Patents

Literature

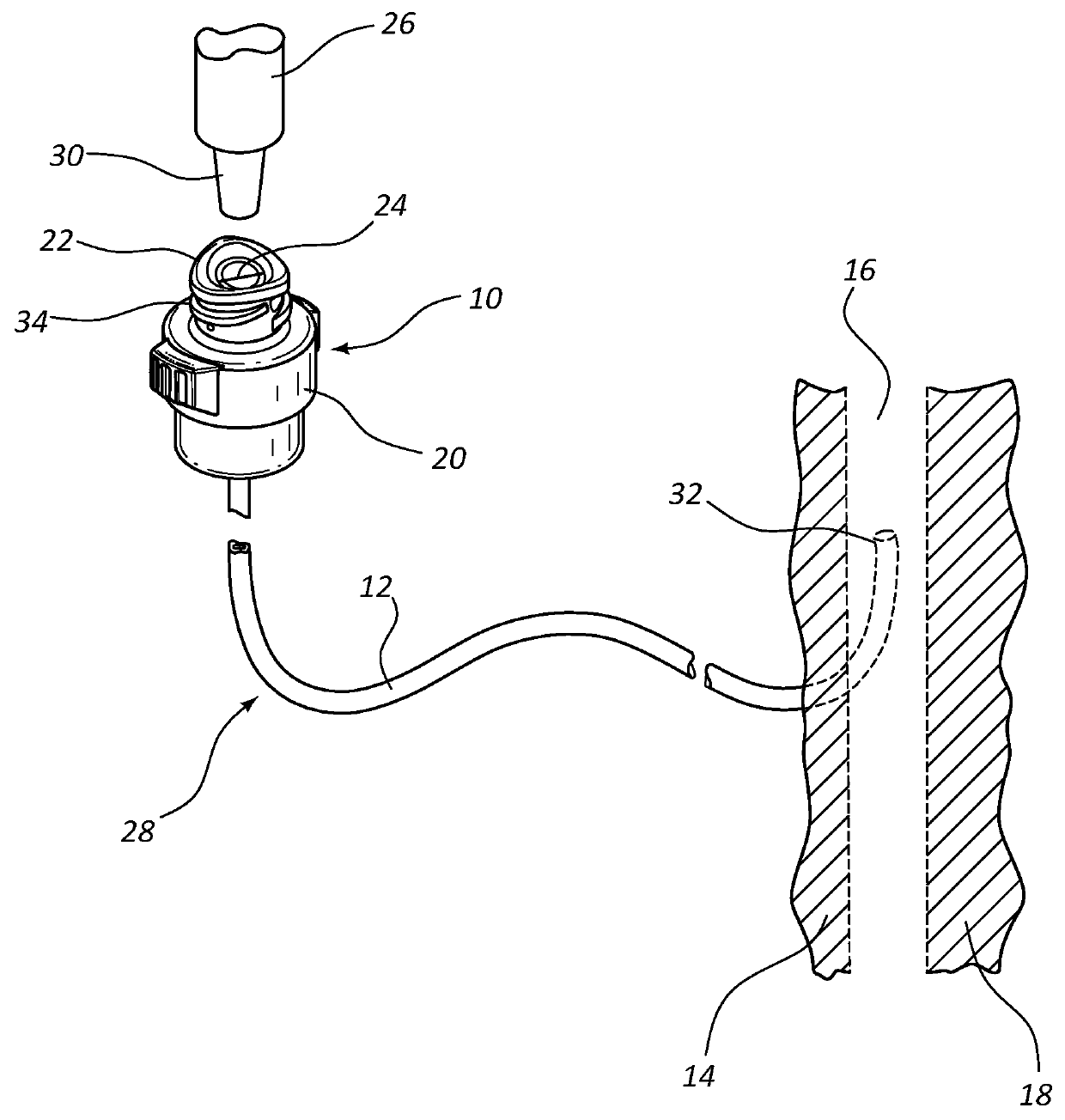

137results about How to "Improve connection security" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

