Patents

Literature

76199 results about "Water flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing lignocellulosic material

InactiveUS6555350B2High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseWater flow

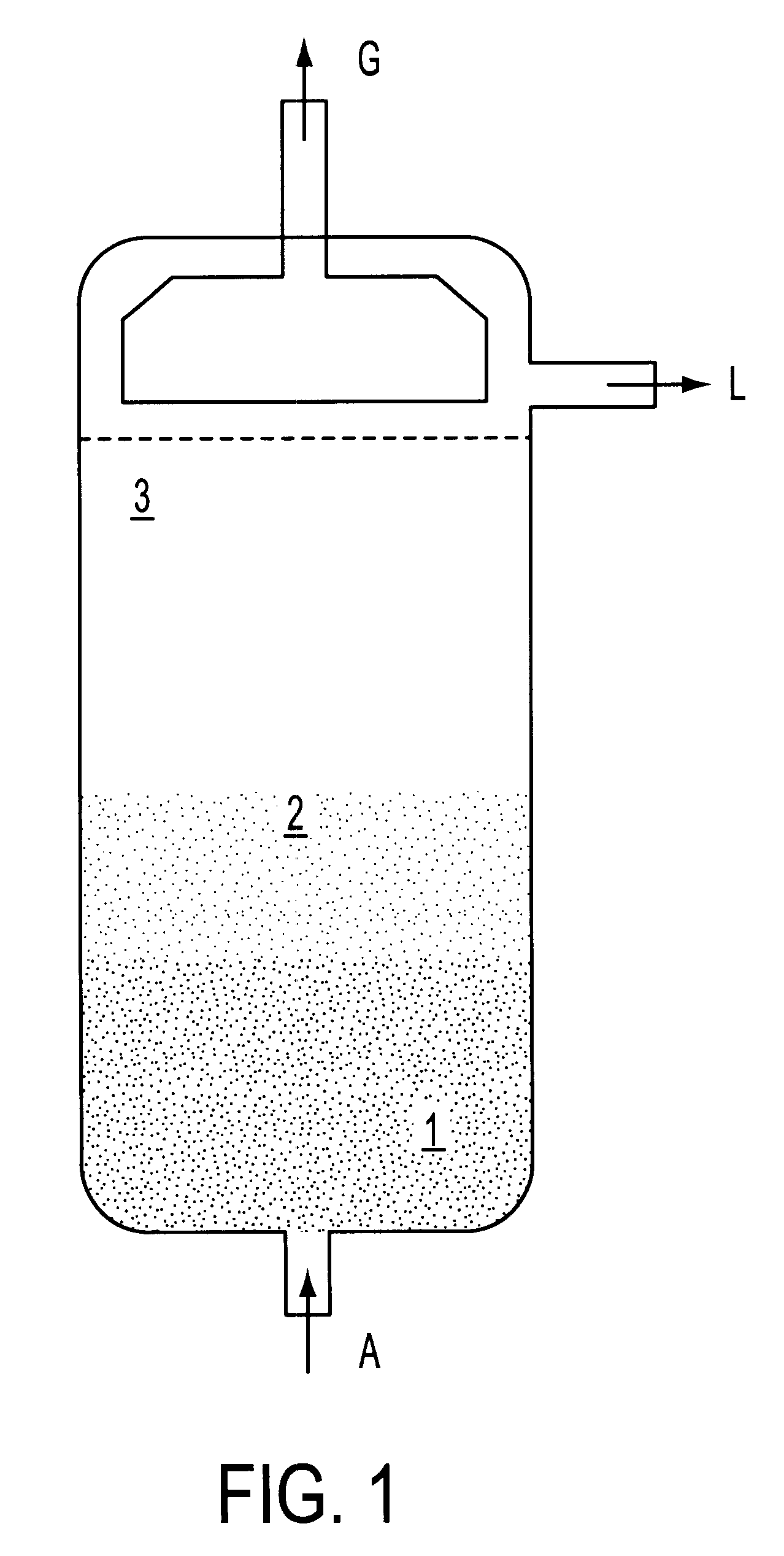

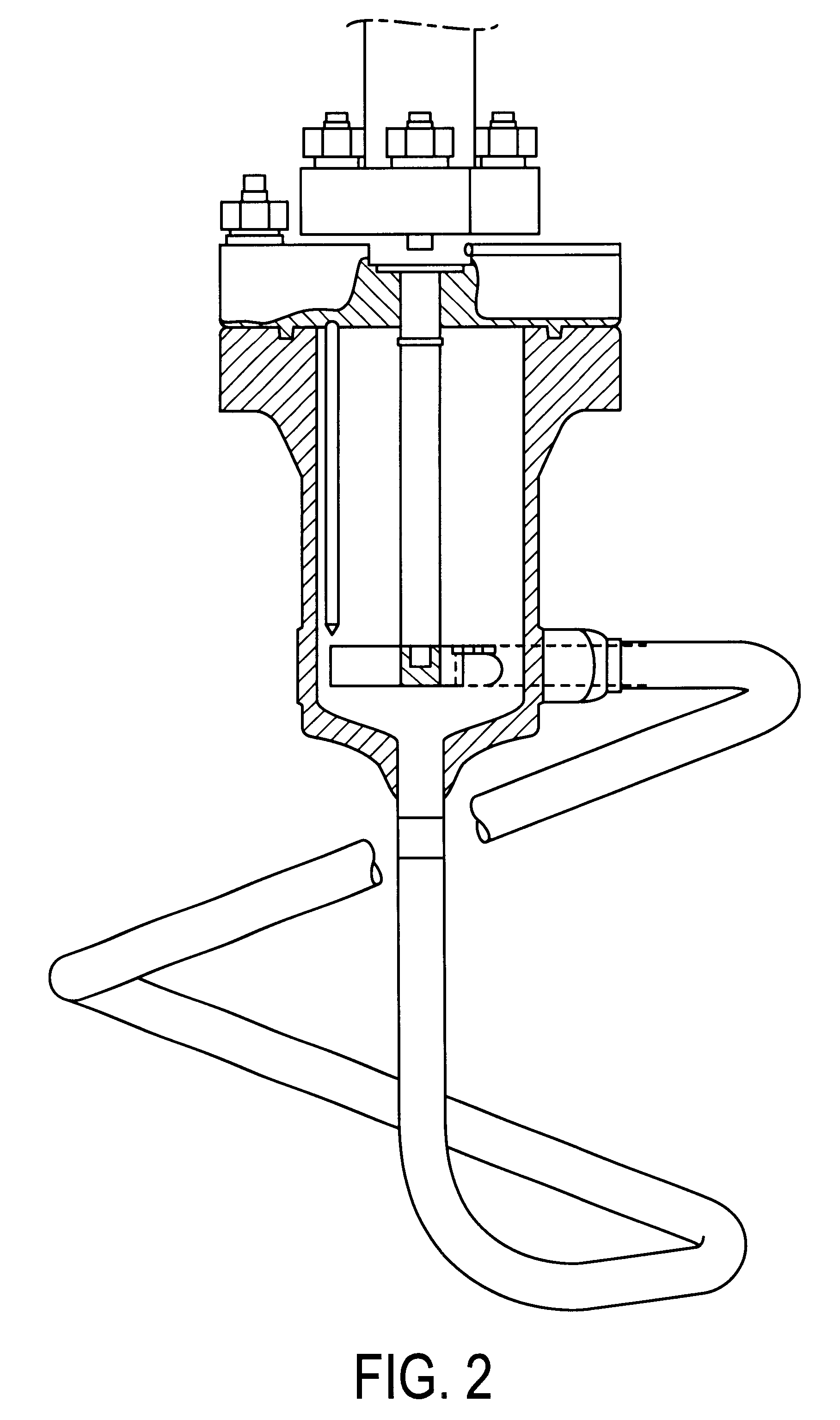

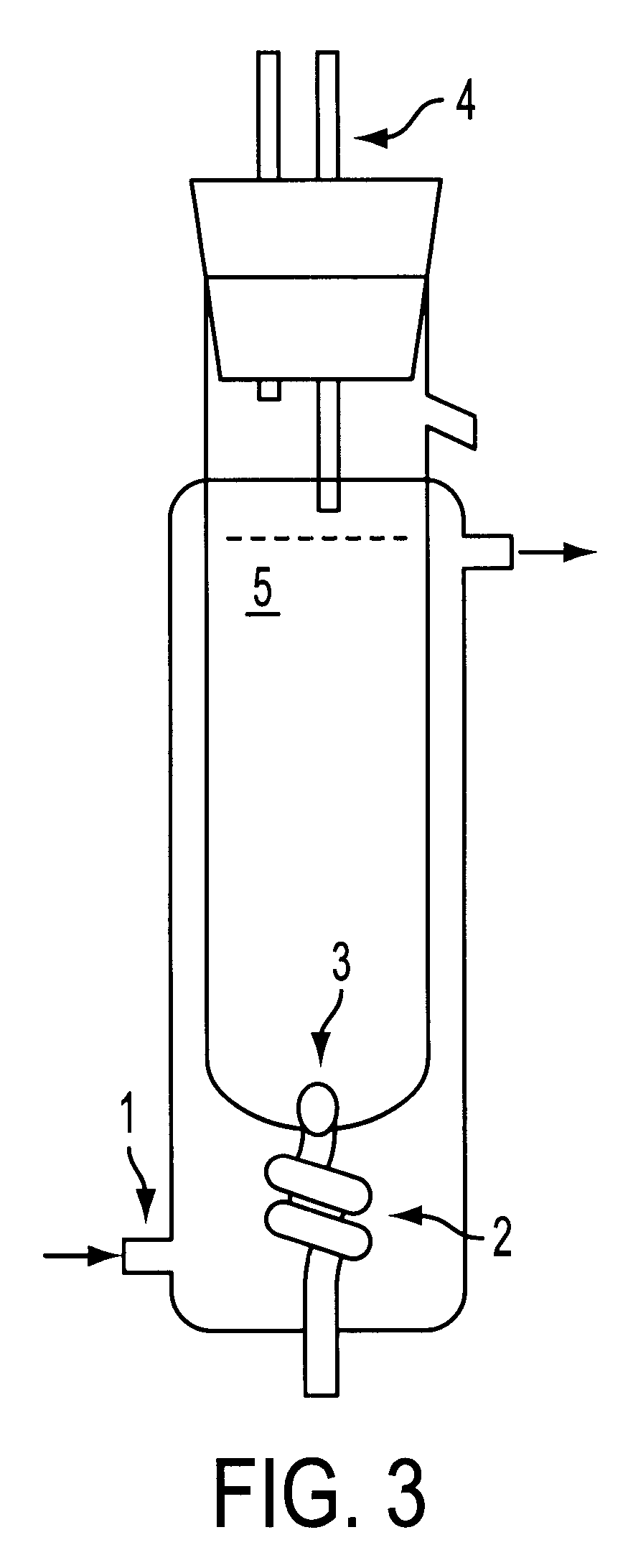

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process, involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

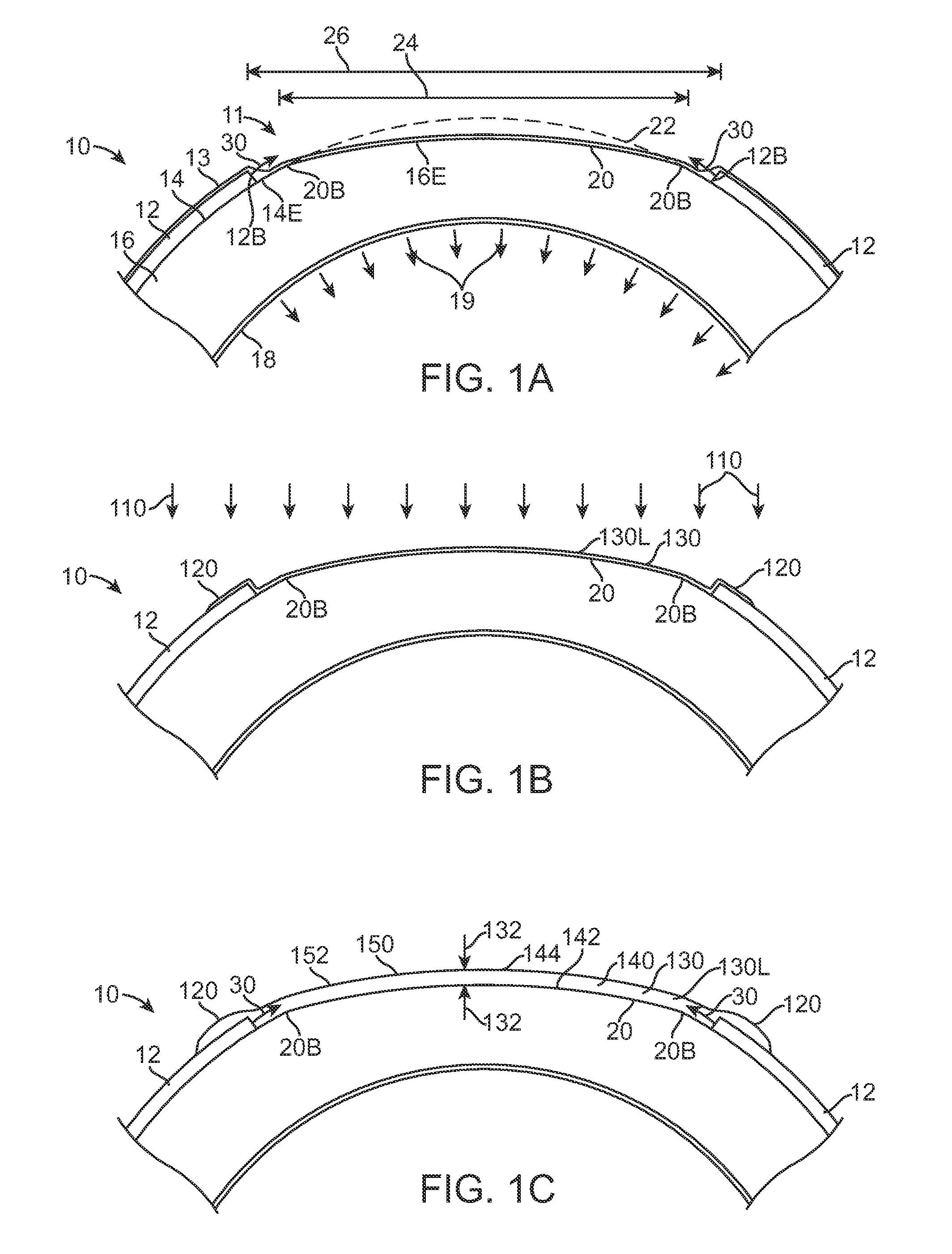

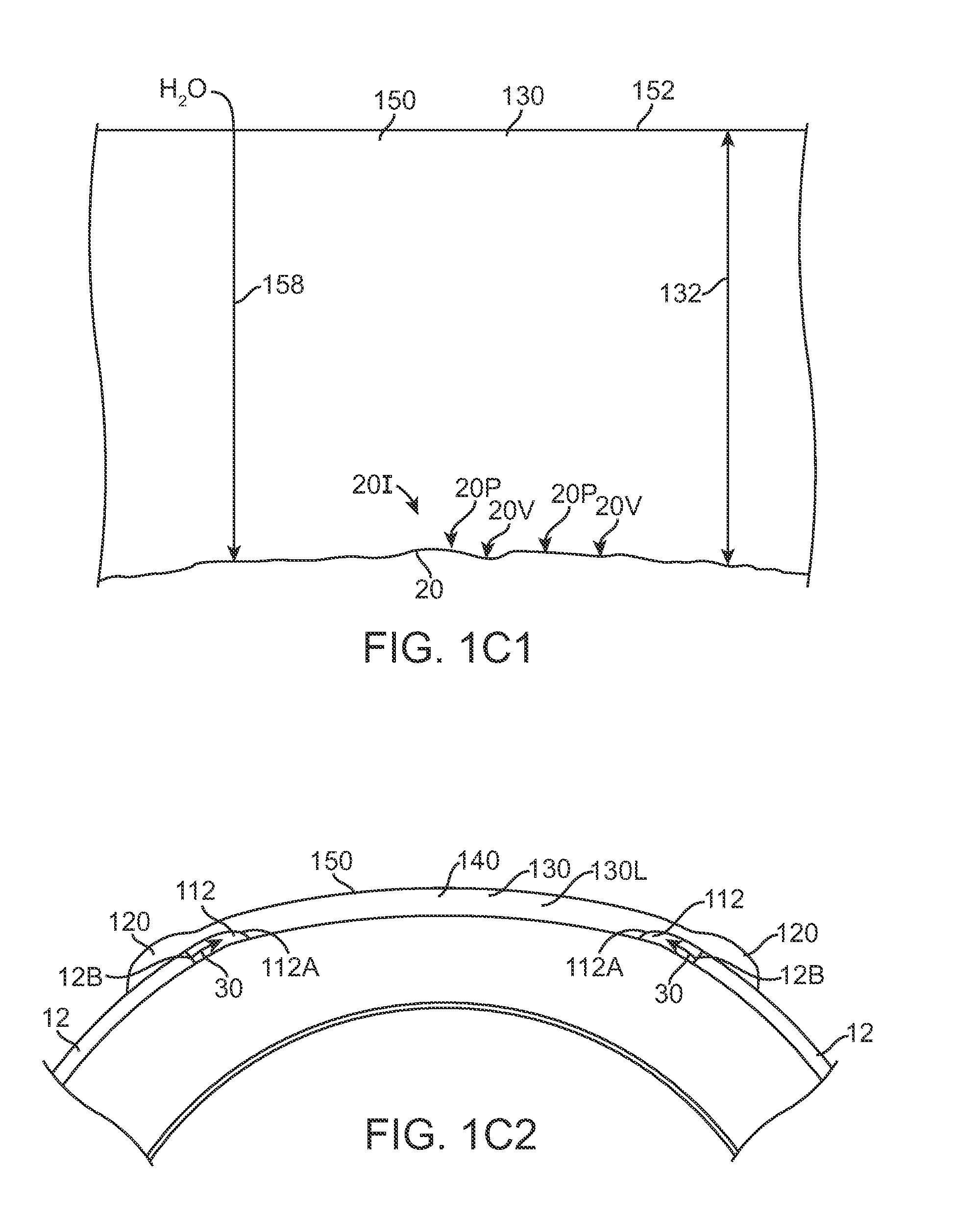

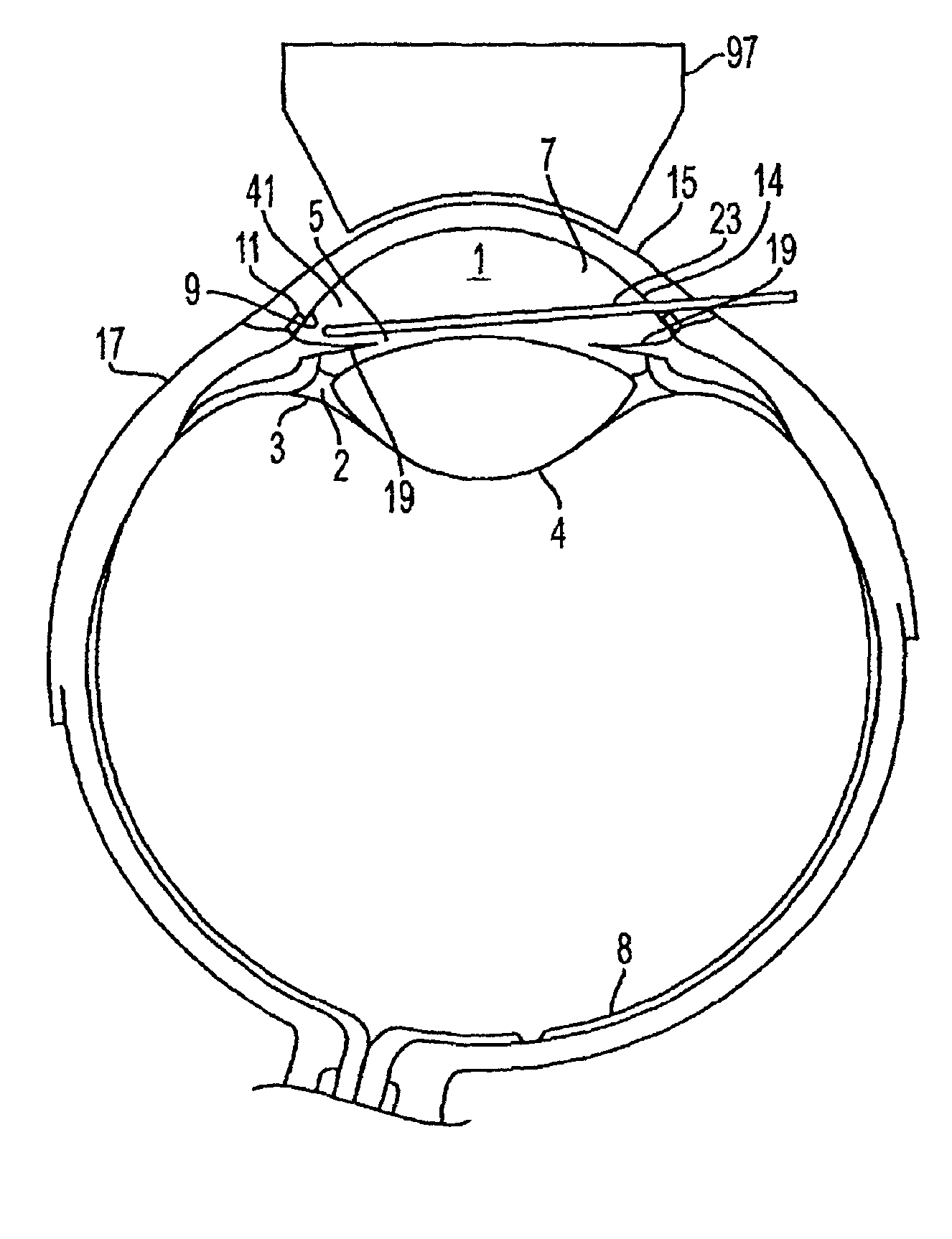

Therapeutic device for pain management and vision

ActiveUS20100036488A1Increase moistureRelieve painSenses disorderEye implantsEpitheliumTherapeutic Devices

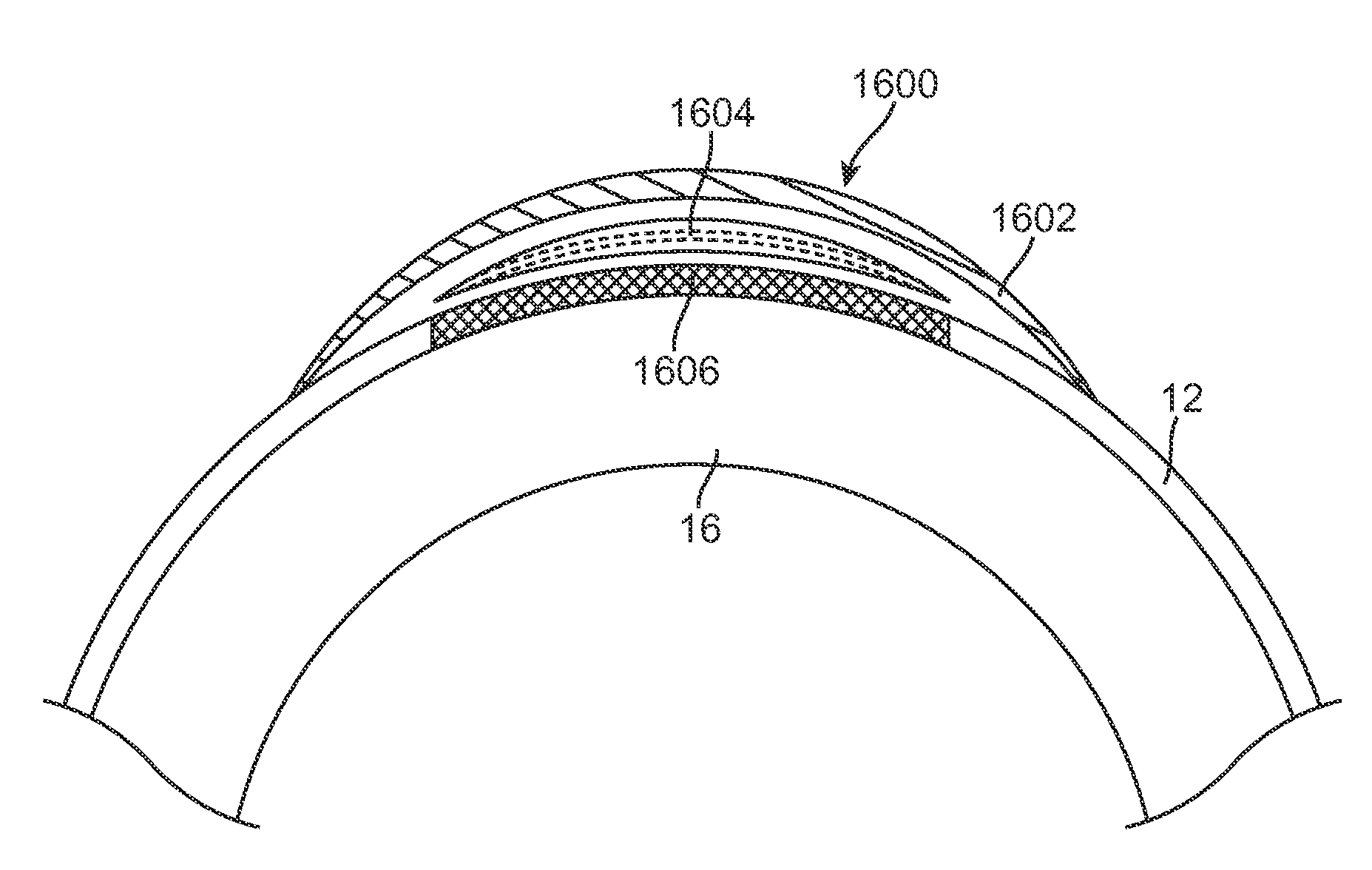

A therapeutic lens for the treatment of an epithelial defect comprises a layer of therapeutic material disposed over the stroma and / or Bowman's membrane to inhibit water flow from the tear liquid to the stroma and / or Bowman's membrane, such that corneal deturgescence can be restored to decrease corneal swelling and light scattering. The layer may cover and protect nerve fibers to decrease pain. The layer may comprise an index of refraction to inhibit light scatter from an anterior surface of the stroma and / or Bowman's membrane. The lens may comprise a curved anterior surface that provides functional vision for the patient when the epithelium regenerates. The layer of therapeutic material can be positioned on the eye in many ways, for example with a spray that is cured to adhere the layer to the exposed surface of the stroma and / or Bowman's membrane.

Owner:NEXIS VISION LIQUIDATING TRUST +2

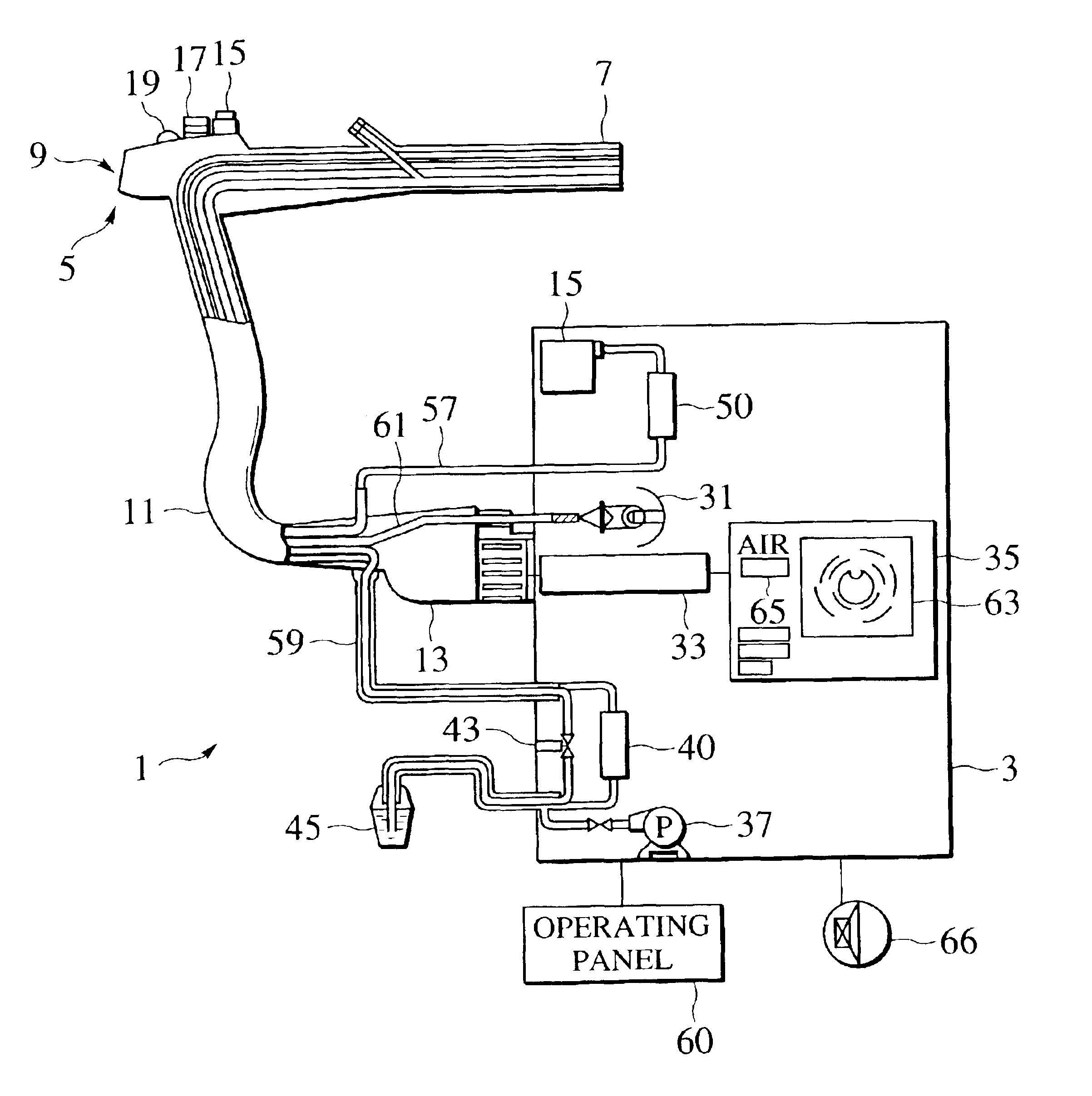

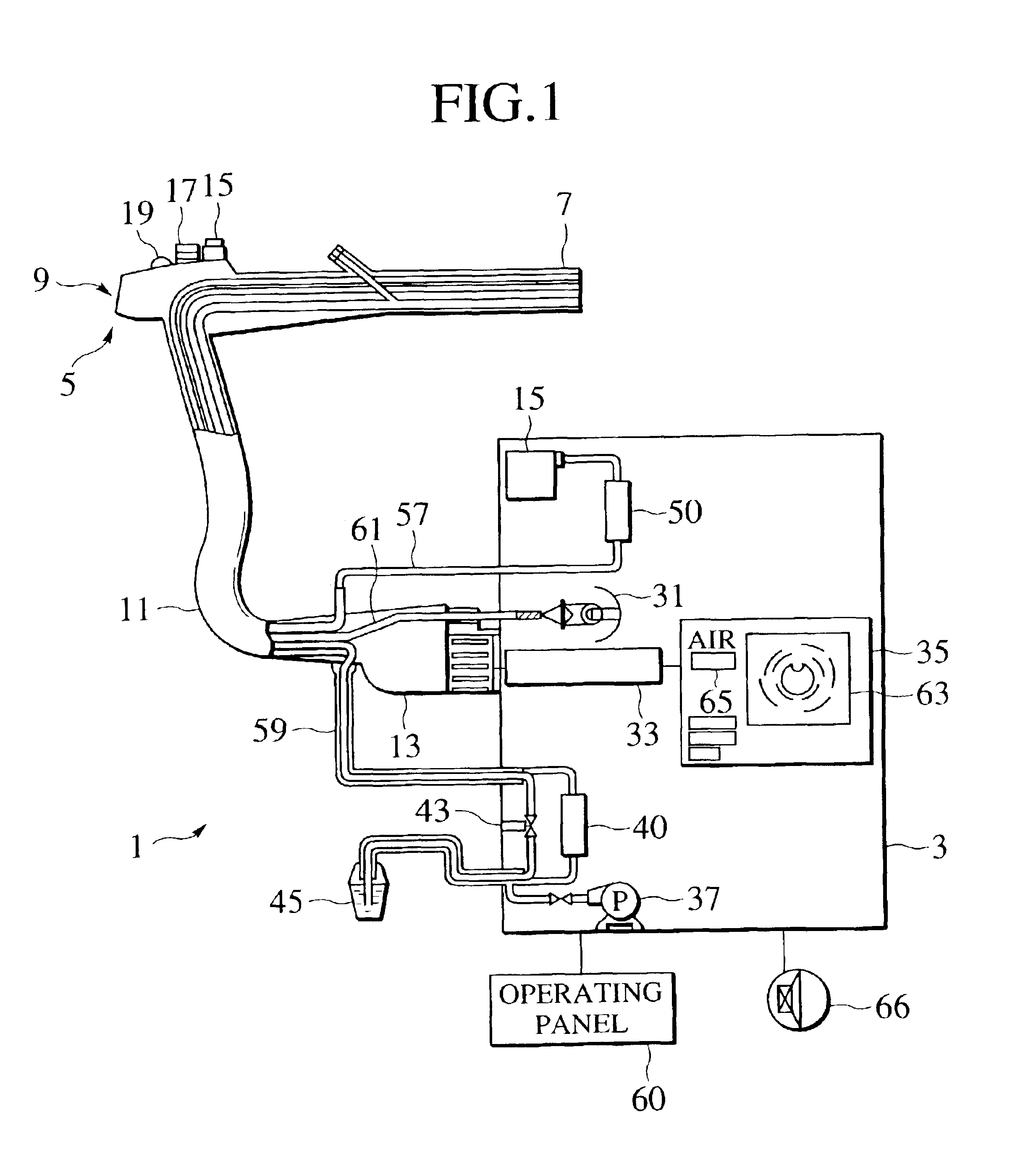

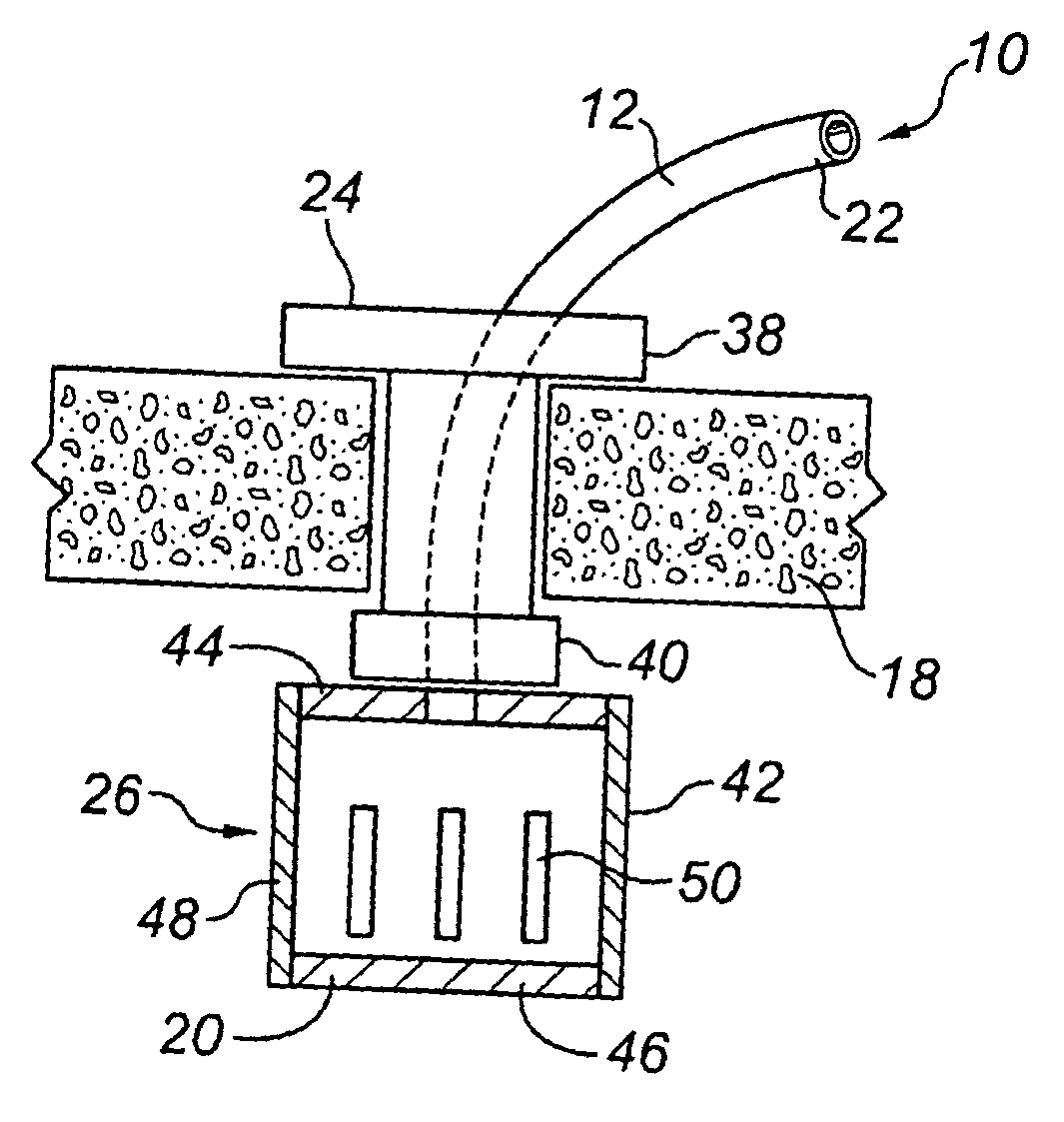

Endoscope apparatus

InactiveUS6929602B2Quick discoveryProvide feedbackSurgeryEndoscopesSignal processing circuitsSuction force

In an endoscope apparatus, an air / water switch (15) that is provided in an operating section (9) of an endoscope (5) each generate an air feed on / off signal and a suction on / off signal, and air feed flow and suction flow signals that are responsive to the amount of depression of each of the switches, these signals being sent to a signal processing circuit (33). The signal processing circuit (33) controls a air / water feed control valve 40 and a suction force control valve 50, so as to control air / water feed flow and suction flow, a flow display being made by an indicator (65) on the screen (63) of a TV monitor (35).

