Patents

Literature

7326 results about "Synthetic resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic resins are industrially produced resins, typically viscous substances that convert into rigid polymers by the process of curing. In order to undergo curing, resins typically contain reactive end groups, such as acrylates or epoxides. Some synthetic resins have properties similar to natural plant resins, but many do not.

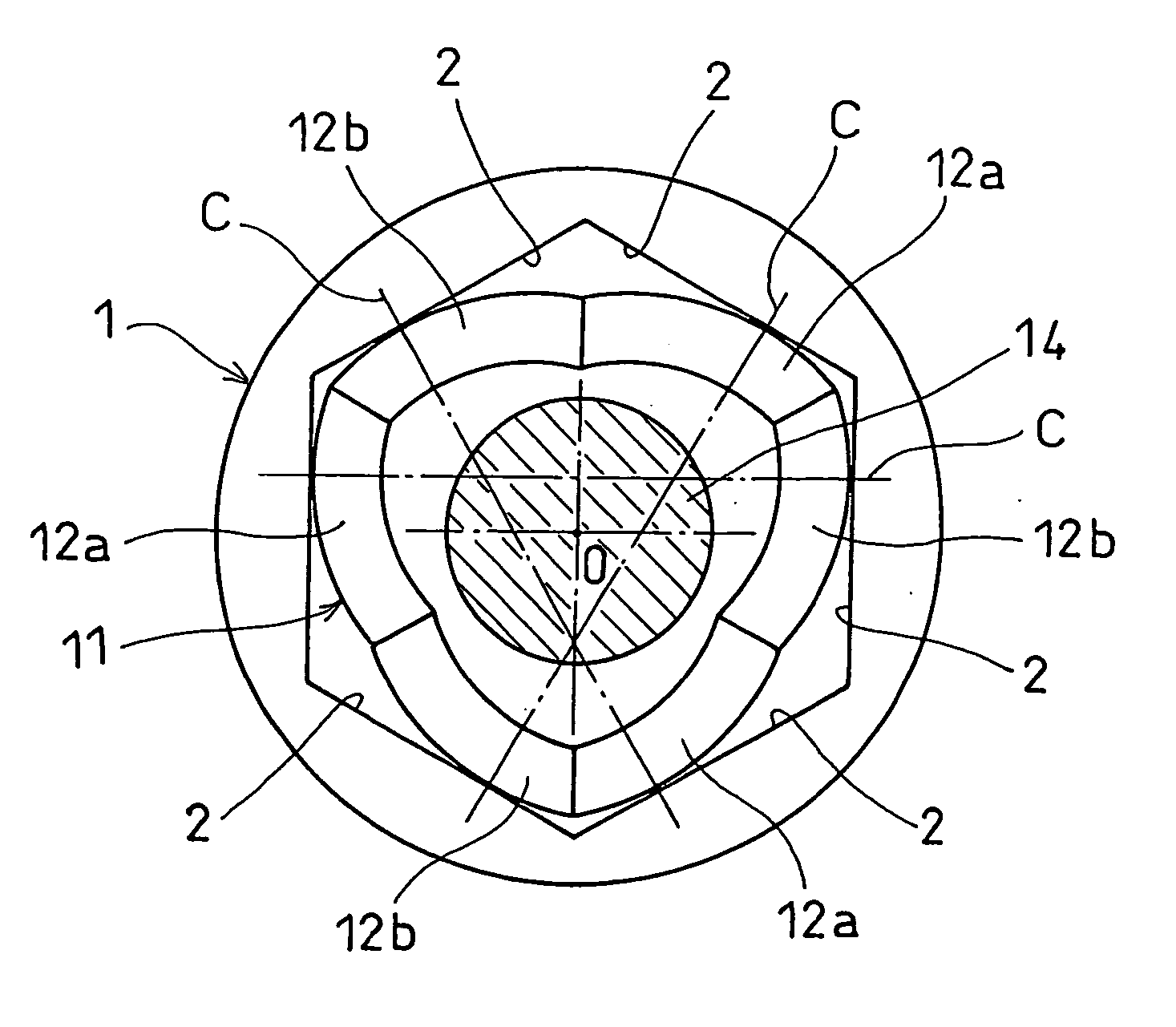

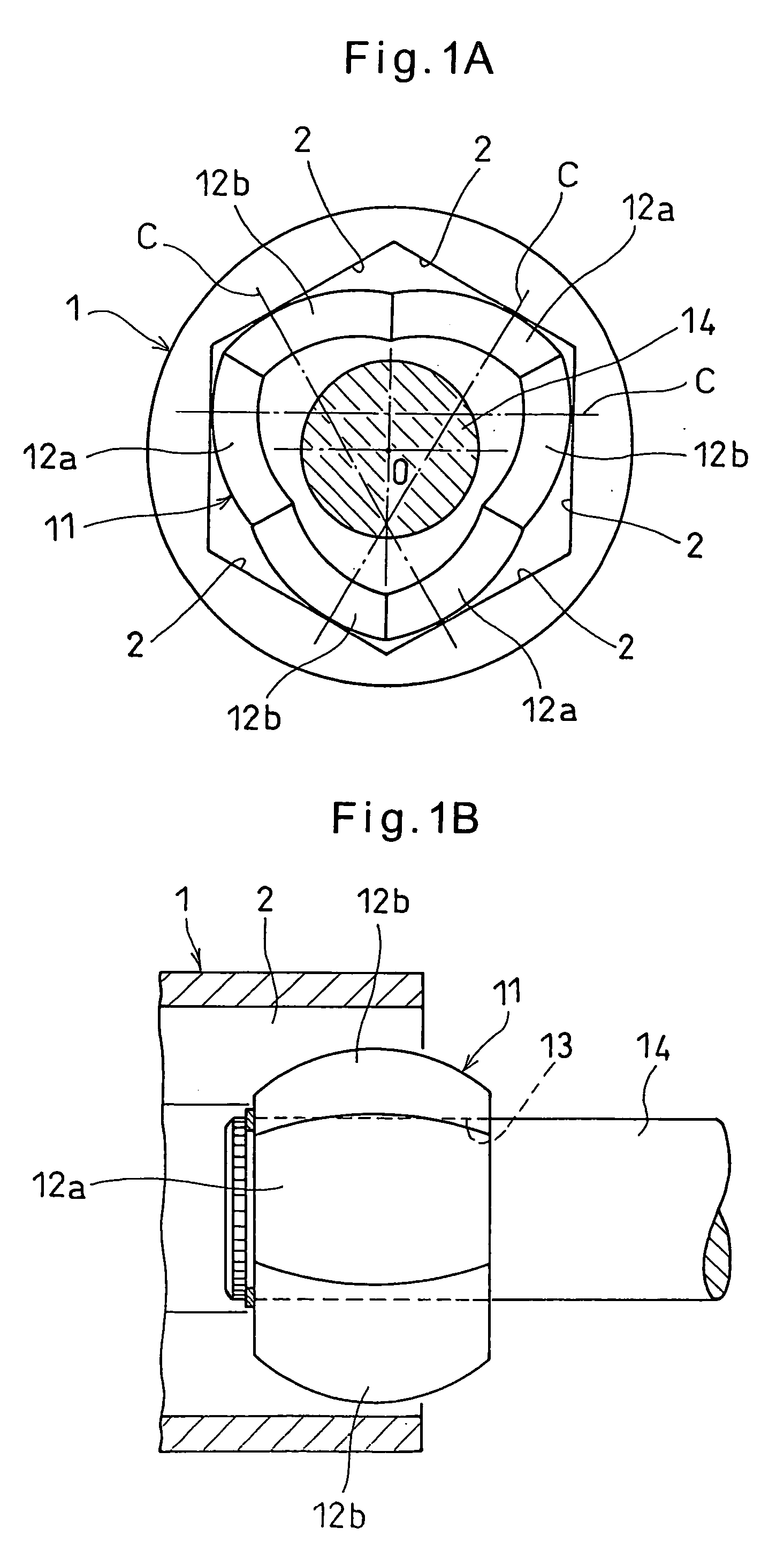

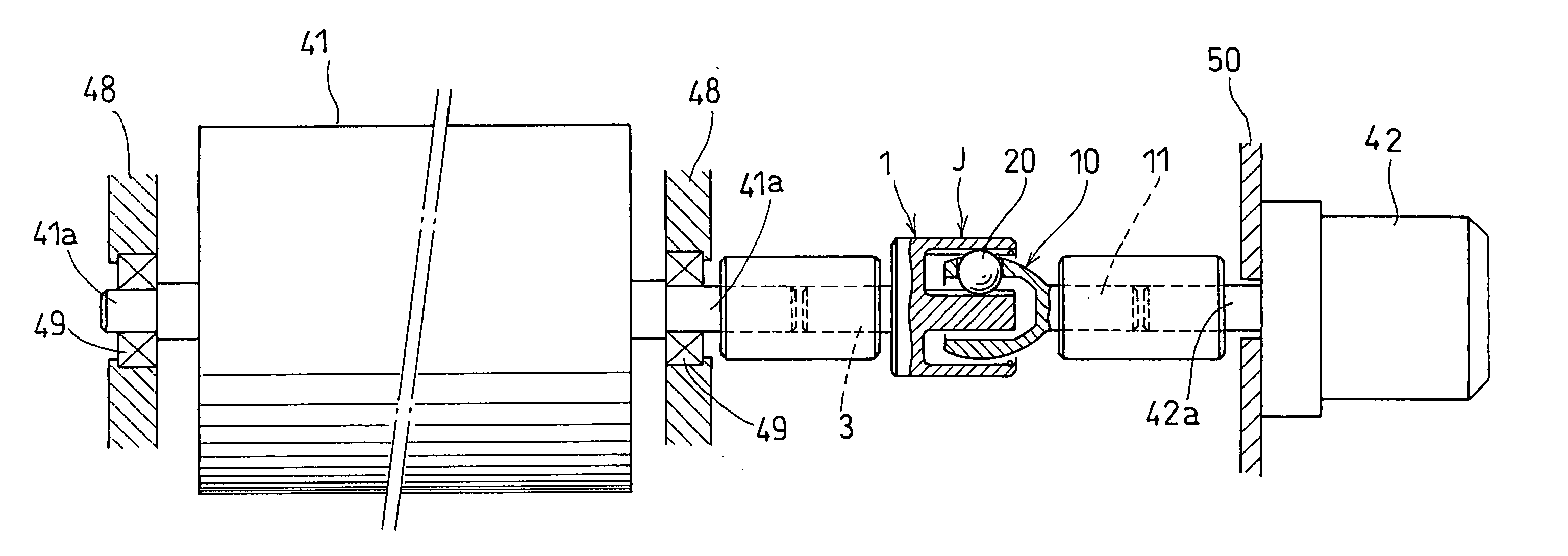

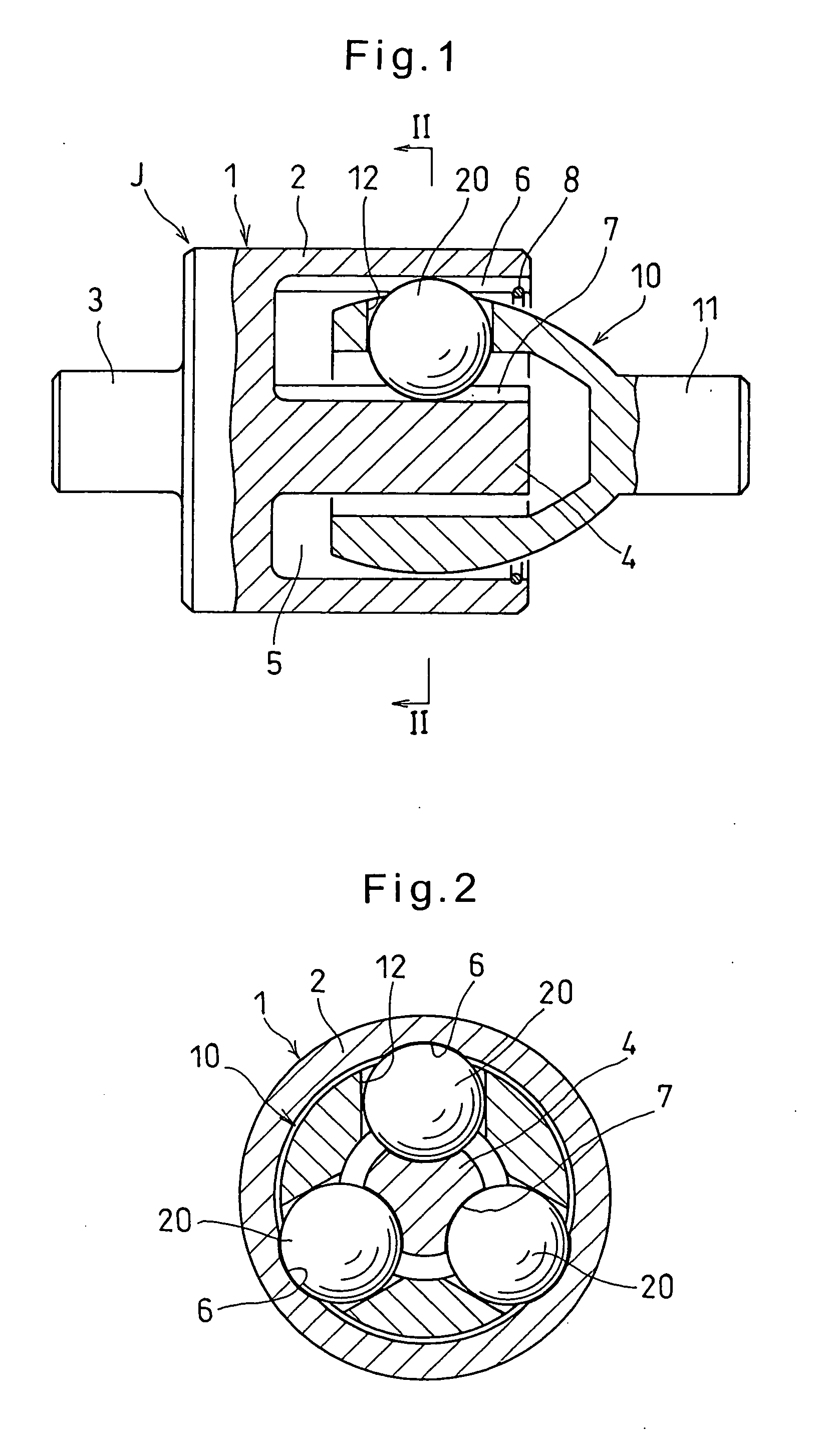

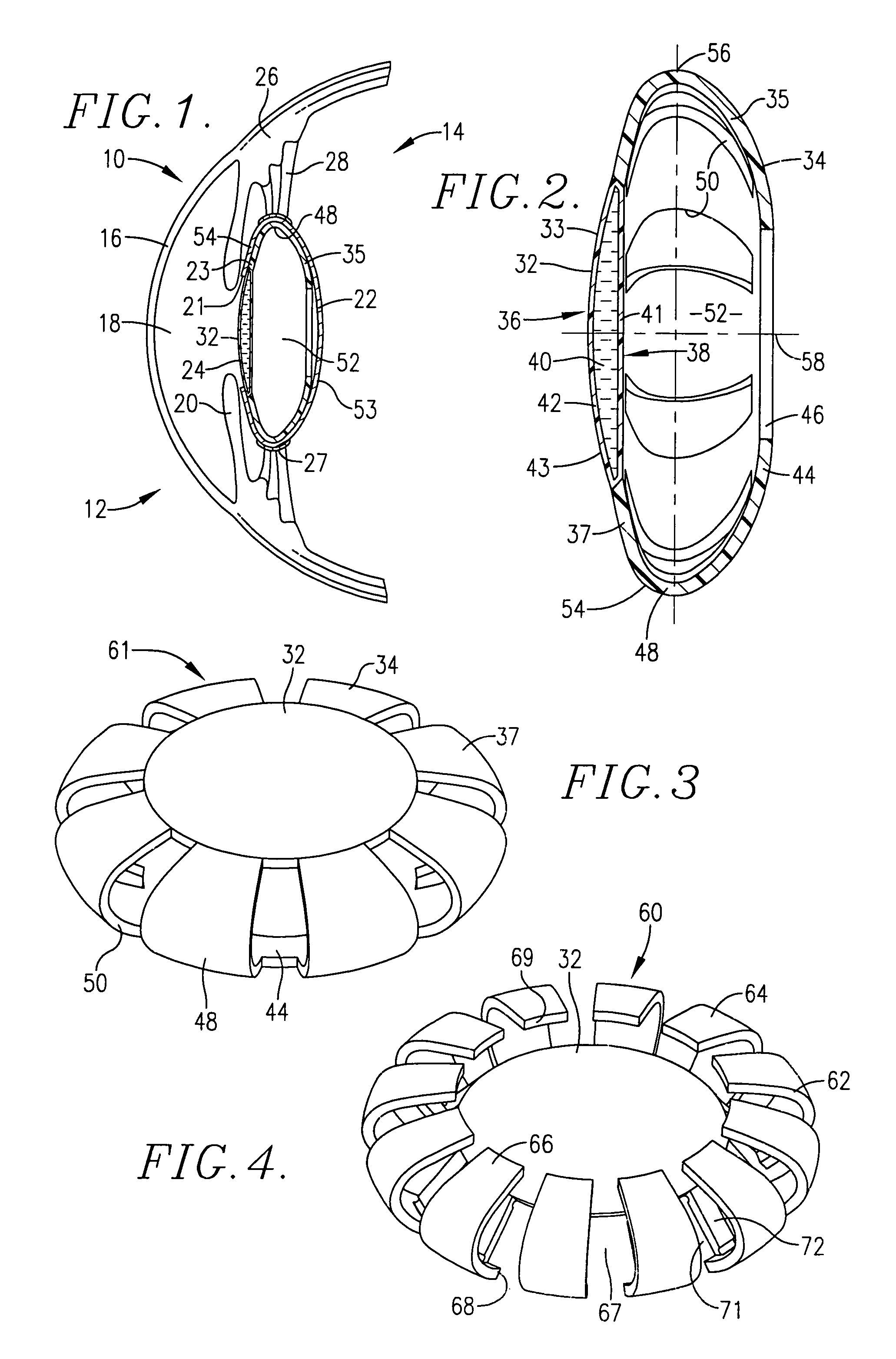

Constant-velocity joint and image forming device

InactiveUS20060240896A1Prevent leakageReduce noiseYielding couplingCouplings for rigid shaftsEngineeringSynthetic resin

A constant-velocity joint includes an outer ring formed formed with a bore defined by six flat surfaces parallel to its axis, and a trunnion member received in the bore of the outer ring. The trunnion member has an outer periphery formed with three first spherical surfaces circumferentially spaced apart from each other and three second spherical surfaces circumferentially spaced apart from each other and each disposed between adjacent first spherical surfaces. Each first spherical surface is in contact with one of the flat surfaces at a point offset from the circumferential center of the flat surface in one circumferential direction. Each second spherical surface is in contact with another flat surface at a point offset from the circumferential center of the flat surface in the other circumferential direction. At least one of the outer ring and the trunnion member is made of a synthetic resin.

Owner:NTN CORP

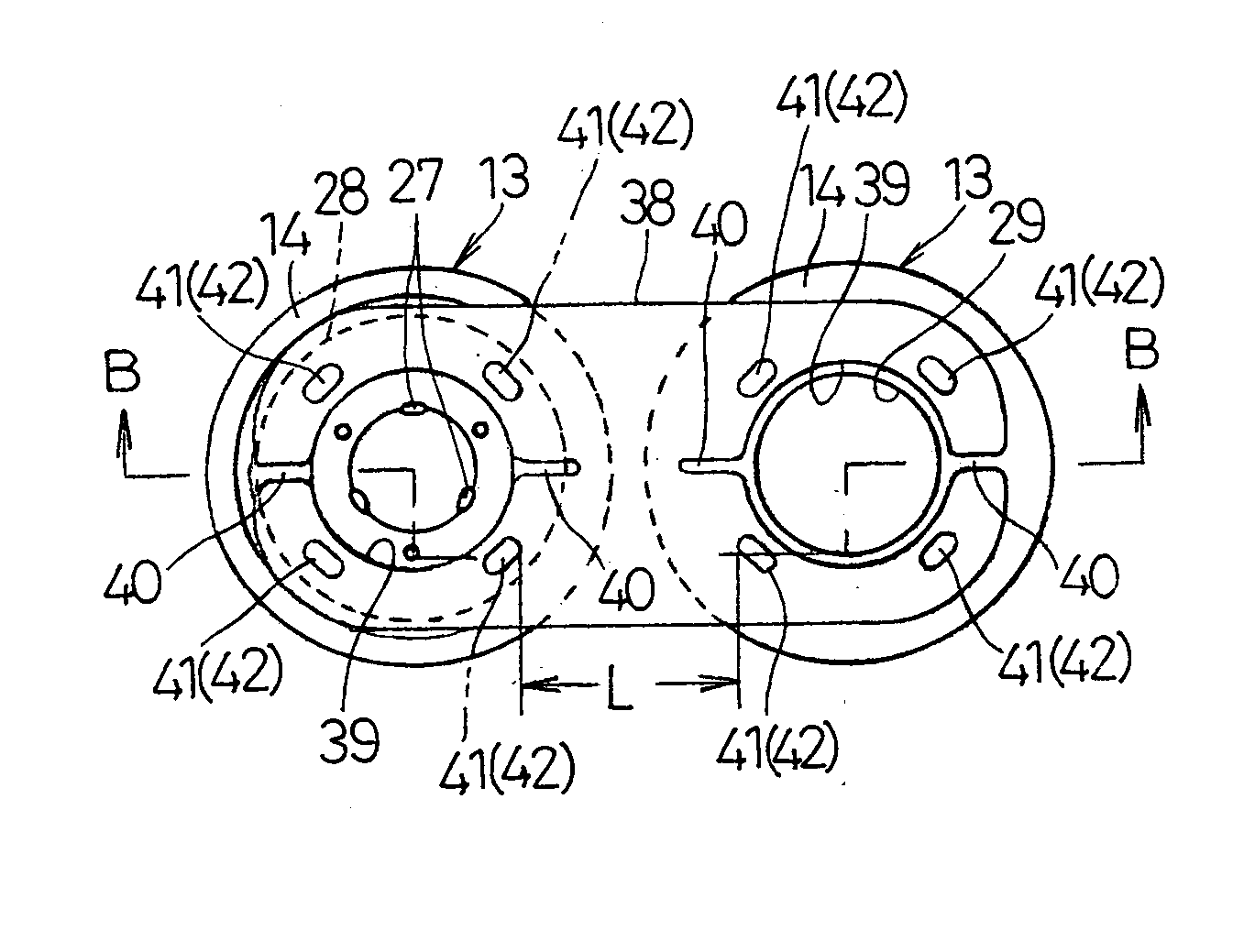

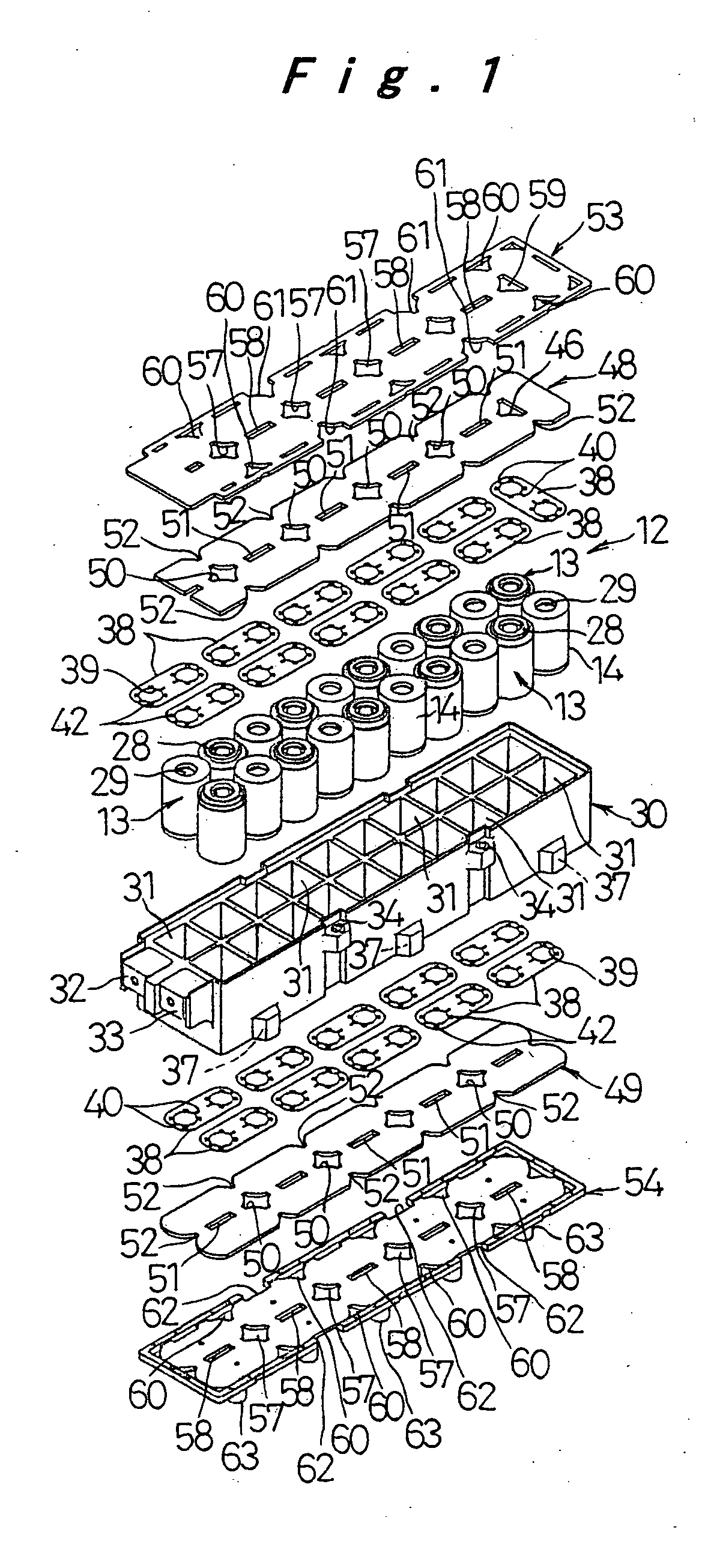

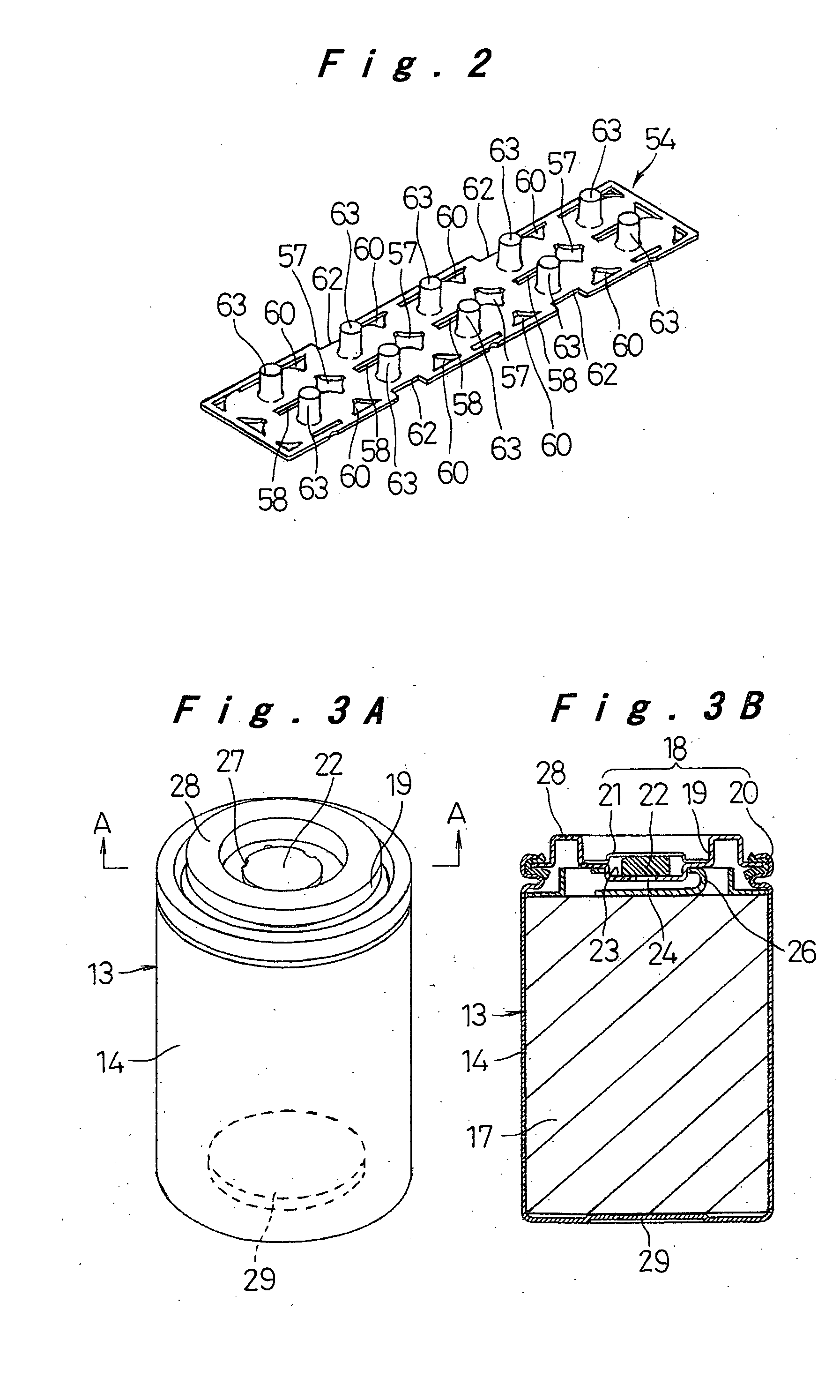

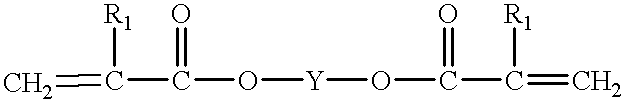

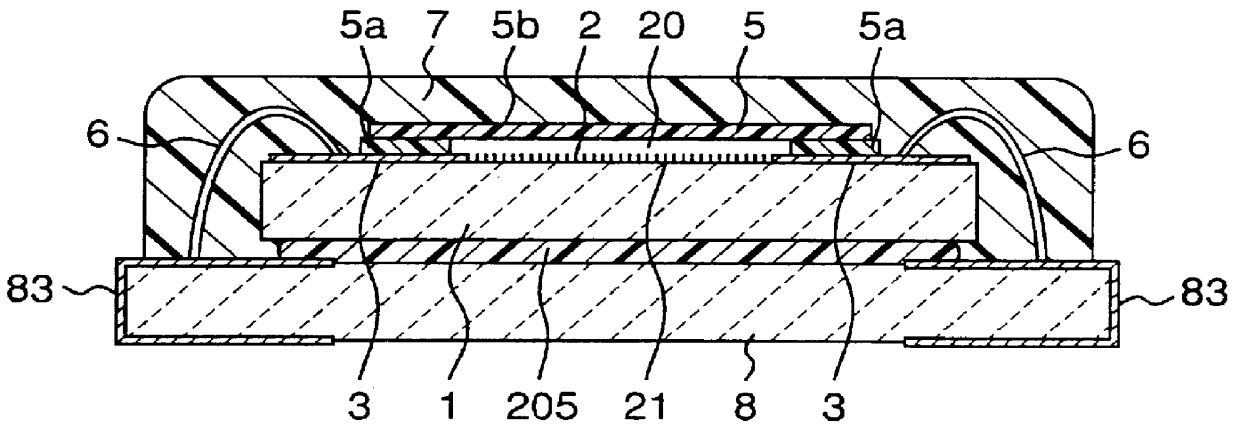

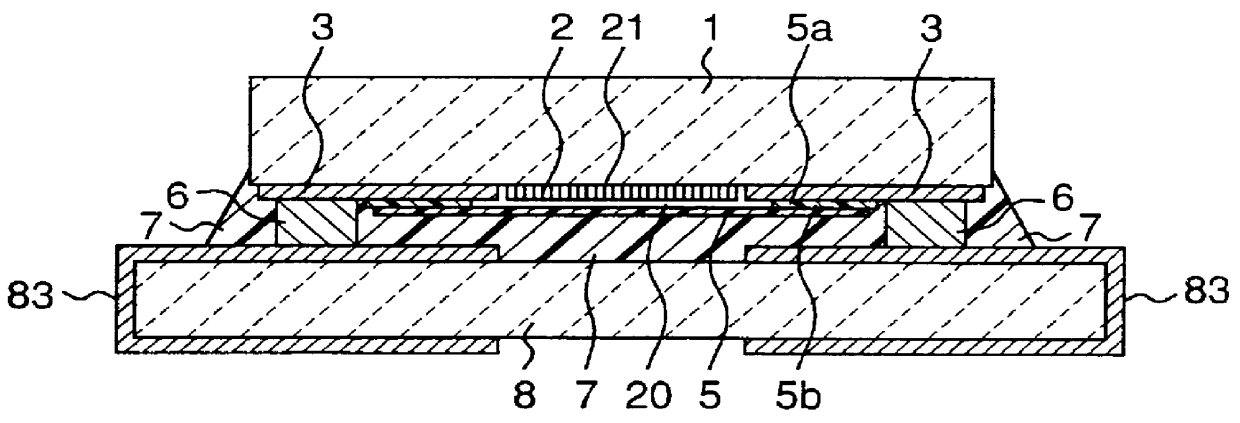

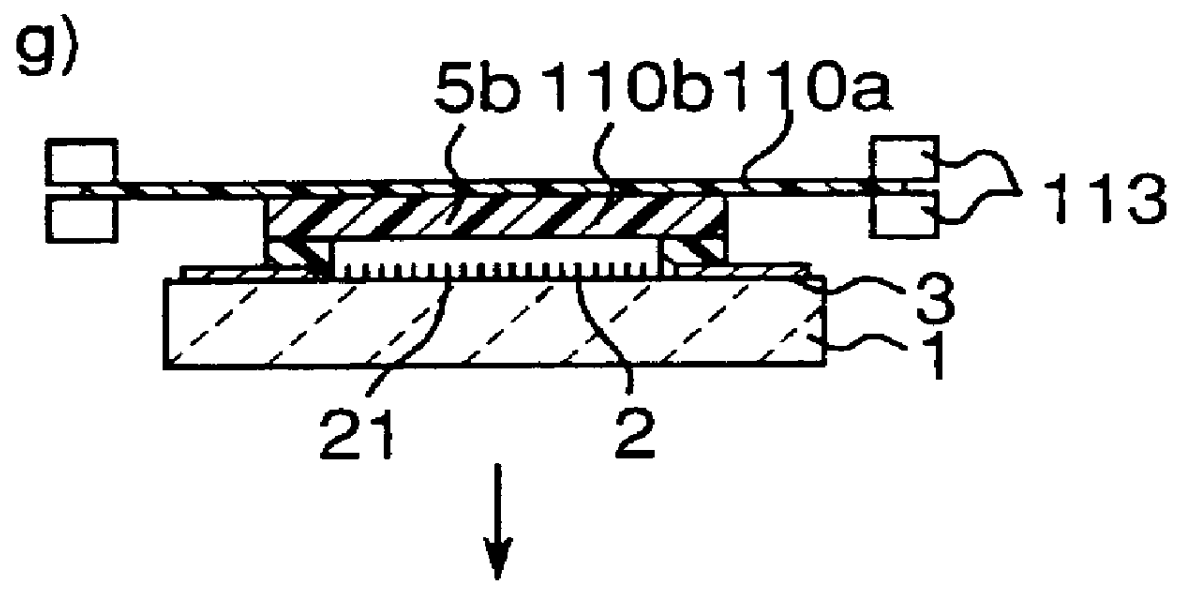

Battery connection structure, battery module, and battery pack

InactiveUS20050079408A1Increase productionReduce in quantityPrimary cell to battery groupingElectric propulsion mountingElectrical resistance and conductanceSolid structure

A connection plate in form of flat plate is welded to be connected to portion that are close to each other, i.e., a connection-electrode portion of one of two adjacent cells and a bottom of a cell case of the other cell, while being bridged between the connection-electrode portion and the bottom of the cell case, thereby forming an inexpensive connecting structure between cells, that reduces the electric resistance, by simple processes. A battery module having a solid structure impervious to vibration or shock is formed by accommodating cylindrical cells in cell-accommodating portions, each of which has a square shape seen from the front, of a holder case made of synthetic resin with their cell axes arranged in parallel, and by closing both sides of the holder case with cover members having radiation holes. Then, a battery pack is formed by attaching outer plates to a plurality of such battery modules that are arranged and integrating them.

Owner:PANASONIC CORP

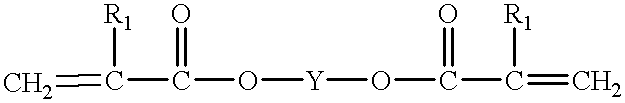

Abrasion resistant urethane coatings

InactiveUS6228433B1Improve wear resistanceResistant to stainsPolyurea/polyurethane coatingsThin material handlingOligomerReactive diluent

A radiation curable and abrasion resistant coating composition is provided comprising: (a) 70% to 98% by weight of an urethane-acrylate oligomer; (b) 2% to 30% of fine particles of a filler capable of imparting abrasion resistance having an average particle size in the range of 1-20 microns; (c) optionally a reactive diluent; and (d) optionally an synthetic resin. The coatings when applied to wood floorings impart superior abrasion resistance.