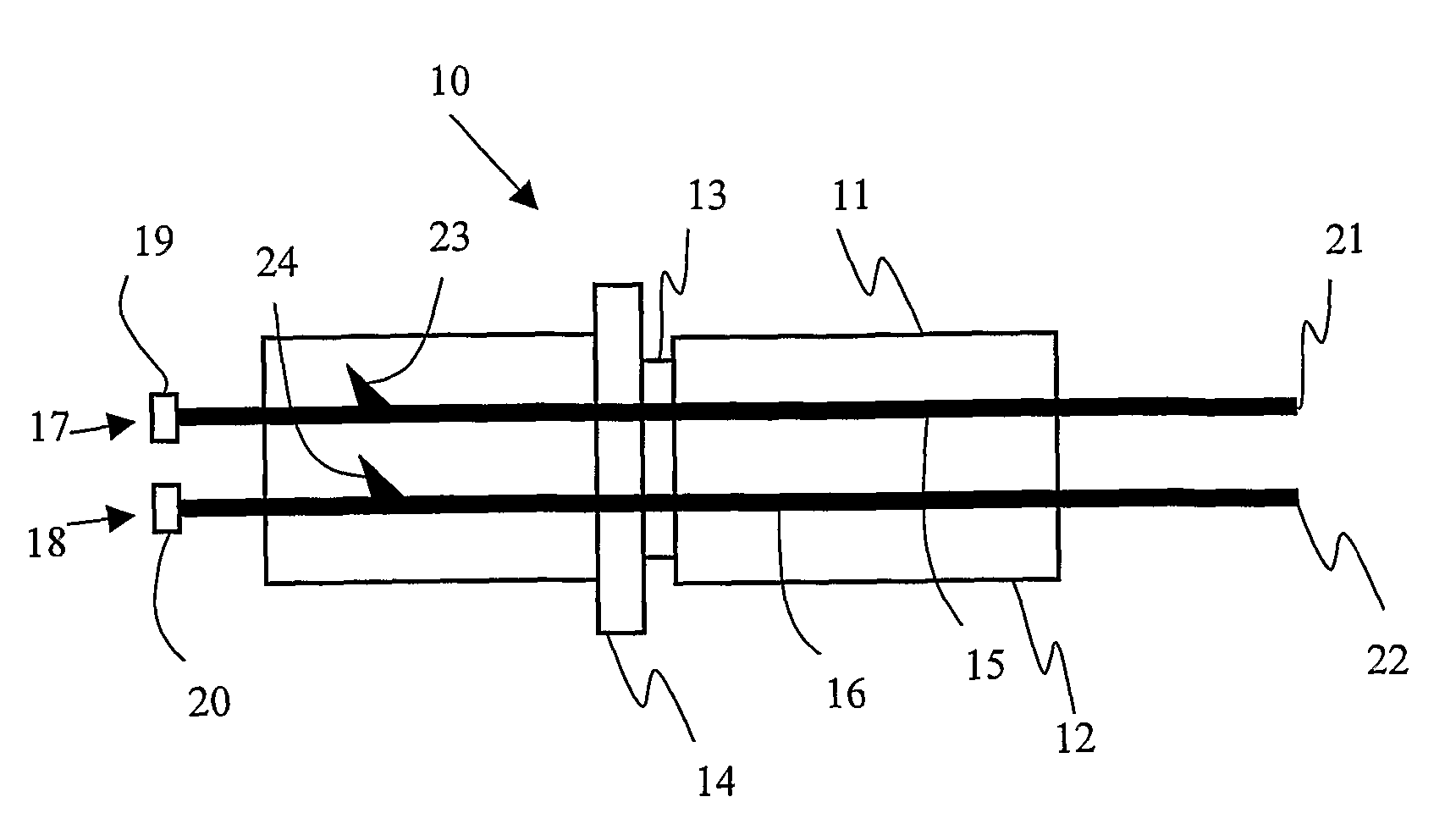

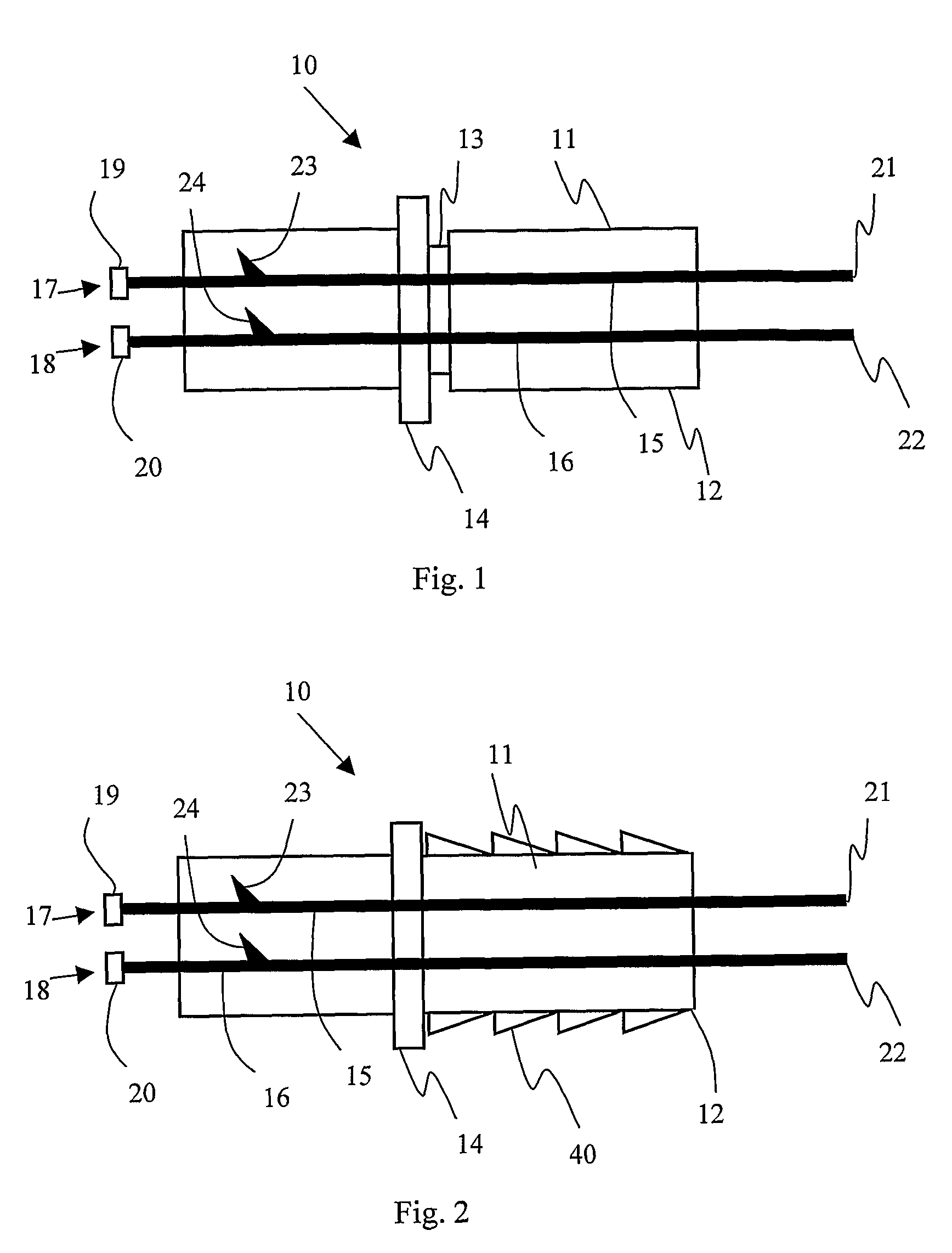

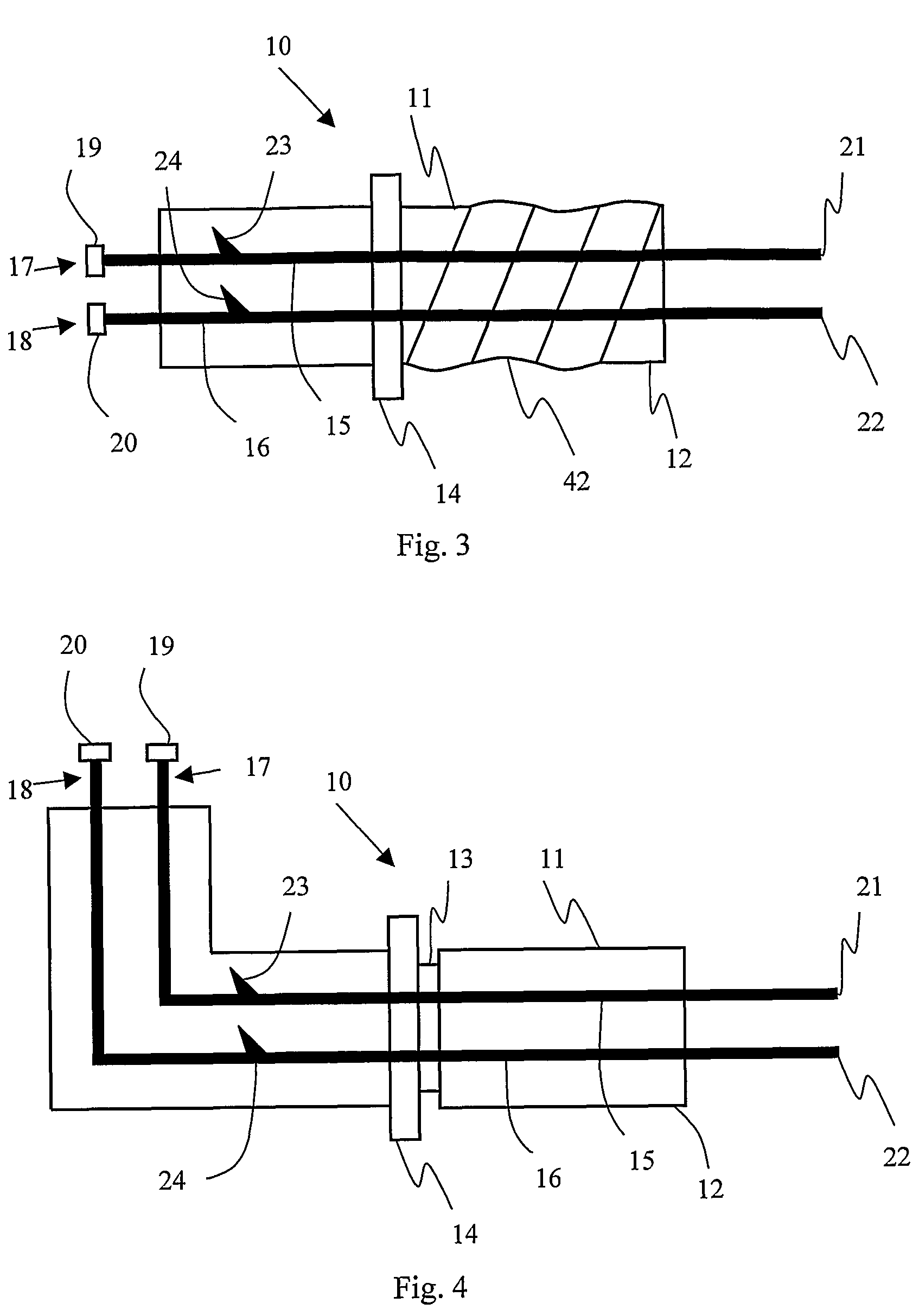

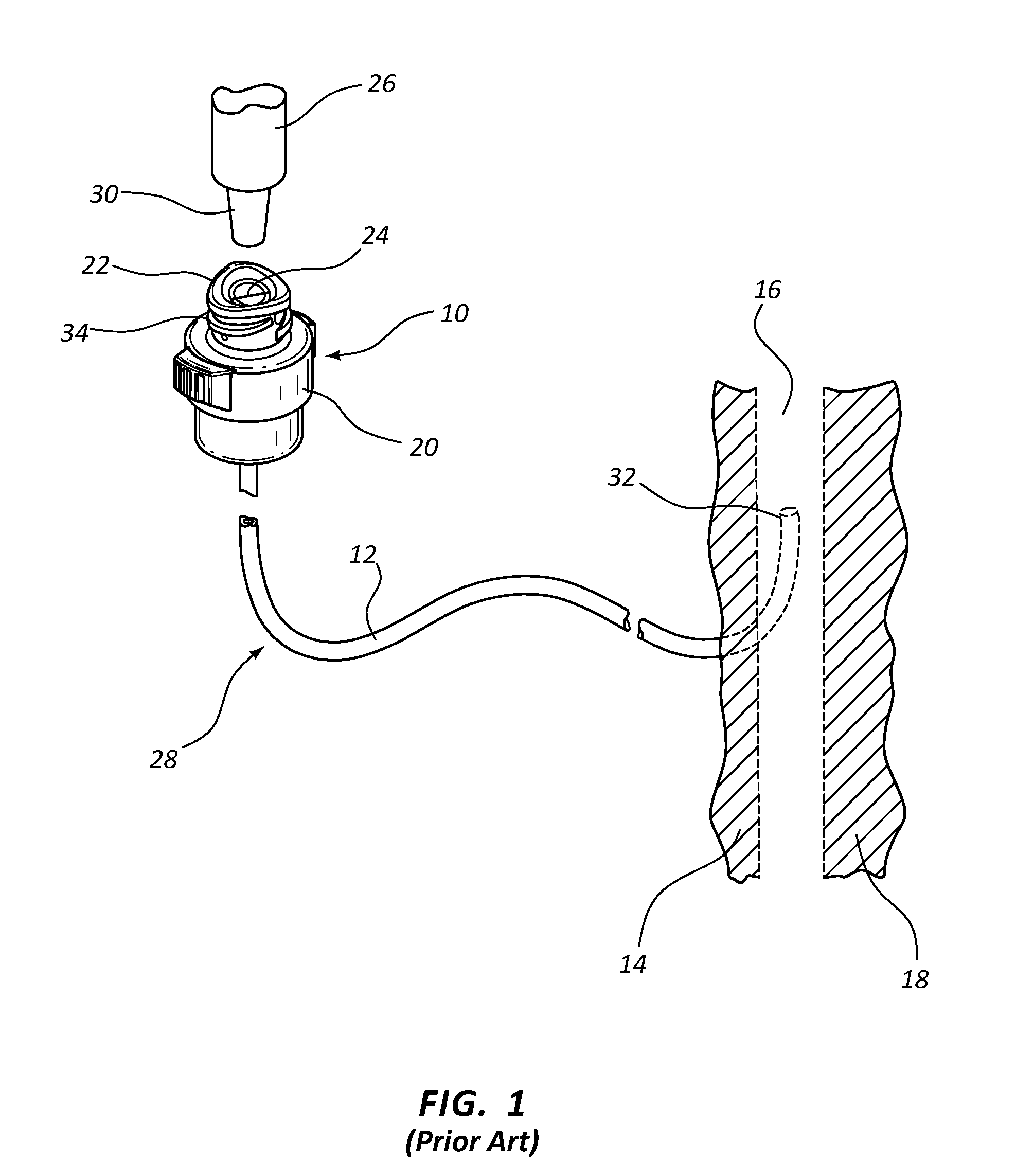

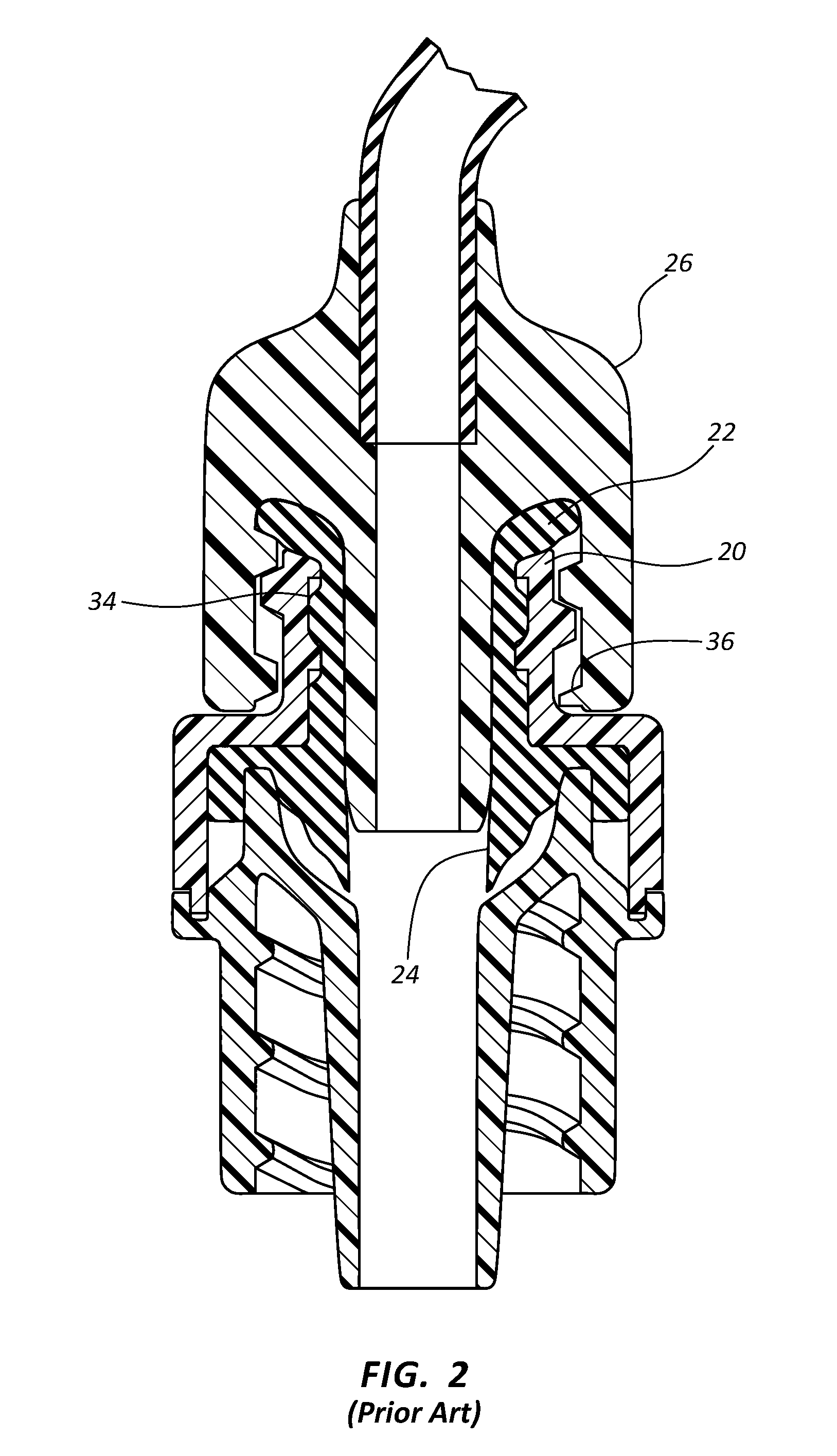

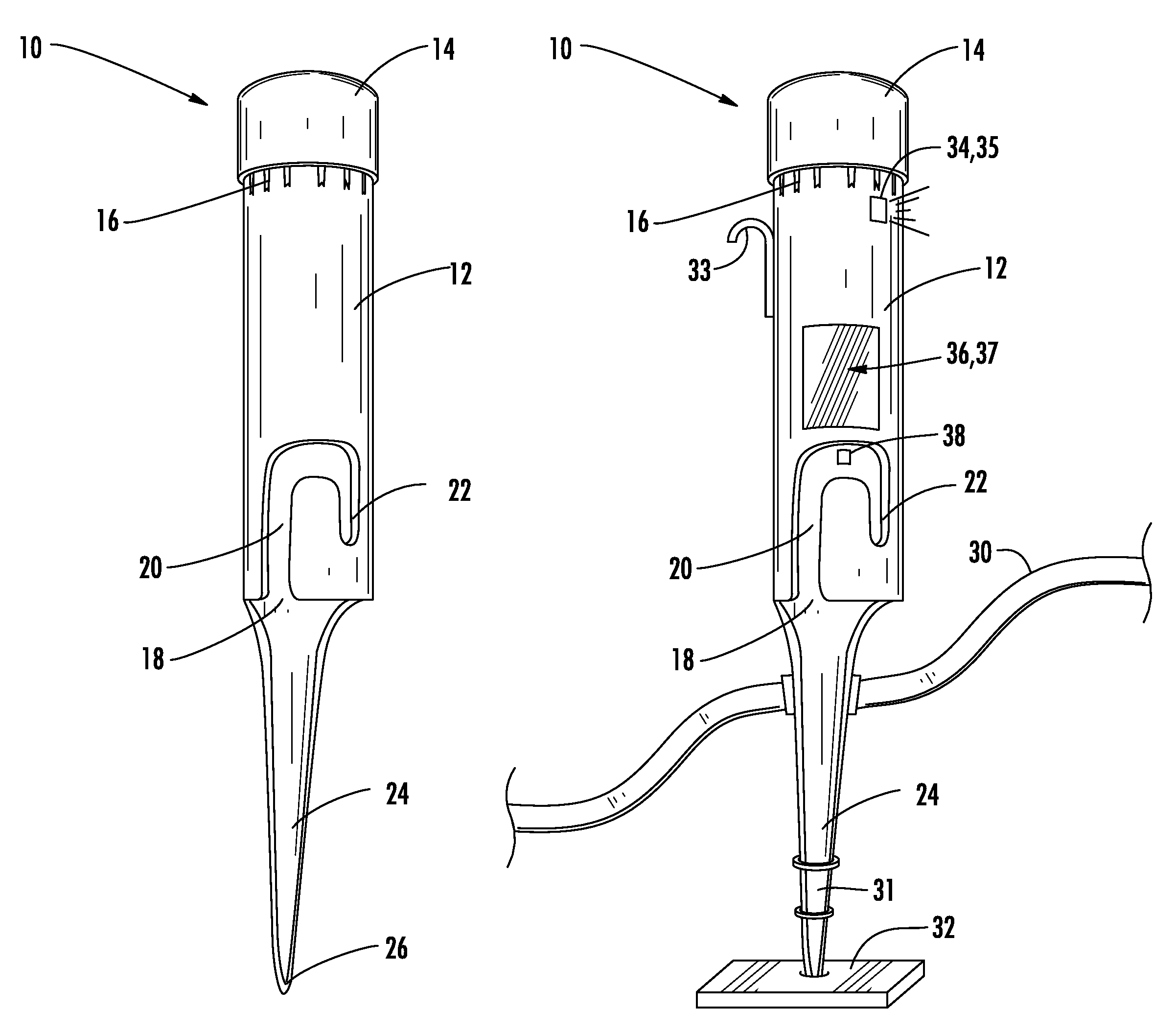

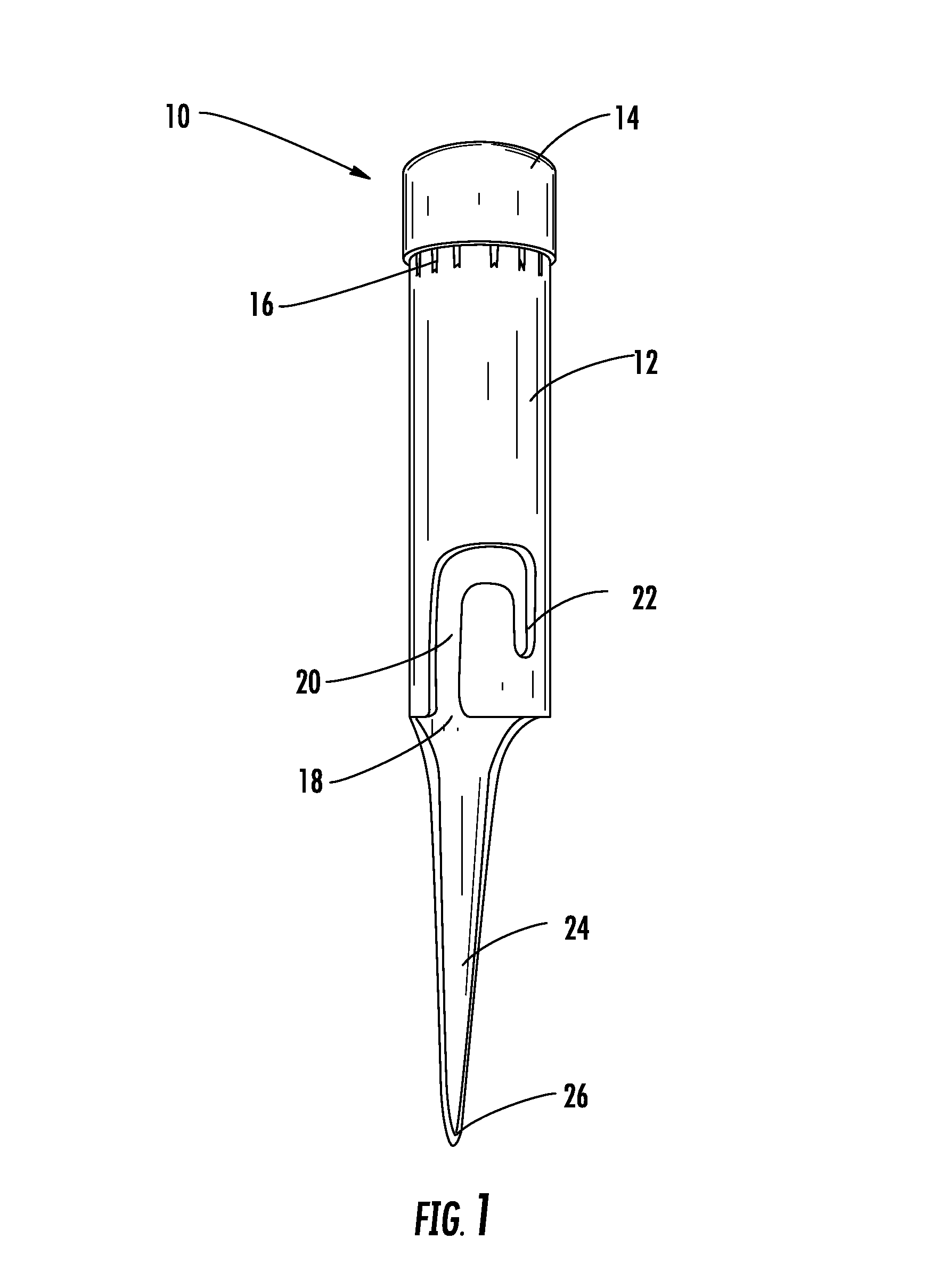

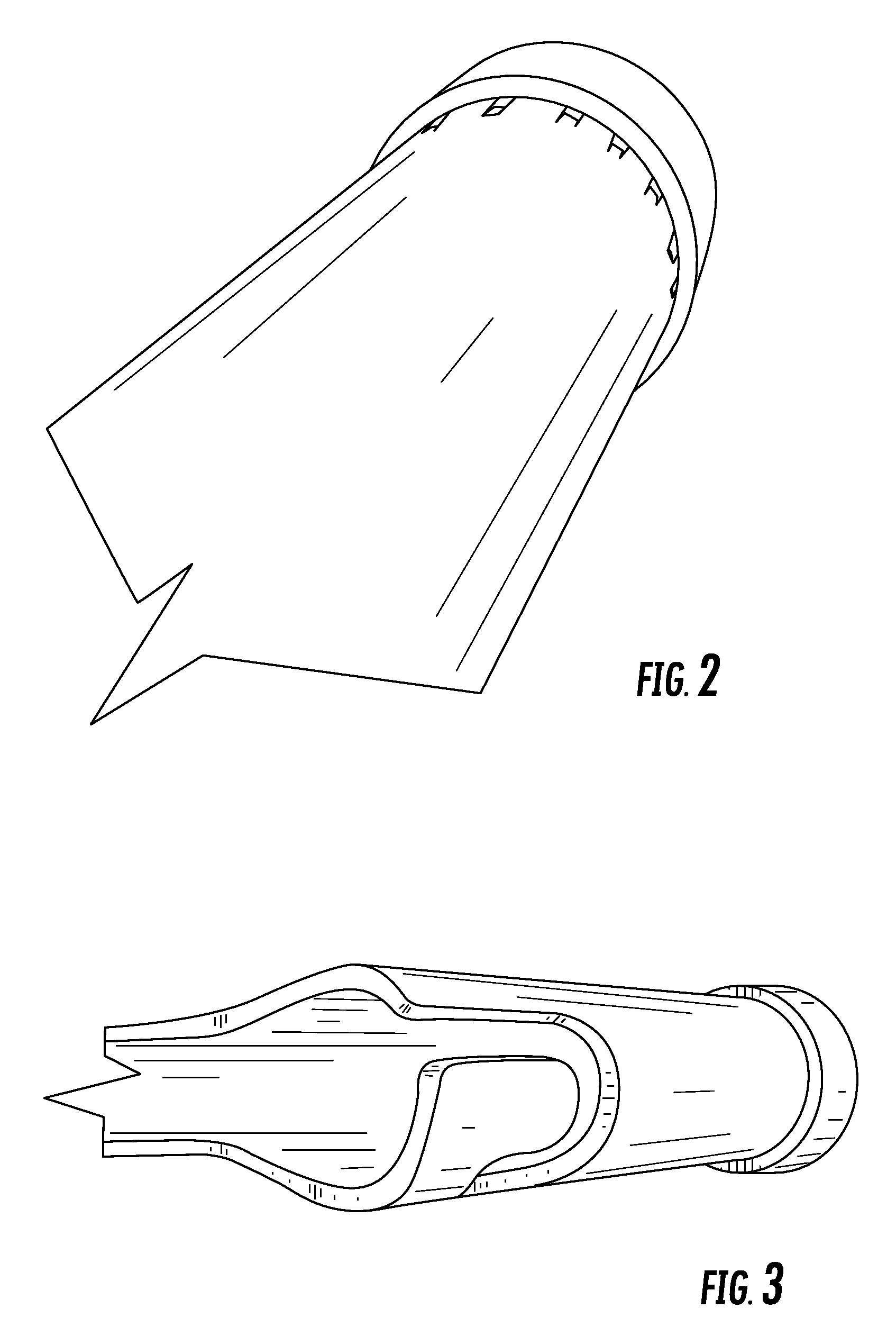

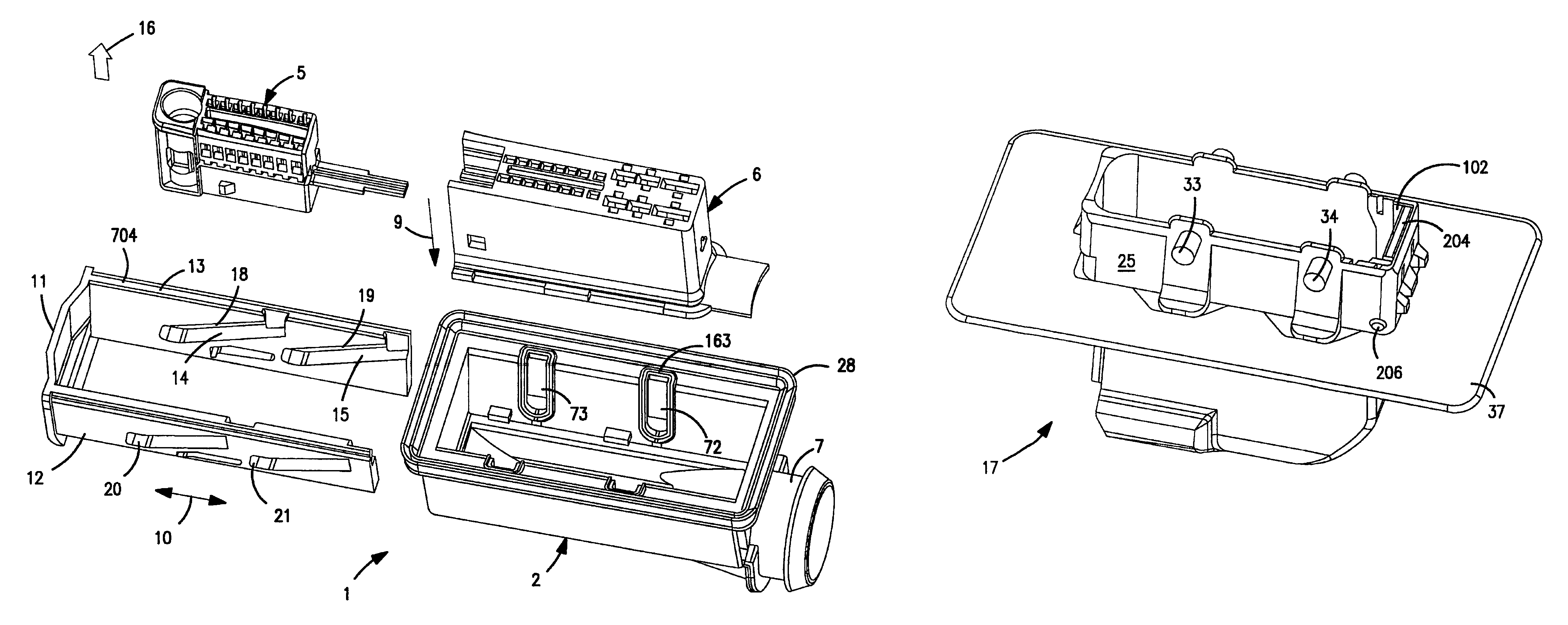

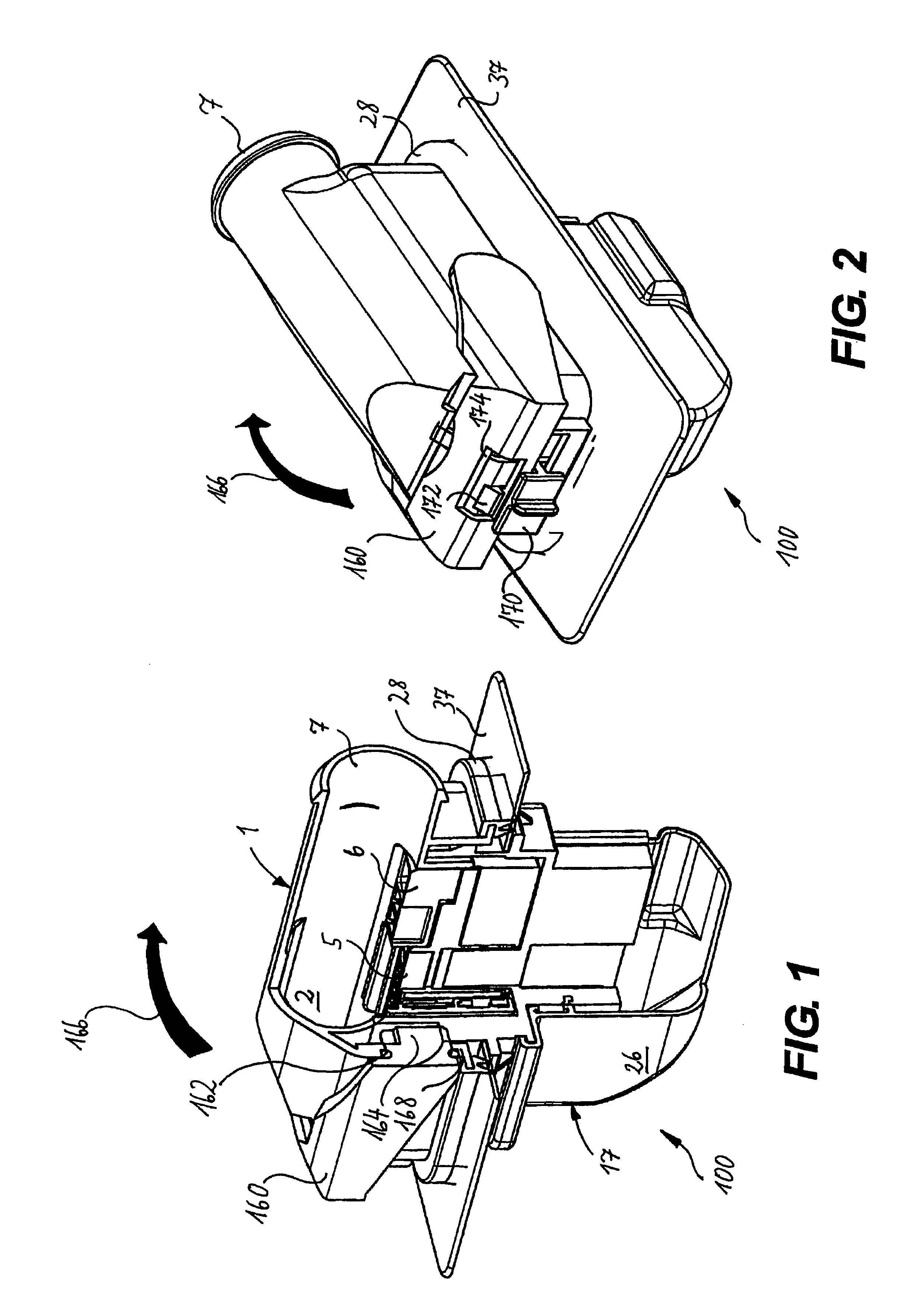

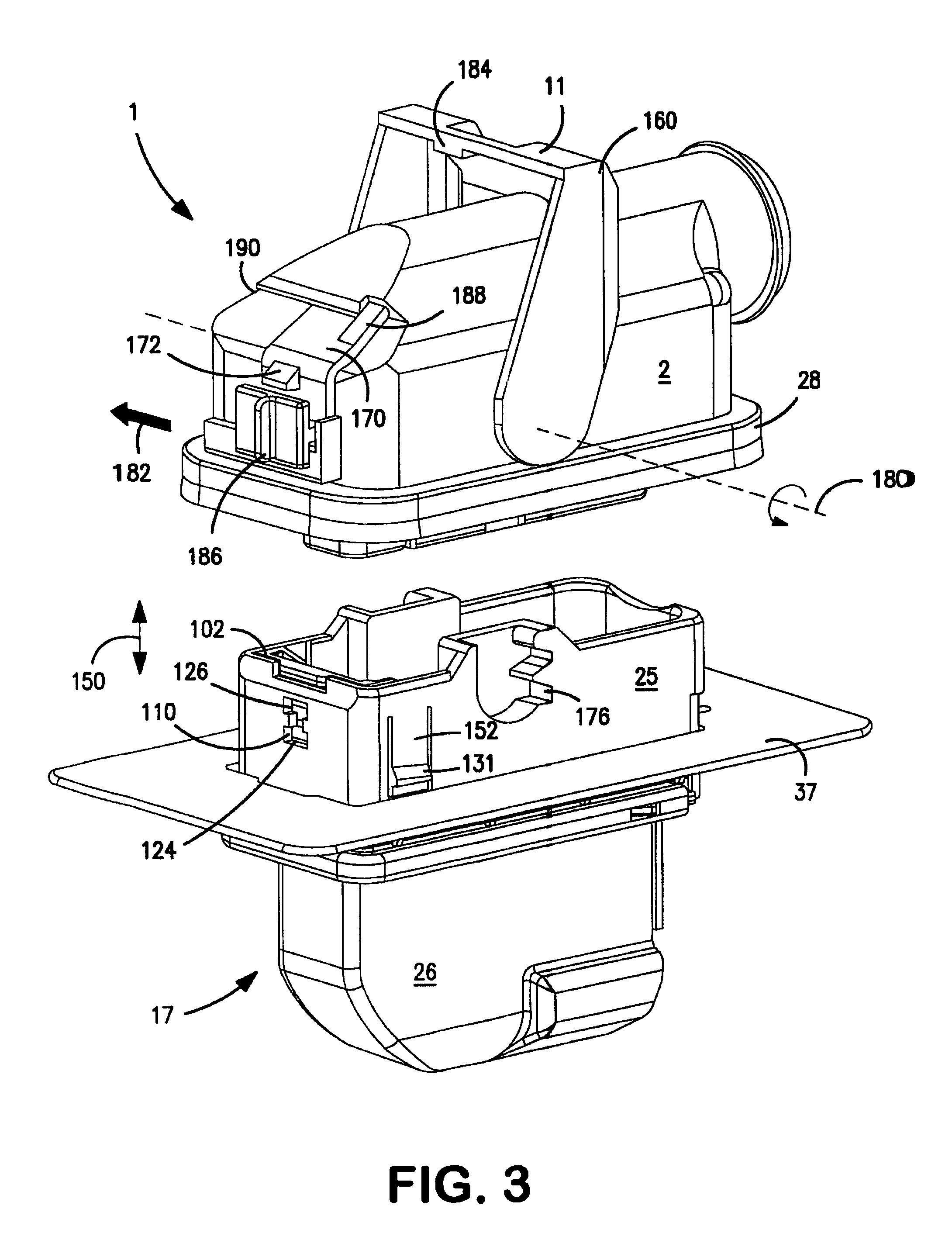

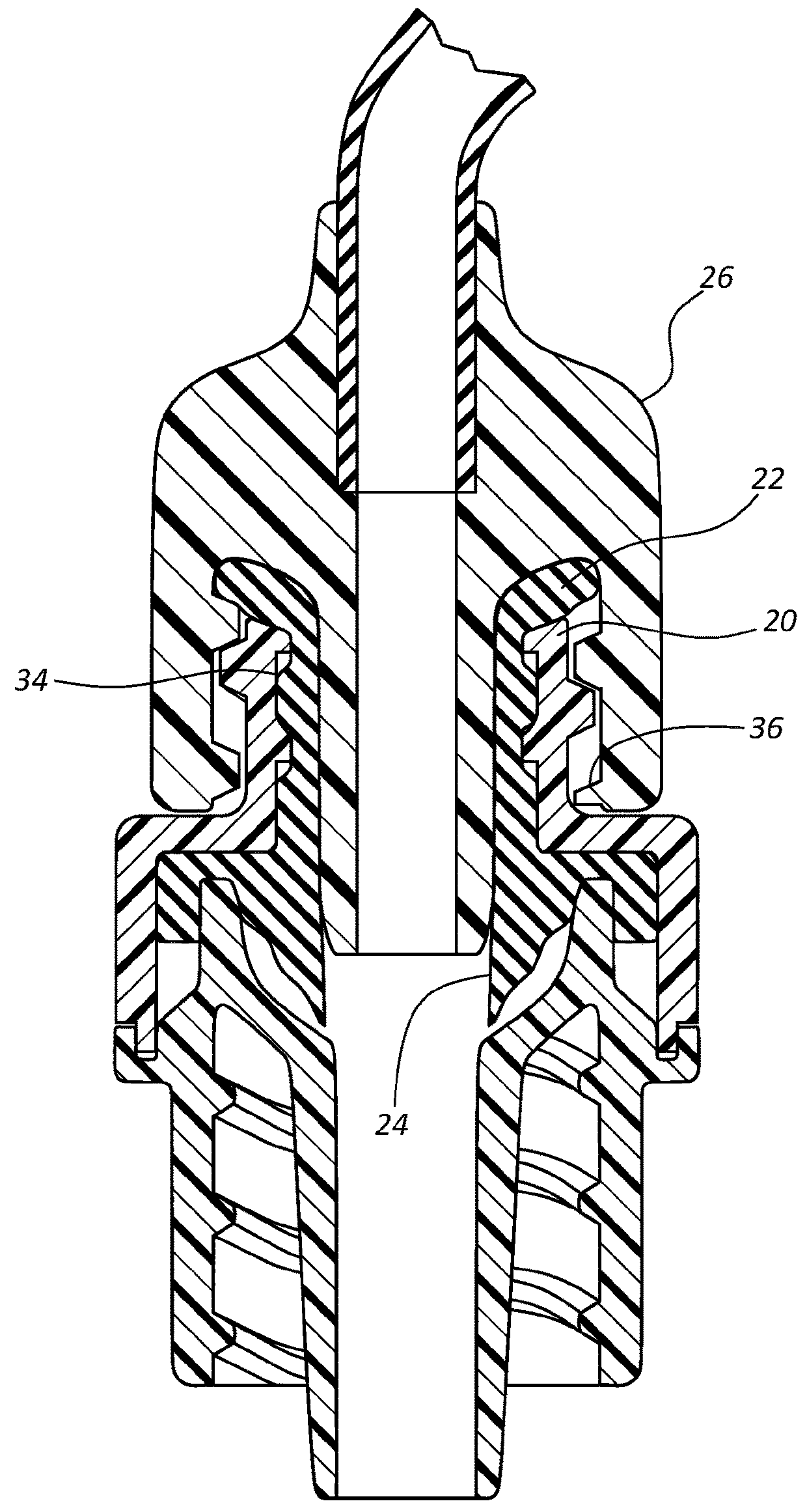

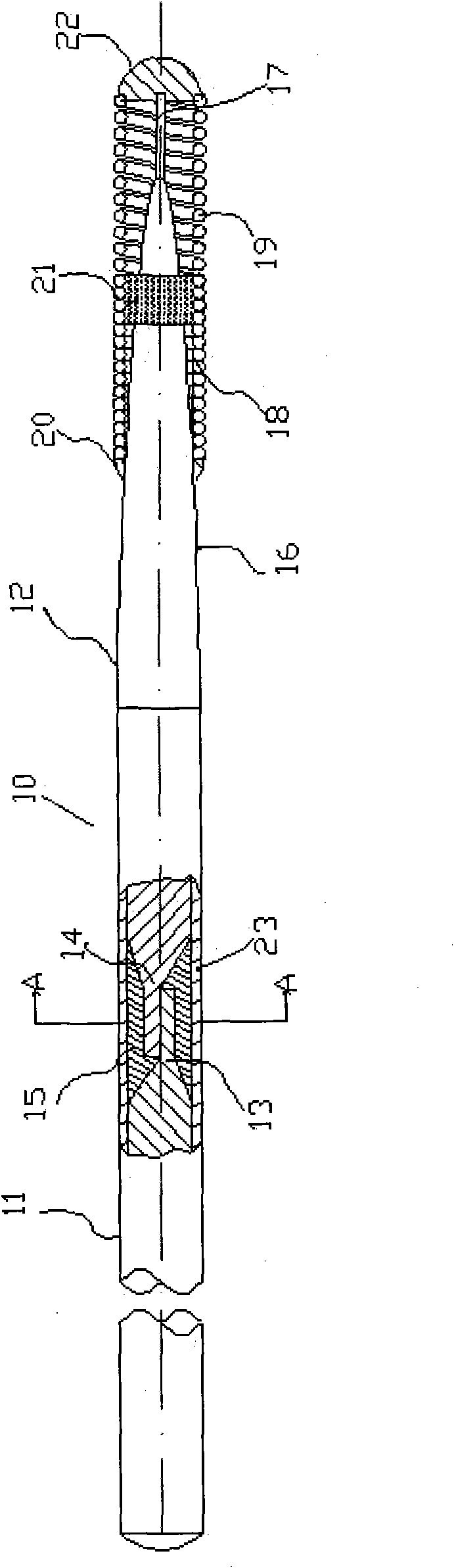

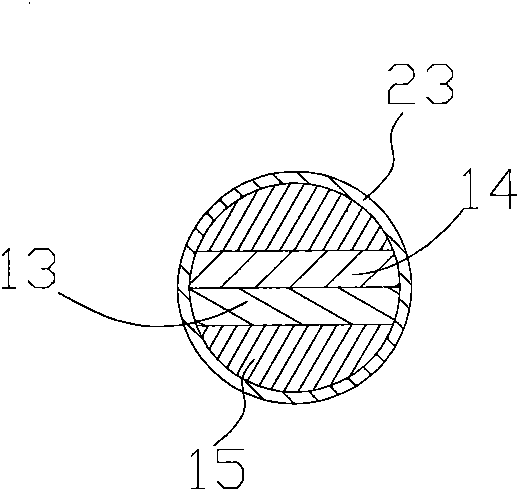

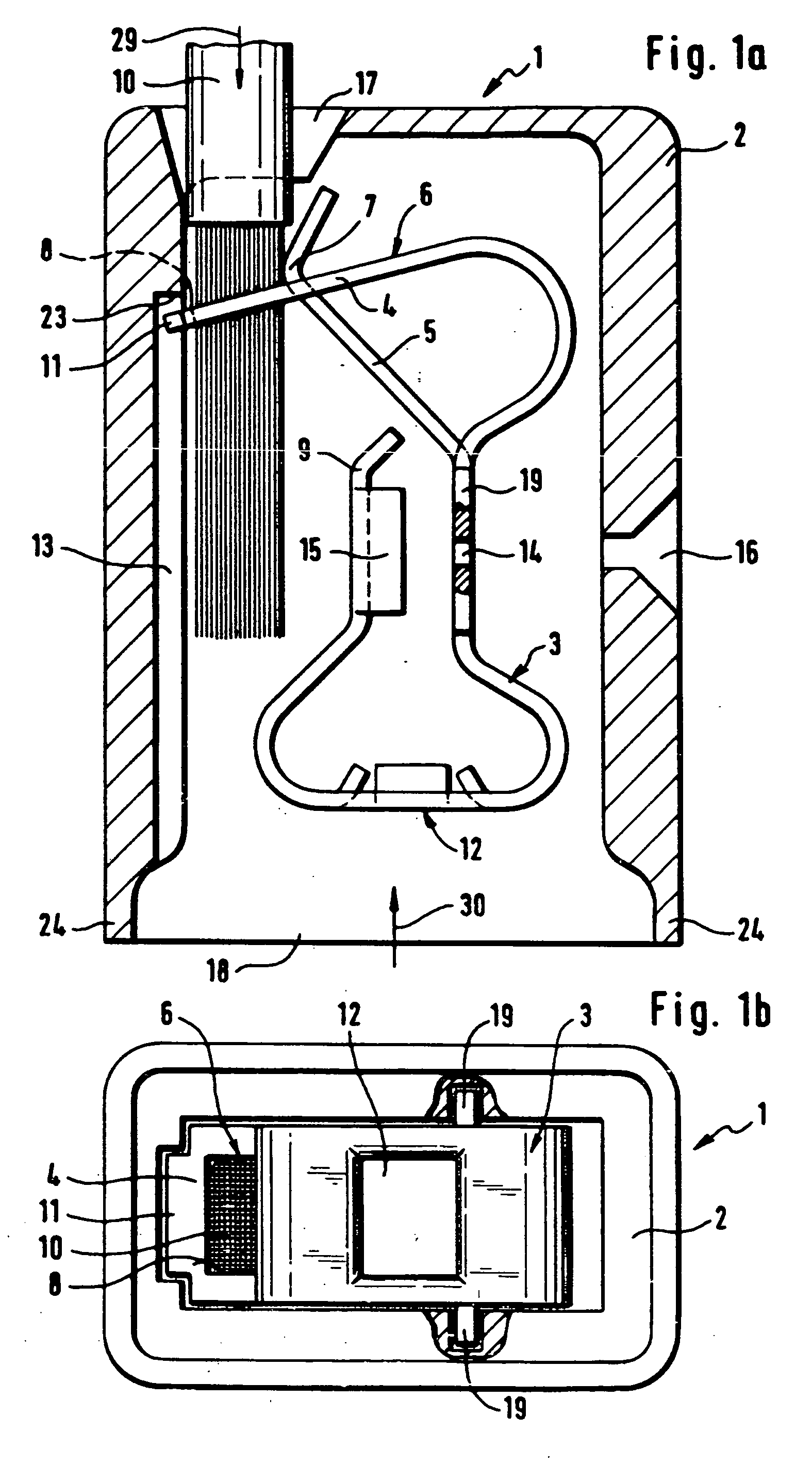

Connector for electronic detonators

ActiveUS8069789B2Avoid unnecessary distractionsImprove connection securityRelieving strain on wire connectionBlasting cartridgesDetonatorElectricity

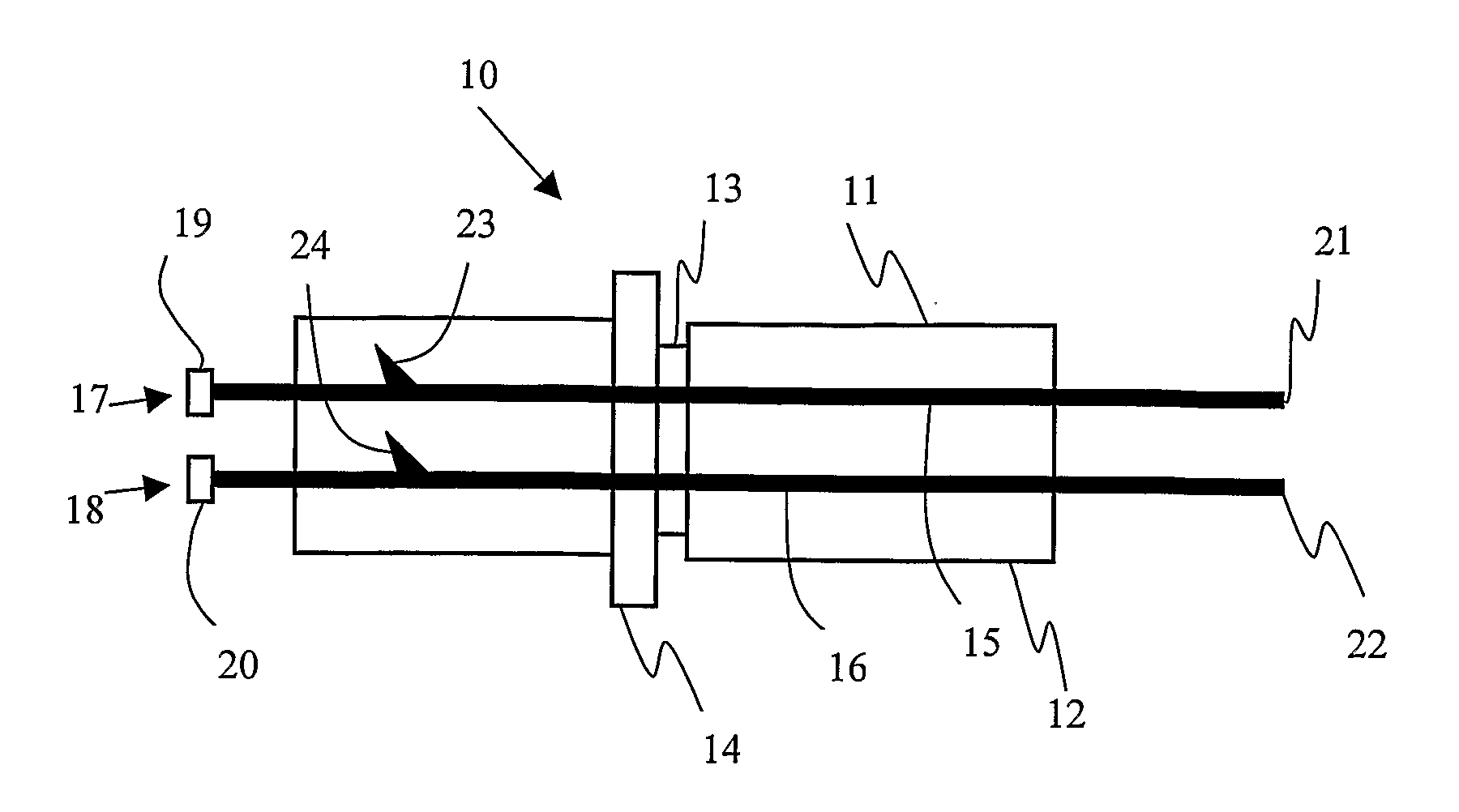

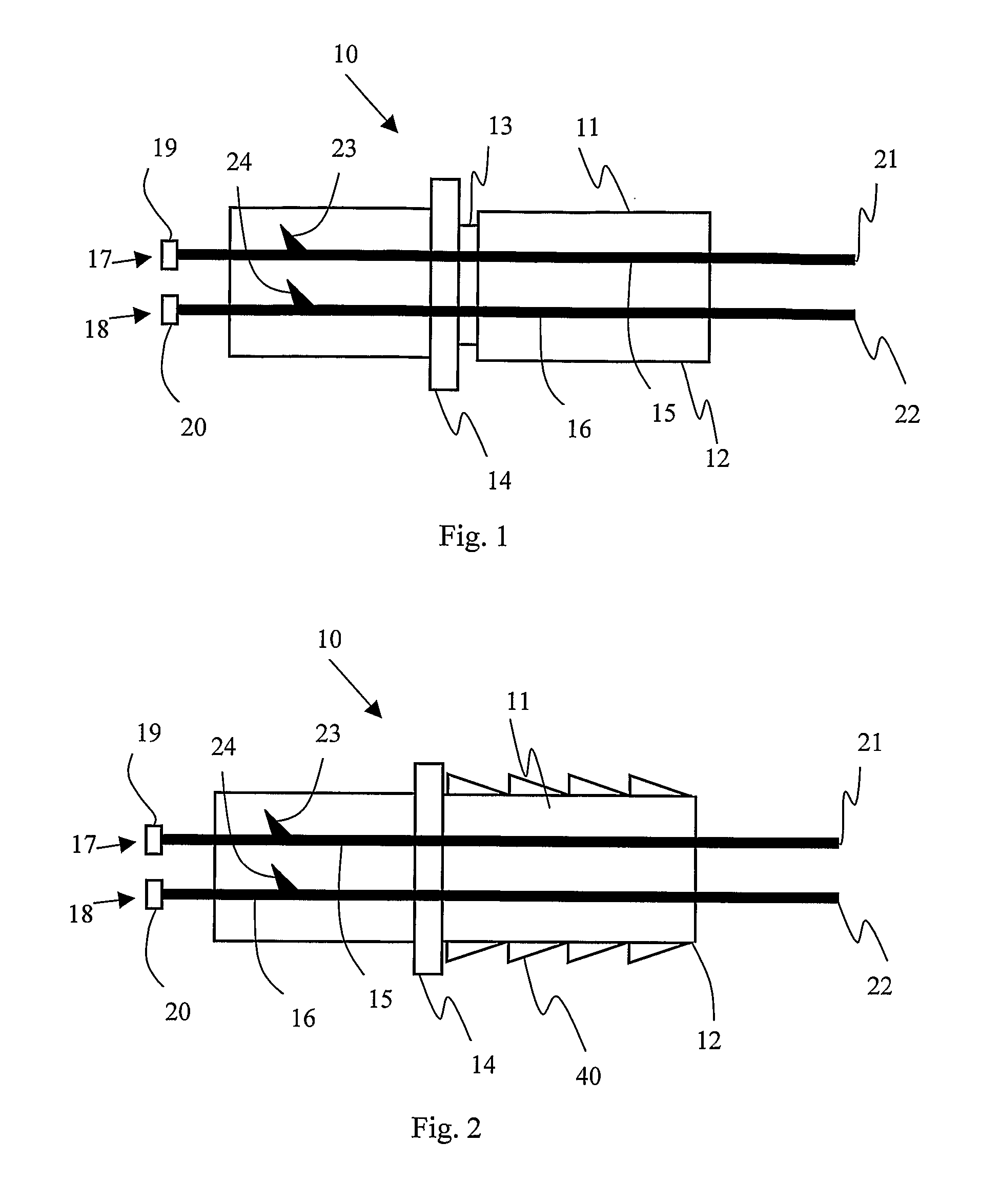

Fire, arm, and disarm signals are typically transmitted to electronic detonators via signal transmission lines. Traditionally, such signal transmission lines include wires wherein one end of each wire is soldered directly to printed circuit boards and / or other signal processing components retained within the shell of a detonator. Other ‘modular’ blasting apparatuses of the prior art provide means to connect signal transmission lines to detonators in the field. Signal transmission line / detonator contacts are susceptible to disruption, particularly when the signal transmission lines are subject to inadvertent tugging or tensile forces at the blast site. The present application discloses an electrical connector that enables secure connection between a signal transmission line and any detonator adapted to receive and optionally process electrical signals from the signal transmission line. Specifically, the electrical connector can be affixed to the signal input end of a detonator, and includes at least one bridge element to provide electrical contact between a signal transmission line, and internal electrical component(s) of the detonator.

