Patents

Literature

77results about How to "Won't fly away" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

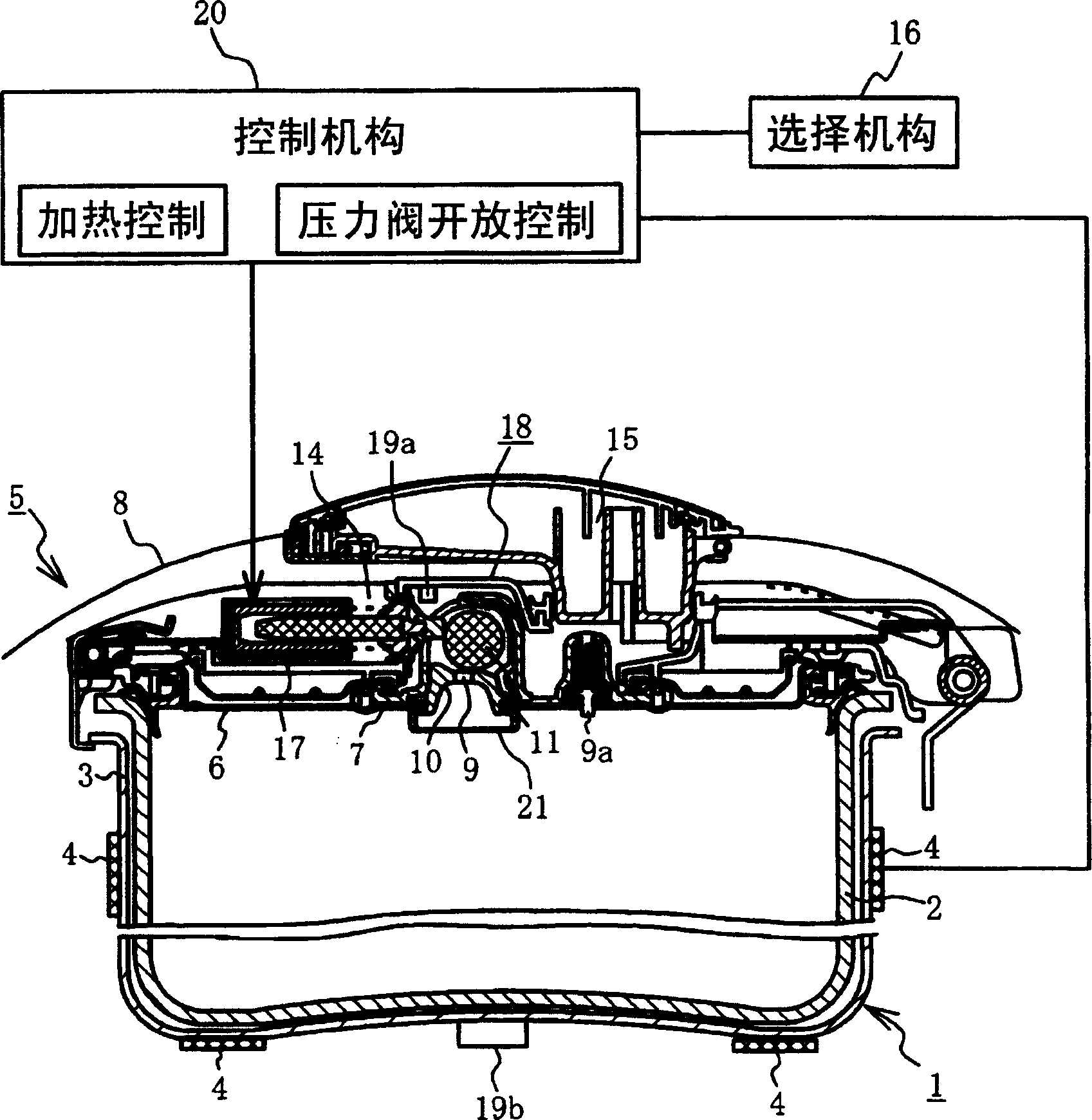

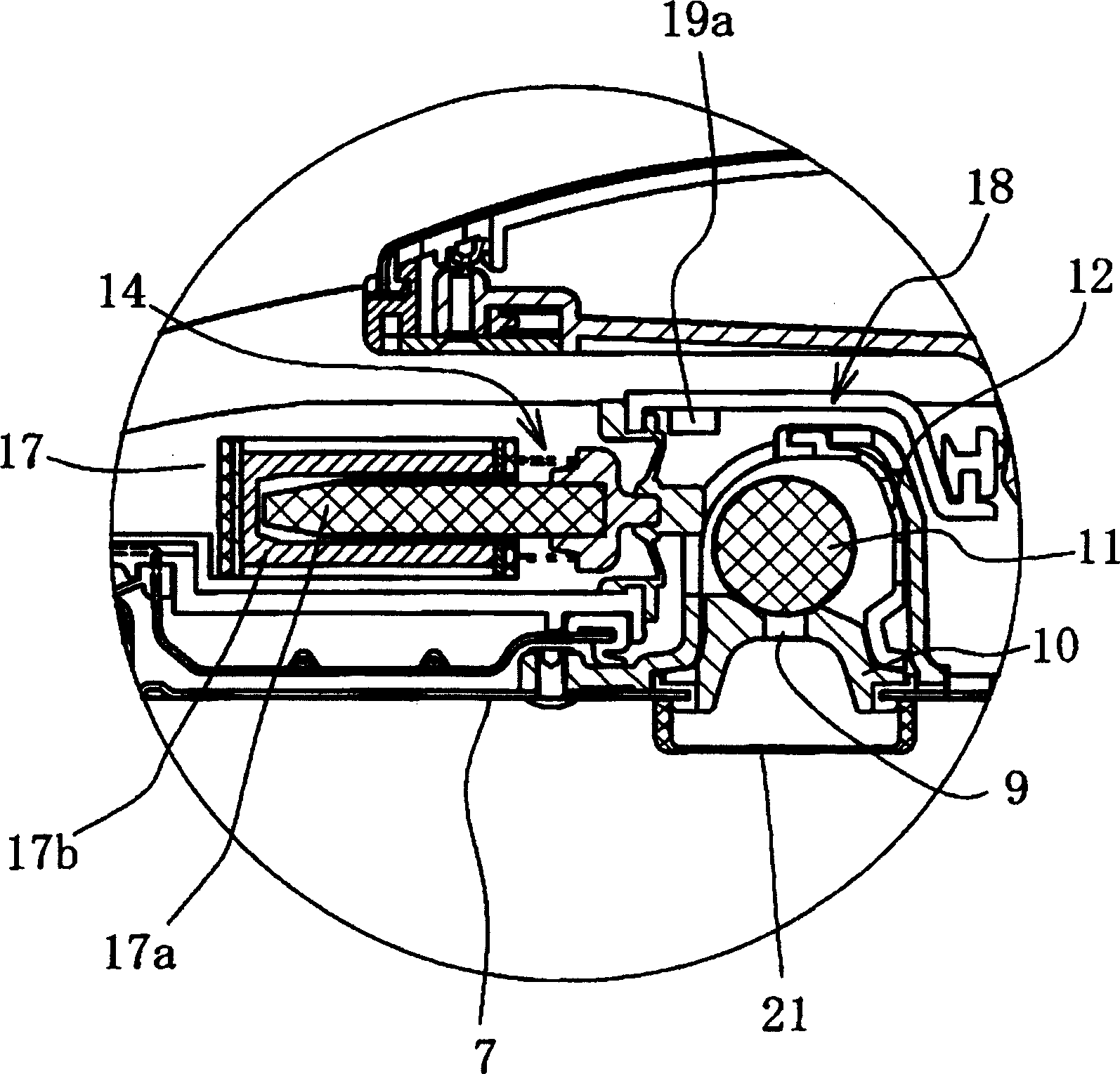

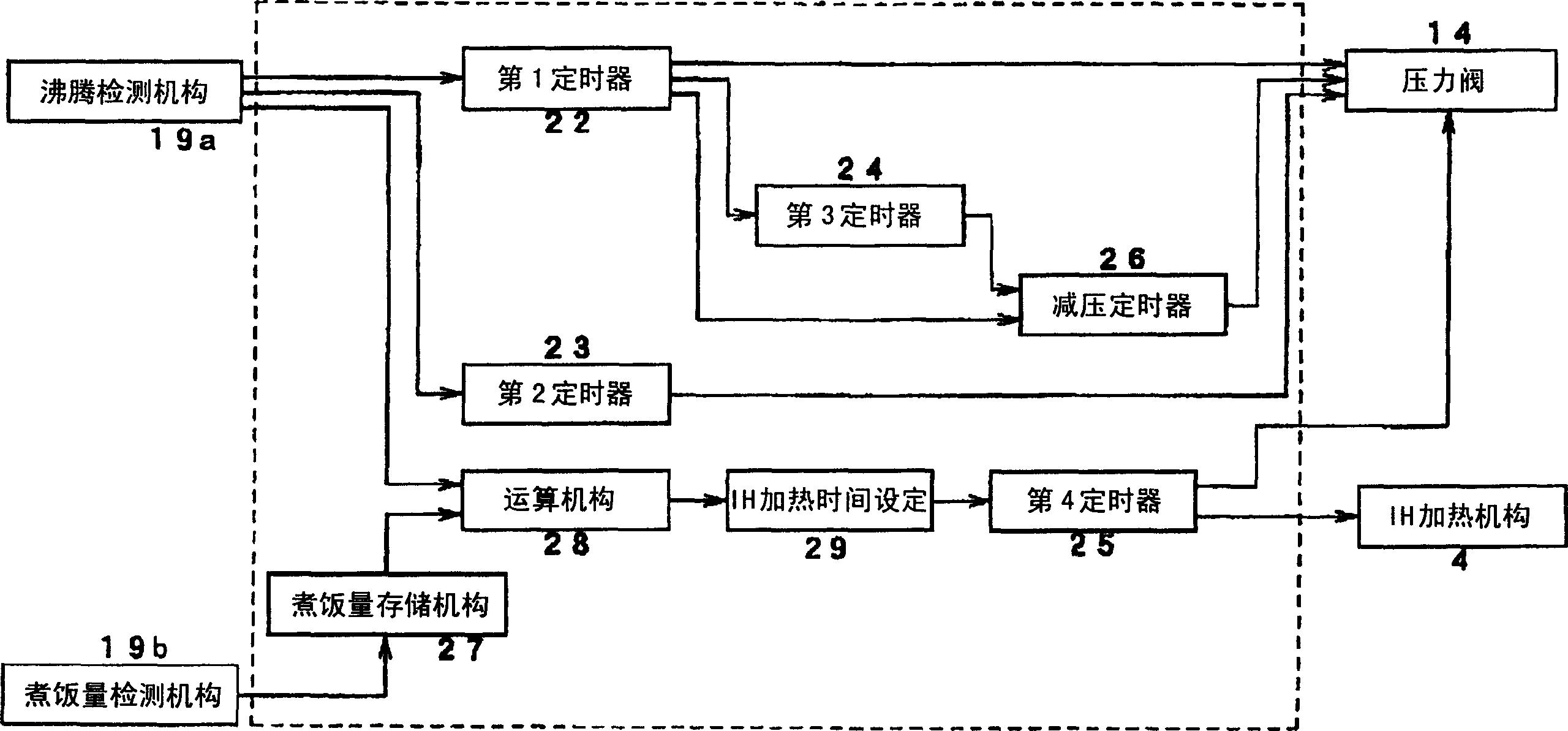

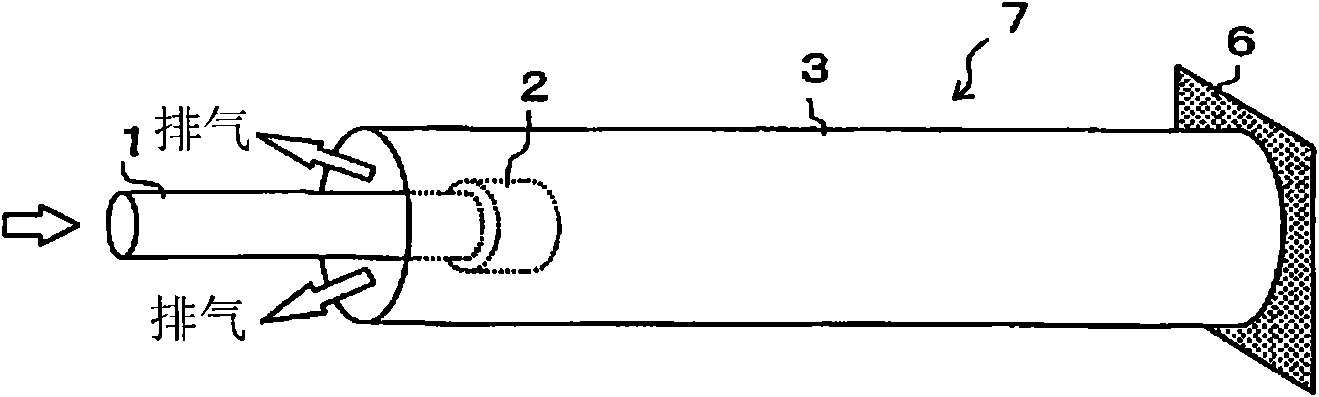

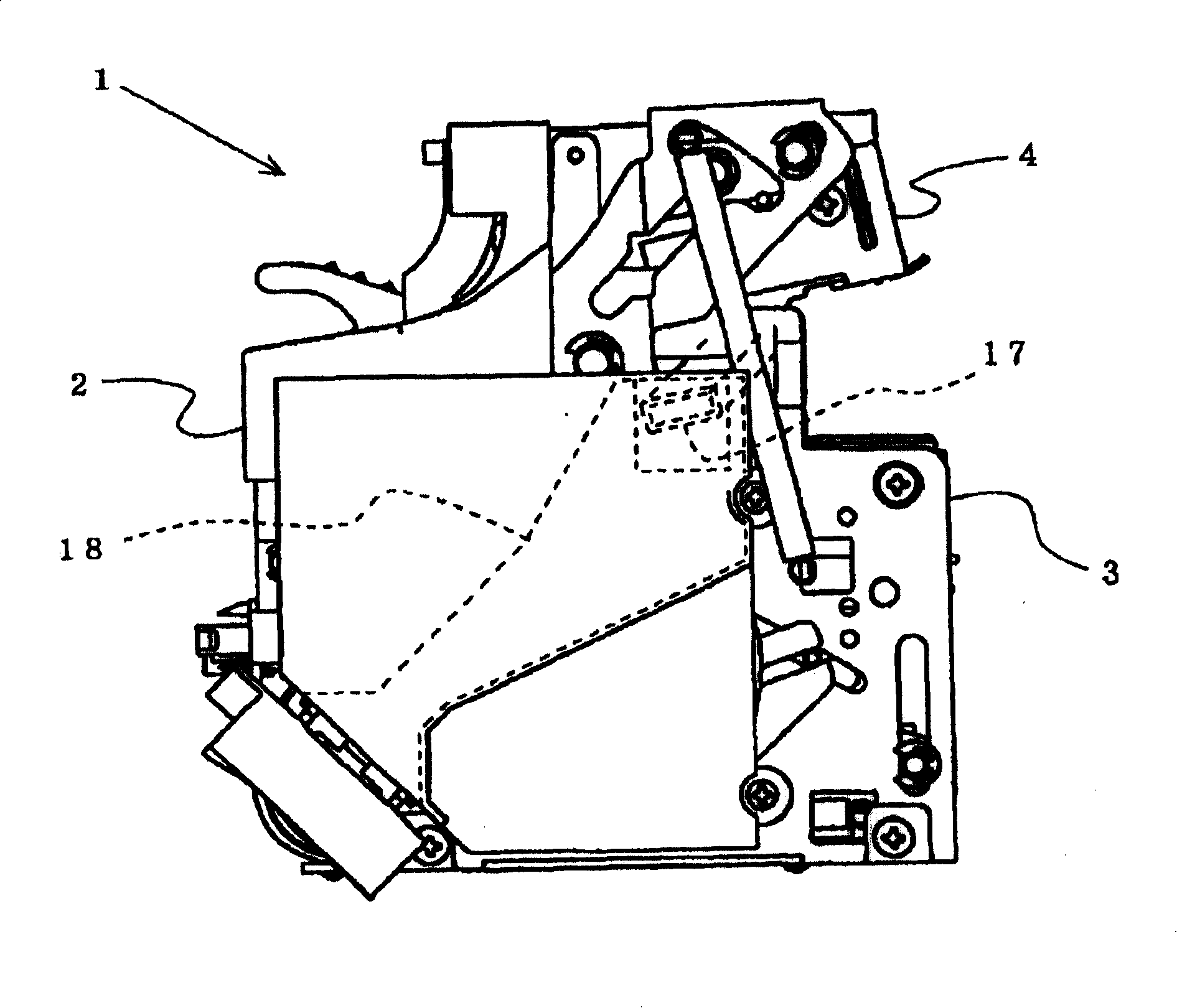

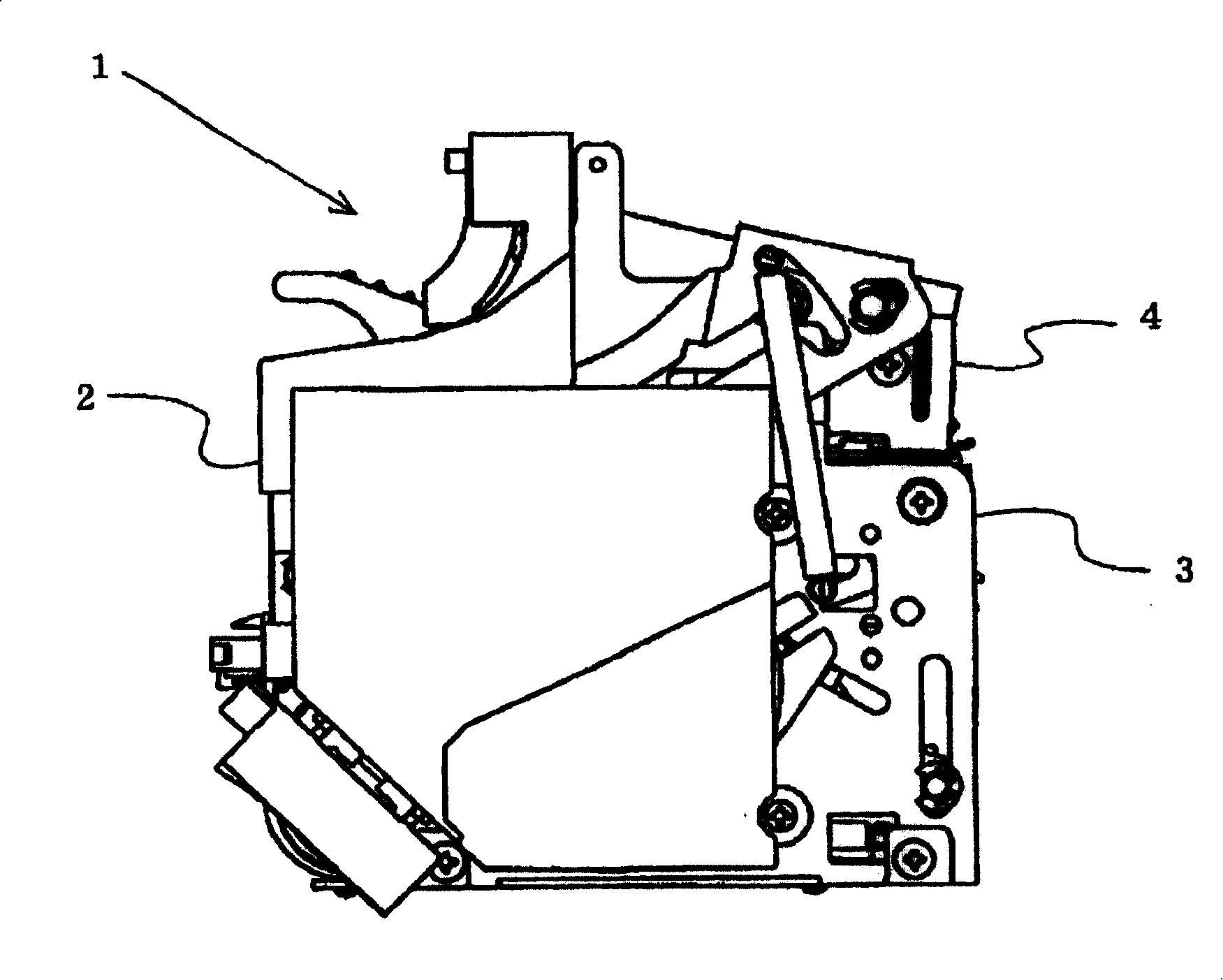

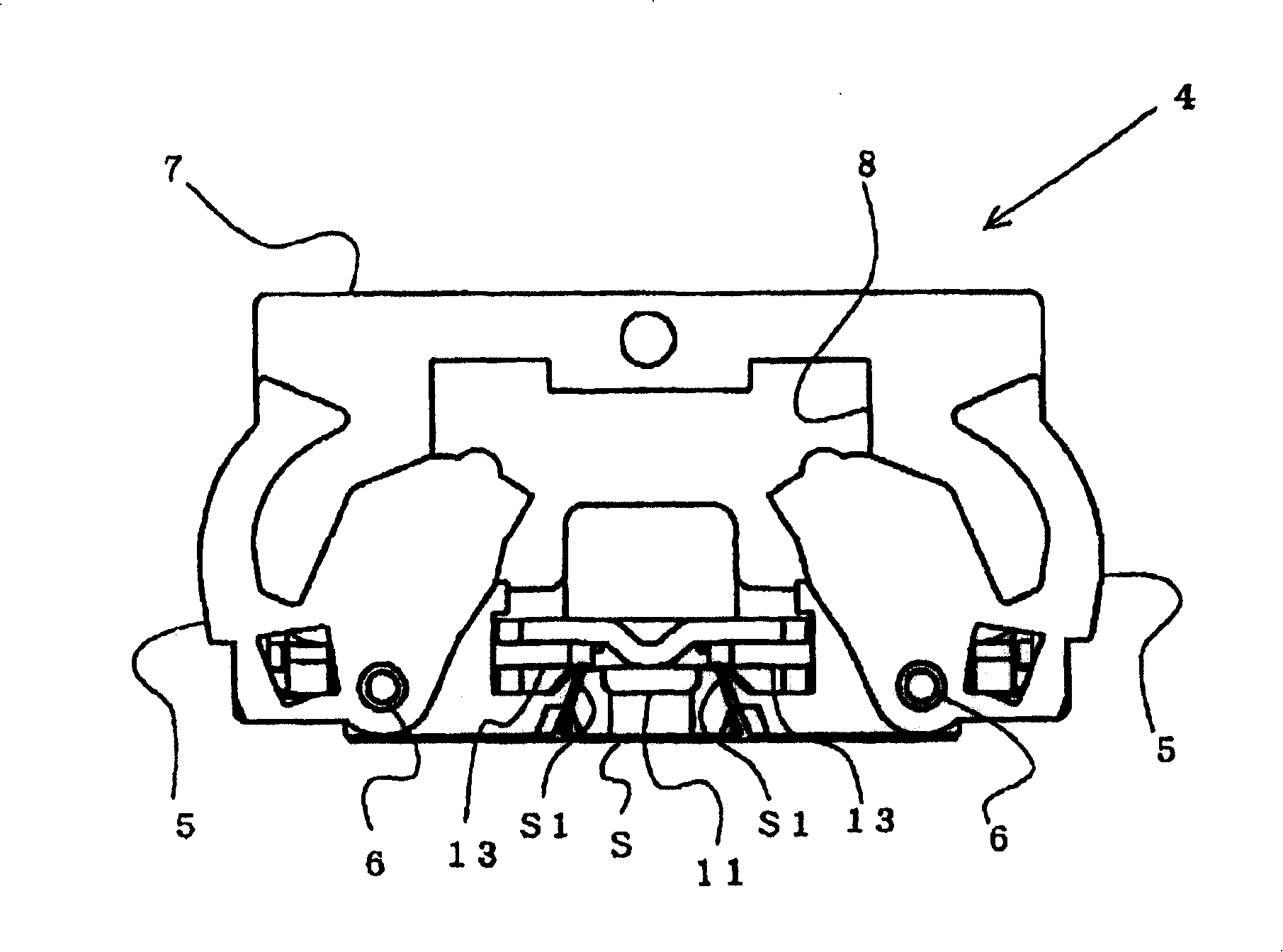

Rice cooker

This rice cooker is equipped with a pot to house water and rice, a heating means, a pressure valve to make the inside of the pot communicate with the outside air or cut off, and a control means for the heating means and the pressure valve. The rice to be cooked is processed by a starting-up process to rapidly heat rice and then a boiling keeping process wherein the rice to be cooked is heated by the heating means when the pressure valve is open.The invention provides a rice cooker in which rice can be sufficiently agitated during boiling and uniformly cooked, and the upper face of cooked rice is flat causing visual artistic effect after rice is completely cooked.

Owner:SANYO ELECTRIC CO LTD +1

Molten metal anti-oxidation reducing agent, preparation method and application thereof

InactiveCN101532130AReduce scumSpeed up the flowMetallic material coating processesO-Phosphoric AcidPhytic acid

The invention relates to a molten metal anti-oxidation reducing agent and a preparation method and application thereof. The molten metal anti-oxidation reducing agent comprises the following main compositions in portion by weight: 51.19 to 91.19 portions of nonylphenol polyoxyethylene ether, 3 to 15 portions of organic amine, 0.3 to 5 portions of phosphoric acid and 0.5 to 8 portions of phytic acid; the anti-oxidation reducing agent can further comprise essence in proper amount; and the molten metal anti-oxidation reducing agent is water-soluble oily liquid. The reducing agent has no flash point, does not splash when being added into molten metal and can automatically and rapidly diffuse; the molten metal anti-oxidation reducing agent is lighter than molten metal liquid and can overspread the whole flowing liquid level to isolate air and effectively prevent oxidation; contained active substances and organic or inorganic acid can disperse the inner gravitation of oxidized metal scruff, and actively scatter an inner structure of the oxidized metal scruff to reduce useful metal out; the reduction efficiency is 95 percent or so; cost performance is high; the residual scruff is little, soluble in water and convenient to clean; and the molten metal anti-oxidation reducing agent is convenient to maintain equipment.

