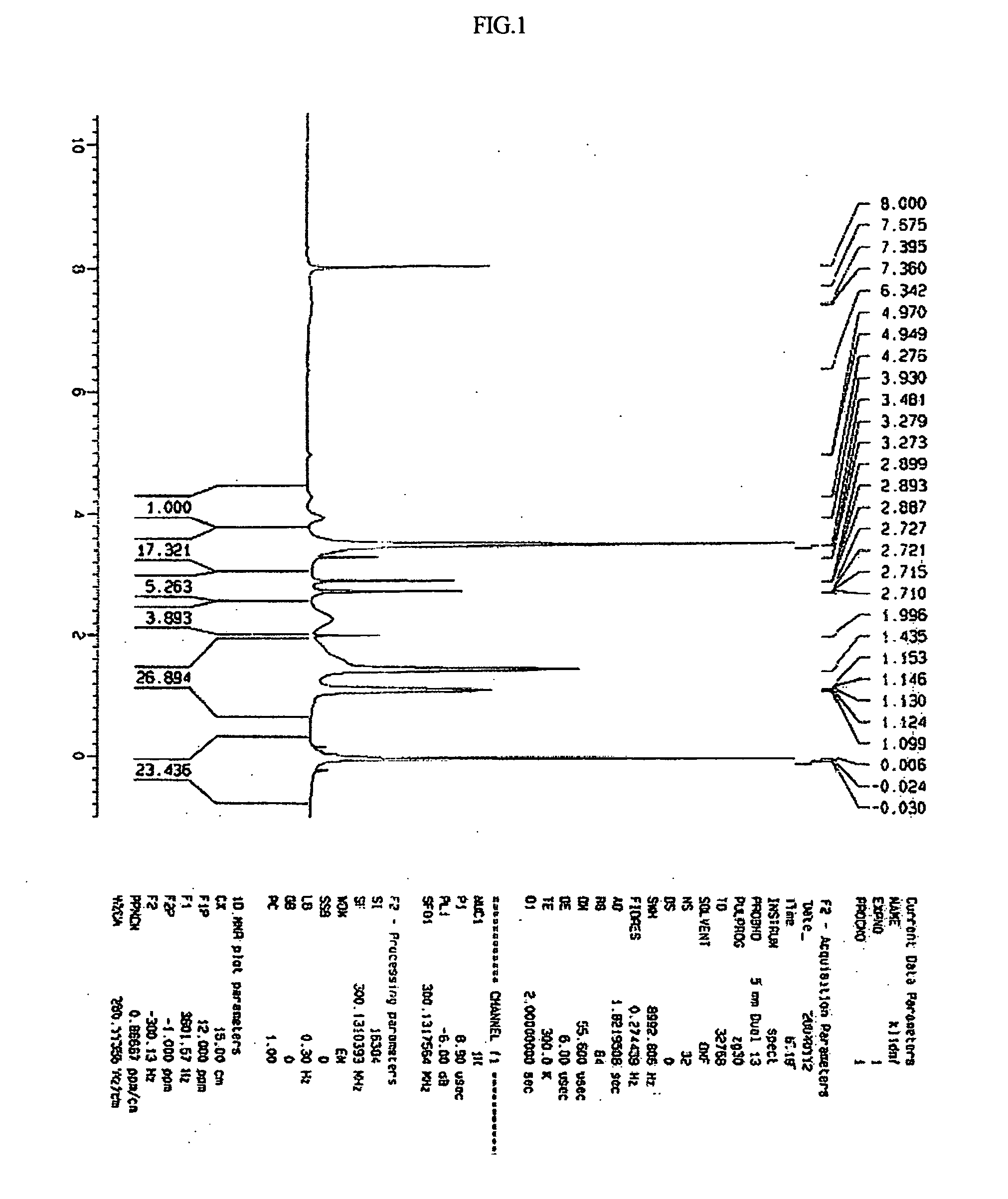

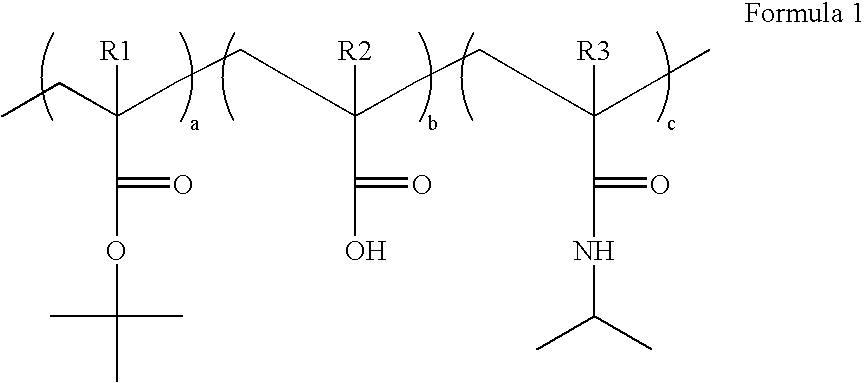

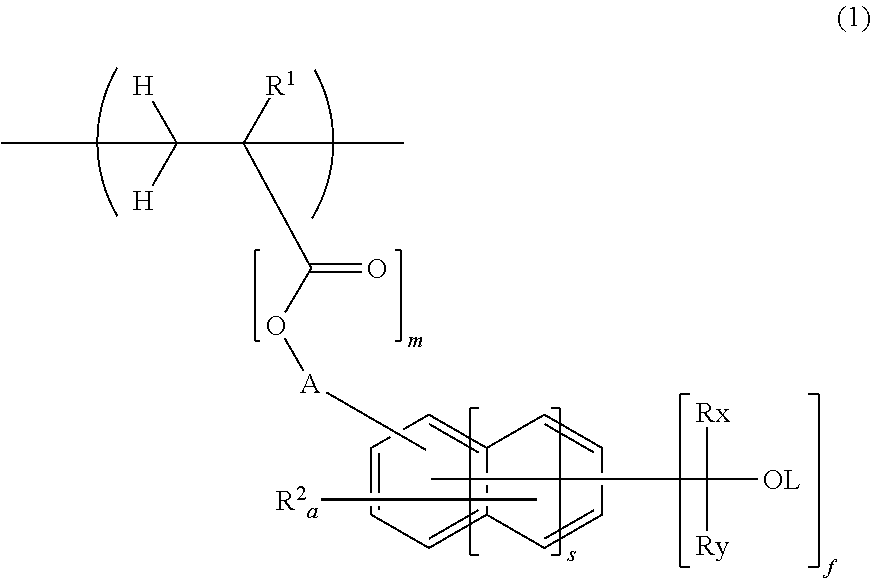

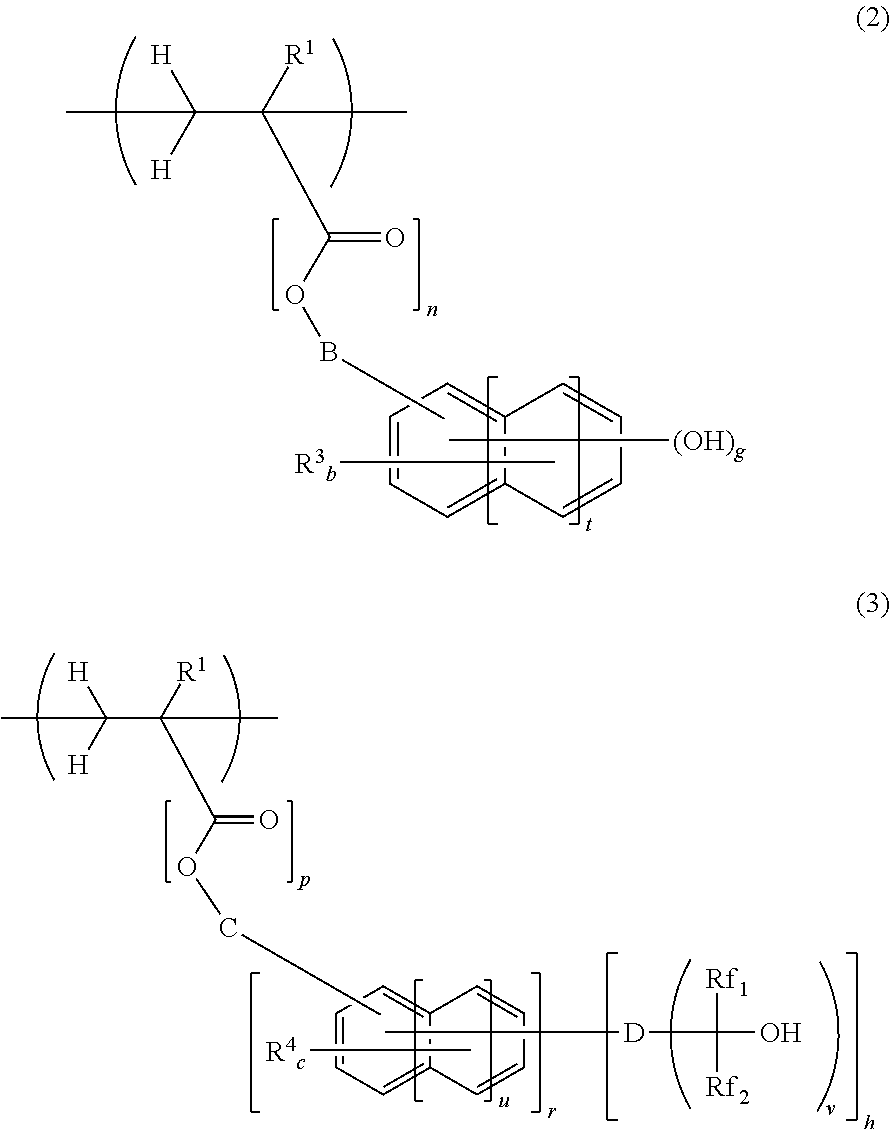

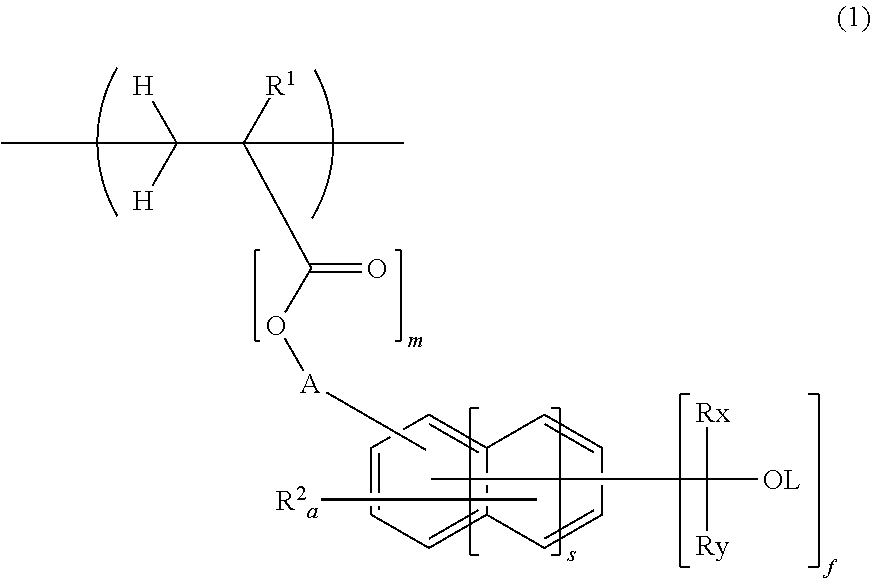

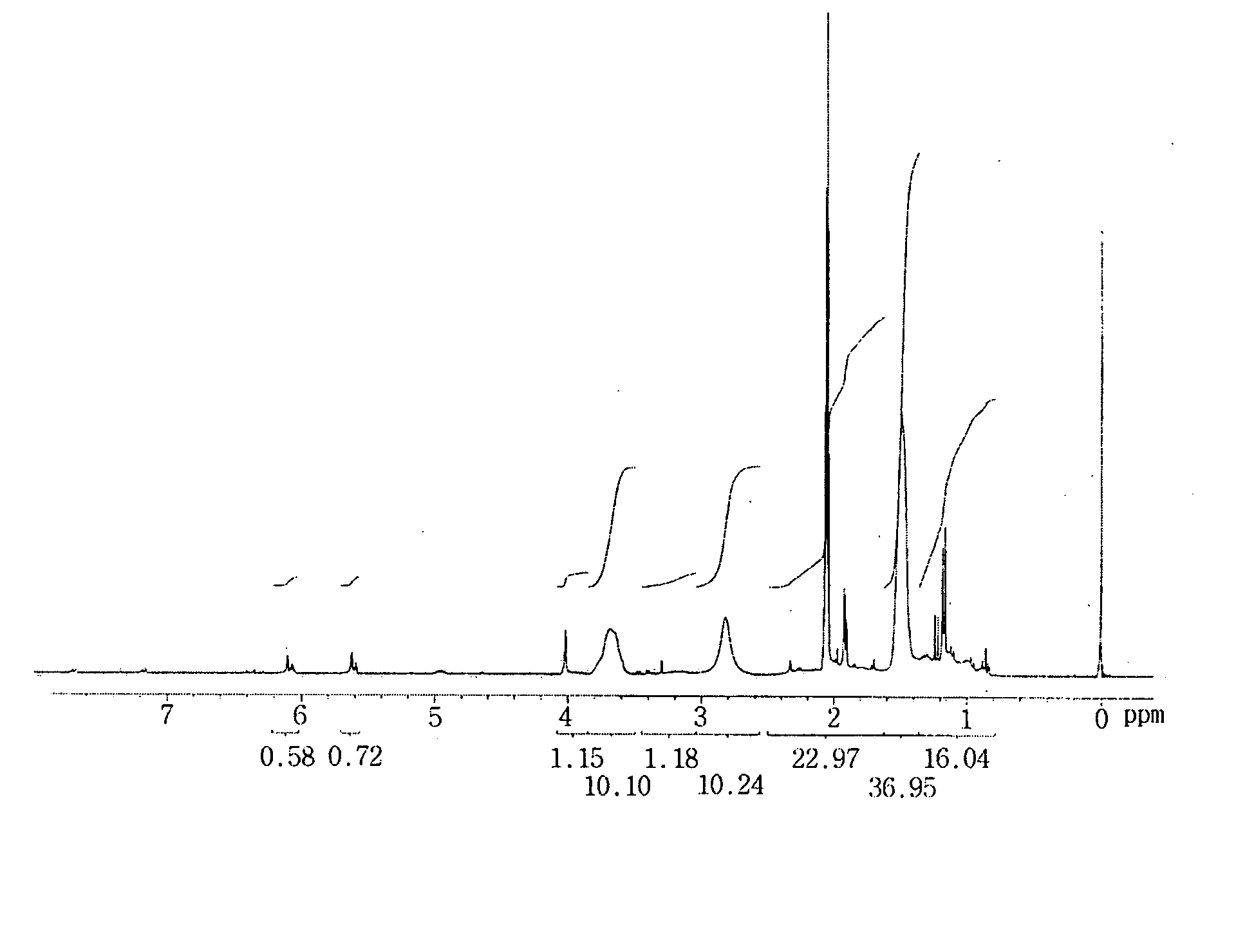

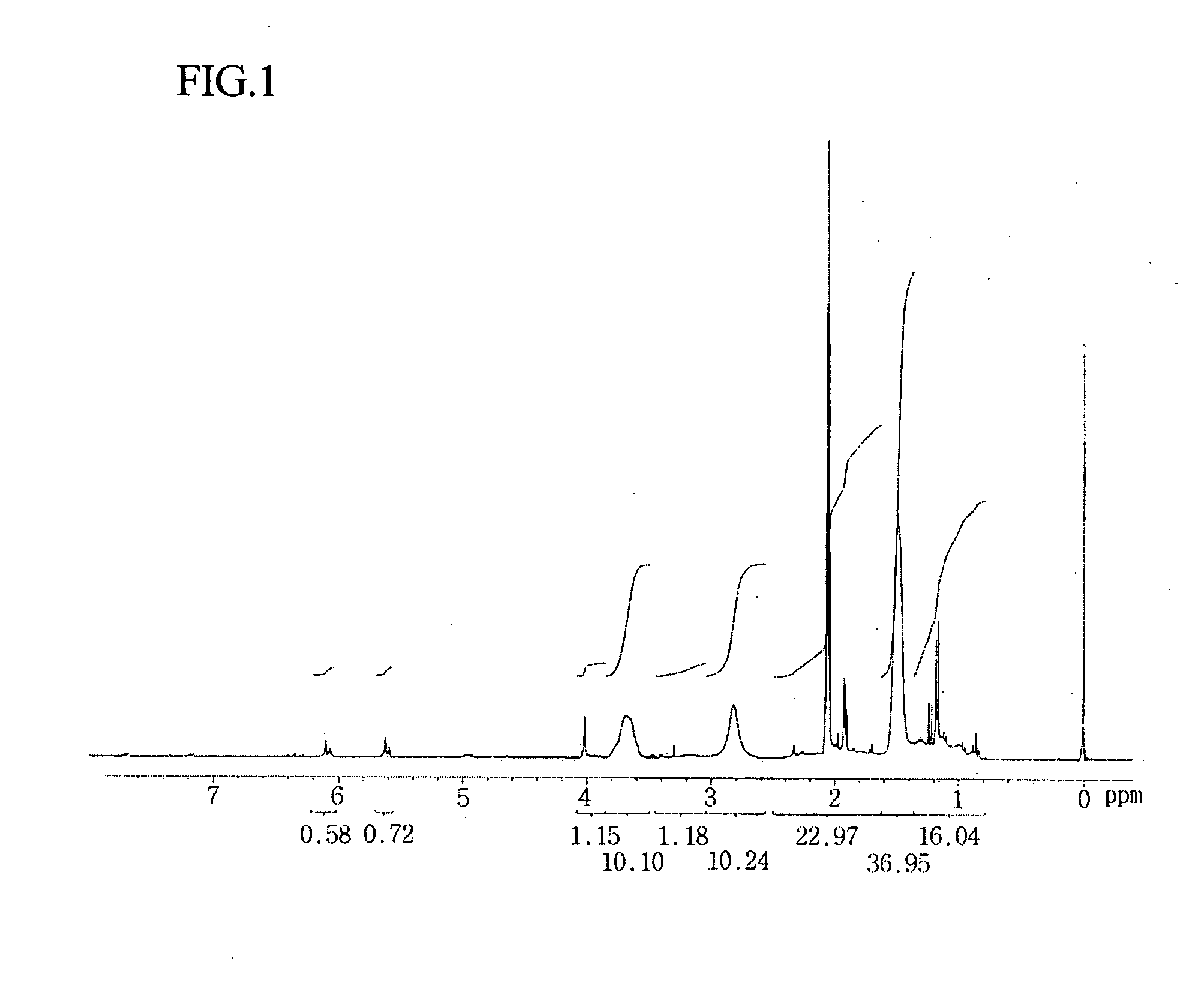

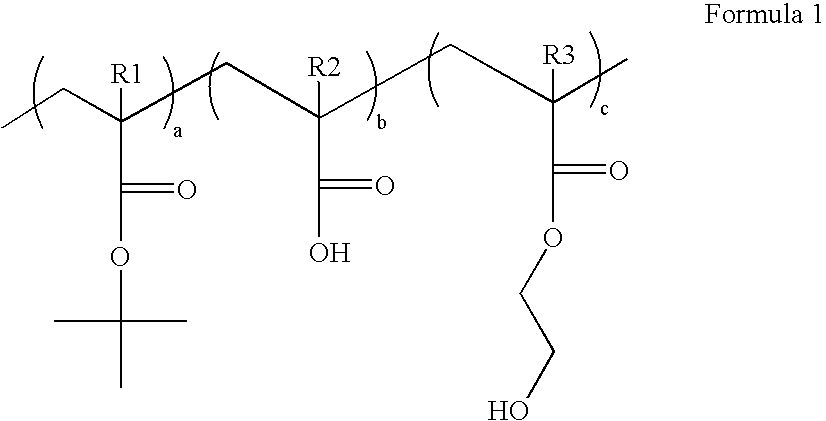

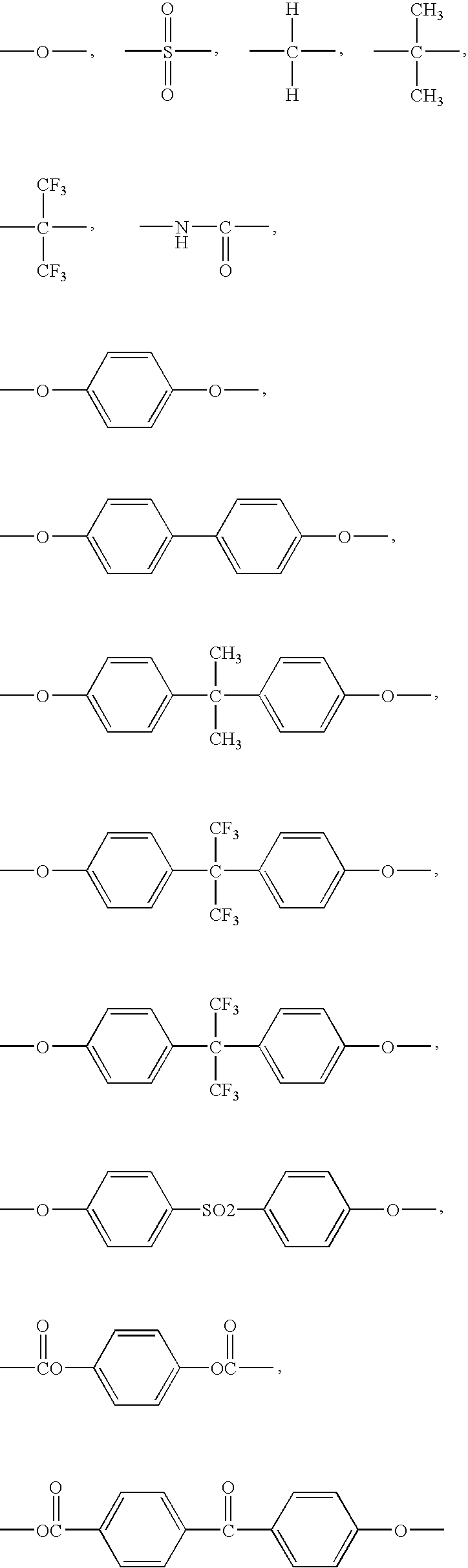

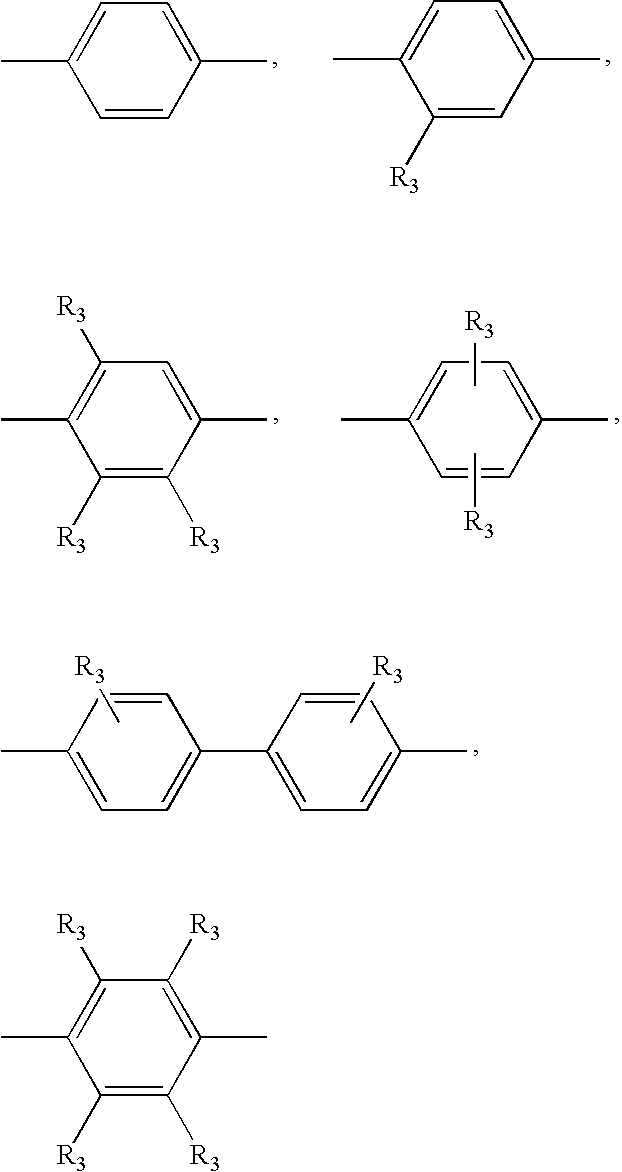

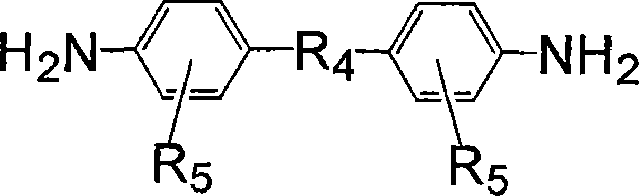

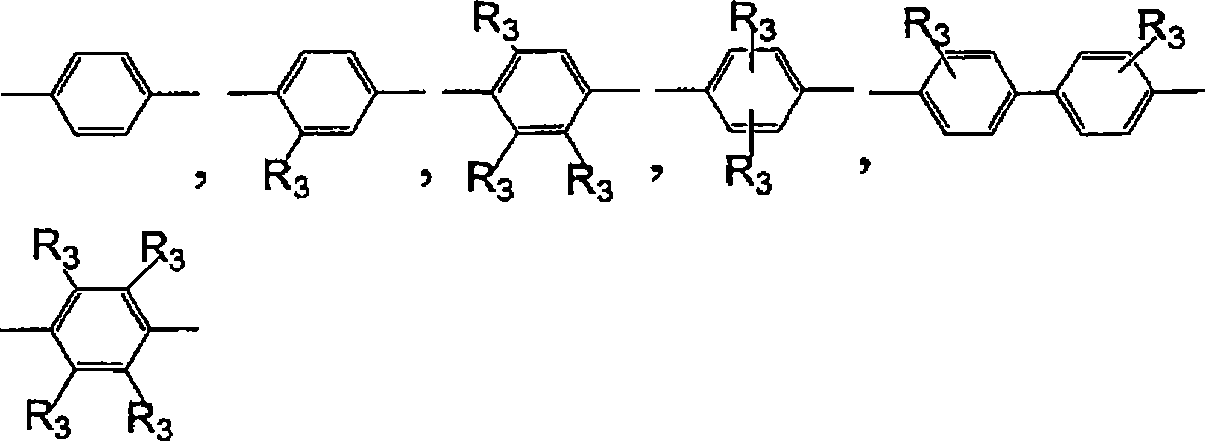

Disclosed herein are a top anti-reflective coating polymer used in a photolithography process, a method for preparing the anti-reflective coating polymer, and an anti-reflective coating composition comprising the anti-reflective coating polymer. The disclosed top anti-reflective coating polymer is used in immersion lithography for the fabrication of a sub-50 nm semiconductor device. The top anti-reflective coating polymer is represented by Formula 1 below: wherein R1, R2 and R3 are independently hydrogen or a methyl group; and a, b and c represent the mole fraction of each monomer, and are in the range between 0.05 and 0.9. The top anti-reflective coating formed using the anti-reflective coating polymer is not soluble in water and can be applied to immersion lithography using water as a medium for a light source. Since the disclosed top anti-reflective coating can reduce the reflectance from an underlayer, the uniformity of CD is improved, thus enabling the formation of an ultrafine pattern.