Owner:ORICA EXPLOSIVES TECH PTY LTD

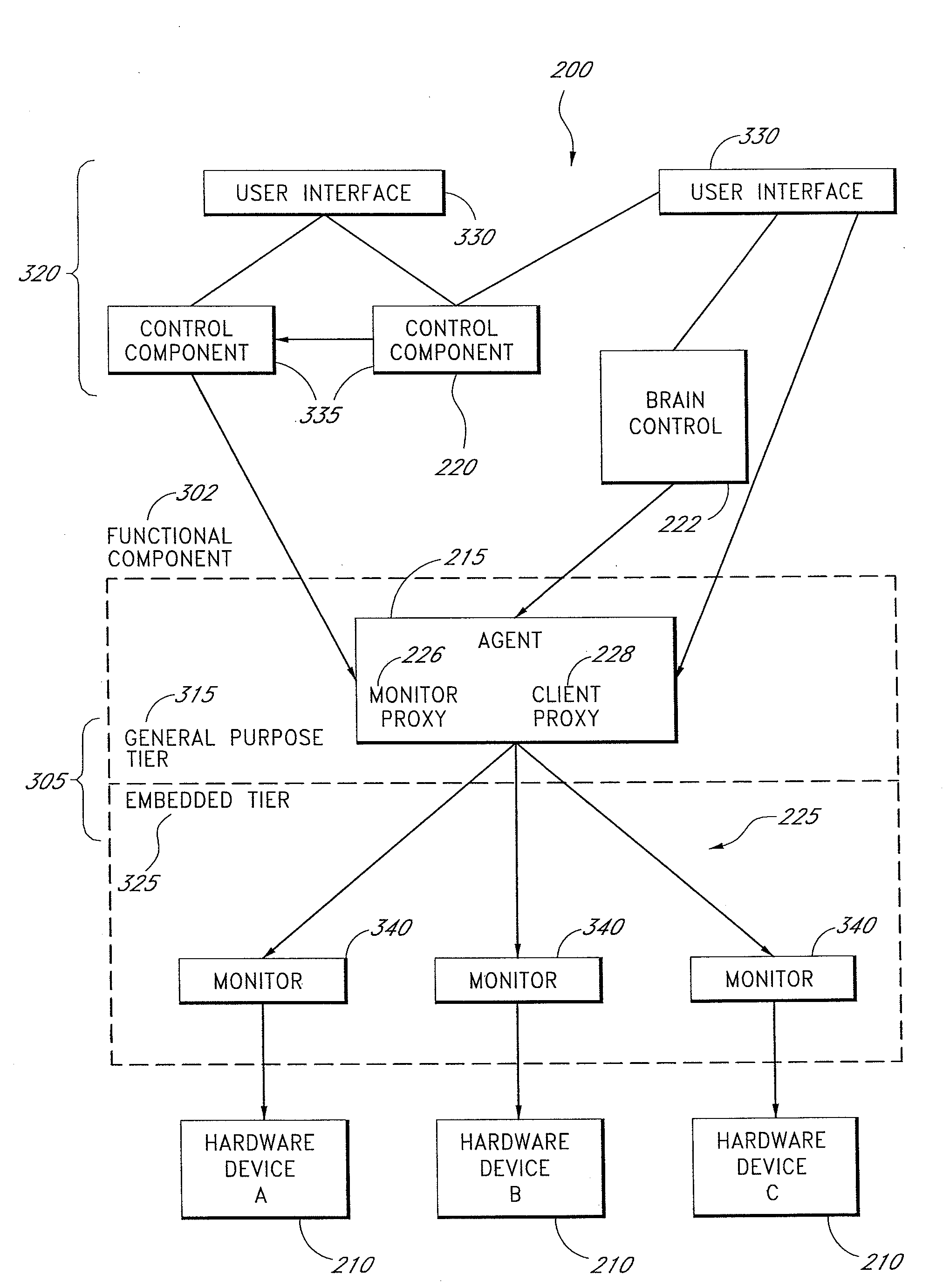

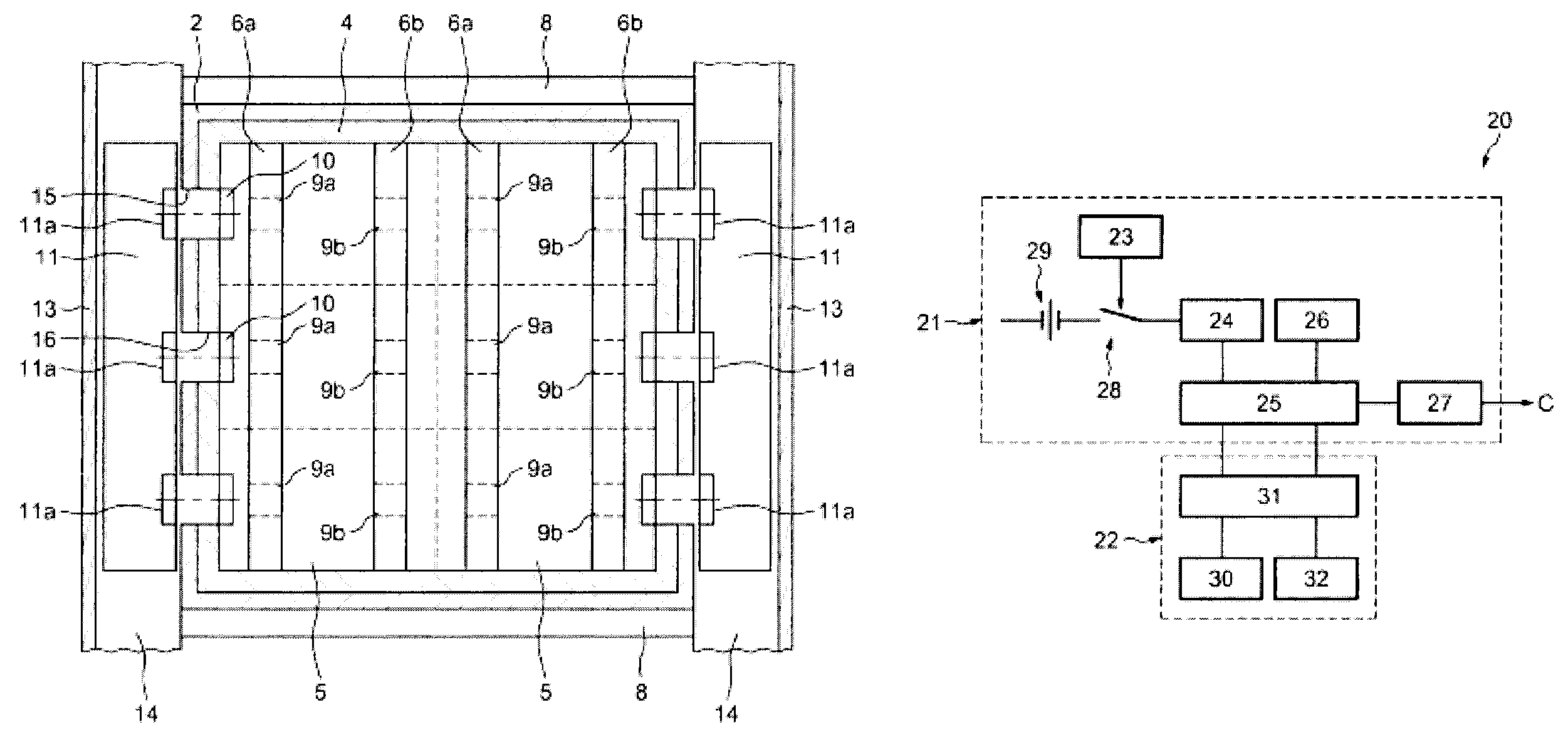

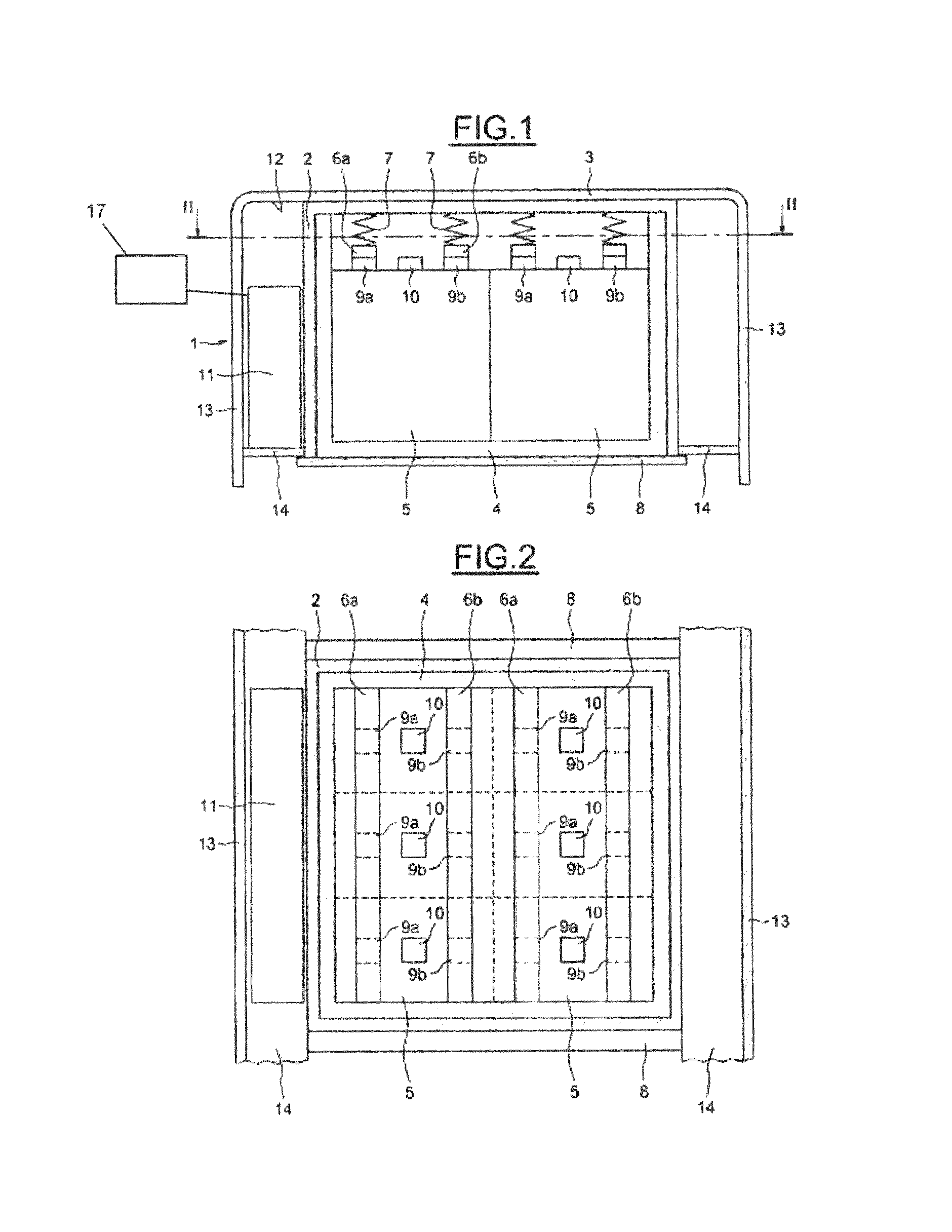

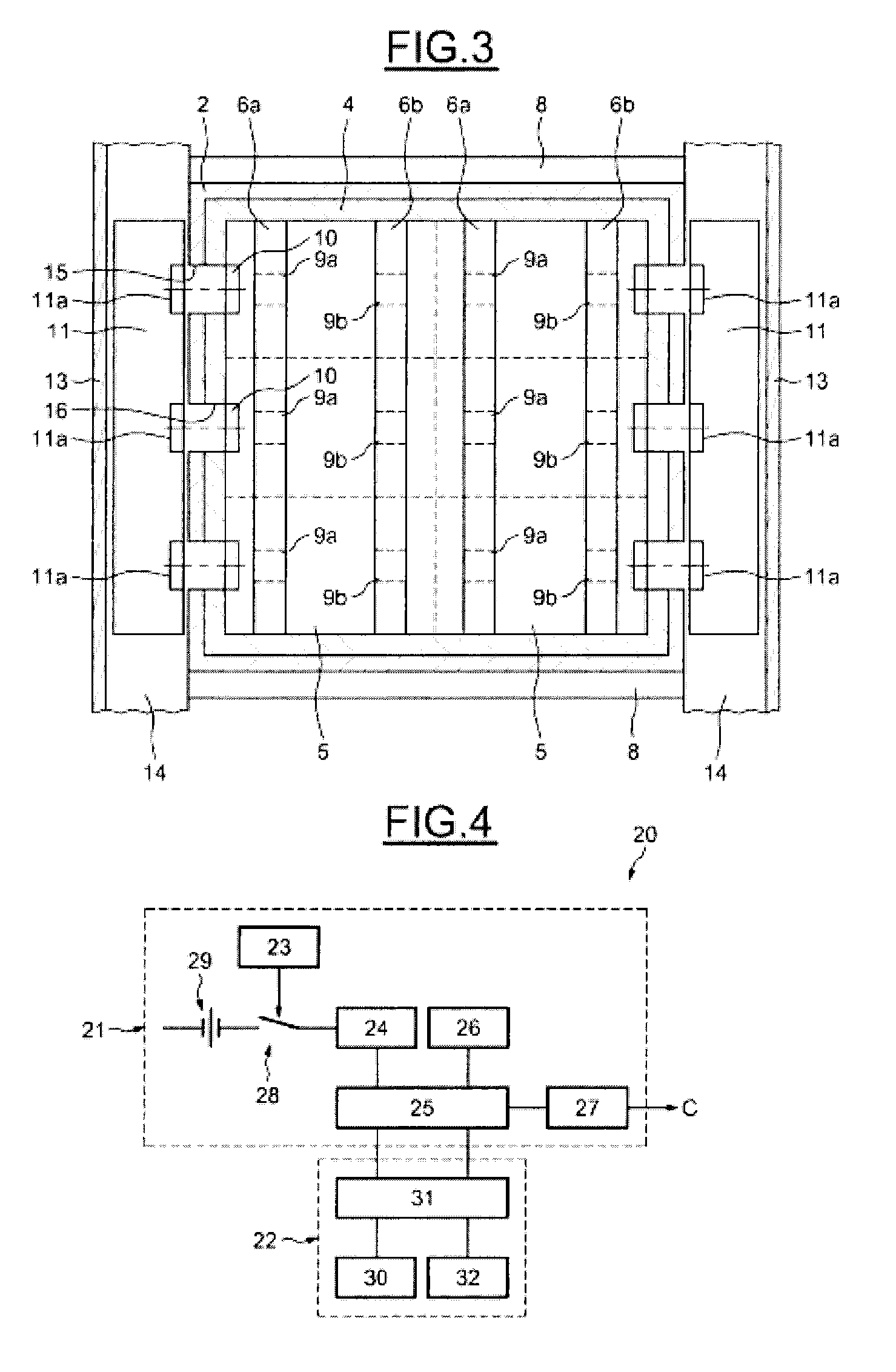

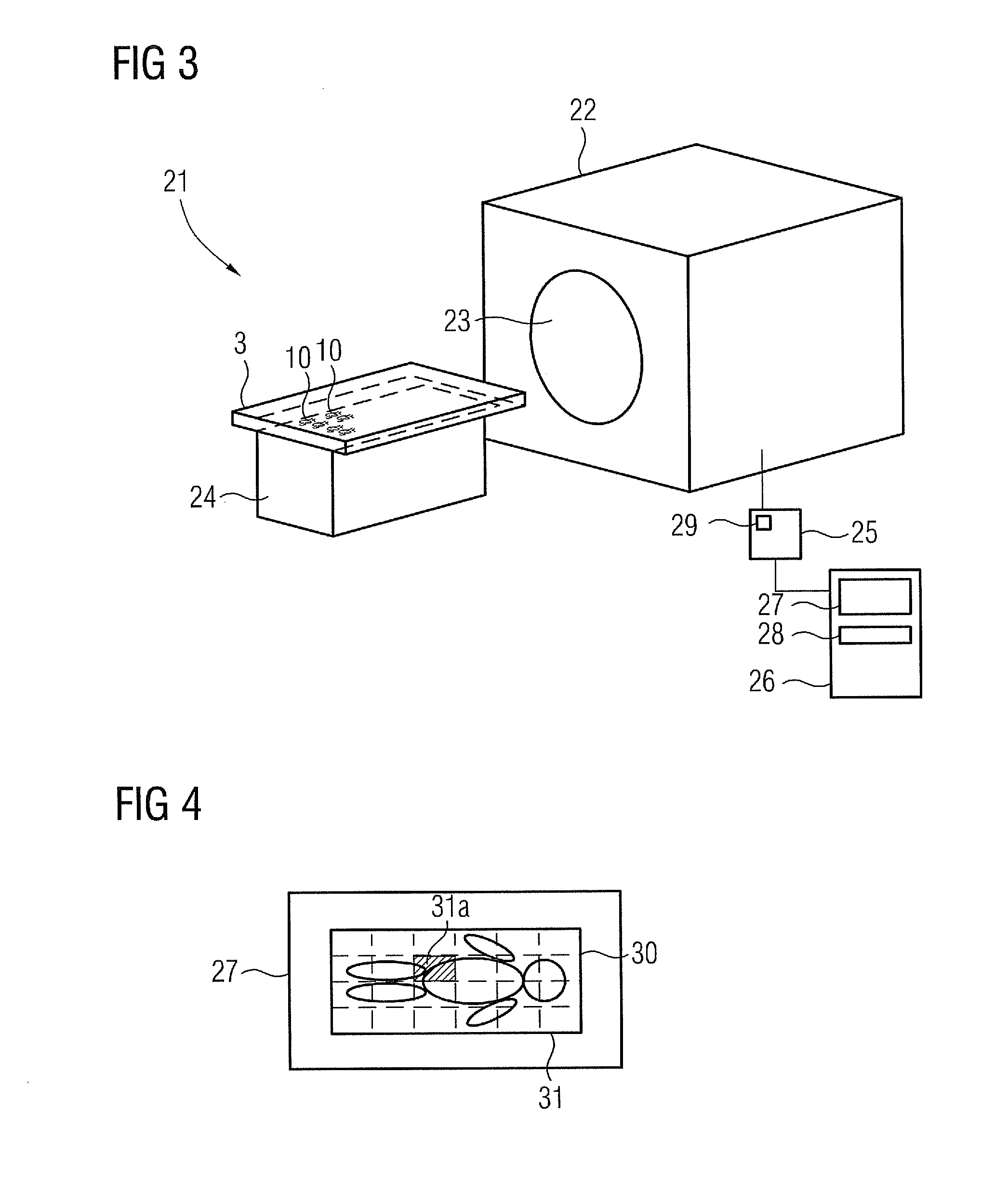

Proton beam therapy control system

InactiveUS20080270517A1Reduce utilizationReduce complexityLocal control/monitoringMultiprogramming arrangementsTraffic capacityControl system

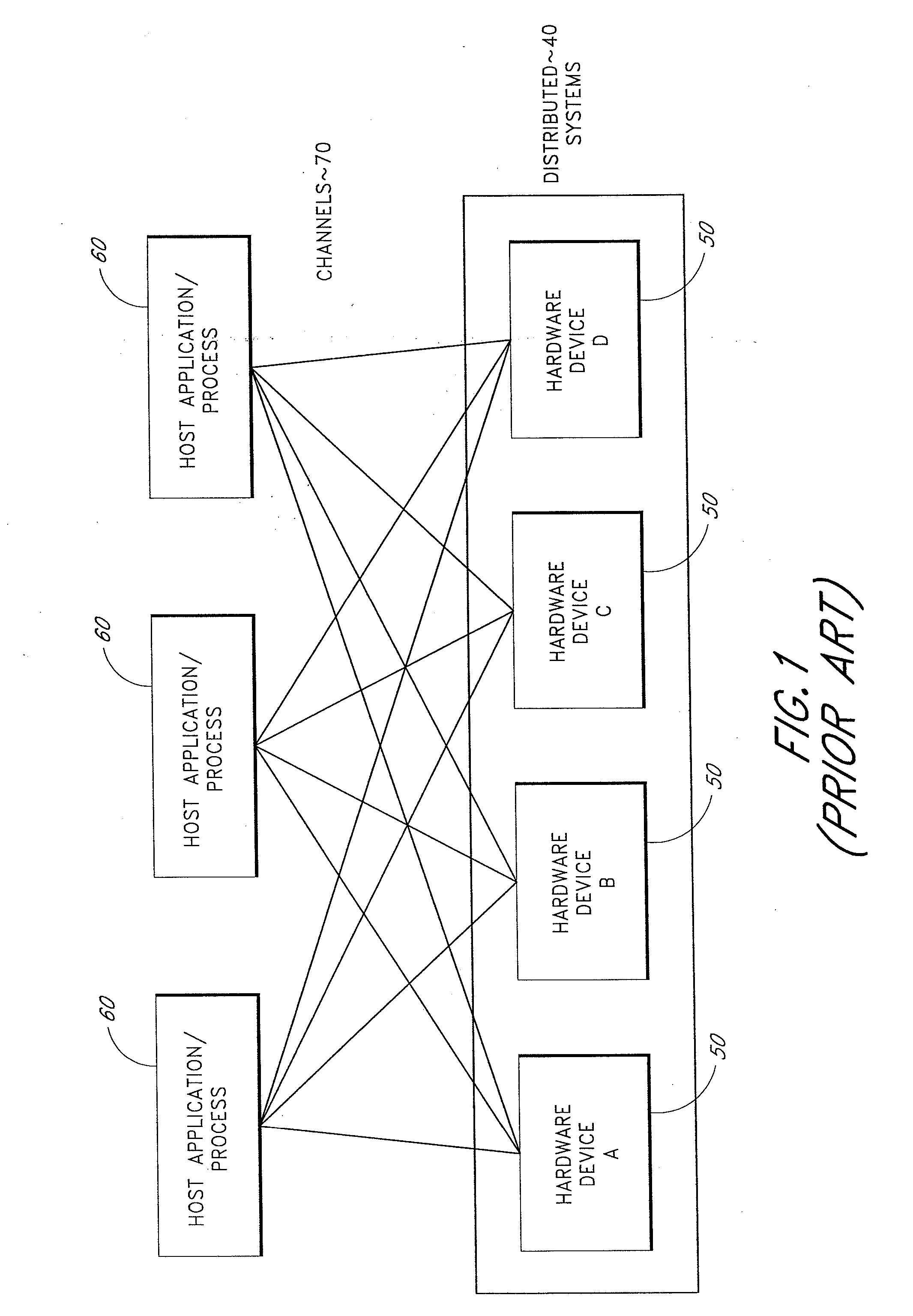

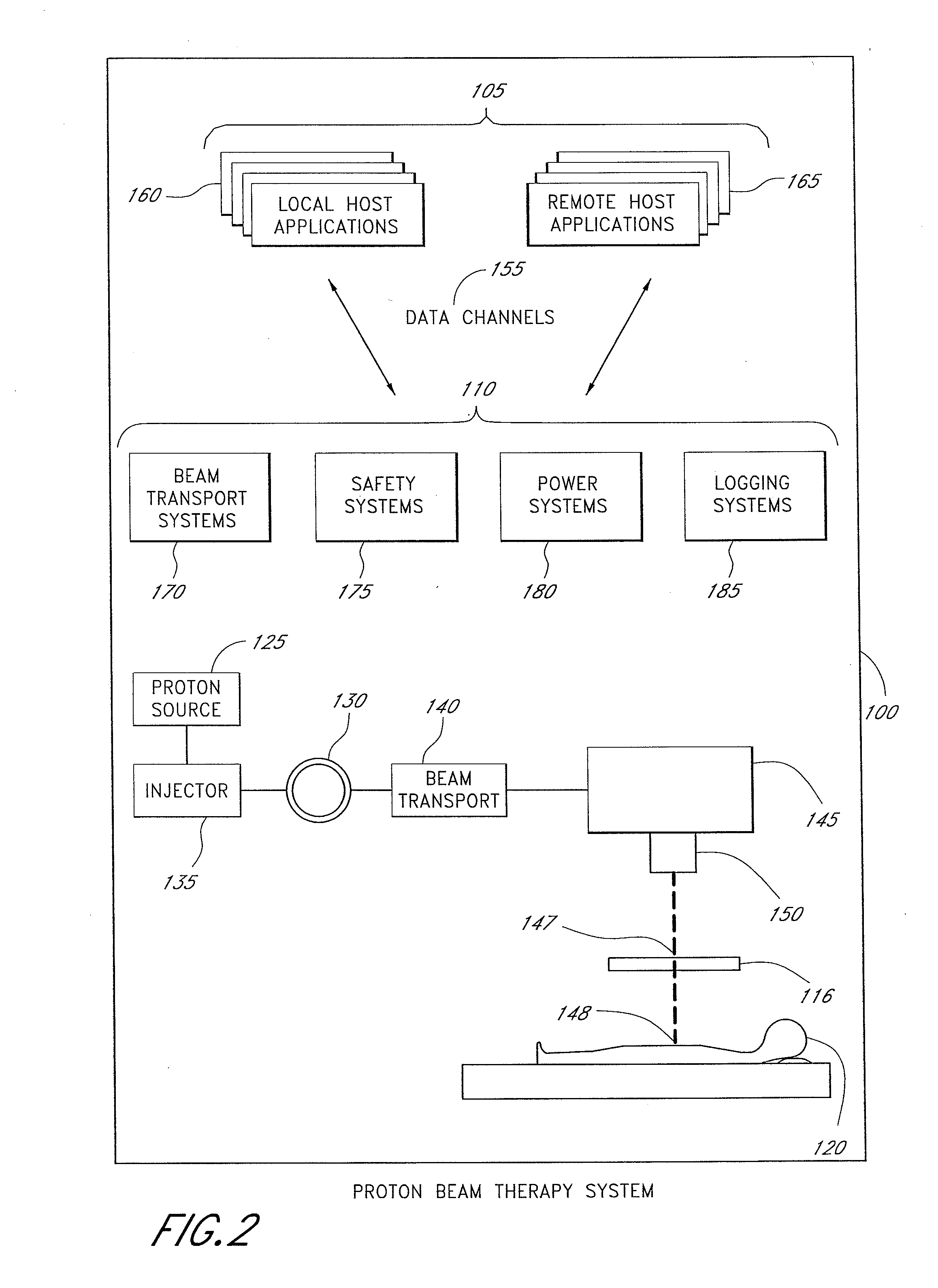

A tiered communications architecture for managing network traffic in a distributed system. Communication between client or control computers and a plurality of hardware devices is administered by agent and monitor devices whose activities are coordinated to reduce the number of open channels or sockets. The communications architecture also improves the transparency and scalability of the distributed system by reducing network mapping dependence. The architecture is desirably implemented in a proton beam therapy system to provide flexible security policies which improve patent safety and facilitate system maintenance and development.

Owner:LOMA LINDA UNIV MEDICAL CENT

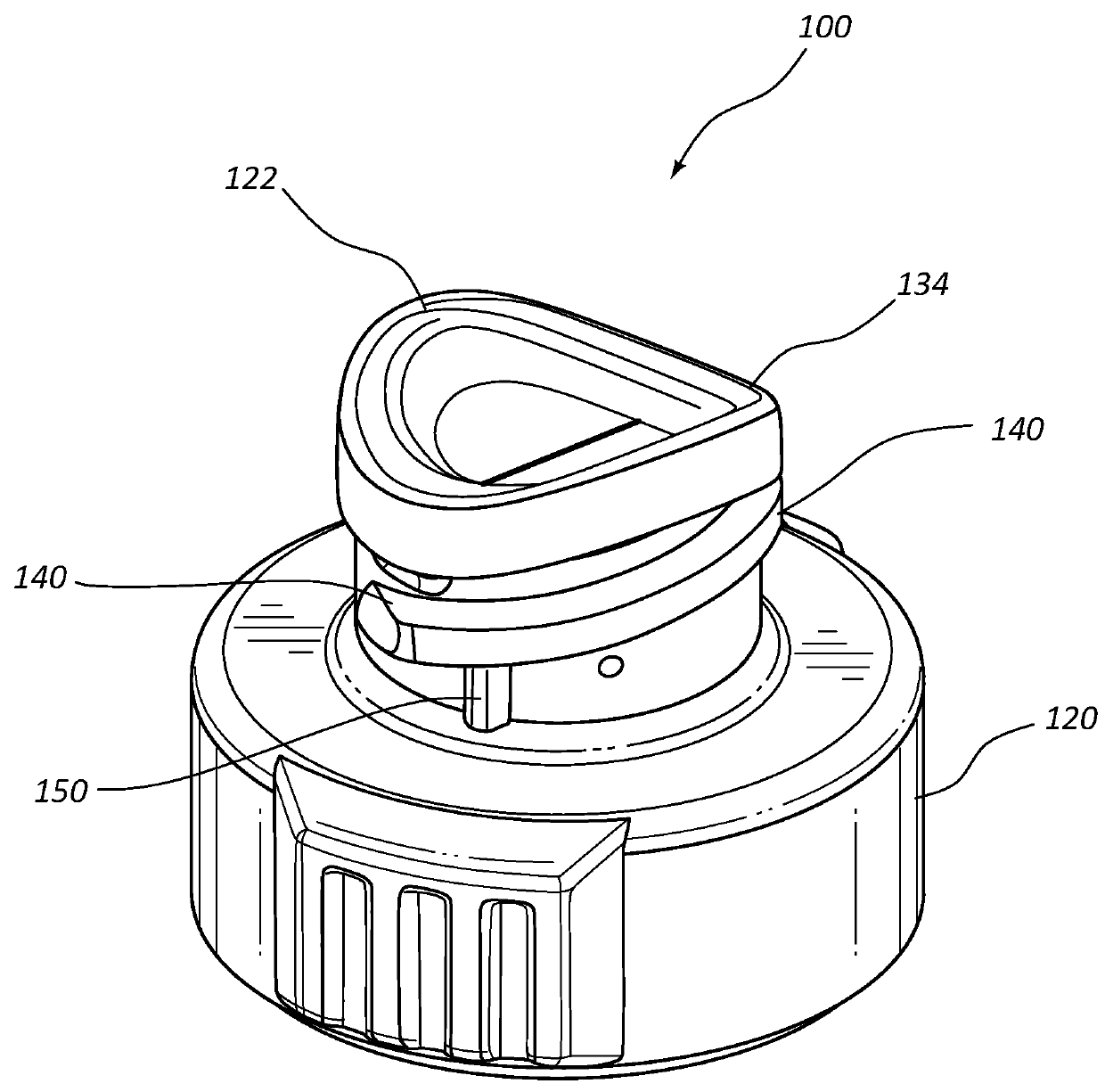

Retention feature for soft interface connection

ActiveUS20150119863A1Increase contactImprove connection securityCatheterTube connectorsTactile sensationRetention function

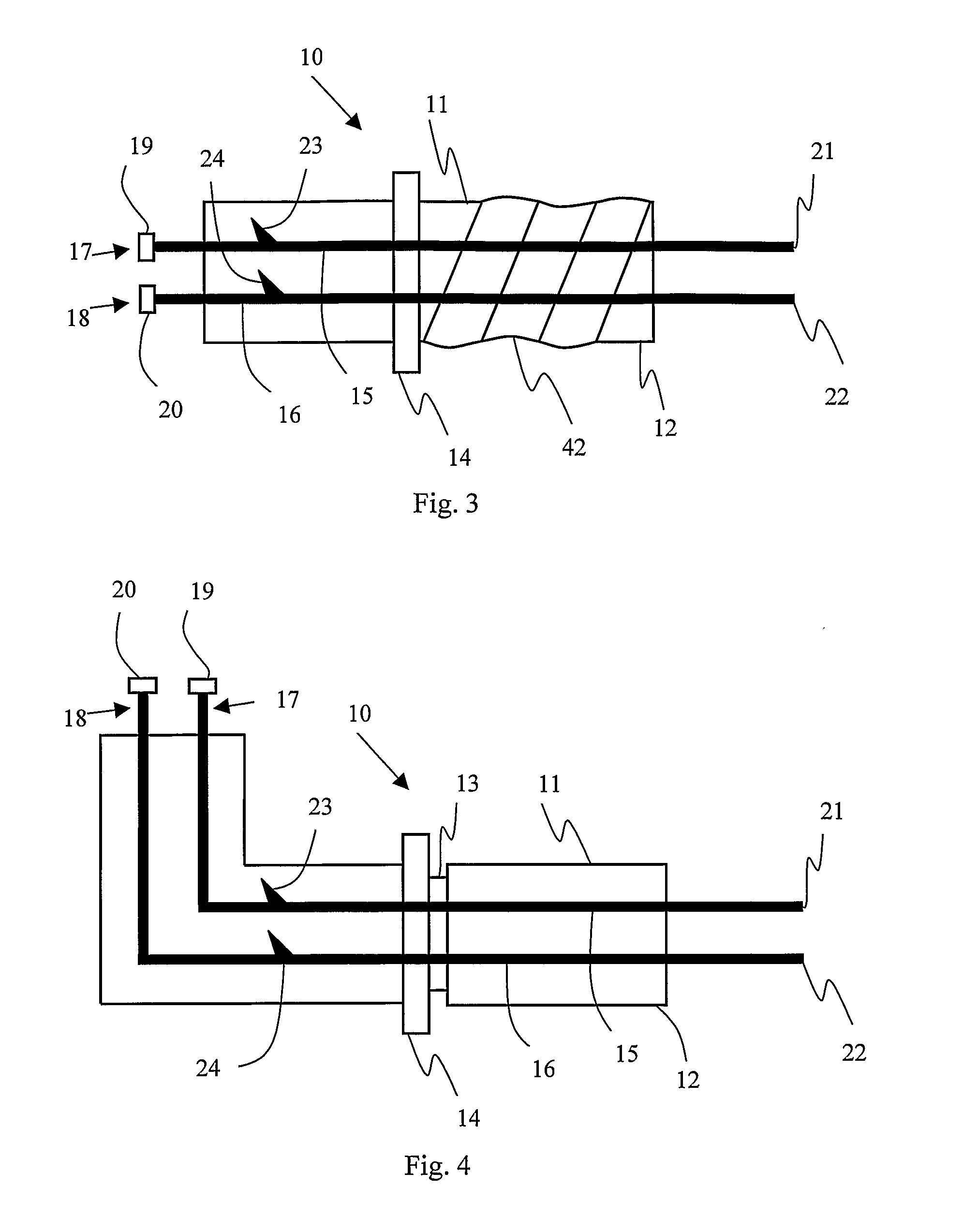

A retention feature configured to provide interference between a threaded connection of a Luer access device and a separate device, wherein the Luer access device further comprises a septum that provides a soft interfaced between the two threadedly connected devices. The retention features of the instant invention are designed to provide the user with a tactile sensation of a tightening threaded connection, despite a soft interface between the interconnected devices. The retention features of the instant invention further prevent “spring back” and unintentional disengagement of the interconnected devices.

Owner:BECTON DICKINSON & CO

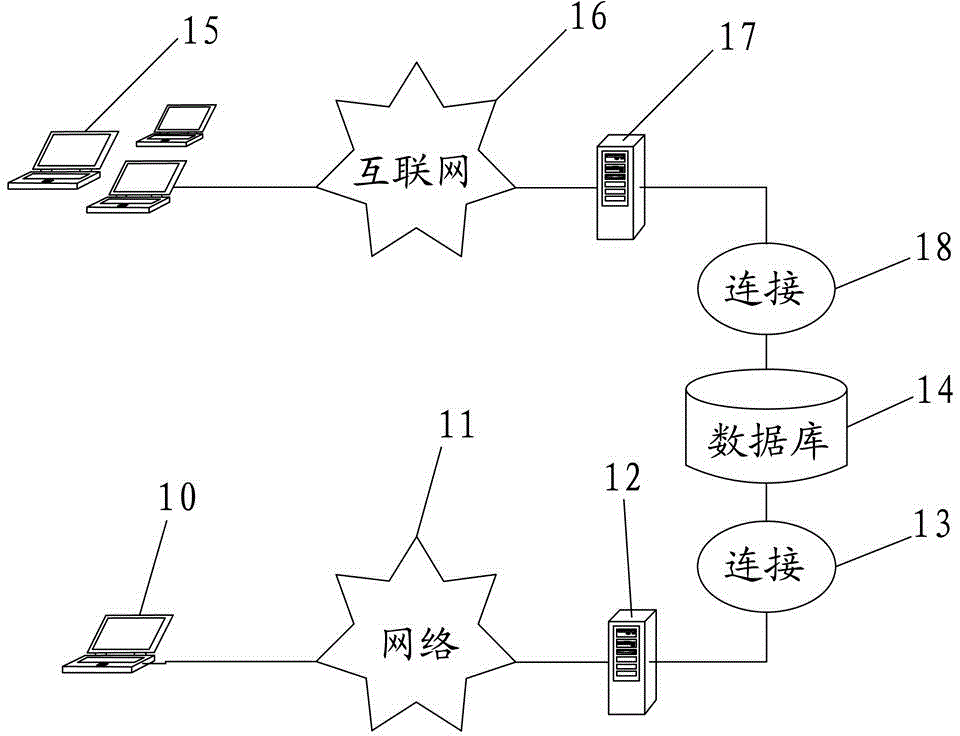

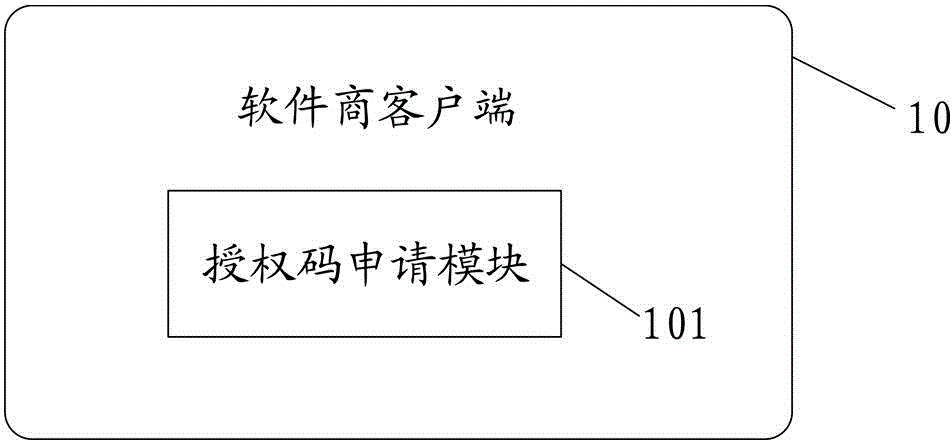

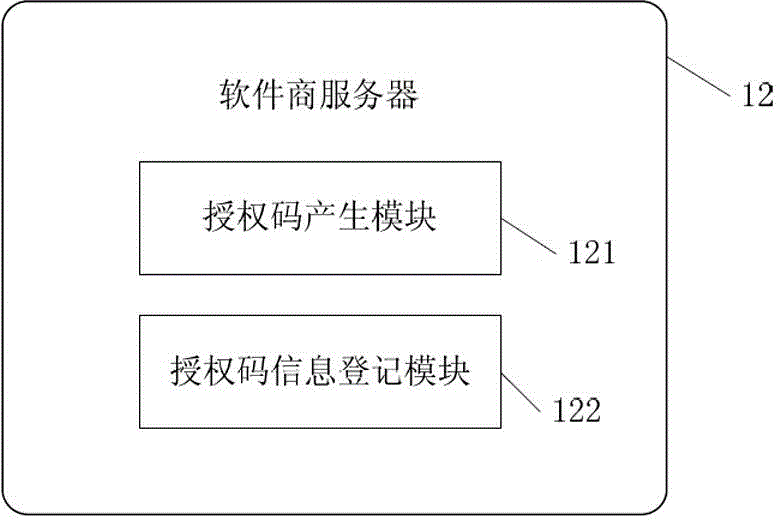

Software authorization and protection device and method based on asymmetric cryptographic algorithm

ActiveCN104361267AThe authorization process is simple and easy to useLow costDigital data protectionProgram/content distribution protectionApplication serverPrivate network

The invention relates to a software authorization and protection device and method based on an asymmetric cryptographic algorithm. The device comprises a software seller client computer, a plurality of client computers, a software seller server, a database and a user server, wherein the software client computer is connected with the software seller server through wireless and / or wired networks, the software seller server is connected with the database through a first VPN (virtual private network), the user server is connected with the database through a second VPN, and a plurality of client computers are connected with the user sever through Internet. The invented device adopts double-backup connection between the application server and the database, and the database safety performance is improved. The invention also has another goal of providing the software authorization and protection method based on the asymmetric cryptographic algorithm. The method provided by the invention adopts an asymmetric cryptographic technology, the safety is high, the technology realization is not complicated, and the mode for obtaining the authorization by a user is simpler.