Owner:PRISM ENTERPRISES

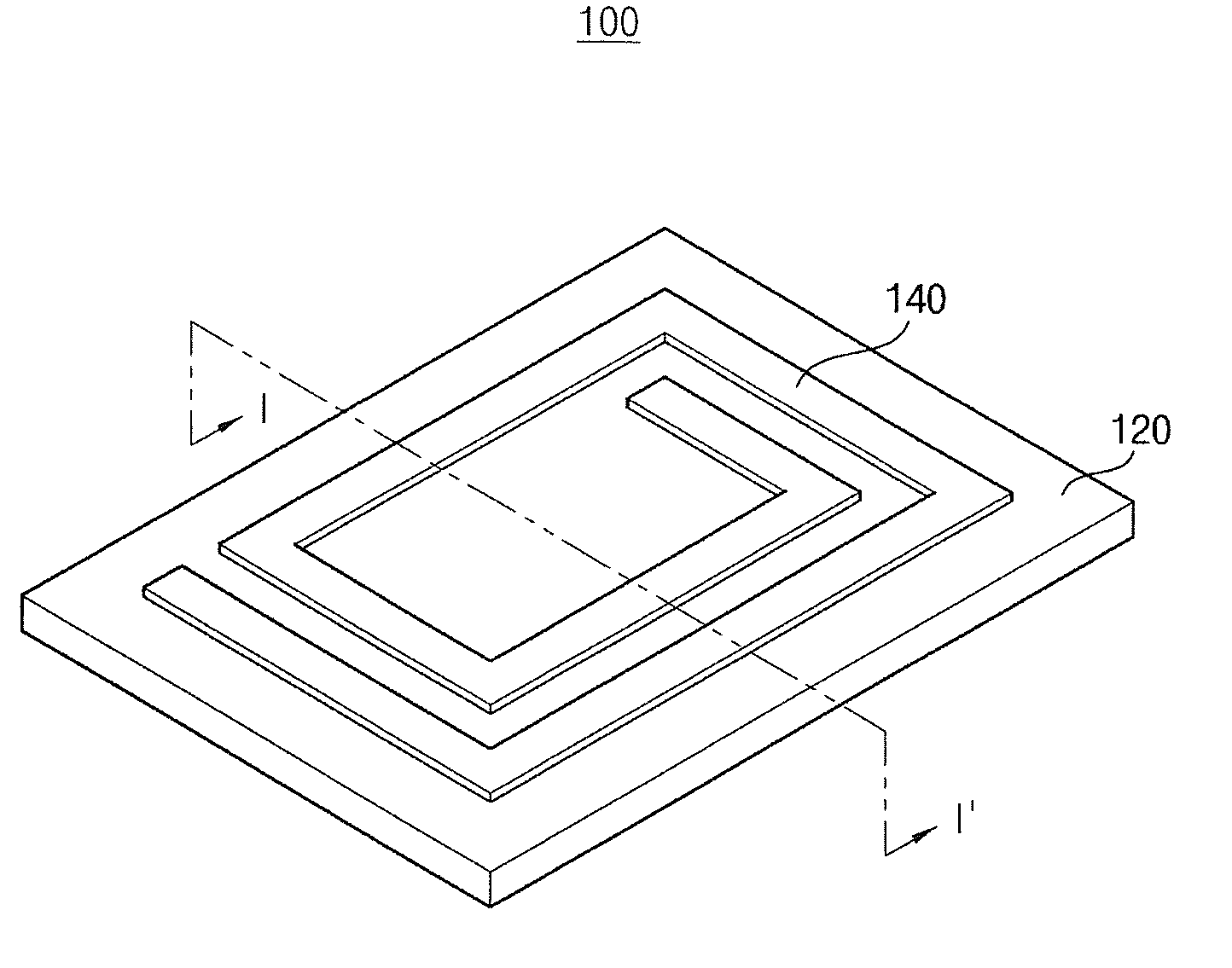

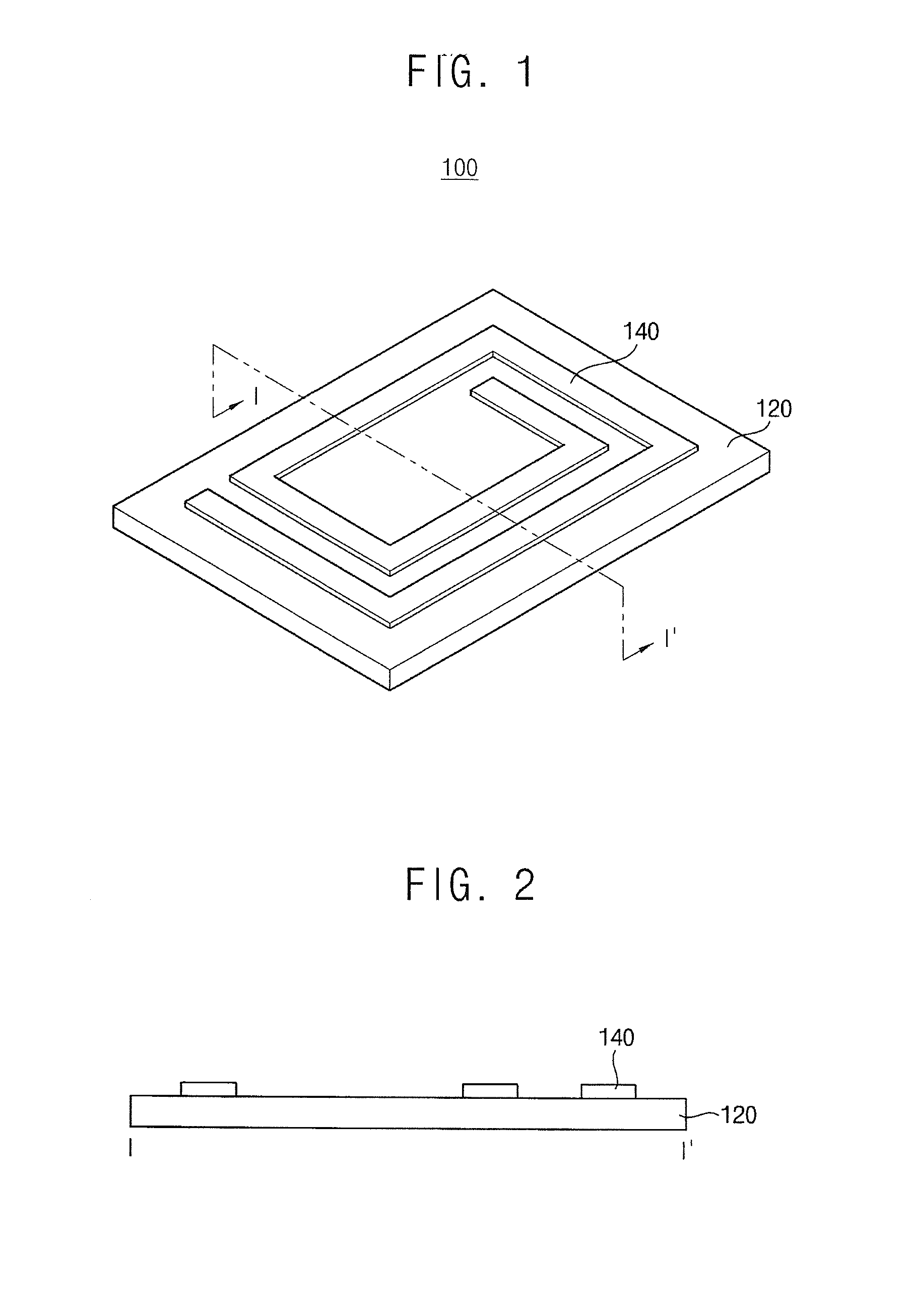

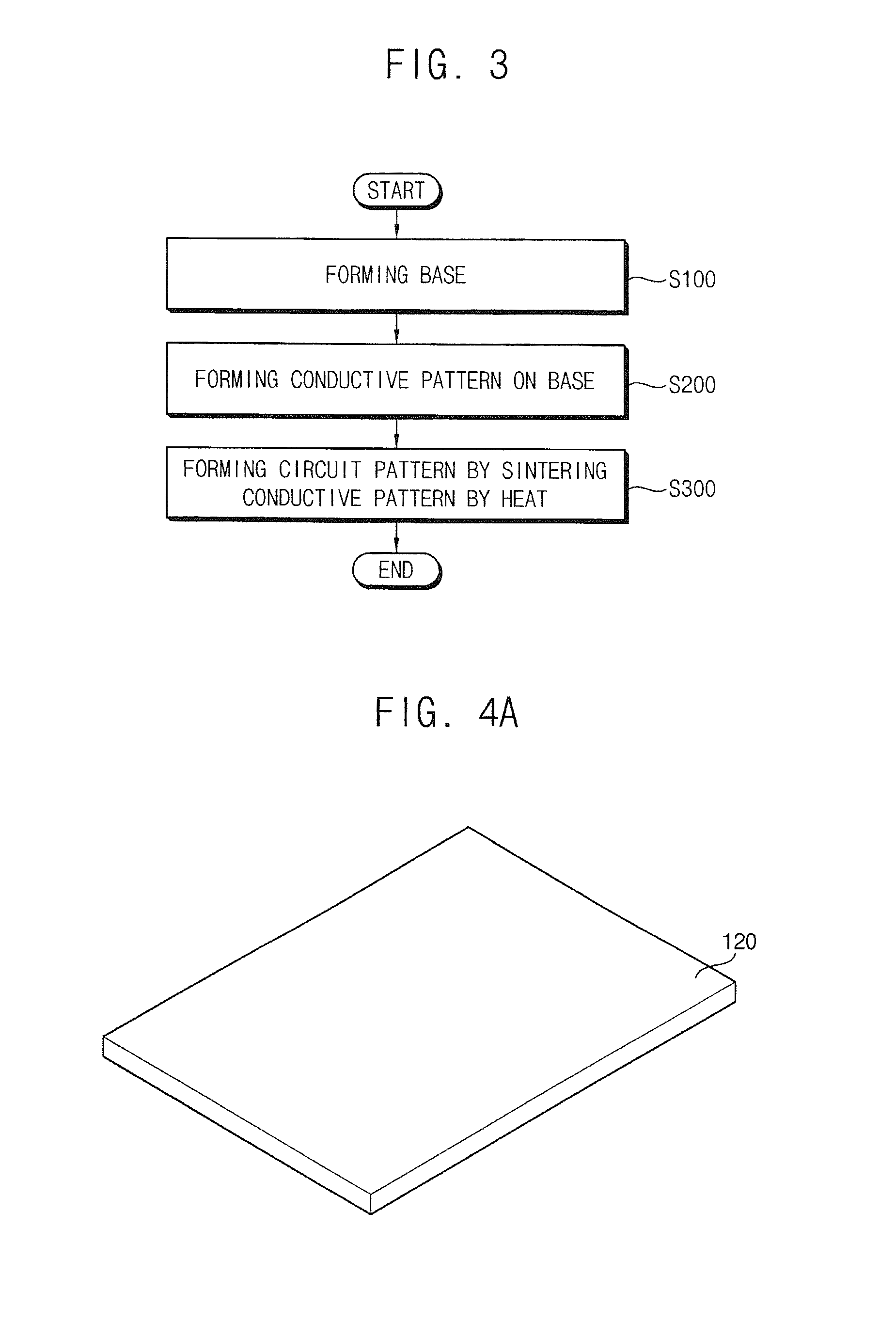

Method of manufacturing antenna using sintering of metal and antenna manufactured by the same

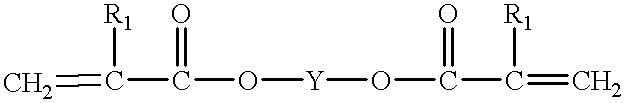

InactiveUS20120038514A1Reduce adverse effectsEasy to useSimultaneous aerial operationsPrinted electric component incorporationConductive pasteSynthetic resin

A method of manufacturing an antenna includes forming a base including a synthetic resin, forming a conductive pattern on the base and forming a circuit pattern by sintering the conductive pattern by applying heat. The conductive pattern includes a conductive paste and a binding material binding the base and the conductive pattern. The conductive paste includes a metal.

