Patents

Literature

390results about How to "Reduce the number of pieces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

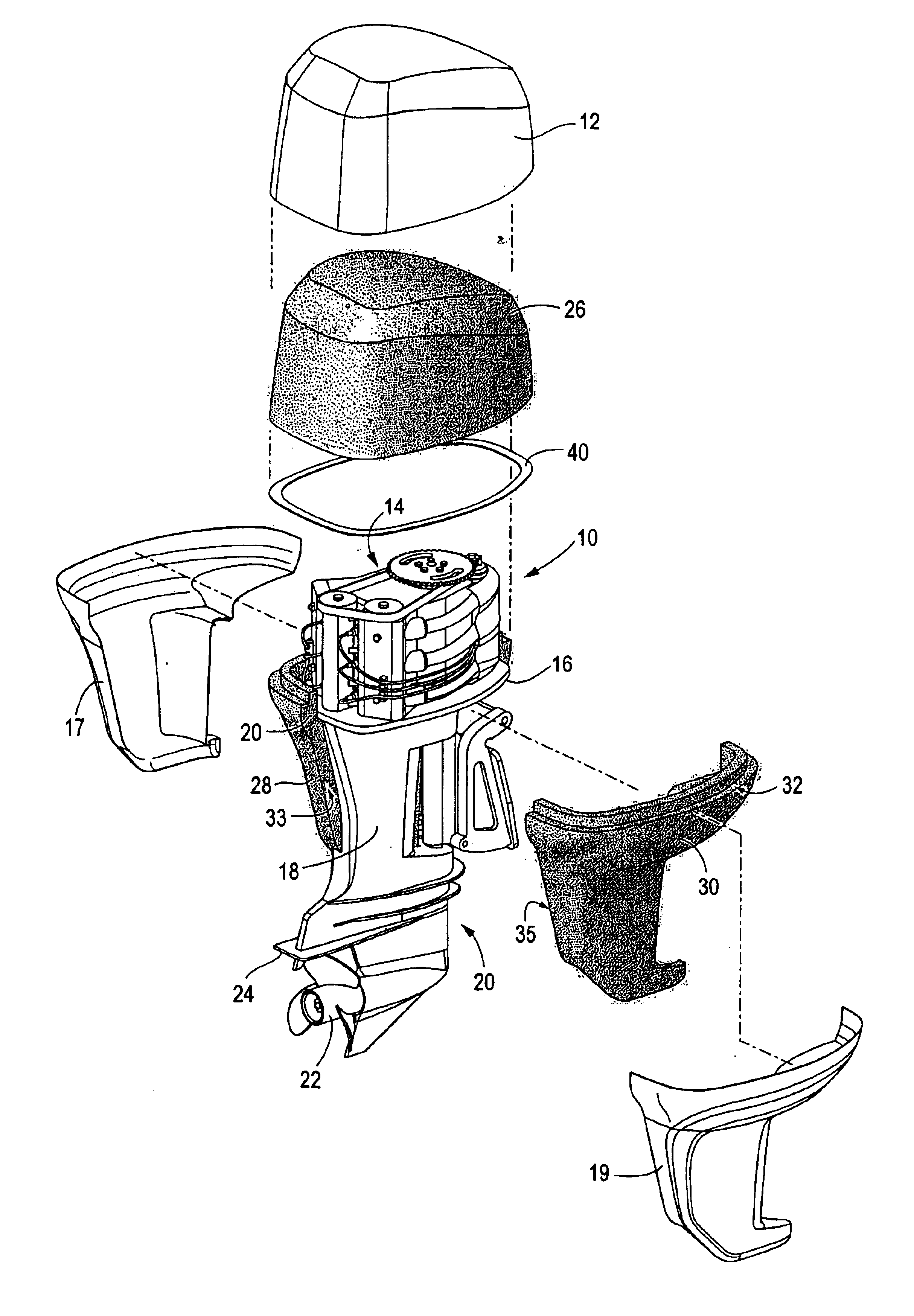

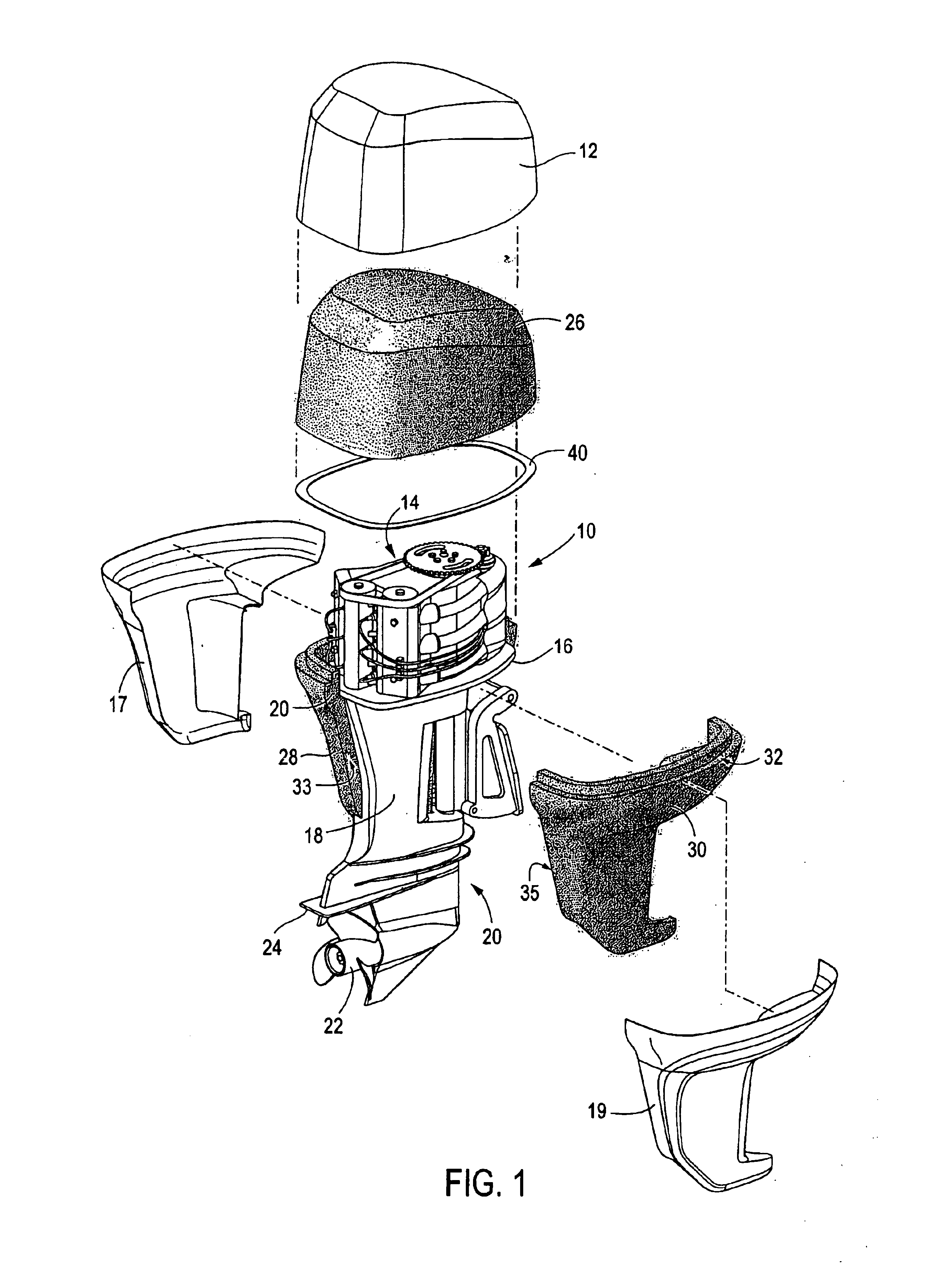

Sound insulation for outboard motors

InactiveUS6875066B2Reduce decreaseGood surface fitExhaust apparatusPropulsion power plantsPulp and paper industrySurface matching

Sound insulation for an engine contained within an outer casing, the insulation made up from a minimal number of interlocking molded foam insulation pieces forming a substantially continuous shroud surrounding the operating parts of the engine and having an outer surface matching the inner shape of the outer casing and in contact therewith. Preferably the outer casing is used to generate the molds used to manufacture the molded sound insulation pieces, thereby providing a good surface fit between the outer insulation surface and the inner casing surface.

Owner:POLYMER TECH CORP

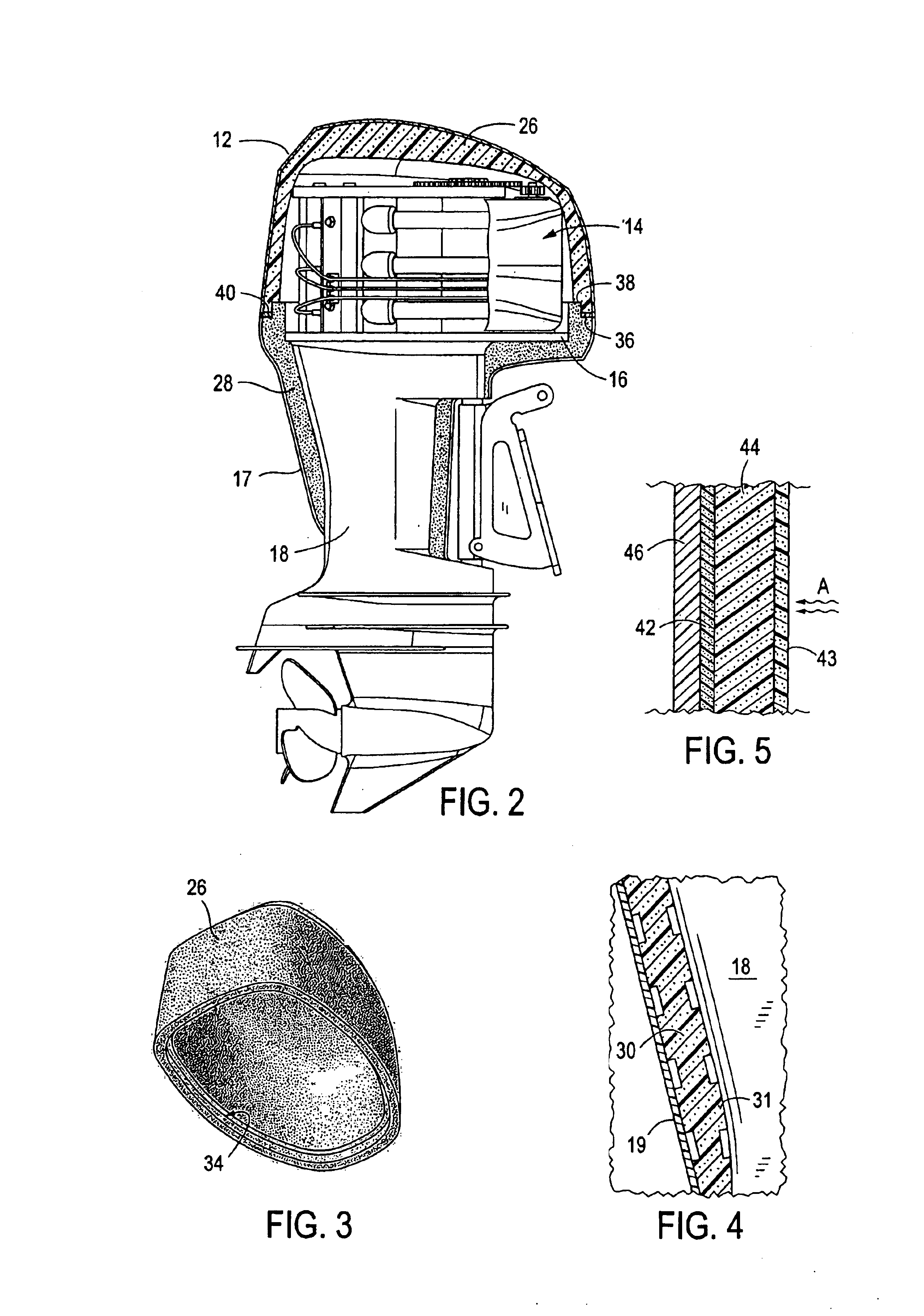

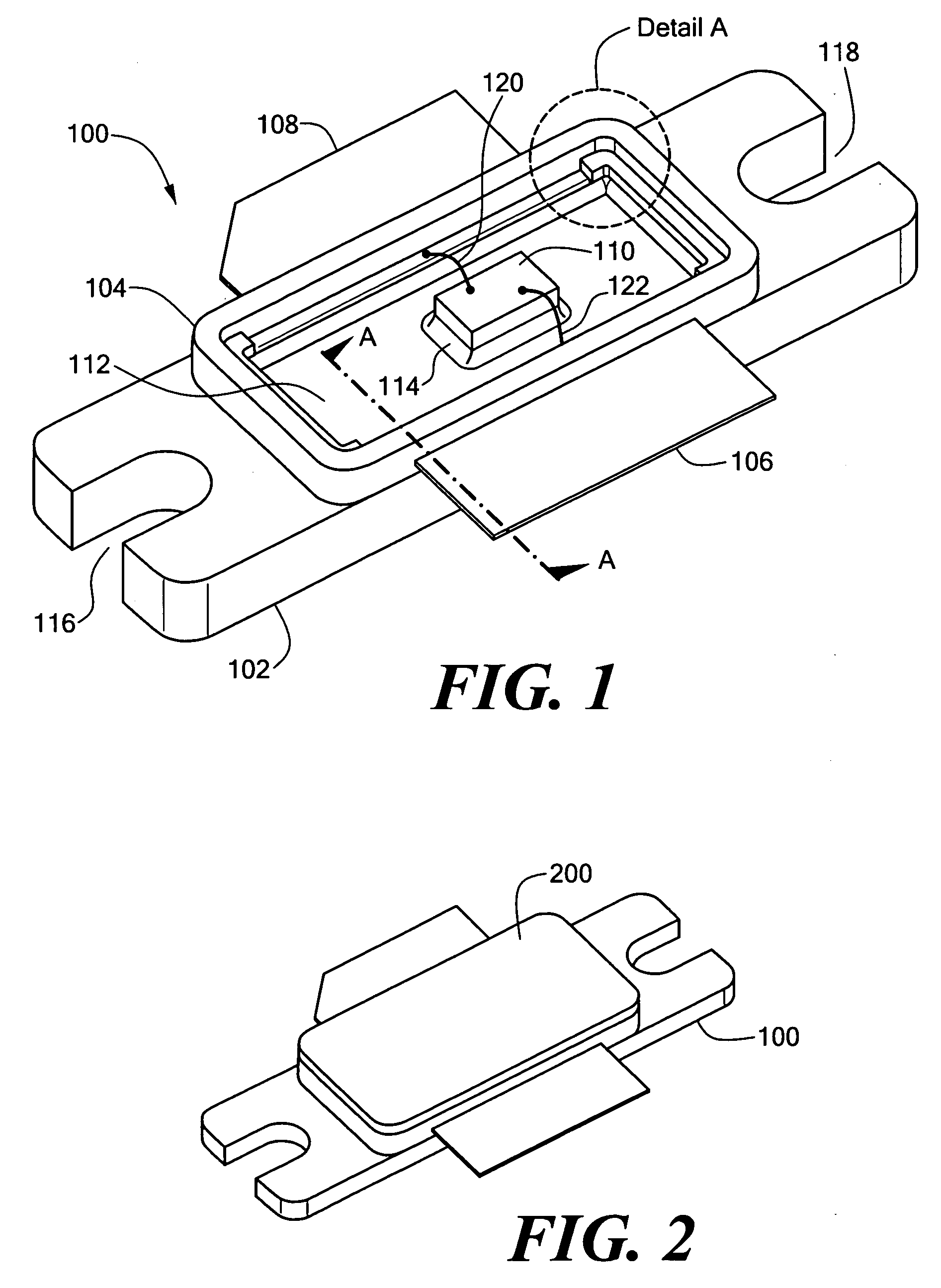

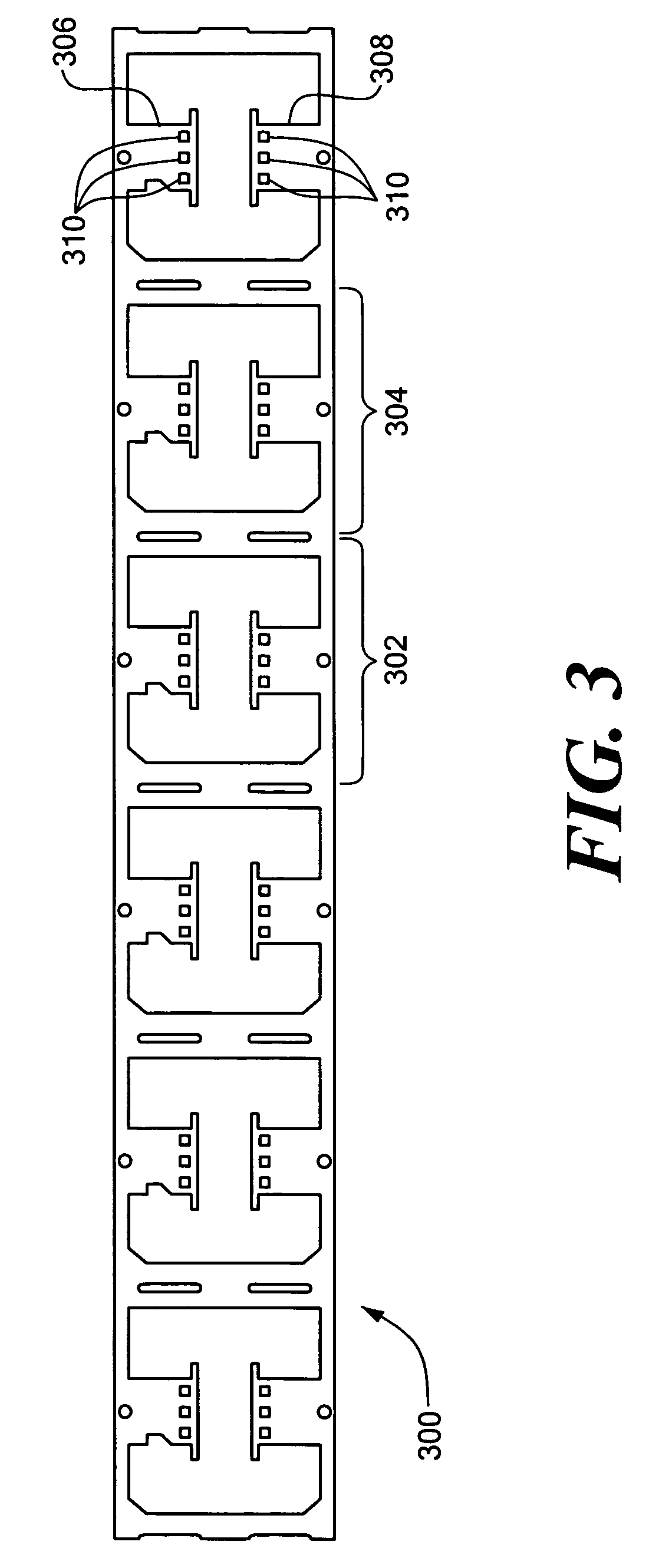

Methods for enclosing a thermoplastic package

InactiveUS20050016750A1Reduce the number of piecesHigh die-attach temperatureSemiconductor/solid-state device detailsCoupling device detailsSemiconductorPolymer