Owner:XIAMEN HYMAKE TECH

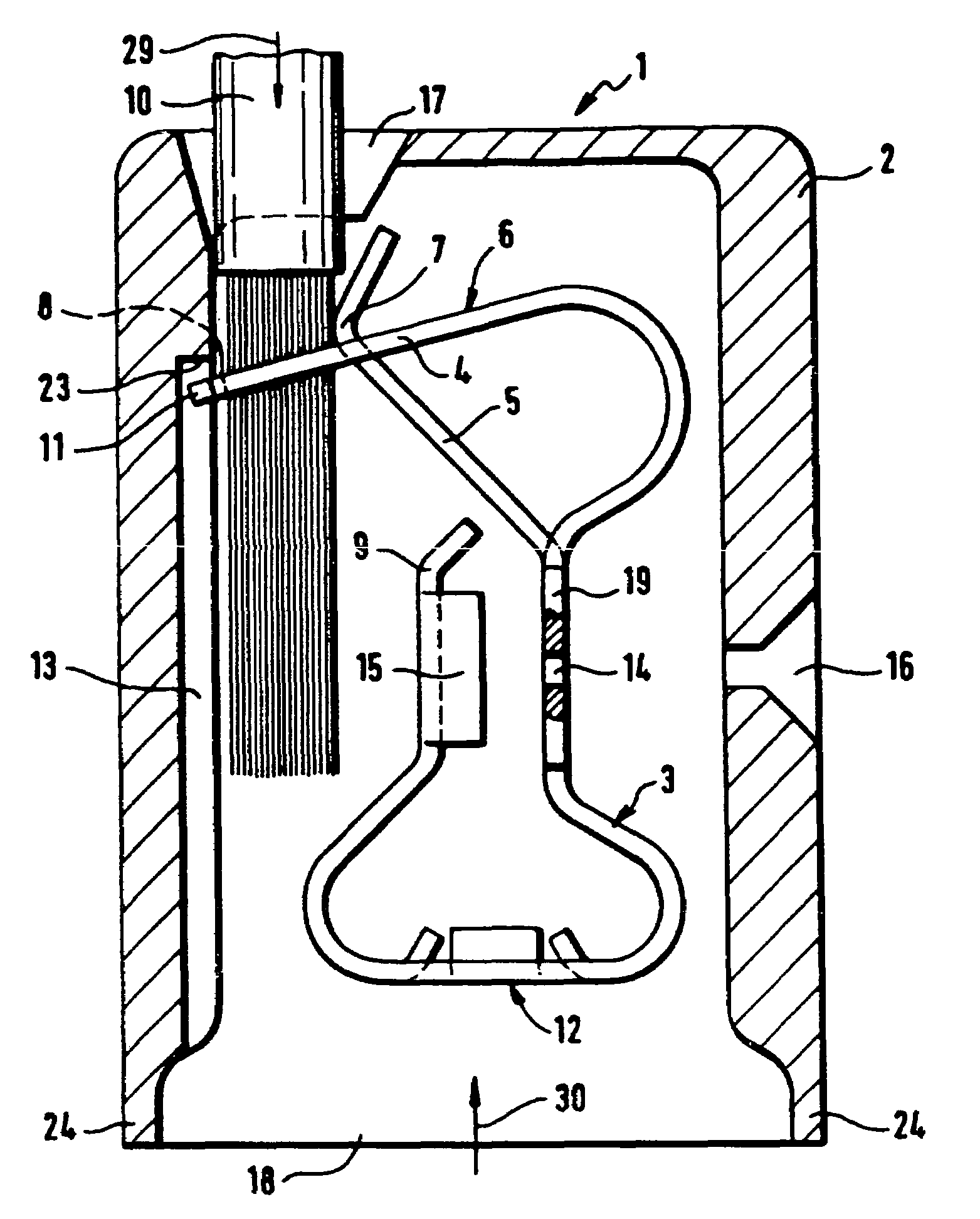

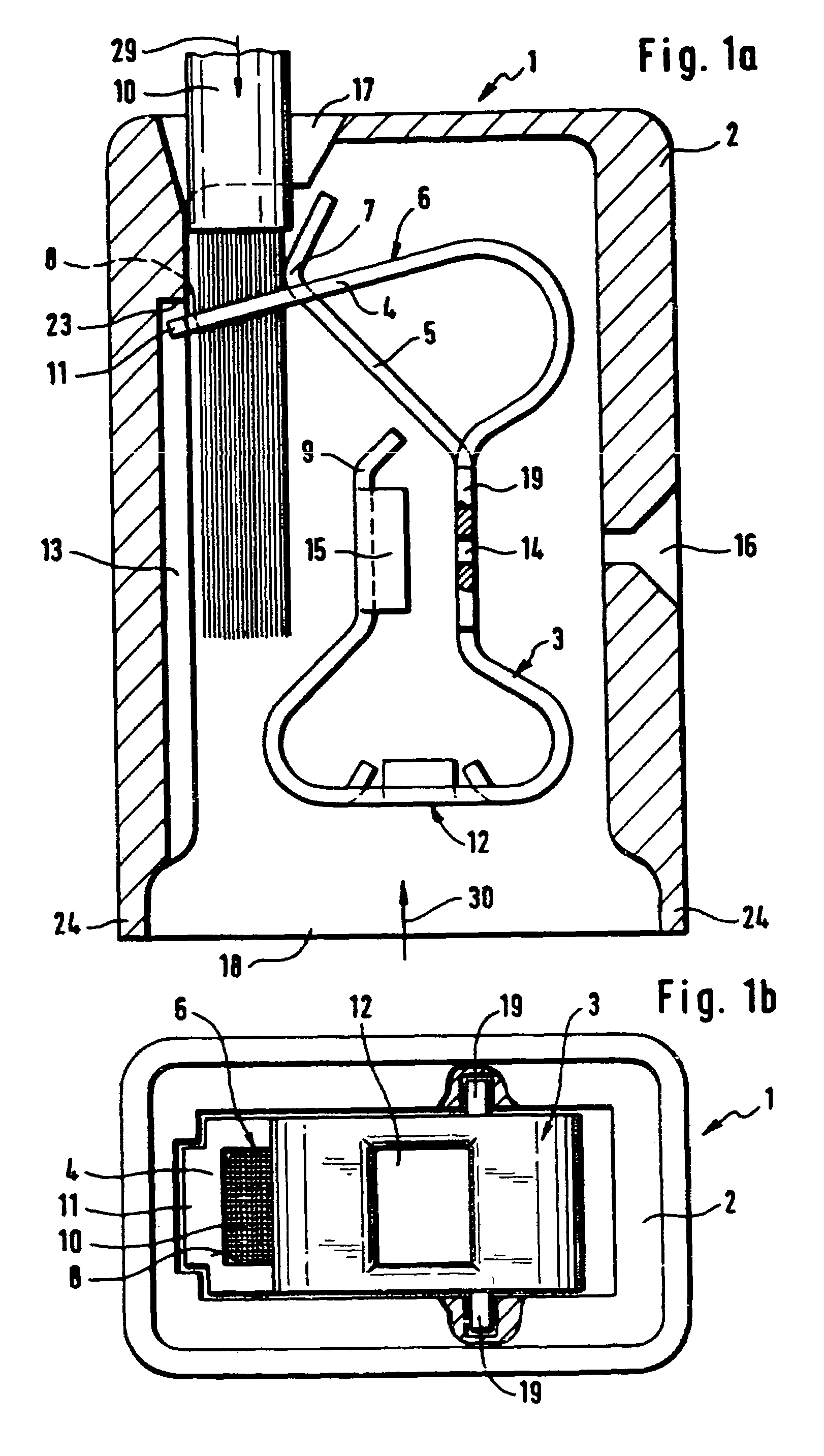

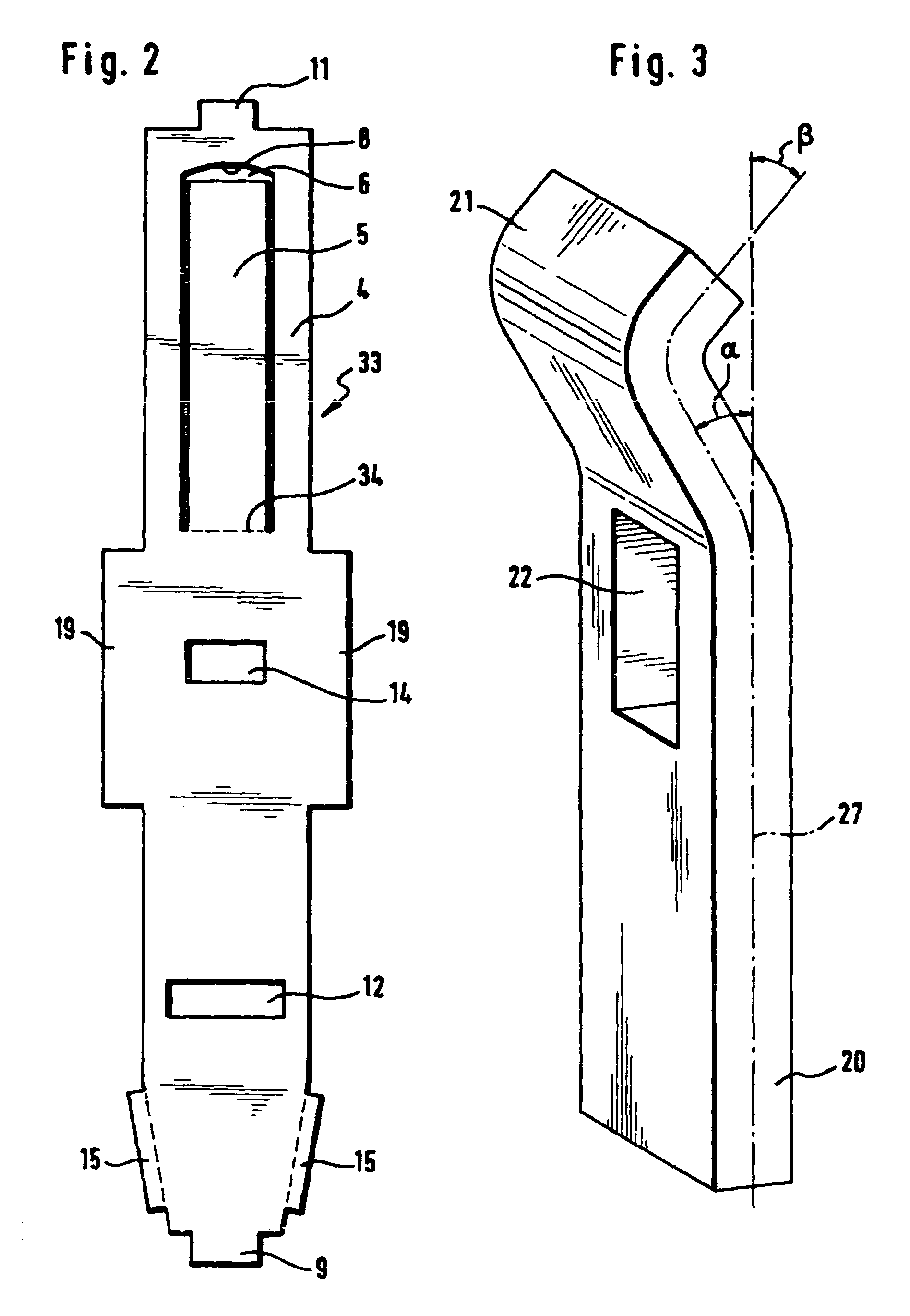

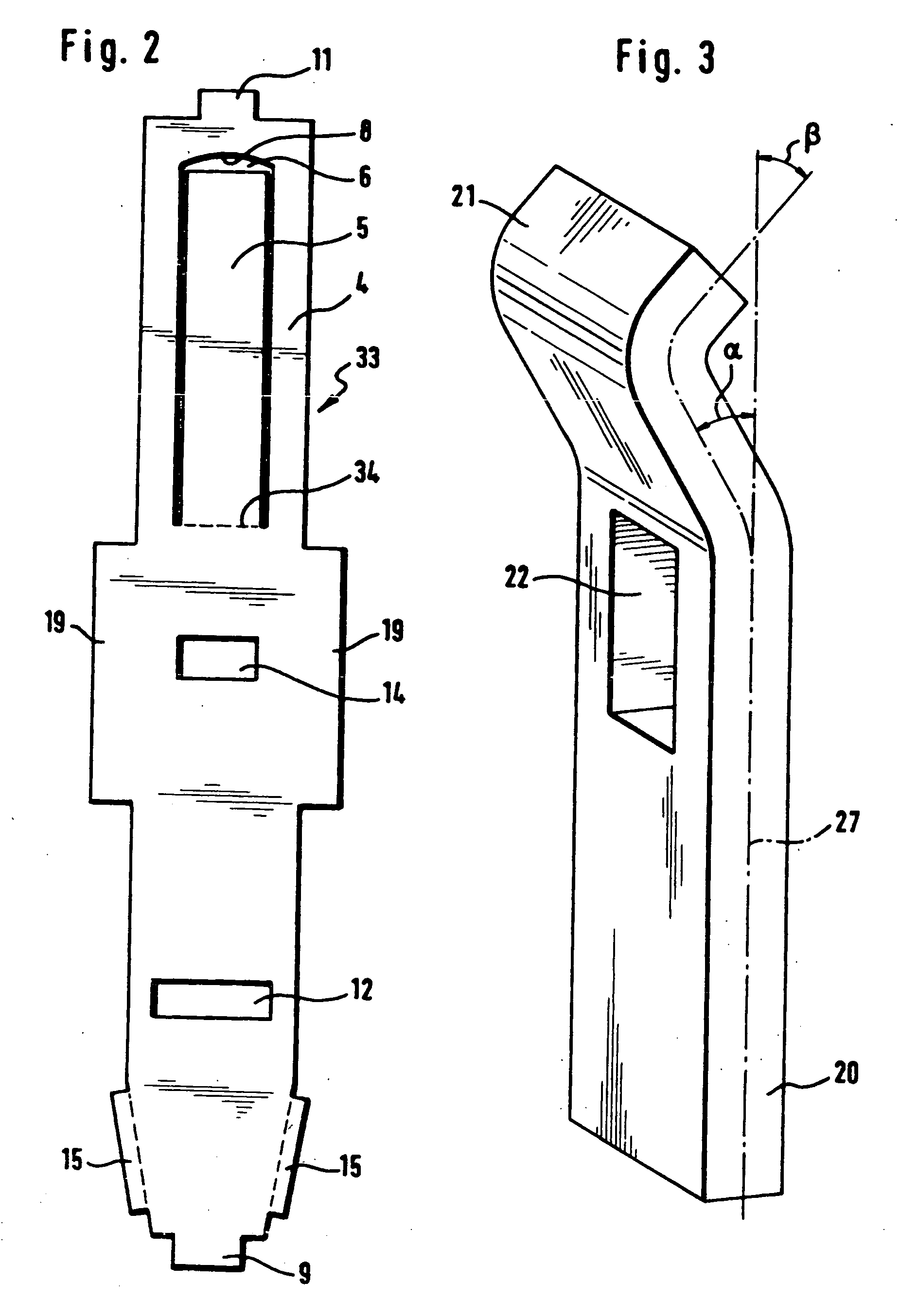

Electrical plug, holder, system having an electrical plug and a holder, and method of making a connection between an electrical plug and a holder

InactiveUS7131857B2Done quickly and without toolsSmall transition resistanceLine/current collector detailsContact members penetrating/cutting insulation/cable strandsElectrical connectionEngineering

An electrical plug includes a housing and a spring clamp to connect a flexible electric conductor to an end piece of a rigid holder. The clamp spring includes a contact leg and a clamp leg. The clamp leg is bent closed in a loop onto the contact leg end providing a clamp opening through which the contact leg end protrudes. The clamp leg and a clamp opening edge positioned opposite to the clamp leg form a clamp location in which the electric conductor passed through the clamp opening is clamped before mounting the plug on the holder. After mounting, the holder extends through the clamp opening displacing the contact leg from the electric conductor. The holder and clamp spring clamp the electric conductor and form an electrical connection between the holder and electric conductor.

Owner:NEWFREY

Electrical connection guard

InactiveUS7544082B1Improve connection securityEfficient use ofEngagement/disengagement of coupling partsInsulated cablesElectricityElectrical connection

The present invention provides new weatherproof outdoor electrical connection guard for protecting electrical extension cord plug connections, especially in wet environments. The guard includes a protective housing for covering the point of connection between an extension cord plug and the mating plug from a power-consuming device inserted therein. A catch is provided to removably secure the connected cords within the housing. An elongated stake is provided for securing the connection guard in an elevated position above the ground. The connection guard further includes ventilation for moisture and heat dissipation.

Owner:HALVORSEN LEIF

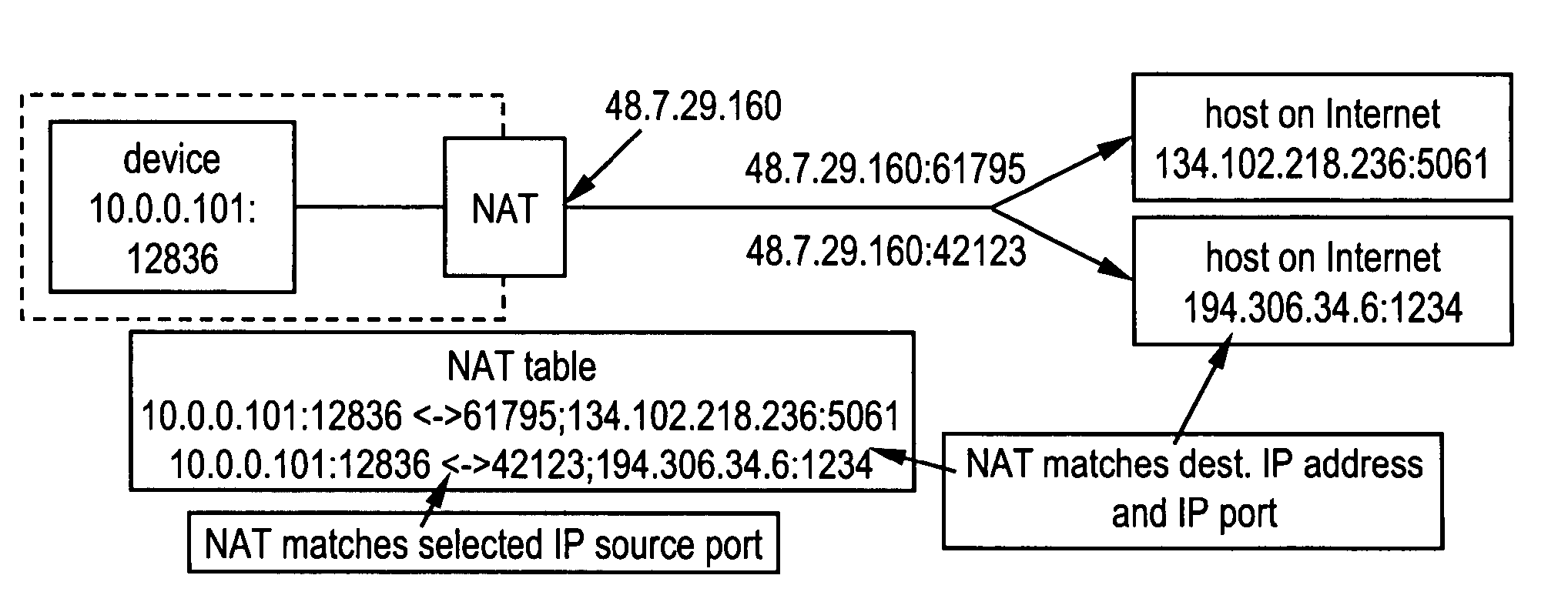

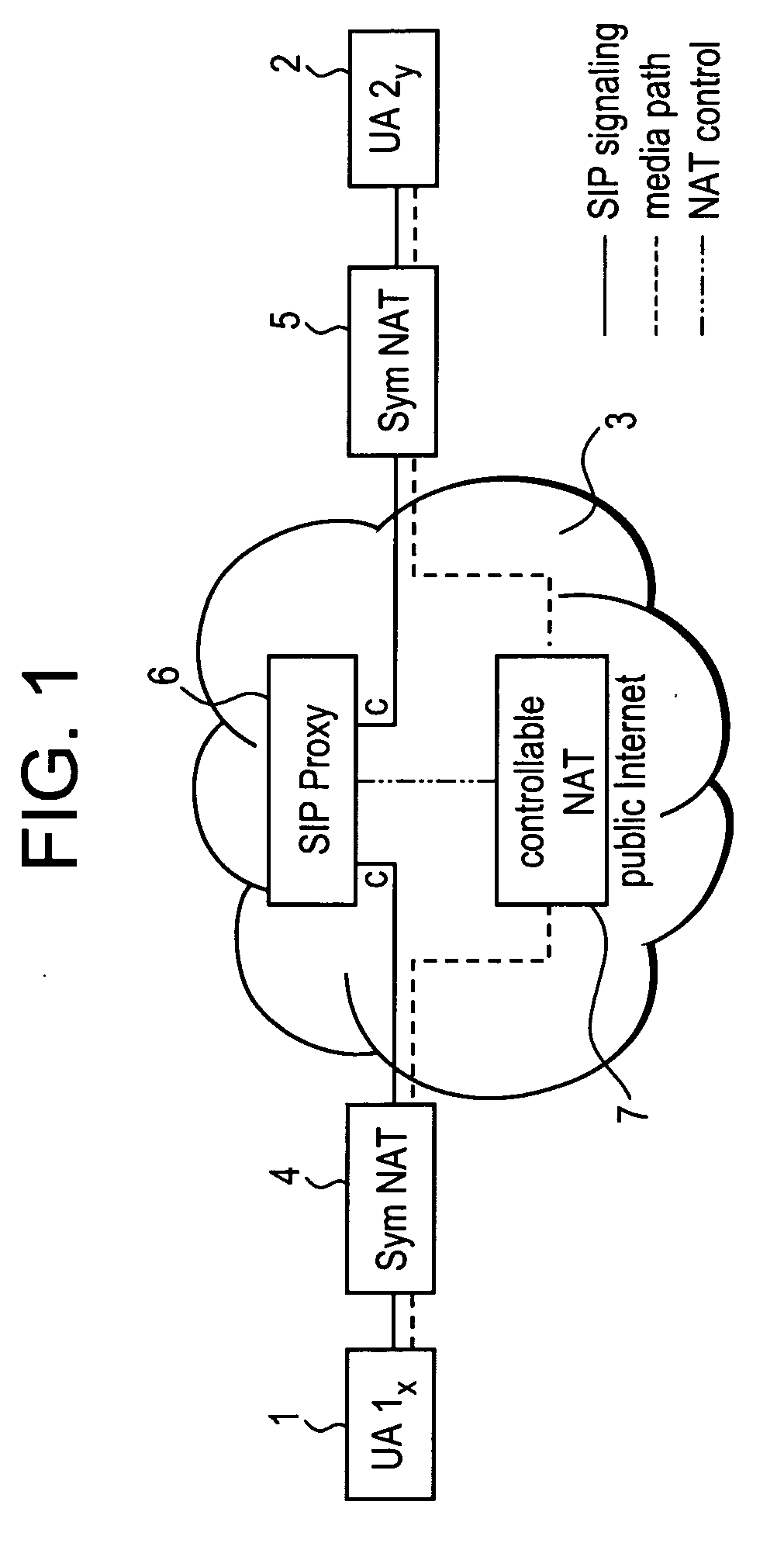

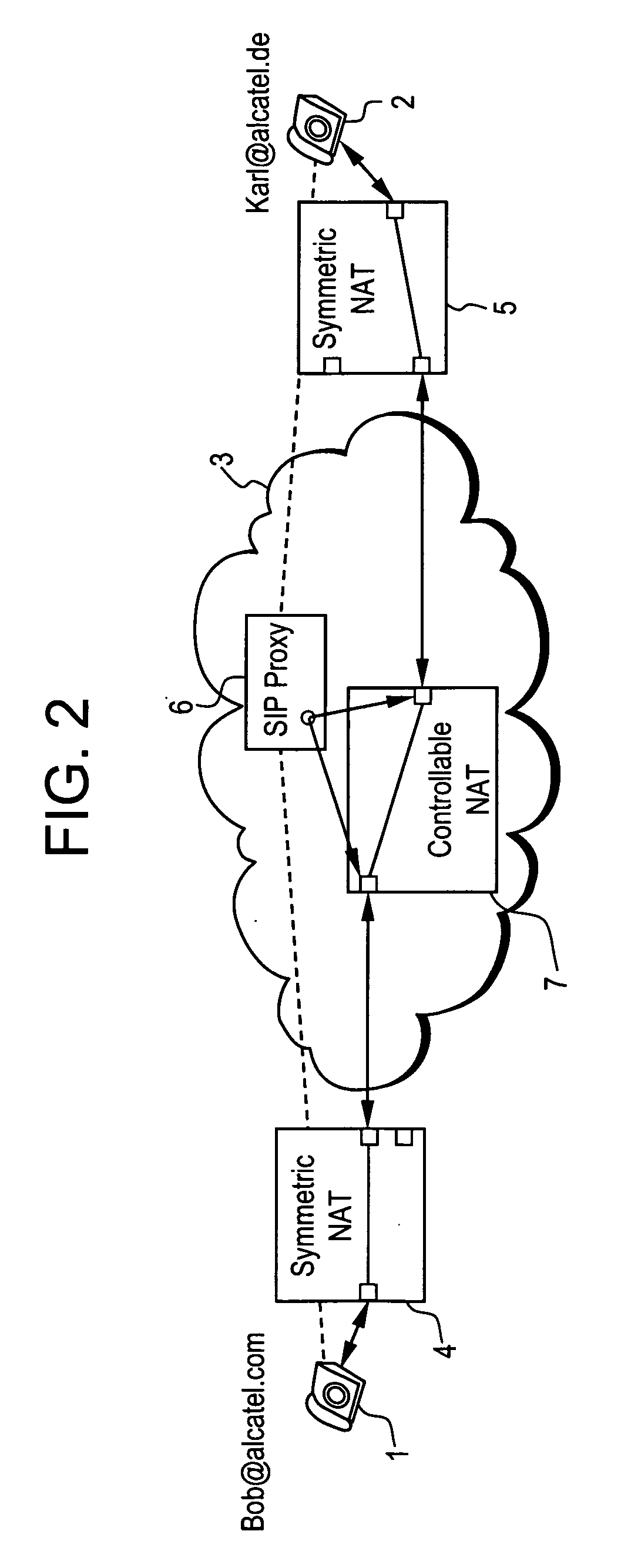

Method to establish a peer-to-peer connection between two user agents located behind symmetric NATs

InactiveUS20060182111A1Improve connection securityEasy to addData switching by path configurationIp addressThe Internet

A method to establish an Internet connection between a first (1) and a second (2) user agent is described, wherein a NAT-table entry in a controllable NAT (7) located in the Internet (3) is generated, wherein said NAT-table entry comprises public IP-address:Port pairs that are communicated to the user agents (1, 2), wherein the user agents (1, 2) use said public IP-address:port pairs for establishing an Internet connection between each other via the controllable NAT (7).

Owner:ALCATEL LUCENT SAS

Sealed plug connection through a partition wall and method of fitting

ActiveUS7704086B2Improve connection securityEasy to installEngagement/disengagement of coupling partsIncorrect coupling preventionEngineeringMechanical engineering

Owner:TE CONNECTIVITY GERMANY GMBH

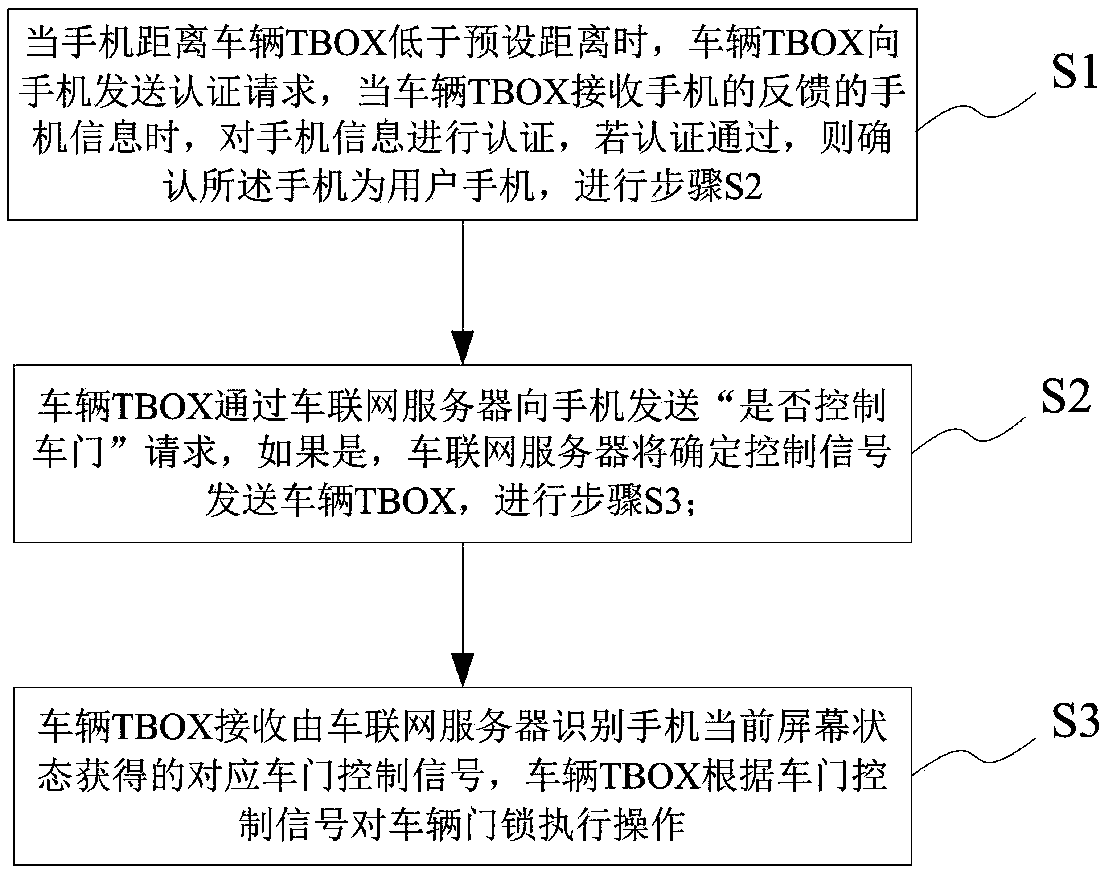

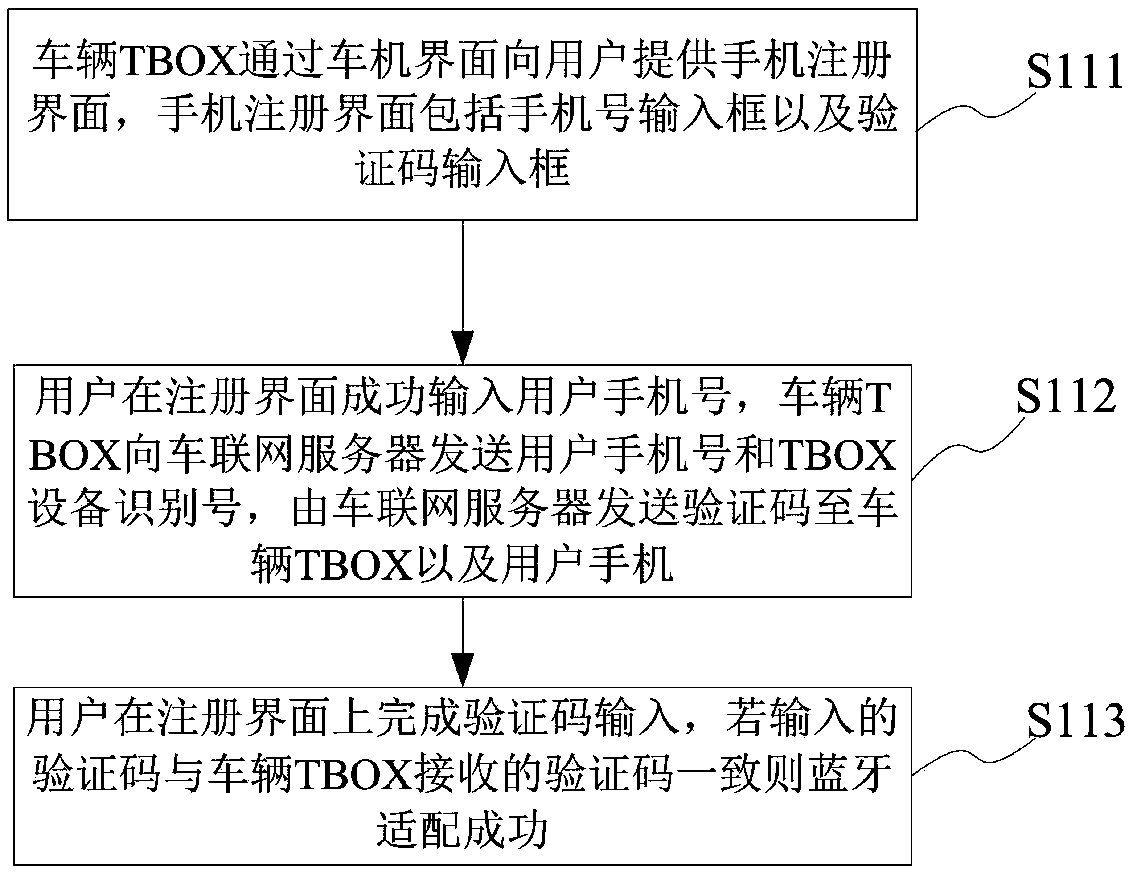

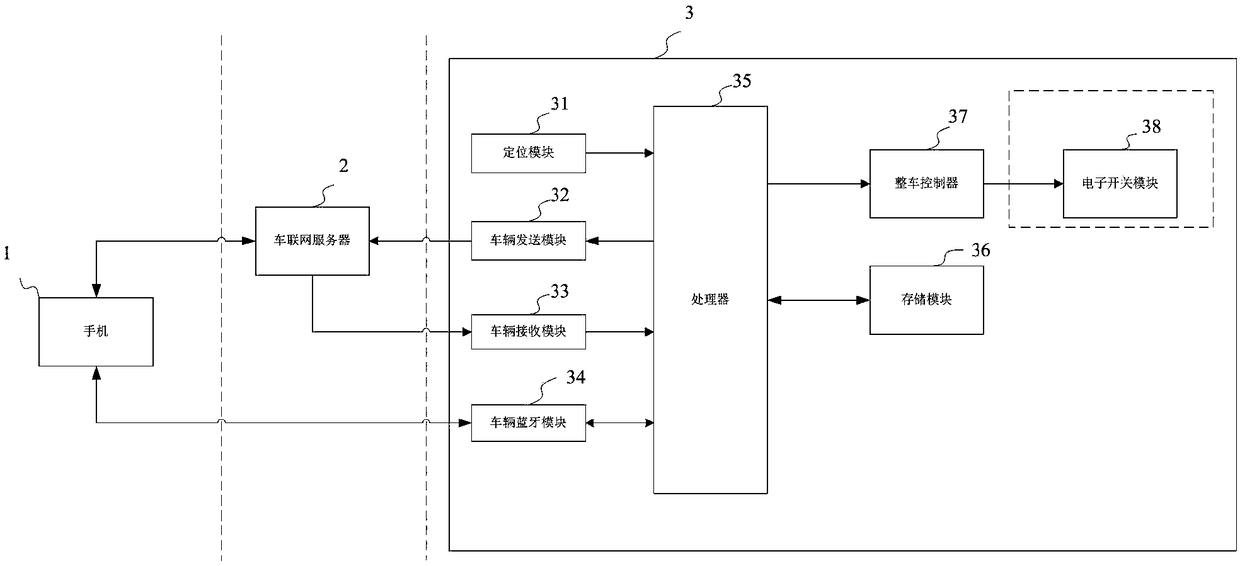

Vehicle door lock state synchronization method, server and synchronization system based on mobile phone screen

InactiveCN109466507AEasy to operateImprove connection securityParticular environment based servicesAnti-theft devicesControl signalBluetooth

The invention provides a vehicle door lock state synchronization method, server and synchronization system based on a mobile phone screen, wherein the synchronization system comprises a vehicle TBOX and a vehicle networking server, when the mobile phone is lower than the vehicle TBOX by a preset distance, the vehicle TBOX sends an authentication request to the mobile phone, the vehicle TBOX receives the feedback mobile phone information and carries out authentication, and if the authentication is passed, the mobile phone is considered as a user mobile phone; the vehicle TBOX sends a request of'whether to control the vehicle door' to the mobile phone through the vehicle networking server, if so, the vehicle networking server determines that a control signal is sent to the vehicle TBOX, andthe vehicle TBOX receives a corresponding vehicle door control signal obtained by identifying the current screen state of the mobile phone by the vehicle networking server to perform operation on thevehicle door lock. The system adopts a mode of combining the mobile phone number with a Bluetooth address to ensure the unique safety matching relationship between the mobile phone of the user and the TBOX of the vehicle, the opening and closing of the vehicle door are controlled through the screen state of the mobile phone, the user does not need to download another client to control the vehicledoor, and the system is convenient to operate.