Owner:DYNATRON

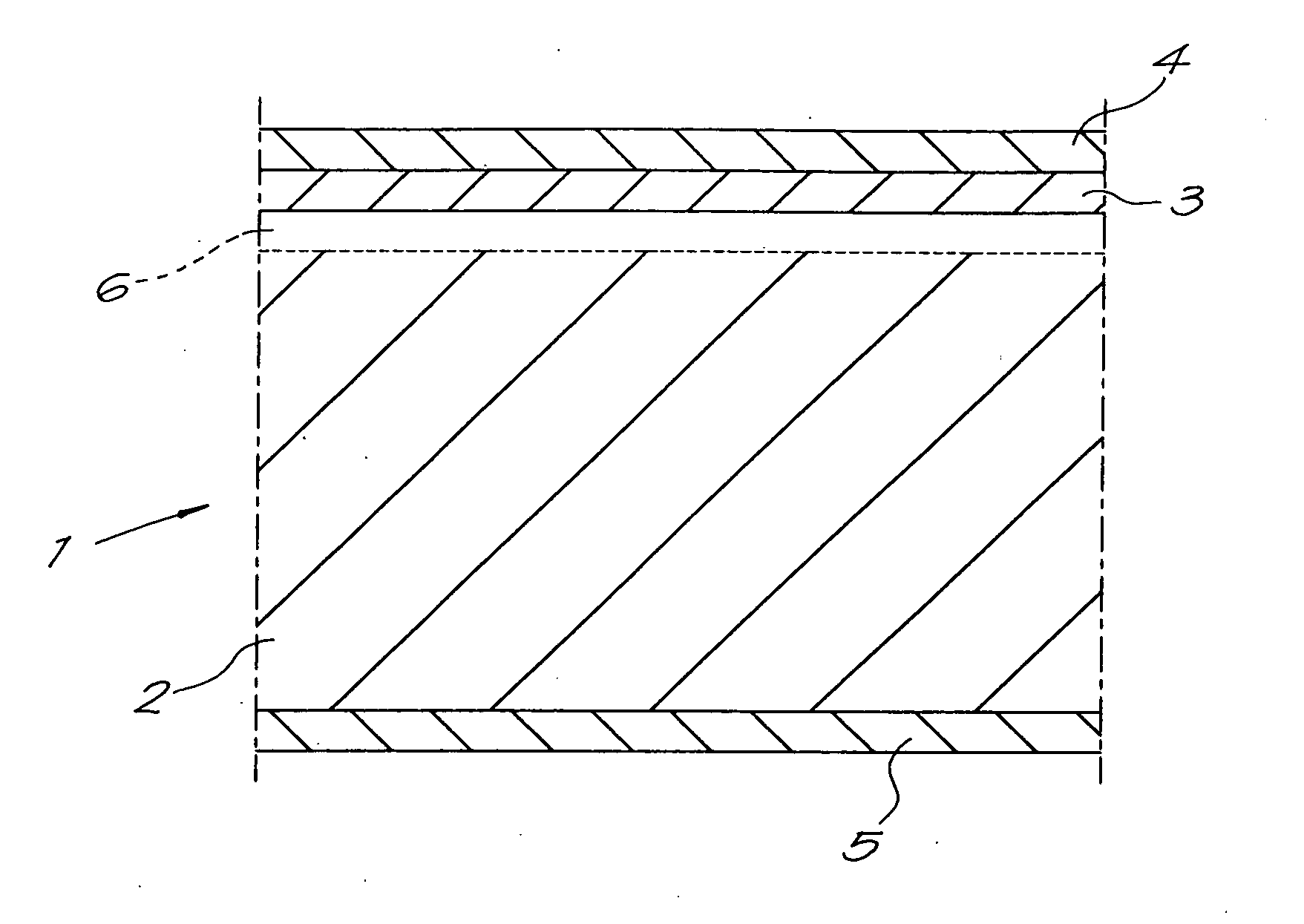

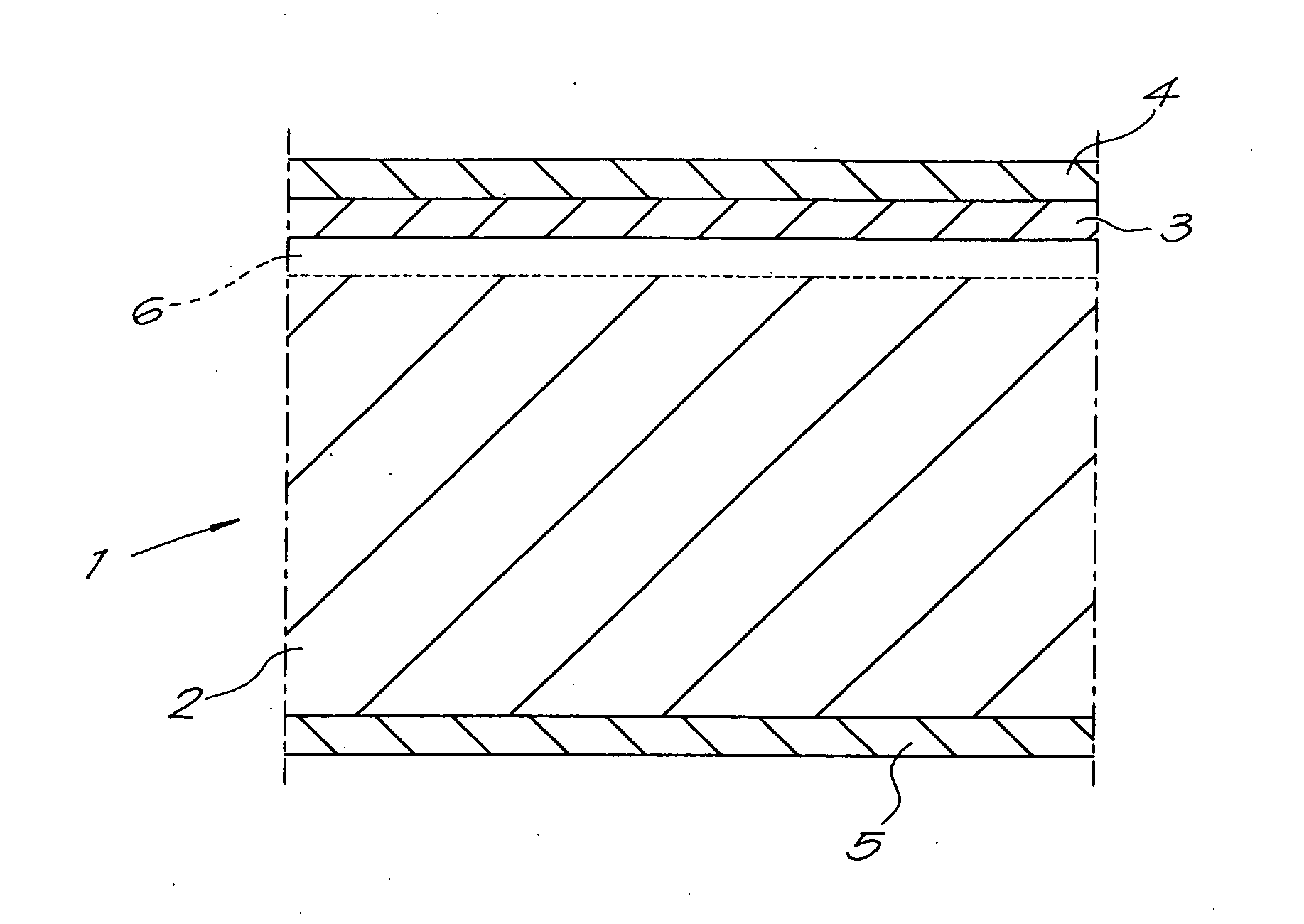

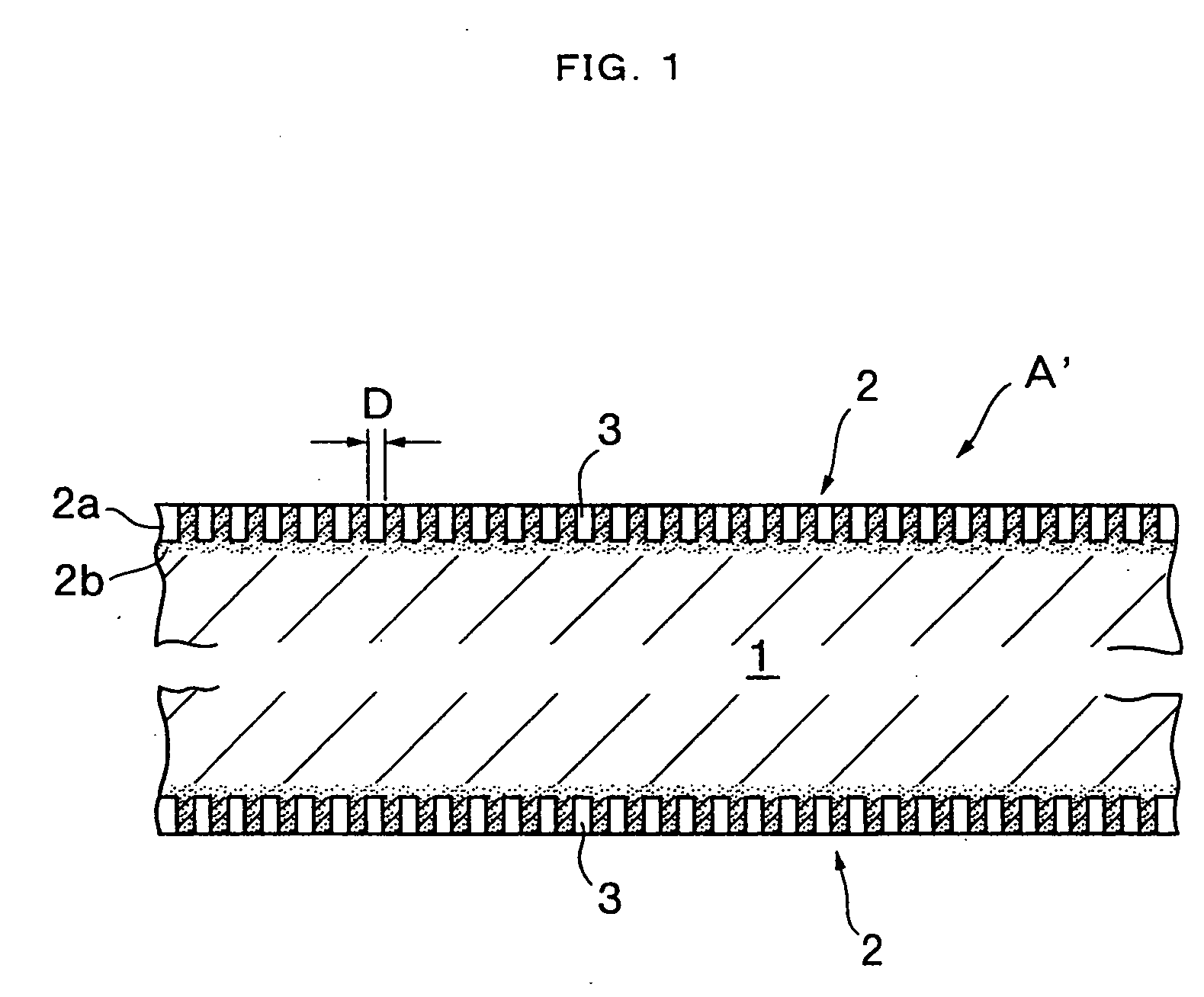

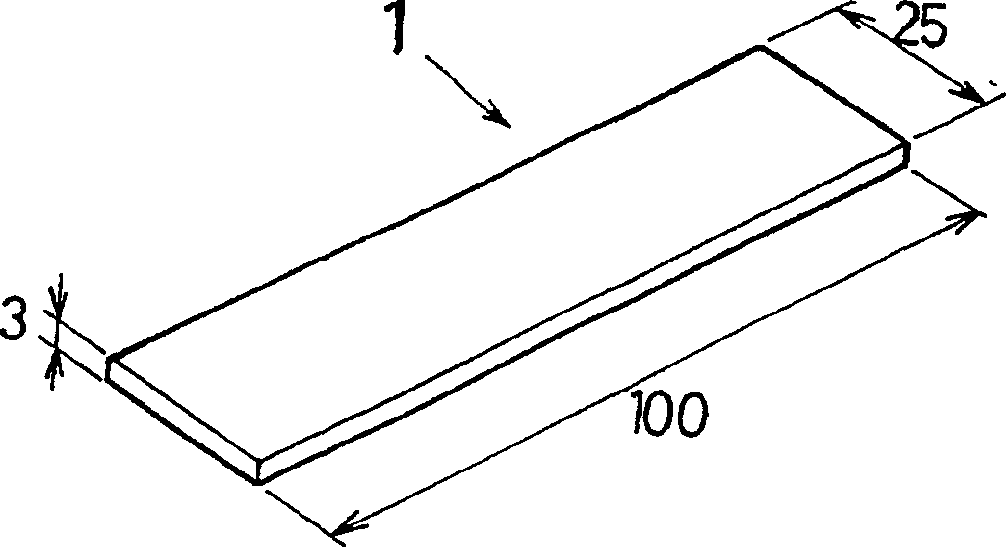

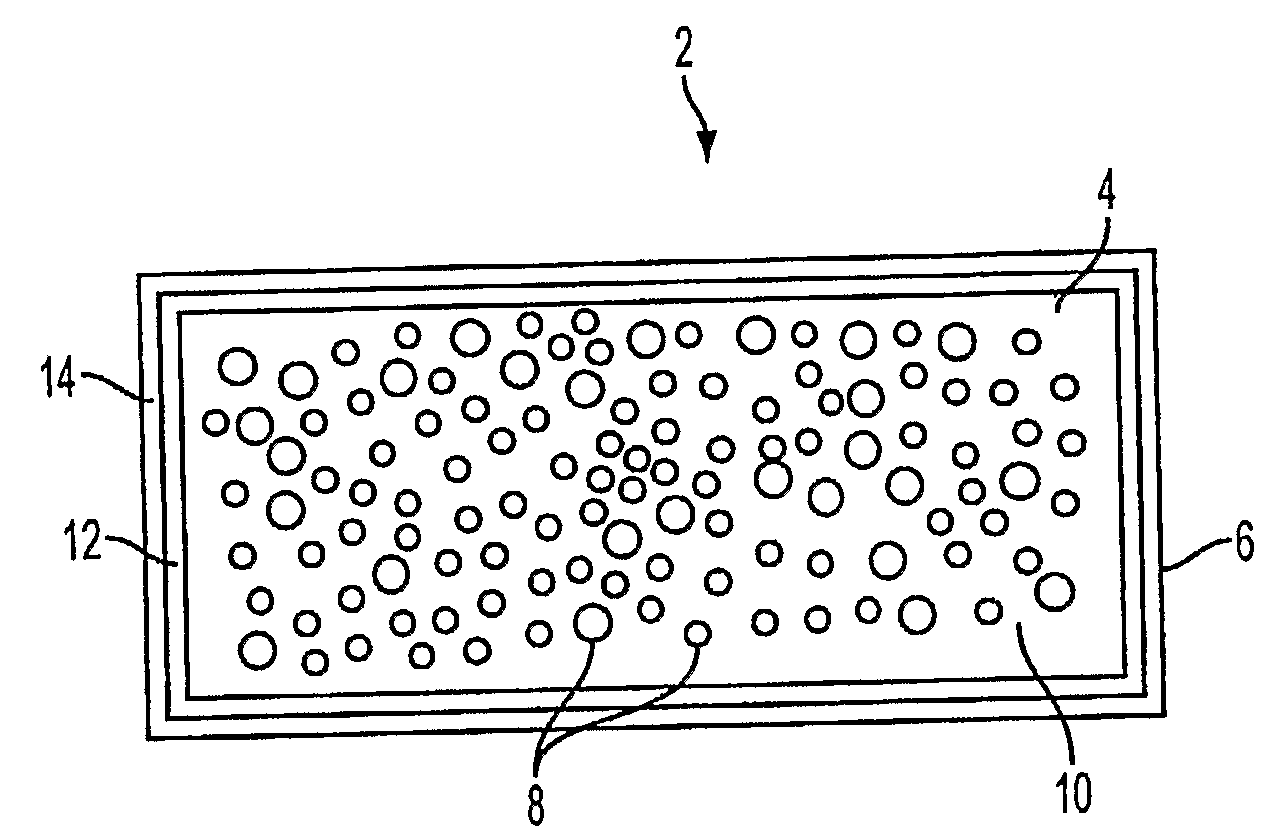

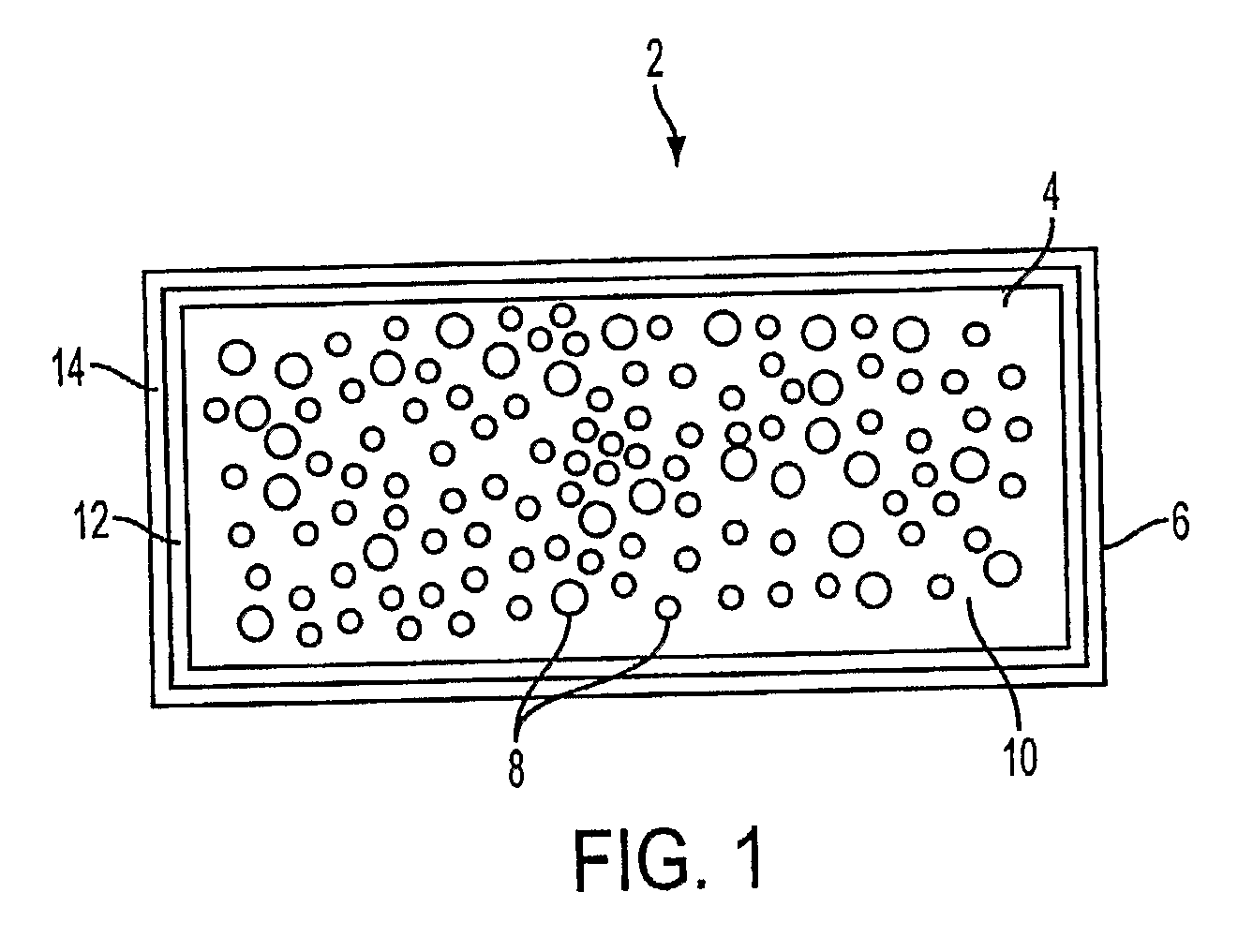

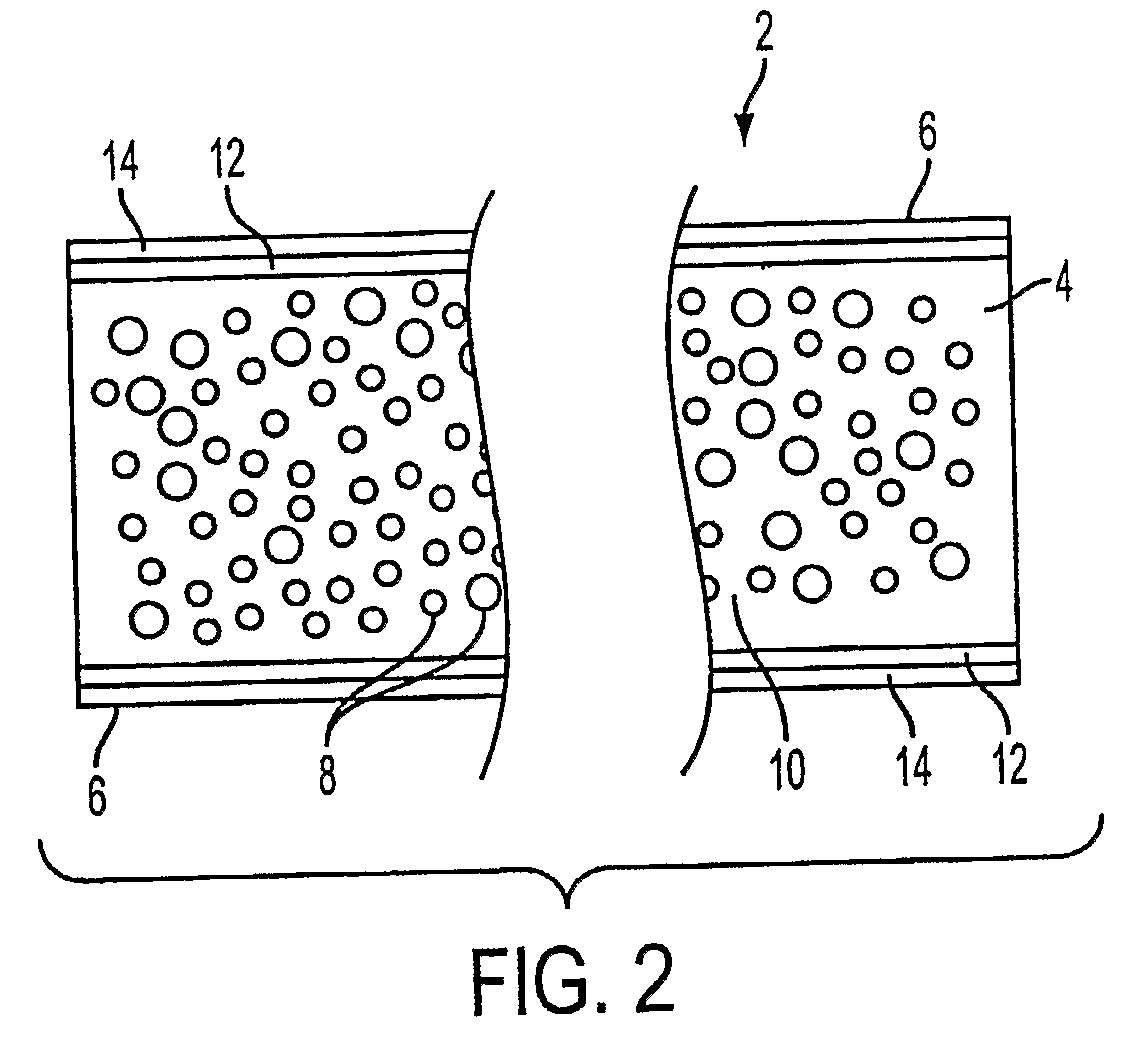

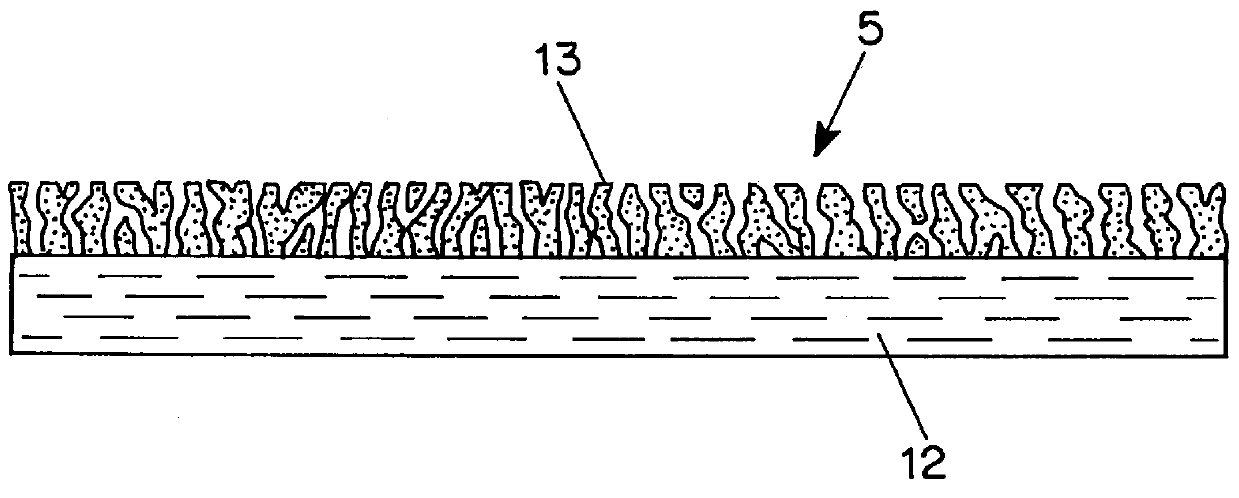

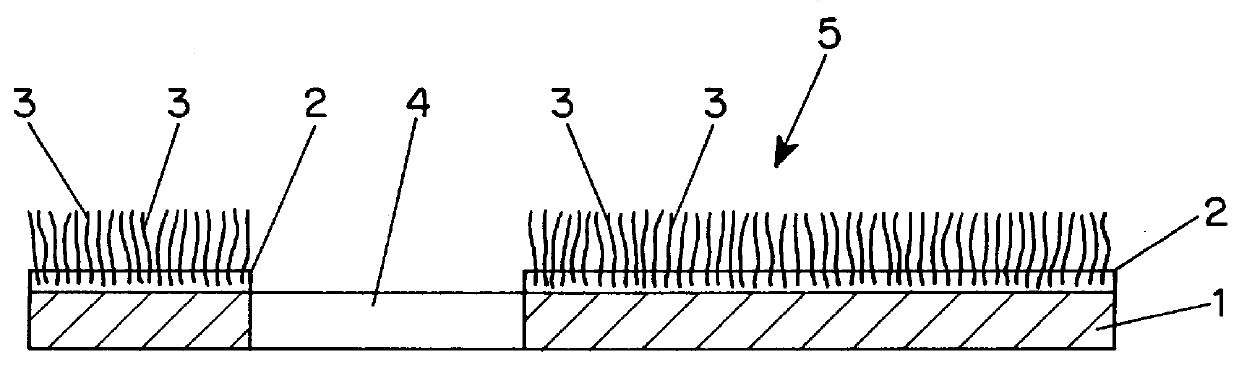

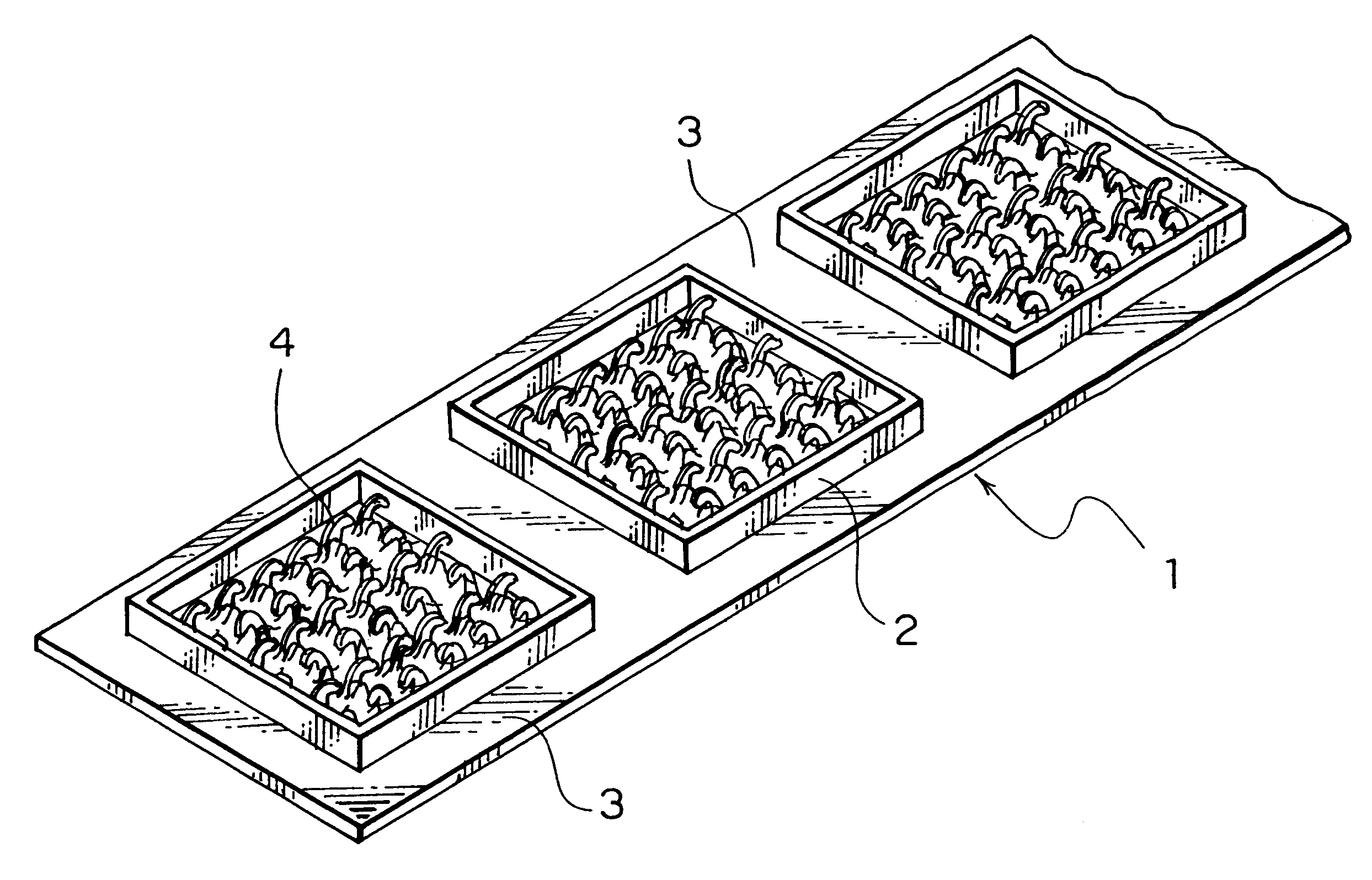

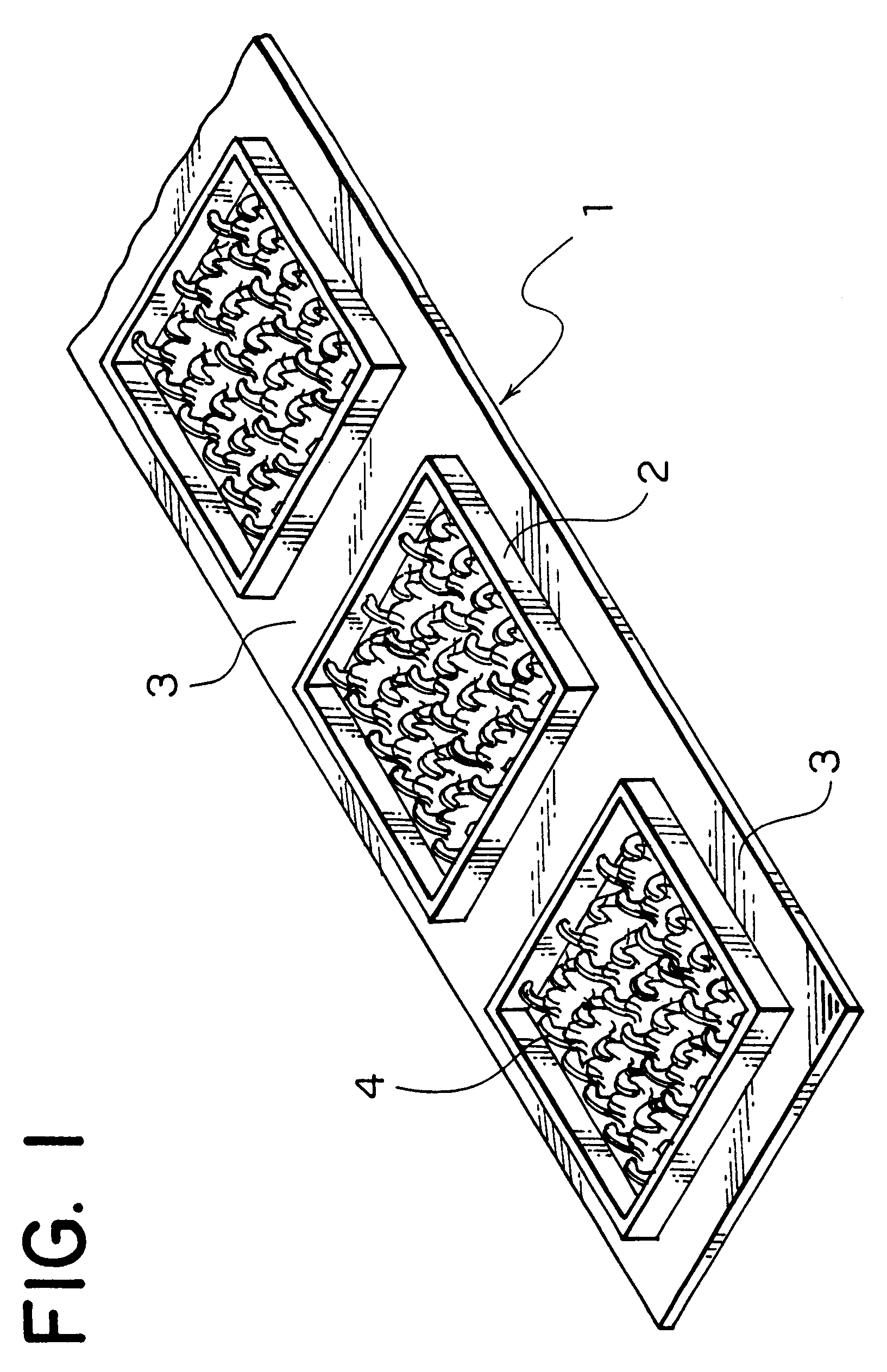

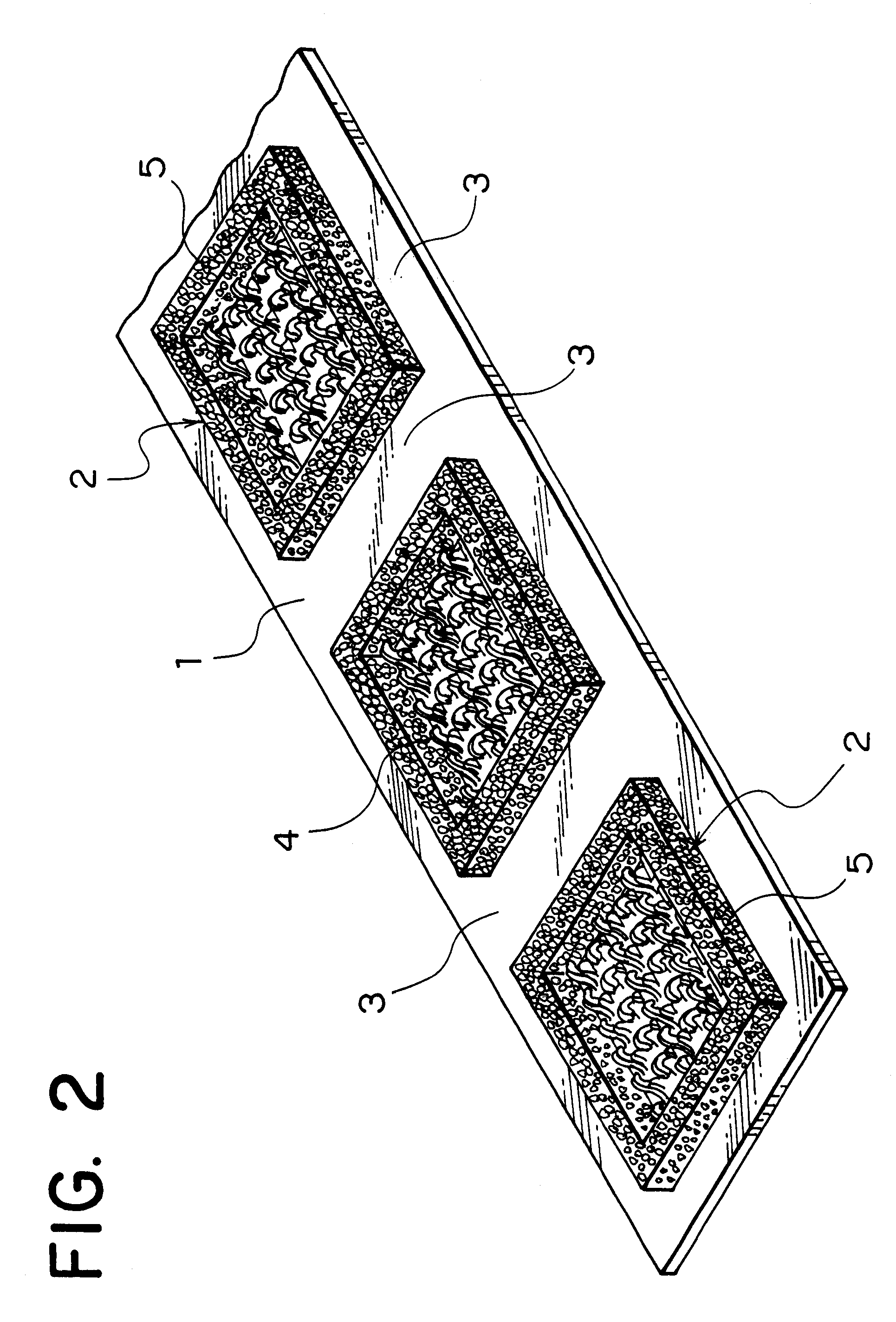

Antistatic layered panel and method of its manufacture

InactiveUS20060008630A1Simple and economic and durable mannerSynthetic resin layered productsPretreated surfacesAntistatic agentEngineering

The invention relates to an antistatic layered panel (1) including a substrate (2) and one or more layers (3, 4) on top of said substrate, said one or more layers comprising a decorative covering layer (3). At least one of the layers on top of said substrate comprises a synthetic resin and is consolidated by pressure with one or more of the other layers. The panel contains at least one antistatic agent evenly distributed in said synthetic resin over the surface of the panel. The invention relates also to methods of its manufacture and in particular to such antistatic laminated floor panels.

Owner:FLOORING IND LTD

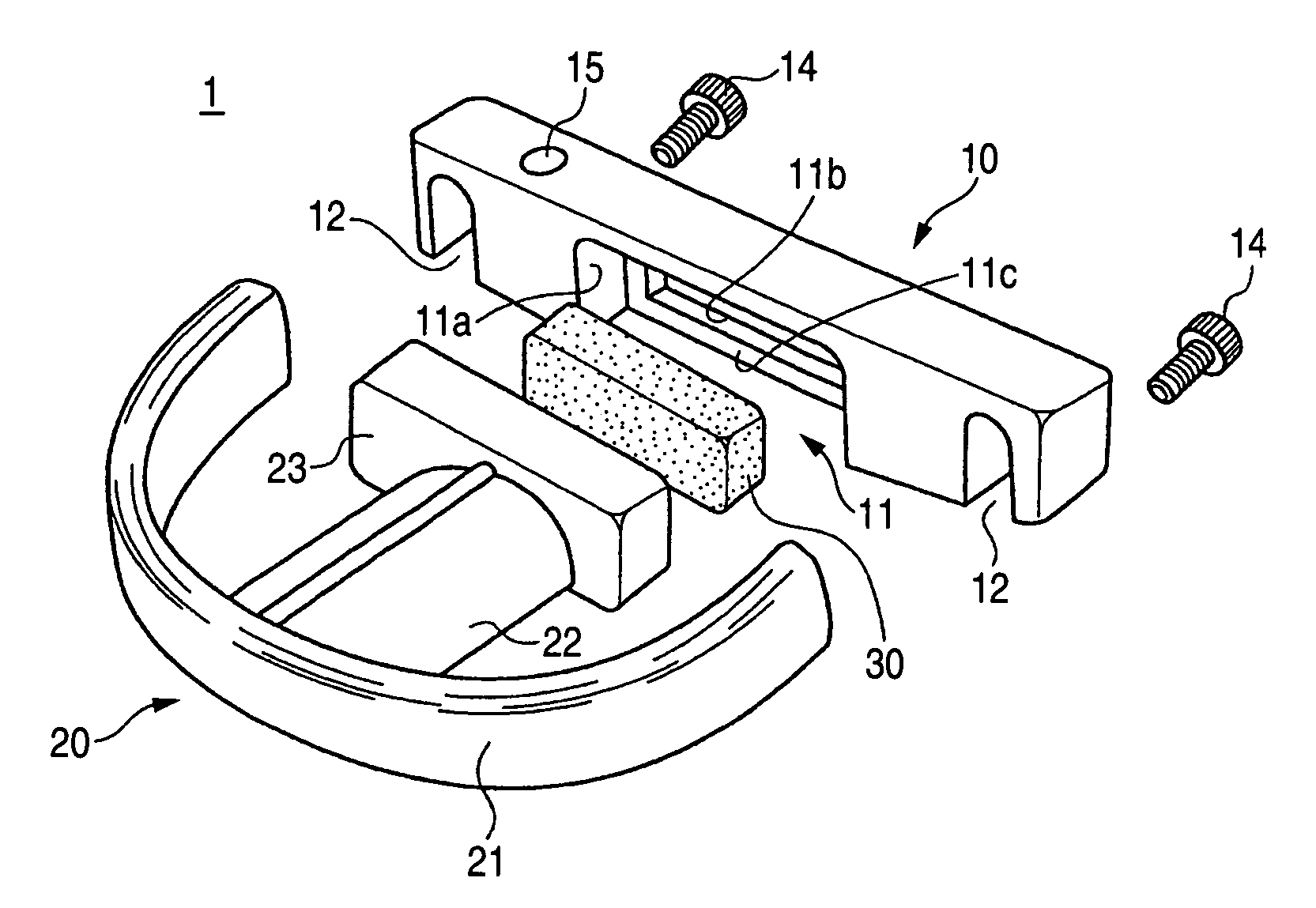

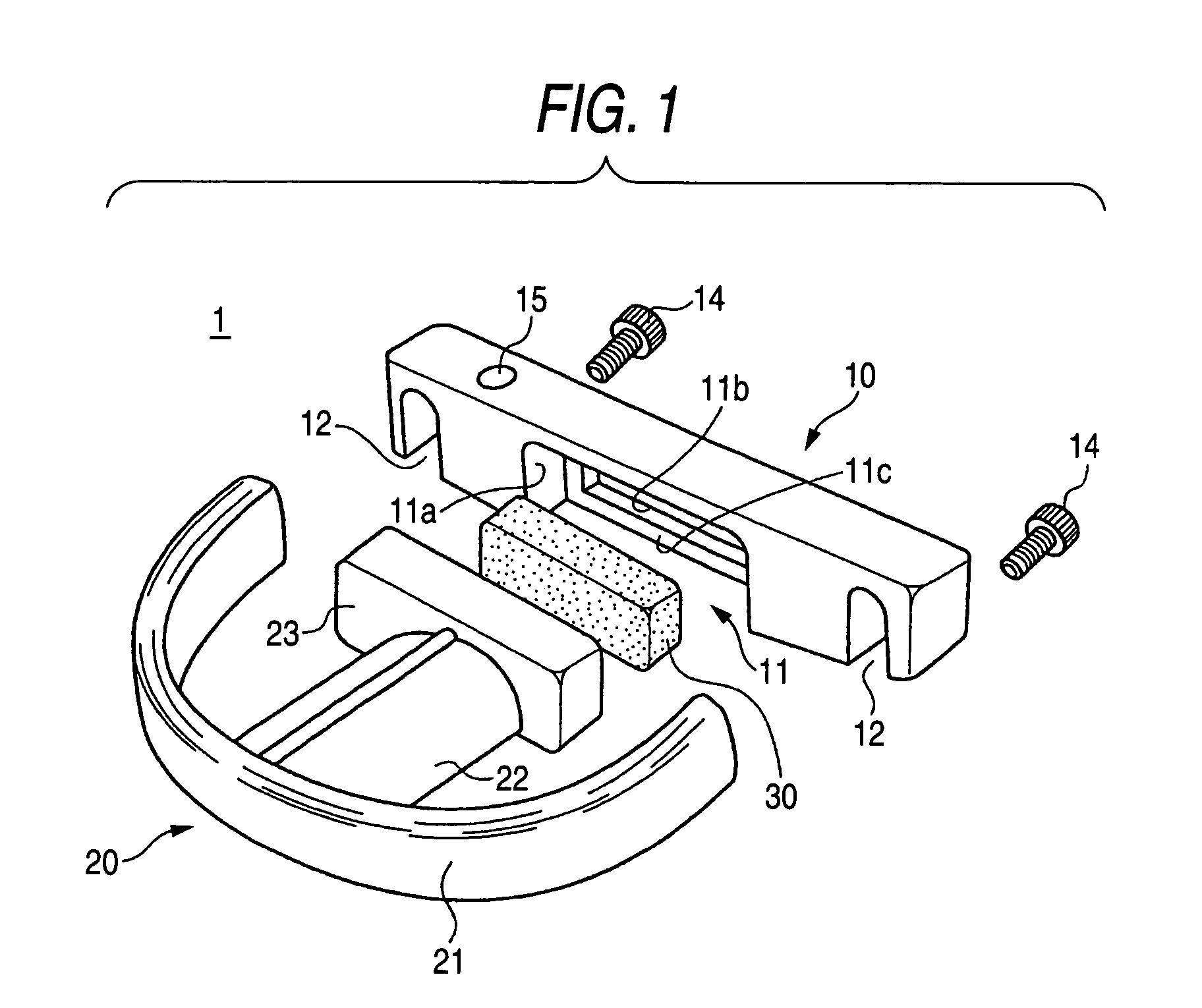

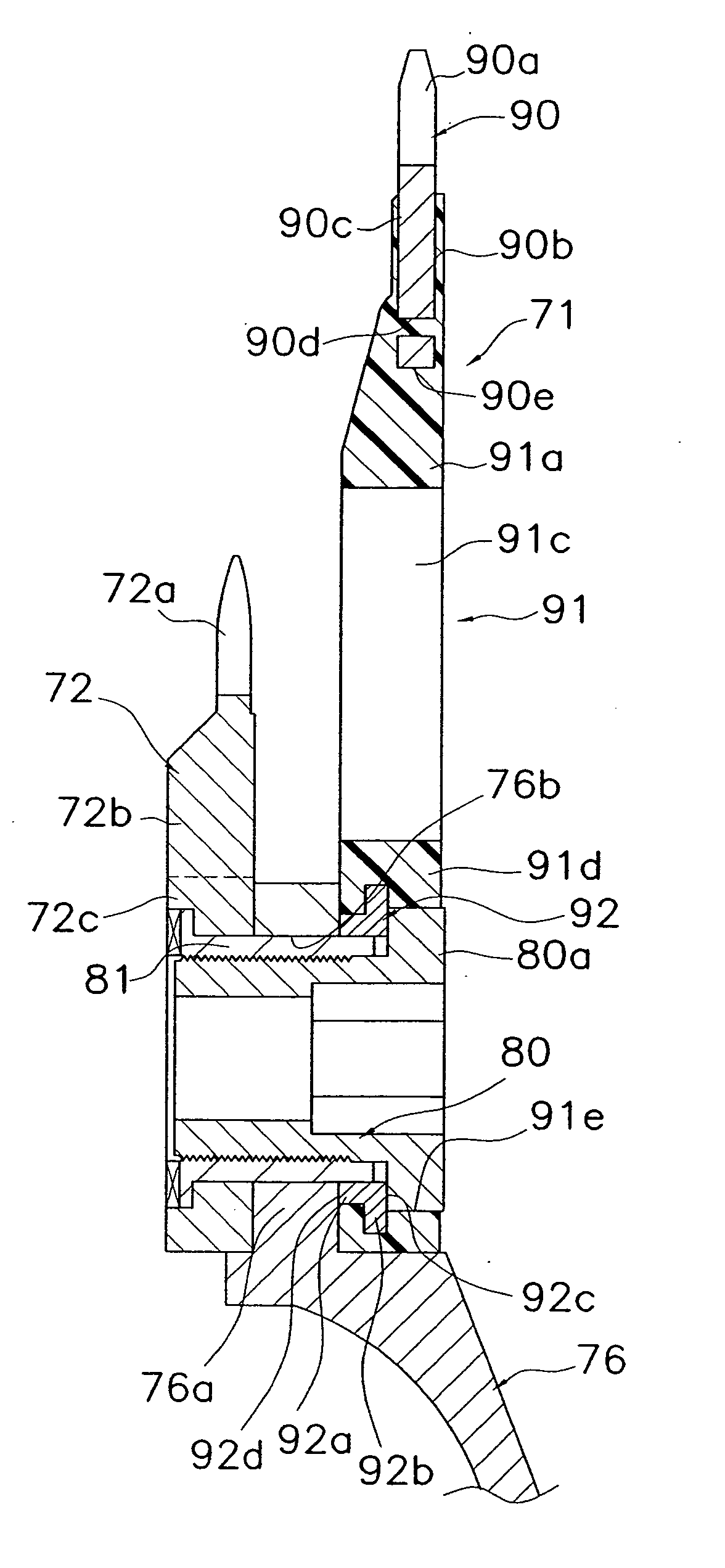

Putter head

Owner:BRIDGESTONE SPORTS

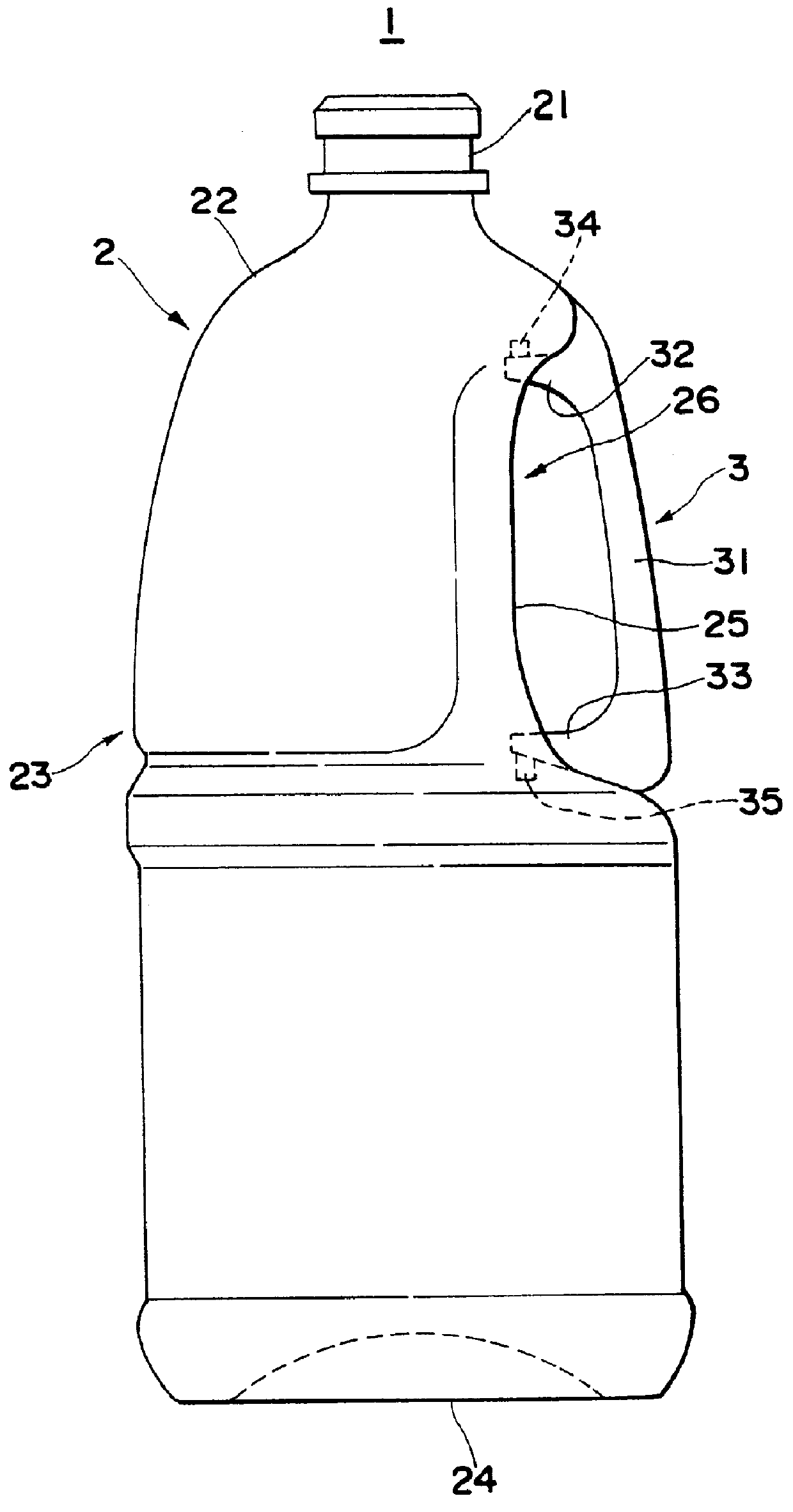

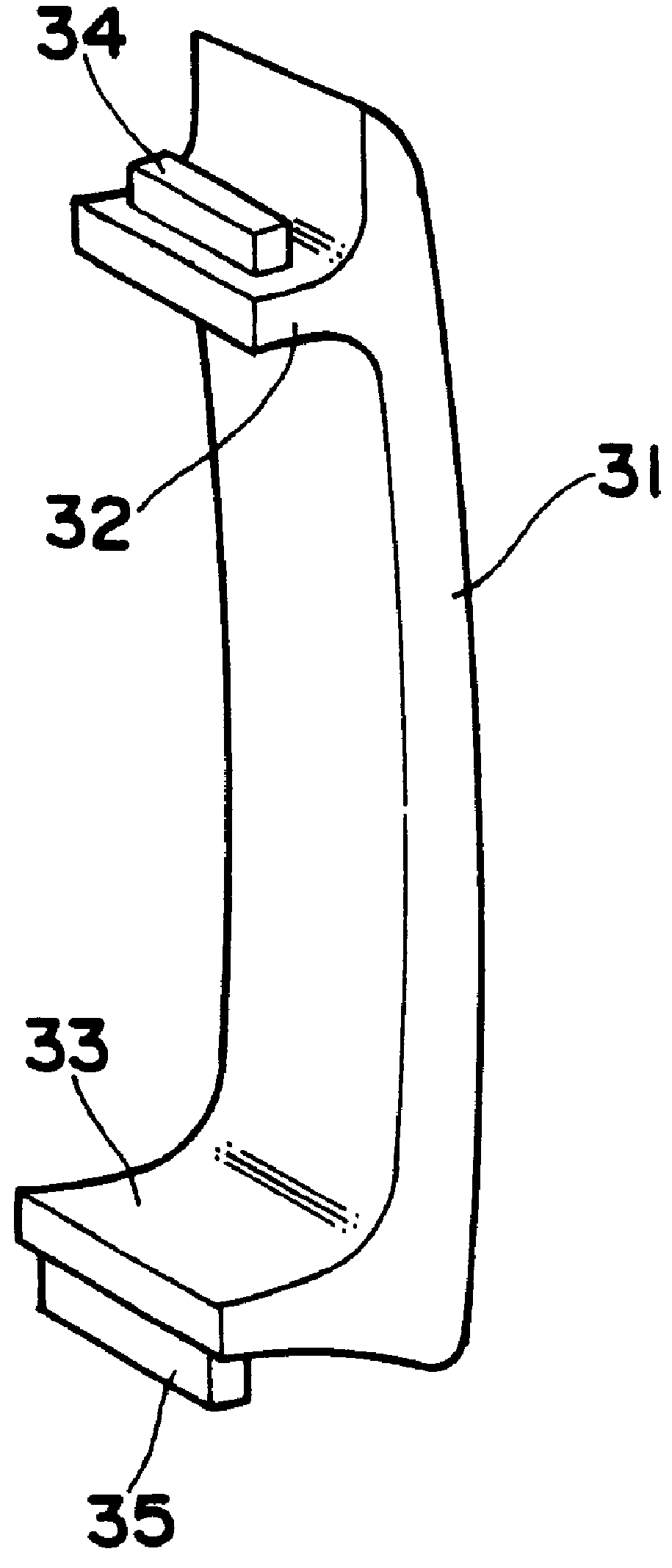

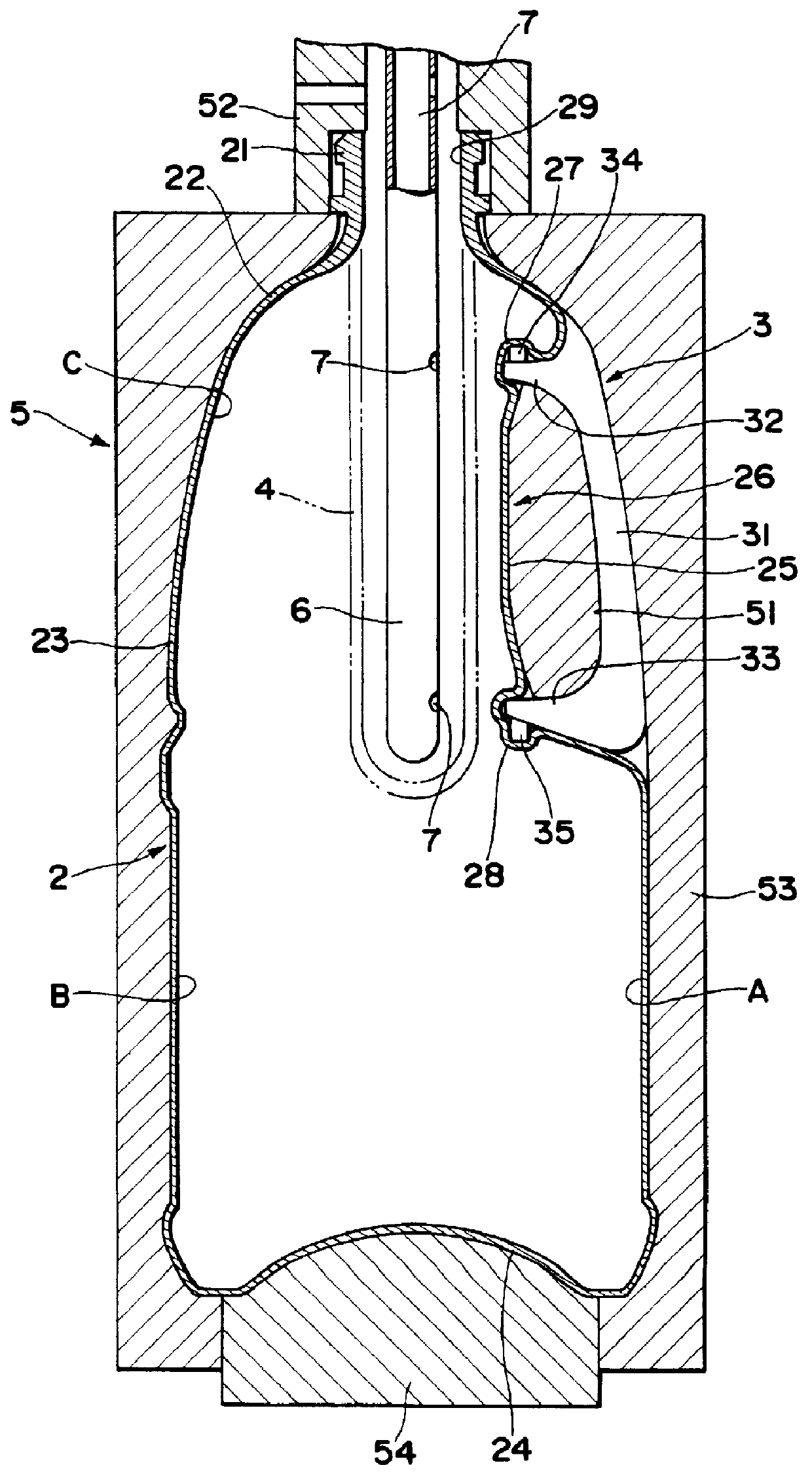

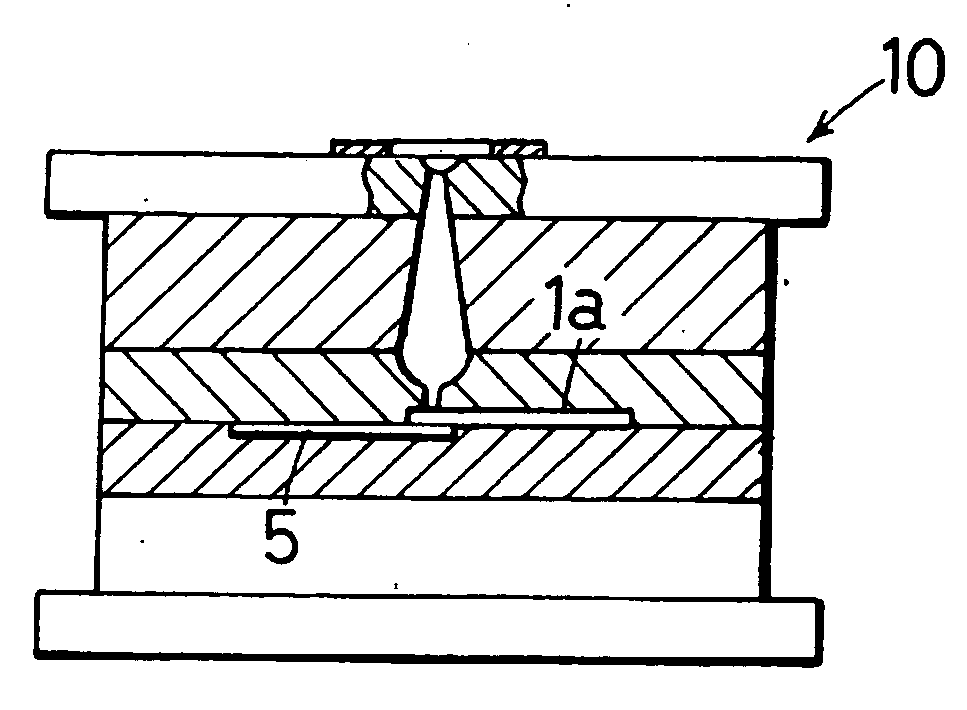

Polyester bottle with a handle and method of manufacturing the same

The present invention relates to polyester bottle with a handle comprising a polyester bottle body and a synthetic resin handle body mounted to said bottle body, and the method of manufacturing the same. Said bottle body comprises a neck portion, a shoulder portion continuous from said neck portion, a body portion continuous from said shoulder portion, a bottom portion continuous from said body portion and a handle mounting portion on the wall surface of said body portion formed by blowing air into a preform which is set to a cavity of a mold for biaxial stretch blow molding. Said handle body comprises a grip portion and a fixing portion continuous from said grip portion. Said fixing portion is connected to said handle mounting portion for mounting said handle body to said bottle body. Heat treatment is performed to at least said handle connecting portion of said handle mounting portion by heated air being blown into said bottle body. Said handle body could either be molded separately in advance, or molded after the blow molding of said bottle body by injection molding. Said heat treatment will be performed either after or simultaneously with the blow molding of said bottle body.

