Thin polarizer and image display apparatus using the same

A technology of polarizing plates and polarizers, applied in the field of polarizing plates, can solve problems such as the characteristics or effects of adhesives that are not recorded, and achieve the effects of thinning durability, excellent durability, and suppression of dimensional changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

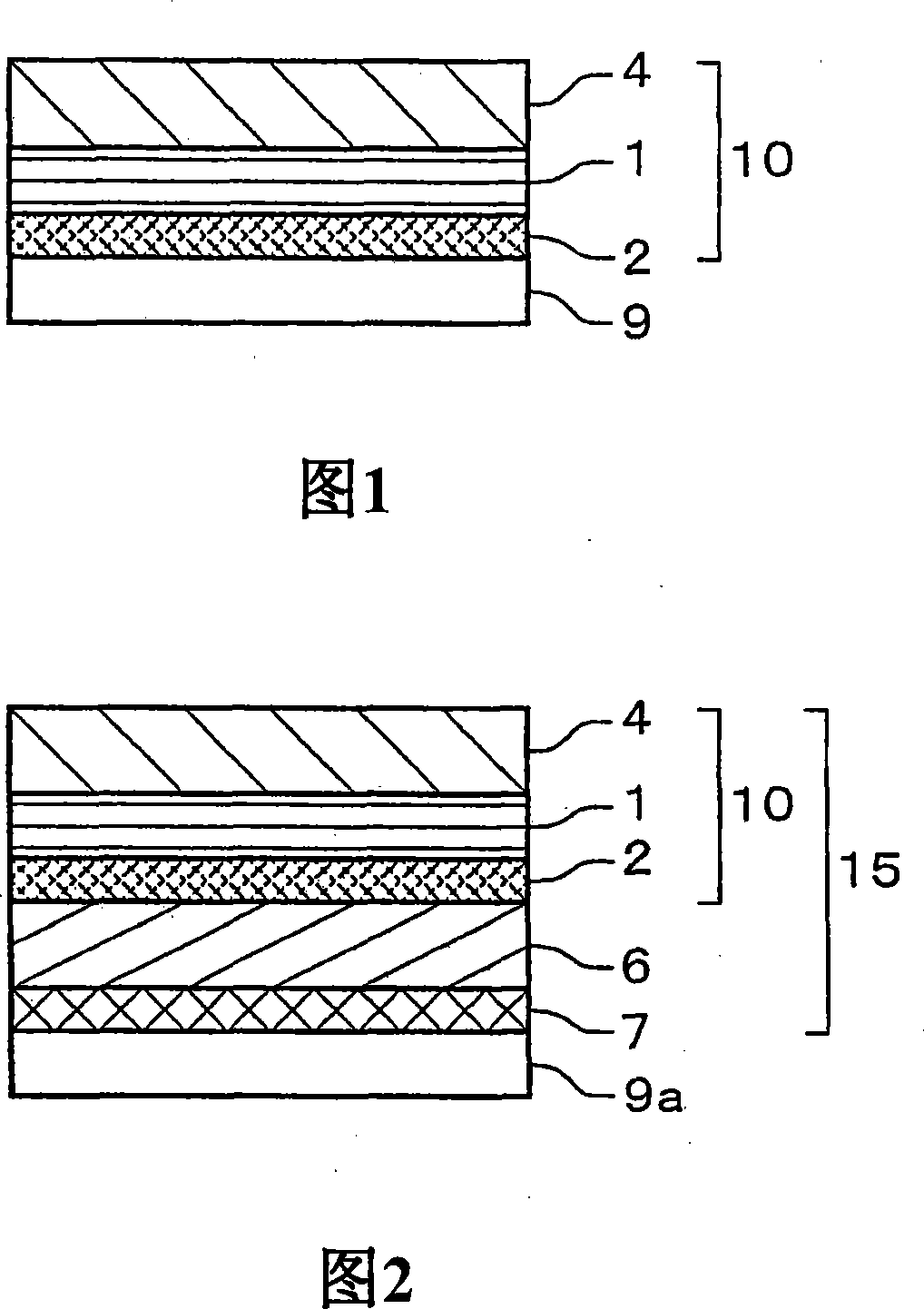

[0094] On one side of a polarizer made of a film with a thickness of 25 μm in which iodine is adsorbed and oriented on polyvinyl alcohol, triacetyl cellulose with a thickness of 40 μm is pasted with an adhesive composed of an aqueous solution containing polyvinyl alcohol and a water-soluble epoxy resin The film constitutes the protective film, thereby preparing the polarizing plate. The pressure-sensitive adhesive A was attached to one side of the polyvinyl alcohol film to obtain a thin polarizing plate corresponding to FIG. 1 .