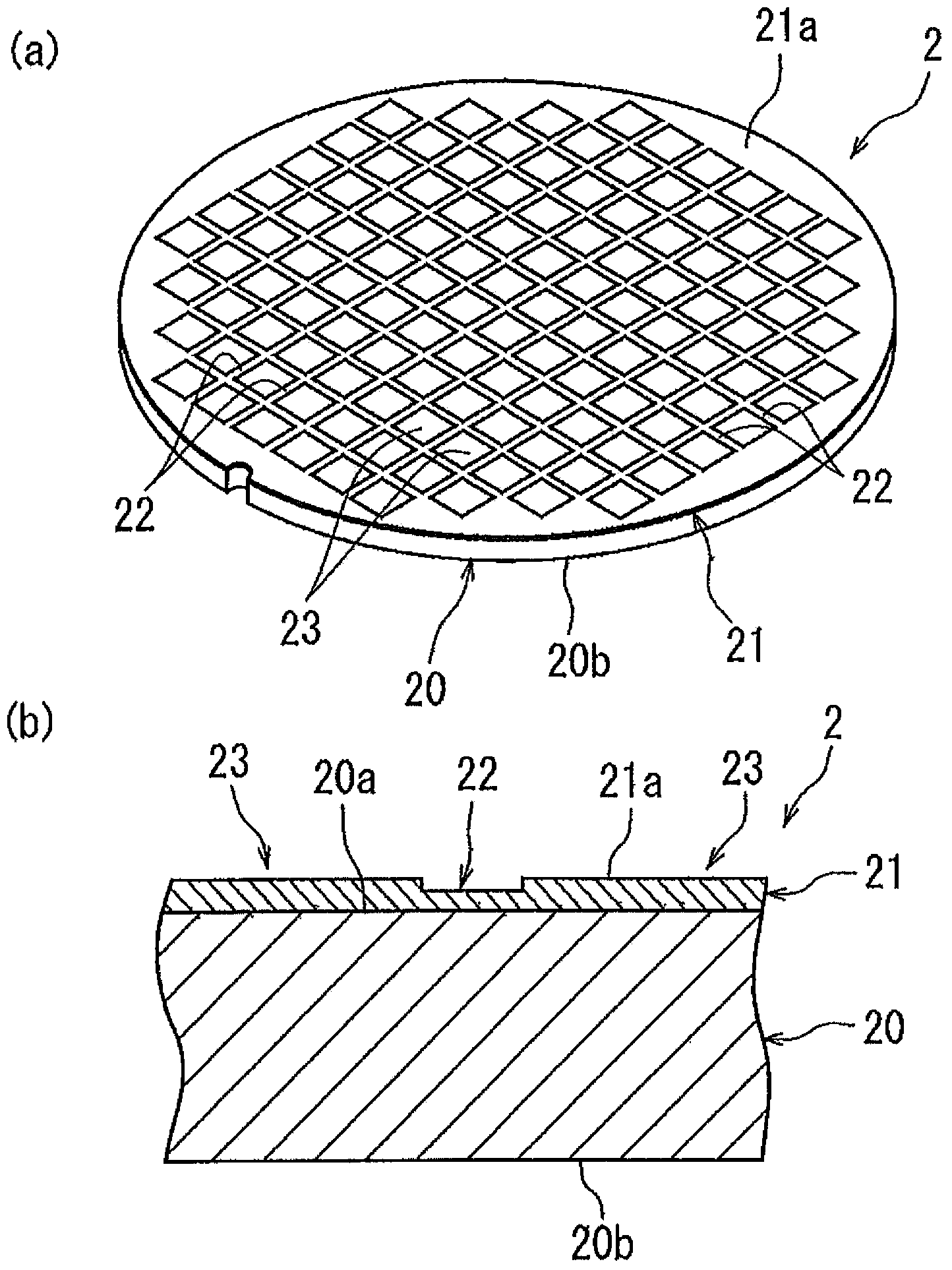

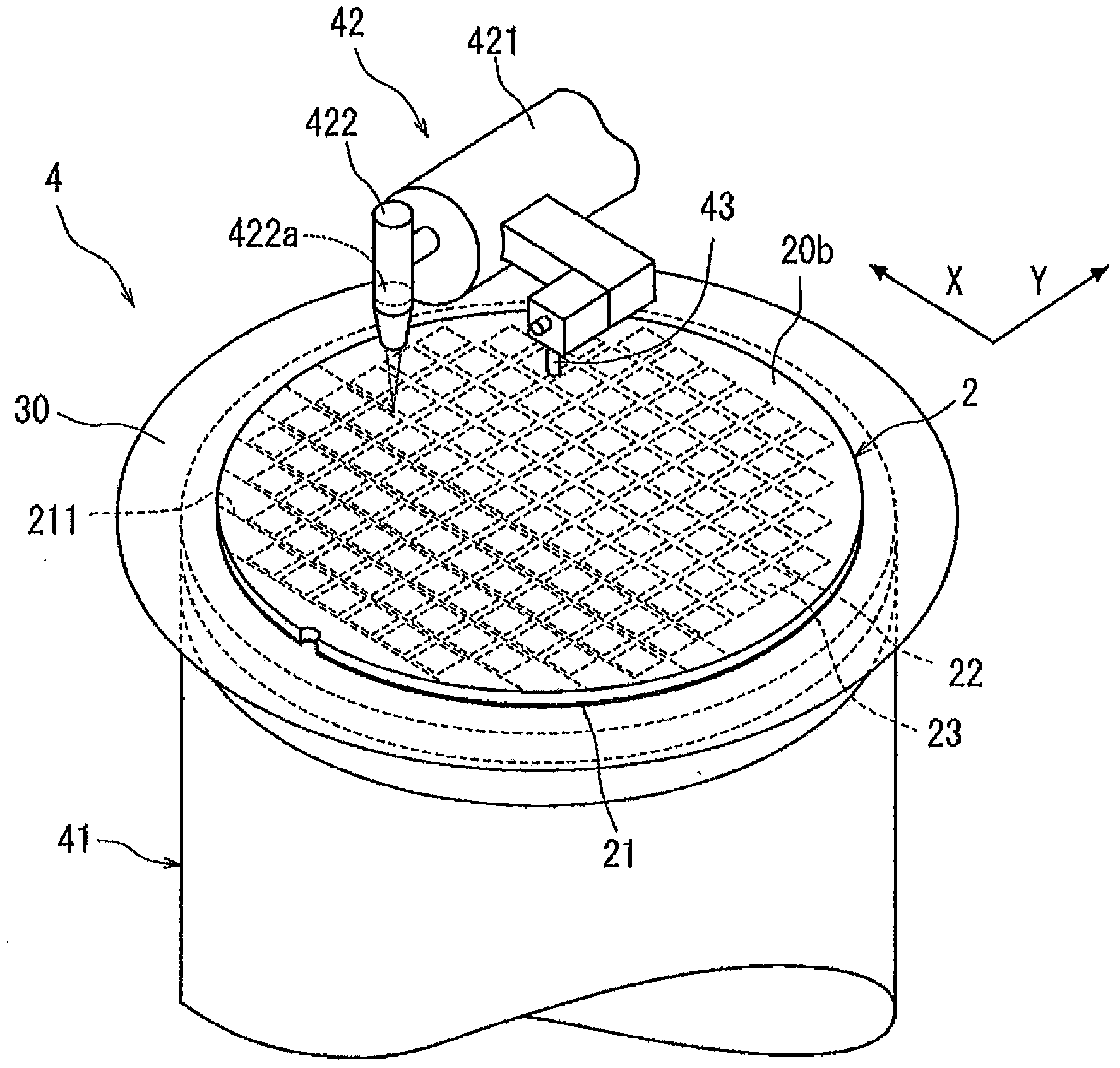

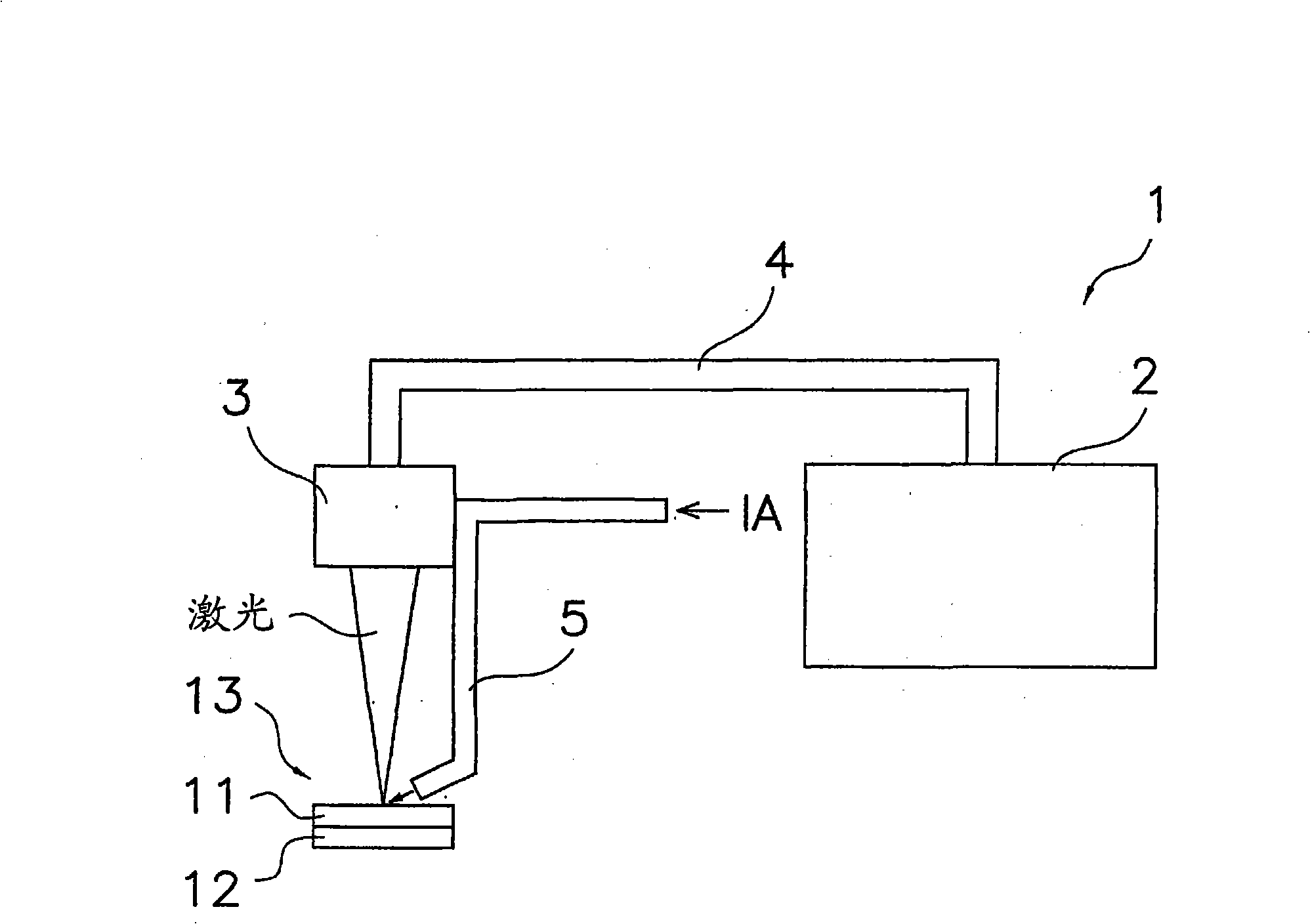

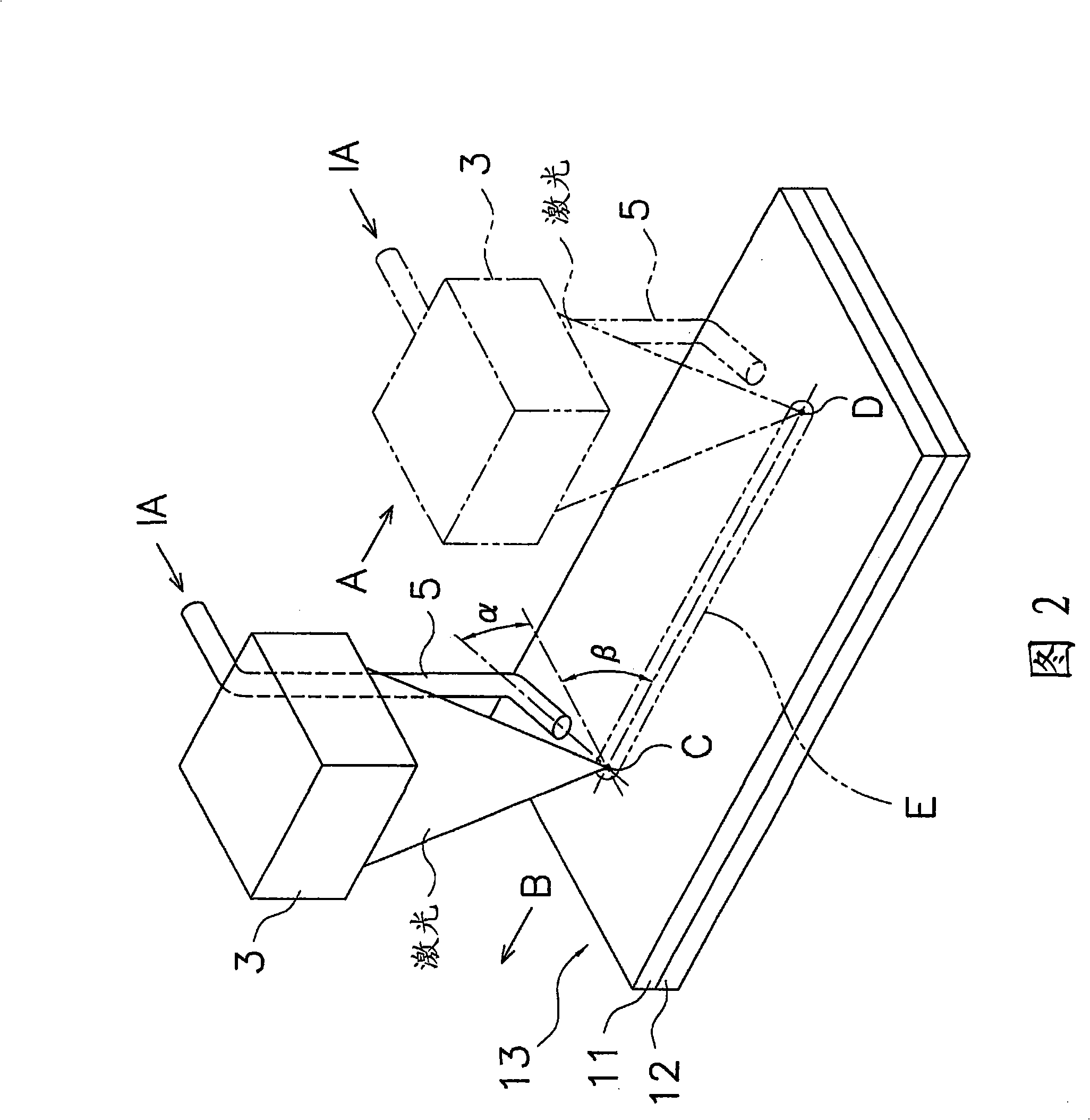

Optical device wafer processing method

ActiveCN104339090AWon't hurtWon't fly awaySemiconductor/solid-state device manufacturingLaser beam welding apparatusRefractive indexSingle crystal

In an optical device wafer processing method, a light emitting layer on the front side of a wafer is removed by applying a pulsed laser beam to the wafer along division lines from the back side of a substrate with the focal point of the beam set near the light emitting layer, thereby partially removing the light emitting layer along the division lines. A shield tunnel is formed by applying the beam to the wafer along the division lines from the back of the substrate with the focal point of the beam set near the front of the substrate. This forms a plurality of shield tunnels arranged along each division line, each shield tunnel extending from the front side of the substrate to the back side thereof. Each shield tunnel has a fine hole and an amorphous region formed around the fine hole for shielding the fine hole.

Owner:DISCO CORP

Molten metal oxidation resistance reducing agent

InactiveCN101215712AReduce scumSpeed up the flowWelding/cutting media/materialsSoldering mediaPhosphoric acidPhytic acid

The invention relates to metal melting antioxidative reducing agent, wherein the main component and the content of weight by parts comprises nonyl phenol polyoxyethylene thioether 51.19-91.19 parts, cyclohexylamine hydrobromate 5-20 parts, diphenyl guanidine hydrobromate 3-15 parts, phosphoric acid 0.3-5 parts, and phytic acid 0.5-8 parts, and further contains right amount of perfume compounds. The invention is oil liquid, since the invention is added with surface-active substance, when two liquids contact, relative / infrequent two-way molecular linkage can be generated, the surface tension of high-melting metal can be reduced, and simultaneously antioxidative reducing liquid is promoted to automatically diffuse rapidly. The invention is lighter than metal melting liquid, which can bespread whole flowing liquid and isolate air, and effectively prevent oxidation, while active substance and organic or inorganic acid which are contained in the invention can disperse inner gravity of oxygenized metal dross, take the initiative to break the inner structure of oxygenized metal dross, deacidize available metal, and deacidizing efficiency is about 95%, and the invention has high performance price ratio, less residual dross, cleanness and convenience, which is convenient for equipment maintenance.

Owner:SHENZHEN KUNQI XINHUA

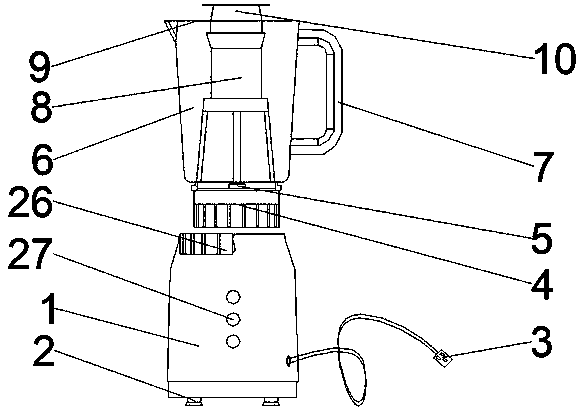

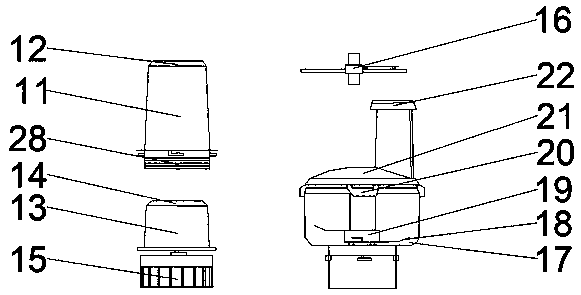

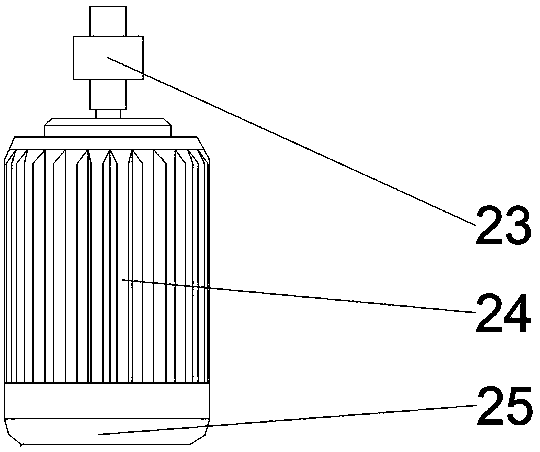

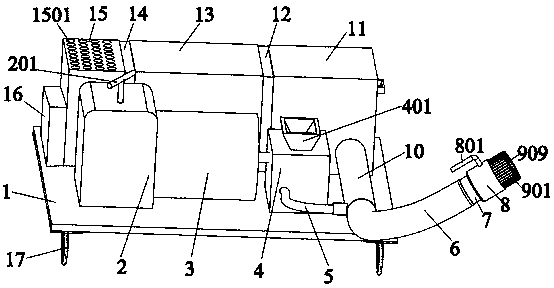

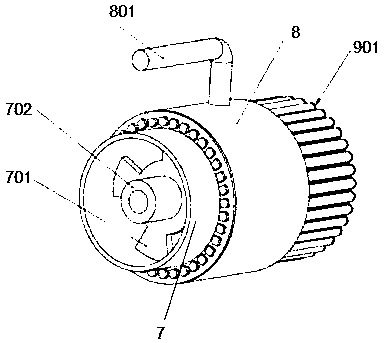

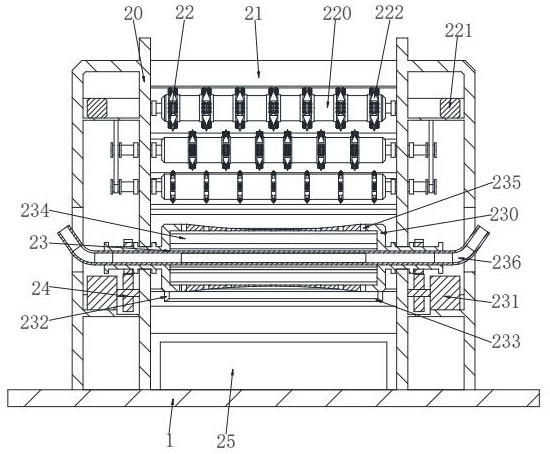

Kitchen juice squeezing and stirring machine

The invention provides an improved kitchen juicer blender, which includes a device body, a stirring cup, a cooking cup, a dry grinding cup, a shredding and slicing knife, and a meat grinder cup. An electric motor is fixedly connected to the inside of the device body. The lower side of the device body is fixedly connected with a triangular plug, the upper part of the conditioning cup is movably connected with a conditioning cup cover, the lower part of the conditioning cup is closely connected with a conditioning knife seat, and the upper part of the dry grinding cup is movably connected with a dry grinding cup. A cup cover, the bottom of the dry grinding cup is tightly connected with a dry sharpening seat, the top of the stirring cup and the upper part of the stirring cup cover are tightly connected with a measuring cup, the inside of the device body is fixedly connected with a motor, the The lower part of the motor is closely connected with a motor cover, and the upper part of the motor is movable with a motor heat insulation ring. The device is easy and fast to operate, novel in design, safe and practical, and is suitable for popularization and use in various families, restaurants and hotels.