Owner:MITSUBISHI PLASTICS INC

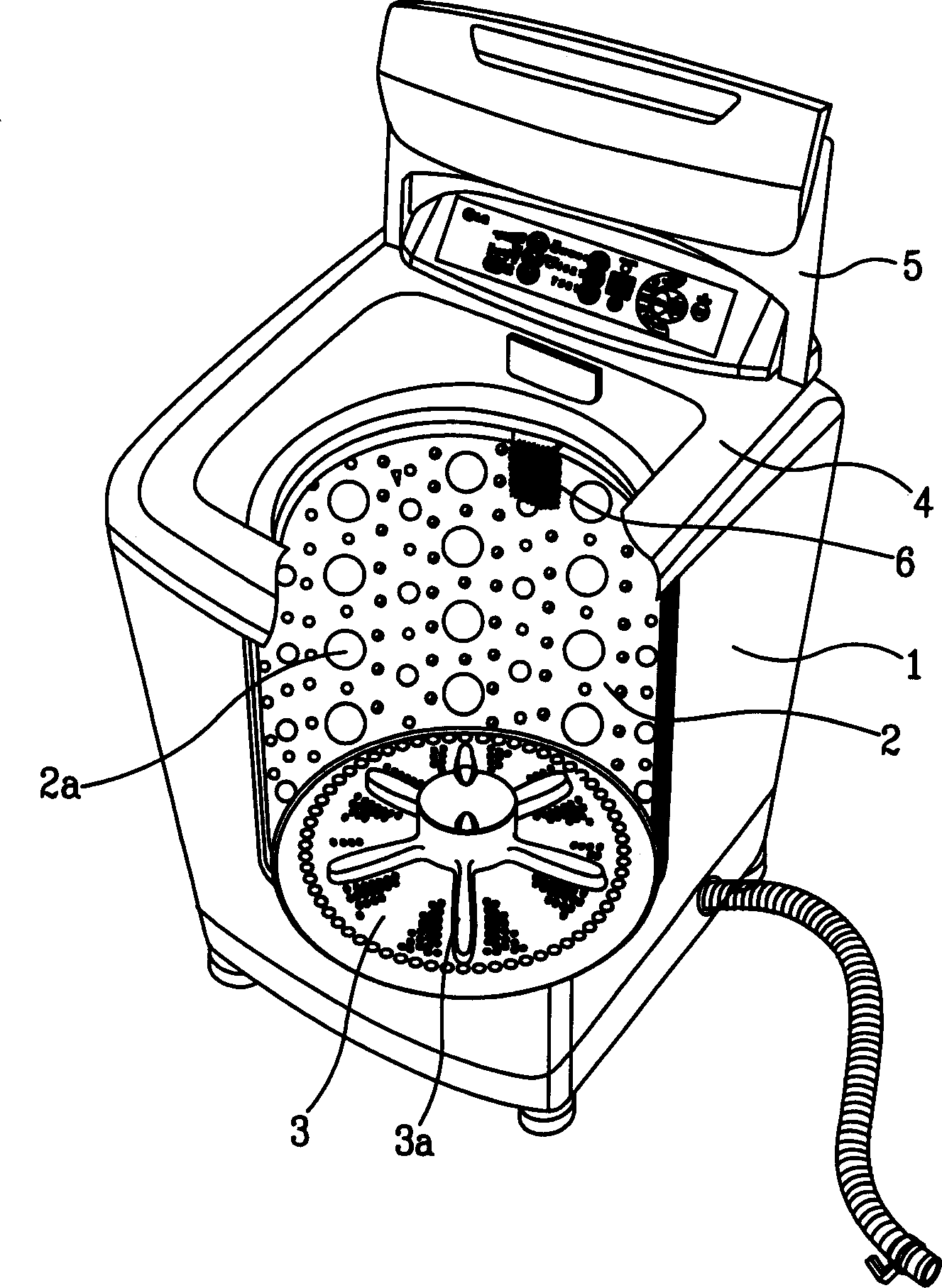

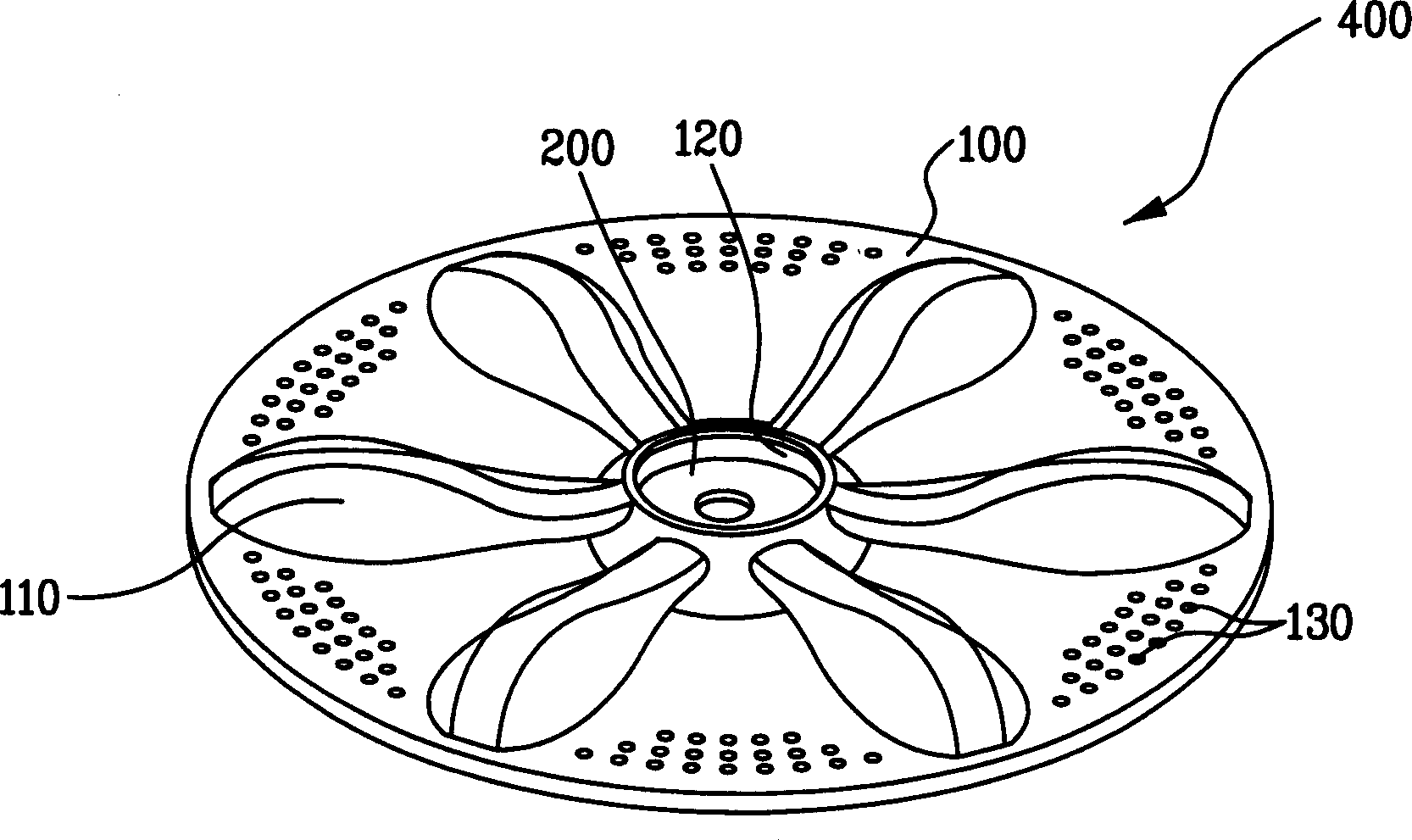

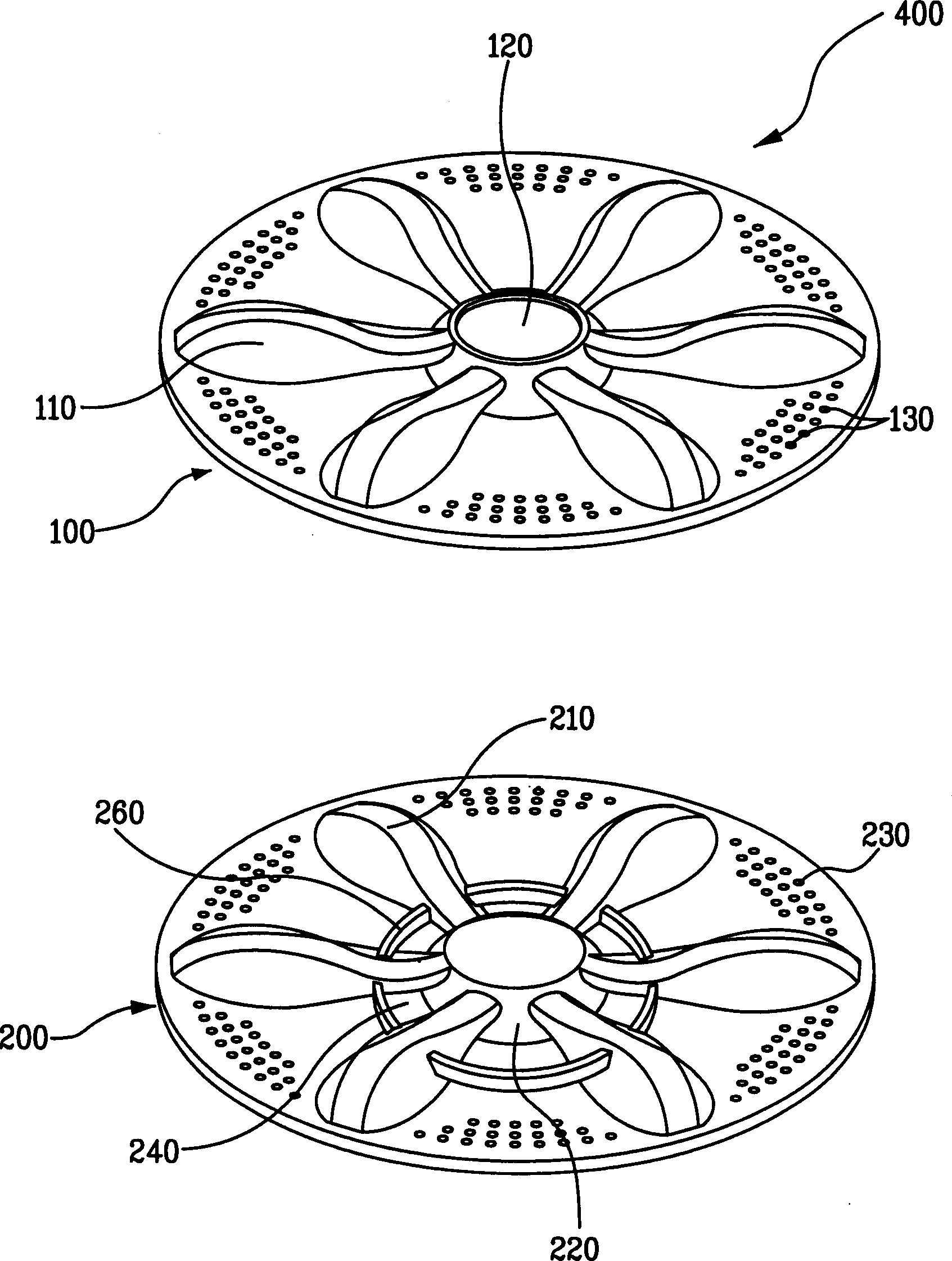

Pulsator and washing machine using same

InactiveCN1451803AImprove aestheticsStrong movementOther washing machinesWashing machine with receptaclesImpellerDrive shaft

A pulsator comprising: a metal upper pulsator having an inlet at its center and an upper washing rib protruding radially upward around the inlet; and a synthetic resin lower pulsator having an upwardly projecting a lower washing rib, in contact with the lower surface of the upper washing rib, a flow guide surface, spaced a distance from the lower surface of the upper pulsator, defining a flow channel to guide water flow through the inlet, and An outlet at the end of the guide surface for discharging the water flowing in the flow channel. The lower pulsator can rotate with a drive shaft of the washing machine and is fixed on the drive shaft. A pulsator includes a synthetic resin pulsator body with an inlet, the pulsator body has a washing rib and a metal plating layer on its outer surface, and the outlet and the flow channel are arranged in the pulsator body.

Owner:LG ELECTRONICS INC

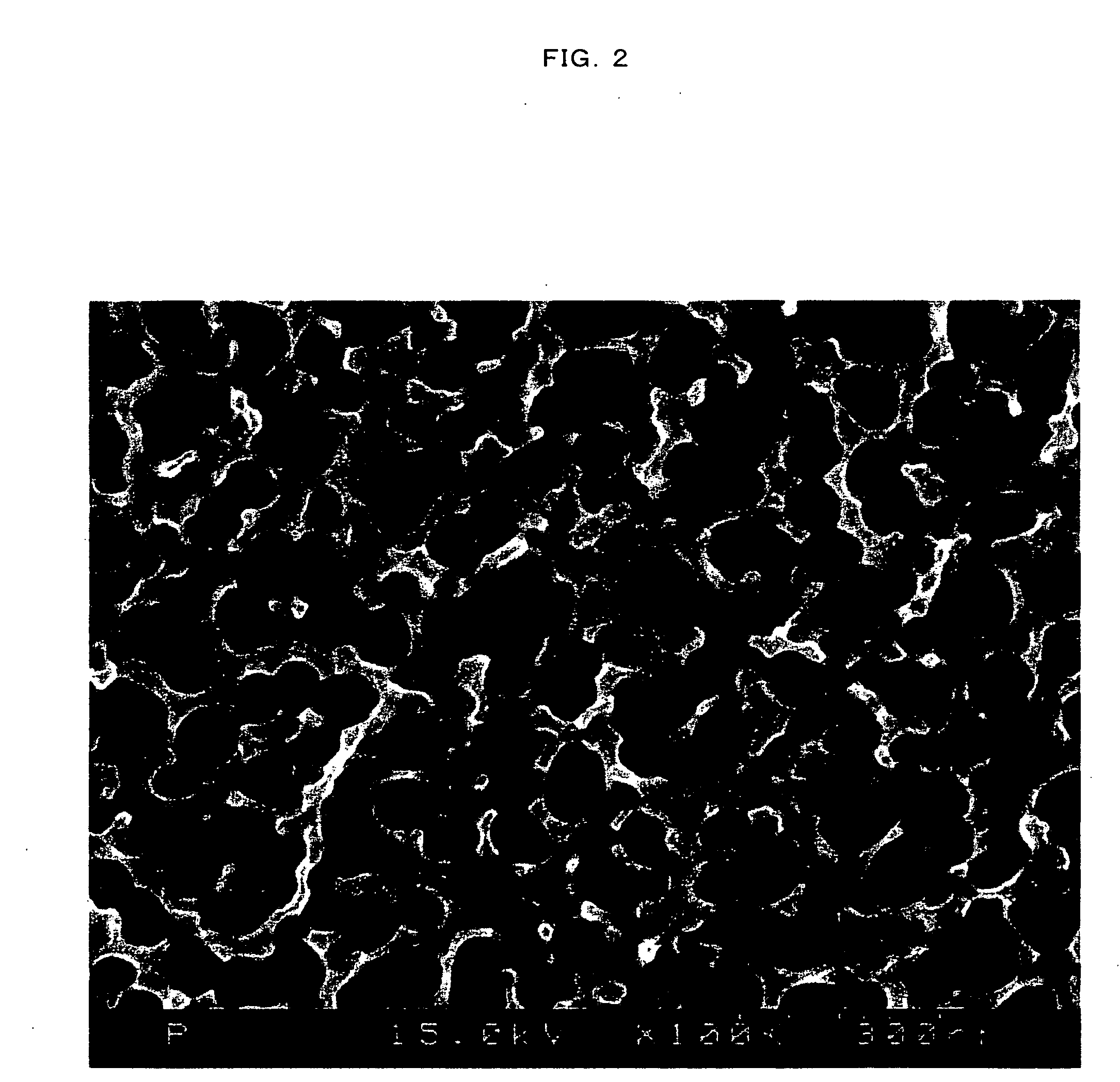

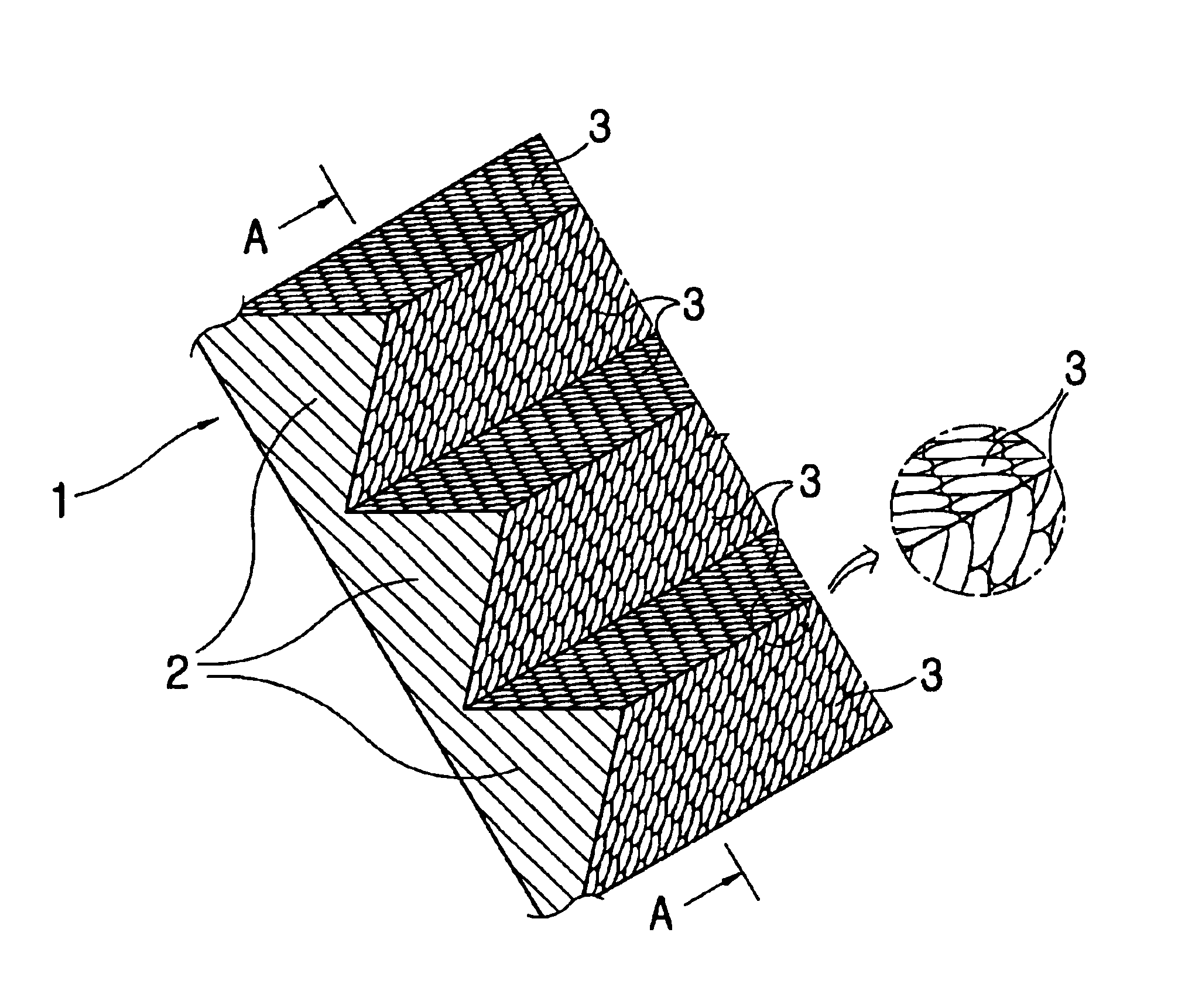

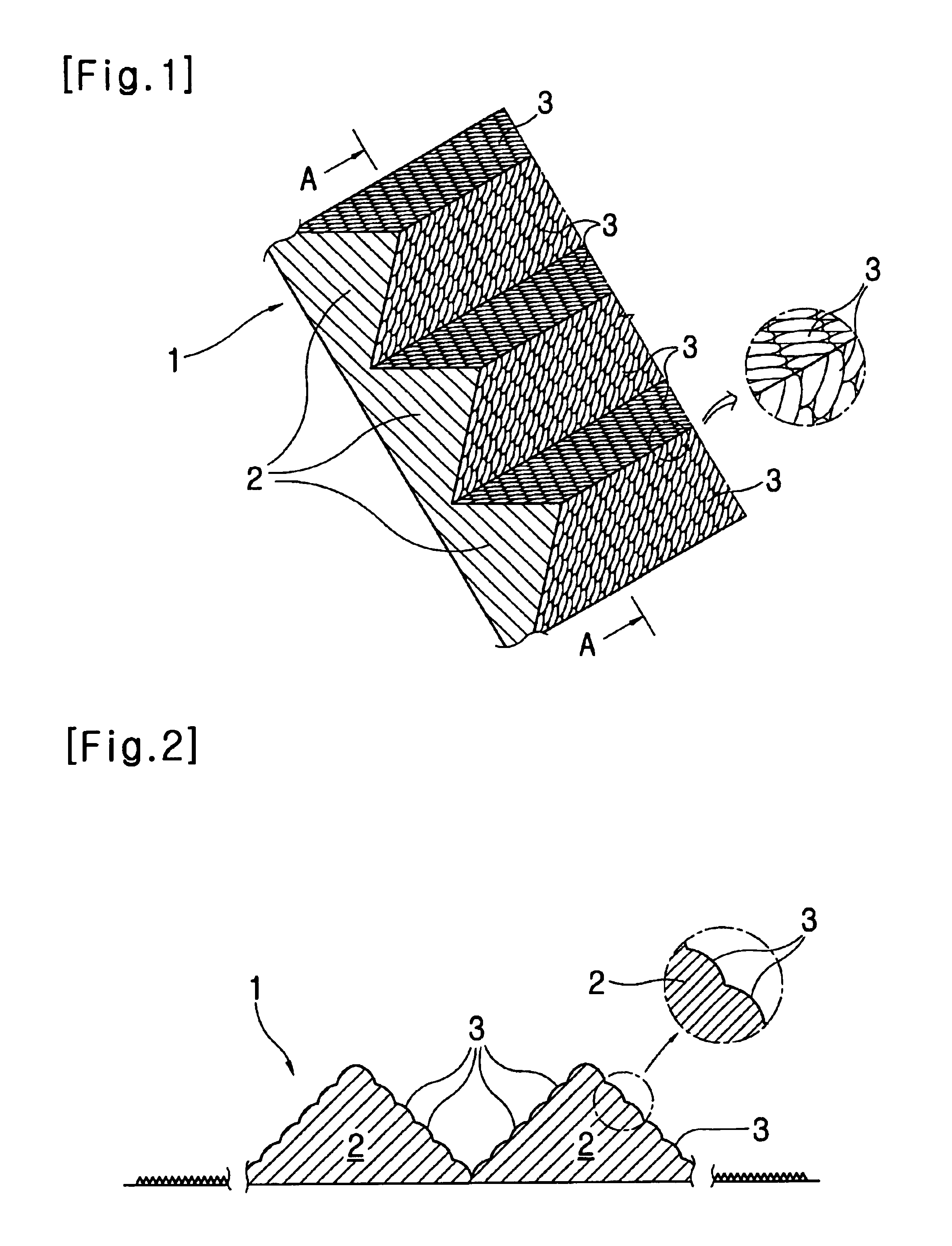

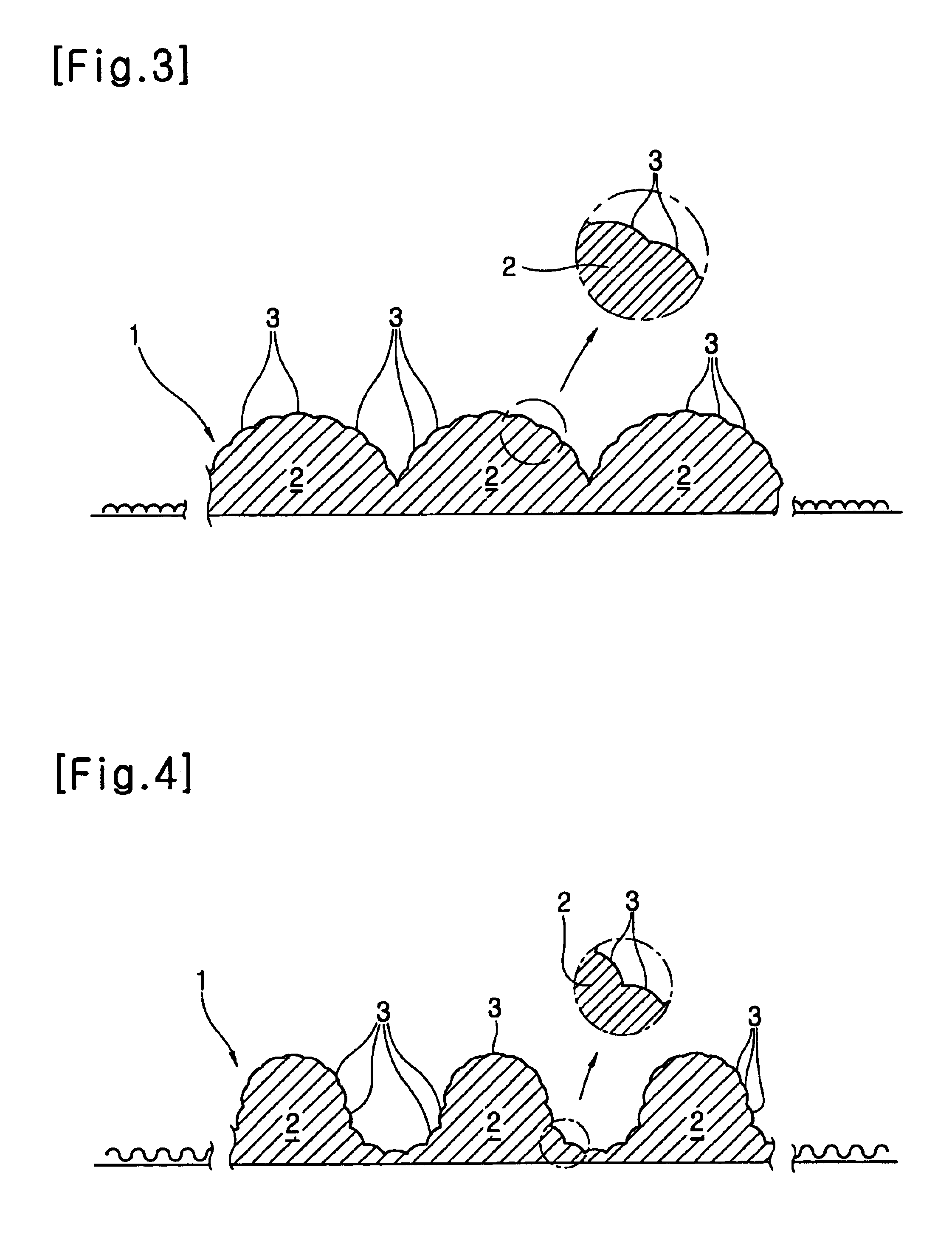

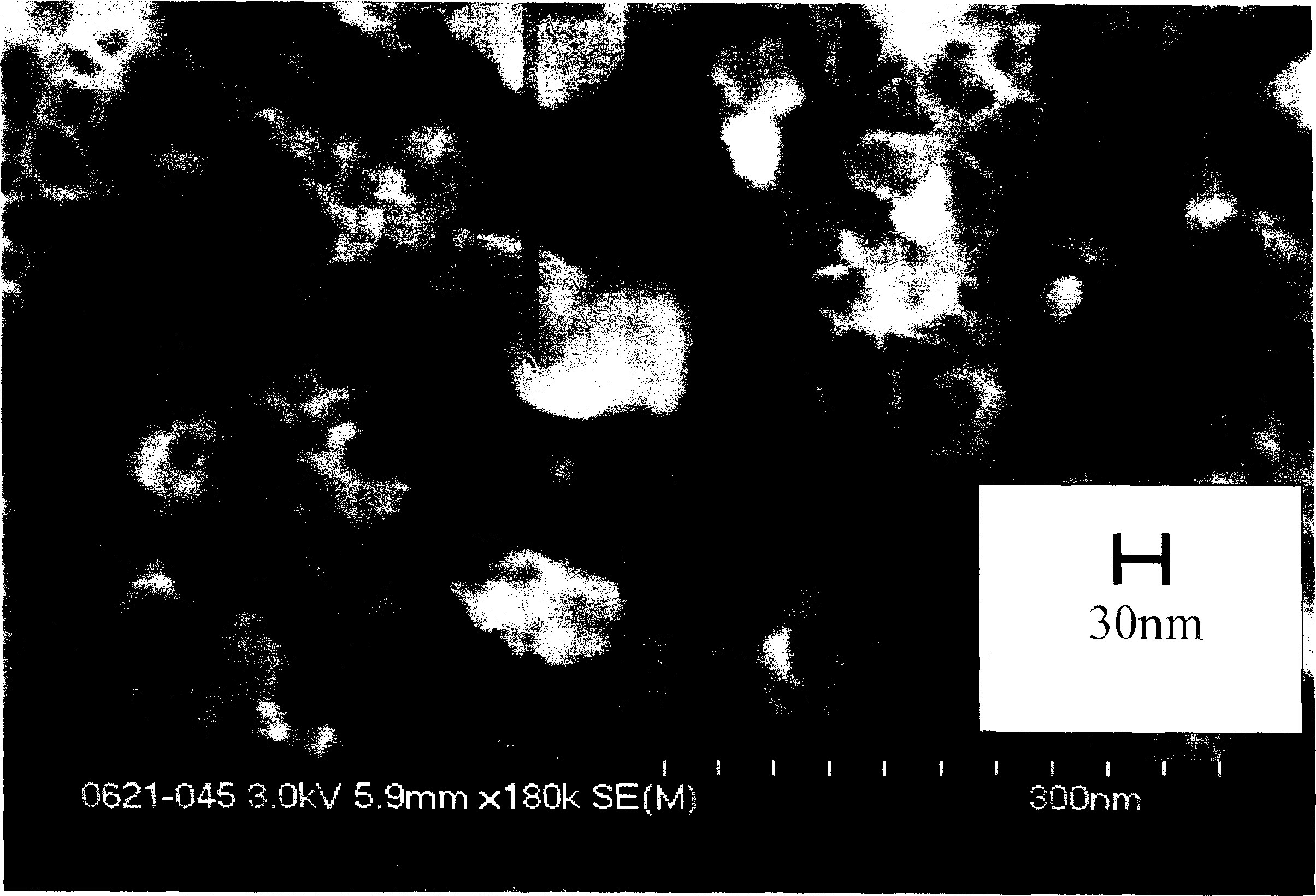

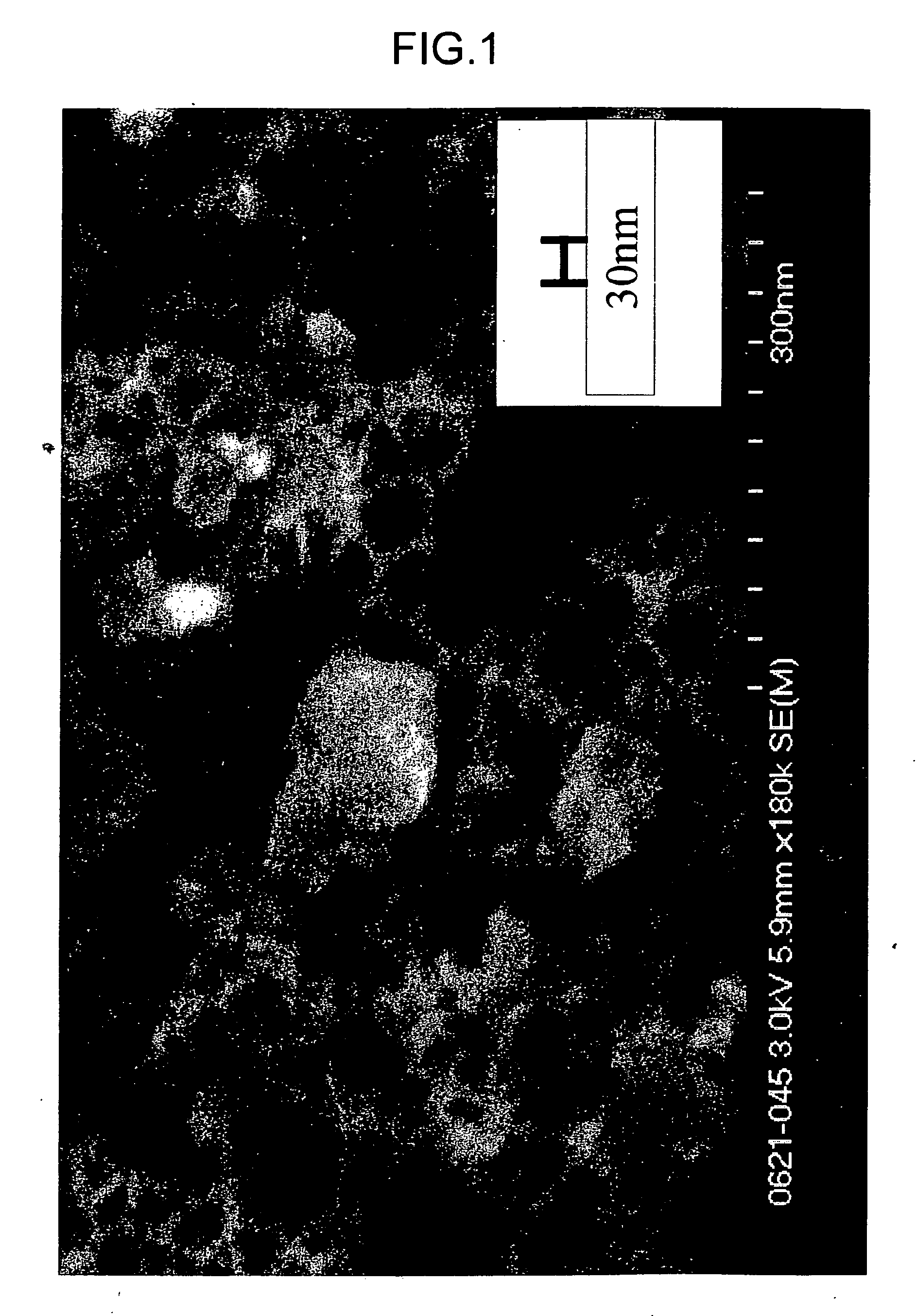

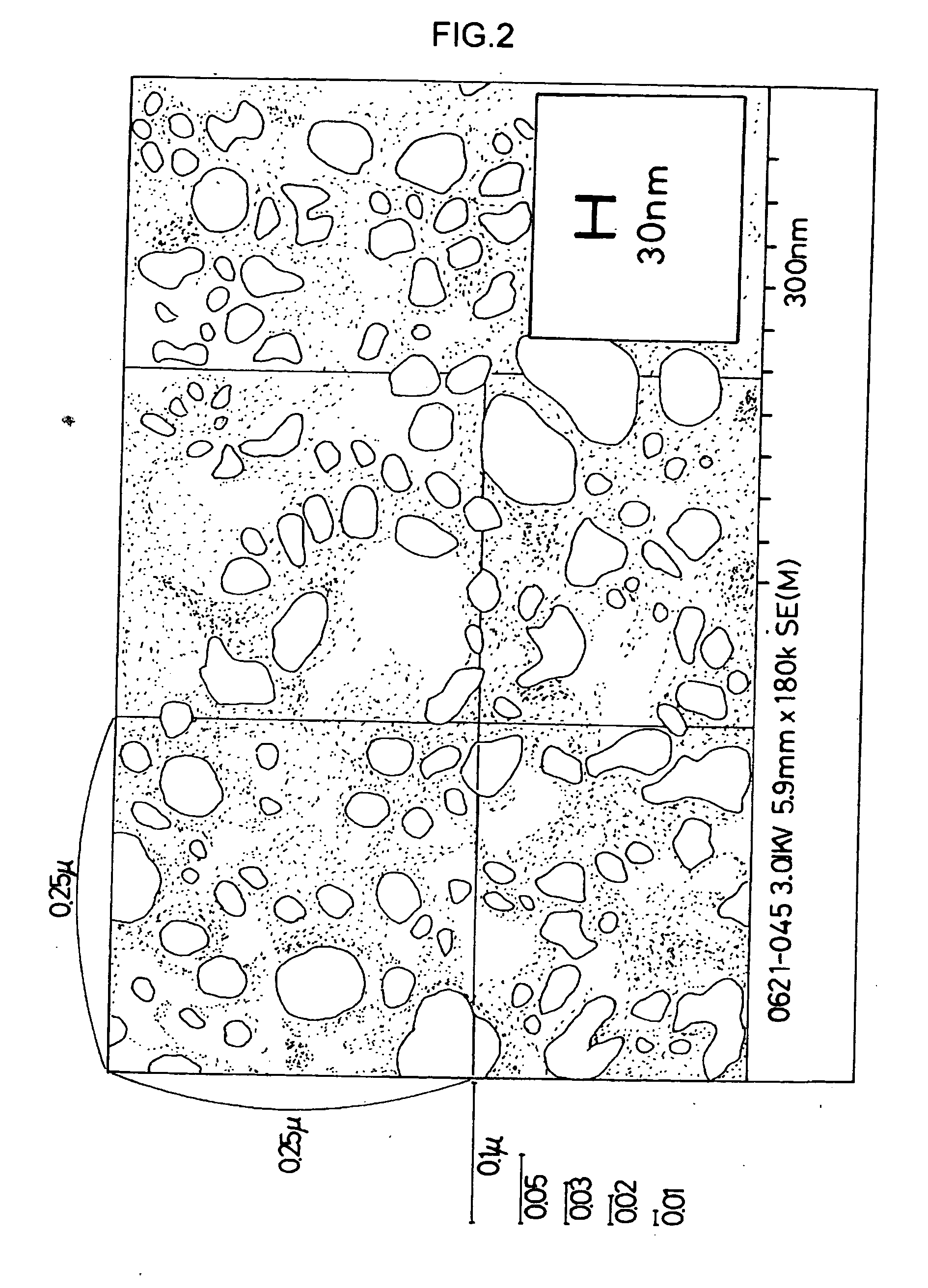

Composite of aluminium material and synthetic resin molding and process for producing the same

ActiveUS20060055084A1Stable and fast compositeHigh tensile strengthAnodisationNatural mineral layered productsO-Phosphoric AcidSynthetic resin

The present invention is to provide a process for producing a composite of an aluminum material and a synthetic resin molding that can be produced at a high efficiency and to provide a stable and fast composite that is large in a peel strength and a mechanical strength. The process for producing a composite according to the present invention is characterized in that an aluminum raw material is oxidized in an electrolytic bath of phosphoric acid or sodium hydride, thereby an anodic oxidation coating provided with innumerable pores 3 having a diameter of 25 nm or more made open in the surface thereof is formed thereon, and a synthetic resin mold 6 is coupled with the anodic oxidation coating 2 in such a condition that the part 6a thereof is intruded in the innumerable pores.