Owner:KK TOSHIBA

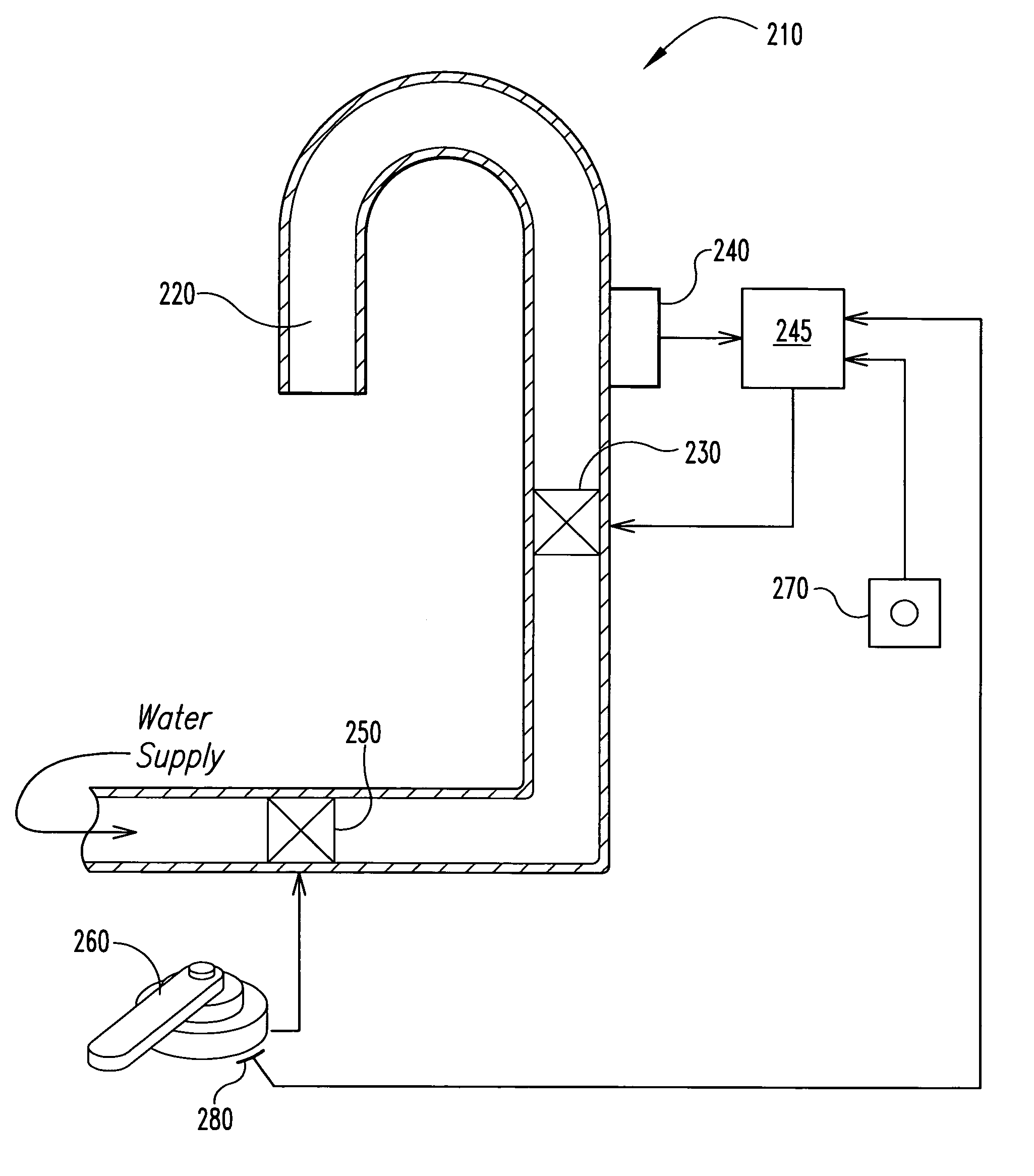

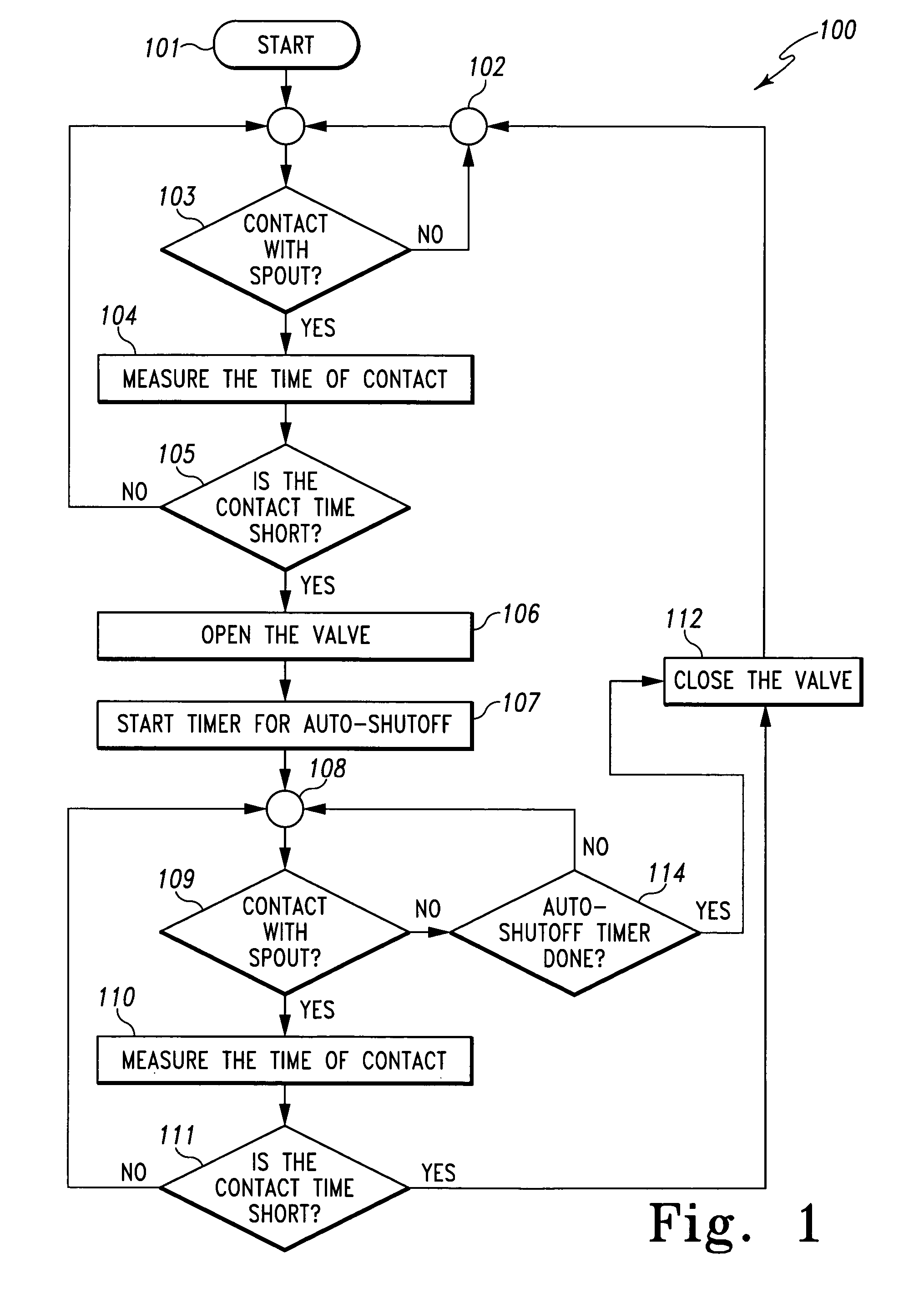

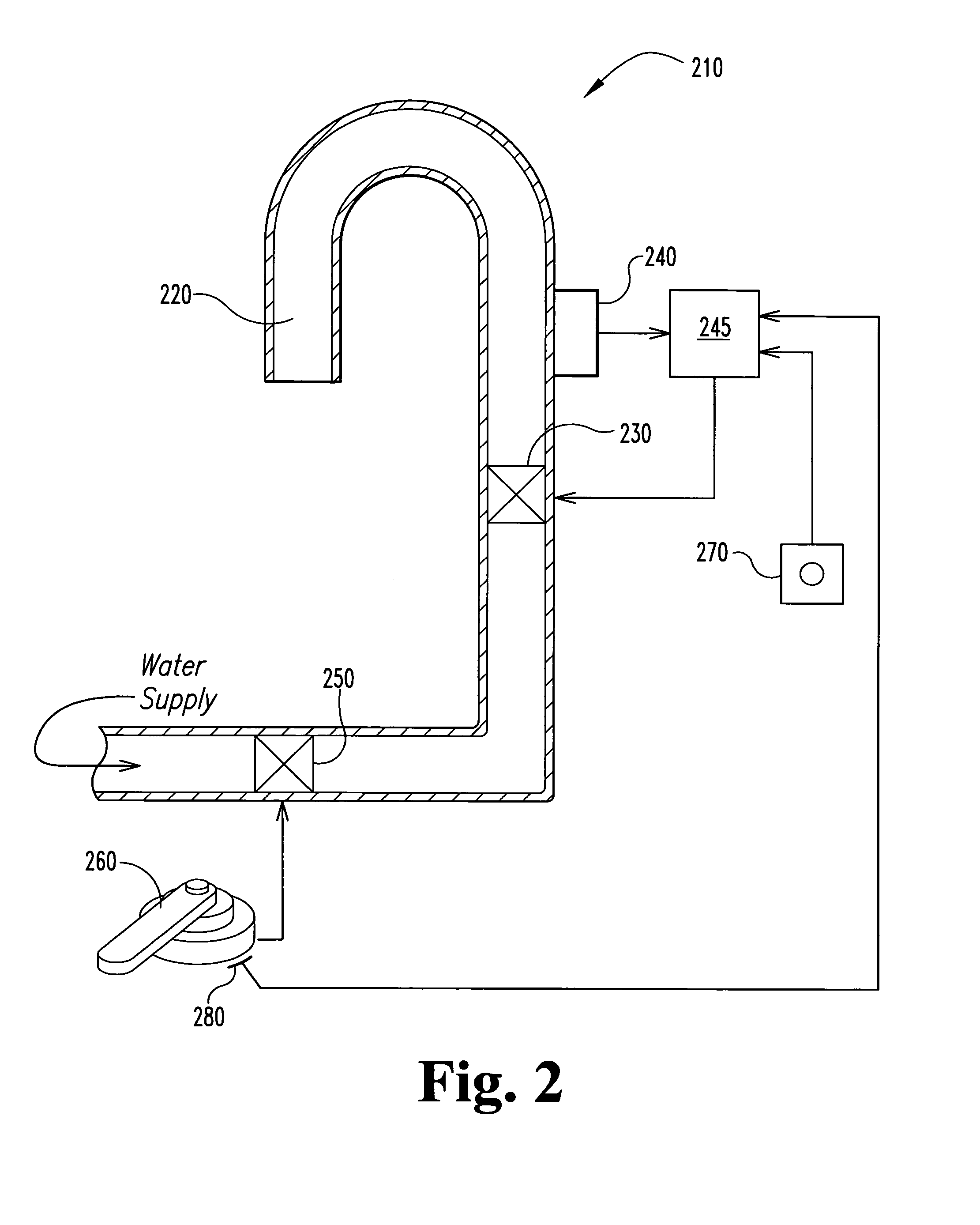

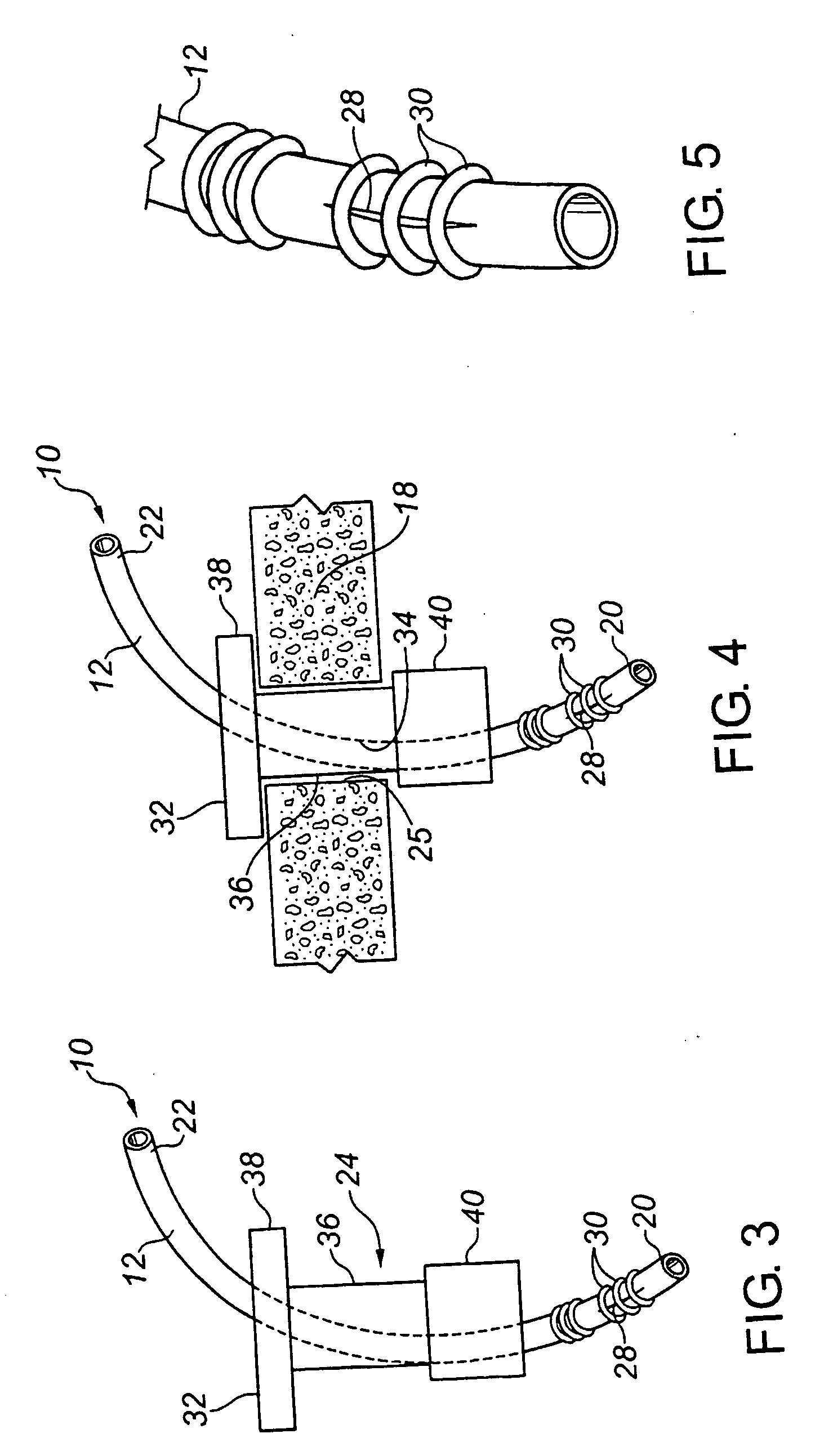

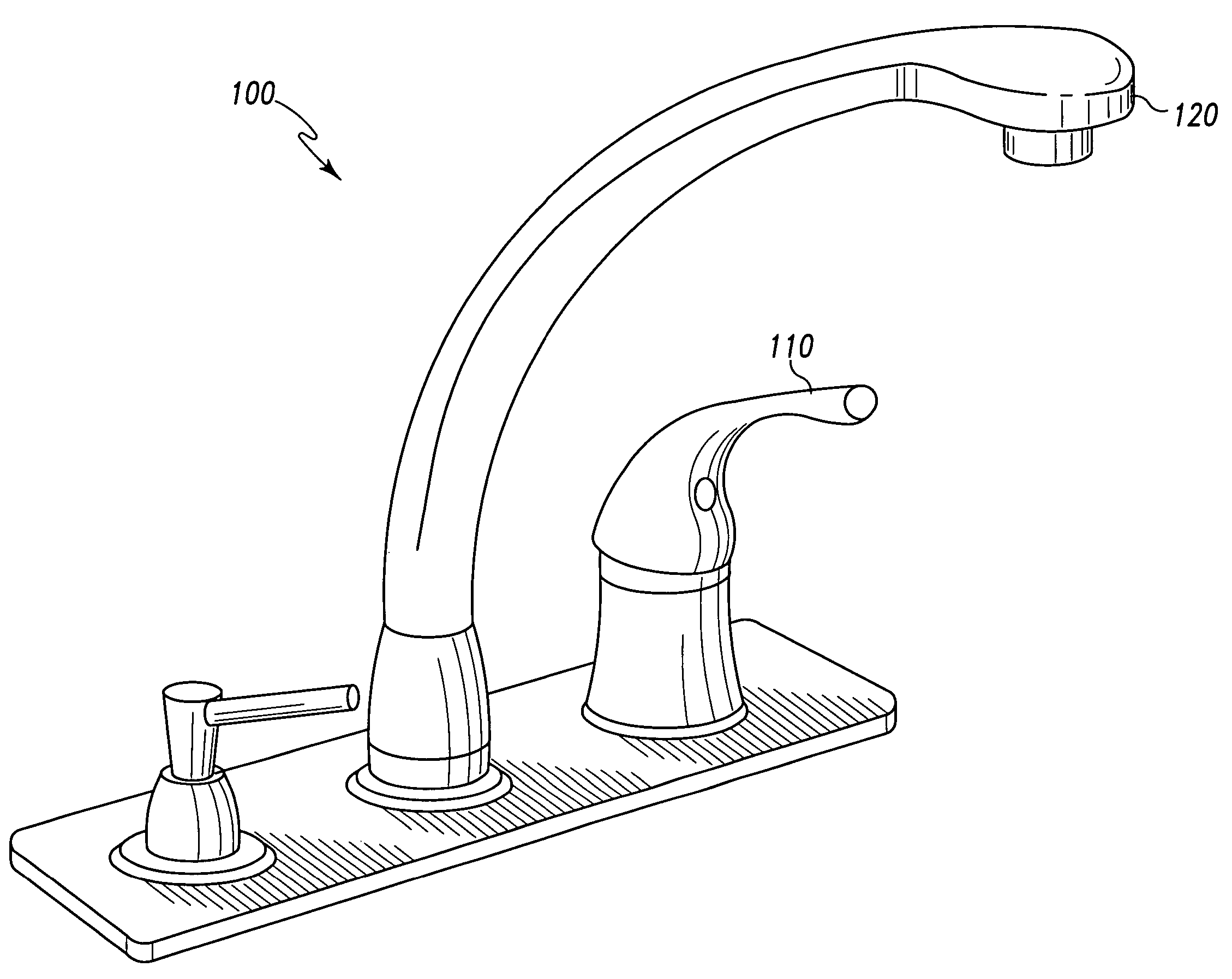

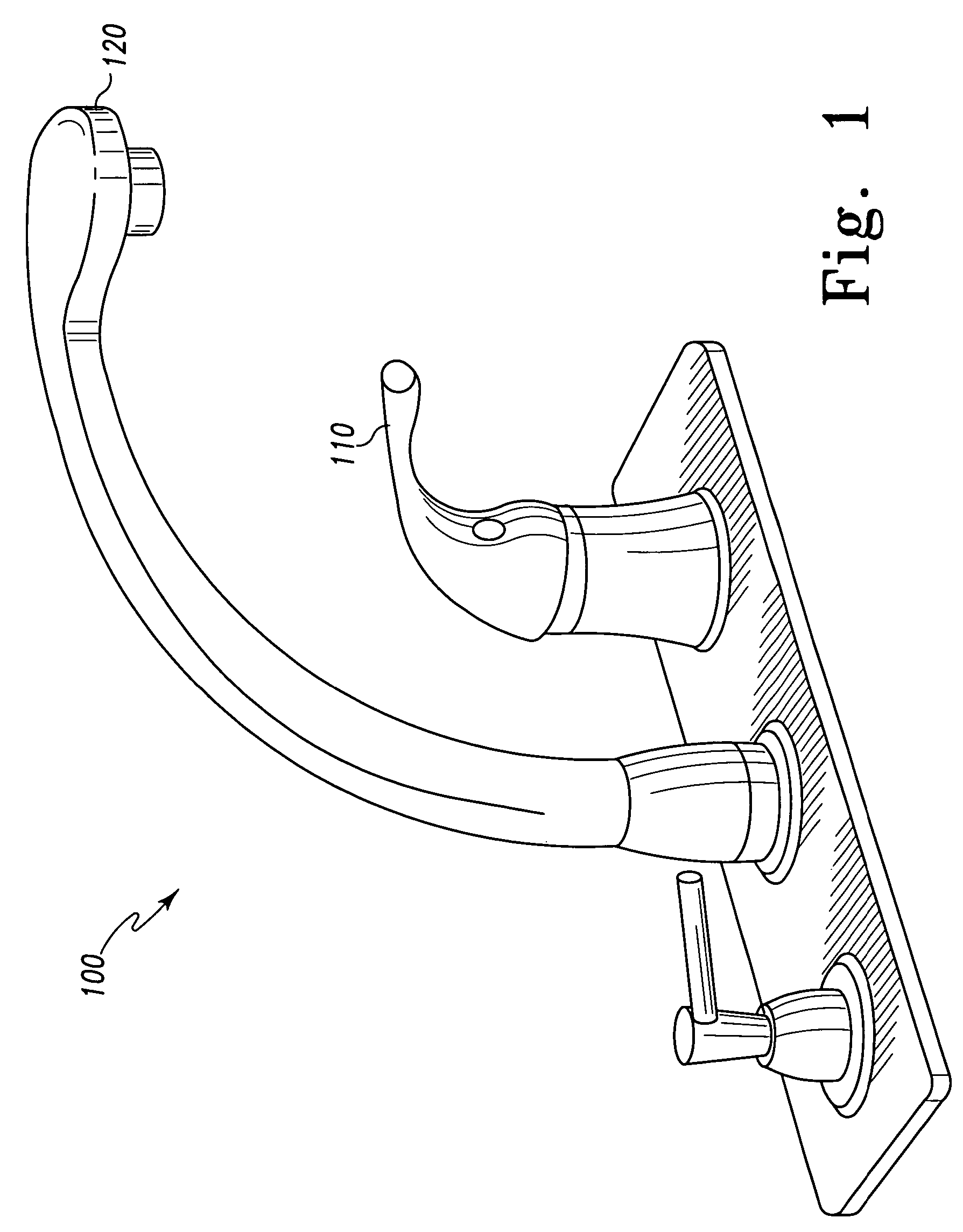

Capacitive touch on/off control for an automatic residential faucet

ActiveUS6962168B2Operating means/releasing devices for valvesServomotor componentsProximity sensorWater flow

A capacitive touch-controlled automatic faucet comprises: a spout, a magnetically latching valve, a proximity sensor, a handle, a capacitive touch-control, and a logical control. The proximity sensor is sensitive to motion of objects within a detection zone of the proximity sensor. The handle determines a water flow rate and temperature. The capacitive touch-control is positioned in the spout and generates an output signal while the touch-control is in contact with a user. The logical control receives the output signal, and toggles the magnetically latching valve when the output signal begins and ends within a period of time less than a predetermined threshold, but does not toggle the magnetically latching valve when the output signal persists for a period longer than the predetermined threshold. The faucet has a manual mode, wherein the proximity sensor is inactive, and a hands-free mode, wherein water flow is toggled in response to the proximity sensor.

Owner:DELTA FAUCET COMPANY

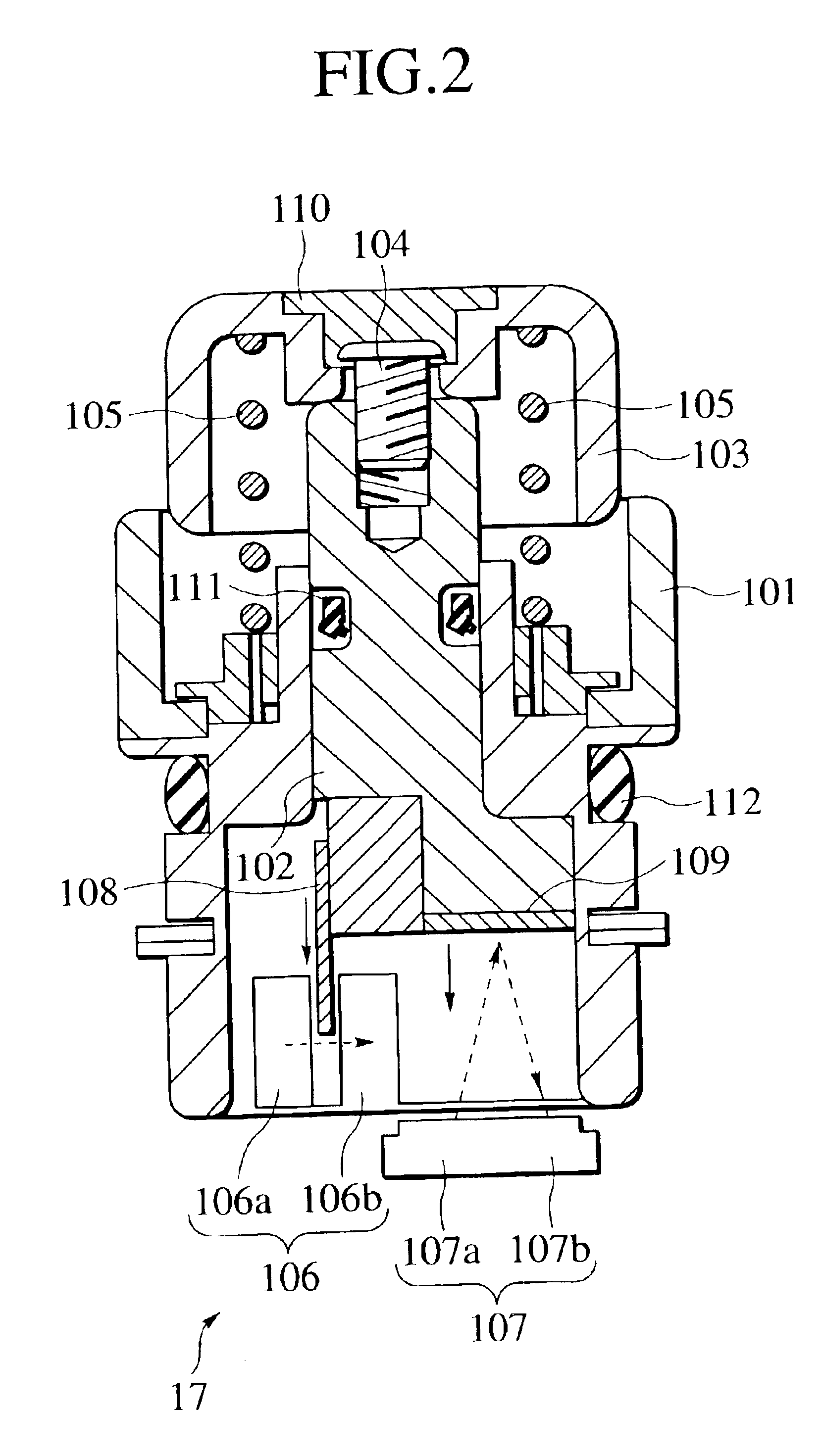

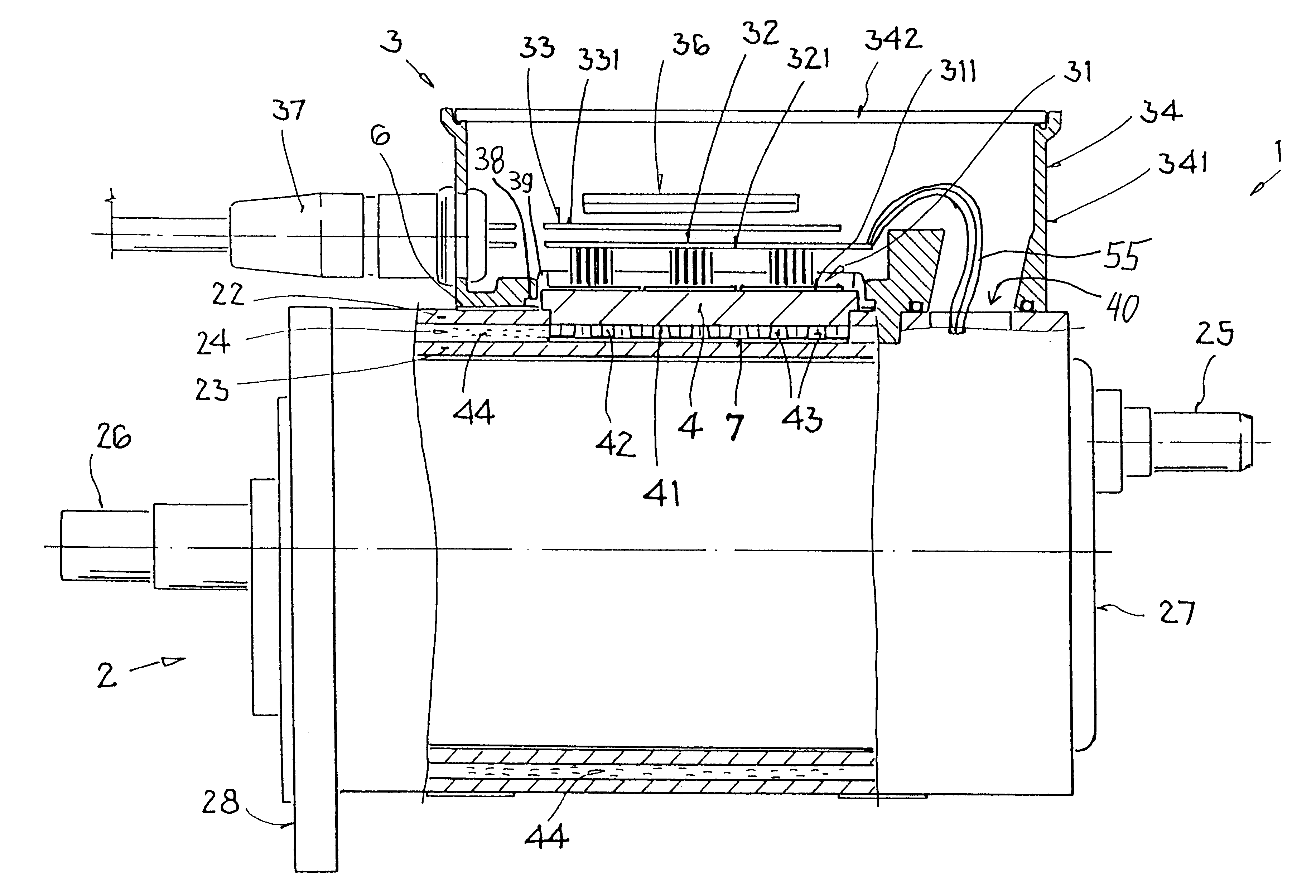

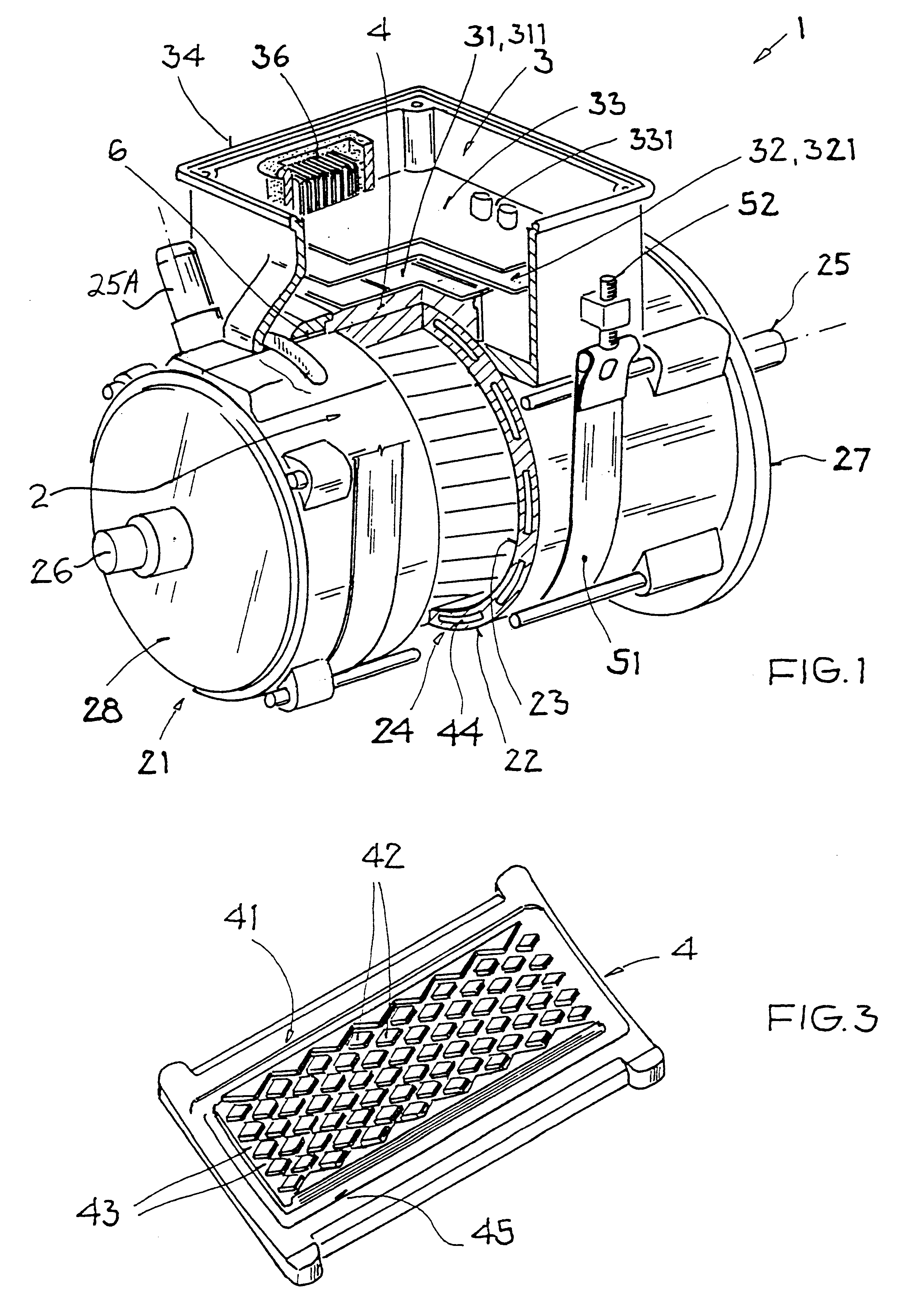

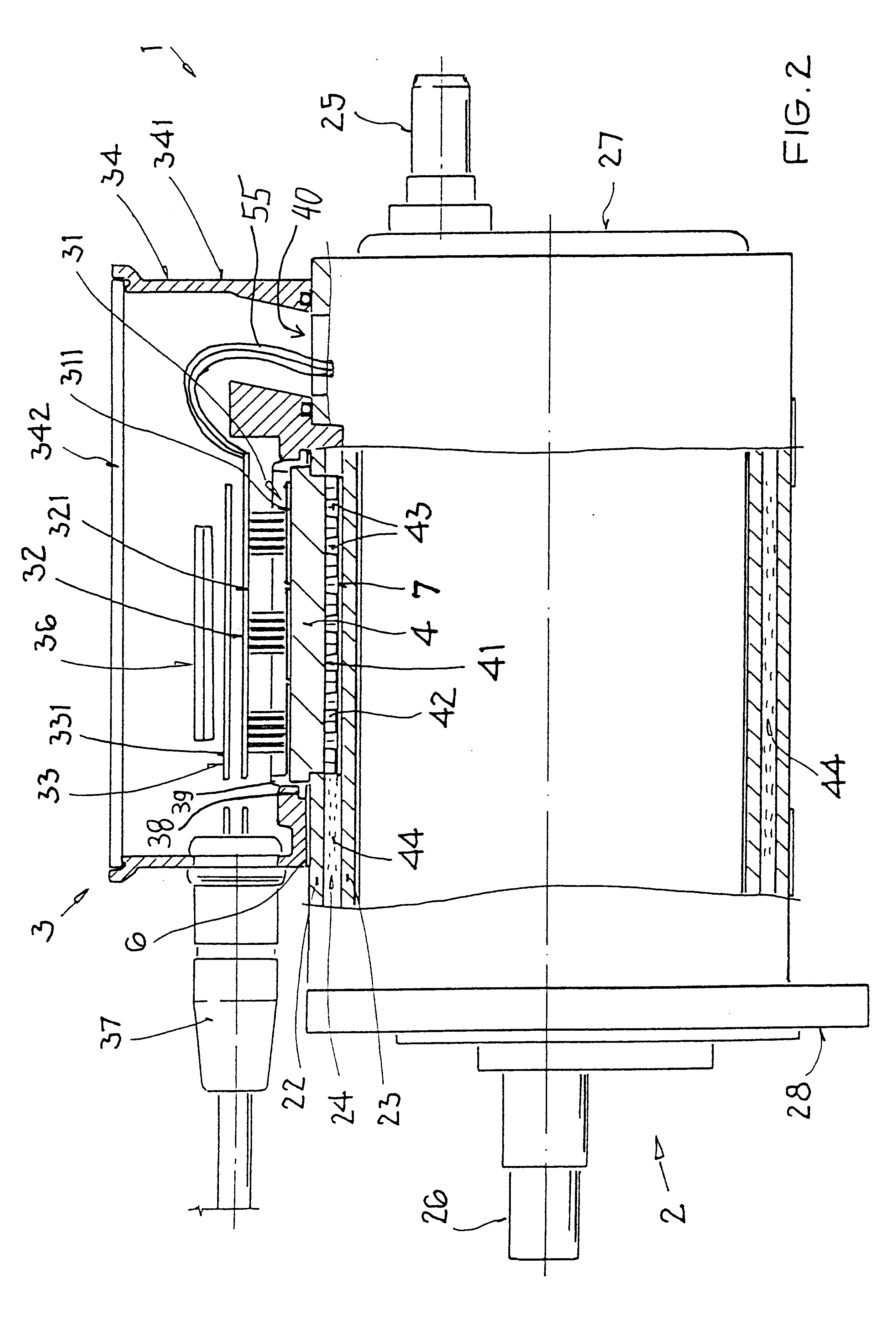

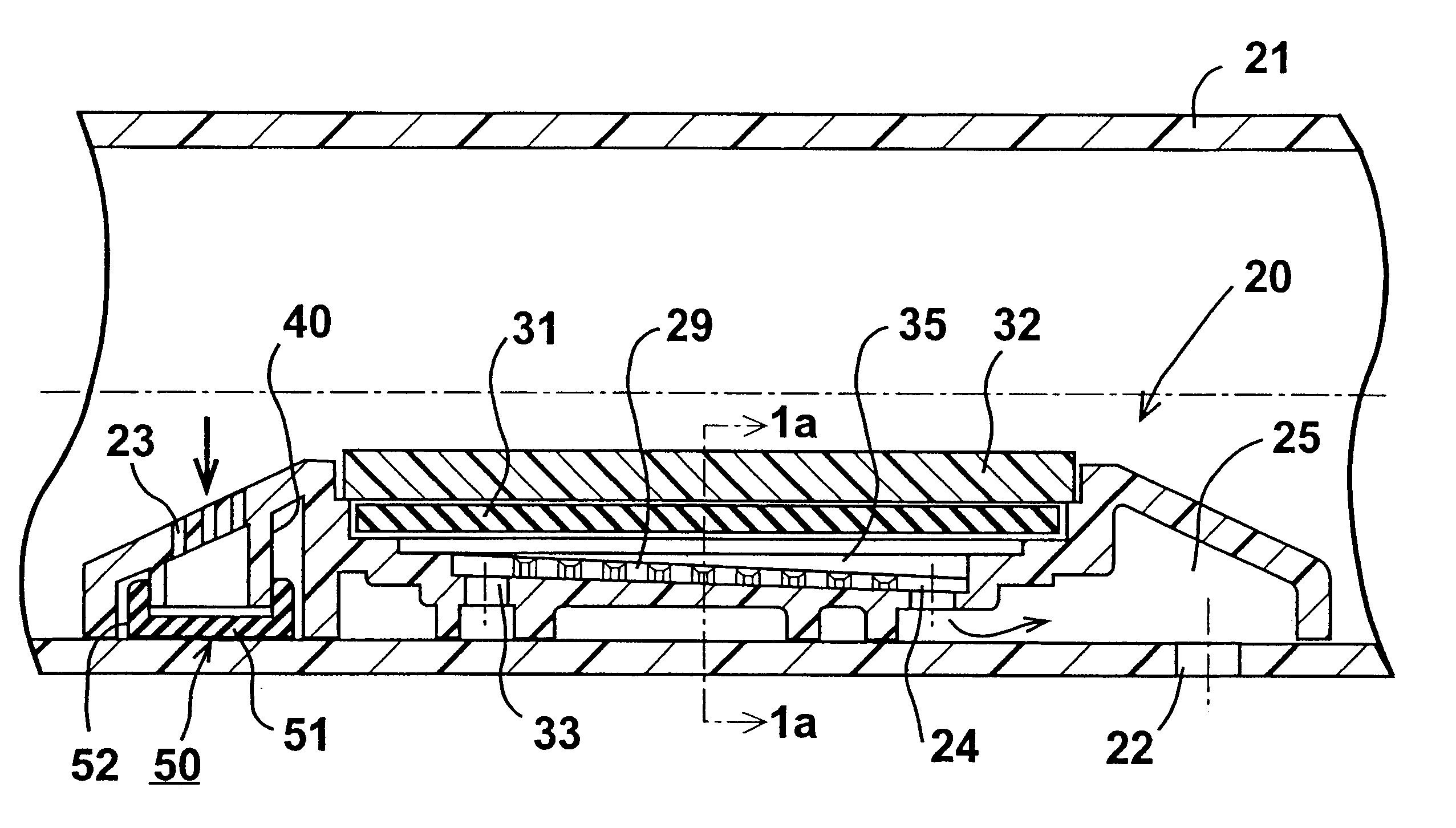

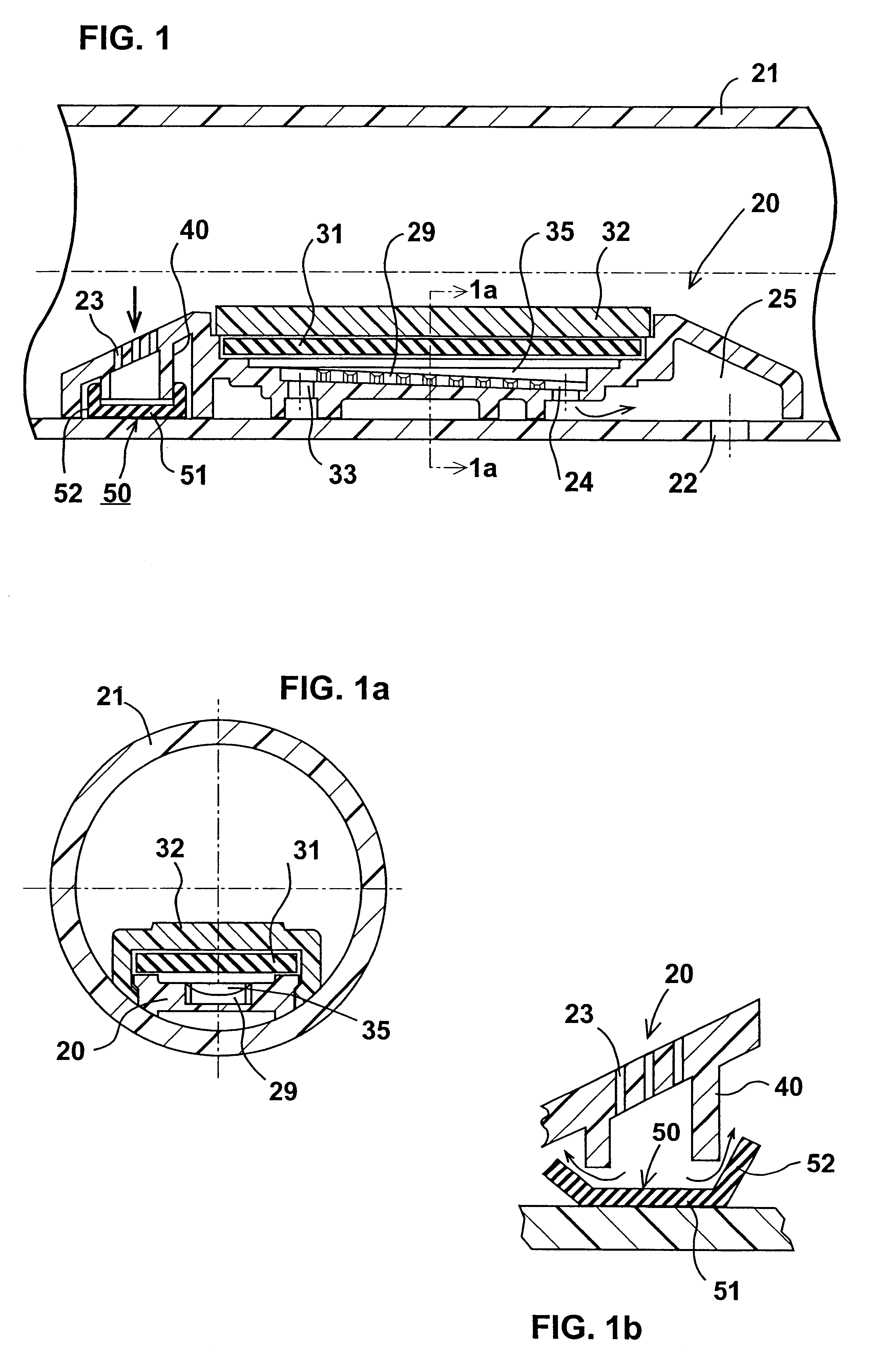

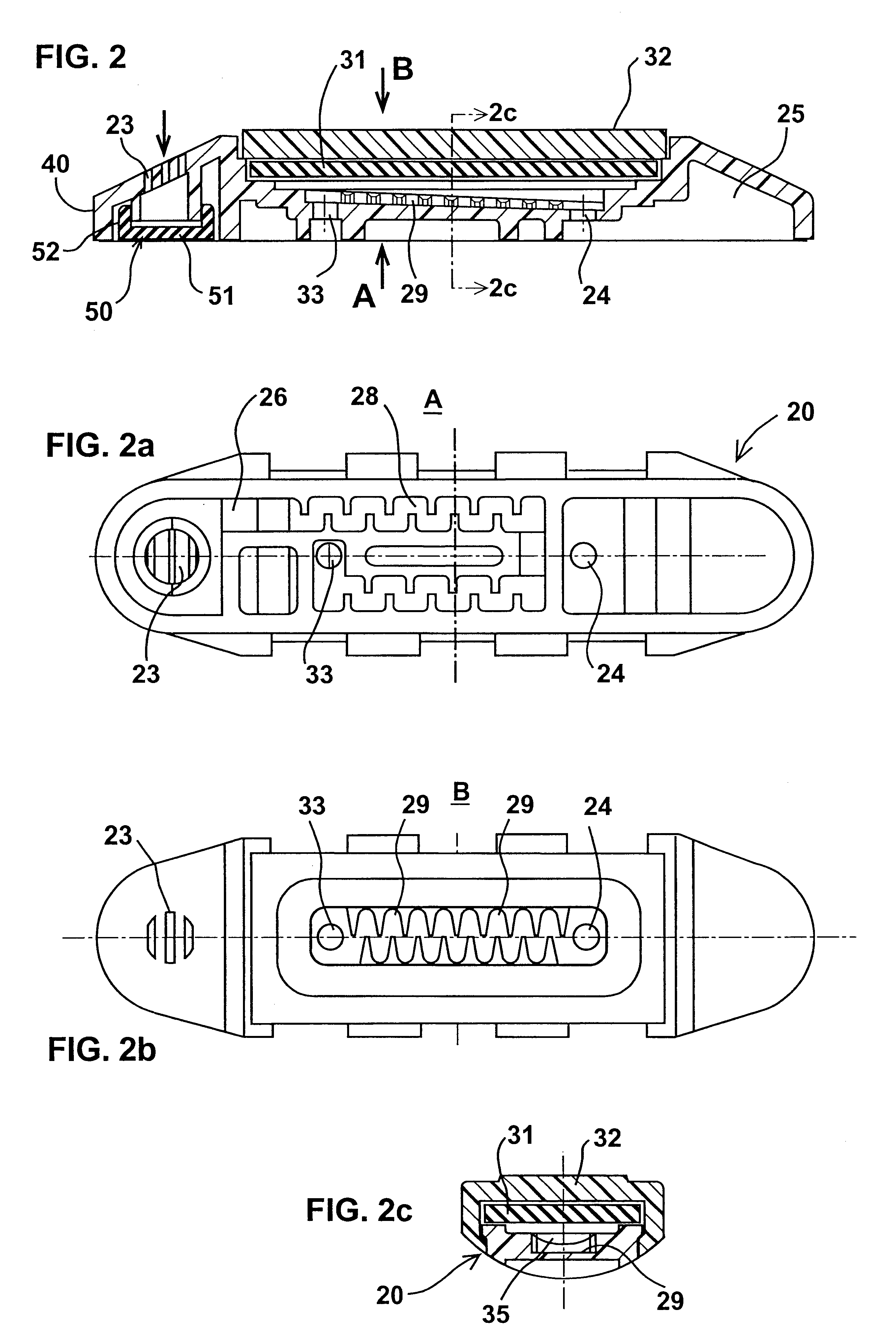

Integrated electric drive unit including an electric motor and an electronic control and monitoring module

