Grounding device of sensitometric drum and sensitometric drum unit of image forming device

A technology of grounding device and photosensitive drum, which is applied in the direction of equipment, optics, and electrical recording technology using charge patterns, etc., and can solve the problems of reduced strength of the drum shaft 3, difficulty in forming images, and overflow of grease 8, etc. problem, to achieve the effect of preventing poor image formation, preventing abrasion, and preventing abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

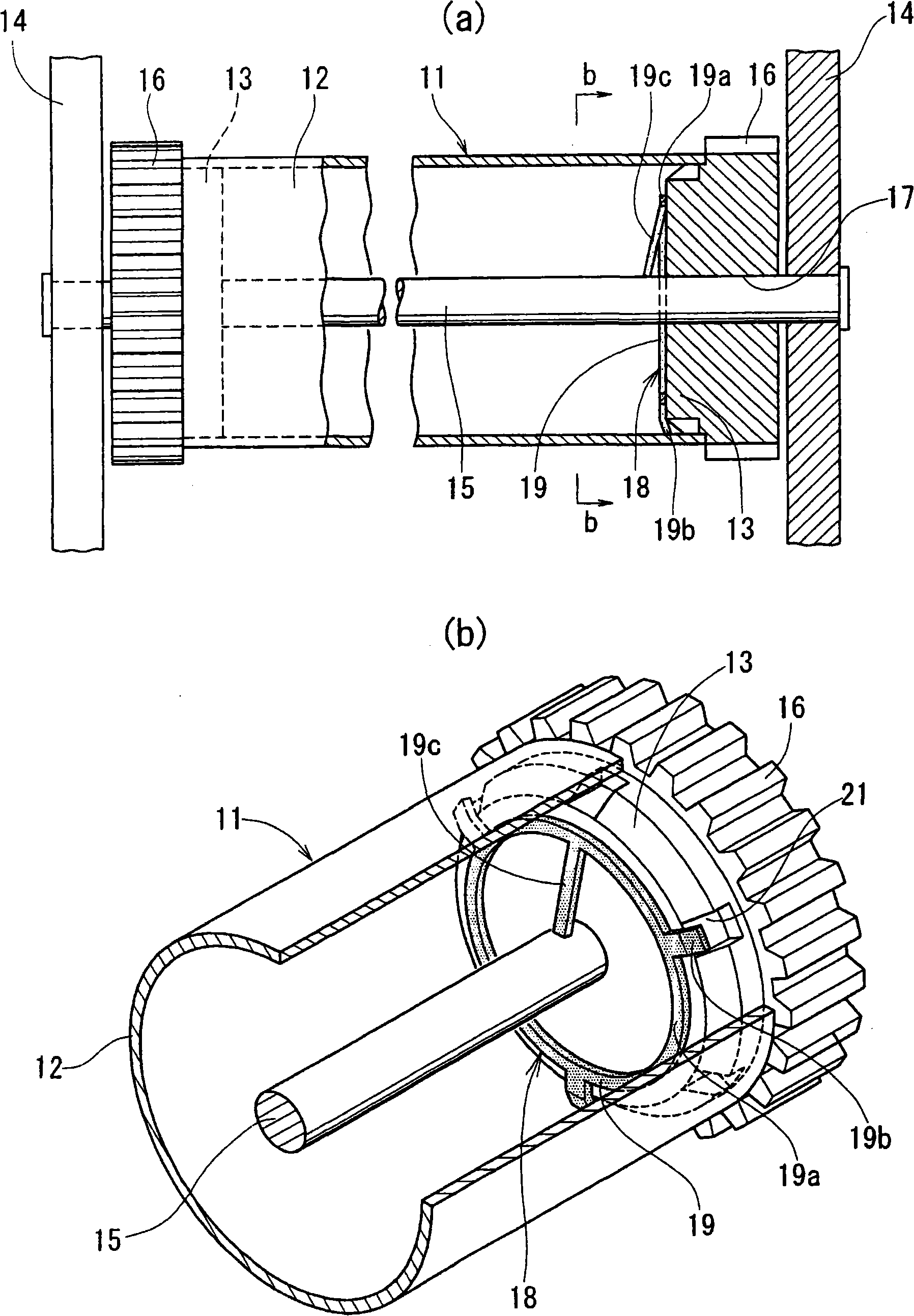

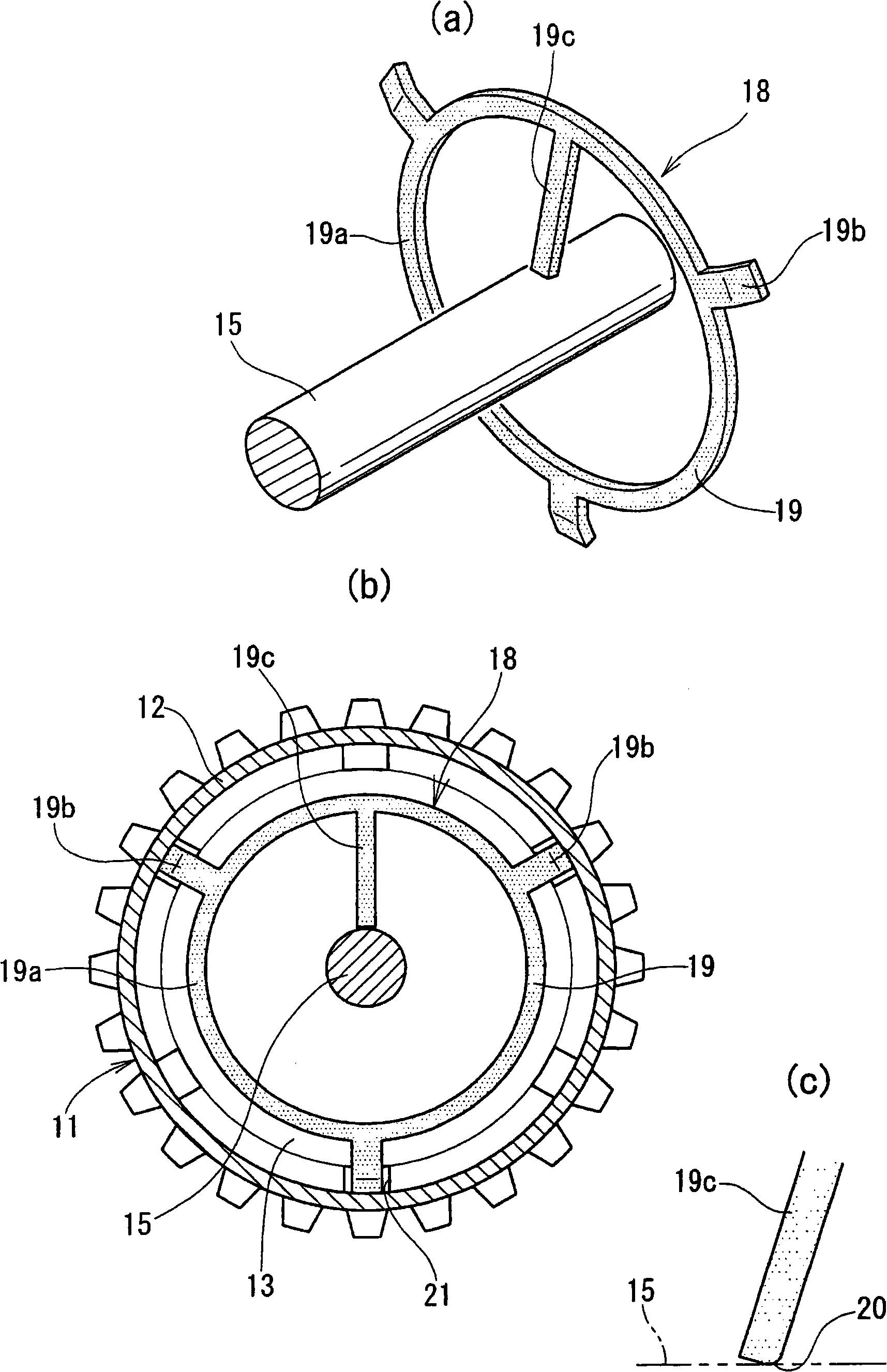

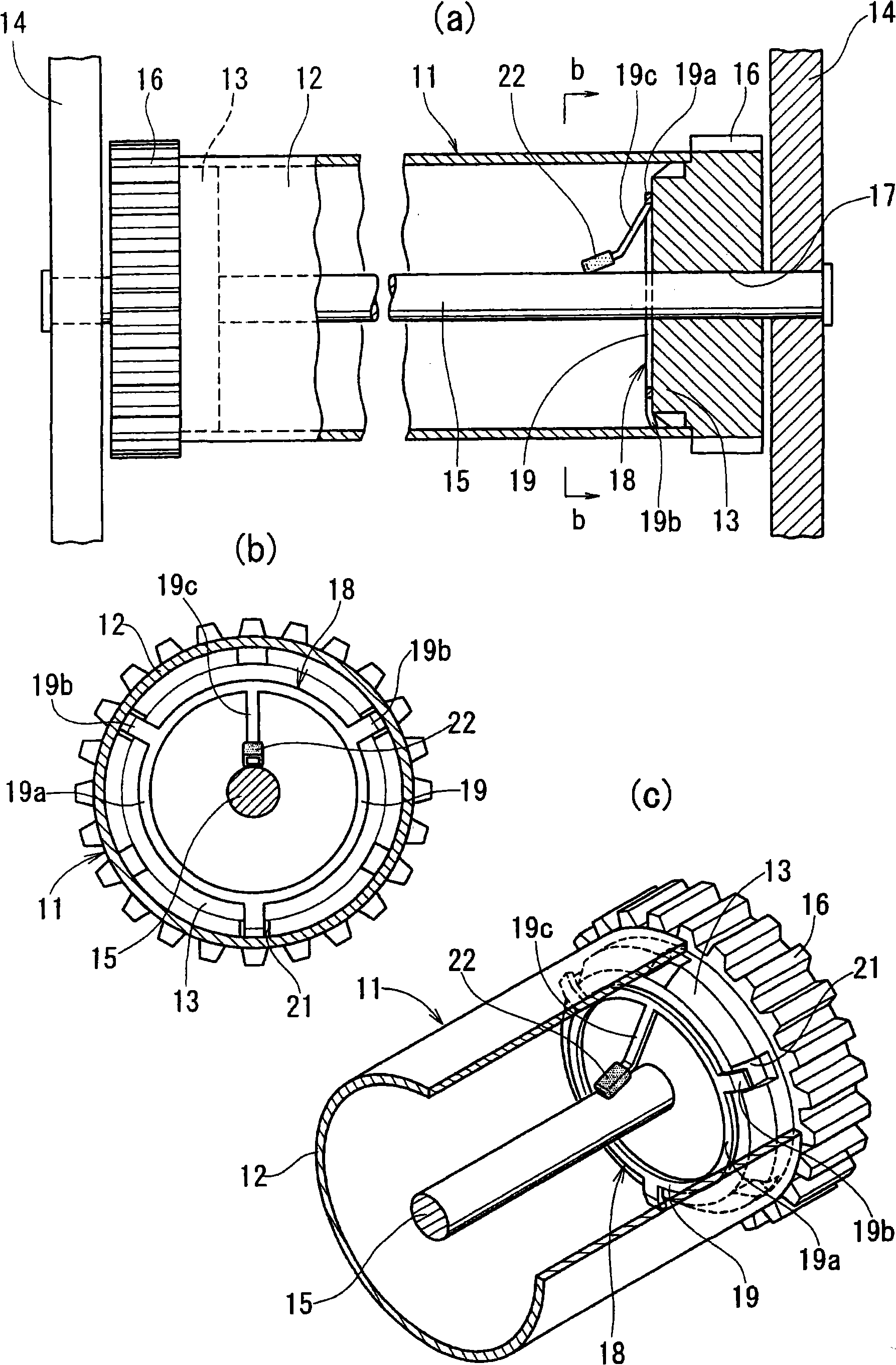

[0039] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0040] first as figure 1 As shown in (a) and (b), the photosensitive drum unit 11 of the copier is fixed by fitting and fixing an insulating flange 13 (hereinafter simply referred to as a flange) made of synthetic resin at both ends of the photosensitive drum 12. The photosensitive drum 12 is coaxially arranged via the flange, and is rotatably mounted on a ground potential conductive drum shaft 15 that is erected non-rotatably relative to the frame 14 of the copier, and passes through the flanges on one or both sides. A gear 16 provided at 13 is rotatably connected to a rotational drive source.

[0041] The flange 13 is formed into a disc shape whose outer diameter is suitable for the inner diameter of the photosensitive drum 12. For the purpose of light weight and cost reduction, synthetic resin is used, and the gear 16 located on the outer end surface is integrally formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com