Owner:陈钦旺

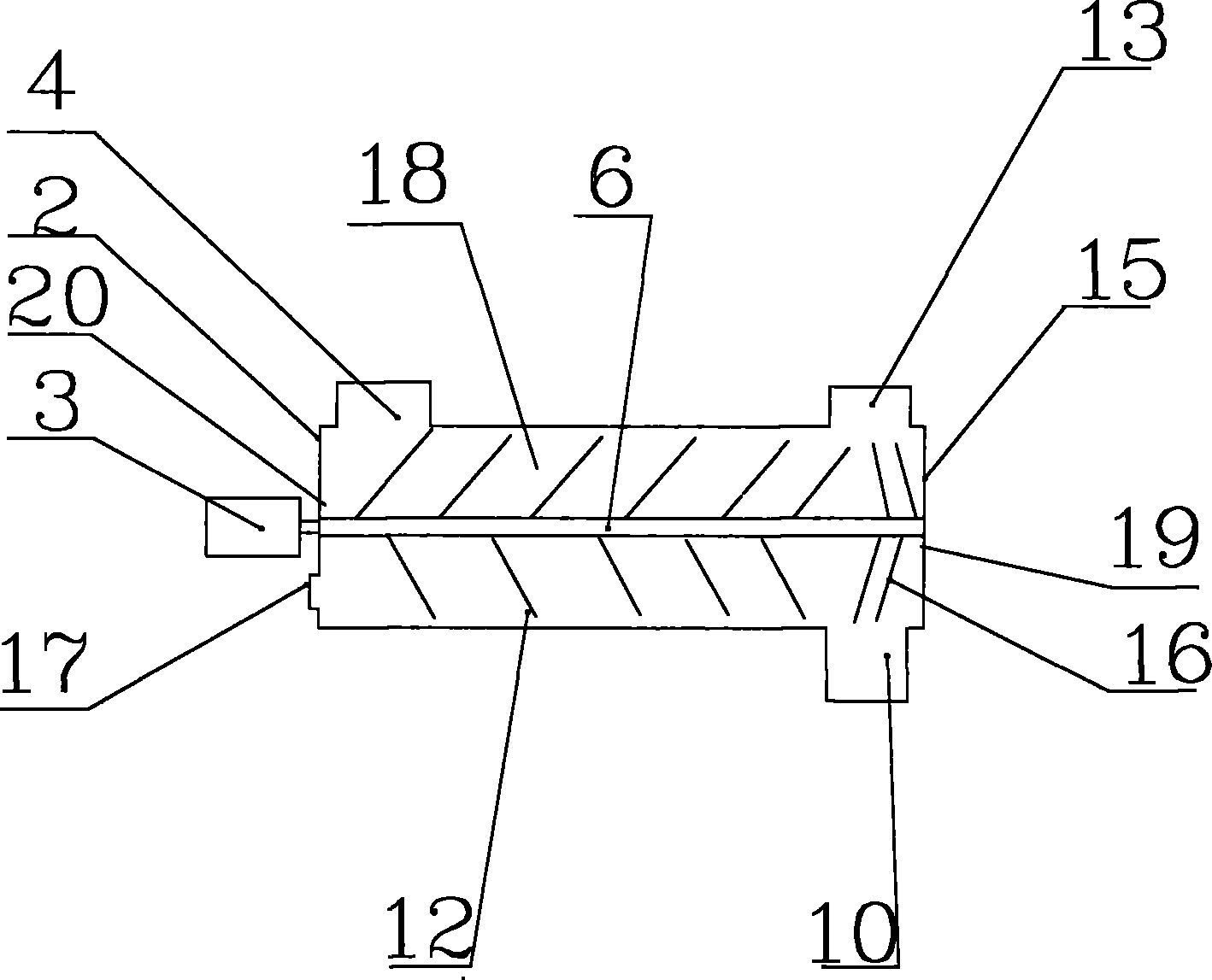

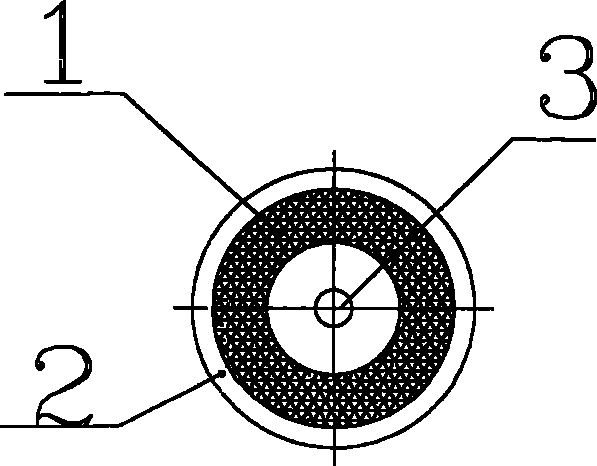

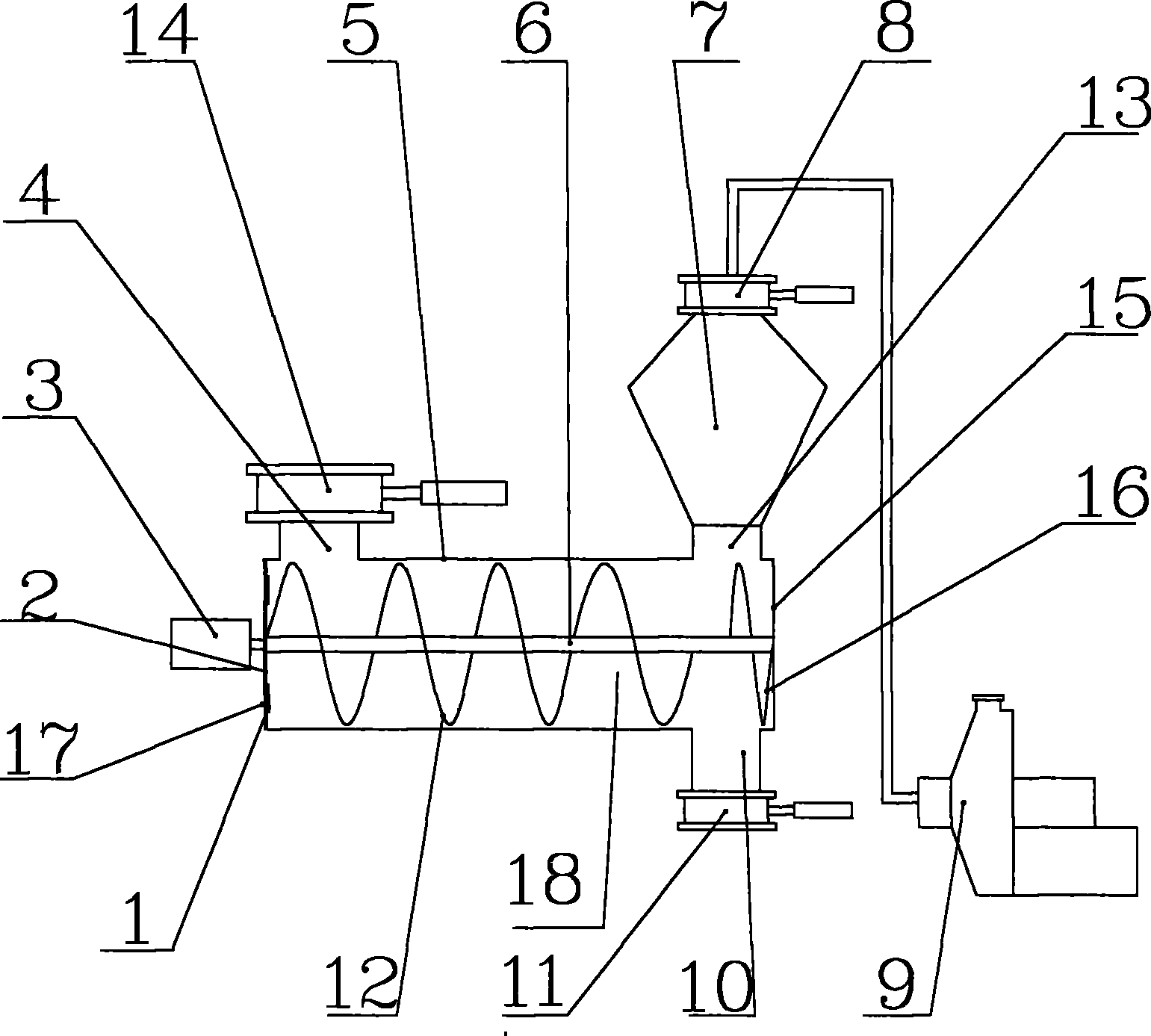

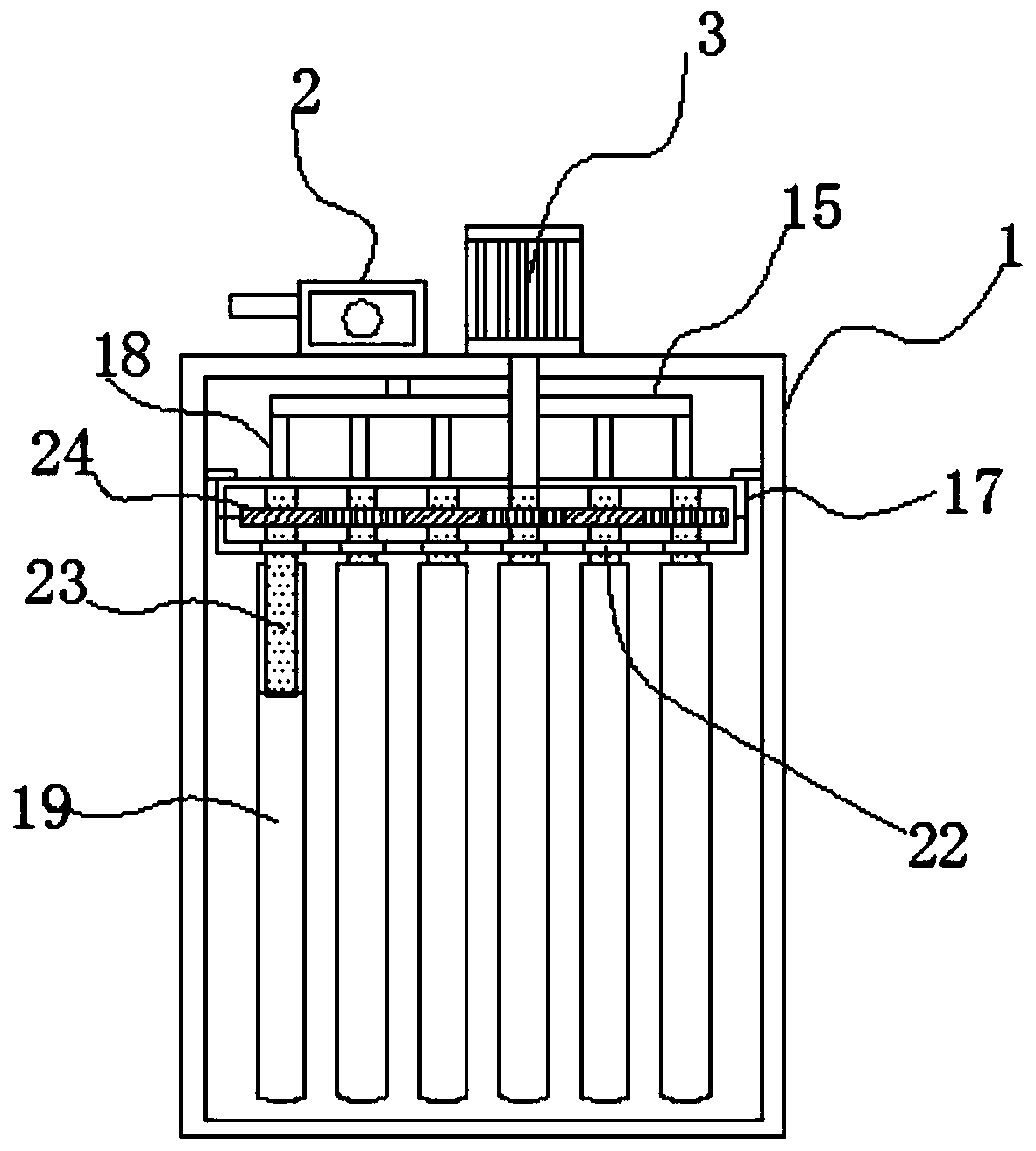

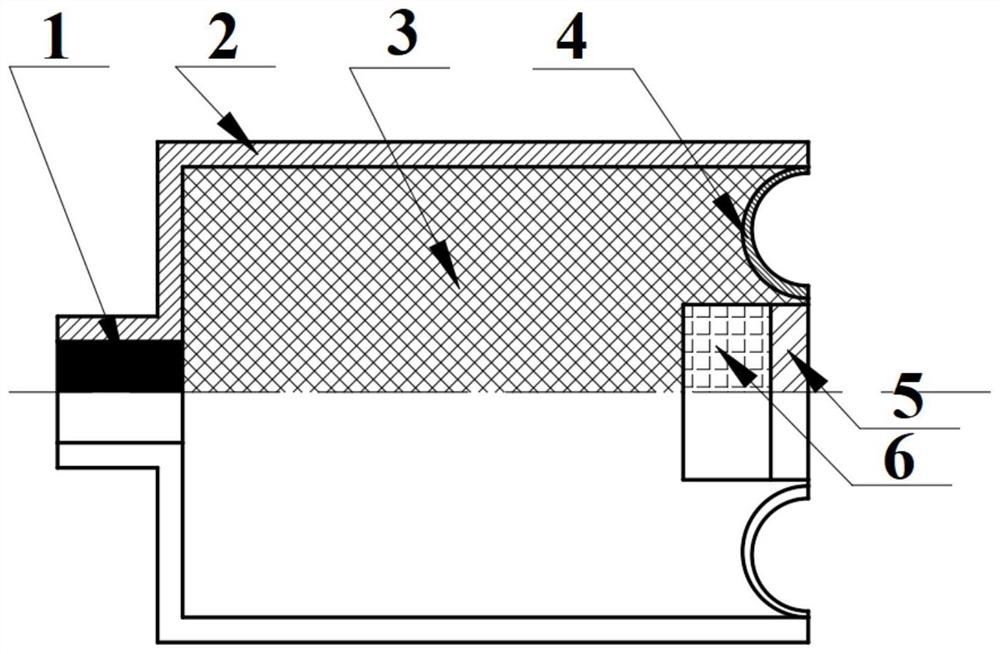

Cooling device

A cooling device comprises a cooling bin. The cooling bin is provided with a front end cover, a rear end cover, a material inlet, a material outlet, a cooling air inlet, a cooling air outlet and a helical mixing conveyor, wherein the helical mixing conveyor comprises a transmission shaft connecting the front end cover and the rear end cover; the transmission shaft is provided with positive helical slices and reverse helical slices; and the transfer directions of the positive helical slices and the reverse helical slices are opposite. The cooling device solves the problem that the materials are piled at the ends because the helical mixing conveyors arranged in the cooling devices in the prior art transfer the materials only towards one direction, and the problem of indirect cooling effect of the cooling air in the prior art, and can avoid the transfer efficiency from being affected because the materials are piled at the ends of the helical mixing conveyors and improve the cooling effect of the cooling air while ensuring normal transfer of the materials.

Owner:TIBET QIZHENG TIBETAN MEDICINE

Chlorate oxygen column as ignitor and production thereof

ActiveCN1817824AIncrease oxygen contentMature and stable manufacturing processExplosivesOxygenPotassium perchlorate

An ignition medicine with chlorate oxygen column and its production are disclosed. The ignition medicine consists of sodium chlorate 30~50% with grain size 60~300 meshes, lithium hyperchlorate or sodium perchlorate 10~30% with grain size 60~300 meshes, barium dioxide 0.1~6% with grain size 80~200 meshes, metal oxide ironic oxide or cuprous oxide 5~9% with grain size 20~200 meshes, metal powders 15~25% with grain size 100~300 meshes and cobalt salt 5~15% with grain size 40~200 meshes. It has shorter gas-take time and higher starting success probability of engine.

Owner:中国航天科技集团公司第四研究院第四十二所

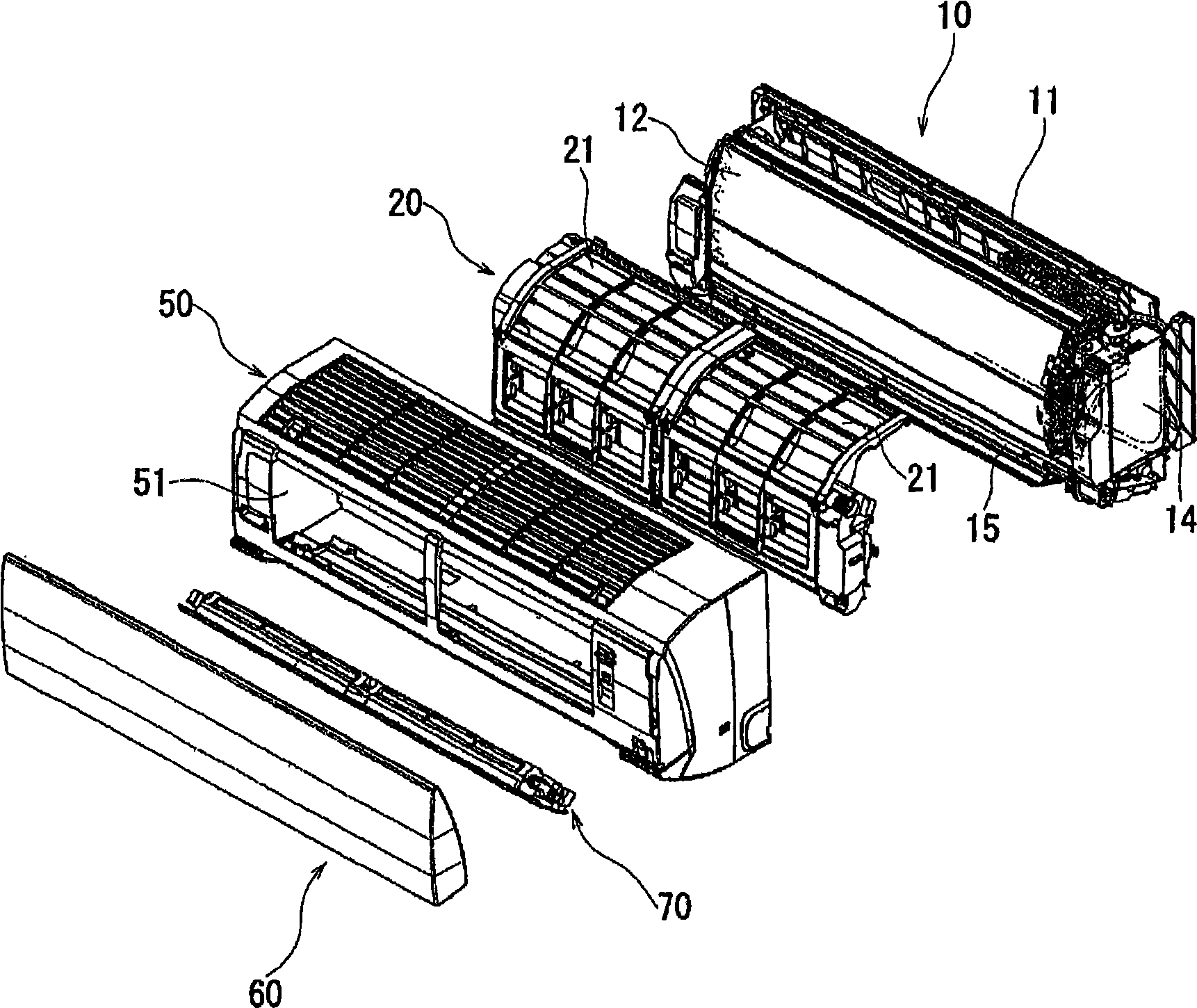

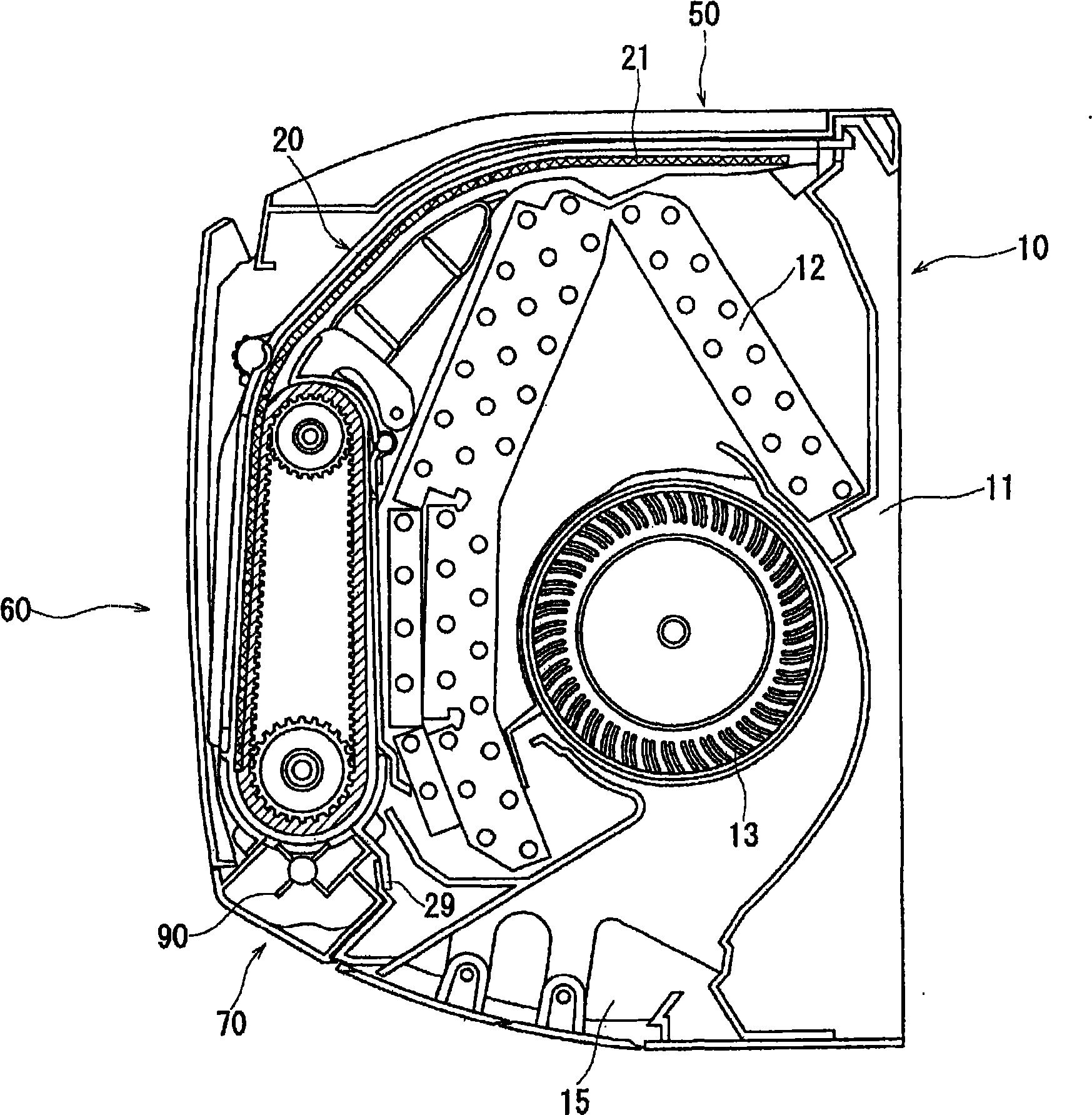

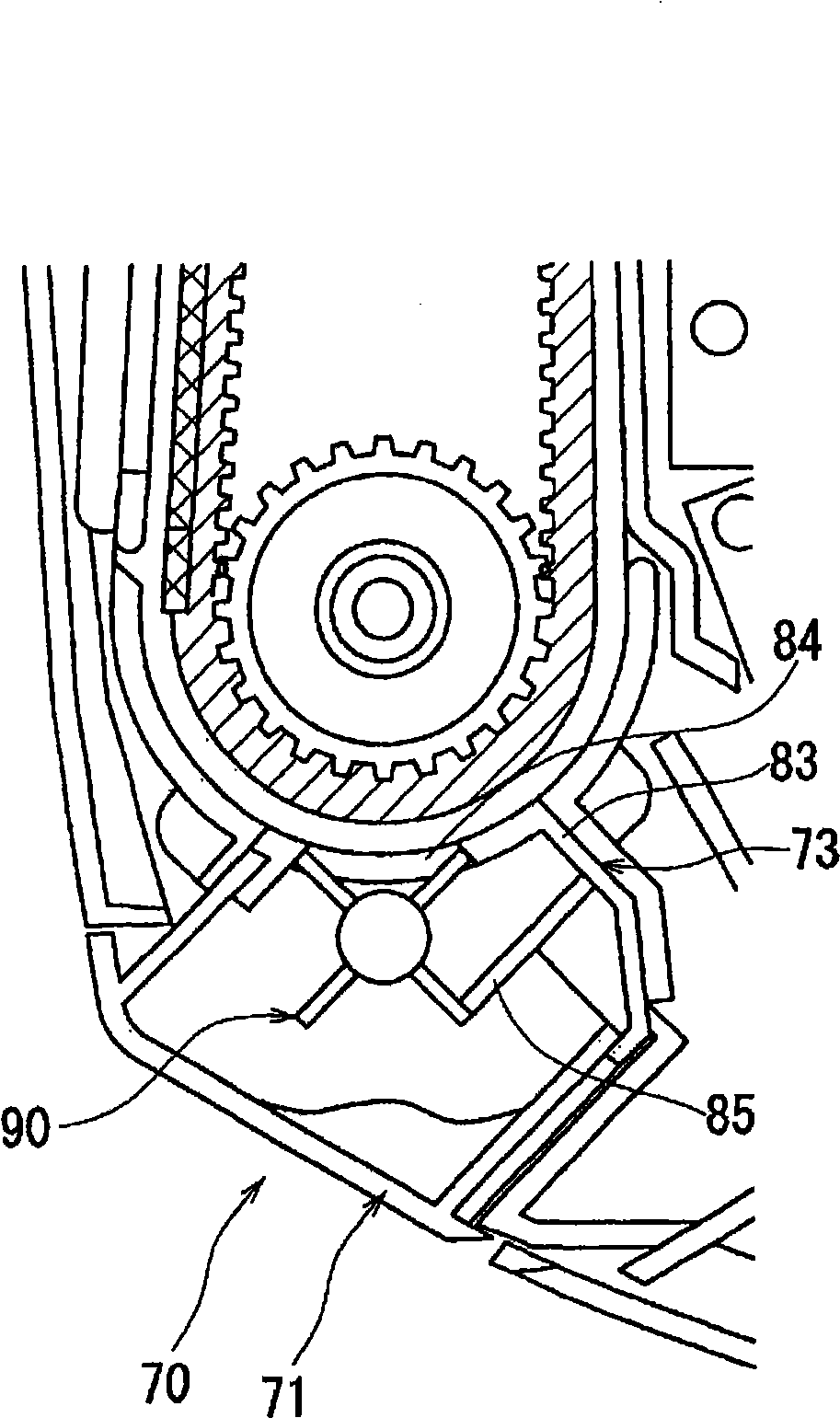

Air conditioner

ActiveCN101501408AEasy to handleWon't fly awayDispersed particle filtrationLighting and heating apparatusAir filterMechanical engineering

Provided is an air conditioner having an automatic air filter cleaning function. In the air conditioner, a dust box (70) is removably attached to a main body unit. The dust box (70) is composed of a box main body (71) and a cover body (73) arranged on the box main body (71) to be freely opened and closed. A cleaning brush (90) is arranged on the cover body (73) to be freely rotated.

Owner:DAIKIN IND LTD

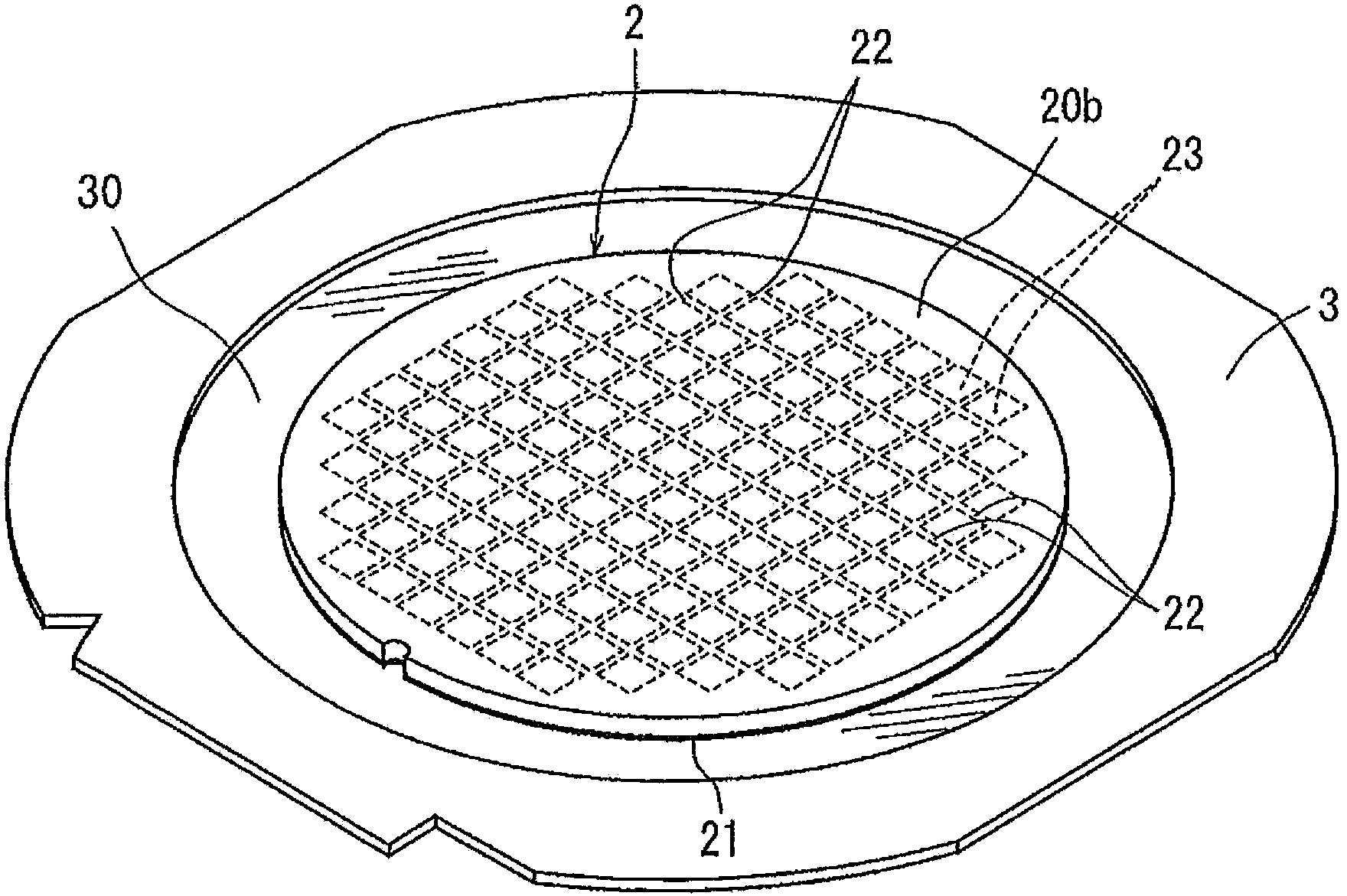

Thermal-release adhesive tape and cutting method of electronic component

InactiveCN104130723AWon't fly awayMacromolecular adhesive additivesEster polymer adhesivesAdhesiveThermal expansion

The invention relates to a thermal-release adhesive tape and a cutting method of an electronic component. An object of the invention is to provide an adhesive tape capable of fully fixing a chip even when being cut off, preventing chip flyoff in a cutting process, and increasing yield of the chip in the cutting process. The thermal-release adhesive tape has a thermal-expansion adhesive layer. When a probe tack value of the thermal-expansion adhesive is set as B0 and the probe tack value of the thermal-expansion adhesive after being stood for 1 week at a temperature of 0 DEG C as B, a variable rate of the probe tack value shown as a formula 1 is below 19.0%. W=|(B0-B) / B0*100|

Owner:NITTO DENKO CORP

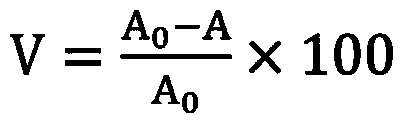

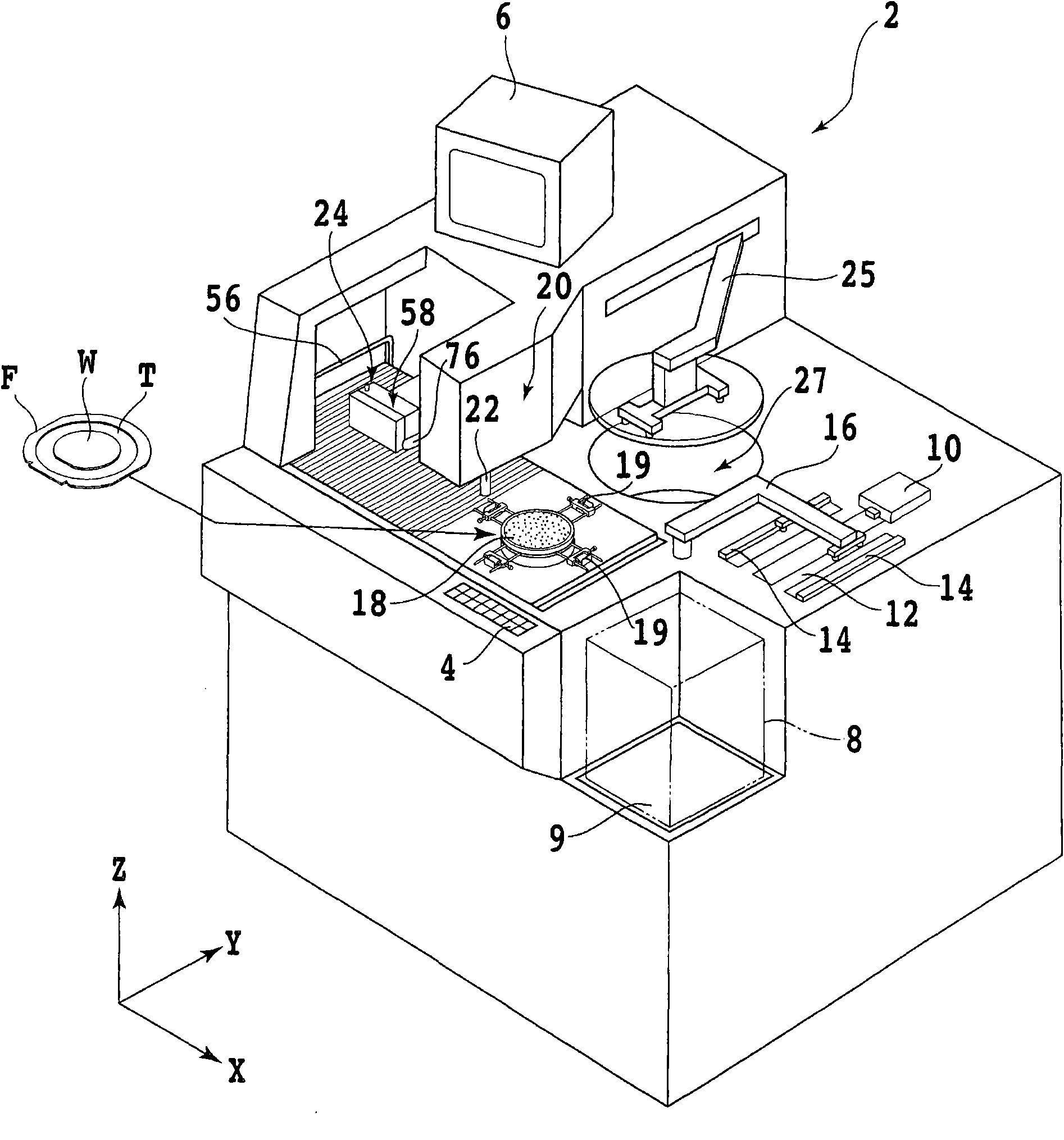

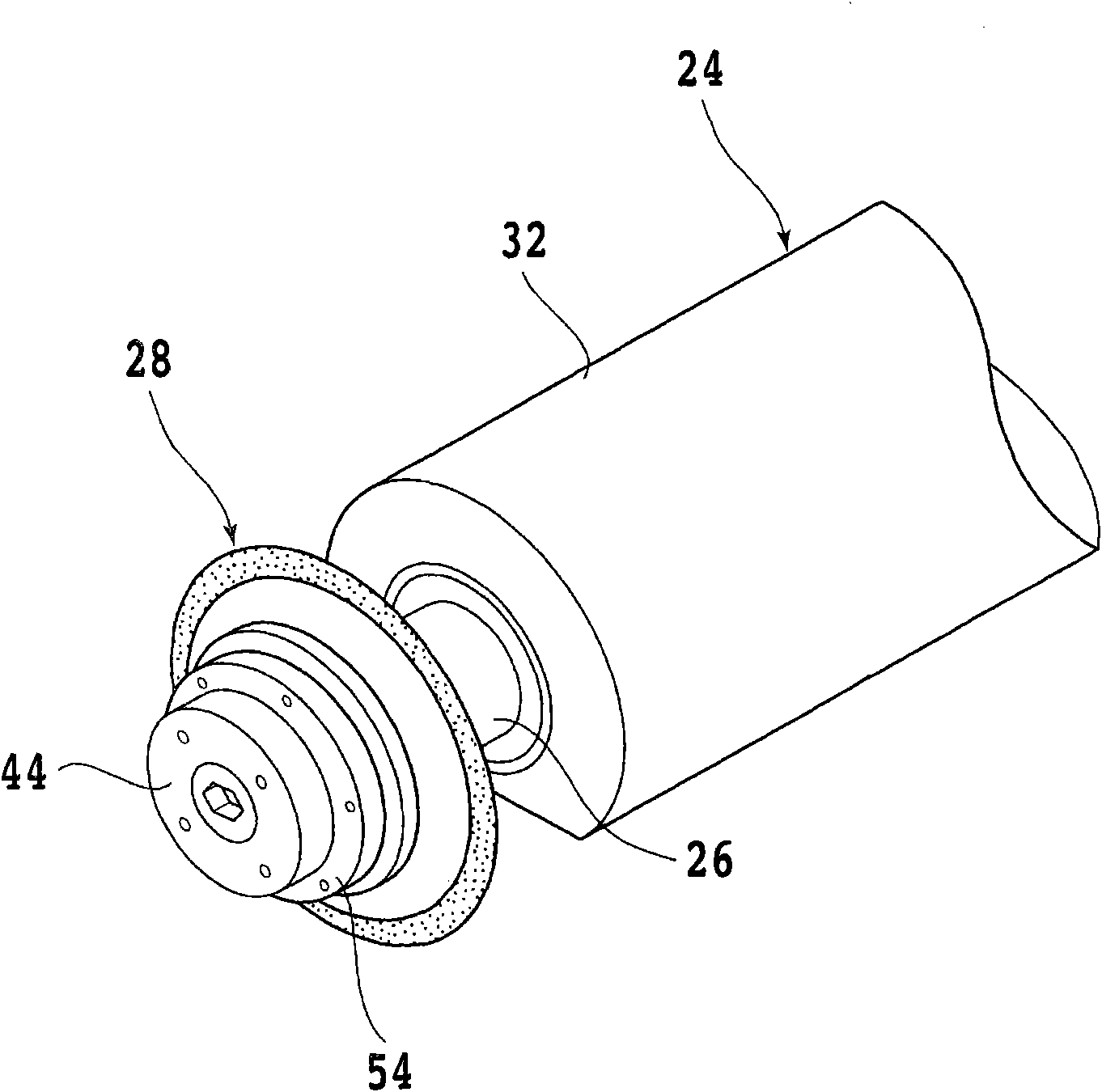

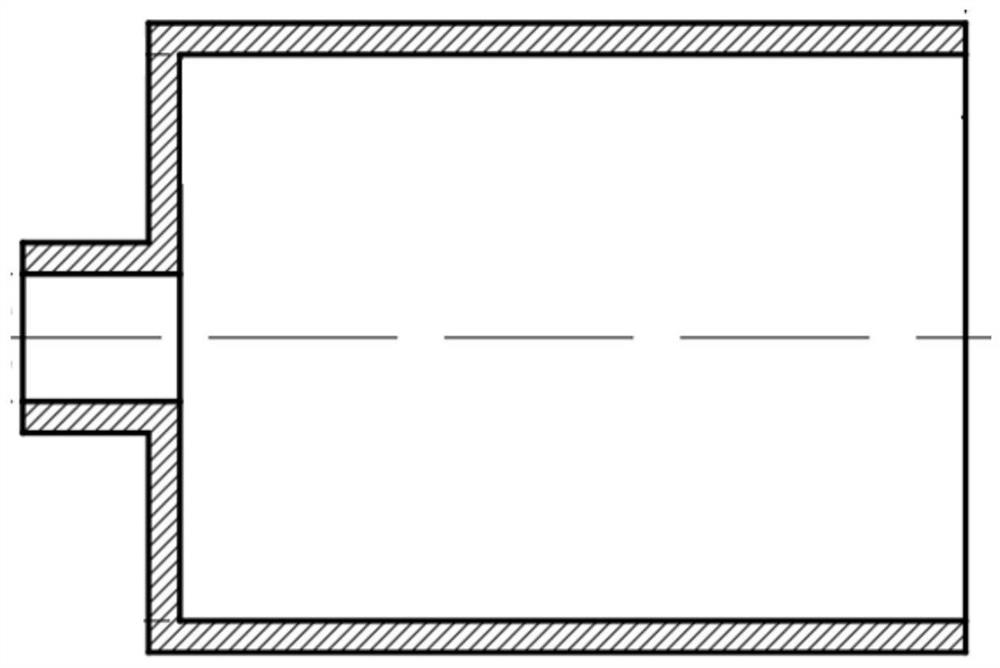

Cutting device

InactiveCN101992504APrevent fasteningWon't fly awayWorking accessoriesFine working devicesEngineeringMechanical engineering