Owner:IQLP

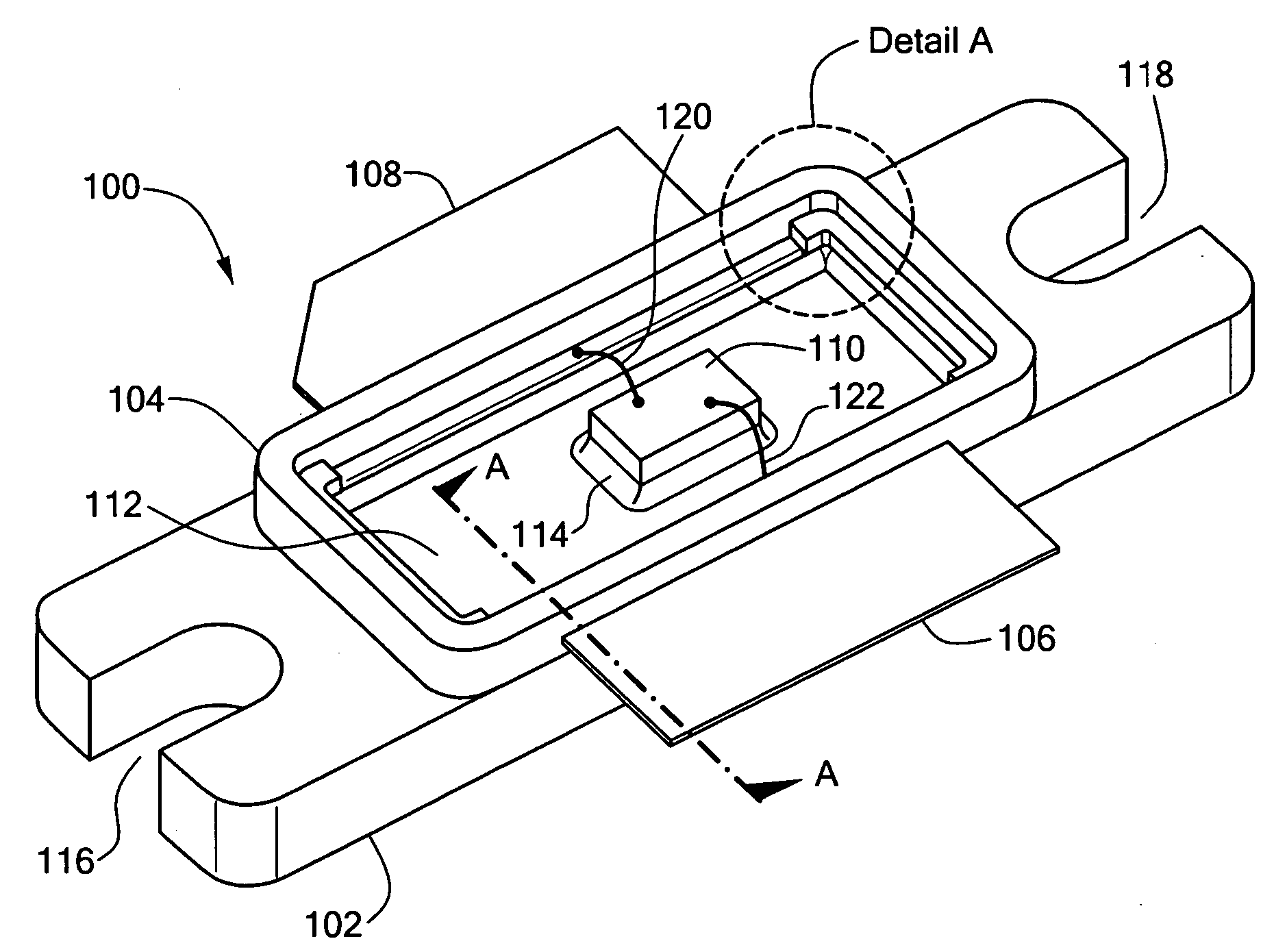

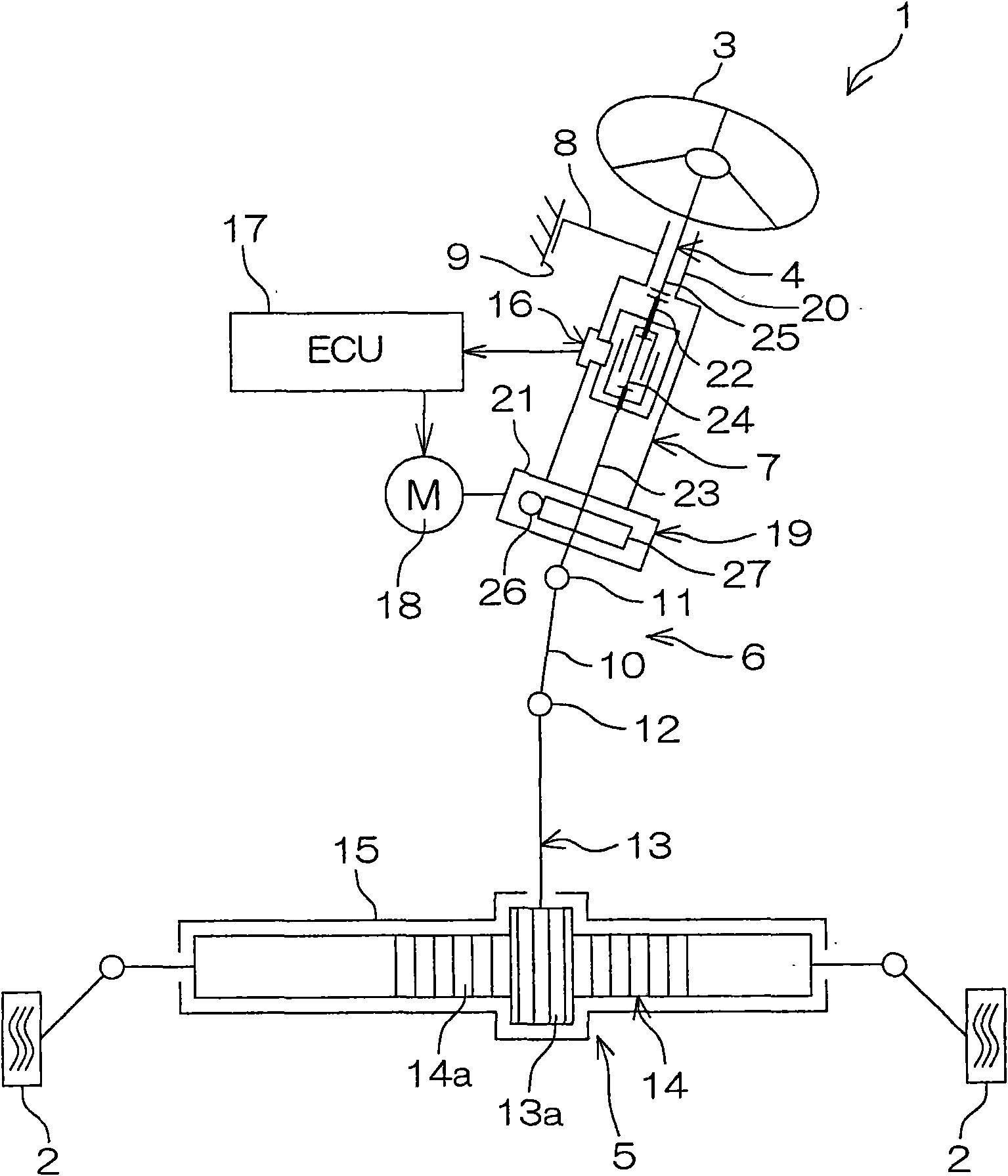

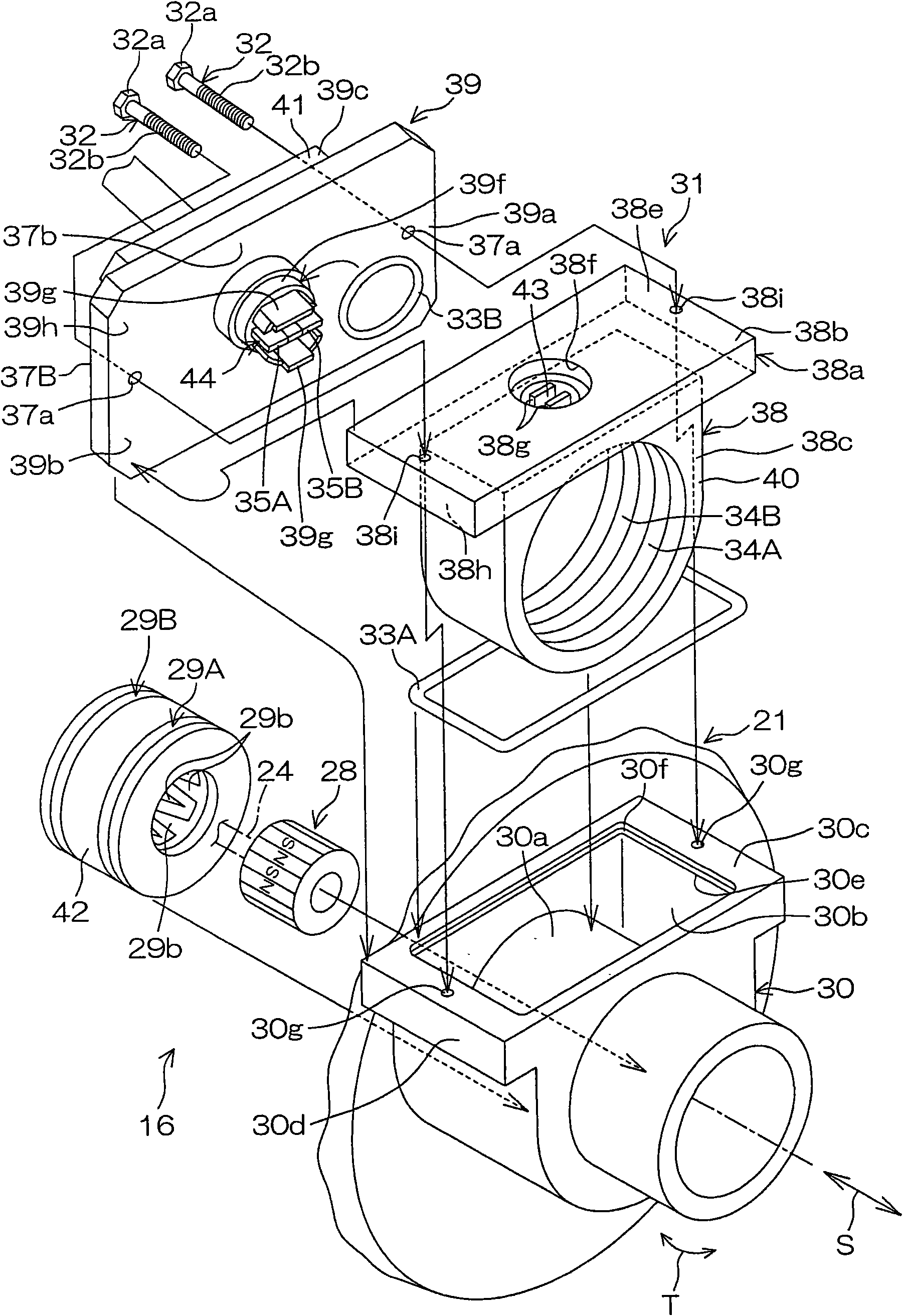

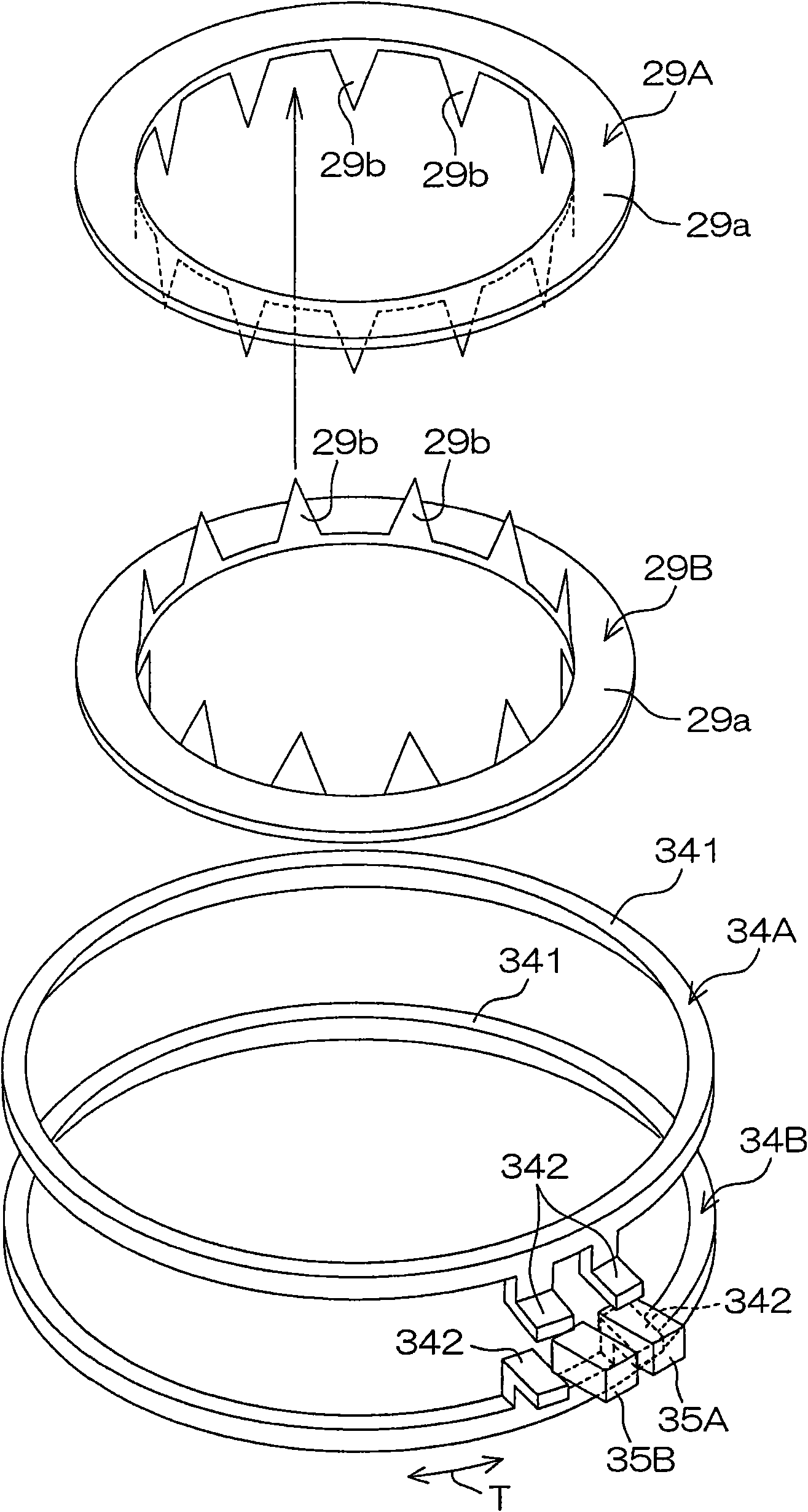

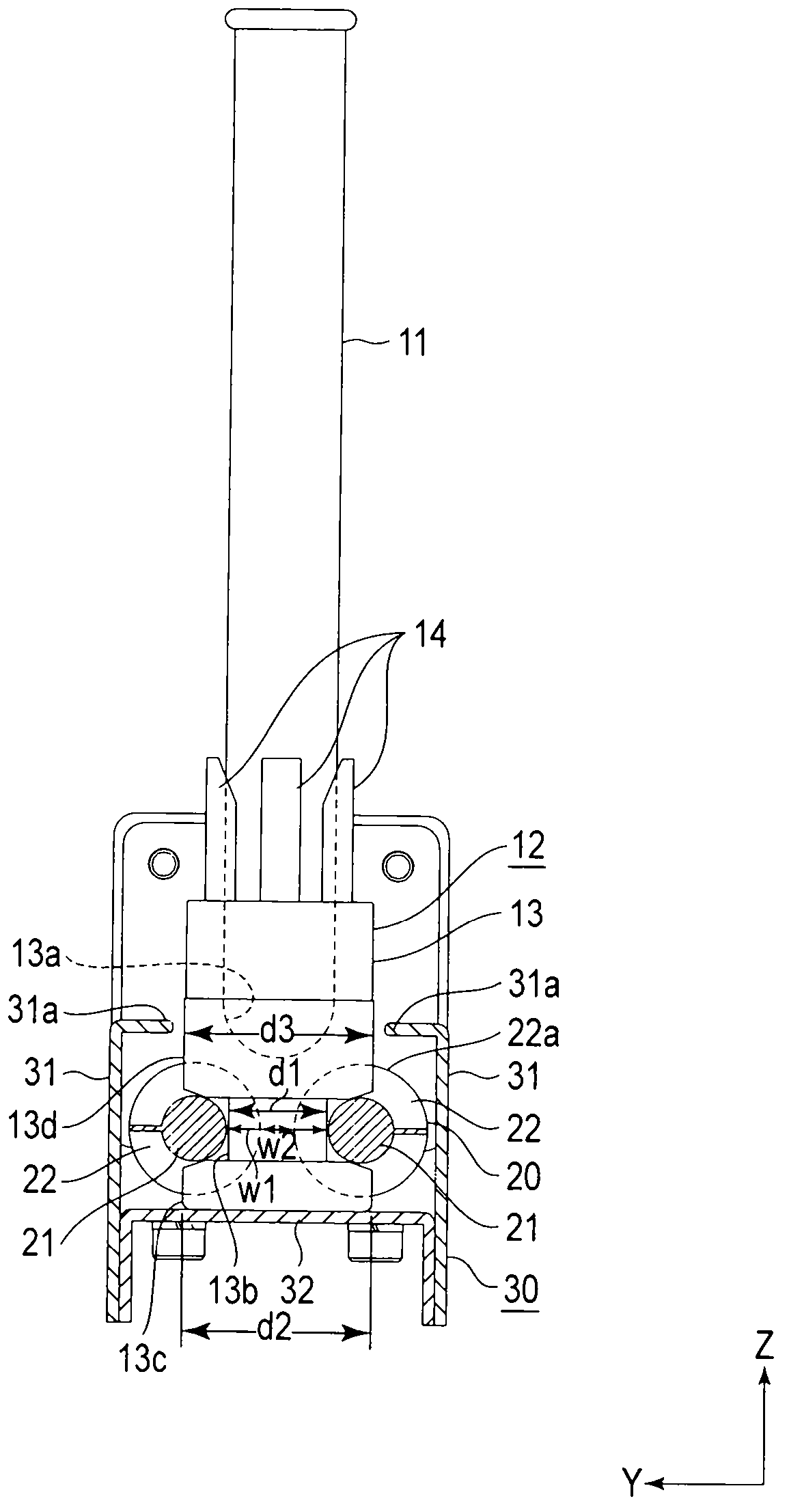

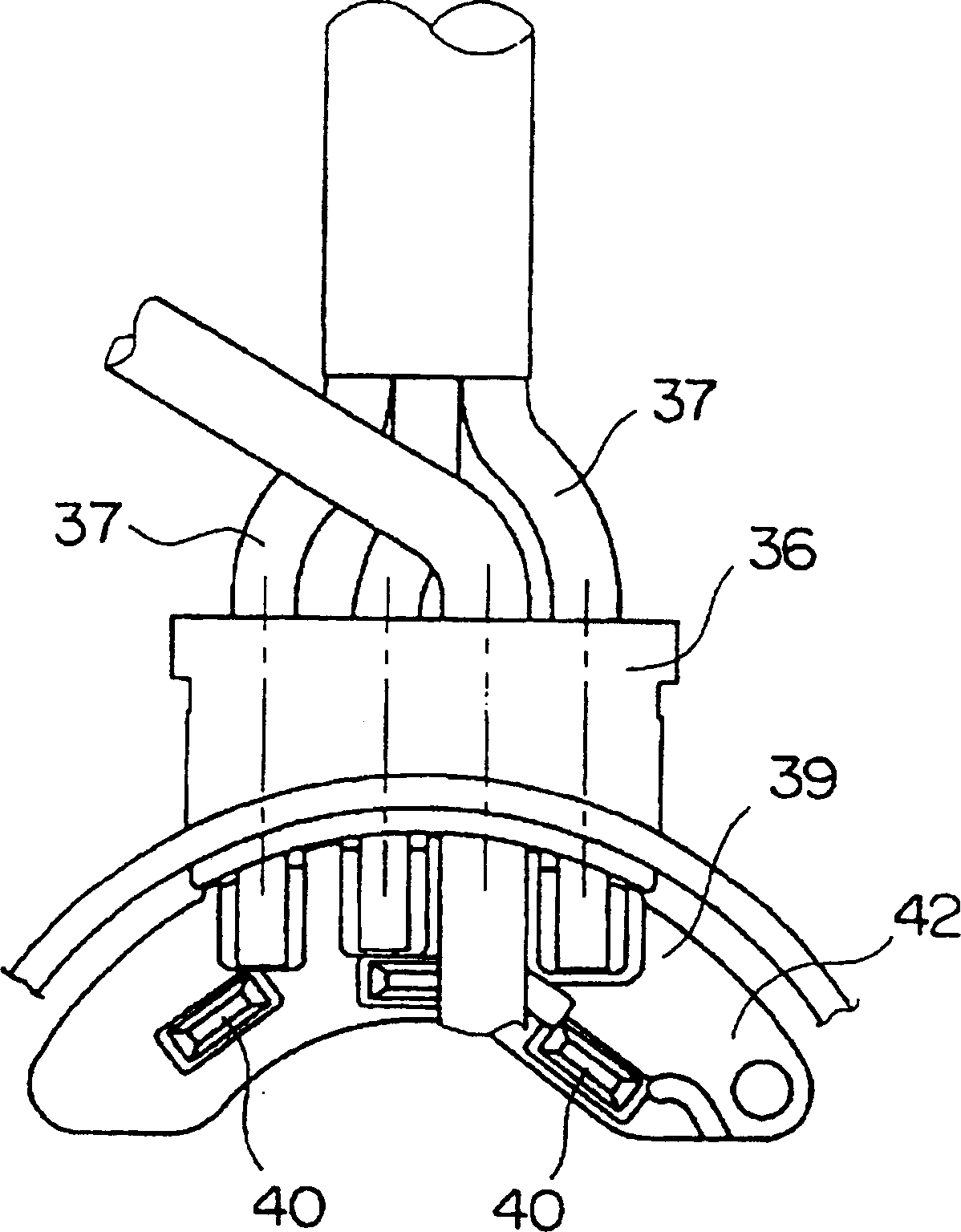

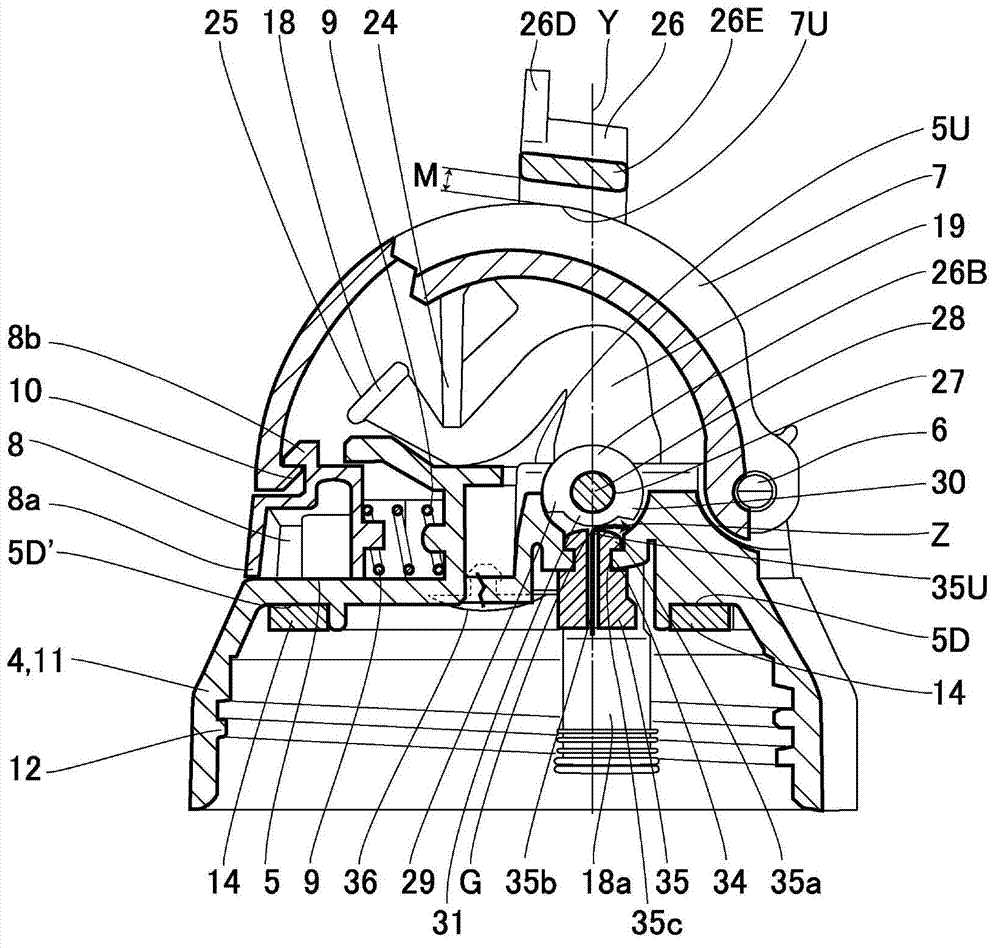

Torque detecting device

InactiveCN101646931AReduce the number of piecesReduce manufacturing costWork measurementElectrical steeringEngineeringMagnetic shield

A torque detecting device (16) is provided with first and second units (38, 39). The first unit (38) includes a first synthetic resin (40) formed by molding a pair of magnetic flux inducing rings (34A, 34B). The second unit (39) includes a second synthetic resin (41) fixed to a magnetic shield plate (37B) containing a metal; an inserting protruding section (44) arranged on the synthetic resin (41); and magnetic sensors (35A, 35B) held by the inserting protruding section (44). The first synthetic resin (40) includes a receiving plate (38a) whereupon a base (38e) for receiving the magnetic shield plate (37B) is formed. In a status where the receiving plate (38a) exists between the magnetic shield plate (37B) and an object (30) to be attached, both the magnetic shield plate (37B) and the receiving plate (38a) are fastened to the object (30) by a pair of fixing screws (32).

Owner:JTEKT CORP

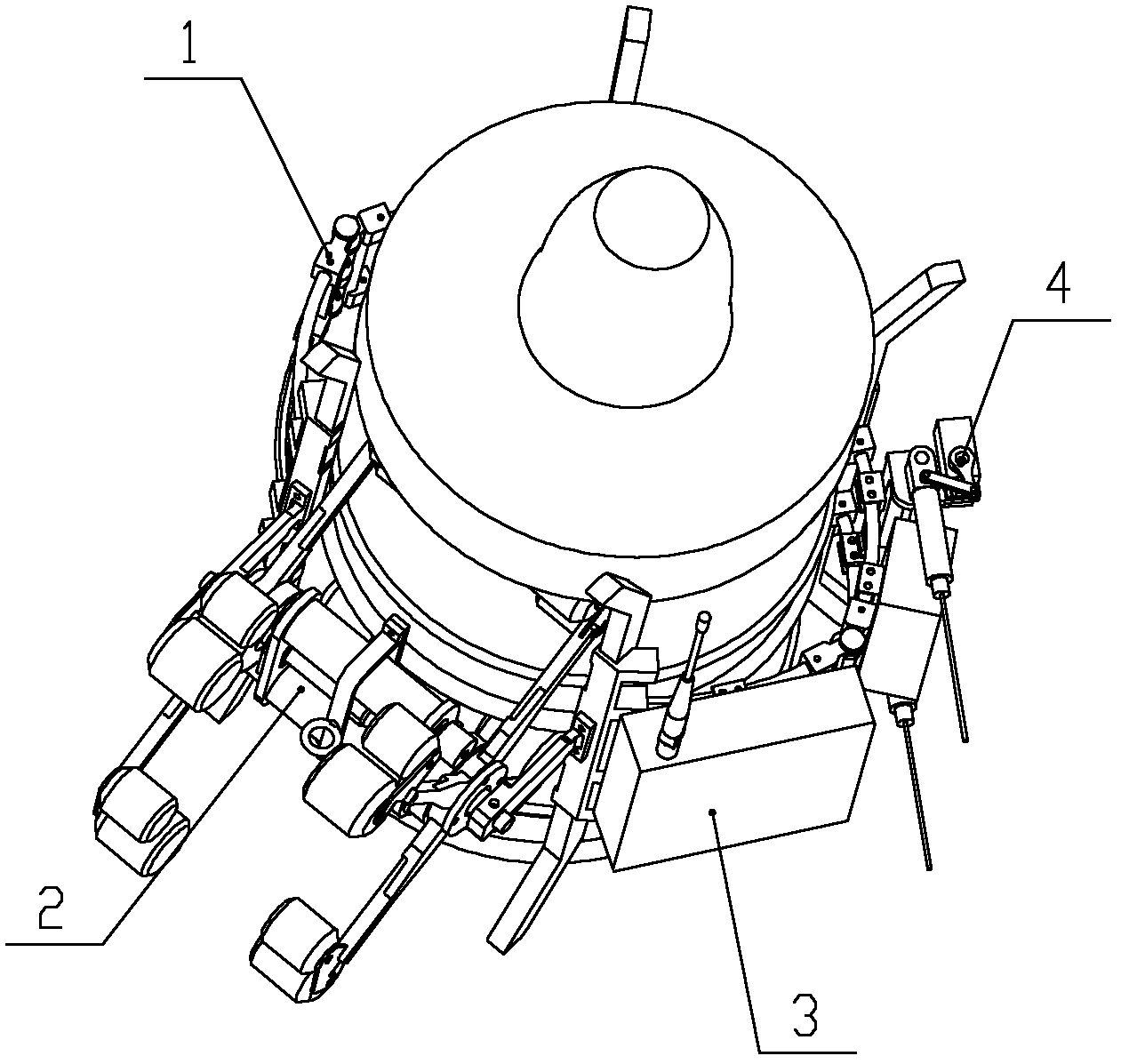

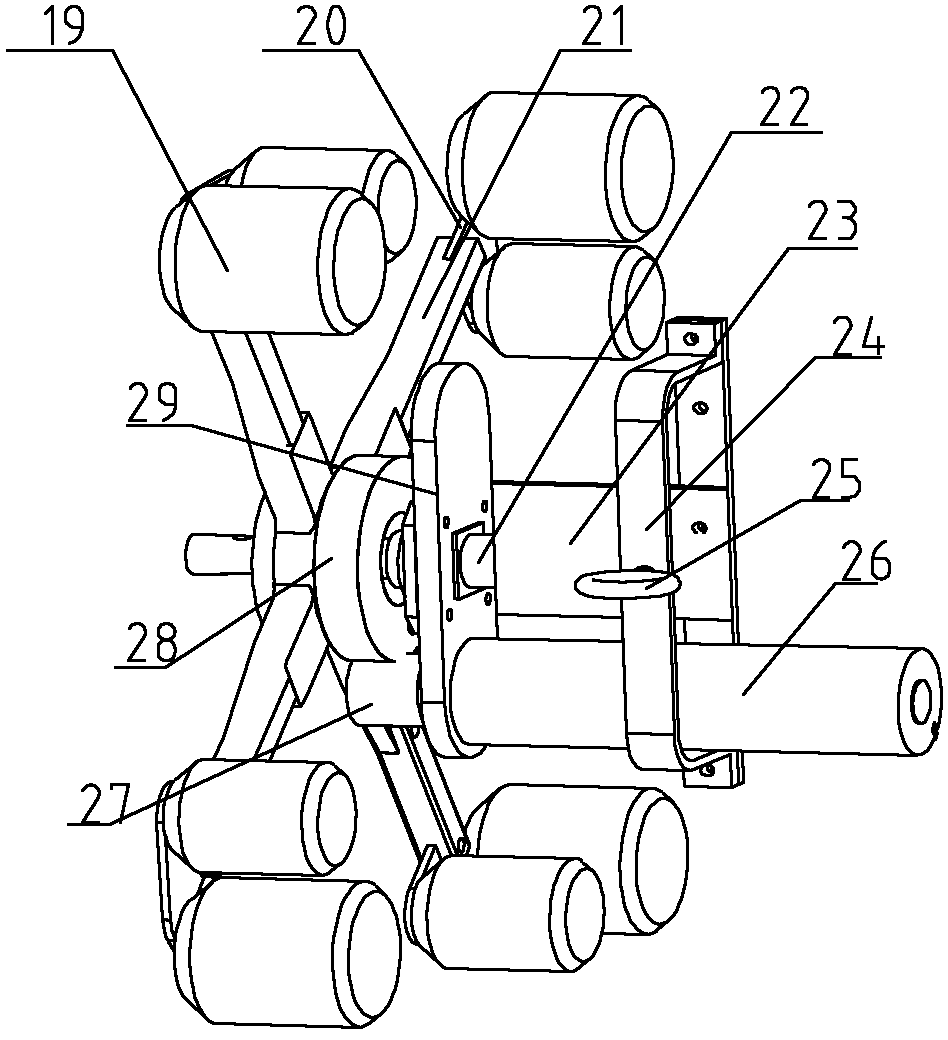

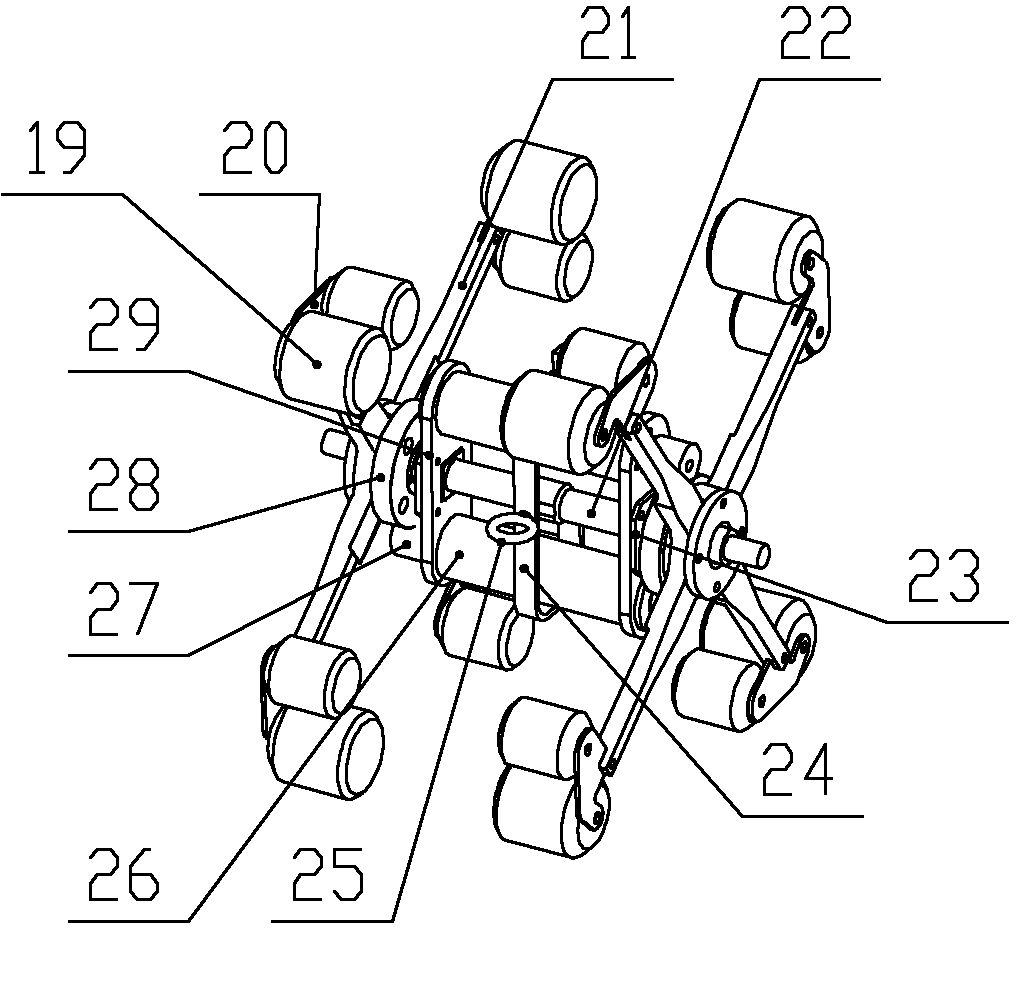

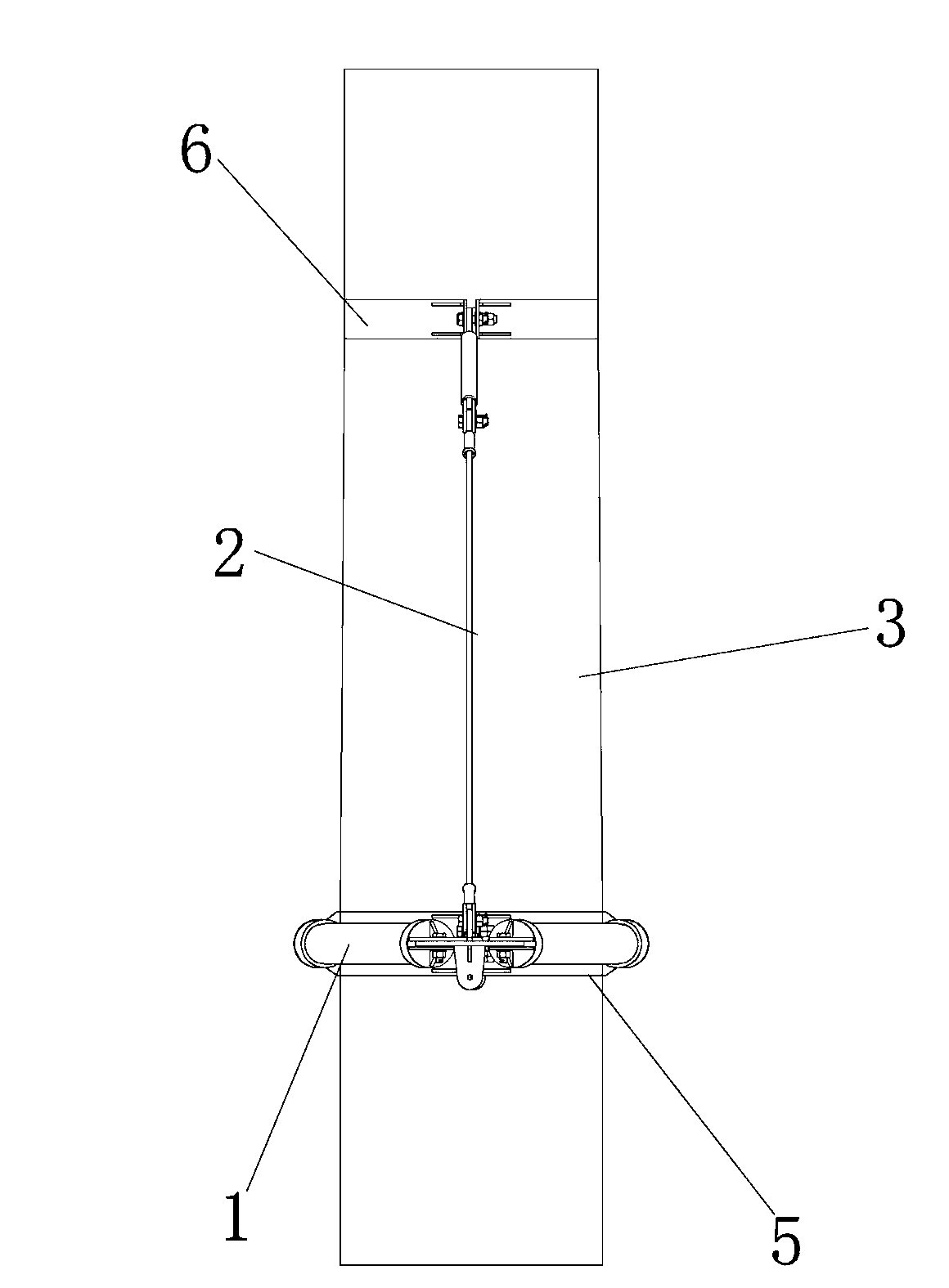

Robot for electrified detection insulator string

ActiveCN102608474AReduce wearGood continuity of motionElectrical measurement instrument detailsElectrical testingElectricityElectric machine

The invention discloses a robot for electrified detection of an insulator string. The robot comprises a plurality of guide rod mechanisms, at least one insulator detection device, a control device and at least one rotary driving device, wherein the guide rod mechanisms are connected on the two sides of the rotary driving device, the control device and the insulator detection device are all fixed on the guide rod mechanisms, and the insulator detection device and a driving motor of the rotary driving device are all electrically connected with the control device. According to the robot, the structure is compact, the movement speed is quick, the number of short-circuit insulator sheets is few, the abrasion on the insulators is little, the safety protection is good, the using range is wide, and the robot is suitable for duplex-parallel insulator strings, single strain insulator strings, suspension insulator strings and V-shaped insulator strings.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

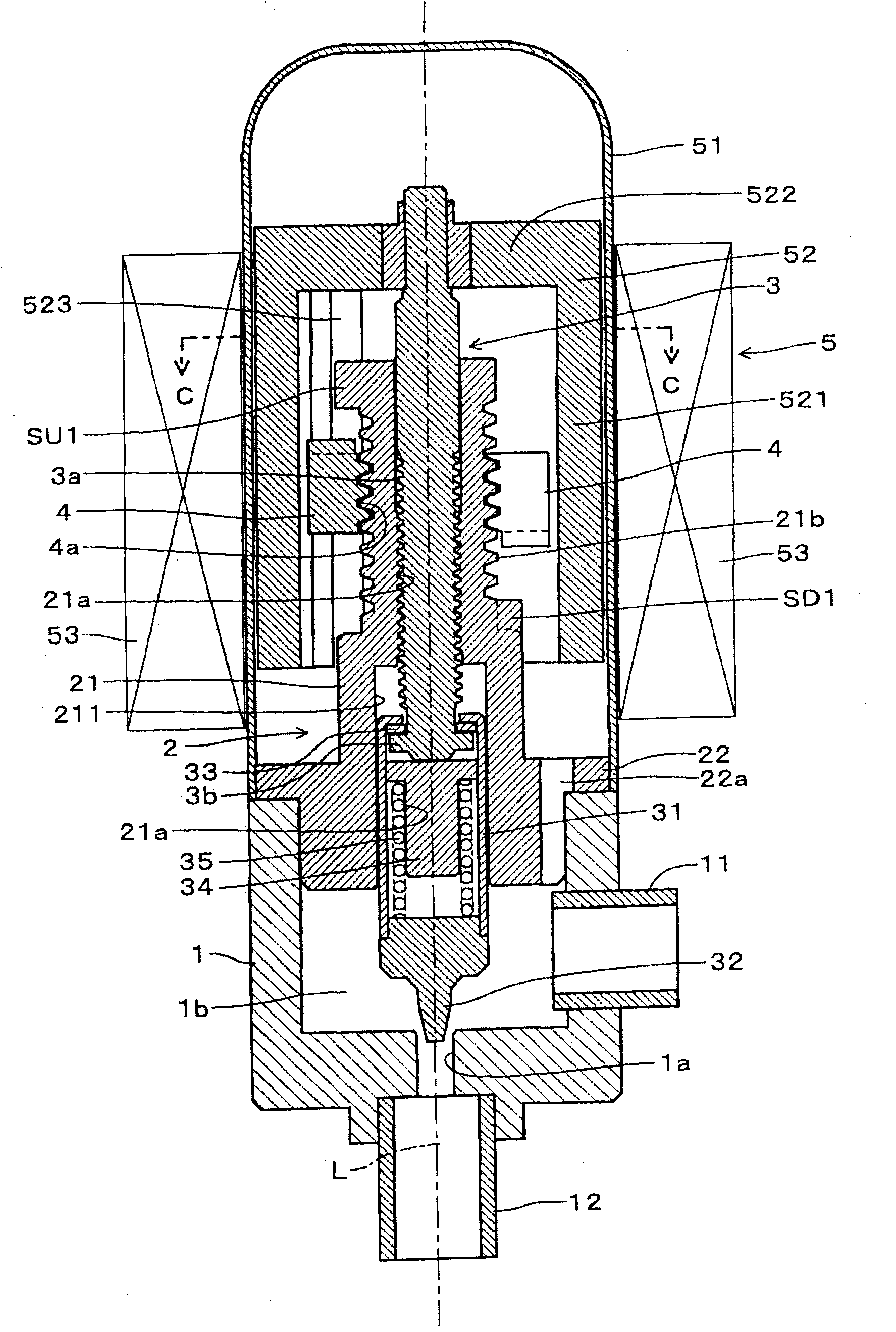

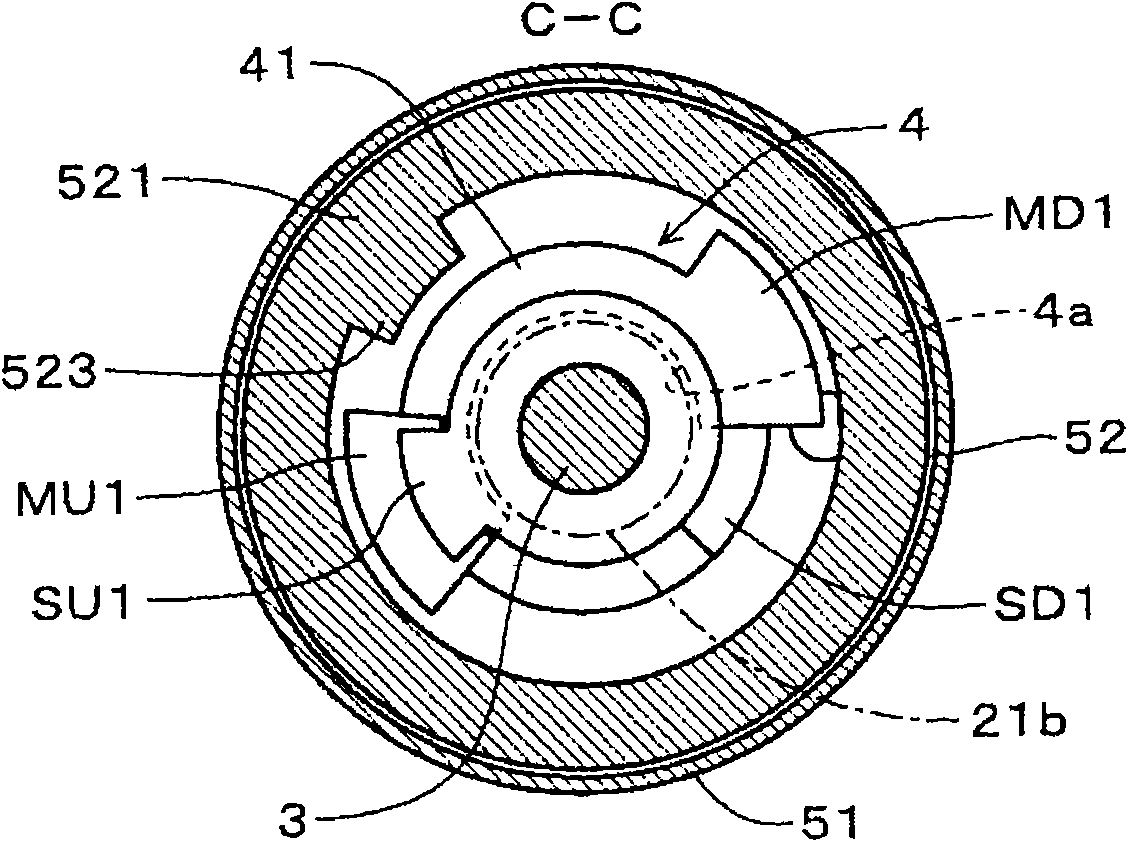

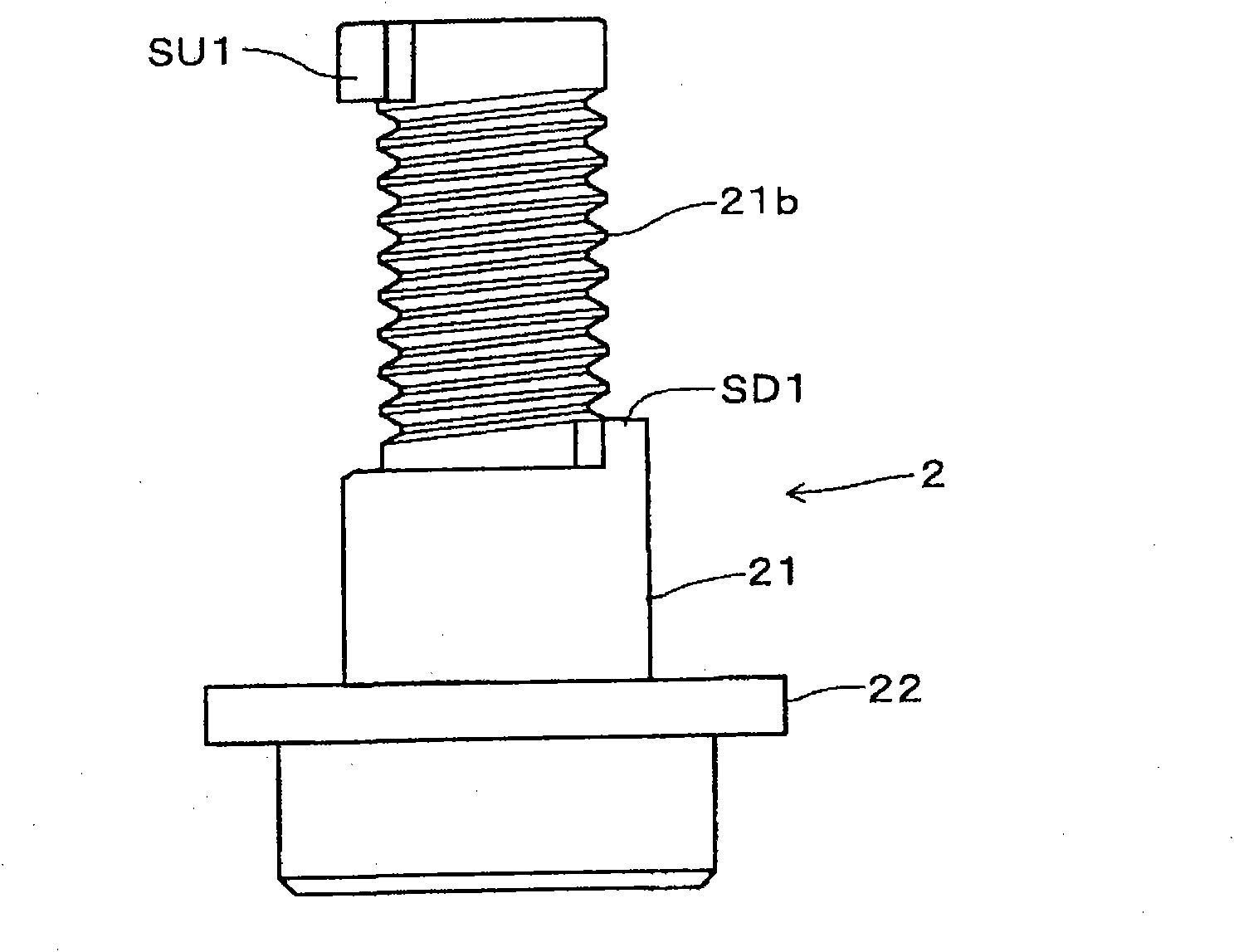

Electric valve

ActiveCN101644337ALimit range of movementReduce the number of piecesOperating means/releasing devices for valvesLift valveElastic componentEngineering

In an electric valve of the invention, the number of components of a motion limiting mechanism relatively to a rotor shaft (3) and a magnetic rotor (52) is reduced, and the precision is increased. Theguiding external thread (21b) is integrated with a bracket part at the periphery of the bracket part (21) of the bracket component (2). A driven slider (4) of a guiding internal thread (4a) which isscrewed with one part on the periphery of the guiding external thread is provided. A projection strip (523) is provided at the inner periphery of the magnetic rotor. A fixed lower end limiter (SD1) isintegrated with the bracket part at the lower end of the guiding external thread. A fixed upper end limiter (SU1) is integrated with the bracket part at the upper end of the guiding external thread.The driven slider is formed by the synthetic resin which is taken as the elastic component. When the magnetic rotor rotates, the projection strip is used for rotating the driven slider and abutting against the fixed lower end limiter or the fixed upper end limiter thereby restraining the lower position and upper position.