Owner:CHERRY CHIEF MAF CORP

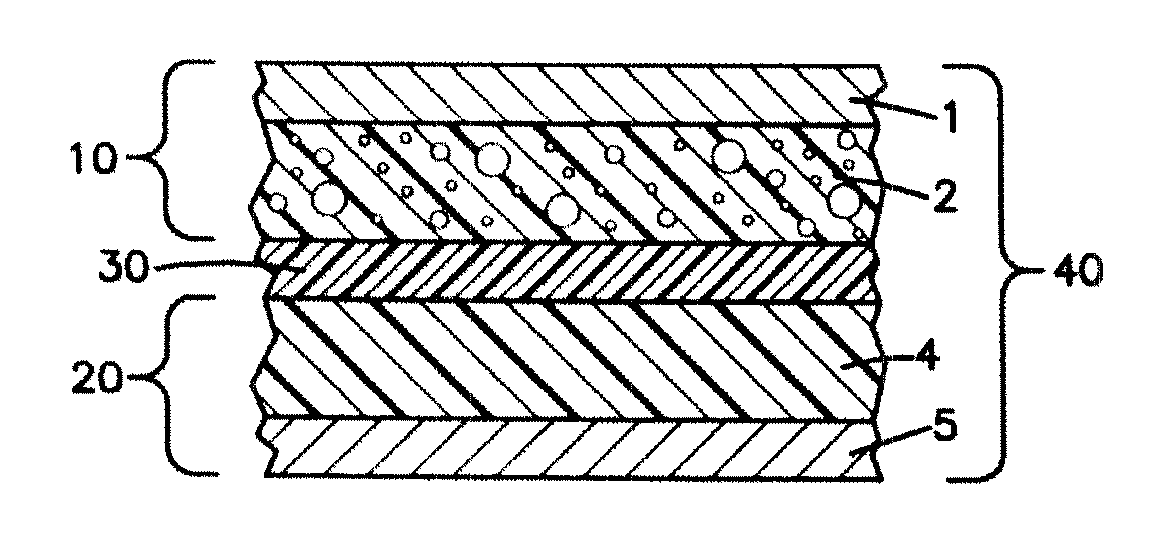

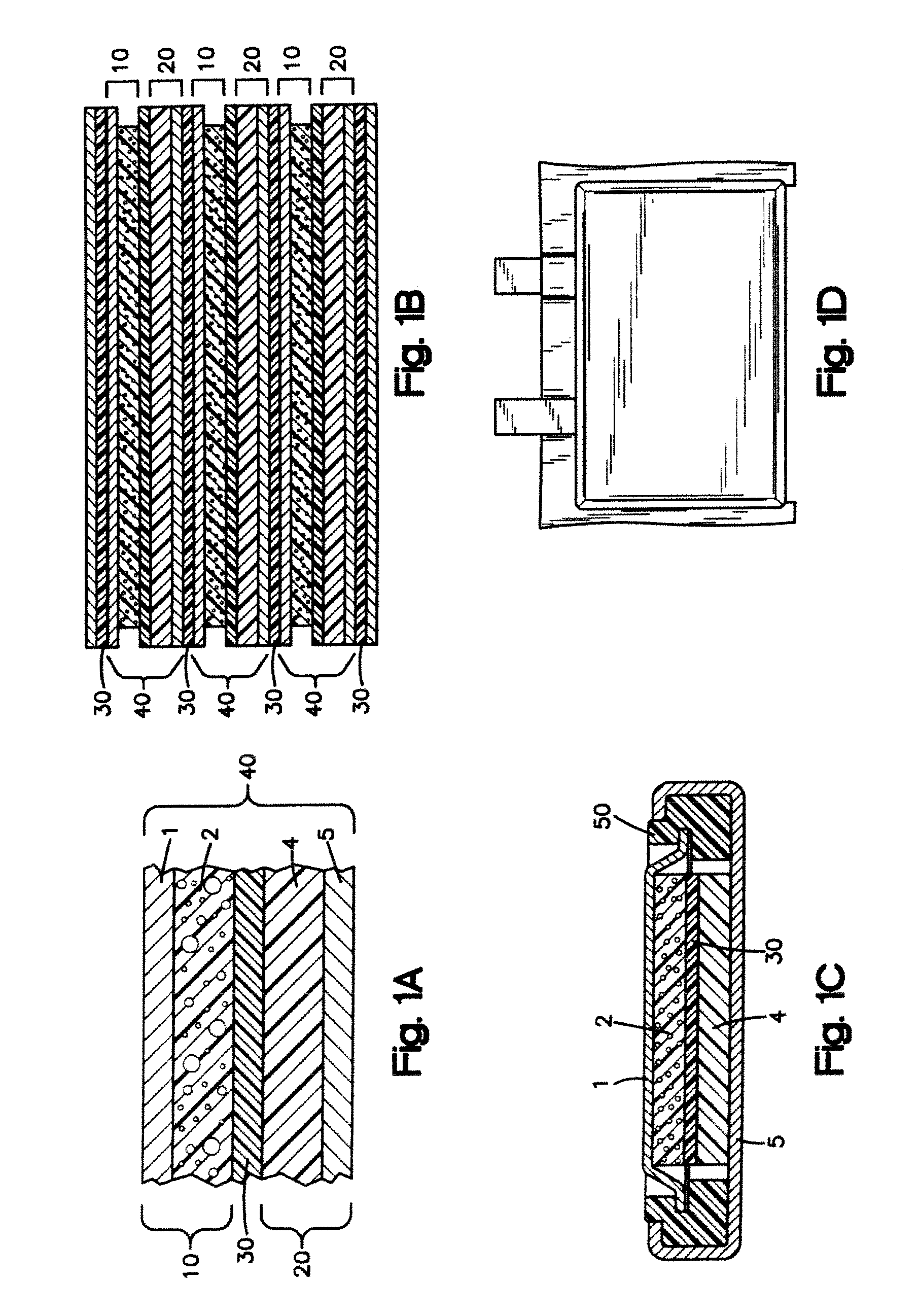

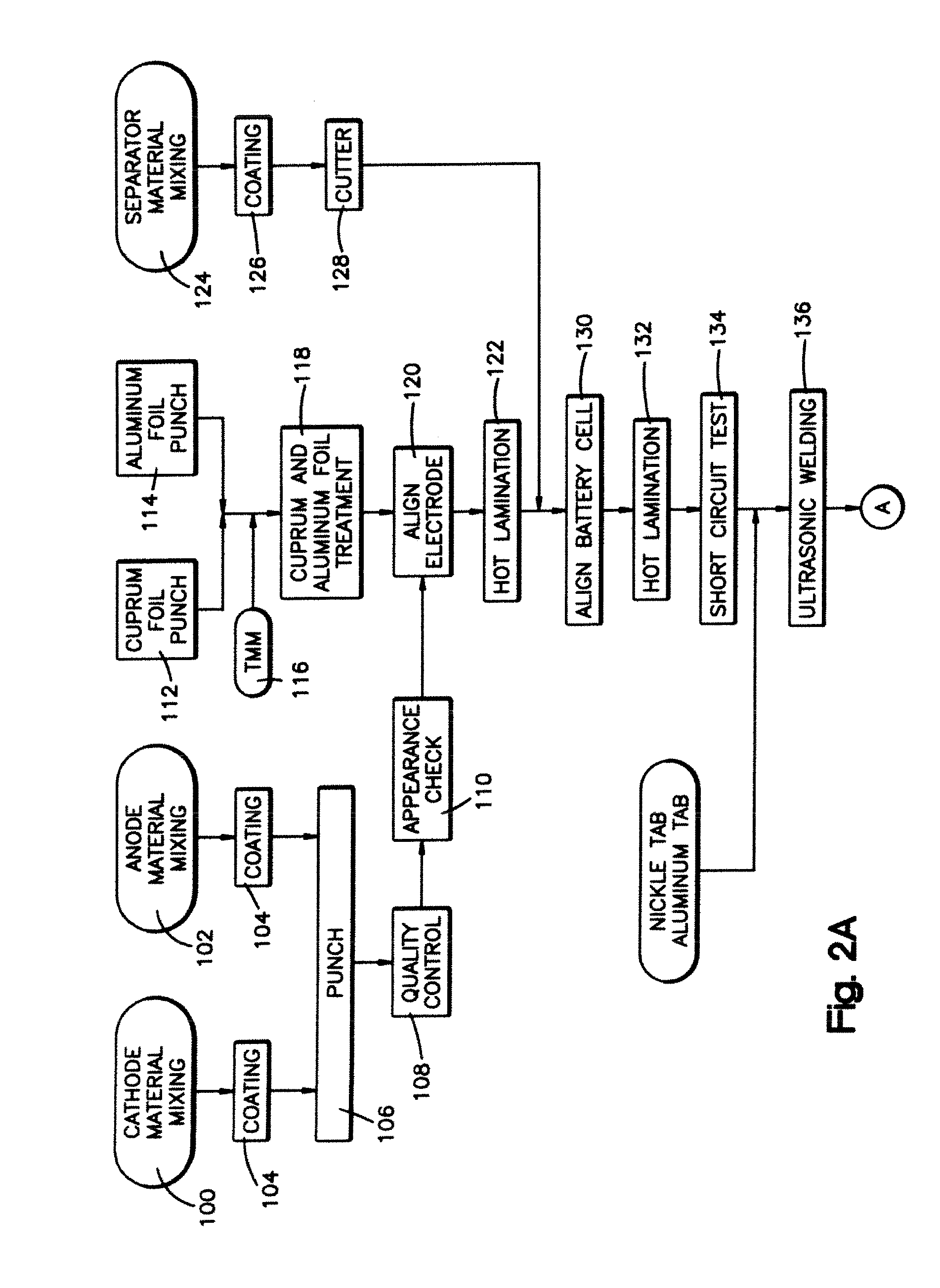

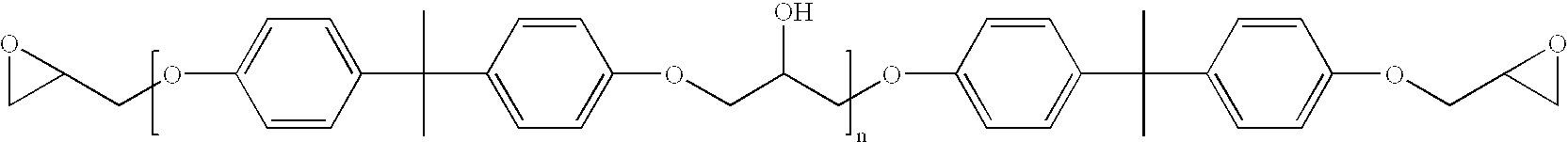

Nano-lithium-ion batteries and methos for manufacturing nano-lithium-ion batteries

The disclosure describes nano-lithium-ion batteries having a cathode, an anode including lithium titanium oxide nanoparticles, a separator including silicon dioxide nanoparticles and an electrolyte. In a preferred embodiment, the cathode is composed of 70-95 wt % lithium cobalt oxide, 1-6 wt % of a conductive carbon, and a synthetic resin including at least one thermoplastic; the anode is composed of 75-90 wt % lithium titanium oxide nanoparticles, 1-5 wt % of a conductive carbon, and a synthetic resin including at least one thermoplastic; and the separator is composed of silicon dioxide nanoparticles and a synthetic resin comprising at least one thermoplastic. The disclosure also describes methods of manufacturing the nano-lithium-ion batteries.

Owner:FU ZHIGUO +2

Composition and process for lubricated plastic working of metals

InactiveUS6455476B1Work treatment devicesMetallic material coating processesInorganic saltsPhosphate

A lubricant composition for the plastic working of metals that does not require a phosphate undercoating, is waterborne, requires only a simple application process of immersion or spraying followed by drying, and provides an excellent lubricating performance comprises synthetic resin, water-soluble inorganic salt, and water. The weight ratio of the content of salt to that of synthetic resin is from 0.25:1 to 9: 1. This composition can also contain liquid and / or solid lubricating agent(s) and an extreme pressure additive.

Owner:HENKEL KGAA

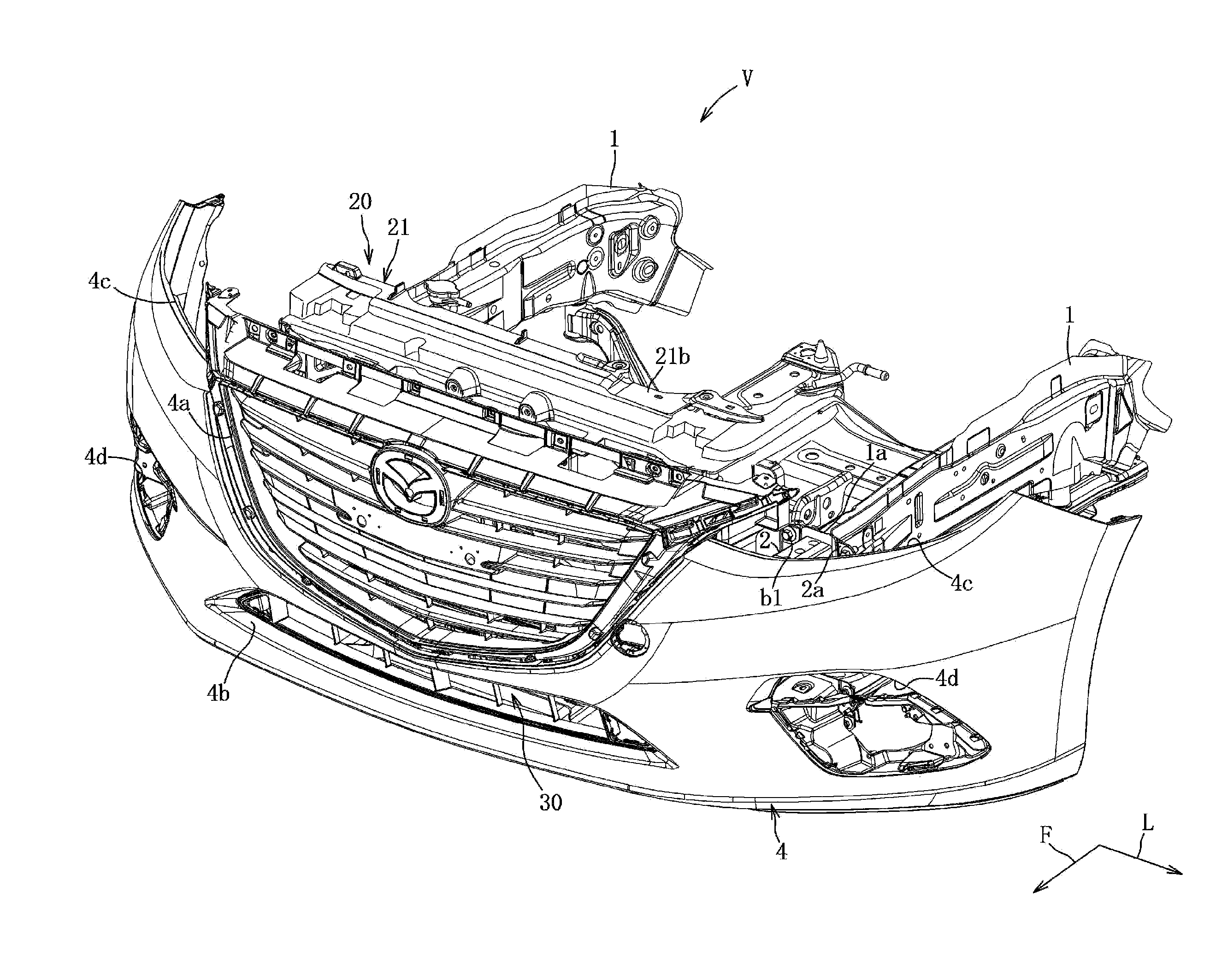

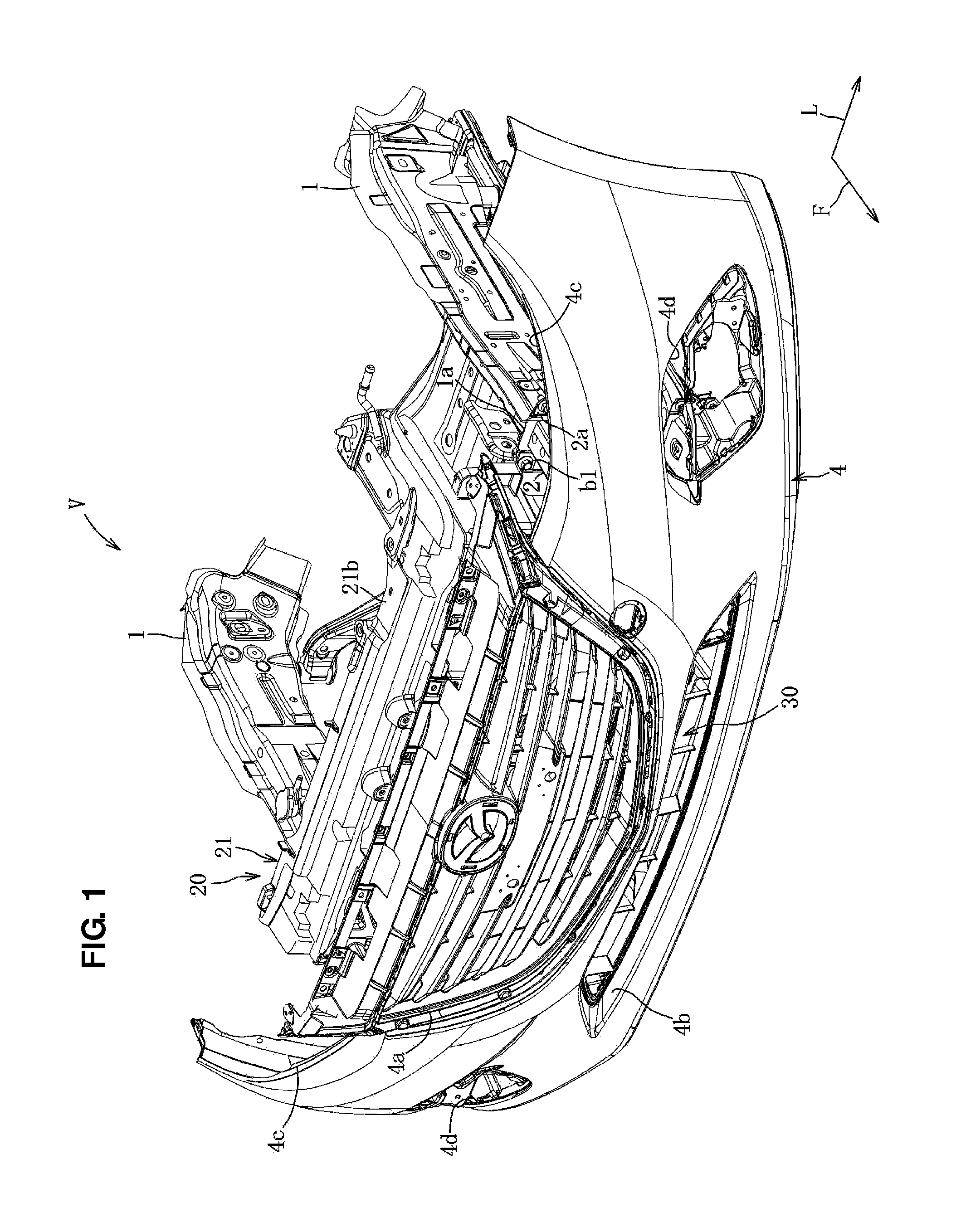

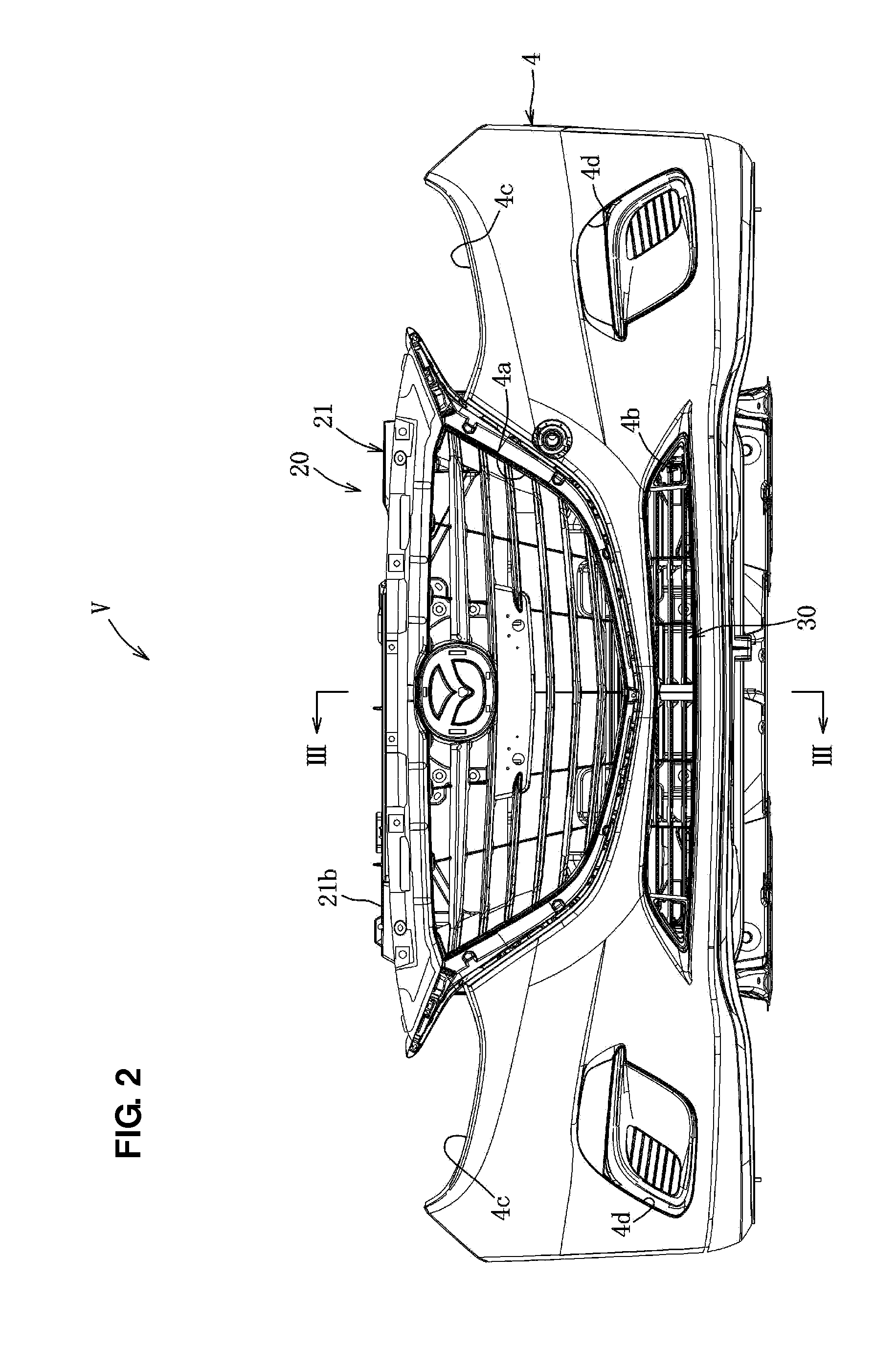

Grill shutter structure of vehicle

ActiveUS20140291056A1Ensuring fuel economyImprove fuel economyVehicle sub-unit featuresAutomatic initiationsWindow shutterEngineering

A grill shutter unit comprises a shutter unit provided in back of a traveling-air introductory port formed at a front end of a vehicle body and including shutter members, and a traveling-air guide member including a guide frame portion provided at an outer peripheral edge portion of the shutter unit and a seal portion provided to extend forward continuously from a front end of the guide frame portion and be made from soft synthetic resin having more flexibility than the frame portion, wherein the grill shutter unit is configured such that when the shutter members are closed, a seal portion of the traveling-air guide member is pressed against an outer peripheral wall face of the traveling-air introductory port by pressure of traveling air shut off by the shutter members closed.

Owner:MAZDA MOTOR CORP

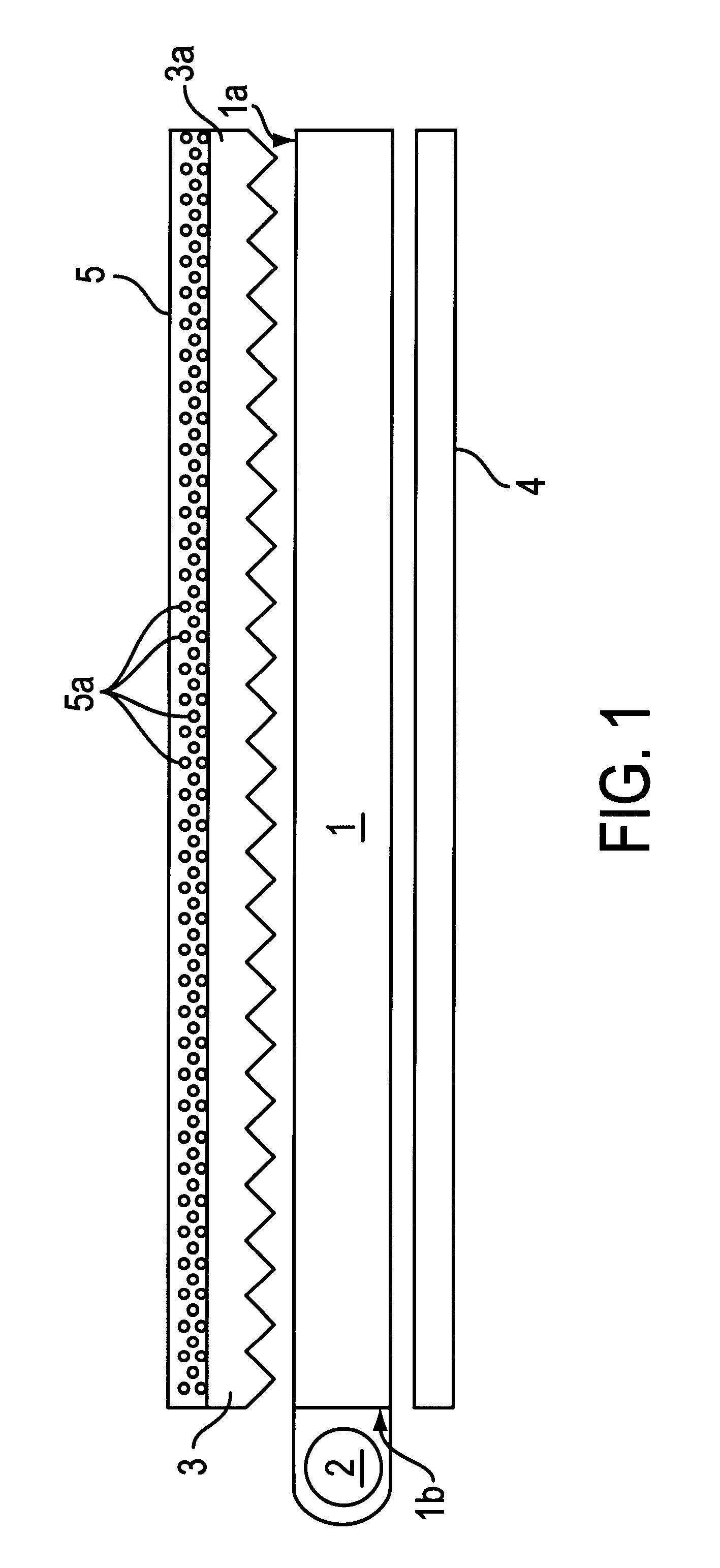

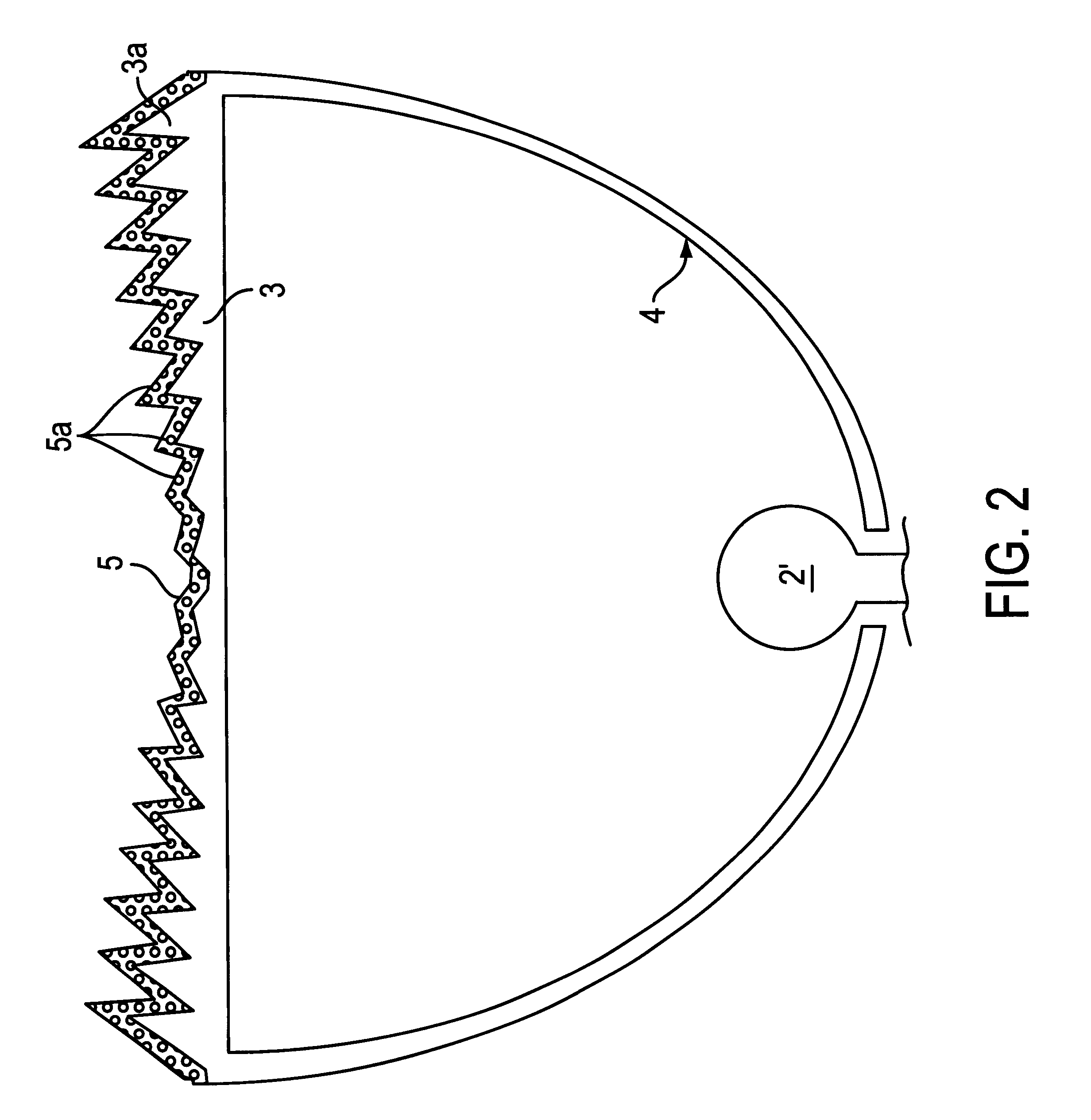

Prism diffuser for diffracting and spreading light

Owner:CHEIL IND INC

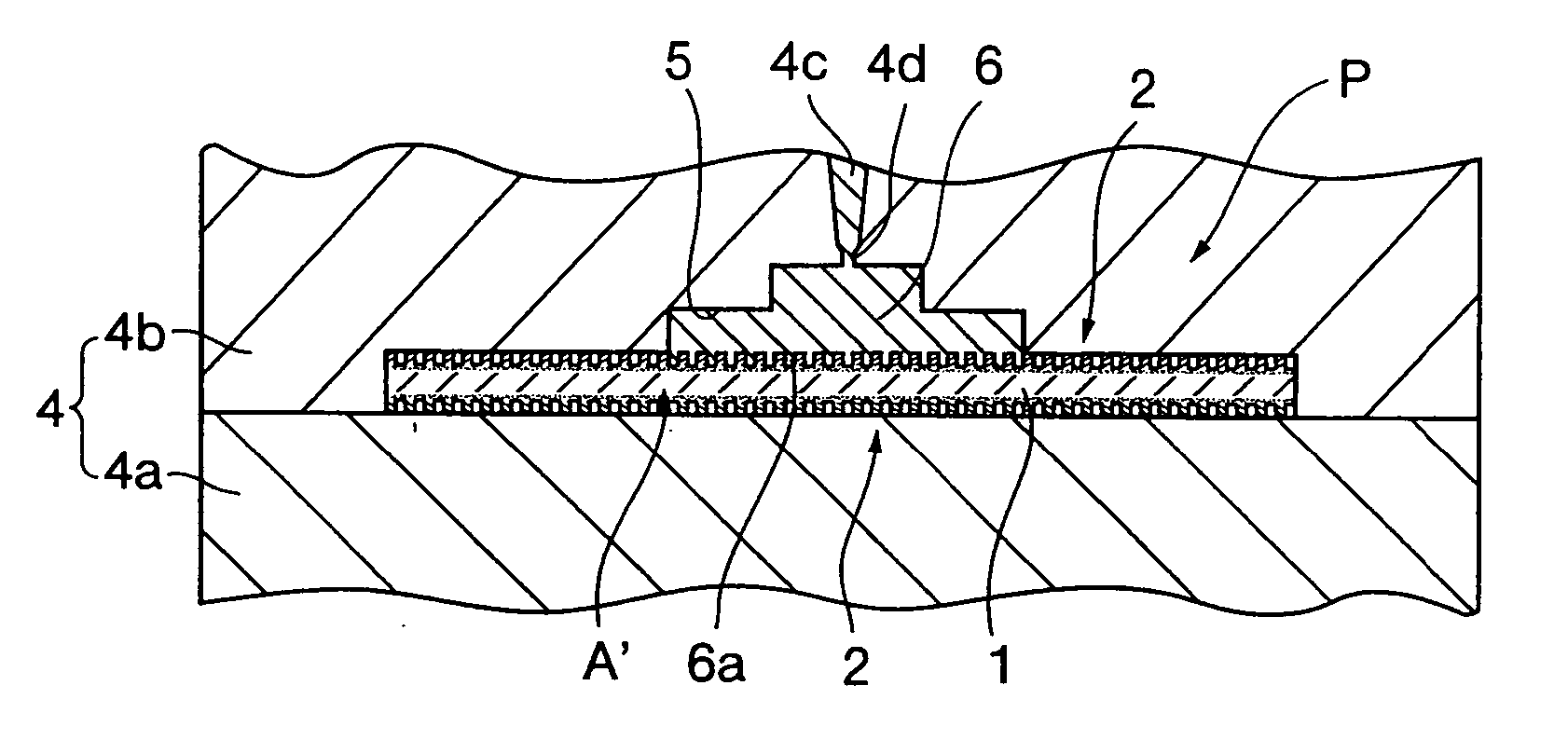

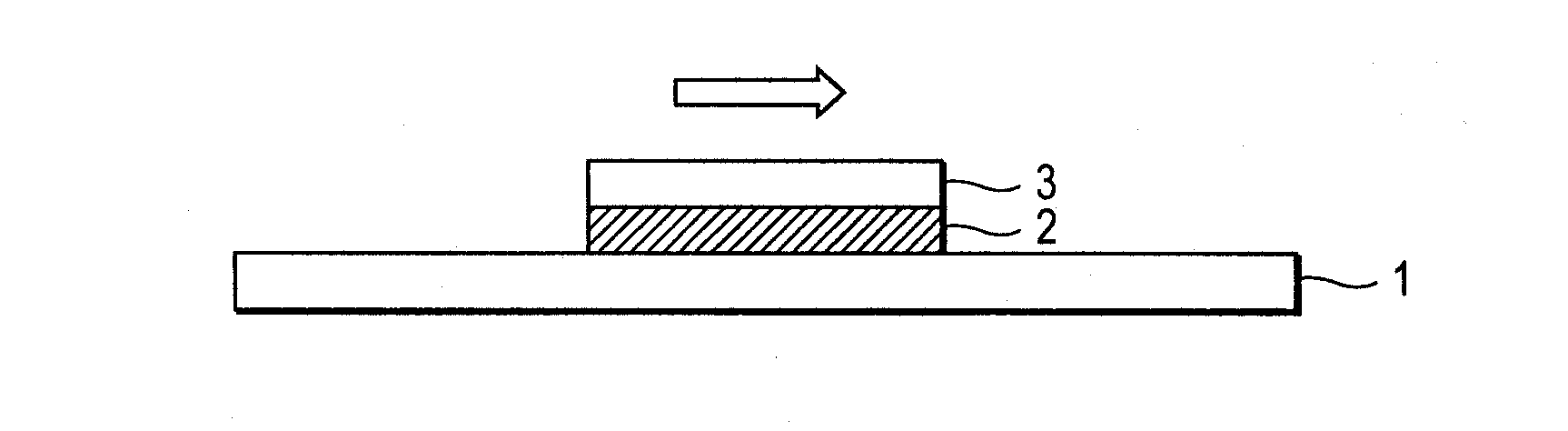

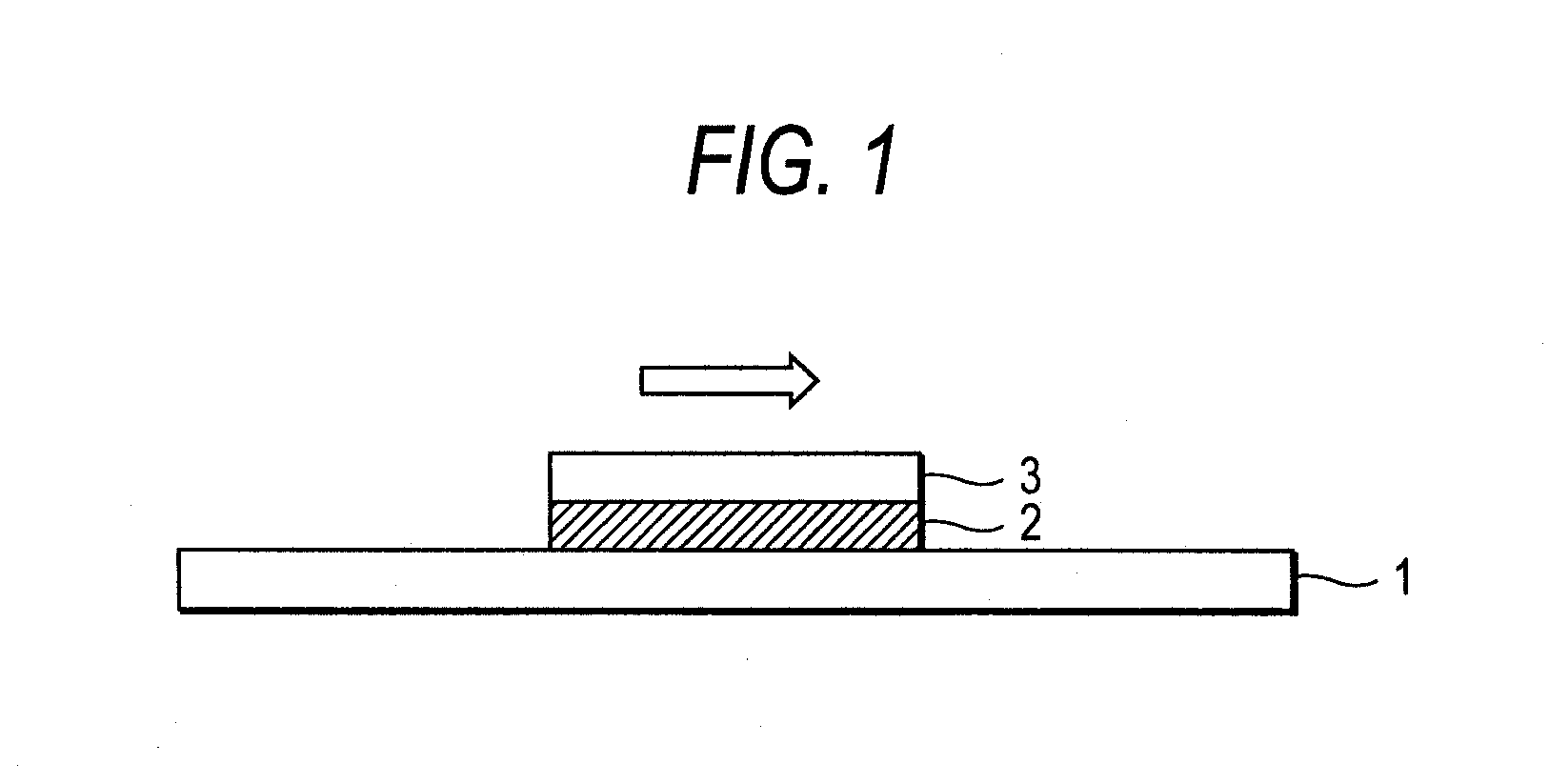

Electronic part and a method of production thereof

InactiveUS6154940APrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyHermetic sealInterconnection

The present invention relates to an electronic part used for mobile communications apparatuses and the like, and more particularly to an electronic part, such as an acoustic surface-wave device, a piezoelectric ceramic device or the like, which requires an oscillation space near the surface of the functional device chip thereof, and a method of production thereof. With this method, a space retainer for forming a sealed space at the functional portion of the chip can be hermetically sealed and have high moisture resistance, and the process of forming the space retainer can be carried out easily. The electronic part of the present invention comprises a functional device chip, a space retainer for forming a sealed space at the functional portion of the chip, a circuit substrate to which the chip is secured, electrode interconnection portions for establishing electric connection between the chip and the circuit substrate, and a sealing resin for covering and sealing at least the space retainer, wherein the space retainer comprises a support layer made of a synthetic resin film, provided with an opening enclosing the functional portion and joined onto the main surface, and a cover formed and joined onto the support layer so as to cover the functional portion and form a sealed space between the cover and the functional portion.