Owner:SK HYNIX INC

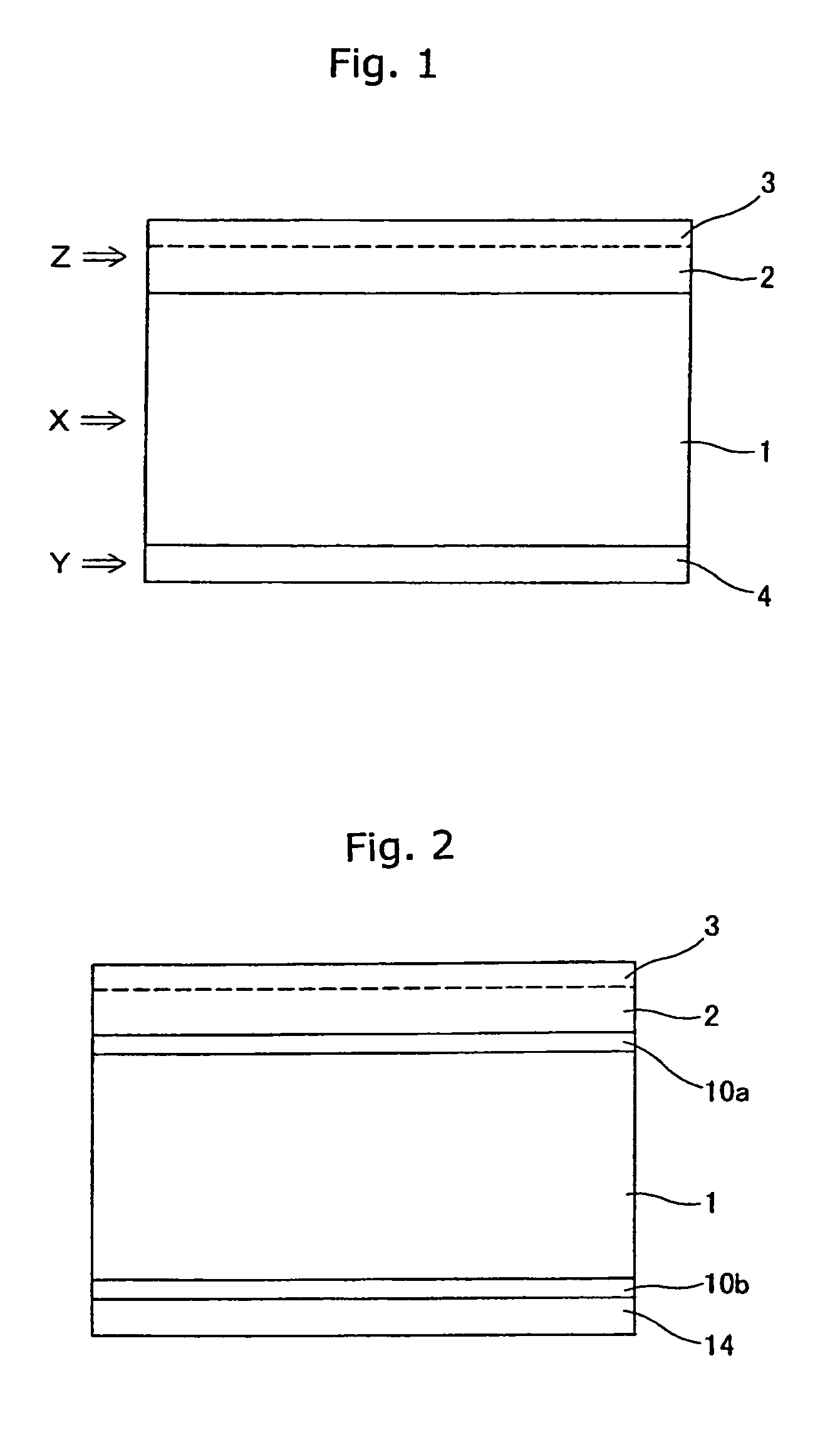

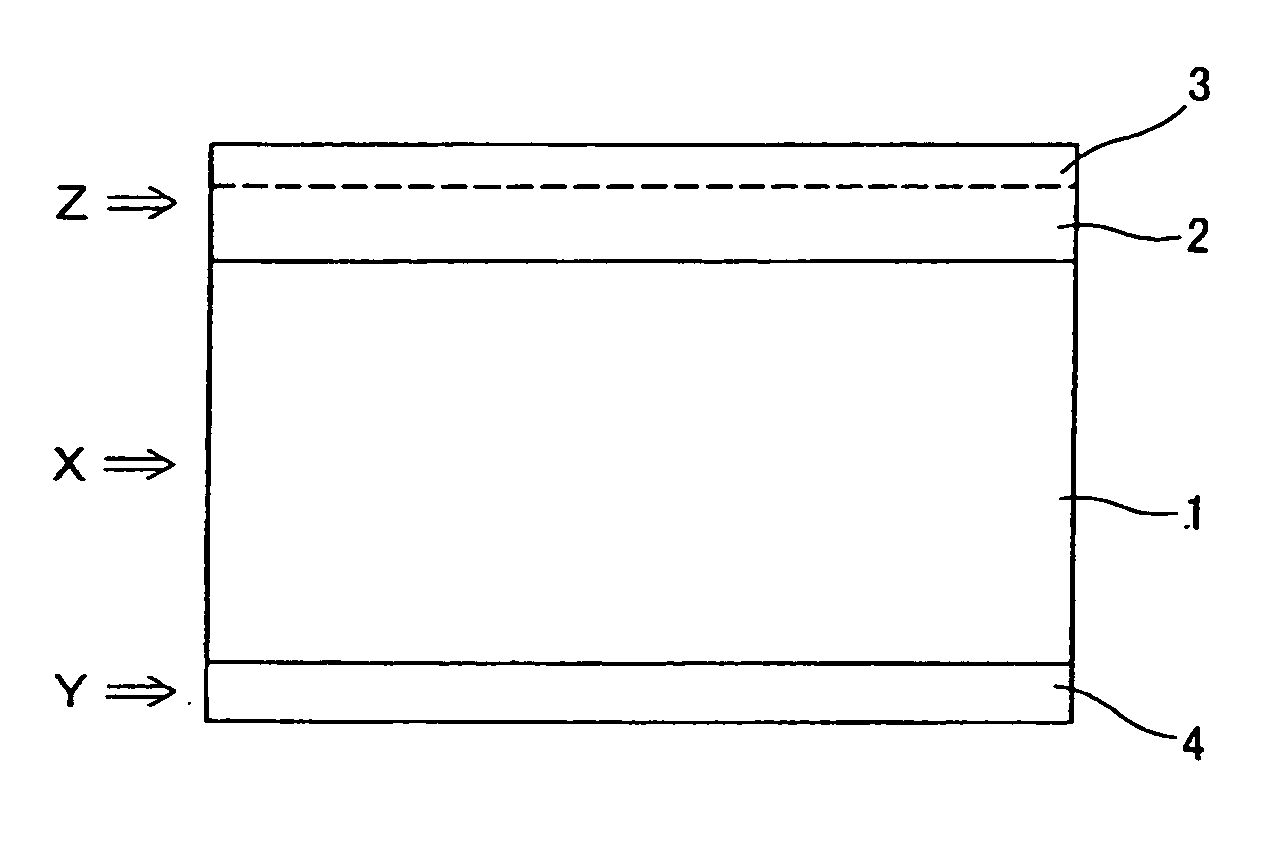

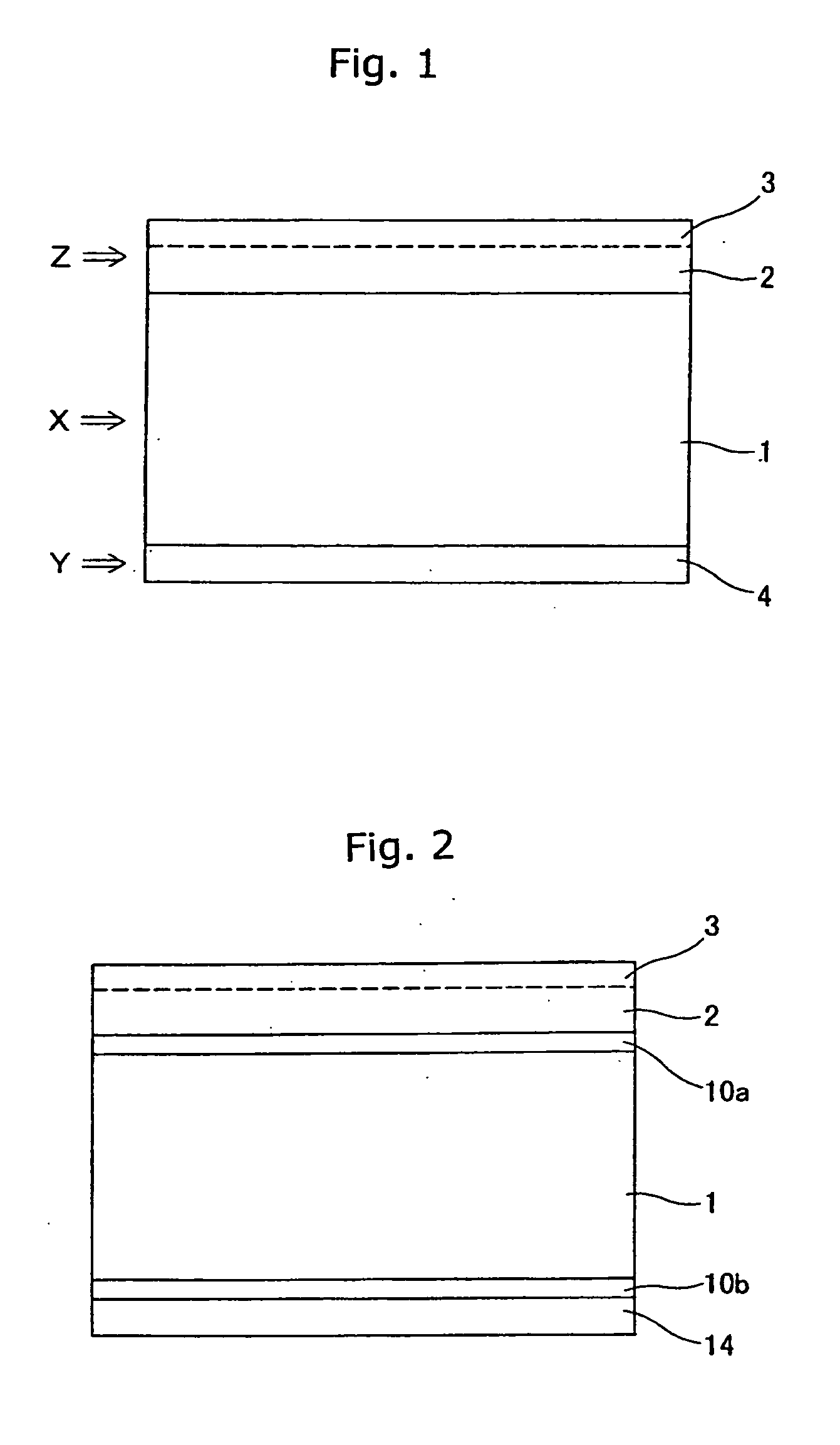

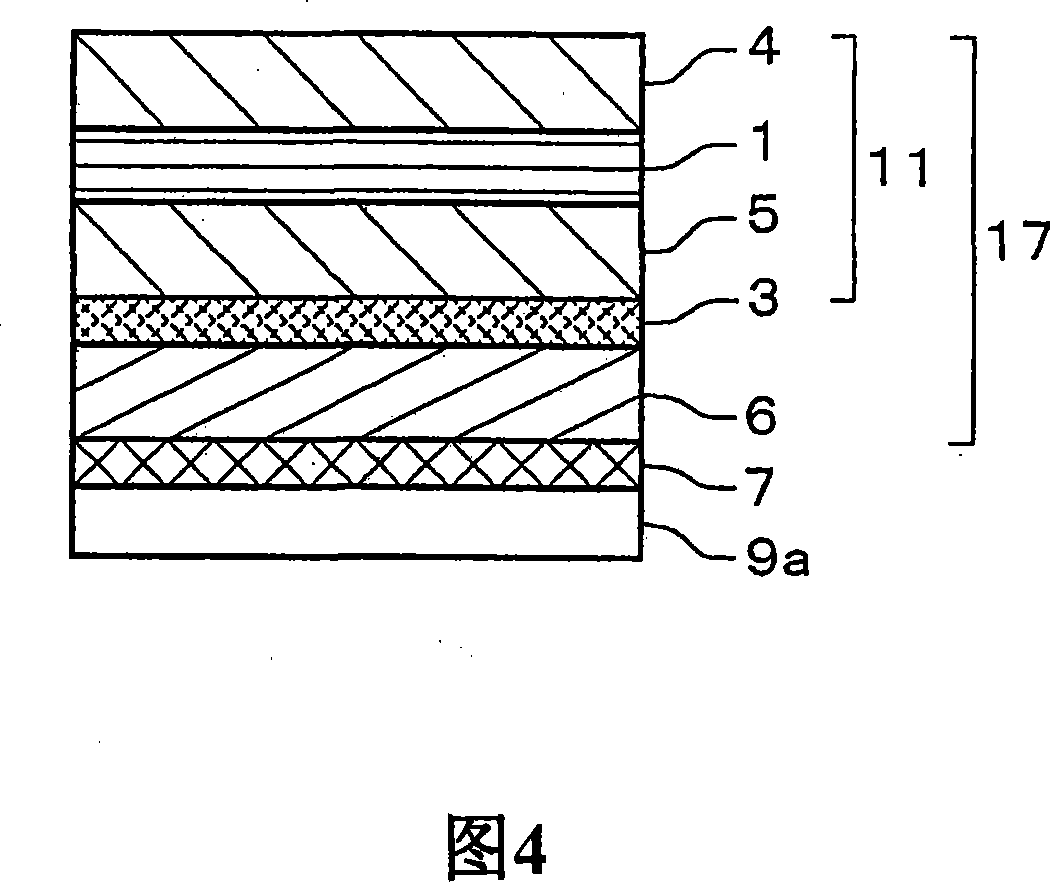

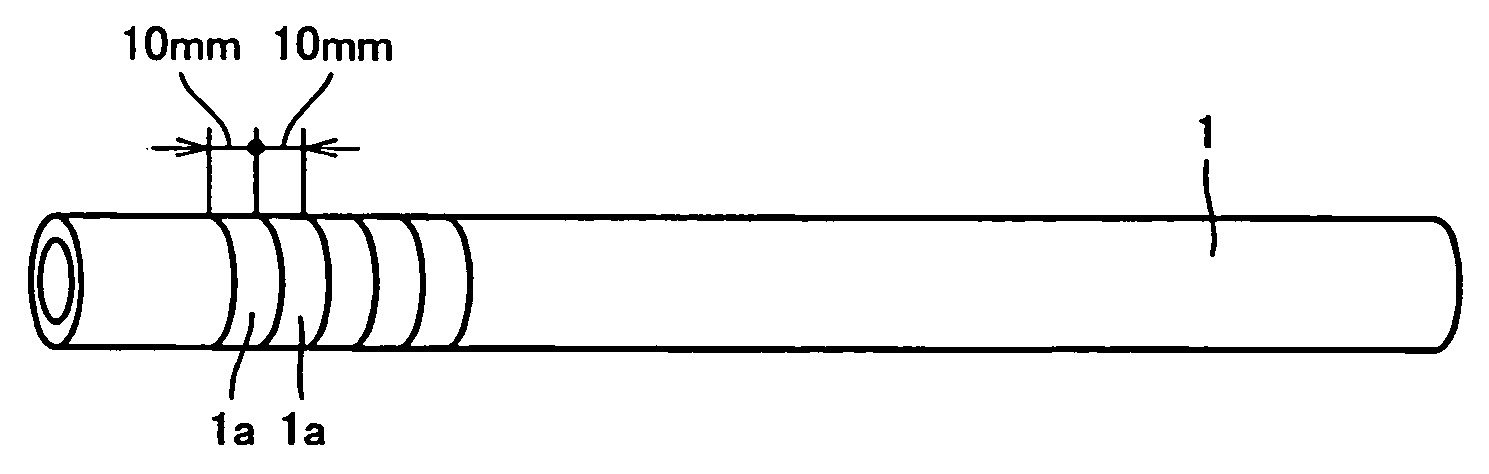

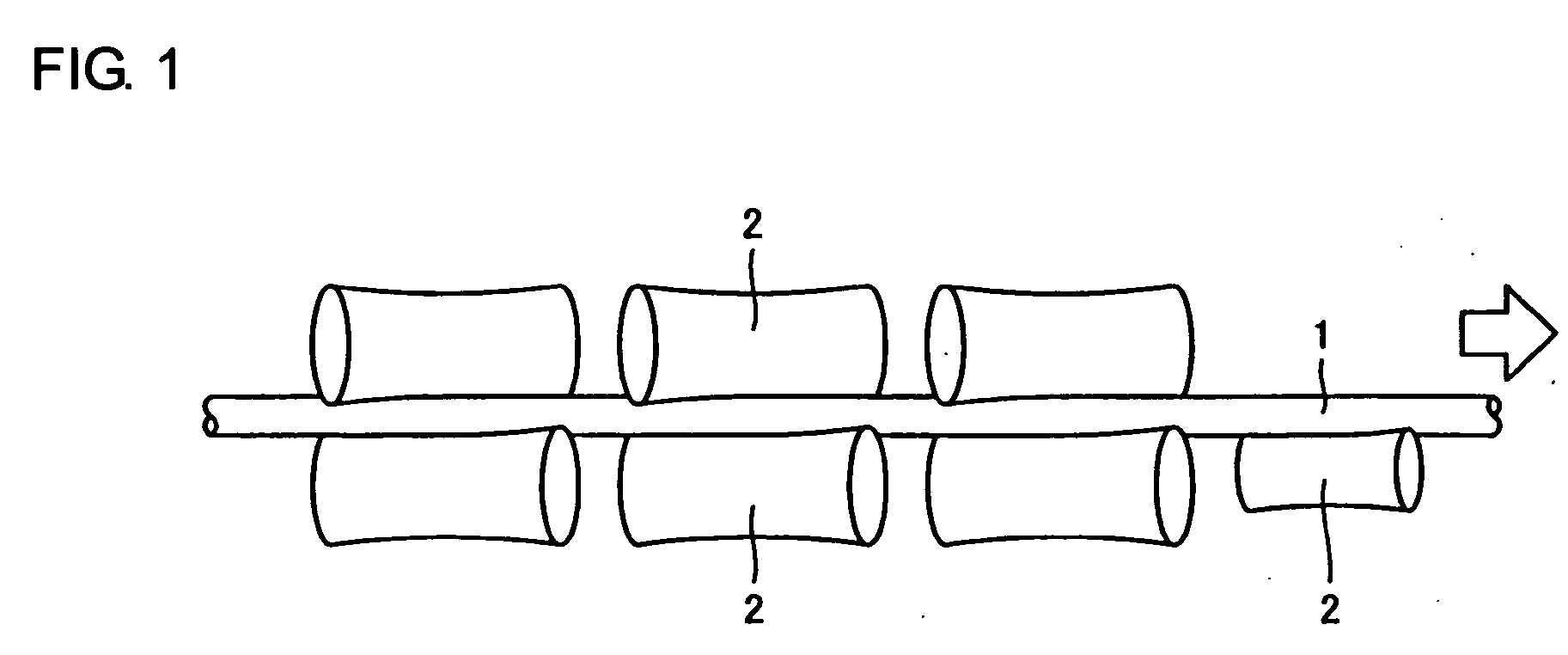

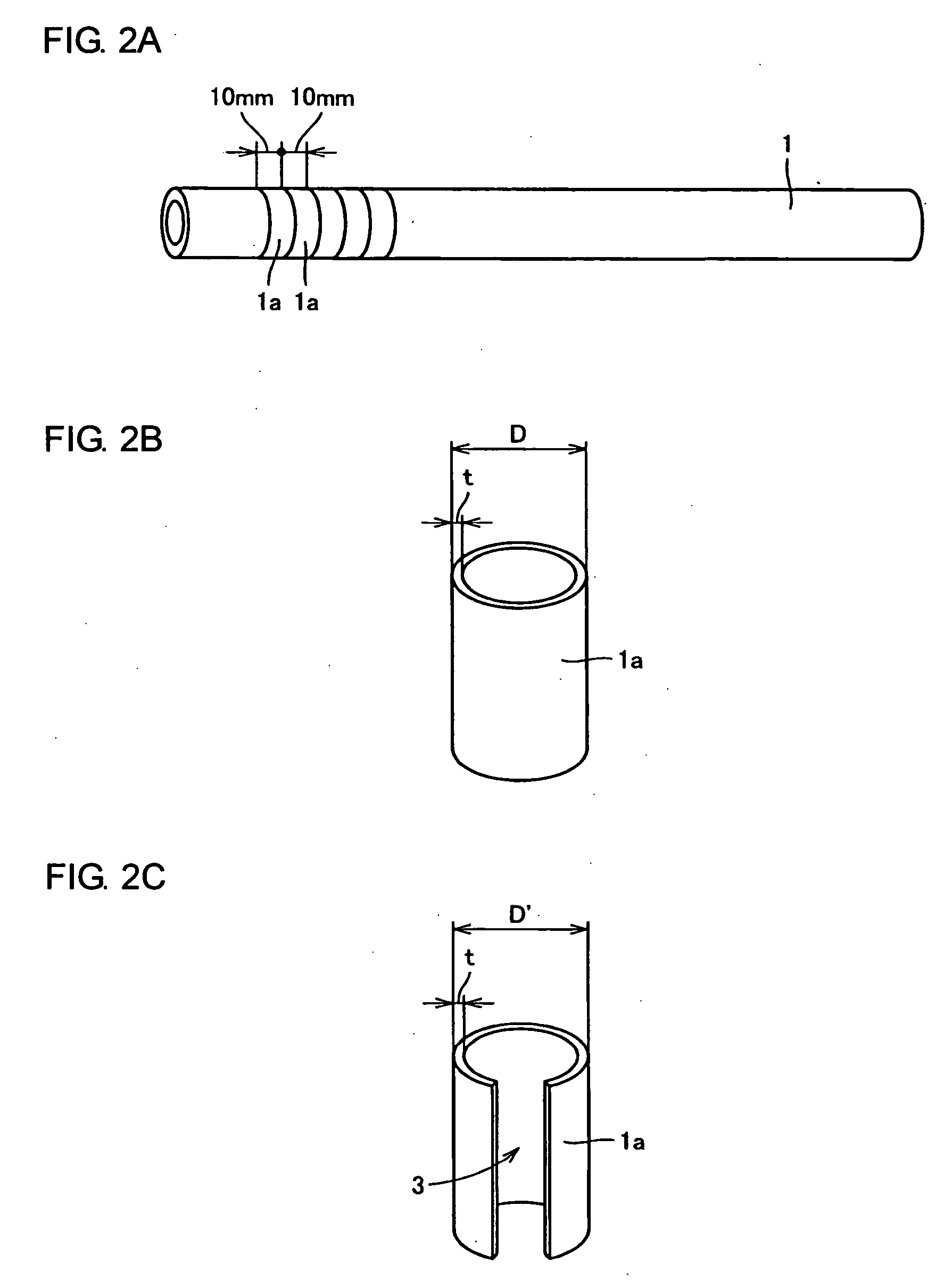

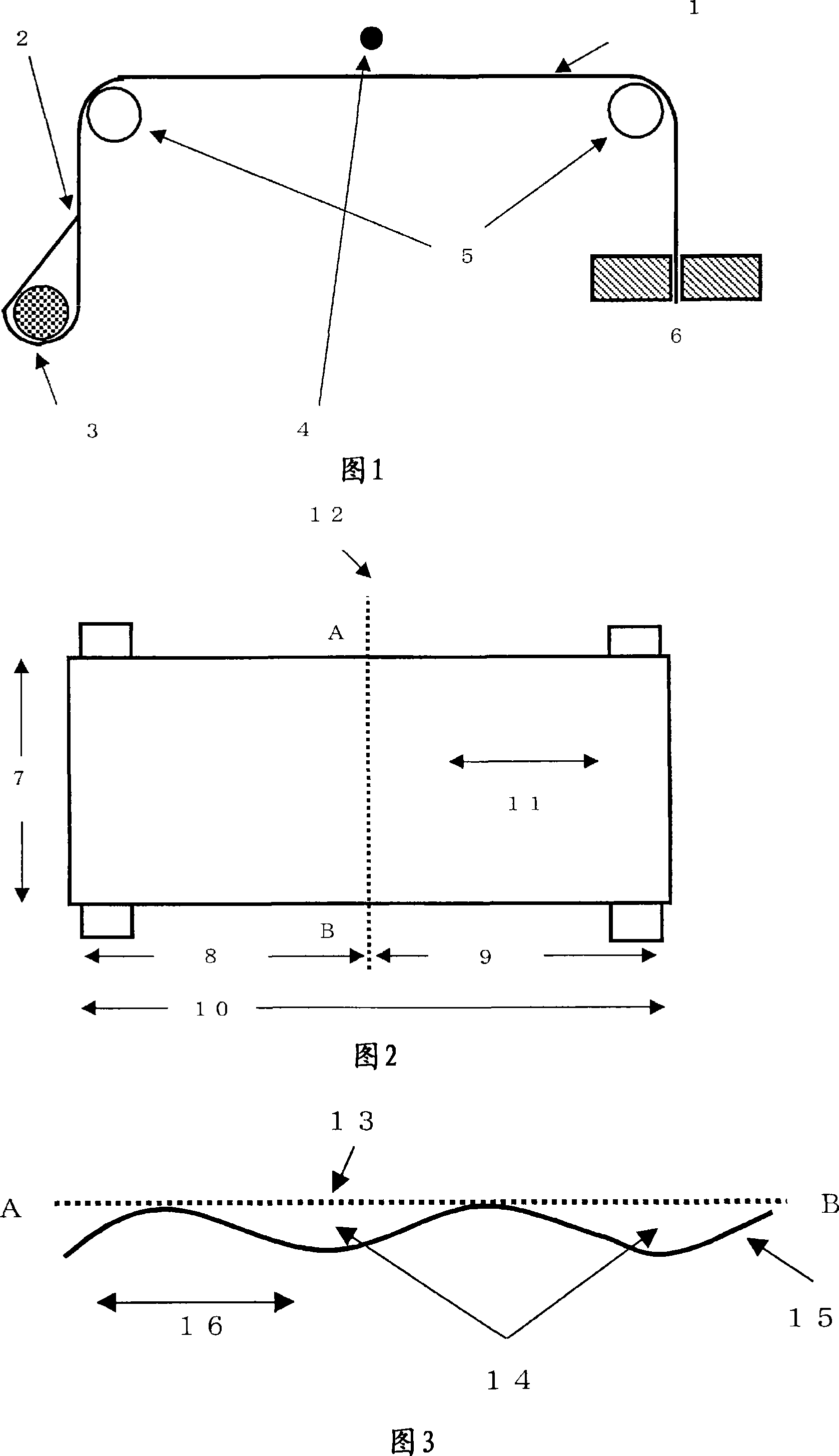

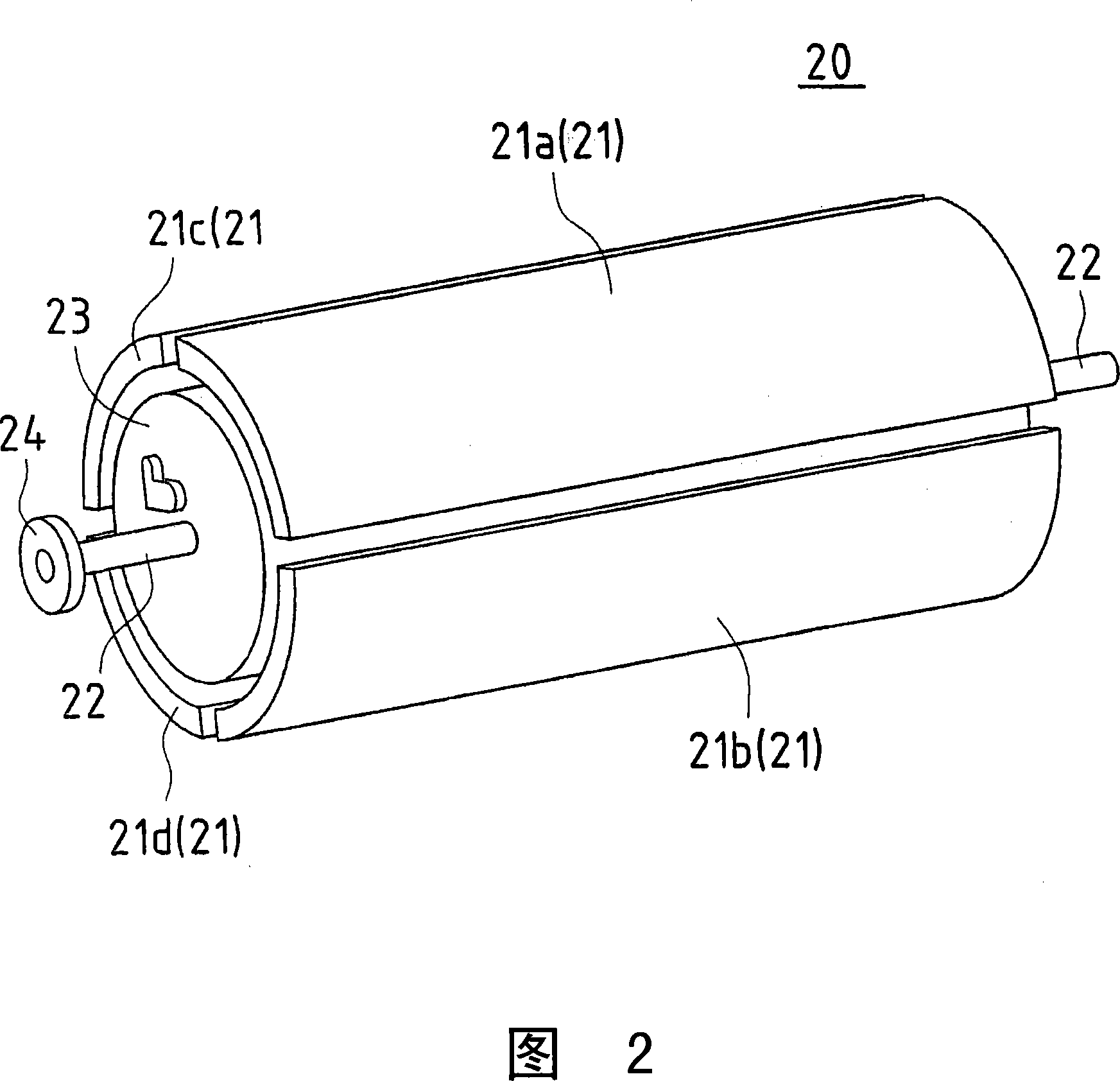

Magnetic tape medium

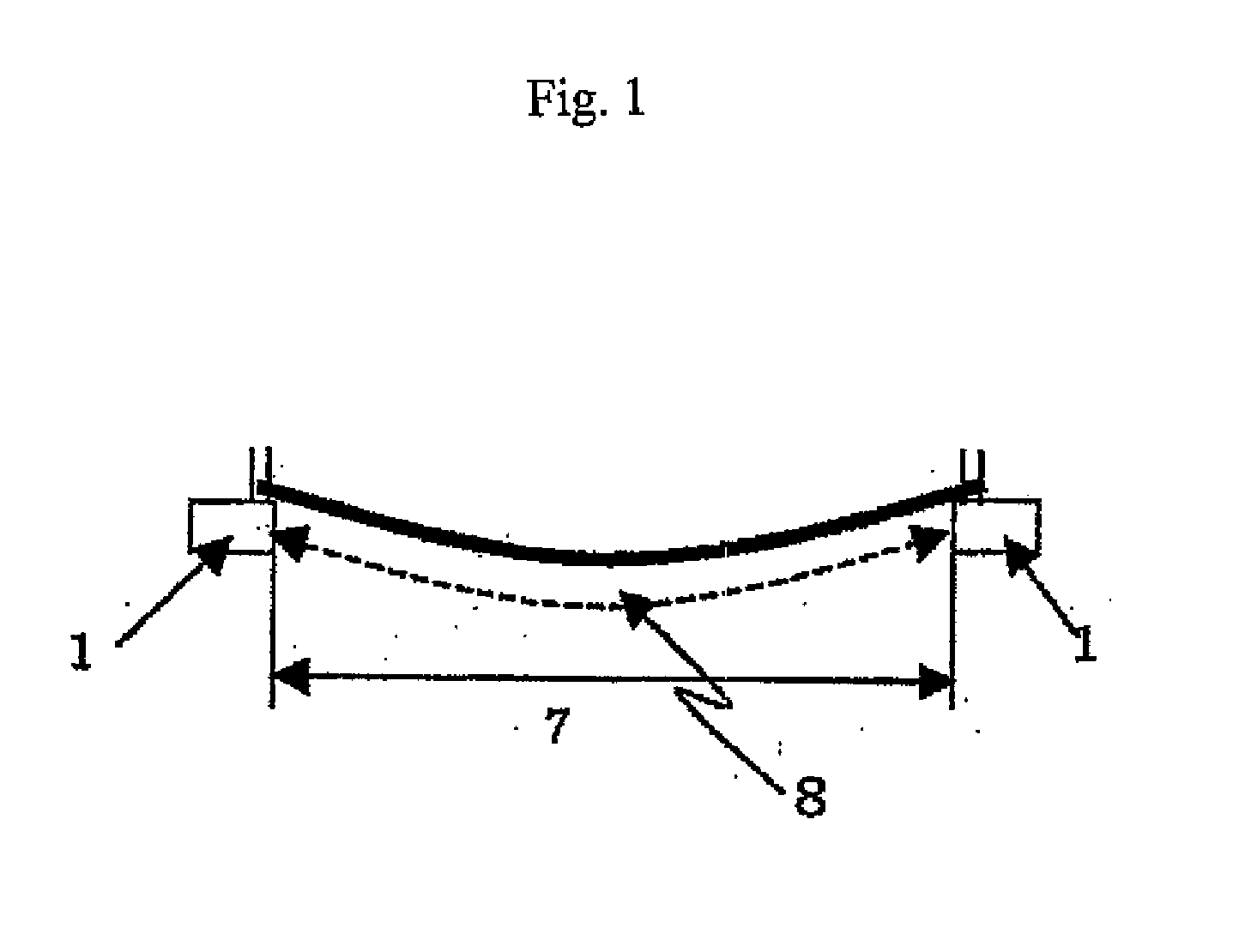

InactiveUS7341798B2Suppresses dimensional changesStable characteristicsMagnetic materials for record carriersBase layers for recording layersTrack densityMagnetic tape