The present invention provides a cutting device capable of preventing borings from being attached to an object to be machined. The cutting device comprises a chuck worktable, a cutter and a cutter cover. The cutting device also comprises a pool liquid supply component for supplying a pool liquid to the object to be machined between the bottom of the cutter cover and the object to be machined; a cutting liquid supply component for supplying a cutting liquid to the cutter from a cutting liquid ejecting port; and a waste liquid recovering component arranged on one side where the cutting liquid is sprayed along the rotation of the cutter. The waste liquid recovering component includes a barrel in which one end is connected with a side wall of an cutting liquid discharge opening part of the cutter cover in a manner of a prescribed angle relative to a holding surface of the chuck worktable; and a pumping source connected with the other end of the barrel. The barrel is provided with an opening part facing to the holding surface of the chuck worktable on one end side, parts of the cutting liquid and the pool liquid rotating along with the rotation of the cutter are discharged from the object to be machined by means of the pumping source.

Owner:DISCO CORP

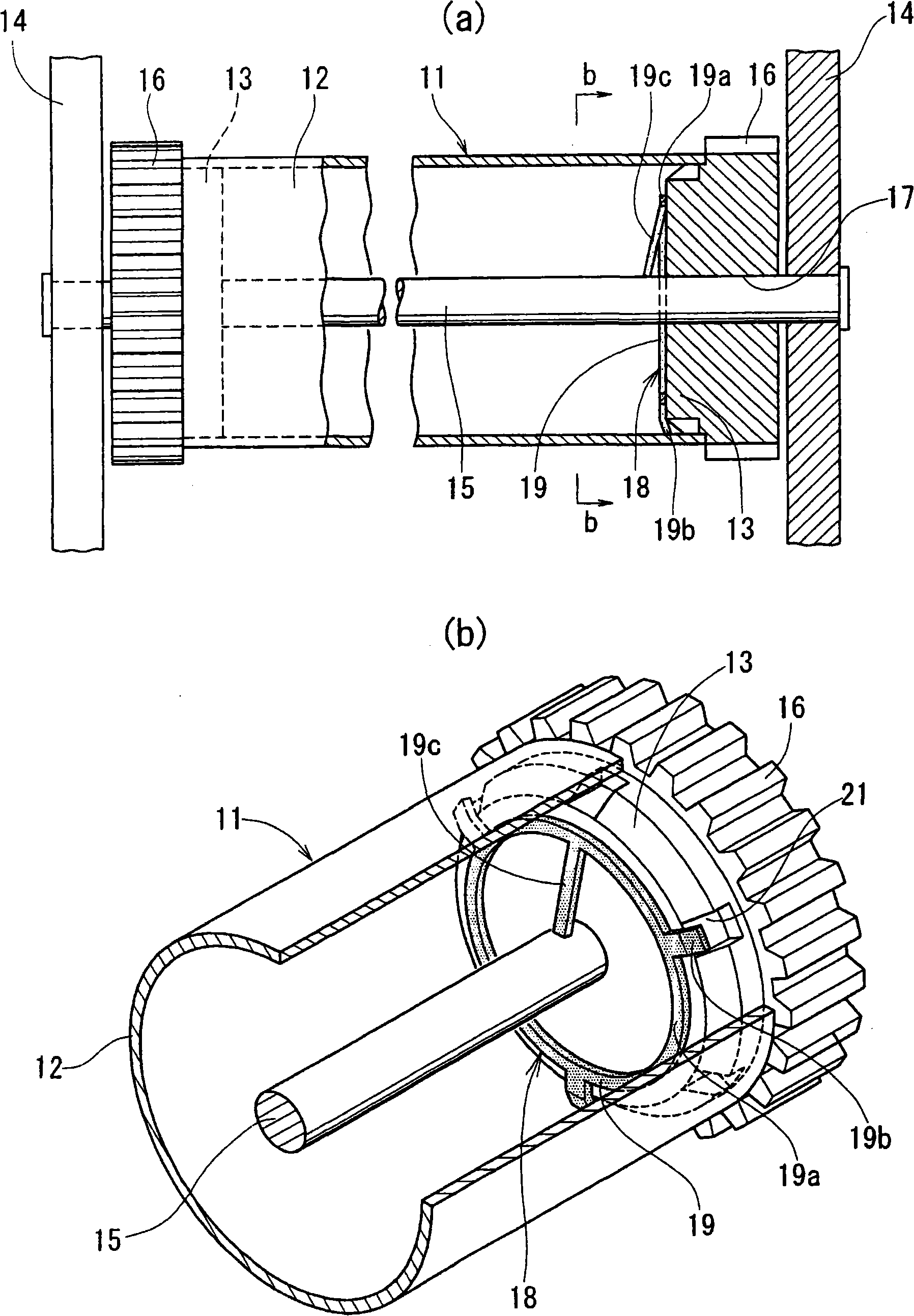

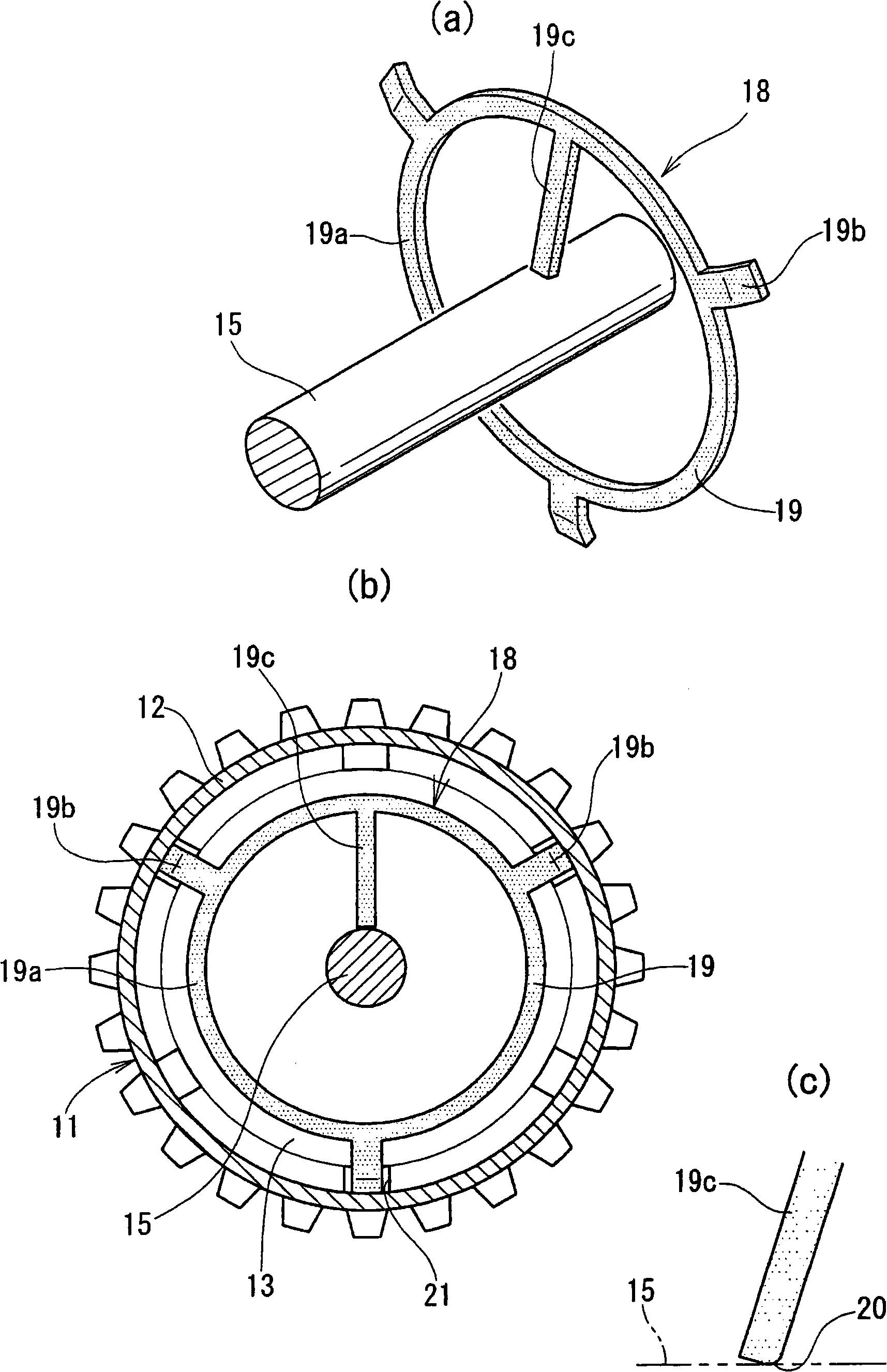

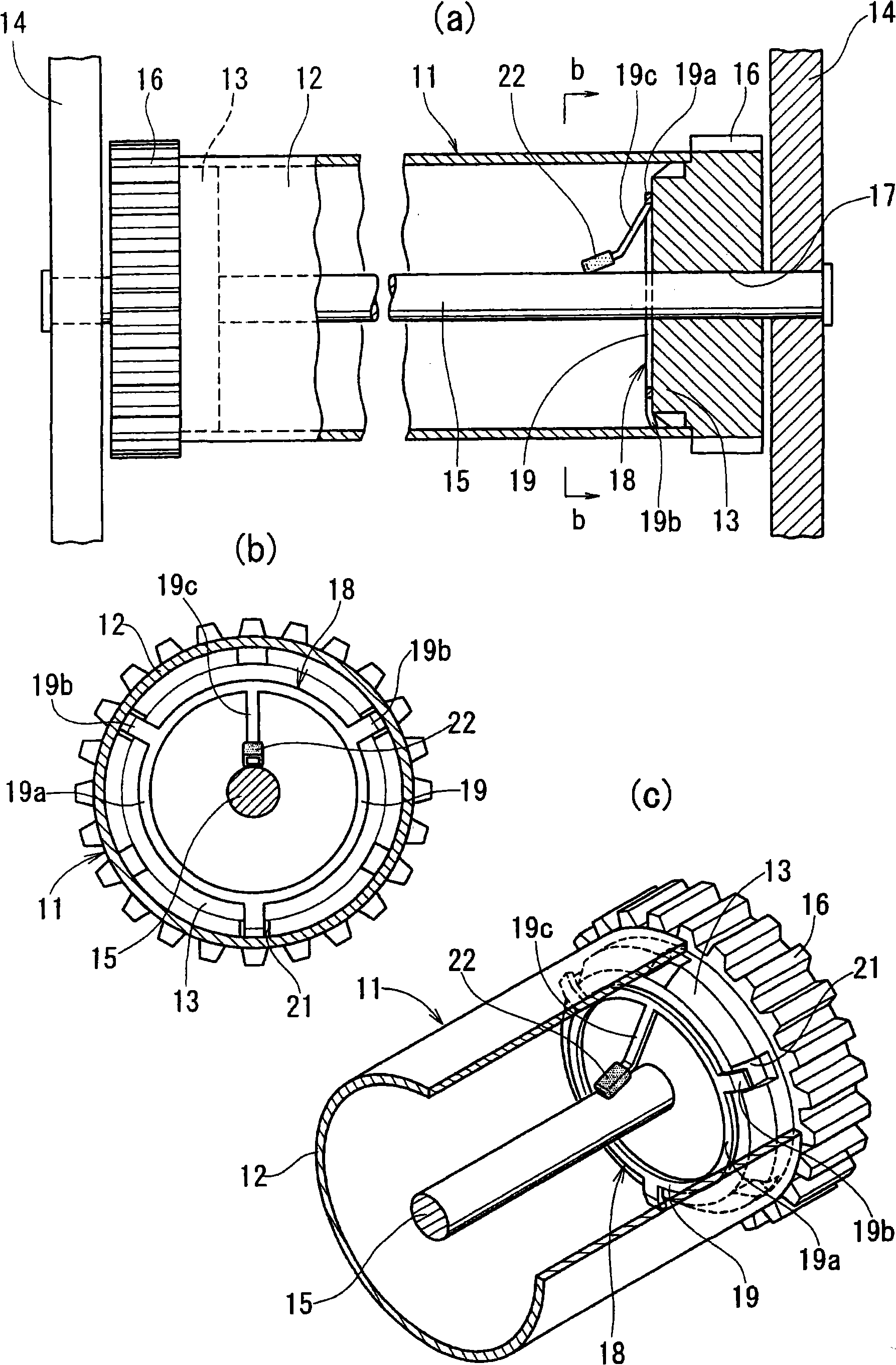

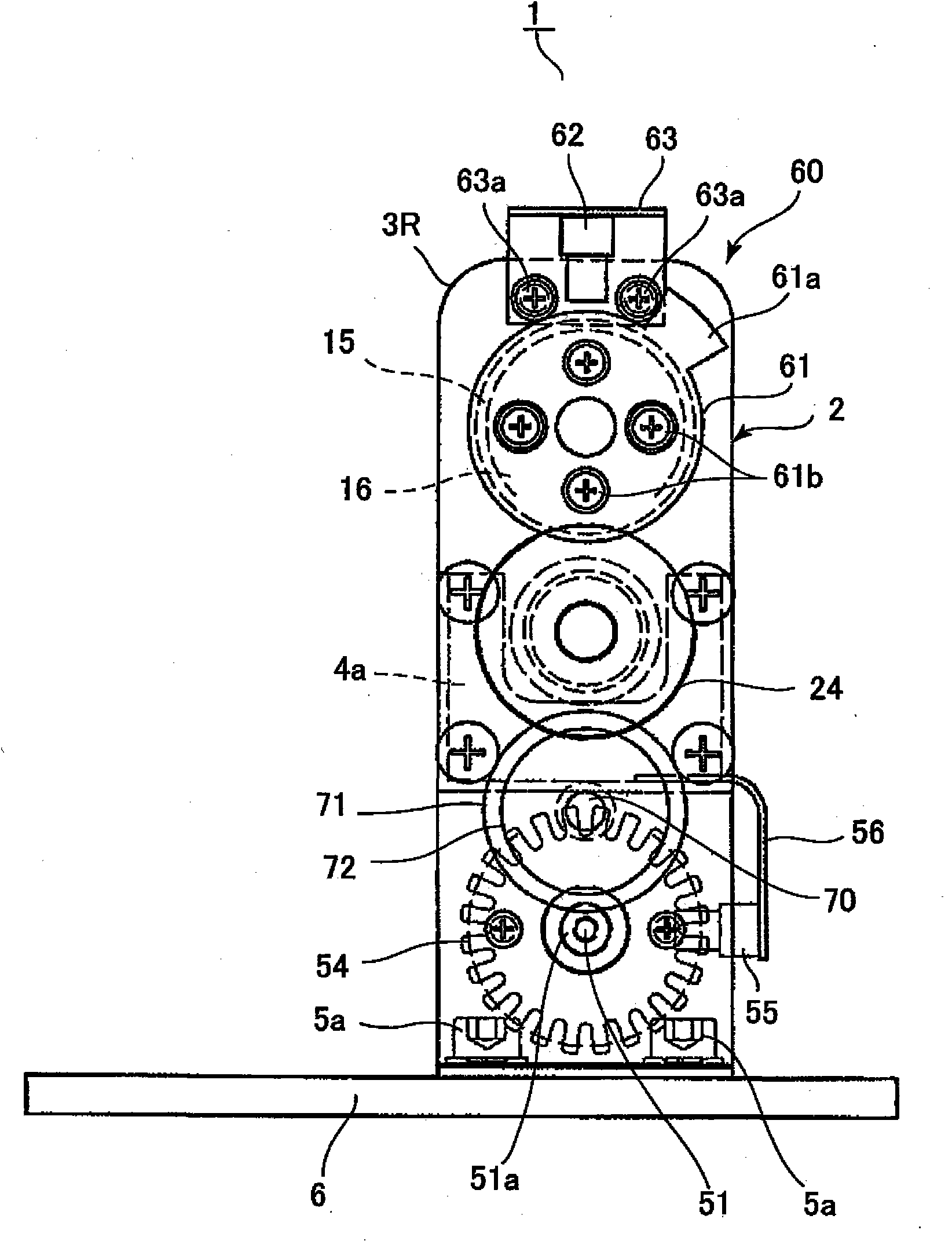

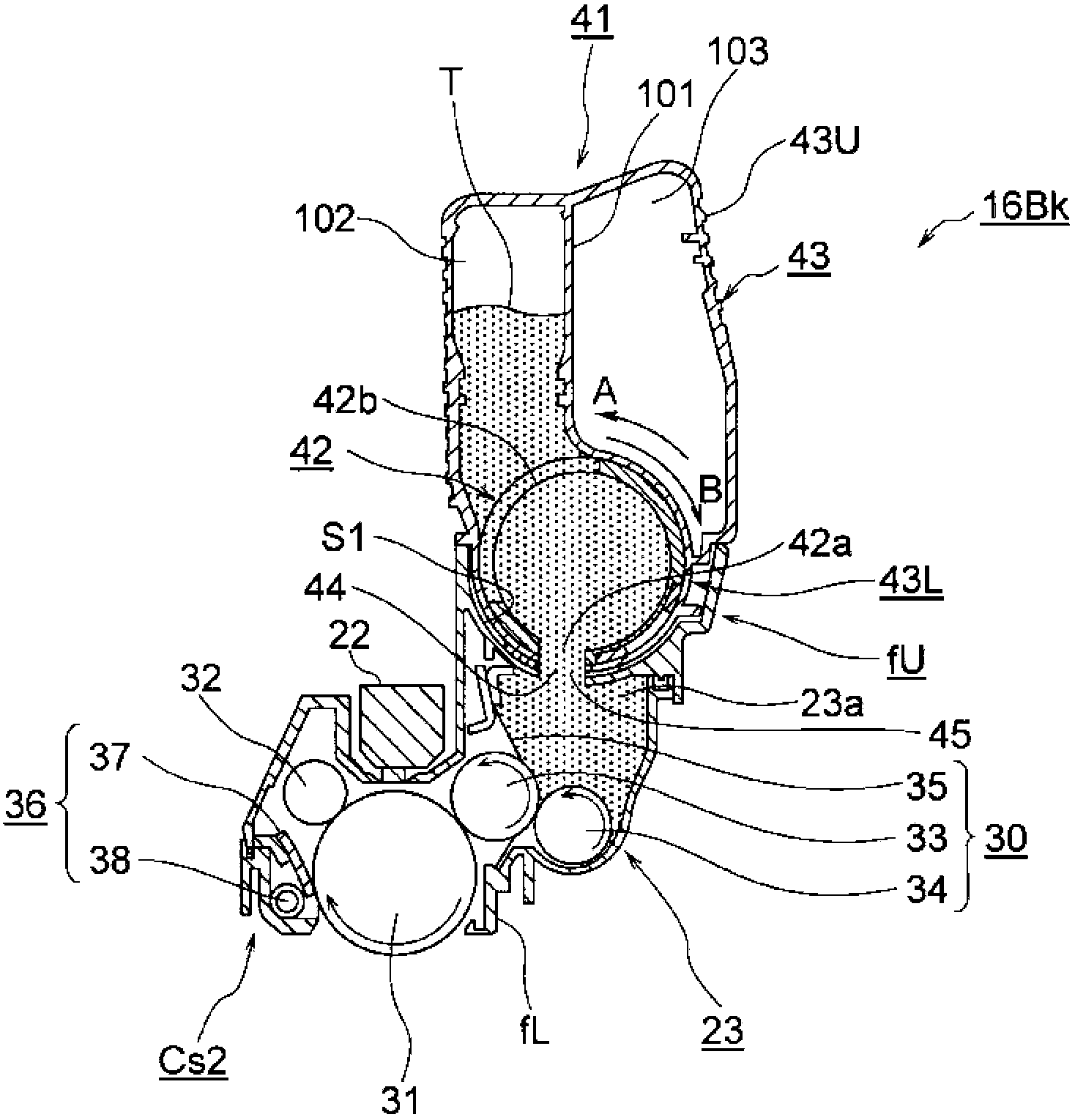

Grounding device of sensitometric drum and sensitometric drum unit of image forming device

InactiveCN101308342AAvoid noiseEasy to slideElectrographic process apparatusElectricityImage formation

The invention provides a grounding device of a photosensitive drum, which can avoid the noise of the connection portion of the drum shaft and the grounding component without reducing the intensity of the drum shaft to obtain a great image. The grounding device of the photosensitive drum is electrically connected to the drum shaft (15) with conductivity to the photosensitive drum (12) rotatablely installed on the drum shaft (15) via the grounding component (19); the conductive resin forms the grounding component (19); the grounding component (19) is provided with the contact sheet (19b) contacting to the photosensitive drum (12) on the grounding plate (19a), a flexible contact sheet (19c) contacting to the drum shaft (15); the drum shaft (15) and the photosensitive drum (12) are electrically connected.

Owner:NTN CORP

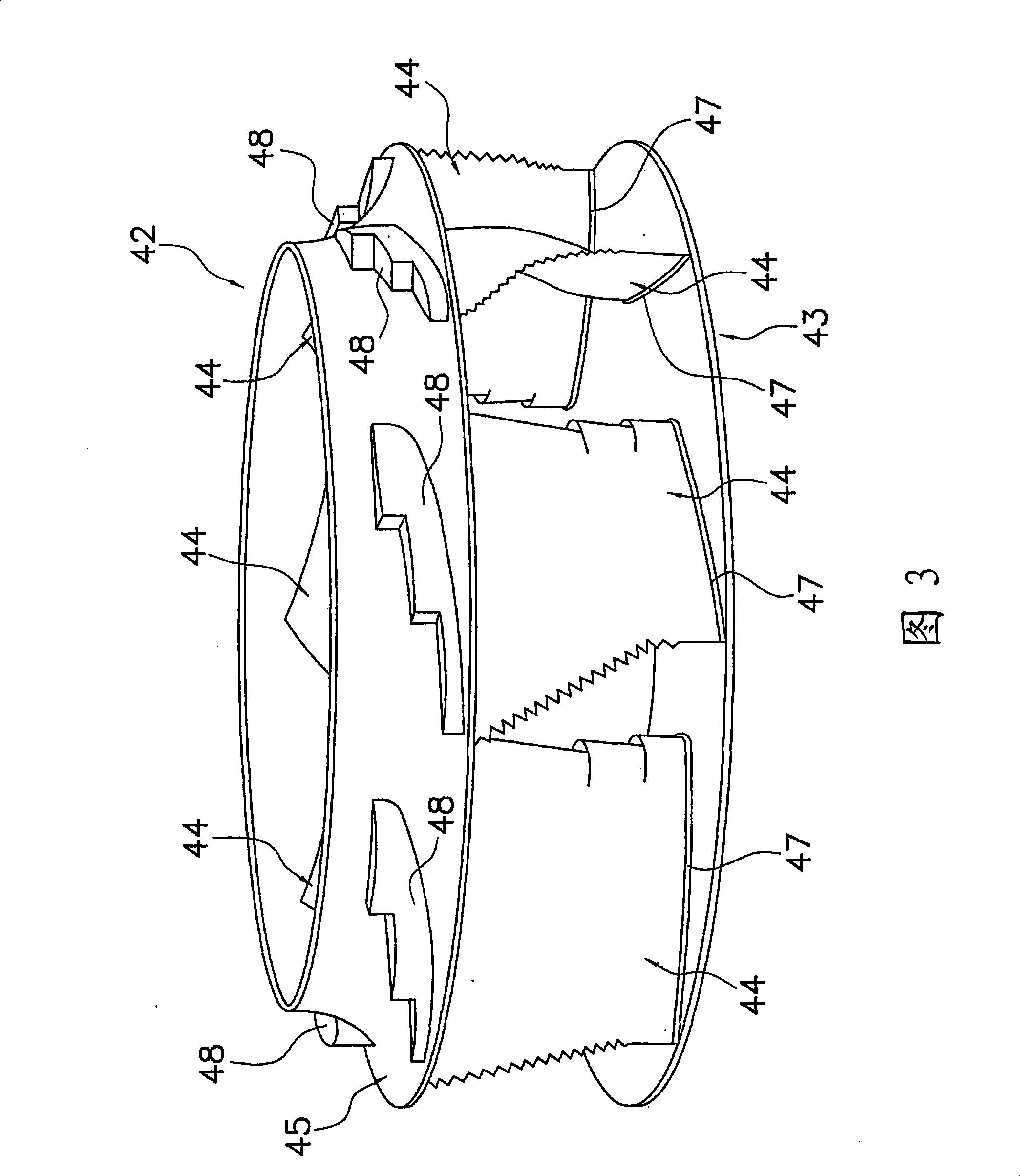

Laser welding method, laser welding device, and production method of blower-use impeller

A laser welding method for performing laser irradiation while moving an irradiation position, wherein the possibility of a combustion trace remaining on a laser beam irradiation path is minimized even dust, metal powder or the like deposited on the overlapped portion of resin members is ignited by laser irradiation. A laser welding method, wherein overlapped portion (13) is formed by laying a transmitting resin member (11) over an absorbing resin member (12) lower in light transmittance than the transmitting resin member (11), the overlapped portion (13) is then irradiated with laser from the transmitting resin member (11) side while the irradiation position is moved, and nonflammable gas is sprayed onto the irradiation position from the transmitting resin member (11) side in association with a moving laser beam irradiation position.