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD

System for connecting batteries for an electric vehicle and associated set of batteries

InactiveUS8939245B2Minimizing energyMitigate such drawbackCharging stationsElectric devicesMobile vehicleElectrical battery

A system for connecting a set of batteries configured to supply at least one electric motor for powering a motor vehicle and configured to be accommodated inside a compartment provided on the vehicle. Each battery includes a logic processing unit, a communication module, and a mechanism for connecting to the motor. The vehicle includes a logic processing unit connected to a stationary auxiliary battery, a communication module capable of communicating with the communication module of each battery, and a mechanism for locking and blocking the batteries in position.

Owner:RENAULT SA

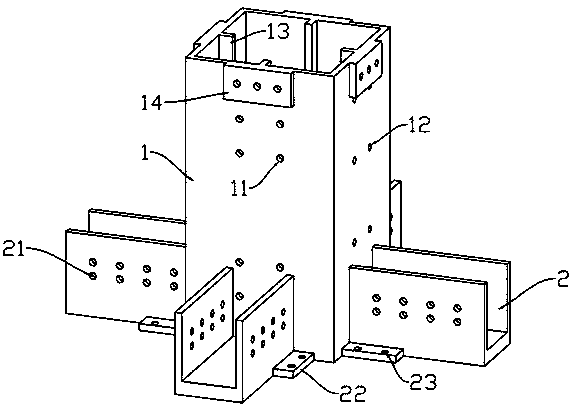

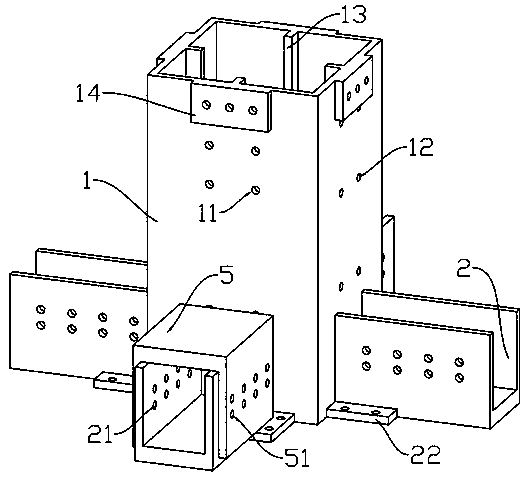

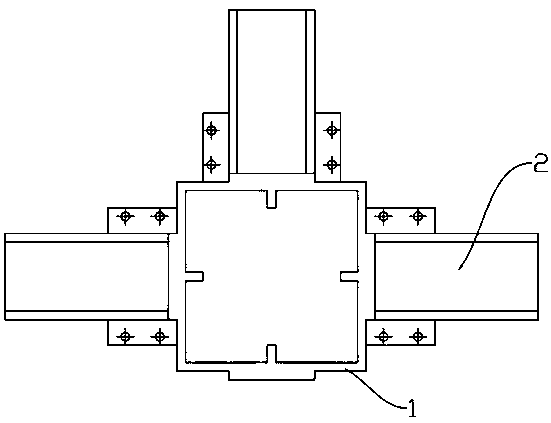

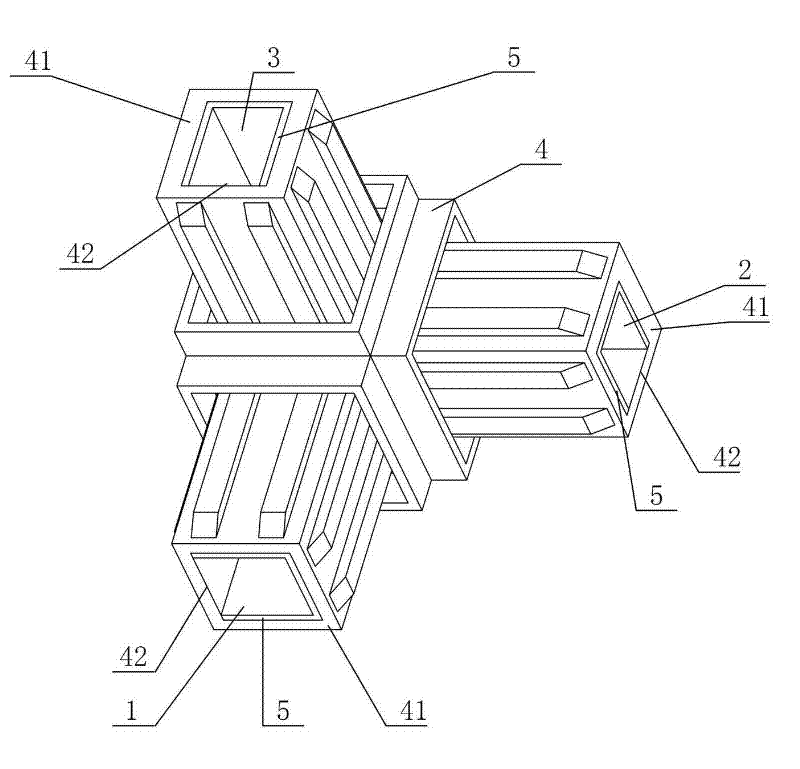

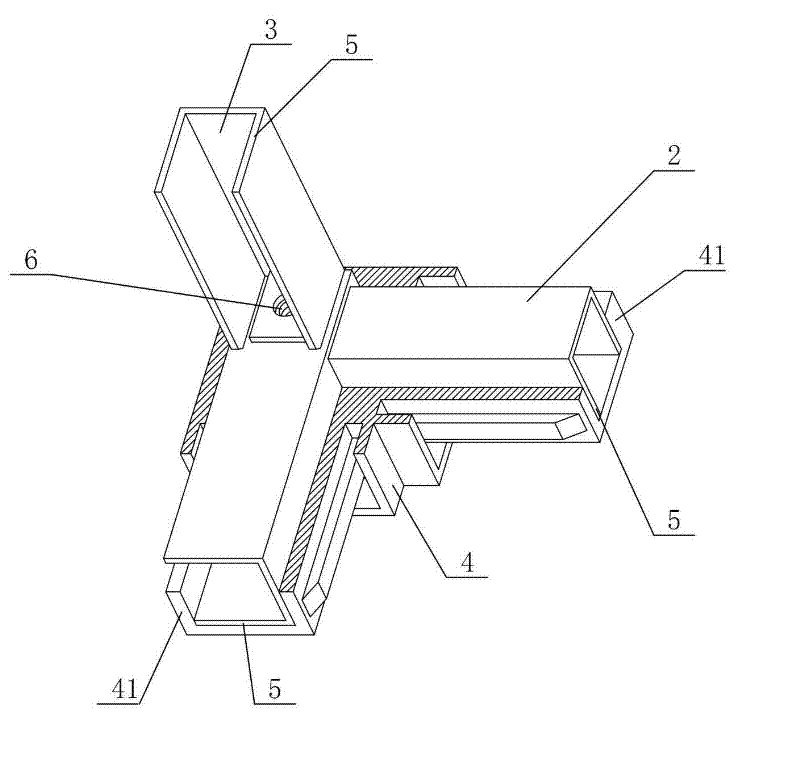

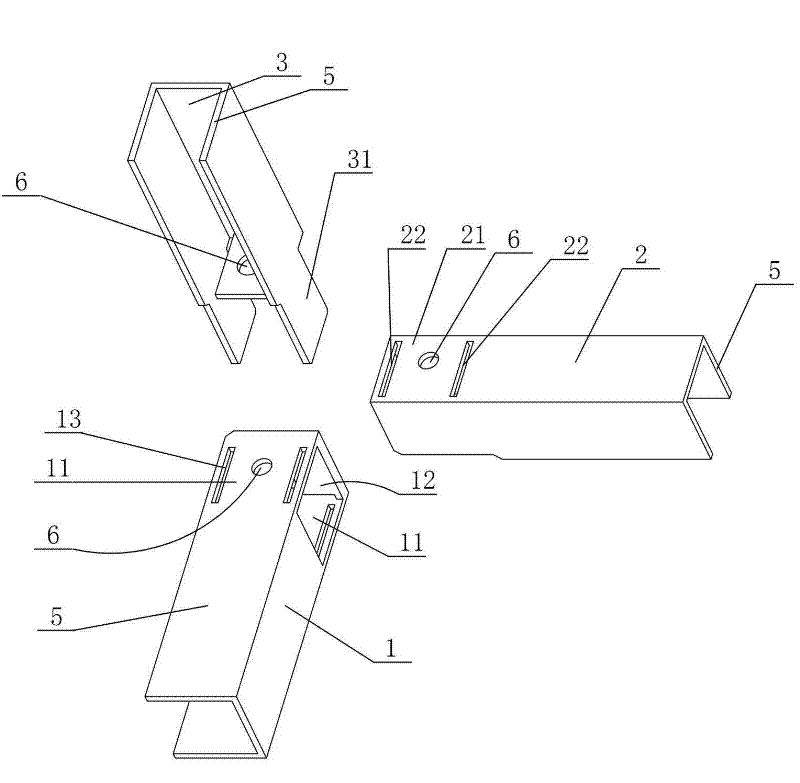

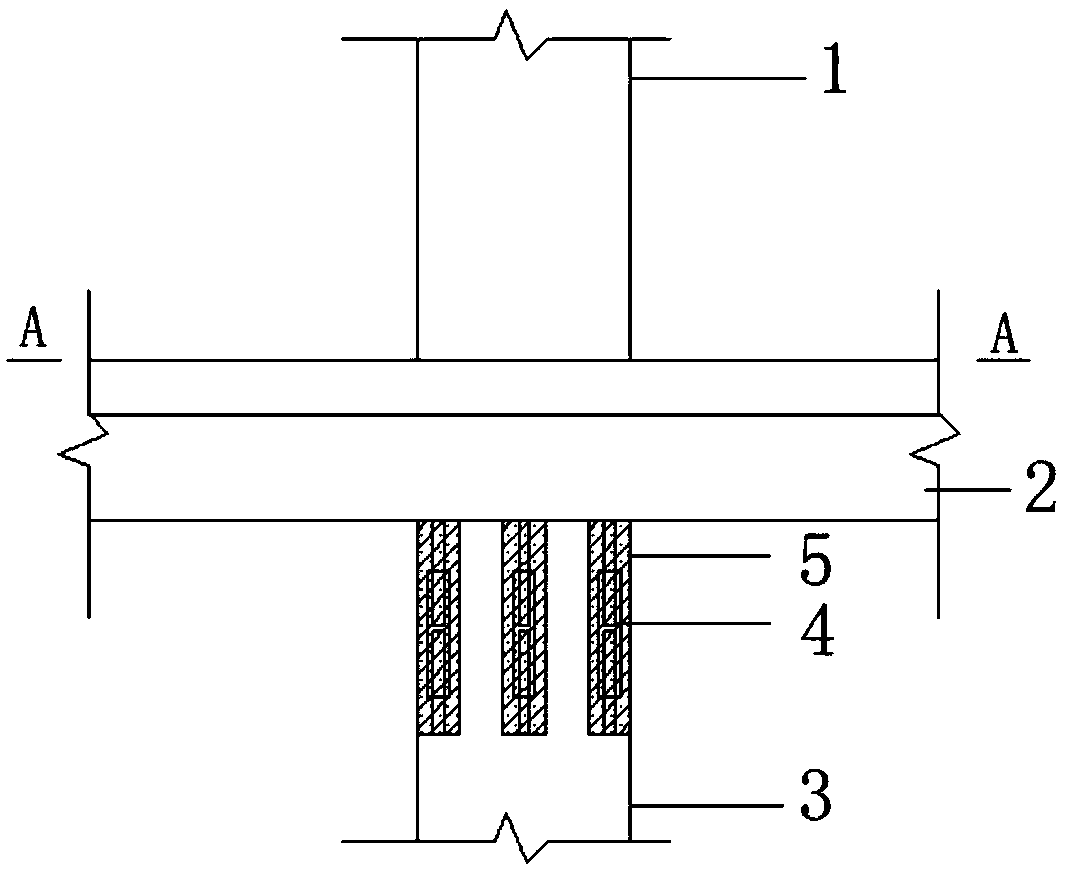

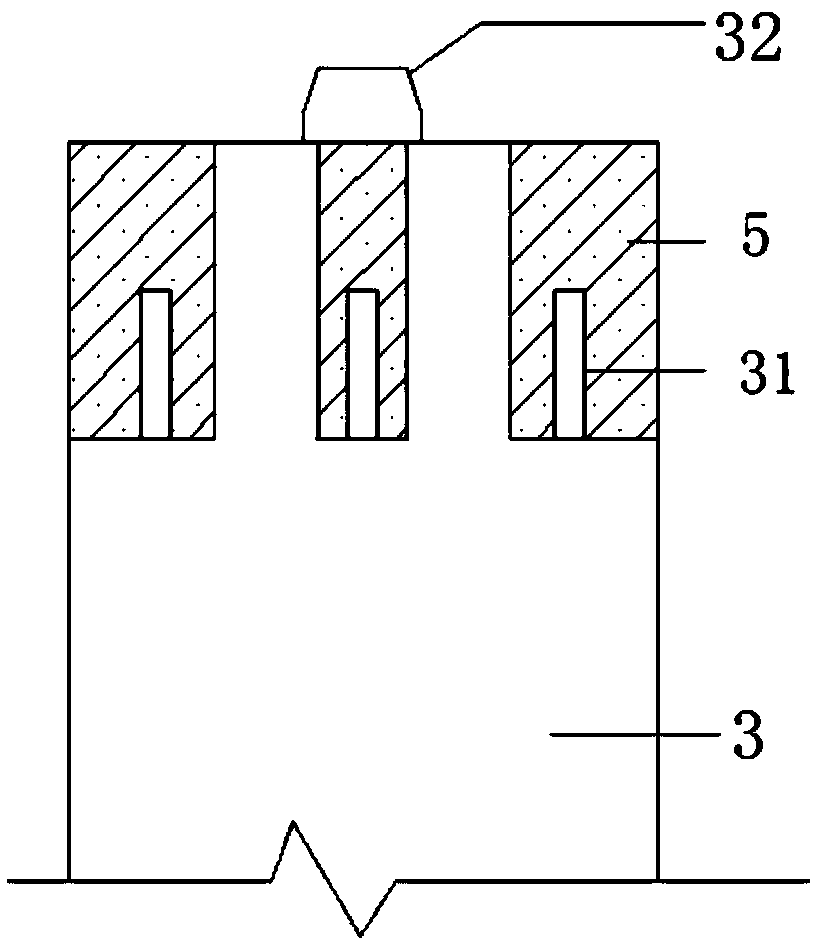

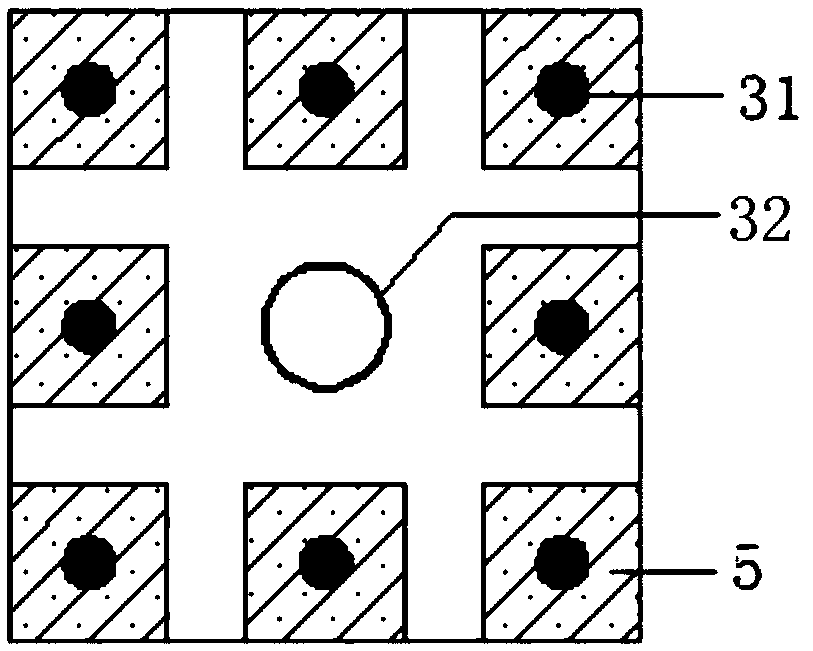

Cap type beam-column connection piece, beam-column assembly structure using beam-column connection piece and mounting method

PendingCN108678167AChange link structureChange connection strengthBuilding constructionsPhotovoltaic energy generationEngineeringUltimate tensile strength

The invention discloses a cap type beam-column connection piece. The cap type beam-column connection piece is characterized by comprising a rectangular sleeve, a plurality of penetrating first mounting holes are formed on the two opposite side faces of the sleeve from top to bottom, a plurality of penetrating second mounting holes are formed in other two opposite side faces of the sleeve, the first mounting holes and the second mounting holes are formed alternately, at least one clamping groove is formed in at least one side face outside the sleeve, the clamping groove is integrally in a U shape, the opening faces up, the two ends are open, the end with the inner cavity being rectangular is welded with the side wall of the sleeve, the outer bottom face of the clamping groove is flush withthe edge of the bottom face of the sleeve, and a plurality of penetrating third mounting holes are formed in the two opposite side walls of the clamping groove. Meanwhile, the invention discloses a beam-column assembly structure using the beam-column connection piece and an assembling method, and the beam-column assembly structure has the characteristics that the connection strength is high, and the structure can be assembled simply and rapidly.

Owner:四川建安装配式工程科技有限公司

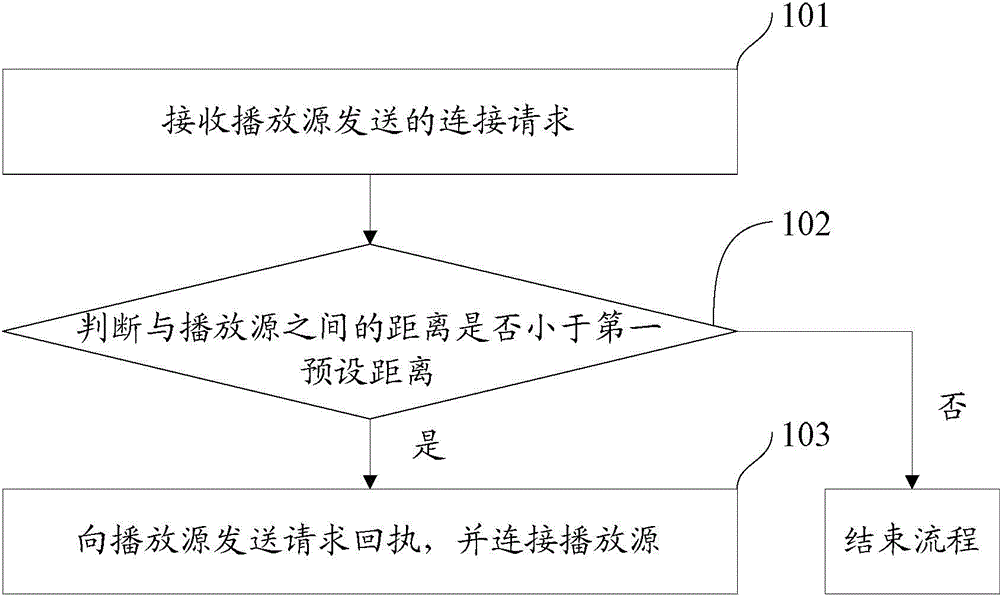

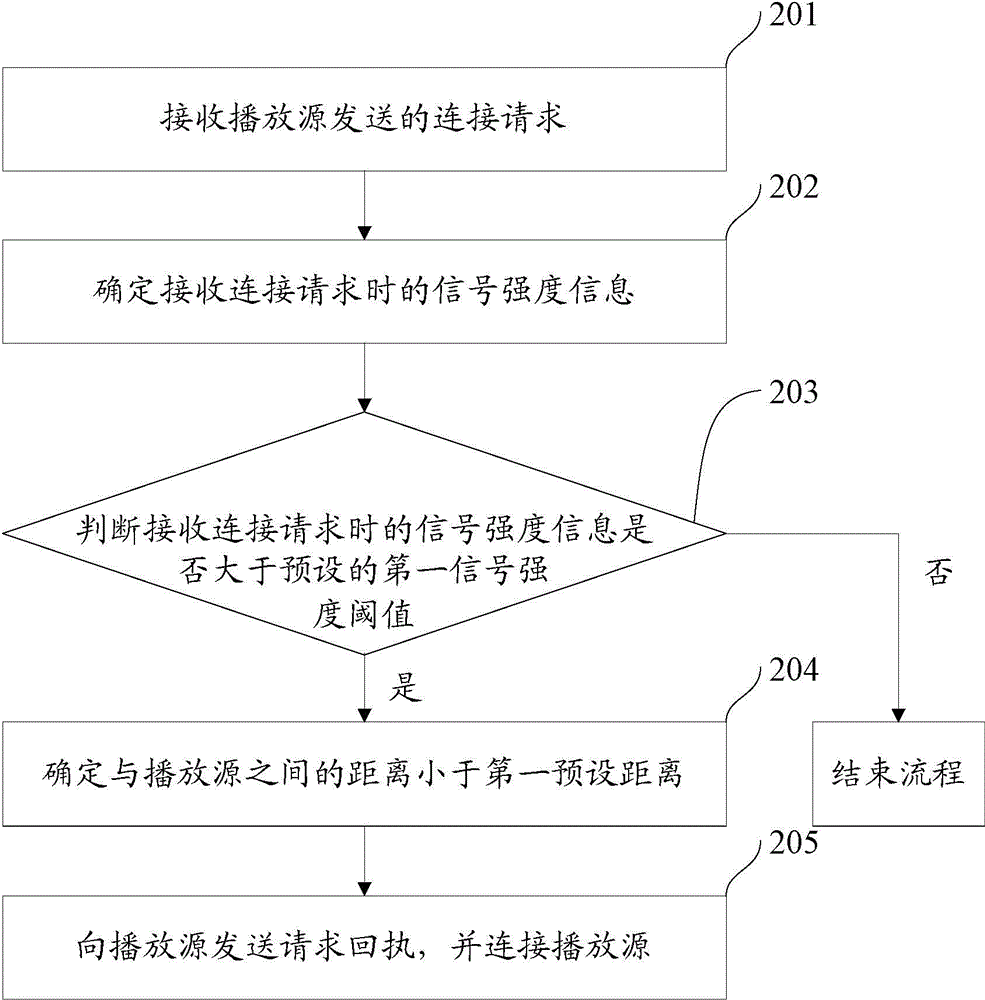

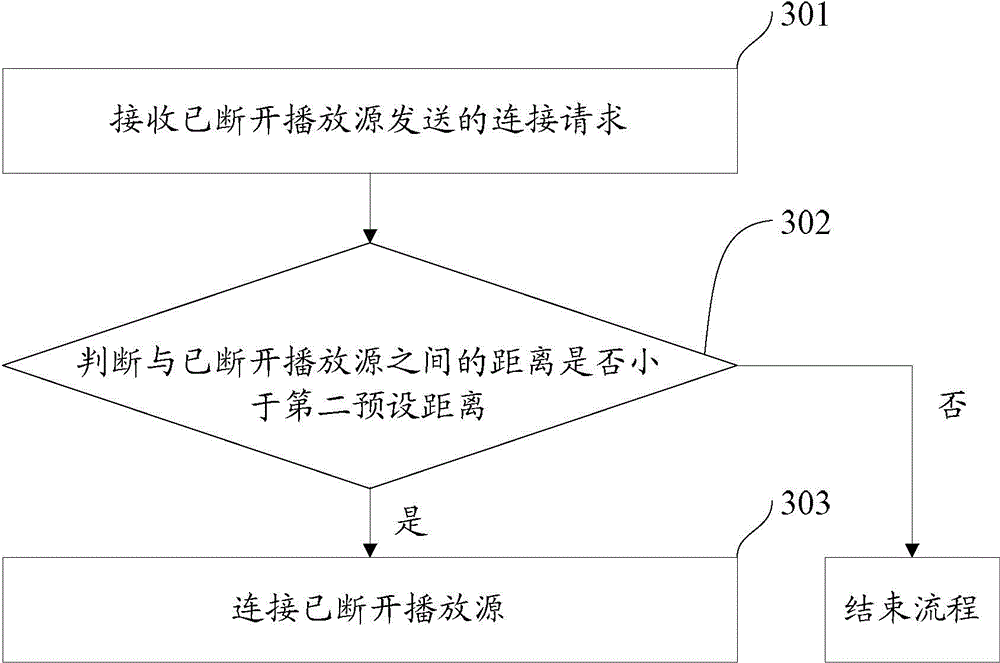

Method and device for connecting playing source

InactiveCN104468971AImprove connection securityEasy to operateSubstation equipmentSelective content distributionBluetoothEmbedded system

The invention relates to a method and device for connecting a playing source. The method and device for connecting the playing source are used for a Bluetooth playing terminal. The method comprises the steps that a connecting request transmitted by the playing source is received; according to the connecting request, whether the distance between the Bluetooth playing terminal and the playing source is smaller than a first preset distance or not is judged; when the distance between the Bluetooth playing terminal and the playing source is smaller than the first preset distance, a request receipt is transmitted to the playing source, and the Bluetooth playing terminal is connected to the playing source. Whether the Bluetooth playing terminal can be connected with the playing source or not is determined by judging the distance between the Bluetooth playing terminal and the playing source; in this way, the operation in the process of connecting the playing source is simplified, and the connecting security of the Bluetooth playing terminal is improved.

Owner:XIAOMI INC

Connector for electronic detonators

ActiveUS20070207669A1Avoid unnecessary distractionsImprove connection securityRelieving strain on wire connectionBlasting cartridgesDetonatorElectricity

Fire, arm, and disarm signals are typically transmitted to electronic detonators via signal transmission lines. Traditionally, such signal transmission lines include wires wherein one end of each wire is soldered directly to printed circuit boards and or other signal processing components retained within the shell of a detonator. Other ‘modular’ blasting apparatuses of the prior art provide means to connect signal transmission lines to detonators in the field. Signal transmission line / detonator contacts are susceptible to disruption, particularly when the signal transmission lines are subject to inadvertent tugging or tensile forces at the blast site. The present application discloses an electrical connector that enables secure connection between a signal transmission line and any detonator adapted to receive and optionally process electrical signals from the signal transmission line. Specifically, the electrical connector can be affixed to the signal input end of a detonator, and includes at least one bridge element to provide electrical contact between a signal transmission line, and internal electrical component(s) of the detonator.

Owner:ORICA EXPLOSIVES TECH PTY LTD

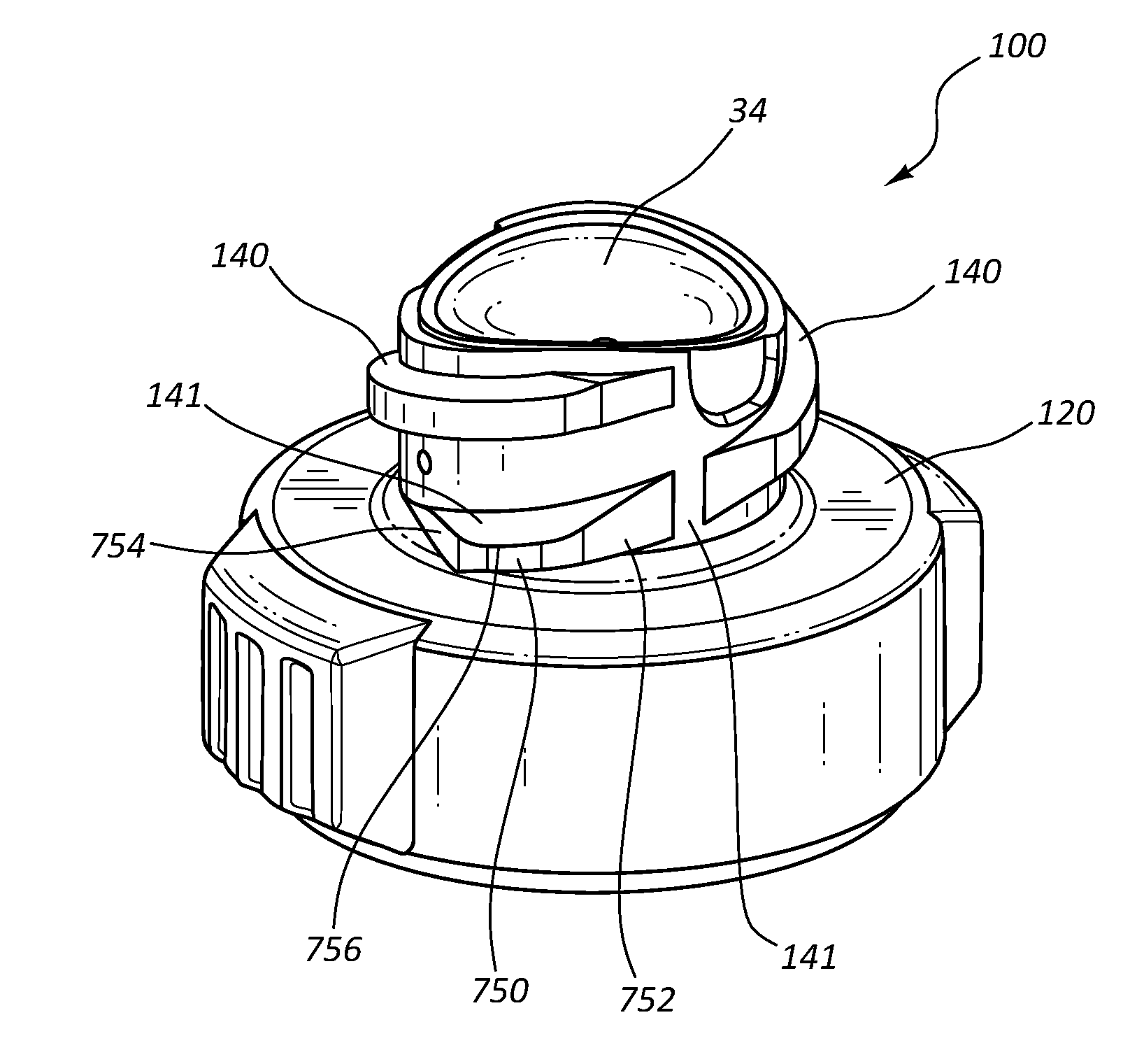

Retention feature for soft interface connection

ActiveUS9993634B2Increase contactImprove connection securityTube connectorsRetention functionTactile sensation

A retention feature configured to provide interference between a threaded connection of a Luer access device and a separate device, wherein the Luer access device further comprises a septum that provides a soft interfaced between the two threadedly connected devices. The retention features of the instant invention are designed to provide the user with a tactile sensation of a tightening threaded connection, despite a soft interface between the interconnected devices. The retention features of the instant invention further prevent “spring back” and unintentional disengagement of the interconnected devices.