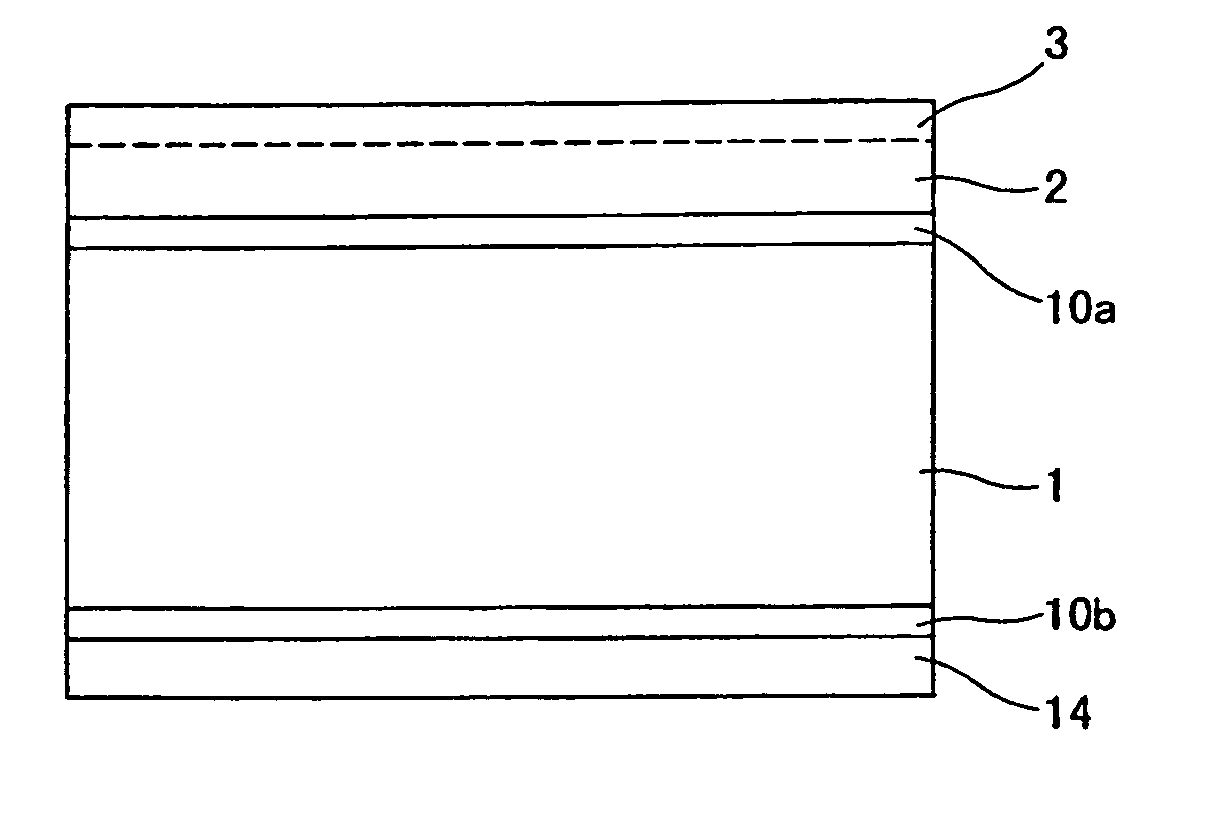

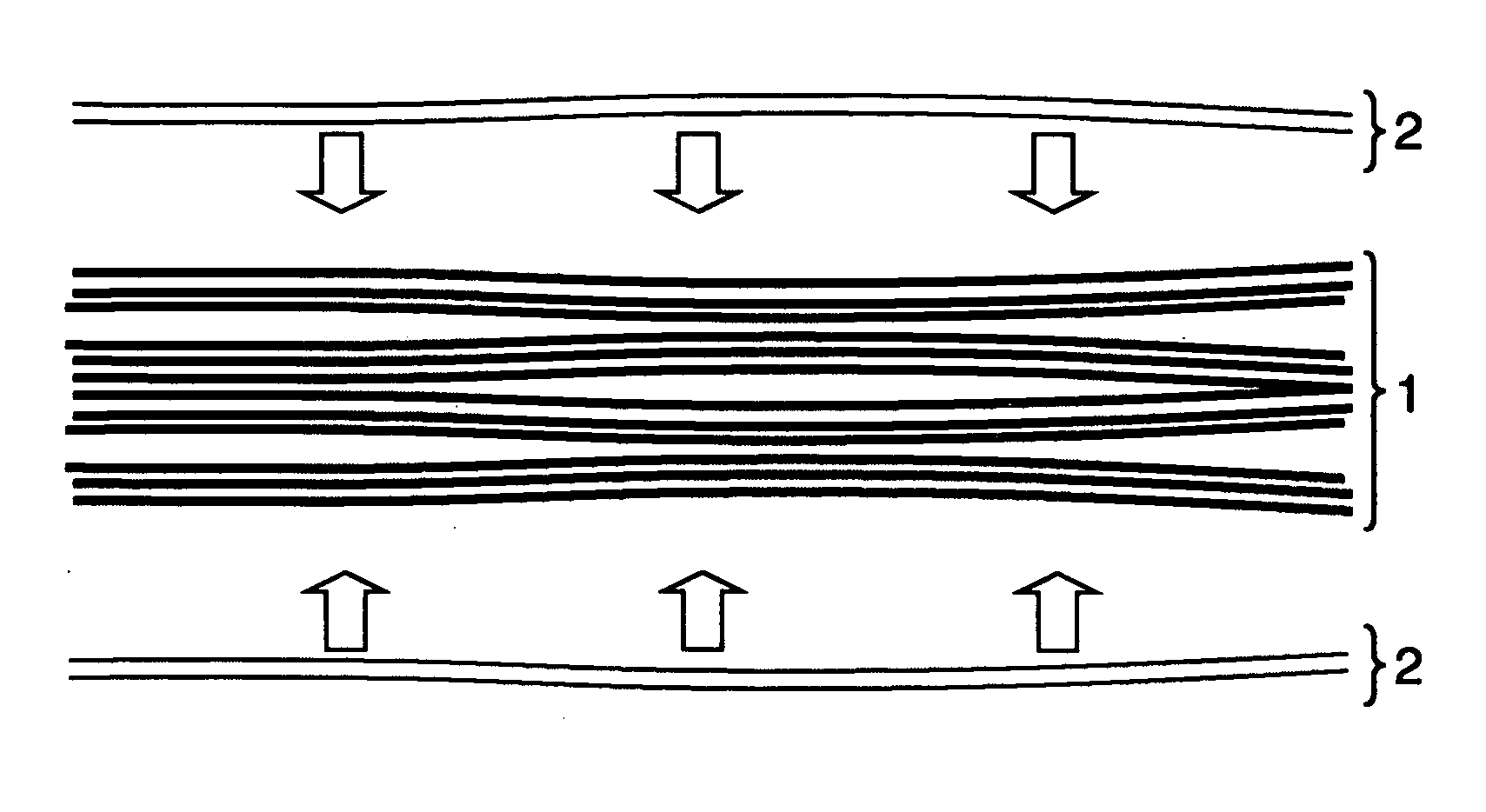

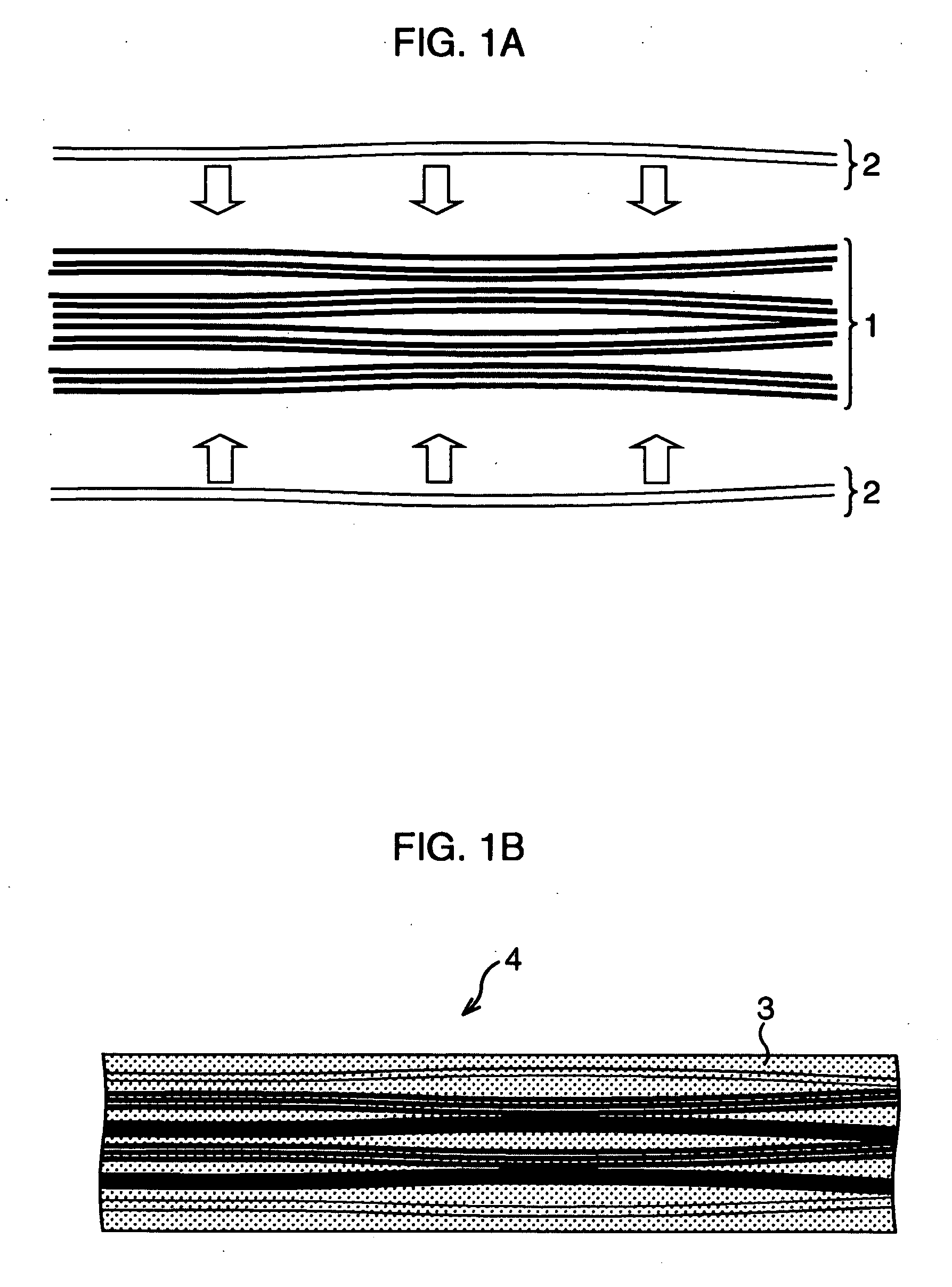

A magnetic recording medium is provided that can ensure stable recording and reproducing characteristics with little off-track even when a track density in the direction of width of the tape is very high and 50 lines / mm or more, an off-track margin is 5 μm or smaller, and a variation that is permitted at maximum as a dimensional variation in the direction of width of the tape itself due to environmental factors such as the change of temperature and humidity, the change of tension, a creep, etc. is small as low as 0.10% or less. Assuming that Young's modulus in the direction of width of a non-magnetic substrate is X and Young's modulus in the direction of width of the back layer is Y, X is 850 kg / mm2 or more, or when X is less than 850 kg / mm2, X×Y is 6×105 or more, and assuming that Young's modulus in the direction of width of a layer including a magnetic layer is Z, Y / Z is not larger than 6.0.

Owner:SONY CORP

Top anti-reflective coating polymer, its preparation method and top anti-reflective coating composition comprising the same

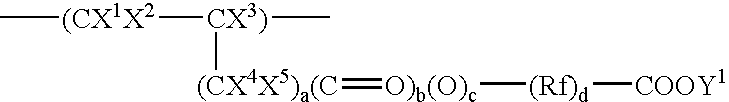

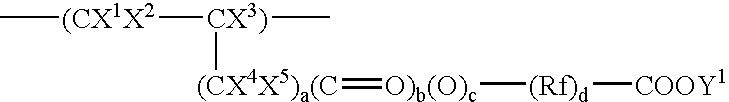

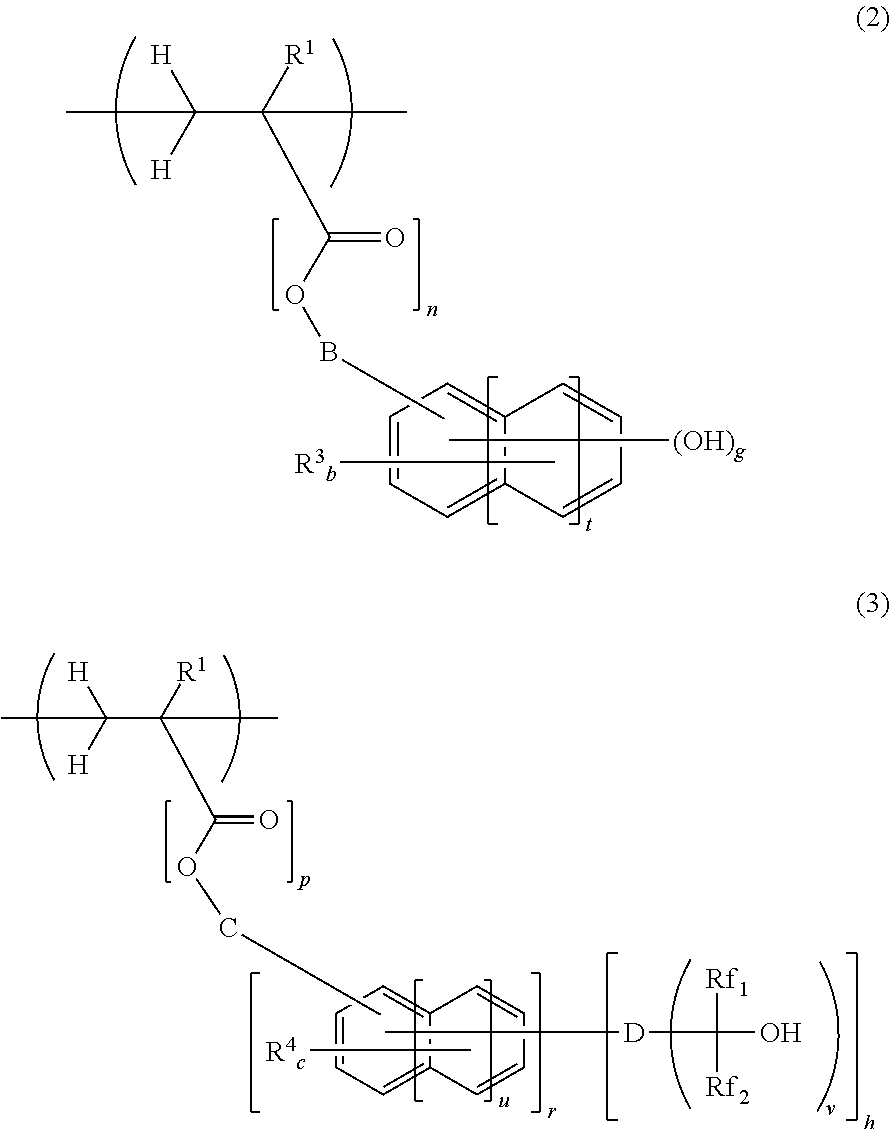

InactiveUS20060127803A1Suppresses dimensional changesSemiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersAnti-reflective coatingHydrogen

Disclosed herein is a top anti-reflective coating polymer and its composition comprising the same represented by Formula 1 below: wherein R1 and R2 are independently, hydrogen, methyl or fluoromethyl; R3 and R4 are independently, a C1-10hydrocarbon or a C1-10 hydrocarbon in which the hydrogen atoms are wholly or partly replaced by fluorine atoms; and a, b, c, d and e represent the mole fraction of each monomer and are in the range between about 0.05 and about 0.9, such that the sum of a, b, c, d, and e equals one.

Owner:SK HYNIX INC

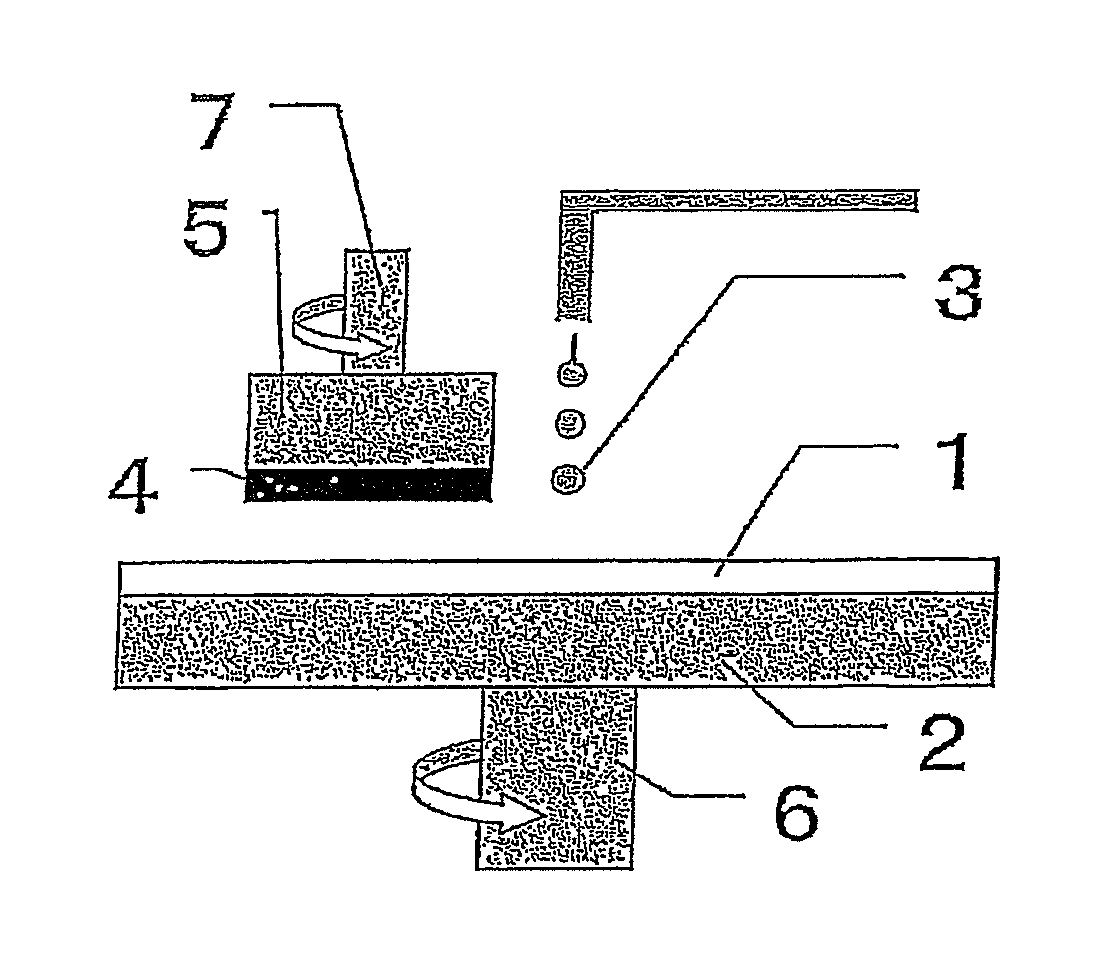

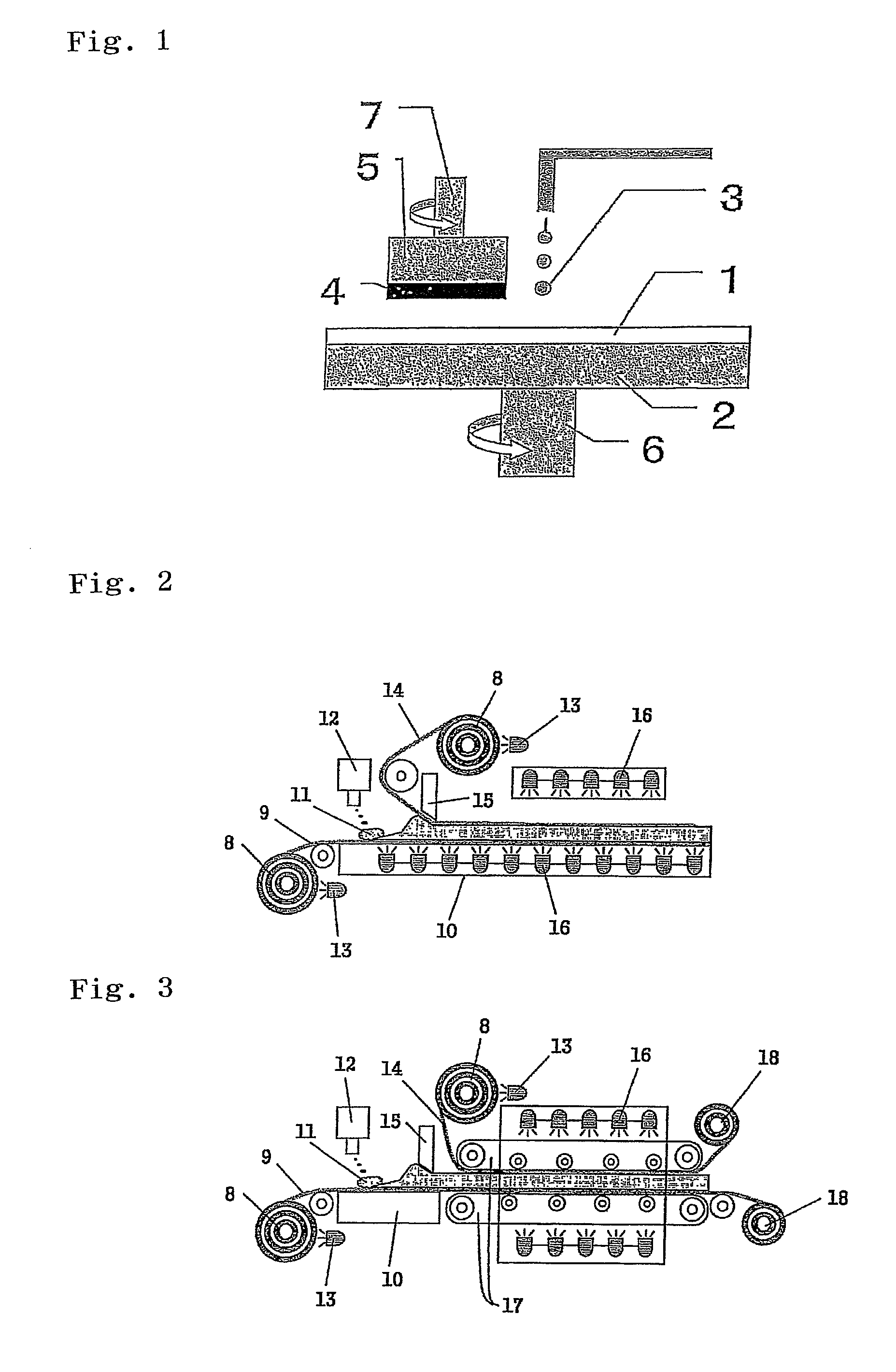

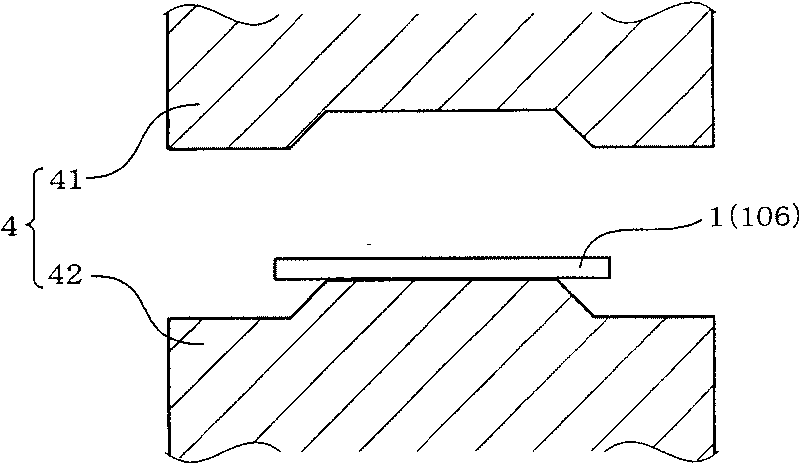

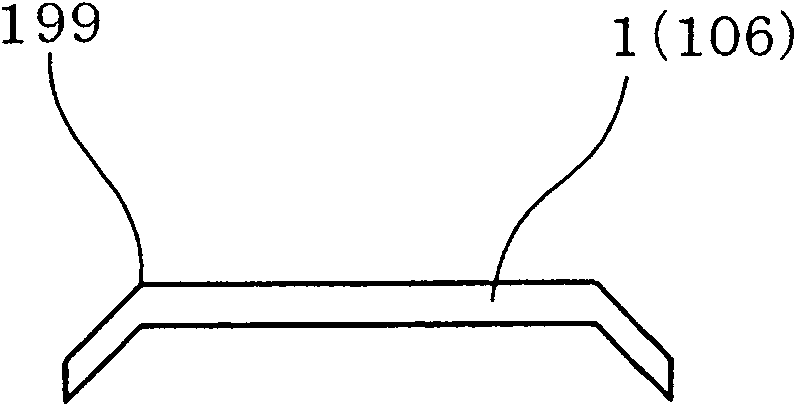

Process for producing polyurethane foam

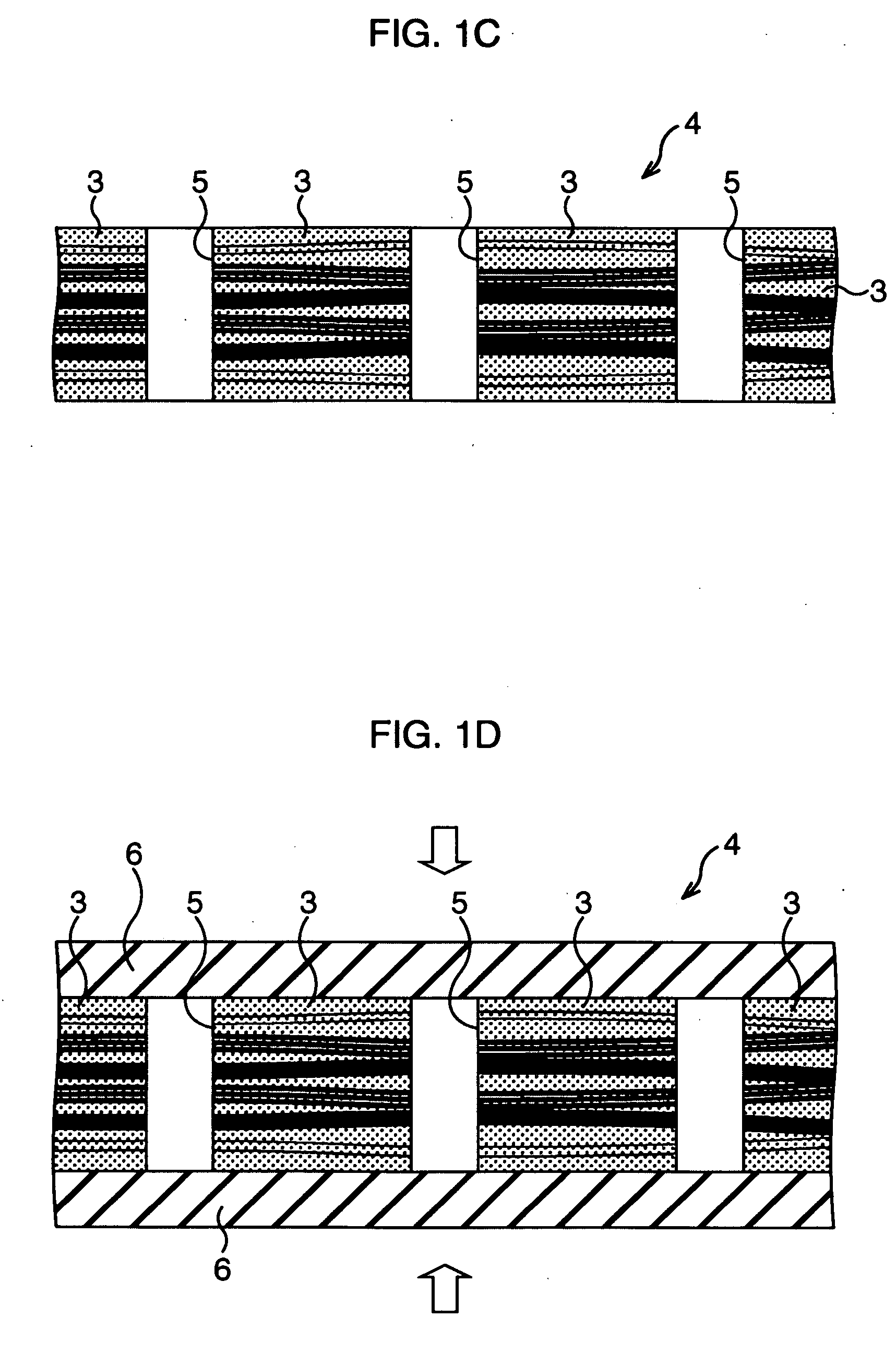

InactiveUS8314029B2High thickness accuracyAir can be trappedOther chemical processesDecorative surface effectsCarbamateSpherical cell

A method for manufacturing a polishing pad containing substantially spherical cells and having high thickness accuracy includes preparing a cell-dispersed urethane composition by a mechanical foaming method; continuously discharging the cell-dispersed urethane composition from a single discharge port to a substantially central portion in the width direction of a face material A, while feeding the face material A; laminating a face material B on the cell-dispersed urethane composition; then uniformly adjusting the thickness of the cell-dispersed urethane composition by thickness adjusting means; curing the cell-dispersed urethane composition with the thickness adjusted in the preceding step without applying any additional load to the composition so that a polishing sheet including a polyurethane foam is formed; and cutting the polishing sheet.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