Owner:DAIKIN IND LTD

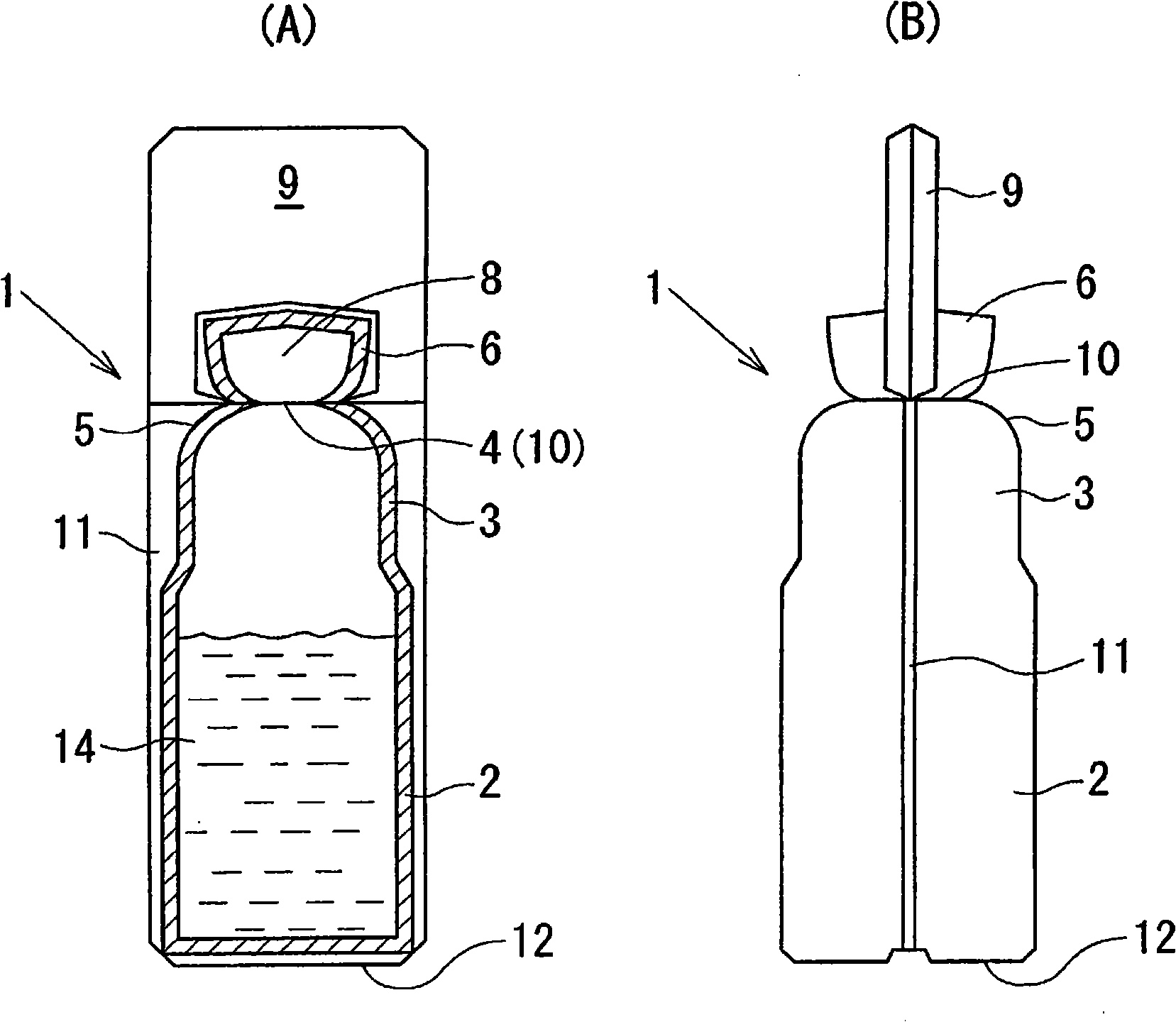

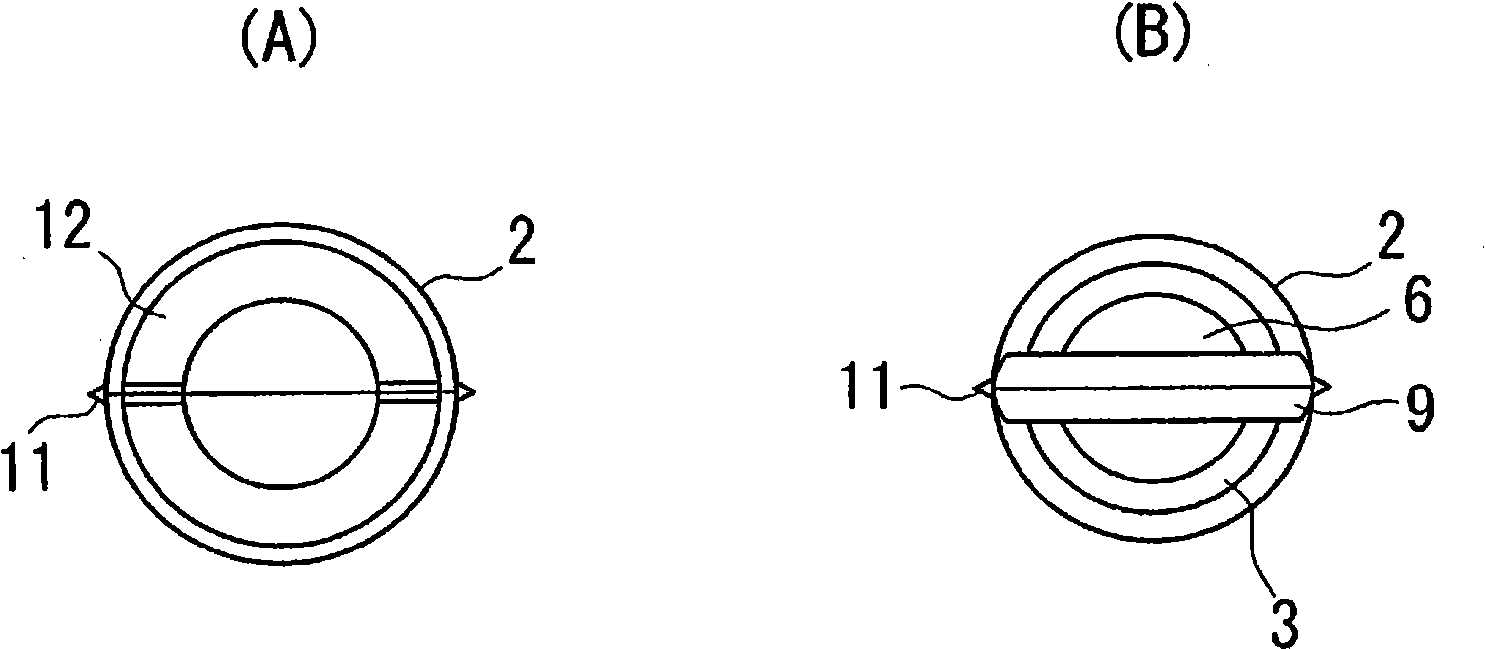

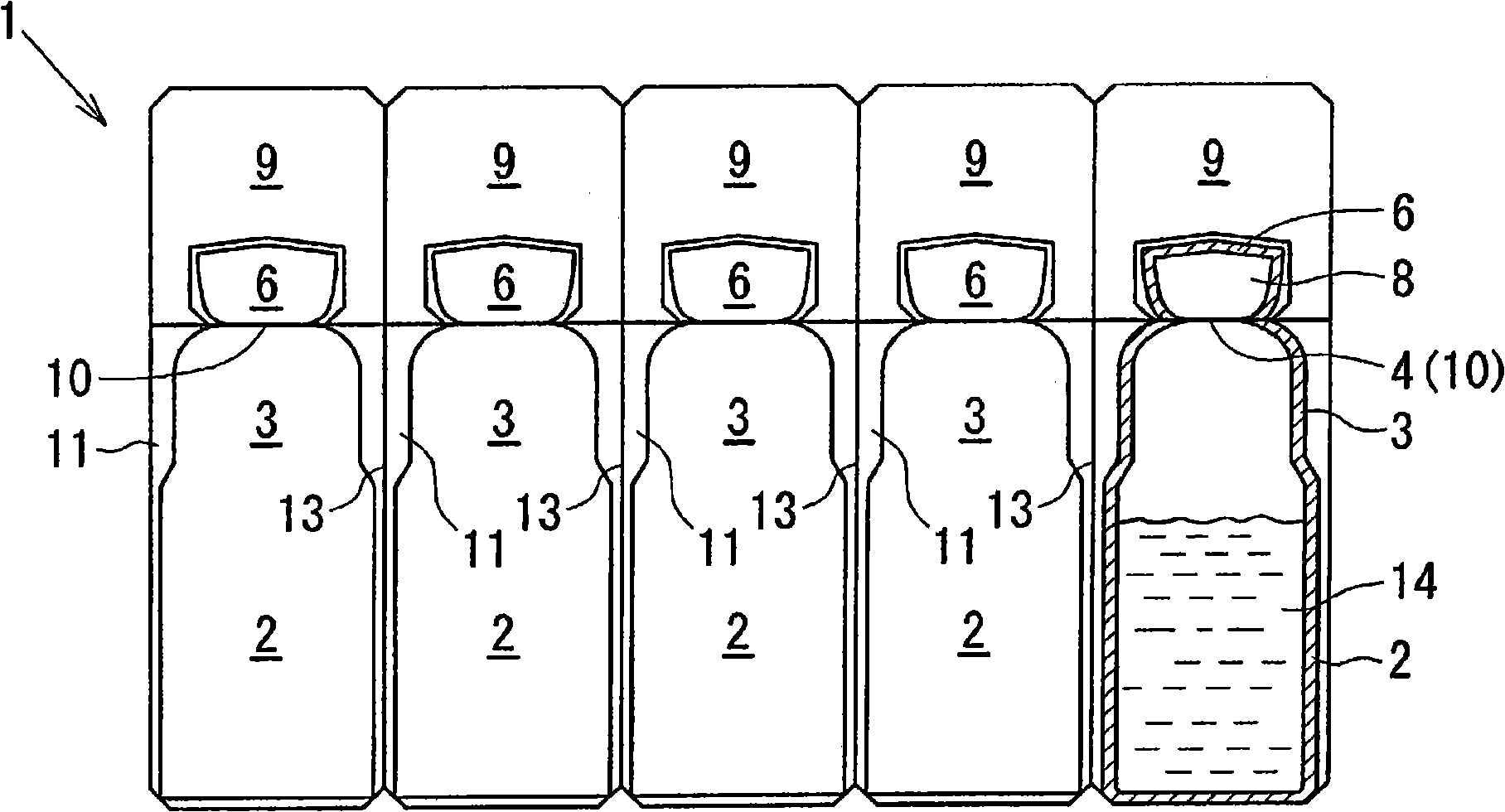

Plastic ampule

ActiveCN102014845AEasy to removeImprove draining effectBottlesPharmaceutical containersAmpouleEngineering

Provided is a plastic ampule being handled suitably at the time of unsealing wherein remaining content liquid can be removed easily by performing a removal operation for dropping the remaining content liquid into a body portion by shaking the plastic ampule before use even when the content liquid remains in the hollow portion of a head portion. The plastic ampule comprises a body portion, a head portion (6) provided continuously to the mouth portion (3) of the body portion through a cut-off portion (10), and a knob portion (9) provided continuously to the head portion (6), the ampule being unsealed by twisting the knob portion (9) with fingers to cut the head portion (6) off the mouth portion (3), wherein the hollow portion (8) in the head portion (6) is formed in the shape of a bowl. Since the hollow portion (8) is formed in the shape of a bowl, content liquid remaining in the hollow portion (8) can be discharged easily, the plastic ampule can be unsealed easily, and the content liquid remaining in the hollow portion (8) is not scattered easily at the time of unsealing.

Owner:NIPPON ZOKI PHARM CO LTD

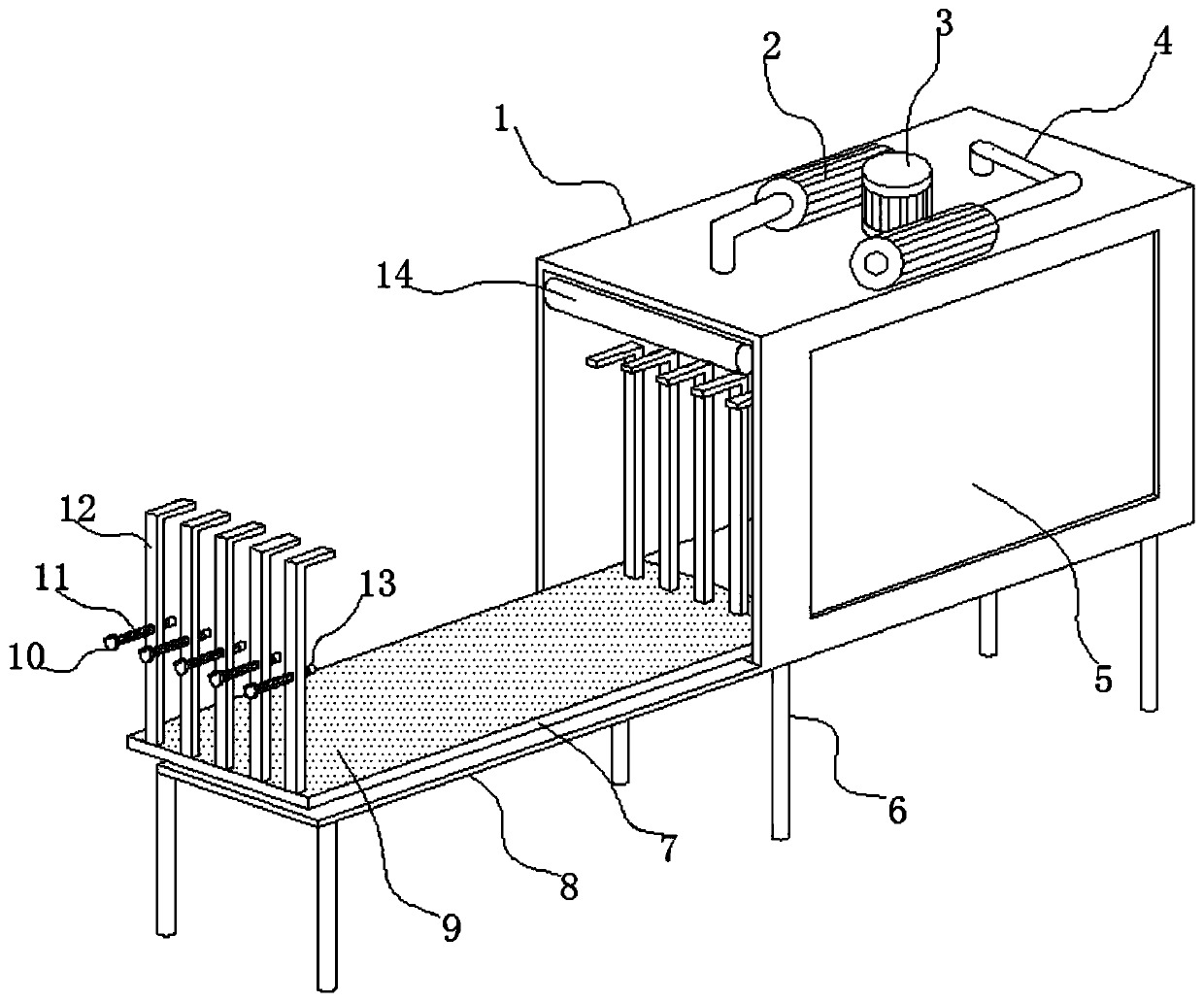

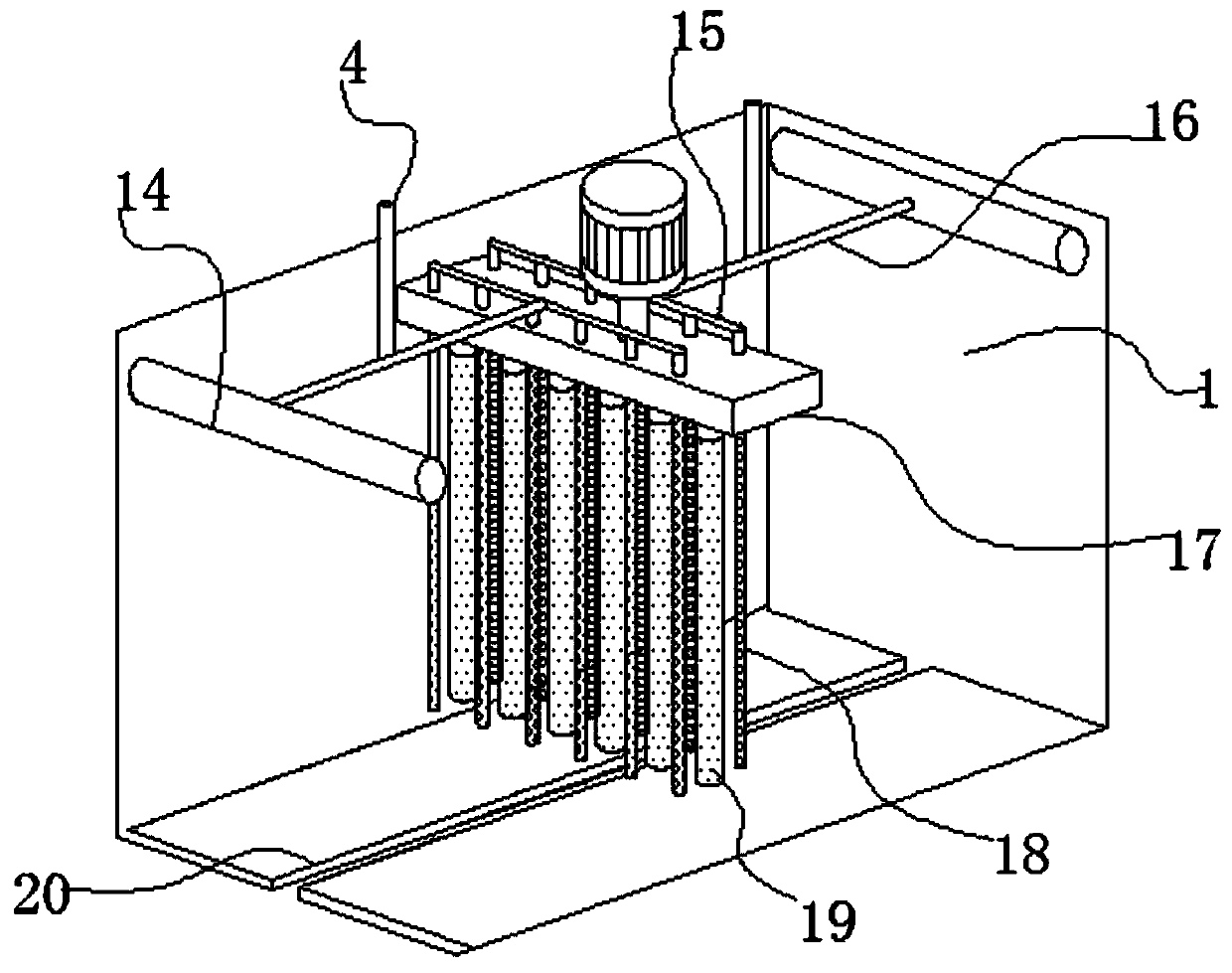

Surface treatment device used before wooden door painting

ActiveCN111438095AWon't fly awayImprove cleanlinessPretreated surfacesDirt cleaningGear wheelDust control

The invention provides a surface treatment device used before wooden door painting. The device comprises a dedusting box and a movable supporting plate, wherein a supporting table plate is fixedly connected to the lower portion of the left side of the dedusting box, supporting legs are fixedly connected to four corners of the bottom of the dedusting box in a vertically downward mode, supporting legs are fixedly connected to four corners of the bottom of the supporting table plate in a vertically downward mode, a driving motor is fixedly connected to the middle position of the upper portion ofthe dedusting box in a vertically downward mode, and dust suction pumps are fixedly connected to the left side and right side of the upper portion of the dedusting box respectively. According to the surface treatment device, a driving gear is driven by a servo motor to rotate so as to drive a rack to move, and consequently the movable supporting plate is driven to move into the dedusting box; at the moment, multiple wooden doors enter the space between two adjacent brush rollers, and the brush rollers rotate to sweep dust on the front side and back side of each wooden door; and moreover, the two dust suction pumps operate to suck dust generated in an inner cavity of the dedusting box through a suction main pipe, a communicating horizontal pipe, multiple dust suction pipes and two suction cylinders, so that the dust is removed more thoroughly, and two side edges of each wooden door are cleaned at a time.

Owner:重庆顺鼎木制品有限公司

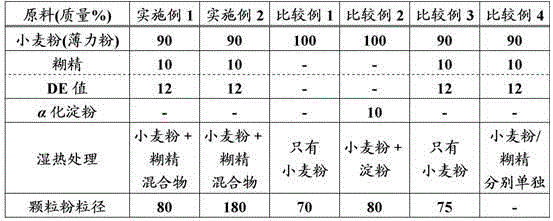

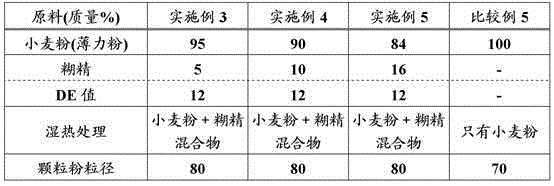

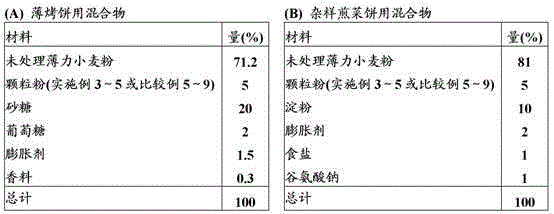

Granular powder

Provided is a wheat flour-containing granular powder for food, having good adhesion when sprinkled on foodstuff, having good handling with no scattering of powder dust, which provides both a fluffy and soft texture internally and a crispy surface texture, and is capable of maintaining good texture even if time has passed since being cooked. The granular powder comprises wheat flour and dextrin that have been hydrothermically treated.