Owner:SKYWORKS PANASONIC FILTER SOLUTIONS JAPAN

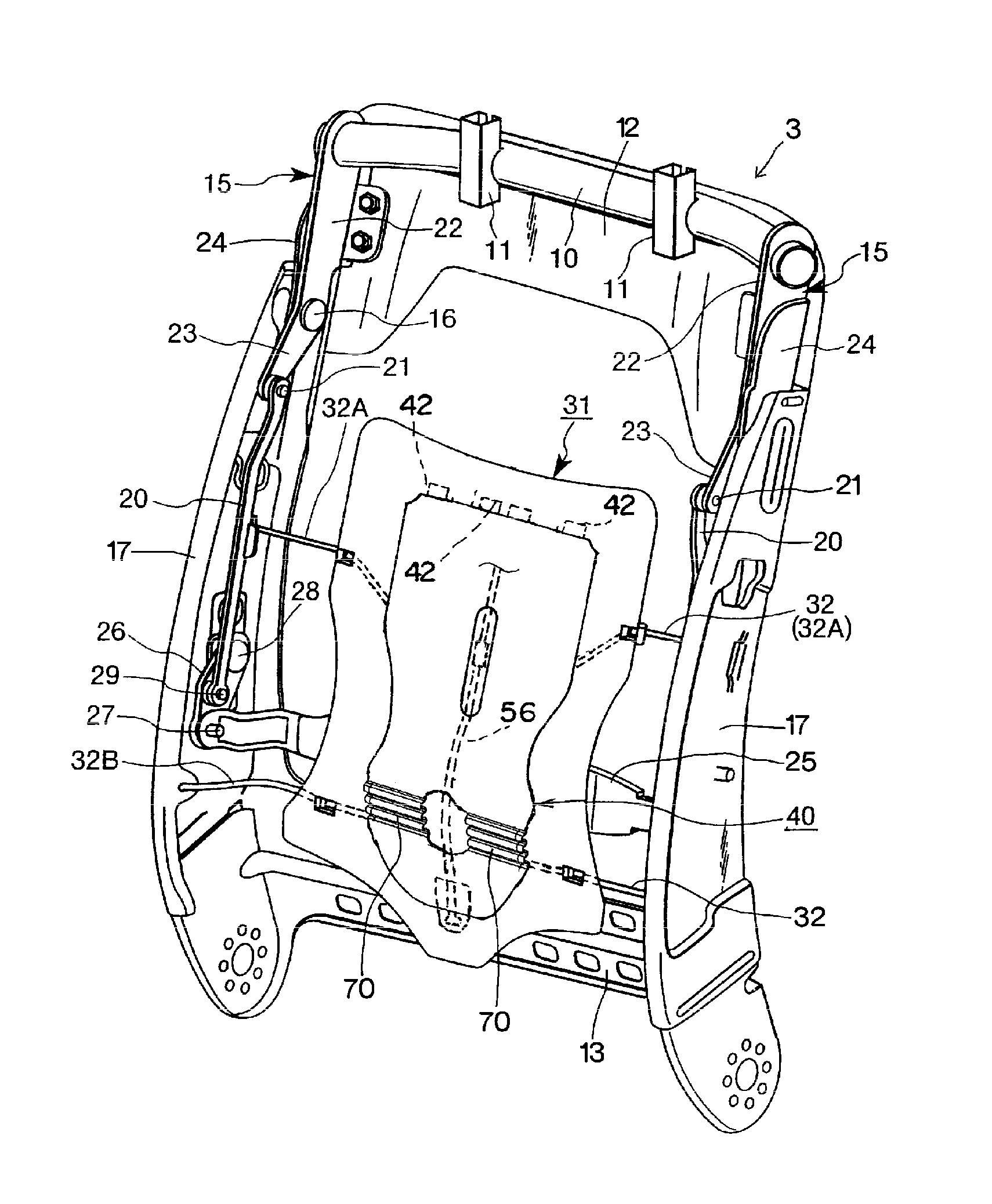

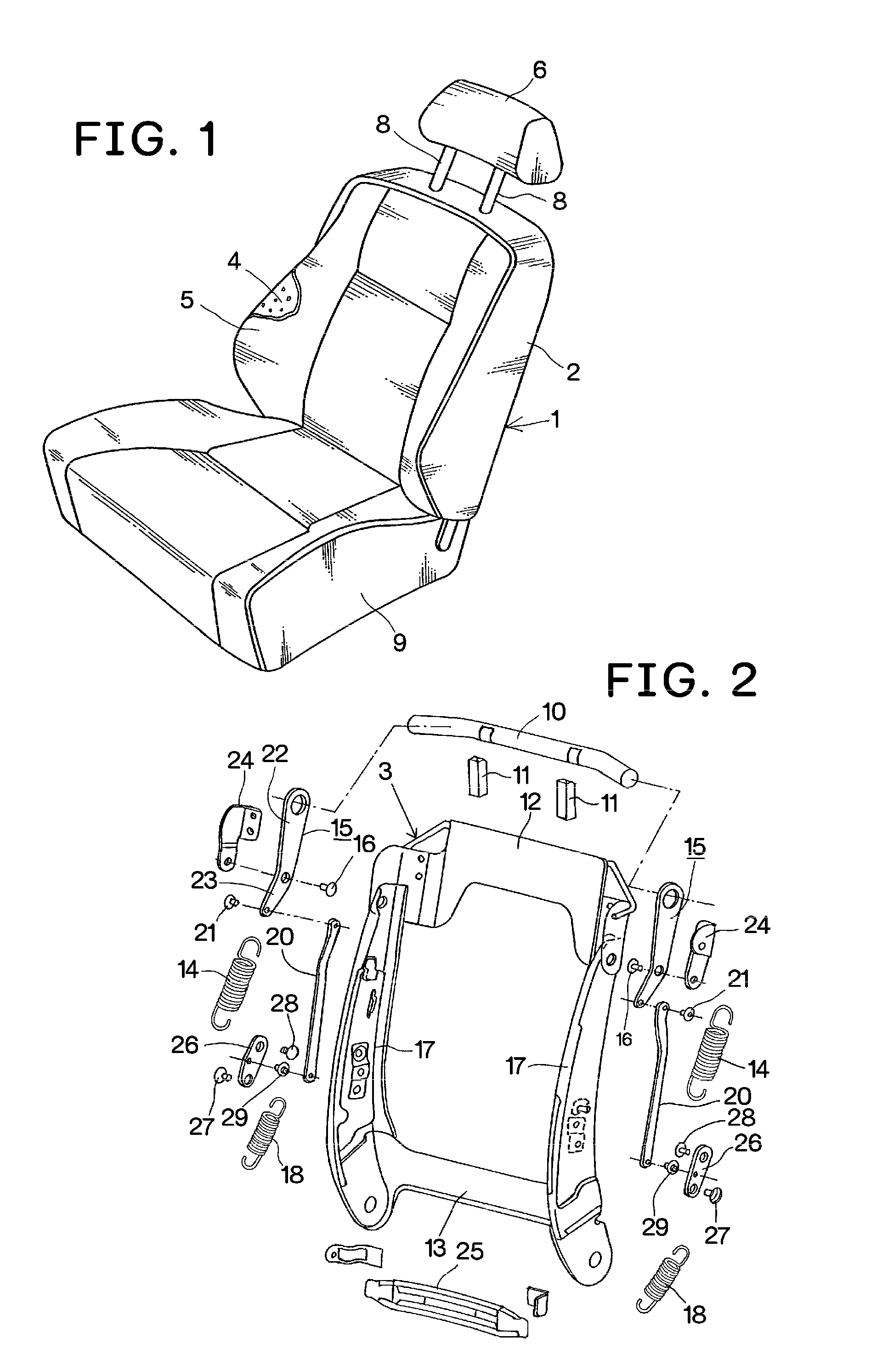

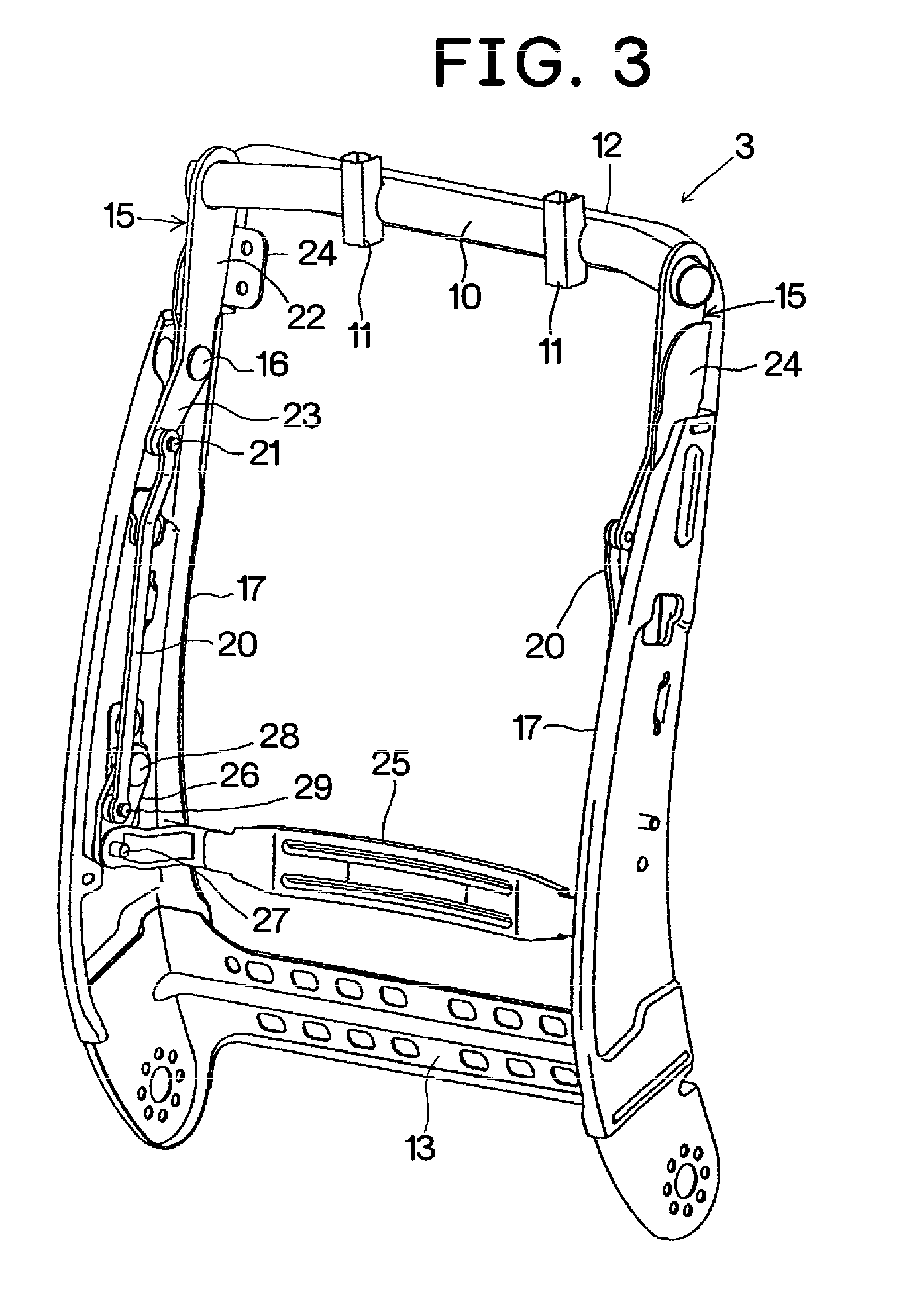

Vehicle seat

InactiveUS8226165B2Satisfactory supportReduce the cushioning forceBack restsStoolsEngineeringSynthetic resin

A vehicle seat comprises a synthetic resin cushion plate (31) attached to a back frame (3) by way of seat springs (32) so as to be movable forward or backward, a single elastic auxiliary plate (40) attached to the cushion plate (31) so as to be movable forward or backward relative to the cushion plate (31), a specific section of the auxiliary plate (40) formed as a push-out section (70) protruding forward when a distance between an upper edge and a lower edge of the auxiliary plate (40) is shortened by moving the lower edge upward. Elasticity of the auxiliary plate (40) supporting the body of the seated passenger is adjusted by moving the auxiliary plate (40) near the push-out section (70) forward or backward. The push-out section (70) has a corrugated part (71) formed from a sideways projection that projects forward or / and backward as viewed from a side.

Owner:TS TECH CO LTD

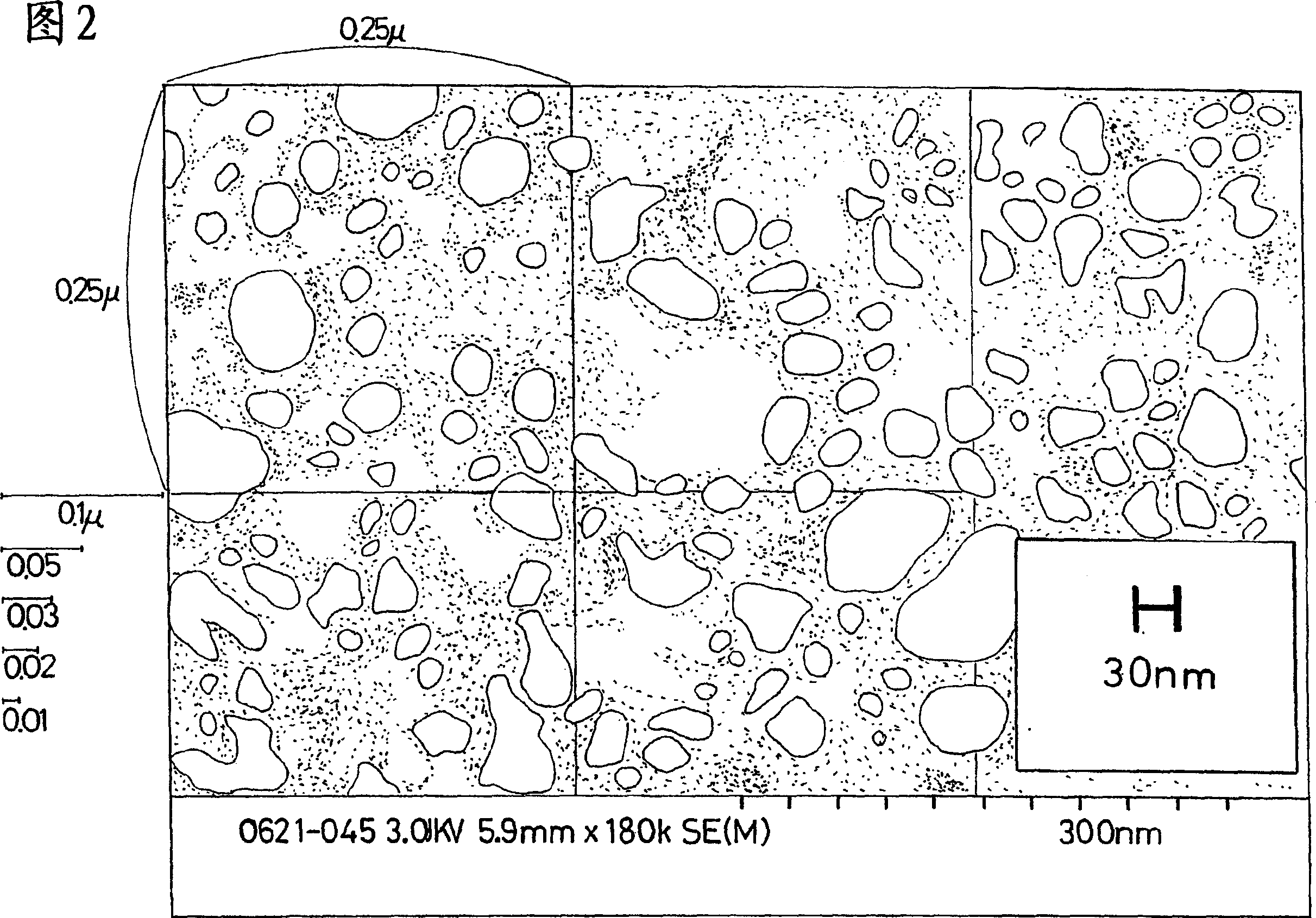

Composite of aluminum alloy and resin composition and process for producing the same

InactiveCN1717323ASynthetic resin layered productsThin material handlingPolytetramethylene terephthalateSurface roughness

The invention relates to a complex, which is characterized in that the complex consists of an aluminium alloy shape and a thermoplastic resin combination; the roughness of surface of the complex is more than 5 to 50 Mu m; the surface is provided with the aluminium alloy shape with minute recessed parts or raised parts, the diameter of which is less than 1 Mu m; the aluminium alloy shape is fixed through the recessed parts or raised parts; with the longitudinal and transverse average coefficientof linear expansion ranging from 2X<-5> DEG C<-1> to 4X<-5> DEG C<-1>, the thermoplastic resin combination is primarily made of polybutylene terephthalate resin or polyphenyl thioether; as the thermoplastic resin combination is not peeled off easily from the aluminium alloy shape, the invention has the advantages of metal enclosers and synthetic resin structures in electronic machines and electric appliances. The production efficiency is high, and the complex can be produced on large scale with shape and structure to be designed freely.

Owner:TAISEI PLAS CO LTD

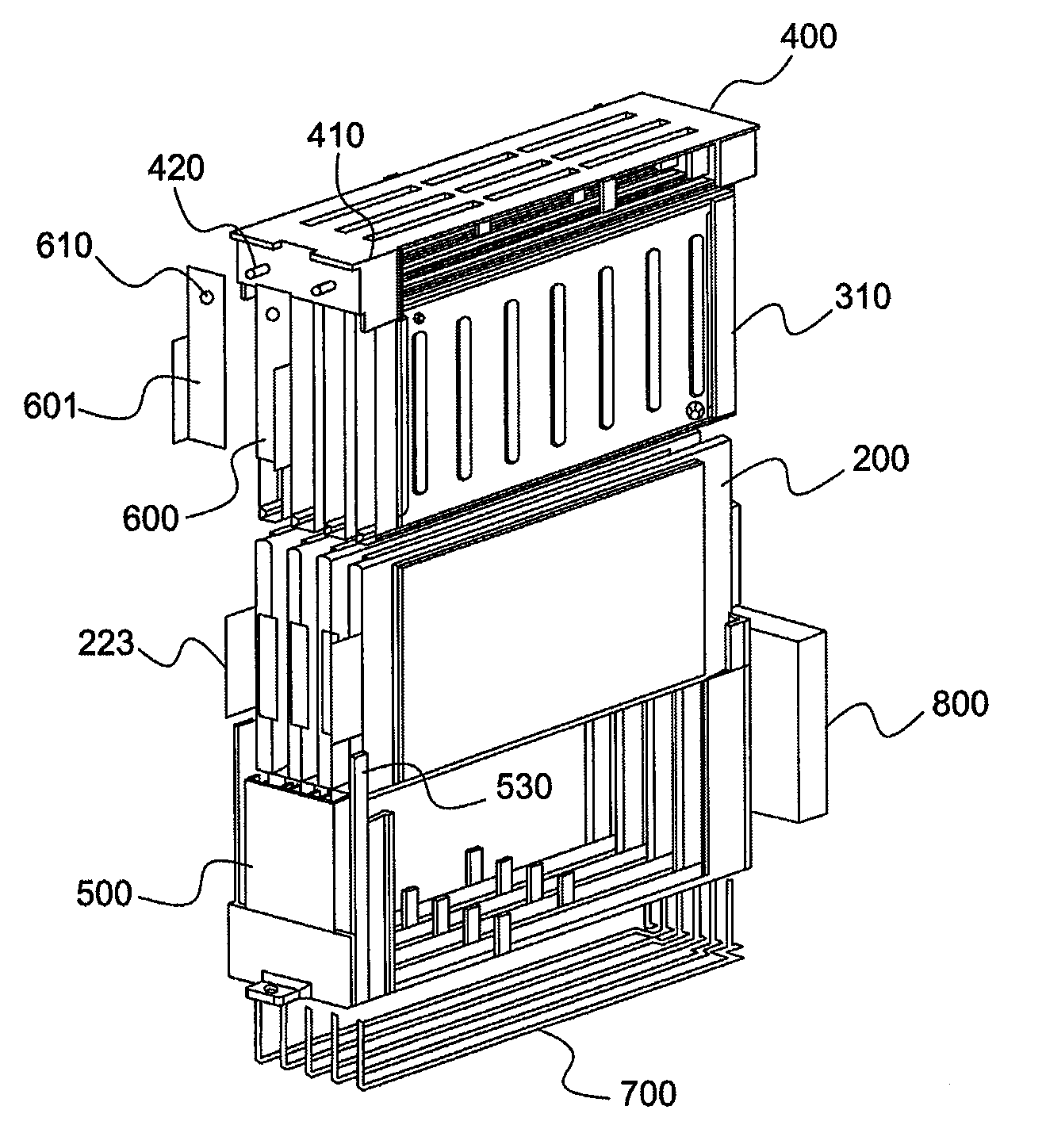

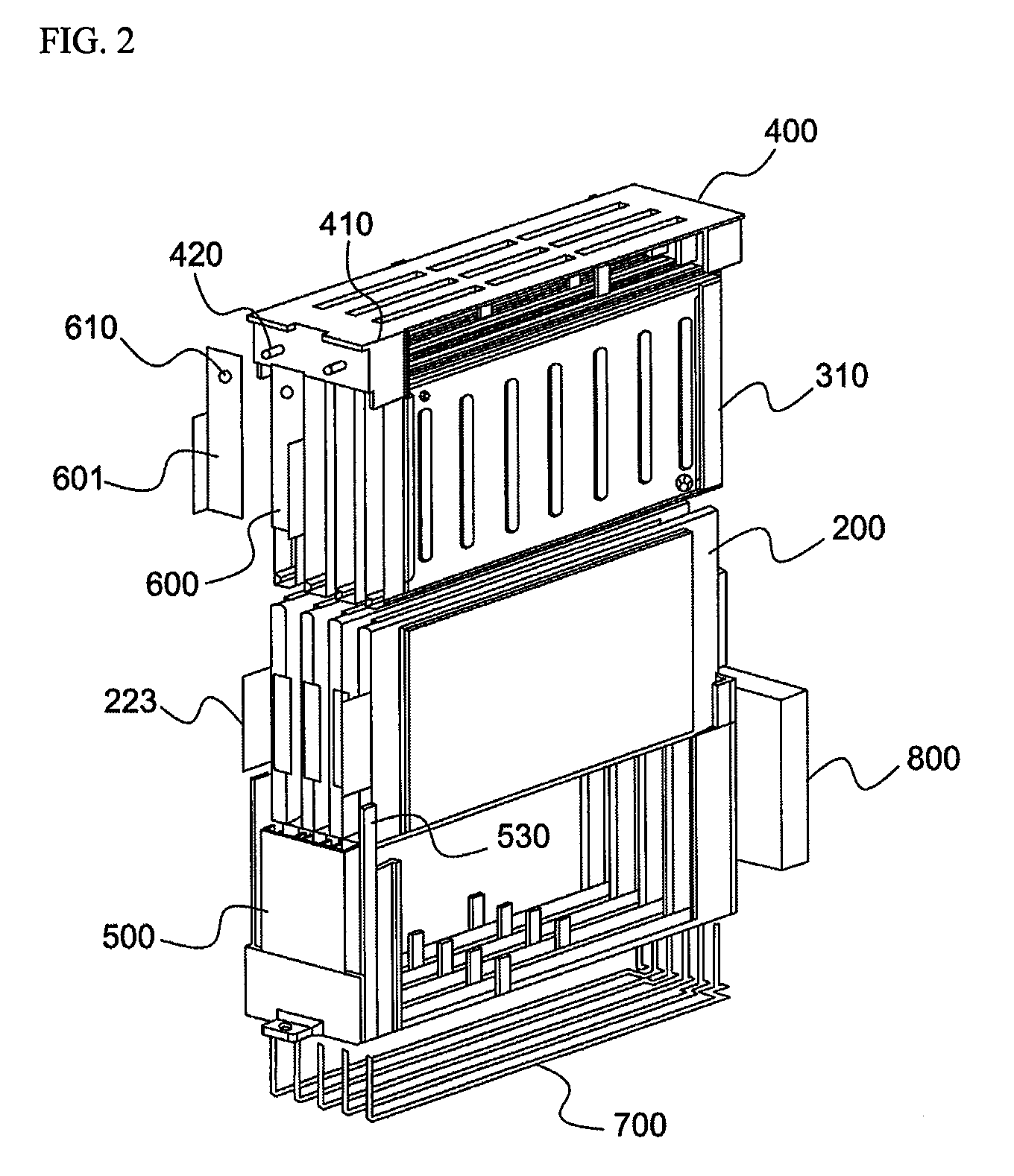

Middle or large-sized battery module

ActiveUS20100021802A1Stably accomplishedReduce in quantityPrimary cell to battery groupingSecondary cellsElectricityCoupling

Disclosed herein is a middle- or large-sized battery module including two or more unit modules each having one or more plate-shaped battery cells, as unit cells, surrounded by a high-strength sheathing member made of synthetic resin or metal, and separable upper and lower frame members coupled with each other in an assembly-type coupling structure such that the unit modules are vertically mounted in the upper and lower frame members. The present invention has the effect of easily mounting a sensing unit that is capable of minimizing the weight and size of battery cells while effectively reinforcing the low mechanical strength of the battery cells and sensing the operation state of the battery cells to a middle- or large-sized battery module. In addition, the present invention has the effect of manufacturing the battery module by a simple assembly process without using a plurality of members for mechanical coupling and electrical connection, thereby decreasing the manufacturing costs of the battery module, and effectively preventing the battery module from being short-circuited or damaged during the manufacture or the operation of the battery module. Furthermore, the present invention has the effect of manufacturing a middle- or large-sized battery system having desired output and capacity using the battery module as a unit body.

Owner:LG ENERGY SOLUTION LTD

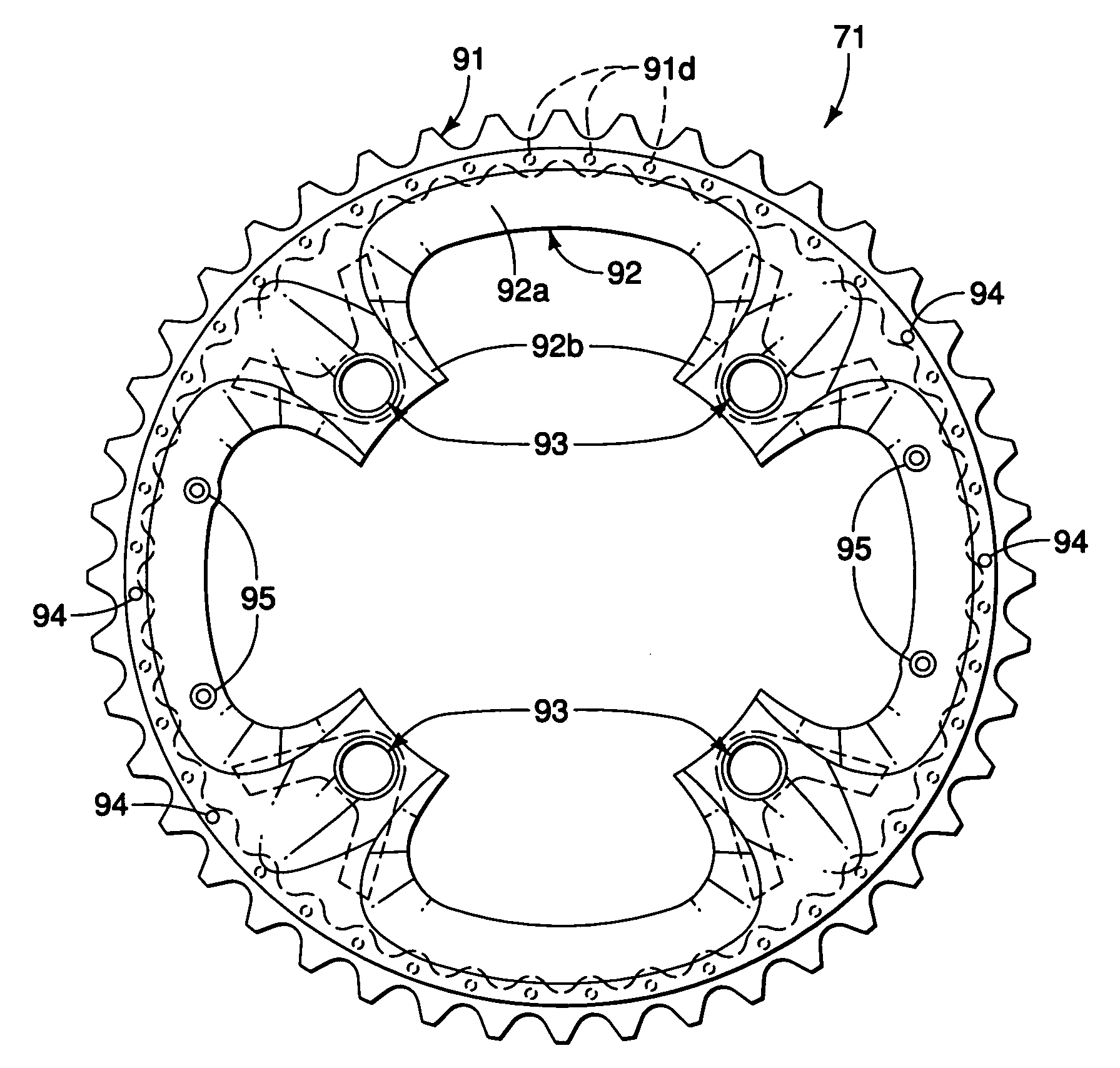

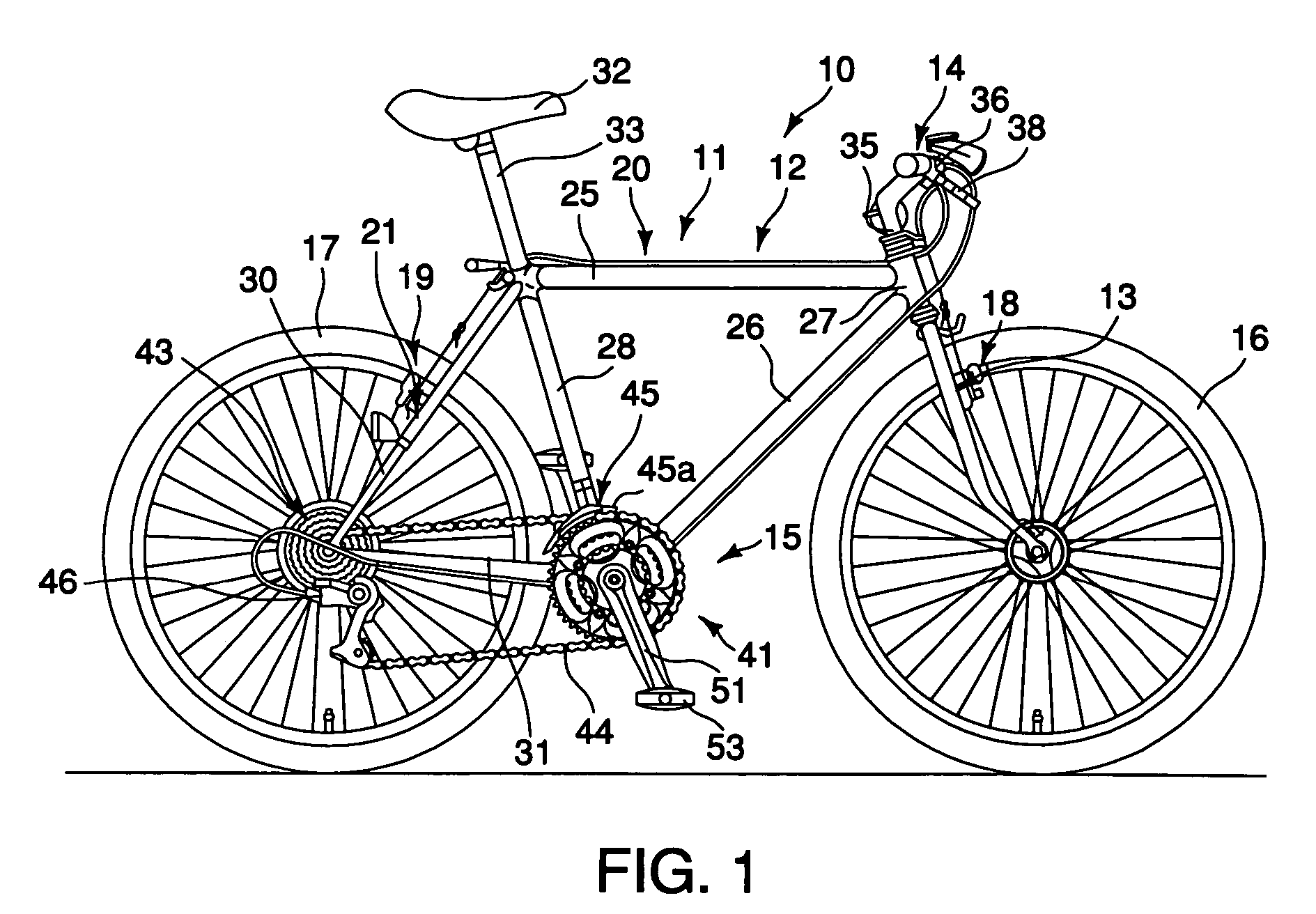

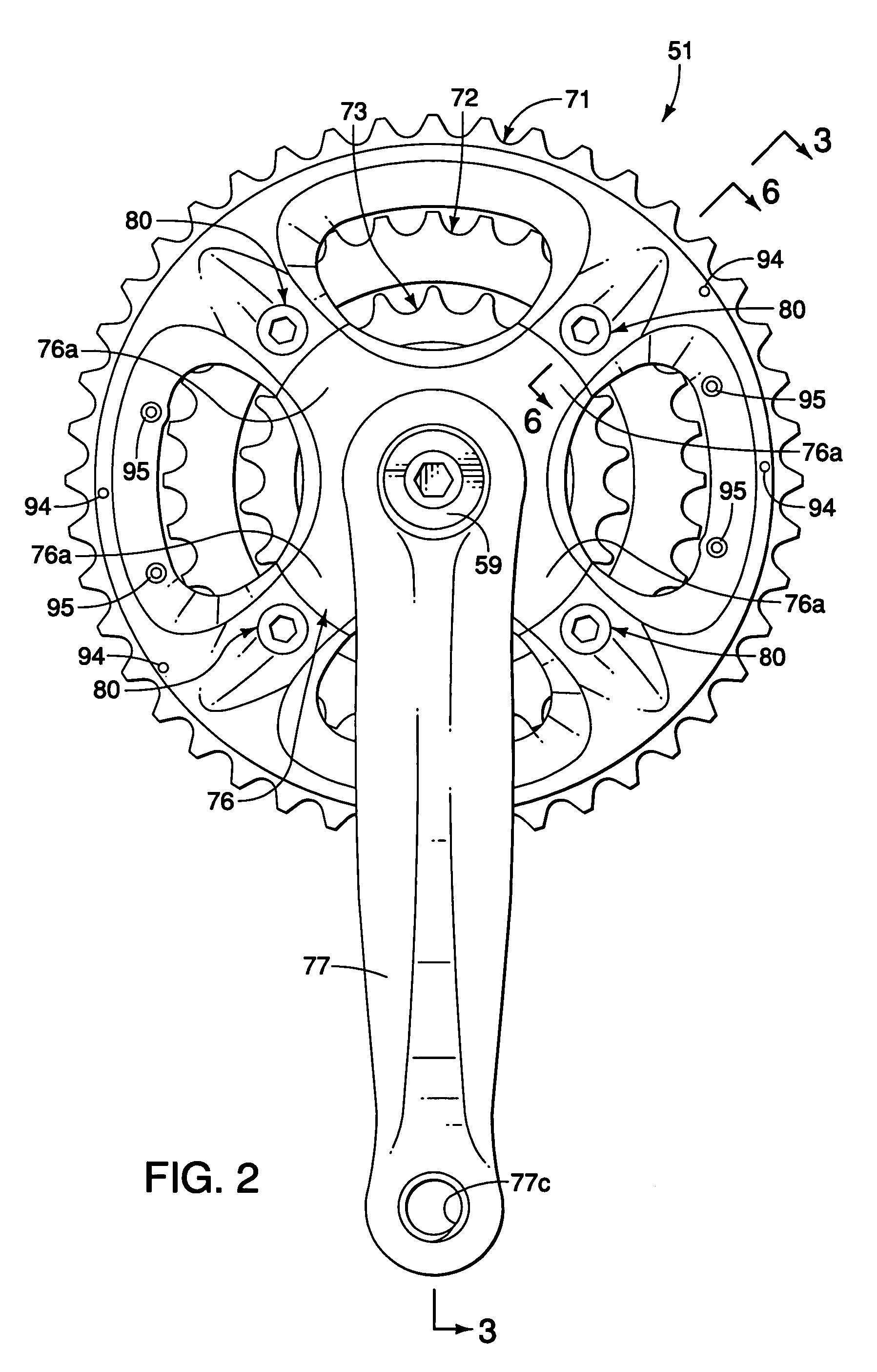

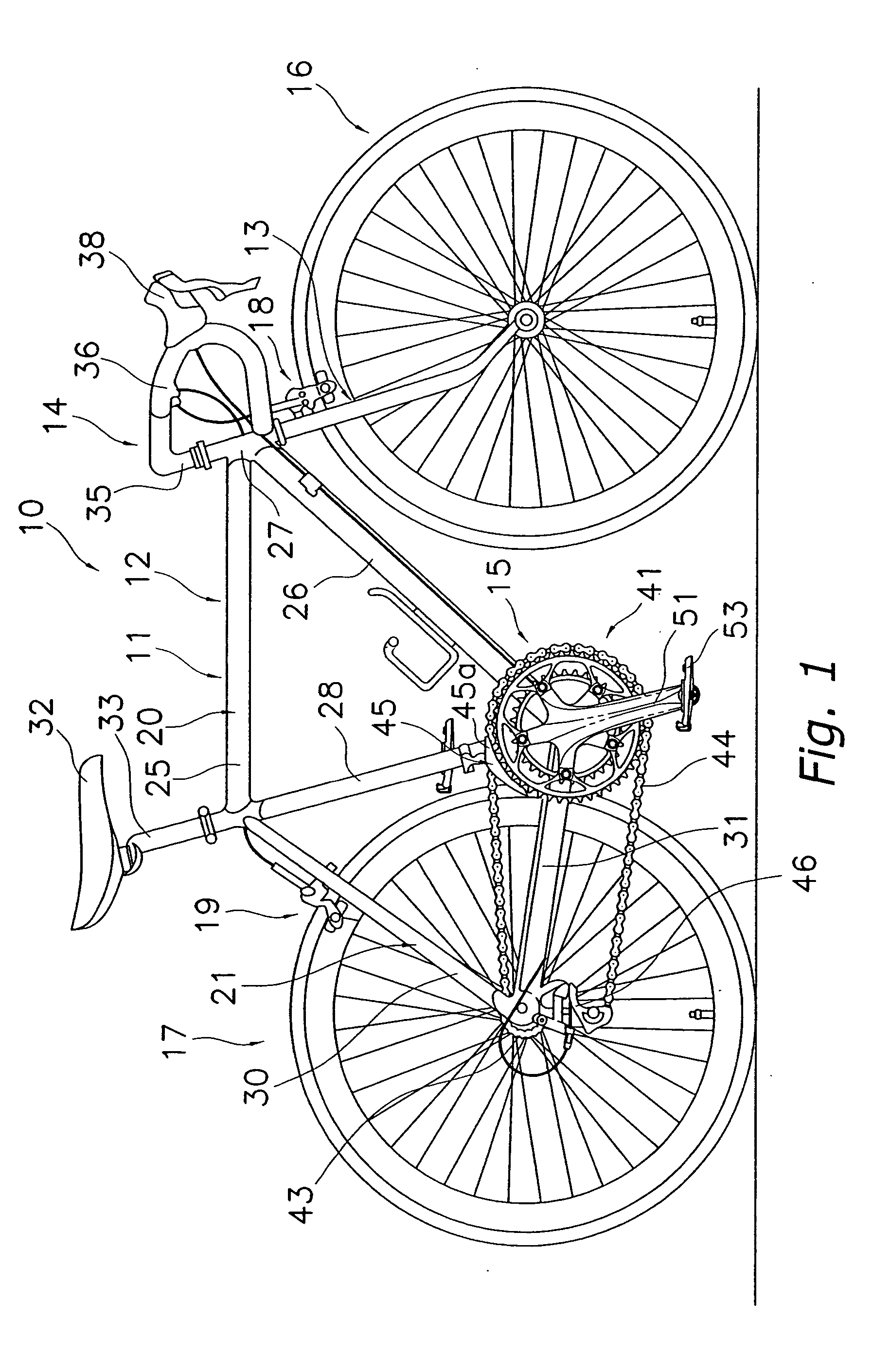

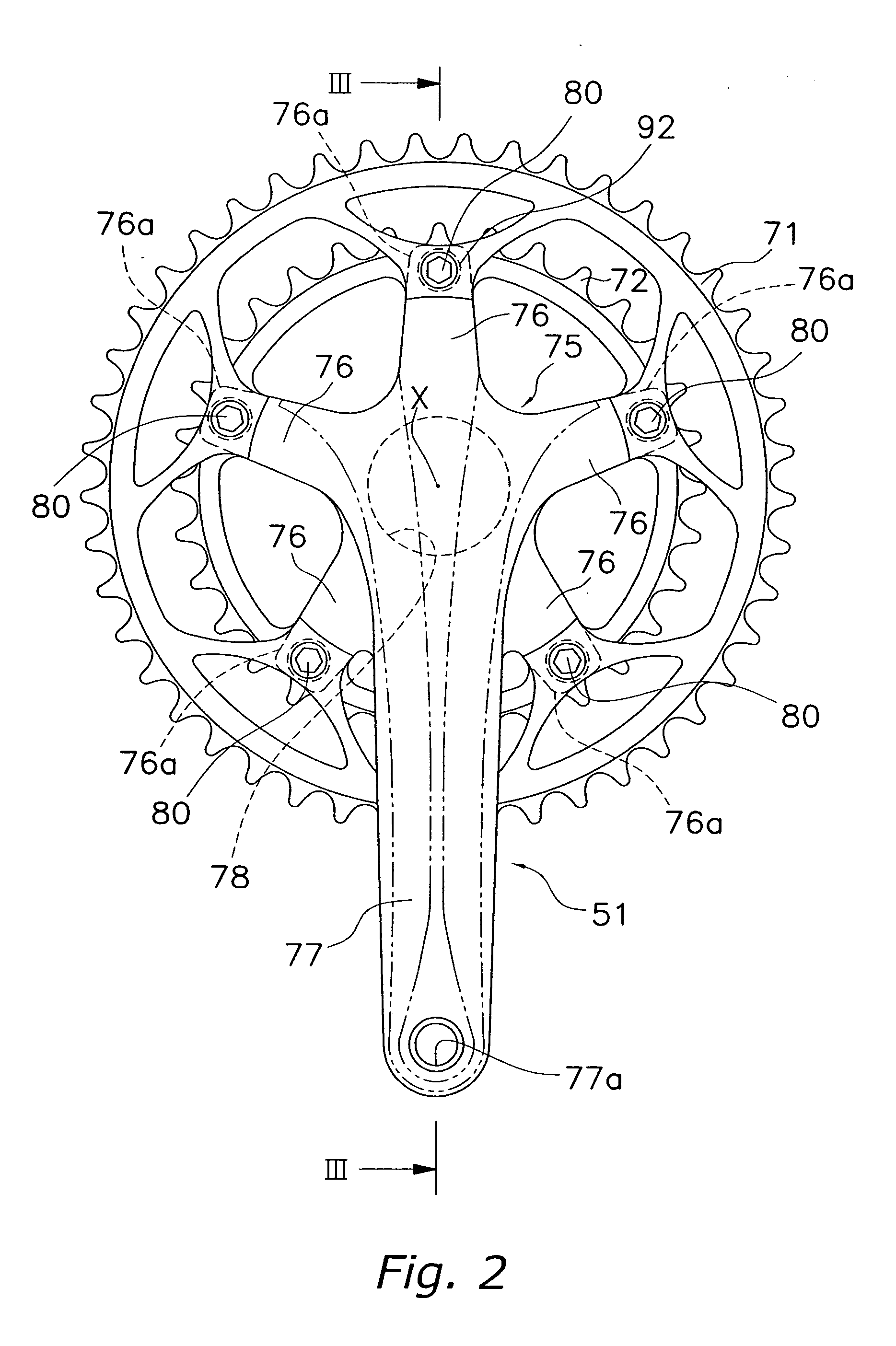

Bicycle sprocket

InactiveUS7824287B2Stay rigidPrevents looseness and playChain/belt transmissionPortable liftingEngineeringSprocket