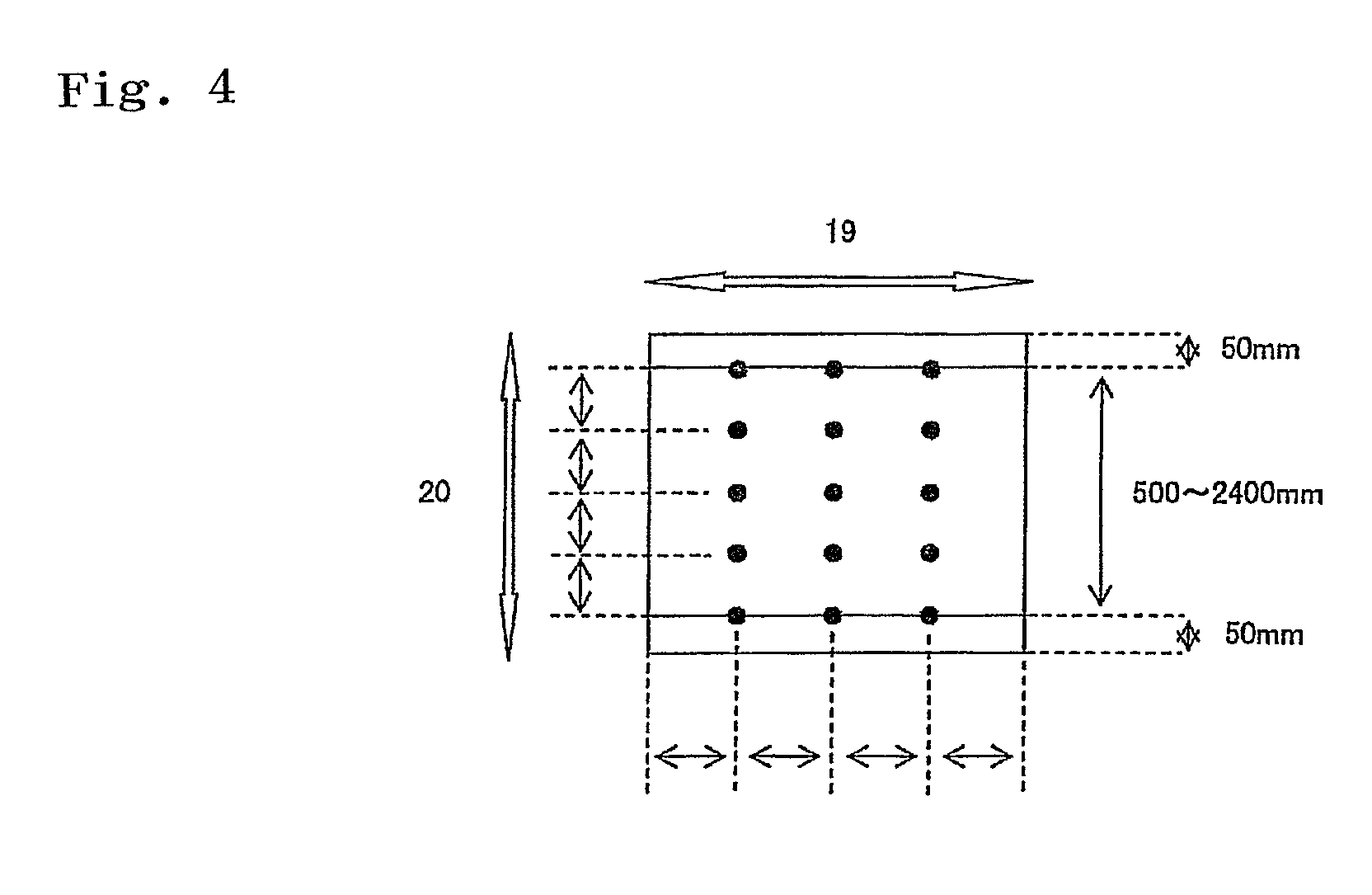

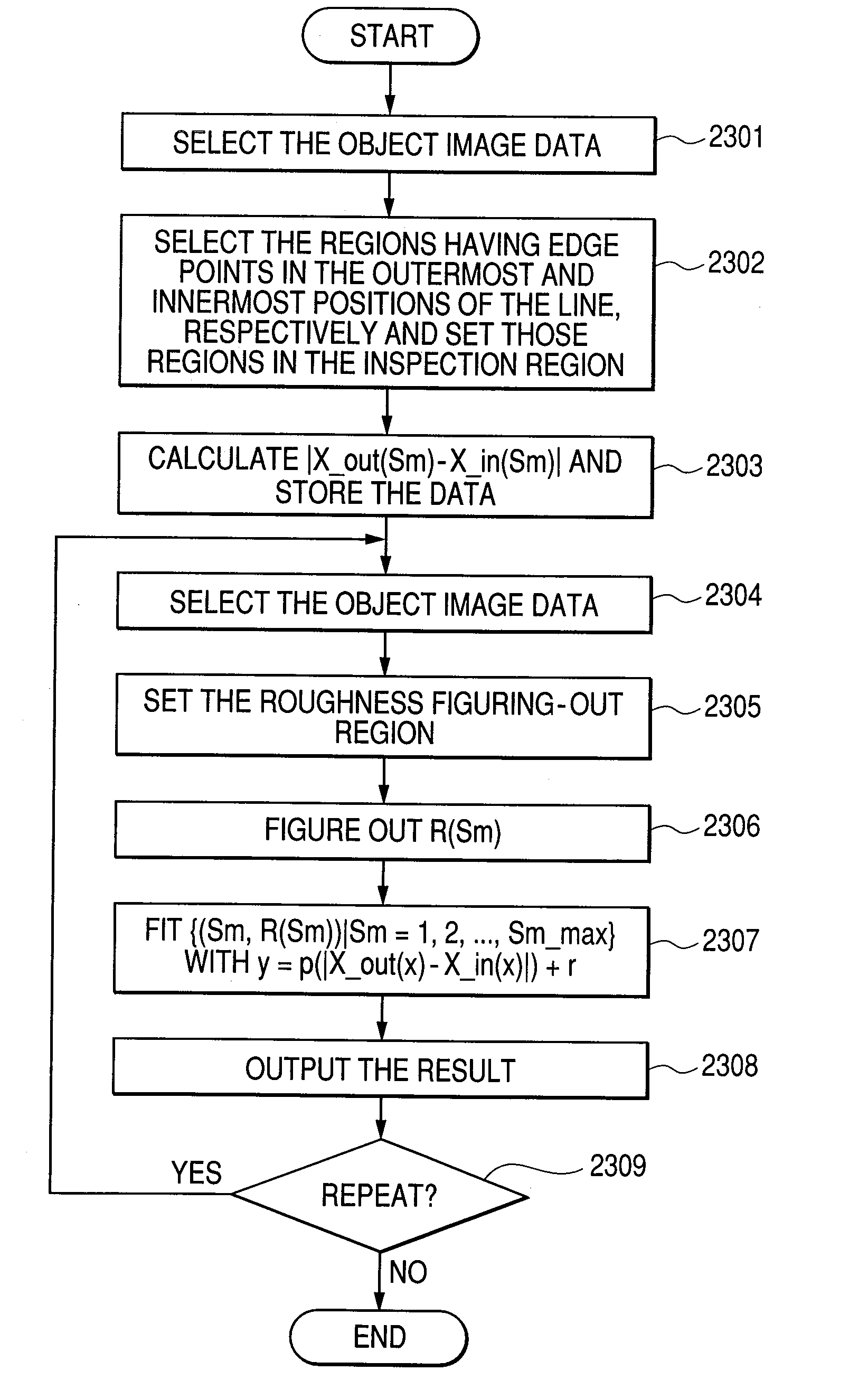

Length measurement system

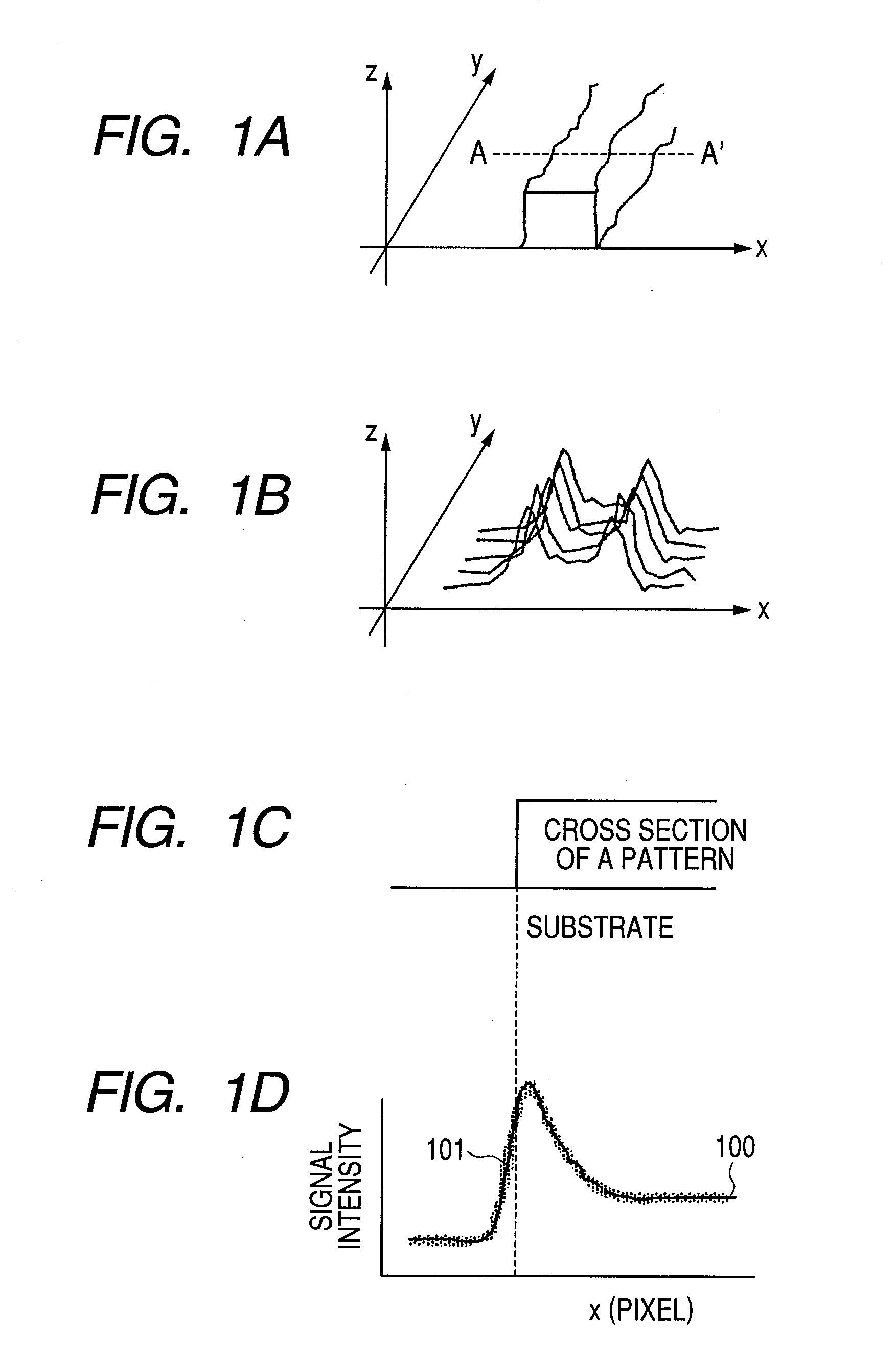

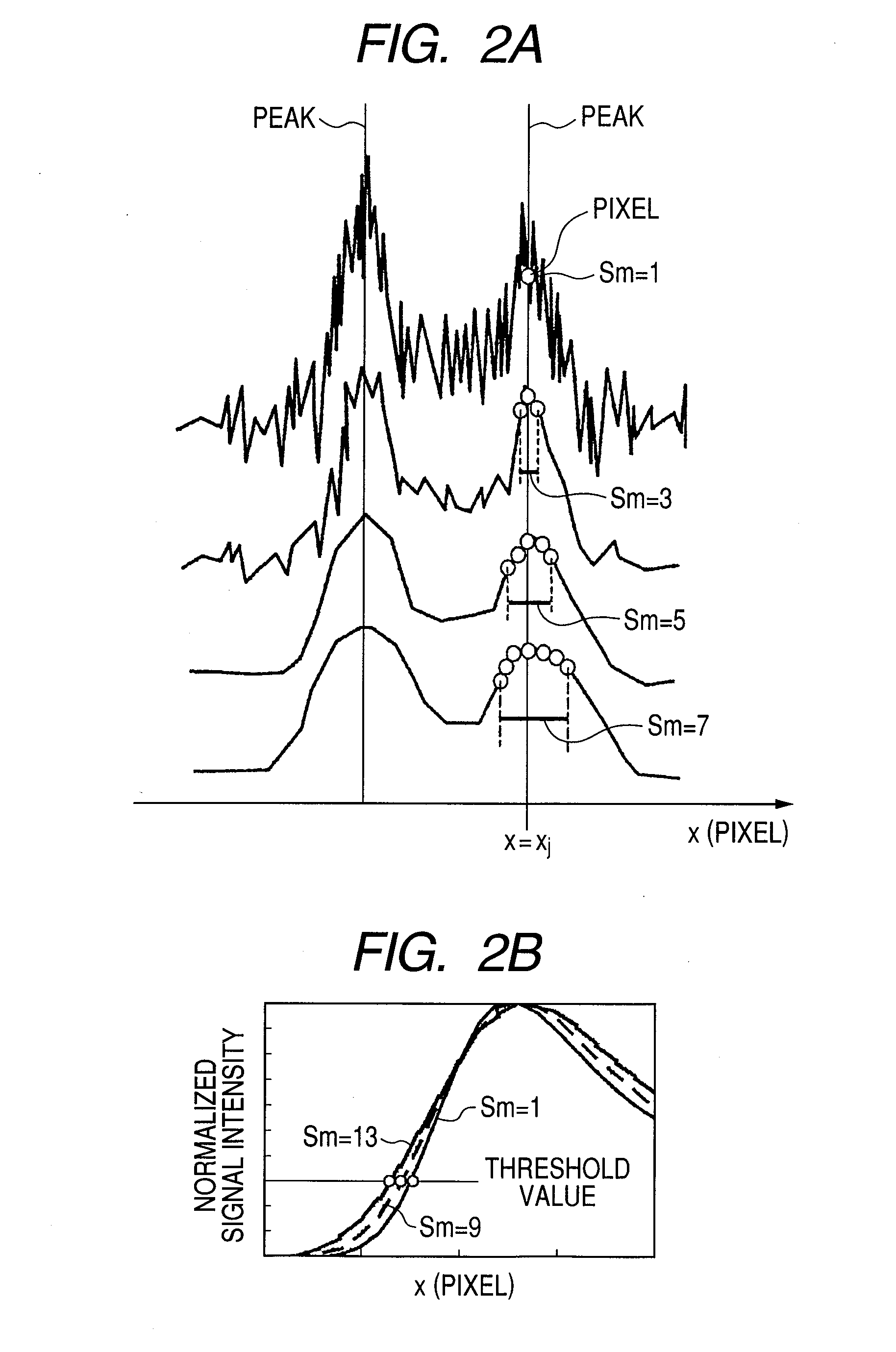

ActiveUS20090046896A1Easy to set upMore measurement accuracyImage enhancementImage analysisImaging processingBand shape

Disclosed herewith is a length measurement system, which obtains a value closer to its true one when figuring out the size and edge roughness of a pattern from a noise-included pattern image. Among plural band-like regions representing a portion around an edge in an image respectively, the system calculates the dependency of the edge point position on the image processing parameter at each of a narrow width band-like portion and a wide width band-like portion to calculate an image processing condition that calculates each measured value closer to its true value or estimates the true value itself.

Fine pattern forming method

InactiveUS20040101787A1Well formedSuppresses dimensional changesPhotosensitive materialsSemiconductor/solid-state device manufacturingPhoto irradiationIrradiation

There is provided a method of forming a fine resist pattern in which a highly practicable photo-sensitive composition obtained from a material having a high transparency against an exposure light having a short wavelength such as F2 excimer laser beam is used as a resist, and the method of forming a fine resist pattern comprises a step for forming a photo-sensitive layer on a substrate or on a given layer on a substrate using a photo-sensitive composition comprising at least a compound generating an acid by irradiation of light and a compound having fluorine atom in its molecular structure, a step for exposing by selectively irradiating a given area of said photo-sensitive layer with energy ray, a step for heat-treating the exposed photo-sensitive layer, and a step for forming a fine pattern by developing the heat-treated photo-sensitive layer to selectively remove the exposed portion or un-exposed portion of the photo-sensitive layer.

Owner:SEMICON LEADING EDGE TECH +1

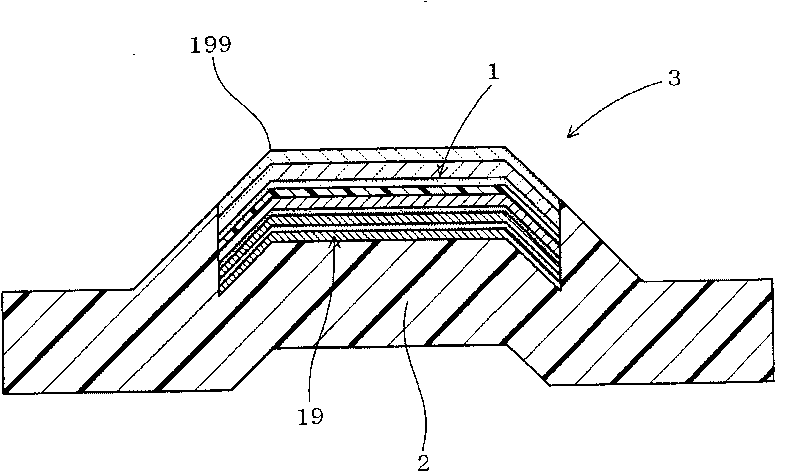

Semiconductor acceleration sensor device and fabrication method thereof

InactiveUS7513154B2Suppresses dimensional changesIncrease changeAcceleration measurement using interia forcesSolid-state devicesSemiconductorAcceleration Unit

A semiconductor acceleration sensor device has an acceleration sensor chip and a hollow package to house the acceleration sensor chip. A concave section is formed in a predetermined area on a bottom face inside the package. The semiconductor acceleration sensor device also has a low elasticity element with adhesiveness. The low elasticity element is filled in the concave section. The acceleration sensor chip is mounted on the low elasticity element. The adhesive surface between the low elasticity element and the acceleration sensor chip is higher than the bottom face.

Owner:LAPIS SEMICON CO LTD

Foamed tile and its manufacturing method

InactiveUS20050276951A1Avoid the growth of bacteriaFormation of mold be preventedCovering/liningsLayered productsCeramicMelting point

To manufacture in thin structure, easily and at low cost. By forming a foaming glaze layer on the surface of a base material made of ceramics, the product strength is assured in a base material formed densely, and the heat insulation in the foaming glaze layer is assured, and after applying a foaming glaze on a base material or a formed body adjusted to be formed as base material, and by baking the glazed material at temperature higher than the melting and foaming point of the foaming glaze and at temperature lower than the softening temperature of the base material, dimensional changes of base layer (base material) at the time of baking are suppressed, and strict management during manufacture is not needed.

Owner:FUJIMI CERAMIC

Decorative sheet and decorative molded article

InactiveCN101712223AGood flexibilityImprove resistance to damageSynthetic resin layered productsPaper/cardboard layered productsPolyurethane adhesivePolyethylene terephthalate

Owner:TOYODA GOSEI CO LTD

Top anti-reflective coating polymer, its preparation method and top anti-reflective coating composition comprising the same

ActiveUS20050238991A1Suppresses dimensional changesHigh light transmittanceOriginals for photomechanical treatmentSilver halide emulsionsAnti-reflective coatingHydrogen

Disclosed herein are a top anti-reflective coating polymer used in a photolithography process, which is one of the fabrication processes for a semiconductor device, a method for preparing the anti-reflective coating polymer, and an anti-reflective coating composition comprising the anti-reflective coating polymer. Specifically, the top anti-reflective coating polymer is used in immersion lithography for the fabrication of a sub-50 nm semiconductor device. The top anti-reflective coating polymer is represented by Formula 1 below: wherein R1, R2 and R3 are independently hydrogen or a methyl group; and a, b and c represent the mole fraction of each monomer, and are in the range between about 0.05 and about 0.9. Since a top anti-reflective coating formed using the above anti-reflective coating polymer is not soluble in water, it can be applied to immersion lithography using water as the medium for a light source. In addition, since the top anti-reflective coating can reduce the reflectance from an underlayer, the uniformity of CD is improved, thus enabling the formation of an ultrafine pattern.

Owner:SK HYNIX INC

Multilevel interconnection board and method of fabricating the same

InactiveUS20070077391A1Suppresses dimensional changesSemiconductor/solid-state device detailsSolid-state devicesThermal expansionInterconnection

A stack of 50 layers of a first pitch-base carbon fiber sheet is formed, two sets of stack each having two second pitch-base carbon fiber sheets stacked therein are fabricated. At this time, the second carbon fiber sheets have a thermal expansion coefficient larger than that of the first carbon fiber sheet. Next, the stack of the first carbon fiber sheet is then held between two sets of stack of the second carbon fiber sheets. The stack of the first and second carbon fiber sheets are then impregnated with an epoxy-base resin composition and the resin is solidified. As a result a prepreg composed of the first and second carbon fiber sheets and the resin component composed of the epoxy-base resin composition is obtained. Thereafter, interconnections and the like are then formed on the prepreg, to thereby complete a multilevel interconnection board.