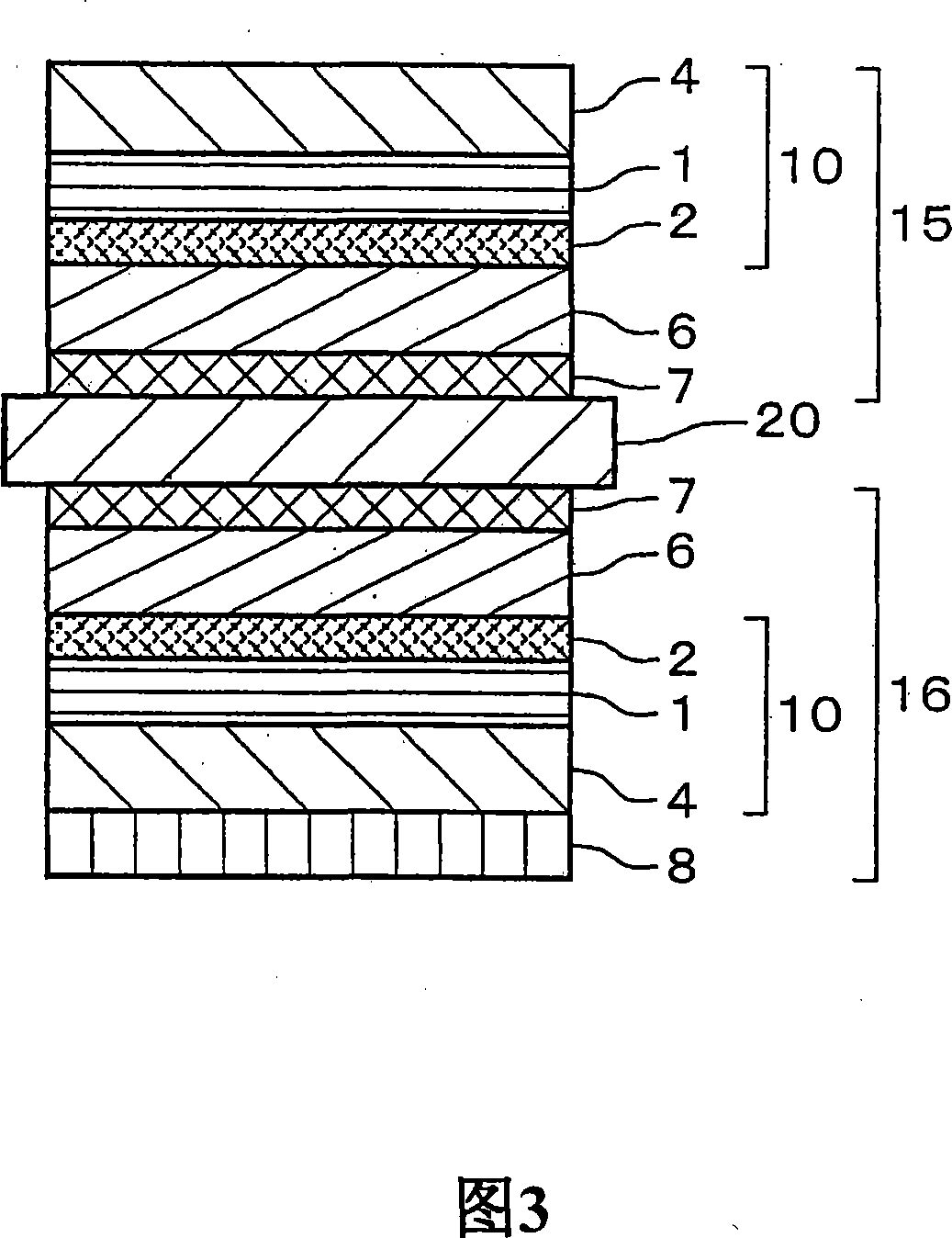

[0095] In addition, a retardation film with a pressure-sensitive adhesive was prepared, which was made of a norbornene-based resin with a thickness of 40 μm and an in-plane retardation of 140 nm. Acrylic pressure-sensitive adhesive with a thickness of 25 μm is provided on one side of the film, and the surface is covered with a spacer. After the spacer of the previously obtained thin polarizing plate was peeled off, the side of the phase difference p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com