Owner:SHIMANO INC

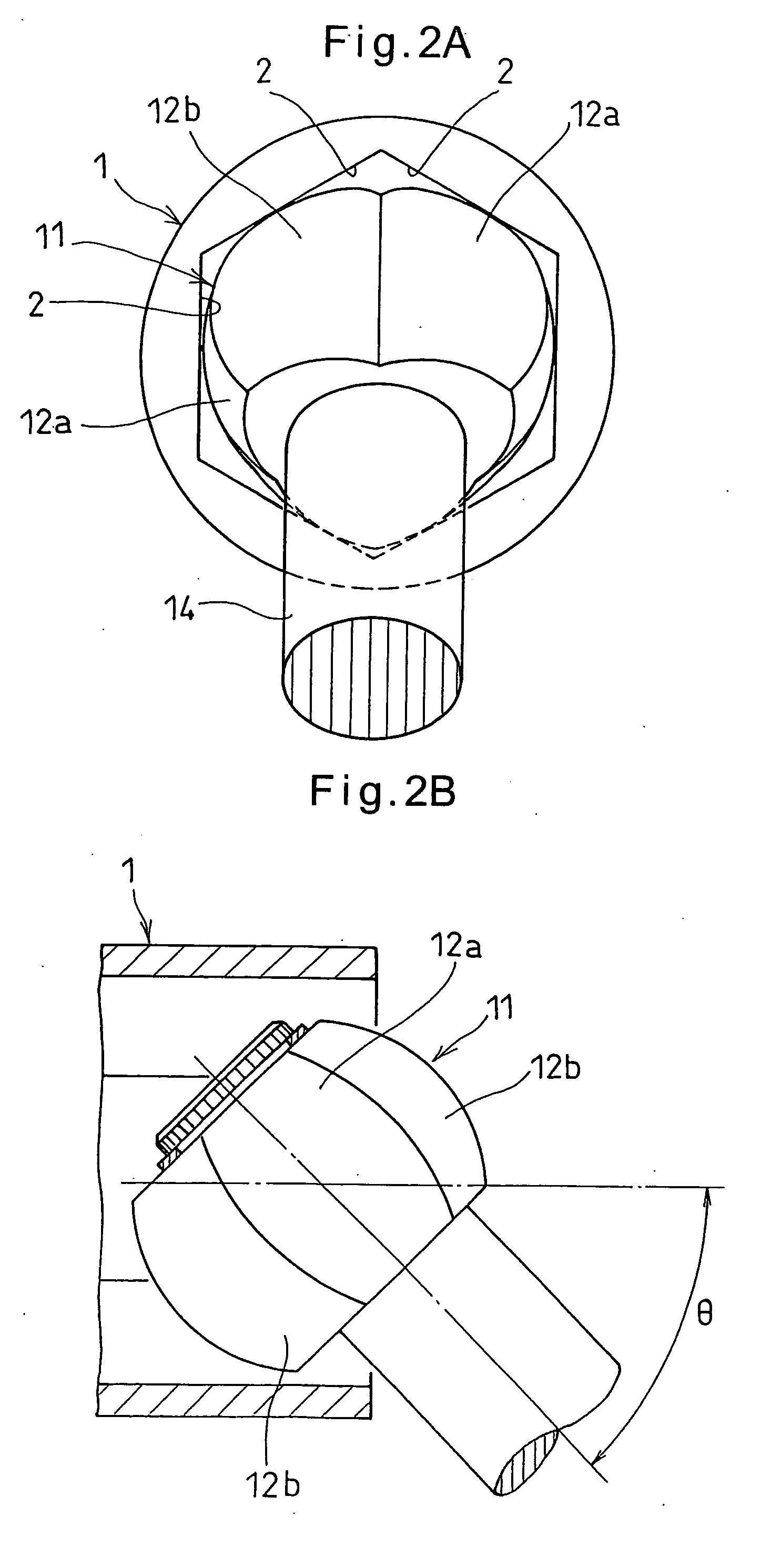

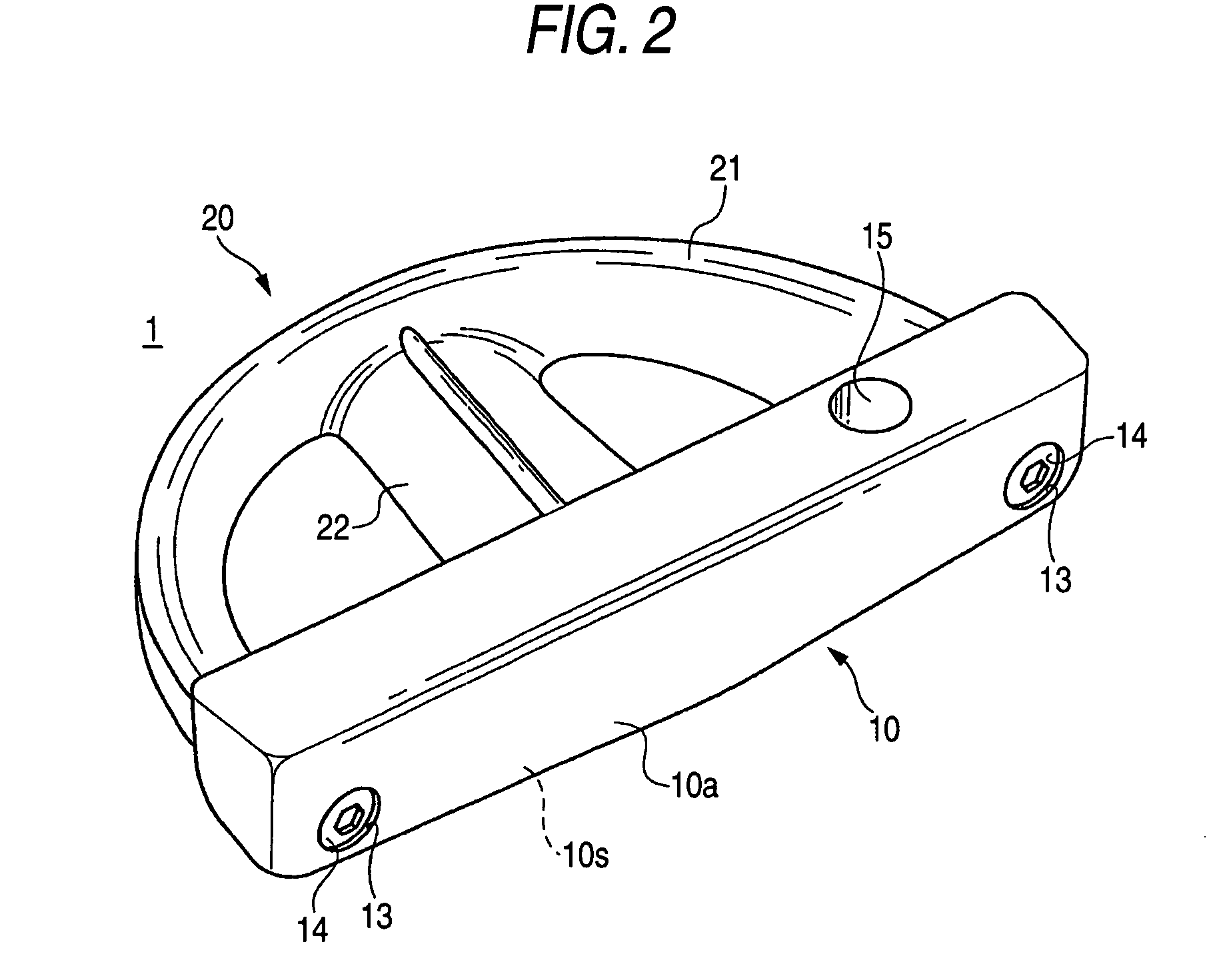

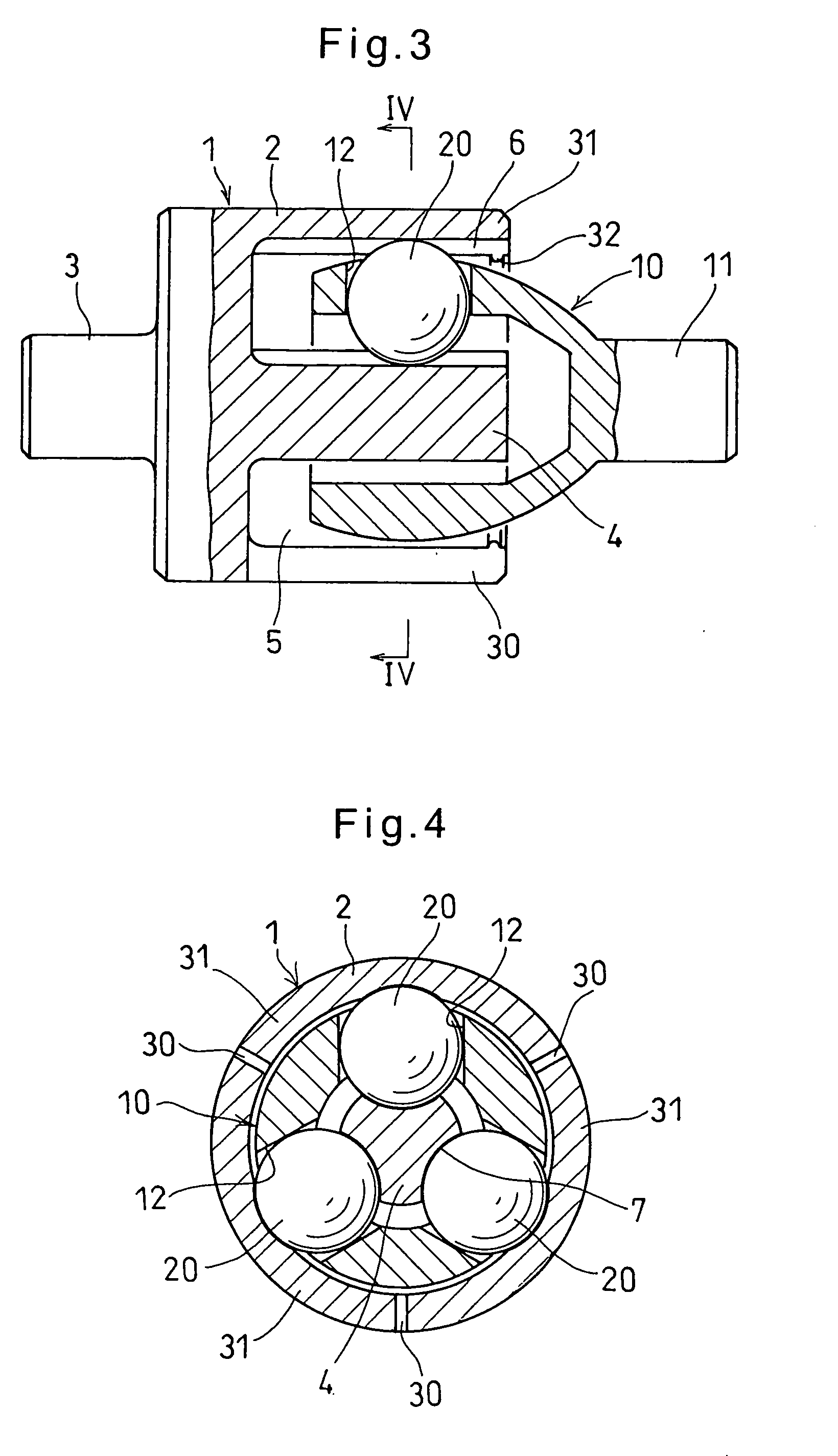

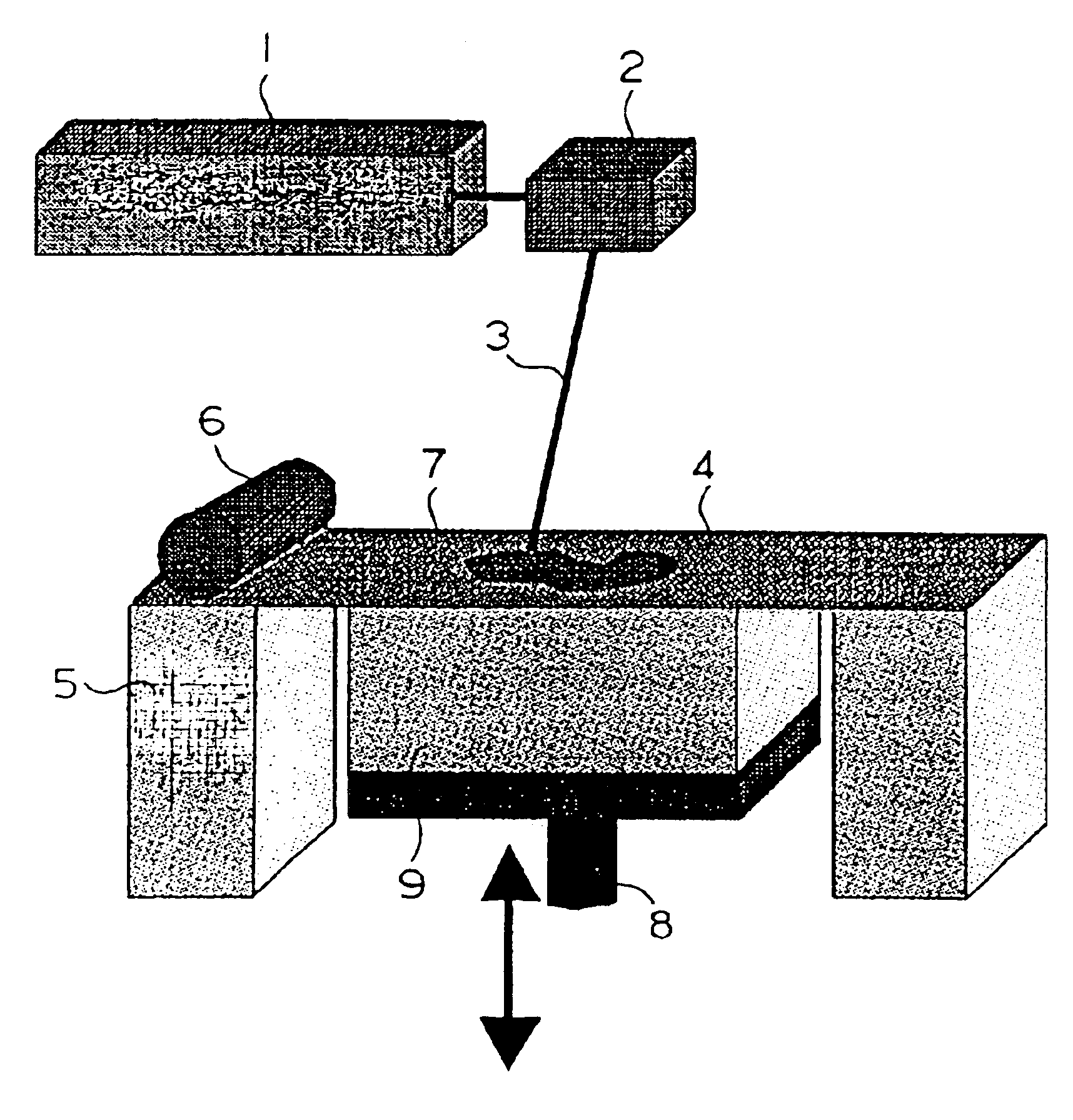

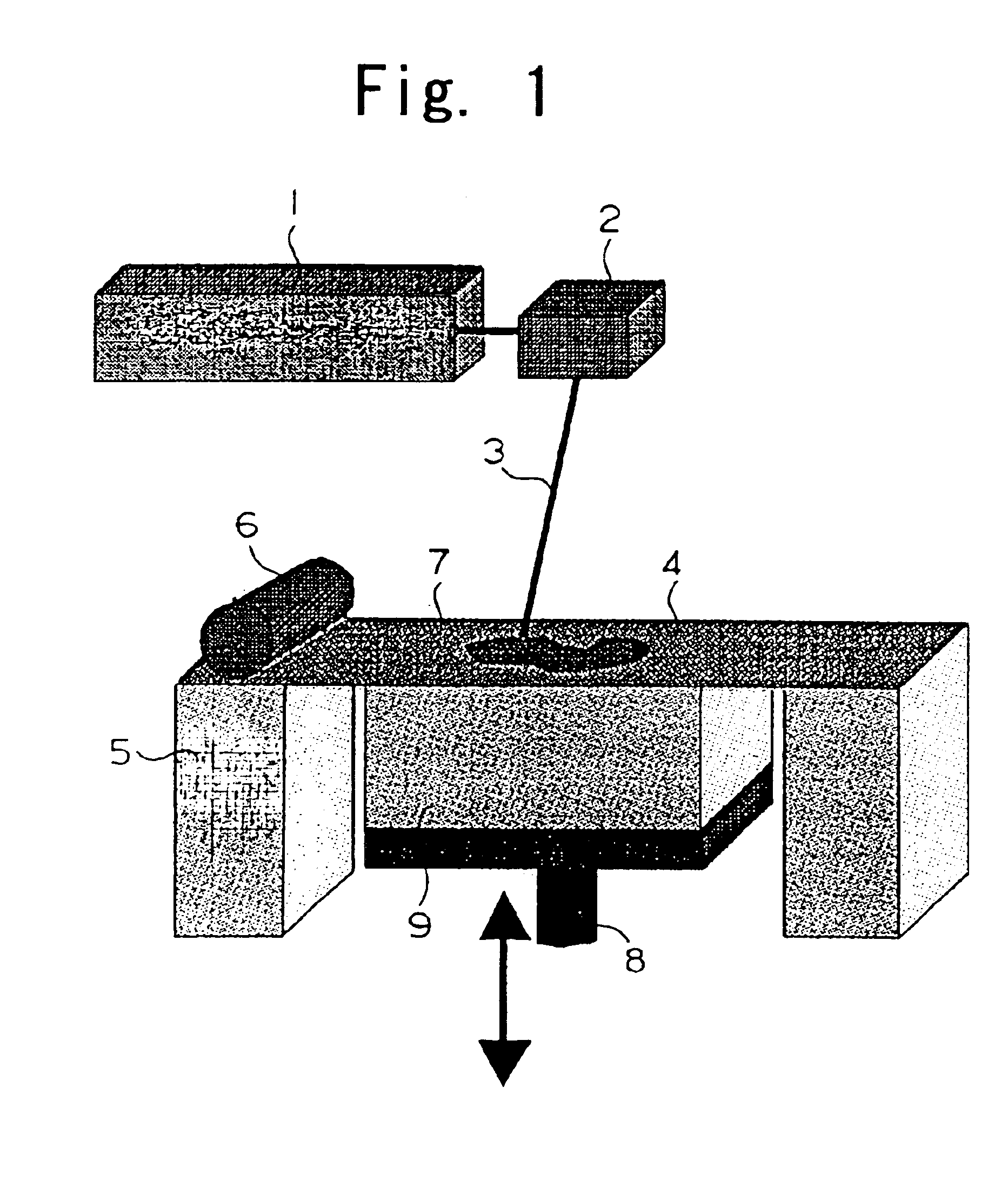

Constant-velocity joint and image-forming device

InactiveUS20050281586A1Minimizes operating noiseSimple structureYielding couplingElectrographic process apparatusEngineeringSynthetic resin

A constant-velocity joint includes an outer ring formed with an annular space therein having an opening at one end thereof. The annular space is defined by a radially outer wall and a radially inner wall. One of the radially inner and outer walls is formed with three axially extending track grooves circumferentially spaced apart from each other by 120 degrees. A cage is inserted in the annular space with one end thereof protruding from the opening of the annular space. A second shaft is provided on the one end of the cage. Balls are retained by the cage and adapted to roll in the track grooves. At least one of the outer ring and the cage is formed of a synthetic resin.

Owner:NTN CORP

Bicycle sprocket

A bicycle sprocket is provided that has a synthetic resin fastening part, to facilitate weight saving and prevent the reduction of fastening power (strength) due to deterioration or deformation of the synthetic resin. The sprocket includes a sprocket ring part and a synthetic resin fastening part. The sprocket ring part includes an inner periphery and an outer periphery with a plurality of sprocket teeth arranged on the outer periphery. The sprocket ring part extends around a central rotation axis. The fastening part is non-movably coupled to the sprocket ring part at a location radially inwardly of the sprocket teeth relative to the rotation axis. The fastening part includes at least one through hole with a metallic tubular member mounted therein and configured to be fixedly coupled to a rotational drive unit of a bicycle. The tubular member has a first fastener contact surface configured to receive a fastening force.

Owner:SHIMANO INC

Composite Structural Material and Method of Making the Same

A composite structural material suitable, for example, as a replacement for wooden boards, sheets, or posts, is disclosed. It comprises a dimensionally stable core material substantially surrounded by a dimensionally stable, laminar covering that is adherent to the core material. The laminar covering is comprised of at least one band of substantially parallel reinforcing cords bonded to at least one layer of a dimensionally stable web material selected from the group consisting of rigidified paper and rigidified cloth. Preferably the band of reinforcing cords is sandwiched between two layers of rigidified paper or cloth. The core material can be, for example, a foamed synthetic resin with or without filler. A continuous process for manufacturing the material is disclosed.

Owner:CODA CAPITAL MANAGEMENT GROUP

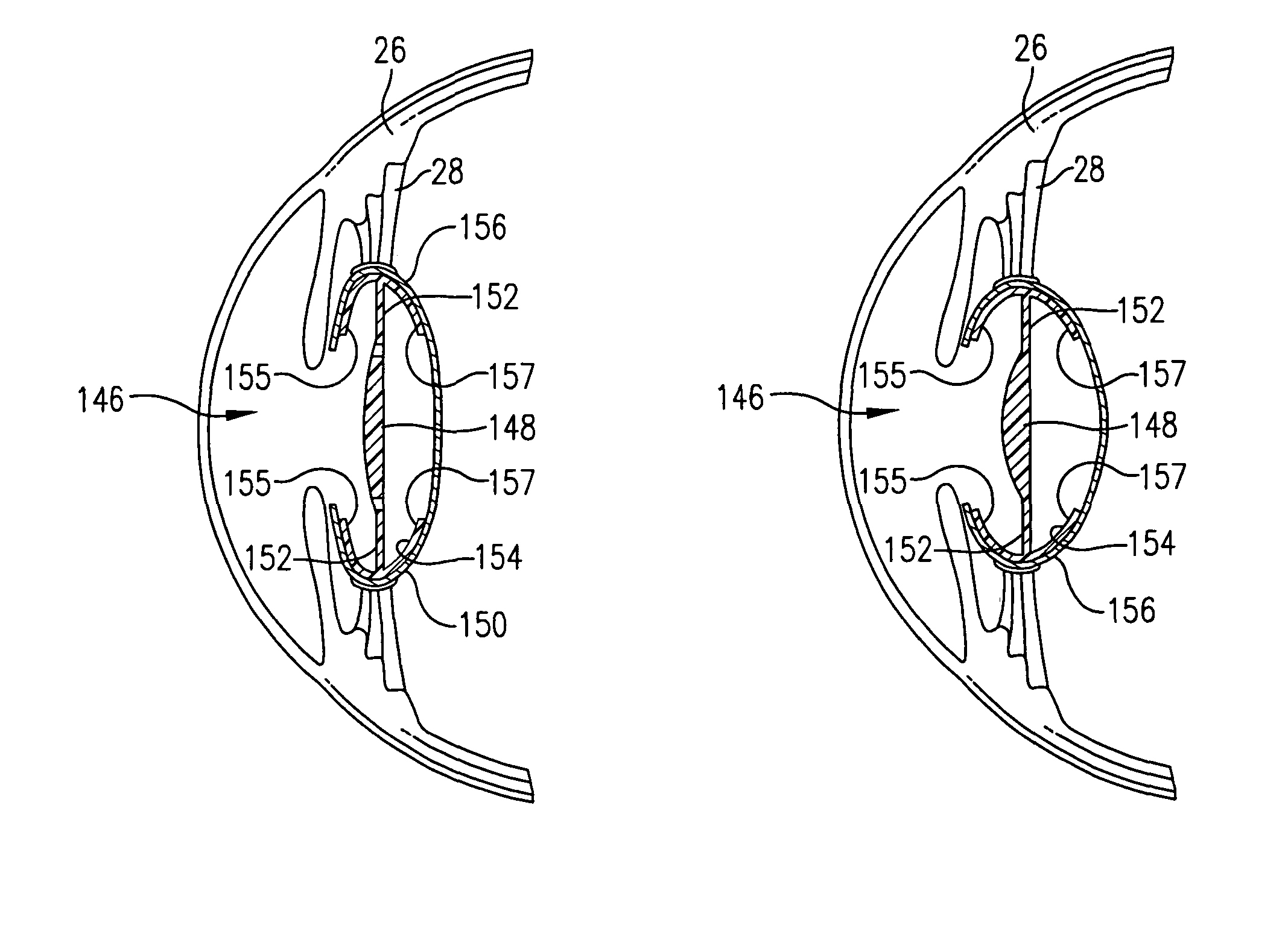

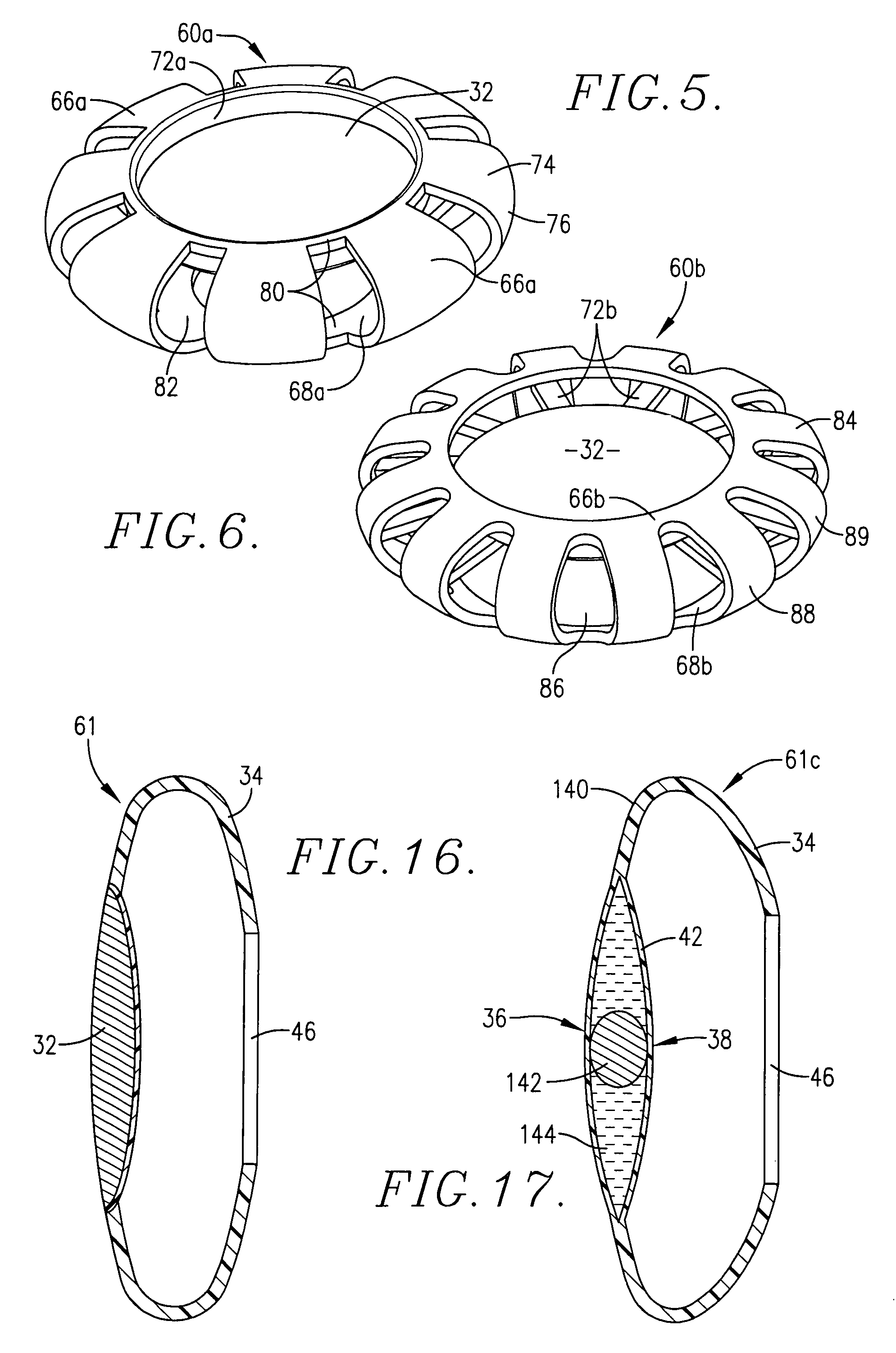

Capsular intraocular lens implant having a refractive liquid therein

InactiveUS8052752B2Long-term use safetyTreatment safetyIntraocular lensRefractive errorRefractive index

Owner:ABBOTT MEDICAL OPTICS INC

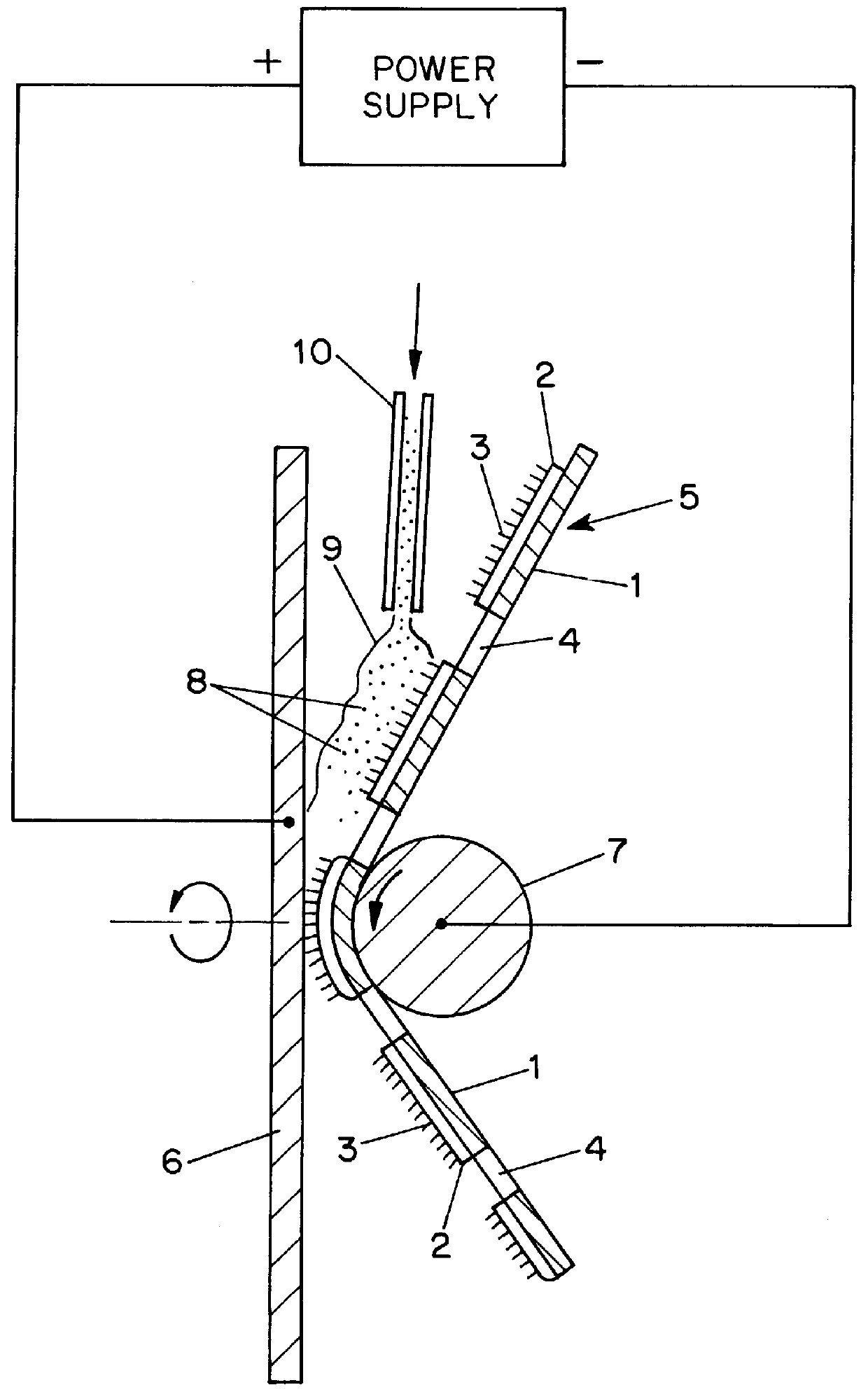

Combination electrolytic polishing and abrasive super-finishing method

InactiveUS6074284AHigh surface finishEfficient supplyBelt grinding machinesAbrasion apparatusFiberElectrolytic agent

An abrasive super-finishing method for workpieces, such as metallic thin-film magnetic discs, employs a polishing / texturing material having a backing, such as synthetic resin film or woven material or non-woven cloth, and a layer which can hold abrasive grains on the backing, such as flocked fibre or a porous polymer foam, on one surface of the backing. An electrolytic solution in which abrasive grains are suspended is supplied to the polishing / texturing material to conduct polishing or texturing of the workpiece surfaces. The workpiece is connected to an anode and a pressure roller or a cathode bar is connected to a cathode. A voltage is applied between the workpiece and the pressure roller or cathode bar to conduct simultaneously electrolytic polishing and abrasive polishing / texturing.

Owner:UNIQUE TECH INT PTE

Composite of aluminum alloy and resin composition and process for producing the same

InactiveUS20060257624A1Mass productivityMold shrinkage factor should be smallSynthetic resin layered productsRecord information storagePolytetramethylene terephthalateHigh volume manufacturing

A composite characterized by comprising an aluminum alloy shaped item having a surface roughness of 5 to 50 μm or more, the surface provided with 1 μm or less fine depressions or protrusions, and a thermoplastic resin composition composed mainly of a polyphenylene sulfide or polybutylene terephthalate resin whose average of lengthwise and crosswise linear expansion coefficients is in the range of 2 to 4×10−5° C.−1, the thermoplastic resin composition penetrating and anchored in the depressions or protrusions. The thermoplastic resin composition is not easily detached from the aluminum alloy shaped item. Thus, in, for example, electronic equipments and household electrical appliances, the advantage of metallic cage body can be reconciled with the advantage of synthetic resin structure. This composite can ensure high production efficiency and is suitable for mass production. Further, morphology and structure designing thereof can be accomplished freely.