Owner:FUJITSU LTD

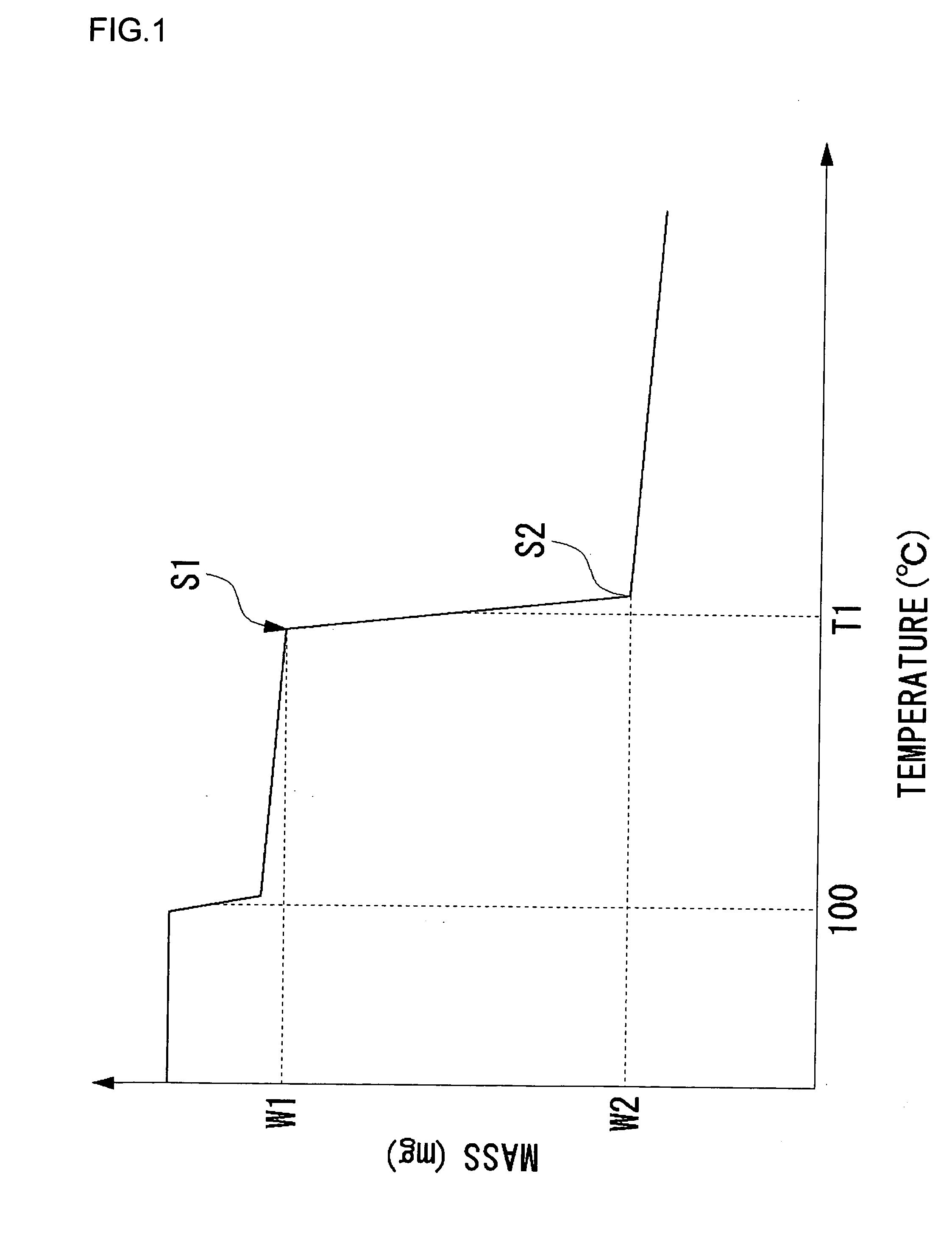

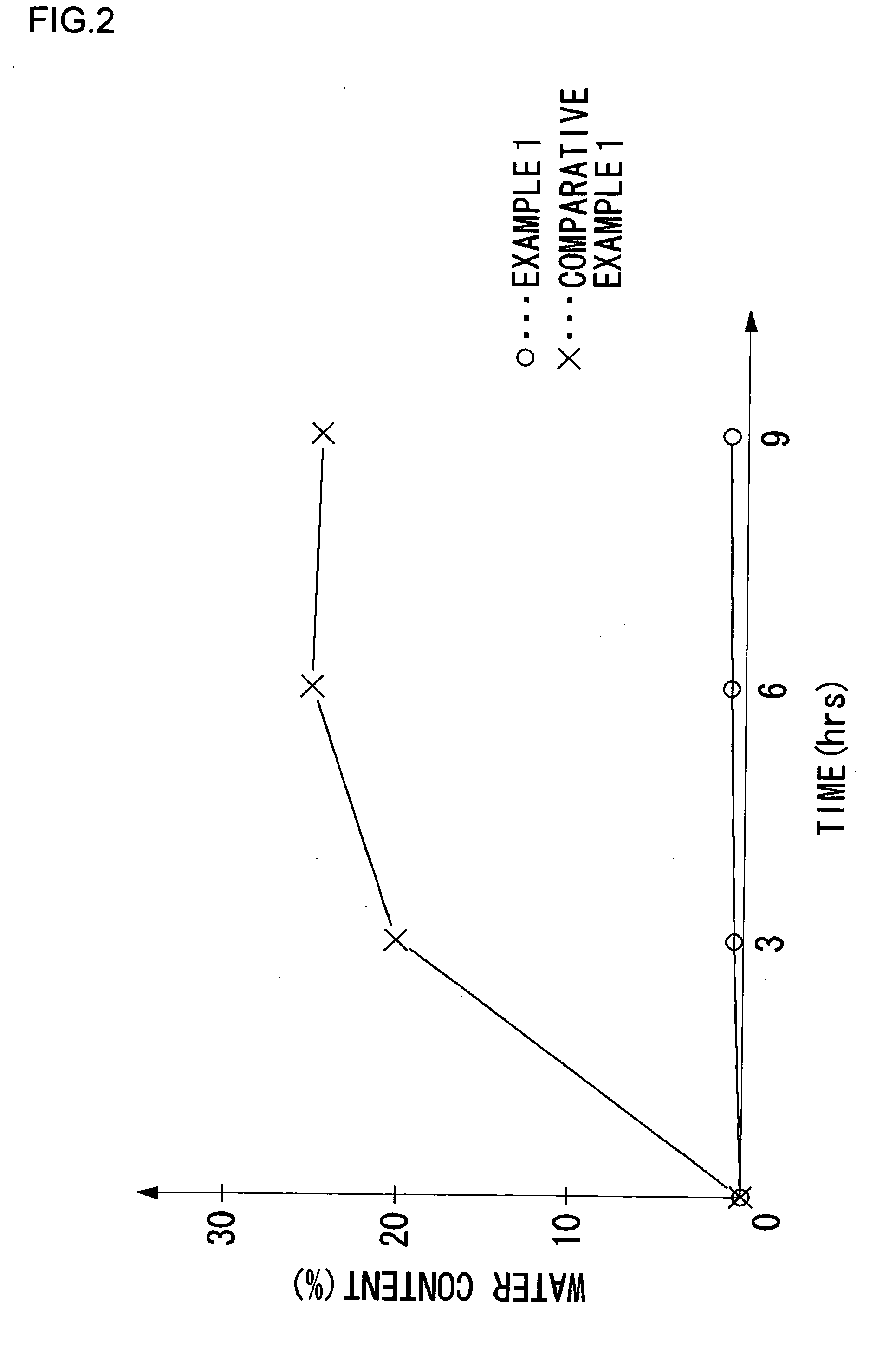

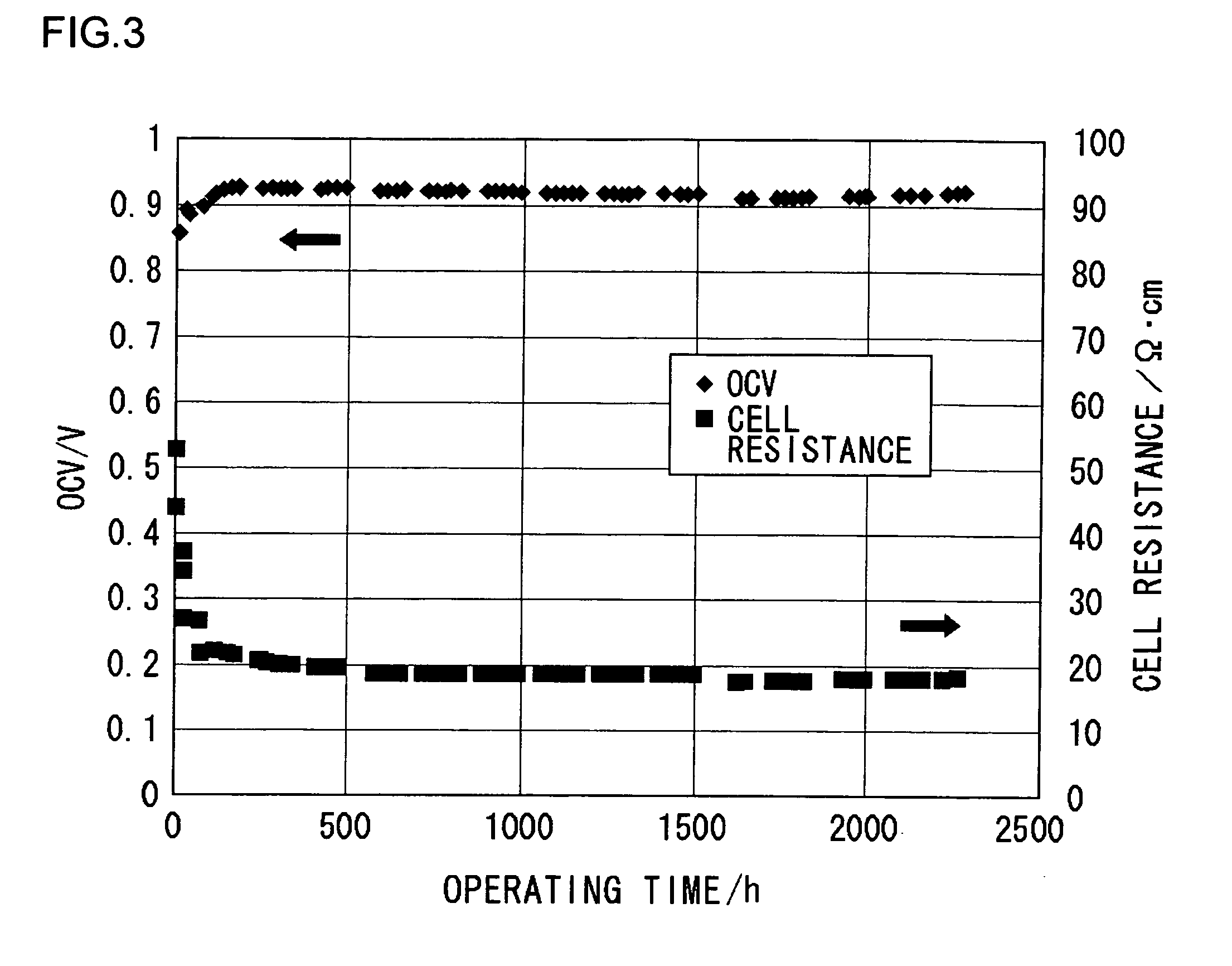

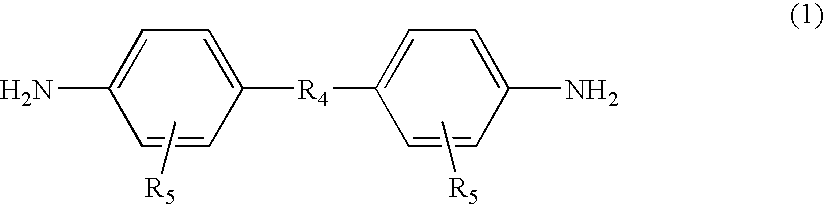

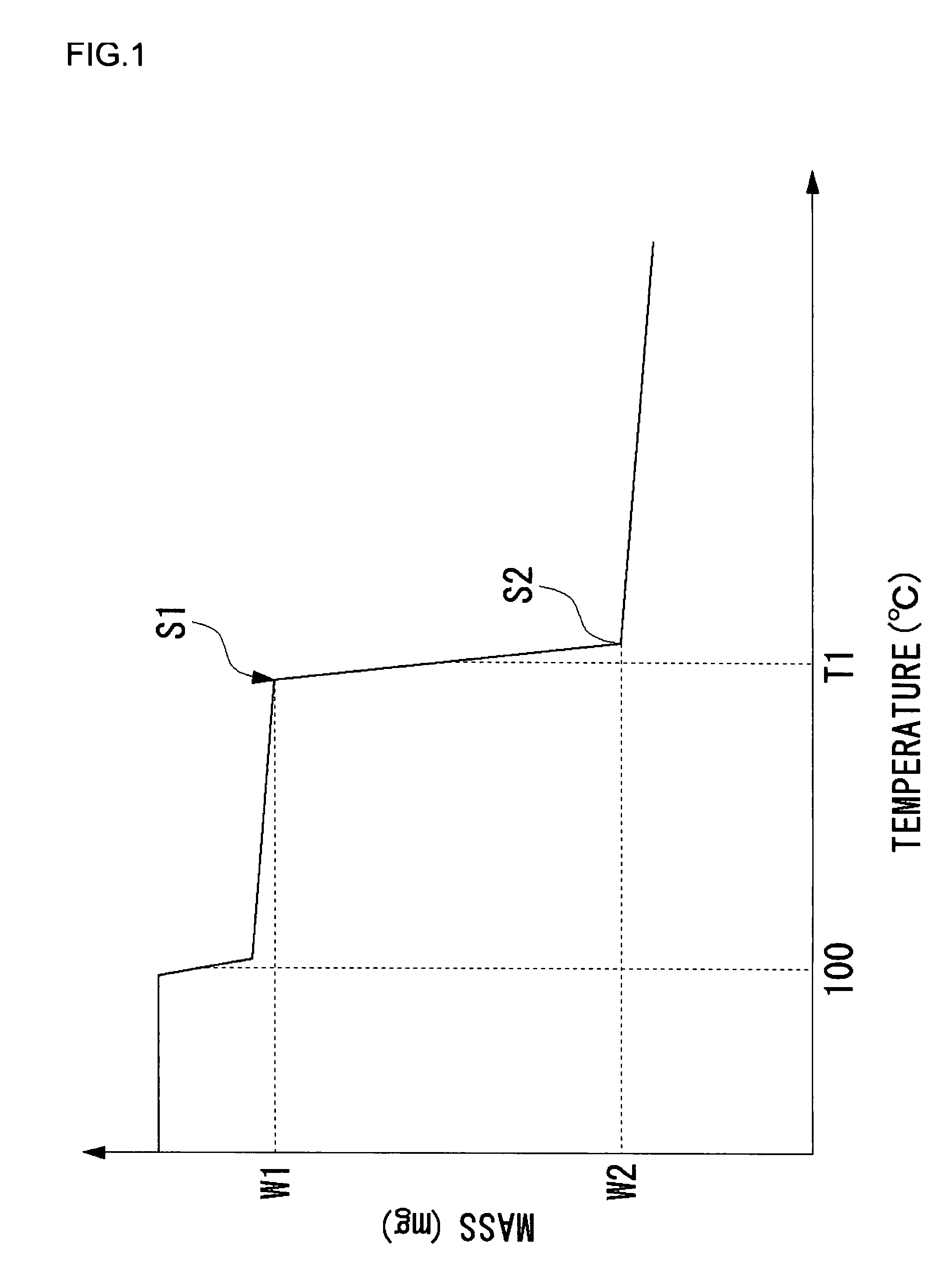

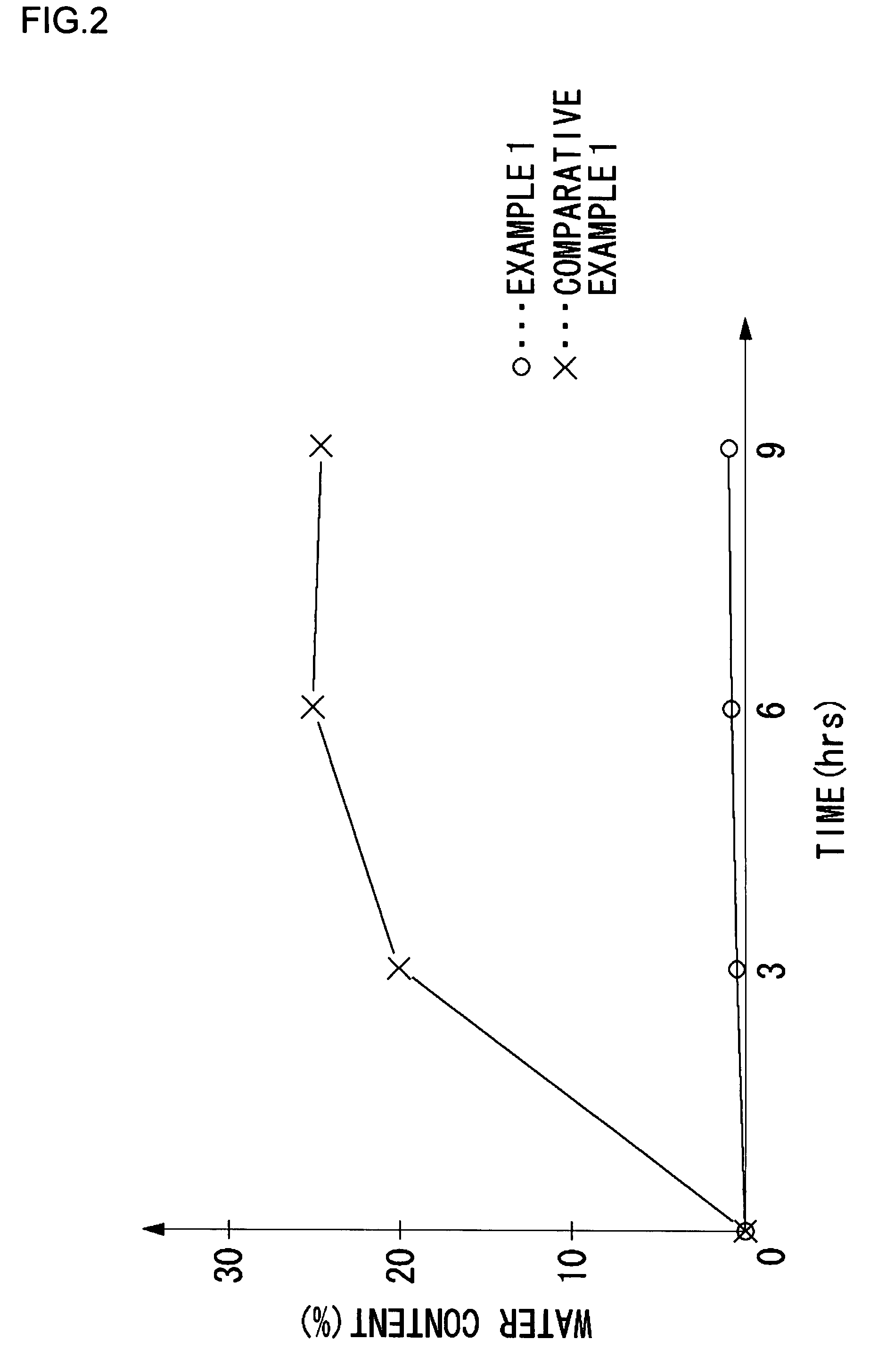

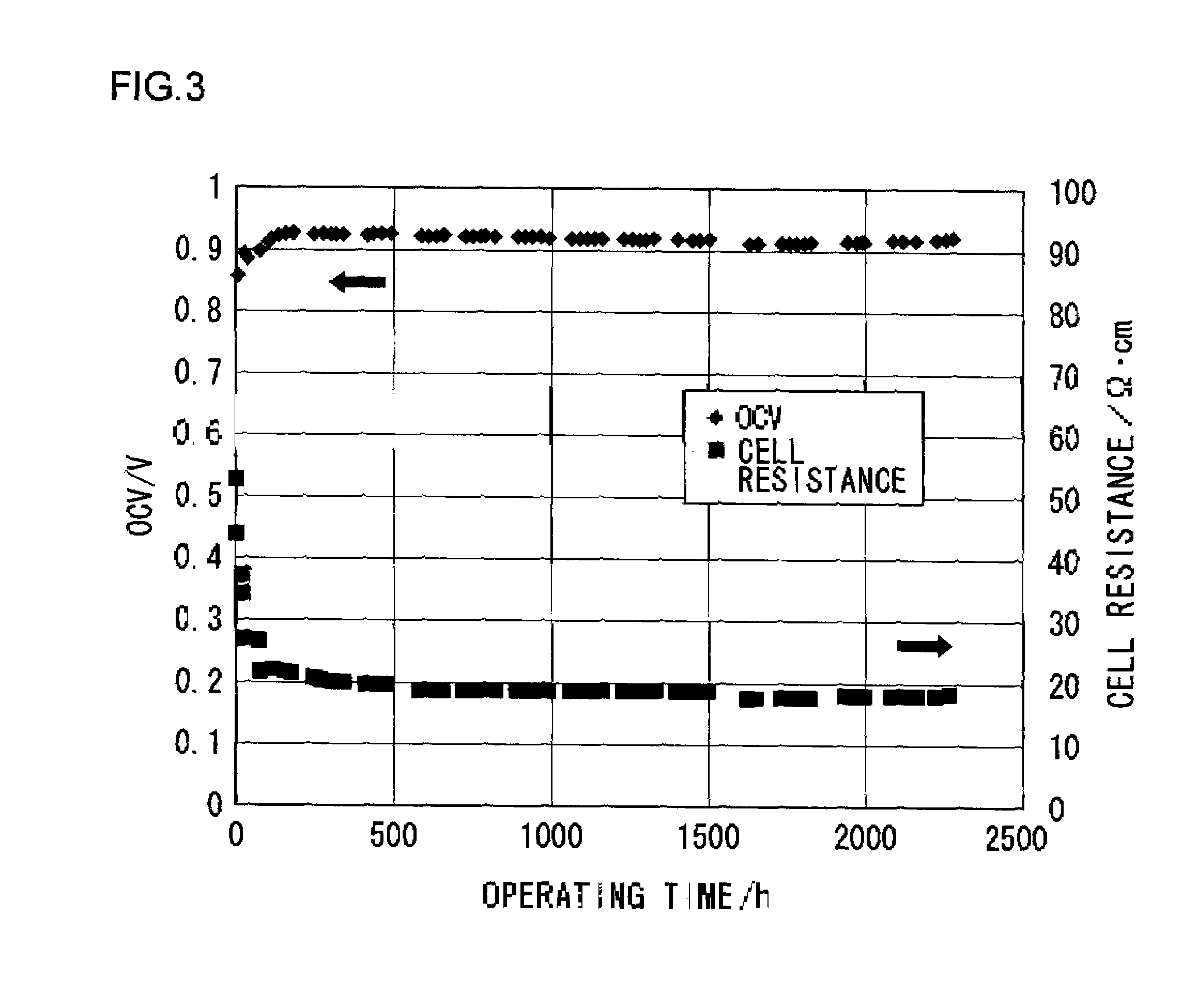

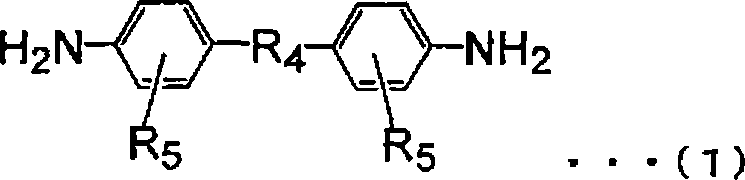

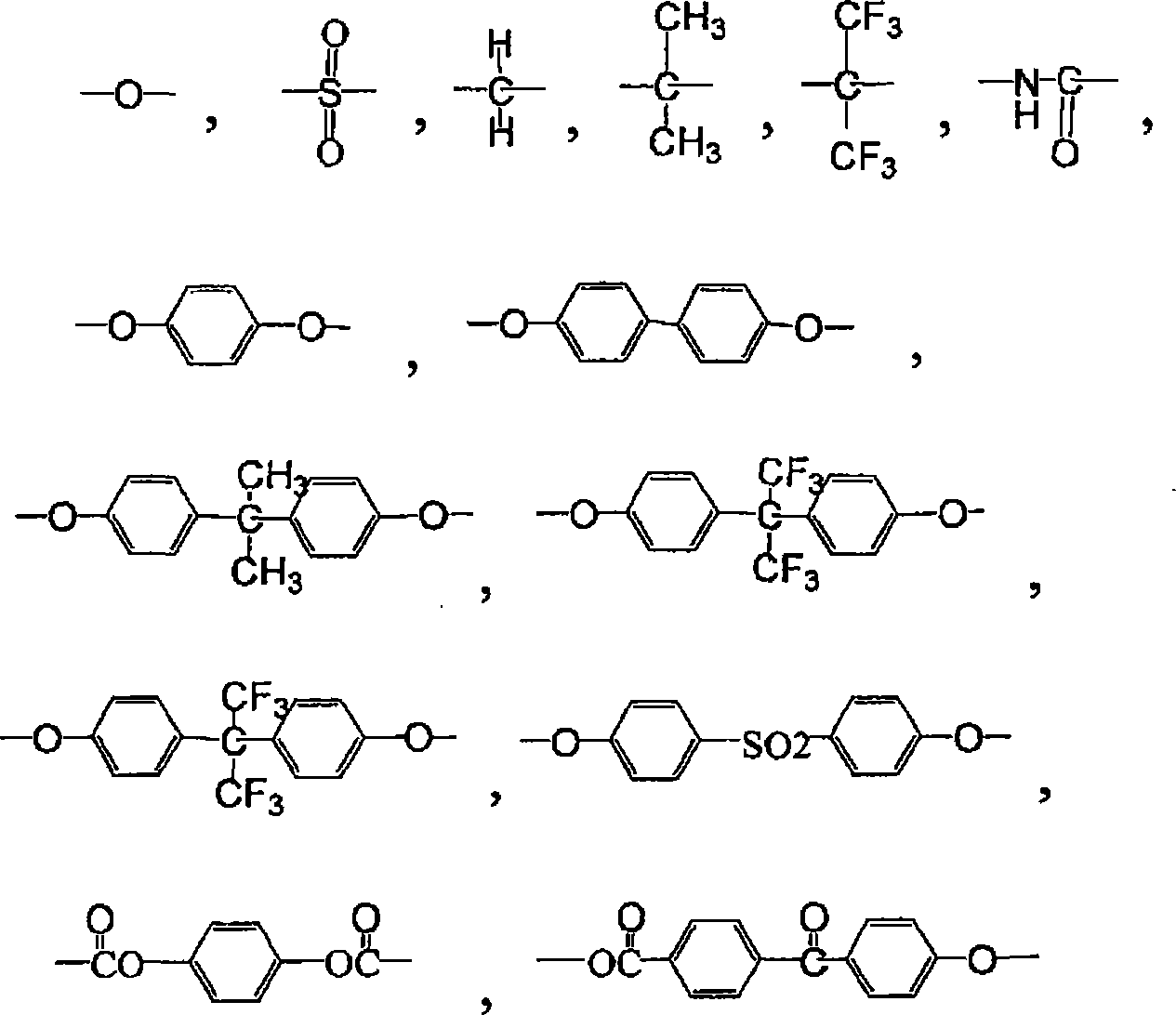

Fuel cell electrolyte, membrane electrode assembly, and method of manufacturing fuel cell electrolyte

InactiveUS20060257705A1Reduce productionGood gas diffusionSolid electrolytesIon-exchanger regenerationArylFuel cells

Dimensional change occurring in a fuel cell electrolyte including a basic polymer after the electrolyte is doped with acid is regulated and the occurrence of wrinkles and the like is reduced. A fuel cell electrolyte comprises a basic polymer and an organic phosphonic acid expressed by the following general formula (1): where R represents an alkyl, aryl, acyl, amino, phosphonic group or a derivative of the functional group, and n is 1 or 2

Owner:SANYO ELECTRIC CO LTD +2

Magnetic tape medium

InactiveUS20050260458A1Less off-trackSuppresses dimensional changesMagnetic materials for record carriersBase layers for recording layersTrack densityMagnetic layer

A magnetic recording medium is provided that can ensure stable recording and reproducing characteristics with little off-track even when a track density in the direction of width of the tape is very high and 50 lines / mm or more, an off-track margin is 5 μm or smaller, and a variation that is permitted at maximum as a dimensional variation in the direction of width of the tape itself due to environmental factors such as the change of temperature and humidity, the change of tension, a creep, etc. is small as low as 0.10% or less. Assuming that Young's modulus in the direction of width of a non-magnetic substrate is λ and Young's modulus in the direction of width of the back layer is Y, X is 850 kg / mm2 or more, or when X is less than 850 kg / mm2, X×Y is 6×105 or more, and assuming that Young's modulus in the direction of width of a layer including a magnetic layer is Z, Y / Z is not larger than 6.0.

Owner:SONY CORP

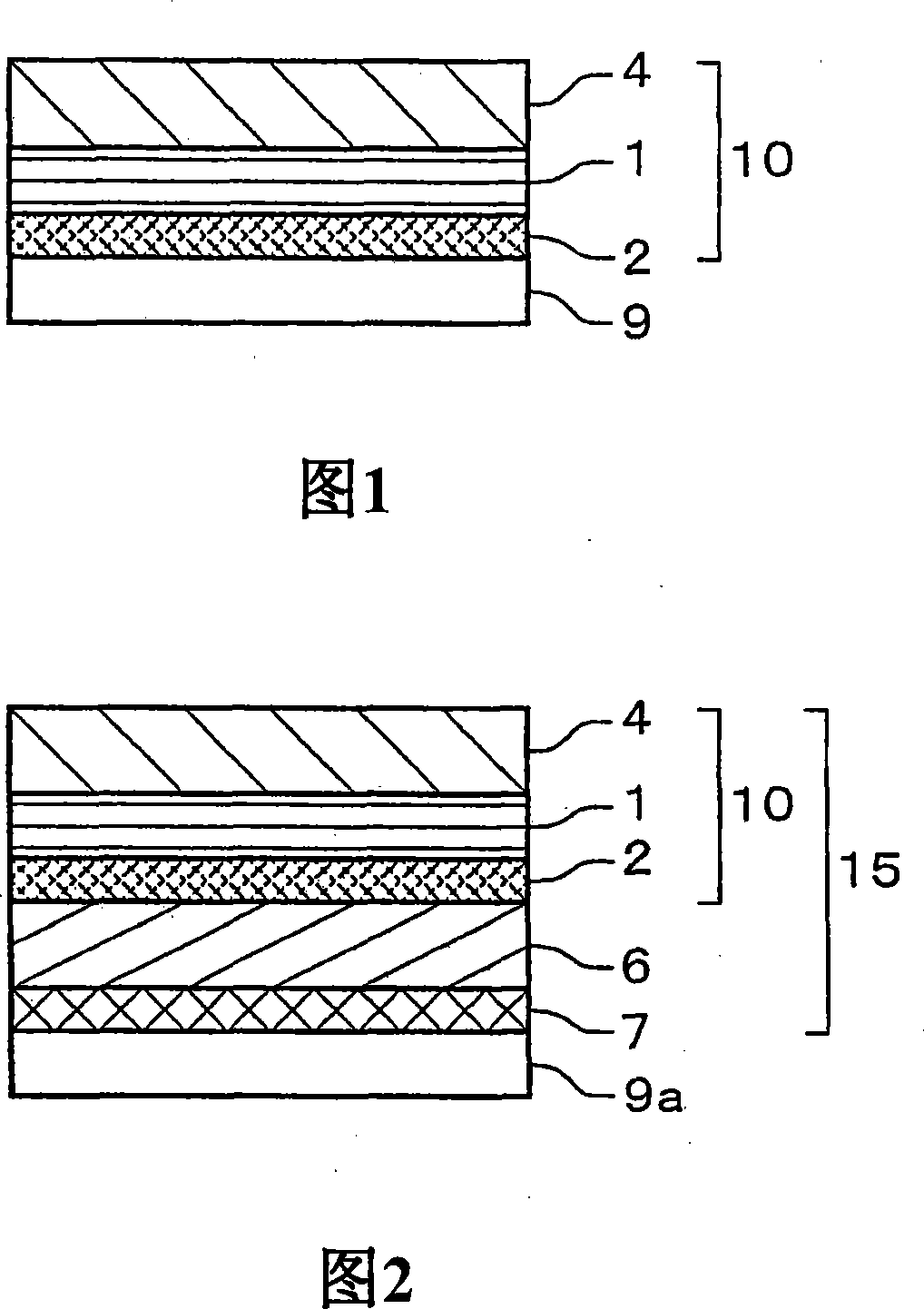

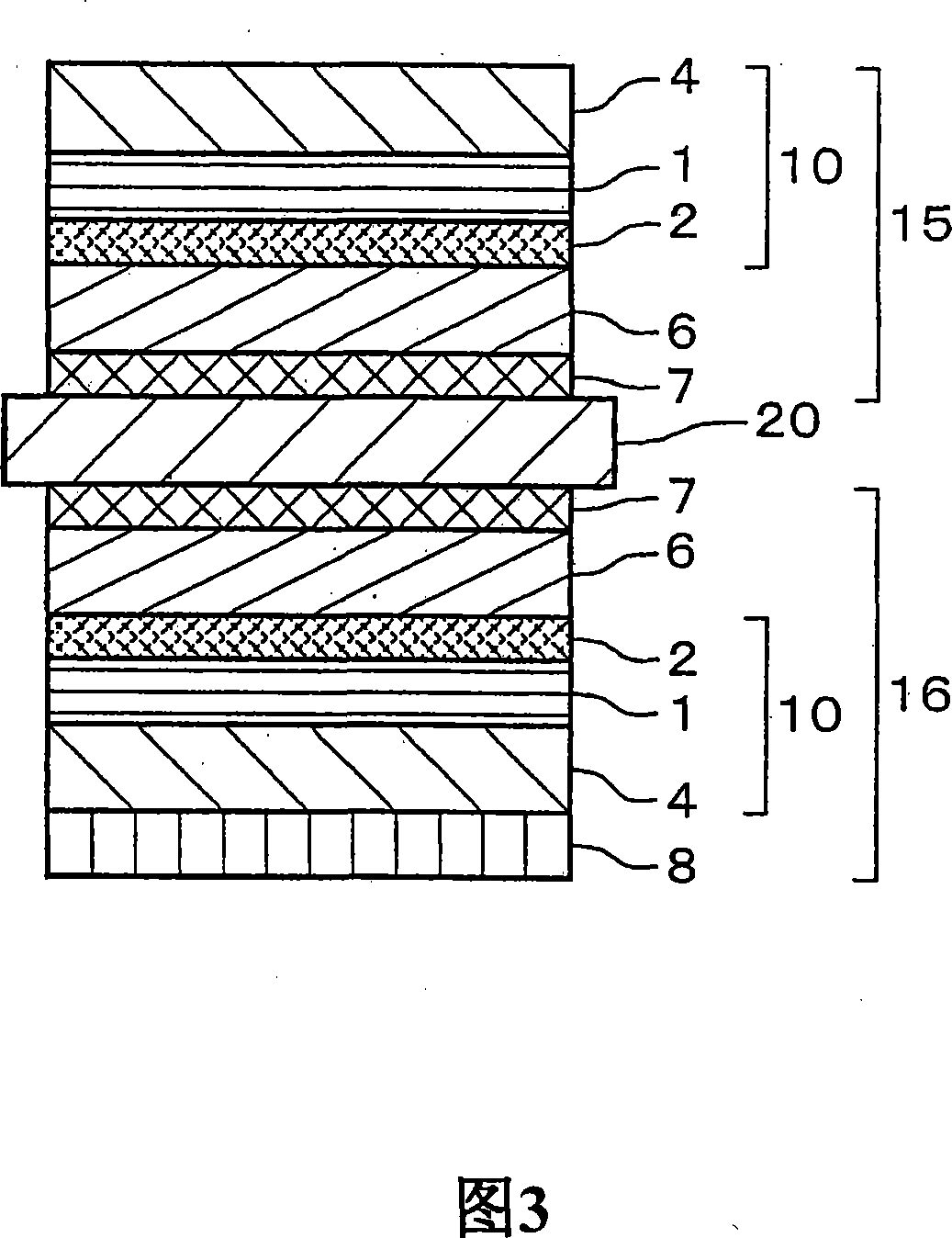

Thin polarizer and image display apparatus using the same

InactiveCN101246233AIncrease brightnessSuppresses dimensional changesLayered productsPolarising elementsPressure sensitivePolarizer

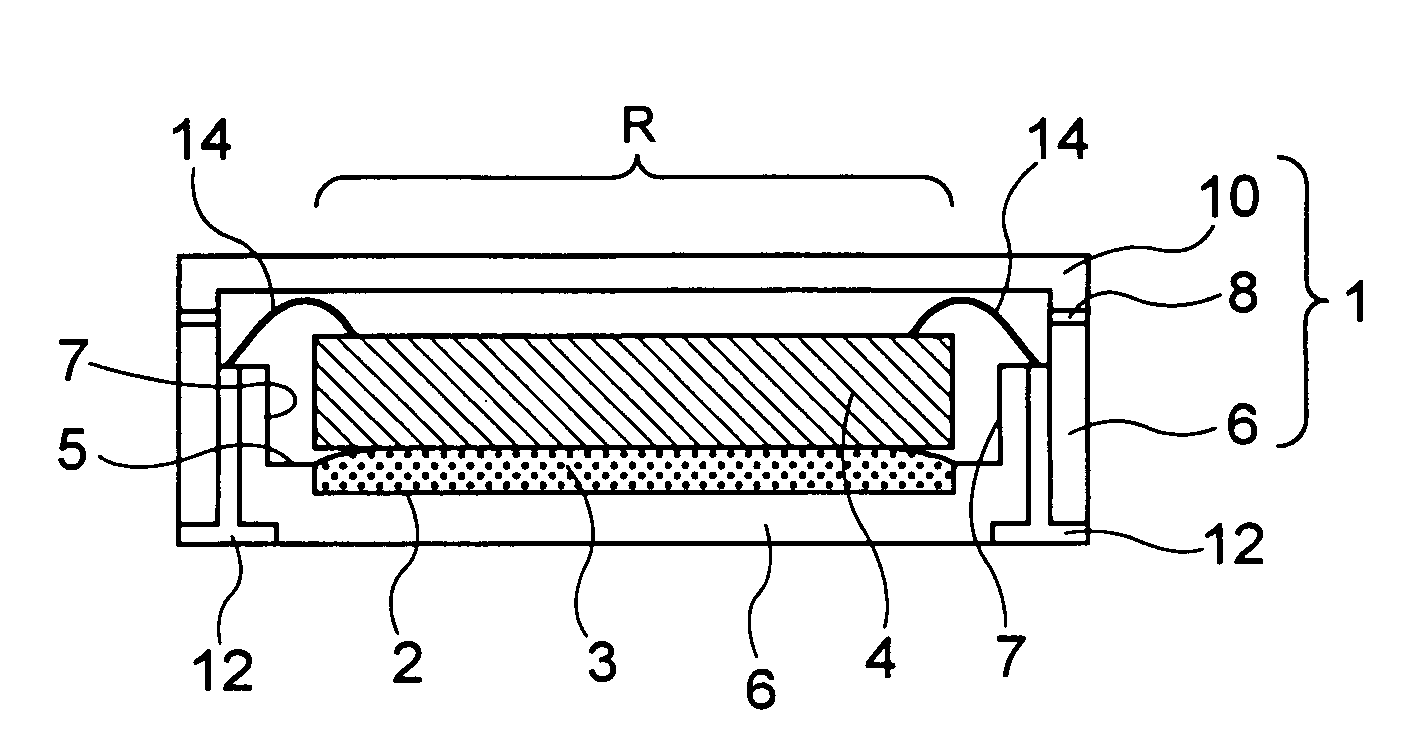

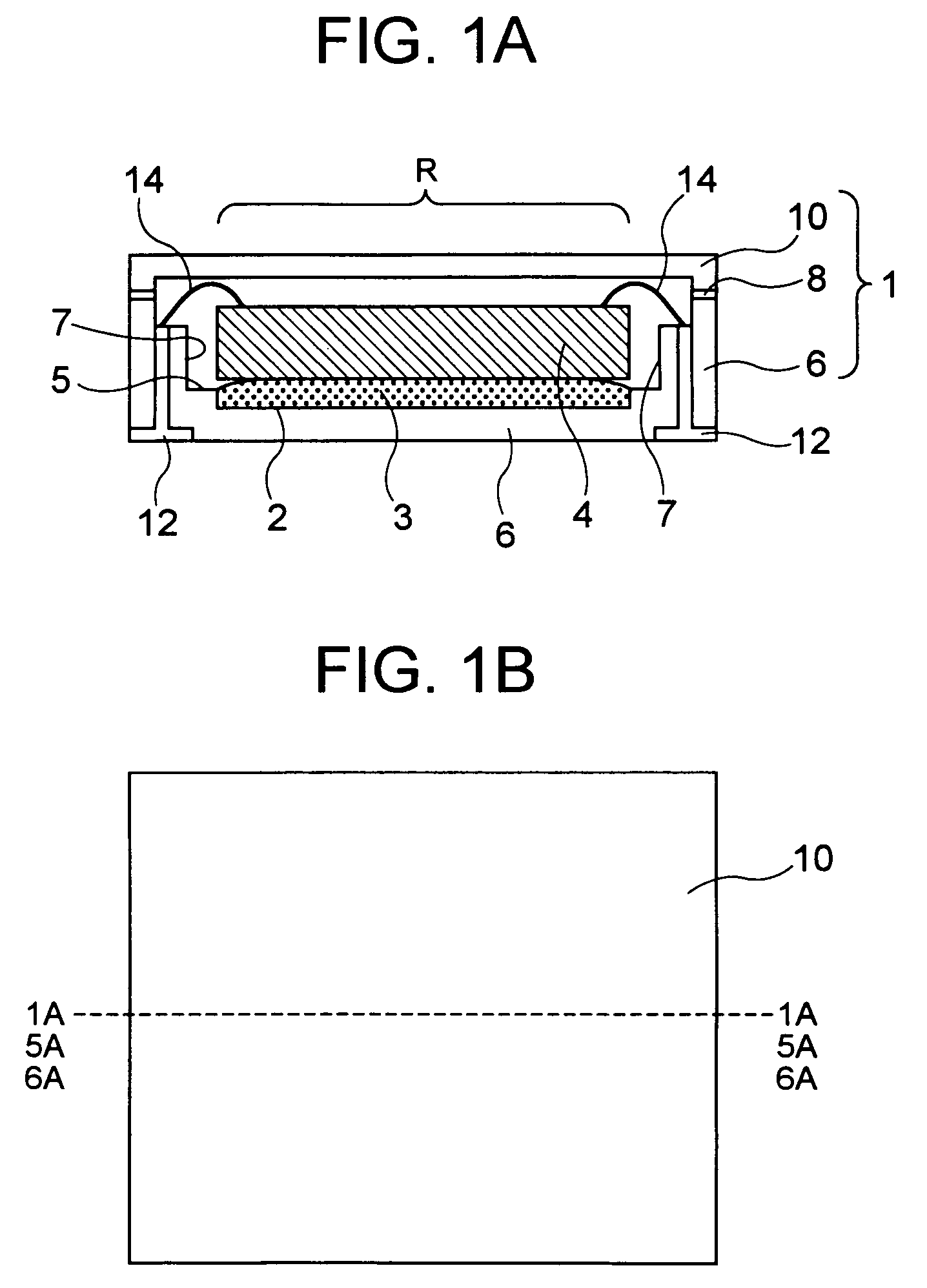

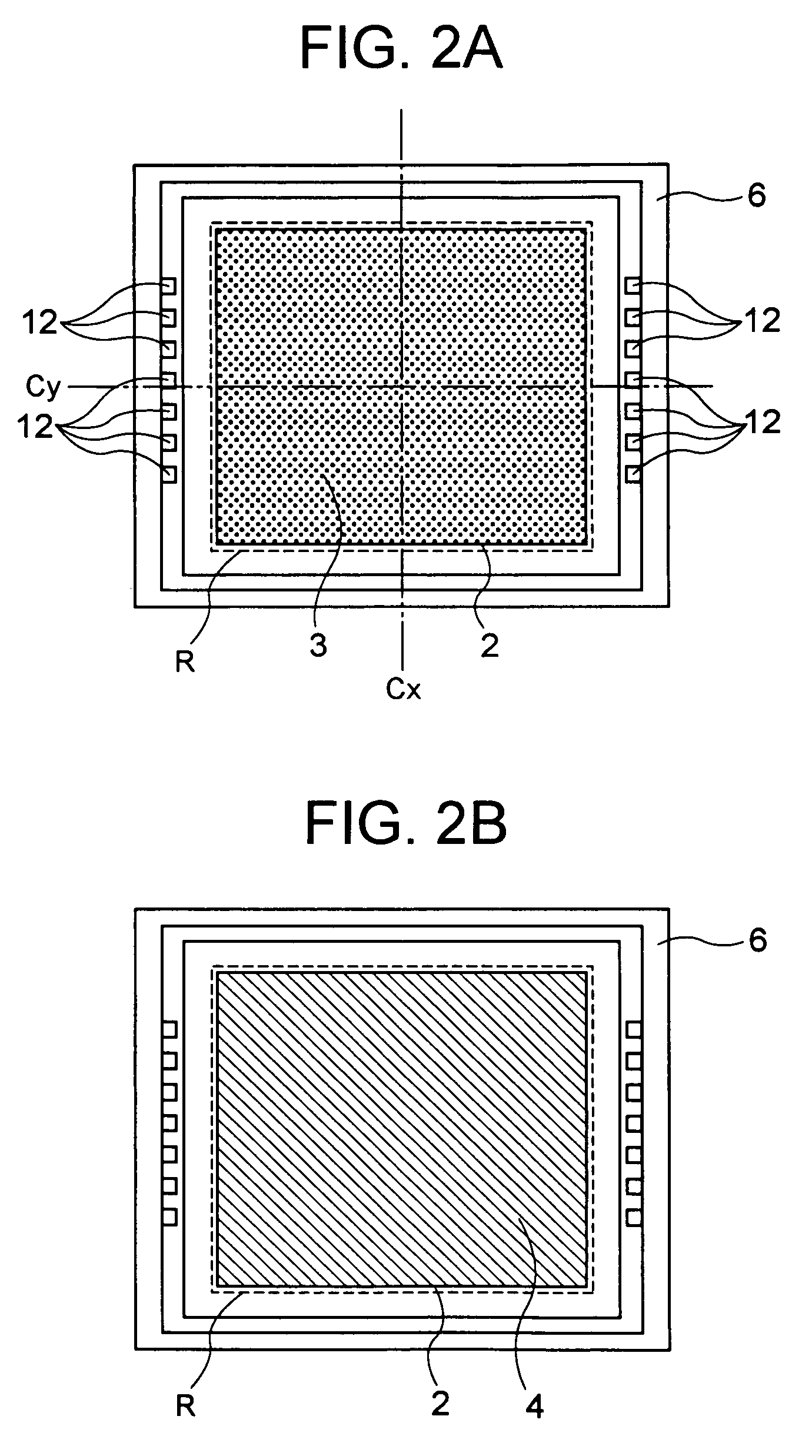

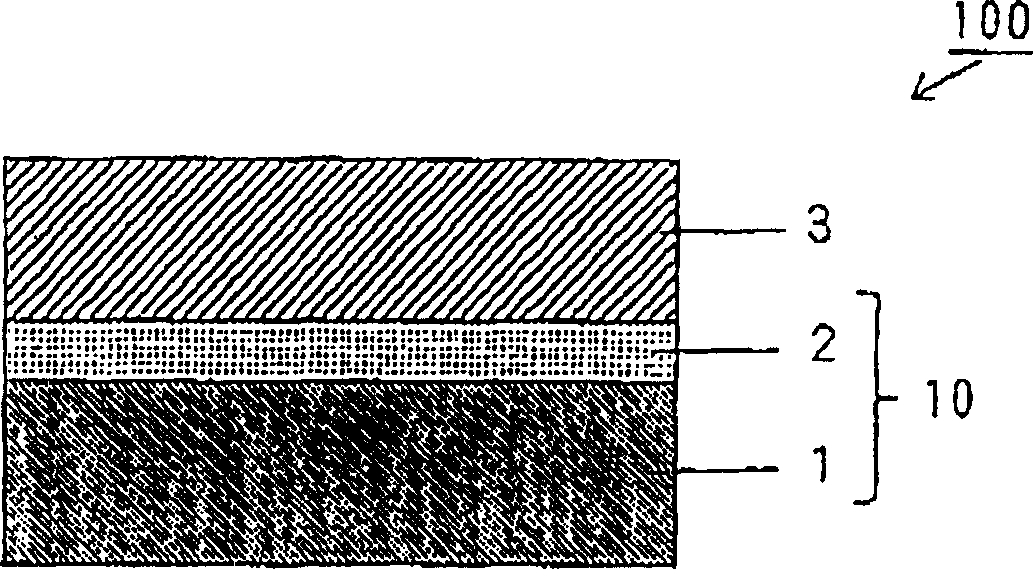

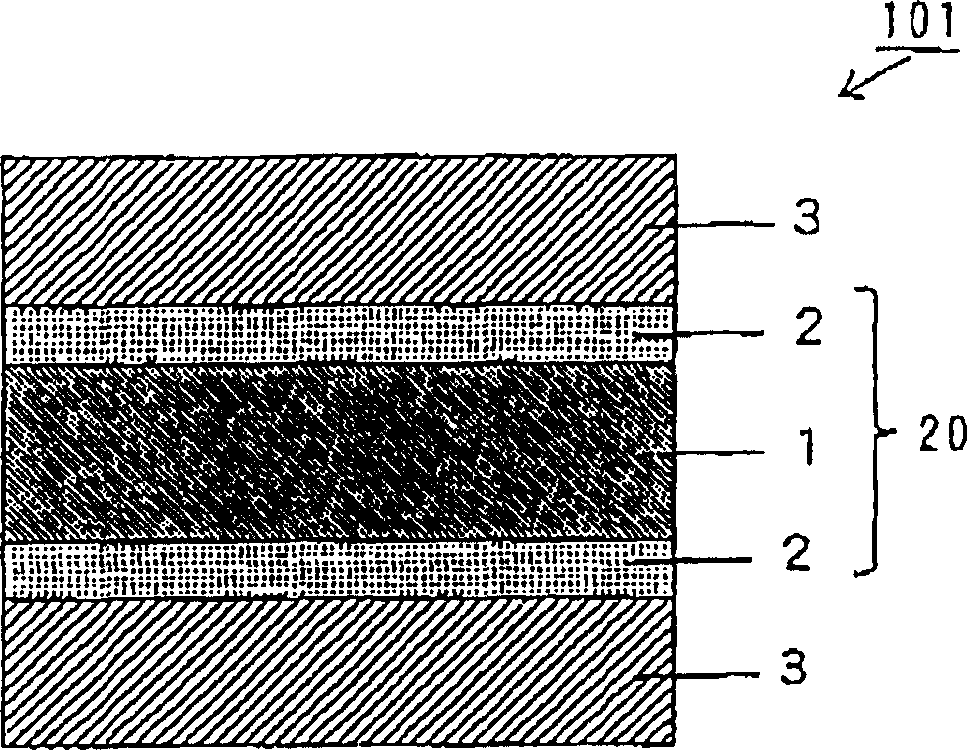

A polarizing plate provided with a pressure-sensitive adhesive layer on at least one side of the polarizer imparts good durability even in a high-temperature environment, and can laminate a polymer film thereon without troublesome workability. The polarizing plate with pressure-sensitive adhesive is laminated with a polymer film such as a phase difference plate to obtain a thinner composite polarizing plate, which is applied to an image display device. A polarizing plate (10) in which a pressure-sensitive adhesive layer (2) is provided on at least one side of a polarizer (1), wherein the pressure-sensitive adhesive layer (2) exhibits a storage capacity of 0.15-1 MPa at a temperature range of 23-80°C Elastic modulus of the pressure-sensitive adhesive layer. The pressure-sensitive adhesive layer (2) exhibiting a high storage elastic modulus suppresses dimensional changes caused by expansion and contraction of the polarizer (1) in a high-temperature environment. A polymer film (6) such as a phase difference plate is arranged on the outside of the pressure-sensitive adhesive layer (2) to make a composite polarizer (15, 16), and it is combined with an image display element such as a liquid crystal cell (20) to obtain an image display device.