Owner:BECTON DICKINSON & CO

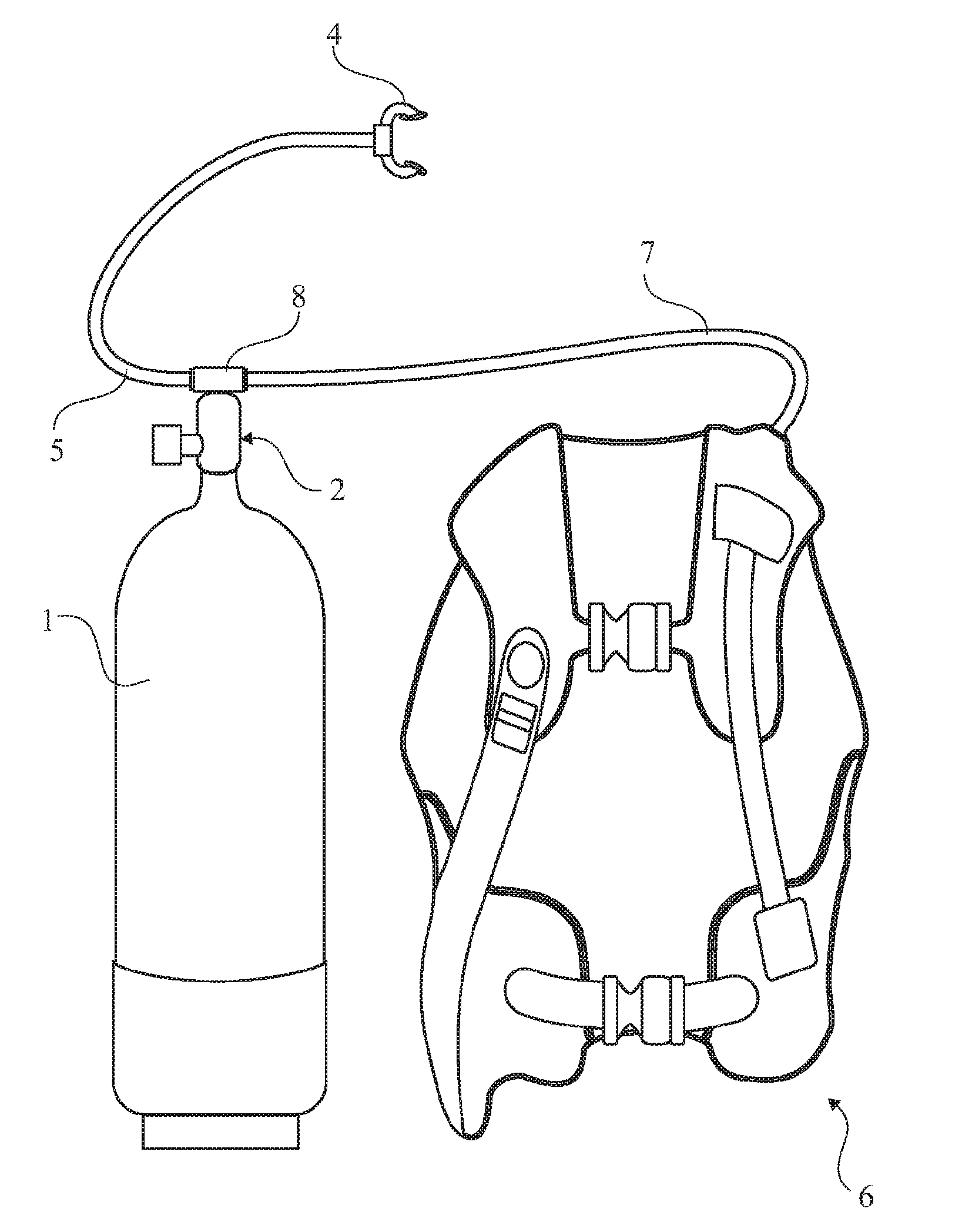

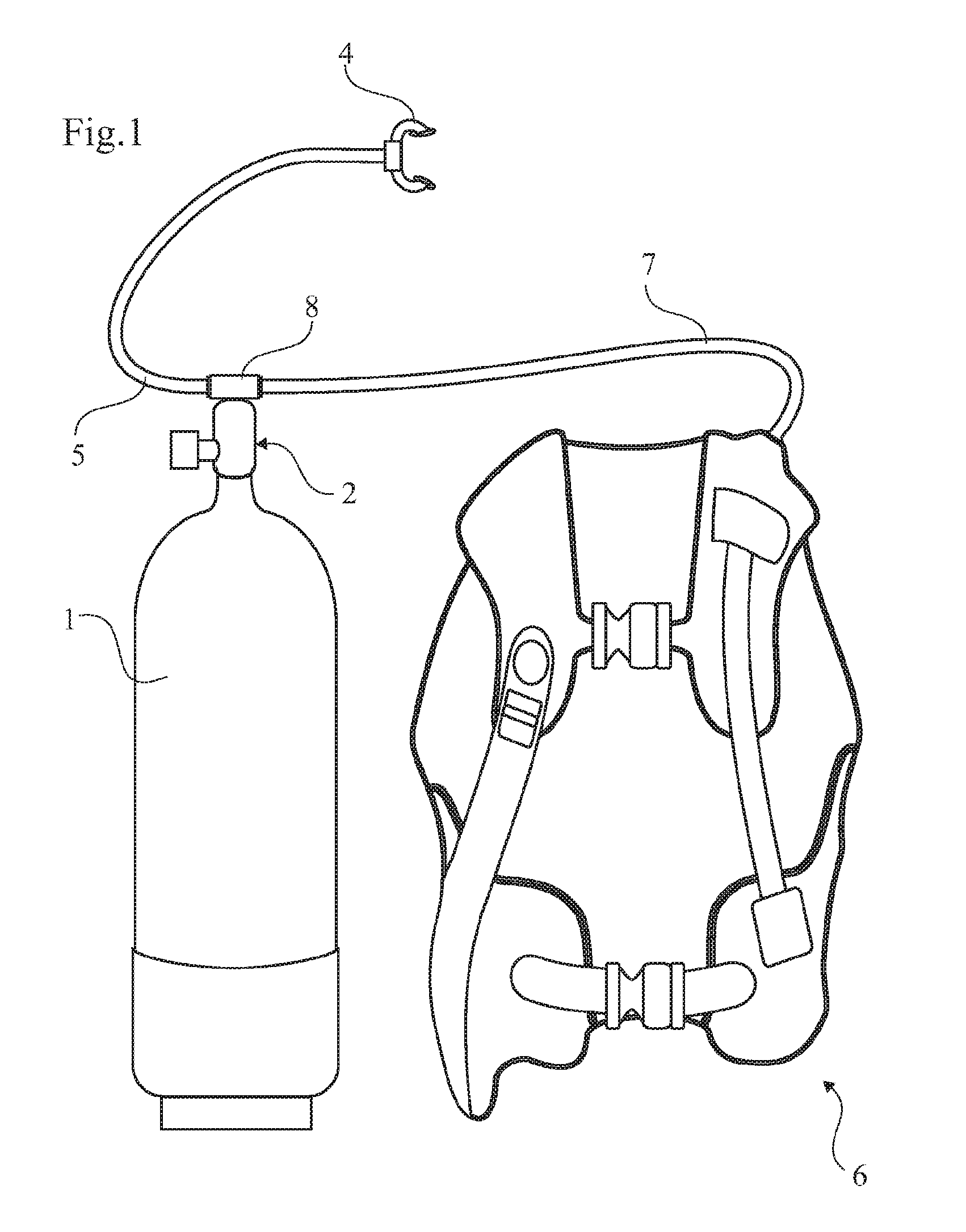

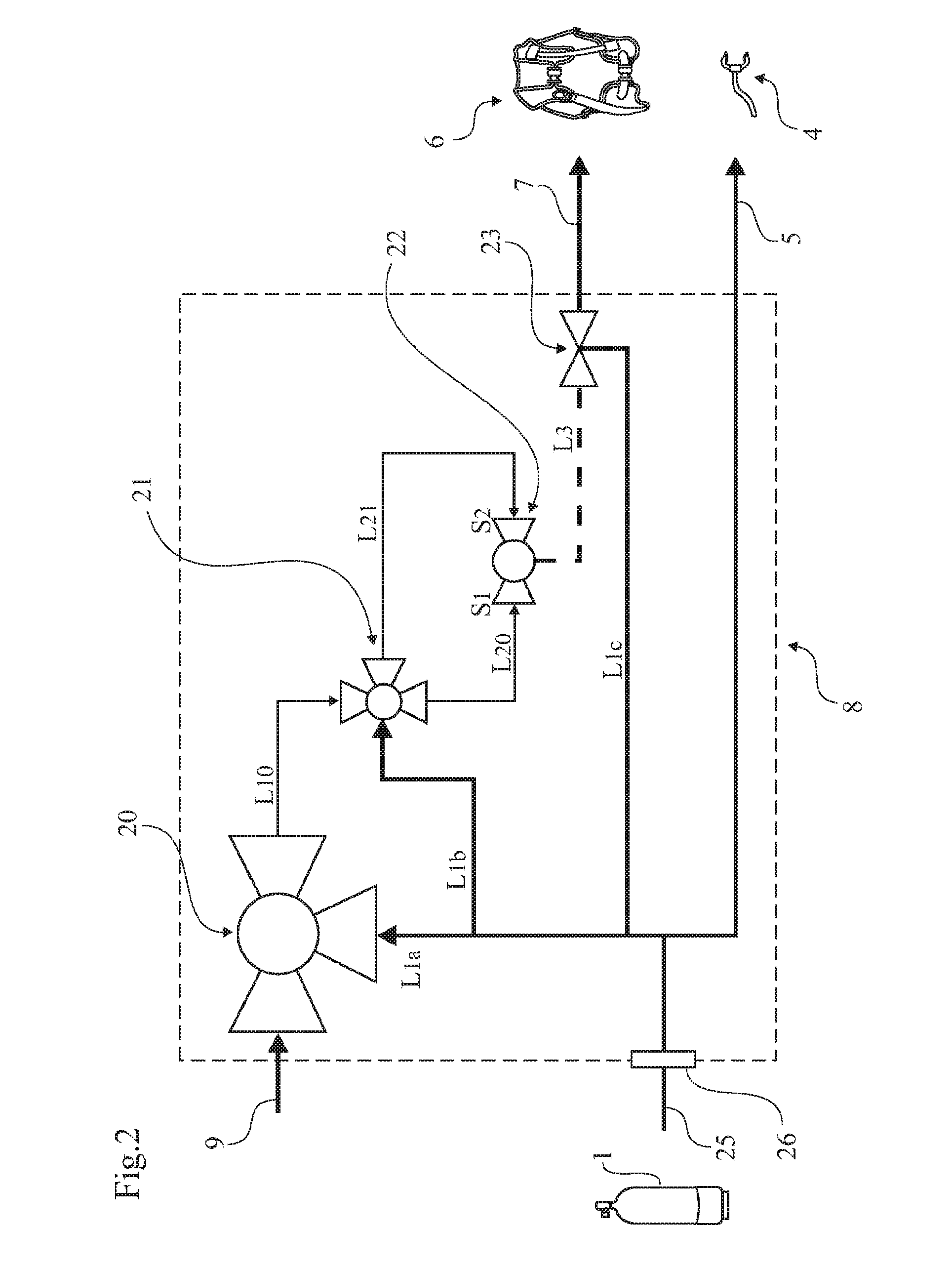

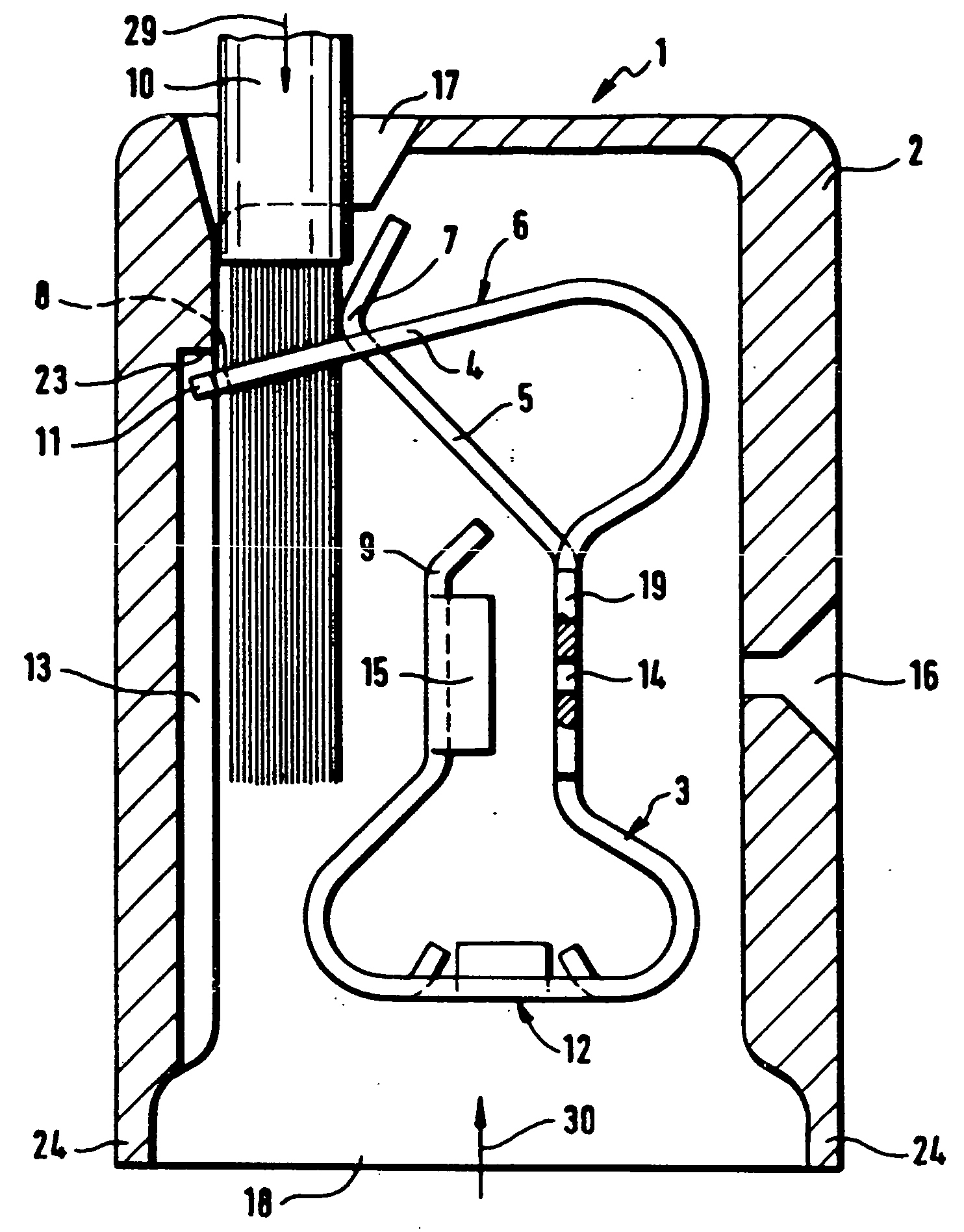

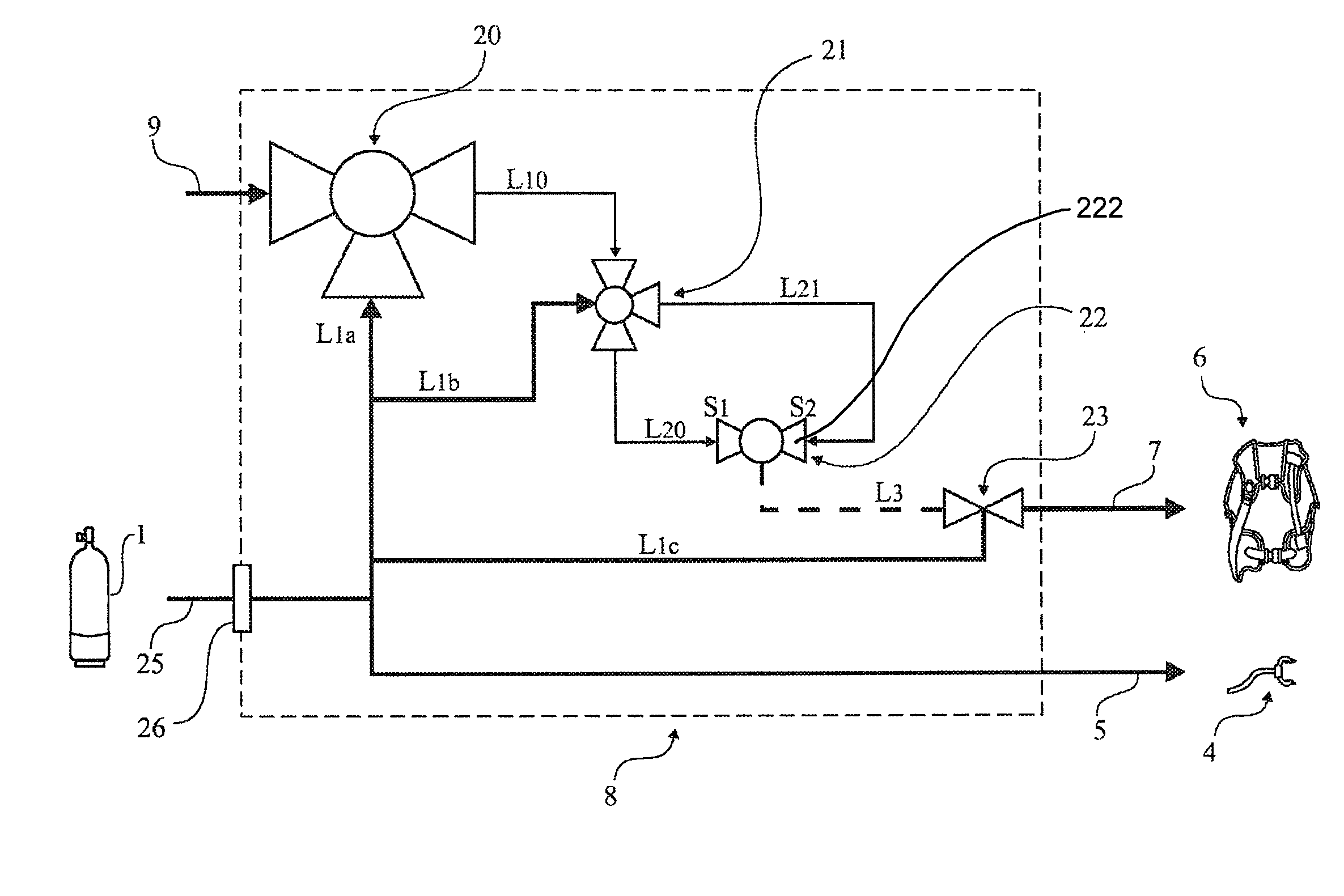

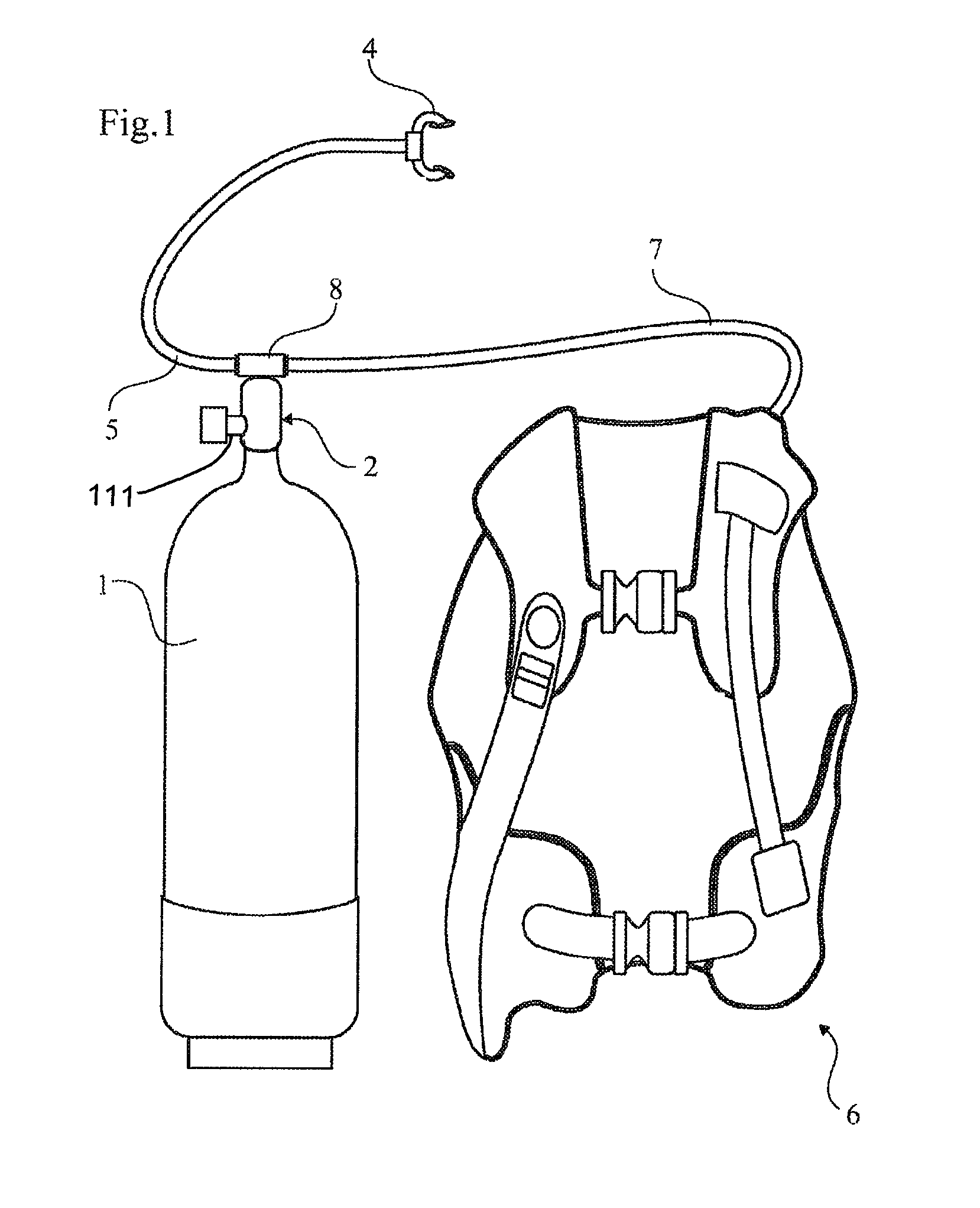

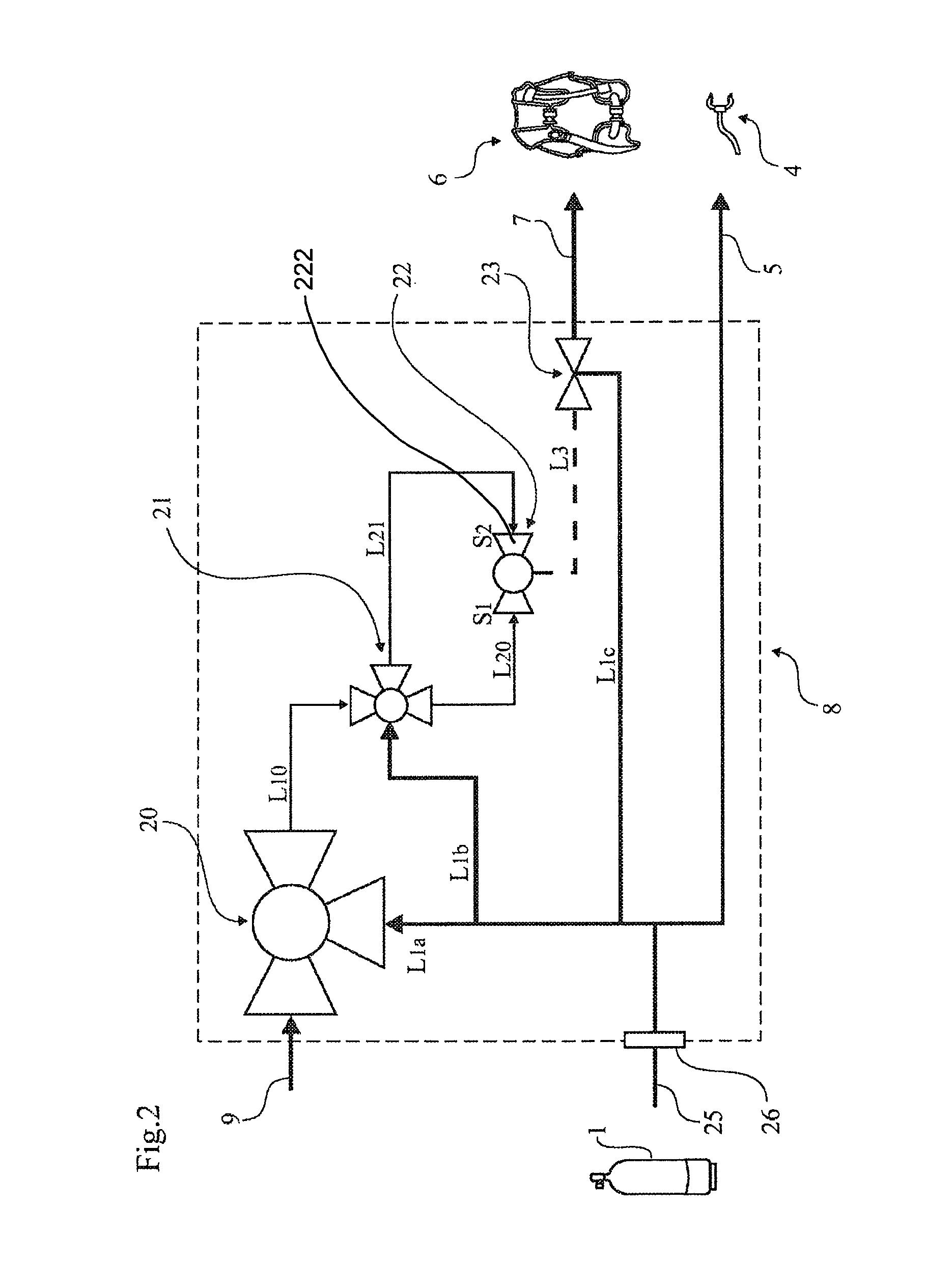

Safety device, diving equipment and safety method for scuba diving

ActiveUS20090217927A1Improved safety methodImprove reliabilityFire rescueLife-savingEngineeringBuoyancy

The present invention relates to a method in connection with SCUBA diving to control a diver's buoyancy, in which method the diver (11) is equipped with diving equipment comprising at least one air pressure tank (1), a valve device (2) connected to the pressure tank (1) and arranged to supply air from said pressure tank via first supply means (5) to a breathing regulator (4) and via second supply means (7) to an inflatable diving jacket (6) in order to control the diver's buoyancy, inflation of the diving jacket being initiated when the diver has not affected the air flow through the breathing regulator (4) for a certain time period. The invention also relates to a safety device and diving equipment.

Owner:SCUBATECH SWEDEN AB

Guide wire

The invention discloses a guide wire. The body of the guide wire comprises a near-end wire with good rigidity and a hyperelastic soft far-end wire, wherein the far-end side of the near-end wire and the base end side of the far-end wire respectively contain a flat surface. The flat surface of the near-end wire and the flat surface of the far-end wire are coincident and are connected by welding. Theguide wire structure adopts a welding method to combine the far-end wire rich in elasticity and the near-end wire with high rigidity, which ensures the obtained guide wire to have enough flexibilityand restoration property at the far end and have good push performance and twisting control performance at the near end, thereby lowering the possibility of the damage to blood vessels by the guide wire and enabling the guide wire to smoothly reach a diseased region. Moreover, due to increasing the welding combination area and effectively transferring a weak stress surface, the connection safety of the guide wire is increased.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

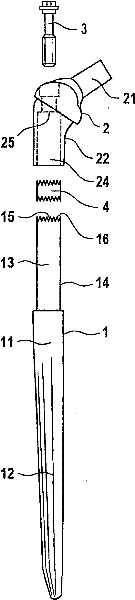

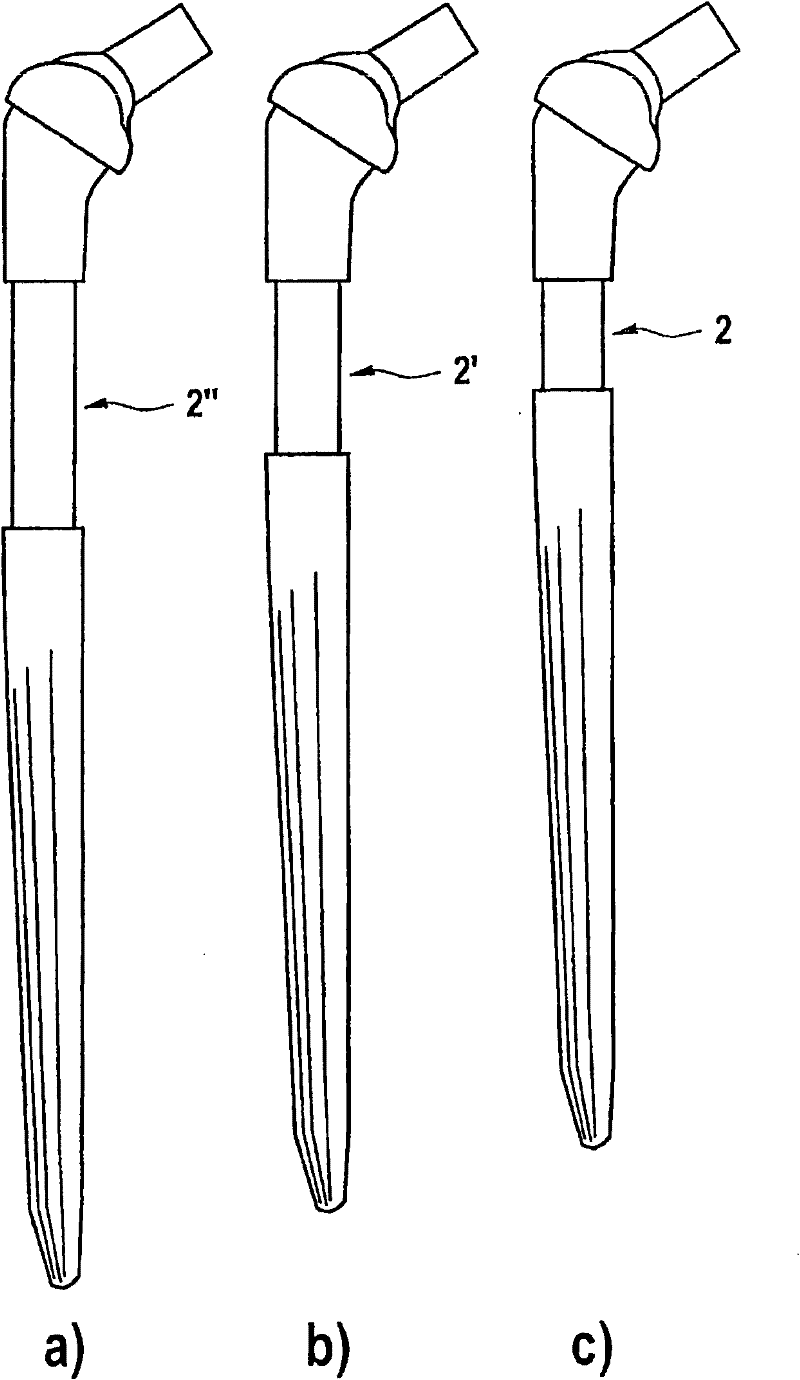

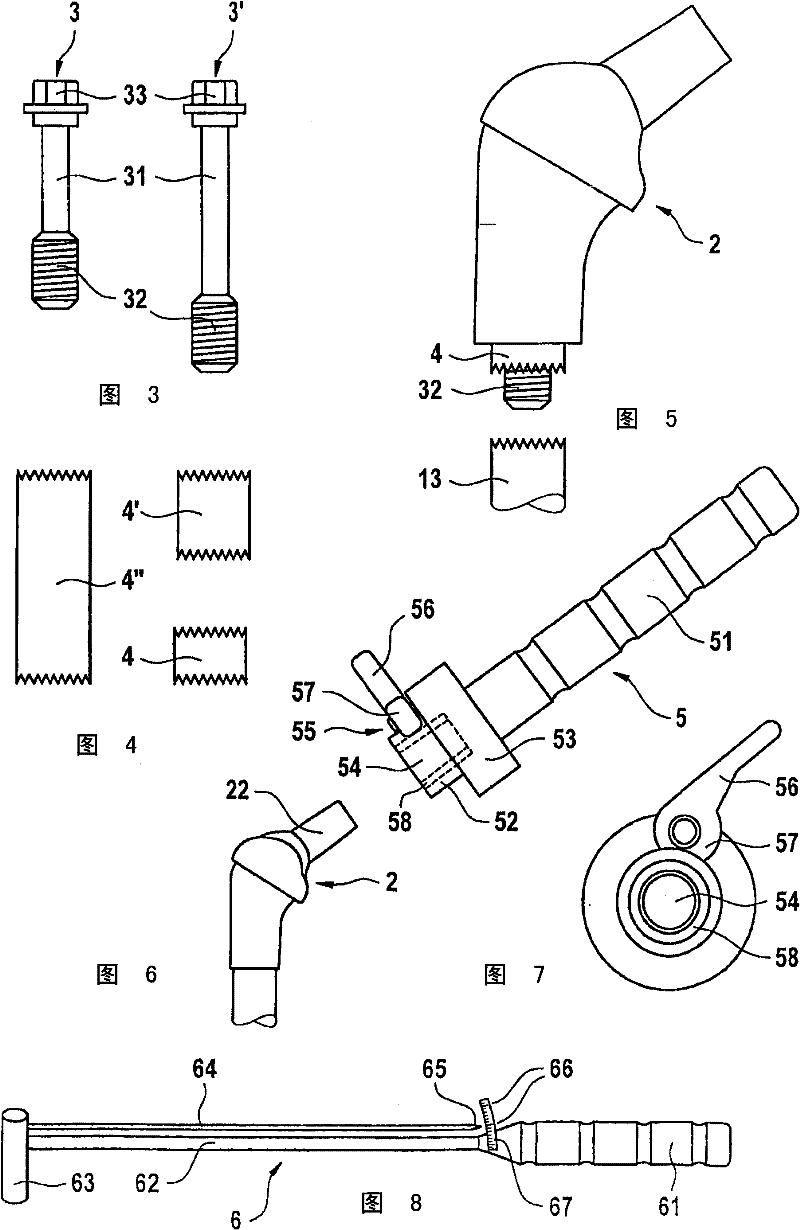

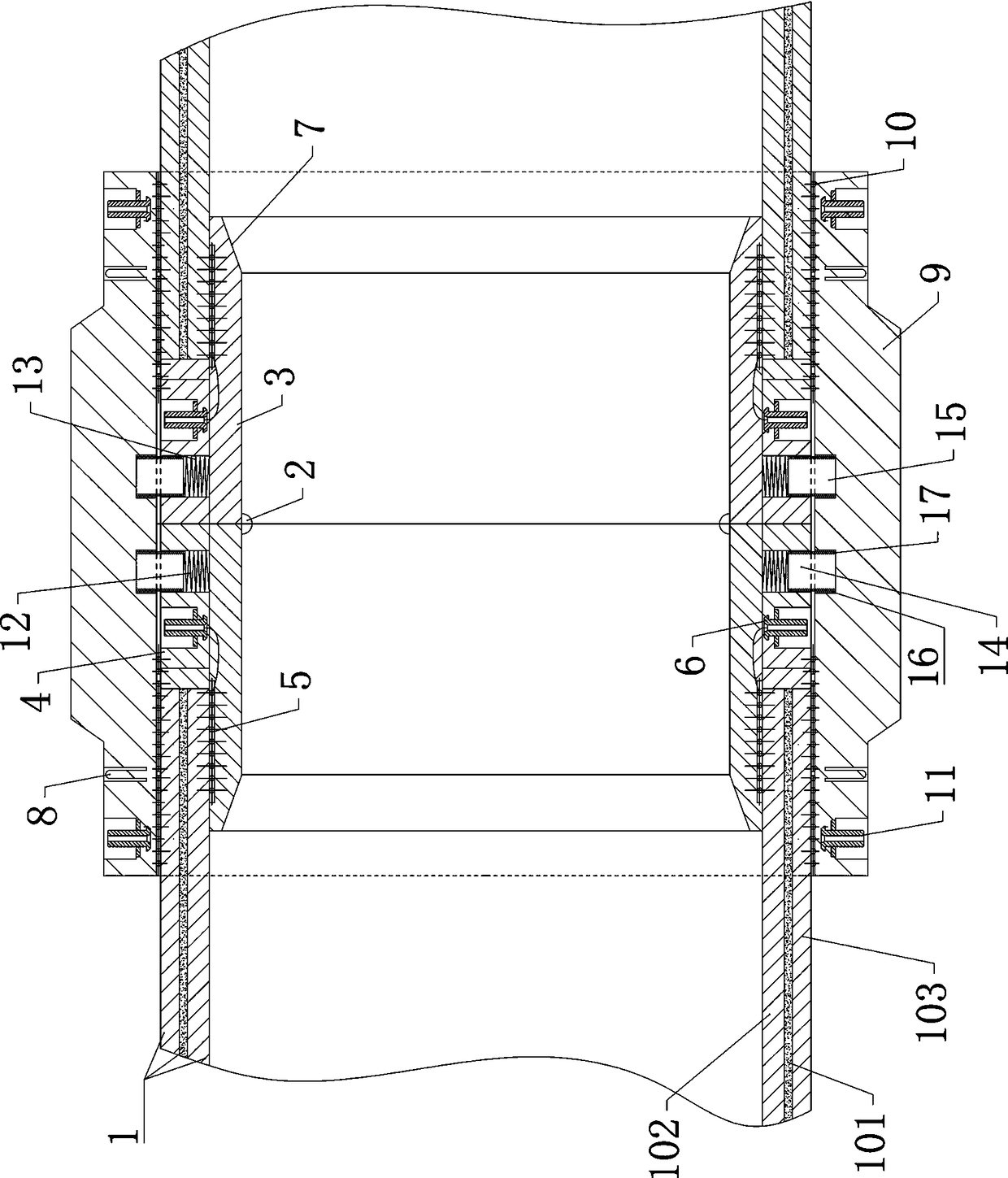

Modular femur-head prosthesis

InactiveCN102056572AImprove connection securityReduce the number of piecesJoint implantsFemoral headsProsthesisLeft femoral head

The invention relates to a modular femur-head prosthesis comprising a shaft part (1) for inserting into a medullary opening of a femur and a neck part (2) comprising a receiving surface (25), said neck part being fixed to a supporting surface (15) in the end region of the shaft part (1) by means of a screw element (3). According to the invention, at least one separate intermediate ring (4) is provided, said ring being situated between the supporting surface (15) of the shaft part (1) and the receiving surface (25) of the neck part (2) and being fixed by means of the screw element (3). This allows femur head-prostheses of differing sizes to be made available by a simple substitution of a component and allows the operating surgeon to also adapt the length of the prosthesis to solve problems that are discovered intraoperatively.

