Pulsator and washing machine using same

A washing machine and pulsator technology, applied in the field of washing machines, can solve the problems of poor aesthetics, damaged clothes, a large amount of lint, etc., and achieve the effect of improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings for the same or like parts.

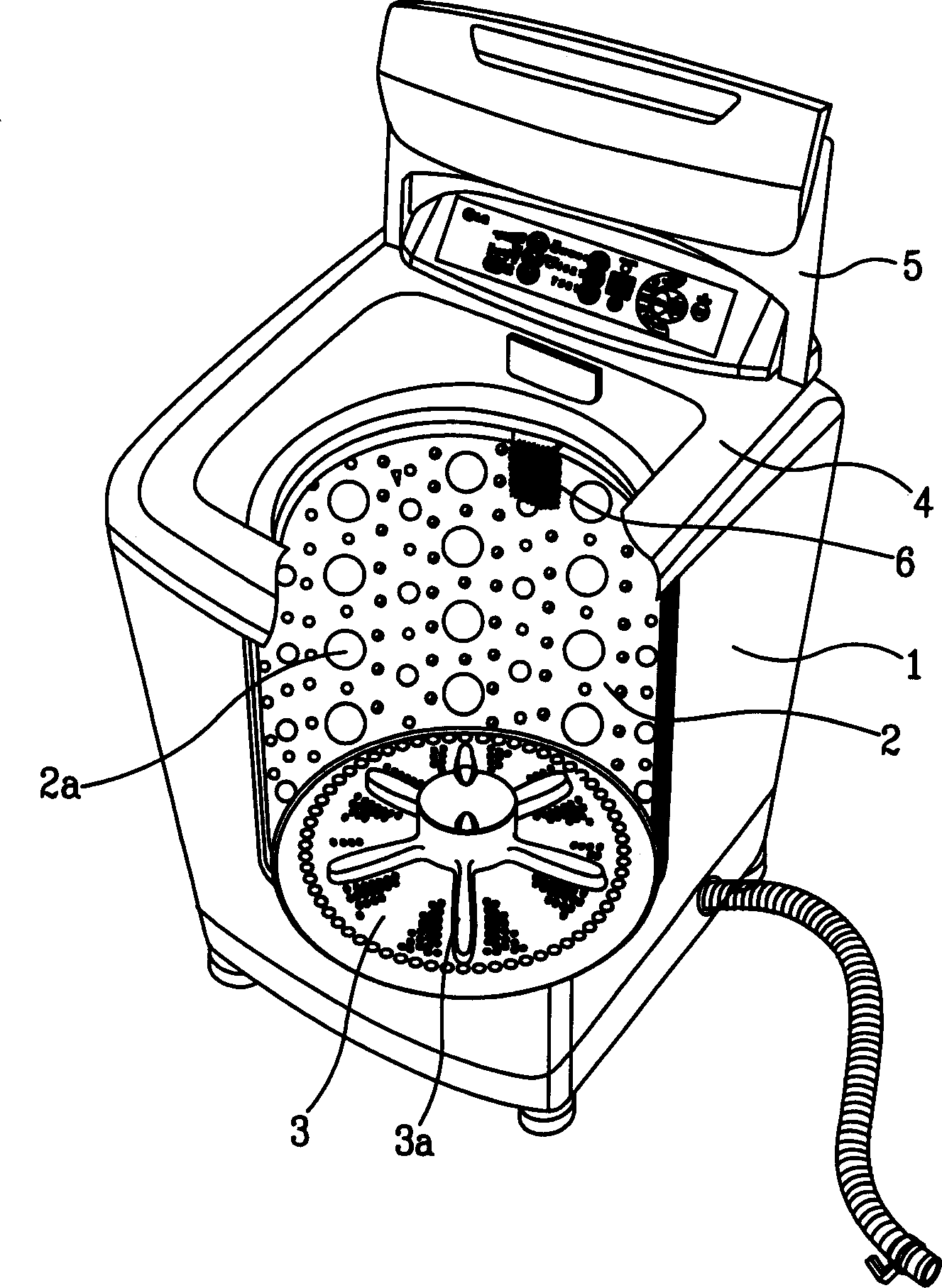

[0057] Figure 2 to Figure 9 A pulsator proposed according to the principle of the first aspect of the present invention is shown.