Owner:SUMITOMO CHEM CO LTD

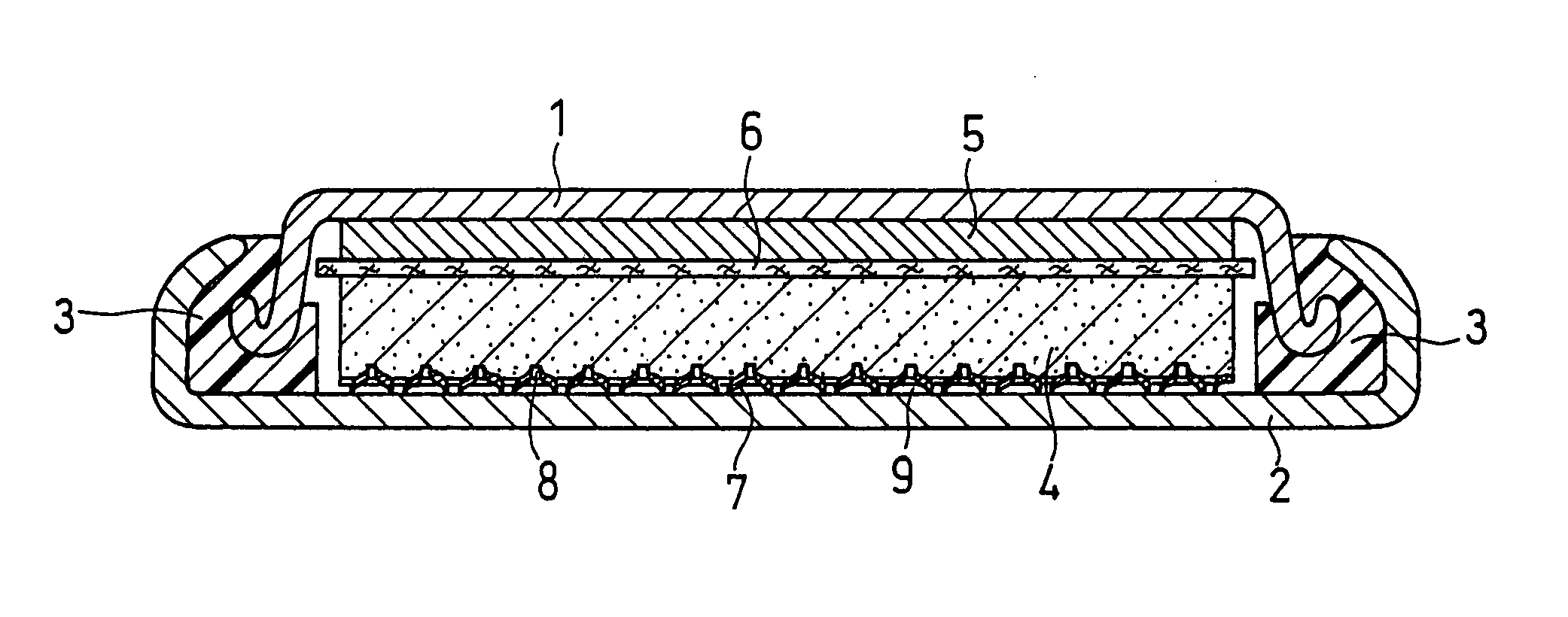

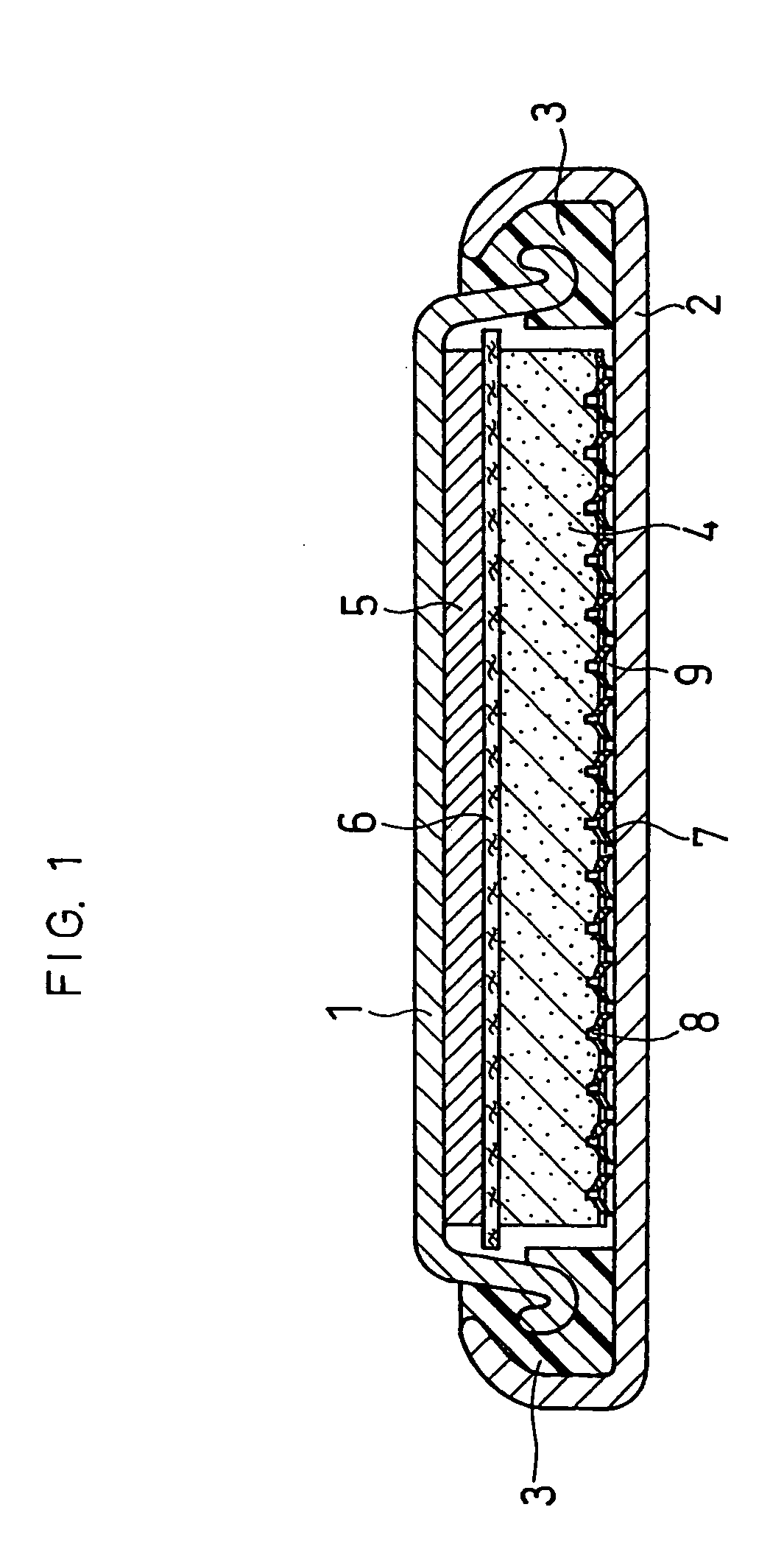

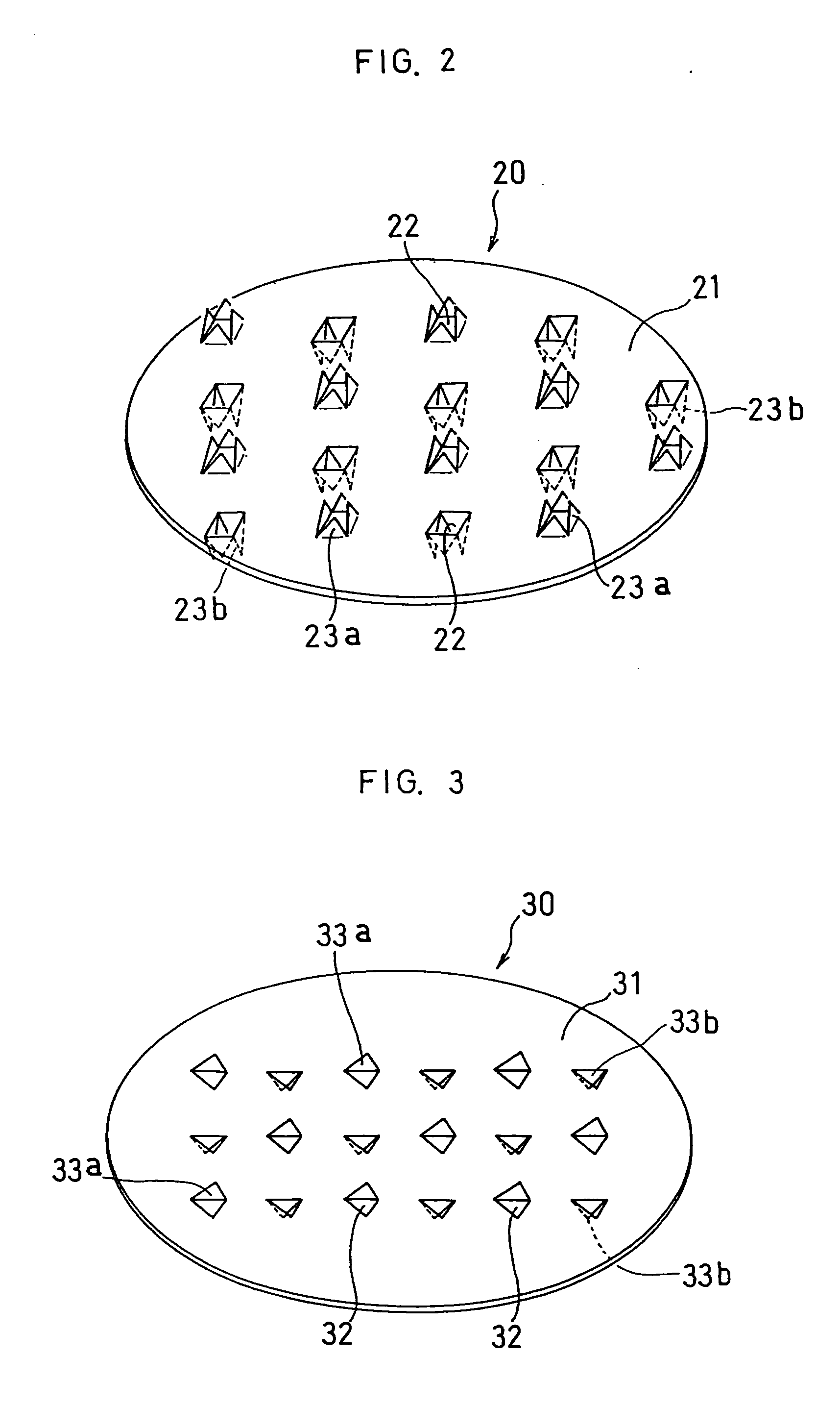

Alkaline storage battery

InactiveUS20050147876A1Suppresses dimensional changesReduce contact resistanceFinal product manufactureElectrode carriers/collectorsEngineeringElectrical and Electronics engineering

An alkaline storage battery includes: [a] a shallow case having an opening and a bottom; [b] a sealing plate covering the opening of the case; [c] a first electrode adjacent to an inner face of the bottom of the case; [d] a second electrode adjacent to an inner face of the sealing plate; [e] a separator interposed between the first electrode and the second electrode; [f] an alkaline electrolyte; and [g] at least one current collector plate selected from the group consisting of (g1) a conductive current collector plate joined to the inner face of the bottom of the case and forming a gas transfer path distributed two-dimensionally between the inner face of the bottom of the case and the first electrode and (g2) a conductive current collector plate joined to the inner face of the sealing plate and forming a gas transfer path distributed two-dimensionally between the inner face of the sealing plate and the second electrode.

Owner:PANASONIC CORP

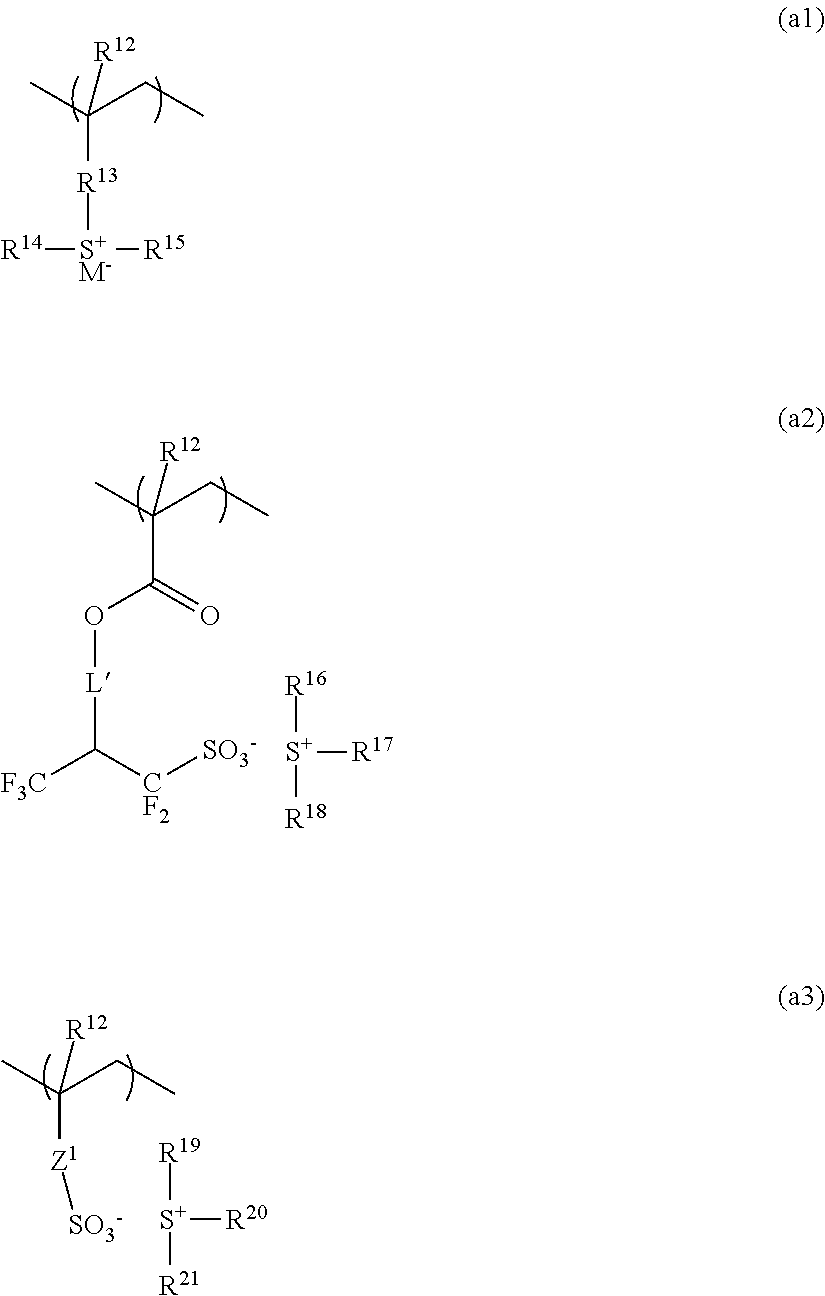

Negative resist composition and pattern forming process

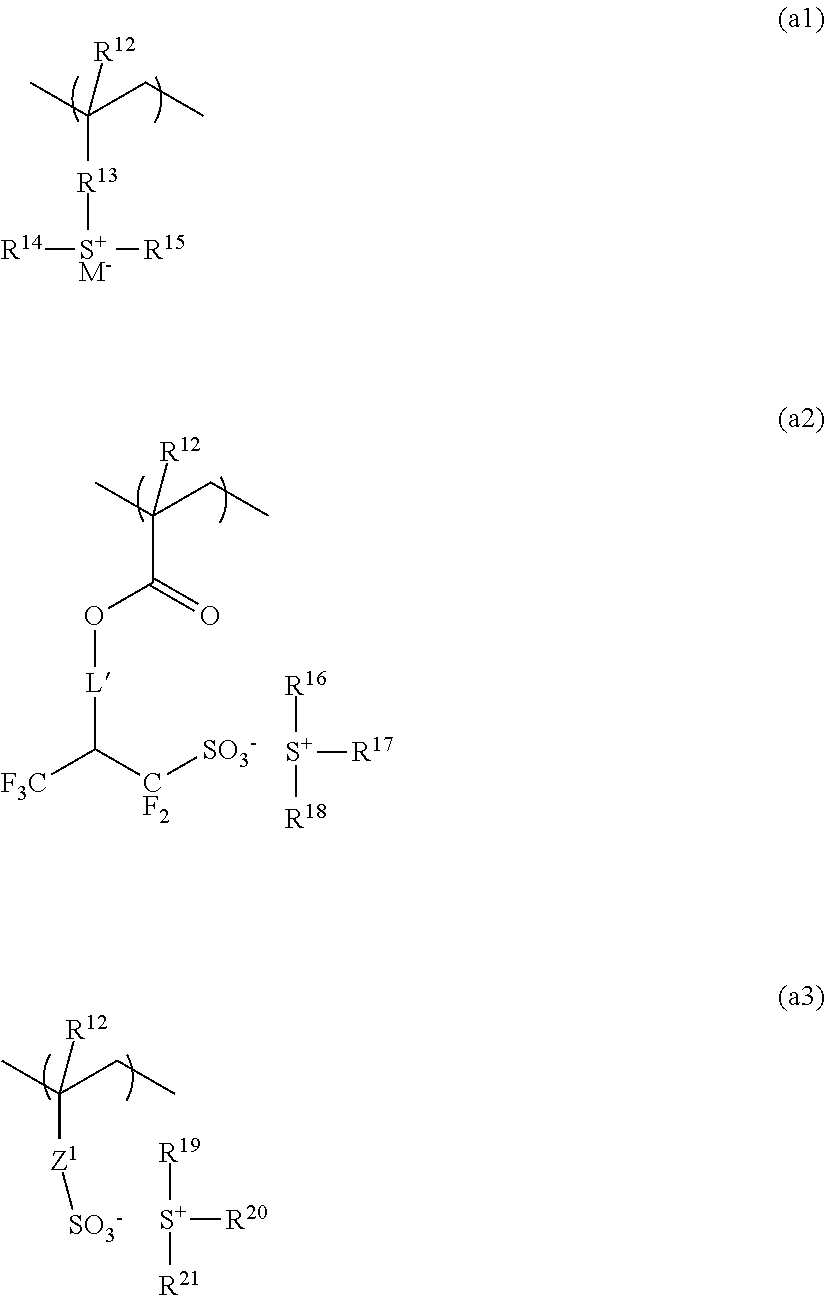

ActiveUS9645493B2High resolutionSuppresses dimensional changesOrganic chemistryPhotomechanical exposure apparatusPolymer scienceImage resolution

Owner:SHIN ETSU CHEM CO LTD

Cold finished seamless steel tubes

ActiveUS20050191509A1Efficient executionImprove machinabilityLayered productsBearing componentsResidual strainCarbide

Cold finished seamless steel tubes are made such that the residual stress F to be generated at the stage of the correction process after cold working is controlled to be 30 MPa or more and the scattering thereof is 30 MPa or less, when measured by Crampton method. Further, by adjusting the average grain size of spheroidized carbides, the dimensional change which emerges in lathe turning of the outside and inside diameter of relevant steel tubes due to the residual strain can be suppressed, and the strict roundness as well as the excellent machinability can be secured at the final processing stage of the work pieces for bearing parts. Consequently, steel tubes with high dimensional accuracy and less dimensional change at the final steps such as lathe turning, heat treatment and the like, can be made for use as bearing parts.

Owner:NIPPON STEEL CORP

Negative resist composition and pattern forming process

ActiveUS20160299430A1High resolutionMinimal LEROrganic chemistryPhotomechanical exposure apparatusResistImage resolution

A negative resist composition is provided comprising (A) a polymer comprising recurring units having an acid-eliminatable group and recurring units capable of generating acid upon exposure and (B) a carboxylic acid onium salt. When the negative resist composition is processed by the microprocessing technology, especially EB lithography, it forms a pattern having a very high resolution and minimal LER.

Owner:SHIN ETSU CHEM IND CO LTD

Top anti-reflective coating polymer, its preparation method and top anti-reflective coating composition comprising the same

InactiveUS20060008732A1Suppresses dimensional changesHigh light transmittancePhotomechanical apparatusOriginals for photomechanical treatmentAnti-reflective coatingHydrogen

Disclosed herein are top anti-reflective coating polymers used in a photolithography process, methods for preparing the anti-reflective coating polymer, and anti-reflective coating compositions comprising the disclosed anti-reflective coating polymers. The top anti-reflective coating polymers are used in immersion lithography for the fabrication of a sub-50 nm semiconductor device. The top anti-reflective coating polymer is represented by Formula 1 below: wherein R1, R2 and R3 are independently hydrogen or a methyl group; and a, b and c represent the mole fraction of each monomer, and are independently in the range between about 0.05 and about 0.9. Because the disclosed top anti-reflective coatings are not soluble in water, they can be used in immersion lithography using water as a medium for the light source. In addition, since the top anti-reflective coatings can reduce the reflectance from an underlayer, the uniformity of CD is improved, thus enabling the formation of ultrafine patterns.

Owner:SK HYNIX INC

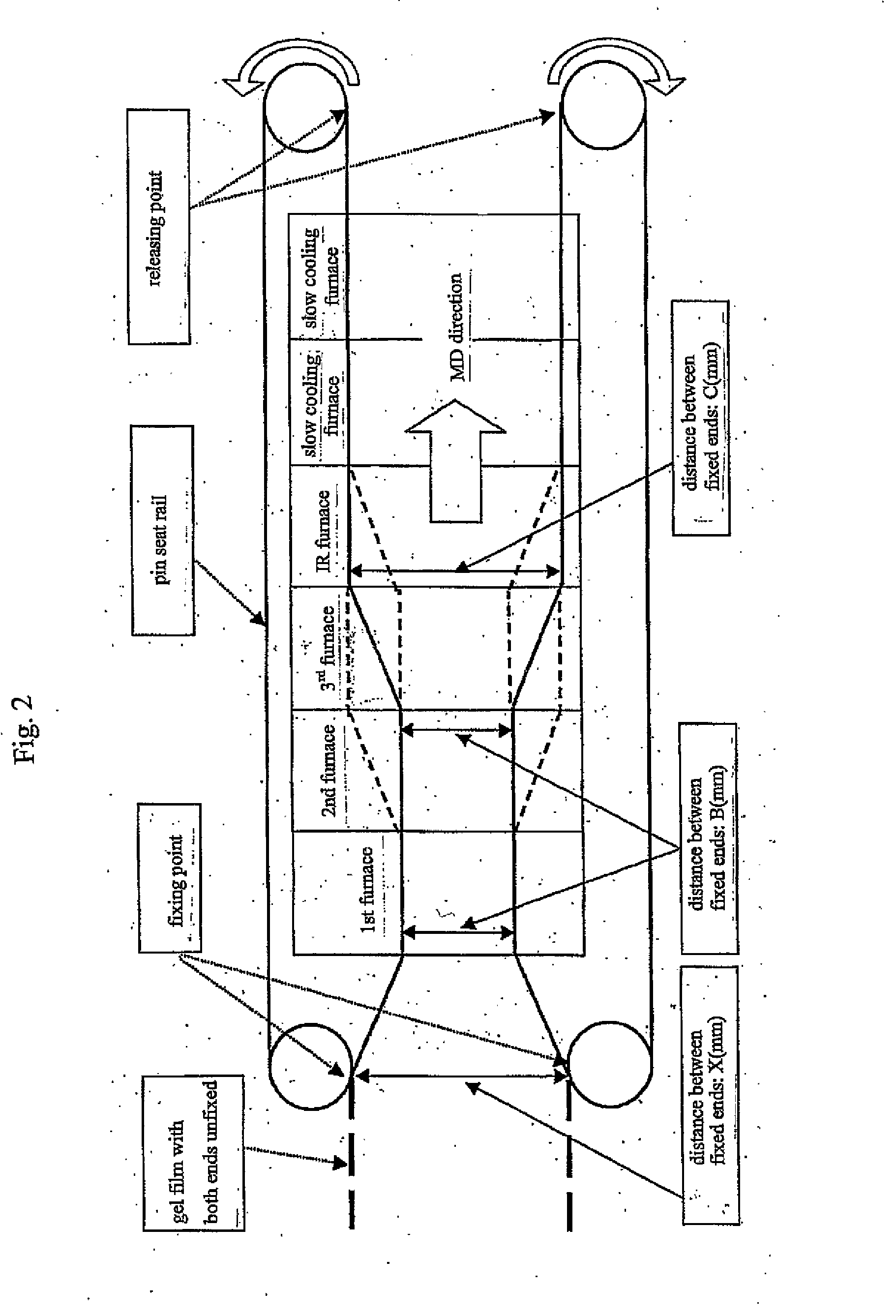

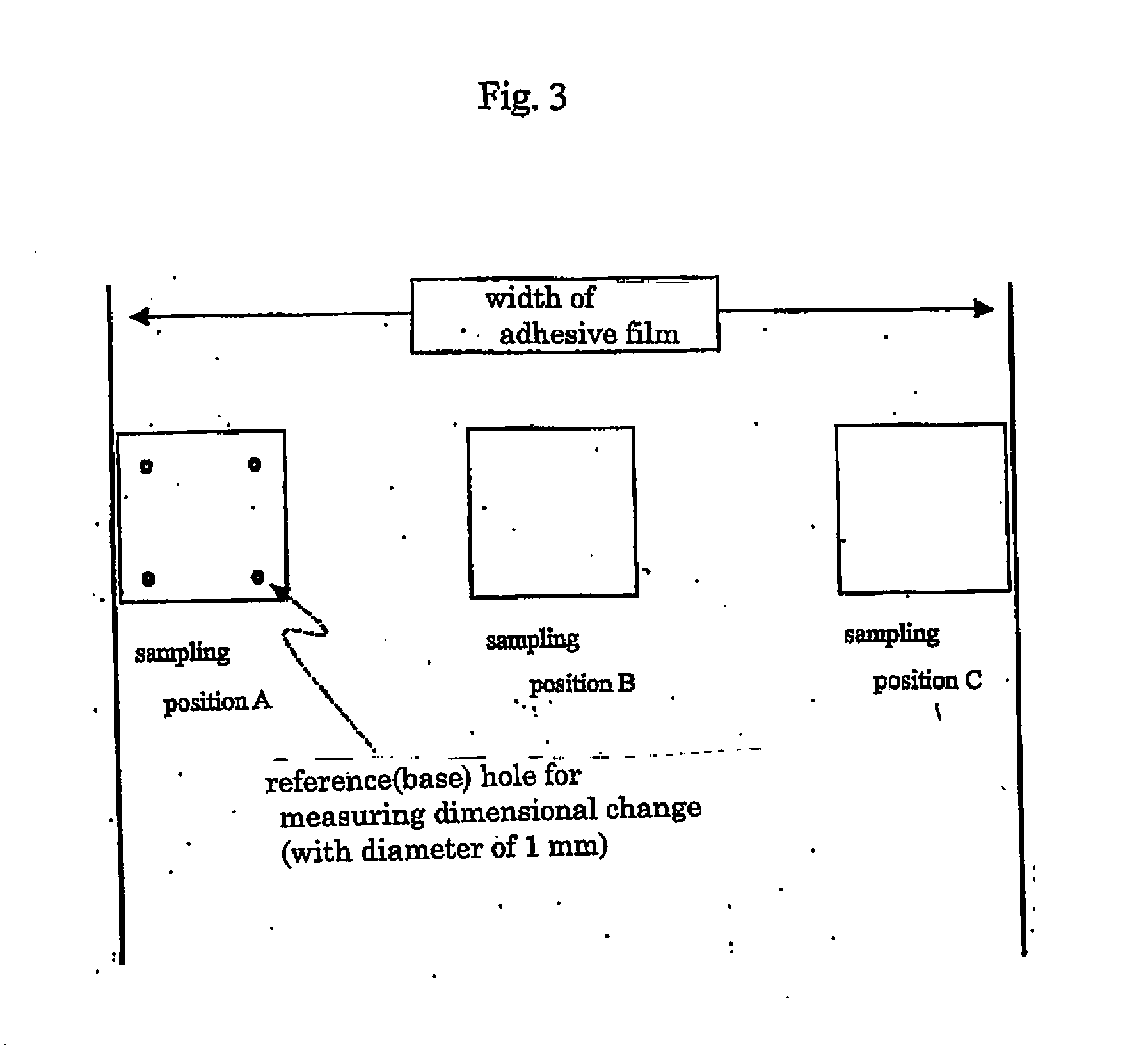

Adhesive Film, Flexible Metal-Clad Laminate, and Processes for Producing These

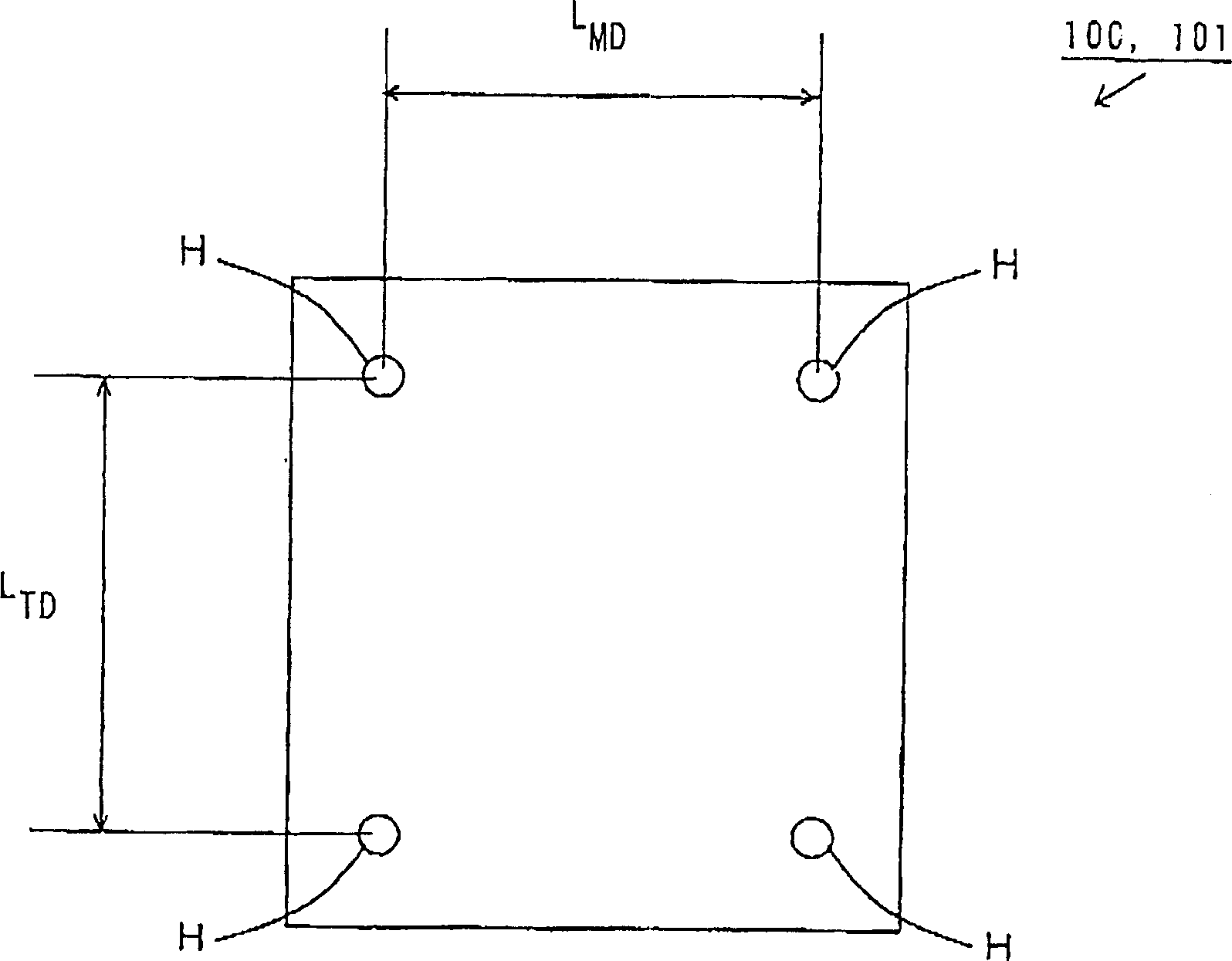

ActiveUS20070218277A1Small size changeDimensional differenceInsulating substrate metal adhesion improvementSynthetic resin layered productsMetal foilPolyimide membrane