Owner:WALDEMAR LINK GMBH & CO

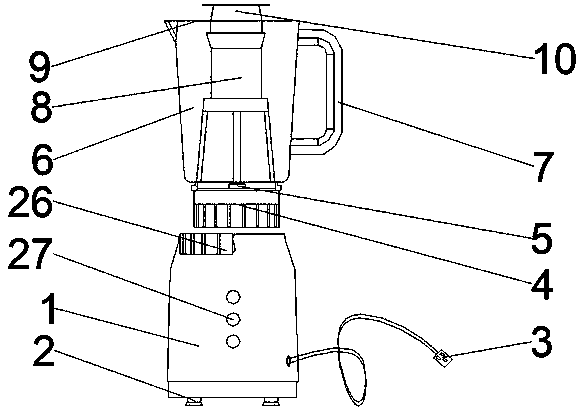

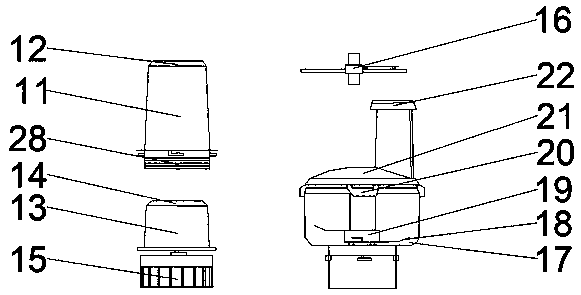

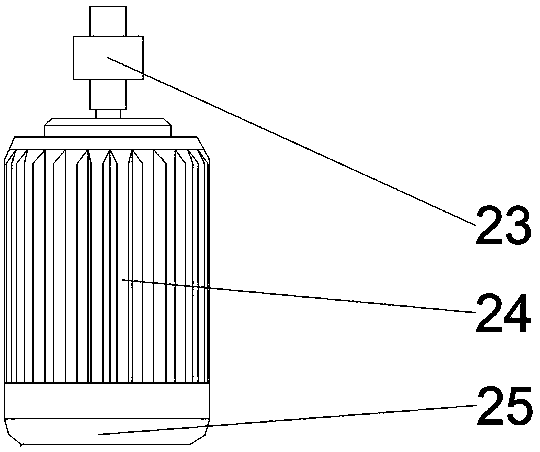

Kitchen juice squeezing and stirring machine

The invention provides an improved kitchen juicer blender, which includes a device body, a stirring cup, a cooking cup, a dry grinding cup, a shredding and slicing knife, and a meat grinder cup. An electric motor is fixedly connected to the inside of the device body. The lower side of the device body is fixedly connected with a triangular plug, the upper part of the conditioning cup is movably connected with a conditioning cup cover, the lower part of the conditioning cup is closely connected with a conditioning knife seat, and the upper part of the dry grinding cup is movably connected with a dry grinding cup. A cup cover, the bottom of the dry grinding cup is tightly connected with a dry sharpening seat, the top of the stirring cup and the upper part of the stirring cup cover are tightly connected with a measuring cup, the inside of the device body is fixedly connected with a motor, the The lower part of the motor is closely connected with a motor cover, and the upper part of the motor is movable with a motor heat insulation ring. The device is easy and fast to operate, novel in design, safe and practical, and is suitable for popularization and use in various families, restaurants and hotels.

Owner:陈钦旺

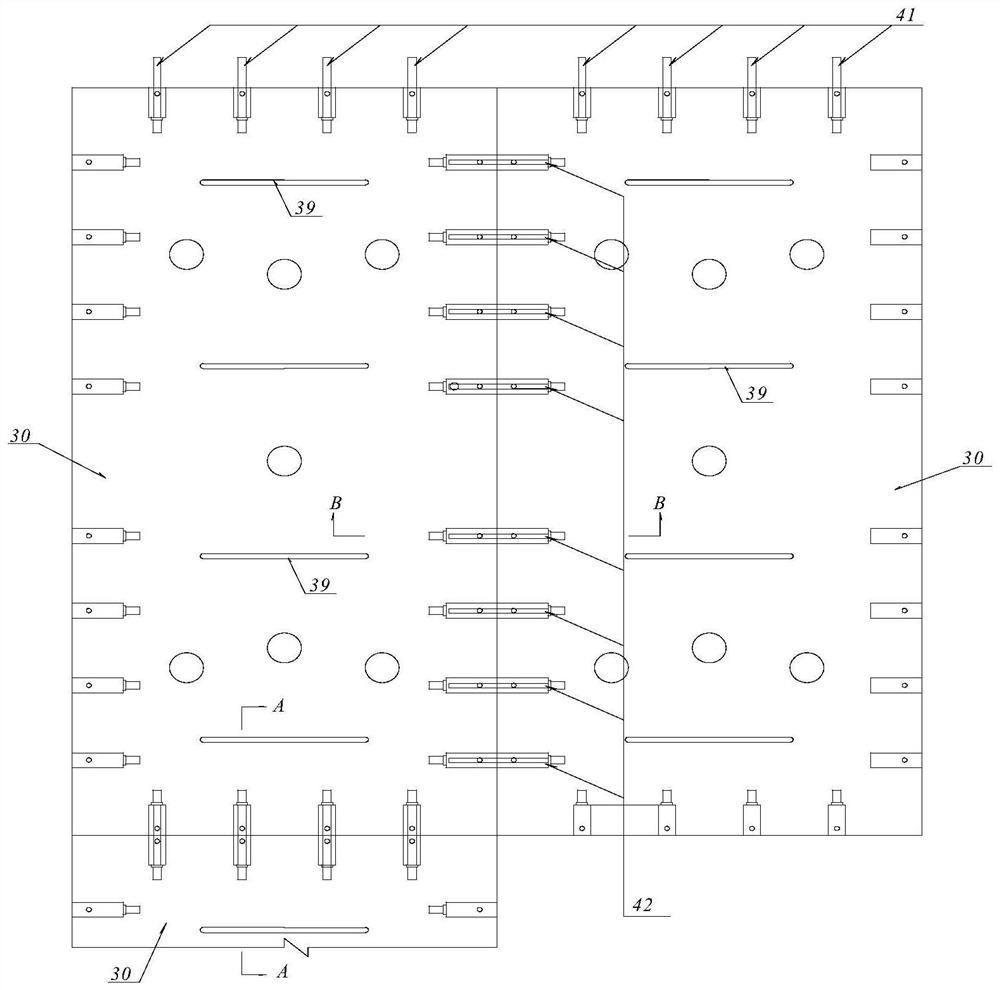

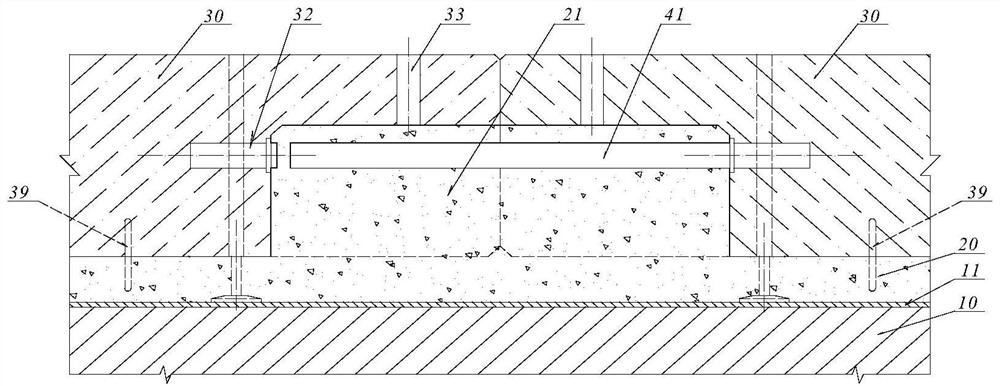

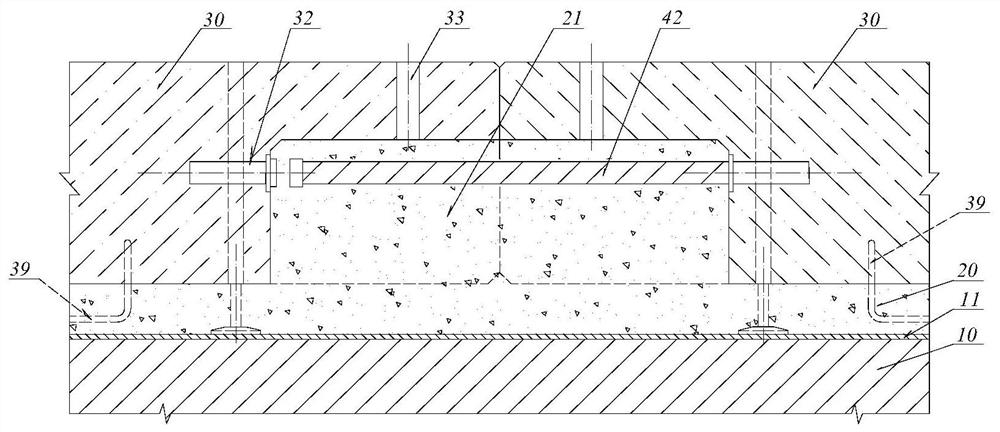

Assembly type pavement structure and construction method

PendingCN112626962AImprove connection securityHigh strengthSingle unit pavingsReinforced concreteArchitectural engineering

The invention discloses an assembly type pavement structure and a construction method, and aims to effectively improve the connection safety, the adjustment capability and the repairable capability of a prefabricated pavement, facilitate the manufacturing and transportation of the prefabricated pavement, and facilitate the assembly, repair, replacement and construction. Prefabricated pavement slabs are assembled on a roadbed to form an assembled pavement, each prefabricated pavement slab is of a prestressed reinforced concrete structure, longitudinal lower grooves are formed in the two longitudinal connecting ends of each prefabricated pavement slab at intervals in the width direction, and transverse lower grooves are formed in the two transverse connecting ends of each prefabricated pavement slab at intervals in the width direction. Rod-shaped connecting components are arranged in the corresponding longitudinal lower grooves or the corresponding transverse lower grooves of every two adjacent prefabricated pavement slabs. An isolation layer is laid on the surface of the roadbed, after the assembled prefabricated pavement slab is leveled, self-compacting concrete is densely poured into a gap between the laid isolation layer and the prefabricated pavement slab to form an adjusting layer, and positioning bosses which protrude upwards and are embedded into longitudinal lower grooves and transverse lower grooves of the prefabricated pavement slab are formed on the adjusting layer.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

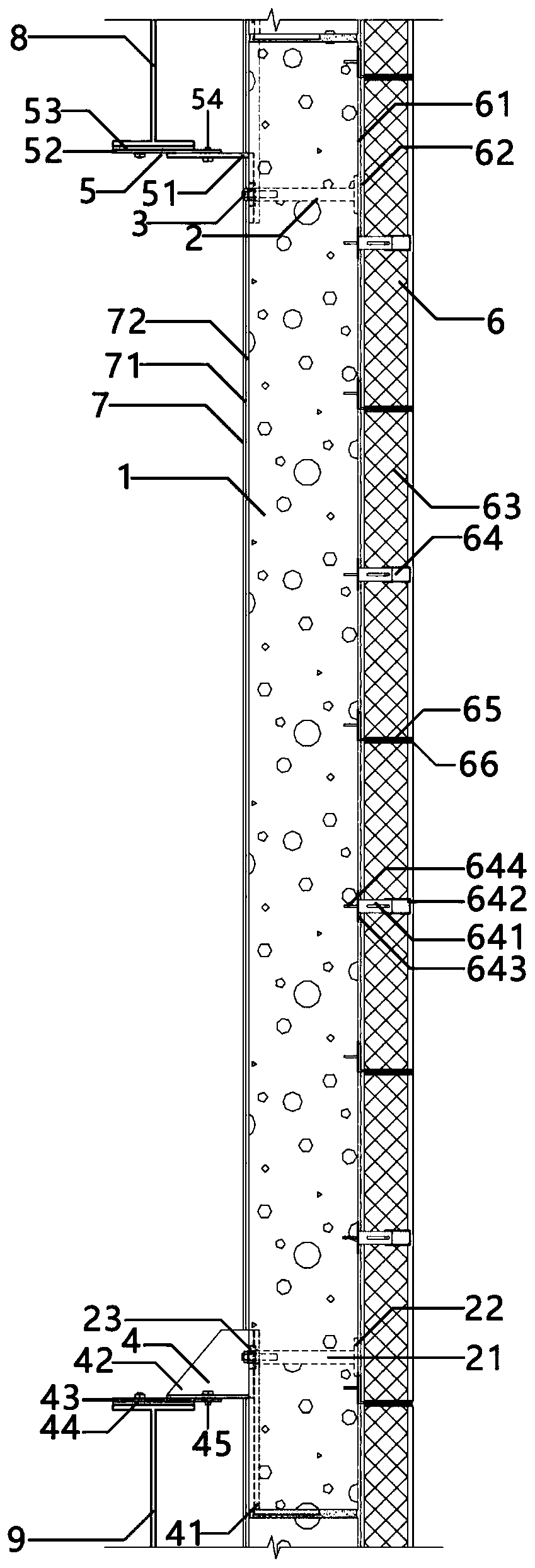

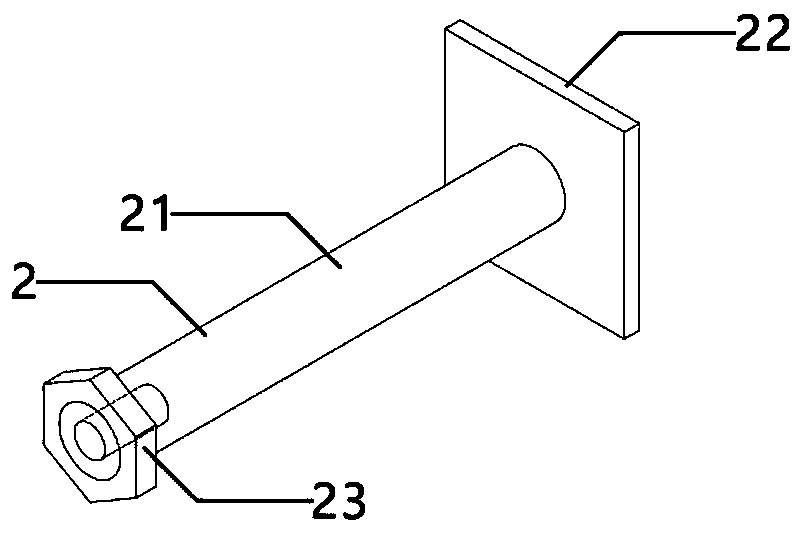

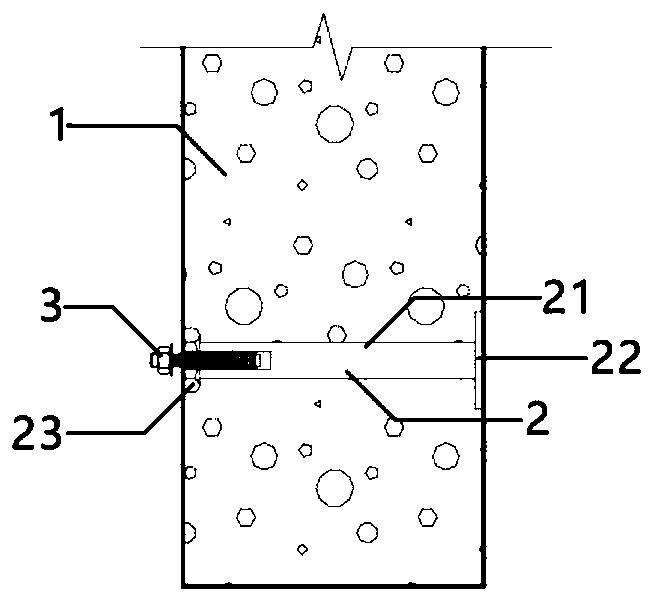

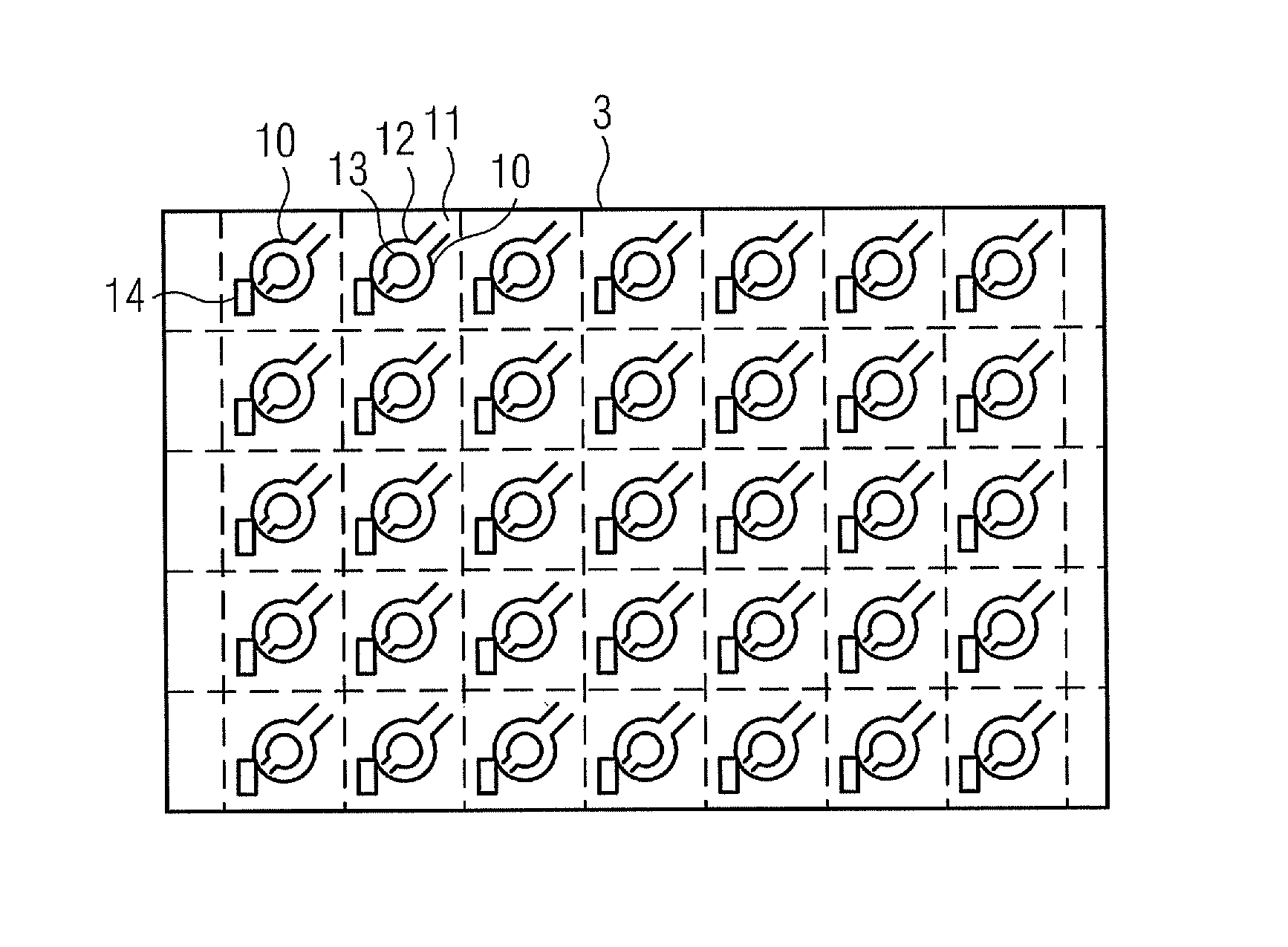

Three-dimensional adjustable assembled light-weight batten outer wall system and construction method thereof

The invention belongs to the field of building engineering, and particularly relates to a three-dimensional adjustable assembled light-weight batten outer wall system used for an assembled steel structure building. The three-dimensional adjustable assembled light-weight batten outer wall system is used for the assembled steel structure building, and comprises light-weight battens, sleeves, connecting screw bolts, supporting elements, tensioning elements, an outer side heat insulation decoration plate system and an inner side veneer system, wherein one sleeve is respectively arranged in a position, near the batten end part, of each of the upper and lower ends of each light-weight batten; the lower end of each light-weight batten is connected with a lower layer framework steel beam through the sleeves, the connecting screw bolts and the supporting elements; the three-dimensional adjustability of the lower end connection of the light-weight battens in the thickness, width and height directions of a wall plate is realized; the upper end of each light-weight batten is connected with an upper layer framework steel beam through the sleeves, the connecting screw bolts and the tensioning rods; and the three-dimensional adjustability of the upper end connection of the light-weight battens in the thickness, width and height directions of the wall plate is realized. The requirements on thethermal performance of the wall body in cold and severe cold areas are met; the problem of heavy object nailing and hanging on a wall body and groove formation for pipeline arrangement are solved; the three-dimensional adjustability of the wall plate installation is realized; the requirement on the installation precision of the wall plate is met; and the construction efficiency is improved.

Owner:SHANDONG JIANZHU UNIV

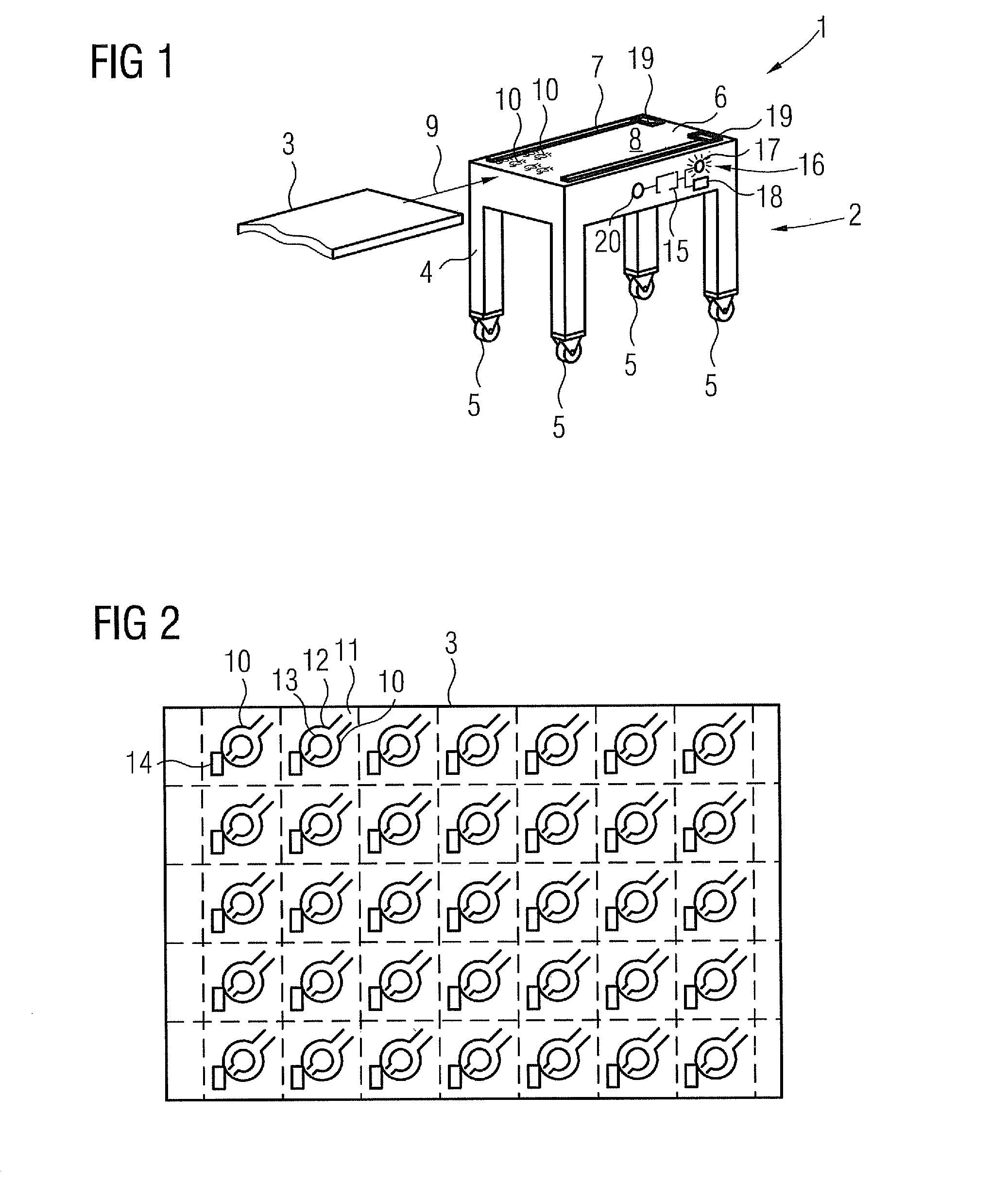

Patient support and/or transport means and magnetic resonance system

InactiveUS8798717B2Improve connection securityHigh clinical safetyOperating tablesStretcherResonanceEngineering

A patient support and / or transport device is proposed. The patient support and / or transport device comprises a receptacle in particular for a push-in patient support plate. At least one metal detection device is provided on the receptacle adjacent to the patient support plate when the patient support plate is pushed in.

Owner:SIEMENS HEALTHCARE GMBH

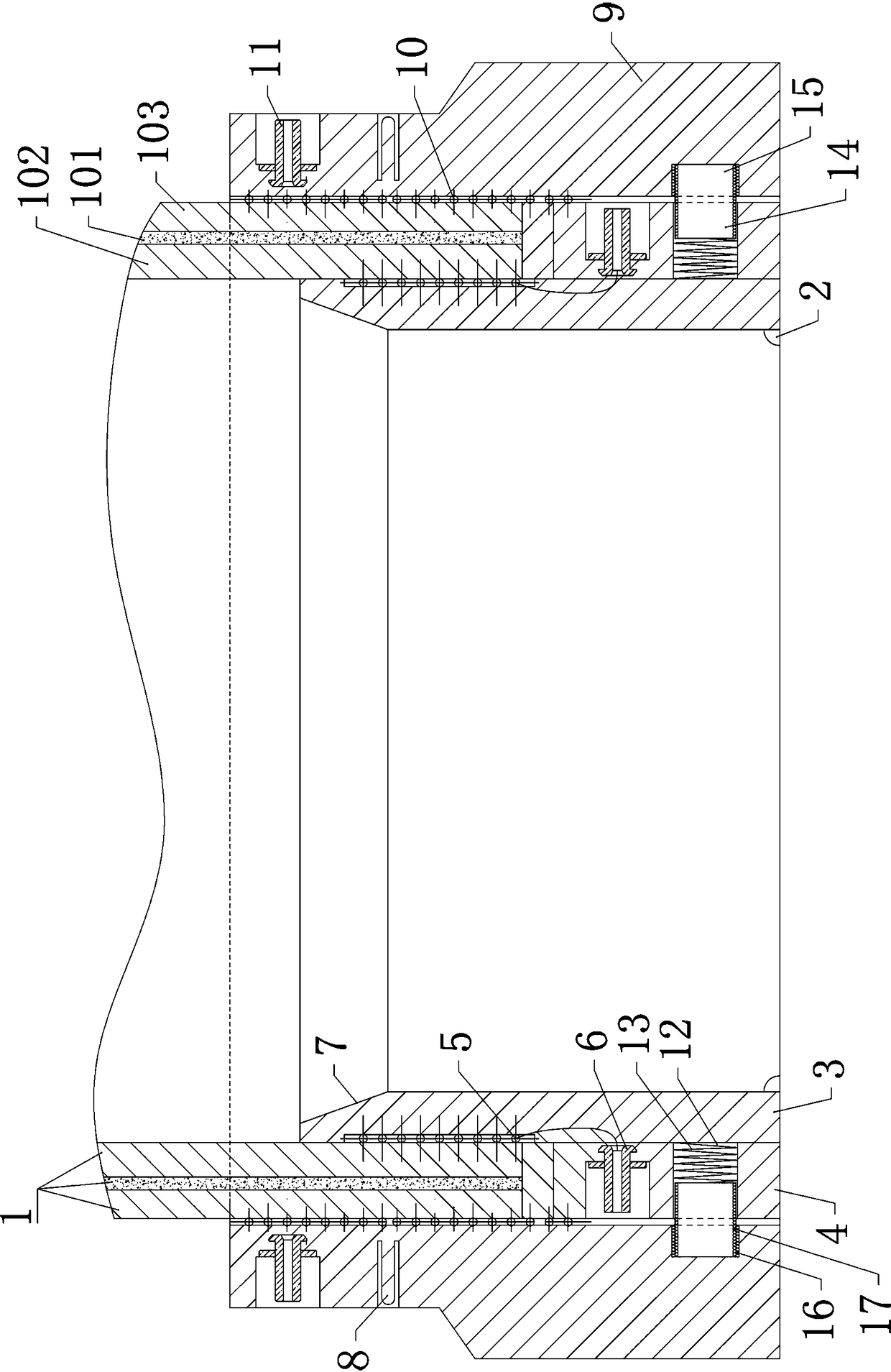

Full-plastic joint connecting device for steel wire skeleton plastic composite pipes and construction method

PendingCN108458196AGuaranteed structural strengthFever continuesPipe elementsCoatingsEngineeringHigh pressure

The invention relates to the field of water supply and water drainage of buried polyethylene steel wire skeleton composite pipes, and particularly relates to a full-plastic joint connecting device forsteel wire skeleton plastic composite pipes and a construction method. The full-plastic joint connecting device comprises the two steel wire skeleton plastic composite pipes opposite to each other; acorresponding inner layer connecting piece is arranged in the middle of each of the two steel wire skeleton plastic composite pipes; outer side walls of the two sides of the corresponding inner layerconnecting piece are connected with inner walls of the steel wire skeleton plastic composite pipes arranged on the corresponding parts of the corresponding inner layer connecting piece in a hot melting manner; a corresponding outer layer connecting piece is arranged on the outer side of the corresponding inner layer connecting piece in a sleeving manner; and inner walls of the two sides of the corresponding outer layer connecting piece are respectively connected with outer side walls of the corresponding steel wire skeleton plastic composite pipe arranged on one side in a hot melting manner.The full-plastic joint connecting device disclosed by the invention has the advantages that structural design is reasonable, an operation is simple, structural strength of a connection part can be effectively ensured, and the structure is stable and is good in high pressure resistance, and is good in sealing performance.

Owner:SHANDONG DONGHONG PIPE IND

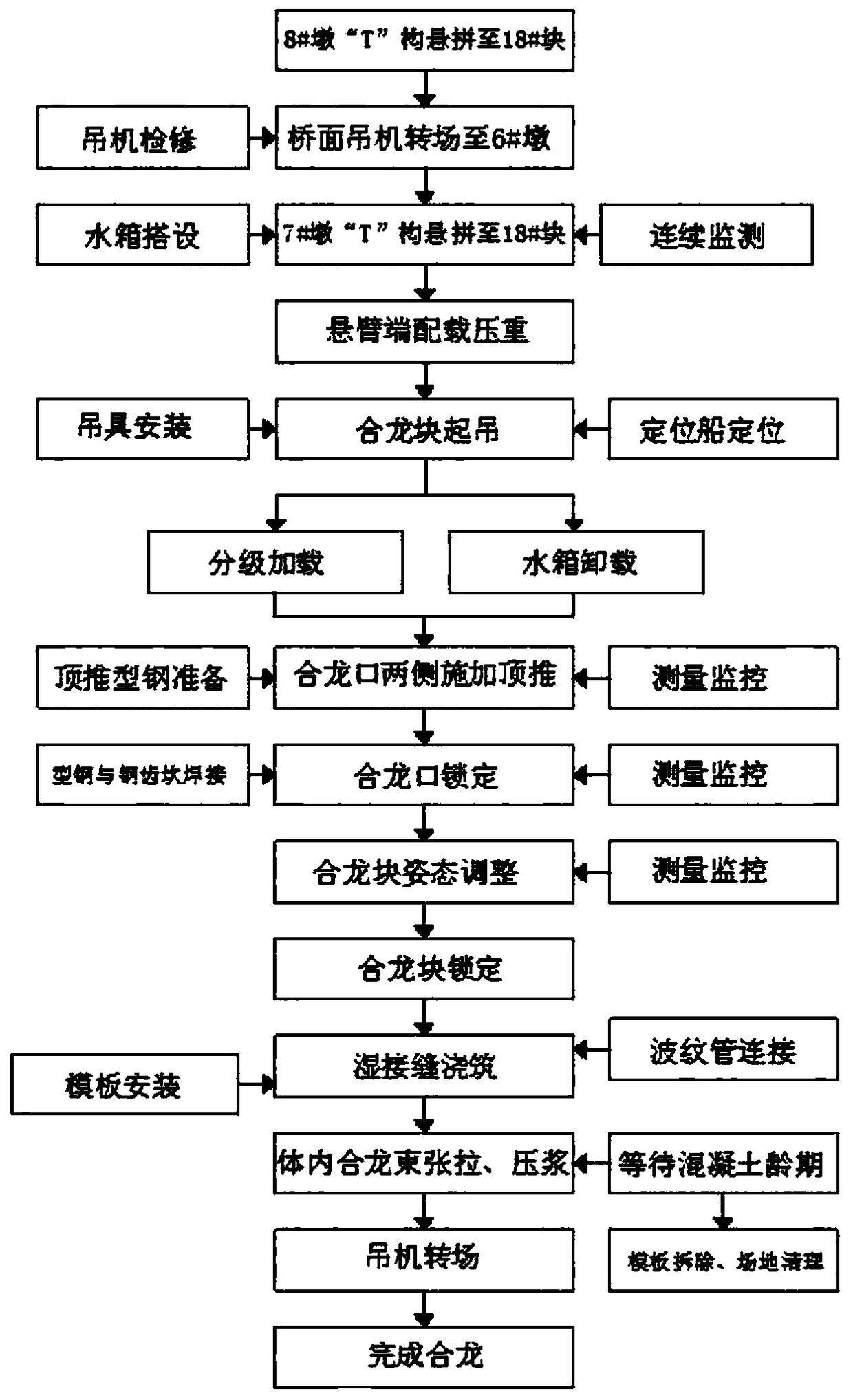

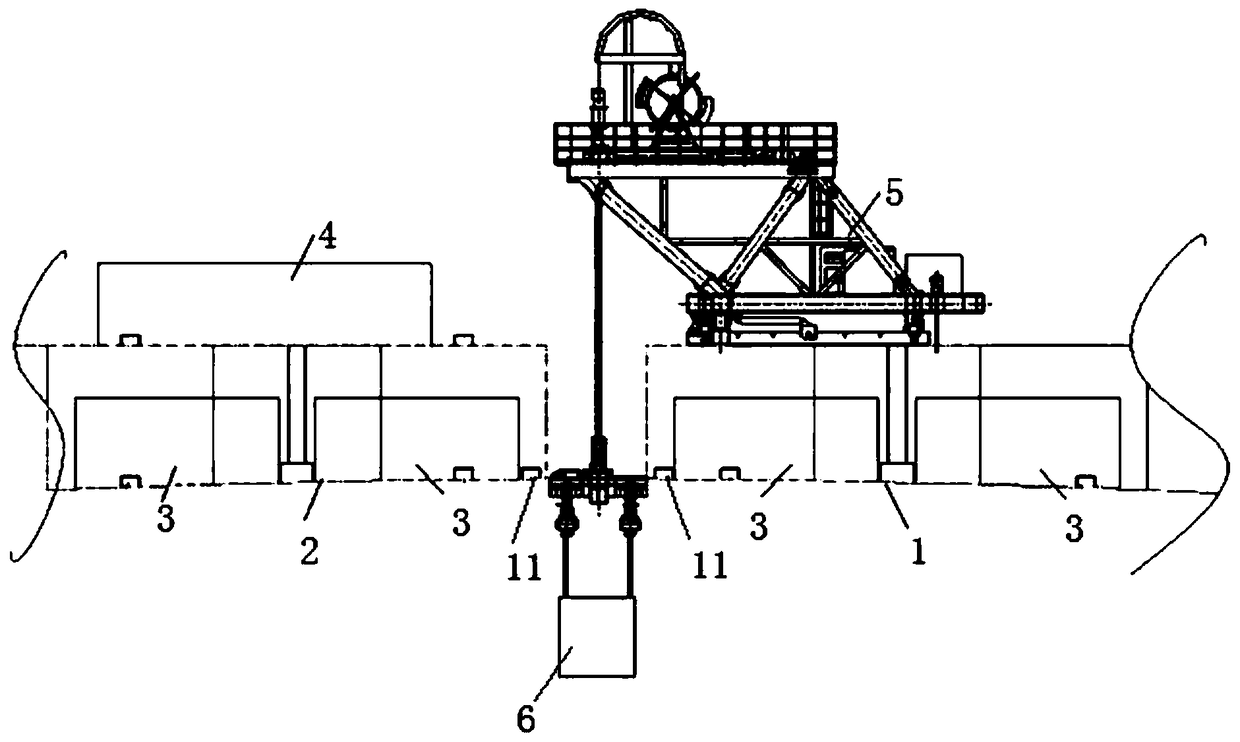

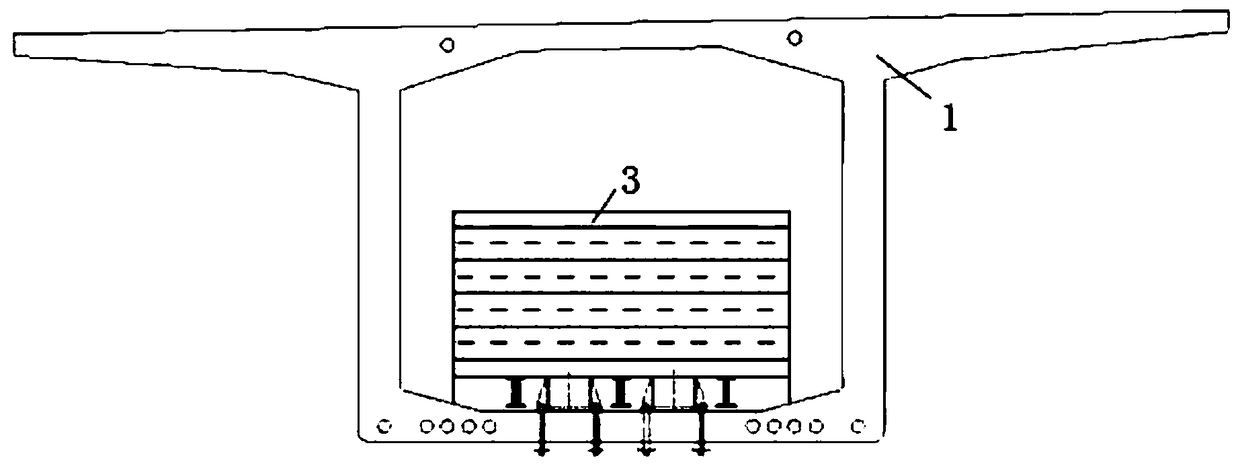

Large-span T-type steel structure segmental beam mounting and closing method for isle-connecting bridge

InactiveCN108716189AImprove connection stabilityImprove connection securityBridge erection/assemblyCantileverSpandrel

The invention discloses a large-span T-type steel structure segmental beam mounting and closing method for an isle-connecting bridge. The method comprises the following steps that a, water tank balance weight systems are installed at the cantilever ends of adjacent T-type steel structure segmental beams respectively, and a bridge floor crane is preserved at the top of one segmental beam; b, a closure block is hoisted by the bridge floor crane, the plane position and elevation of the closure block are adjusted to be within the designed parameter standard, and the closure block is locked temporarily; c, jacking force is applied to the segmental beams on the two sides of a closure opening, the bridge profile of the closure block and the closure segment is adjusted, and finally the closure block is locked; d, wet joint vertical formwork pouring and closure strand stretching are completed. According to the method, mounting and closure of the large-span T-type steel structure beams with thespan above 150 m can be guided, the connecting stability and safety of the T-type steel structure segmental beams are effectively improved, investment of offshore large mounting equipment is reduced,the construction cost is reduced, the construction efficiency is improved, and the precision requirement of bridge closure mounting is met.