Owner:SAGINOMIYA SEISAKUSHO INC

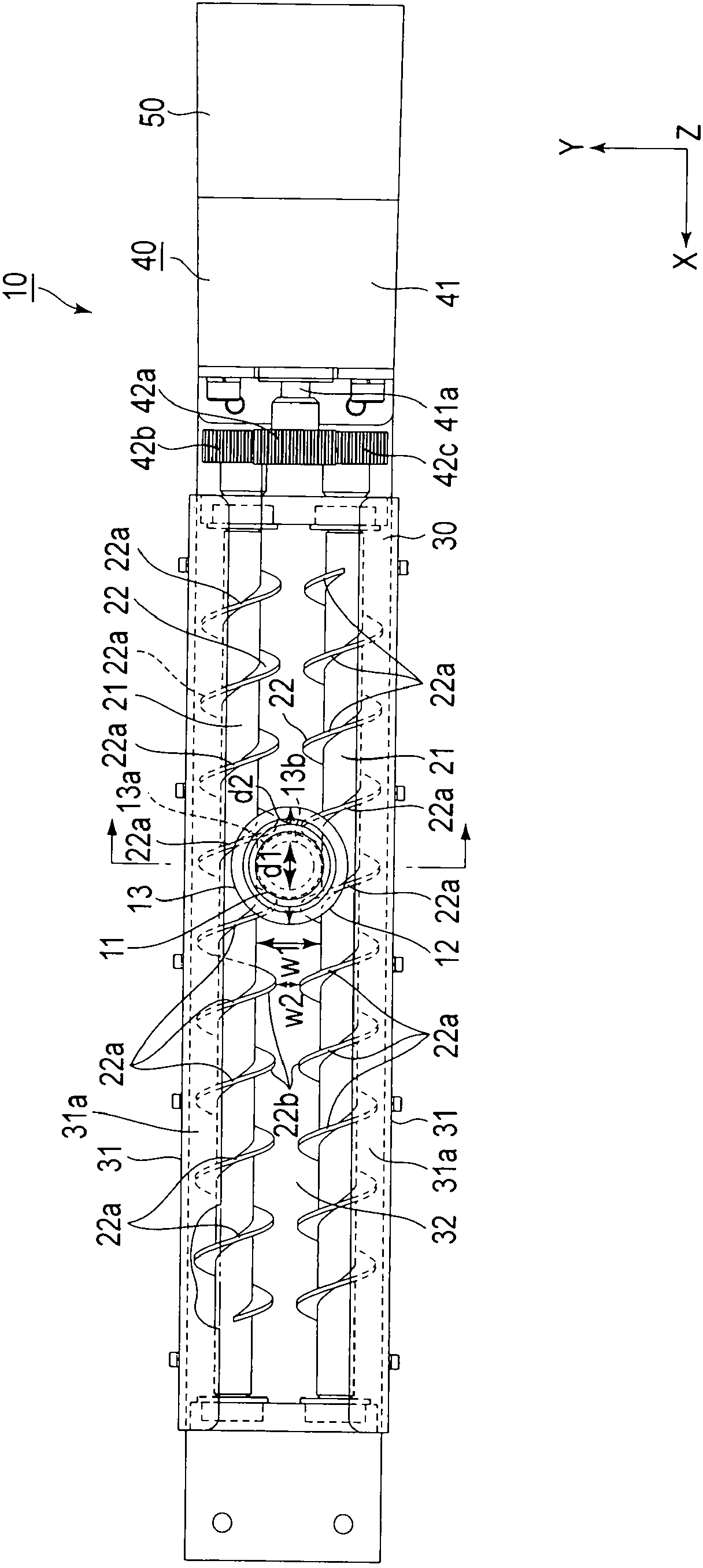

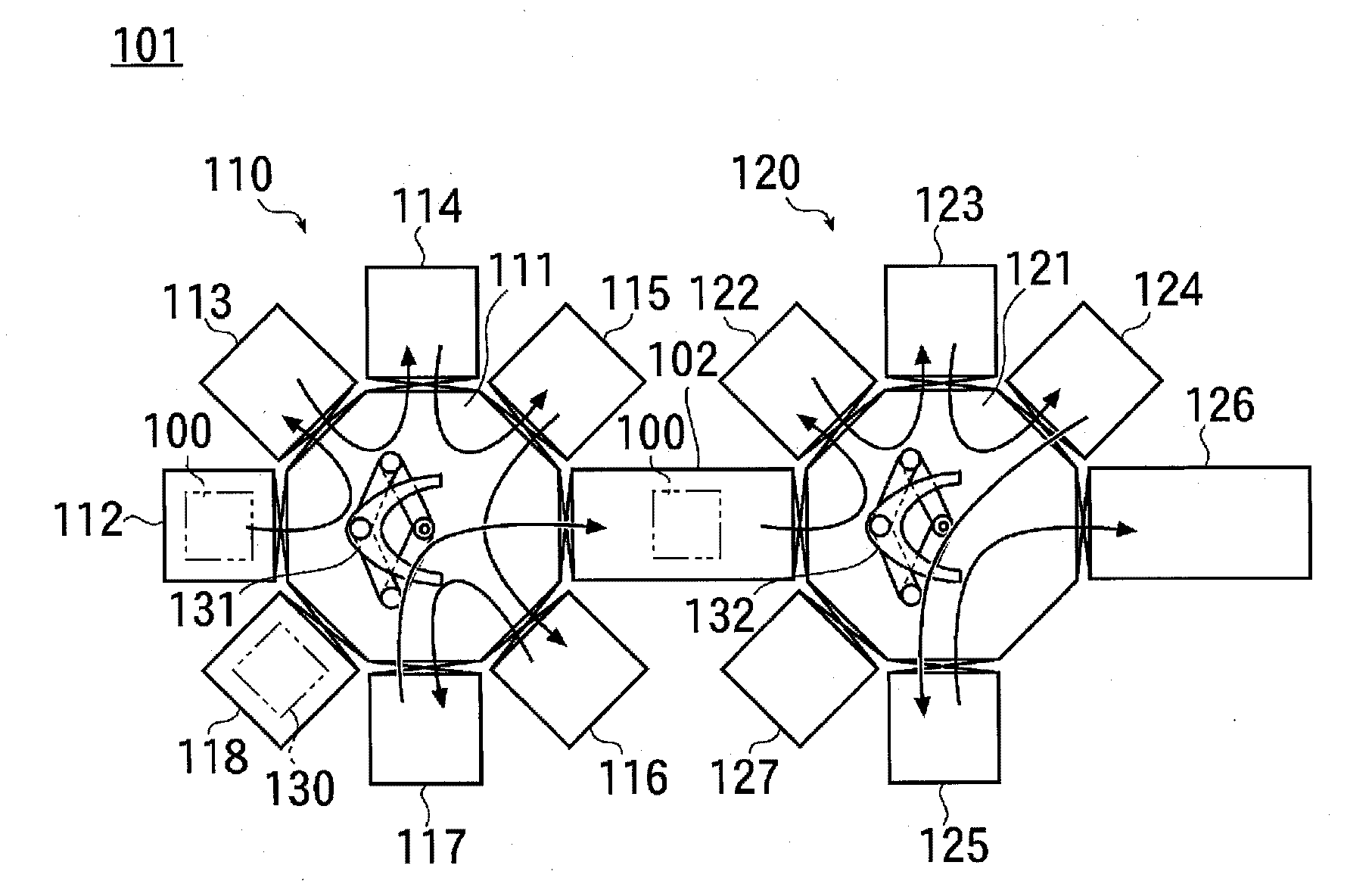

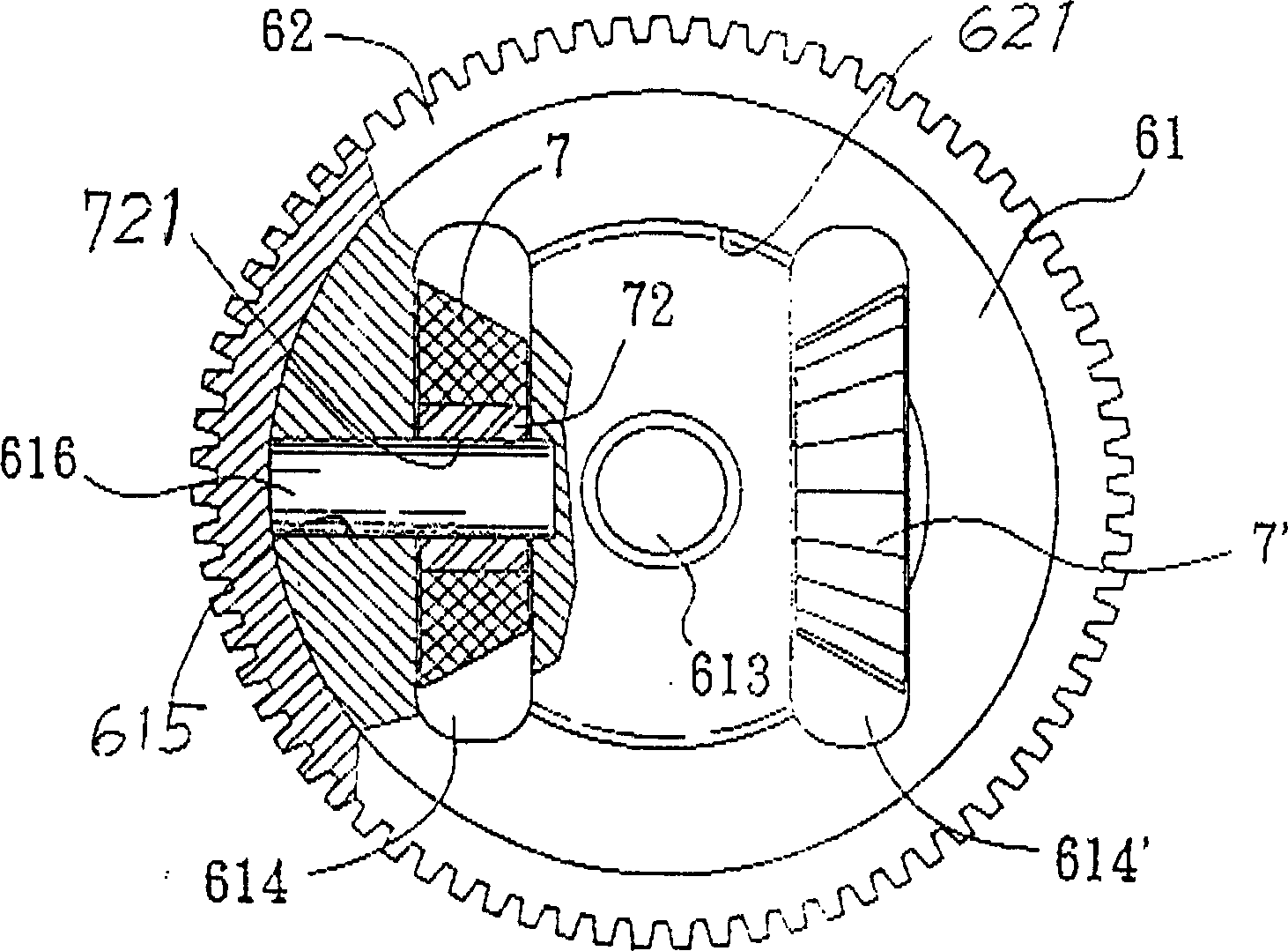

Transport system and transport method

InactiveCN103303639AReduced inspection workReduced parts countGearingBiological testingTransport systemTransport engineering

According to an embodiment, a transport system configured to transport a receptacle which accommodates an upright sample holder containing a sample, characterized by comprising, a screw comprising a rotatable shaft disposed along a predetermined transport path and a helical ridge protruding outward from an outer peripheral surface of the shaft, and a drive unit configured to rotate the screw. The transport method according to another shape utilizes a pair of parallel screws for conveying the receptacle, and conveys the receptacle which is held among a plurality of ridges which are arranged in an axial direction in a transportation path. The transport system and transport method of the invention have the following advantages: small number of components, simplified device structure, and reduced manufacturing cost.

Owner:AOI SEIKI

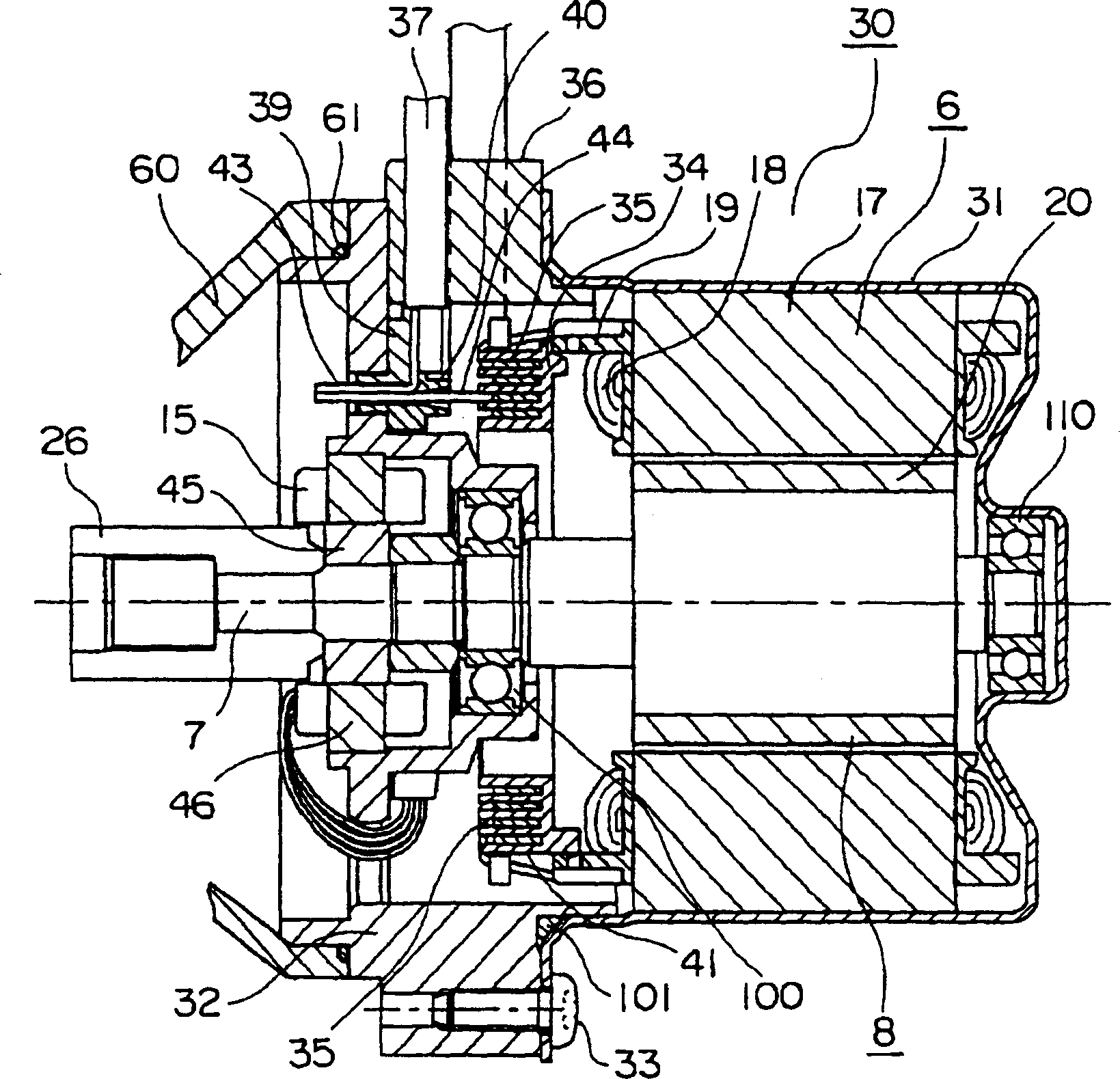

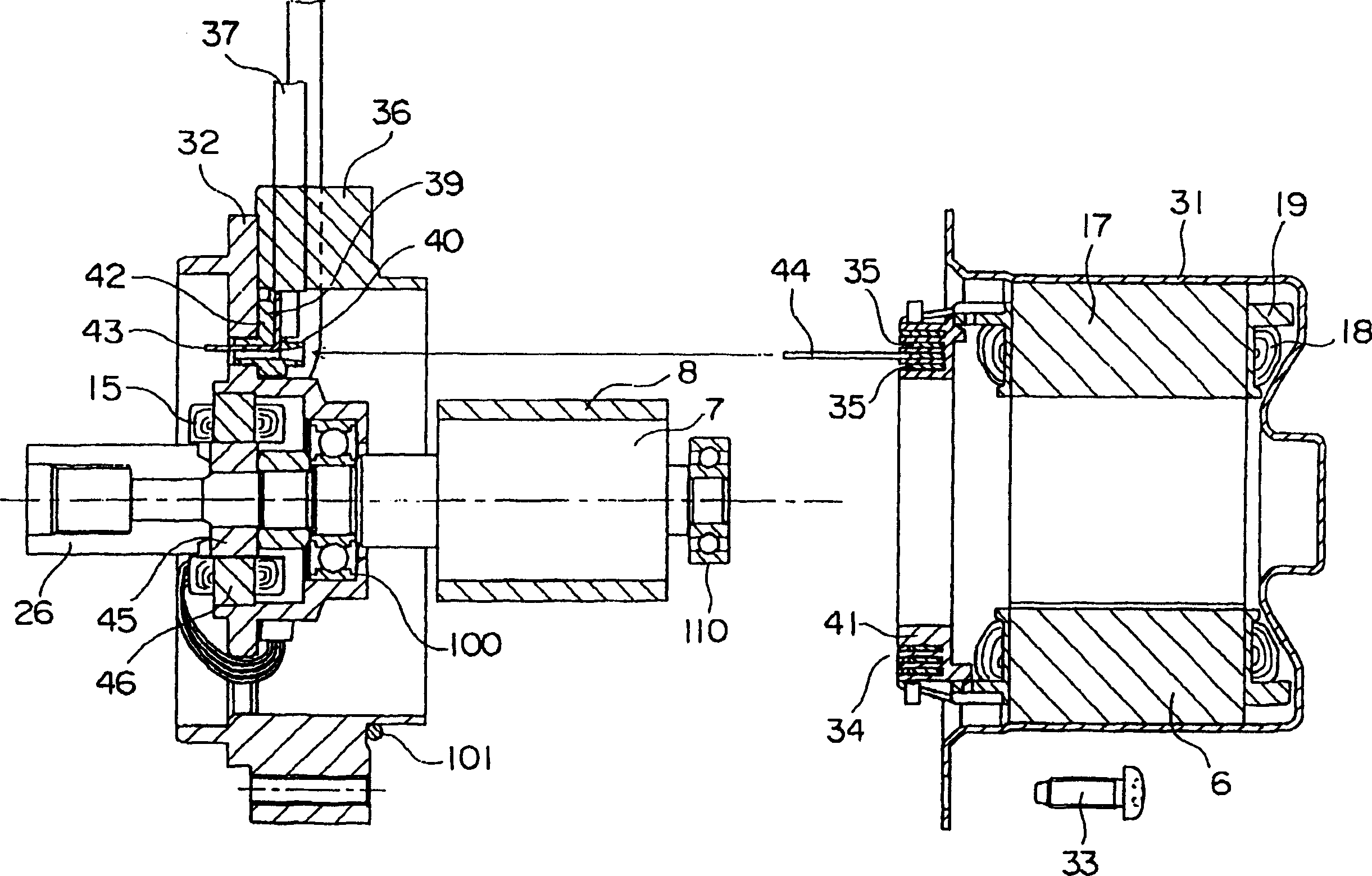

Electric machine for electrodynamic steering gear

InactiveCN1388627AReduce the number of piecesImprove assembly efficiencyWindingsElectrical steeringElectric machineMiniaturization

A motor for use with a motorized power steering apparatus is provided in which the number of component members can be reduced, and workability in assembling the component members can be improved, while enabling miniaturization of the entire motor. The motor includes a bottomed cylindrical frame (31), a bracket (32) fixedly secured to the frame (31), a rotating element (8) having a shaft (7) rotatably supported by a frame side bearing (110) fixedly mounted on the frame (31) and a bracket side bearing (100) fixedly mounted on the bracket (32), a stationary element (6) fixedly attached to the frame (31) around an outer periphery of the rotating element (8) and having a stator winding (18) wound therearound, a rotation sensor (15) provided on the bracket (32) at a housing side of the bracket side bearing (100), and a plurality of sensor signal wires (38) for supplying and receiving signals to and from the rotation sensor (15).

Owner:MITSUBISHI ELECTRIC CORP

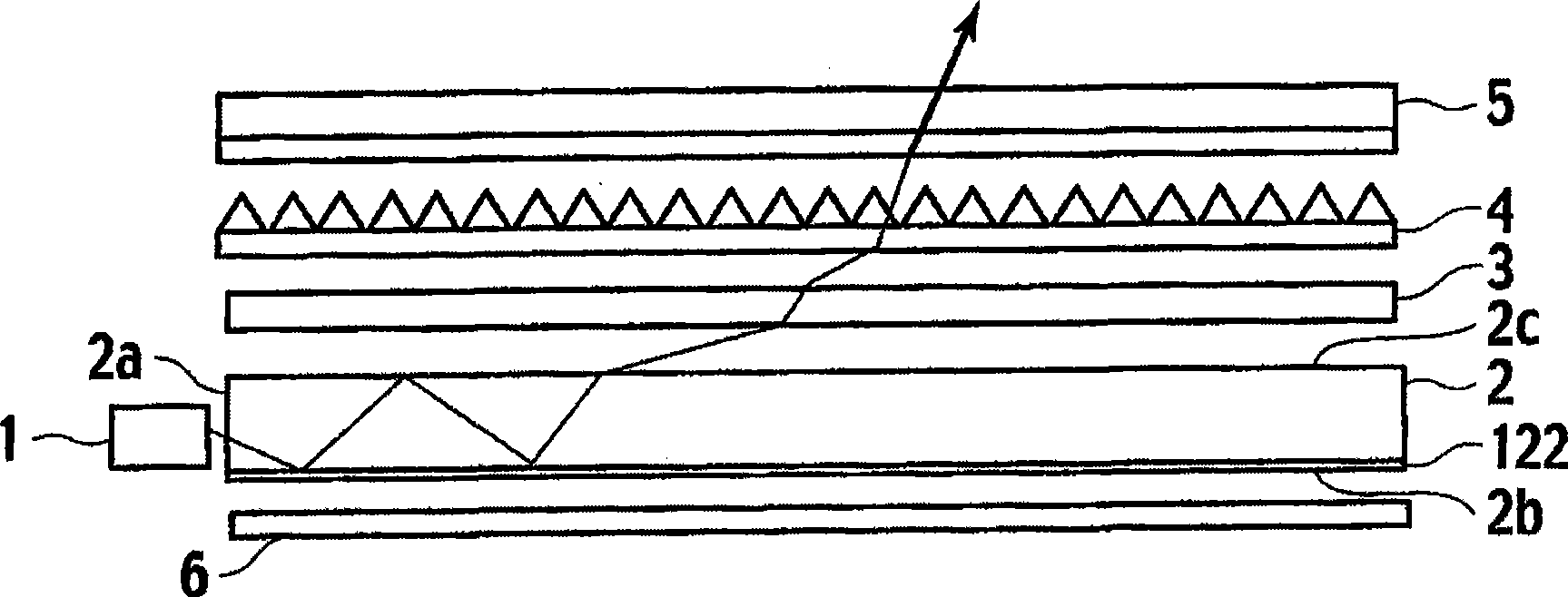

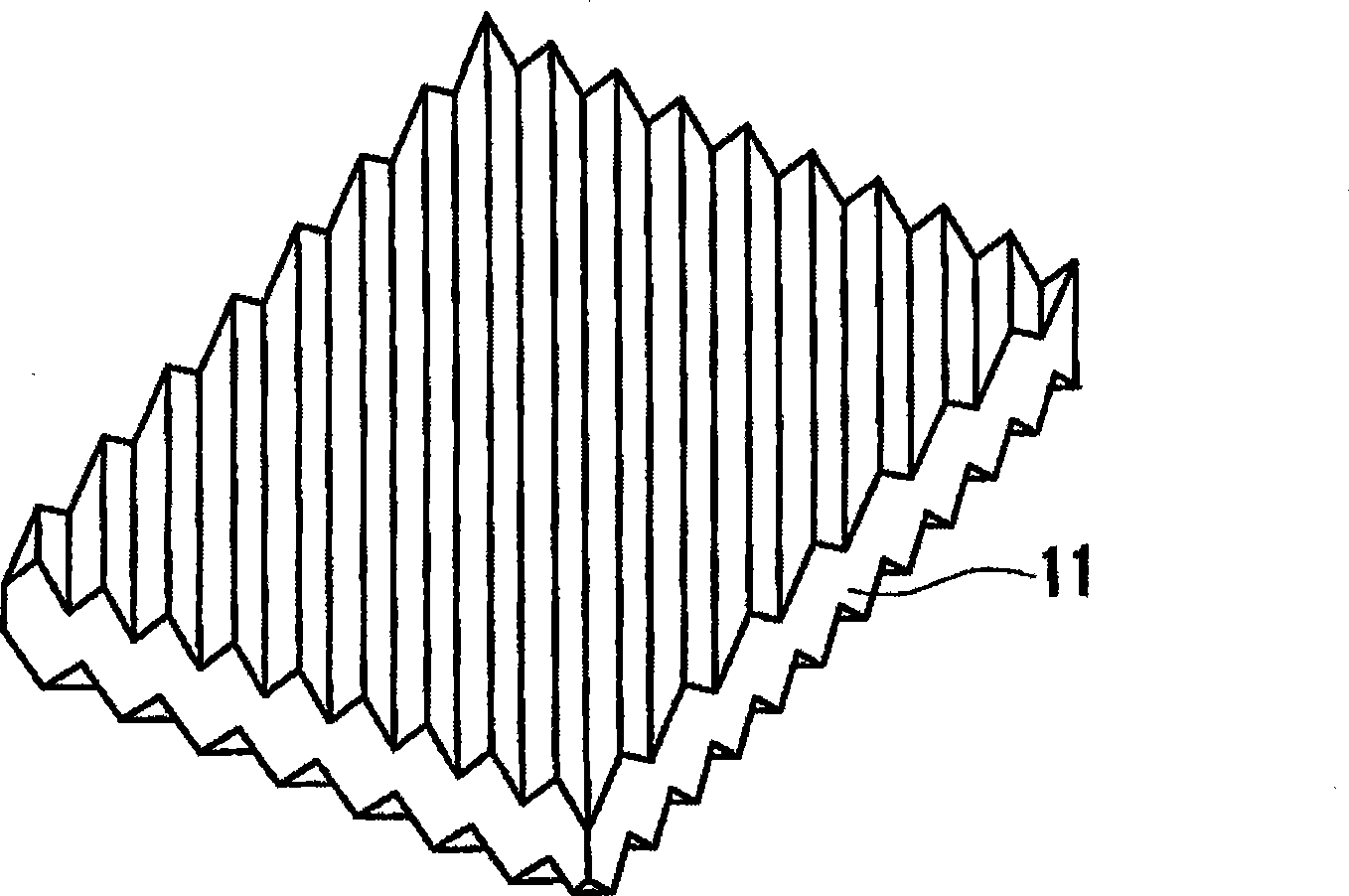

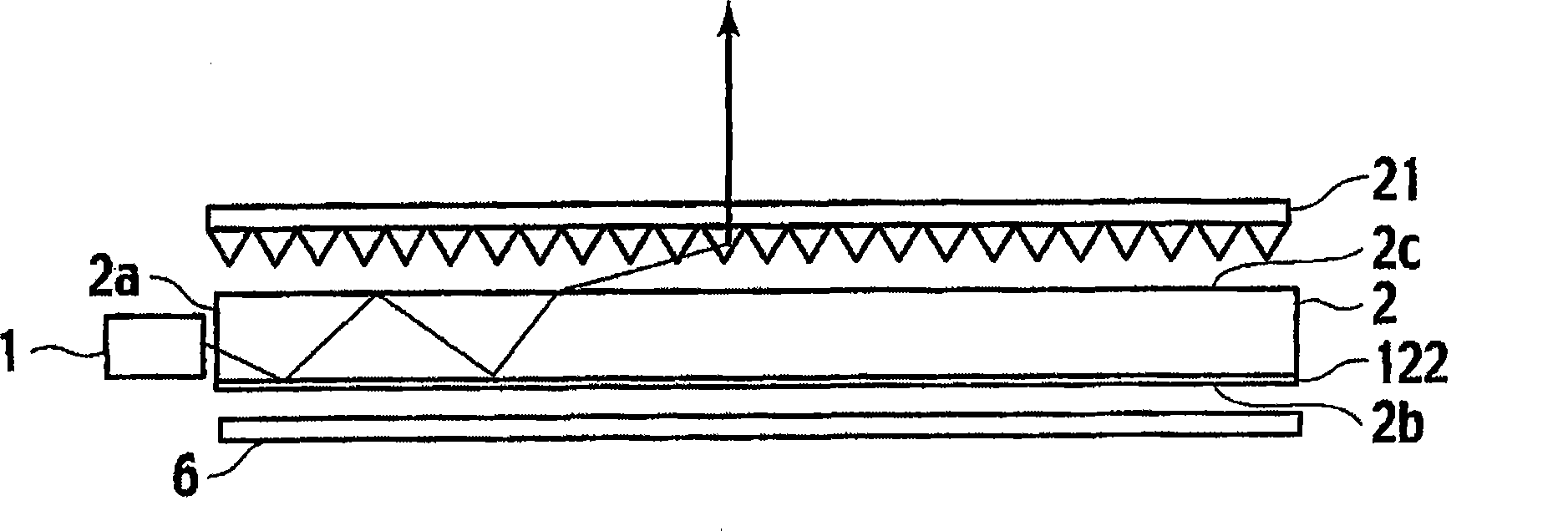

Backlight unit

InactiveCN101457906AReduce the number of piecesReduce light unevennessMechanical apparatusPoint-like light sourceLight guideOptoelectronics

A backlight unit includes: light source; light guide plate surrounded by main surfaces and end surfaces, one end surface facing a light source designated as entrance surface, one main surface designated as emitting surface; first prism sheet provided above the light guide plate, having first prism columns on a top surface and second prism columns on a bottom surface, each first prism column has first ridge line parallel or perpendicular to the entrance surface, each second prism column has second ridge line extending in a different direction from the first ridge line; second prism sheet provided above the first prism sheet, having third prism columns abutting each other on a top surface, each third prism column has third ridge line extending in a direction different from the first and second ridge lines; and reflection sheet facing the light guide plate below the light guide plate.

Owner:HITACHI CHEM CO LTD

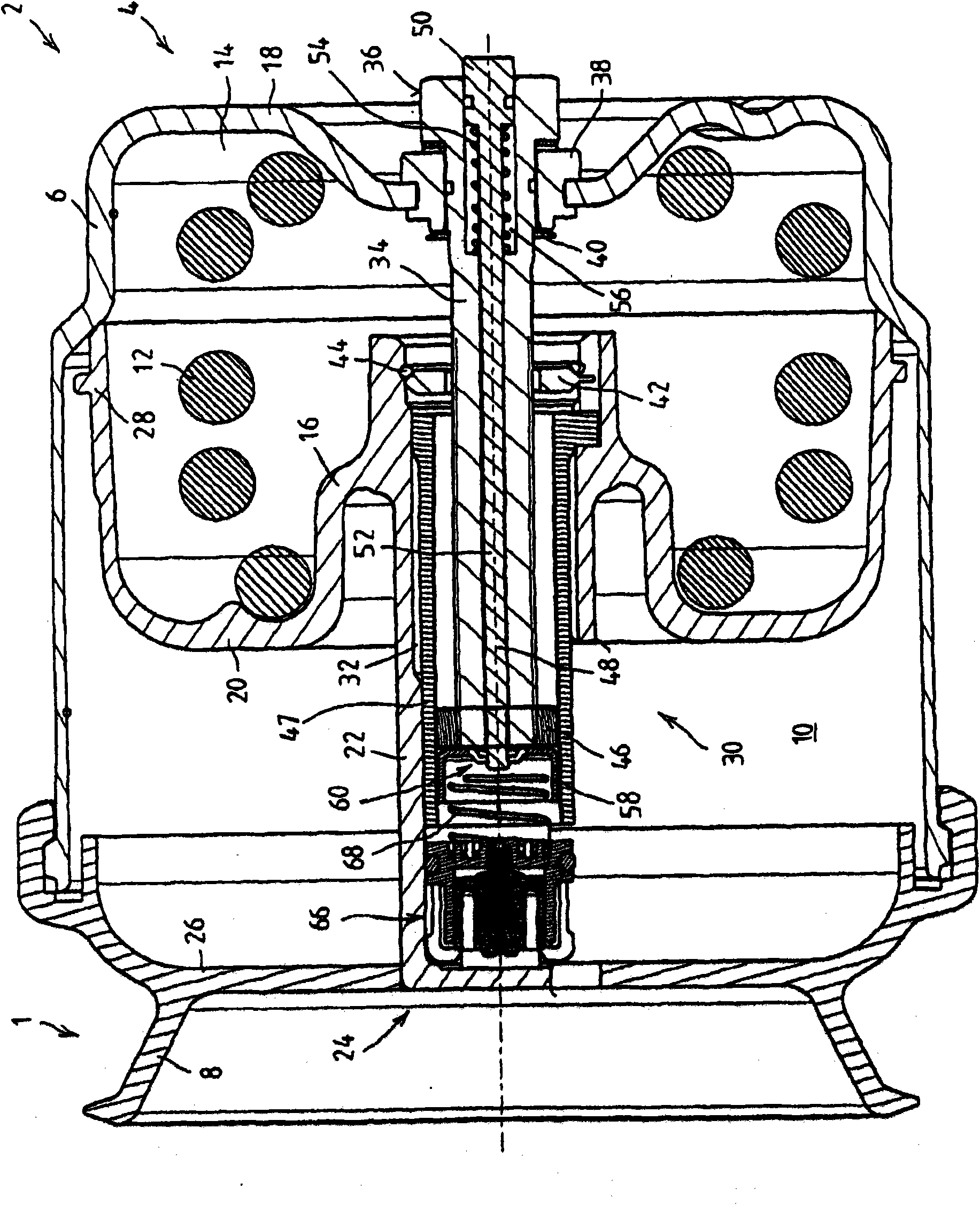

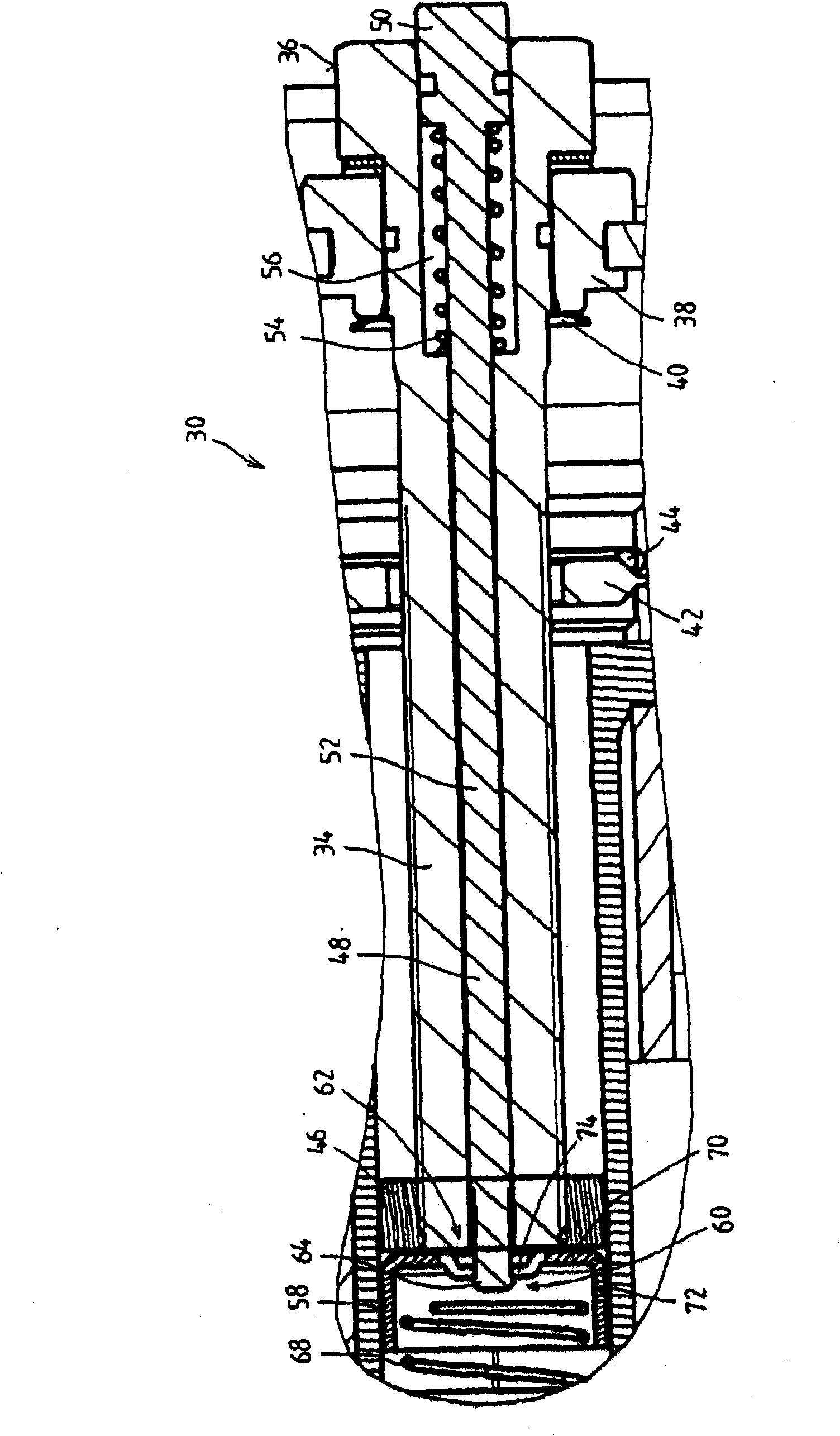

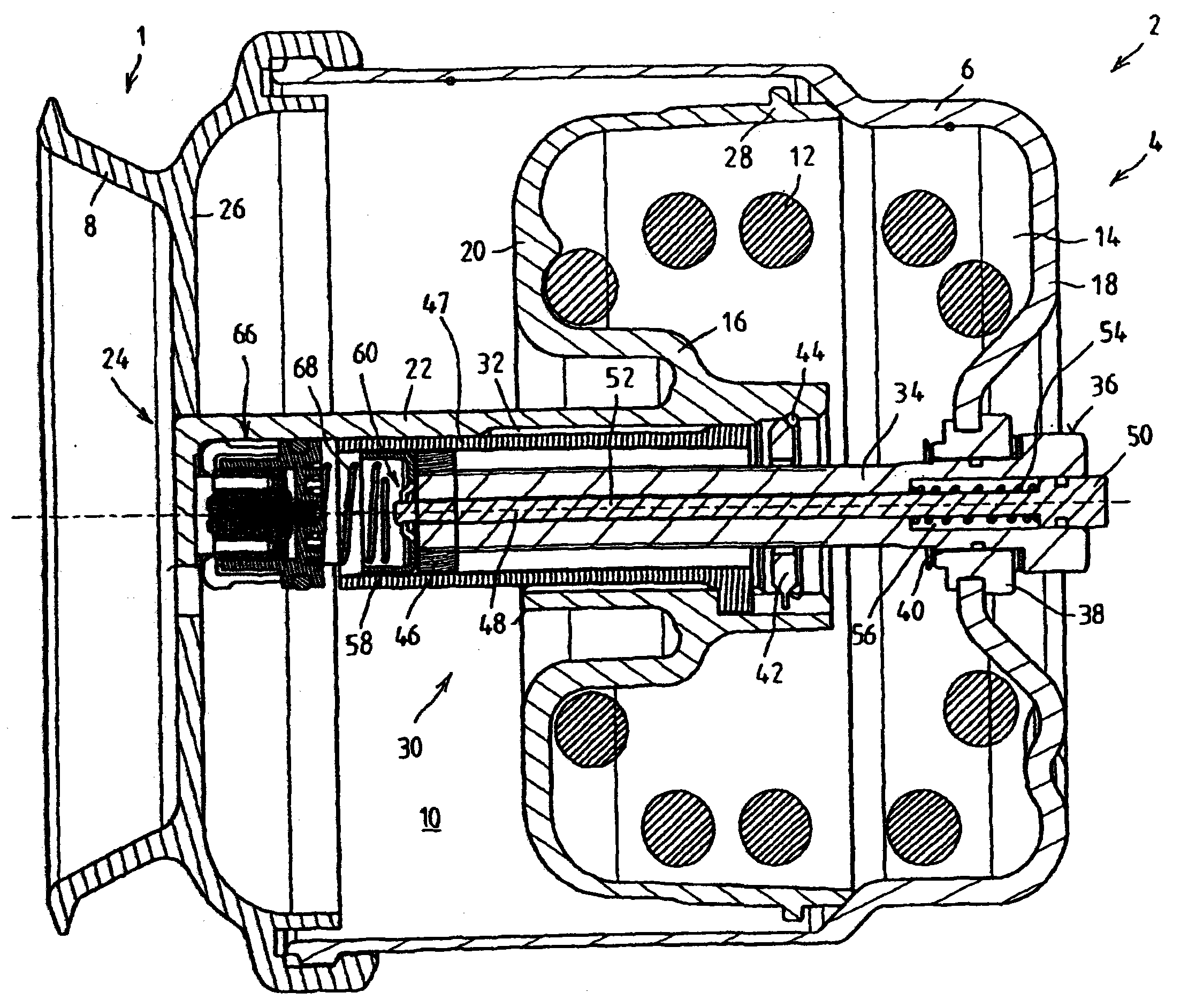

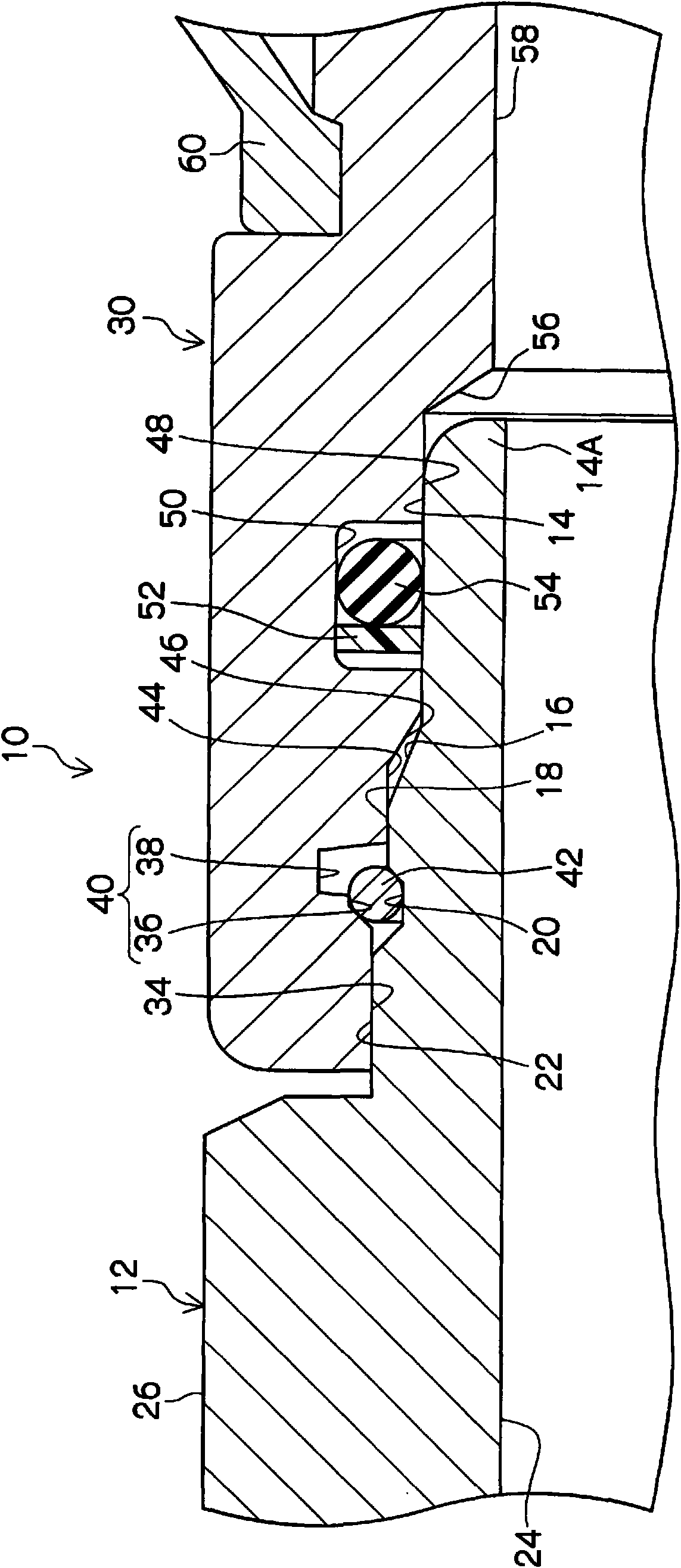

Spring-loaded brake cylinder having locked stop body

ActiveCN101795911AReduce manufacturing costsIncrease elasticityBrake actuating mechanismsBrake cylindersAxial displacementDetent

The invention relates to a spring-loaded brake cylinder (4) for vehicles, comprising at least one spring-loaded brake piston (16) that can be actuated by a pre-loaded spring (12) and is supported in a housing (6), said brake piston being delimited on one side by a spring-loaded brake chamber (10) and on the opposite side by a spring chamber (14) receiving the pre-loaded spring (12) and being connected to a spring-loaded brake piston rod (22), and further comprising a mechanical emergency release device (30) for the emergency release of the spring-loaded brake cylinder (4), wherein by means of the emergency release device (30) an axial displacement of the spring-loaded brake piston (16) against the prestress of the pre-loaded spring (12) can be brought about, and the emergency release device (30) comprises a threaded spindle (34), which is rotationally mounted on the housing (6) and in engagement with an axially movable transfer device (46) held non-rotatably in the emergency release device (30), wherein the transfer device (46) can be brought in contact with a contact surface (42) on the spring-loaded brake piston (16) for the emergency release of the spring-loaded brake cylinder (4), and further comprising an indicator device having an indicator rod (48) indicating the position of the spring-loaded brake piston (16), said rod traversing the threaded spindle (34) and being movable thereto in the axial direction, wherein a stop body (58) is disposed in the region of one end of the indicator rod (48), said body being engageable in the transfer device (46). According to the invention, the stop body (58) is positively connected to the indicator rod (48) by a detent connection (60) produced by means of an axial relative movement between the indicator rod (48) and the stop body (58).