InactiveUS6198183B1Small structural installation volumeReduce manufacturing costAssociation with control/drive circuitsMagnetic circuit rotating partsElectricityDouble wall

An electric drive unit includes an electronic control and monitoring module integrally connected to an electric motor. The housing of the electric motor has a double-walled construction to form a water jacket with cooling water passages therein. The electronic module includes at least one high power component that requires cooling. This component is mounted directly on a cooling insert that extends through a recess in the electronic module housing and is inserted in an opening provided in the outer wall of the motor housing. In this manner, the cooling insert is integrated into the water jacket of the motor housing and is directly cooled by the cooling water flowing in the cooling passages. A very compact and reliable construction is achieved, in which the electric motor and the electronic module share a common water cooling circuit. External water hoses and external electrical connections between the electric motor and the electronic module are avoided.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

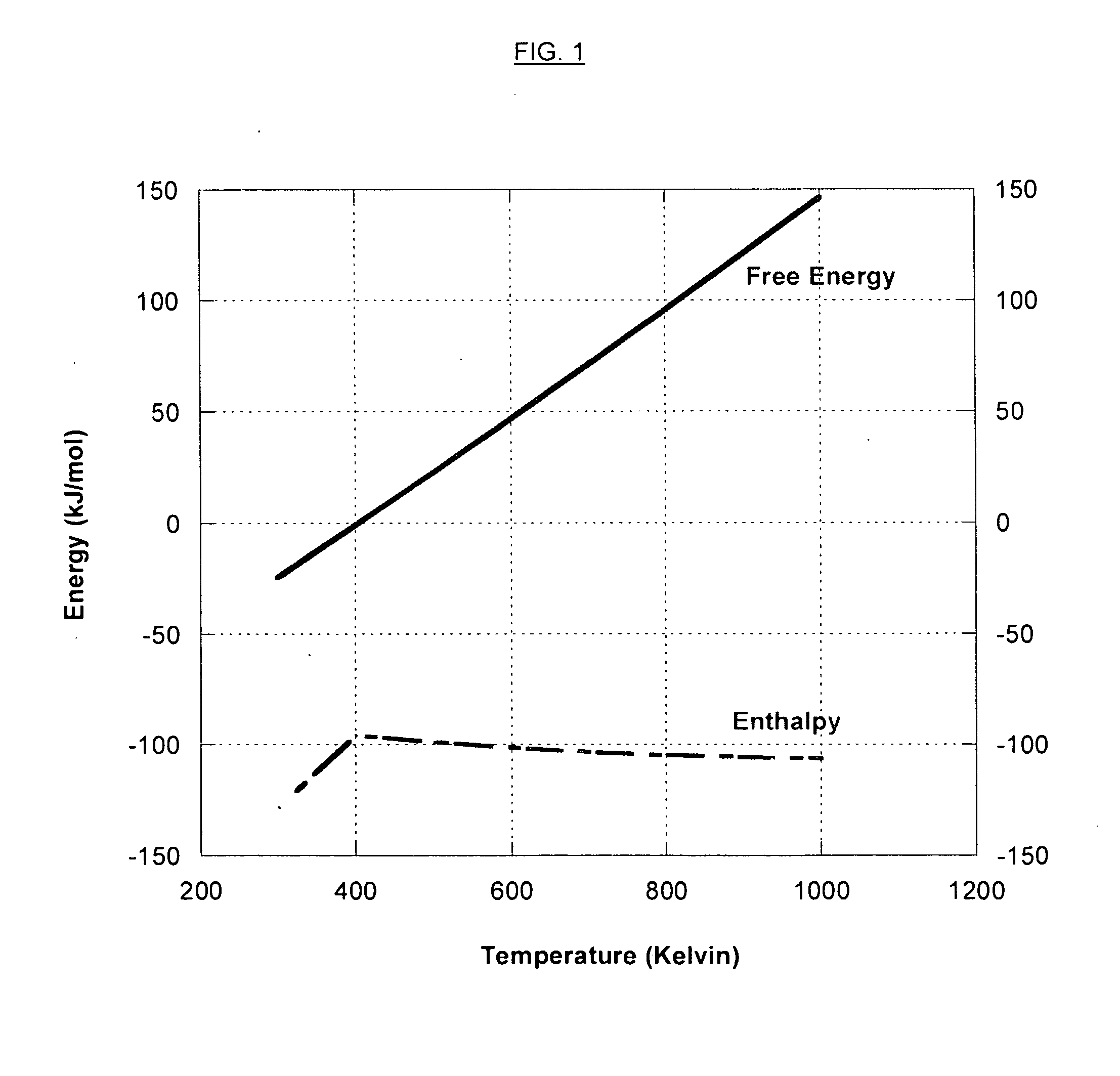

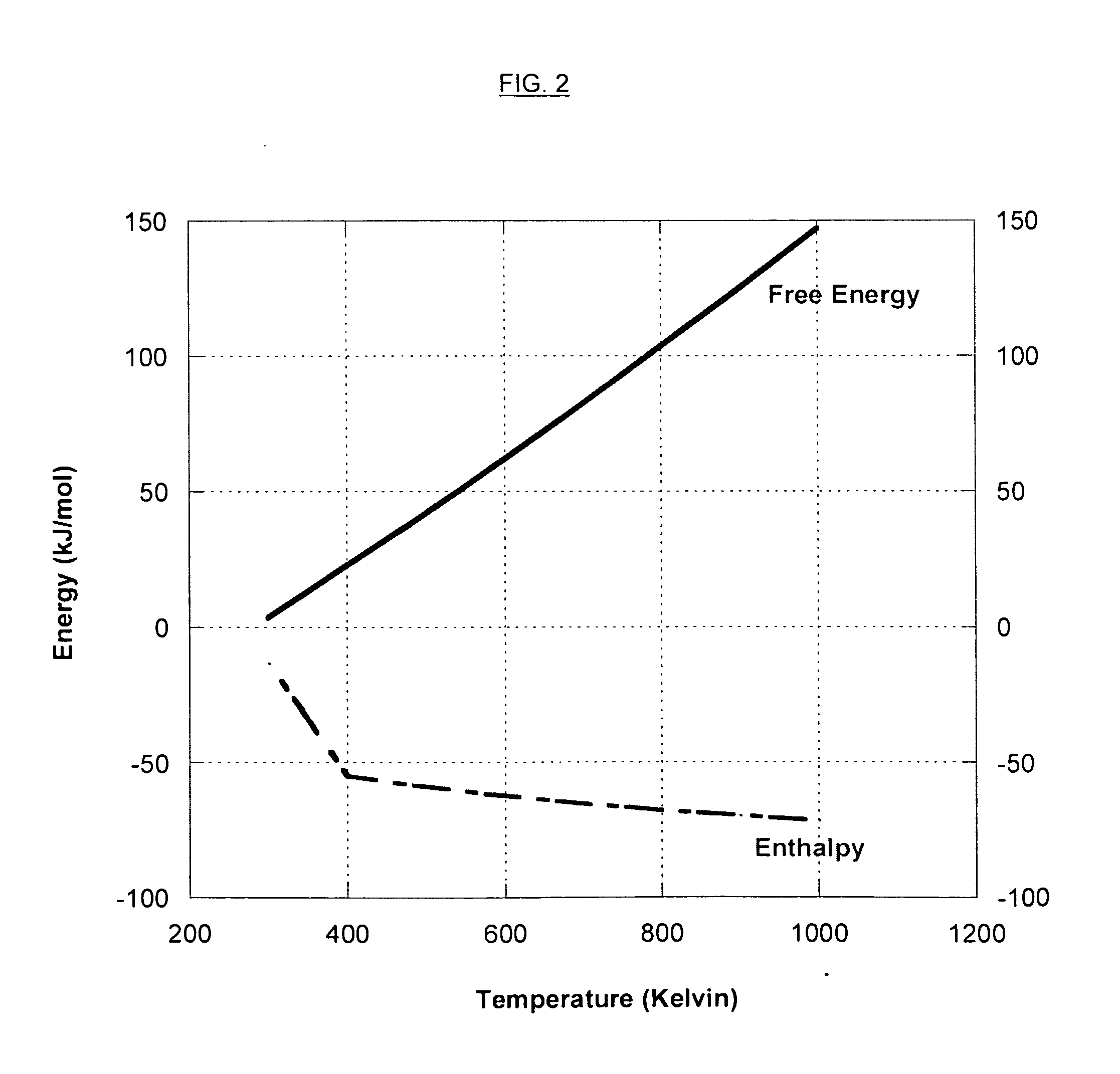

Methods and devices for the production of Hydrocarbons from Carbon and Hydrogen sources

InactiveUS20080283411A1Reduce the environmentEasy to controlPhotography auxillary processesInternal combustion piston enginesElectrolysisAtmospheric air

Devices and methods are described for converting a carbon source and a hydrogen source into hydrocarbons, such as alcohols, for alternative energy sources. The influents may comprise carbon dioxide gas and hydrogen gas or water, obtainable from the atmosphere for through methods described herein, such as plasma generation or electrolysis. One method to produce hydrocarbons comprises the use of an electrolytic device, comprising an anode, a cathode and an electrolyte. Another method comprises the use of ultrasonic energy to drive the reaction. The devices and methods and related devices and methods are useful, for example, to provide a fossil fuel alternative energy source, store renewable energy, sequester carbon dioxide from the atmosphere, counteract global warming, and store carbon dioxide in a liquid fuel.

Owner:PRINCIPLE ENERGY SOLUTIONS

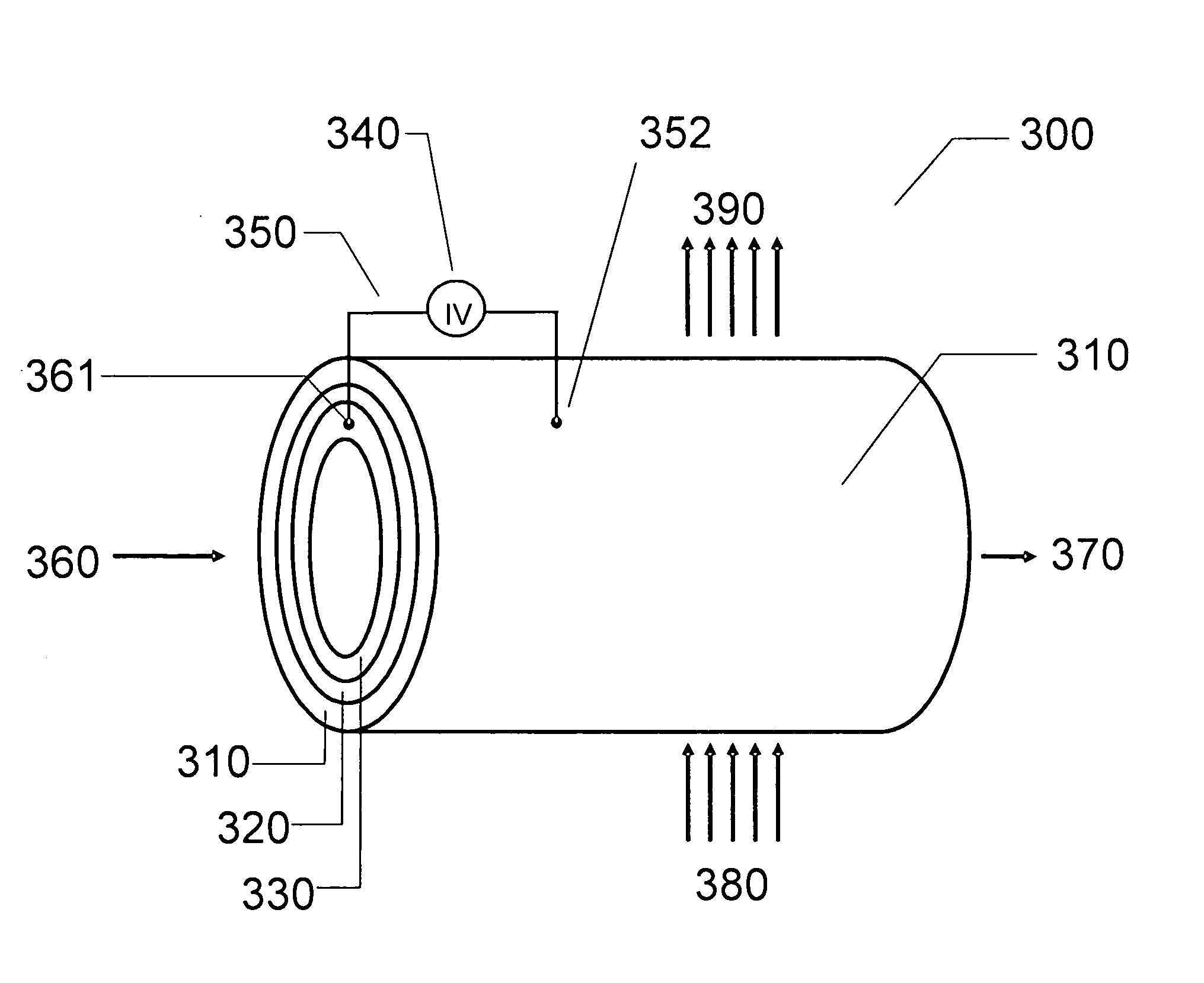

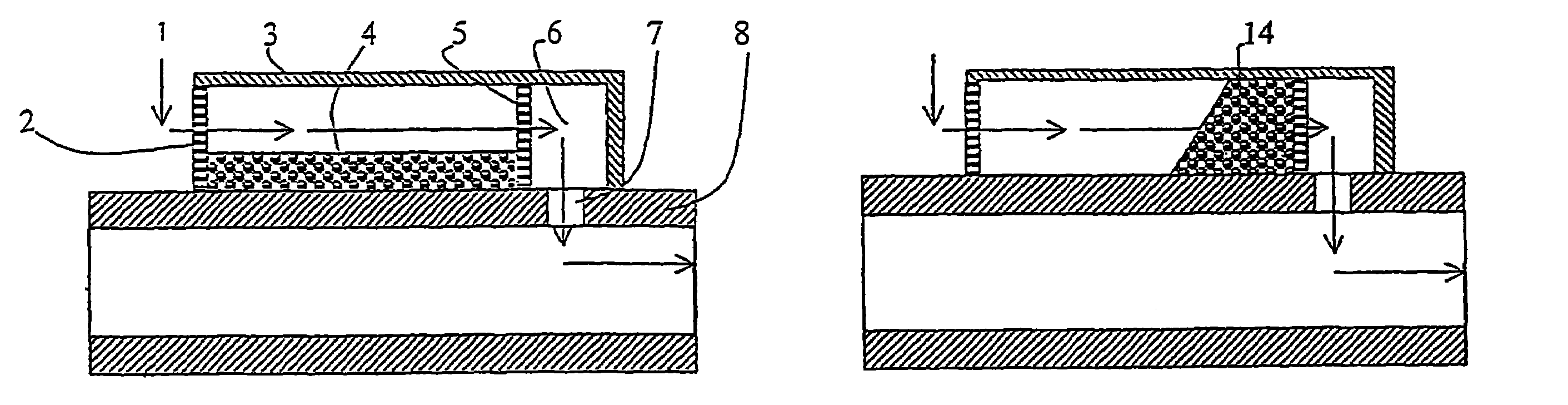

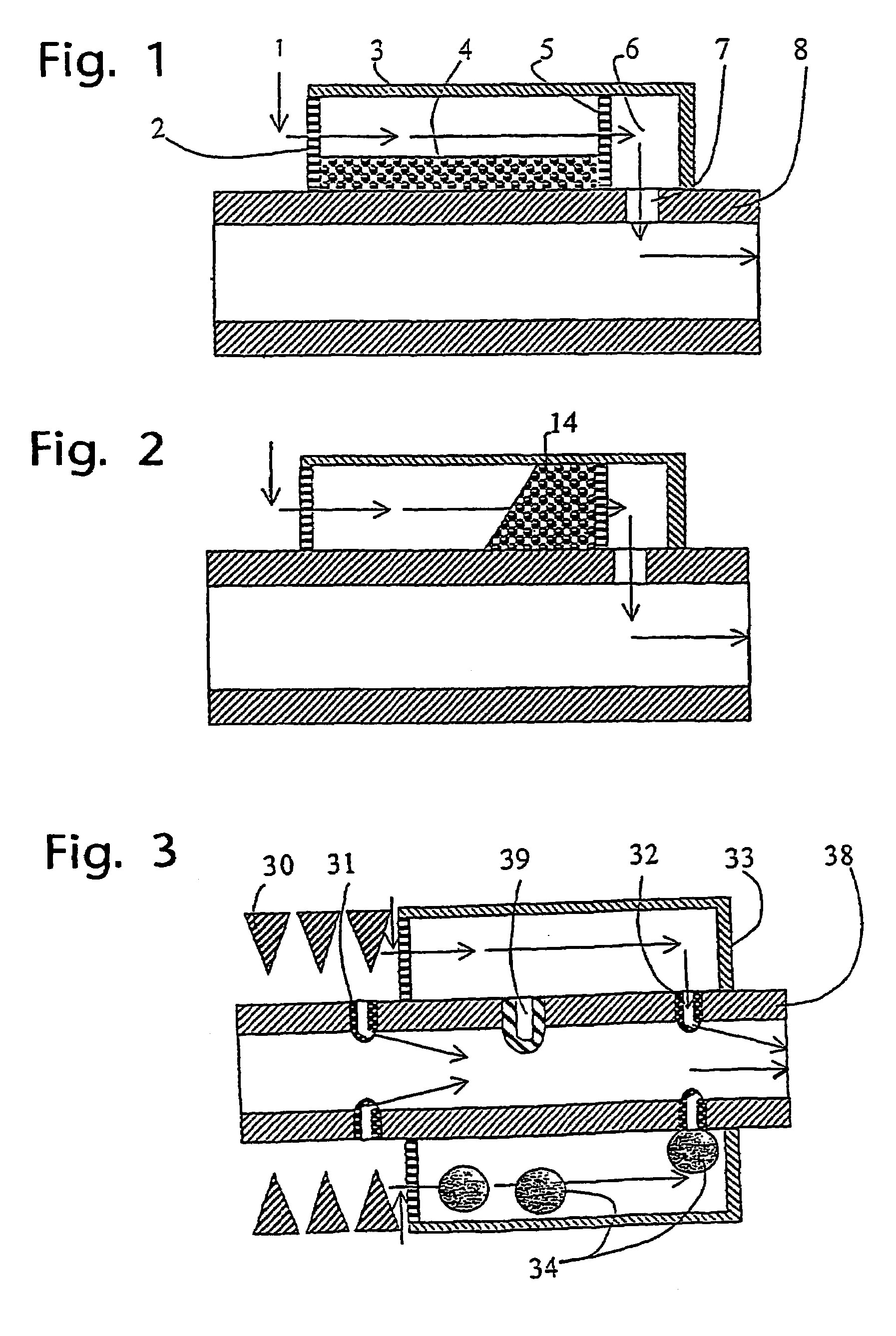

Arrangement for and method of restricting the inflow of formation water to a well

InactiveUS7185706B2Low mobilityNeutral buoyancyDrilling rodsFluid removalWater flowVolumetric Mass Density

An arrangement for restricting the inflow of formation water from an underground formation to a hydrocarbon producing well, where, between the underground formation and a production tubing (38) located in the well, there is disposed at least one flow chamber (3, 33) connected to the production tubing (38), the flow chamber (3, 33), preferably via a filter (2) in one portion, being open to inflow of formation fluid and in communication with the production tubing (38) via at least one opening (7, 32), and where the flow chamber (3, 33) is provided with at least one free-floating body (4, 34) with approximately the same density as the formation water, the at least one body (4, 34) being designed by means of the closing of at least one opening (32) or choking, to reduce the inflow of formation water to the production tubing (38).

Owner:HALLIBURTON ENERGY SERVICES INC

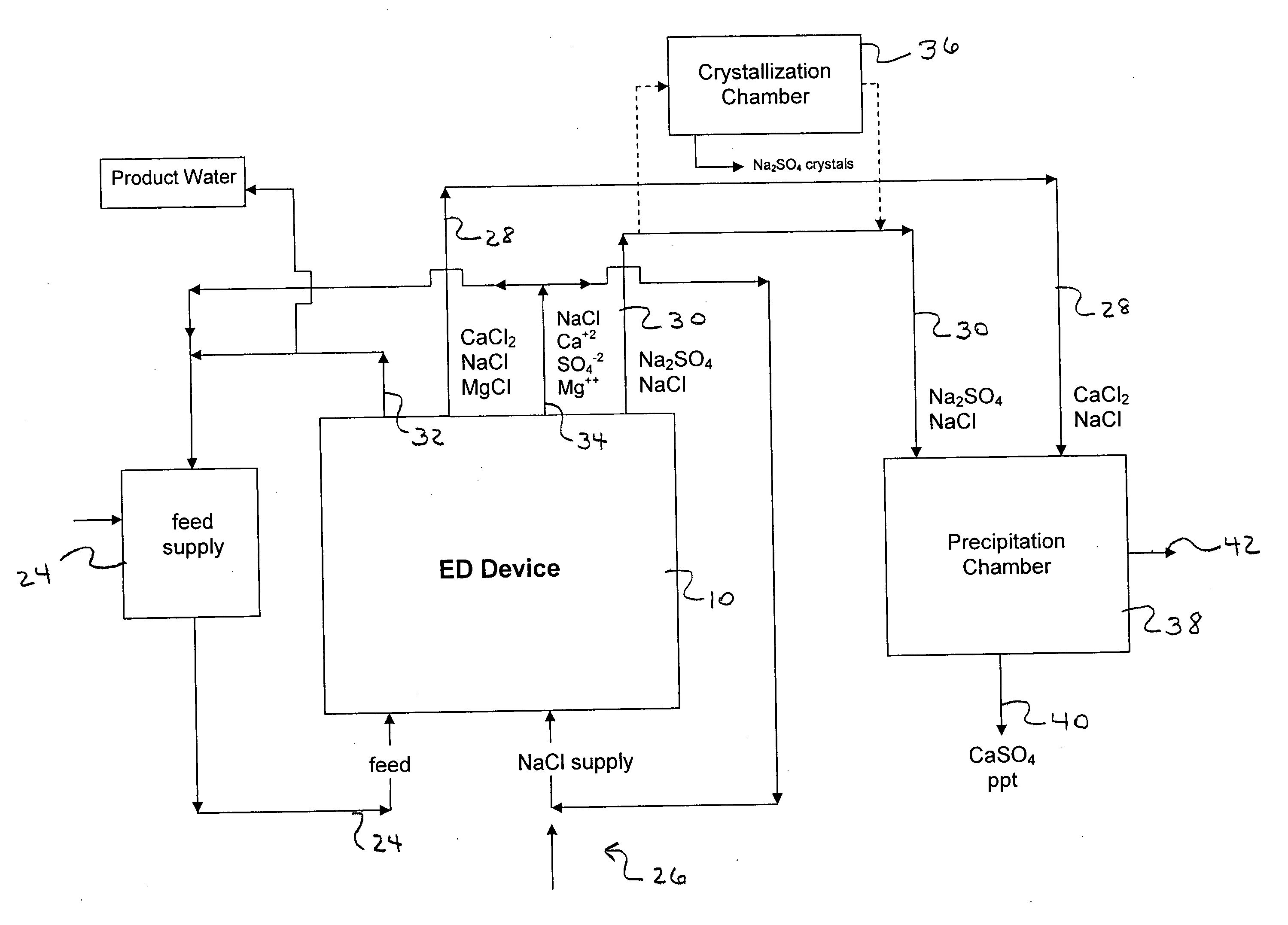

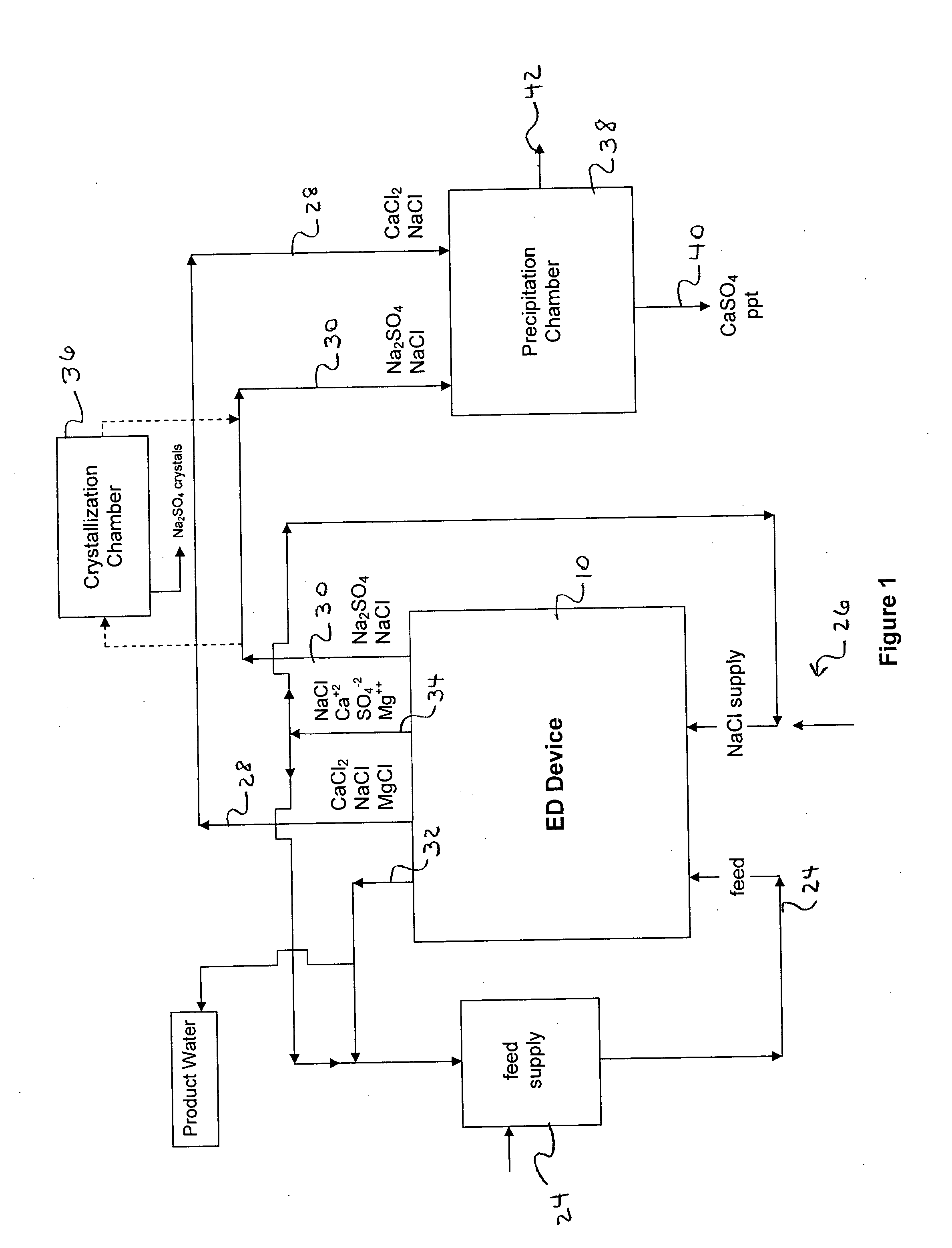

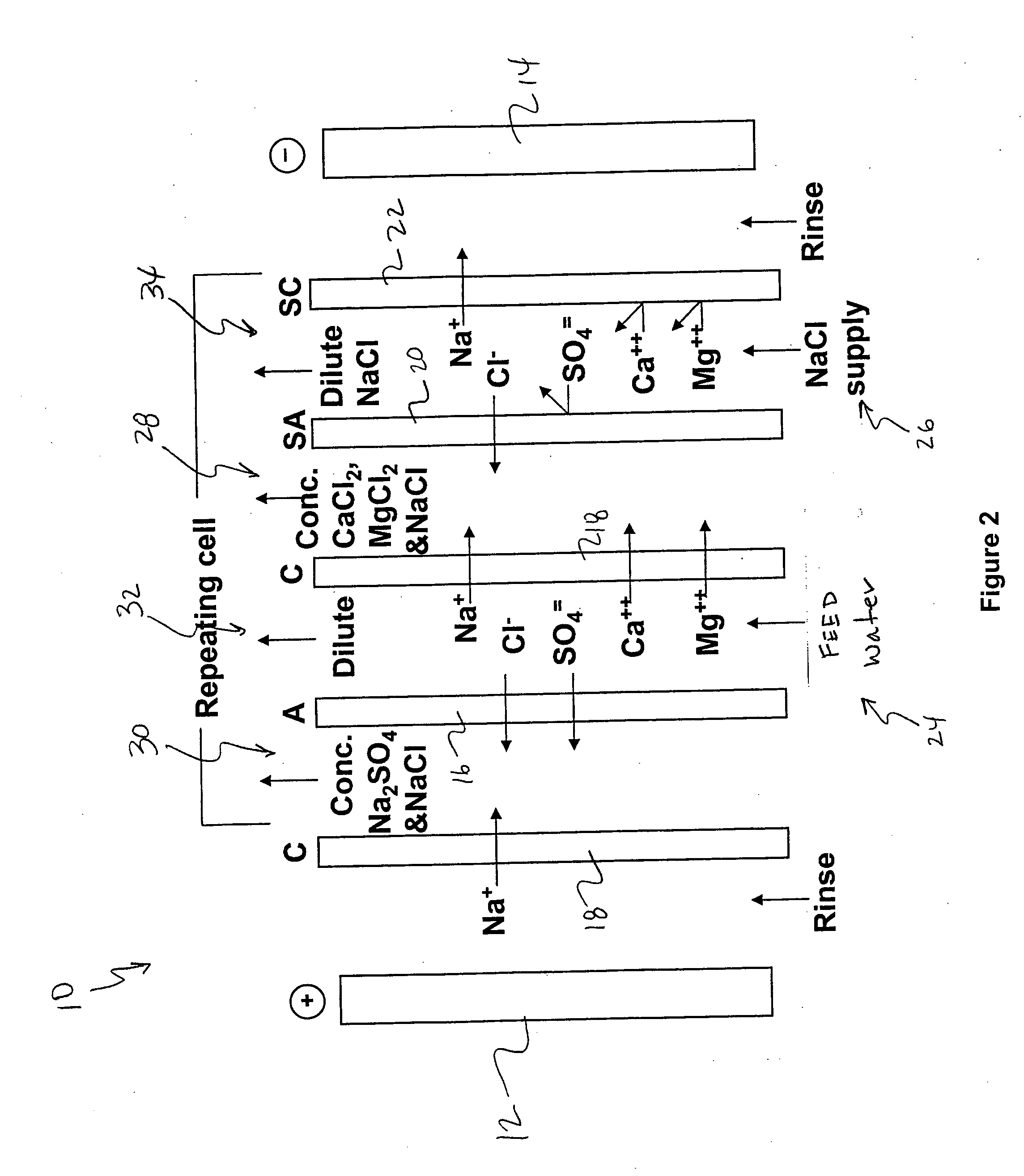

Water desalination process and apparatus

ActiveUS20060060532A1Electrolysis componentsGeneral water supply conservationSolubilityWater desalination

A process and system for purifying water is disclosed. For example, in one embodiment, the process may be used to remove a divalent salt, such as calcium sulfate, from a water source in order to prevent the divalent salt from precipitating during the process. The water source, for instance, may be fed to an ion separating device, such as an electrodialysis device. In the electrodialysis device, an ion exchange takes place between the divalent salt and another salt, such as a monovalent salt to produce two concentrated salt streams that contain salts having greater solubility in water than the divalent salt. In one embodiment, the two salt streams that are produced may then be combined to precipitate the divalent salt in a controlled manner. During the process, various other components contained within the water feed stream may also be removed from the stream and converted into useful products. In one particular embodiment, the process is configured to receive a byproduct stream from a reverse osmosis process.

Owner:SOUTH CAROLINA THE UNIV OF

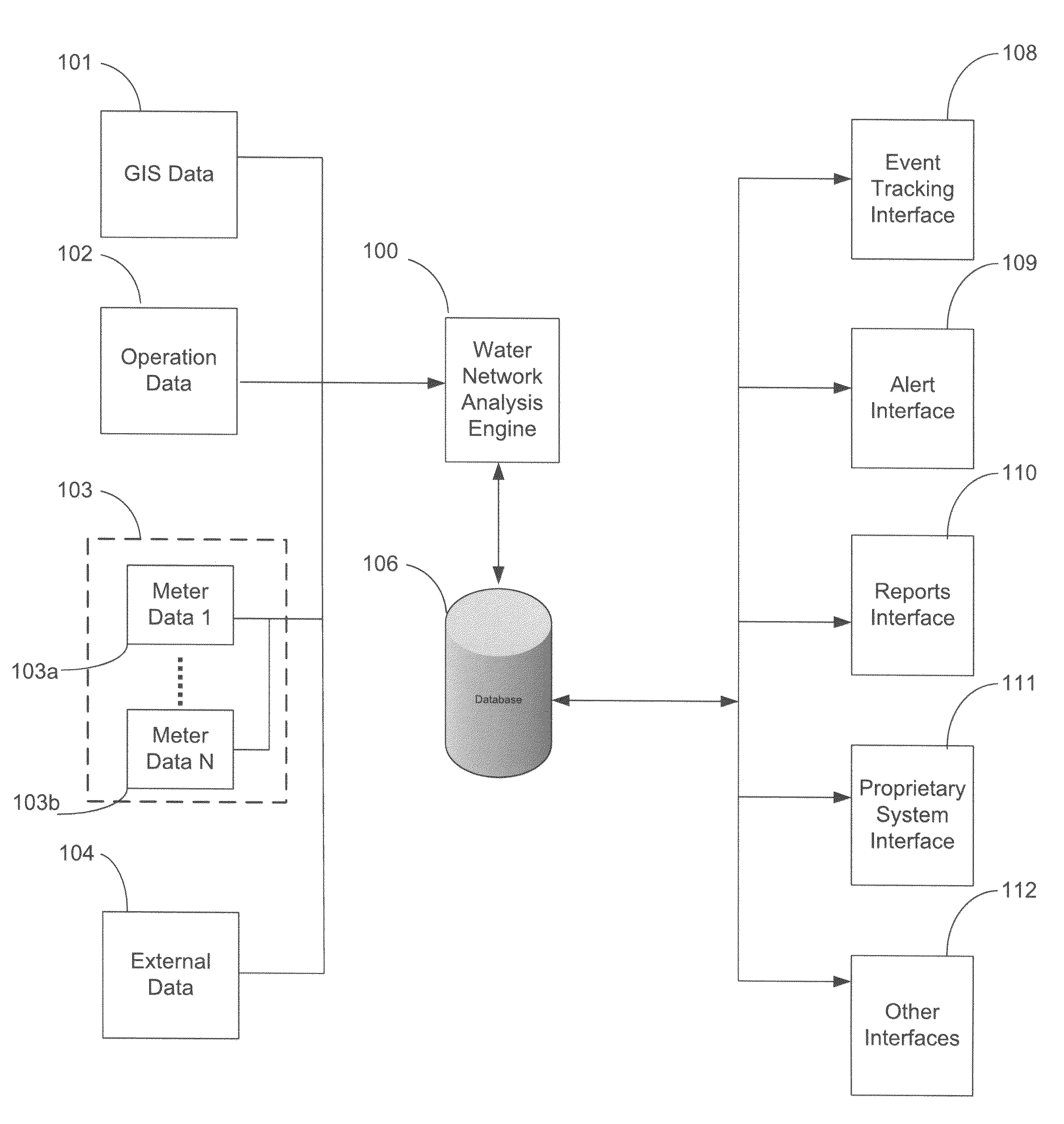

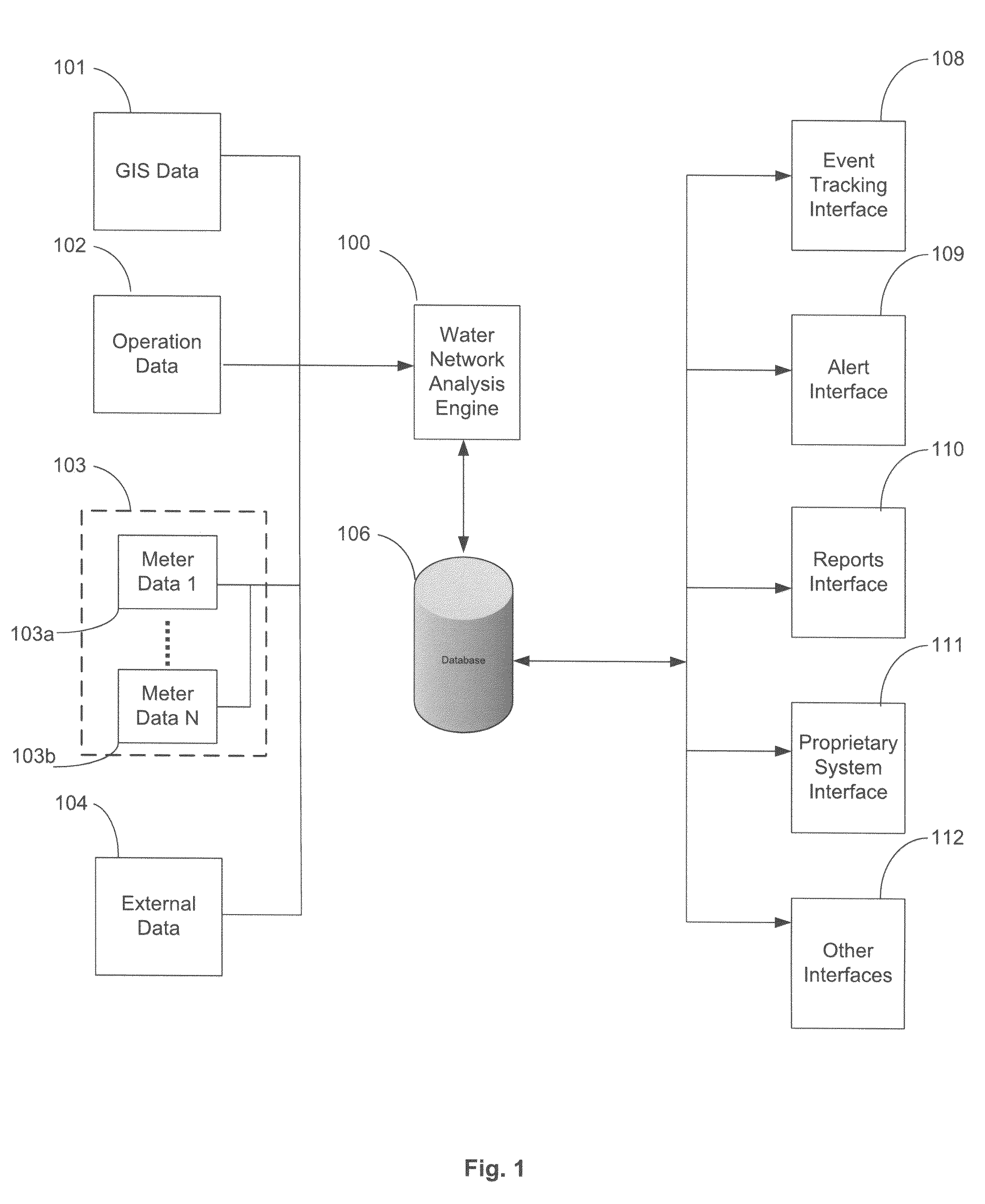

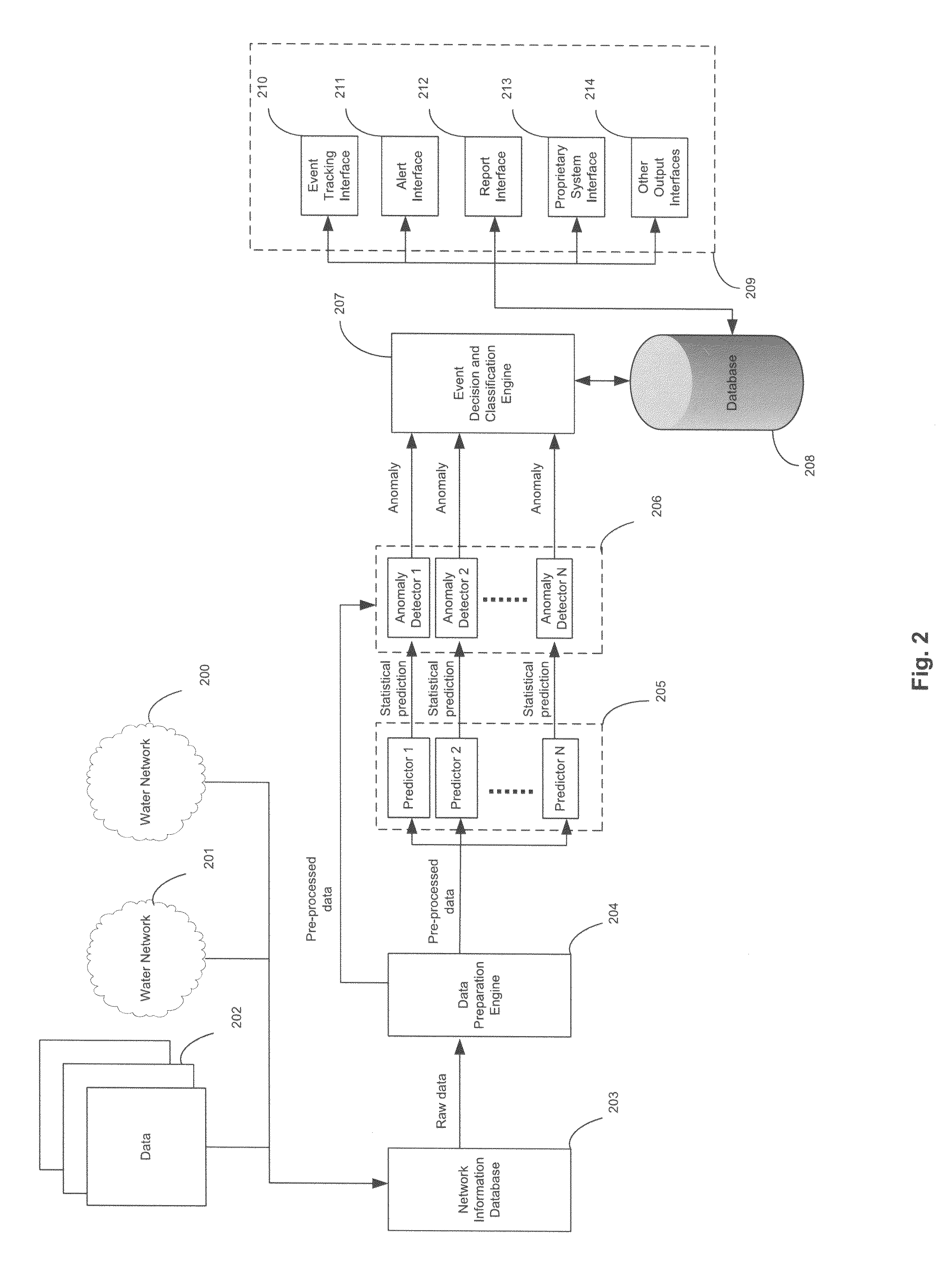

System and method for monitoring resources in a water utility network

ActiveUS7920983B1Easy to detectIncrease consumptionElectric signal transmission systemsTesting/calibration apparatusWater utilityUtility industry

A computerized method for monitoring a water utility network, the water utility network comprising a network of pipes for delivering water to consumers and a plurality of meters positioned within the pipes across the water distribution network. The method includes receiving meter data representing parameters measured by the meters, such as flow, pressure, chlorine level, pH and turbidity of the water being distributed through the pipes. The method also includes receiving secondary data from sources external to the meters and representing conditions affecting consumption of water in a region serviced by the water utility network such as weather and holidays. The meter and secondary data is analyzed using statistical techniques to identify water network events including leakage events and other events regarding quantity and quality of water flowing through the pipes and operation of the water network. The events are reported to users via a user interface.