The present invention relates to an adhesive film with which a flexible metal-clad laminate is obtained with suppressed dimensional changes occurred when produced by a laminating method; and a flexible metal-clad laminate comprising the adhesive film and a metal foil bonded thereto. The adhesive film comprises a polyimide film and, formed on at least one side thereof, an adhesive layer comprising a thermoplastic polyimide and has coefficients of linear expansion satisfying the relationship 1.0>(coefficient of linear expansion in the MD direction) / (coefficient of linear expansion in the TD direction)>0.1. This adhesive film may be one produced continuously and further satisfying the relationship 1.70>(elastic modulus in the MD direction) / (elastic modulus in the TD direction)>1.05 when the adhesive film has an MD modulus of 5 GPa or higher throughout the whole width thereof. That adhesive film may be one produced continuously and further satisfying the relationship 2.00>(elastic modulus in the MD direction) / (elastic modulus in the TD direction)>1.10 when the adhesive film has an MD modulus less than 5 GPa throughout the whole thereof.

Owner:KANEKA CORP

Novel Polyimide Film and Use Thereof

ActiveUS20080305316A1Suppresses dimensional changesSuppression of deformationSynthetic resin layered productsPrinted circuit aspectsThermal deformationPolyimide membrane

The present invention provides a polyimide film and its usage. The polyimide film according to the present invention does not cause dimensional change due to thermal stress. The present invention particularly relates to a polyimide film and its usage, which polyimide film has a characteristic of suppressing thermal deformation of the material in lamination of a polyimide film and a metal layer by a laminate method. The polyimide film according to the present invention has the following characteristics:(1) an inflexion point of storage modulus ranges from 270° C. to 340° C.;(2) tan δ, which is a value obtained by dividing a loss elastic modulus by a storage modulus, has a peak-top in a range of 320° C. to 410° C.;(3) a storage modulus at 380° C. ranges from 0.4 GPa to 2.0 GPa; and(4) a storage modulus α1 at the inflexion point (GPa) and a storage modulus α2 at 380° C. (GPa) satisfy: 85≧{(α1−α2) / α1}×100≧65. With these characteristics, the polyimide film gives an effect of suppressing thermal deformation of the material in lamination of a polyimide film and a metal layer by a laminate method.

Owner:KANEKA CORP

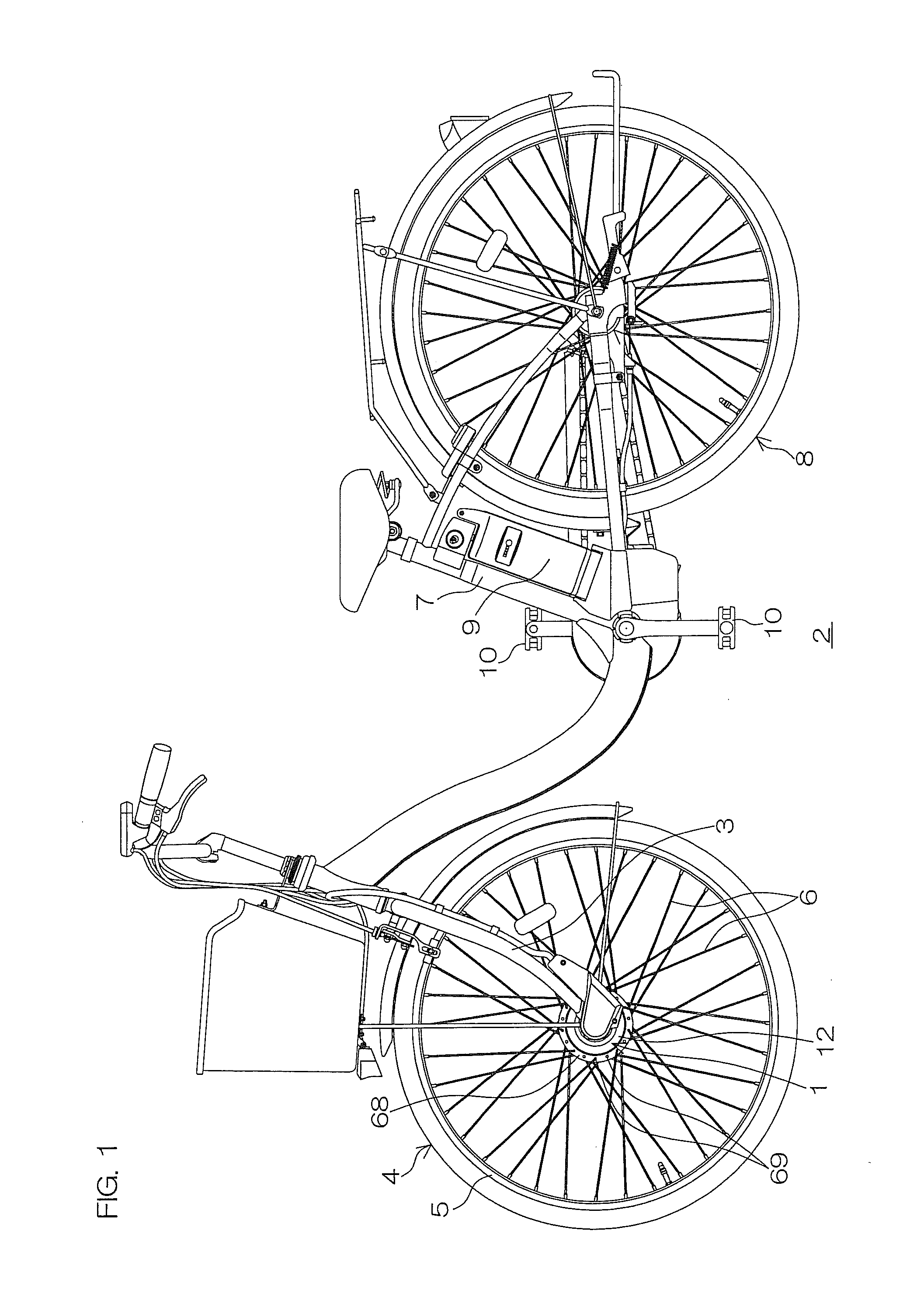

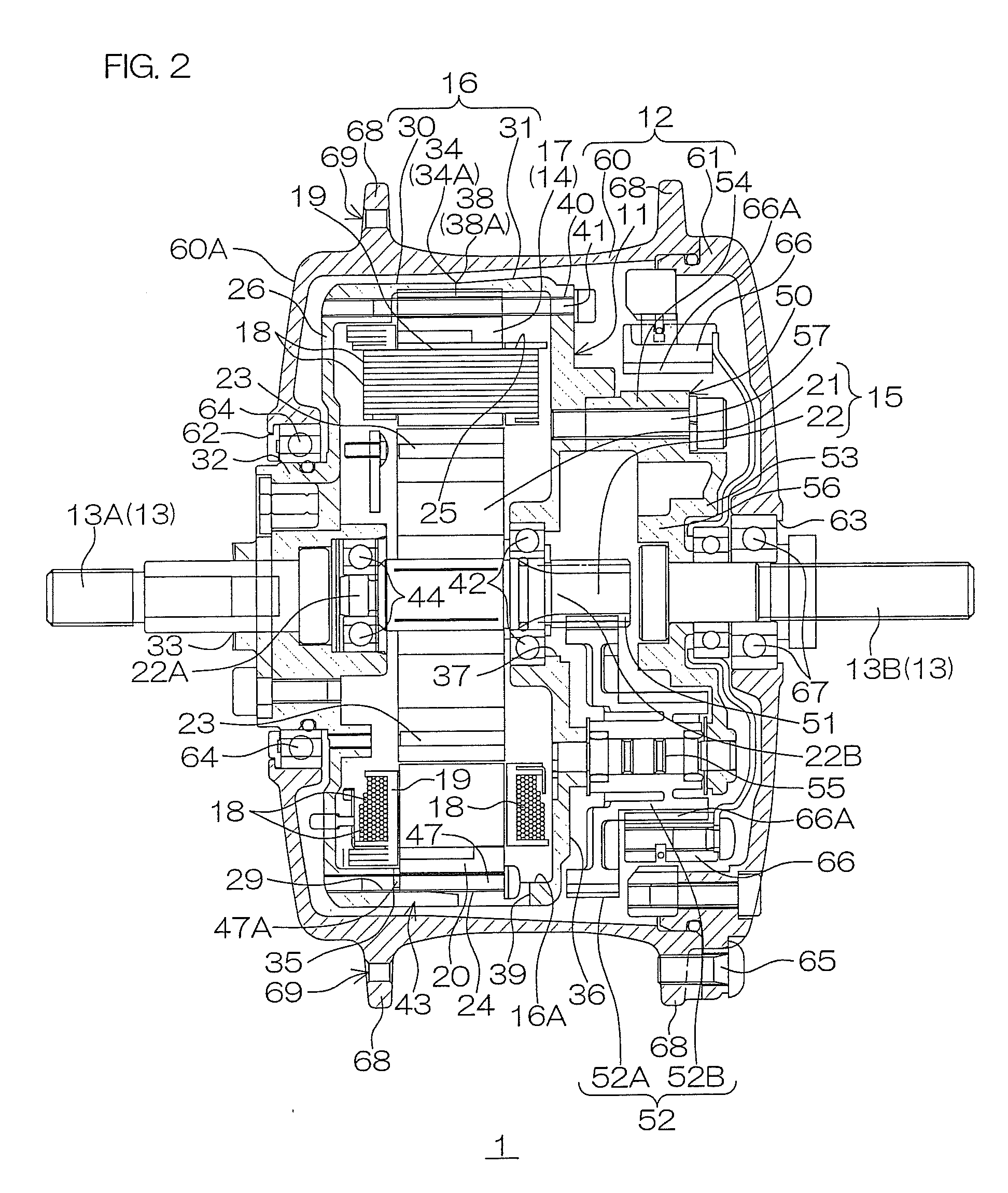

Direct-current motor and hub unit

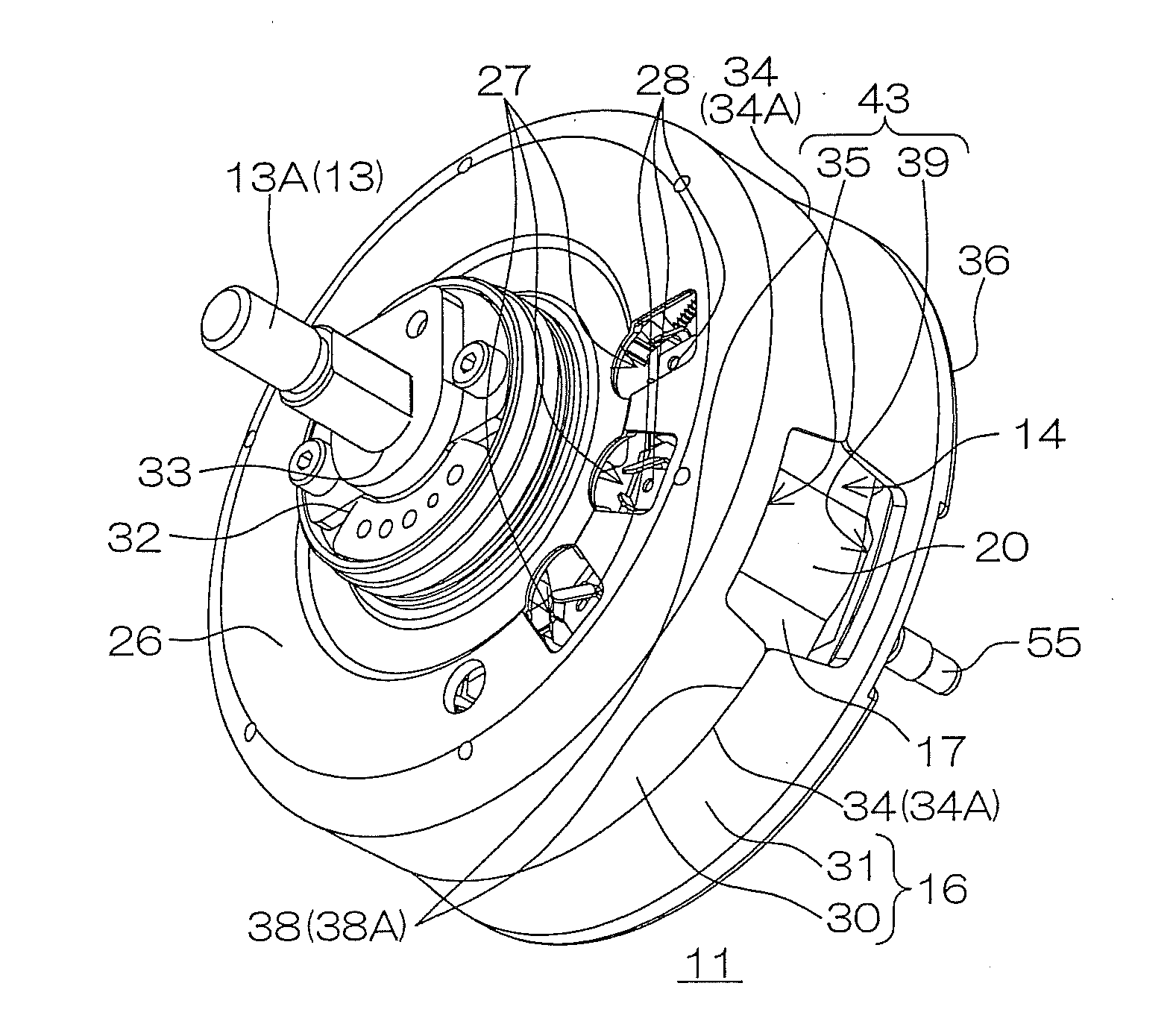

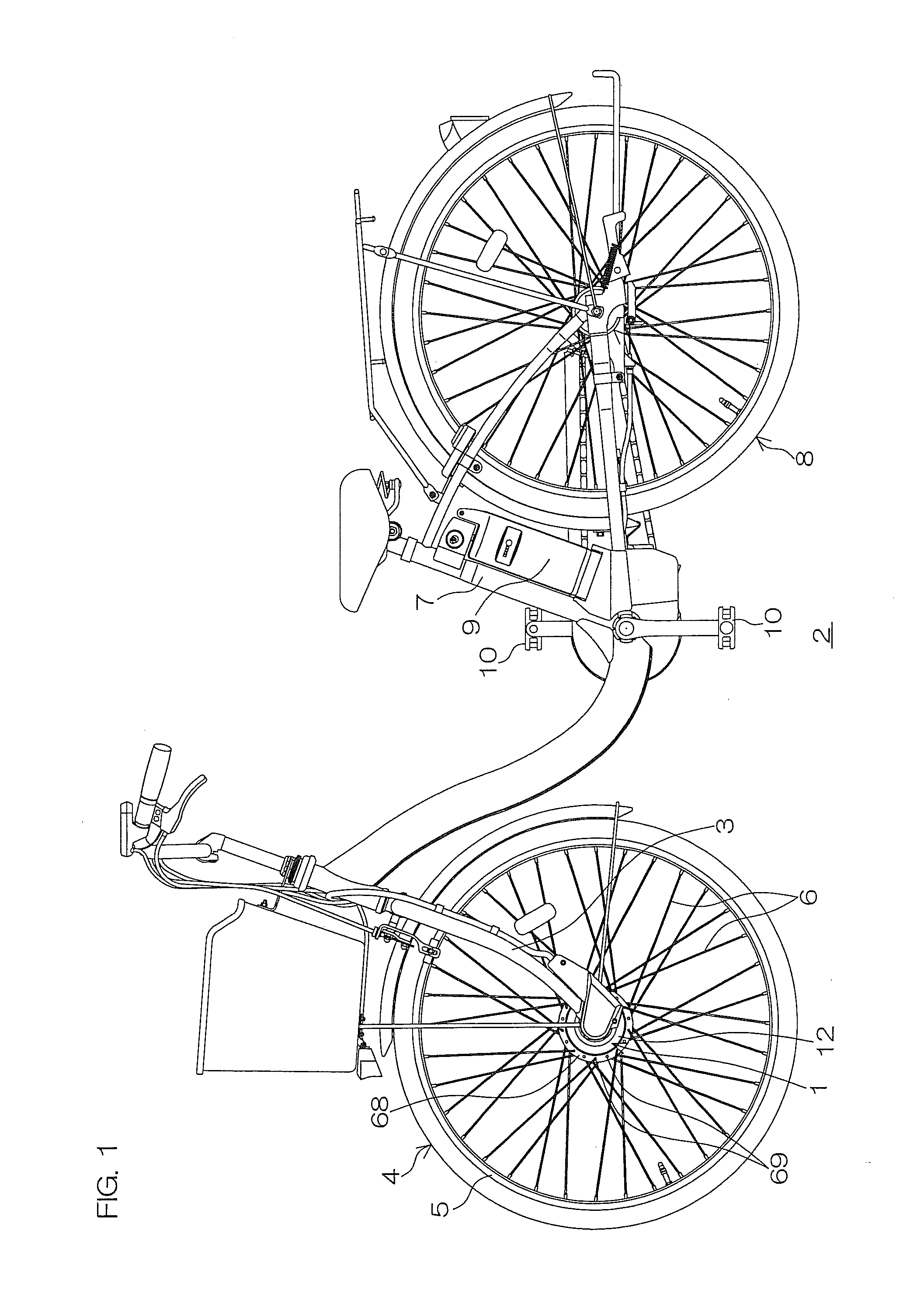

ActiveUS20120025677A1Avoid overall overheatingSuppresses dimensional changesMagnetic circuitPropulsion by batteries/cellsMechanical engineeringDirect current

In a motor, a motor case includes a first case and a second case separable from each other in a direction of an axis of a rotation shaft of a rotor. The first case and the second case each have cut-away portions extending parallel to the axis from a separation edge (open side edge) thereof. The separation edges of the first and second cases each have abutment portions not formed with the cut-away portions, and the abutment portions of the first case respectively abut against the abutment portions of the second case. The cut-away portions cooperatively define a plurality of windows disposed in a periphery of the motor case. The stator has a plurality of bulges projecting radially outward from a peripheral surface thereof in association with the windows.

Owner:SANYO ELECTRIC CO LTD +1

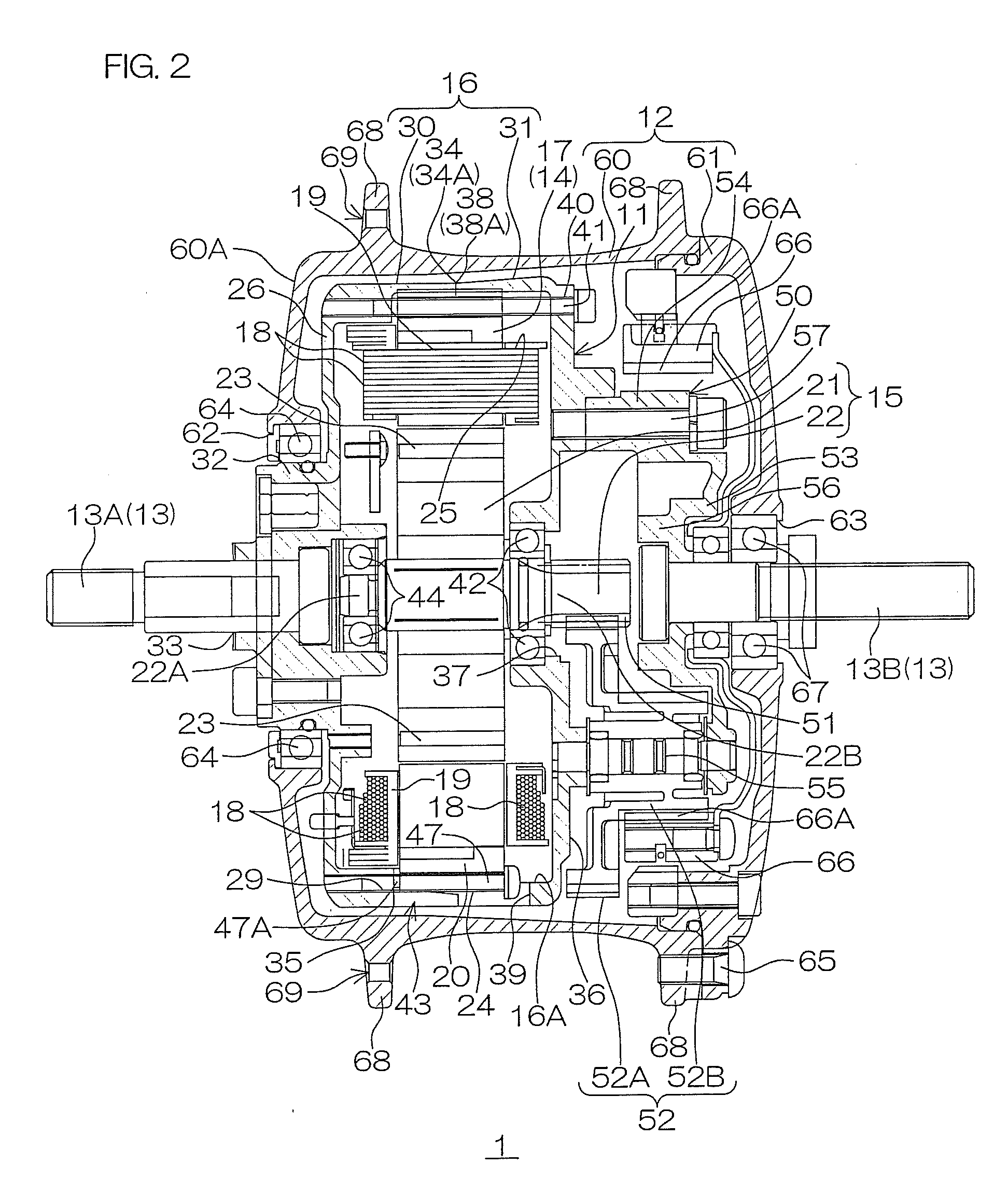

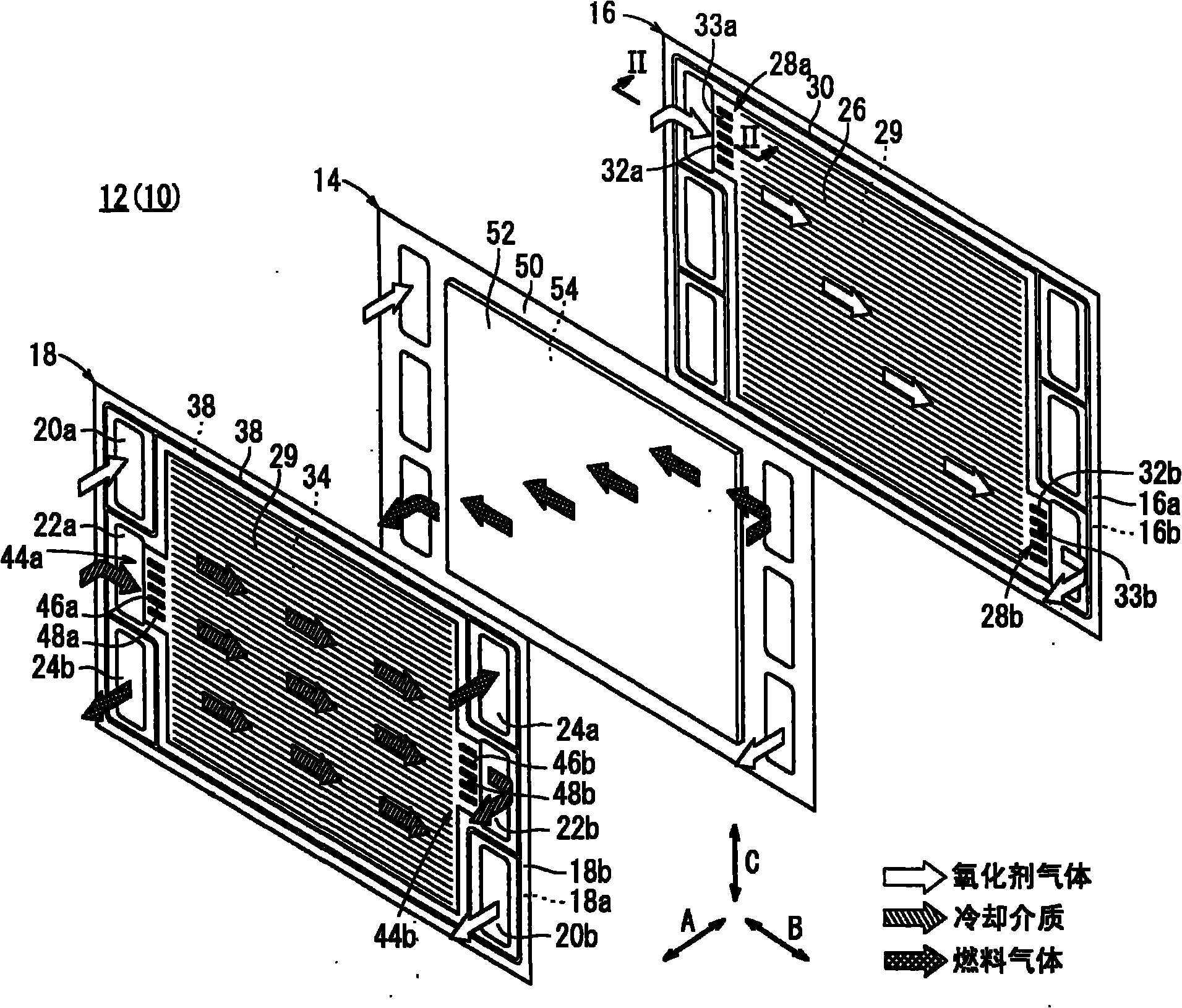

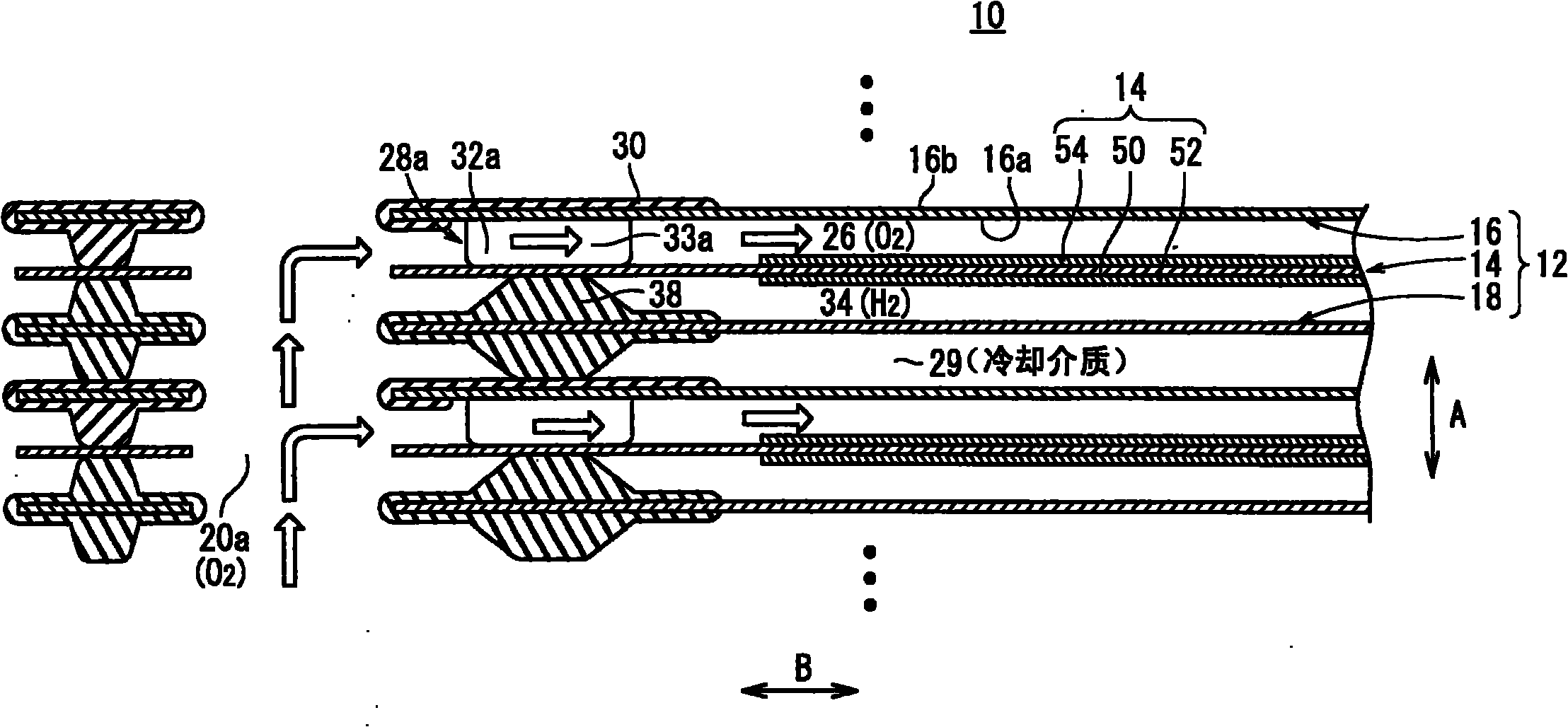

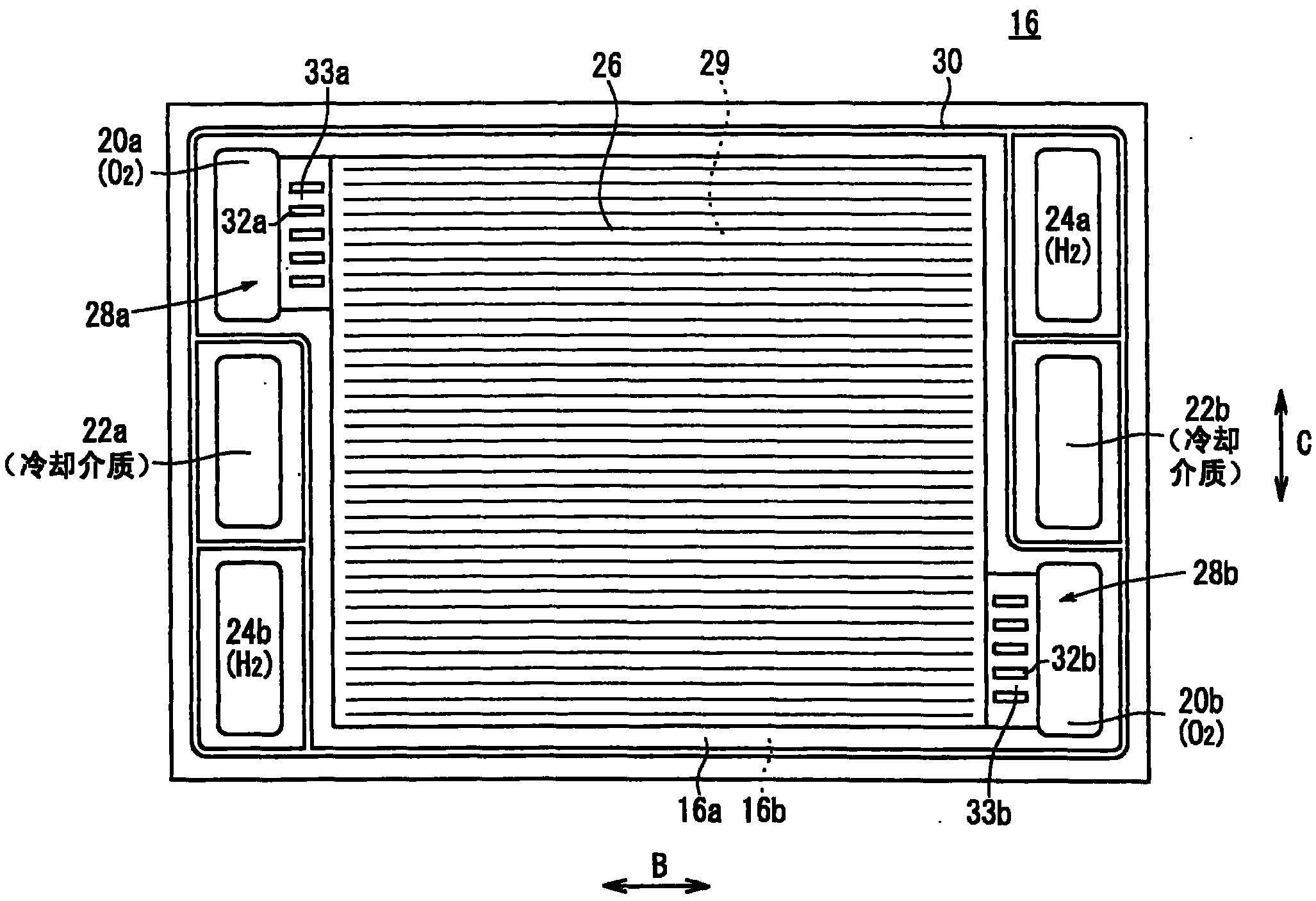

Fuel battery pile

ActiveCN101964425AAvoid cloggingSpeed up the flowCell component detailsSolid electrolyte fuel cellsFuel cellsEngineering