Owner:KNORR BREMSE SYST FUER NUTZFAHRZEUGE GMBH

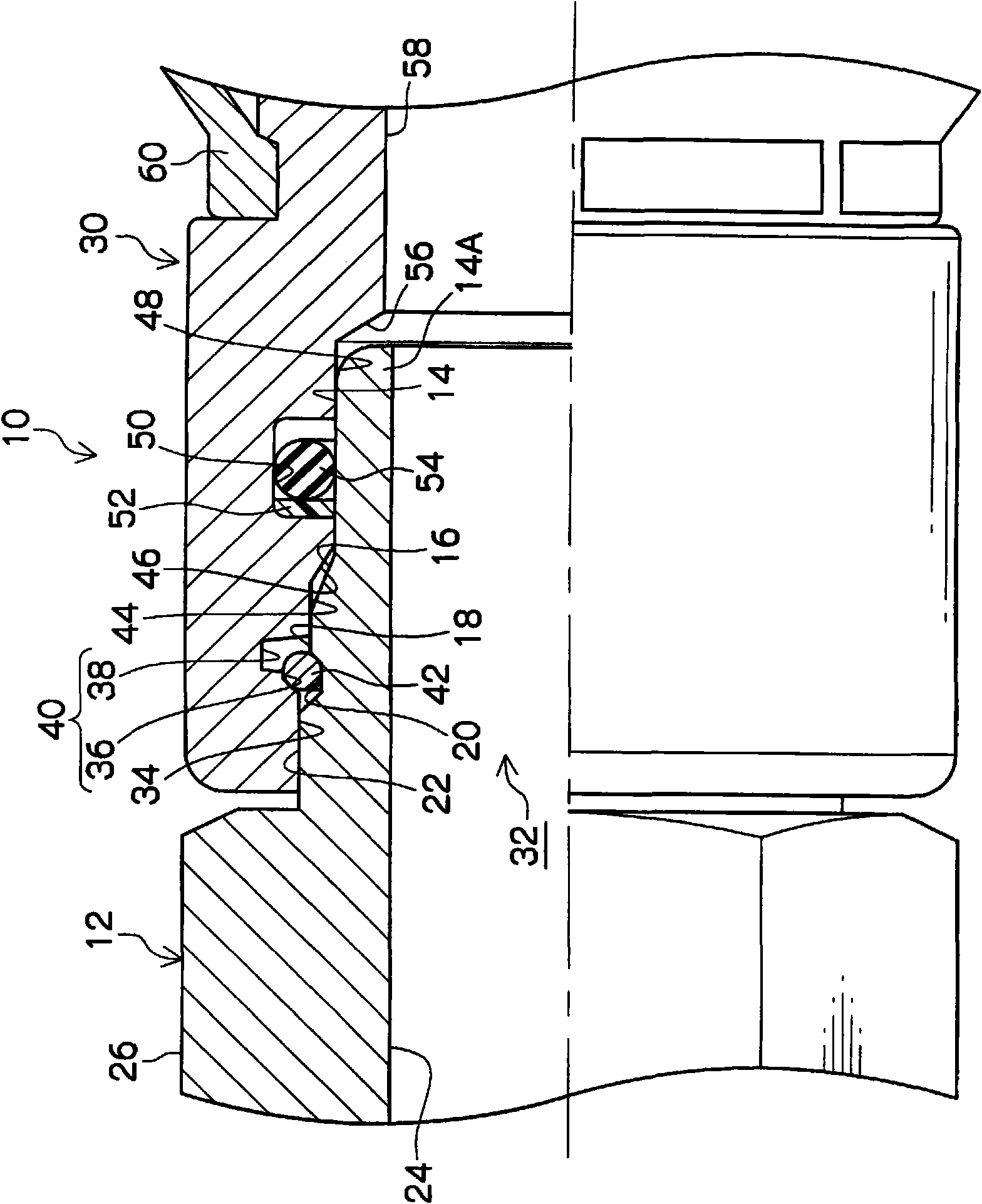

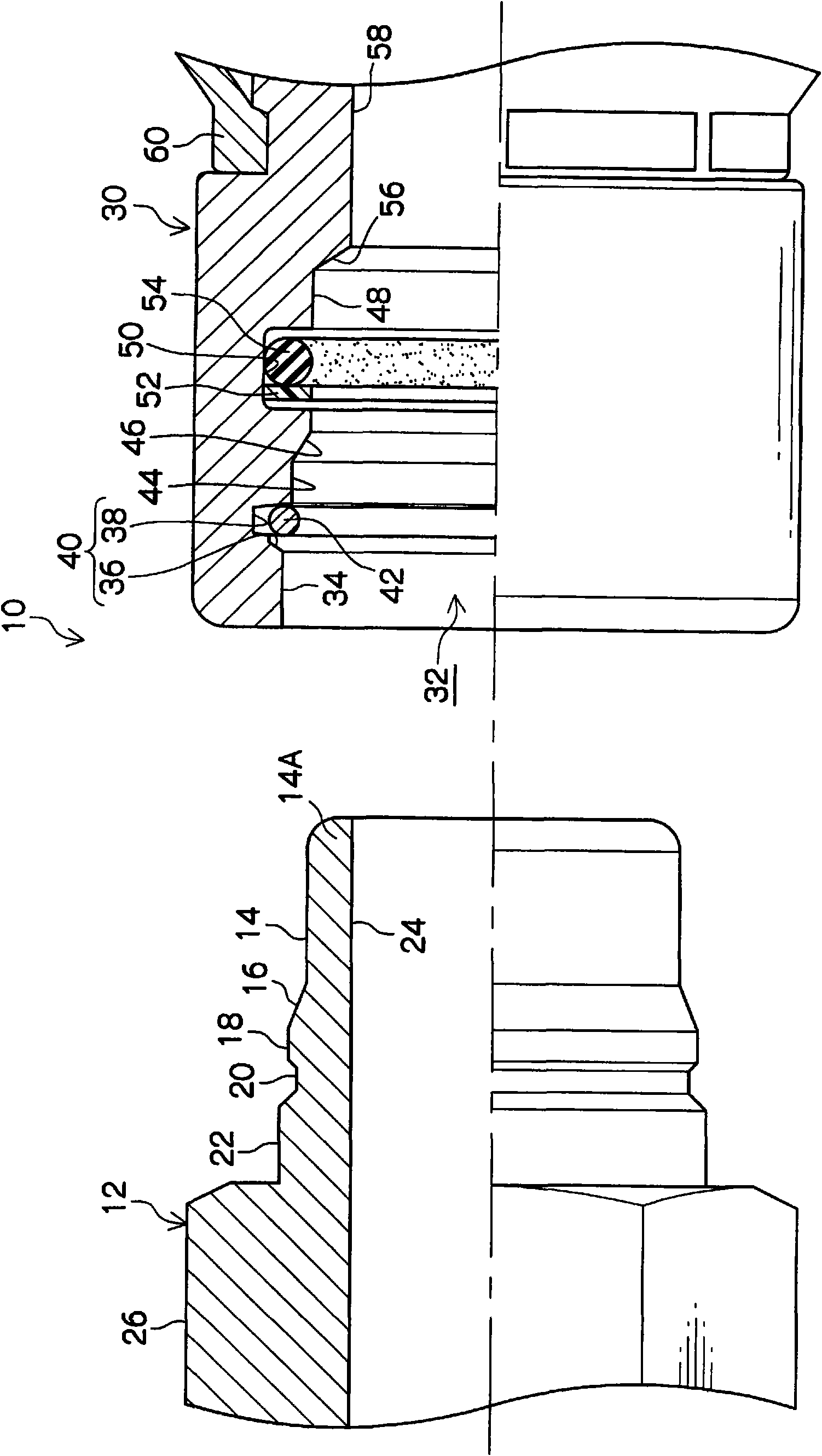

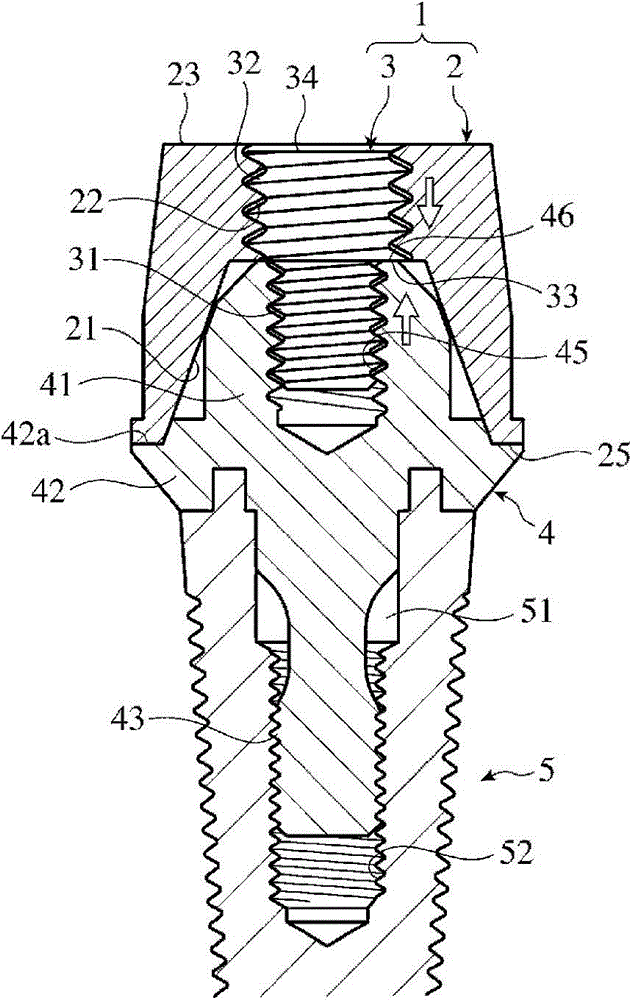

Pipe fitting and hose

InactiveCN101617160AReduce vibrationIncrease production capacityCouplingsHose connectionsPipe fittingBiomedical engineering

A small pipe fitting in which a male body and a female body cannot be separated after they are coupled once. The pipe fitting (10) consists of a male body (12), and a female body (30) into which the male body (12) is inserted. The male body (12) has a smaller outside diameter on the distal end side and includes, sequentially from the distal end, a third cylindrical portion (14), an outer tapered portion (16), a second cylindrical portion (18), an annular groove (20) locked with a resilient stop ring body (42), and a first cylindrical portion (22). The female body (30) has a smaller inside diameter on the rear side and includes, sequentially from the distal end and from the inlet side of an opening (32), a first inner wall face (34), a two-step groove (40) consisting of a locking groove (36) and a containing groove (38) and containing the resilient stop ring body (42), a second inner wall face (44), an inner tapered portion (46), and a third inner wall face (48). The resilient stop ring body (42) has a gap (43) formed by cutting a part of an annular member, wherein the outer circumferential diameter when the resilient stop ring body (42) is deformed resiliently to allow the end faces (42A, 42B) of the gap (43) to touch each other is set smaller than the inside diameter of the first inner wall face (34).

Owner:BRIDGESTONE CORP

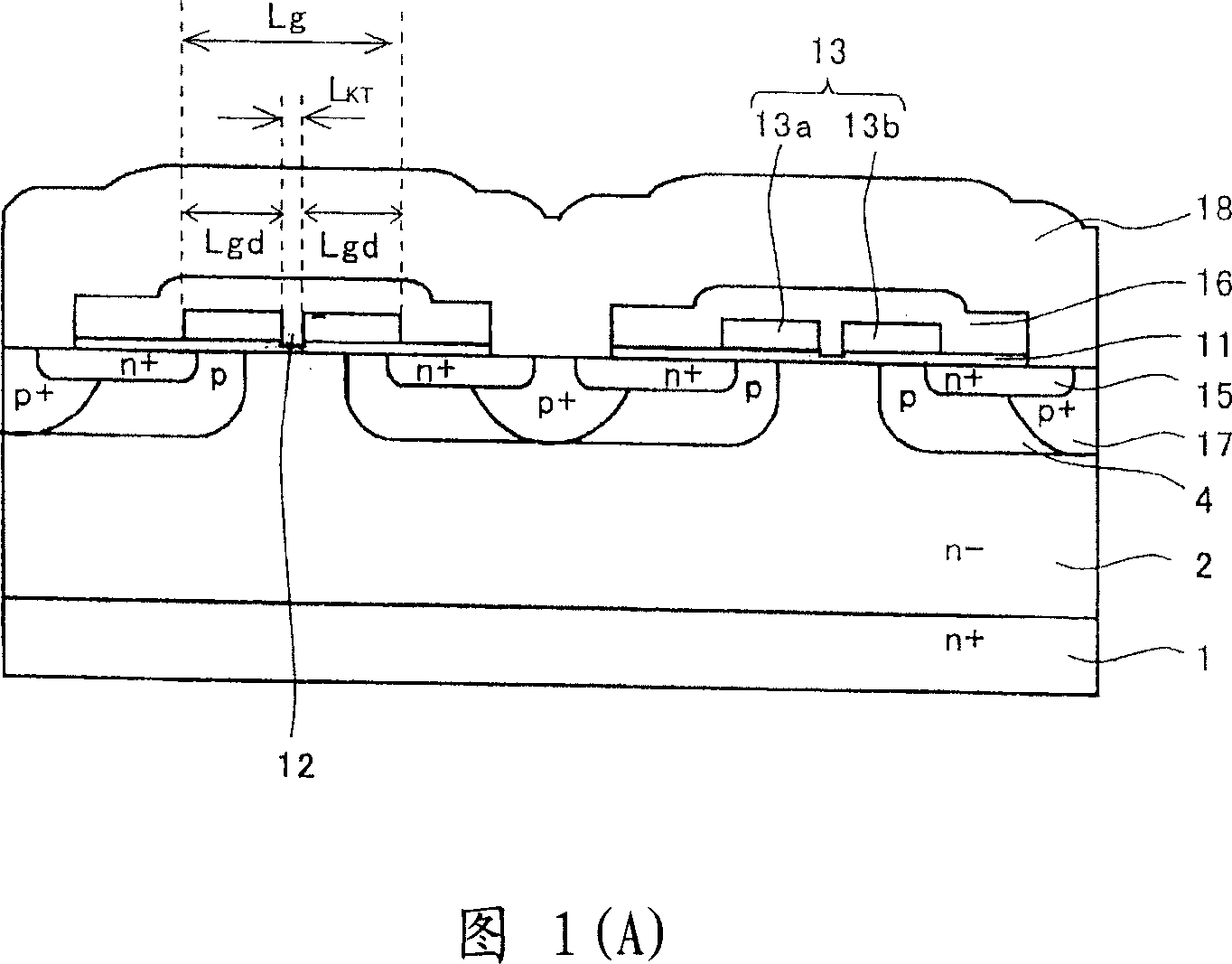

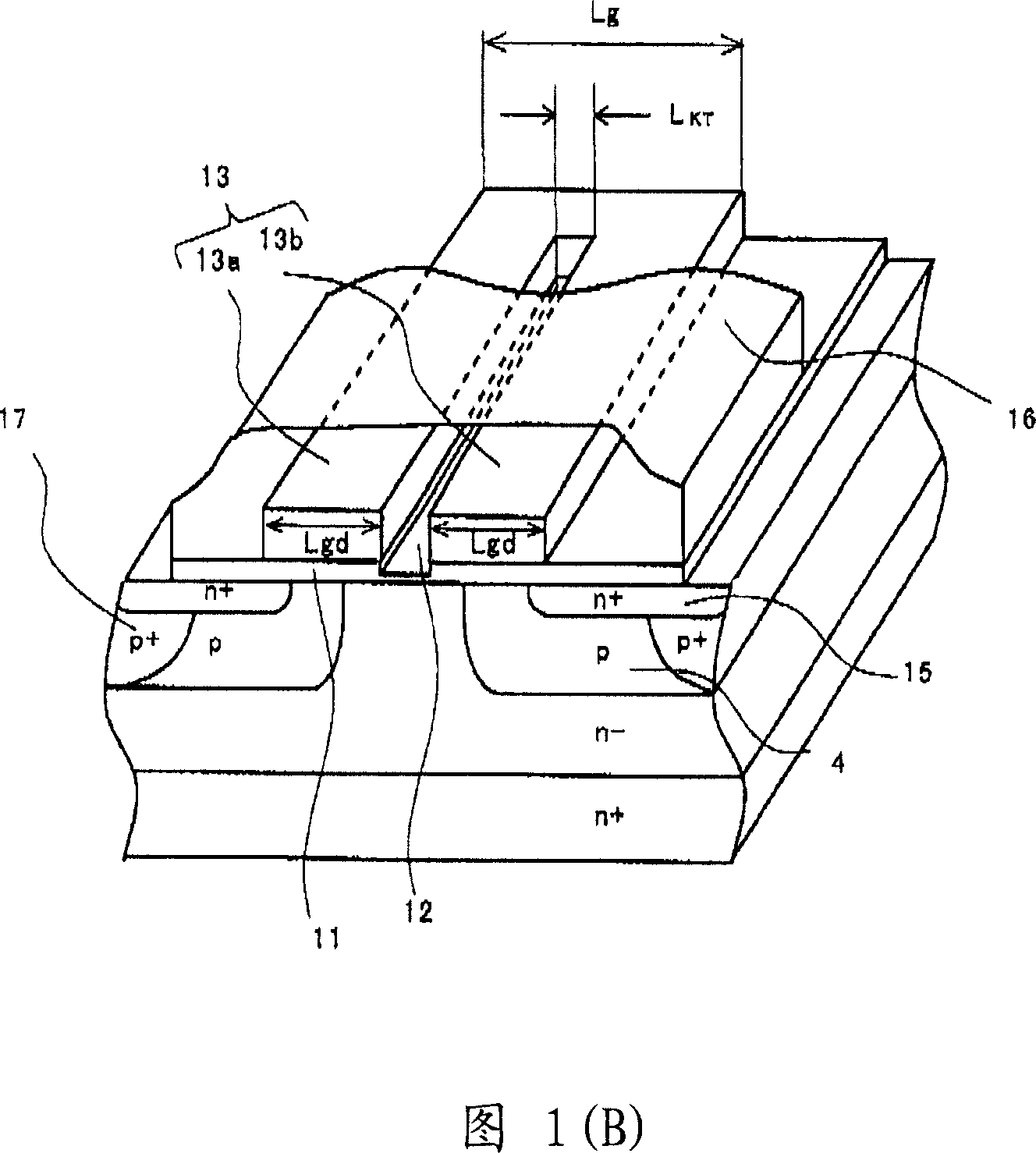

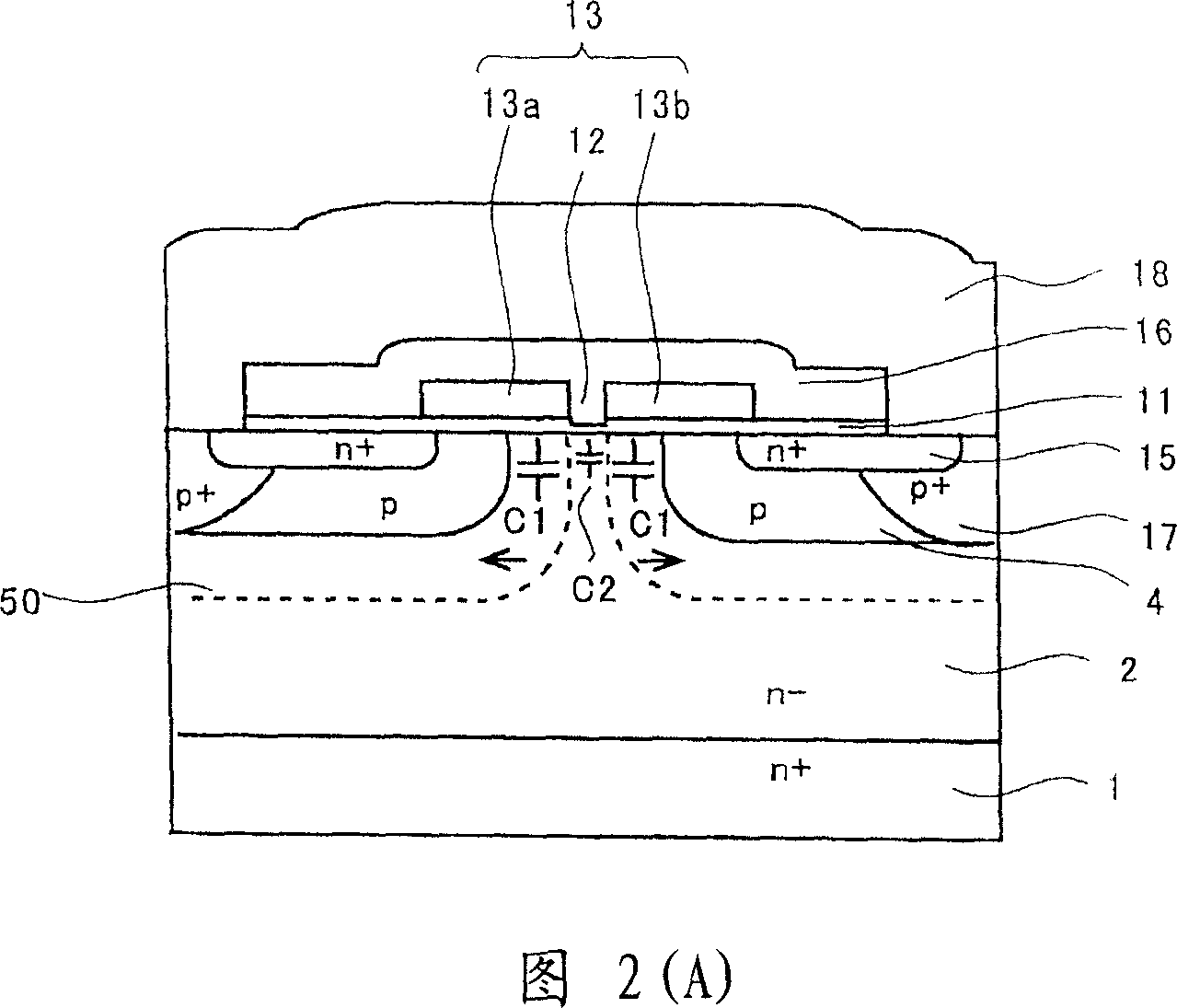

Insulated gate field effect transistor and manufacturing method thereof

InactiveCN1941413ALower resistanceLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical resistance and conductanceCapacitance

A separation hole is provided in the center of the gate electrode. Accordingly, it is possible to suppress a drastic increase in feedback capacitance Crss in the case where drain-source voltage VDS is decreased and the width of the depletion layer is narrowed. Thus, high-frequency switching characteristics are improved. Moreover, n type impurities are implanted from the separation hole to form an n type impurity region between channel regions. Since a resistance in a portion below the gate electrode can be reduced, an on-resistance can be reduced. The n type impurity region can be formed in a self-aligning manner.

Owner:SANYO ELECTRIC CO LTD

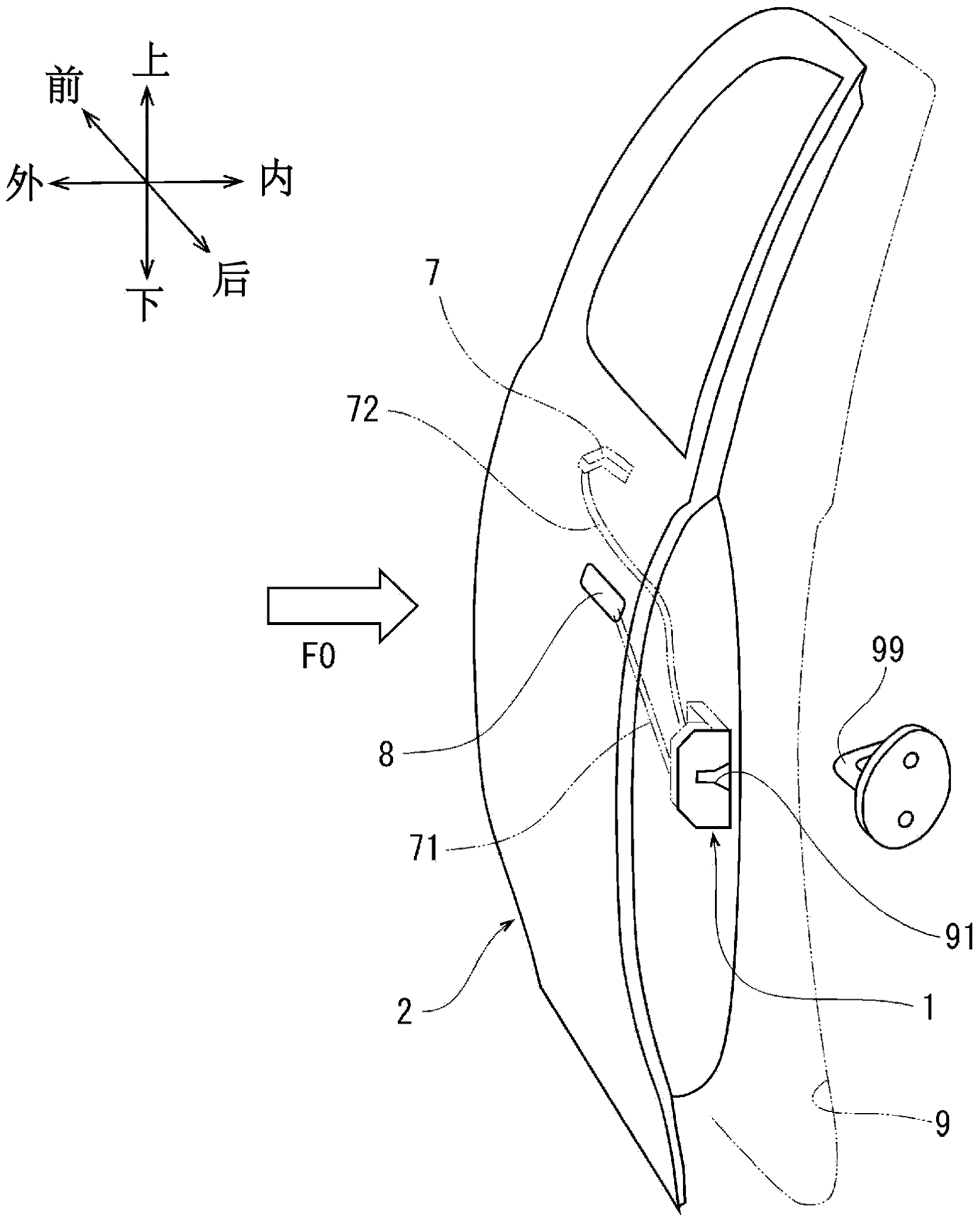

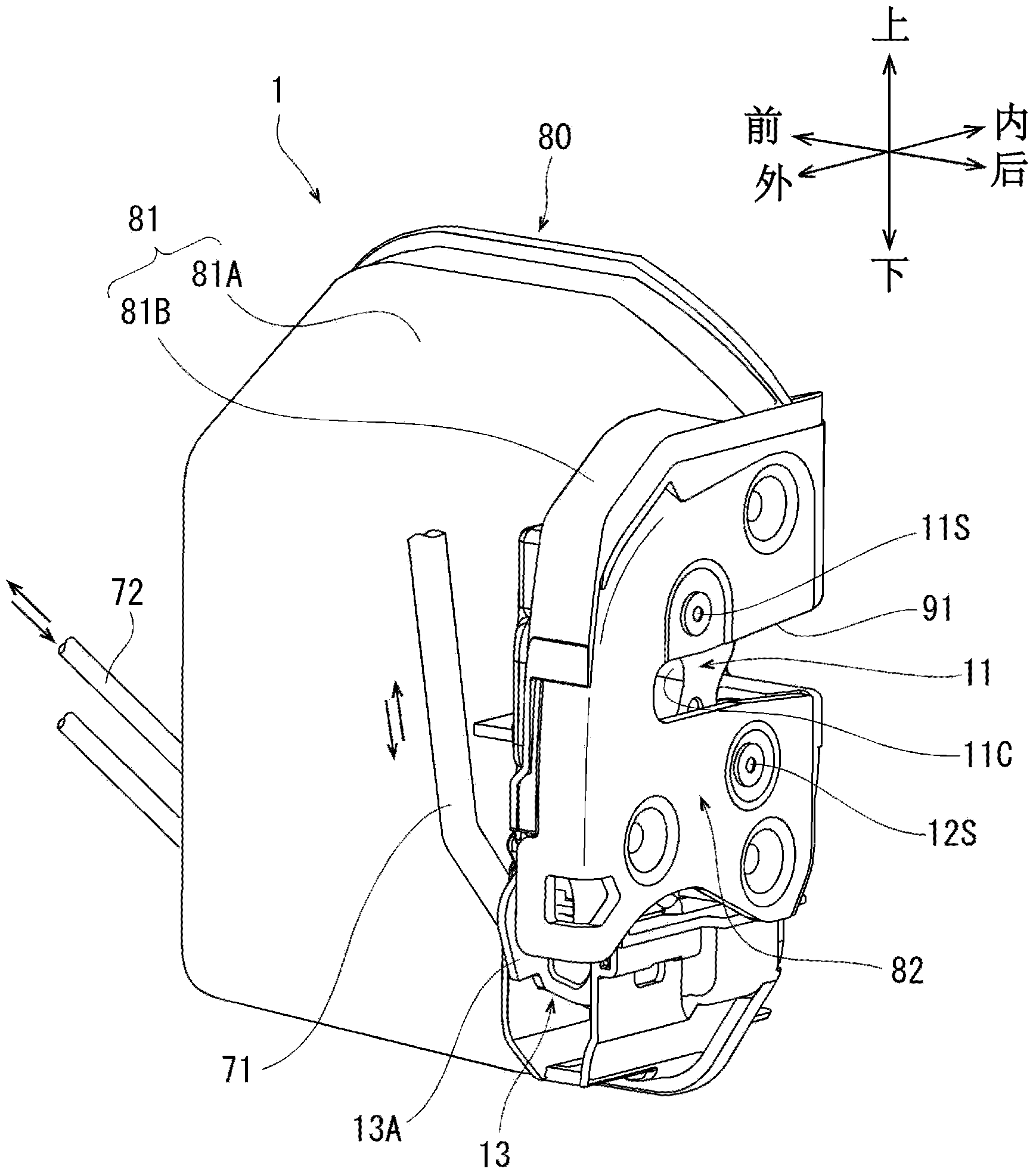

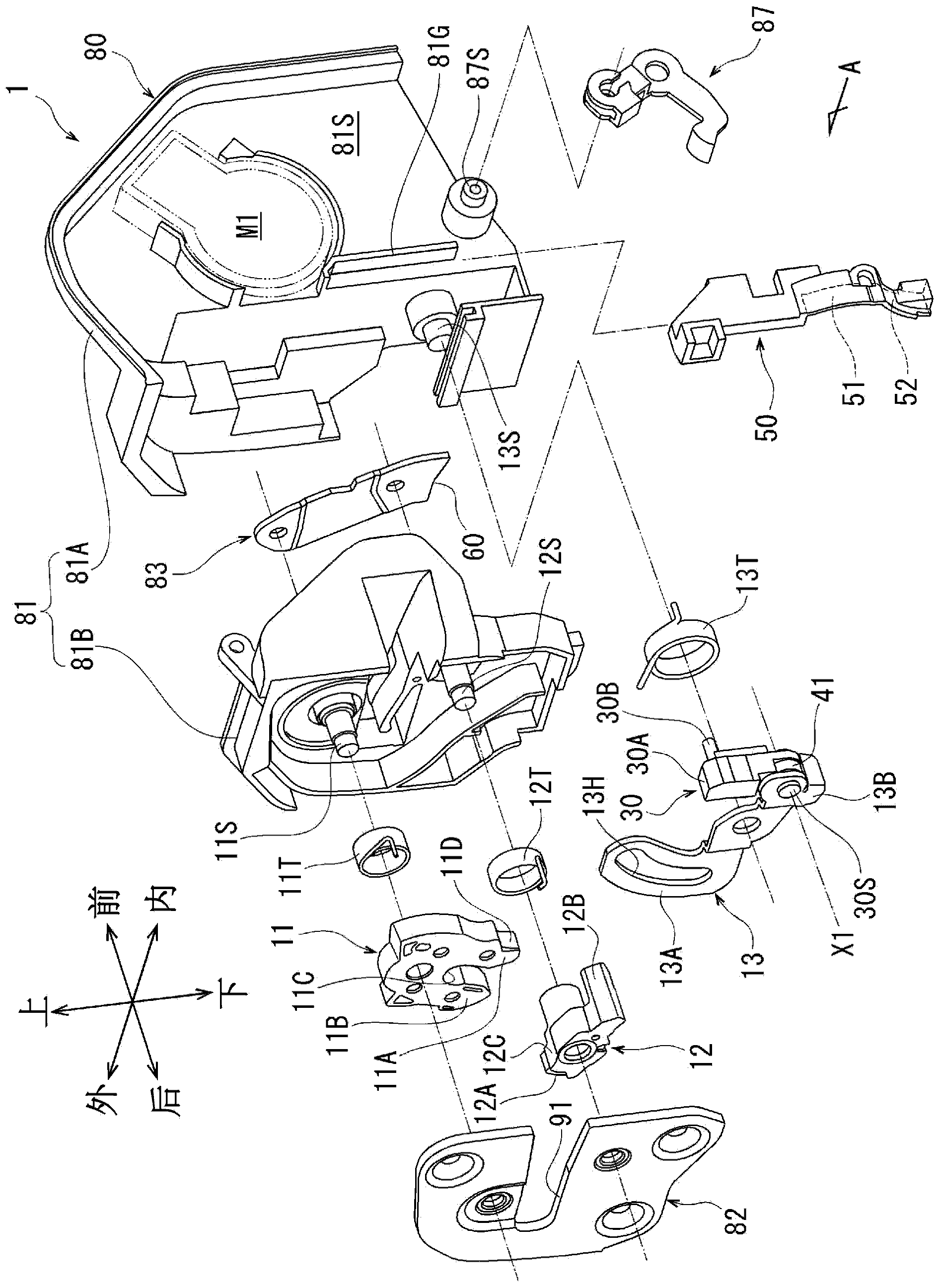

Door locking device for vehicle

ActiveCN103597155AReliable abutmentEasy to assembleAccident situation locksElectrical locking actuatorsEngineeringMechanical engineering

Owner:ANSEI CORP

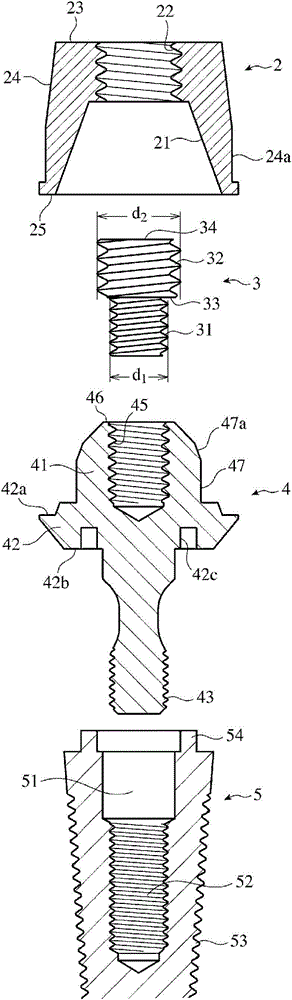

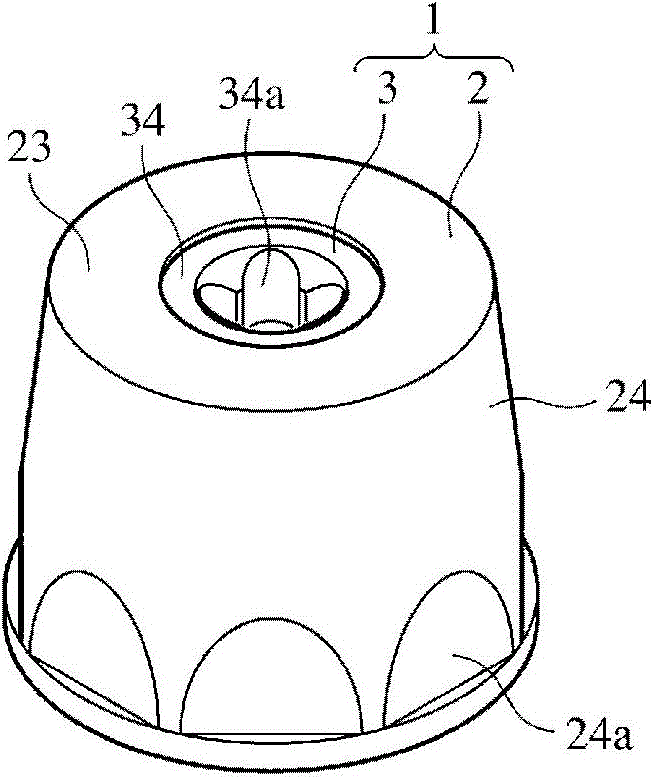

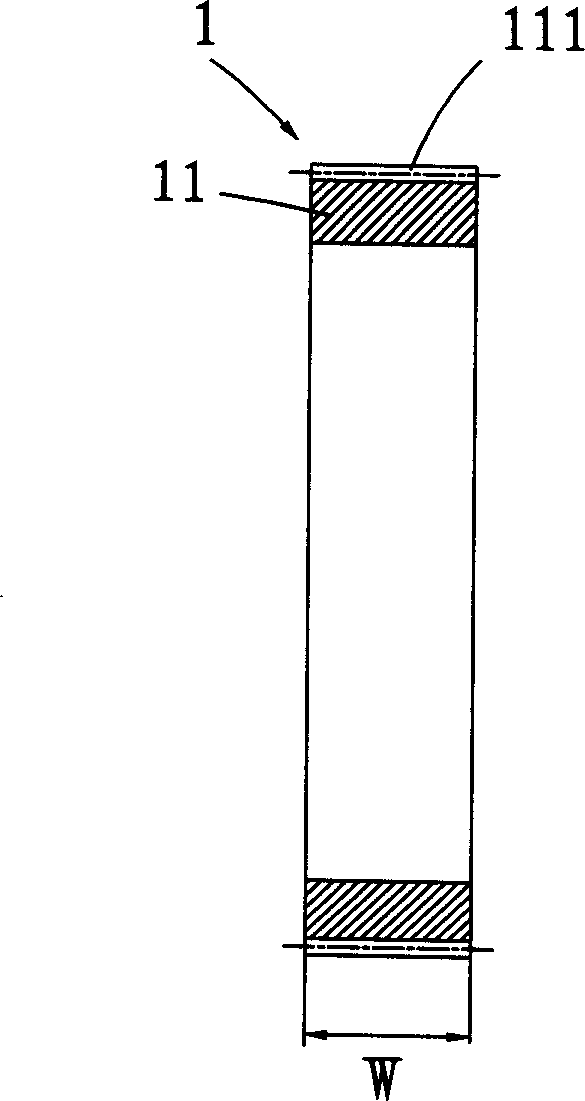

Keeper for implant, assembly thereof, and method for affixing keeper

InactiveCN103561679AAvoid misalignmentNo relaxationDental implantsFastening prosthesisAbutmentBiomedical engineering

A keeper for an implant is provided with: (a) a keeper body consisting of a soft magnetic material, the keeper body having a recess which receives the head of an abutment which has a female thread section and also having a female thread section which is provided along the center axis so as to communicate with the recess and which has a greater nominal diameter than the female thread section of the abutment; and (b) a two-stage threaded member having a small-diameter threaded section which engages with the female thread section of the abutment and also having a large-diameter threaded section which engages with the female thread section of the keeper body. The keeper for an implant is characterized in that, when the keeper body is rotated in the engaging direction after the small-diameter threaded section is engaged with the female thread section of the abutment and the large-diameter threaded section is engaged with the female thread section of the keeper body, the keeper body is firmly fastened to the abutment by the two-stage threaded member.