Owner:TAKADU

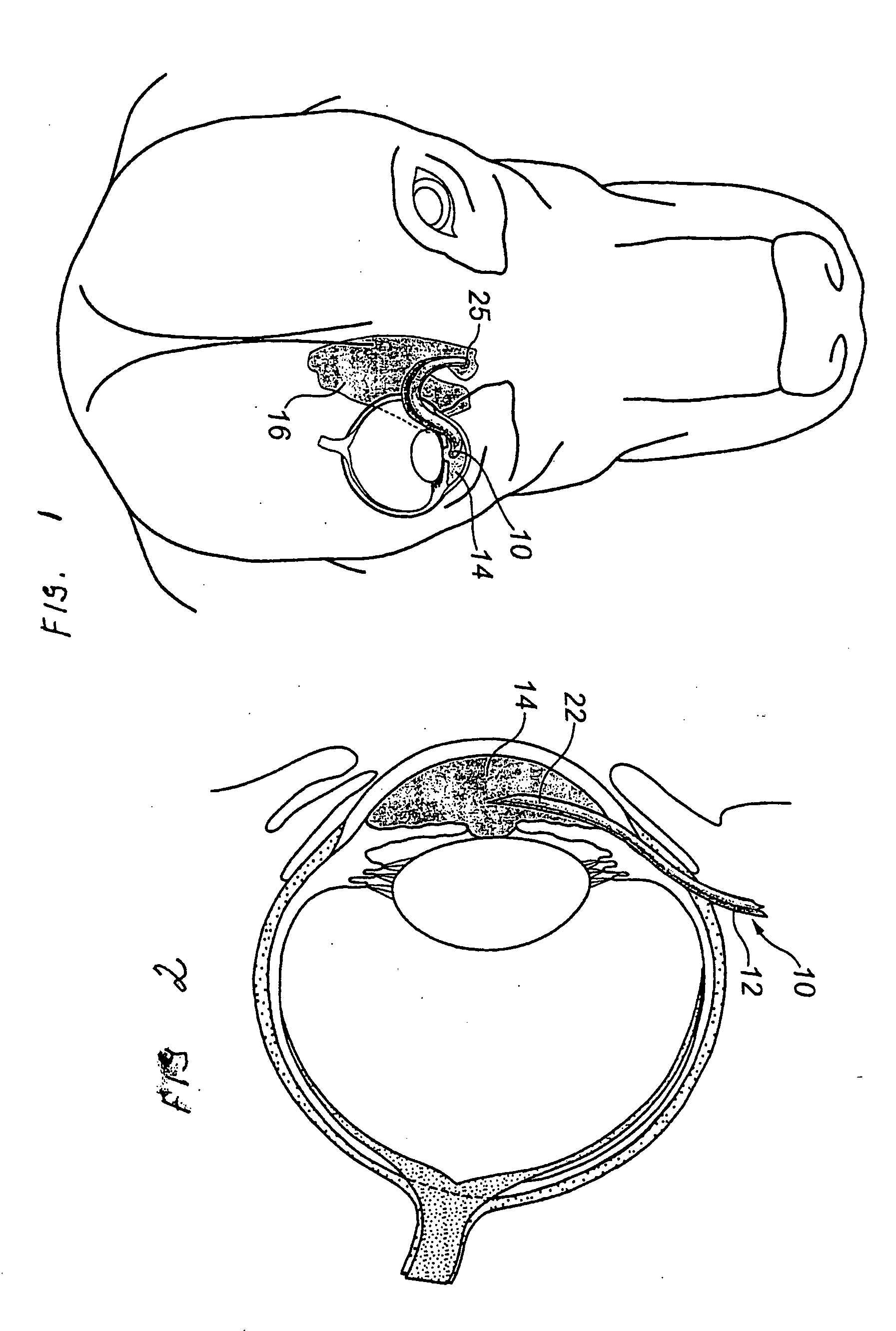

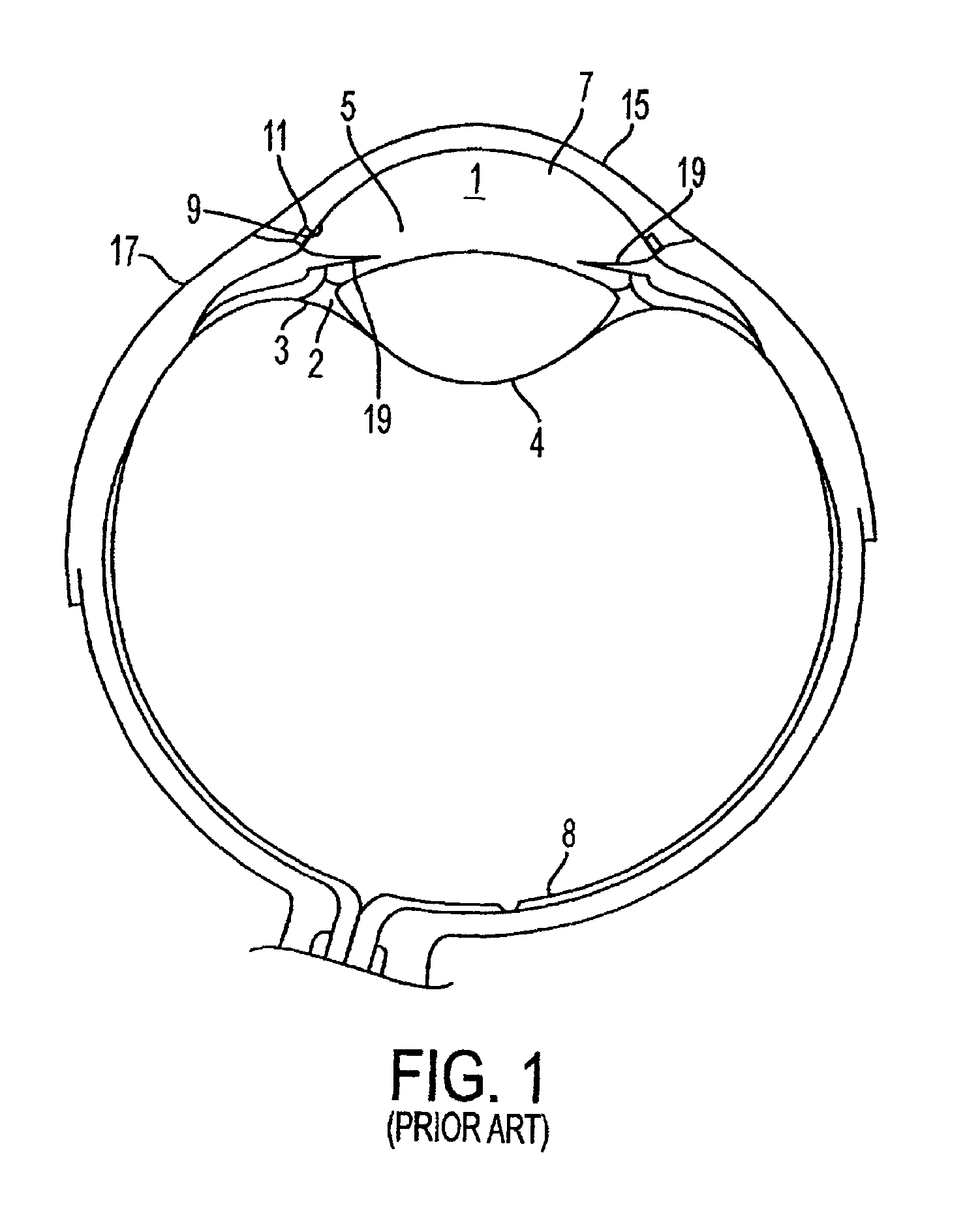

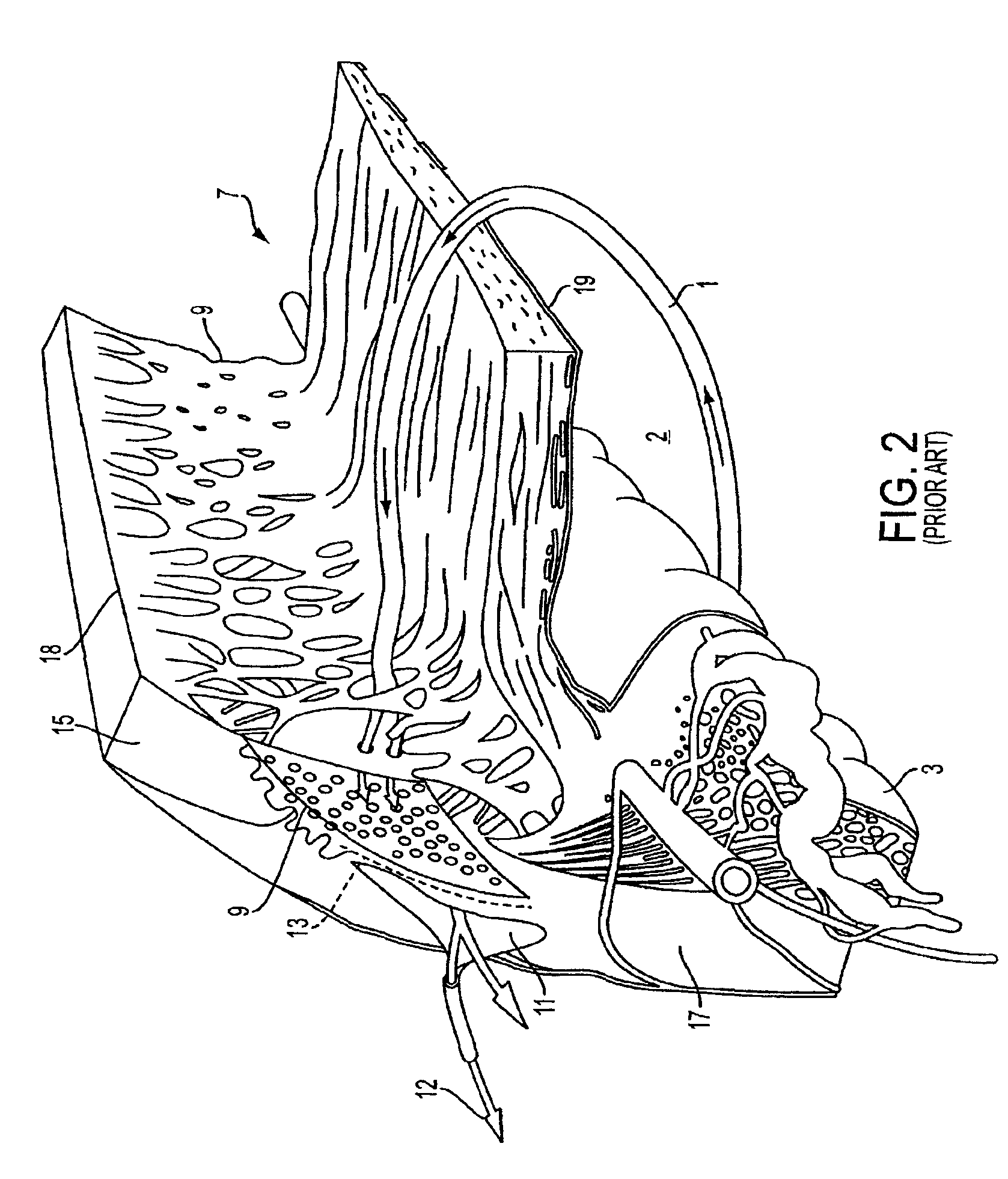

Shunt and method treatment of glaucoma

InactiveUS20050273033A1Avoid insufficient lengthEye surgeryWound drainsAqueous humorLeft frontal sinus

This invention provides a shunt for implantation between the anterior chamber of the eye and the epithelial-lined space through the frontal sinus bone of a patient for the treatment of glaucoma. The shunt includes a tube having a length sufficient to span the distance between the anterior chamber of the eye and the epithelial-lined space of the patient, the tube having an open anterior chamber end and a closed epithelial-lined space end, and a seal device associated with the tube between the anterior chamber and epithelial-lined space ends, for sealing a hole in the frontal sinus bone, and for anchoring the tube against movement from the frontal sinus bone. The shunt also includes a fluid pressure openable valve in the tube, located at or near the epithelial-lined space sinus end, allowing for controlled flow of aqueous humor through the tube when implanted. The invention also extends to a method of treating glaucoma in a patient by surgically implanting the shunt between the anterior chamber of the eye and the frontal sinus.

Owner:UNIVERSITY OF SASKATCHEWAN

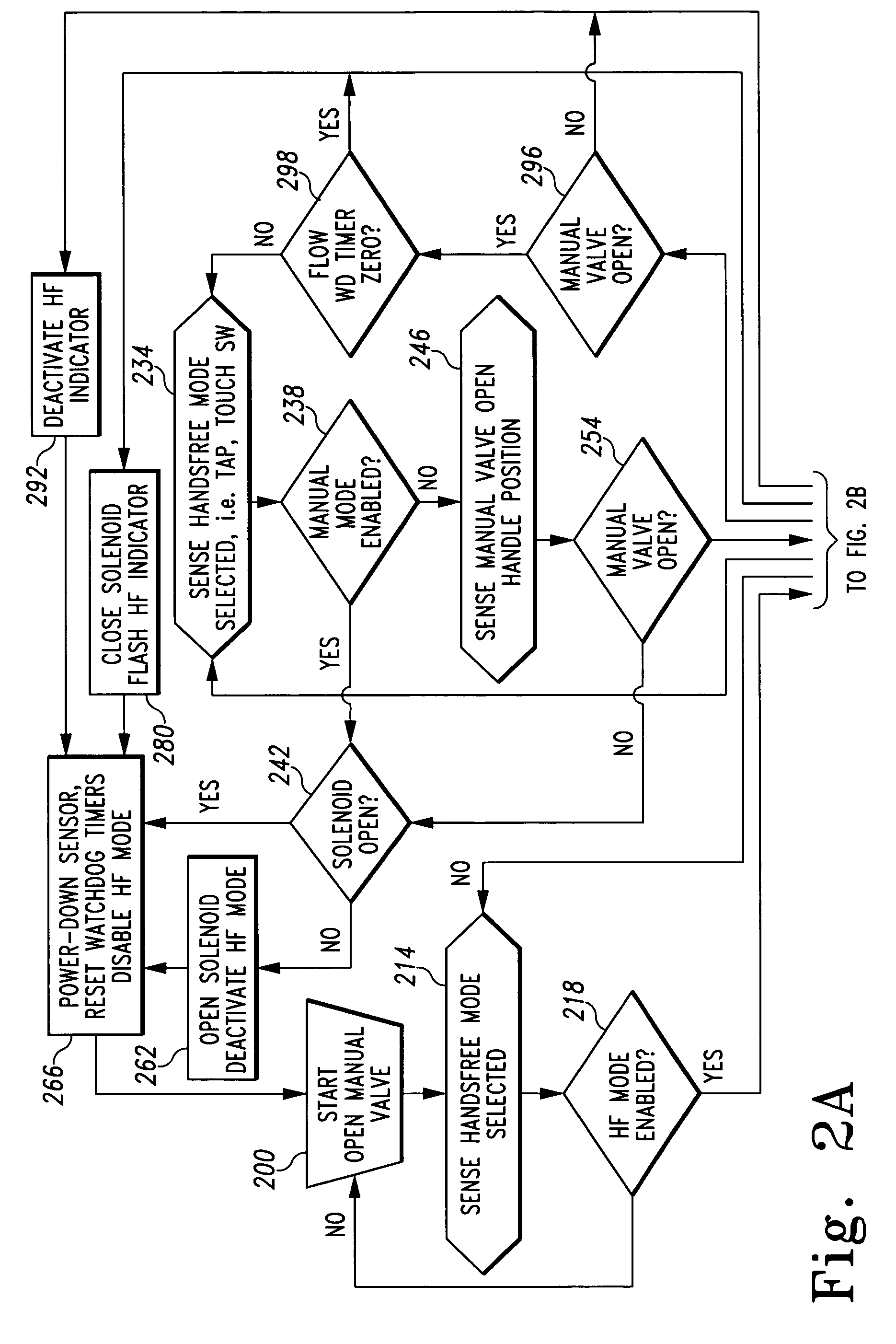

Multi-mode hands free automatic faucet

ActiveUS7150293B2Operating means/releasing devices for valvesServomotor componentsProximity sensorWater flow

A hands-free faucet comprises a proximity sensor, a logical control, a handle including a first touch control, a second touch control, and a mode indicator. The logical control has a manual mode (wherein the proximity sensor is inactive, and water flow is toggled on and off by positioning the handle) and a hands-free mode (wherein water flow is toggled on and off in response to the proximity sensor). The first touch control puts the faucet in the hands-free mode when touched by a user. The second touch control toggles the logical control between the hands-free mode and the manual mode when touched by a user. The mode indicator indicates which mode the faucet is presently in. The water flow has a temperature and a flow rate that are determined by the position of the handle.

Owner:DELTA FAUCET COMPANY

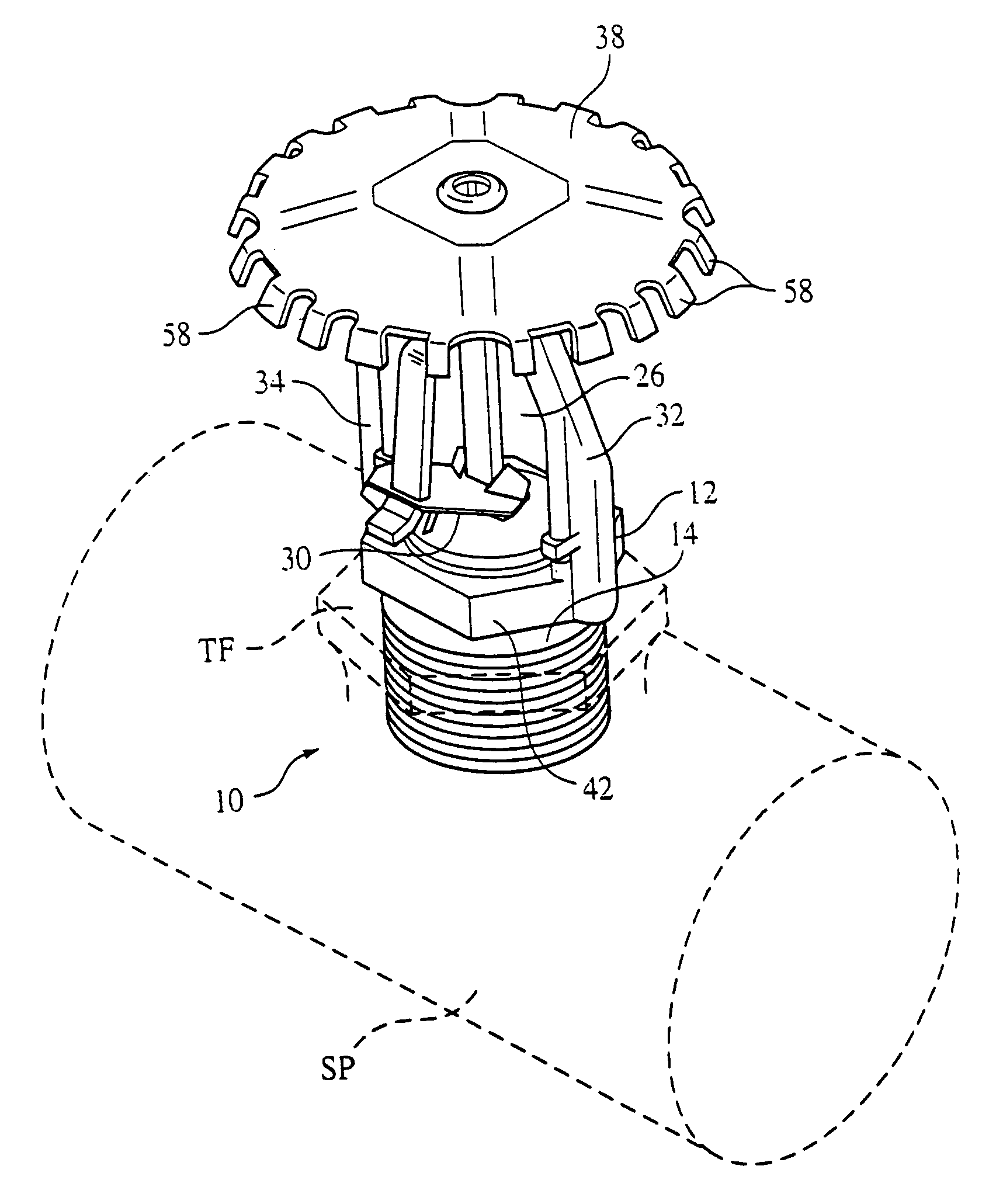

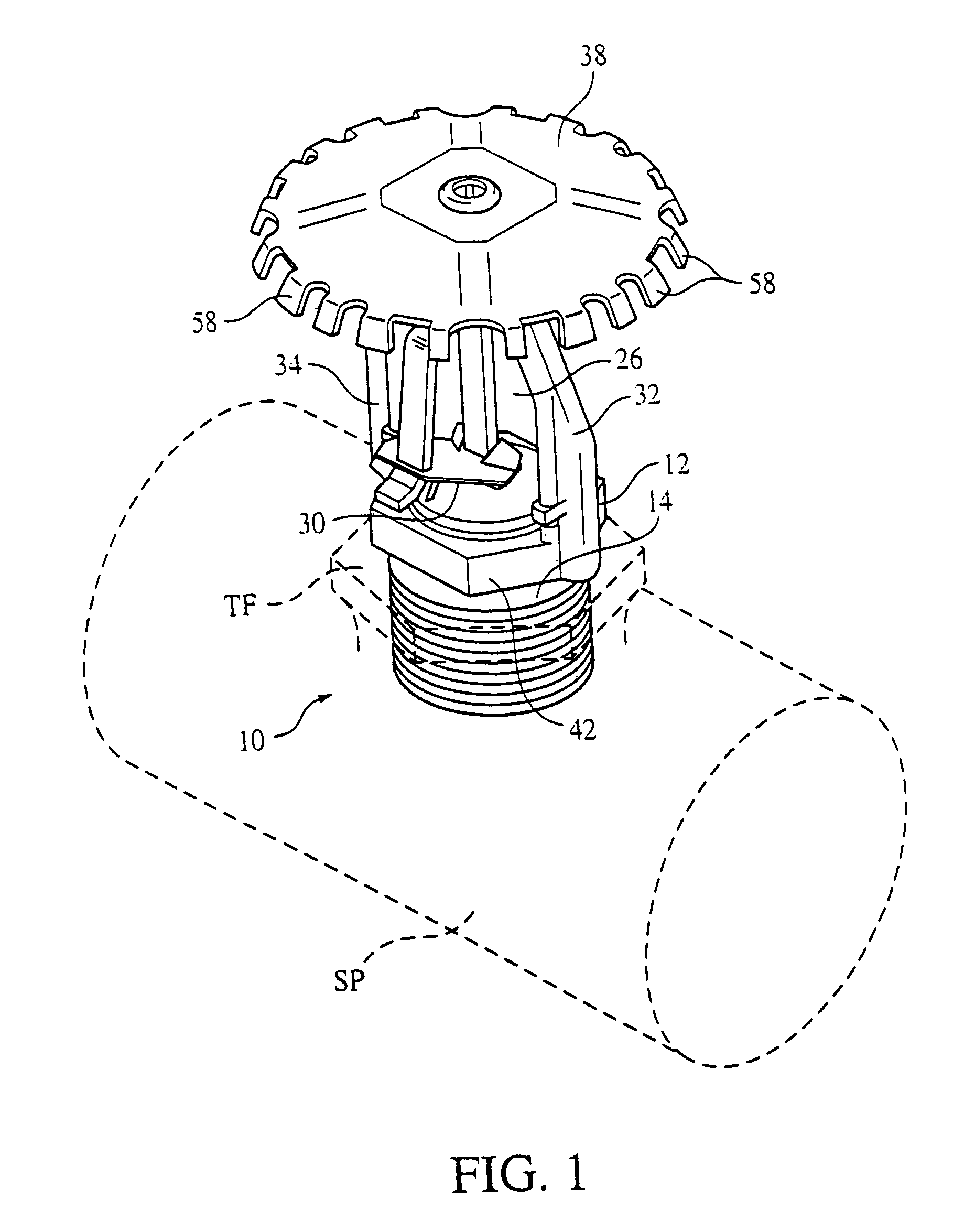

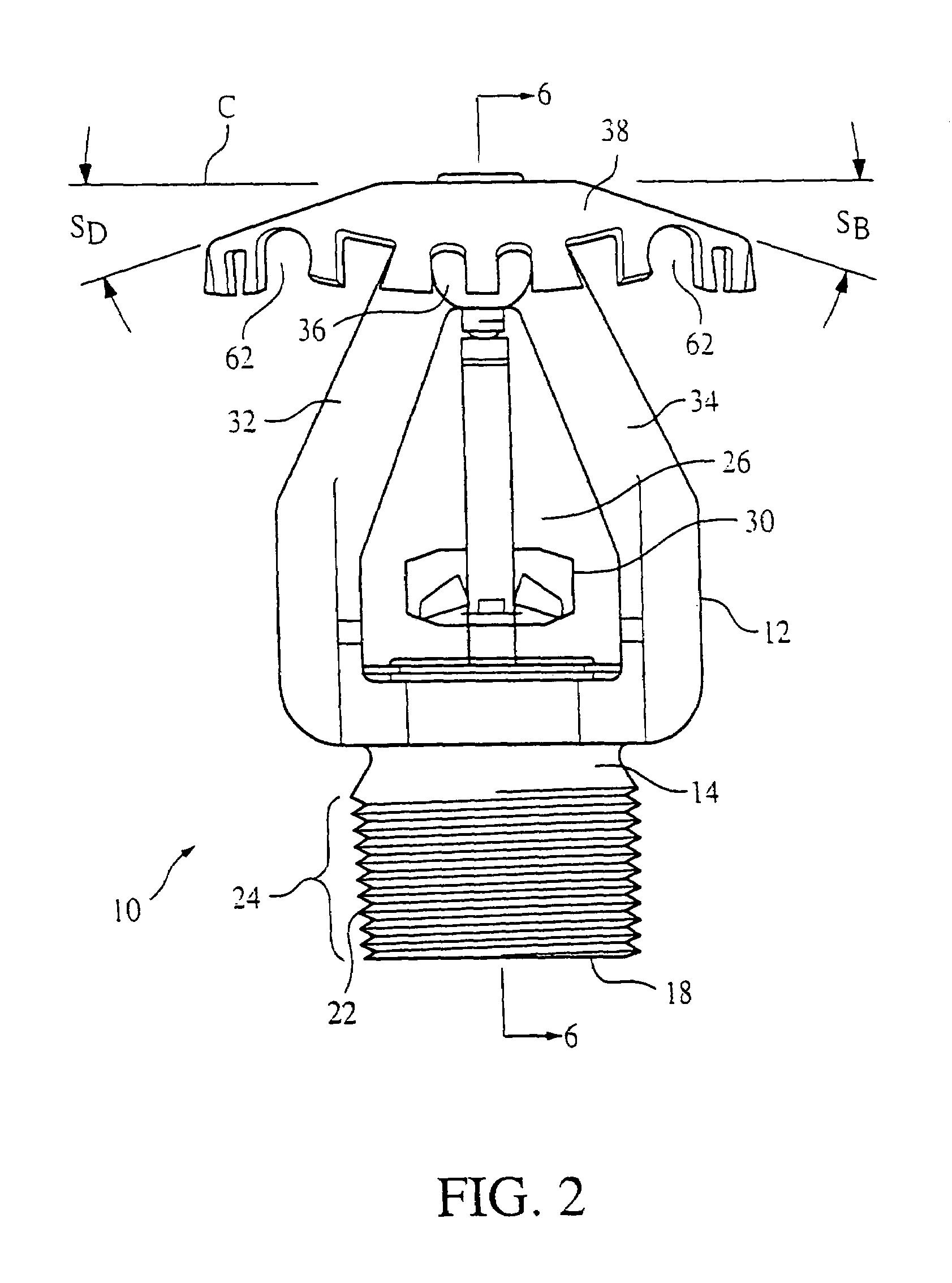

Low pressure, extended coverage, upright fire protection sprinkler

InactiveUS6976543B1Increased heat release rateDeplete supplySpray nozzlesFire rescueExtended coverageFire protection

A low pressure, extended coverage, fire protection sprinkler, e.g., of the upright type, suitable for use in protection of at least extra hazard and high piled storage occupancies, in accordance with the 1999 Edition of NFPA 13, has a body with an internal passageway extending between an inlet end and an opposite outlet end, and a deflector mounted to the body by at least one support arm and disposed in alignment with the axis and generally spaced from the outlet end of the internal passageway. The sprinkler has a predetermined K-factor, e.g., of greater than about 16.0. The sprinkler is configured and arranged to deflect flow of water generally radially outwardly and downwardly of the sprinkler in a predetermined spray pattern. Preferably, the predetermined spray pattern has a generally polygonal shape, e.g., a rectangular shape, when viewed at a predetermined distance below the deflector.

Owner:TYCO FIRE PRODS LP

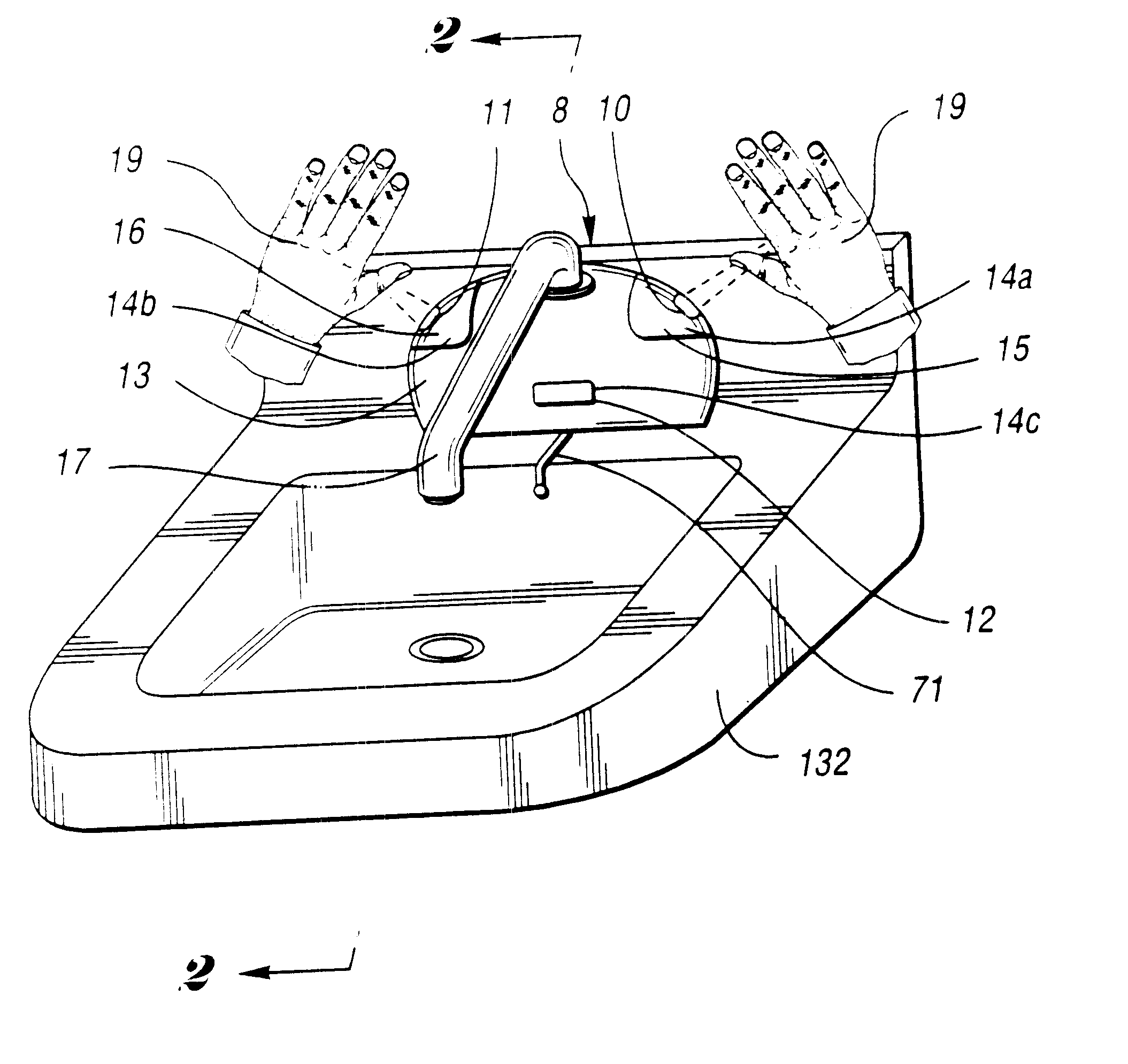

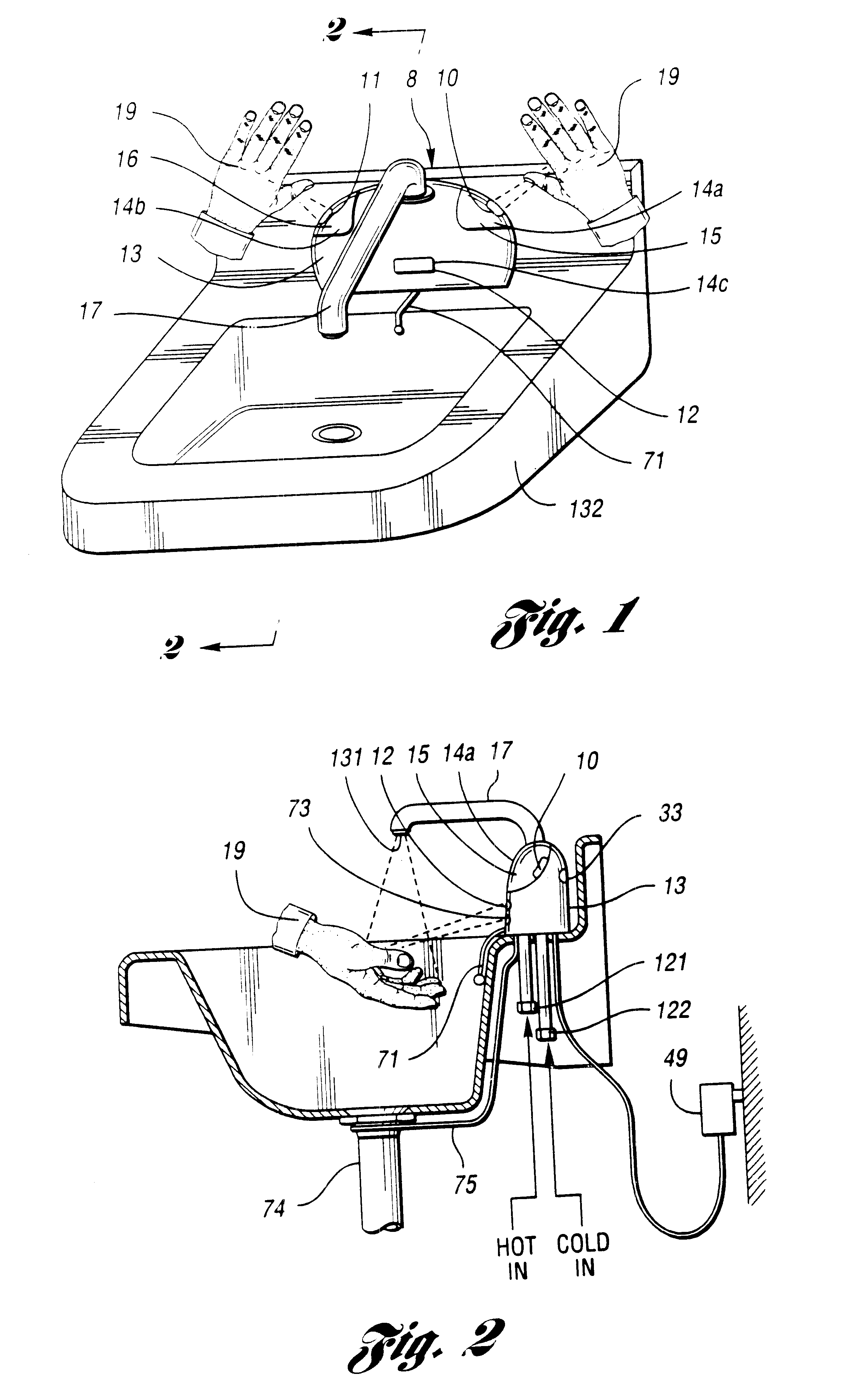

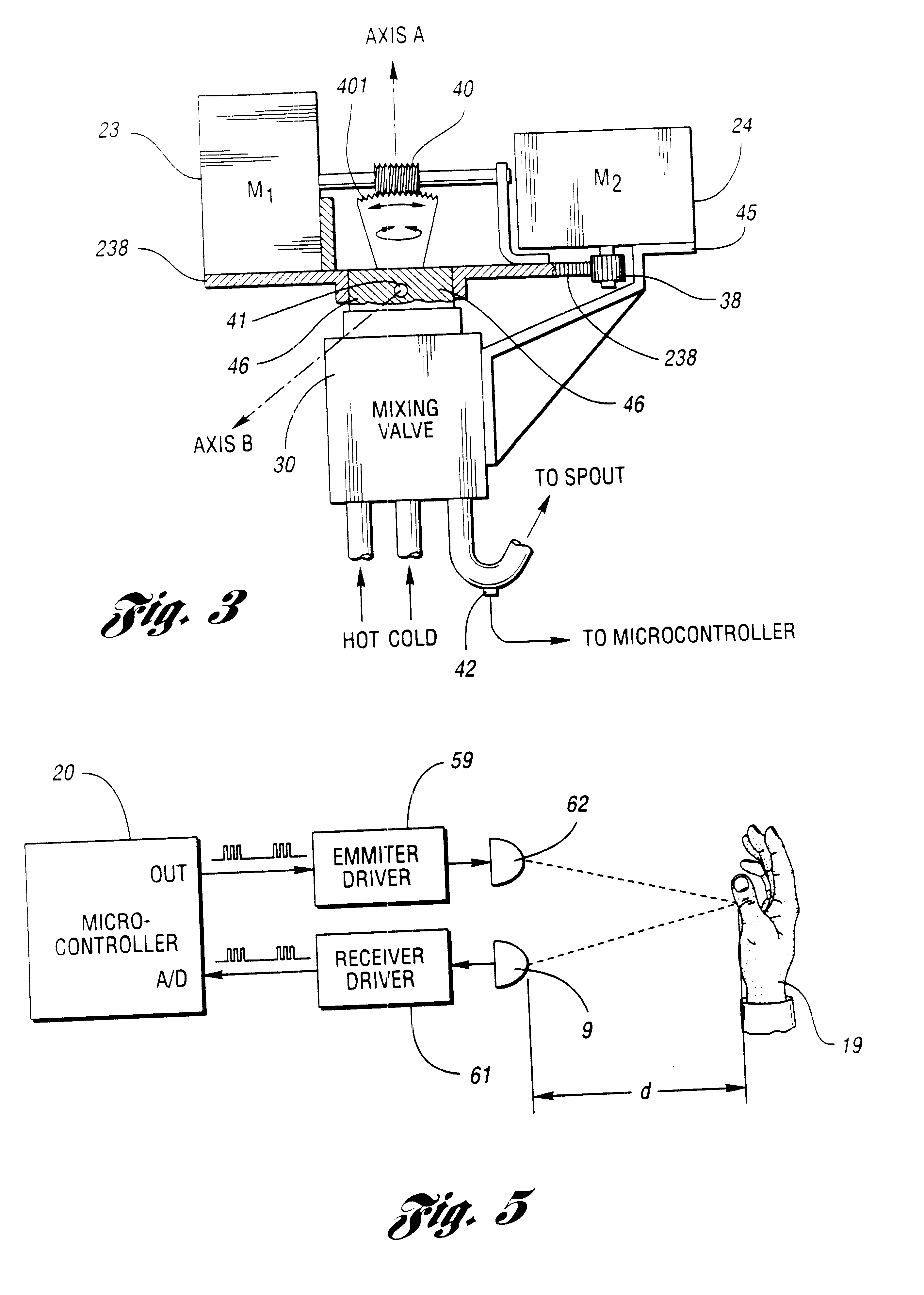

Water faucet with touchless controls

InactiveUSRE37888E1Suitable for useMaintain water temperatureTemperature control without auxillary powerOperating means/releasing devices for valvesMicrocomputerProximity sensor

A water faucet assembly providing touchless water temperature and water flow adjustment. The assembly comprises a spout, a water mixing valve, at least one proximity sensor, and a microcomputer. The water mixing valve provides a mix and controls the flow of hot water from a hot water supply and cold water from a cold water supply to the spout. The at least one proximity sensor provides a water temperature or water flow input signal having a value corresponding to the distance of an object from the sensor. The microcomputer is responsive to the value of the water temperature input signal to control the water mixing valve and generate a mixture of the hot and cold water corresponding to the distance of the object from the proximity sensor. The microcomputer is also responsive to the value of the water flow input signal to provide a flow of water from the spout corresponding to the distance of the object from the proximity sensor.