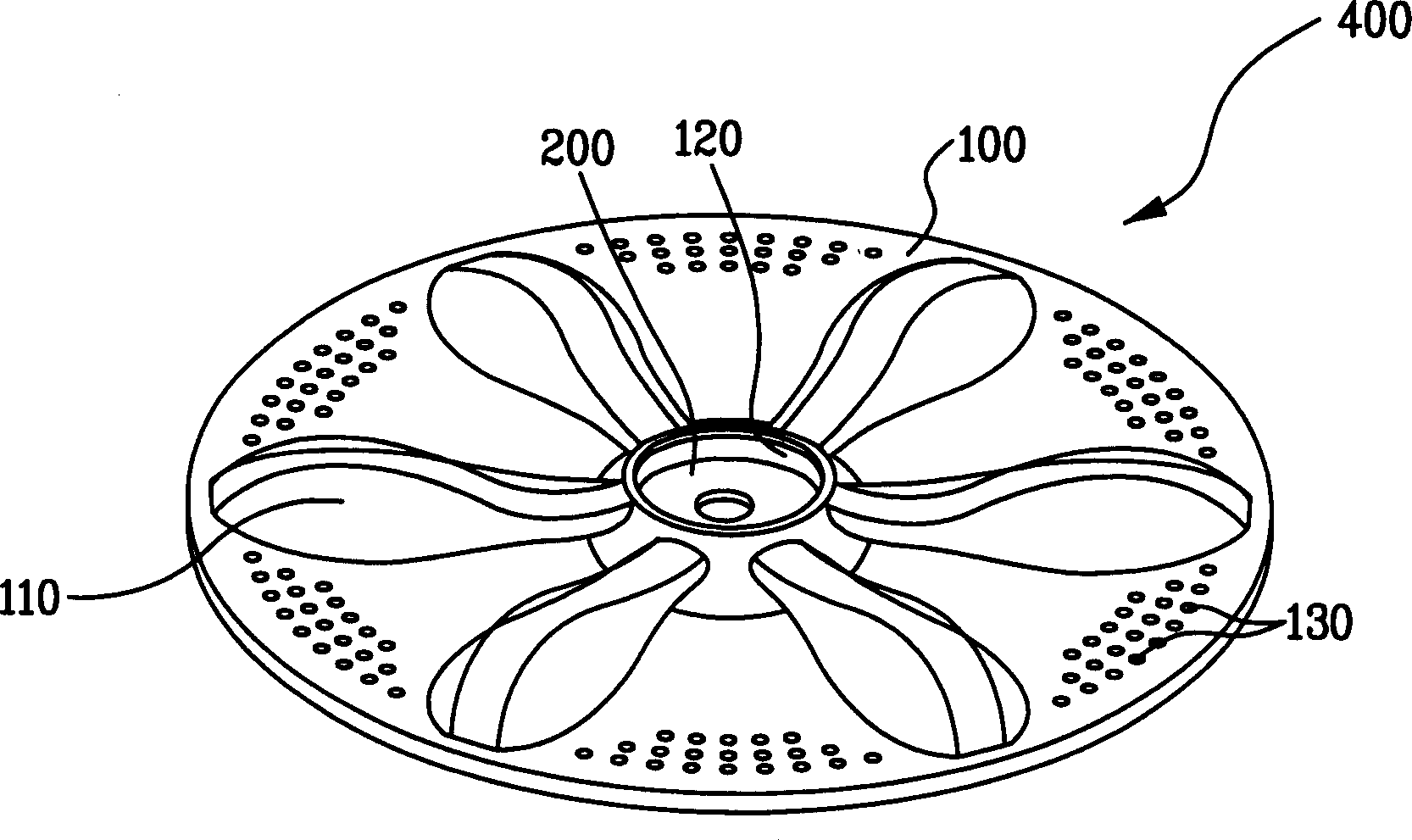

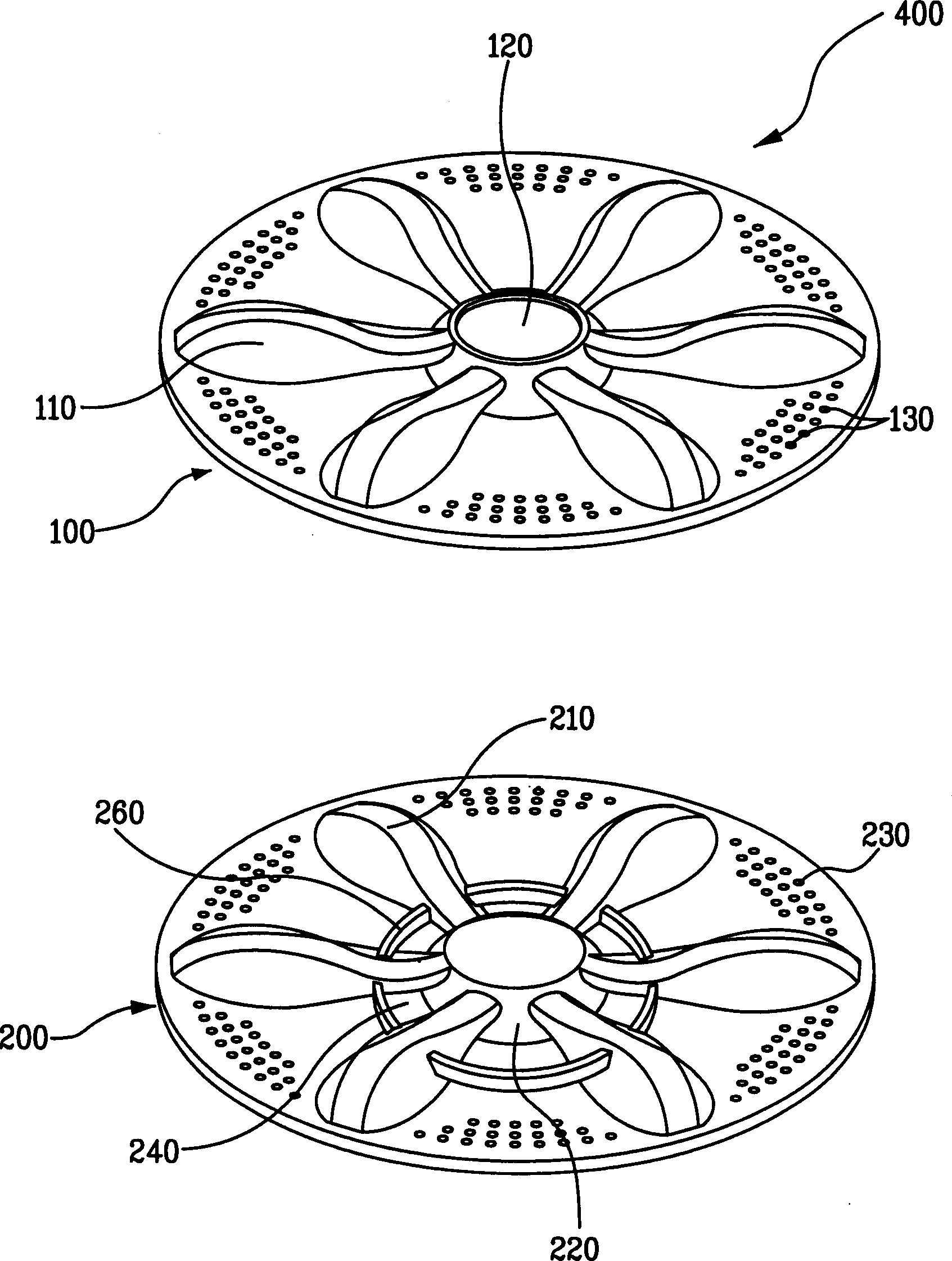

[0058] see Figure 2 to Figure 9 For example, a pulsator assembly 400 may include an upper pulsator 100 made of metal material and a lower pulsator 200 made of non-metal material.

[0059] For details, see Figure 2 to Figure 5 , the upper pulsator 100 can be roughly in the shape of a plate, which has an inlet 120, the inlet 120 penetrates the center of the upper pulsator 100, and protrudes from the edge of the upper pulsator 100, on the upper pulsator An inclined plane is defined on the upper surface of the wheel 100 . A plurality of upper washing ribs 110 protruding upward radially extend f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com