Owner:HITACHI METALS LTD

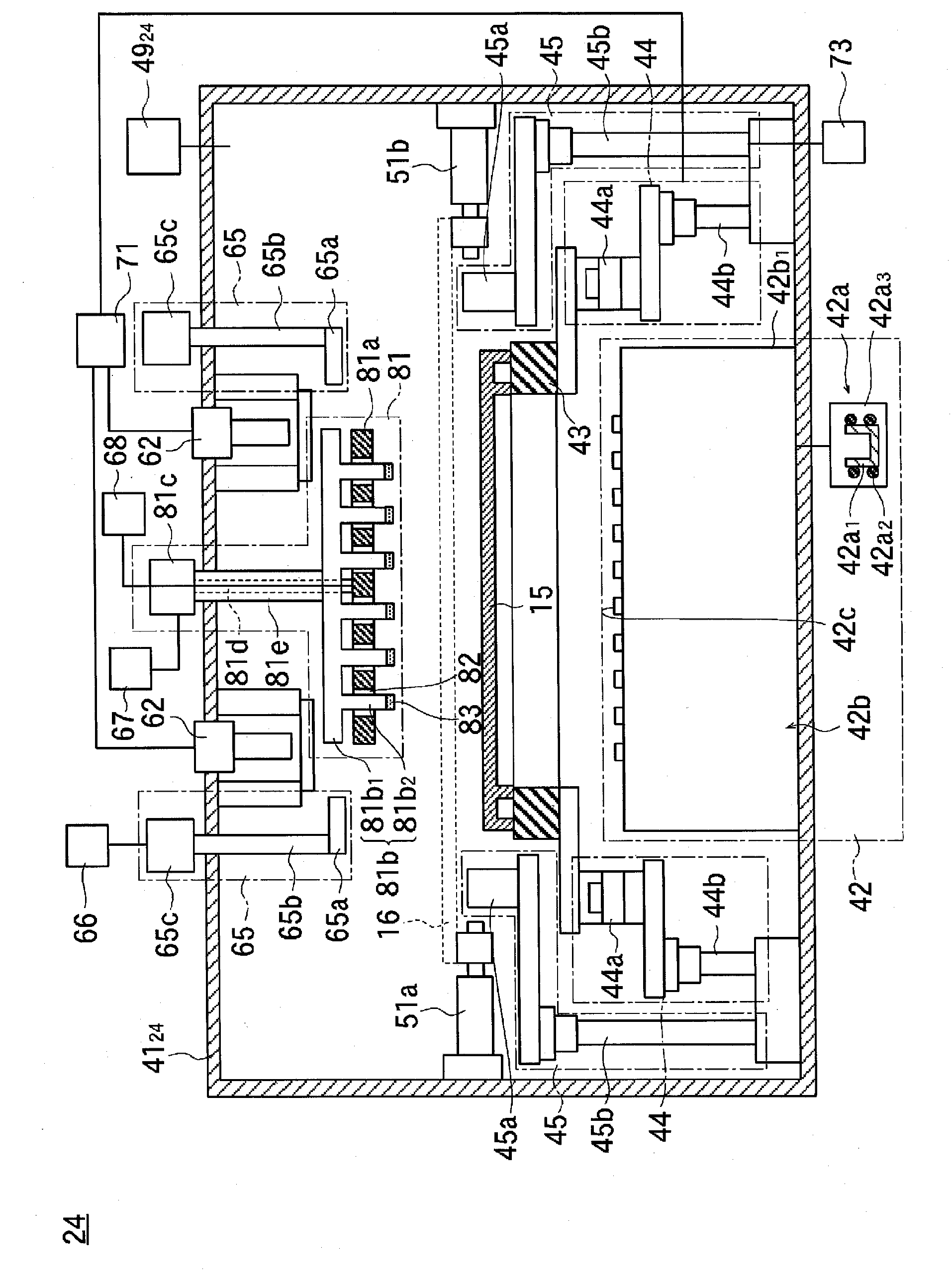

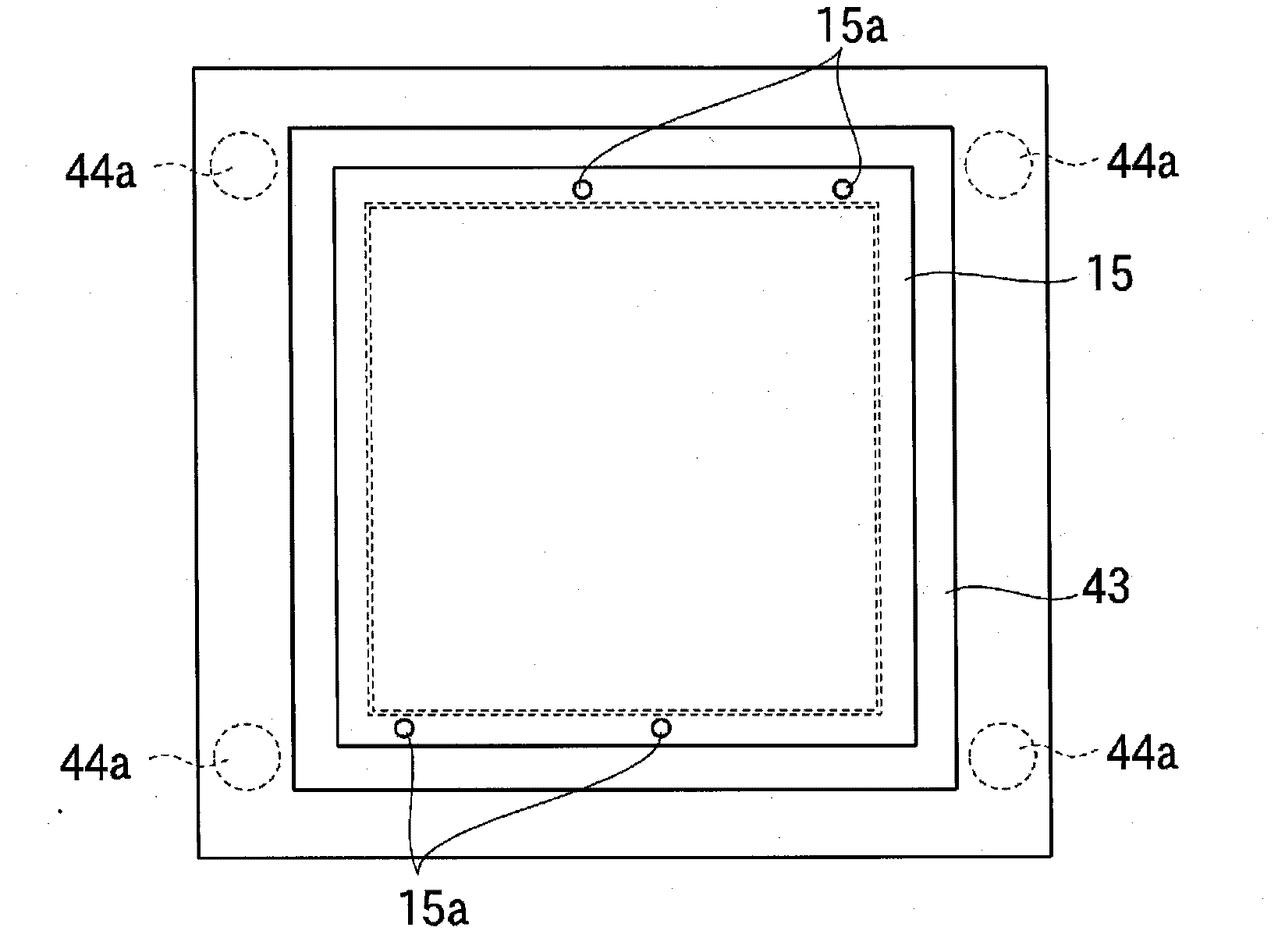

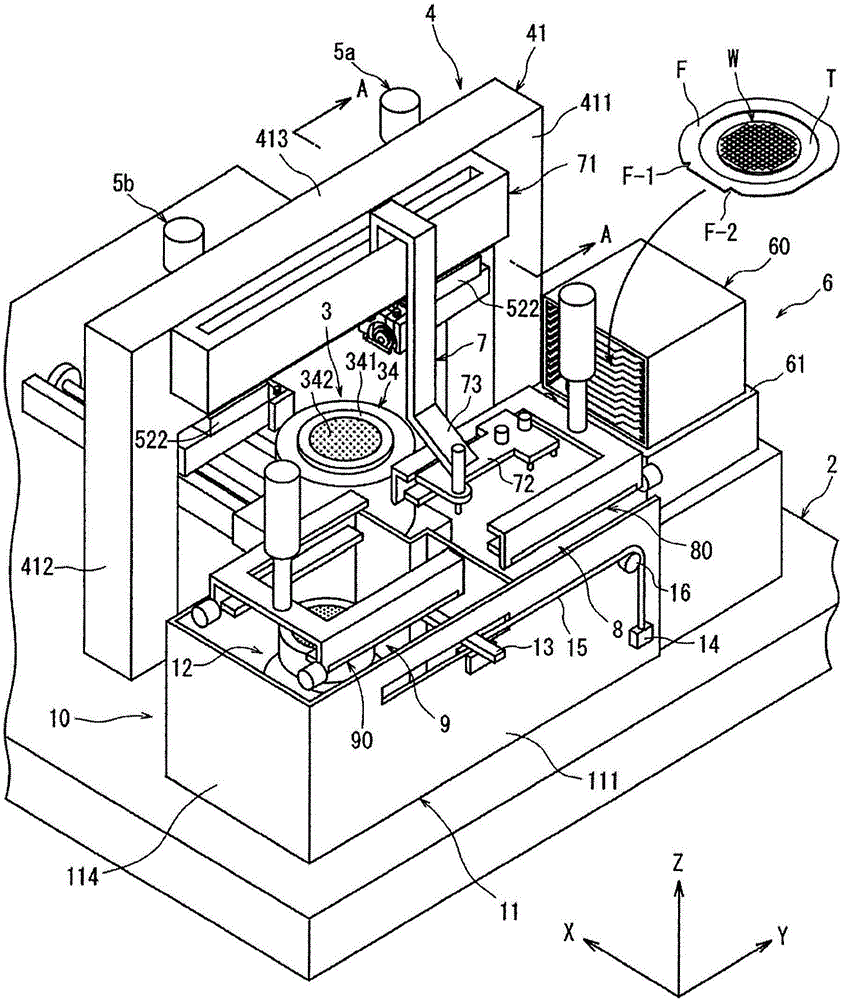

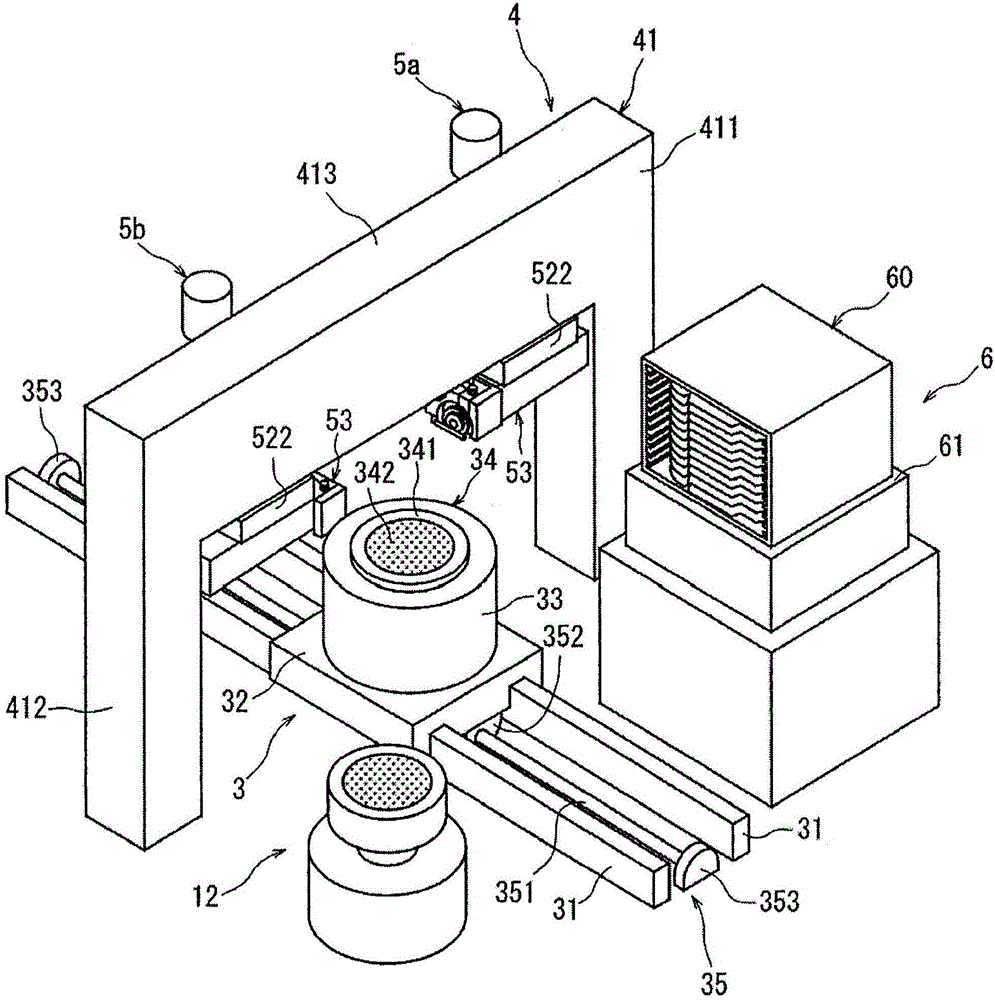

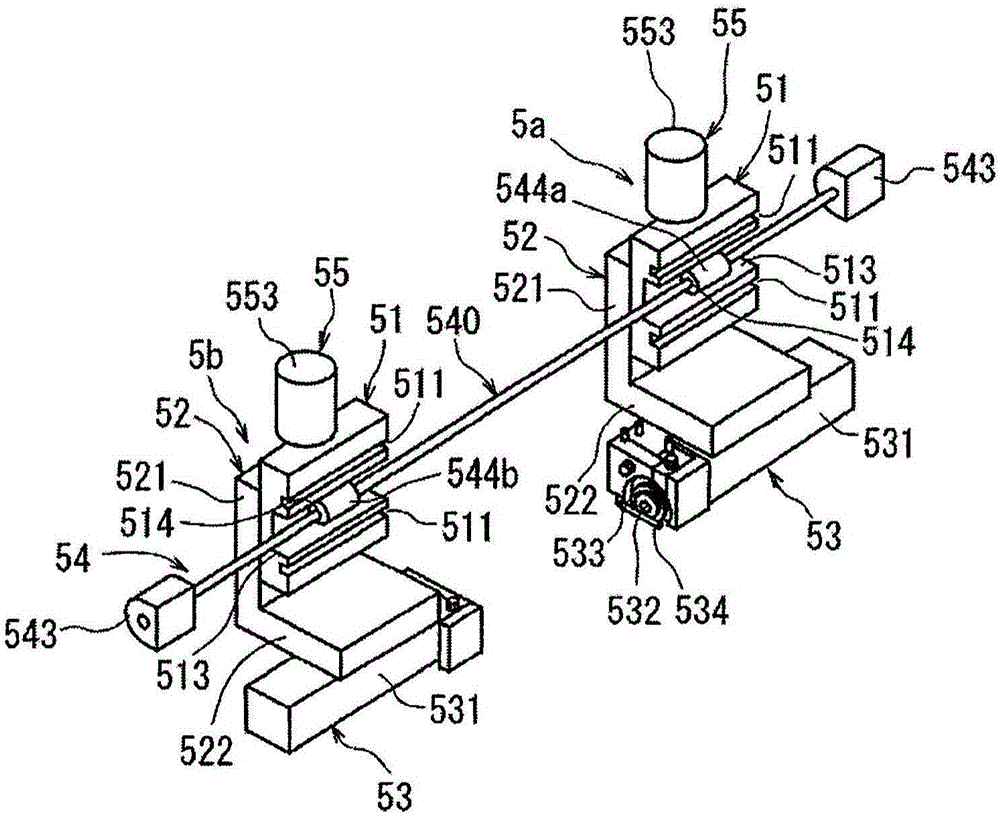

Film forming device and film forming method

ActiveCN102686764ASmall sizeReduce the number of piecesElectroluminescent light sourcesSolid-state devicesVacuum chamberElectrical and Electronics engineering

Disclosed are a film forming device and film forming method which are low cost, adaptable to larger sized substrates, and have a short tact time. A substrate holding frame (12), onto which a substrate (11) is mounted, is loaded into an evacuated vacuum chamber (41). The substrate (11) on the substrate holding frame (12) is brought to rest at a position facing a mask (15) on a mask holding frame (43) which is disposed between a substrate conveyance path and outlets (42c) of a vapor deposition source (42). The substrate holding frame (12) is then detached from conveyance members on a conveyance mechanism (51) and the underside of the substrate (11) is held to the surface of a substrate attraction plate (81b) by electrostatic attraction. Subsequently, the mask (15) is aligned to the substrate (11), and with both the substrate (11) and the mask (15) brought to rest facing the vacuum chamber (41), the vapor of a film-forming material is emitted from the outlets (42c), forming a film on the surface of the substrate (11) from the vapor. After the film is formed, the substrate holding frame (12) on which the substrate (11) is mounted is unloaded to the outside of the vacuum chamber (41) while the mask remains mounted on the mask holding frame (43) in the vacuum chamber (41).

Owner:ULVAC INC

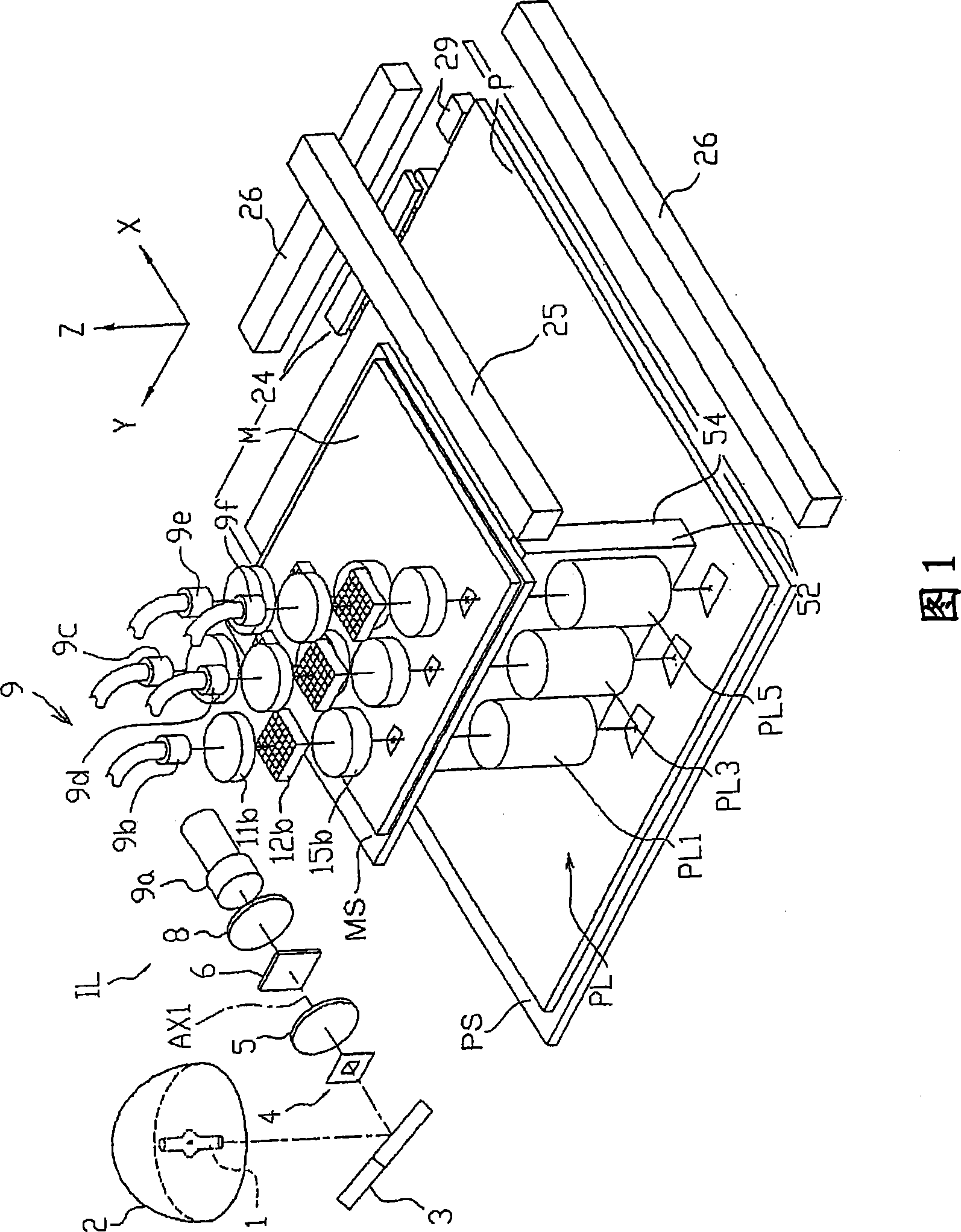

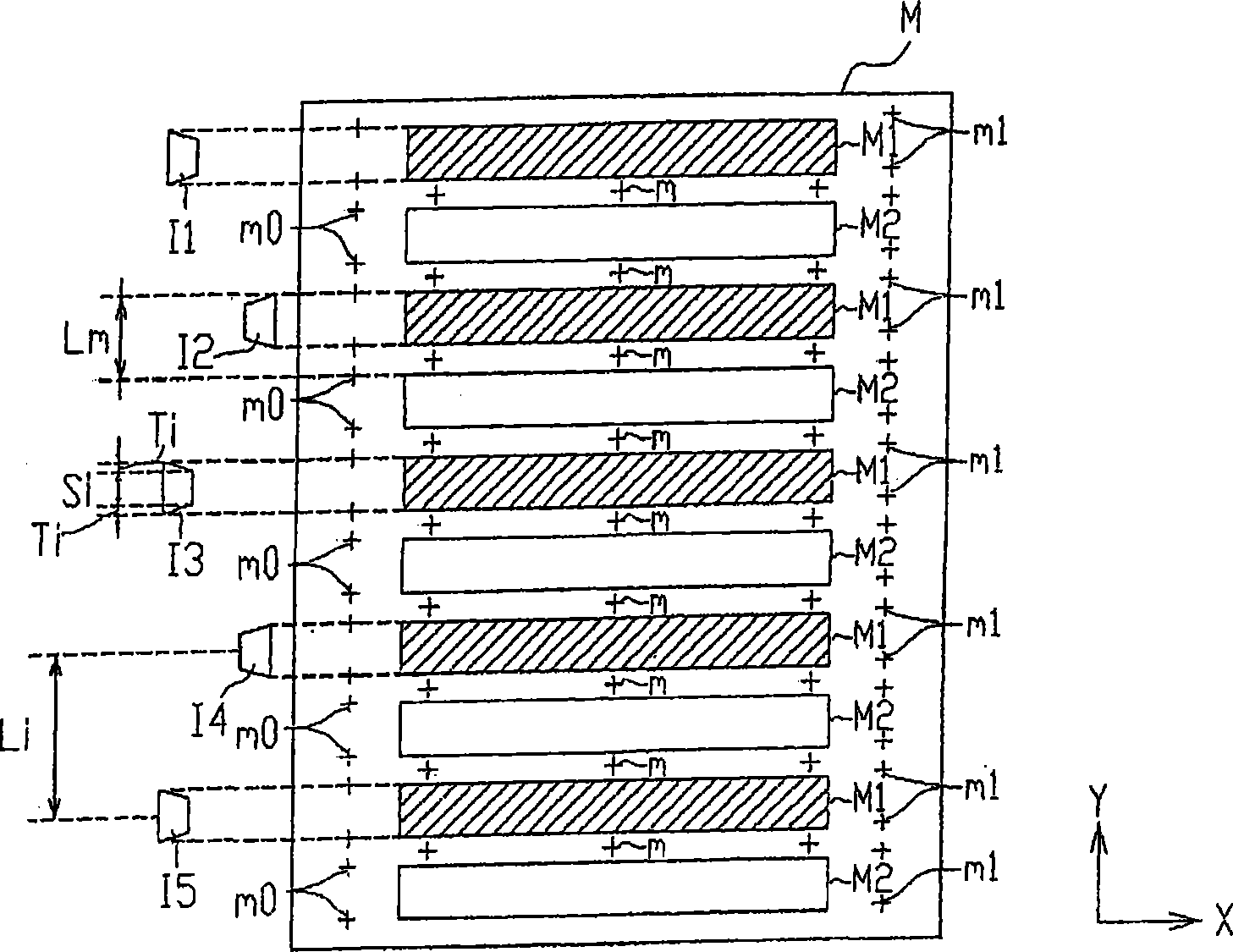

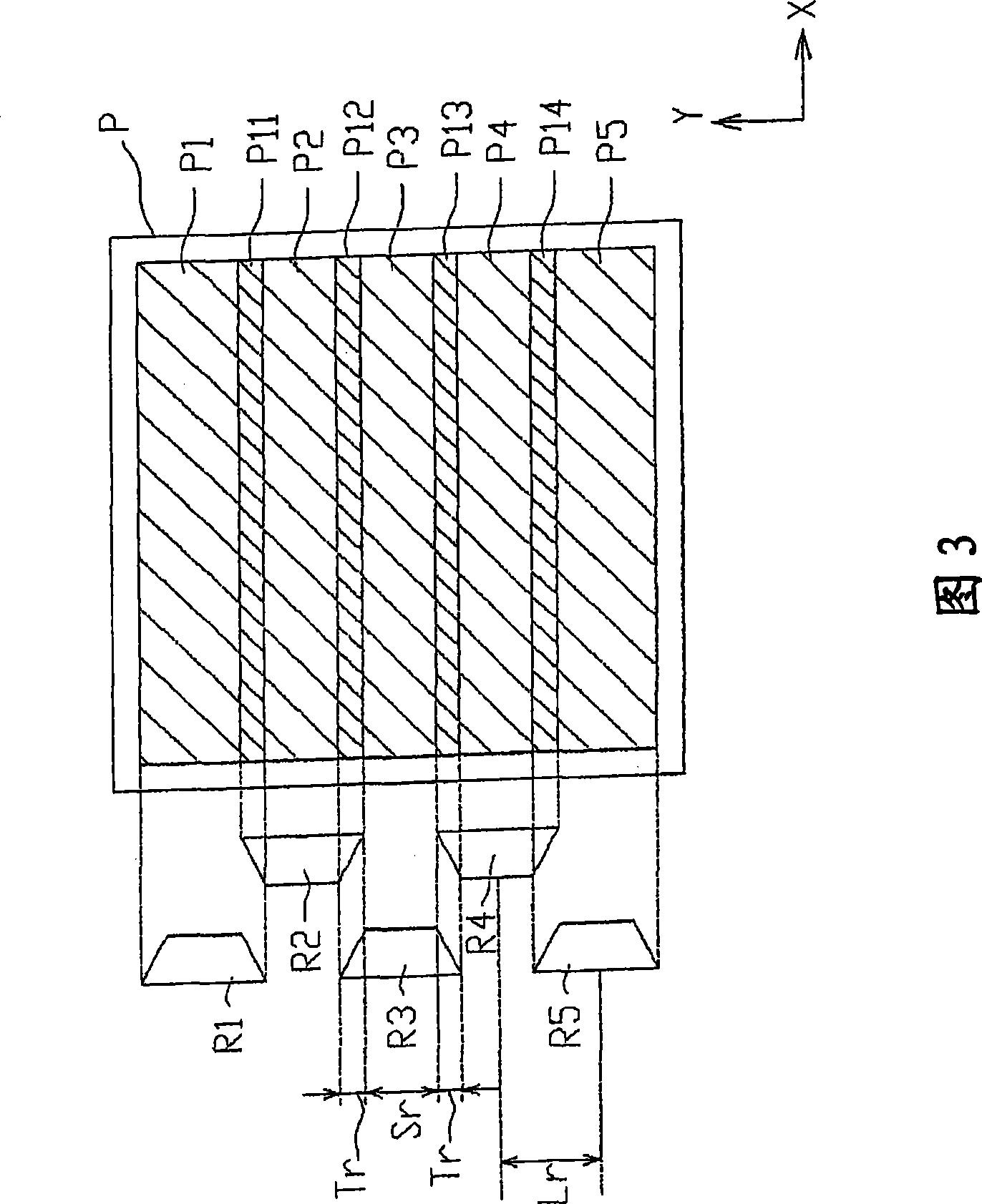

Exposure method, exposure apparatus, photomask and photomask manufacturing method

ActiveCN101375372AAvoid oversizingImprove utilization efficiencySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMagnificationImage plane

There is disclosed an exposure method is a method of projecting patterns (M1, M2) of a mask (M) onto a substrate to effect exposure thereof, through a plurality of projection optical units each having an enlargement magnification, and the exposure method comprises: placing the mask (M) having first pattern regions (M1) arranged discontinuously in a positional relation corresponding to the enlargement magnification, and second pattern regions (M2) provided at least in part between the first pattern regions (M1), on the object plane side of the projection optical units; projecting enlarged images of either of the first pattern regions (M1) and the second pattern regions (M2) onto the substrate disposed on the image plane side of the projection optical units to effect exposure thereof; and then projecting enlarged images of the other pattern regions onto the substrate to effect exposure thereof.

Owner:NIKON CORP

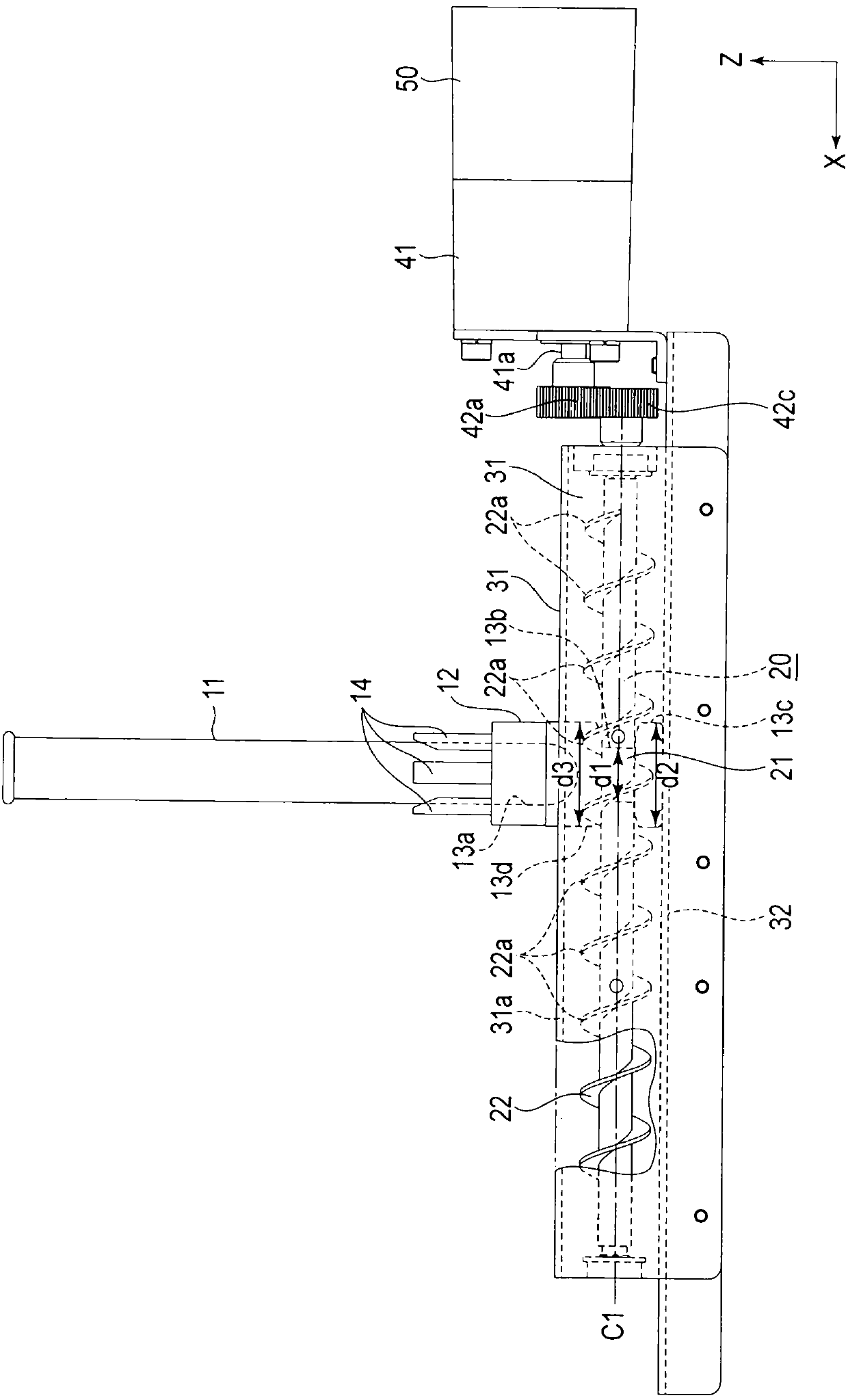

Cutting device

ActiveCN106098621AReduced number of partsReduce the number of piecesSemiconductor/solid-state device manufacturingManufacturing cost reduction

The invention provides a cutting device which has the advantages that the overall structure of the device is simple and miniaturized; and the quantity of components is reduced, so that the manufacture cost is reduced. The cutting device comprises a processing feeding mechanism, a moving-out / moving-in mechanism, a holding component, a pair of limiting pins, a carrying and moving component, a temporary placement mechanism, an openable component and a lifting component, wherein the processing feeding mechanism comprises an X-axis guide rail, and the X-axis guide rail can ensure that a working table can be supported to move between a processed object assembly and disassembly area equipped with the temporary placement mechanism and a processing area equipped with a cutting mechanism in the X-axis direction; the moving-out / moving-in mechanism comprises a supporting base table; the holding component is disposed on the supporting base table and used to hold a processed object stored in a box; the pair of limiting pins limit the processed object at a stipulated position; the carrying and moving component enables the supporting base table to move in the Y-axis direction; the temporary placement mechanism comprises a pair of supporting rails, the supporting rails constitute a bottom part and a side part which extend in the Y-axis direction and support two side parts of the processed object, and the bottom part is openable; the openable component is used to open and close the bottom part of the pair of supporting rails; and the lifting component is used to move the pair of supporting rails up and down.