Owner:CRETU PETRA EUGEN

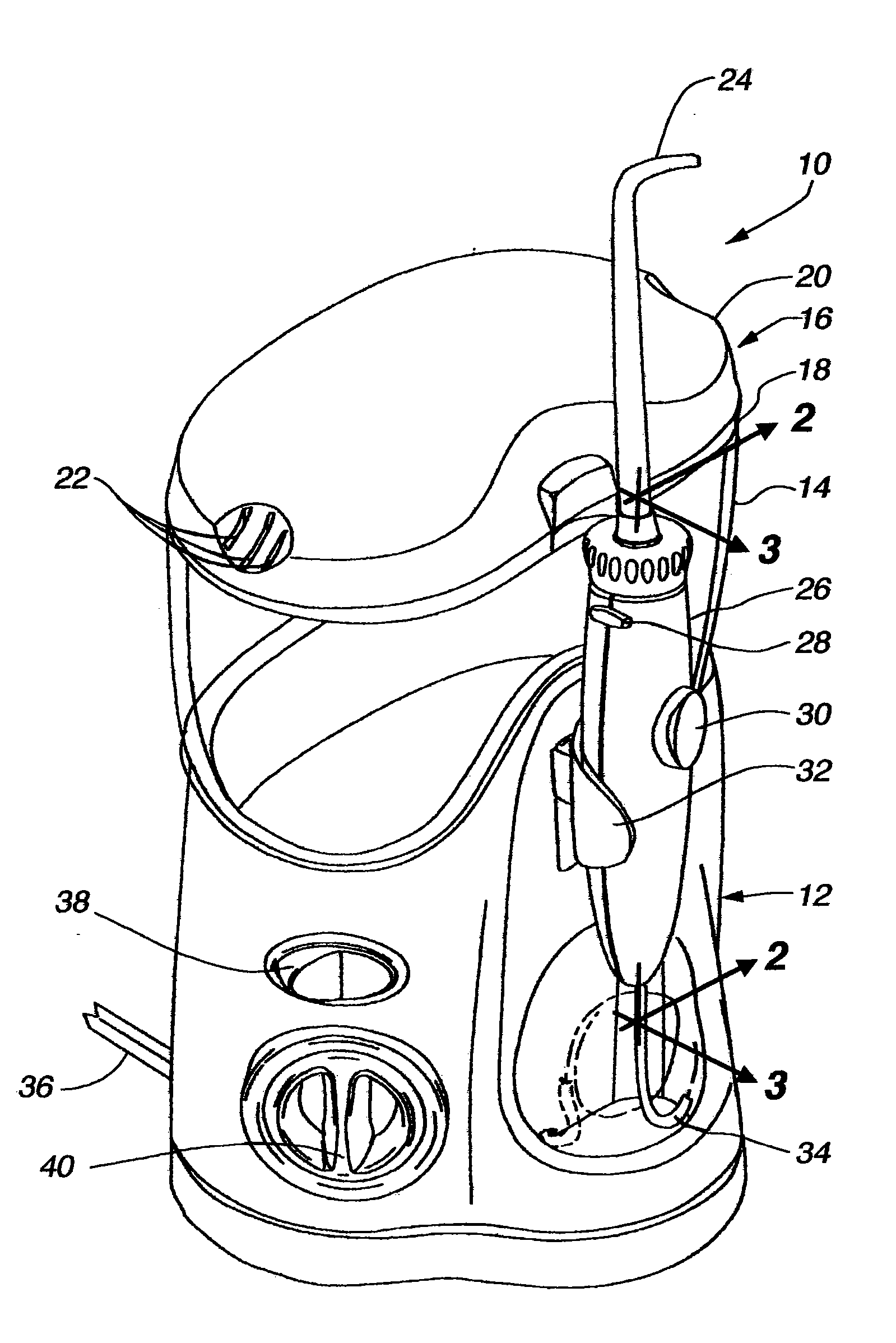

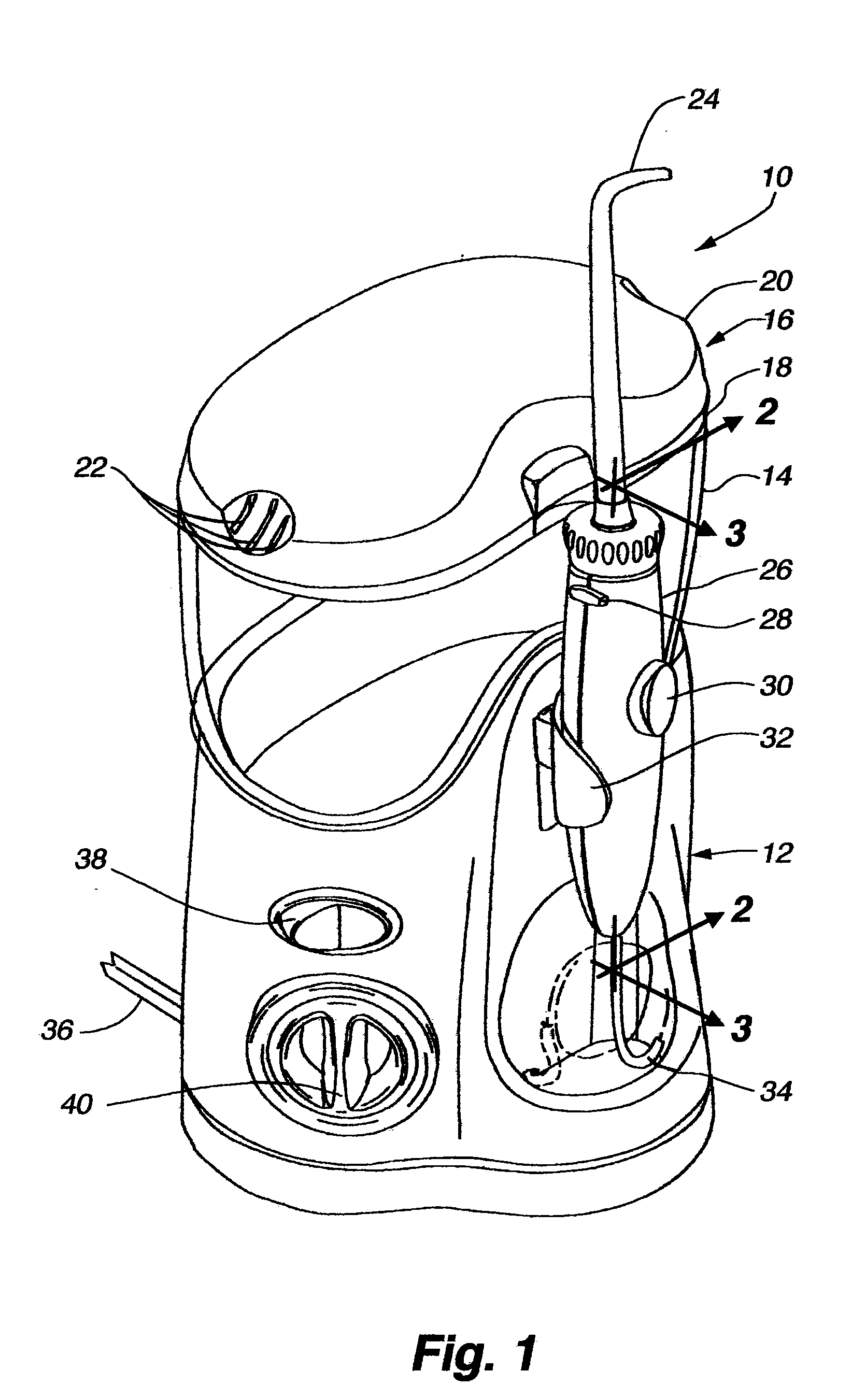

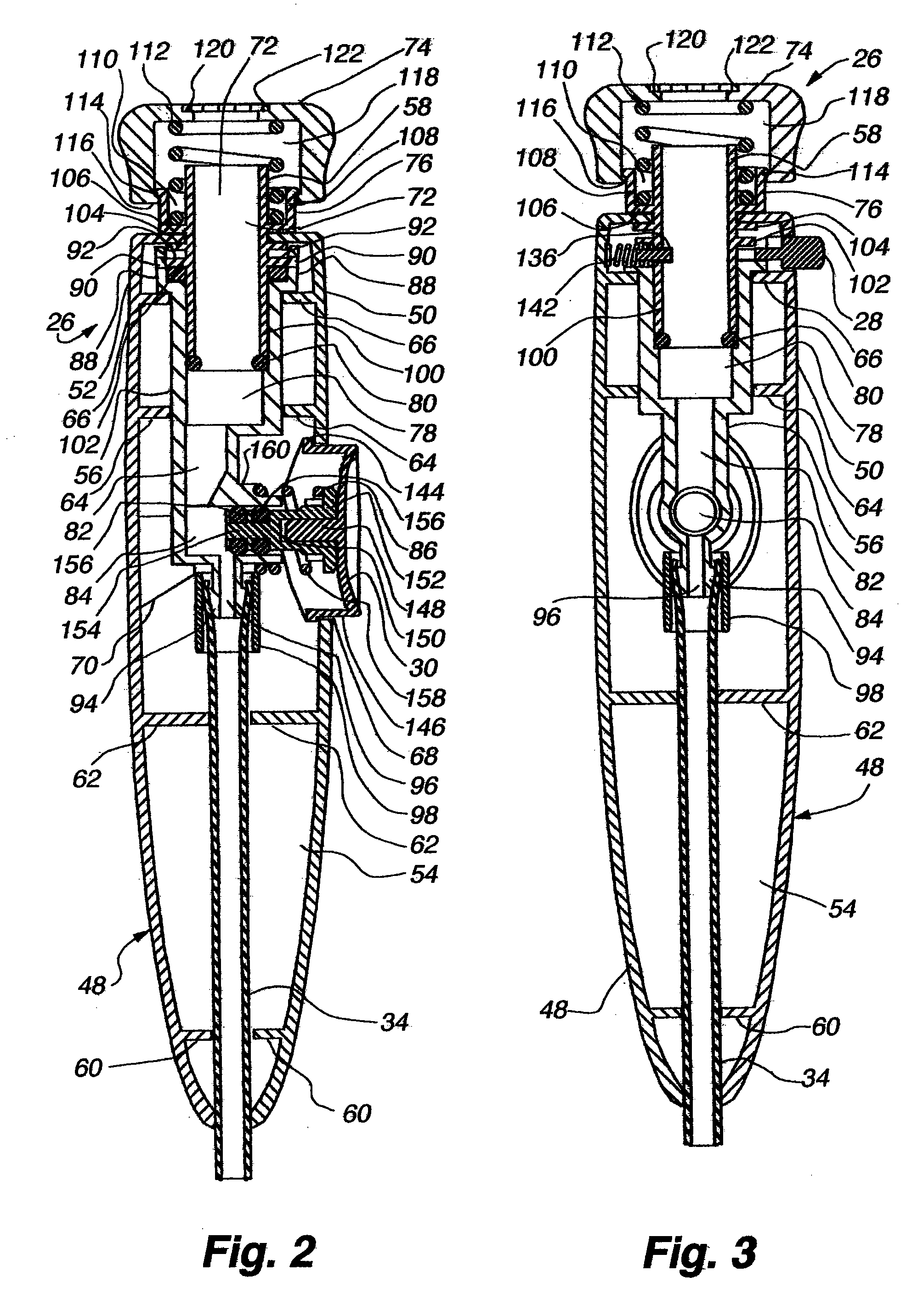

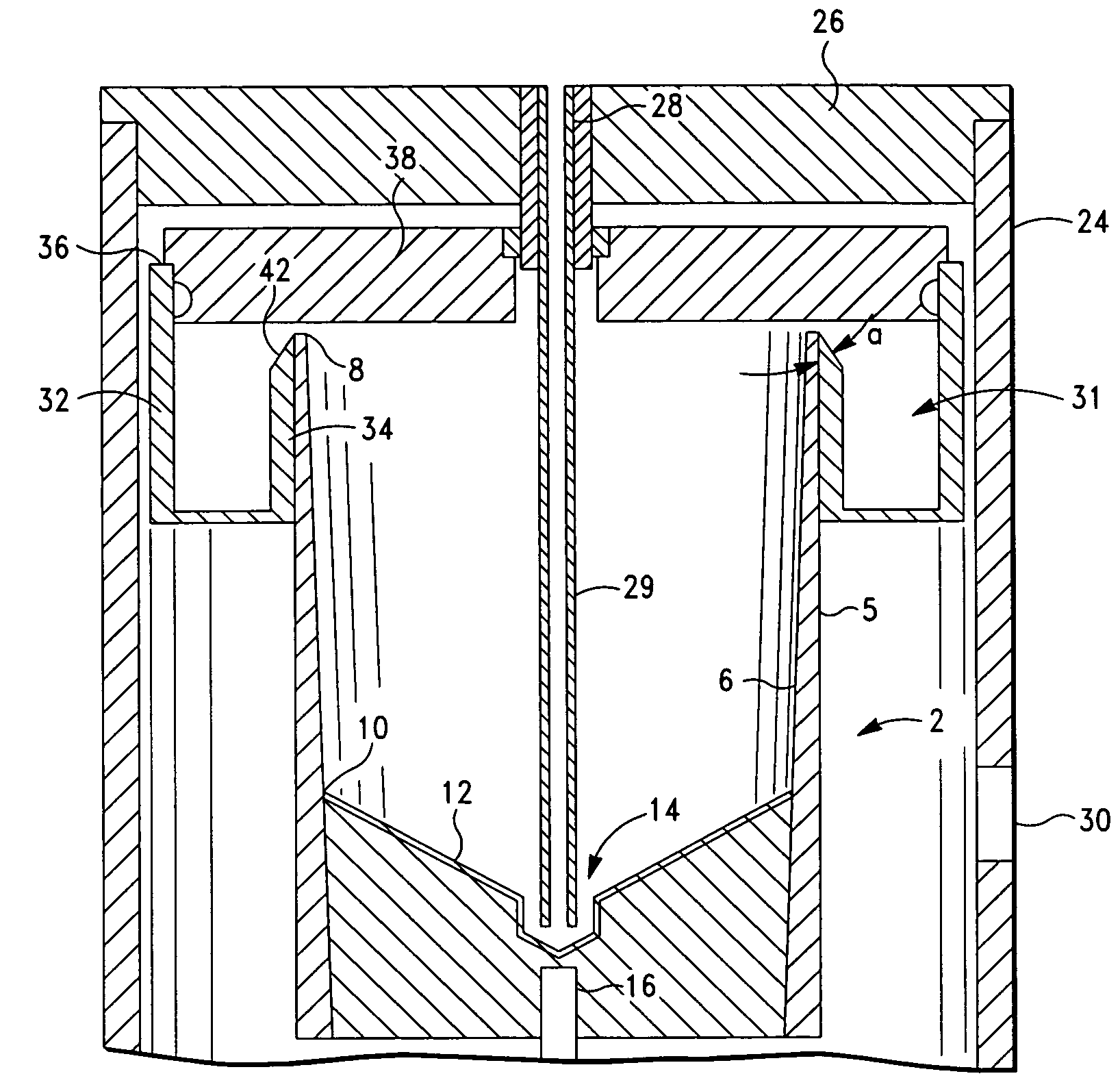

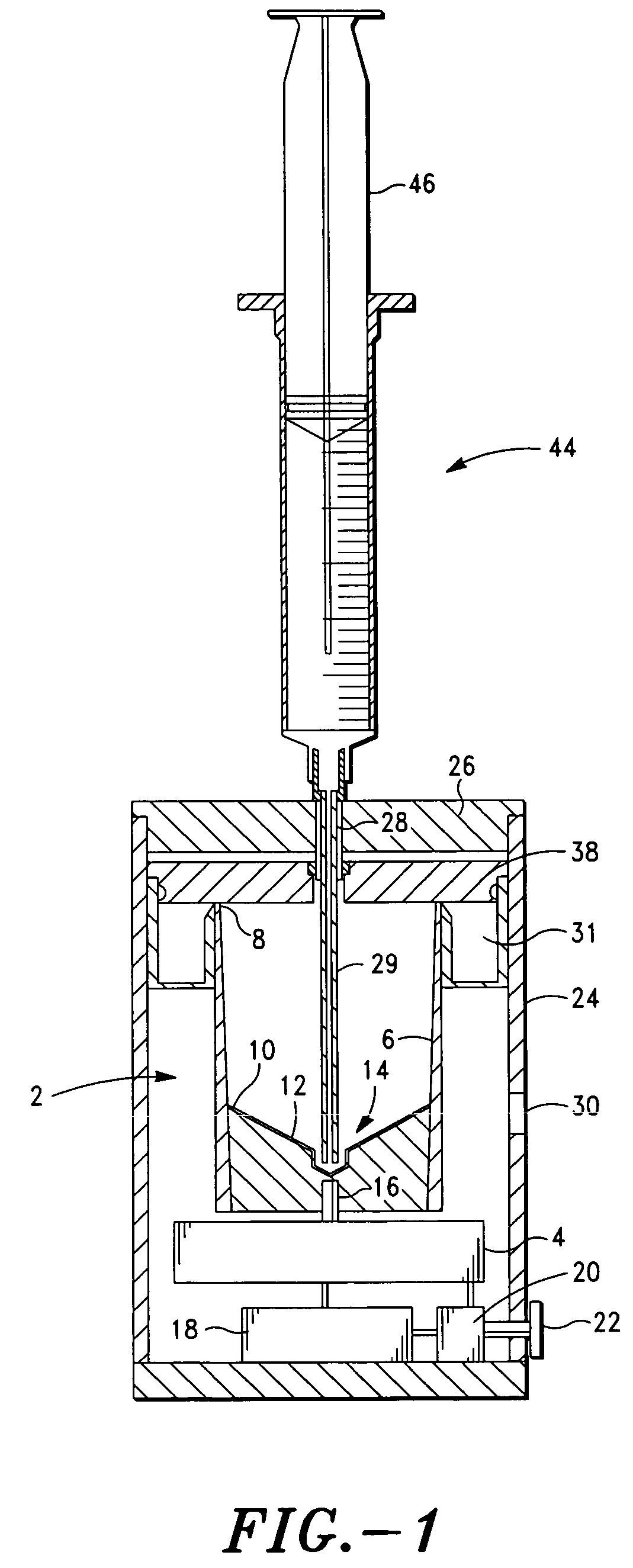

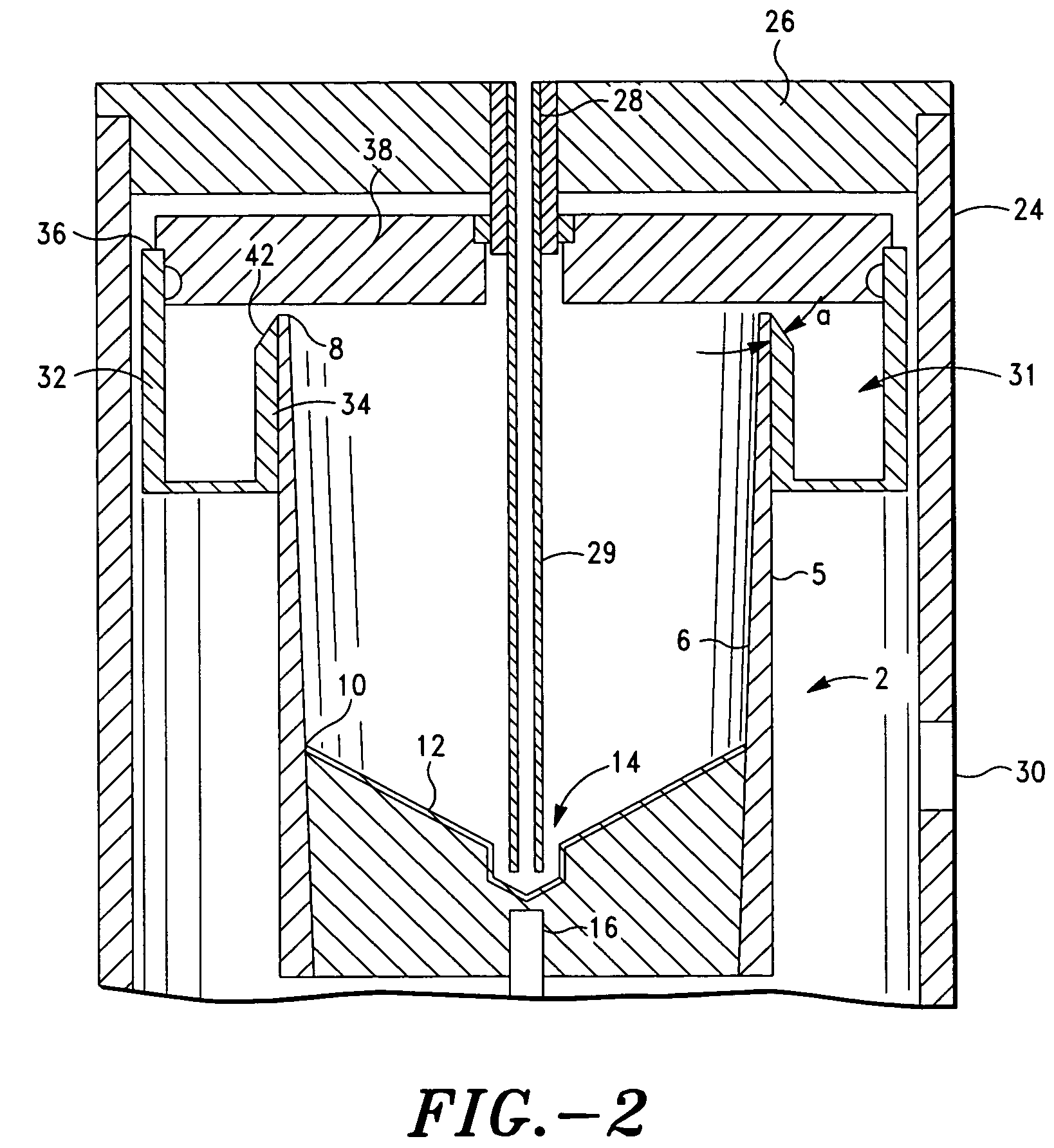

Water jet unit and handle

An apparatus for providing a pressurized water stream for cleaning gums and teeth. The embodiment includes a base unit defining a cavity. The cavity contains a pump, which may move pressurized water from a reservoir to a tip in fluid communication with the pump. A flow control knob may be turned to selectively adjust the water pressure supplied by the tip between a minimum and a maximum value. The reservoir may be removed from the base unit so that it may be filled with the fluid. The reservoir may support a container for storing tips or other items. Fluid may flow from the reservoir and ultimately into the tip to provide oral irrigation and / or cleaning of the teeth, gums, and tongue.

Owner:WATER PIK INC

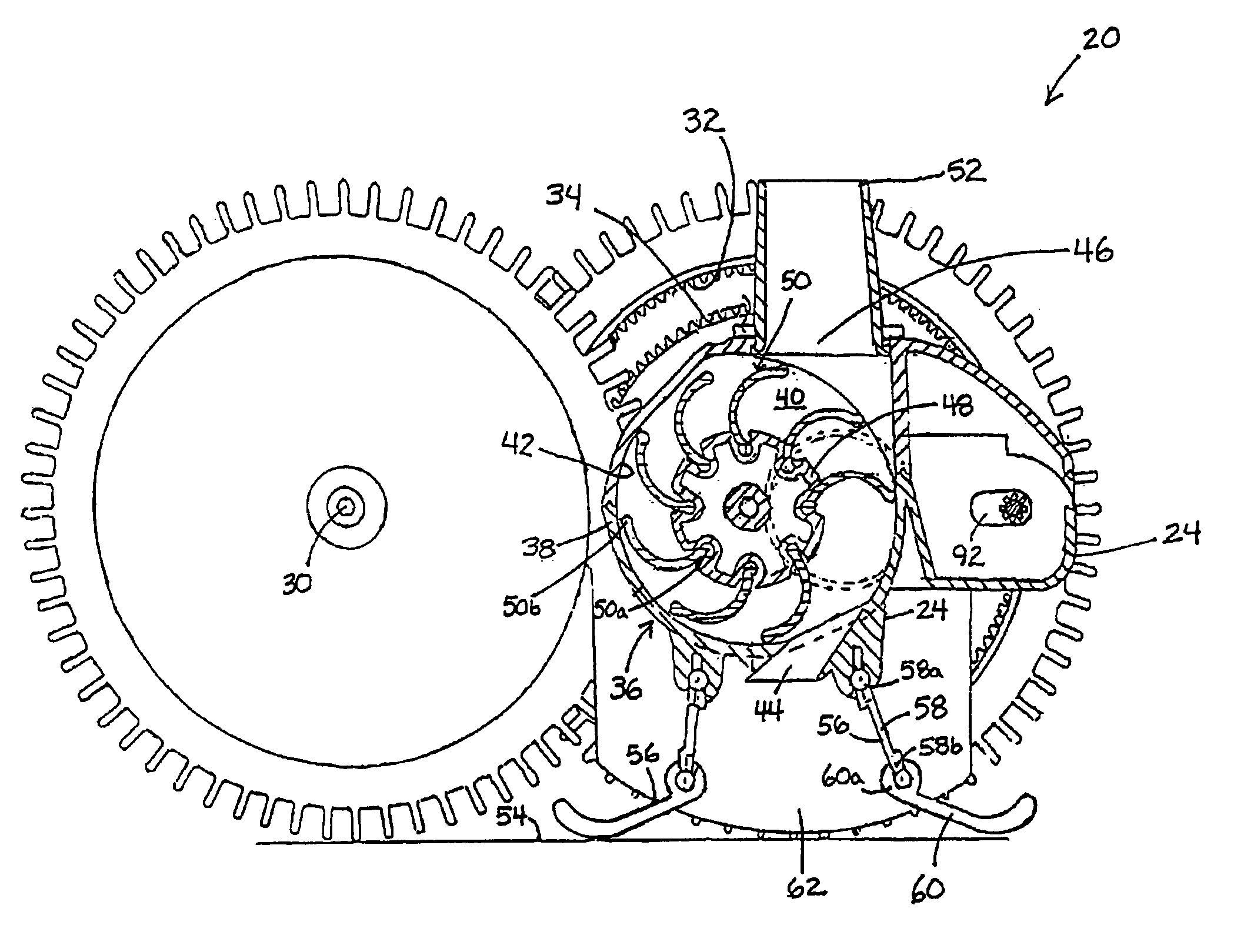

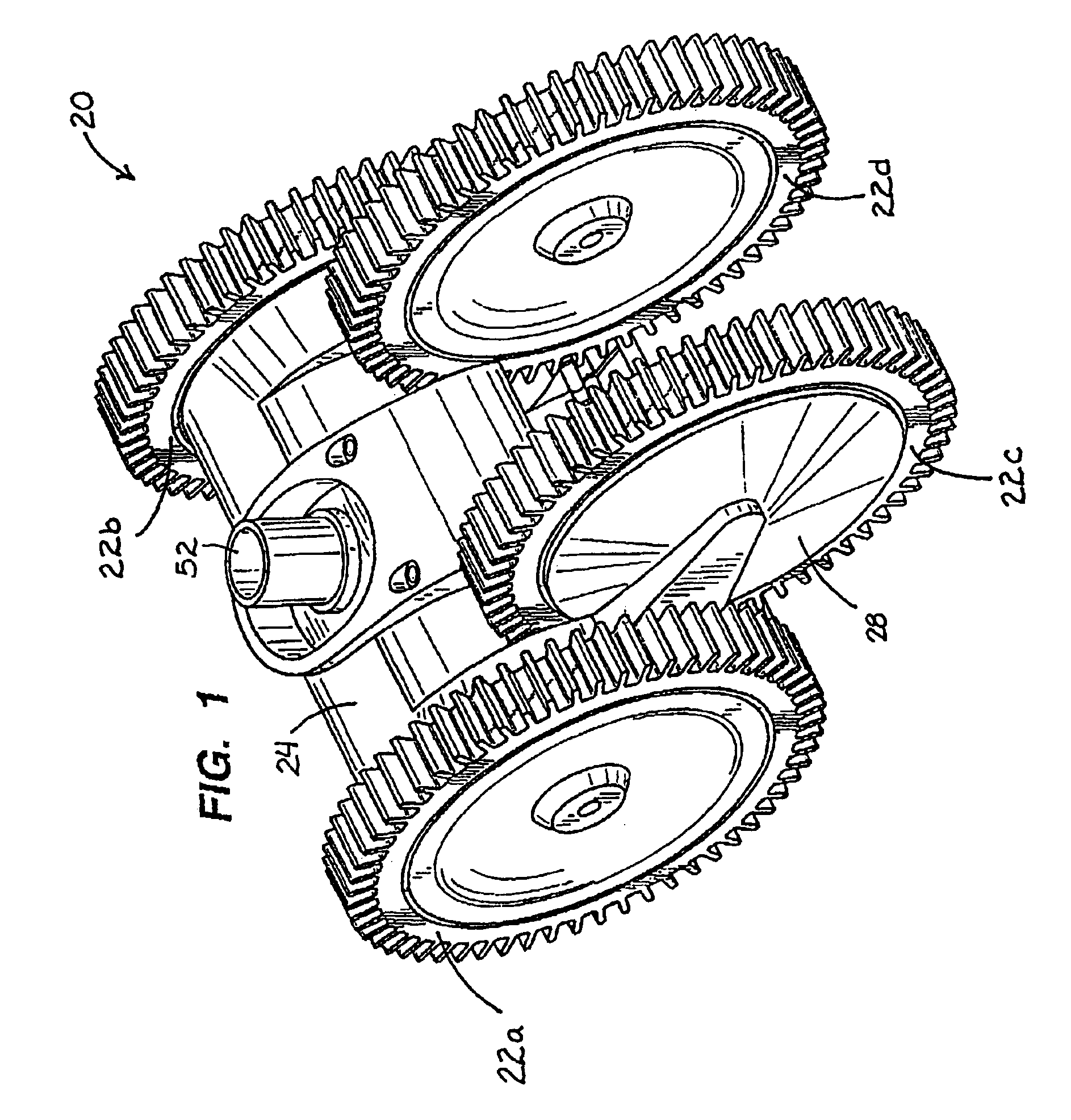

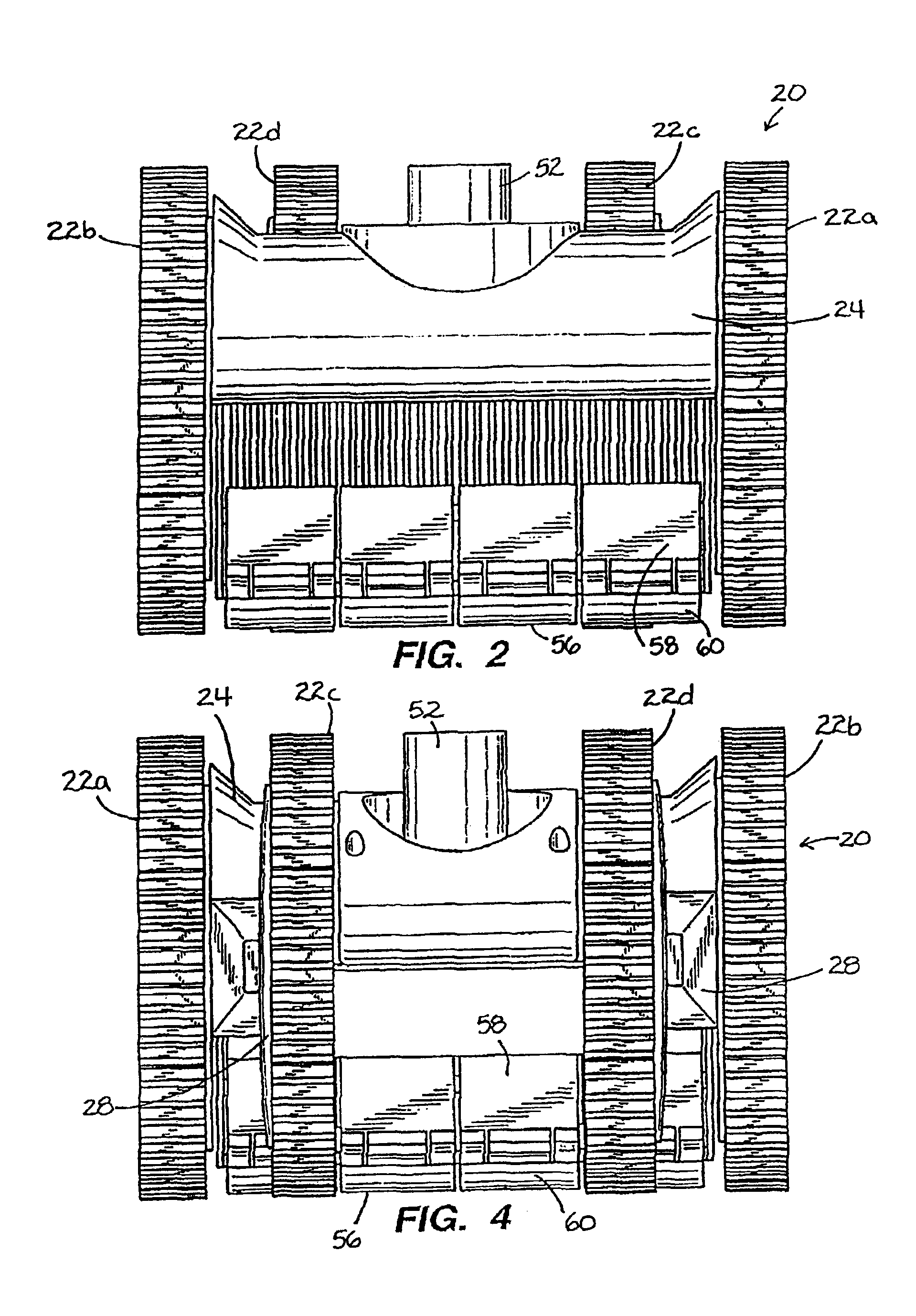

Four-wheel-drive automatic swimming pool cleaner

InactiveUS6854148B1Great tractionExcellent ability to traverse pool surfaceGymnasiumSwimming poolsDrive shaftWater flow

A four-wheel pool cleaner (20) motivated by water flow to move along a pool surface, and having: a body (24); the four wheels rotatably mounted thereon and including two sets of two wheels (22) each, one wheel of each set on each side; a drive mechanism (36) in position to be moved by water flow and having a rotatable drive member (76); a drive train extending to the first wheel set (22a, b) and to the second wheel set (22c, d), to drive all four wheels. Preferred embodiments include: wheel-to-wheel drive links (88) along the side; a turbine (36) as drive mechanism; a pair of spaced wheelgears (32, 34), preferably integrally formed with the wheel, facilitating drive linkages and steering; a pair of end-to-end drive shafts (80, 82) joined by a coupler (84c), one shaft end (80a) being a ball joint allowing fore-and-aft movement of a drive-shaft distal end; a spring (102) and cam (100) for alternately moving that distal end between a driving position engaging one of the spaced wheelgears (32), and a steering position engaging the other of the spaced wheelgears (34); wheel treads (108) with radial fingers (110), some (110a-c) of longer length; and a segmented articulated skirt (56) to help enclose a plenum beneath the pool cleaner.

Owner:HAYWARD IND INC

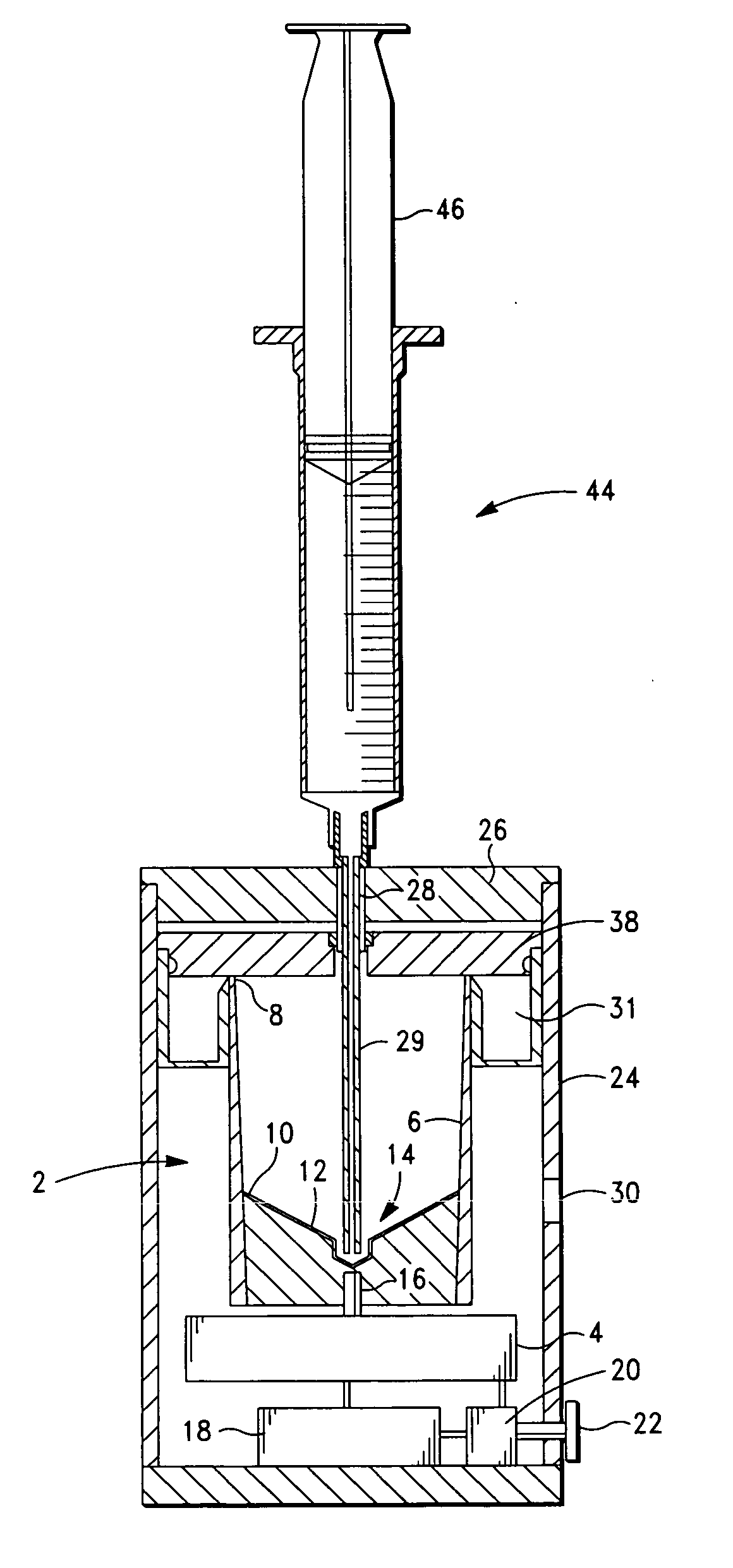

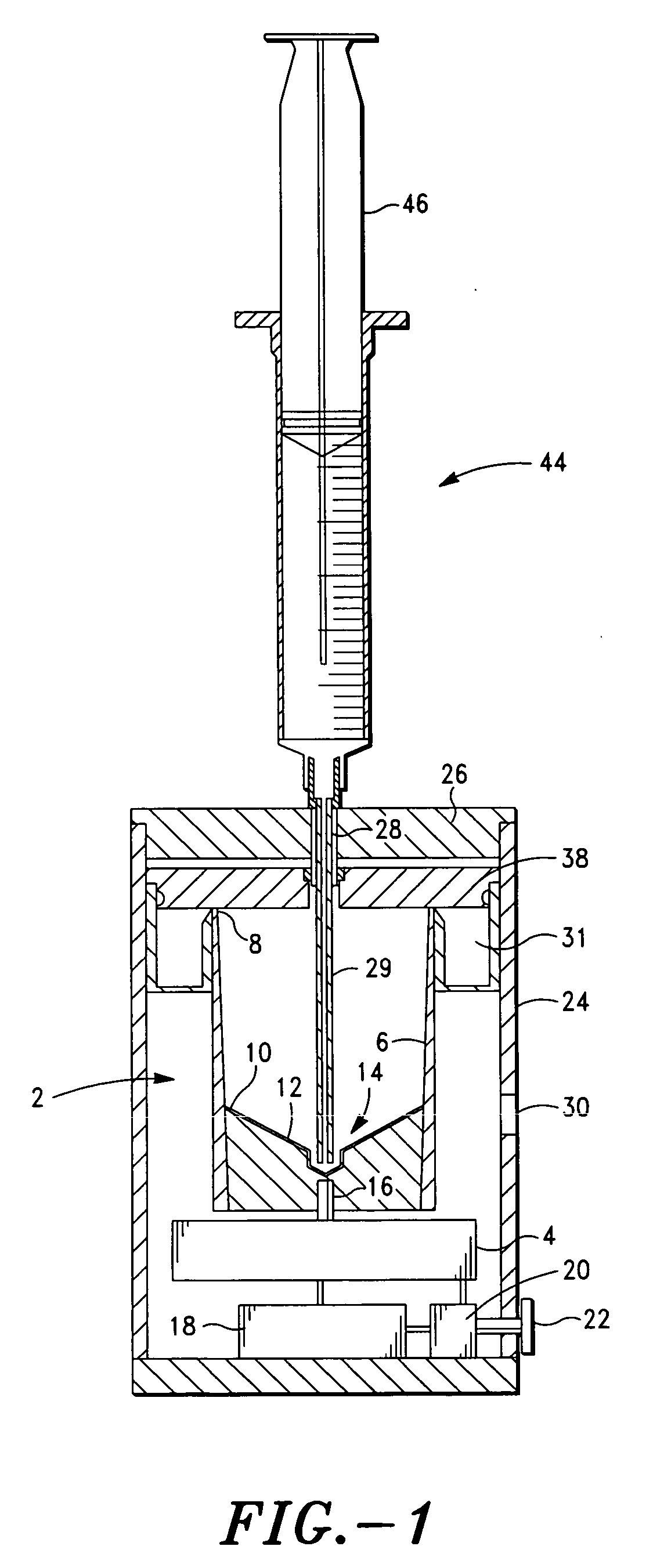

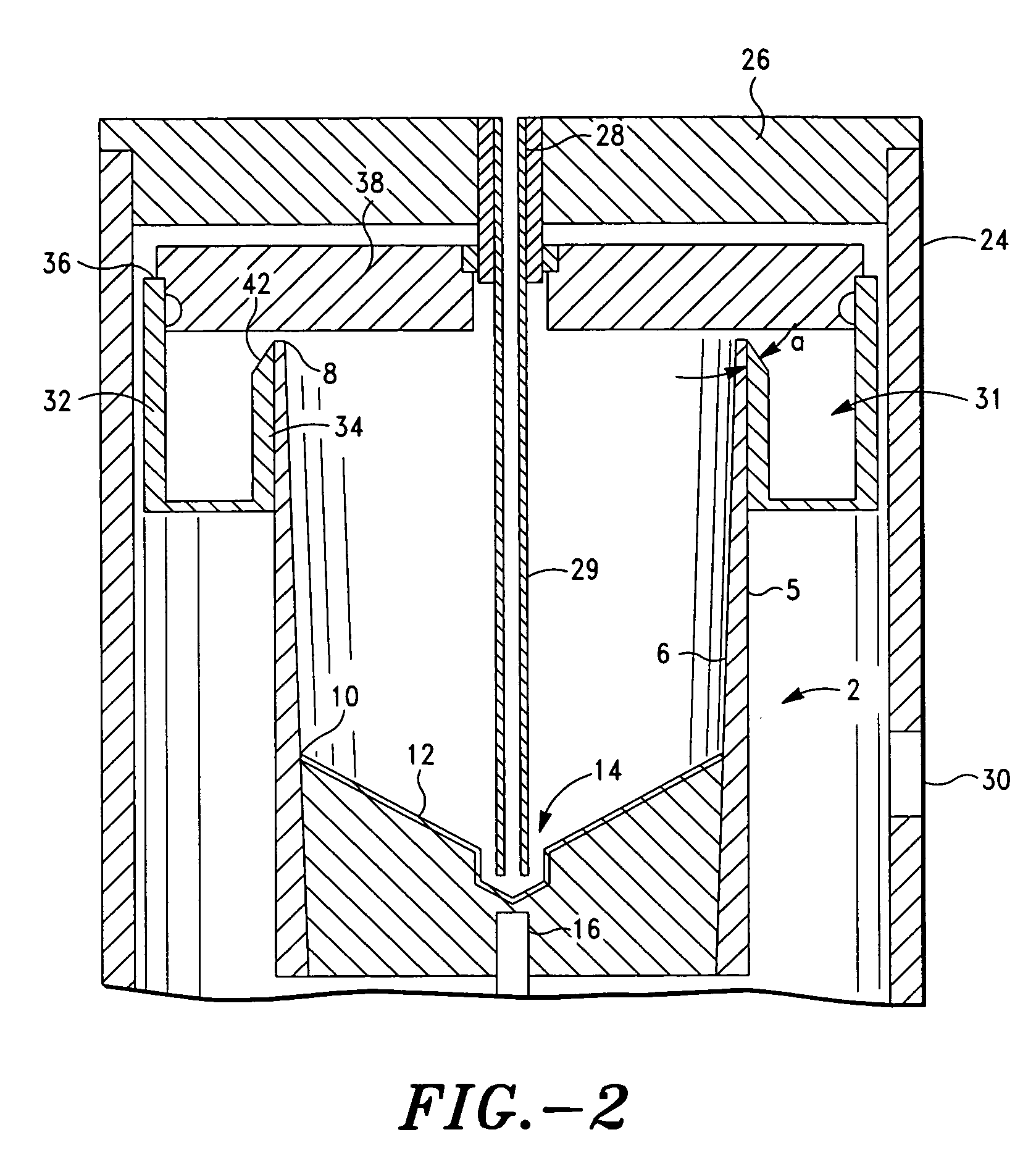

Method and apparatus for preparing platelet rich plasma and concentrates thereof

ActiveUS20060175242A1Shaking/oscillating/vibrating mixersTransportation and packagingFiberRed blood cell

The PRP separator-concentrator of this invention is suitable for office use or emergency use for trauma victims. The PRP separator comprises a motorized centrifugal separation assembly, and a concentrator assembly. The centrifugal separator assembly comprises a centrifugal drum separator that includes an erythrocyte capture module and a motor having a drive axis connected to the centrifugal drum separator. The concentrator assembly comprises a water-removal module for preparing PRP concentrate. The centrifugal drum separator has an erythrocyte trap. The water removal module can be a syringe device with water absorbing beads or it can be a pump-hollow fiber cartridge assembly. The hollow fibers are membranes with pores that allow the flow of water through the fiber membrane while excluding flow of clotting factors useful for sealing and adhering tissue and growth factors helpful for healing while avoiding activation of platelets and disruption of any trace erythrocytes present in the PRP.