Owner:NISSHIN DCA FOODS INC

Washer and dryer

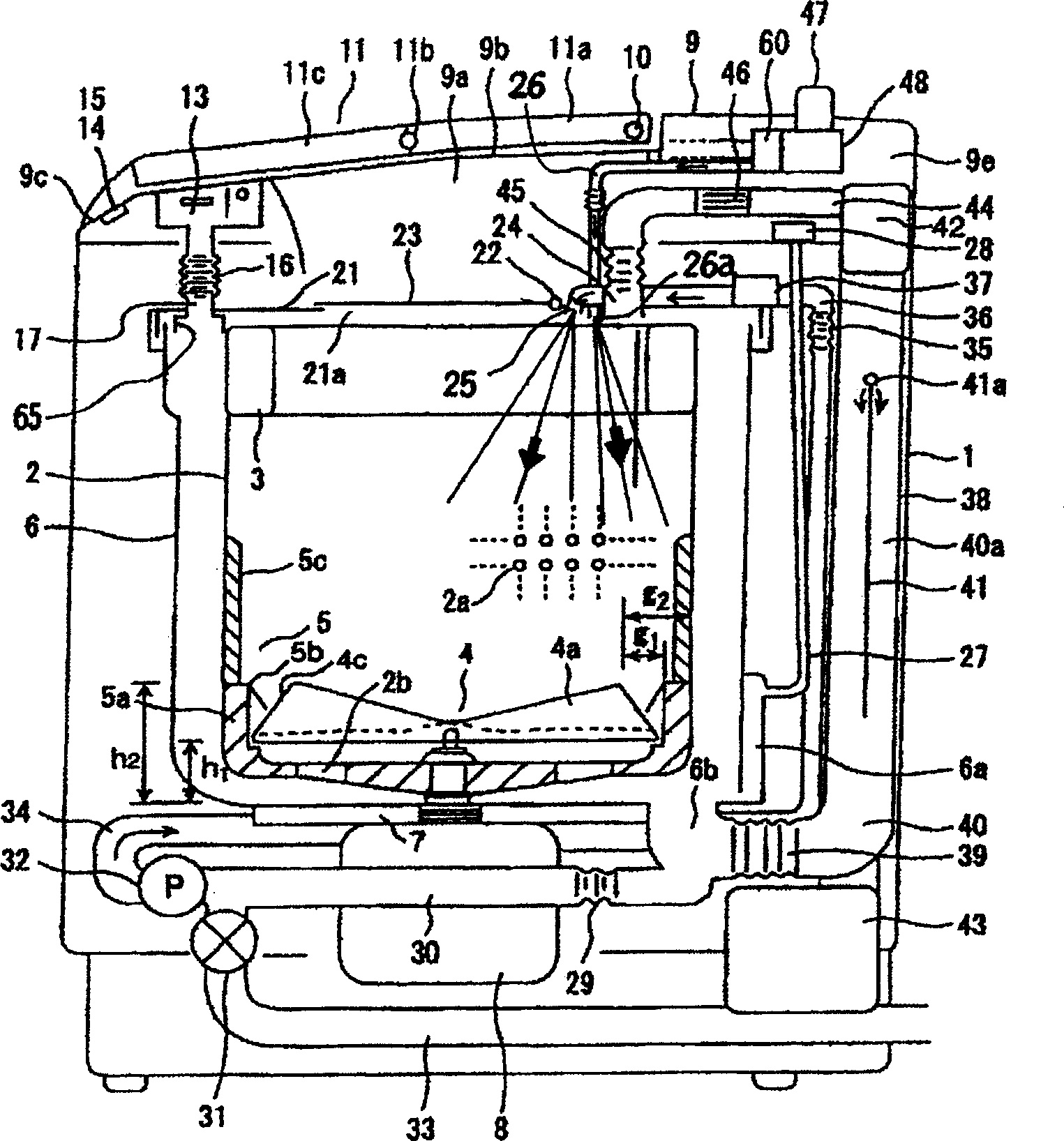

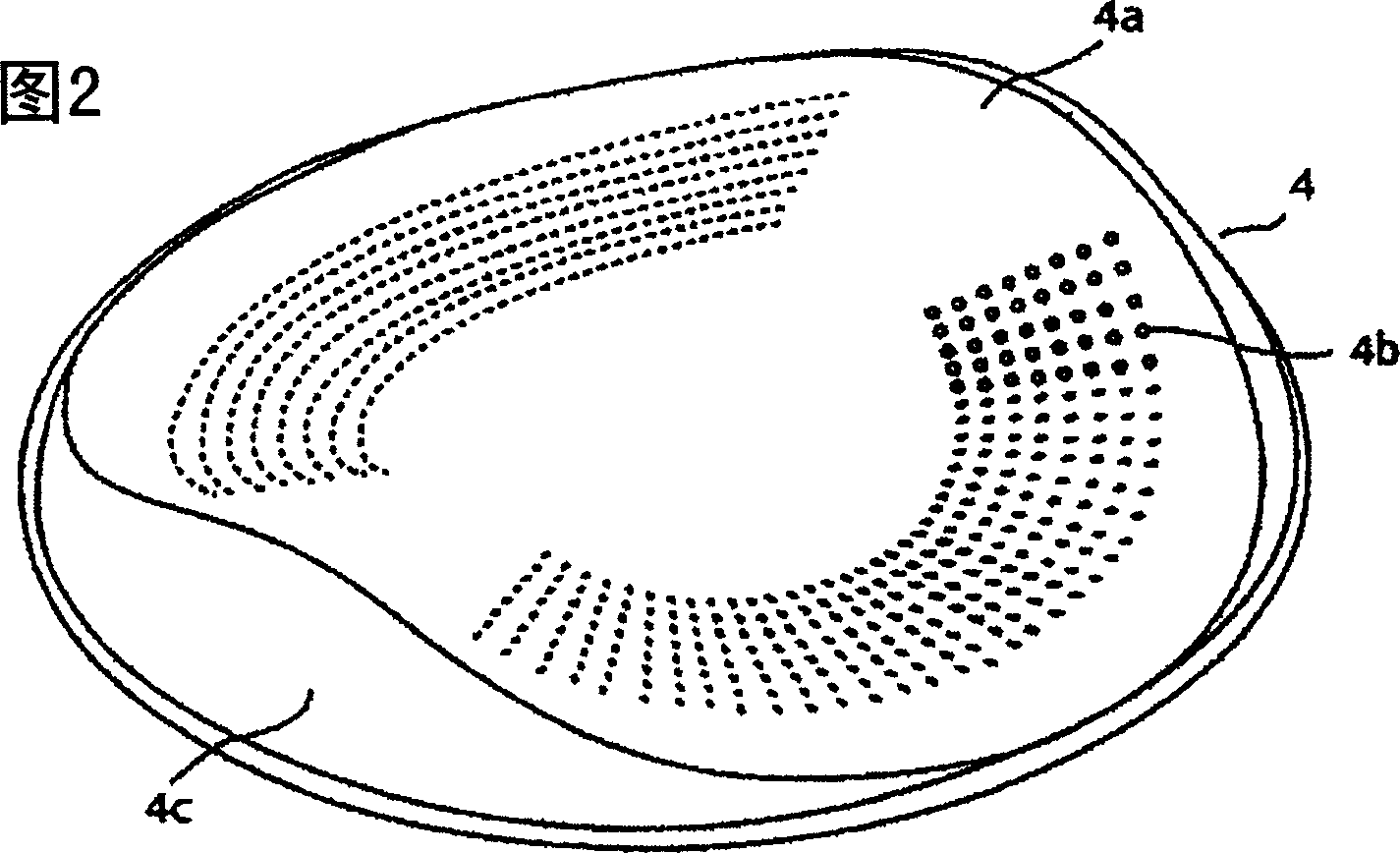

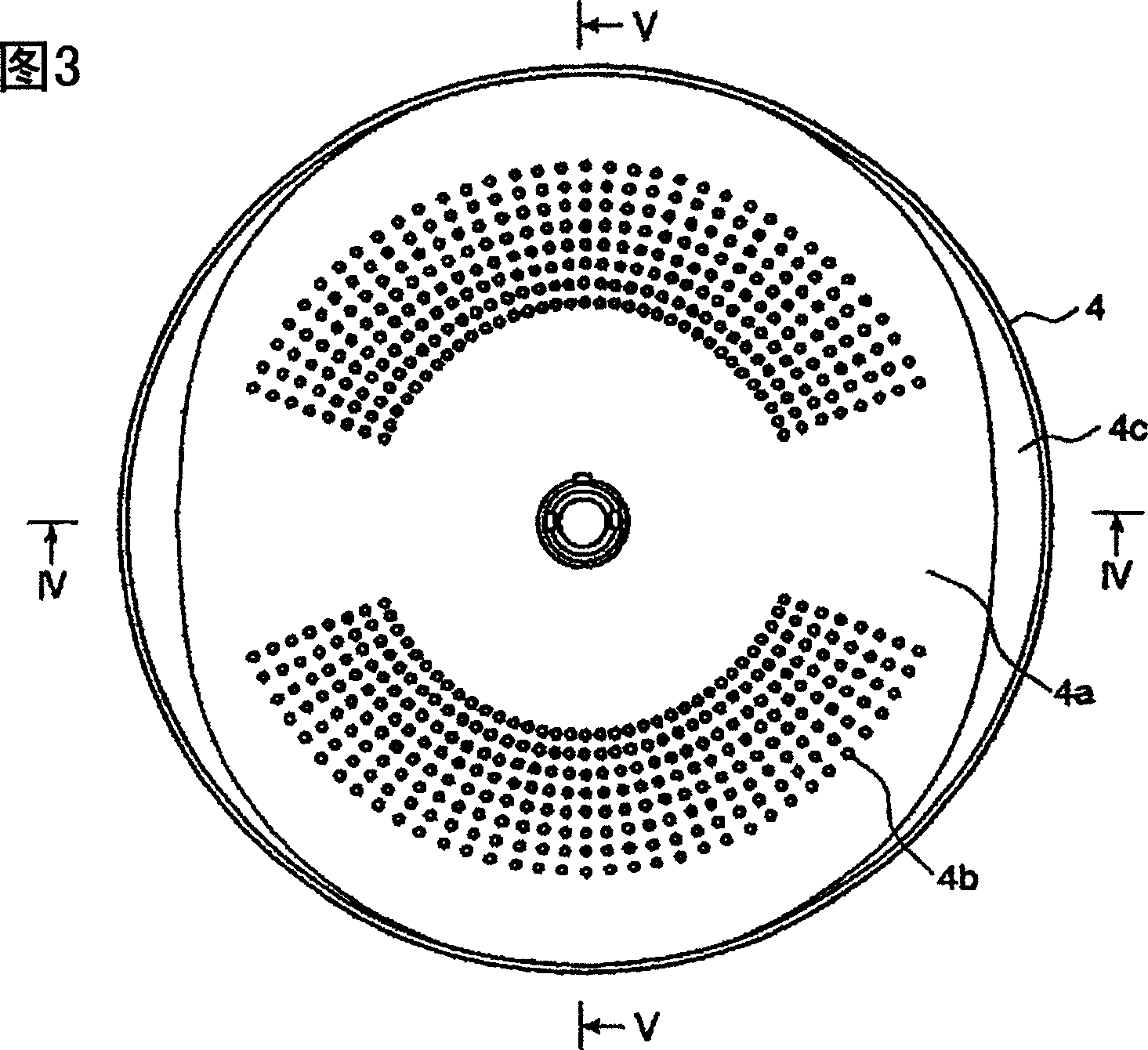

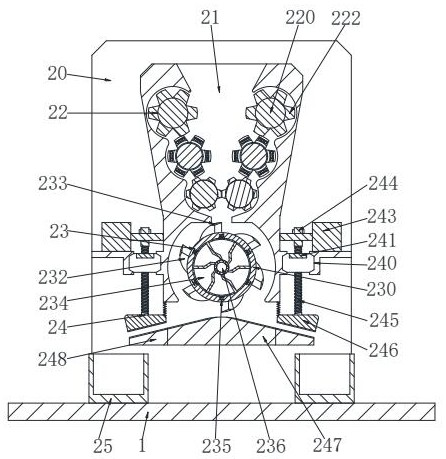

ActiveCN1880545AImprove chemical performanceIncrease temperatureControl devices for washing apparatusWashing machine with receptaclesWater savingImpeller

An object of the present invention is to provide a washing and drying machine capable of saving water and obtaining high cleaning power. It sprinkles the washing water with high detergent concentration in the inner cylinder (2), and while soaking the laundry, discharges the washing water from the bottom of the outer cylinder (6) to form a reliable air passage for the air circulation mechanism, while letting the pulsating impeller (4) Make forward and reverse rotation, while using the electric air blower (43) to suck the air in the outer cylinder, and blow the hot air heated by the PTC heater (46) into the inner cylinder to improve the washing and soaking. The temperature of the washing water in the laundry, and then supply water so that the water is accumulated at the bottom of the above-mentioned outer cylinder, and the washing water is kept at a water level not exceeding the above-mentioned pulsating impeller, and then, while allowing the washing water accumulated at the bottom of the above-mentioned outer cylinder The water is circulated, and it is sprinkled on the laundry on the above-mentioned pulsating impeller, while the above-mentioned pulsating impeller is rotated positively and negatively, to implement the washing that the upward force is repeatedly applied to the laundry by the pulsating impeller.

Owner:HITACHI HOME & LIFE SOLUTIONS INC

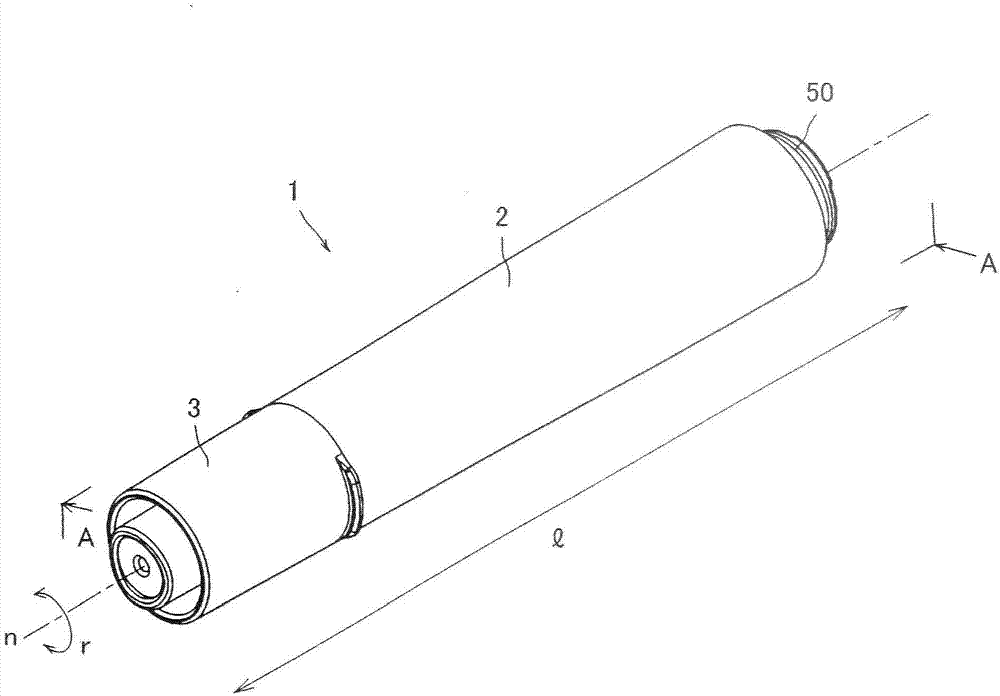

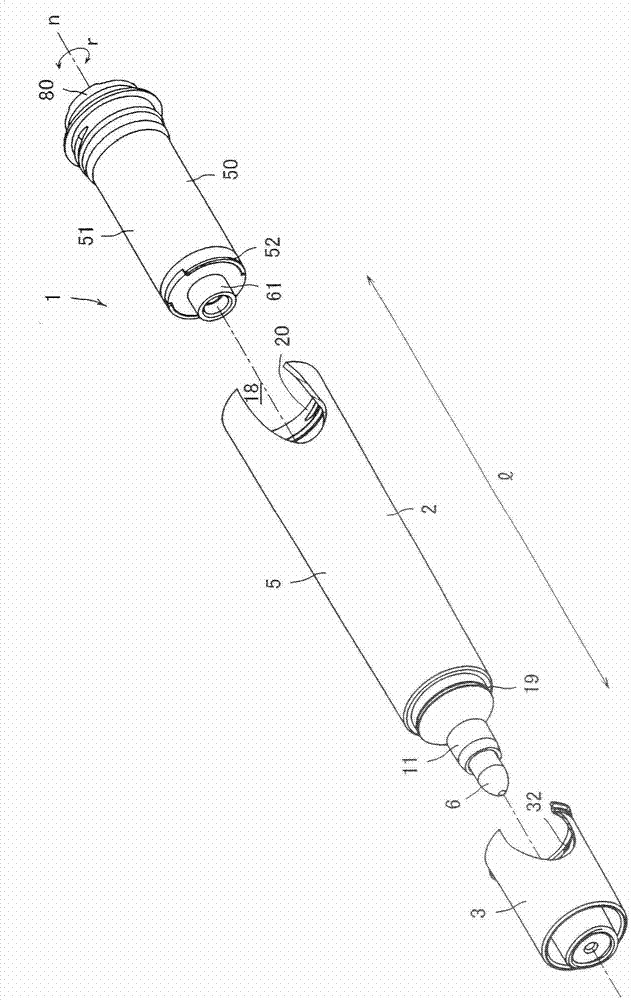

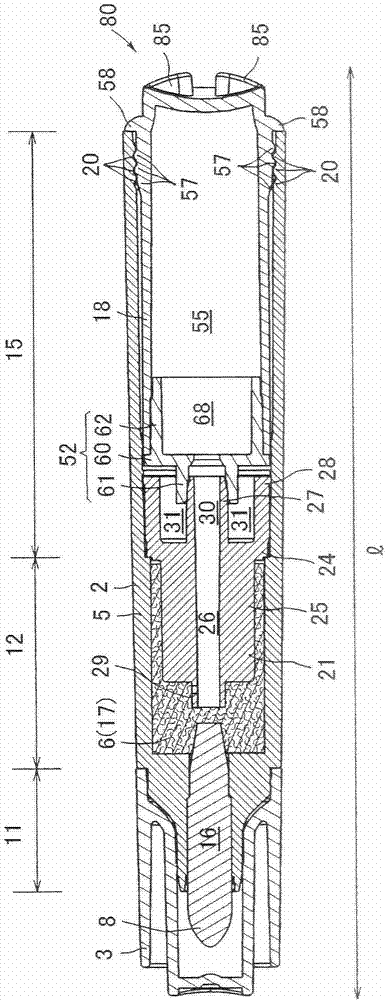

Coating implement and coating liquid box

InactiveCN103241034AWon't fall off by mistakeWon't fly awayOther pensEngineeringMechanical engineering

The invention aims to provide a coating implement which prevents a problem that an ink box falls slowly even when part of the ink box is touched by accident in use of the coating implement. The coating implement has a structure which is characterized in that: on an occasion that the ink box is mounted on a coating tool body, the most part of the ink box is in a cylinder and only the back end part is exposed from the cylinder which is the body cylinder (5) of the coating tool body (2); the back end of a changed ink box (50a) which is totally exhausted is provided with a jointing part (80a); and the jointing part (80a) of the totally exhausted ink box (50a) in mounting of the coating tool body is jointed with one part of a new ink box (50b) to be replaced, thereby placing the ink box.

Owner:SAKURA COLOR PRODUCTS CORPORATION

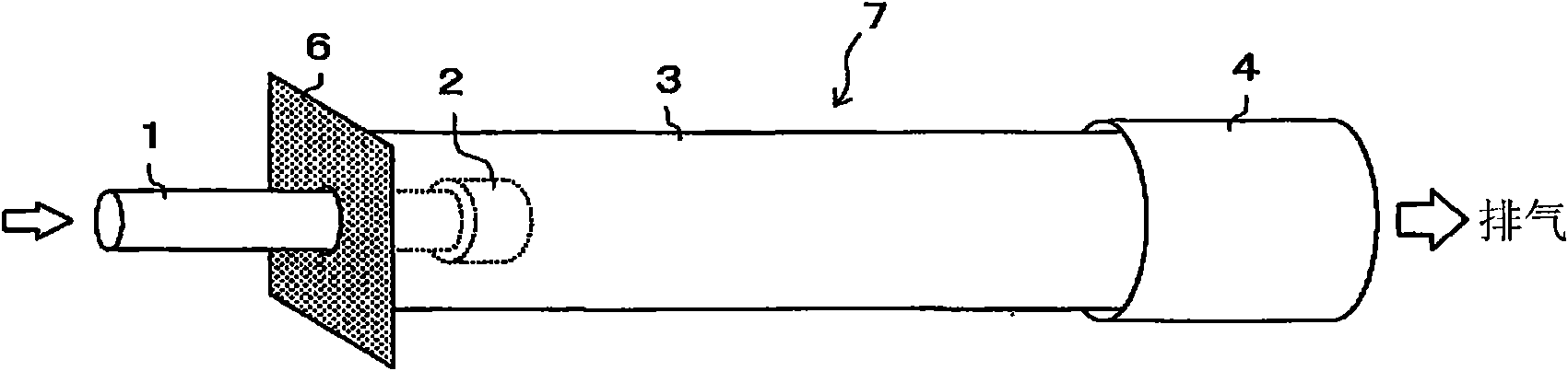

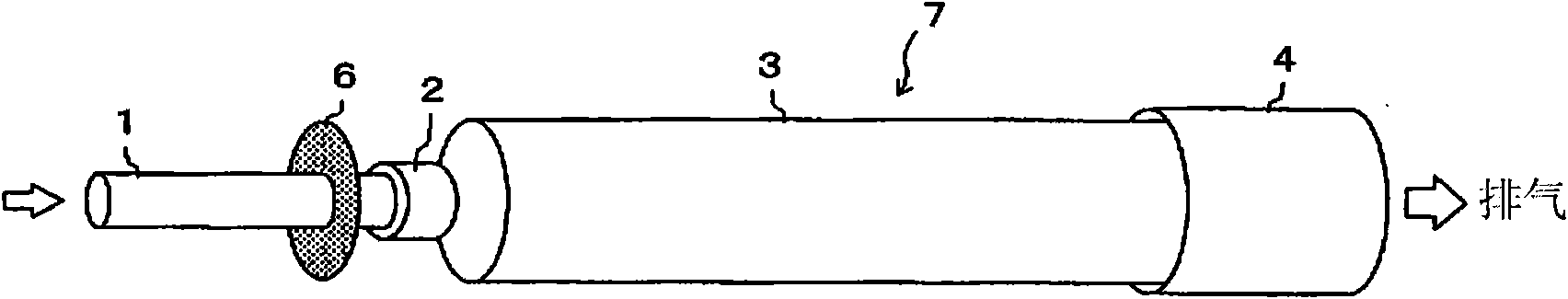

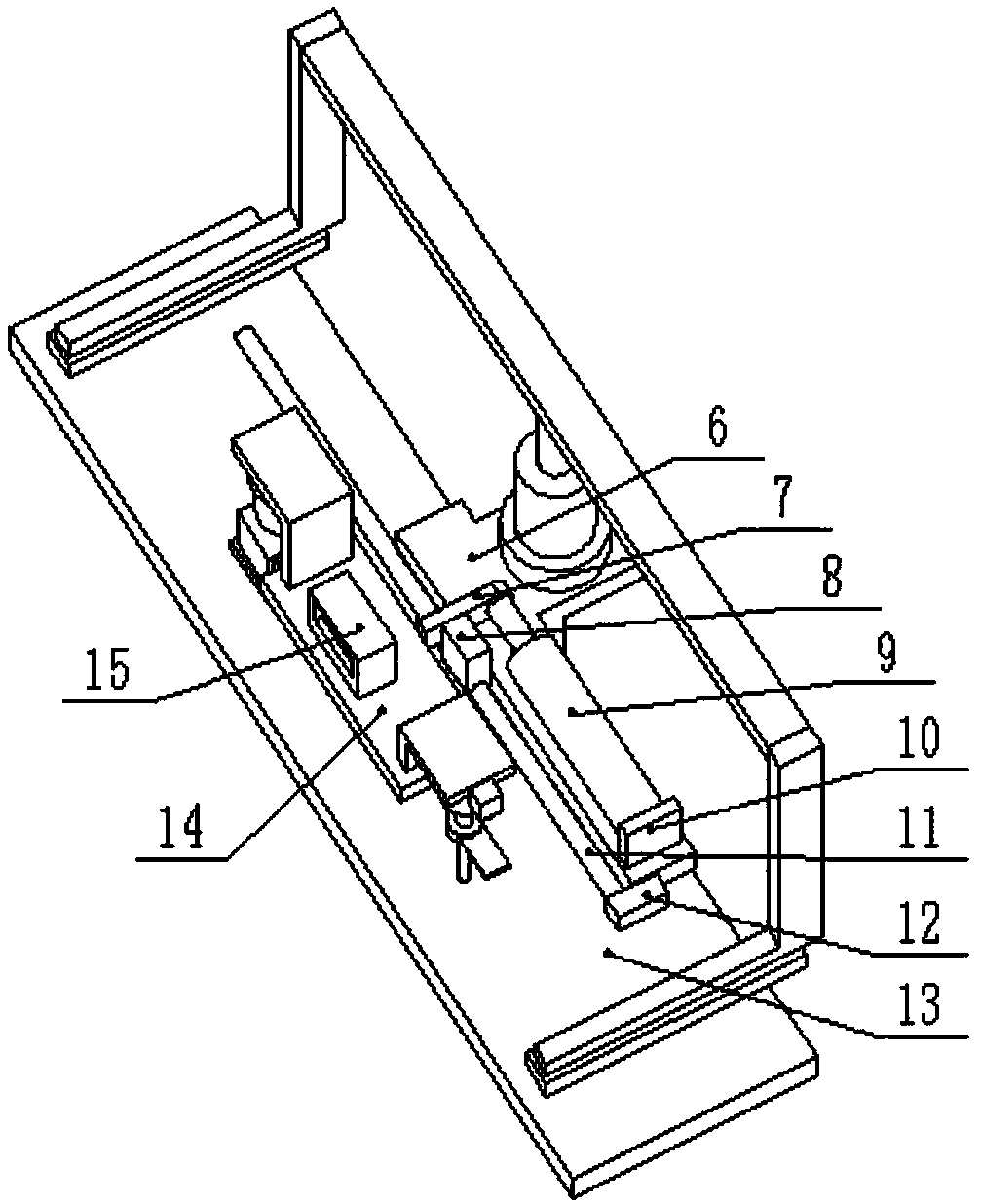

Scale removing method and scale removing device

InactiveCN101980834ADust flyingWon't fly awayAbrasive machine appurtenancesAbrasive blasting machinesMetallurgyHigh pressure

A scale removing device (7) performing blast processing of the inner surface of a steel tube (3) by causing a grinding and cleaning material (not shown) ejected from a high-pressure nozzle (2) to collide with the inner surface of the steel tube (3). The scale removing device (7) has the high-pressure nozzle (2) for ejecting the grinding and cleaning material, a dust collector (4) for collecting powder dust after blast processing, and a suppressing means (6) for suppressing inflow of air into a steel tube (3) from an end of the steel tube (3) occurring as the grinding and cleaning material ejected from the high-pressure nozzle (2) moves. Even if the dust collector has a small power capacity, the scale removing device (7) can remove scale without causing the powder dust to disperse into the atmosphere.

Owner:SUMITOMO METAL IND LTD

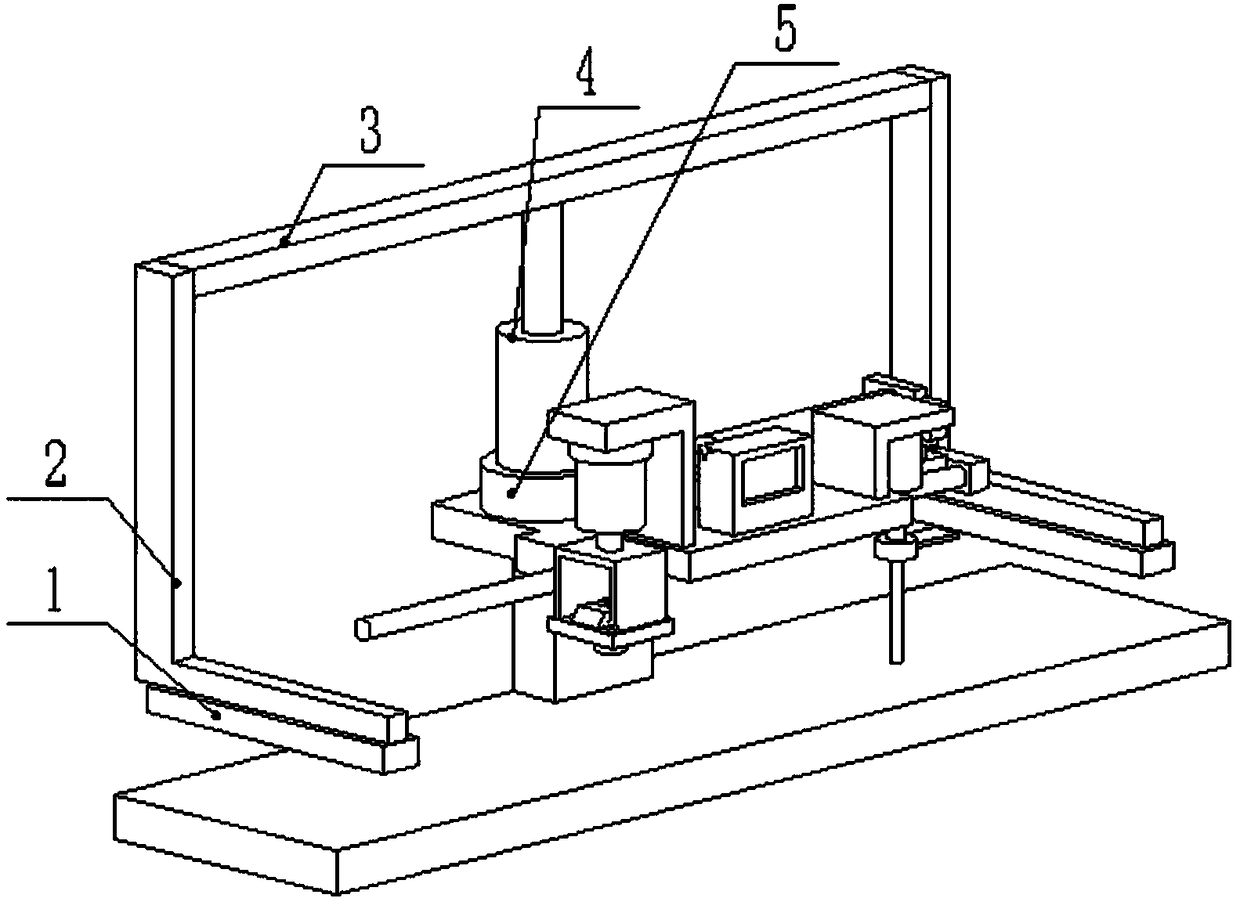

Automatic installation device for rivets for aluminum alloy machining

ActiveCN108421949AImprove processing efficiencyFully fixedMeasurement/indication equipmentsPositioning apparatusHydraulic cylinderUltrasonic sensor

The invention discloses an automatic installation device for rivets for aluminum alloy machining, and belongs to the field of building construction equipment. The upper side of the middle of a workbench is fixedly connected with a controller; the tail end of a six bracket is fixedly connected with an ultrasonic sensor, and the lower side of the six bracket is fixedly connected with a third hydraulic cylinder; the lower end of the third hydraulic cylinder is fixedly connected with a seventh bracket, and the lower portion of the seventh bracket is fixedly connected with a drilling machine; the drilling machine is fixedly connected with a drill bit; the lower side of a eighth bracket is fixedly connected with a second pressure sensor, and the lower end of the second pressure sensor is fixedlyconnected with a fourth hydraulic cylinder; and the lower side of the fourth hydraulic cylinder is fixedly connected with an installation device. According to the automatic installation device, the work of knocking the rivets in aluminum alloy is completed through hydraulic cylinder driving and the installation device, the situation that two different tools are separately utilized to operate therivets is not needed, the process is quite simple, the machining speed is greatly increased, the aluminum alloy machining efficiency is improved, and engineering construction is accelerated.

Owner:太仓耀展金属制品有限公司

Reductant composition and preparation method thereof, and welding method

InactiveCN103212921AReduce scumSpeed up the flowWelding/cutting media/materialsSoldering mediaTherapeutic effectReducing agent

The invention provides a reductant composition which comprises a nonionic surfactant, an antioxidant and ammonium metaphosphate. Meanwhile, the invention further discloses a preparation method of the reductant composition and a welding method. The reductant composition provided by the invention used in wave-soldering is excellent in scum treatment effect, and convenient and safe to use.

Owner:SHENZHEN KUNQI XINHUA

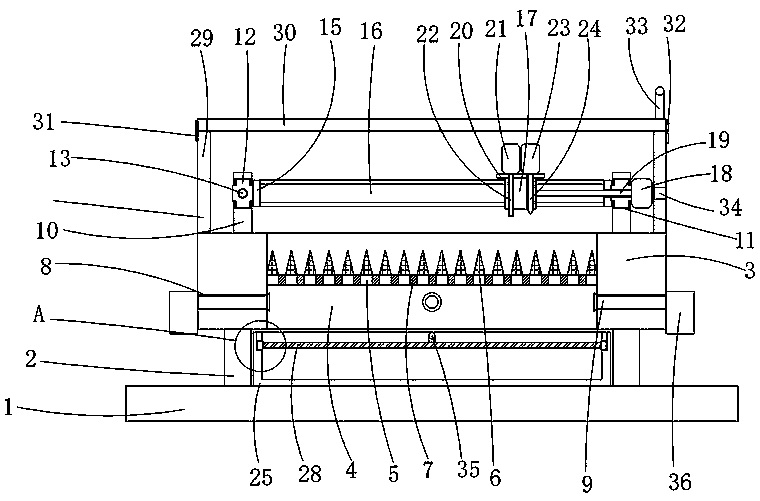

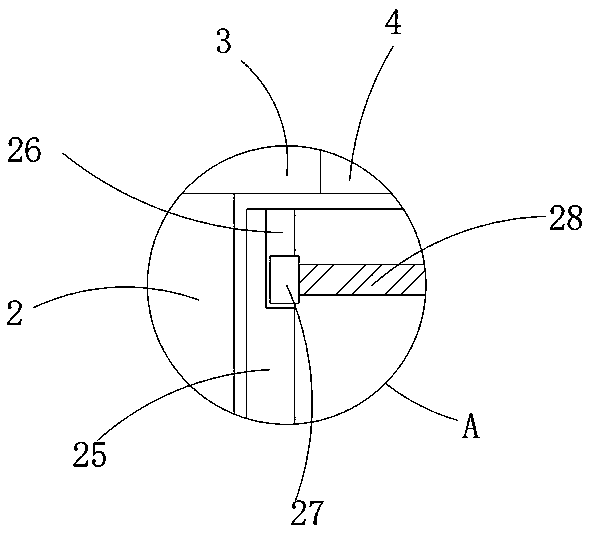

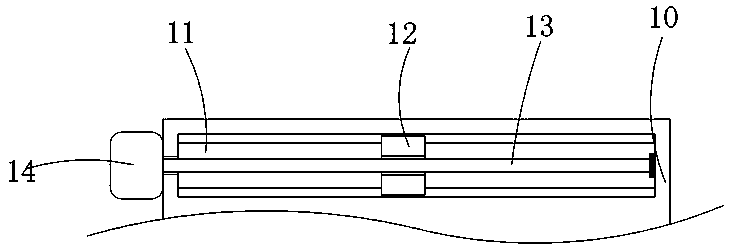

Efficient dust removal type laser cutting machine for machining thick metal plates

InactiveCN111136388AEnsure safetyHealth effectsLaser beam welding apparatusDust controlStructural engineering

The invention discloses an efficient dust removal type laser cutting machine for machining thick metal plates. The efficient dust removal type laser cutting machine comprises a base, wherein two symmetrically-arranged supporting bases are fixedly connected to the upper end face of the base, the two supporting bases are arranged away from each other, and the ends, away from the base, of the two supporting bases are jointly and fixedly connected with a workbench; and a working groove is formed in the workbench and located between the two supporting bases, a supporting plate is fixedly connectedto the inner wall of the working groove, and the supporting plate is arranged away from the base. According to the efficient dust removal type laser cutting machine for machining the thick metal plates, a user can conveniently complete clearing work of cutting dust, the user also can be protected from being hurt by the dust, the safety of the user is guaranteed while the working efficiency of theuser is improved, and cutting residues can be rapidly separated from the metal plates in the working process, so that the cutting quality of the metal plates is greatly improved.