Owner:DISCO CORP

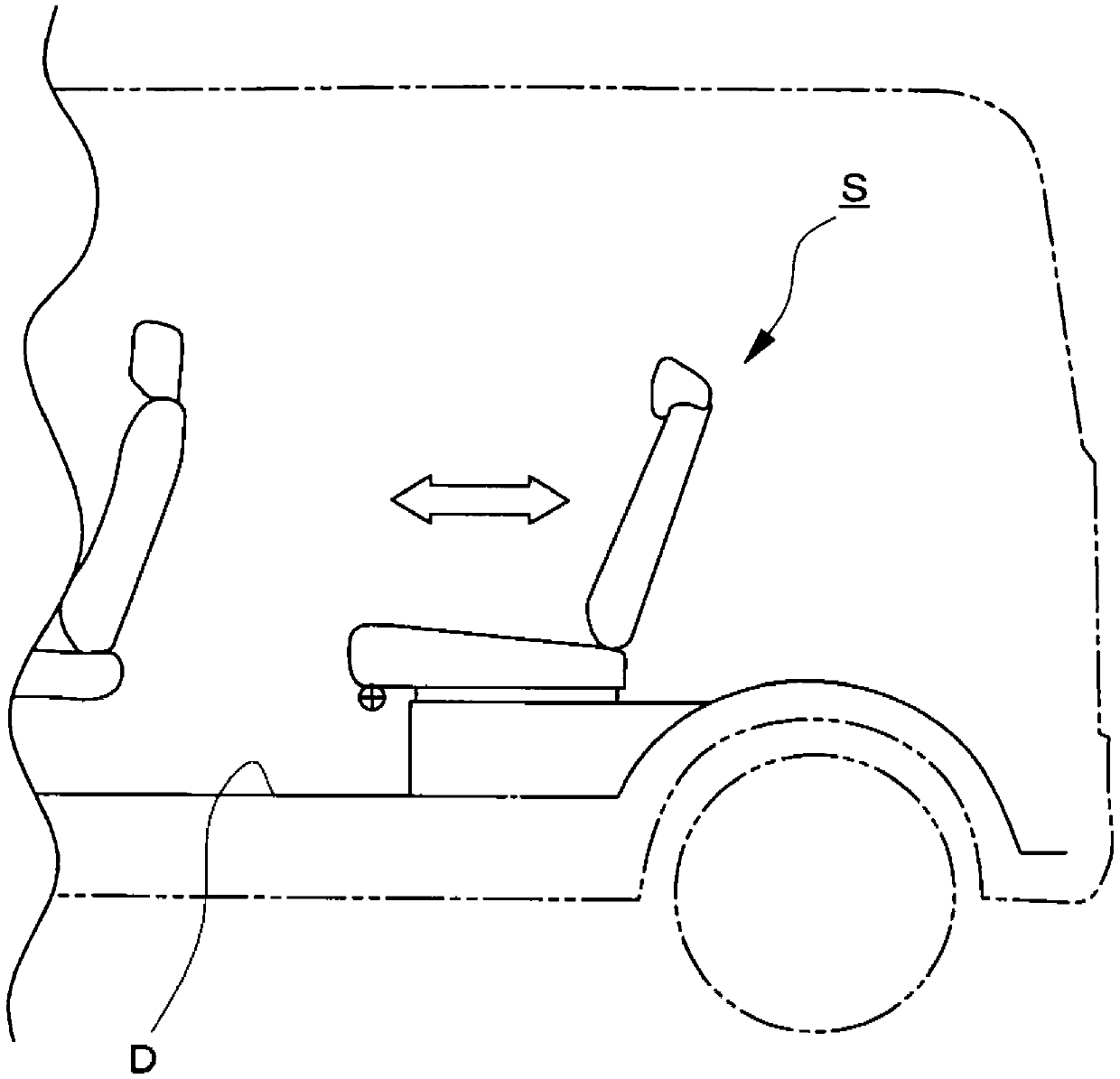

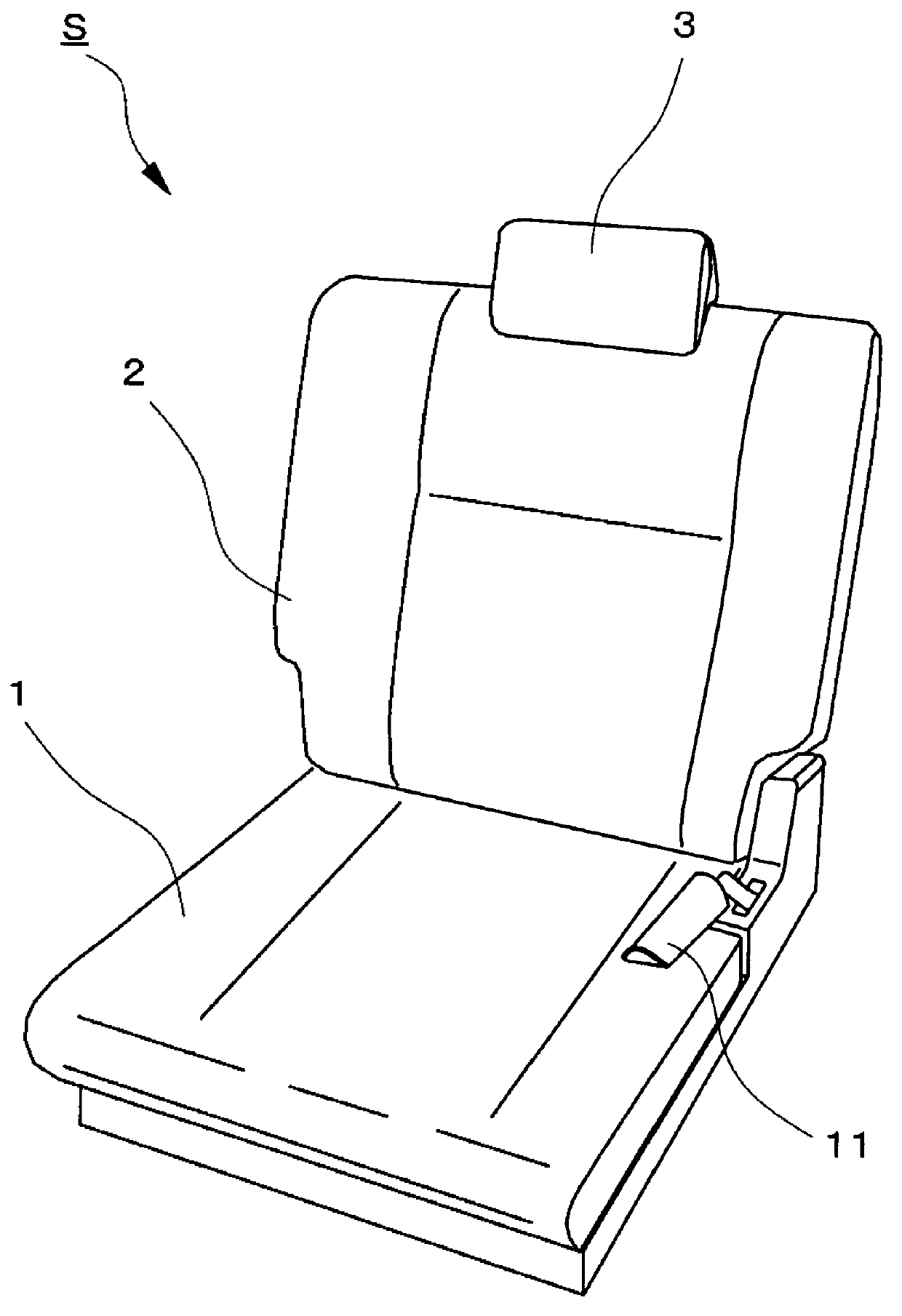

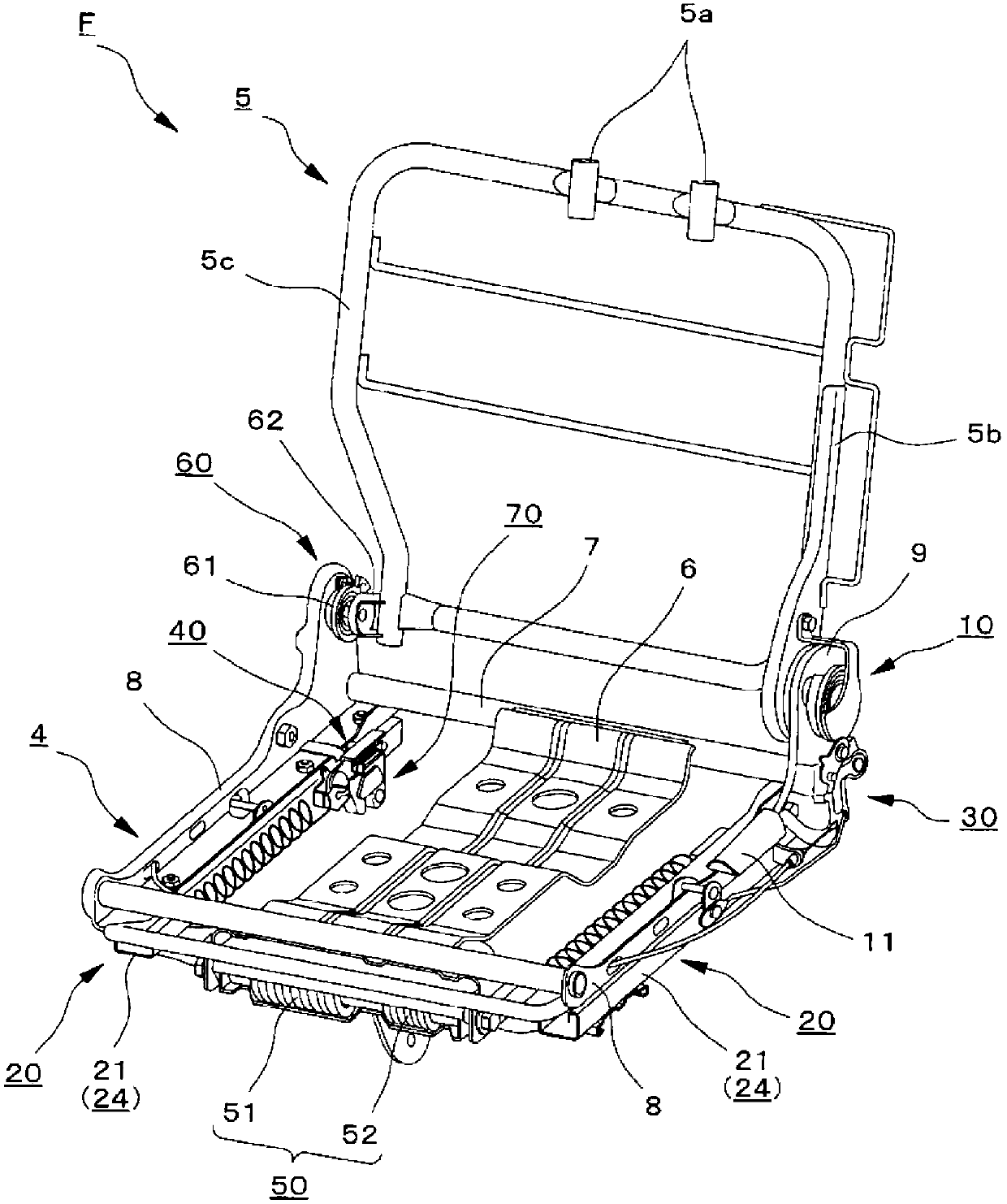

Seat frame and stowable vehicle seat with same

InactiveCN103313875ASmooth storage operationEasy to operateMovable seatsDismountable/non-dismountable seatsLocking mechanismEngineering

The present invention aims to provide a seat frame and a stowable vehicle seat which can be assembled with high work efficiency and which can be stowed easily. The present invention is provided with: a reclining mechanism (10); a seat slide mechanism (20) for sliding a seating frame (4); a slide lock mechanism (30) which, in conjunction with the reclining mechanism (10), prohibits or permits the action of the seat slide mechanism (20); a striker lock mechanism (70); and an assist mechanism (50) for assisting the stowing operation and the returning operation of a stowable vehicle seat (S). The seat slide mechanism (20) has a lower rail (21), an upper rail (22), and a slide pressing member (23) which automatically slides the upper rail (22) in association with the movement of a seat back frame (5) which is tilted to a predetermined angle during the stowage of the stowable vehicle seat (S). The seat slide mechanism (20) and the slide lock mechanism (30) are mounted to the seating frame (4).

Owner:TS TECH CO LTD

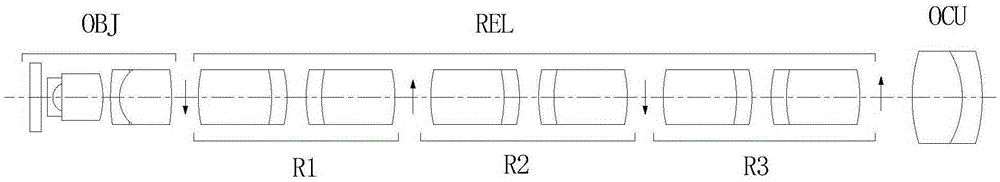

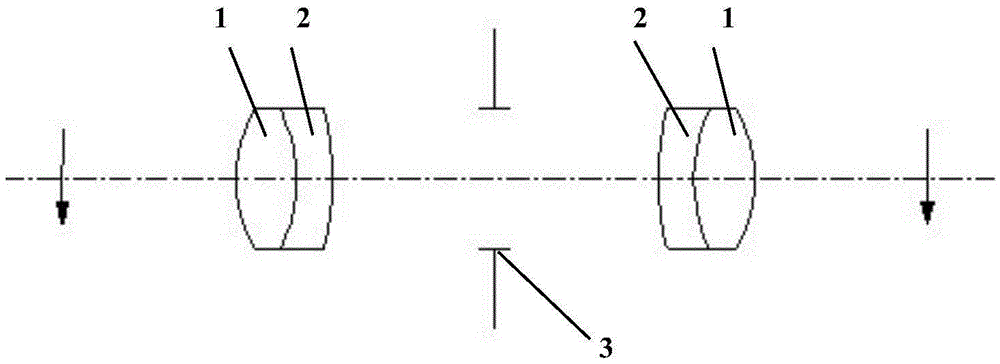

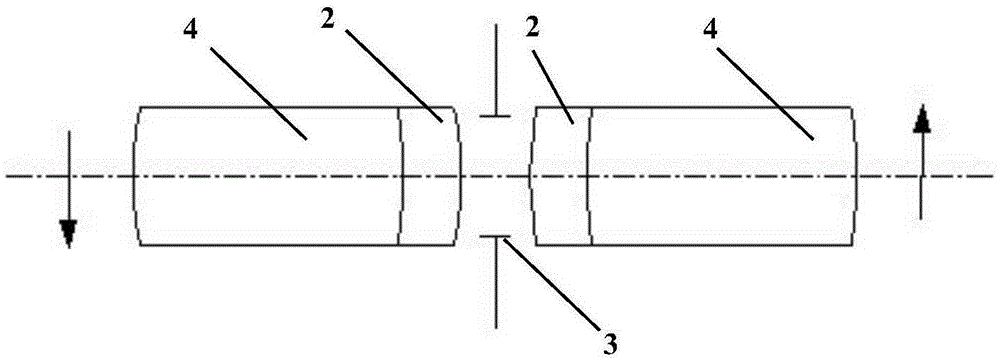

Stereoscopic endoscope electronic imaging optical system

The invention discloses a stereoscopic endoscope electronic imaging optical system. Hopkins rod lenses, more than one of image transferring doublet lenses, rhombic prisms, imaging doublet lenses, single lenses and protective windows are sequentially arranged behind an objective lens and a 1:1 image transferring system composed of three groups of rod lenses which are in structural symmetry along a light ray transmitting direction; the stereoscopic endoscope electronic imaging optical system directly magnifies an image of the image transferring system to a CCD or CMOS pixel surface, and the axial magnification ranges from 1.1 to 2; the Hopkins rod lenses are used for increasing the working length of the system, and effectively reduce the number of lenses; the rhombic prisms are used for increasing the distance between the optical axes of lens groups behind two optical channels of a stereoscopic endoscope, and satisfy spatial layout requirements of two CCD or CMOS devices; and the imaging doublet lenses and the single lenses are used for magnifying images, and participate in system distortion correction so as to reduce the distortion of the system.

Owner:TIANJIN UNIV

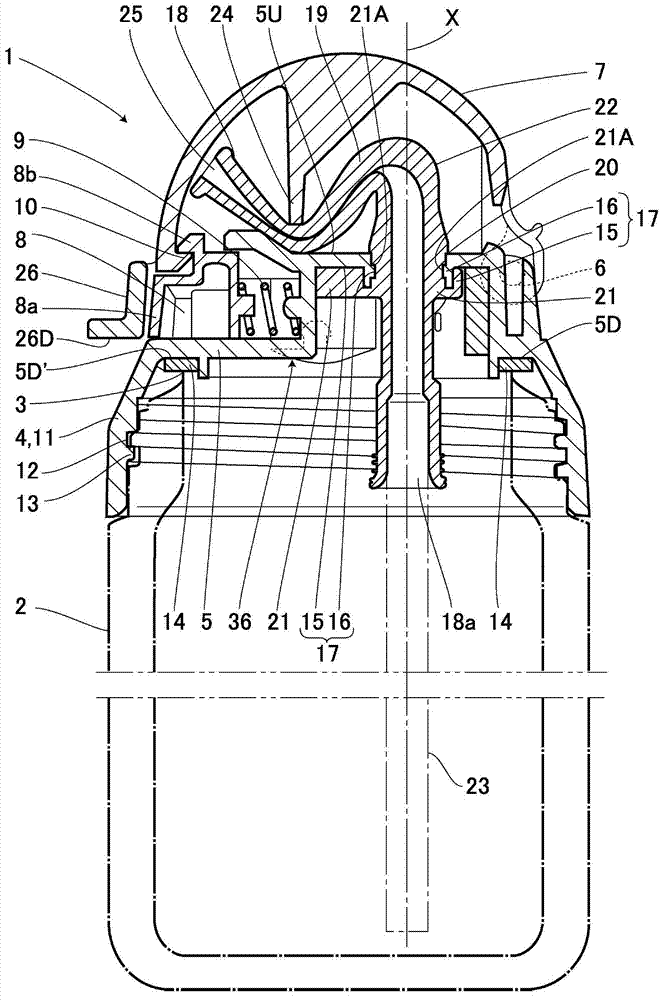

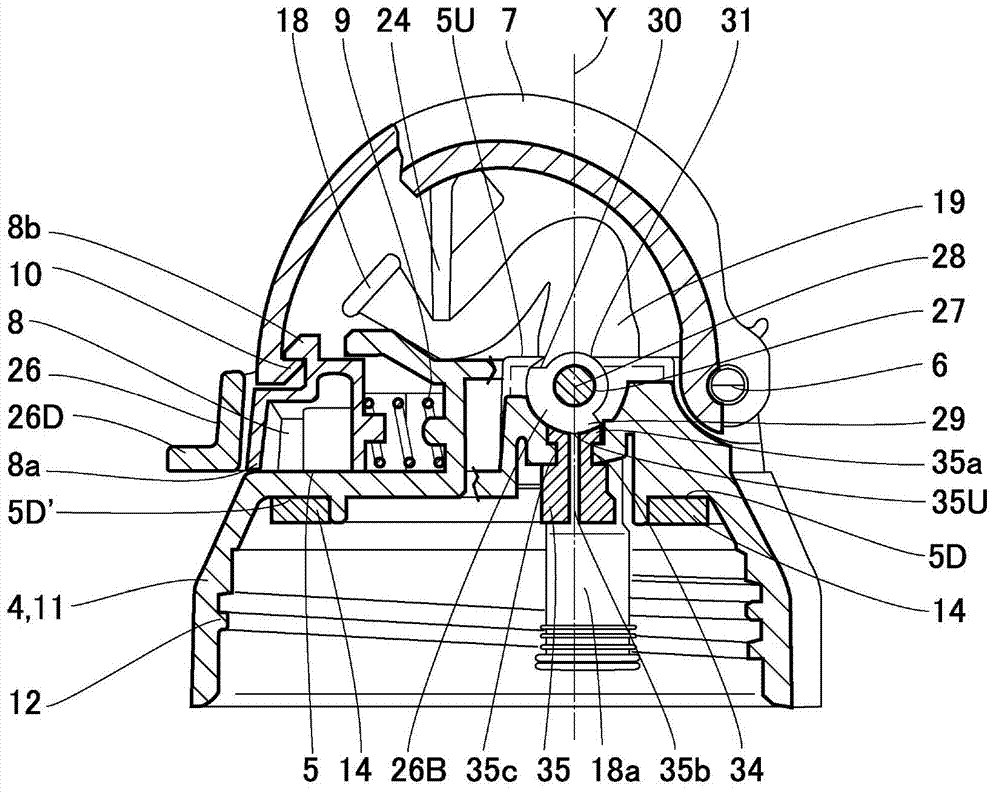

Plug of beverage vessel

The invention provides a plug of a beverage vessel. The plug cannot be easily opened due to misoperations or the like, and the operation and closure states of a locking mechanism are definite so that content liquid is prevented from spraying from the front end of a sucker. The plug comprises a plug main body (11), a shaft supporting cover (7), a clamping part (8), a drinking port member (22), and a blocking member (14). The clamping part (8) is arranged in a manner allowing a cover to be kept in or released from the closure state. The drinking port member (22) is clamped in the plug main body (11). The blocking member (14) is pressed against a vessel opening (3) and blocks a vessel main body. The blocking member (14) is clamped in a hole (34), and a ventilation hole (35b) is formed in the through part of the hole (34). The ventilation hole is in the closure state when the cover is in the closure state and temporarily in the open state when a reversing handle member is in a circumferential reversing process, and the ventilation hole is back to the closure state again by virtue of further reversing the reversing handle member, so that the closure state is enabled to be definite and the closure / open / closure action time of the ventilation hole is delayed accurately.

Owner:THERMOS LLC +1

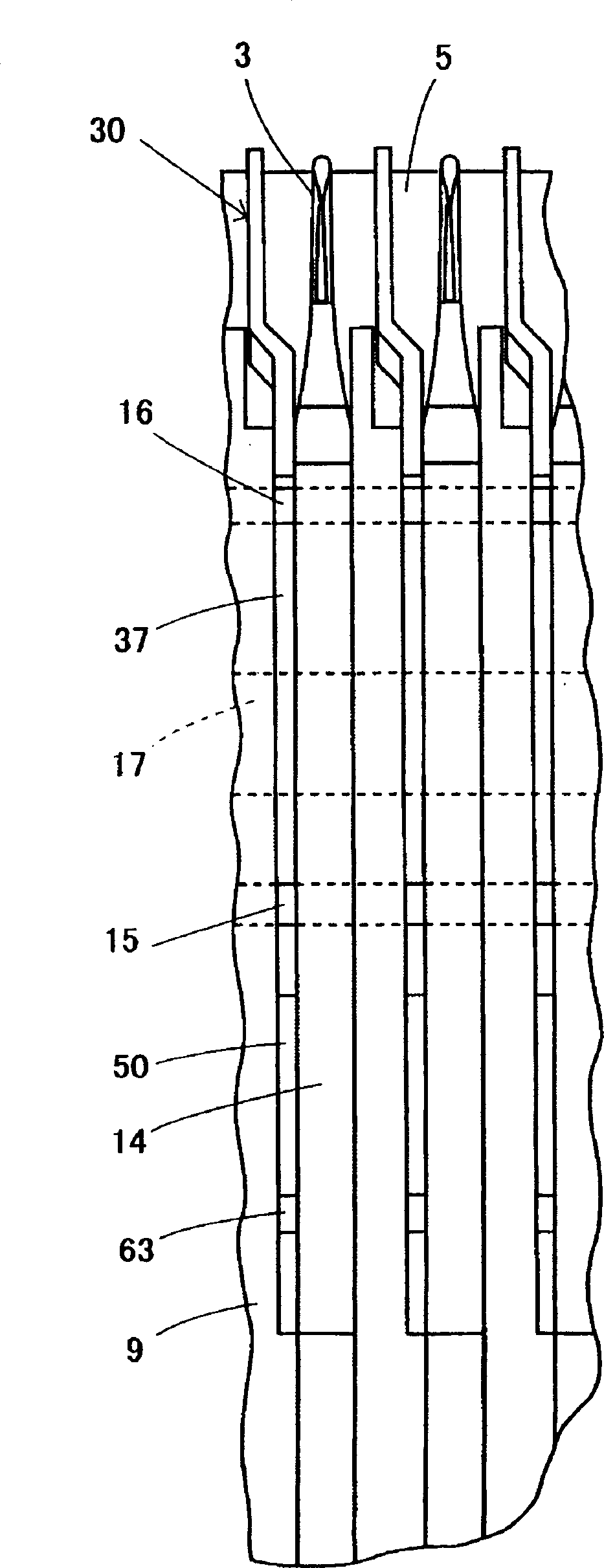

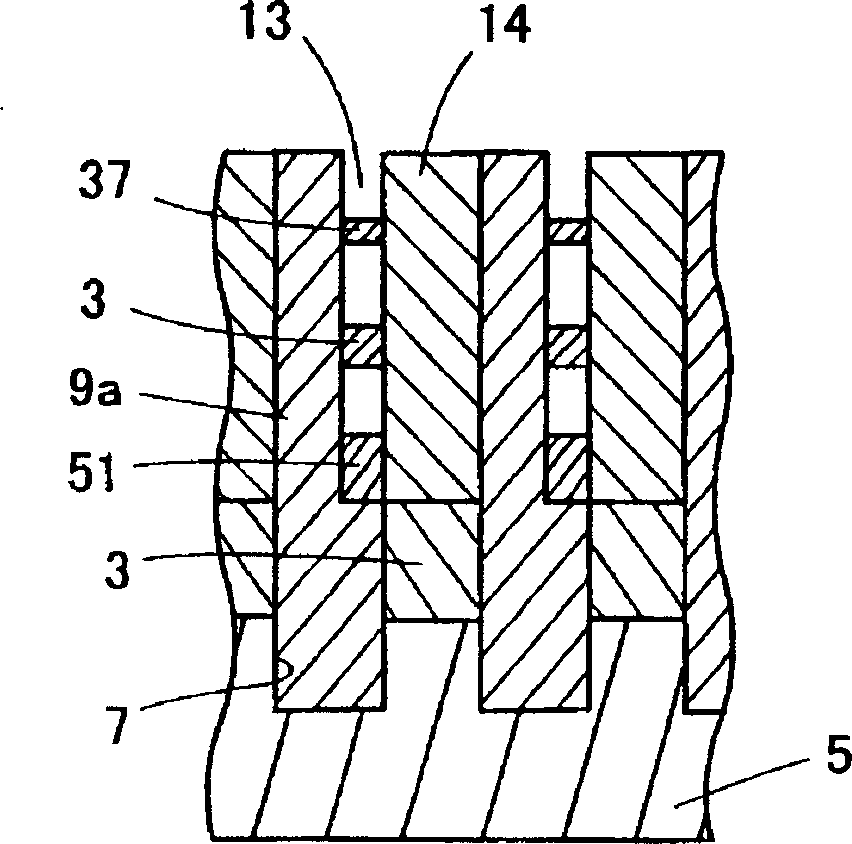

Sinker device of flat knitting machine

InactiveCN1391620AShort tripReduce the number of piecesWeft knittingMechanical engineeringEngineering

Owner:SHIMA SEIKI MFG LTD

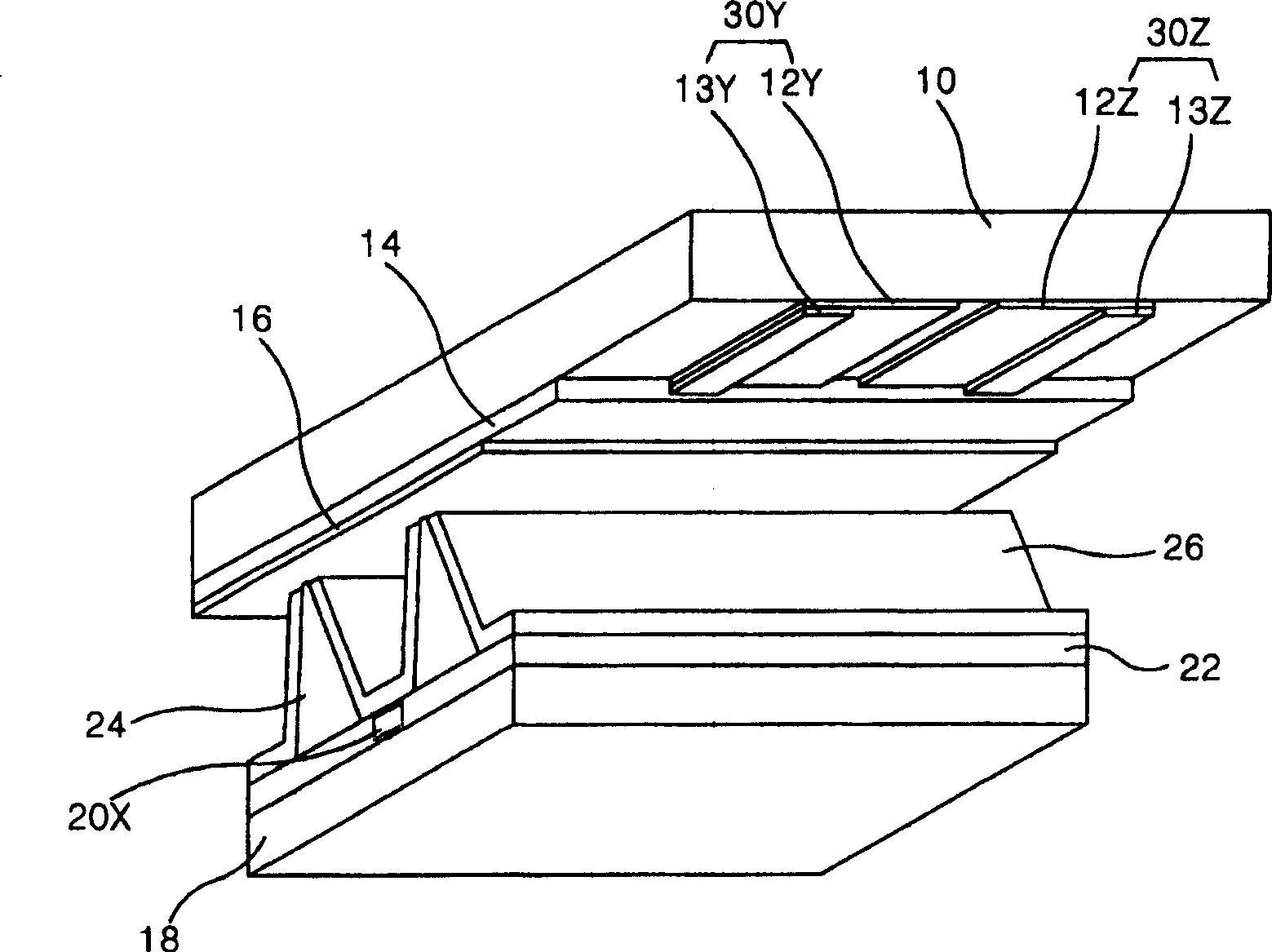

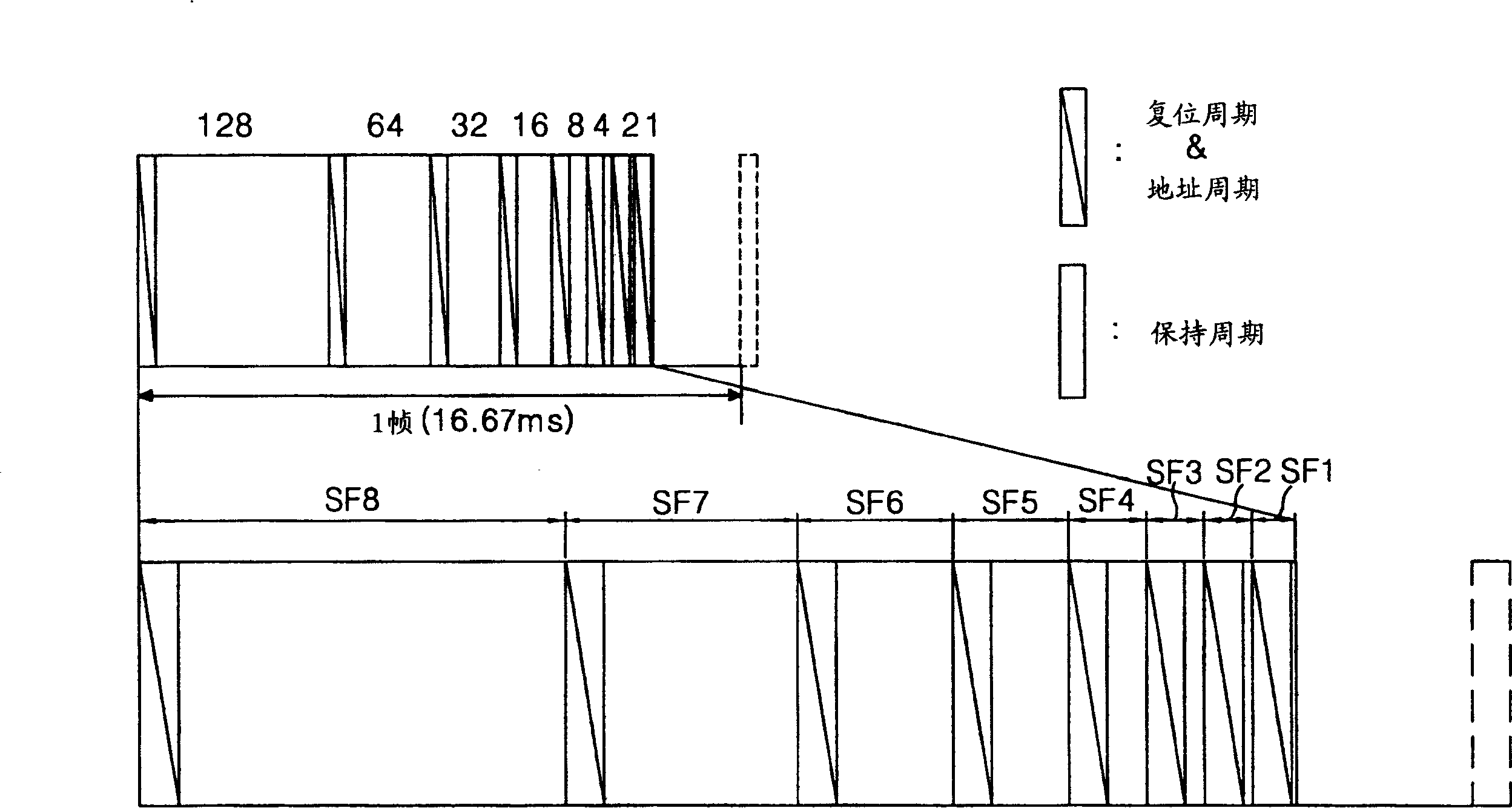

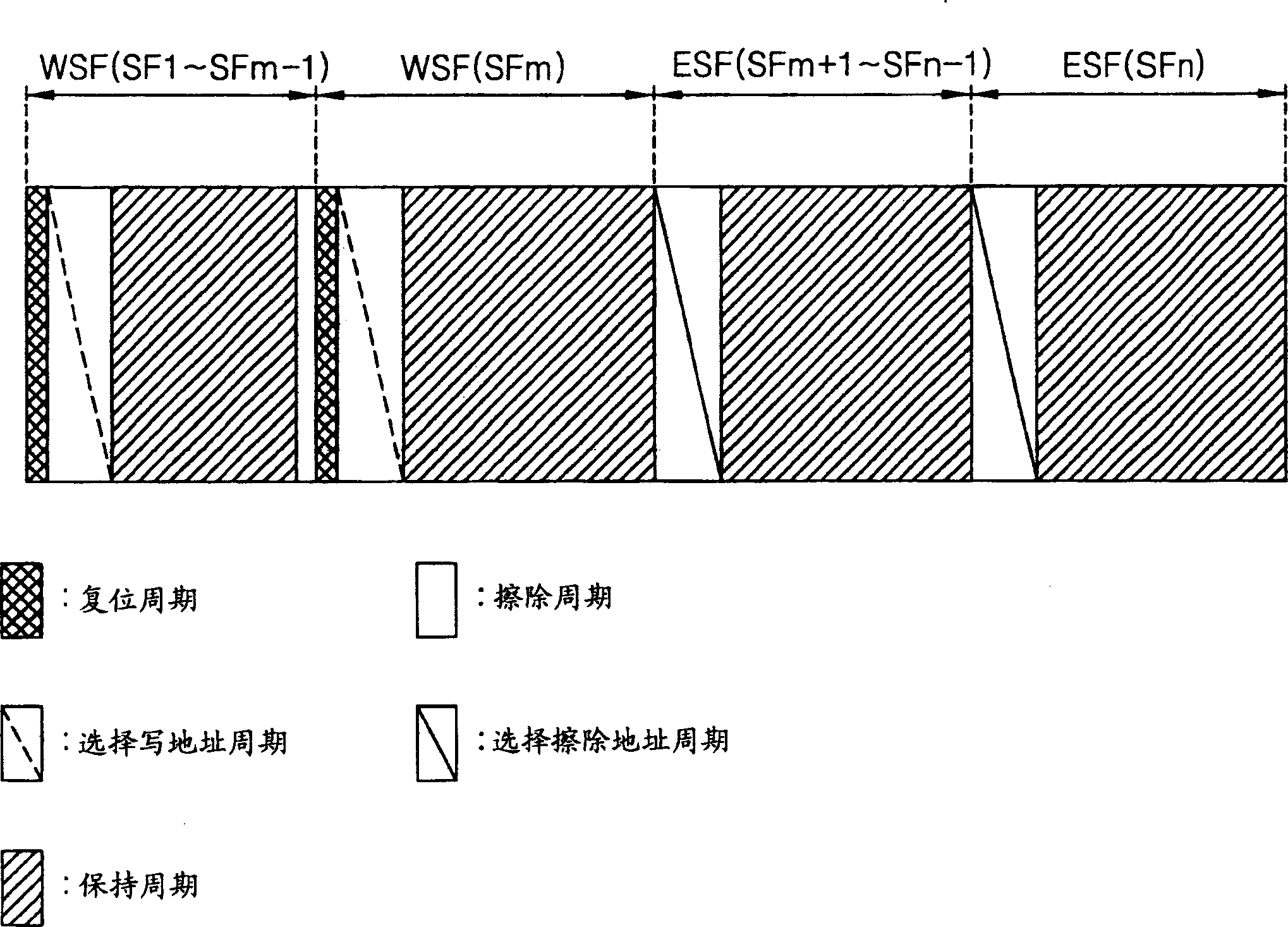

Plasma display plate and its driving method

InactiveCN1536548ASolve the real problemReduce manufacturing costStatic indicating devicesWave formEnergy recovery

The present invention relates to a drive device and method of a plasma display panel in which the manufacturing cost of a PDP can be reduced. The plasma display panel in accordance with the present invention has a drive device comprising: a IC circuit supplying drive voltage to scan electrodes; a energy recovery circuit supplying sustain voltage to the IC circuit; a set up supply part supplying rising ramp wave form to the IC circuit during set up period; and a set down supply part supplying falling ramp wave form to the IC circuit during set down period, wherein said drive device includes a switch which connects the set up supply part to the set down supply part and is turned on or off responding to voltage supplied to the IC drive circuit during the set down period.