Owner:HANUMAN +1

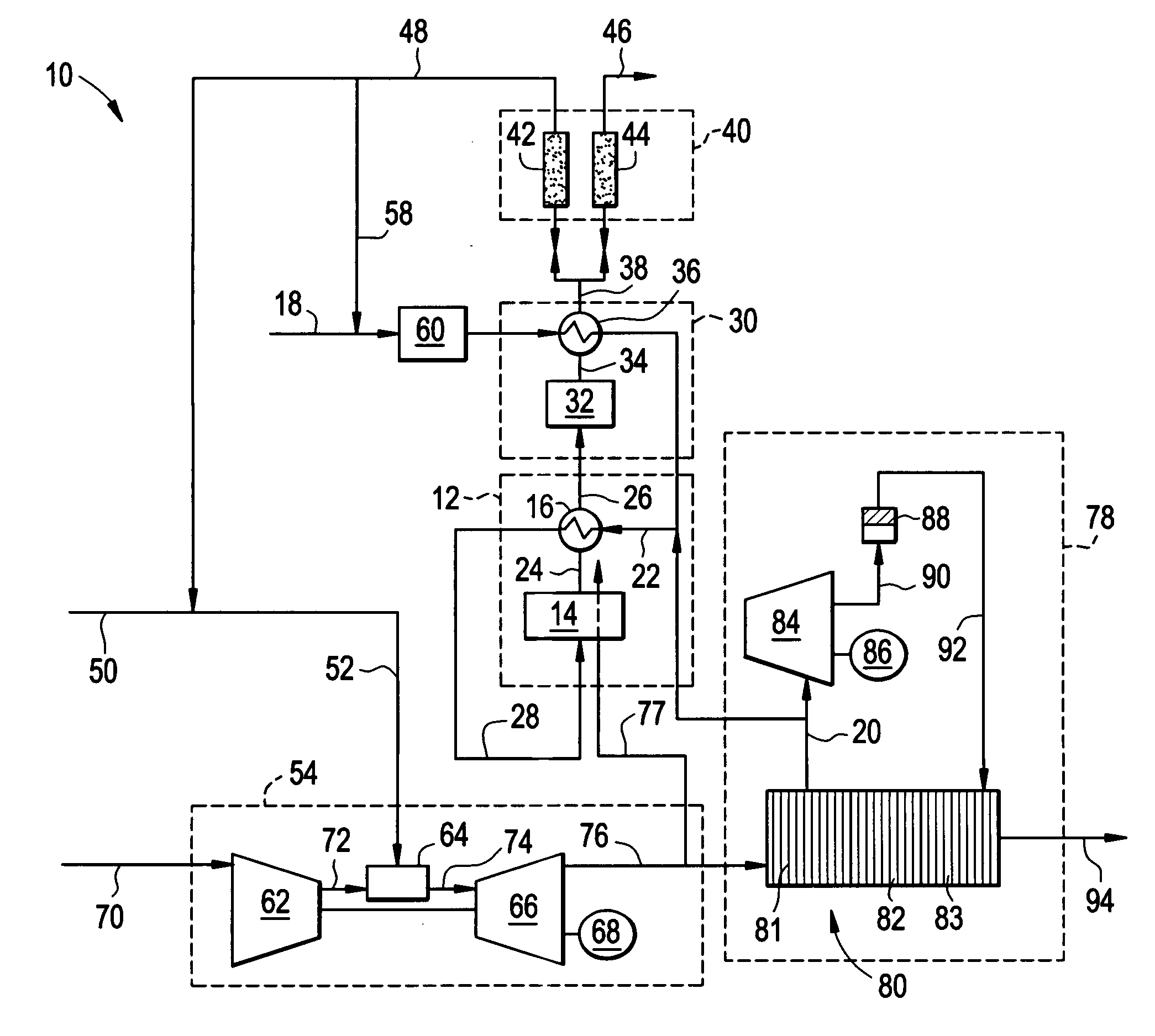

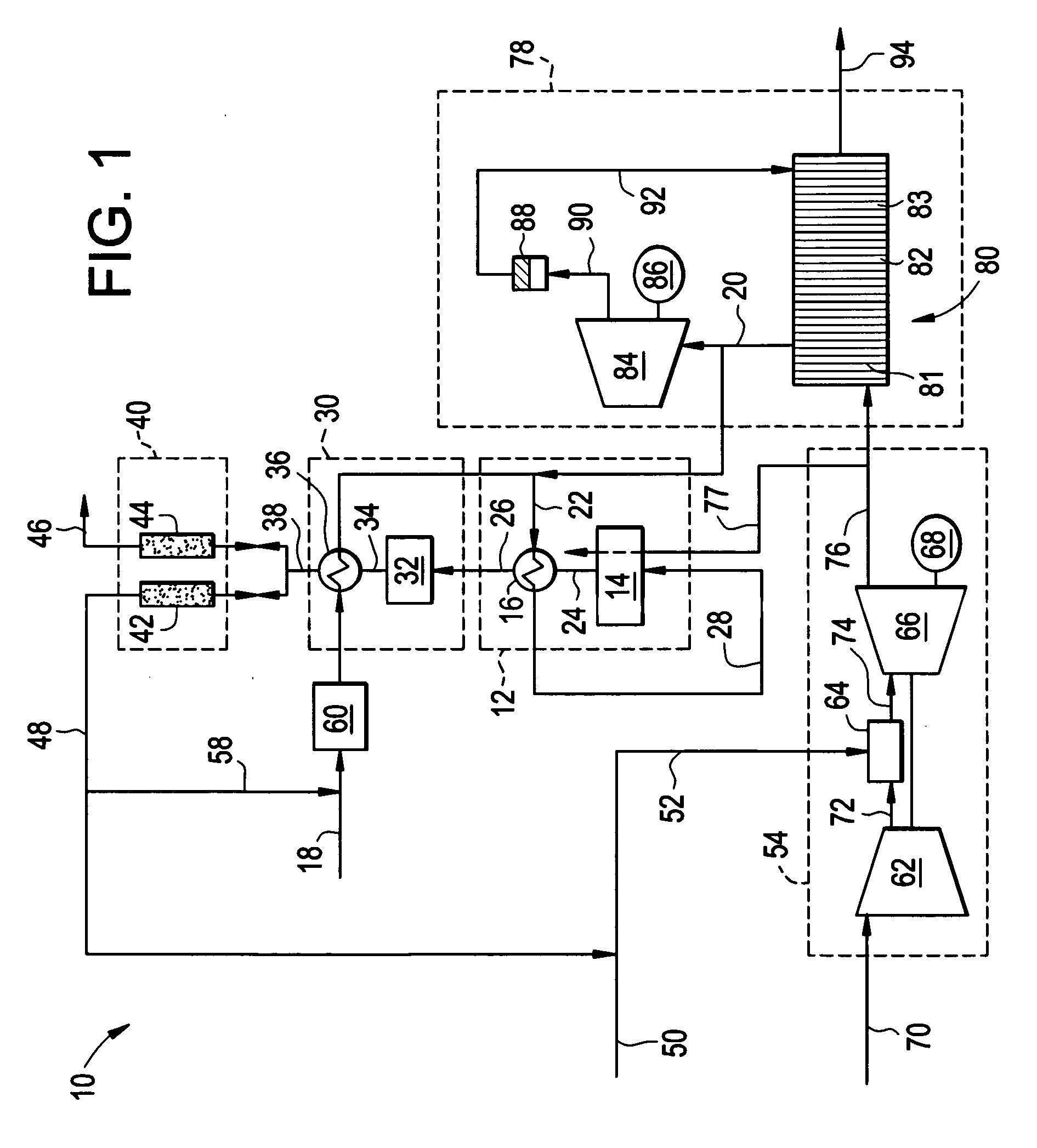

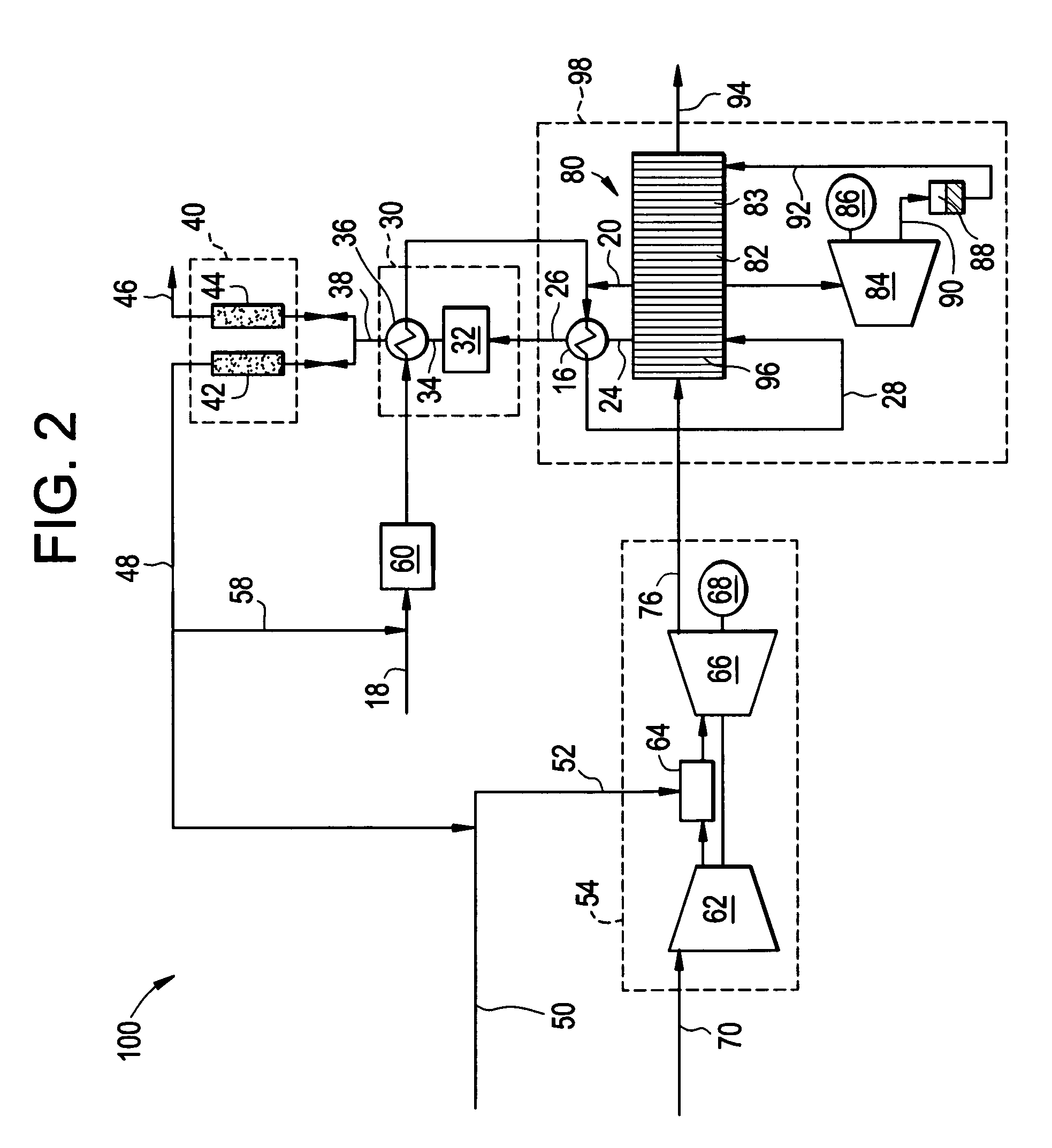

Reforming system for combined cycle plant with partial CO2 capture

A combined cycle system includes, a pre-steam-methane-reformer operating at a temperature of less than about 800 degrees Celsius to reform a mixed fuel stream to generate a first reformate stream, a water-gas-shift reactor to convert carbon monoxide in the first reformate stream to carbon dioxide and form a second reformate stream, a carbon dioxide removal unit for removing carbon dioxide from the second reformate stream and form a carbon dioxide stream and a third reformate stream; wherein less than about 50 percent of the carbon contained in the mixed fuel stream is recovered as carbon dioxide by the removal unit, a gas turbine unit for generating power and an exhaust stream, and a steam generator unit configured to receive the exhaust stream, wherein the heat of the exhaust stream is transferred to a water stream to generate the steam for the mixed fuel stream and for a steam turbine.

Owner:GENERAL ELECTRIC CO

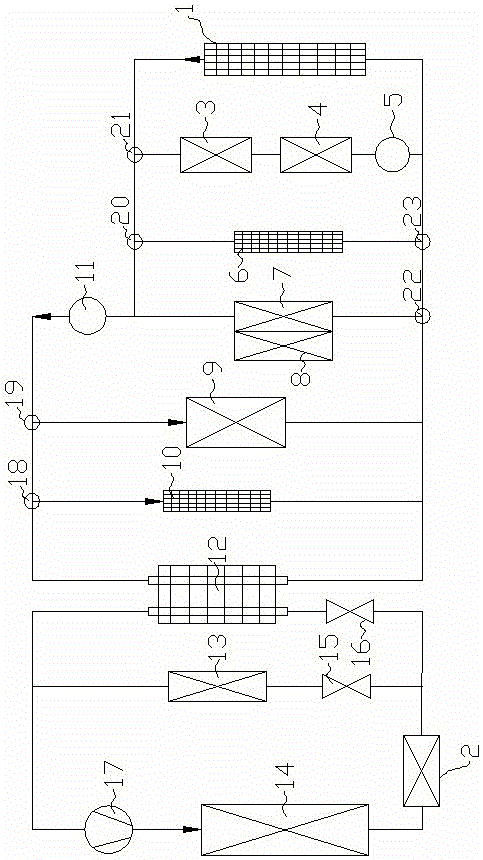

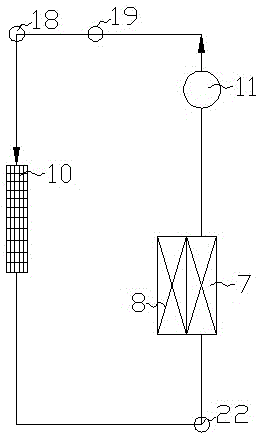

Integrated thermal cycling system of electric vehicle

ActiveCN102941791AAchieve mutual integrationMeet the high requirements of the service temperatureAir-treating devicesCell temperature controlAir conditioningElectric vehicle

The invention relates to the field of heat management of electric vehicles, and in particular to an integrated thermal cycling system of an electric vehicle. The integrated thermal cycling system of the electric vehicle comprises a motor system heat dissipation device, a motor, a motor controller, an air-conditioning system, a first water pump, an air heater, a water cooling jacket, a battery pack, a heater, a battery pack heat dissipation device, a second water pump, a heat exchanger and an evaporator; and a refrigerant pipeline and a water pipeline are connected onto the heat exchanger, the water cooling jacket is installed on the battery pack, and the motor system heat dissipation device, the first water pump, the motor controller and a motor are sequentially and circularly connected with each other according to the circulating water flowing direction, so that a motor cooling cycling circuit is formed. When the environment temperature is low, the battery pack is preheated and heated and an air conditioner in the vehicle is warmed up before the electric vehicle is started, when the environment temperature is high, the battery pack is cooled, a cab is refrigerated and the motor and the motor controller are cooled, accordingly, high requirements on the self operating temperatures of the motor system and a battery are satisfied, so that the service lives and efficiency of the motor system and the battery are increased.

Owner:SAIC MOTOR

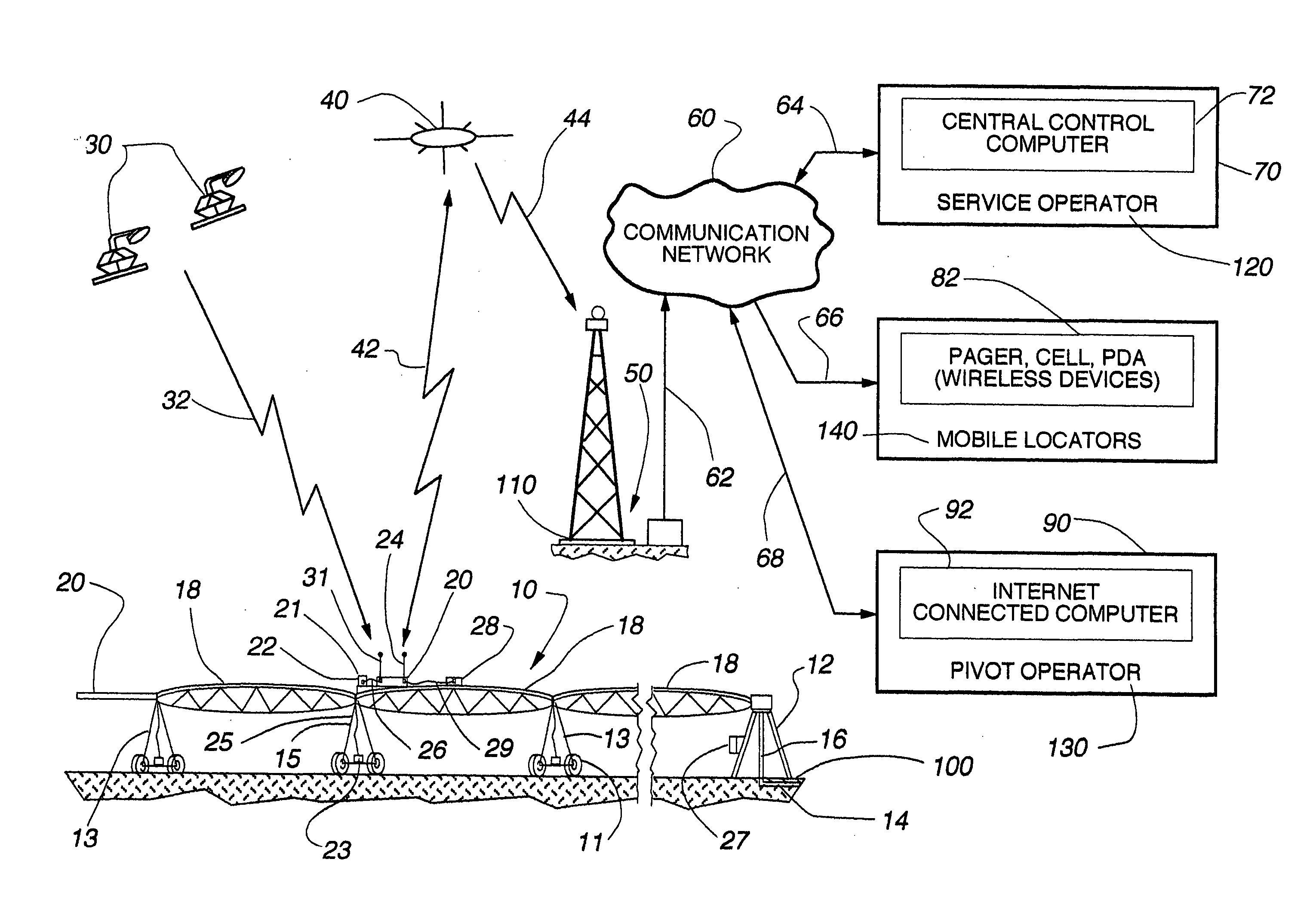

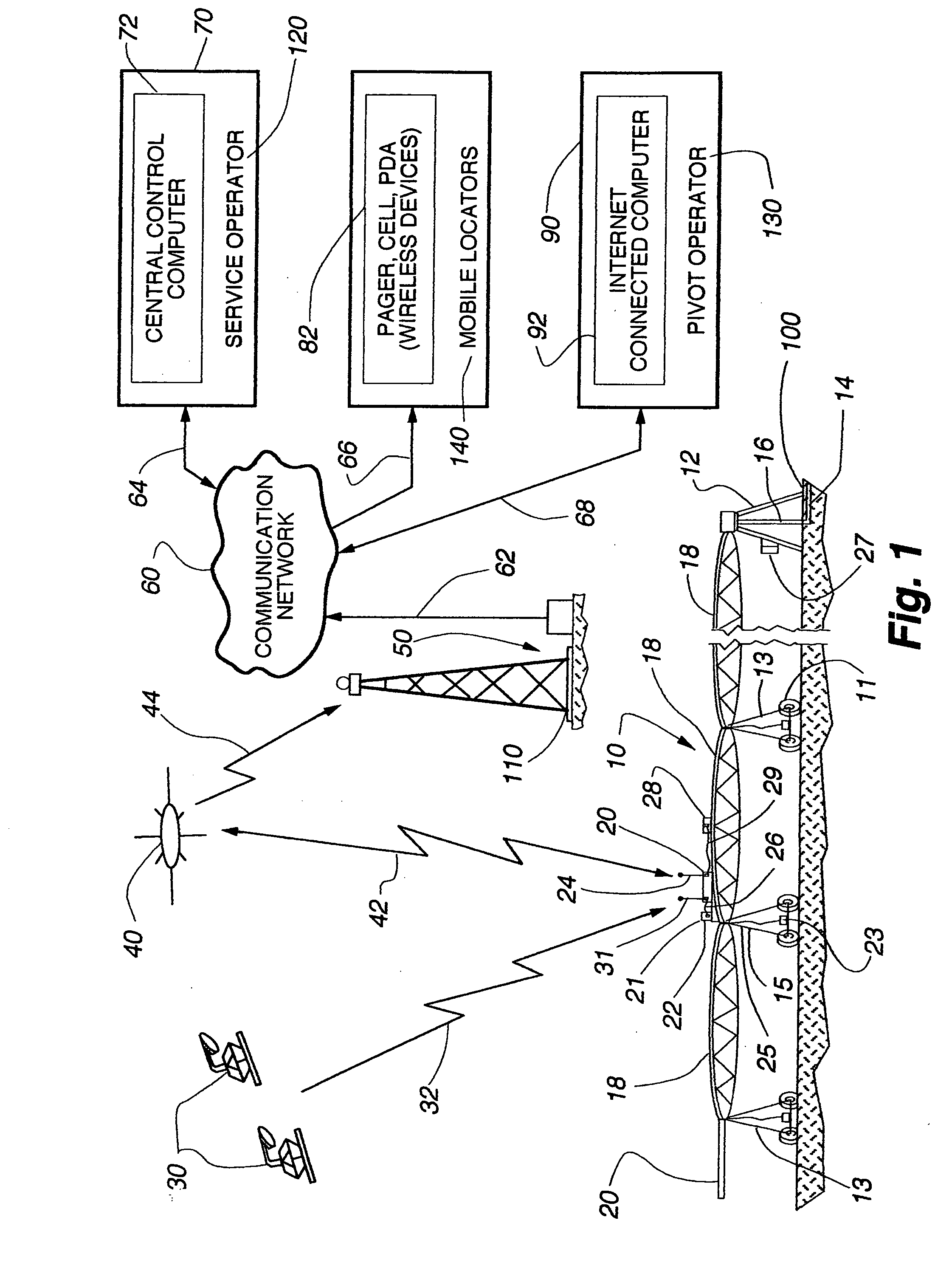

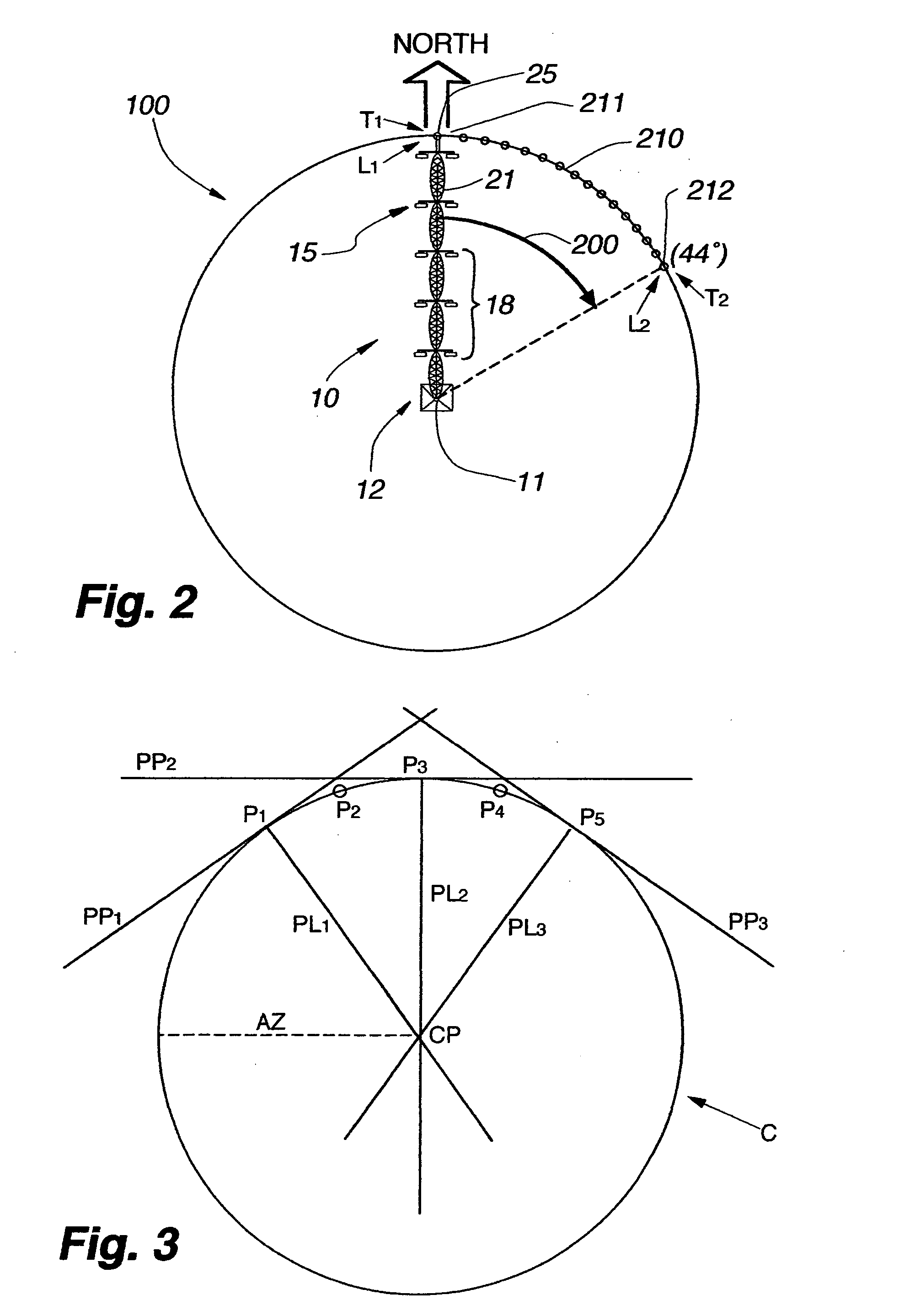

Remote current sensor monitoring system and GPS tracking system and method for mechanized irrigation systems

ActiveUS20060027677A1Low costImprove reliabilitySelf-acting watering devicesWatering devicesTransceiverCurrent sensor

A wireless interface remote monitoring system for self-propelled irrigation systems (center pivot and lateral move sprinklers) includes a remote terminal unit (RTU) mounted on an outer drive tower of the irrigation system. The RTU includes a radio transceiver capable of sending and receiving data packets over a satellite or terrestrial telemetry backbone to and from a central control computer. The RTU further includes a current sensor and a GPS receiver both for detecting movement or non-movement of the sprinkler, a microprocessor with nonvolatile memory for storing current data and GPS coordinate data from readings taken in series over time, and a pressure or flow sensor for detecting the presence or absence of water flow at the outer drive tower of the sprinkler. The current sensor connected between the RTU and a tower drive motor, allows the RTU to calculate the “movement” or “non-movement” of the irrigation system over a specified time period. Redundantly, the GPS receiver records changes in position to indicate movement or non-movement within the GPS error tolerance. Once a change from movement to non-movement or vice-versa is determined, the RTU transmits the data by satellite or radio telemetry to a central control computer which logs the movement or non-movement of the monitored drive tower, the GPS coordinate data and the water status readings, all with time and date stamp. The central control computer creates “page message” and “text message” updates as necessary on the status of individual irrigation systems and “groups” of irrigation systems that are in turn delivered to wireless devices and computers for sprinkler operators.

Owner:HAALAND KARLYLE

Glaucoma surgery methods and systems

InactiveUS20080082078A1Reducing collateral tissue damageObviating benefitLaser surgeryElectrotherapyAqueous flowSchlemm's canal

Methods and systems are disclosed for creating an aqueous flow pathway in the trabecular meshwork, juxtacanalicular trabecular meshwork and Schlemm's canal of an eye for reducing elevated intraocular pressure. Some embodiments described apparatus and methods useful in photoablation of tissues. In some embodiments, a photoablation apparatus is used to perforate a tissue, forming an aperture into a space behind the tissue. Gases formed during a photoablation process can be used to pressurize the space behind the tissue to enhance patency of the space. In some embodiments the tissue is the trabecular meshwork of the eye and a wall of Schlemm's canal, and the space behind the tissue is a portion of the lumen of Schlemm's canal. In some embodiments, the method is useful in the treatment of glaucoma by improving outflow from the anterior chamber of the eye into Schlemm's canal, reducing intraocular pressure.

Owner:BERLIN MICHAEL S

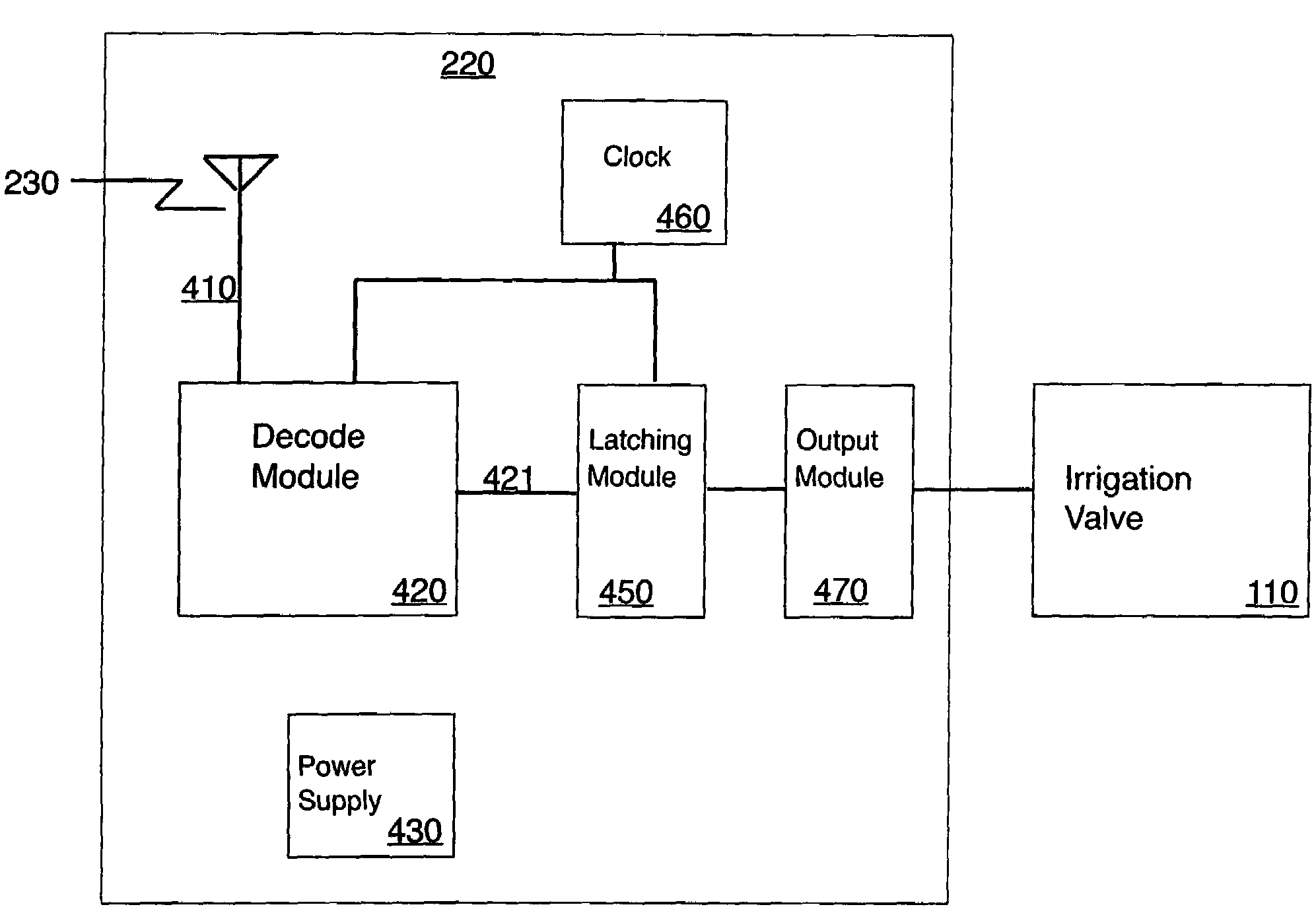

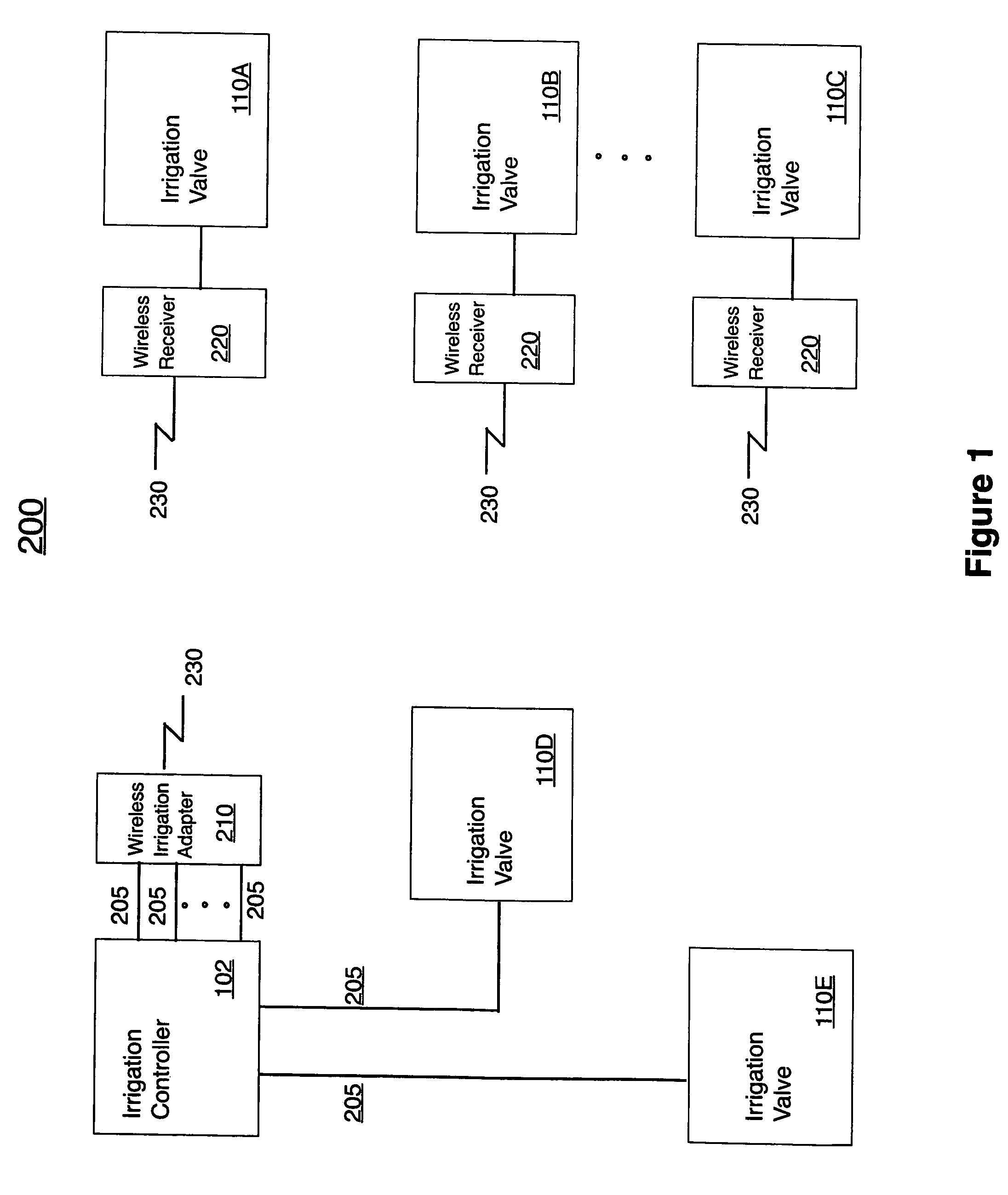

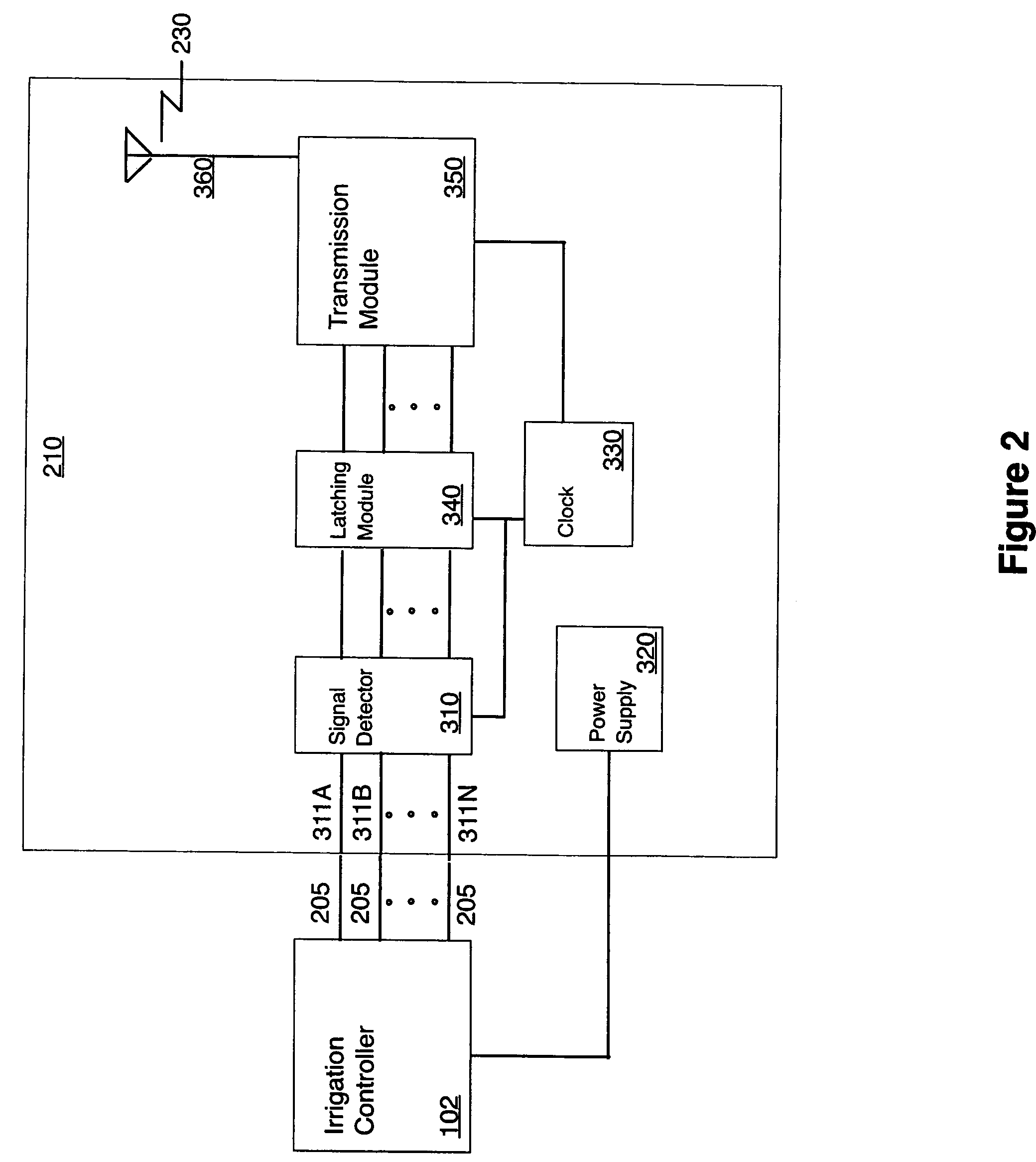

Systems and methods for adaptation to wireless remote control of irrigation valves from existing hardwired control devices

InactiveUS7286904B2Low costReduce the possibilityEnergy efficient ICTElectric signal transmission systemsWireless controlRemote control

A low cost system and method for retrofitting an existing control device to communicate wirelessly with one or more water-flow devices is provided. For example, an existing wired irrigation system may be adapted to allow wireless communication between a commercially available irrigation controller and commercially available water-flow devices, such as sprinkler valves. A wireless irrigation adapter receives control signals from an existing irrigation controller and transmits a wireless representation of the control signals. Water-flow devices may be coupled to one or more wireless receivers that receive the wireless representation of the control signals and operate the water-flow device(s) accordingly. The wireless irrigation receiver(s) listen(s) for the wireless control signals occasionally, thus reducing power consumption by the wireless receiver(s). This system and method may also wirelessly adapt control devices to irrigation that may never have been intended for that purpose when they were fabricated.