Owner:李光普

Gypsum sculpture cleaning device

InactiveCN110977792AWon't fly awayProtect healthAbrasive feedersAbrasive machine appurtenancesSand blastingDust control

The invention provides a gypsum sculpture cleaning device. The gypsum sculpture cleaning device comprises a base, a cleaning mechanism and a dust removal mechanism, wherein the cleaning mechanism andthe dust removal mechanism are both arranged above the base; the cleaning mechanism comprises an air booster pump, an air storage tank, a sand blasting box, a sand blasting pipe, an exhaust pipe and acleaning head, the input end of the air storage tank communicates with the air booster pump, the output end of the air storage tank communicates with the sand blasting box, one end of the sand blasting pipe communicates with the sand blasting box, the other end of the sand blasting pipe is arranged in the exhaust pipe, the sand blasting pipe at the end communicates with the cleaning head, one endof the exhaust pipe communicates with the dust removal mechanism through a connecting pipe, and the other end of the exhaust pipe communicates with the cleaning head; and the dust removal mechanism comprises an exhaust box and an exhaust fan, the exhaust pipe communicates with the exhaust box through a connecting pipe, and the exhaust fan is arranged at one end of the exhaust box. The device causes no damage to gypsum sculptures in a cleaning process, can clean gypsum surfaces conveniently and causes no dust pollution to the environment and an operator.

Owner:洛阳湛兰文化传播有限公司

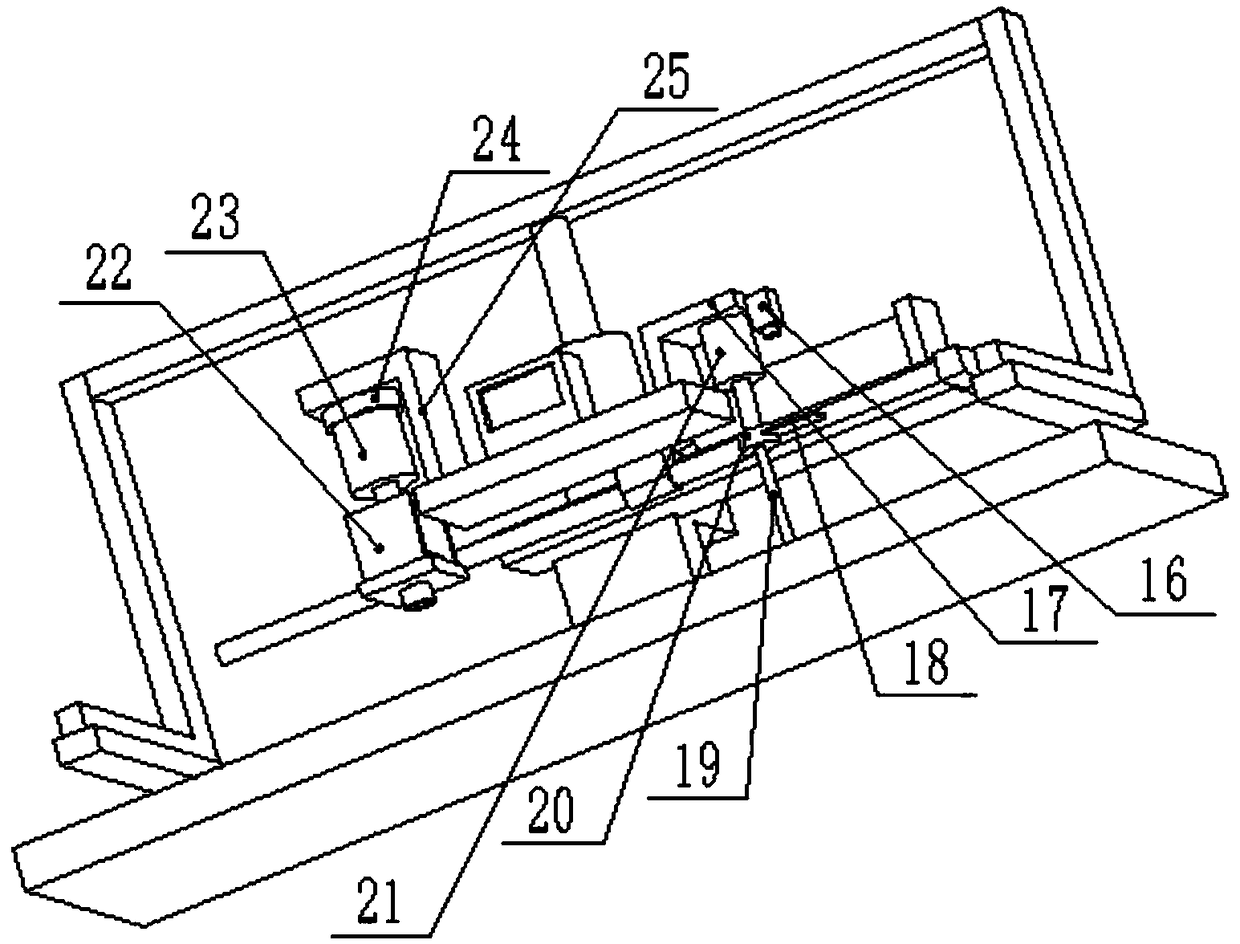

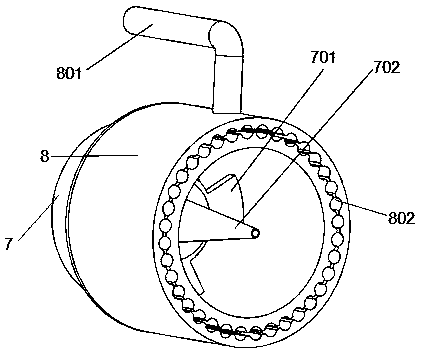

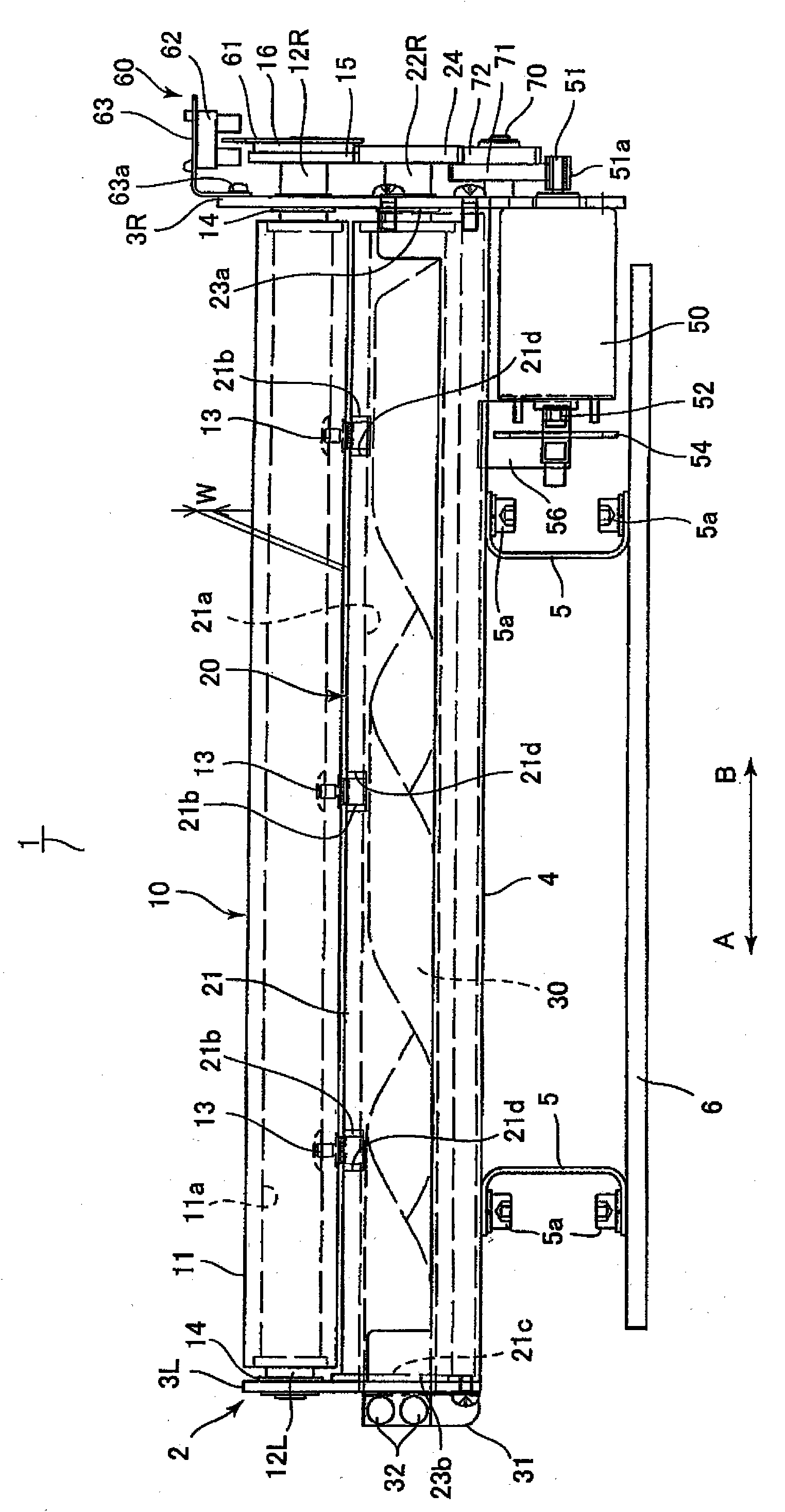

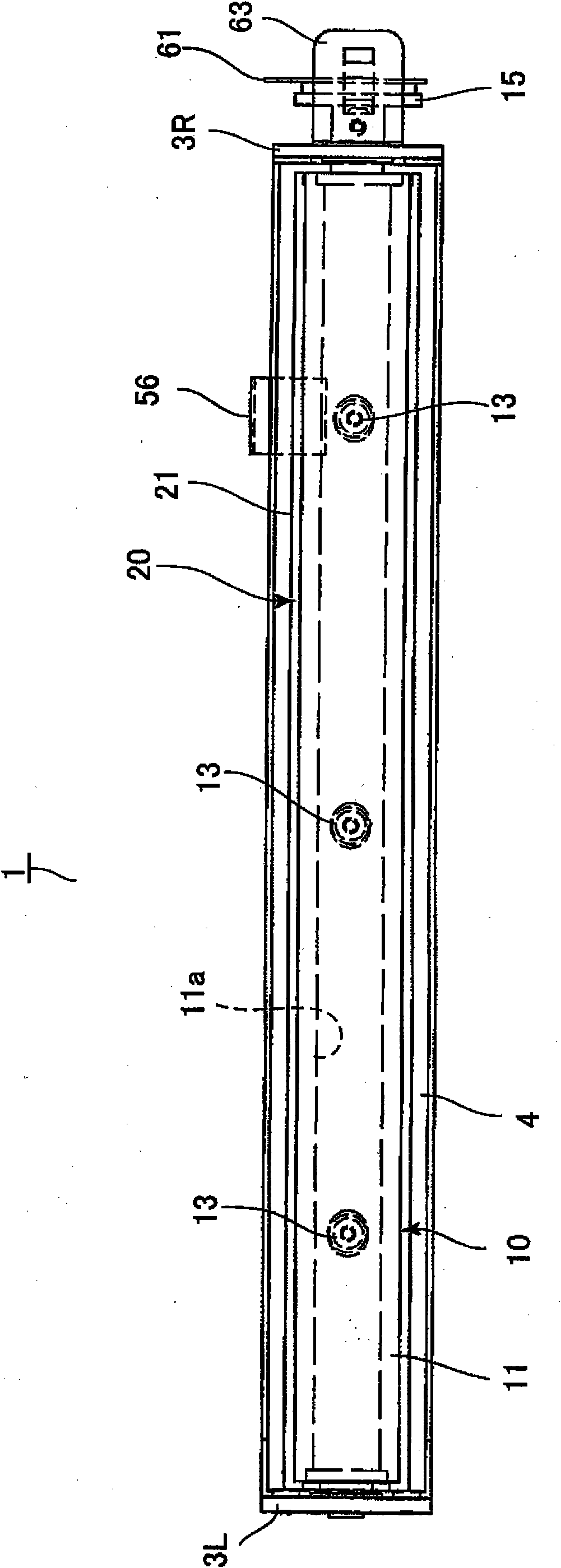

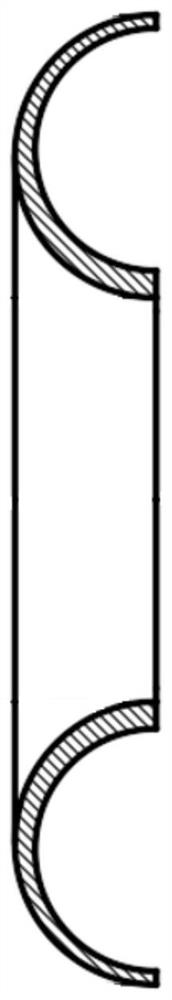

Punch unit

A punch shaft (10) and a die shaft (20) are supported by side plates (3L, 3R) in a parallel and vertically spaced apart relationship, and the punch shaft (10) and the die shaft (20) form a structural member (strength retaining member). The die shaft (20) has a die shaft body (21) formed in a hollow circular cylindrical shape. Dies (21b) corresponding to punches (13) of the punch shaft (10) are mounted on the outer periphery of the die shaft body (21) by being fitted in die holes (21d) penetrating through up to a hollow (21a) in the die shaft (20). A waste discharge screw plate (30) fixed to the side plate (3R) is placed in the hollow (21a) in the die shaft (20). As the die shaft (20) rotates, punch waste is transferred along a sloped surface of the waste discharge screw plate (30) and discharged from a punch waste discharge hole (21c). The punch unit can be easily adjusted, can form high quality holes in a sheet, and can reliably discharge punch waste.

Owner:DAIDO KOGYO CO LTD

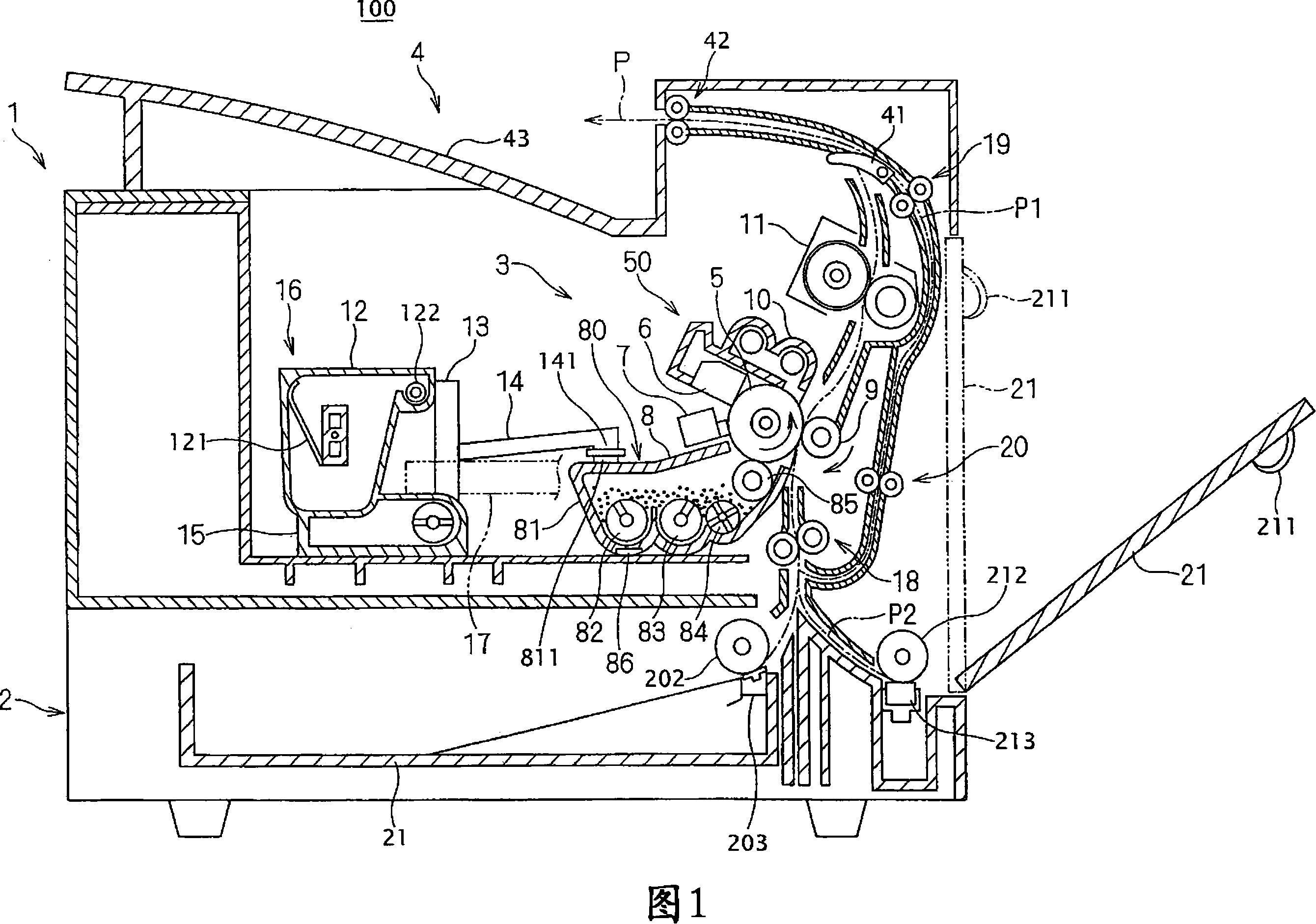

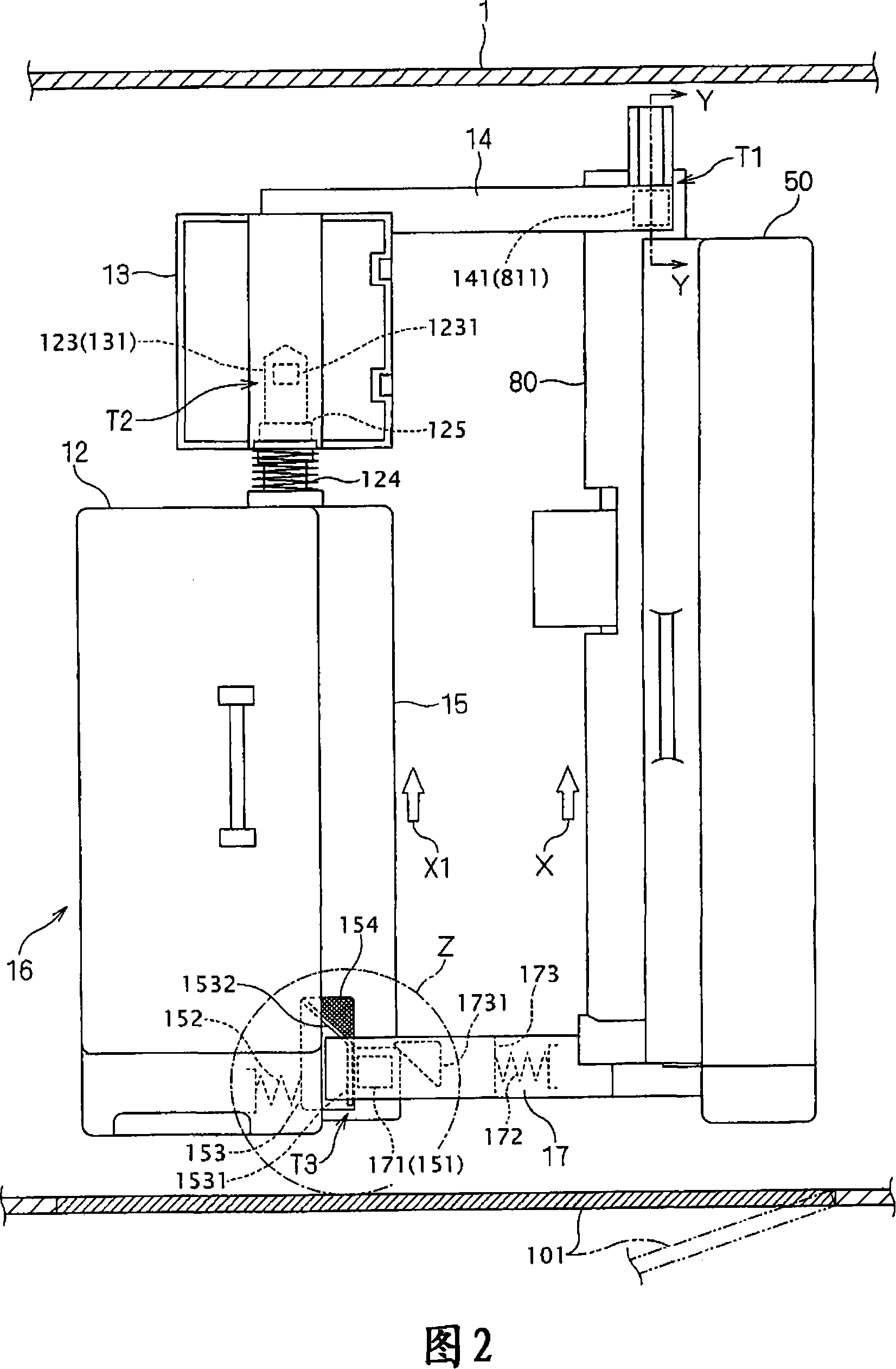

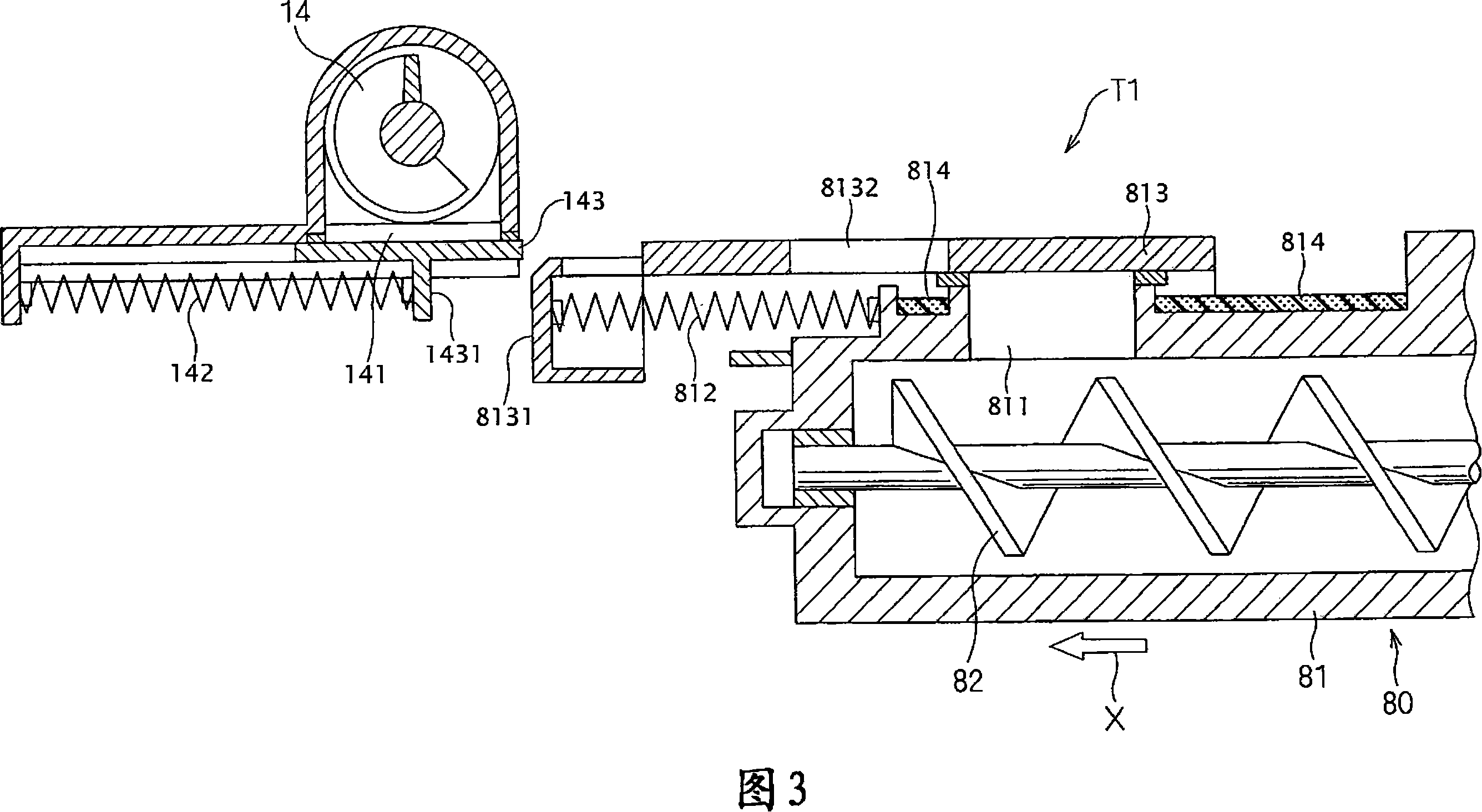

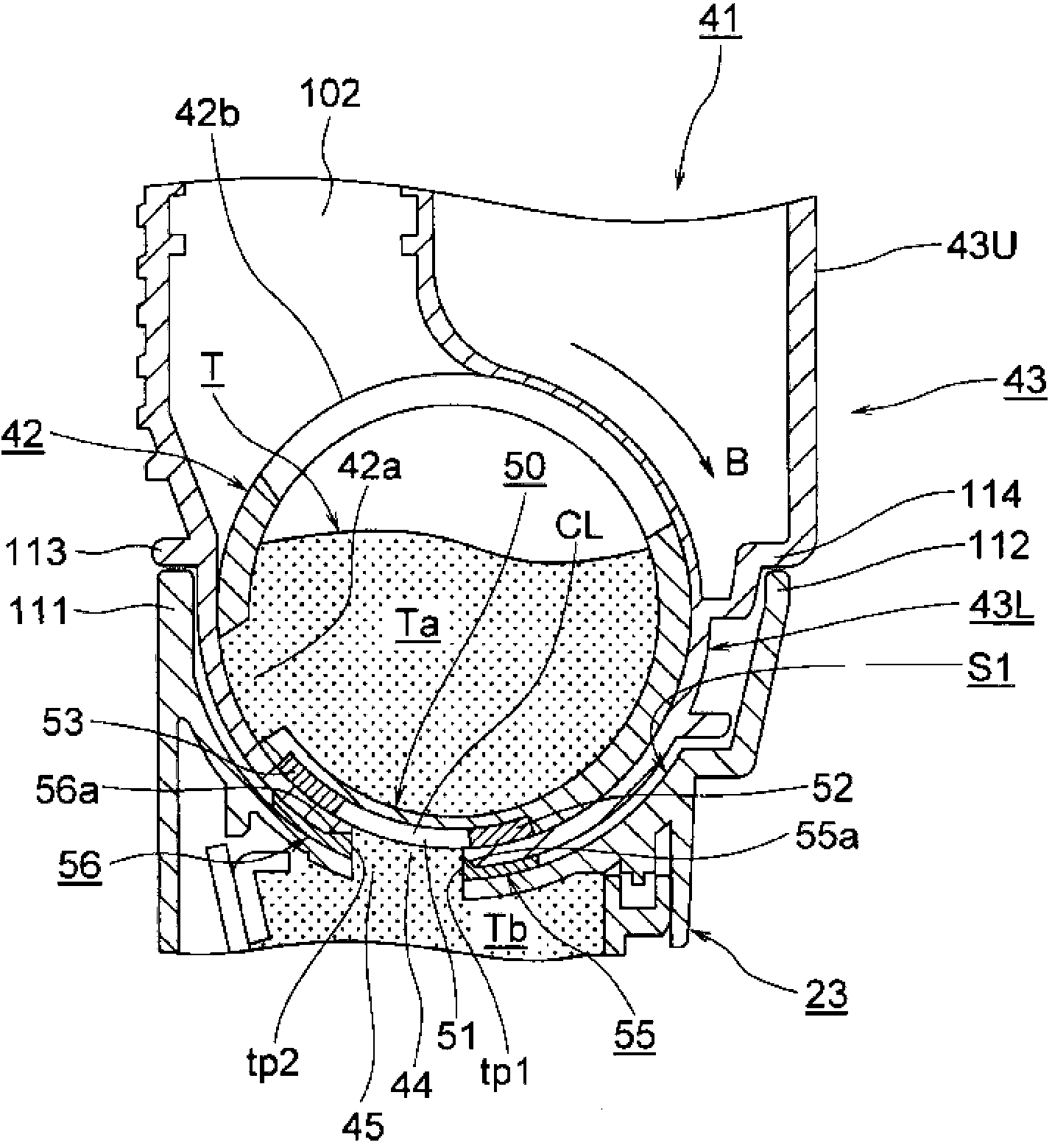

Image forming device

InactiveCN101145021AWon't fly awayContainment leakElectrographic process apparatusImage formationDelivery system

An image forming device (100) includes a process unit (50,80), a toner containing portion (12,15), and a trapping member (8,14). The toner containing portion (12,15) is arranged in relationship to the process unit (50,80) and connected to the process unit (50,80) so as to construct a toner transporting mechanism. The toner transporting mechanism includes a toner receiving / supplying portion (T1,T3) having a toner receiving port and a toner supplying port such that the toner receiving port and the toner supplying port can be disconnectably connected to each other. The trapping member (8,14) is attached to a surface of a portion adjacent to the toner receiving / supplying portion (T1,T3) and traps leaked toner.