Owner:LG ELECTRONICS INC

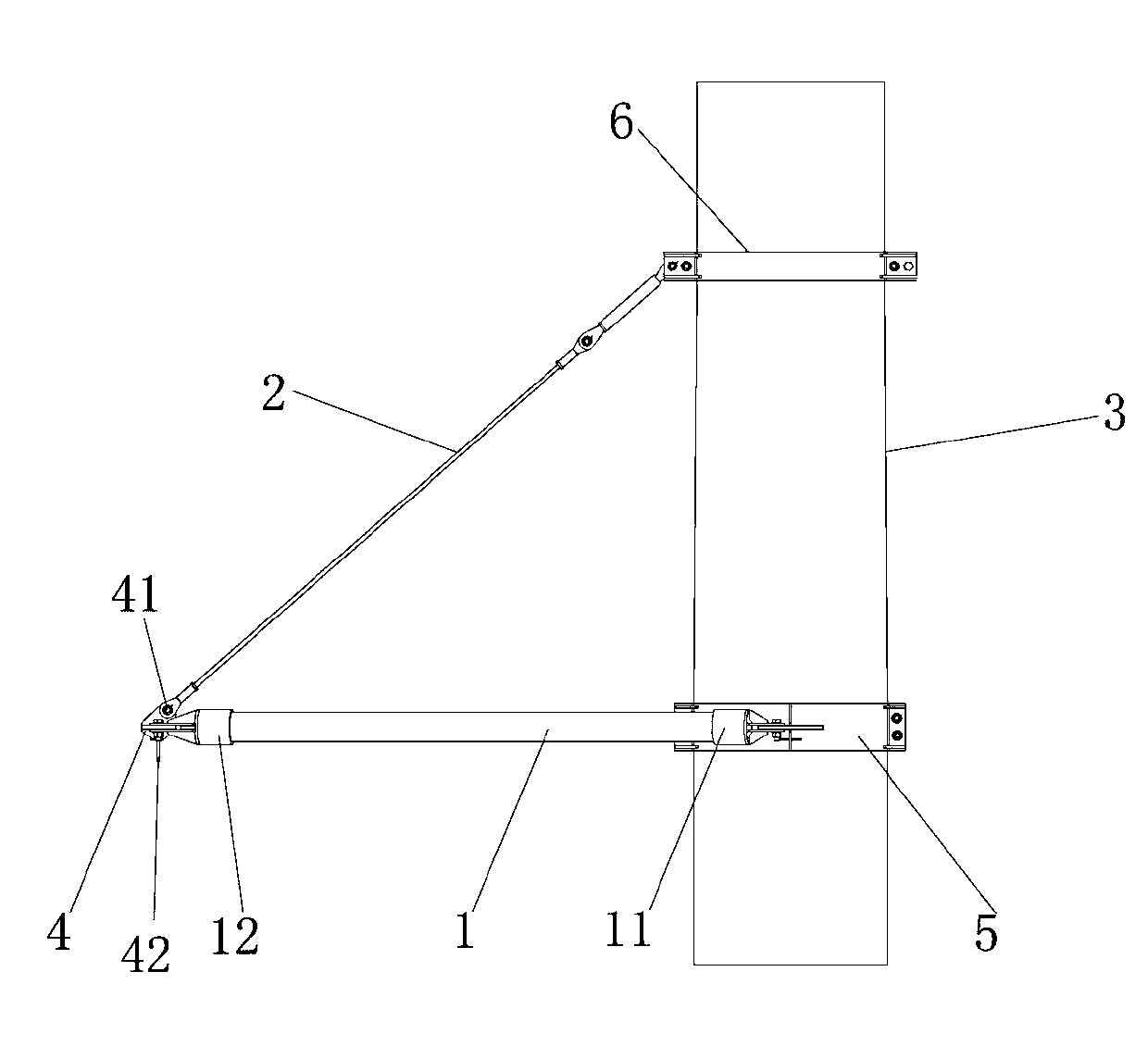

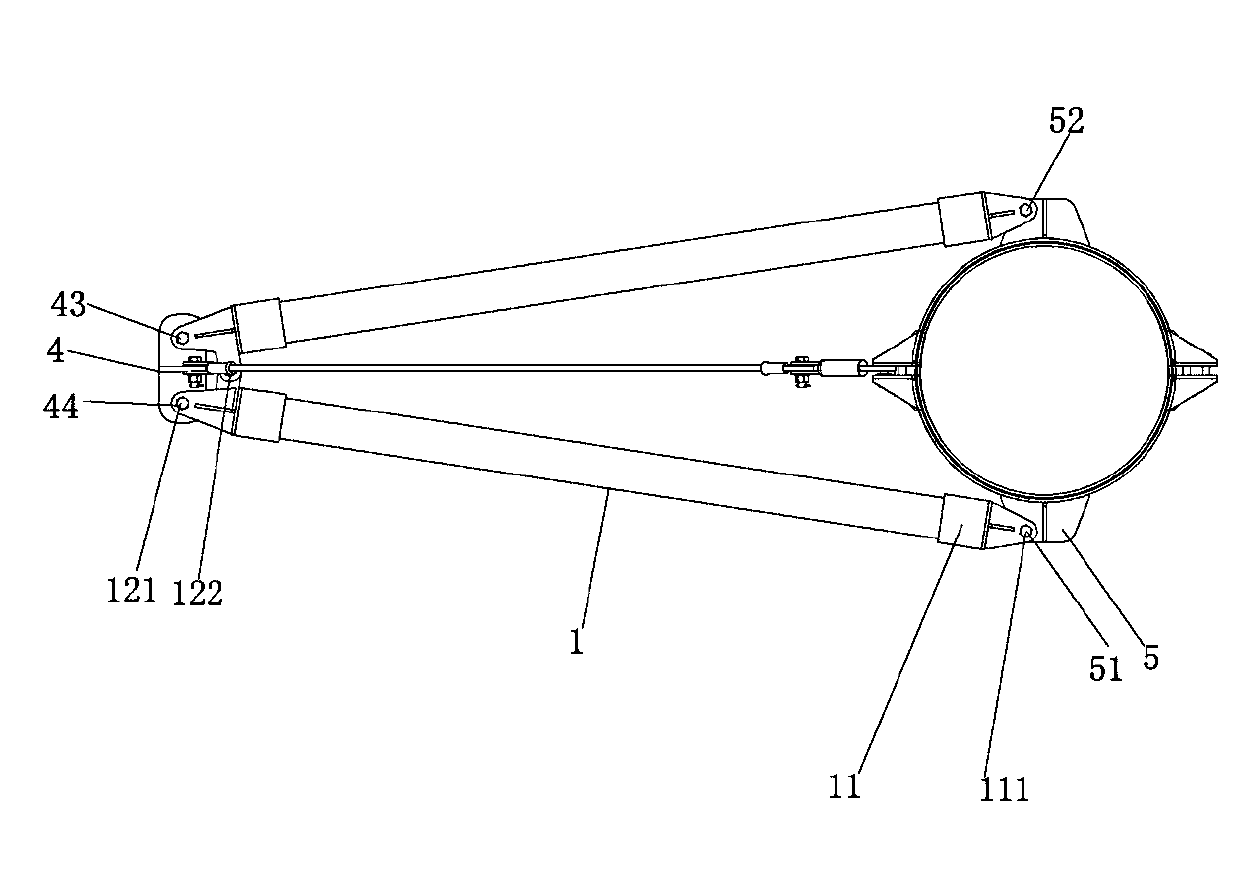

Combined composite cross arm

InactiveCN102900261ASolve the problem of heavy, inconvenient installationReduce the cross-sectional areaTowersMaterial consumptionEngineering

The invention relates to a combined form of composite cross arms, which comprises a draw bar hoop and a cross arm hoop, wherein the draw bar hoop and the cross arm hoop are sleeved on a bar body in an up-and-down sequence, the upper and lower surfaces of a hanging point are respectively provided with a draw bar connecting hole and a conductor grip hanging hole, the left and right ends of the hanging point are respectively provided with a hanging point connecting hole, the two ends of a draw bar are respectively connected with the hanging point and the draw bar hoop, the two ends of a cross arm are provided with a link fitting, one end of the cross arm is hinged with the cross arm hoop, the other end of the cross arm is connected with the hanging point through the hanging point connecting hole, and two cross arms are hinged through a hinging hole. According to the invention, a three-hanging-shaft connecting structure is fixedly formed among two cross arms and a cross arm hoop, and the stability of the three-hanging-shaft connecting structure is strengthened by using a draw bar, so that the problem that an insulating composite cross arm is relatively heavy in tooling fittings and inconvenient to install is solved, meanwhile, when the requirements on compression strength, tensile strength and stability are satisfied, the cross sectional area of the composite cross arm is reduced, the material consumption is reduced, and the project cost is greatly reduced.

Owner:DANDONG ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +2

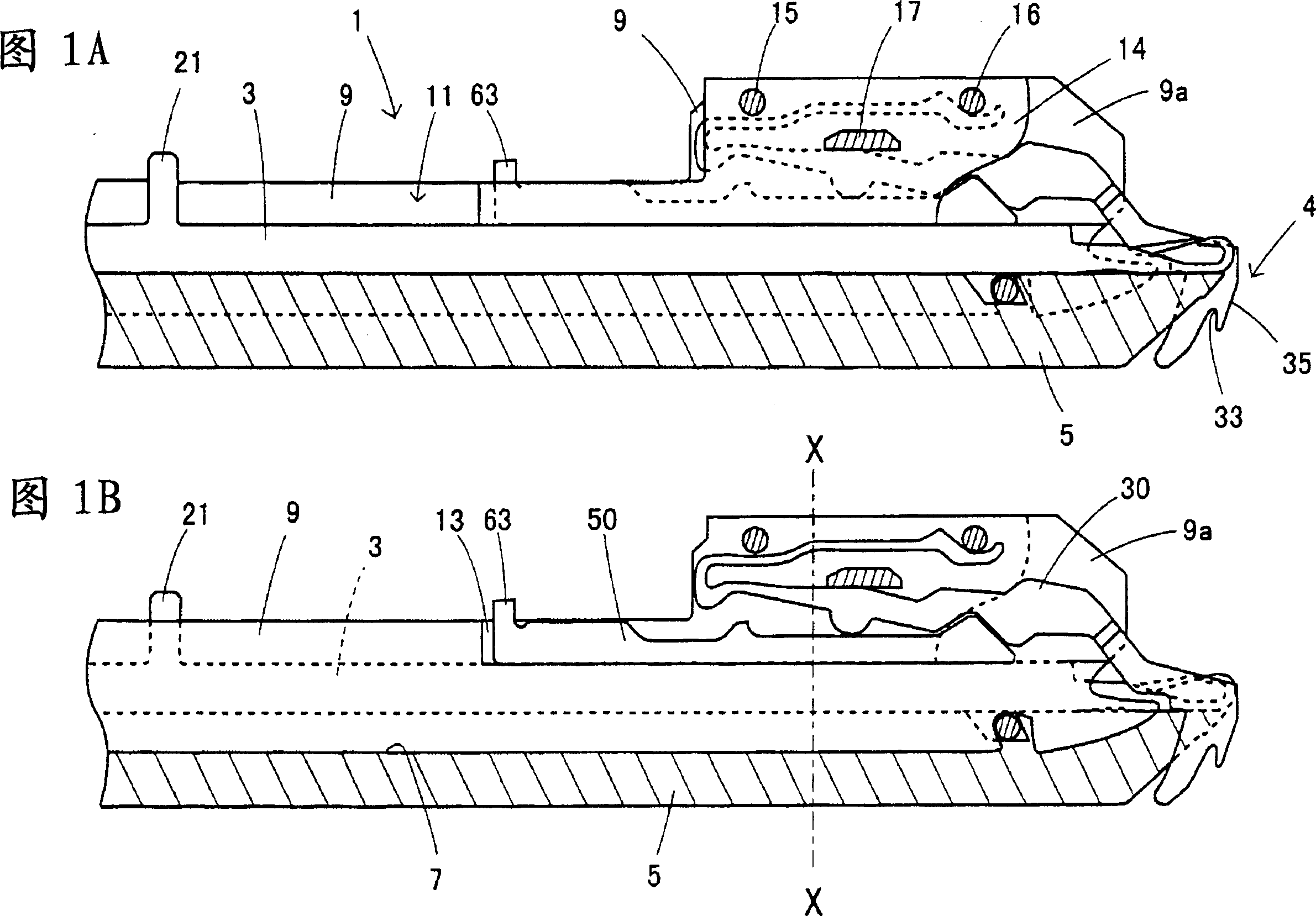

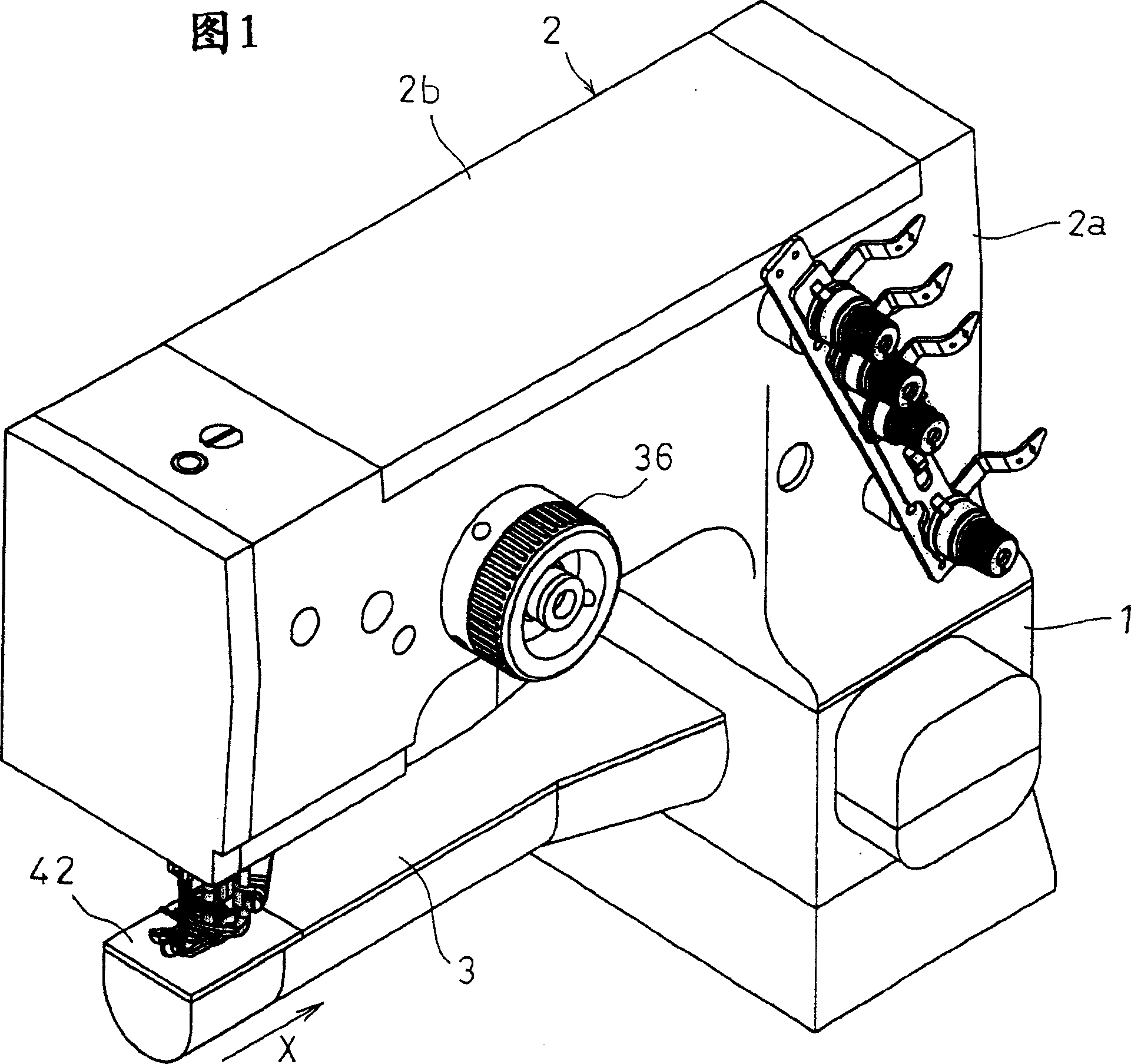

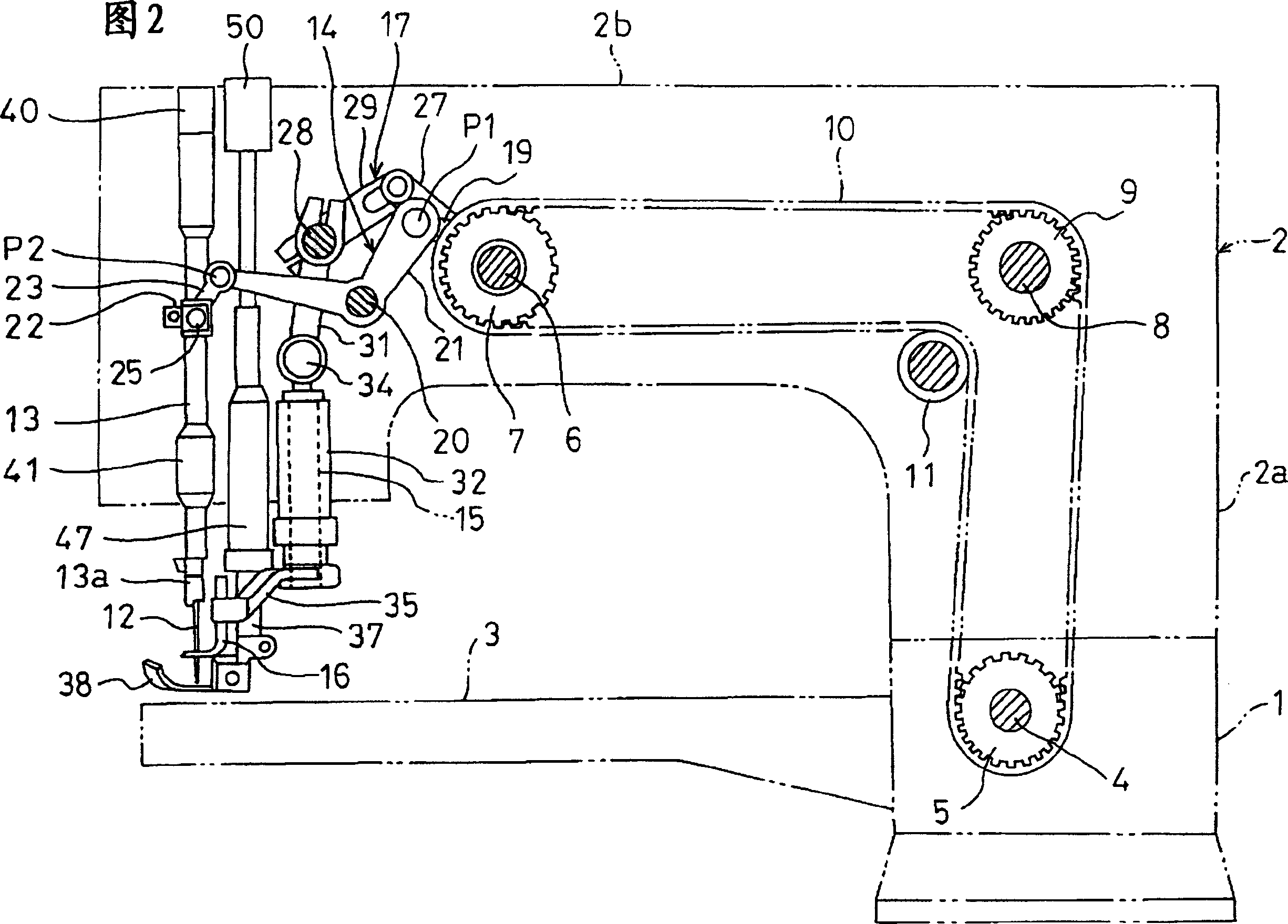

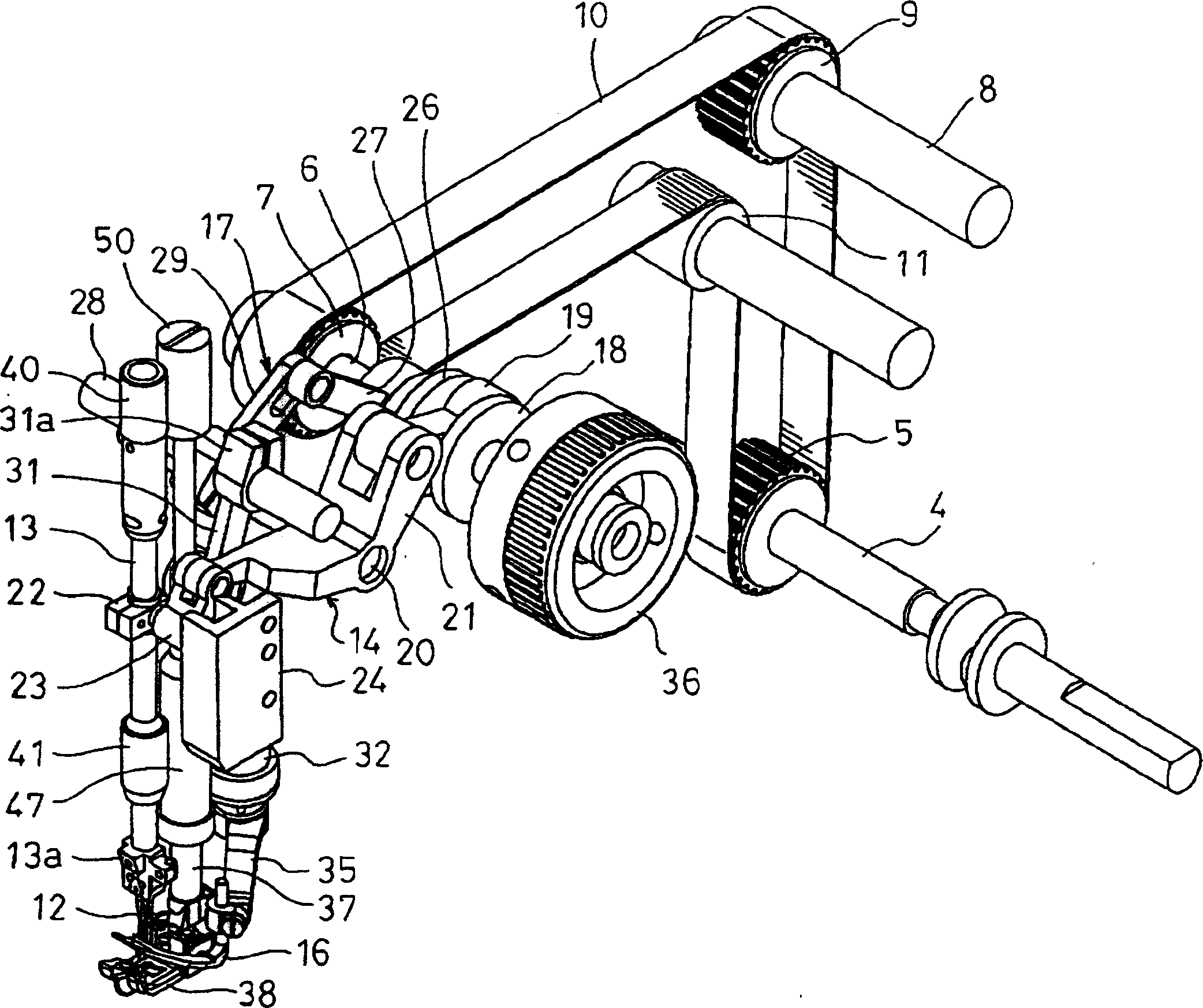

Sewing machine for barrel type curtain upside decoration cloth

InactiveCN1702221ASmall sizeAchieve compactnessSewing-machine control devicesNeedle barsDrive shaftMiniaturization

This invention provides a cylinder type valance stitch sewing machine where simplification of structure and miniaturization can be realized in addition to following belt drive and which is suitable for valance flat sewing with cylinder type multiple needles. The cylinder type valance stitch sewing machine is provided with: a sewing machine bed 1; a nearly L-shaped arm 2 formed projecting on the side of the upper surface of the bed 1; and a cylinder 3 formed projecting forward so as to oppose the lower side of an arm head part 2b from the front side face of the sewing machine bed 1 so as to feed cloth backward from the tip of the cylinder. A drive shaft 4 arranged in the bed 1 is belt-driven with a driven shaft 6 arranged in the arm head part 2b. The tip side of the arm head part 2b is provided with: a needle bar drive mechanism 14 which changes the rotation of the driven shaft to the vertical movement of a needle bar 13 with a plurality of sewing machine needles 12 fitted to its lower end to drive the needle bar; and a spreader drive mechanism 17 which changes the rotation of the driven shaft to the rocking movement of a spreader 16 for valance threads fitted to the lower end of a spreader rotary shaft 15 to drive the spreader.

Owner:PEGASUS SEWING MACHINE MFG

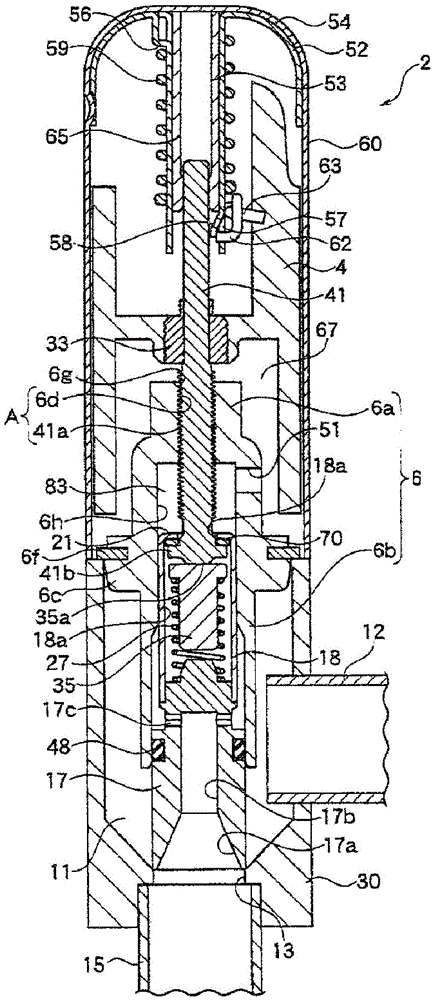

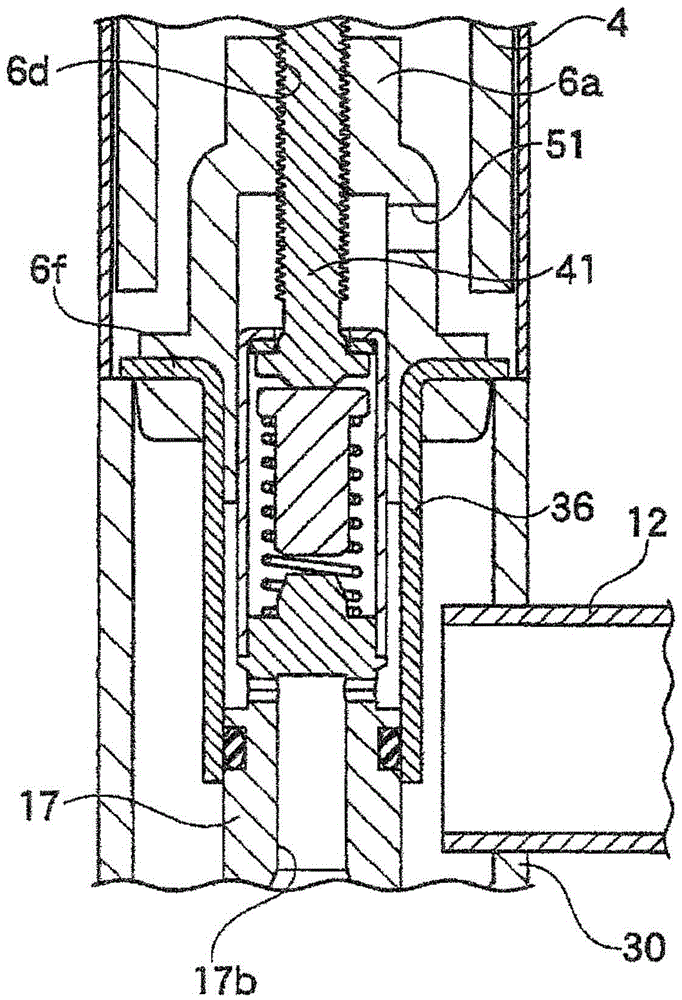

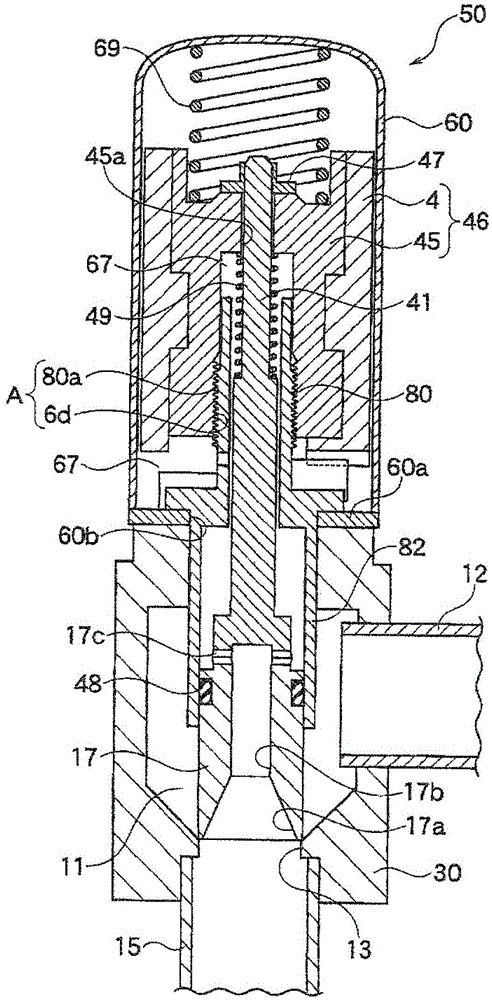

Electrically operated valve

InactiveCN105937644AReduce the number of piecesEasy to assembleOperating means/releasing devices for valvesLift valveLinear motionEngineering

The present invention provides an electrically operated valve which can reduce the number of components and facilitate assembling and downsizing particularly when a back pressure chamber is arranged in a large-sized electrically operated valve. In the electrically driven valve, a screw joint (A) formed between an outer thread part (41) of which an outer peripheral surface is provided with an outer thread (41a) and an inner thread part (6a) on which an inner peripheral surface is provided with an inner thread (6d) turns rotational motion of the rotor (4) into linear motion and enables the valve element (17) to move linearly in the axial direction based on the linear motion. The electrically operated valve is characterized in that the inner thread part (6a) provided with the inner thread (6d) and a valve element guiding part (6b) that guides the valve element (17) to move in the axial direction are integrated into one member, and the valve element (17) is guided in the axial direction in such a way that the valve element (17) slidably contacts with the inner peripheral surface of the valve element guide member (6b).

Owner:SAGINOMIYA SEISAKUSHO INC

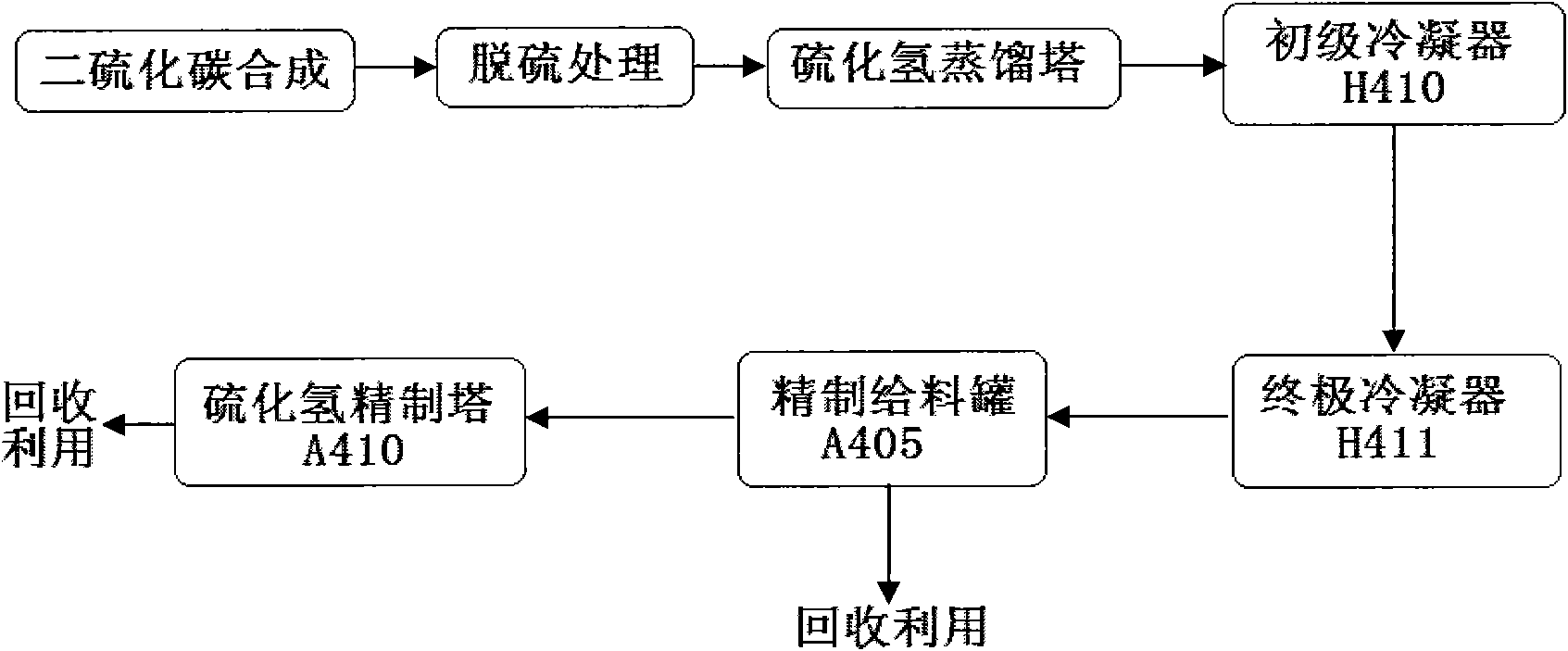

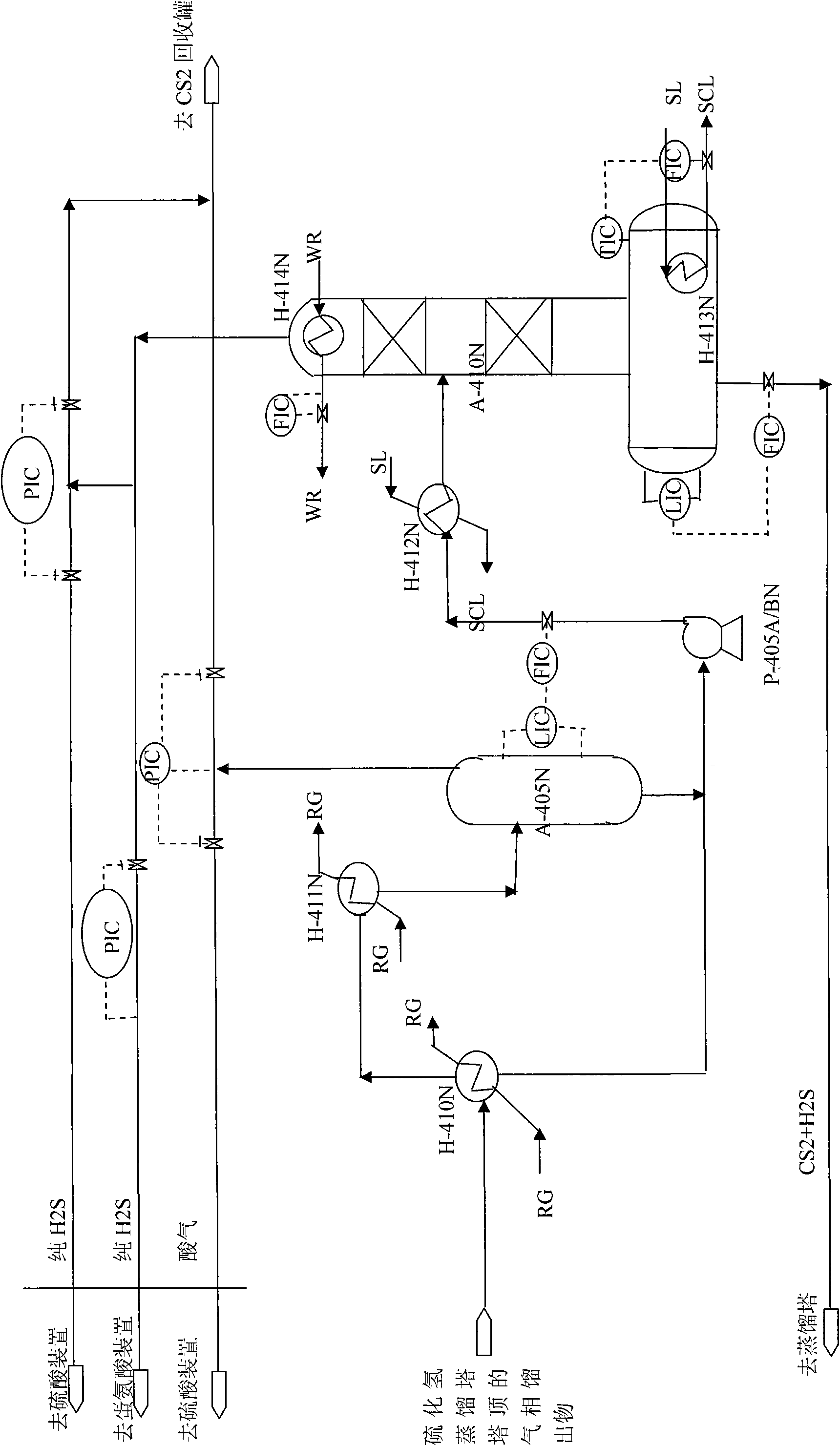

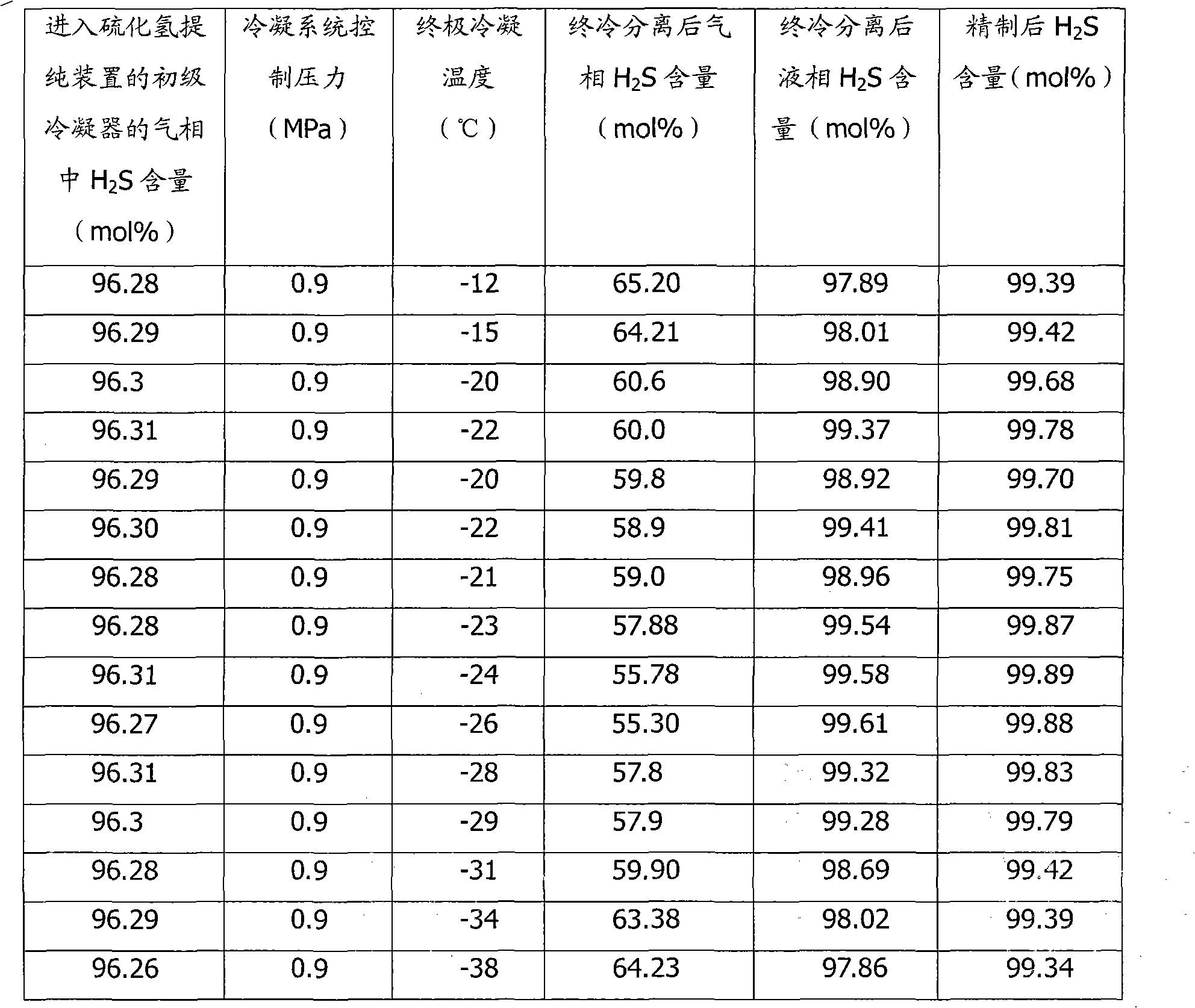

Methods for purifying and comprehensively utilizing hydrogen sulfide byproduct during production of carbon disulfide by methane method

ActiveCN102153053AOvercoming a large number of devicesOvercome stabilityHydrogen sulfidesGas phaseDistillation

The invention relates to a method for purifying a byproduct, namely hydrogen sulfide, during production of carbon disulfide by a methane method, and a method for comprehensively utilizing the byproduct. The method for purifying the byproduct comprises the following steps of: initially separating a mixture of desulfured products through a hydrogen sulfide distillation tower, and further purifying a gaseous phase product; performing two-stage condensation on a gaseous phase distillate at the top of the hydrogen sulfide distillation tower through a primary condenser and an ultimate condenser; and further purifying by using a refining feeding pot and a hydrogen sulfide refining tower so as to finally obtain the high-purity hydrogen sulfide. By adoption of constant-pressure two-level condensation, a lower condensation temperature can be reached to contribute to separation and elimination of inert gases in acidic gases, and the number of sets of equipment is decreased, the safety is enhanced and the equipment investment is reduced at the same time; meanwhile, by the methods, the minimum emission of waste gases and waste liquid during whole purification is realized, so the method is clean and environment-friendly.