The invention provides a fuel battery pile capable of preventing a flow path from being blocked due to destruction of a connection bridge part as much as possible in an economic and simple structure. In the fuel battery (12) for forming the fuel battery pile (10), an electrolyte film-electrode structure (14) is clamped by a first metal separator (16) and a second metal separator (18). The connection bridge part (28a) for communicating an oxidant gas flow path (26) with an oxidant gas inlet communication hole (20a) is arranged on the first metal separator (16) and comprises a plurality of resin passage parts (32a) which are mutually separated and alternatively arranged and a passage (33a) is formed between the resin passage parts (32a).

Owner:HONDA MOTOR CO LTD

Method of making substrate for flexible circuit board

InactiveCN1627883ASuppresses dimensional changesInsulating substrate metal adhesion improvementLayered product treatmentMetallic foilFlexible circuits

The present invention provides a method for producing a substrate for a flexible circuit board, which includes: providing a multi-layer insulating resin layer including an insulating layer and an adhesive layer; and The metal foil is laminated to the insulating layer of the multilayer insulating resin layer through an adhesive layer at a temperature of the glass transition temperature of the layer.

Owner:NITTO DENKO CORP

Direct-current motor and hub unit

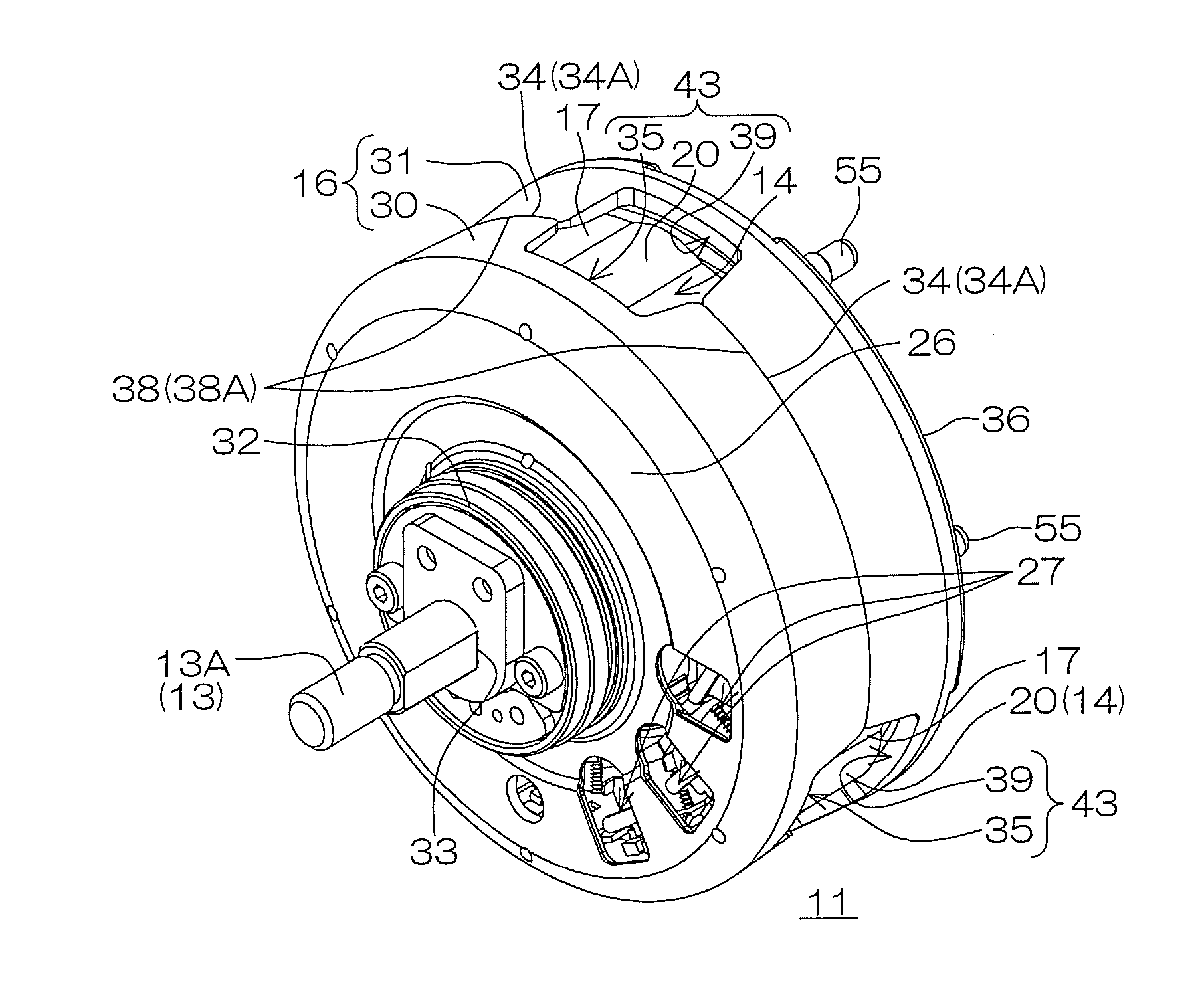

ActiveUS8674573B2Avoid overall overheatingSuppresses dimensional changesPropulsion by batteries/cellsVehicular energy storageEngineeringMechanical engineering

In a motor, a motor case includes a first case and a second case separable from each other in a direction of an axis of a rotation shaft of a rotor. The first case and the second case each have cut-away portions extending parallel to the axis from a separation edge (open side edge) thereof. The separation edges of the first and second cases each have abutment portions not formed with the cut-away portions, and the abutment portions of the first case respectively abut against the abutment portions of the second case. The cut-away portions cooperatively define a plurality of windows disposed in a periphery of the motor case. The stator has a plurality of bulges projecting radially outward from a peripheral surface thereof in association with the windows.

Owner:SANYO ELECTRIC CO LTD +1

Polyimide film

ActiveCN101146850AImprove appearance yieldSuppresses dimensional changesPrinted circuit aspectsCircuit susbtrate materialsWrinkle skinDynamic viscoelasticity

The present invention provides a polyimide film with a small rate of dimensional change in the manufacturing process when used in FPC. In particular, the object is to produce a metal-clad laminate with few abnormal parts such as wrinkles, and obtain dimensional change at a high yield. FPC with a small rate can solve this problem with the following polyimide film, which is a polyimide film having a tan δ peak temperature equal to or greater than 320° C. and less than 380° C. in the measurement of dynamic viscoelasticity, and is characterized in that : The maximum slack of the film is 13mm or less.

Owner:KANEKA CORP

Fuel cell electrolyte, membrane electrode assembly, and method of manufacturing fuel cell electrolyte

InactiveUS7618732B2Reduce productionGood gas diffusionSolid electrolytesCell electrodesArylFuel cells

A fuel cell electrolyte comprises: a basic polymer; an organic phosphonic acid expressed by the following general formula (1); and a hydrolyzable phosphate compound expressed by the following general formula (2):where R represents an alkyl, aryl, acyl, amino, phosphonic group or a derivative of the functional group, and n is 1 or 2, and R represents an alkyl or alkoxyalkyl group, and n is 1 or 2.

Owner:SANYO ELECTRIC CO LTD +2

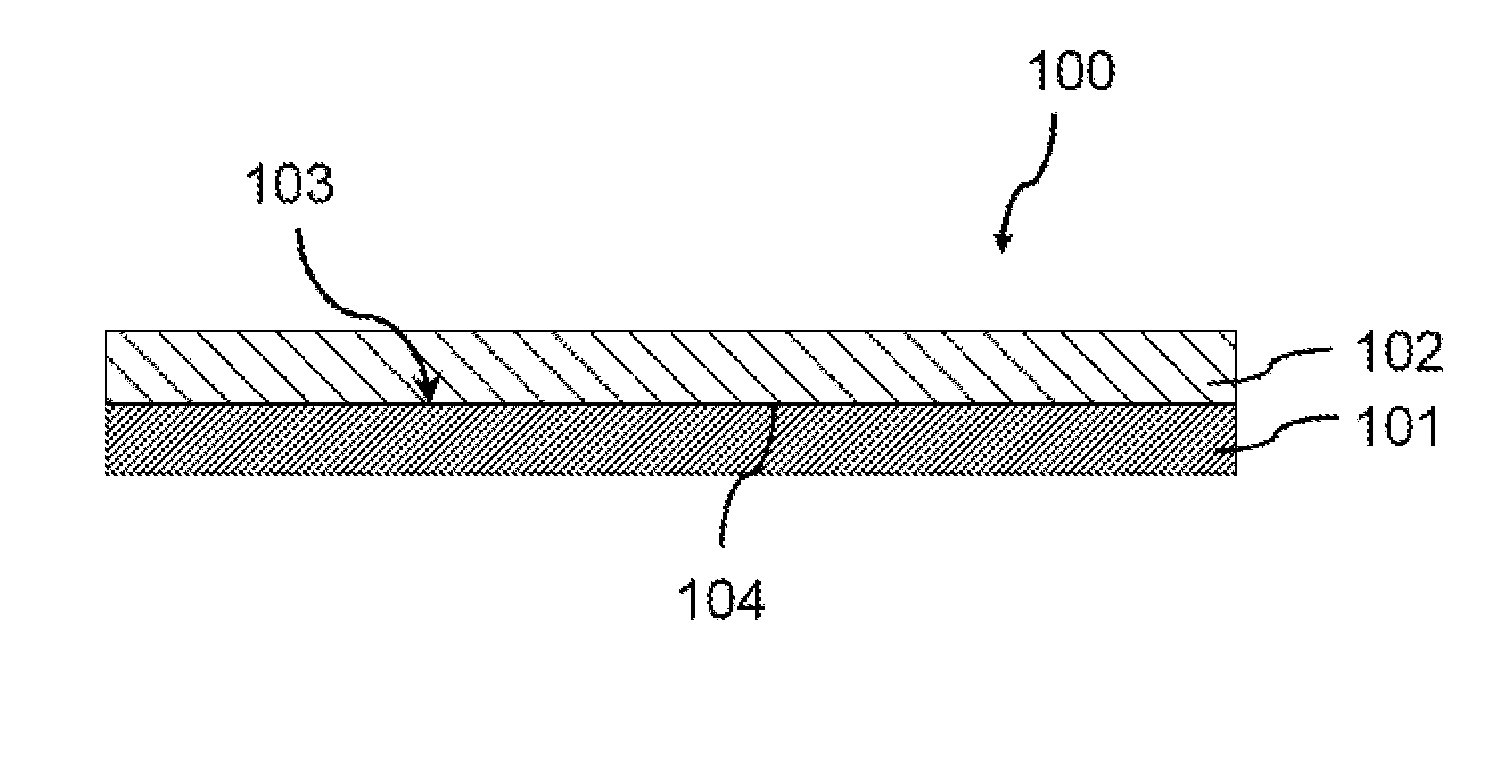

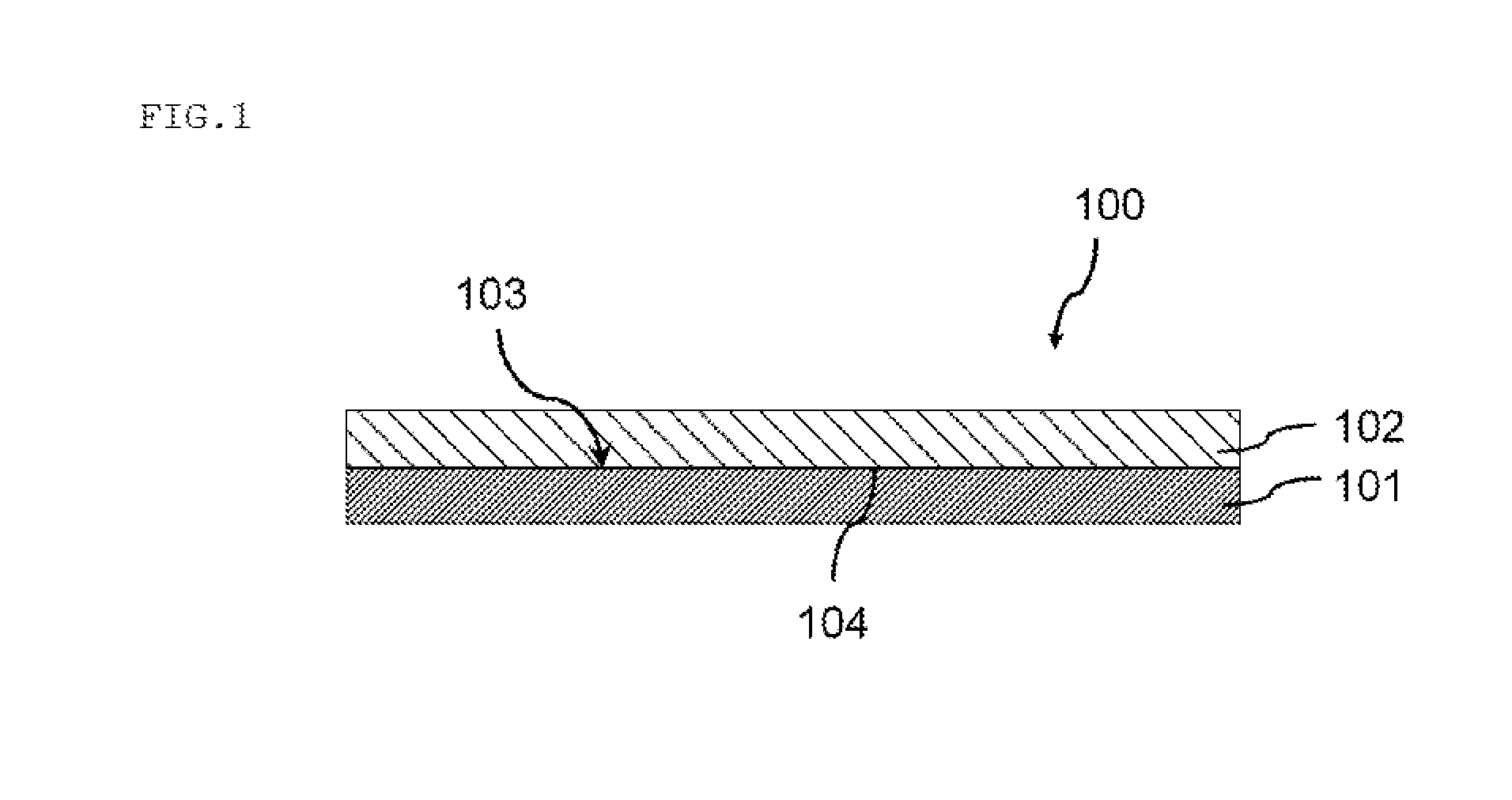

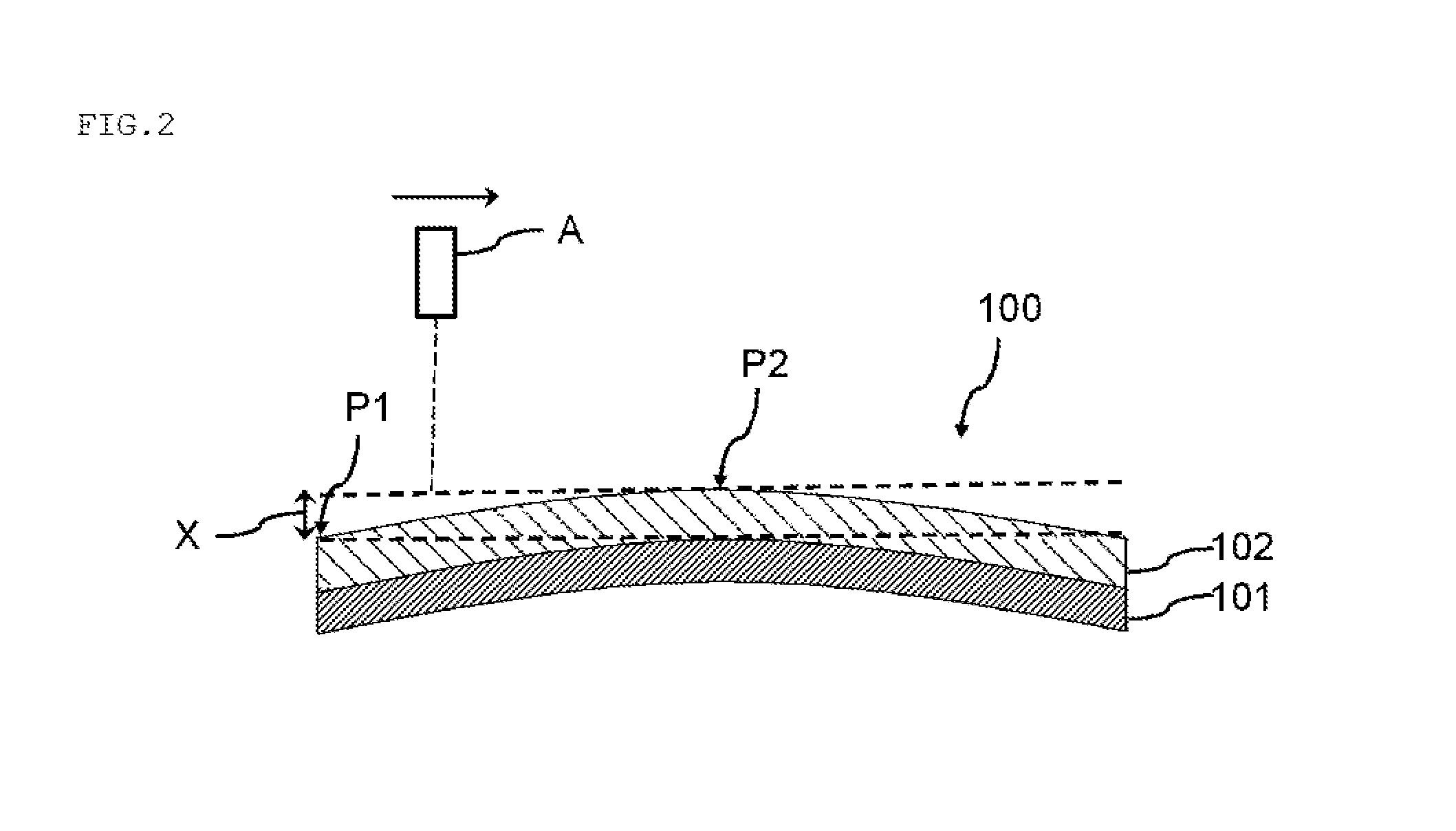

Thermosetting resin composition and metal-resin composite body

InactiveUS20160325526A1Good dimensional stabilitySuppresses dimensional changesSynthetic resin layered productsVehicle componentsMetalMaterials science

A thermosetting resin composition (P) of the present invention is used for forming a resin member (101) in a metal-resin composite body (100) including the resin member (101) and an aluminum-based metal member (102) bonded to the resin member (101) and contains a thermosetting resin (A) and a filler (B), in which a rate of change of warpage is equal to or greater than −35% and equal to or less than 35%.

Owner:SUMITOMO BAKELITE CO LTD

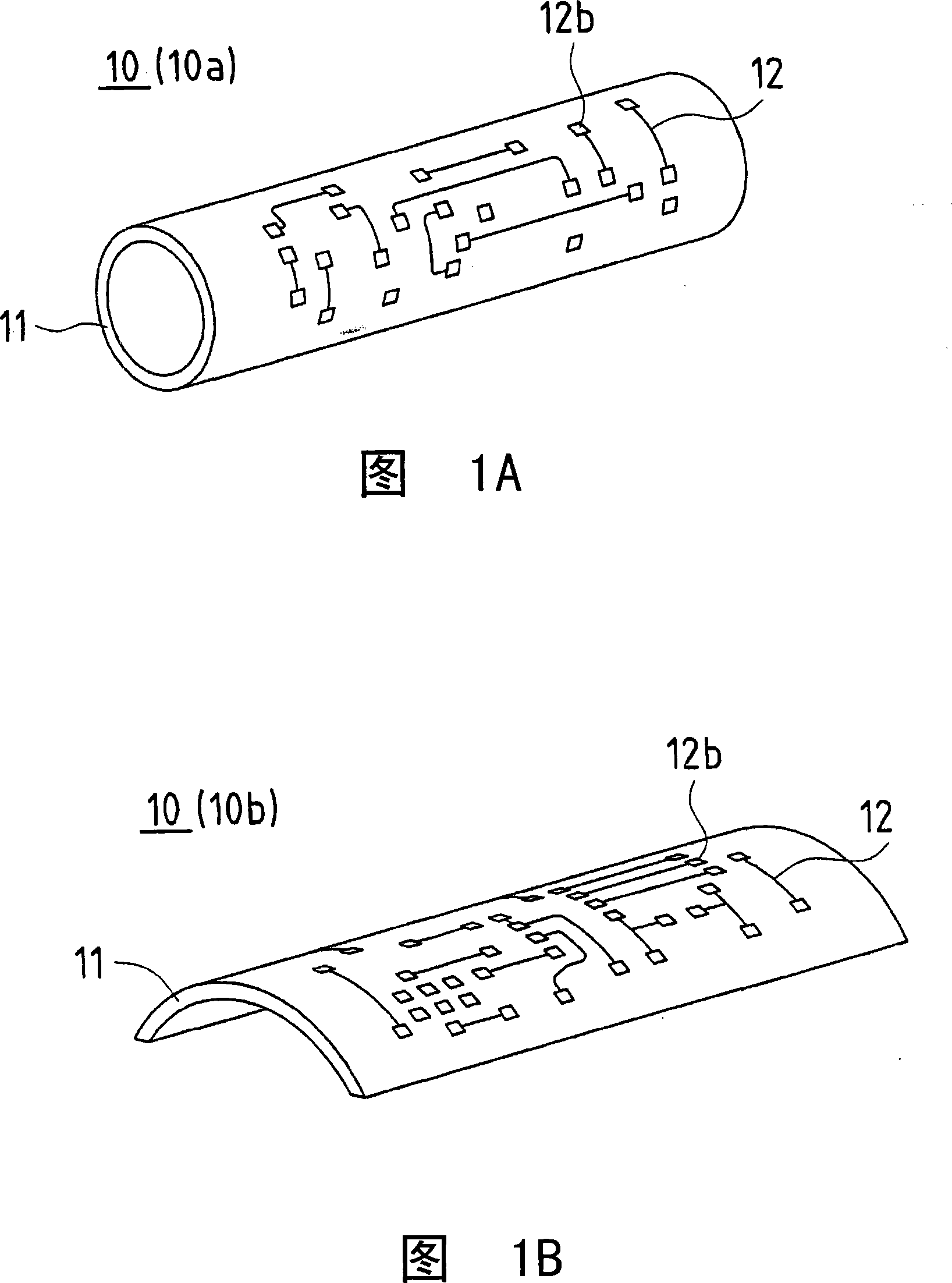

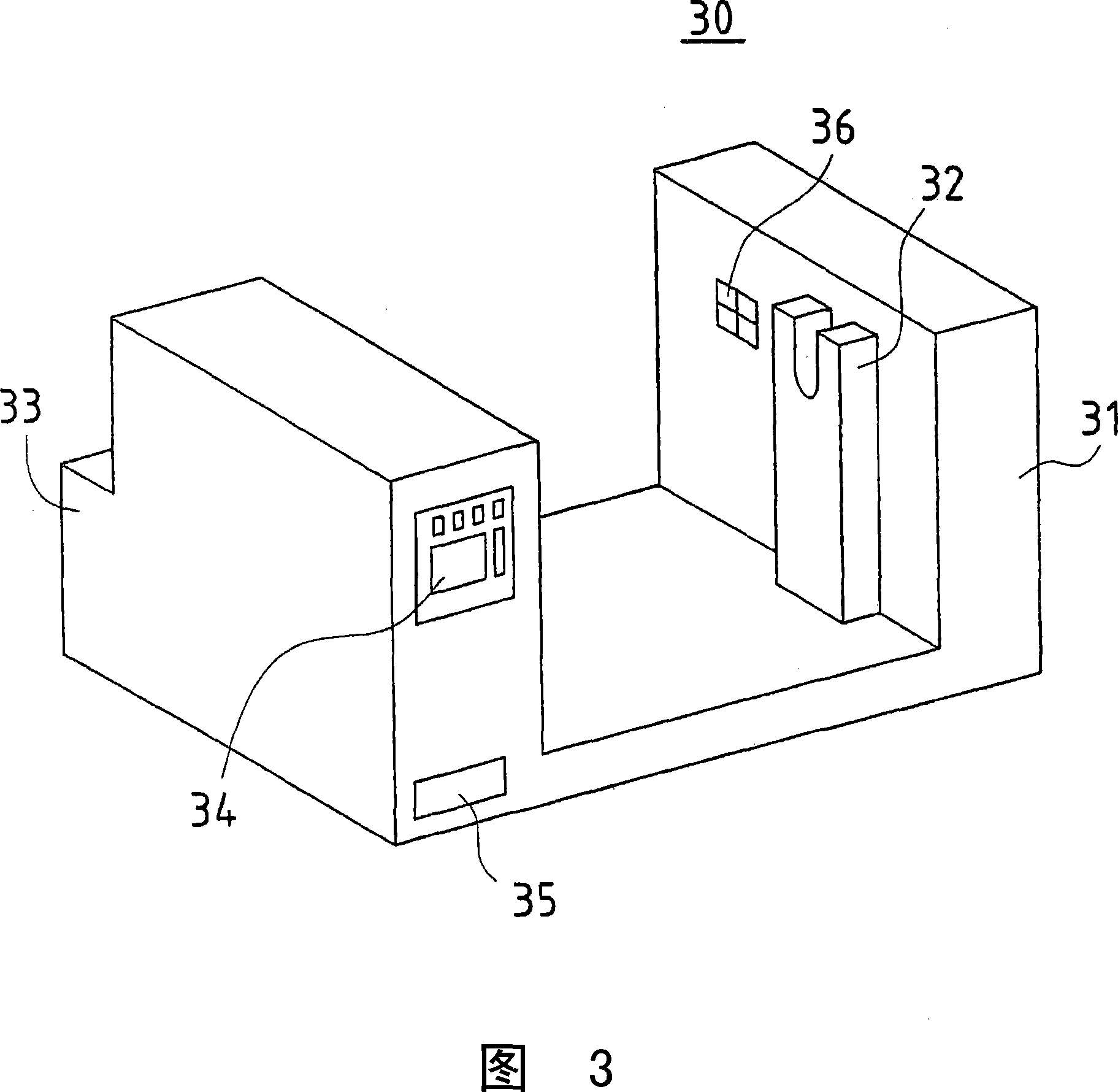

Printed wiring board manufacturing apparatus, printed wiring board, method for manufacturing printed wiring board, and electronic device

InactiveCN101188907AEasy to manufactureHigh dimensional accuracyLamination ancillary operationsLayered product treatmentManufactured apparatusEngineering

According to an embodiment of the present invention, a printed wiring board manufacturing apparatus being provided with a drum unit having a processing cylinder that holds the printed wiring board material and comprises a cylinder outer circumference and a processing unit that performs processing on the printed wiring board material held by the processing cylinder.

Owner:SHARP KK

Novel polyimide film and use thereof

ActiveCN101163734ASuppresses dimensional changesImprove problems such as position deviationSynthetic resin layered productsPrinted circuit aspectsImideThermal deformation

The present invention provides a polyimide film capable of suppressing dimensional changes caused by thermal stress, particularly a polyimide film having a function of suppressing thermal deformation of the material when a metal layer and a polyimide film are laminated by a lamination method. Imide film and its utilization. The polyimide film of the present invention (1) has an inflection point of the storage modulus in the range of 270° C. to 340° C., and (2) the peak of the value tanδ obtained by dividing the loss modulus by the storage modulus is at 320° C. In the range of ℃~410℃, (3) the storage modulus at 380℃ is 0.4GPa~2.0GPa, (4) the storage modulus α1(GPa) at the inflection point and the storage modulus α2 at 380℃ (GPa) is in the range of 85≥{(α1-α2) / α1}×100≥65. Thermal deformation occurring on the material when the metal layer and the polyimide film are laminated by a lamination method is thereby suppressed.

Owner:KANEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com