Owner:NU PHI DELTA

Drip irrigation lines

InactiveUS6302338B1Reduce sensitivityAbility to saveClimate change adaptationWatering devicesWater dischargePore water pressure

A drip irrigation line includes a plurality of emitter units secured within a water supply tube such that each emitter unit defines with the tube a flow-control passageway having an inlet port communicating with the interior of the water supply tube and an outlet port communicating with a water discharge opening in the water supply tube. Each emitter unit includes a one-way valve at one of the ports. Such port has an opening circumscribed by a cylindrical boss, and the one-way valve thereat includes a cap having a skirt of elastomeric material normally engaging the outer surface of the cylindrical boss to block reverse water flow into the flow-control passageway, but is deformable under water pressure to permit forward flow from the tube interior into the flow-control passageway.

Owner:COHEN

Method and apparatus for preparing platelet rich plasma and concentrates thereof

ActiveUS7708152B2Shaking/oscillating/vibrating mixersTransportation and packagingFiberRed blood cell

The PRP separator-concentrator of this invention is suitable for office use or emergency use for trauma victims. The PRP separator comprises a motorized centrifugal separation assembly, and a concentrator assembly. The centrifugal separator assembly comprises a centrifugal drum separator that includes an erythrocyte capture module and a motor having a drive axis connected to the centrifugal drum separator. The concentrator assembly comprises a water-removal module for preparing PRP concentrate. The centrifugal drum separator has an erythrocyte trap. The water removal module can be a syringe device with water absorbing beads or it can be a pump-hollow fiber cartridge assembly. The hollow fibers are membranes with pores that allow the flow of water through the fiber membrane while excluding flow of clotting factors useful for sealing and adhering tissue and growth factors helpful for healing while avoiding activation of platelets and disruption of any trace erythrocytes present in the PRP.

Owner:HANUMAN +1

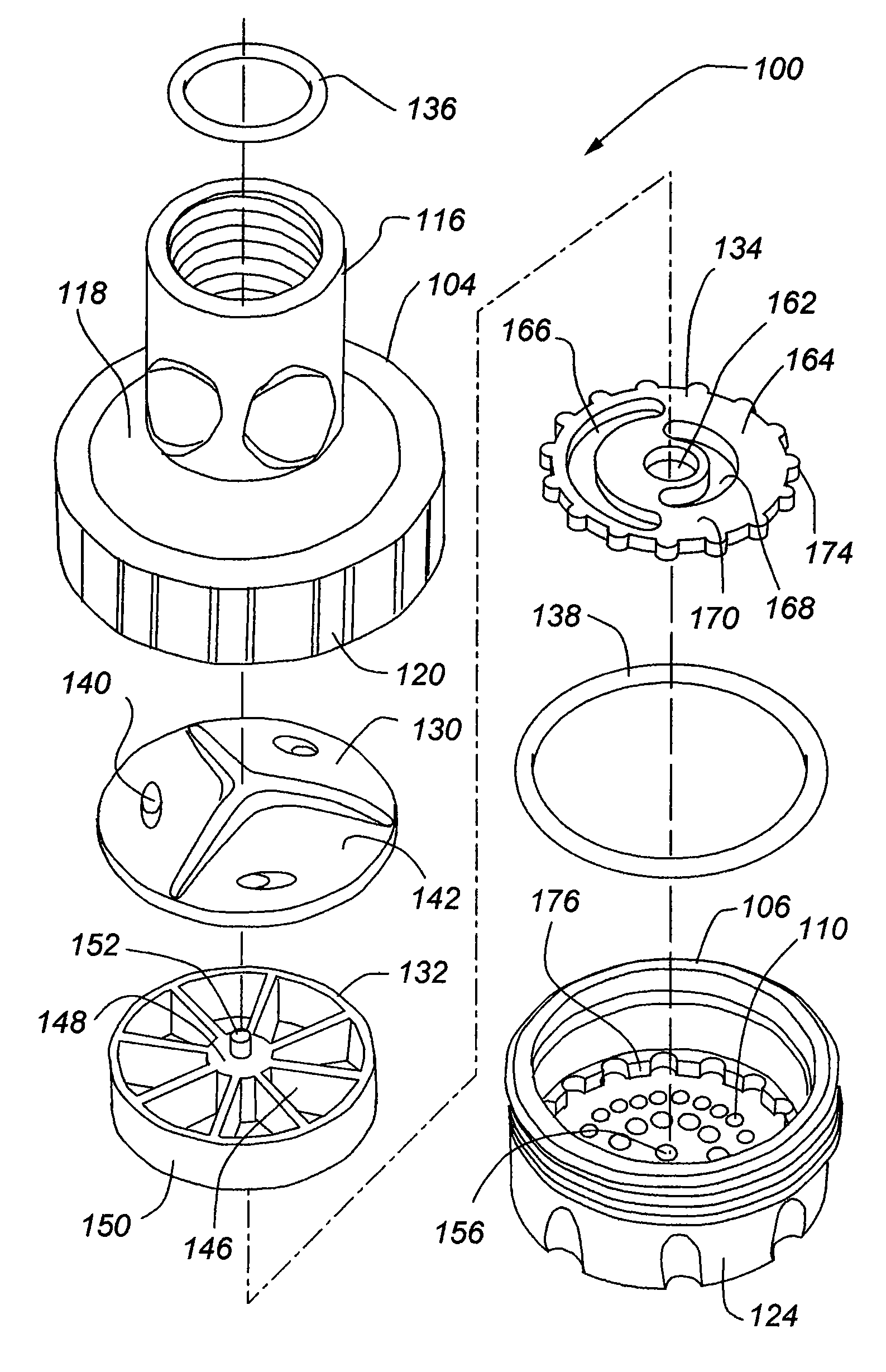

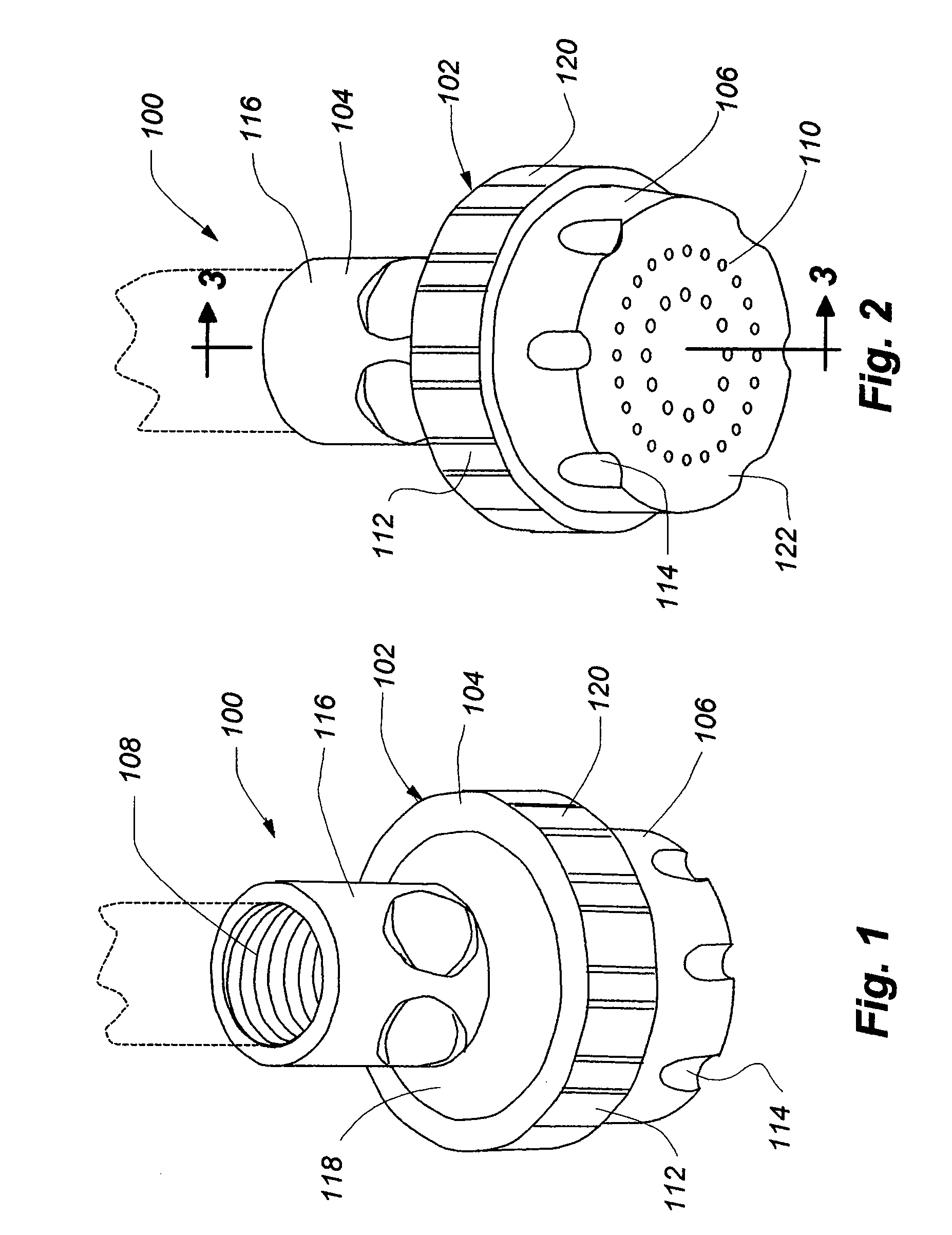

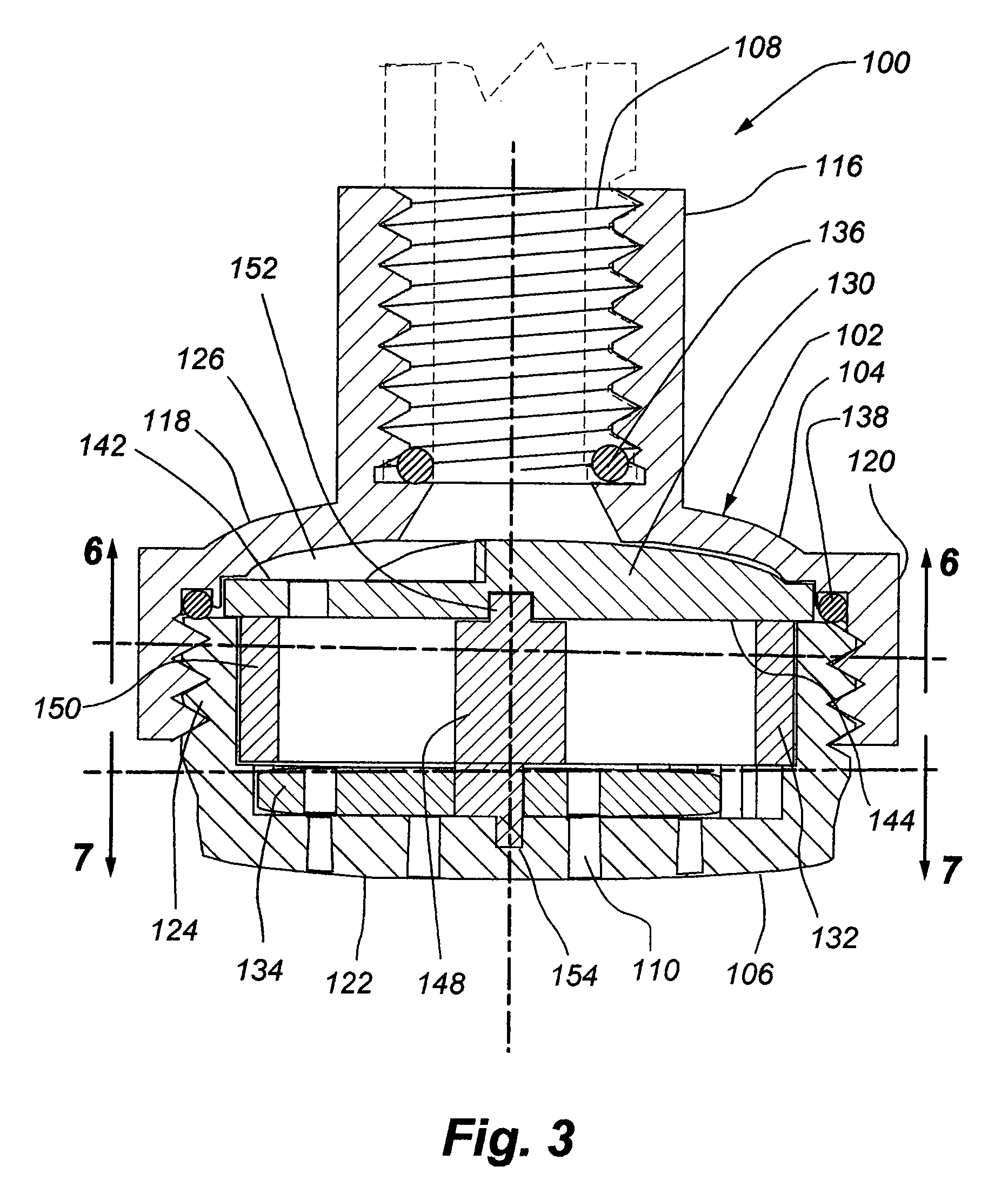

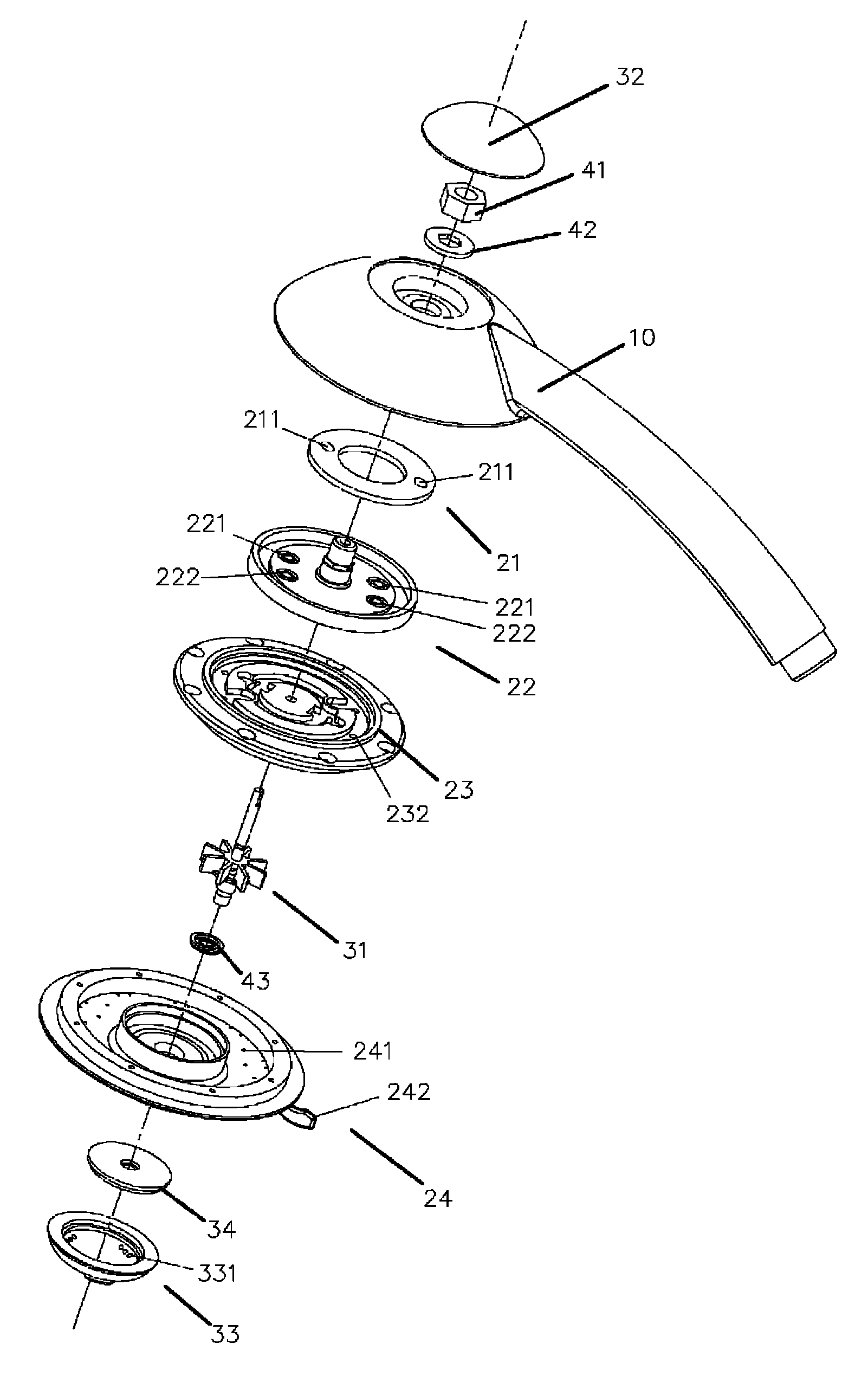

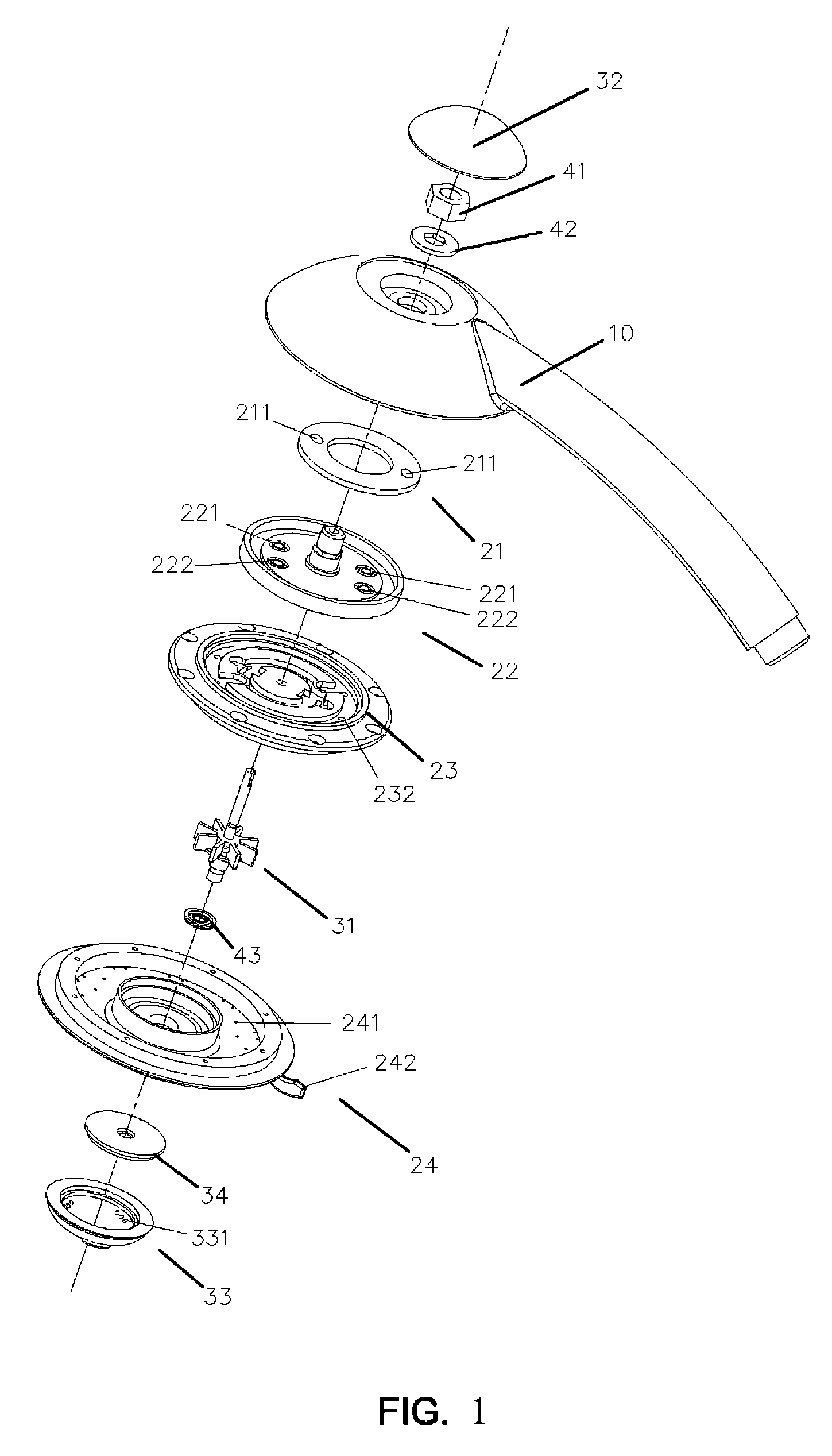

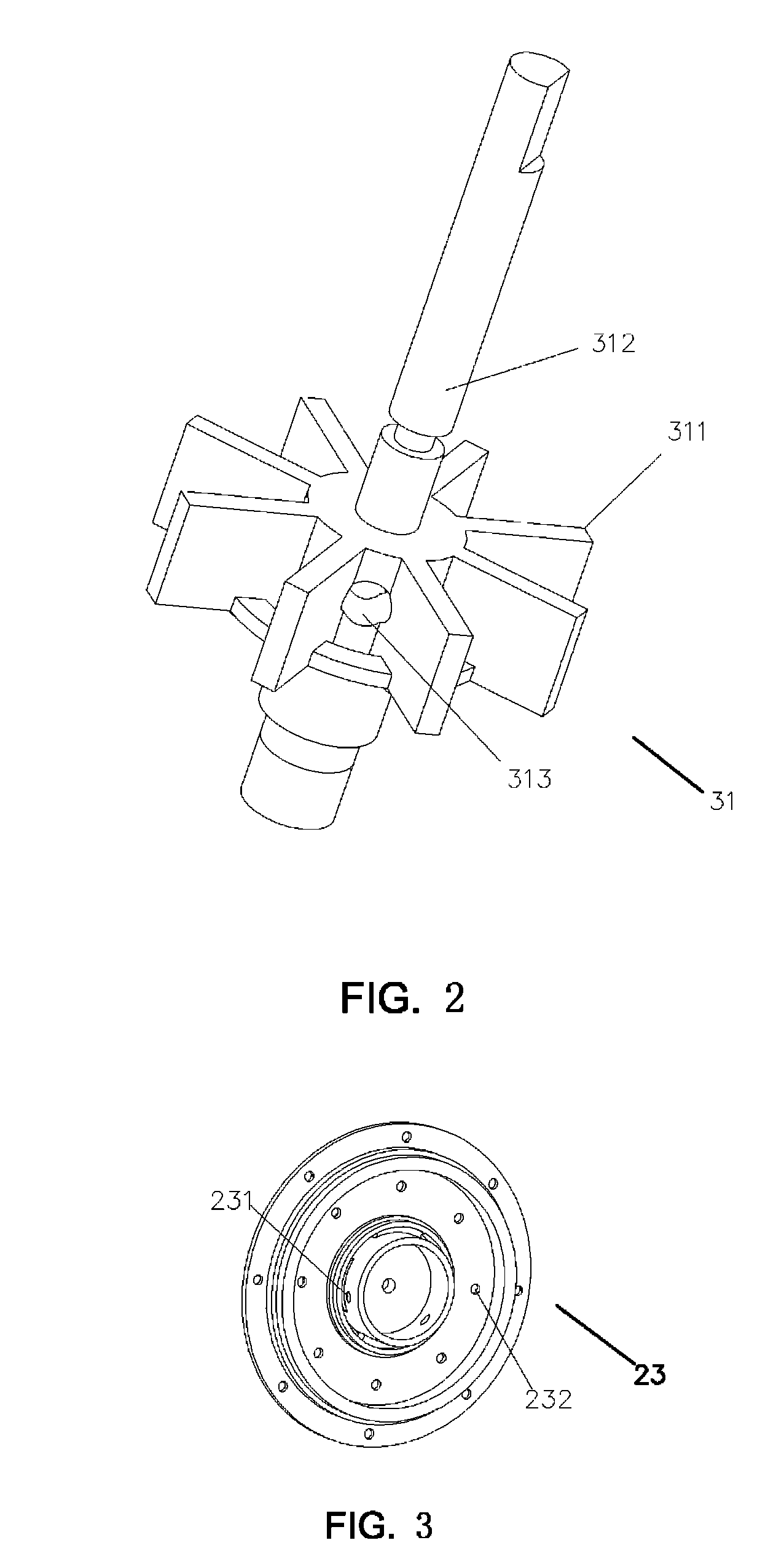

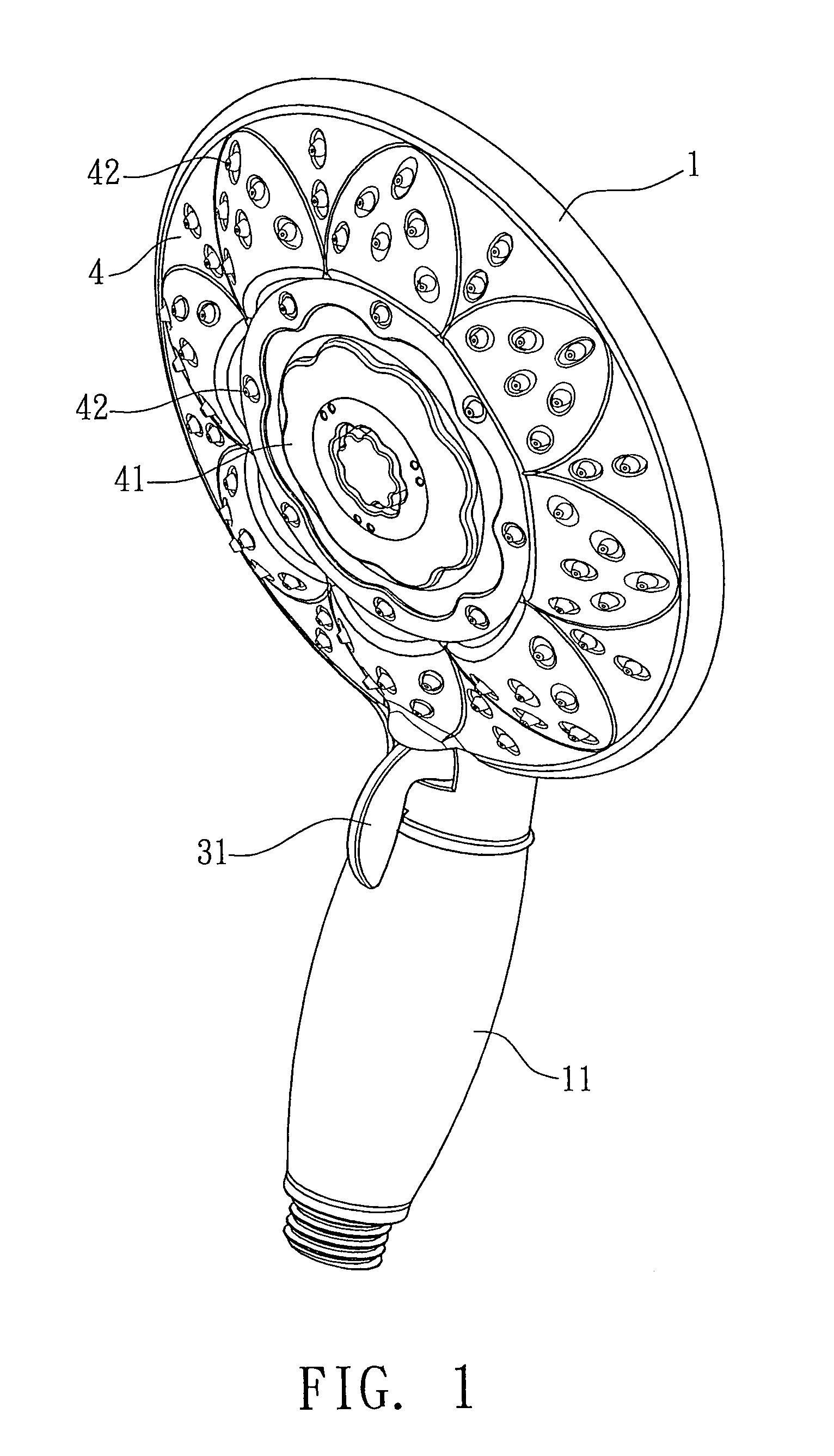

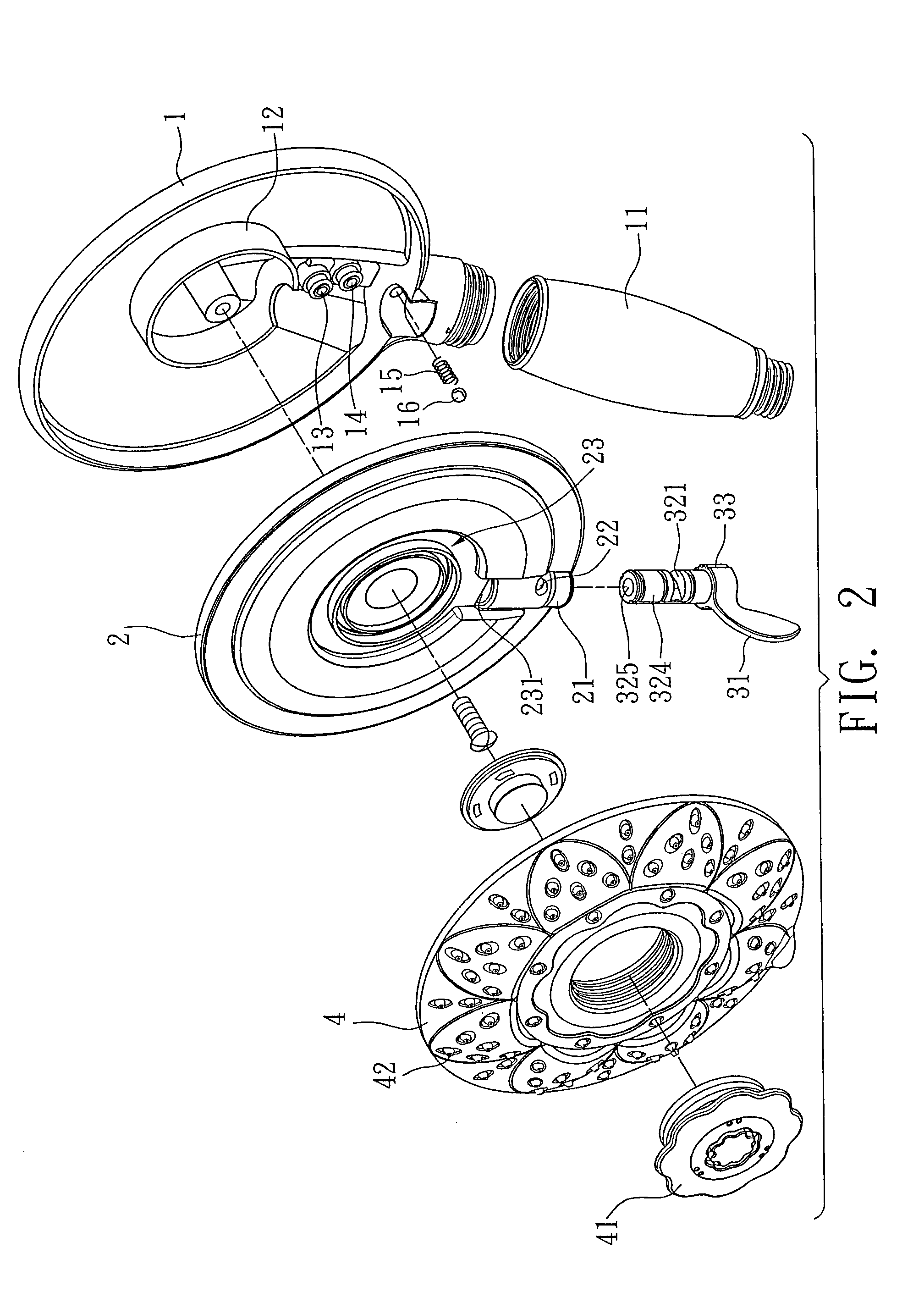

Low speed pulsating showerhead

A showerhead may include a housing, a jet disk, a turbine, and a shutter. The housing may include a fluid inlet, at least one fluid outlet, and a chamber in fluid communication with the inlet and one or more outlets. The jet disk, turbine, and shutter may be placed in the cavity. The shutter may include at least one opening. The shutter may selectively cover and uncover fluid outlets, thus selectively fluidly connecting the fluid outlets with the chamber. Water flowing through the housing causes the turbine to spin. As the turbine spins, the shutter rotates at a slower speed than the turbine to produce a periodic interruption of water flow through the outlets by covering and uncovering the outlets as the shutter rotates within the housing.

Owner:WATER PIK INC

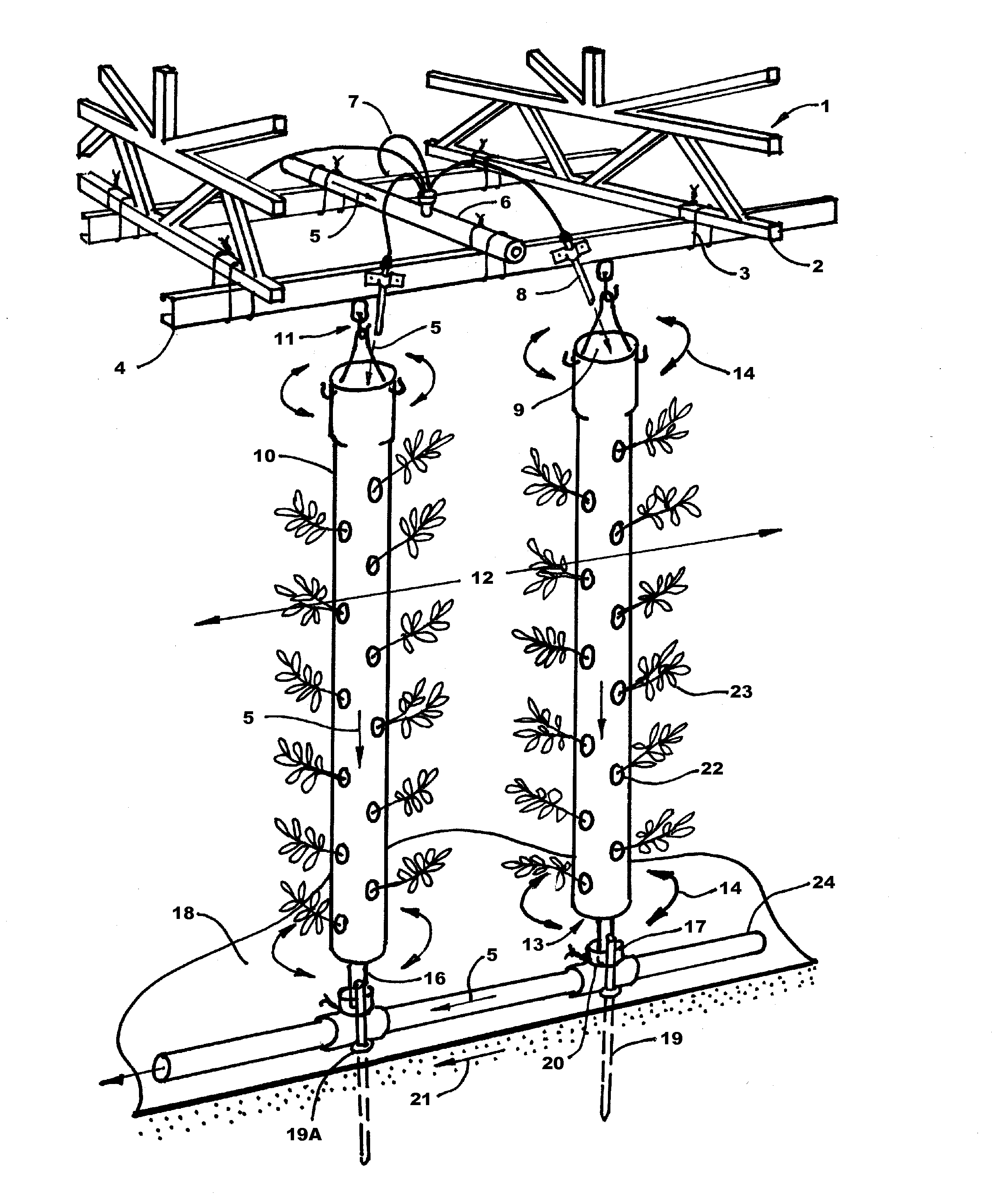

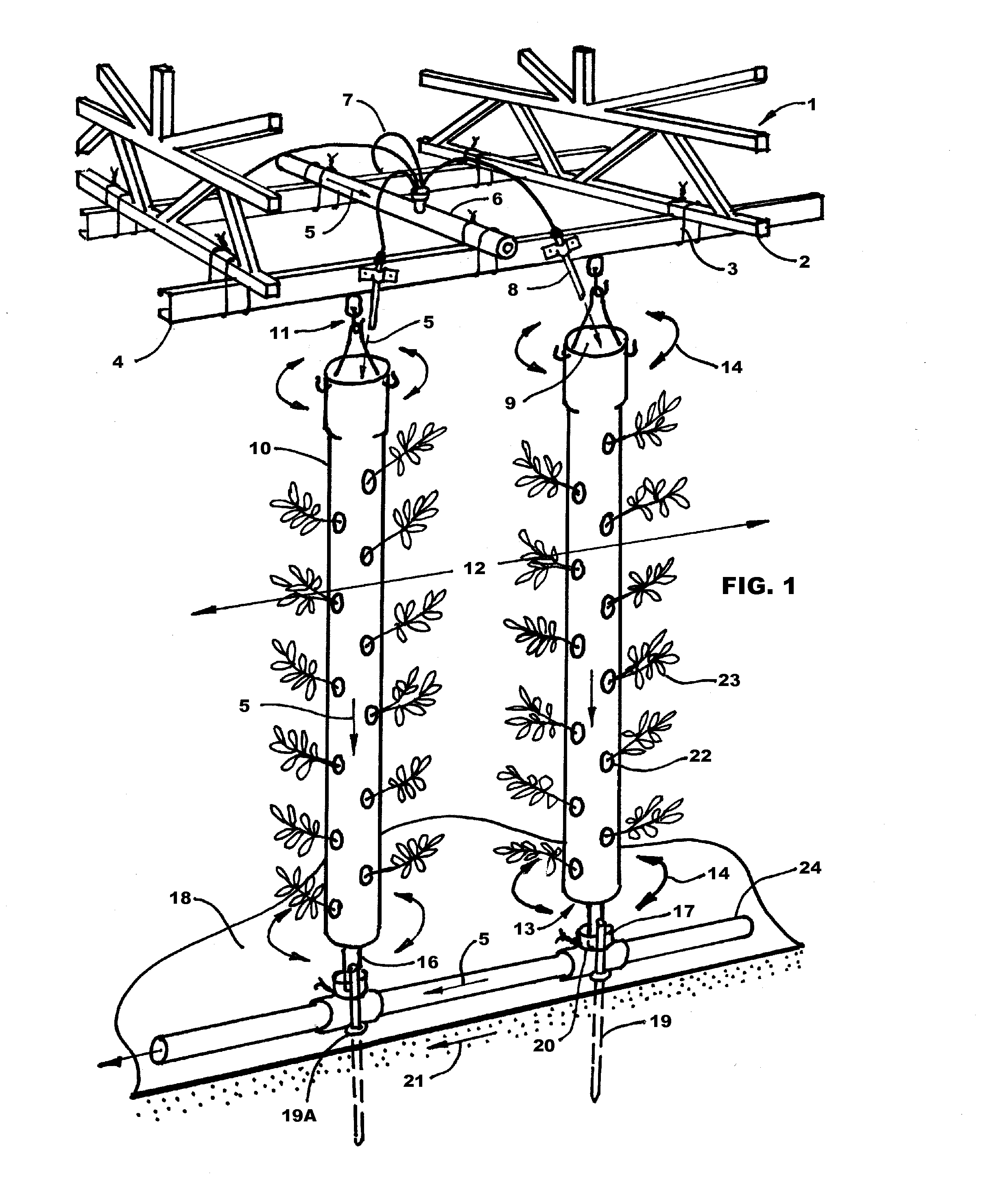

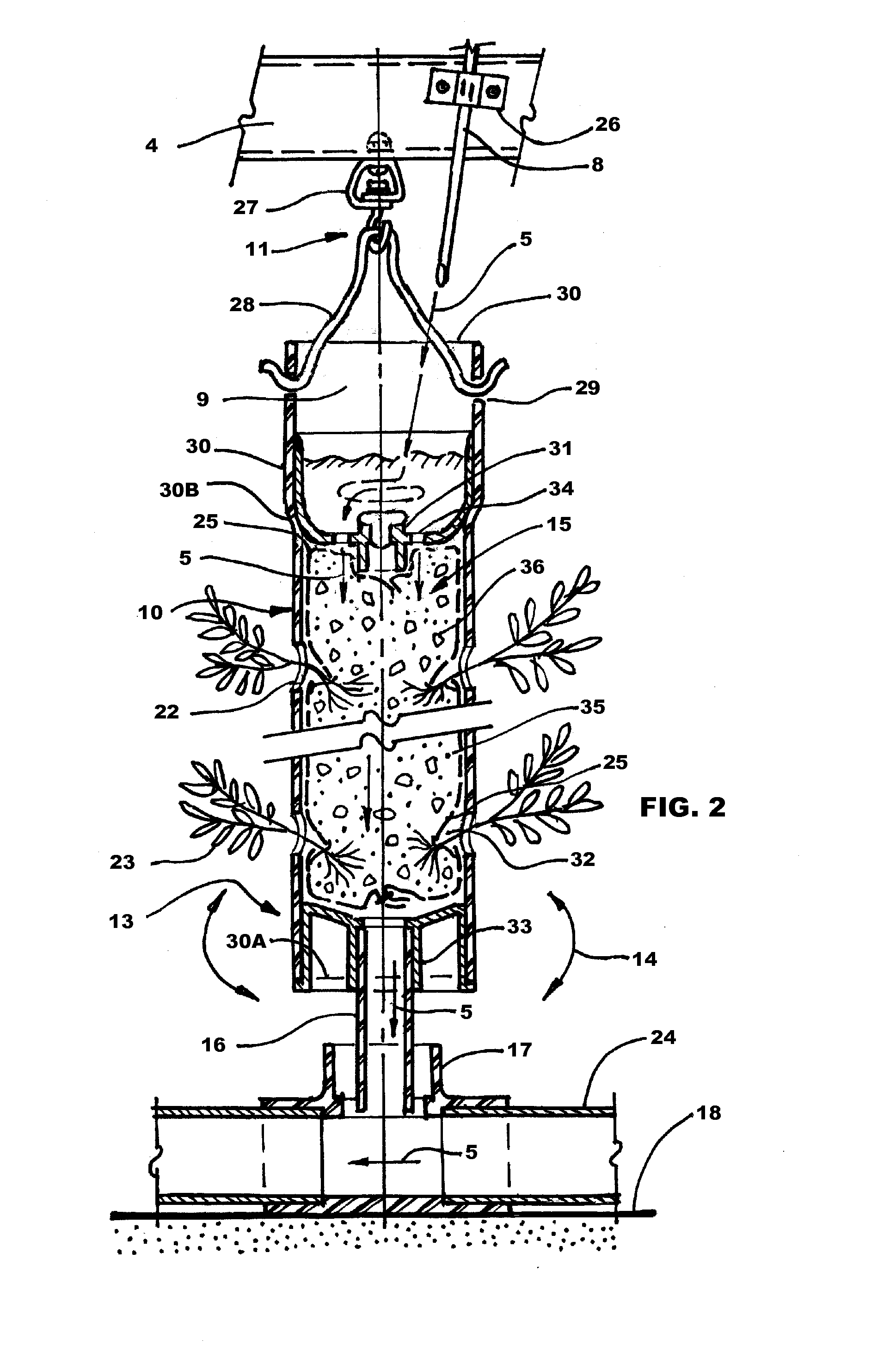

Light-weight modular adjustable vertical hydroponic growing system and method

A light-weight, modular, adjustable vertical hydroponic growing system and method of Native American design for cultivation plants and beneficial soil organisms (BSO's) in symbiotic combination. Forest-like arrays of fully rotatable and demountable grow tubes are suspended within climate-moderating greenhouses, optionally from conveyor tracks. The tubes are filled with light-weight, porous 100% in-organic grow media predominately comprised of expanded volcanic or recycled glass granules. The grow tube arrays are provided with an insulated, overhead-mounted fertigation distribution system delivering metered intermittent flows from insulated mixing and holding tanks. The flows are recycled via an insulated return piping system to maintain cool fertigation temperatures near those of natural ground water. Fertigation supply mains provided with vortex flow induction devices impart rotational momentum to flows for delivery of uniform aerated fertigation to plants and BSO's via a combination of open-tube emitters and gravity flows within grow tubes.