Owner:吉林三源化工有限公司

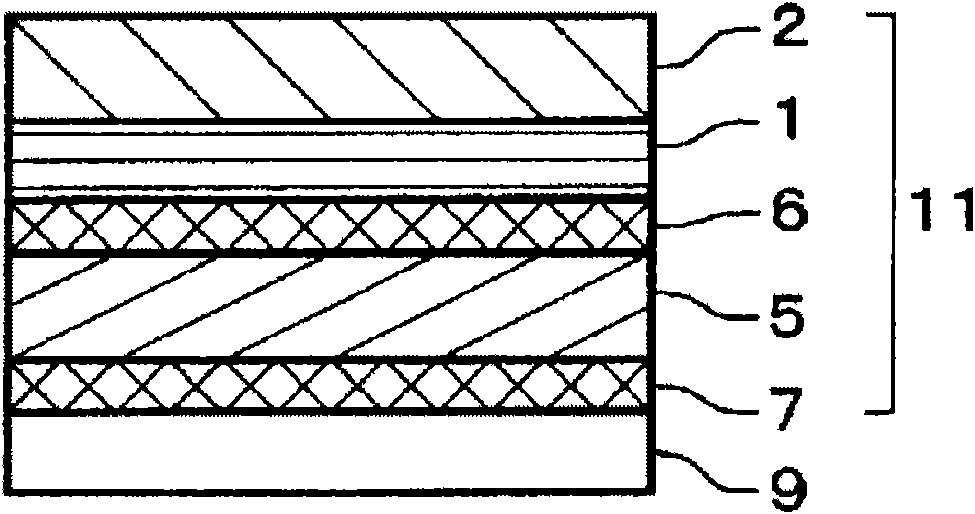

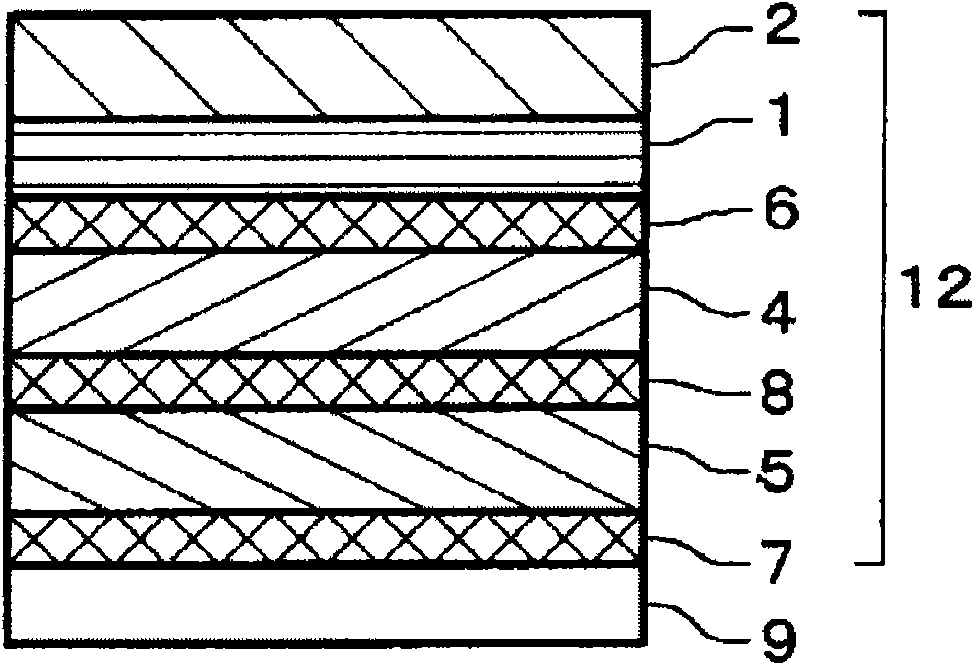

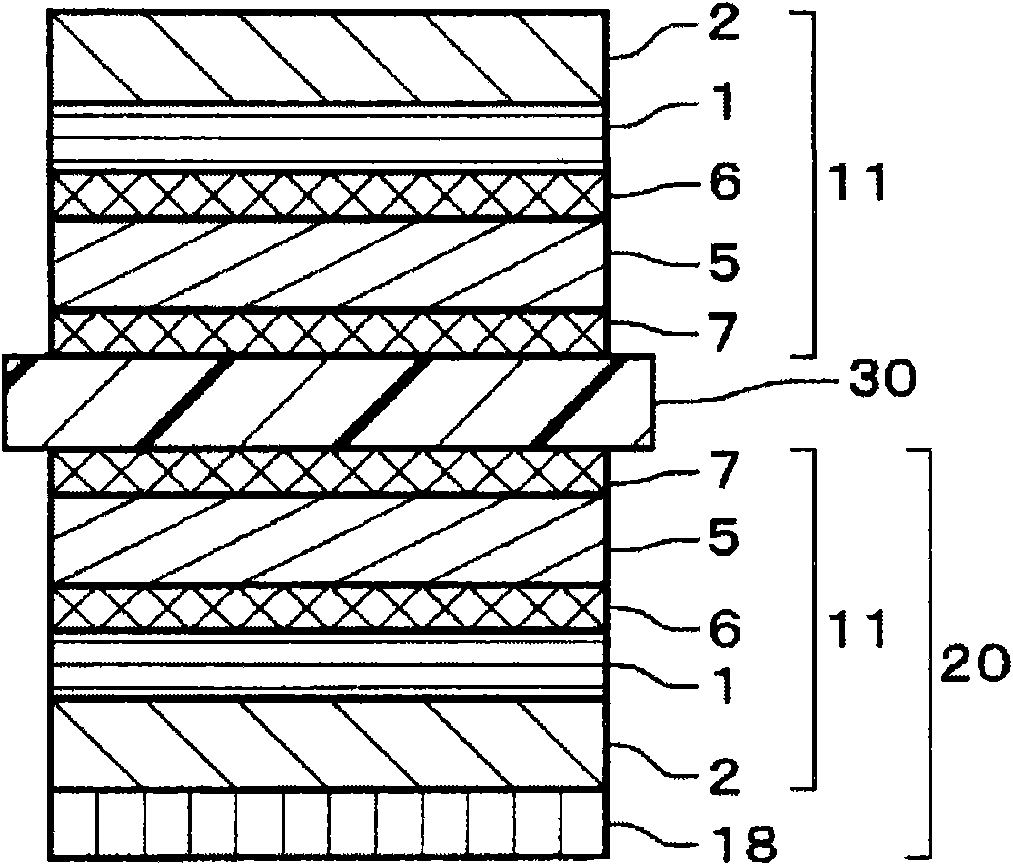

Composite polarizing plate, laminated optical member, and image display device using them

ActiveCN101784923AGuaranteed brightnessImprove visual effectsPolarising elementsNon-linear opticsPolyvinyl alcoholPhase difference

This invention provides a composite polarizing plate comprising a polarizer, a phase difference plate, and a pressure sensitive adhesive layer. The composite polarizing plate is thin and light in weight, can ensure brightness of an image display device to which the composite polarizing plate has been applied, is less likely to cause blurred or unsharp display images, and can develop good durability. A transparent protective layer (2) is disposed on one side of a polarizer (1) formed of a polyvinyl alcohol resin film, and at least one phase difference plate (5) is stacked on the other side of the polarizer (1) through a first pressure sensitive adhesive layer (6). A second pressure sensitive adhesive layer (7) is disposed on the outer side of the phase difference plate located at a position most remote from the polarizer (1) to provide a composite polarizing plate (11). At least one layer of the first pressure sensitive adhesive layer (6), the second pressure sensitive adhesive layer (7), and pressure sensitive adhesive layers located between the first pressure sensitive adhesive layer (6) and the second pressure sensitive adhesive layer (7) contains a light diffusing agent and is formed of a light diffusive pressure sensitive adhesive layer having a storage modulus of 0.15 to 10 MPa at 23 DEG C. This composite polarizing plate (11) is used in combination with an image display element such as a liquid crystal cell (30) to provide an image display device.

Owner:SUMITOMO CHEM CO LTD +1

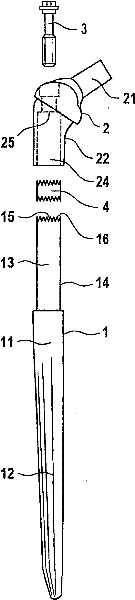

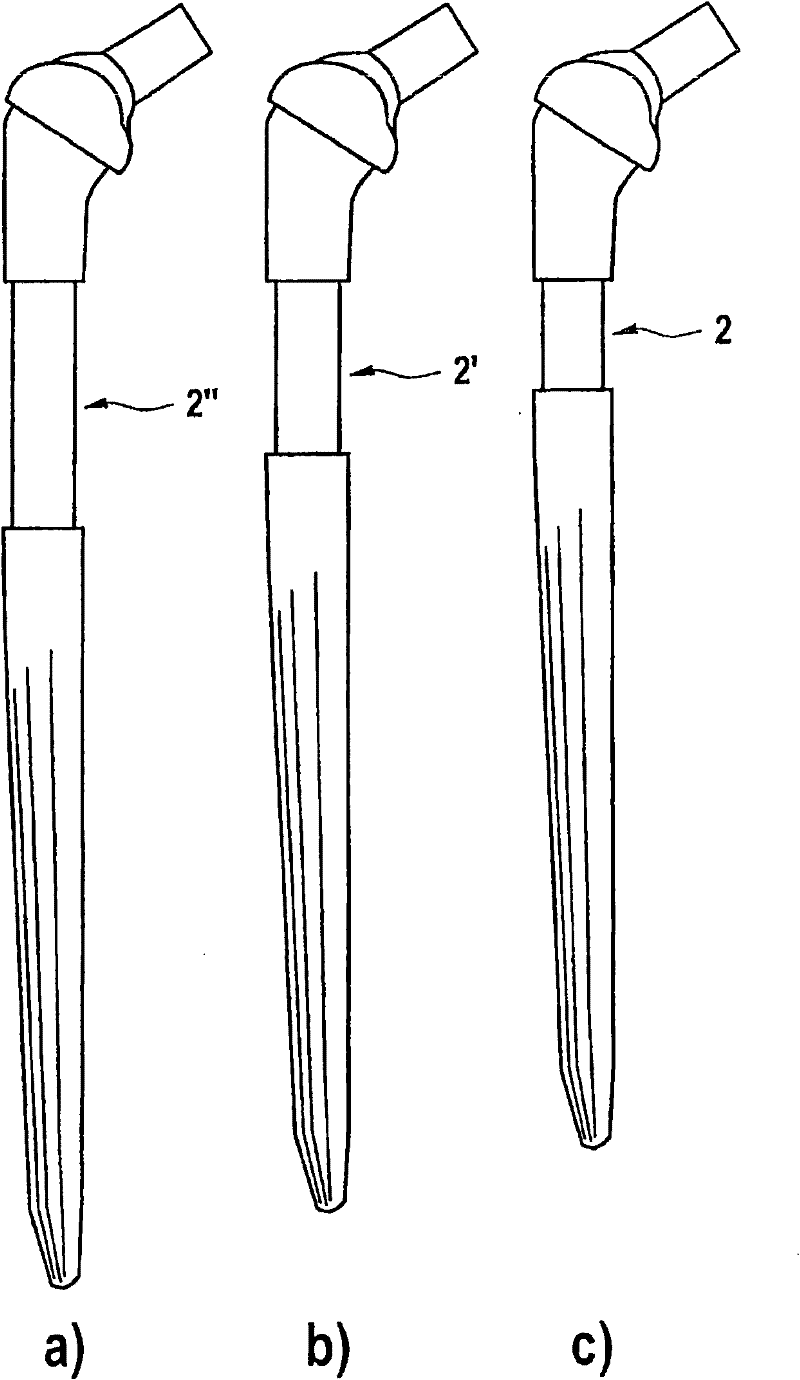

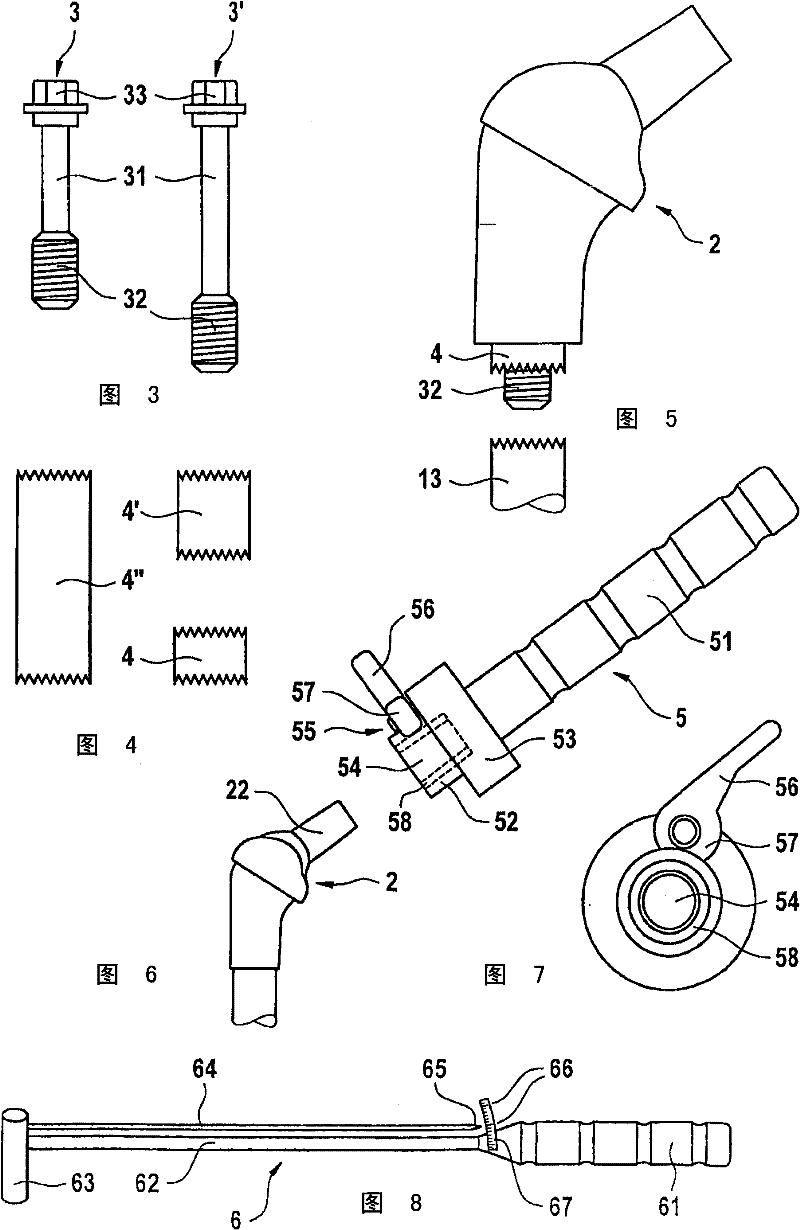

Modular femur-head prosthesis

InactiveCN102056572AImprove connection securityReduce the number of piecesJoint implantsFemoral headsProsthesisLeft femoral head

The invention relates to a modular femur-head prosthesis comprising a shaft part (1) for inserting into a medullary opening of a femur and a neck part (2) comprising a receiving surface (25), said neck part being fixed to a supporting surface (15) in the end region of the shaft part (1) by means of a screw element (3). According to the invention, at least one separate intermediate ring (4) is provided, said ring being situated between the supporting surface (15) of the shaft part (1) and the receiving surface (25) of the neck part (2) and being fixed by means of the screw element (3). This allows femur head-prostheses of differing sizes to be made available by a simple substitution of a component and allows the operating surgeon to also adapt the length of the prosthesis to solve problems that are discovered intraoperatively.

Owner:WALDEMAR LINK GMBH & CO

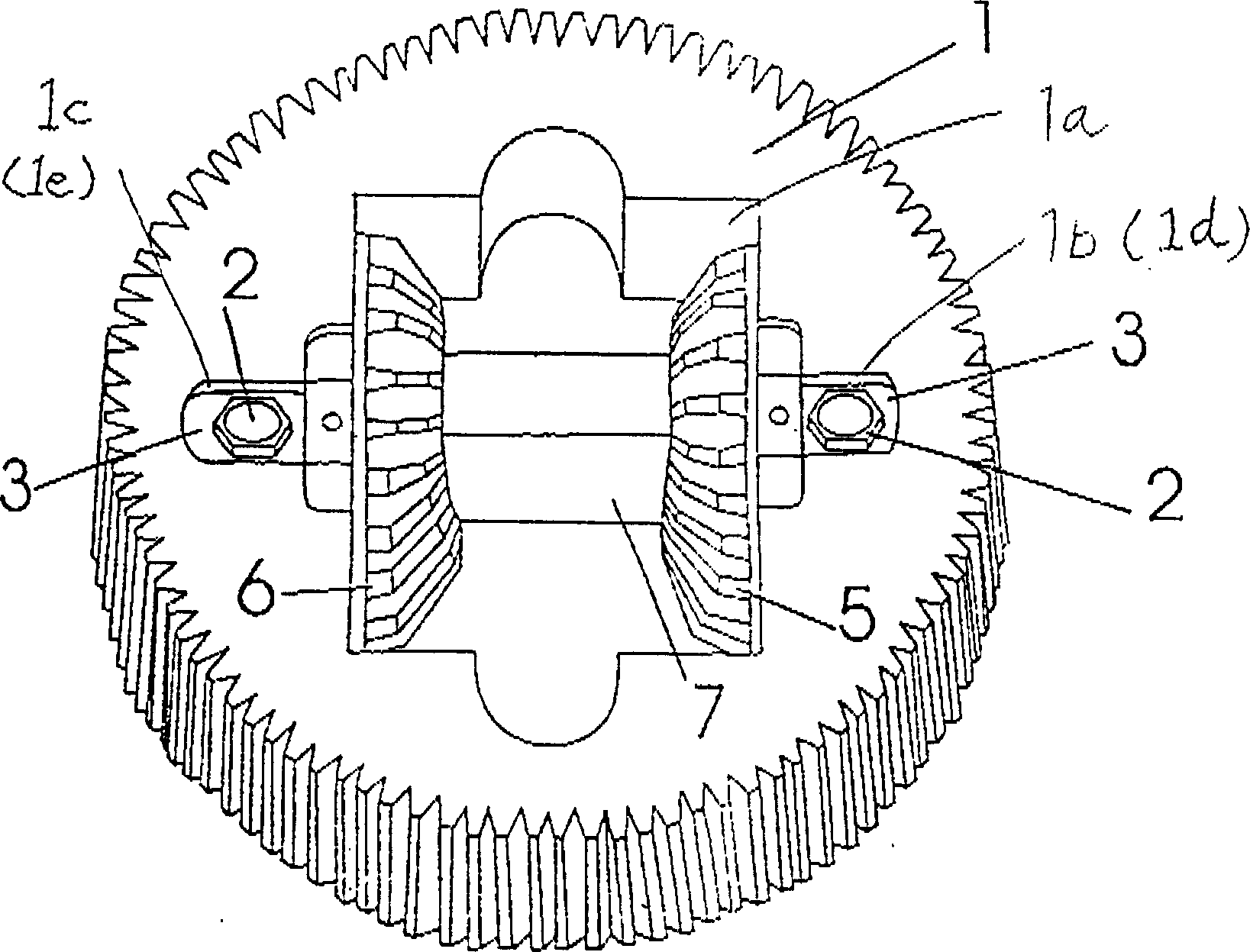

Manufacturing process of differential gear

A method of manufacturing a differential gear comprises, adapting external toothings with thick steel tubes, casting the thick steel tube, the cast aluminium part, two axles of two differential bevelwheels integrally by the cast aluminum method to drive the germule of a gearwheel, then installing and fixing the first pair of differential bevel wheels into the axis; flanges of covers of the rightand left bevel wheels supporting the second pair of differential bevel wheels, are engaged with concaves on two sides of the gearwheels, to drive the gearwheels, two pairs of differential bevel wheels, covers of the right and left bevel wheels, the right and left axles. By the invention, a differential gear could be accurately fixed in the center line, and two axles after assembling wouldn't produce noise and swing, which improves great the quality of the differential gear.

Owner:陈李烨

Welding flux for soldering and soldering paste composition

InactiveCN101138816AQuality improvementImprove wettabilityWelding/cutting media/materialsSoldering mediaClasses of metalsOxygen

A soldering flux contains a base resin and an activating agent. The soldering flux contains, as the activating agent, an oxygen-containing heterocyclic compound having at least one carboxyl group in a molecule. A solder paste composition contains the abovementioned soldering flux and the solder alloy powder. These enable exhibition of excellent wettability to lead-free metals and plating, irrespective of the type of the metals.

Owner:DENSO CORP +1

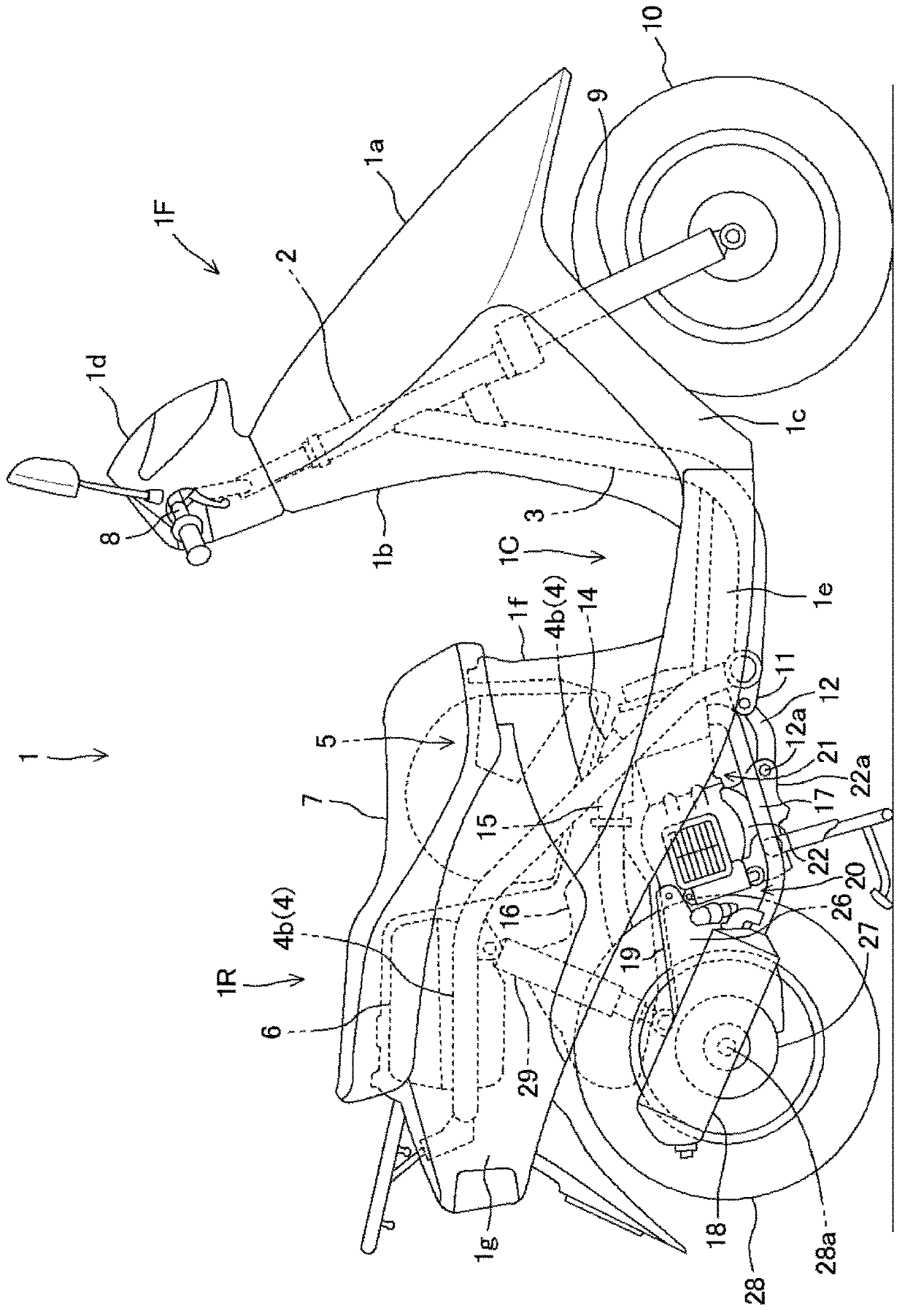

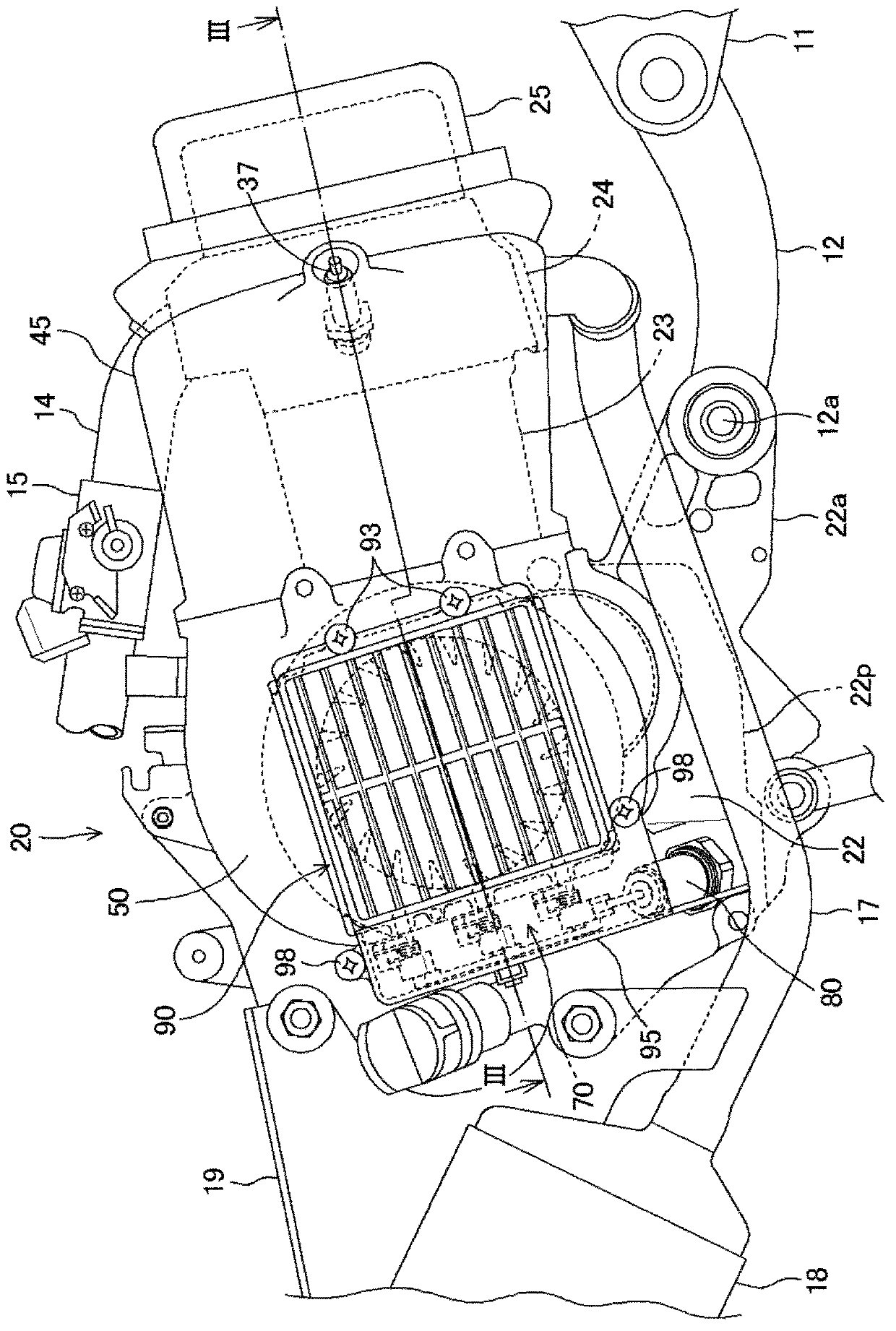

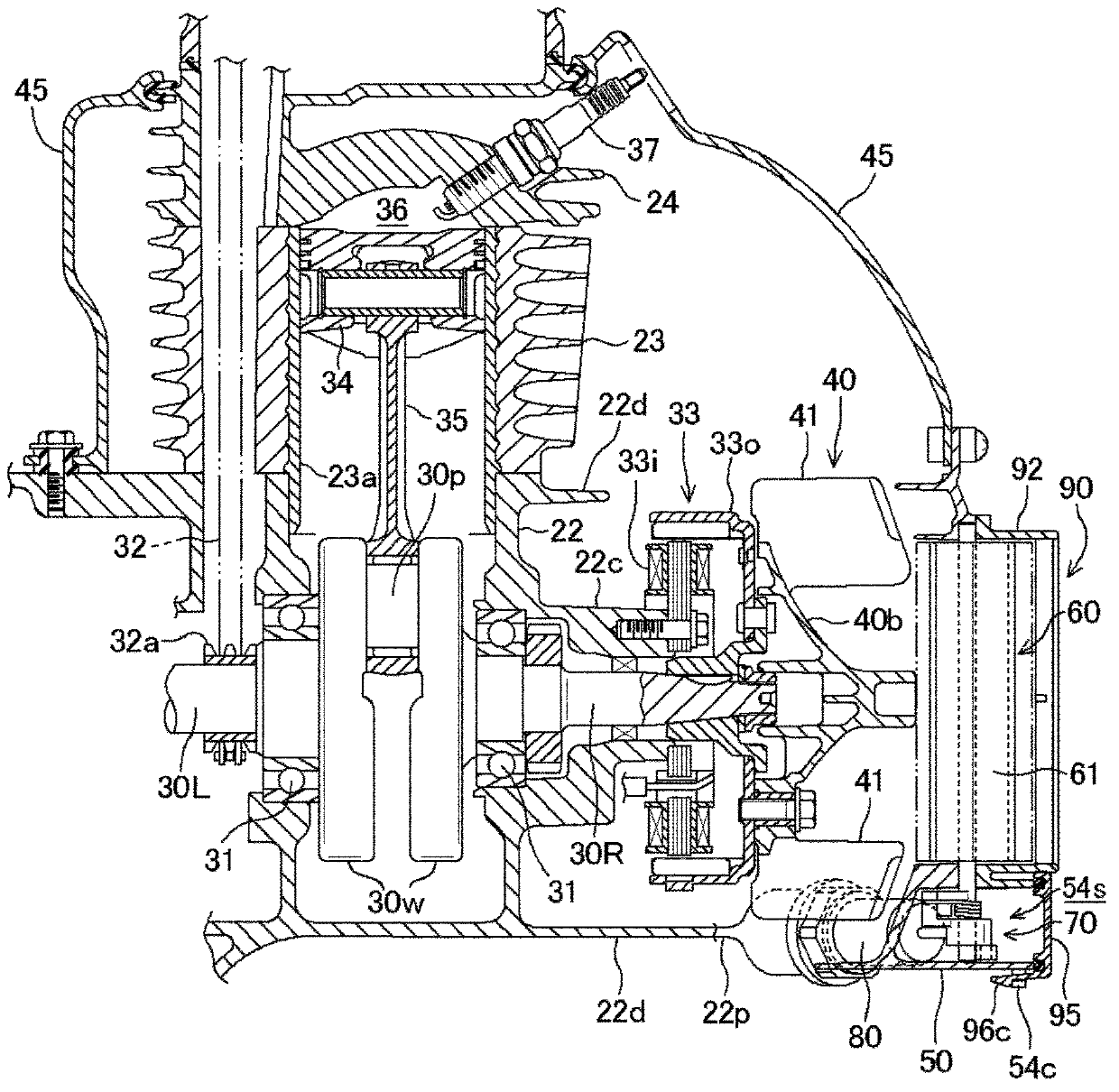

Cooling device for internal combustion engine

ActiveCN102996219APromote warm-upClose fullyCoolant flow controlMachines/enginesBlade plateExternal combustion engine

The present invention provides a cooling device for an internal combustion engine, capable of blocking gaps formed at a peripheral part of a blade plate to fully block a cooling air inlet when a movable blind window closes the cooling air inlet of a fan housing, so as to facilitate a heating machine during cold start. In the cooling device for the internal combustion engine having the movable blind window (60) capable of opening or closing the cooling air inlet (53) of the fan housing (50), housing side step parts (56u, 56l, 57u, 57l) are formed along an opening rim of the cooling air inlet (53) of the fan housing (50), blind window side step parts (61id, 61od) opposite to the housing side step parts (56u, 56l, 57u, 57l) are formed at the peripheral part of the blade plate (61) of the movable blind window (60), the blind window side step parts (61id, 61od) and the housing side step parts (56u, 56l, 57u, 57l) are abutted and superposed when the cooling air inlet (53) is closed through rotation of the blade plate (61).

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com