Owner:TAISEI PLAS CO LTD

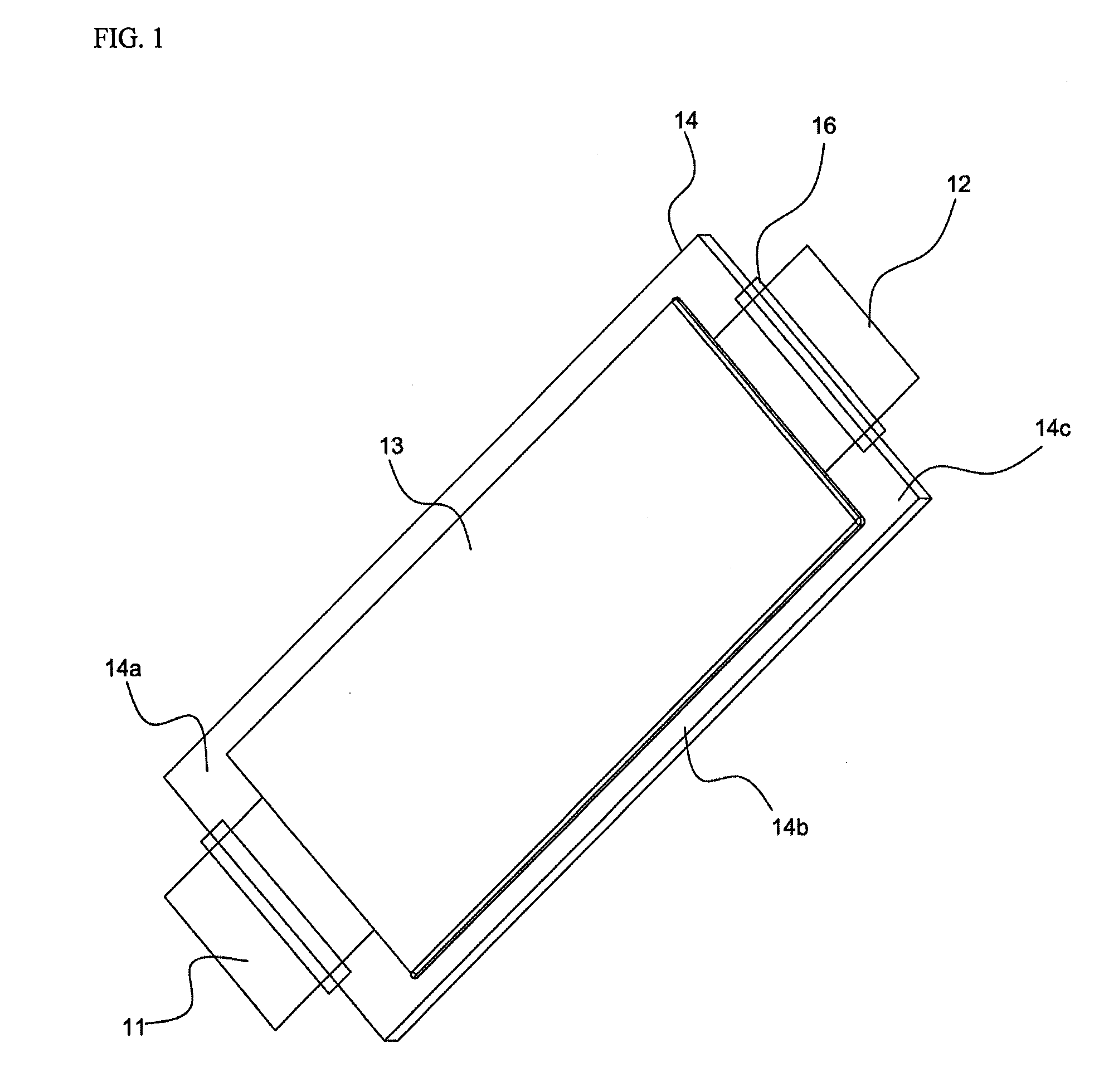

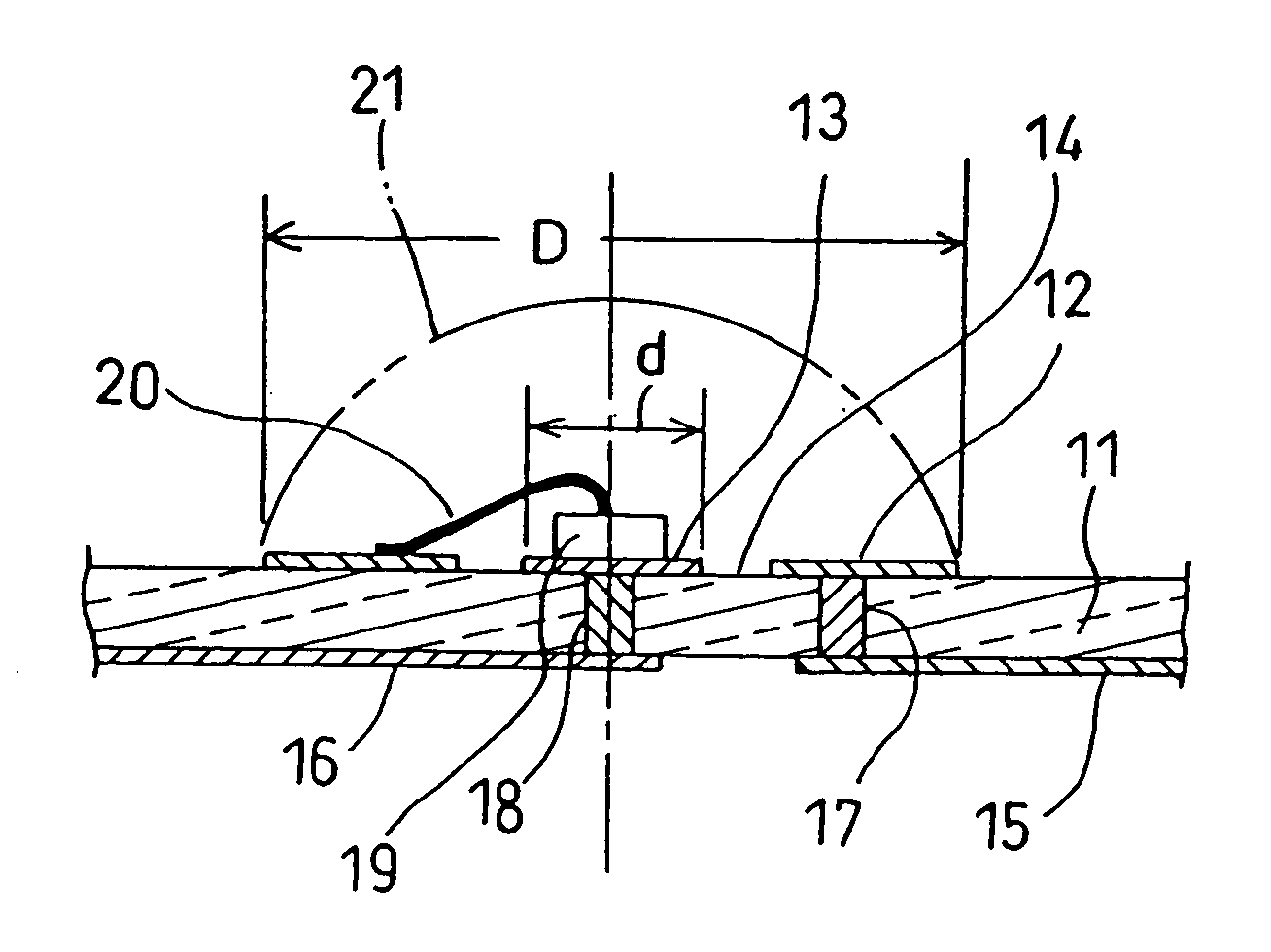

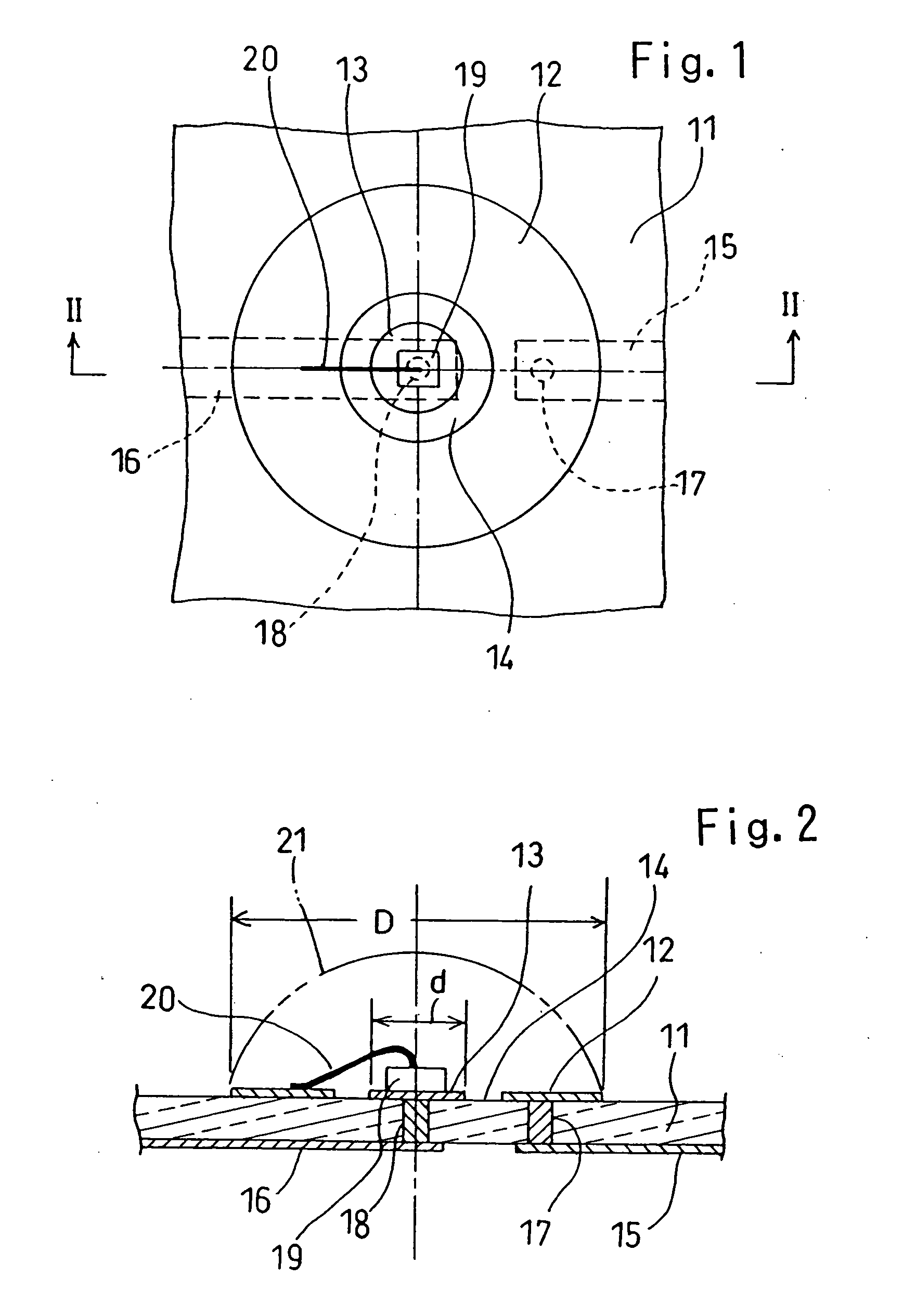

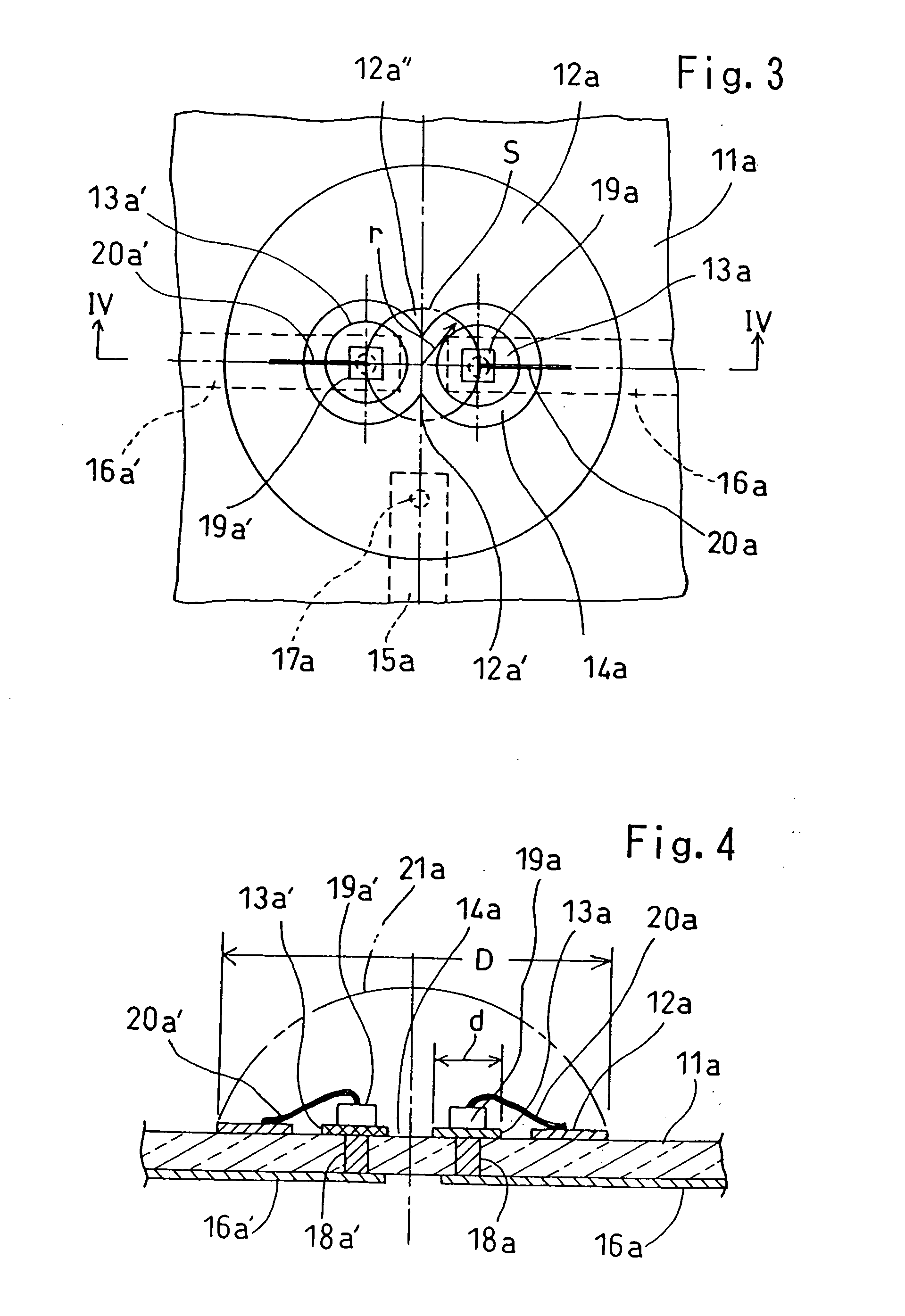

Light-emitting device comprising led chip and method for manufacturing this device

InactiveUS20050122031A1Reduce manufacturing costLow cost manufacturingDischarge tube luminescnet screensLamp detailsEngineeringSynthetic resin

A light emitting device includes a first patterned electrode 12 and a second patterned electrode 13 both of which are formed on a wiring board 11, an LED chip 19 mounted on the second patterned electrode 13, a metal wire 20 electrically connecting the LED chip 19 and the first patterned electrode 12 to each other, and a lens member 21 made of a transparent synthetic resin for packaging the LED chip 19 and the metal wire 20. The first patterned electrode 12 is circular and formed with a cutout 14 at the center thereof. The second patterned electrode 13 is arranged in the cutout 14. With this arrangement, the lens member 21 can be formed into a predetermined configuration, while the reflection of light by the patterned electrodes can be ensured.

Owner:ROHM CO LTD

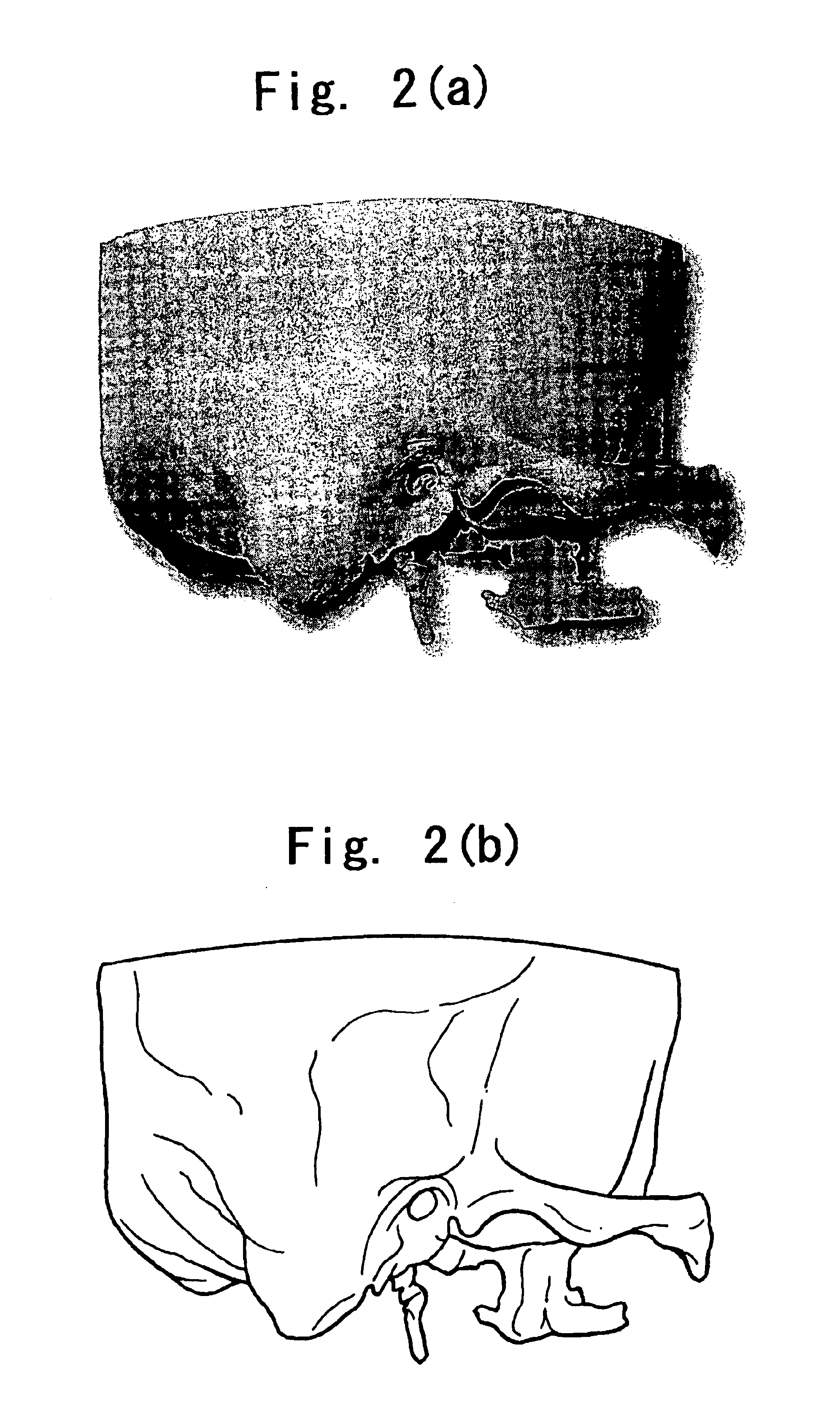

Process for producing an artificial bone model and an artificial bone model produced by the process

ActiveUS6932610B2Improve skillsEasy to getAdditive manufacturing apparatusPharmaceutical delivery mechanismHuman bodySurgical operation

A process for producing an artificial bone model in accordance with the selective laser sintering process which comprises extending a powder material for sintering comprising 30 to 90 parts by weight of powder of a synthetic resin and 10 to 70% by weight of an inorganic filler to form a thin layer and irradiating a portion of the thin layer having the shape formed based on tomograpic information of a natural bone with laser light so that the irradiated portion of the thin layer is sintered. The extension of the powder material for sintering to form the thin layer and the irradiation of the thin layer with laser light for sintering are conducted repeatedly. The artificial bone model can three-dimensionally reproduce steric shapes of natural bones such as bones in the human body precisely and accurately and exhibits the property for cutting closely similar to that of natural bones. The artificial bone model can be used for educational training or for studying a plan for curing before a surgical operation.

Owner:ONO +1

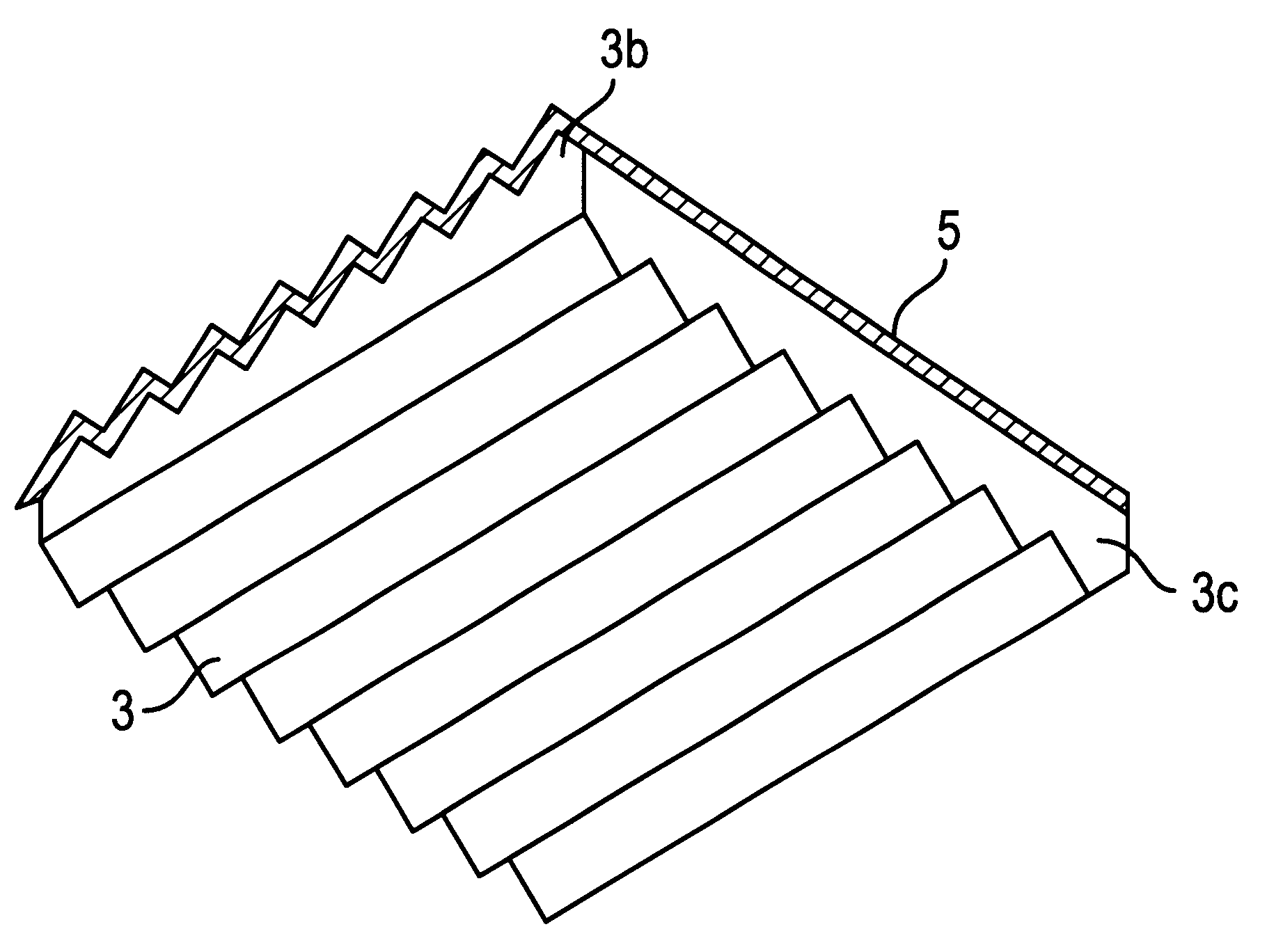

Light regulation device

InactiveUS6275338B1Easy to manufactureSatisfactory viewing anglePrismsMechanical apparatusDiffusionLight guide

A light regulation element regulates both the travelling direction and diffusion state of a light emitted from a surface light source device. Lights from a cylindrical light source 2 such as a cold cathode tube is introduced in a light guide 1. The light guide 1 has an emission surface 1a on the side opposite to a reflection element 4, and a light regulation element 3 is arranged in opposition to the emission surface 1a. Protrusions 3a are formed on one surface or both surfaces of the light regulation element 3. Coated on the surface on the light emission side of the light regulation element 3 is a light diffusion layer 5. The turbidity of the light diffusion layer 5 falls within a range from 1900 cm-1 to 2400 cm-1 . The light emitted from the emission surface 1a of the light guide penetrates the light regulation element 3, thereby causing the light travelling direction to be regulated. Then, the light whose travelling direction has been regulated penetrates the light diffusion layer 5, thereby causing a light diffusion. The light diffusion layer 5 is formed, for example, by mixing fine particles of a glass having a light penetrability or of a synthetic resin such as acryl and silicone, or fine hollow particles of glass, acryl resin or the like, or air bubbles in a coating material having a light penetrability.

Owner:ENPLAS CORP

Resist composition, resin for use in the resist composition, compound for use in the synthesis of the resin, and pattern-forming method using the resist composition

ActiveUS20080081290A1Improve line edge roughnessAvoid it happening againPhotosensitive materialsRadiation applicationsActinic RaysCompound (substance)

A resist composition comprises: (A) a resin capable of increasing its solubility in an alkali developer by action of an acid; (B) a compound capable of generating an acid upon irradiation with actinic ray or radiation; (C) a resin having at least one of a fluorine atom and a silicon atom; and (D) a solvent, wherein the resin (C) has a degree of molecular weight dispersion of 1.3 or less and a weight average molecular weight of 1.0×104 or less.

Owner:FUJIFILM CORP

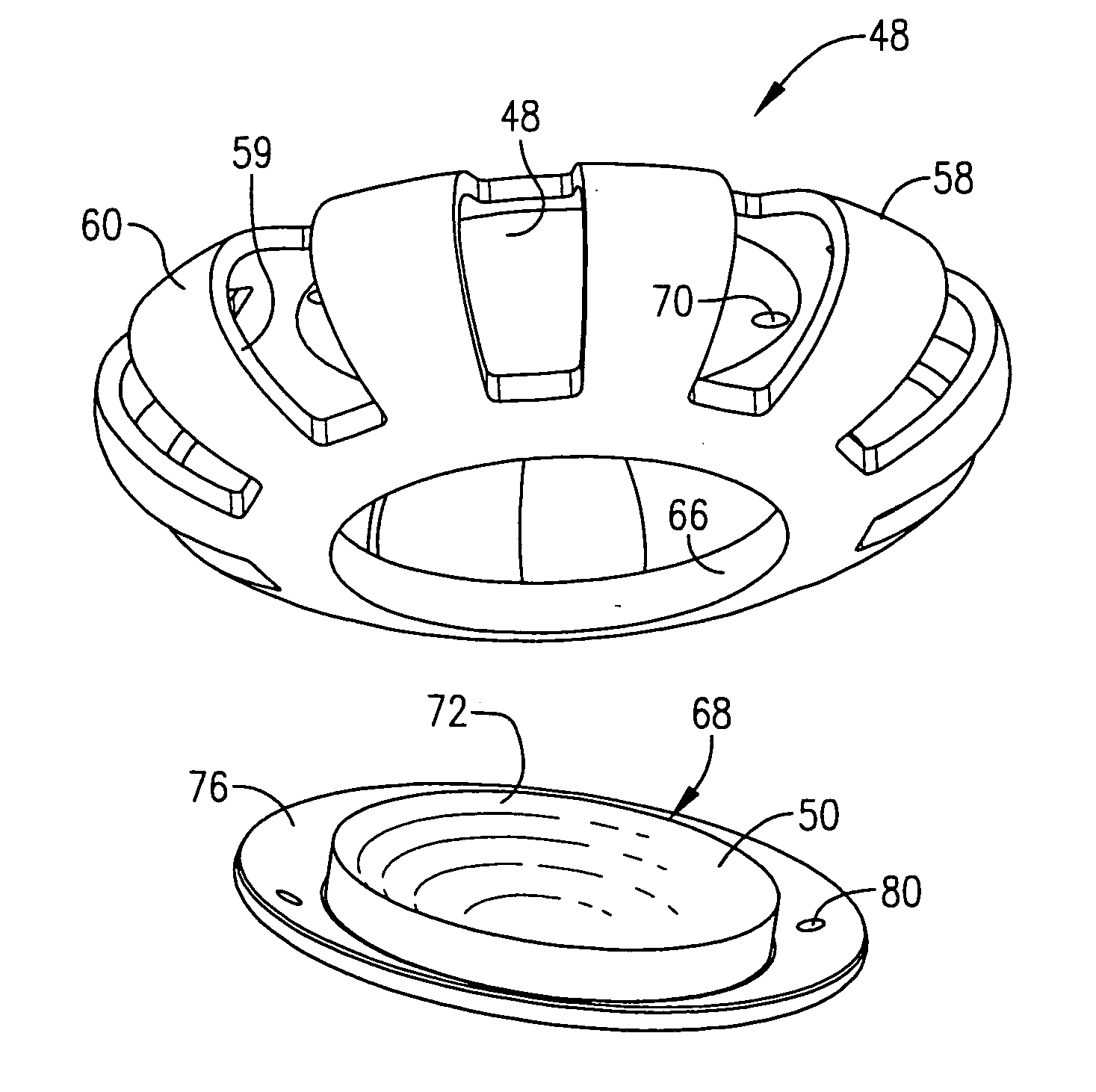

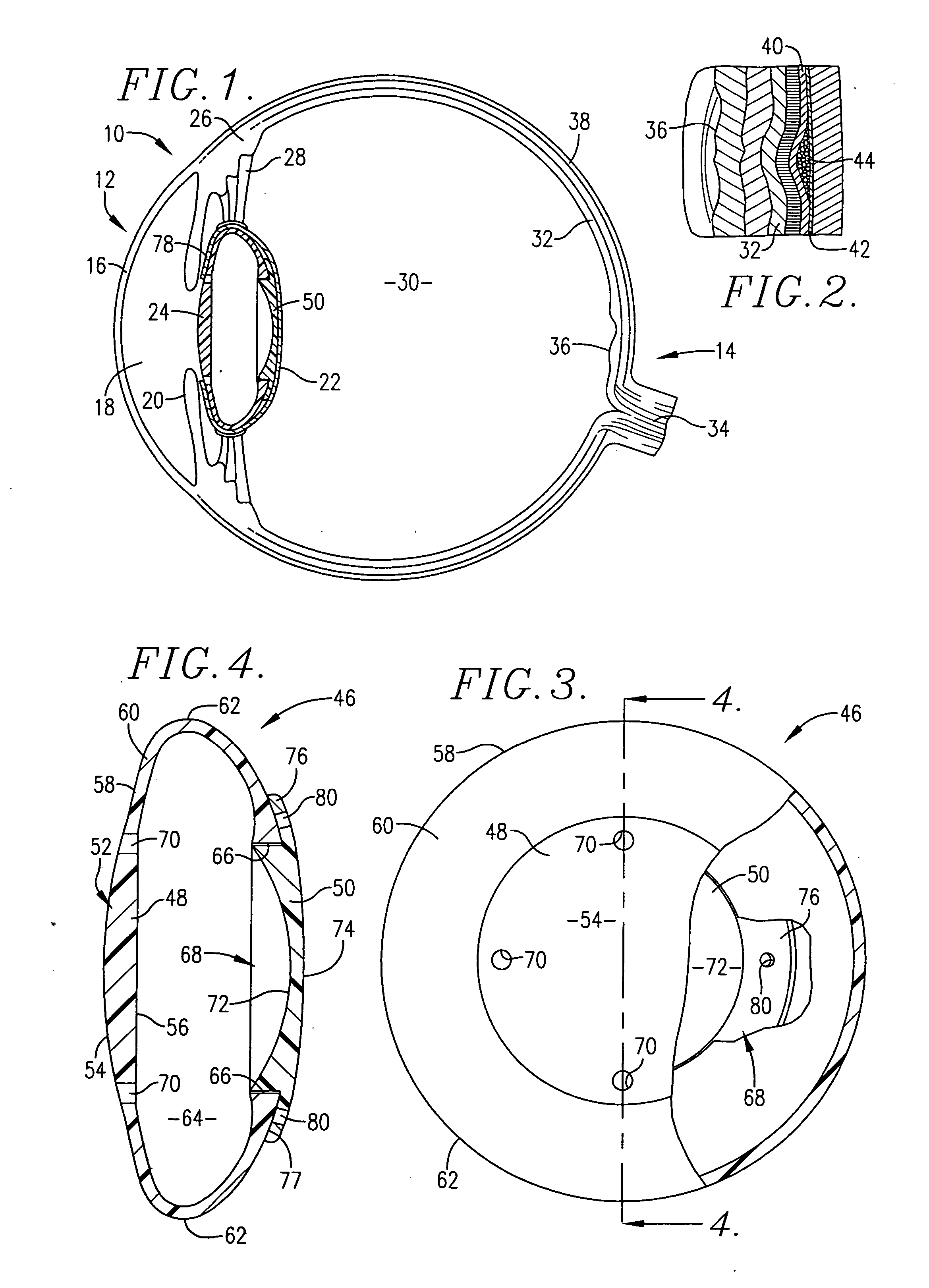

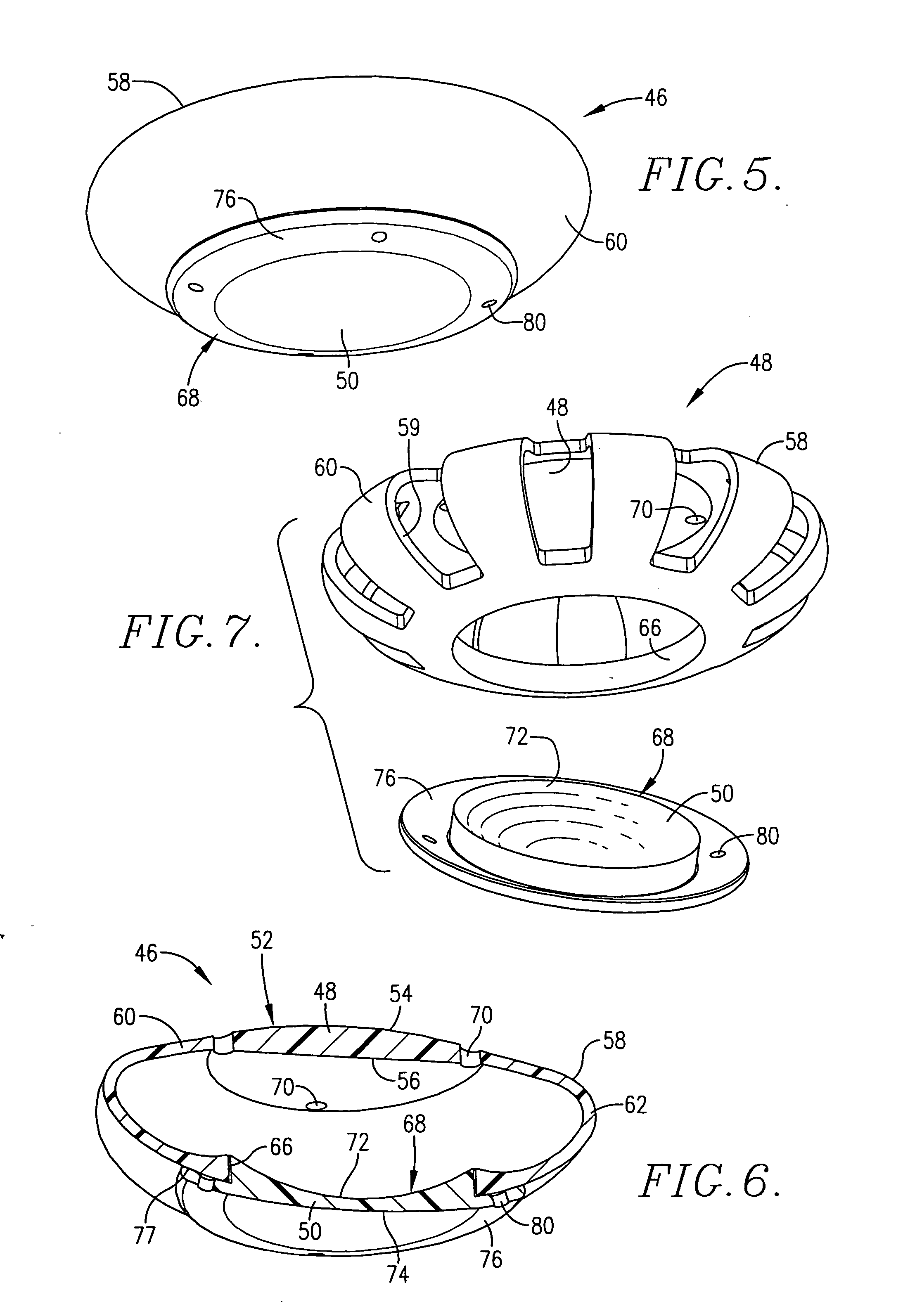

Telescopic intraocular lens implant for treating age-related macular degeneration

InactiveUS20050021138A1Affecting length of lensImprove eyesightIntraocular lensPosterior lensPhakic iol

An intraocular lens having an anterior lens member (48) presenting an anterior light-converging optic (52) and a posterior lens member (50) presenting a posterior light-diverging optic (68) for magnifying an observed image onto large regions of the retina (32) to permit central focus in patients suffering from AMD and a method of implanting the lens into the human eye (10). The anterior light-converging optic (52) is operably coupled with a flexible body (58) which extends radially therefrom and presents opposing bights (62) presenting termini (66) when the lens is viewed in cross-section. The posterior light-diverging optic (68) is operably coupled with an annular flange (76) which is arcuate in cross-section and mates with termini. Both the anterior and the posterior lens members (48, 50) have positioning holes (70, 80) formed therein permitting surgical implantation thereof. The IOL (46) is constructed of a flexible synthetic resin material such as polymethylmethacrylate and permits focusing upon objects located near to and far from the viewer.

Owner:WOODS RANDALL

Surface fastener

InactiveUS6463635B2Improve the forceSimply and strongly fixedSnap fastenersSlide fastenersEngineeringSynthetic resin

In a strip-shaped surface fastener, fence portions, each of which periphery is blocked, integrally stand on a surface of a flat base portion made of synthetic resin. The fence portions may be formed of foam members and bonded to the surface of the flat base portion. Then, male type engaging elements are integrally molded inside each of the fence portions. Alternatively, a woven or knitted male type, female type or male-and-female mixture type surface fastener member, or a male type surface fastener member made of synthetic resin may be pasted or bonded inside each of the fence portions. An attaching portion, in which no engaging elements are disposed, are integrally formed on an outer periphery of each of the fence portions. Therefore, it is possible to prevent foam resin material from penetrating an interior of each of the fence portions during an embedding operation and to effectively embed the surface fastener in a cushion body of a foam resin molding type. Consequently, the surface fastener can be embedded in a stable fashion in a seat molded of foam resin without losing an engaging force of the surface fastener.

Owner:YKK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com