Owner:CCCC SECOND HARBOR ENG

Three-way joint for connecting pipes

The invention discloses a three-way joint for connecting pipes, consisting of a nylon three-way joint body and three metal pieces, wherein the nylon three-way joint body is provided with three sections of joints for connecting the pipes; the three sections of joints are respectively provided with an inner hole; three inner holes are mutually communicated and are respectively provided with one metal piece in an inserting manner; each metal piece comprises a base part and a penetrating-inserting connecting part; and all the three metal pieces are connected in a penetrating and inserting manner to form a whole body by respective penetrating-inserting connecting parts. The three-way joint has the advantages of simple structure, convenient installation, low cost, and great improvement on connection strength and safety factor.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

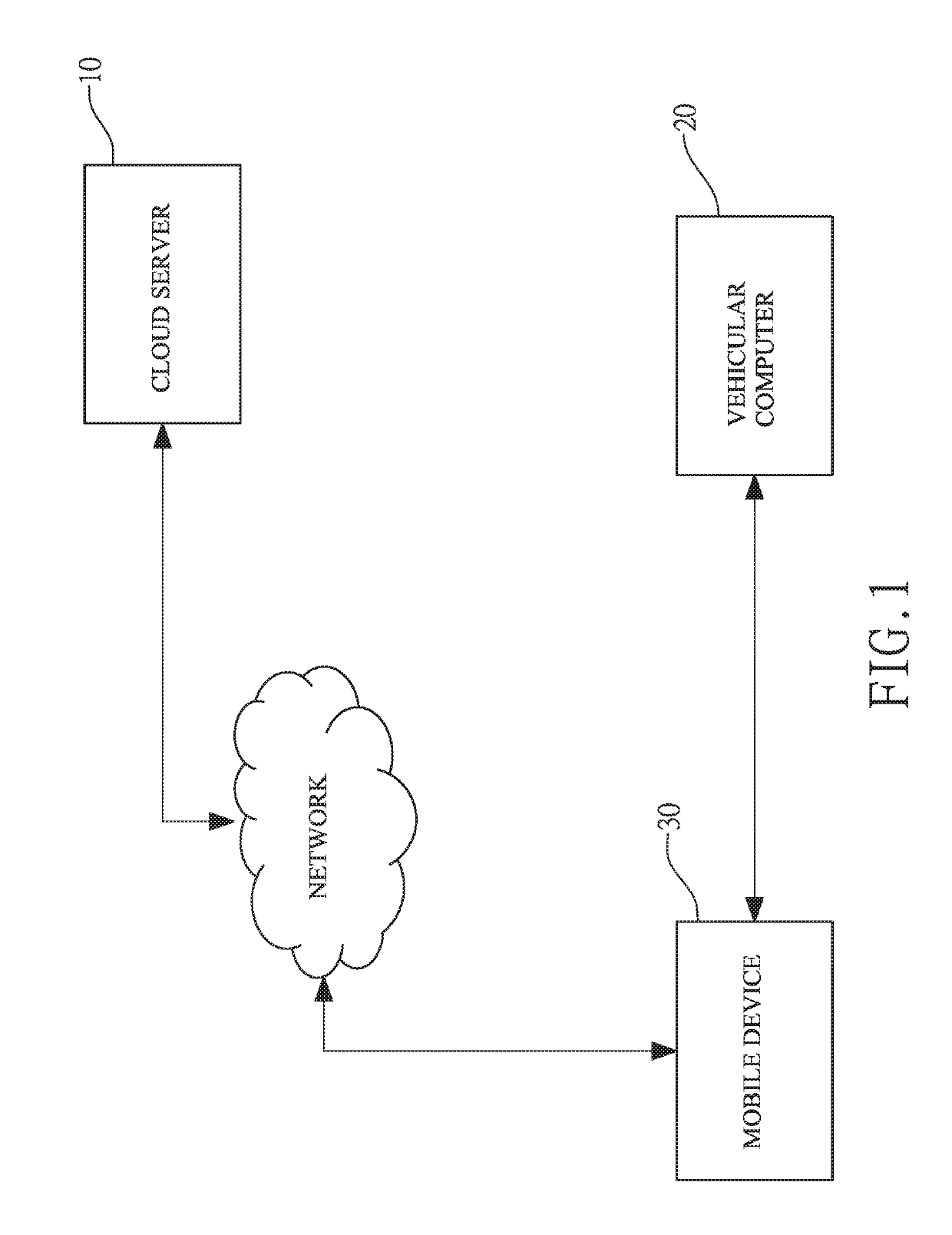

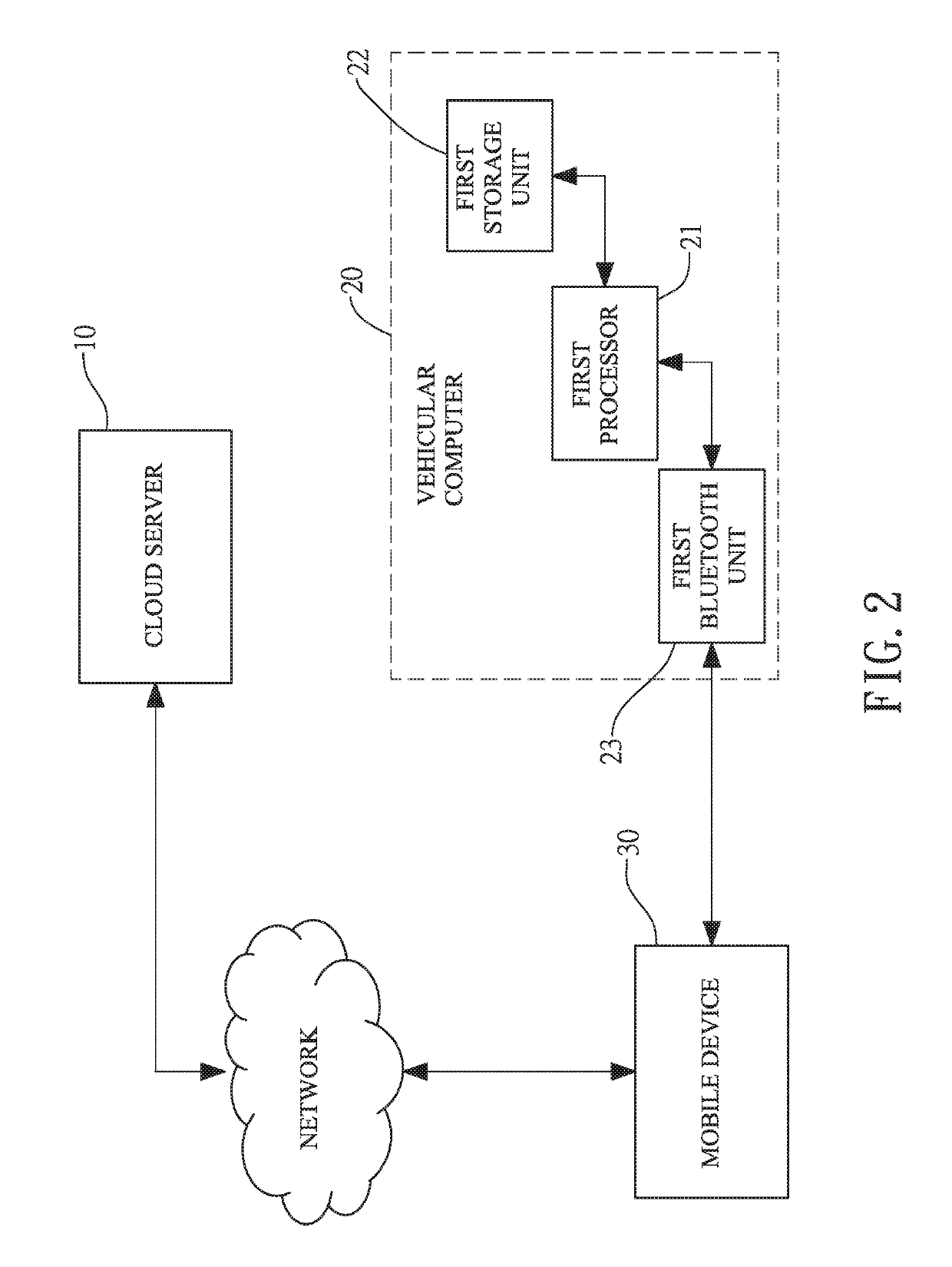

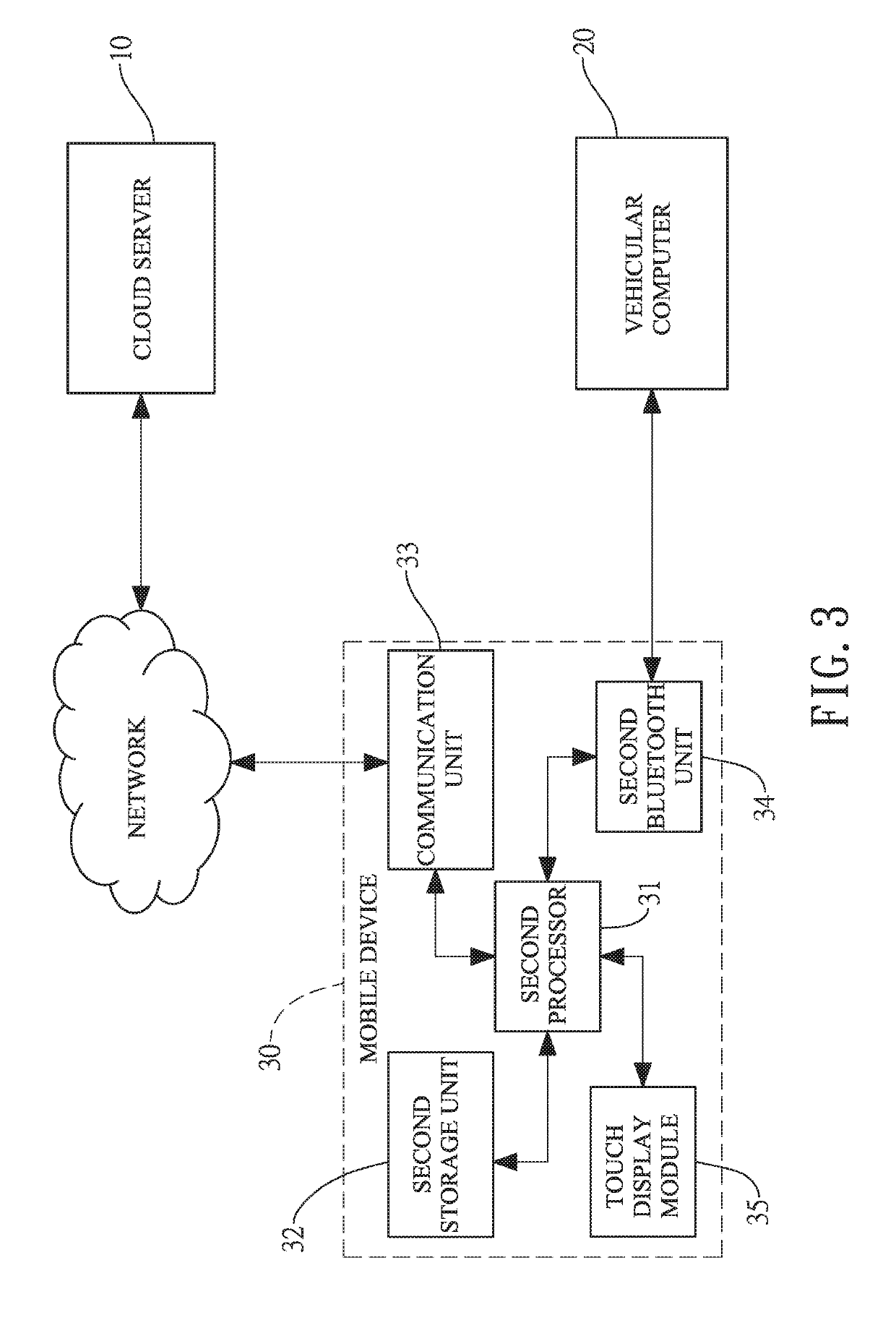

Internet of vehicles system performing connection authentication through a public network and connection method

ActiveUS10493955B1Enhance connection securityImprove connection securityRegistering/indicating working of vehiclesParticular environment based servicesOnline identityData exchange

An Internet of Vehicles system performing connection authentication through a public network and a connection method using the same are disclosed. A mobile device transmits an authentication code to a remote cloud server to complete an online identity authentication, searches a local vehicular computer through a Bluetooth connection after completion of the online identity authentication, exchanges information with the vehicular computer, authenticates the exchanged information, and establishes connection with the vehicular computer after completion of the authentication. For control over the vehicular computer of a vehicle through the mobile device, the online identity authentication must be completed before data exchange and established secure connection, thereby effectively enhancing effectiveness of connection security and lowering the risk of vehicle theft.

Owner:IVTES LTD

Assembly joint of prefabricated column and integrated prefabricated beam plate and construction method of assembly joint

The invention discloses an assembly joint of a prefabricated column and an integrated prefabricated beam plate and a construction method of the assembly joint. The assembly joint comprises the horizontal integrated prefabricated beam plate and the vertical prefabricated column; the prefabricated column includes a lower prefabricated column body and an upper prefabricated column body; concave post-cast connection areas are formed in the upper surface of the lower prefabricated column body, multiple upper reserved longitudinal bars are reserved on the upper surface of the lower prefabricated column body and extend from the bottoms of the post-cast connection areas, the extension length is smaller than the depth of the post-cast connection areas, and a vertical upper steel pipe is embedded inthe upper surface of the lower prefabricated column body in advance; the integrated prefabricated beam plate is arranged on the lower precast column body, and a steel pipe connection hole and multiple rib penetrating holes vertically run through the integrated prefabricated beam plate. The upper prefabricated column body is placed on the integrated prefabricated beam plate, a vertical lower steelpipe is embedded in the lower surface of the upper prefabricated column body, and multiple lower reserved longitudinal bars are reserved on the lower surface of the upper prefabricated column body, are coaxial with the rib penetrating holes and the upper reserved longitudinal bars one to one and penetrate through the rib penetrating holes to extend to the post-cast connection areas; the upper steel pipe and the lower steel pipe both extend into the steel pipe connection hole and are internally provided with connection steel bars.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

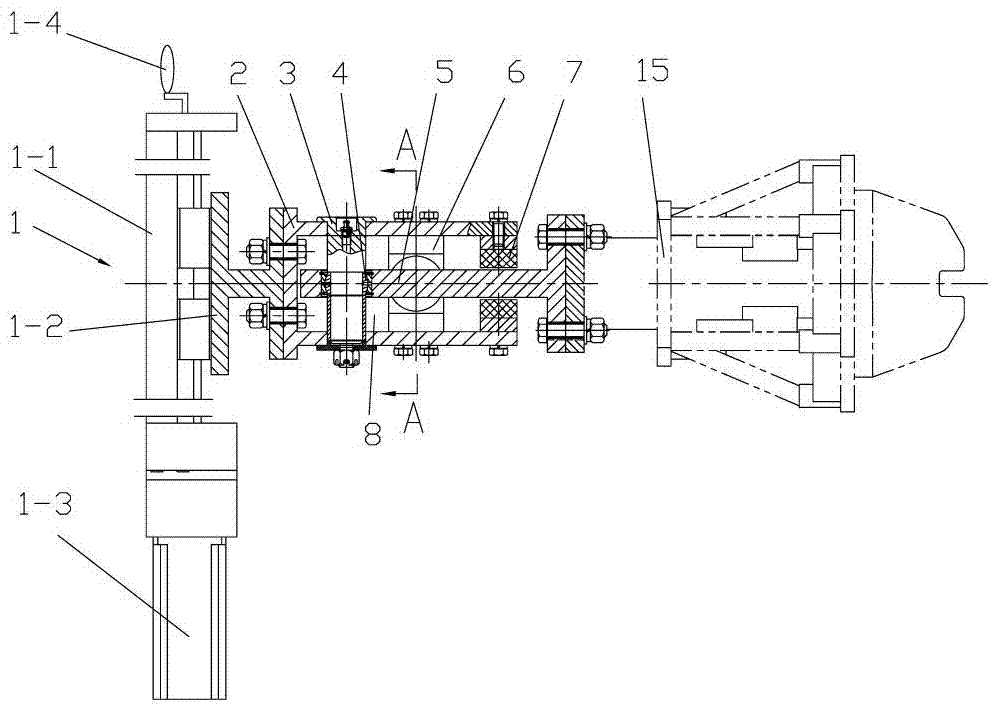

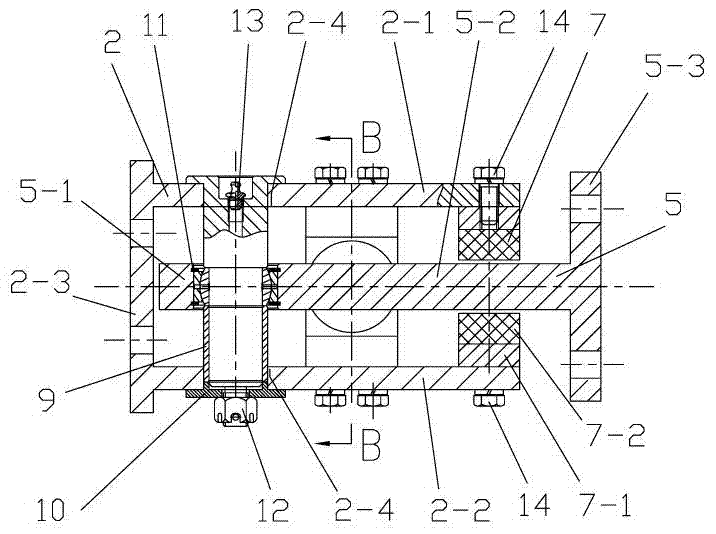

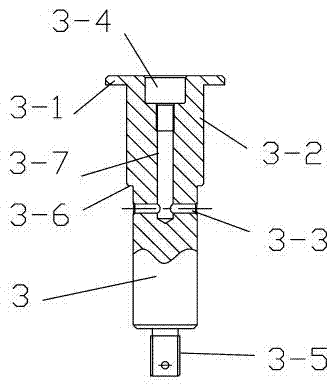

Traction device of road-railer

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

Electrical plug, holder, system having an electrical plug and a holder, and method of making a connection between an electrical plug and a holder

InactiveUS20050112915A1Done quickly and without toolsSmall transition resistanceLine/current collector detailsContact members penetrating/cutting insulation/cable strandsElectrical connectionEngineering

An electrical plug (1), a rigid holder, a system consisting of an electrical plug and a holder, and a method of making a connection between an electrical plug and a holder, are proposed, said electrical plug comprising a housing (2) and a spring clamp connection for connection of a flexible electric conductor (10) to the end piece of a rigid holder (20). The spring clamp connection is made out of a clamp spring (3) made of flat spring material, comprising a contact leg (5) and a clamp leg (4). The clamp leg is bent closed in the manner of a loop onto the end of the contact leg and comprises a clamp opening (6) through which the end of the contact leg protrudes. A clamp edge (8) of the clamp opening located opposed to the clamp leg, together with the clamp leg itself, forms a clamp location in which the electric conductor passed through the clamp opening is clamped before the plug is-mounted on the holder. After mounting of the plug on the holder, the holder extends through the clamp opening between the contact leg and the electric conductor, and the holder and clamp spring are so braced against each other that the electric conductor is clamped between the clamp edge and the holder, thereby forming an electrical connection between holder and electric conductor.

Owner:NEWFREY

Safety device, diving equipment and safety method for scuba diving

The present invention relates to a method in connection with SCUBA diving to control a diver's buoyancy, in which method the diver (11) is equipped with diving equipment comprising at least one air pressure tank (1), a valve device (2) connected to the pressure tank (1) and arranged to supply air from said pressure tank via first supply means (5) to a breathing regulator (4) and via second supply means (7) to an inflatable diving jacket (6) in order to control the diver's buoyancy, inflation of the diving jacket being initiated when the diver has not affected the air flow through the breathing regulator (4) for a certain time period. The invention also relates to a safety device and diving equipment.

Owner:SCUBATECH SWEDEN AB

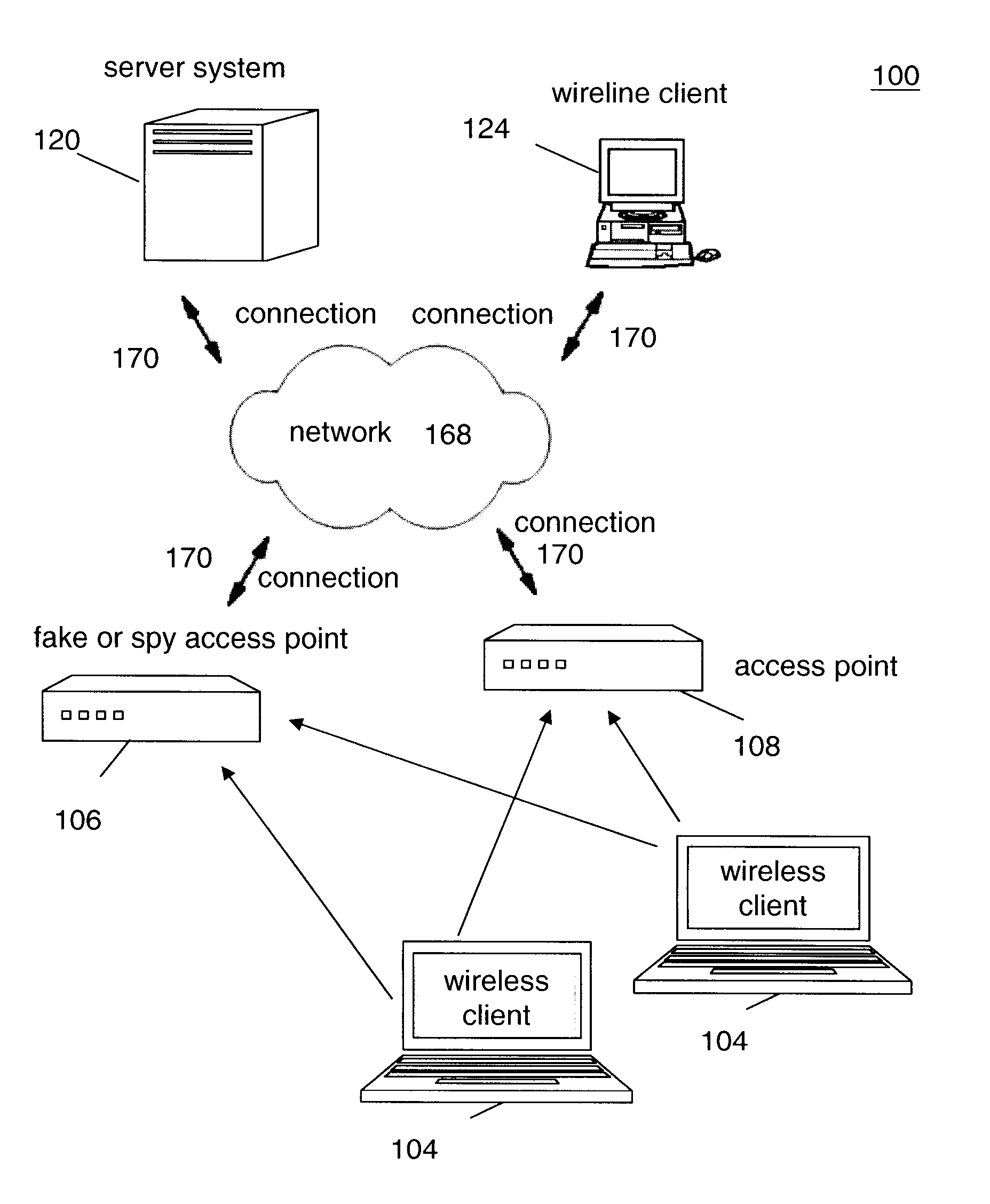

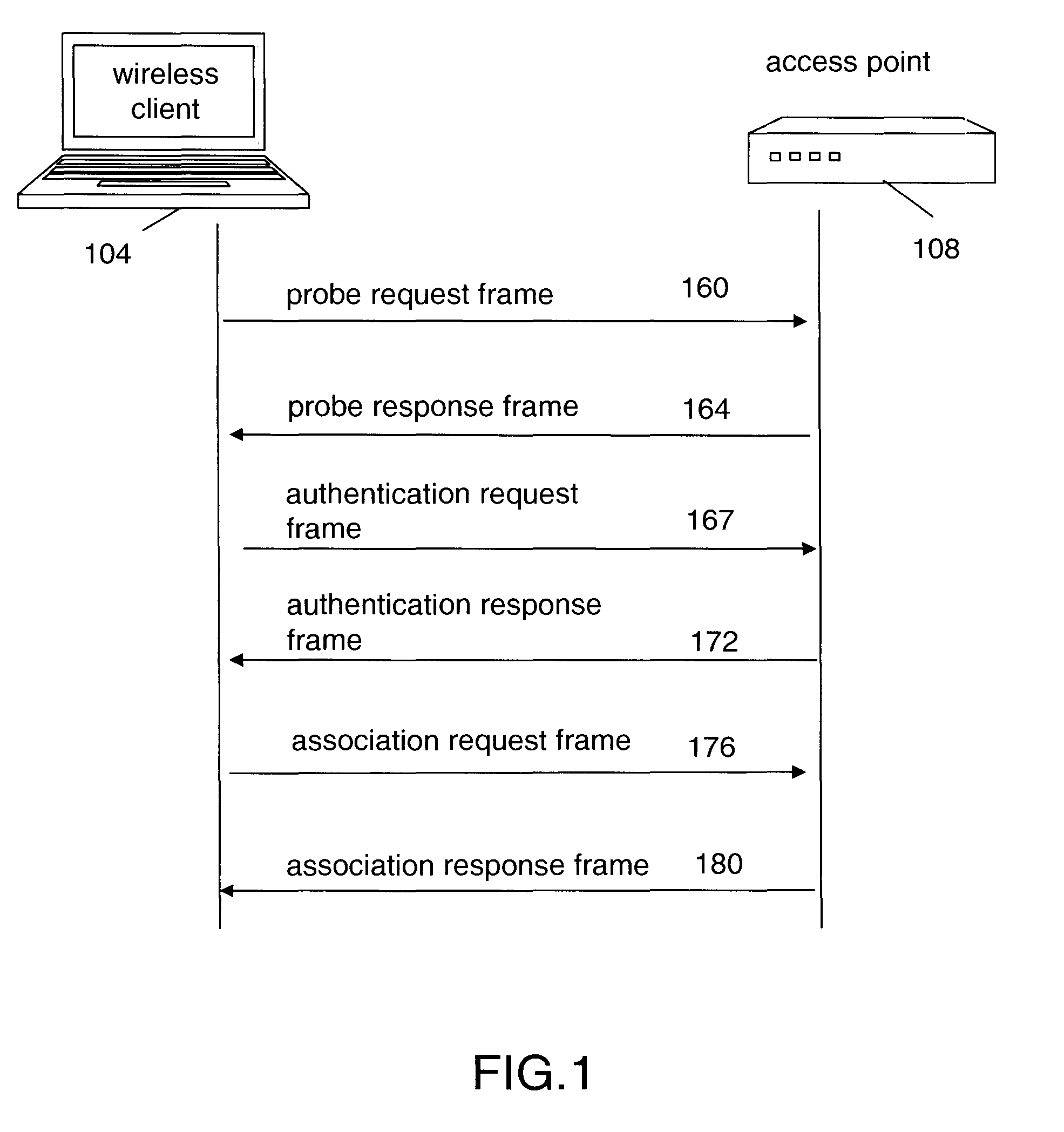

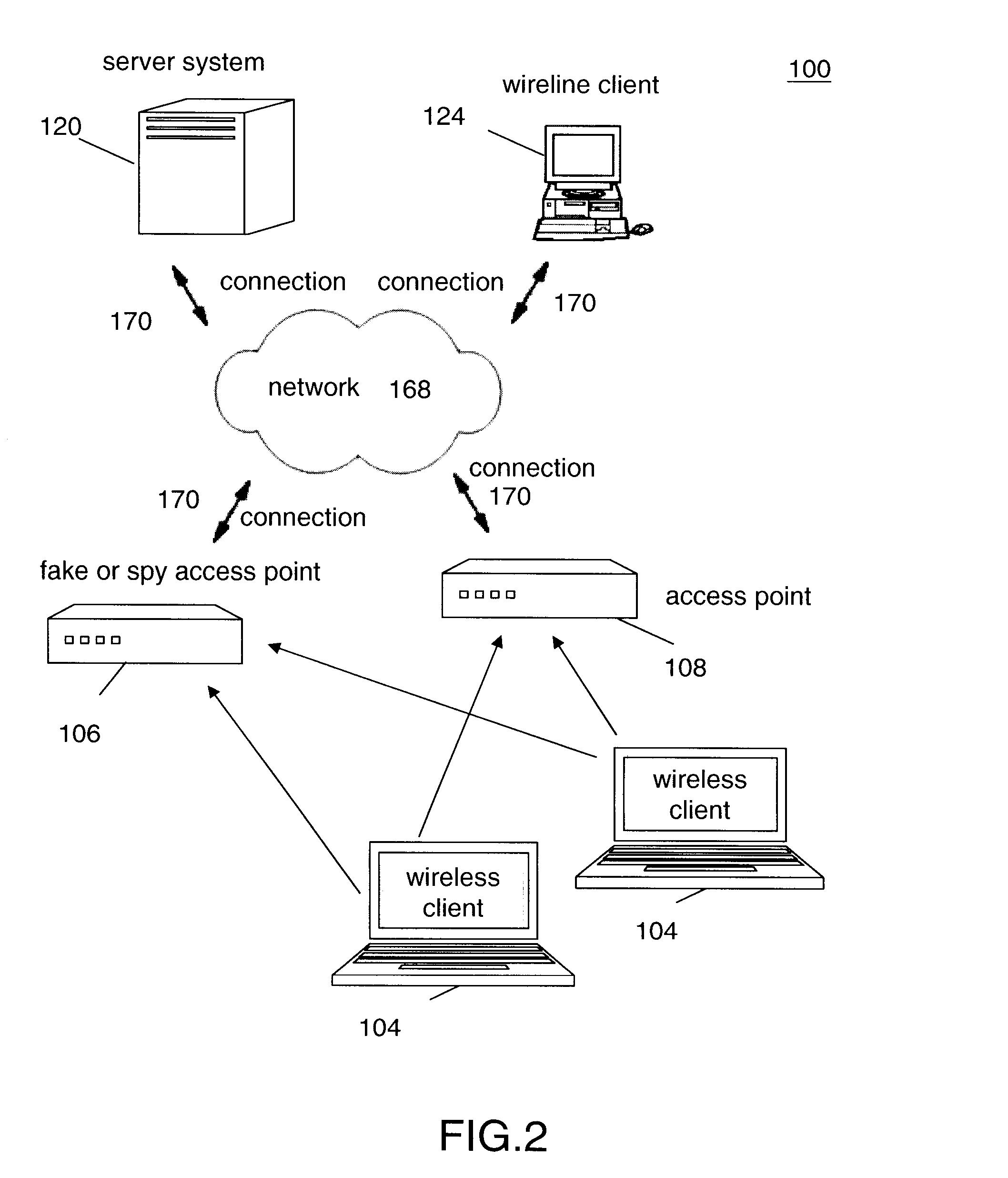

Method, Program Product, and System of Network Connection in a Wireless Local Area Network

InactiveUS20130007843A1Blocking in networkSafe WLAN environmentDigital data processing detailsNetwork topologiesClient-sideData entry

Disclosed is a method of network connection in a wireless local area network. The wireless local area network comprises a client, an access point, and an authentication database coupled to the access point. The authentication database comprises a plurality of collections of data entries, wherein each of the collections of data entries comprises a plurality of data entries. The network connection method comprises: passing messages containing queries relating to data entries in the authentication database and receiving responsive answer tags.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com