Owner:COLLINS FRED +1

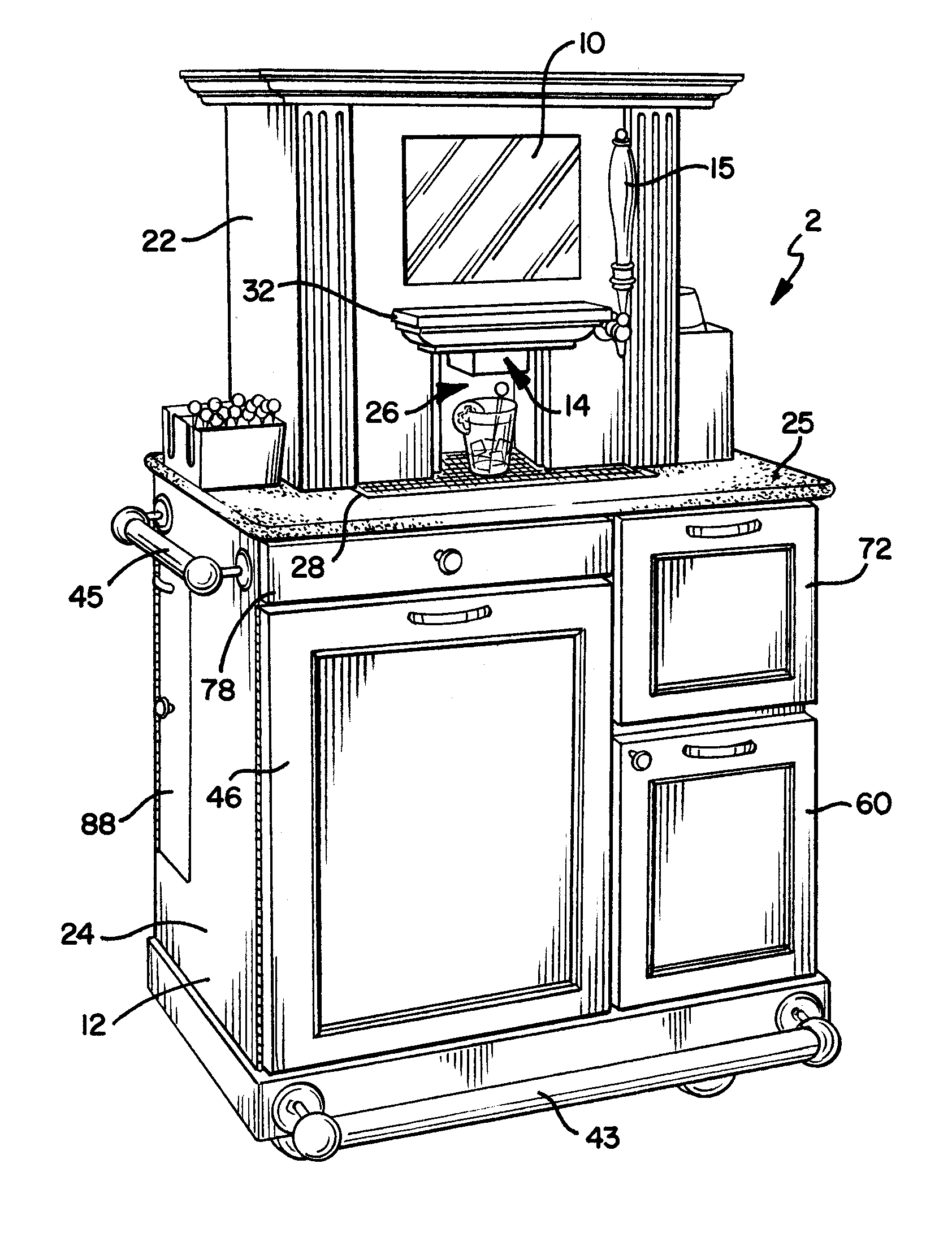

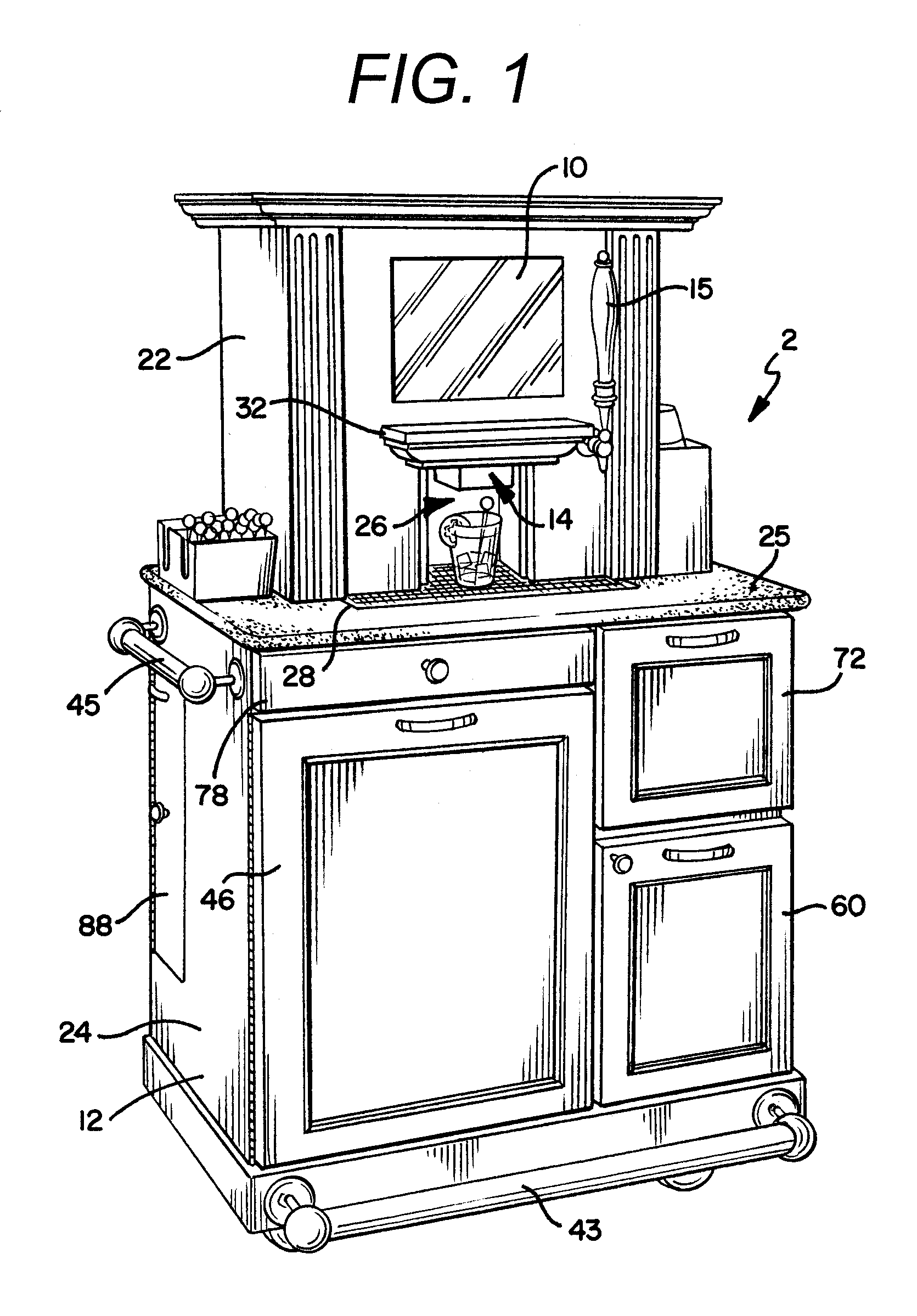

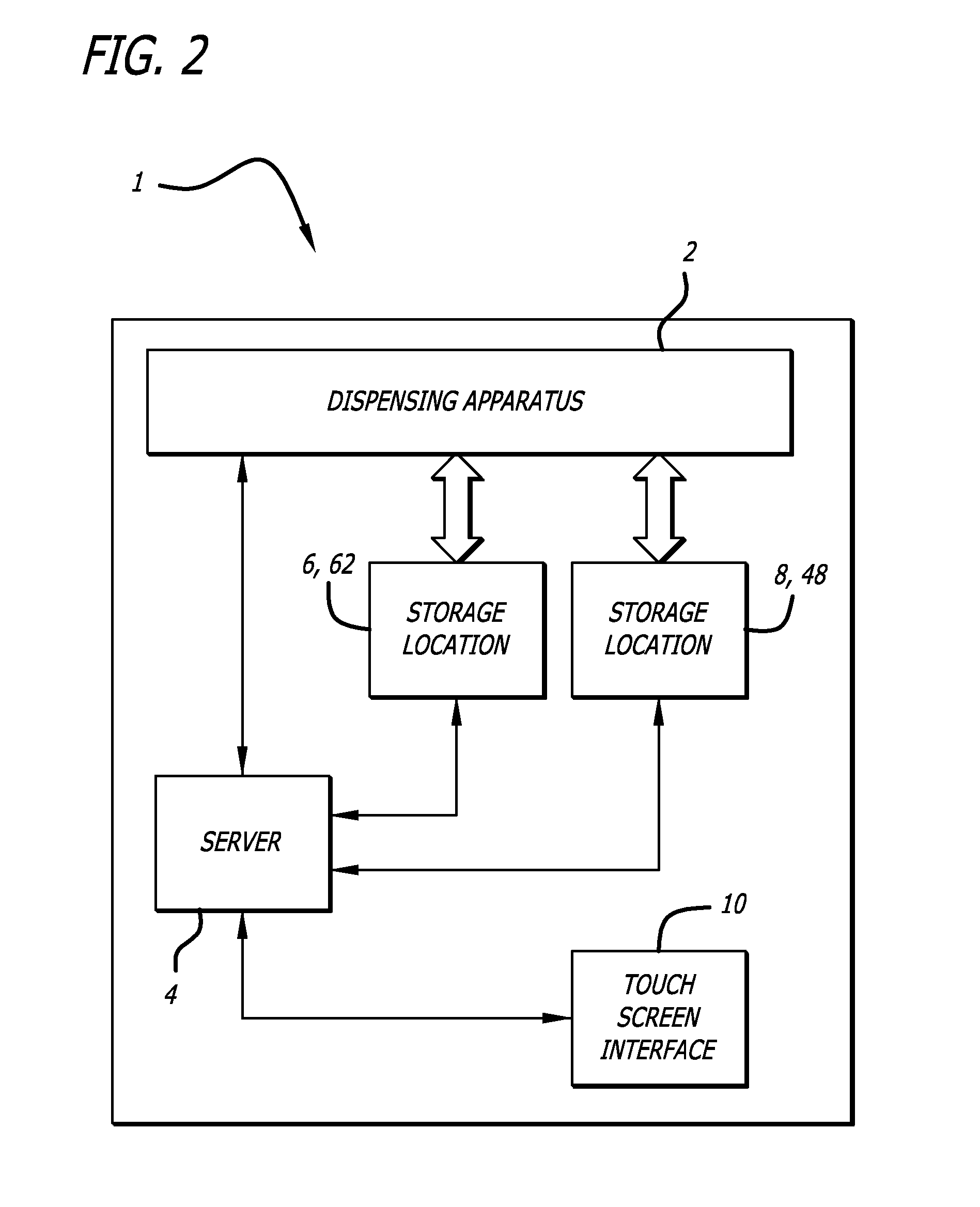

Automatic Beverage Dispenser

A beverage dispenser for providing mixed beverages. The beverage dispenser has a housing containing a plurality of first liquids, a plurality of second liquids, and a water supply, wherein the first liquids comprise liquors, and wherein the second liquids comprise mixer syrup. The beverage dispenser also has an interface, a dispensing spout and a server. The interface is provided on the housing to input variable data and receive variable instructions. The server electrically operates valves to control the flow of first liquids, second liquids and water to the beverage dispenser spout based on instructions entered at the interface and a pouring schema stored in memory.

Owner:SMART BAR USA

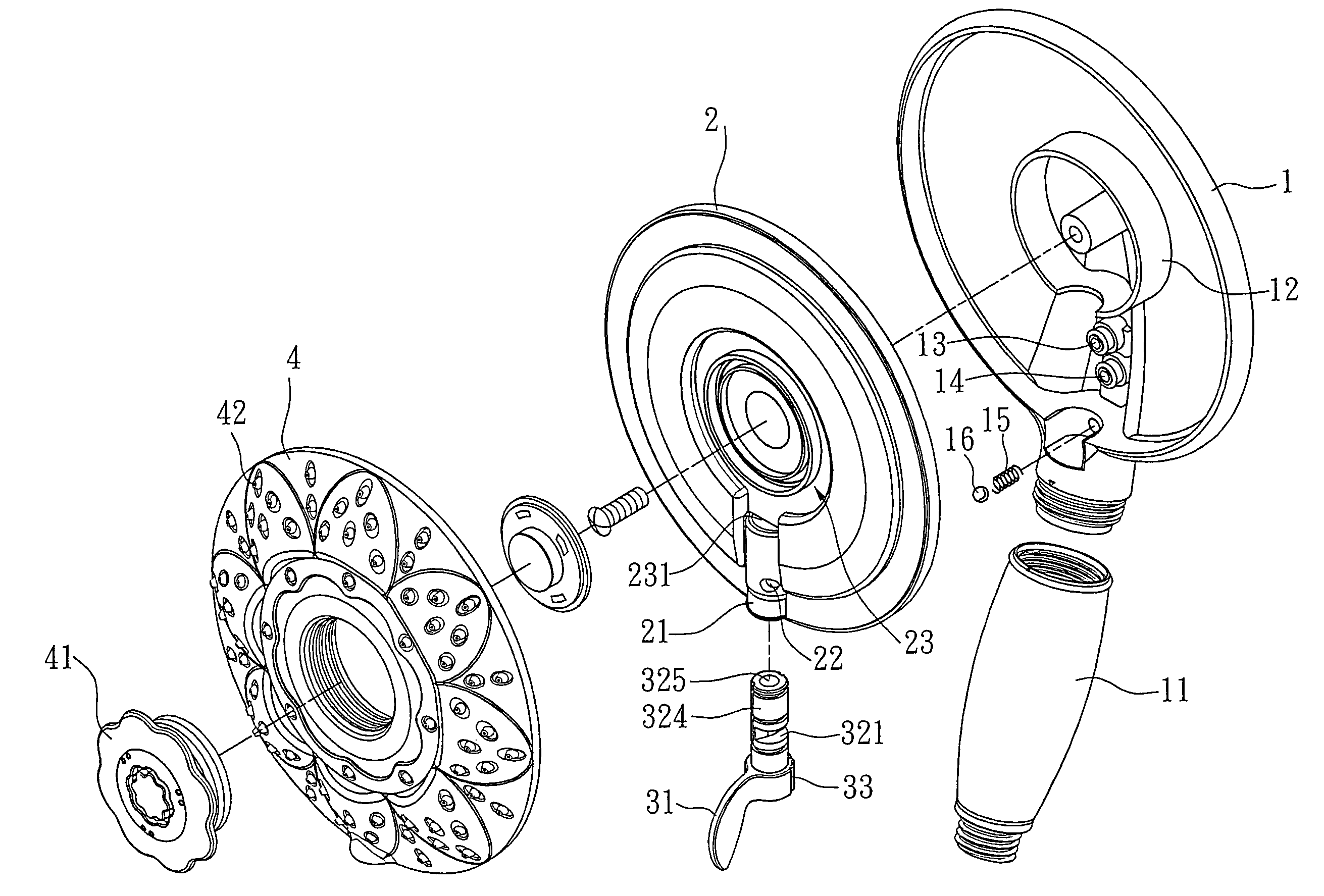

Shower with rotatable top and bottom rotating covers

InactiveUS8297534B2Dramatic watering functionImprove visual effectsBurnersMovable spraying apparatusImpellerWater flow

A shower with rotatable top and bottom rotating covers and a rotatable watering function, comprising: a shower housing, a watering unit having a tilted hole, an impeller set beneath the tilted hole and axially located between the shower housing and the watering unit, a top rotating cover protruding on the shower housing and fixed on the top of the impeller, and a bottom rotating cover protruding under the watering unit and fixed beneath the impeller. The top and bottom rotating covers rotate with the impeller around the same axis. The bottom cover contains an off-center outlet. The water stream from the tilted hole of watering unit will strike the impeller, rotating the top and bottom rotating cover around the same axis. The off-center outlet of the bottom rotating cover then generates a rotating spray.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Switch-equipped sprinkler

InactiveUS7100845B1Easy to operateImprove responseSpray nozzlesFire rescueWater flowMechanical engineering

A switch-equipped sprinkler including a main body, a rotary water-distributing switch and a color-changeable warning facial cap mounted in a facial cap of the sprinkler. The switch is mounted in the main body. The switch has an operating handle arranged between the facial cap and the handle of the sprinkler. In the case that the temperature of the water exceeds a set value, the color-changeable facial cap will warn a user. The switch is operable with single handle to control the path of the water flow and switch the figures of the sprinkled water as necessary.

Owner:HSIEH ELVIS

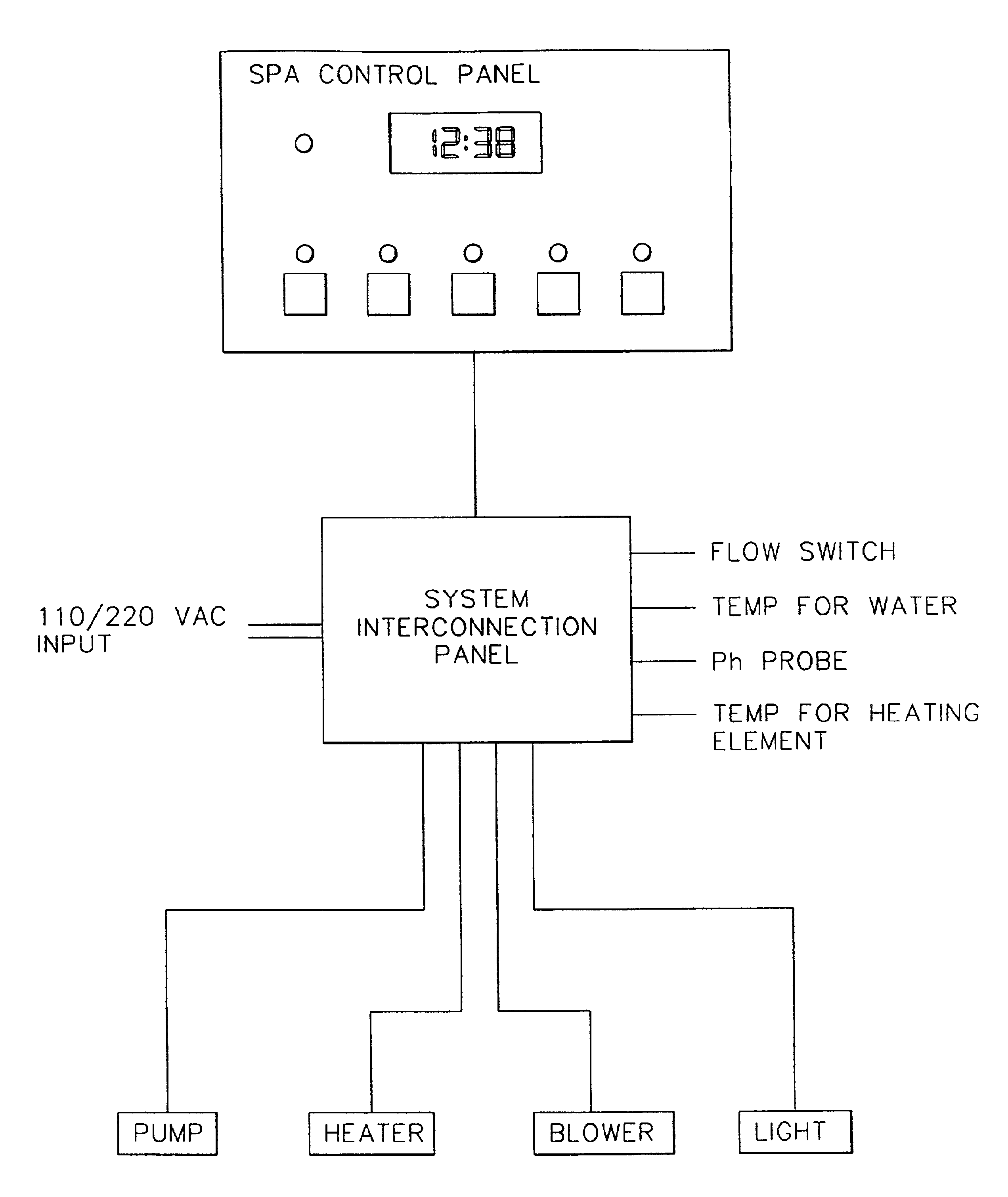

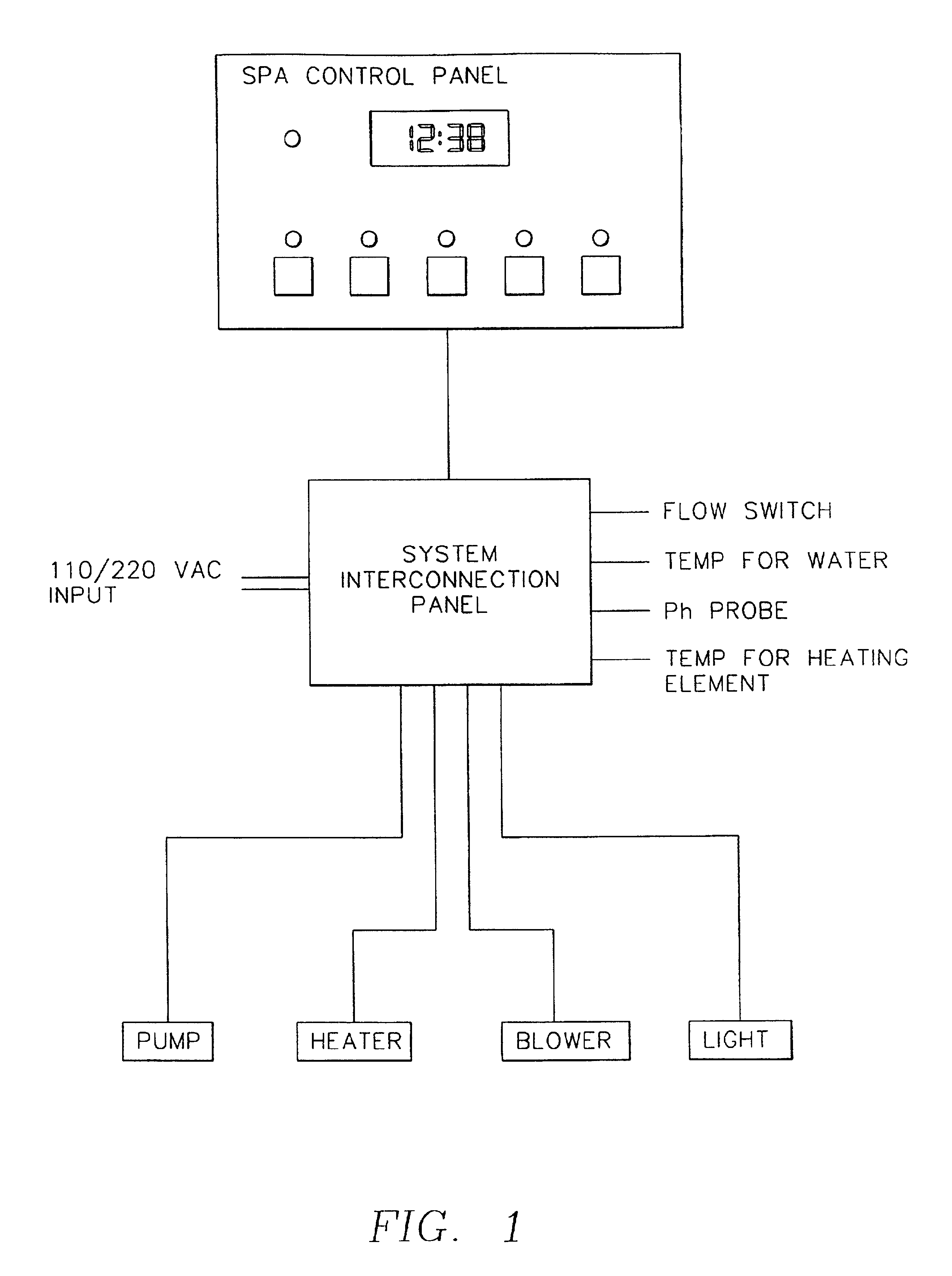

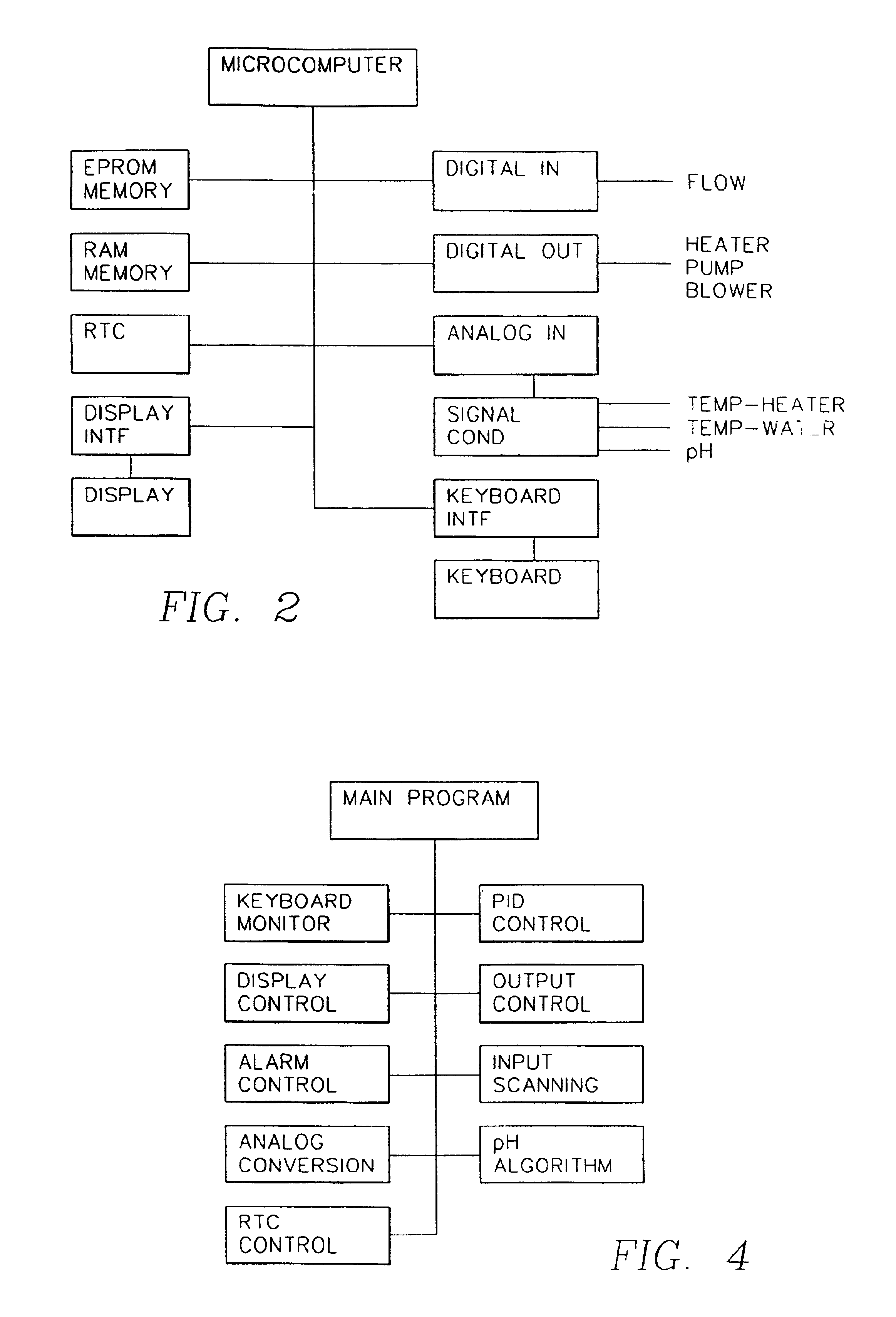

Spa control system

InactiveUS6976052B2Accurately and efficiently controls operationNot adversely affectedTemperatue controlWater/sewage treatmentControl systemWater flow

An improved spa control system is disclosed. The invention describes a spa control system which calculates the time required to heat the water in the spa system to a desired temperature. From that information, the heating rate of the spa system can be determined, and the heating element of the spa system can be activated at the proper time to raise the temperature of the water to a selected temperature by a desired time. The spa system also monitors information which might show errors in the operation of the spa system such as a blockage in the flow of water over the heating element in the spa system.

Owner:DYMAS FUNDING COMPANY +1

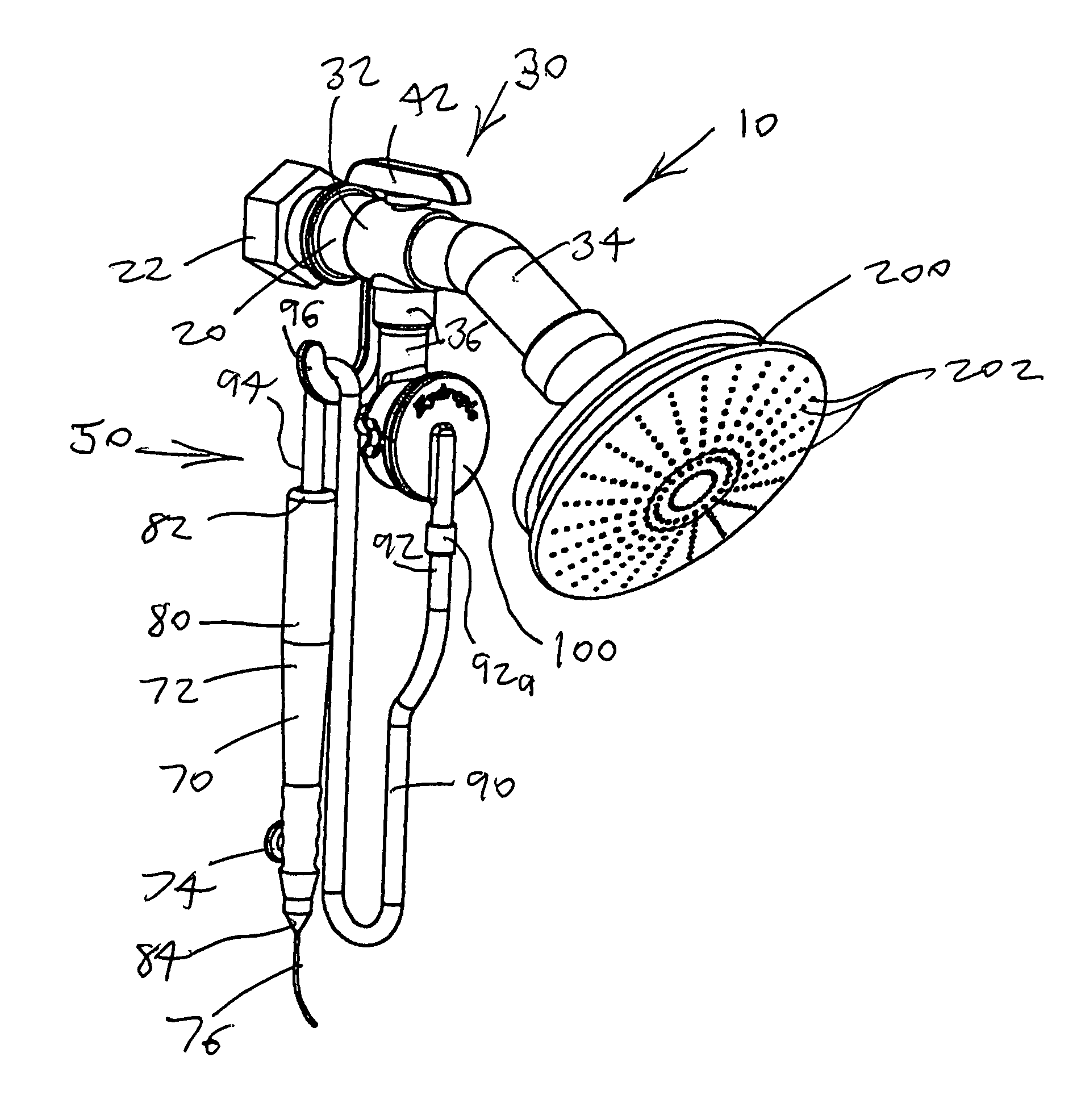

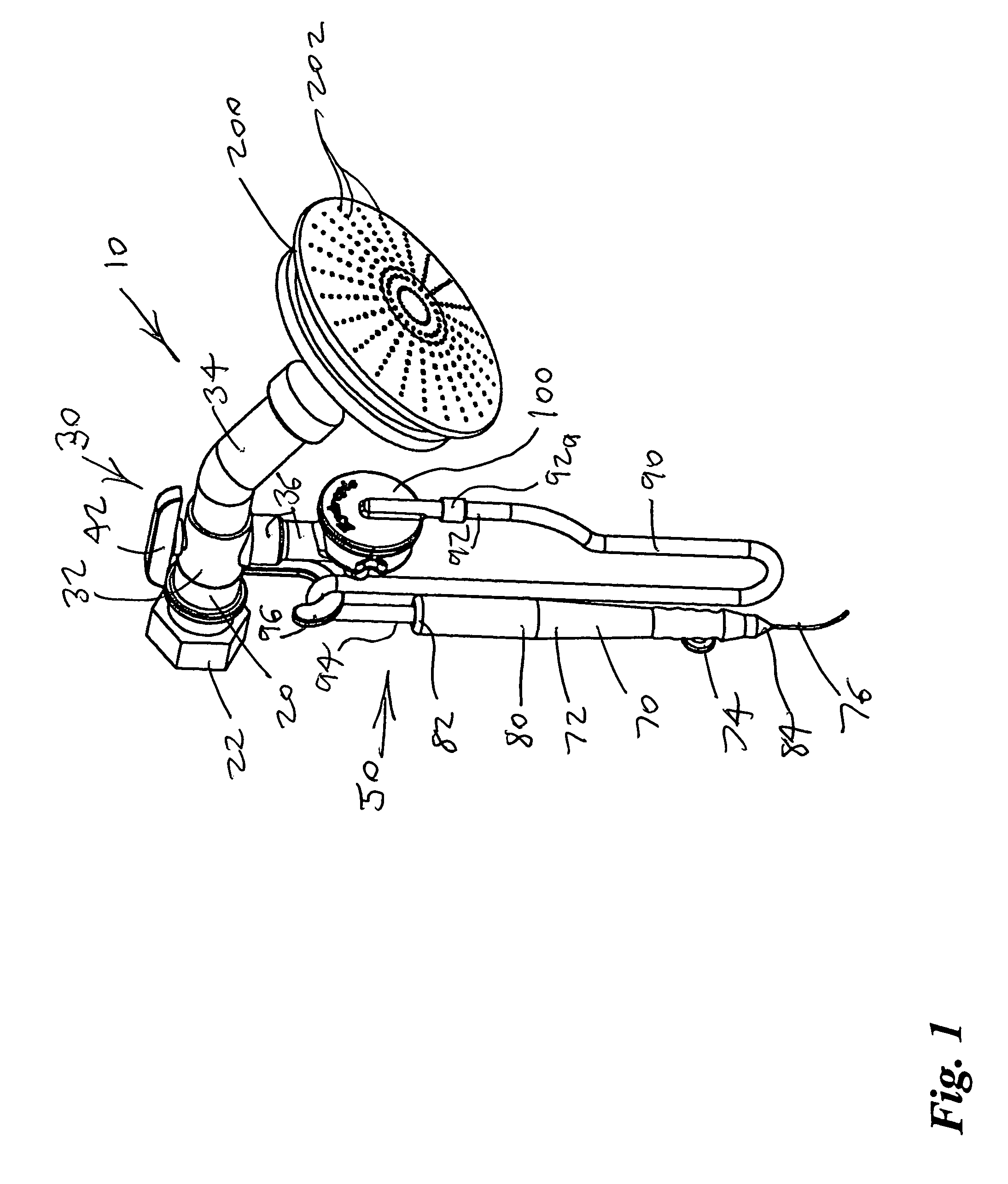

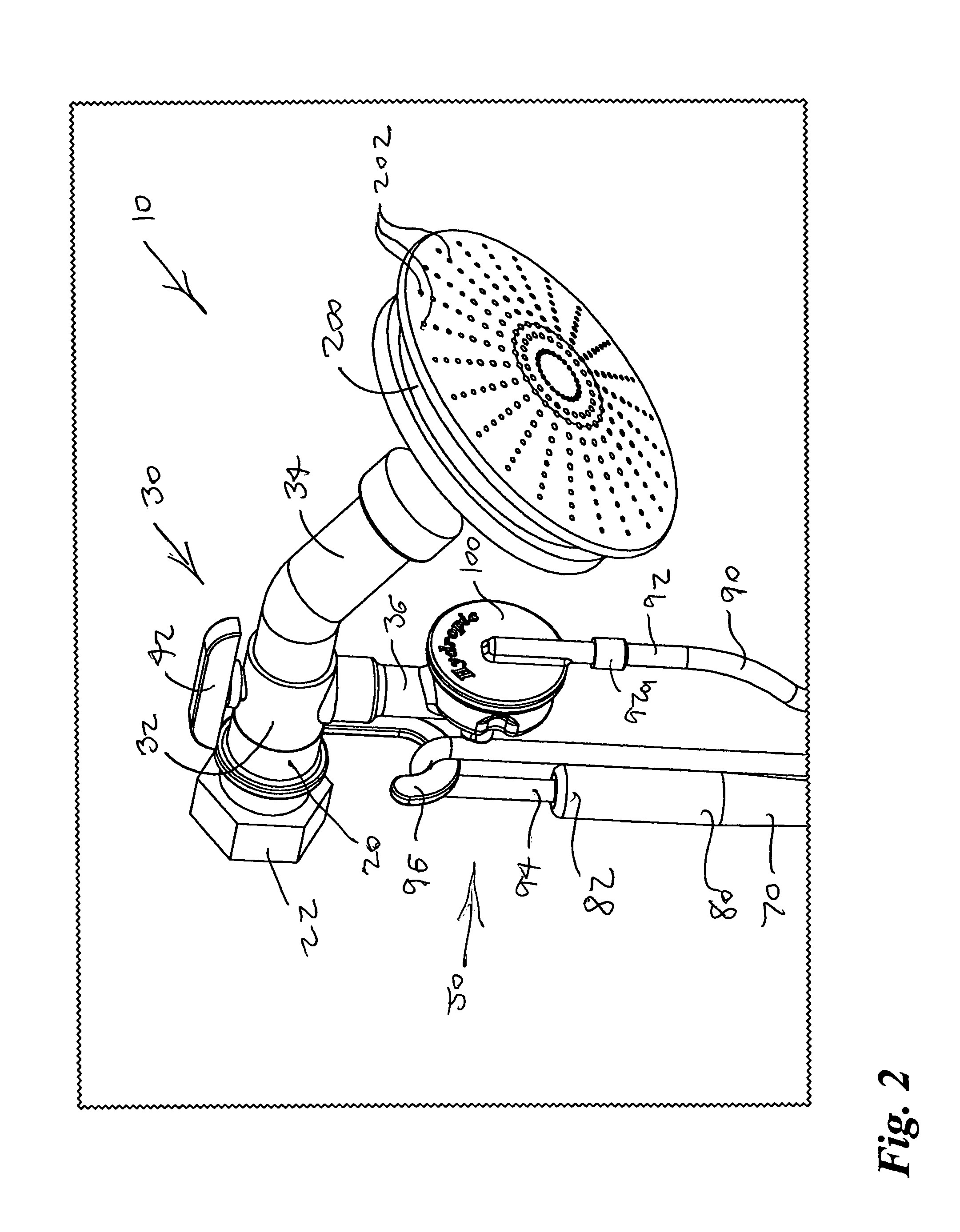

Dental shower water pick

A show head water pick apparatus includes a first pipe segment for attachment to a shower pipe protruding outwardly from shower stall wall and having a first pipe segment outward end; a switch valve having a switch valve intake end connected to the first pipe segment outward end, and having a shower head output branch to which a shower head is connected and a water pick output branch, and having a valve operation handle for delivering water flow alternately to the shower head and to the water pulsing and pick assembly; a water pulsing unit connected to the water pick output branch; a water pick tube having a tube first end and a tube second end, the tube first end being connected to the water pulsing unit; and a water pick secured to the tube second end.

Owner:REICH BONNIE E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com