Owner:MURATA MASCH LTD

Stapler

InactiveCN100400251CDon't worry about getting hurtLarge inclination angleStapling toolsNailing toolsPaper sheetEngineering

A cutter unit (10) is provided, composed of a stationary cutter (11) installed between staple legs and a movable cutter (13) operated from the outside of the staple legs toward the inside. The cutter unit (10) is installed so as to be slidable between a position at which the unit is advanced in an operation region of a movable clincher (5) and a position at which the unit is receded from the operation region of the movable clincher (5). The cutter unit (10) is advanced into a staple hammer-out section to cut the staple legs penetrated through paper sheets to be bound, the cutter unit (10) is receded from the operation region of the movable clincher (5), and then the movable clincher (5) is caused to pivot to bend the staple legs.

Owner:MAX CO LTD

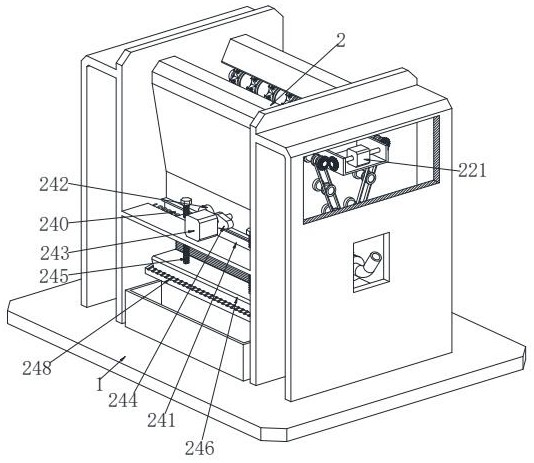

Crushing and recycling machine for leftover materials of log cutting and plate making

ActiveCN113352420AImprove crushing effectReduce volumeWood working apparatusWood splinterProcess engineering

The invention relates to the field of wood recycling, in particular to a crushing and recycling machine for leftover materials of log cutting and plate making. The crushing and recycling machine comprises a base and a material crushing device, wherein the material crushing device is arranged on the base. The crushing and recycling machine solves the problems that existing crushing equipment does not conduct any other auxiliary treatment before crushing the leftover materials, the hardness of the wood leftover materials is different according to different types of trees, if the same crushing mode is adopted, the crushing equipment is damaged, the leftover materials are not thoroughly crushed and the crushing efficiency is low; when the existing crushing equipment crushes the wood leftover materials, generated wood chips fly in the air, the problem that the wood chips fly in the air; and due to the fact that the existing crushing equipment is not provided with a corresponding dust falling mechanism, the wood chips are scattered, air pollution is caused, and meanwhile, the harm to the body of a worker is also caused.

Owner:徐州香梦源家具有限公司

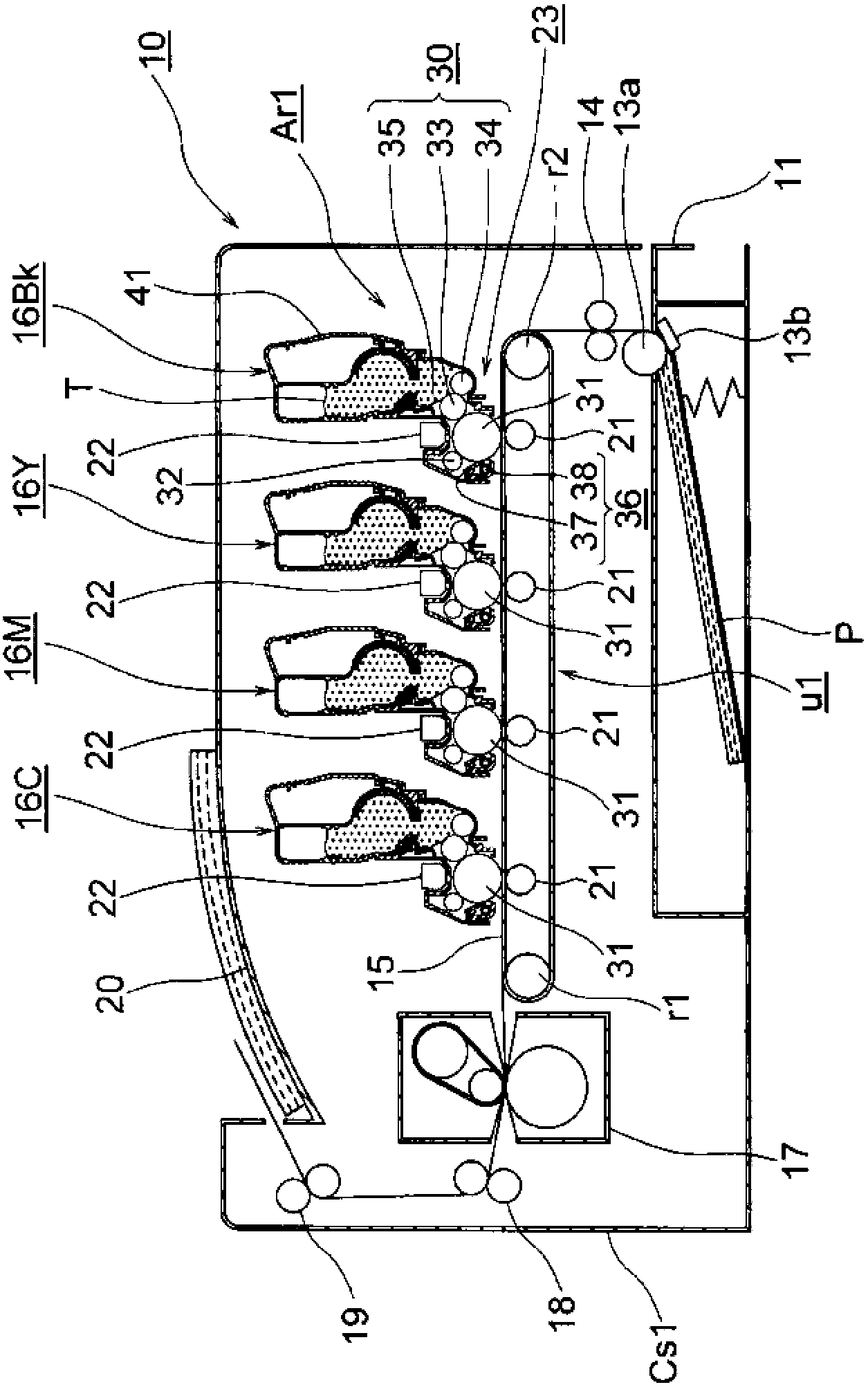

Developer storage container, image forming unit and image forming apparatus

ActiveCN103186073AWon't fly awayWon't get dirtyElectrographic process apparatusEngineeringMechanical engineering

The present invention relates to a developer storage container, an image forming unit and an image forming apparatus, which prevent developer from splashing and polluting the periphery of an opening part when the developer storage container is detached from the body of the image forming unit. The developer storage container comprises a developer storage container housing, a storage part formed in the developer storage container housing for storing the developer, the opening part formed in the developer storage container housing for supplying the developer in the storage part to the outside of the developer storage container housing, and an opening / closing part used for opening and closing the opening part. A recess is formed in the portion, which is opposite to the opening part, of the opening / closing part, so that the developer will not be attached to the outer peripheral surface of the opening / closing part. Therefore, the developer is prevented from splashing and polluting the periphery of the opening part when the e developer storage container is detached from the body of the image forming unit.

Owner:OKI ELECTRIC IND CO LTD

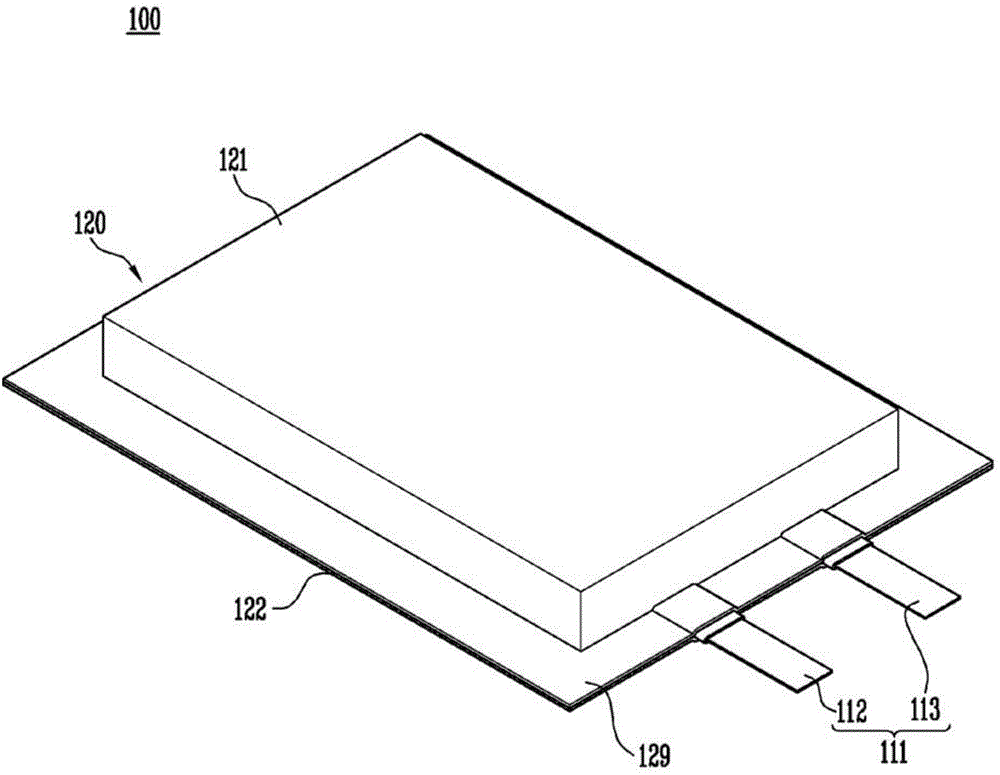

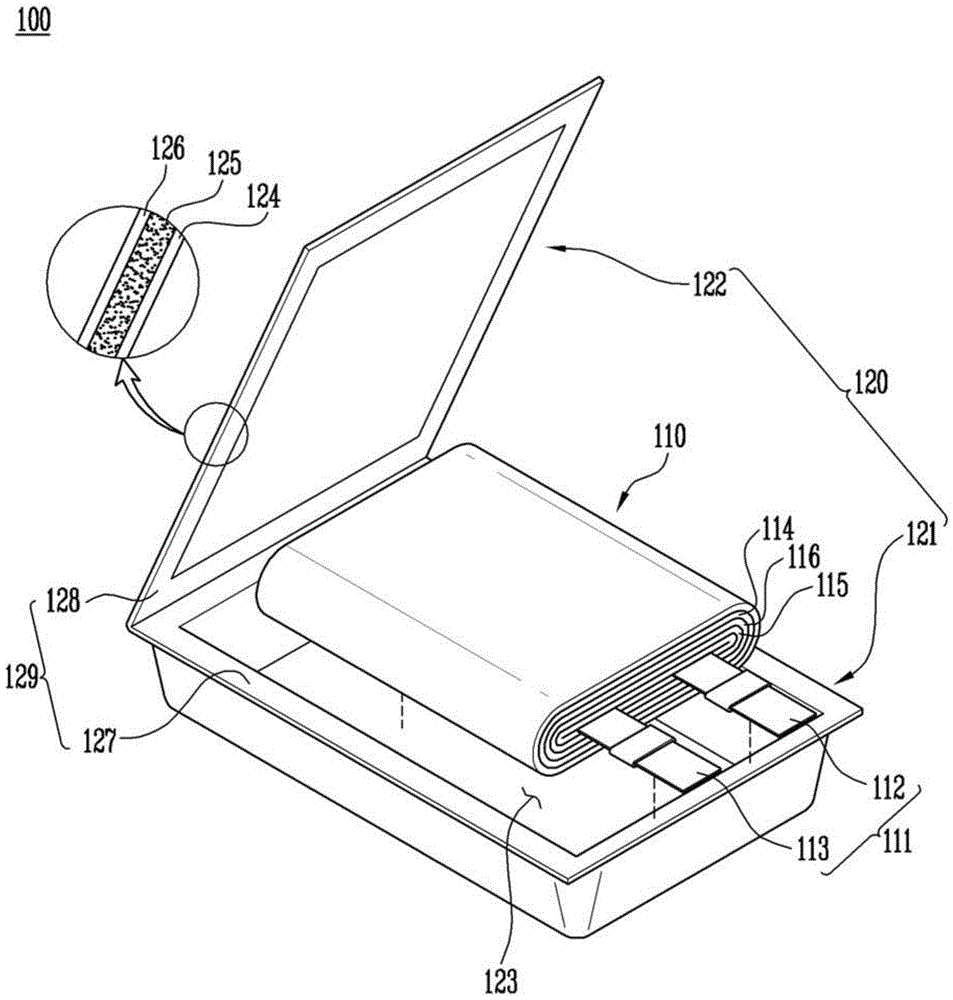

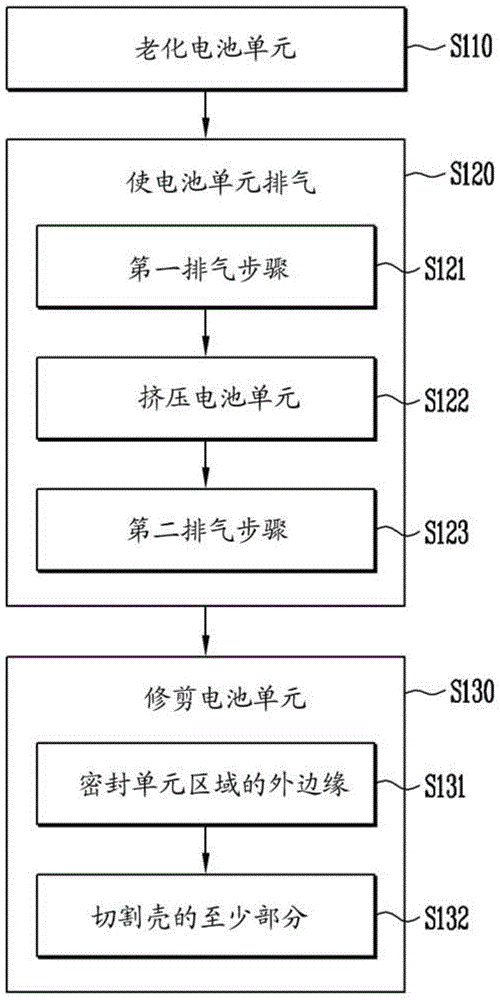

Method of fabricating pouch type battery cell

ActiveCN104810539AWon't fly awayFinal product manufactureSmall-sized flat cells/batteriesBattery cellElectrolyte

The invention provides a method of manufacturing a pouch type battery cell. In the method, the battery cell is aged, and furthermore air exhausting is performed on the battery cell in a state that the battery cell is kept in an aging direction. Therefore, the direction of the battery cell in the aging step does not change in the air exhausting step, and electrolyte does not disperse in the air exhausting step.

Owner:SAMSUNG SDI CO LTD

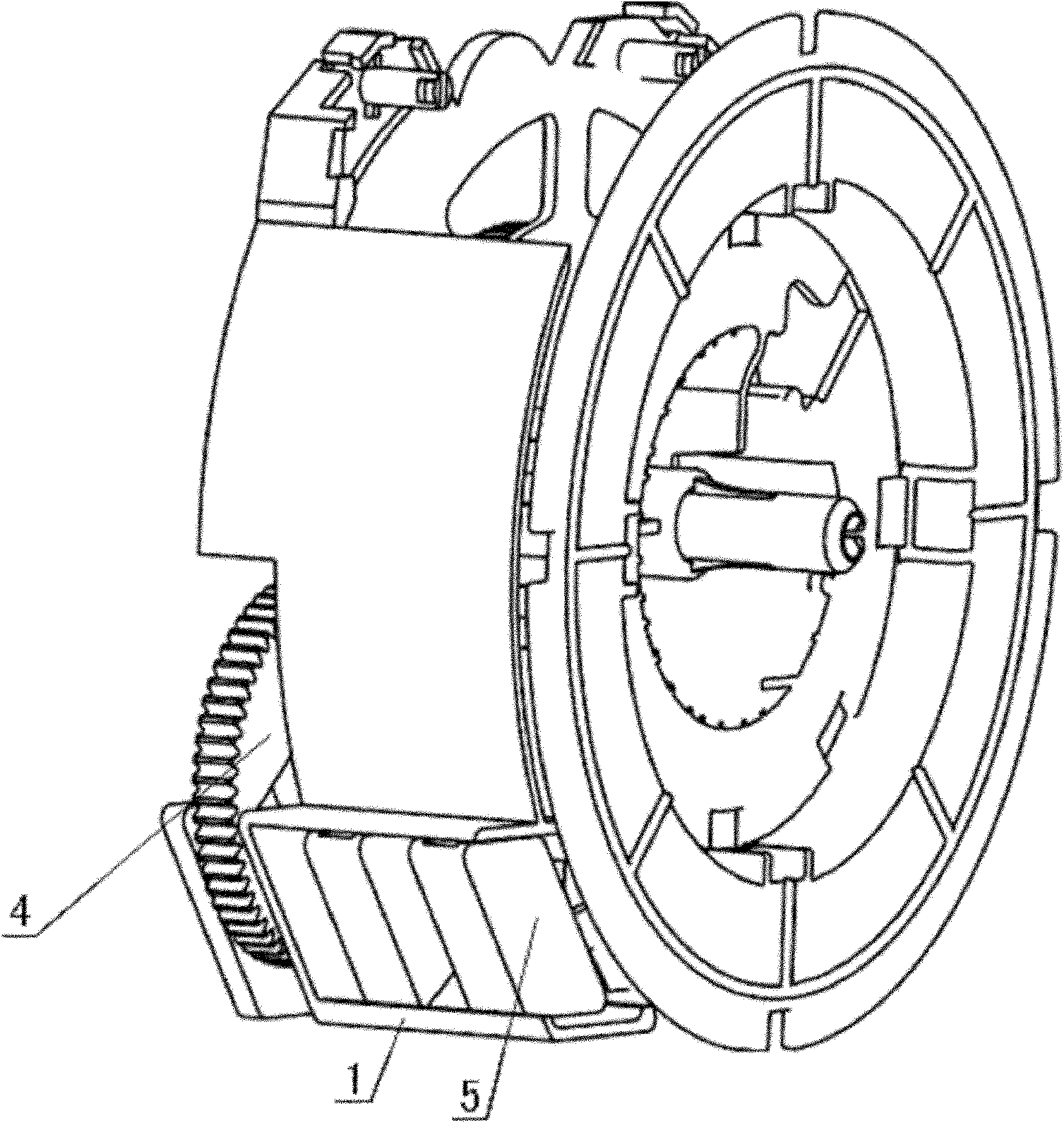

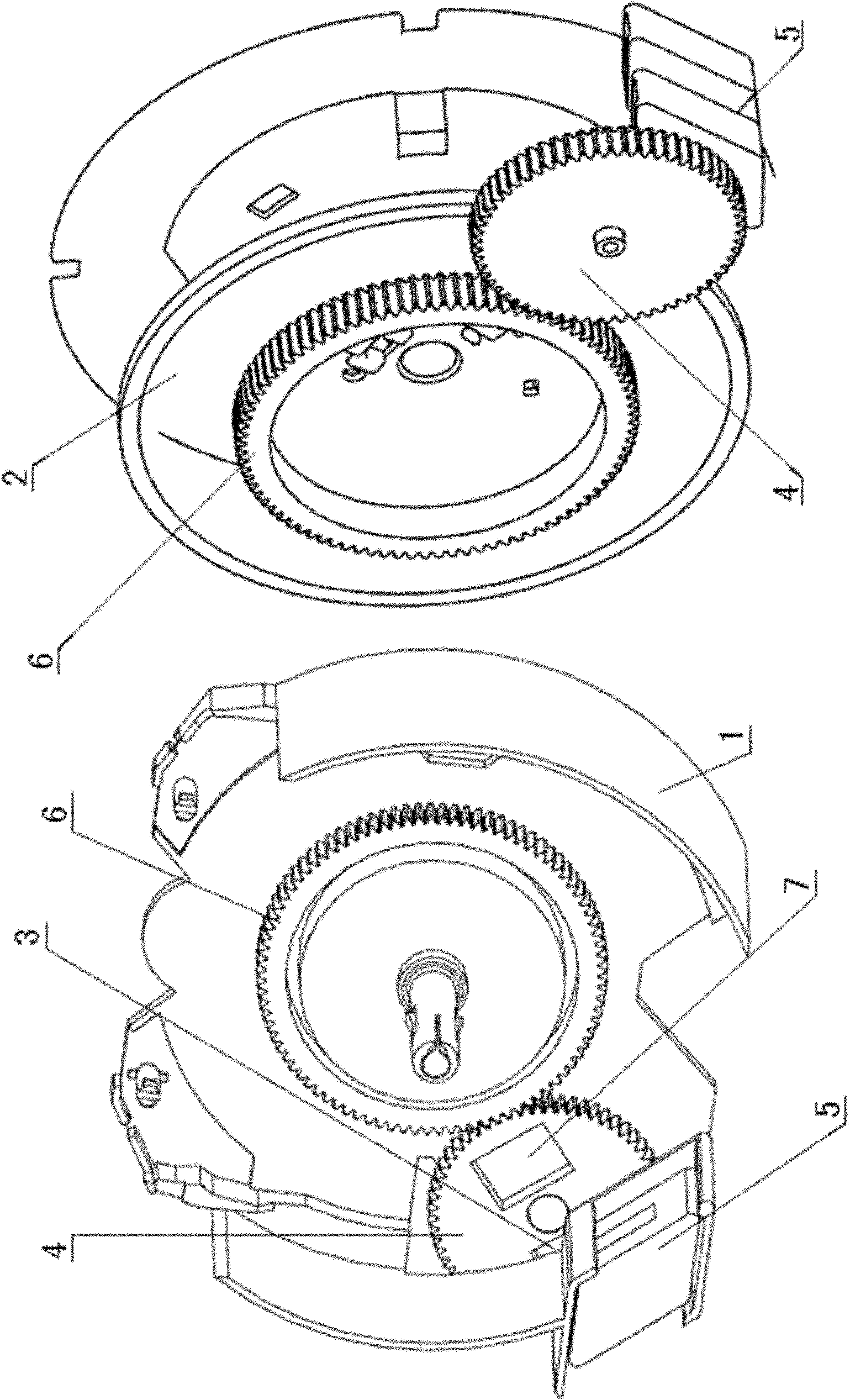

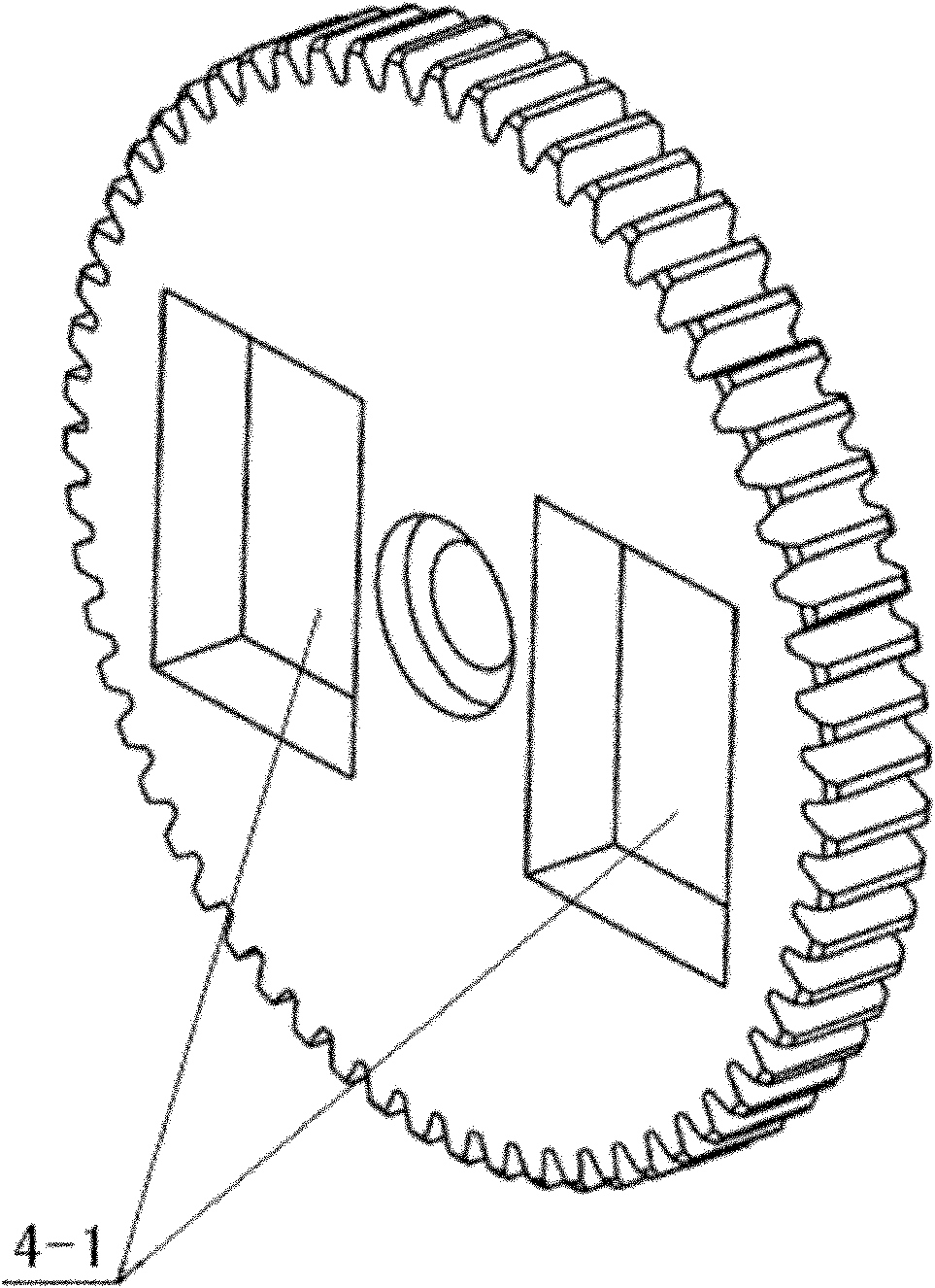

Swinging wire speed reducing device of wire winder

InactiveCN102134023AWon't fly awayReduce return speedGearingCable arrangements between relatively-moving partsWire speedEngineering

The invention relates to a swinging wire speed reducing device of a wire winder. The wire winder comprises a bracket and a wire winding wheel arranged on the bracket; the device comprises a swinging wire block connected on the bracket in a sliding manner, and a transmission mechanism driven by the wire winding wheel. In the swinging wire speed reducing device, leftward and rightward wire swinging in the wire return process is realized, so that the condition that the wires are overlapped into a row to cause no wire return is avoided; and simultaneously, by mutual action between magnetic blocks, the energy is consumed, and the wire return speed is reduced, so that the condition that the wires fly away from the wire winder to cause no wire return is avoided.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Energy-gathered charging structure for assisting in sampling of foreign planet minerals

ActiveCN112240730ALight in massReduce loadBlasting cartridgesWithdrawing sample devicesPhysicsEngineering

The invention discloses an energy-gathered charging structure for assisting in sampling of foreign planet minerals. The energy-gathered charging structure comprises a detonating mechanism, a shell, anexplosive column, an annular shaped charge liner, a flying sheet and a buffer body, wherein the shell is a stepped shaft-shaped circular tube, the two ends of the shell are separately opened, the explosive column is coaxially filled in an inner cavity at the large end of the shell, one end of the explosive column is propped against the inner bottom surface of the shell, the other end of the explosive column is in compression fit with the end part of the shell through the annular shaped charge liner, and the convex surface of the annular shaped charge liner is compressed at the end part of theexplosive column; the flying sheet is arranged between the central end surface of the annular shaped charge liner and the explosive column, and the buffer body is arranged between the flying sheet and the explosive column; the detonating mechanism is arranged in the small end of the shell and used for detonating the explosive column; and the annular shaped charge liner comprises an annular grooveand a circular end face integrally connected to the center of the annular groove, the cross section of the annular groove is in a crescent shape, the end, connected with the circular end face, of theannular groove is the inner side, the end, connected with the shell, of the annular groove is the outer side, and the wall thickness of the inner side of the annular groove is larger than that of theouter side of the annular groove.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com